Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

652results about How to "Low operating pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

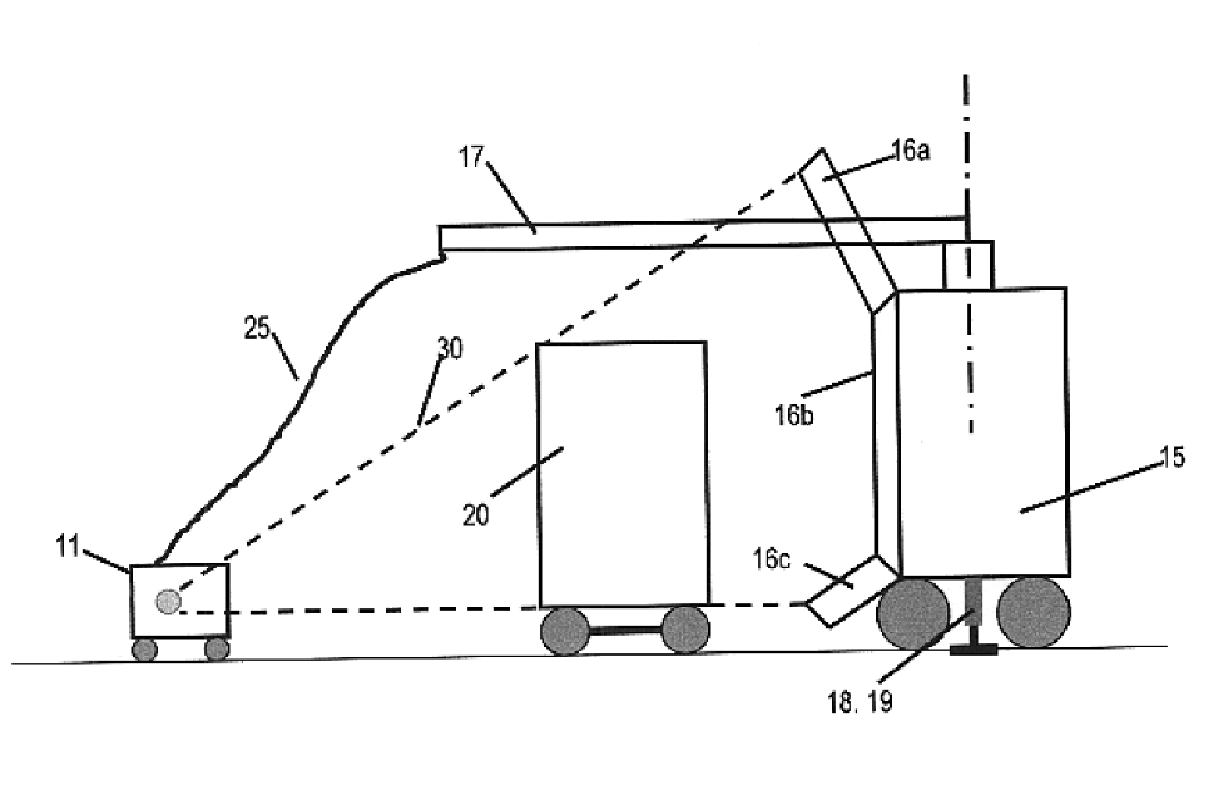

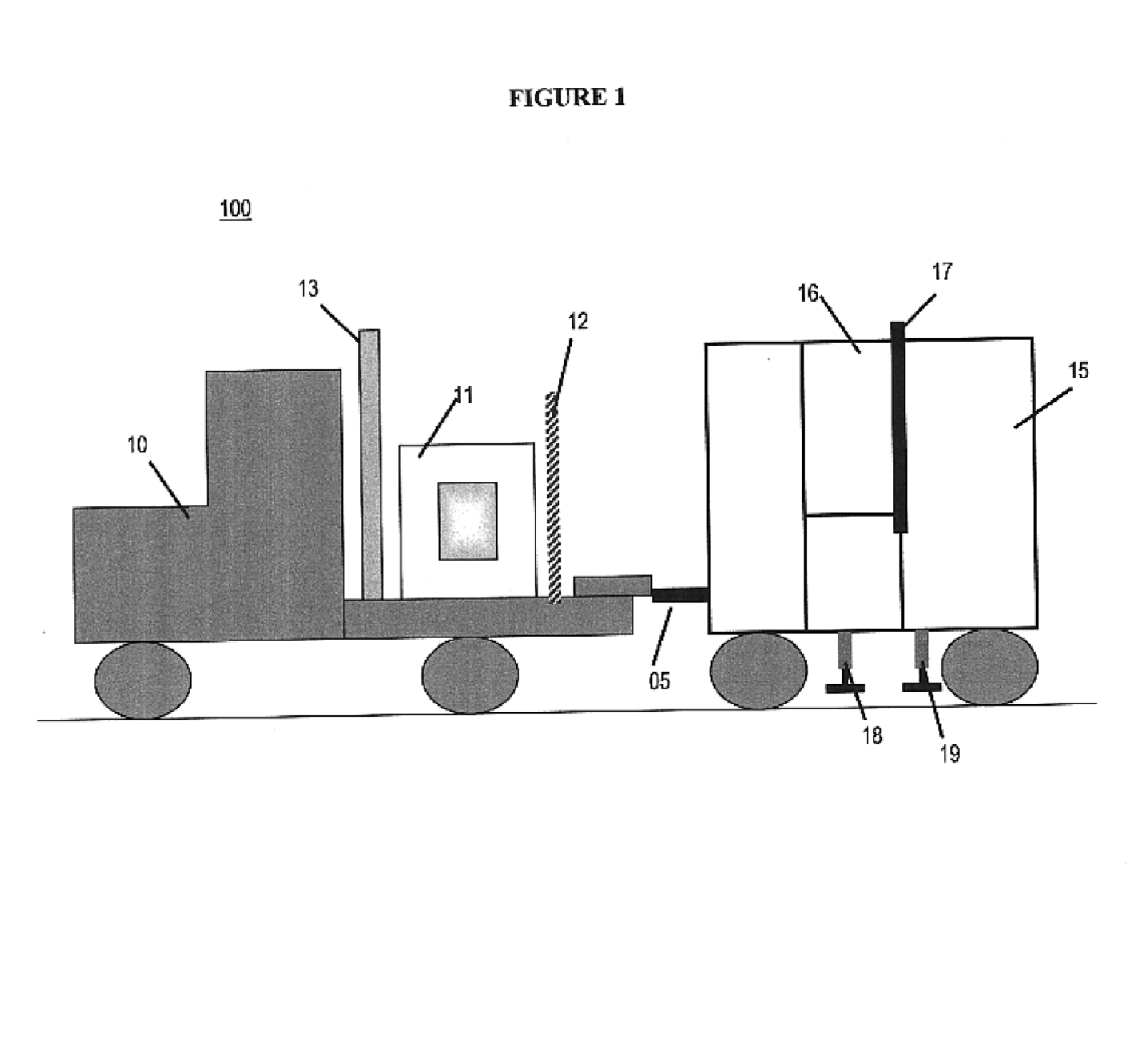

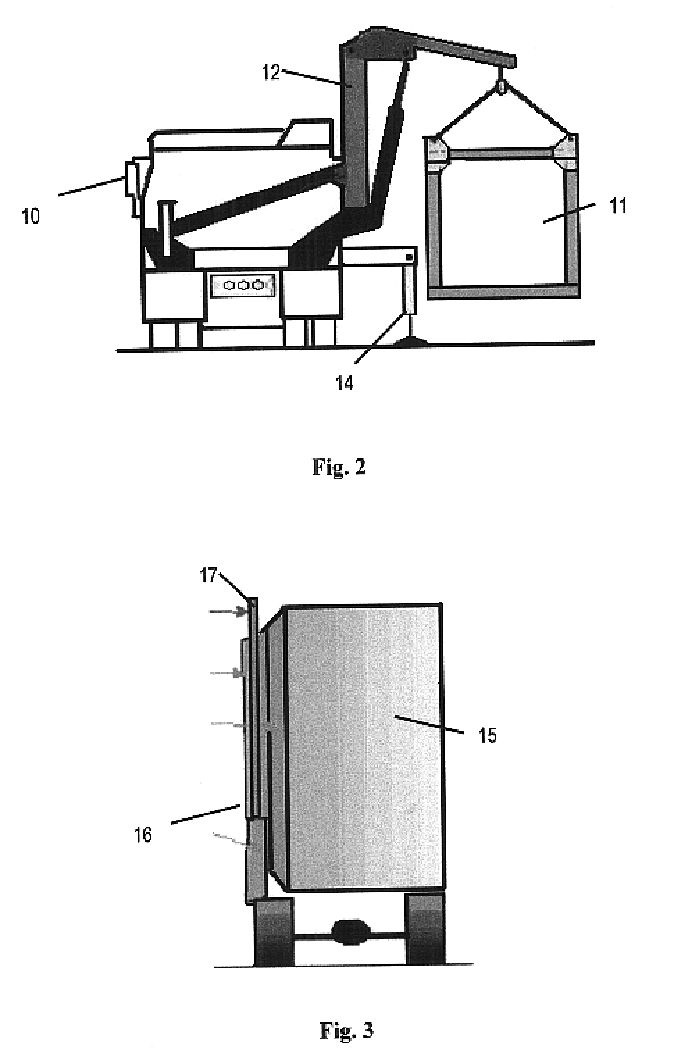

Self-contained, portable inspection system and method

InactiveUS6843599B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationComputer moduleEngineering

The inspection methods and systems of the present invention are mobile, deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The inspection system comprises an inspection module that, in a preferred embodiment, is in the form of a mobile trailer capable of being towed and transported to its intended operating site with the help of a tug-vehicle. The tug-vehicle preferably includes at least one source of electromagnetic radiation, a hydraulic lift system to load and unload the radiation source, and at least one radiation shield plate positioned on the back of the driver cabin of the tug-vehicle.

Owner:RAPISCAN SYST INC (US)

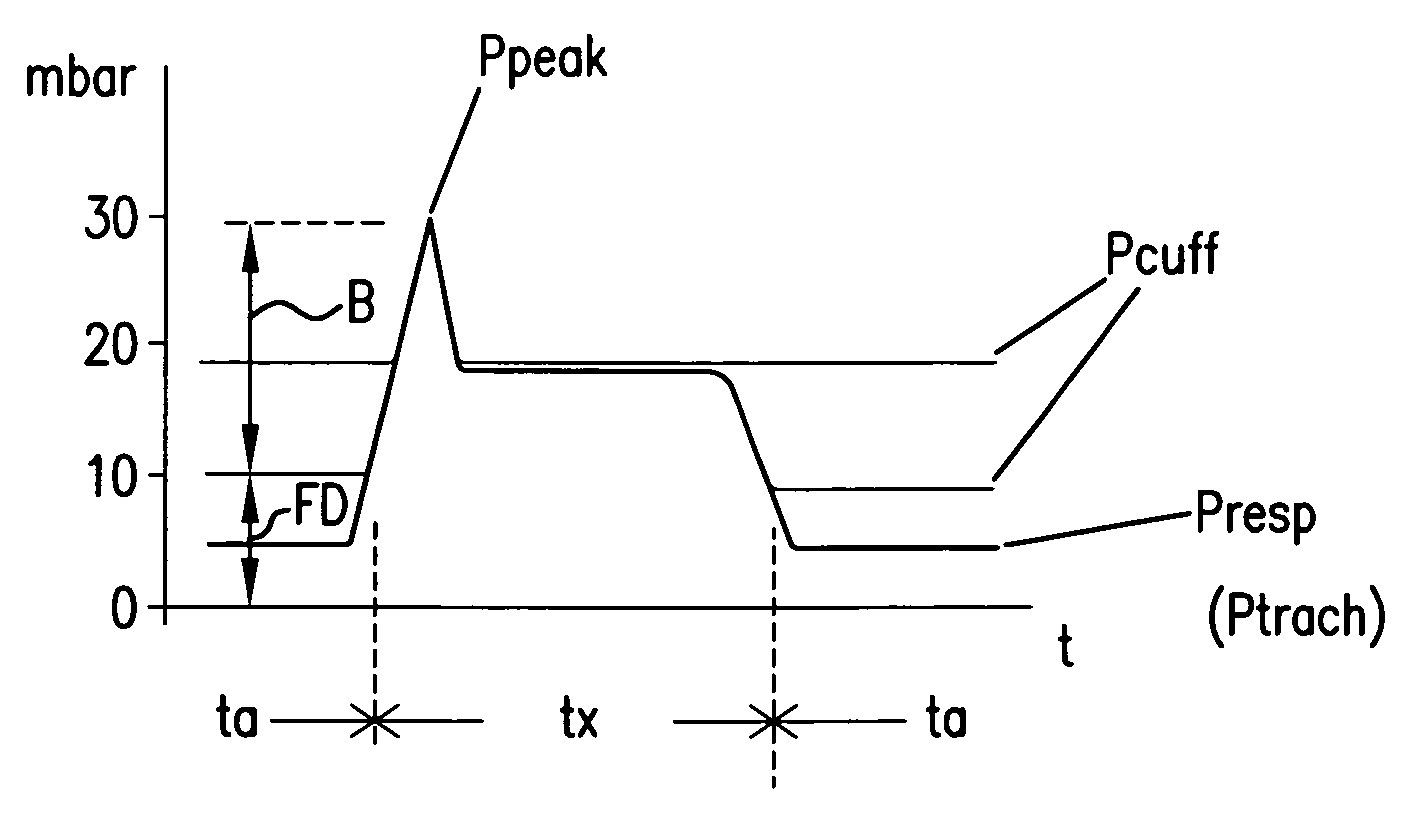

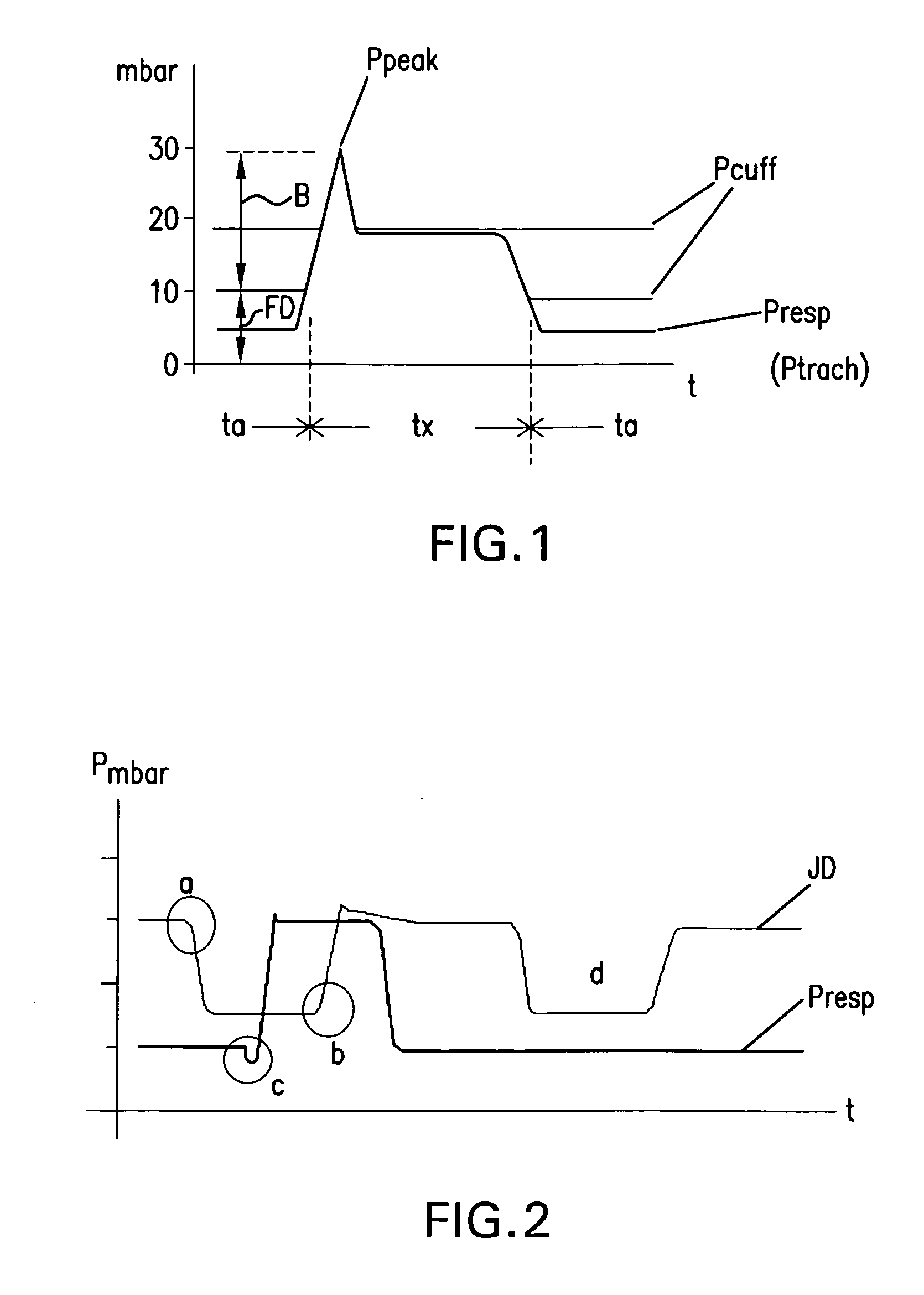

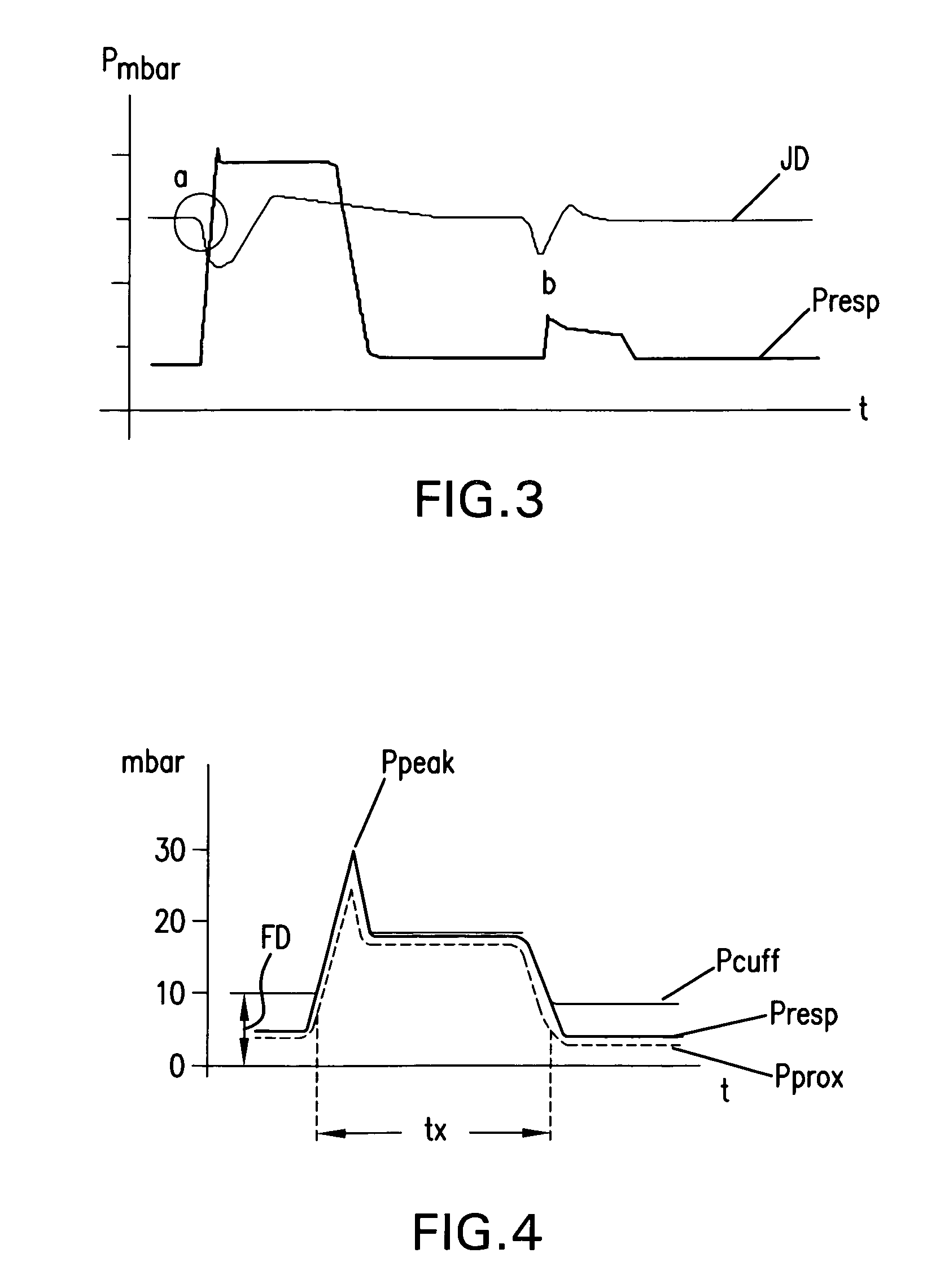

Method for controlling a ventilator, and system therefor

InactiveUS7040321B2Preventing situationEnhanced interactionTracheal tubesOperating means/releasing devices for valvesControlled breathingTracheal tube

A method for controlling breathing gas flow of a ventilator for assisted or controlled ventilation of a patient as a function of a tracheobronchial airway pressure of the patient. A ventilator tube, such as a tracheal tube or tracheostomy tube, can be introduced into a trachea of the patient and subjected to the breathing gas, and has an inflatable cuff and at least one lumen that is continuous from a distal end of the tube to a proximal end of the tube. An apparatus detects an airway pressure, in which the tracheobronchial airway pressure is ascertained by continuous or intermittent detection and evaluation of an intra-cuff pressure prevailing in the cuff of the tube inserted into the trachea. The breathing gas flow of the ventilator is controlled as a function of the intra-cuff pressure detected.

