Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8813 results about "Electrophoresis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrophoresis (from the Greek "Ηλεκτροφόρηση" meaning "to bear electrons") is the motion of dispersed particles relative to a fluid under the influence of a spatially uniform electric field. Electrophoresis of positively charged particles (cations) is sometimes called cataphoresis, while electrophoresis of negatively charged particles (anions) is sometimes called anaphoresis.

Electrophoretic medium and process for the production thereof

Owner:E INK CORPORATION

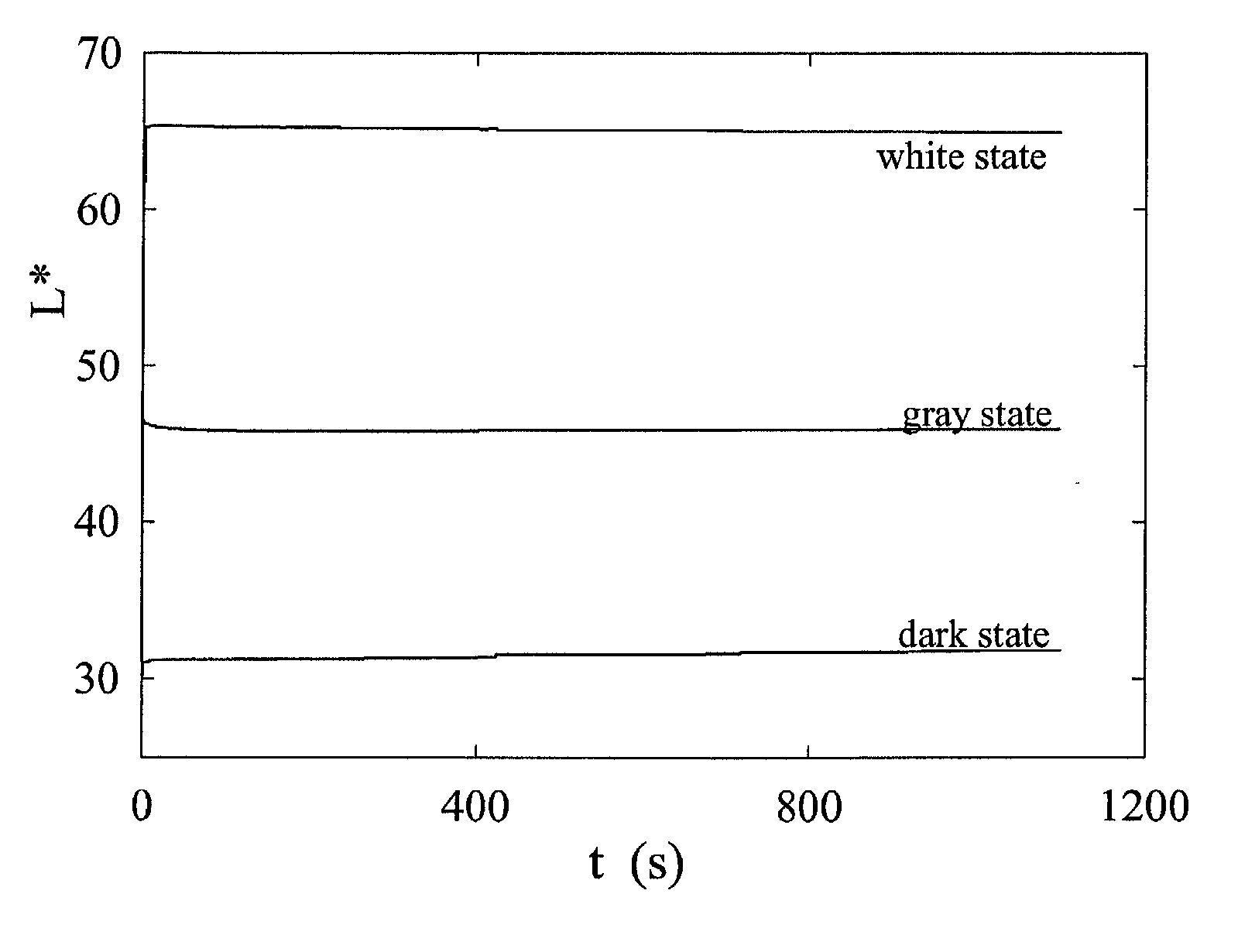

Electrophoretic medium and display with improved image stability

An electrophoretic medium comprises a plurality of particles suspended in a suspending fluid, the particles being capable of moving through the fluid upon application of an electric field to the medium, the fluid having dissolved or dispersed therein a polymer having a number average molecular weight in excess of about 20,000, the polymer being essentially non-absorbing on the particles. The polymer improves the bistability of the display (i.e., the period for which a written image persist without the display being refreshed) but does not greatly increase the viscosity of the suspending fluid, thus keeping the switching time of the display within reasonable limits. The medium may be encapsulated, or may be in the form a polymer-dispersed electrophoretic medium.

Owner:E INK CORPORATION

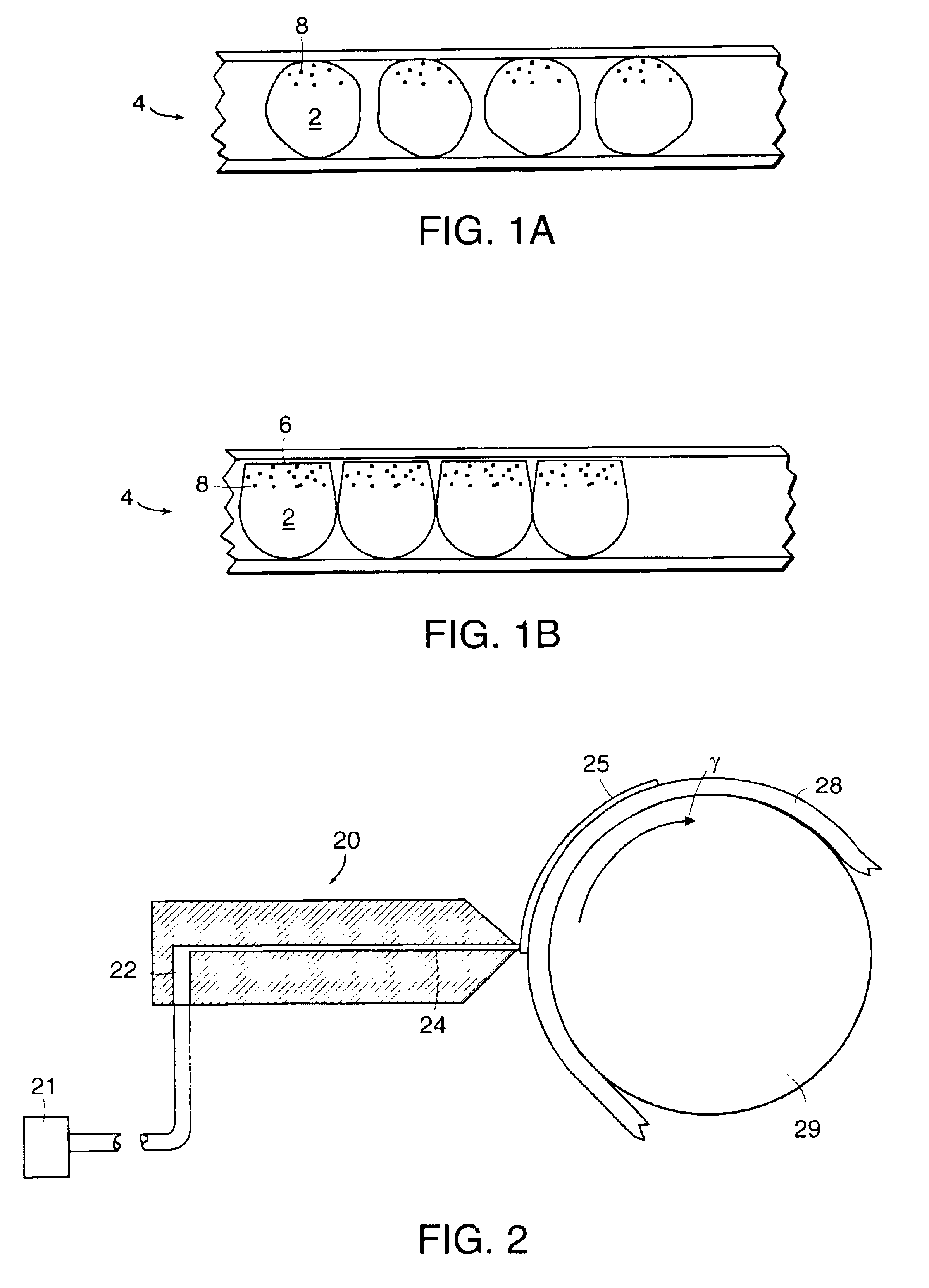

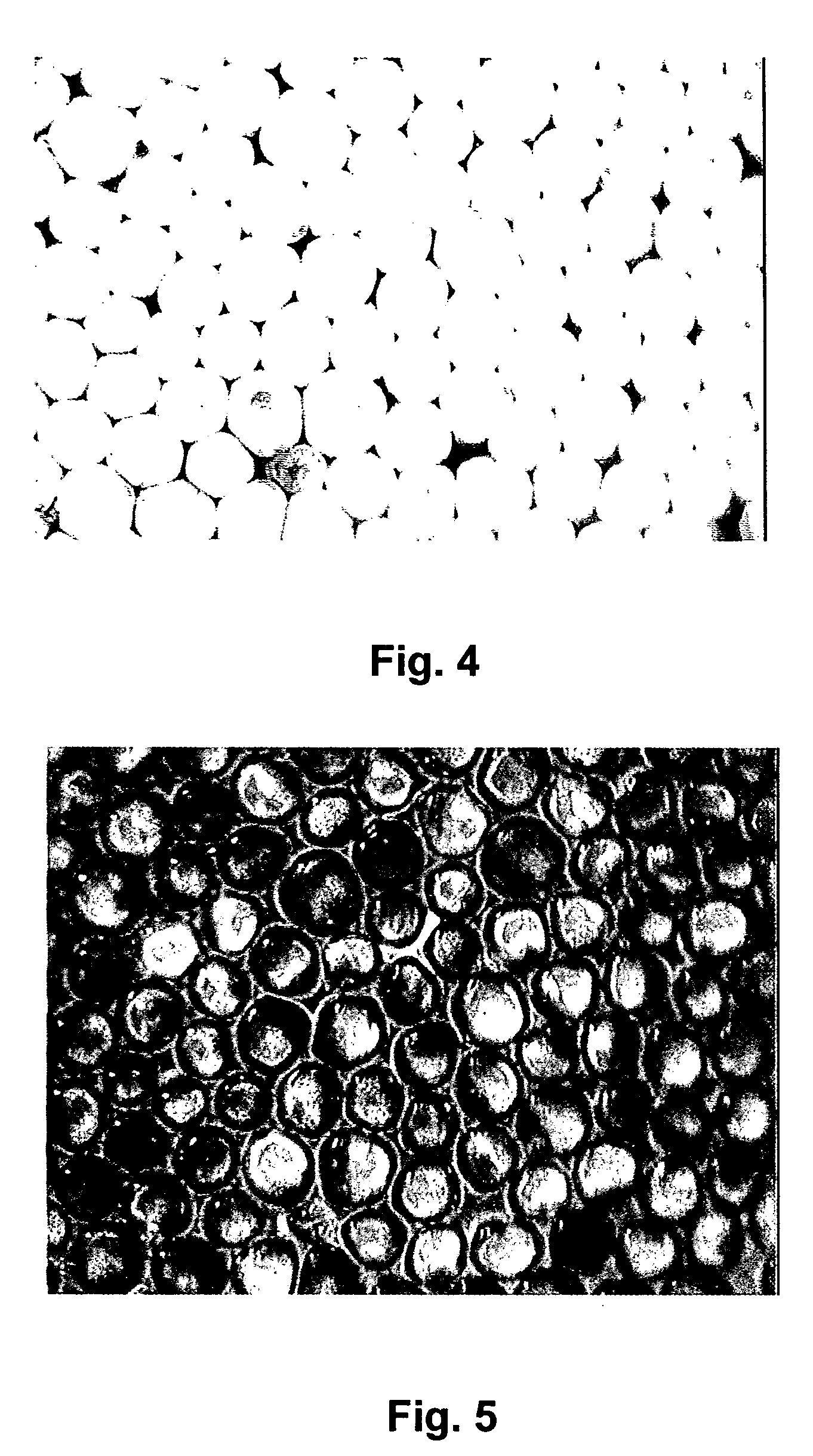

Methods for producing droplets for use in capsule-based electrophoretic displays

Methods are provided for forming a dispersion of substantially uniform droplets. An internal phase that includes a plurality of particles suspended in a first fluid is provided and an external phase including a second fluid is provided. The internal phase is vibrated and the internal phase is applied to the external phase. Either the internal phase or a combination of the internal and external phases form a series of droplets or complex droplets of substantially uniform size.

Owner:E INK CORPORATION

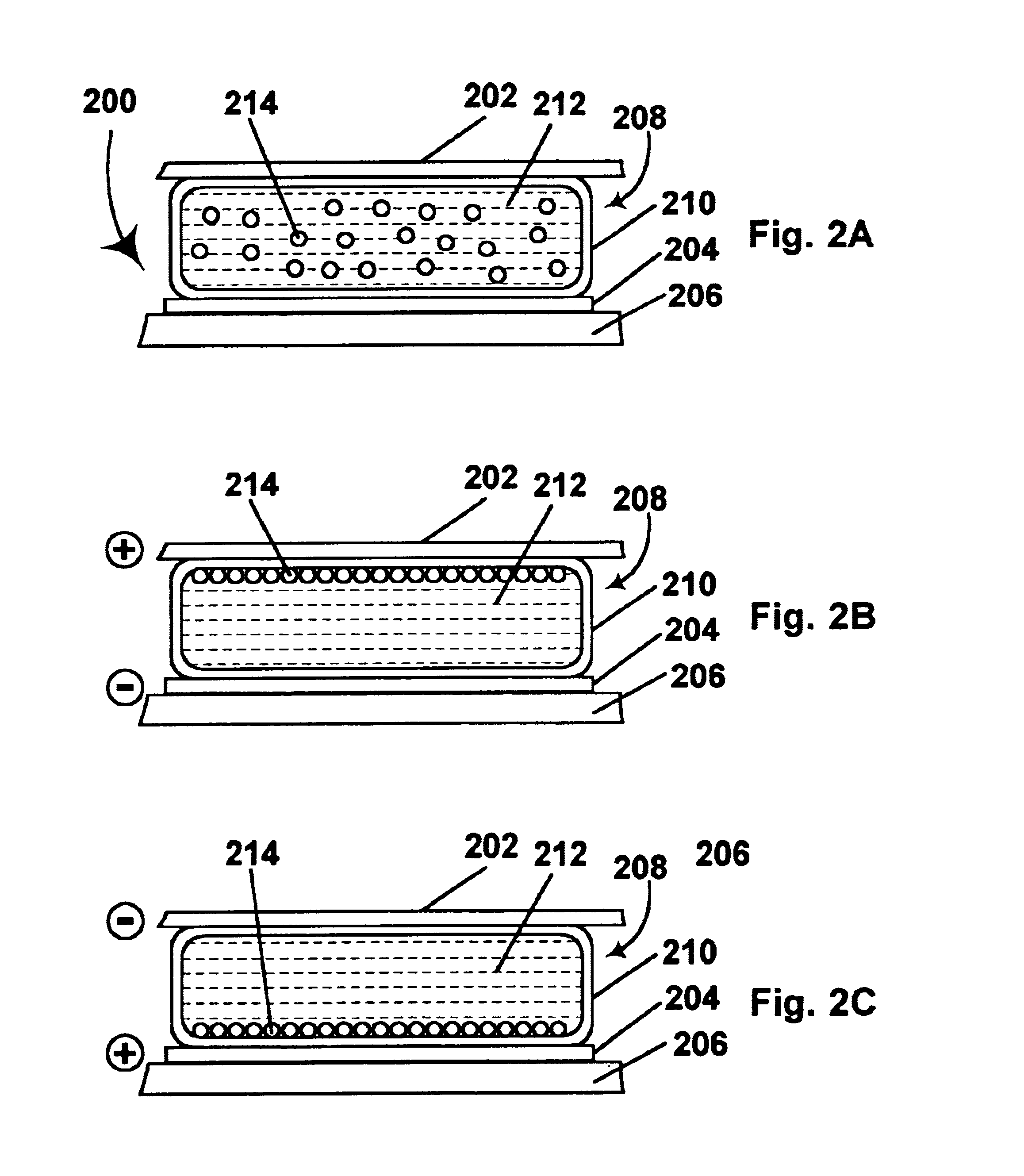

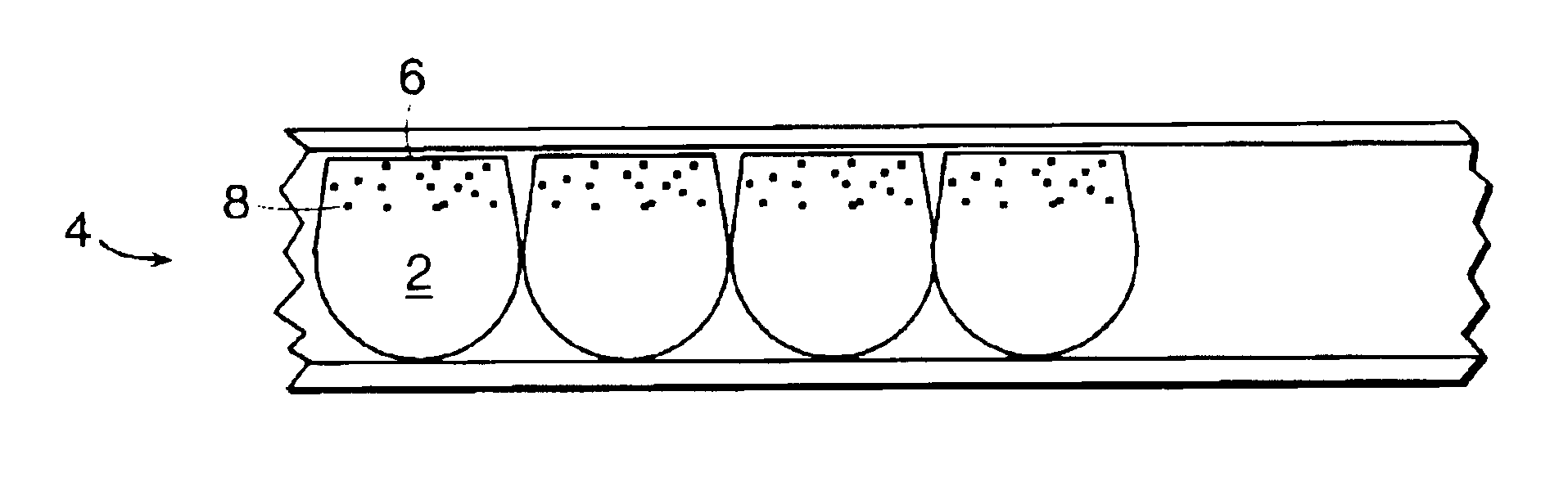

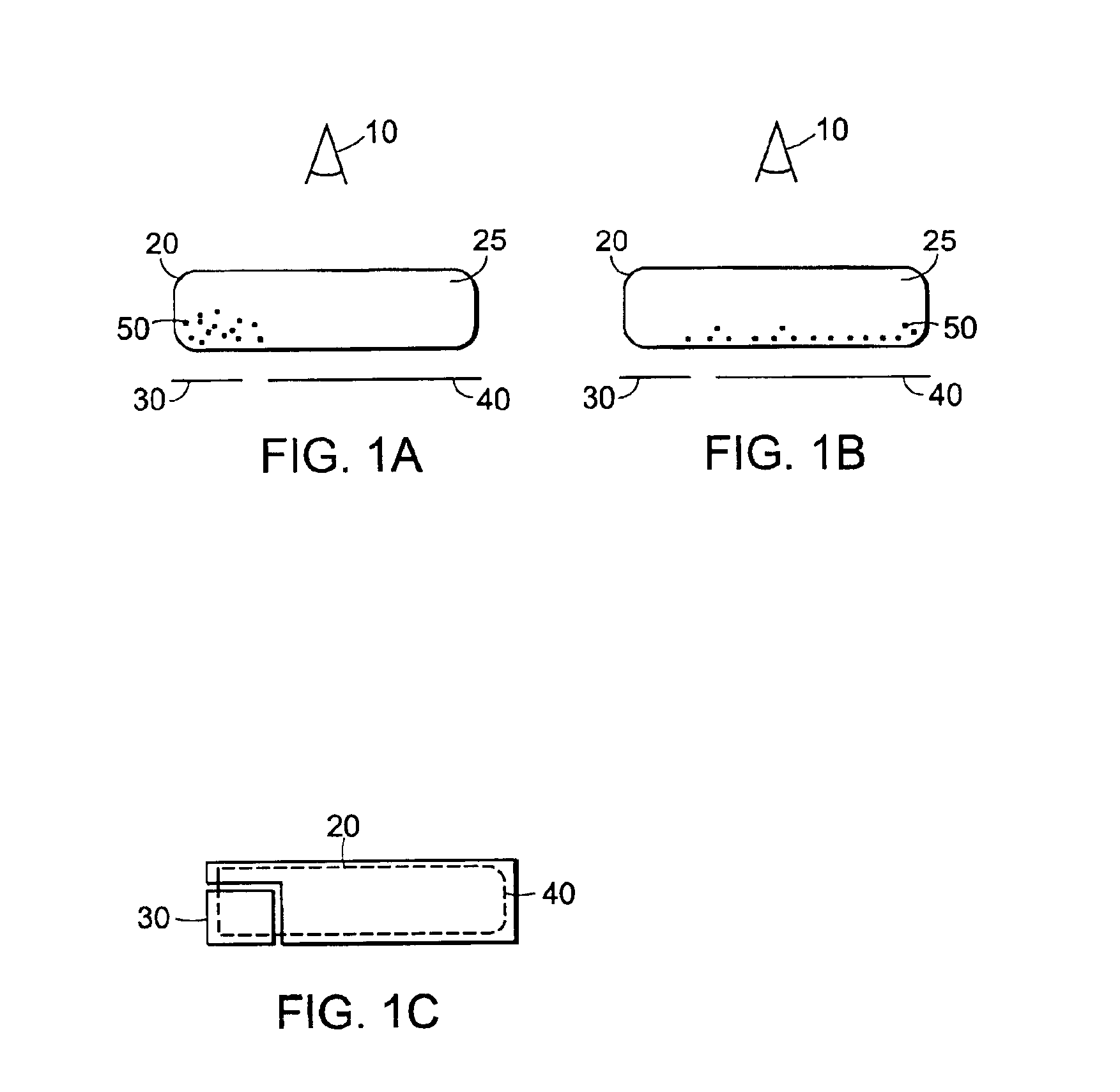

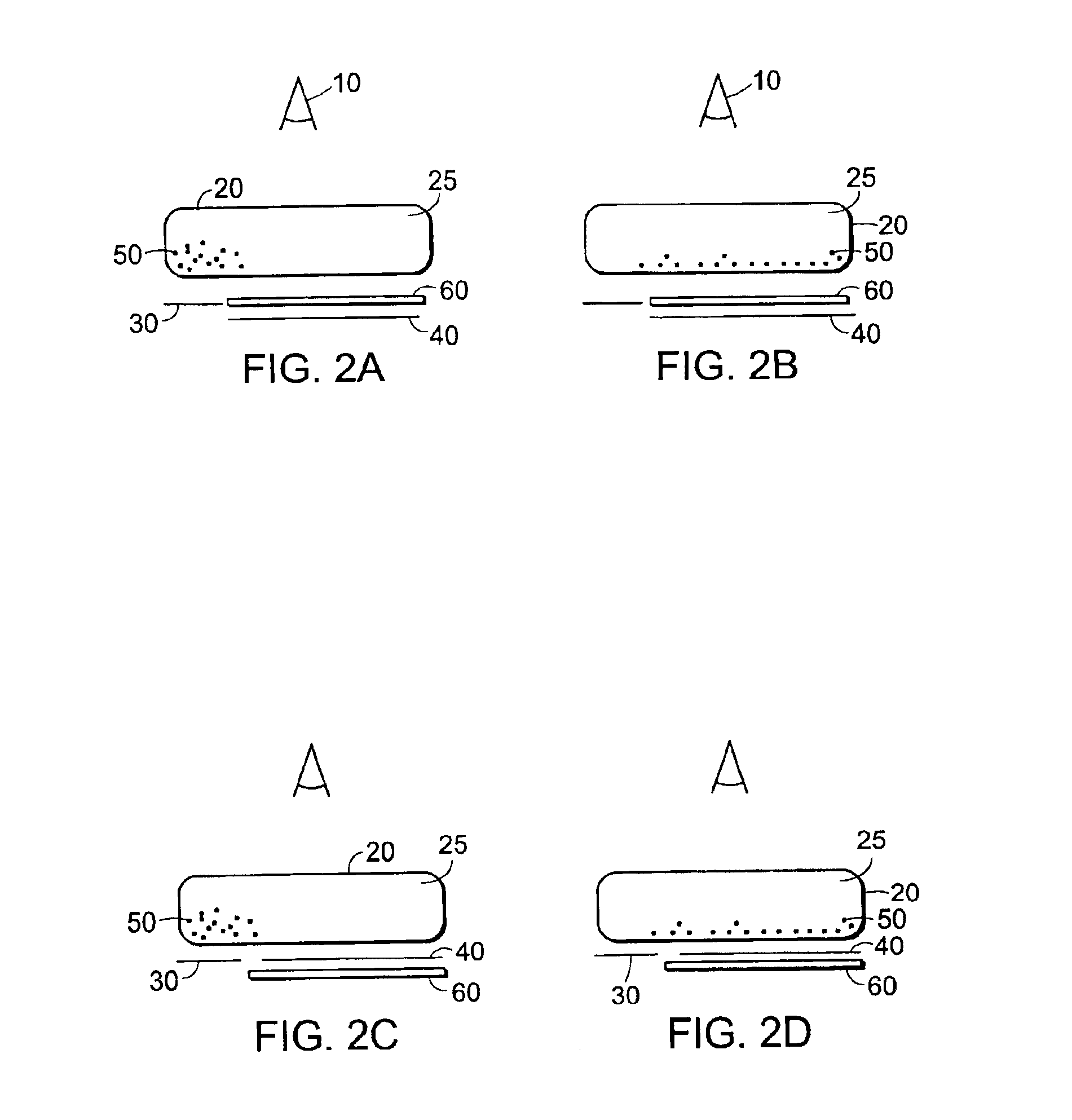

Flexible electro-optic displays

An encapsulated electrophoretic medium comprises a plurality of capsules dispersed in a polymeric binder, each of the capsules comprising a capsule wall, a suspending fluid contained within the capsule wall, and a plurality of electrically charged particles suspended in the suspending fluid and capable of moving therethrough upon application of an electric field to the medium, the polymeric binder having a shear modulus of at least about 10 mPa at 20° C., and preferably over the range of 10-50° C.

Owner:E INK CORPORATION

Electrophoretic medium and process for the production thereof

InactiveUS7411719B2Static indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisElectric field

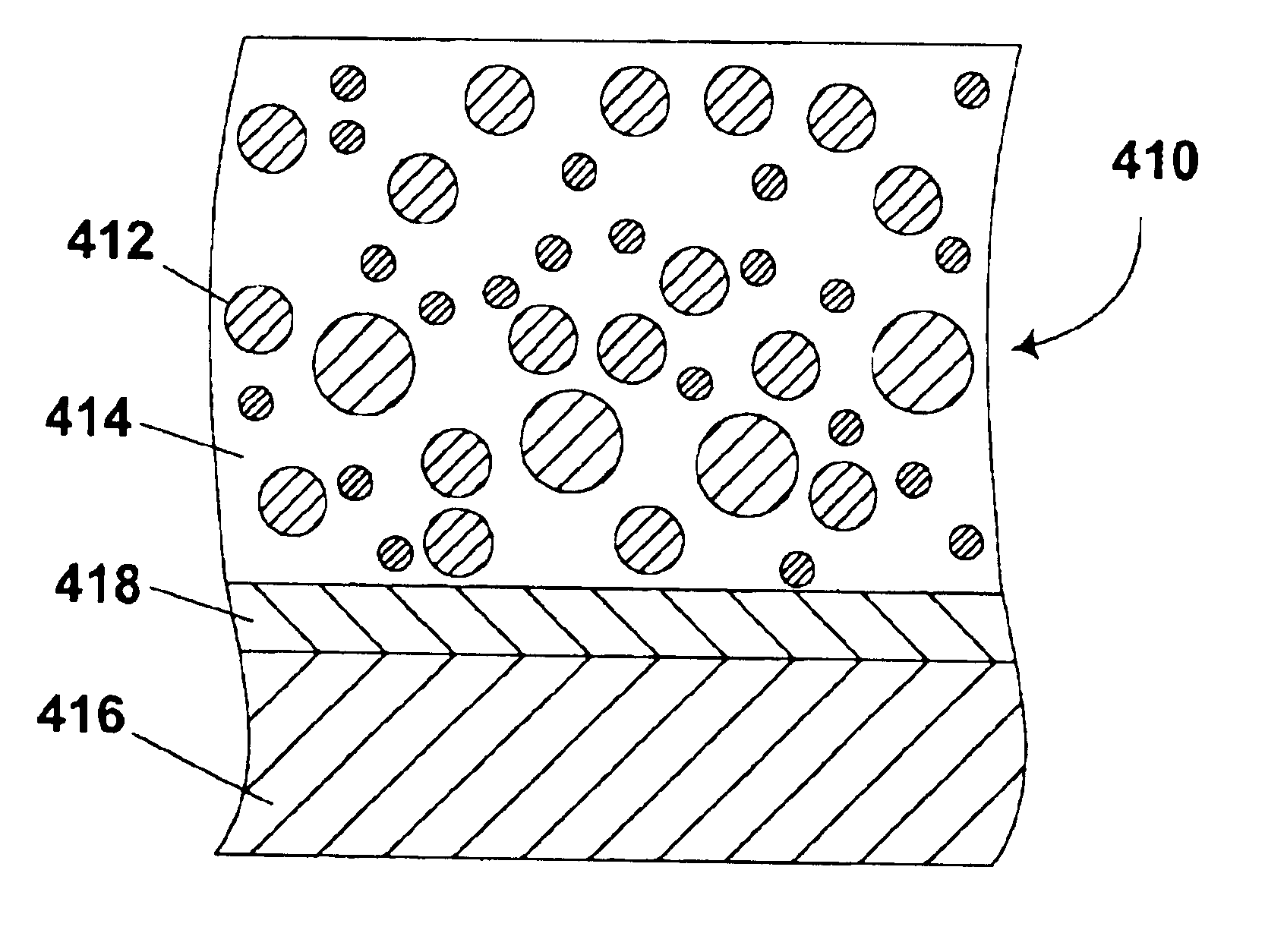

A two-phase electrophoretic medium comprises a continuous phase and a discontinuous phase. The discontinuous phase comprises a plurality of droplets, each of which comprises a suspending fluid and at least one particle disposed within the suspending fluid and capable of moving through the fluid upon application of an electric field to the electrophoretic medium. The continuous phase surrounds and encapsulates the discontinuous phase. To reduce the humidity sensitivity of the medium, a non-ionizable or crystalline polymer may be used as the continuous phase.

Owner:E INK CORPORATION

Electrophoretic displays using nanoparticles

InactiveUS6721083B2Less wavelengthIncrease volumeMechanical clocksSolid-state devicesChemical compoundElectrophoresis

