Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24746 results about "Cantilever" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cantilever is a rigid structural element, such as a beam or a plate, anchored at one end to a (usually vertical) support from which it protrudes; this connection could also be perpendicular to a flat, vertical surface such as a wall. Cantilevers can also be constructed with trusses or slabs. When subjected to a structural load, the cantilever carries the load to the support where it is forced against by a moment and shear stress.

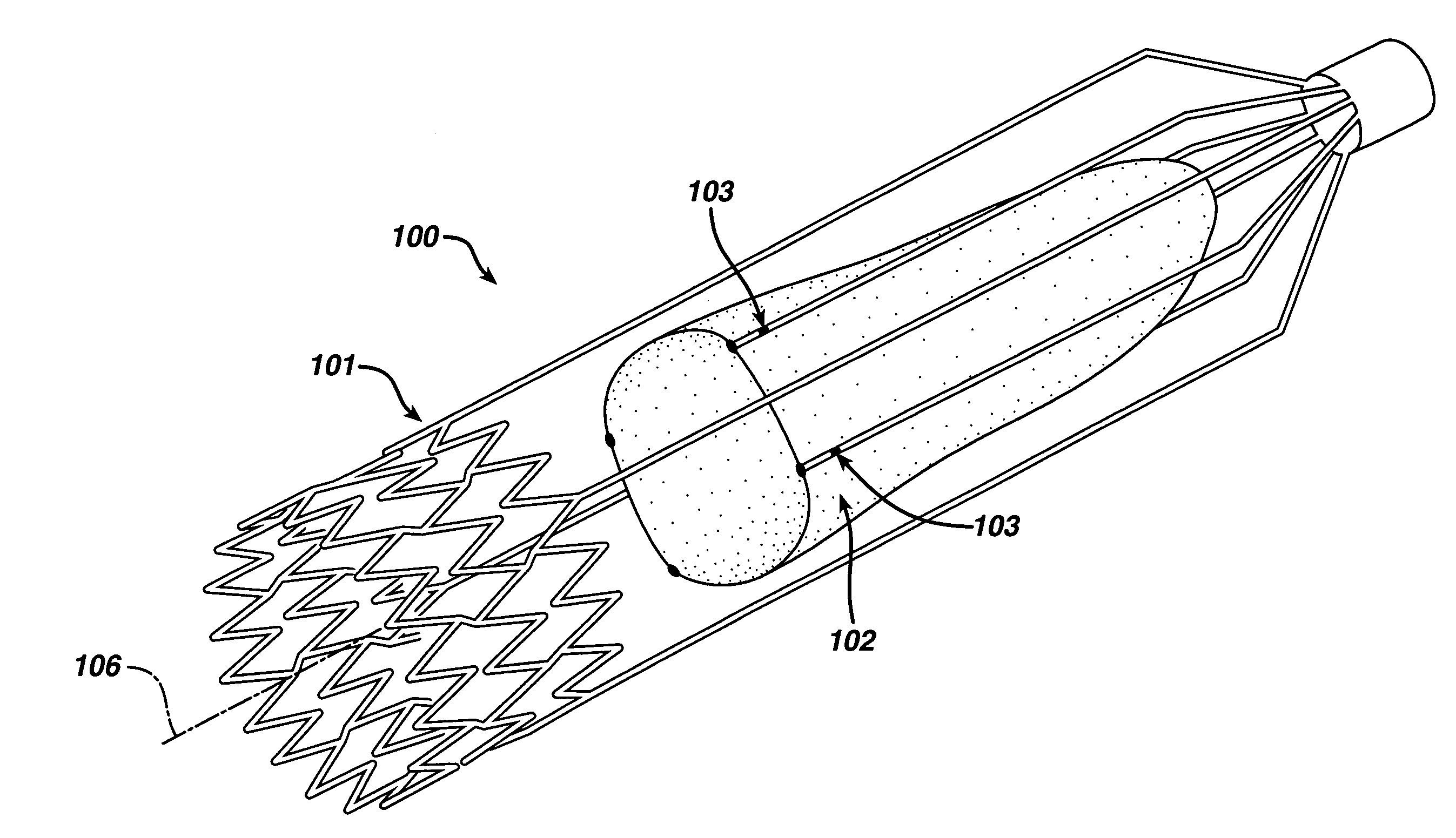

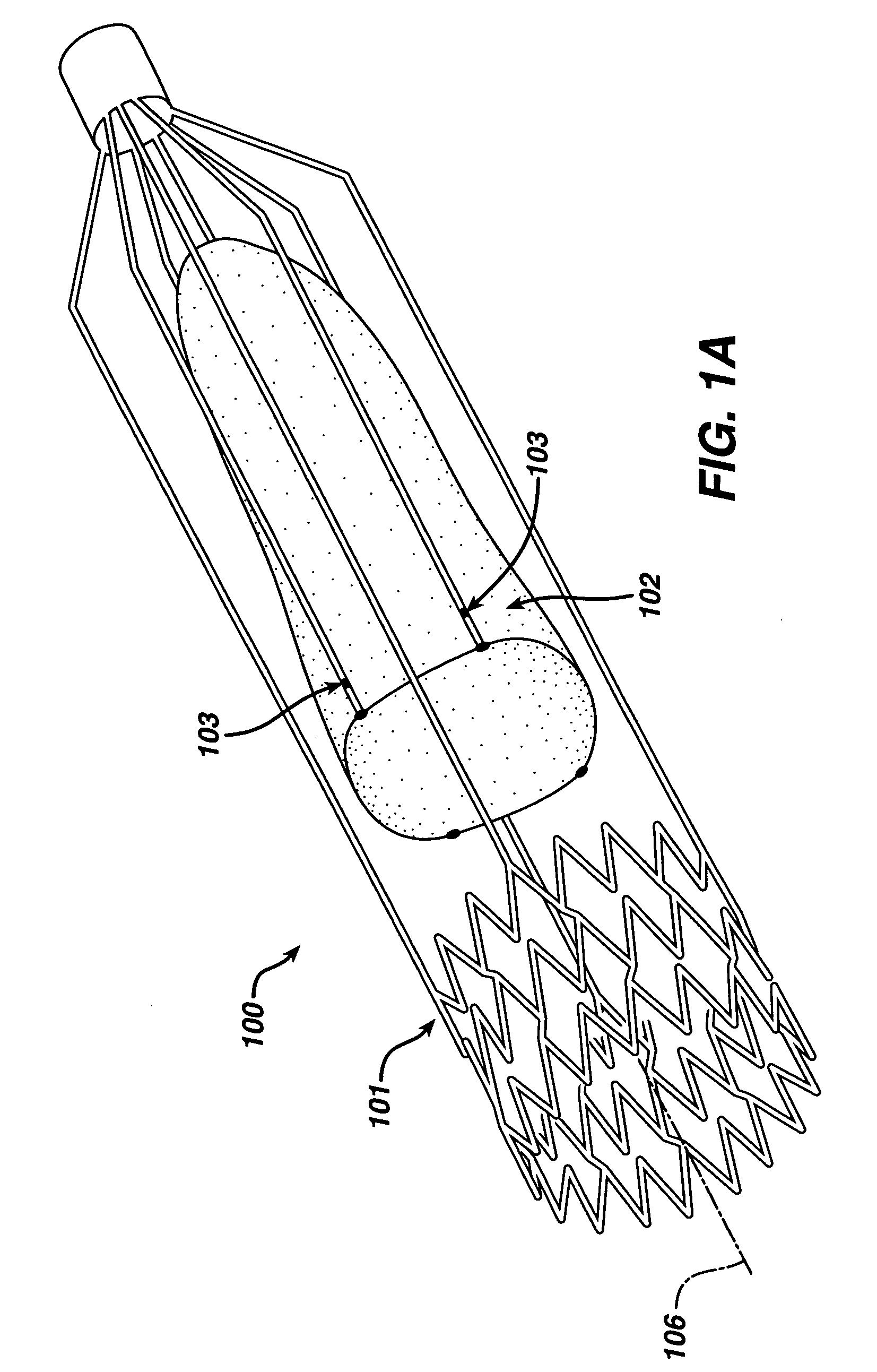

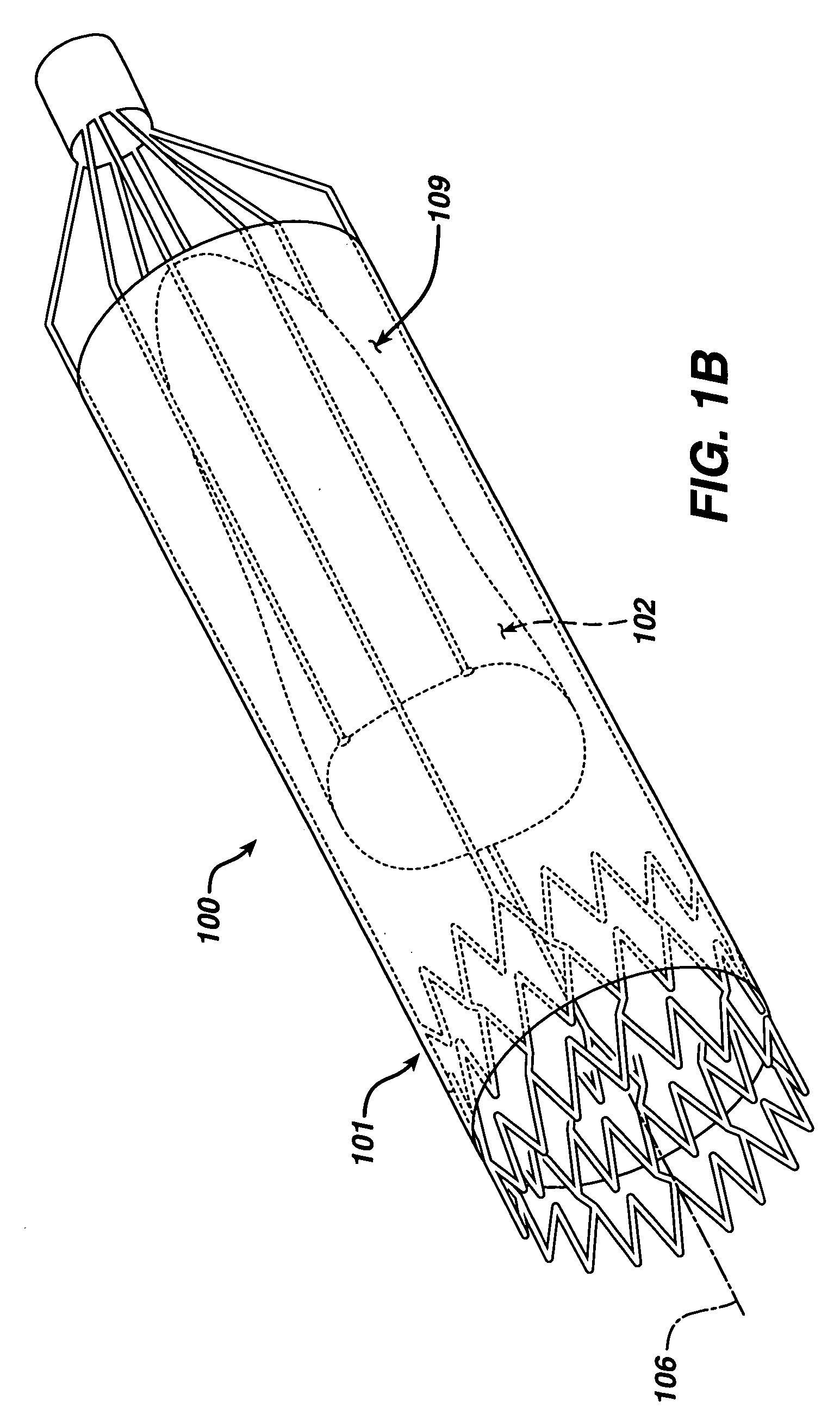

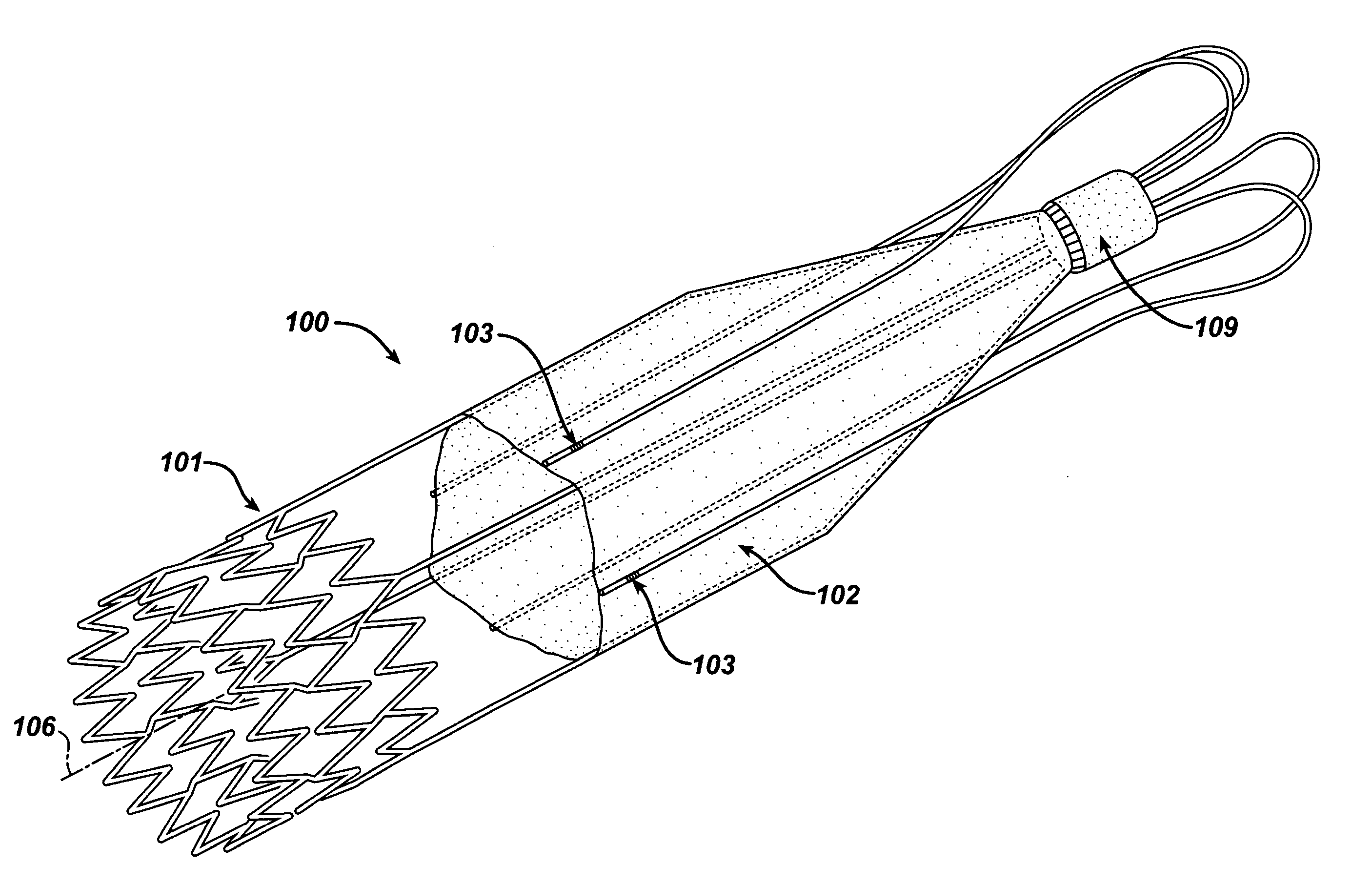

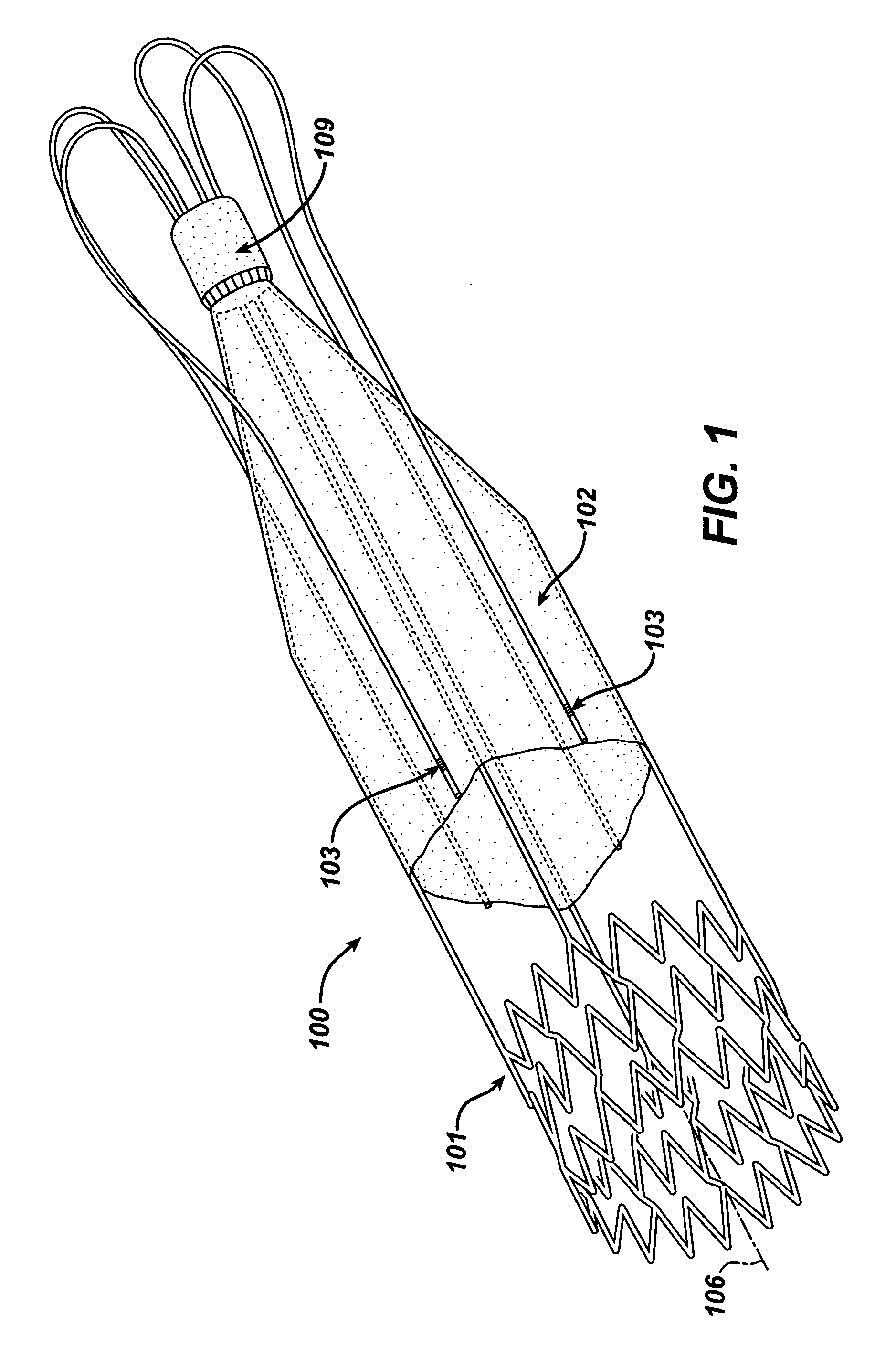

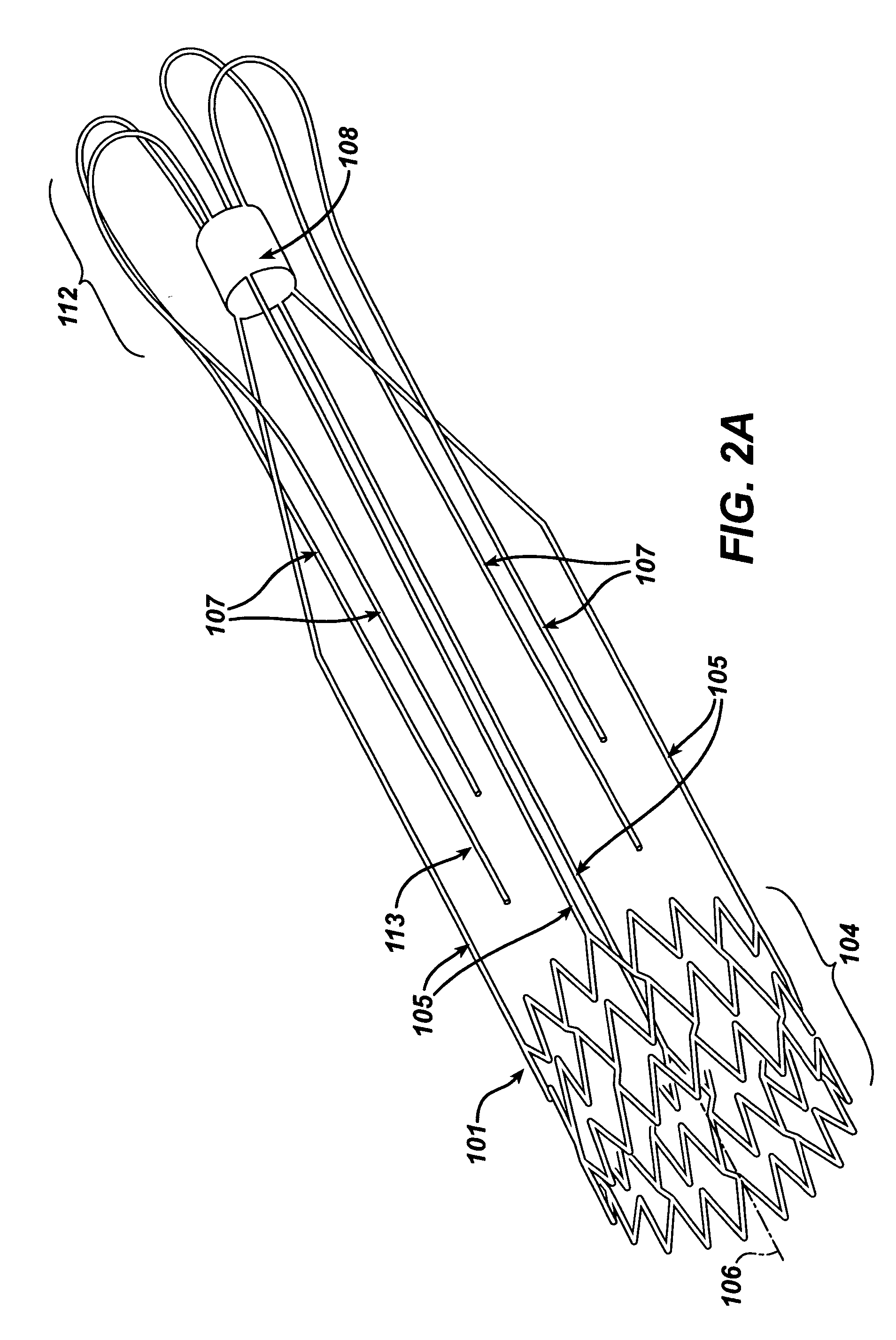

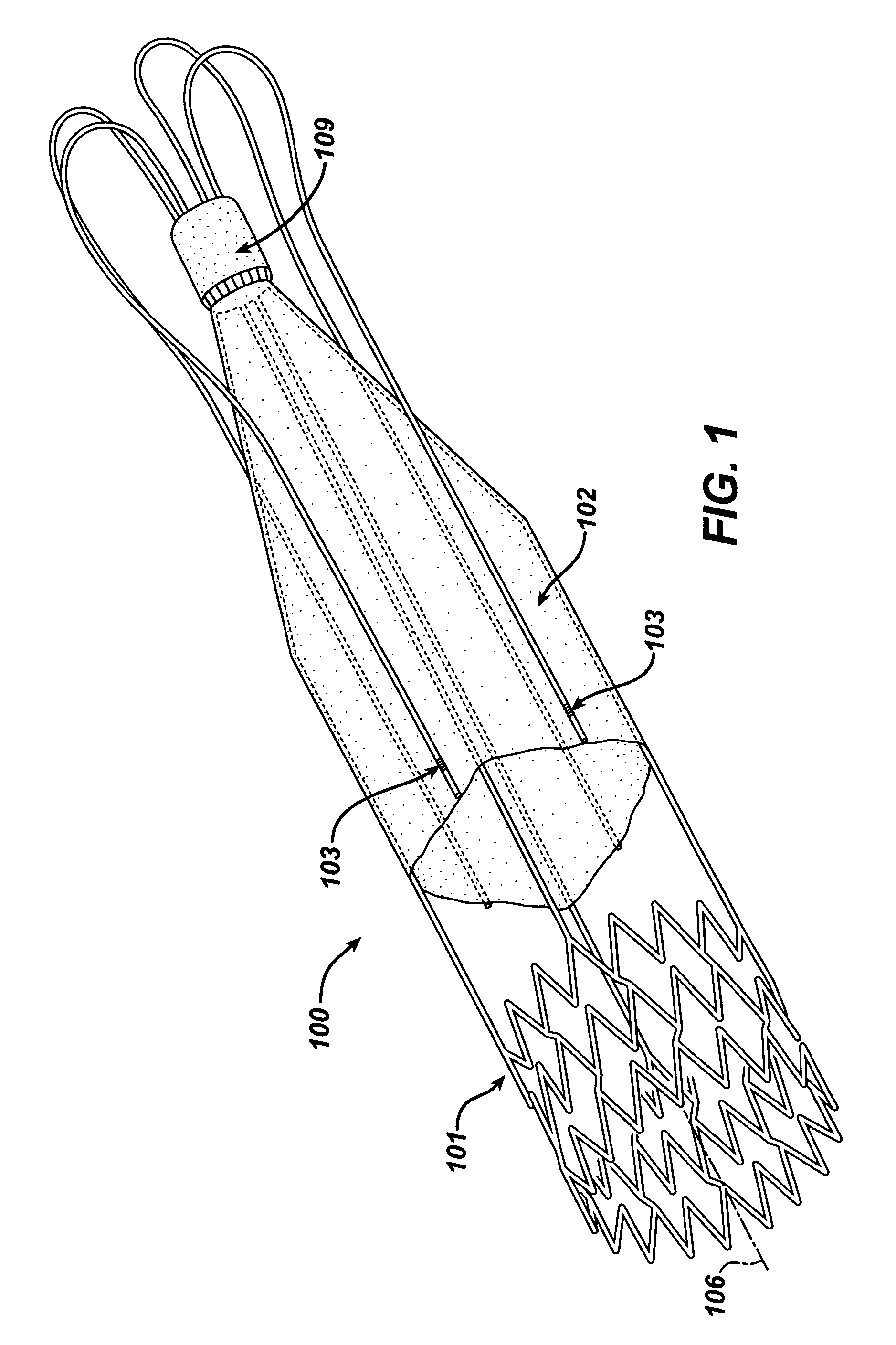

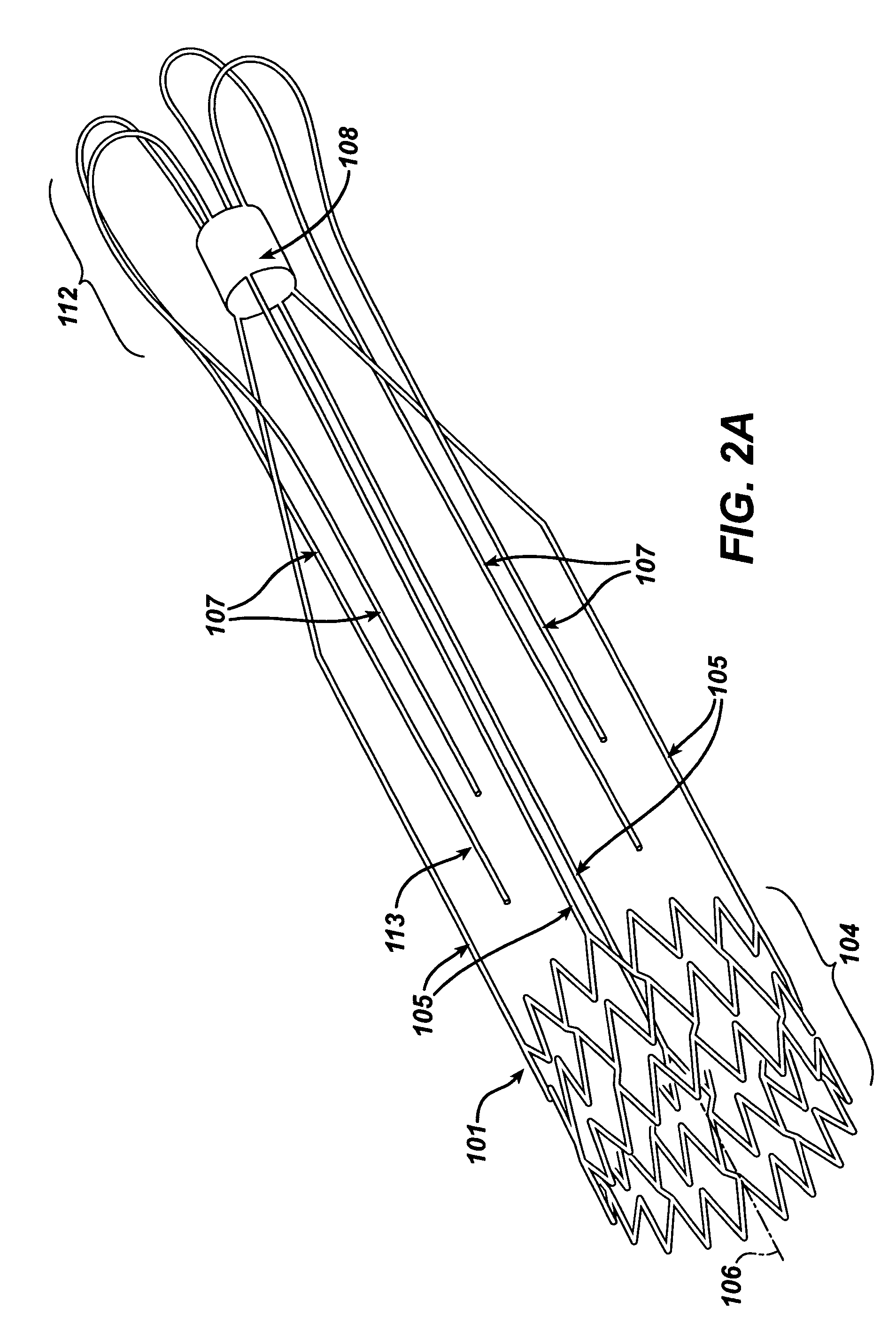

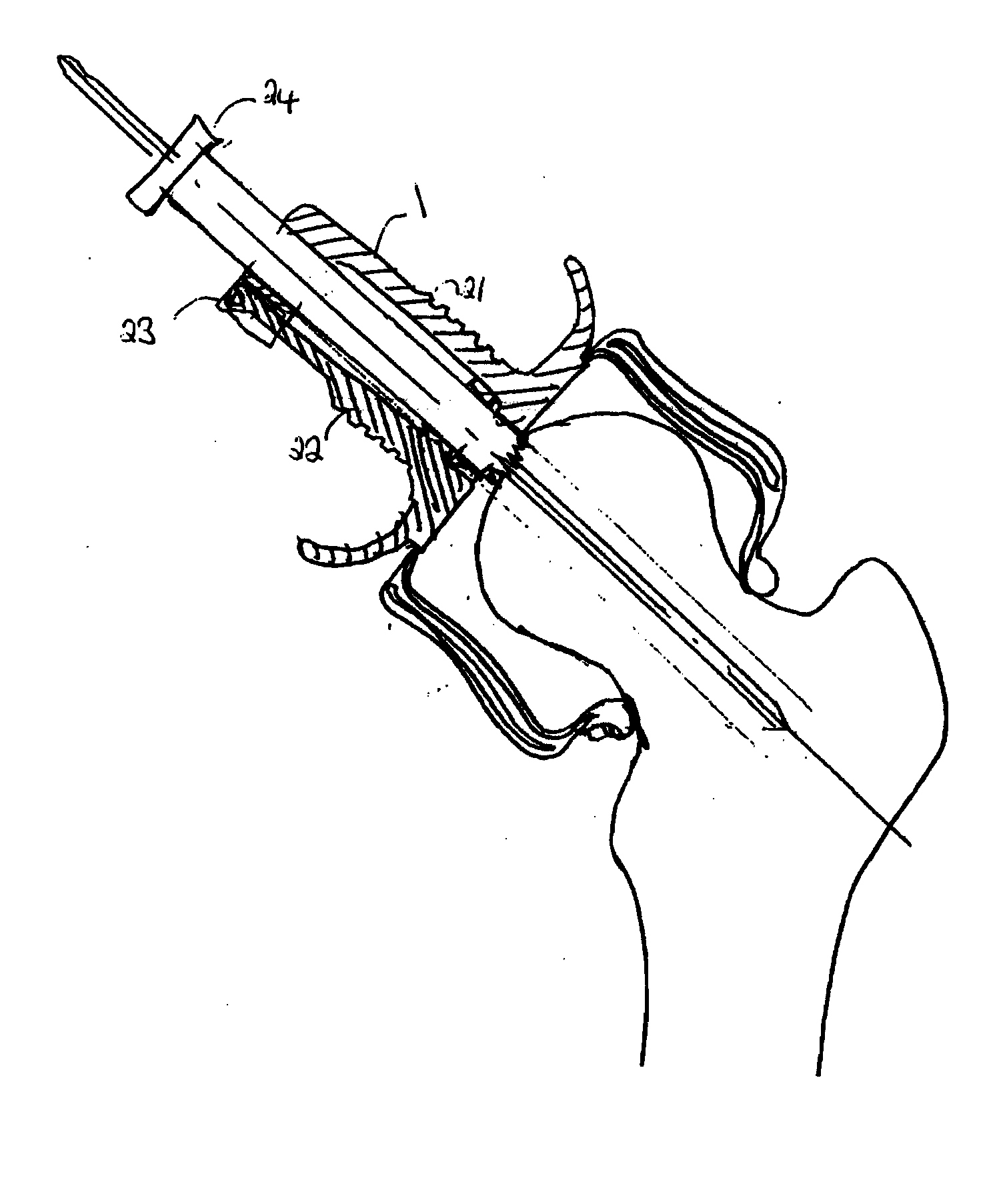

Implantable valvular prosthesis

The present invention relates to a medical device, and in particular, to a stent-based valve. The valve includes a radially expandable structural frame including an anchor structure having a first and a second open end, a connecting member having a first and a second end, and a cantilever valve strut having a first and a second end. The first end of the connecting member is attached to the second end of the anchor structure. The first end of the cantilever valve strut is cooperatively associated with the second end of the connecting member. The prosthetic valve further includes a biocompatible membrane assembly having a substantially tubular configuration about the longitudinal axis, with a first open and a second closed end. The first end of the membrane assembly is attached to the structural frame along the second end of the cantilever valve strut.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Implantable valvular prosthesis

The present invention relates to a medical device, and in particular, to a stent-based valve. The valve includes a radially expandable structural frame including an anchor structure having a first and a second open end, a connecting member having a first and a second end, and a cantilever valve strut having a first and a second end. The first end of the connecting member is attached to the second end of the anchor structure. The first end of the cantilever valve strut is cooperatively associated with the second end of the connecting member. The prosthetic valve further includes a biocompatible membrane assembly having a substantially tubular configuration disposed longitudinally about at least a portion of the connecting member. The membrane assembly has a first end having a first diameter and a second end having a second diameter, wherein the first diameter is greater than the second diameter. The first end of the membrane assembly is attached along the second end of the cantilever valve strut.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

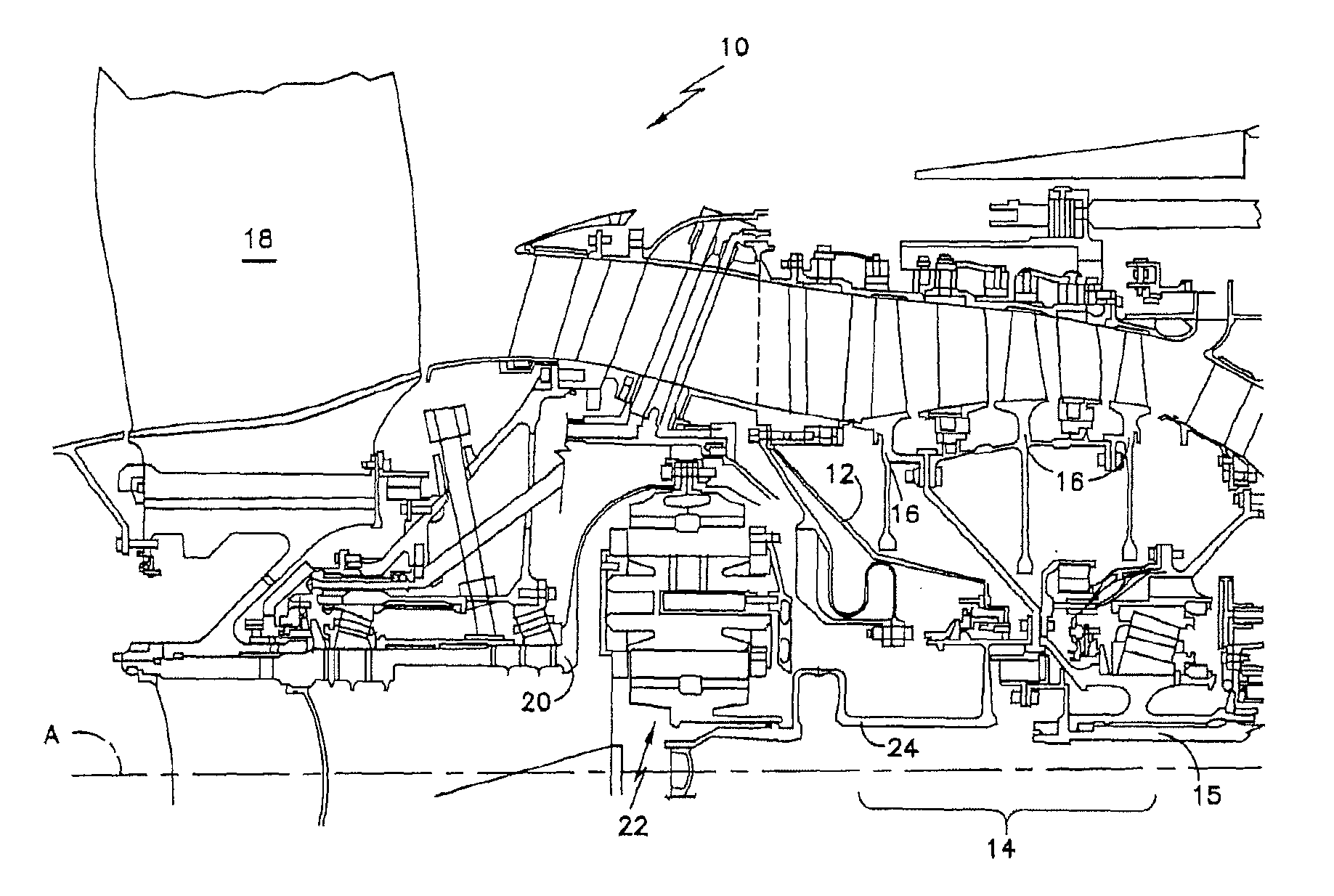

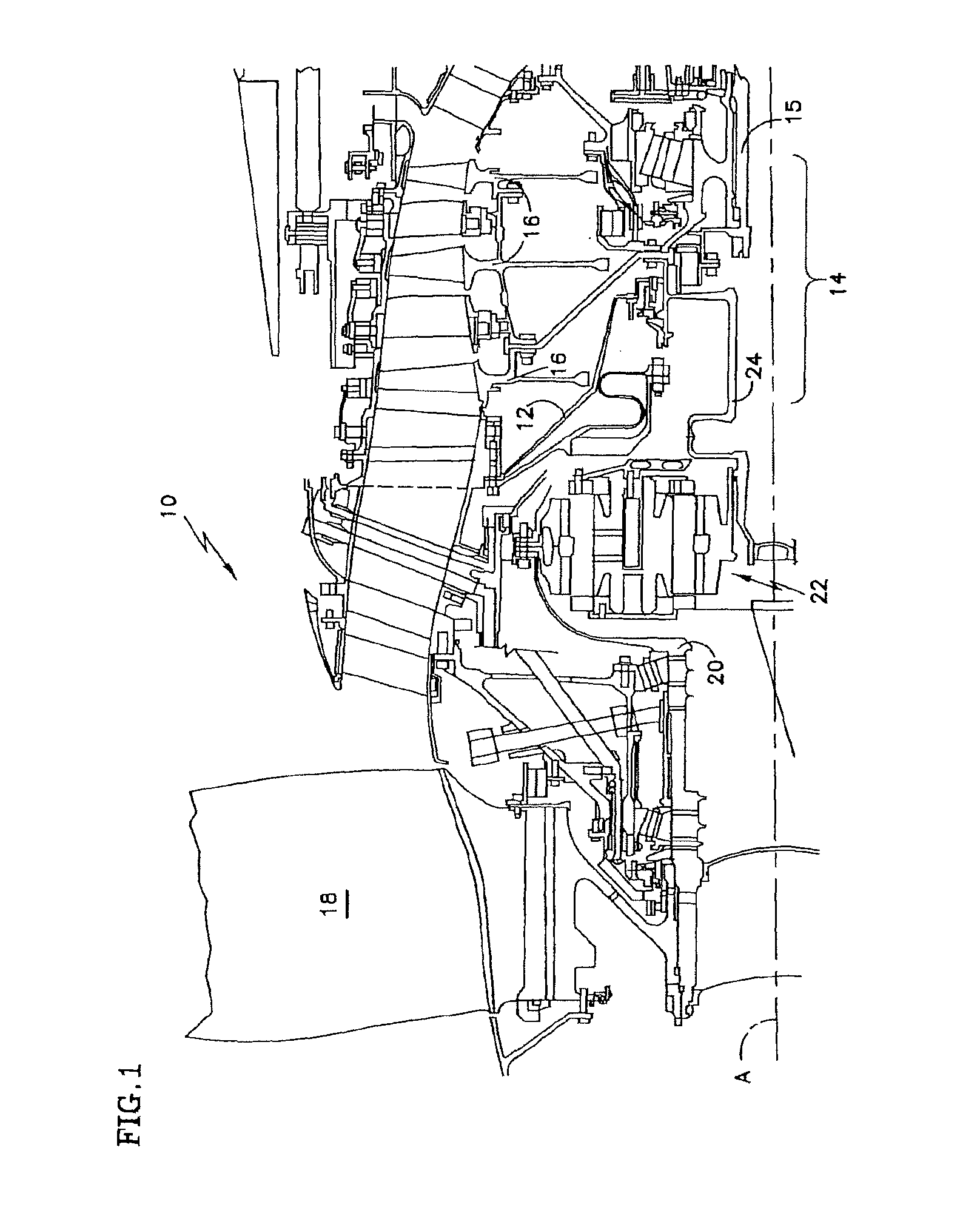

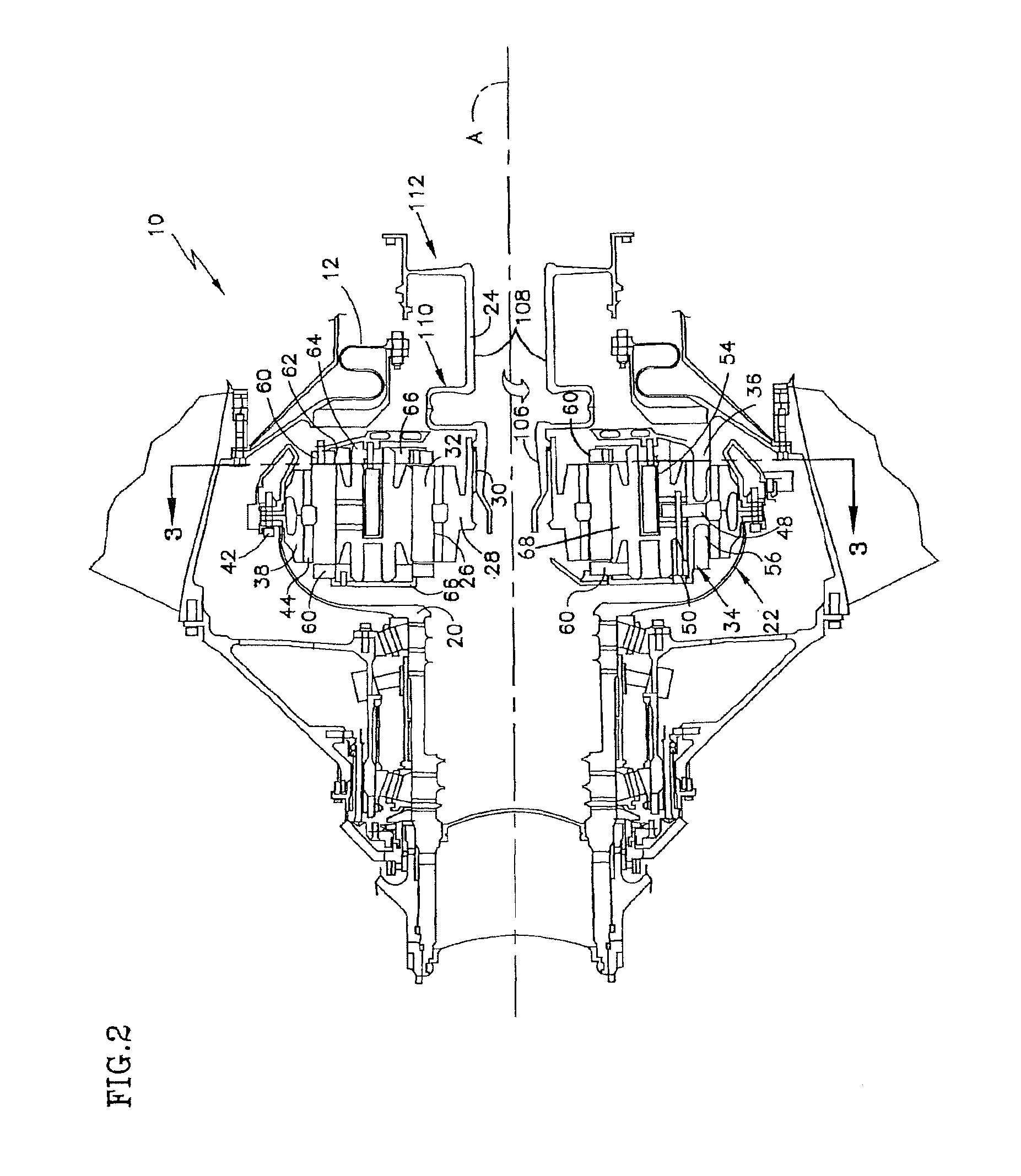

Flexible shaft for gas turbine engine

A shaft for a gas turbine engine is provided that includes a first shaft section, a second shaft section, a first flexible linkage, and a second flexible linkage. The first shaft section extends between a forward axial end and an aft axial end along a first axial centerline. The second shaft section extends between a forward axial end and an aft axial end along a second axial centerline. The first flexible linkage includes a bridge section connected between a first diaphragm and a second diaphragm. The first diaphragm is connected to the aft axial end of the first shaft section. The second diaphragm is connected to the forward axial end of the second shaft section. The second flexible linkage includes a diaphragm and a hub. The second flexible linkage diaphragm cantilevers radially outwardly from an inner radial end to an outer radial end, and is connected to the aft axial end of the second shaft section. The hub is connected to the outer radial end of the second flexible linkage diaphragm, and includes an engine shaft coupling connected to the hub.

