Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Ring dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ring dyeing is a type of dyeing fault in which dyes are partially diffused to the interior of fibre. Most dyes are stained on to the fibre surface that form layer of dyes on to fibre surface. Thus around the fibre a ring-like appearance of the dye can be viewed cross-sectionally. This ring-like dye layer opposes further dye diffusion. This problem leads to poor wash fastness and rubbing fastness of dyed fabric, as well as other staining-related fastness properties.

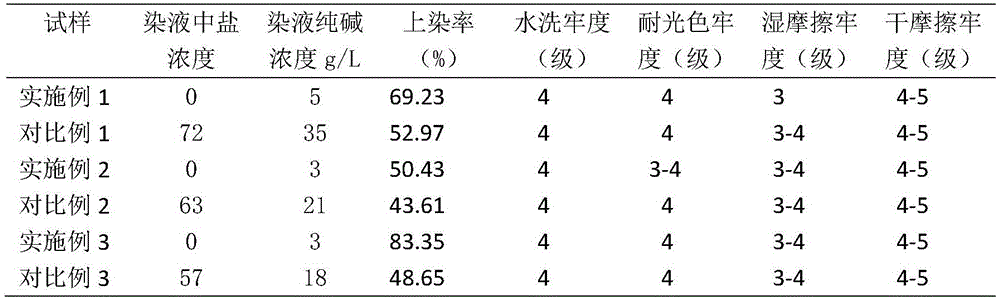

Method for cation modification and salt-free dyeing of cellulose fiber fabric

ActiveCN104233866AImprove permeabilityImprove uniformityDyeing processVegetal fibresRing dyeingSalt free

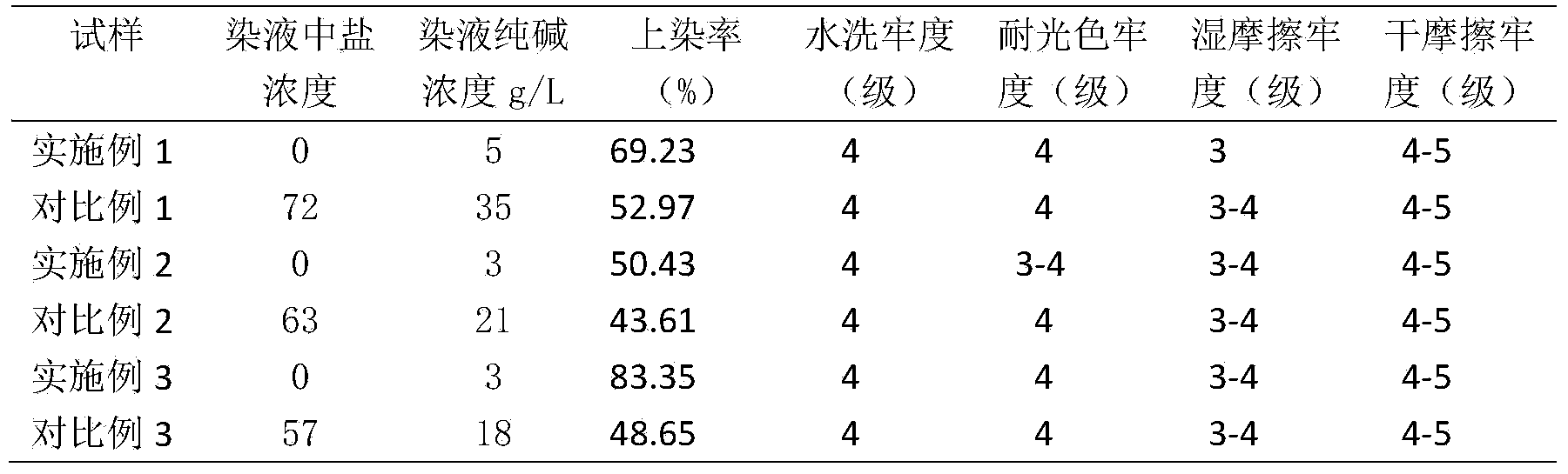

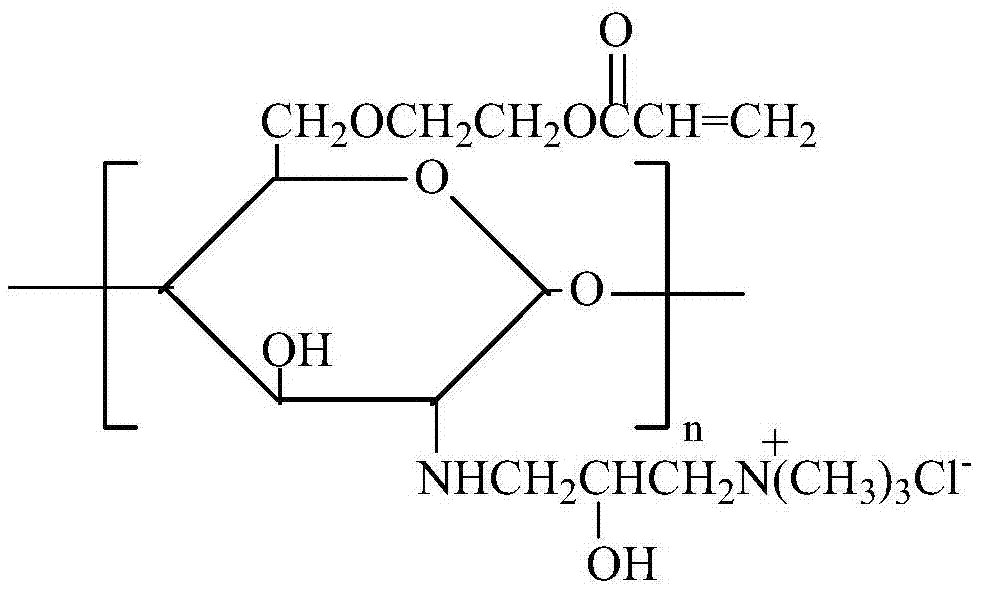

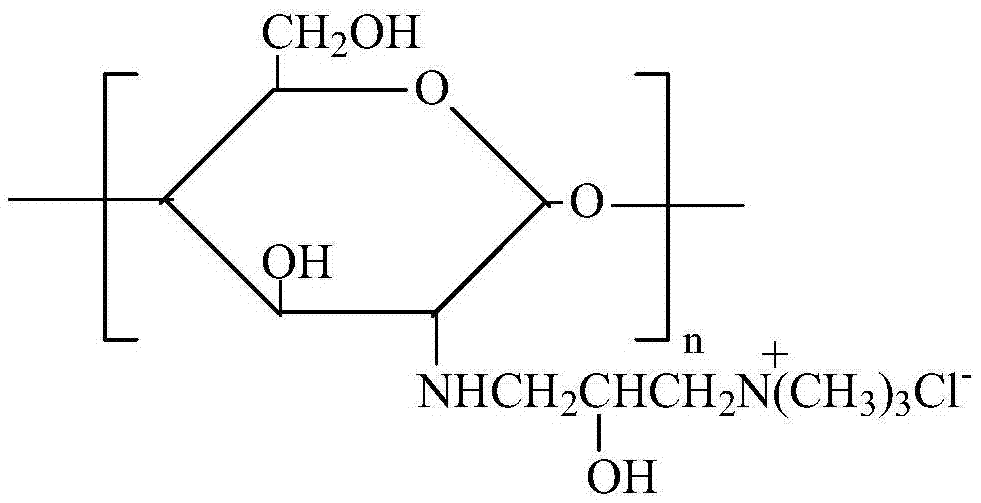

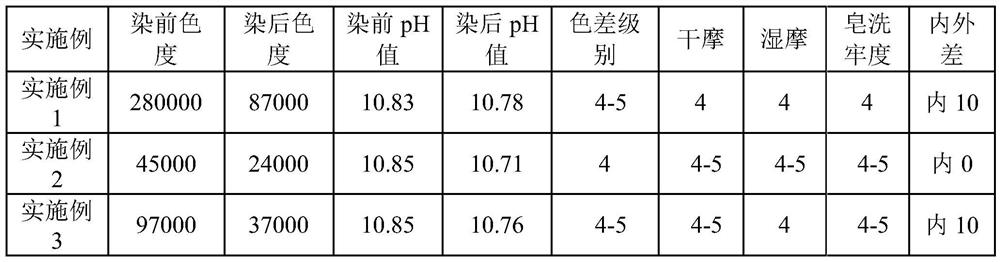

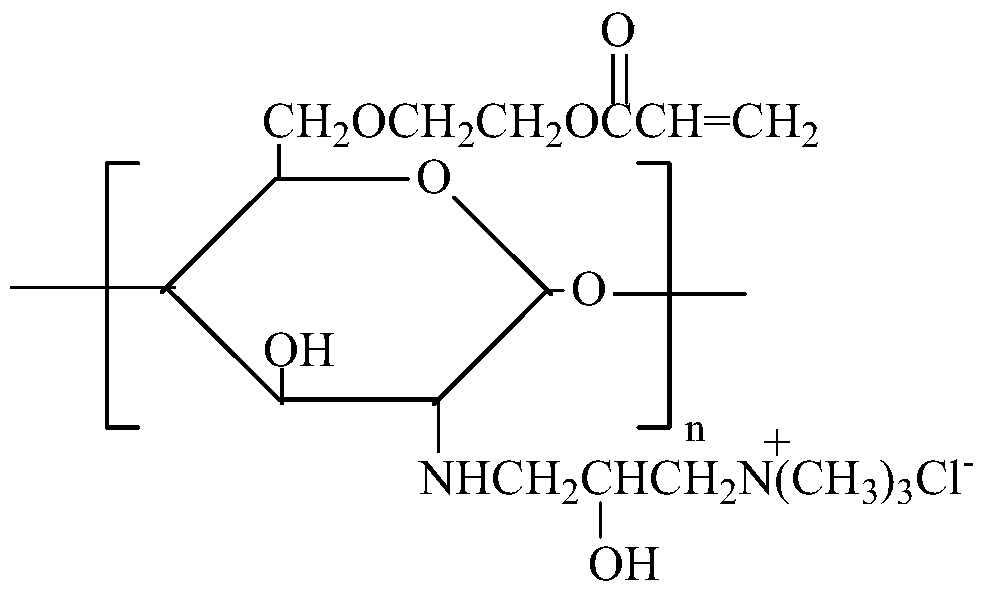

The invention discloses a method for cation modification and salt-free dyeing of a cellulose fiber fabric. The method comprises the steps as follows: preparing a high-polymer cation modifier aqueous solution with soft water, adding the cellulose fiber fabric, then adding NaOH, exerting pressure, heating the solution for a thermostatic reaction, performing cooling and pressure relief, discharging the modifying solution, and performing washing to obtain a cation-modified fabric; placing the cation-modified fabric in a dyeing machine, adding the soft water, sequentially dissolving reactive dye and sodium carbonate with return water, injecting the reactive dye and the sodium carbonate into the dyeing machine, heating the dyeing machine to the dyeing temperature, keeping the temperature, discharging a residual dyeing solution, and dehydrating and drying the fabric after a washing-soaping-washing process to obtain the salt-free low-alkaline dyed fabric. With the adoption of the method, salt-free low-alkali dyeing is realized, the problems of dyeing defects, color sinking and ring dyeing as well as reduction of the color fastness when cellulose fiber fabrics modified by high-polymer cation modifiers are dyed with reactive dyes are solved, a leveling agent is not required to be added during dyeing, the sodium carbonate and the dye can be added into a dyeing vat simultaneously, the sodium carbonate is not required to be added repeatedly during dyeing, and the dyeing operation is simple and easy to control.

Owner:SOUTH CHINA UNIV OF TECH +1

Distressed processing method for colored fabric

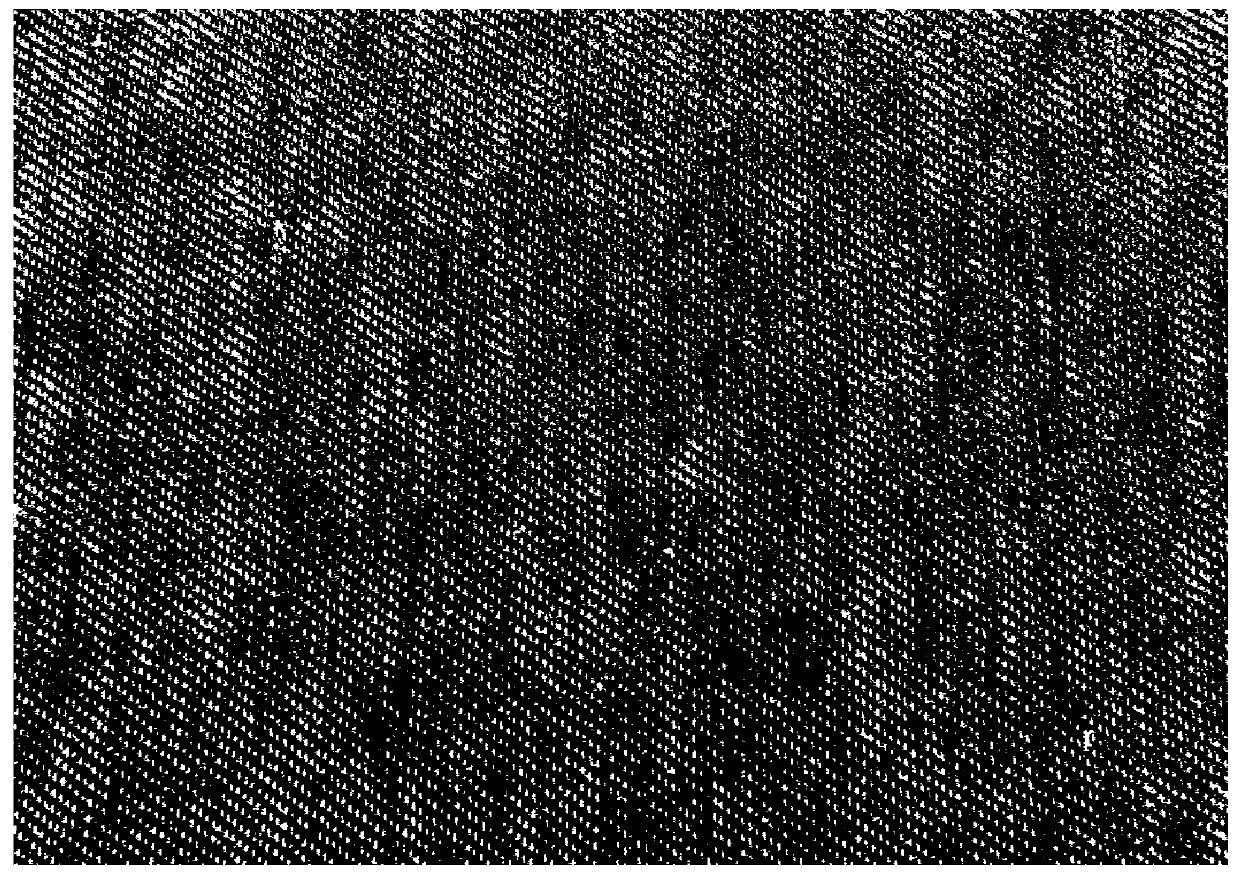

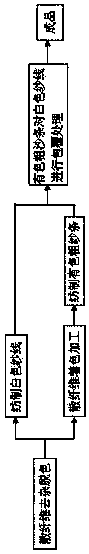

ActiveCN101748601AAdd cationic modificationEvenly colored surfaceFibre treatmentDyeing processRing dyeingTreatment effect

The invention discloses a distressed processing method for colored fabric, which is characterized in that a cation modification technology of yarn is added before the traditional yarn dyeing processing technology, so that the whole processing technology comprises the following steps in sequence: yarn preparation, cation modification of yarn, yarn dyeing processing, sizing, preshrinking, washing and finished products. The distressed processing method has the advantages that the surface layer of the yarn colors up uniformly, and the inner layer of the tarn maintains the original white core, so a clear skin - core effect is formed; the processed fabric has uniform ring dyeing and a uniform distressed treatment effect; by the combination application of a cation modifier and reactive dyes, the dyed fabric achieves the effect which sulfur dyes or indigo dyes can just achieve; and the distressed processing method greatly reduces energy consumption, reduces environmental pollution, ensures the stability and the production efficiency of dyeing, and enhances the quality of products.