Owner:E INK CORPORATION

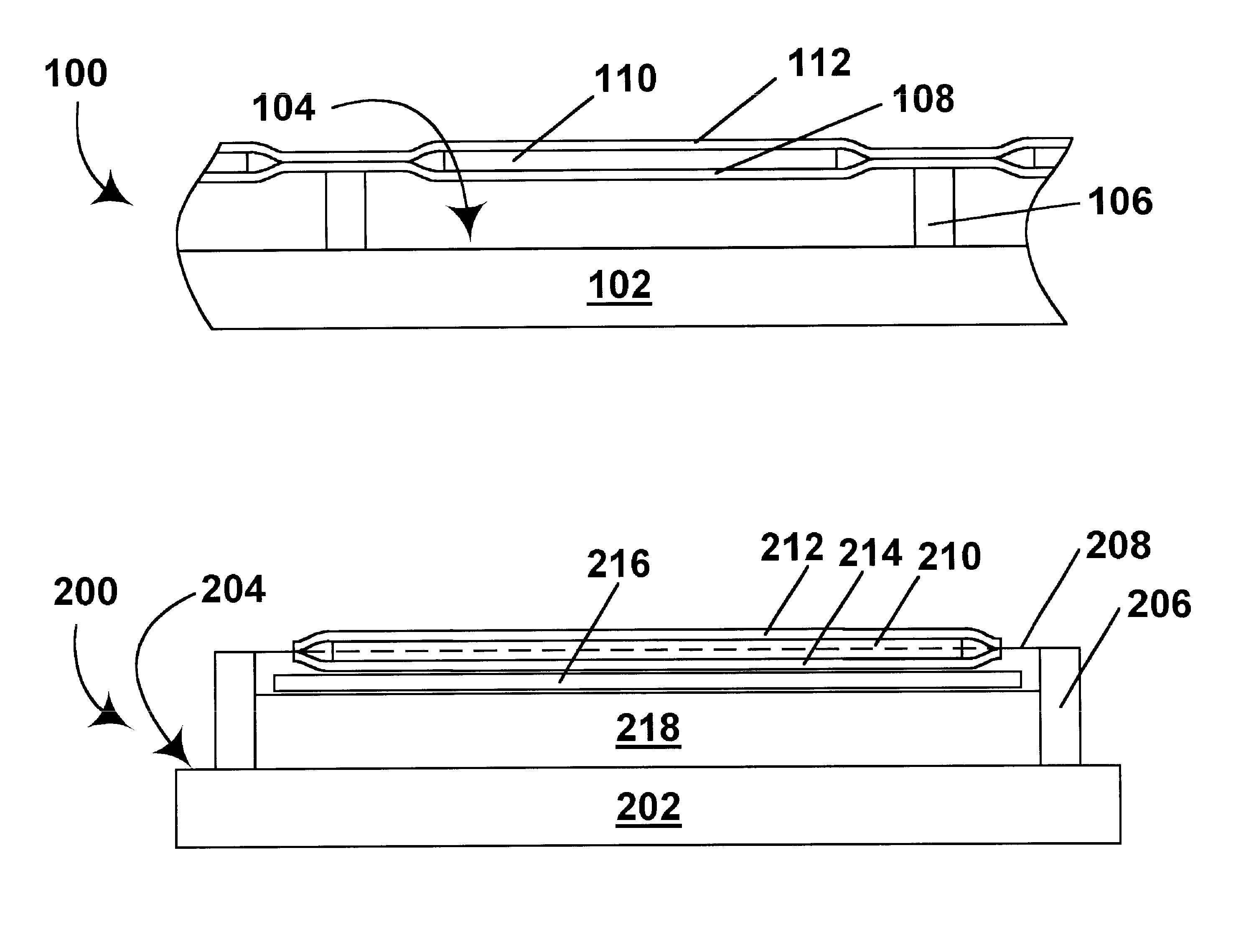

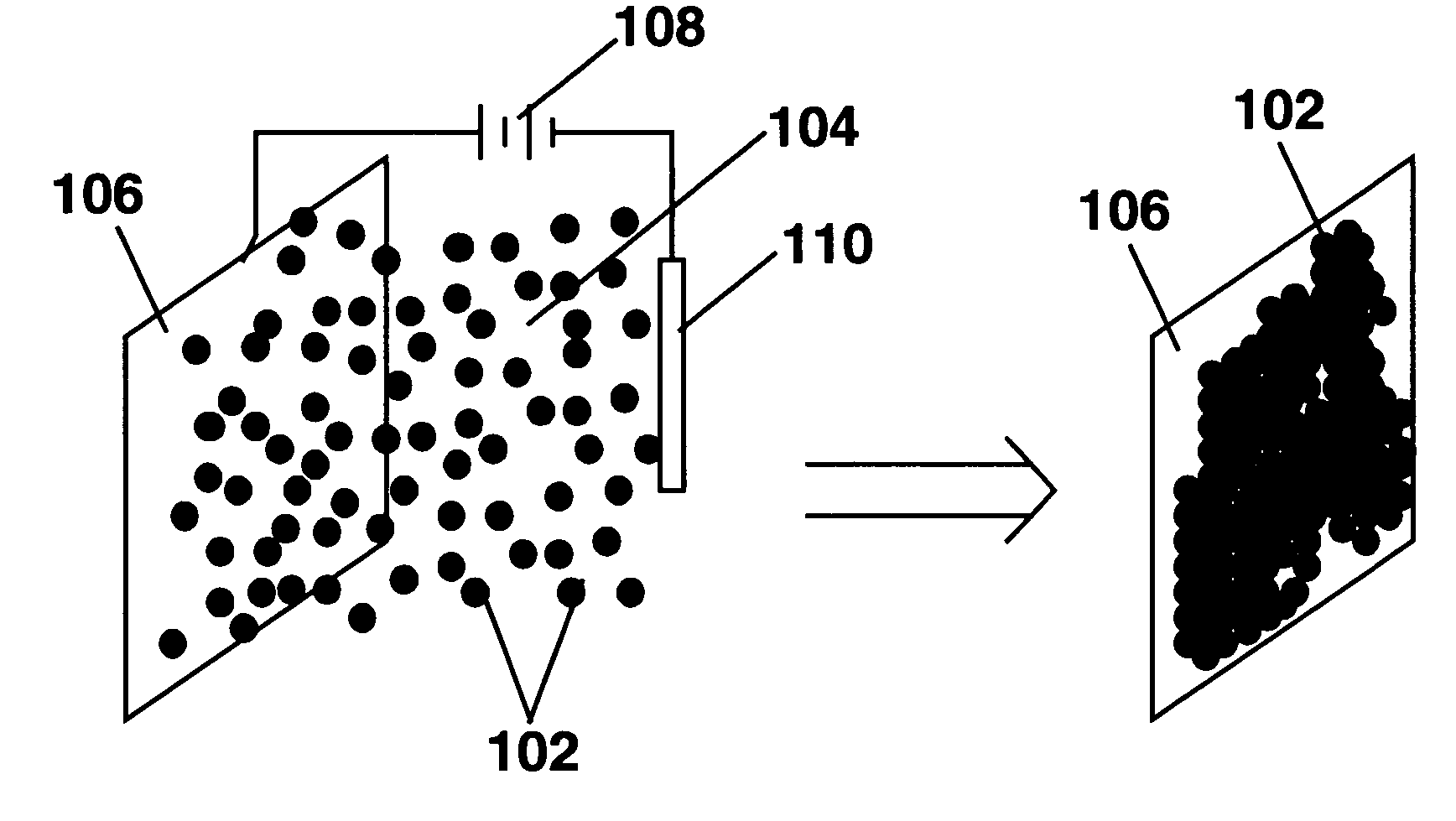

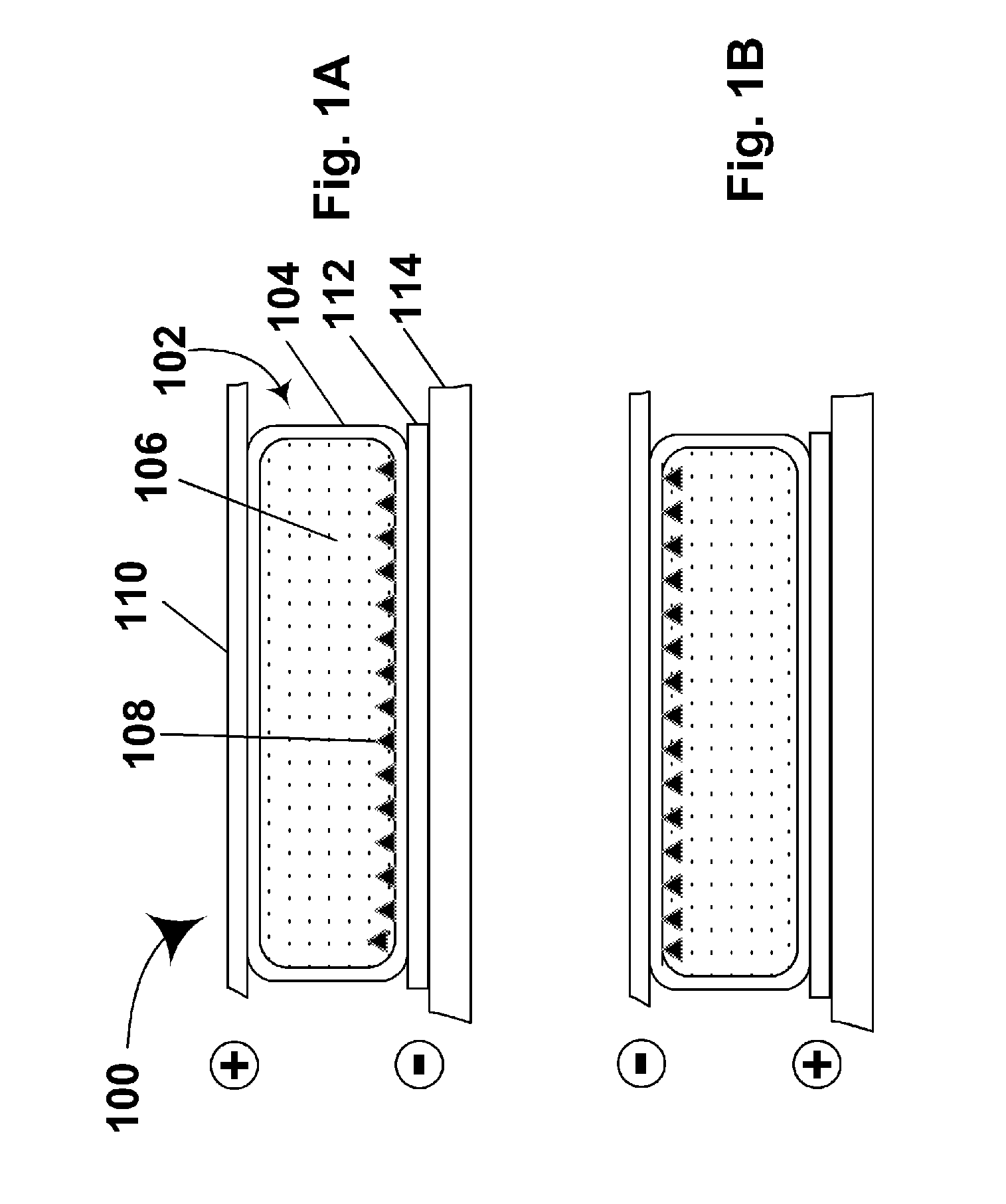

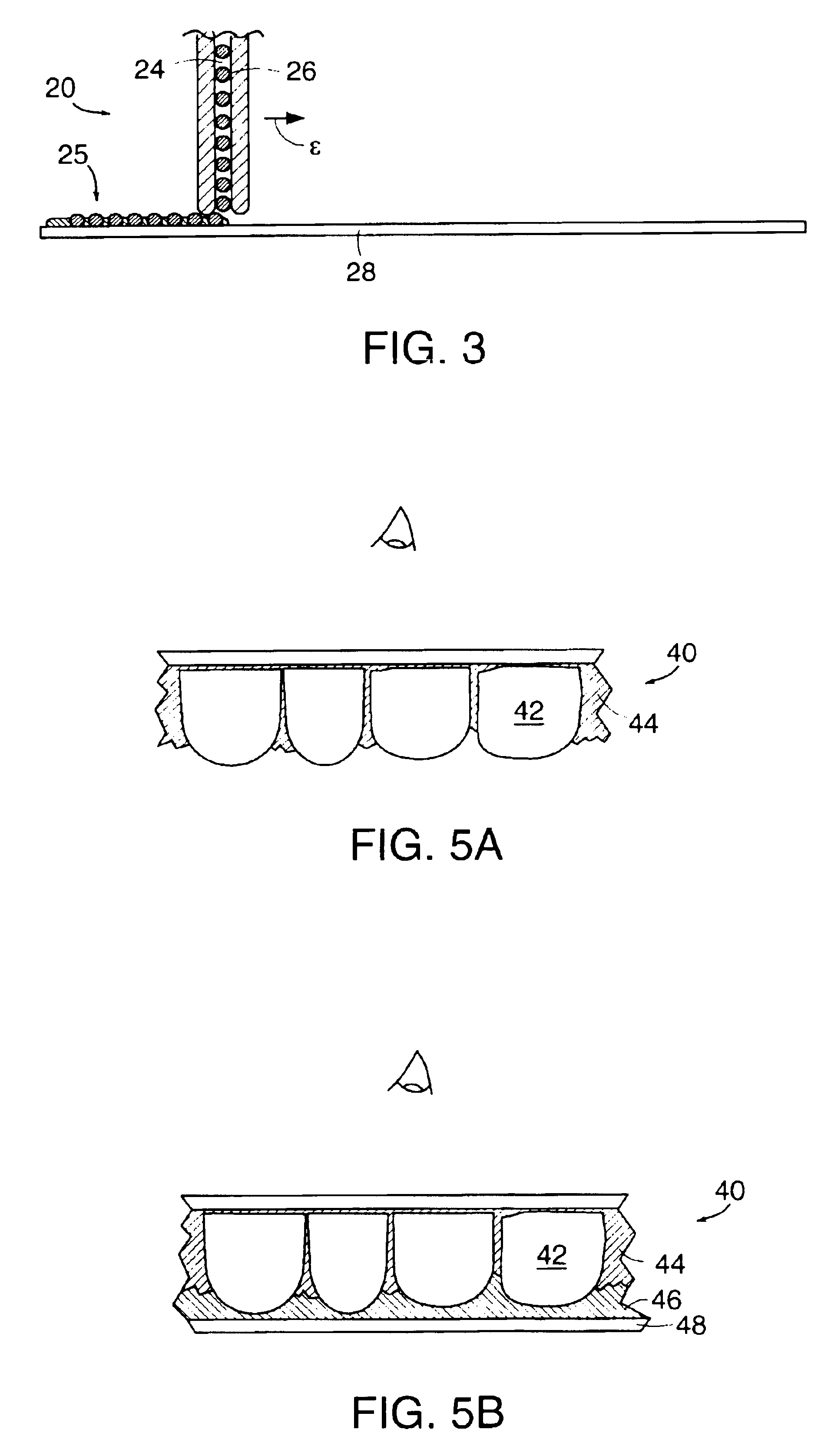

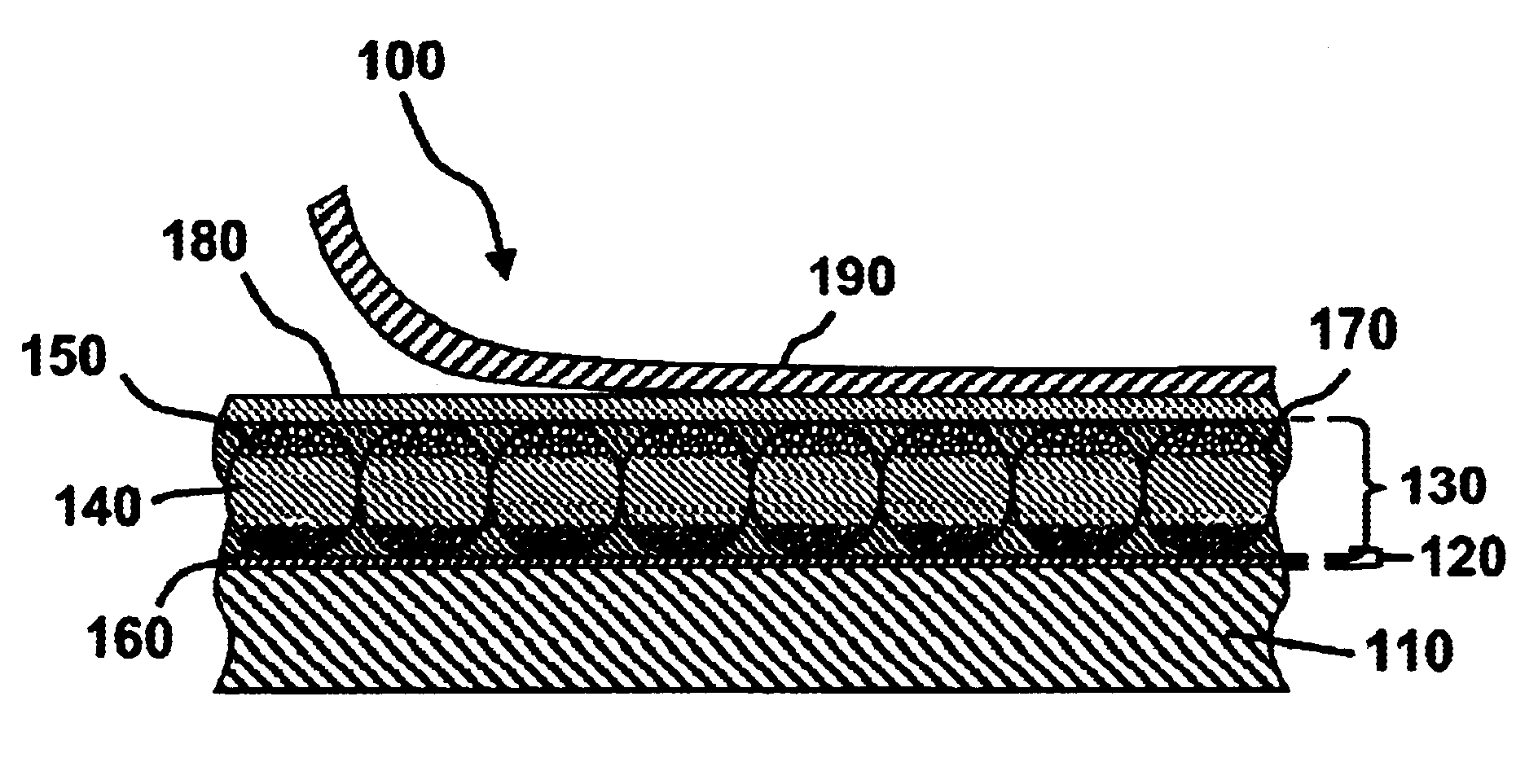

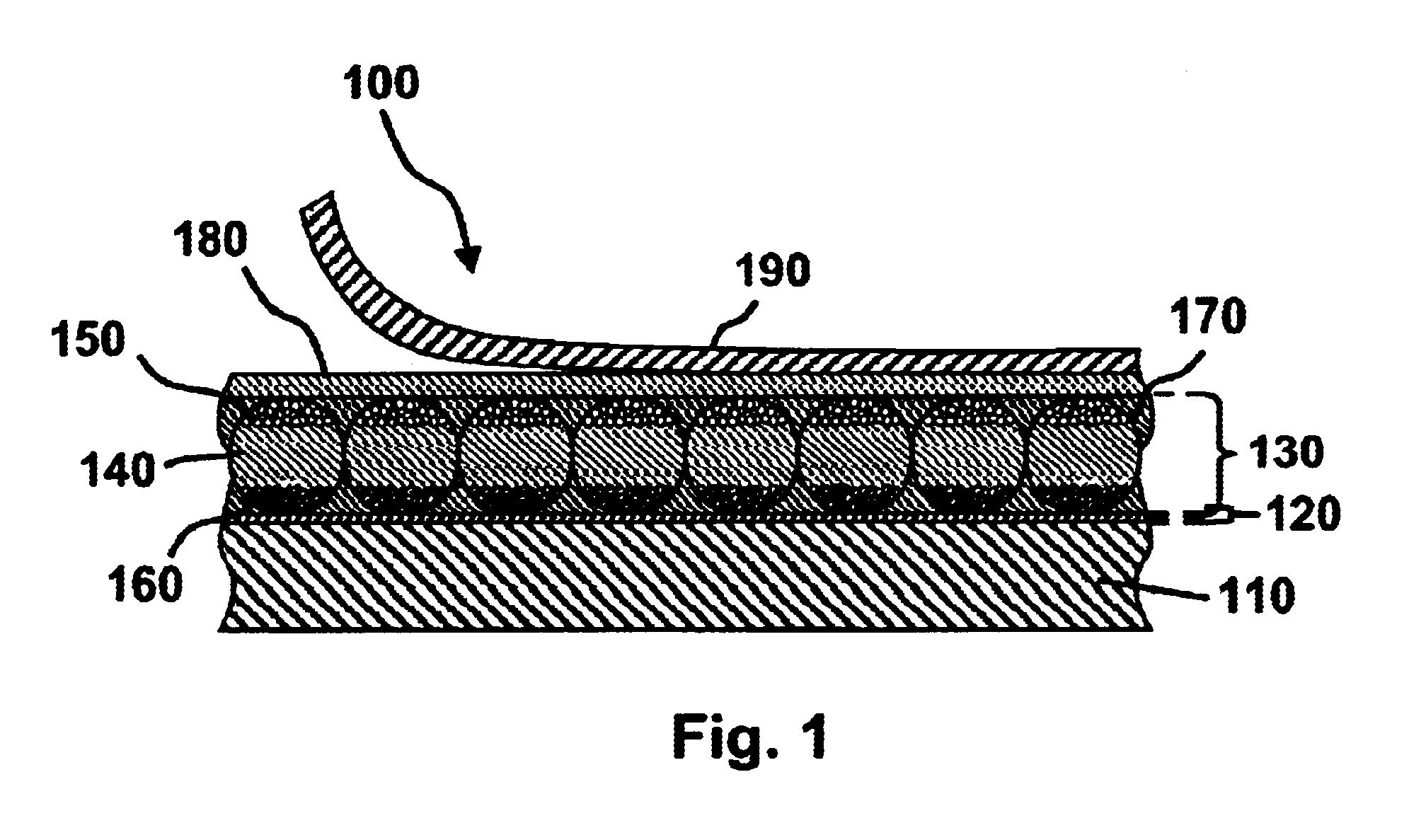

Processes for the production of electrophoretic displays

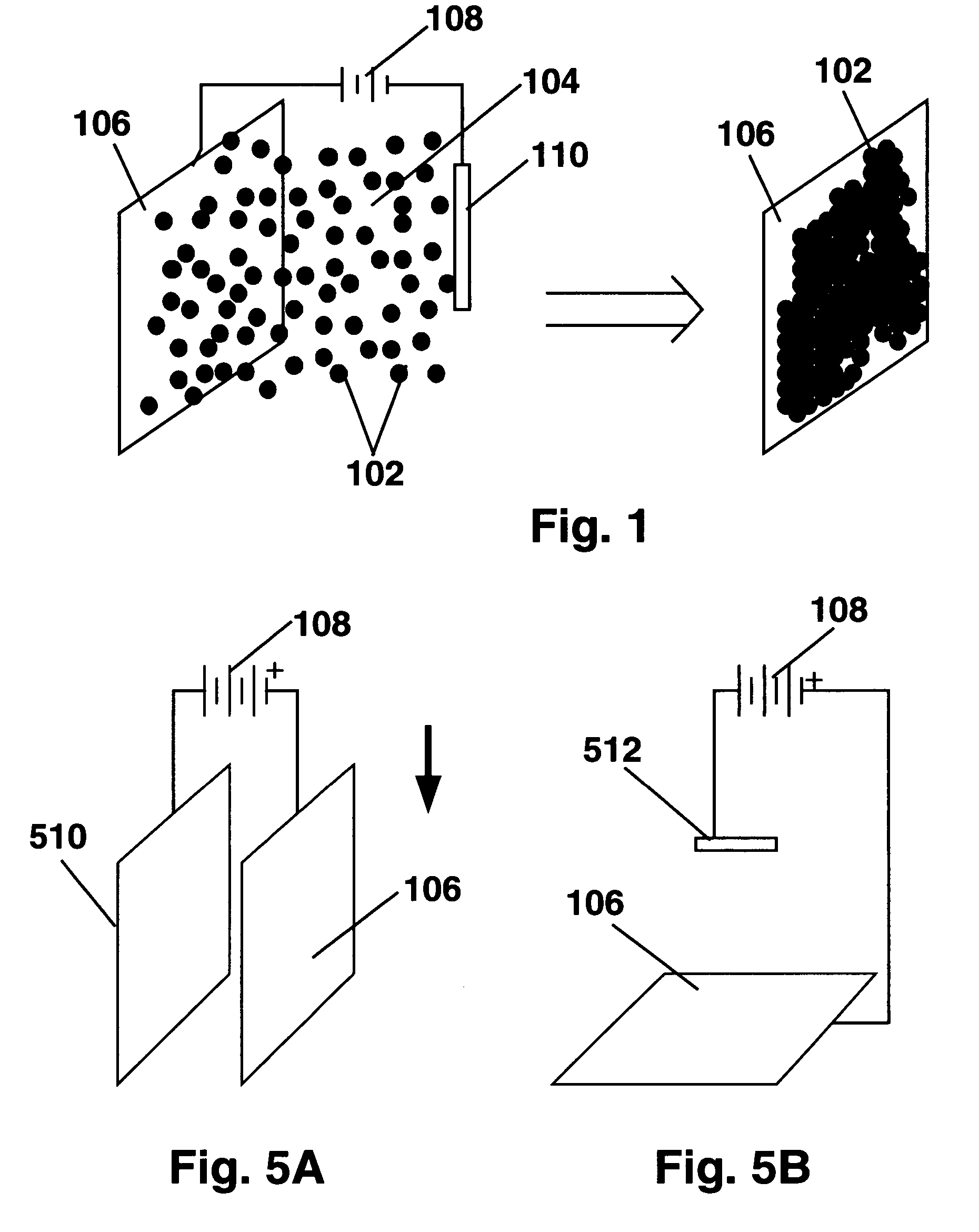

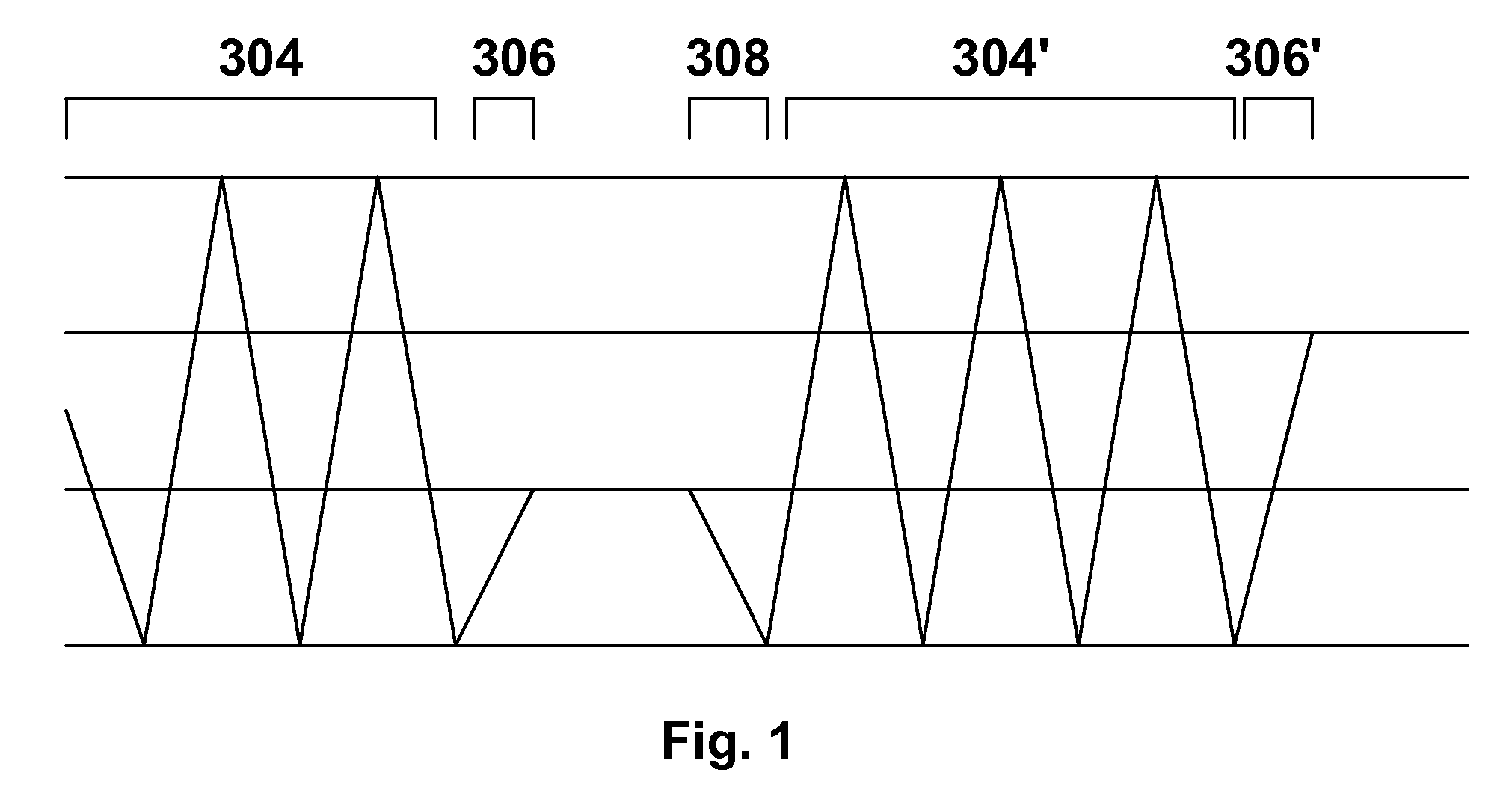

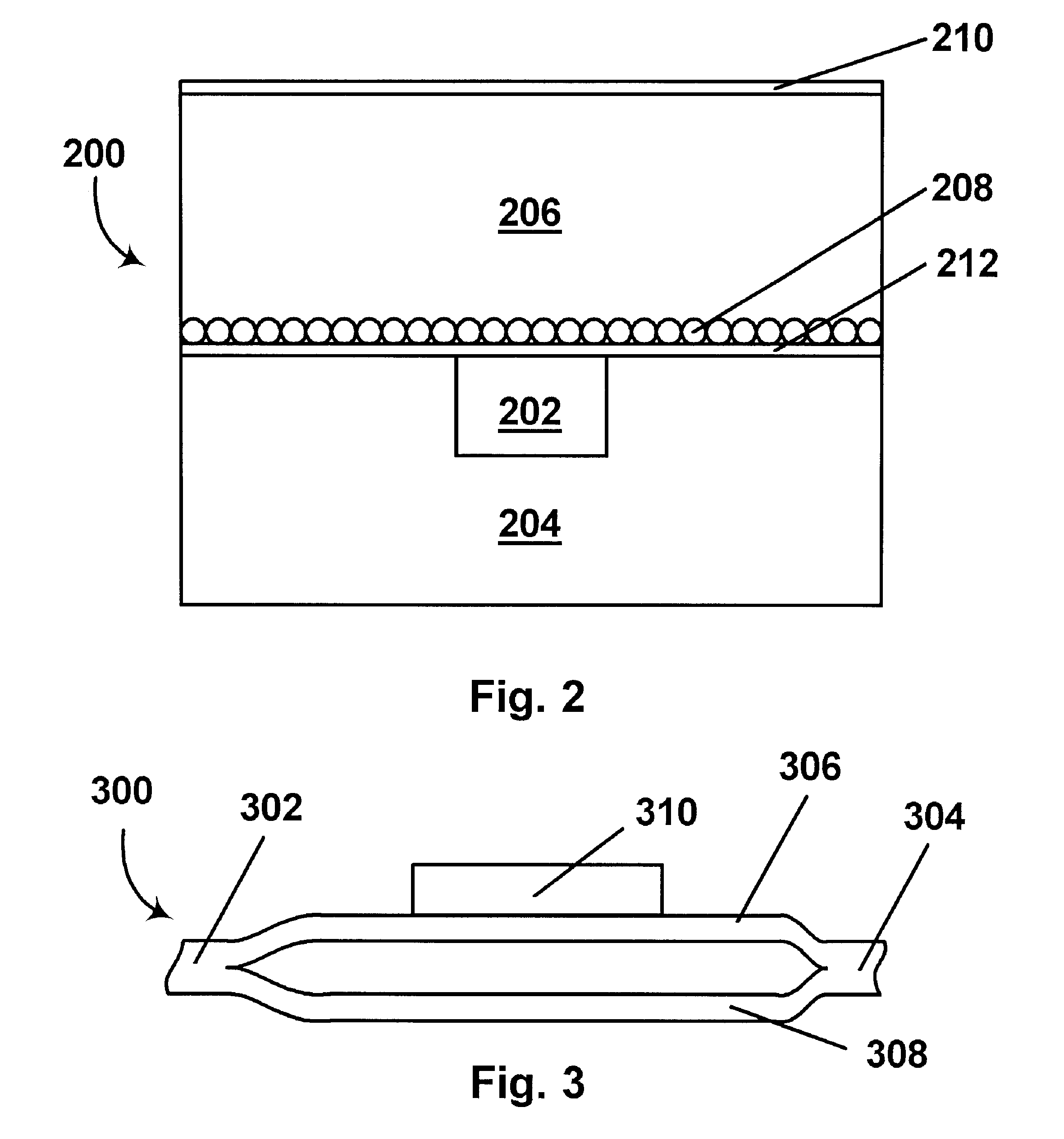

ActiveUS7339715B2Electric shock equipmentsElectrophoretic coatingsElectrophoresisPotential difference

