Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3642 results about "Machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. Materials with good machinability (free machining materials) require little power to cut, can be cut quickly, easily obtain a good finish, and do not wear the tooling much. The factors that typically improve a material's performance often degrade its machinability. Therefore, to manufacture components economically, engineers are challenged to find ways to improve machinability without harming performance.

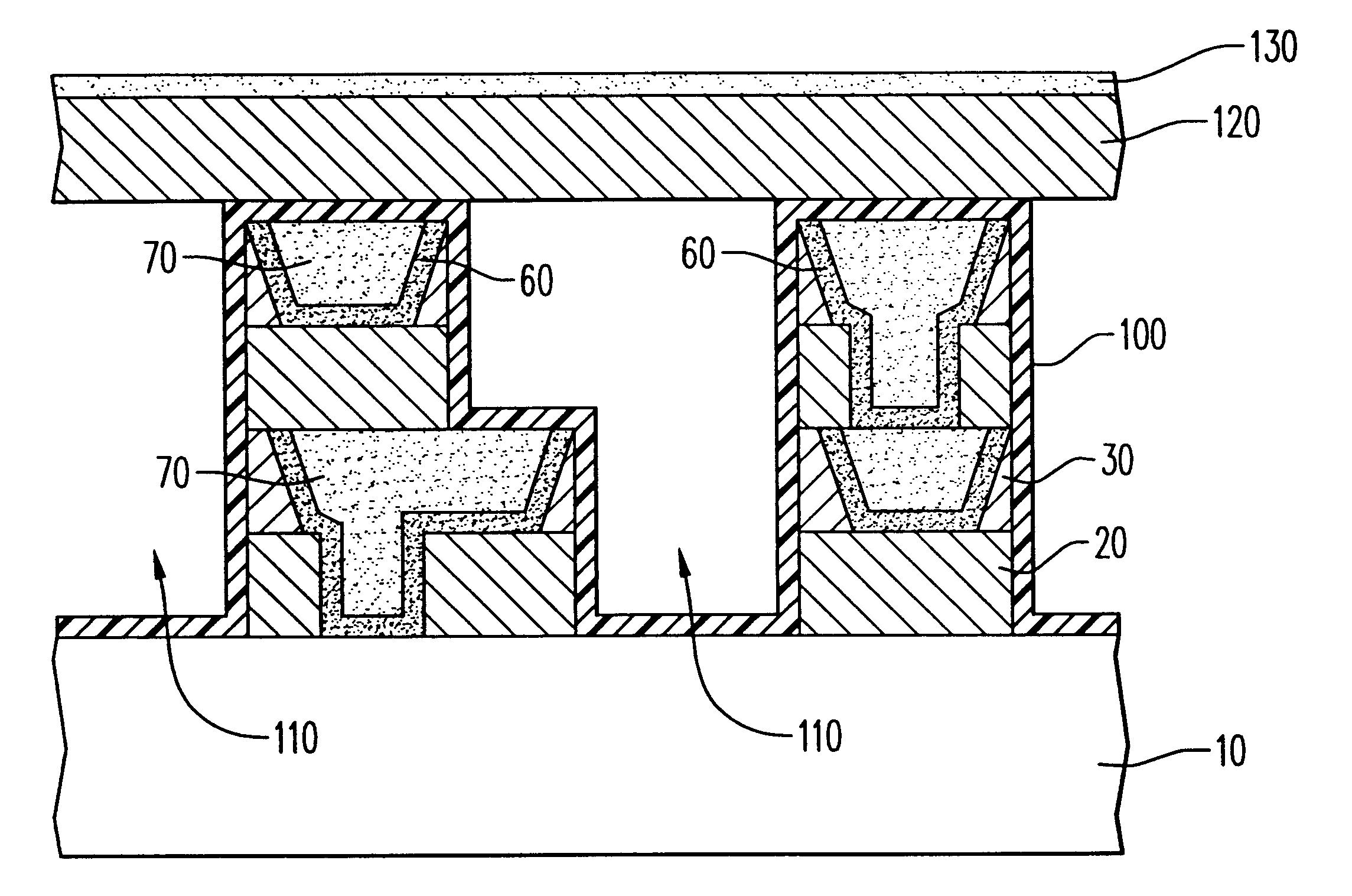

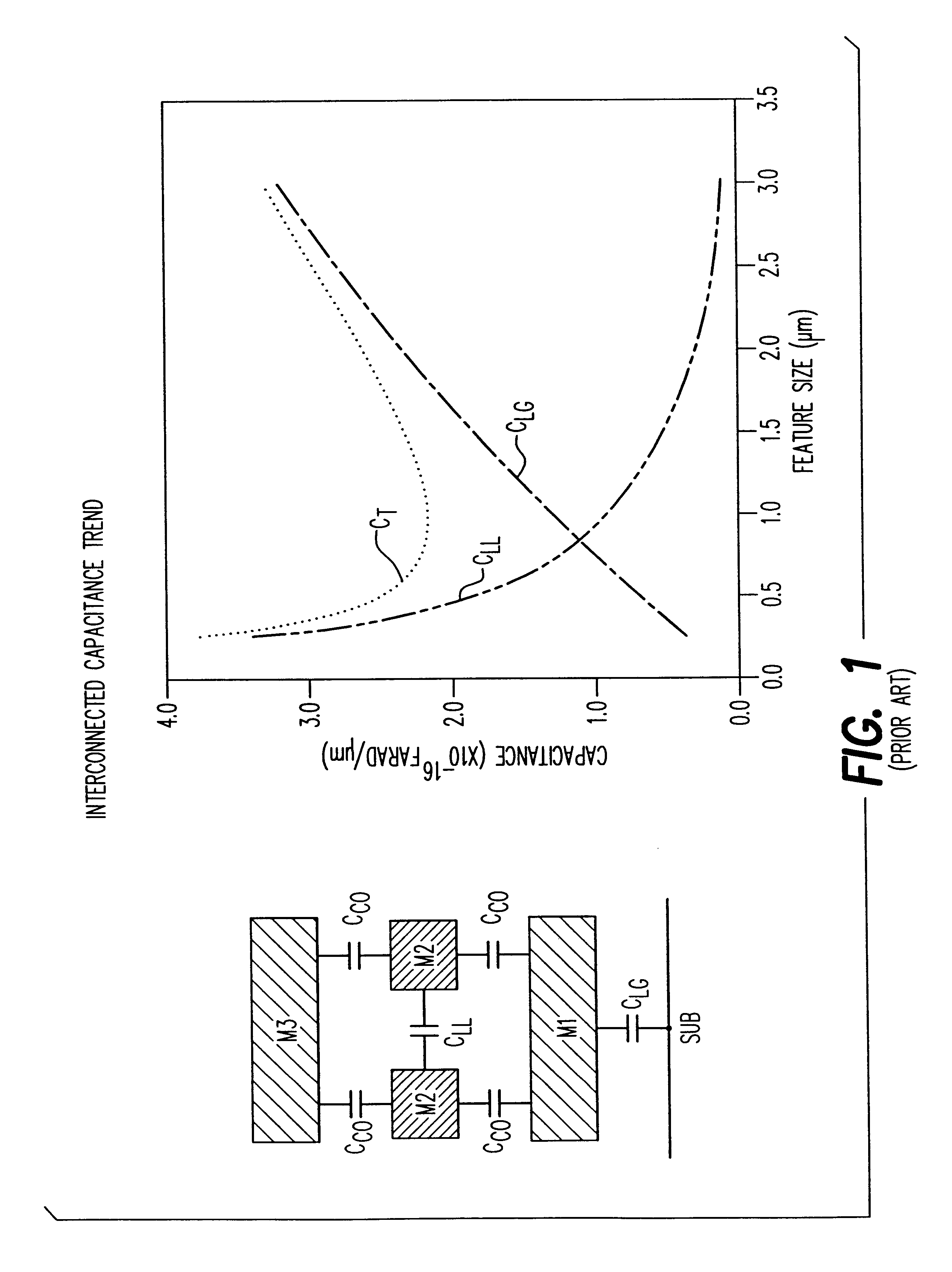

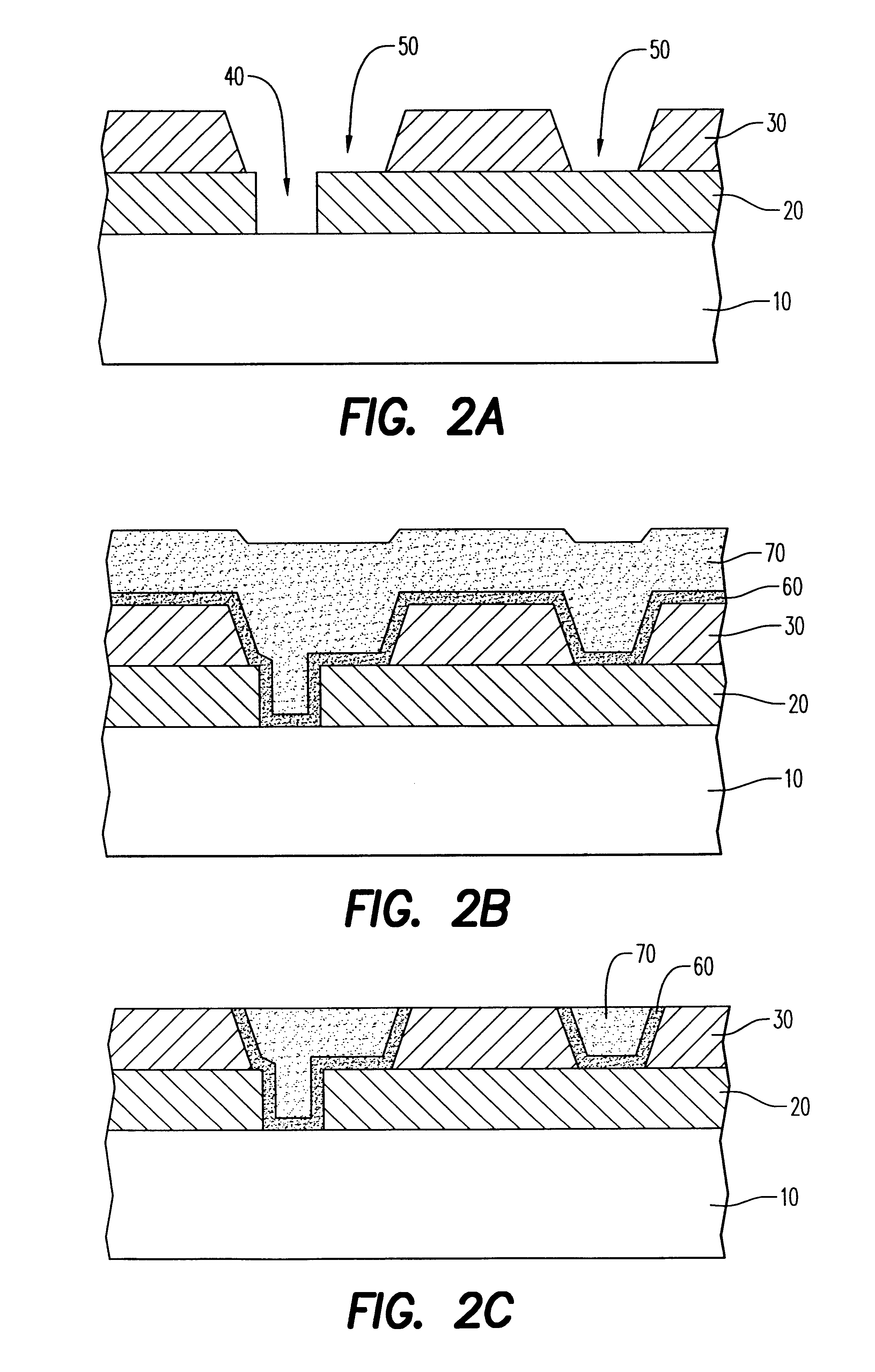

Chip interconnect wiring structure with low dielectric constant insulator and methods for fabricating the same

A method to achieve a very low effective dielectric constant in high performance back end of the line chip interconnect wiring and the resulting multilayer structure are disclosed. The process involves fabricating the multilayer interconnect wiring structure by methods and materials currently known in the state of the art of semiconductor processing; removing the intralevel dielectric between the adjacent metal features by a suitable etching process; applying a thin passivation coating over the exposed etched structure; annealing the etched structure to remove plasma damage; laminating an insulating cover layer to the top surface of the passivated metal features; optionally depositing an insulating environmental barrier layer on top of the cover layer; etching vias in the environmental barrier layer, cover layer and the thin passivation layer for terminal pad contacts; and completing the device by fabricating terminal input / output pads. The method obviates issues such as processability and thermal stability associated with low dielectric constant materials by avoiding their use. Since air, which has the lowest dielectric constant, is used as the intralevel dielectric the structure created by this method would possess a very low capacitance and hence fast propagation speeds. Such structure is ideally suitable for high density interconnects required in high performance microelectronic device chips.

Owner:GLOBALFOUNDRIES INC

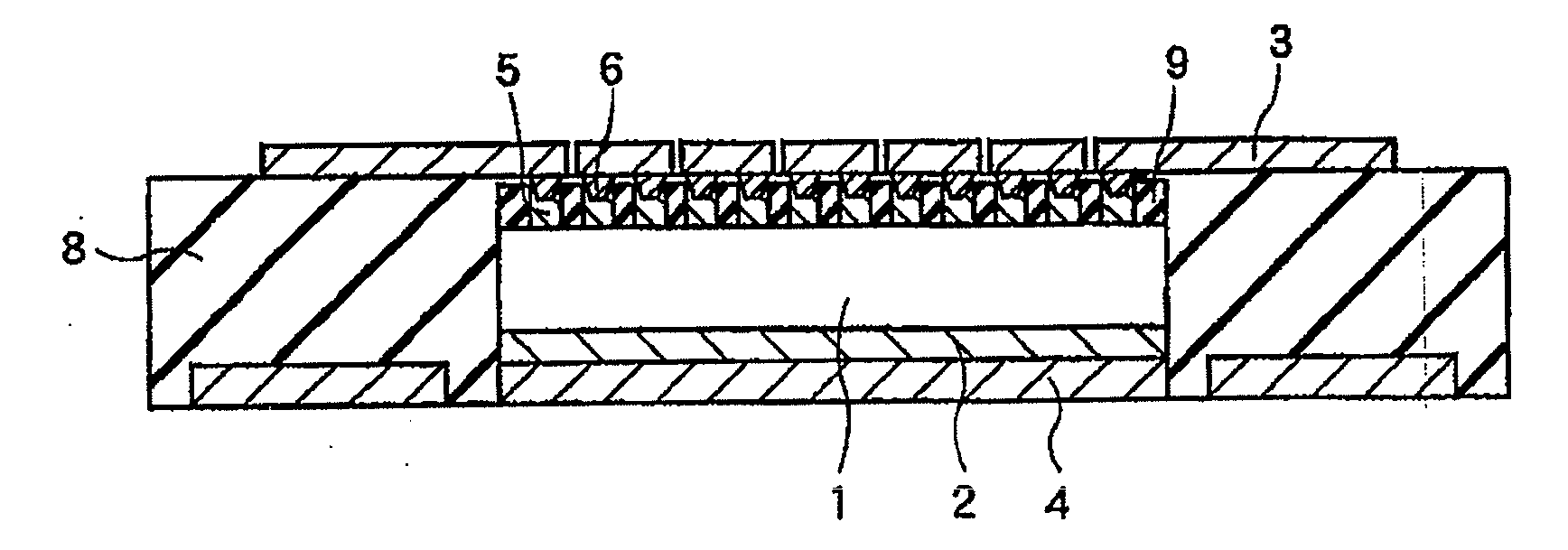

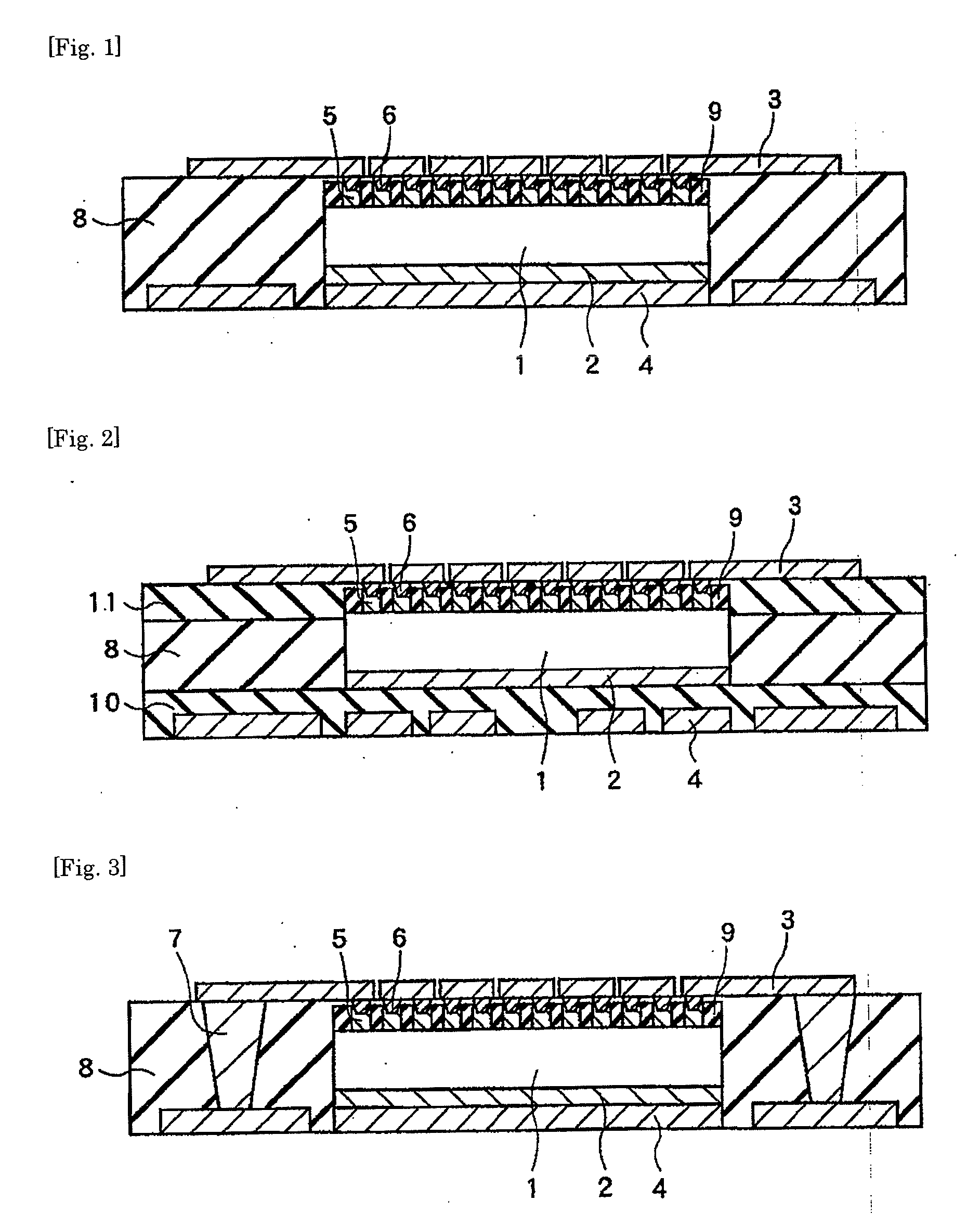

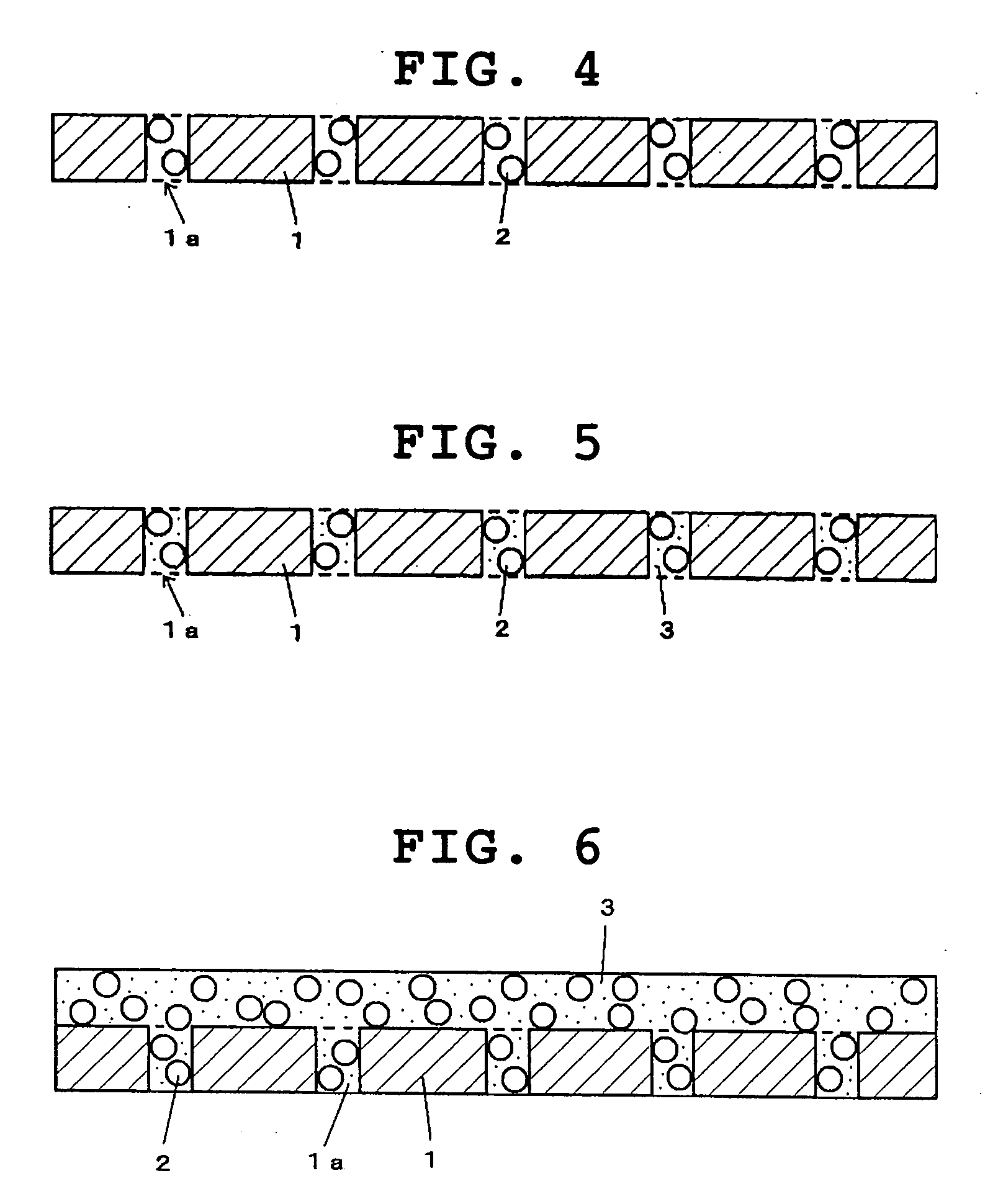

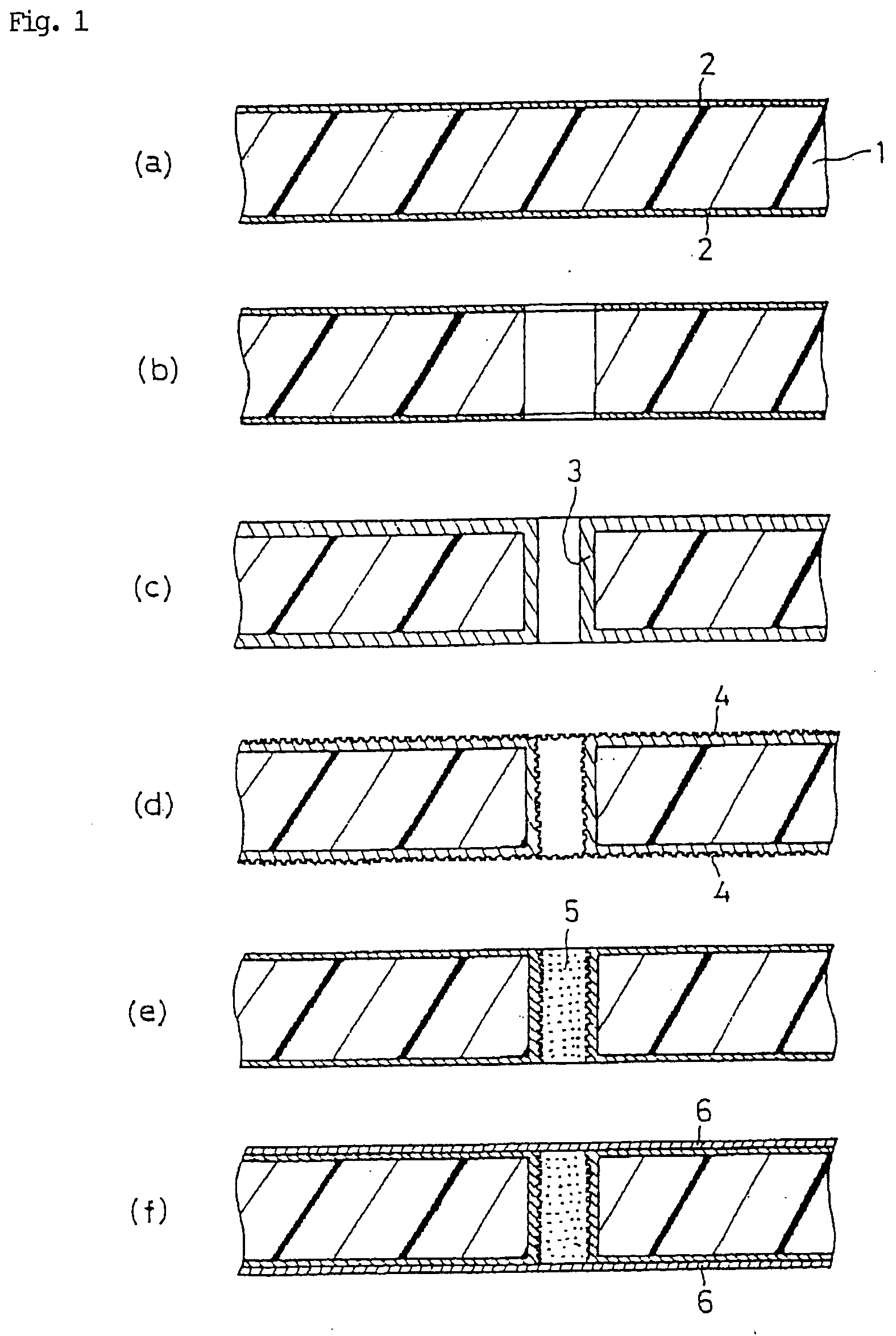

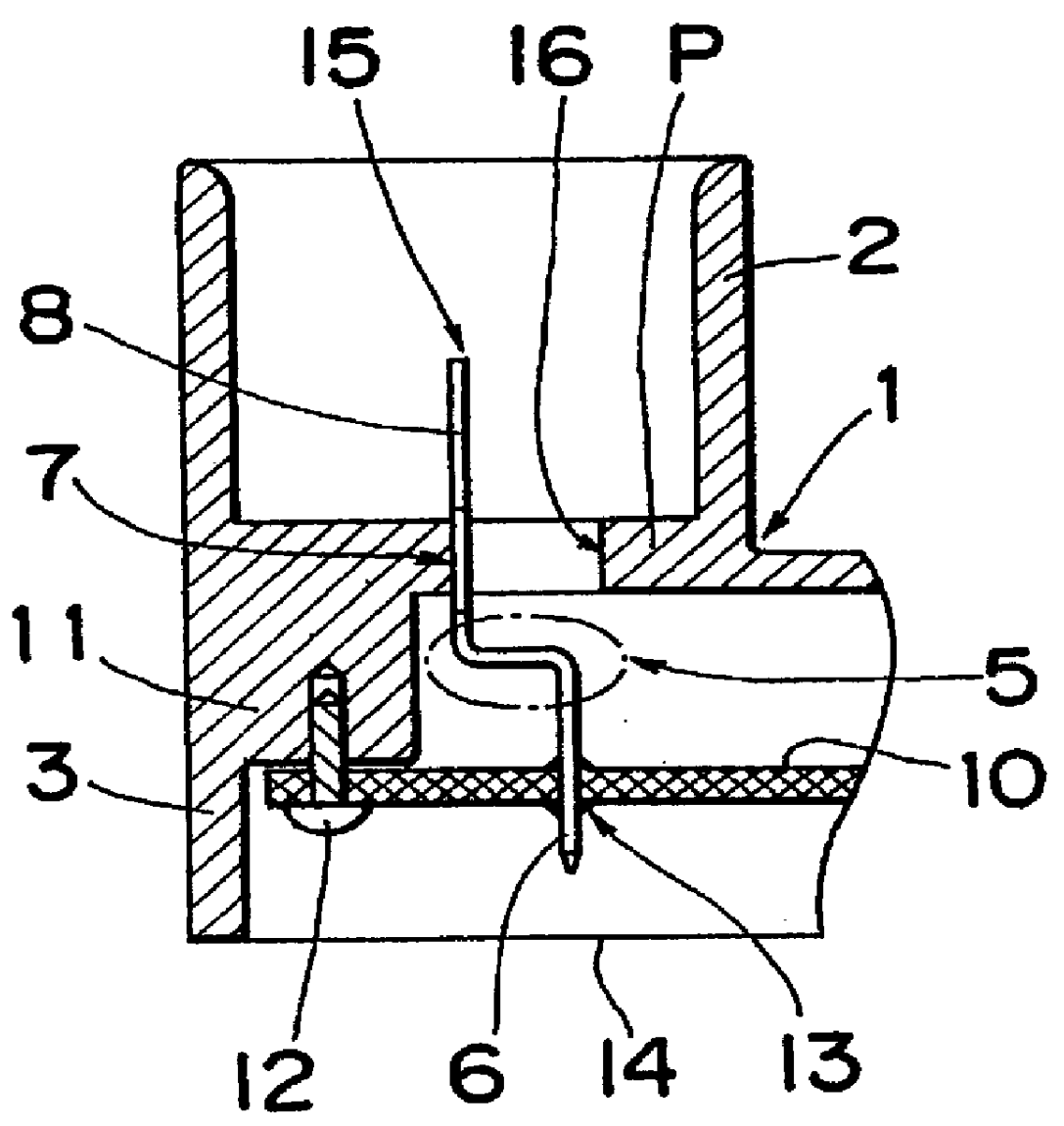

Circuit substrate, an electronic device arrangement and a manufacturing process for the circuit substrate

InactiveUS20100044845A1Improve workabilityImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsResistSurface mounting

[Problem to be Solved] There are provided a circuit substrate, an electronic device arrangement and a manufacturing process for the circuit substrate which enable to directly implement the surface mounting and so on of electronic components on the conductive wiring without forming solder resist, and also which enable to enhance high speed transmission characteristics and to enlarge wiring rule for the electrode terminal of the function element to be contained therein, and to implement with excellent workability and reliability when connecting the electronic device.[Solution] A circuit substrate comprisinga function element 1 with an electrode terminal 5 a base member containing the function element 1 therein and having at least one layer of a conductive wiring formed on its front side face and rear side face respectively, anda via 6 connecting the electrode terminal 5 with the conductive wiring 3 formed on the base member, wherein the conductive wiring formed on either one of the front side face and the rear side face of the base member is arranged such that a surface exposed outside from the base member is in the same plane with or inside a surface of the base member on which the conductive wiring is formed.