Owner:浙江盛泰服装集团股份有限公司

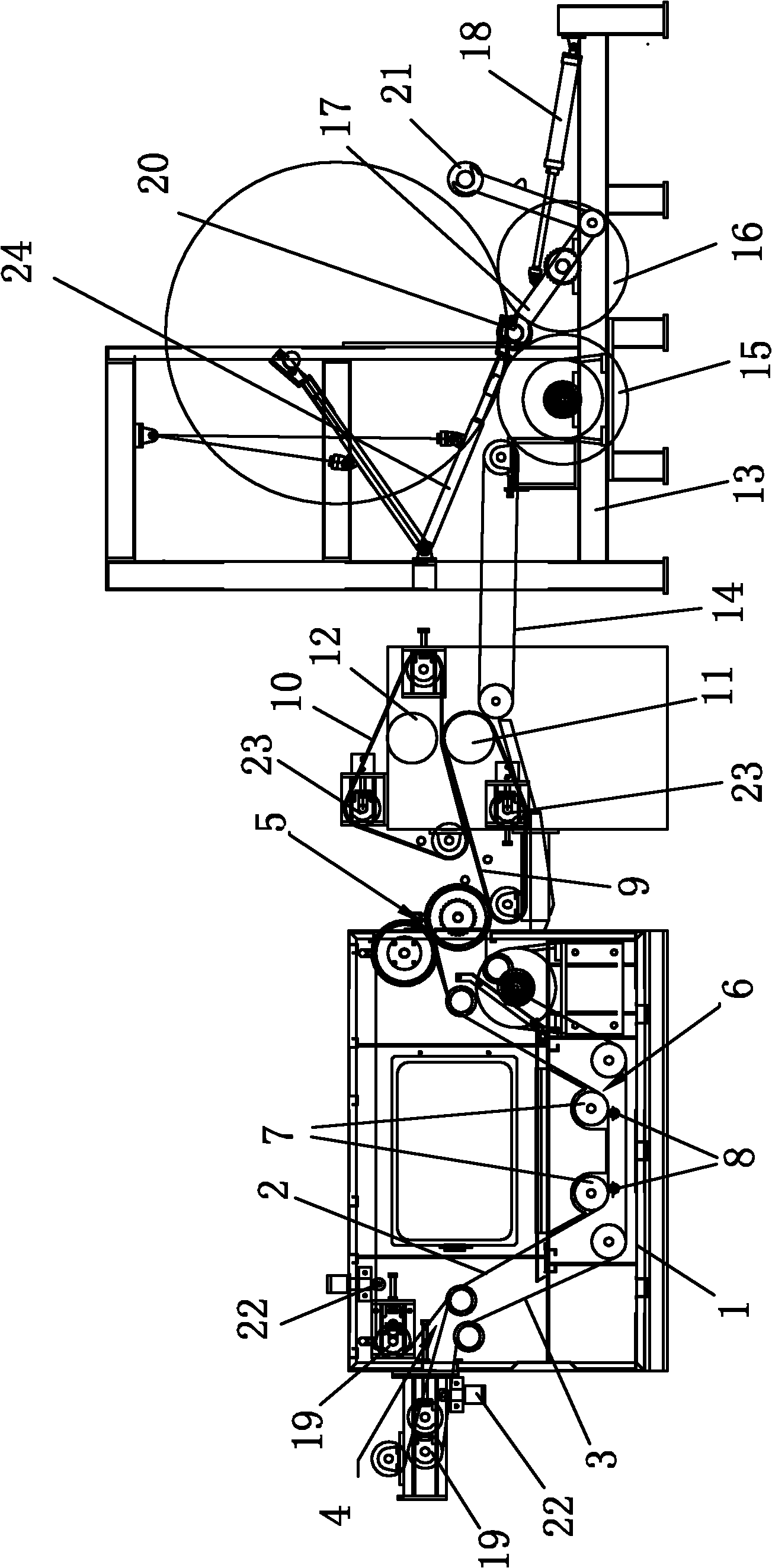

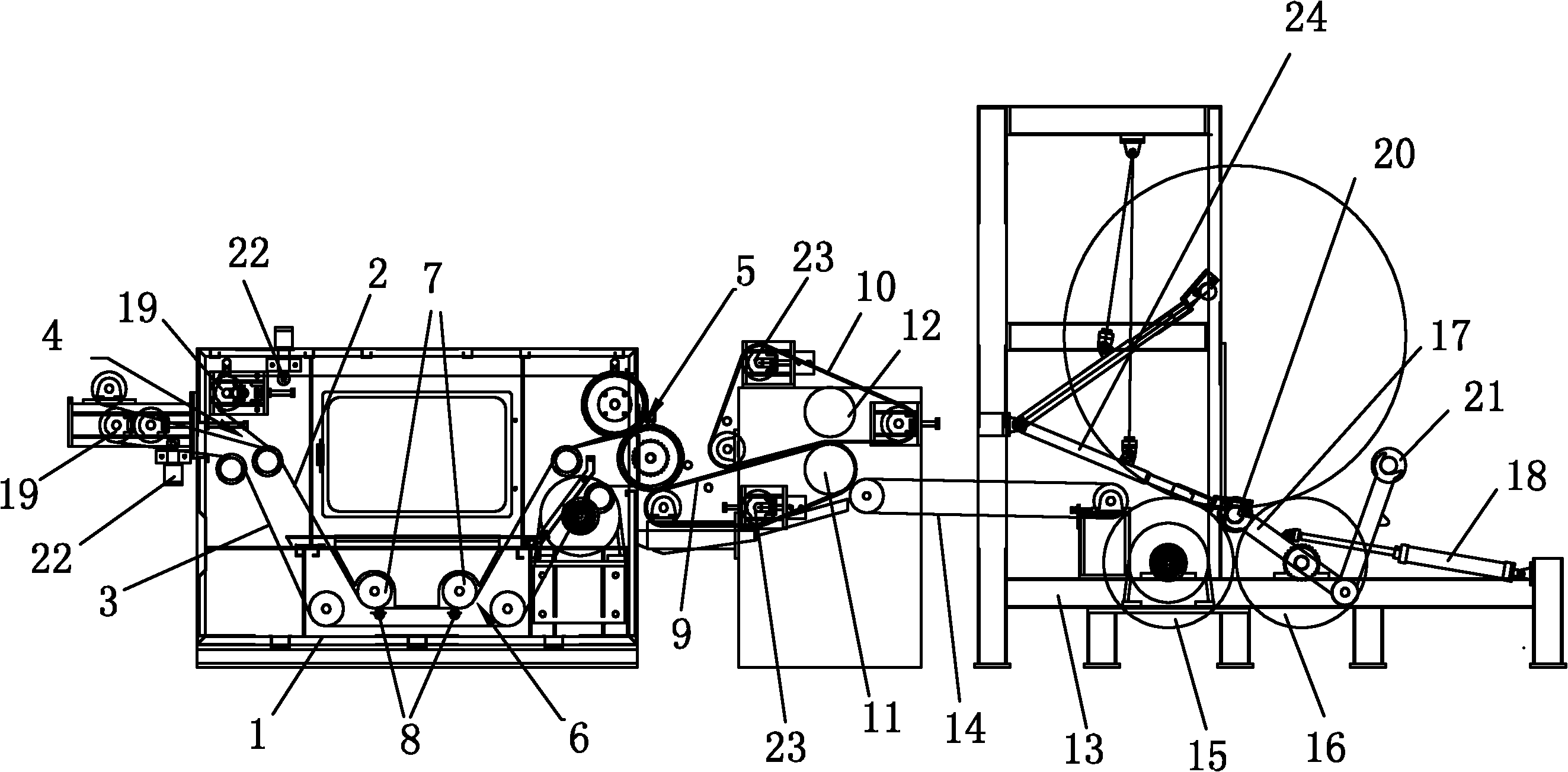

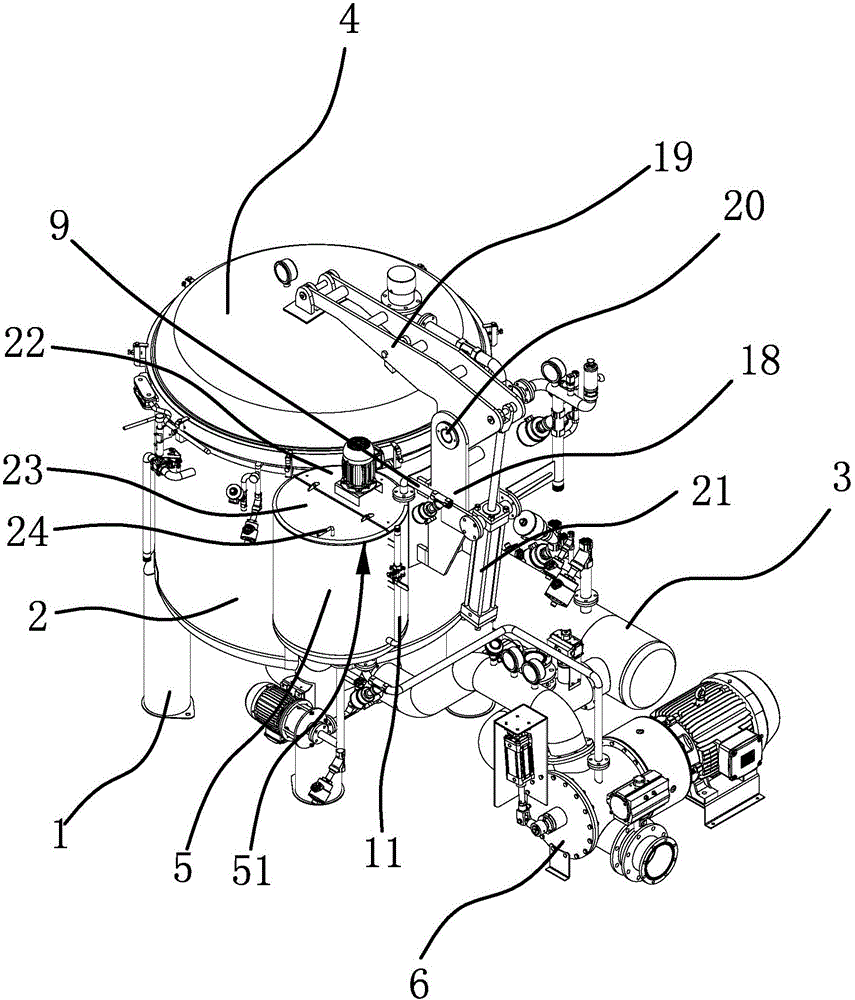

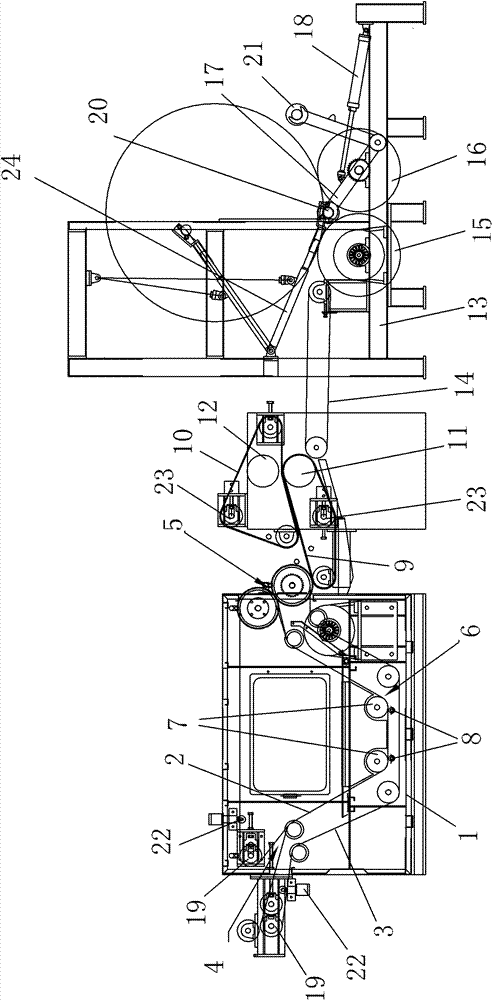

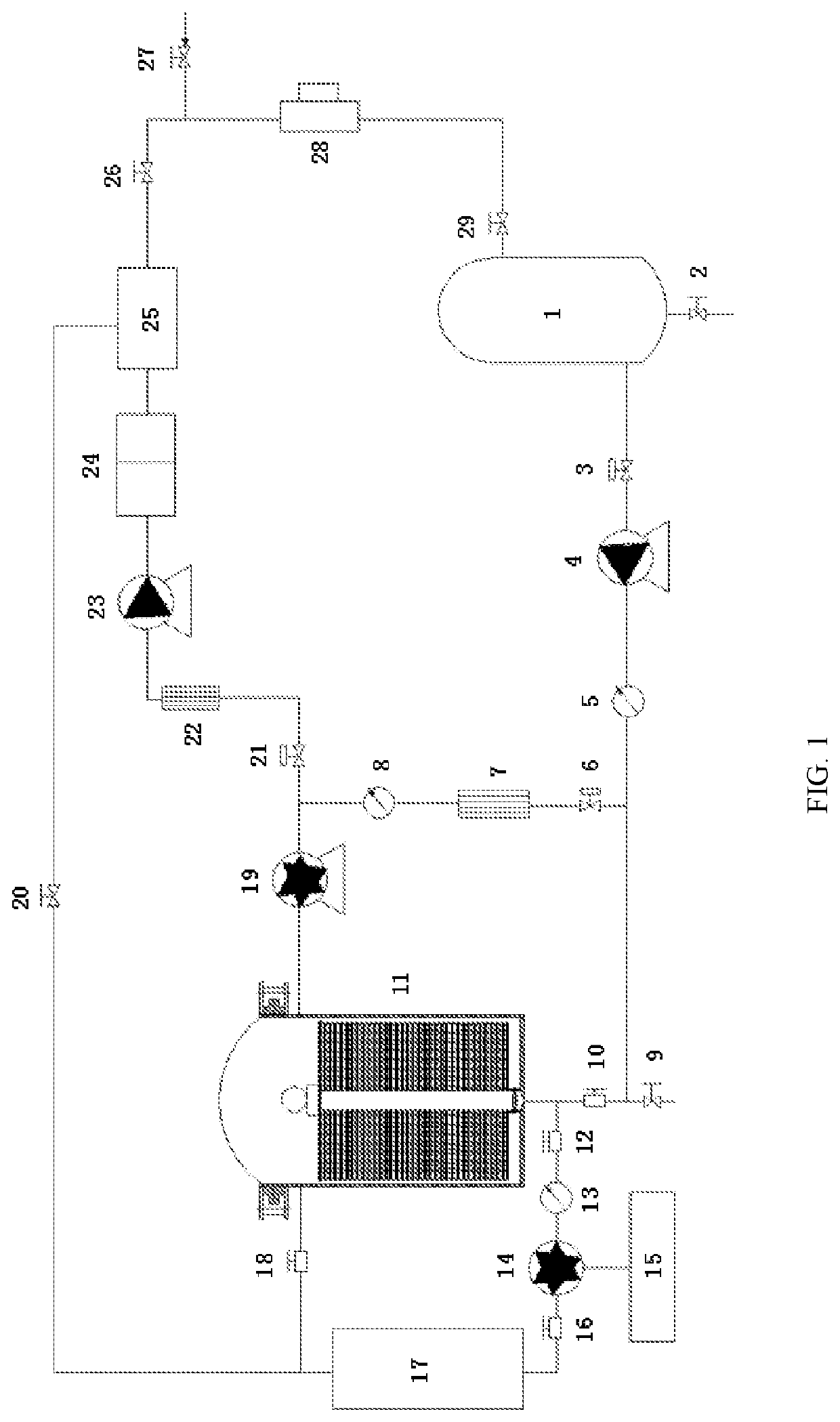

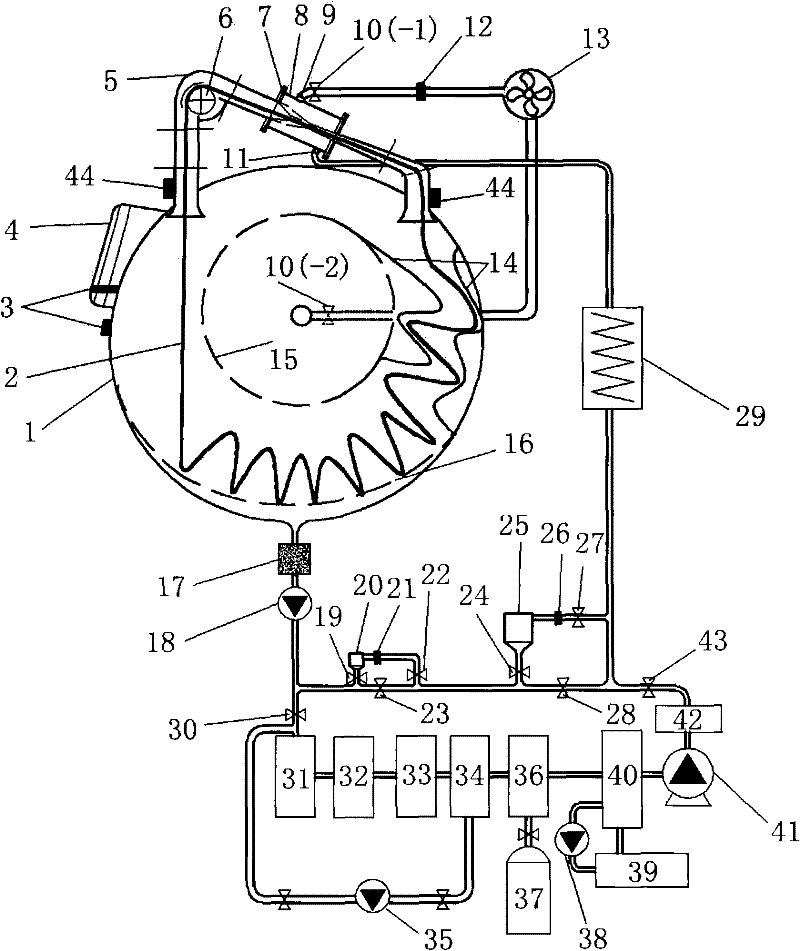

Continuous loose fiber dyeing machine

ActiveCN101949086AReduce consumptionHighlight the substantive effectTextile treatment containersTextile treatment carriersRing dyeingPulp and paper industry

The invention relates to a continuous loose fiber dyeing machine. The continuous loose fiber dyeing machine comprises a dye vat; a mechanism which is fitted with the dye vat and used for conveying loose fibers is a double mesh belt dyeing conveying mechanism, and the double mesh belt dyeing conveying mechanism comprises two closed mesh belts (namely, a ring mesh belt A and a ring mesh belt B) and transmission components which are respectively in transmission fit with each ring mesh belt; two ring dyeing mesh belts in the dye vat are in clearance stacking fit with each other, the two ring dyeing mesh belts respectively fitted with the inlet end and the outlet end of the dye vat respectively form a duckbilled input port and a duckbilled output port, and the two ring dyeing mesh belts arranged outside the dye vat are respectively fitted with the respective transmission components so as to form a circular transmission. The invention has the prominent and substantive effects as follows: because the loose fibers are clamped and then sent to the dye vat for dyeing and the loose fiber is thin, the loose fiber is easy to be dyed completely; and with the help of shower pipes, the dye permeability of the loose fibers is improved, and little dyes are taken away, therefore, the dye consumption is saved.