Owner:AVENT INC

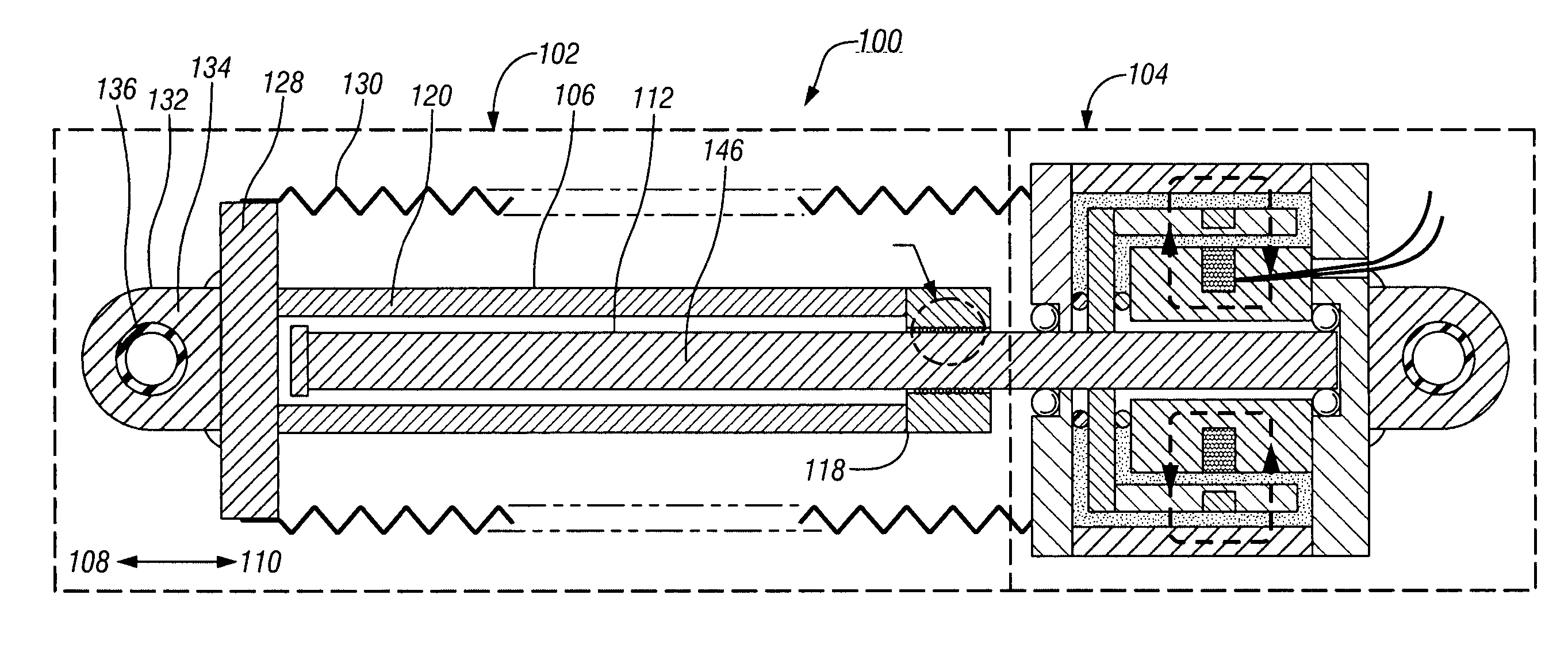

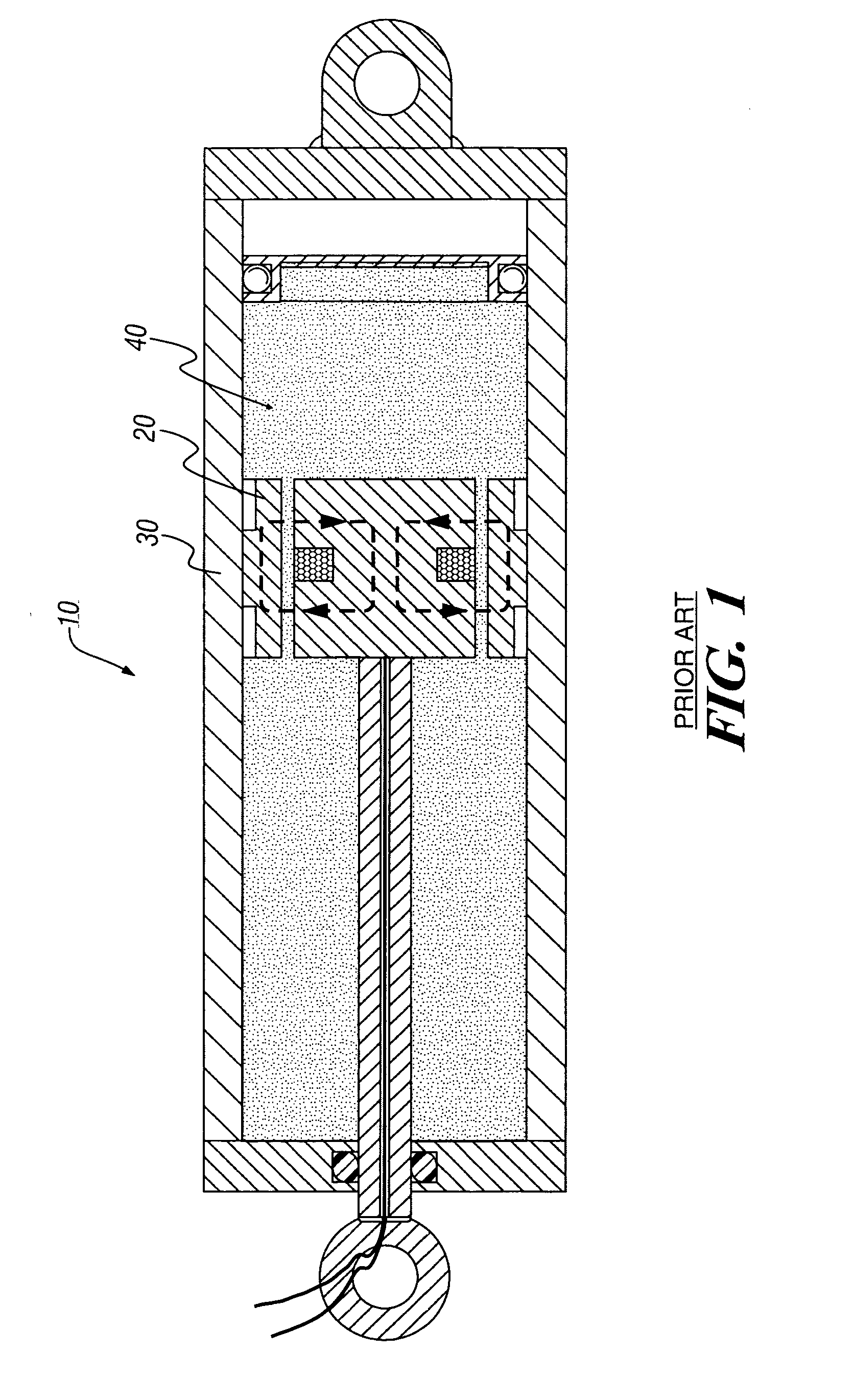

Fluid damper having continuously variable damping response

ActiveUS20050121269A1Reduce manufacturing costLower the volumeSpringsNon-rotating vibration suppressionMagnetorheological fluidEngineering

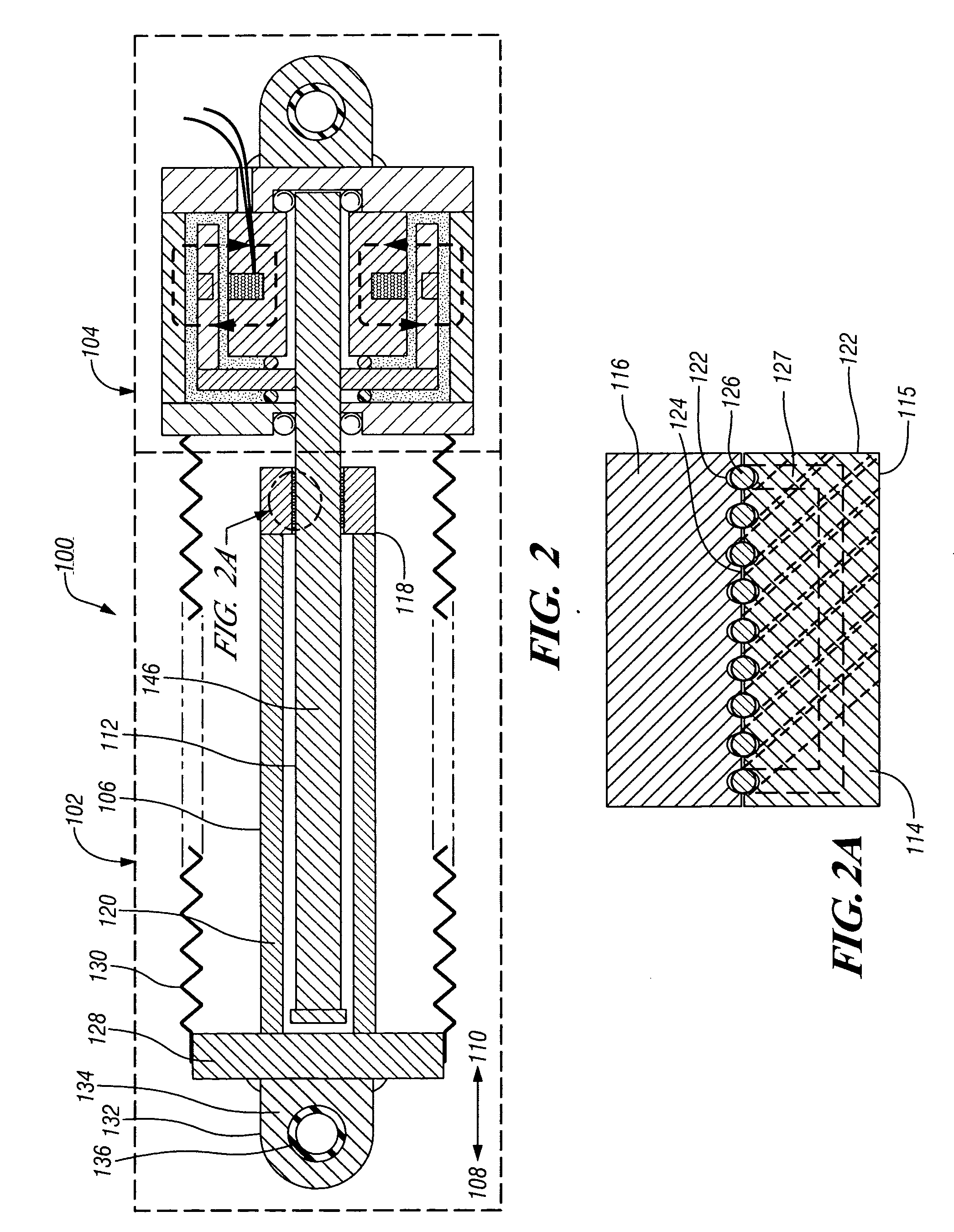

An improved damping apparatus that utilizes a fluid having a viscosity that may be varied by the application of an electromagnetic field, such as a magnetorheological fluid or an electrorheological fluid, to provide the damping response. The damping apparatus includes a linear to rotary conversion mechanism which comprises a translatable member that is adapted for linear translation in a forward and a reverse direction and a rotatable member comprising a rotatable shaft that is rotatably coupled to the translatable member; wherein translation of the translatable member in one of the forward or the reverse directions produces a forward or a reverse rotation of the rotatable member and shaft, respectively. The damping apparatus also includes a damping mechanism which comprises a hub that is fixed to the shaft, a means for generating a variable electromagnetic field in response to an applied electrical signal that may be continuously varied in response to an input signal that is representative of a desired damping force and a fluid having a viscosity that may be continuously varied by application of the electromagnetic field that is in touching contact with the hub. Application of the variable electromagnetic field to the fluid produces changes in the viscosity of the fluid that in turn provides variable resistance to rotation of the hub and resistance to translation of the translatable member, thereby providing a damping apparatus with a continuously variable damping response.