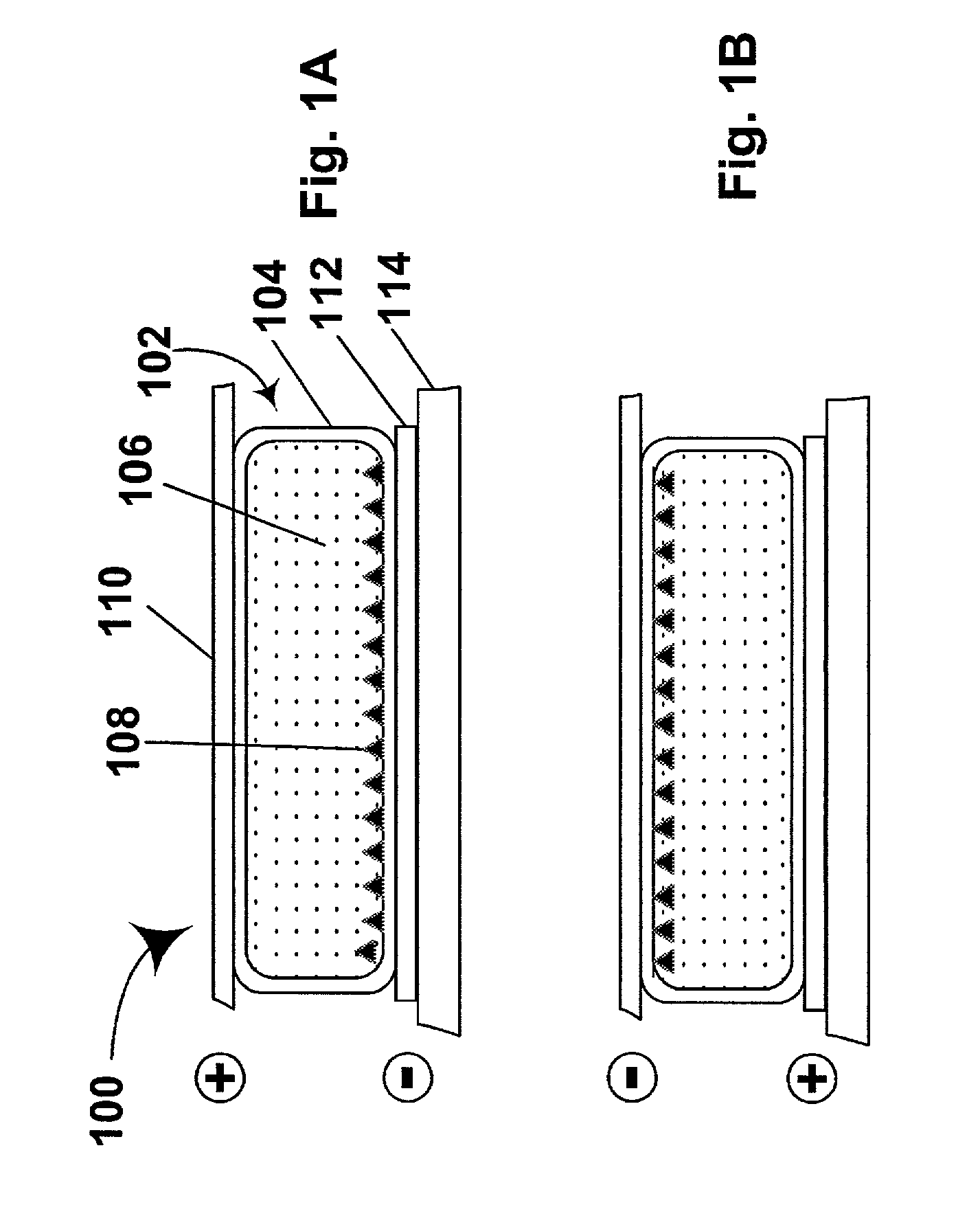

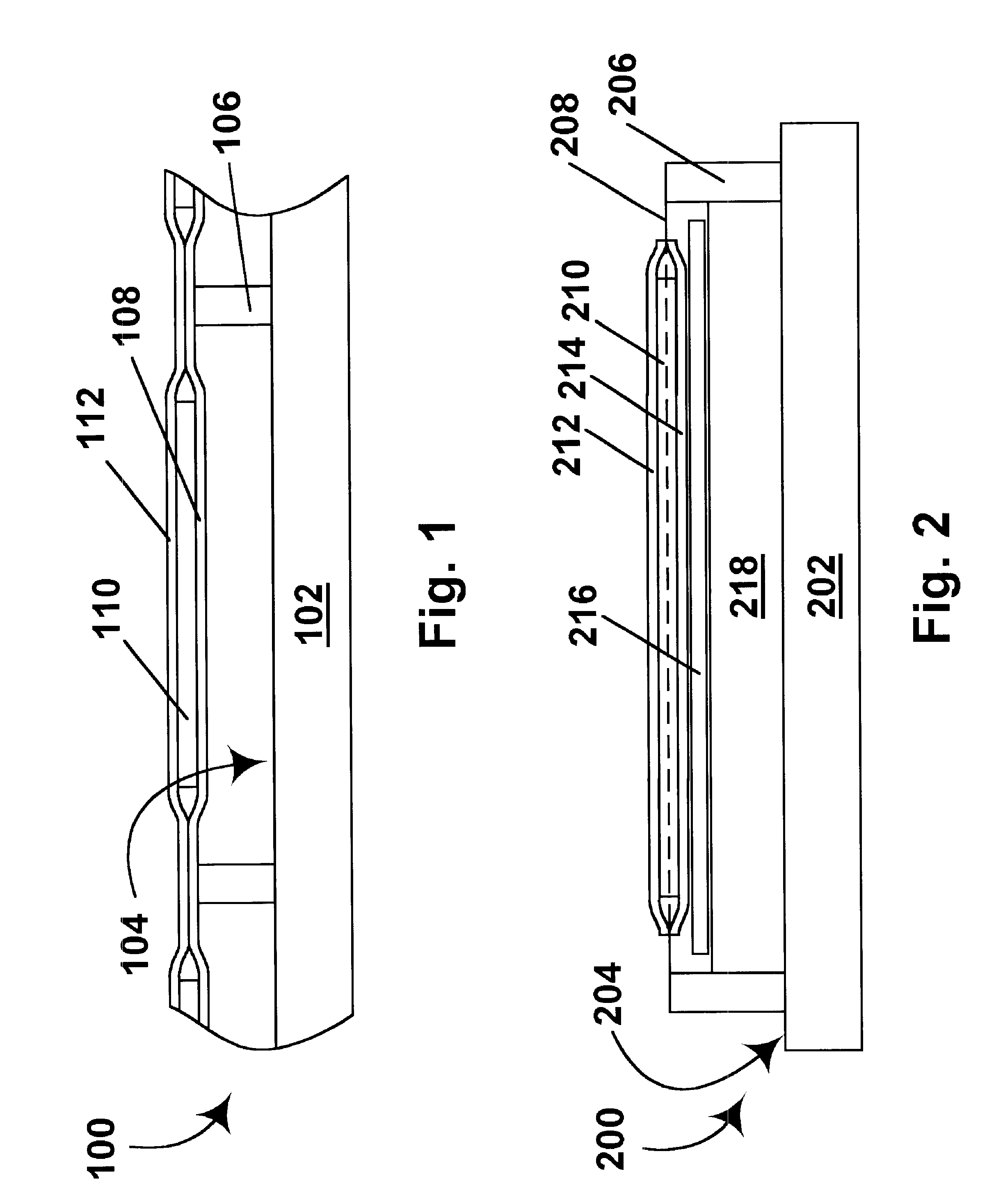

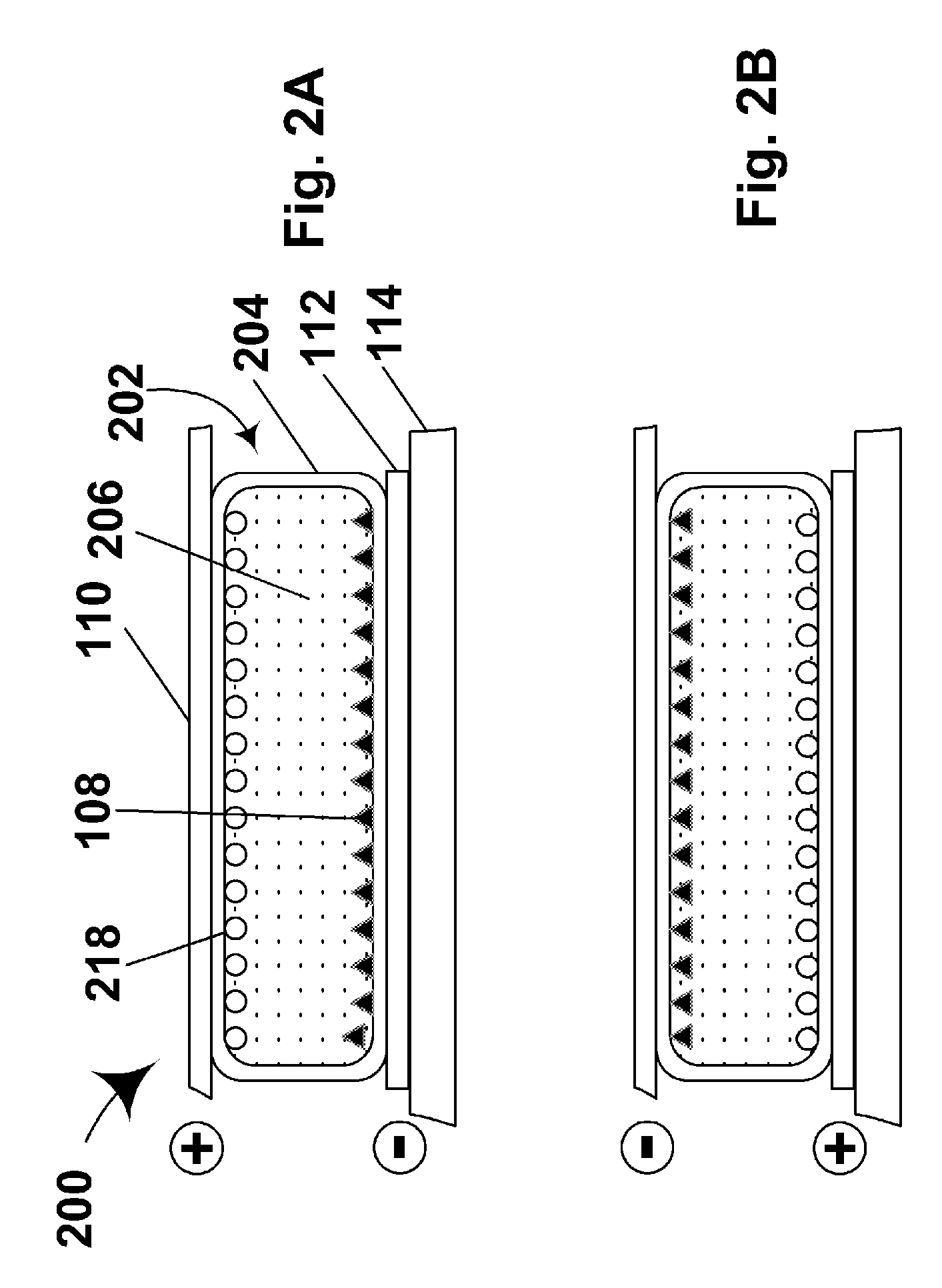

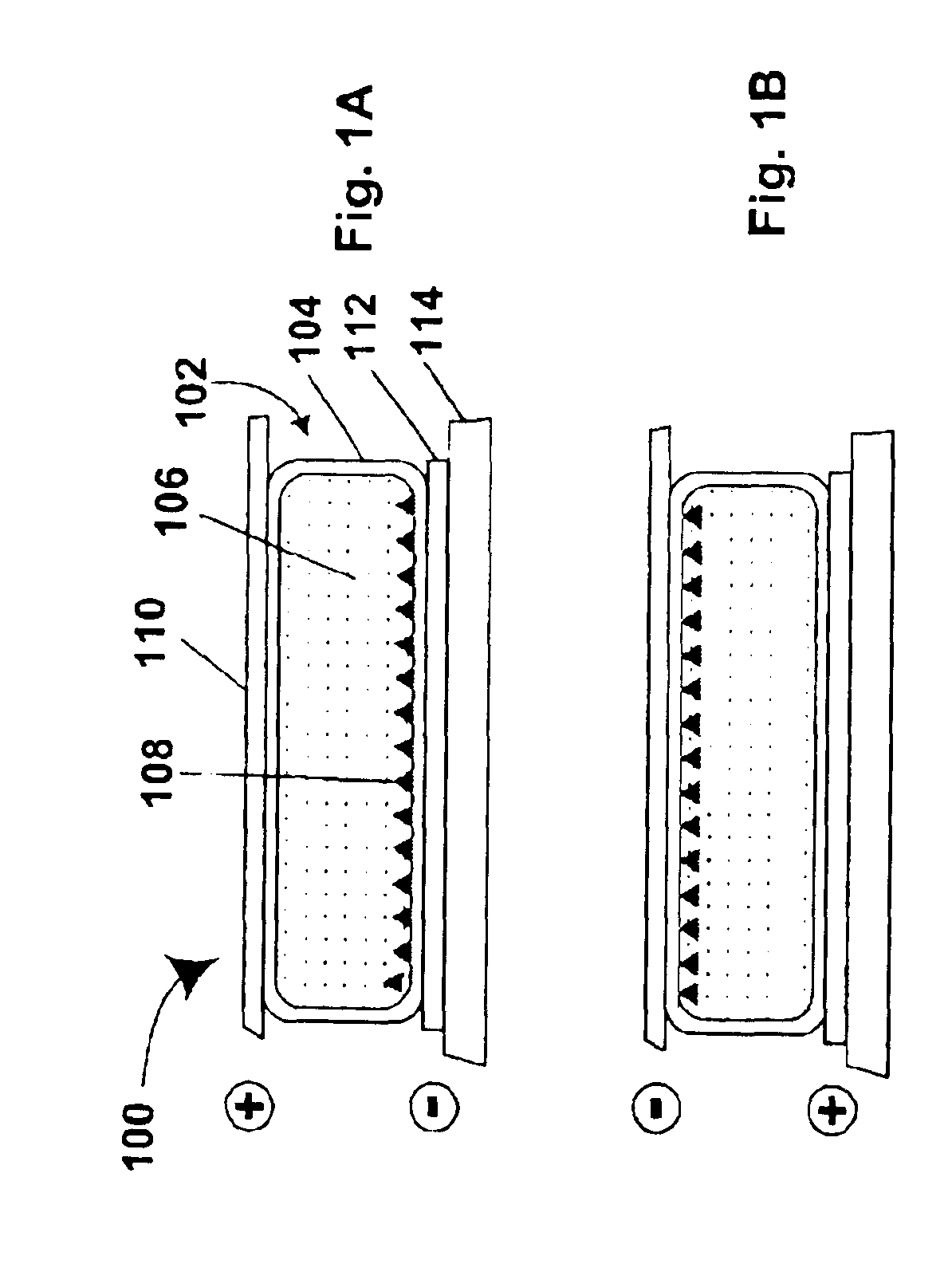

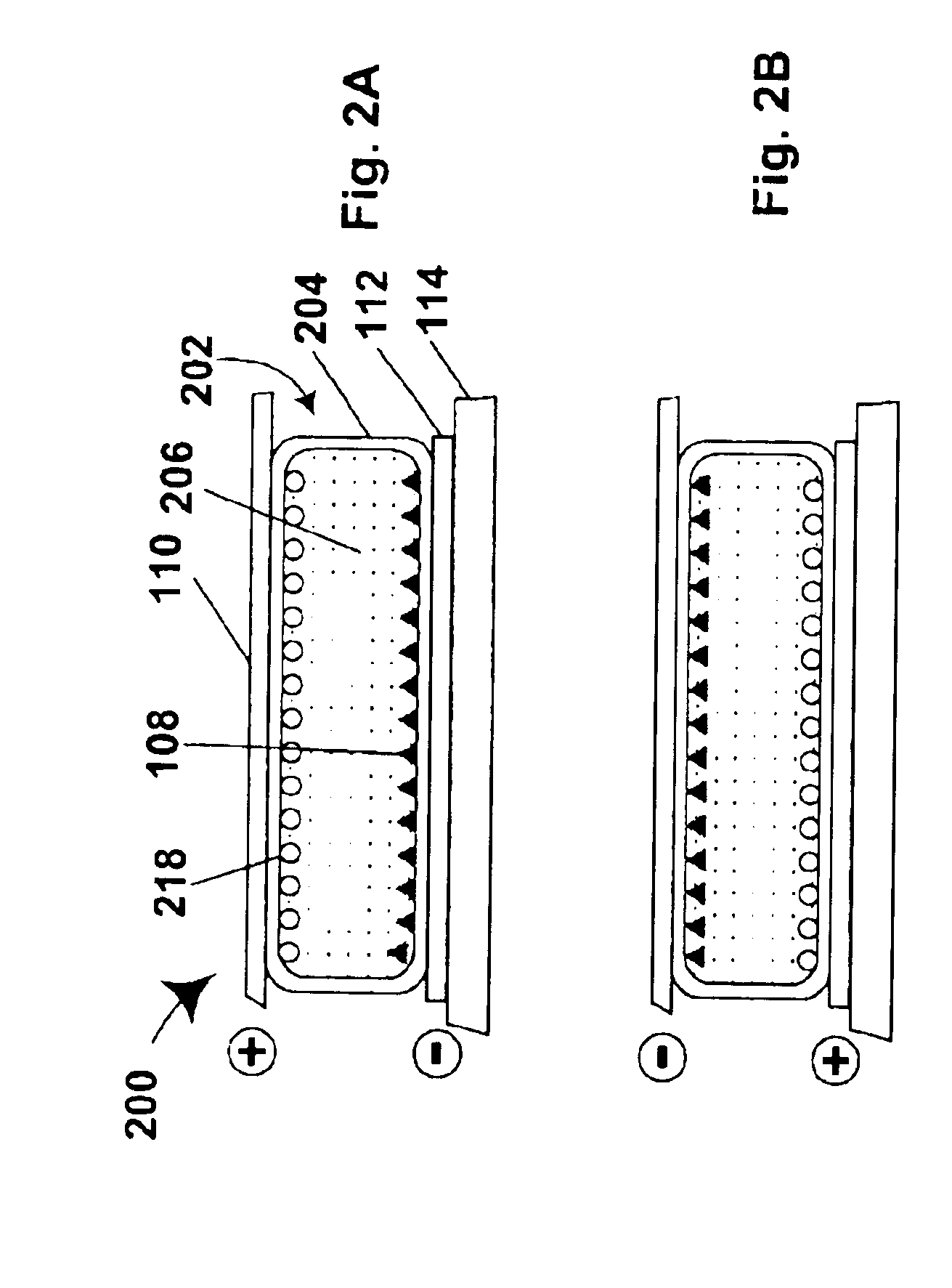

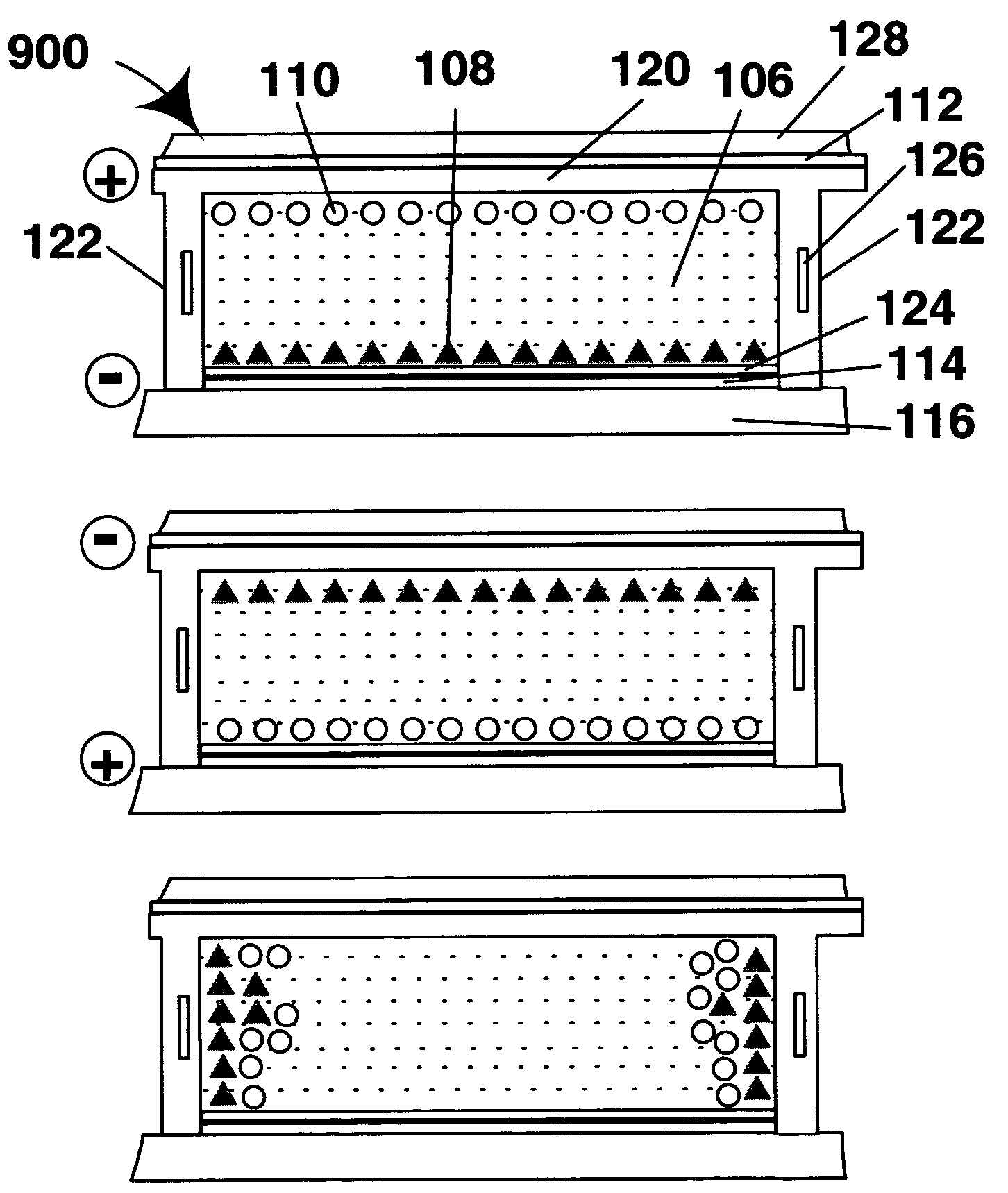

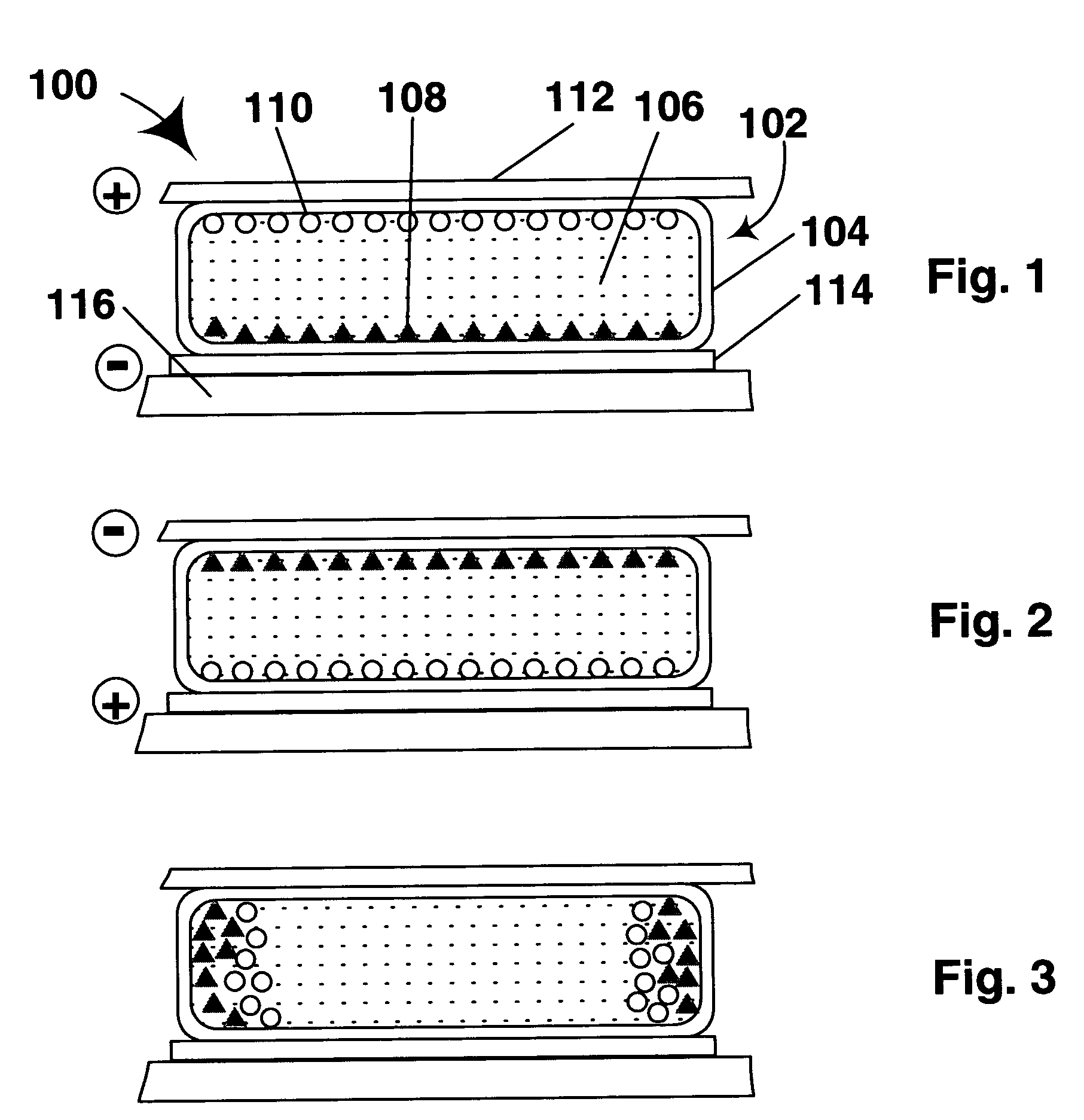

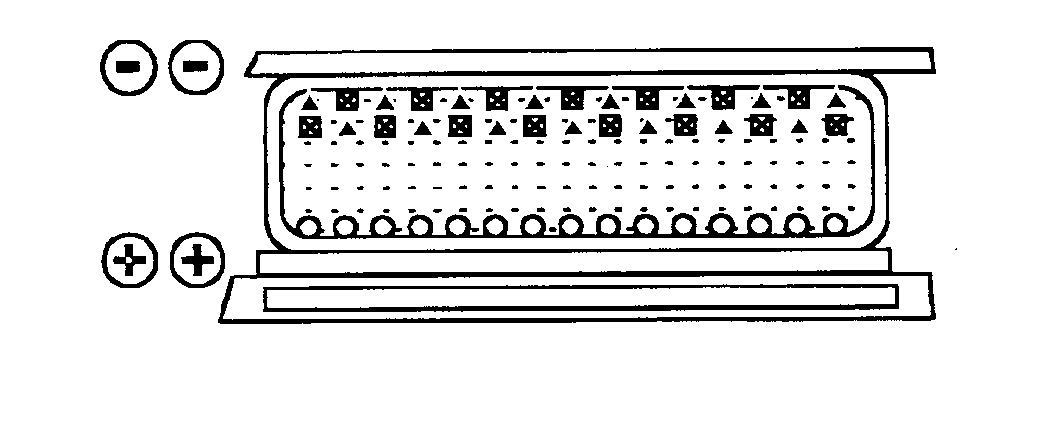

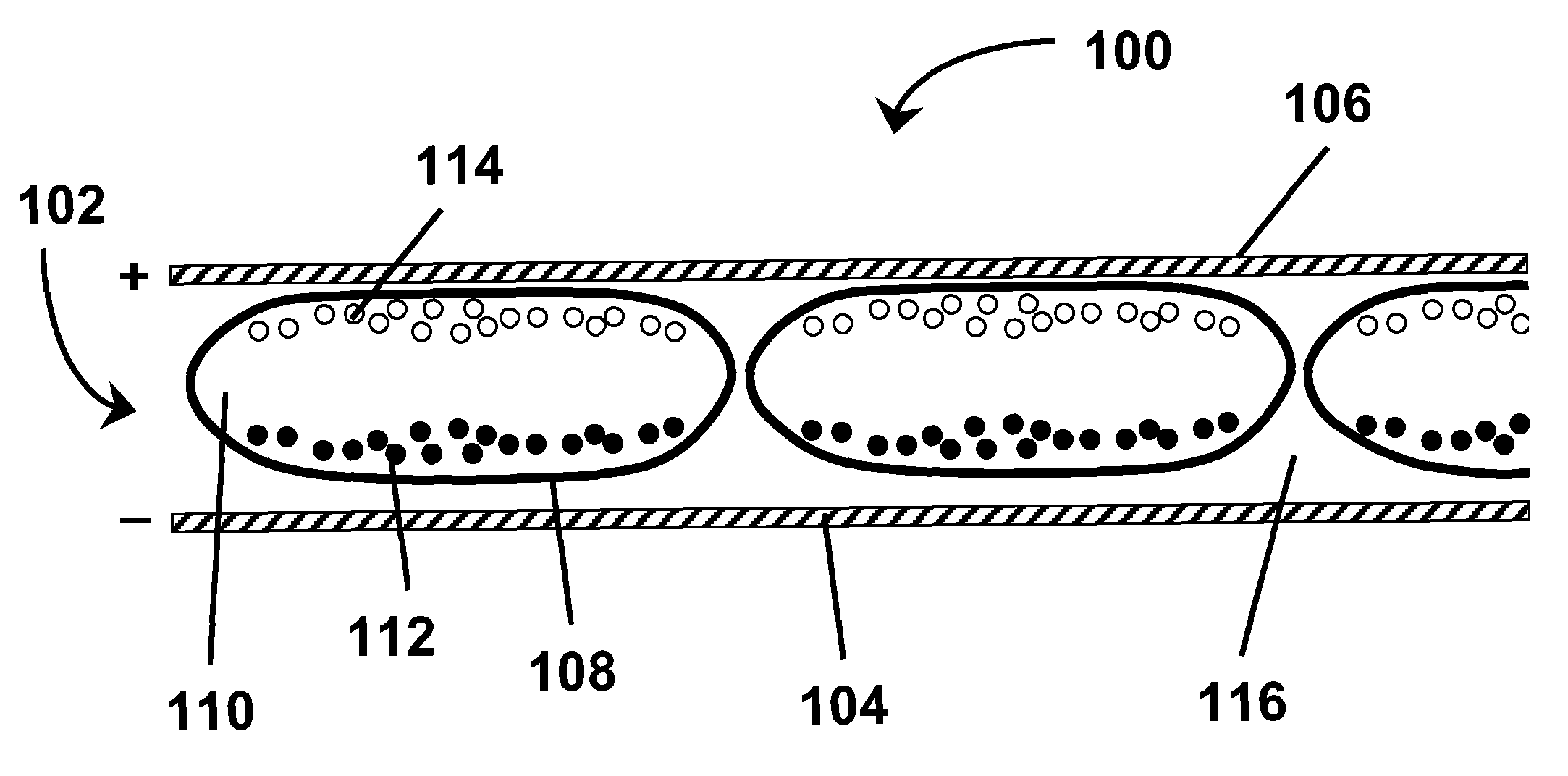

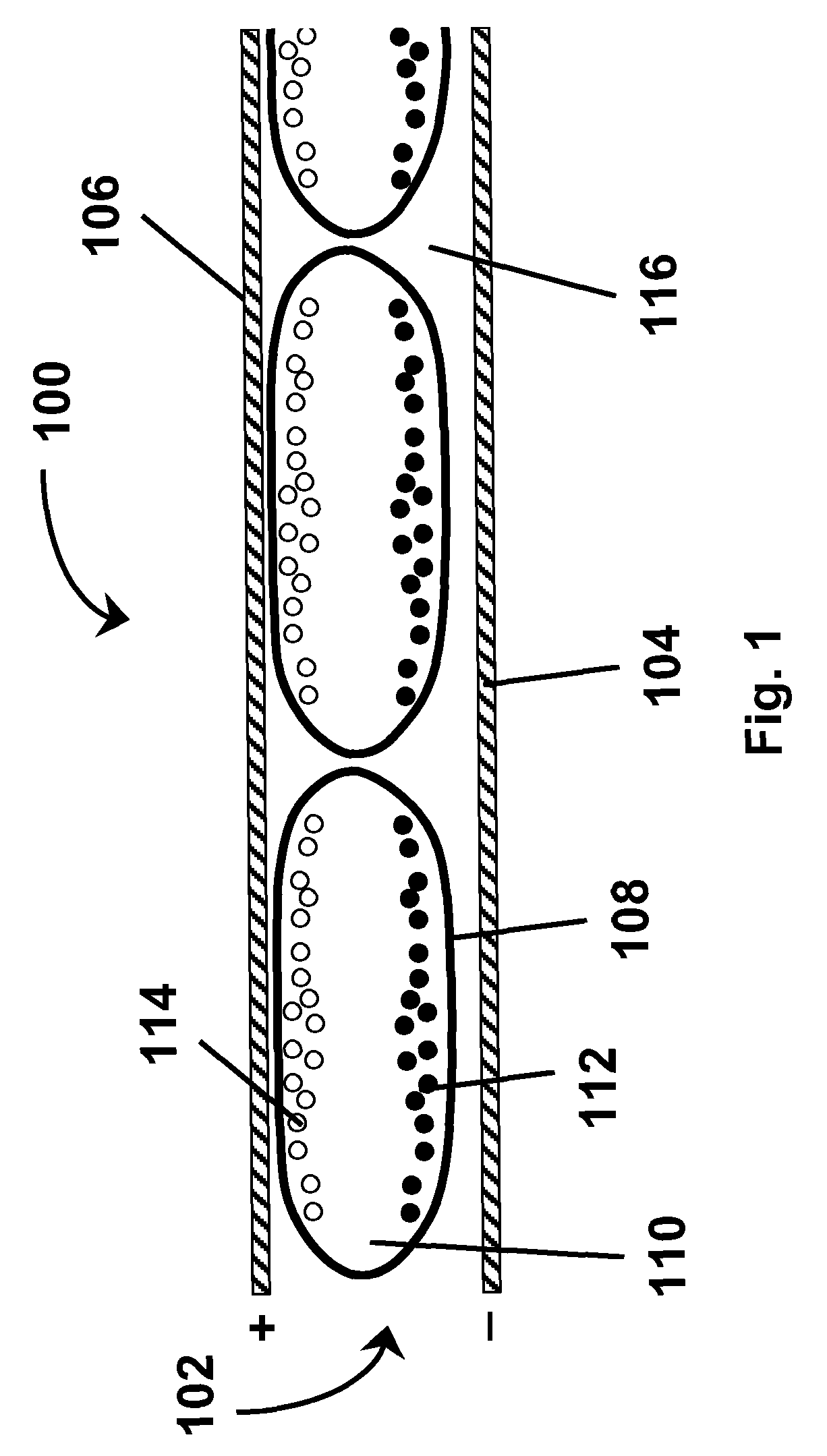

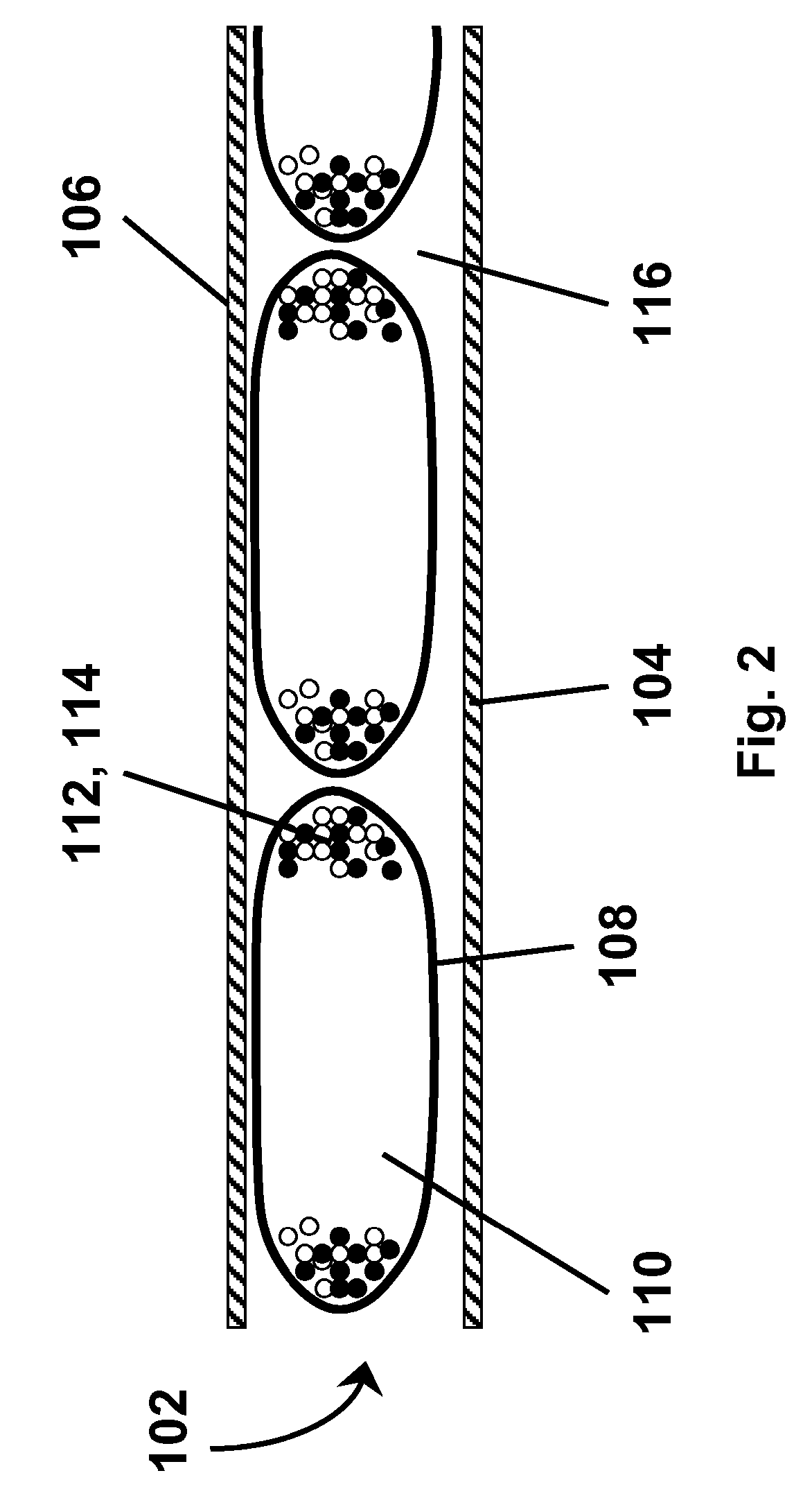

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, a patterned coating may be deposited upon a substrate containing a conductive layer by varying the conductivity of the conductive layer by radiation exposure or by coating portions of the conductive layer with an insulating layer, typically a photoresist.

Owner:E INK CORPORATION

Materials for use in electrophoretic displays

The image stability of electrophoretic media, comprising a plurality of particles disposed in a fluid and capable of moving through the fluid upon application of an electric field to the medium, can be improved by including in the fluid either a polystyrene or an aggregating diblock copolymer which forms micelle-like structures in the fluid, the diblock copolymer having a first block soluble in the fluid and a second block not swellable by the fluid. In variable transmission electrophoretic media, haze can be reduced by using as the fluid a mixture of a partially hydrogenated aromatic hydrocarbon and a terpene.

Owner:E INK CORPORATION

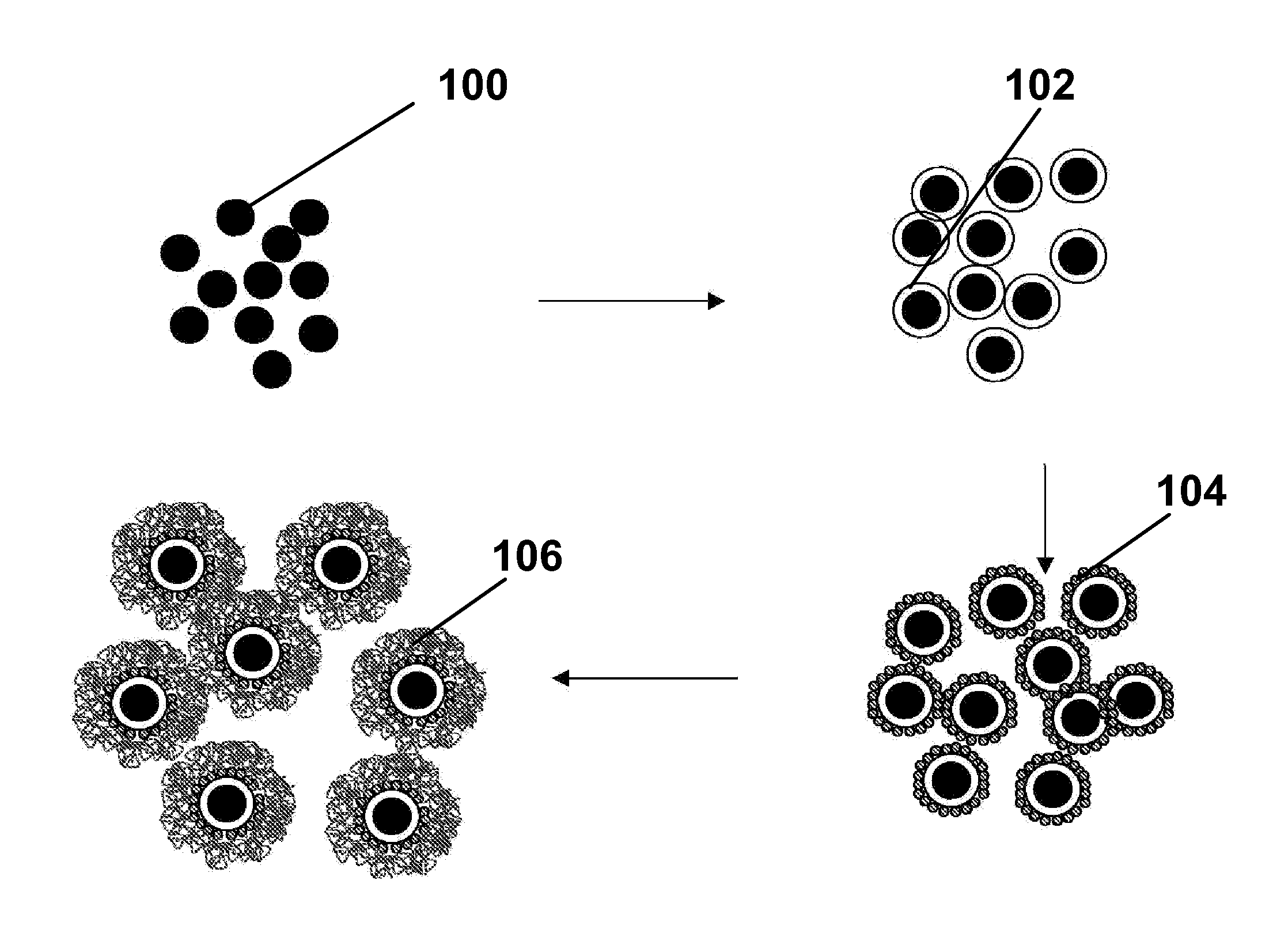

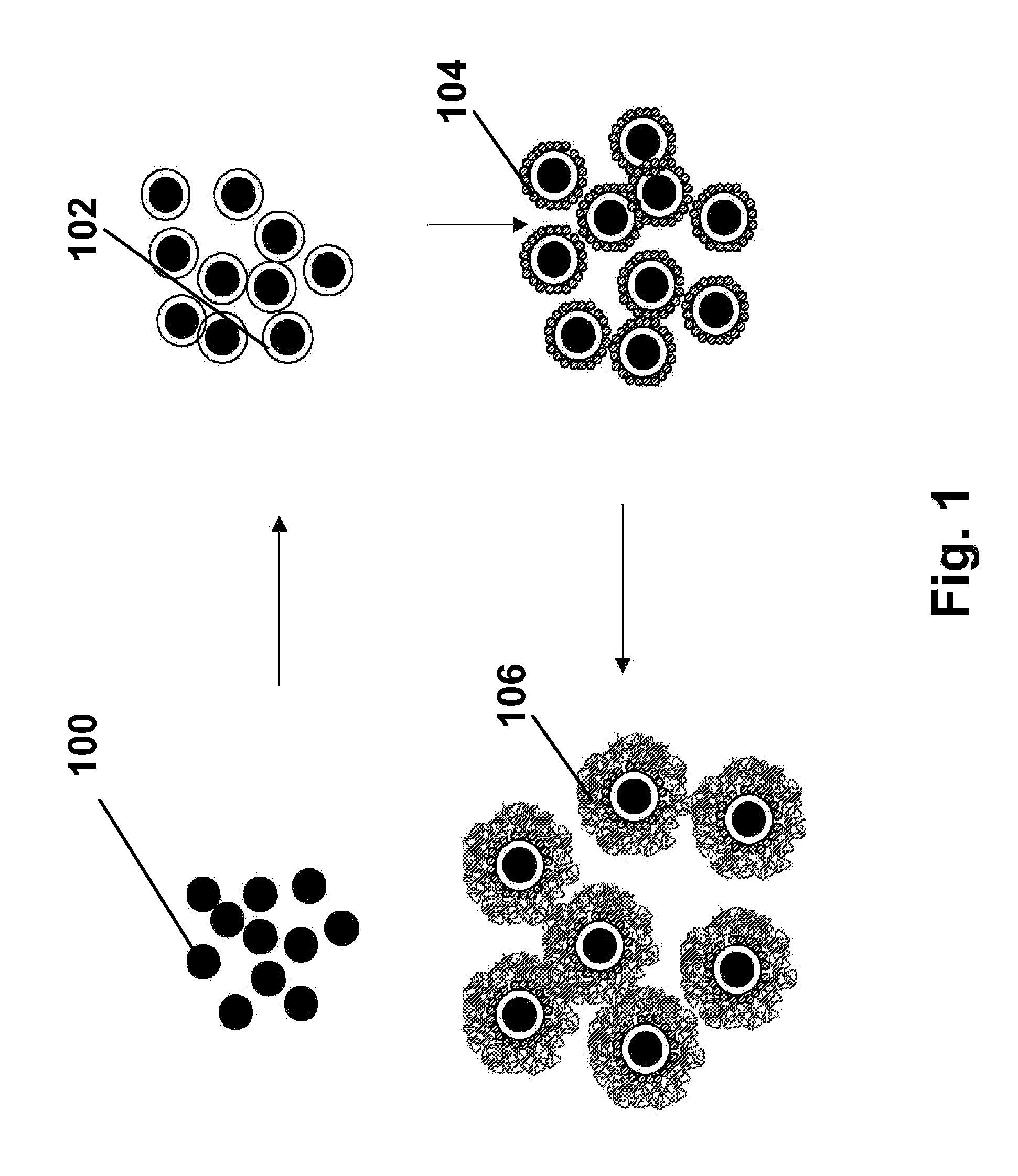

Electrophoretic particles and processes for the production thereof

InactiveUS6822782B2Improve stabilityEasy to adaptMaterial nanotechnologyStatic indicating devicesCross-linkOligomer

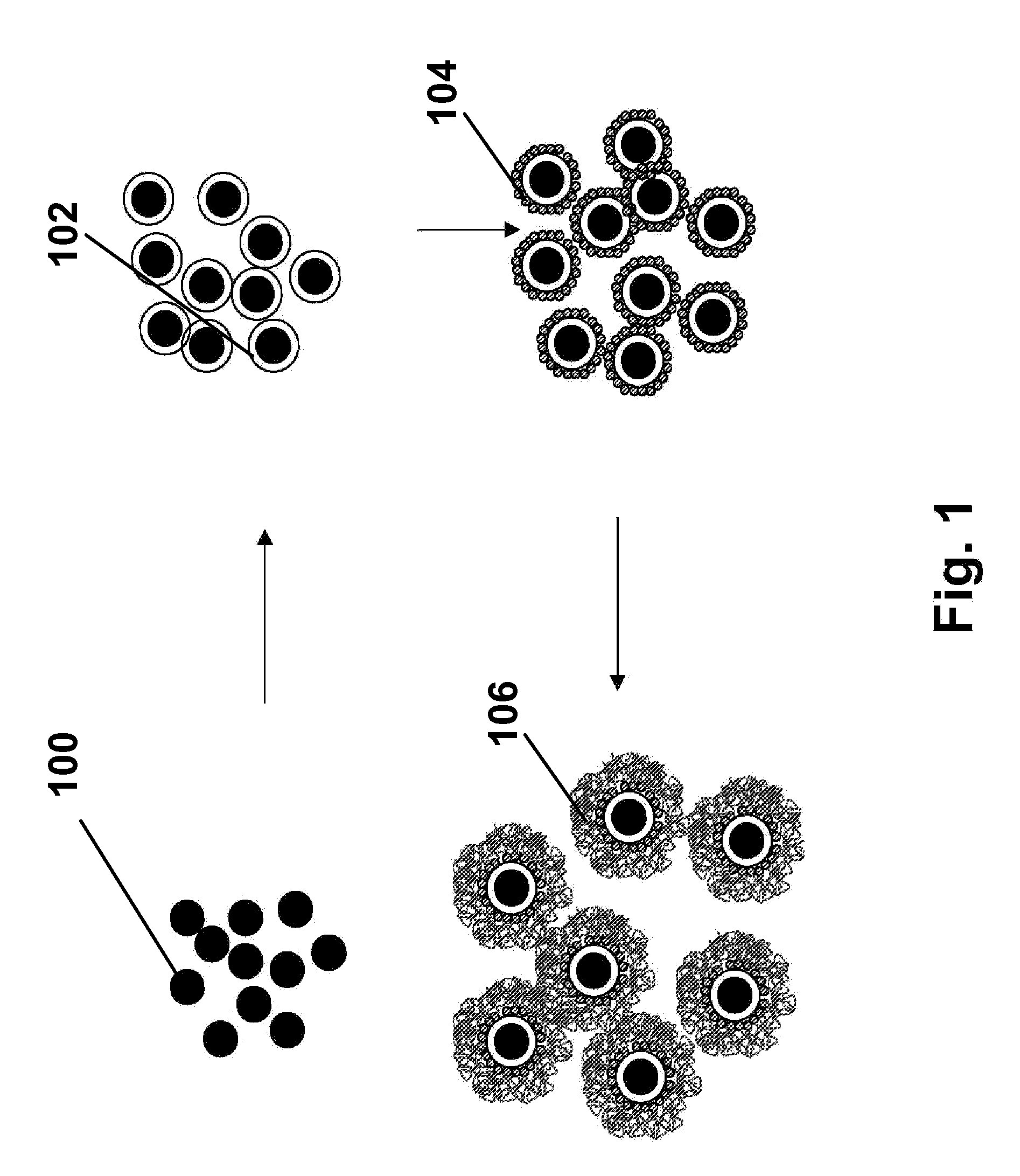

In electrophoretic media, it is advantageous to use pigment particles having about 1 to 15 percent by weight of a polymer chemically bonded to, or cross-linked around, the pigment particles. The polymer desirably has a branched chain structure with side chains extending from a main chain. Charged or chargeable groups can be incorporated into the polymer or can be bonded to the particles separately from the polymer. The polymer-coated particles can be prepared by first attaching a polymerizable or polymerization-initiating group to the particle and then reacting the particle with one or more polymerizable monomers or oligomers.

