Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16575 results about "Polystyrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polystyrene (PS) /ˌpɒliˈstaɪriːn/ is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and rather brittle. It is an inexpensive resin per unit weight. It is a rather poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be coloured with colourants. Uses include protective packaging (such as packing peanuts and CD and DVD cases), containers, lids, bottles, trays, tumblers, disposable cutlery and in the making of models.

Hemostatic compositions for arresting blood flow from an open wound or surgical site

A hemostatic composition for stopping or decreasing blood flow from an open wound or medical or surgical procedure. Compositions of the invention comprise a mixture of a cationic polymer and a cation exchange material. In one embodiment, the composition comprises a mixture: (1) a high molecular weight copolymer of diallyl dimethyl ammonium chloride (DADMAC) and acrylamide [DADMAC copolymer], and (2) the hydrogen form of a crosslinked, sulfonated polystyrene (hydrogen resin). In an exemplified embodiment, a composition of the invention comprises the mixture of DADMAC copolymer and hydrogen resin provided in a dry powdered form. The compositions of the invention may be applied directly to a wound or treatment site, or they may be incorporated into a wound dressing, such as a bandage. The seal formed at a wound or treatment site treated with the present invention is adhesive and exhibits considerable toughness.

Owner:BIOLIFE

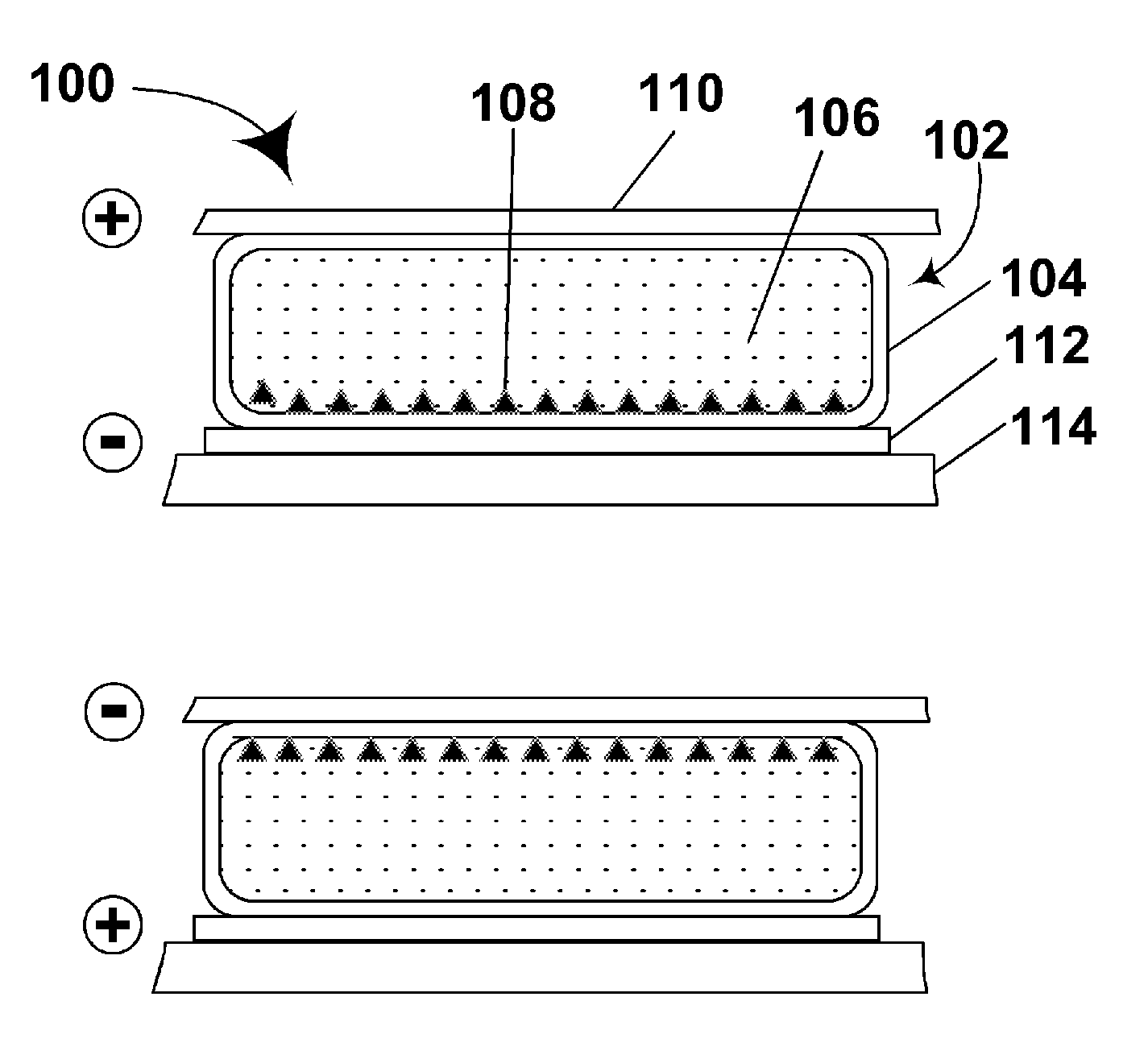

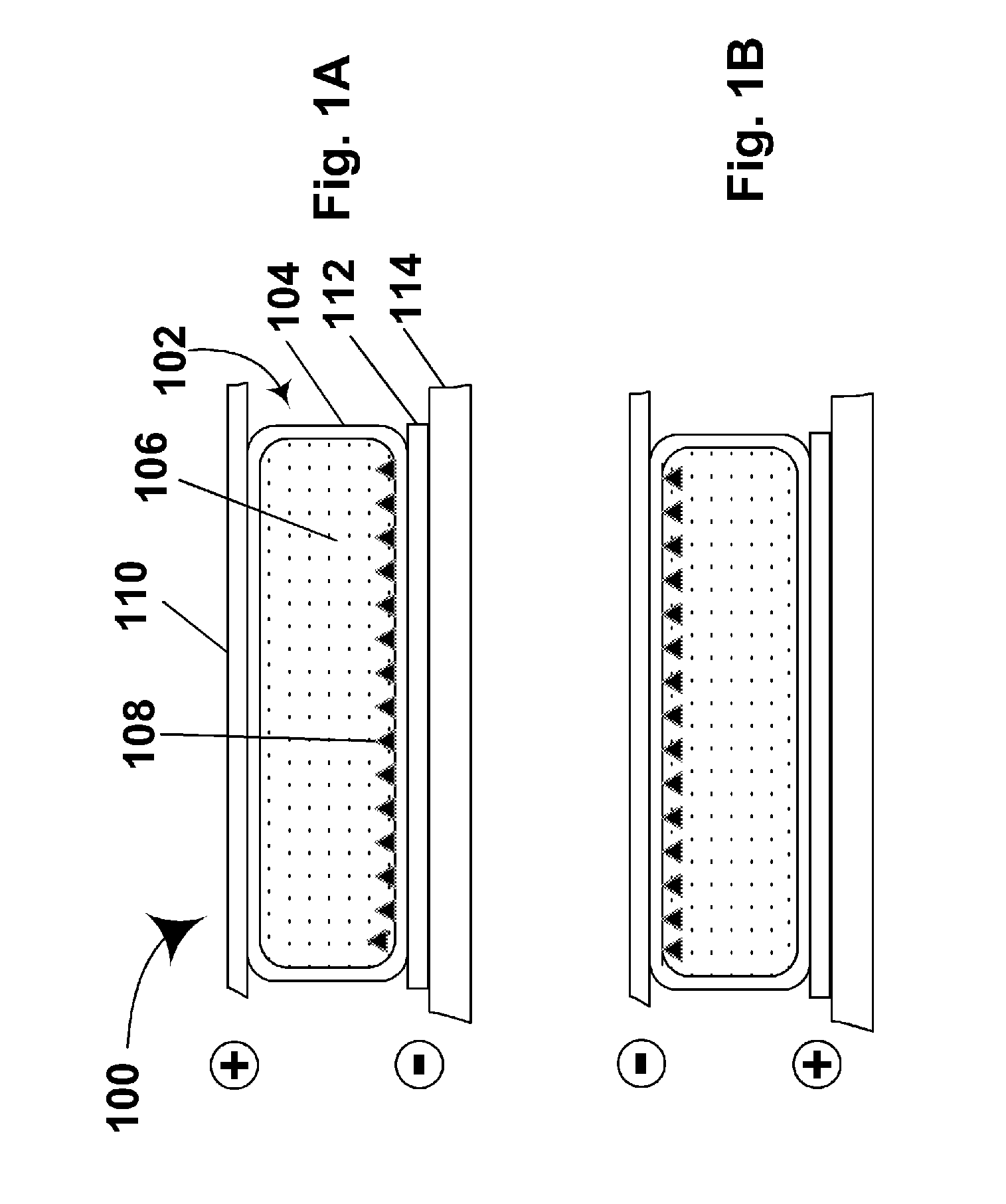

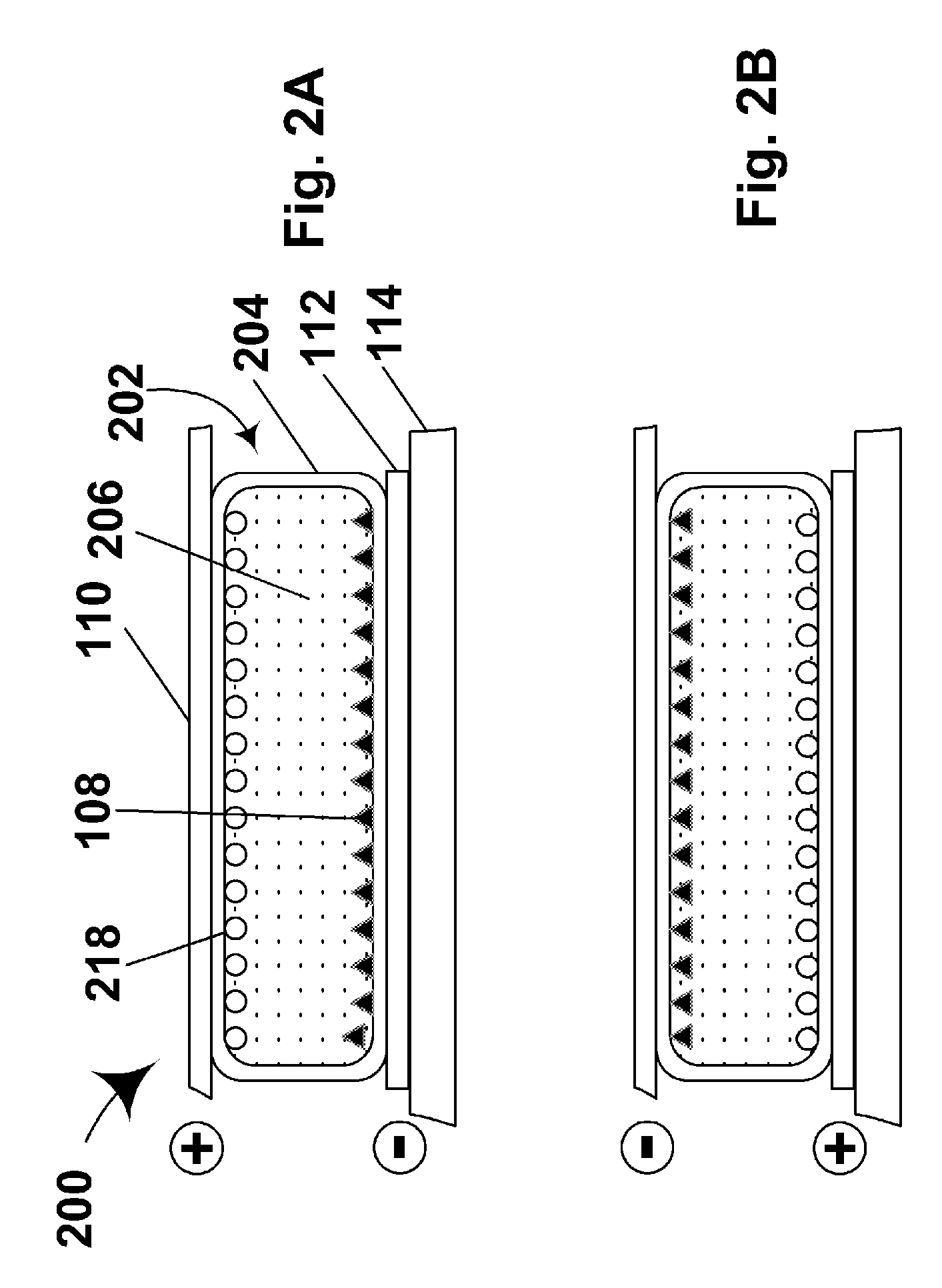

Materials for use in electrophoretic displays

The image stability of electrophoretic media, comprising a plurality of particles disposed in a fluid and capable of moving through the fluid upon application of an electric field to the medium, can be improved by including in the fluid either a polystyrene or an aggregating diblock copolymer which forms micelle-like structures in the fluid, the diblock copolymer having a first block soluble in the fluid and a second block not swellable by the fluid. In variable transmission electrophoretic media, haze can be reduced by using as the fluid a mixture of a partially hydrogenated aromatic hydrocarbon and a terpene.

Owner:E INK CORPORATION

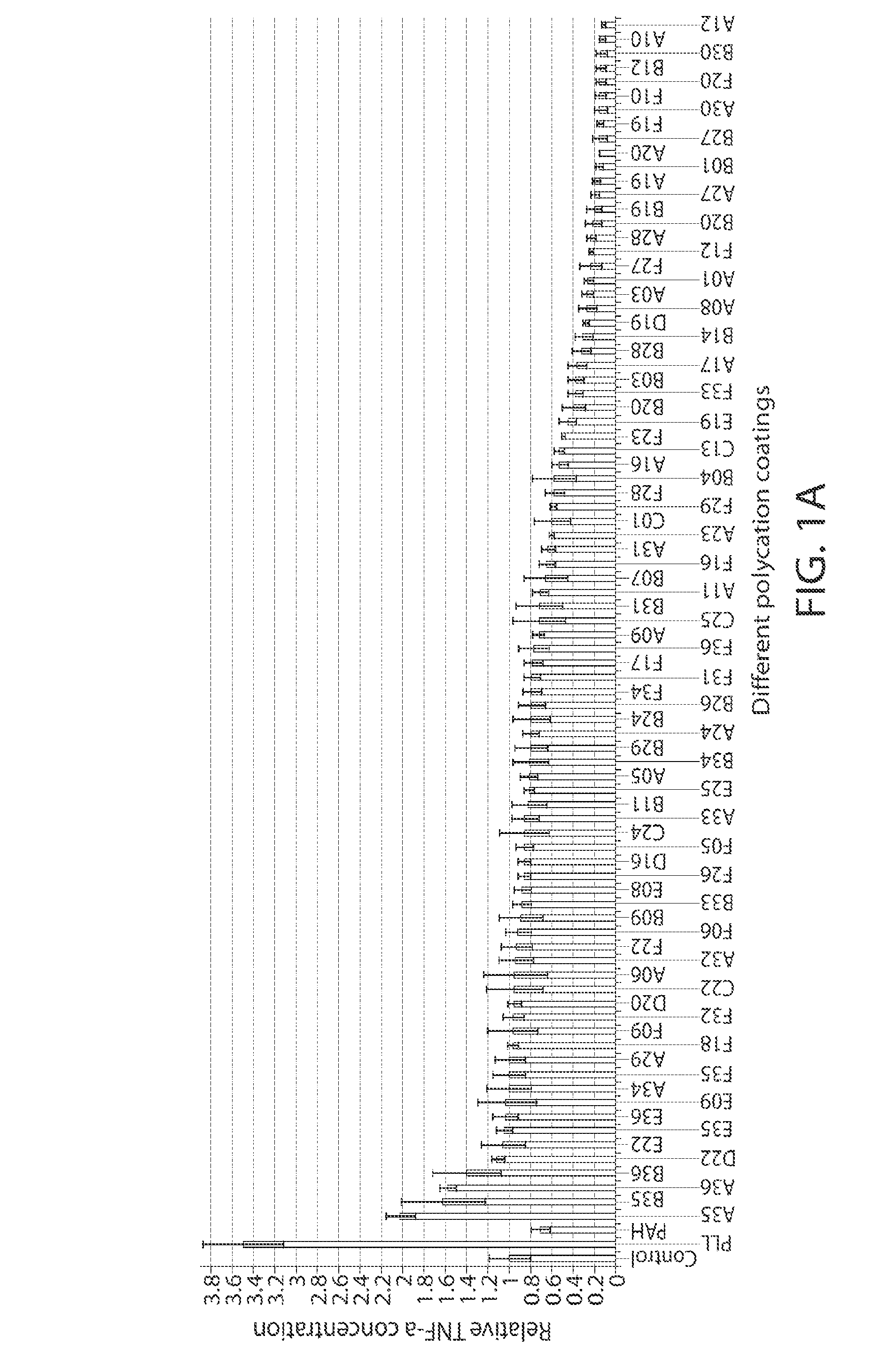

Poly(beta-amino alcohols), their preparation, and uses thereof

ActiveUS20130302401A1Organic active ingredientsPeptide/protein ingredientsChemical structureFibrosis

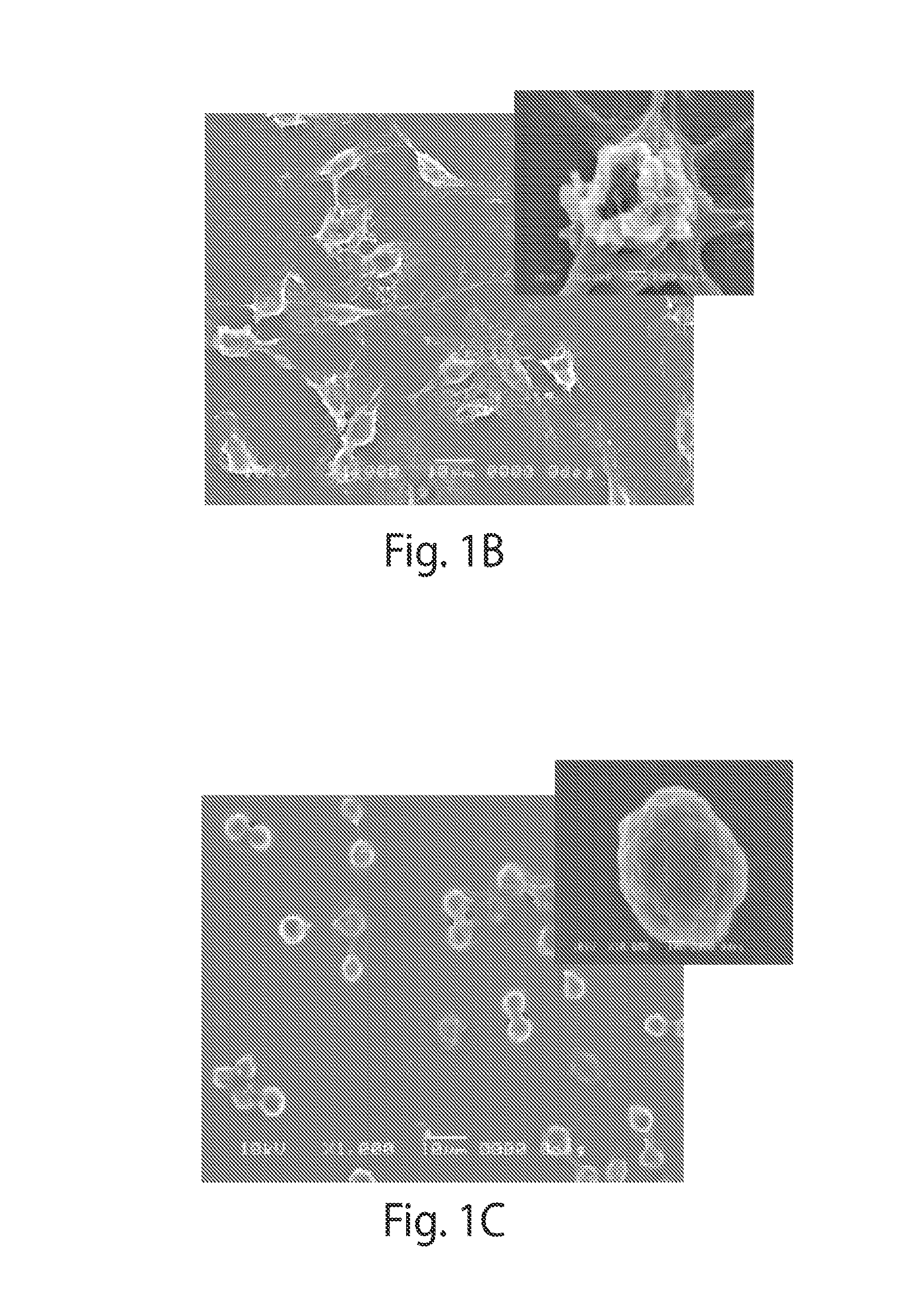

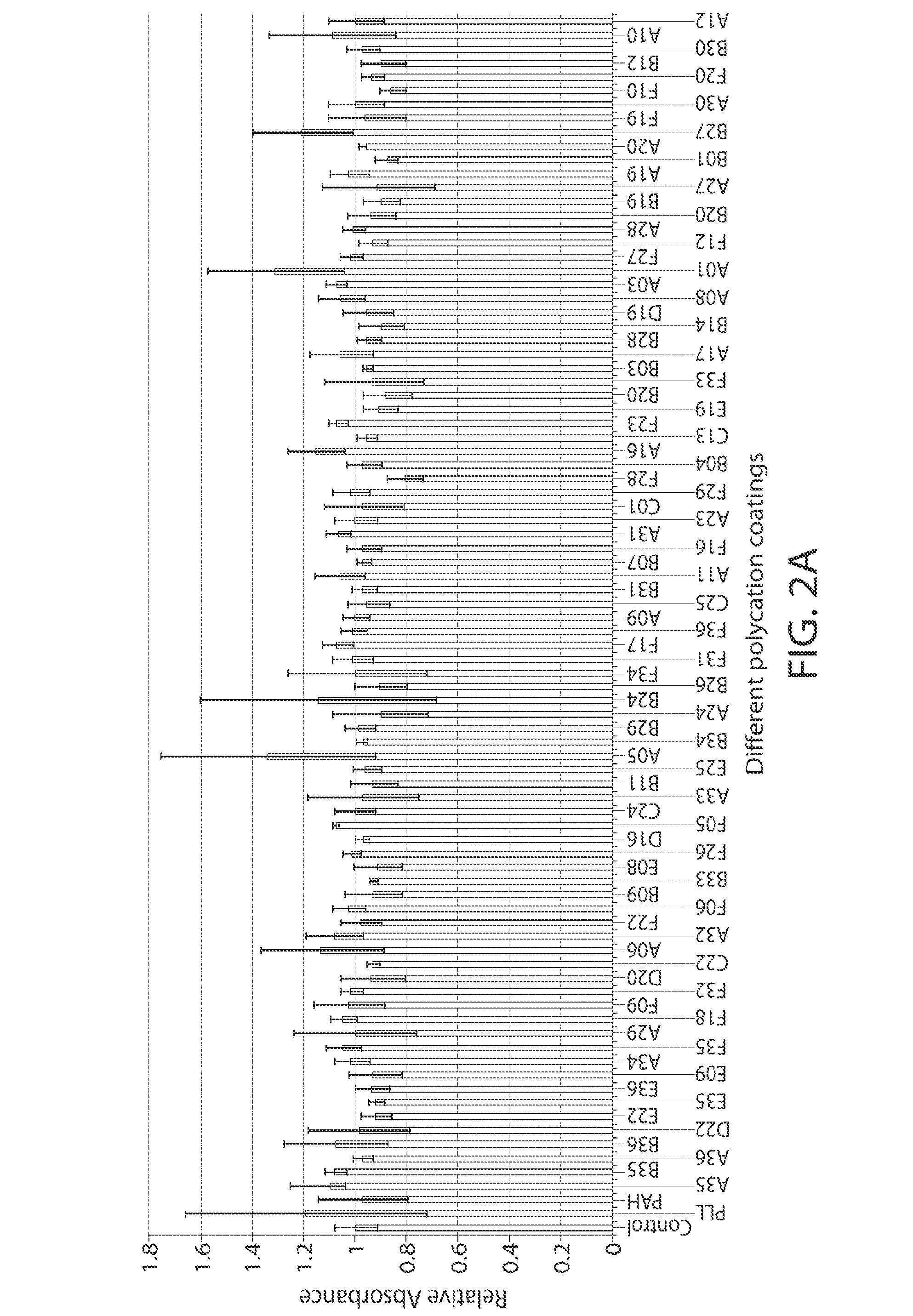

A new class of poly(beta-amino alcohols) (PBAAs) has been prepared using combinatorial polymerization. The inventive PBAAs may be used in biotechnology and biomedical applications as coatings (such as coatings of films or multilayer films for medical devices or implants), additives, materials, excipients, non-biofouling agents, micropatterning agents, and cellular encapsulation agents. When used as surface coatings, these PBAAs elicited different levels of inflammation, both in vitro and in vivo, depending on their chemical structures. The large chemical diversity of this class of materials allowed us to identify polymer coatings that inhibit macrophage activation in vitro. Furthermore, these coatings reduce the recruitment of inflammatory cells, and reduce fibrosis, following the subcutaneous implantation of carboxylated polystyrene microparticles. These polymers may be used to form polyelectrolyte complex capsules for cell encapsulation. The invention may also have many other biological applications such as antimicrobial coatings, DNA or siRNA delivery, and stem cell tissue engineering.