Owner:RTX CORP

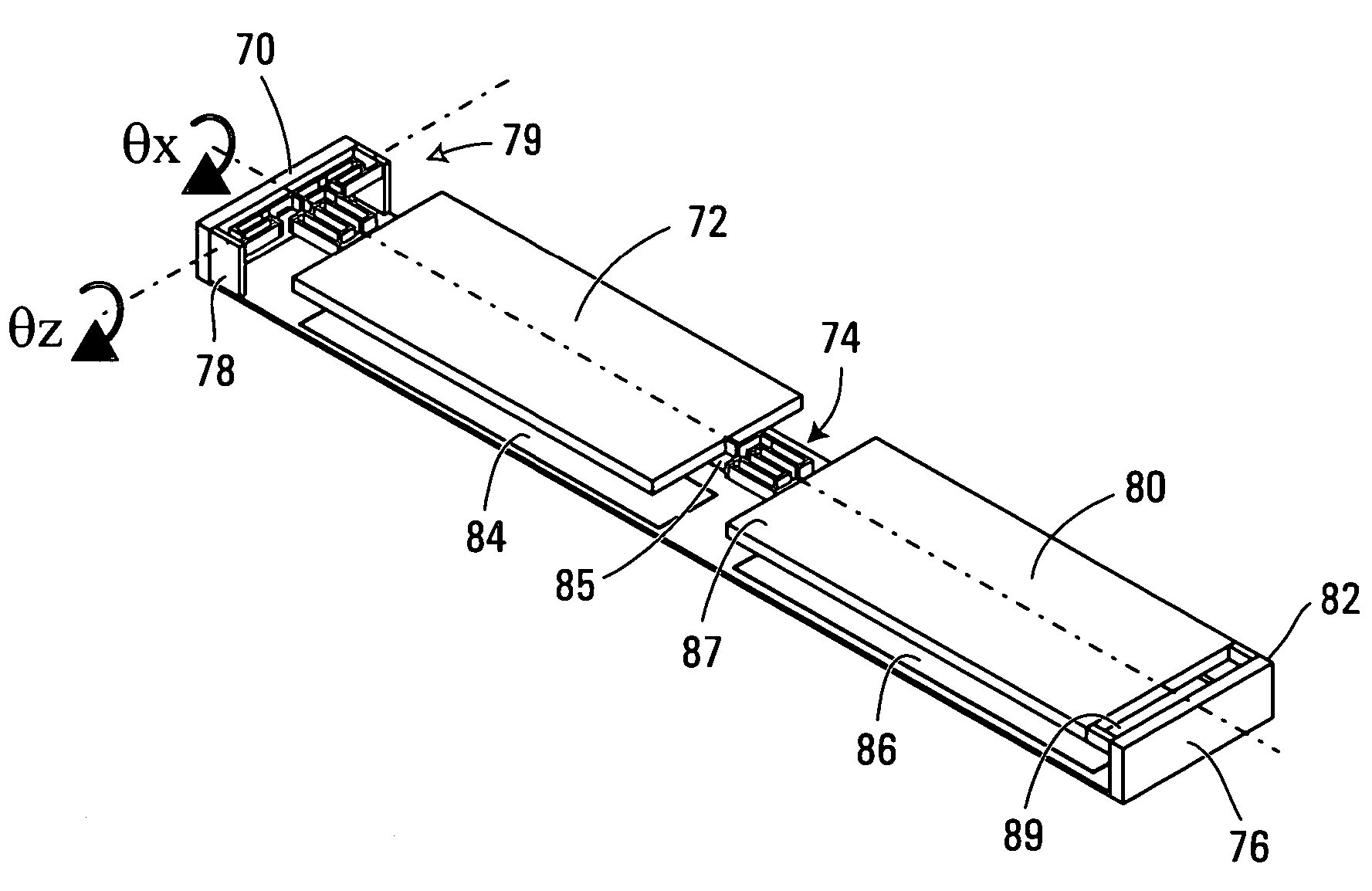

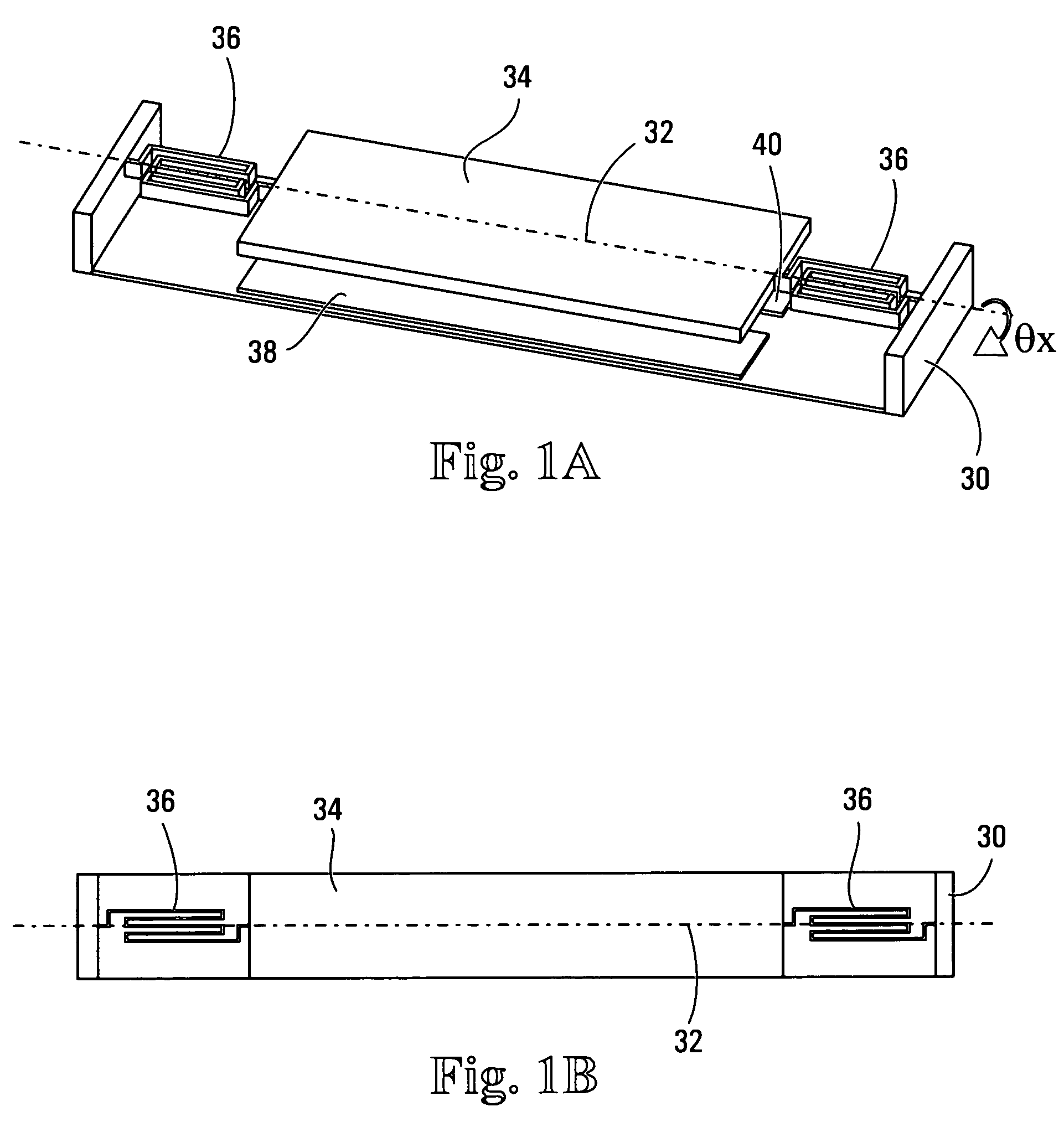

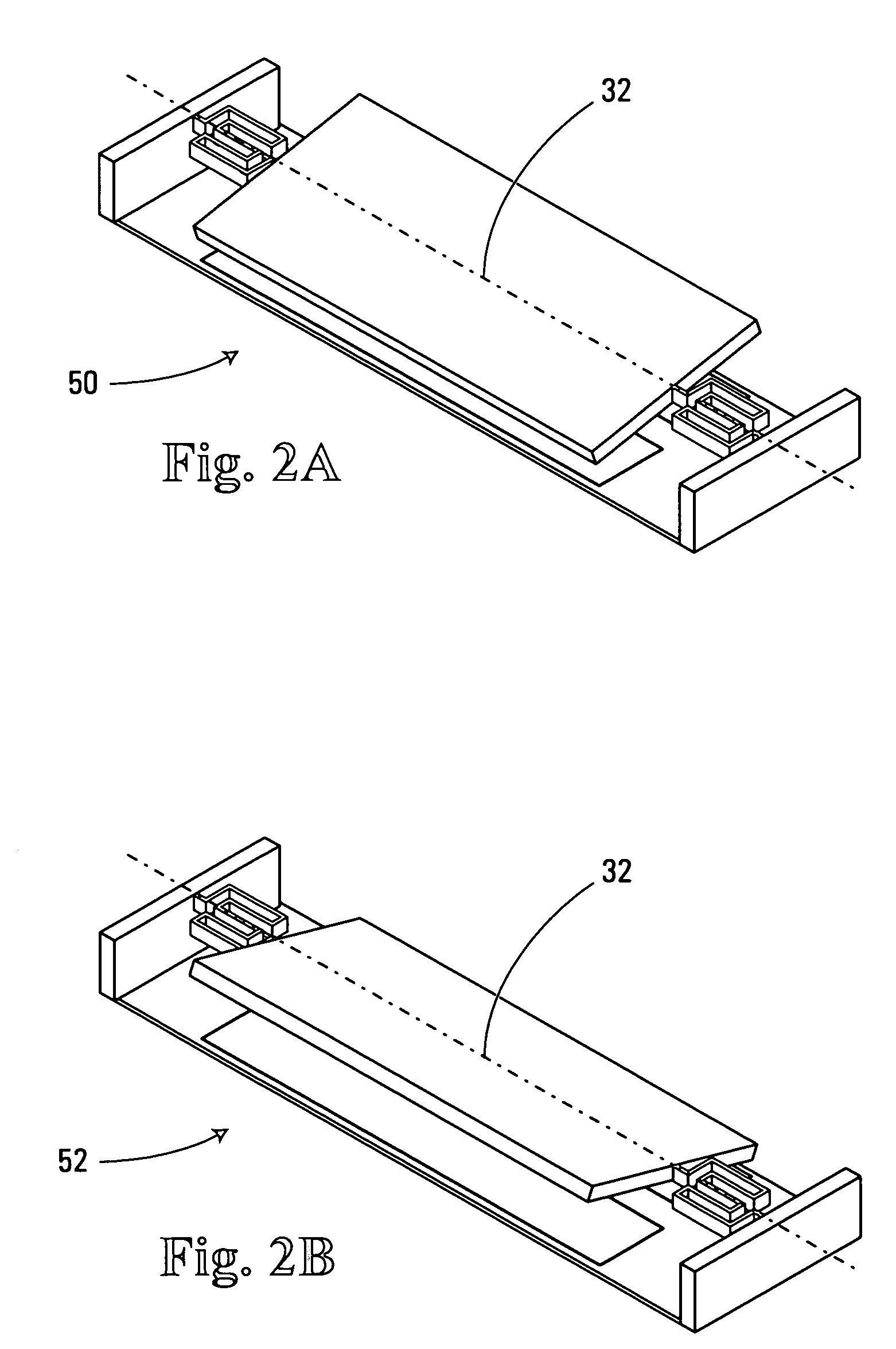

Micro-electro-mechanical-system two dimensional mirror with articulated suspension structures for high fill factor arrays

ActiveUS7095546B2Simple and inexpensive controlTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesFill factorEngineering

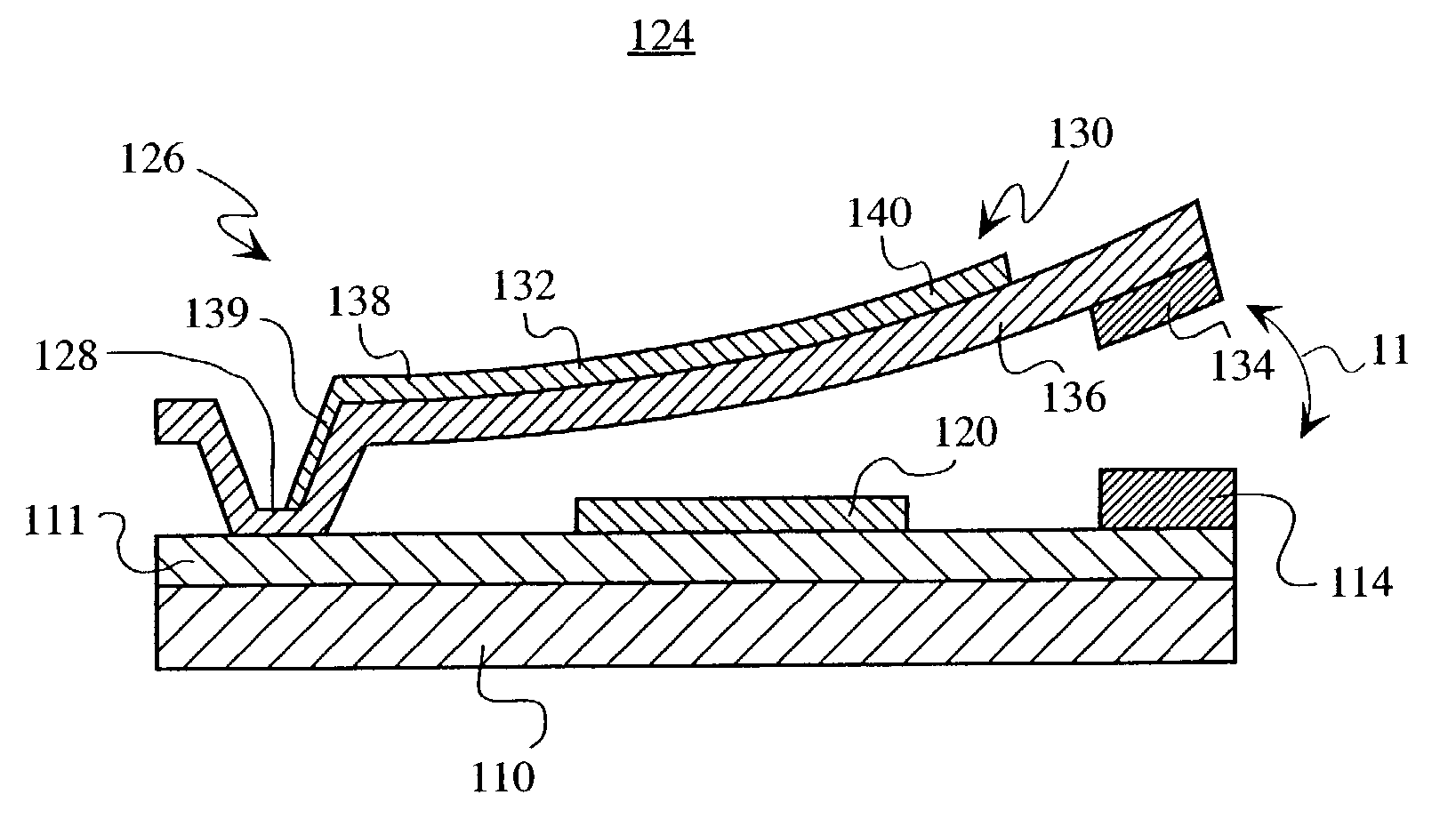

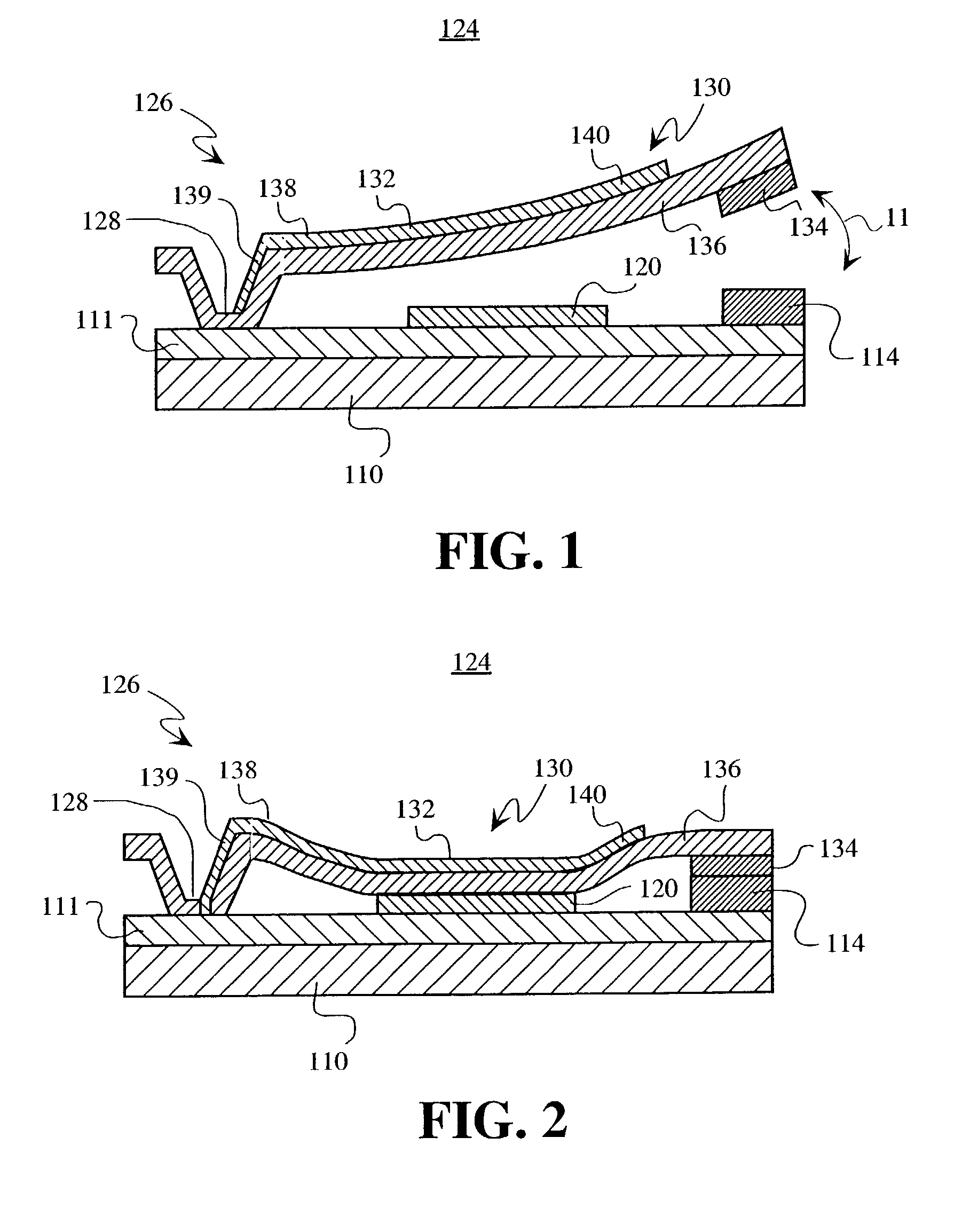

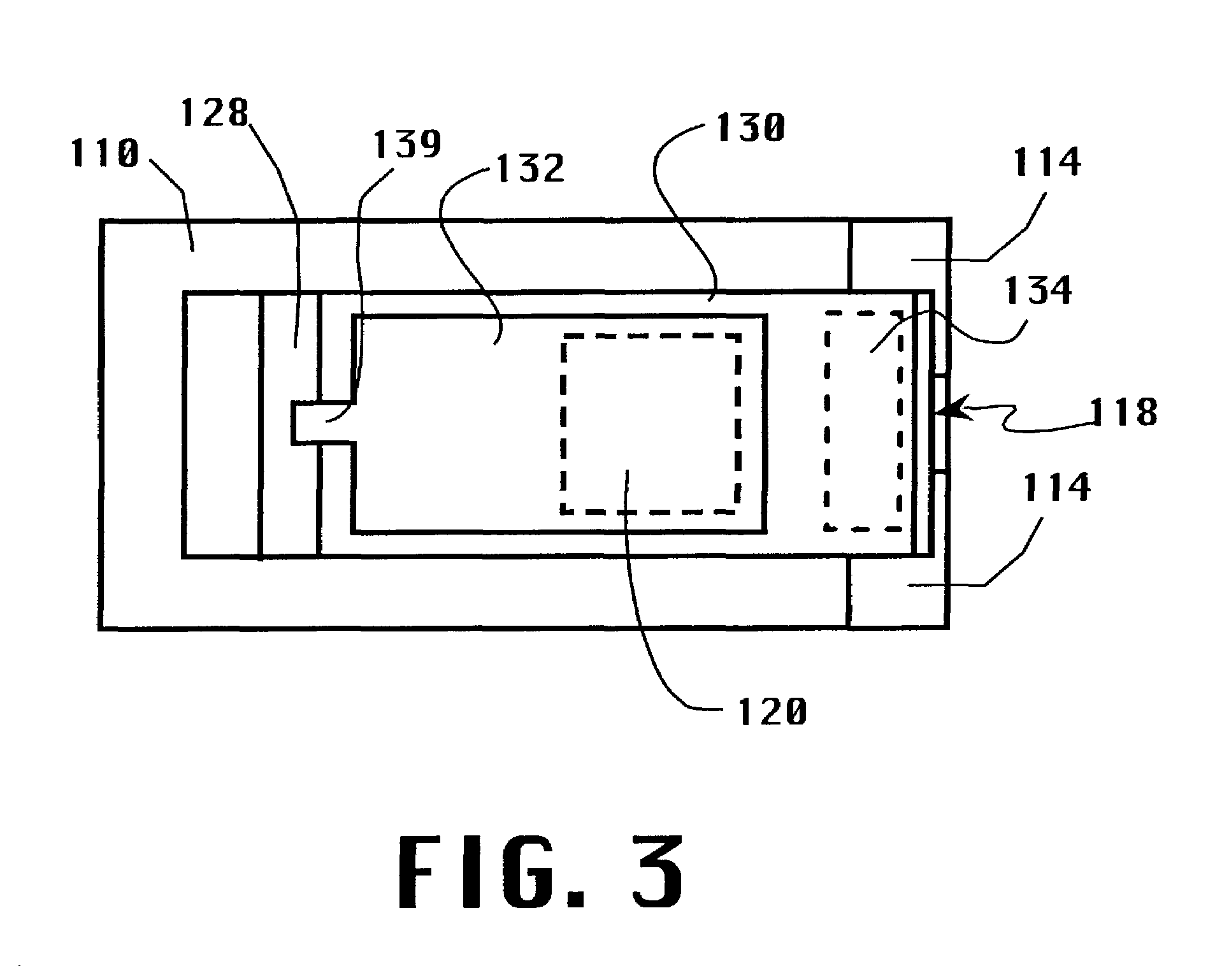

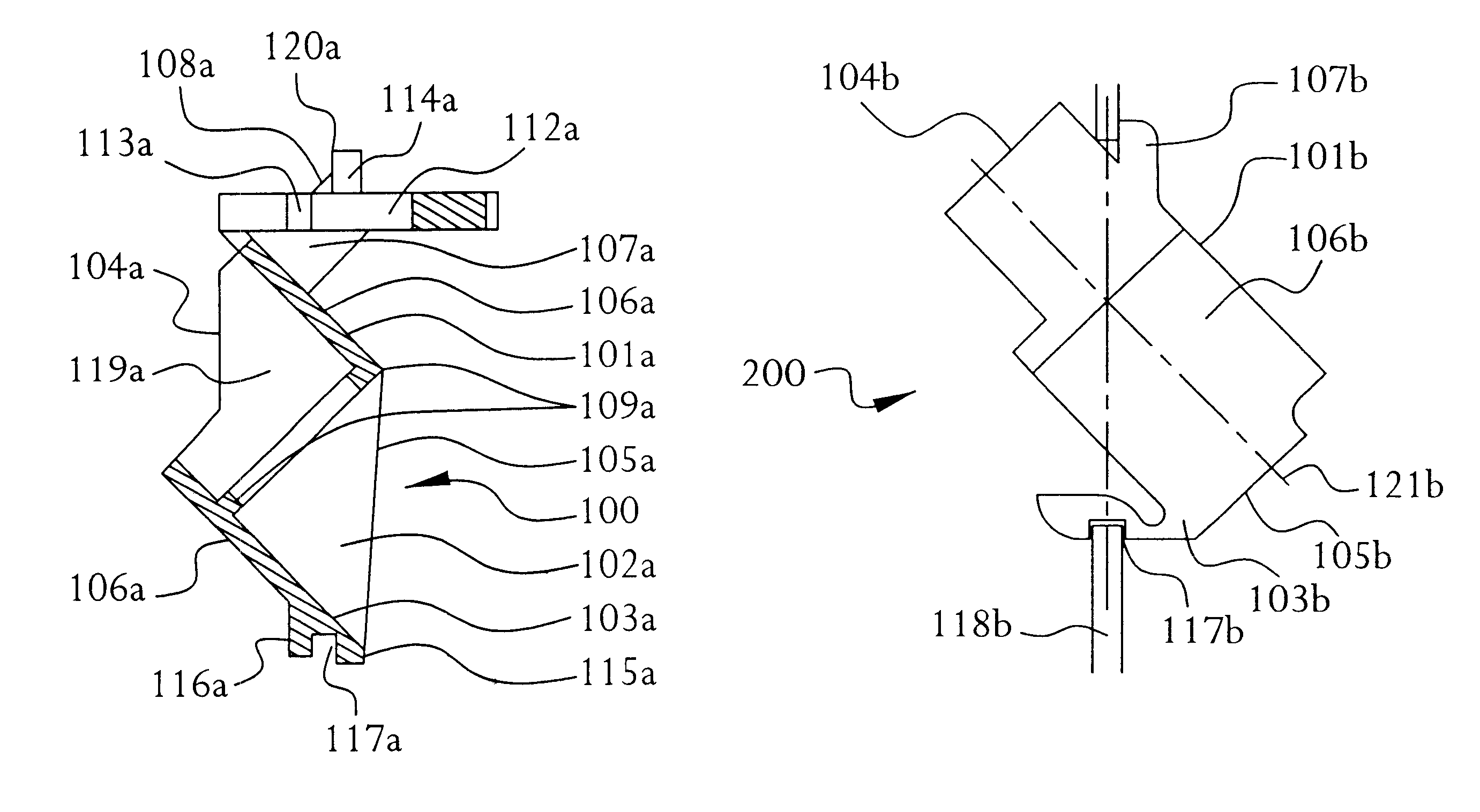

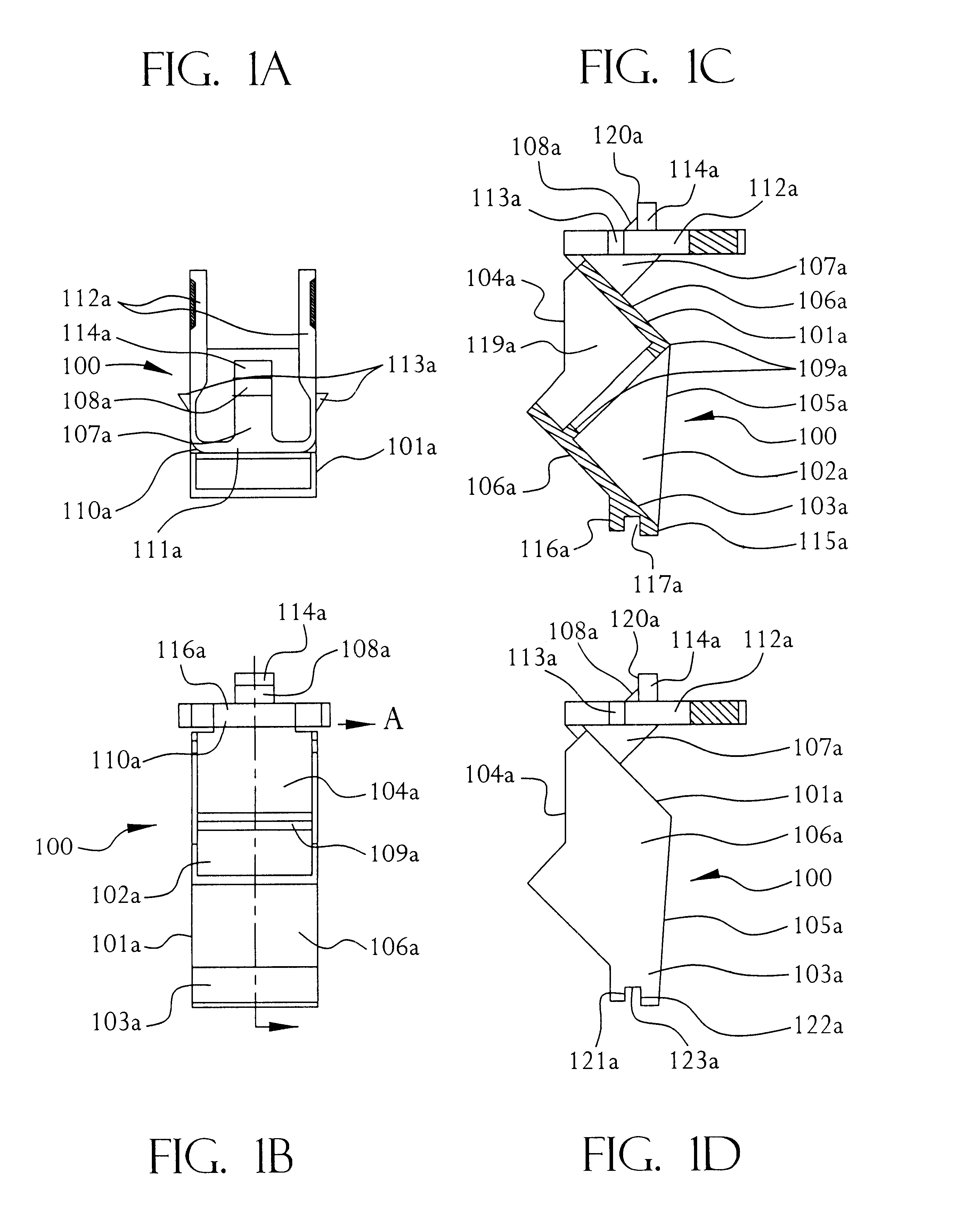

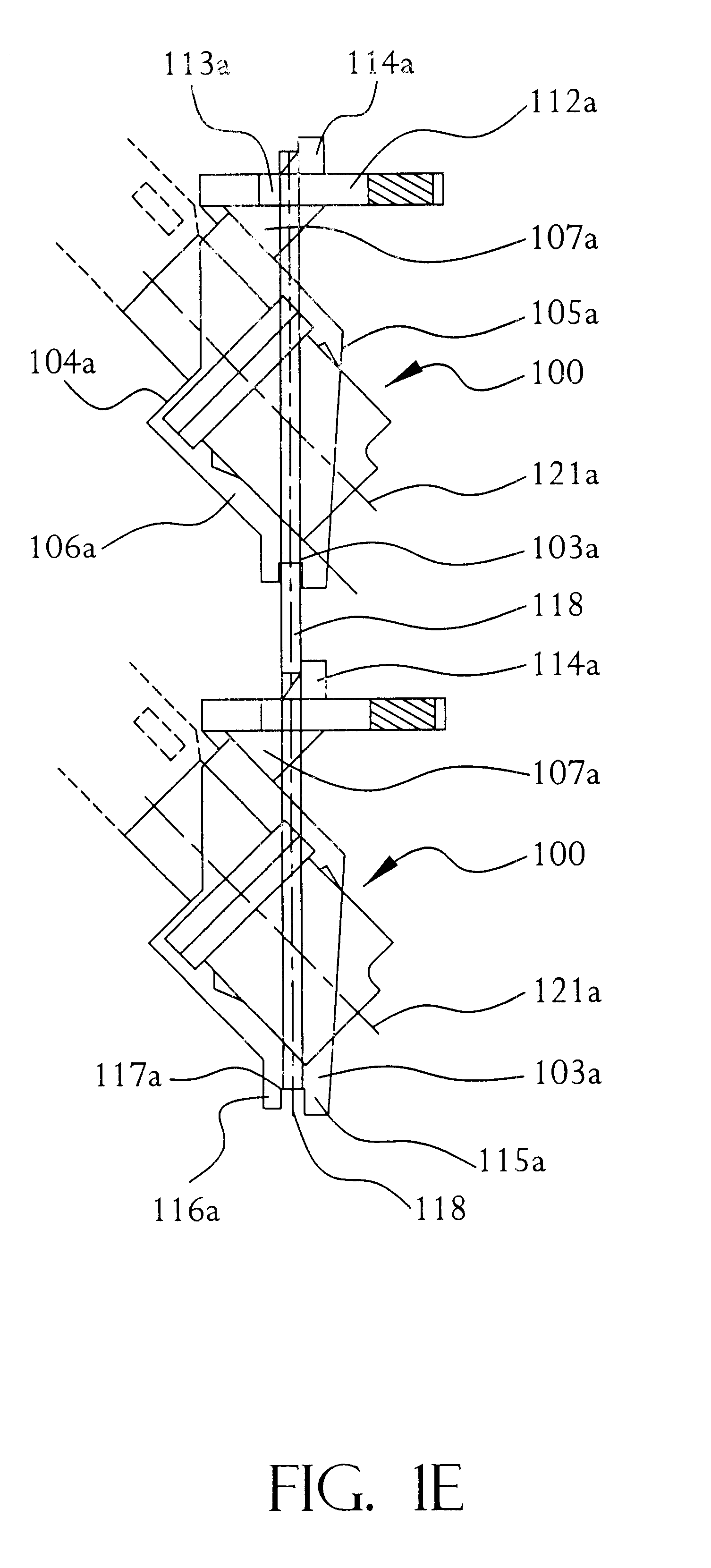

The invention provides a micro-electro-mechanical-system (MEMS) mirror device, comprising: a mirror having a 2-dimensional rotational articulated hinge at a first end, and having a 1-dimensional rotational articulated hinge at a second end opposite the first end; a movable cantilever connected to the mirror through the 1-dimensional rotational articulated hinge; a support structure connected to the mirror through the 2-dimensional rotational articulated hinge and connected to the movable cantilever; whereby movement of said movable cantilever causes rotation of the mirror in a first axis of rotation, and the mirror is also rotatable about a second torsional axis of rotation perpendicular to said first axis of rotation.