Owner:GM GLOBAL TECH OPERATIONS LLC

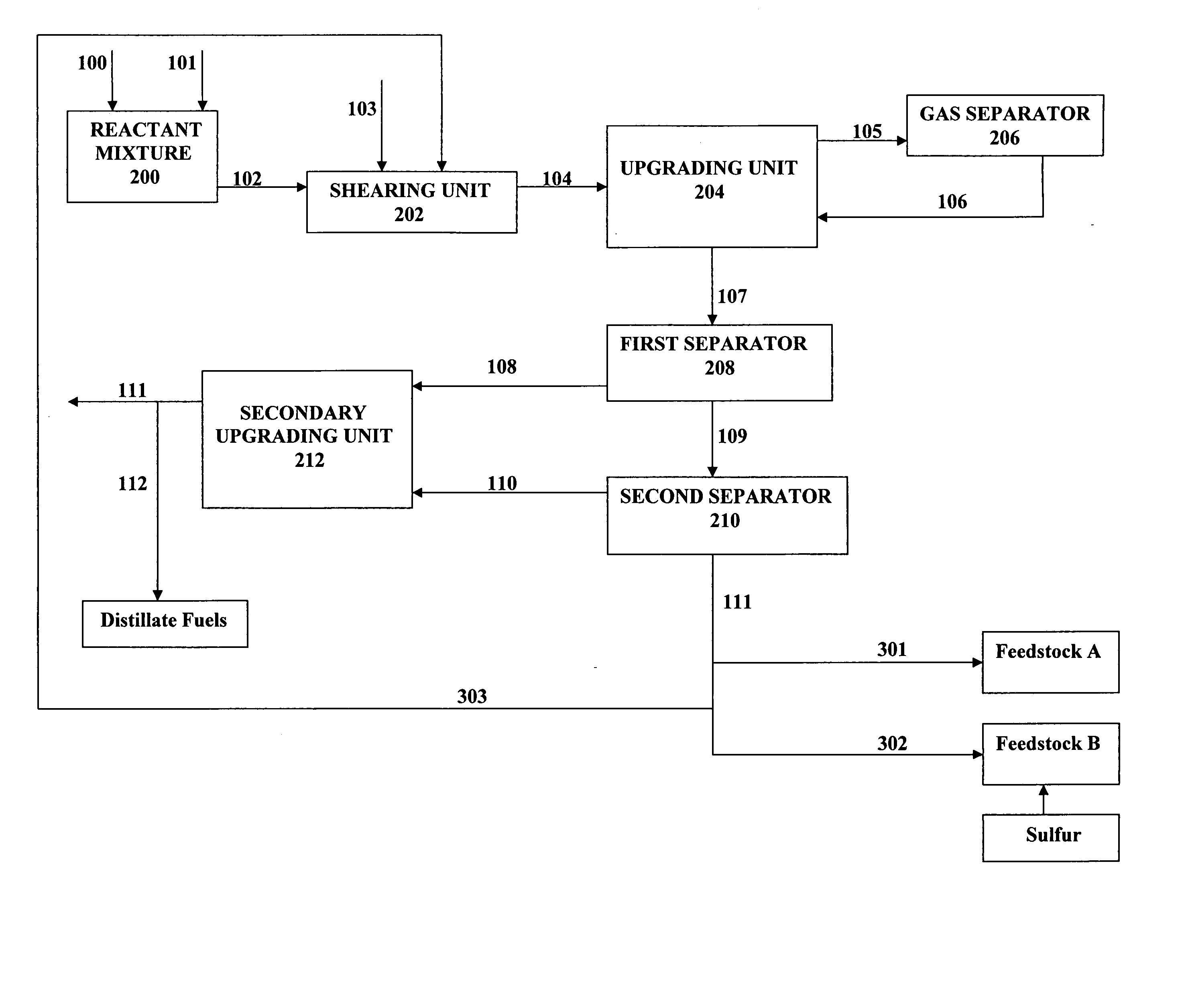

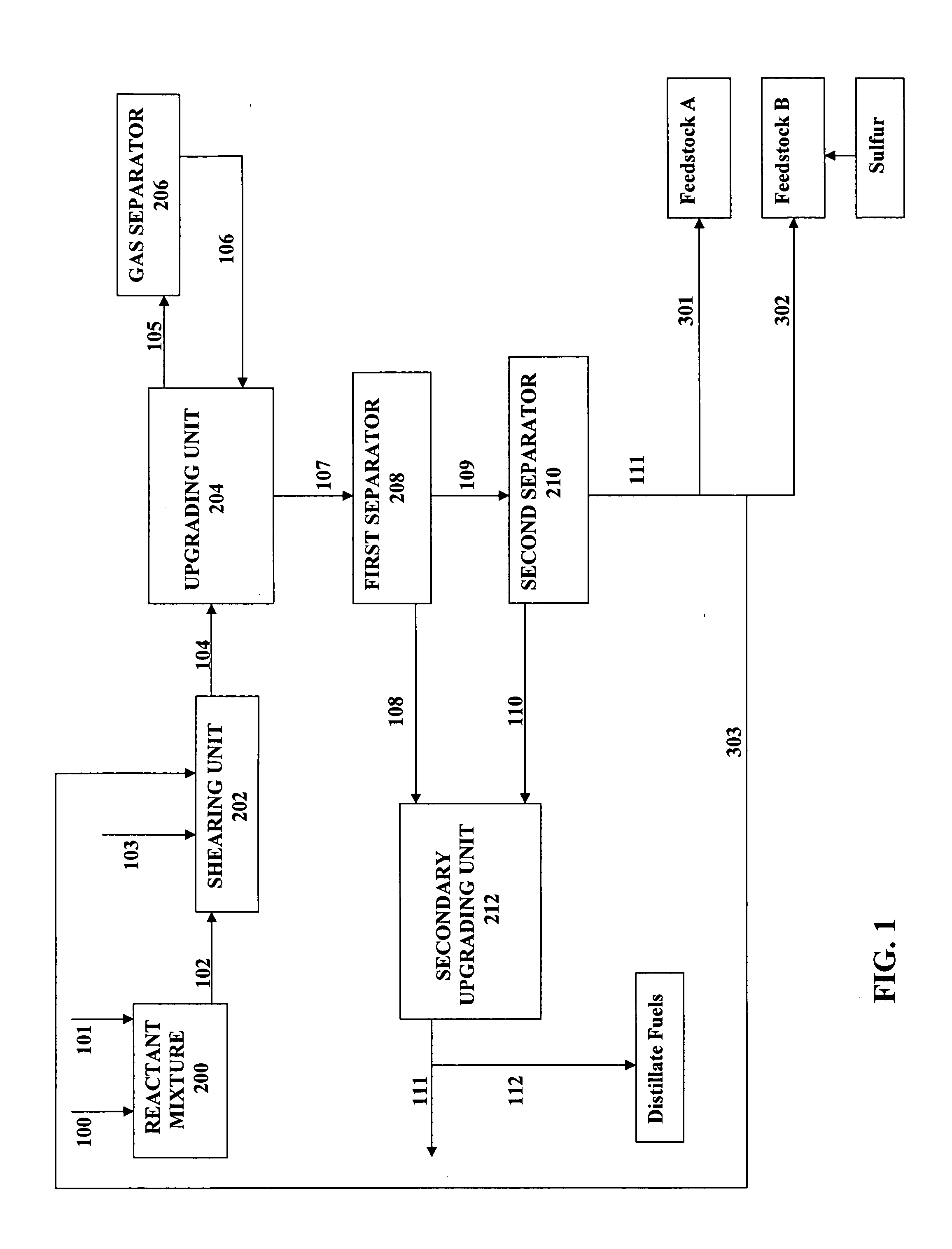

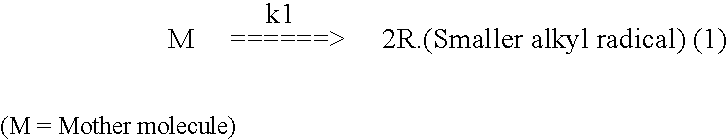

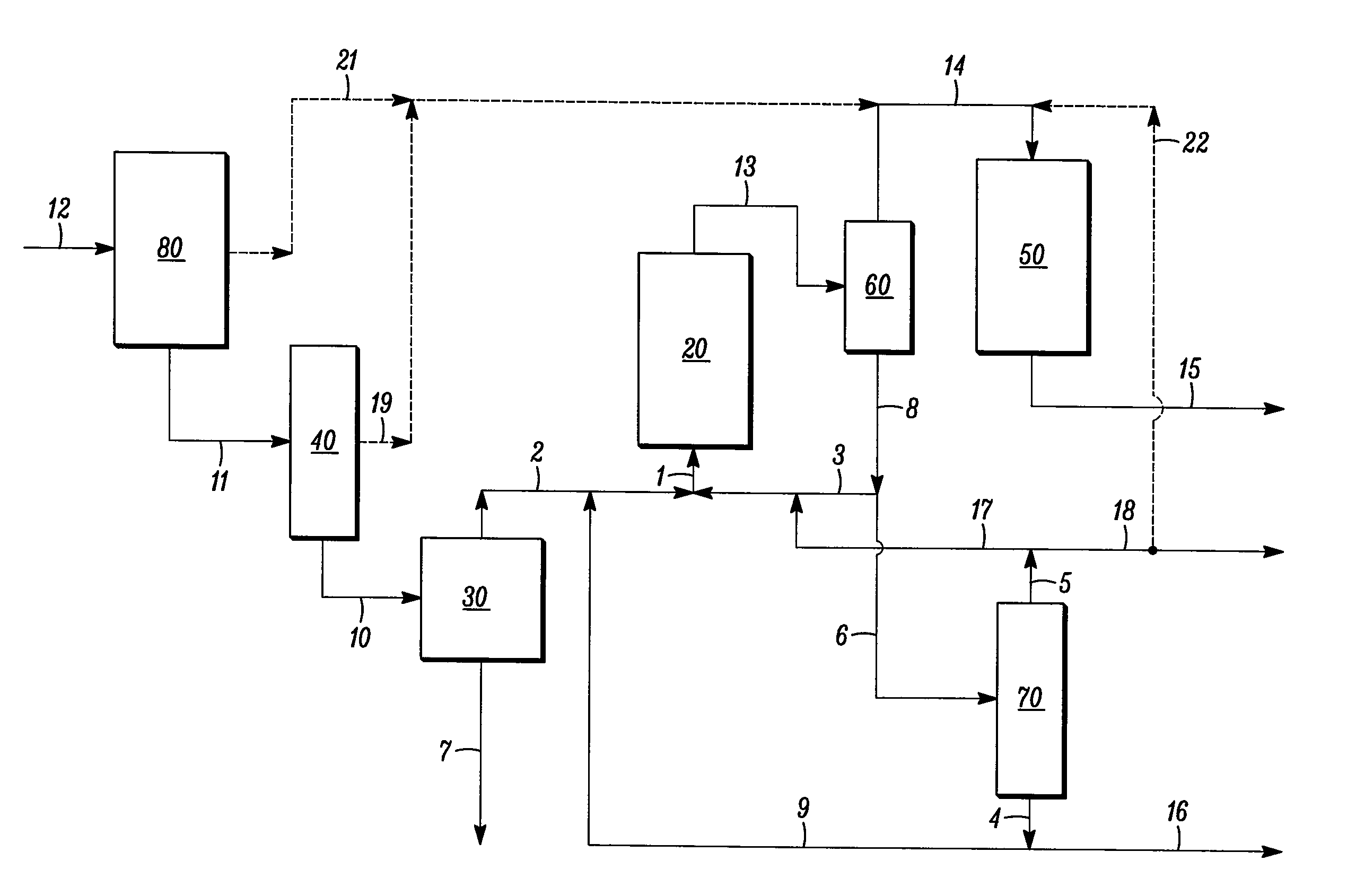

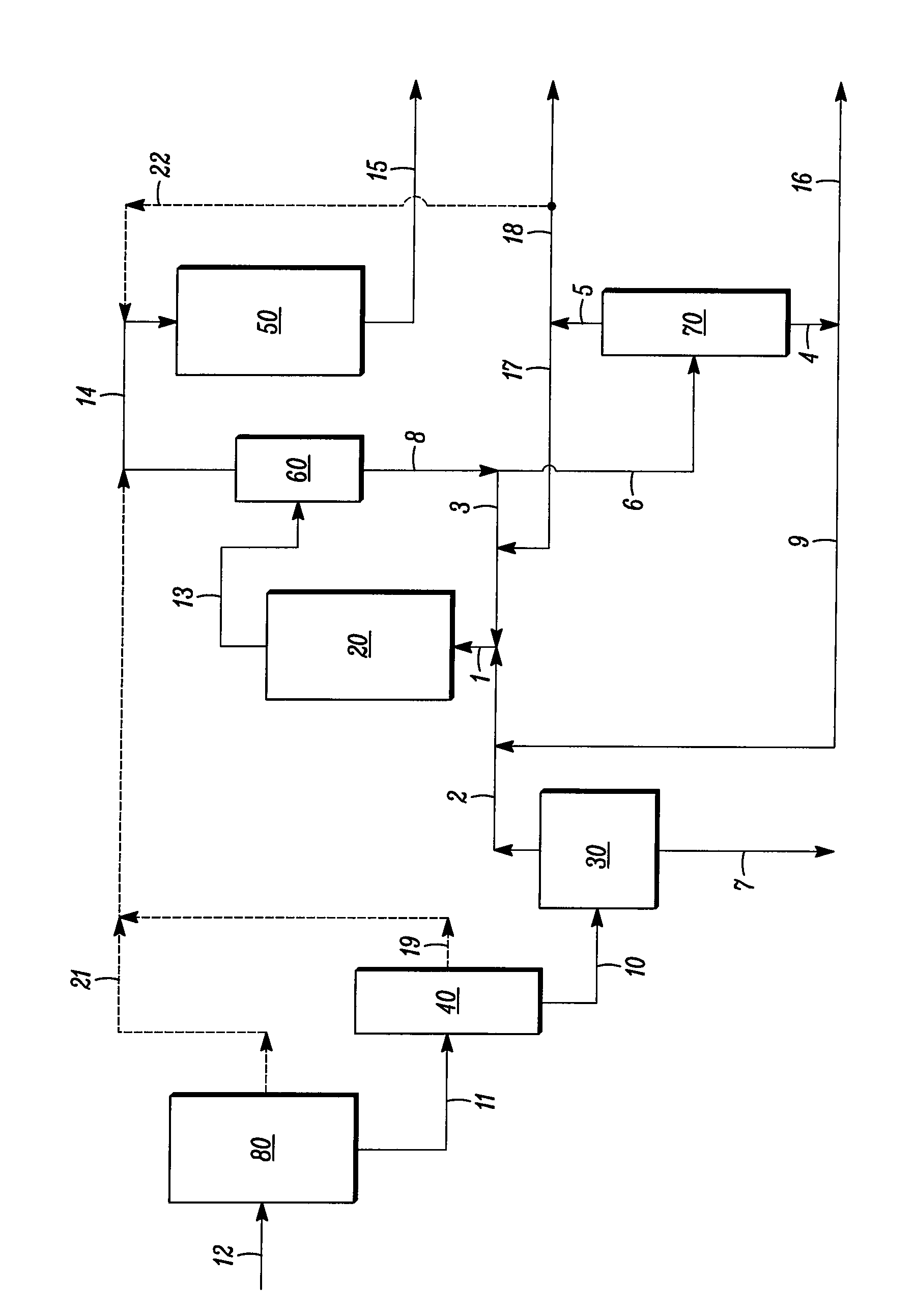

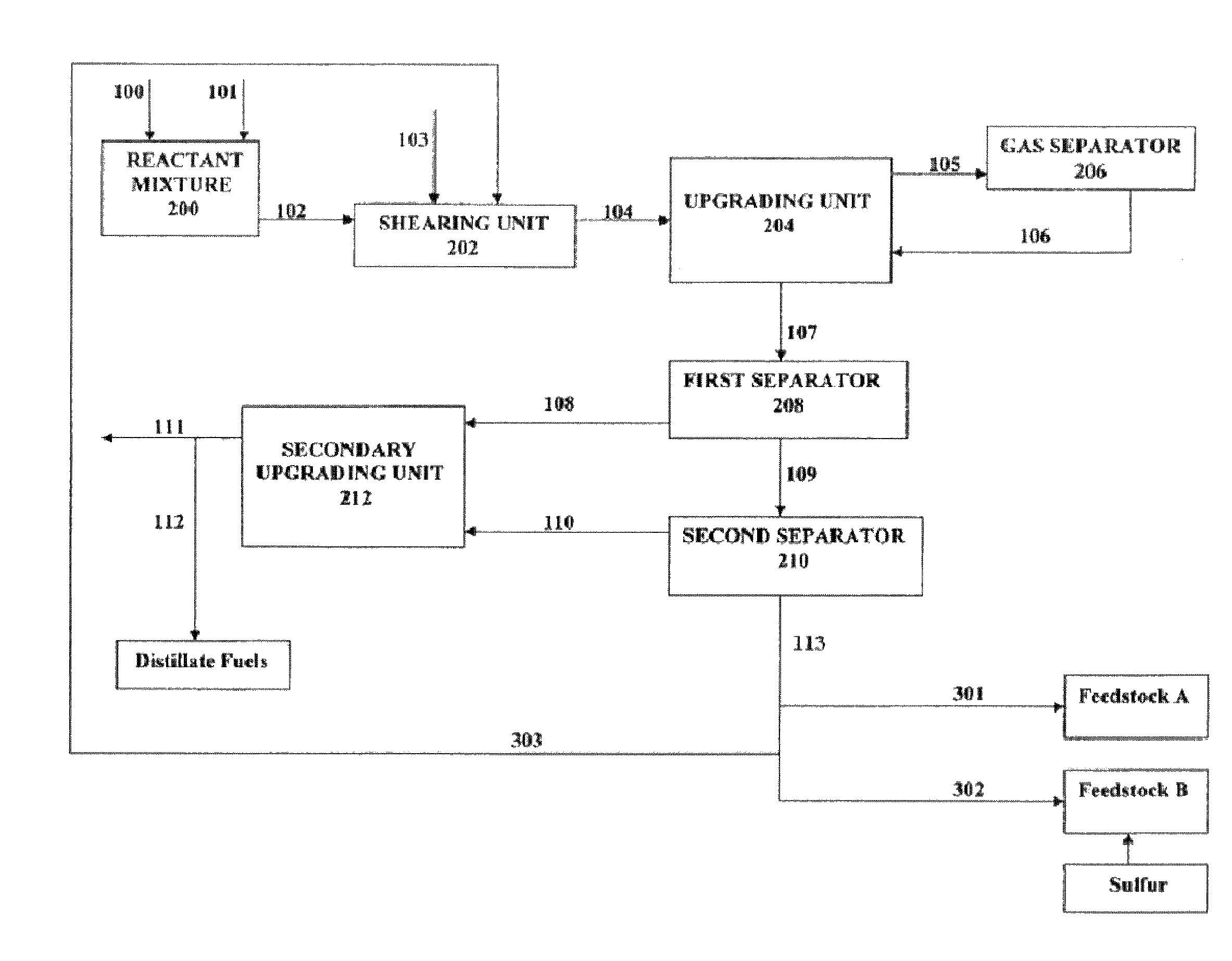

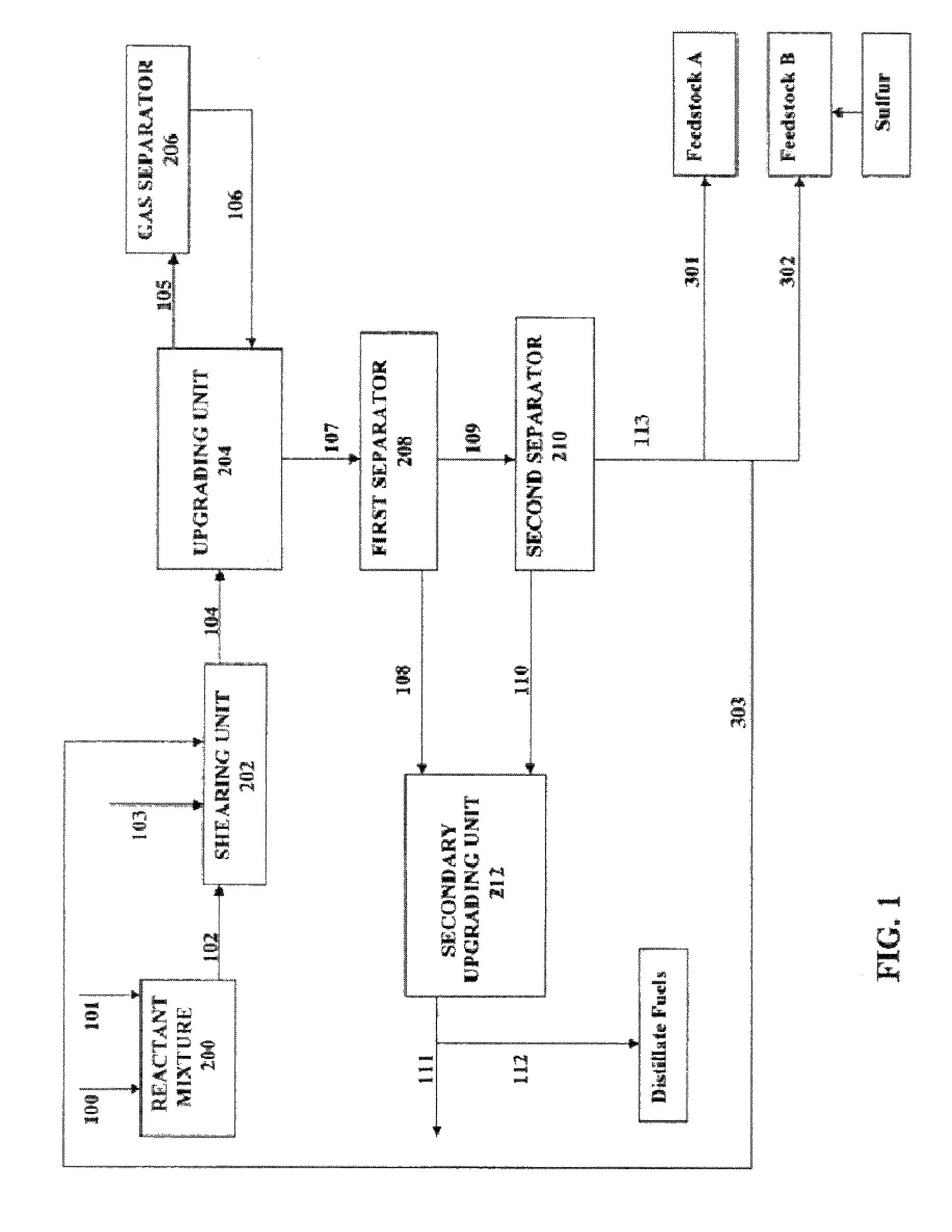

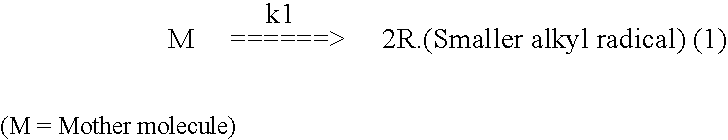

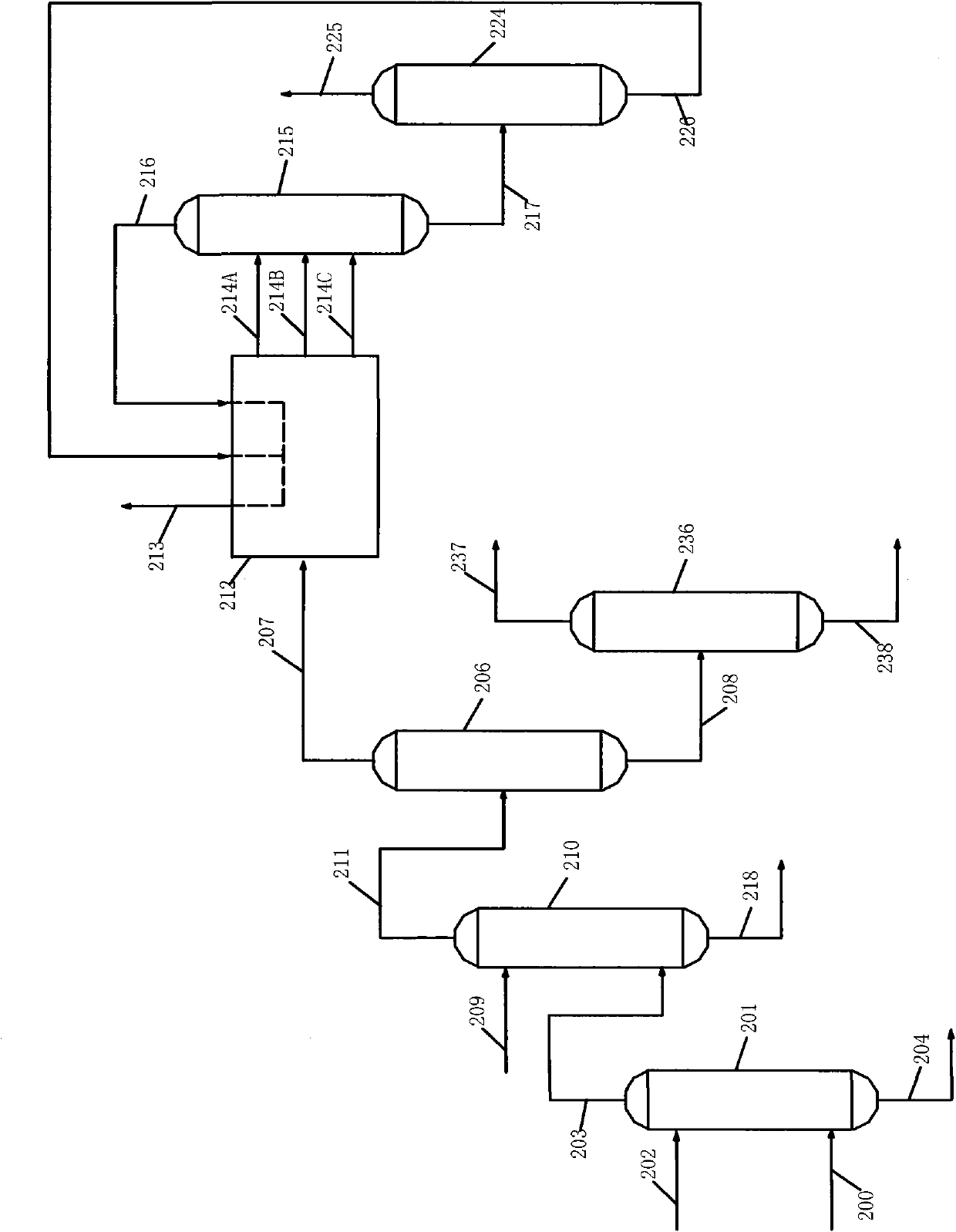

Methods for making higher value products from sulfur containing crude oil

ActiveUS20060254956A1High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

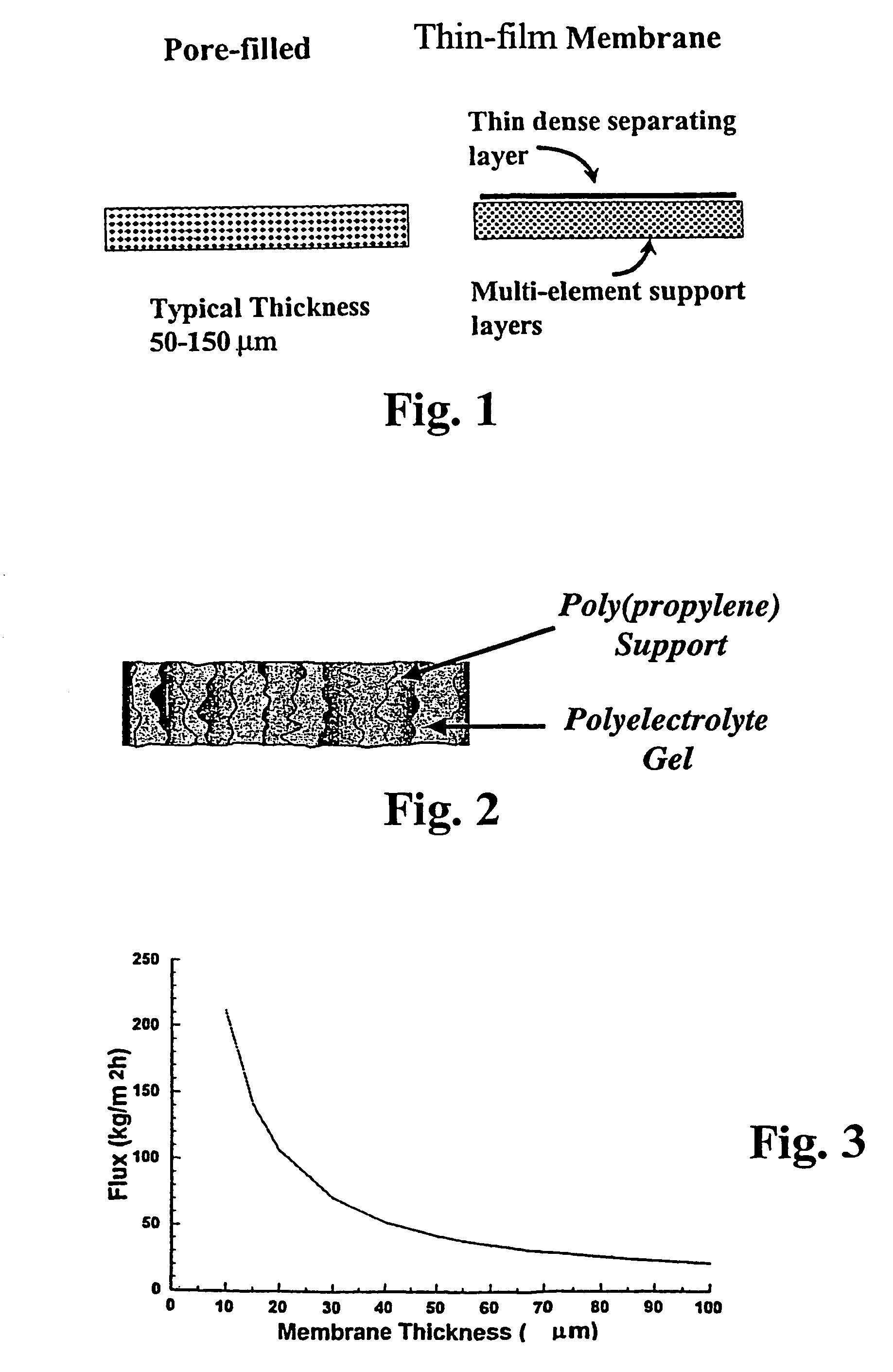

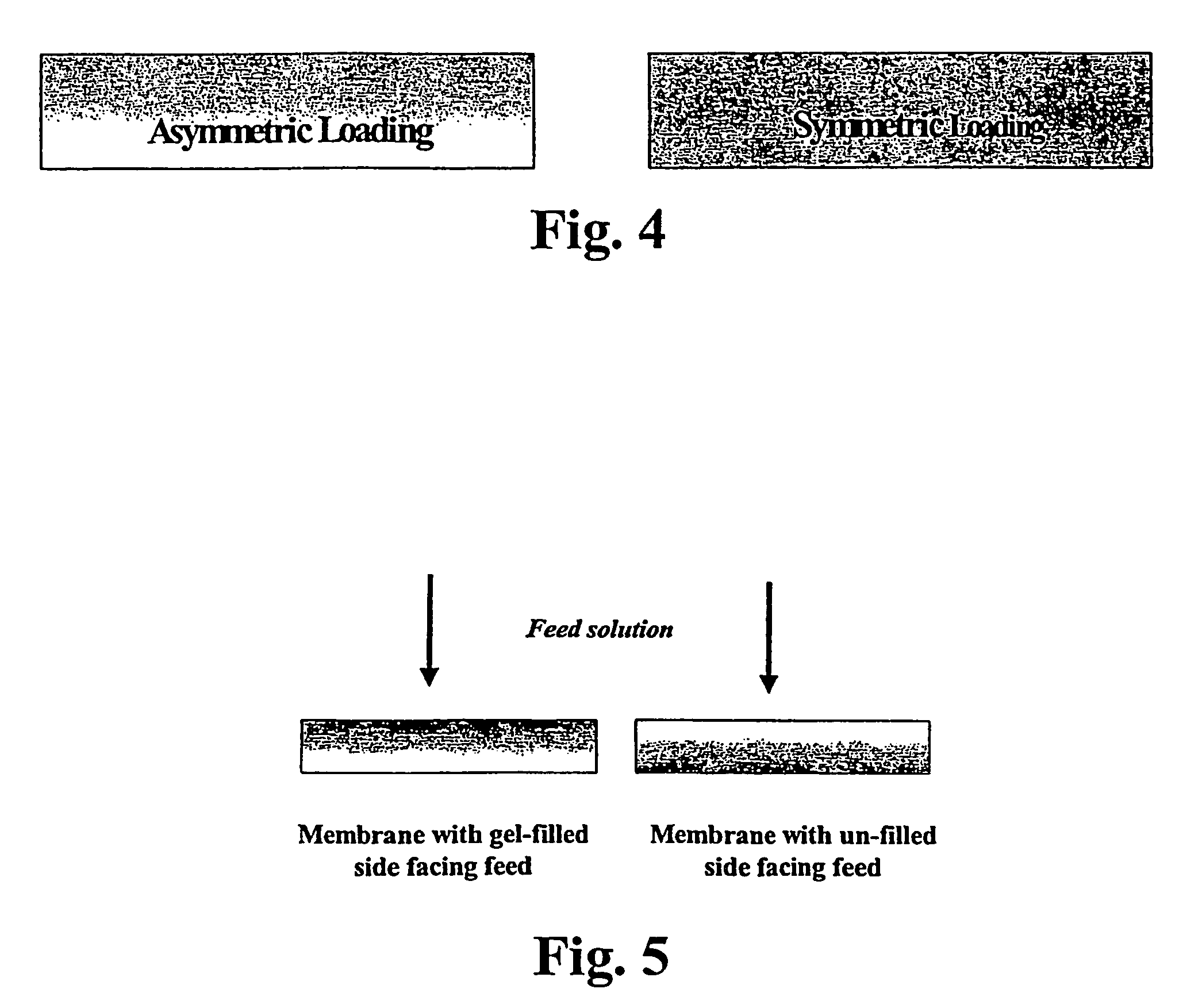

Asymmetric gel-filled microporous membranes

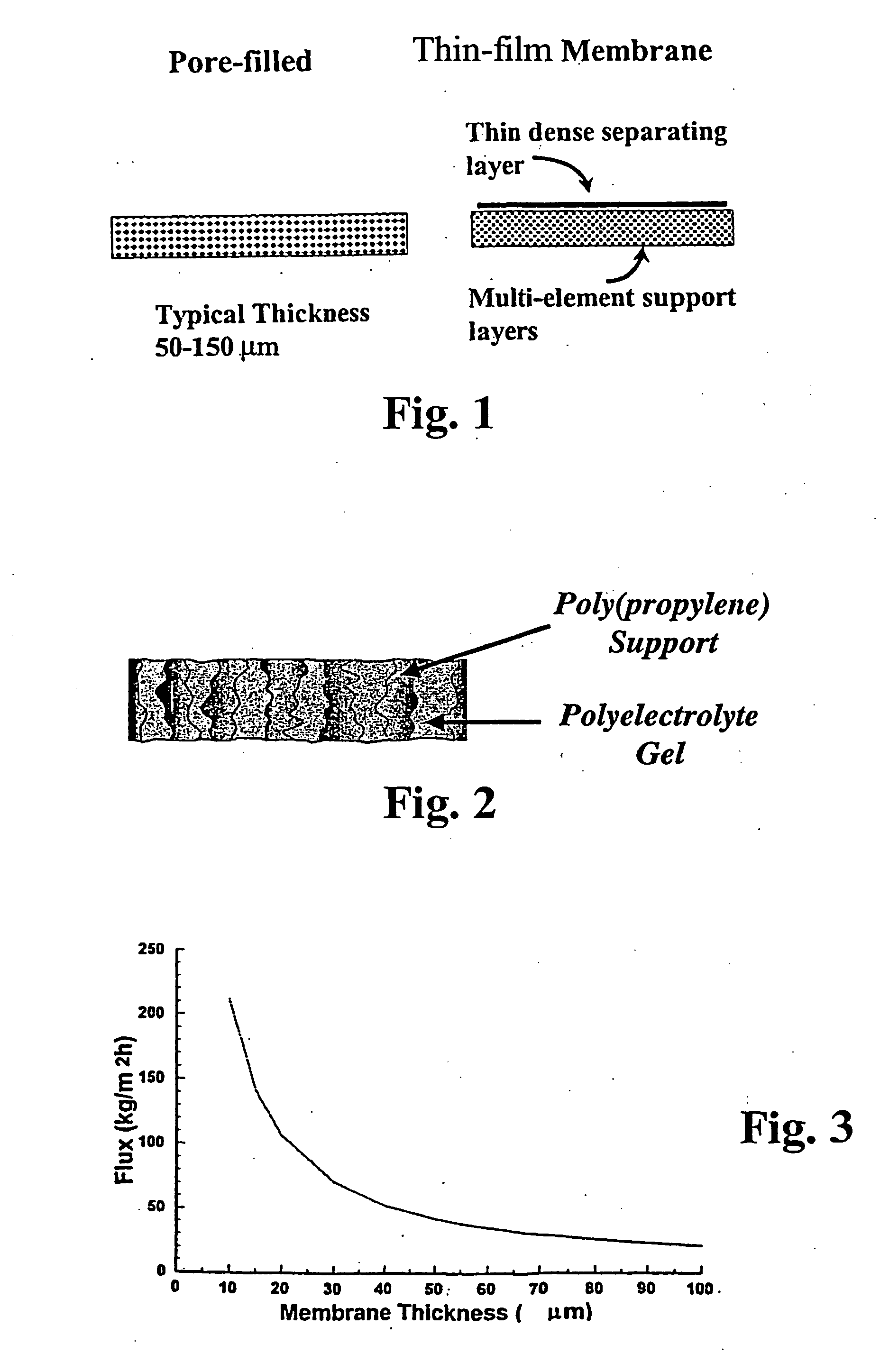

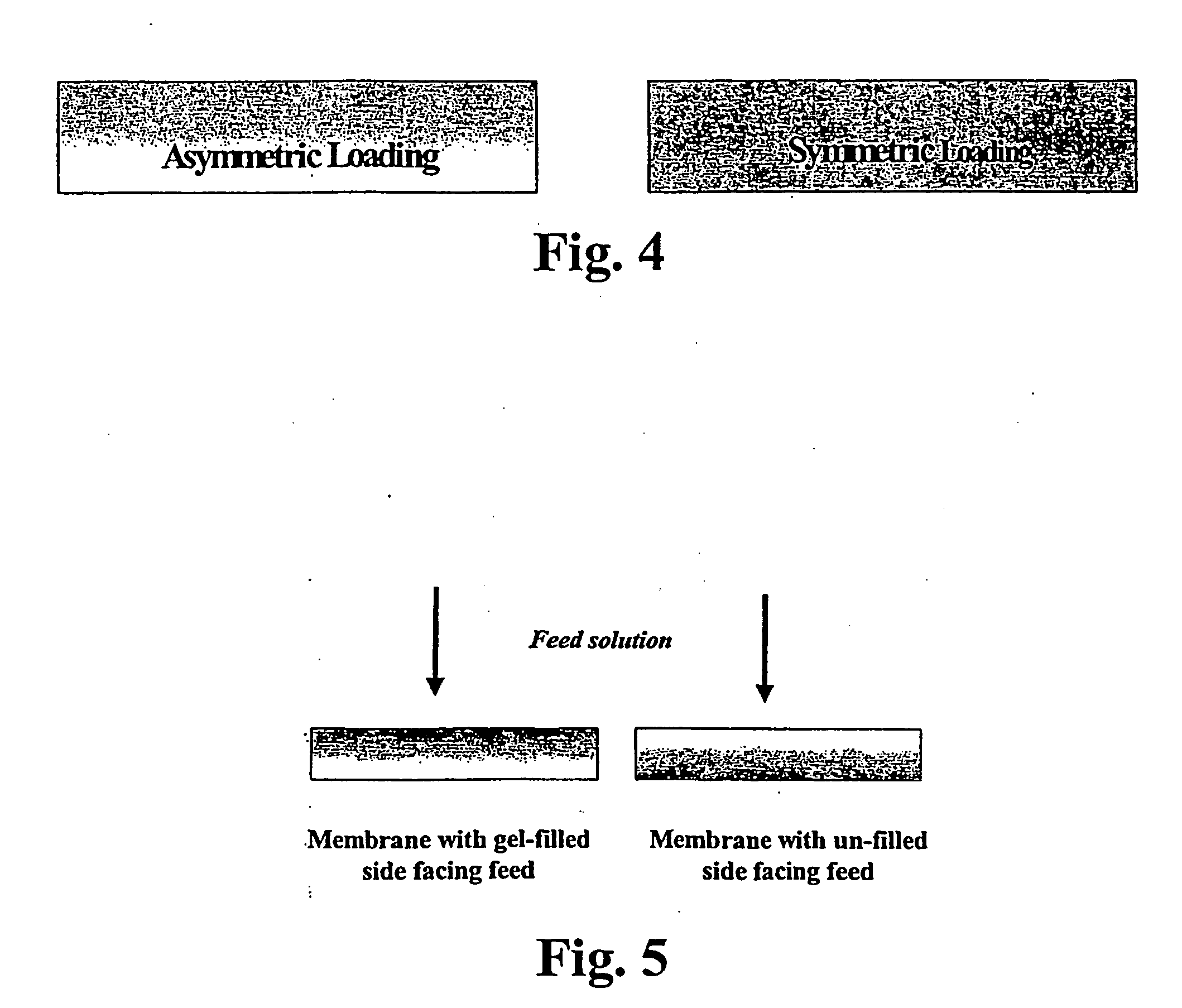

InactiveUS20050011826A1Excellent propertyImprove throughputMembranesSemi-permeable membranesCrystallographyVolumetric Mass Density

The invention provides asymmetric membranes composed of a microporous substrate whose pores contain a crosslinked gel, the density of the crosslinked gel being greater at or adjacent to one major surface of the membrane than the density at the other major surface. The membranes are useful for separating matter from liquids and display good flux and good rejection at low pressure.

Owner:MCMASTER UNIV

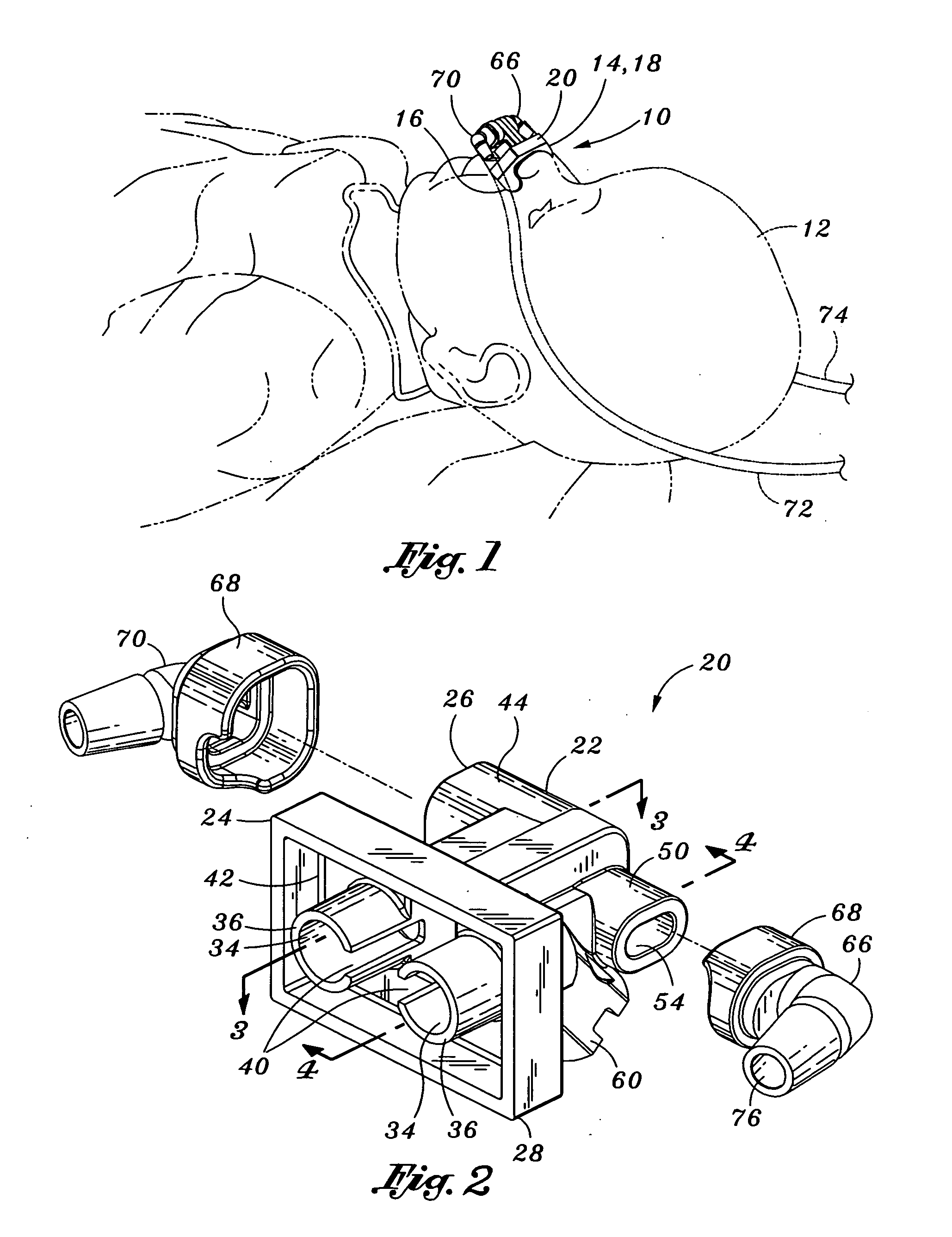

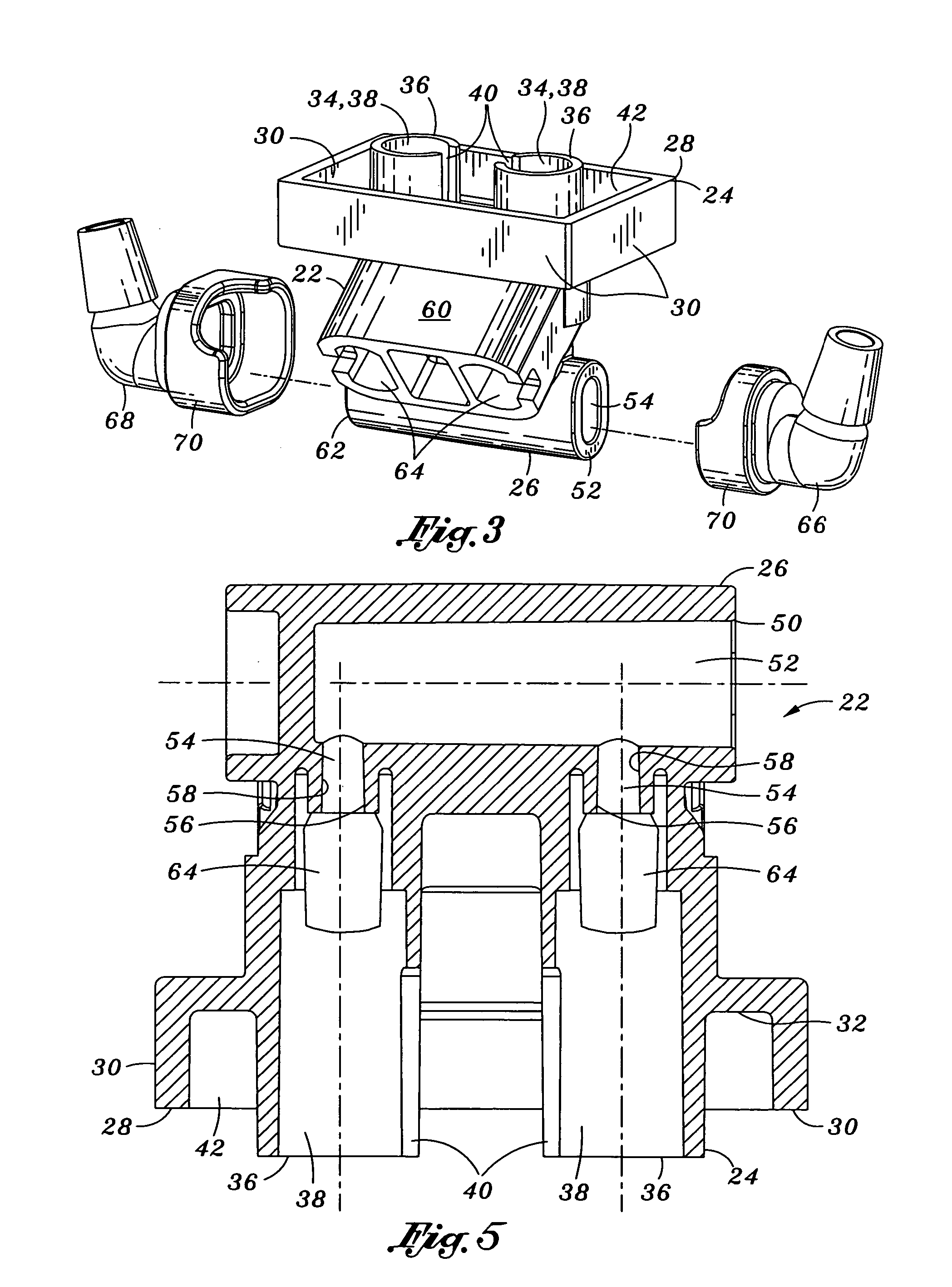

Venturi geometry design for flow-generator patient circuit

ActiveUS20070074724A1Risk minimizationReduce gas pressureRespiratorsFire rescueIntensive care medicineBreathing process

Provided is a universal interface adapted for providing continuous positive airway pressure to a patient when the interface is used with a standard ventilator. The interface is configured to operate at a supply pressure no greater than about 120 centimeters of H2O in order to deliver pressure to the patient of up to about 15 cm of H2O at a flow rate of up to about 12 liters / minute. The universal interface may comprise an interface body having a space pair of breathing passageways intersecting a corresponding of supply passageways. Each one of the breathing passageways is comprised of a patient passageway and an exhalation passageway. Each one of the supply passageways includes a jet venturi having a taper portion. Each one of the exhalation passageways includes a taper portion which tapers outwardly along a direction from the patient passageway toward the exhalation passageway.

Owner:VYAIRE MEDICAL 211 INC

Asymmetric gel-filled microporous membranes

InactiveUS7247370B2Excellent propertyImprove throughputSemi-permeable membranesMembranesCrystallographyVolumetric Mass Density

The invention provides asymmetric membranes composed of a microporous substrate whose pores contain a crosslinked gel, the density of the crosslinked gel being greater at or adjacent to one major surface of the membrane than the density at the other major surface. The membranes are useful for separating matter from liquids and display good flux and good rejection at low pressure.

