Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Rapidly deployable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

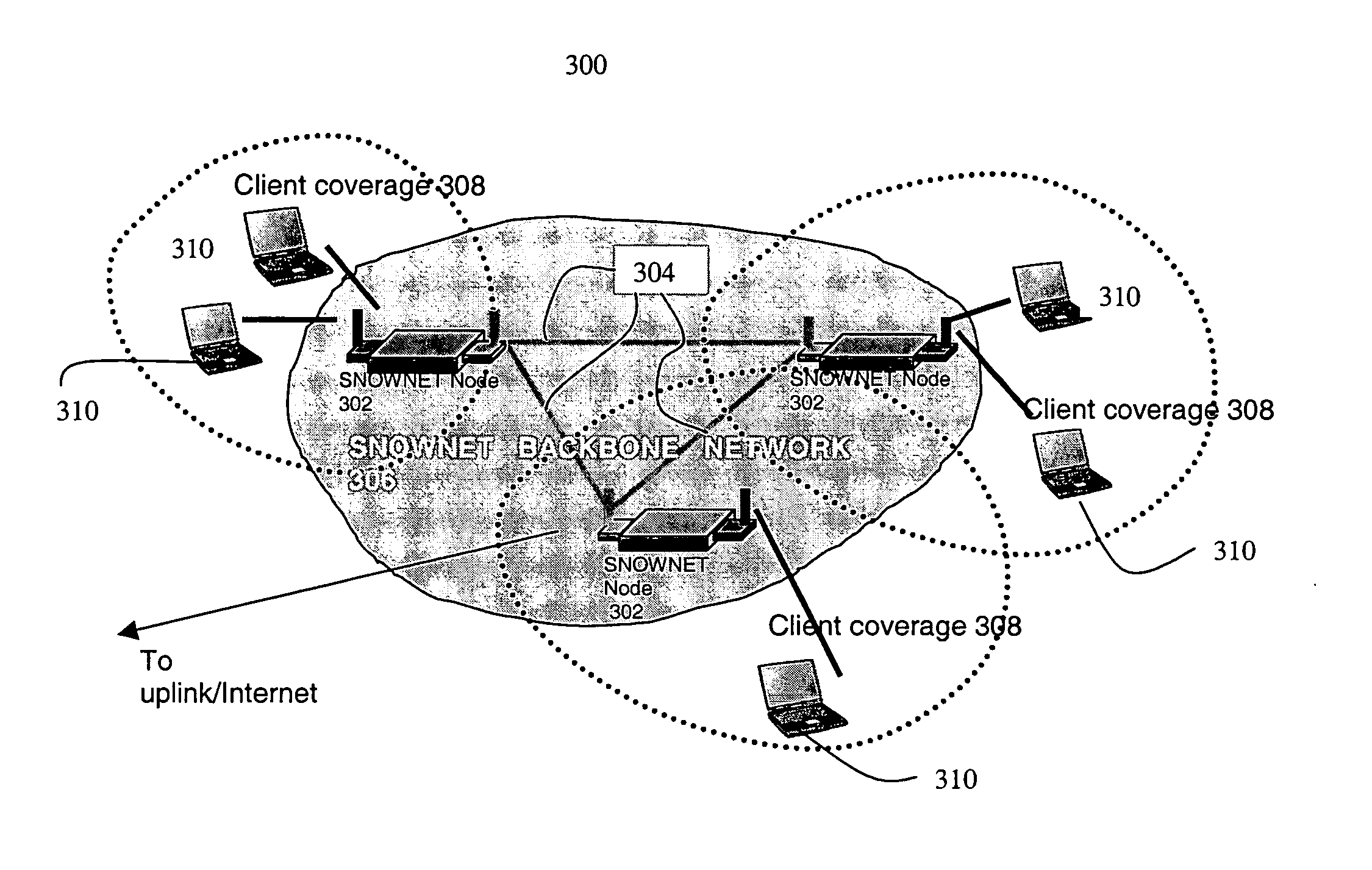

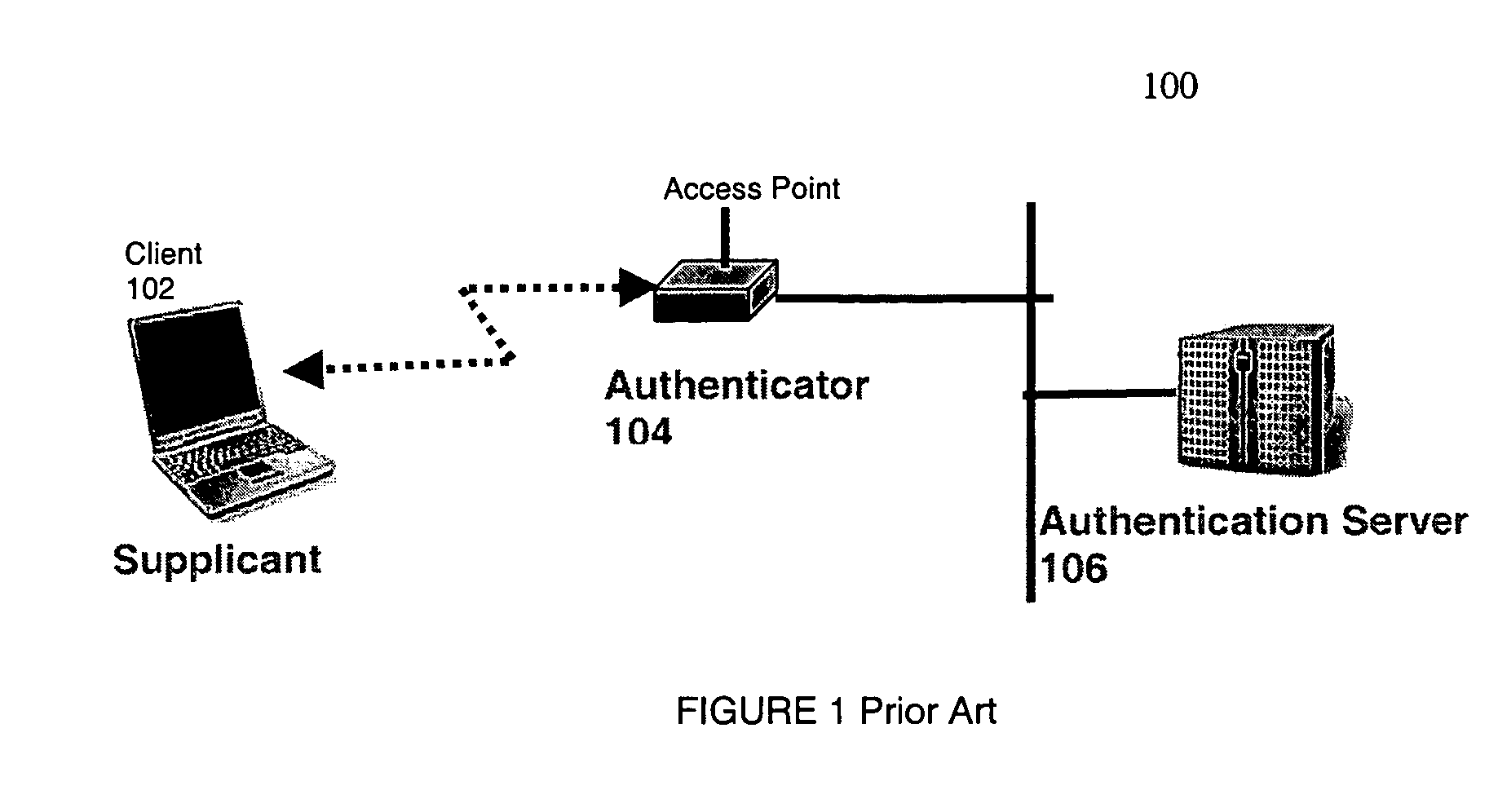

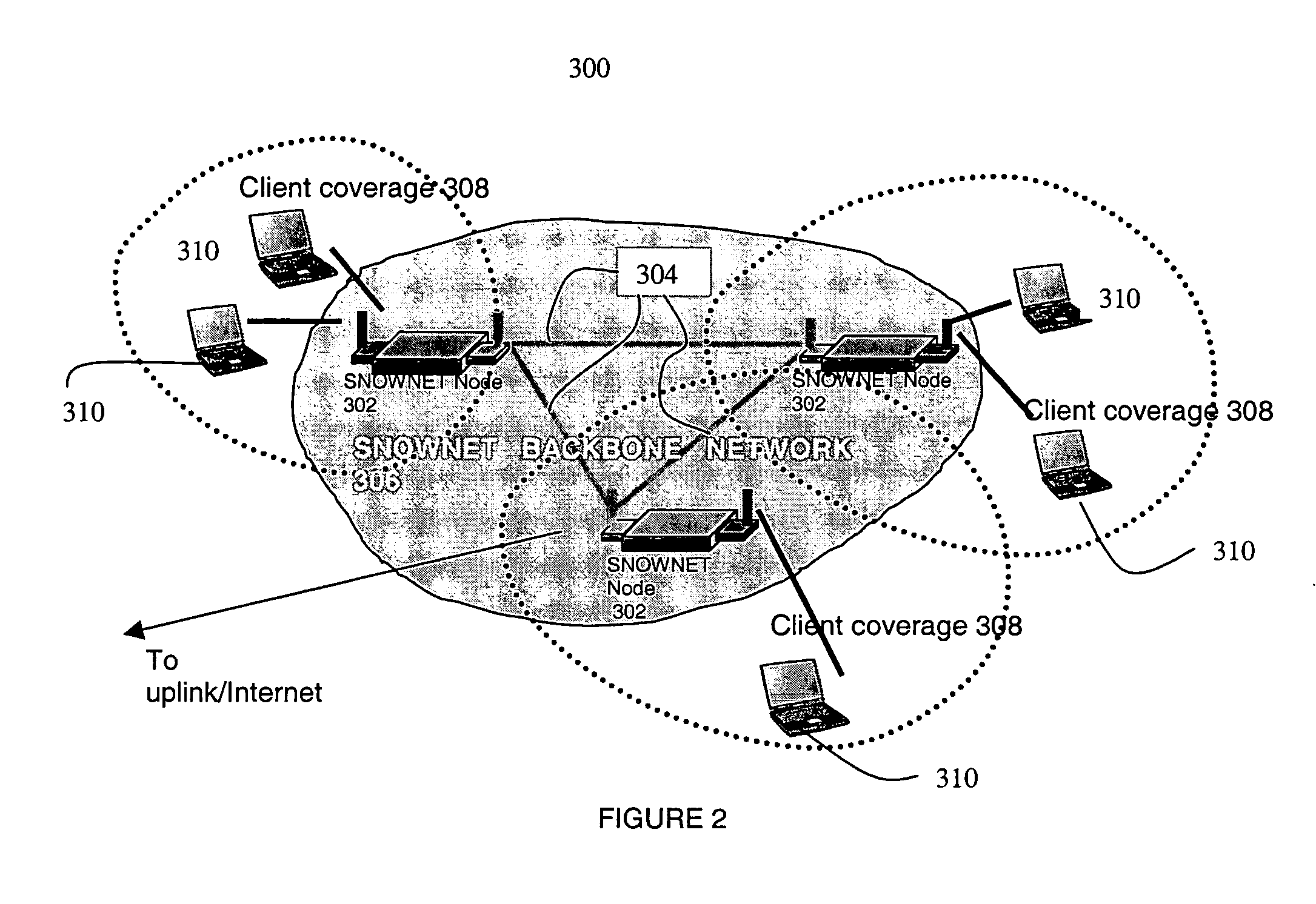

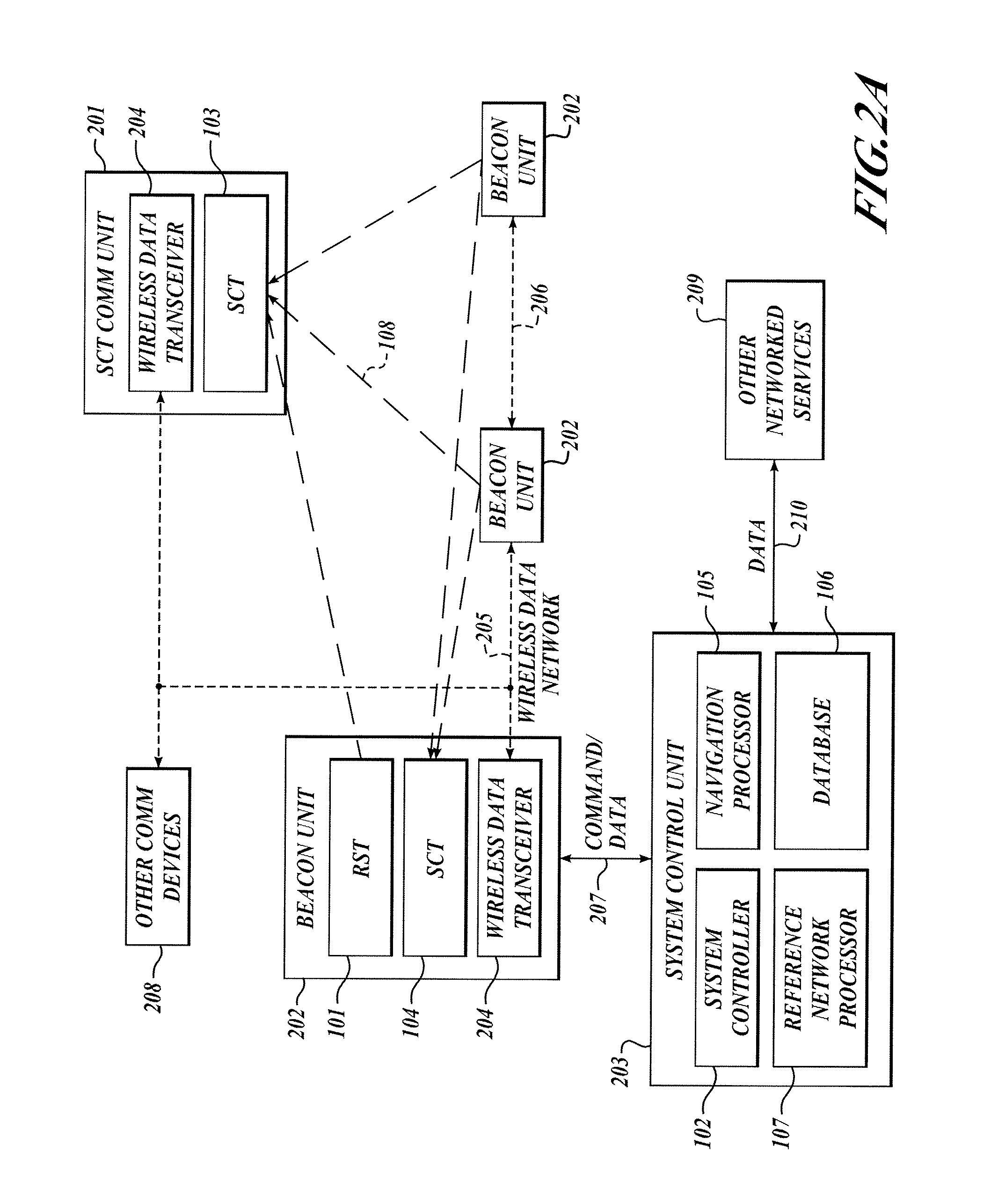

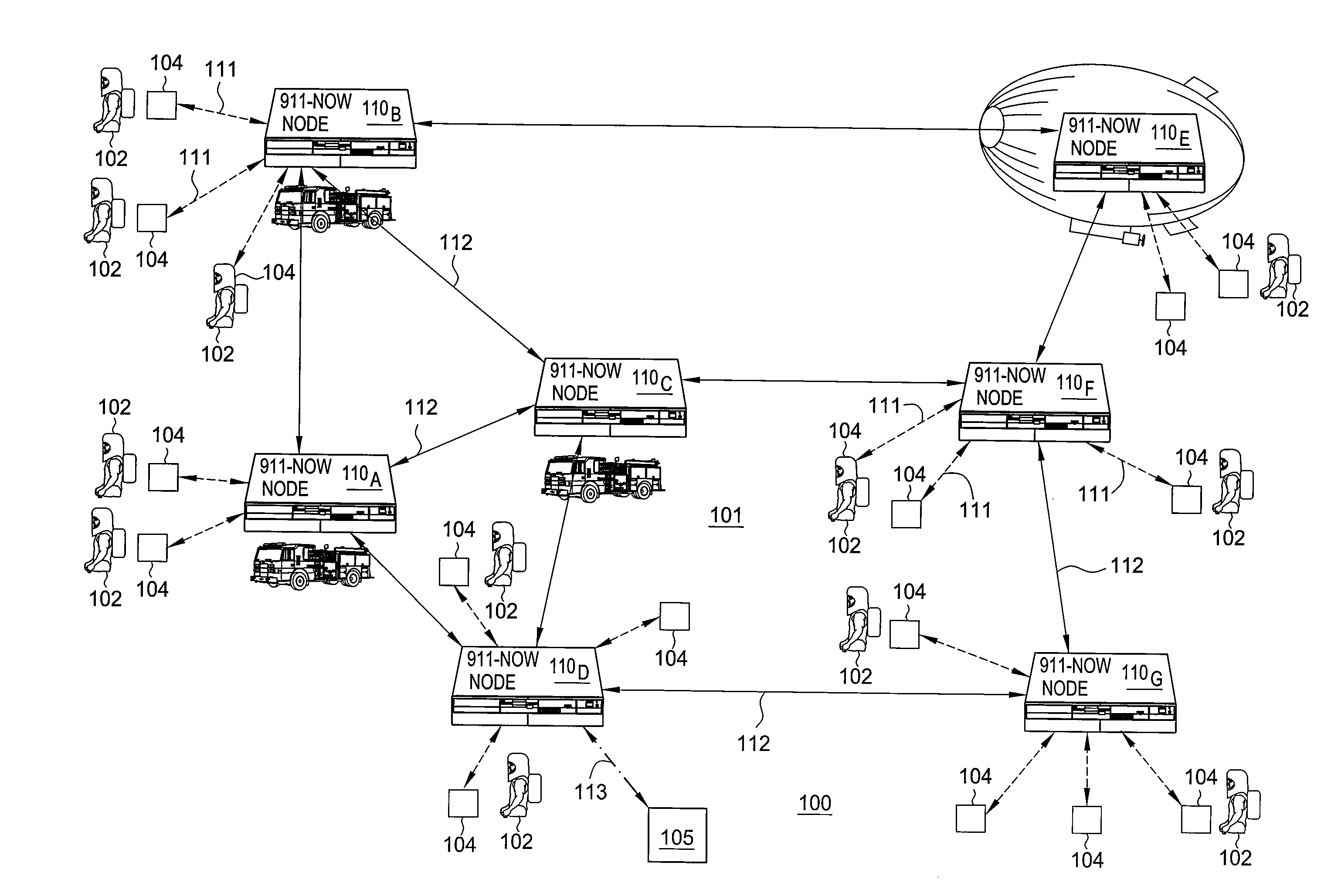

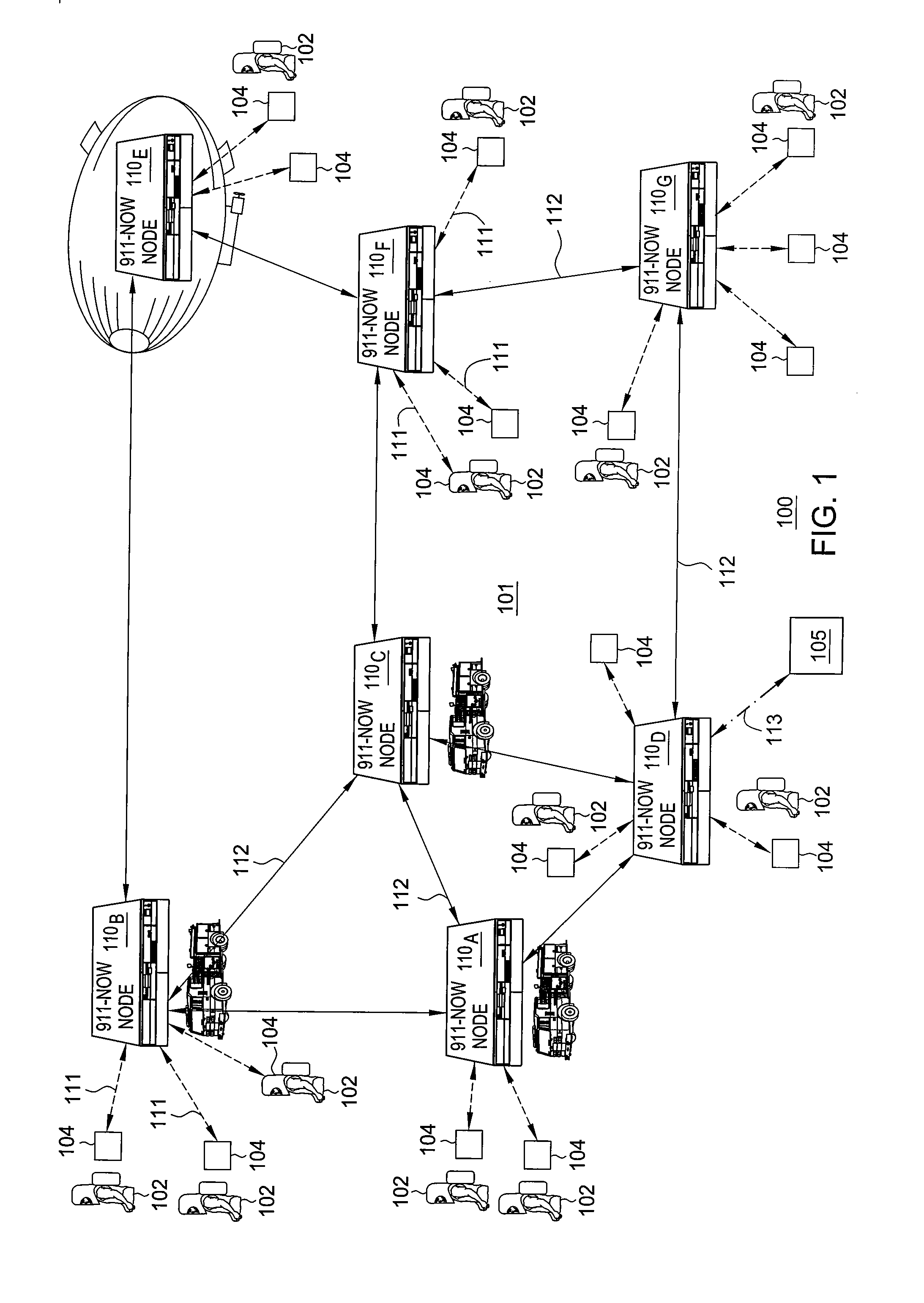

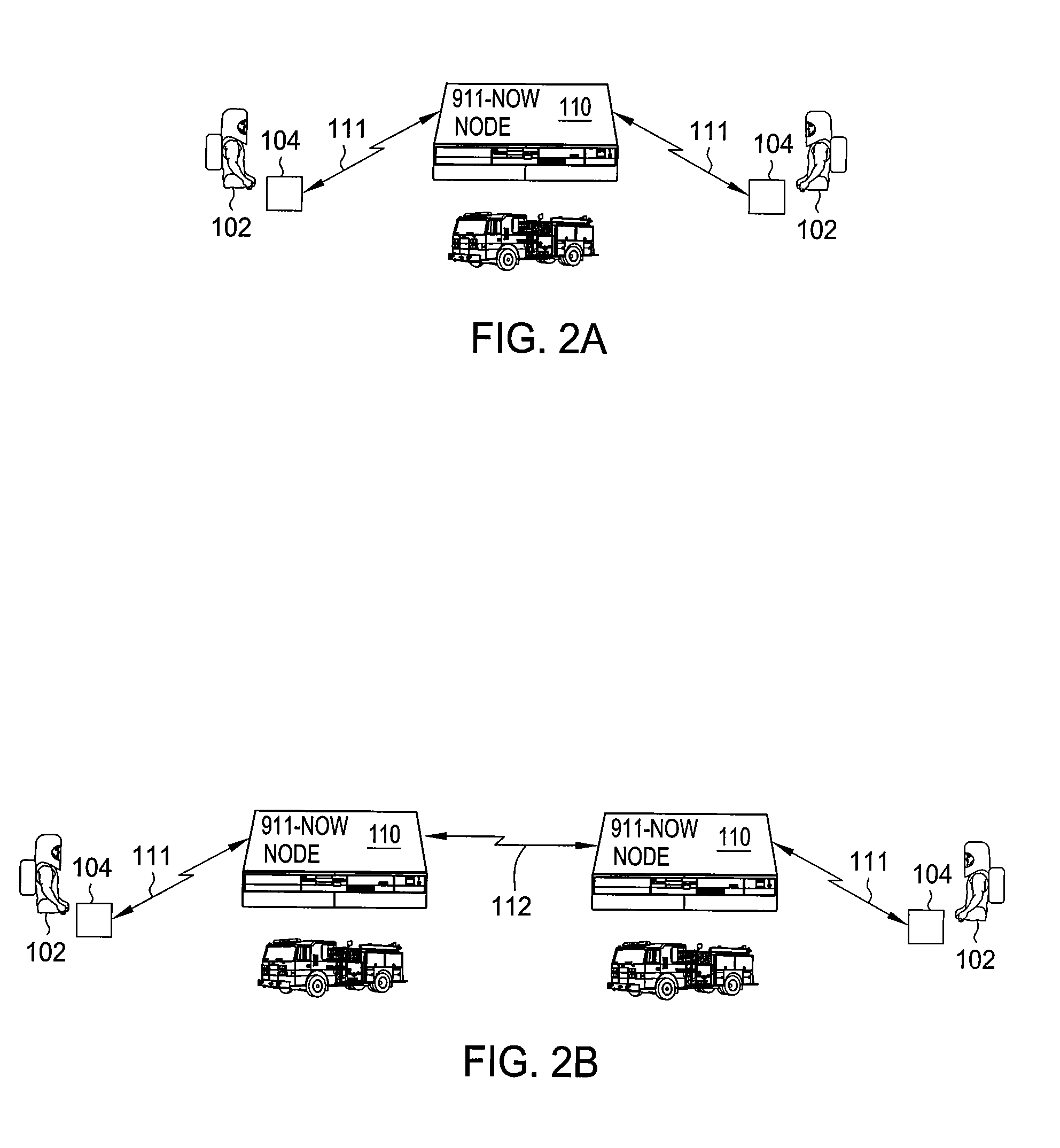

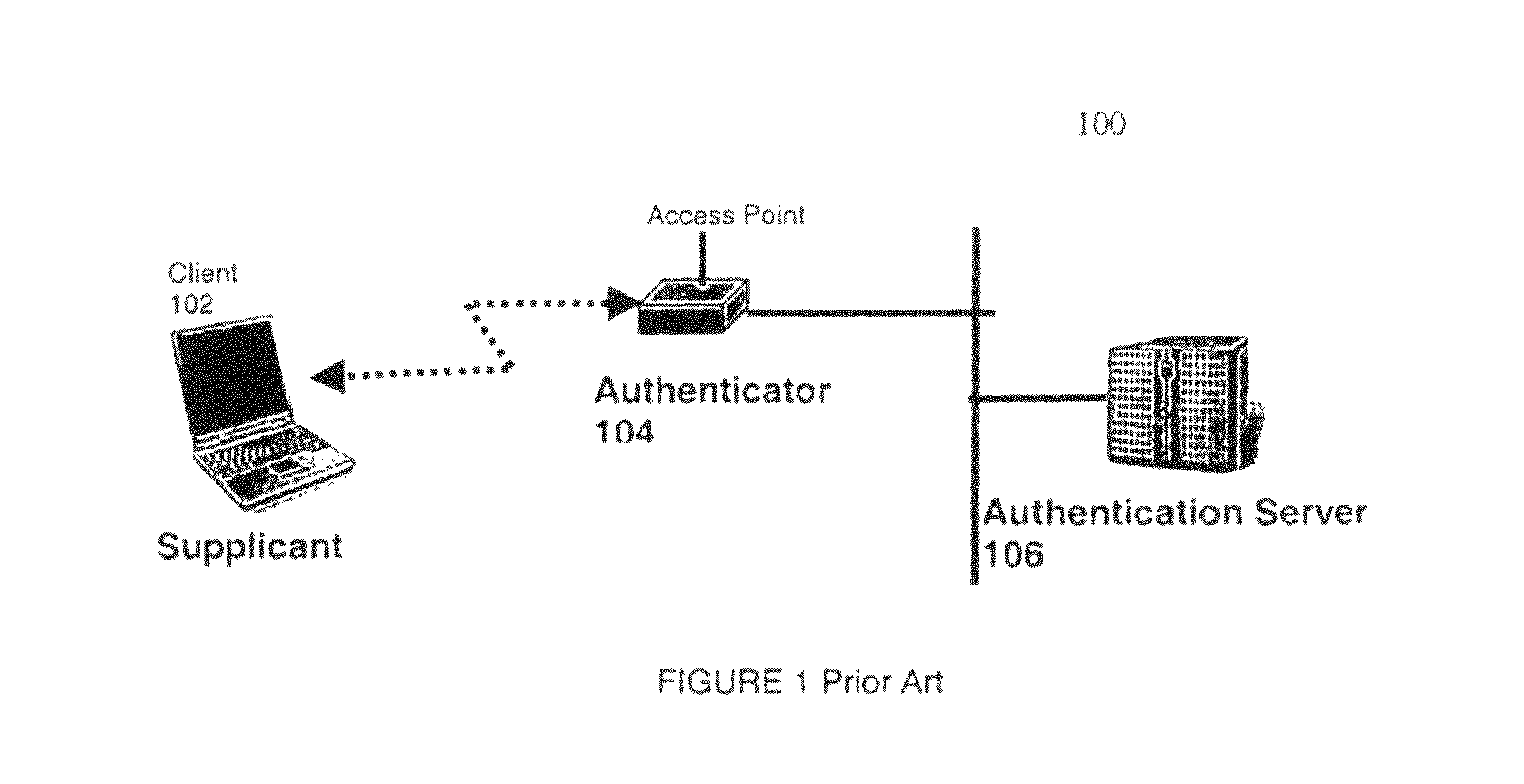

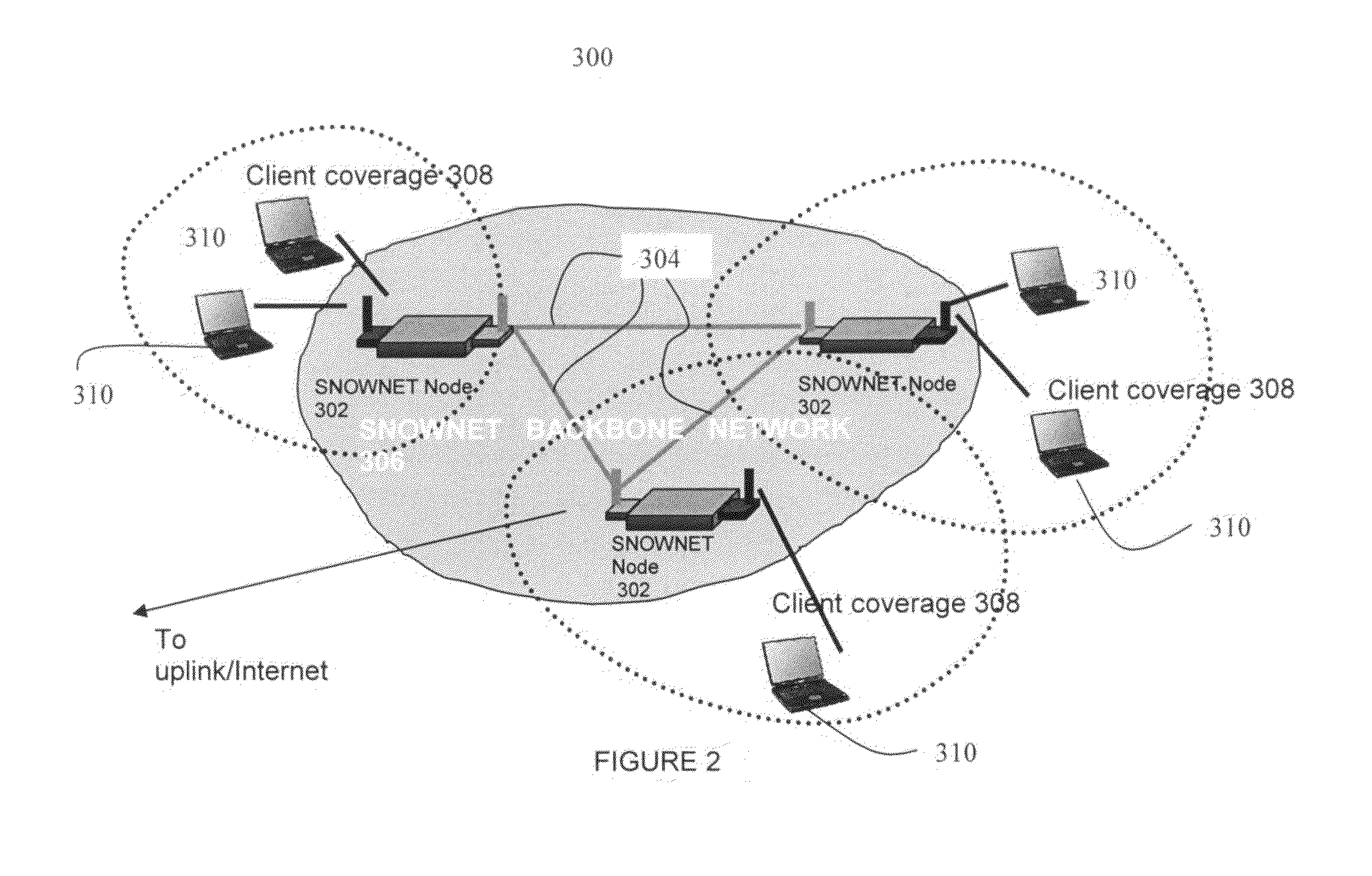

Apparatus, method, and medium for self-organizing multi-hop wireless access networks

InactiveUS20050152305A1Rapidly deployableImprove securityNetwork topologiesData switching by path configurationMutual authenticationAccess network