Owner:新昌县艺力机械有限公司 +1

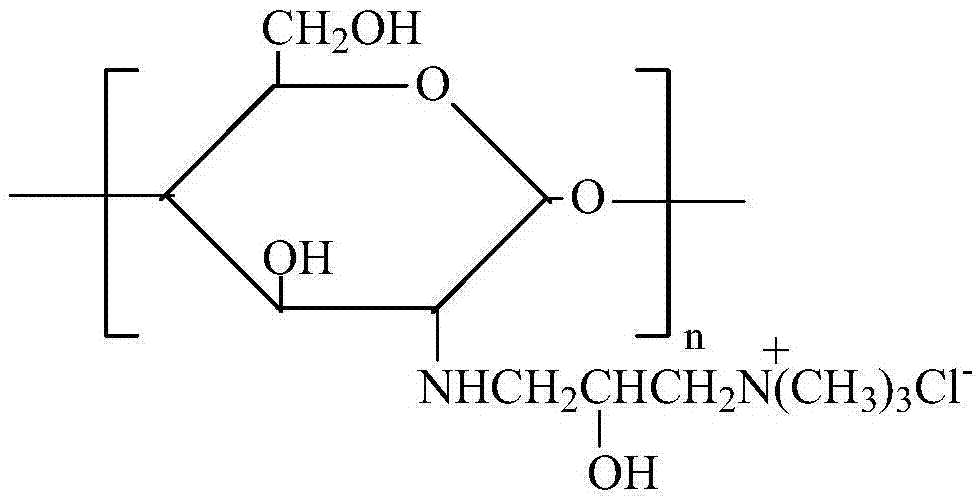

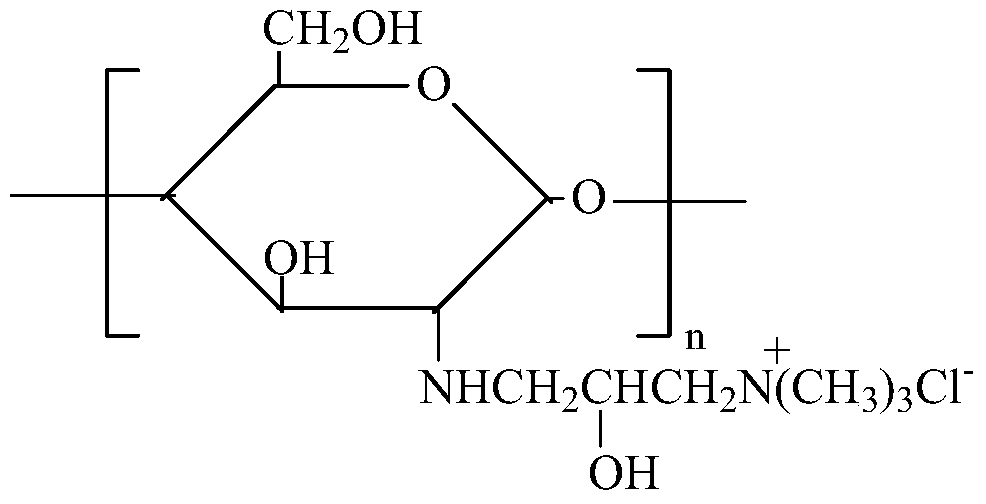

Modification method and dyeing process for salt-free low-alkaline deeply dyed type cellulose fiber fabric

ActiveCN105442353AGood water solubilityImprove functionalityBiochemical fibre treatmentDyeing processRing dyeingSalt free

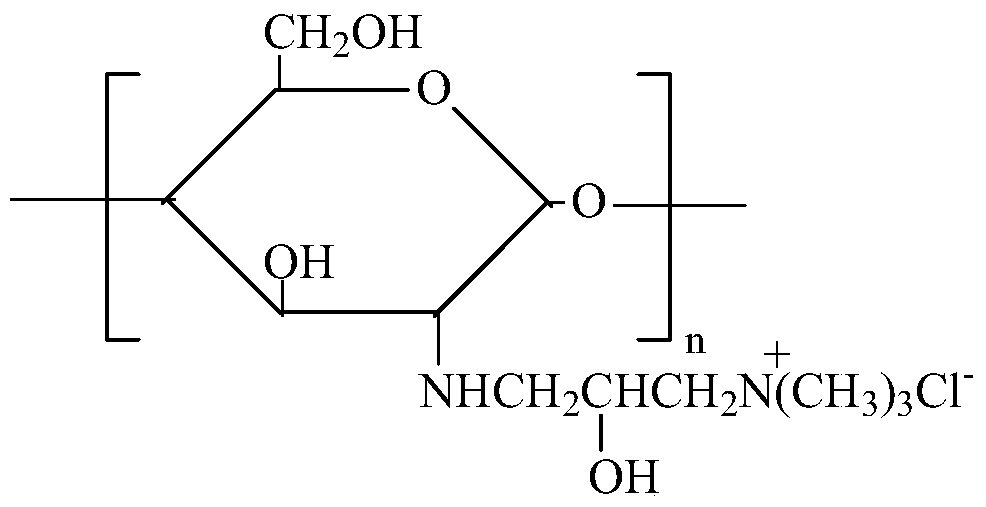

The invention discloses a modification method for a salt-free low-alkaline deeply dyed type cellulose fiber fabric and a dyeing process for the salt-free low-alkaline deeply dyed type cellulose fiber fabric. The modification method is characterized by comprising the following steps: (1) preparation of chitosan oligosaccharide; (2) preparation of reactive chitosan oligosaccharide derivative; (3) modification of cellulose fibers with the reactive chitosan oligosaccharide derivative, and dyeing of a modified cellulose fiber fabric with reactive dyes in a dyeing machine, so as to obtain the salt-free low-alkaline dyed fabric. The method for modification of the cellulose fibers with the reactive chitosan oligosaccharide derivative and the dyeing process have the advantages that the binding strength between the chitosan oligosaccharide and the cellulose fibers can be obviously improved, the adsorption capacity of the obtained chitosan oligosaccharide modified cellulose fiber fabric for the reactive dyes can be obviously enhanced, the cellulose fiber fabric can be dyed under the salt-free low-alkaline condition to achieve a certain deep dyeing effect, the color fastness is improved, the problems of color tone, ring dyeing, color lake and poor deep dyeing property of the salt-free low-alkaline dyeing process can be solved, and the defects of hardening, stiffness, chemical fiber and the like on the surface of the fabric processed with the high molecular weight chitosan oligosaccharide can be overcome; in addition, the best dyeing effect can be obtained through optimizing the dyeing process.

Owner:中国纺织科学研究院江南分院 +1

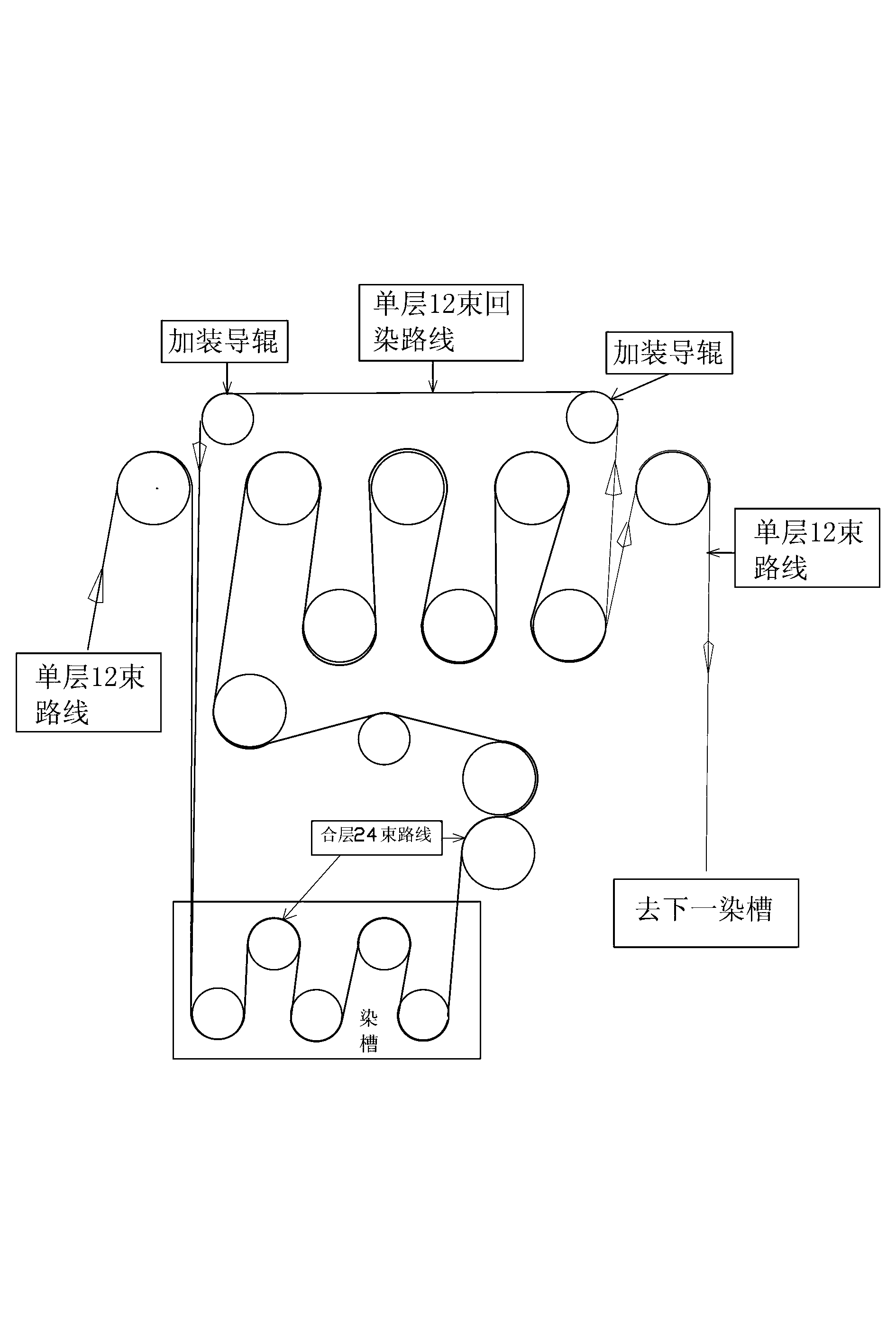

Production process of rope ring-dyeing dark-blue yarn dyed fabric

InactiveCN102936816AImprove dye uptakeFulfil requirementsSucessive textile treatmentsDry-cleaning apparatus for textilesRing dyeingWater rinsing

The invention discloses a production process of a rope ring-dyeing dark-blue yarn dyed fabric. The technological process comprises that (1), the vehicle velocity V is 20.0-30m / min; (2), blooming and boiling are conducted for one process at the temperature of 60-90 DEG C; hot water rinsing is conducted for one process at the temperature of 60-80 DEG C; water rinsing is conducted for one process; dying is conducted by using indigo blue for 14-16 processes; water rinsing is conducted for three processes; softening is conducted for one process at the temperature of 60-80 DEG C and drying; (3), a dying groove contains 0.9-3.0g / L of indigo blue, 2.0-3.52g / L of NaOH, 0.8-2.5g / L of sodium hydrosulfite, 8-10g / L of boiled material, 80-120g / L of a softening agent, 3-10g / L of amino silicon oil and 11-12g / L of pH; the electric potential is 740-760; and (4), the padder pressure is 5.5MPa-6.5MPa. The bundle-type ring-dyeing dark-blue yarn dyed fabric is modified based on an existing Morrison beam dyeing machine, high dye-uptake of jean cloth is achieved, and the requirement of dark-blue jean cloth is met.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

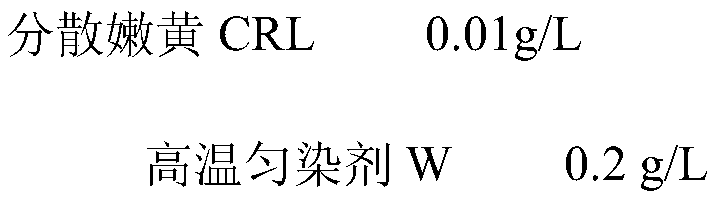

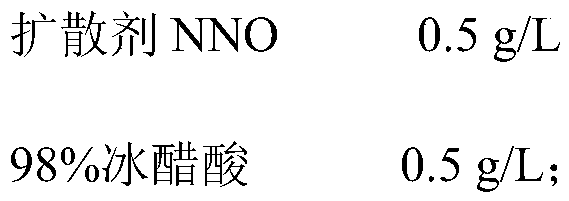

Preparation process of denim-style fabric

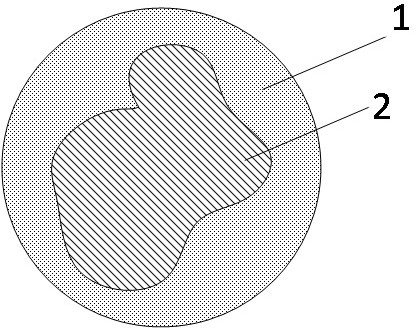

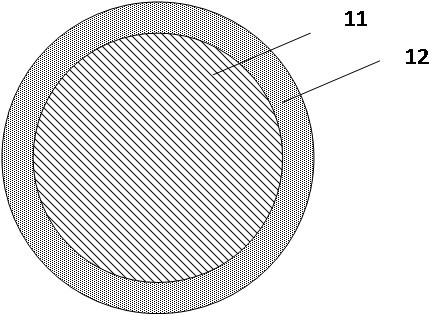

The invention relates to the technical field of preparation of fabrics, and particularly to a preparation process of a denim-style fabric, including the steps of (1), providing core-spun yarn which consists of a core and a covering; (2), weaving, particularly weaving the core-spun yarn into knitted grey cloth; (3), dyeing, to be specific, dyeing the knitted grey cloth, coloring the covering of thecore-spun yarn to obtain dyed cloth; (4), physical rubbing, to be specific, physically rubbing the dyed cloth to remove a part of the covering of the core-spun yarn so as to expose the core. The core-spun yarn consisting of fibers having different properties is adopted in the preparation process, specific dyestuff is utilized in the dyeing process, the covering of the core-spun yarn is colored while the core is not colored, and thus, the effect of ring dyeing of the yarn by the dyestuff is achieved; further, by the brushing process, the core is exposed irregularly, and a denim washing effectis achieved.

Owner:DONGGUAN TEXWINCA HLDG

Preparation of indigo-dyed cotton denim fabrics and garments

Disclosed herein is the preparation of indigo-dyed cotton denim fabrics suitable for use in making cotton denim garments and other denim articles. These indigo-dyed fabrics are prepared from cotton warp yarn which has been pre-treated with an emulsion copolymer prior to being contacted with an aqueous dye liquor comprising a dispersion of an indigo dyestuff. Such copolymer-treated cotton warp yarn can be woven or knitted into cotton denim griege fabrics along with untreated cotton weft yarn. Such griege denim fabric can then be indigo-dyed using the aqueous dye liquor. Alternatively, the emulsion copolymer-treated cotton warp yarn can be indigo-dyed by contact with the aqueous dye liquor before this warp yarn is incorporated into denim fabric along with the untreated cotton weft yarn. The cotton denim fabric produced by either method has the appearance of conventional ring-dyed indigo fabrics. Such methods, however, can be carried out with greater control, precision, reproducibility and less waste than conventional ring dyeing operations.

Owner:CELANESE INT CORP

Yarn dyeing method

ActiveCN105821613AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

High-efficiency polyester fabric dyeing method

The invention discloses a high-efficiency polyester fabric dyeing method, and belongs to the technical field of dyeing. According to the technical scheme, polyester fabrics which do not exceed the maximum load of dyeing equipment are simultaneously dyed in dyeing equipment in a form of a first cloth belt and a second cloth belt, wherein the head and the tail of the first cloth belt are connected to form a ring, the head end of the second cloth belt is connected to the position where the head and the tail of the first cloth belt are connected, and the length of the second cloth belt is less than or equal to the length of the first cloth belt; the first cloth belt comprises one piece of polyester fabric or is formed by splicing at least two pieces of polyester fabrics end to end, and the second cloth belt comprises one piece of polyester fabric or is formed by splicing at least two pieces of polyester fabrics end to end; and the length of the first cloth belt and the length of the secondcloth belt are both smaller than the longest cloth capacity of a single tube of the dyeing equipment. The high-efficiency polyester fabric dyeing method has the advantages of high dyeing efficiency and low water consumption and low energy compared with the conventional single-tube single-ring dyeing.

Owner:常熟市江南印染有限公司

Dyeing process for producing denim yarns by using reactive dye dyeing method

The invention belongs to the technical field of textile dyeing, and particularly relates to a dyeing process for producing denim yarns by using a reactive dye dyeing method. The dyeing process specifically comprises the steps of dye liquor preparation, online dyeing, yarn steaming and color fixation and post-treatment, and is characterized in that a single yarn sizing machine is used as online dyeing equipment, and grey yarns are directly used for dyeing. The purpose of yarn ring dyeing is achieved by utilizing the characteristic of poor hygroscopicity of grey yarn and high-speed operation of equipment, and the denim yarn dyed by the reactive dye is obtained after yarn steaming, color fixation and post-treatment. The denim yarn style that the outer layer of the grey yarn is dyed and the inner layer of the grey yarn is not dyed is achieved through the reactive dye, meanwhile, the dyeing cost is reduced, and production of the colored denim yarn is achieved.

Owner:LUTAI TEXTILE +1

Dyeing treatment process for yarns

InactiveCN107419569AHigh color fastnessNot easy to fadeSucessive textile treatmentsDyeing processColour fastnessRing dyeing

The invention provides a dyeing treatment process for yarns. According to the invention, yarns are dyed through secondary dyeing and the colors of the yarns are fixed by a dye-fixing agent so as to improve the color fastness of the yarns; and warping, bleaching, loosing, primary dyeing, drying, secondary loosing, refined dyeing, fixing and packaging are successively carried out for dyeing of the yarns, so color fastness in yarn dyeing is improved, the yarns are not prone to fading after long-term use, and the service life of the yarns is prolonged.