Owner:E INK CORPORATION

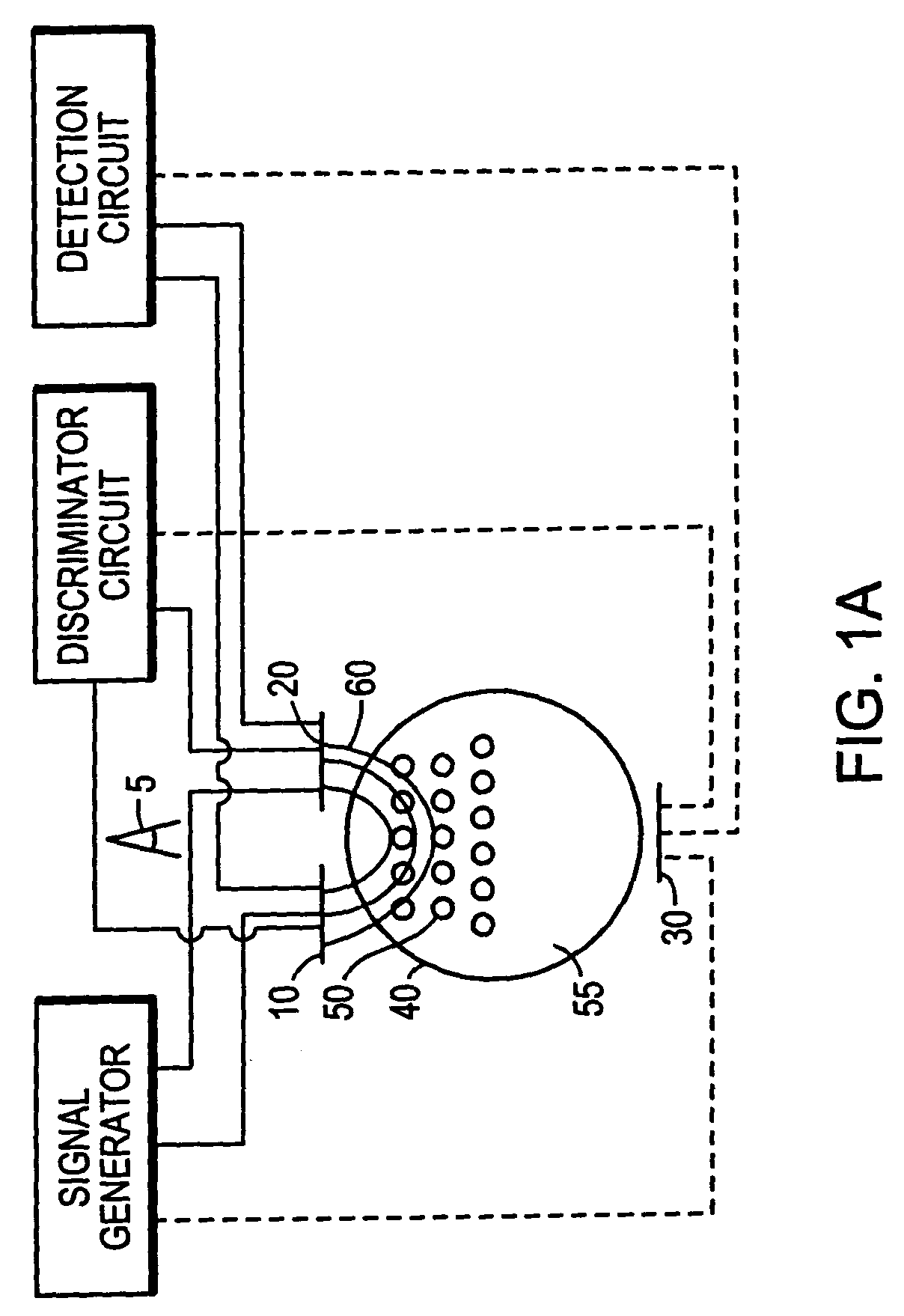

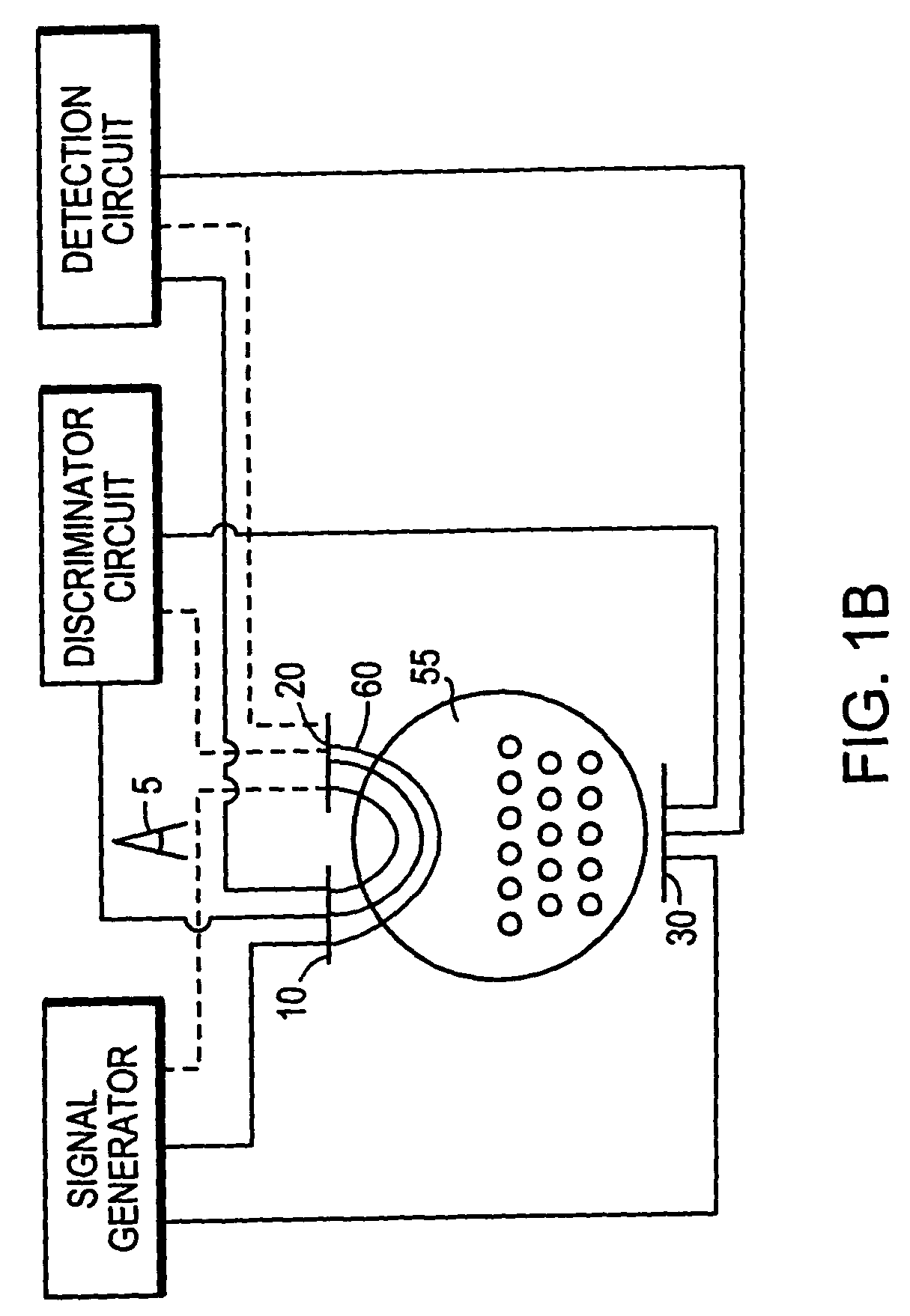

Method and apparatus for determining properties of an electrophoretic display

A method for sensing the state of an electrophoretic display includes the steps of applying an electrical signal to a display element, measuring an electrical response for the display element, and deducing the state of the display element from the measured electrical response. Also, the parameters of the display materials are determined using the encapsulated electrophoretic display media as a sensor, either alone or in conjunction with other sensors.

Owner:E INK CORPORATION

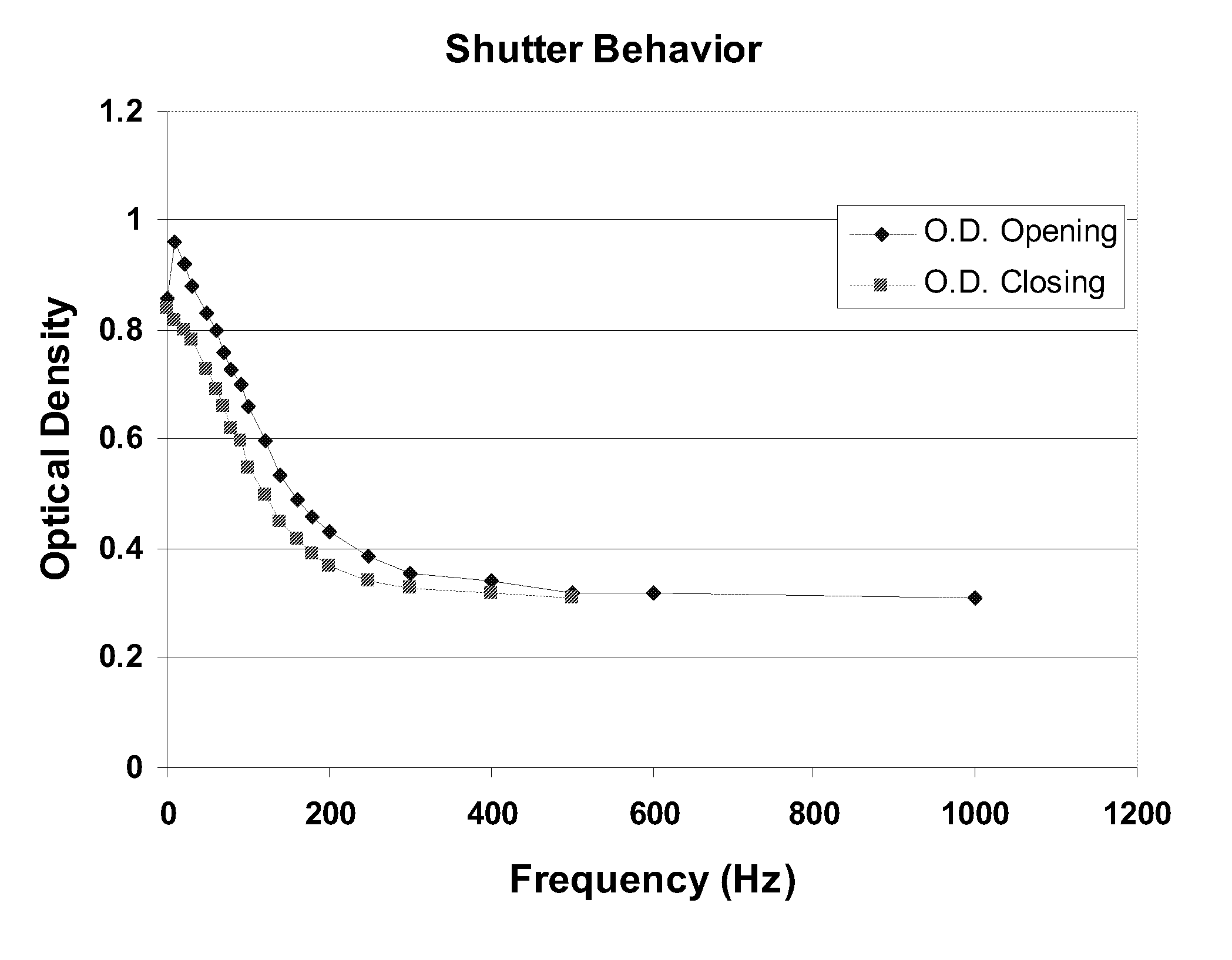

Light modulators

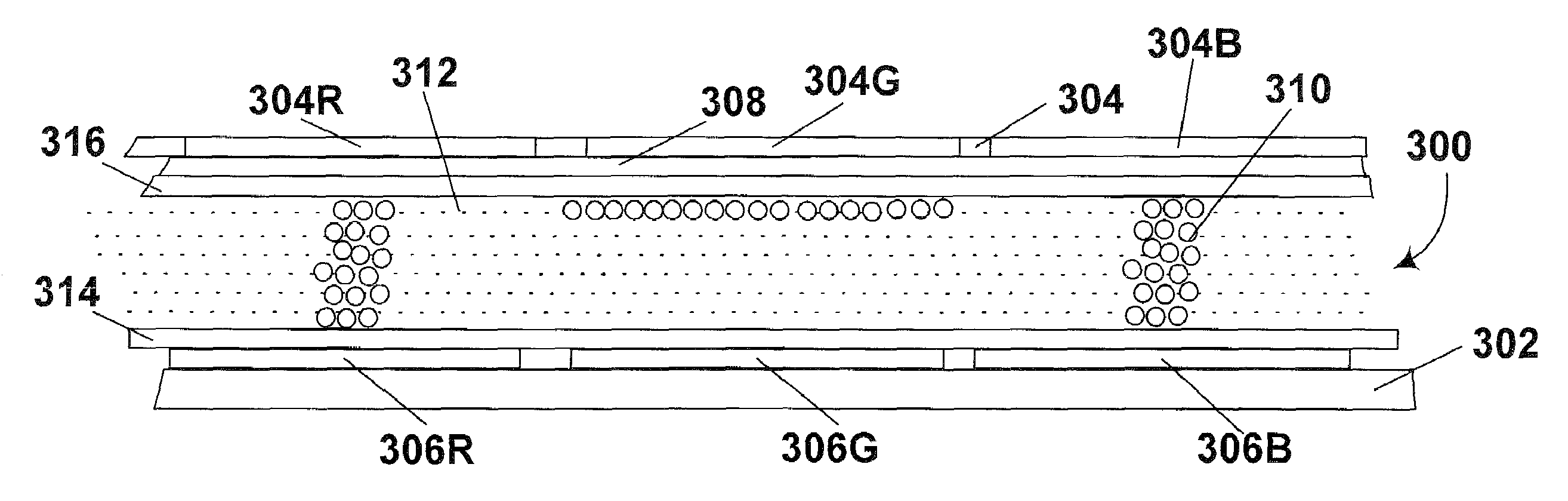

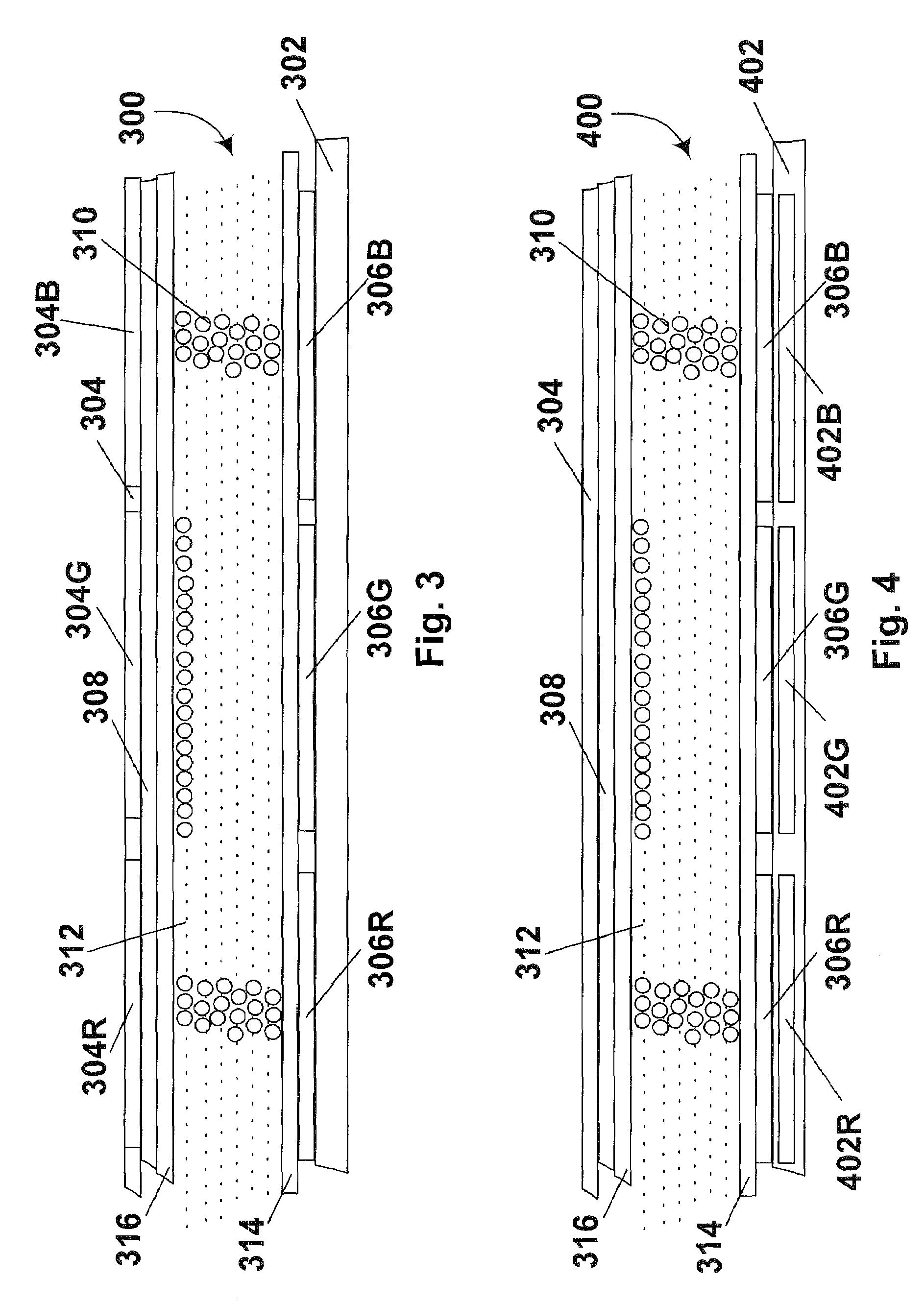

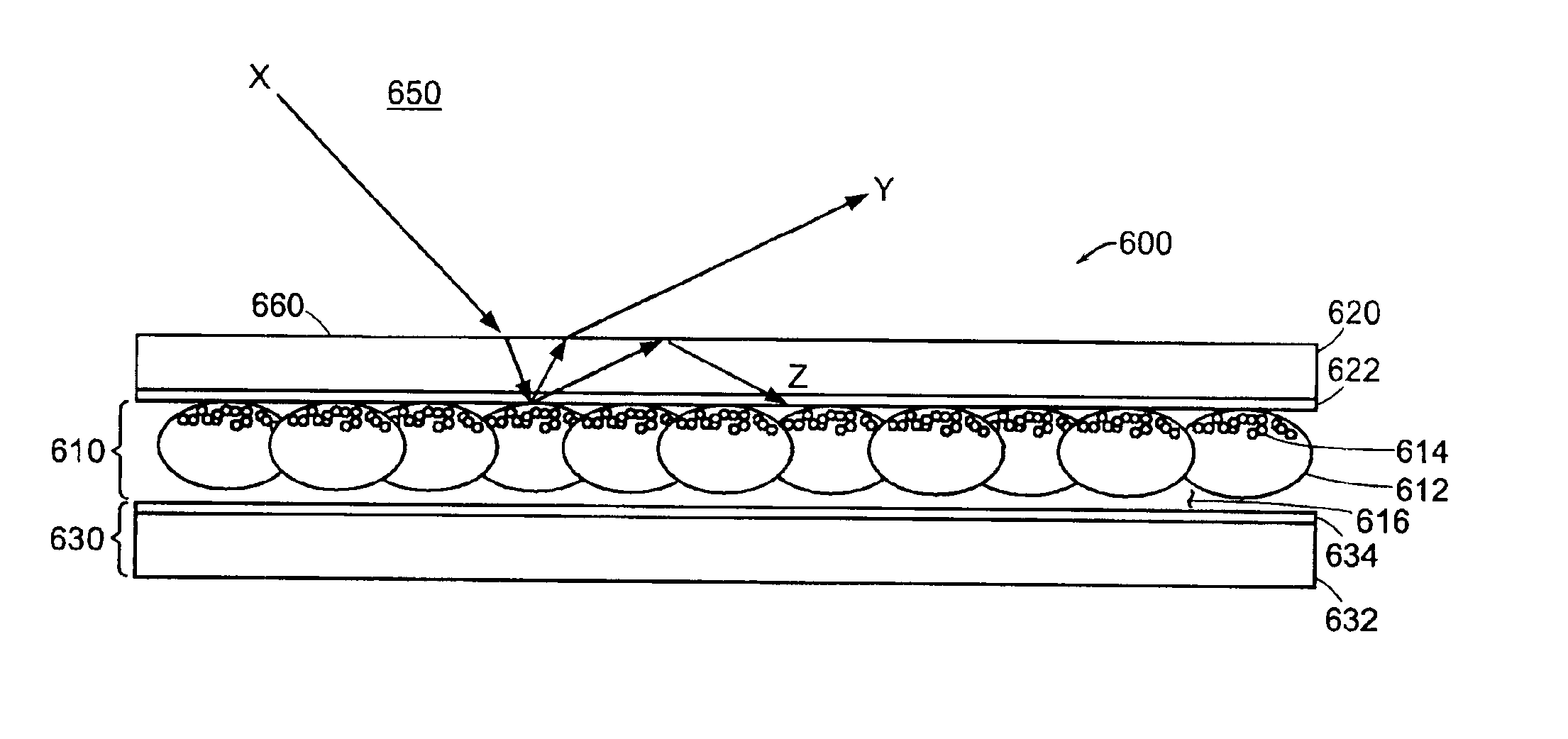

ActiveUS7327511B2Door/window protective devicesStatic indicating devicesElectrophoresisDisplay device

Various improvements in electrophoretic media and displays intended for use in light modulators are described. These improvements include index matching of the suspending fluid to a continuous phase surrounding the fluid, index matching of a capsule wall to a binder, planarization of a layer containing electrophoretic capsules before application of adhesive thereto, methods for concentrating electrophoretic particles into limited areas of sidewalls of electrophoretic capsules or microcells in the light-transmissive state of the display, and, in the case of light modulators comprising an electrophoretic layer sandwiched between two transparent plates, forming at least one of the plates so as to absorb electromagnetic radiation which adversely affects the electrophoretic layer.

Owner:E INK CORPORATION

Encapsulated electrophoretic displays having a monolayer of capsules and materials and methods for making the same

InactiveUS6839158B2Static indicating devicesTime-pieces with integrated devicesElectrophoresisDisplay device

Owner:E INK CORPORATION

Dielectrophoretic displays

A dielectrophoretic display comprises a substrate having walls defining at least one cavity, the cavity having a viewing surface and a side wall inclined to the viewing surface; a suspending fluid contained within the cavity; a plurality of at least one type of particle suspended within the suspending fluid; and means for applying to the substrate an electric field effect effective to cause dielectrophoretic movement of the particles to the side wall of the cavity.

Owner:E INK CORPORATION

Electrophoretic displays containing magnetic particles

InactiveUS6870661B2Easy to fallImprove stabilitySludge treatmentStatic indicating devicesElectrophoresisDisplay device

An electrophoretic medium comprises a plurality of one or more types of particles suspended in a suspending fluid. The particles include at least one electrically charged, electrophoretically mobile particle capable of translating through the suspending fluid upon application of an electric field to the medium and at least one magnetic particle. A magnet is disposed adjacent the electrophoretic medium to introduce a threshold resistance to magnetic particle movement.

Owner:E INK CORPORATION

Electro-optic display and lamination adhesive

InactiveUS6831769B2Reduce adverse effectsGood optical performanceLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveElectrophoresis

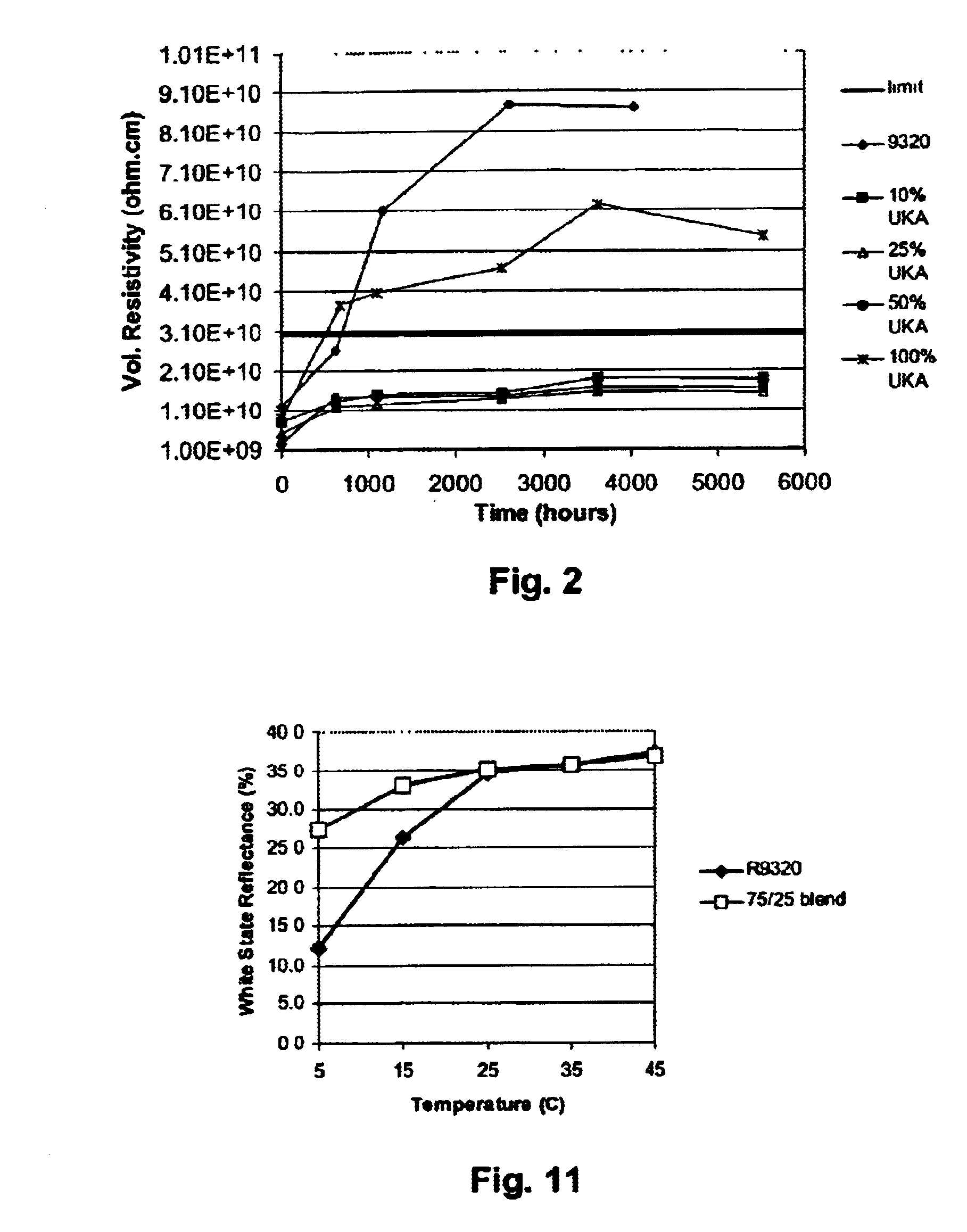

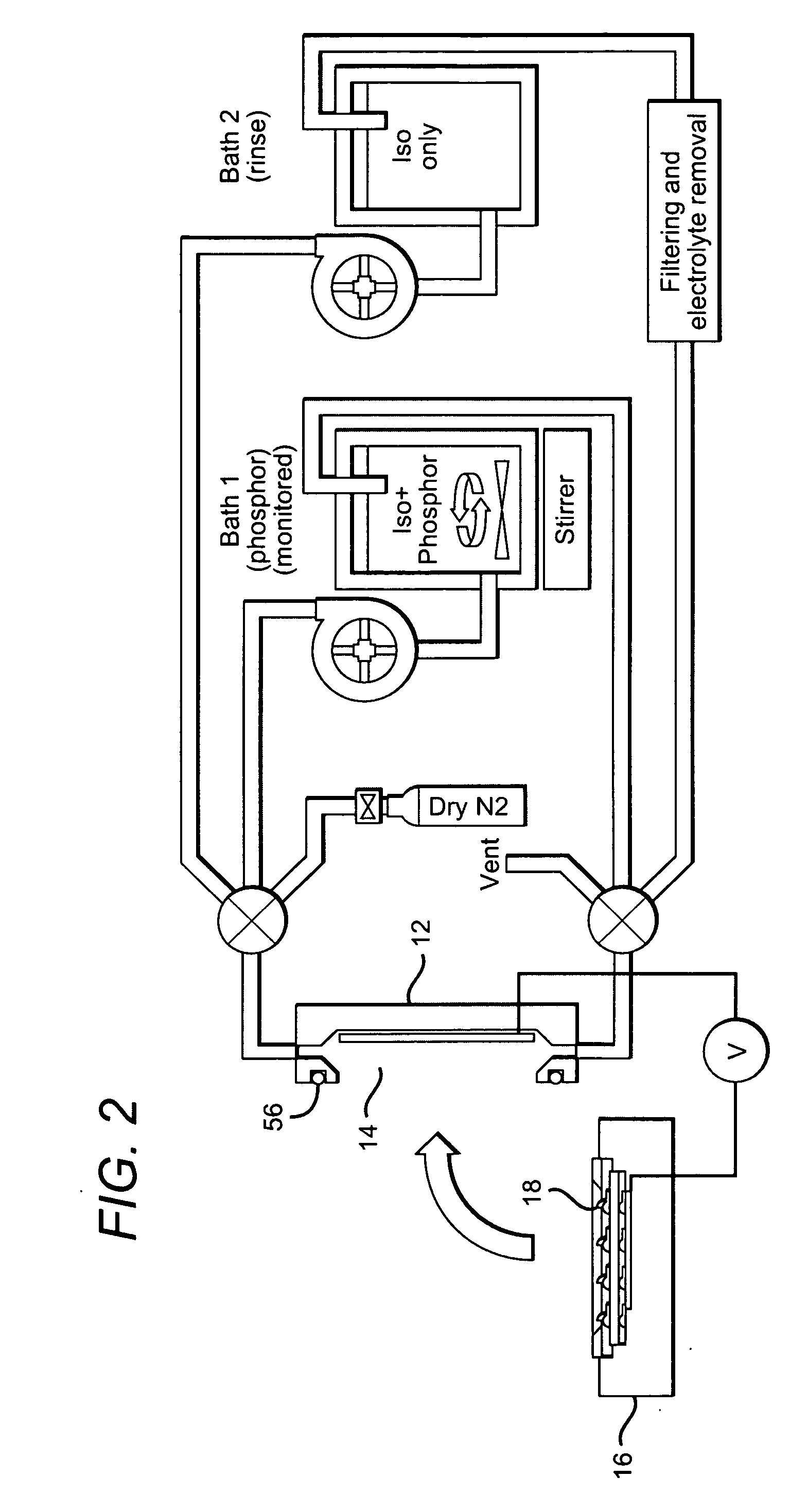

An electro-optic display comprises first and second substrates and a lamination adhesive layer and a layer of a solid electro-optic material disposed between the first and second substrates, the lamination adhesive layer having a volume resistivity, measured at 10° C., which does not change by a factor of more than about 3 after being held at 25° C. and 45 percent relative humidity for 1000 hours. The electro-optic material is preferably an encapsulated electrophoretic material. Other desirable characteristics of lamination adhesives for use in electro-optic displays are also described.