Owner:LUMENTUM OPERATIONS LLC

Implantable valvular prosthesis

The present invention relates to a medical device, and in particular, to a stent-based valve. The valve includes a radially expandable structural frame including an anchor structure having a first and a second open end, a connecting member having a first and a second end, and a cantilever valve strut having a first and a second end. The first end of the connecting member is attached to the second end of the anchor structure. The first end of the cantilever valve strut is cooperatively associated with the second end of the connecting member. The prosthetic valve further includes a biocompatible membrane assembly having a substantially tubular configuration disposed longitudinally about at least a portion of the connecting member. The membrane assembly has a first end having a first diameter and a second end having a second diameter, wherein the first diameter is greater than the second diameter. The first end of the membrane assembly is attached along the second end of the cantilever valve strut.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

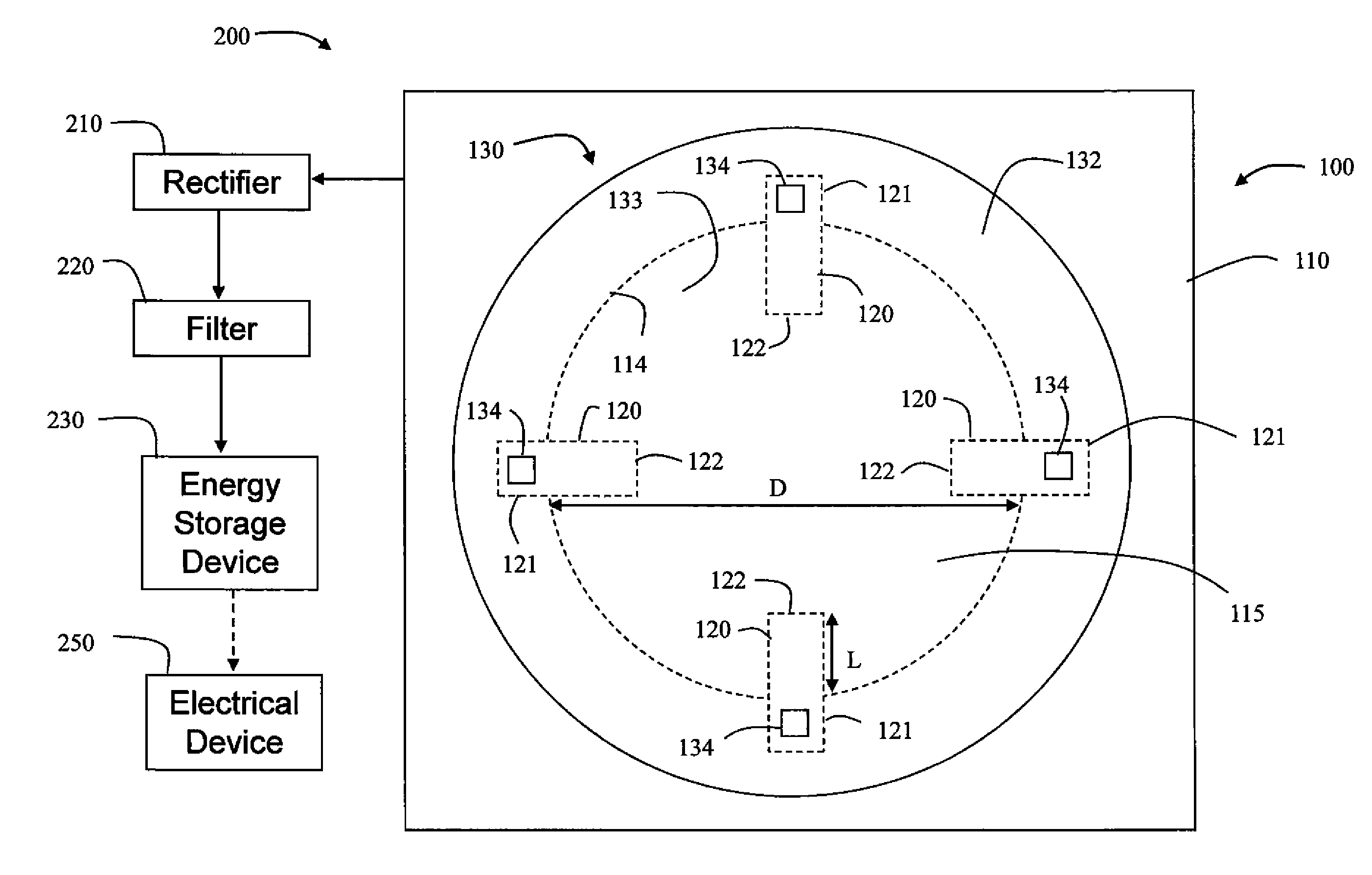

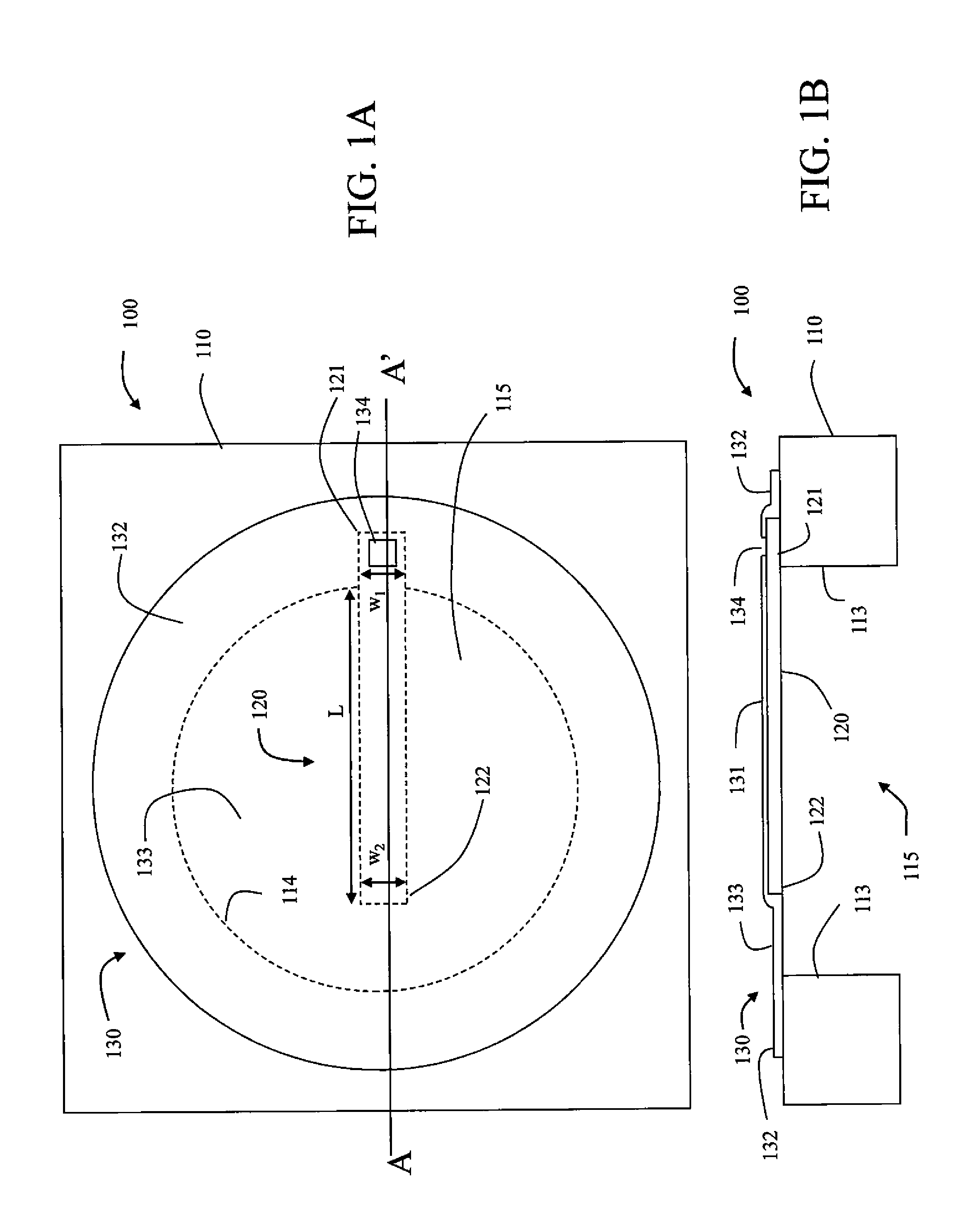

Energy harvesting device including MEMS composite transducer

An energy harvesting device includes a MEMS composite transducer. The MEMS composite transducer includes a substrate. Portions of the substrate define an outer boundary of a cavity. A MEMS transducing member includes a beam having a first end and a second end. The first end is anchored to the substrate and the second end cantilevers over the cavity. A compliant membrane is positioned in contact with the MEMS transducing member. A first portion of the compliant membrane covers the MEMS transducing member. A second portion of the compliant membrane is anchored to the substrate. The compliant member is configured to be set into oscillation by excitations produced externally relative to the energy harvesting device.

Owner:EASTMAN KODAK CO

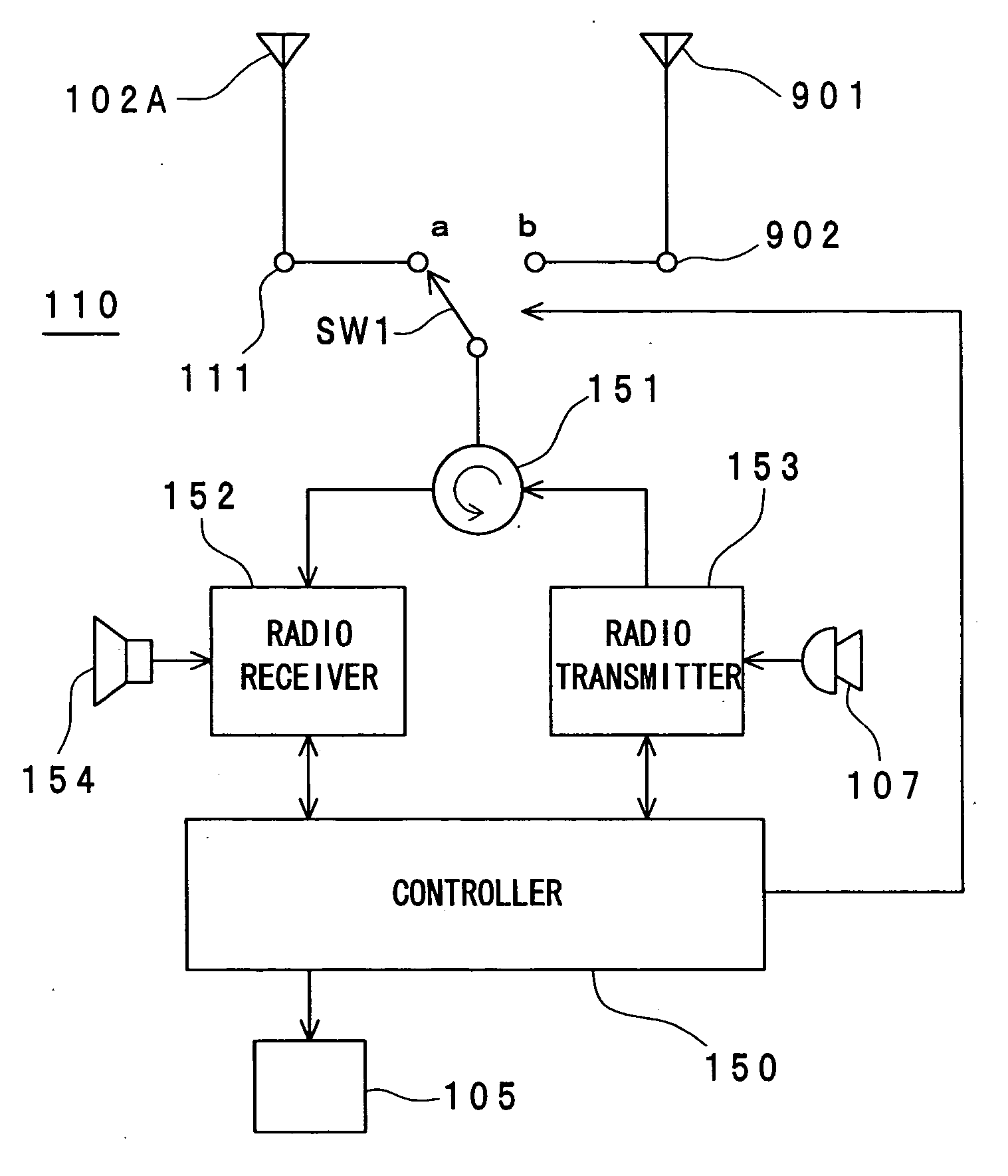

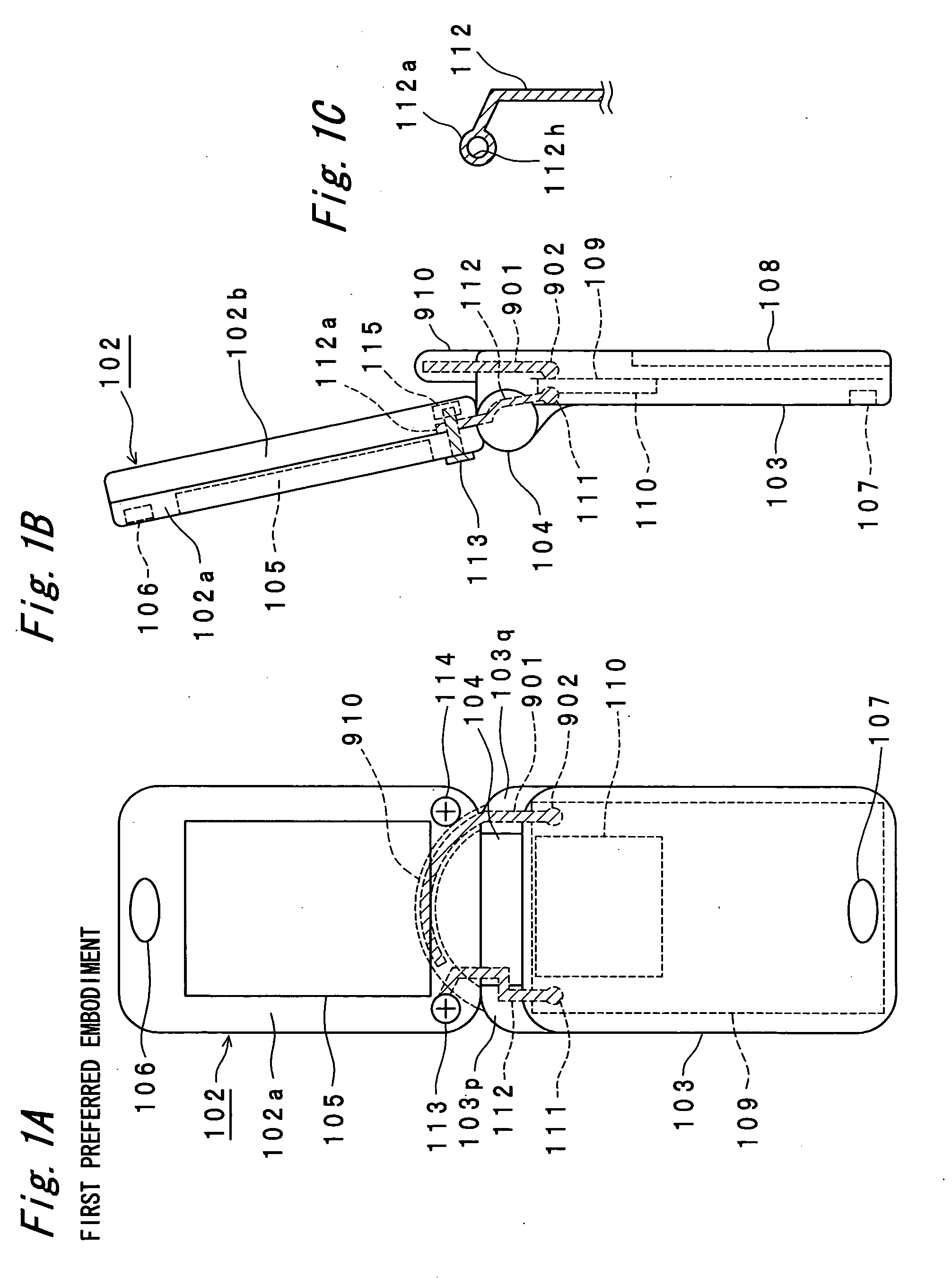

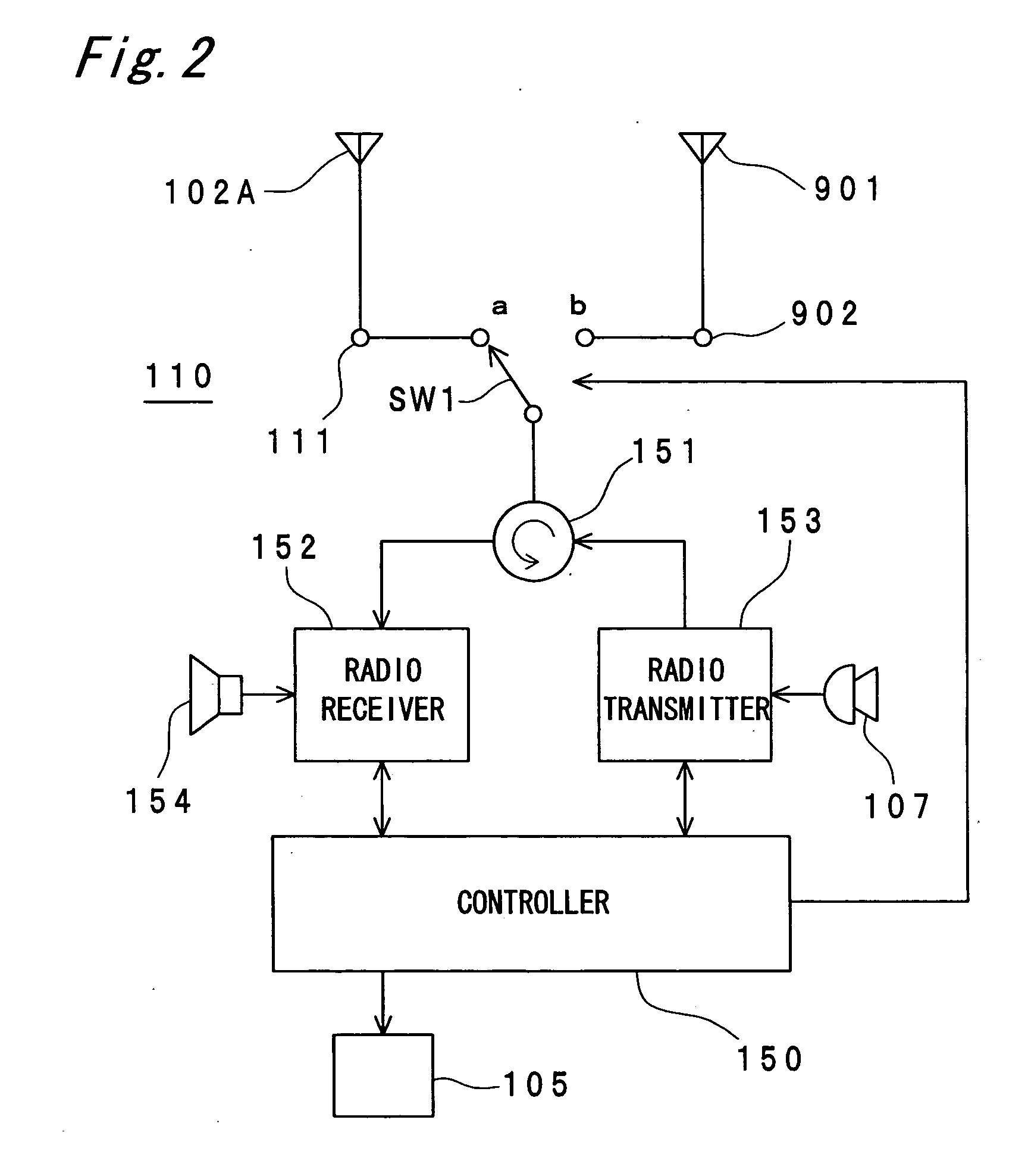

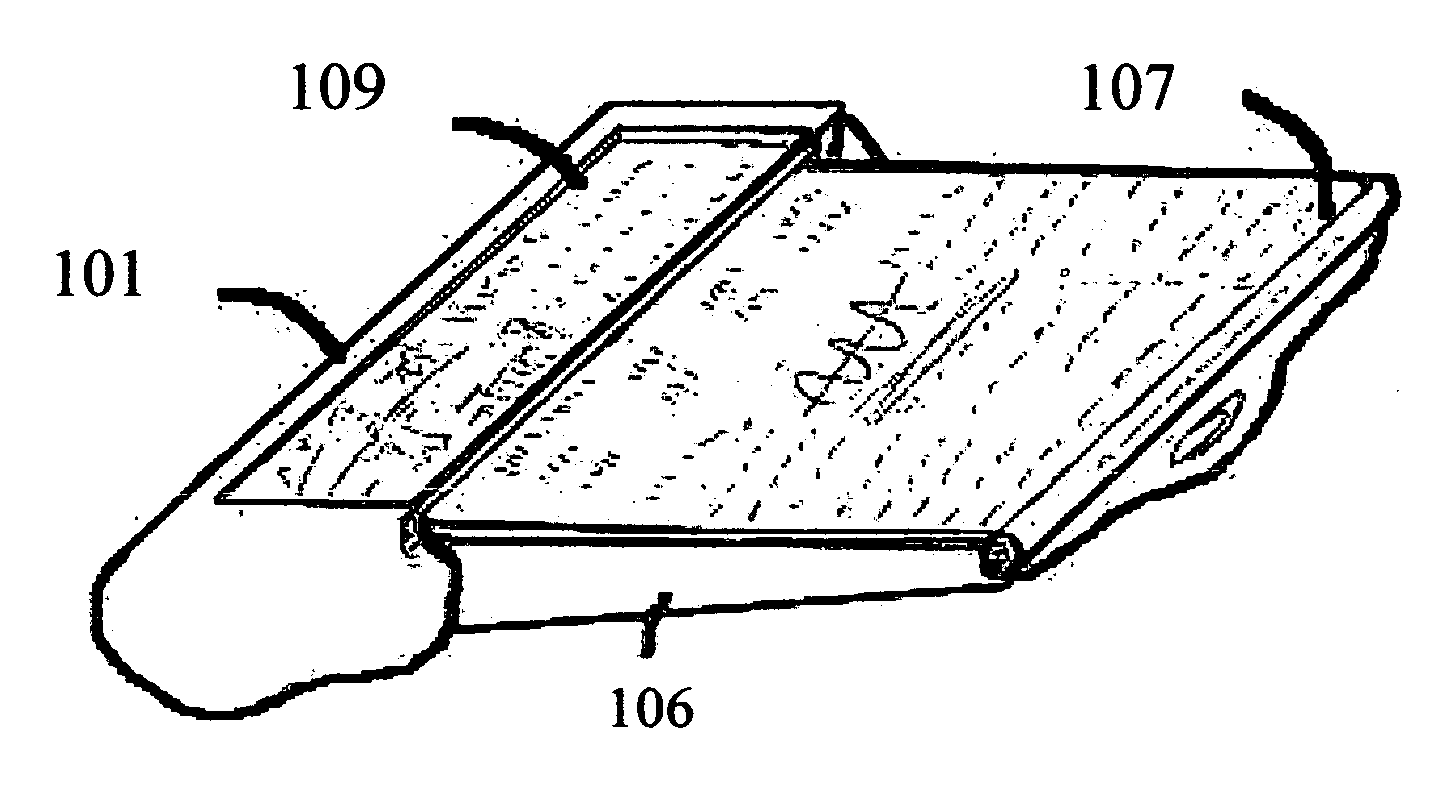

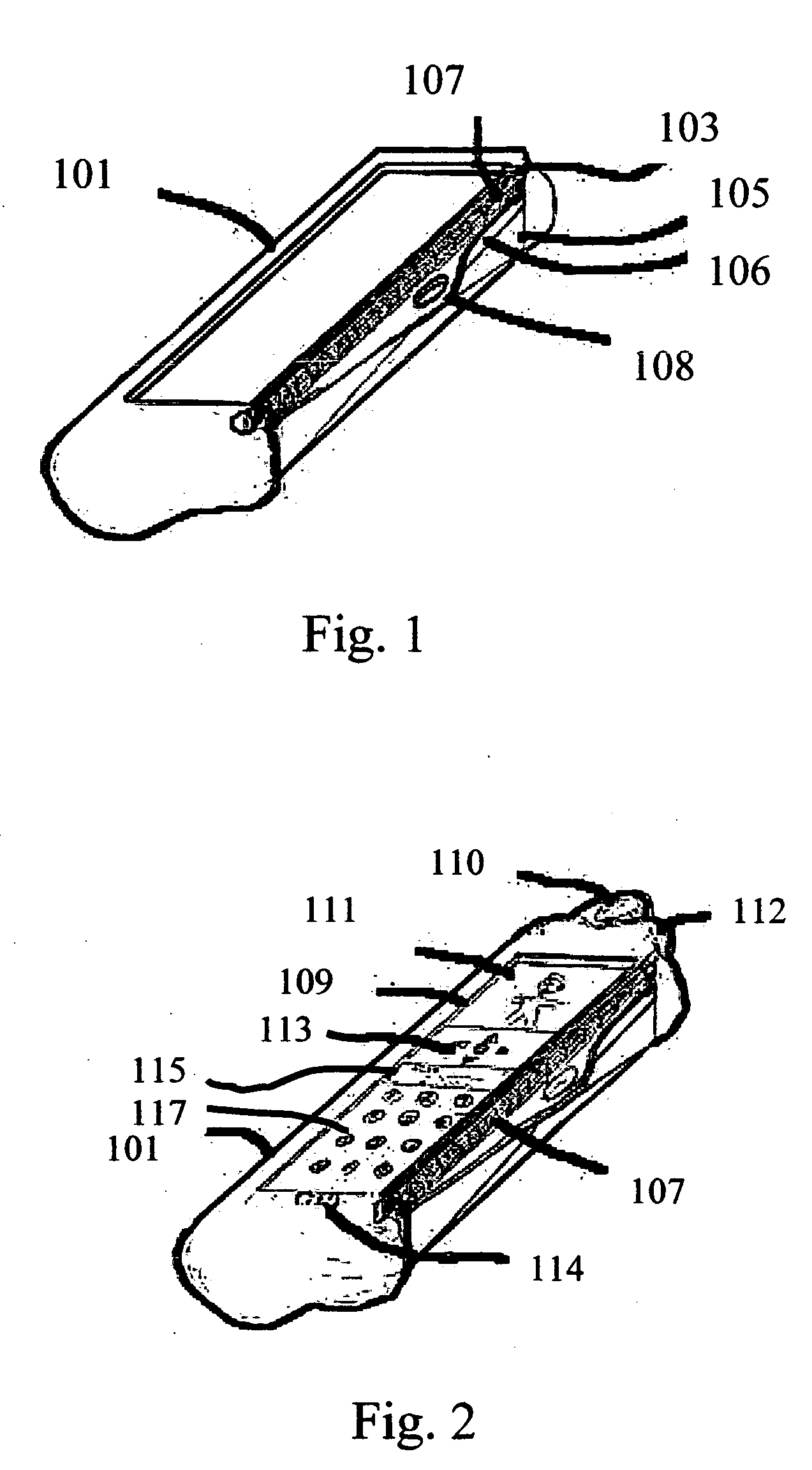

Portable radio communication apparatus provided with a boom portion and a part of housing operating as an antenna

ActiveUS20040219956A1Uniform processImprove featuresAntenna arraysSimultaneous aerial operationsElectrical conductorCantilever

In a portable radio communication apparatus including a housing, at least one part of at least one of the housing is formed as a housing electrical conductor portion by an electrically conductive material. The housing electrical conductor portion is connected with a radio communication circuit of the portable radio communication apparatus so as to operate as at least one part of an unbalanced type antenna of the radio communication circuit. Further, the portable radio communication apparatus further includes a boom portion coupled with the housing at least at two positions so as to provide at least one penetrating hole between the housing and the boom portion.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

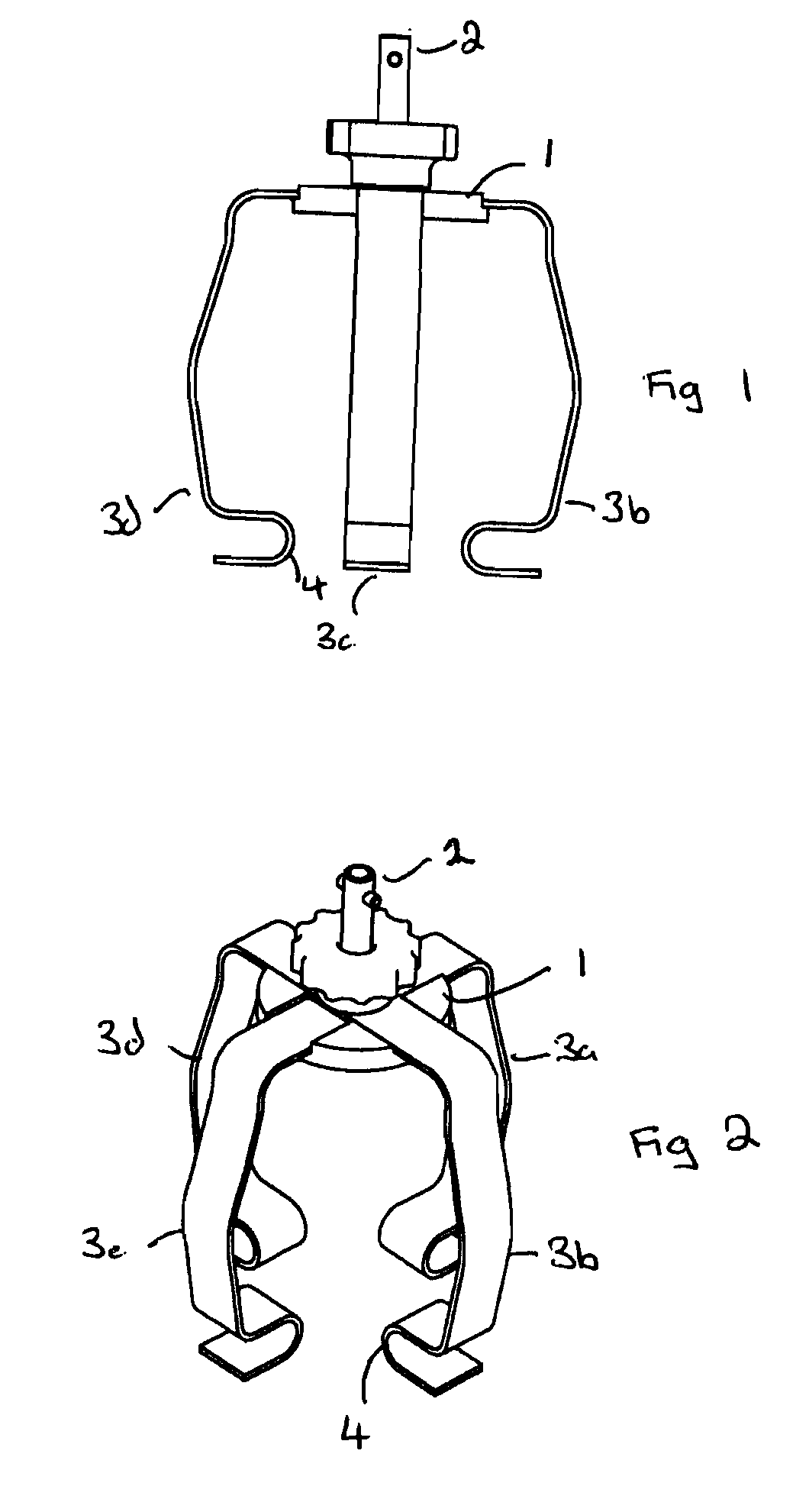

Tool

InactiveUS20070233136A1Prevent movementReadily fitted and removedSurgeryJoint implantsRight femoral headMedicine

An alignment guide for use in femoral head surgery comprising: support member comprising a cannulated rod; at least three locator arms at least a portion of at least one of which comprises a cantilever spring, each of said arms having a proximal end connected to the support member and a distal end having location means for location at the femoral head / neck junction, said at least three locator arms being spaced such that in use they extend around the femoral head and prevent relative movement between the alignment guide and the femoral head.

Owner:FINSBURY DEV

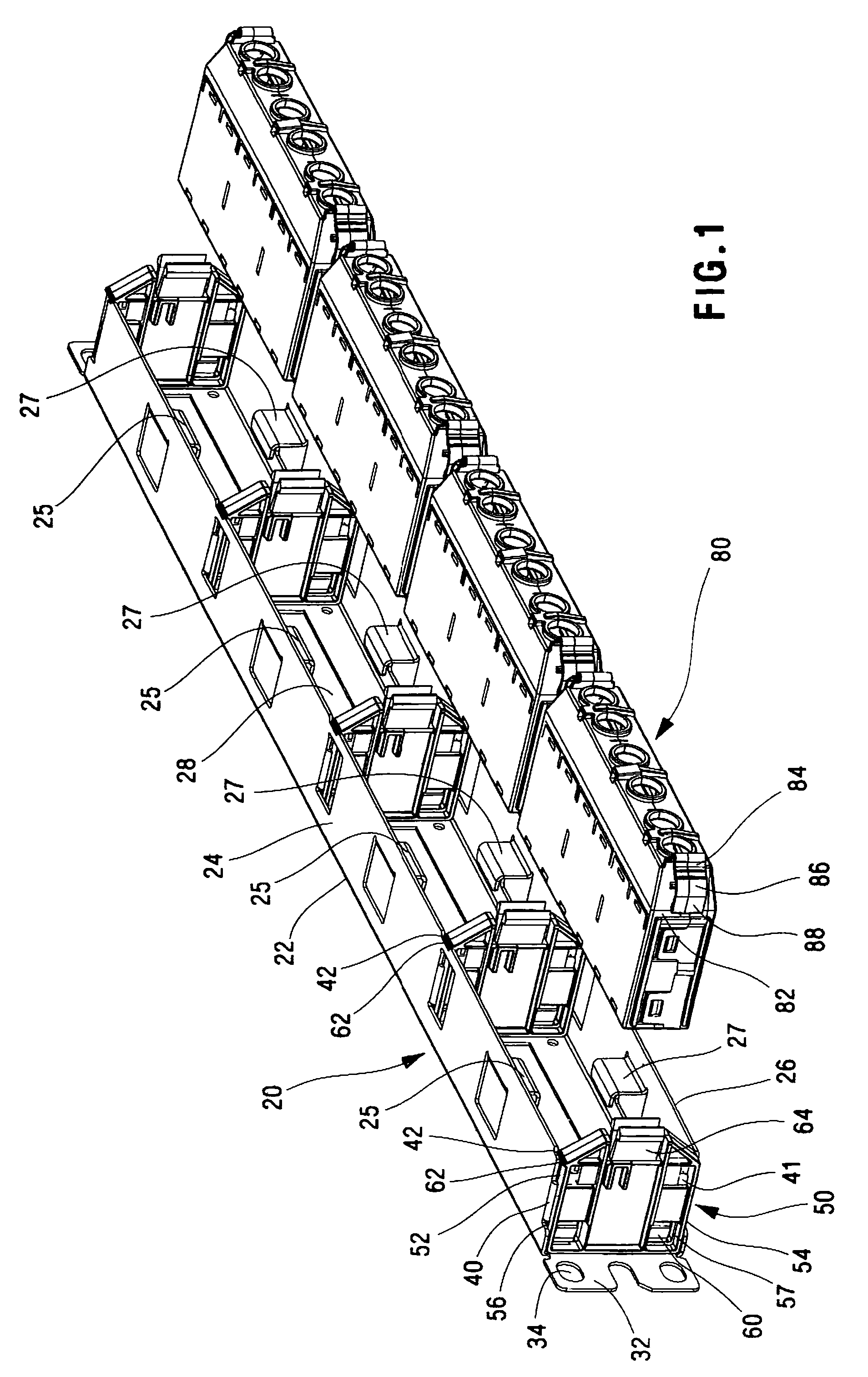

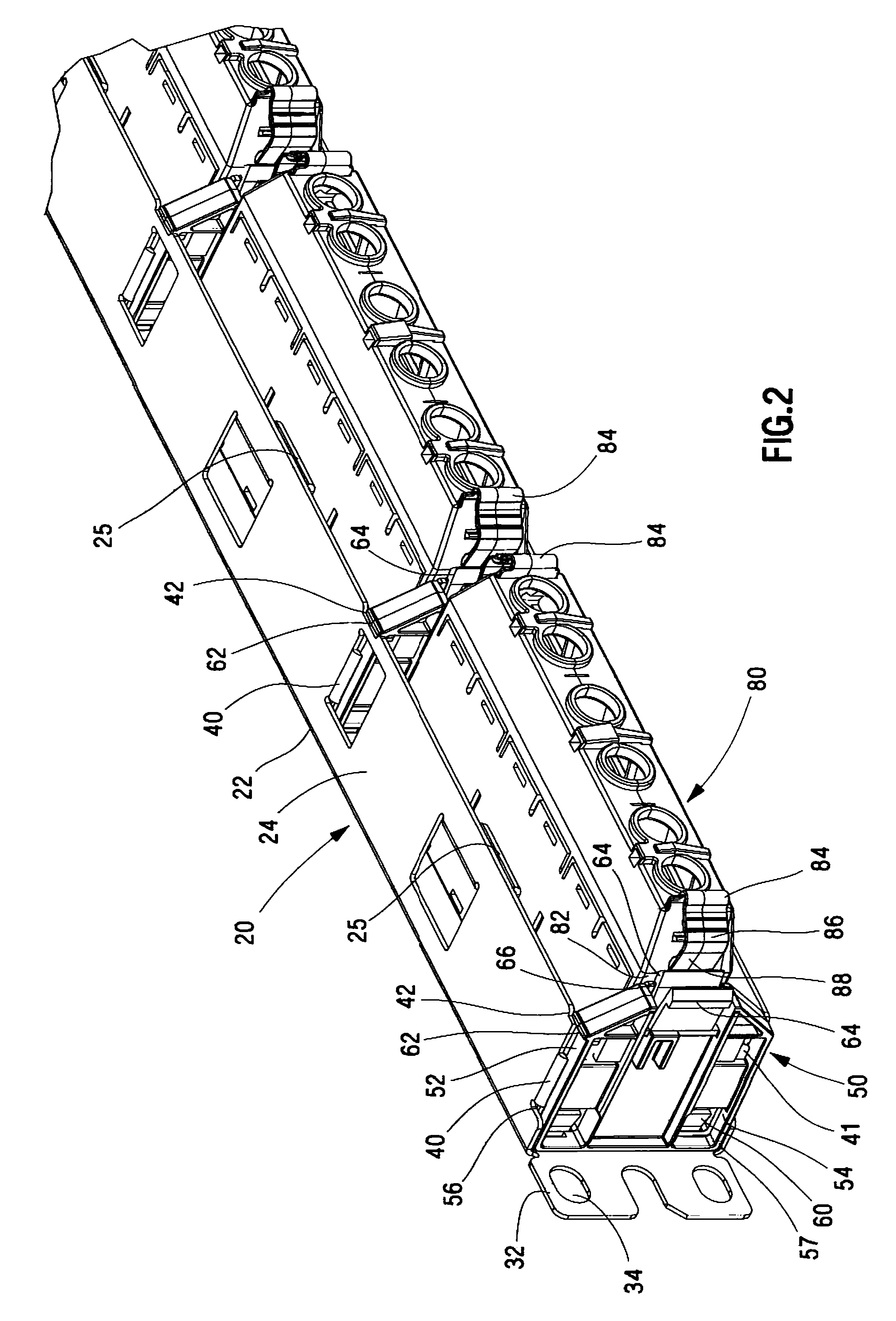

Release latch for pre-terminated cassette

ActiveUS7689089B2Increase deflectionEasy to removeOptical light guidesSelection arrangementsPatch panelMagnetic tape

A release latch for a pre-terminated cassette is described. The pre-terminated cassette includes a release latch to allow removal of the pre-terminated cassette from a patch panel, where the patch panel includes a retaining feature for retaining the pre-terminated cassette. The release latch includes a cantilever beam located on the sidewall of the pre-terminated cassette. The cantilever beam has a hinge point that allows the beam to deflect with respect to the sidewall. The release latch further includes a depressing tab provided at the distal end of the cantilever beam and a latch tab protruding from the surface of the cantilever beam between the hinge point and the depressing tab. The latch tab is capable of engagement with the retaining feature of the patch panel when the cassette is installed in the patch panel.