Owner:WUHU FUCHUN DYEING & WEAVING

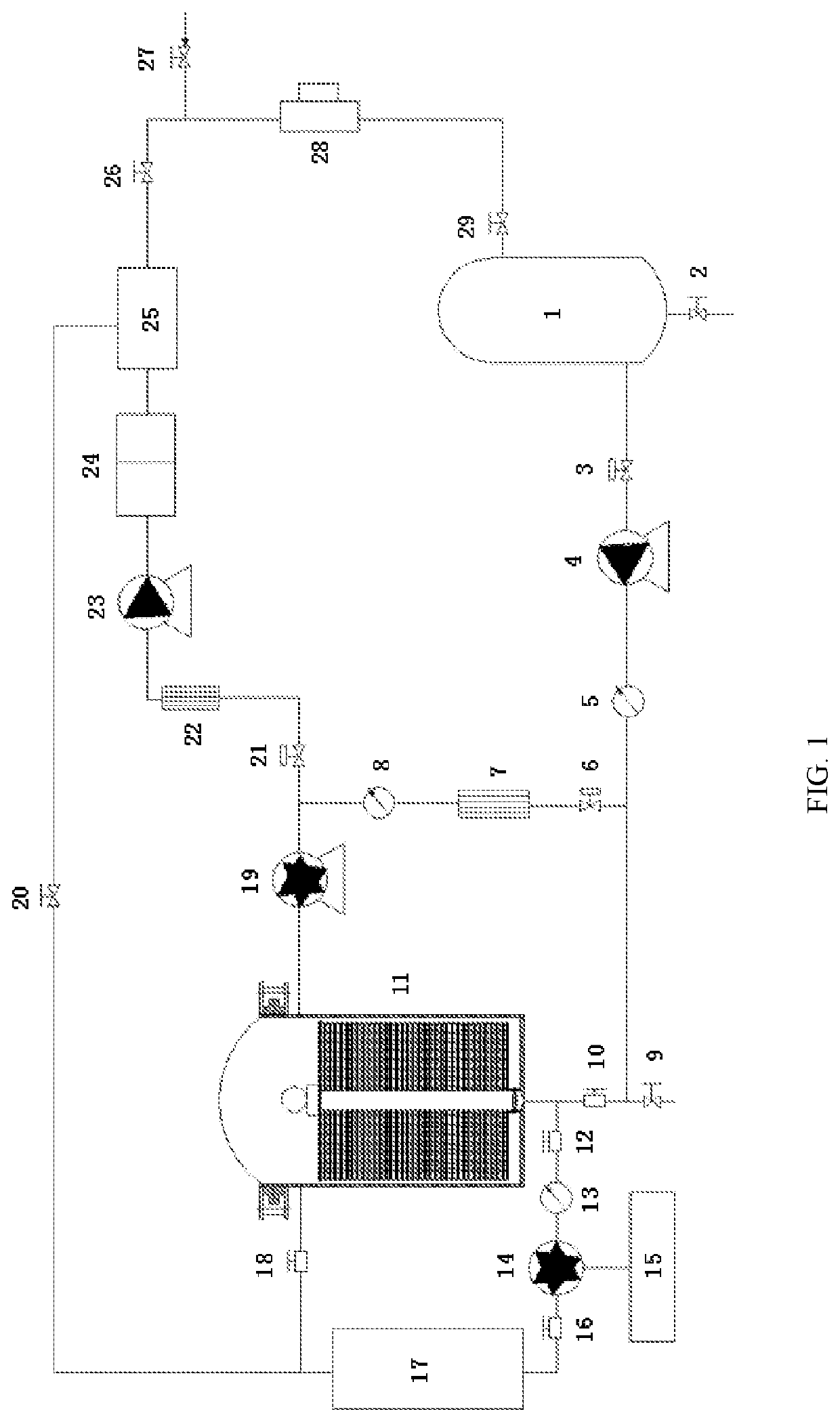

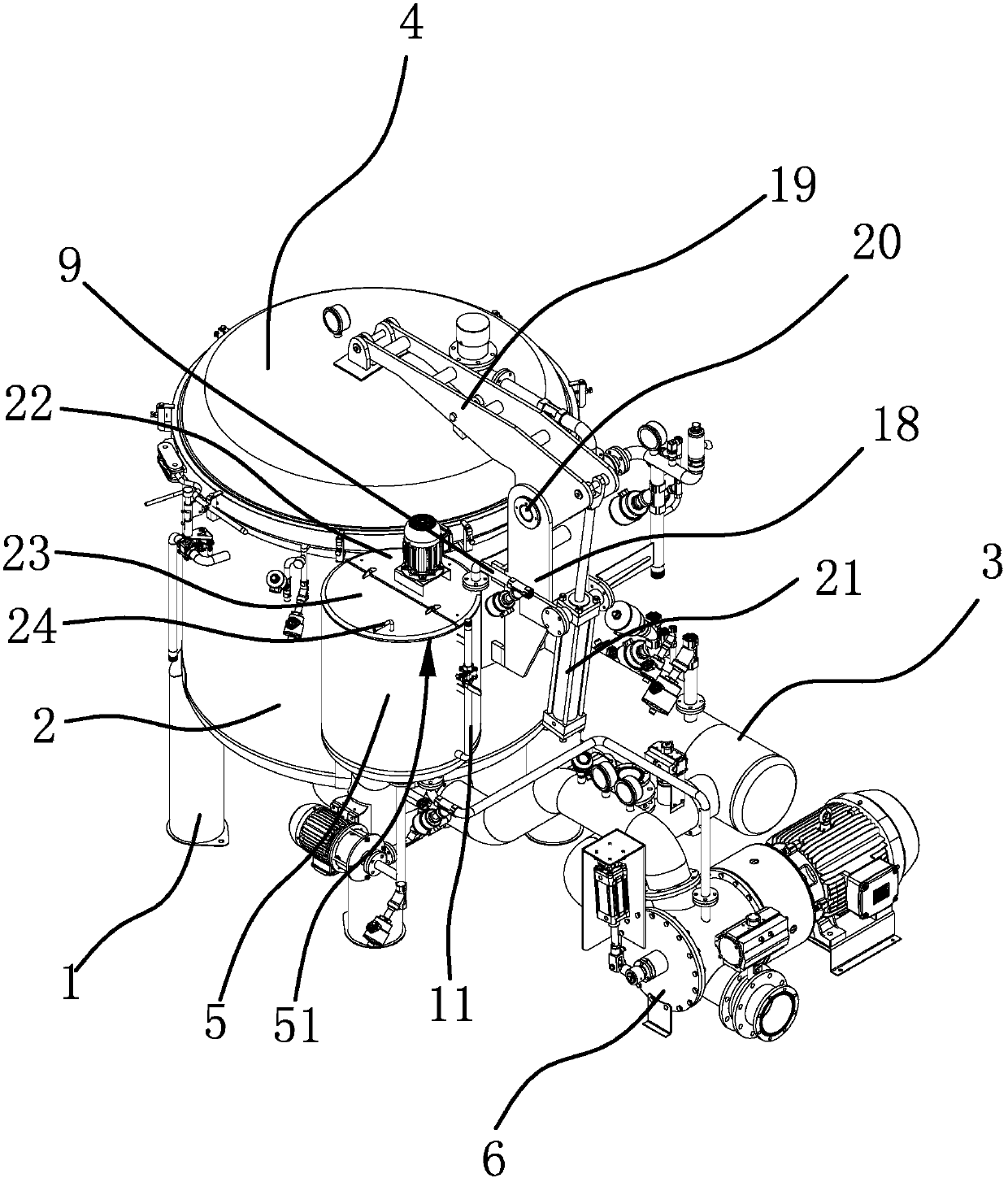

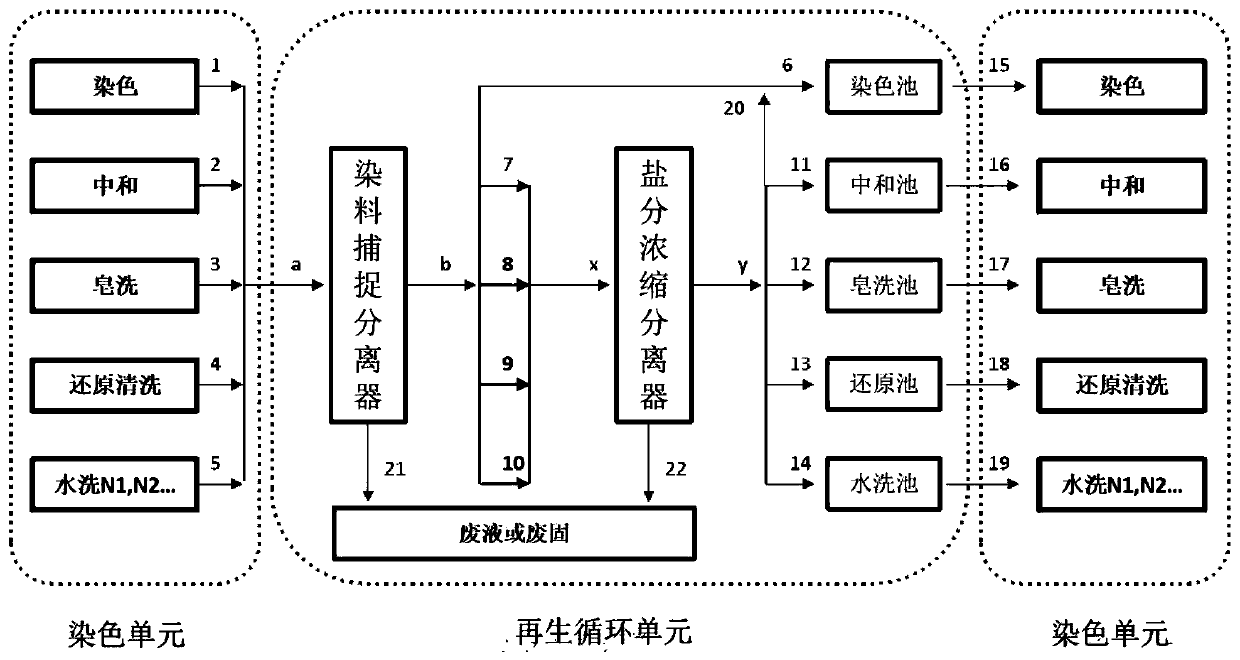

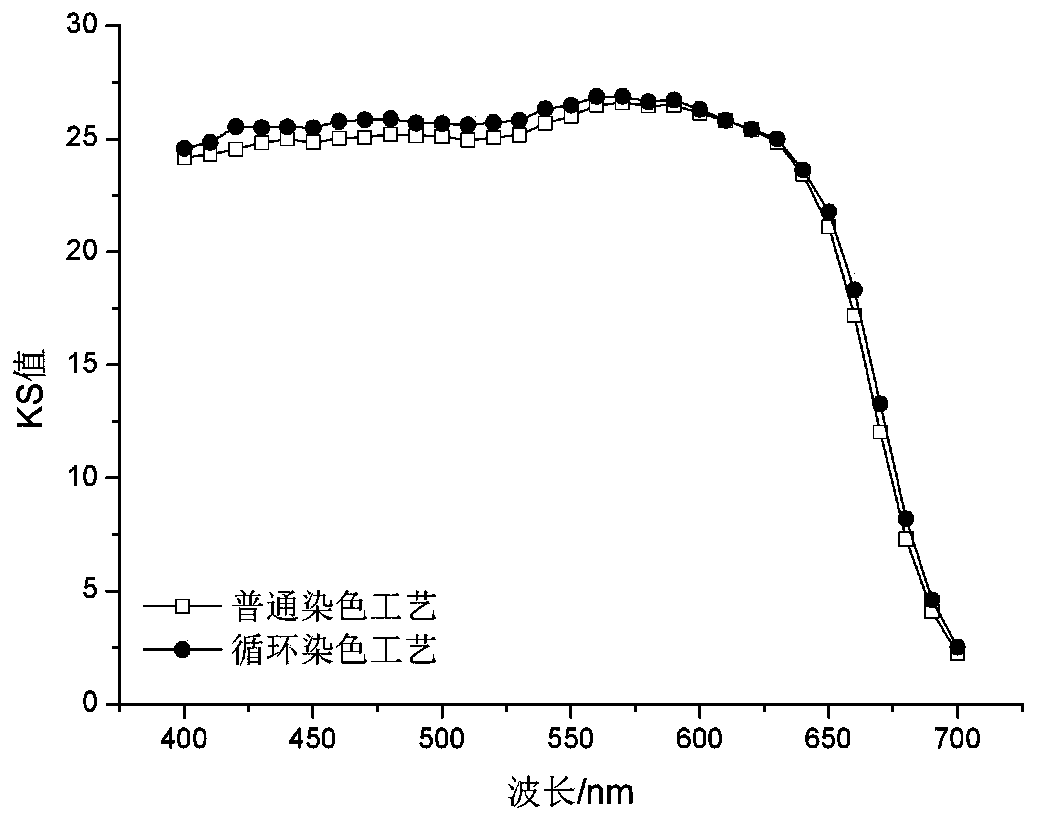

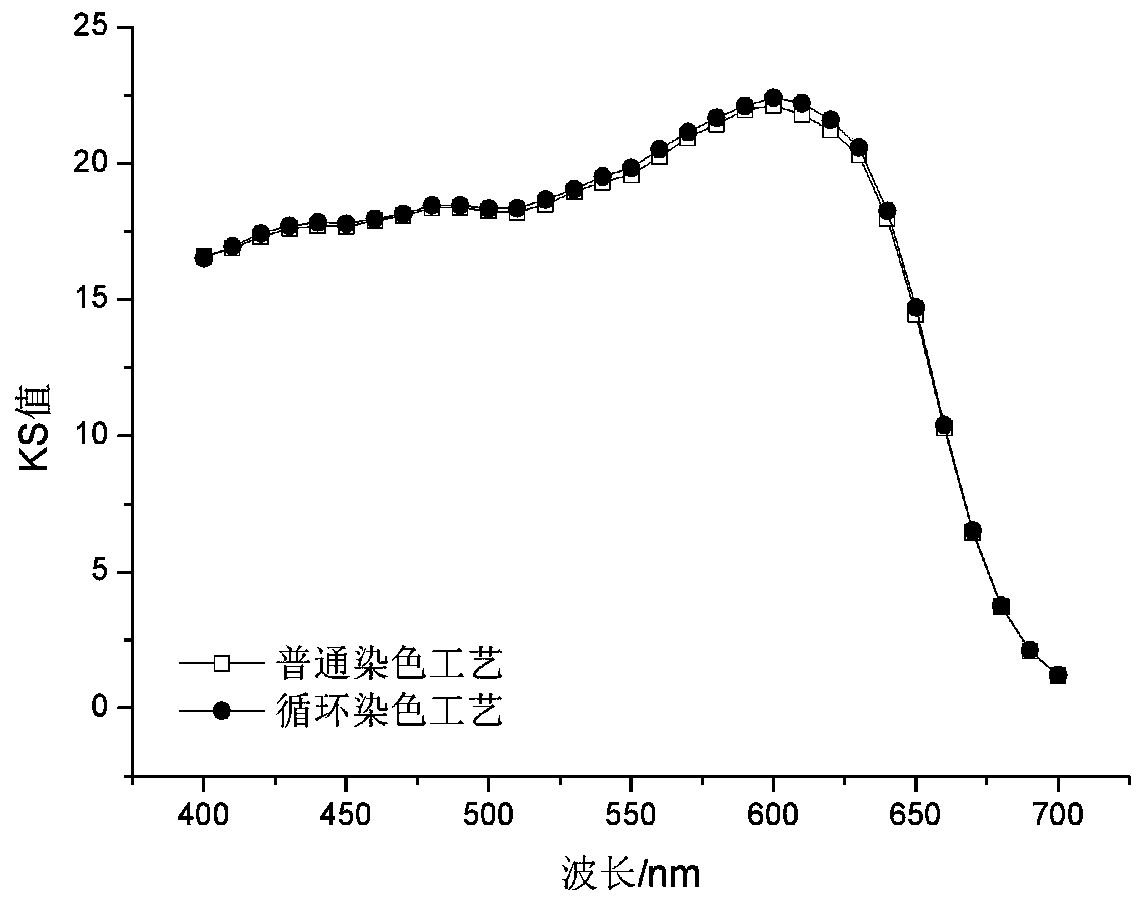

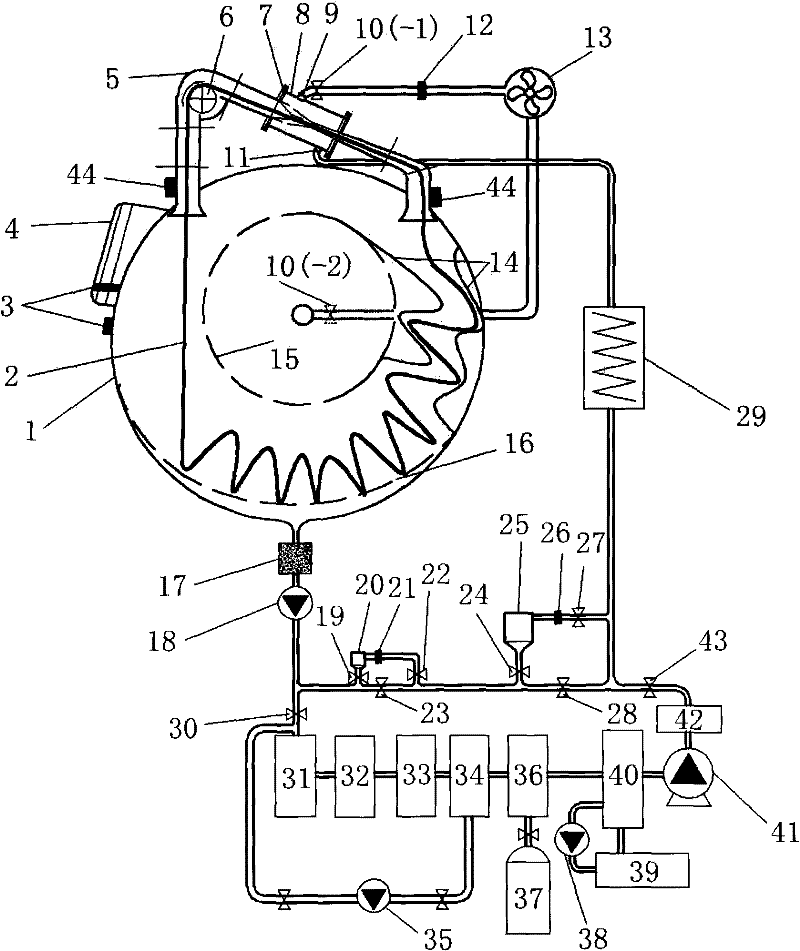

Whole-process circular dyeing method of real silk fabric and dyeing system

ActiveCN110983684AIncrease the difficulty of the processIncrease processing costTextile treatment machine arrangementsTextile/flexible product manufactureRing dyeingPulp and paper industry

The invention relates to a whole-process circular dyeing method of a real silk fabric and a dyeing system, and belongs to the technical field of printing and dyeing. The method comprises the followingsteps that (1) a reactive dye is used for dyeing, meanwhile, residual dyeing liquid is separated by a dyeing wastewater pool and a first dye separator to obtain colorless clear water, and the colorless clear water is stored in a dyeing clear water pool and is circularly used for a dyeing section; (2) wastewater in a soaping section is separated by a soaping wastewater pool and a second dye separator to obtain colorless clear water, and the colorless clear water is stored in a soaping clear water pool and is circularly used for the soaping section and the dyeing section or is discharged; and (3) wastewater in a water washing section is separated by a water washing wastewater pool and the second dye separator to obtain colorless clear water, and the colorless clear water is stored in a water washing clear water pool and is circularly used for the water washing section, the soaping section and the dyeing section or is discharged; and (4) wastewater in a color fixing section is directly circularly used for the color fixing section or is discharged after being temporarily stored in a color fixing wastewater and clear water pool.