Owner:E INK CORPORATION

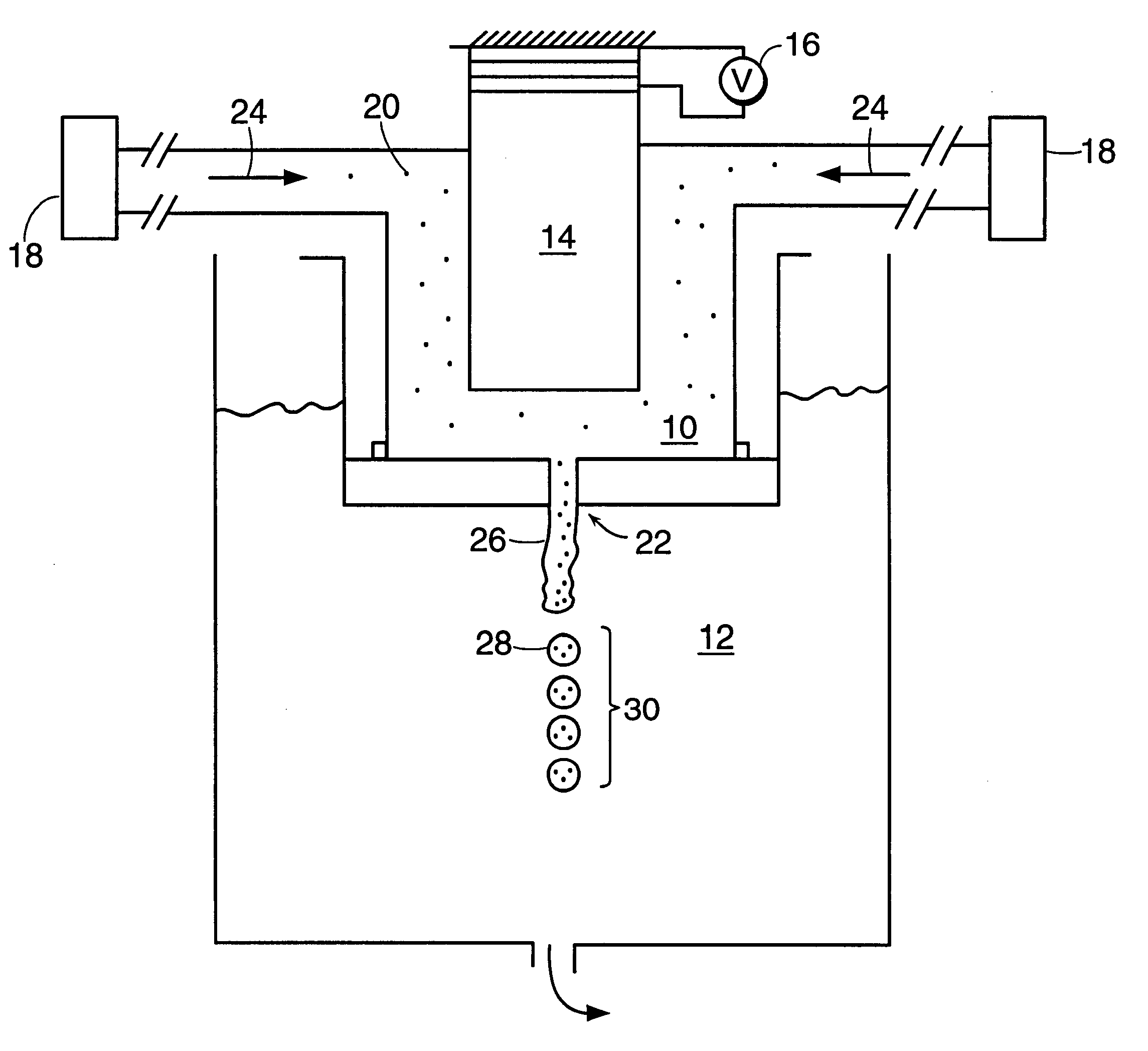

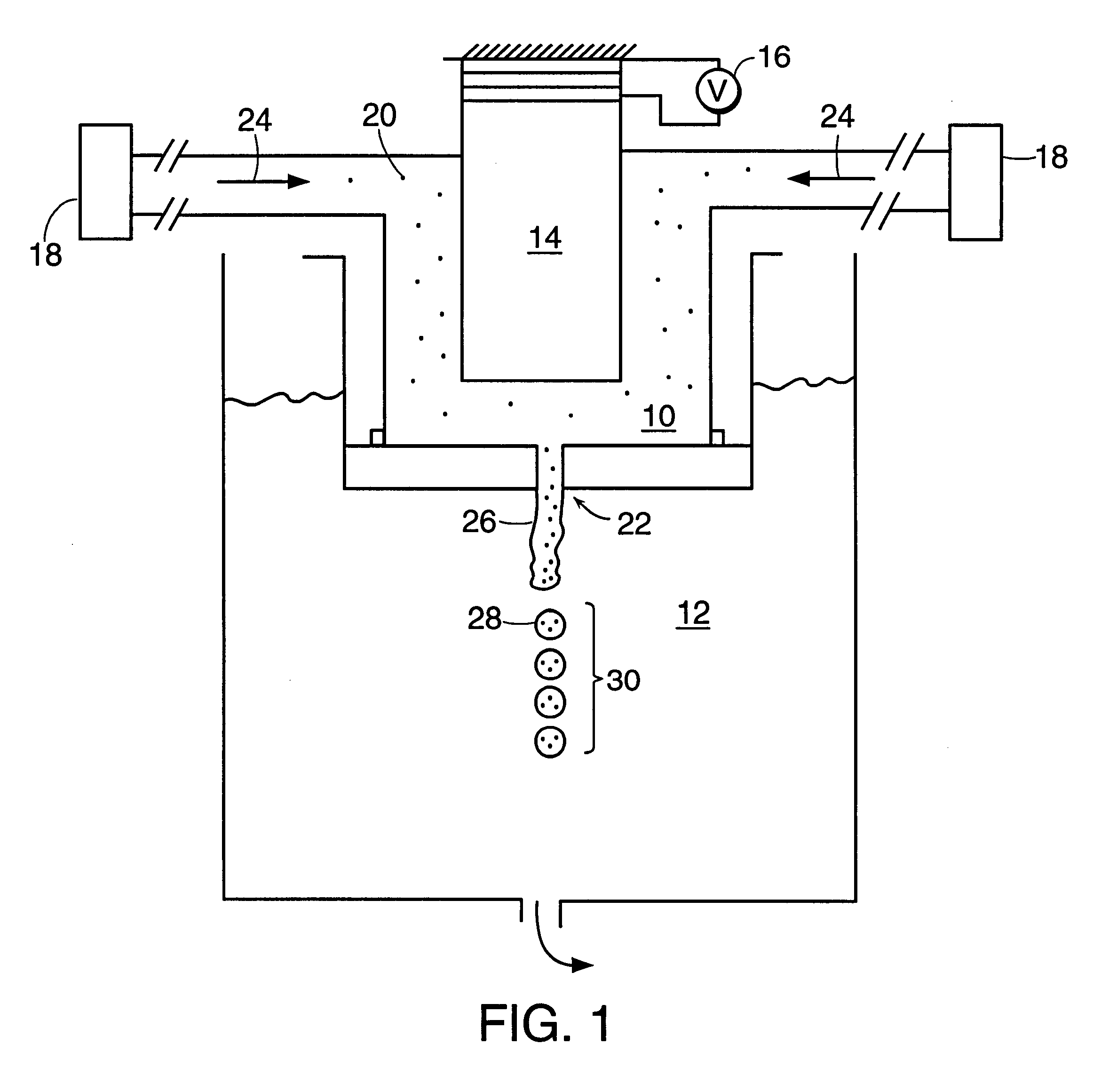

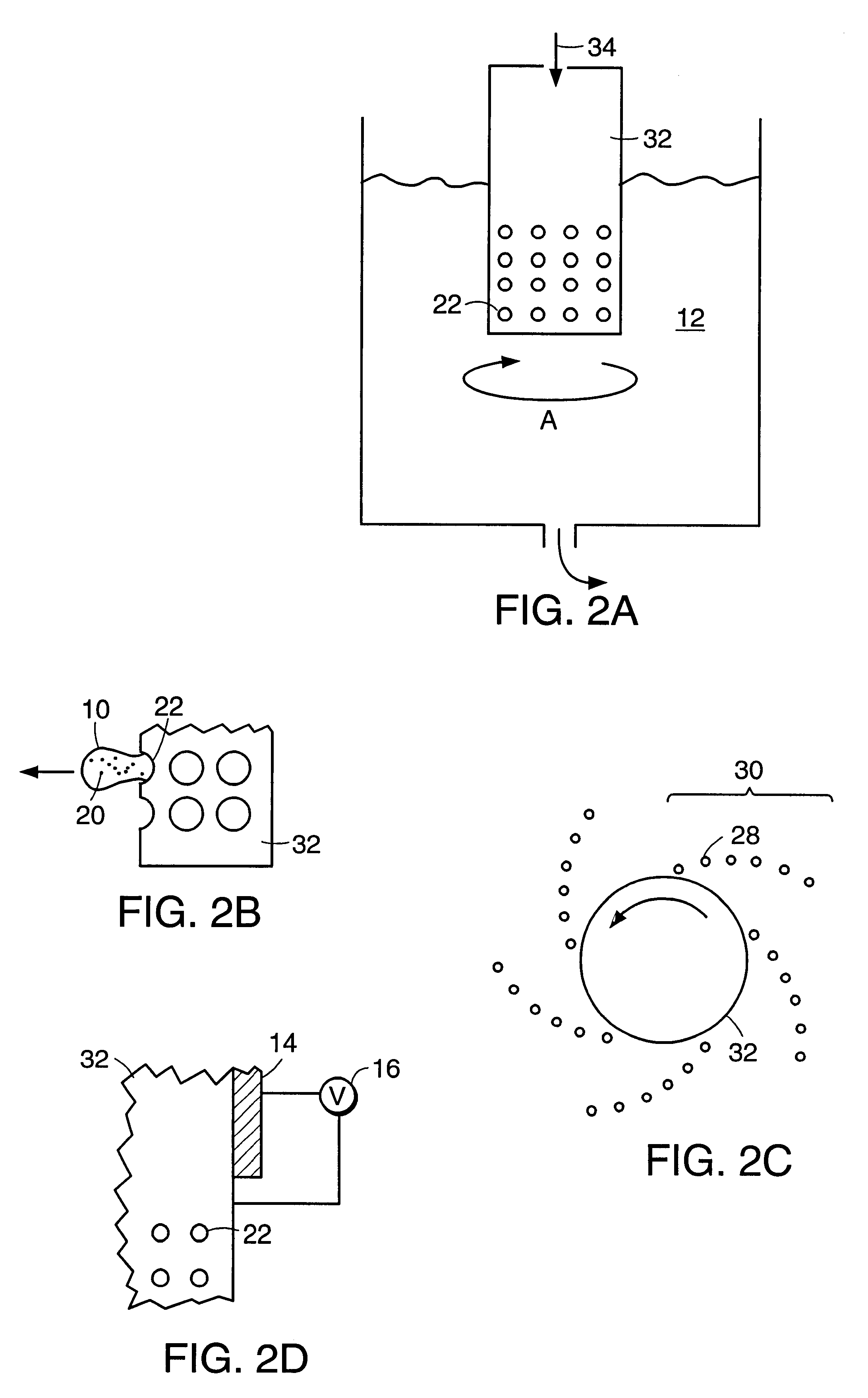

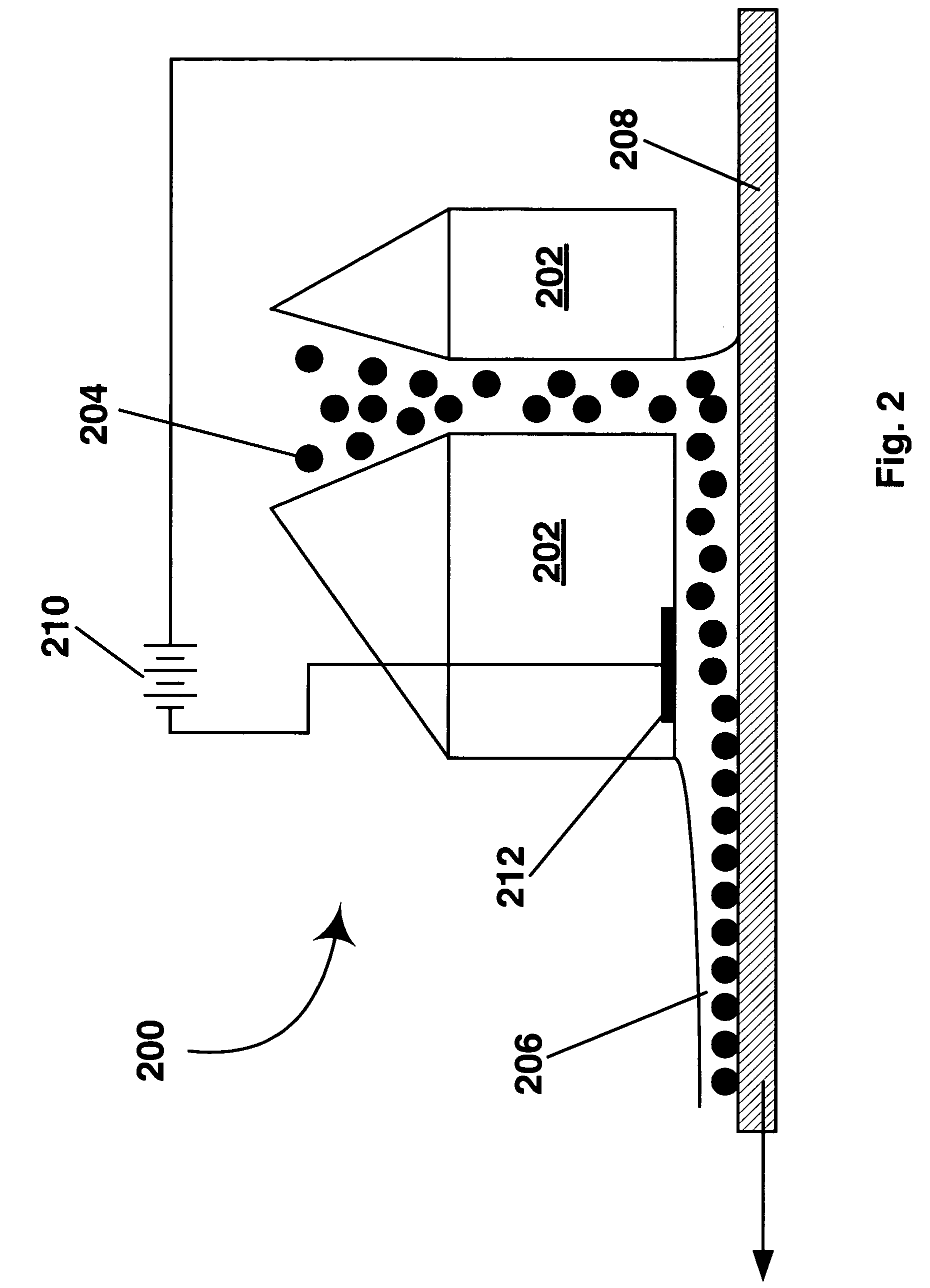

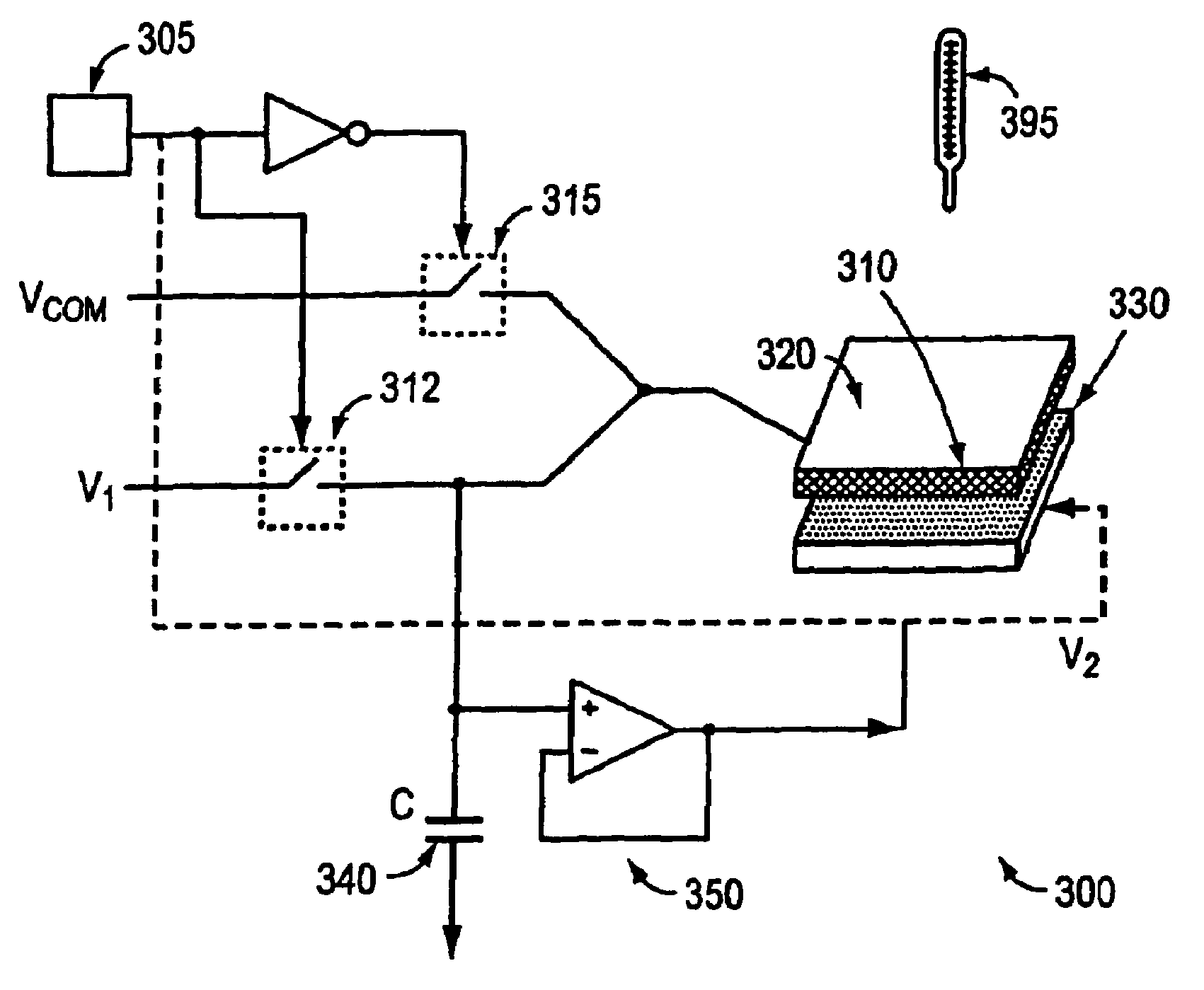

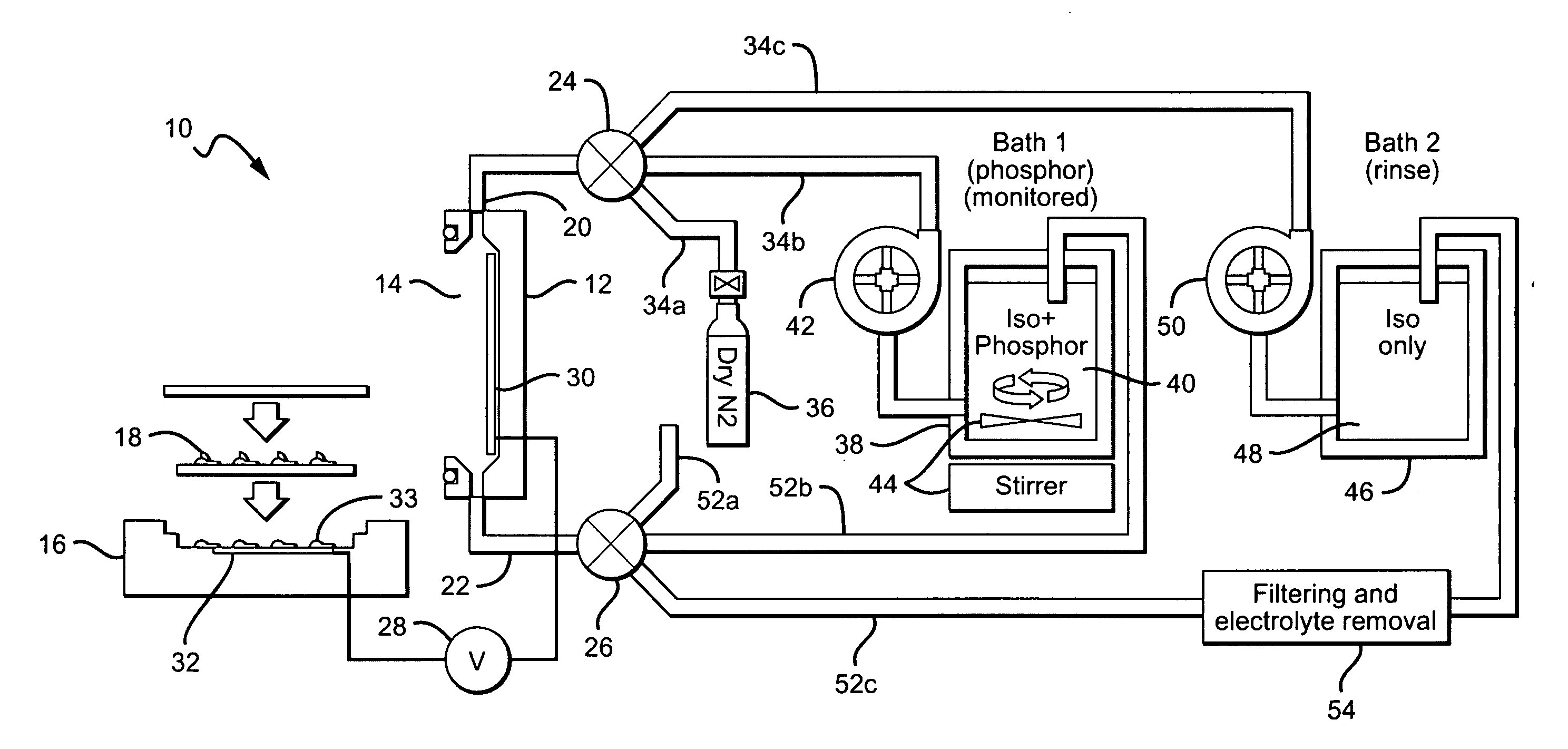

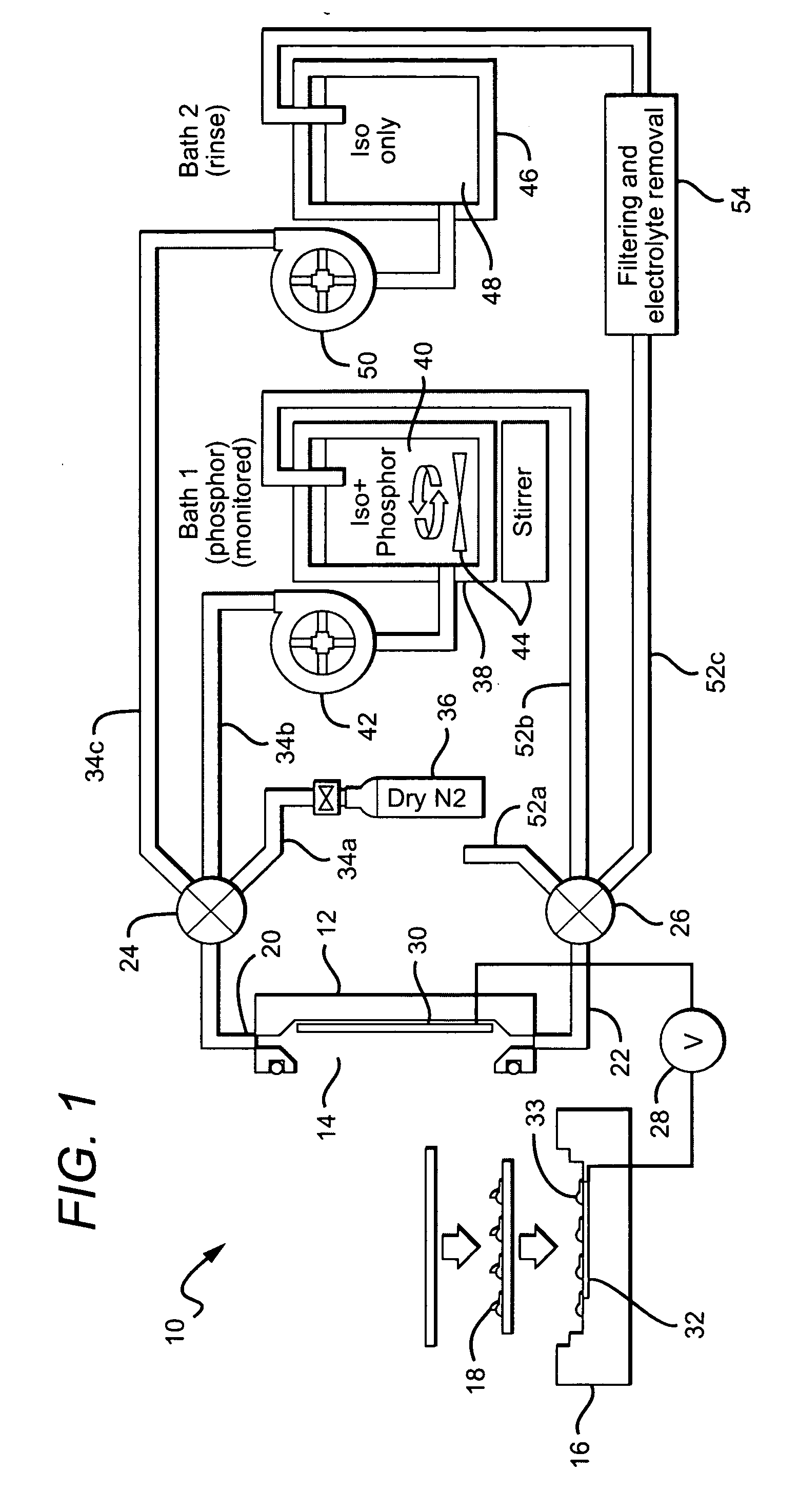

Close loop electrophoretic deposition of semiconductor devices

One close loop system and method for electrophoretic deposition (EPD) of phosphor material on light emitting diodes (LEDs). The system comprises a deposition chamber sealed from ambient air. A mixture of phosphor material and solution is provided to the chamber with the mixture also being sealed from ambient air. A carrier holds a batch of LEDs in the chamber with the mixture contacting the areas of the LEDs for phosphor deposition. A voltage supply applies a voltage to the LEDs and the mixture to cause the phosphor material to deposit on the LEDs at the mixture contacting areas.

Owner:CREELED INC

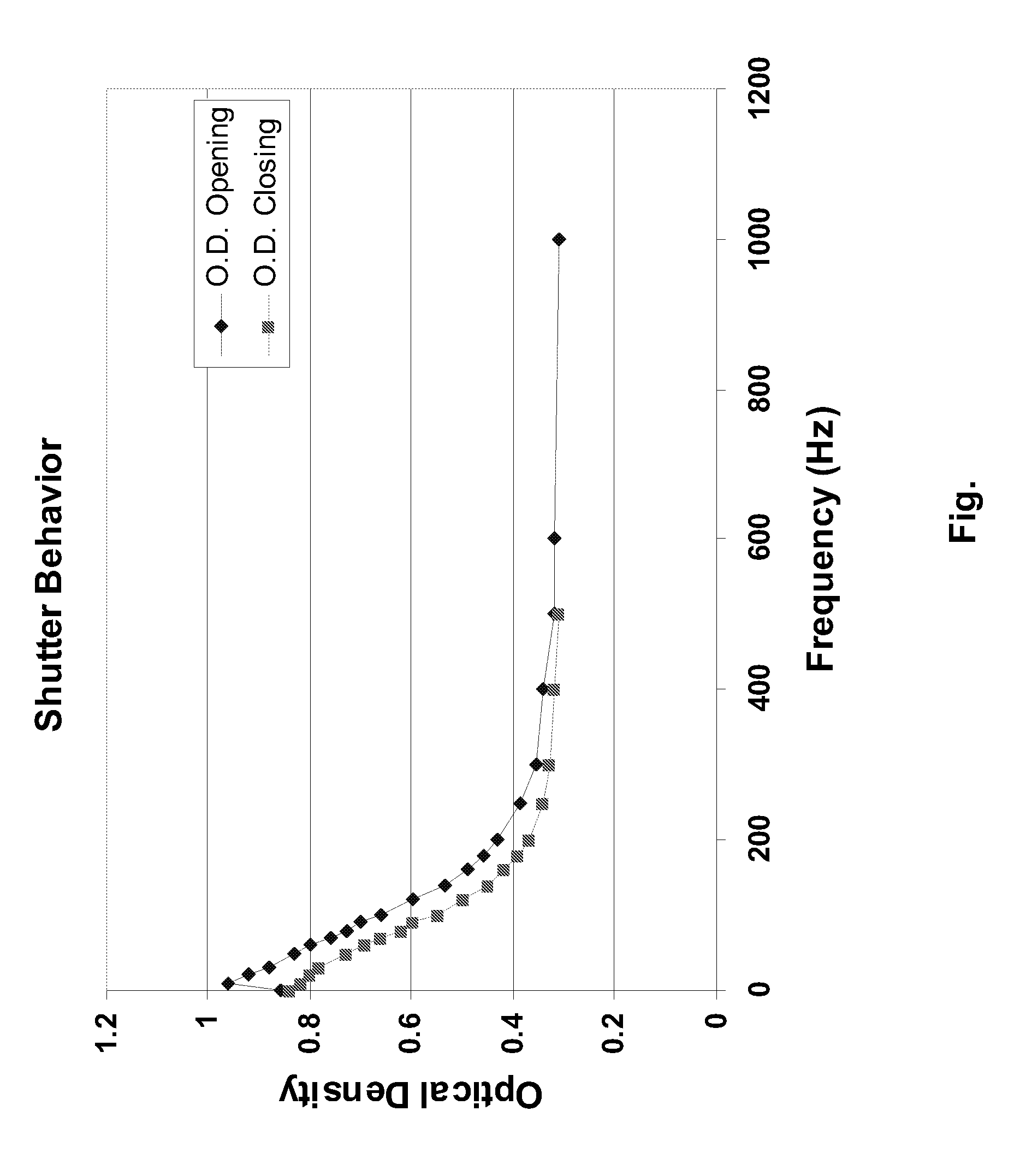

Electro-optic displays

An electrophoretic display comprises an electrophoretic medium having a plurality of charged particles suspended in a suspending fluid, and two electrodes disposed on opposed sides of the electrophoretic medium. At least one of the electrodes is light-transmissive and forming a viewing surface. The display has a closed optical state in which the charged particles are spread over substantially the entire viewing surface so that light cannot pass through the medium, and an open optical state in which the electrophoretic particles form chains extending between the electrodes so that light can pass through the electrophoretic medium. Insulating layers are disposed between the electrodes and the electrophoretic medium. Similarly electrophoretic displays are provided equipped with color filter arrays or reflectors.

Owner:E INK CORPORATION

Electrophoretic electronic displays with low-index films

InactiveUS6865010B2Increase productionEasy constructionNon-linear opticsOptical elementsElectrophoresisDisplay device

The invention features a reflective display device and a method of making a reflective display device that has reduced light loss and / or pixel cross talk due to internal reflection. The device includes a window layer, a plurality of reflective particles, a material portion disposed between the window layer and the plurality of reflective particles, and a refractive layer disposed between the window and the material portion. The plurality of reflective particles scatters light received from the ambient environment. The window layer has an index of refraction that is greater than an index of refraction of the ambient environment. The refractive layer has an index of refraction that is less than the index of refraction of the window layer and less than an index of refraction of the material portion.

Owner:E INK CORPORATION

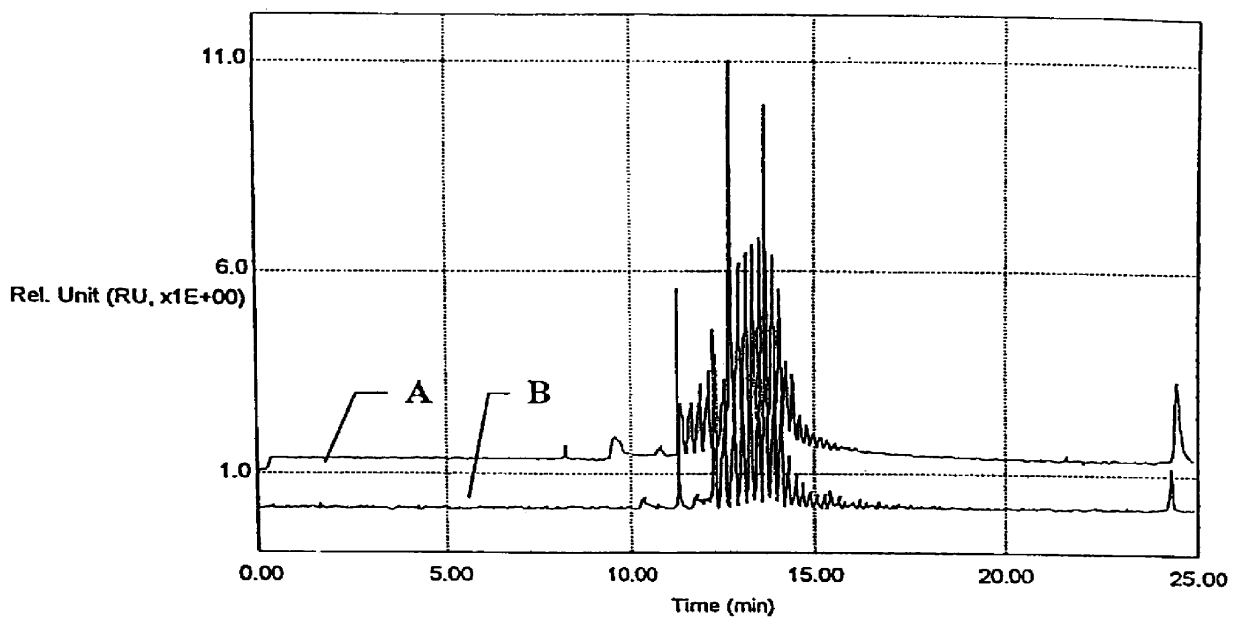

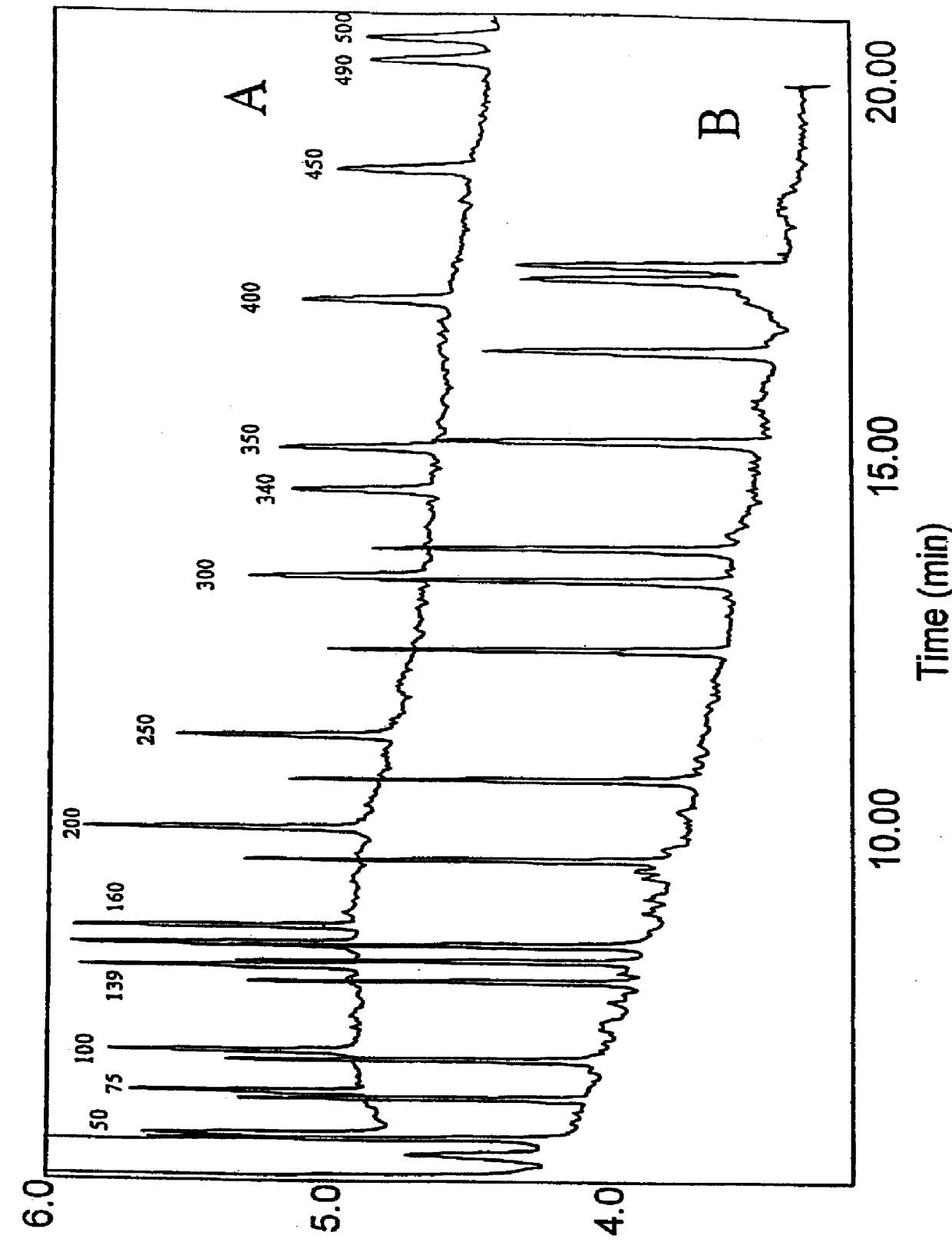

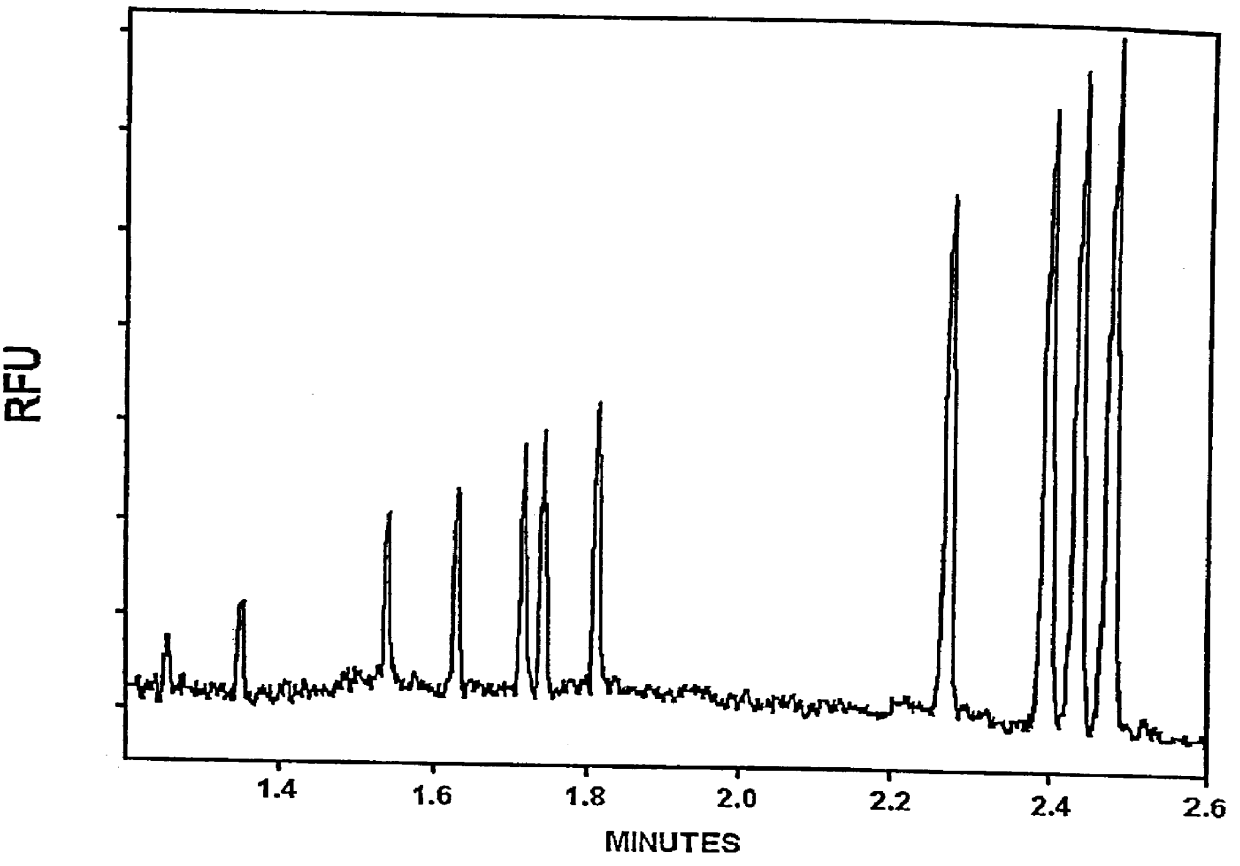

Acrylic microchannels and their use in electrophoretic applications

Microchannels having at least an acrylic inner surface and methods of their use in electrophoretic applications are provided. The subject microchannels may be in the form of a variety of configurations suitable for holding an electrophoretic medium. The subject microchannels give rise to substantially reduced EOF and / or adsorption as compared to fused silica under conditions of electrophoresis and find use in a variety of electrophoretic applications in which charged entities are moved through a medium under the influence of the an applied electric field.