Owner:PANDUIT

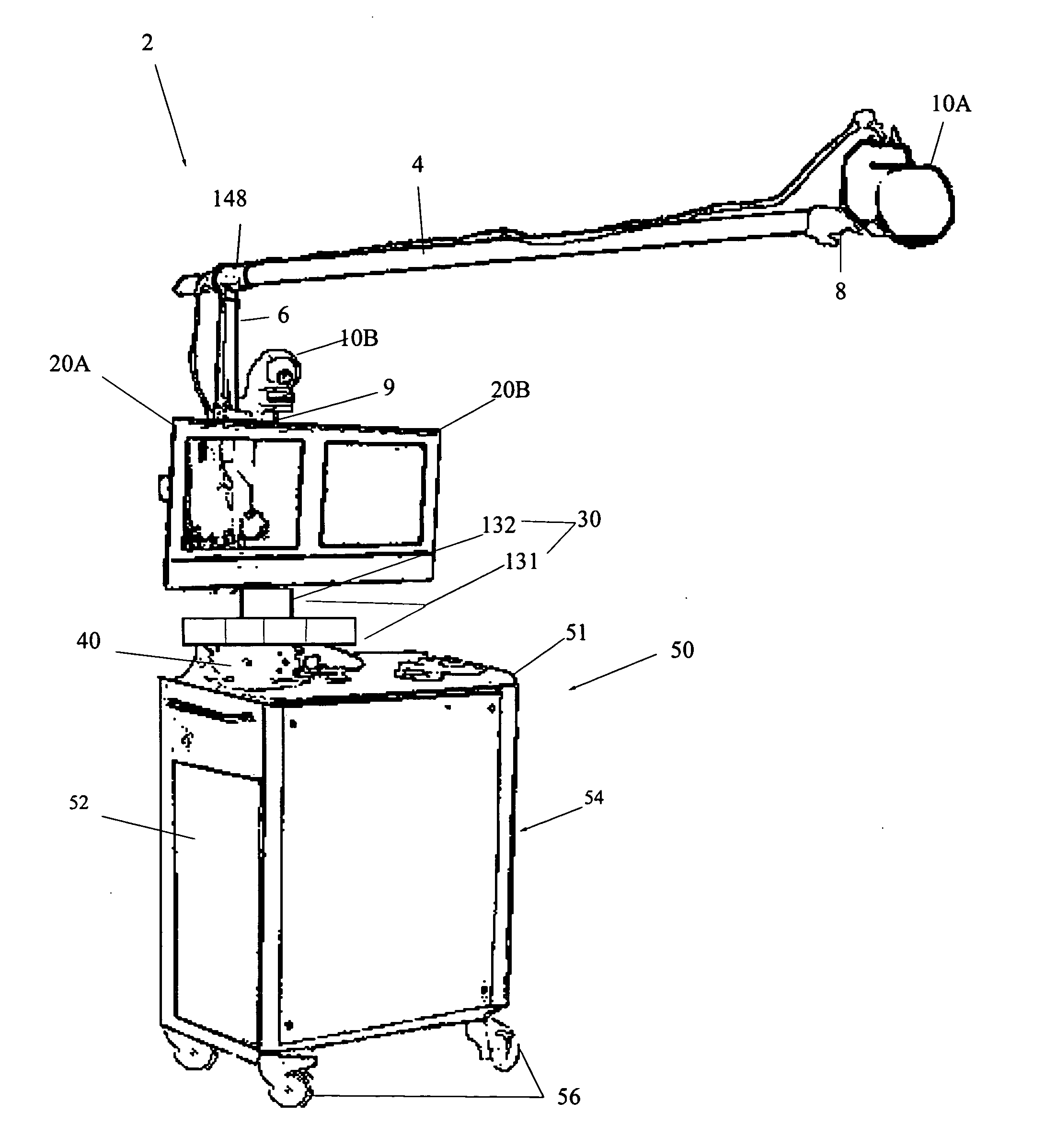

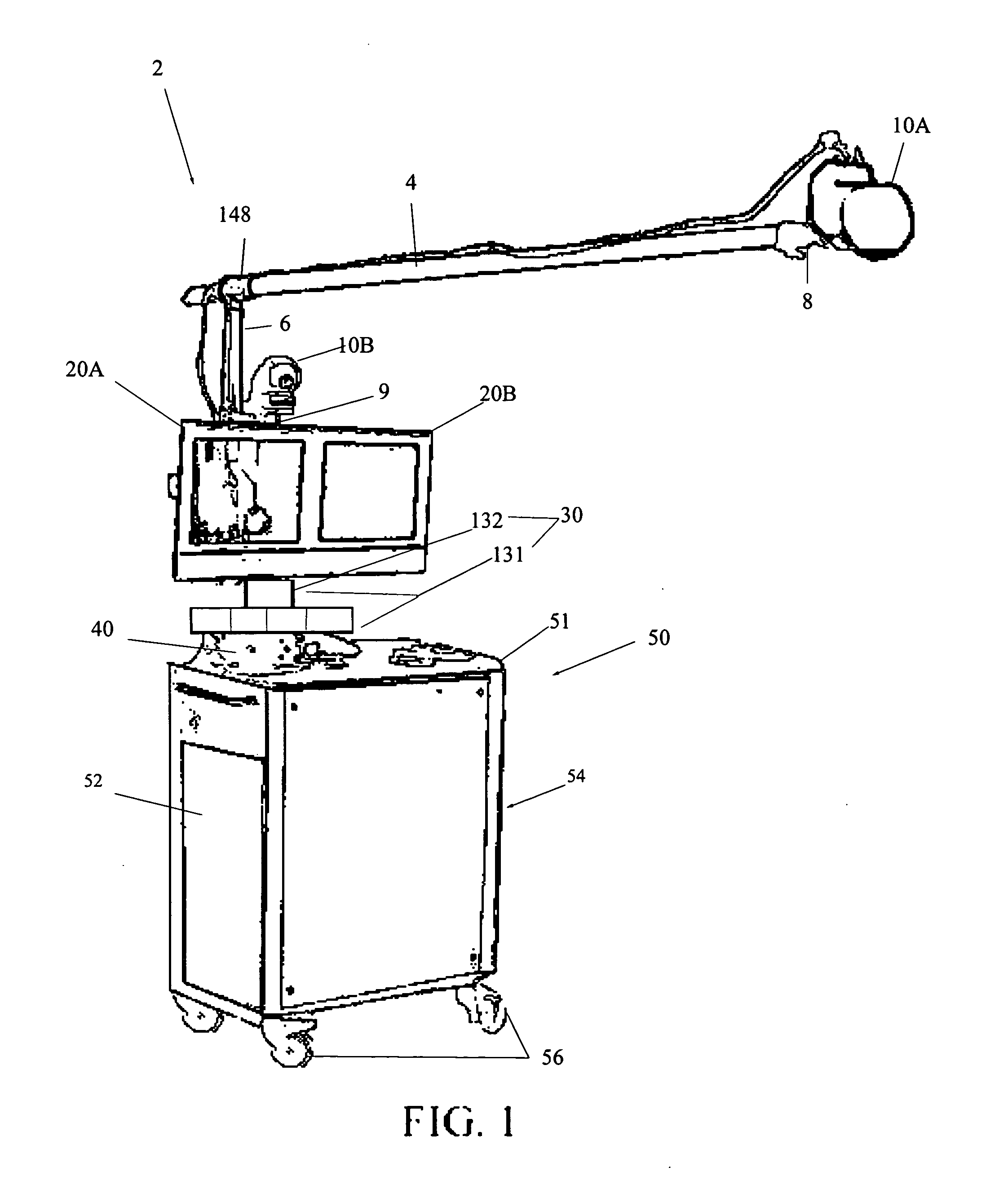

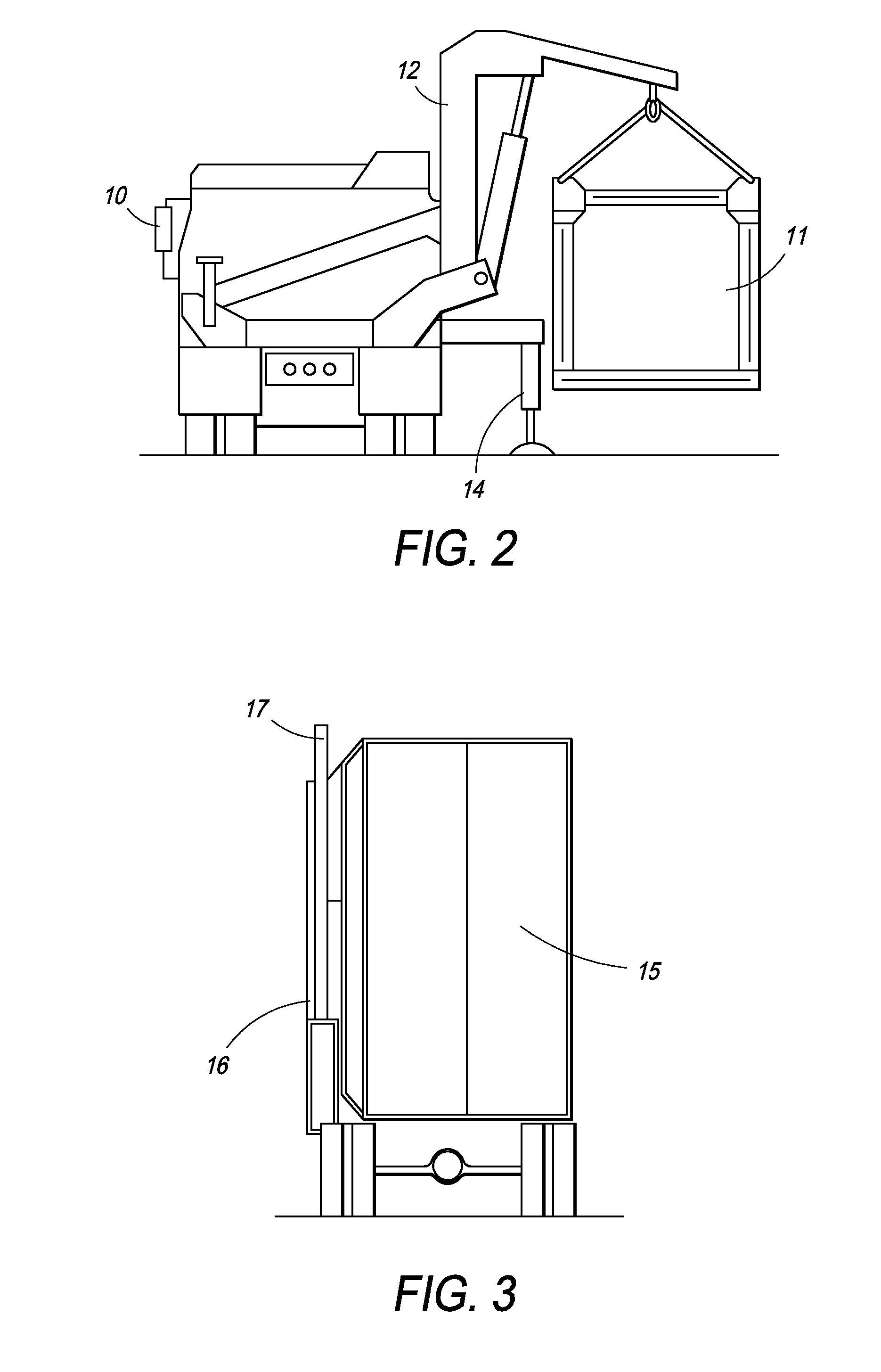

Mobile videoimaging, videocommunication, video production (VCVP) system

A mobile self-powered videoimaging, video communication, video production (VCVP) system designed specifically for health care industry that provides high-resolution audio, video and data communications, production and recording capabilities at hospital operating room / procedure room or field environments for transmission to other remote locations. The VCVP system generally comprises a mobile platform with a plurality of cameras, at least one being mounted on an extensible boom for overhead imaging of surgical procedures. An array of video production equipment is rack-mounted inside the platform, as is an array of network teleconferencing equipment. The mobile imaging system may be parked at a convenient location in an operating room or other environment and controlled by a single operator. As the surgery proceeds, the operator can multiplex the camera signals into a live high resolution video / audio feed that is networked in real time for teleconferencing, and / or recorded to a hard drive or in any known format such as Mini-DV, S-VHS, VHS and DVD as desired.

Owner:REMY CHRISTOPHE +1

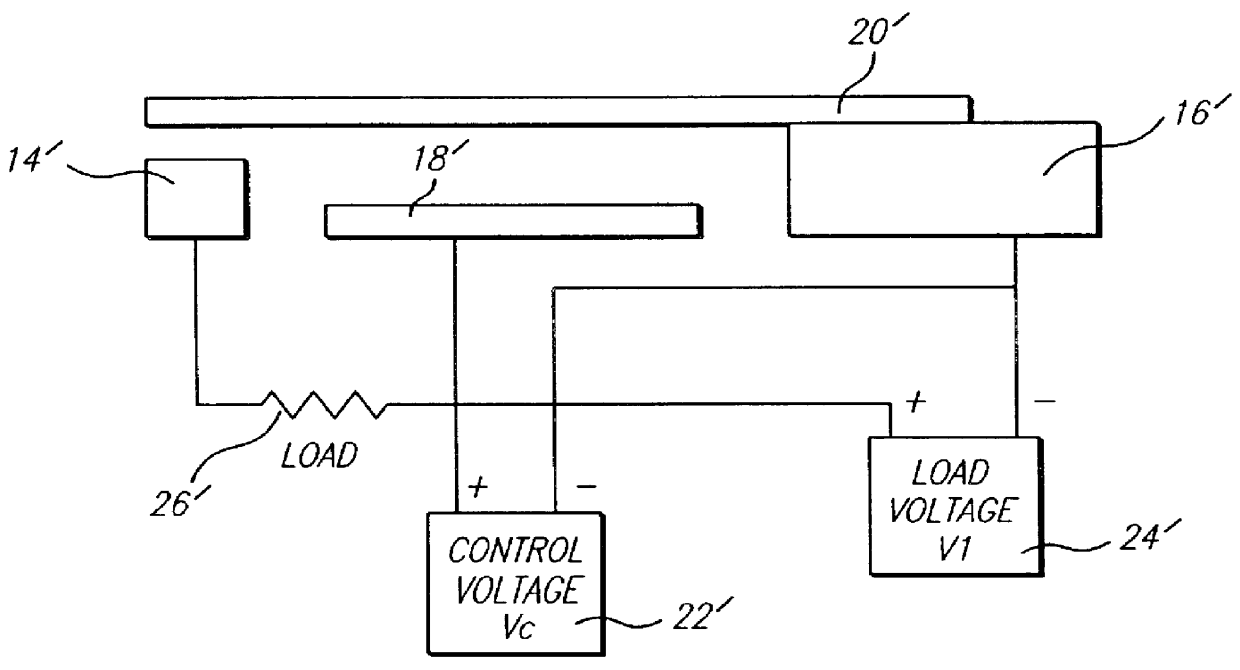

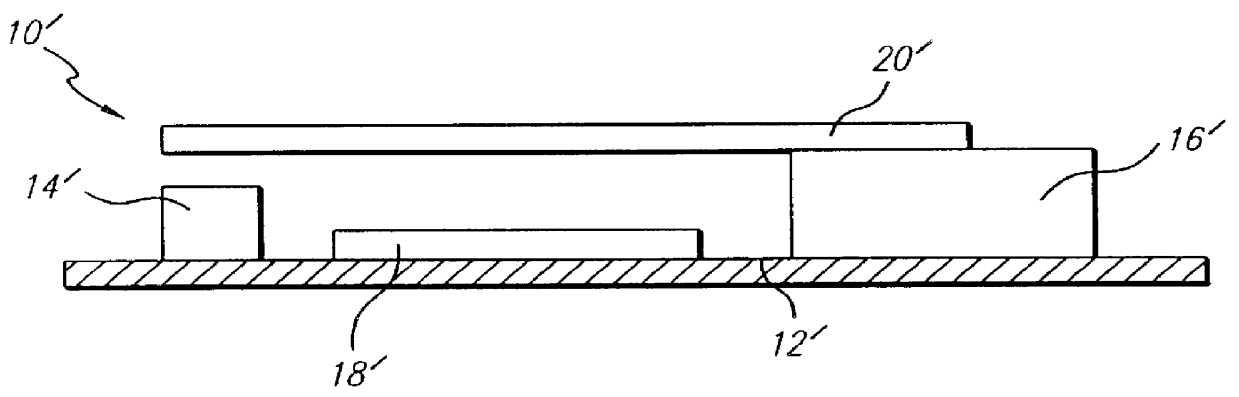

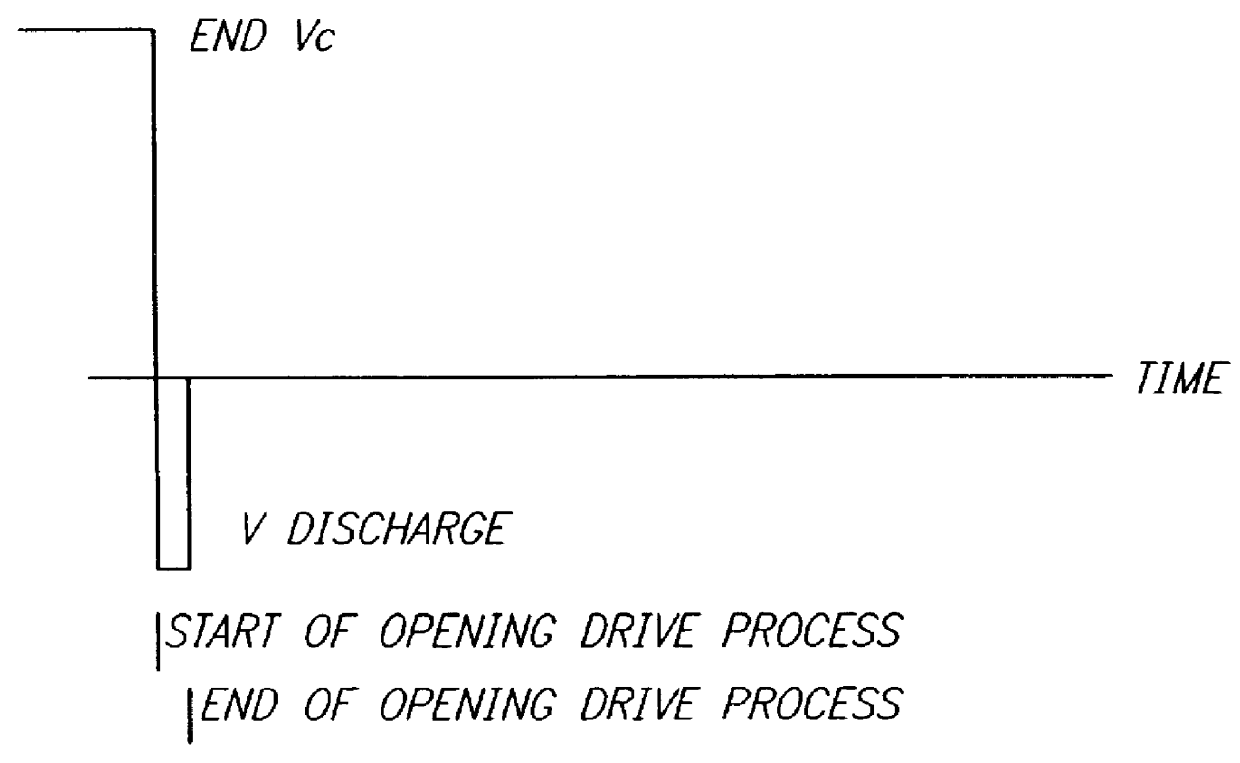

Method and apparatus for an improved single pole double throw micro-electrical mechanical switch

InactiveUS6160230AElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationRepulsion forceCantilever

A single pole, double throw micro-electromechanical (MEM) switch. The inventive switch includes a first contact providing a first terminal of the switch. A second contact provides a second terminal of said switch. A cantilever beam provides a third terminal of the switch. The inventive switch includes a system for electrostatically pushing or pulling the beam to disengage the first contact and engage the second contact. In an illustrative implementation, the system for electrostatically operating the switch includes a first charge storage structure on the beam, a second charge storage structure on the switch, and an electrical supply for creating an electrical charge on the first and the second charge storage structures. The first and second charge storage structures are effective to create a force of repulsion therebetween on the application of an electrical charge thereto. The "pull" electrostatic force closes the MEM switch. The "push" force aids in opening the switch. The "push" capability is the result of the use of like (same polarity) electrostatic charges on the control surfaces. The like charges provide an electrostatic repulsion force during the switch opening process.