Owner:MASSACHUSETTS INST OF TECH

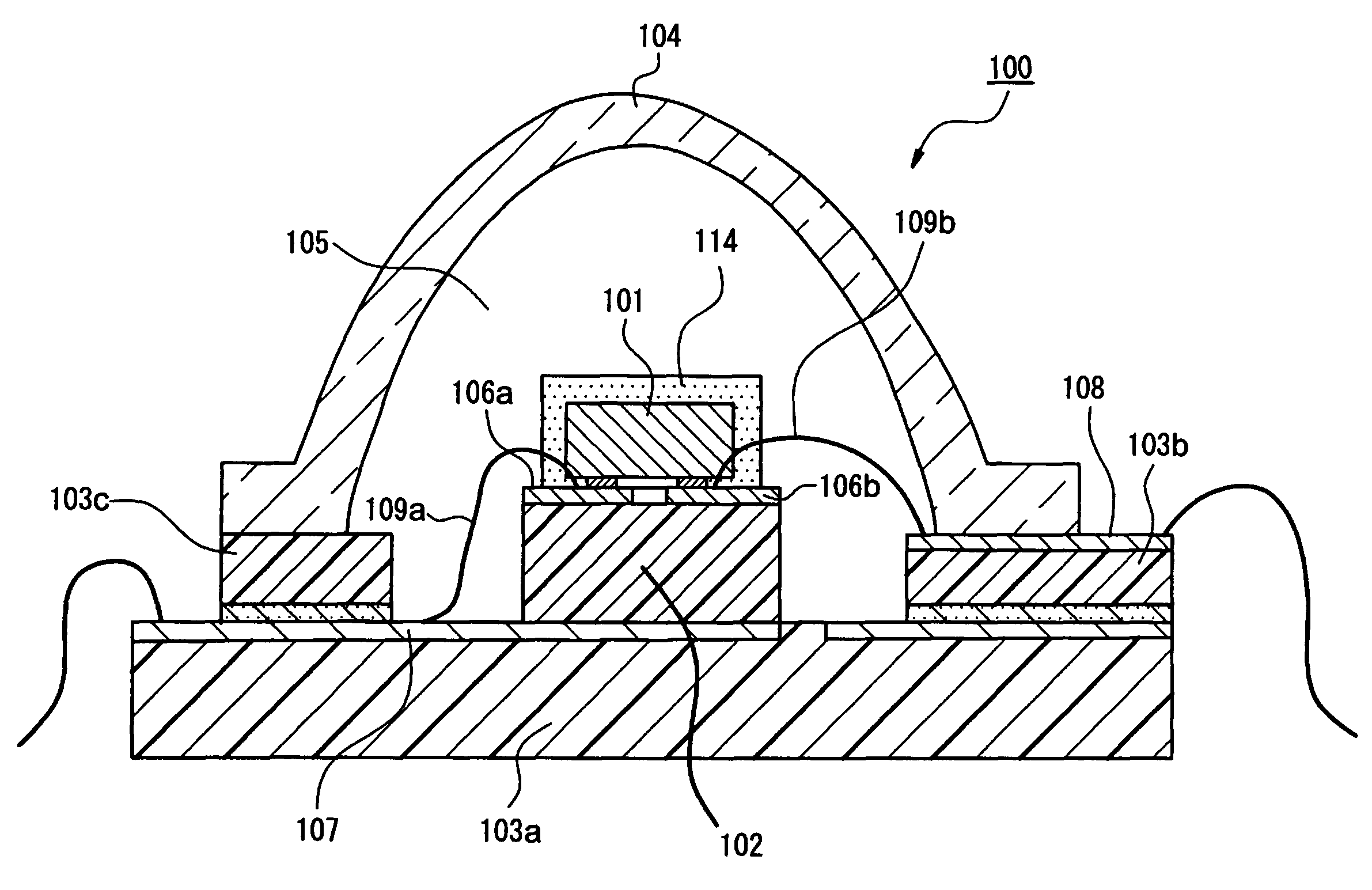

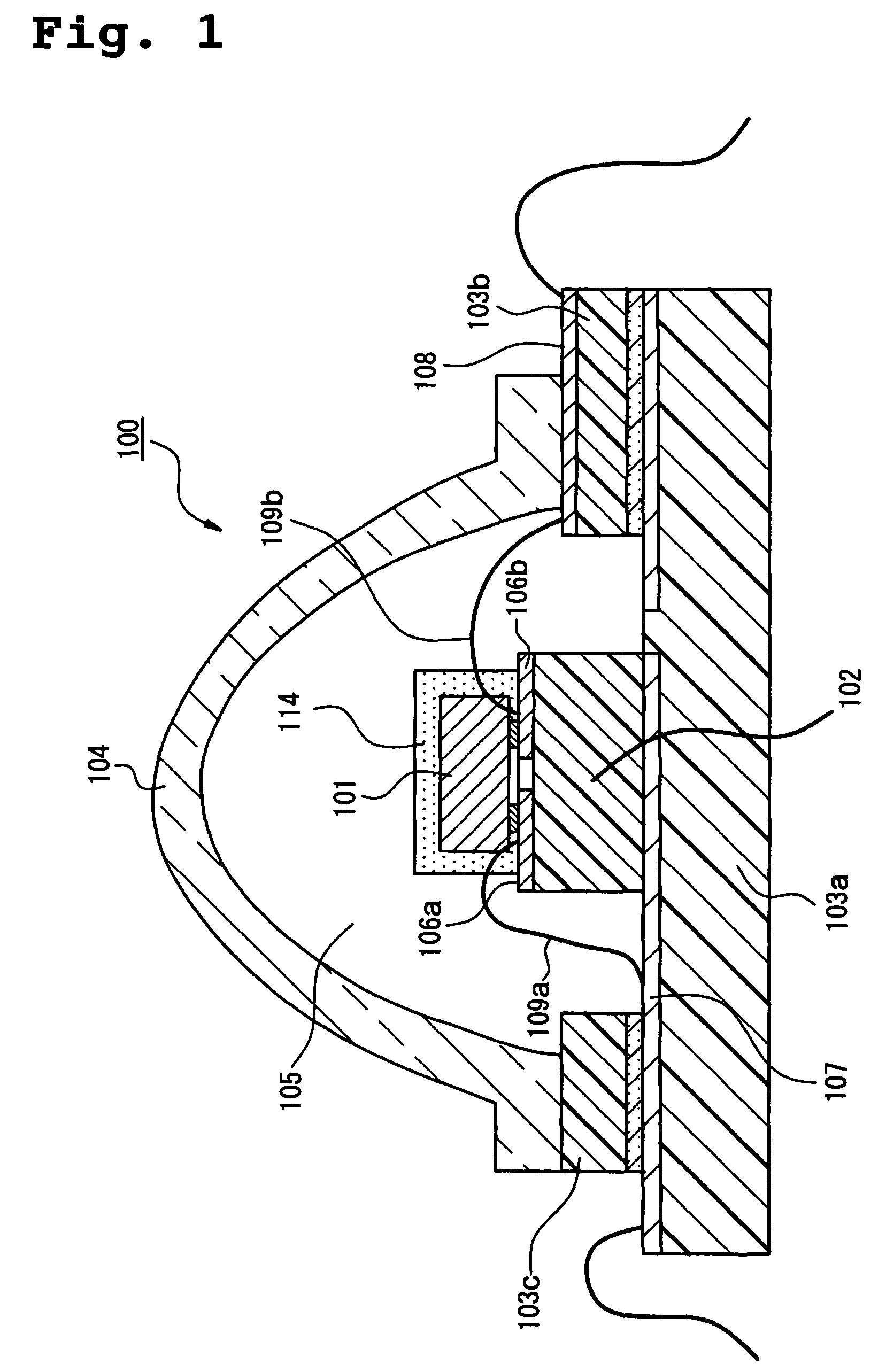

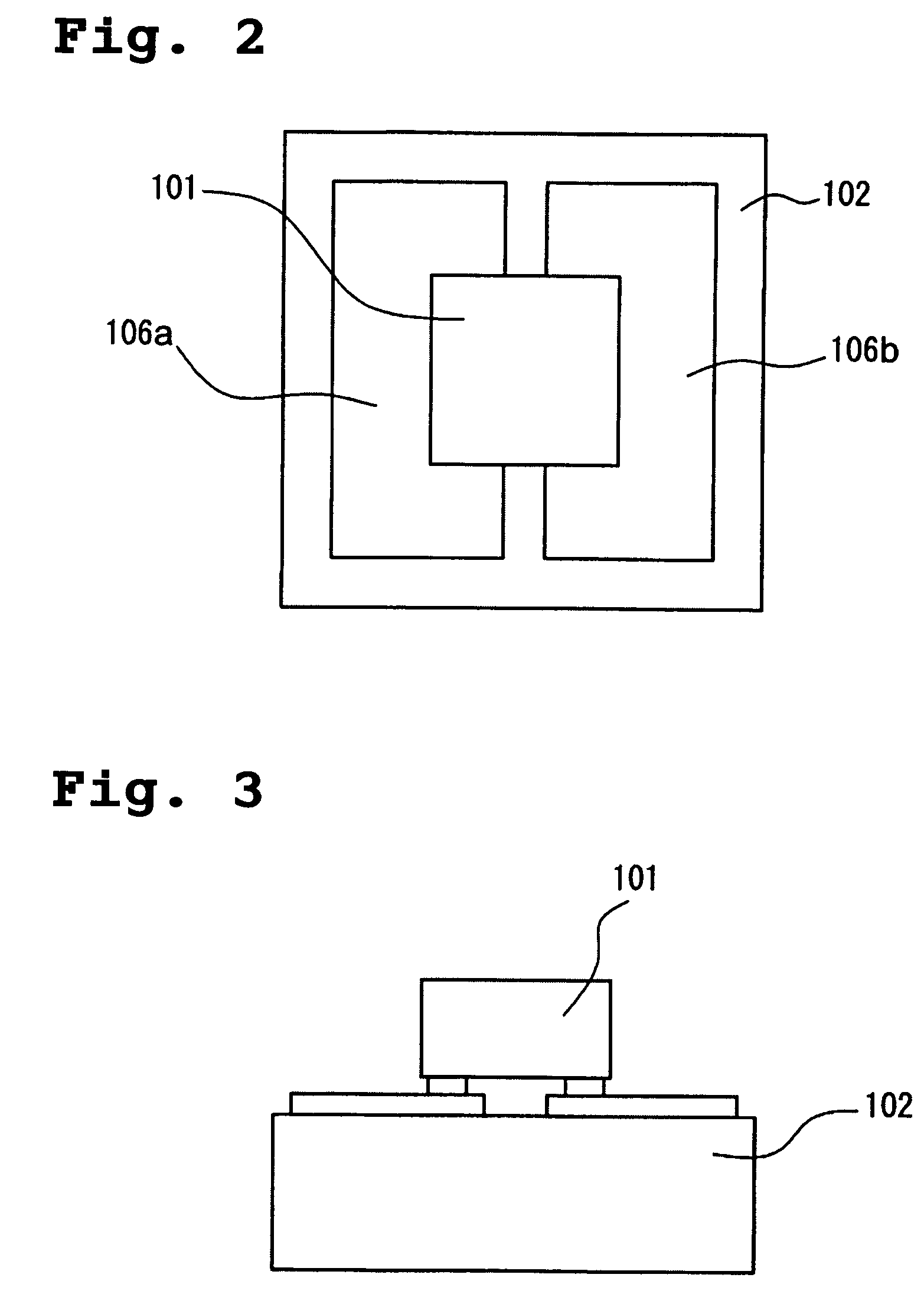

Light emitting device with silicone resin layer formed by screen printing

ActiveUS7745818B2Improve heat resistanceConvenient lightingDischarge tube luminescnet screensLamp detailsScreen printingPolystyrene

Owner:NICHIA CORP

Process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and such (CO)polymers

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and having a number average molecular weight of at least 10,000 (as determined by GPC based on polystyrene standards) includes a first step where a prepolymer is made having the 2,5-furandicarboxylate moiety within the polymer backbone, followed in a second step by a polycondensation reaction. In the first step a 2,5-furandicarboxylate ester is transesterified with a compound or mixture of compounds containing two or more hydroxyl groups, in the presence of a tin(IV) based transesterification catalyst. In the second step at reduced pressure and under melt conditions the prepolymer prepared in the first step is polycondensed in the presence of a tin (II) based polycondensation catalyst until the polymer is obtained. This polymer may then be subjected to Solid State Polycondensation. Polymers so produced may have a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 20,000 (as determined by GPC based on styrene standards), and an absorbance as a 5 mg / mL solution in a dichloromethane:hexafluoroisopropanol 8:2 at 400 nm of below 0.05.

Owner:FURANIX TECH BV

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Thermoset materials with improved impact resistance

The present invention relates to a thermoset material with improved impact resistance comprising:99 to 20% of a thermoset resin, and1 to 80% of an impact modifier comprising at least one copolymer comprising S-B-M, B-M and M-B-M blocks,wherein:each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond,M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of methyl methacrylate,B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, andS is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature is greater than the Tg of B.S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