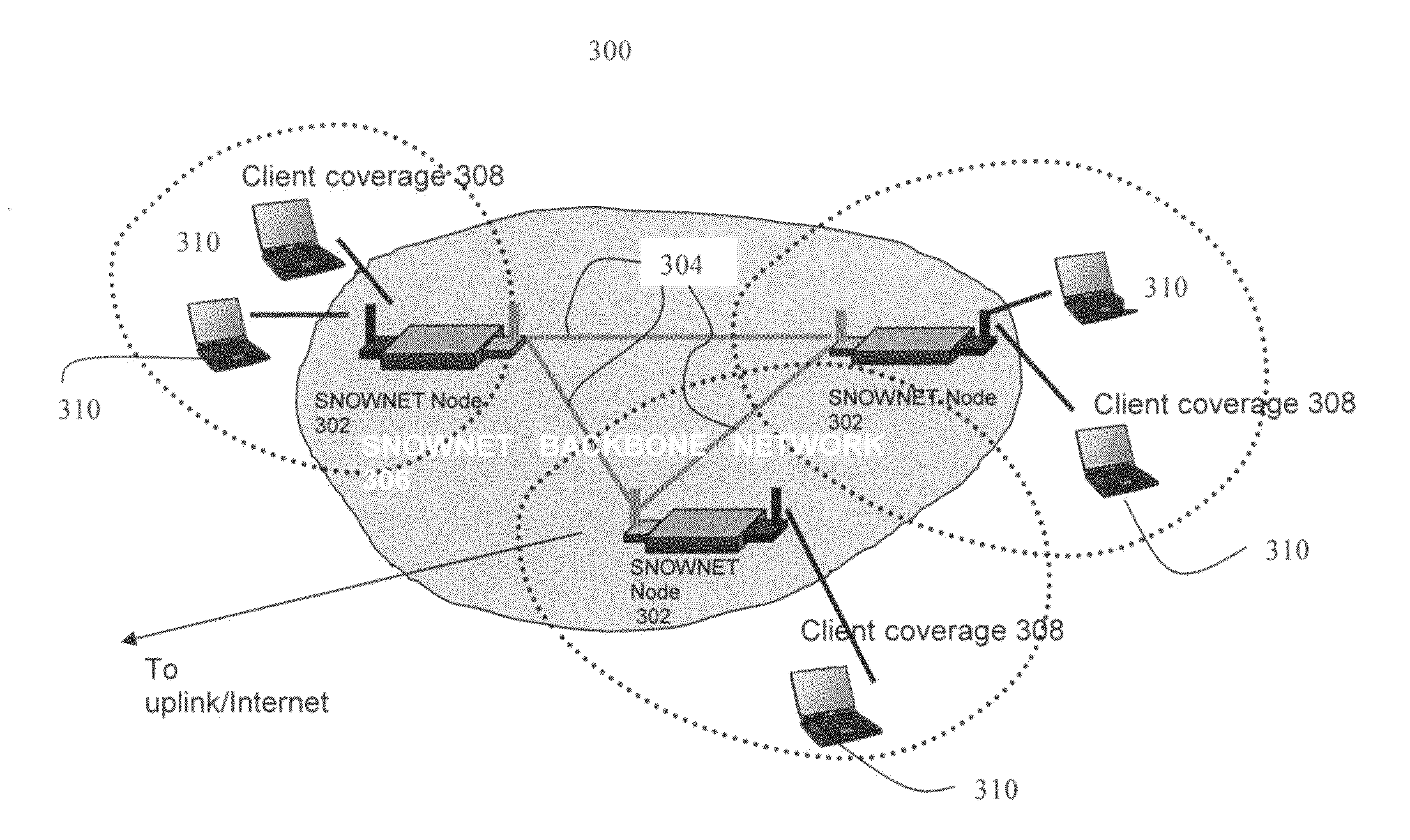

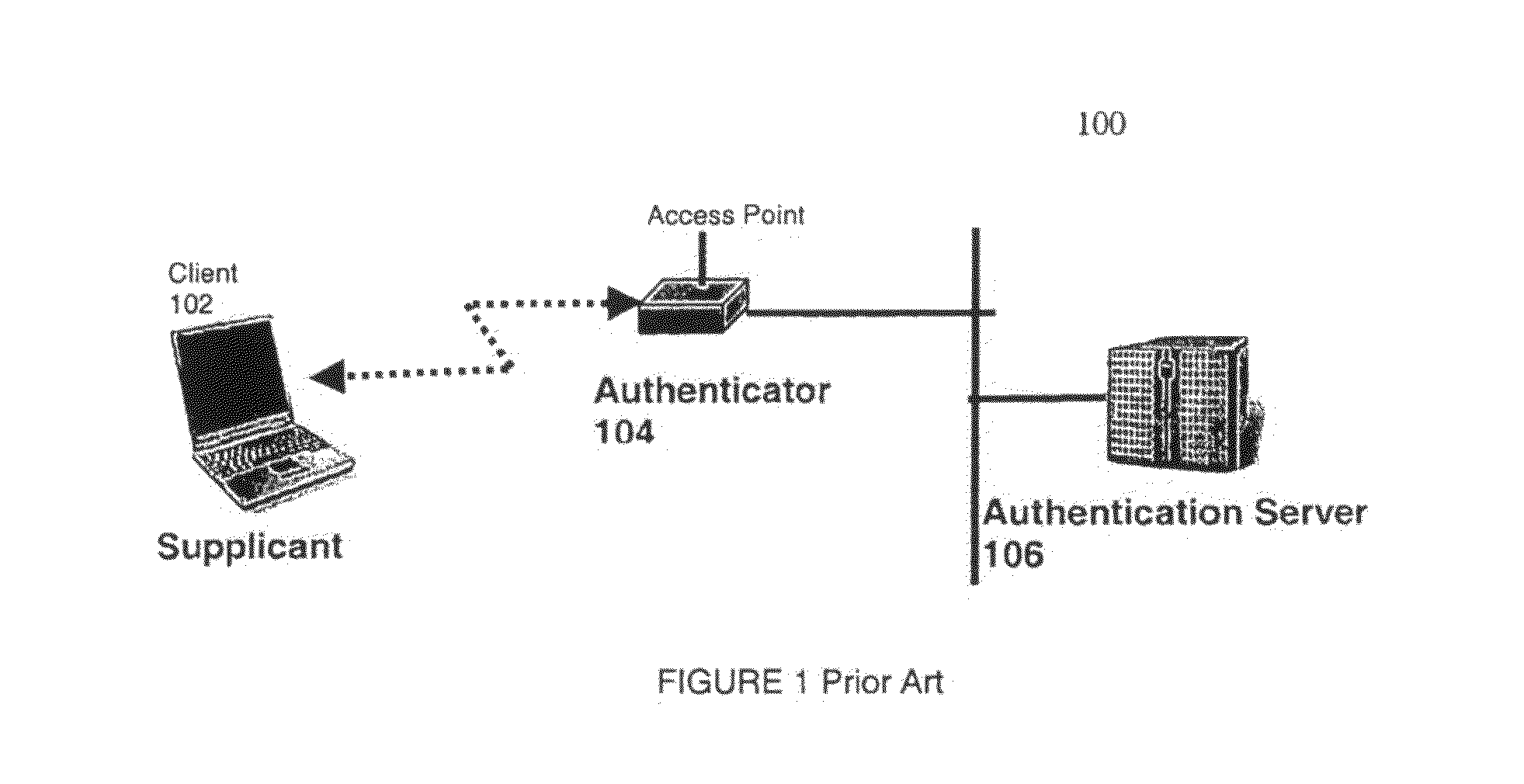

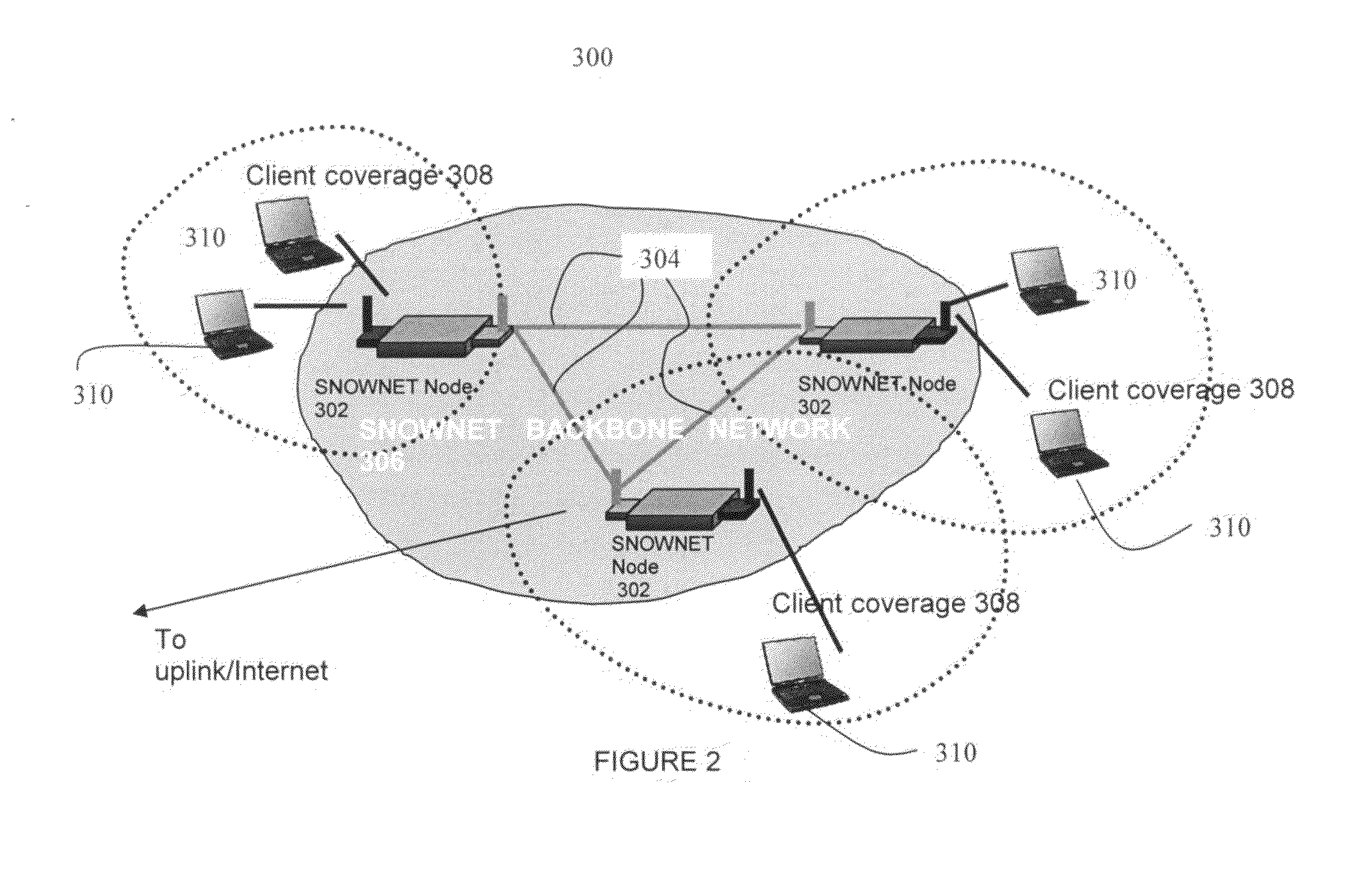

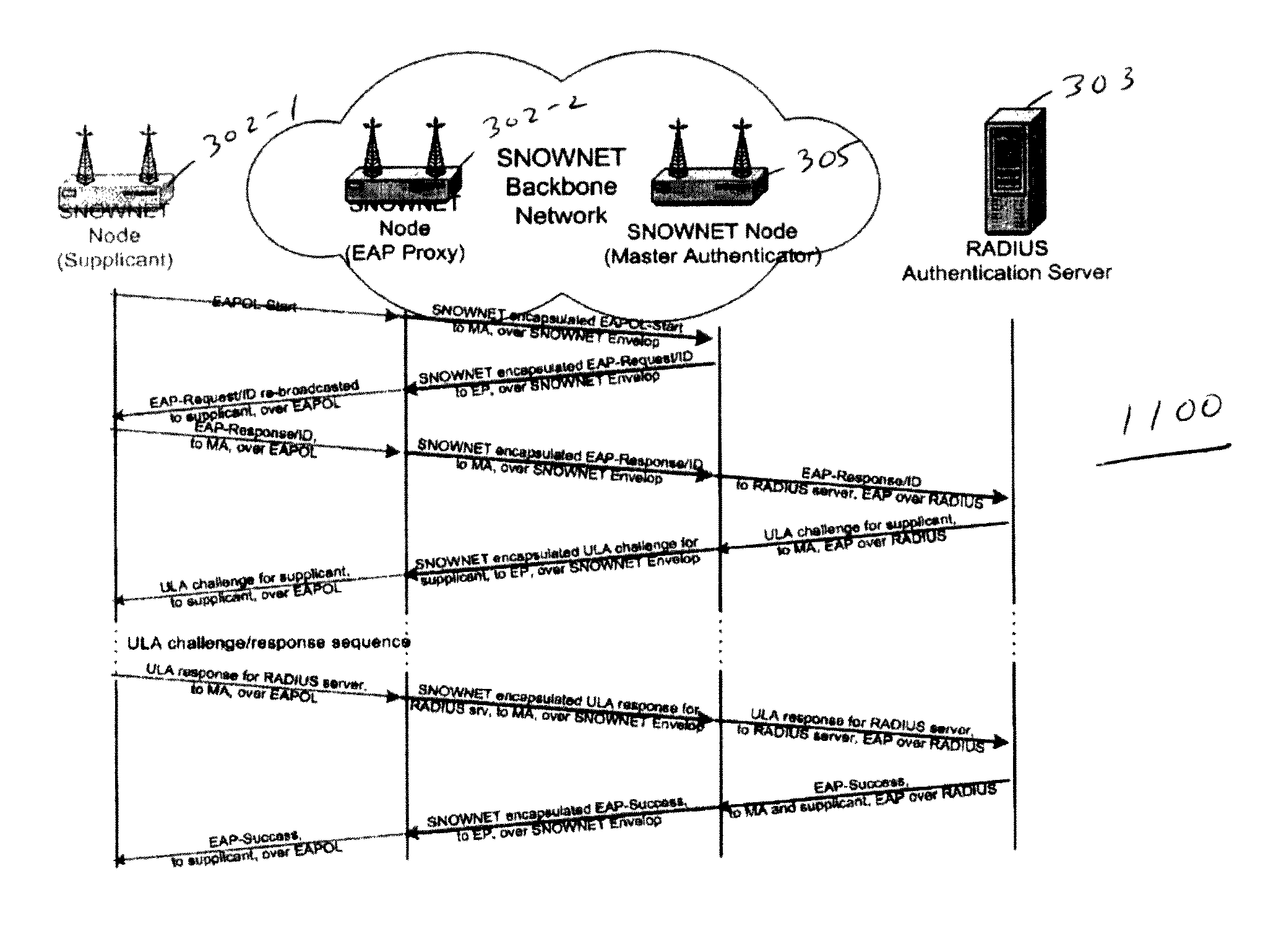

A wireless computer network includes a backbone network including backbone network nodes authenticated to each other and in communication with each other. The wireless computer network also includes a master authenticator node and a proxy authenticator node among the backbone network nodes. When an unauthenticated new node requests authentication to the backbone network and the unauthenticated new node is in communication with at least one of the backbone network nodes, the at least one of the backbone network nodes becoming the proxy authenticator node for the unauthenticated new node and communicates with the master authenticator node to authenticate the unauthenticated new node to the backbone network.