Owner:MCMASTER UNIV

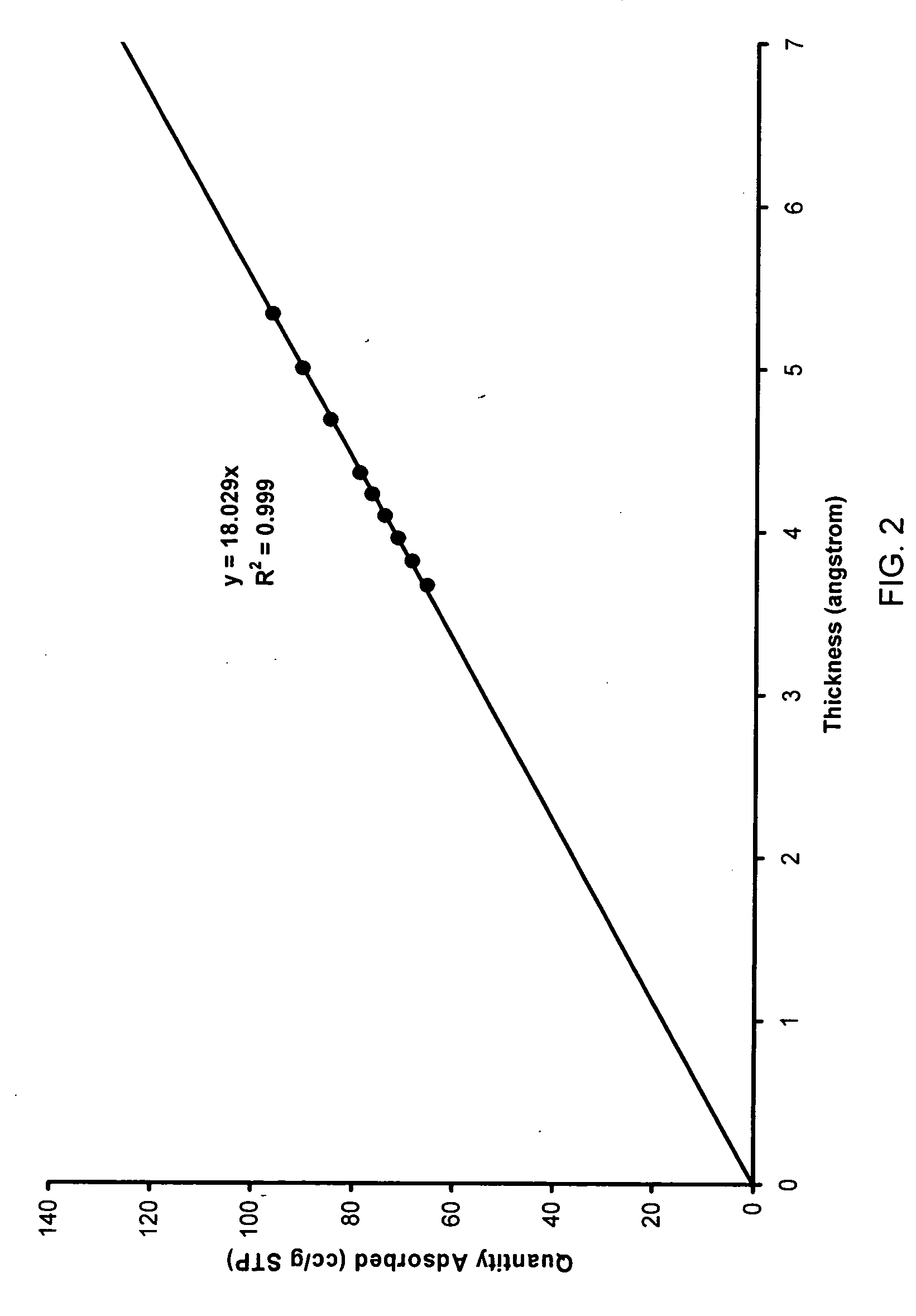

Ultraporous sol gel monoliths

ActiveUS20060131238A1Shorten the timeEasy to optimizeIon-exchange process apparatusPhysical/chemical process catalystsPorosityHYDROSOL

Ultraporous sol gel monoliths and methods for preparing the same are provided, having superior flow characteristics for chromatography and analytical chemistry applications. The methods for forming an ultra porous sol-gel monolith include (a) forming a solution comprising a porogen, a matrix dissolving catalyst and a sol gel precursor; (b) allowing the solution to form a gel; and (c) drying the gel at an elevated temperature. The ultraporous sol gel monoliths are characterized by a porosity of up to about 97%, a BET surface area of at least about 50 m2 / g and substantially no micropores.

Owner:AGILENT TECH INC

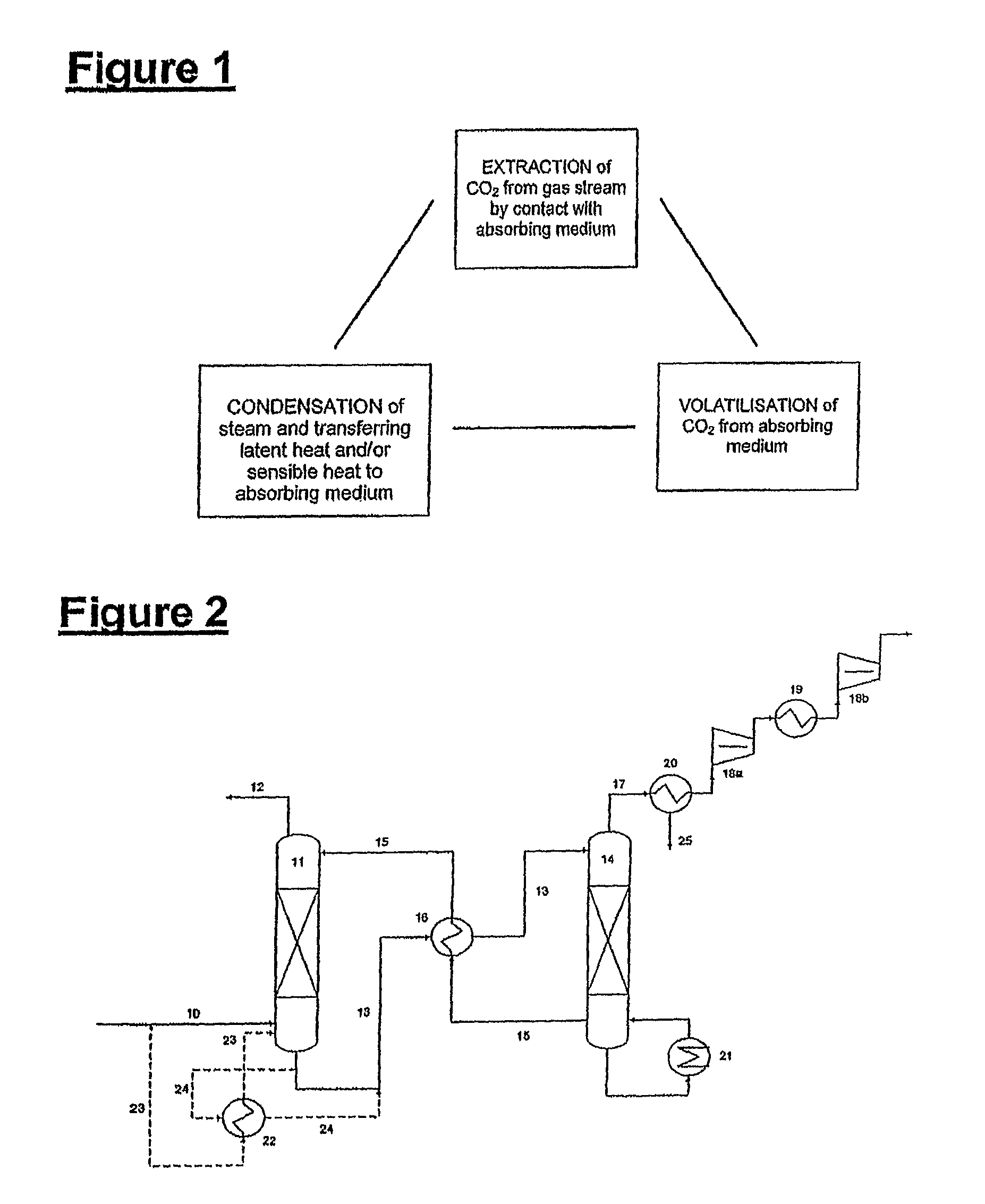

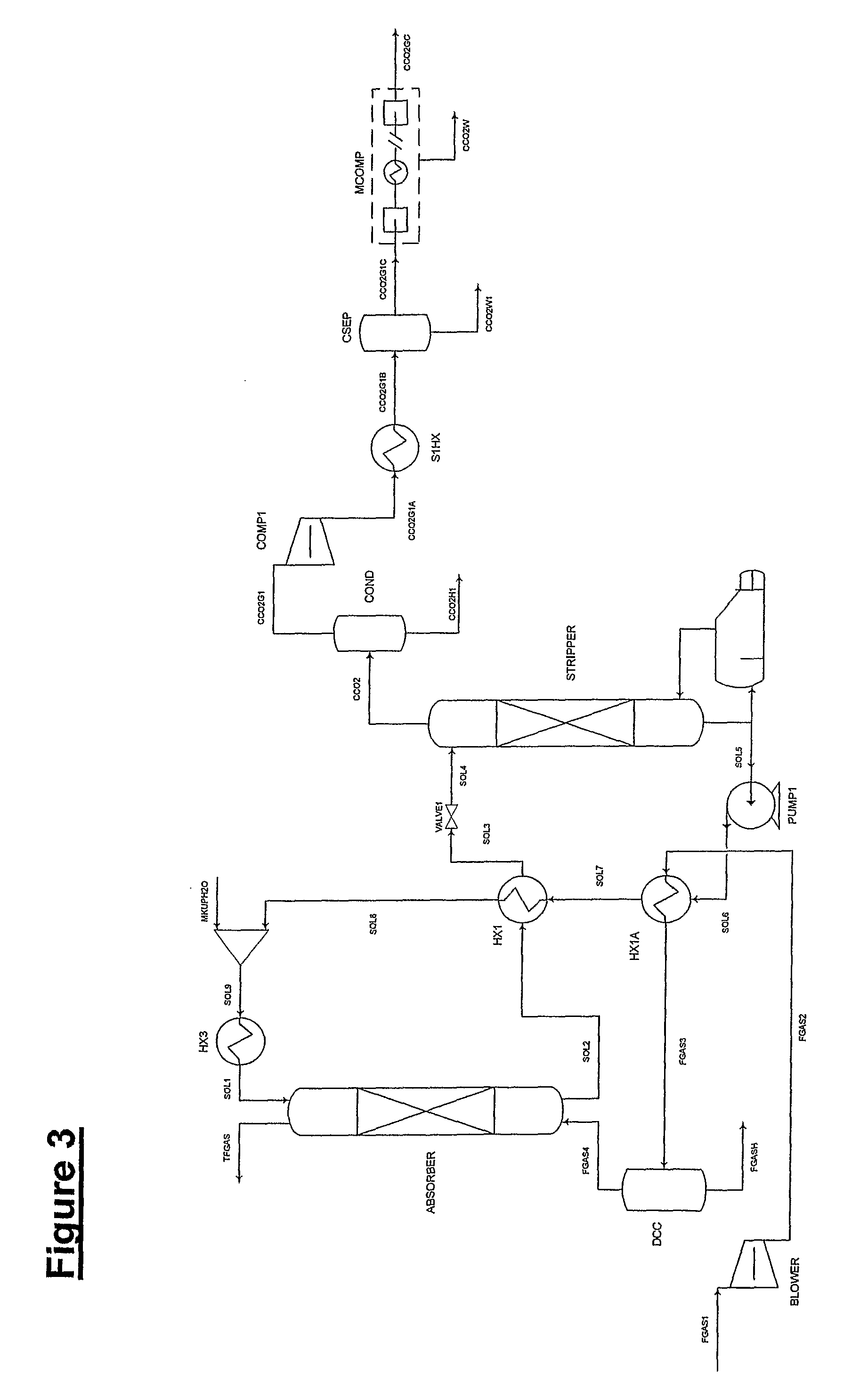

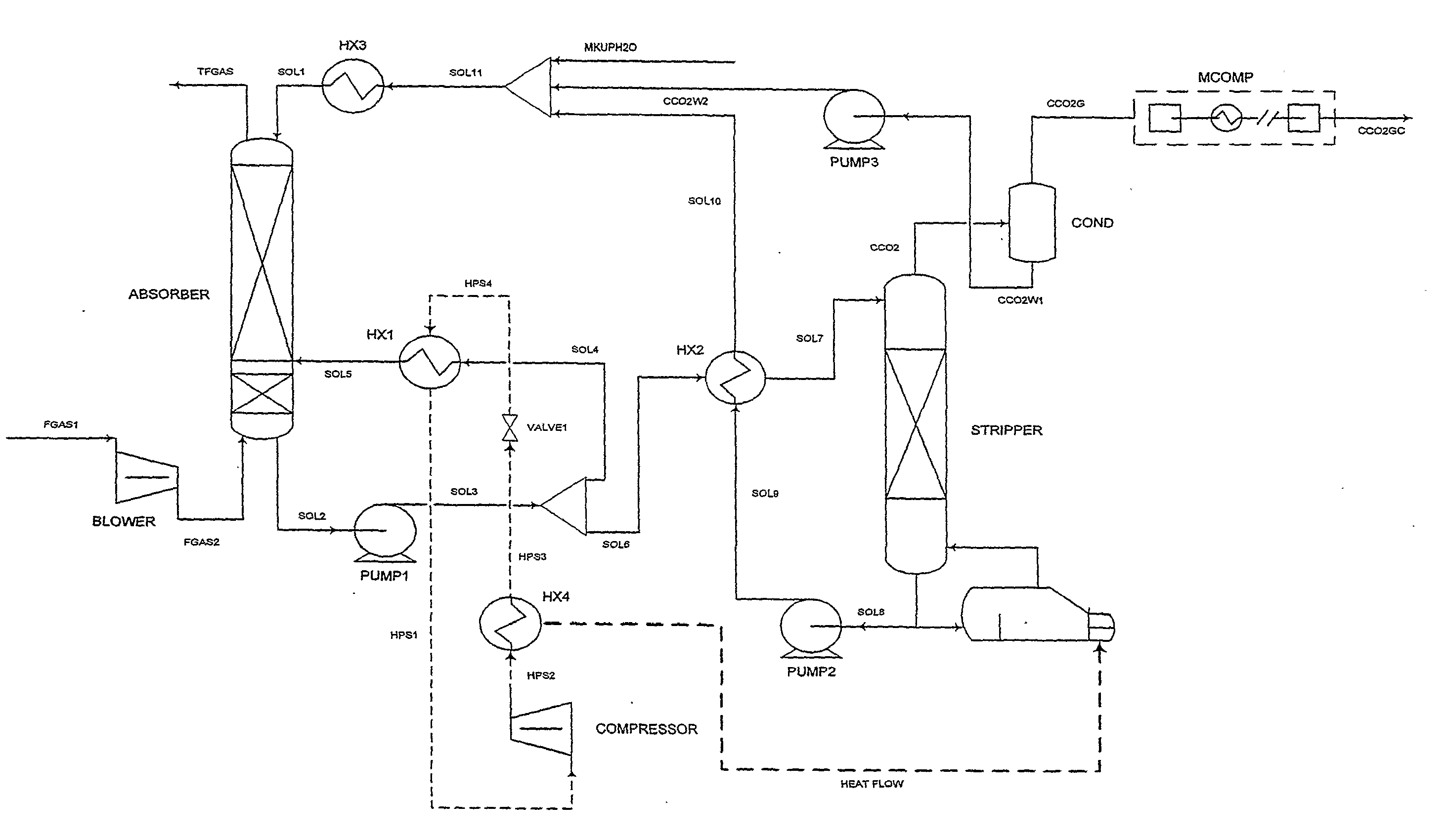

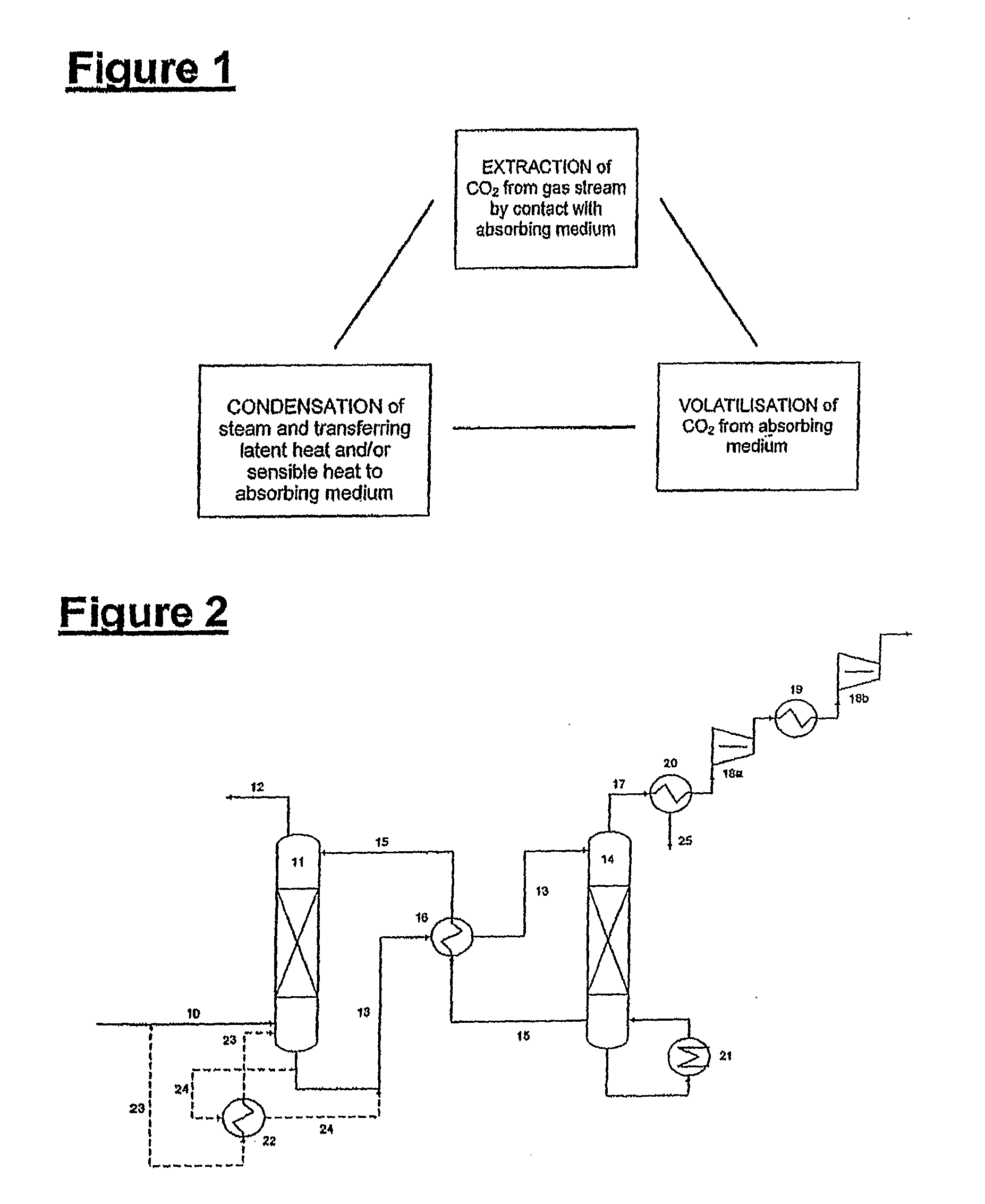

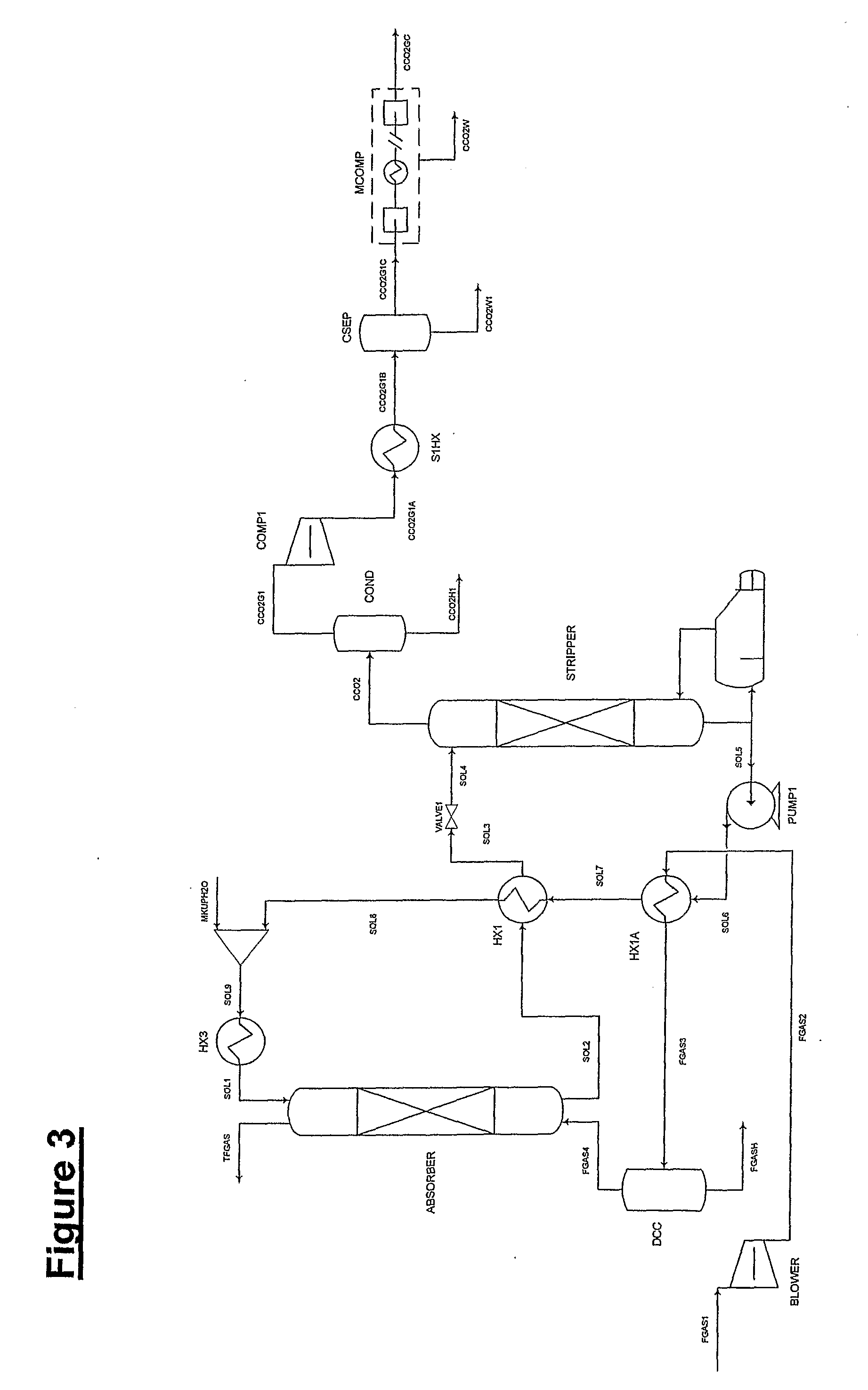

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

Plant And Process For Removing Carbon Dioxide From Gas Streams

ActiveUS20080317651A1Minimizing overall energy requiredAssist in volatilizationExhaust apparatusDispersed particle separationBy-productChemistry