Owner:NEC CORP

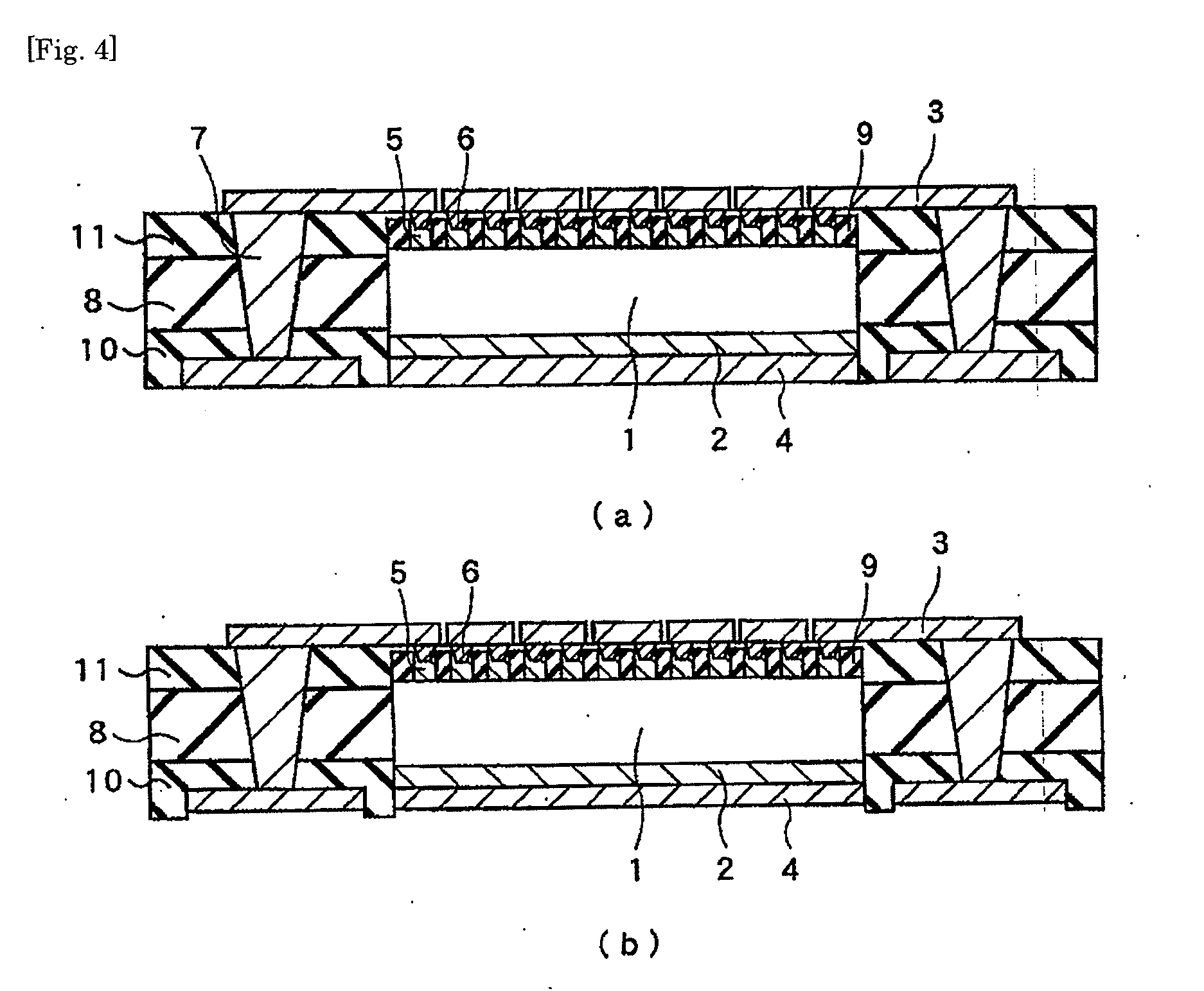

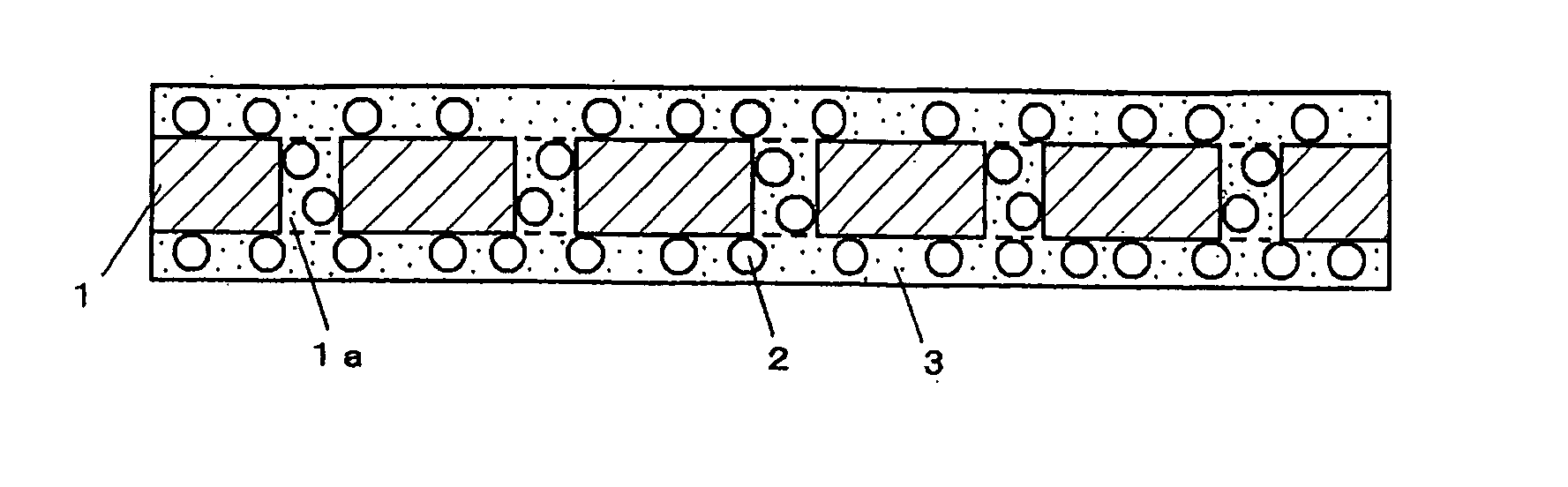

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

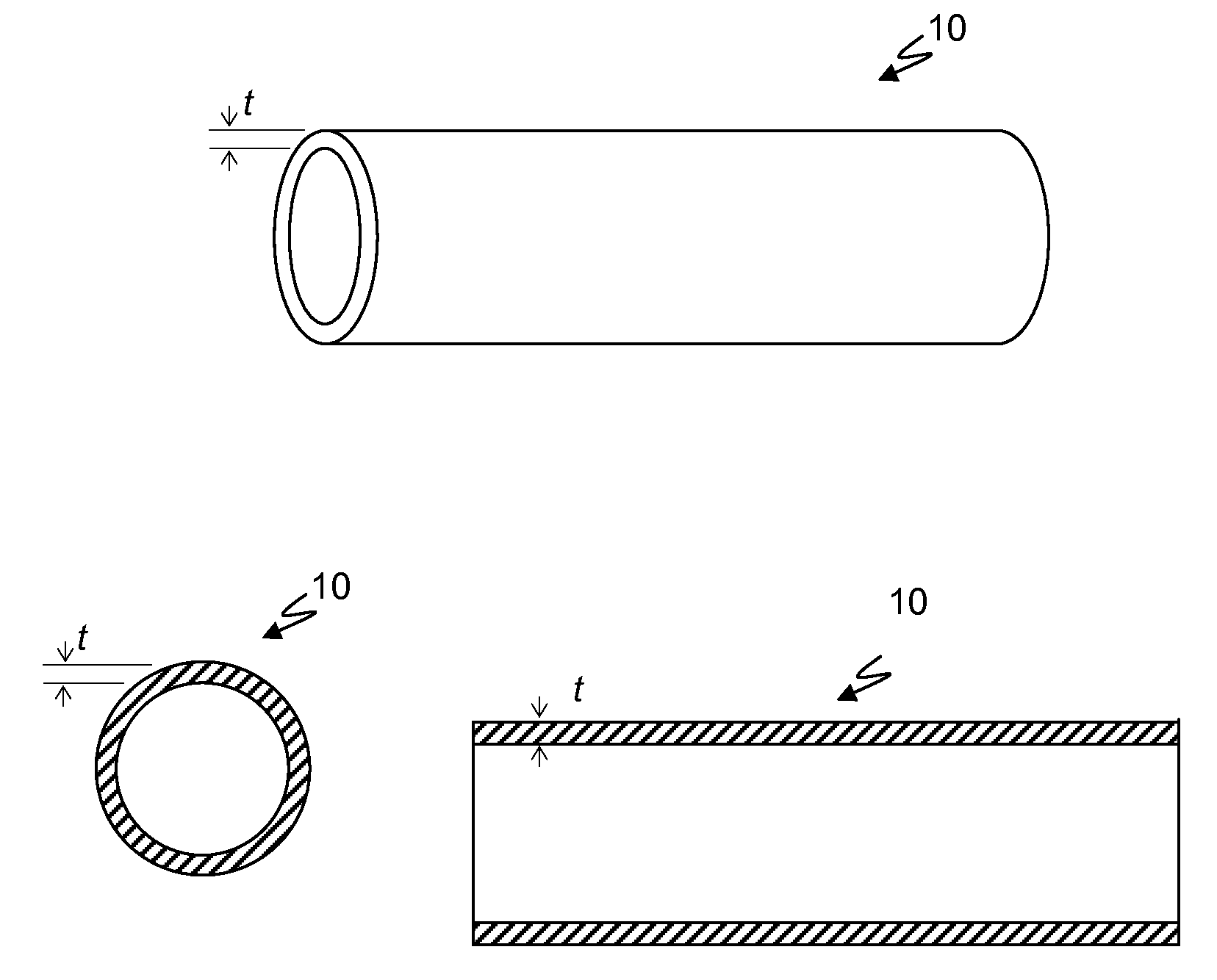

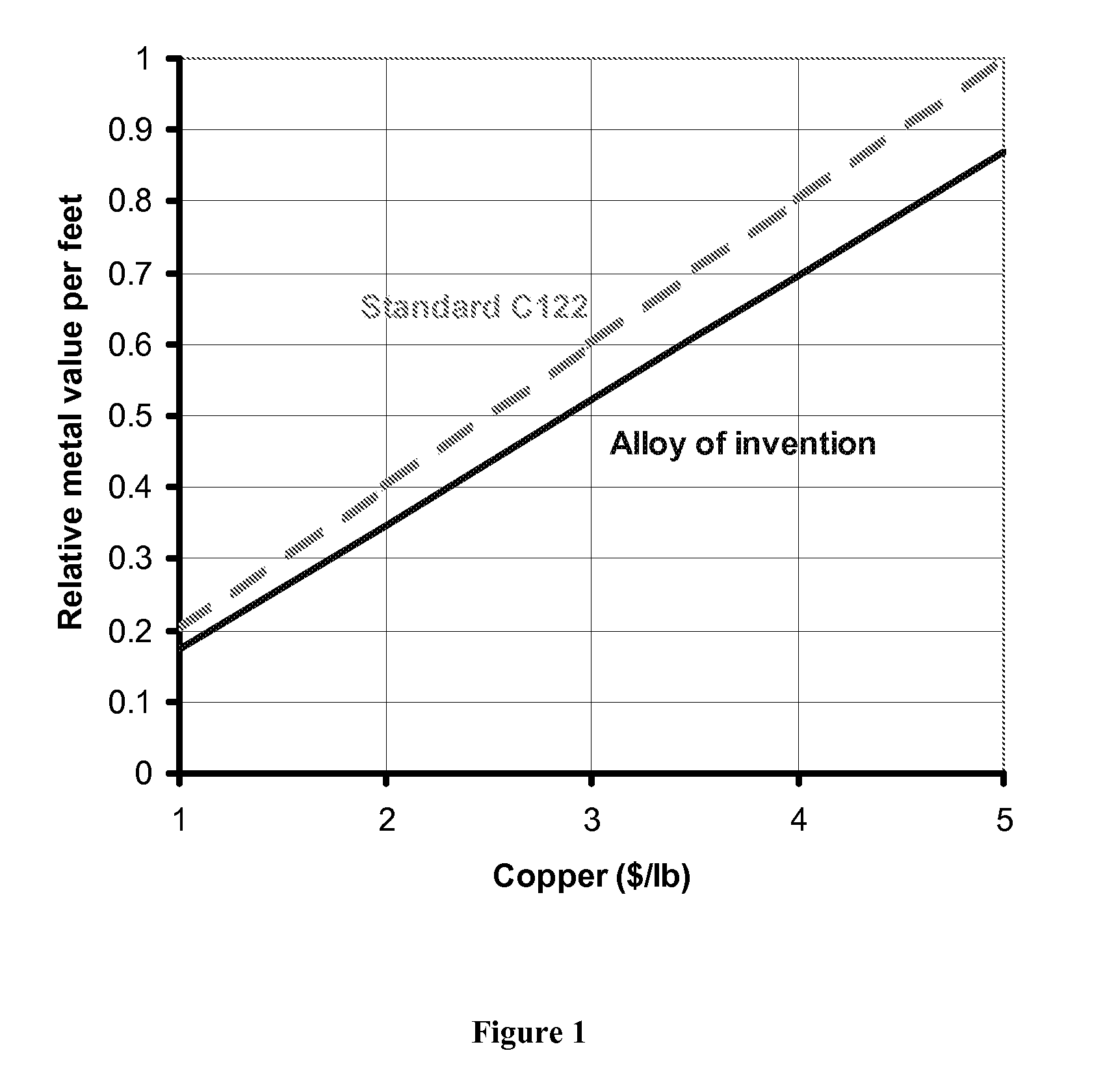

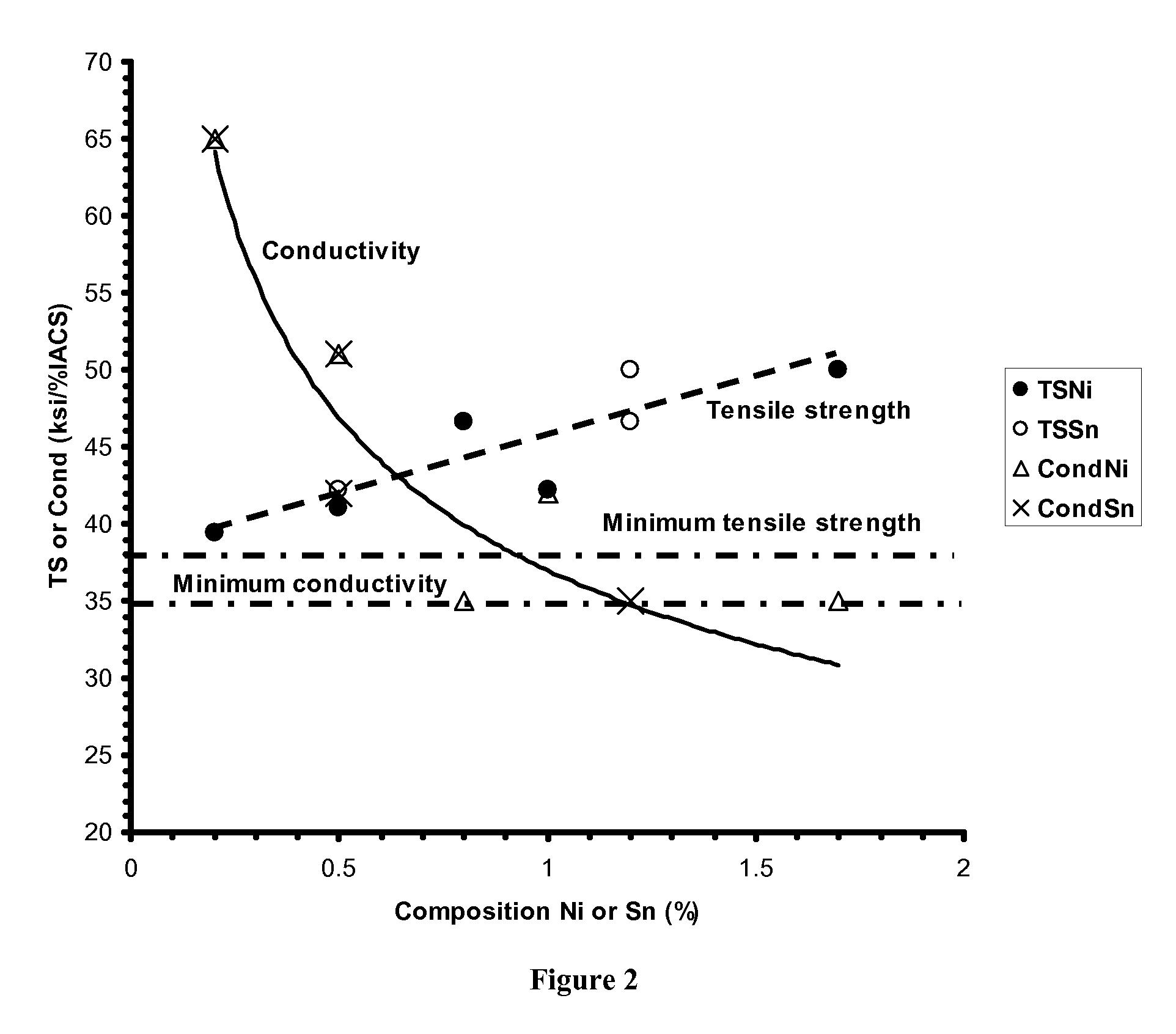

Copper Alloy for Heat Exchanger Tube

InactiveUS20110005739A1High tensile strengthEasy to processTubular elementsPlate heat exchangerHigh pressure

An alloy comprising copper, nickel, tin and, optionally, phosphorus which can be used in, for example, a copper alloy tube for heat exchangers that provides excellent fracture strength and processability for reducing the weight of the tube and for use in high pressure applications with cooling media such as carbon dioxide.

Owner:VIRTUS PRECISION TUBE LLC

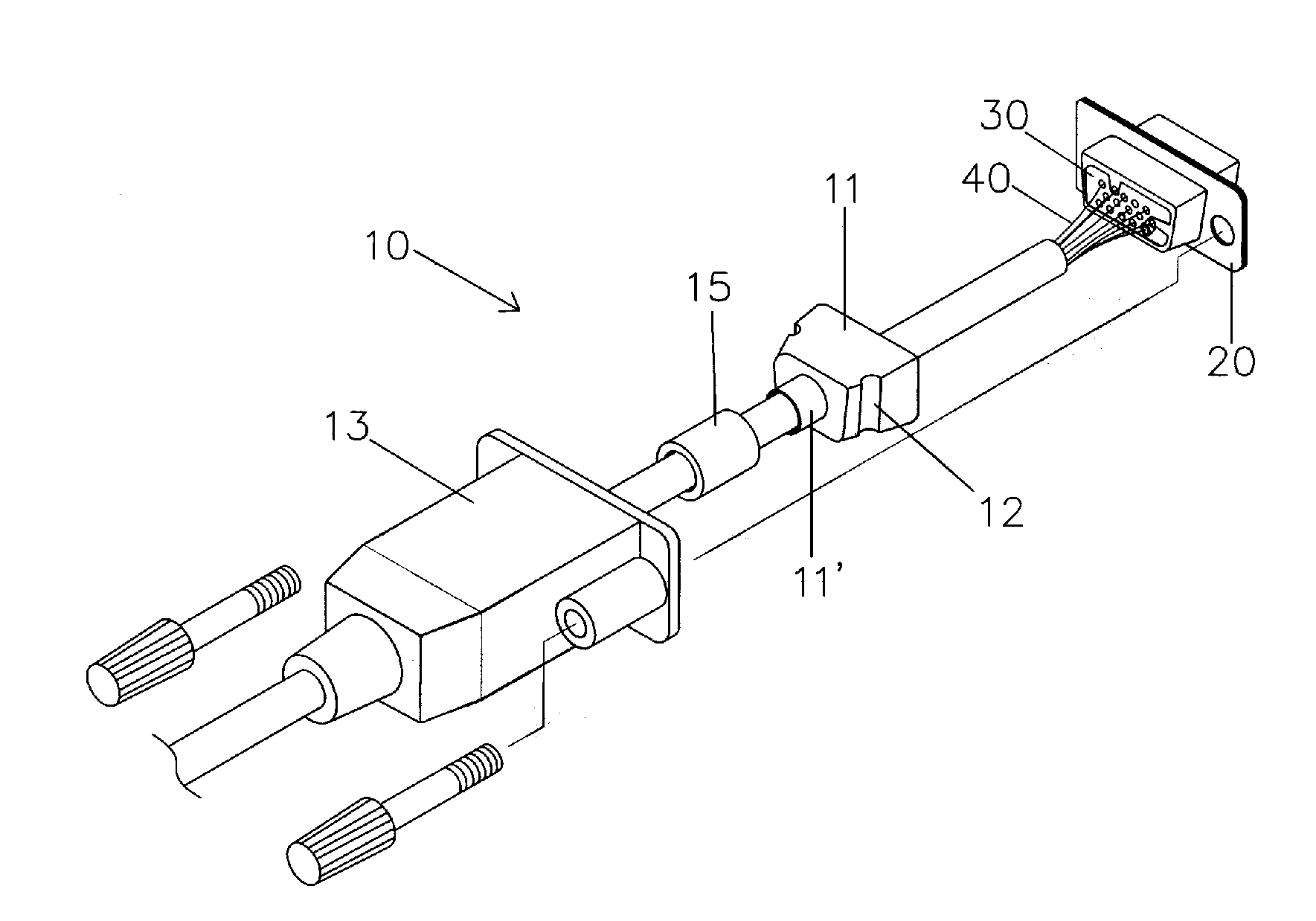

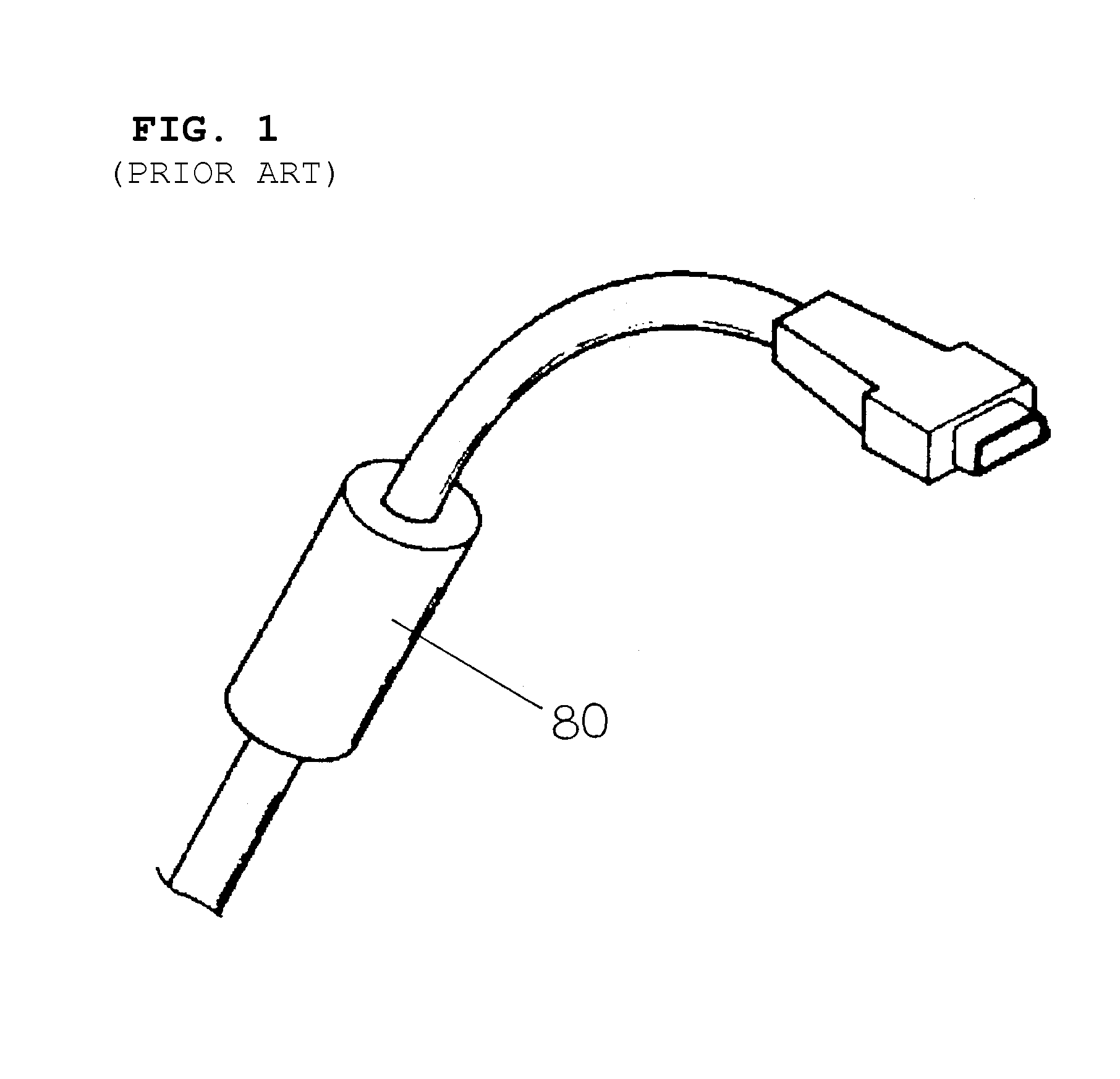

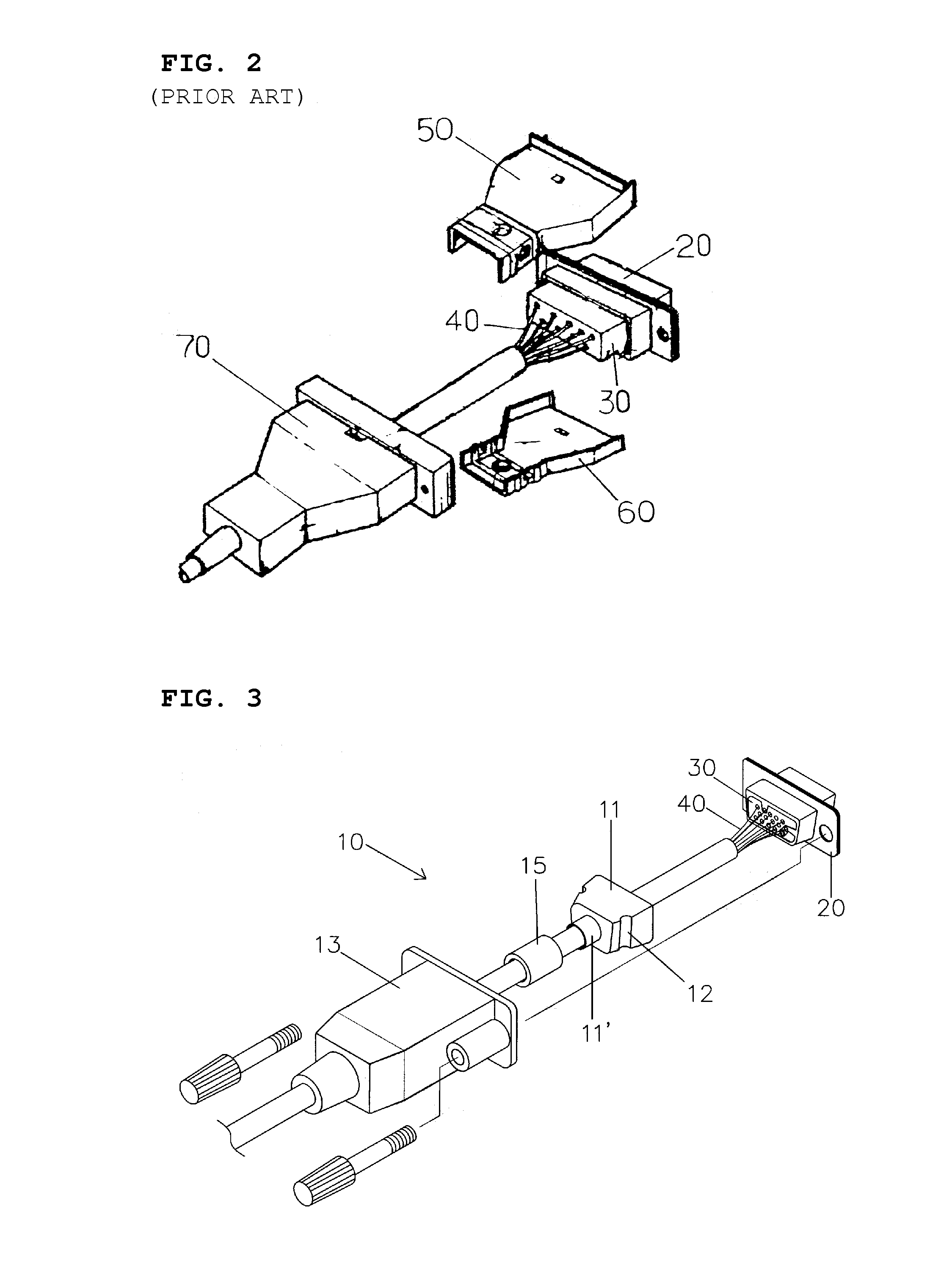

Signal cable of electronic machine

InactiveUS7588464B2Easy to assembleReduce in quantityElectrically conductive connectionsCoupling protective earth/shielding arrangementsEngineeringMachinability

The present invention relates to a signal cable of an electronic machine, in which a shield can is constructed in an integral type and a ferrite core is built inside a hood of a connector. In the signal cable of the present invention, the shield can for covering and protecting an insulator and a pin is constructed in an integral type. Therefore, since the shield can has no seamed portion, a shielding effect thereof is excellent, and further the number of unnecessary and complicated processes is considerably reduced. In addition, as the cylindrical ferrite core is built inside the hood of the connector of the signal cable, the process of attaching the ferrite core to the cable is omitted, so that the workability is enhanced, and an effect of blocking electromagnetic waves is also excellent.

Owner:KIM MI KYONG +1

Printed wiring board and method for producing the same

InactiveUS20050258522A1Satisfactory in adhesionSatisfactory in dielectric constantInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorPolyolefin

The present invention has for its object to provide a multilayer printed circuit board which is very satisfactory in facture toughness, dielectric constant, adhesion and processability, among other characteristics. The present invention is directed to a multilayer printed circuit board comprising a substrate board, a resin insulating layer formed on said board and a conductor circuit constructed on said resin insulating layer, wherein said resin insulating layer comprises a polyolefin resin.

Owner:IBIDEN CO LTD

Low-dielectric-constant glass fiber and glass fiber fabric made thereof

InactiveUS20030054936A1Maintain good propertiesImprove meltabilityWoven fabricsCircuit susbtrate materialsProduction rateTO-18

Disclosed are a low-dielectric-constant glass fiber having a glass composition comprising, by weight %, 50 to 60% of SiO2, 10 to 18% of Al2O3, 14% to less than 20% of B2O3, 1% to less than 6% of MgO, 2 to 5% of CaO, 0.5 to 5% of TiO2, 0 to 0.3% of Li2O, 0 to 0.3% of Na2O, 0 to 0.5% of K2O and 0 to 2% of F2, the content of MgO+CaO being 4 to 11% and the content of Li2O+Na2O+K2O being 0 to 0.6%, and a glass fiber fabric made of the low-dielectric-constant glass fiber. The glass fiber of the present invention has a low dielectric constant and a low dielectric tangent, is excellent in productivity and workability and is also excellent in water resistance, and the glass fiber is suitable for reinforcing printed wiring boards for high-density circuits.