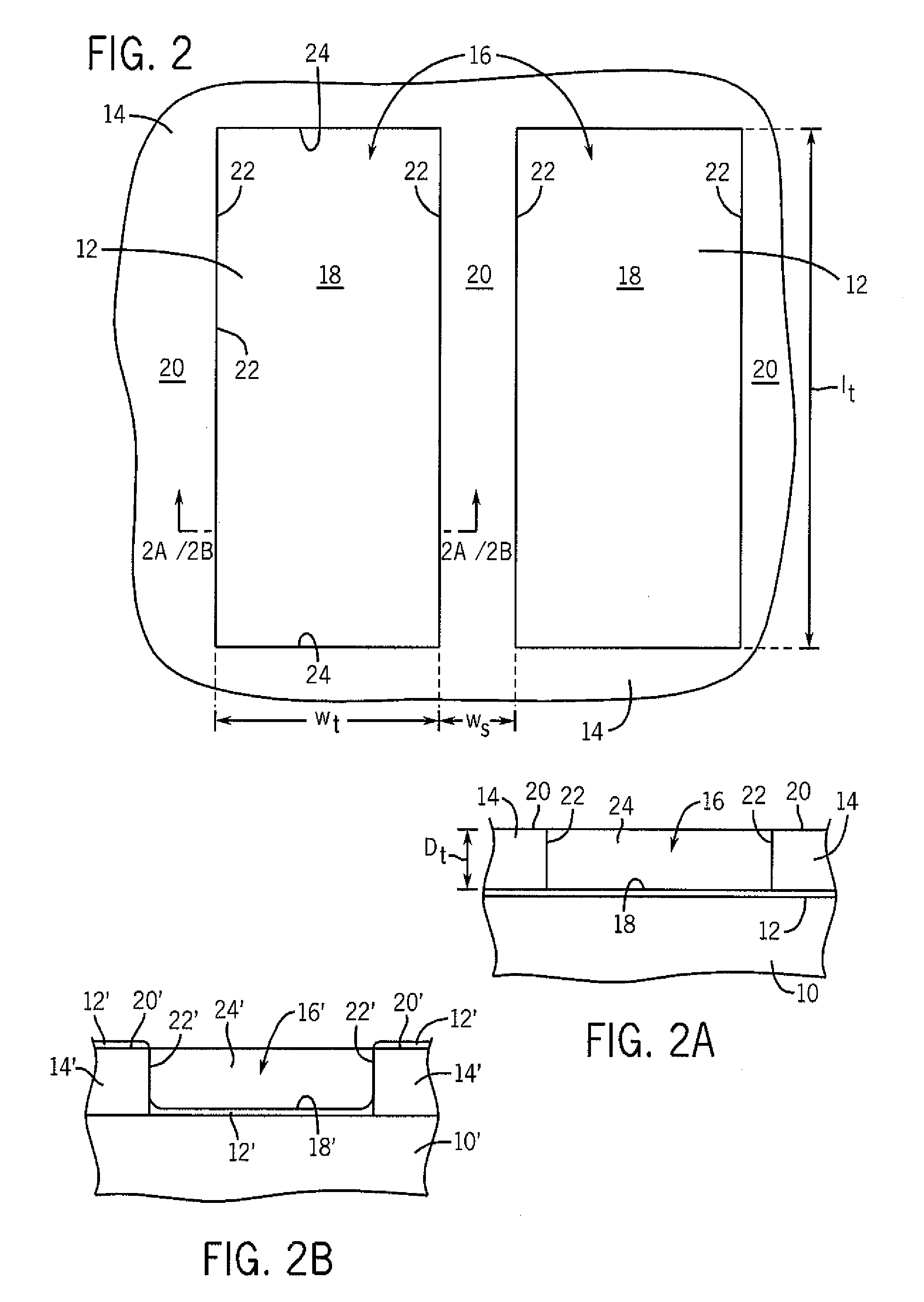

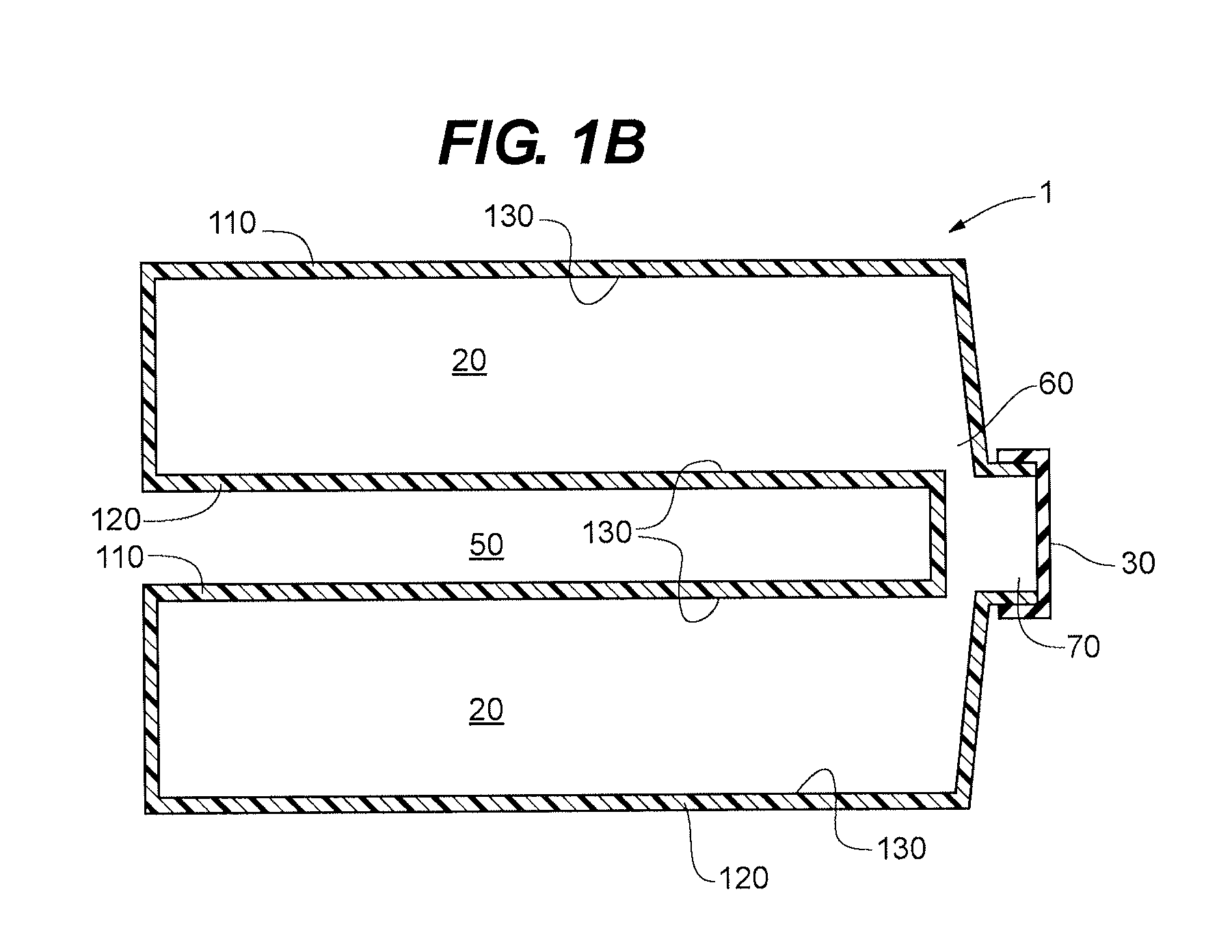

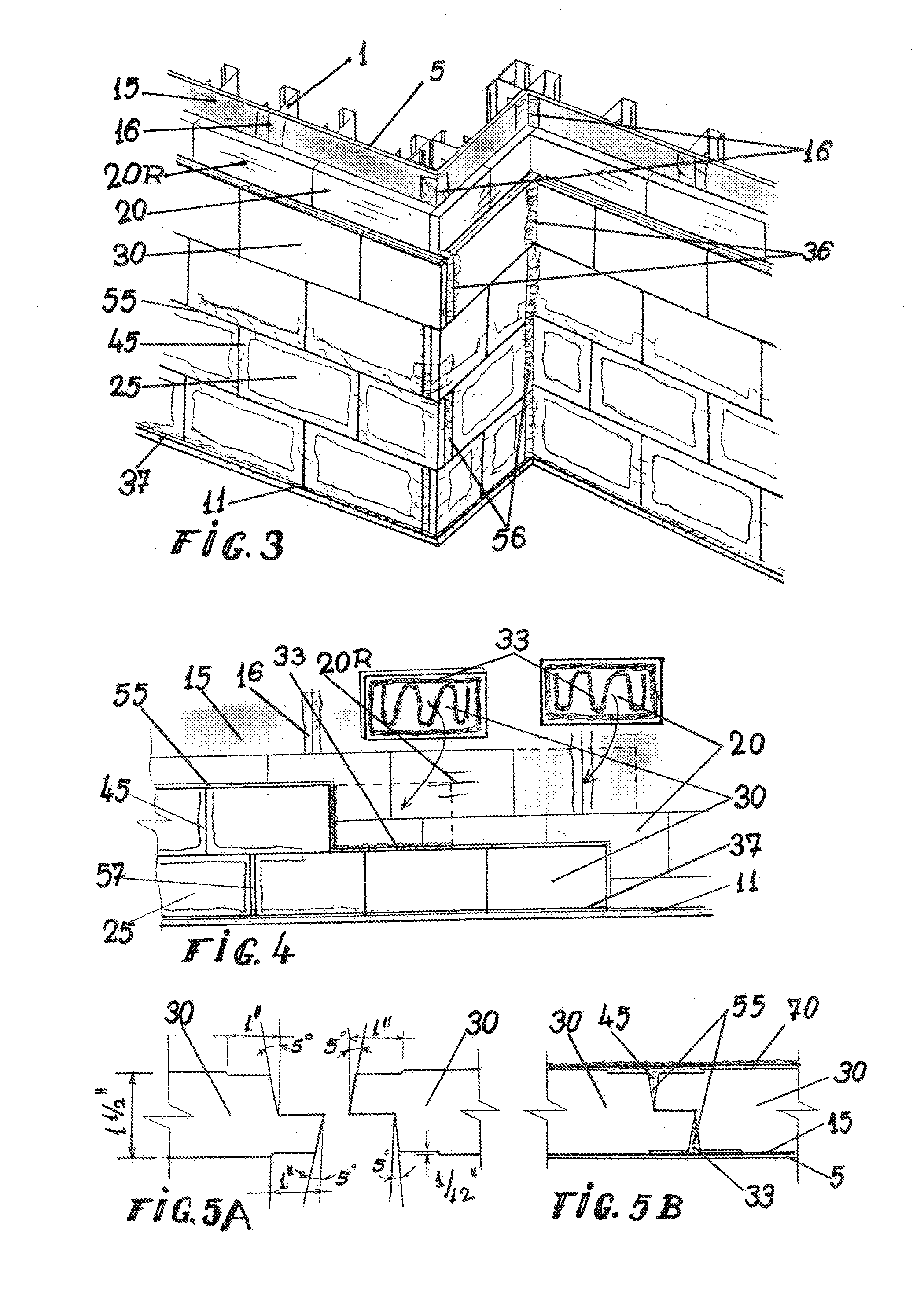

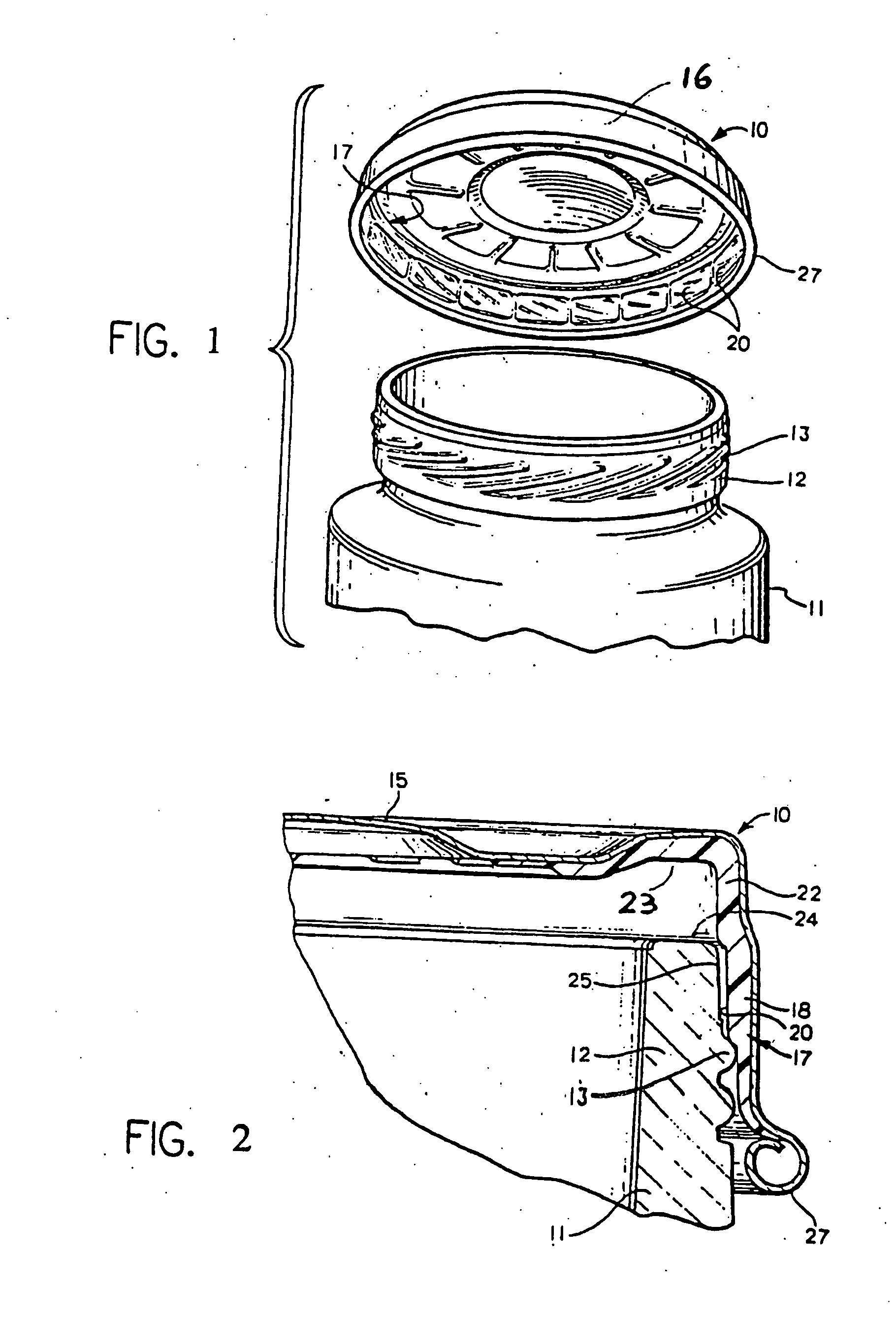

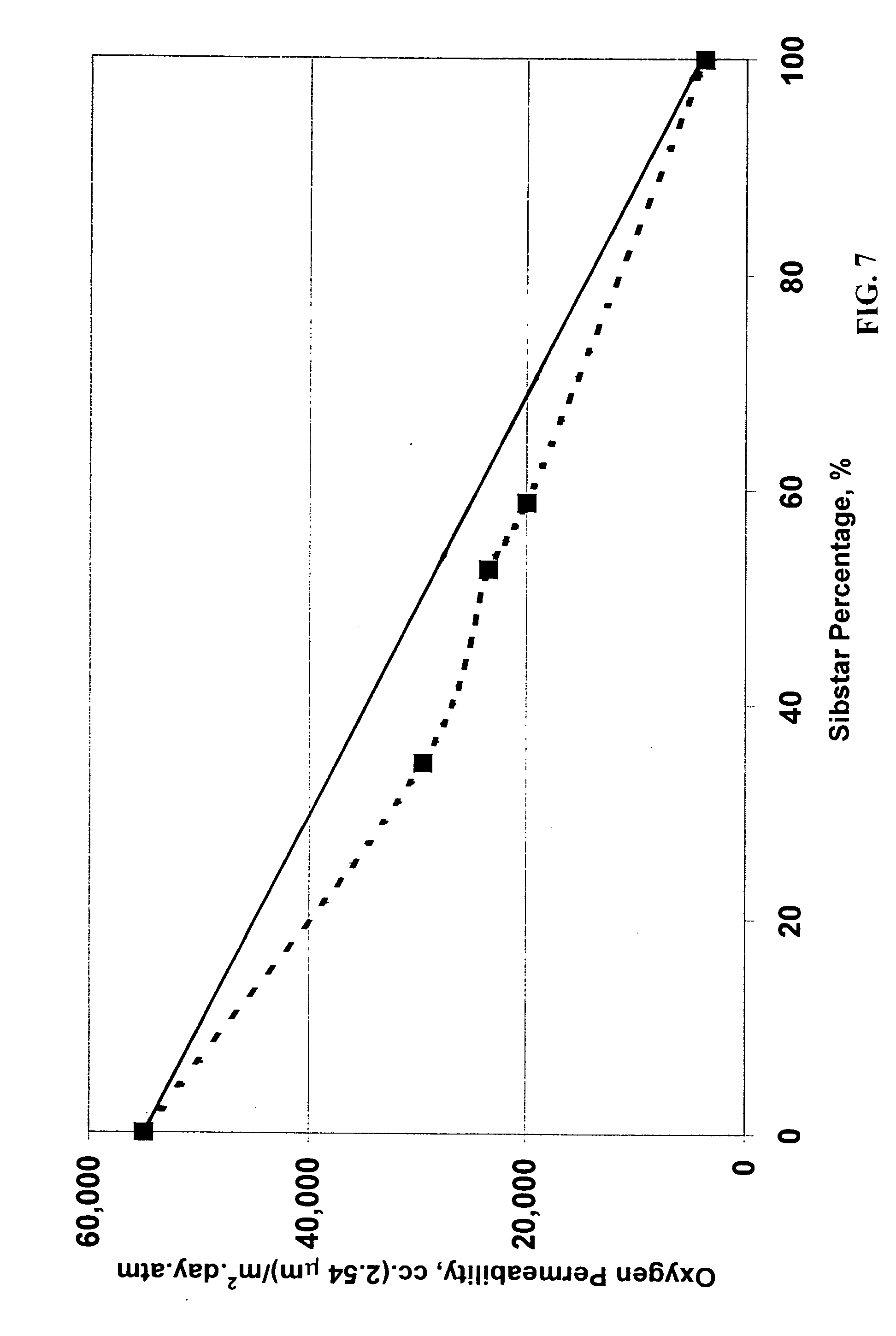

Multilayer gas-permeable container for the culture of adherent and non-adherent cells

InactiveUS6297046B1Promote cell growthStrength and resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsPolyolefinPolystyrene