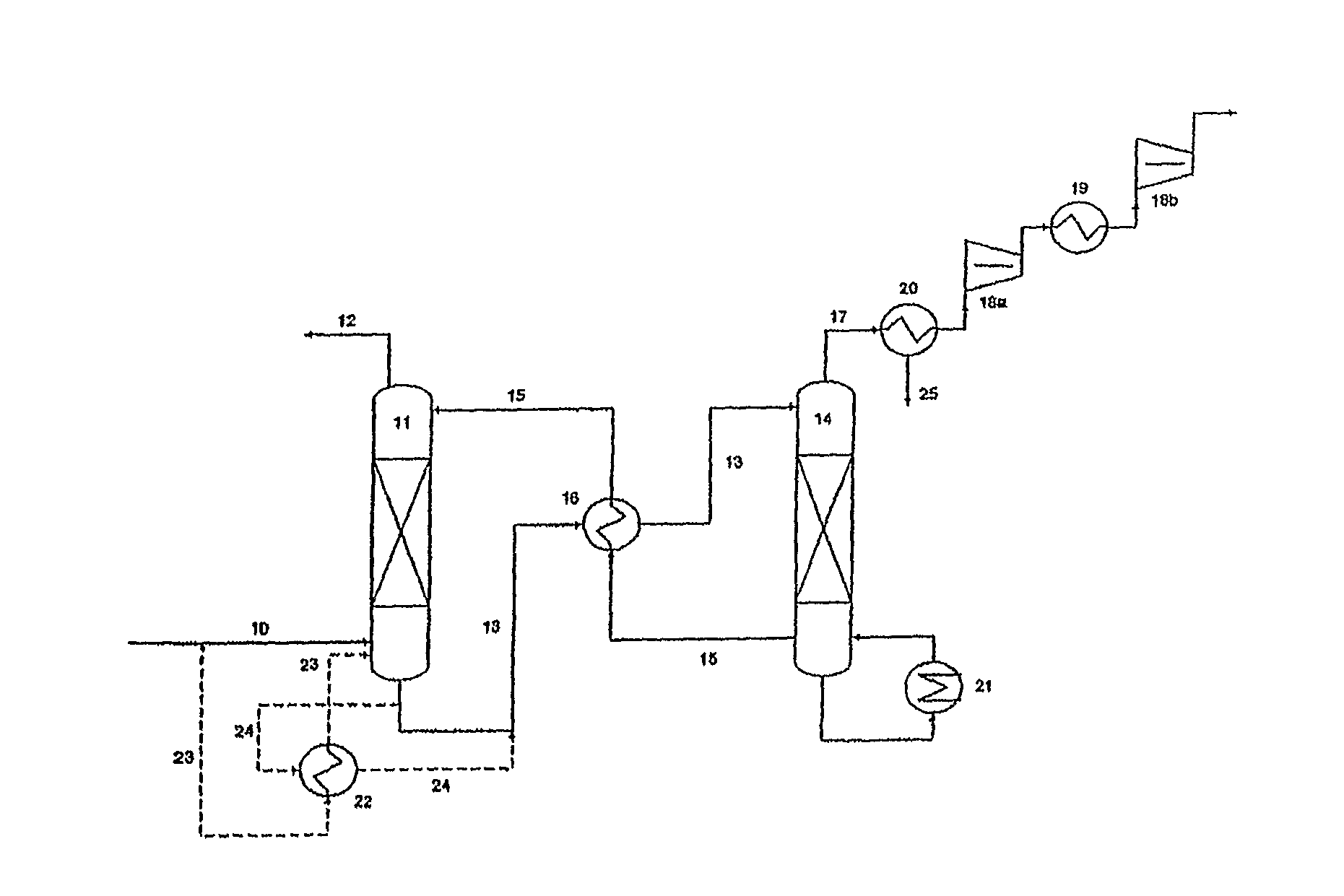

The present invention is based on the realization that the carbon dioxide component of industrial gas streams also containing steam can be processed so to utilize either as latent and / or sensible heat the heat available from the steam component to assist in separating carbon dioxide from the remainder of the gas stream. For example, flue gases produced by power stations burning brown coal, black coal or natural gas inherently contain a useful amount of energy that can be harnessed according to the present invention. According to particular preferred forms of the invention, nitrogen and sulphur constituent such as SOx and NOx, H2S and other nitrogen containing compounds may also be removed from the gas stream through direct contact with the absorbing medium and used to produce by-products such as fertiliser material.

Owner:KC8 CAPTURE TECH LTD

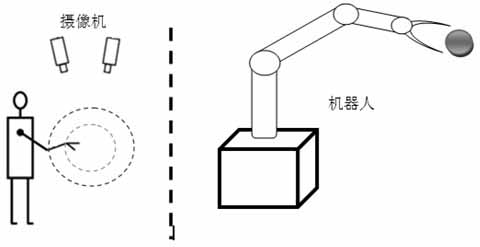

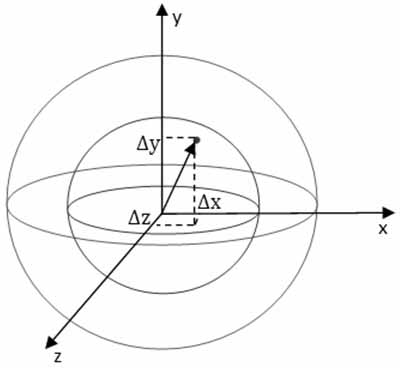

Method for controlling robot based on visual sense

InactiveCN102350700AEasy to controlFlexible controlProgramme-controlled manipulatorRobot controlCharacteristic point

The invention provides a method for controlling a robot based on visual sense. The method comprises the following steps of: (1) acquiring a gesture image of a human hand by using a camera; (2) extracting characteristic points of the human hand from the gesture image; (3) performing three-dimensional reconstruction on the characteristic points to obtain a position relation of the characteristic points of the human hand in a three-dimensional space; (4) converting coordinate points corresponding to the characteristic points of the human hand to be under a base coordinate of the robot; (5) performing inverse-solution calculation by using the position relation of the human hand under a base coordinate system of the robot to obtain a joint angle of the robot; and (6) driving the robot to run by using the calculated joint angle. The method has the advantages that: 1) the control is intuitive, and the holding gesture of the robot directly corresponds to the gesture of the human hand; 2) the control is flexible without contacting an onerous exchange tool; 3) an operator can be assisted to operate more accurately and safely by imitating the prior art; 4) the recovery is allowed to be interrupted or the operator is allowed to be replaced in midway; and 5) the operator does not need to walk in a wide range so that the operating pressure of the operator is reduced.

Owner:SOUTH CHINA UNIV OF TECH

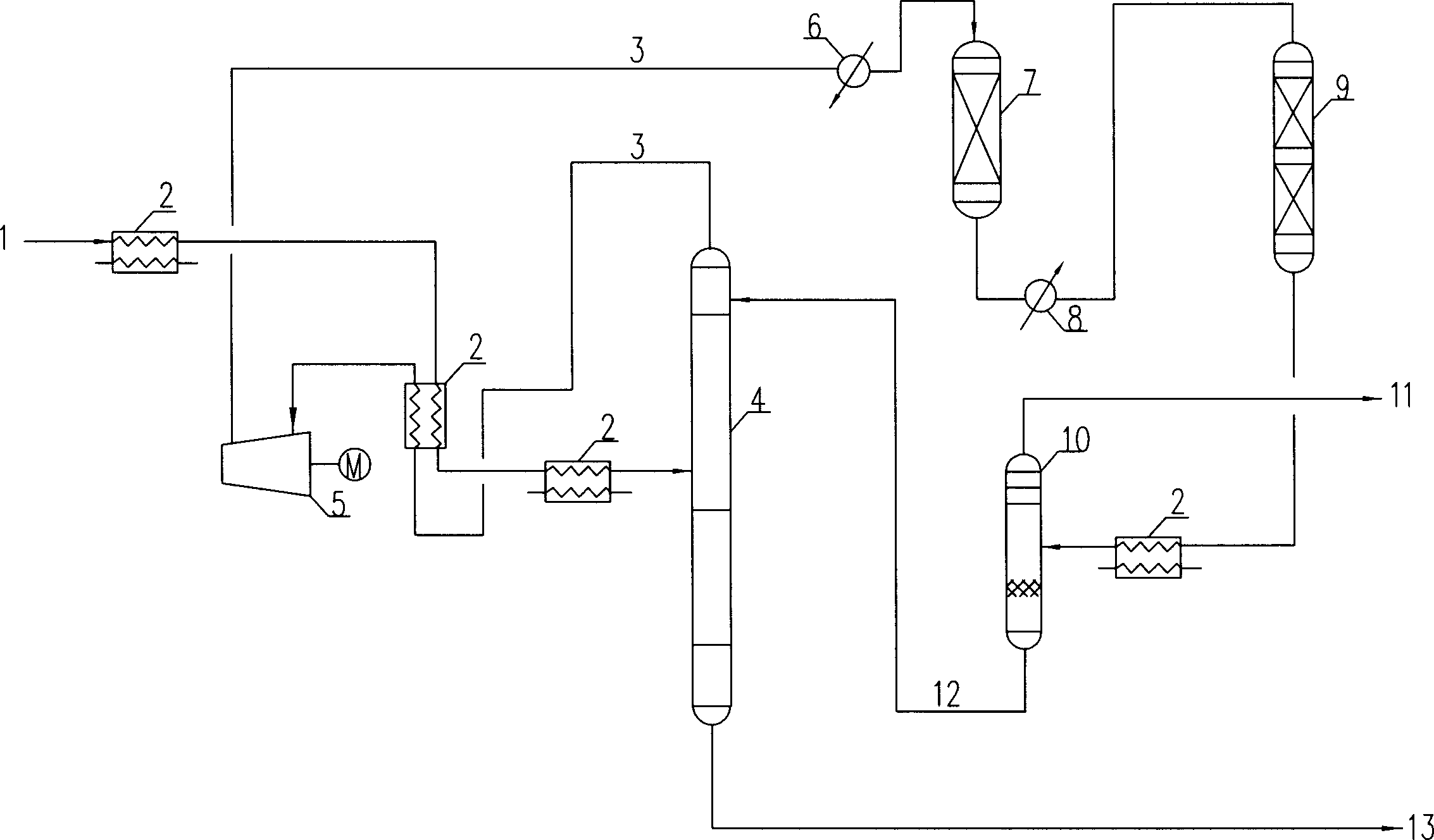

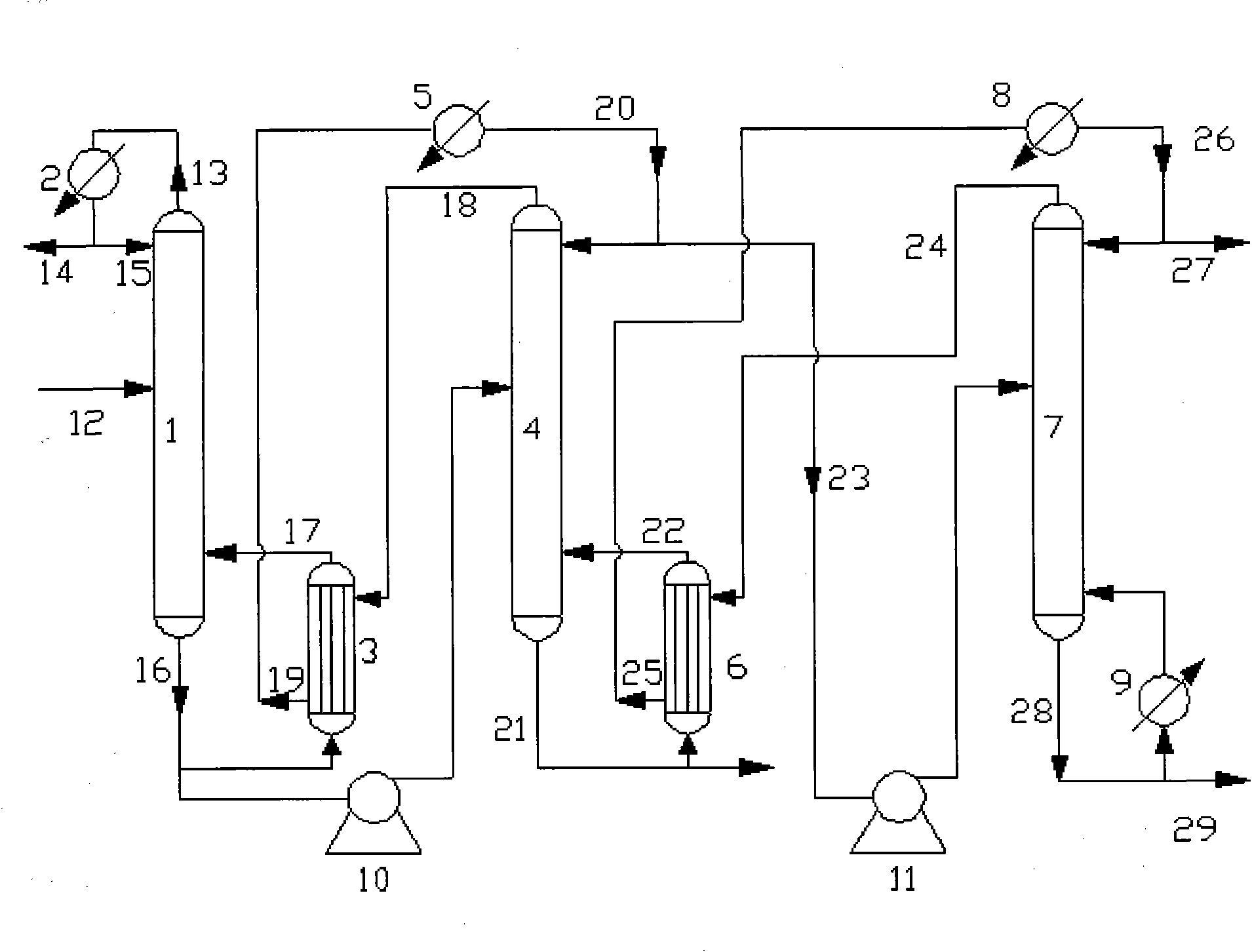

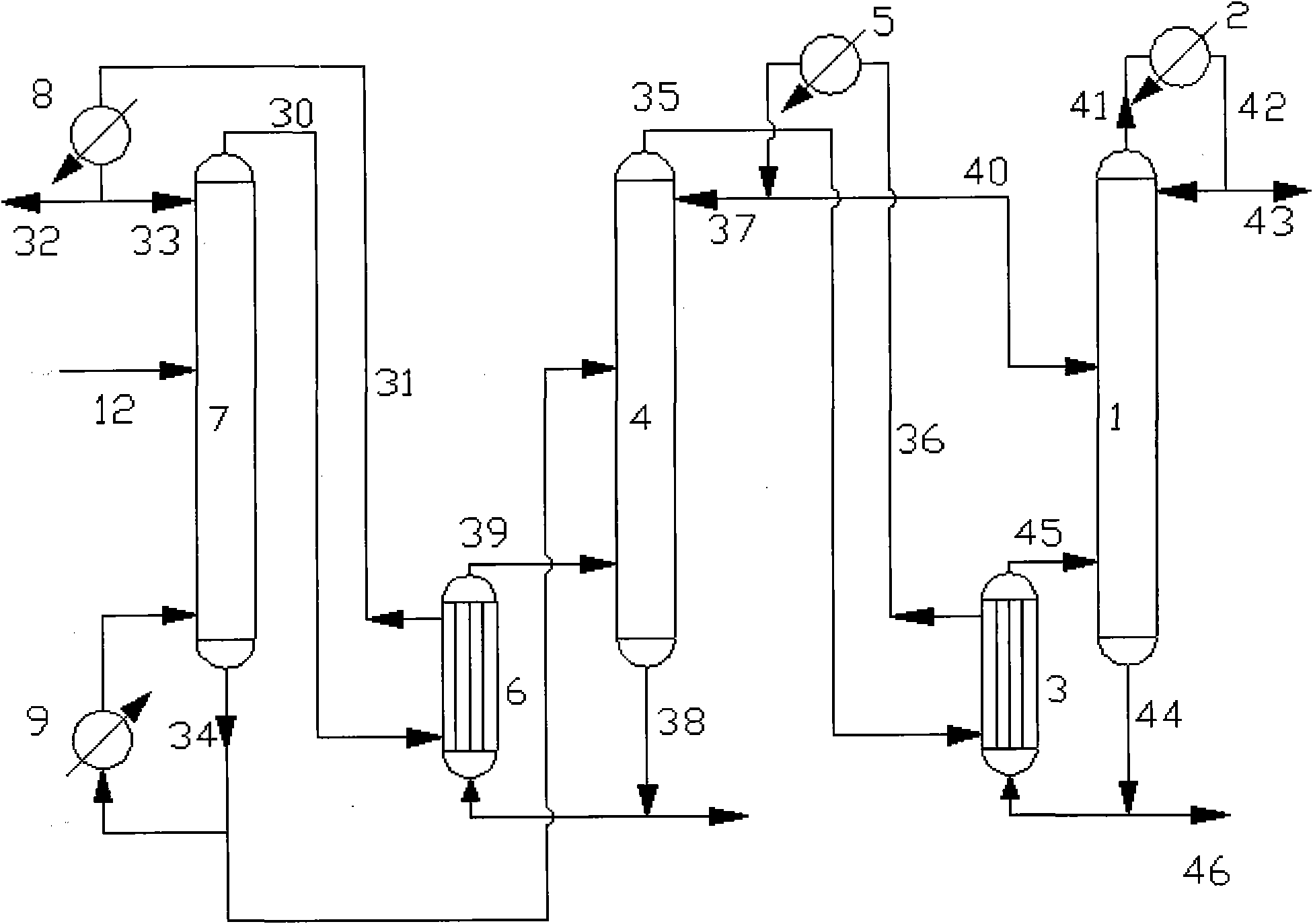

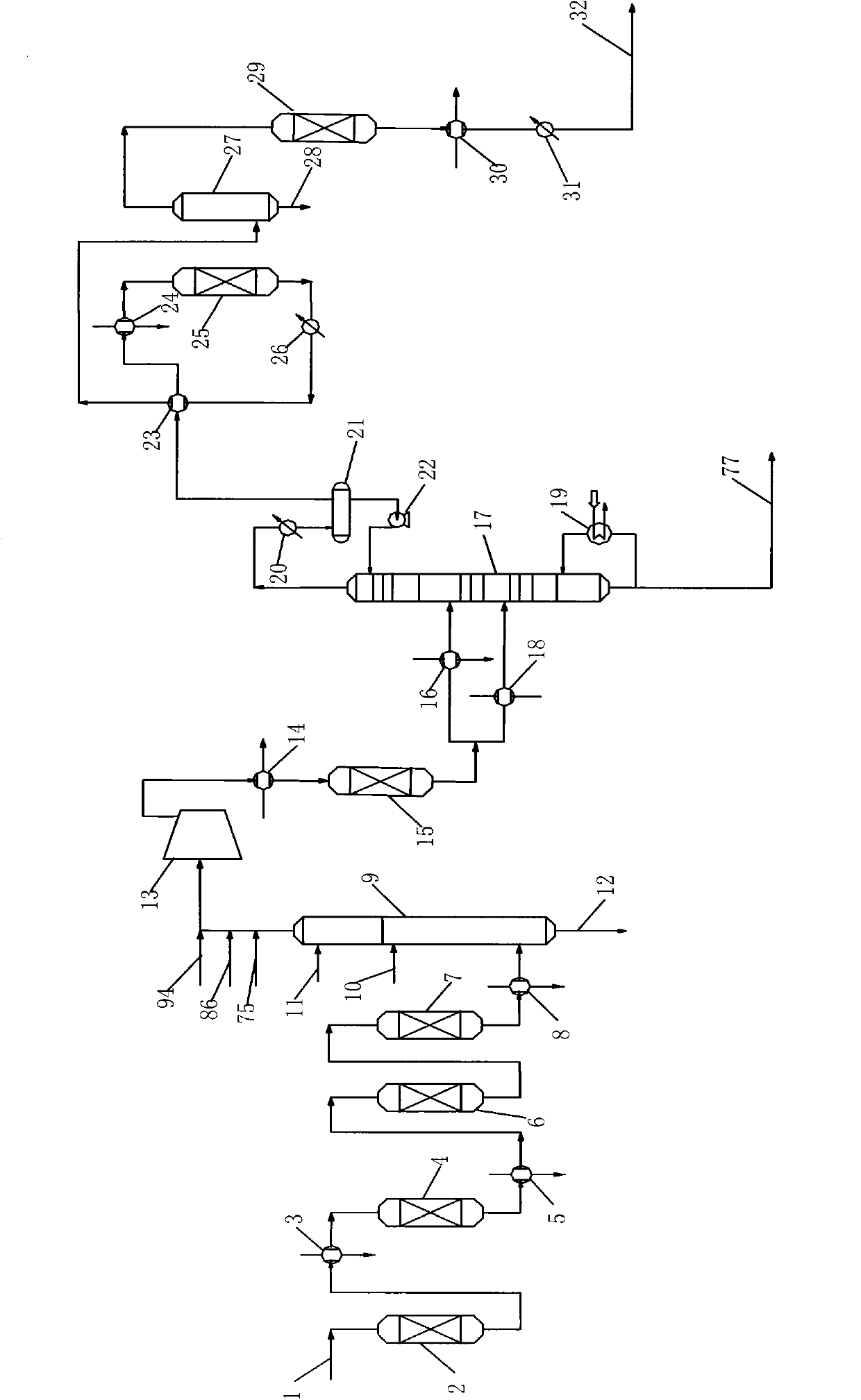

Separating method for converting methanol to prepare low carbon olefin gas

ActiveCN1847203AAvoid enteringReduce power consumptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseTower

The present invention discloses separating method for converting methanol to prepare DMTO gas, and has improved process after four section compression in the front ethane eliminating process. The present invention has one increased hydrogenating oxygen conversion step between the five section compression and the reflux accumulator of ethane eliminating tower to eliminate acetylene and oxygen produced in the regeneration. Of the condensed and cooled material through the reflux accumulator of ethane eliminating tower, the liquid phase serves as the reflux liquid of the ethane eliminating tower, the gas phase is fed to the deep cooling methane eliminating system and the material after condensing and cooling enters the high pressure methane eliminating tower directly. The DMTO gas separating process can obtain ethylene recovering rate as high as 99.5 %.