Owner:FUJITSU LTD

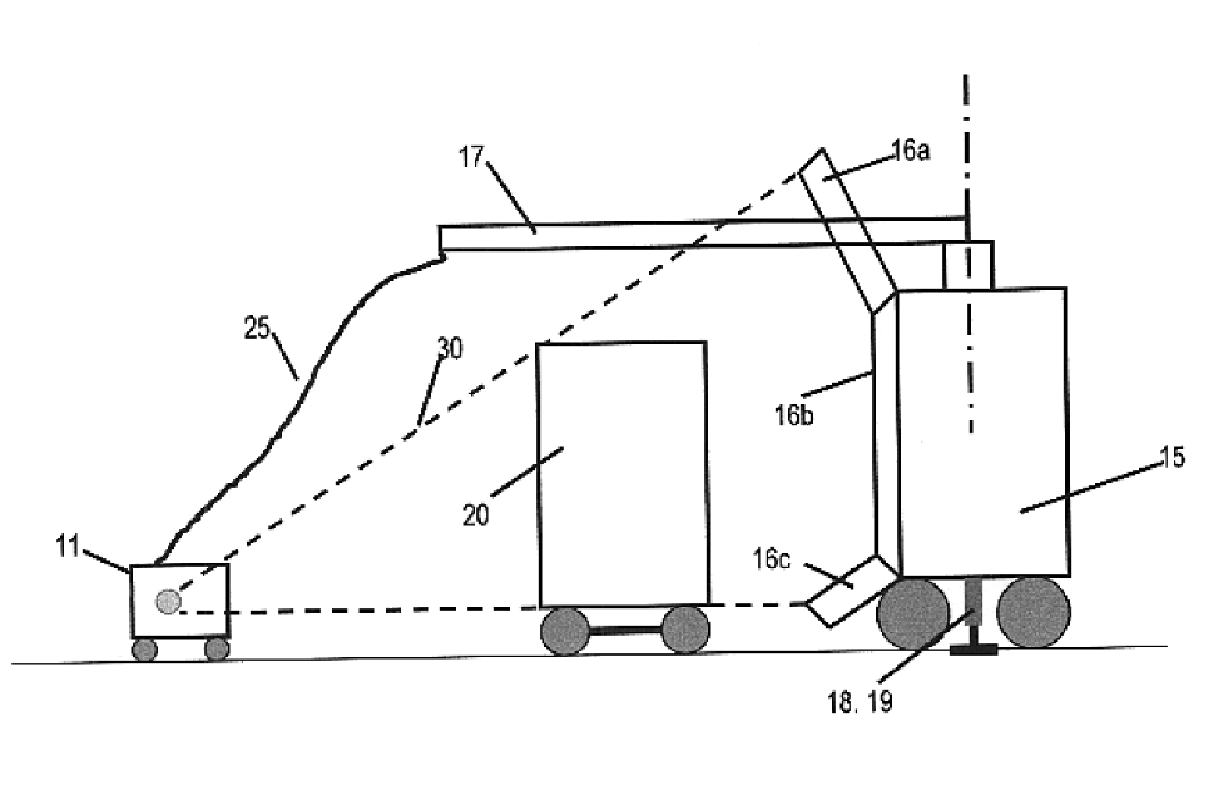

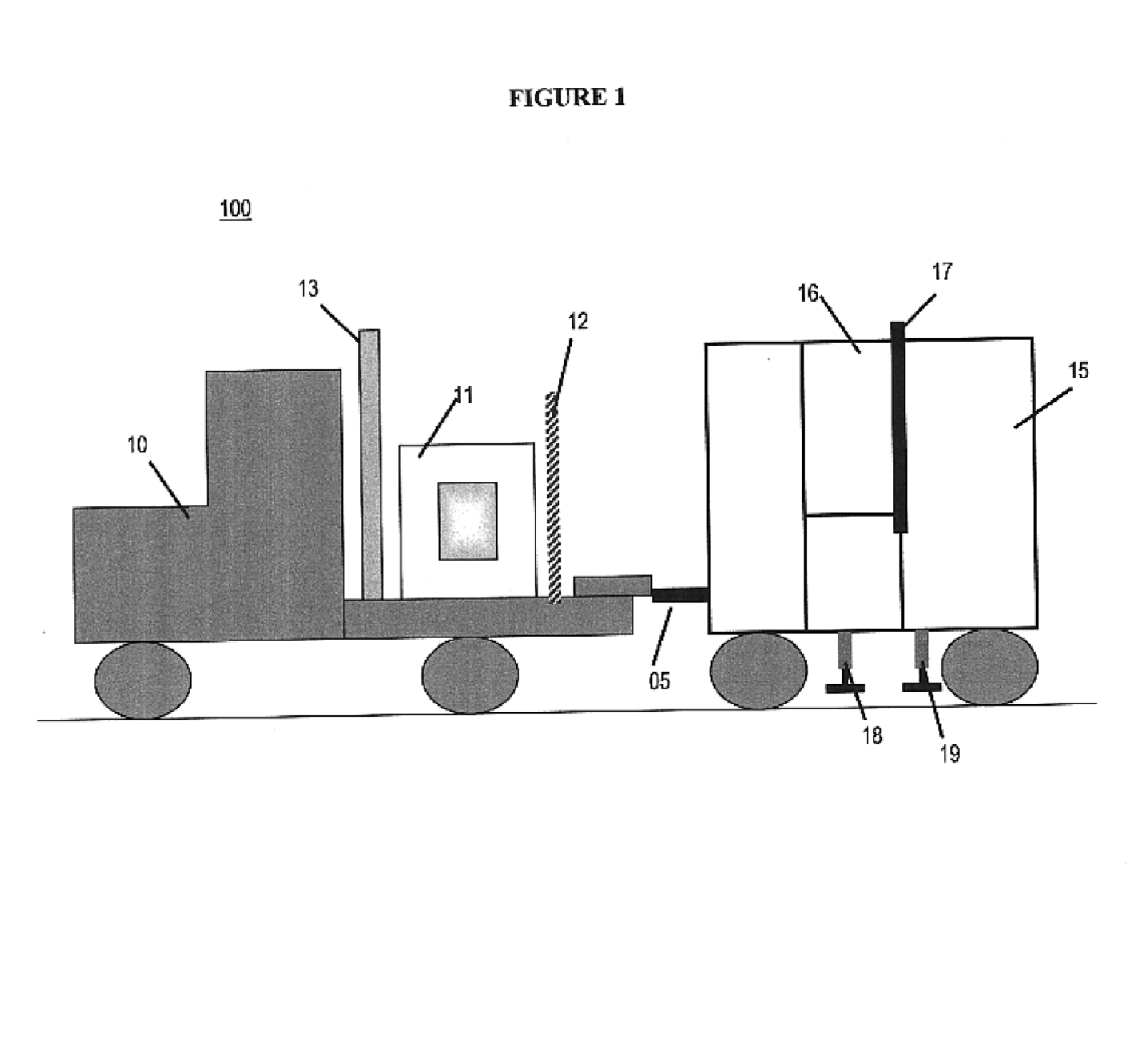

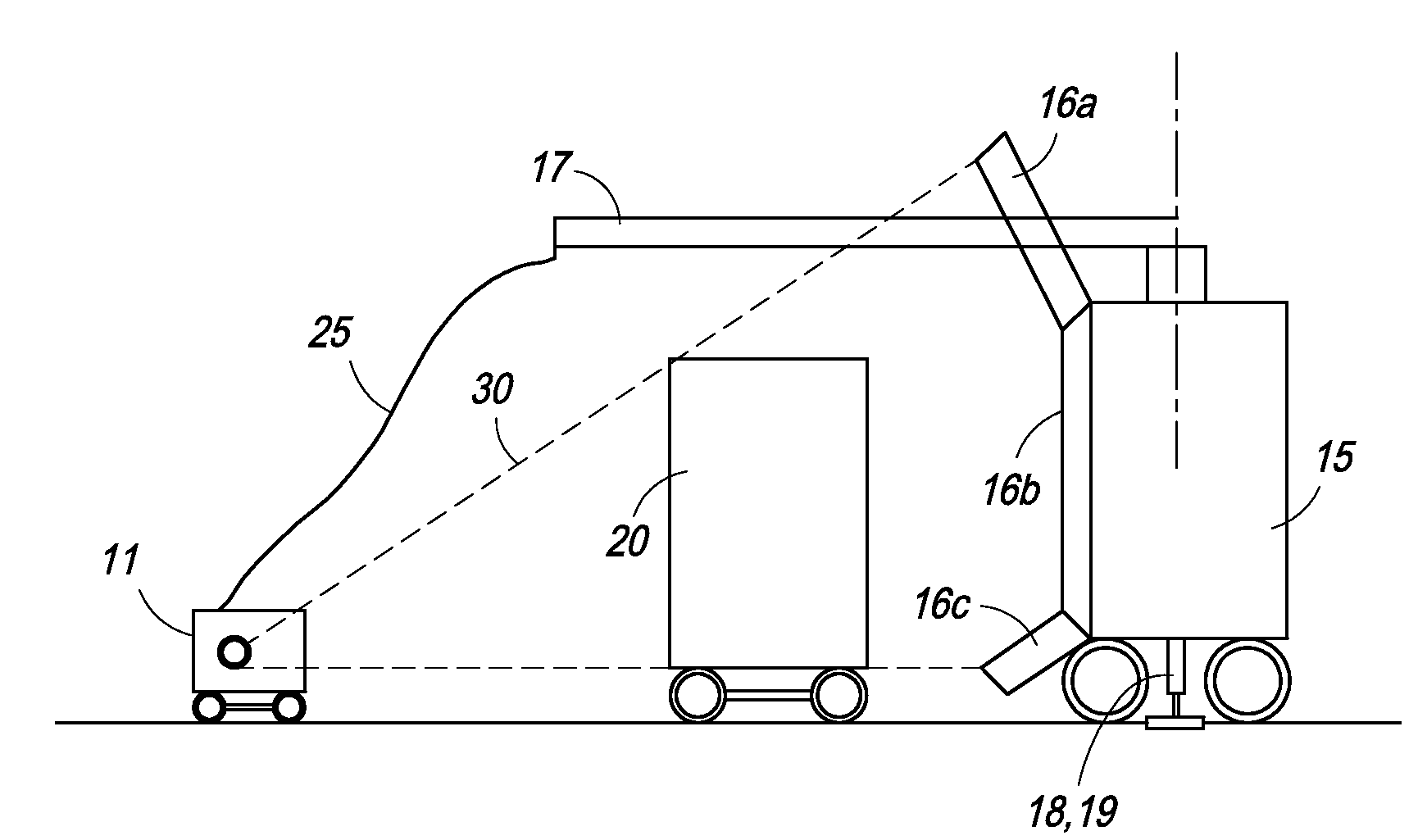

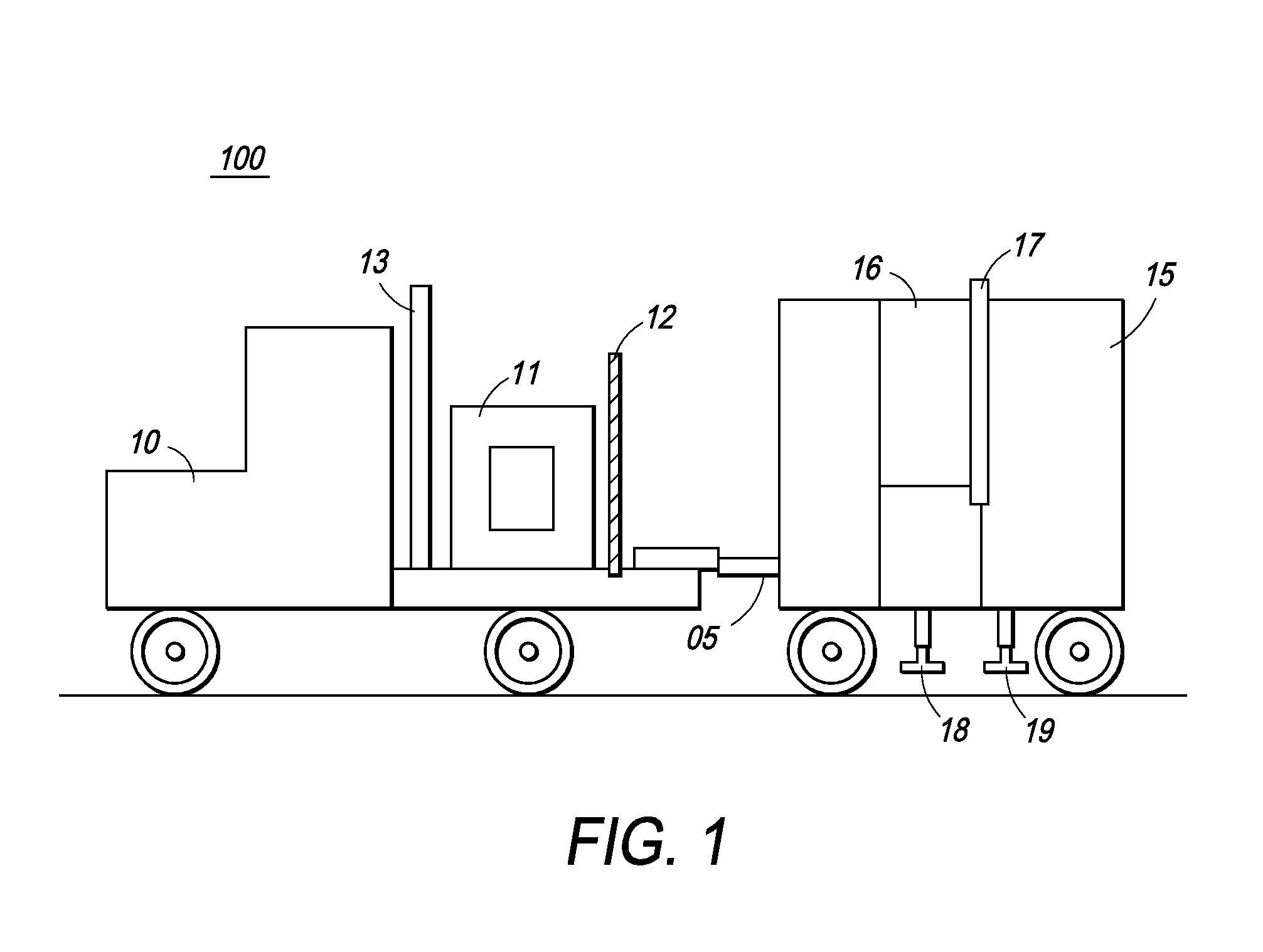

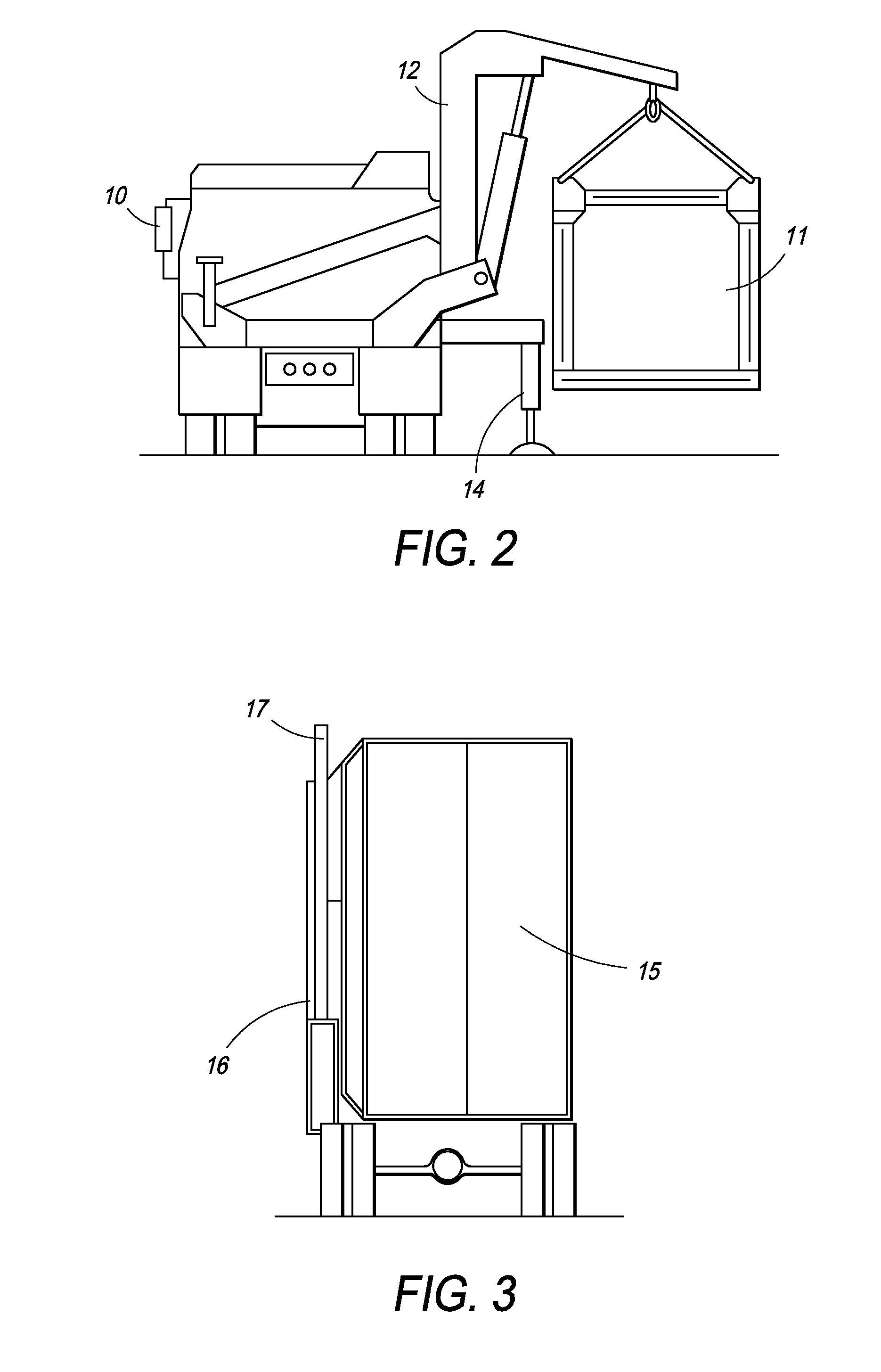

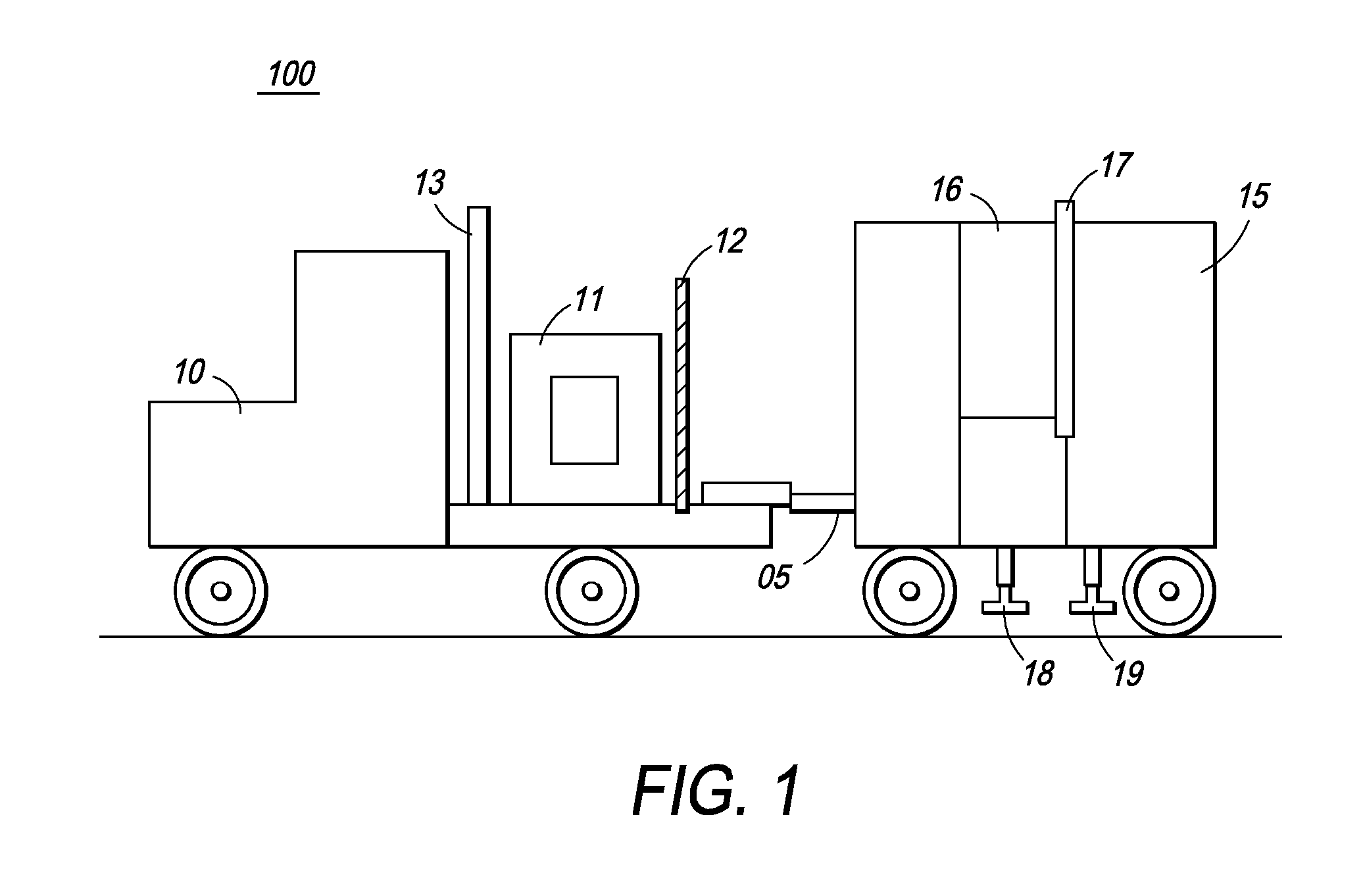

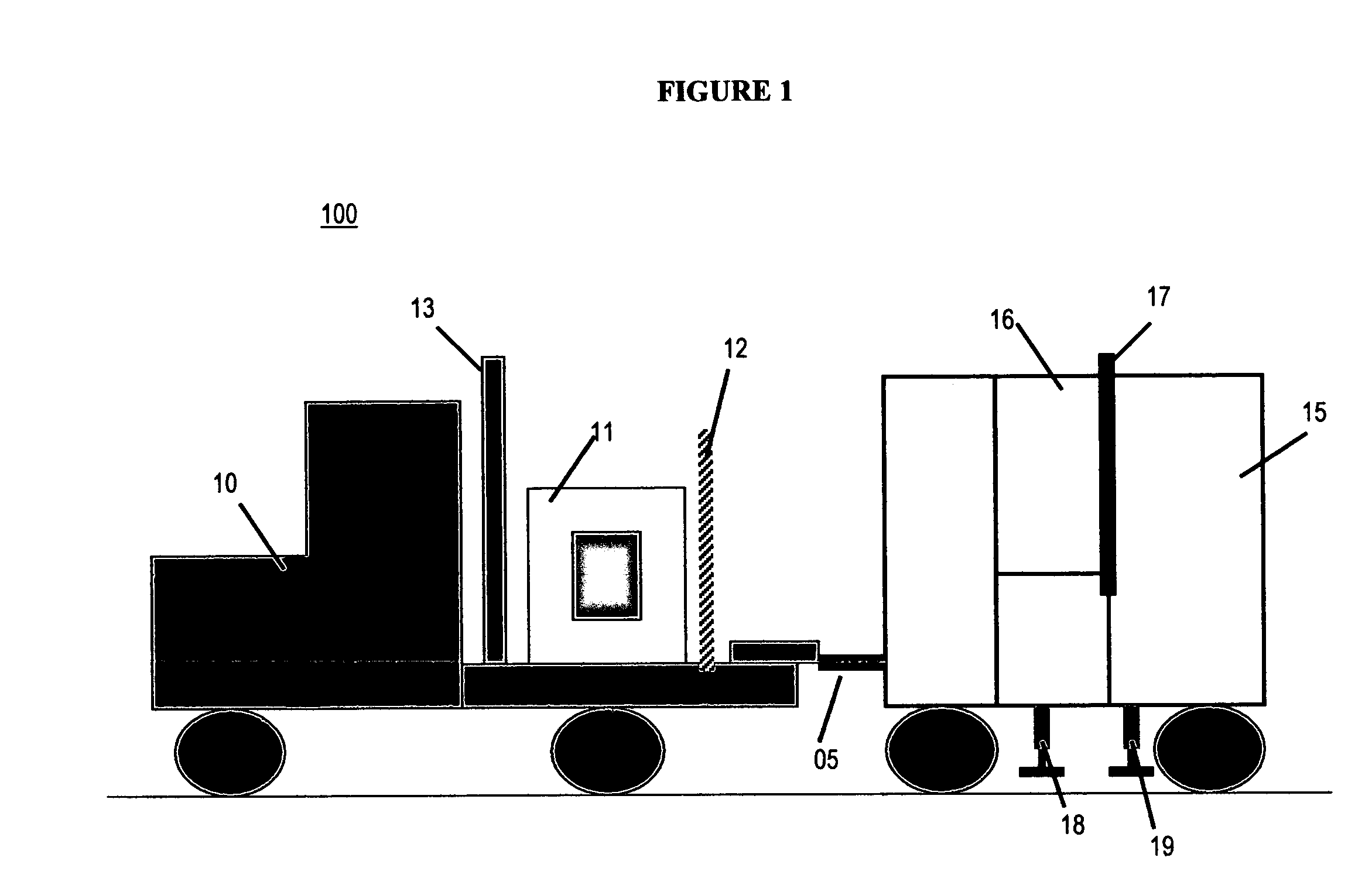

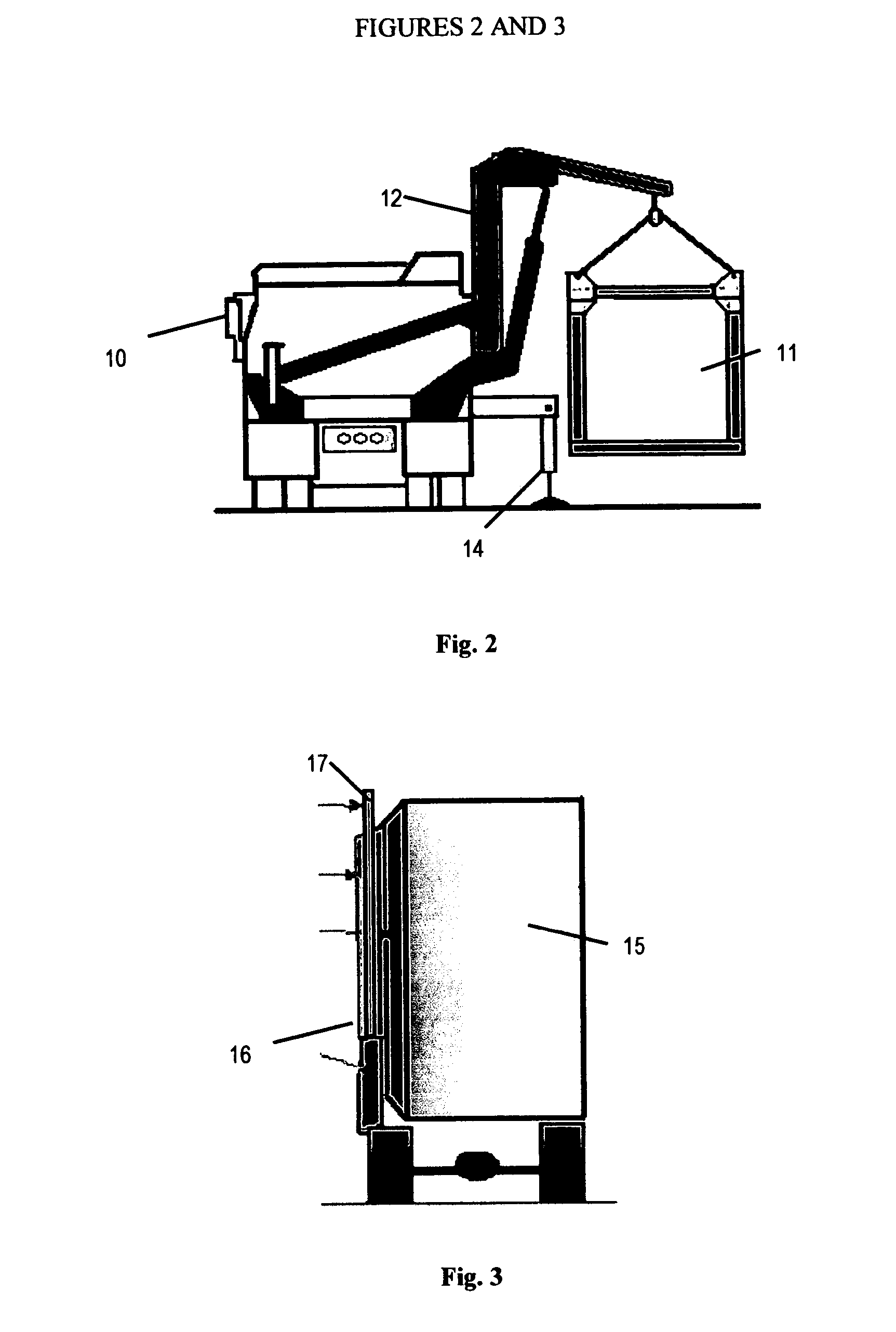

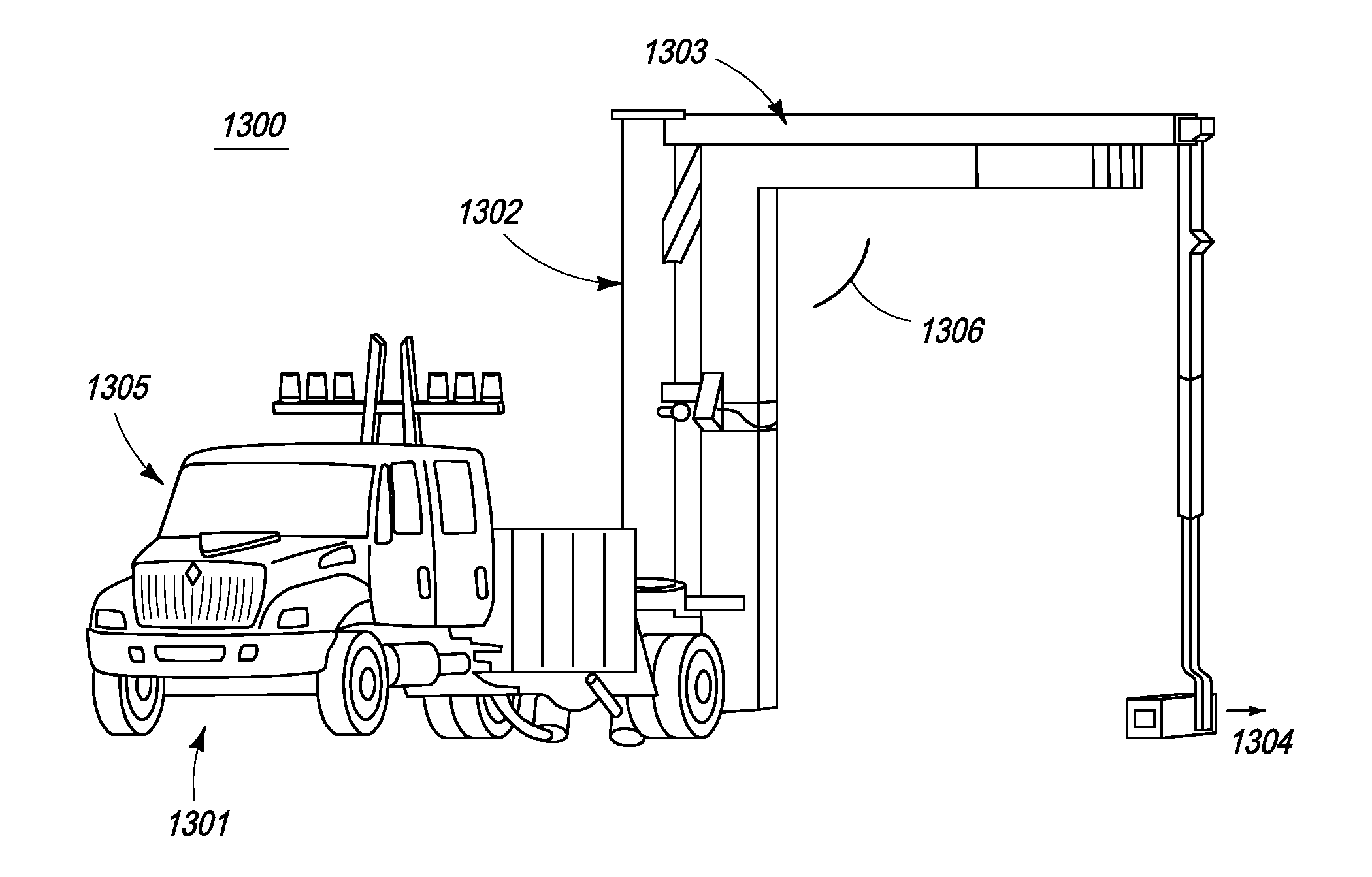

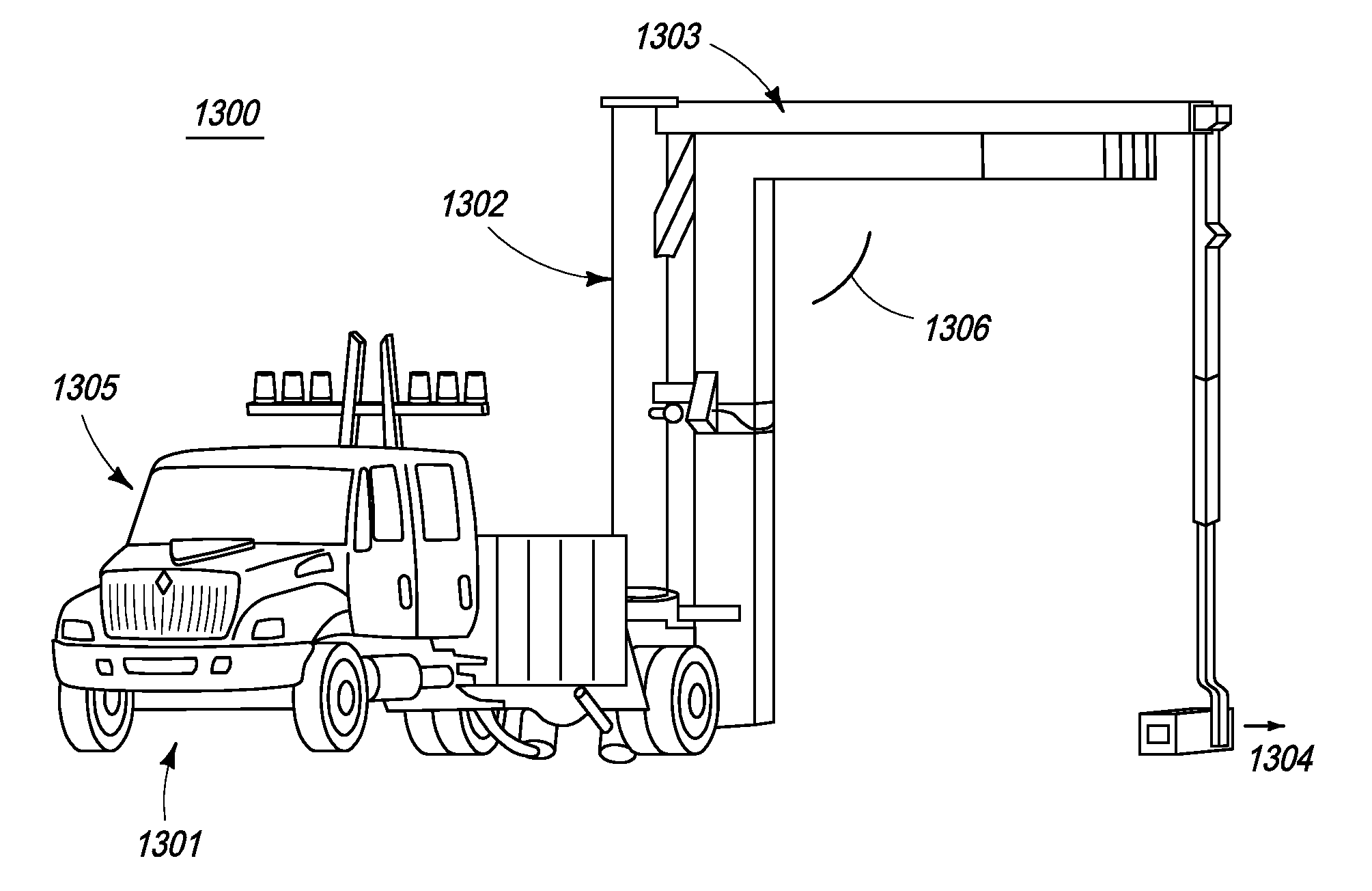

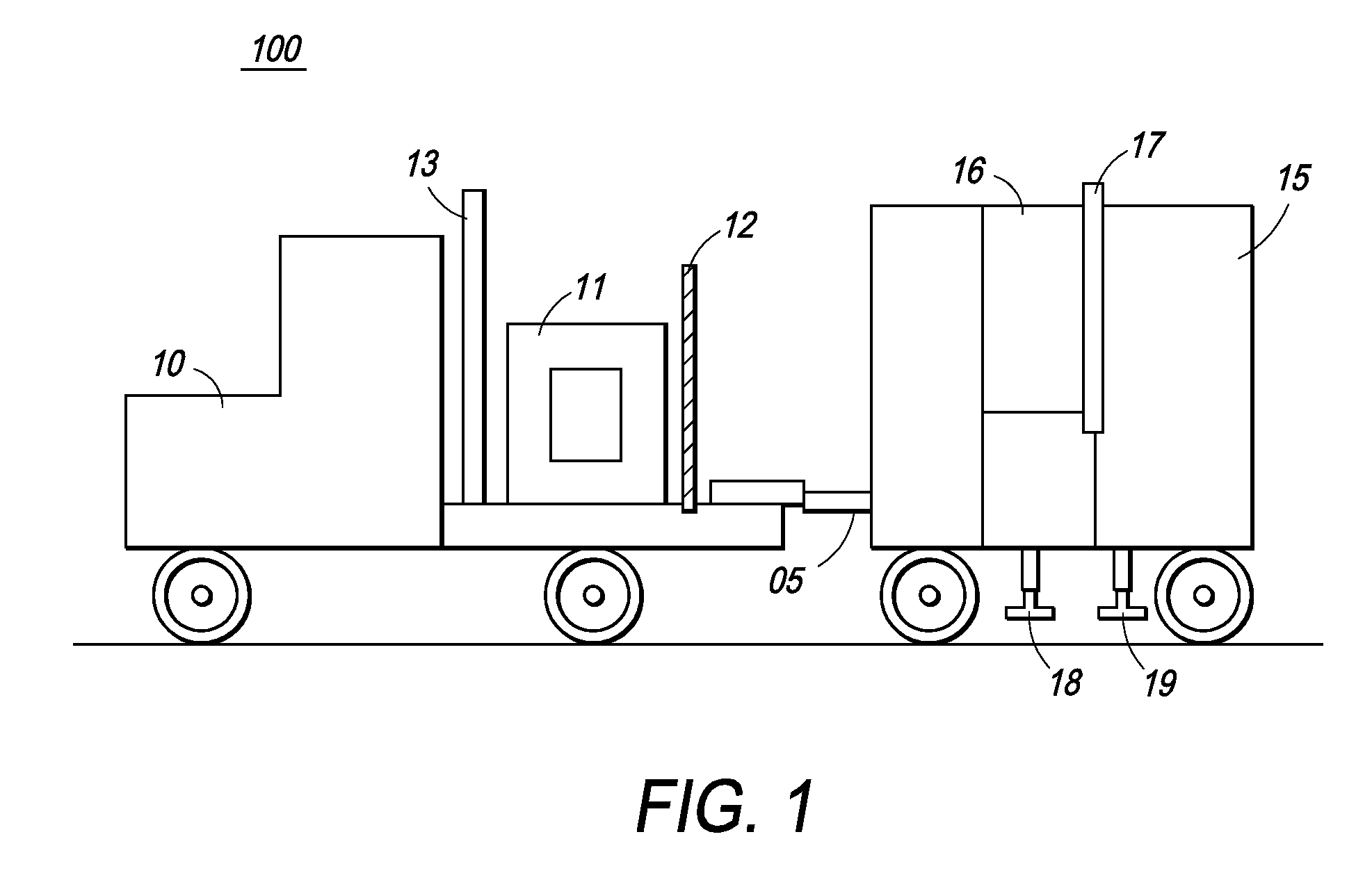

Self-contained, portable inspection system and method

InactiveUS6843599B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationComputer moduleEngineering

The inspection methods and systems of the present invention are mobile, deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The inspection system comprises an inspection module that, in a preferred embodiment, is in the form of a mobile trailer capable of being towed and transported to its intended operating site with the help of a tug-vehicle. The tug-vehicle preferably includes at least one source of electromagnetic radiation, a hydraulic lift system to load and unload the radiation source, and at least one radiation shield plate positioned on the back of the driver cabin of the tug-vehicle.

Owner:RAPISCAN SYST INC (US)

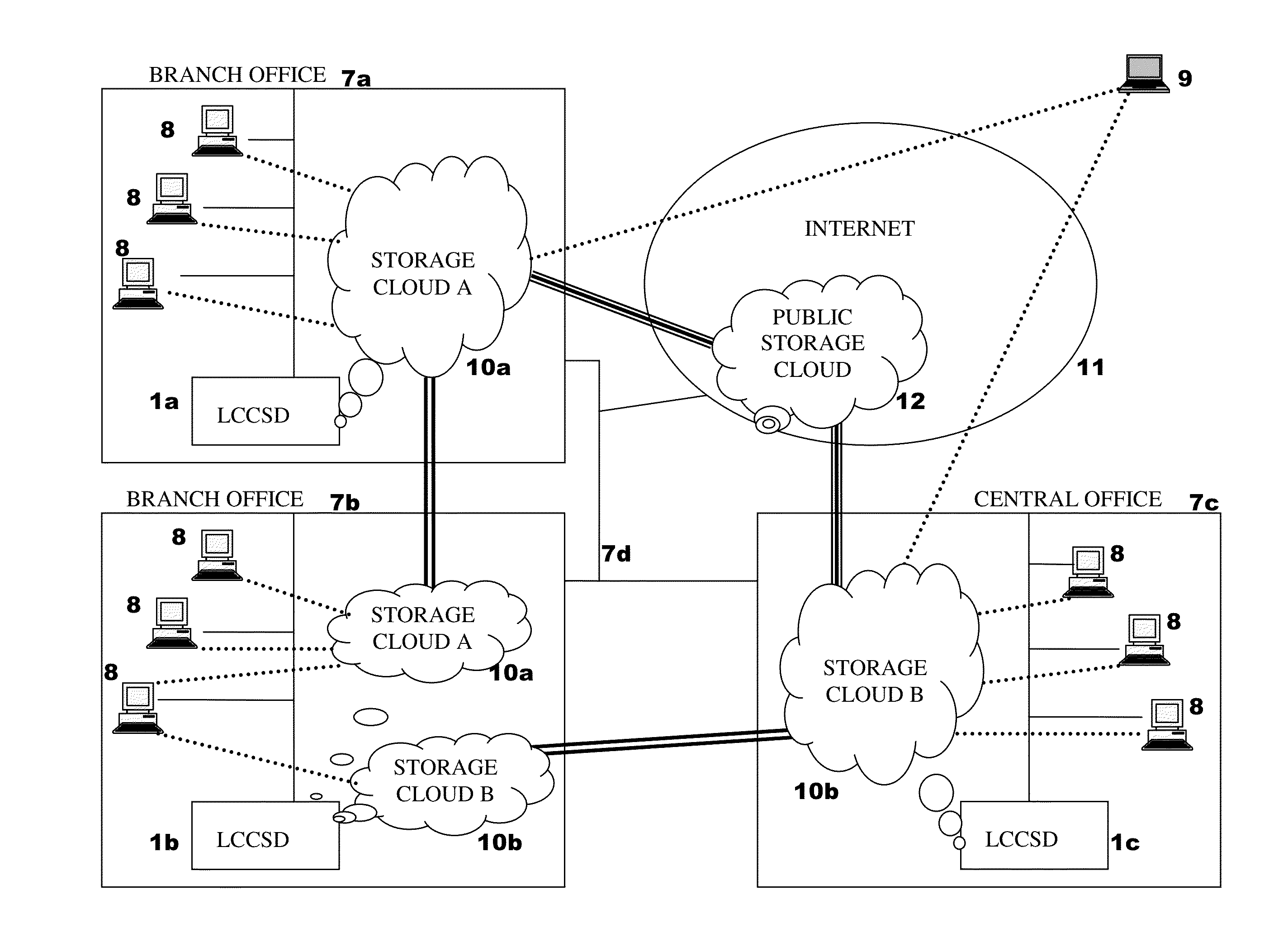

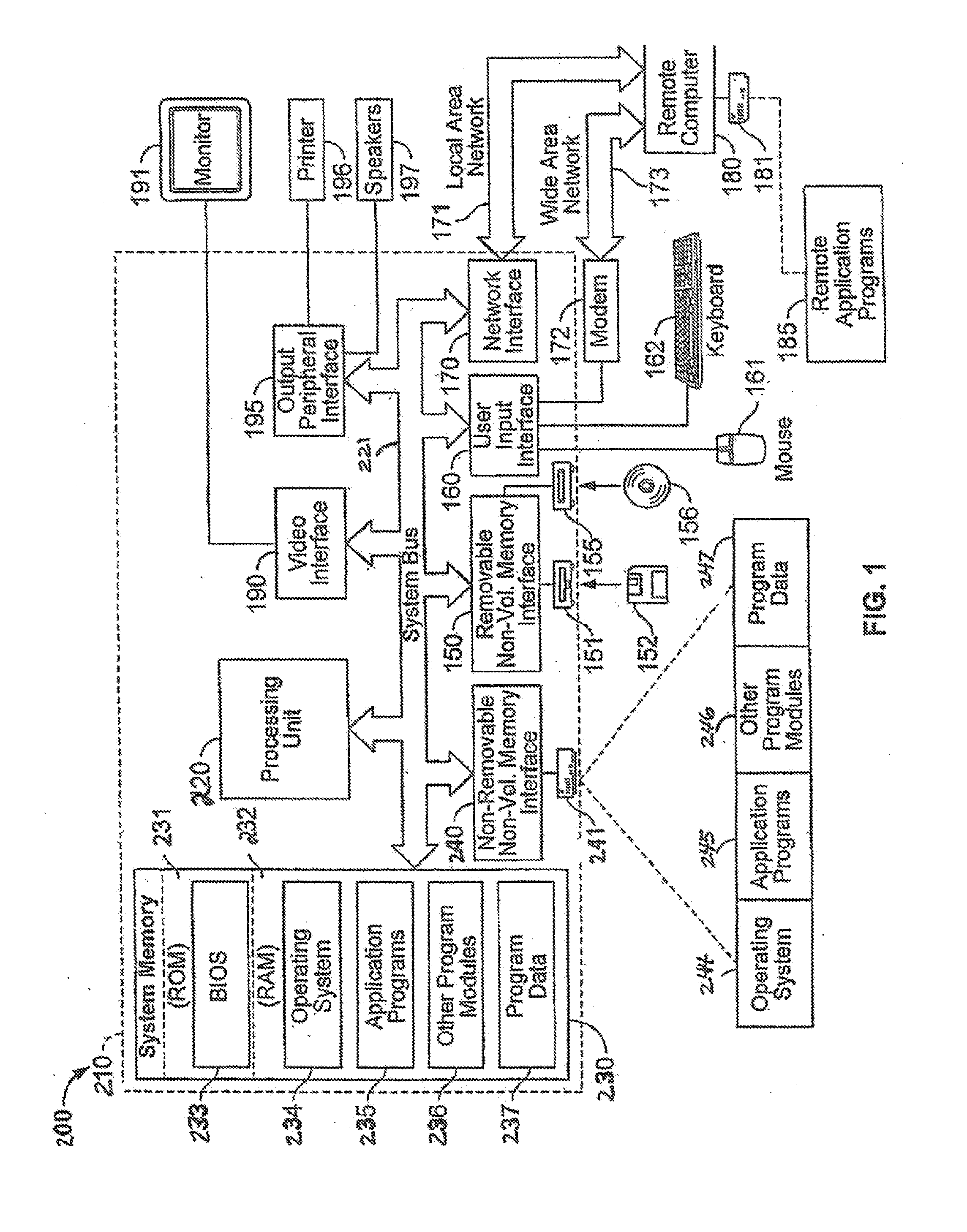

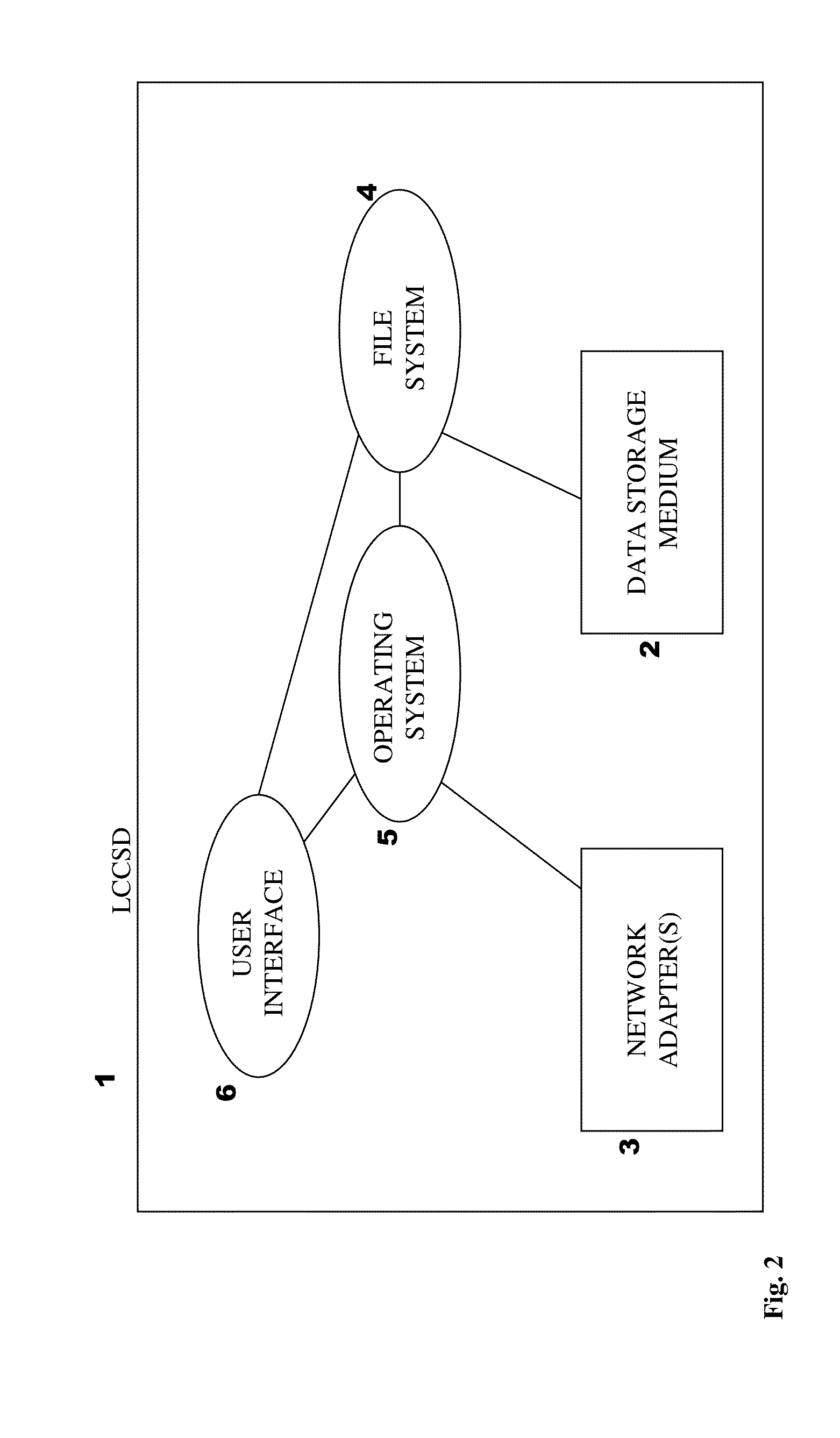

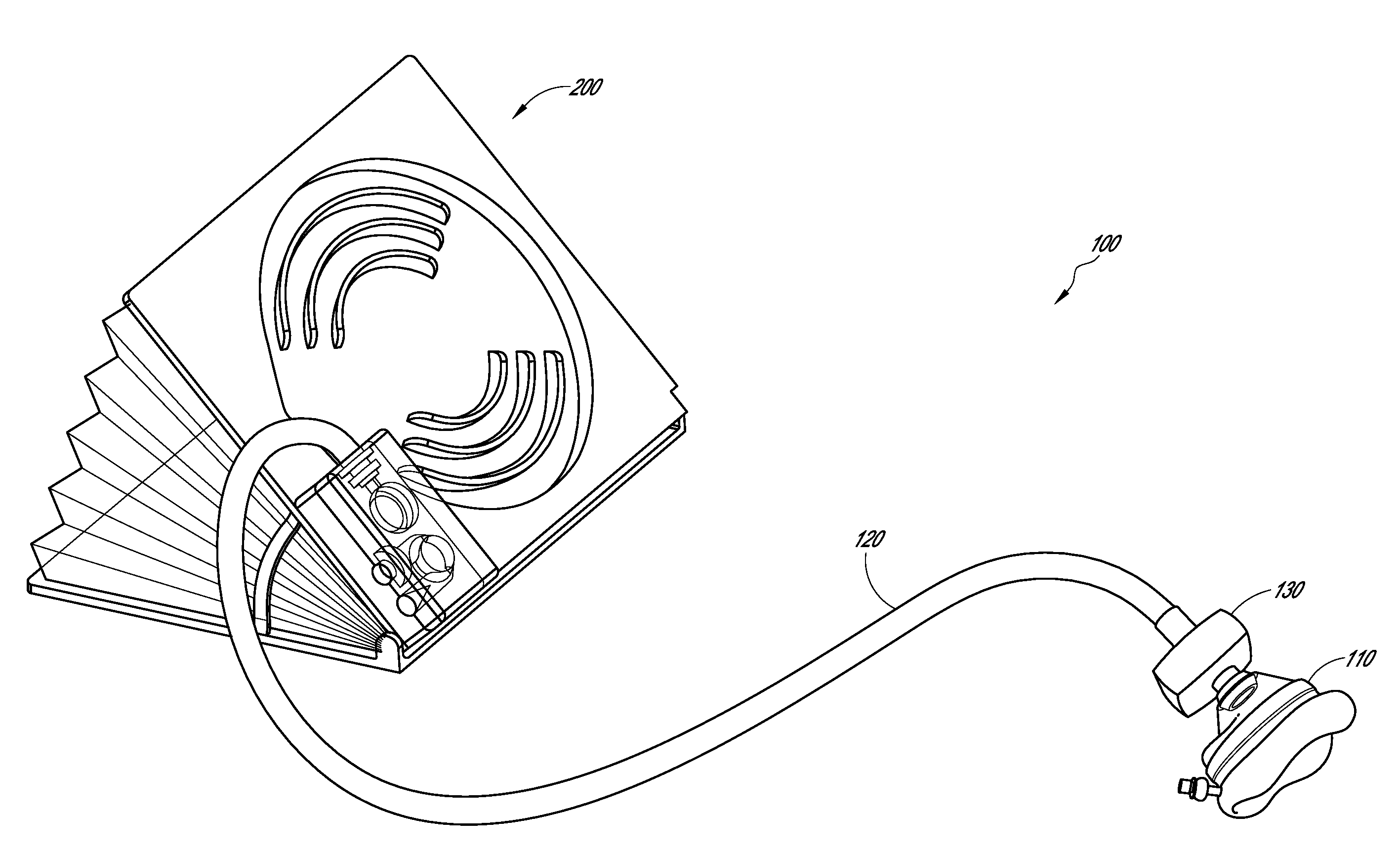

Locally Connected Cloud Storage Device

InactiveUS20130117337A1Rapidly deployableReduce riskDigital data information retrievalSpecial data processing applicationsFile systemComputer terminal

The present invention includes systems and methods for implementing a locally connected cloud storage device. The locally connected cloud storage device includes a data storage medium; one or more network adapters capable of connecting the cloud storage device to a network; a file system; and an operating system. The operating system and file system are capable of providing an end user access to at least one storage cloud having at least one volume for data stored in the data storage medium. The cloud storage device also includes a user interface capable of receiving commands reflecting desired settings for the end user and the volume. The user interface, upon receiving a command reflecting desired settings, interacts with the file system and the operating system to effectuate the desired settings.

Owner:ICEWEB STORAGE

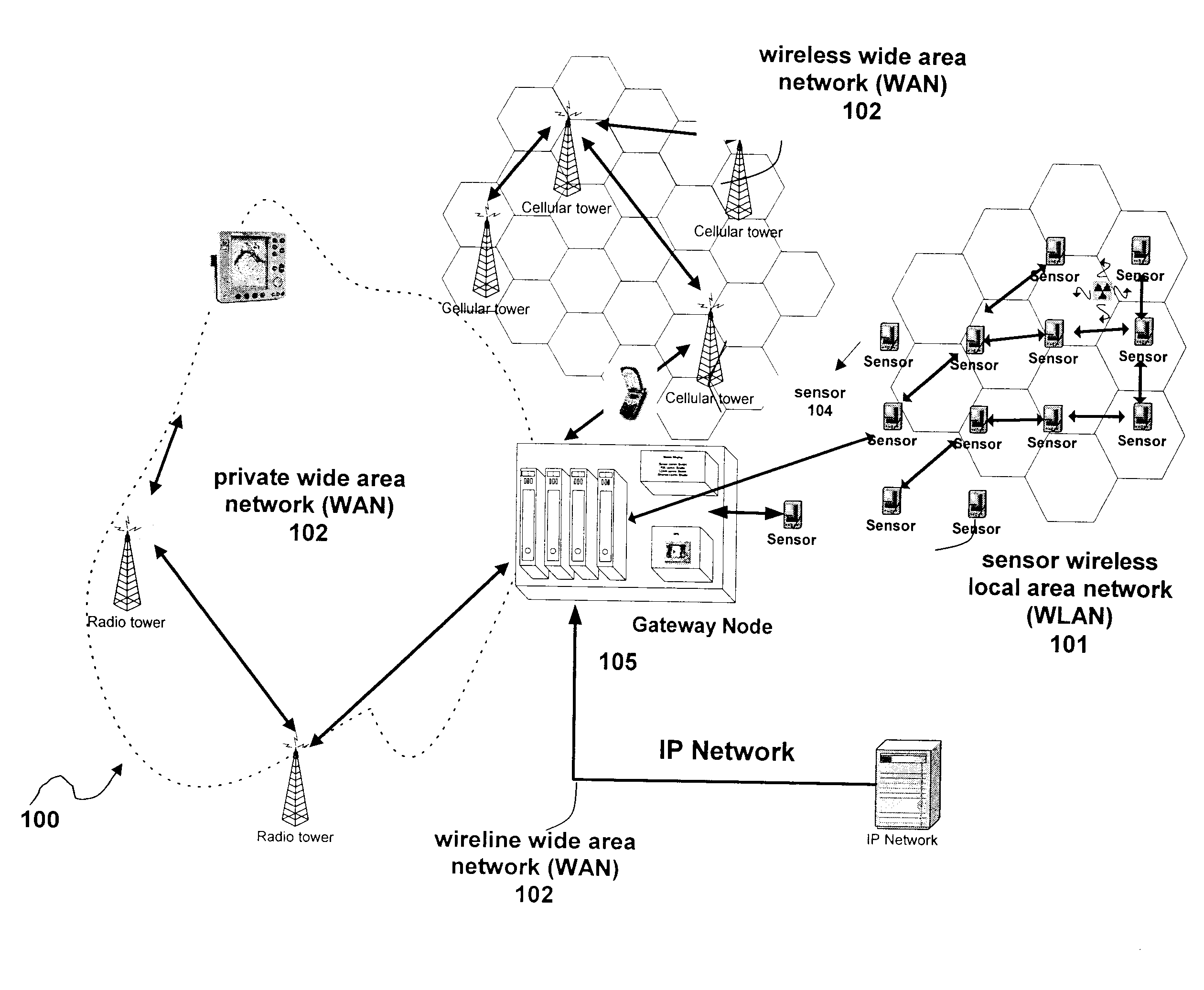

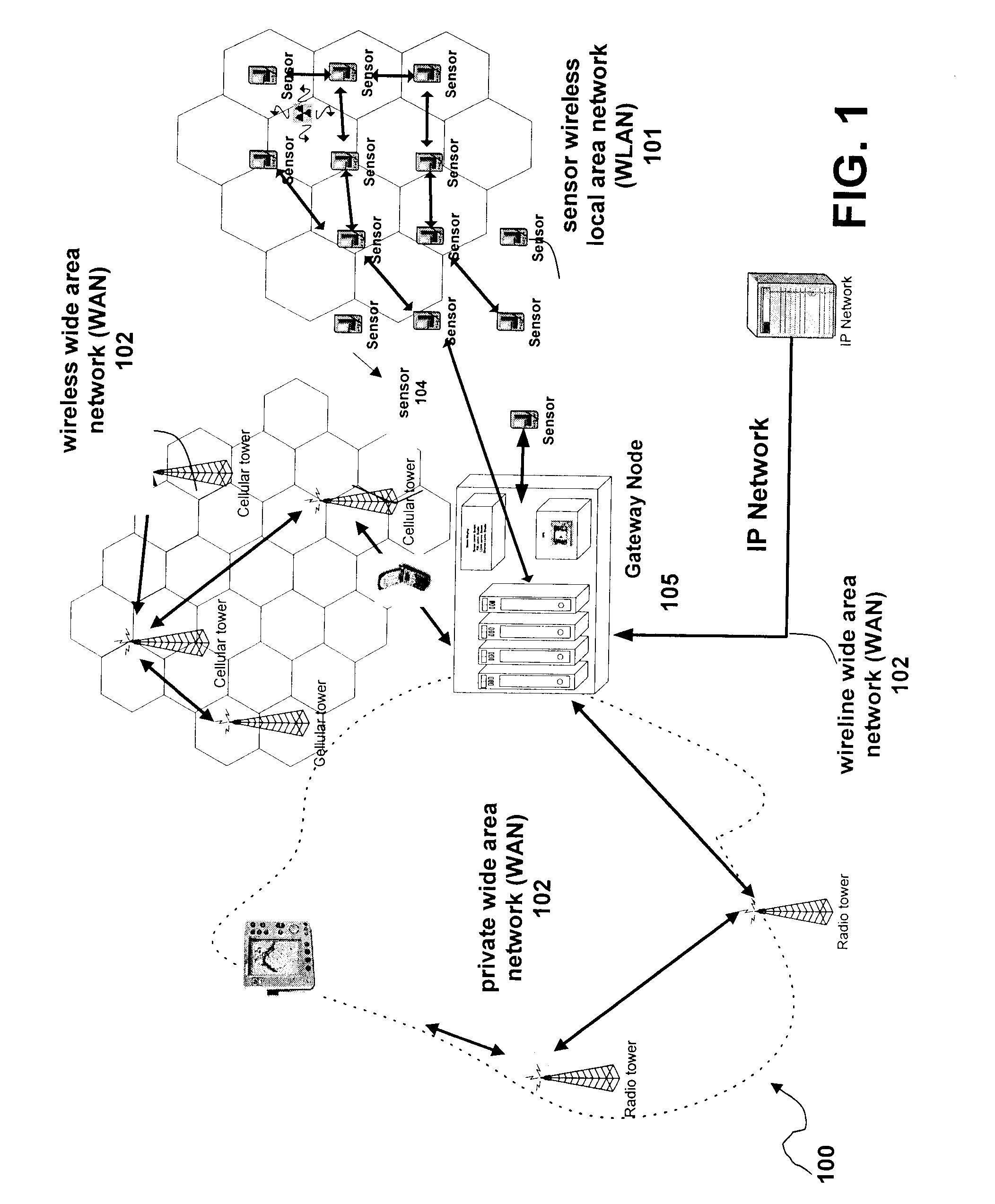

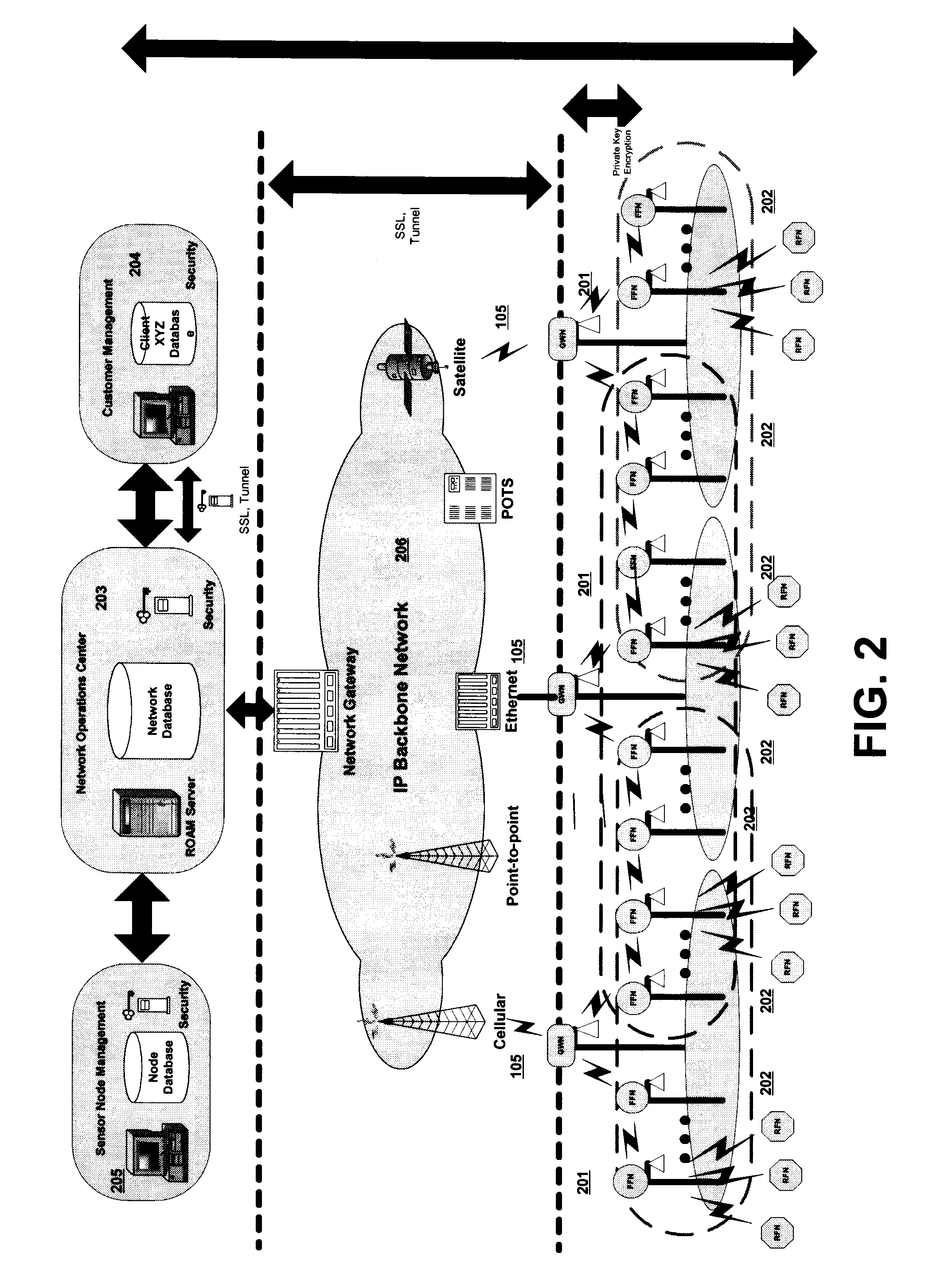

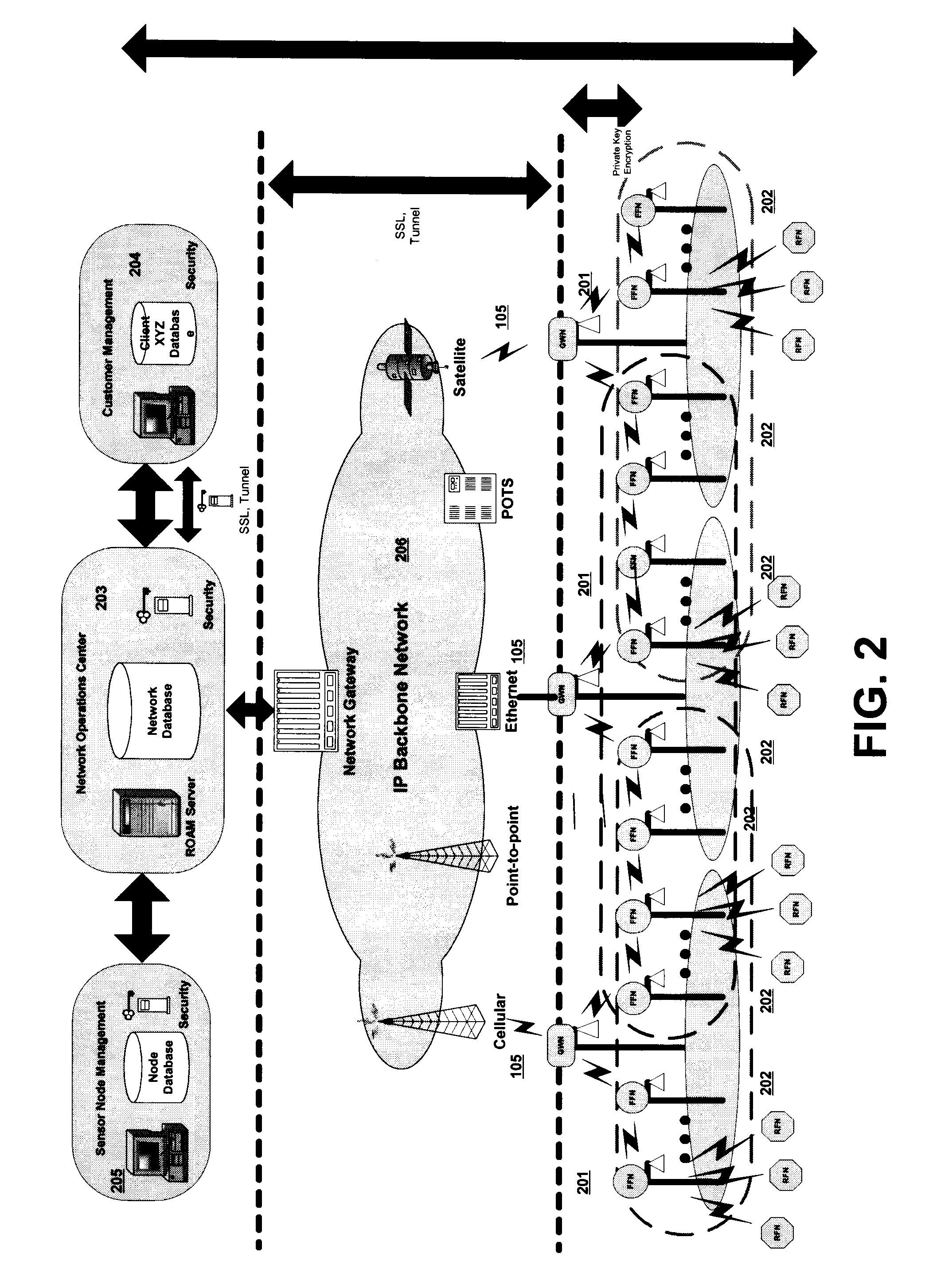

Method and Apparatus for Management of a Global Wireless Sensor Network

ActiveUS20080137624A1Rapidly deployableLow costNetwork topologiesRadio/inductive link selection arrangementsInterconnectivityTelecommunications link

Methods and apparatus for global wireless sensor network architecture and protocol for remote supervision, asset control and operational management based on localized clusters of autonomous sensor / supervision / operational sensor nodes capable of ad hoc interconnection with nearby nodes and connection to gateway nodes with increased network functionality. These localized cluster nodes send data to gateway nodes either directly or through multi-hop transactions. The gateway nodes are, in turn, connected to other gateway nodes and operations control centers either through wireless or wired data communications links. Utilizing the Internet for long range interconnectivity, the network is scaleable to a global level. The resulting network is based on an ad hoc mesh topology to allow flexibility in network modification and expansion and is comprised of a tiered structure defined by increasing functionality. A current application for this technology is the remote control and supervision of lighting systems for facilities and municipalities on a local, national and / or global basis from centralized regional operations centers.