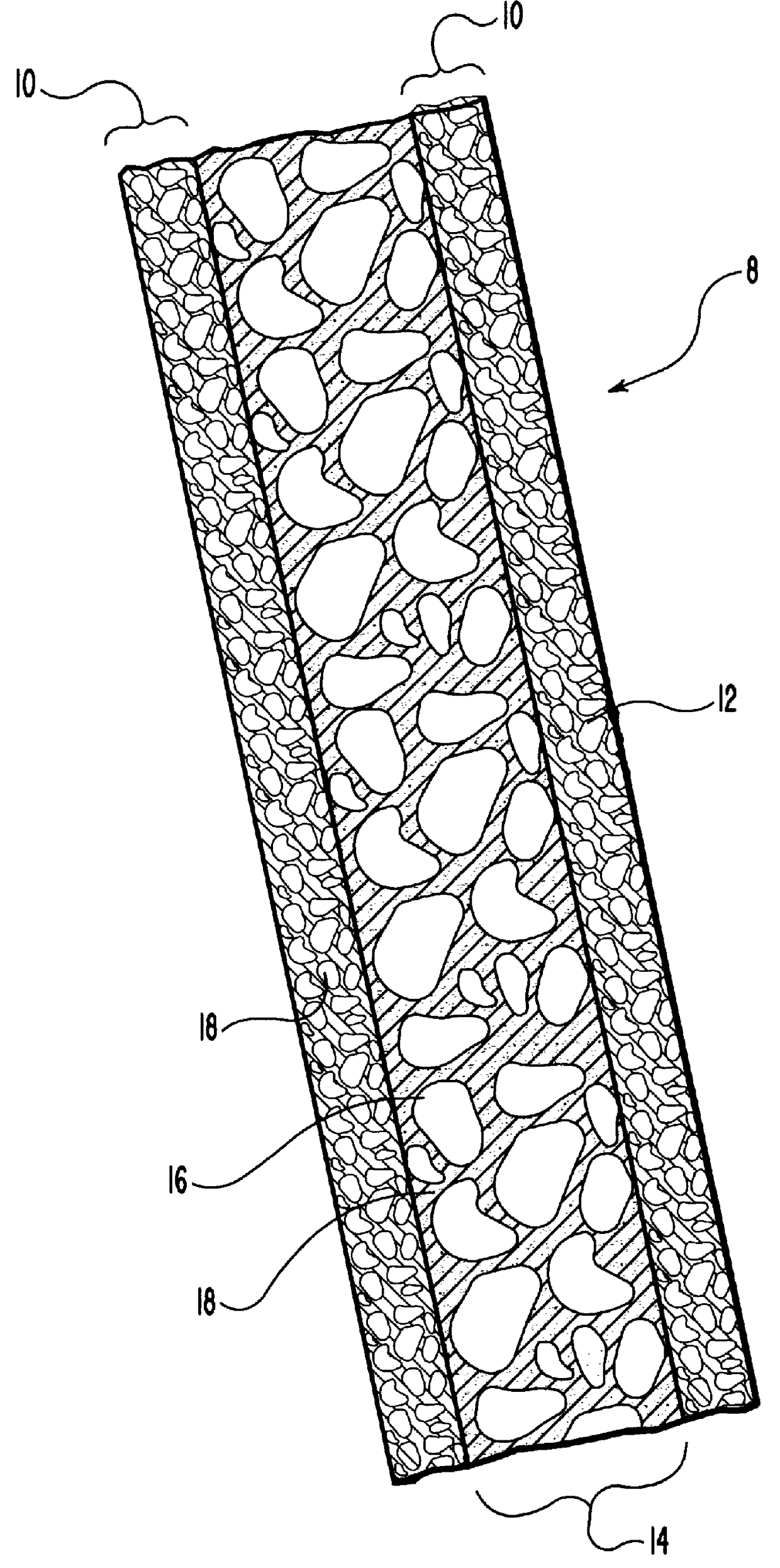

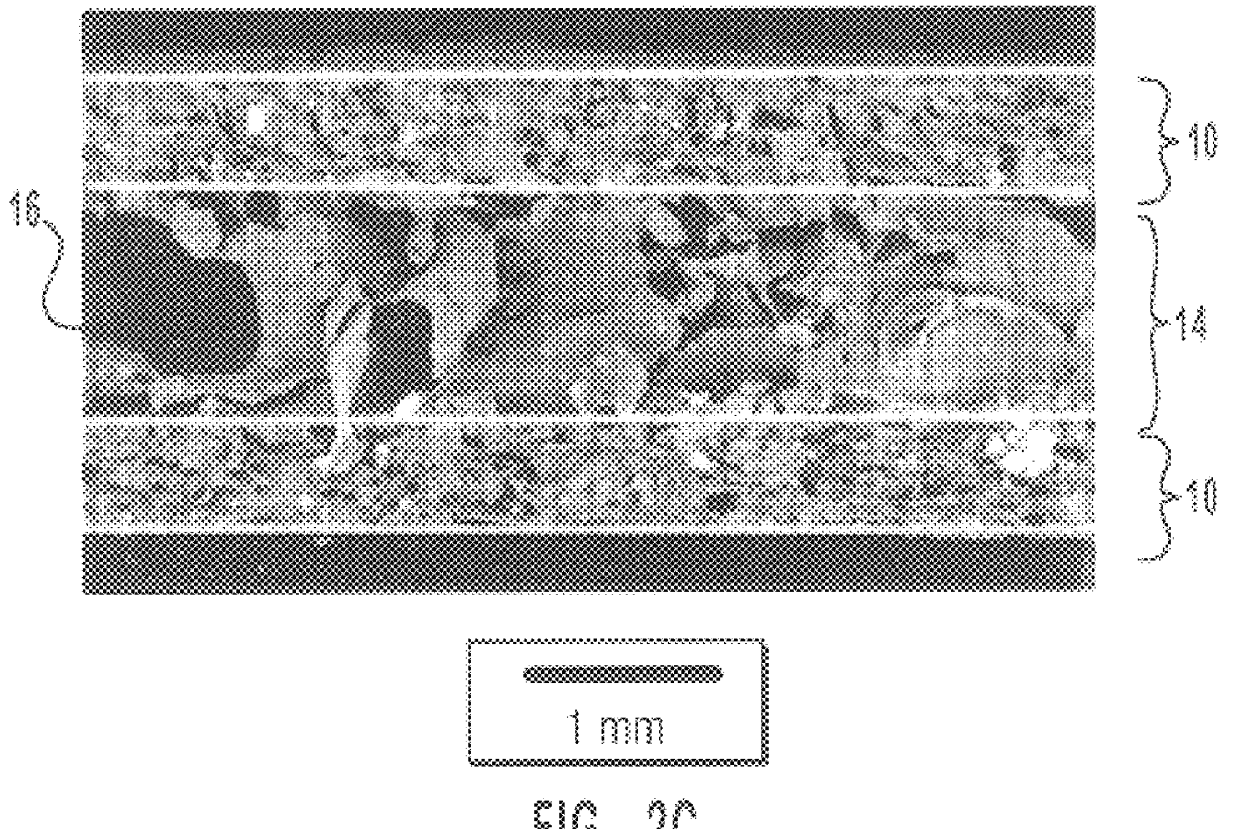

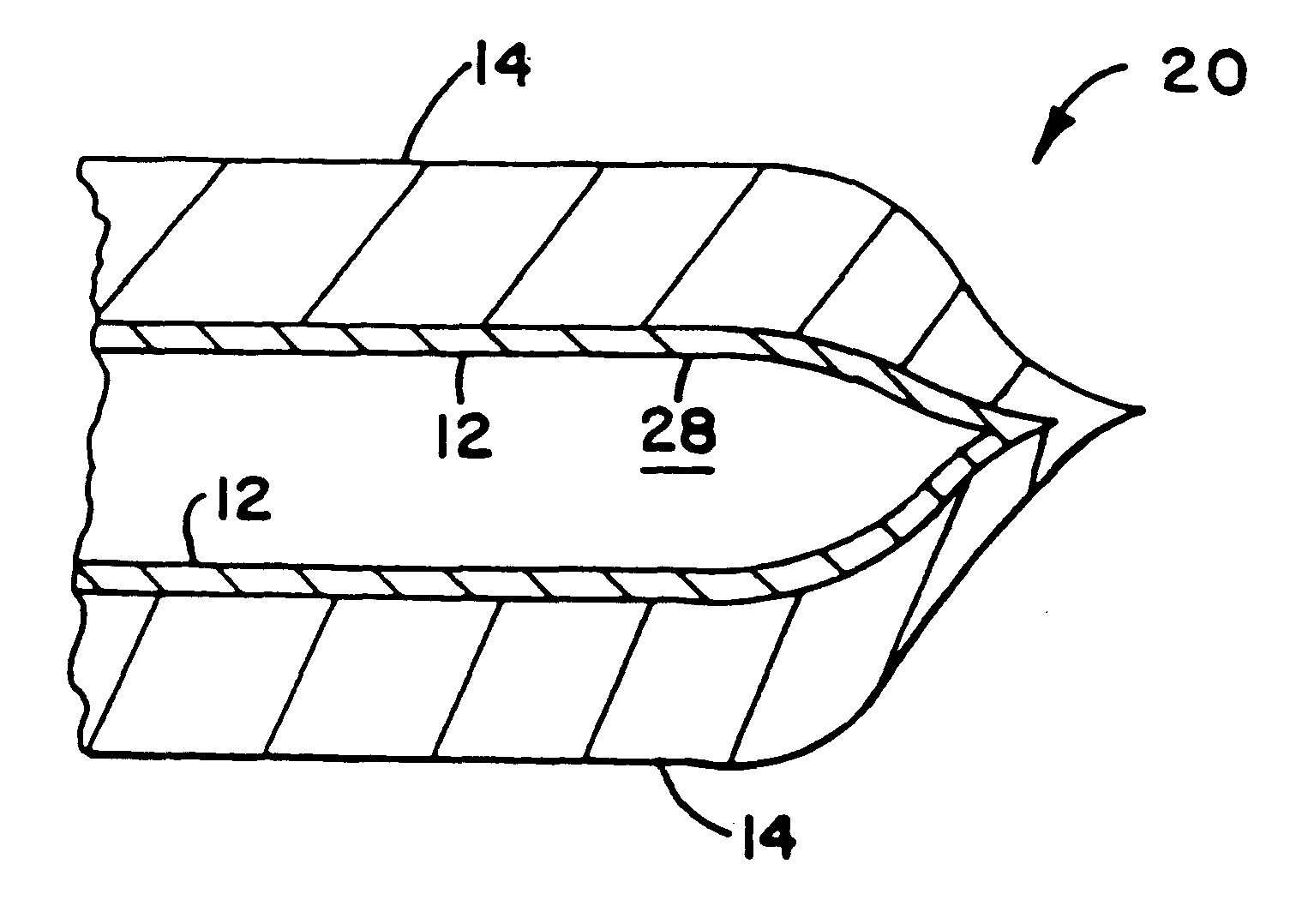

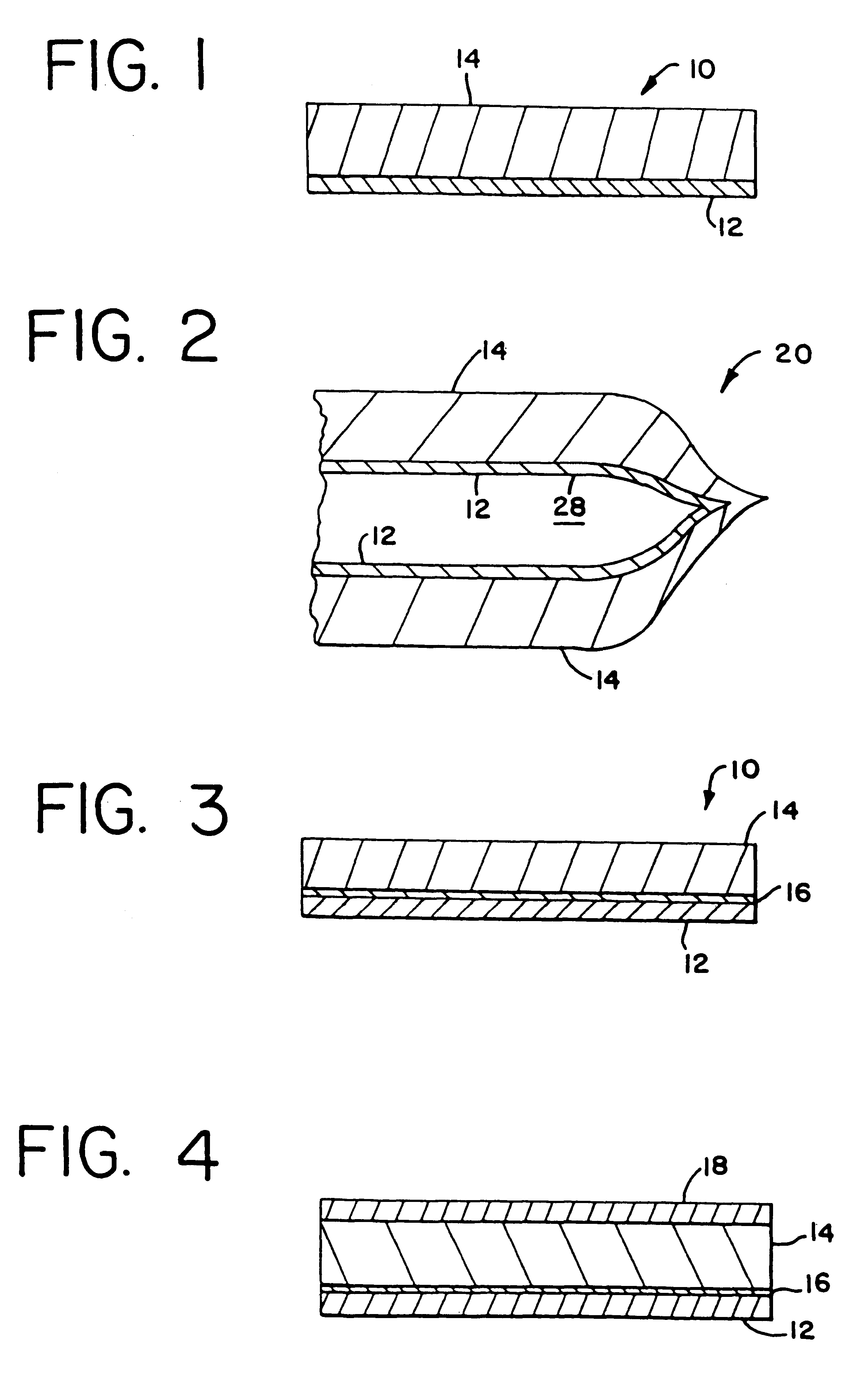

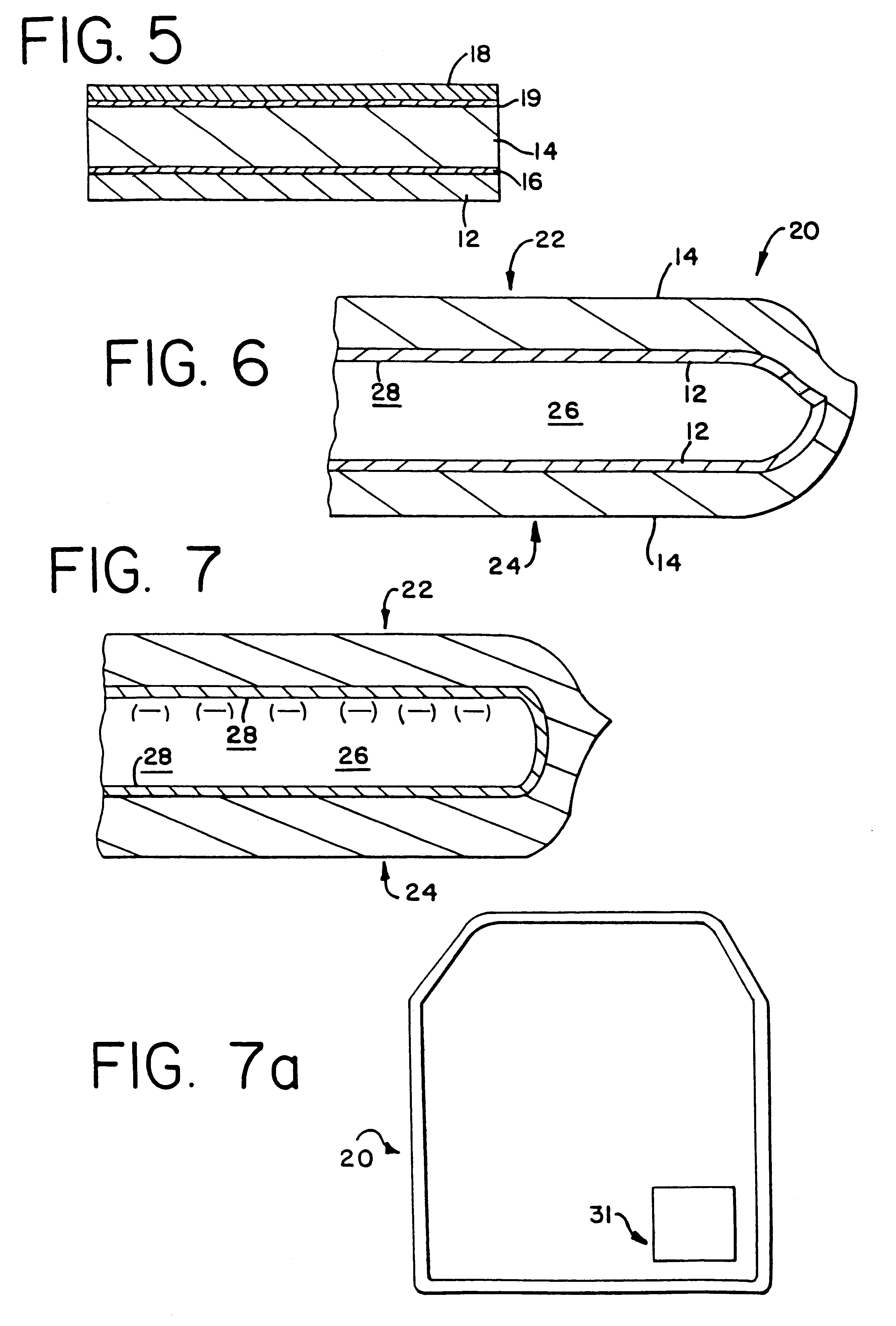

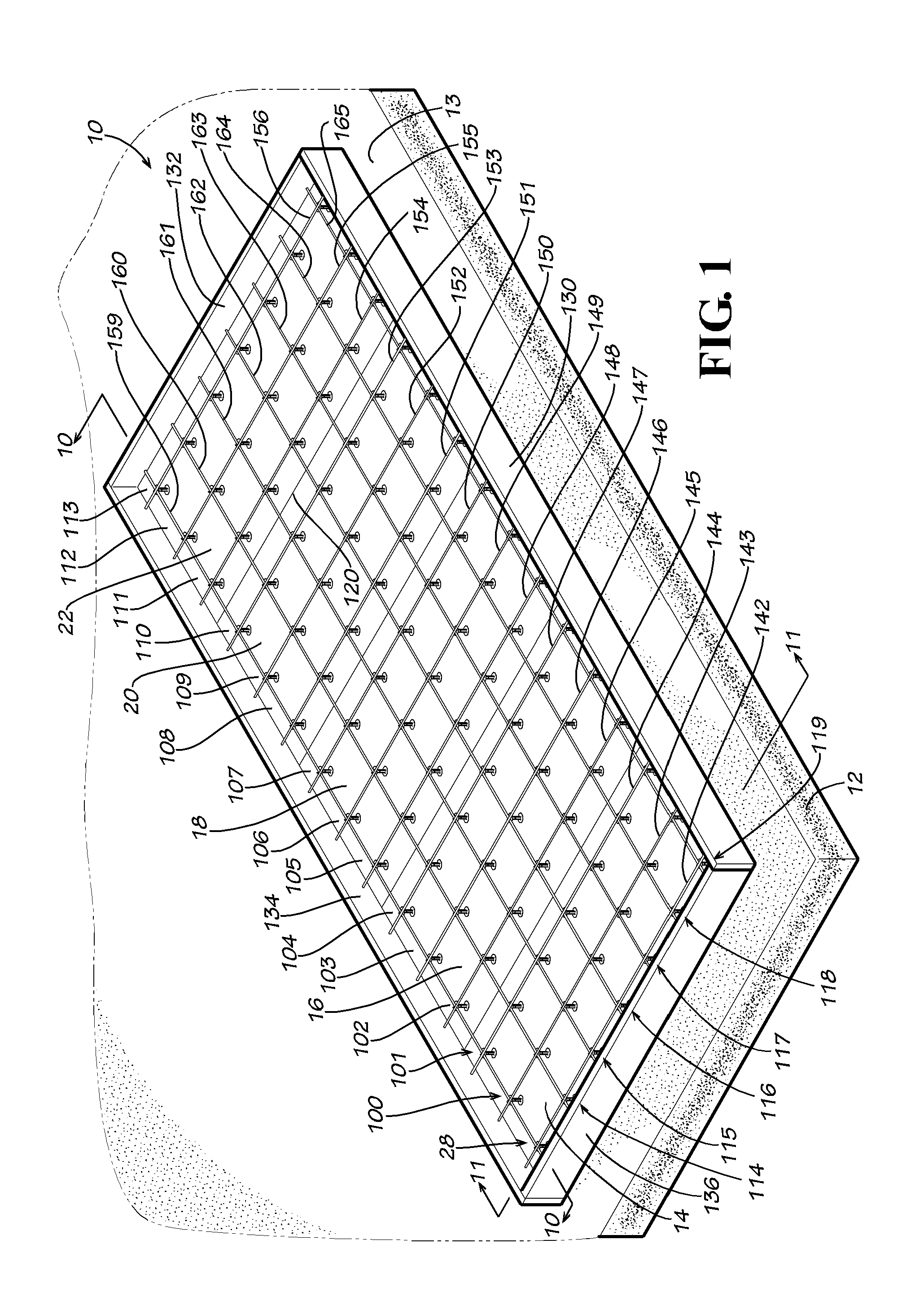

A multi-layer, flexible, gas-permeable film (10) suitable for forming a cell culture container (20), the film (10) comprising a first layer (12) composed of a polystyrene having a thickness within the range of 0.0001 inches to about 0.0010 inches and, a second layer (14) adhered to the first layer (12) composed of a polyolefin having a thickness within the range of 0.004 inches to about 0.015 inches.