Owner:MONOGRAM BIOSCIENCES

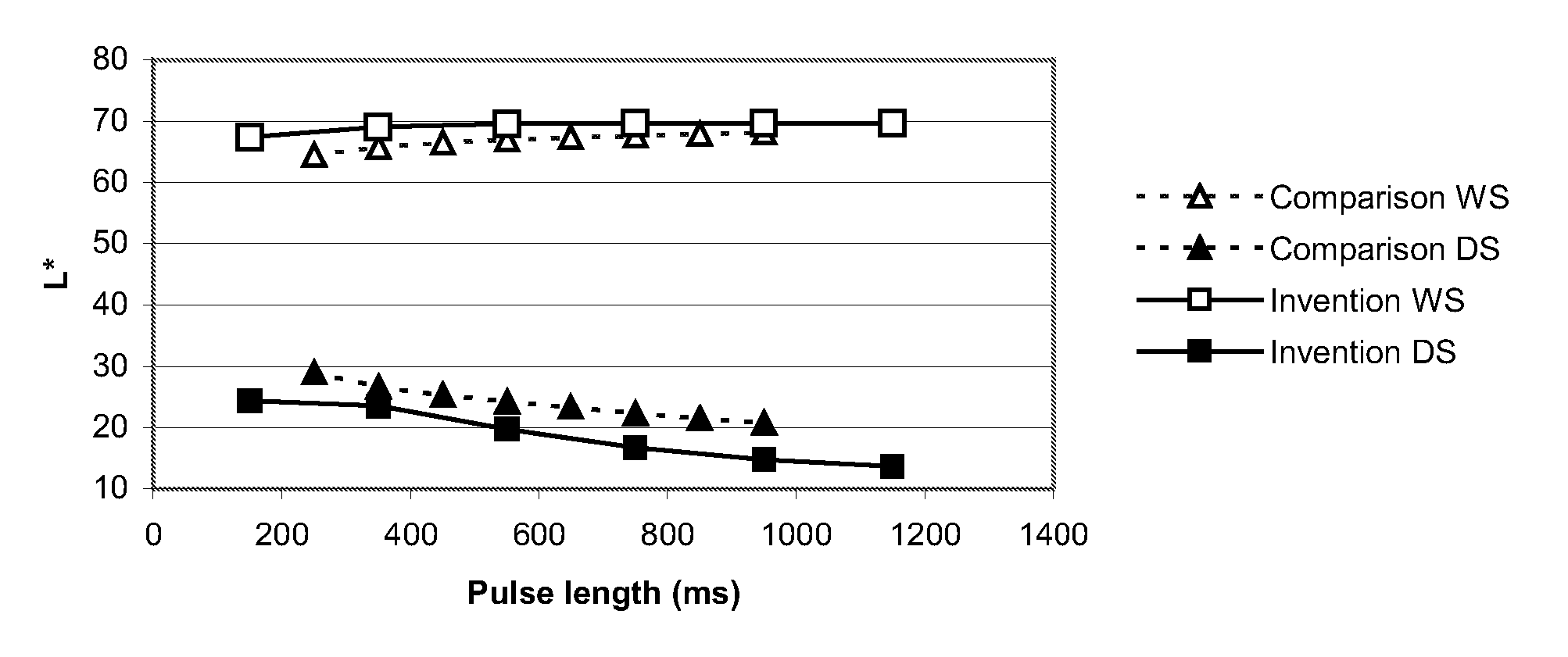

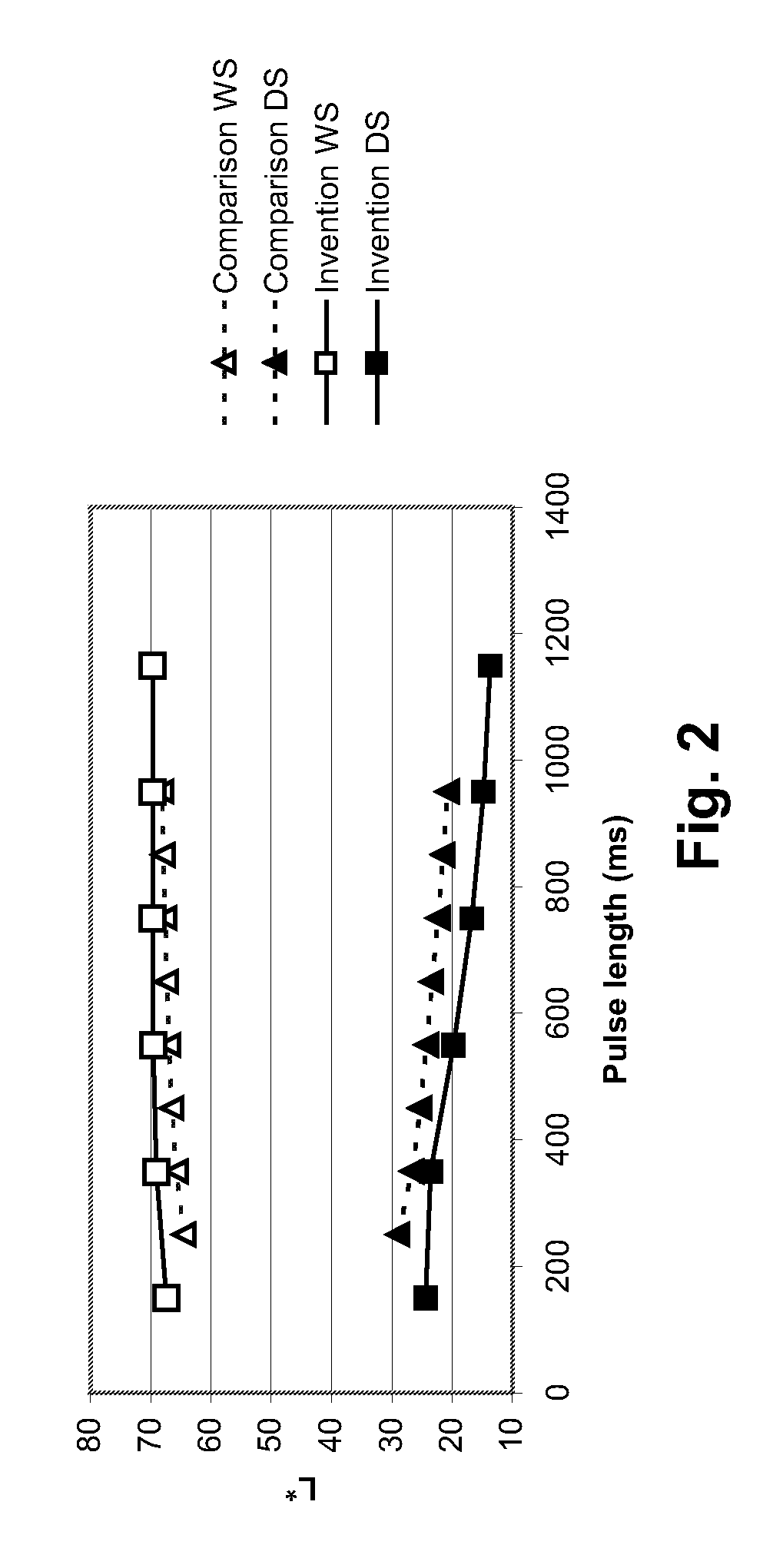

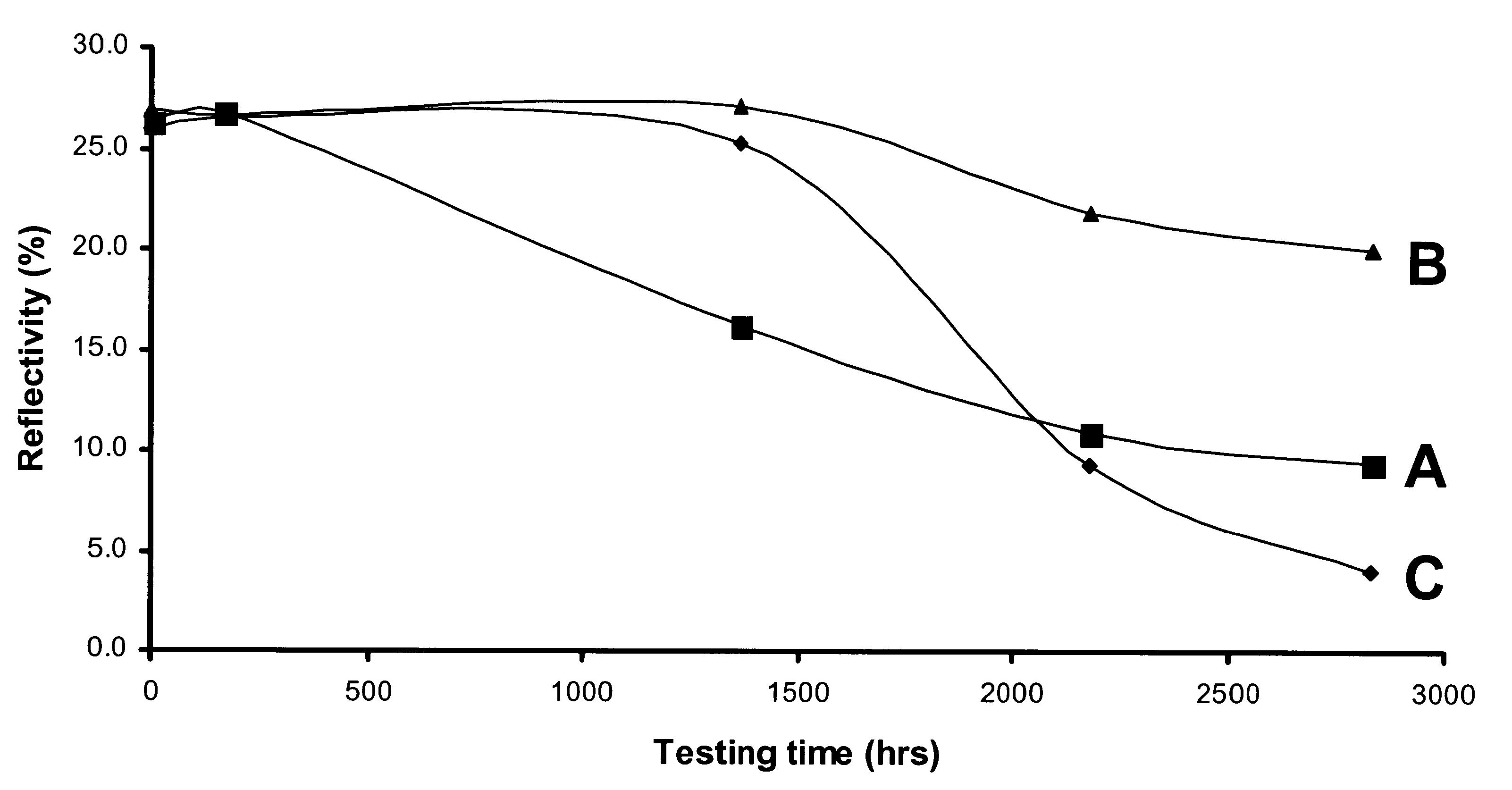

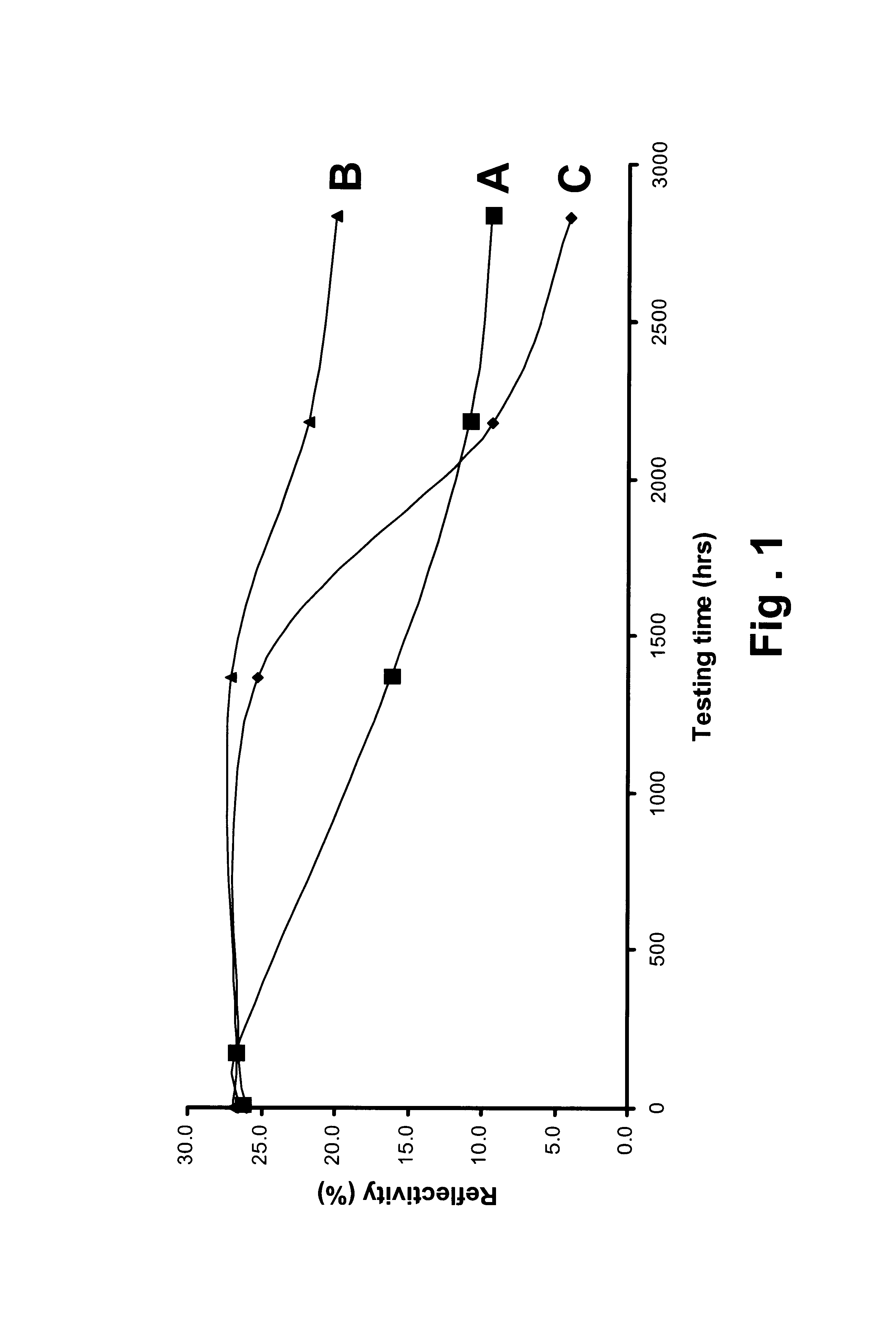

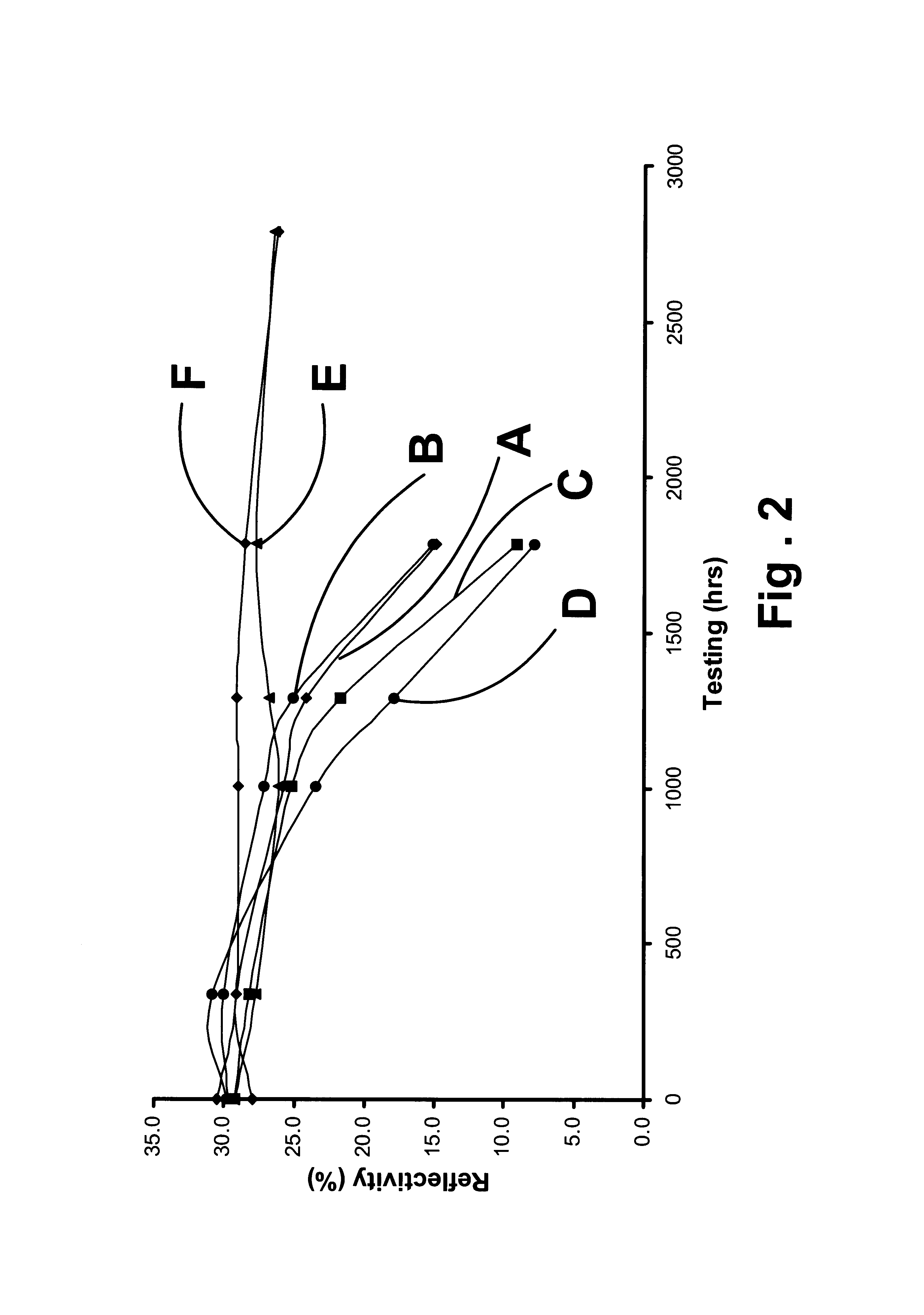

Electrophoretic medium and display with improved image stability

InactiveUS20020180687A1Improve imaging stabilityExtend switching timeStatic indicating devicesNon-linear opticsPolymer scienceElectrophoresis

An electrophoretic medium comprises a plurality of particles suspended in a suspending fluid, the particles being capable of moving through the fluid upon application of an electric field to the medium, the fluid having dissolved or dispersed therein a polymer having a number average molecular weight in excess of about 20,000, the polymer being essentially non-absorbing on the particles. The polymer improves the bistability of the display (i.e., the period for which a written image persist without the display being refreshed) but does not greatly increase the viscosity of the suspending fluid, thus keeping the switching time of the display within reasonable limits. The medium may be encapsulated, or may be in the form a polymer-dispersed electrophoretic medium.

Owner:E INK CORPORATION

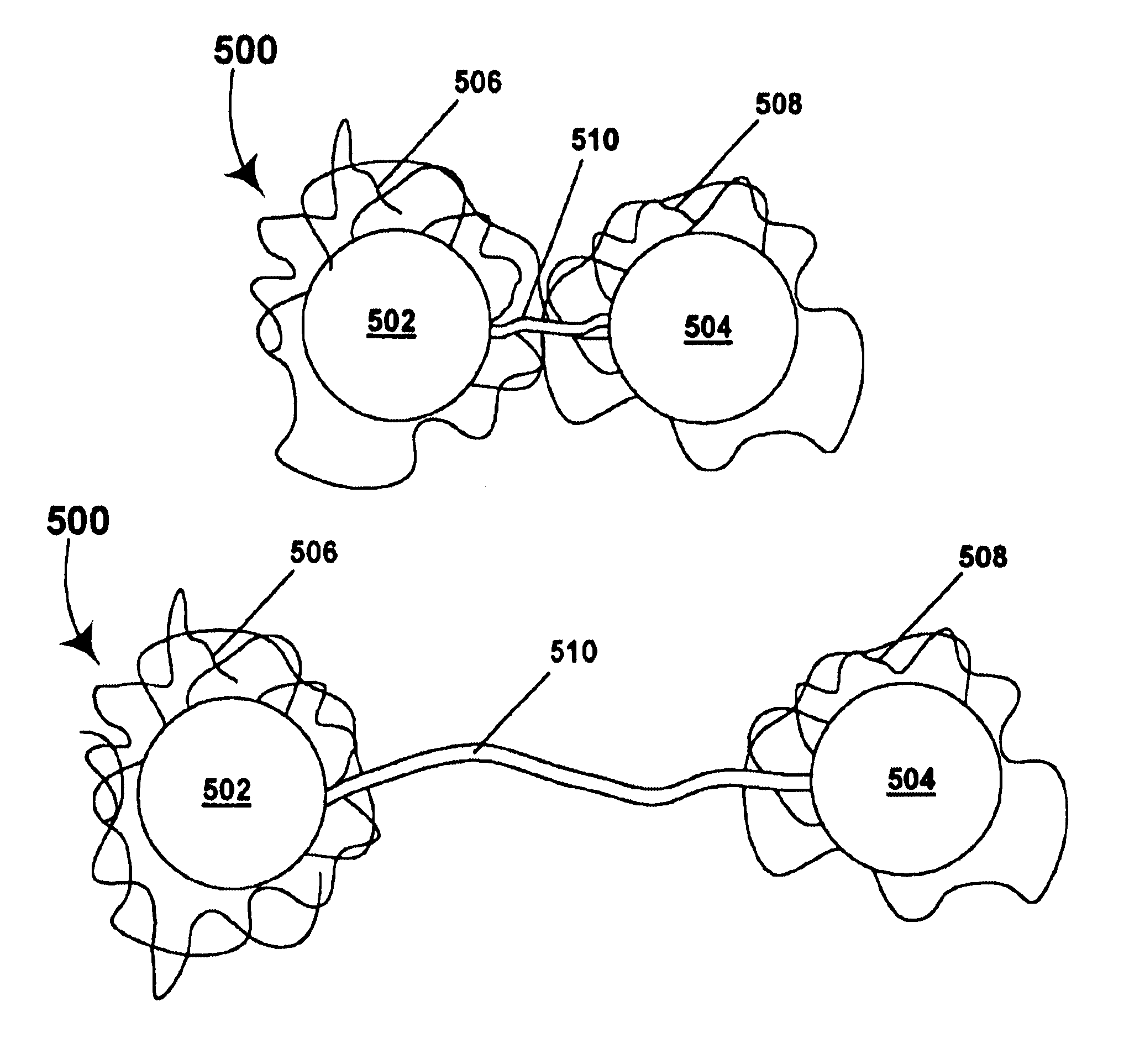

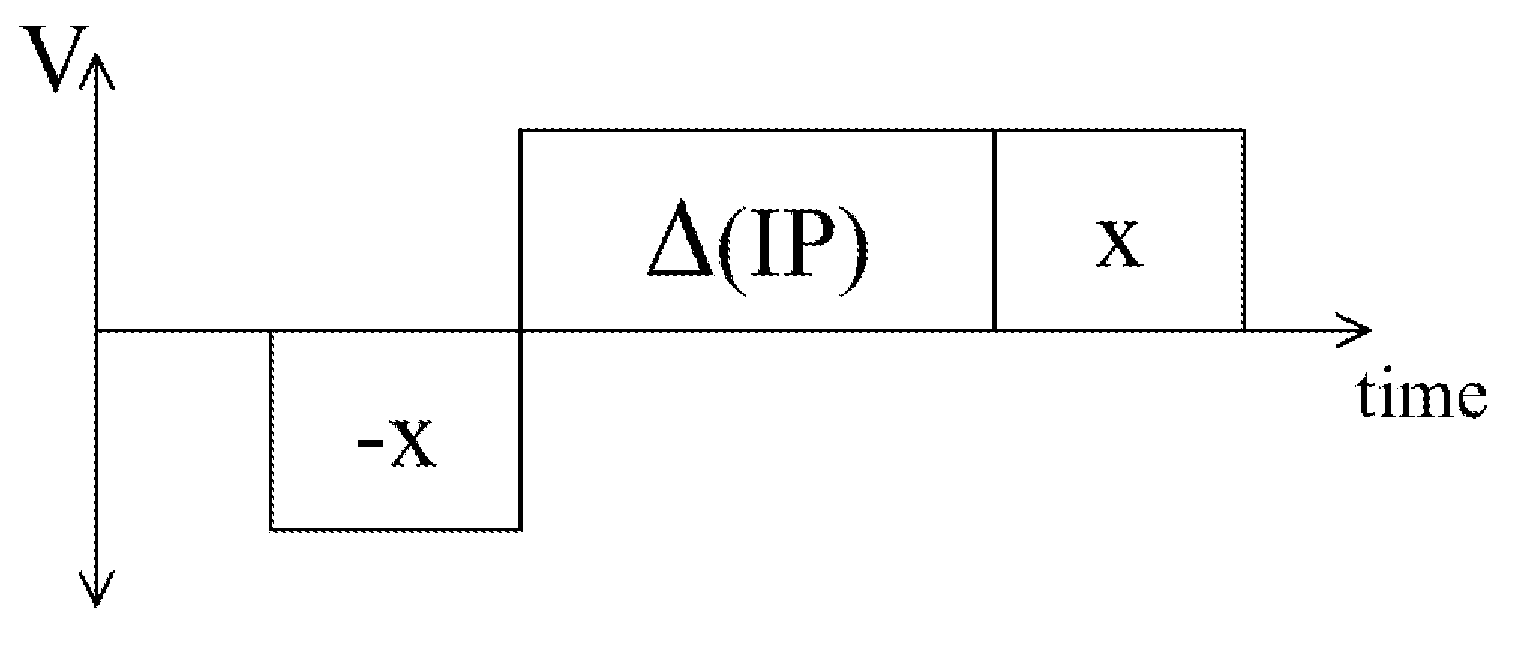

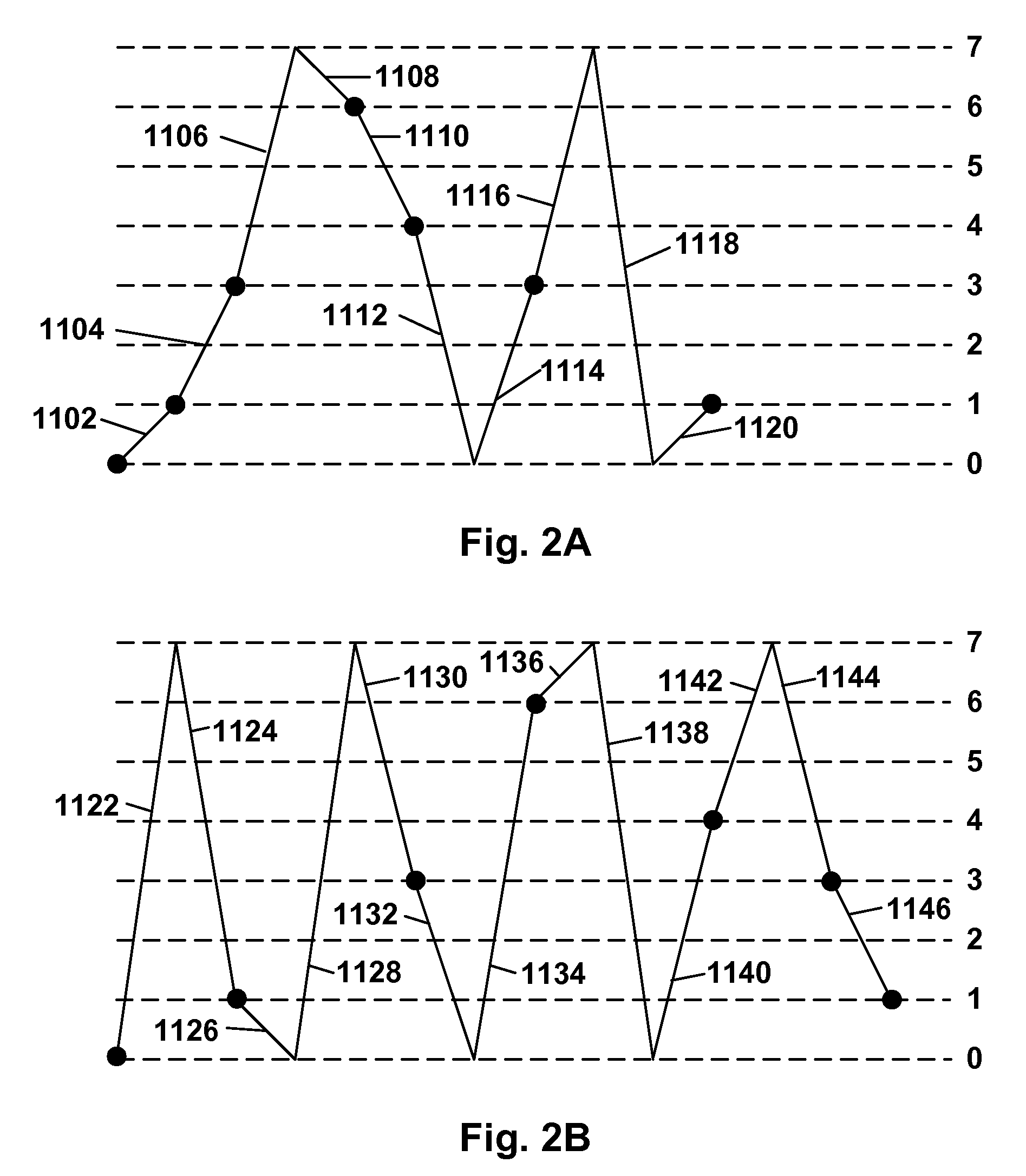

Methods for driving electrophoretic displays using dielectrophoretic forces

InactiveUS7999787B2Static indicating devicesLight protection screensElectrophoresisDielectrophoretic force

Owner:E INK CORPORATION

Electrophoretic displays using gaseous fluids

InactiveUS20080024429A1Reduce the impactIncrease the lengthStatic indicating devicesElectrophoresisDisplay device

An electrophoretic display comprises a pair of facing substrates, at least one of which is transparent, a plurality of particles and a gas between the substrates, and means for applying an electric field to cause the particles to move and thus change the electro-optic state of the display. The electric field means is arranged to increase the impulse applied to the display with increasing time since a reference time, or with increasing number of images written on the display. In another embodiment, an alternating current pulse is applied to the display, and the duration and / or amplitude of the alternating current pulse is increased with increasing time since a reference time.

Owner:E INK CORPORATION

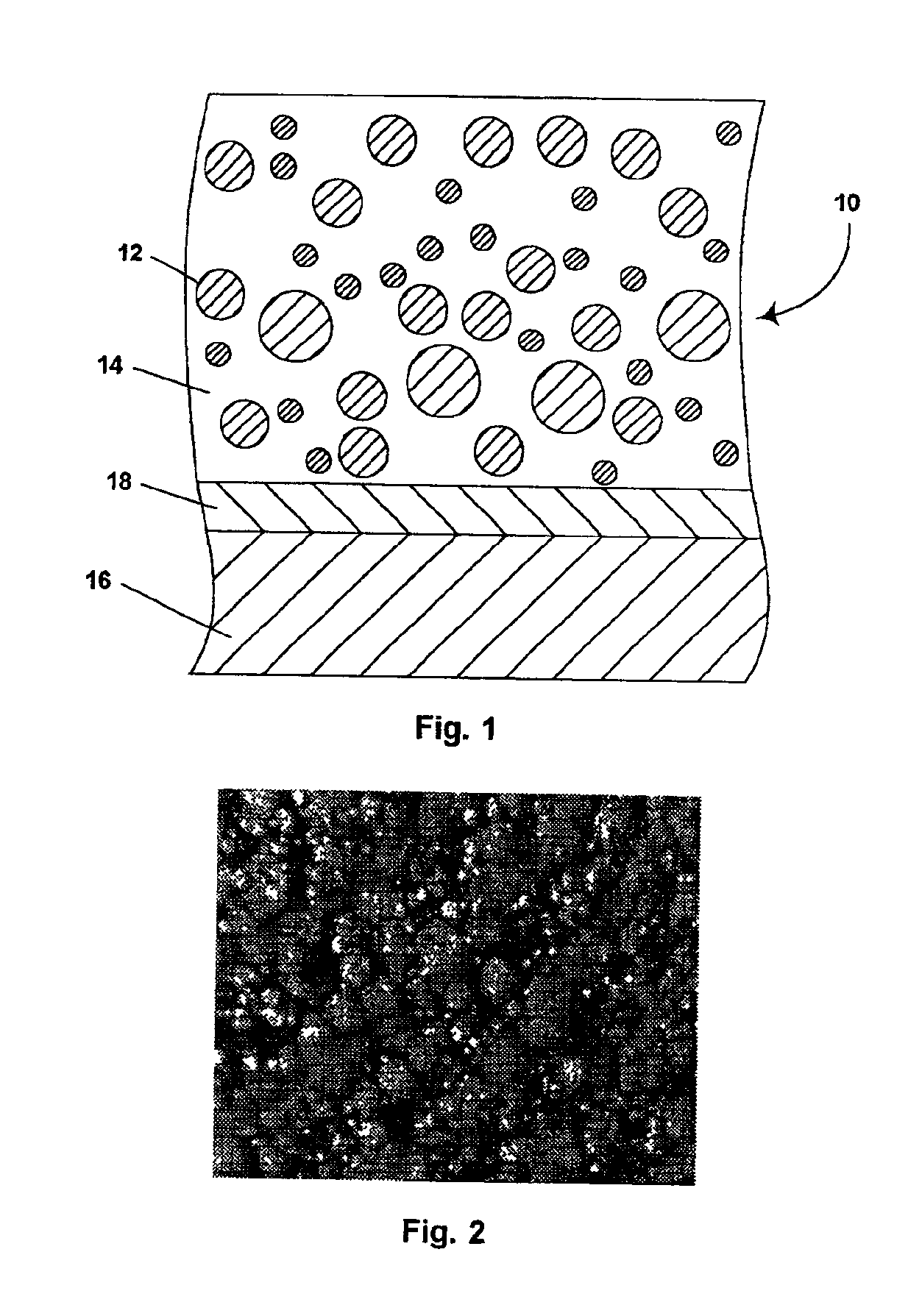

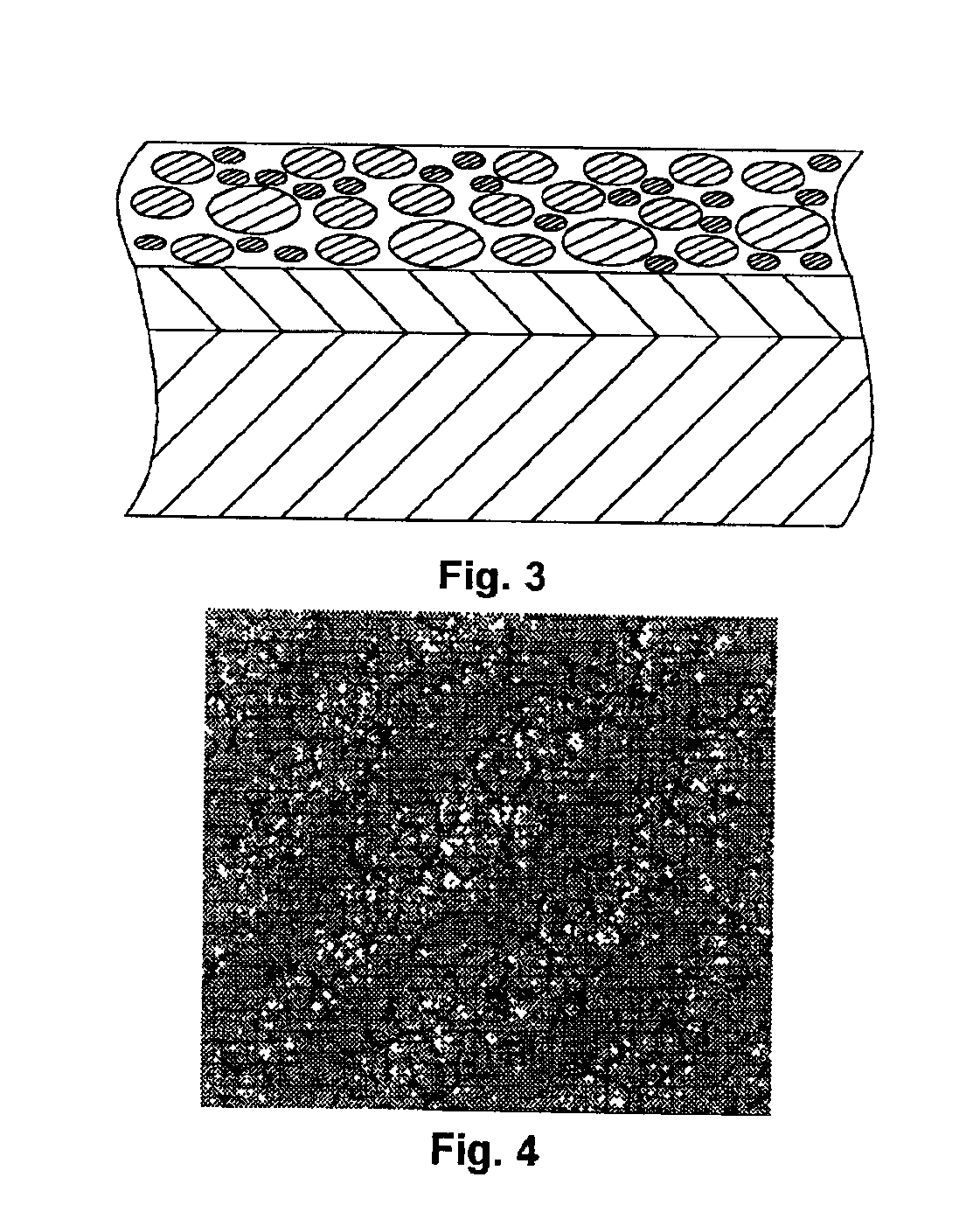

Electrophoretic displays with controlled amounts of pigment

InactiveUS20050012980A1Good optical performanceAvoid artifactsNon-linear opticsOptical elementsElectrophoresisDisplay device

An electrophoretic medium has walls defining a microcavity containing an internal phase. This internal phase comprises electrophoretic particles suspended in a suspending fluid and capable of moving therethrough upon application of an electric field to the electrophoretic medium. The average height of the microcavity differs by not more than about 5 μm from the saturated particle thickness of the electrophoretic particle divided by the volume fraction of the electrophoretic particles in the internal phase.