Owner:NITTO BOSEIKI CO LTD

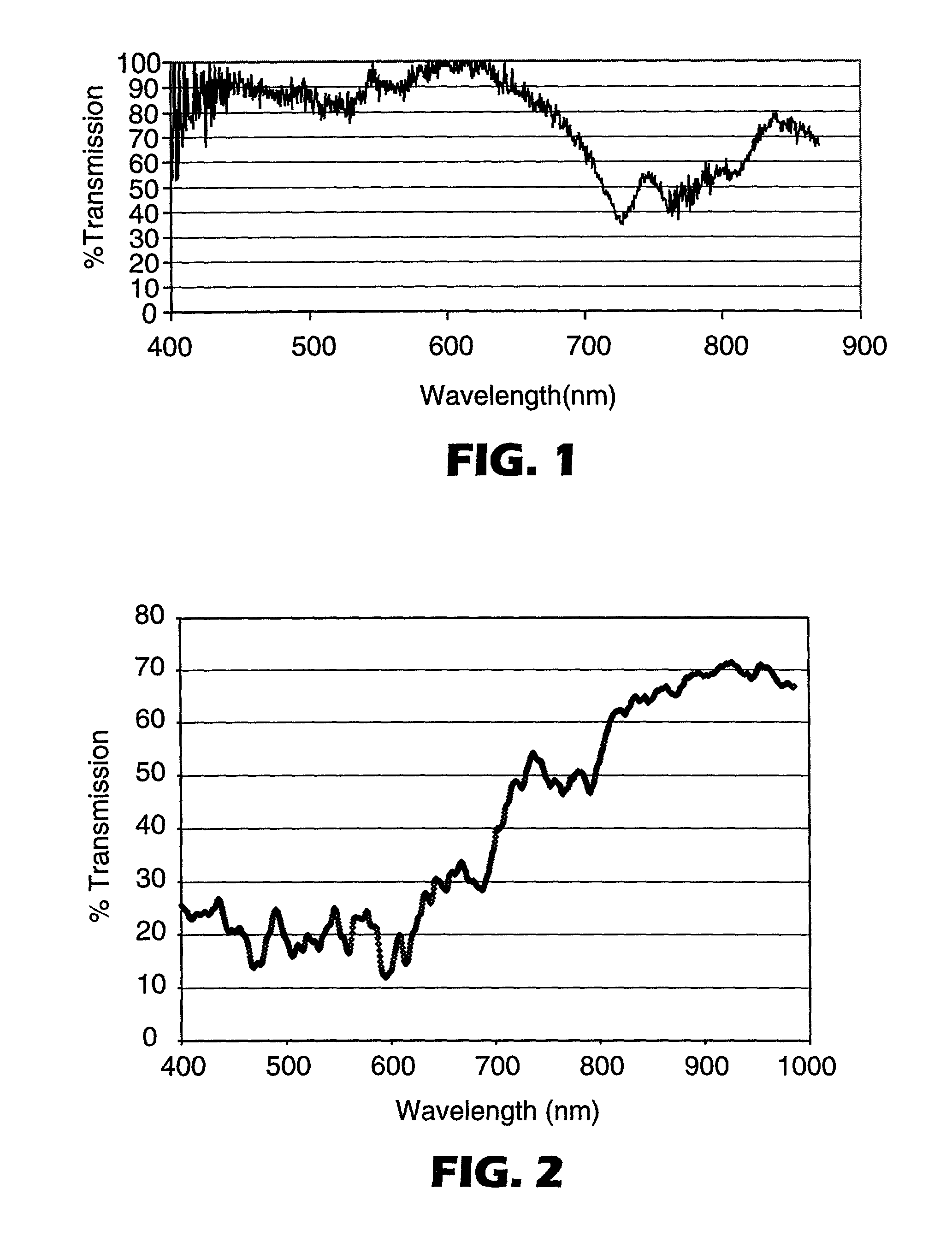

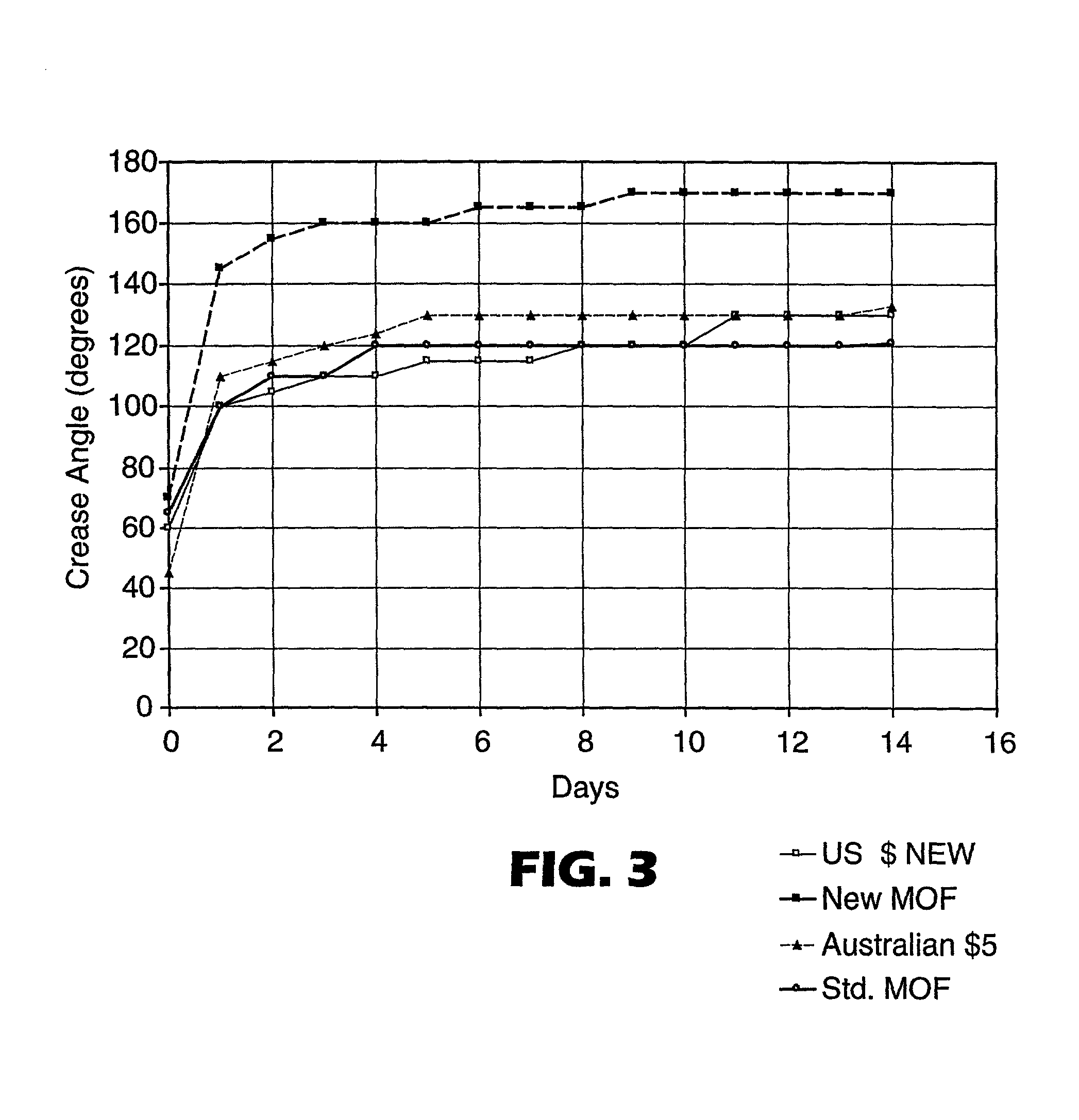

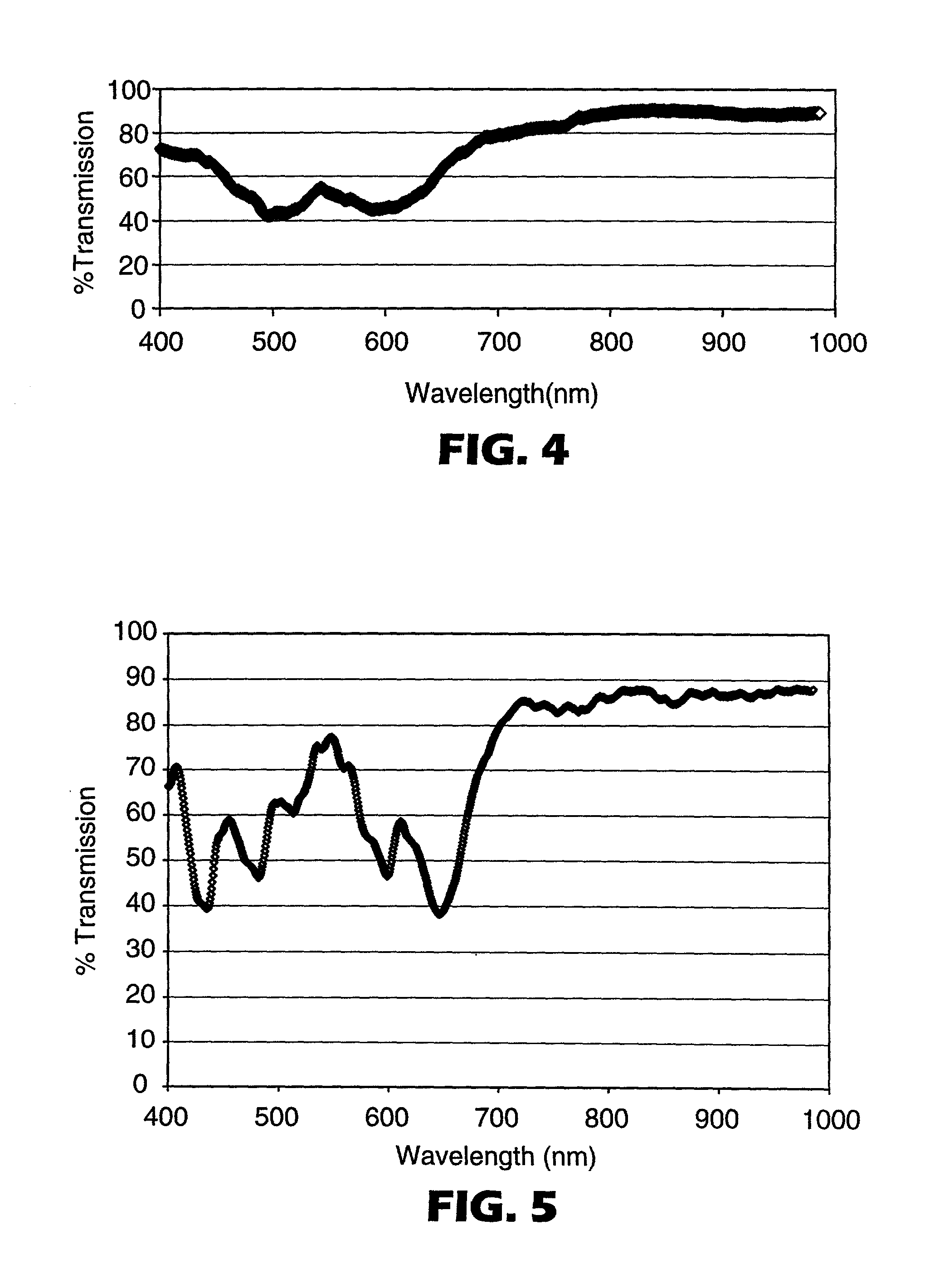

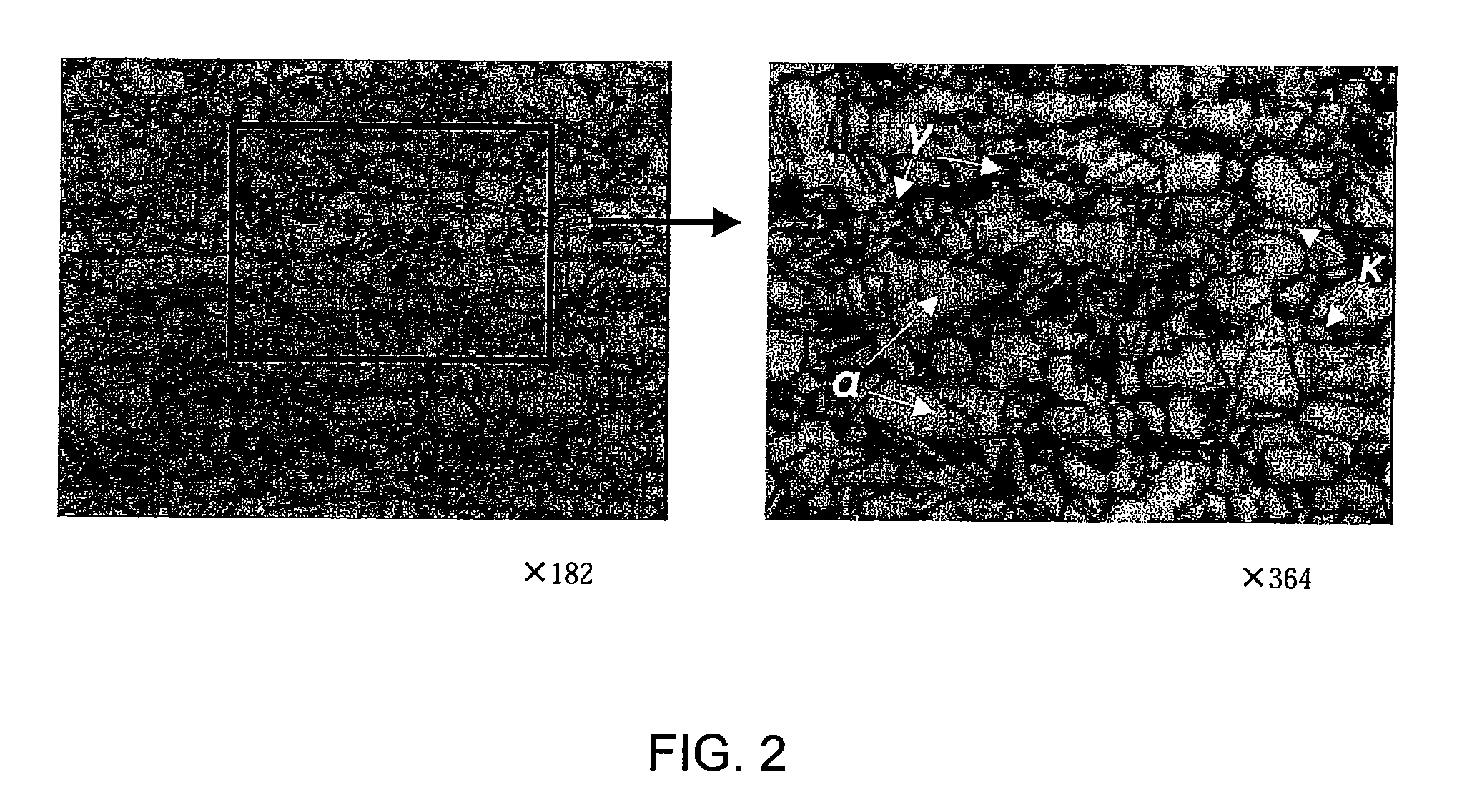

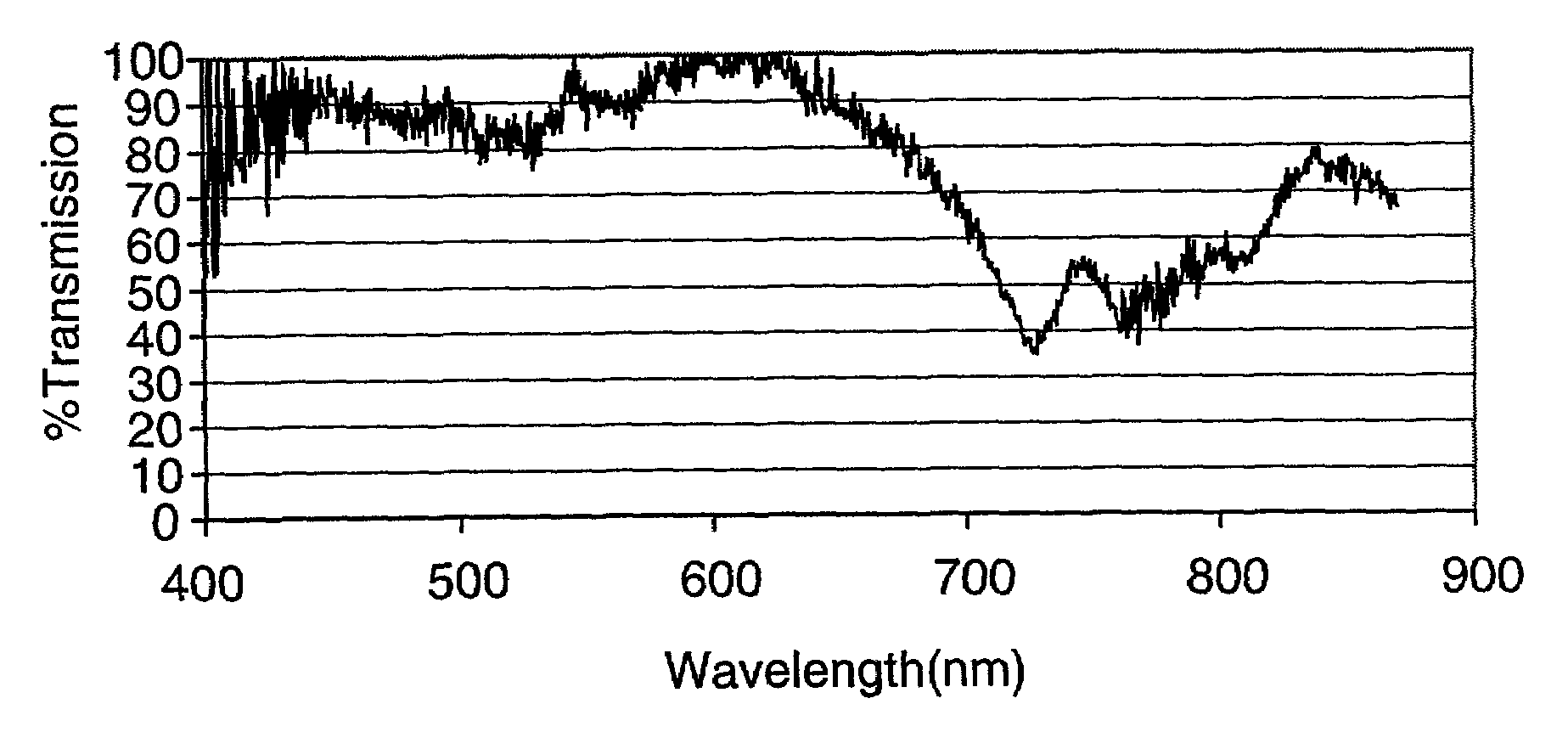

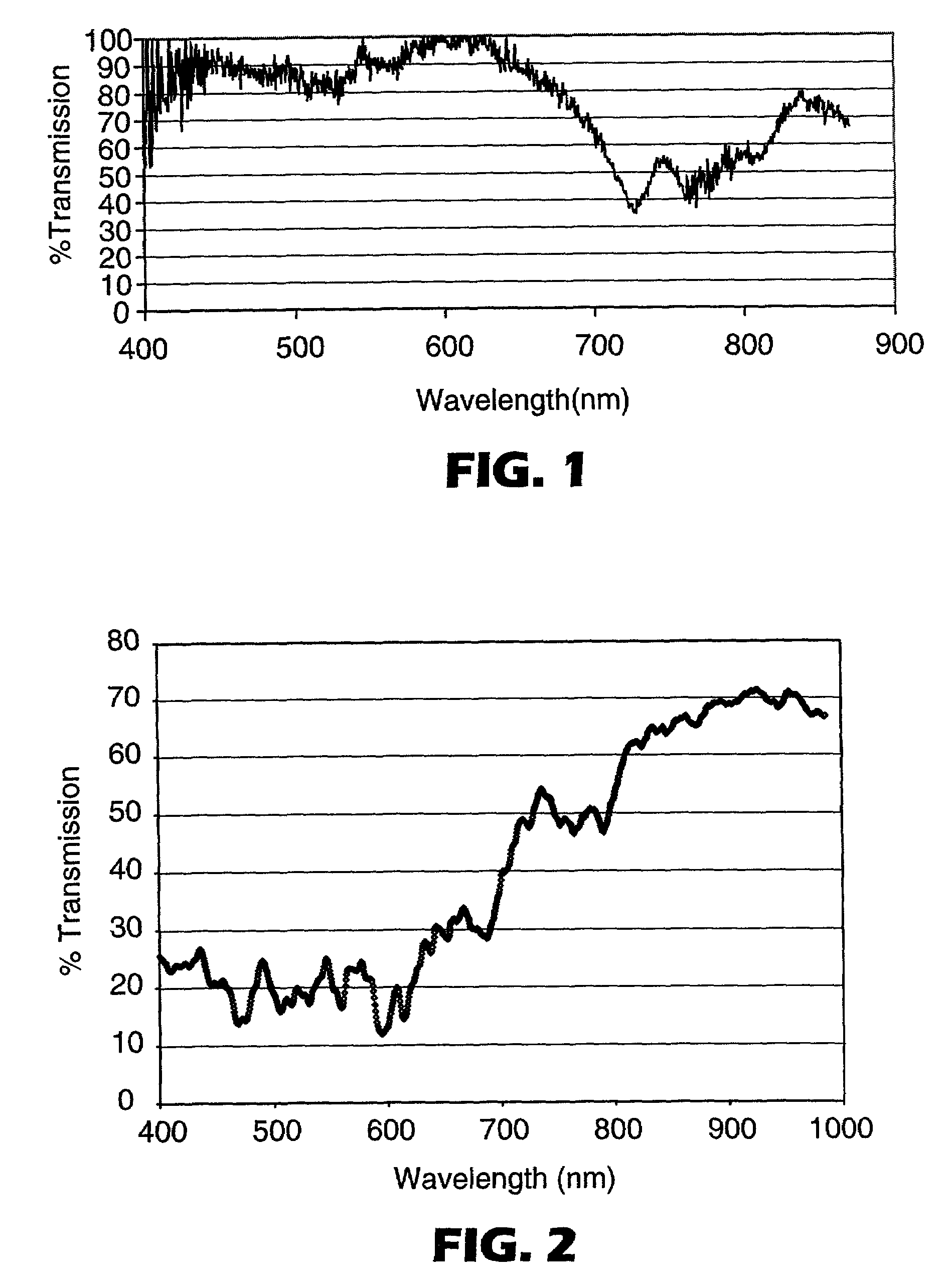

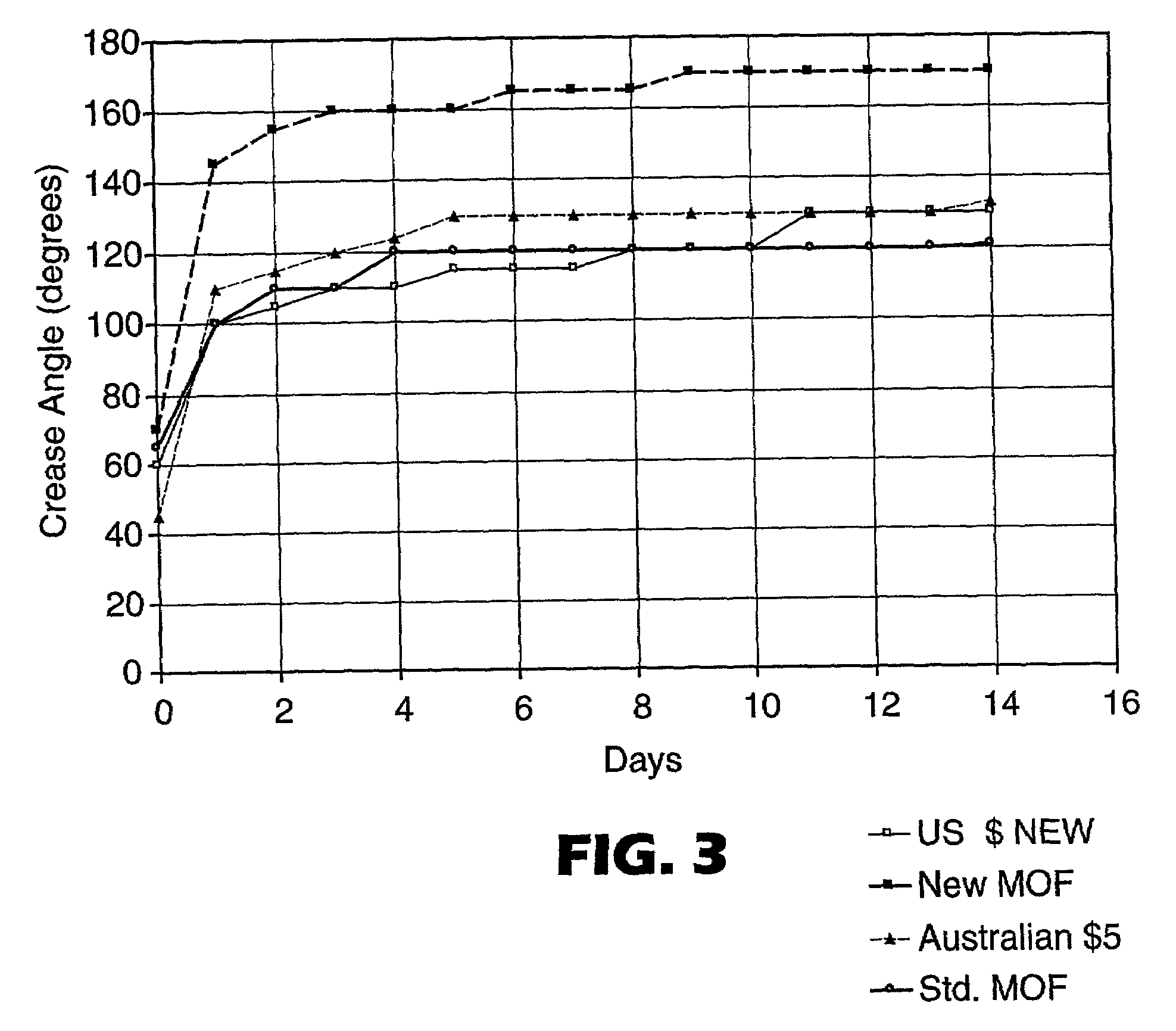

Low Tg multilayer optical films

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

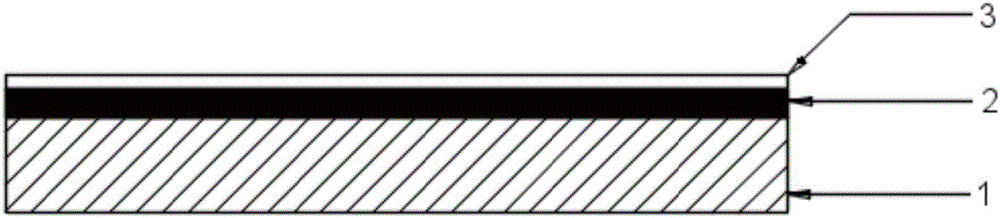

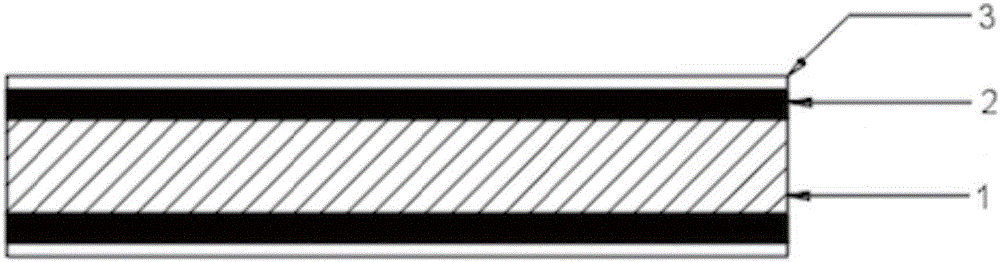

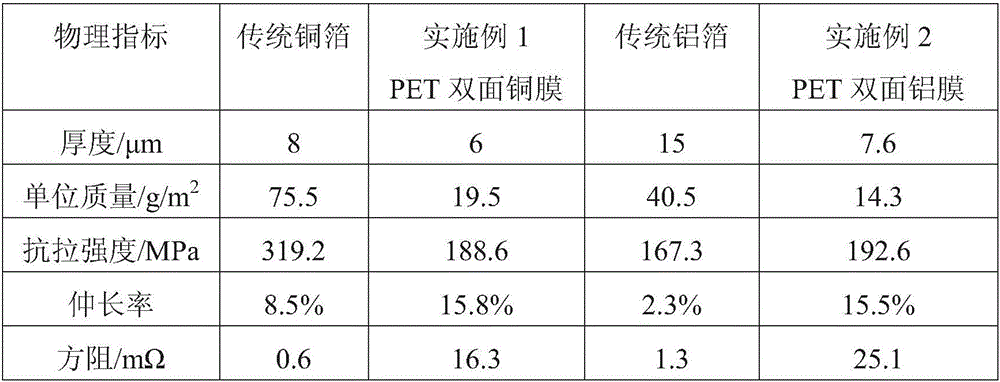

Flexible current collector for lithium battery and preparation method thereof

ActiveCN106654285AEnhanced machinabilityLow mass densityElectrode carriers/collectorsFiberPolyethylene terephthalate glycol

The invention discloses a flexible current collector for a lithium battery and a preparation method thereof. The flexible current collector comprises a flexible substrate layer, a metal conductive plated layer and a conductive anti-oxidization layer which are combined tightly in sequence, wherein the flexible substrate layer is one of polyvinyl chloride, polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polydimethylsiloxane and polyimide; the thickness of the flexible substrate layer is 1-20 microns; the metal conductive plated layer is one of Cu, Al, Ni, Au and Ag and the thickness of the metal conductive plated layer is 0.1-5 microns; and the conductive anti-oxidization layer is at least one of conductive graphite, graphene, carbon nanotubes and carbon nano-fibers, and the thickness of the conductive anti-oxidization layer is more than 0 and smaller than 1 micron. The flexible current collector disclosed by the invention has high machinability and relatively high thermal stability and anti-oxidization energy; and the quality density of a whole body is small.