Owner:BAXTER INT INC

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

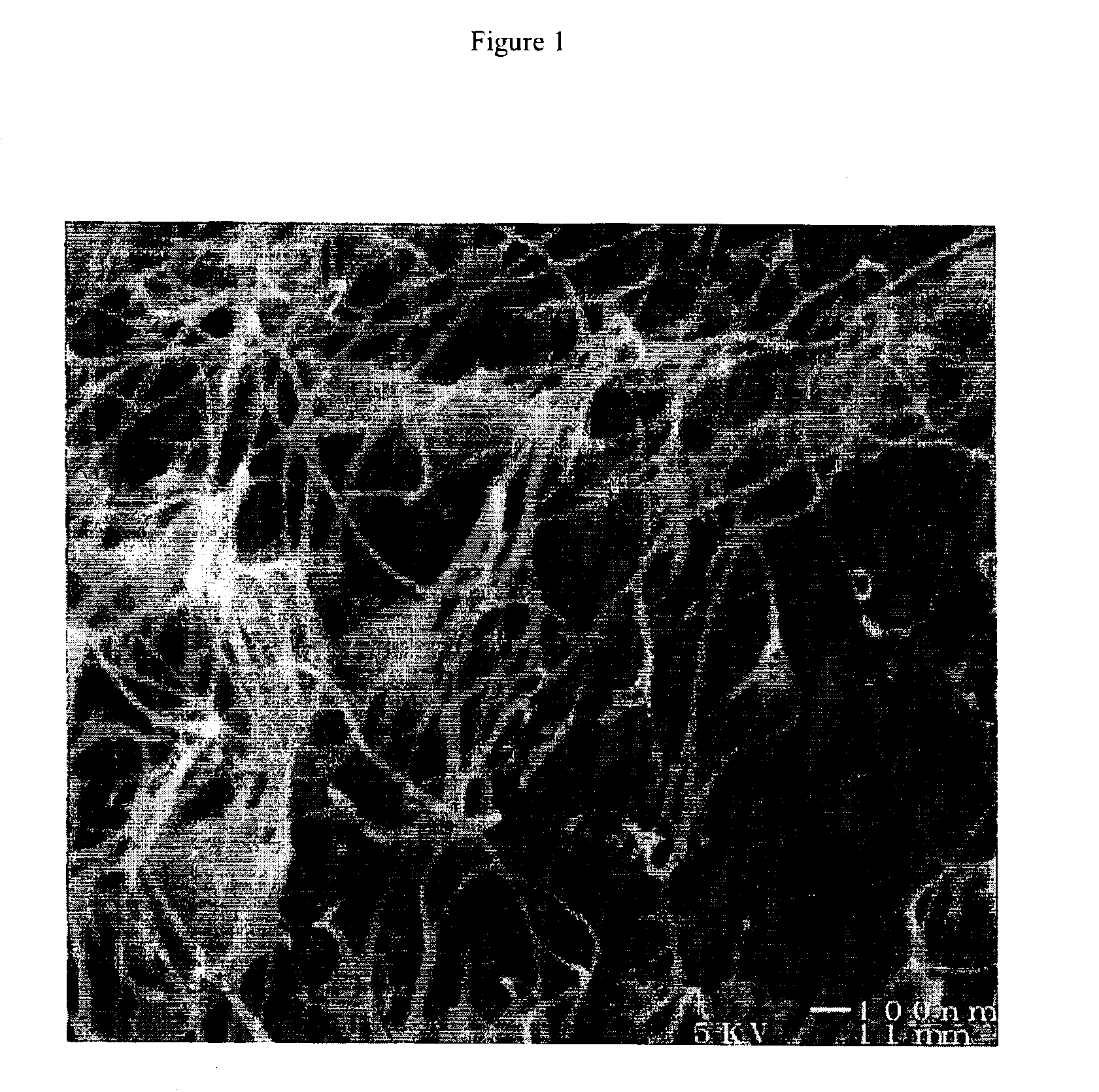

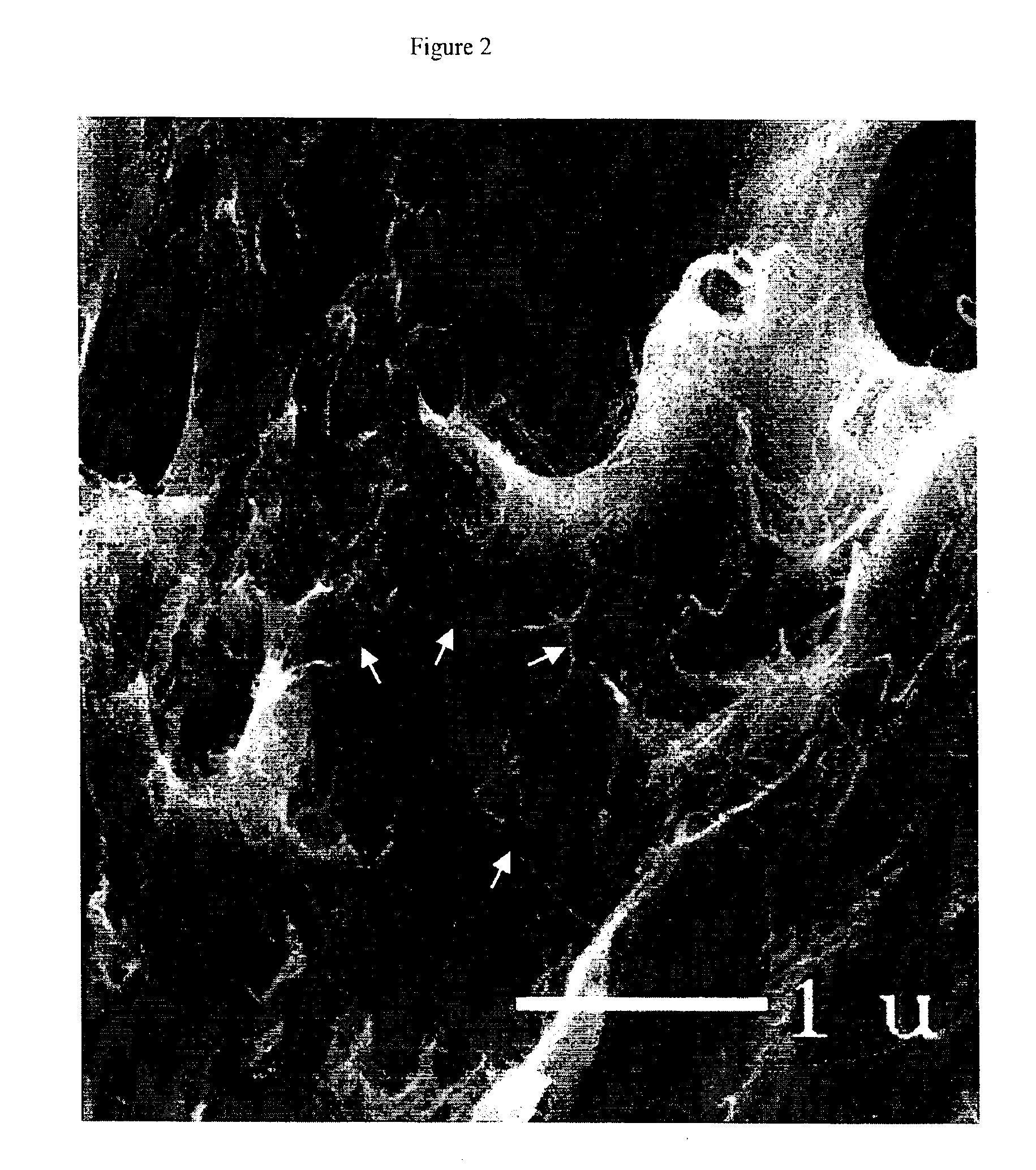

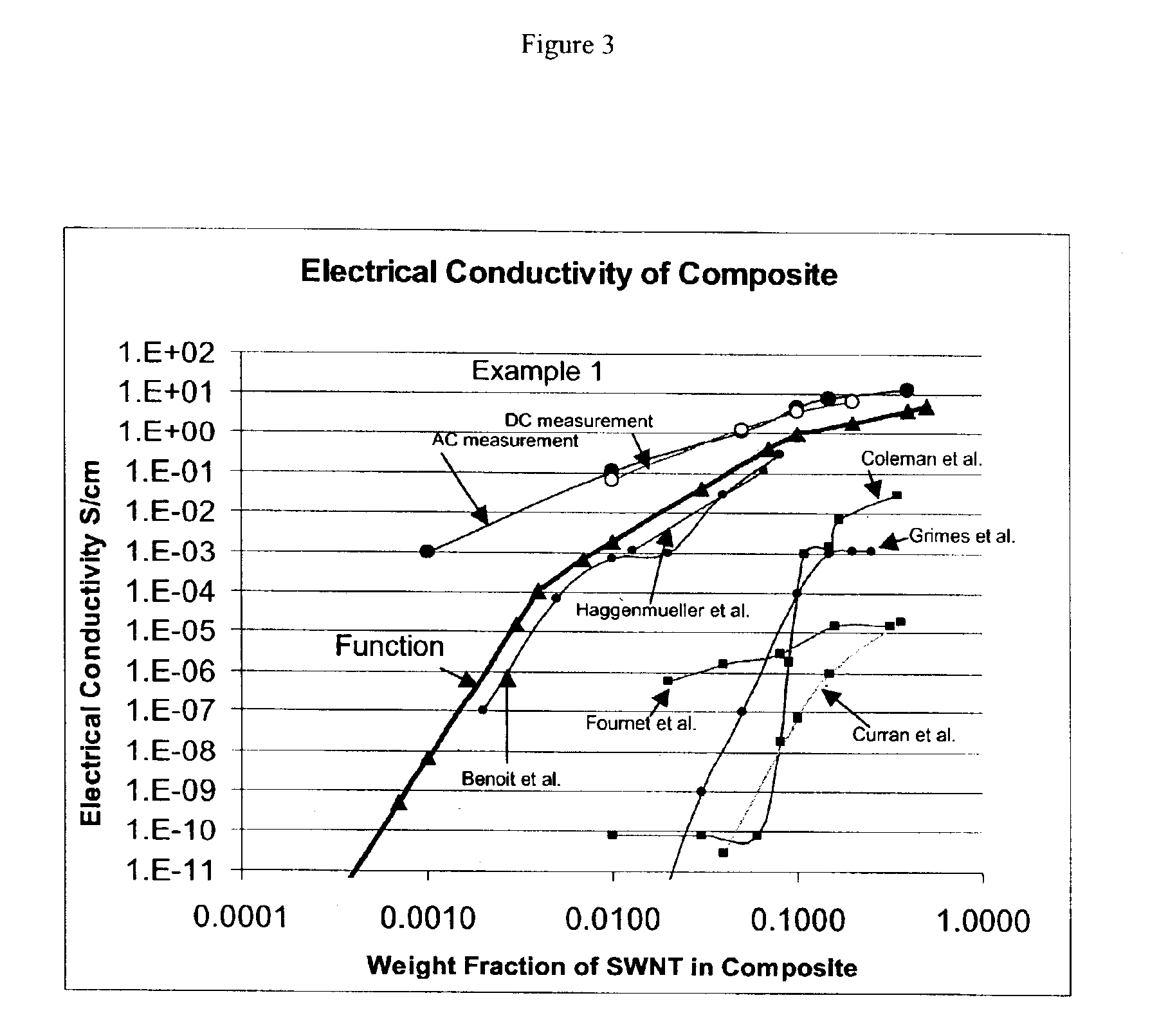

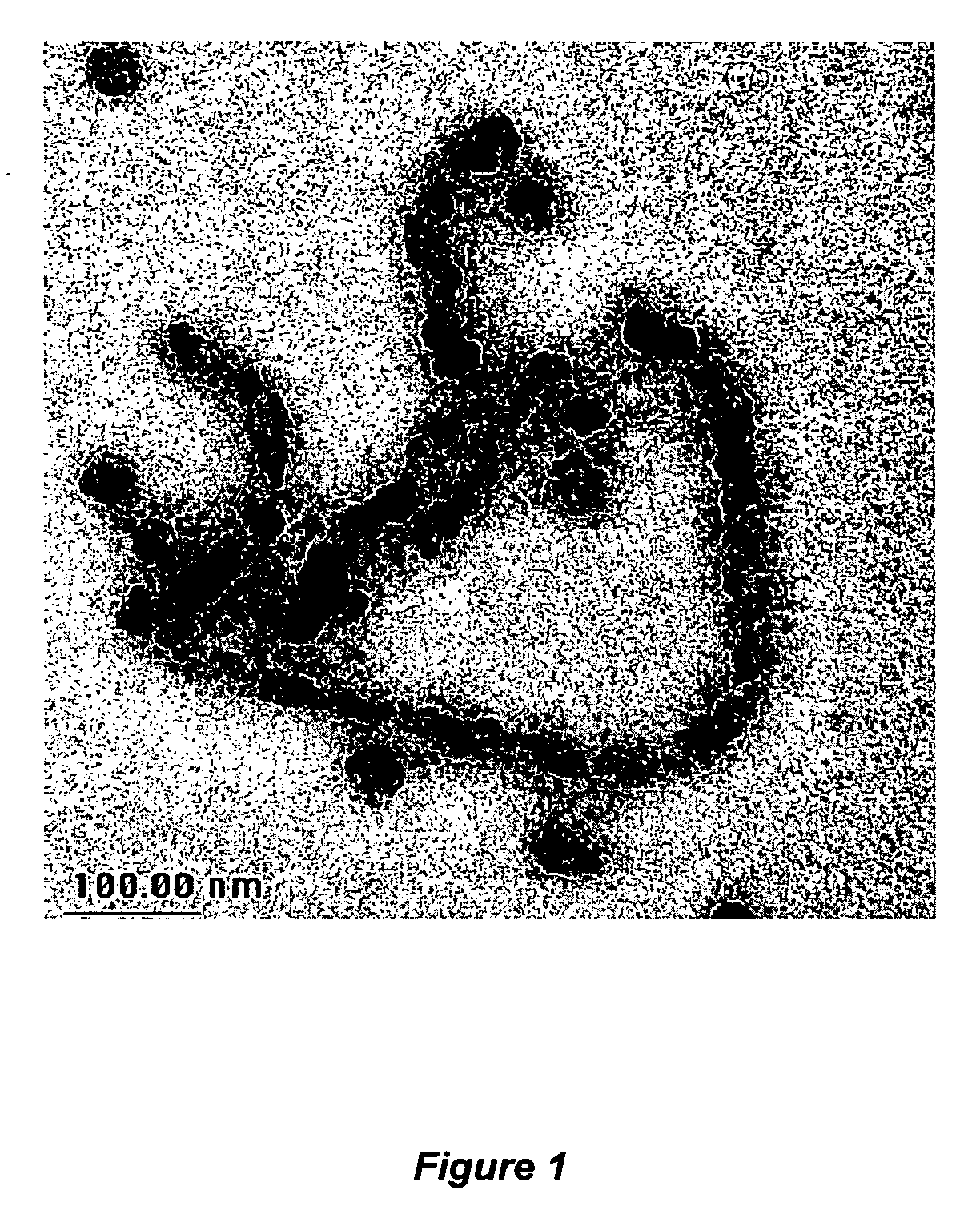

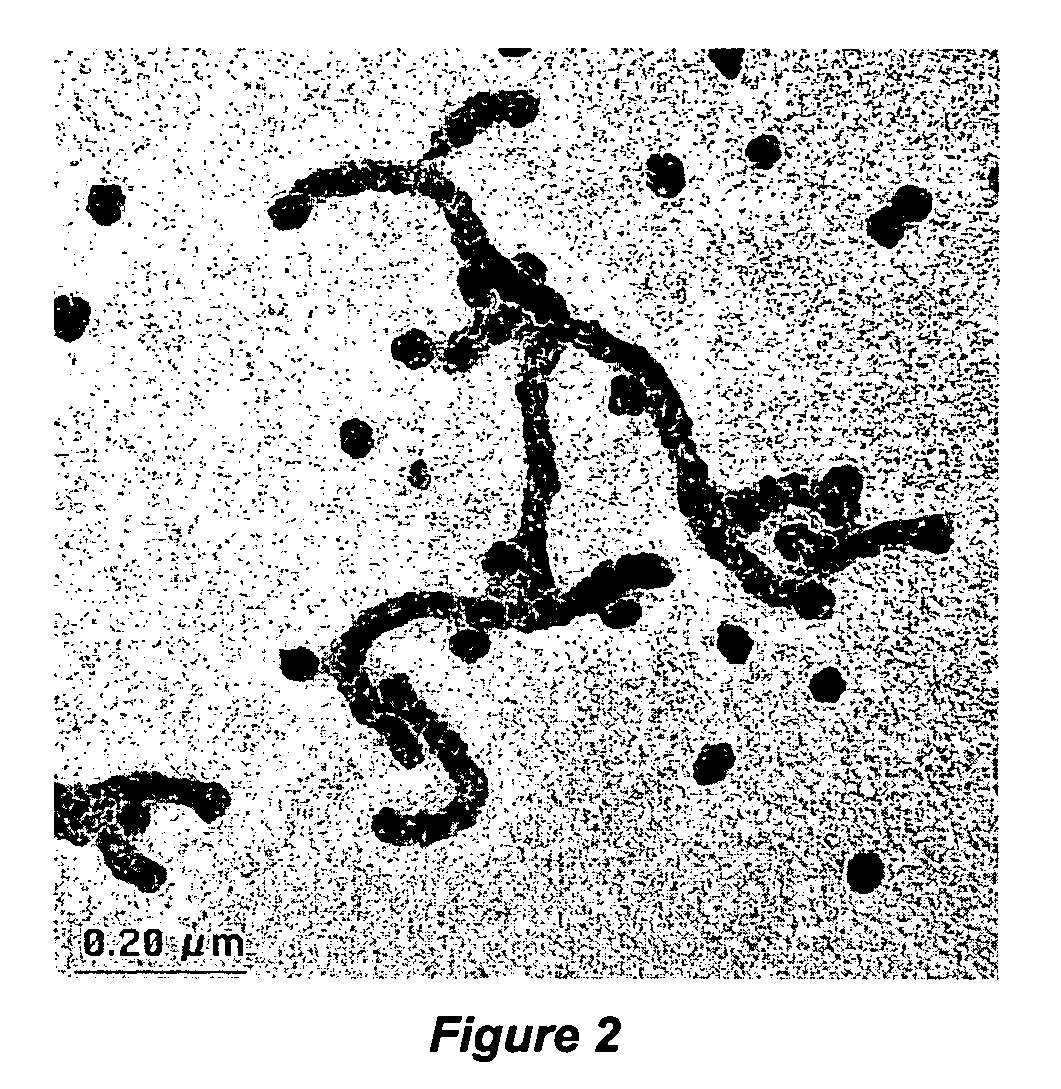

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

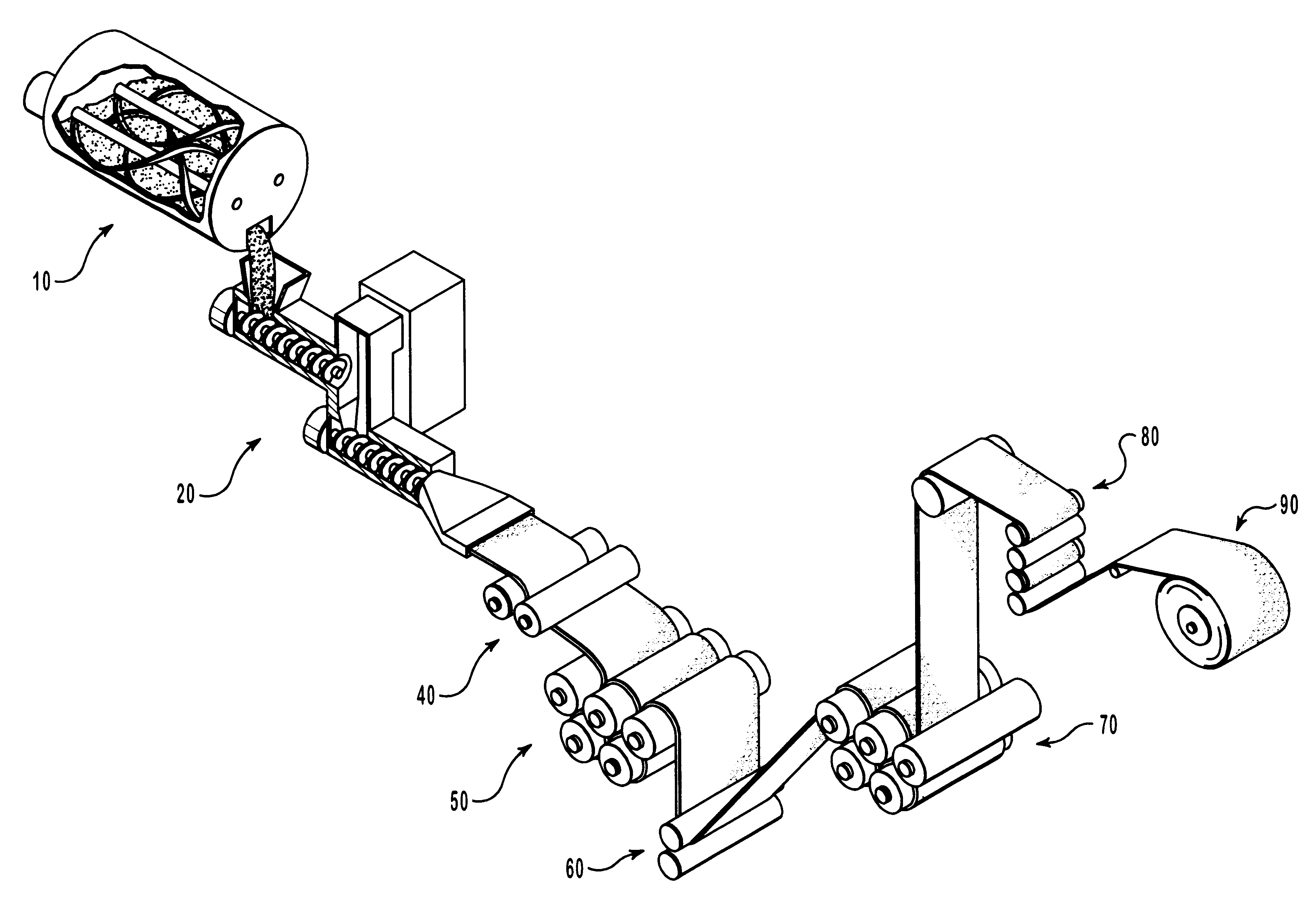

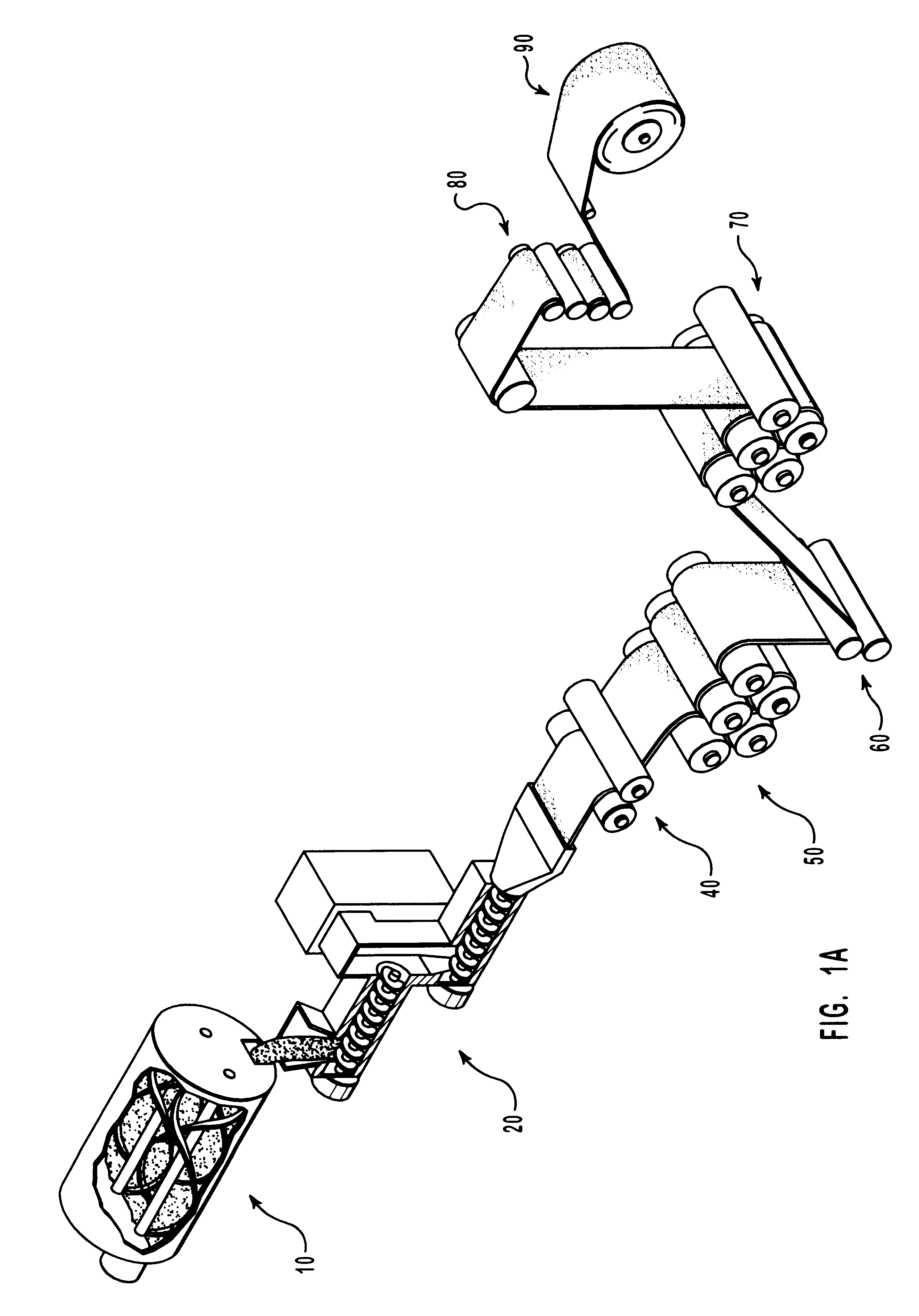

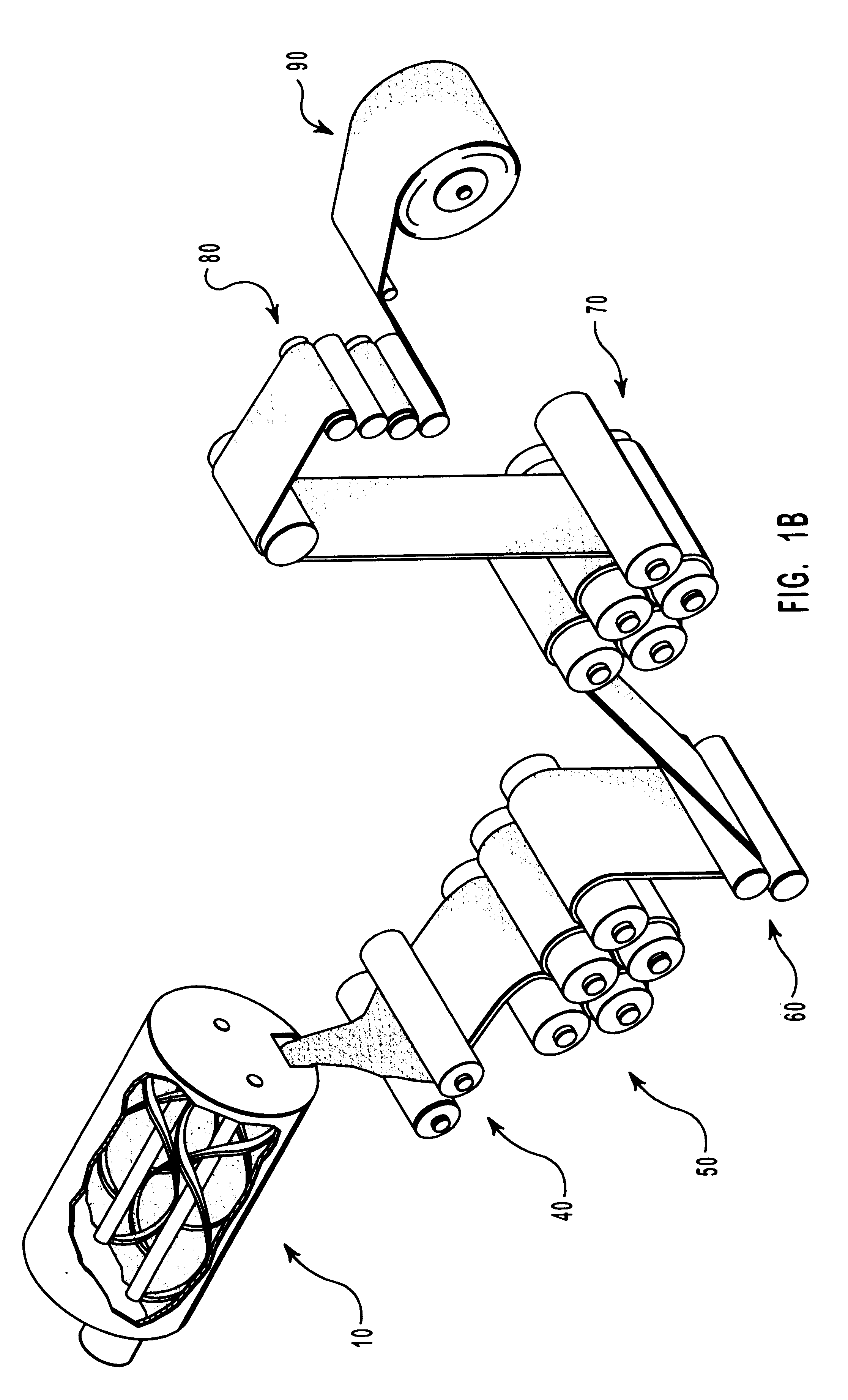

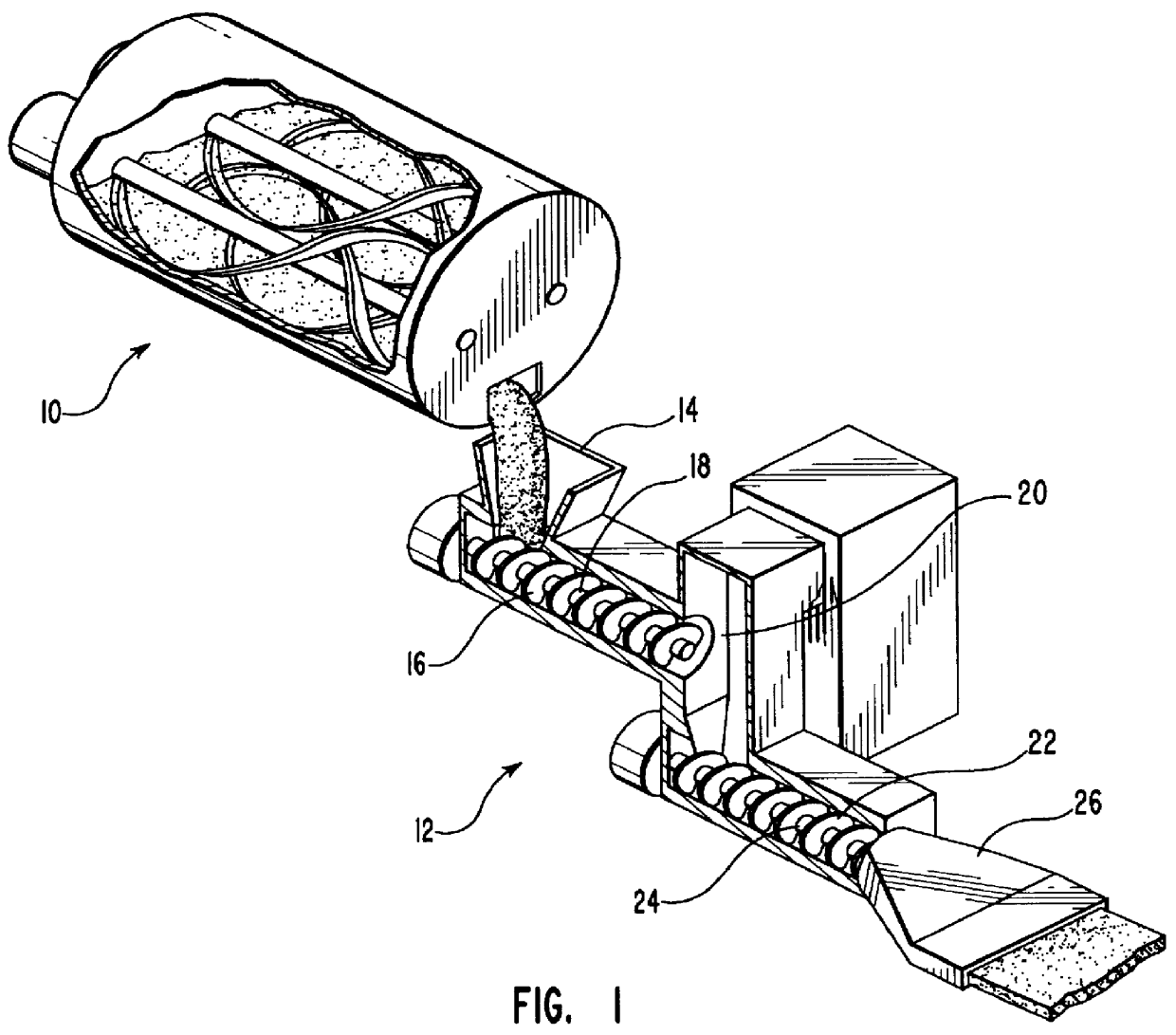

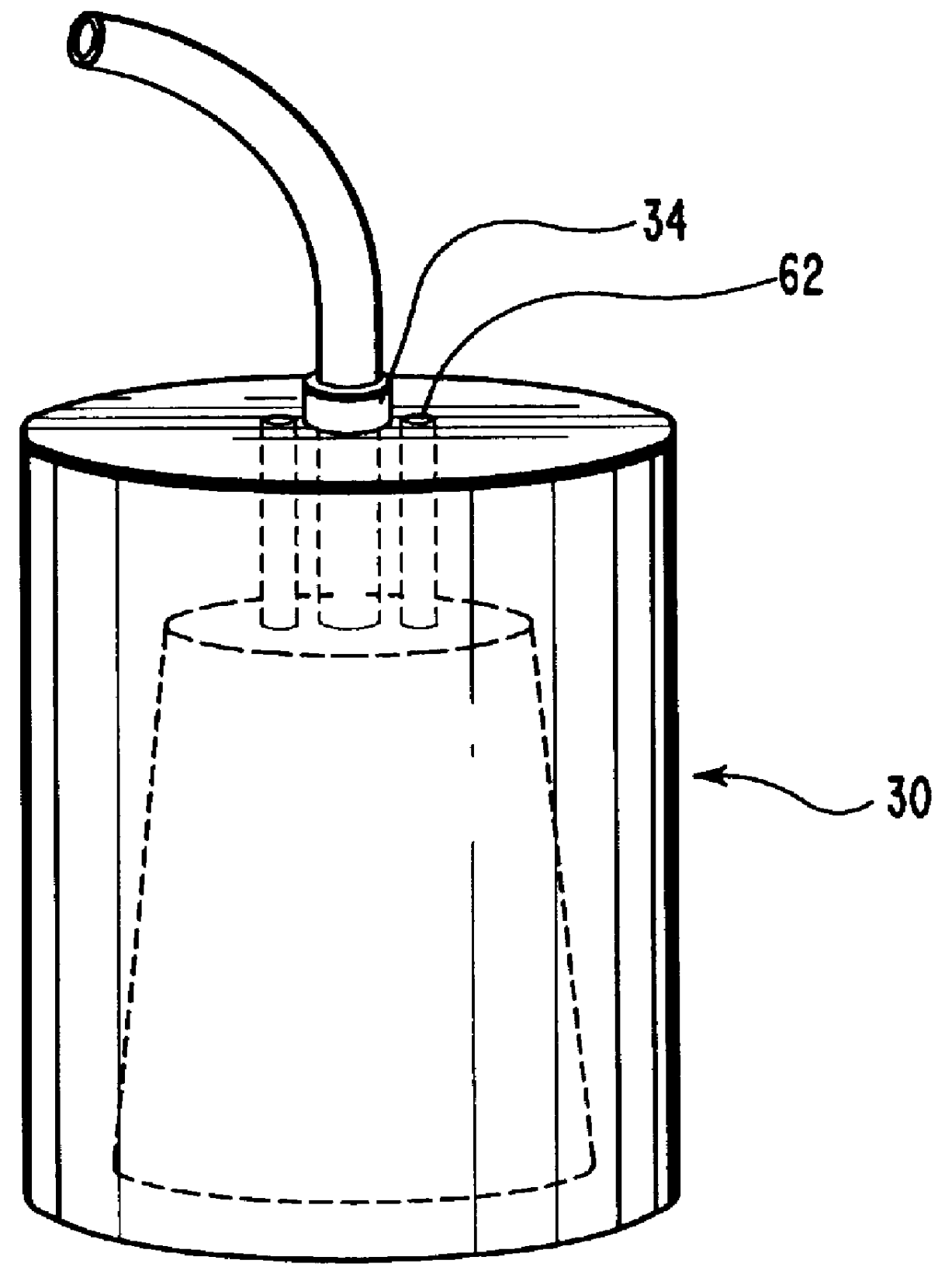

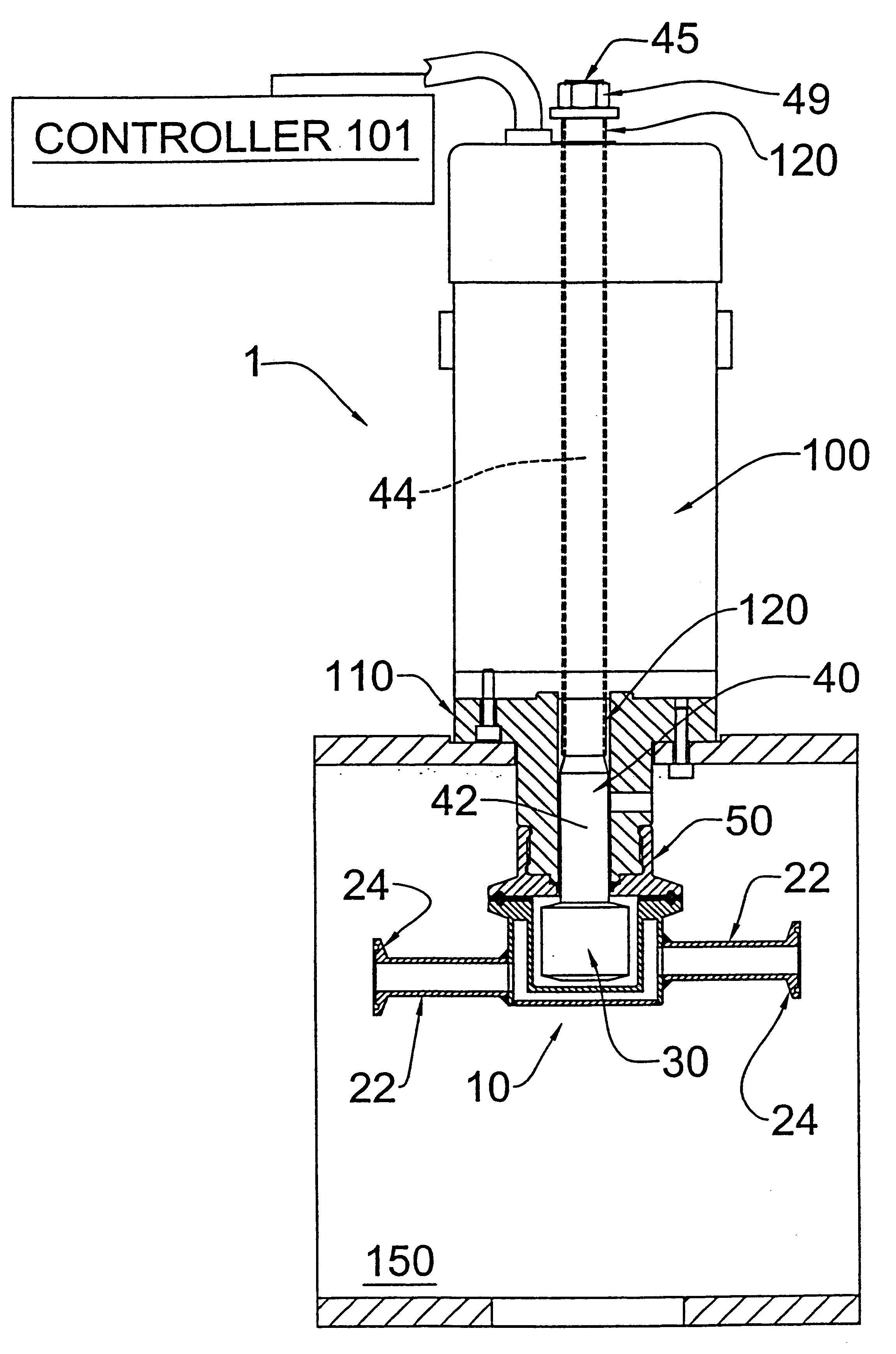

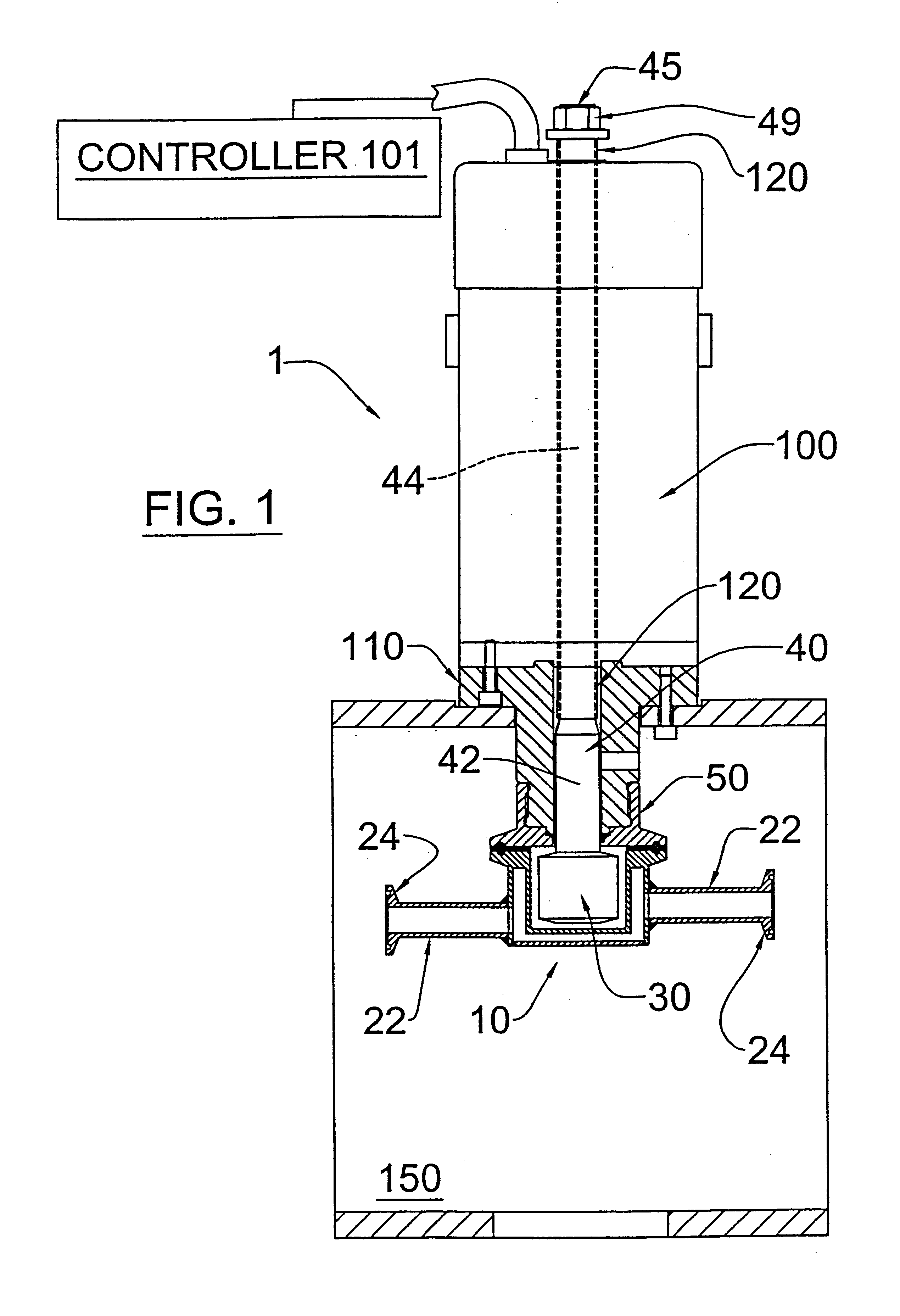

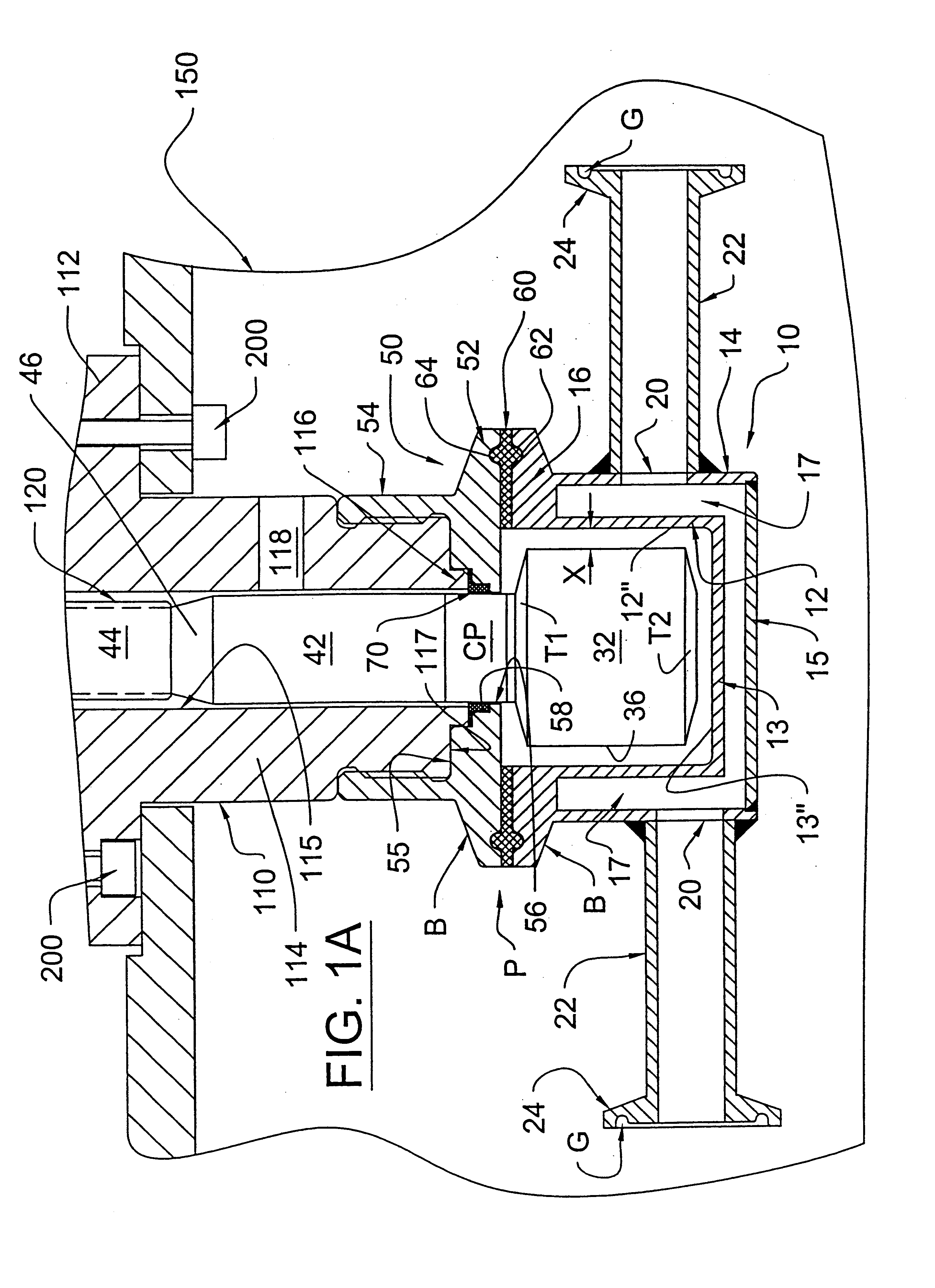

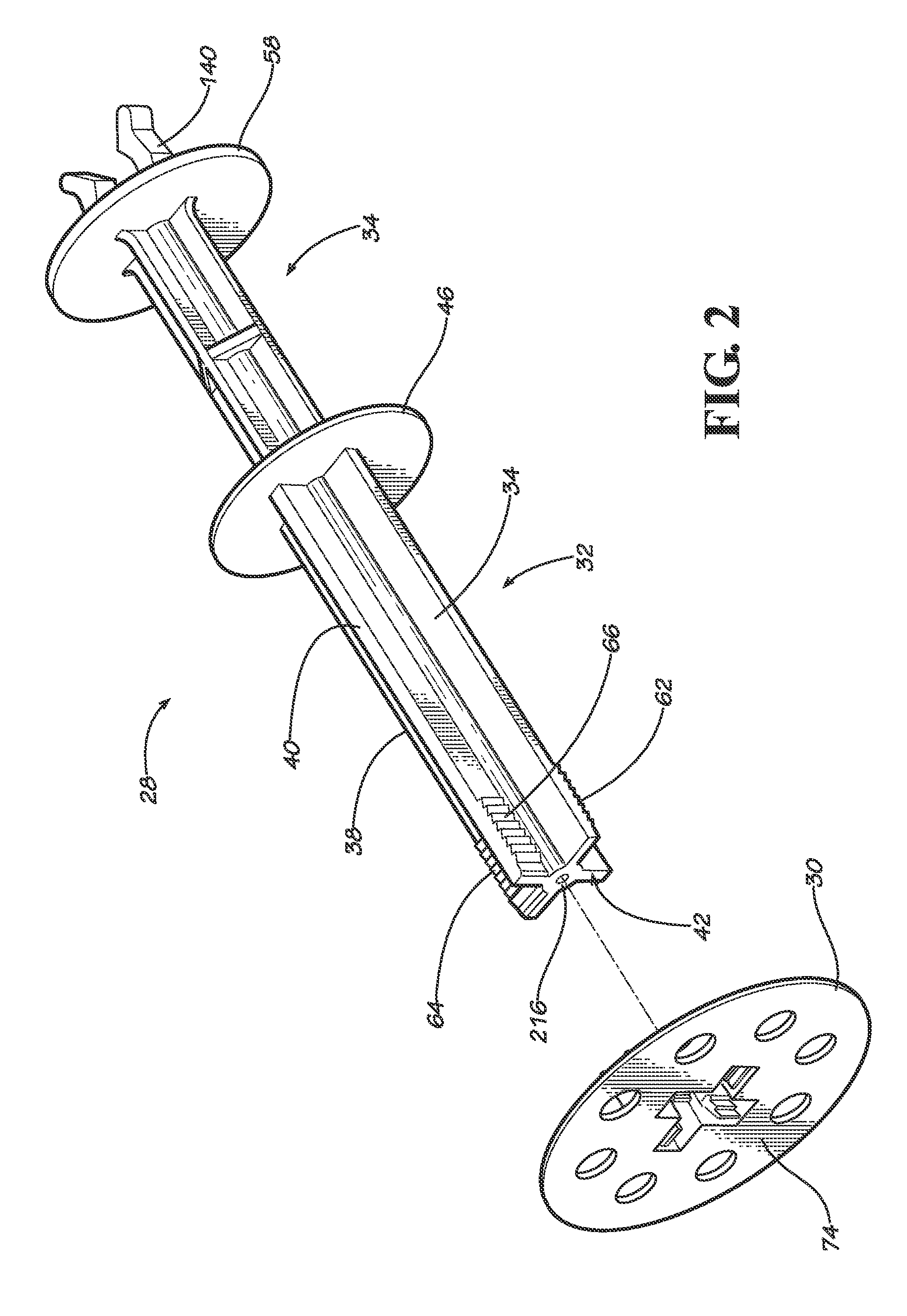

Small-scale mill and method thereof

A small-scale or micro media-mill and a method of milling materials or products, especially pharmaceutical products, use a dispersion containing attrition milling media and the product to be milled. The milling media can be polymeric, formed of polystyrene or cross-linked polystyrene, having a nominal diameter of no greater than 500 microns. Other sizes include 200 microns and 50 microns and a mixture of these sizes. The mill has a relatively small vessel having an opening, an agitator, a coupling and a motor. The agitator can have a rotor and a shaft extending therefrom. The rotor can be cylindrical or have other configurations, and can have tapered end surfaces. The coupling can close the vessel opening, or attaching the coupling to the motor can close the opening. The coupling has an opening through which the rotor shaft extends into the motor. A sealing mechanism, such as a mechanical or lip seals the shaft while permitting the rotor shaft to rotate. The vessel can contain one or more ports for circulating the dispersion, where milling can be made in batches or recirculated through the milling chamber. The media can be retained in the vessel or recirculated along with the process fluid. The rotor is dimensioned so that its outer periphery is spaced with a small gap from an inner surface of the vessel. The vessel also can have a way of cooling the dispersion.

Owner:ALKERMES PHARMA IRELAND LTD

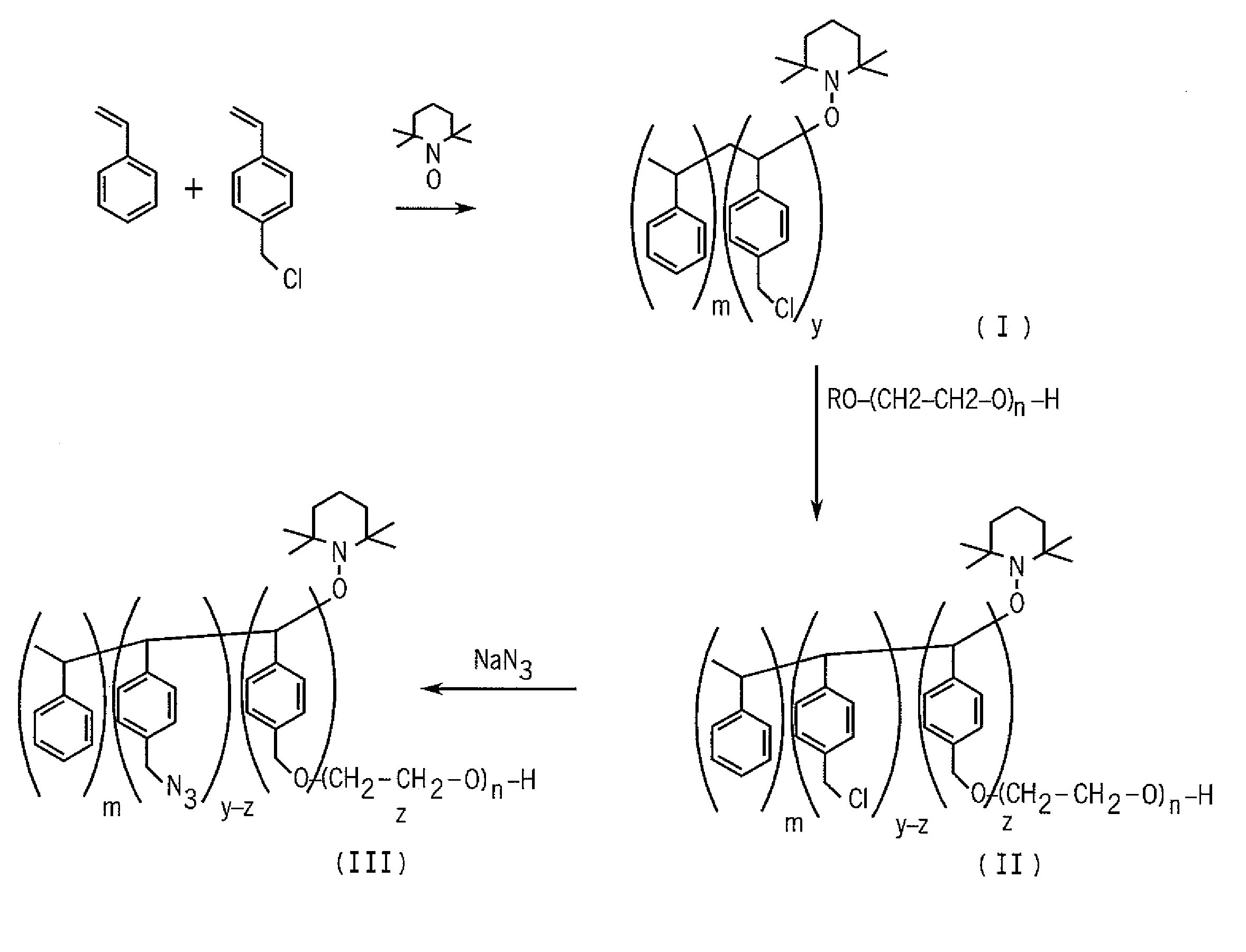

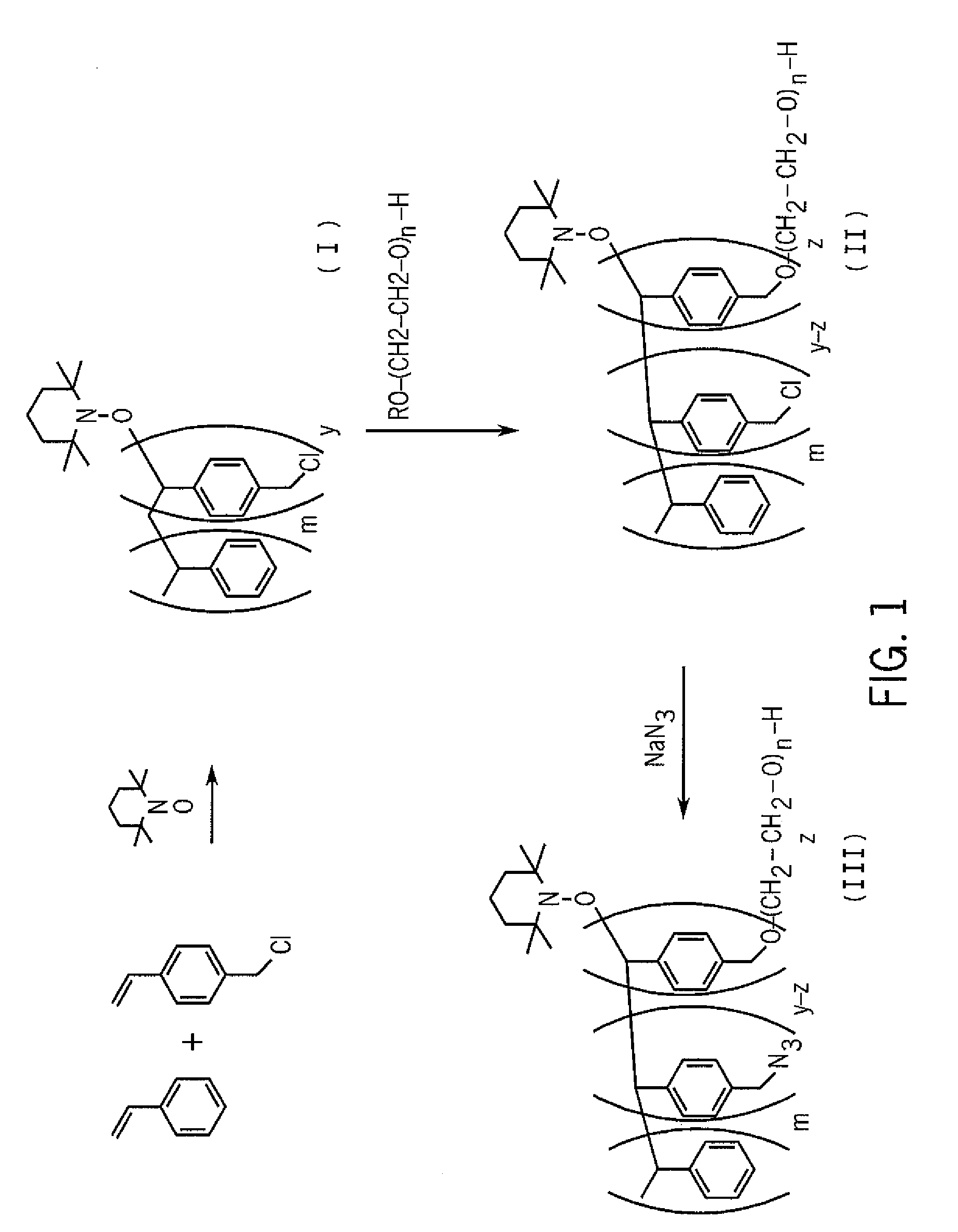