Owner:INNOVATIVE WIRELESS TECH

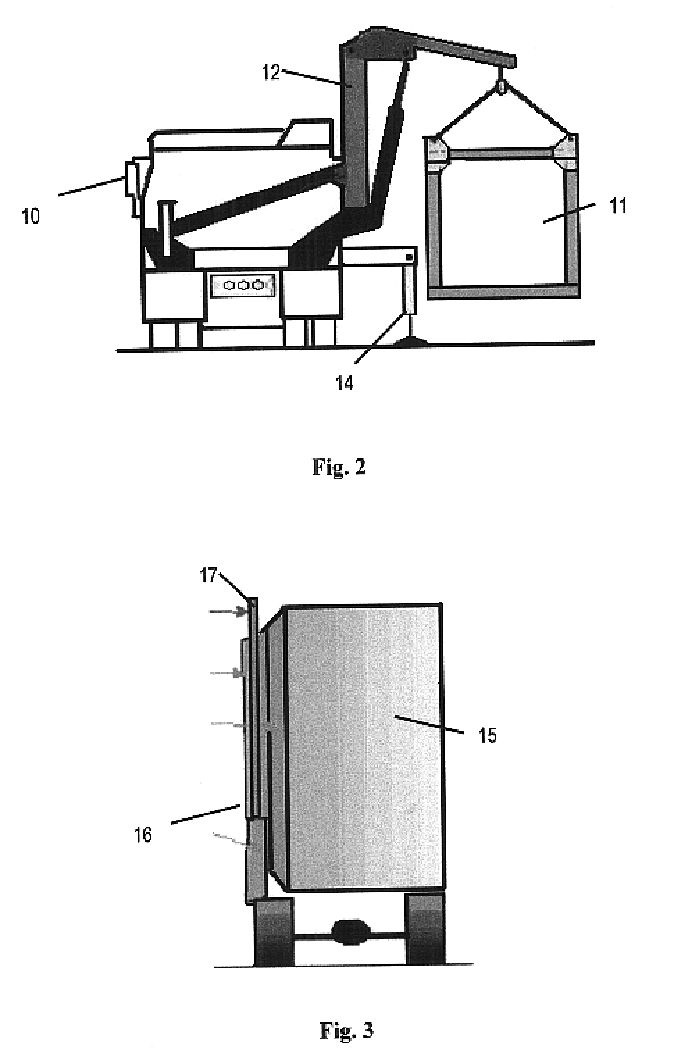

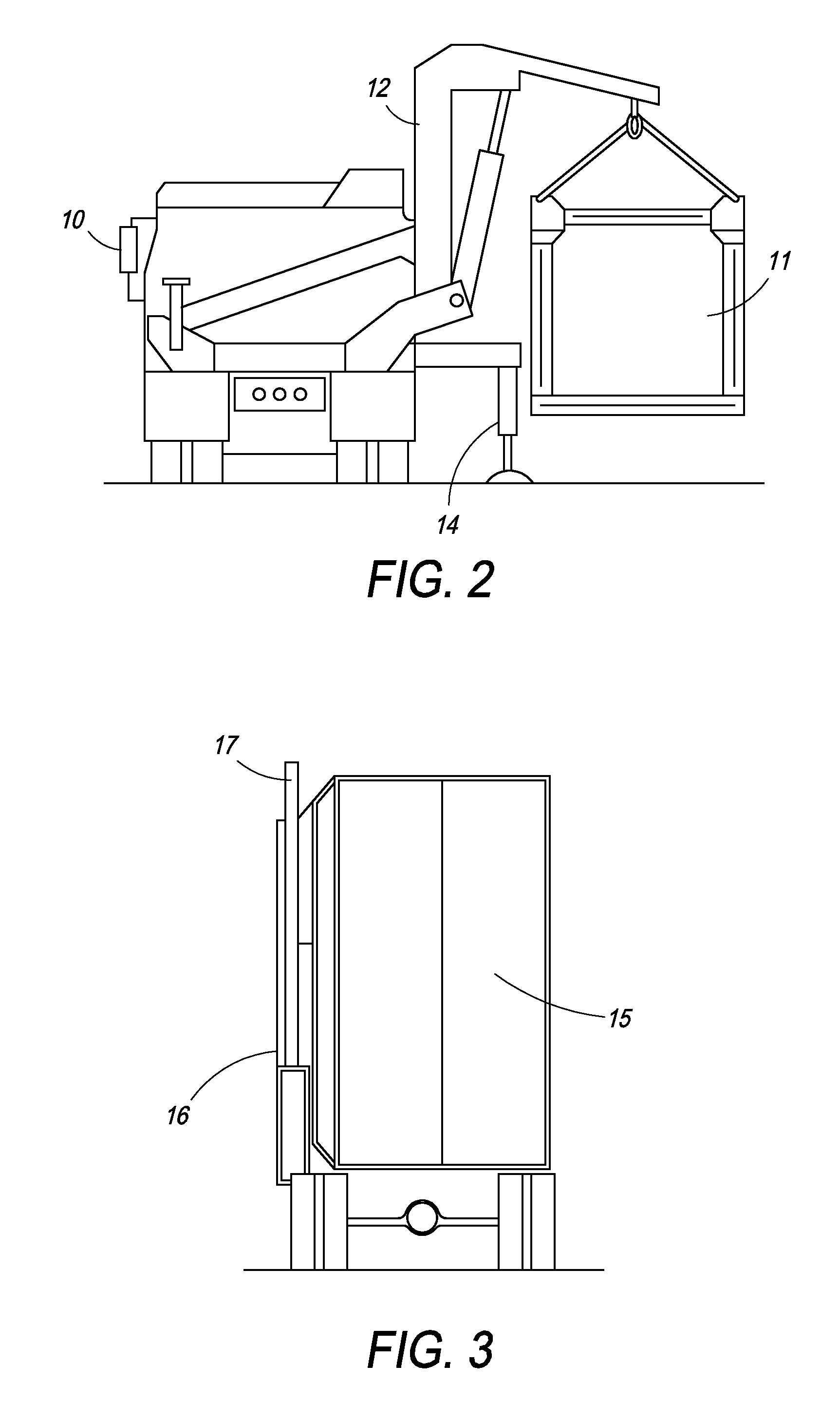

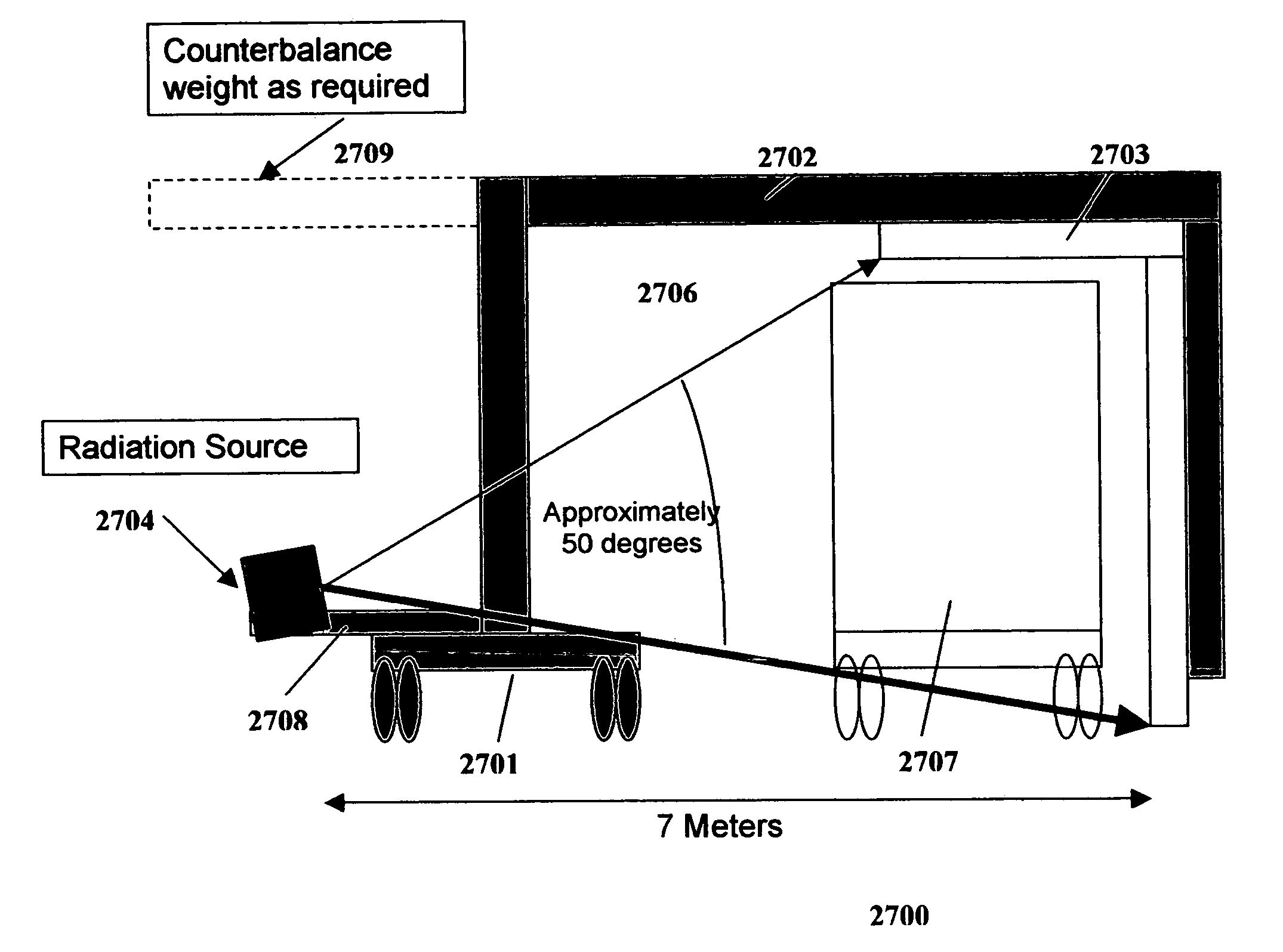

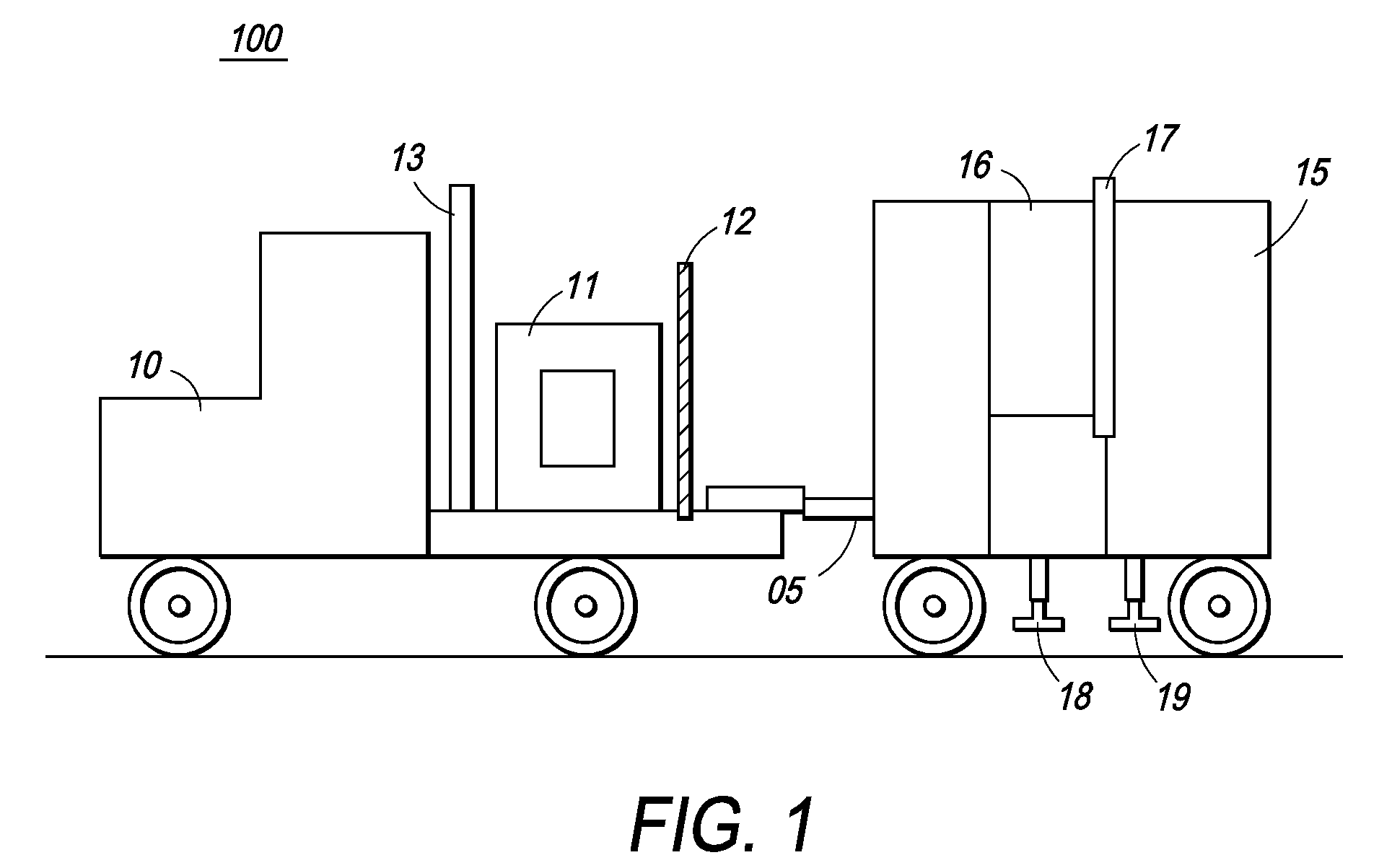

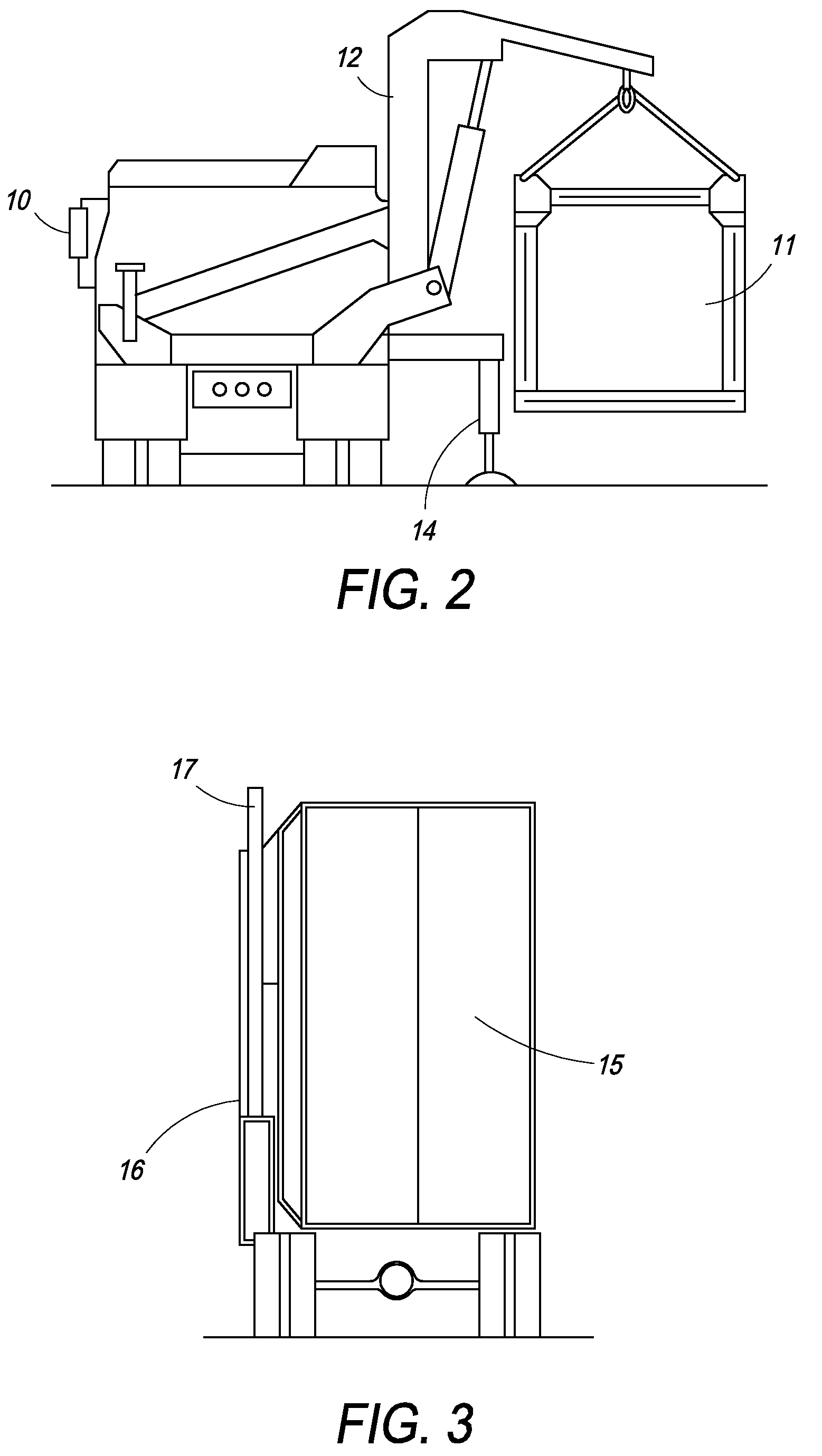

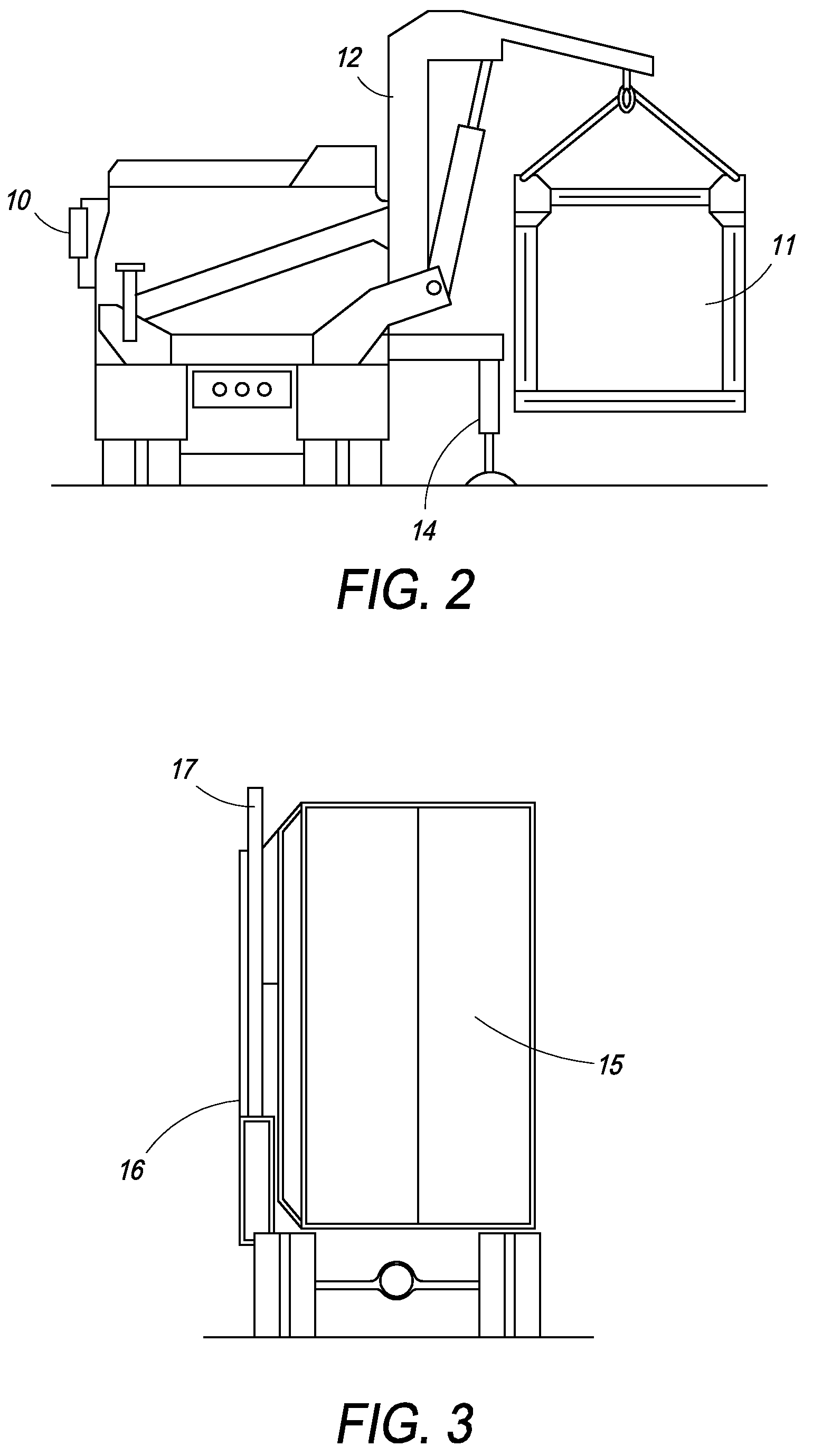

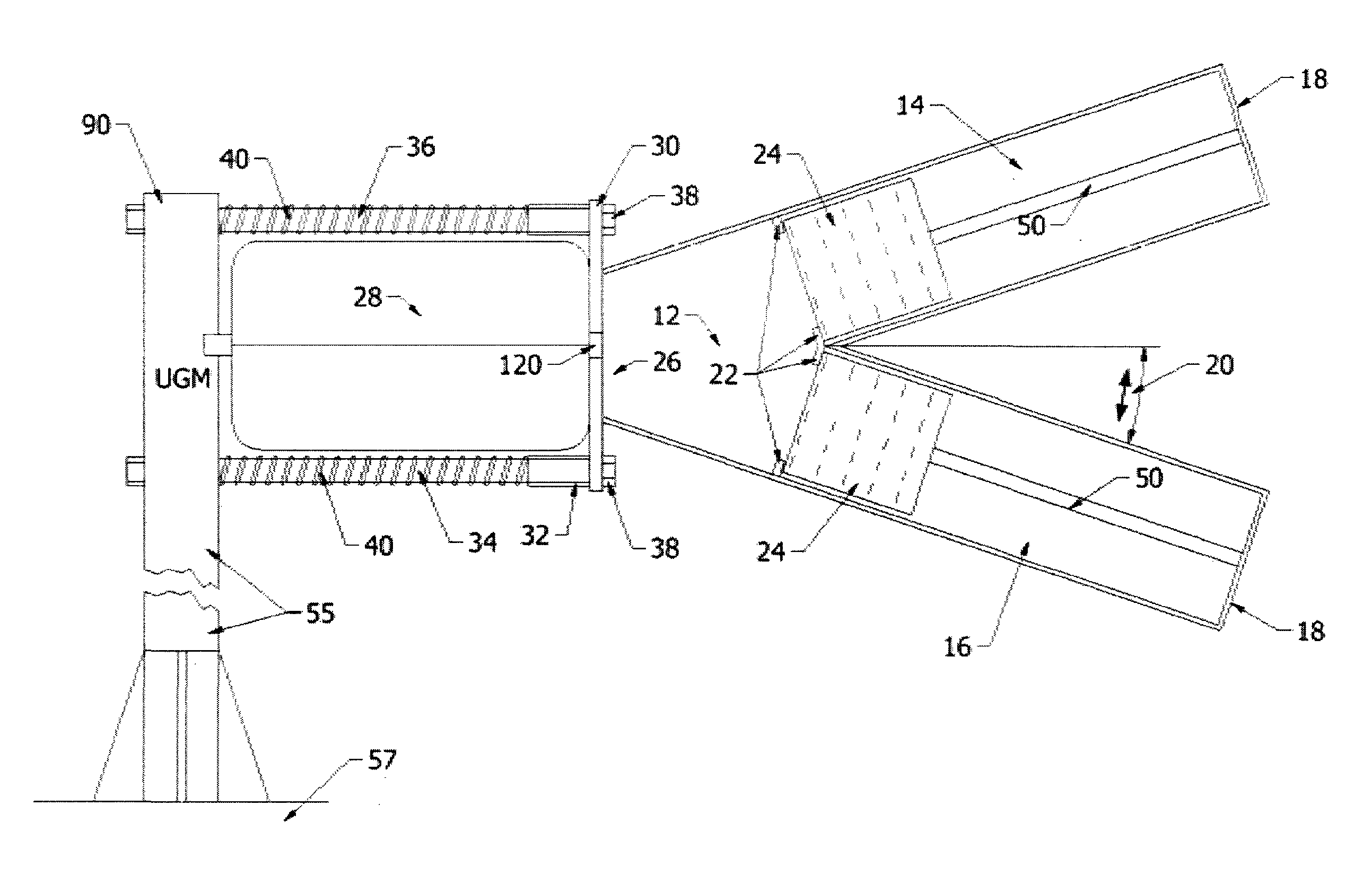

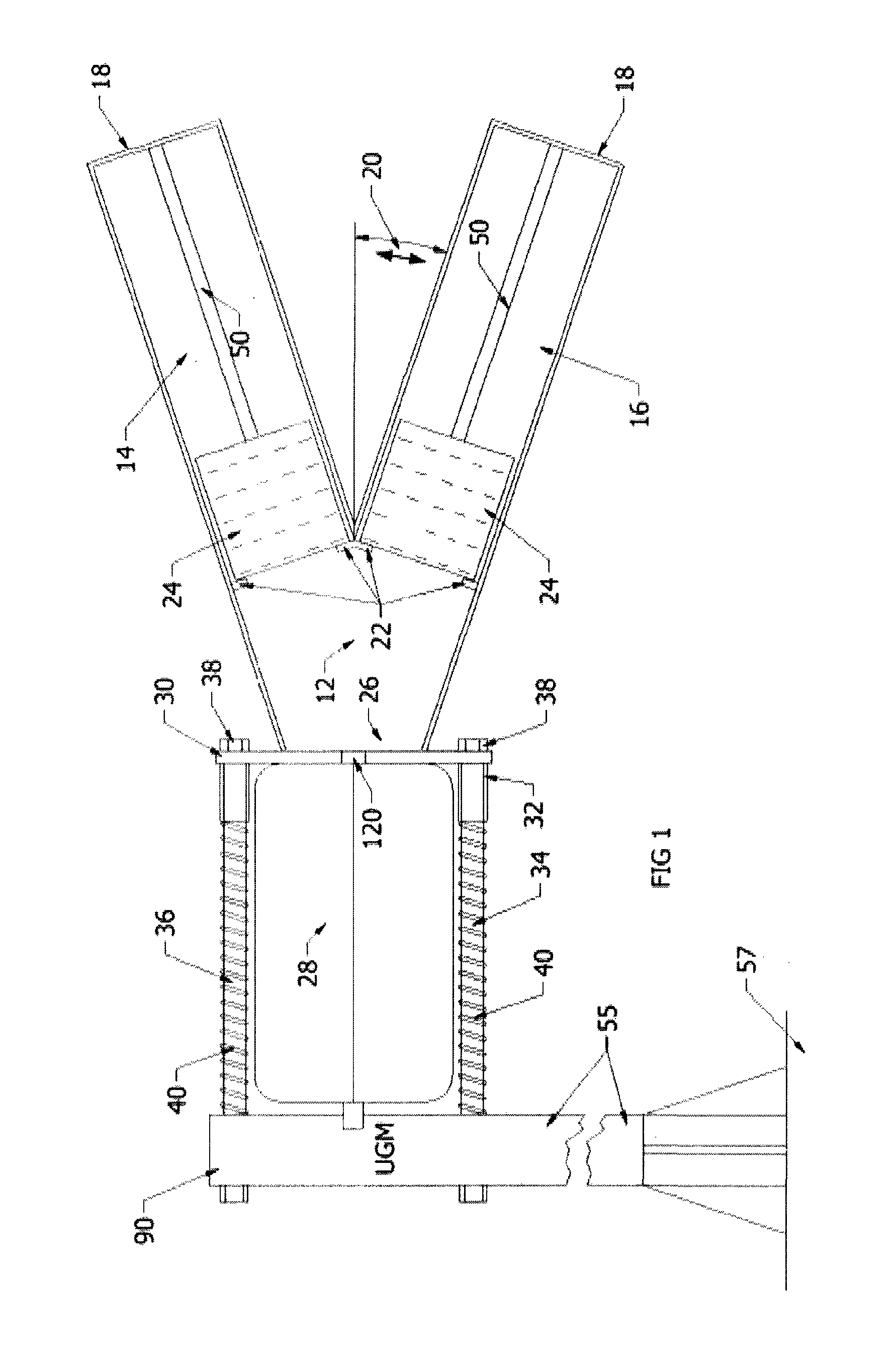

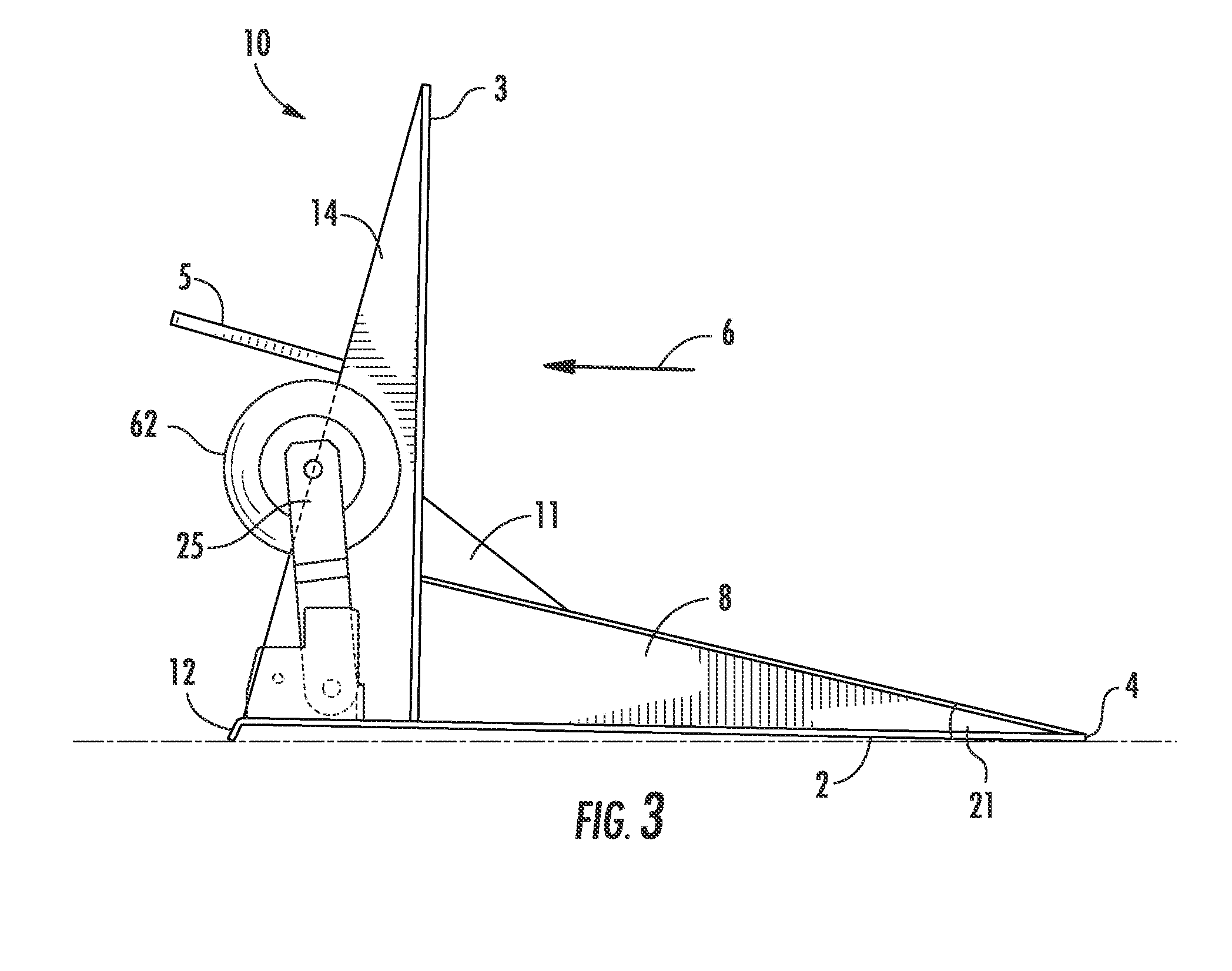

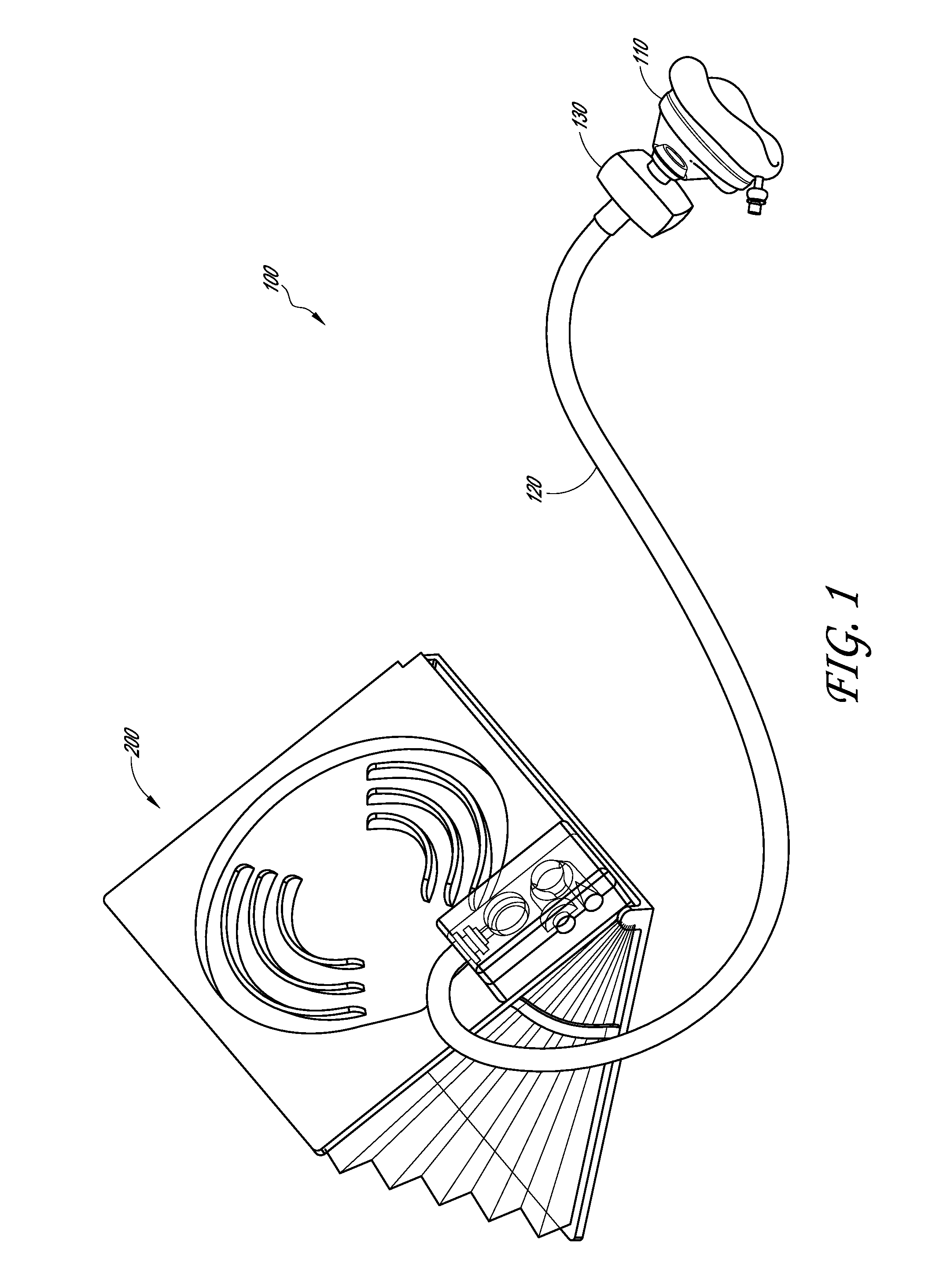

Single boom cargo scanning system

InactiveUS7322745B2Rapidly deployableCost-effectively and accurately on uneven surfaceRadiation/particle handlingParticle suspension analysisMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