Owner:ZHEJIANG UNIV

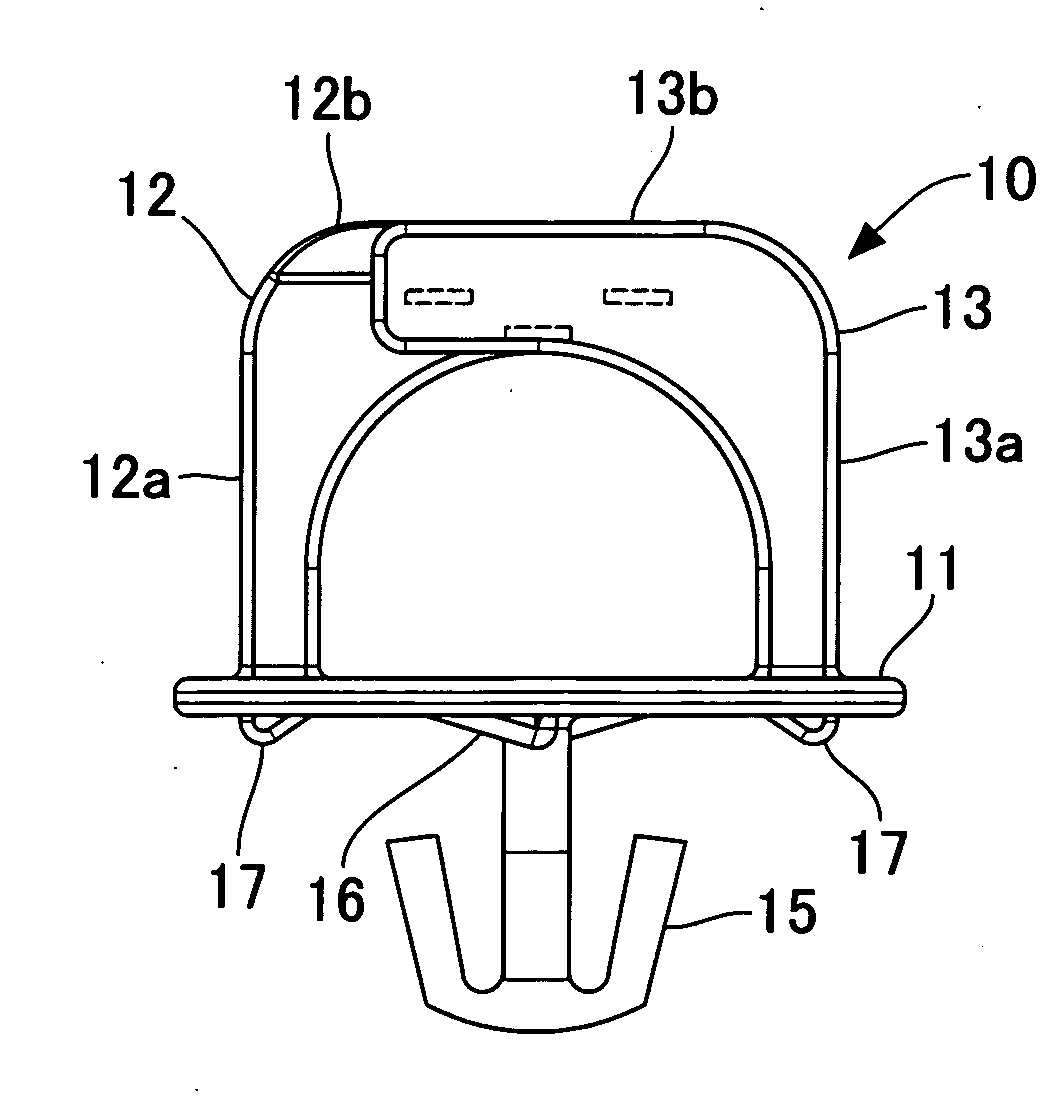

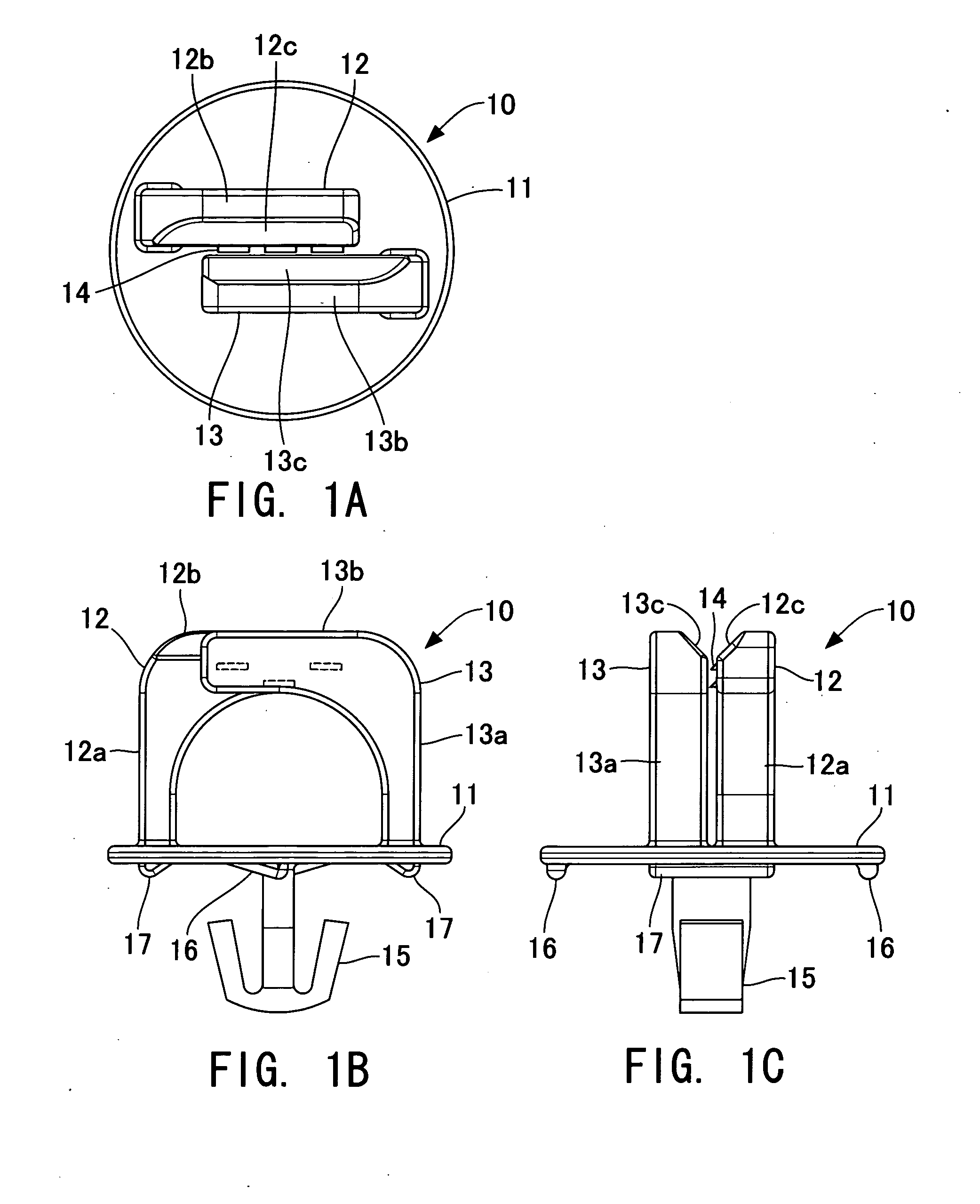

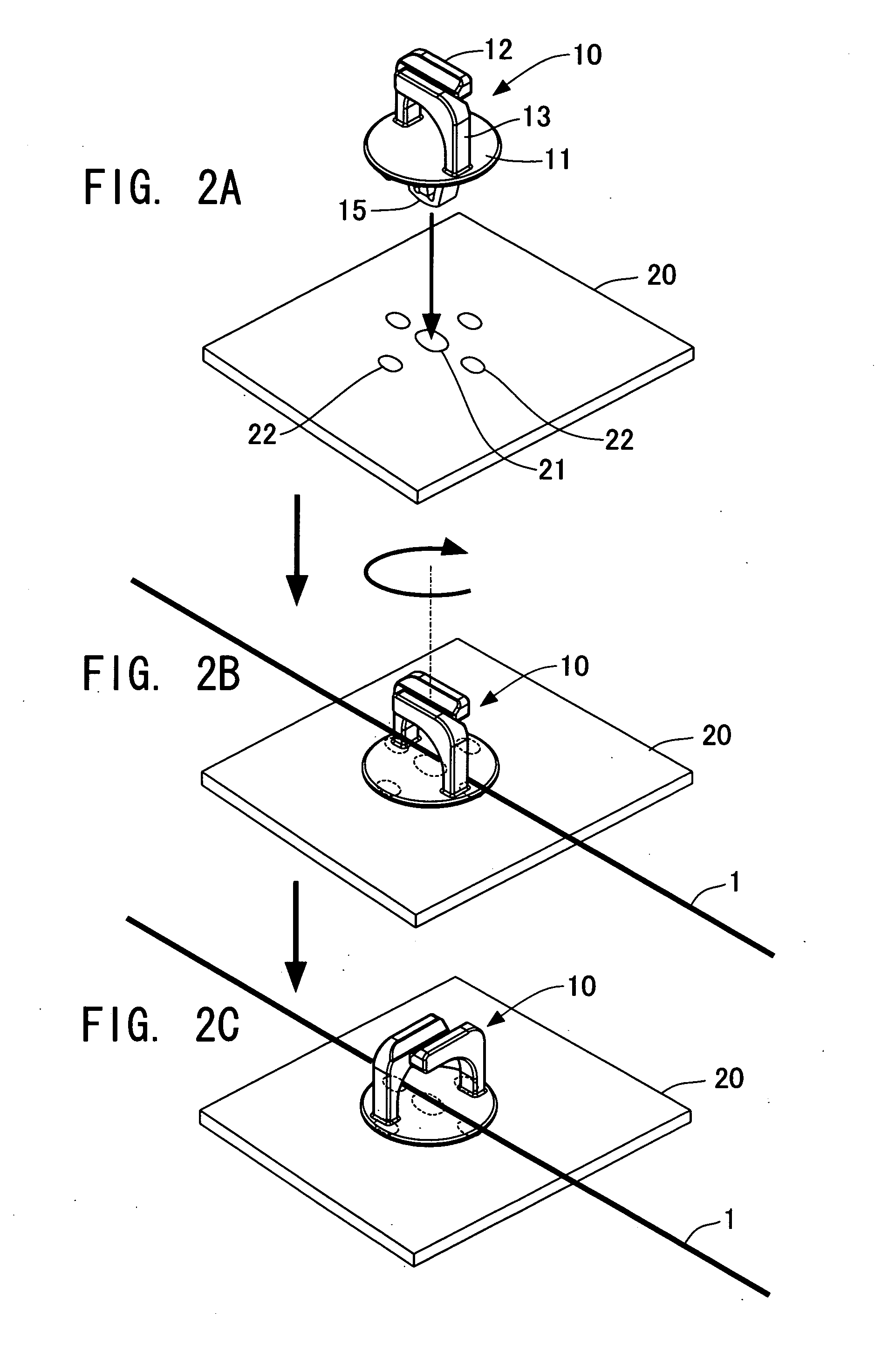

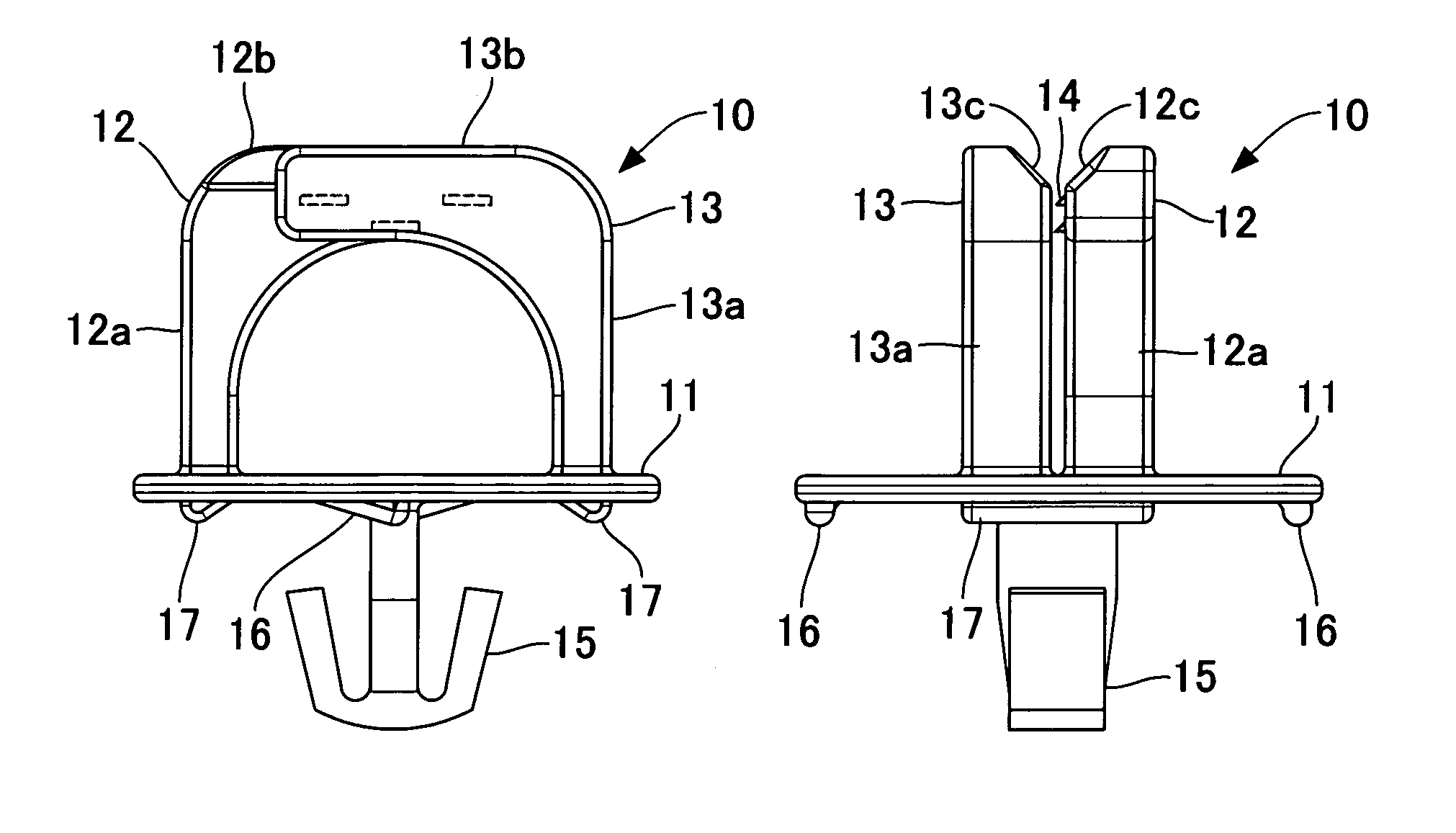

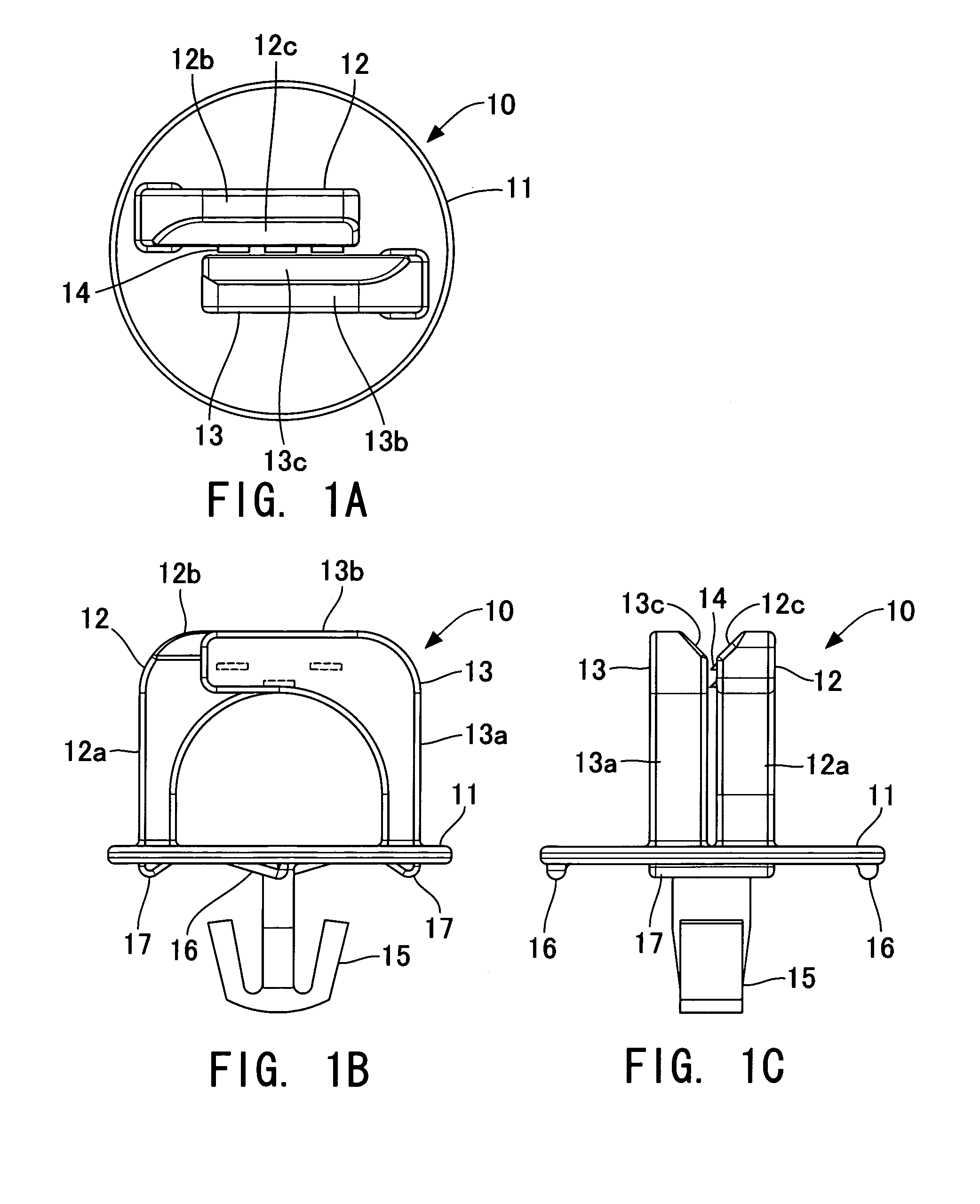

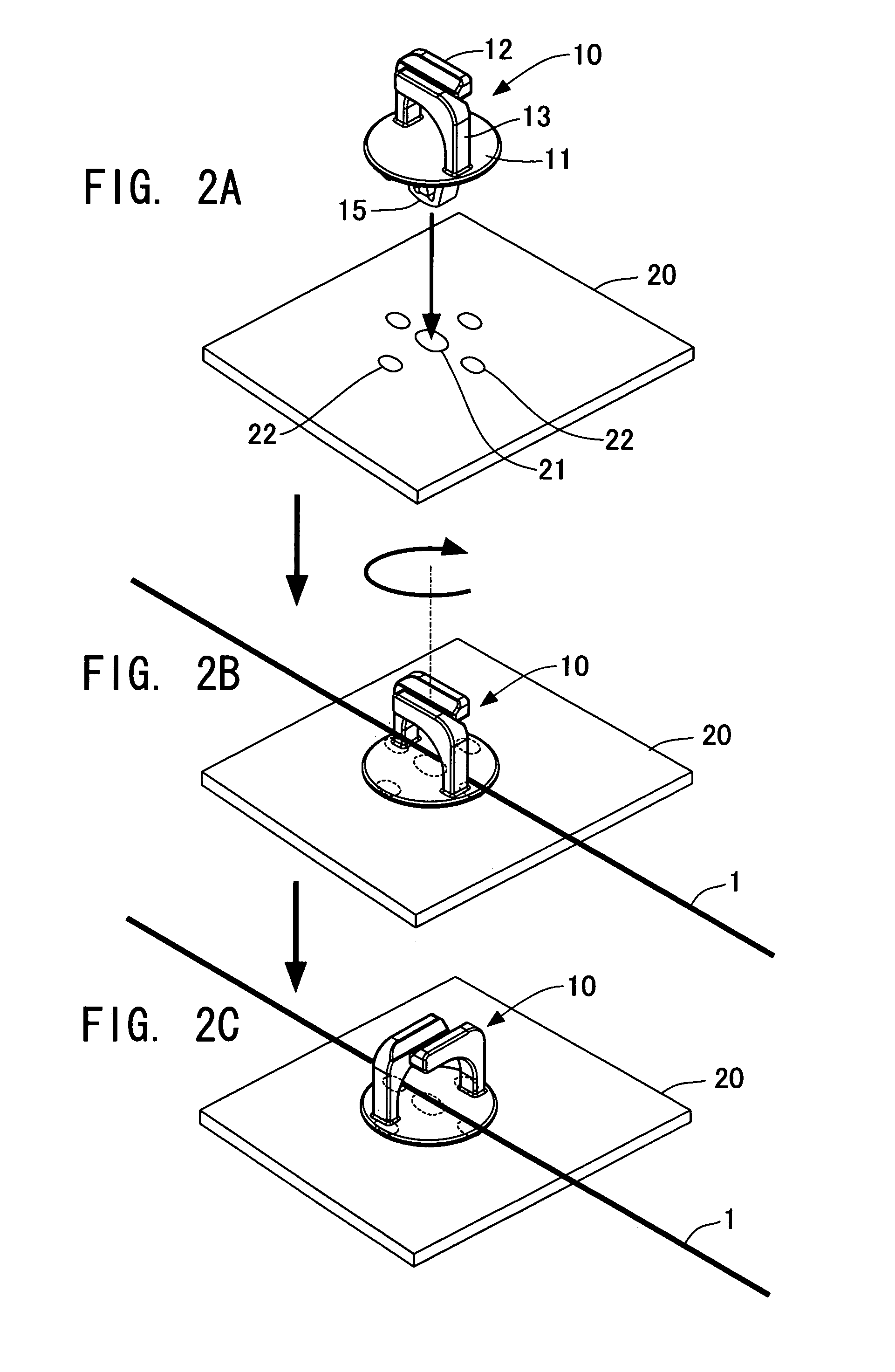

Cable clamp

InactiveUS20070221793A1Improve workabilityEasy to carryPipe supportsElectrical apparatusEngineeringCantilever

A cable clamp which is capable of preventing even a very fine cable to be treated from coming off or extending off therefrom, without any fear of the cable being damaged or broken, and is easy to carry out a clamping treatment and an extra length-bunching treatment on cables, with enhanced workability. The cable clamp includes a pair of cable-holding bodies each including a pillar portion vertically extending from the base, and a cantilever portion extending from an end of the pillar portion, remote from the base, in a direction substantially at right angles to the pillar portion. The pair of cable-holding bodies are configured such that the pillar portions are arranged to extend in opposite directions, with one of respective side surfaces of the respective cantilever portions being opposed to the other with a predetermined space therebetween.