Crosslinkable Graft Polymer Non-Preferentially Wetted by Polystyrene and Polyethylene Oxide

ActiveUS20080318005A1Material nanotechnologyDecorative surface effectsPolyethylene oxidePolymer science

Methods for fabricating a random graft PS-r-PEO copolymer and its use as a neutral wetting layer in the fabrication of sublithographic, nanoscale arrays of elements including openings and linear microchannels utilizing self-assembling block copolymers, and films and devices formed from these methods are provided. In some embodiments, the films can be used as a template or mask to etch openings in an underlying material layer.

Owner:MICRON TECH INC

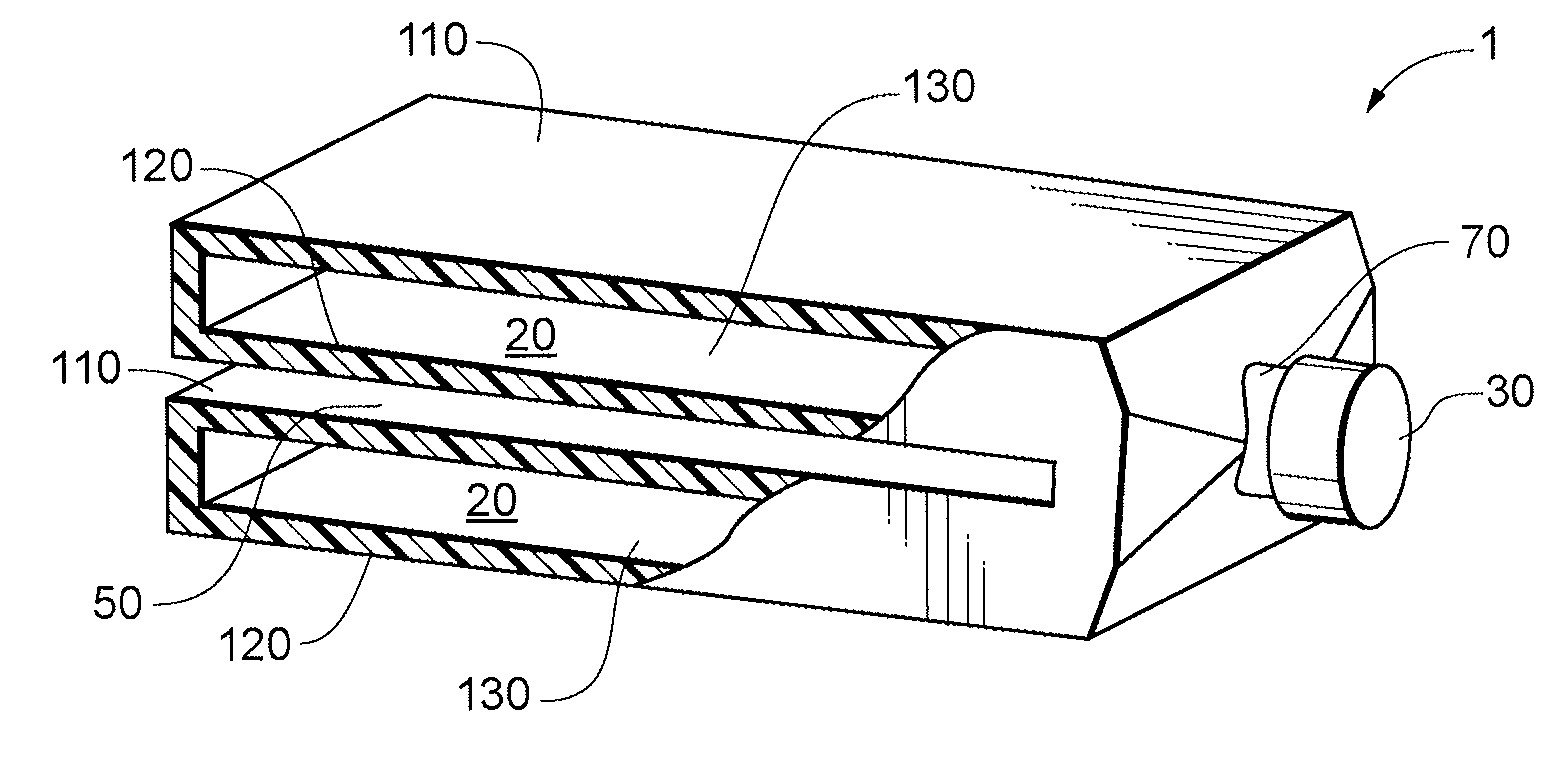

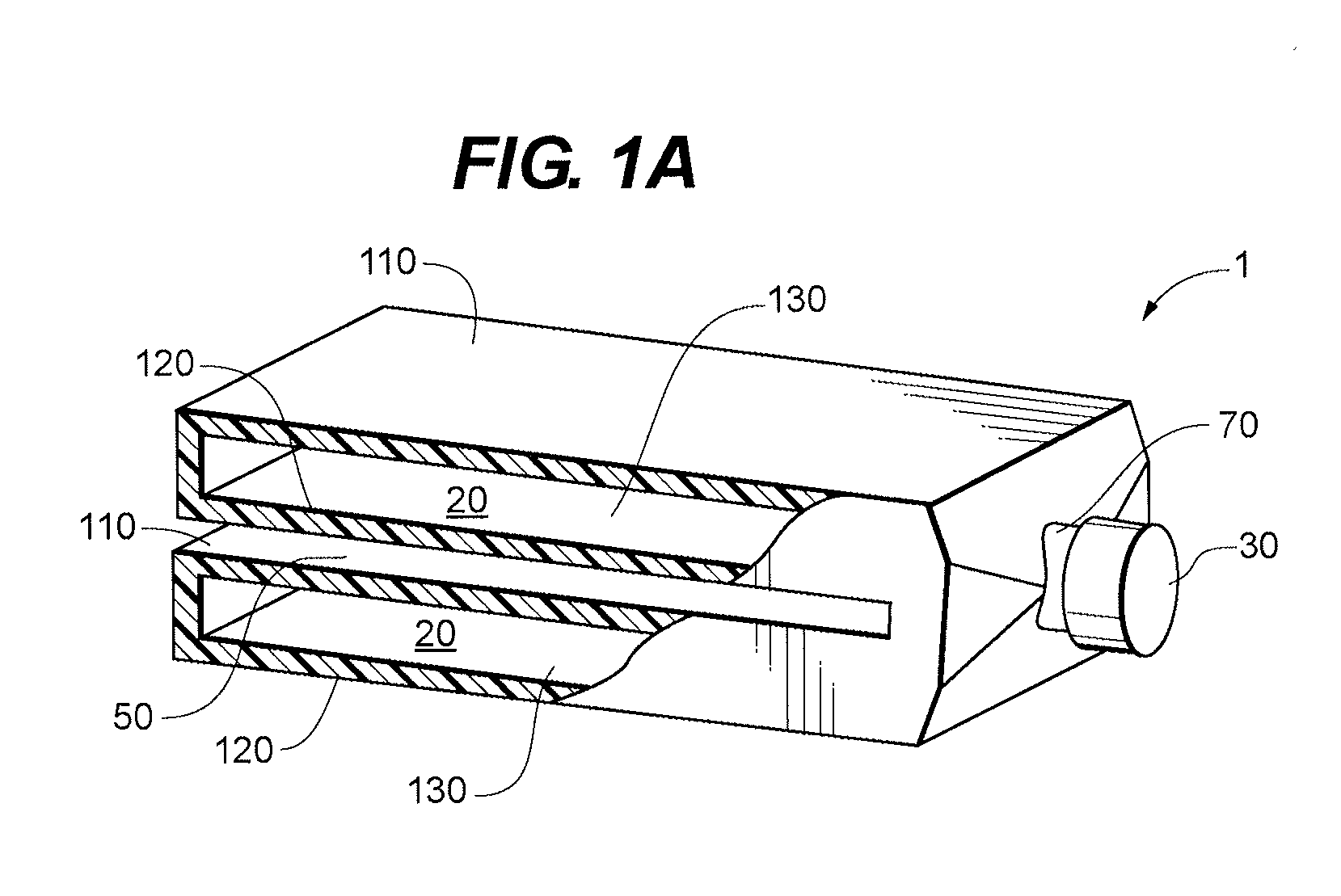

Highly efficient gas permeable devices and methods for culturing cells

ActiveUS20080227176A1Minimize potentialEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsCulture cellPolystyrene

Owner:WILSON WOLF MFG

Flame-proof smoke-inhibiting wood-plastic composite material

A flame retardant smoke resistant wood plastic composite material relates to a wood plastic composite material, which solves the disadvantages of low flame retardant performance, big smoke mass, large addition of flame retardants, increased cost and decreased mechanical property of existing wood plastic composite materials. The product of the invention is mainly formed by polystyrene and / or polyvinyl chloride fortified with heat stabilizers, lignocellulose, intumescent flame retardant, compatibilizer, lubricant. The flame retardant and smoke-resistant performance of the product of the invention is greatly improved. For wood powder / polystyrene composite material, compared with no addition of flame retardant, the average heat release rate is decreased by 48 percent, the quantity of smoke yield is reduced by 30 percent and the CO yield is decreased by 28 percent during combustion. The product of the invention has high oxygen-index, long ignition time and no droplet, which greatly reduces the fire hazard of the material, and the appearance of the material is similar with wood. The product of the invention also has low cost, wide application range and good creep resistance, forming performance and mechanical property.