Owner:CHINA PETROCHEMICAL CORP +1

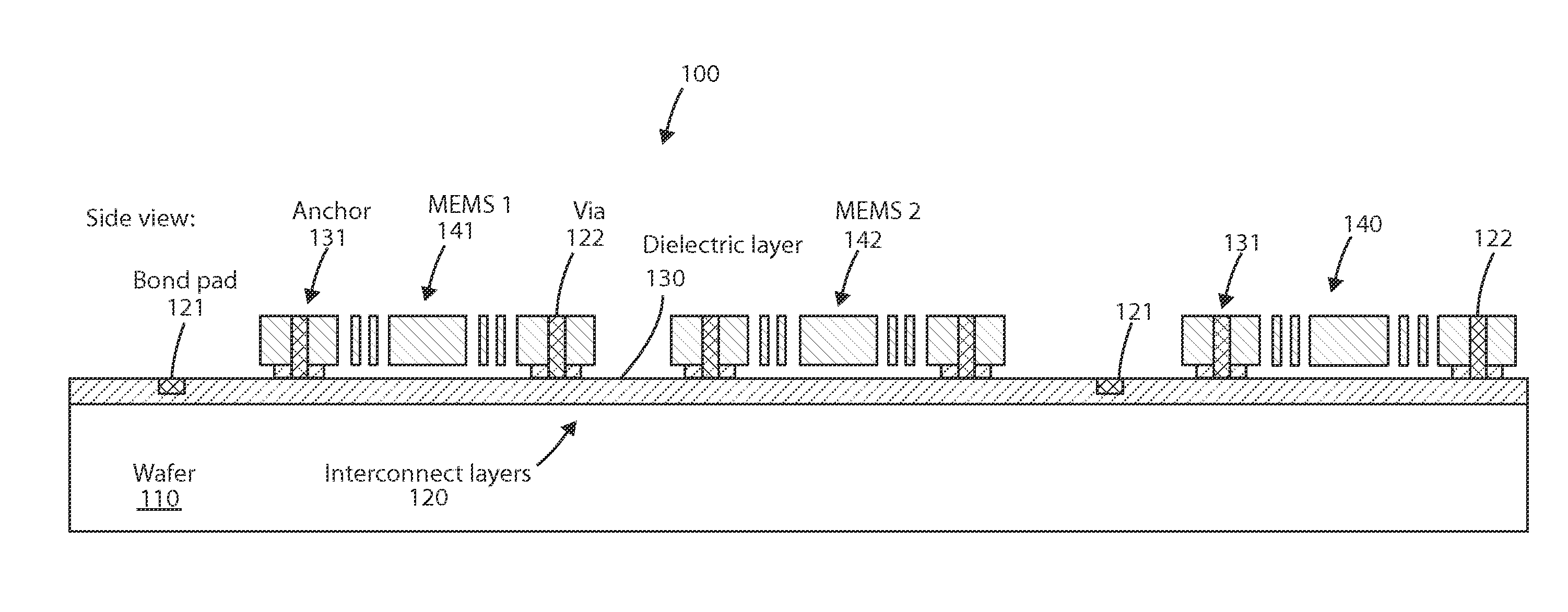

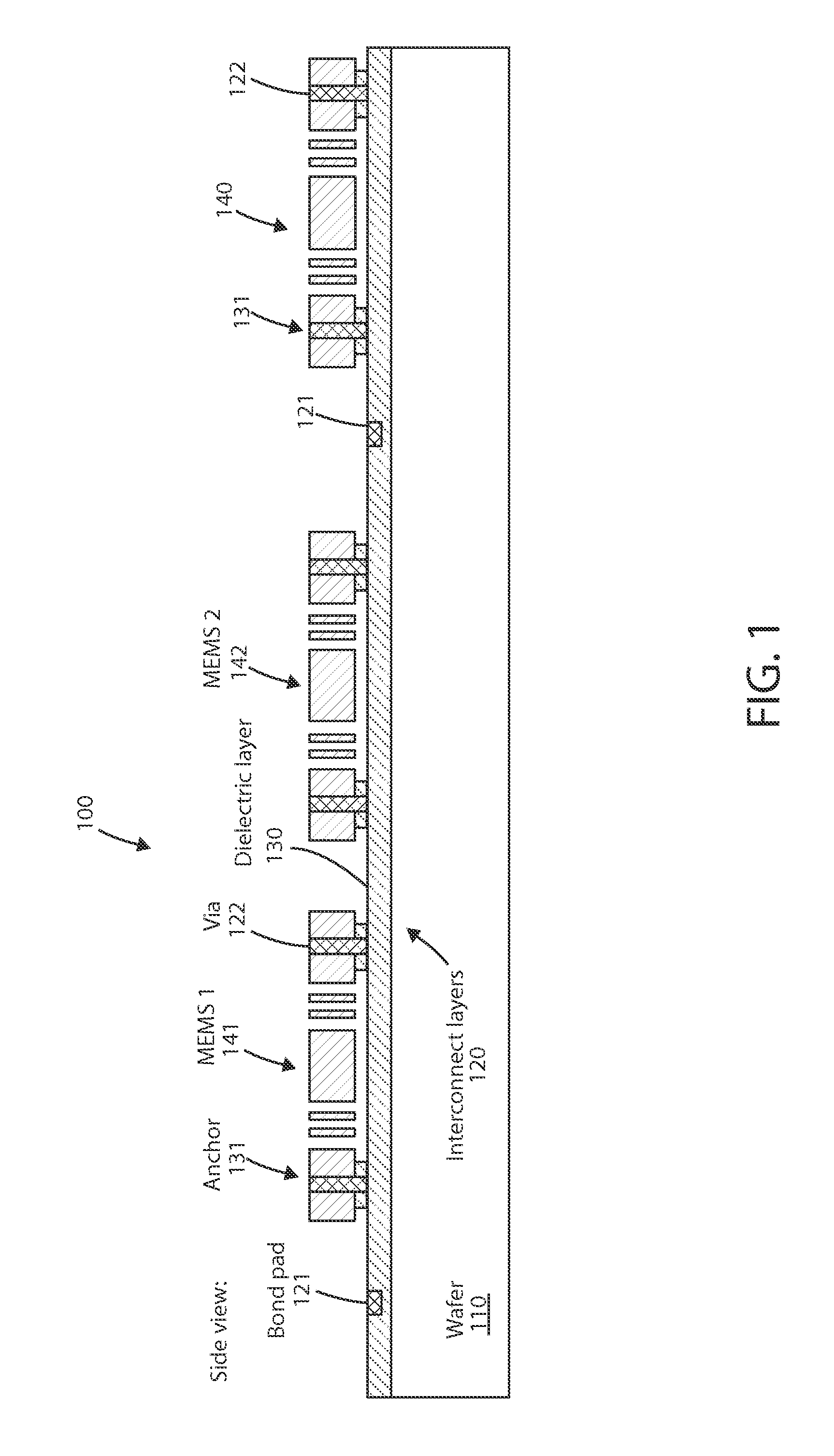

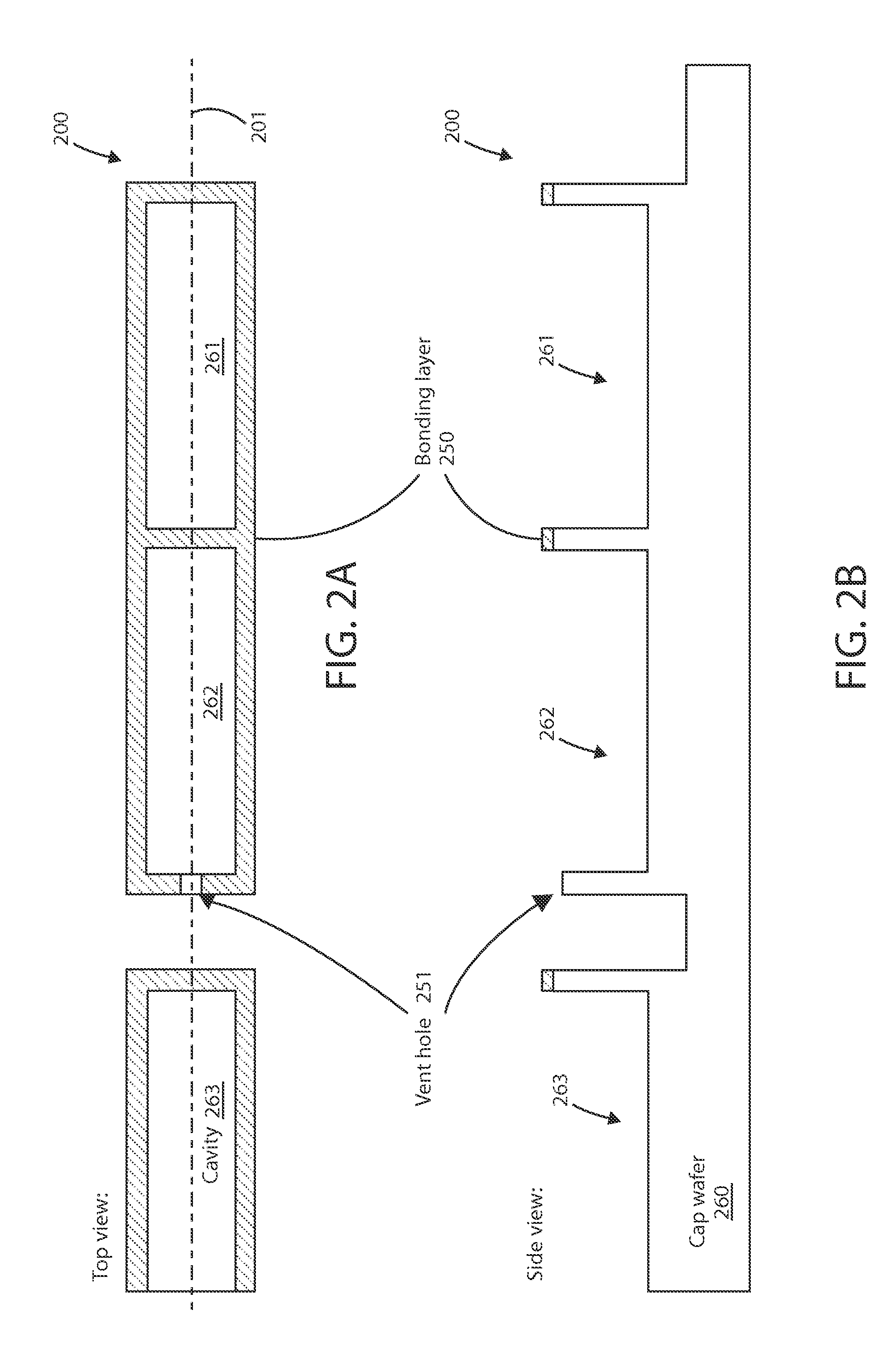

Method to package multiple MEMS sensors and actuators at different gases and cavity pressures

ActiveUS20140227816A1Increase dampingPerformanceDecorative surface effectsSemiconductor/solid-state device manufacturingCavity pressureMems sensors

A method for fabricating a multiple MEMS device. A semiconductor substrate having a first and second MEMS device, and an encapsulation wafer with a first cavity and a second cavity, which includes at least one channel, can be provided. The first MEMS can be encapsulated within the first cavity and the second MEMS device can be encapsulated within the second cavity. These devices can be encapsulated within a provided first encapsulation environment at a first air pressure, encapsulating the first MEMS device within the first cavity at the first air pressure. The second MEMS device within the second cavity can then be subjected to a provided second encapsulating environment at a second air pressure via the channel of the second cavity.

Owner:MOVELLA INC

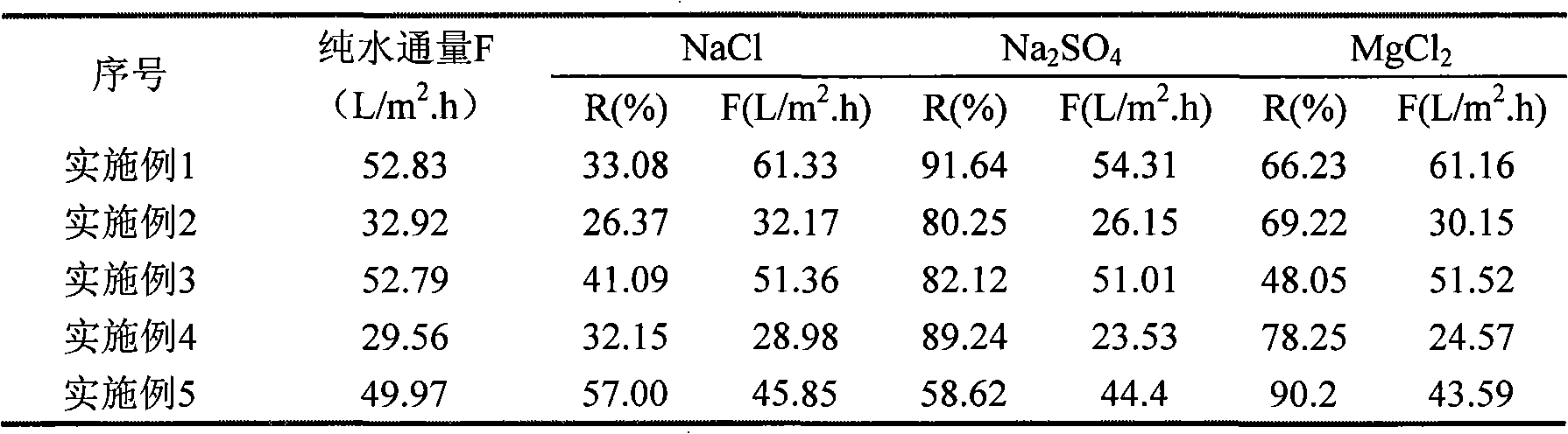

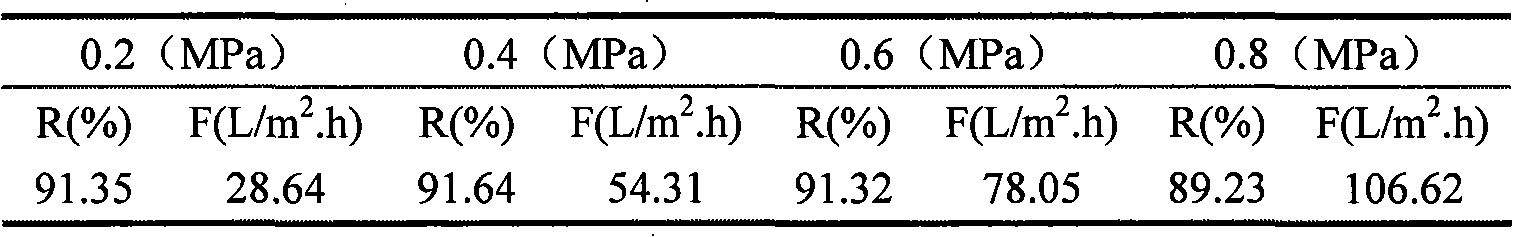

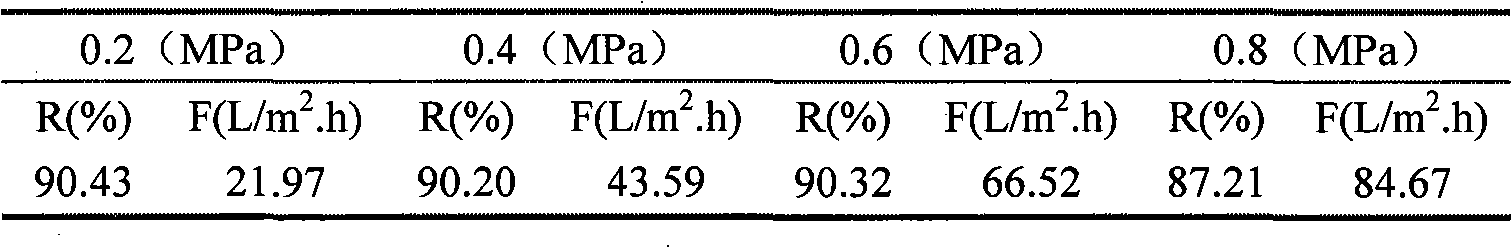

Dynamic self-assembled process for preparing low-pressure high-throughput charged nanofiltration membrane

InactiveCN101274222AImprove efficiencySimple methodSemi-permeable membranesFiltration membraneLow voltage

The invention discloses a method for preparing low-voltage high-flux charged nano-filtration membrane by dynamic self-assembly, which is characterized in that polymer ultra-filtration membrane is taken as a basic film; polycation electrolyte and polyanion electrolyte are alternatively and dynamically self-assembled on the surface of the basic film to gain a selective separation layer and to prepare the nano-filtration membrane of charged surface; wherein, the used ultra-filtration membrane molecular weight cutoff is less than 0.1 million; the ultra-filtration membrane material is surface-charged or modified-charged polymer. Nano-filtration membrane preparation by polyelectrolyte dynamic self-assembly has high efficiency, simple and convenient method and controllable assembly process and film structure; pure water solution is used in the whole preparation process, which is green and environmental protective; the applicable polyelectrolyte has a plurality of types; the separation films with different performances can be obtained by adjusting the types of the polyelectrolyte and the assembly conditions. Furthermore, the prepared nano-filtration membrane has low operation pressure, high removal rate on high valence inorganic salts and far greater flux than the current commercial nano-filtration membrane and the nano-filtration membrane preparation method has good application prospect.