Owner:ZHEJIANG SILK TECH

Short-fiber ring dyeing yarn preparation method

The invention relates to a preparation method for yarns in the textile field, and discloses a short-fiber ring dyeing yarn preparation method. The method comprises the following steps: 1, allowing loose fiber to be subjected to impurity-removing and decolorizing processing; 2, allowing the loose fiber to be subjected to coloring processing; 3, spinning the fibers not colored into fine yarns; 4, spinning colored coarse sliver; and 5, spinning the ring dyeing yarn with white core. The method is simple in process, convenient to operate, consumes less dyestuff additive and energy, is small in environment pollution, and large in fiber selectivity for preparing the ring dyeing yarn. Moreover, the prepared yarn has obvious ring dyeing effect, and the ratio of the 'skin layer' to 'core layer' is adjustable.

Owner:SHAOXING UNIVERSITY

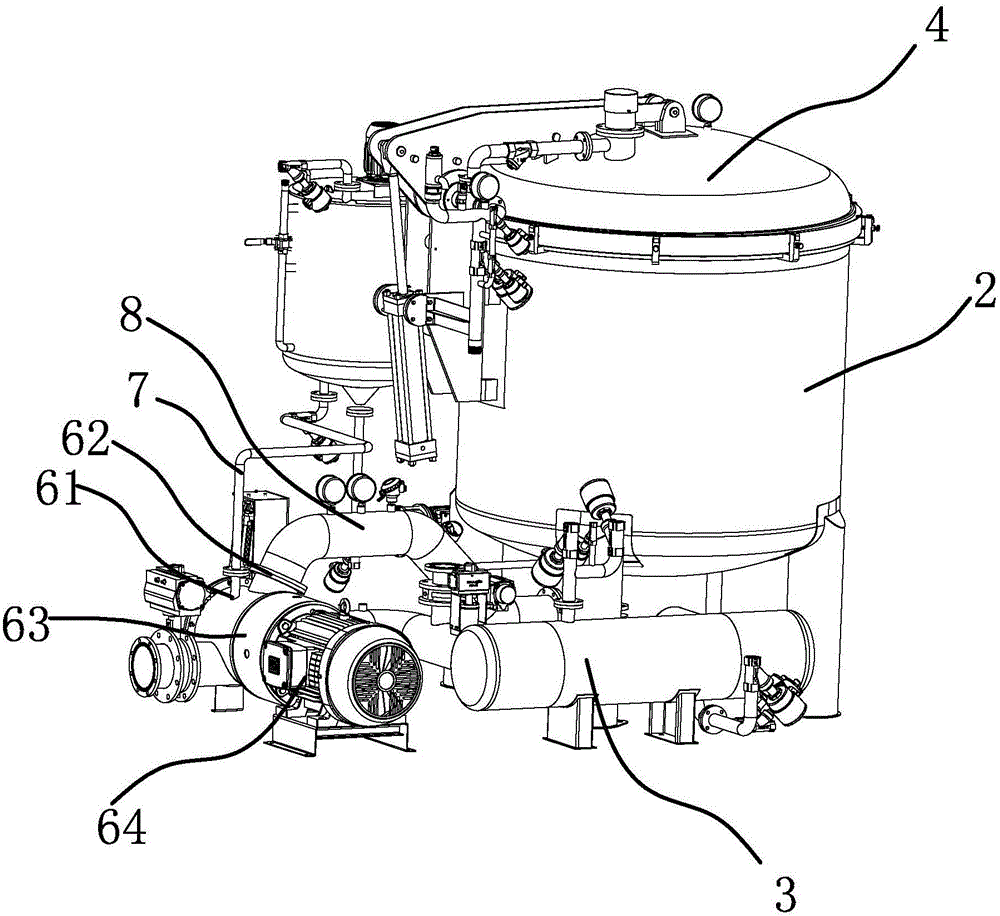

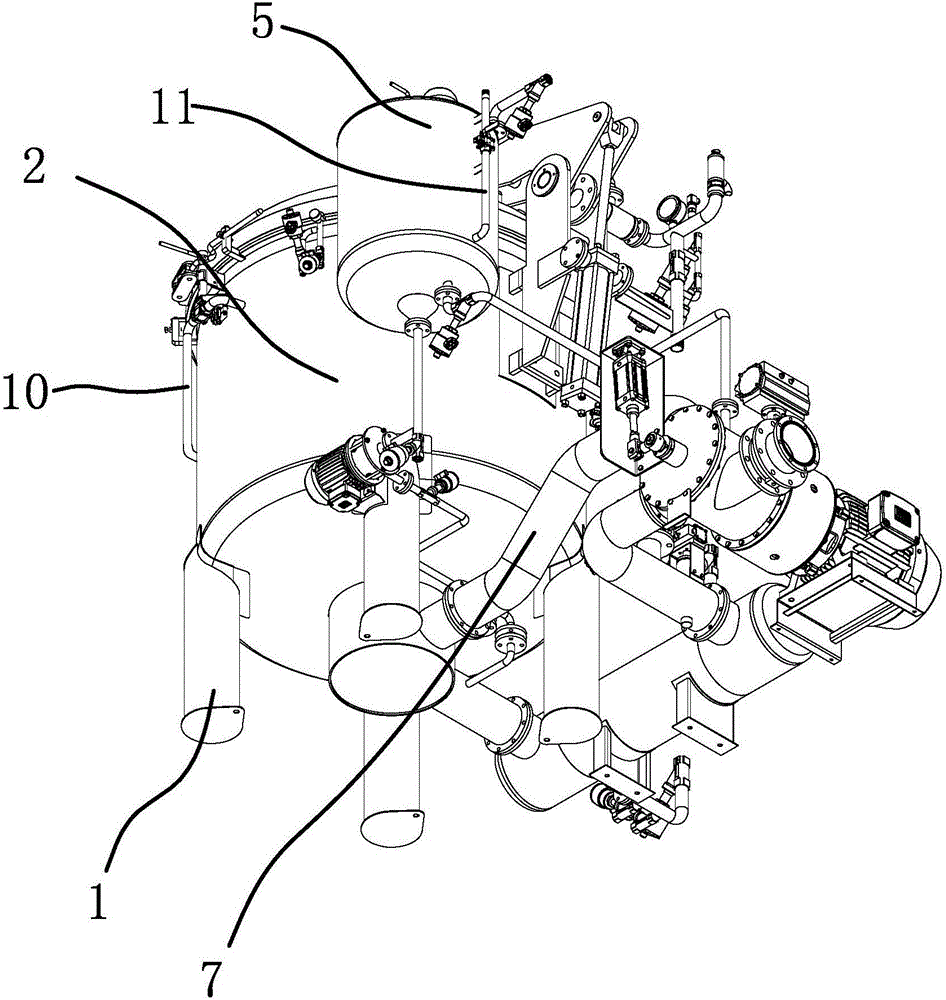

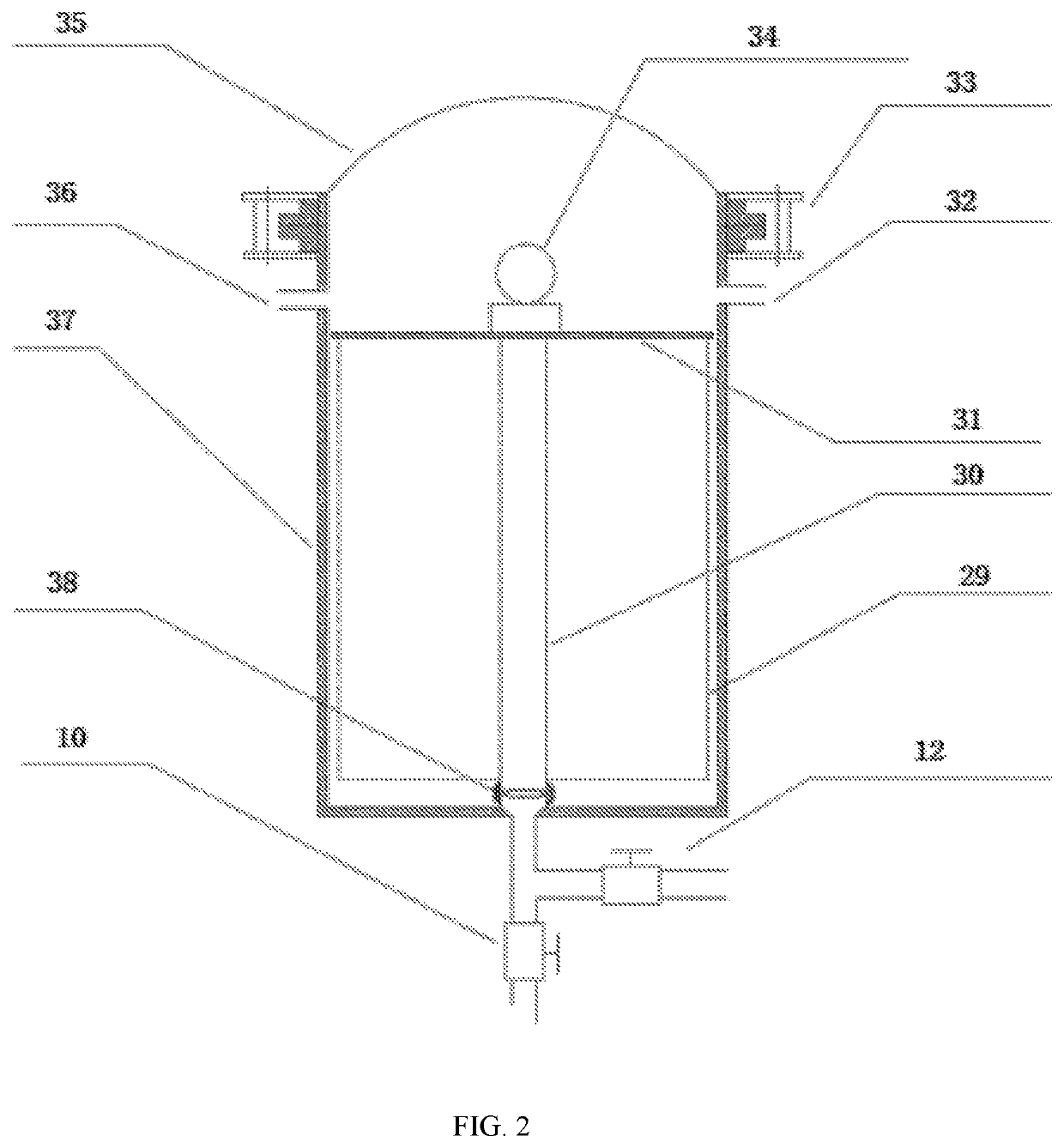

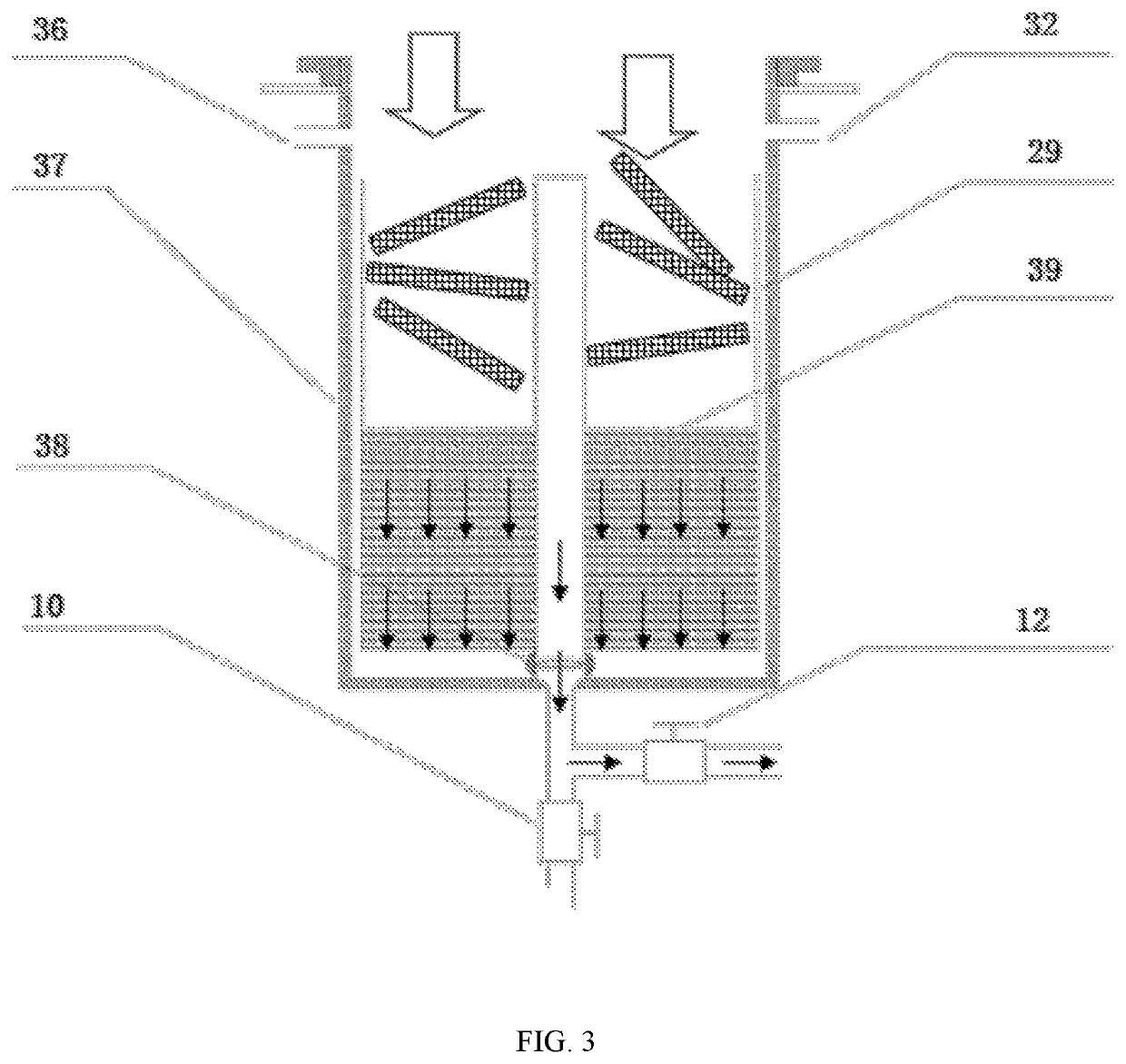

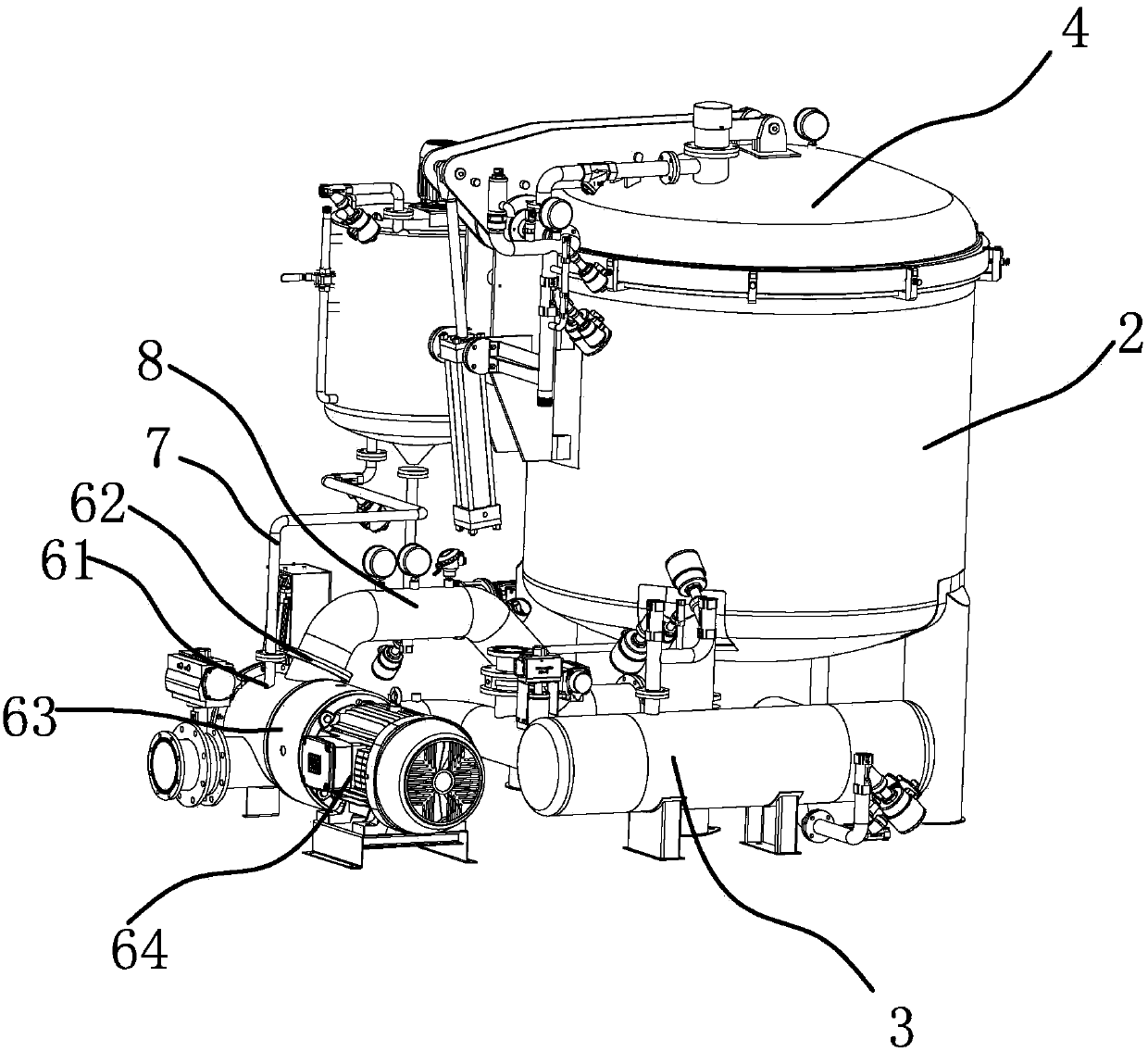

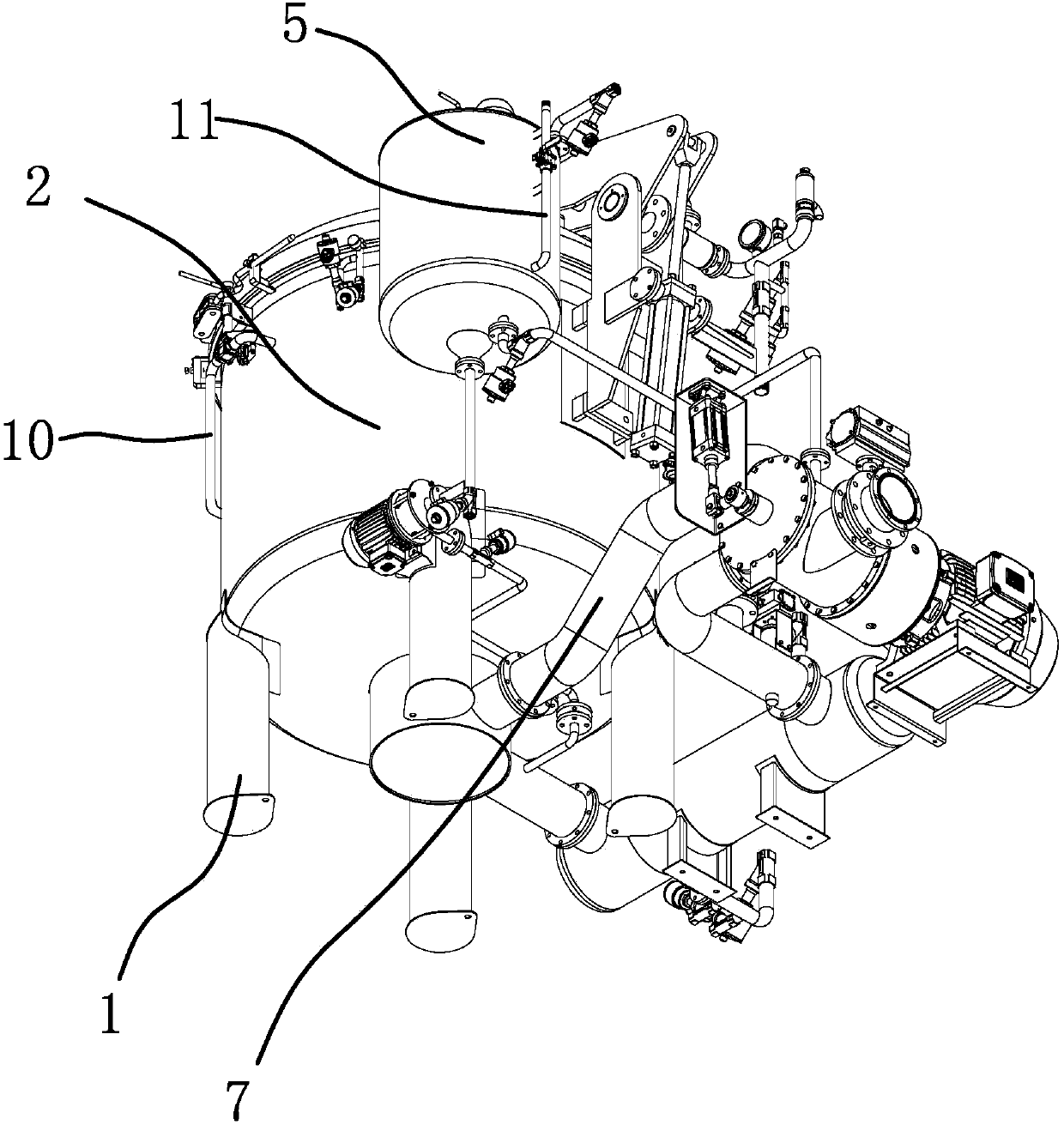

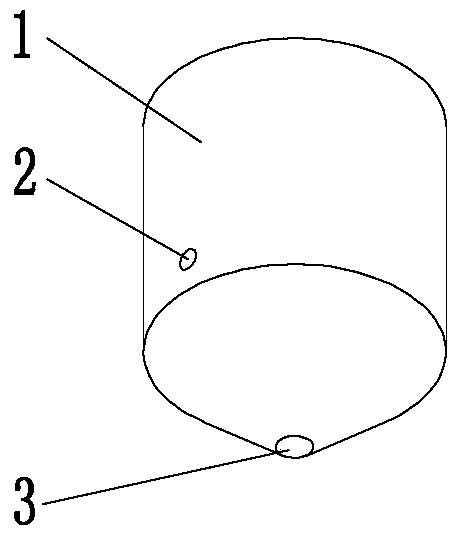

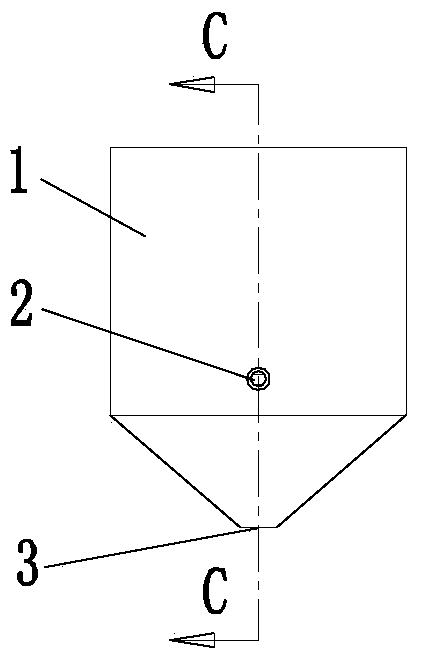

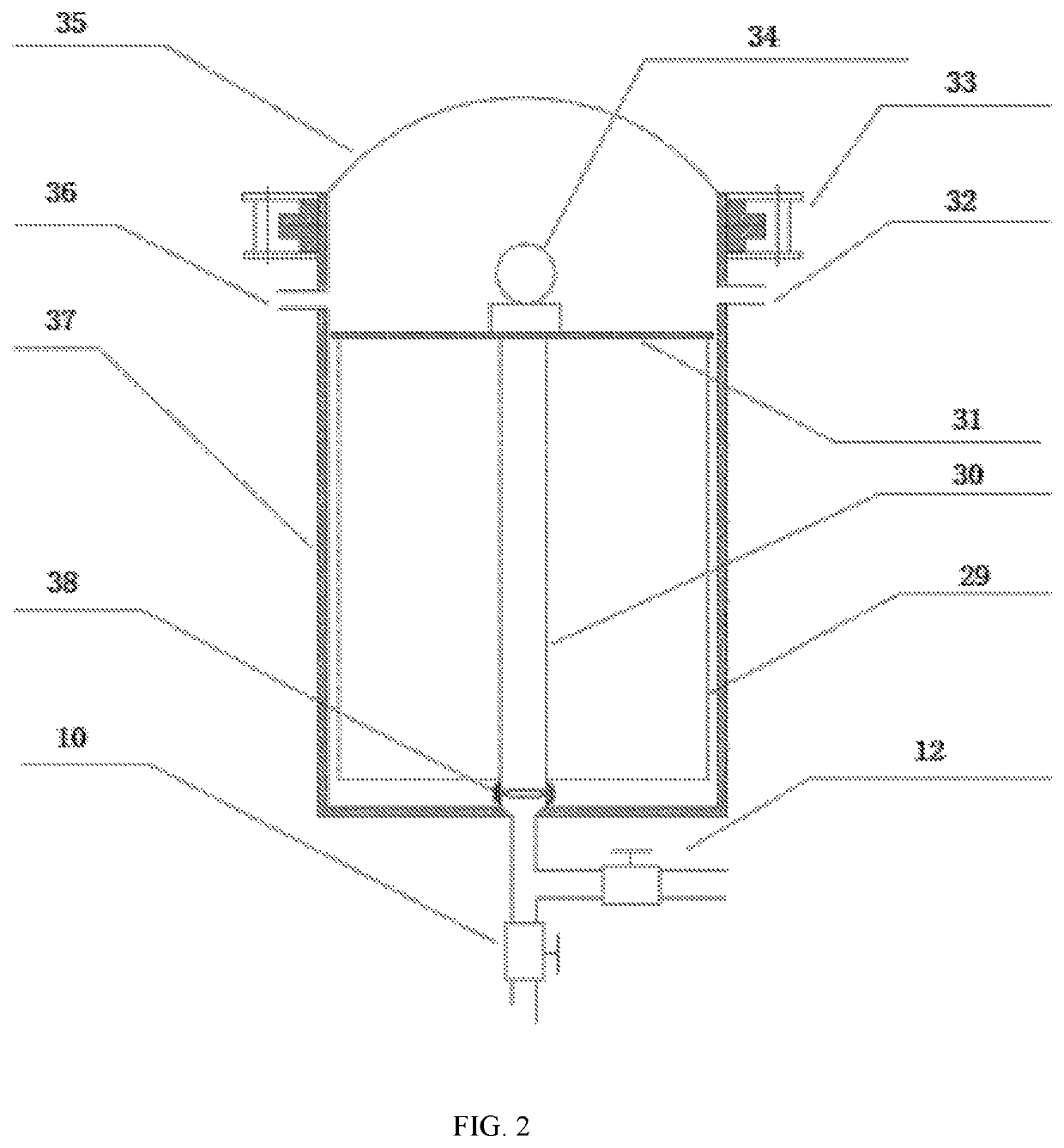

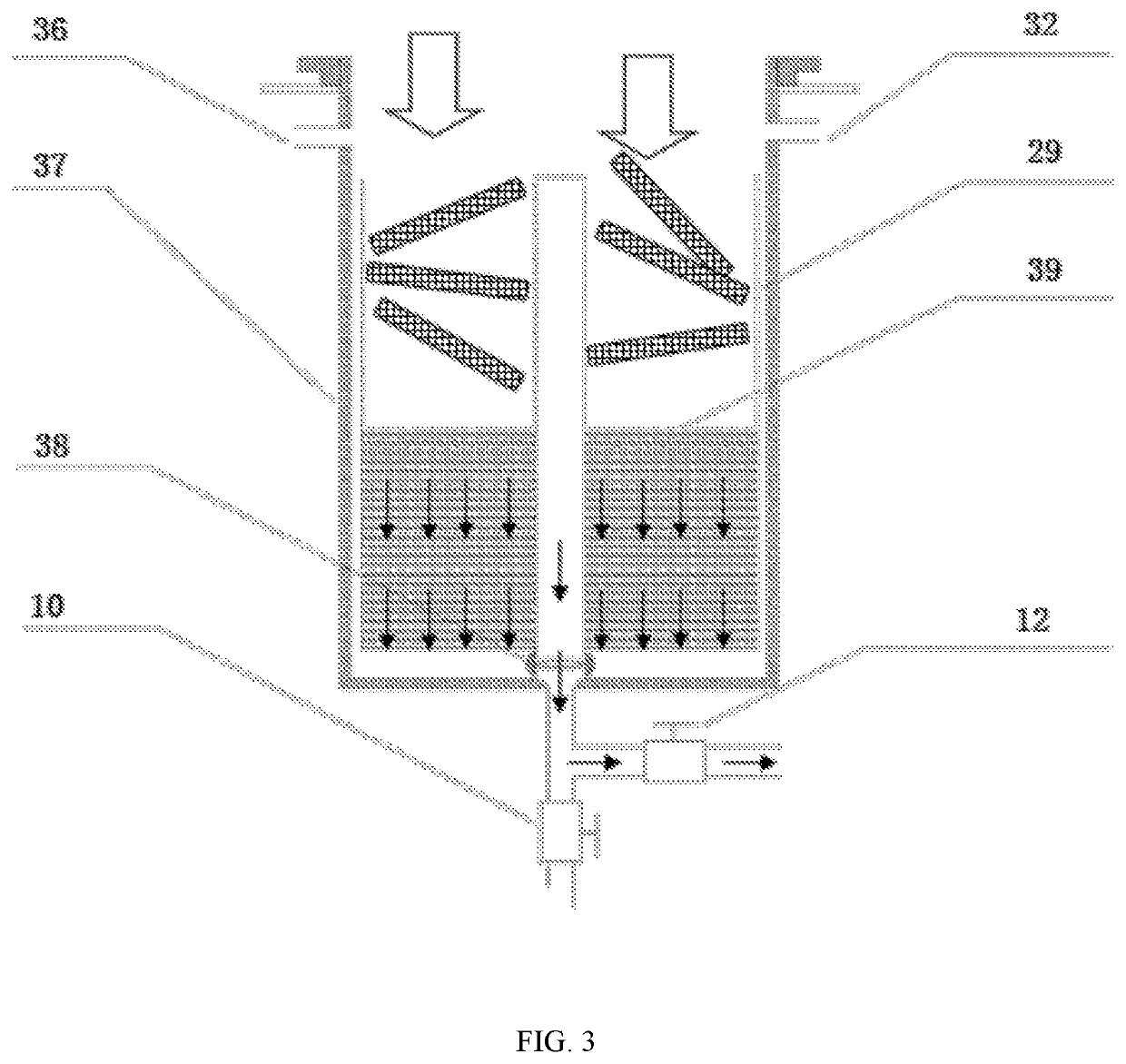

Waterless dyeing machine suitable for mixed fluid medium

ActiveUS20200115836A1Improve processing effectivenessWide applicabilityTextile treatment containersTextile treatment machine arrangementsRing dyeingProcess engineering

The invention discloses a waterless fiber dyeing machine suitable for mixed fluid medium, including a dyeing tank, a carbon dioxide pressurizing system and a polar medium pressurizing system, a fiber loading system, a circulating dyeing system, a carbon dioxide recycling system, a polar medium separating and recycling system and an automatic unloading system. Since there are pressurizing systems and separating and recycling systems for carbon dioxide