Owner:NORTHEAST FORESTRY UNIVERSITY

Polymer Compound And Polymer Light-Emitting Device Using The Same

ActiveUS20080138651A1High luminous intensityHigh fluorescence intensityConductive layers on insulating-supportsOrganic chemistryCompound (substance)Polystyrene

High-molecular compounds comprising repeating units represented by the general formula (1) or (2) and having number-average molecular weights of 103 to 108 in terms of polystyrene: (1) [wherein Ar1 and Ar2 are each independently a trivalent aromatic hydrocarbon group or a trivalent heterocyclic group; and X1 and X2 are each independently O, S, C(═O), S(═O), SO2, C(R1)(R2), Si(R3)(R4), N(R5), B(R6), P(R7), or P(═O)(R8), with the provisos that X1 and X2 must not be the same and that X1 and Ar2 are bonded respectively to the adjacent carbon atoms constituting the aromatic ring of Ar1, and X2 and Ar1 are bonded respectively to the adjacent carbon atoms constituting the aromatic ring of Ar2] (2) [wherein Ar3 and Ar4 are each independently a trivalent aromatic hydrocarbon group or a trivalent heterocyclic group; and X3 and X4 are each independently N, B, P, C(R9), or Si(R10), with the provisos that X3 and X4 must not be the same and that X3 and Ar4 are bonded respectively to the adjacent carbon atoms constituting the aromatic ring of Ar3, and X4 and Ar3 are bonded respectively to the adjacent carbon atoms constituting the aromatic ring of Ar4].

Owner:SUMITOMO CHEM CO LTD

Nanoparticles with controlled architecture and method thereof

The present invention provides polymer nanoparticles with a controlled architecture of nano-necklace, nano-cylinder, nano-ellipsoid, or nano-sphere. The polymer nanoparticle comprises a core polymerized from multiple-vinyl-substituted aromatic hydrocarbons, a shell polymerized from alkyl-substituted styrene, and a polystyrene layer between the core and the shell. The present invention also provides a method of preparing the polymer nanoparticles and a rubber article such as a tire manufactured from a formulation comprising the polymer nanoparticles.

Owner:BRIDGESTONE CORP

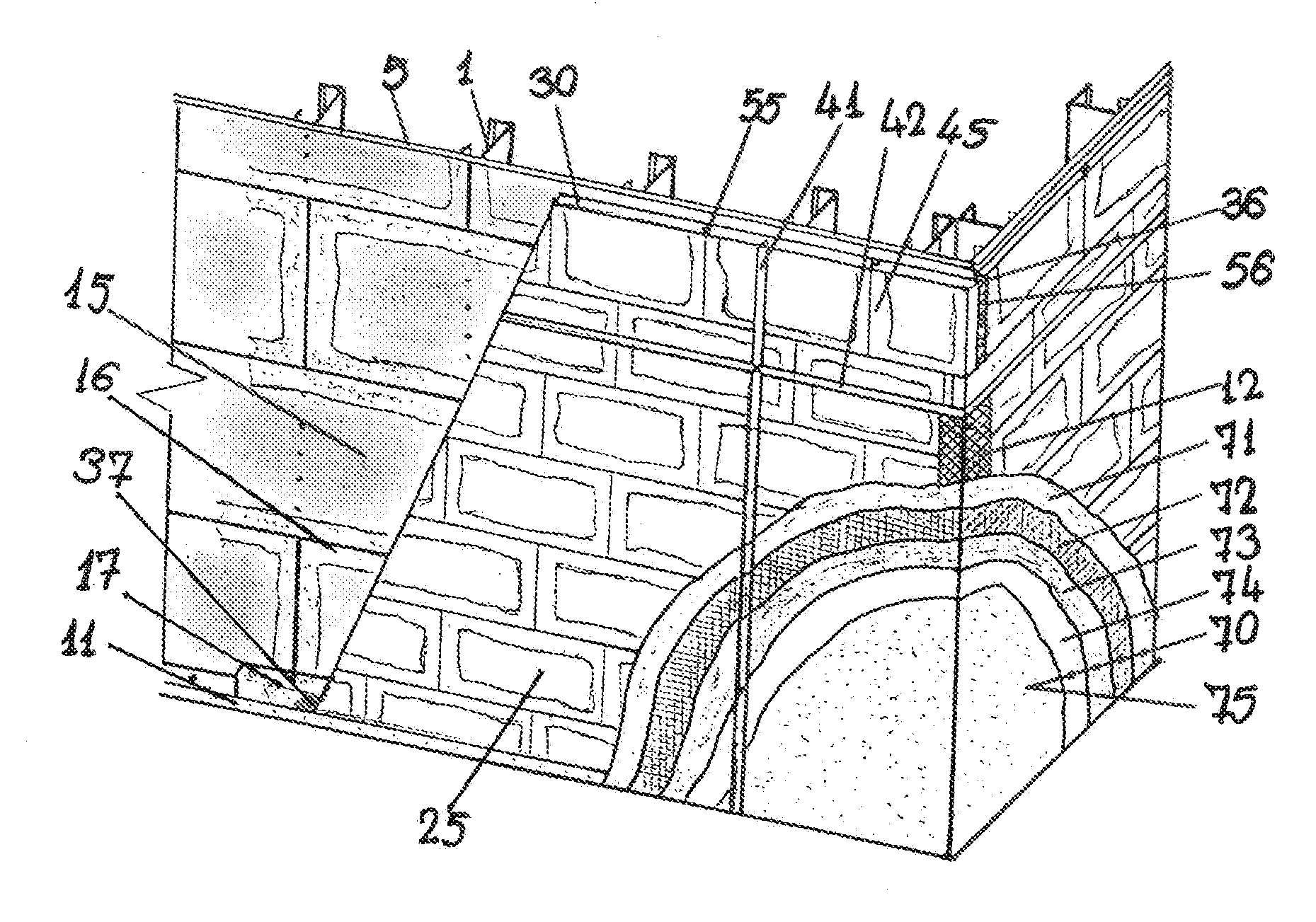

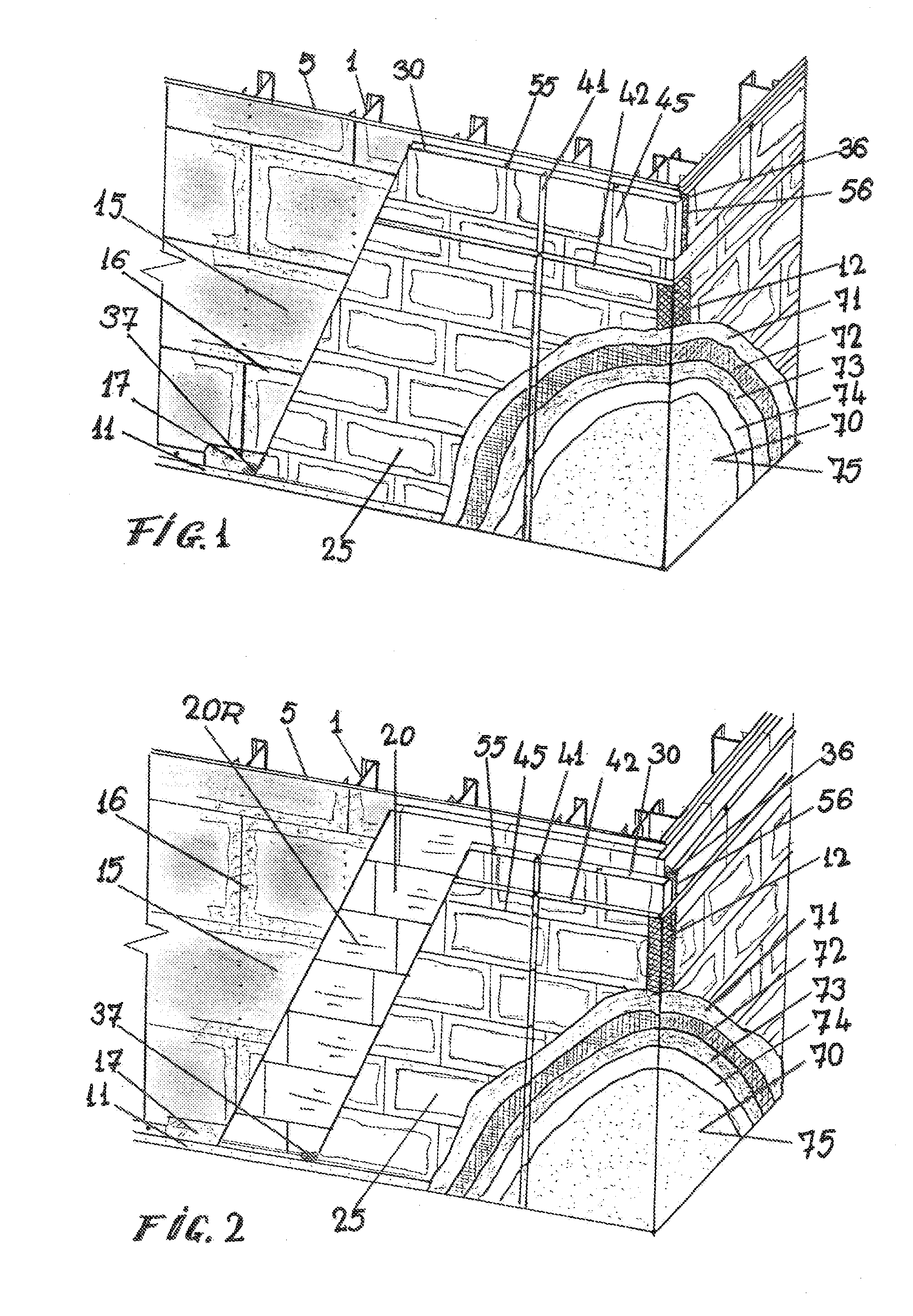

NP-EIFS Non-Permissive Exterior Insulation and Finish Systems concept technology and details

A new concept wall system is provided, wherein the Exterior Insulation and Finish System cladding is created using components with no water absorption, a very low vapor permeability and sealing properties, accommodated with an installation technology which extend the materials properties to the assembly, together with bonding and sealing the intersections and terminations, creating a Non-Permissive to water and vapor diffusion, Exterior Insulation and Finish System (NP-EIFS). The present invention relates to an EIFS cladding having two air and vapor barriers, one applied to the substrate, a continuous liquid membrane with sheathing joints sealed to be moisture barrier for inside vapors, and an exterior weather and vapor barrier which is created using closed cell extruded polystyrene insulation boards, special assembled with joints sealed, to create a non-permissive insulation envelope of the enclosure. Another object of the invention is to provide waterproof and air / vapor-proof details, a new concept of flashing and sealant application around windows / doors and other constructive elements to avoid thermal bridges and air leakage inside thermal envelope and wall assembly. Methods of installation are included.

Owner:RADOANE MARIUS

Method of forming a mold and molding a micro-device

A method of forming a device including a plurality of micron or sub-micron sized features is provided. A master having a surface contour defining a plurality of features is provided. The surface contour of the master is coated with at least one layer of material to form a shell. The master is removed from the shell to form a negative image of the surface contour in the shell. The negative image in the shell is filled with material, for example, polycarbonate, polyacrylic, or polystyrene, to form a device having features substantially the same as the master. The negative image may be filled using injection molding, compression molding, embossing or any other compatible technique.

Owner:BECTON DICKINSON & CO

Thermoset materials with improved impact resistance

The present invention relates to a thermoset material with improved impact resistance comprising: 99 to 20% of a thermoset resin, 1 to 80% of an impact modifier comprising at least one copolymer chosen from copolymers comprising S-B-M, B-M and M-B-M blocks, in which: each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond, M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of m thyl methacrylate, B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, S is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature M.t. is greater than the Tg of B. S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

Foamable interpolymer resin particles containing limonene as a blowing aid

ActiveUS20040152795A1Lower Level RequirementsImprove acceleration performanceFoundry mouldsFoundry coresPolyolefinFoaming agent

Interpolymer resin particles comprised of 20% to 80% by weight polyolefin, e.g. polyethylene and 80% to 20% by weight of an in situ polymerized vinyl aromatic resin, e.g. polystyrene or poly(styrene-butyl acrylate) and forming an interpenetrating network of polyolefin and vinyl aromatic resin particles. The interpolymer particles are impregnated with a volatile hydrocarbon blowing agent, and limonene, e.g. d-limonene, ranging from about 0.1 to about 5 parts, preferably 0.1 to 1 part by weight, based on 100 parts by weight of the interpolymer particles, for improved expandability and a pleasant fragrance.

Owner:BVPV STYRENICS LLC

Processes for producing polymer blends and polymer blend pellets

InactiveUS7803876B2Beneficial performance characteristicBeneficial storage and handling characteristicCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsLow-density polyethylenePolyester

Owner:EXXONMOBIL CHEM PAT INC

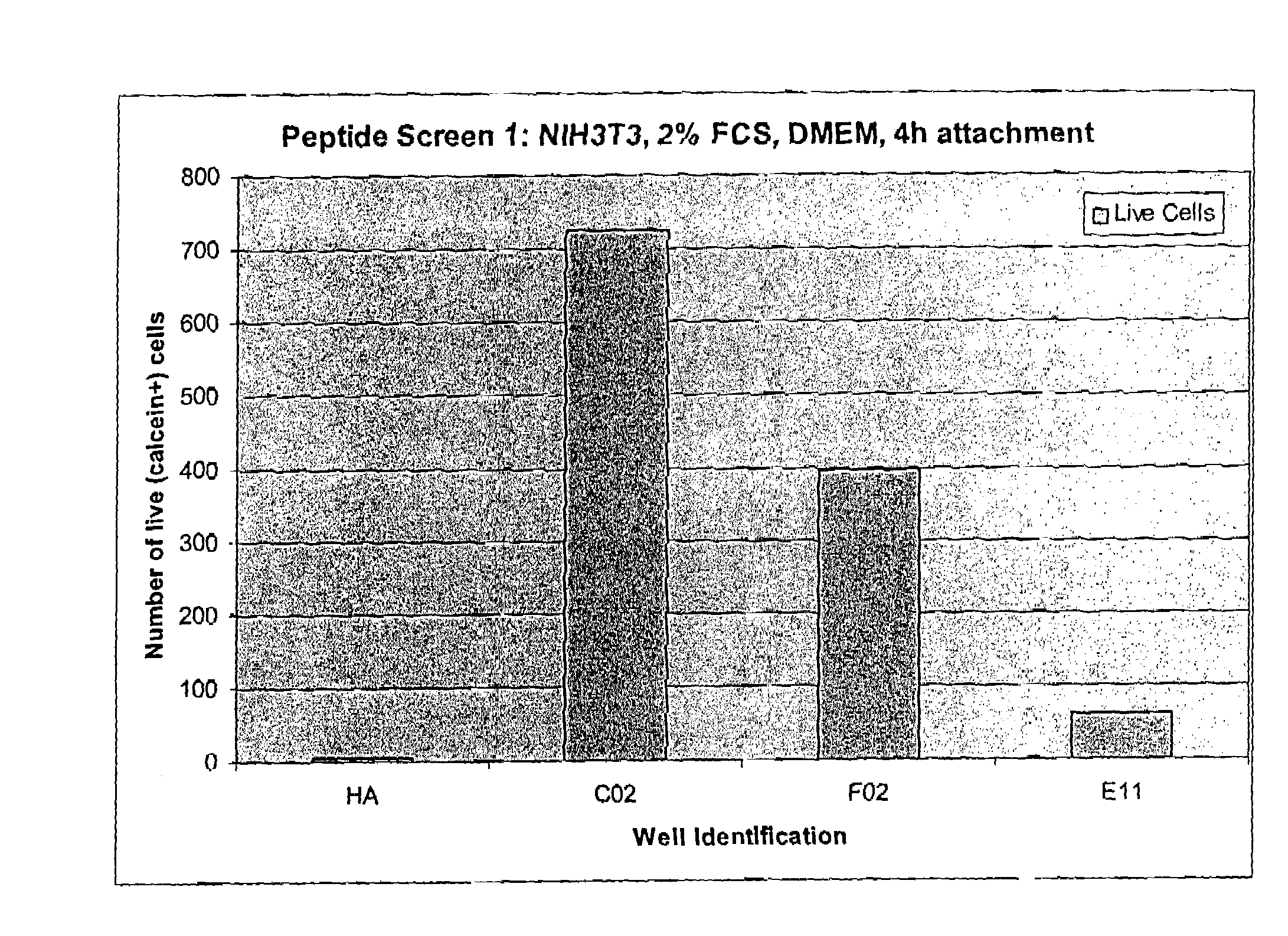

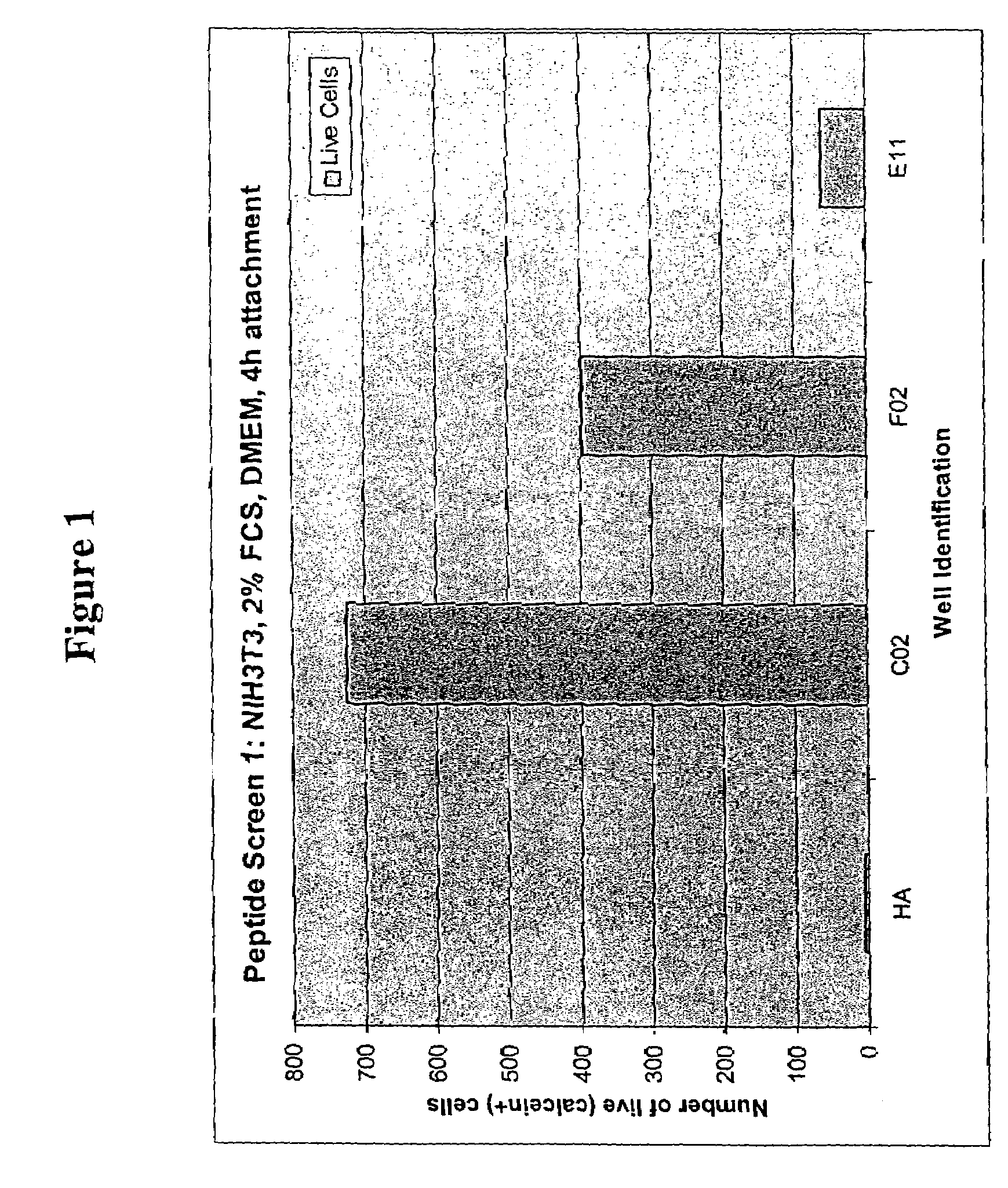

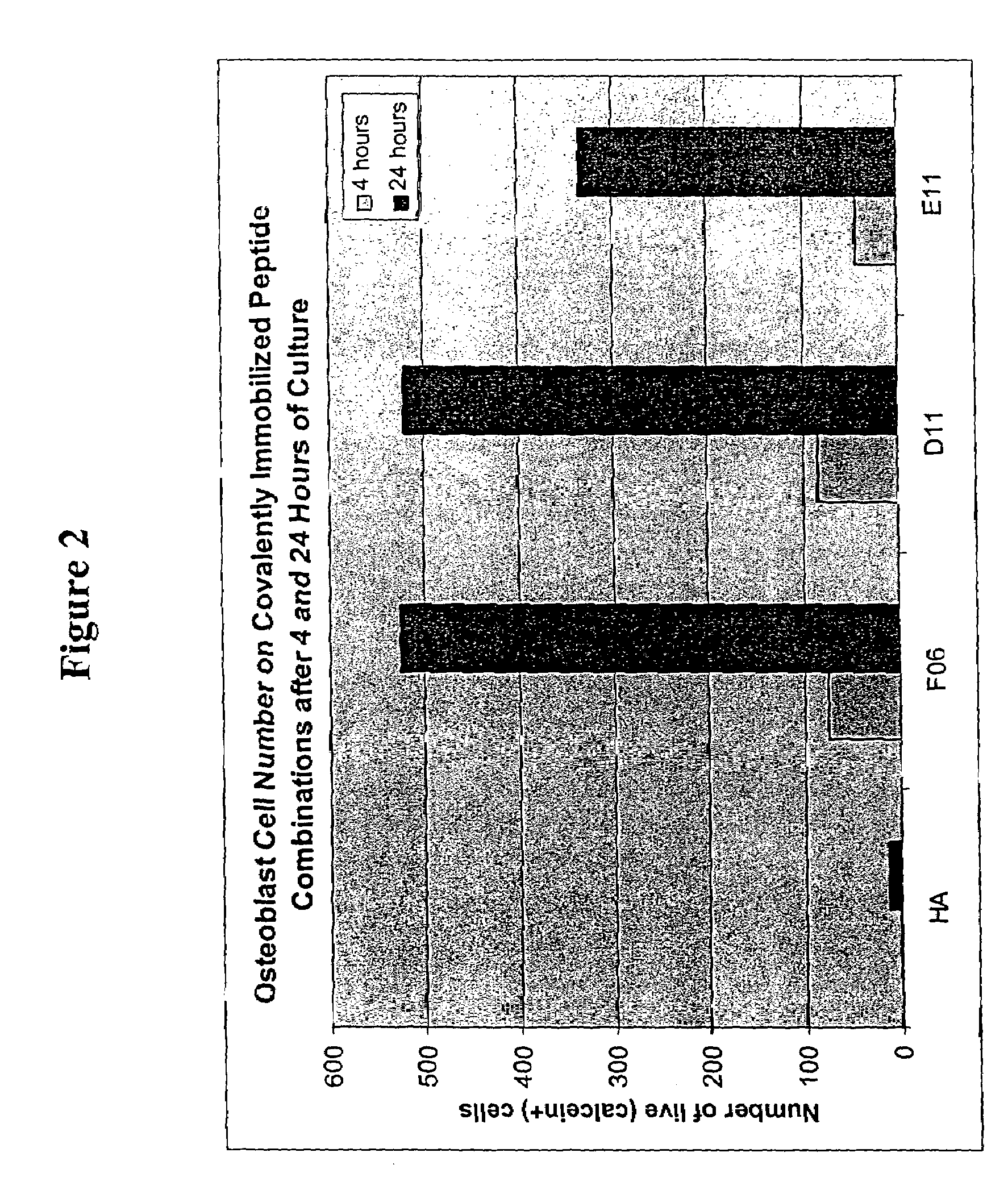

Peptides for enhanced cell attachment and growth

InactiveUS7157275B2Promotes attachment and growth and differentiation and further functionConnective tissue peptidesAdditive manufacturing apparatusCell adhesionAdhesion process

The present invention relates to cell adhesion promoting (“CAP”) peptide combinations that promote cell attachment or cell adhesion to culture surfaces that are otherwise cell adhesion resistant “CAR”. The invention provides combination of peptides that, when covalently coupled to a CAR layer such as hyaluronic acid that has been created on a polystyrene surface, promote cell attachment, growth differentiation, and execution of other desired cellular functions in culture.