Owner:E INK CORPORATION

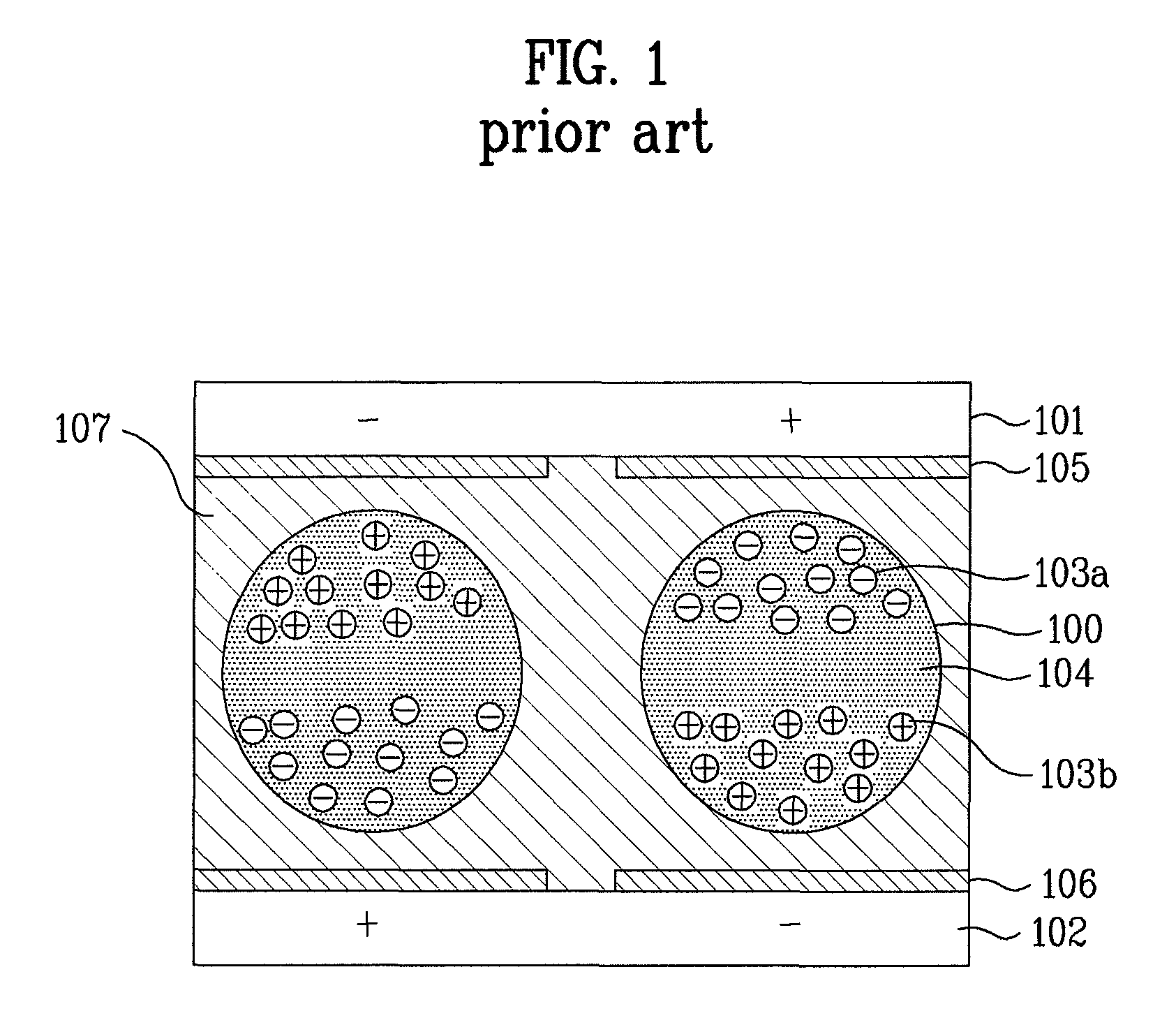

Electrophoretic device, method of driving electrophoretic device, and electronic apparatus

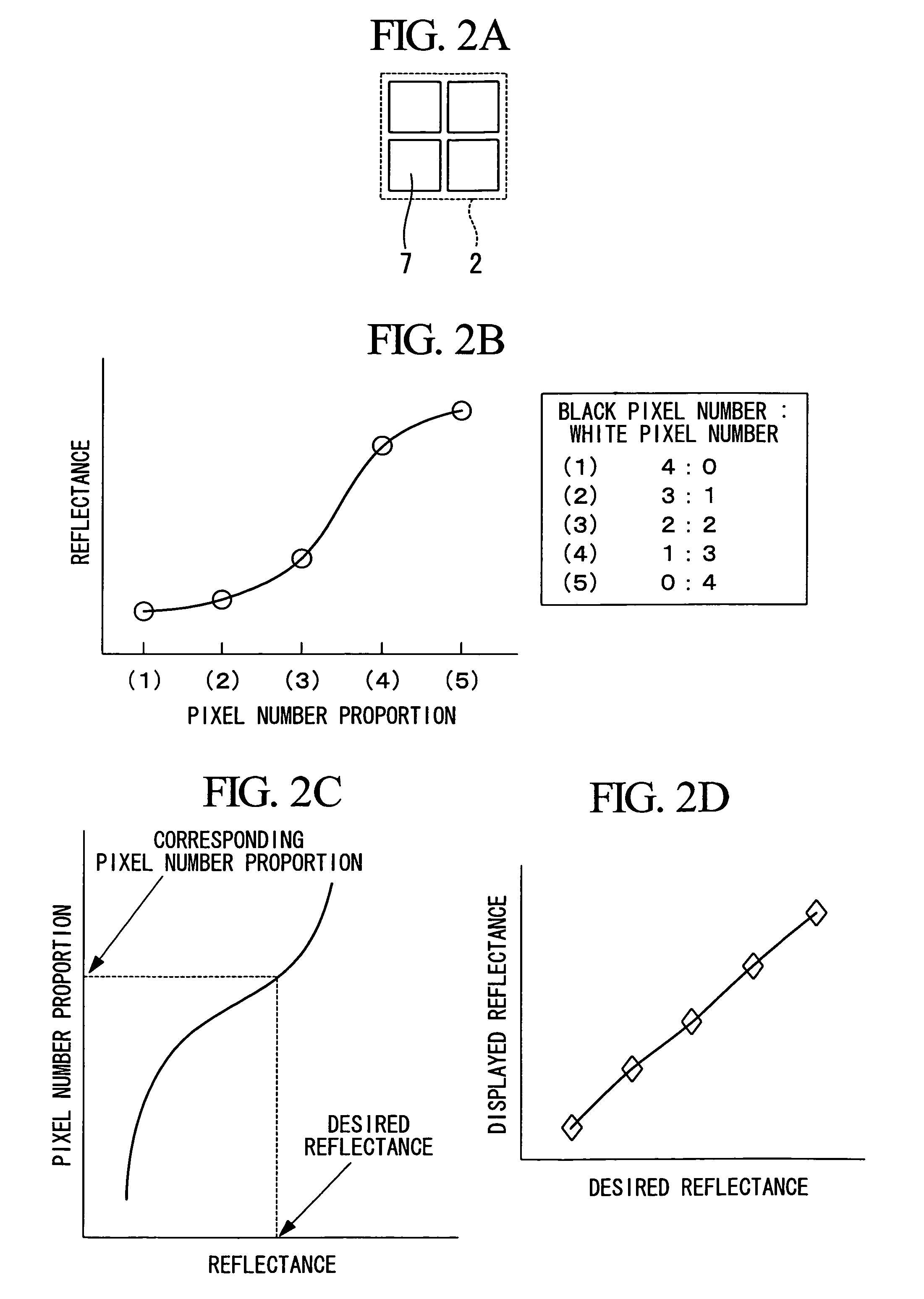

ActiveUS7679599B2Reliably realize desired optical characteristicAccurate calculationStatic indicating devicesElectrophoresisEngineering

Owner:E INK CORPORATION

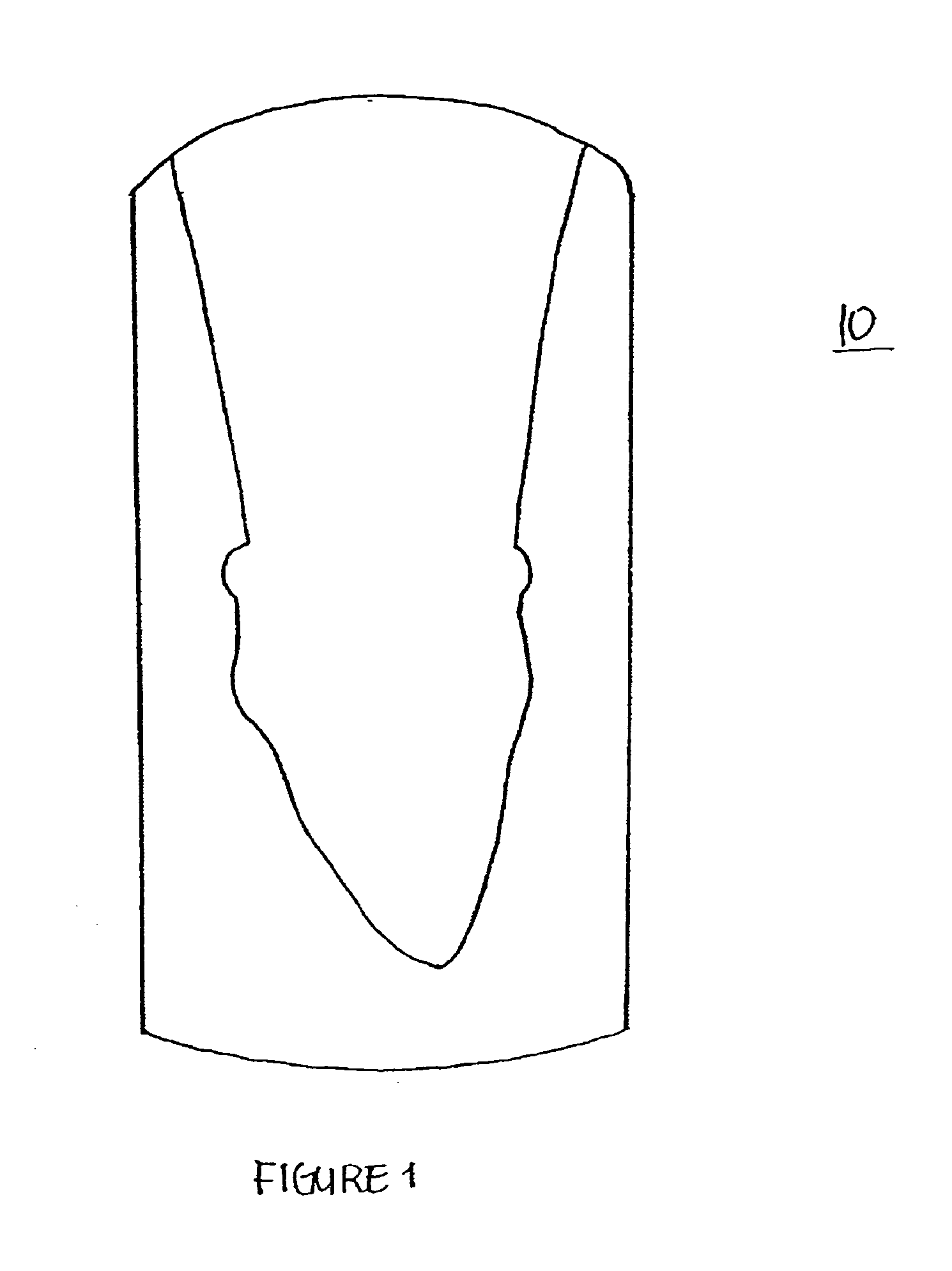

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

Electrophoretic medium with improved stability

ActiveUS7236290B1Electrolysis componentsStatic indicating devicesElectrophoresisFree radicals scavenger

An electrophoretic medium comprises a liquid and at least one particle disposed within the liquid and capable of moving therethrough on application of an electric field to the medium. The medium further comprises a free radical scavenger selected from the group consisting of (a) stable free radicals; and (b) polymeric free radical scavengers comprising a plurality of free radical scavenging groups attached to a polymeric chain. The medium is desirably encapsulated.