medium and polar medium, dyeing with the mixed fluid medium is realized in the waterless dyeing tank and the circulating dyeing system thereof; the hydrophobic carbon dioxide fluid medium is effectively modified, so that the dyeing performance and effect of the dye molecules on the hydrophilic natural fiber are improved. The fiber loading system and the unloading system can significantly improve the fiber loading efficiency, the discharging efficiency of the products.

Owner:SUZHOU UNIV +1

Method for cationic modification and salt-free dyeing of cellulose fiber fabric

ActiveCN104233866BImprove permeabilityImprove uniformityDyeing processVegetal fibresPolymer scienceSalt free

The invention discloses a method for cationic modification and salt-free dyeing of cellulose fiber fabrics. The method is as follows: prepare an aqueous solution of a polymer cationic modifier with soft water, add cellulose fiber fabrics, add NaOH, apply pressure, heat up, and react at a constant temperature , lower the temperature and relieve the pressure, discharge the modified liquid, wash with water, and obtain the cationic modified fabric; place the cationic modified fabric in the dyeing machine, add soft water, dissolve reactive dyes and soda ash in turn with backflow water, inject the dyeing machine, and raise the temperature to The dyeing temperature is constant, and the dyeing residue is discharged. The fabric is washed-soaped-washed, dehydrated, and dried to obtain a salt-free and low-alkali dyed fabric. The invention realizes salt-free and low-alkali dyeing, solves the disadvantages of color flower, color sinking, ring dyeing, and reduced color fastness in the dyeing of reactive dyes of cellulose fiber fabrics modified by polymer cationic agents, and does not need to add leveling agent and soda ash during dyeing. It can be added to the dye vat at the same time as the dye, so there is no need to add soda ash several times during the dyeing process, and the dyeing operation is simple and easy to control.