Single boom cargo scanning system

InactiveUS7369643B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

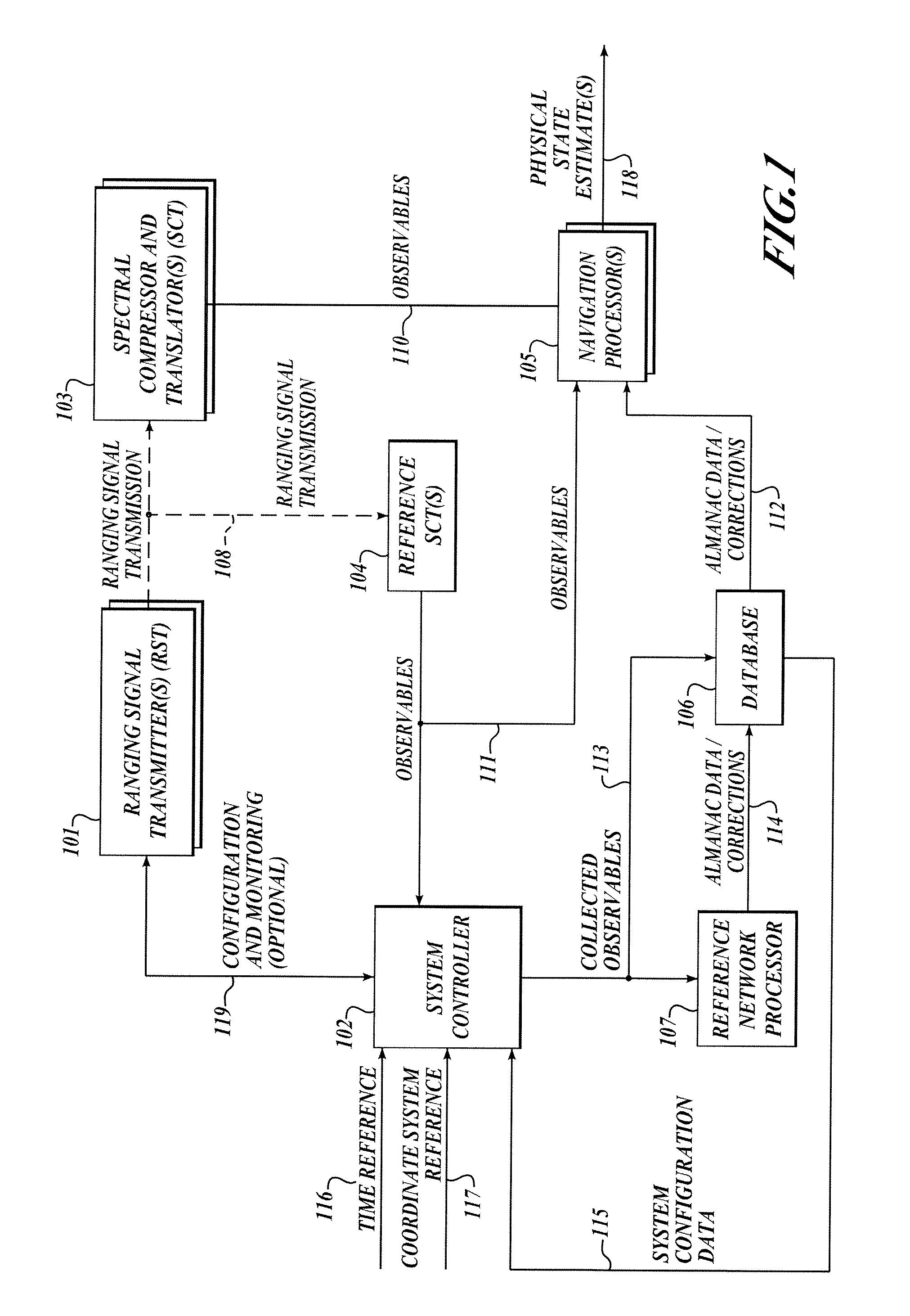

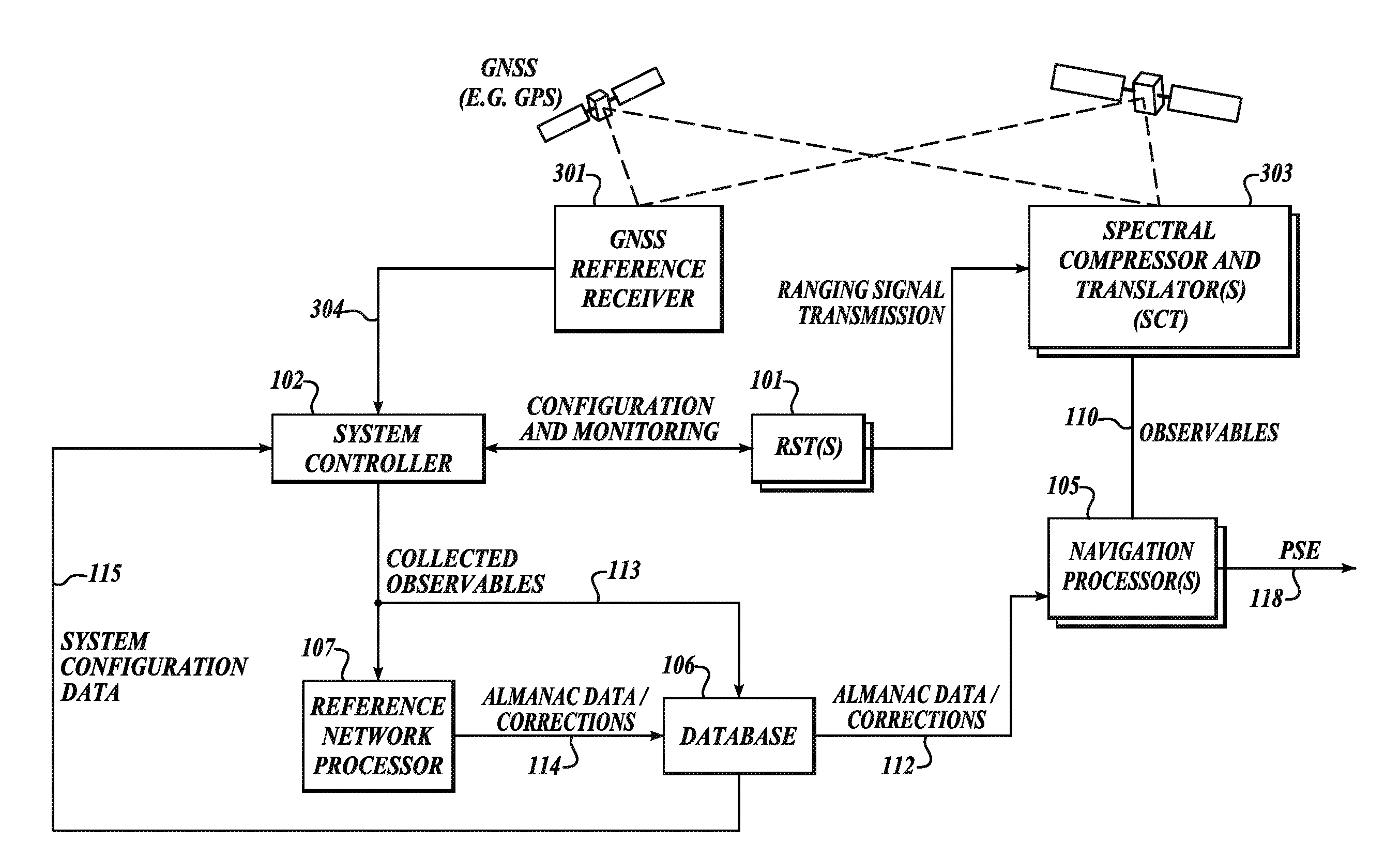

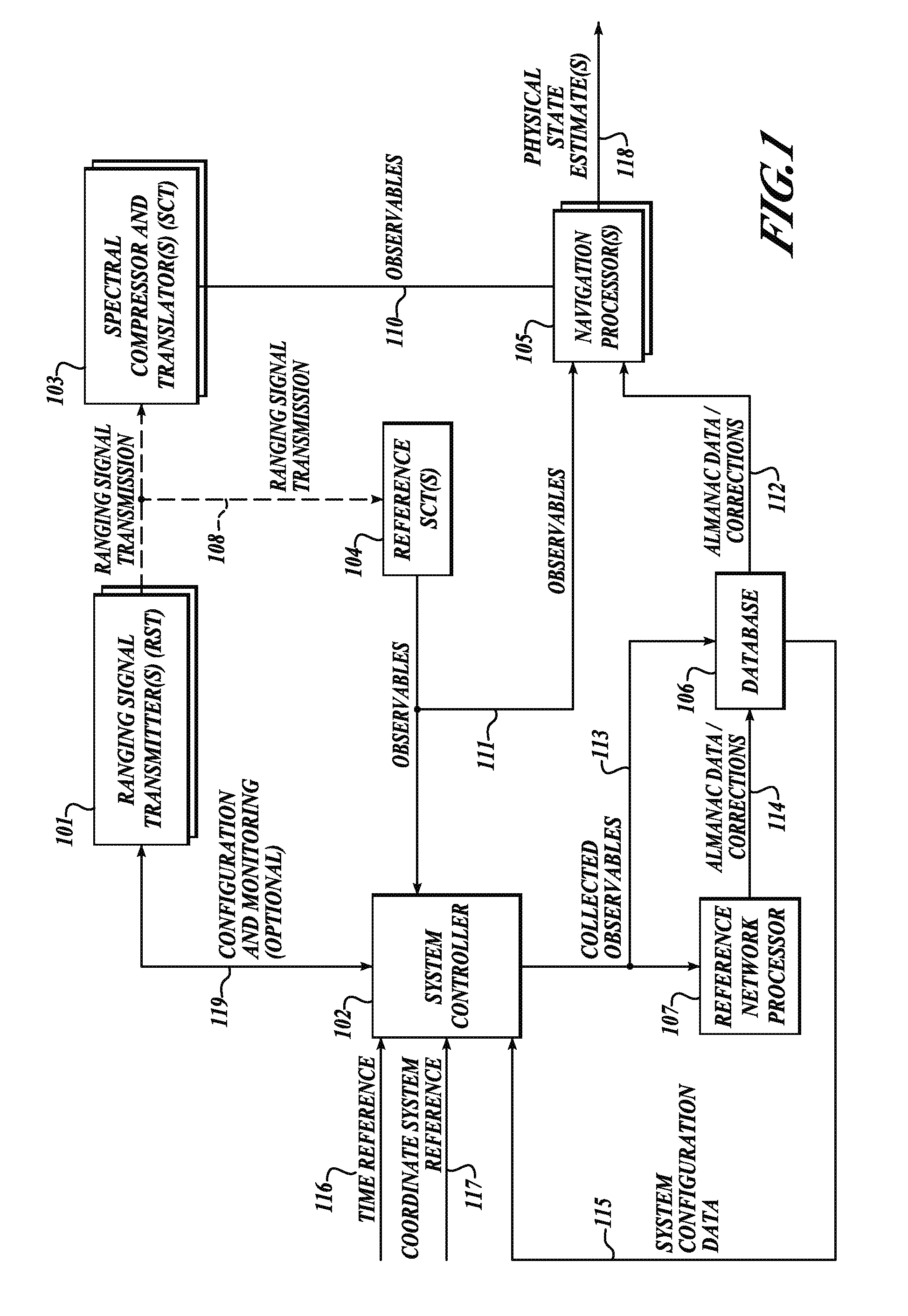

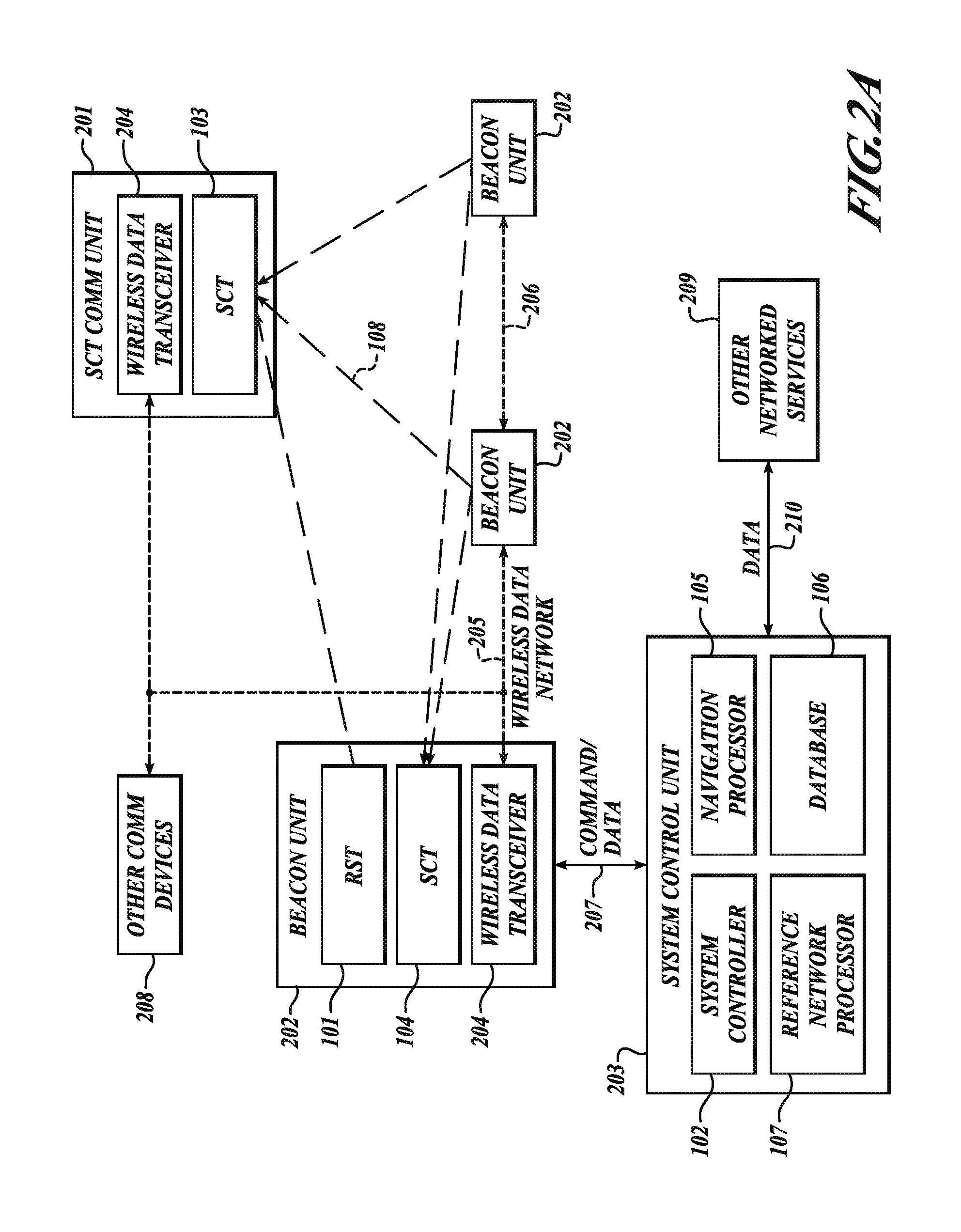

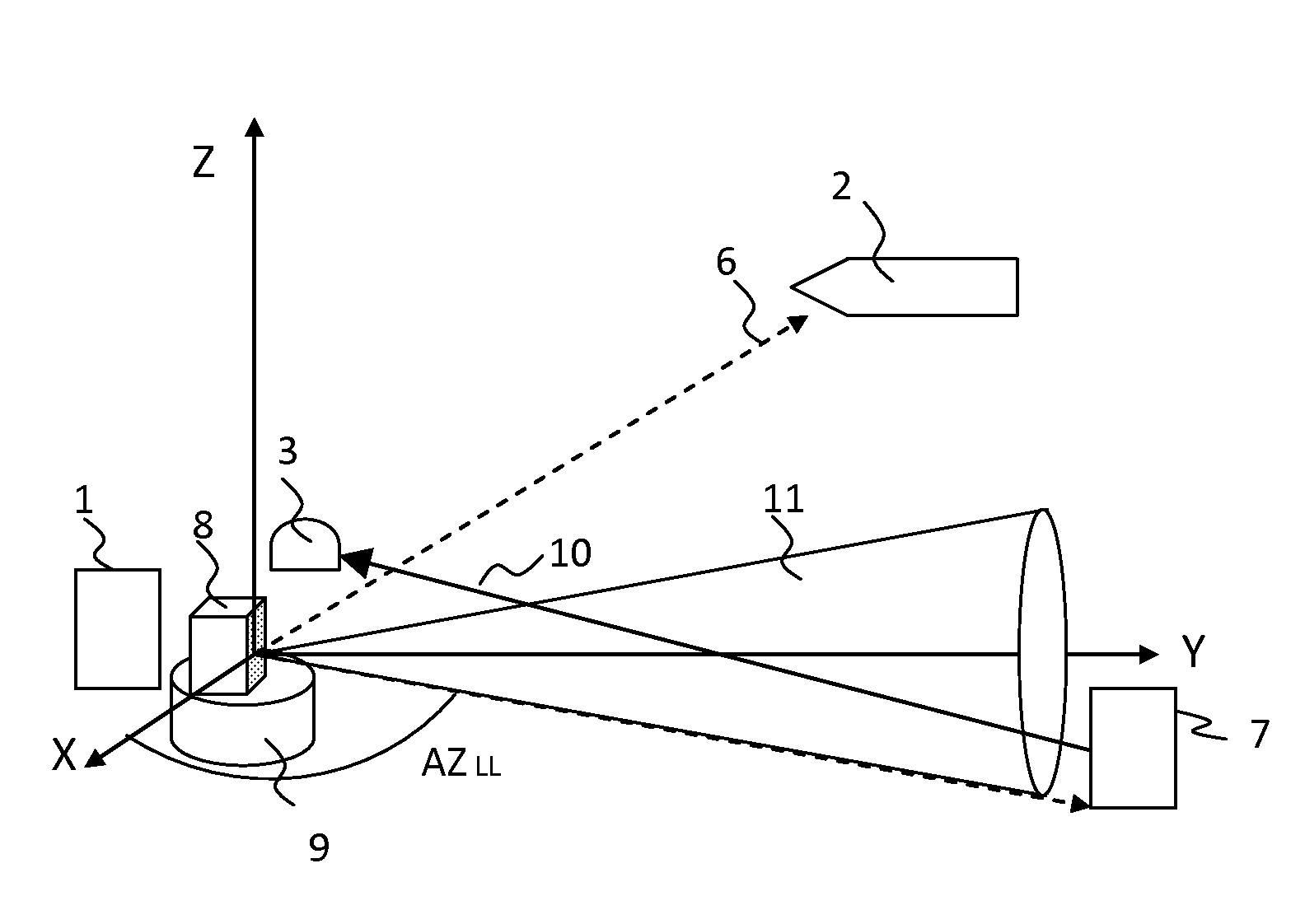

System and method for positioning in configured environments

ActiveUS20070257831A1Easy to implementRapidly deployableDirection finders using radio wavesPosition fixationFrequency spectrumCdma signal

The present invention relates to a system and method for providing location determination in a configured environment in which Global Navigation Satellite System Signals are not available. In this regard, local beacon systems generate spread spectrum CDMA signals that are received by spectral compression units that derive physically meaningful observations without a requirement for correlation of the intercepted energy by means of the known spreading codes. The invention can coexist with communication assets already in place, and the design allows for self calibration, which simplifies installation and usage. The invention has utility in applications in which GNSS signals are unavailable or limited, for example, in warehouse inventory management, in search and rescue operations and in asset tracking in indoor environments.

Owner:TELECOMM SYST INC

Self-contained mobile inspection system and method

InactiveUS7486768B2Rapidly deployableCost-effectively and accurately on uneven surfaceHandling using diaphragms/collimetersRadiation beam directing meansMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

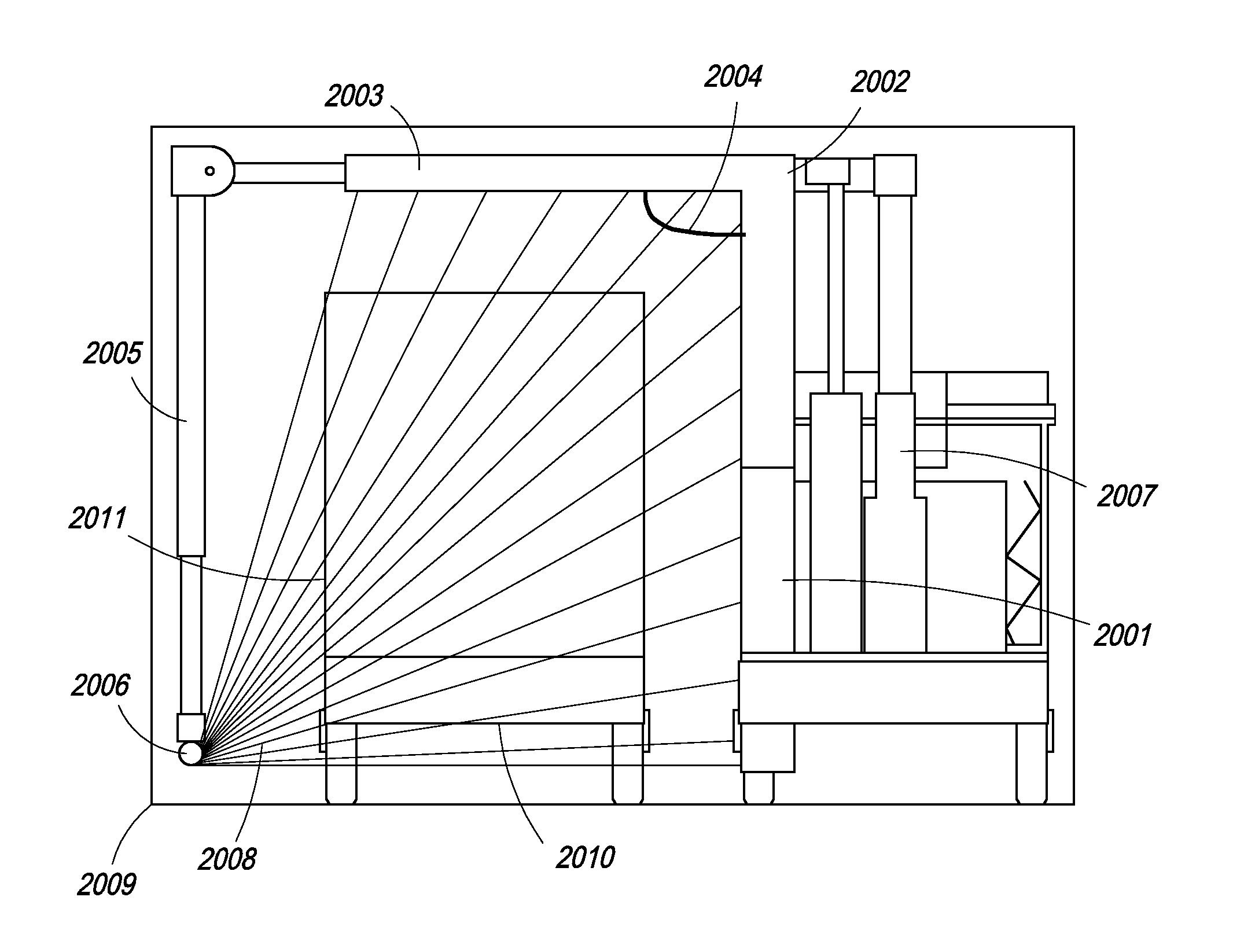

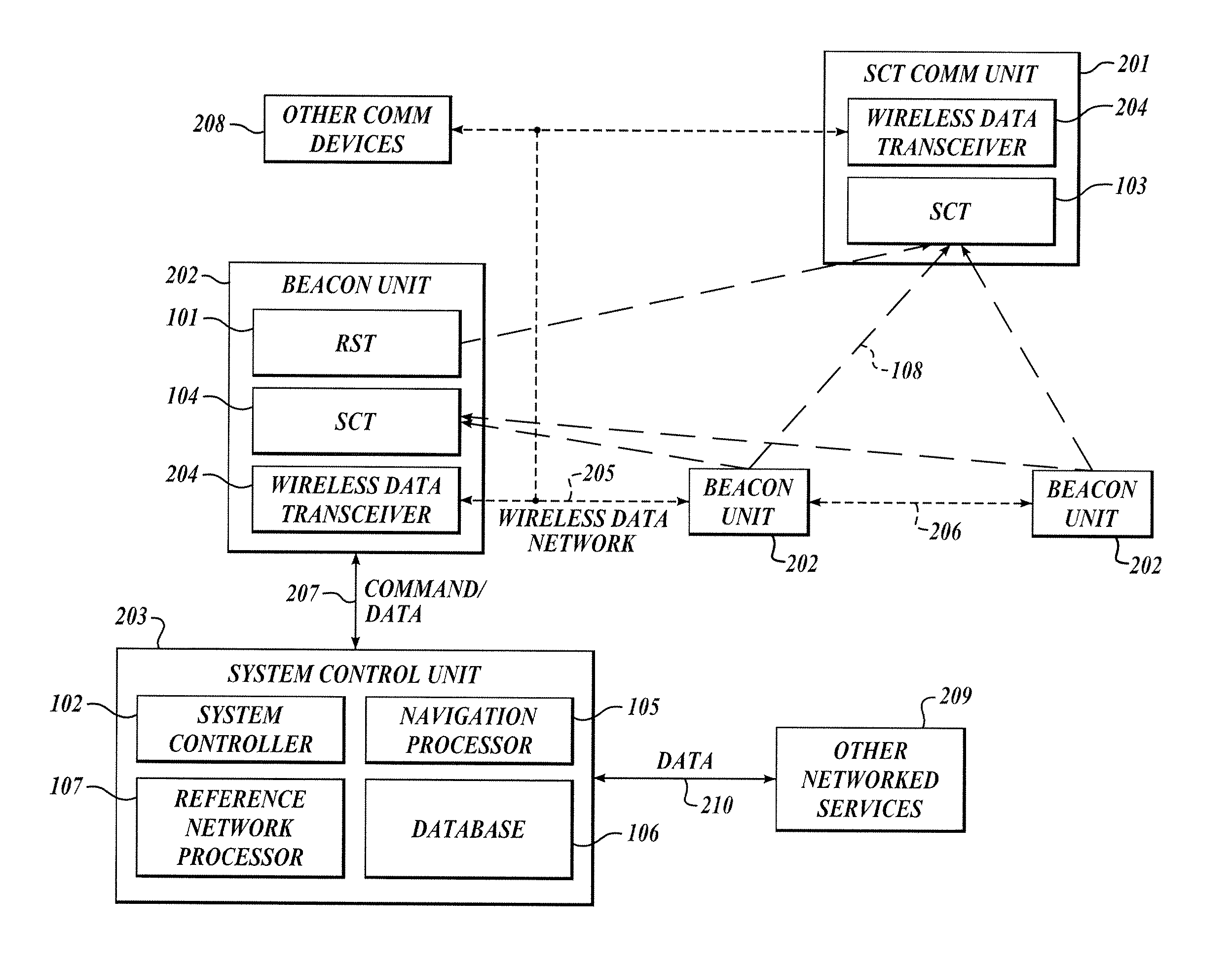

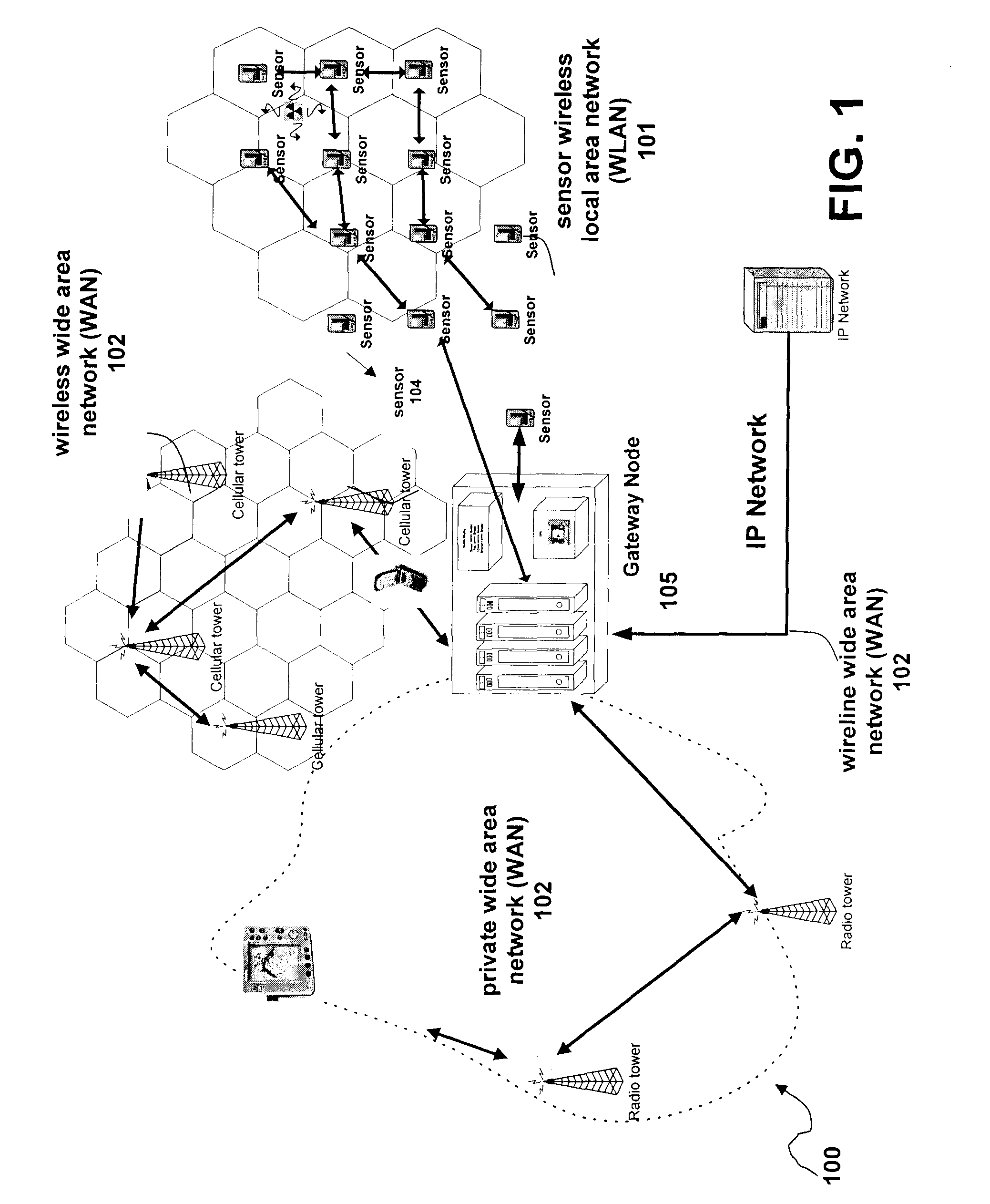

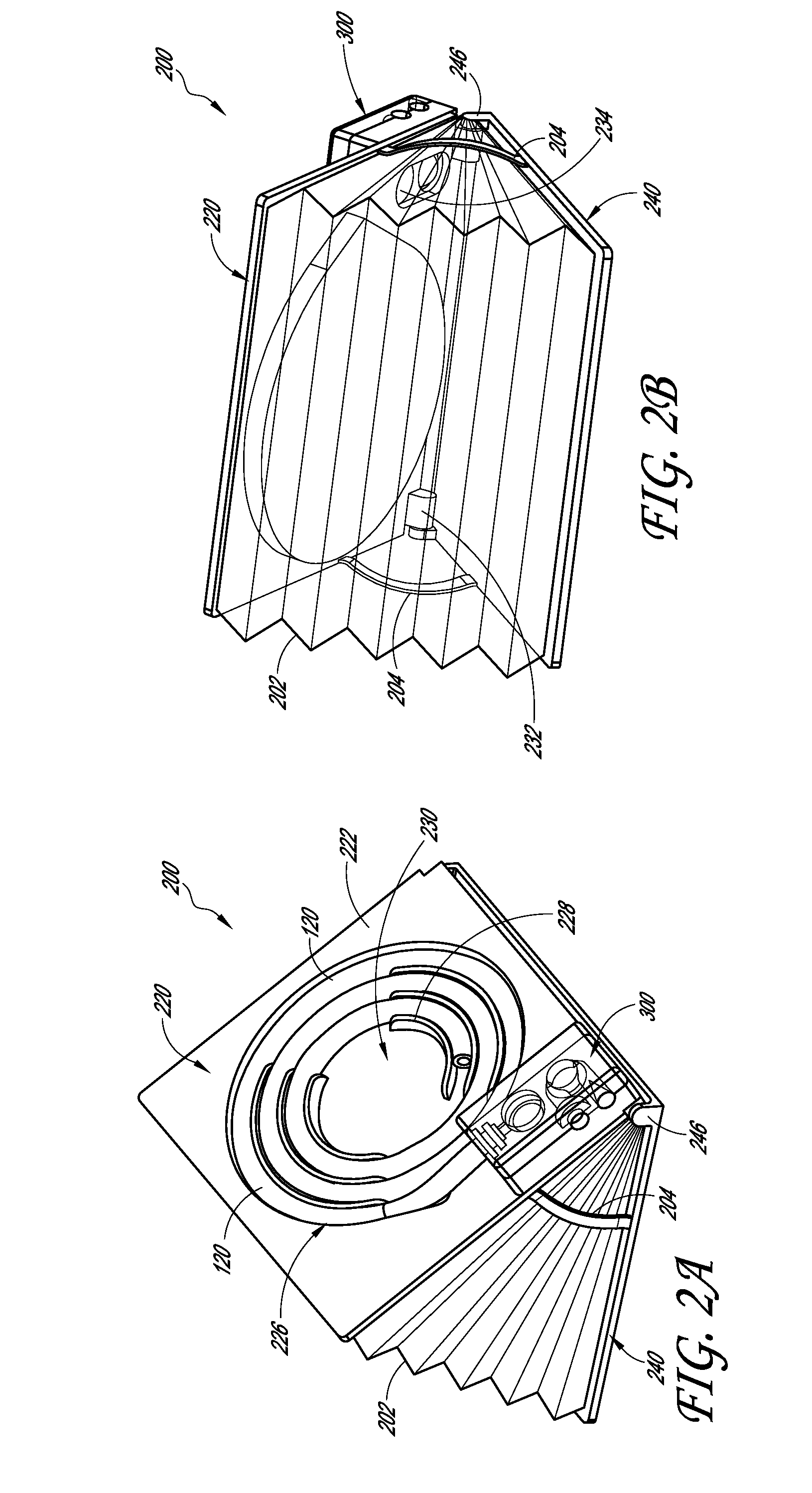

Cargo scanning system

InactiveUS7783004B2Cost-effectively and accurately on uneven surfaceRapidly deployableX-ray apparatusMaterial analysis by transmitting radiationDetector arrayTranslational energy

The present invention is directed to a portable inspection system for generating an image representation of target objects using a radiation source. A detector array having a first configuration and a second configuration is connected to a housing and at least one source of radiation. The radiation source is capable of being transported to a site by a vehicle and of being positioned separate from the housing. The radiation source is housed in a radiation source box and movable within the radiation source box using an actuator. The actuator is operably connected to the radiation source and provides a translational energy that moves the radiation source between an operational position and a stowed position.

Owner:RAPISCAN SYST INC (US)

Cargo Scanning System

InactiveUS20090116614A1Cost-effectively and accurately on uneven surfaceRapidly deployableX-ray apparatusMaterial analysis by transmitting radiationImage representationDetector array

The present invention is directed to a portable inspection system for generating an image representation of target objects using a radiation source. A detector array having a first configuration and a second configuration is connected to a housing and at least one source of radiation. The radiation source is capable of being transported to a site by a vehicle and of being positioned separate from the housing. The radiation source is housed in a radiation source box and movable within the radiation source box using an actuator. The actuator is operably connected to the radiation source and provides a translational energy that moves the radiation source between an operational position and a stowed position.

Owner:RAPISCAN SYST INC (US)

Method and apparatus for management of a global wireless sensor network

ActiveUS7983685B2Rapidly deployableLow costNetwork topologiesAlarmsInterconnectivityTelecommunications link

Methods and apparatus for global wireless sensor network architecture and protocol for remote supervision, asset control and operational management based on localized clusters of autonomous sensor / supervision / operational sensor nodes capable of ad hoc interconnection with nearby nodes and connection to gateway nodes with increased network functionality. These localized cluster nodes send data to gateway nodes either directly or through multi-hop transactions. The gateway nodes are, in turn, connected to other gateway nodes and operations control centers either through wireless or wired data communications links. Utilizing the Internet for long range interconnectivity, the network is scaleable to a global level. The resulting network is based on an ad hoc mesh topology to allow flexibility in network modification and expansion and is comprised of a tiered structure defined by increasing functionality. A current application for this technology is the remote control and supervision of lighting systems for facilities and municipalities on a local, national and / or global basis from centralized regional operations centers.

Owner:INNOVATIVE WIRELESS TECH

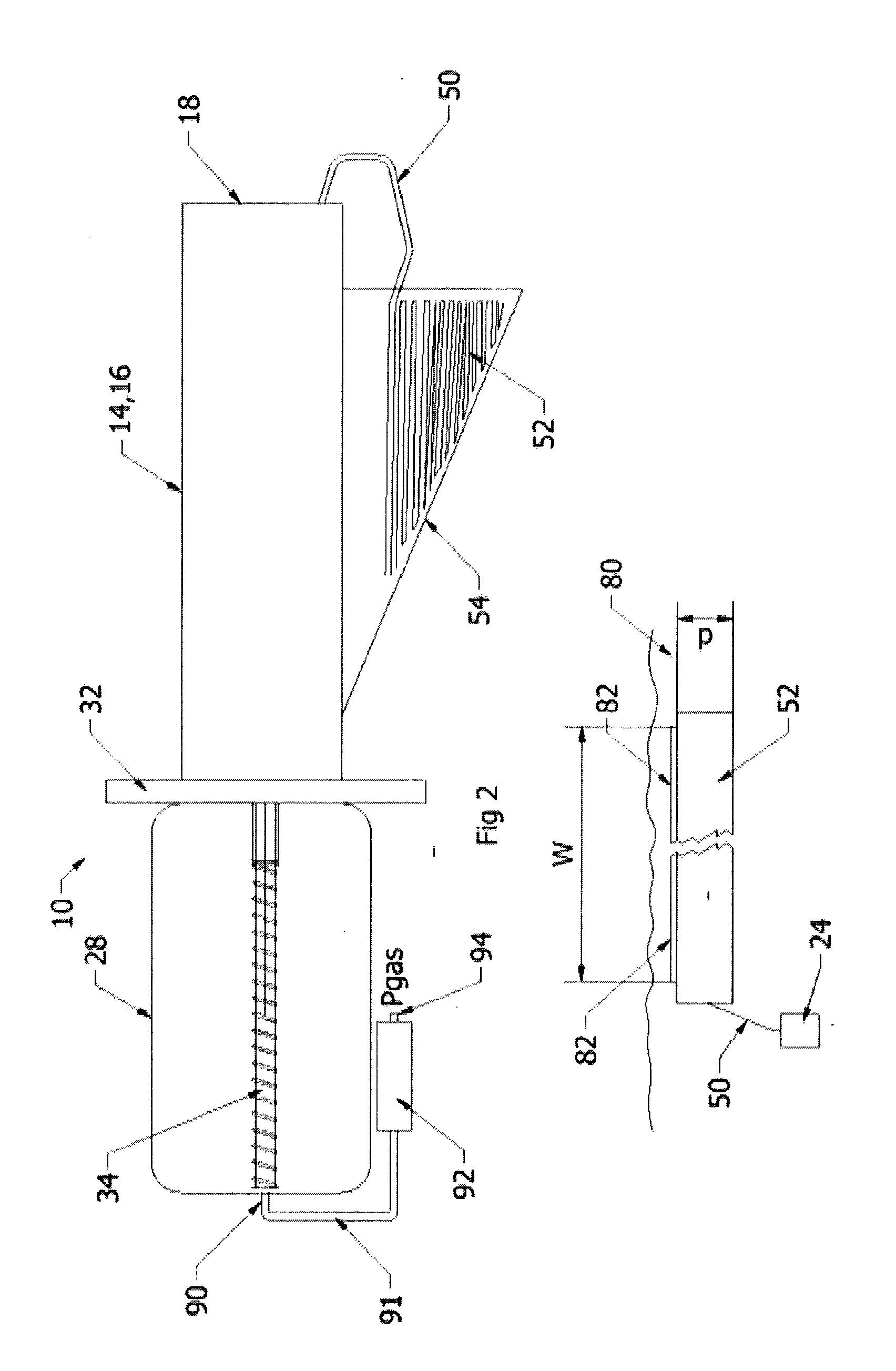

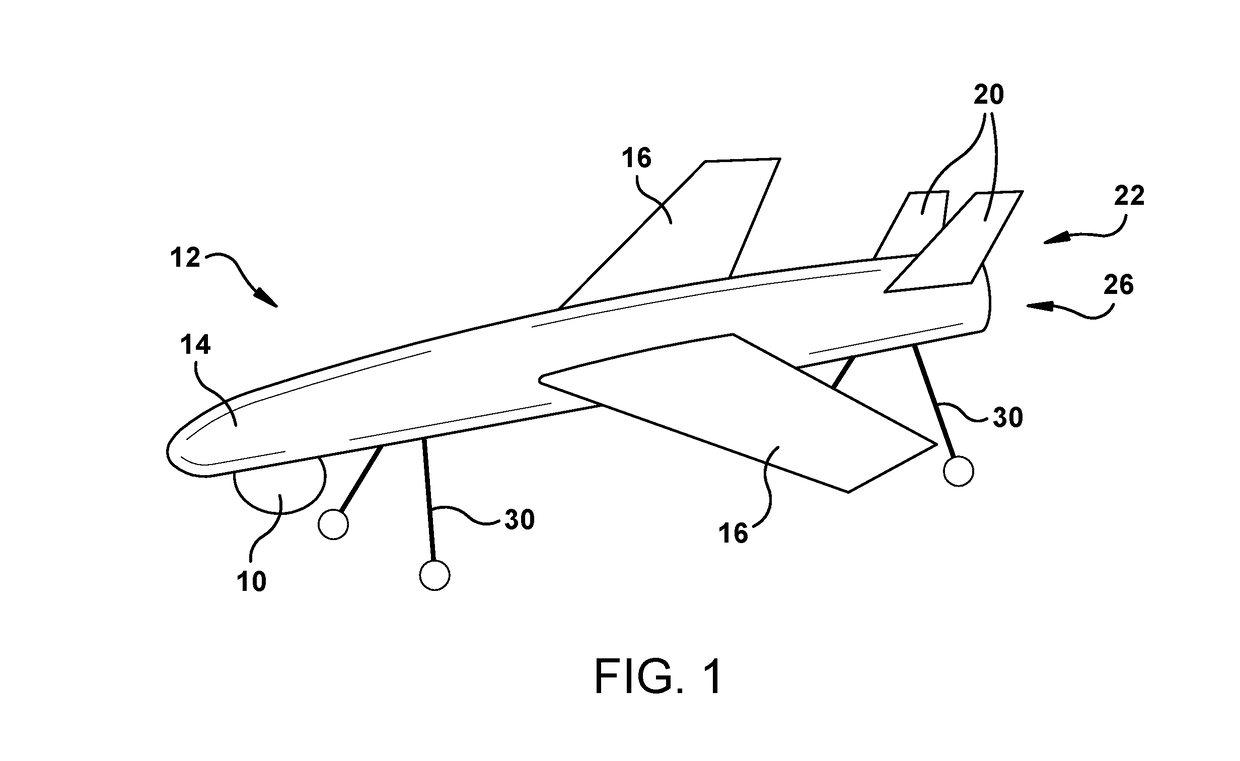

Air cannon and associated launch canister for a line-fouling system

ActiveUS20160161225A1Rapidly deployableDirect forceDefence devicesPeptide/protein ingredientsCouplingEqualization

FIG. 7 shows an air cannon system loaded with a launch canister containing a prop-fouler. A pressure vessel (28) contains an inlet including a poppet valve (100) that, upon command, can be selectively placed in either a one-way flow position to permit charging of the pressure vessel or otherwise opened to trigger rapid discharge through pressure equalization with the ambient environment. The air cannon may include multiple splayed barrels or a single barrel (158). A launch canister (202), realized in the form of a tube, has a driving plate (350) that closes an end of the launch tube. The driving plate is the first point loaded into the barrel. Within the launch canister (202) a first portion of a floating prop-fouling line is stored. The prop-fouling line, such as made from Dyneema®, has at its ends two drogues that, upon entry into the water, fill with water to produce drag resistance to movement of the prop-fouling line. To avoid undue stress on canopy panels of each drogue and to avoid twisting of shroud lines (312) to the canopy, a rotating shackle (310a, 310b) acts as a coupling point between the shroud lines (312) and the prop-fouling line. Only one drogue (306), its associated coupling and a selected length prop-fouling line are loaded into the launch canister, with the other drogue and its rotating shackle (310b) loaded into a cradle (166). Upon firing, gas expansion causes the rapid acceleration and ejection of the launch tube (202) and generally straight line deployment of the prop-fouling line (302).

Owner:BCB INT

Apparatus and Method for Providing a Rapidly Deployable Wireless Network

InactiveUS20080194246A1Fast replacementRapidly deployableNetwork topologiesConnection managementControl functionAir interface

The invention includes apparatus and method for providing a rapidly deployable wireless network. An apparatus includes means for providing radio access network (RAN) functions, means for providing at least one core (CORE) networking function, and means for providing at least one service. The RAN functions include at least one air interface, at least one control function, and at least one network gateway function. The CORE networking functions include at least one of an AAA function, a DNS function, a DHCP function, a call / session control function, and the like. The apparatus may further include means for providing at least one additional wireless interface, including one or more of a wireless mesh interface, a wireless backhaul interface, and a wireless management interface. The apparatus is adapted for being deployed on a mobile platform. The apparatus may be used to provide a standalone wireless network independent of existing network infrastructure, or an integrated wireless network utilizing existing network infrastructure.

Owner:LUCENT TECH INC

GNSS long-code acquisition, ambiguity resolution, and signal validation

ActiveUS20140062781A1Easy to implementRapidly deployablePosition fixationSatellite radio beaconingFrequency spectrumData acquisition

The present invention relates to a system and method using hybrid spectral compression and cross correlation signal processing of signals of opportunity, which may include Global Navigation Satellite System (GNSS) as well as other wideband energy emissions in GNSS obstructed environments. Combining spectral compression with spread spectrum cross correlation provides unique advantages for positioning and navigation applications including carrier phase observable ambiguity resolution and direct, long-code spread spectrum signal acquisition. Alternatively, the present invention also provides unique advantages for establishing the validity of navigation signals in order to counter the possibilities of electronic attack using spoofing and / or denial methods.