Owner:RAYTHEON CO

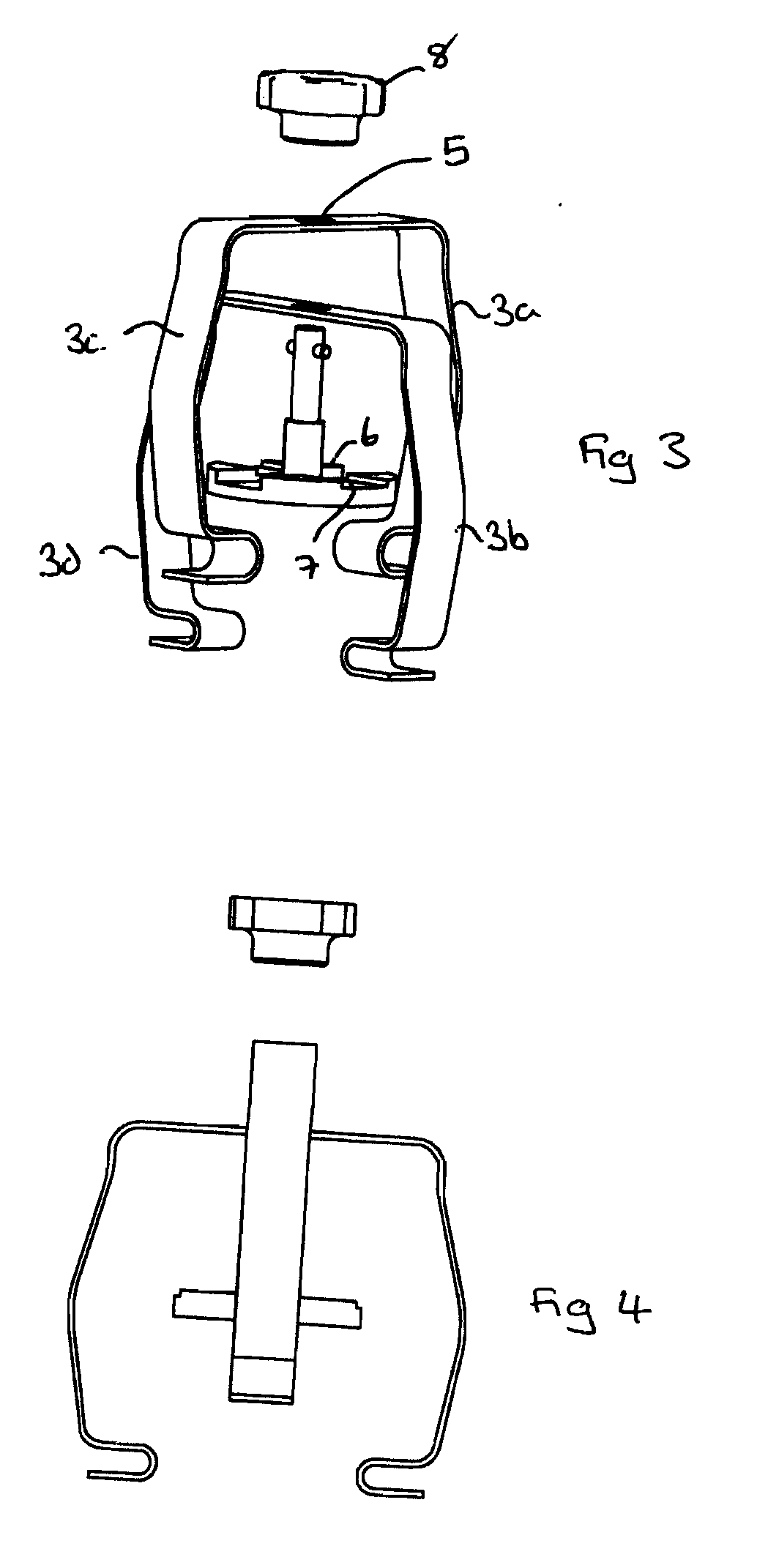

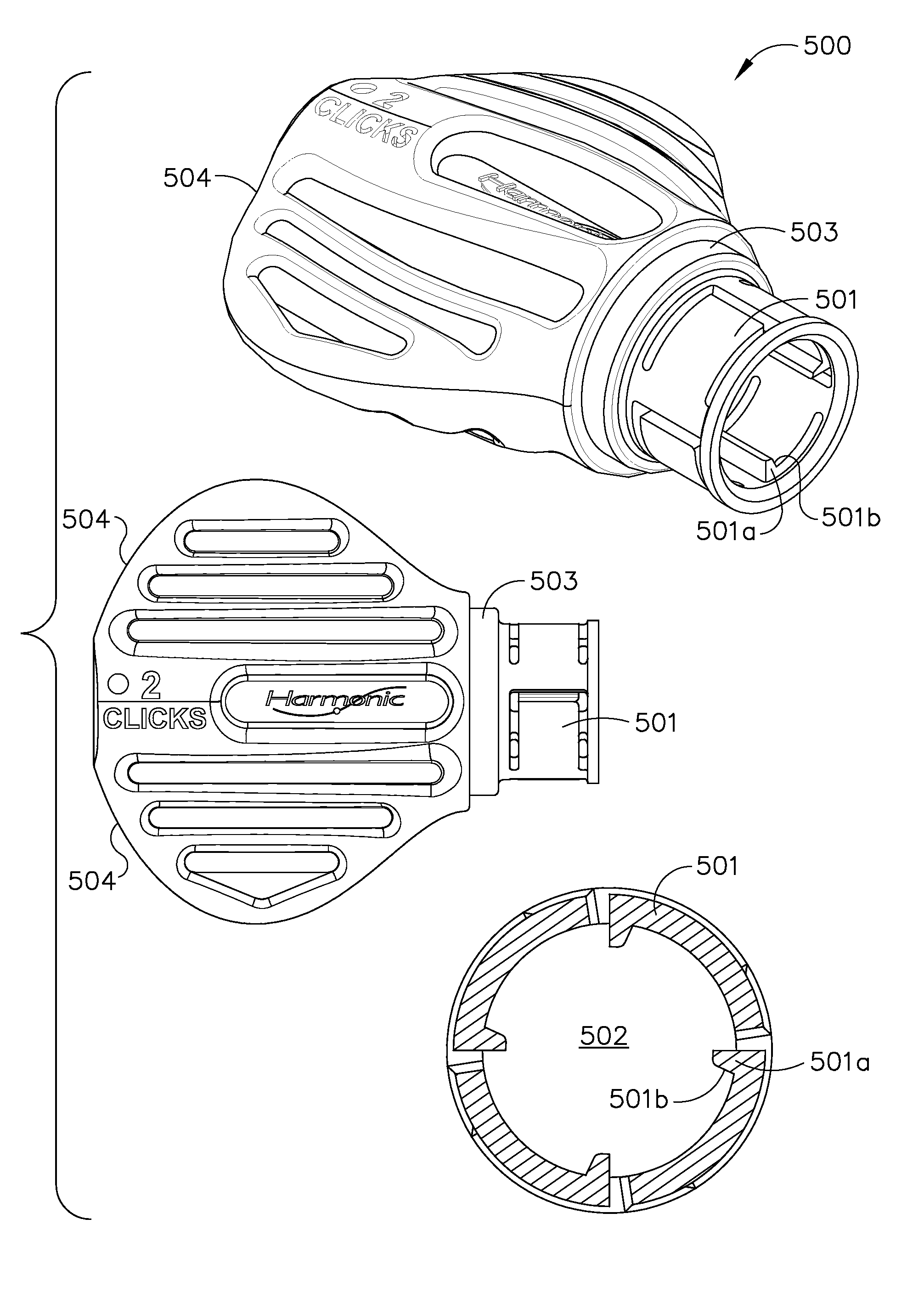

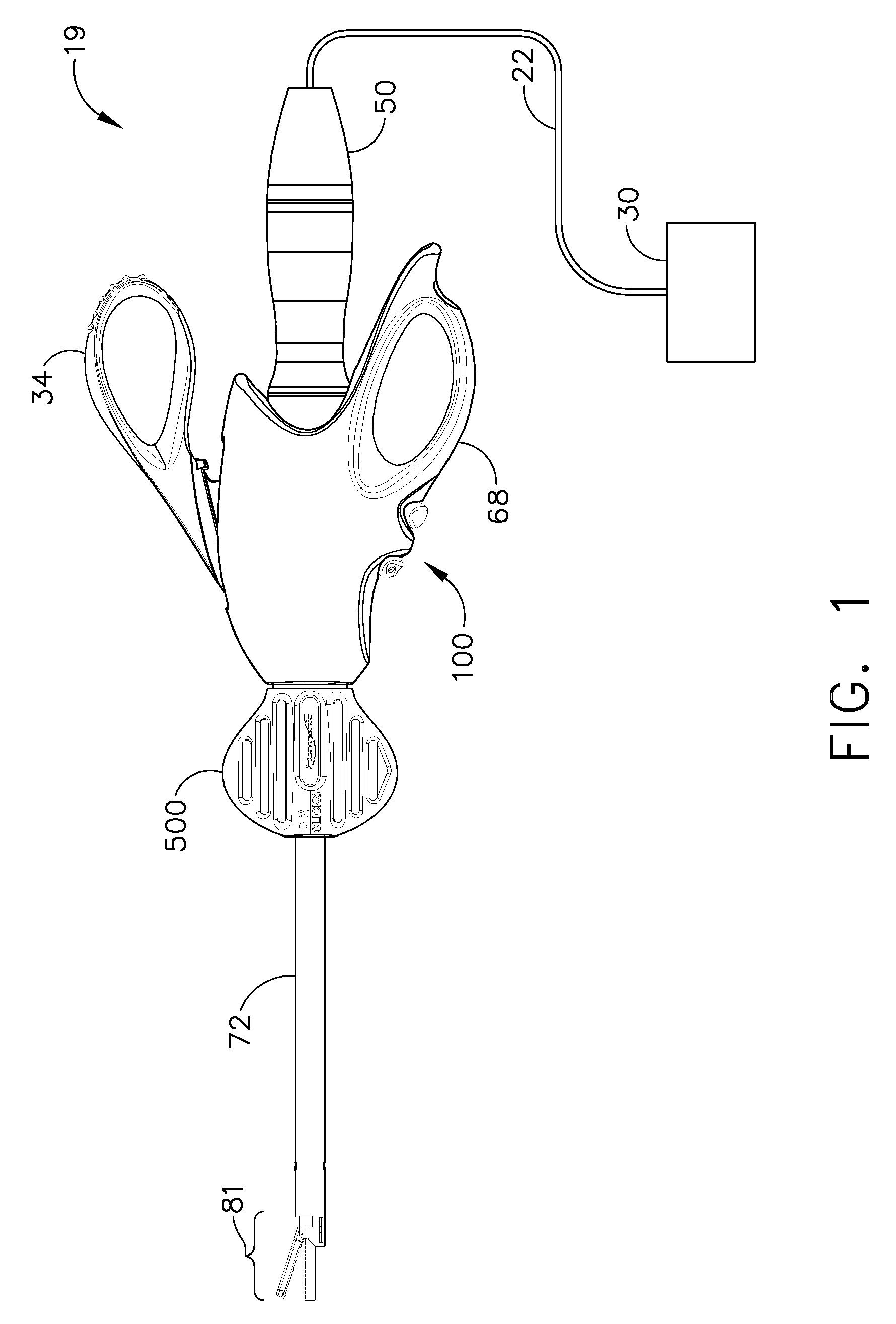

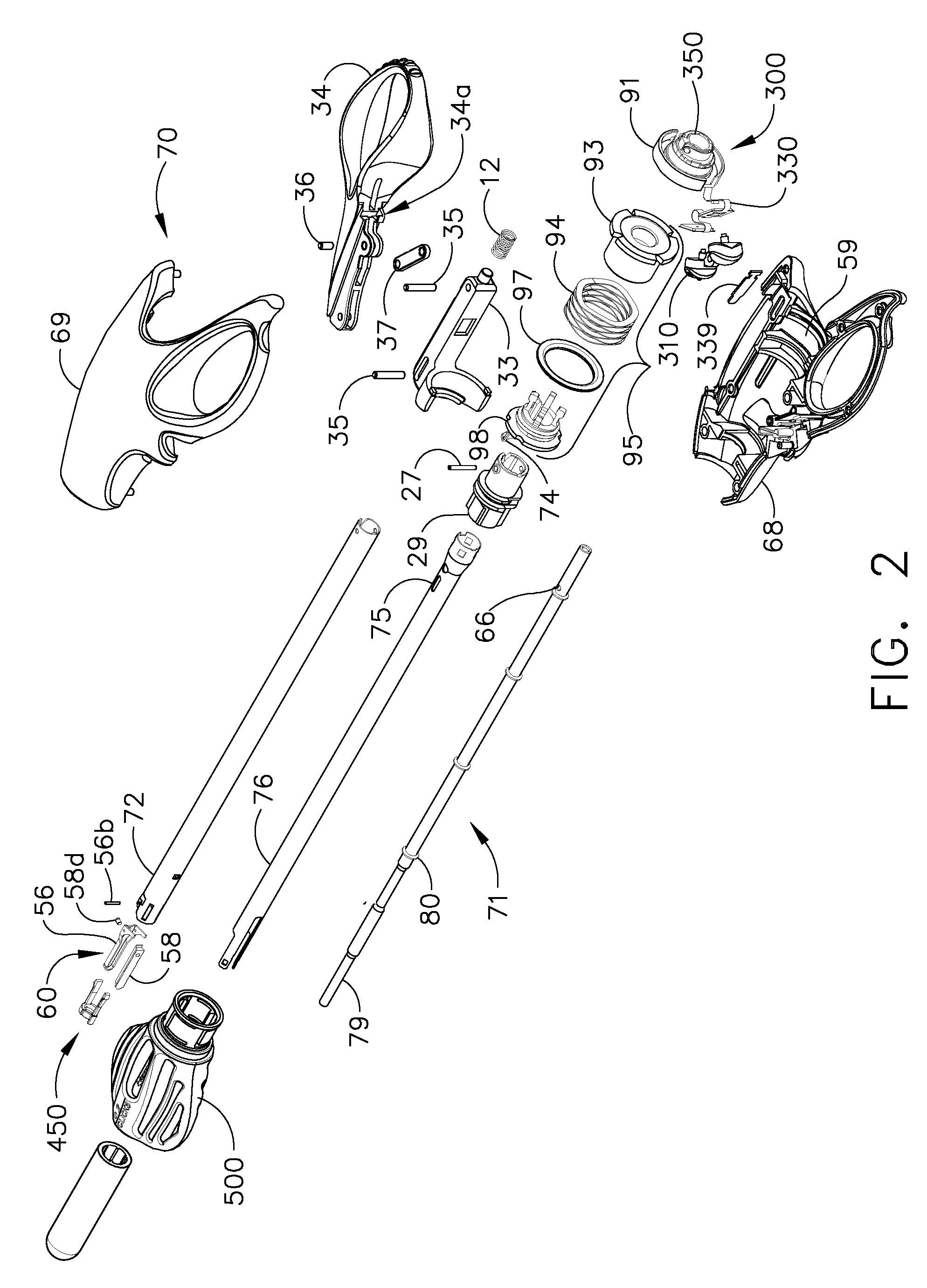

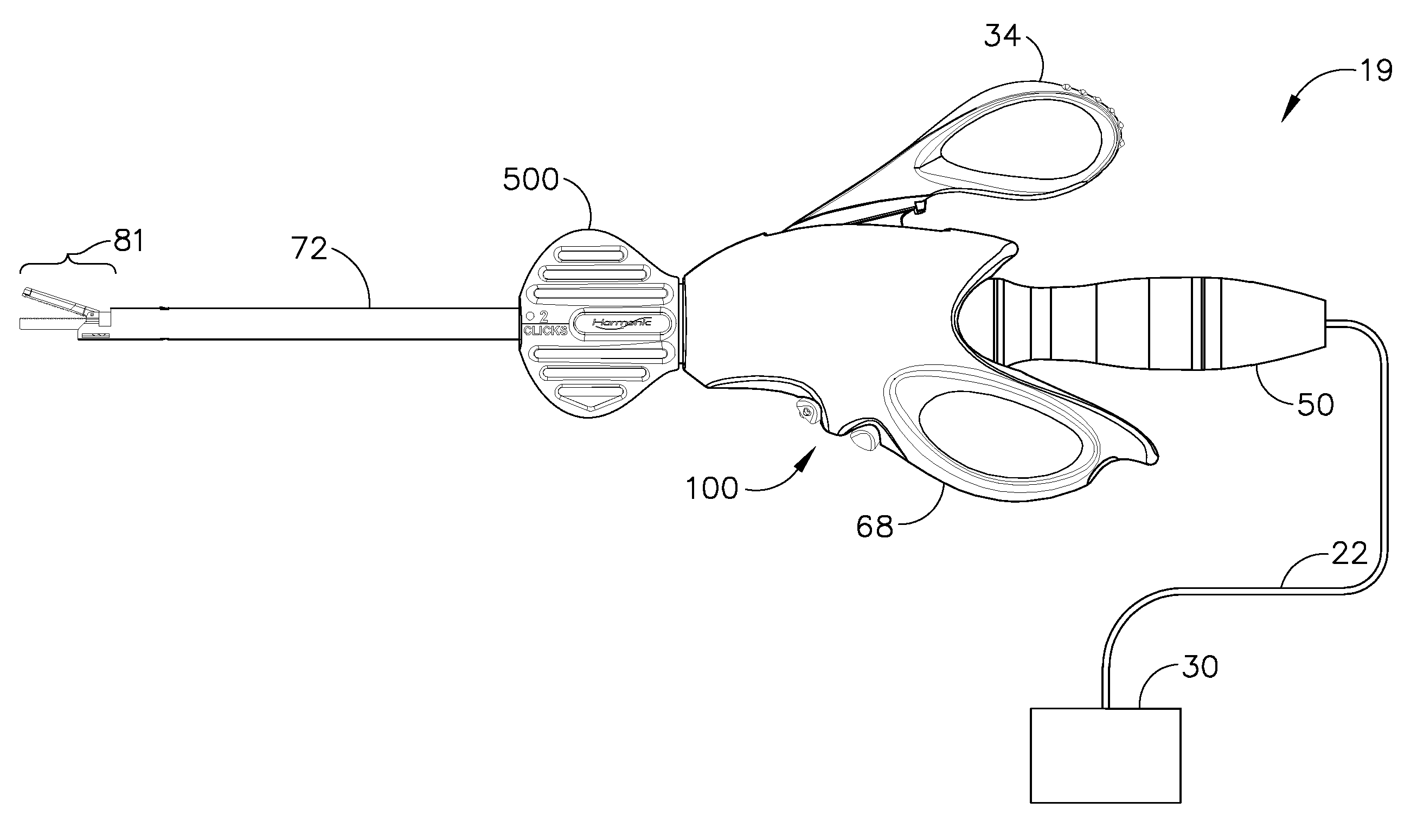

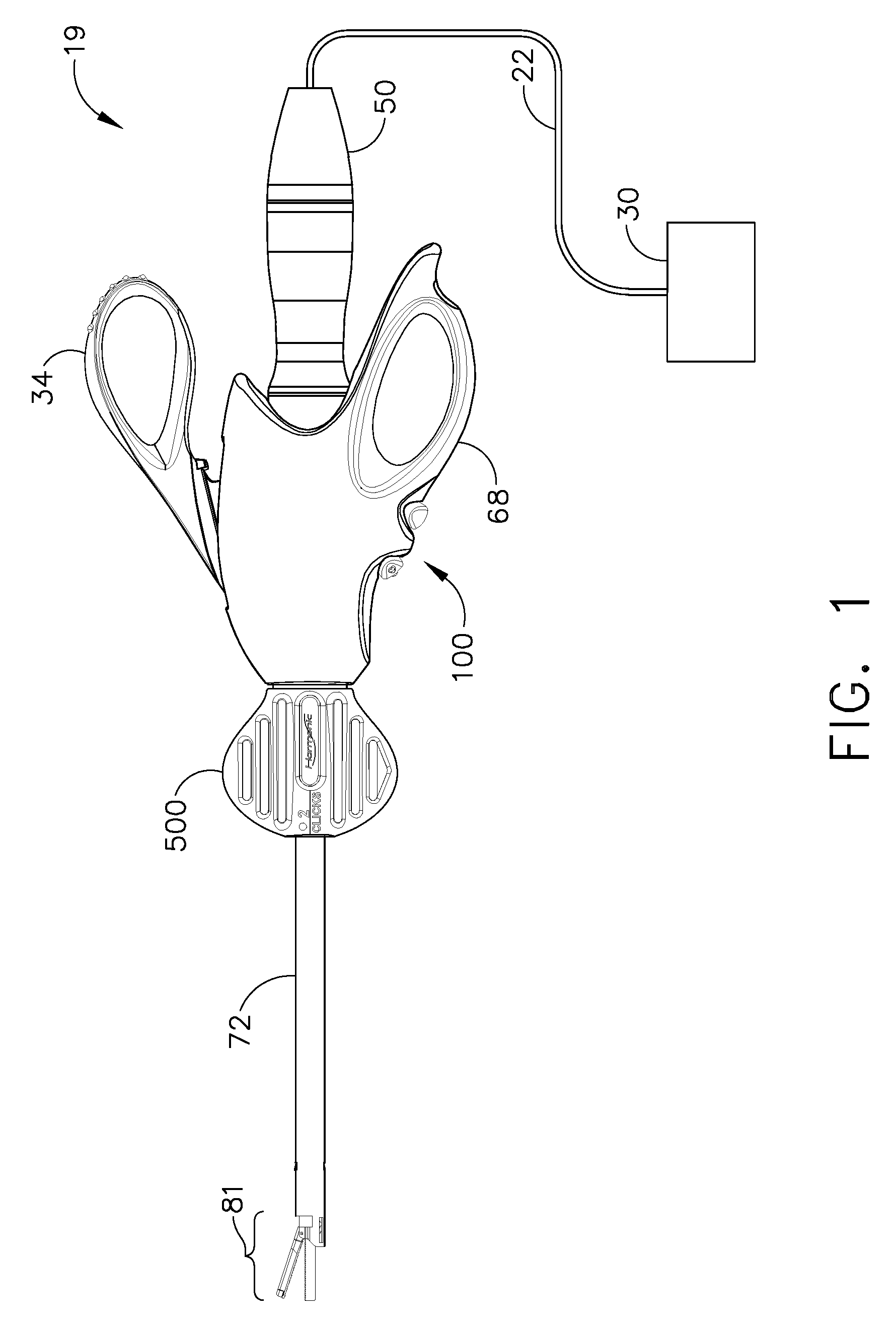

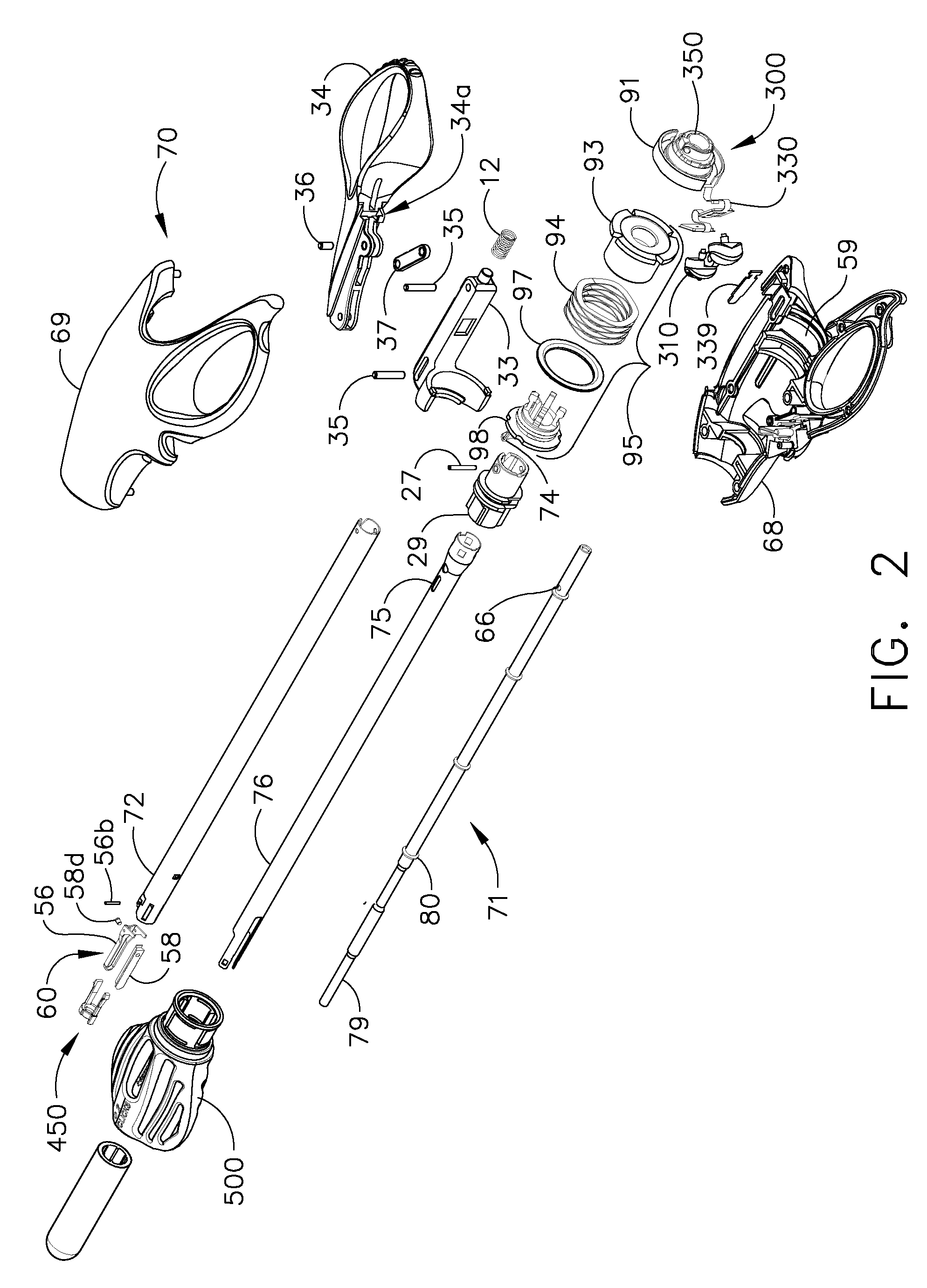

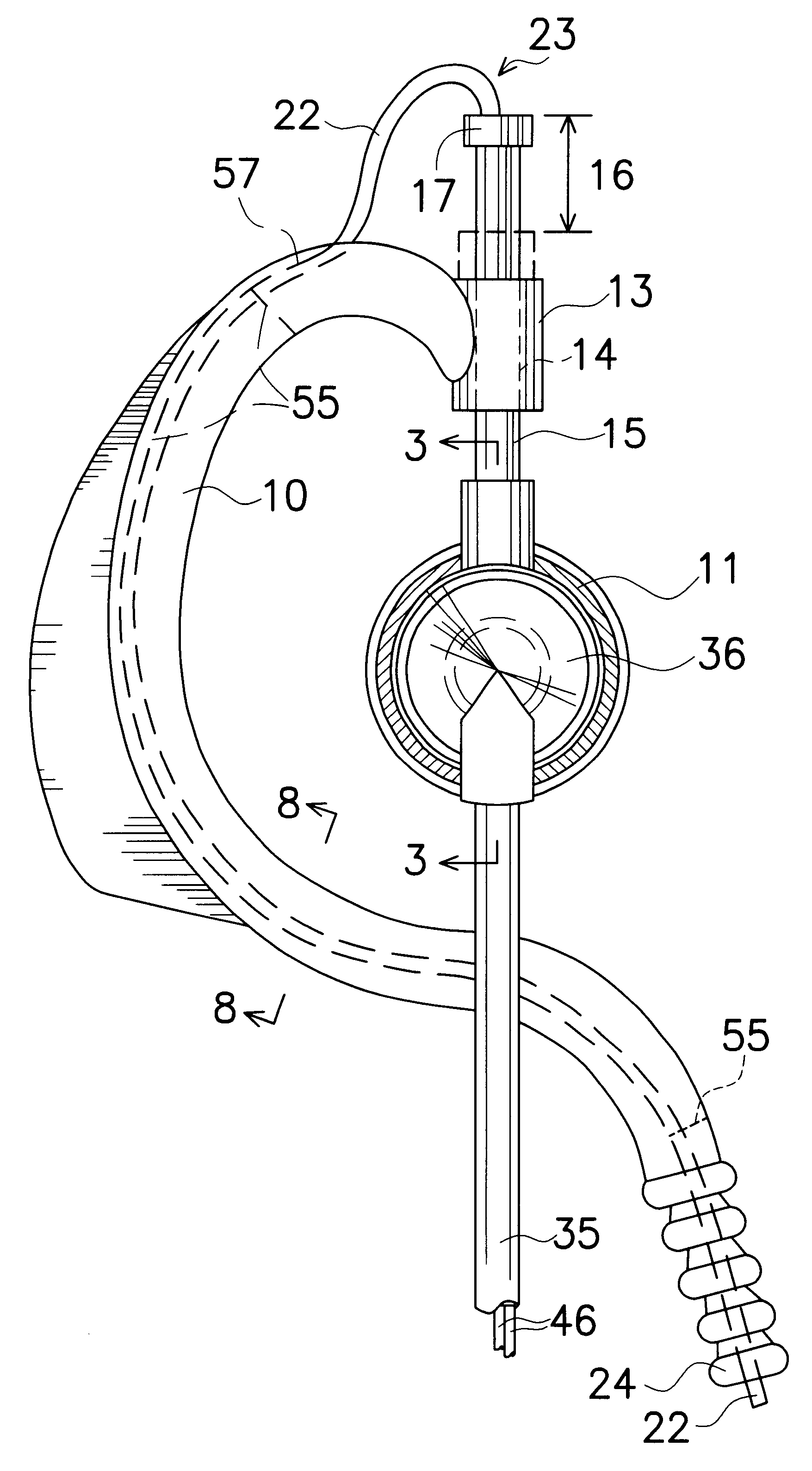

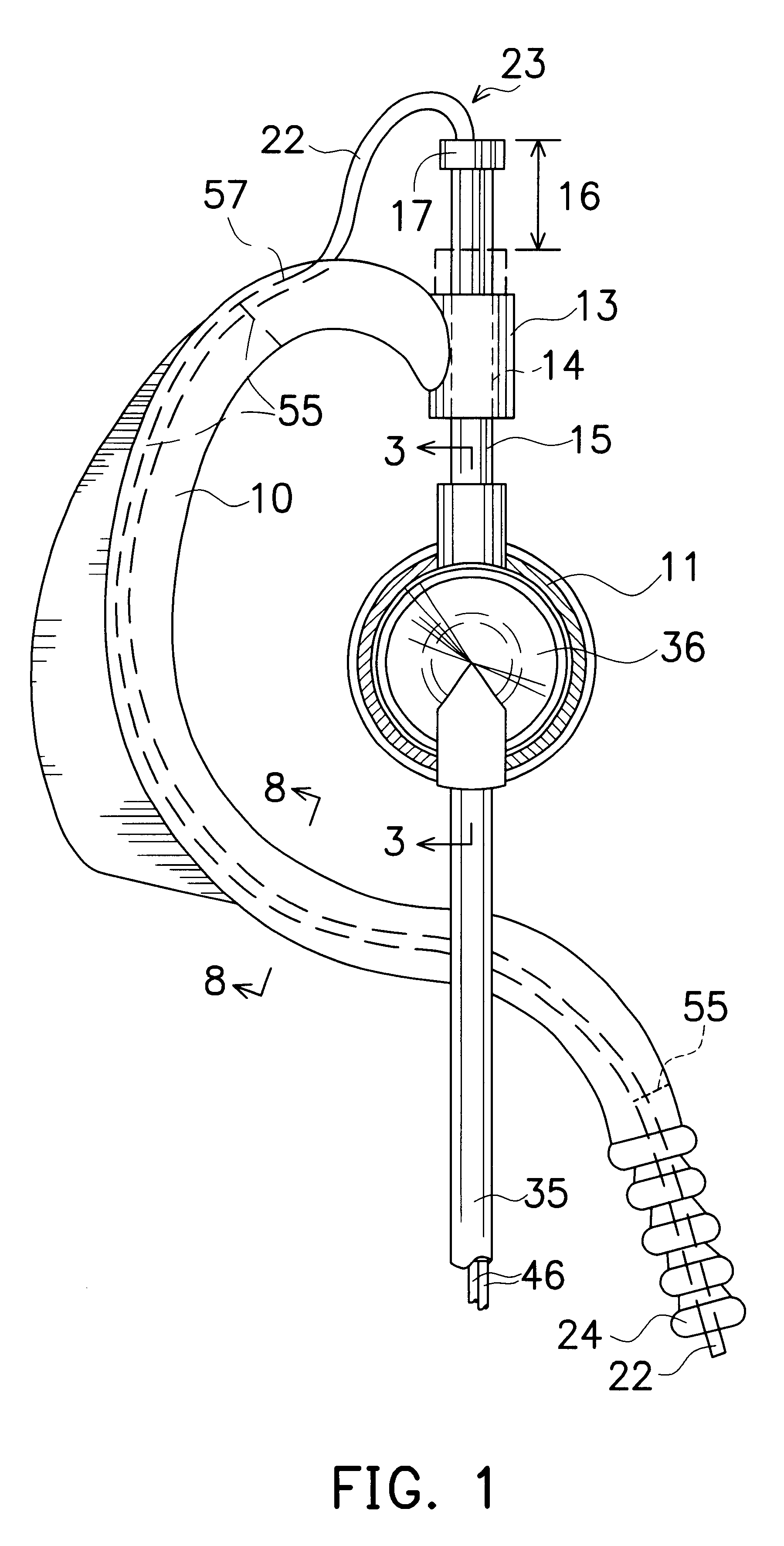

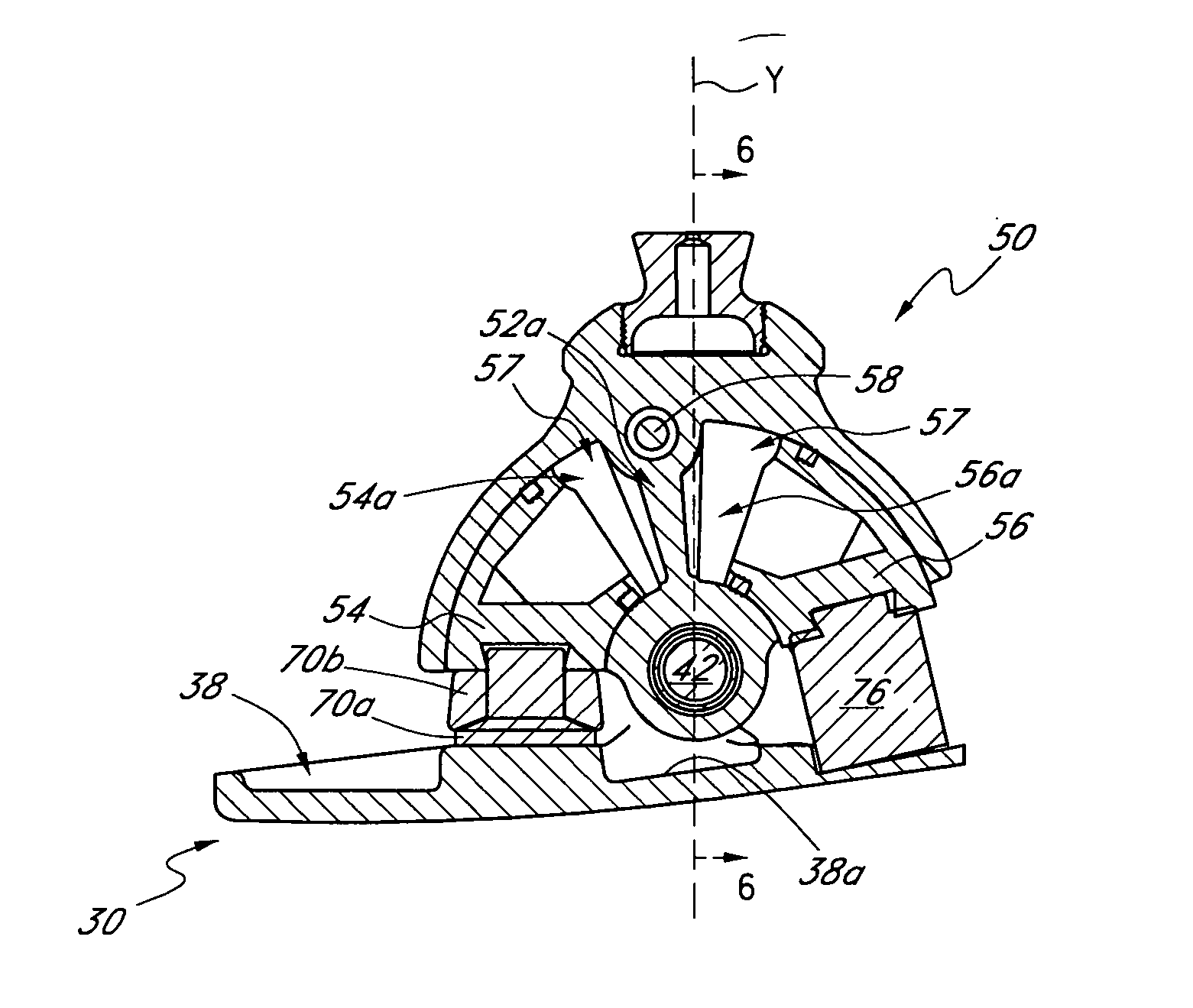

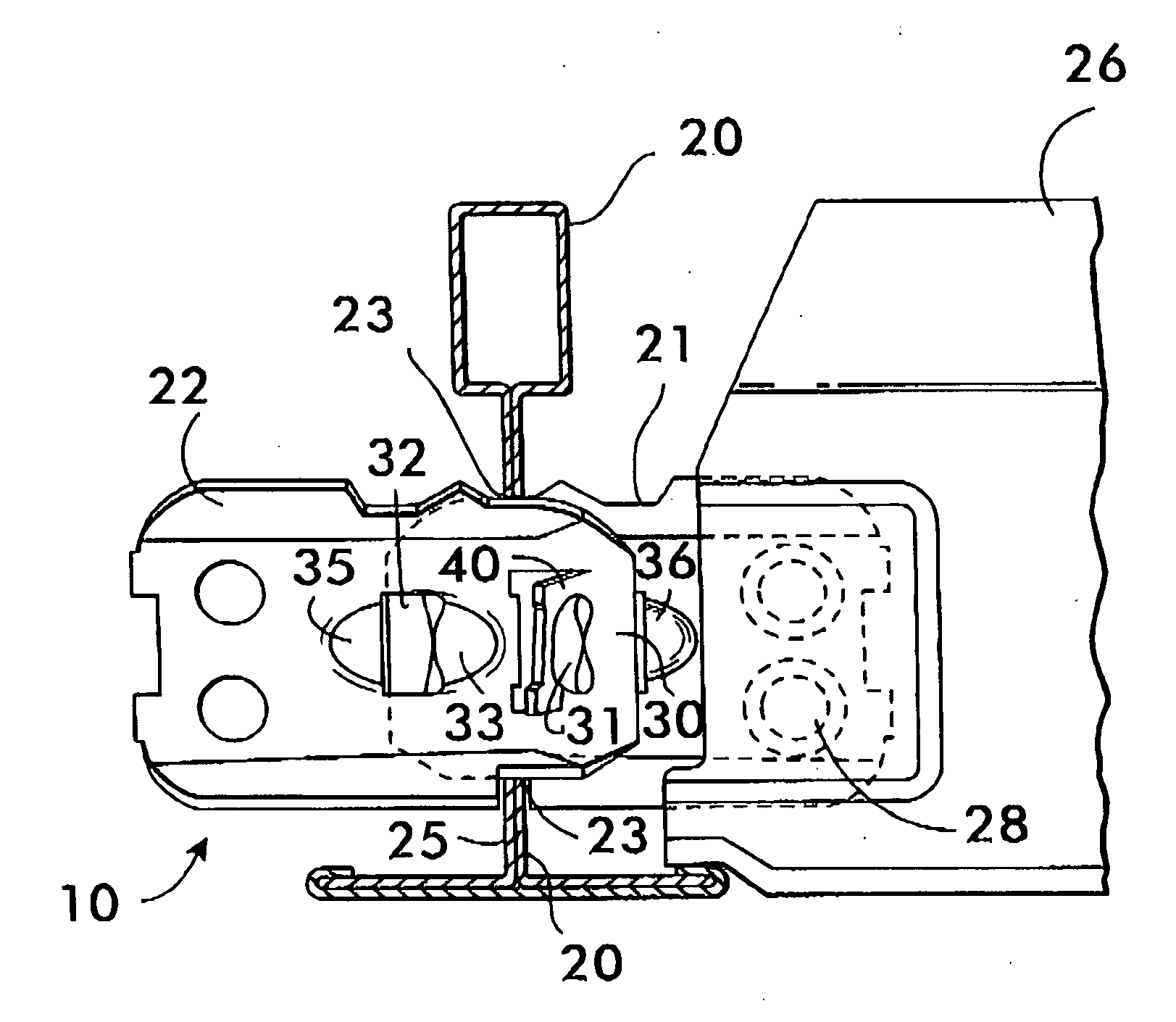

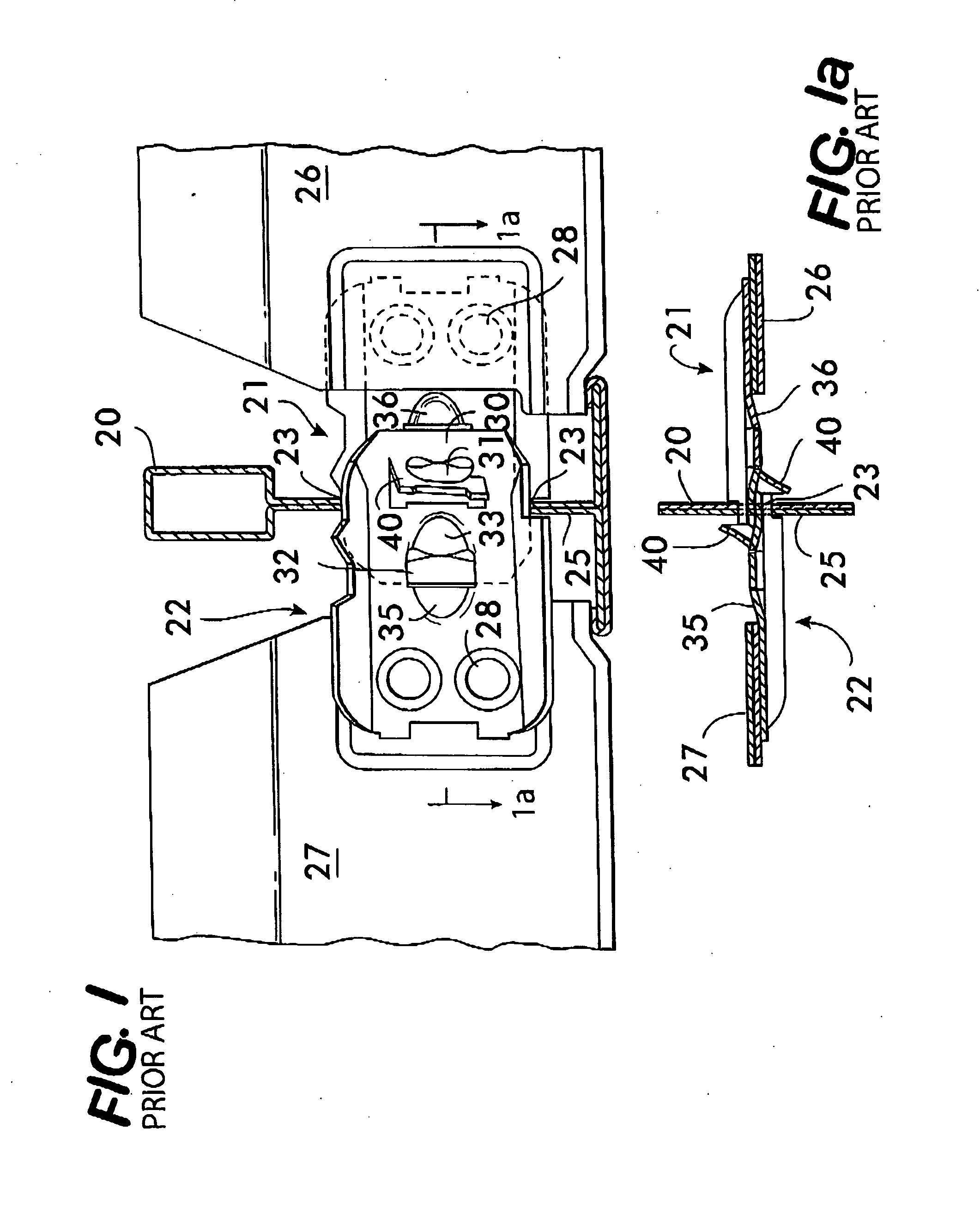

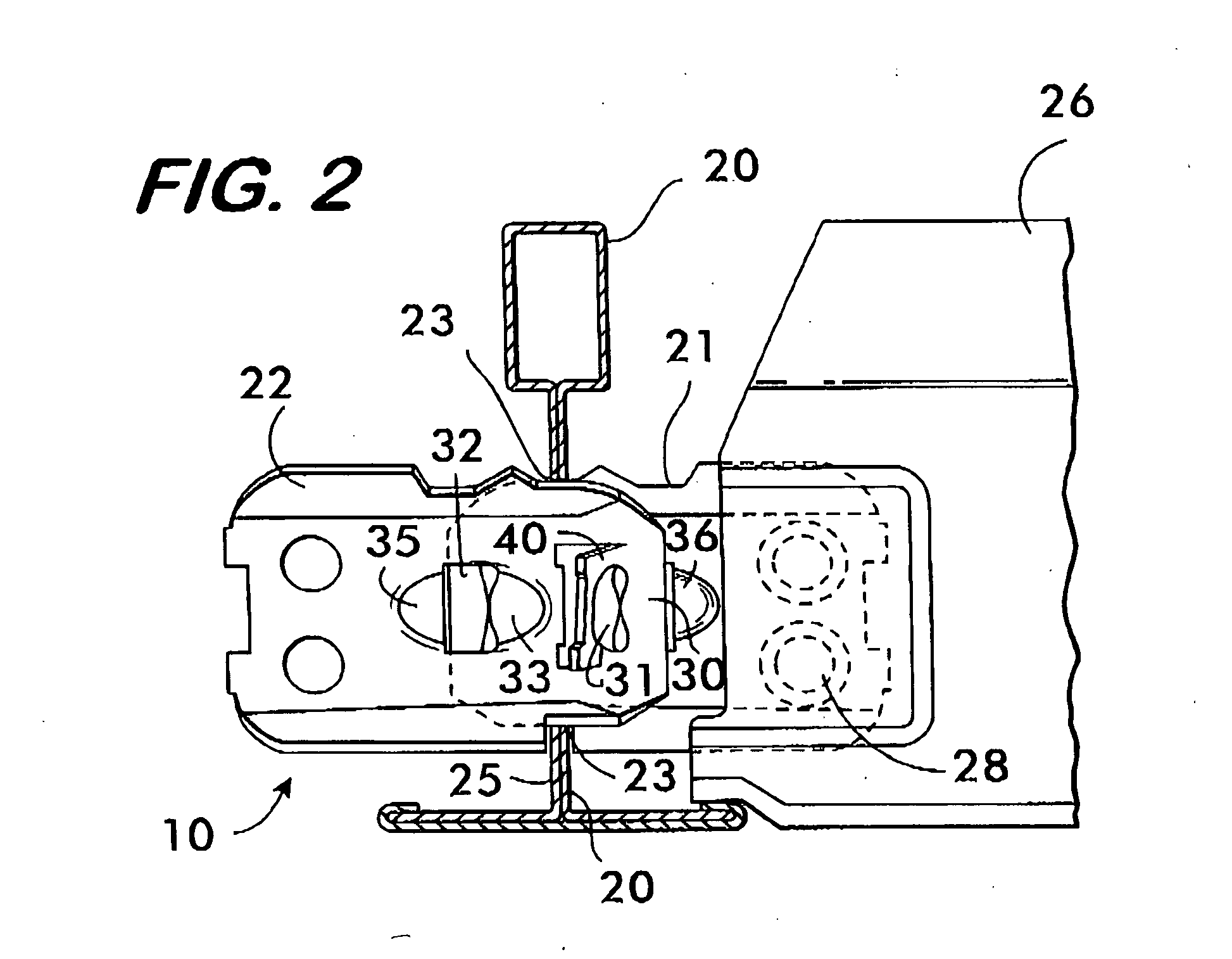

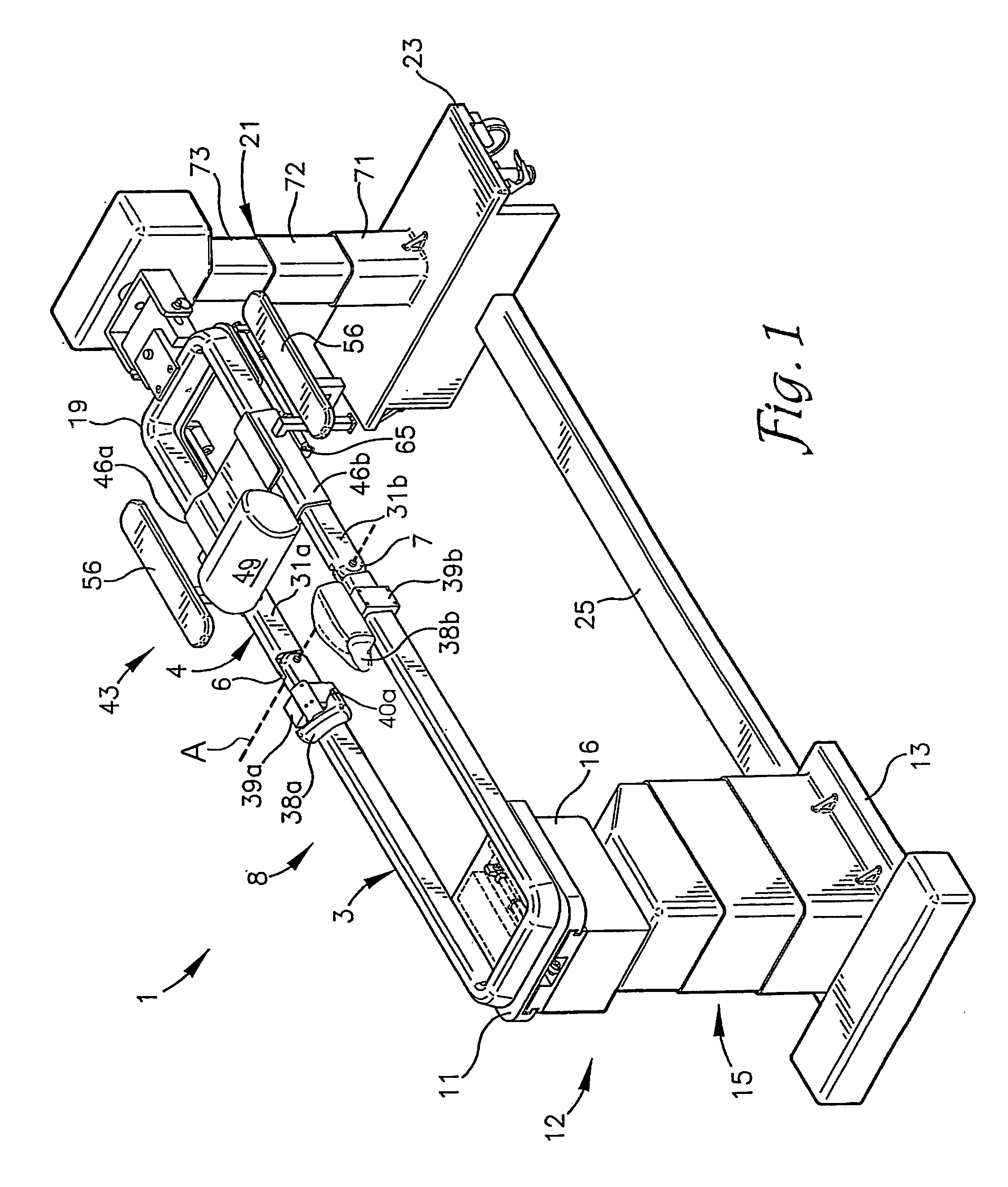

Mechanism for assembly of ultrasonic instrument

An ultrasonic clamp coagulator system that is configured to permit selective cutting, coagulation and clamping of tissue during surgical procedures. An elongated portion of the instrument can be configured for endoscopic applications and has an outside diameter of less than 6 mm. The system includes a one-piece torque wrench that is provided with cantilever arms aligned in an annular fashion about the centerline of the torque wrench. The cantilever arms include teeth in an inward perpendicular fashion in relation to cantilever arms. The clamp coagulator includes an outer tube retainer that includes spline gears projecting in a perpendicular fashion along the outer circumference of retainer. Torque is transmitted through the cantilever arms to the spline gears for attaching a handpiece to the clamp coagulator.

Owner:CILAG GMBH INT

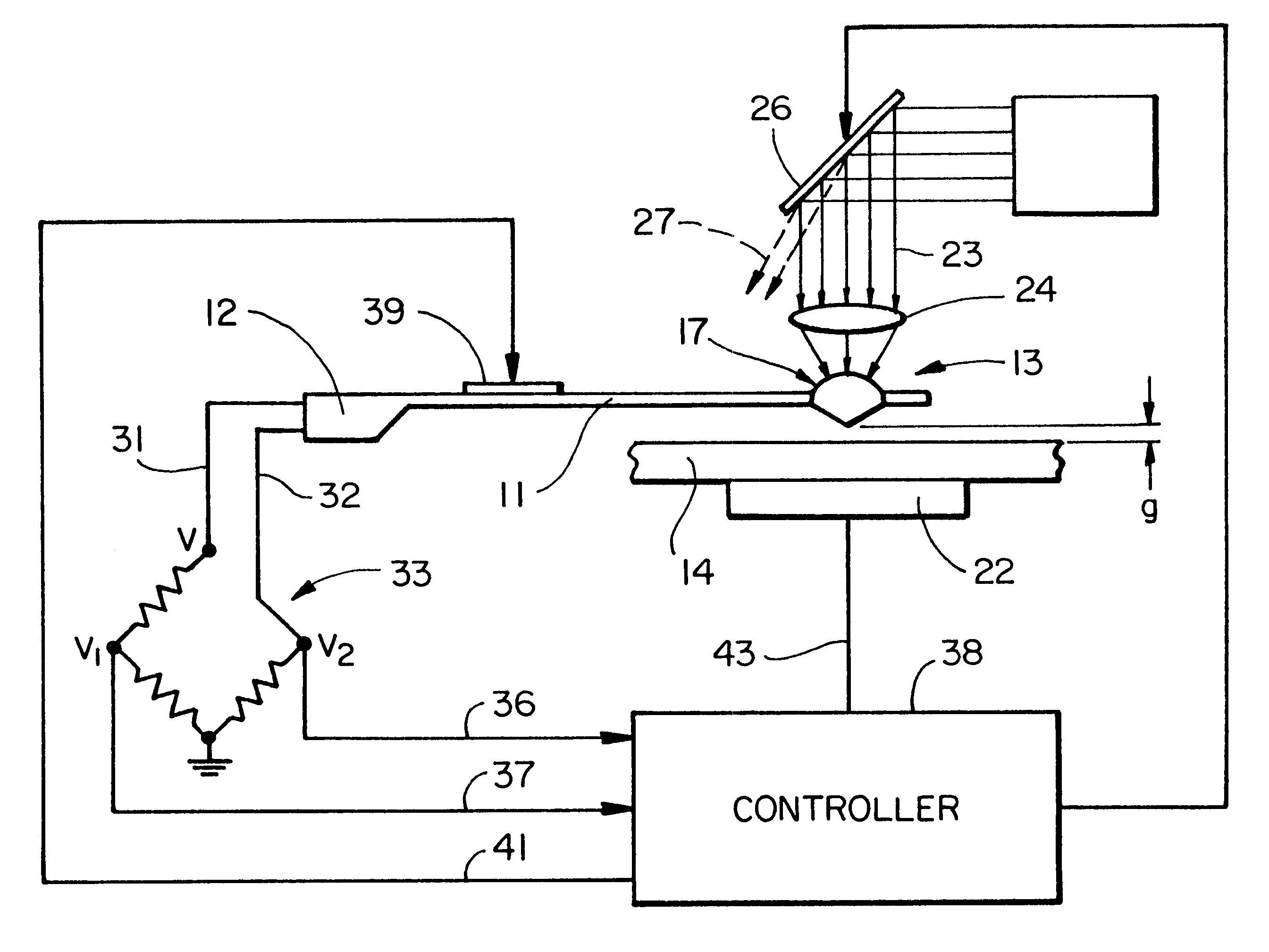

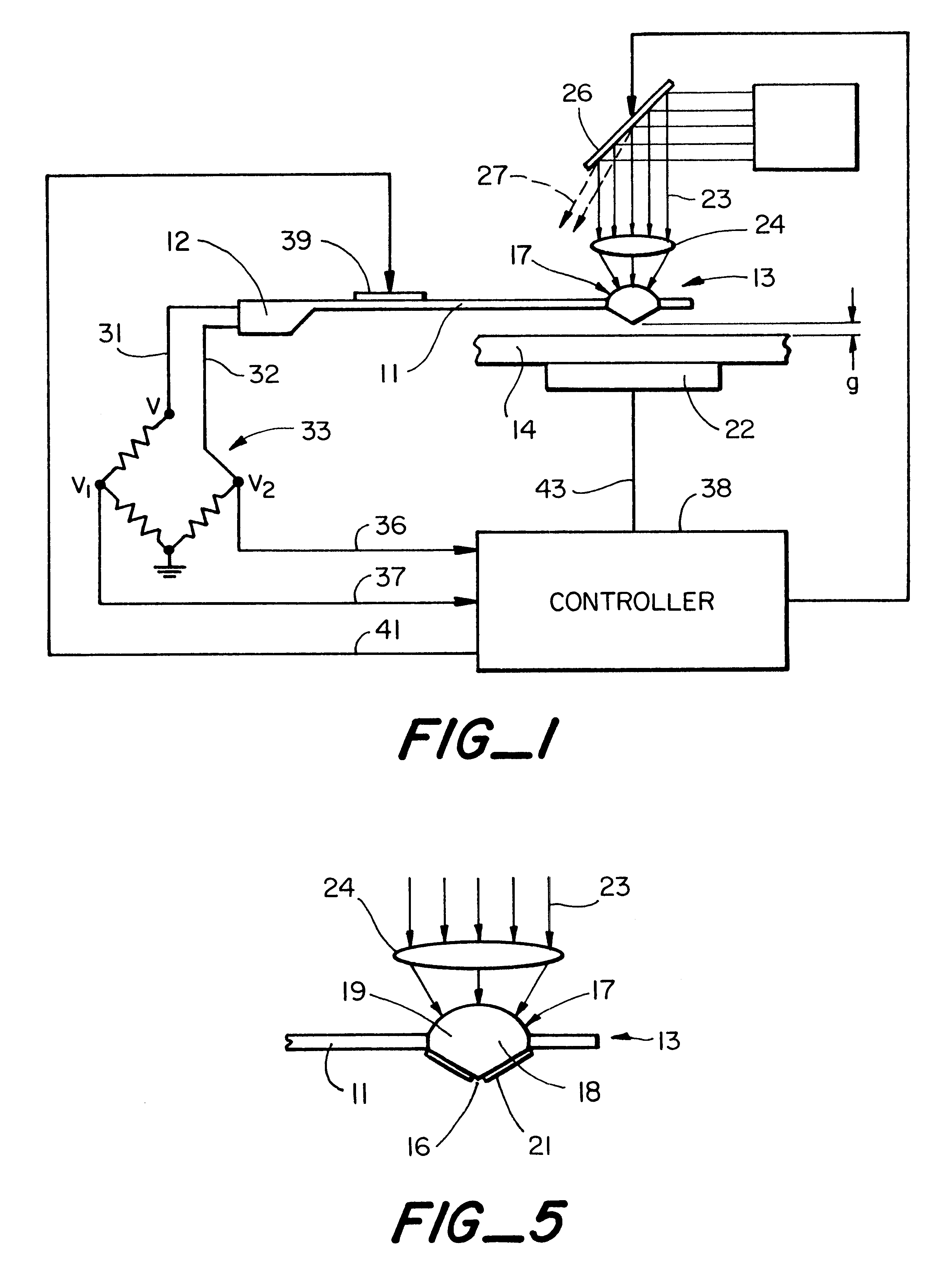

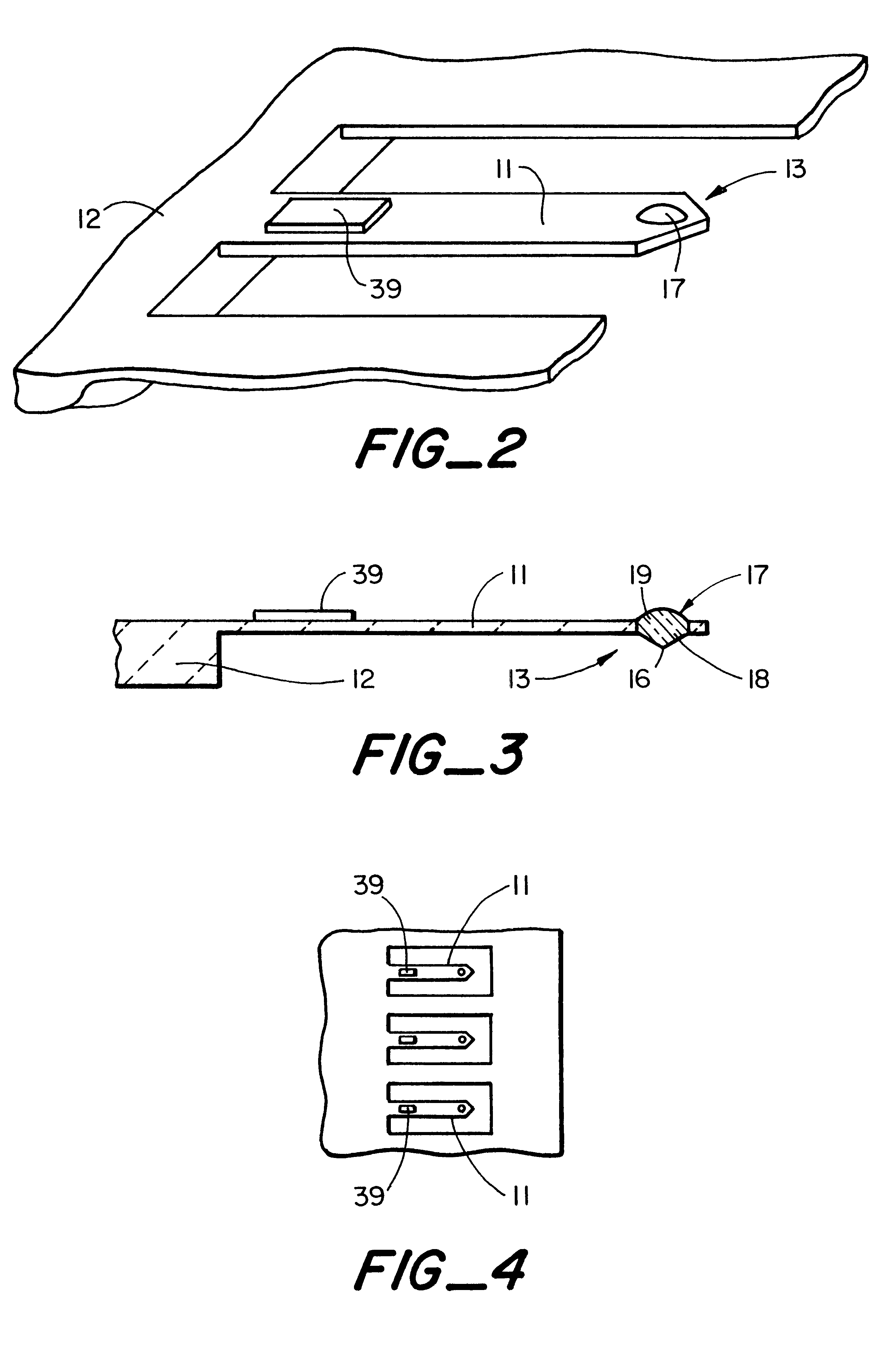

Near field optical scanning system employing microfabricated solid immersion lens

A solid immersion lens integrated on a flexible support such as a cantilever or membrane is described, together with a method of forming the integrated structure.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Mechanism for assembly of ultrasonic instrument

ActiveUS20070282335A1Improve wear resistanceDiagnosticsSurgical instrument detailsGear wheelEngineering

An ultrasonic clamp coagulator system that is configured to permit selective cutting, coagulation and clamping of tissue during surgical procedures. An elongated portion of the instrument can be configured for endoscopic applications and has an outside diameter of less than 6 mm. The system includes a one-piece torque wrench that is provided with cantilever arms aligned in an annular fashion about the centerline of the torque wrench. The cantilever arms include teeth in an inward perpendicular fashion in relation to cantilever arms. The clamp coagulator includes an outer tube retainer that includes spline gears projecting in a perpendicular fashion along the outer circumference of retainer. Torque is transmitted through the cantilever arms to the spline gears for attaching a handpiece to the clamp coagulator.