Owner:E INK CORPORATION

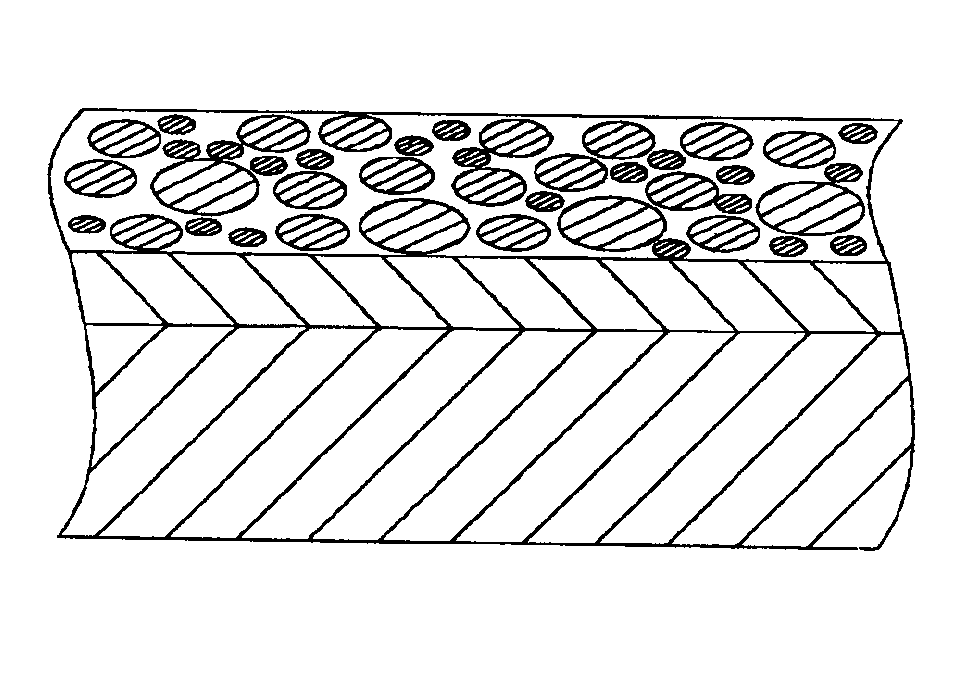

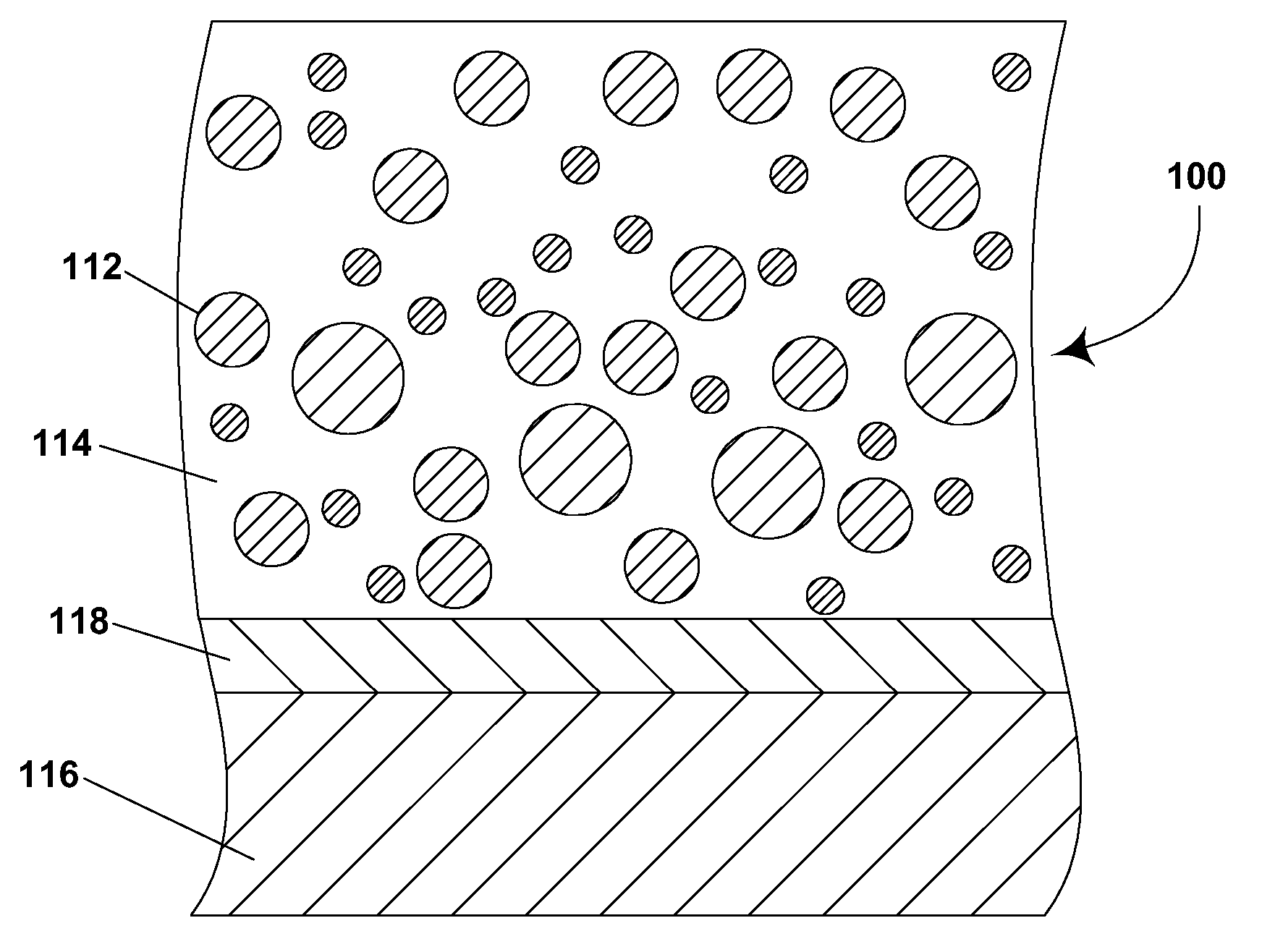

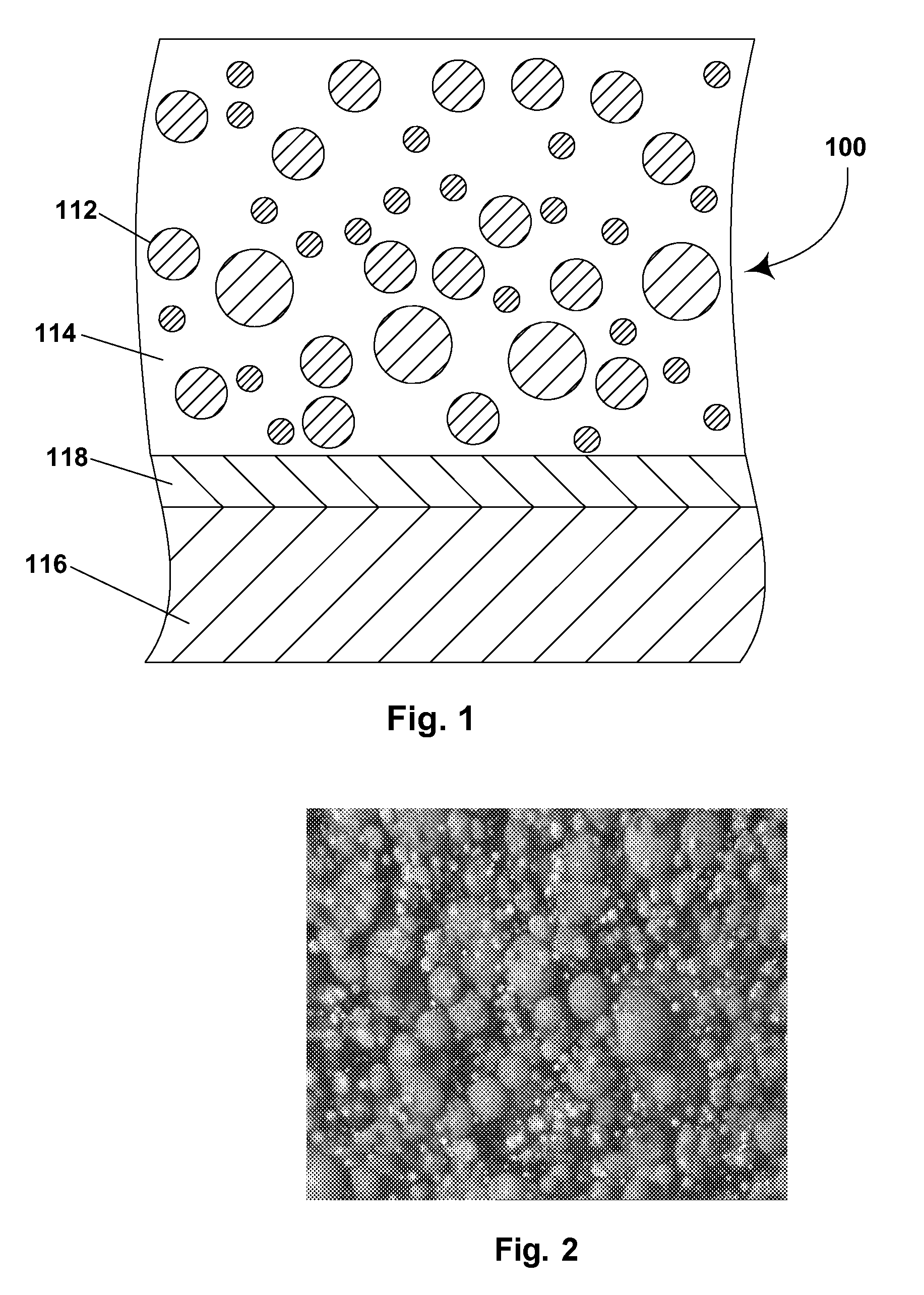

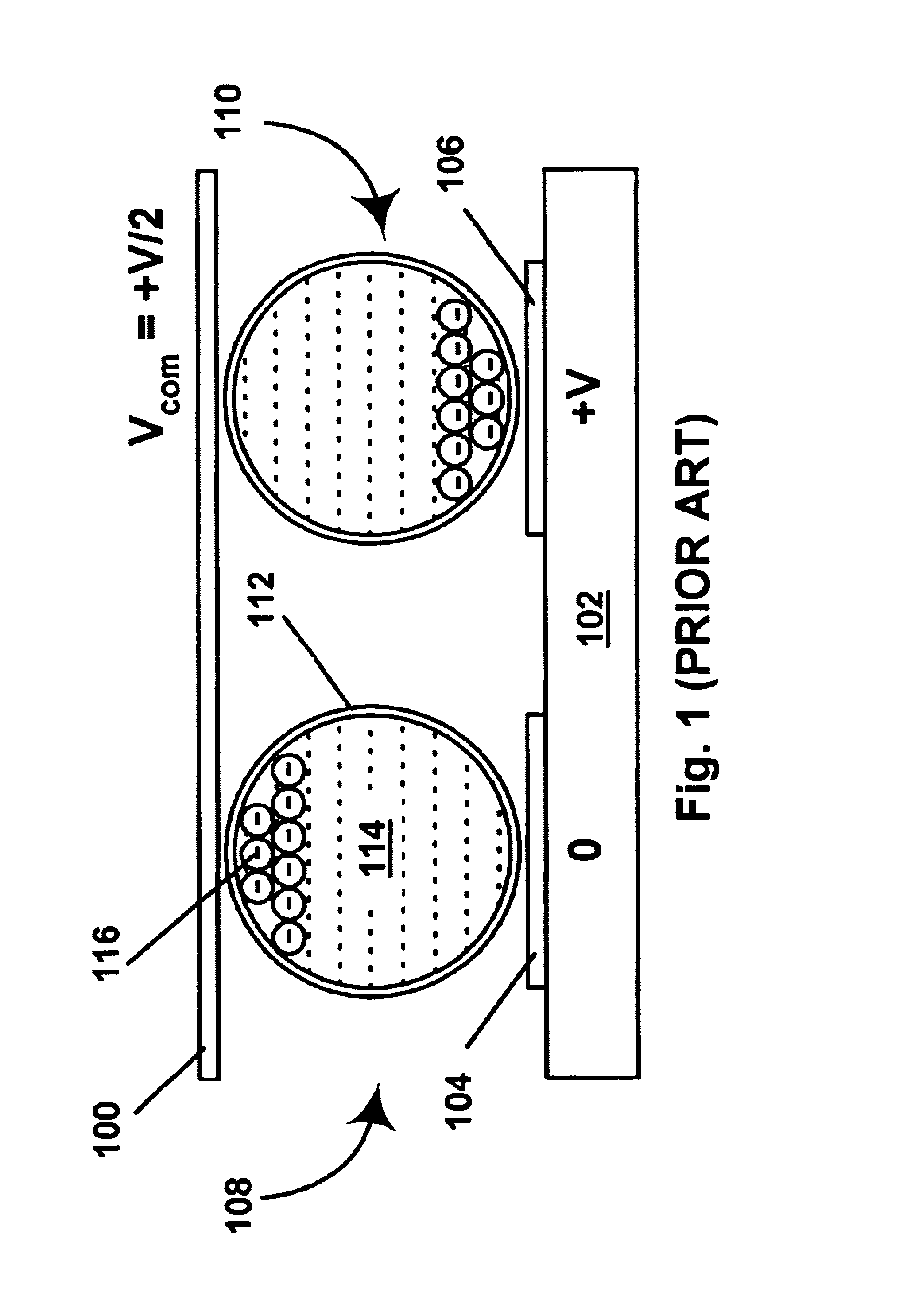

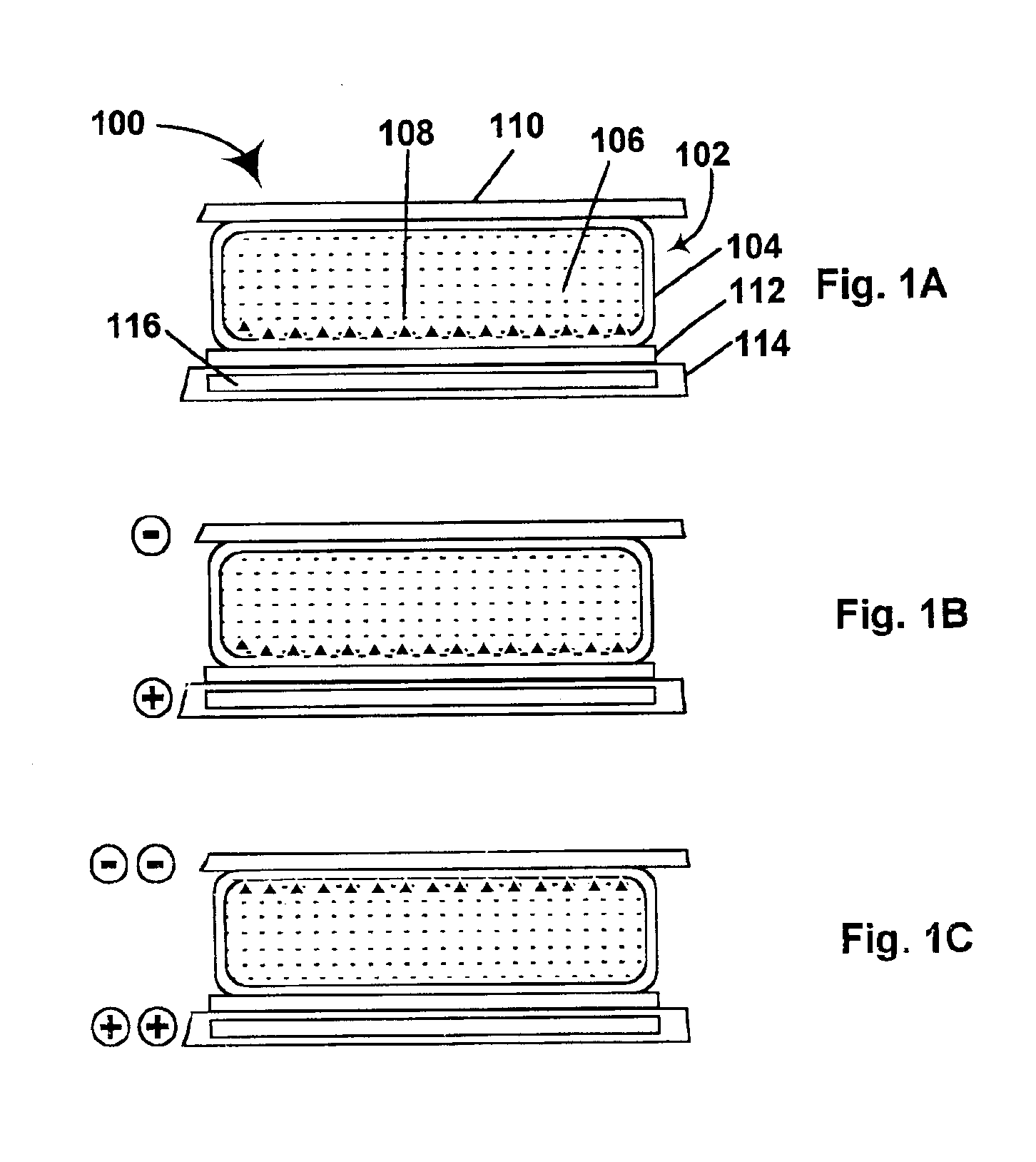

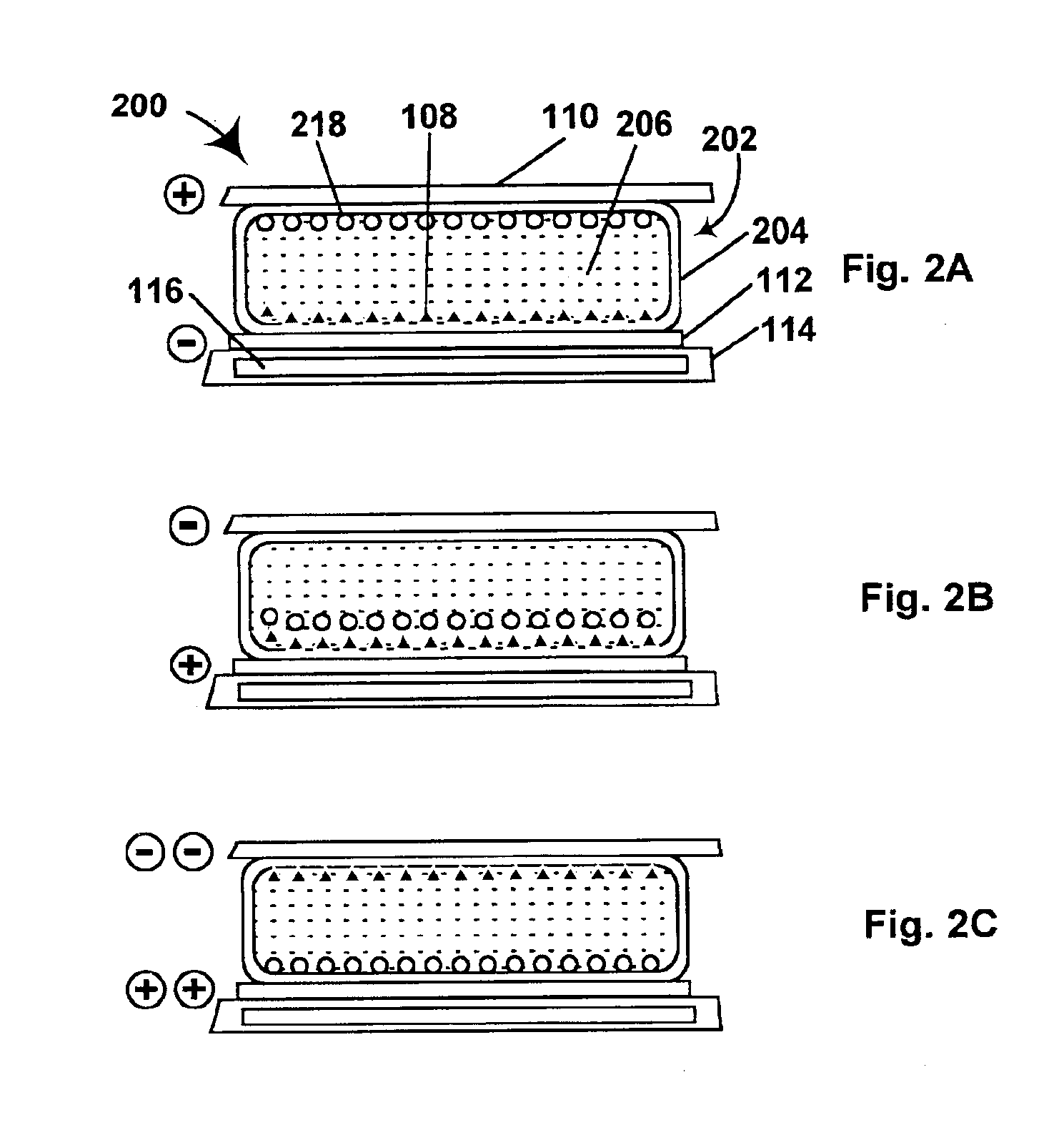

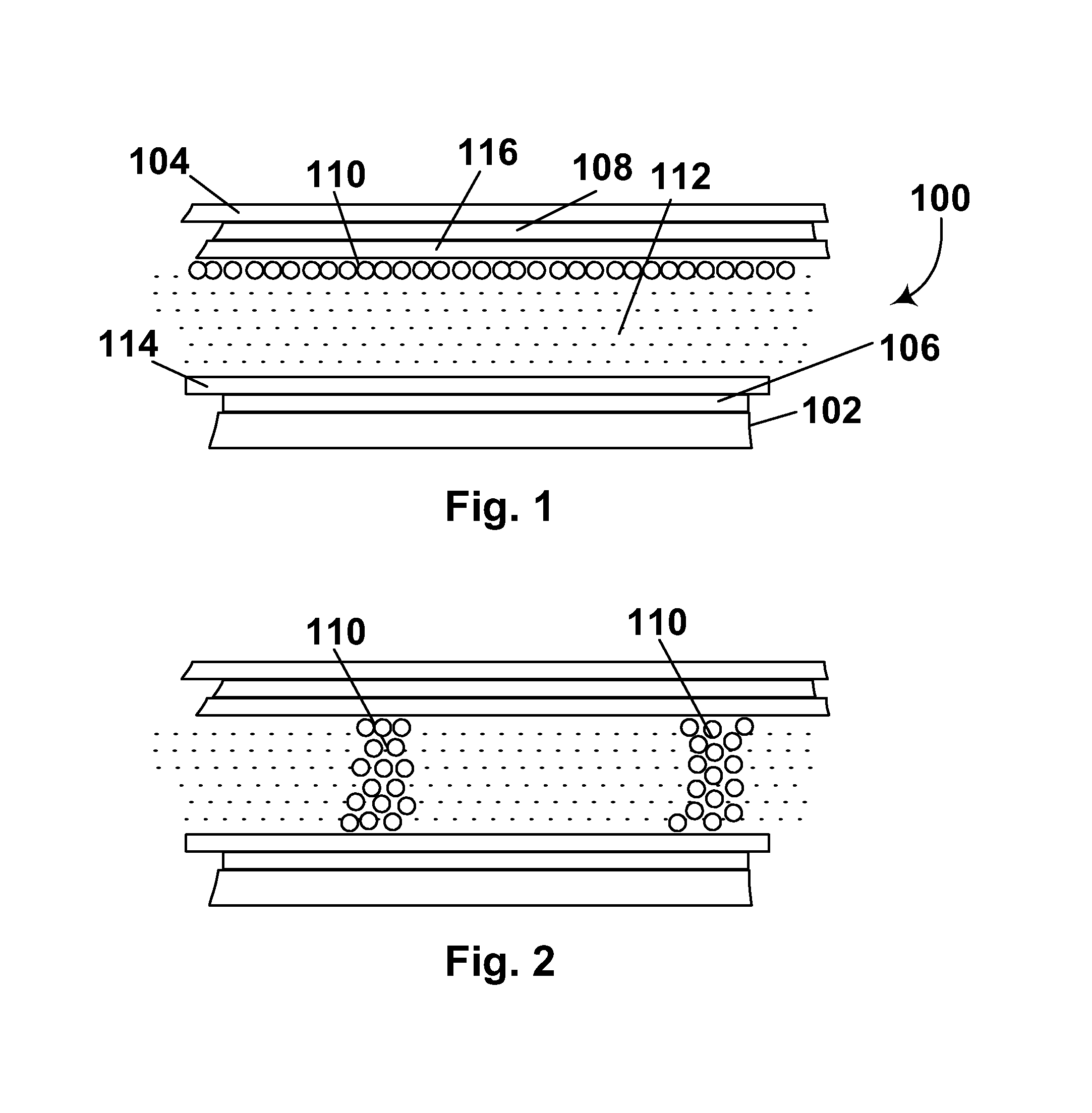

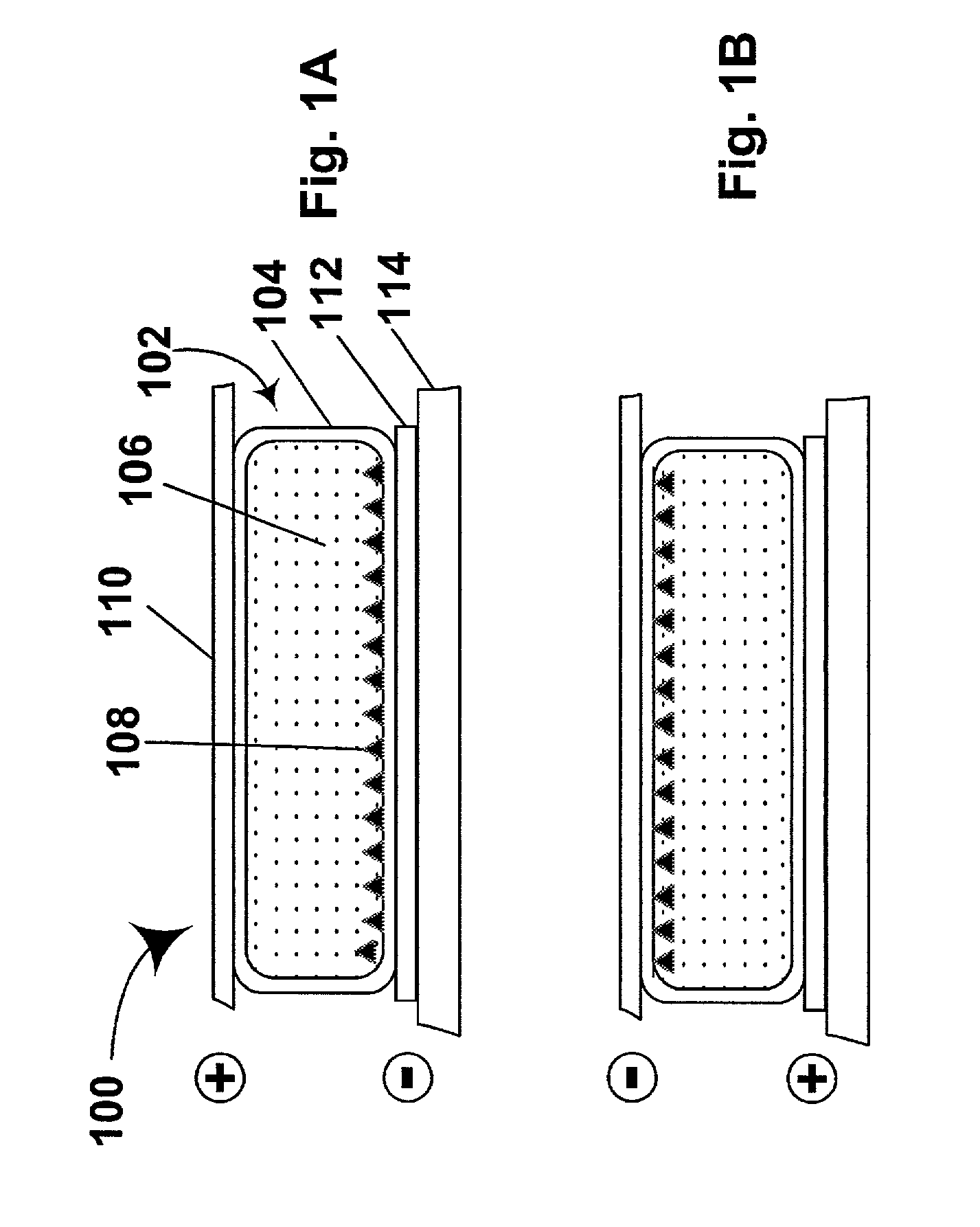

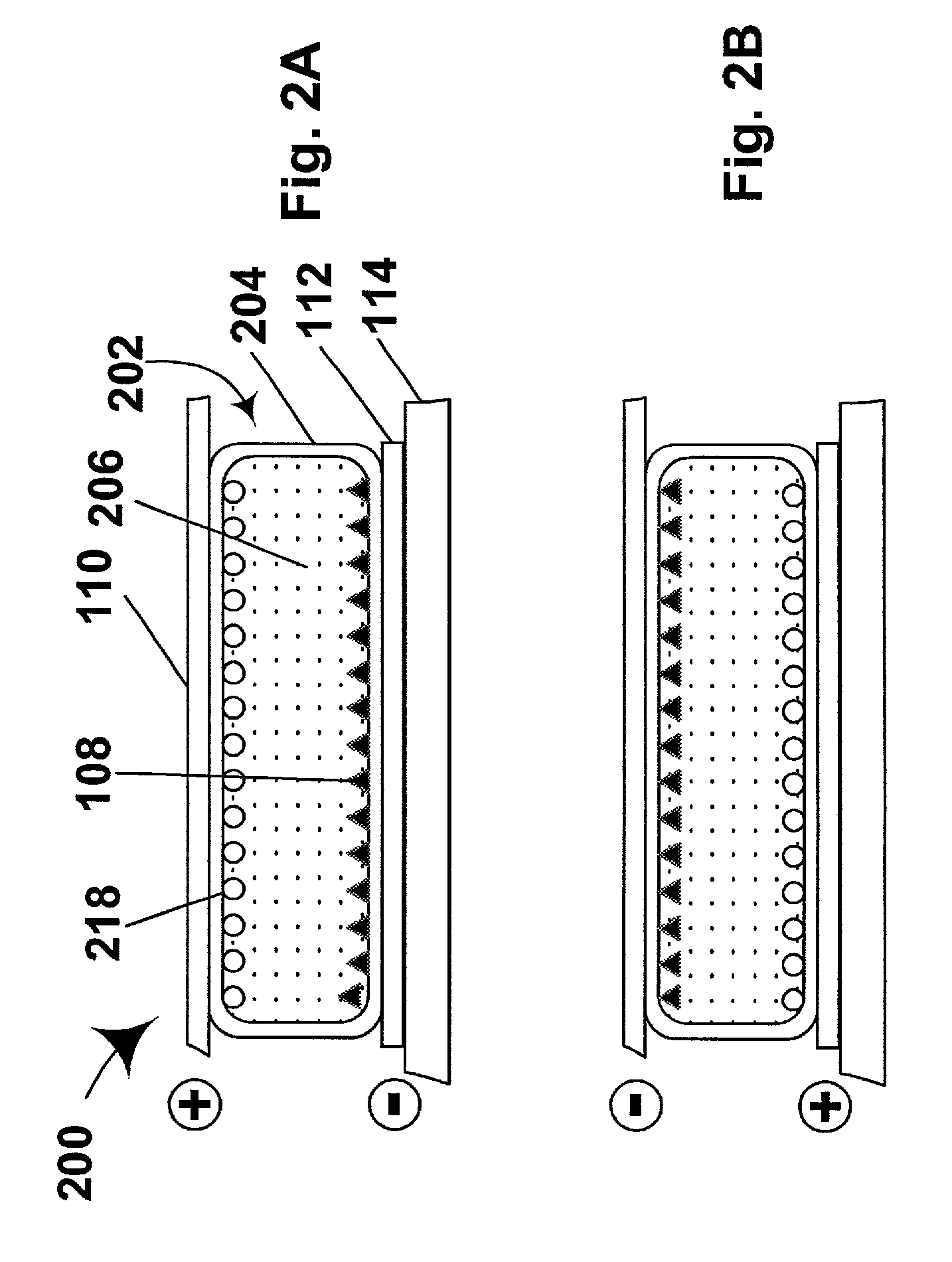

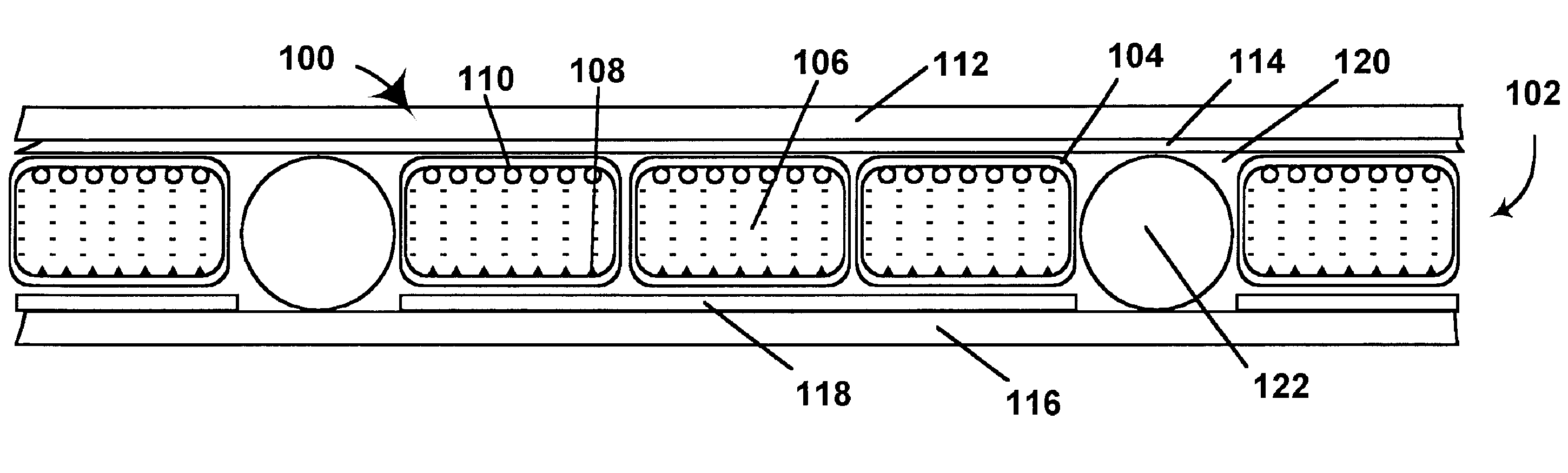

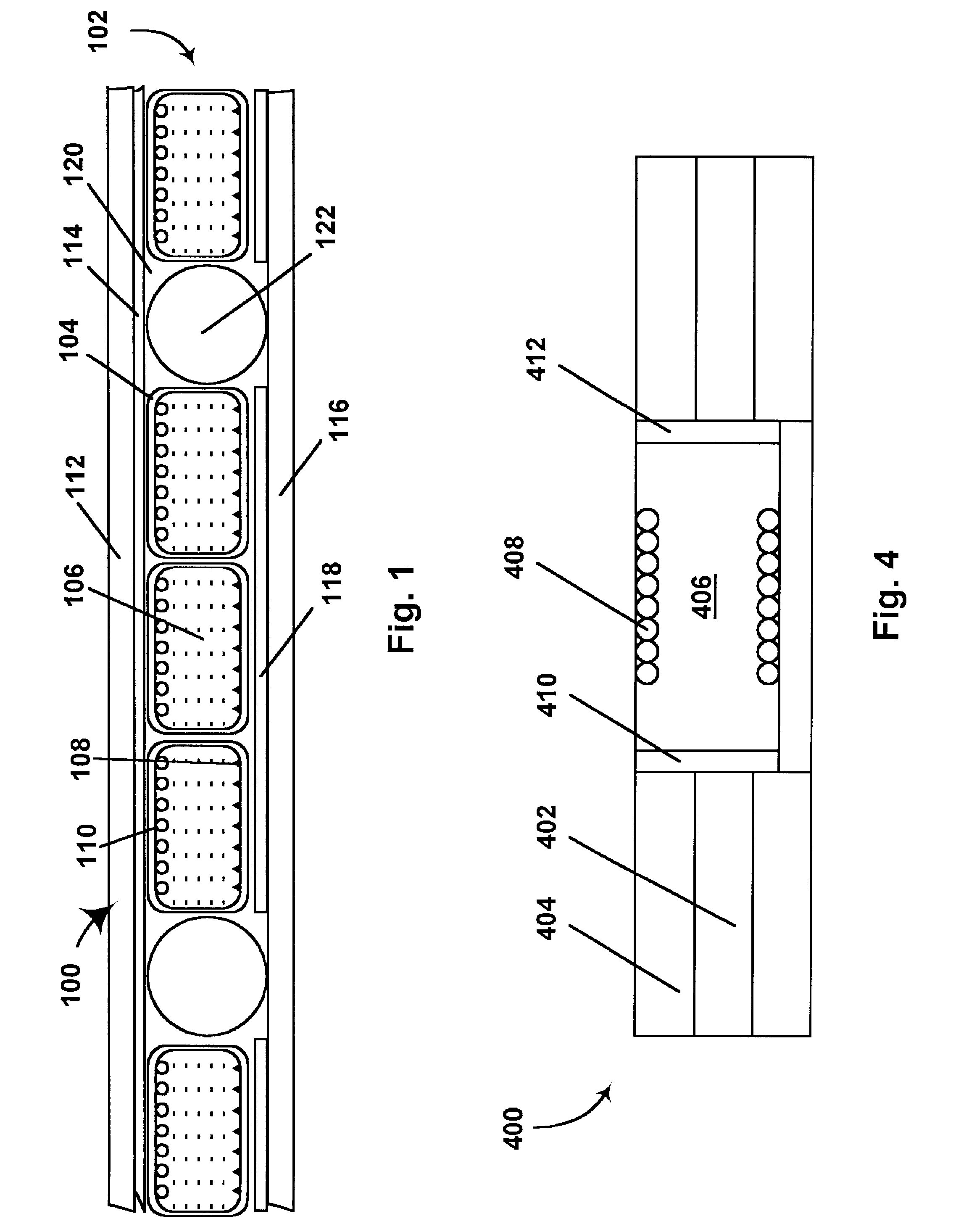

Construction of electrophoretic displays

An electrophoretic display (100) comprises a front light-transmissive substrate (112), a rear substrate (116) spaced from the front substrate (112) so as to leave a cavity, and an electrophoretic medium (102) in the cavity, the electrophoretic medium (102) comprising a liquid external phase (120) and a plurality of capsules (104) suspended in the liquid external phase (120), each of the capsules comprising a capsule wall, a suspending fluid (106) held within the capsule wall and at least one electrically charged particle (108, 110) suspended in the suspending fluid (106).

Owner:E INK CORPORATION

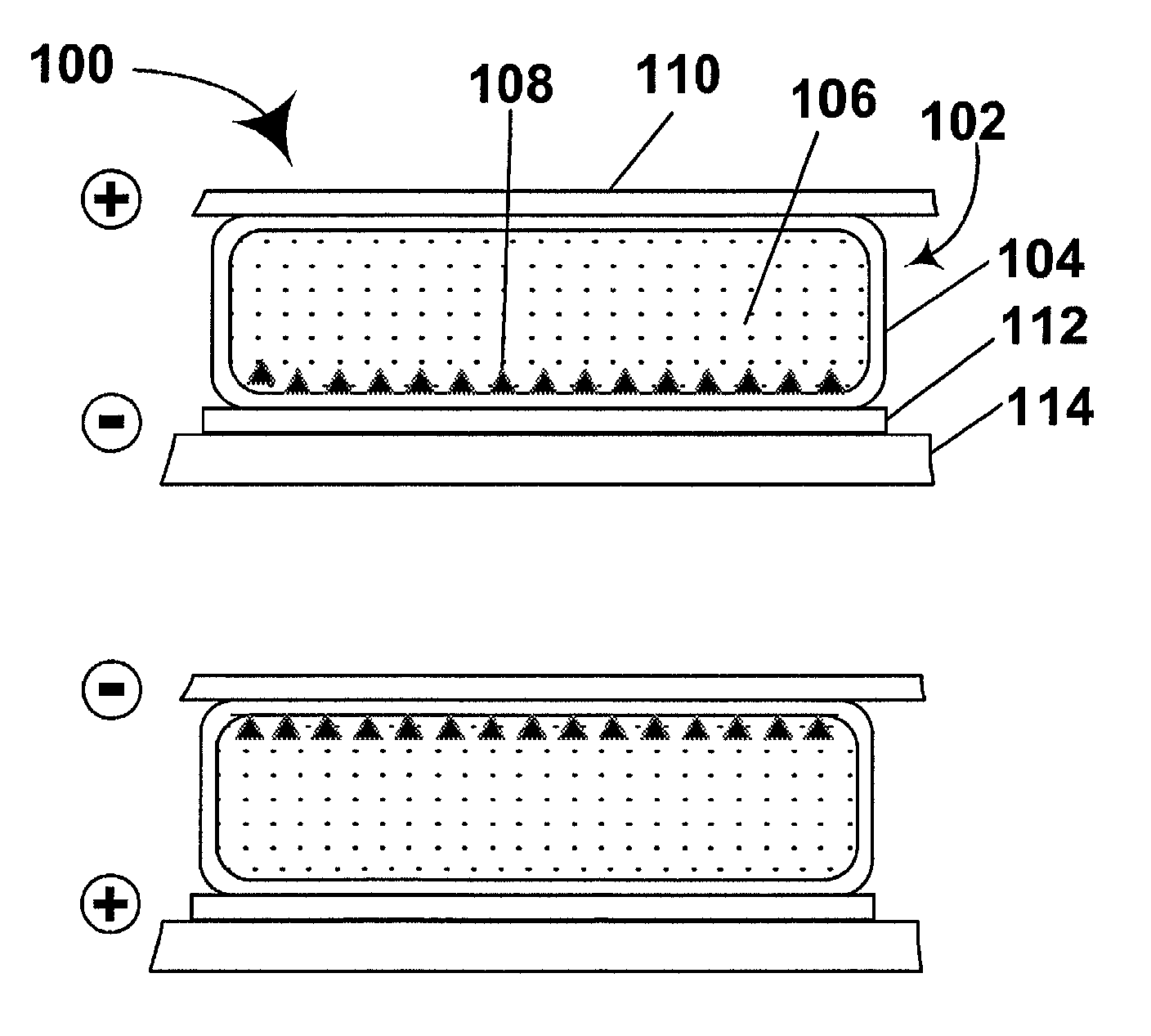

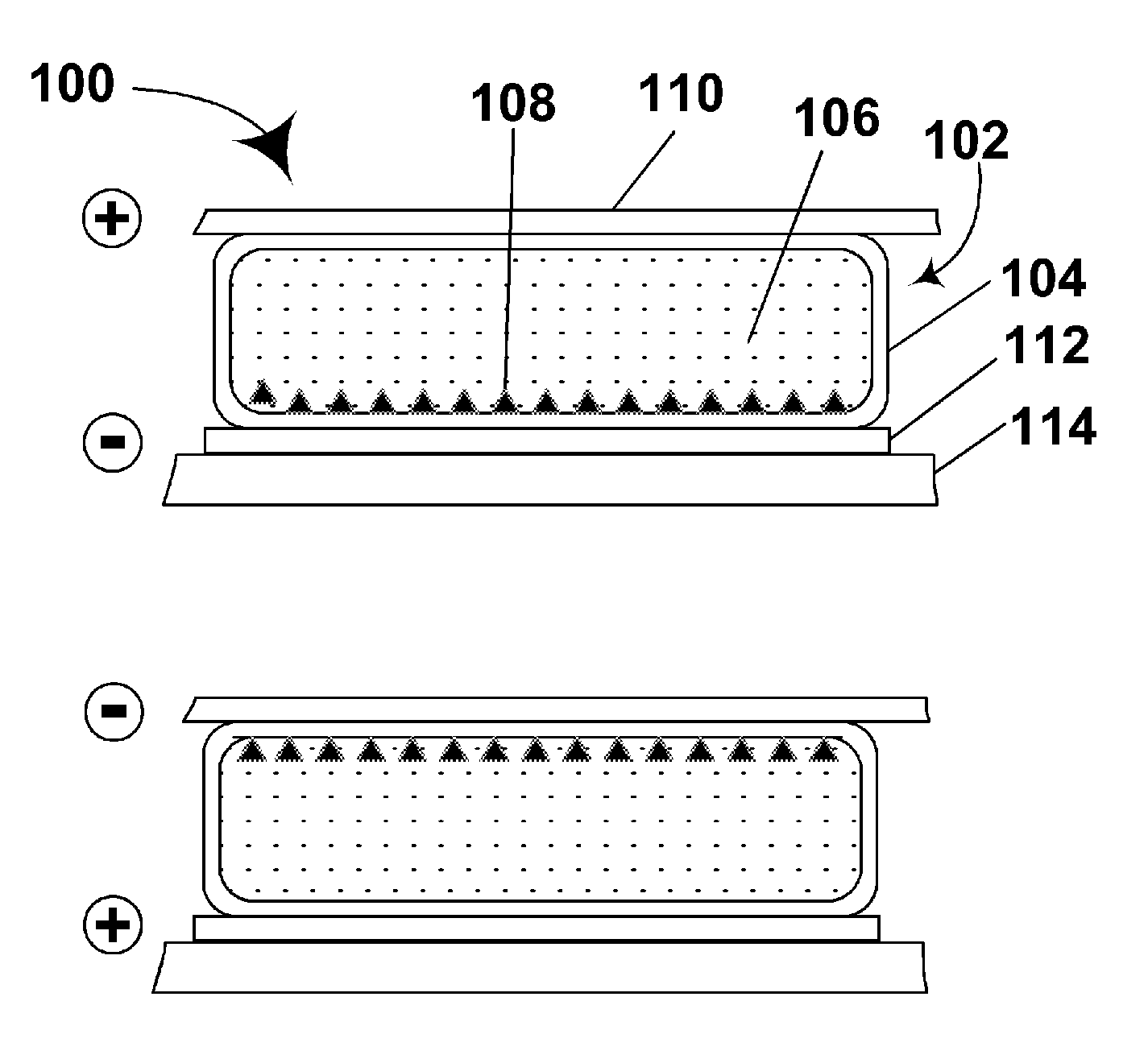

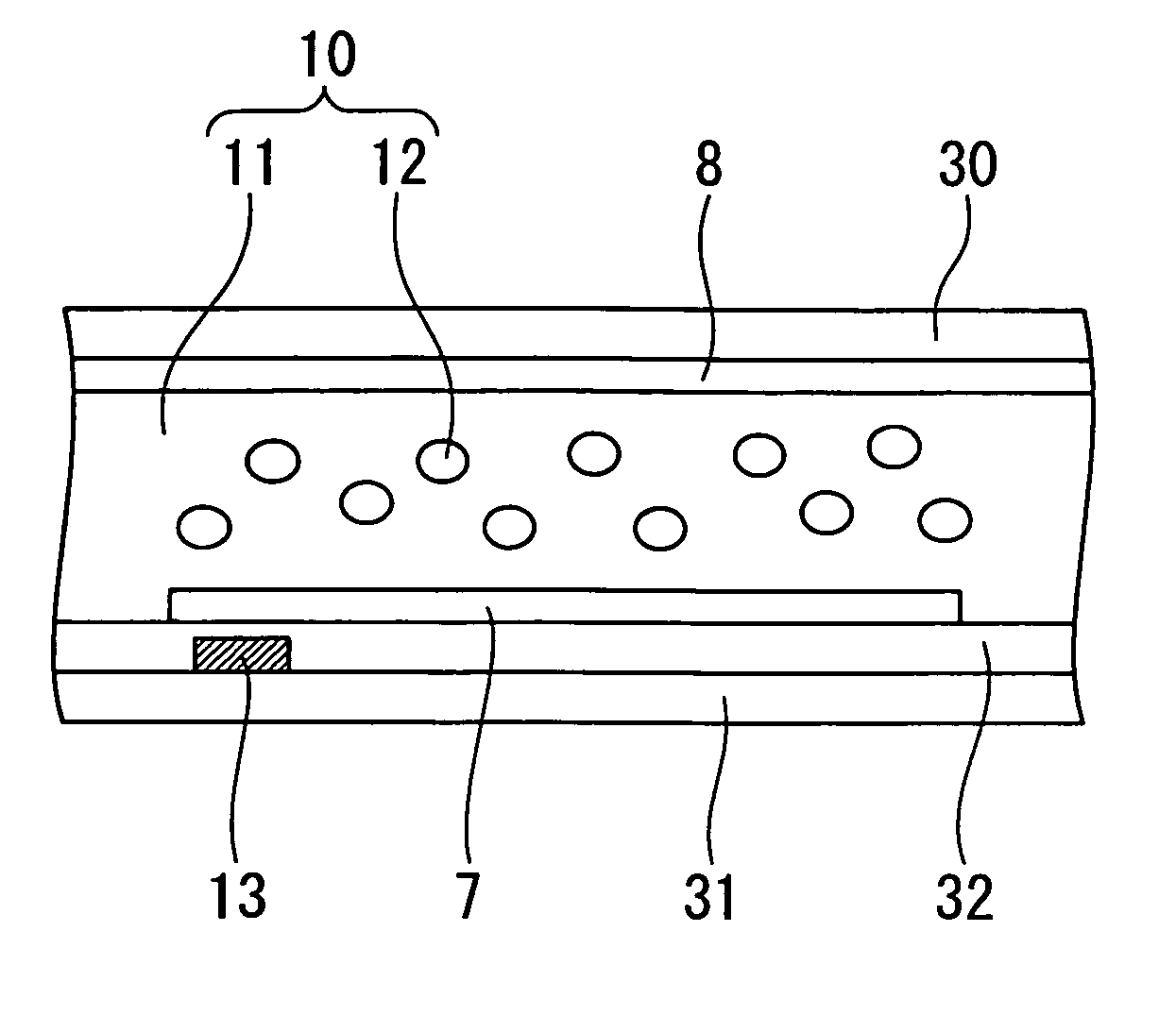

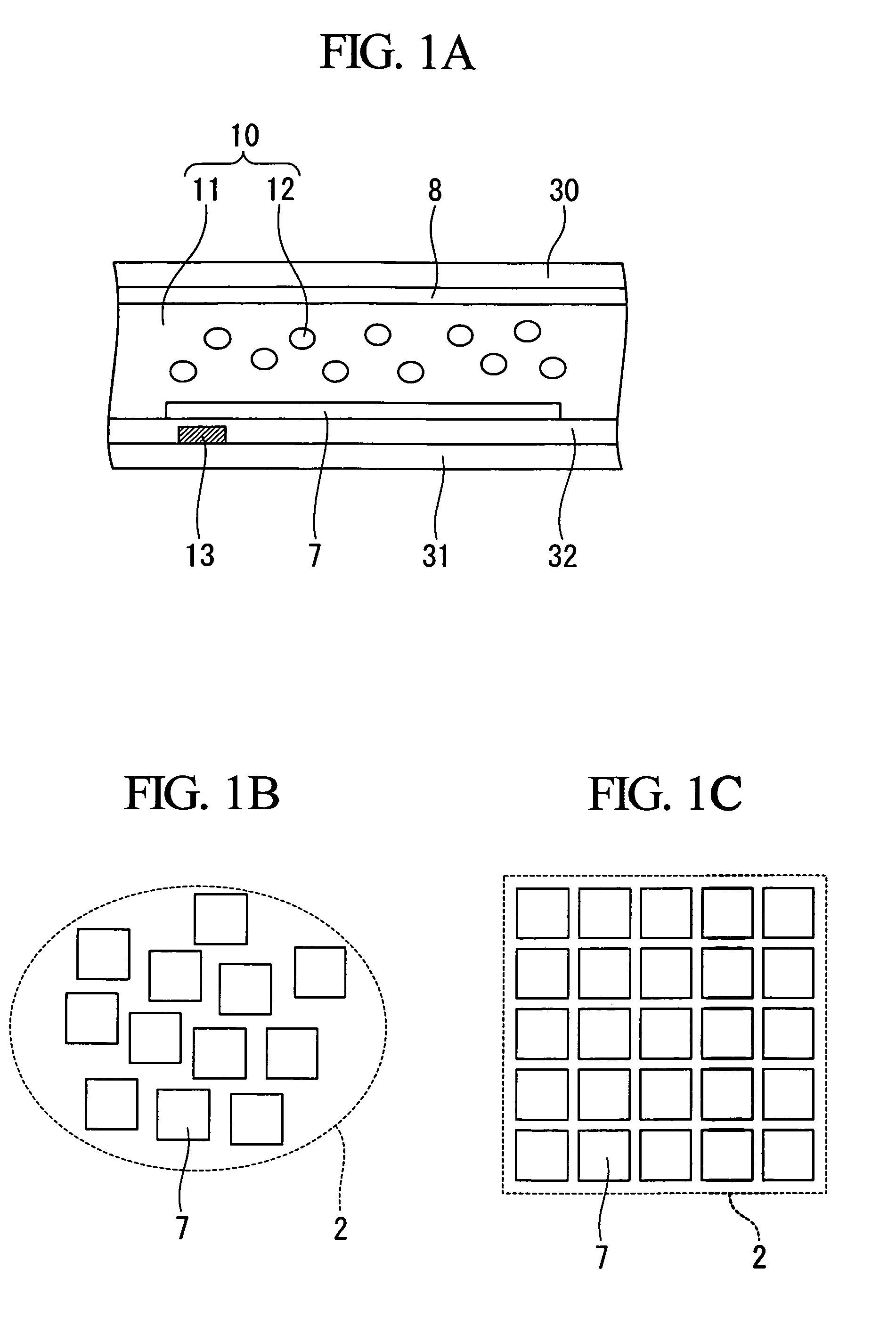

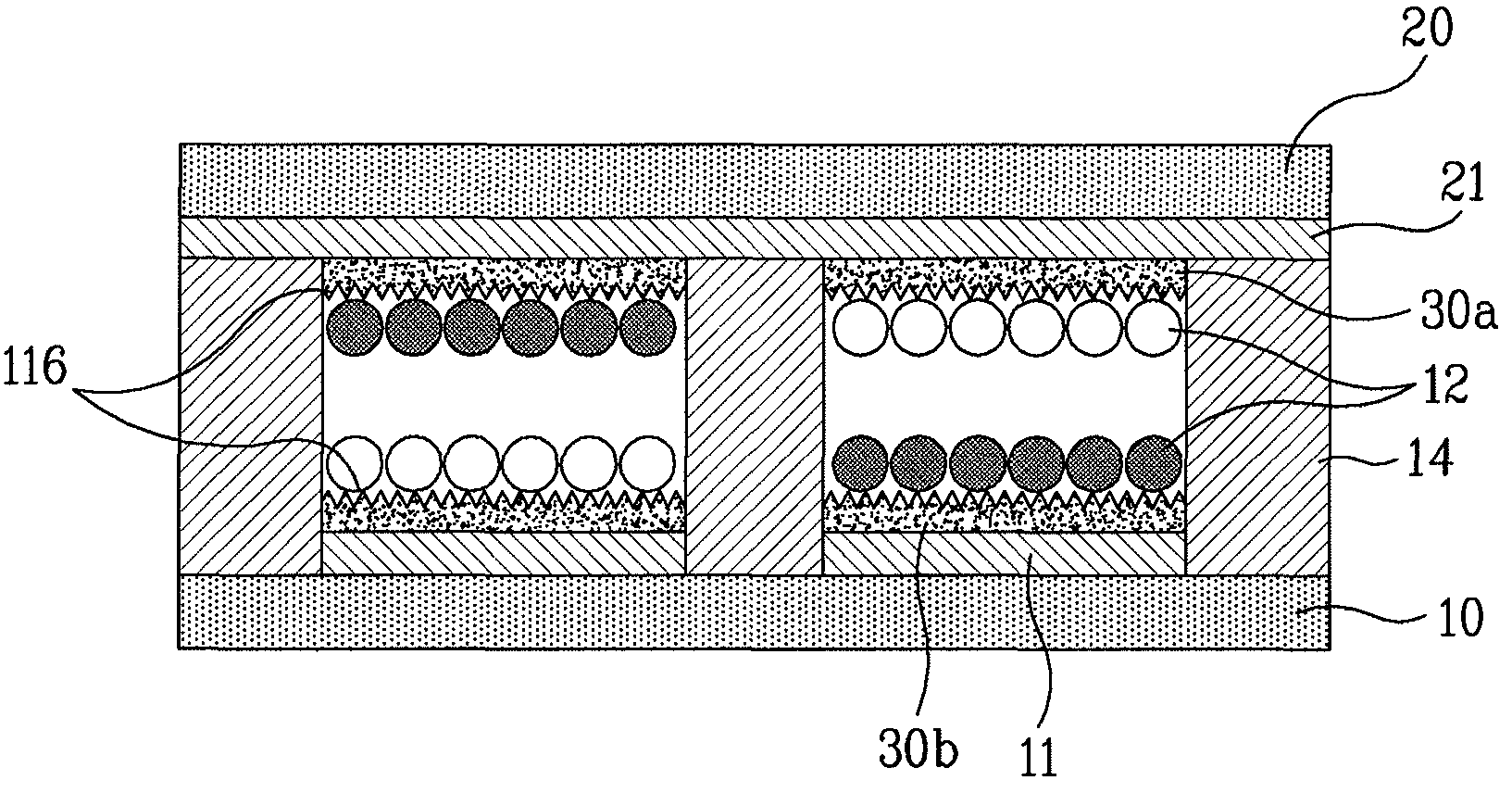

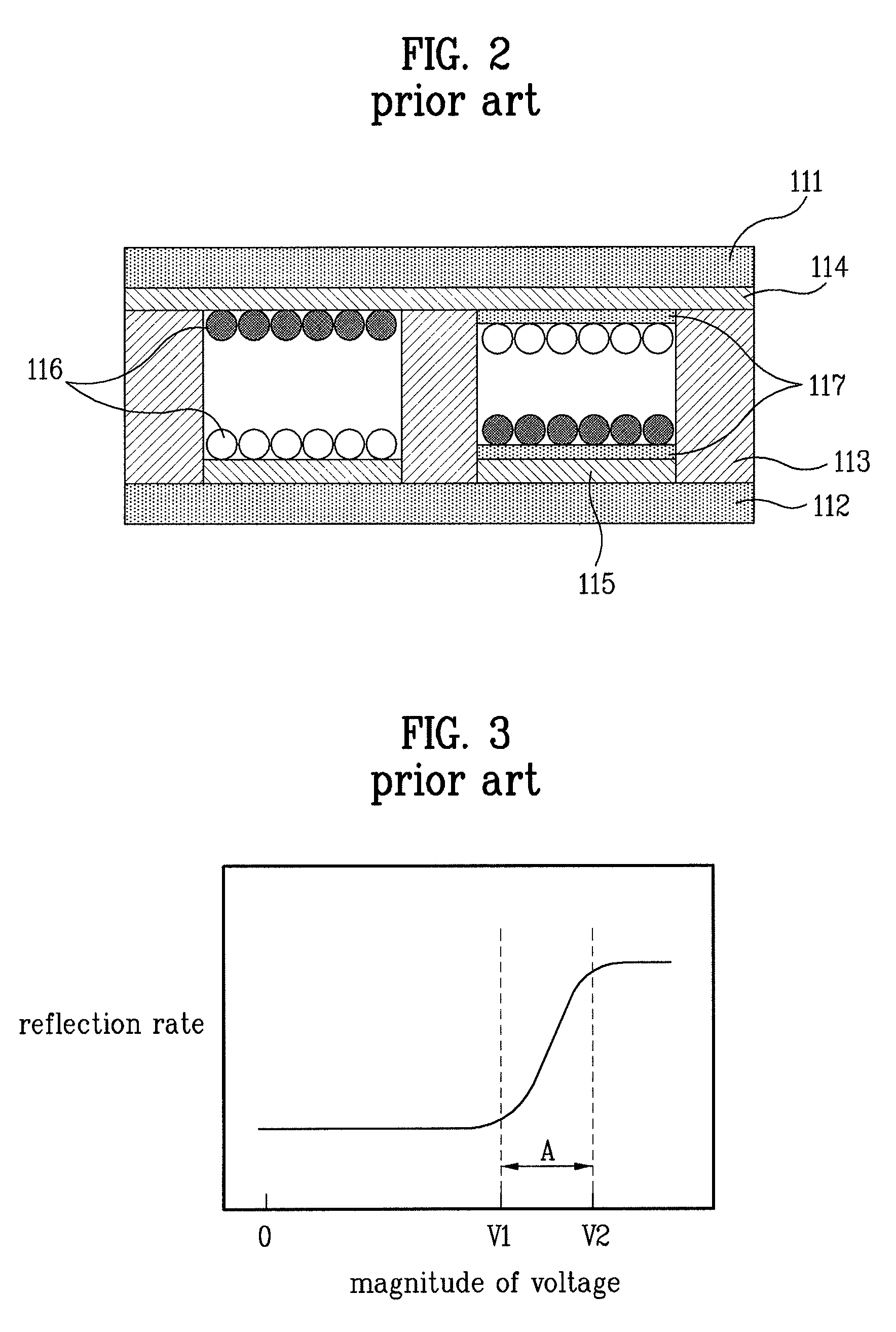

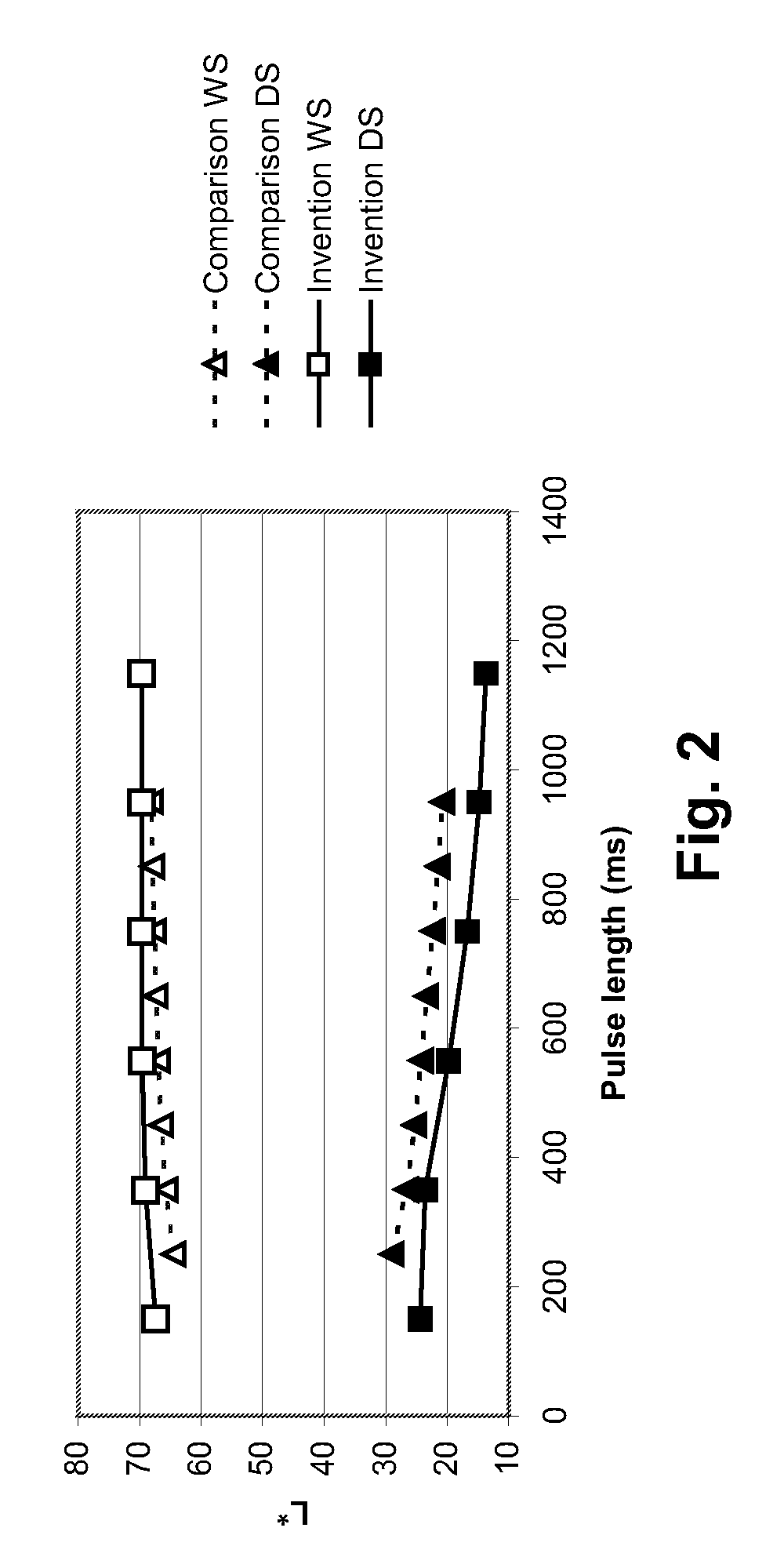

Electronic paper display device, manufacturing method and driving method thereof

InactiveUS7751115B2Quick responseReduce voltageStatic indicating devicesNon-linear opticsVoltage pulseElectrophoresis

An electronic paper display device, a manufacturing method and a driving method thereof are disclosed. Micro protrusion members are formed at electrodes or at insulating layers. Consequently, the electrophoretic particles are prevented from being securely attached to an upper or the lower structure, and therefore, the quality of pictures is improved, and the contrast ratio of the pictures is increased. The relative sizes and the injection amounts of two kinds of electrophoretic particles are changed such that the relative sizes and the injection amounts of the electrophoretic particles are different from each other. Consequently, the driving voltage is lowered by excessively electrifying the electrophoretic particles of one kind. Protrusions are formed at the corresponding electrode such that a relatively large electric field is distributed around the electrode at which electrophoretic particles are located in the initial stage of voltage application. Consequently, the electrophoretic particles are easily separated from the electrode and moved even at low driving voltage. As such, the voltage level of the driving voltage pulse is lowered. Consequently, it is possible to further increase the response speed of the driving devices and to lower the internal voltage of the devices, thereby reducing the costs related to the driving devices.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com