Owner:BECTON DICKINSON & CO

Cement compositions containing flexible, compressible beads and methods of cementing in subterranean formations

Cement compositions comprising flexible, compressible beads, processes for preparing such cement compositions, and methods of cementing in subterranean formations using such cement compositions. One or more flexible, compressible beads are mixed with the cement before pumping the cement into a well bore. The flexible, compressible beads are preferably composed of an elastomeric material such as a copolymer of methylmethacrylate and acrylonitrile; a terpolymer of methylmethacrylate, acrylonitrile, and dichloroethane; a styrene-divinylbenzene copolymer; and polystyrene. The flexible, compressible beads may be heated to expand the beads before mixing with the cement such that the ensuing cement composition will have a desired density. Non-flexible beads such as spherulites may also be added to the cement compositions.

Owner:REDDY B RAGHAVA +2

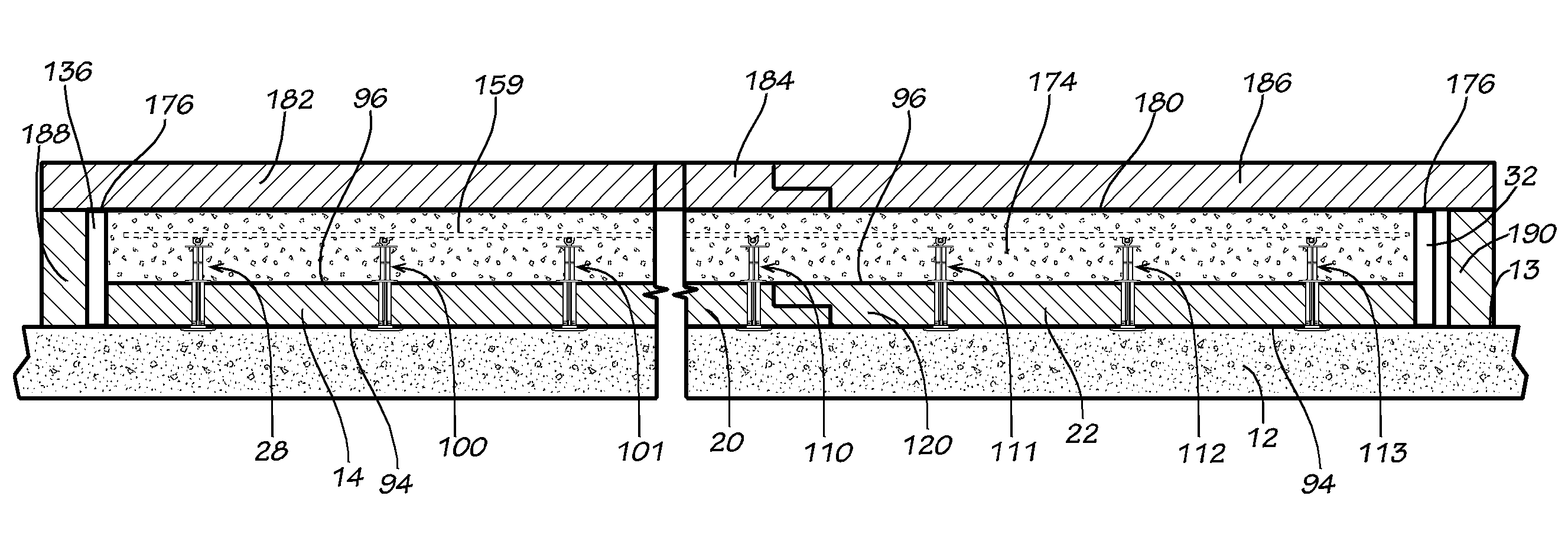

Precast concrete structures, precast tilt-up concrete structures and methods of making same

ActiveUS8555584B2Reduce internal stressReduce the amount requiredConstruction materialCovering/liningsPolystyreneExpanded polystyrene

Owner:CIUPERCA ROMEO ILARIAN

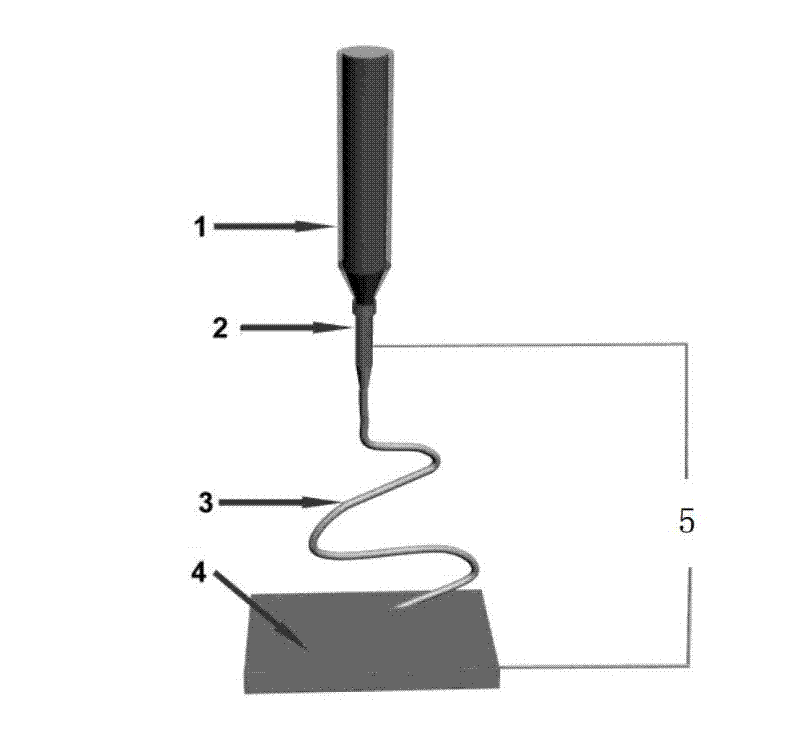

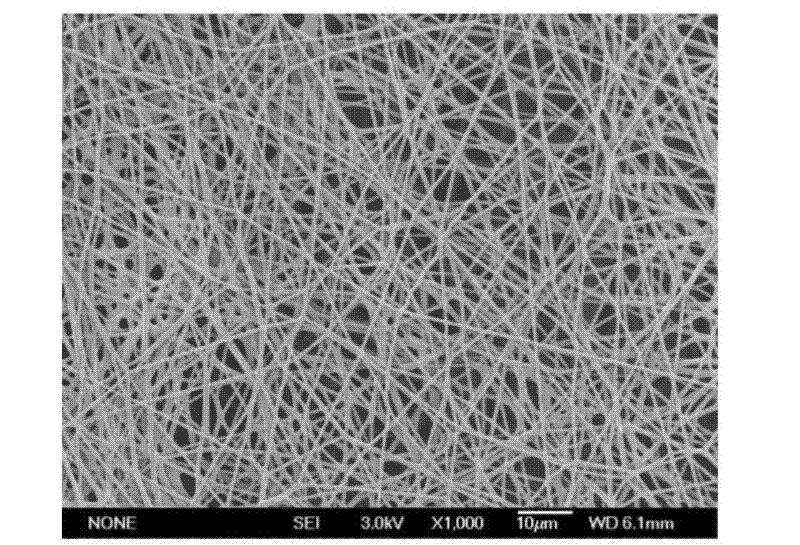

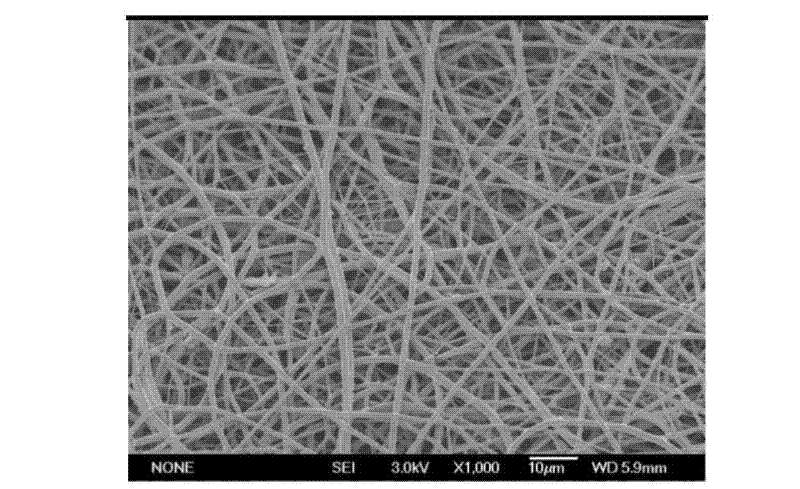

Composite fibre membrane with unidirectional water permeable performance and preparation method thereof

The invention discloses a composite fibre membrane with an unidirectional water permeable performance and a preparation method of the composite fibre membrane, belonging to the field of functional micron / nano composite fibre materials; the composite fibre membrane is composed of a two-layer structure; a hydrophile layer is a nano-scale fibre membrane composed of hydrophile polymers such as polyvinyl alcohol, cellulose acetate, polyacrylate and the like; fibre diameter is 100-800nm; thickness is 25-35 microns; a lyophobic layer is the micron-scale fibre membrane composed of lyophobic polymers such as polyurethane, polystyrene, polymethylmethacrylate or polycaprolactone and the like; thickness is 5-10 microns; and fibre diameter is1.0-3.0 microns. The composite fibre membrane can be controlled by regulating technical parameters and has hydrophile / lyophobic differences and an excellent directional water permeable performance; and the preparation method is characterized by simple operation, low energy consumption, high efficiency and is widely used for fields of perspiring-type waterproof dress materials, fuel cell electrolyte membranes, unidirectional liquid transmission and separation and the like.

Owner:BEIHANG UNIV

Polymer blend for matte injection moulded parts

The invention relates to a polymer mixture, comprising a) a polymer matrix which is composed of a (meth)acrylate(co)polymer or of a mixture of (meth)acrylate(co)polymers with a Vicat softening point VSP (ISO 306-B50) of at least 104° C. and / or of a (meth)acrylimide(co)polymer, b) an impact modifier which is based on crosslinked poly(meth)acrylates and which does not have covalent bonding to the polymer matrix a), c) from 1 to 15% by weight of plastics particles composed of crosslinked polymers based on polymethyl methacrylate, on polystyrene and / or on polysilicones. The polymer mixture can be used to obtain injection mouldings with matt surfaces and Vicat softening points VSPs (ISO 306-B50) of at least 90° C.

Owner:EVONIK ROEHM GMBH

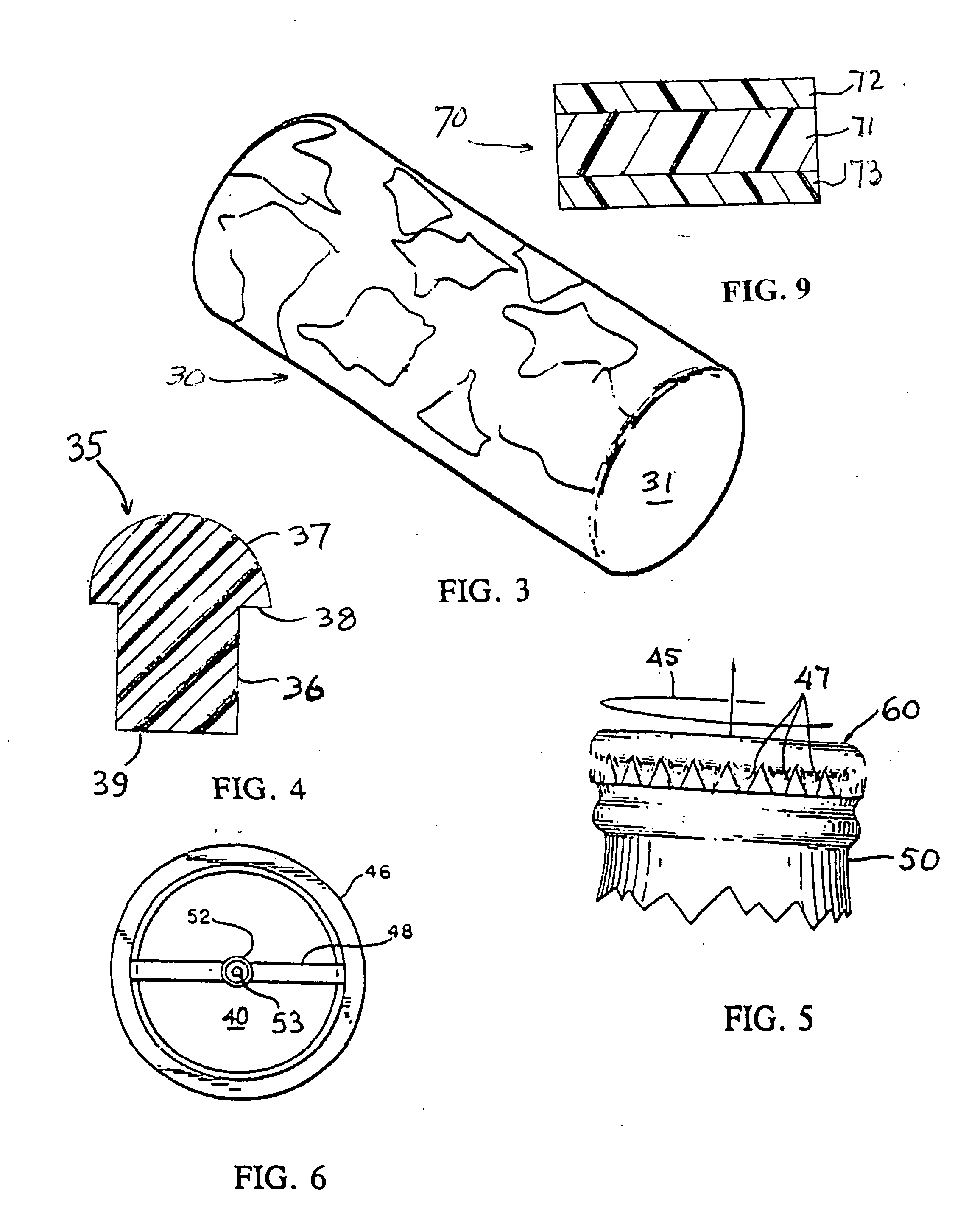

Essentially gas-impermeable thermoplastic sealant

InactiveUS20060229402A1Improve barrier propertiesExtended shelf lifeCapsClosure using stoppersThermoplasticPolymer science

A thermoplastic essentially oxygen-impermeable plasticized sealant is formed by melt-blending a hydrogenated styrene-conjugated diene-styrene (SMS) block copolymer rubber with a polystyrene-polyisobutylene-polystyrene (SIBS) block copolymer rubber and a polyolefin plastic with a liquid polyisobutylene (PIB) oil plasticizer provided the PIB oil is present (i) in the range from 5% to less than 50% by weight of the sealant and (ii) in relation to total rubber, in the range from 0.3 to 0.8. The required minor amount of PIB oil, relative to total rubber, in combination with SIBS present in a minor amount relative to the amount of plasticized sealant, provides the sealant with unexpectedly better oxygen barrier properties and load bearing at 82° C. (180 ° F.) than a comparable blend of SIBS with mineral oil; the sealant is also essentially free of tack, adhesive properties and oil-bleed, with essentially no detackifier present. The PIB-oil plasticized SIBS sealant has a haze of less than 15%; a composite made by melt-bonding a core layer between polyC2-C3olefin sheets, maintains a haze less than 14%. The plasticised sealant is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:GLS

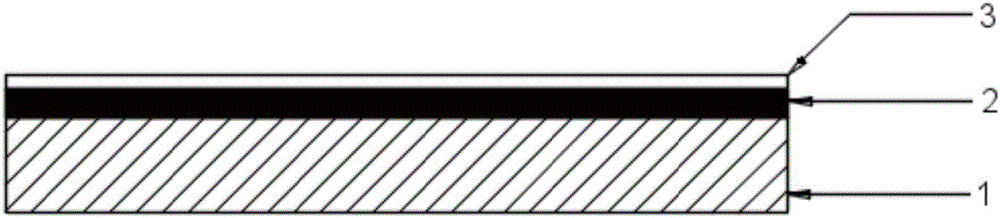

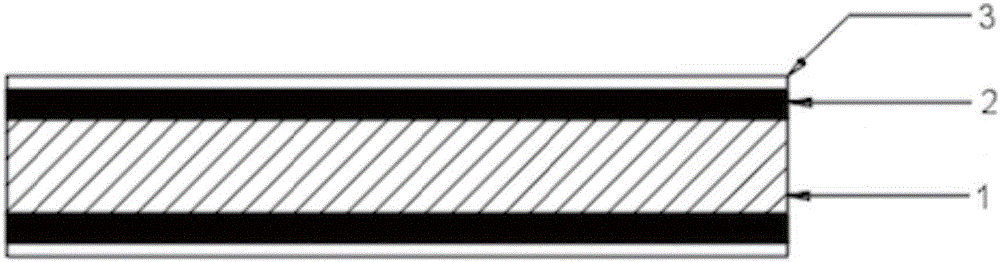

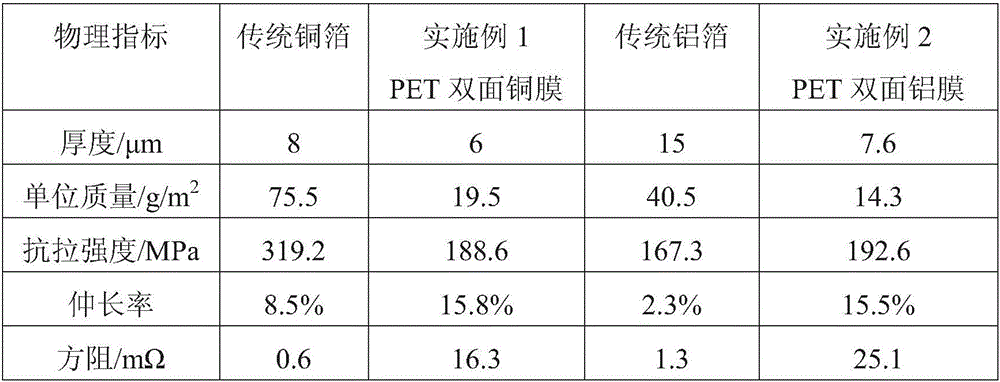

Flexible current collector for lithium battery and preparation method thereof

ActiveCN106654285AEnhanced machinabilityLow mass densityElectrode carriers/collectorsFiberPolyethylene terephthalate glycol

The invention discloses a flexible current collector for a lithium battery and a preparation method thereof. The flexible current collector comprises a flexible substrate layer, a metal conductive plated layer and a conductive anti-oxidization layer which are combined tightly in sequence, wherein the flexible substrate layer is one of polyvinyl chloride, polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polydimethylsiloxane and polyimide; the thickness of the flexible substrate layer is 1-20 microns; the metal conductive plated layer is one of Cu, Al, Ni, Au and Ag and the thickness of the metal conductive plated layer is 0.1-5 microns; and the conductive anti-oxidization layer is at least one of conductive graphite, graphene, carbon nanotubes and carbon nano-fibers, and the thickness of the conductive anti-oxidization layer is more than 0 and smaller than 1 micron. The flexible current collector disclosed by the invention has high machinability and relatively high thermal stability and anti-oxidization energy; and the quality density of a whole body is small.

Owner:ZHEJIANG UNIV

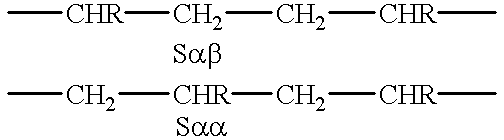

Viscosity modifier for lubricating oil and lubricating oil composition

InactiveUS6589920B2Improve the lubrication effectMaintain good propertiesOrganic chemistrySolid fuelsChemical compositionPolystyrene

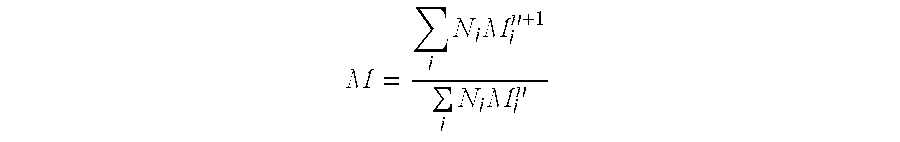

The lubricating oil composition of the invention comprises a lubricating oil base (A) and a copolymer (B) of ethylene and an alpha-olefin of 3 to 20 carbon atoms. The copolymer (B) of ethylene and an alpha-olefin of 3 to 20 carbon atoms is contained in the composition in an amount of 1 to 20% by weight and has the following properties:(1) the ethylene content (E) is in the range of 40 to 77% by weight,(2) the weight-average molecular weight (Mw) in terms of polystyrene, as measured by GPC, is in the range of 80,000 to 400,000,(3) Mw / Mn is not more than 2.4,(4) the melting point (Tm), as measured by DSC, is not higher than 60° C.,(5) the ethylene content (E, % by weight) and the melting point (Tm, ° C.), as measured by DSC, satisfy the following relation (I):and(6) the intensity ratio, Salphabeta / Salphaalpha, measured by 13C-NMR spectrum is not more than 0.5.

Owner:MITSUI CHEM INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com