Owner:SOUTH CHINA UNIV OF TECH +1

Technology for processing soft anti-fading denim fabric

InactiveCN107287934AFeel comfortableNot easy to fadeHeating/cooling textile fabricsBiochemical treatment with enzymes/microorganismsRing dyeingLacquer

The invention discloses a technology for processing a soft anti-fading denim fabric. The technology comprises the following specific steps: treating a base denim fabric in a laccase solution, performing enzyme deactivation, cleaning and drying; dipping the base fabric subjected to enzyme treatment in dye liquor, rinsing and airing; performing soap boiling on the dyed denim fabric in soap boiling liquor containing soap powder and anhydrous sodium carbonate; finishing in an aqueous solution of softening agent; and setting. The technology disclosed by the invention has the beneficial effects that xylogen in the base fabric can be removed by utilizing laccase in the processing technology disclosed by the invention, the dyeing property is improved, and water resources are not polluted after removal; the dye liquor can be uniformly distributed on the inner and outer layers of yarns in the dyeing process, a ring dyeing phenomenon is avoided, the diffusive force of the dye liquor is high, and the dyed fabric is high in dye-uptake and uniform in dyeing; and due to the soap boiling, the distribution condition of dyes on the denim fabric can be changed, partial flooding can be removed, the brightness of the denim fabric is increased, and the fading phenomenon of the denim fabric is improved.

Owner:宁波市海曙区伊万卡农业科技有限公司

Method for cyclic dyeing by using wastewater after dyeing in yarn-dyeing field

InactiveCN112048926AChange the status quo that can only be dyed with clean demineralized waterChange the status quo of dyeingDyeing processRing dyeingPulp and paper industry

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a method for cyclic dyeing by using wastewater after dyeing in yarn-dyeing field. According tothe invention, a reactive dye is added into reactive dyeing wastewater in the yarn-dyeing field, then yarns are dyed, the reactive dye is added into wastewater after dyeing, and then dyeing is continued, so that recycling is achieved. The current situation that the yarns can only be dyed with clean softened water is thoroughly changed, and the output of the dyeing wastewater can be reduced to a great extent. The dyeing wastewater does not need to be subjected to sewage treatment steps of decoloration and flocculation, and the reactive dyeing wastewater is directly used for dyeing the yarns again, so that the original wastewater treatment step is omitted. The method provided by the invention can save water and the usage amount of the dye, finally reduces the comprehensive production and processing cost of a yarn-dyed fabric, and has more obvious benefits for large-batch continuous production varieties.

Owner:LUTAI TEXTILE

Yarn dyeing method with controllable ring dyeing effect and indigo-dyed yarn

ActiveCN113373704AAchieving PenetrationReduce manufacturing costBiochemical treatment with enzymes/microorganismsDyeing processPolymer scienceRing dyeing

The invention discloses a yarn dyeing method with a controllable ring dyeing effect and an indigo-dyed yarn. The yarn dyeing method comprises the following steps of performing boiling-off treatment on cotton yarns ; performing soft finishing on the cotton yarns; performing waterproof treatment on the cotton yarns; performing baking treatment on the cotton yarns; performing polyurethane padding treatment on the cotton yarns; by taking short fibers as an outer wrapping fiber layer and the cotton yarns as core yarns, carrying out core-spun yarn process treatment on a spinning frame to form a core-spun yarn structure; carrying out beaming; carrying out indigo dyeing treatment on core-spun yarns; carrying out oxidation treatment on the core-spun yarns; washing the core-spun yarns with water; and drying the core-spun yarns. According to the yarn dyeing method with the controllable ring dyeing effect provided by the invention, boiling-off treatment does not need to be conducted on the yarns, original wax and impurities of the yarns are combined with a waterproof layer, outer wrapping fibers of the core-spun yarns are colored, and core yarns are not colored, so that the effect that the yarns are subjected to ring dyeing through the indigo dye is achieved, and the ring dyeing effect of the yarns can be adjusted by controlling the thickness of the core yarns and the thickness of the outer wrapping fibers.

Owner:GUANGDONG FORWARD DENIM

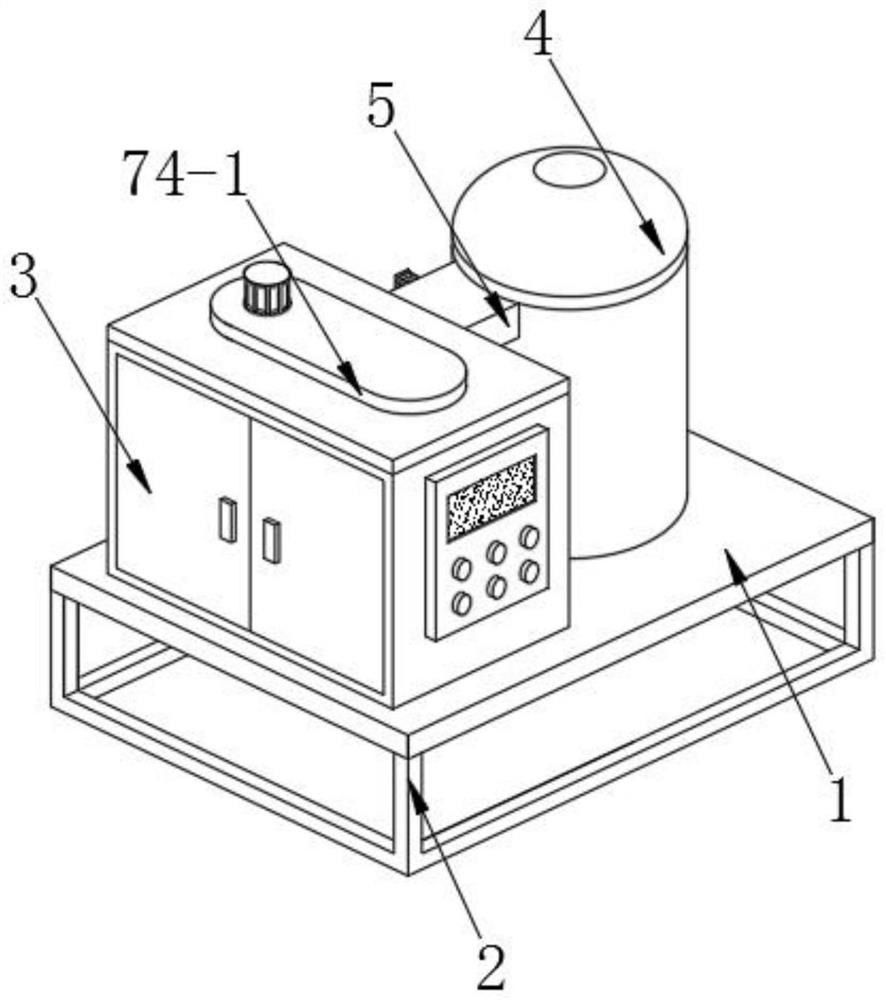

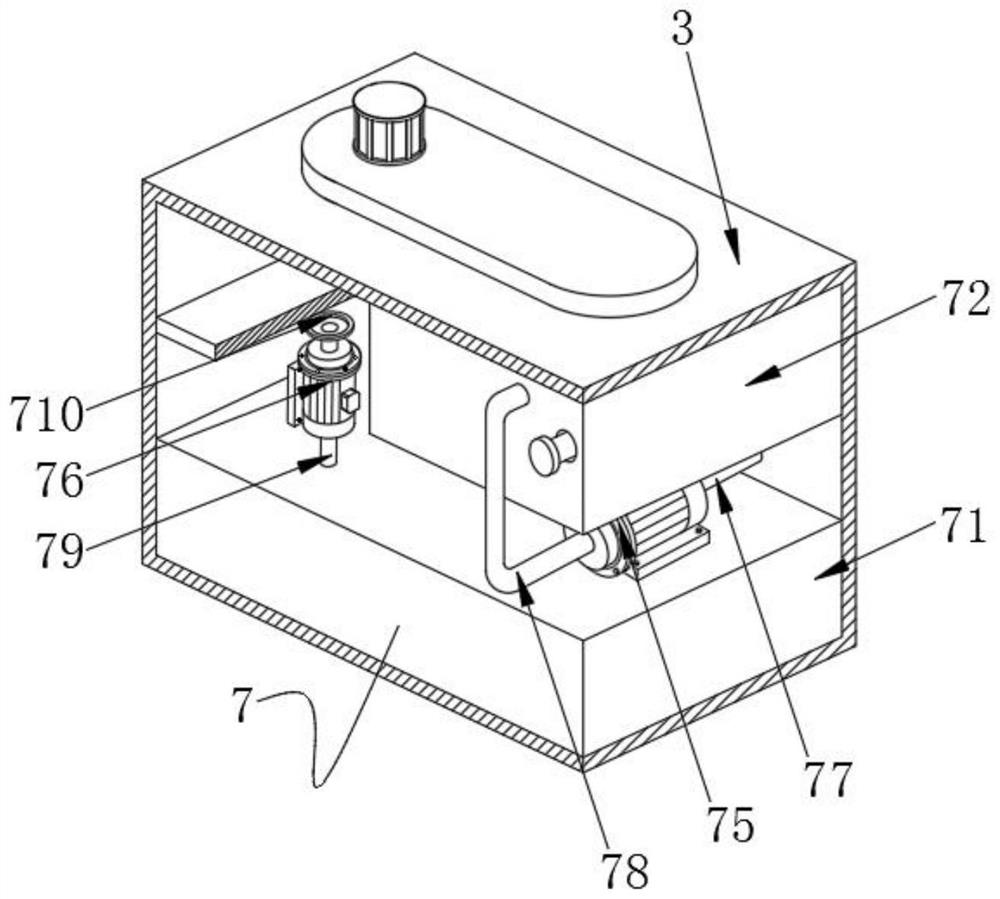

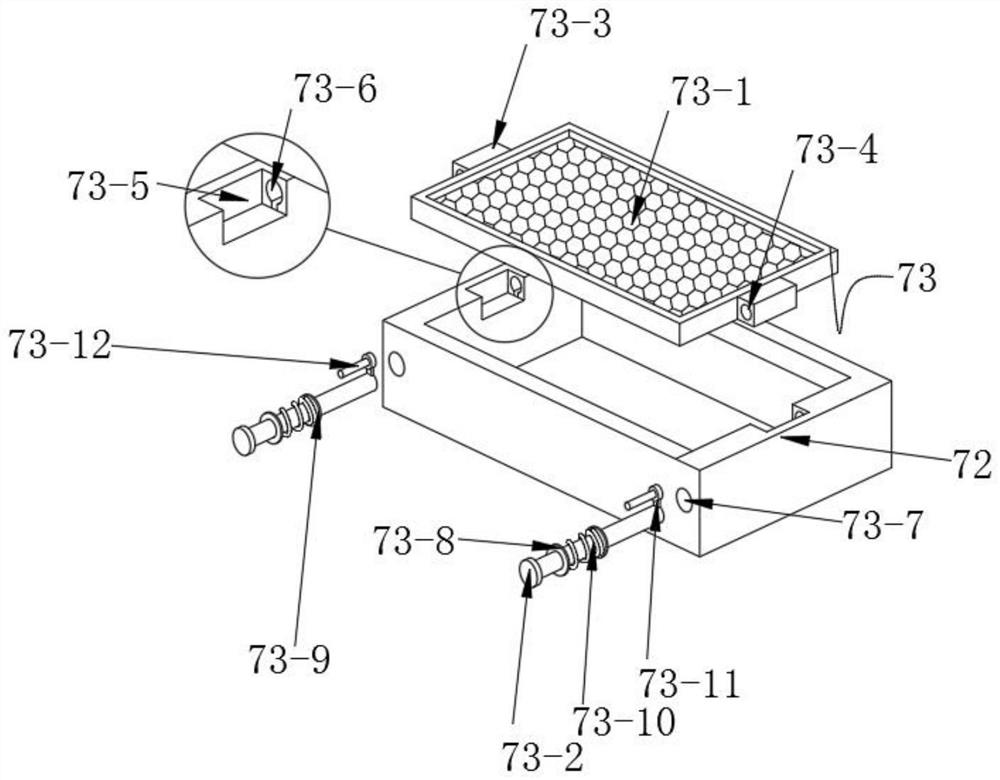

Wastewater circulating dyeing system and method based on ultra-low bath ratio dyeing process

PendingCN113818174APrevent fallingAchieve recyclingTextile treatment machine arrangementsRing dyeingWastewater

The invention discloses a wastewater circulating dyeing system and method based on an ultra-low bath ratio dyeing process. The wastewater circulating dyeing system based on the ultra-low bath ratio dyeing process comprises a supporting plate, wherein the bottom of the supporting plate is fixedly connected with a supporting frame; the top of the supporting frame is fixedly provided with a circulating box and a dyeing tank; the circulating box and the dyeing tank are communicated through a feeding pipe; a material control mechanism is arranged in the feeding pipe; and a wastewater circulating mechanism is arranged in the circulating box. The wastewater circulating dyeing system and method based on the ultra-low bath ratio dyeing process provided by the invention relates to the technical field of dyeing processes. According to the wastewater circulating dyeing system and method based on the ultra-low bath ratio dyeing process, the wastewater circulating mechanism and a filtering unit are arranged, a first water pump and a second water pump are used for conveying water liquid, a filtering plate is used for filtering the water liquid, and the filtering plate is mounted by clamping a clamping rod and a mounting block, so that the recycling of waste liquid is realized, impurity particles can be prevented from falling into the next use, and the subsequent filtering efficiency is improved through disassembly and cleaning.

Owner:杭州萧越染织有限公司

Aging processing method for colored fabric

ActiveCN101748601BAdd cationic modificationEvenly colored surfaceFibre treatmentDyeing processSurface layerRing dyeing

The invention discloses a distressed processing method for colored fabric, which is characterized in that a cation modification technology of yarn is added before the traditional yarn dyeing processing technology, so that the whole processing technology comprises the following steps in sequence: yarn preparation, cation modification of yarn, yarn dyeing processing, sizing, preshrinking, washing and finished products. The distressed processing method has the advantages that the surface layer of the yarn colors up uniformly, and the inner layer of the tarn maintains the original white core, so a clear skin - core effect is formed; the processed fabric has uniform ring dyeing and a uniform distressed treatment effect; by the combination application of a cation modifier and reactive dyes, thedyed fabric achieves the effect which sulfur dyes or indigo dyes can just achieve; and the distressed processing method greatly reduces energy consumption, reduces environmental pollution, ensures the stability and the production efficiency of dyeing, and enhances the quality of products.

Owner:盛泰智造集团股份有限公司

Preparation method of staple fiber ring dyed yarn

The invention relates to a preparation method for yarns in the textile field, and discloses a short-fiber ring dyeing yarn preparation method. The method comprises the following steps: 1, allowing loose fiber to be subjected to impurity-removing and decolorizing processing; 2, allowing the loose fiber to be subjected to coloring processing; 3, spinning the fibers not colored into fine yarns; 4, spinning colored coarse sliver; and 5, spinning the ring dyeing yarn with white core. The method is simple in process, convenient to operate, consumes less dyestuff additive and energy, is small in environment pollution, and large in fiber selectivity for preparing the ring dyeing yarn. Moreover, the prepared yarn has obvious ring dyeing effect, and the ratio of the 'skin layer' to 'core layer' is adjustable.