Owner:FUJITSU LTD

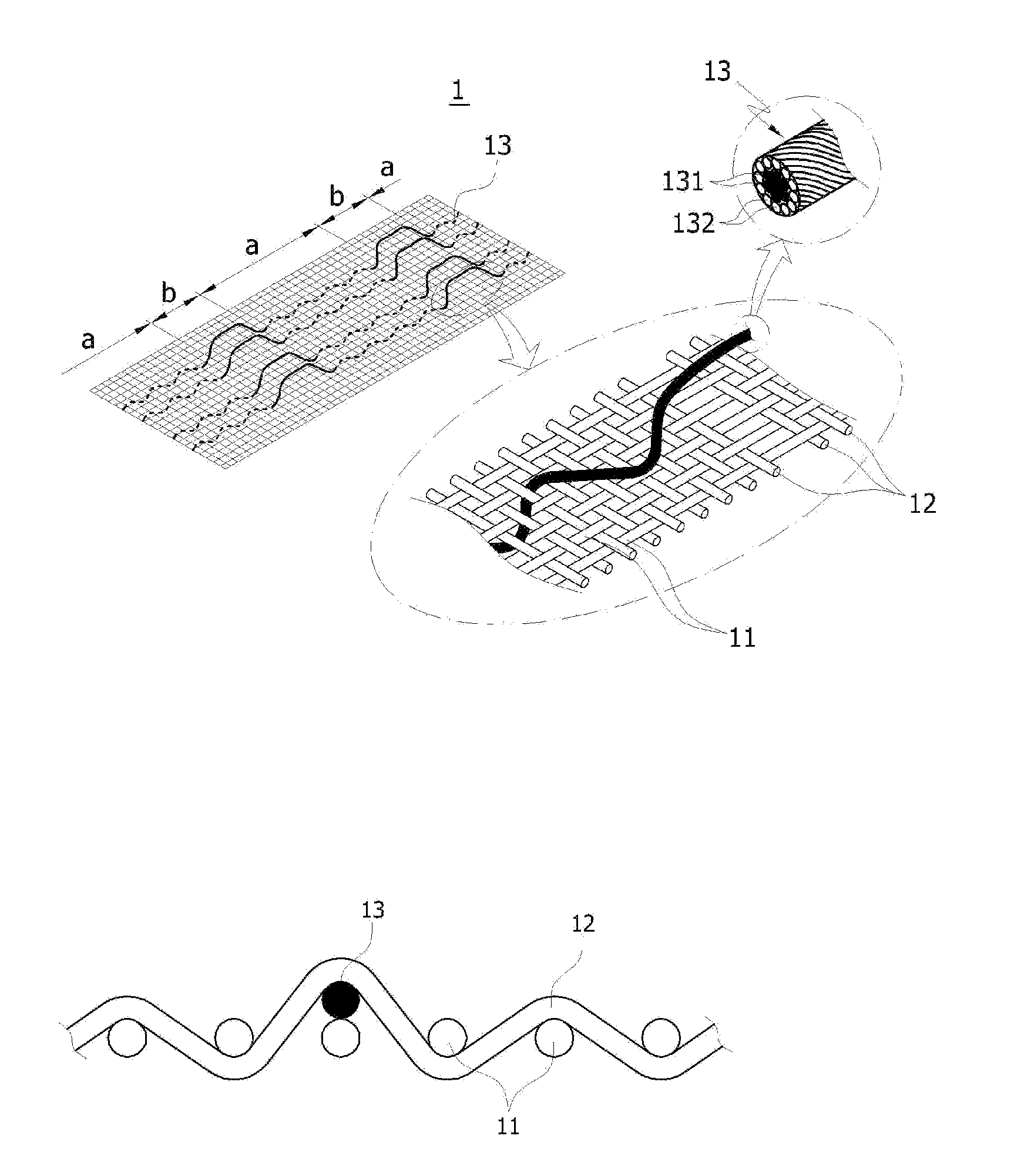

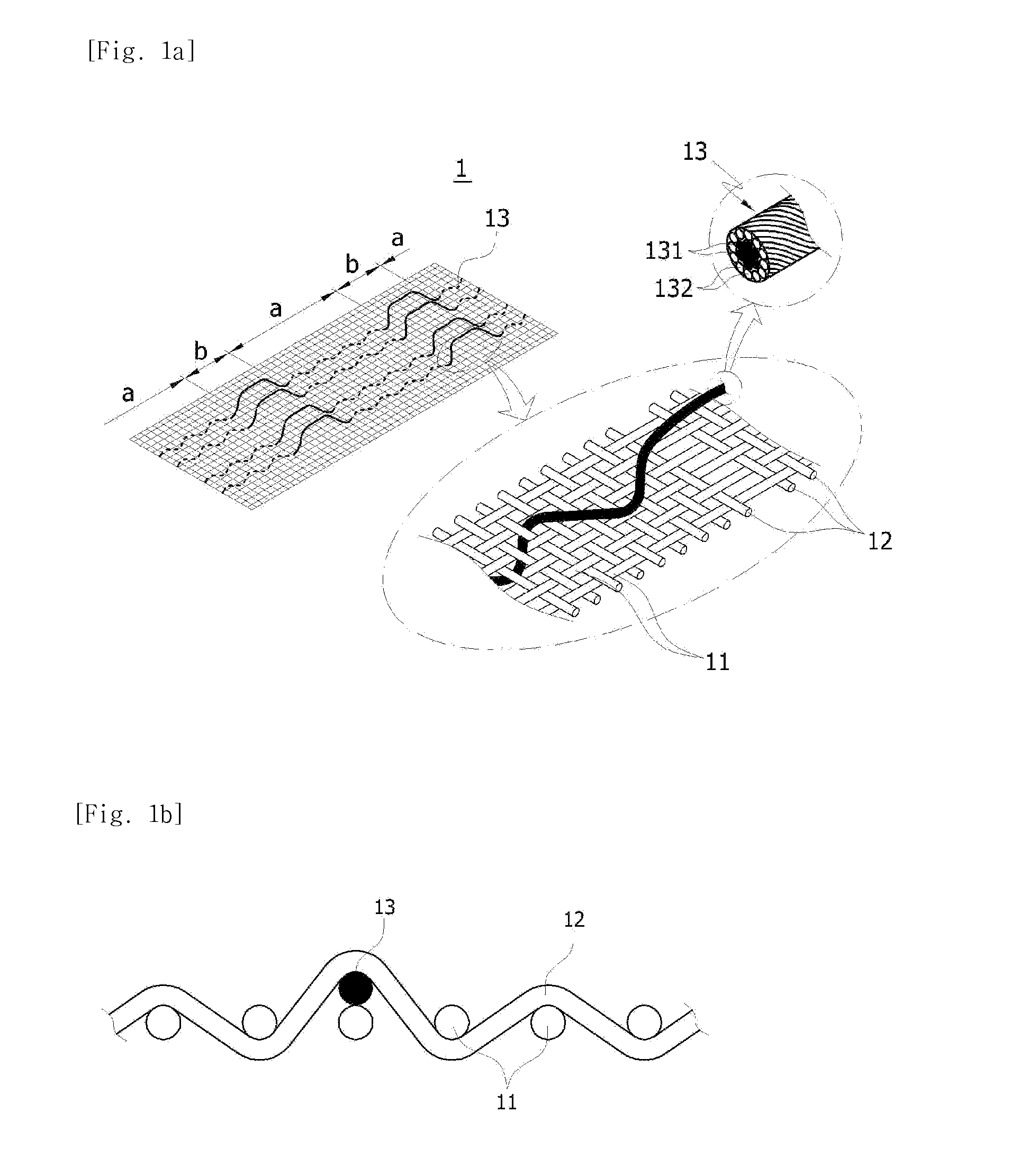

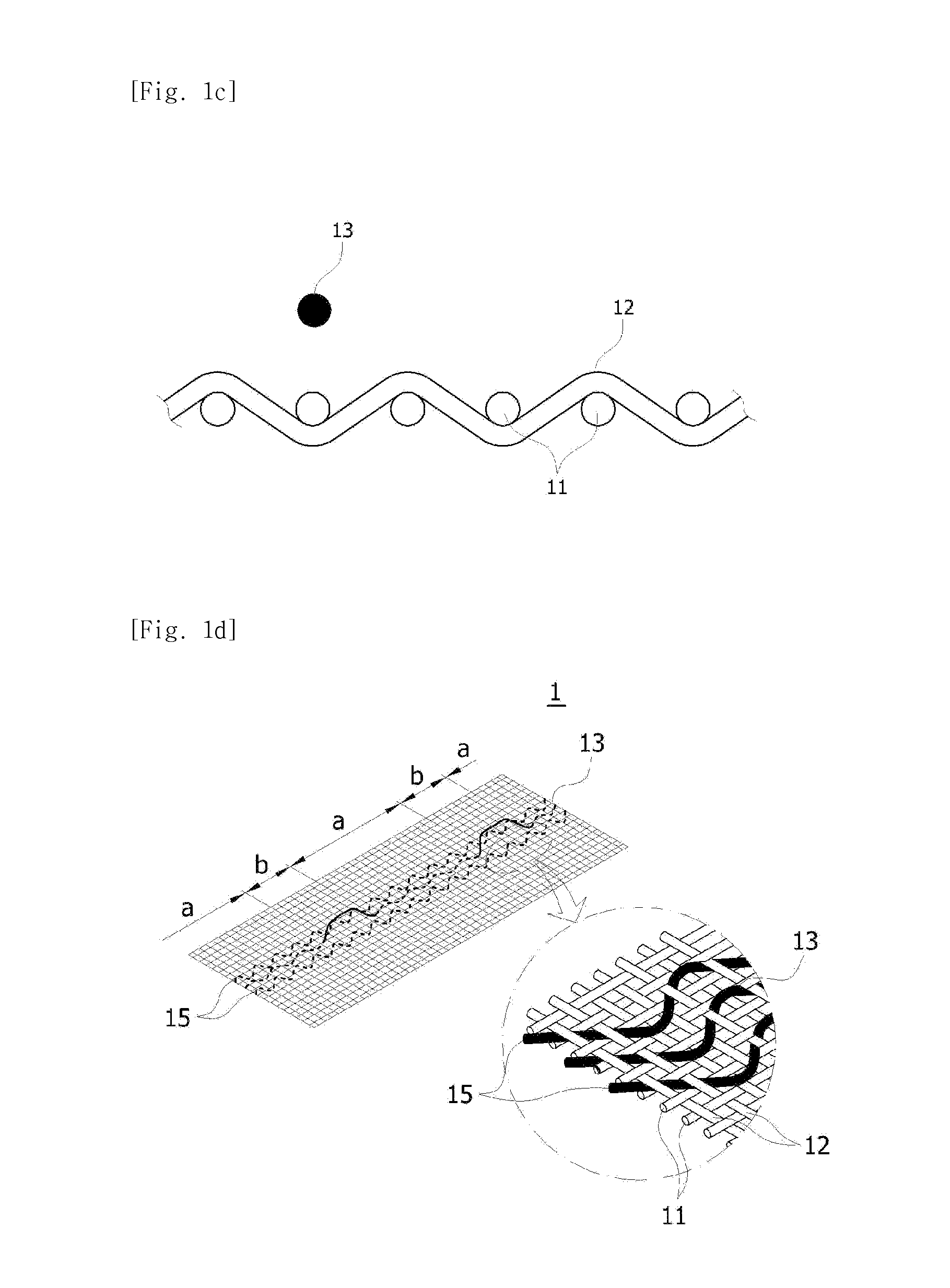

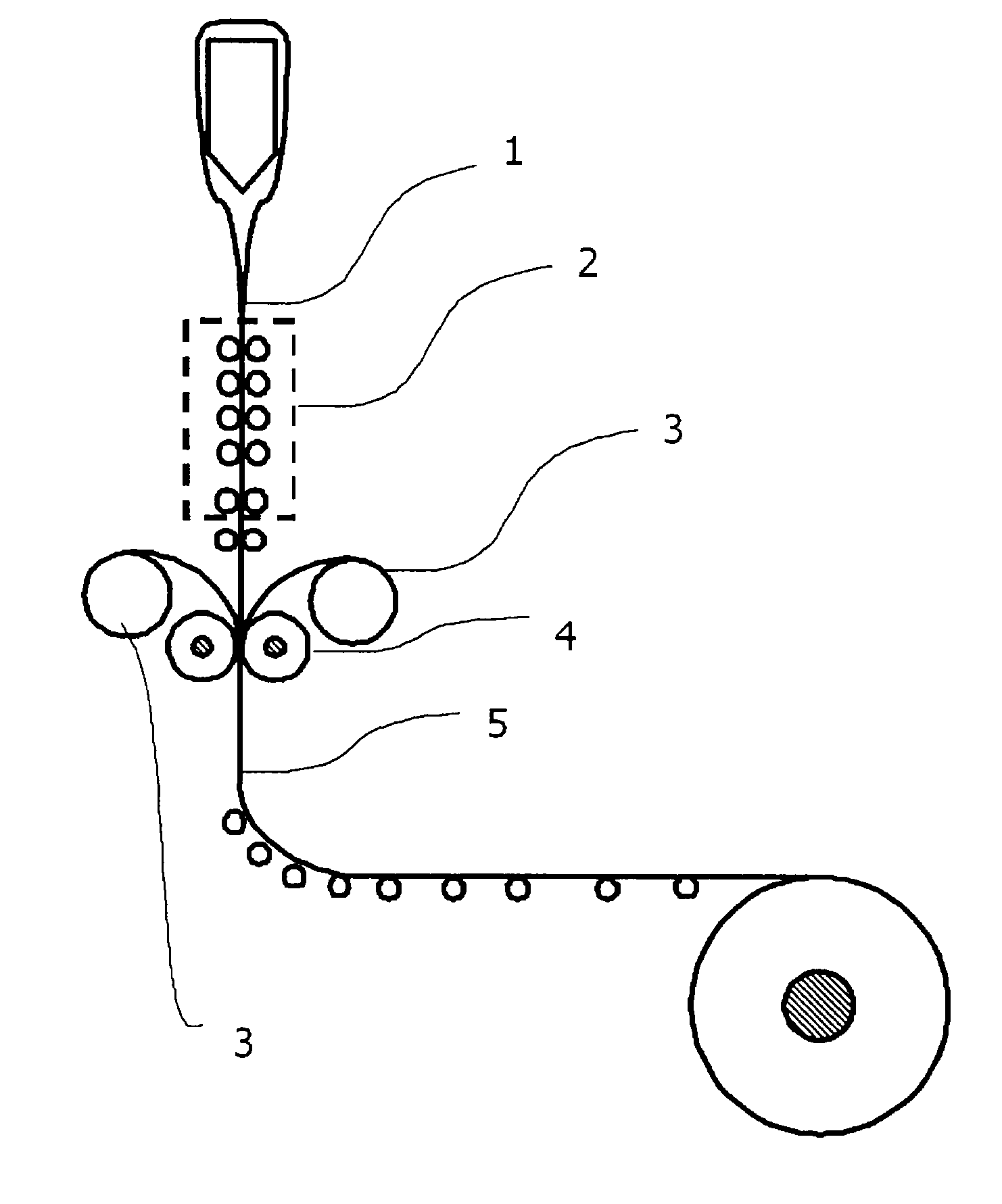

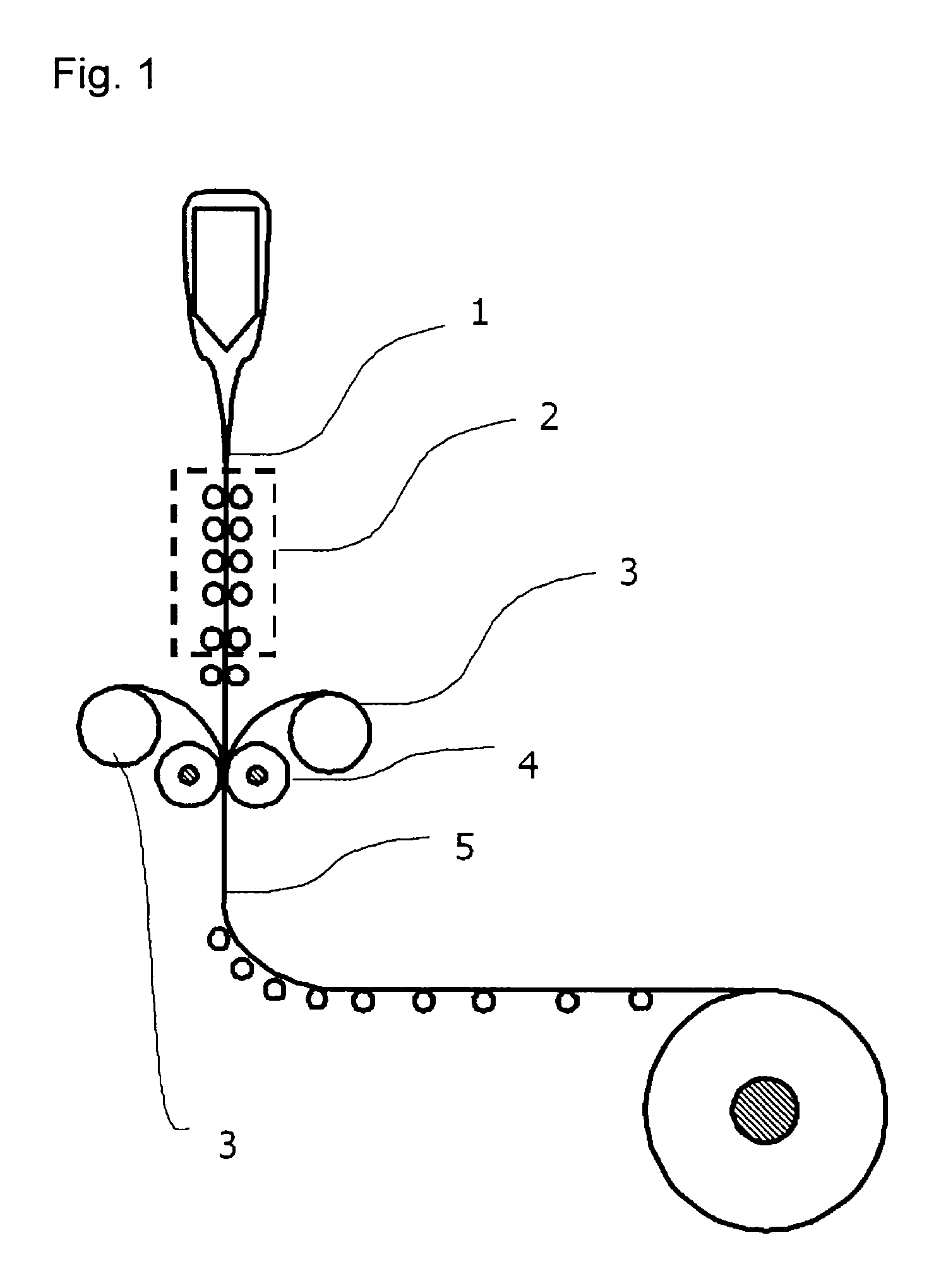

Electrically conductive fabric and manufacturing method and apparatus thereof

InactiveUS20130102217A1Improve workabilityIncrease productivityLoomsWarp knittingComputer moduleEngineering

The present invention discloses to relates to an electrically conductive fabric, and a manufacturing method and an apparatus thereof, and more specifically to an electrically conductive fabric, and a manufacturing method and an apparatus thereof, wherein part of electrically conductive wire woven together into fabric is selectively exposed to the outside of the fabric to perform the tying of electrically conductive wires and the connection of various elements and modules quickly and conveniently, so that workability and productivity can be improved.

Owner:SILVERAY CO LTD

Wood plastic composite material and its preparation method and application

A wood-plastics composition is prepared from used or waste plastics, wooden fibres for modifying plastics, and resin compatibilizer through fusing and proportionally mixing. Said resin compatibilizer is prepared from EVA, acrylic acid or acrylate and polyvinyl chloride through mixing. Its advantages are high strength toughness, and improved machinability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Leadless easy cutted brass ally material and its manufacturing method

An easily cutted lead-free brass alloy is prepared from Cu (60-62 wt.%), Bi (0.5-2.2), Al (0.01-0.1), Sn (0.5-1.6), P (0.04-0.15) and Zn (rest) through heat treating at 460-600 deg.C for 30 min-4 hr, and slow cooling at speed lower than 70 deg.C / hr.

Owner:SAN ETSU METALS

Cable clamp

InactiveUS7527226B2Improve workabilityEasy to carryPipe supportsElectrical apparatusCantileverMechanical engineering

A cable clamp which is capable of preventing even a very fine cable to be treated from coming off or extending off therefrom, without any fear of the cable being damaged or broken, and is easy to carry out a clamping treatment and an extra length-bunching treatment on cables, with enhanced workability. The cable clamp includes a pair of cable-holding bodies each including a pillar portion vertically extending from the base, and a cantilever portion extending from an end of the pillar portion, remote from the base, in a direction substantially at right angles to the pillar portion. The pair of cable-holding bodies are configured such that the pillar portions are arranged to extend in opposite directions, with one of respective side surfaces of the respective cantilever portions being opposed to the other with a predetermined space therebetween.

Owner:FUJITSU LTD

Electronic control unit with electrical connector

InactiveUS6155856ALine/current collector detailsElectrically conductive connectionsElectricityElectrical connection

An electronic control unit has a connector intervening between an external load and a printed circuit board inside the unit housing including a circuit casing and a connector casing both formed integrally therewith. At least one connector terminal of the connector is provided with a buffering portion effective to absorb an external stress. This connector terminal can be accurately and precisely constrained in a housing and can provide a stabilized electrical connection with a high workability.

Owner:ADVICS CO LTD

Workable solid buoyancy material for deep sea and method for preparing same

The invention provides a deep-sea machinability solid buoyancy material and its method for preparing, in which the said solid buoyancy material includes epoxide resin; flexibilizer; curing agent; accelerating agent; dispersing agent; deflocculating agent; hollow zeeosphere and coupling agent, and the hollow zeeosphere can be ceramic and / or glass zeeosphere; the hollow of the said hollow glass zeeosphere is filled with gases or vacuum; the weigh parts of the hollow zeeosphere are: 15-90; the weigh parts of the said epoxide resin are: 82-98. The method consists of adding each component into kneader, heating to 80-100 DEG C, agitating to be even; taking-up the even mixtures into the die to consolidate, then laying them into the curing press for heating and forcing, after solidified modeling, producing the needed solid buoyancy material according to the requirement. The buoyancy material can be sawed, dug, grinded, milled and adhibitted and the standard model can be produced to various shapes according to the drawing requirement to meet the application needs.

Owner:MARINE CHEM RES INST

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

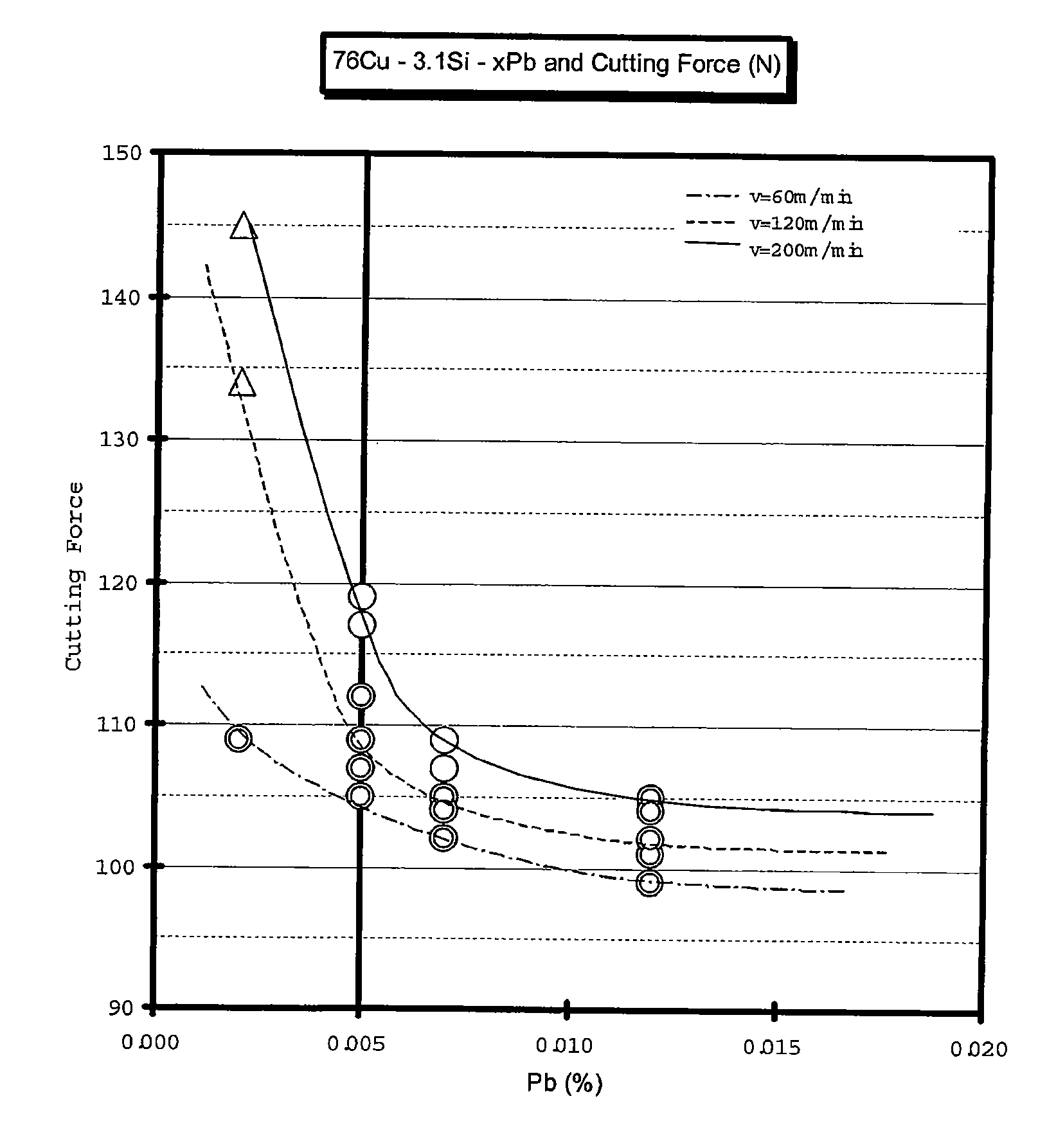

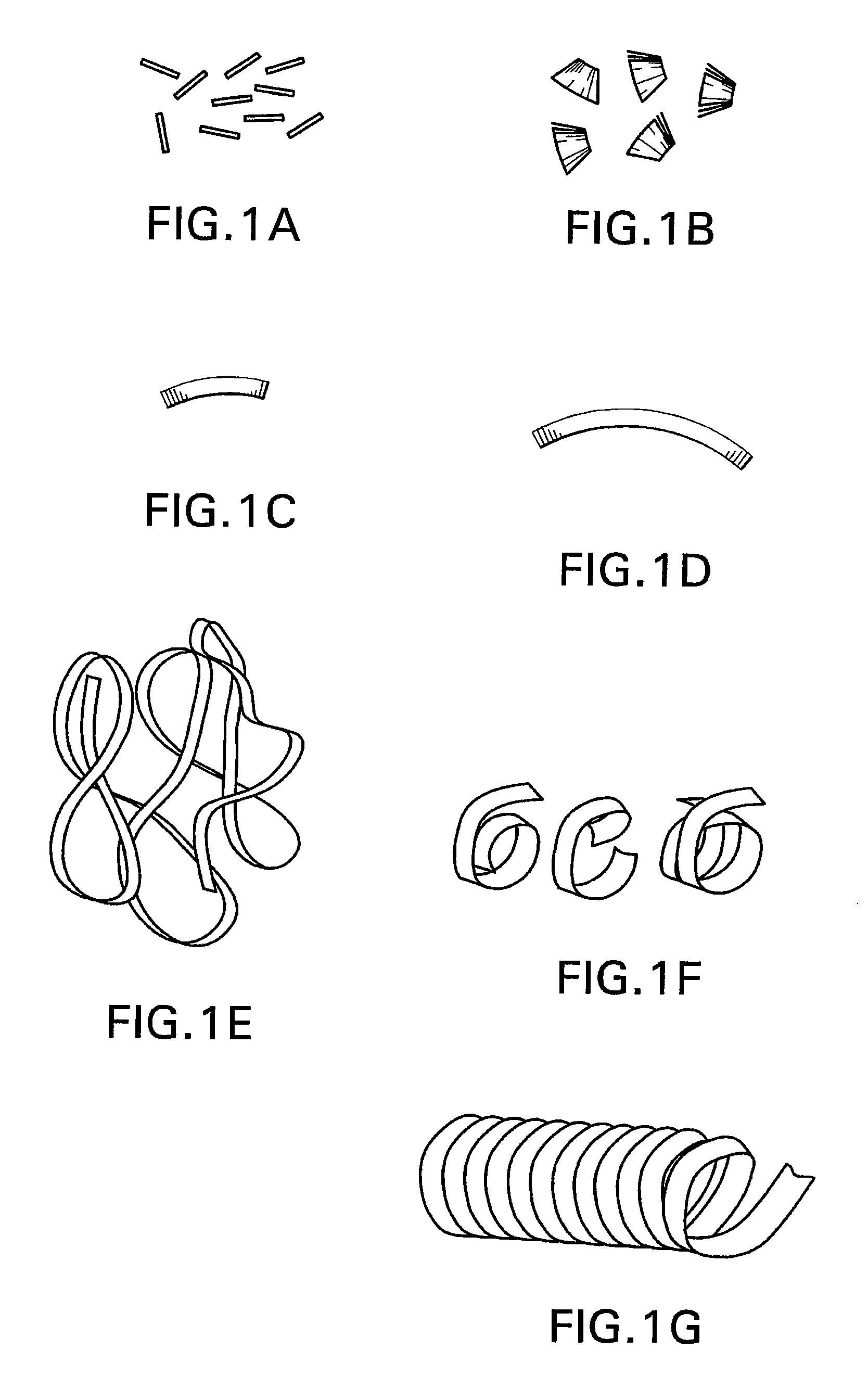

Free-cutting copper alloy containing very low lead

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 71.5 to 78.5 percent, by weight, of copper, 2.0 to 4.5 percent, by weight, of silicon, 0.005 percent up to but less than 0.02, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:SANBO SHINDO KOGYO CO LTD

Low Tg multilayer optical films

InactiveUS7052762B2Excellent crease and crumple recoveryHigh refractive indexOther printing matterLayered productsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

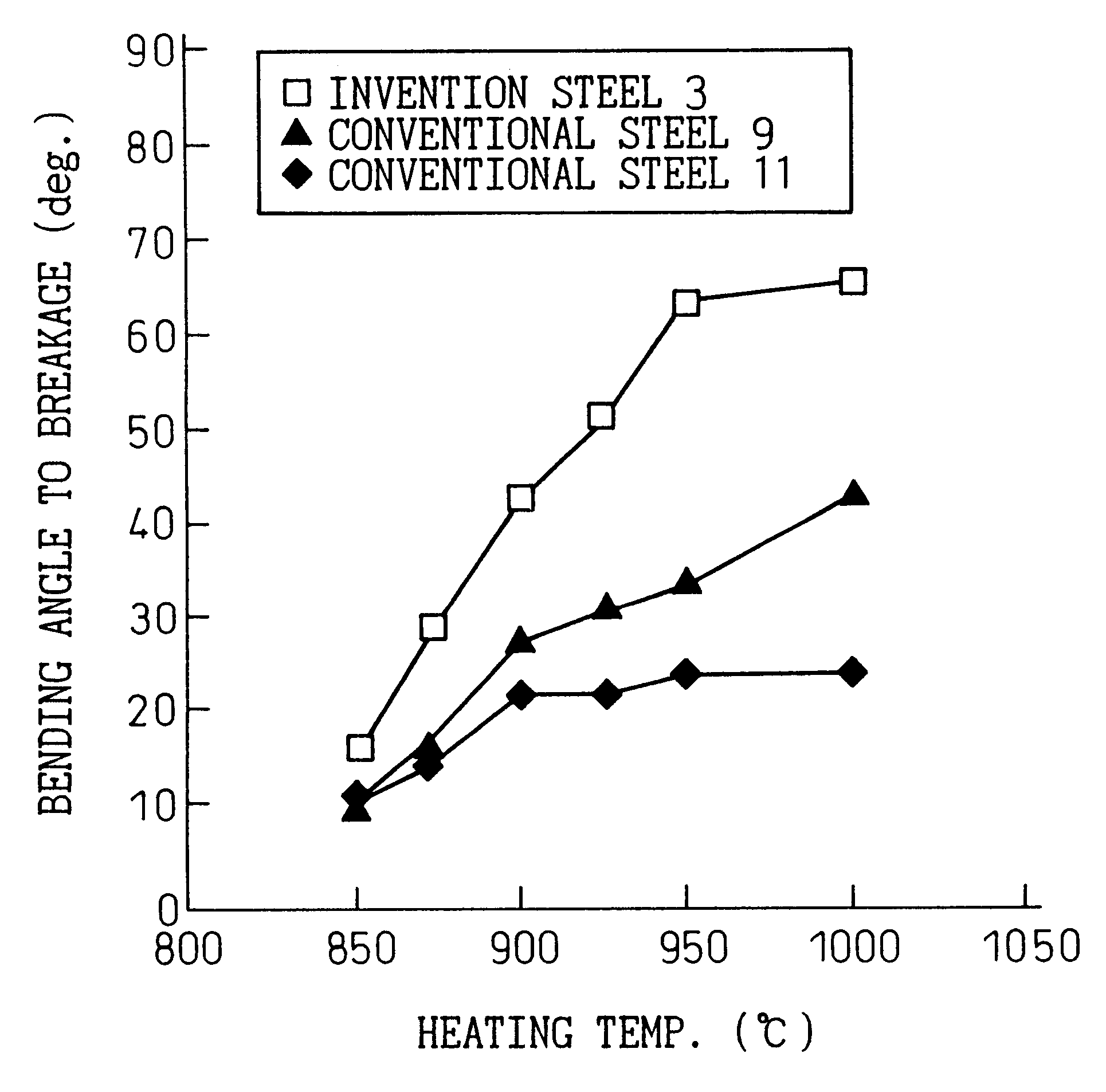

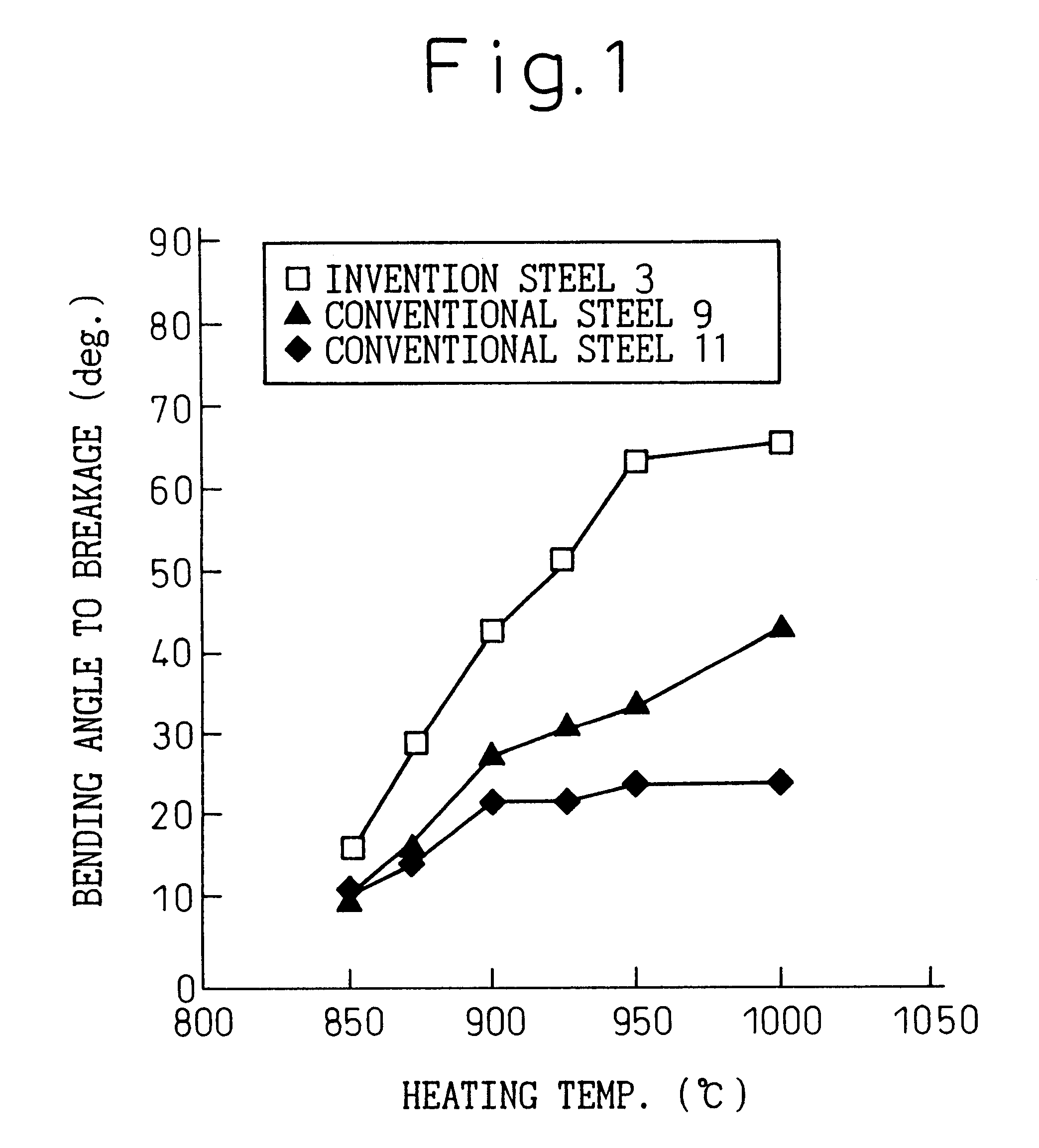

Steel wire for high-strength springs and method of producing the same

InactiveUS6338763B1Reduce contentReduce sizeFurnace typesHeat treatment furnacesNon-metallic inclusionsHigh intensity

This invention provides an oil-tempered wire having high strength (tensile strength of not less than 1960 MPa) and excellent workability and specifically provides a steel wire for high-strength springs comprising as steel components, in weight percent,the balance being Fe and unavoidable impurities, the steel wire having no nonmetallic inclusions of a size greater than 15 mum, a tensile strength of not less than 1960 MPa, and a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and not greater than 0.9 or a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and an amount of residual austenite of not greater than 6%. This invention also provides a method of producing the steel wire.

Owner:NIPPON STEEL CORP +1

Copper-base sintered sliding material excellent in slipperiness and machaniability

InactiveUS6165246AImprove machinabilityImproved sliding characteristic and machinabilityPlungersShaftsHardnessAlloy

PCT No. PCT / JP98 / 04685 Sec. 371 Date Jun. 16, 1999 Sec. 102(e) Date Jun. 16, 1999 PCT Filed Oct. 16, 1998 PCT Pub. No. WO99 / 20806 PCT Pub. Date Apr. 29, 1999In order to make the wear-resistance and machinability of the copper-based sliding material, in which such particles as AlN, Al2O3, NiB, Fe2B, SiC, TiC, WC, Si3N4, Fe3P, Fe2P and / or Fe3B are dispersed in the matrix consisting of sintered Cu or Cu alloy, the dispersion is performed such that the weight proportion and the average particle diameter of the medium-hardness particles of Hv 500 or more and 1000 or less are greater than those of the high-hardness particles having Hv 1100 or more.