Owner:CILAG GMBH INT

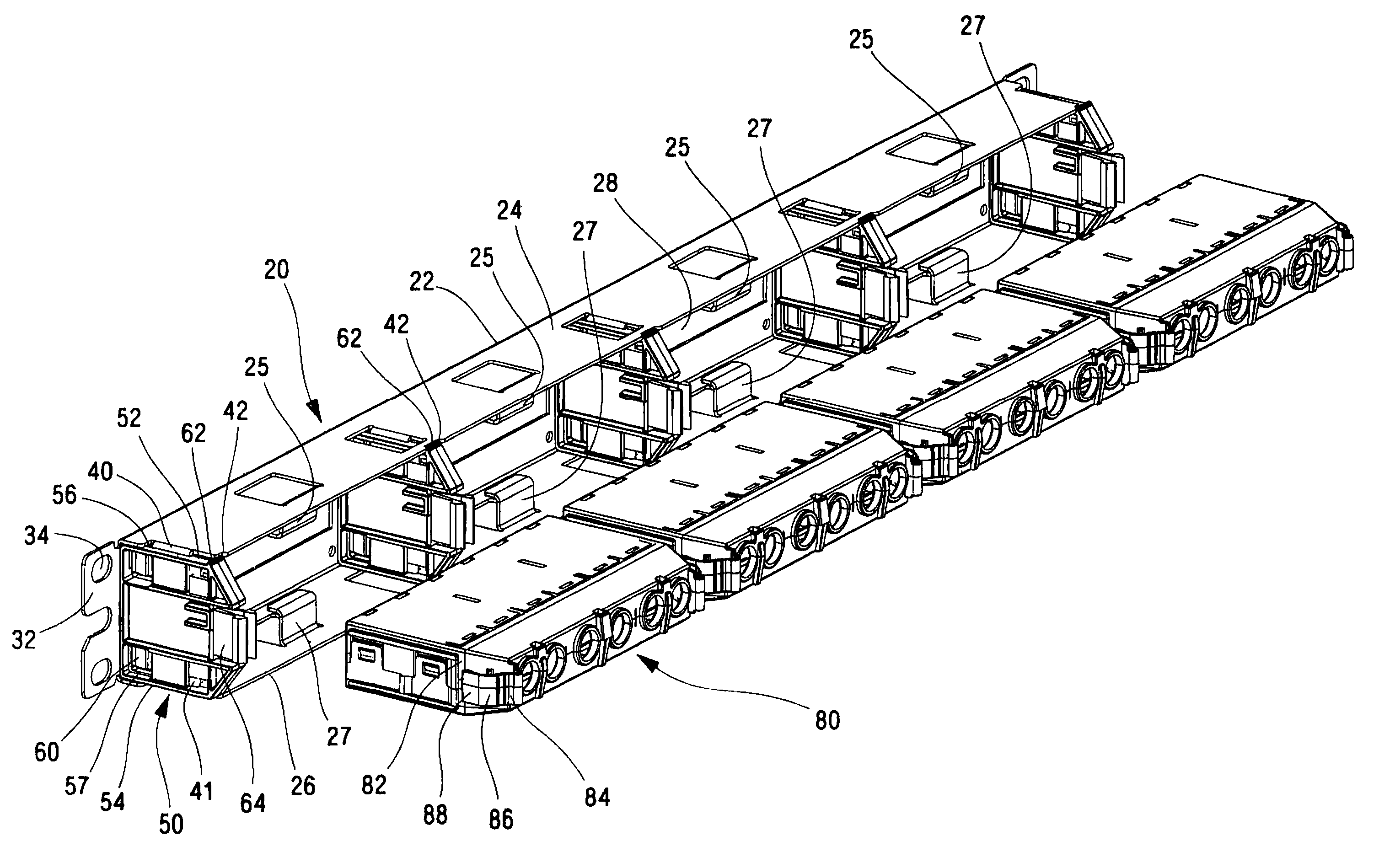

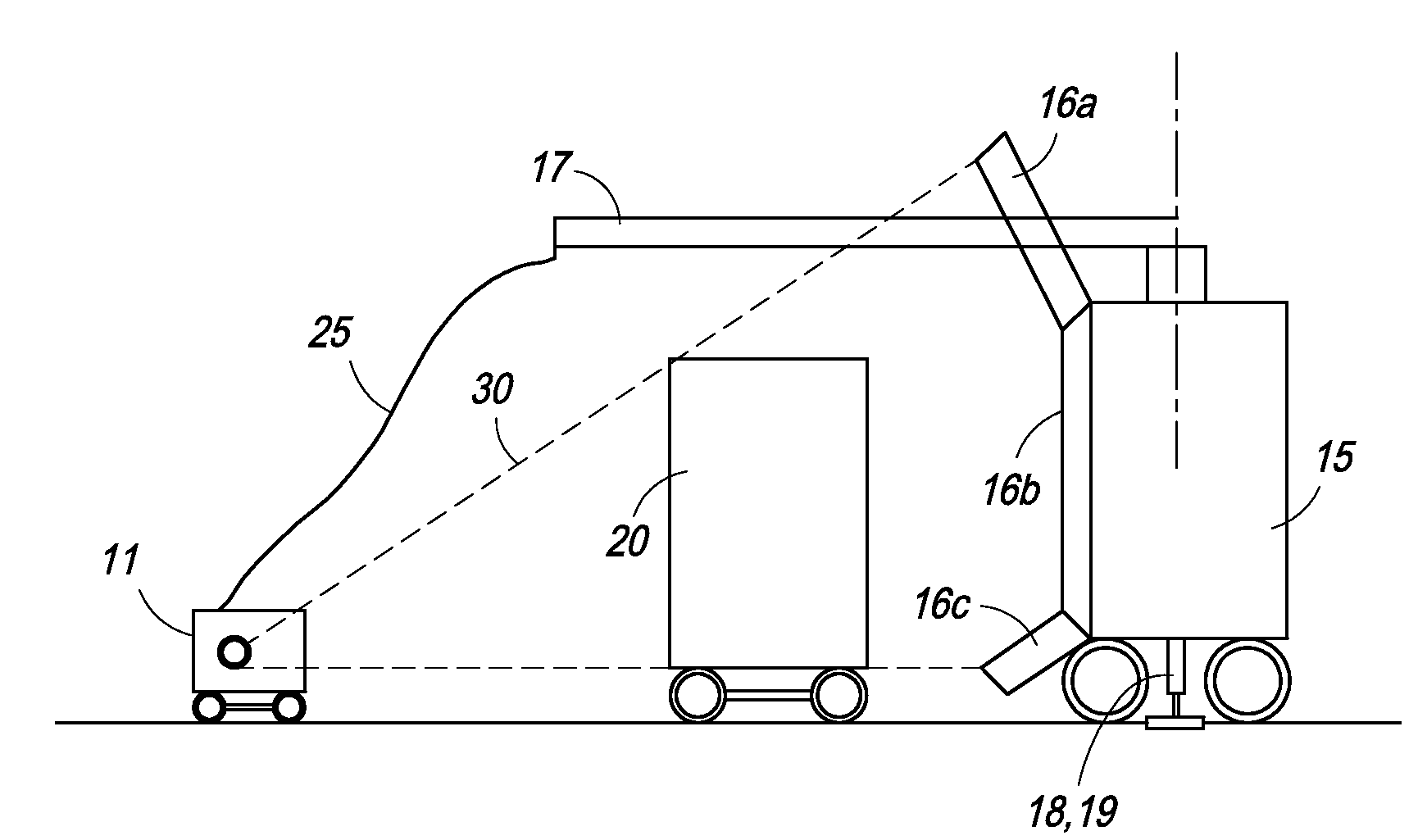

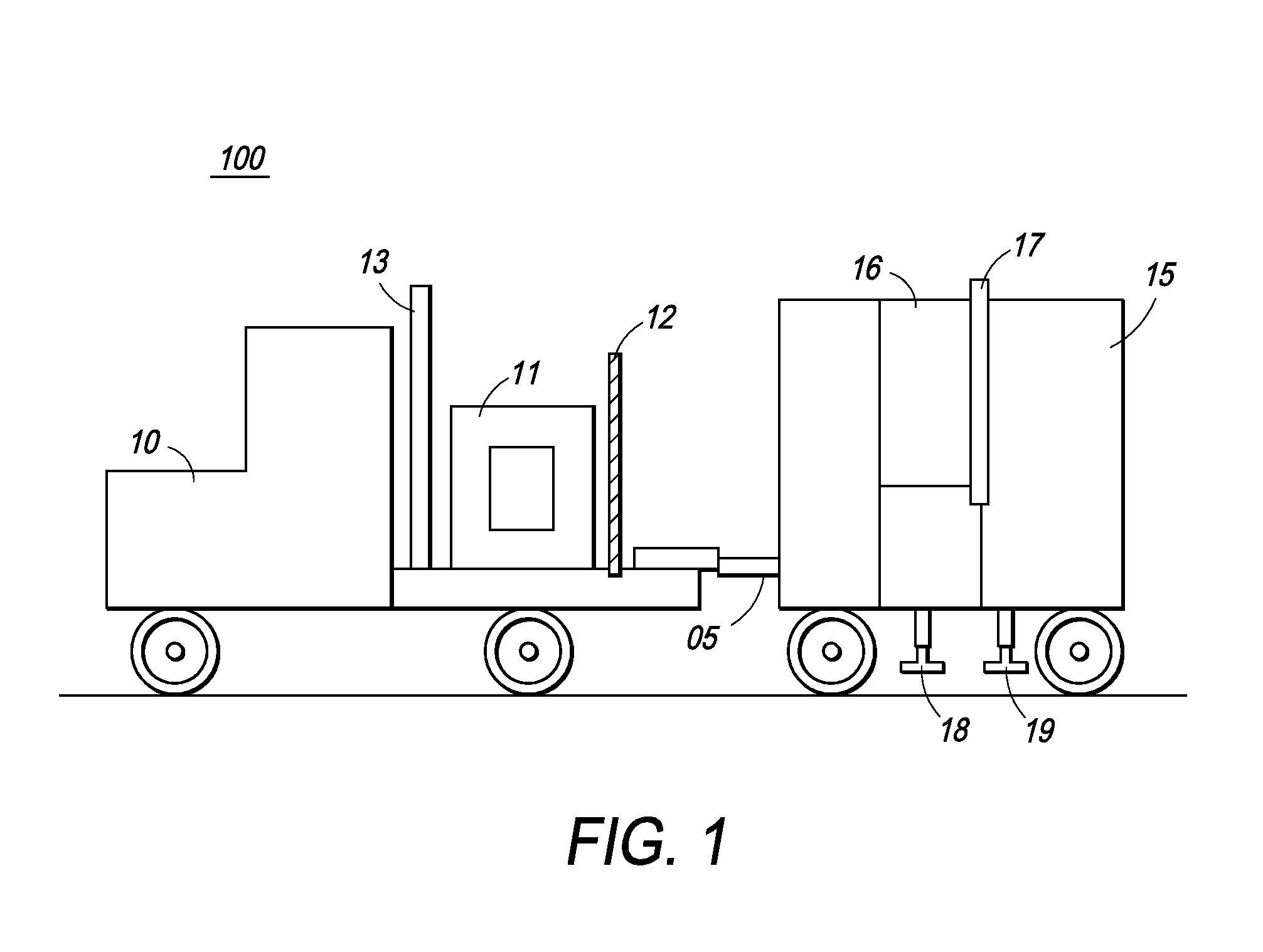

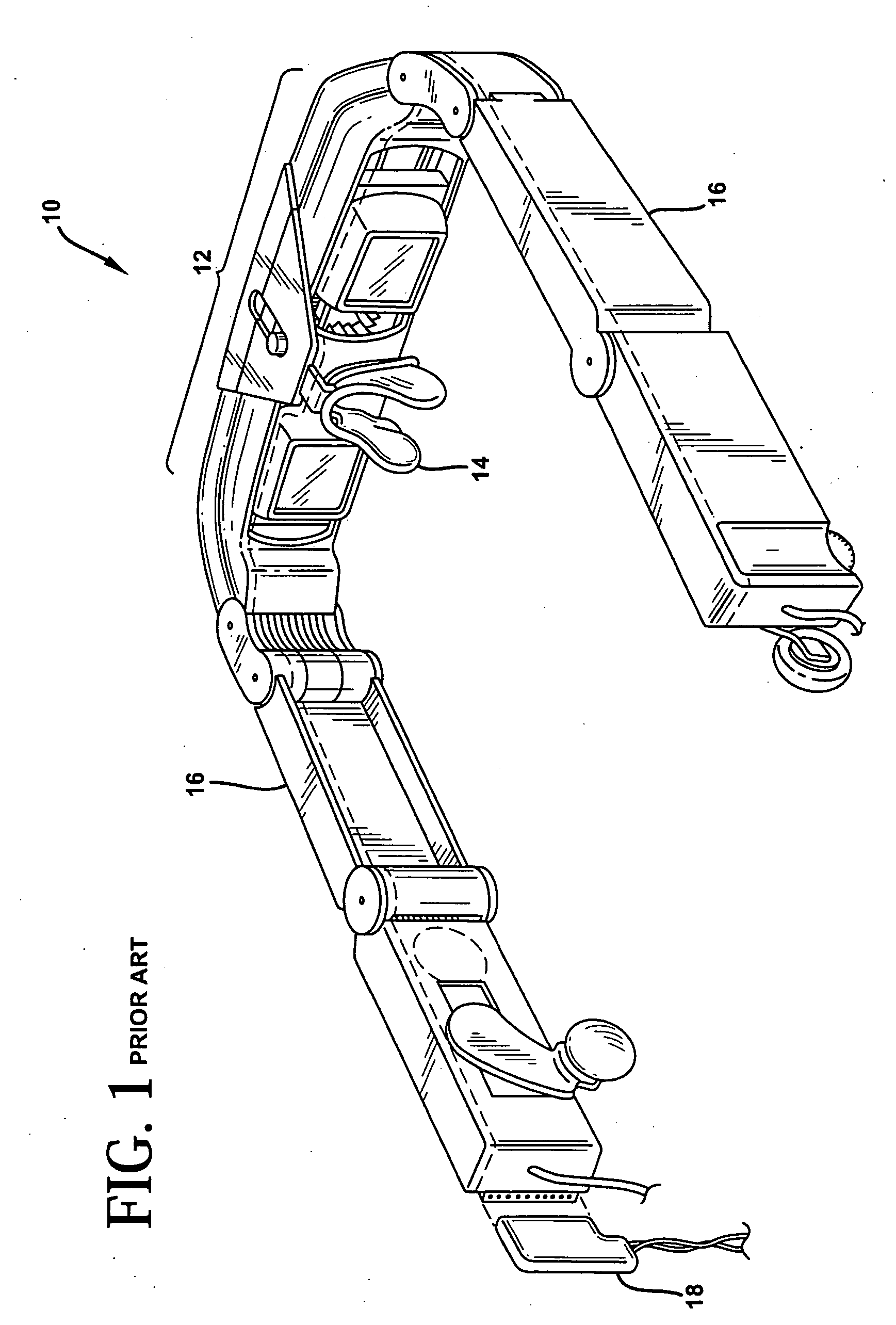

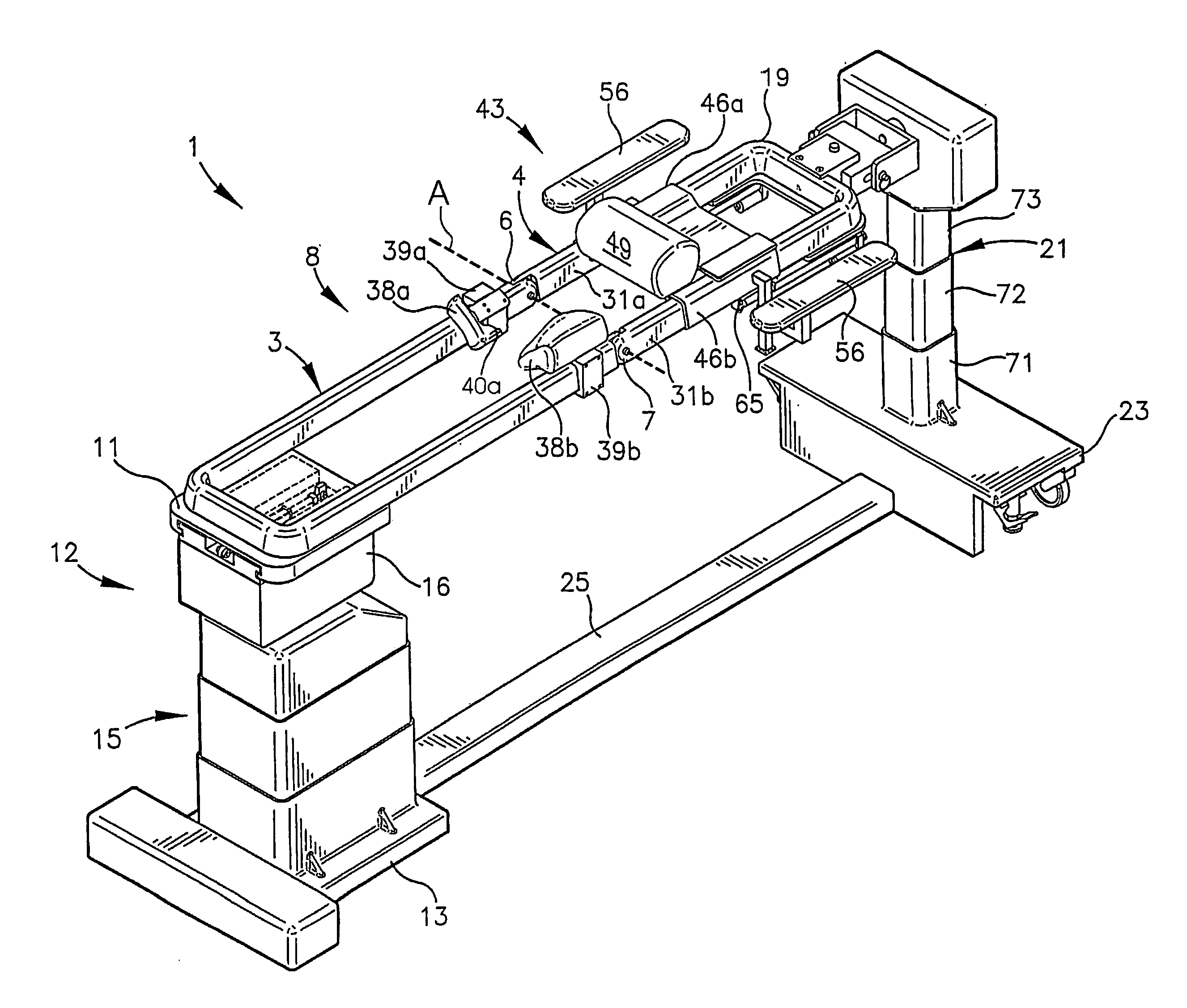

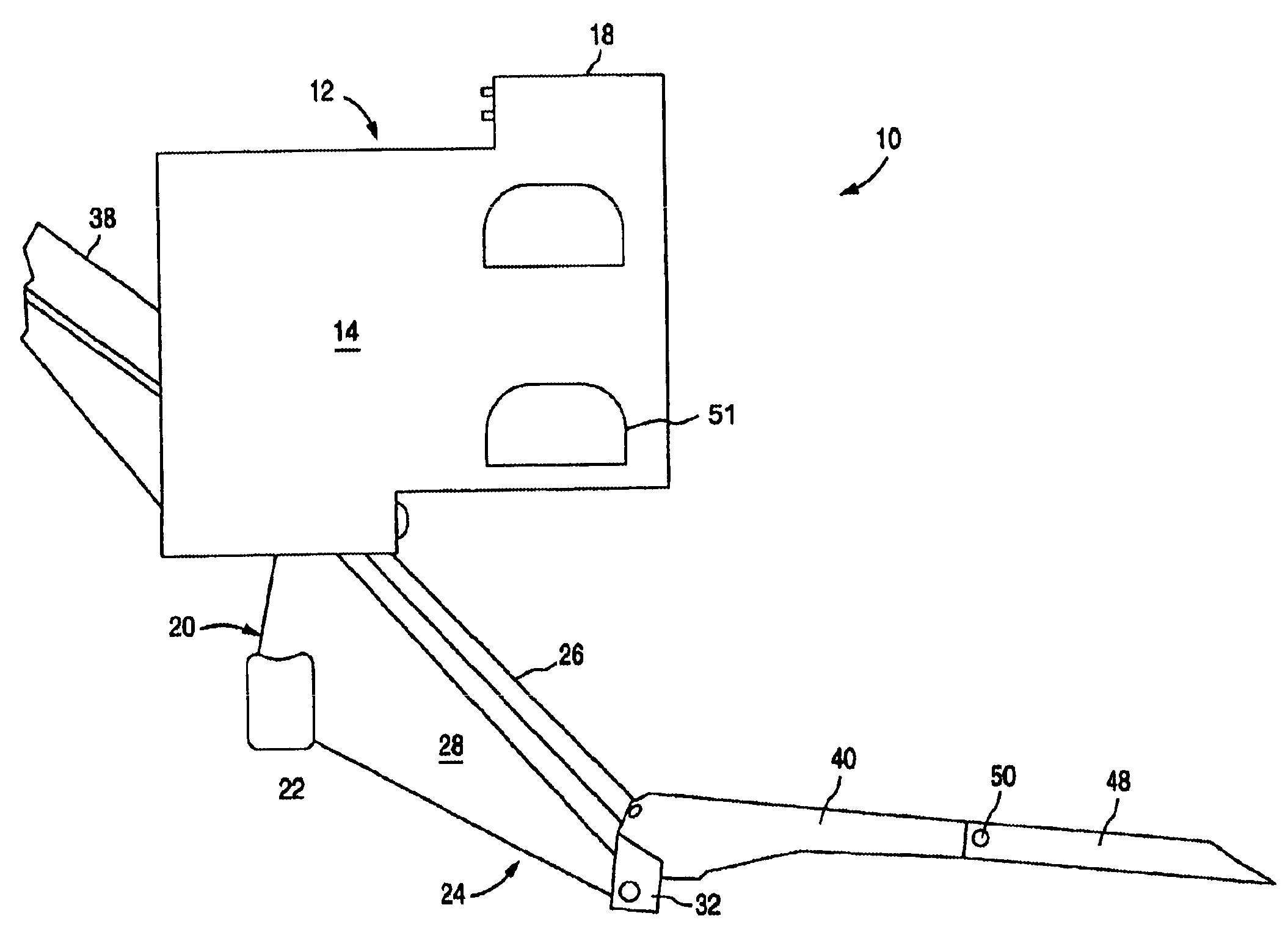

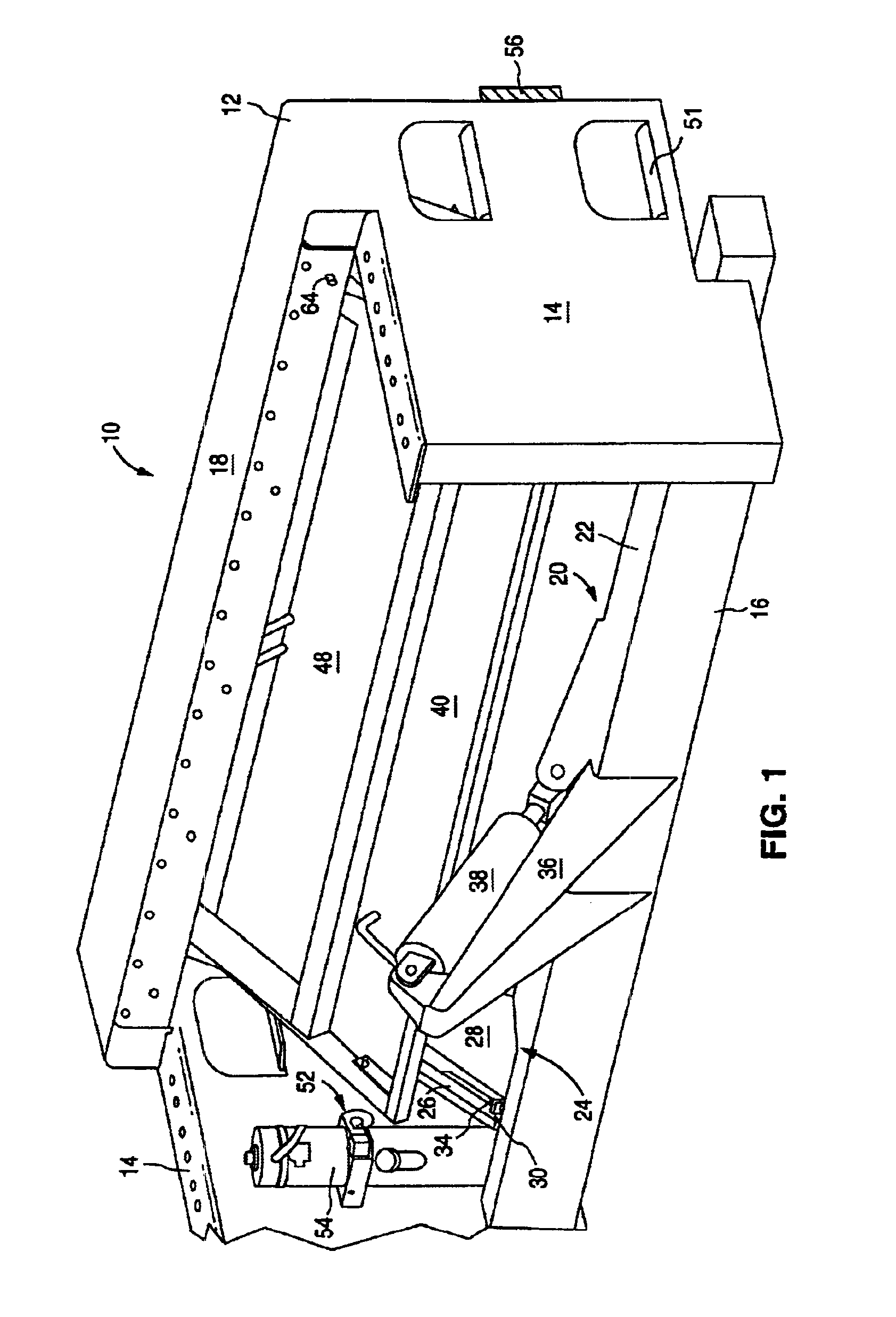

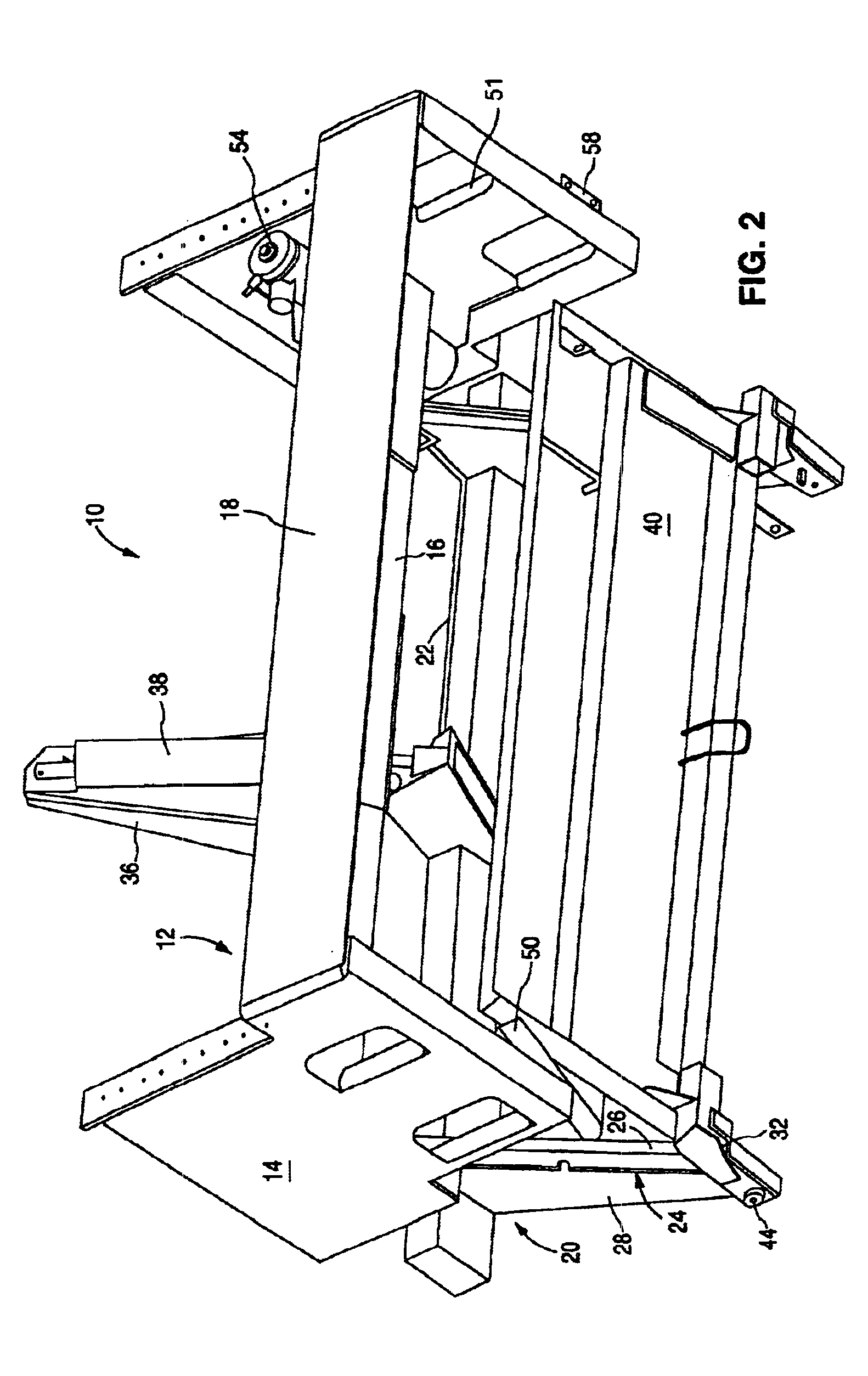

Single boom cargo scanning system

InactiveUS7322745B2Rapidly deployableCost-effectively and accurately on uneven surfaceRadiation/particle handlingParticle suspension analysisMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

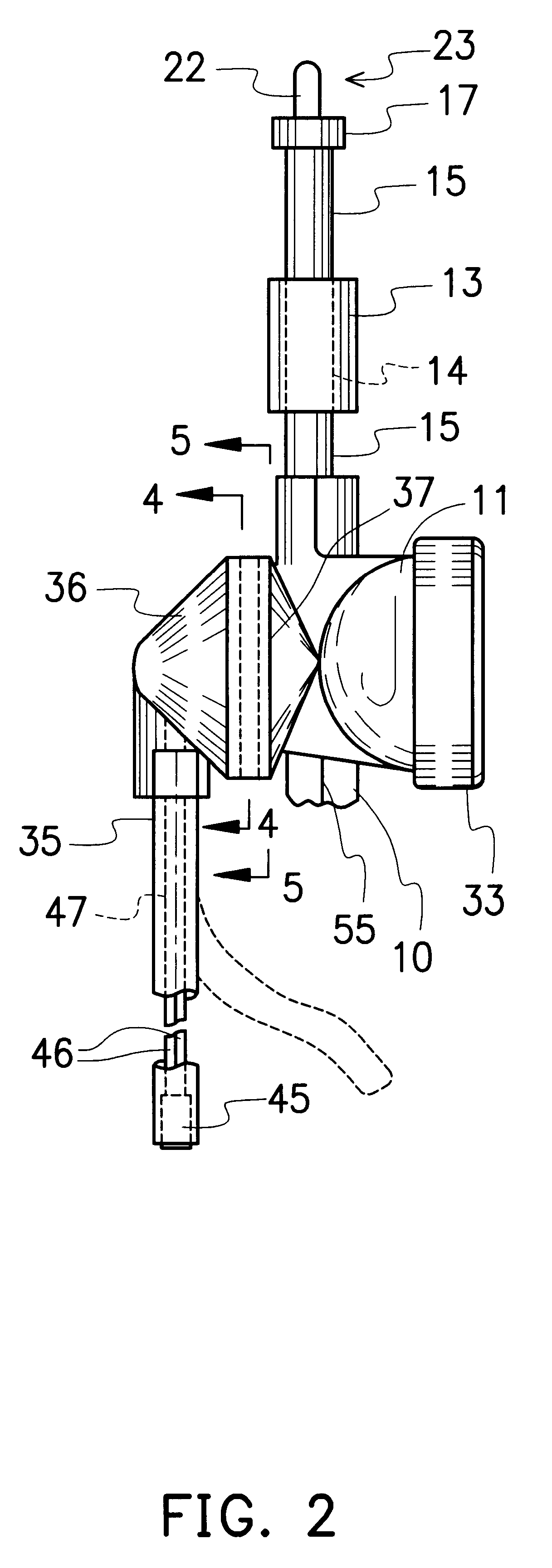

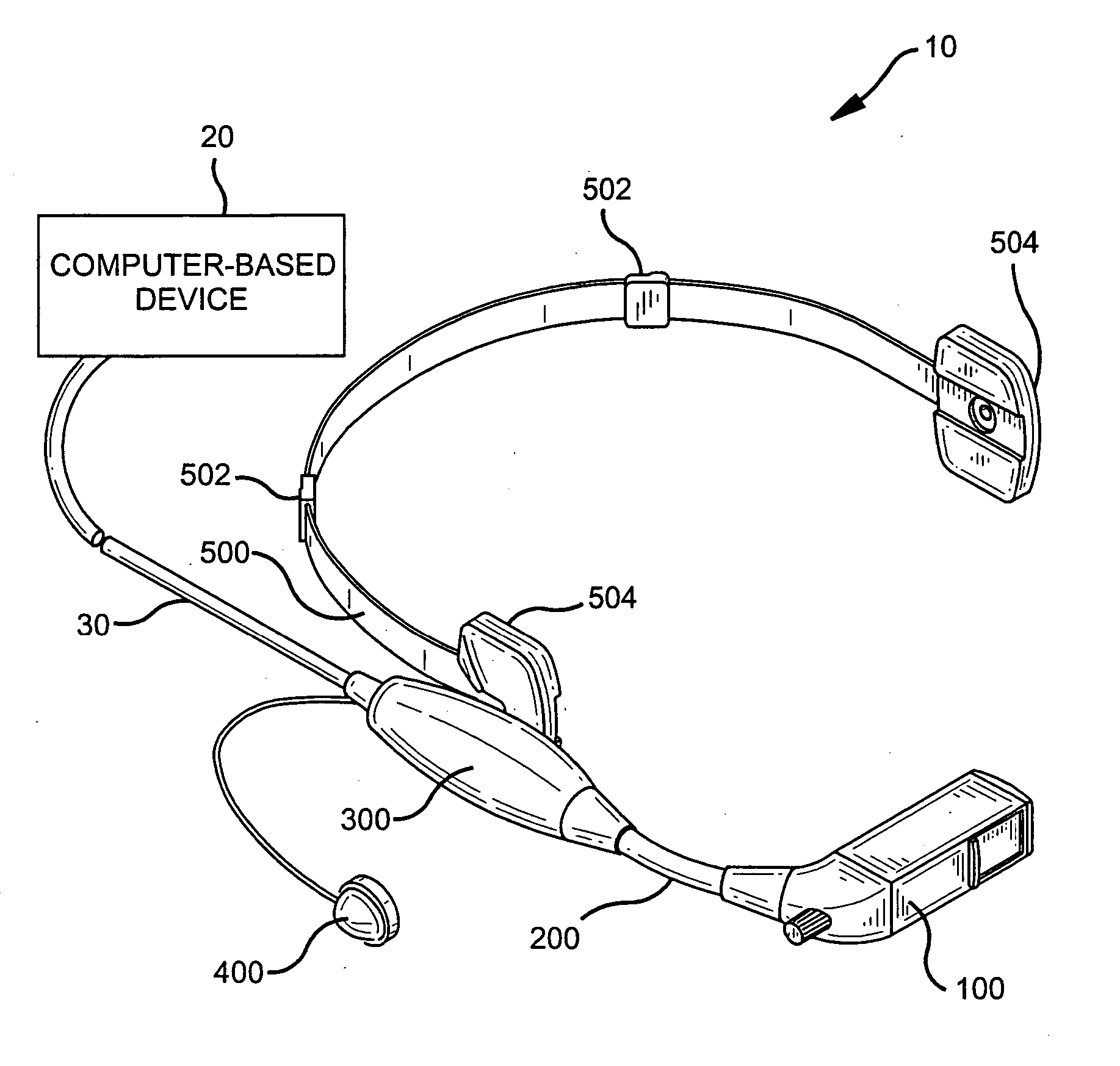

Adjustable earphones for personal audio and communication systems

InactiveUS6427018B1Prevent rusting and other corrosionAvoid partialMicrophonesLoudspeakersCommunications systemEngineering

An ear mounted earphone includes a speaker housing for positioning a speaker at the entrance to the auditory canal of an ear of a user. An elongate boom extends from the speaker housing and through a sleeve at one end of an earpiece so that the boom may be moved longitudinally and rotationally within the sleeve for adjustment purposes and will be frictionally held in adjusted position by the sleeve during use. A microphone arm with microphone may be rotatably mounted on the speaker housing to provide a microphone when the earphones are used with a communication system. The rotatability of the microphone arm allowing the same earphone and microphone arm to be adjusted for use with either the right or left ear of a user. An earpiece may be conveniently integrally molded as a single piece with a slit formed therein intermediate its length so the wire to the speaker and microphone can be positioned within the earpiece. The speaker may be waterproofed by a thin waterproof material such as mylar.

Owner:COTRON

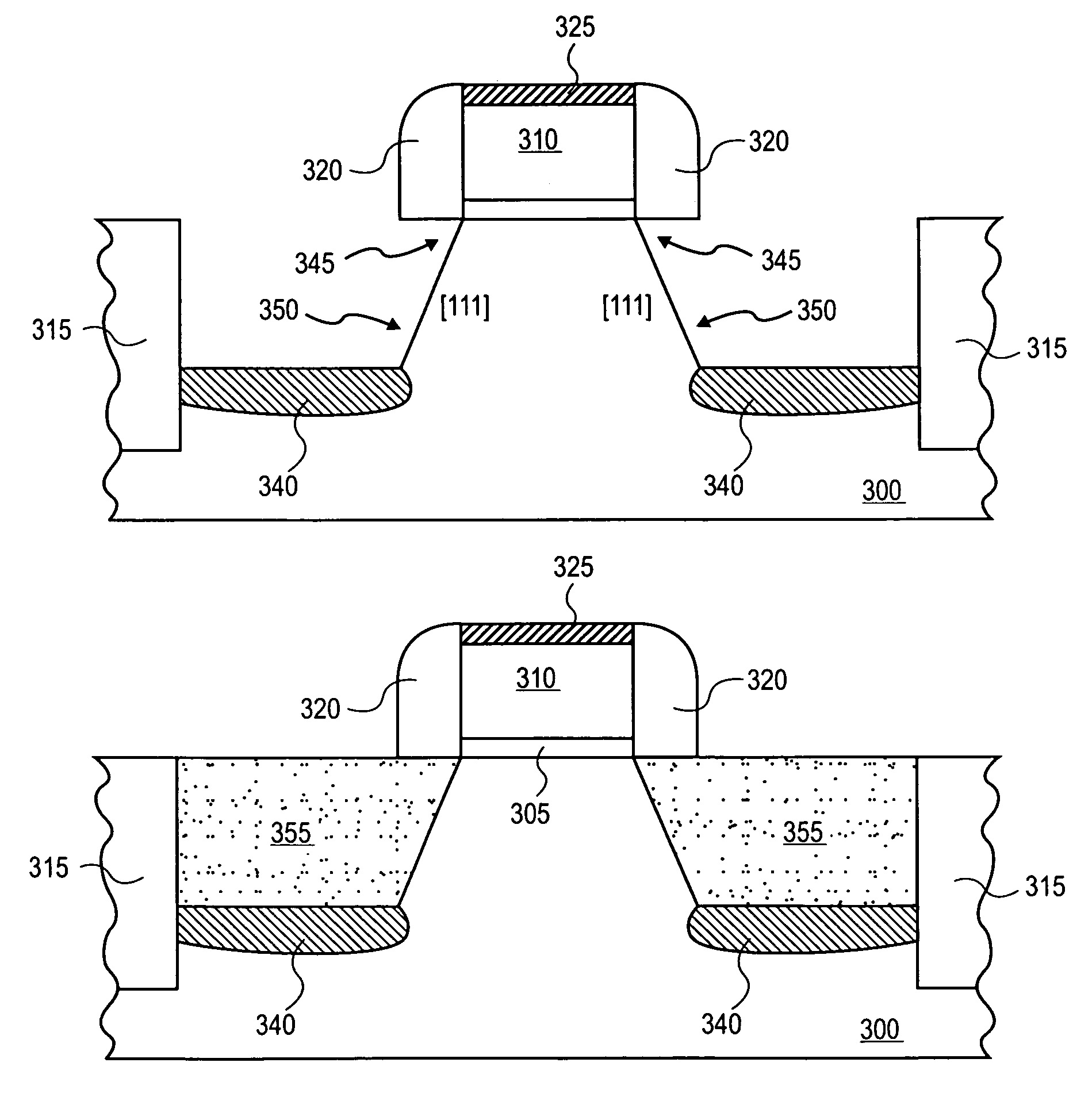

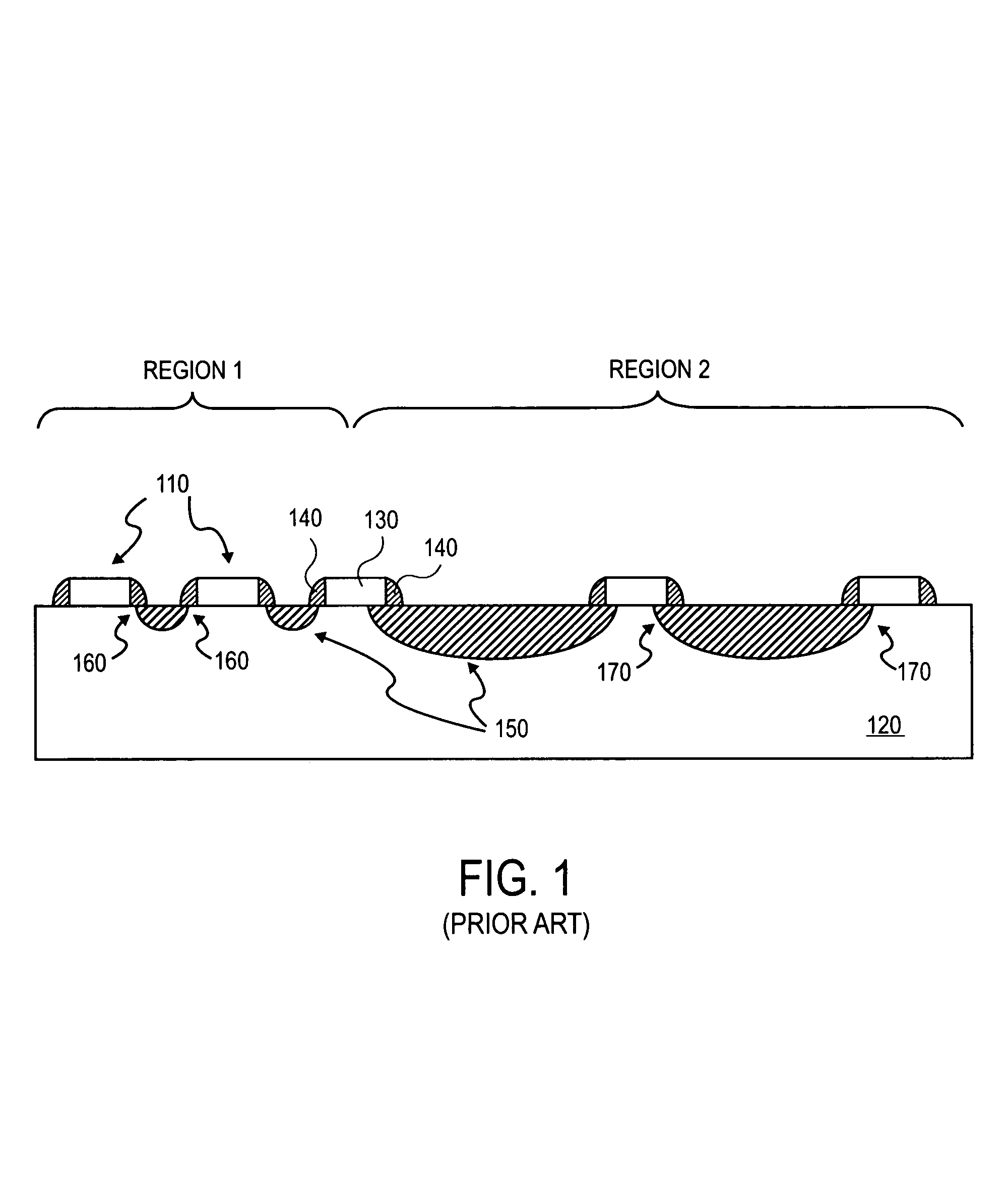

Amorphous etch stop for the anisotropic etching of substrates

ActiveUS7045407B2Semiconductor/solid-state device manufacturingSemiconductor devicesAnisotropic etchingCantilever

Methods of forming an amorphous etch stop layer by implanting a substrate with an element that is electrically neutral within the substrate are described. The use of elements that are electrically neutral within the substrate prevents electrical interference by the elements if they diffuse to other areas within the substrate. The amorphous etch stop layer may be used as a hard mask in the fabrication of transistors or other devices such as a cantilever.

