Automatic dyeing and decolorizing device

A dyeing box and silver dyeing solution technology, applied in the field of medical equipment, can solve the problems of no flow power structure, unsmooth liquid flow, and affecting the health of operators, so as to reduce costs and avoid a large number of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

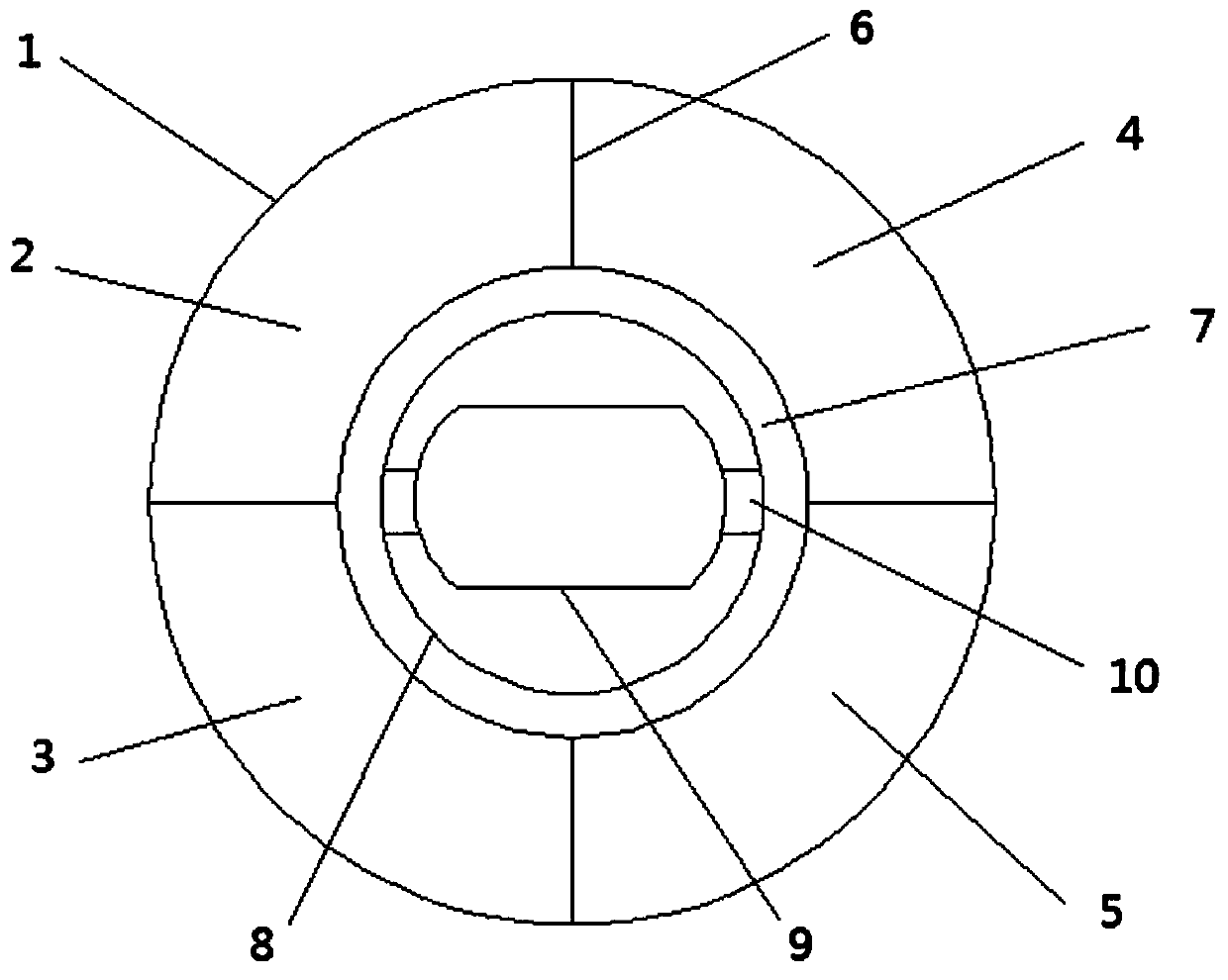

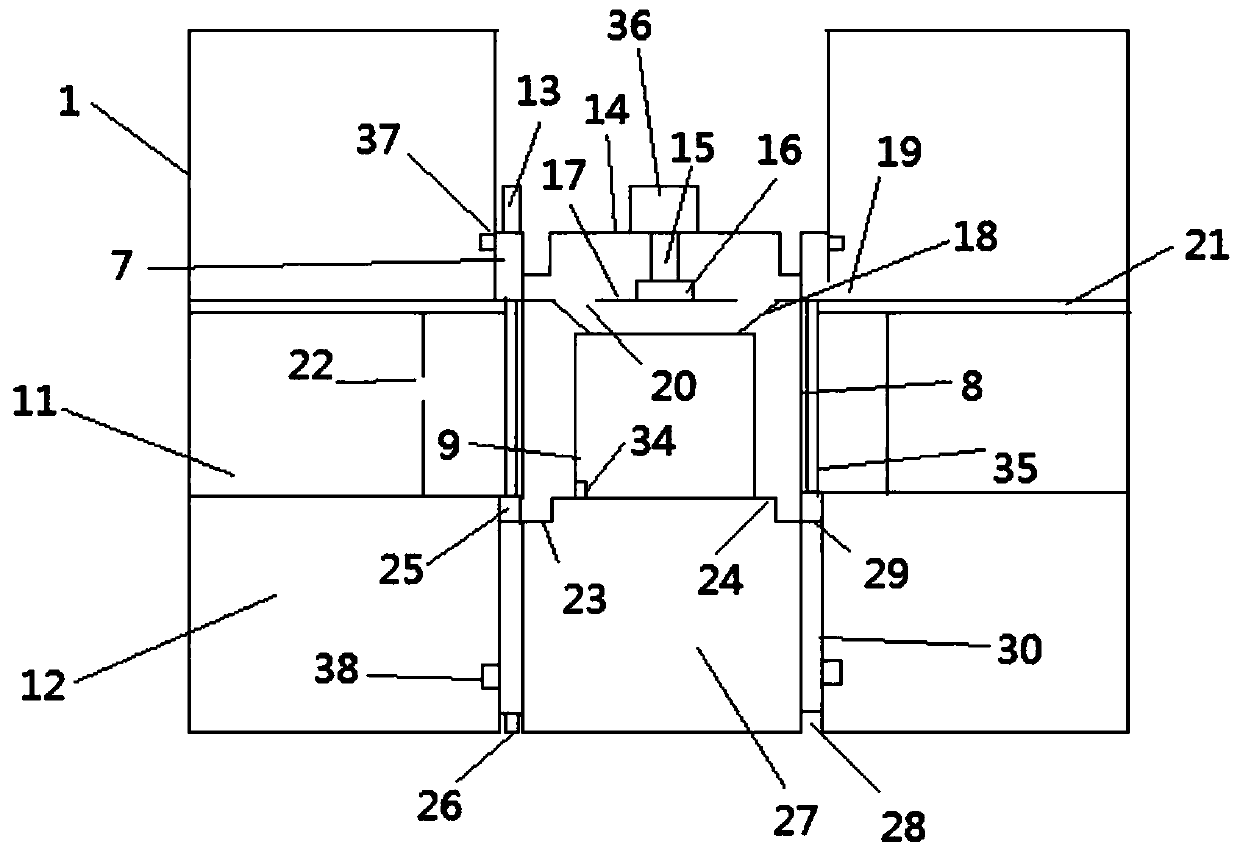

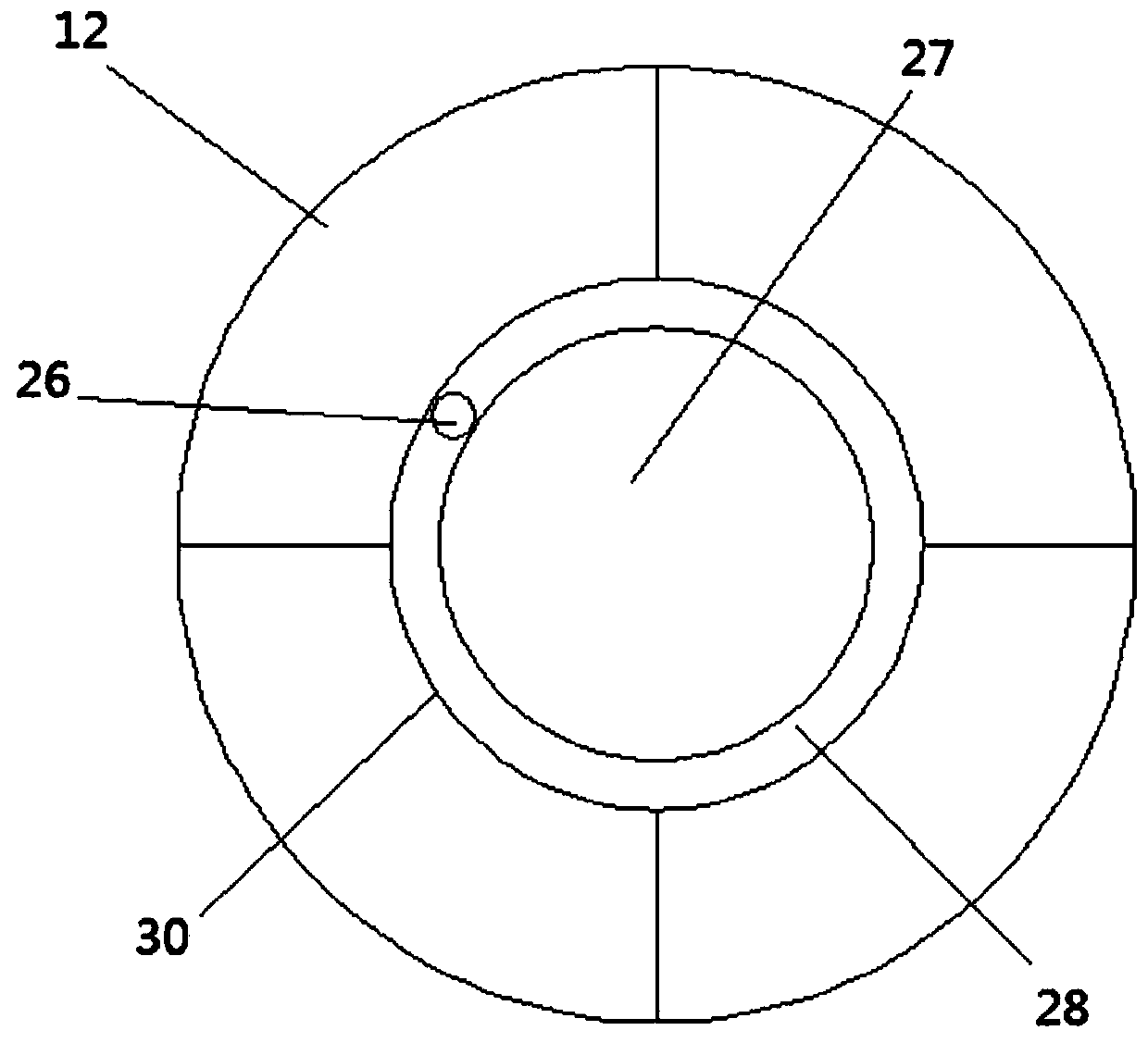

[0046] As shown in the figure: an automatic dyeing and decoloring device, including a main body, a fixing liquid box, a silver dyeing liquid box, a color developing liquid box, a washing liquid box, a partition, an adapter ring, a dyeing chamber, a dyeing box, a connecting shaft, and a loose Air box, drain box, first handle, flow cover, column, foot, upper cover, liquid inlet, support plate, vent, groove, shoulder, shaker, adapter sleeve, support, control valve , Motor, connecting rod, upper snap ring, lower snap ring; wherein the upper cover is provided with an upper hole and a deflector; the adapter sleeve includes a drain ring, a spacer ring, a recess, and a second handle;

[0047] The main body is provided with a support plate, four partitions are provided above the support plate, and the four partitions separate four spaces respectively containing the fixing liquid box, the silver dyeing liquid box, and the color developing Liquid box, the washing liquid box, the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com