Owner:TAIHO INDUSTRIES CO LTD

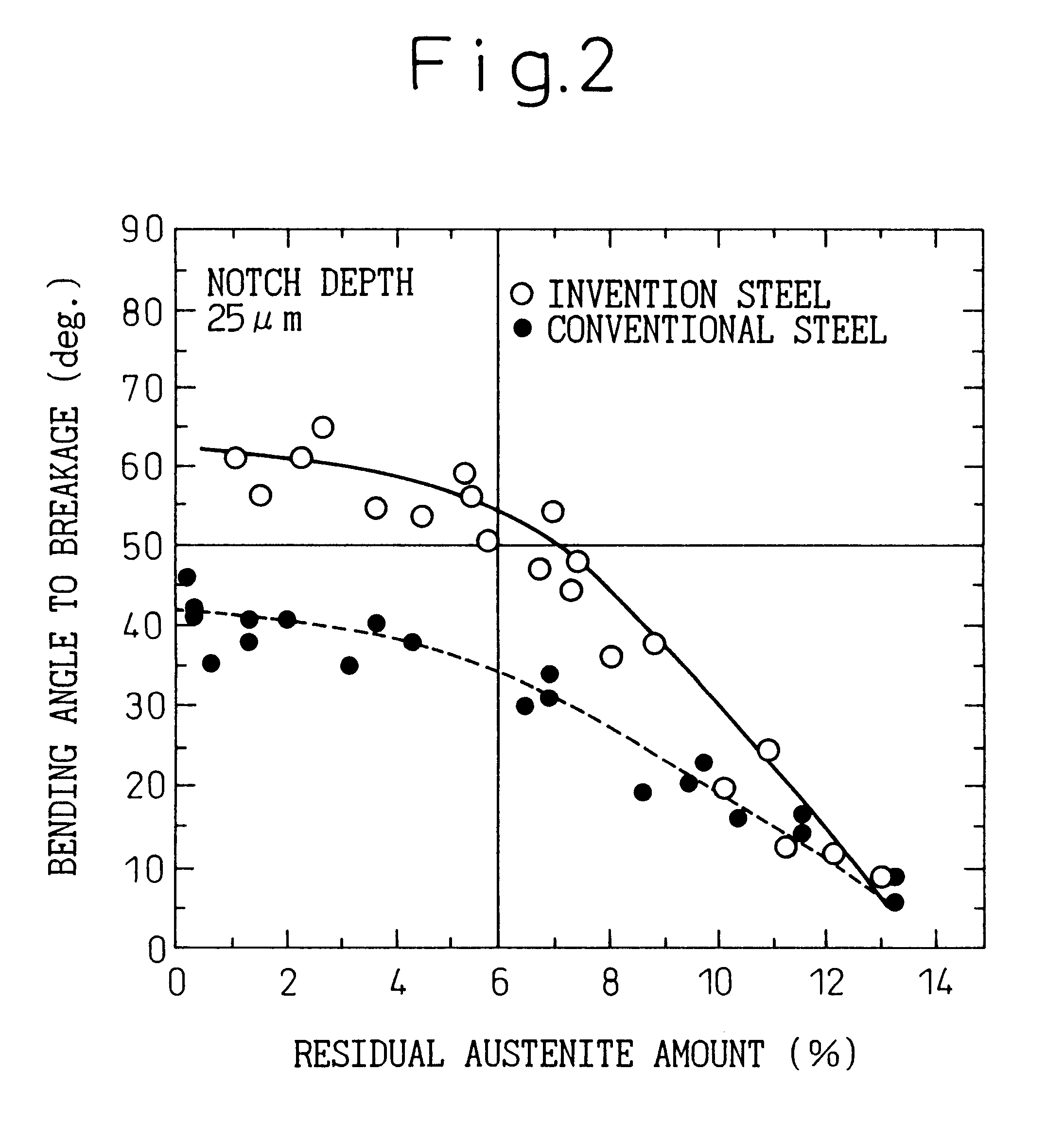

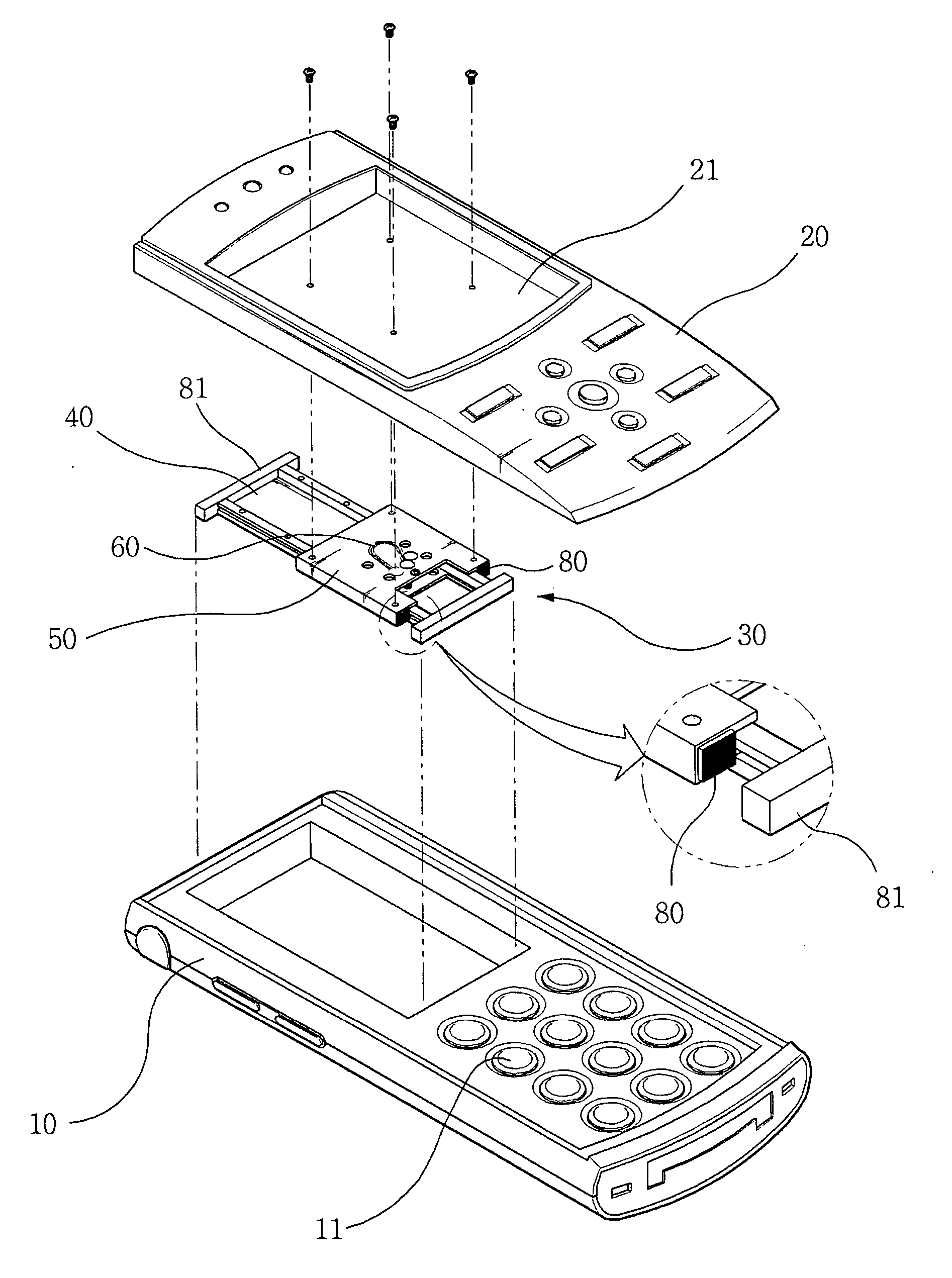

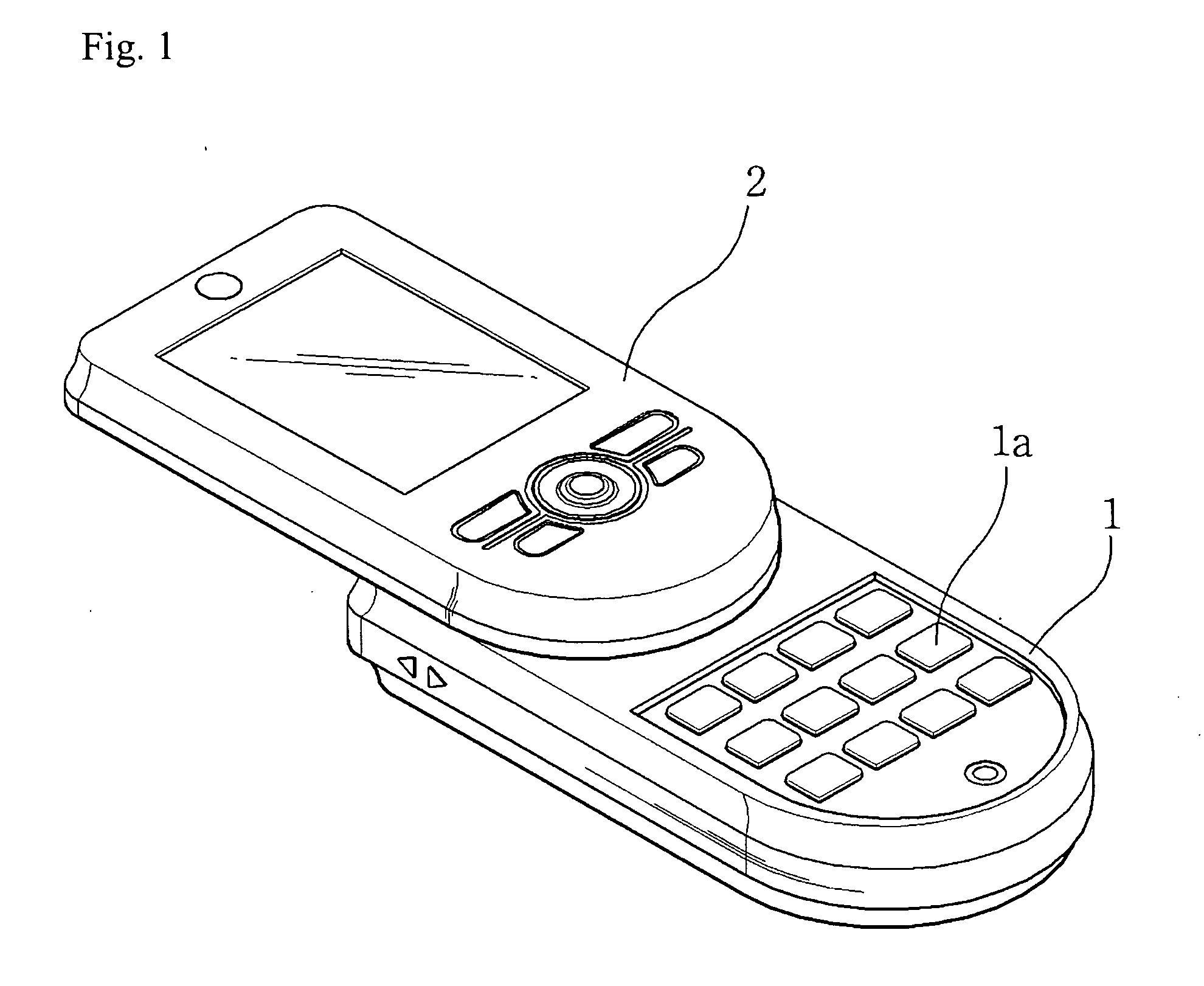

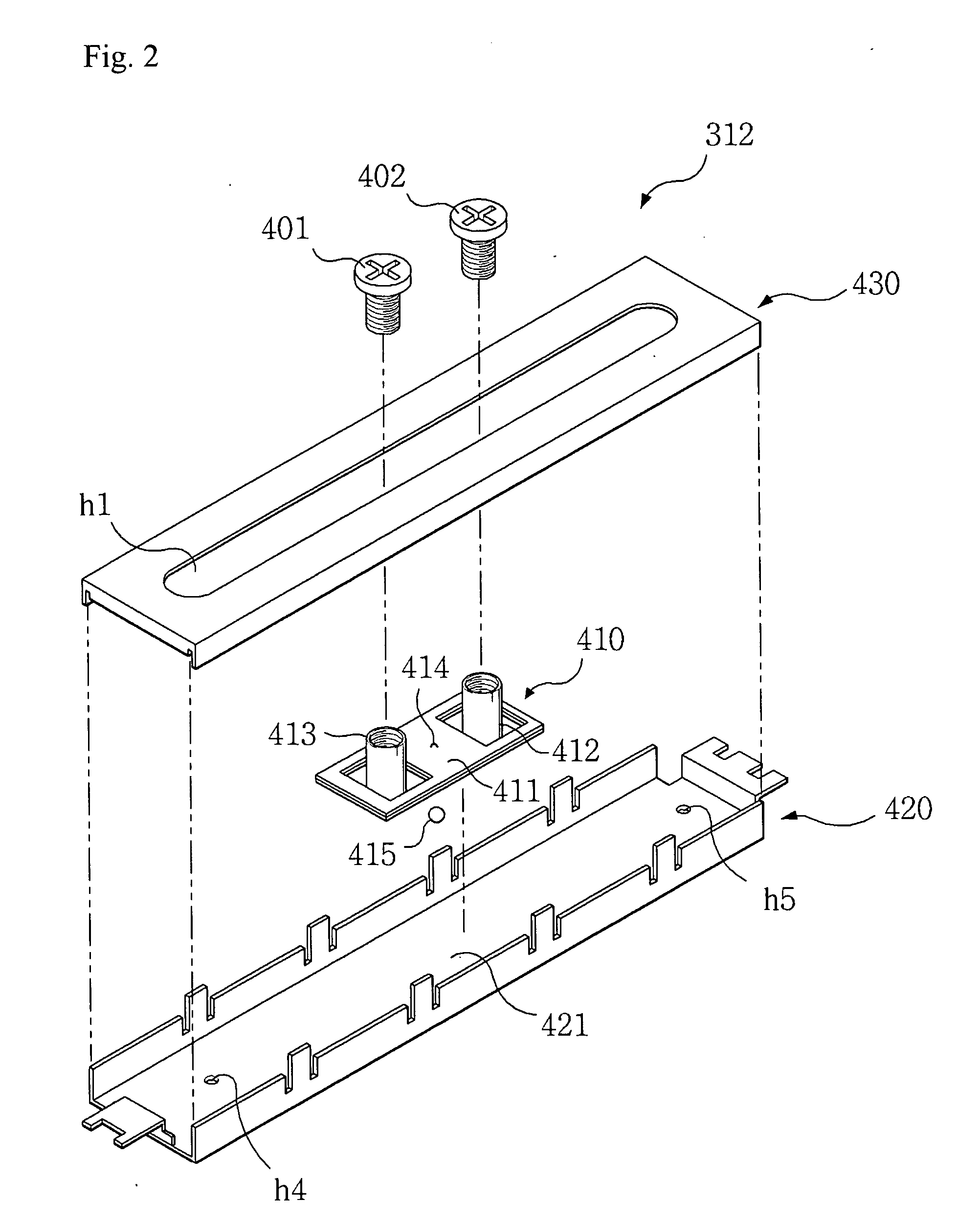

Slide type mobile phone module

InactiveUS20050215298A1Improve reliabilitySmooth movementCasings/cabinets/drawers detailsTransmissionEngineeringMechanical engineering

Disclosed is a slide type mobile phone module for sliding a cover over a main body with keypads. The slide type mobile phone of the present invention features smooth sliding motion, a minimum number of components in the module, improved workability, and reduced cost of manufacture.

Owner:LEE GEUN JU

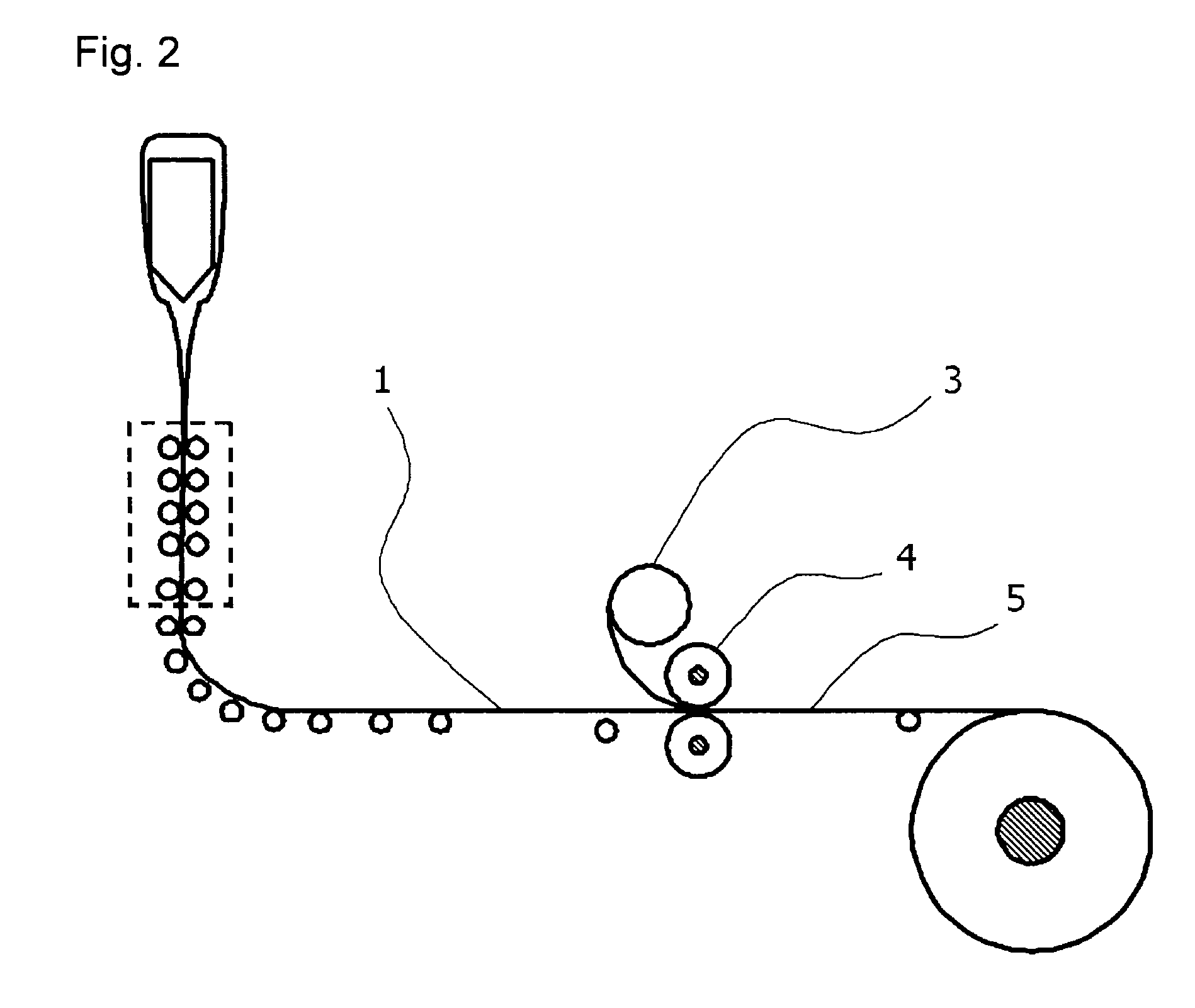

Process for producing glass/resin composite

InactiveUS20100192634A1High mechanical strengthReduce the possibilityLayered product treatmentLaminationCutting glassPolyresin

To provide a process for producing a glass / resin composite having a sufficient transportability, handling efficiency and processability, even though the thickness of the glass is very thin, without impairing excellent properties of glass.A process for producing a glass / resin composite, which comprises forming molten glass into a glass ribbon and forming a resin layer on at least one surface of the glass ribbon is provided. The resin layer is preferably formed by bonding to a glass ribbon, applying a heat melt resin or applying a curable resin. Further, a process for producing a glass / resin composite, wherein a cut glass substrate is bonded on a continuously supplied resin film is provided.

Owner:ASAHI GLASS CO LTD

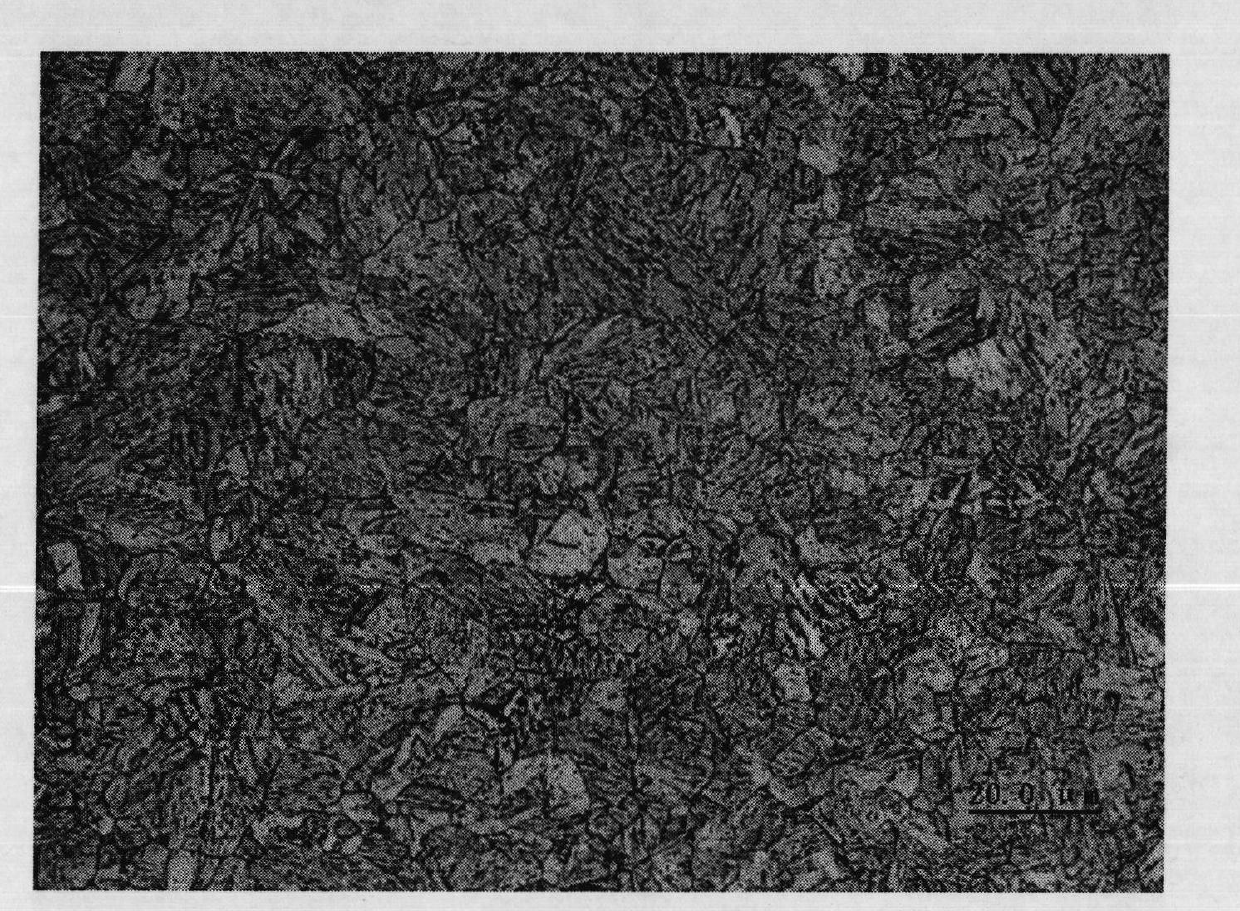

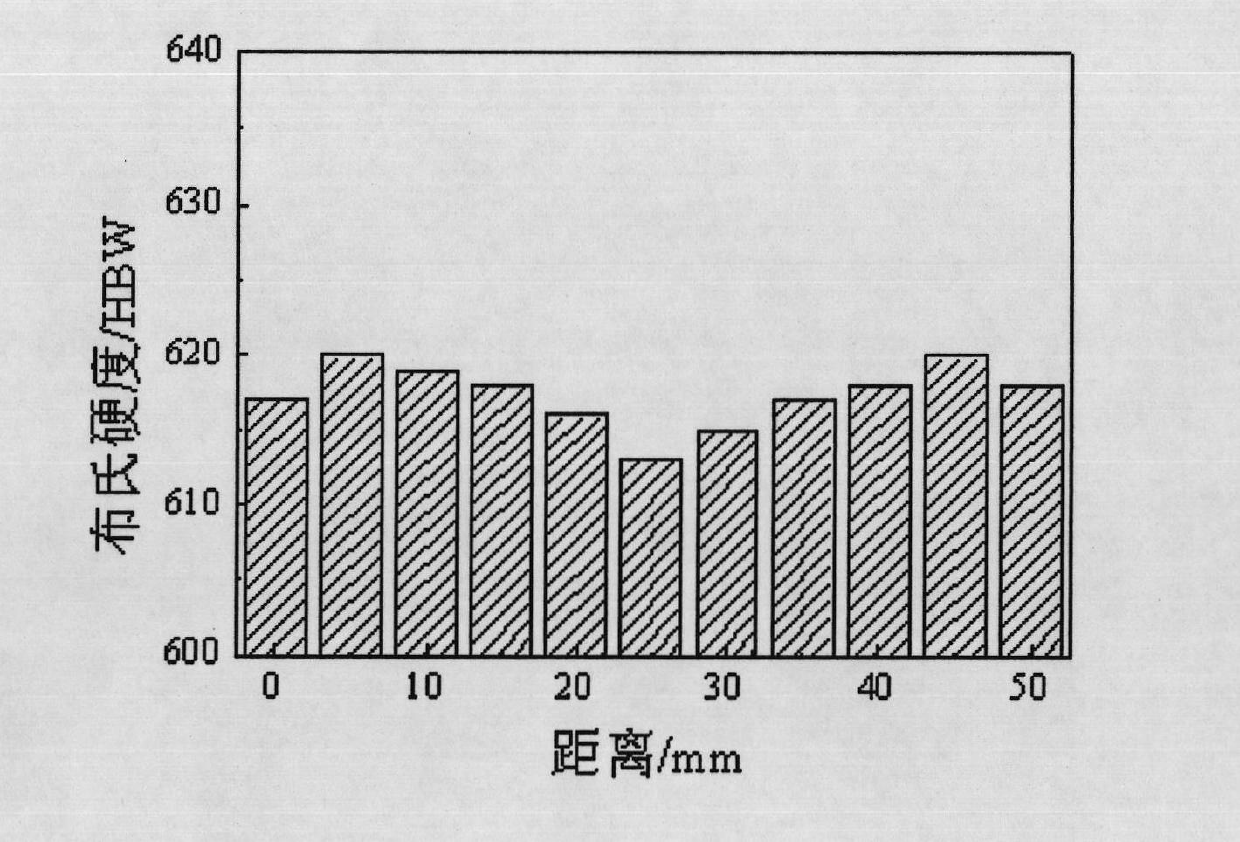

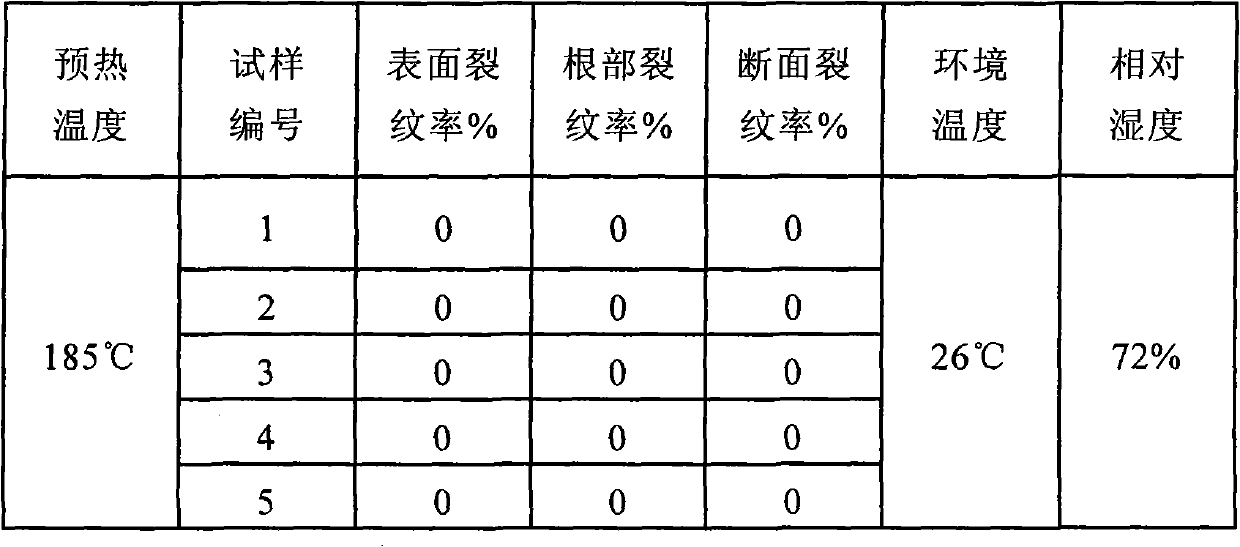

600HB-grade wear resistant steel plate and its manufacturing method

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balance Fe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance and excellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