Owner:INTEL CORP

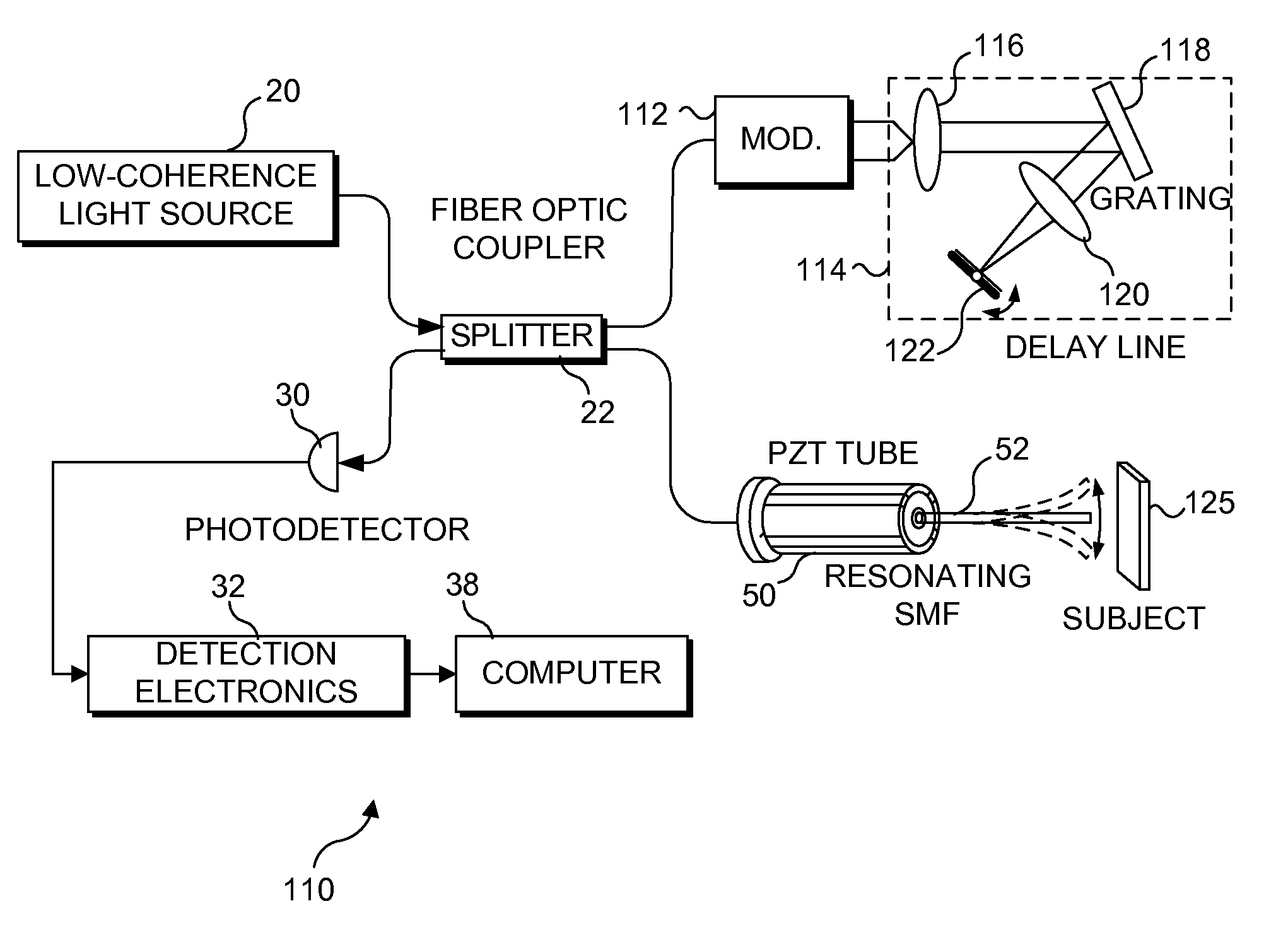

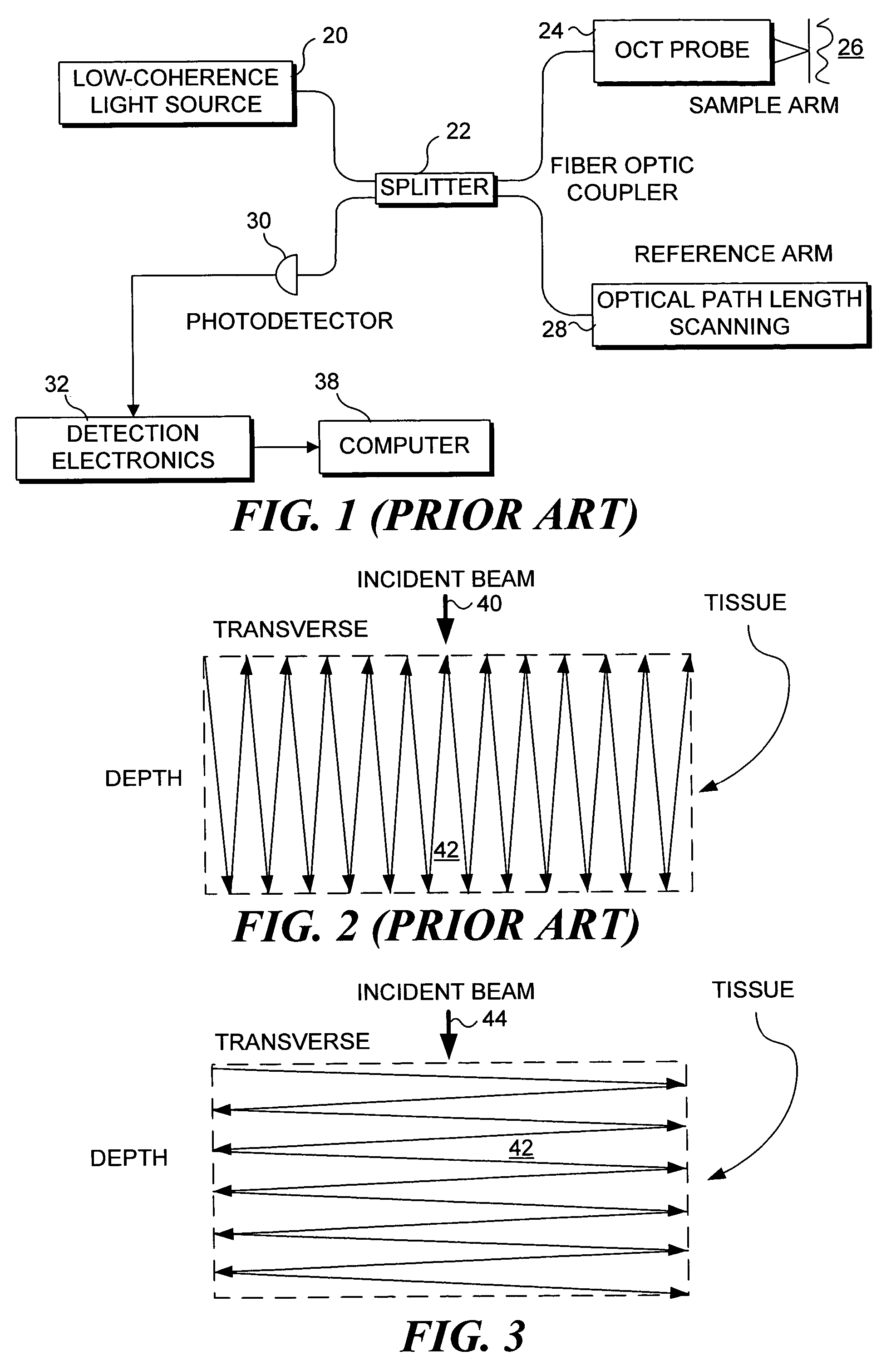

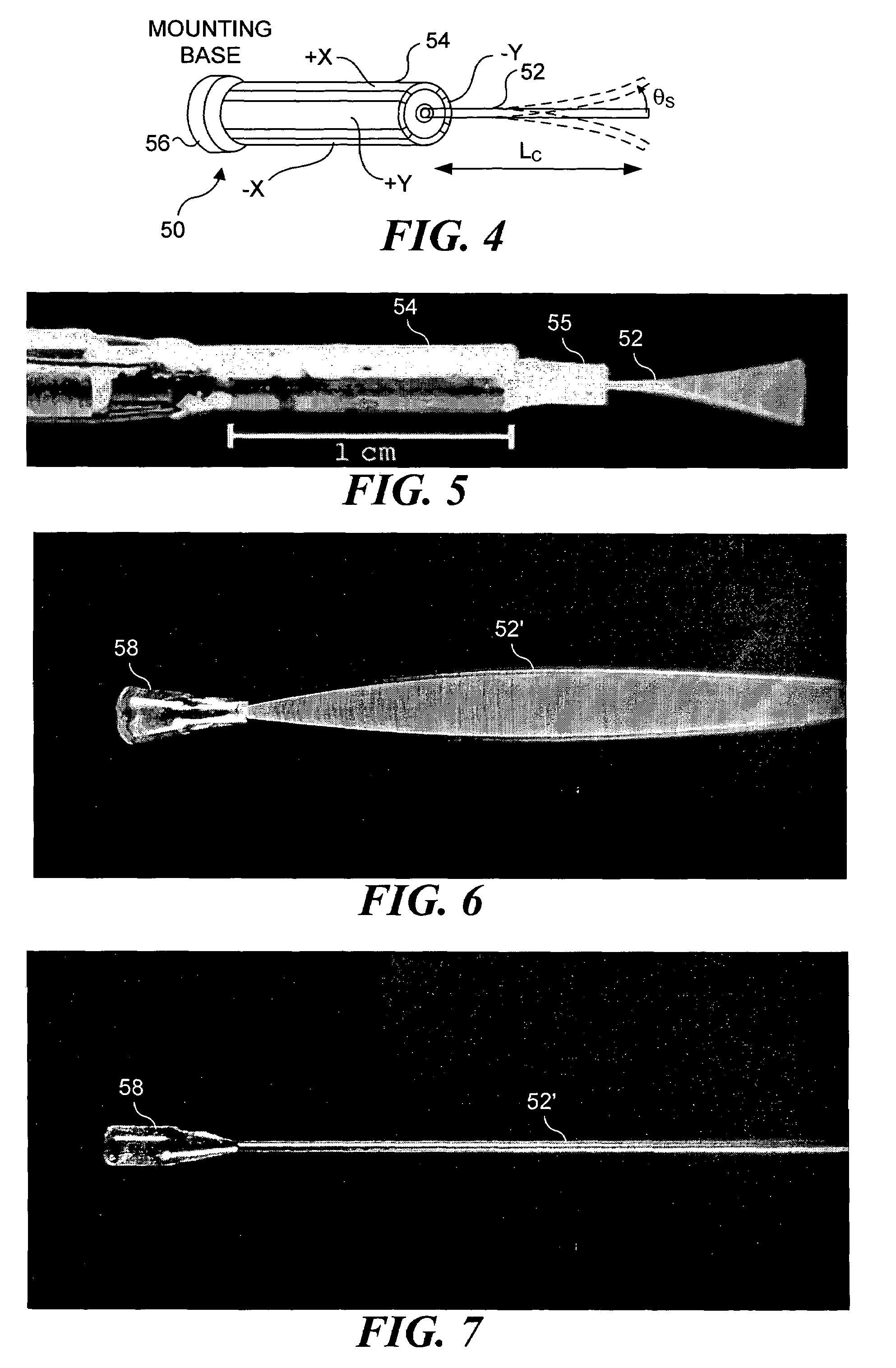

Optical fiber scanner for performing multimodal optical imaging

InactiveUS7616986B2Focus shiftReduce back reflectionBoxes/cartons making machineryBox making operationsActuatorFrequency modulation

An optical fiber scanner is used for multiphoton excitation imaging, optical coherence tomography, or for confocal imaging in which transverse scans are carried out at a plurality of successively different depths within tissue. The optical fiber scanner is implemented as a scanning endoscope using a cantilevered optical fiber that is driven into resonance or near resonance by an actuator. The actuator is energized with drive signals that cause the optical fiber to scan in a desired pattern at successively different depths as the depth of the focal point is changed. Various techniques can be employed for depth focus tracking at a rate that is much slower than the transverse scanning carried out by the vibrating optical fiber. The optical fiber scanner can be used for confocal imaging, multiphoton fluorescence imaging, nonlinear harmonic generation imaging, or in an OCT system that includes a phase or frequency modulator and delay line.

Owner:UNIV OF WASHINGTON

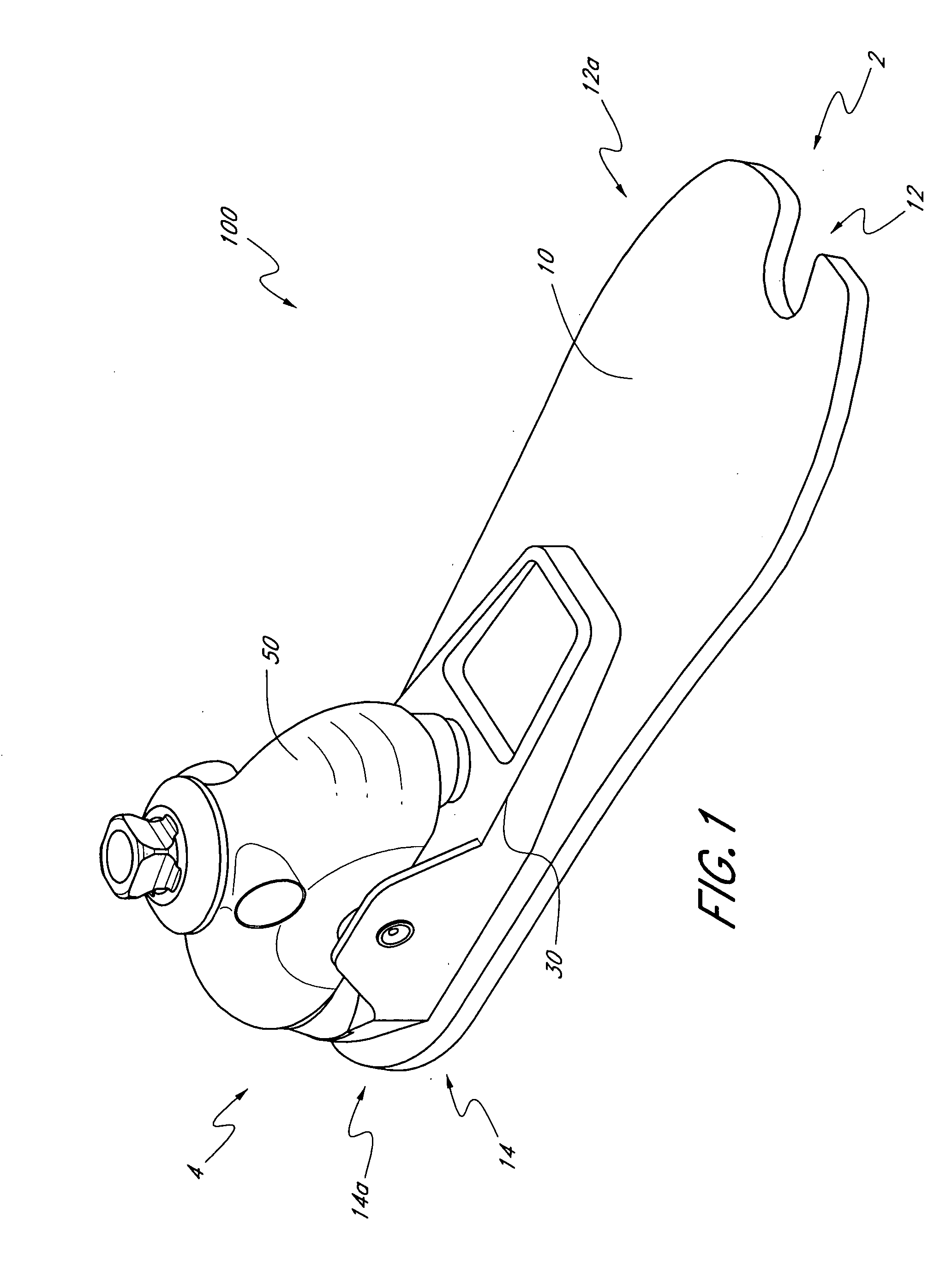

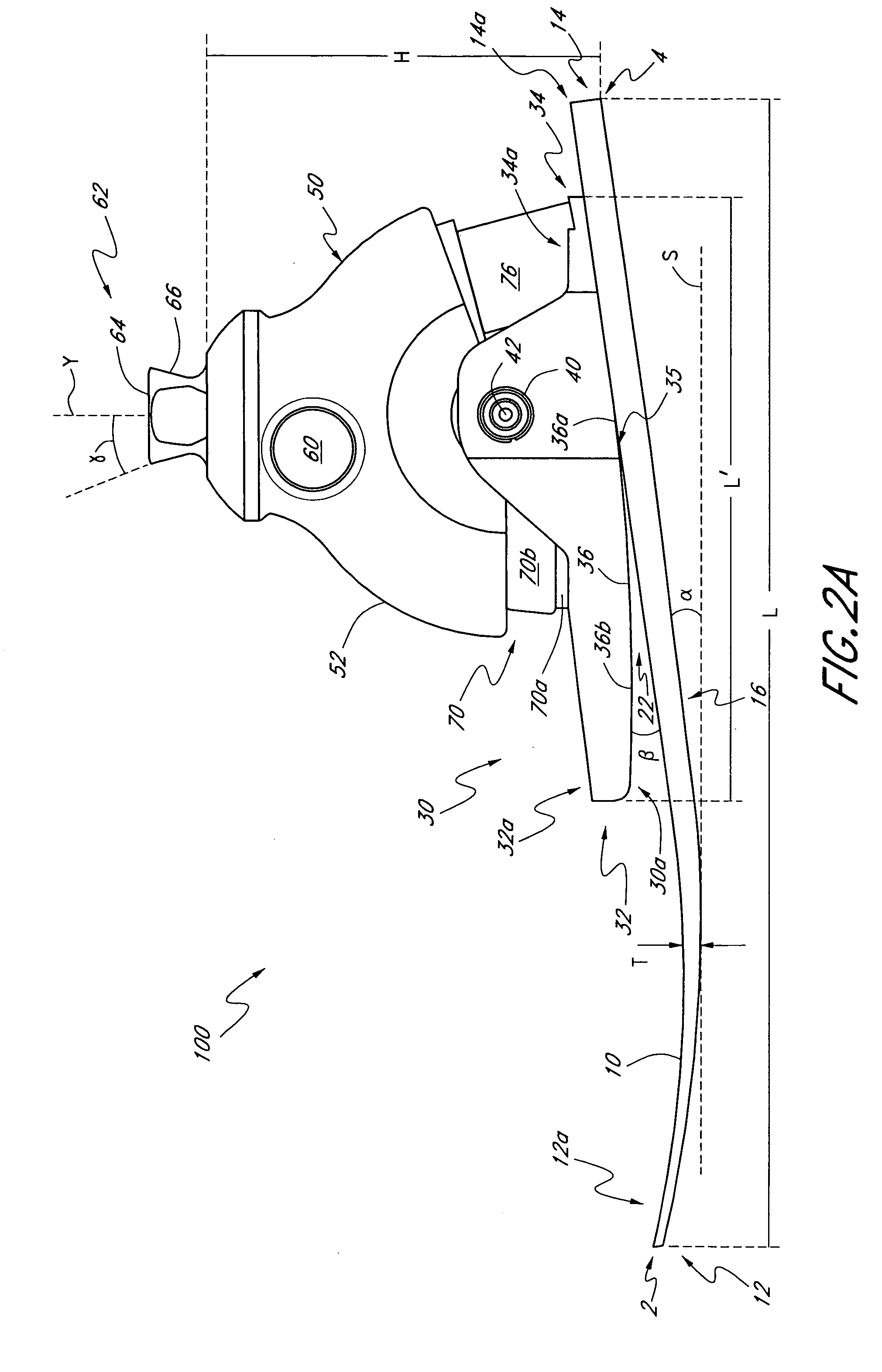

Prosthetic foot with rocker member

InactiveUS20050137717A1Easy introduction intoEasy to removeArtificial legsPhysical medicine and rehabilitationCantilever

A prosthetic foot comprises a foot member, a rocker member connected in cantilever fashion to the foot member, and an ankle module movably connected to the rocker member about an axis, wherein an anterior section of the rocker member is configured to roll-up onto the foot member an amount corresponding to the load applied on the foot, and wherein the foot member is configured to facilitate the initial roll-up of the rocker member.

Owner:GRAMTEC INNOVATION +1

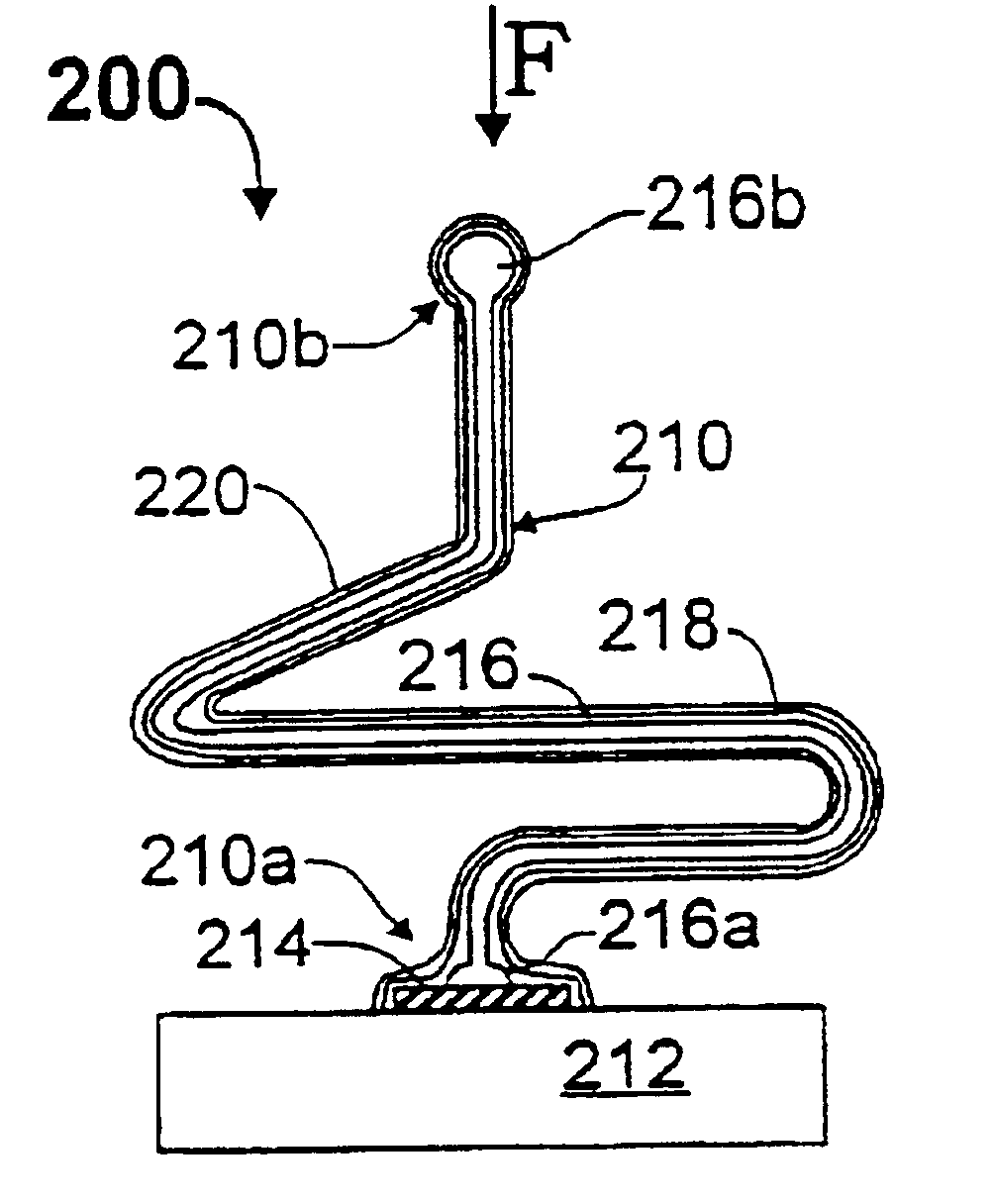

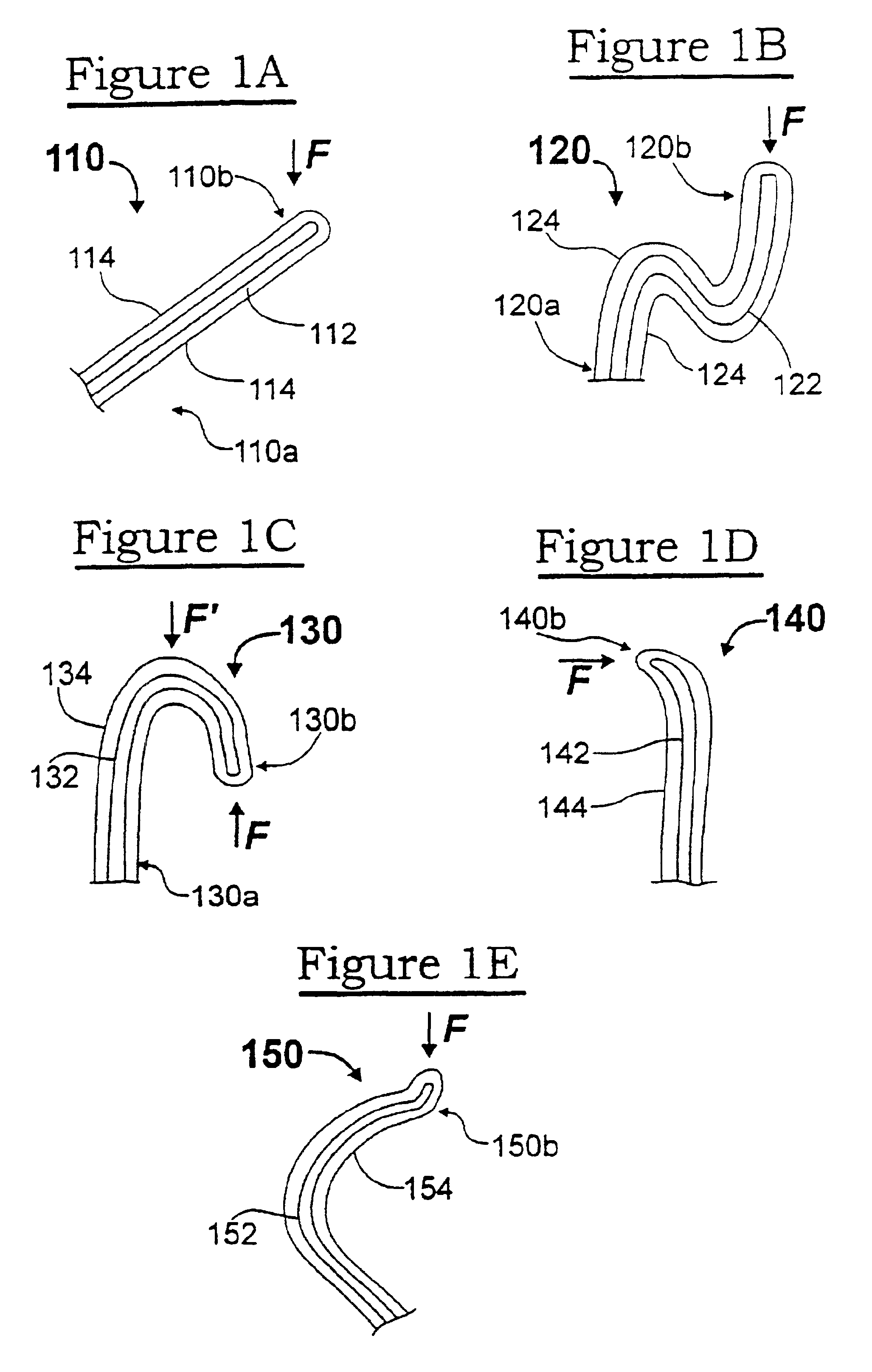

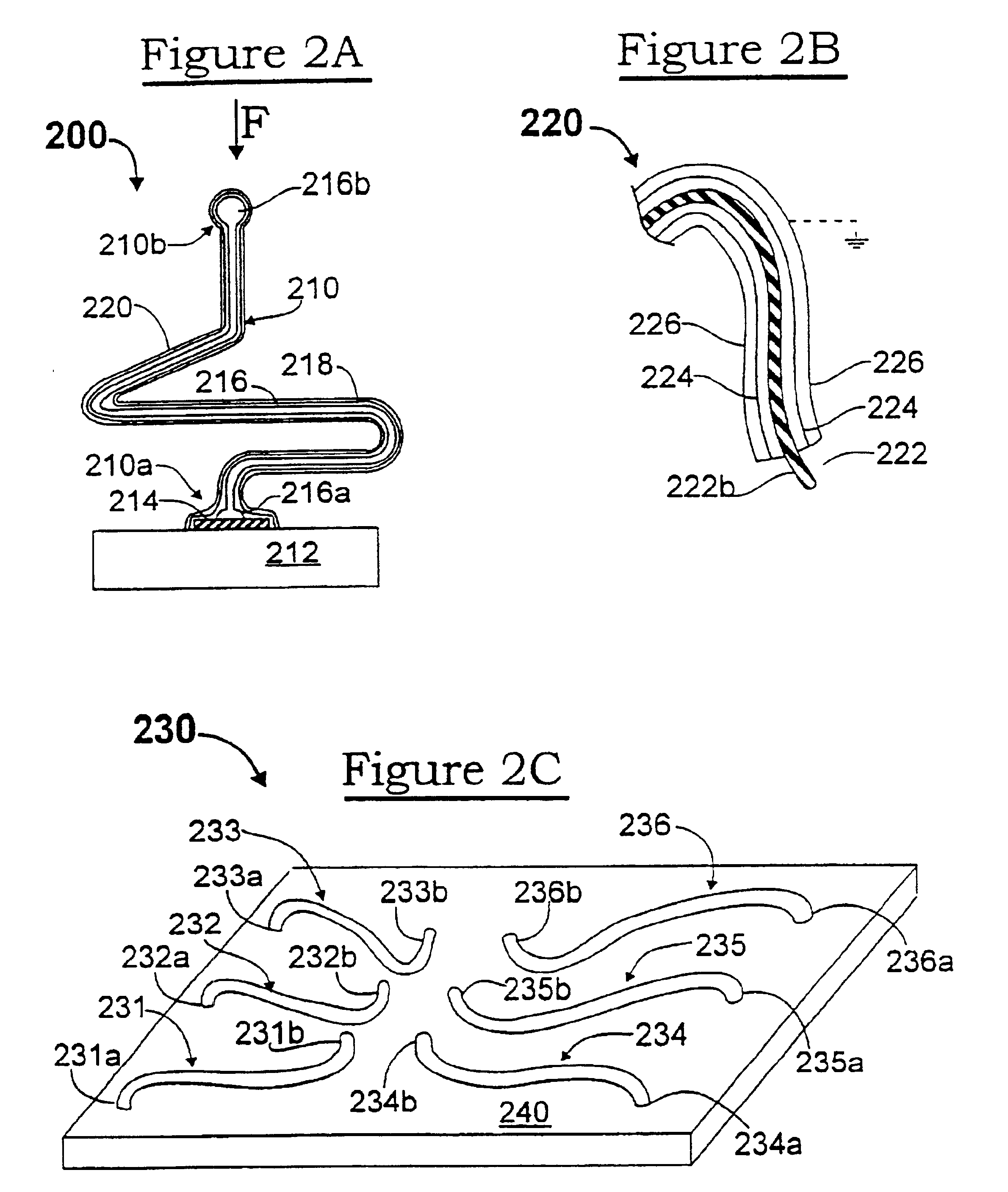

Method and apparatus for shaping spring elements

InactiveUS6836962B2Easy to disassembleEasy to manufactureElectrically conductive connectionsContact member assembly/disassemblyProbe cardCopper wire

Interconnection elements for electronic components, exhibiting desirable mechanical characteristic (such as resiliency, for making pressure contacts) are formed by using a shaping tool (512) to shape an elongate core element (502) of a soft material (such as gold or soft copper wire) to have a springable shape (including cantilever beam, S-shape, U-shape), and overcoating the shaped core element with a hard material (such as nickel and its alloys), to impart to desired spring (resilient) characteristic to the resulting composite interconnection element. A final overcoat of a material having superior electrical qualities (e.g., electrical conductivity and / or solderability) may be applied to the composite interconnection element. The resulting interconnection elements may be mounted to a variety of electronic components, including directly to semiconductor dies and wafers (in which case the overcoat material anchors the composite interconnection element to a terminal (or the like) on the electronic component), may be mounted to support substrates for use as interposers and may be mounted to substrates for use as probe cards or probe card inserts. The shaping tool may be an anvil (622) and a die (624), and may nick or sever successive shaped portions of the elongate elements, and the elongate element may be of an inherently hard (springy) material. Methods of fabricating interconnection elements on sacrificial substrates are described. Methods of fabricating tip structures (258) and contact tips at the end of interconnection elements are also described.

Owner:FORMFACTOR INC

Beam support

InactiveUS20150085474A1Easily manually inserted into connectorLine/current collector detailsCeilingsEngineeringCantilever

Selected connections in a prior art suspended panel ceiling are modified to provide fixed cantilevered extensions that support aluminum beams (ABs) with light emitting diode (LED) lights. The ABs with LED lights can be installed in the suspended ceiling to the fixed cantilevered extensions after the prior art portion of the suspended ceiling is completed.To create a fixed cantilevered extension, a second cross beam connector, preferably modified to provide an extended portion, is alone stabbed into a connection, without any attached second cross beam. Such fixed cantilevered extension is capable of subsequently having attached thereto, for support, a rolled aluminum beam (AB) with LED lights, after the prior art suspended ceiling is installed.The installation of the ABs with LED lights, subsequent to the construction of the suspended ceiling with the supports of the invention, does not affect the ceiling resistance to earthquakes.

Owner:WORTHINGTON ARMSTRONG VENTURE

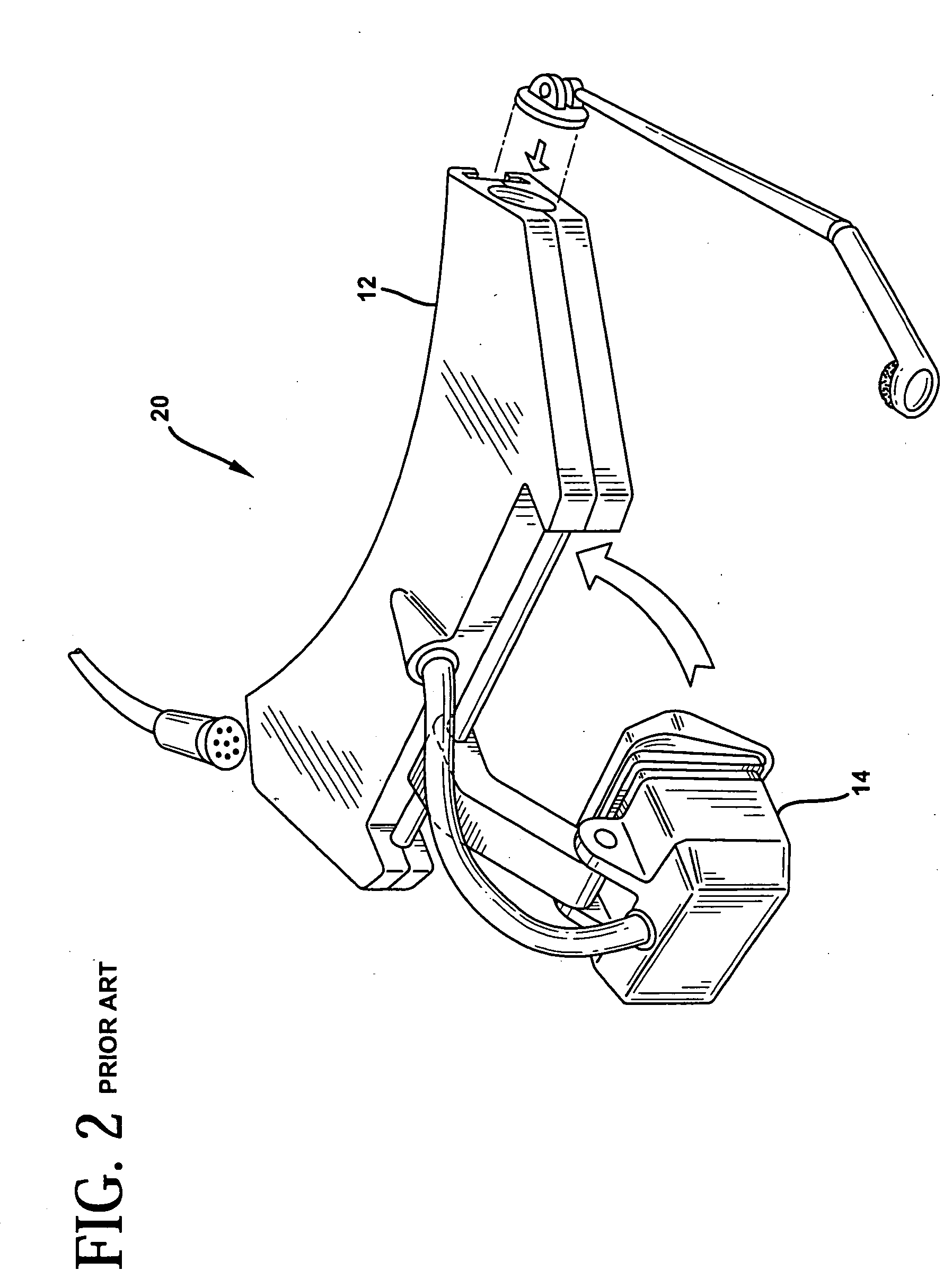

Compact optical system and packaging for head mounted display

ActiveUS20050219152A1Improve convenienceHigh acceptabilityTelevision system detailsPrismsDisplay deviceEngineering

A head mounted virtual image display unit is provided which is compact in size and weight, and incorporates a high performance optical system offering a clear see-through capability. A sliding light shield may be incorporated for those instances when see-through capability is not desired. A focus adjustment may be incorporated to permit the focusing of the image, for example, at a distance of approximately 18 inches to infinity. An adjustable headband may be incorporated that adapts to fit the users head. A flexible boom structure may be incorporated to facilitate fine positional adjustment of the optical assembly. A slider and ball joint mechanism may also be incorporated to facilitate positional adjustment of the optical assembly. A built-in microphone may be incorporated to enable speech input by the user. The head mounted virtual image display unit may be used comfortably in conjunction with eye or safety glasses, and provides a useful image to the user without blocking his view of the surrounding environment. The unit is designed to have a pleasing appearance so as to greatly enhance user acceptability.

Owner:IBM CORP

Stress bimorph MEMS switches and methods of making same

InactiveUS7053737B2Reduce capacitanceMinimize OFF-state capacitanceElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringCantilever

A micro-electromechanical system (MEMS) switch formed on a substrate, the switch comprising a transmission line formed on the substrate, a substrate electrostatic plate formed on the substrate, and an actuating portion. The actuating portion comprises a cantilever anchor formed on the substrate and a cantilevered actuator arm extending from the cantilever anchor. Attraction of the actuator arm toward the substrate brings an electrical contact into engagement with the portions of the transmission line separated by a gap, thus bridging the transmission line gap and closing the circuit. In order to maximize electrical isolation between the transmission line and the electrical contact in an OFF-state while maintaining a low actuation voltage, the actuator arm is bent such that the minimum separation distance between the transmission line and the electrical contact is equal to or greater than the maximum separation distance between the substrate electrostatic plate and arm electrostatic plate.