Owner:TELECOMM SYST INC

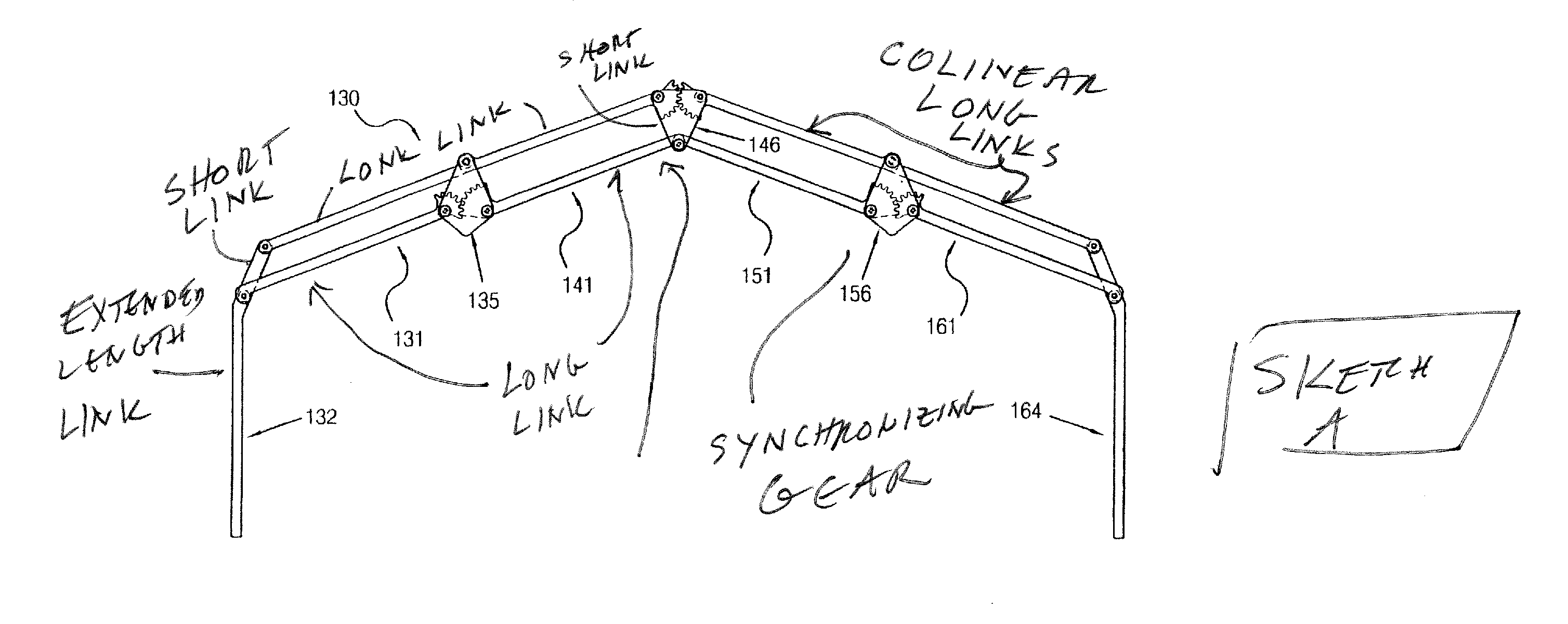

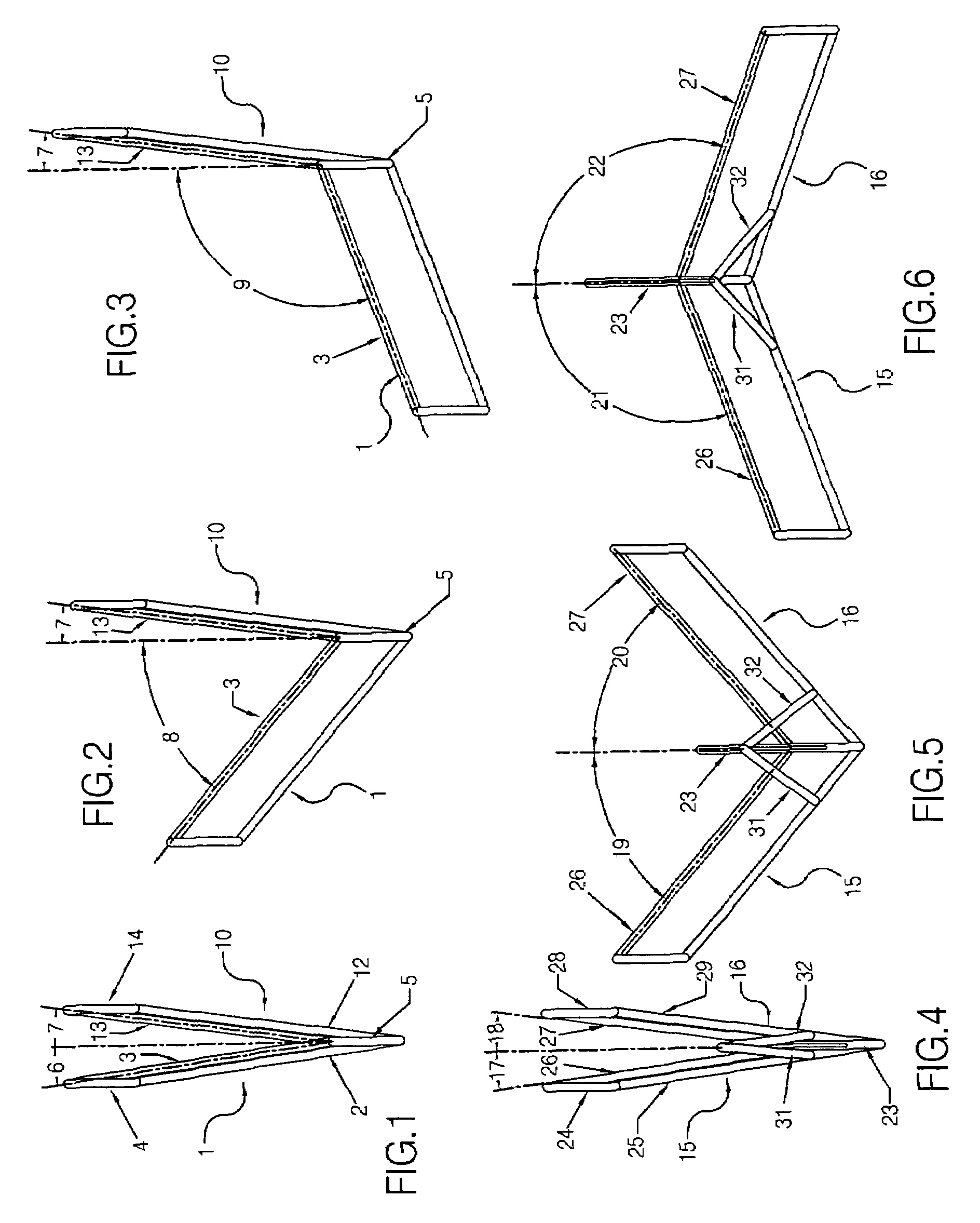

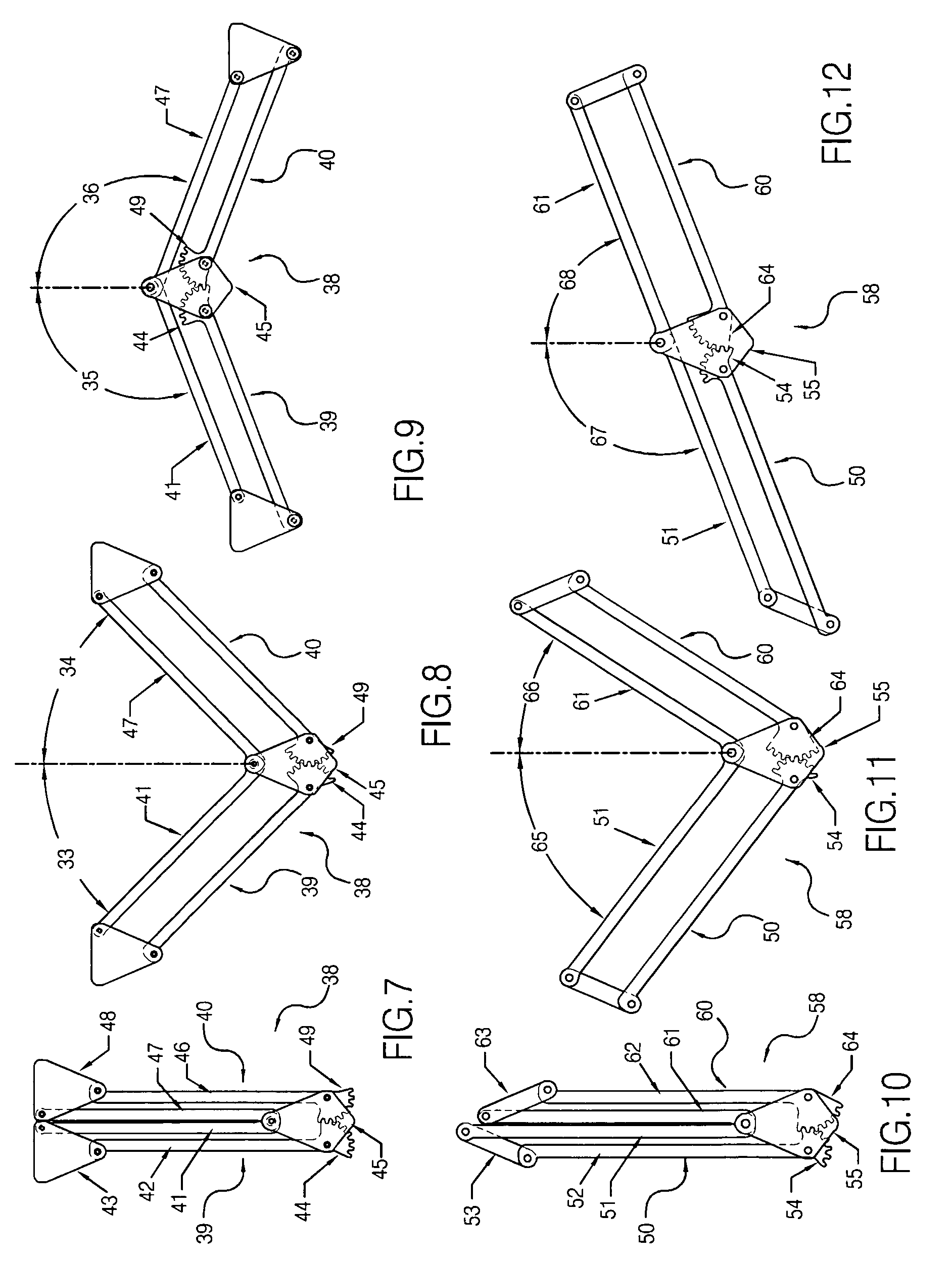

Synchronized four-bar linkages

ActiveUS7644721B2Rapidly deployableEasy to deployBuilding roofsPaper/cardboard articlesEngineeringLinkage concept

Owner:RAPID DEPLOYABLE SYST LLC

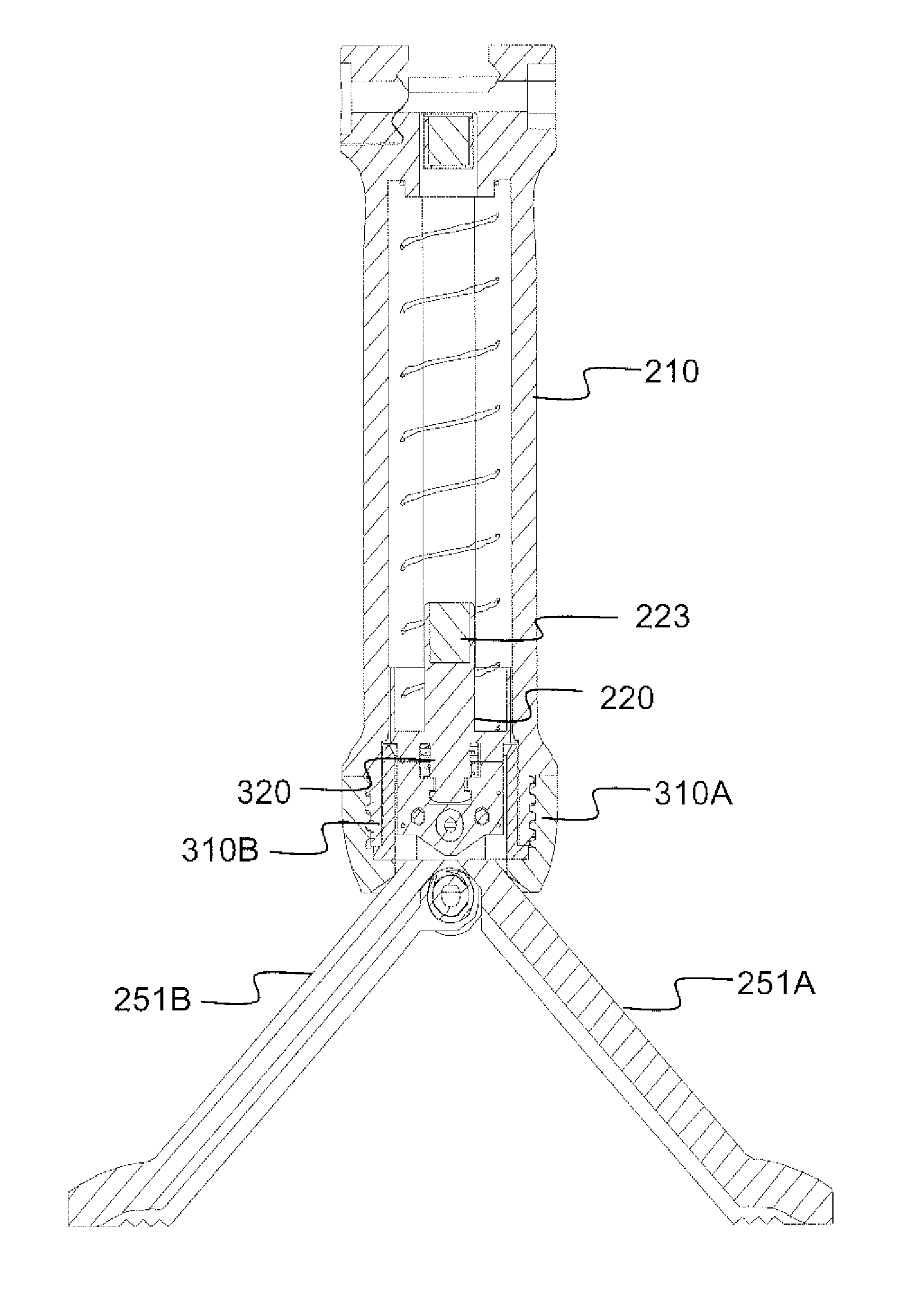

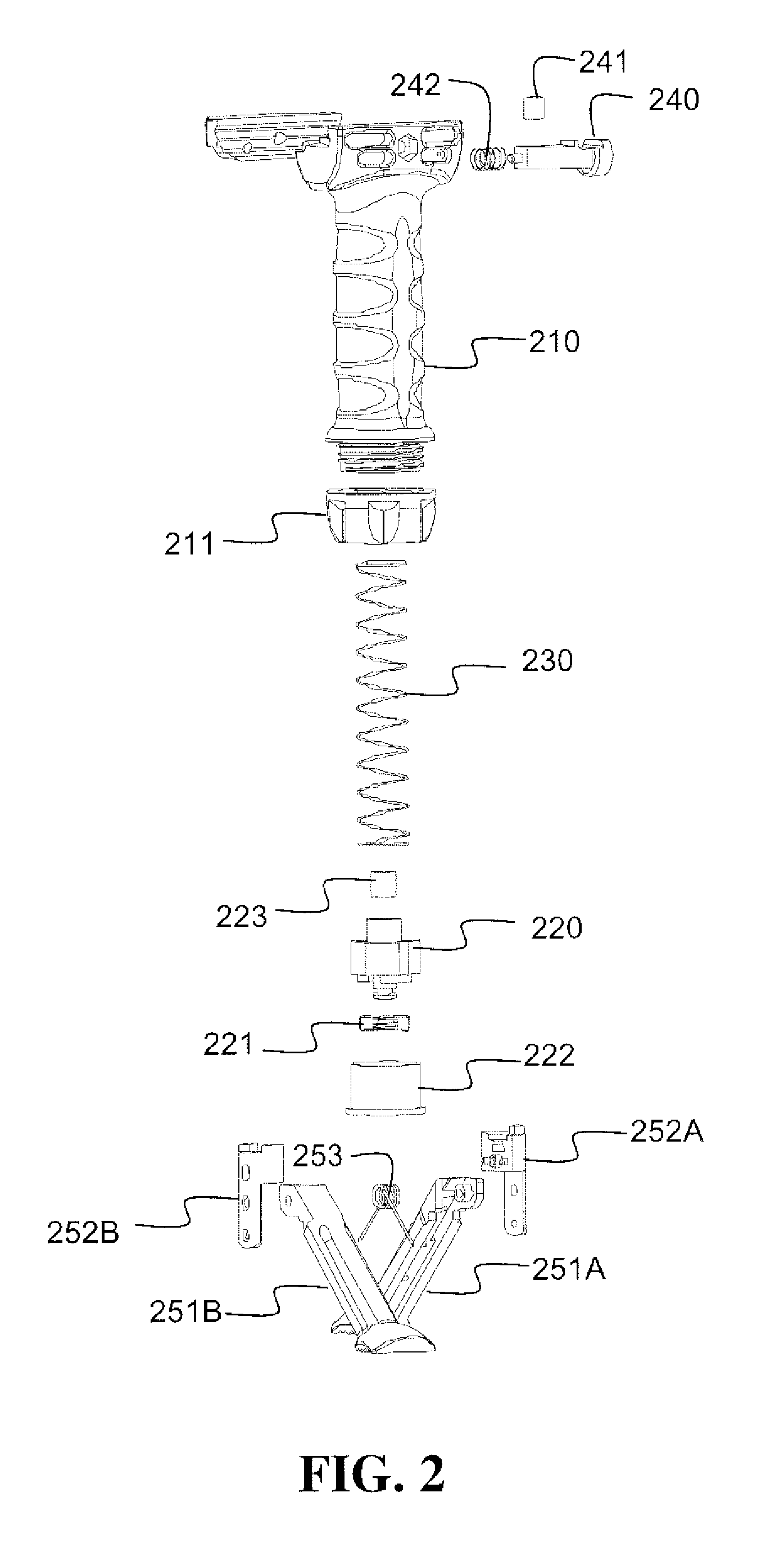

Firearm handgrip with a horizontal angle tracking bipod

InactiveUS20090038199A1Rapidly deployableReliable release mechanismAmmunition loadingWeapon cleaningEngineeringHorizontal angle

A firearm handgrip with a collapsible and concealable bipod positioned within the handgrip. The bipod enables tracking of the horizontal angle of the firearm. Specifically, the bipod is quickly deployable by pressing a button that activates a highly reliable release mechanism. Upon bipod deployment, the shooter is free to place the bipod on any surface, including uneven surfaces wherein the bipod legs are positioned on different heights so that the bipod maintains stability. The bipod enables panning (horizontal rotation), tilting (up-down) and canting (right-left) of the firearm. Additionally, after panning the firearm and subsequently lifting the bipod from the surface it lies on, the bipod's legs automatically realign to a plane perpendicular to the firearm, thus tracking and adjusting to the new horizontal angle of the firearm.

Owner:OZ MOSHE

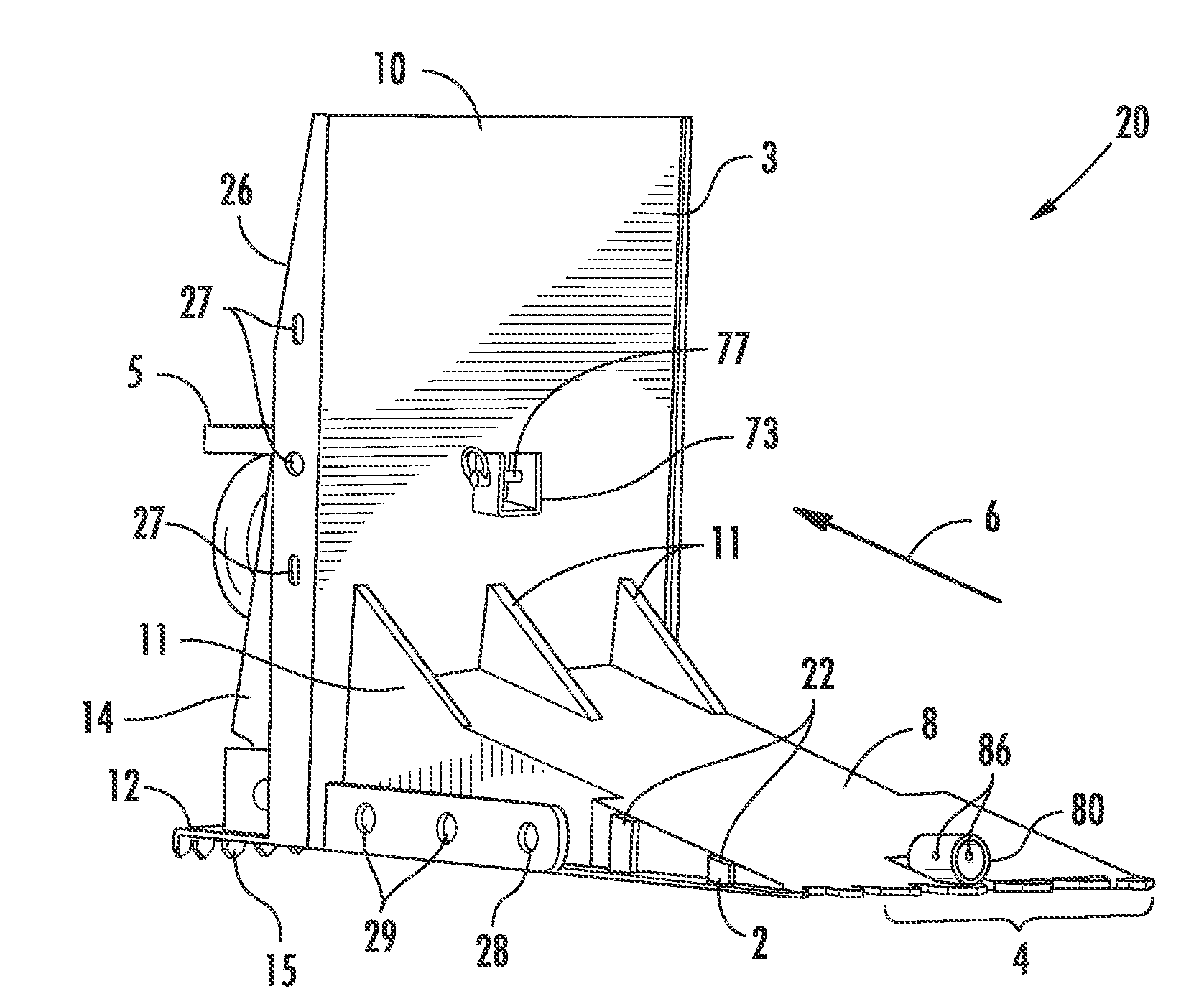

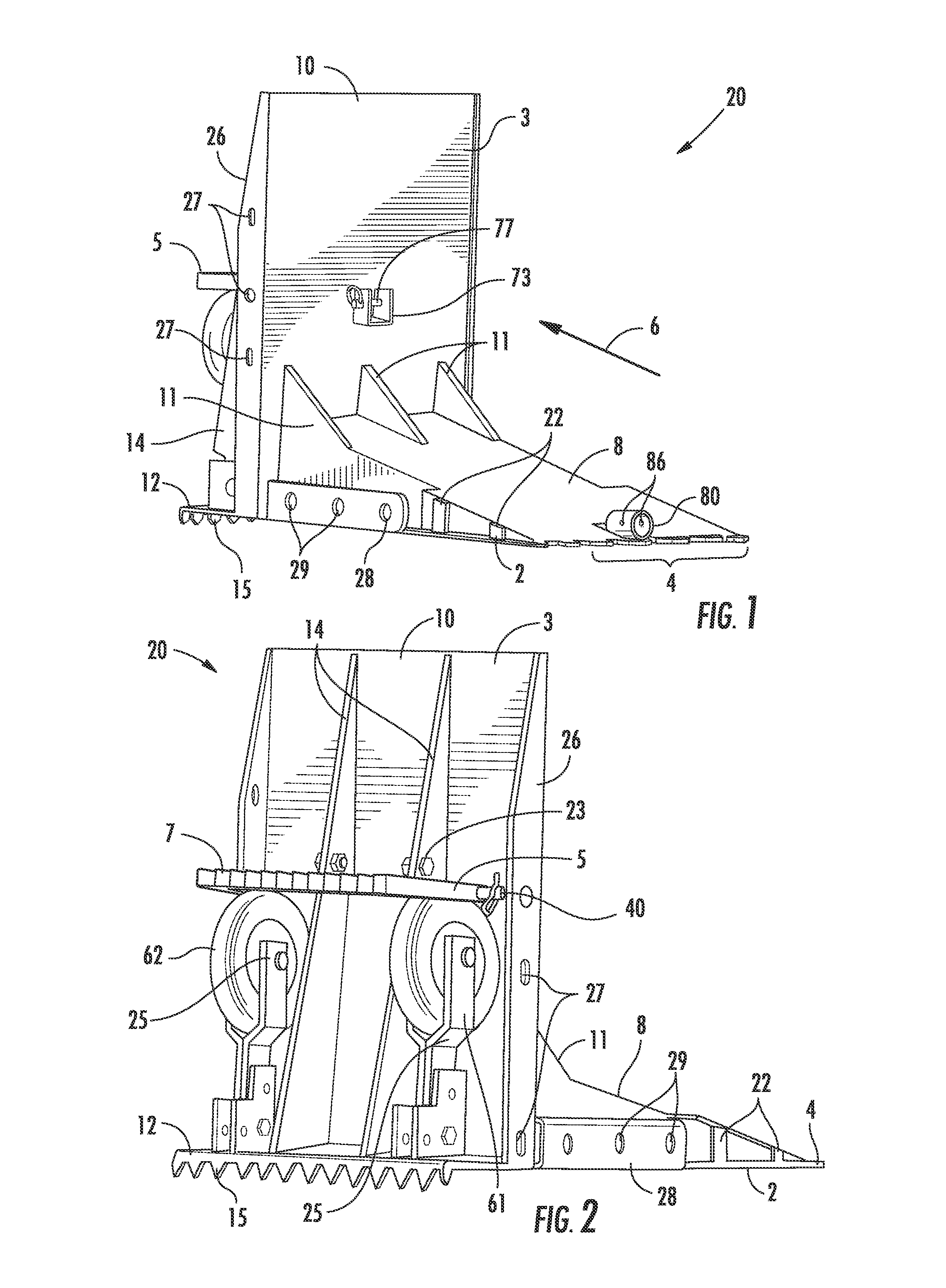

Portable perimeter defense barrier and system

ActiveUS20100290833A1Prevent intrusionOvercomes shortcomingDefence devicesFencingElectricityMobile vehicle

A portable perimeter defense system is provided that is configured for preventing unwanted intrusions by vehicles or other heavy and fast-moving vehicles into a protected area while also providing requisite ballistic resistance capabilities. The defense system includes at least one individual modular barrier that can be readily transported to a point of use and can be secured in place without requiring heavy equipment or power sources, such as electricity. The modular barrier includes a front plate configured to provide ballistic protection in the direction of impact and to provide an impact surface capable of withstanding impact. The front plate extends upwardly from a base plate and a kick plate extends outwardly from the rear or aft side of the front plate. The front or fore edge of the base plate defines a vehicle engaging interface, the rear or aft edge of the base plate is arcuate and defines a ground engaging interface, and the rear or aft edge of the kick plate defines a ground engaging interface. A ramp is positioned on the base plate in front of the front plate facing the impact direction. When circumstances warrant additional protection and / or a greater span of protection, a plurality of modular barriers may be provided in predetermined configurations. Adjacent barriers may be secured to one another along side edges thereof. The portable perimeter defense system including modular barriers provides exceptional protection to a protected area and may be rapidly deployed.

Owner:MERIDIAN RAPID DEFENSE GRP LLC

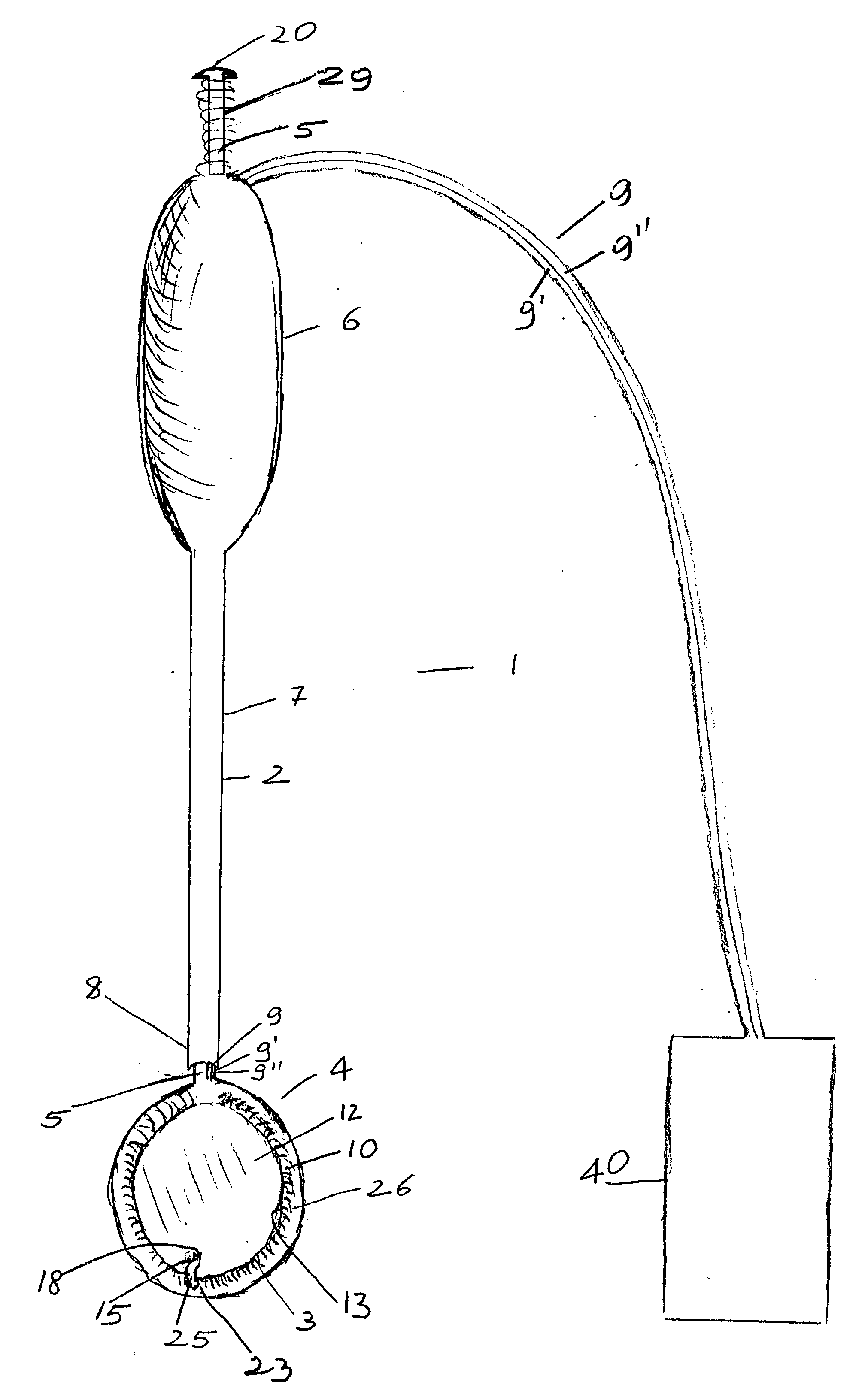

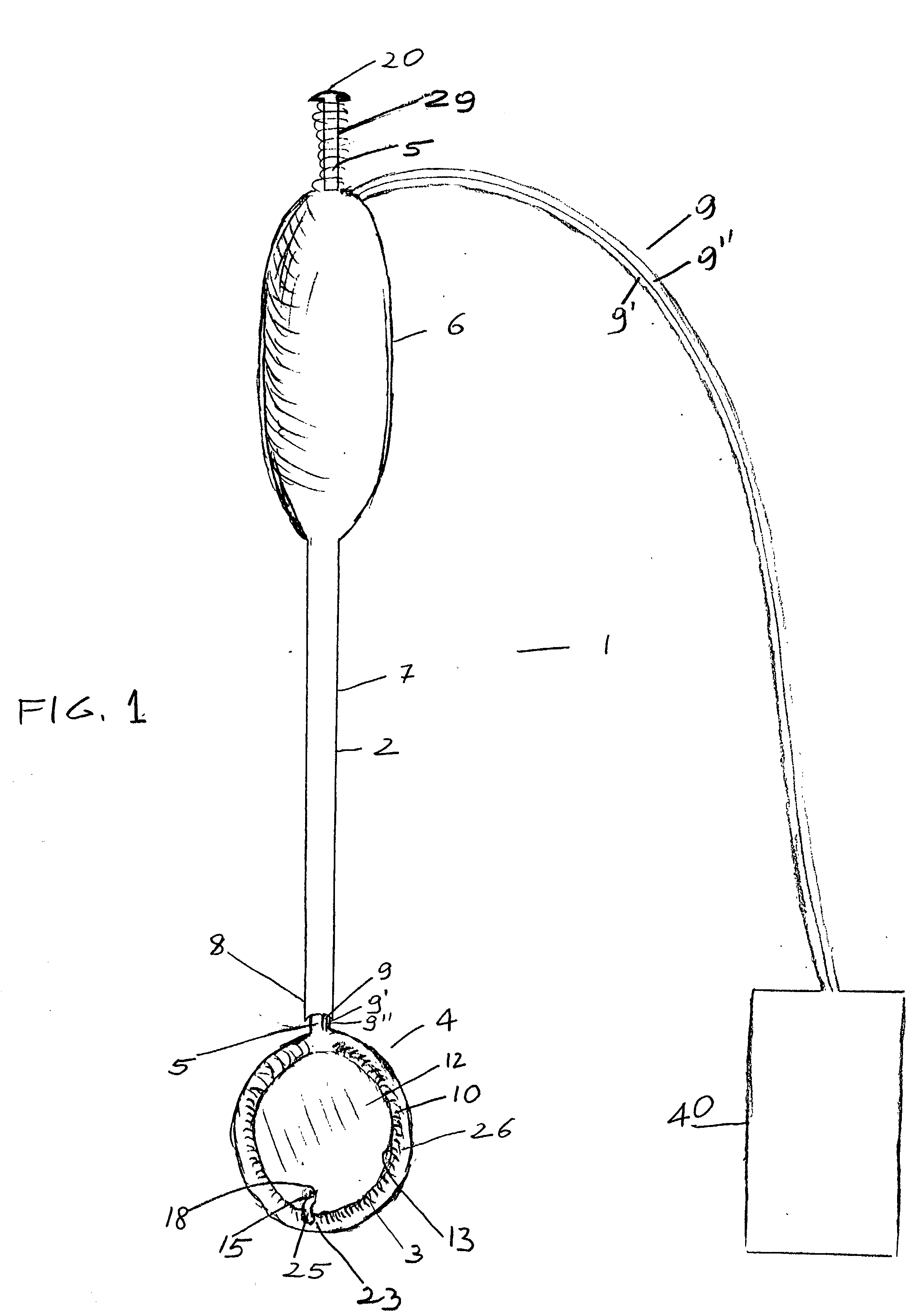

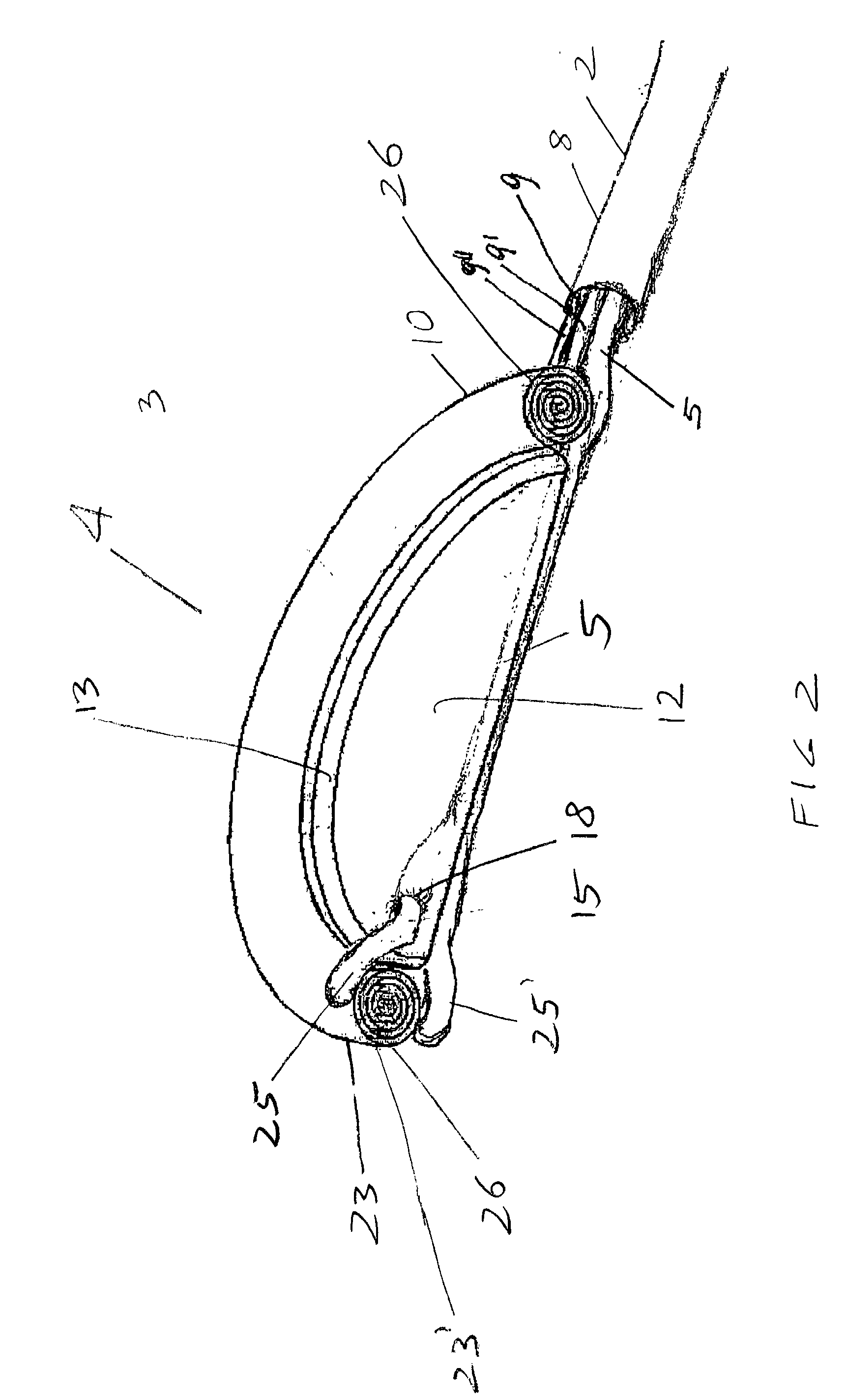

Minimally invasive percutaneous ventricular assist device

InactiveUS20040102674A1The process is simple and fastHigh outputControl devicesSurgeryCardiorespiratory arrestVentricular assistance

A Minimally Invasive Ventricular Assist Device for circulatory support of a failing heart apt to be inserted percutaneously bluntly via a thoracostomy a into a chest cavity of a patient in cardiac failure or cardiac arrest without the need for wide surgical opening of the chest. The device once deployed inside the chest is capable of compressing and decompressing the heart via pneumatic or mechanical means providing circulatory support to patients in cardiac failure or cardiac arrest. Due to its design and structure the Minimally Invasive Percutaneous Ventricular Assist Device can be deployed rapidly and safely at bedside by health care professionals properly trained in the procedure.

Owner:ZADINI FILIBERTO P +1

Point-of-use water treatment assembly

InactiveUS7014782B2Rapidly deployableEasy to operateTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisPotable waterDisinfectant

A point-of-use filtering and water treating kit includes a container, a plurality of membrane-type filter elements and a filter basket to support the filter elements during use. The filter elements are contained within a reclosable package that is fitted within the container during storage. At least one ladle or other drinking cup is also contained within the container to provide a complete assembly for producing potable water. In use, the package containing the filter elements is removed from the container and a single filter element is placed in the filter basket. The filter basket is nested in the top end of the container and the water to be filtered is poured through the filter element. The filtered and purified water is collected within the container. In one embodiment, the filter elements contain a purifying agent, disinfectant or antimicrobial agent impregnated within the filter element to treat the water as the water is being filtered.