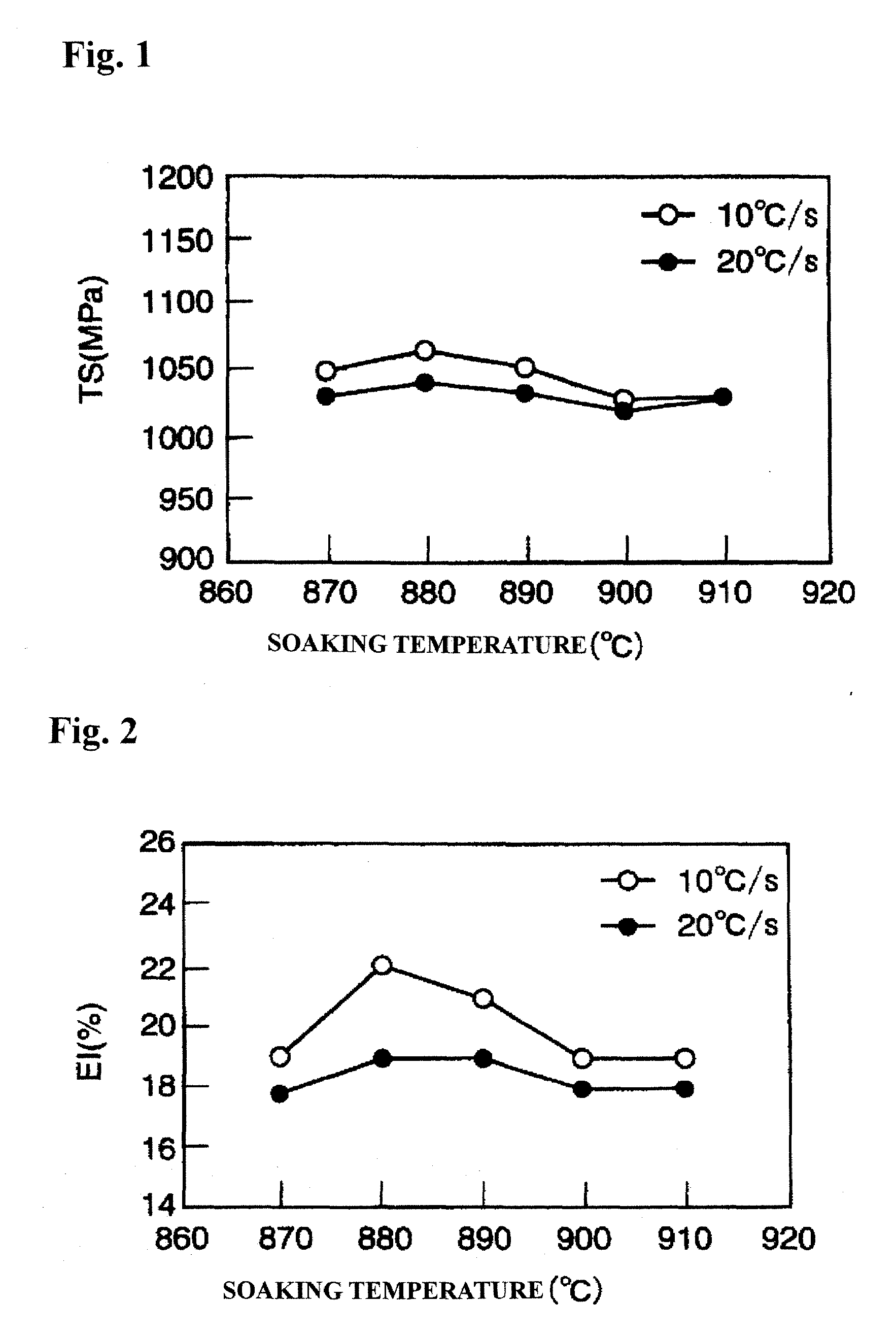

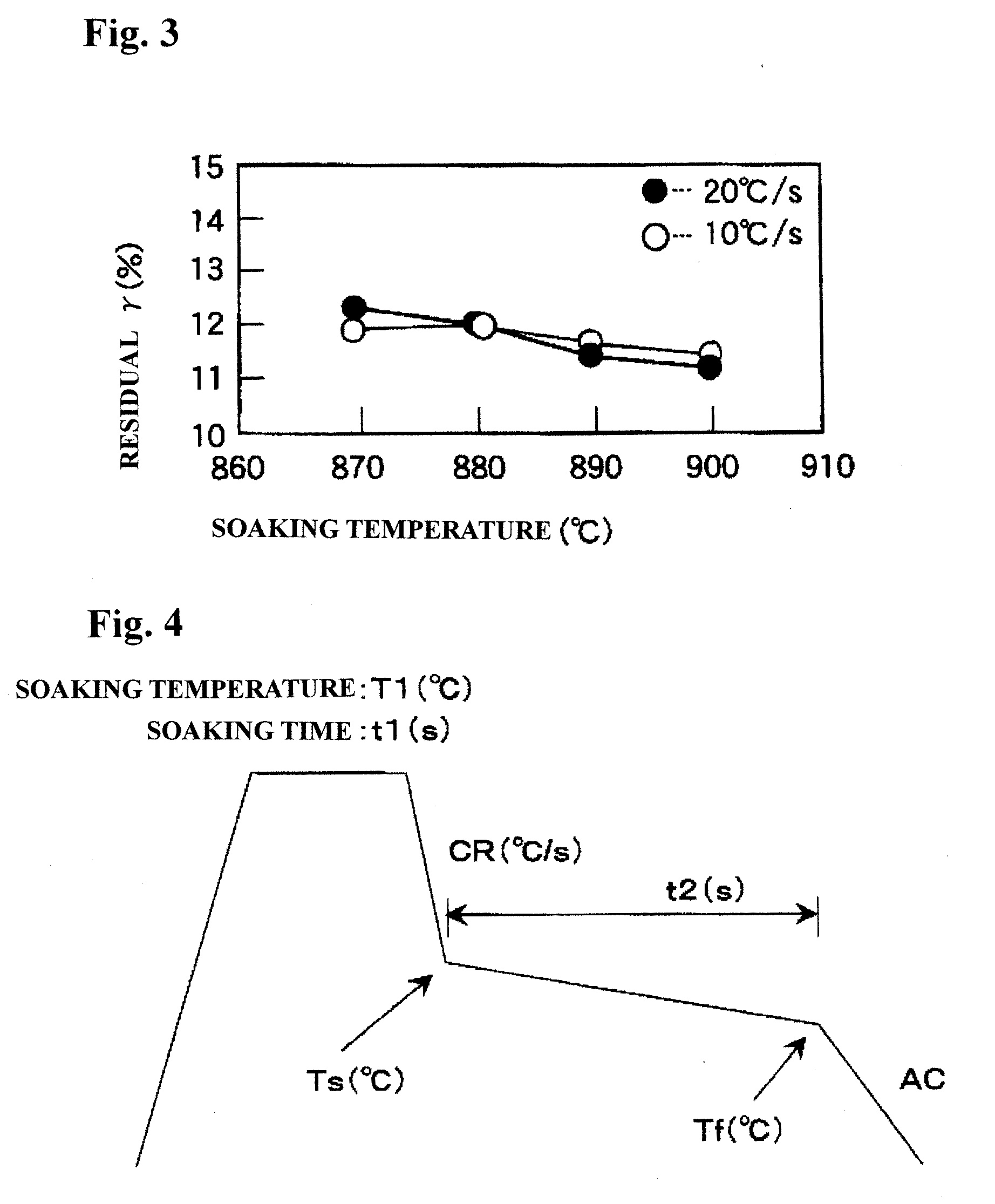

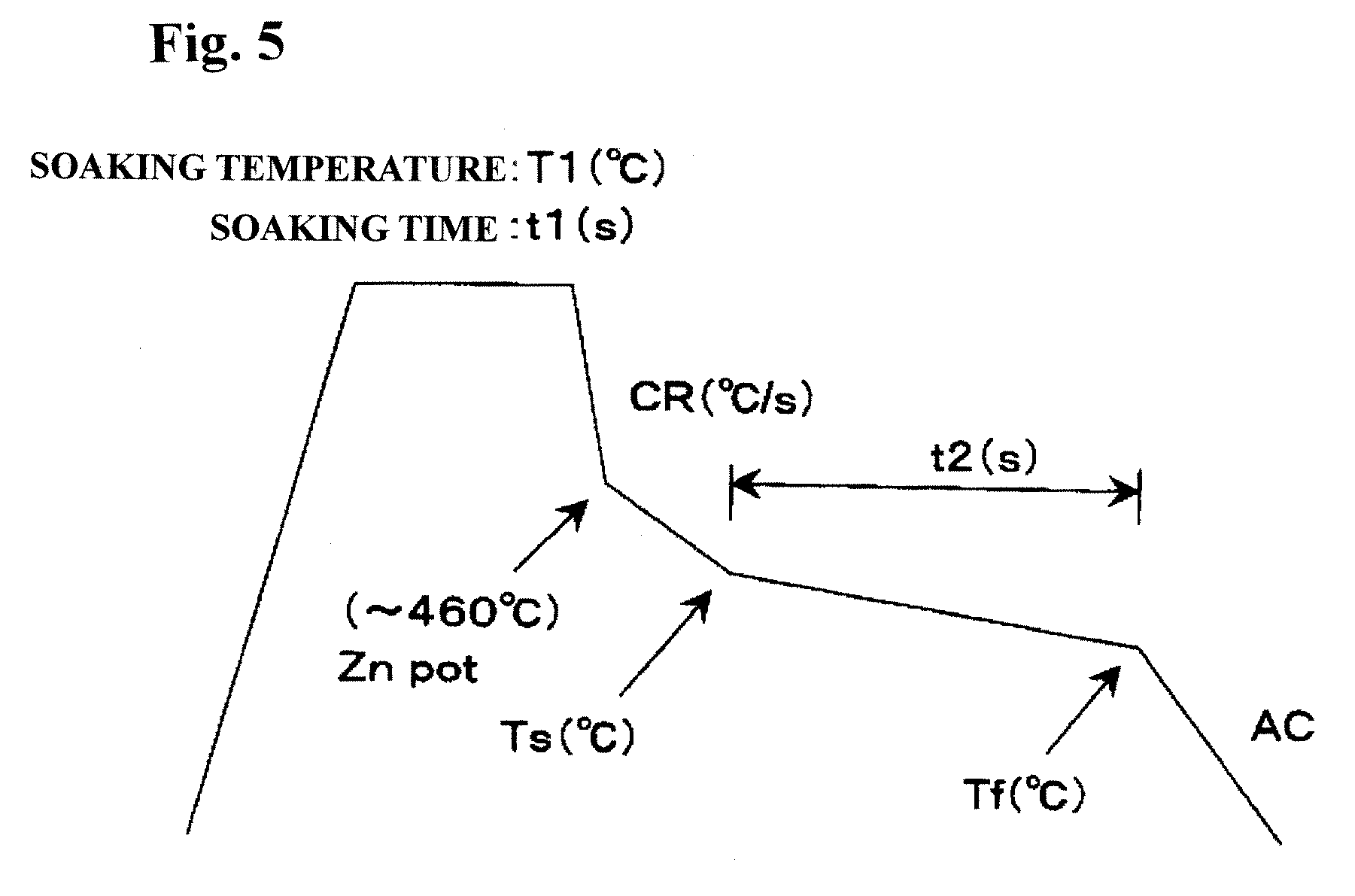

High Strength Cold Rolled Steel Sheet and Plated Steel Sheet Excellent in the Balance of Strength and Workability

A high-strength cold-rolled steel sheet exhibiting an excellent strength-workability balance, including in percent by mass:0.10-0.25% of C;1.0-2.0% of Si;1.5-3.0% of Mn;0.01% or less (not including 0%) of P;0.005% or less (not including 0%) of S;0.01-3.0% of Al; andremaining part consisting of iron and inevitable impurities,wherein the space factor of bainitic ferrite to the entire structure is 70% or more,the space factor of residual austenite to the entire structure is 5-20%,the hardness (HV) is 270 or greater, andthe half-value width of an X-ray diffraction peak on a (200)-surface of α-iron is 0.220 degrees or smaller.

Owner:KOBE STEEL LTD

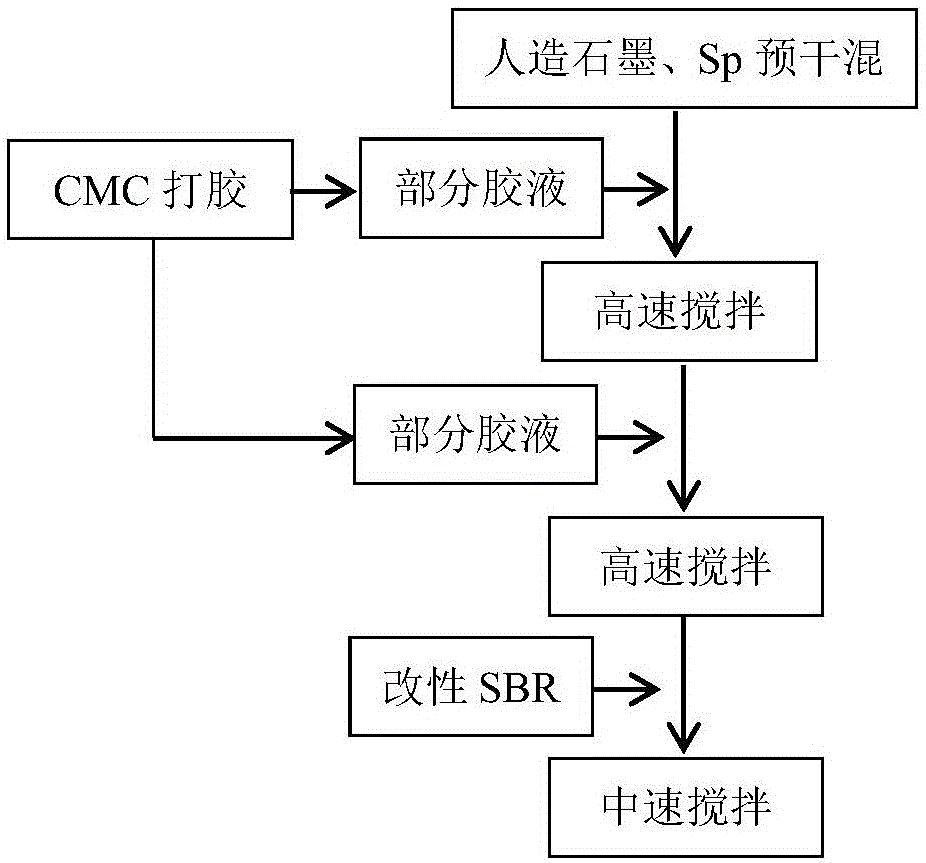

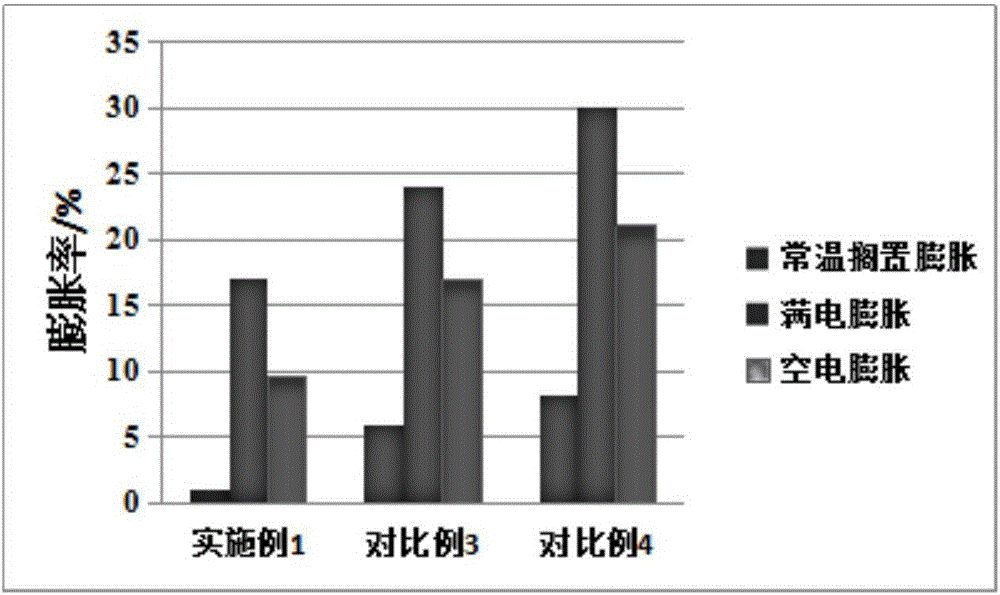

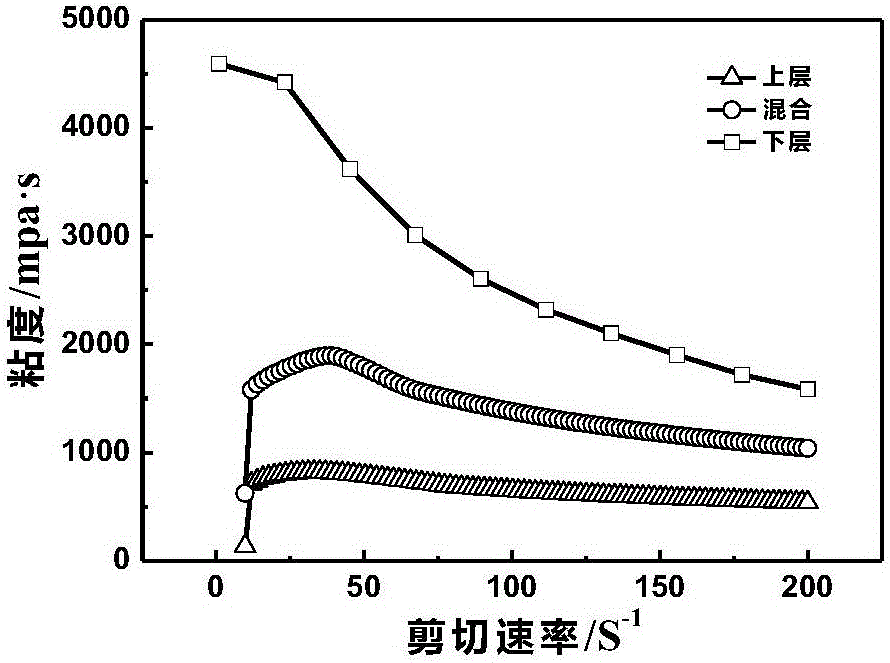

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

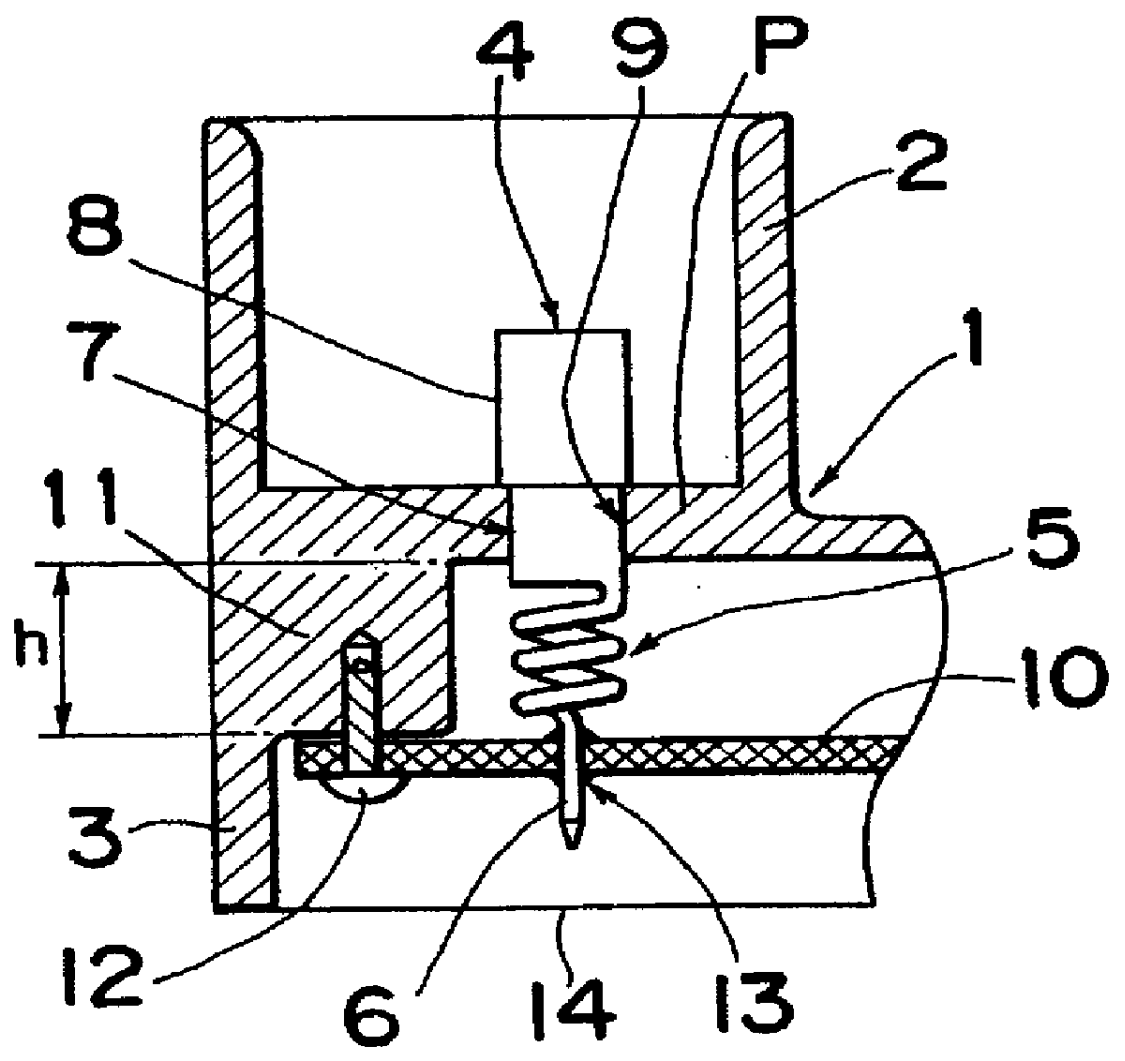

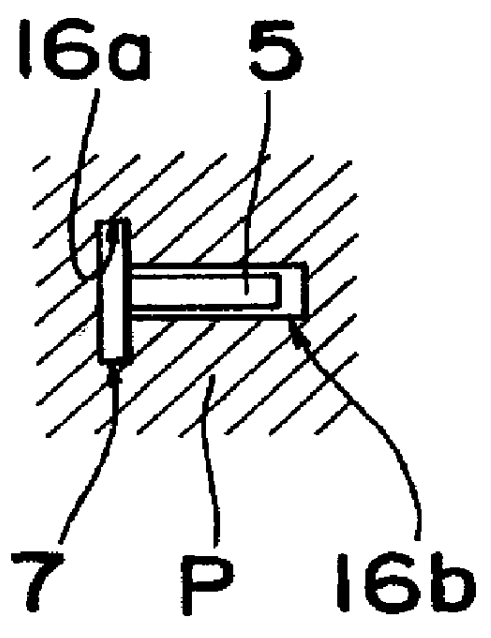

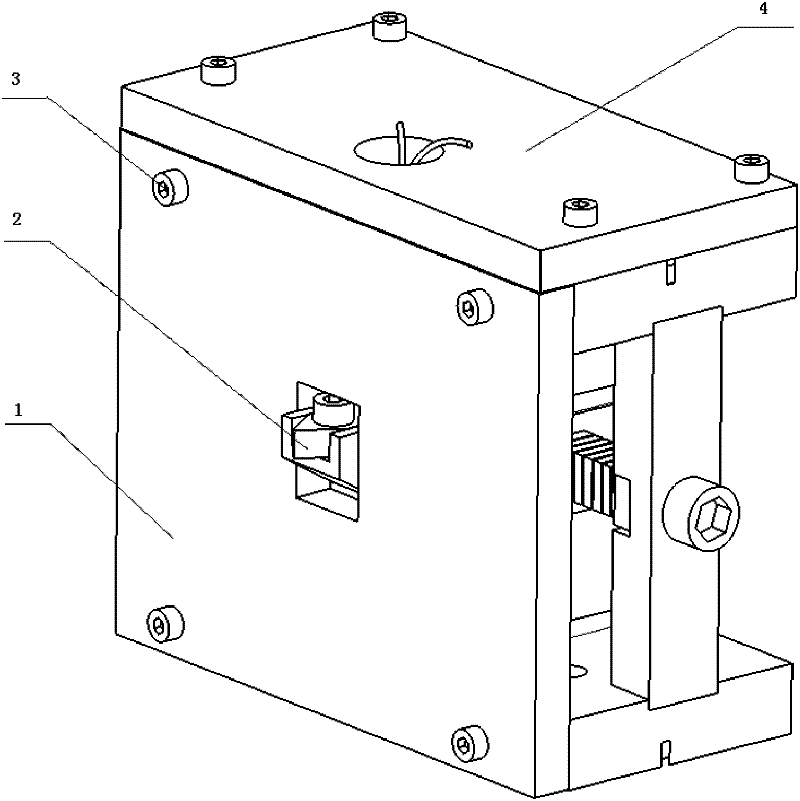

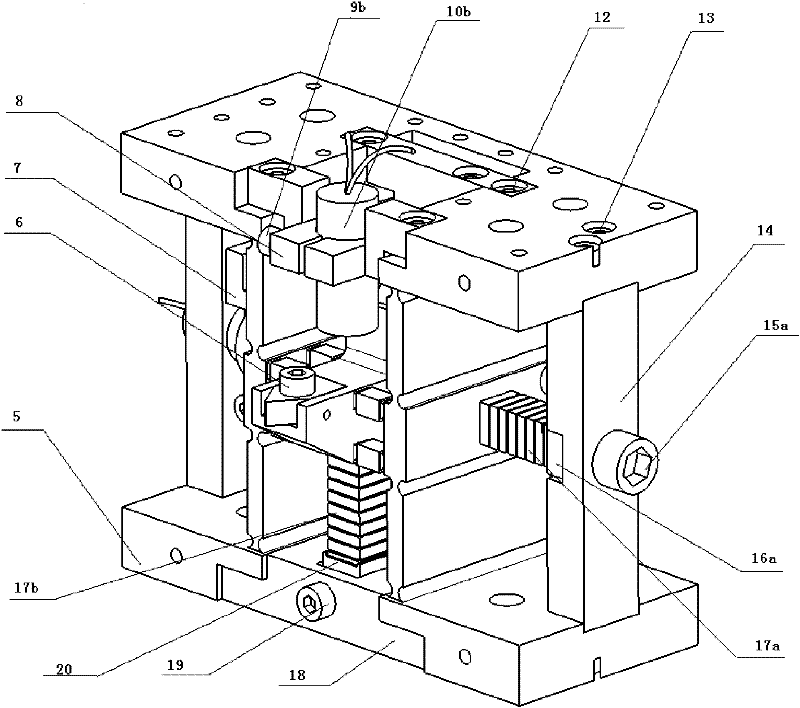

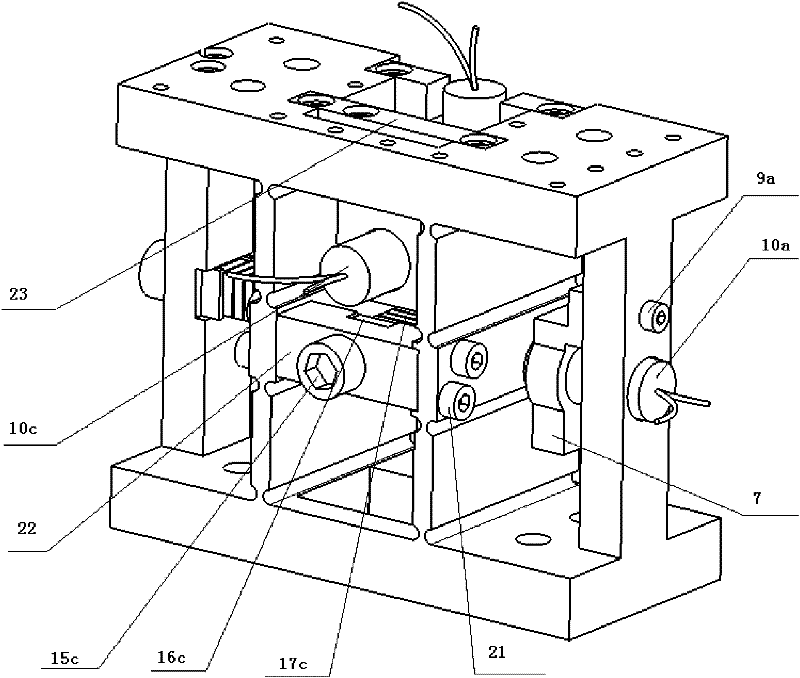

Three-dimensional elliptical vibration cutting device

ActiveCN102371359AImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

The invention relates to a three-dimensional elliptical vibration cutting device, belonging to the field of cutting and ultra-precision cutting machining of materials which are difficult to machine. A diamond cutter is guided through flexible hinge mechanisms respectively along an X direction, a Y direction and a Z direction, and further, is driven by three piezoelectric stacks respectively alongthe X direction, the Y direction and the Z direction; the piezoelectric stacks of the X direction and the Z direction are preloaded by preloading screw bolts along respective axial direction; the piezoelectric stack of the Y direction is preloaded through a screw bolt screwing wedge; the preloading processes of the three directions are mutually independent; through regulating and matching the initial phase position and the amplitude of a driving signal for each of the three piezoelectric stacks, the projections of the cutter location point movements of the diamond cutter in an X-Y plane and aY-Z plane are elliptical motions, and the projection of the cutter location point movements of the diamond cutter in an X-Z plane is reciprocating elliptical motion or linear motion. The three-dimensional elliptical vibration cutting device has a novel and simple structure, is easy to implement, and is beneficial to obtaining the best cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