Owner:HRL LAB +1

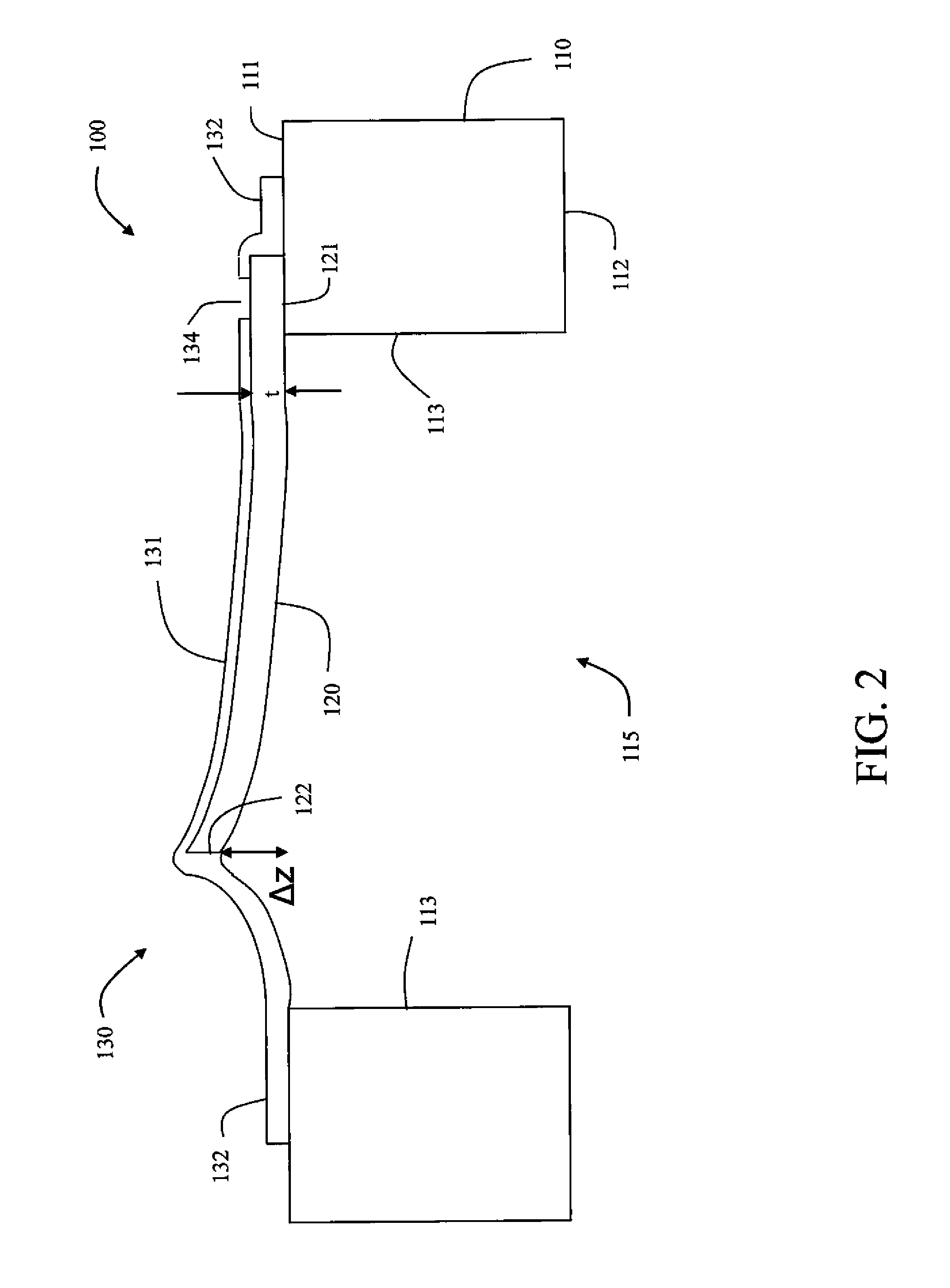

Patient positioning support structure

An articulating patient support table comprises first and second patient support sections hingedly connected together along respective hinge ends. A longitudinal translation subassembly connected to a base by a position adjustable pedestal supports the first patient support section in cantilevered relationship. The position adjustment assembly includes a lift mechanism operable to raise and lower the longitudinal translation subassembly relative to the base and a pivot assembly operable to pivot the longitudinal translation subassembly fore and aft and side to side relative to the base.

Owner:WARSAW ORTHOPEDIC INC

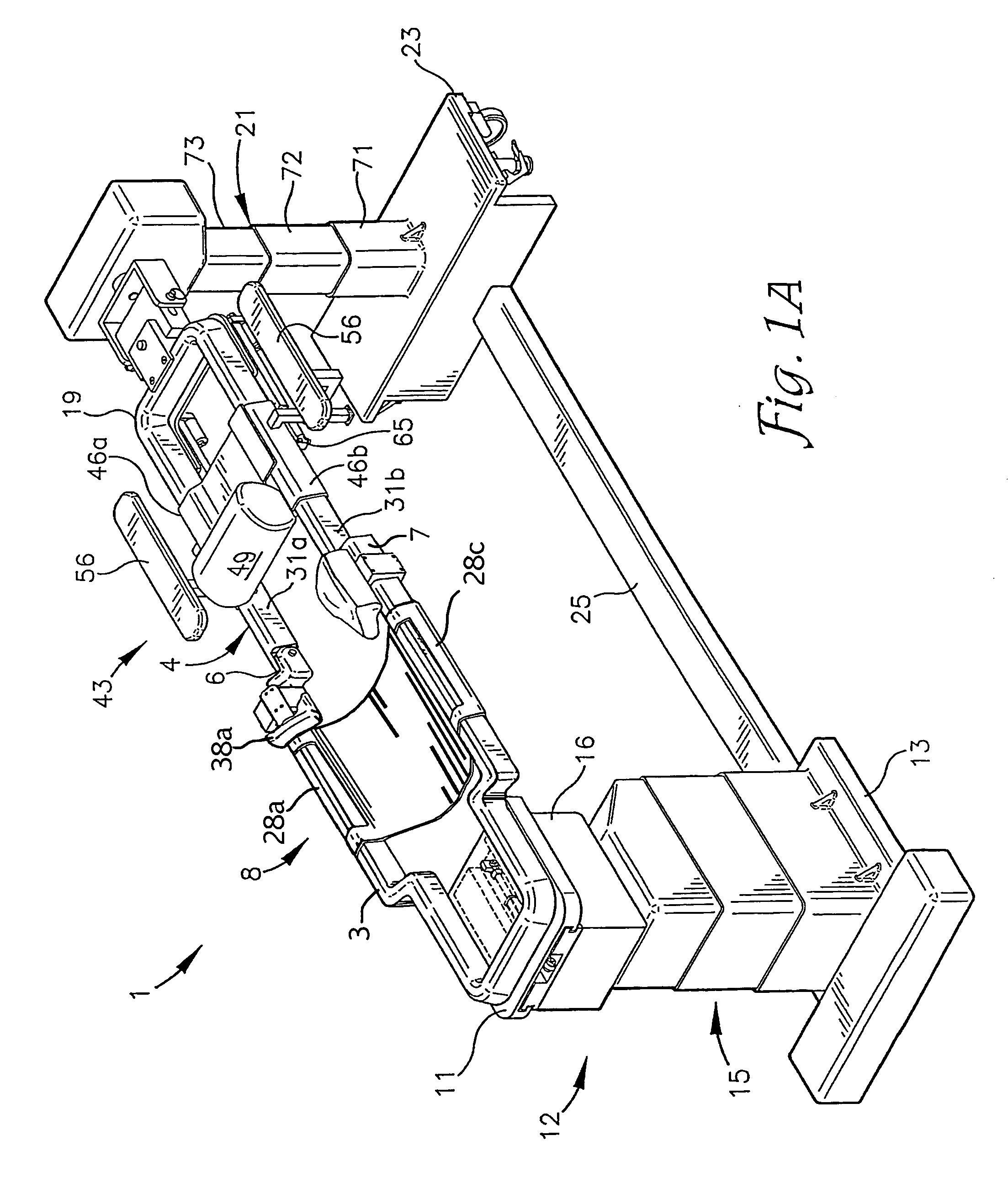

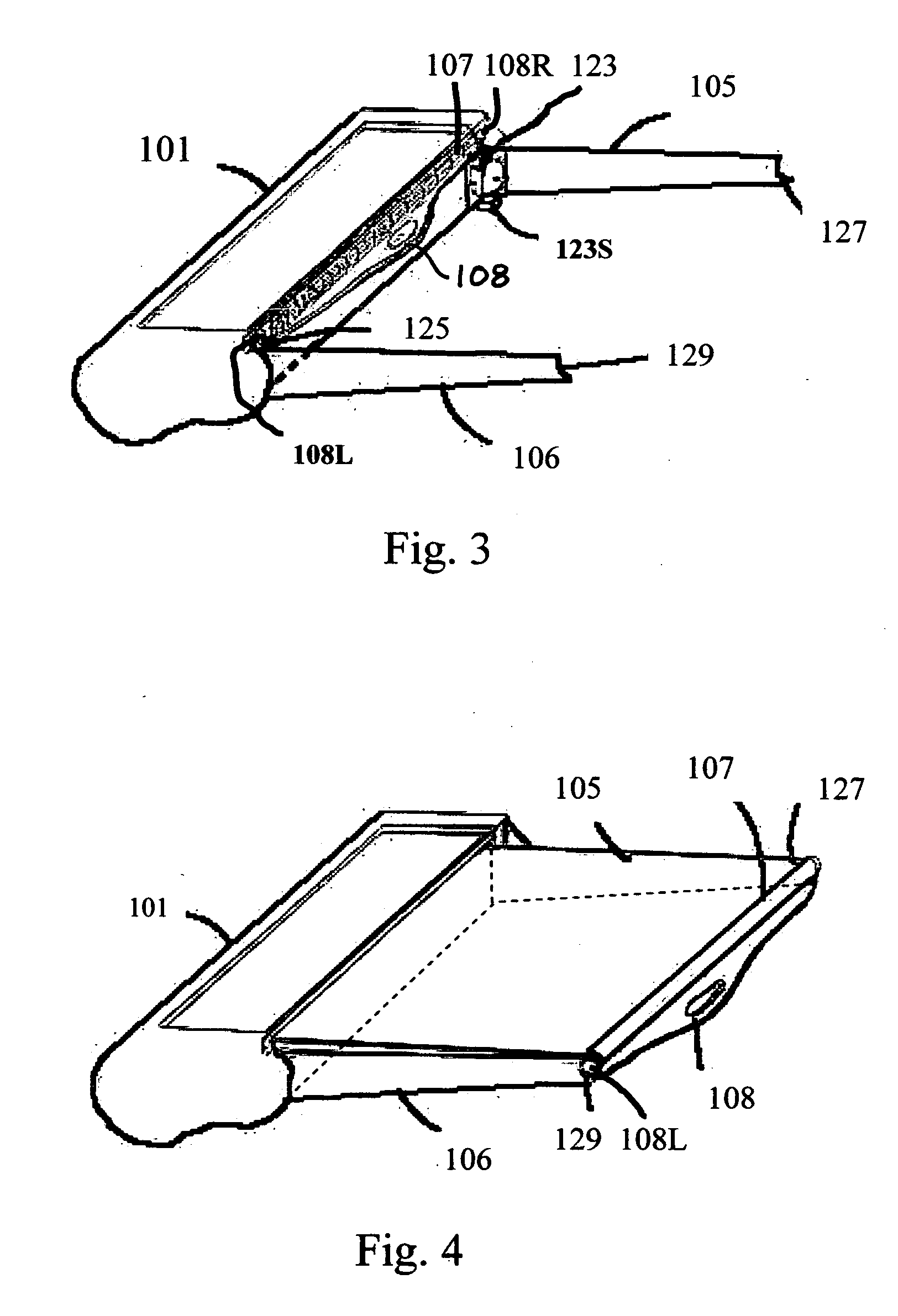

Roll-out touch screen support system (ROTS3)

InactiveUS20070211036A1Satisfying and complete computer interactionInput/output for user-computer interactionCathode-ray tube indicatorsSupporting systemWindow shutter

A method for providing interactive self-supporting screen with scalable flexibility. Such a support combined with a flexible computer screen enables reliable touch, writing, mobile drawing, accurate selection, and virtual typing without requiring desk or table space. A flexible screen when rolled up will provide a reduced footprint device for storage or transport and the selective deployment to the required size as the operator desires. Consisting of Protective layer (Flexible-paper feel surface, can be touch enabled), Organic Light Emitting Display (OLED) layer, back light layer (if required), Backing (flexible, slat seam filling; blotter feel), Slats or slabs (Curtin or blinds like), and pullout, telescoping, or swing out cantilever supports.

Owner:PERKINS MICHAEL T

Angular mounted optical connector adaptor frame

InactiveUS6623170B2Substation/switching arrangement detailsCoupling light guidesEngineeringOblique angle

Owner:FCI AMERICAS TECH LLC

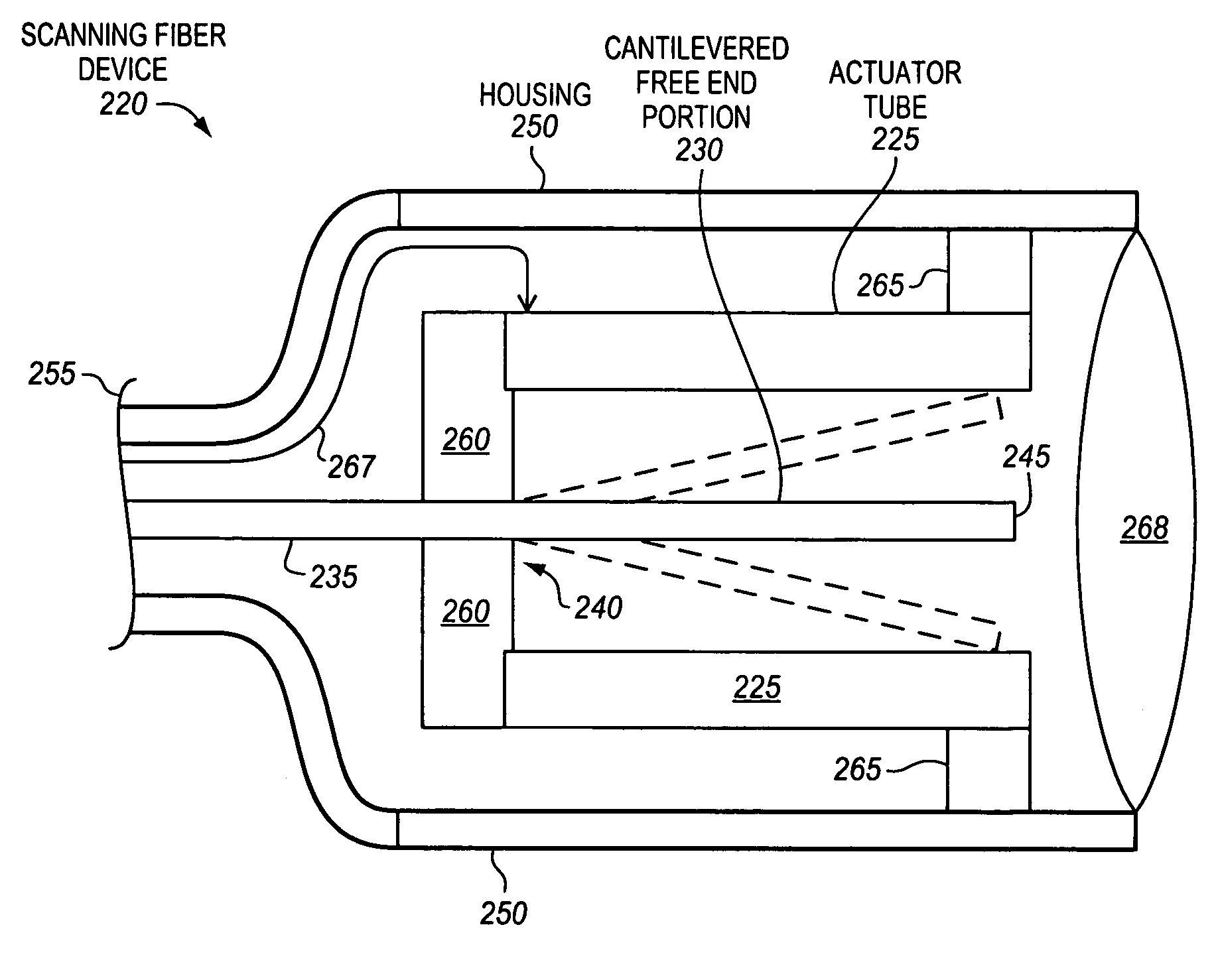

Compact scanning fiber device

Scanning fiber devices are disclosed. In one aspect, a scanning fiber device may include an actuator tube. The scanning fiber device may also include a cantilevered free end portion of an optical fiber. The cantilevered free end portion of the optical fiber may have an attached end that is coupled with the actuator tube. The cantilevered free end portion of the optical fiber may also have a free end to be moved by the actuator tube. At least a portion of a length of the cantilevered free end portion of the optical fiber may be disposed within the actuator tube. Methods of using scanning fiber devices are also disclosed.

Owner:UNIV OF WASHINGTON

Unitary liftgate

InactiveUS6948903B2Less timeVehicle with raised loading platformRefuse receptaclesEngineeringCantilever

The invention is a unitary cantilever liftgate that attaches to the vehicle body instead of the vehicle chassis. The liftgate may be fully assembled and tested prior to installation on the vehicle body. This greatly reduces installation time while improving performance and reliability. Various features such as steps, bumpers and brackets are integrated into the liftgate. Further, the liftgate is preferably configured so that multiple units can be stacked together for shipping and ease of unloading and loading. The stackability of the liftgates simplifies storing as well, by removing the necessity of storing several components separately.

Owner:MAXON LIFE

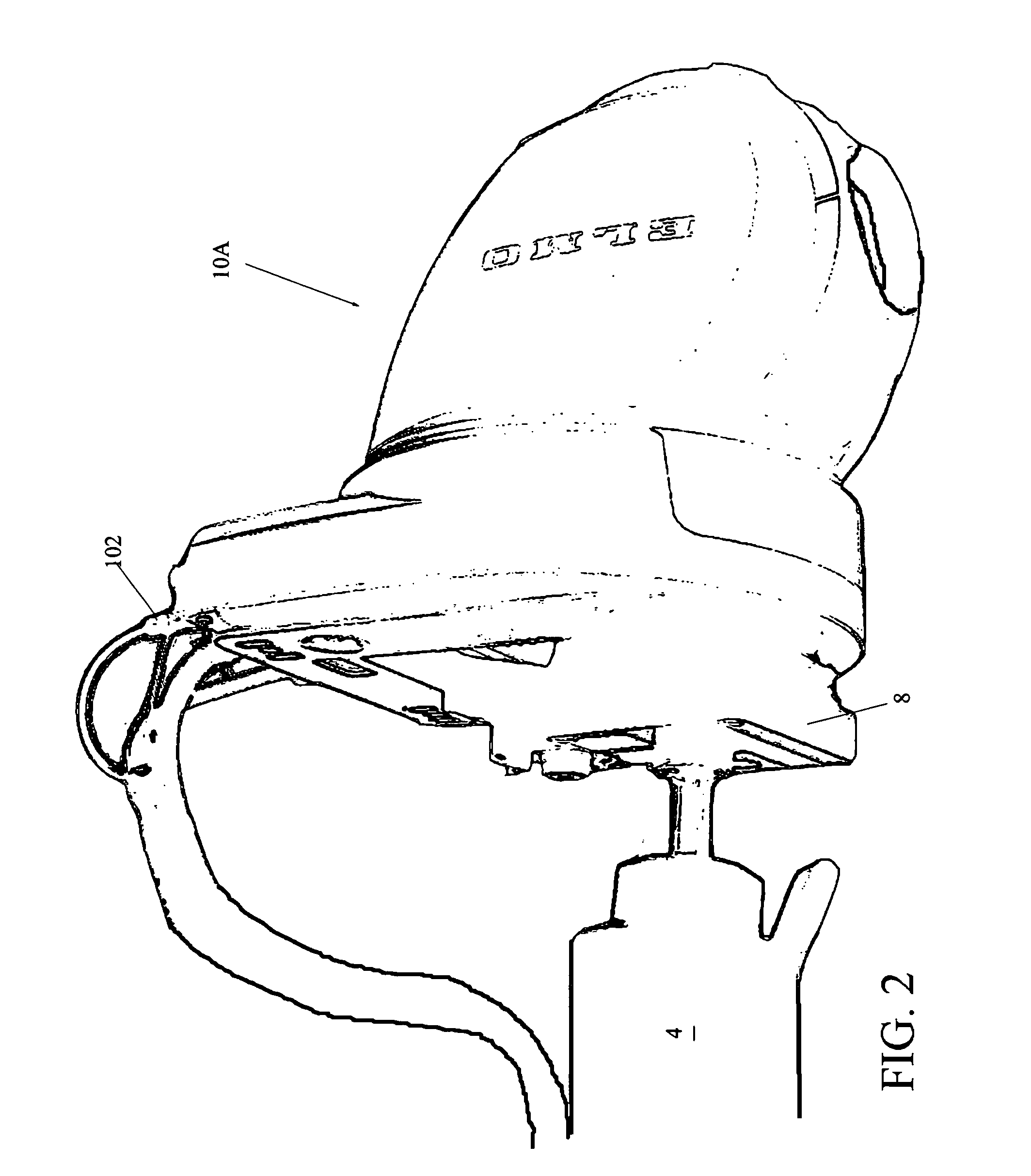

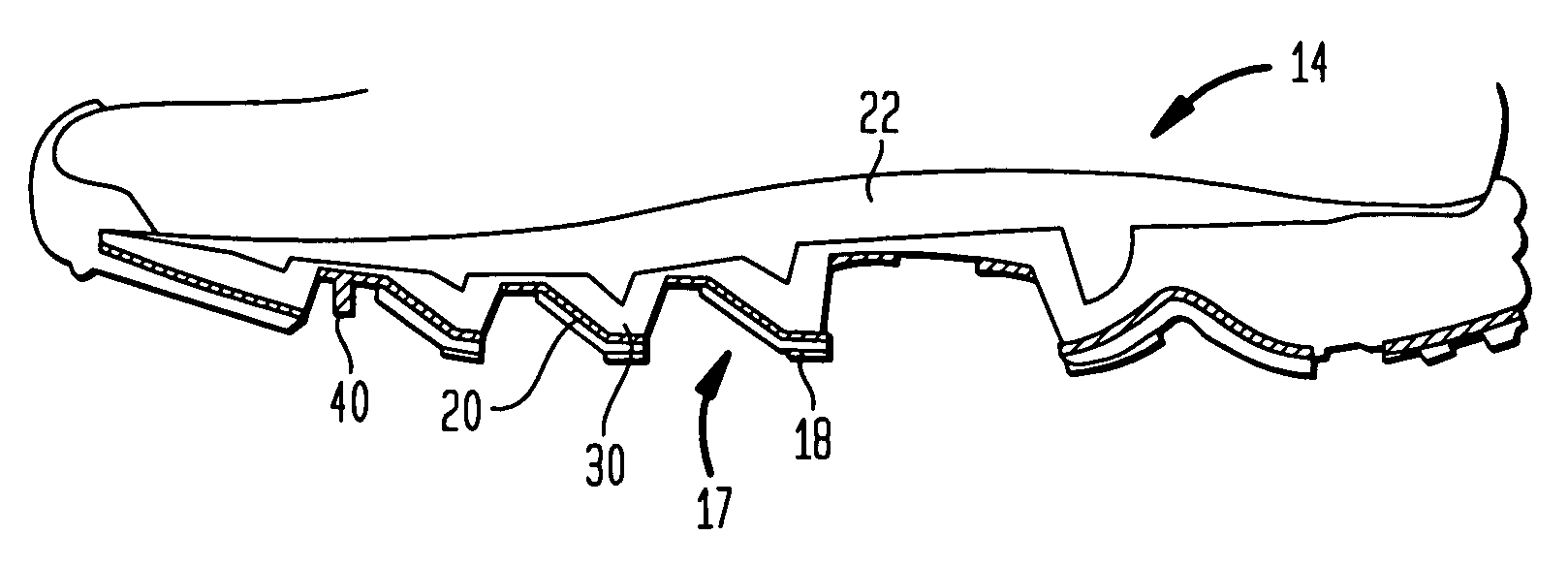

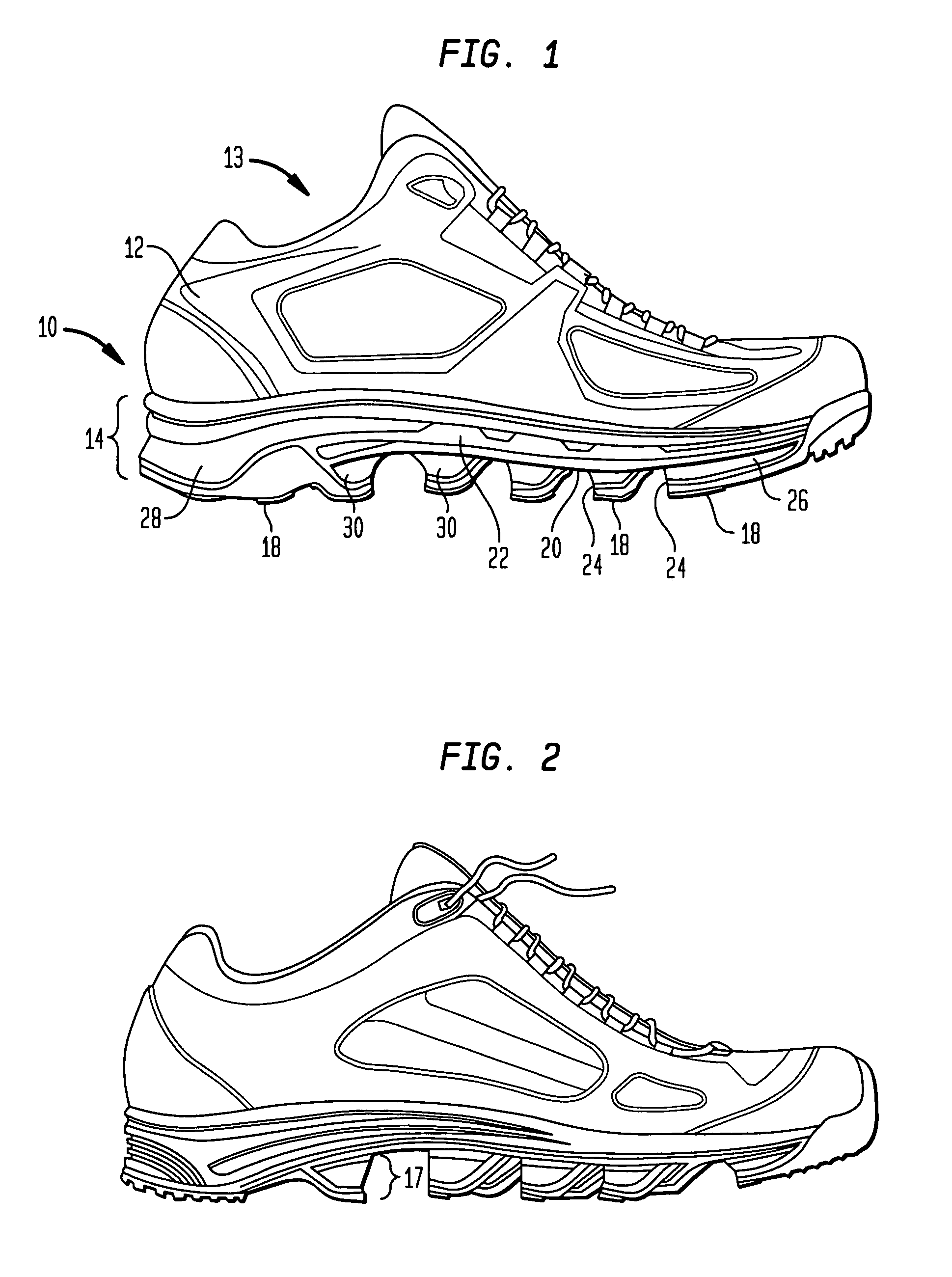

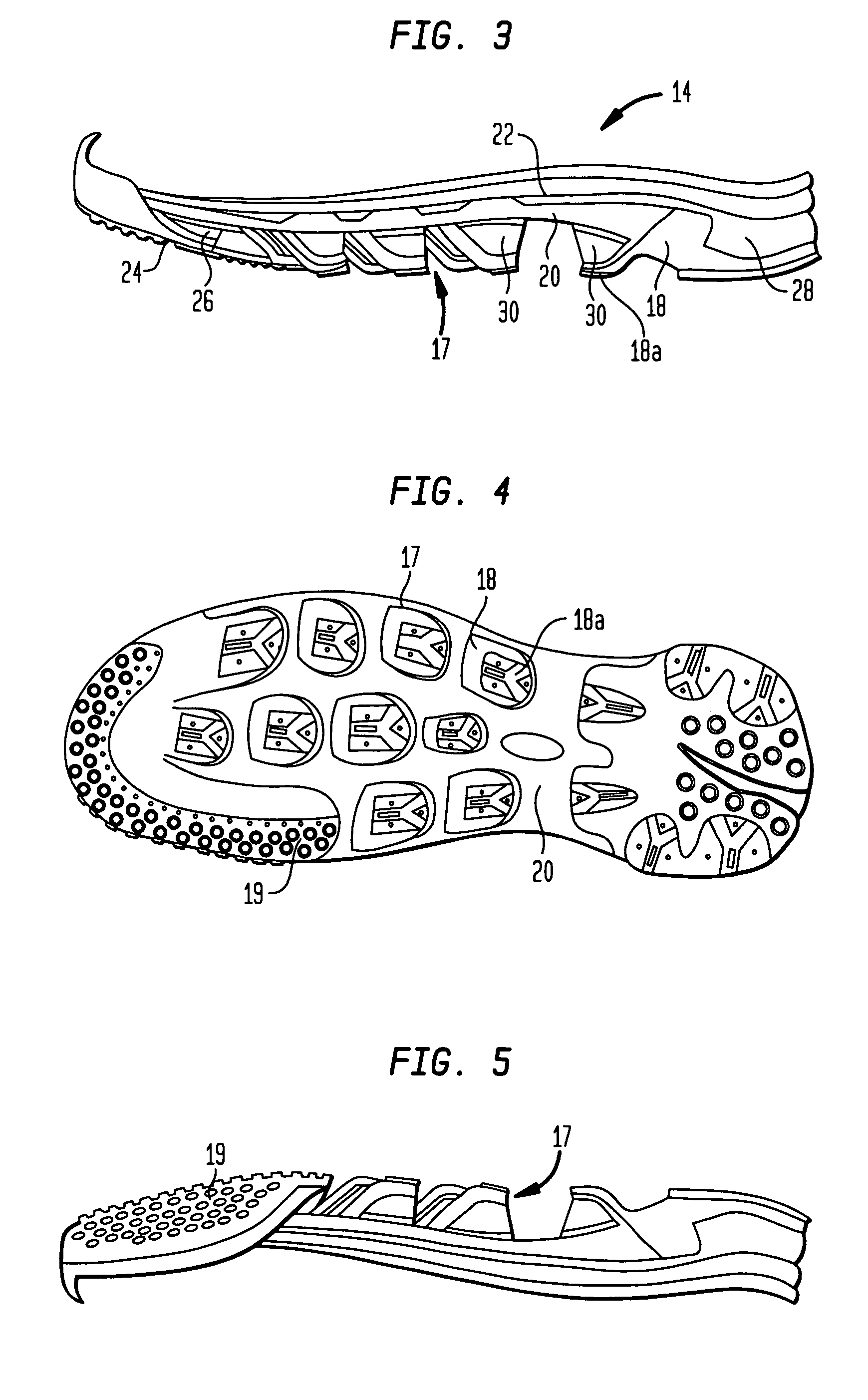

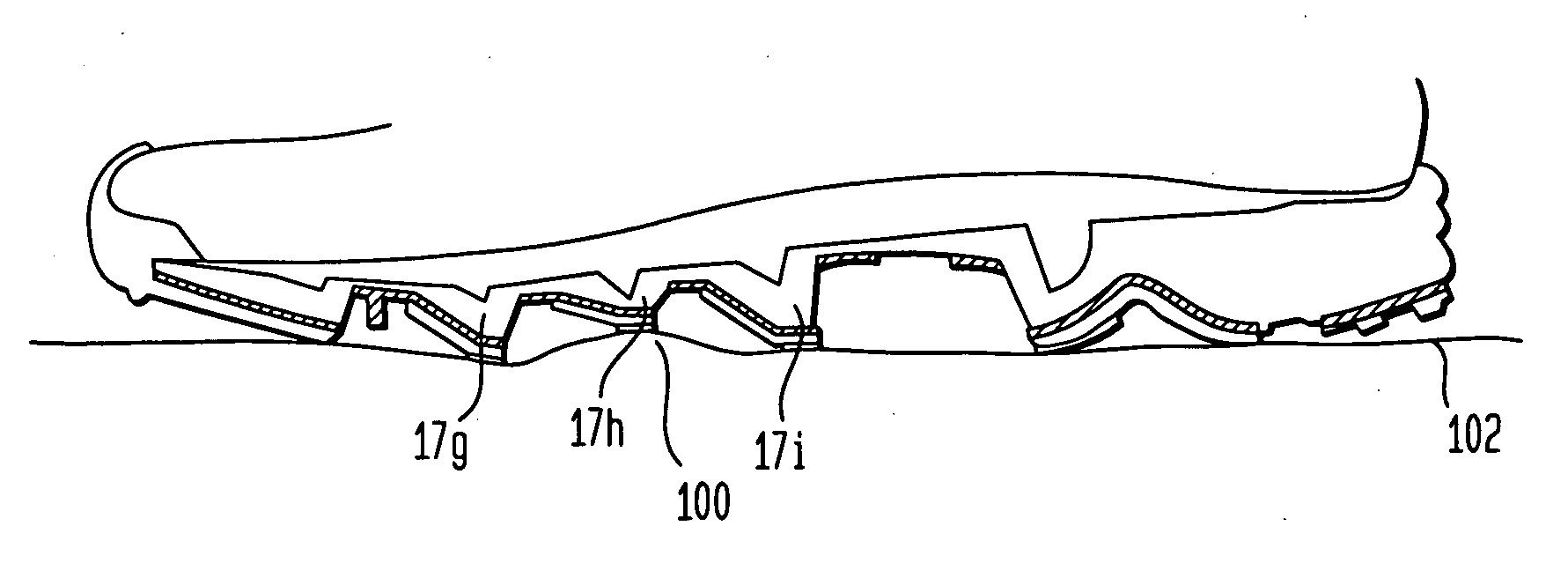

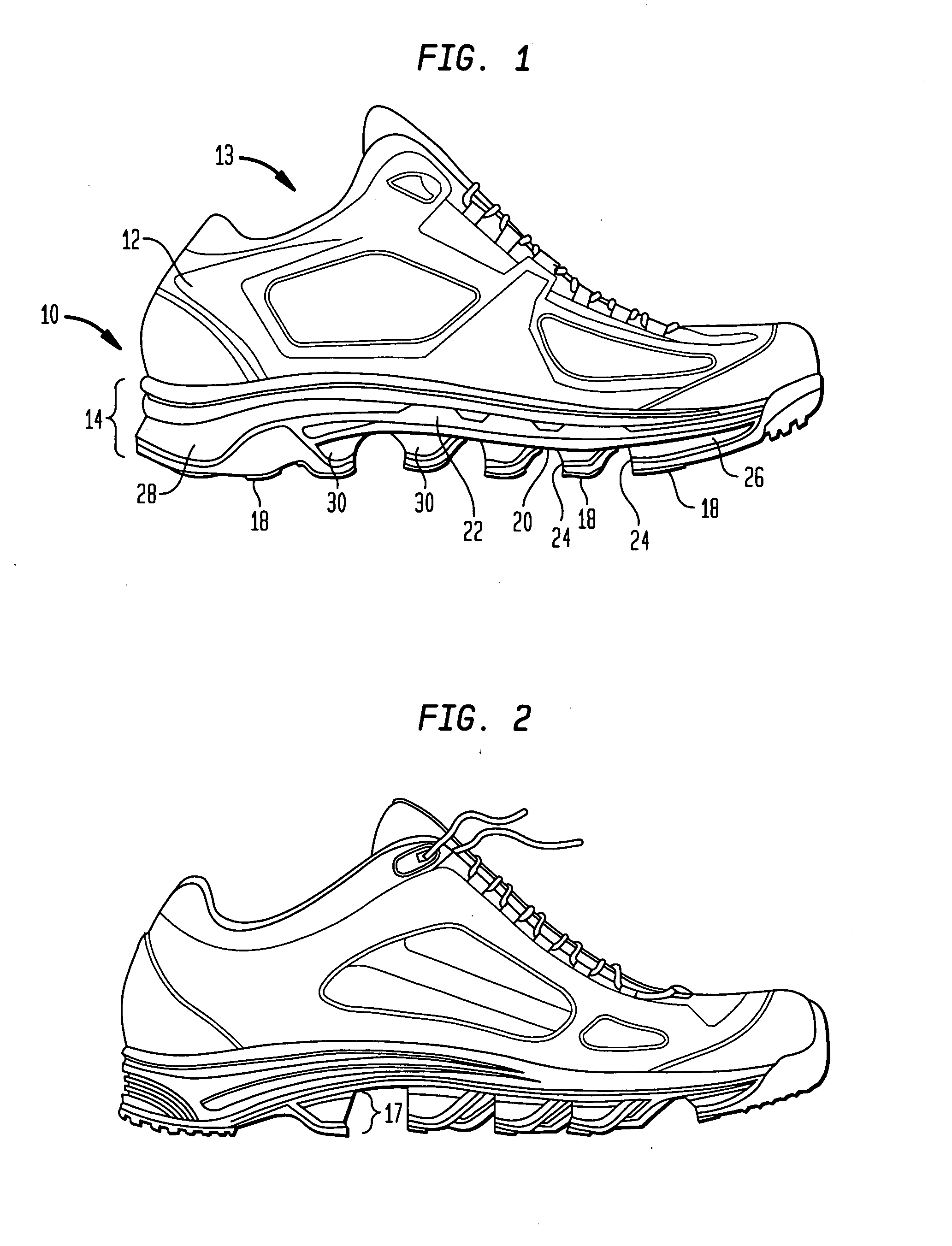

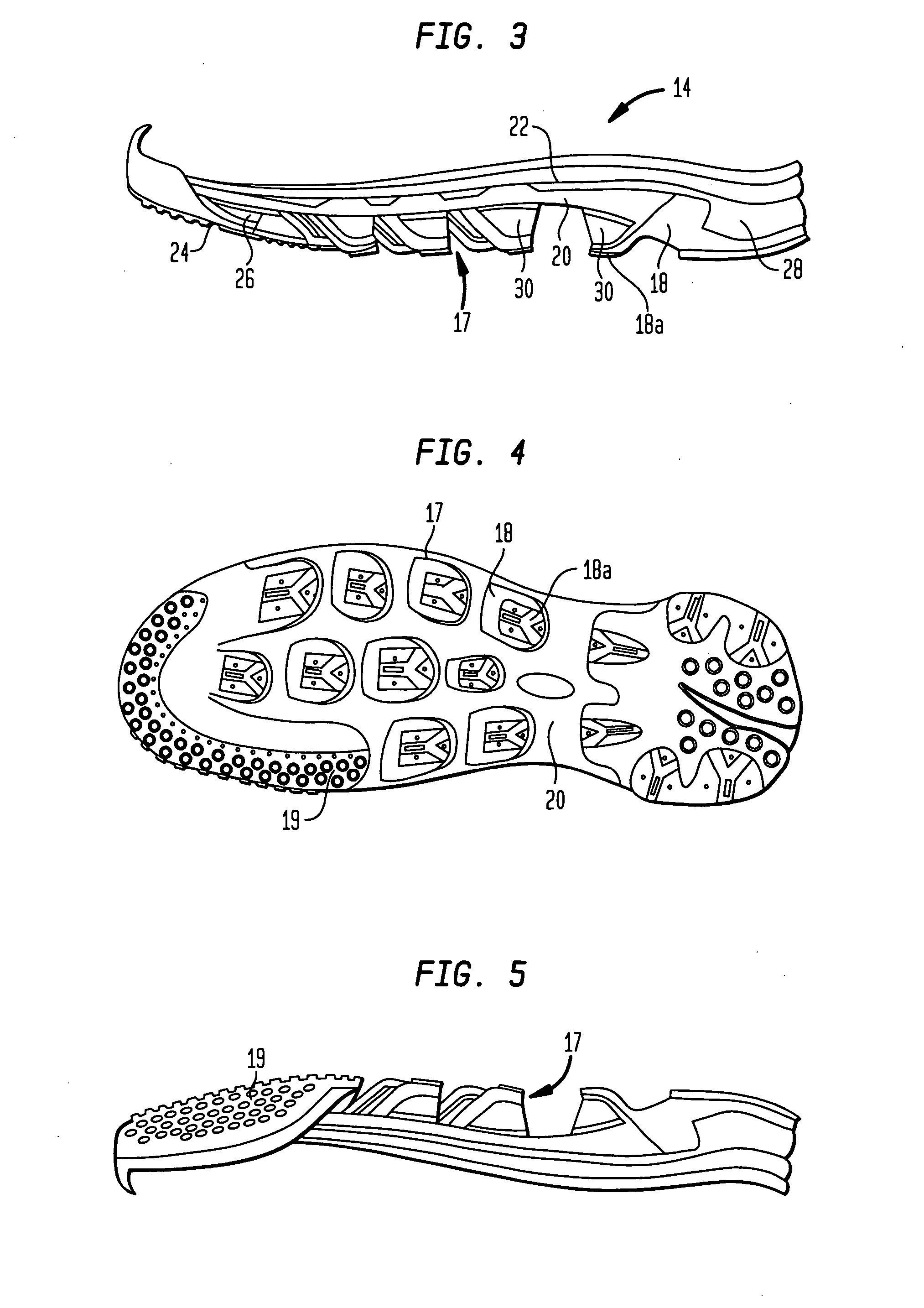

Footwear with independent suspension and protection

An article of footwear having an upper and a sole is disclosed. The sole of the article of footwear includes a midsole having a support portion and a plurality of projections extending from the support portion. The sole of the article of footwear also includes a plate contacting the support portion having a body positioned in an area between the plurality of projections. The plate further includes a plurality of openings which correspond to the plurality of projections and allow the projections to extend below the body of the plate. The plate further includes a plurality of cantilever elements extending on at least one side and on the bottom of each of the plurality of projections. The projections and the corresponding cantilever elements interact with one another to form a plurality of lugs located on the sole of the article of footwear.

Owner:JABIL CIRCUIT INC

Footwear with independent suspension and protection

An article of footwear having an upper and a sole is disclosed. The sole of the article of footwear includes a midsole having a support portion and a plurality of projections extending from the support portion. The sole of the article of footwear also includes a plate contacting the support portion having a body positioned in an area between the plurality of projections. The plate further includes a plurality of openings which correspond to the plurality of projections and allow the projections to extend below the body of the plate. The plate further includes a plurality of cantilever elements extending on at least one side and on the bottom of each of the plurality of projections. The projections and the corresponding cantilever elements interact with one another to form a plurality of lugs located on the sole of the article of footwear.

Owner:JABIL CIRCUIT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com