Owner:SHAOXING UNIVERSITY

A kind of yarn dyeing method

ActiveCN105821613BImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

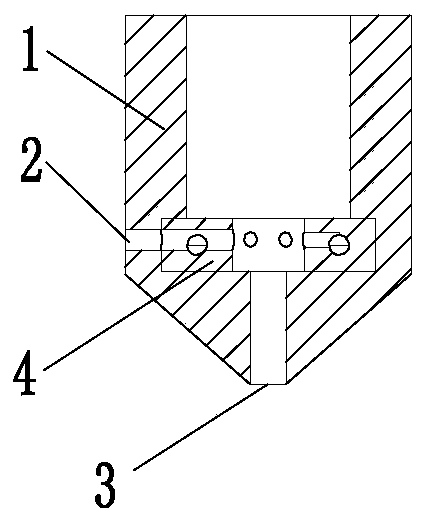

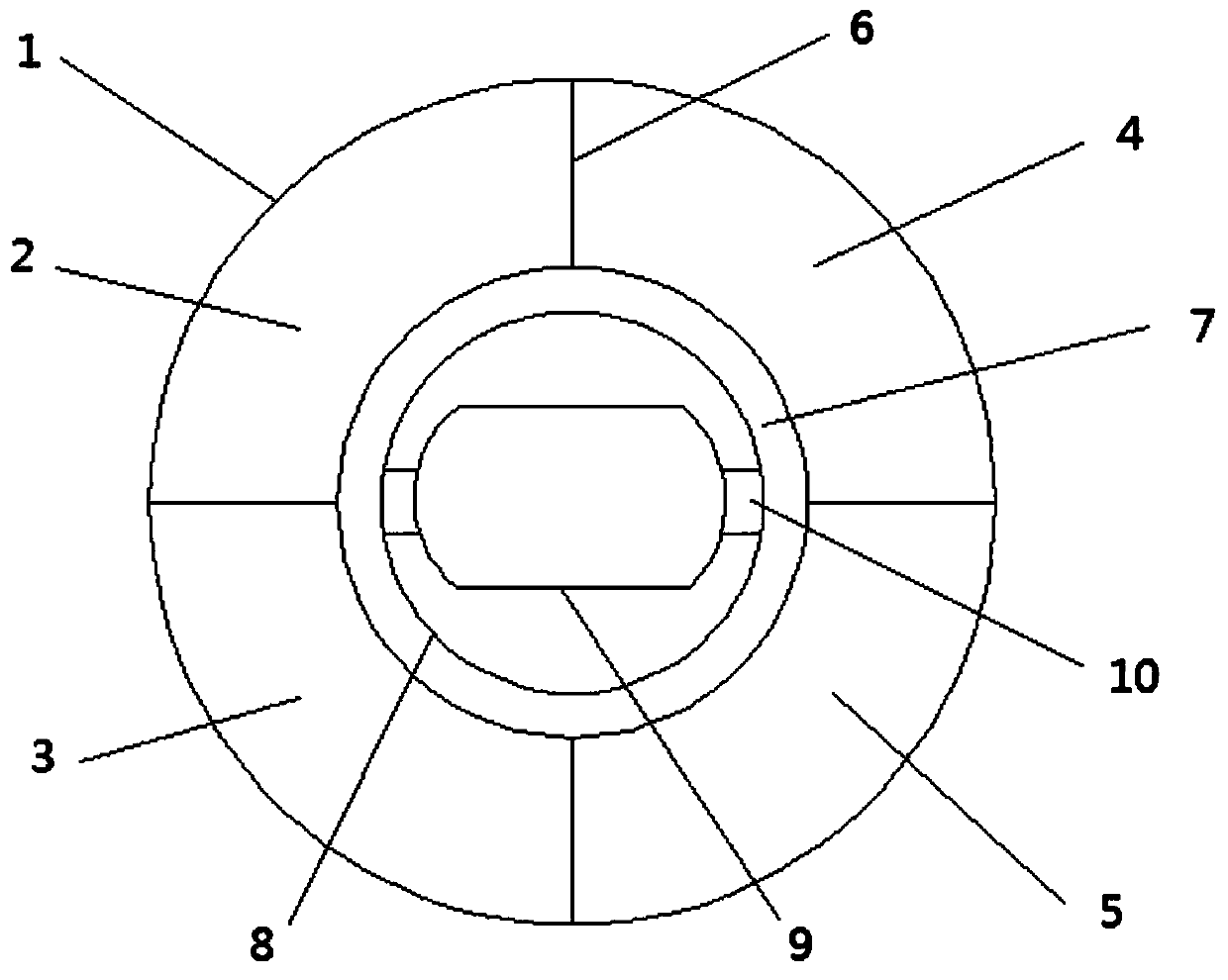

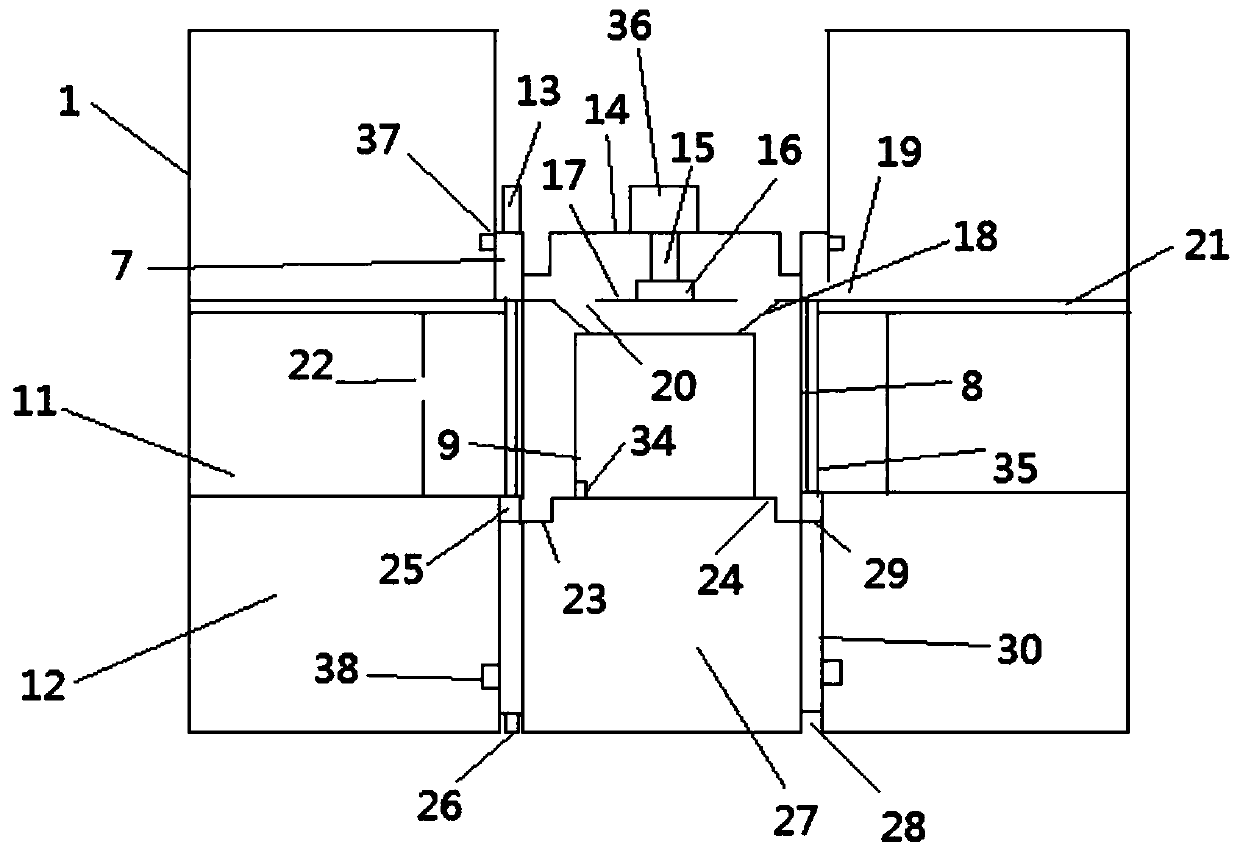

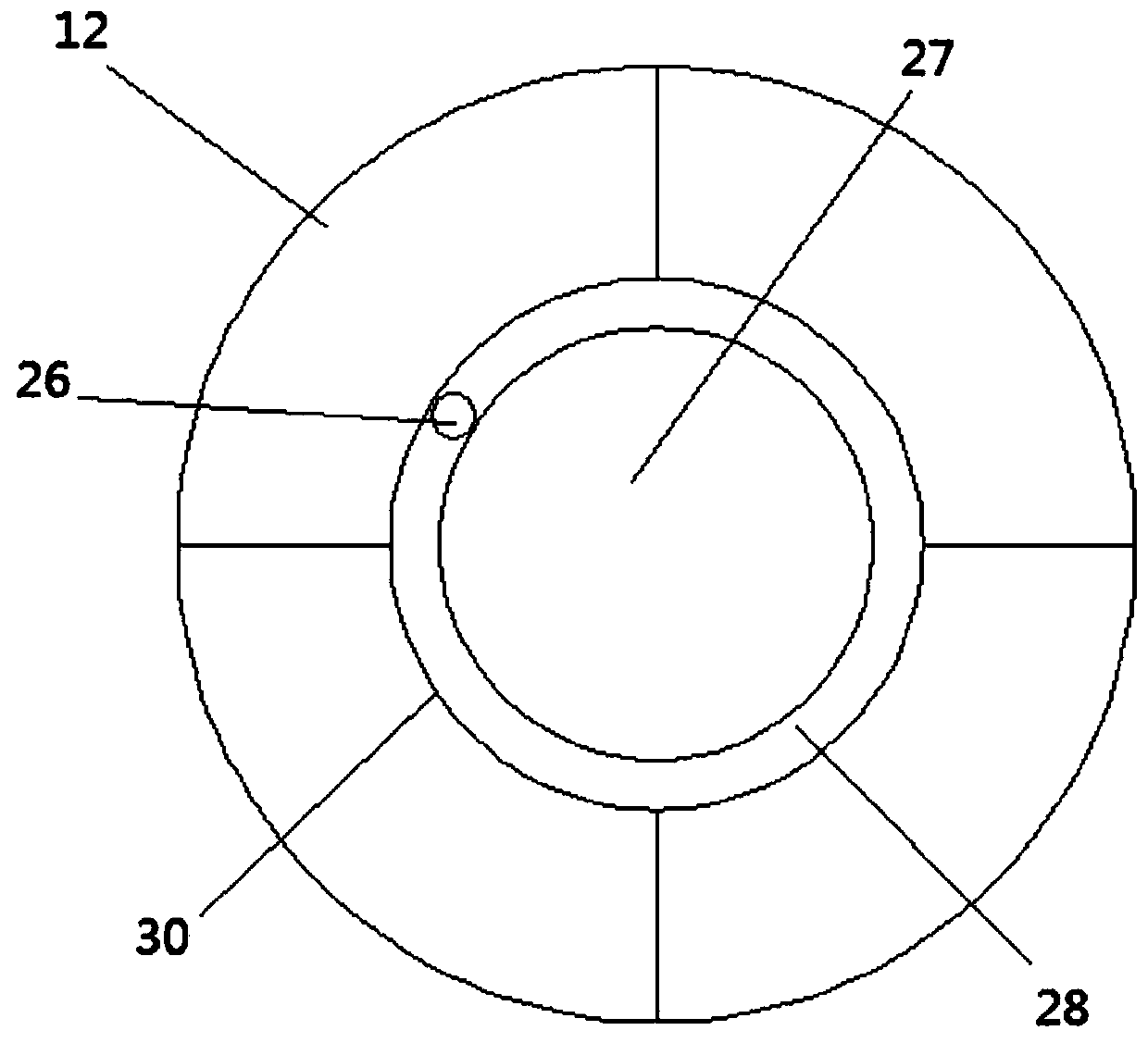

A fdm type 3D printing nozzle and method based on the principle of color mixing and dyeing

ActiveCN106541569BRealize full color 3D printingSimple structureAdditive manufacturing with liquidsApplying layer meansRing dyeingEngineering

The invention provides an FDM type 3D print head based on the color mixing and dyeing principle. The print head comprises a heating chamber and a conical nozzle, wherein the heating chamber and the conical nozzle are integrated; an annular dyeing ring is arranged in the heating chamber, a round feed port allowing raw print materials to pass is formed in the center of the annular dyeing ring, an annular channel with the symmetry center of the dyeing ring as the circle center is arranged in a real body of the dyeing ring, a dyeing ring ink inlet communicating with the annular channel is formed in the outer circle wall of the dyeing ring in the radial direction in a penetrating mode, a plurality of ink guide pipes communicating with the annular channel and the feed port are uniformly arranged on the inner circle wall of the dyeing ring in the radial direction in a penetrating mode, and a nozzle ink inlet communicating with an externally-connected color mixer and the dyeing ring ink inlet is arranged in the outer peripheral wall of the heating chamber in a penetrating mode. The invention further discloses an FDM type 3D printing method based on the color mixing and dyeing principle. According to the FDM type 3D print head and the method based on the color mixing and dyeing principle, free color blending can be realized according to models, formation can be completed in one step, real full-color 3D printing can be realized, the structure is simple, and the operation is convenient.

Owner:SOUTH CHINA UNIV OF TECH

Continuous Loose Fiber Dyeing Machine

ActiveCN101949086BReduce consumptionHighlight the substantive effectTextile treatment containersTextile treatment carriersRing dyeingPulp and paper industry

The invention relates to a continuous loose fiber dyeing machine. The continuous loose fiber dyeing machine comprises a dye vat; a mechanism which is fitted with the dye vat and used for conveying loose fibers is a double mesh belt dyeing conveying mechanism, and the double mesh belt dyeing conveying mechanism comprises two closed mesh belts (namely, a ring mesh belt A and a ring mesh belt B) and transmission components which are respectively in transmission fit with each ring mesh belt; two ring dyeing mesh belts in the dye vat are in clearance stacking fit with each other, the two ring dyeing mesh belts respectively fitted with the inlet end and the outlet end of the dye vat respectively form a duckbilled input port and a duckbilled output port, and the two ring dyeing mesh belts arranged outside the dye vat are respectively fitted with the respective transmission components so as to form a circular transmission. The invention has the prominent and substantive effects as follows: because the loose fibers are clamped and then sent to the dye vat for dyeing and the loose fiber is thin, the loose fiber is easy to be dyed completely; and with the help of shower pipes, the dye permeability of the loose fibers is improved, and little dyes are taken away, therefore, the dye consumption is saved.

Owner:新昌县艺力机械有限公司 +1

Full-process cyclic dyeing system and process and application thereof

ActiveCN110606587AEasy to operateTo achieve the purpose of capture and adsorptionSucessive textile treatmentsWater contaminantsSalt freeWastewater

The invention discloses a full-process circulation dyeing system, which comprises a dyeing unit, a cleaning unit and a regeneration circulation unit; wherein the regeneration circulation unit comprises a dye capture separator, a salt concentration separator, a dyeing pool and a cleaning pool; based on the dyeing system, a textile is dyed by adopting a conventional dyeing process, and the wastewater in the dyeing process is captured and separated by the dye to obtain circulating water for dyeing, so that the circulating water is circularly used for next dyeing process; the wastewater in the processes of soaping, reduction cleaning, water washing and the like sequentially passes through a dye capture separator and a salt concentration separator respectively to obtain salt-free or low-salt-content colorless clear water, which is circularly used for next water washing process respectively. In the invention, all procedures are treated and circulated respectively from the source, so that themethod has the advantages of being simple, low in comprehensive cost, good in dyeing reproducibility, high in wastewater circulation rate, suitable for industrial application and the like.

Owner:ZHEJIANG SILK TECH

Automatic dyeing and decolorizing device

ActiveCN111323285AReduce usageLow costPreparing sample for investigationRing dyeingElectric machinery

An automatic dyeing and decolorizing device comprises a main body, a fixed liquid box, a silver dyeing liquid box, a developing liquid box, a washing liquid box, a partition plate, an adapter ring, adyeing bin, a dyeing box, a connecting shaft, an air dispersing box, a liquid discharging box, a first handle, a through-flow cover, stand columns, supporting legs, an upper cover, a liquid inlet, a supporting plate, vent holes, grooves, convex shoulders, shaking tables, an adapter sleeve, supporting pieces, a control valve, a motor, a connection rod, an upper clamping ring and a lower clamping ring. The upper cover is provided with an upper hole and a guide plate; the adapter sleeve comprises a liquid discharge ring, a spacer ring, a recess and a second handle; and the supporting plate is arranged in the main body, four partition plates are arranged above the supporting plate, and the four partition plates divide four spaces for containing the fixed liquid box, the silver dyeing liquid box, the developing liquid box and the washing liquid box respectively.

Owner:GUILIN MEDICAL UNIVERSITY

Waterless dyeing machine suitable for mixed fluid medium

ActiveUS10968553B2Improve processing effectivenessWide applicabilityTextile treatment containersTextile treatment machine arrangementsRing dyeingProcess engineering

Owner:SUZHOU UNIV +1

Supercritical fluid dyeing machine

ActiveCN101760914BSave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine, which consists of a horizontal cylindrical dyeing kettle, a magnetic power cloth lifting wheel, a spray chamber, a wave-shaped cloth guide channel in the dyeing kettle, a heat exchanger, a dye kettle or / and an entraining agent. The kettle and circulation pump are the main components that form the dyeing circulation system; the two ends of the fan are connected to the spray chamber and the fluid outlet below the dyeing kettle respectively. Together with the magnetic cloth lifting wheel, the spray chamber and the operating port, it forms the cloth feeding system. The rope-like fabric is cyclically dyed under the combined action of the magnetic power lifting wheel and the fluid in the spray chamber. The fluid in the dyeing kettle is forced to circulate through the circulation pump. After dyeing, the dye and fluid can be recycled through the separation and recovery system, and the entire dyeing cycle system and the separation and recovery system itself can be cleaned to meet the requirements for color change and dyeing. This supercritical fluid dyeing machine can realize water-free dyeing processing of fabrics in a loose tension-free state, without the generation and emission of pollutants, and has the characteristics of ecological environmental protection and wide adaptability to fabric varieties.

Owner:SUZHOU UNIV +2

A kind of recycling dyeing process of nylon fabric printing and dyeing wastewater

ActiveCN107500369BShorten heating timeLow costDyeing processWater/sewage treatment by degassingRing dyeingThermal insulation

Owner:石狮市万峰盛漂染织造有限公司

Modification method and dyeing process of a salt-free and low-alkali deep-dyed cellulose fiber fabric

ActiveCN105442353BGood water solubilityImprove functionalityBiochemical fibre treatmentDyeing processRing dyeingSalt free

The invention discloses a modification method for a salt-free low-alkaline deeply dyed type cellulose fiber fabric and a dyeing process for the salt-free low-alkaline deeply dyed type cellulose fiber fabric. The modification method is characterized by comprising the following steps: (1) preparation of chitosan oligosaccharide; (2) preparation of reactive chitosan oligosaccharide derivative; (3) modification of cellulose fibers with the reactive chitosan oligosaccharide derivative, and dyeing of a modified cellulose fiber fabric with reactive dyes in a dyeing machine, so as to obtain the salt-free low-alkaline dyed fabric. The method for modification of the cellulose fibers with the reactive chitosan oligosaccharide derivative and the dyeing process have the advantages that the binding strength between the chitosan oligosaccharide and the cellulose fibers can be obviously improved, the adsorption capacity of the obtained chitosan oligosaccharide modified cellulose fiber fabric for the reactive dyes can be obviously enhanced, the cellulose fiber fabric can be dyed under the salt-free low-alkaline condition to achieve a certain deep dyeing effect, the color fastness is improved, the problems of color tone, ring dyeing, color lake and poor deep dyeing property of the salt-free low-alkaline dyeing process can be solved, and the defects of hardening, stiffness, chemical fiber and the like on the surface of the fabric processed with the high molecular weight chitosan oligosaccharide can be overcome; in addition, the best dyeing effect can be obtained through optimizing the dyeing process.

Owner:中国纺织科学研究院江南分院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com