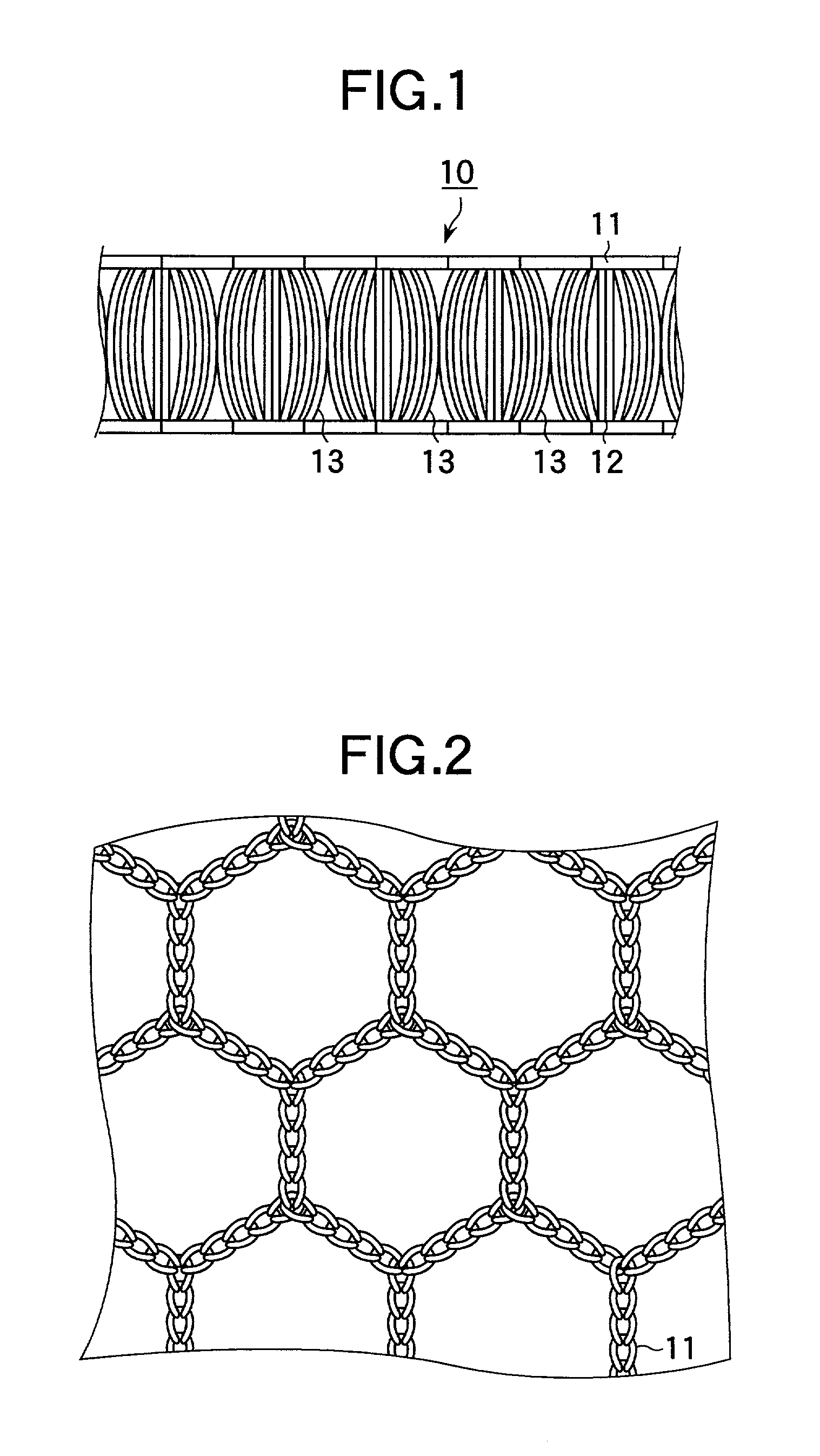

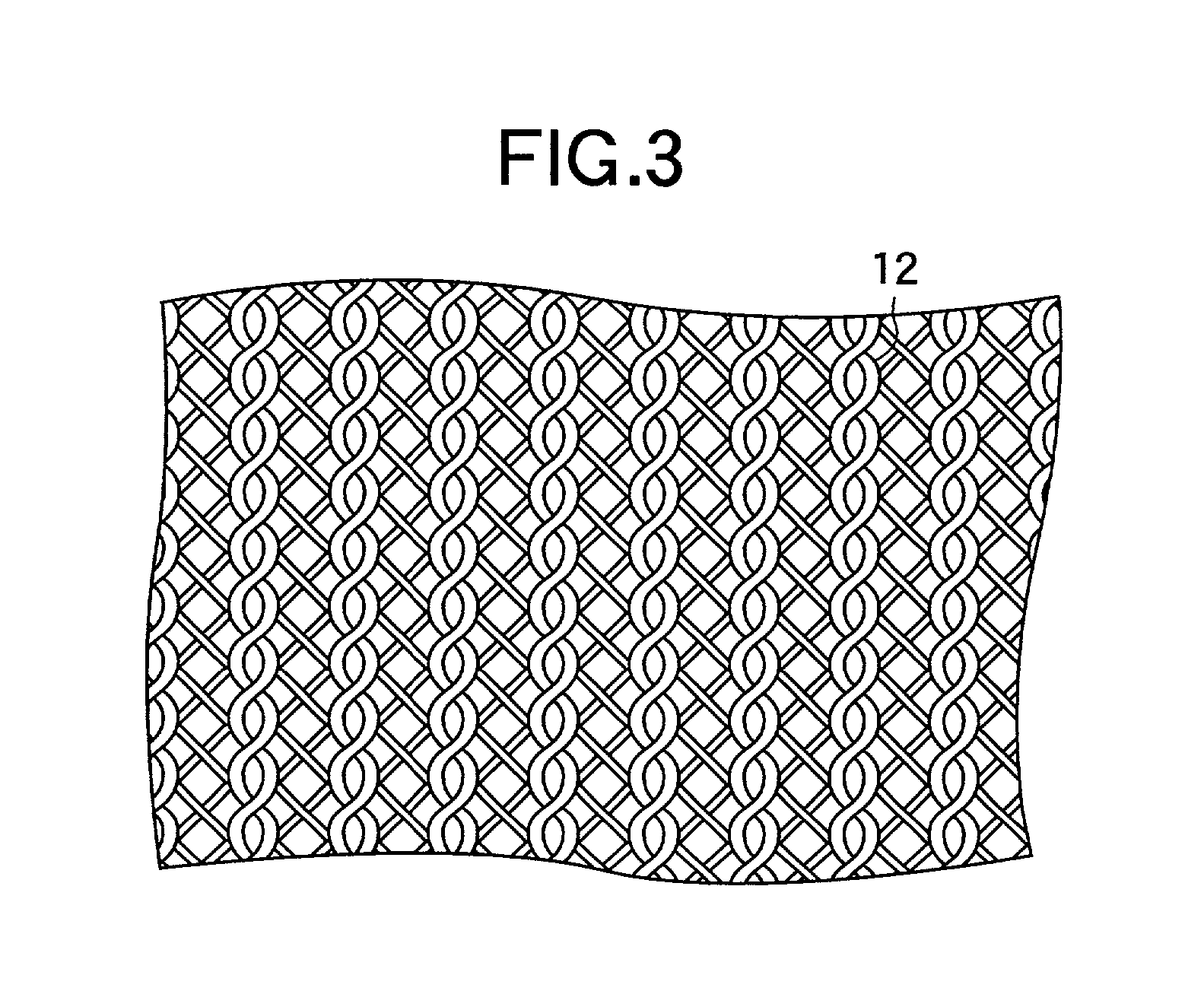

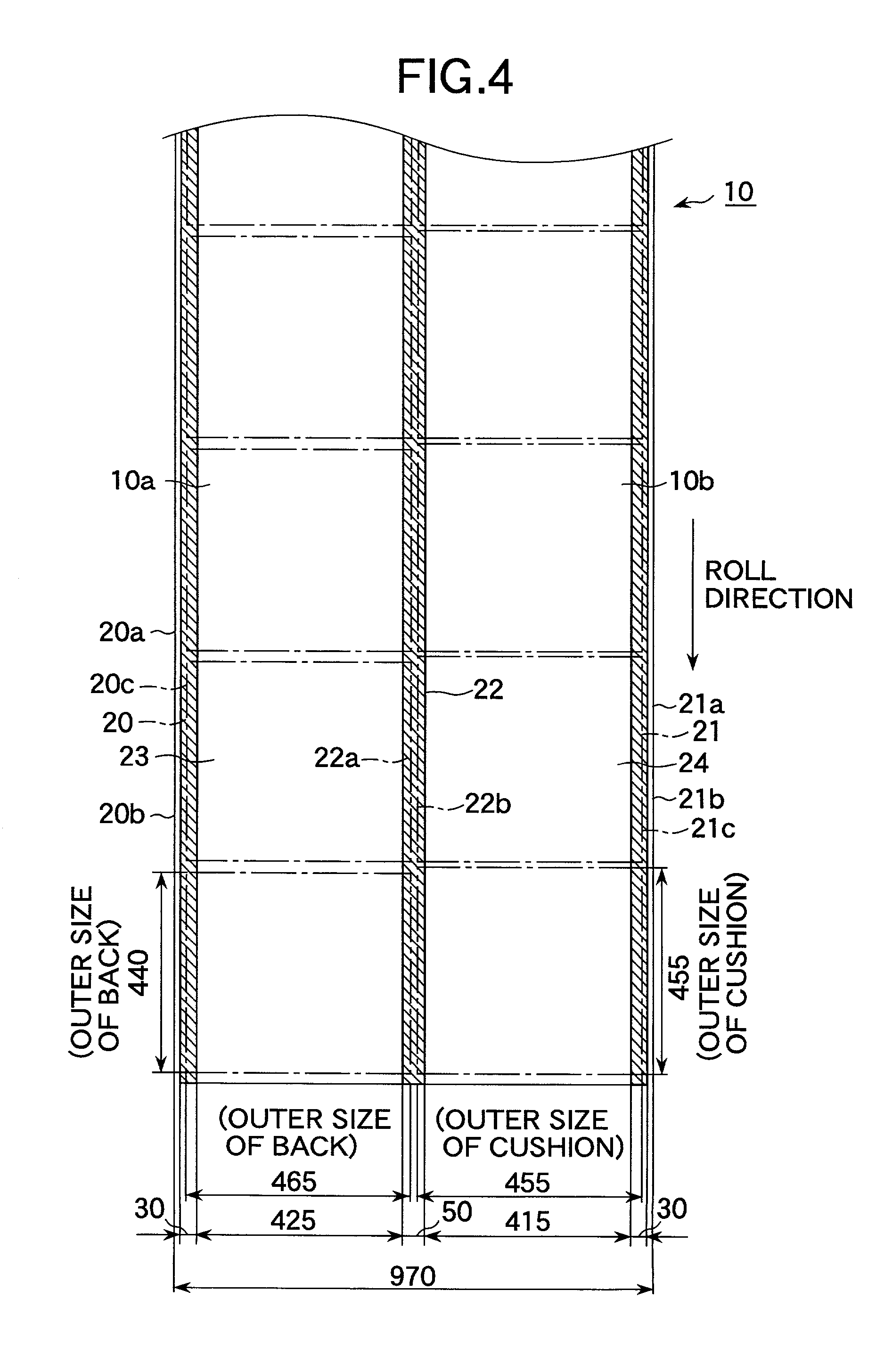

Net fabric to be processed into net product

InactiveUS20020034901A1Easy to processSimple processOrnamental textile articlesLayered productsCompressibilityPulp and paper industry

A net fabric to be processed into a net product capable of simplifying processing during manufacturing of a net product, leading to a reduction in manufacturing cost of the net product is disclosed. The net fabric is so constructed that the side edge portions of the net fabric, which are subjected to processing such as cutting, vibrational welding or the like, have a higher compressibility in the thickness direction than the middle portions of the net fabric. This ensures that the net fabric exhibits a better workability during the manufacturing of the net product using the net fabric in order to simplify the manufacturing process, and to lead to a reduction in manufacturing cost, even though the net fabric has a three-dimensional structure.

Owner:DELTA TOOLING CO LTD +1

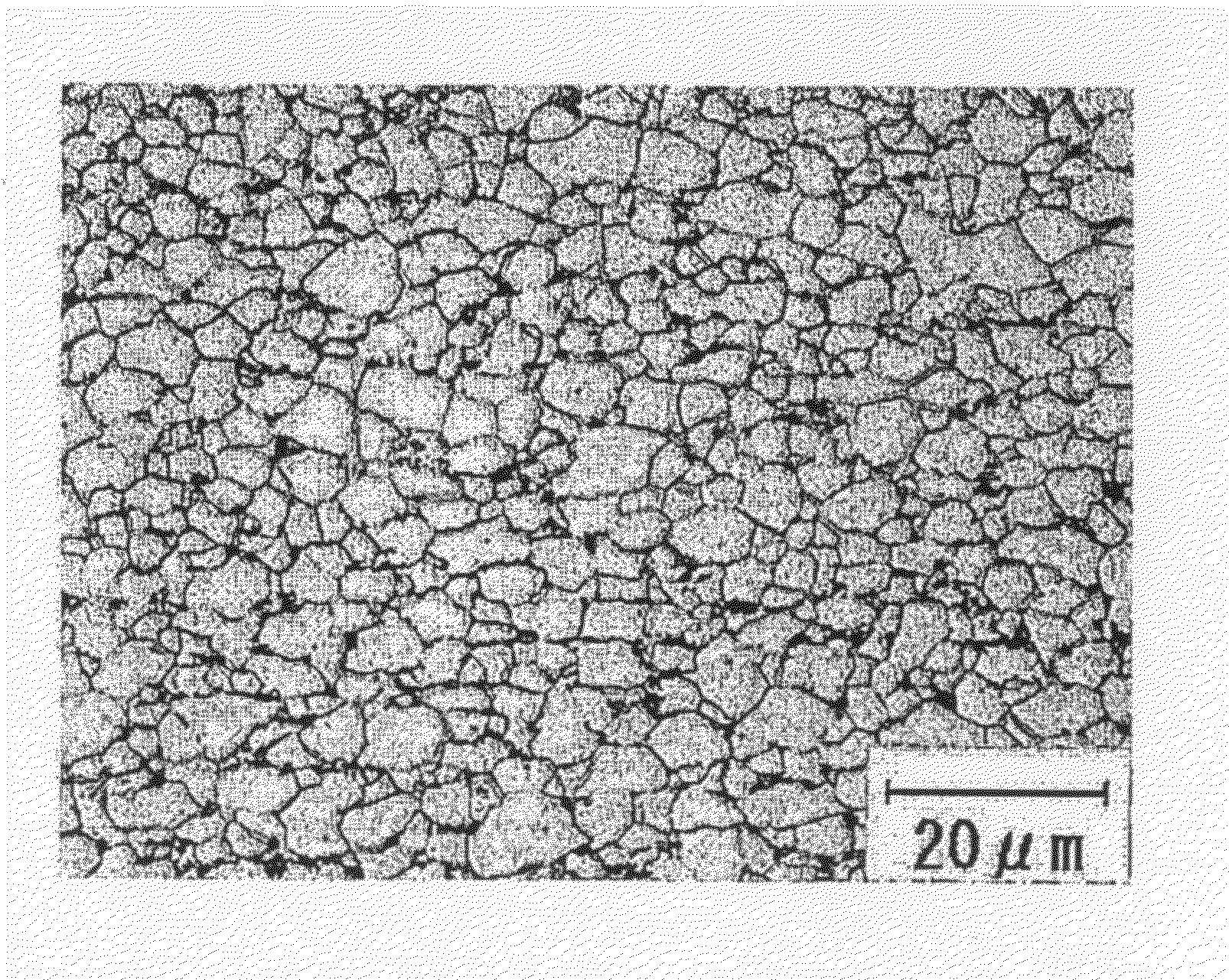

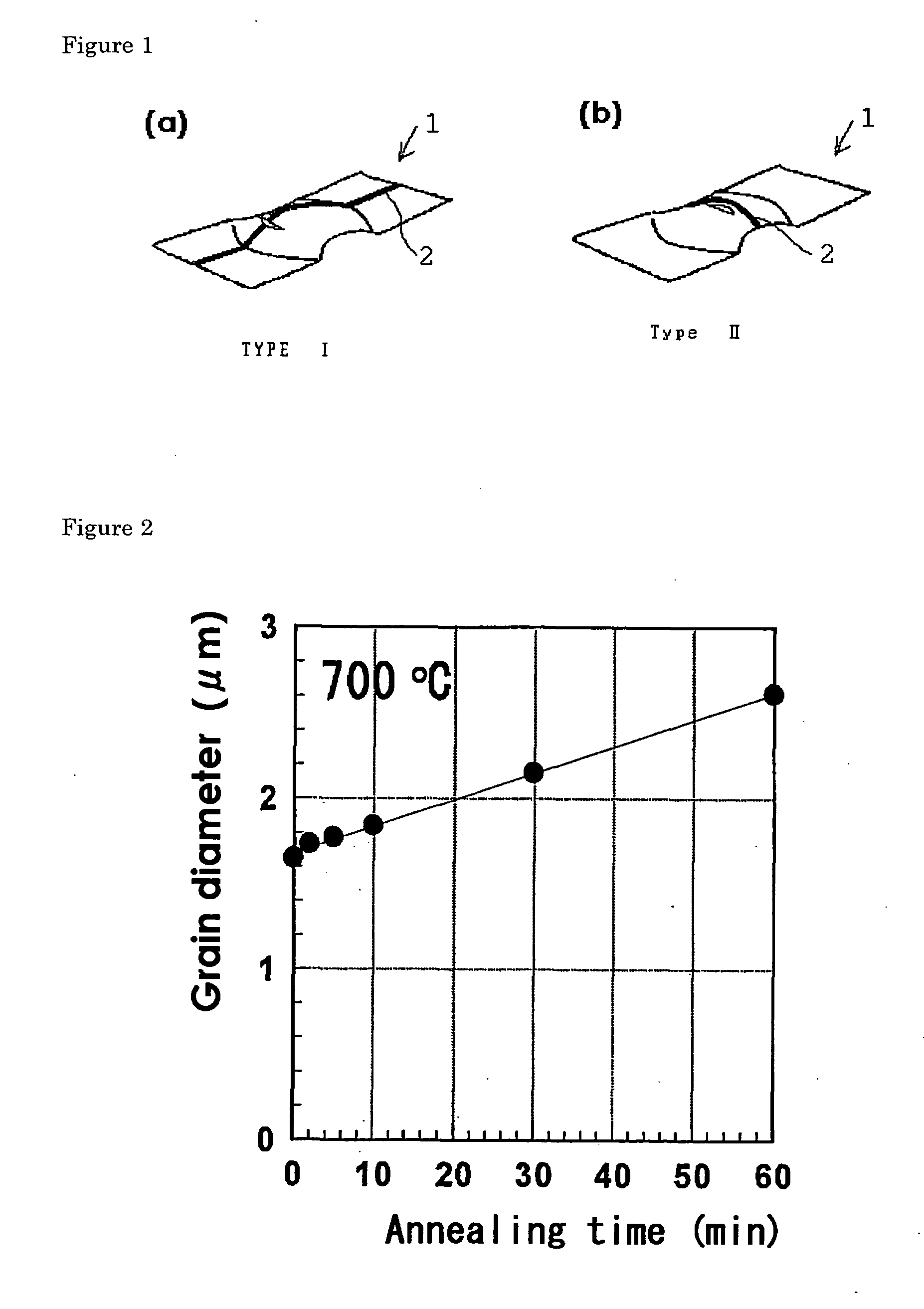

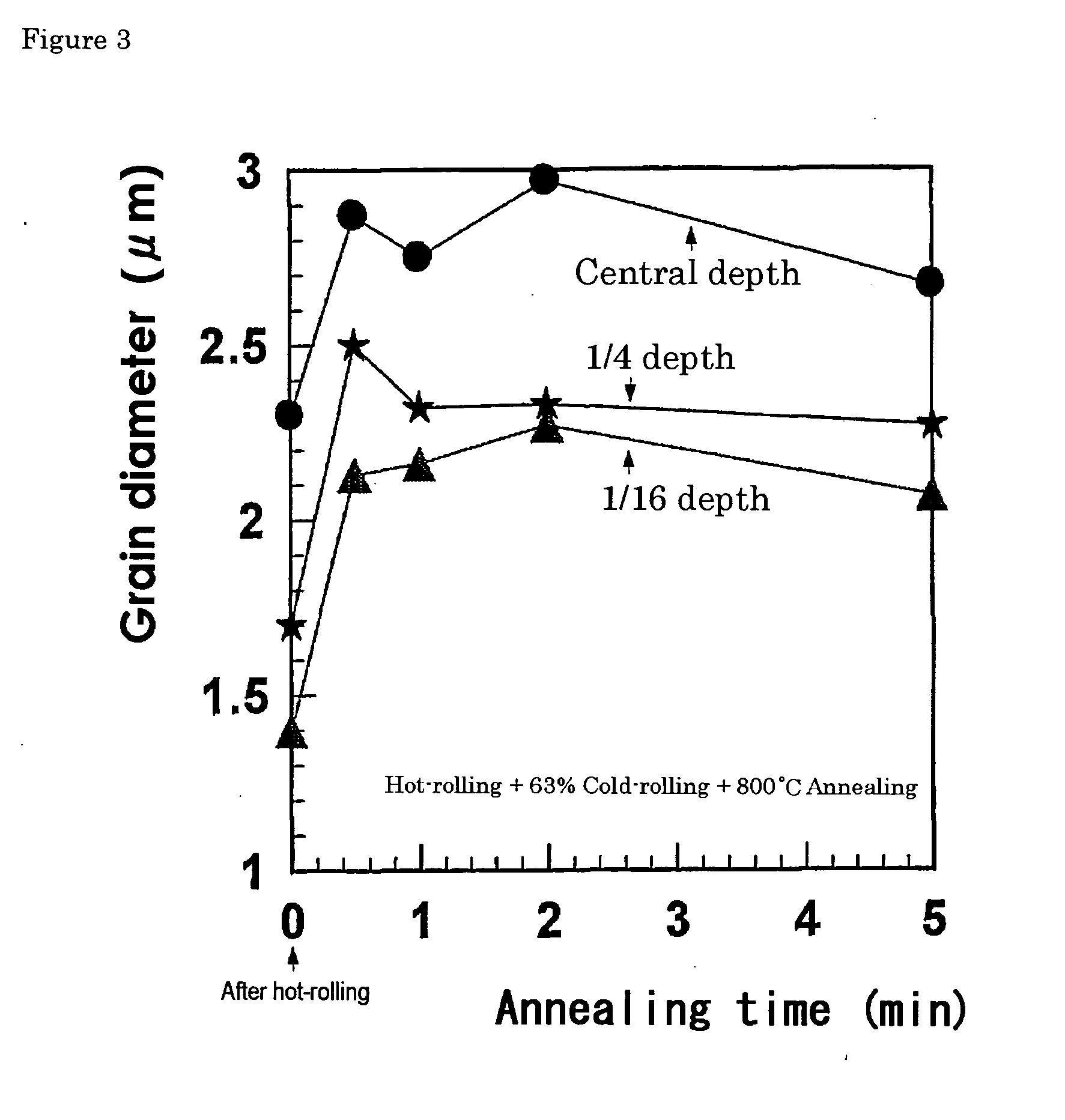

Hot-rolled steel sheet and cold-rolled steel sheet and manufacturing method thereof

InactiveUS20080202639A1Excellent mechanical propertiesLower transition temperatureHot-dipping/immersion processesFurnace typesMaterials scienceRaw material

A steel sheet excellent in mechanical strength, workability and thermal stability and suited for use as a raw material in such fields of manufacturing automobiles, household electric appliances and machine structures and of constructing buildings, and a manufacturing method thereof. are provided.The steel sheet is a hot-rolled steel sheet of carbon steel or low-alloy steel, the main phase of which is ferrite, and is characterized in that the average ferrite crystal grain diameter D (μm) at the depth of ¼ of the sheet thickness from the steel sheet surface satisfies the relations respectively defined by the formulas (1) and (2) given below and the increase rate X (μm / min) in average ferrite crystal grain diameter at 700° C. at the depth of ¼ of the sheet thickness from the steel sheet surface and said average crystal grain diameter D (μm) satisfy the relation defined by the formula (3) given below:1.2≦D≦7 formula (1)D≦2.7+5000 / (5+350·C+40·Mn)2 formula (2)D·X≦0.1 formula (3)wherein C and Mn represent the contents (in % by mass) of the respective elements in the steel.

Owner:NIPPON STEEL CORP

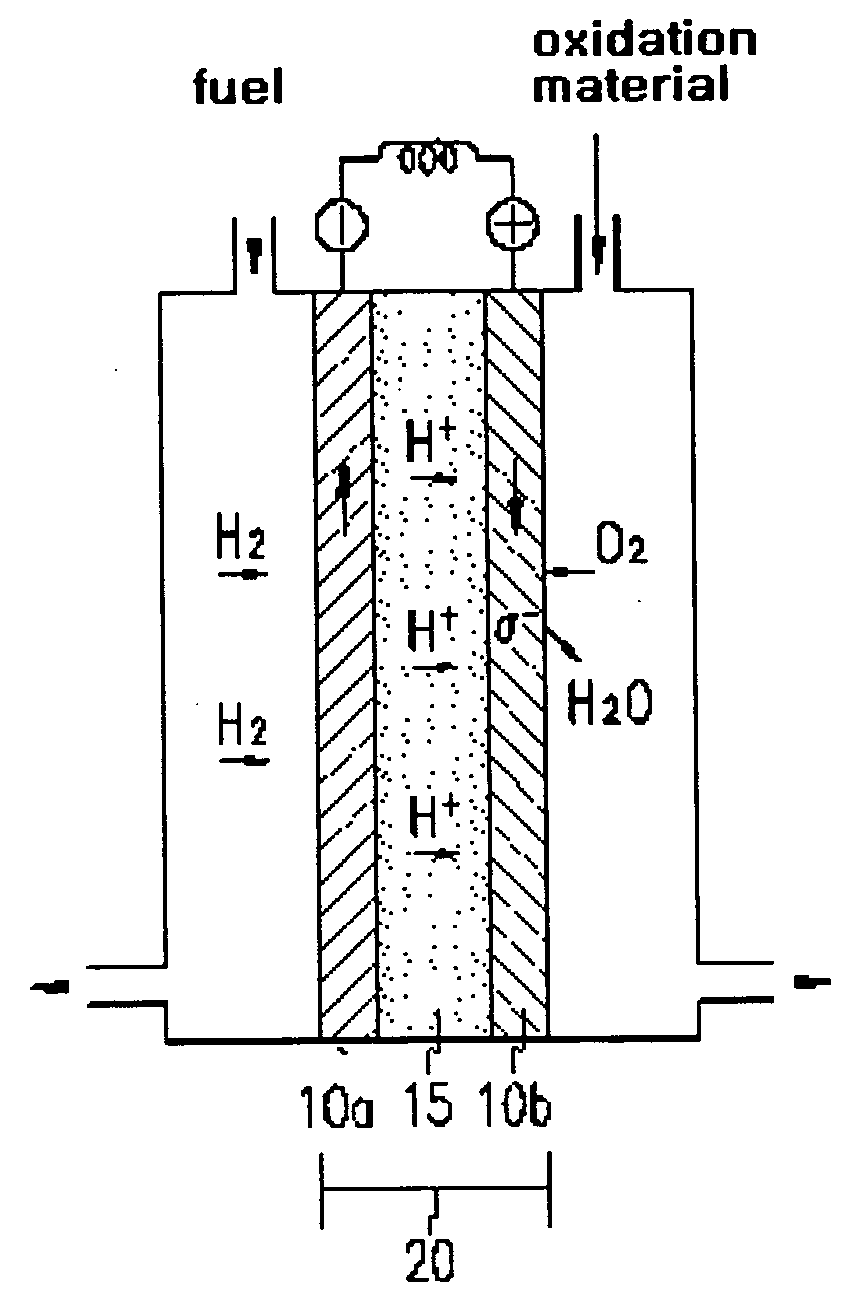

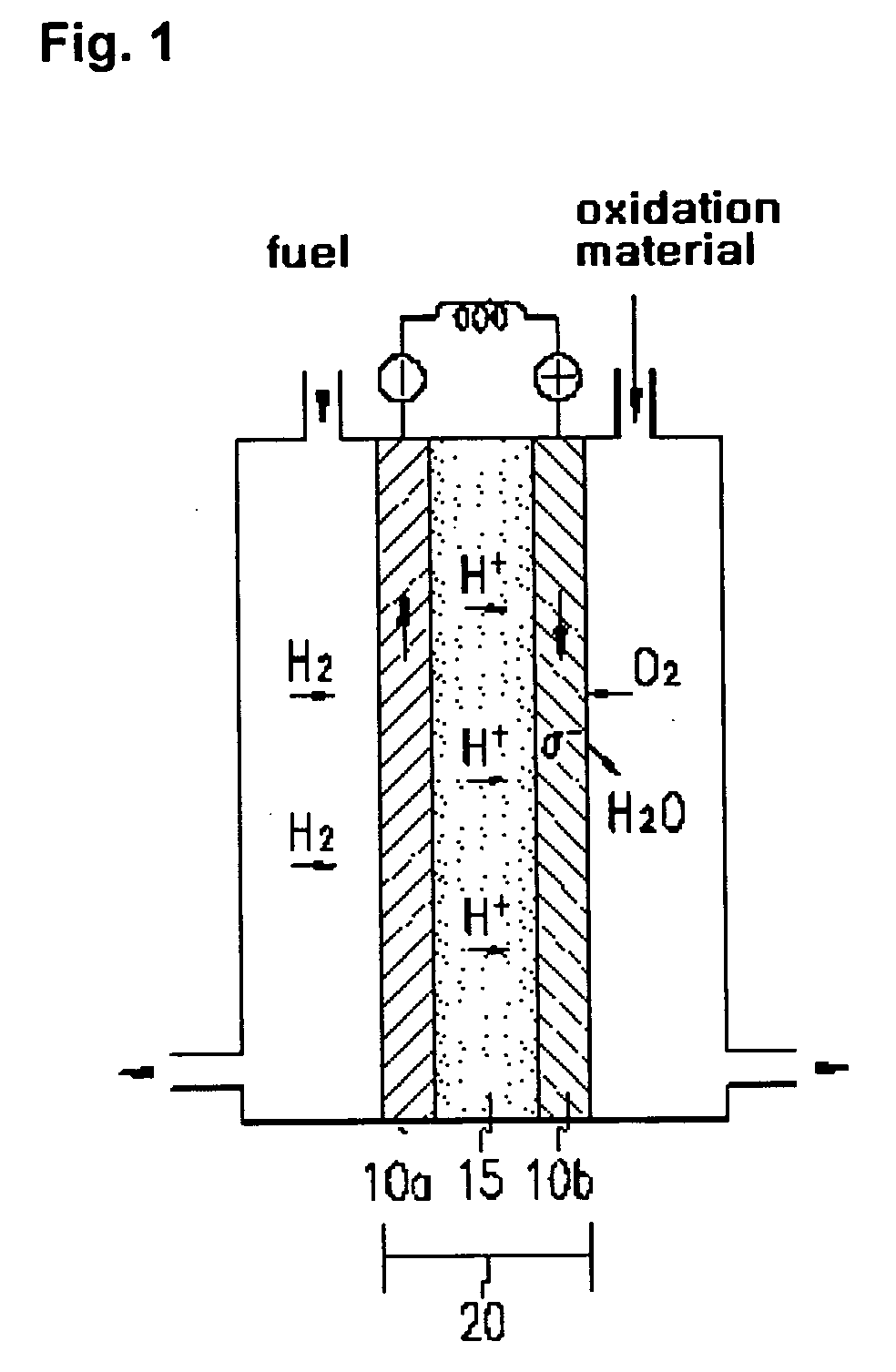

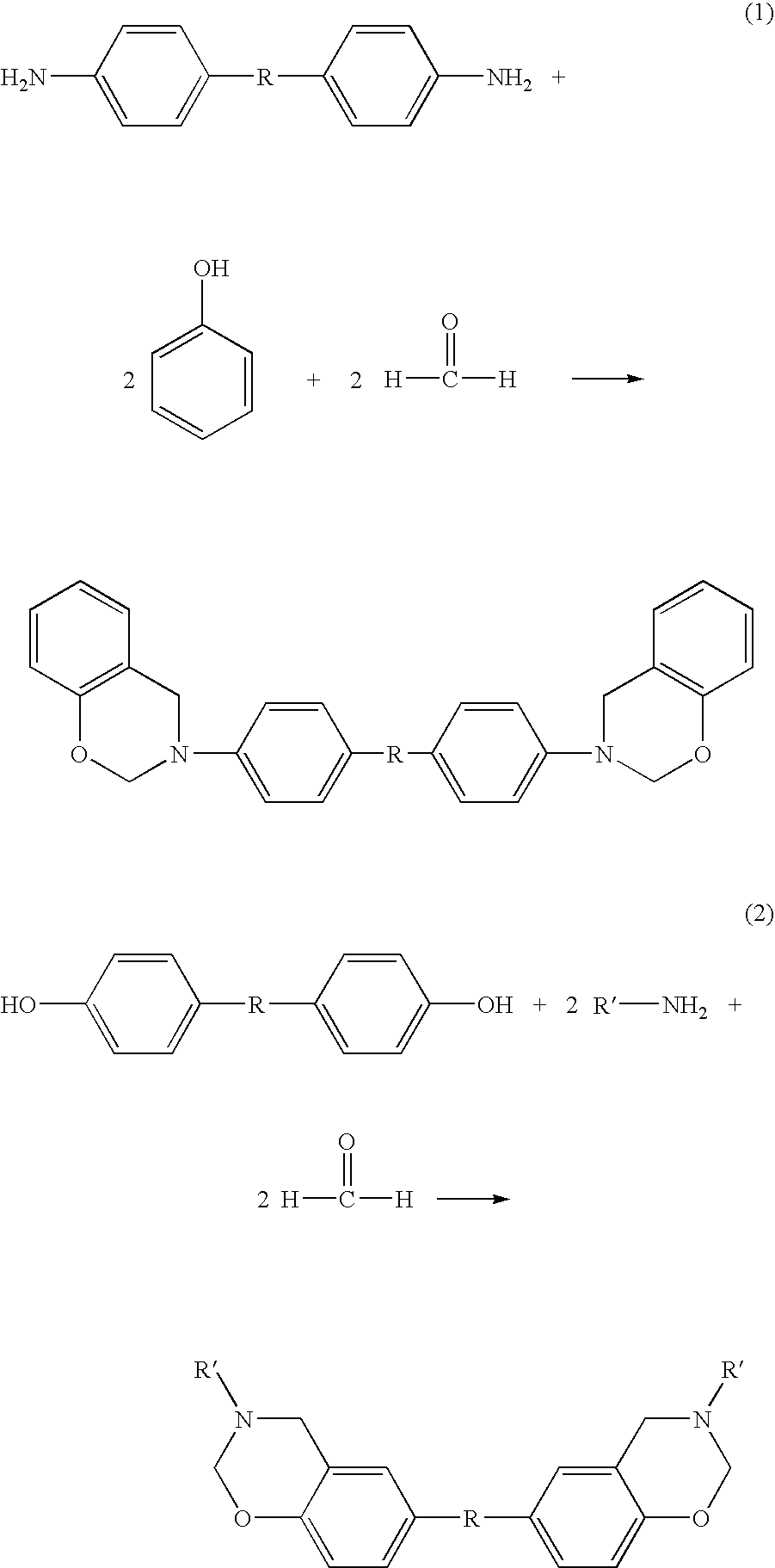

Composite material for bipolar plate

InactiveUS20050089744A1Reduce manufacturing costChemical and mechanical stabilityNon-metal conductorsFinal product manufactureFuel cellsPercentage reduction

A composite material for a bipolar plate of fuel cells is comprised of conductive carbon dispersed in polybenzoxazine matrix. The present invention also provides a composite material for preparing a bipolar plate for fuel cells comprising a polymer where a volume reduction percent is less than 5%, preferably 3%, and more preferably 1% after polymerization of the monomers with respect to total volume of the monomers before the polymerization thereof, and conductive carbon. The polymers of the present invention have good workability since there is little volume change during polymerization, and good mechanical and chemical properties, and they can be manufactured at a low cost.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com