Owner:DEMIDIO JOSEPH A

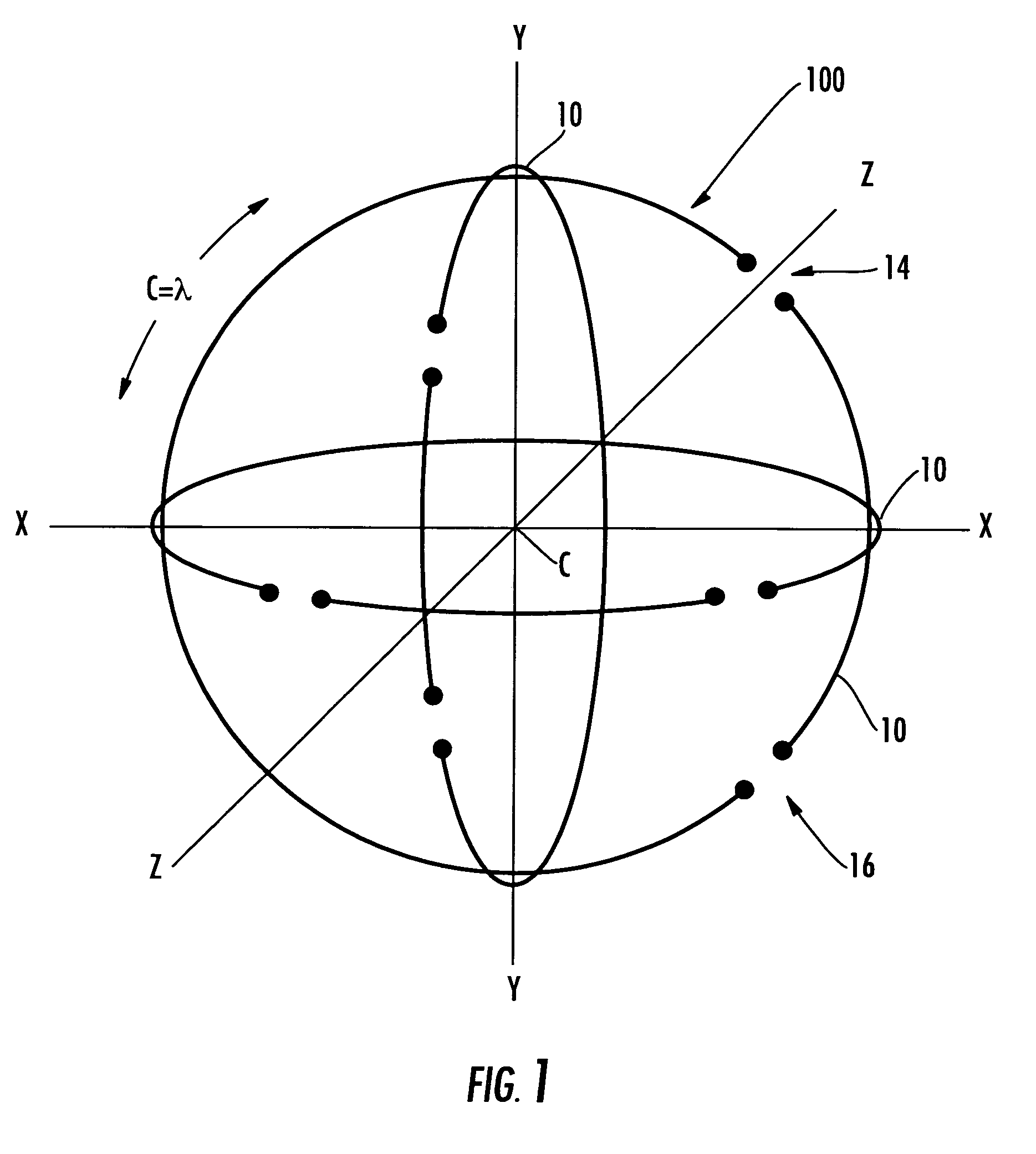

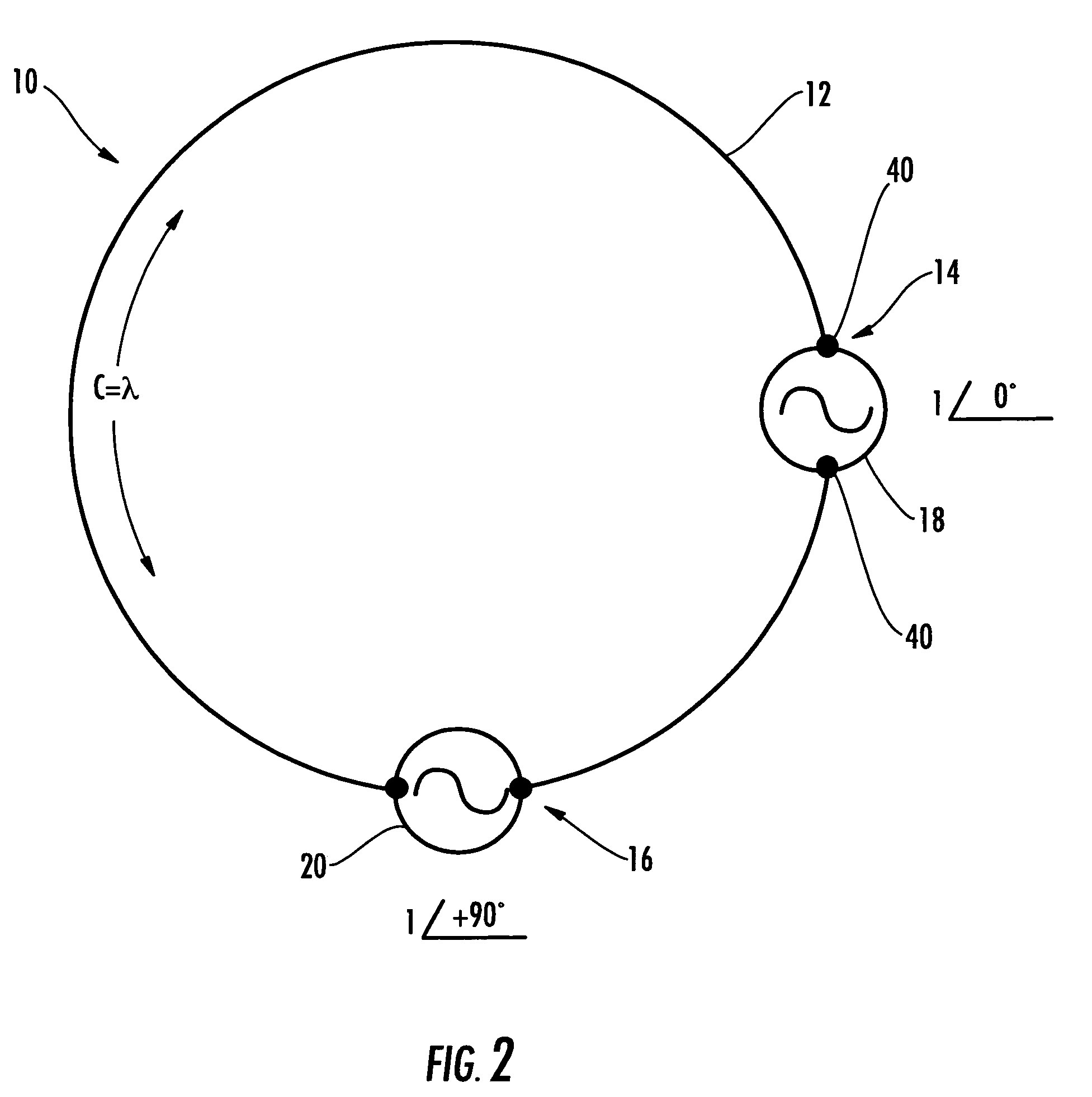

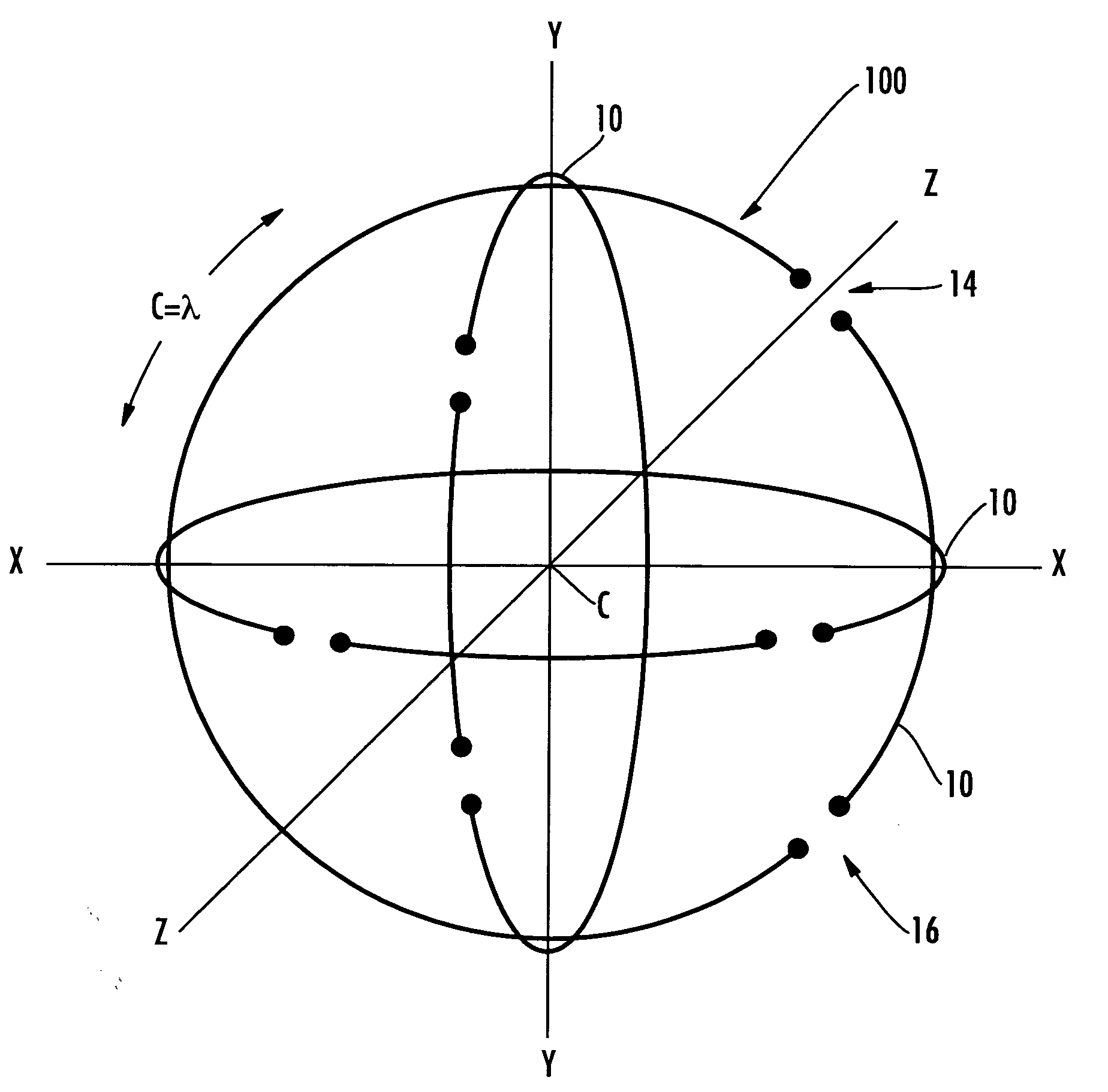

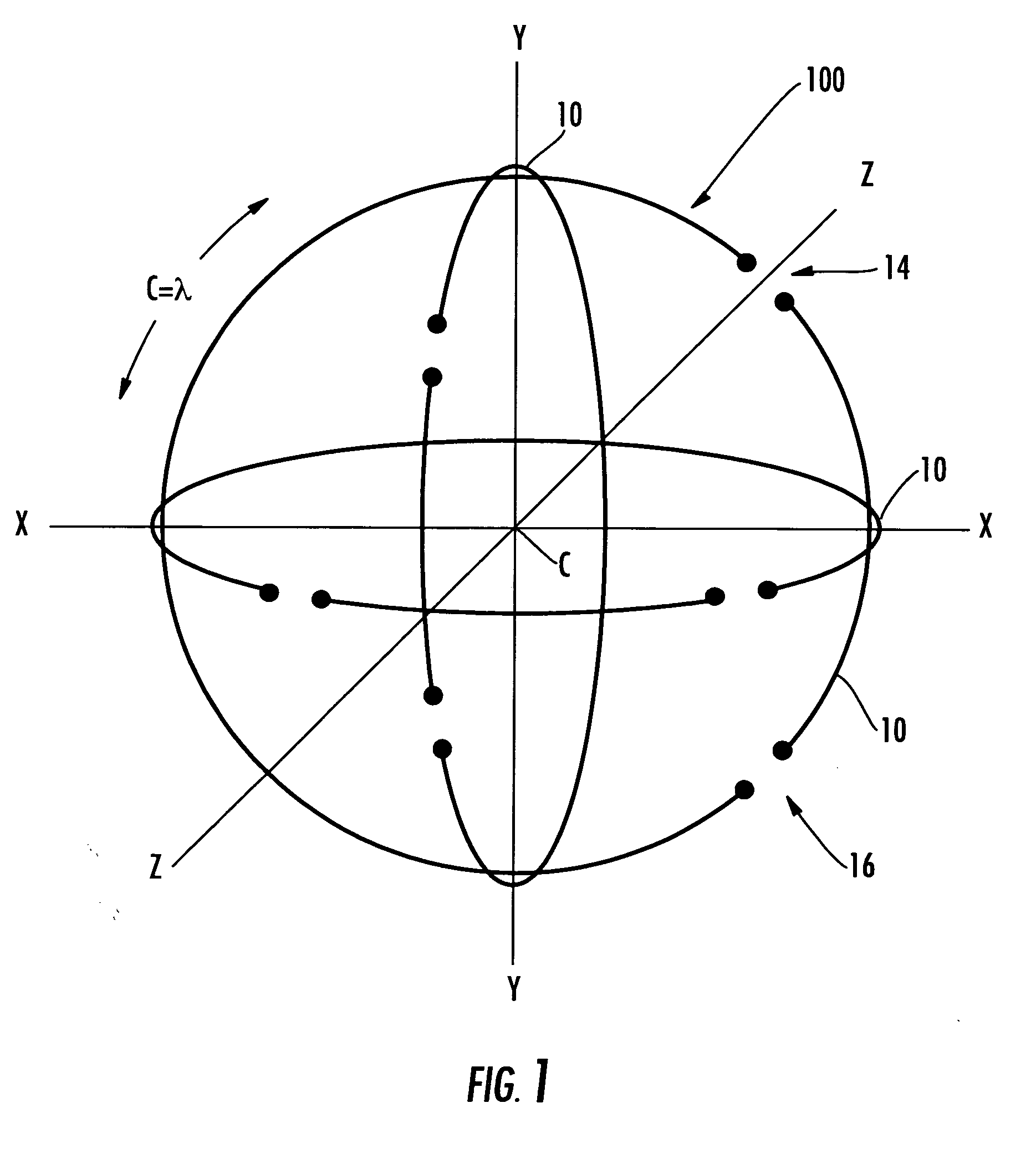

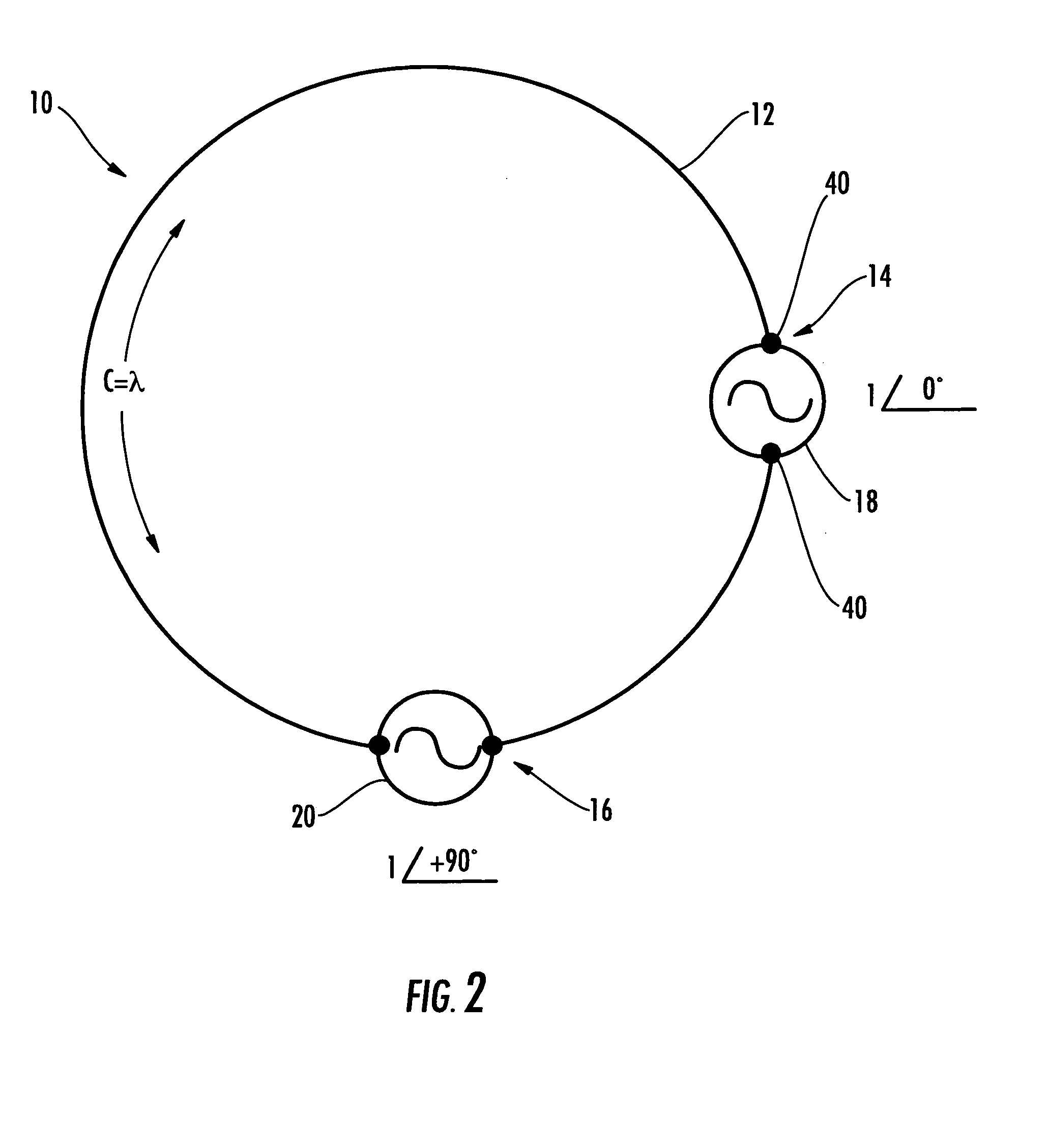

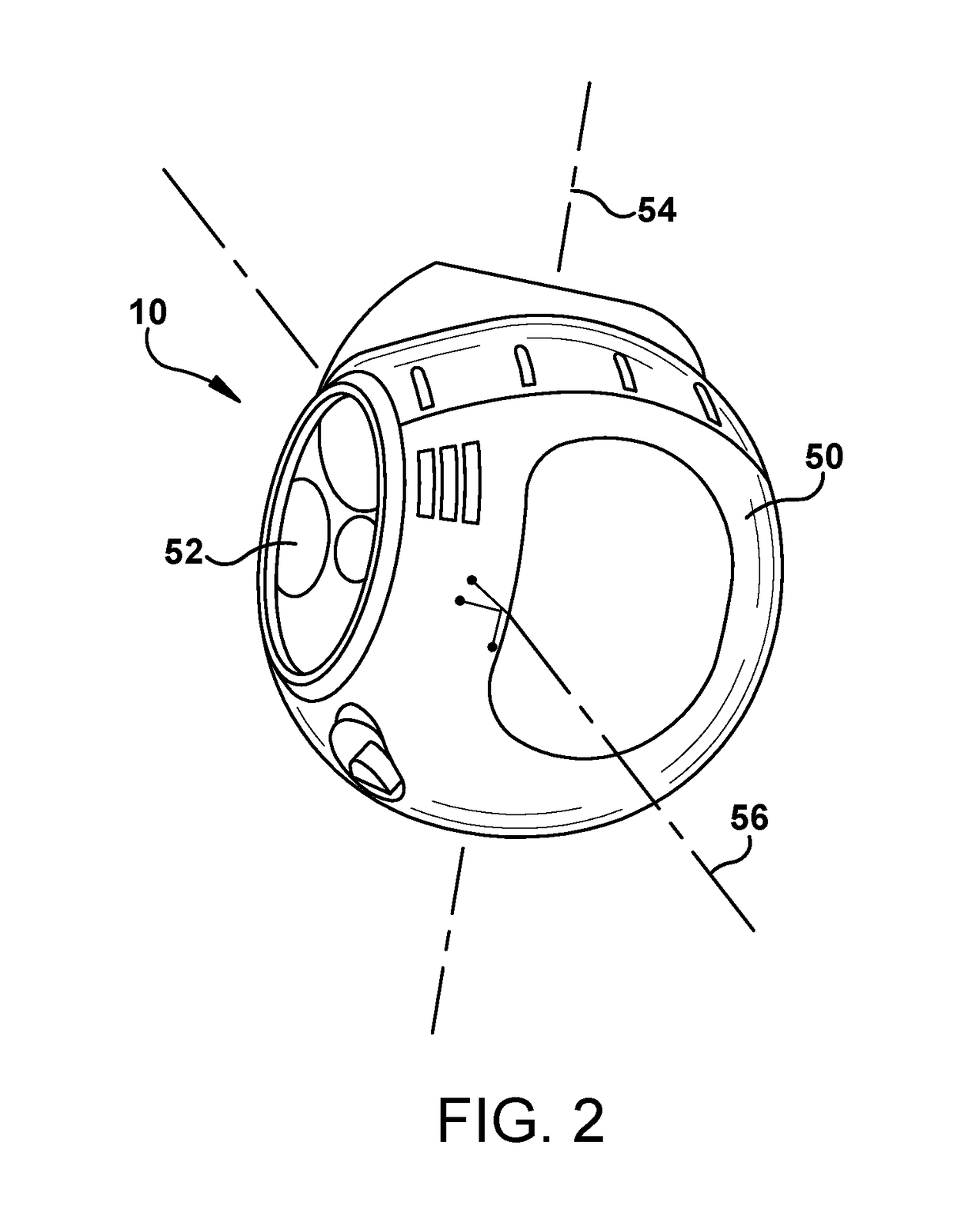

Polarization-diverse antenna array and associated methods

InactiveUS7505009B2Rapidly deployableResonant long antennasIndividually energised antenna arraysPolarization diversityElectrical conductor

The polarization-diverse antenna array includes three orthogonal loop antennas having a common center, e.g. together defining a sphere. Each loop antenna includes a loop electrical conductor. Two signal feedpoints are along the loop electrical conductor and separated by a fraction of a length of the loop electrical conductor. Each of the signal feedpoints includes a series signal feedpoint so that a polarization diversity controller coupled thereto may selectively provide vertical, horizontal, lefthand circular and righthand circular polarization for a single loop electrical conductor, including simultaneous (dual) polarizations. These signal feedpoints may supply signals with vertical, horizontal, lefthand circular and righthand circular polarization from each of the three orthogonal look-angles provided by the three loop electrical conductors. Thus the antenna array may provide a compact facility for using Diversity Combining to improve communications performance and / or Multiple-Input, Multiple-Output (MIMO) schemes that furthermore also increase capacity. The polarization-diverse antenna array provides a rigorous polarization and look angle approach for communications diversity.

Owner:HARRIS CORP

Countermeasure system

ActiveUS20140147116A1Low costLarge beam spreadWave based measurement systemsDirection controllersCountermeasureOptical axis

A laser jammer configured for being a part of a countermeasure system. The system comprises a stage having an axis of rotation and laser source mounted on the stage. The laser source is configured for emitting a laser beam having an optical axis perpendicular to the axis of rotation. The laser has a first spread in a first plane parallel to the rotation axis of the stage and including the optical axis, and a second spread in a second plane perpendicular to the first plane and including the optical axis. The first spread is greater than the second spread.

Owner:ACTIVE AIR

Polarization-diverse antenna array and associated methods

InactiveUS20080136721A1Rapidly deployableResonant long antennasIndividually energised antenna arraysPolarization diversityElectrical conductor

The polarization-diverse antenna array includes three orthogonal loop antennas having a common center, e.g. together defining a sphere. Each loop antenna includes a loop electrical conductor. Two signal feedpoints are along the loop electrical conductor and separated by a fraction of a length of the loop electrical conductor. Each of the signal feedpoints includes a series signal feedpoint so that a polarization diversity controller coupled thereto may selectively provide vertical, horizontal, lefthand circular and righthand circular polarization for a single loop electrical conductor, including simultaneous (dual) polarizations. These signal feedpoints may supply signals with vertical, horizontal, lefthand circular and righthand circular polarization from each of the three orthogonal look-angles provided by the three loop electrical conductors. Thus the antenna array may provide a compact facility for using Diversity Combining to improve communications performance and / or Multiple-Input, Multiple-Output (MIMO) schemes that furthermore also increase capacity. The polarization-diverse antenna array provides a rigorous polarization and look angle approach for communications diversity

Owner:HARRIS CORP

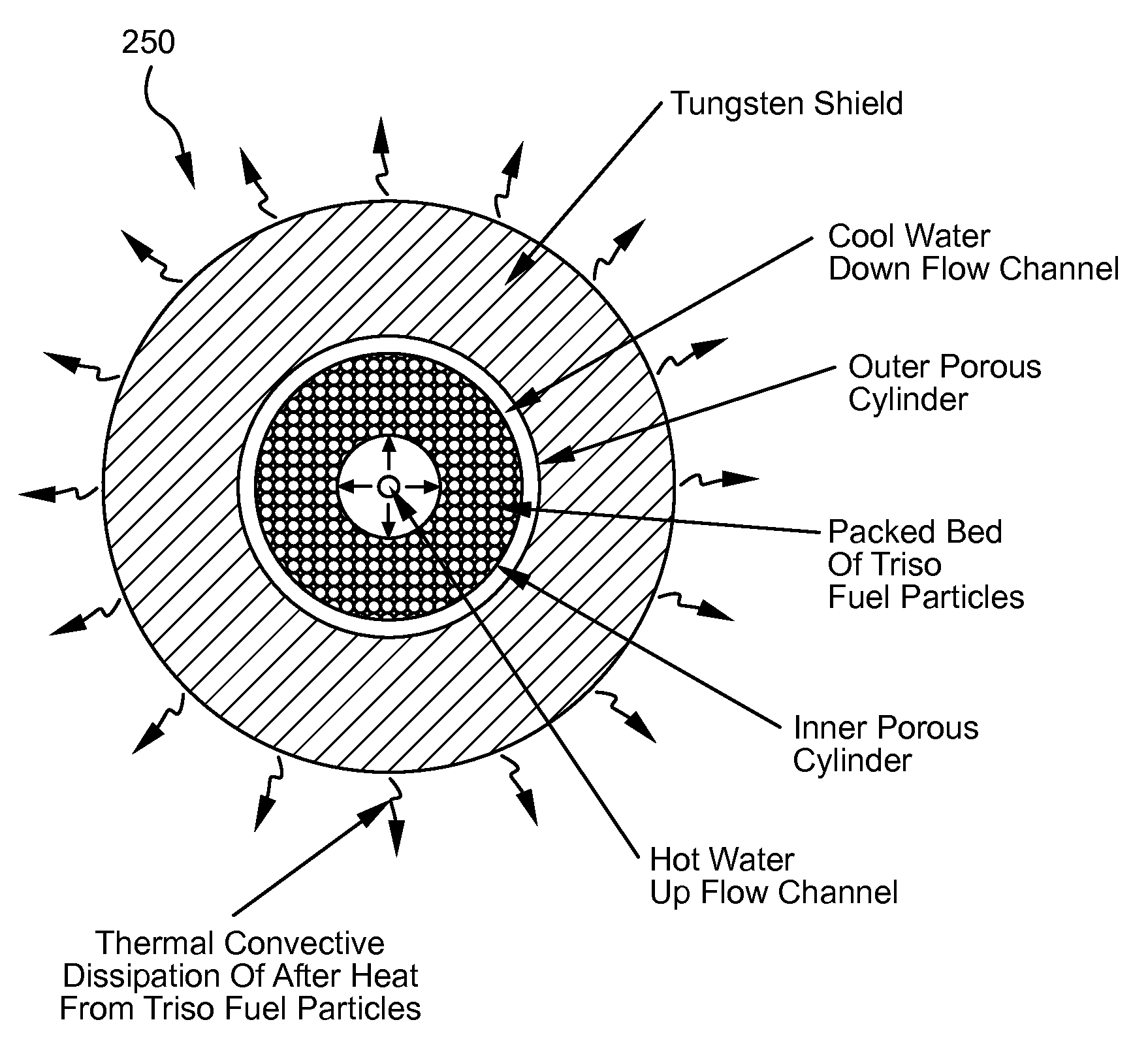

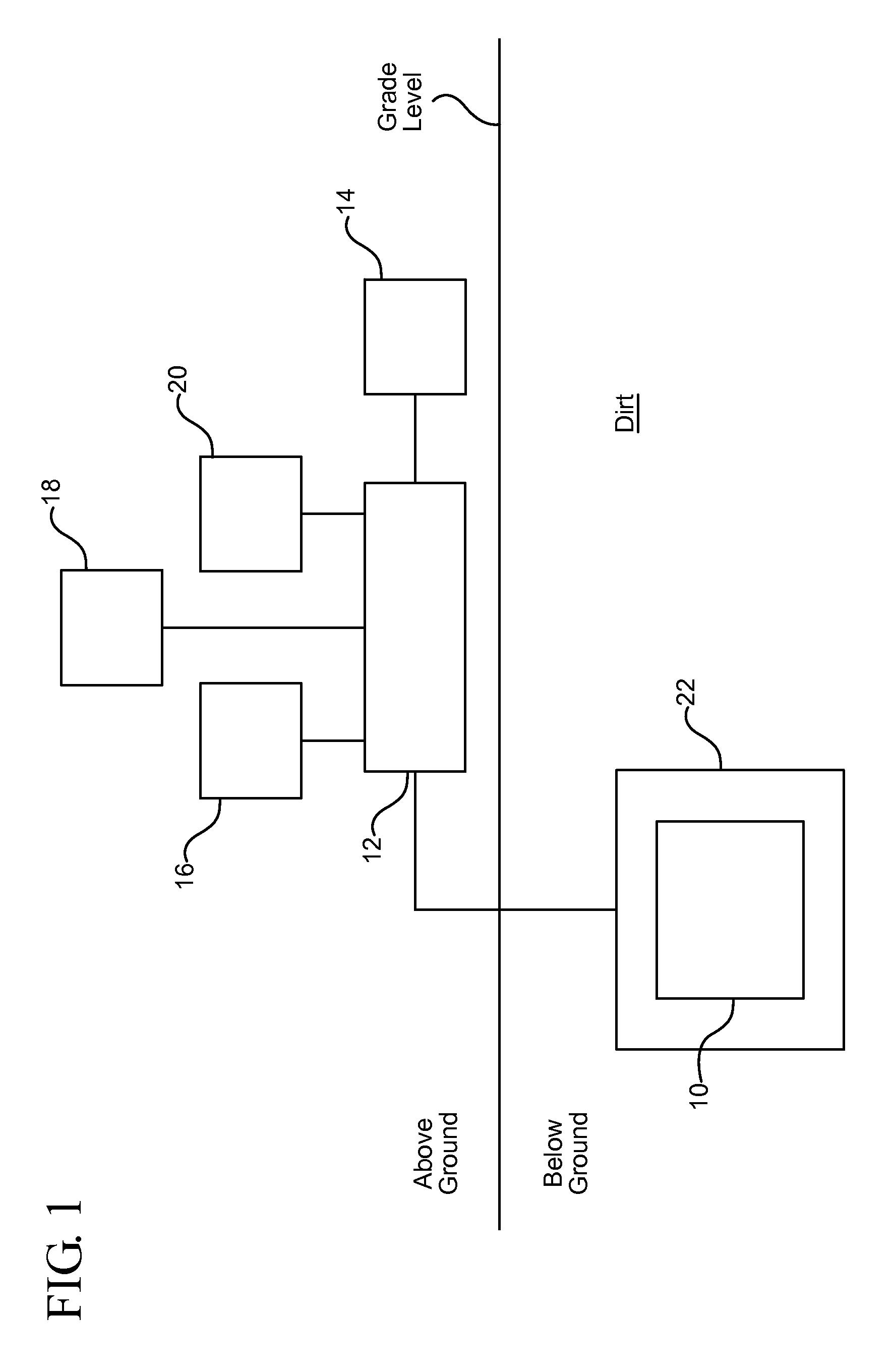

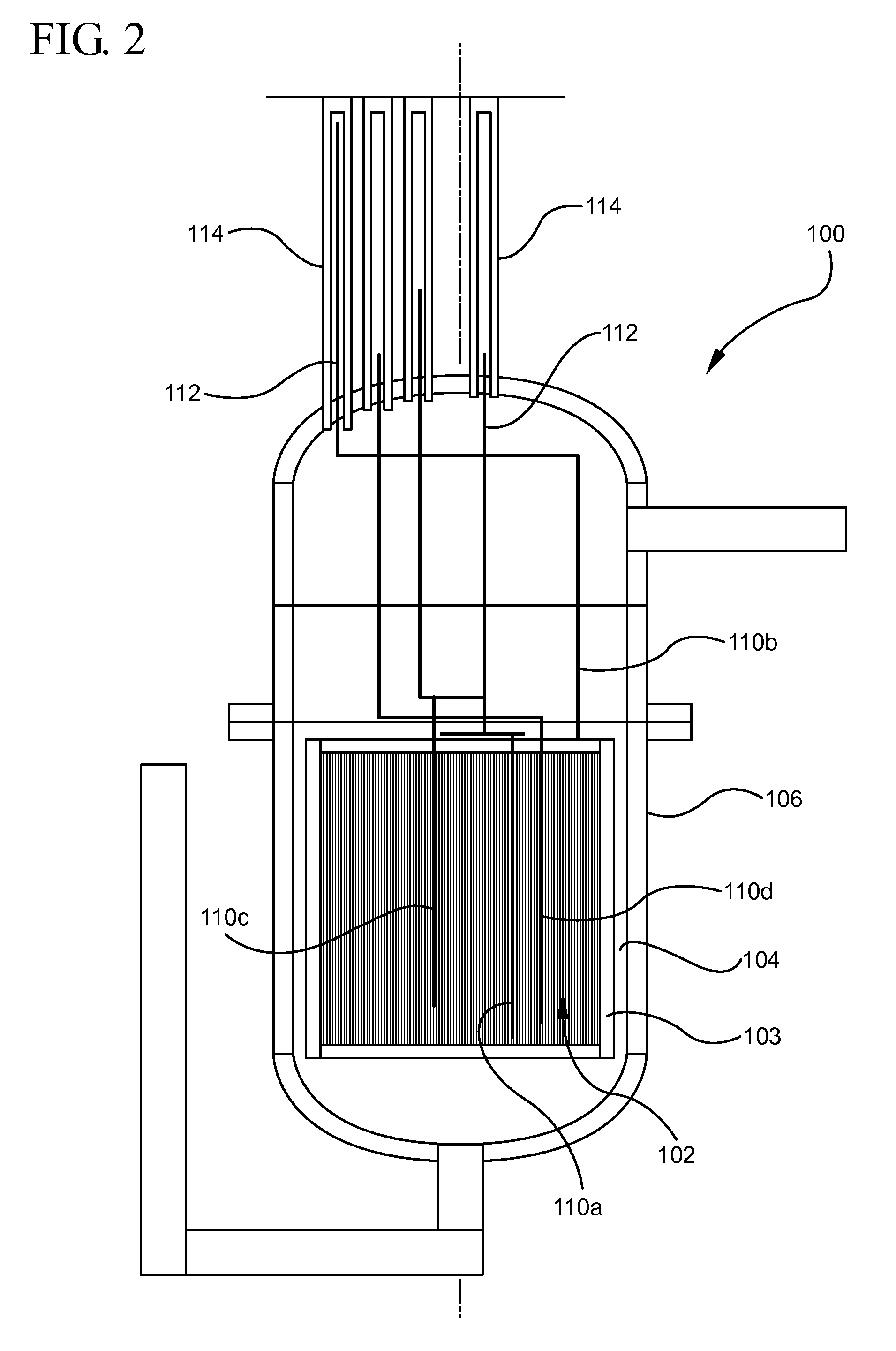

Deployable electric energy reactor

InactiveUS20100290578A1Compact and quickly deployableConvenient to accommodateFuel elementsNuclear energy generationUranium hydrideElectric energy

A nuclear fission reactor device including a core having an array of fissile material and which is capable of being transported to and from the place of operation using conventional transportation vehicles. In a first embodiment, the fissile material is a uranium hydride enriched 15%-to-20% with U-235. In a second embodiment, the fissile material is a uranium oxide enriched to 18% to 20% with U-235.

Owner:RADIX POWER & ENERGY CORP

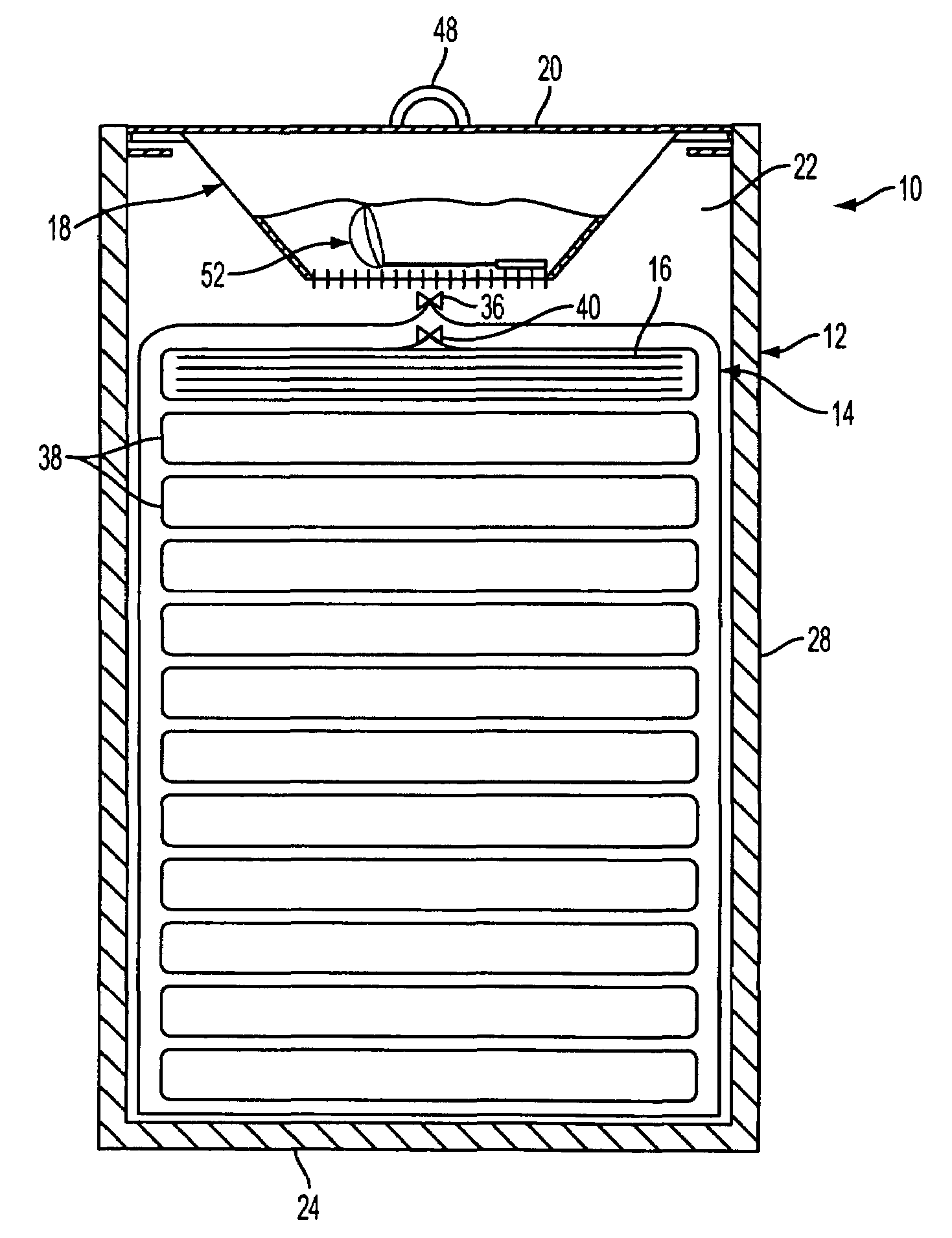

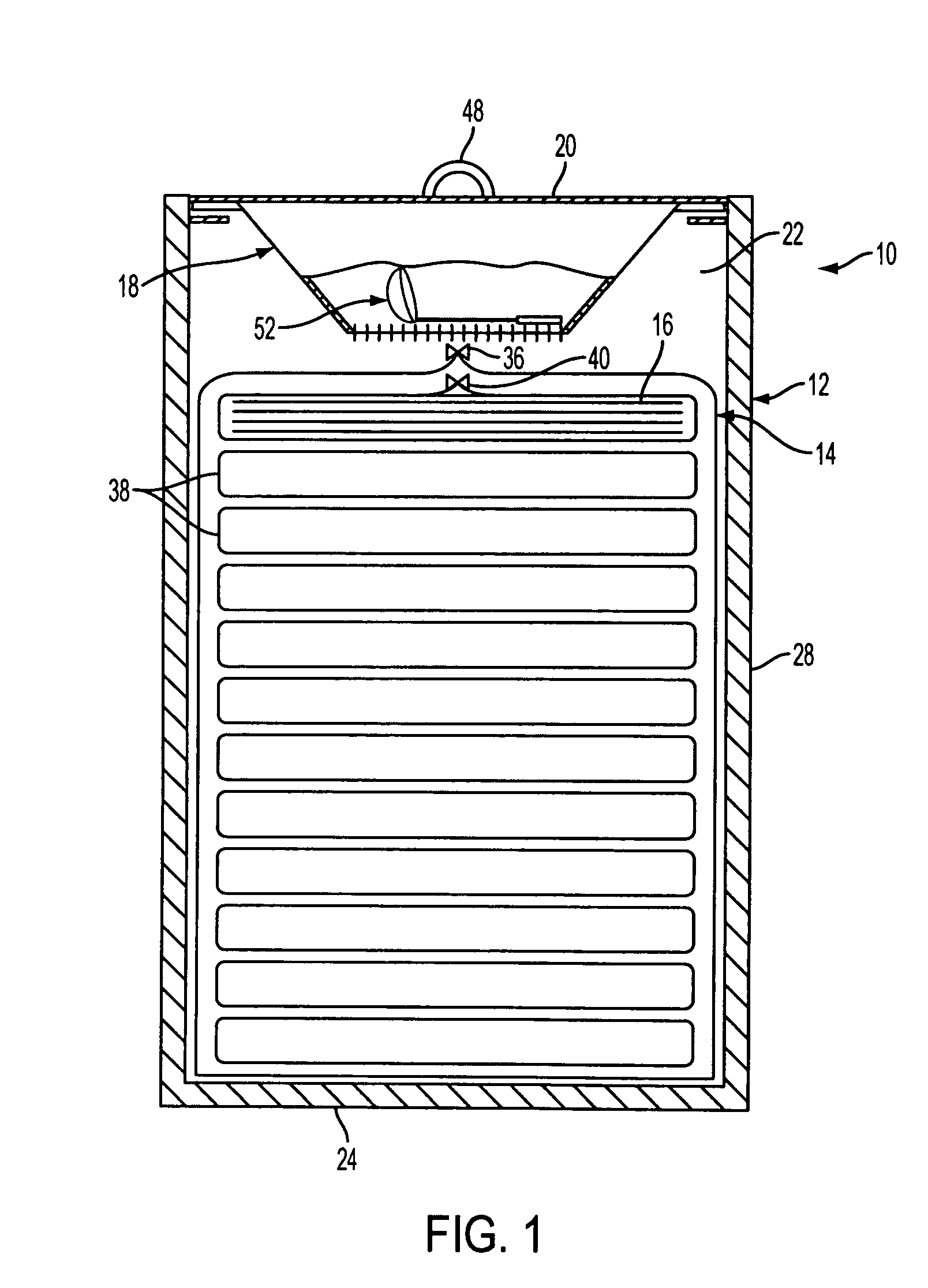

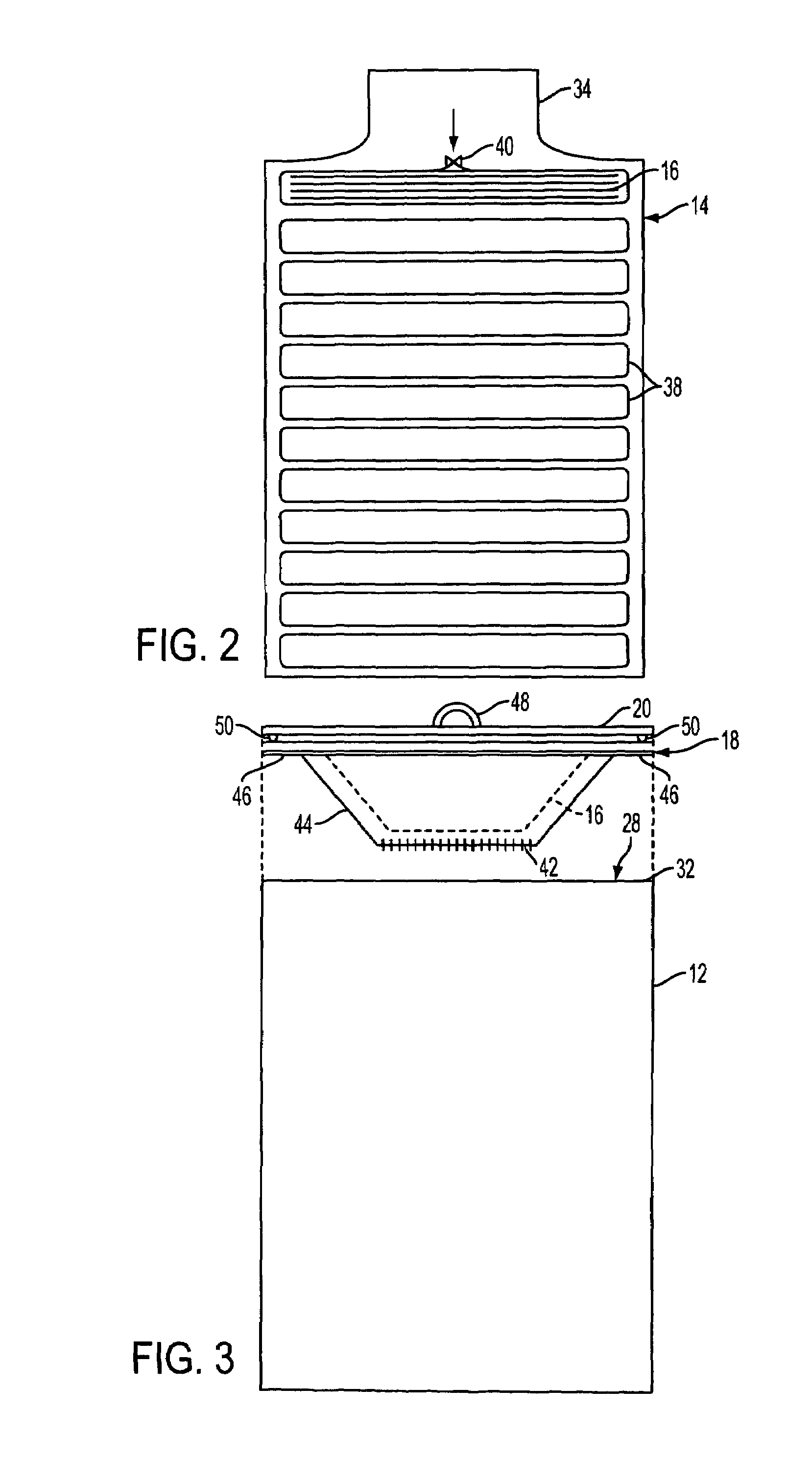

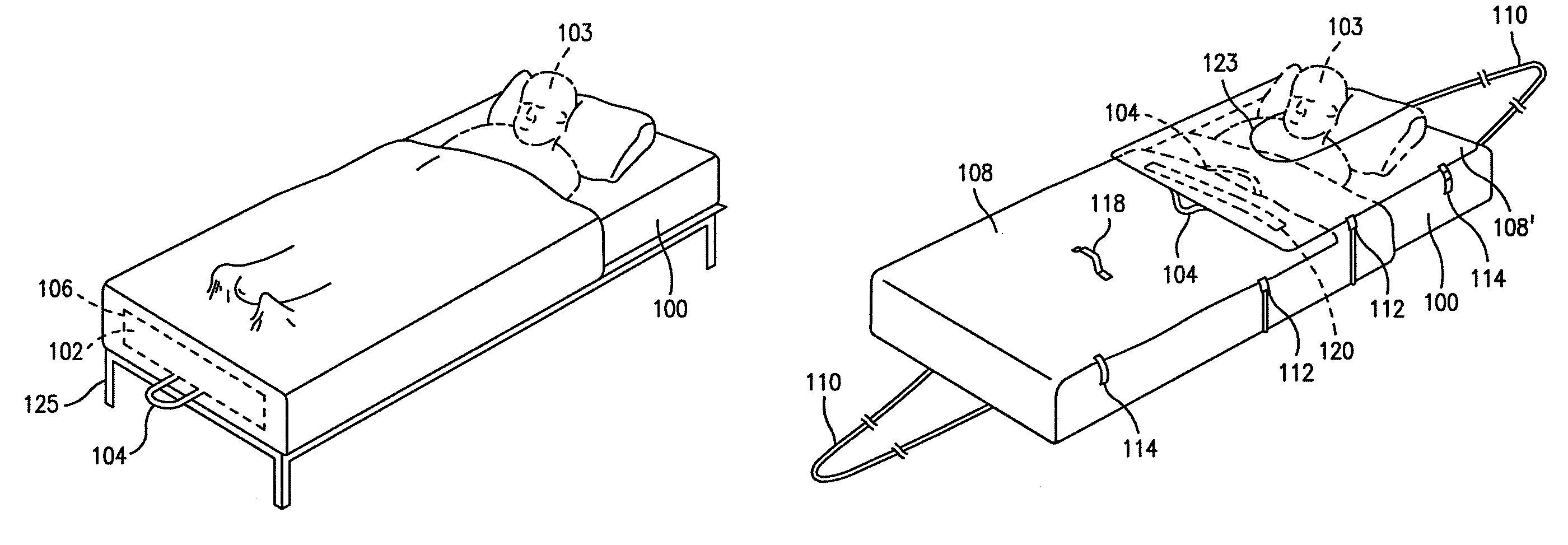

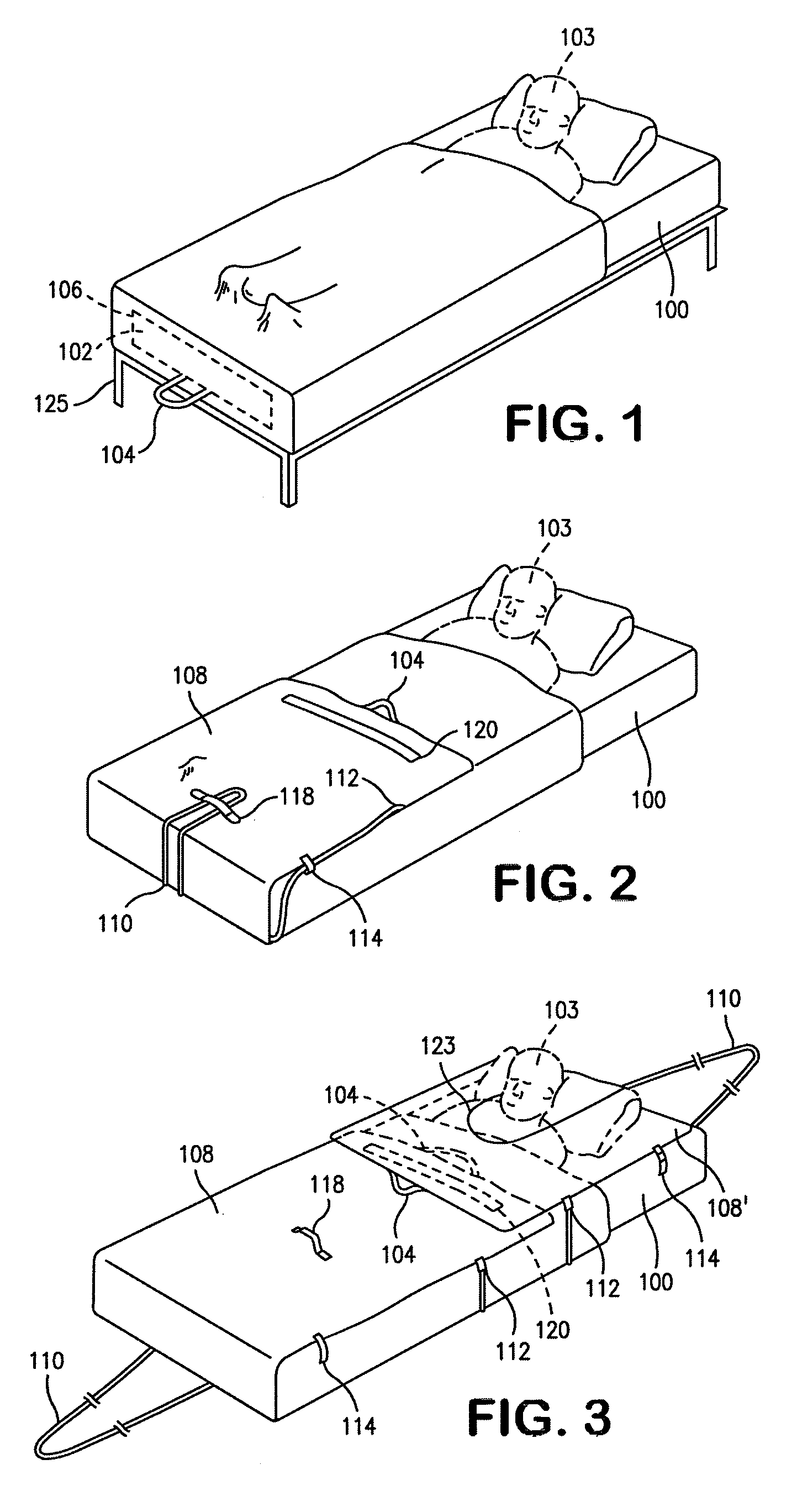

Evacuation mattress

An evacuation mattress comprises an integral mattress including a mattress interior, a mattress top face sheet, four mattress side face sheets, and a bottom sheet. The bottom sheet forms both the mattress bottom face sheet and an evacuation bottom sheet. The integral evacuation mattress also includes a top evacuation sheet configured to be deployed over a patient who is disposed above the mattress top face sheet. The integral evacuation mattress further includes securing structure configured to secure the top evacuation sheet to the patient and the integral mattress. Transport structure is also included in the integral evacuation mattress and is configured for a person to drag the secured patient and integral mattress from a hospital.

Owner:KENALTY CHRISTOPHER +1

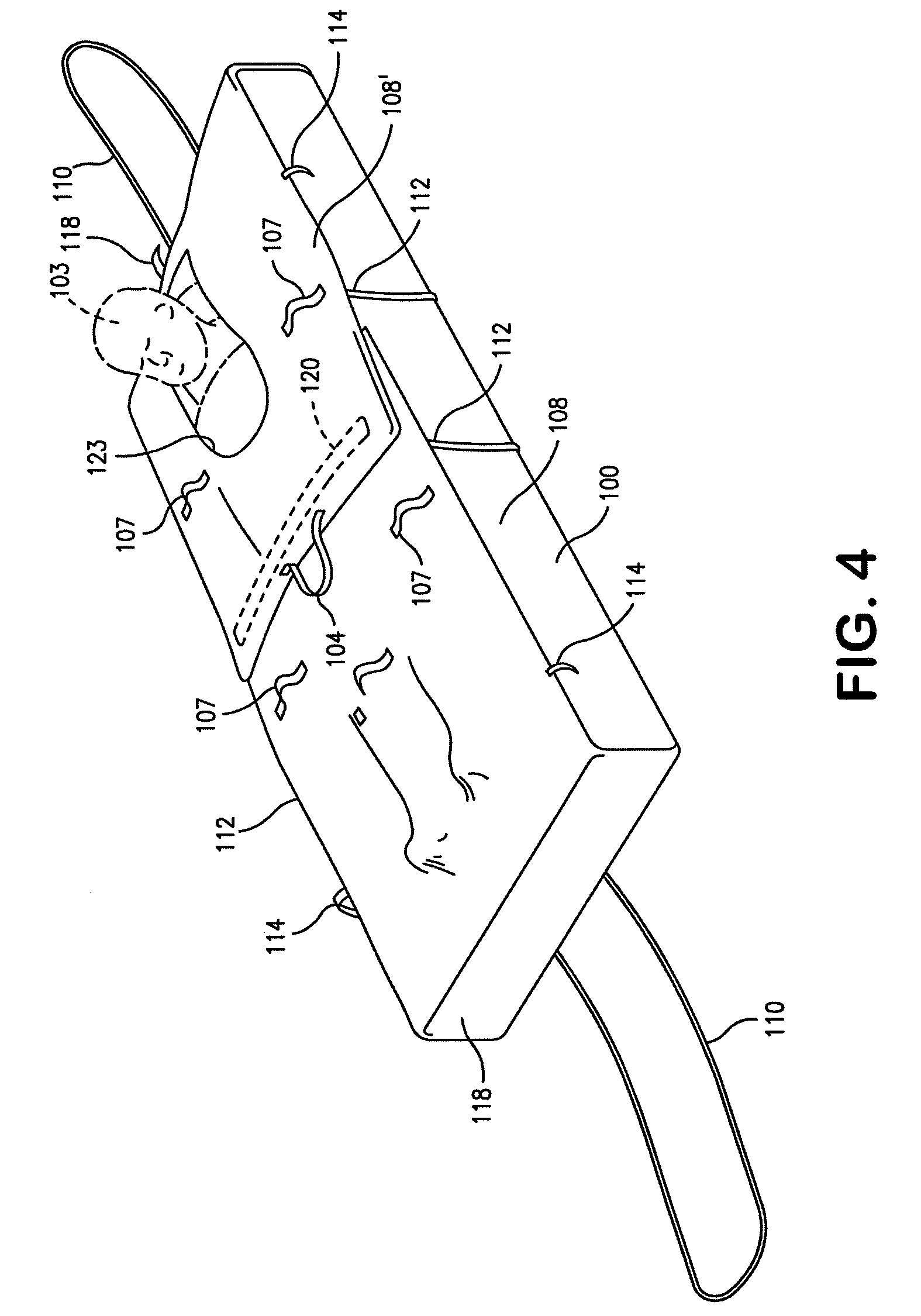

Resuscitator device

ActiveUS20140318544A1Reduce riskInflation difficultRespiratory masksMedical devicesTidal volumePositive pressure

A manually actuated, self-inflating bag valve mask provides users with a positive pressure ventilation device that reliably provides a proper tidal volume to the patient and controls the rate of ventilation of the patient. The bag valve mask is lightweight, compact, durable, and quickly deployable in the field. The device is preferably operable with one hand and can be configured for use in low-light environments.

Owner:SAFEGUARD MEDICAL HOLDCO LLC

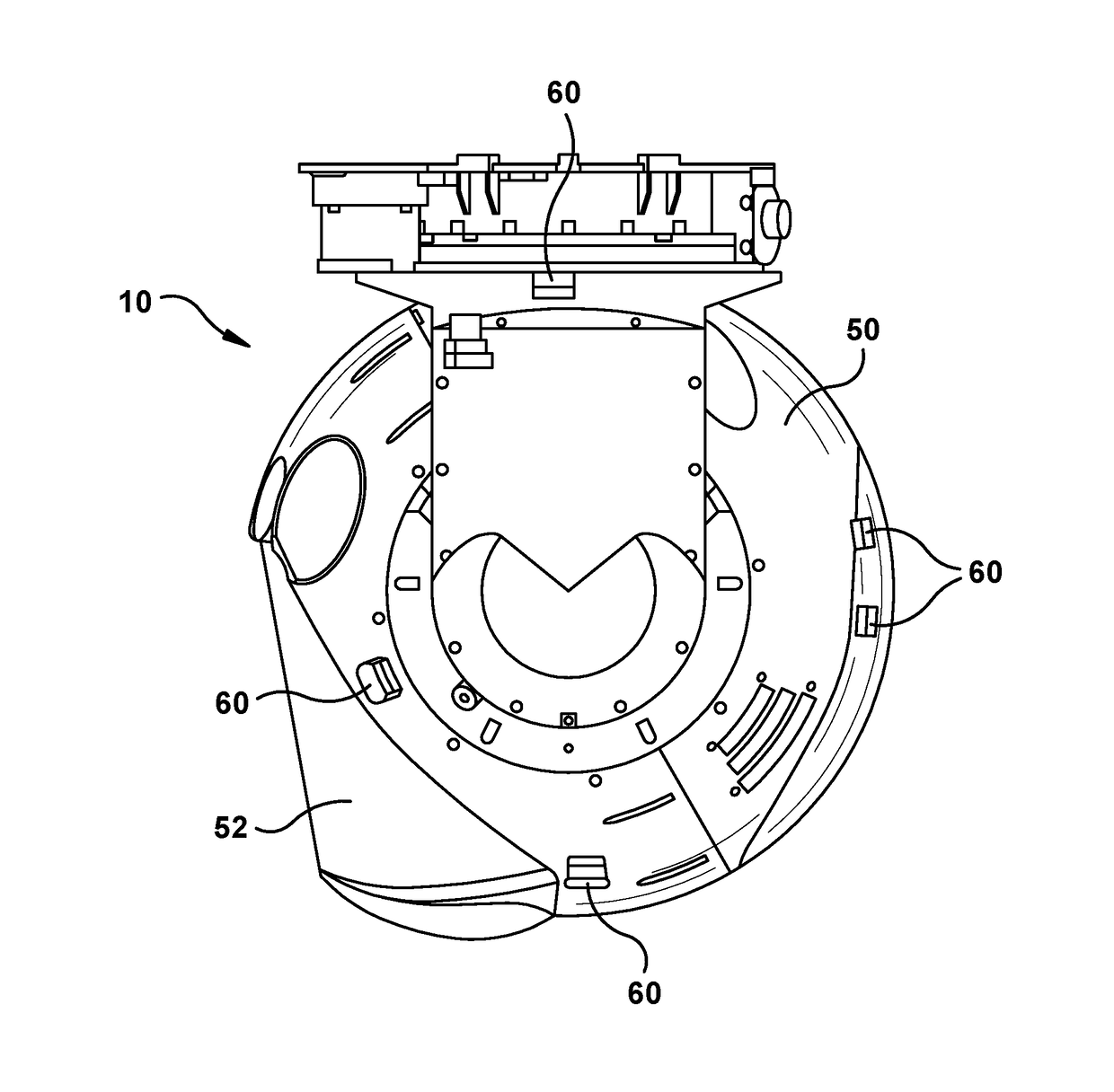

Shock-resisting device and method

ActiveUS20170291719A1Rapidly deployableAircraft componentsMachine supportsGimbalBiomedical engineering

A shock-resisting device includes a snubber that may be selectively moved from a retracted position to an engaged position to selectively create a stiff attachment between a vibration-isolated gimbal of the device, and an outer shell of the device. The gimbal is movable relative to the outer shell. The snubber includes a retainer maintaining the snubber in the retracted position, wherein the snubber is configured to move from the retracted position to the engaged position in response to loss of power to the retainer.

Owner:RAYTHEON CO

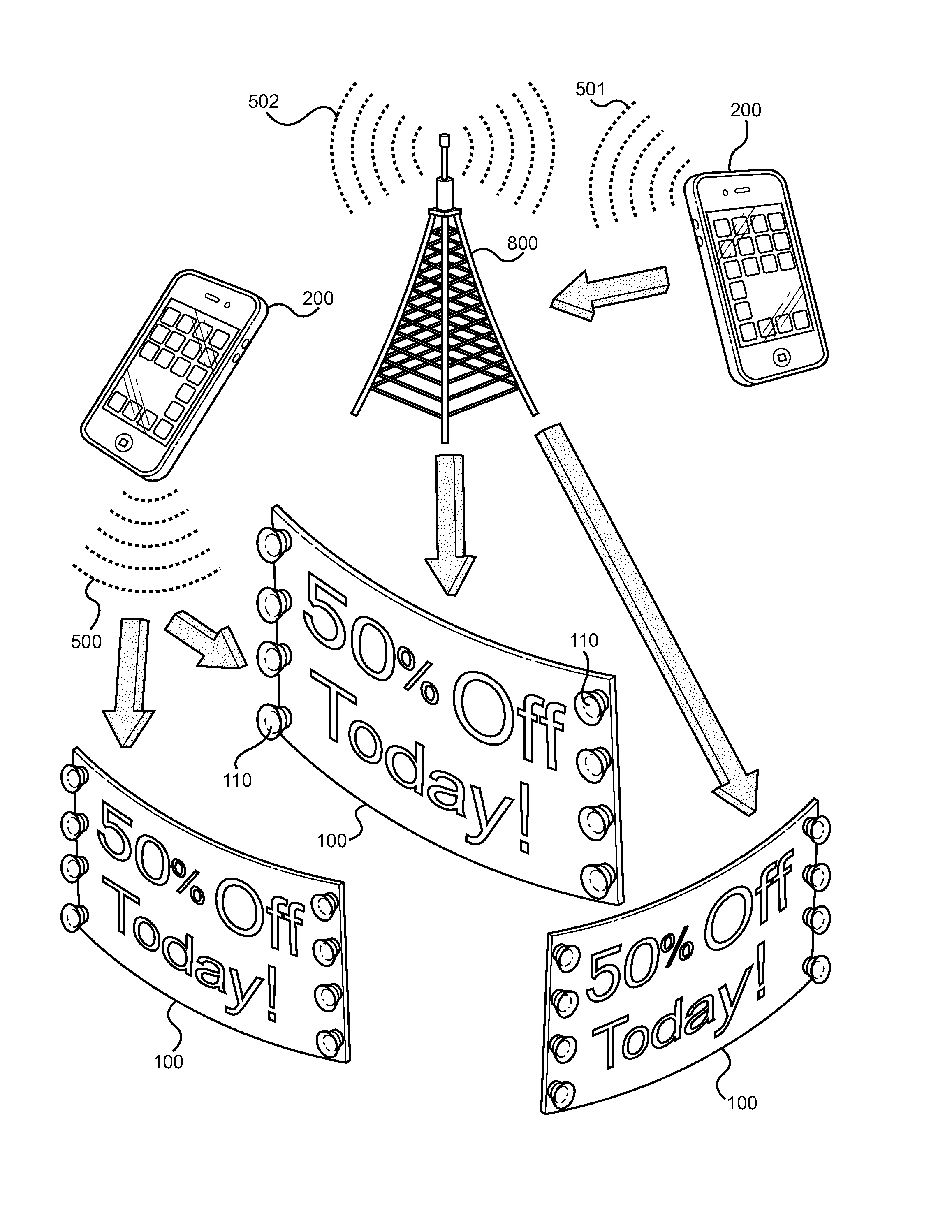

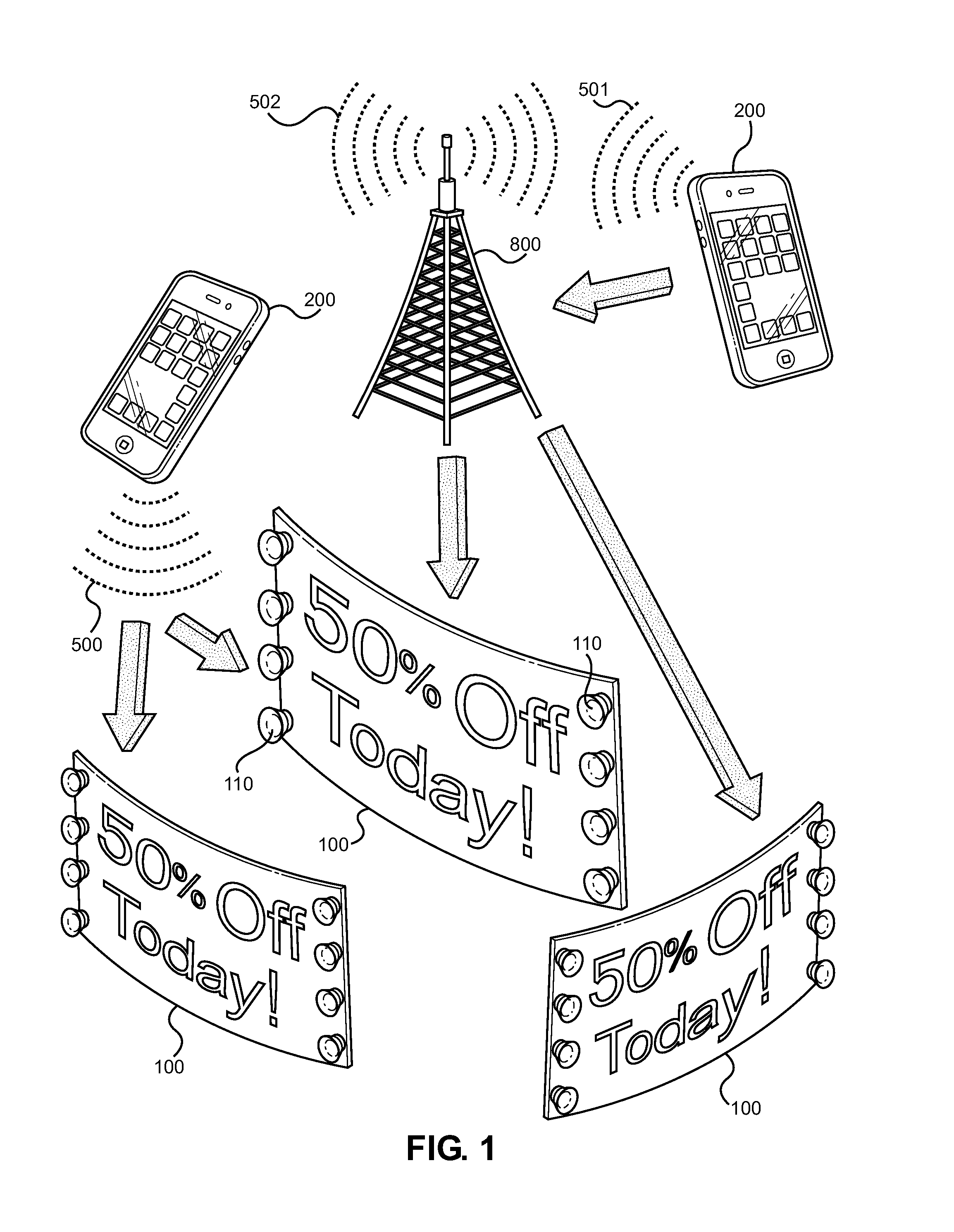

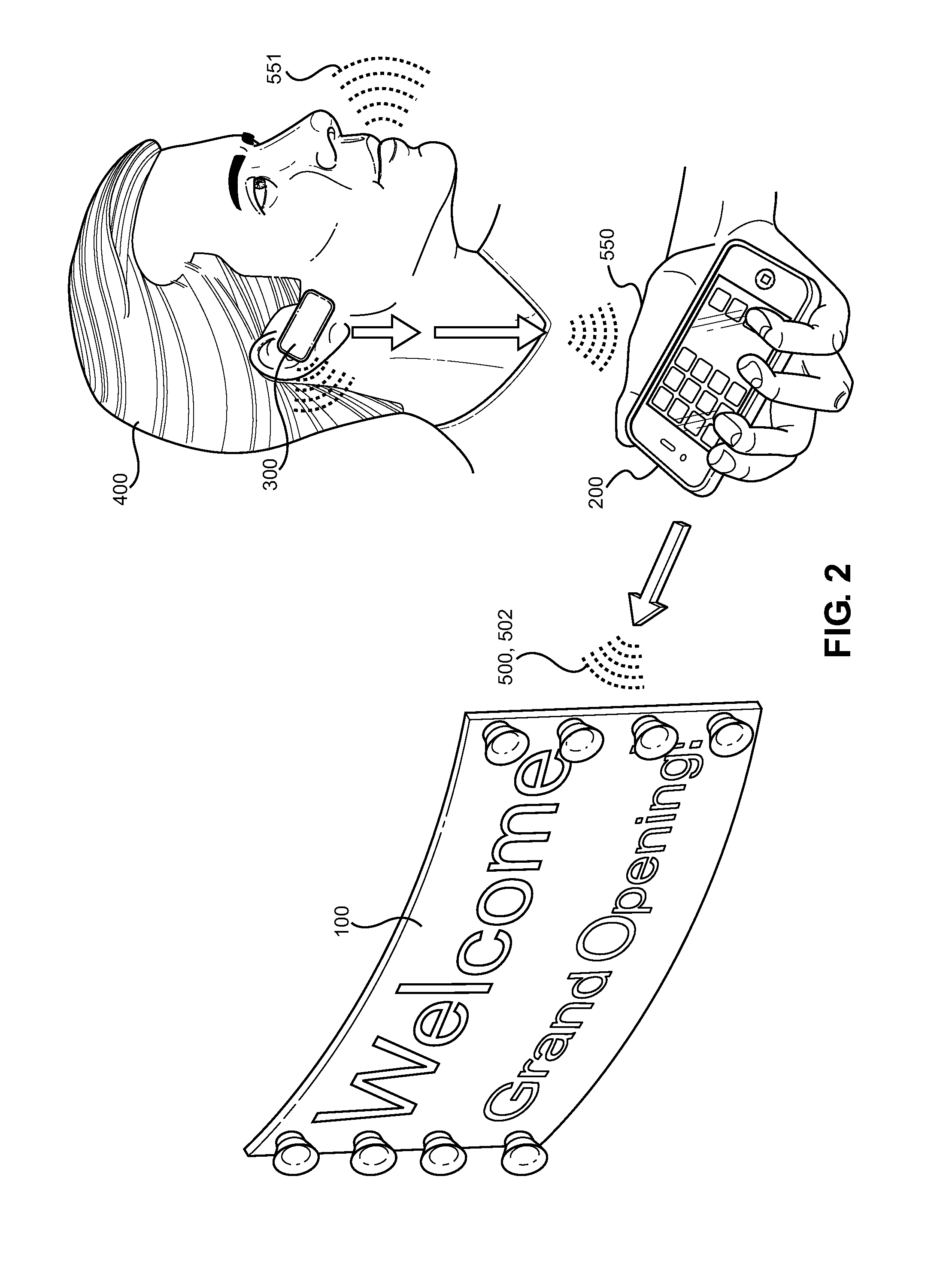

Remotely Connected Digital Messageboard System and Method

InactiveUS20150170212A1Easy to makeEasy to useStatic indicating devicesConnection managementDigital dataMessage board

Provided is a system and method of updating a message or image displayed on an electronic screen via wireless communications device or remote website. Messages are entered into the communications device (an input terminal) or web interface using one or more input methods. Input methods include alphanumeric text input, verbal commands translated into text input, visual content stored on the input device, or written input via the input device. The input is then transmitted as digital data to one or more electronic screens, where the input is then displayed. The input can be modified and edits prior to transmission. Thus, users can update an electronic display remotely. One or more input devices can modify one display, or alternatively one input device can be used to modify multiple displays. Each electronic display is in enabled to wirelessly communicate over a wireless network such as a Wi-Fi, cellular, or Bluetooth network.

Owner:VERBALIZED SIGNS

Apparatus, method, and medium for self-organizing multi-hop wireless access networks

InactiveUS20110200026A1Rapidly deployableImprove securityNetwork topologiesData switching by path configurationAccess networkWireless computing

A wireless computer network includes a backbone network including backbone network nodes authenticated to each other and in communication with each other. The wireless computer network also includes a master authenticator node and a proxy authenticator node among the backbone network nodes. When an unauthenticated new node requests authentication to the backbone network and the unauthenticated new node is in communication with at least one of the backbone network nodes, the at least one of the backbone network nodes becoming the proxy authenticator node for the unauthenticated new node and communicates with the master authenticator node to authenticate the unauthenticated new node to the backbone network.

Owner:FUJITSU LTD

Apparatus, method, and medium for self-organizing multi-hop wireless access networks

InactiveUS8630275B2Rapidly deployableImprove securityNetwork topologiesData switching by path configurationAccess networkWireless computing

A wireless computer network includes a backbone network including backbone network nodes authenticated to each other and in communication with each other. The wireless computer network also includes a master authenticator node and a proxy authenticator node among the backbone network nodes. When an unauthenticated new node requests authentication to the backbone network and the unauthenticated new node is in communication with at least one of the backbone network nodes, the at least one of the backbone network nodes becoming the proxy authenticator node for the unauthenticated new node and communicates with the master authenticator node to authenticate the unauthenticated new node to the backbone network.

Owner:FUJITSU LTD

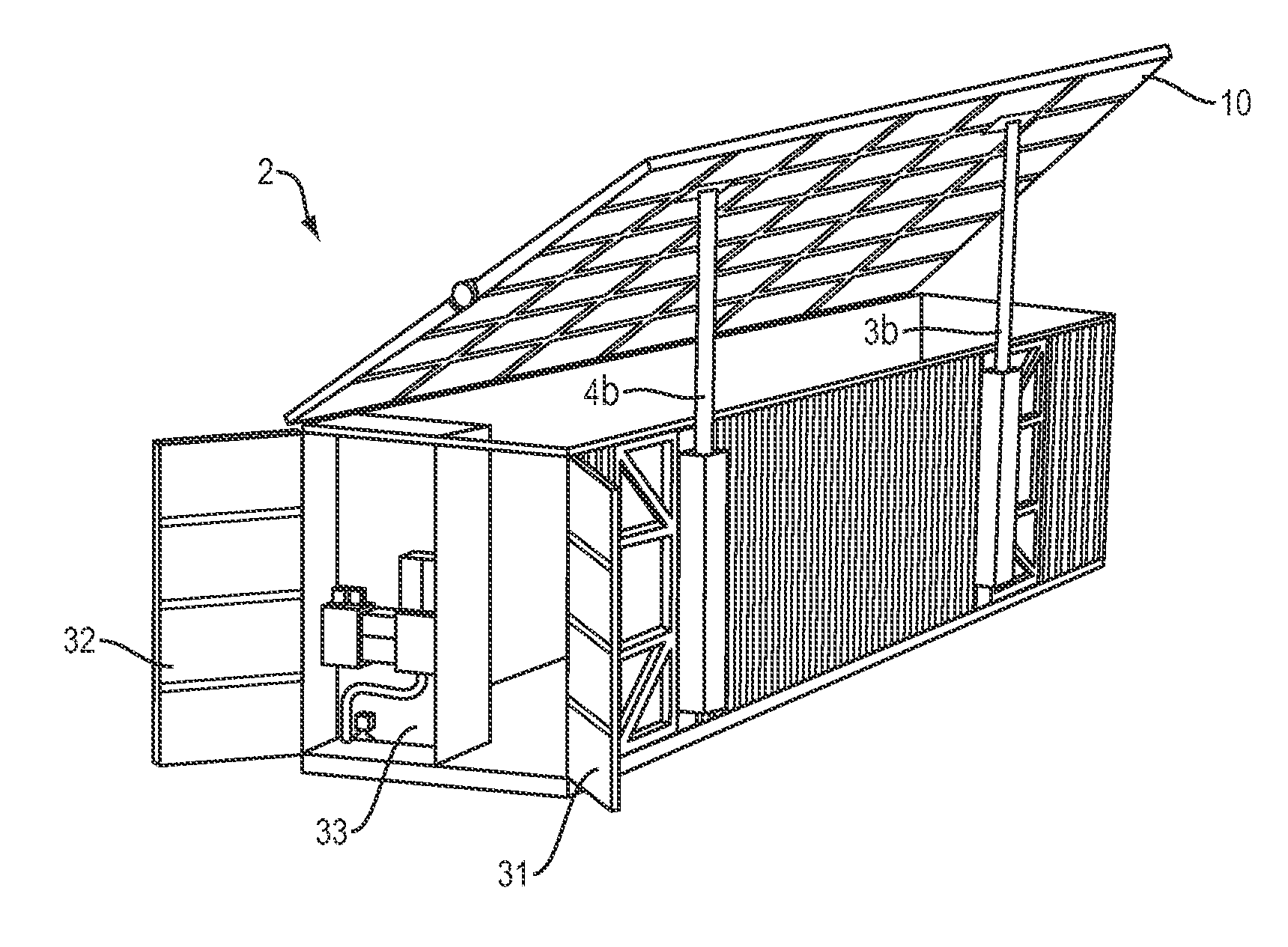

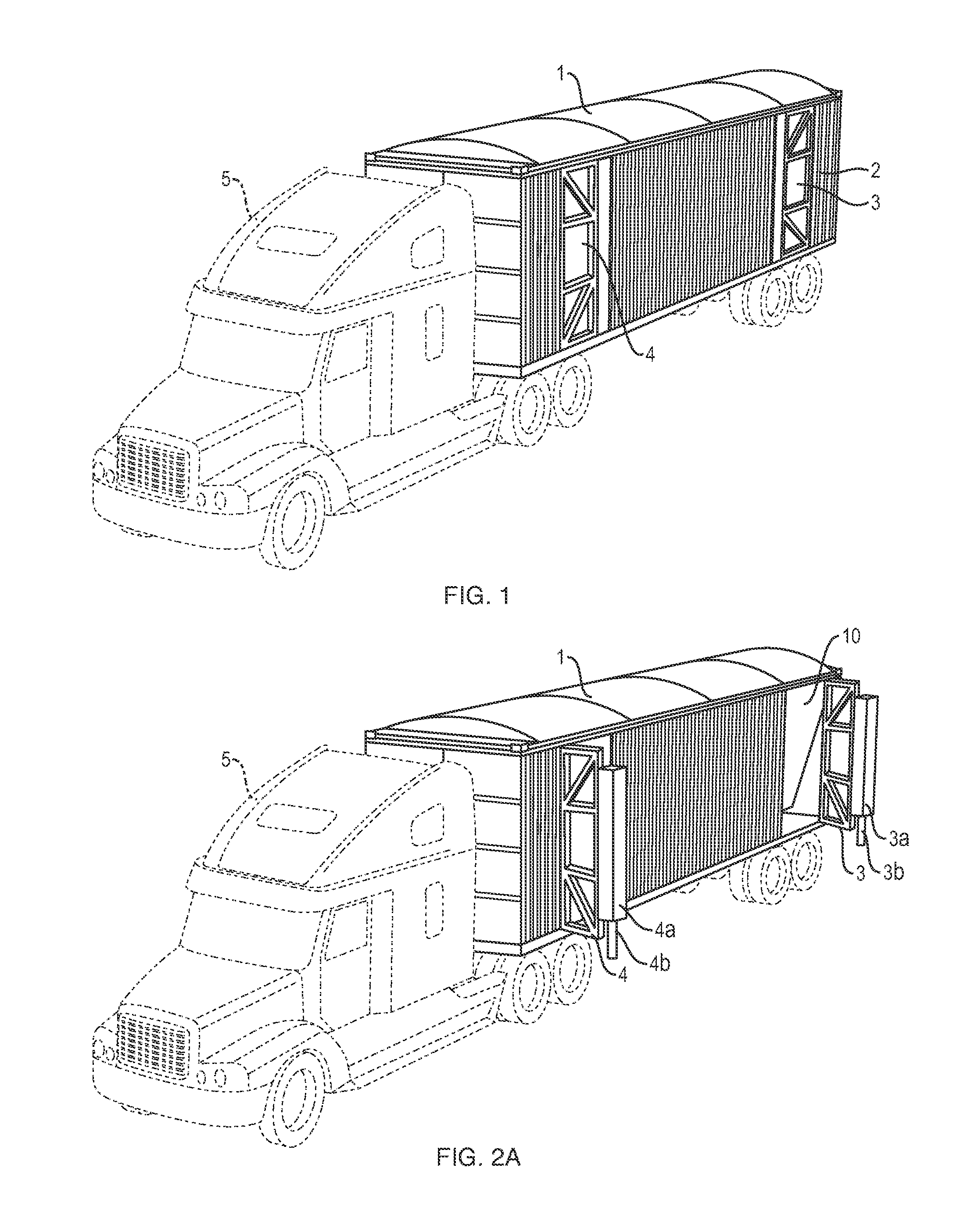

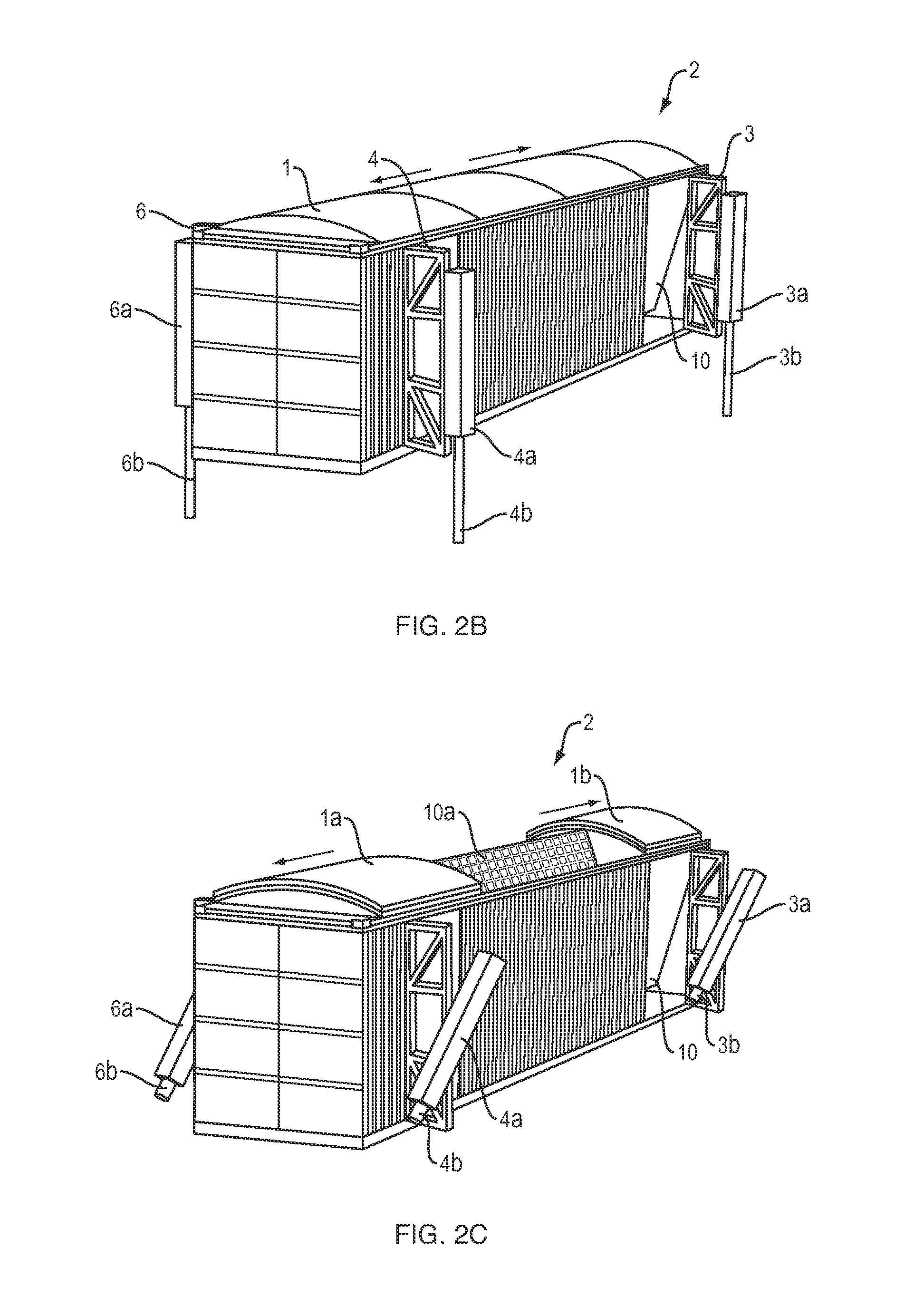

Photovoltaic power apparatus for rapid deployment

InactiveUS20150162865A1Rapidly deployableQuickly and easily establishedSolar heating energyBatteries circuit arrangementsEngineeringDual function

A rapidly deployed photovoltaic (PV) apparatus (2) providing a PV array (10) housed within an easily transportable standardized container. The PV array (10) is movable between a stowed position in a V-shape configuration and a fully deployed flat position. Dual function hydraulic cylinders are provided for movement of the array (10) in the fully deployed position and movement of the container when the array (10) is in the stowed position. Solar tracking of the array (10) is facilitated by linear compensation translators which are attachable to the hydraulic cylinders upon full deployment. A retractable roof structure is provided which allows trickle charging to occur when the array (10) is in the V-shaped stowed position.

Owner:COWHAM WALTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com