Owner:ZHEJIANG UNIV

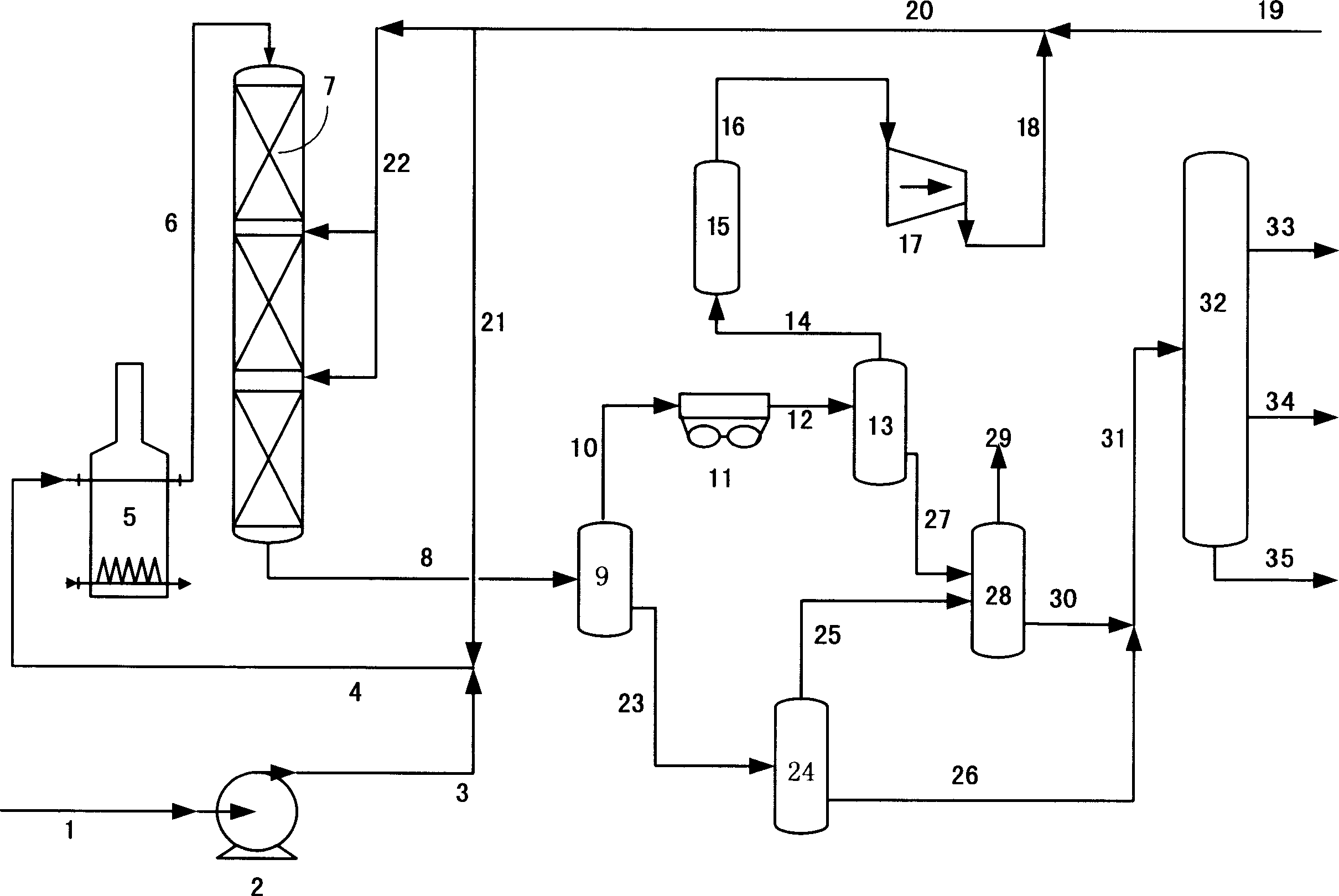

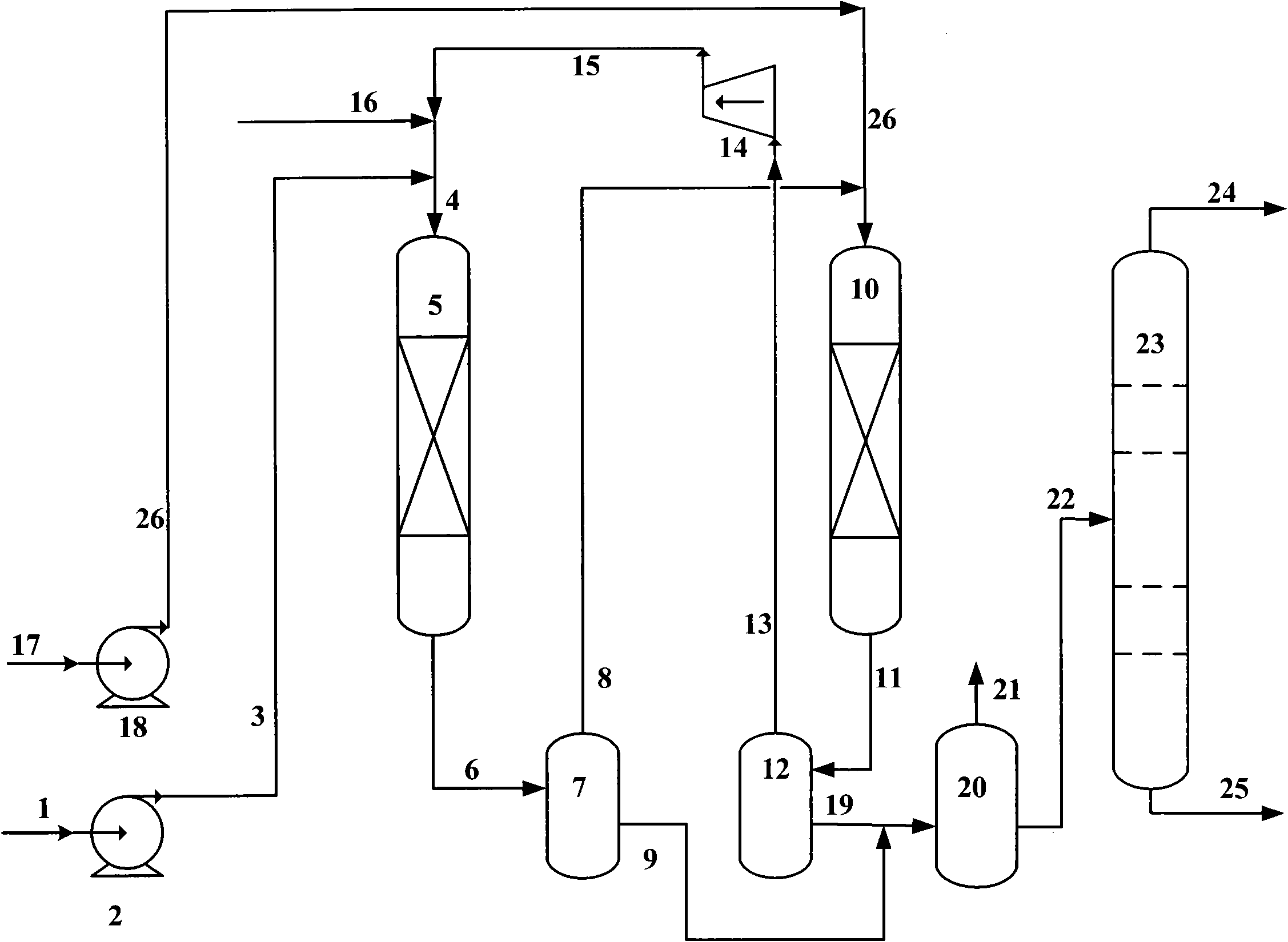

Hydrogenation method for producing good quality catalytic cracking material

ActiveCN101007964AReduced activityDelay pressure drop riseRefining to eliminate hetero atomsHydrogenNaphtha

The invention relates to a hydrogenation method for high- quality catalytic cracking material. It comprises: carrying out hydrogenation and modifying reaction for mixture of raw oil and hydrogen gas in hydrogenation preservative, any hydrogenation demetalation catalyst and hydrogenation treating catalyst in turn; and the filling volumetic percentage of mentioned preservative and catalyst are 2- 15%, 0- 30% and 55-95%, cooling reactant and separating and getting a large amount of refined gas oil fraction, part of low-sulphur diesel fraction and little amount of benzine naphtha fraction, and the refined gas oil fraction is the catalytic cracking material. The invention can prolong the operation cycle for device under high percentage of desulfurization, the activity of employed catalyst is high, and the rational packing method ensures better catalyst activity, and reduces production cost. The invention is characterized by simple process, low operation pressure, low device investment and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

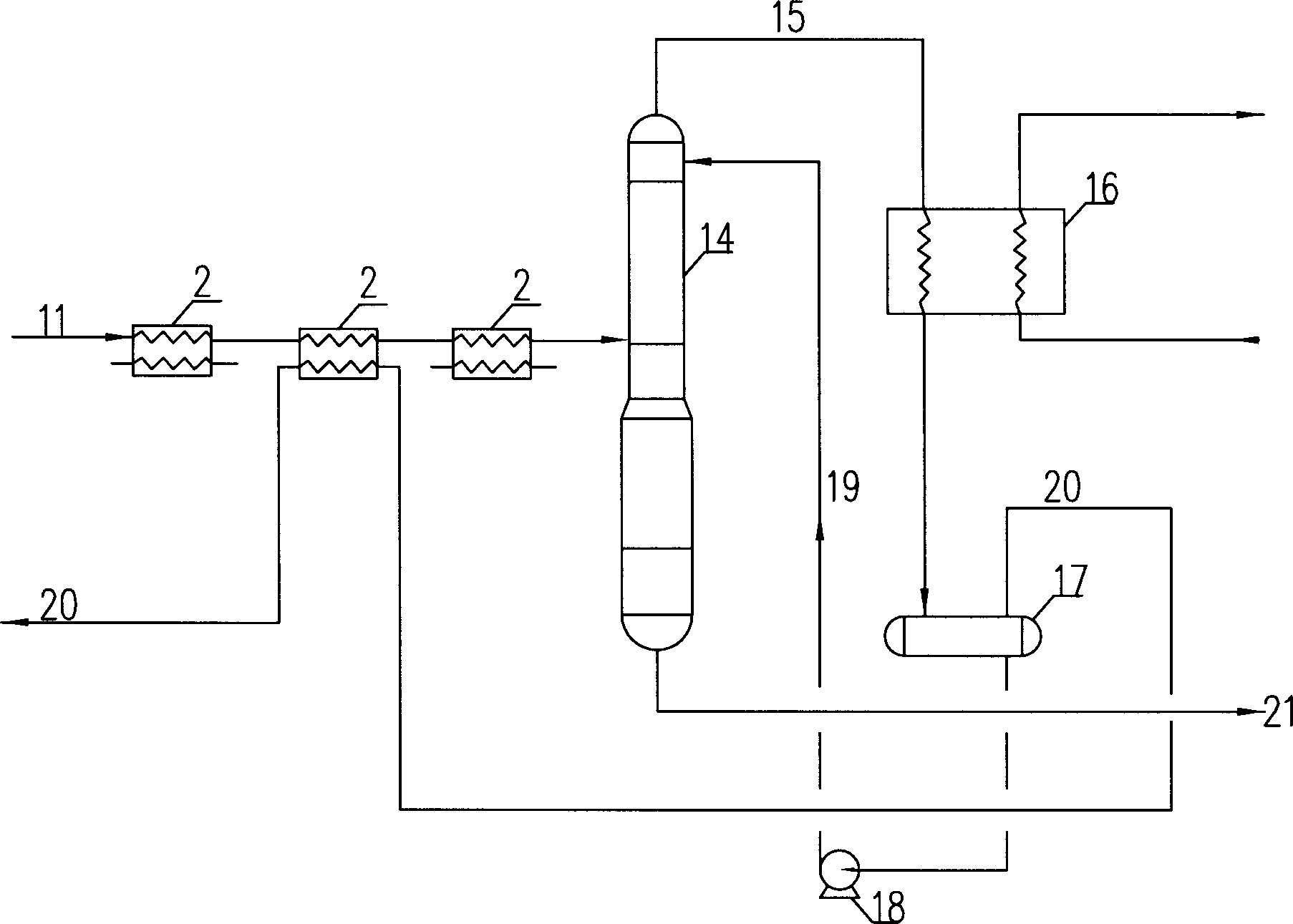

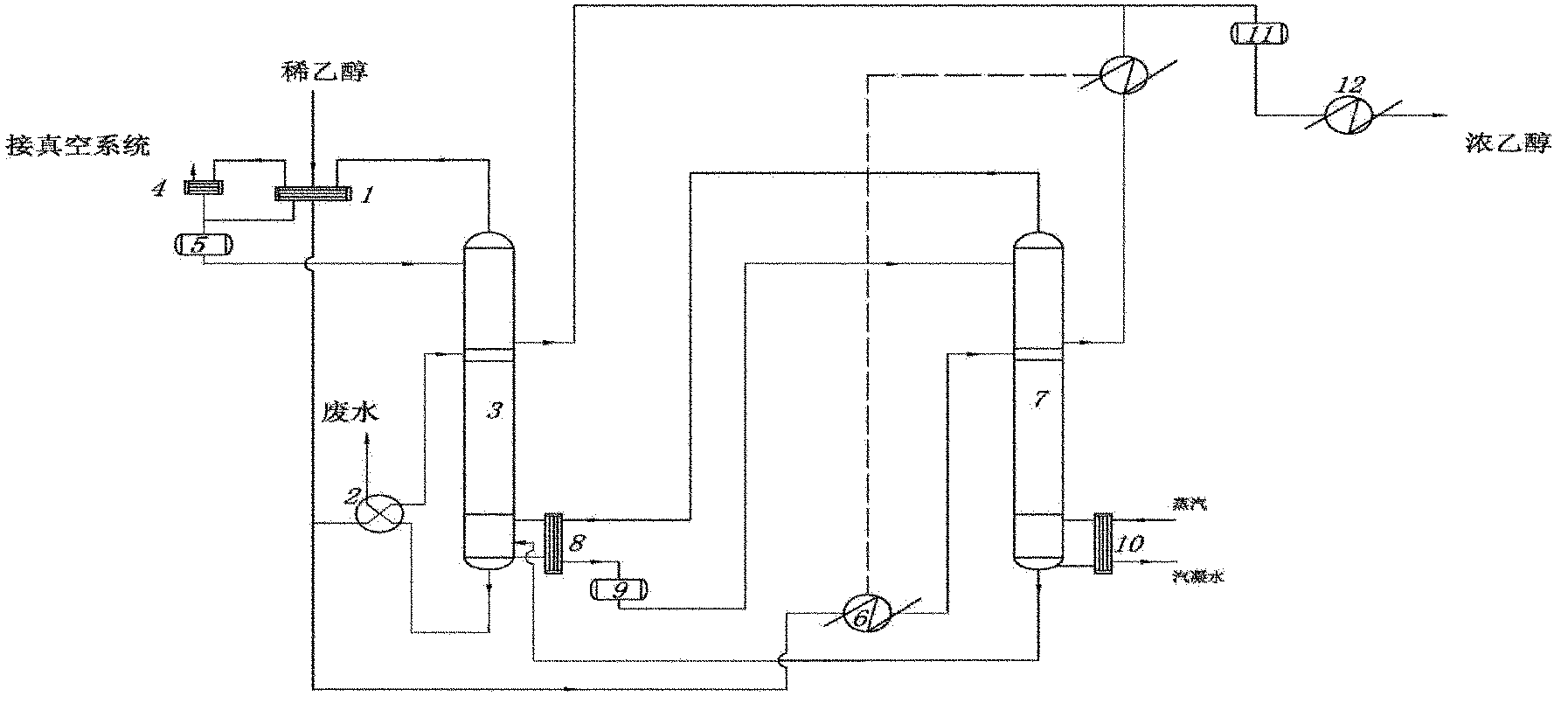

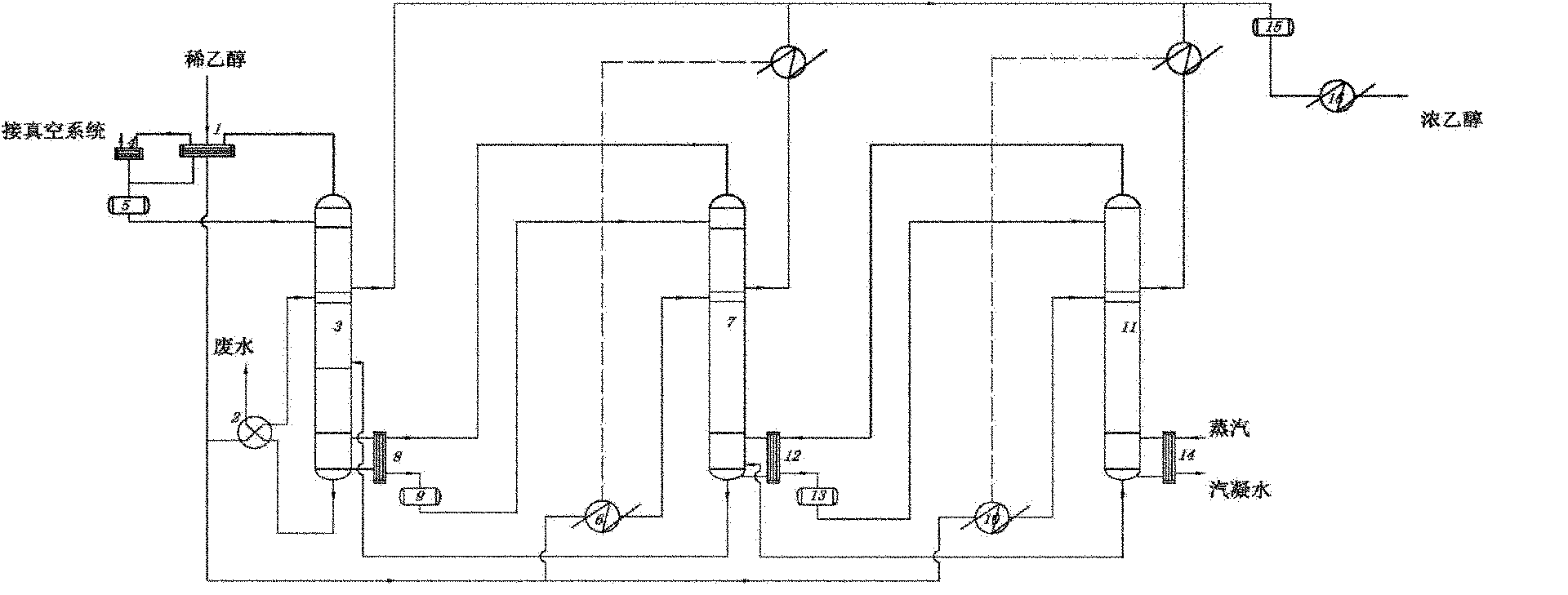

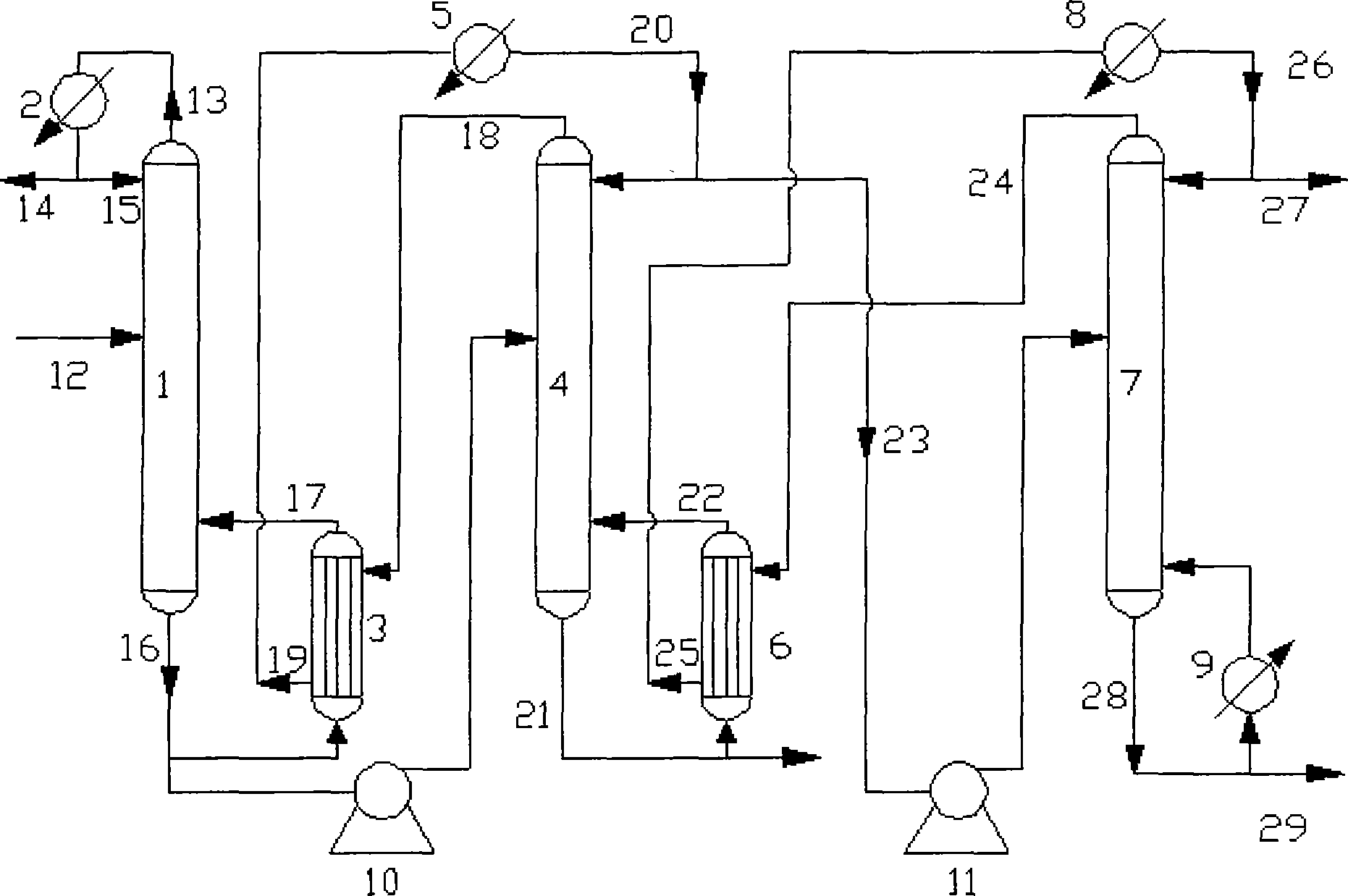

Low-pressure ethanol recovery device and method with triple effect rectification

ActiveCN102091429AReduce energy consumptionReduce lossesOrganic compound preparationHydroxy compound preparationRecovery methodReboiler

The invention discloses a low-pressure ethanol recovery device and method with triple effect rectification. The low-pressure ethanol recovery device with triple effect rectification comprises a first rectifying tower, a second rectifying tower, a third rectifying tower, a rectifying tower reboiler, a rectifying tower feed preheater, a condenser, a return tank, a dilute ethanol feed preheater, a temporary finished product storage tank and a finished product cooler. In the ethanol recovery method with triple effect rectification, by controlling the recovery of the finished ethanol in the second rectifying tower, the content of ethanol in tower bottom wastewater of the second rectifying tower is 5wt%-30wt%, the temperature of the tower bottom wastewater is 100-120 DEG C, and the working pressure of the third rectifying tower is 250-400kPa. The invention adopts the low-pressure triple effect rectification technique and reduces energy loss in the technical process, thus greatly reducing the energy consumption; and the operating pressure and temperature of the third rectifying tower are greatly reduced, and the requirements on the high temperature resistant and corrosion resistant properties of equipment are reduced, thereby reducing the equipment investment and the maintenance cost.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Integrated Solvent Deasphalting and Slurry Hydrocracking Process

InactiveUS20100122934A1High value distillateEfficient integrationWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a deasphalted oil (DAO) produced in a solvent deasphalting (SDA) process, optionally with recycled SHC gas oil and recycled SHC pitch, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Recovery and recycle of SHC gas oil and pitch from the SHC effluent improves the overall conversion to naphtha and distillate products and decreases catalyst requirements.

Owner:UOP LLC

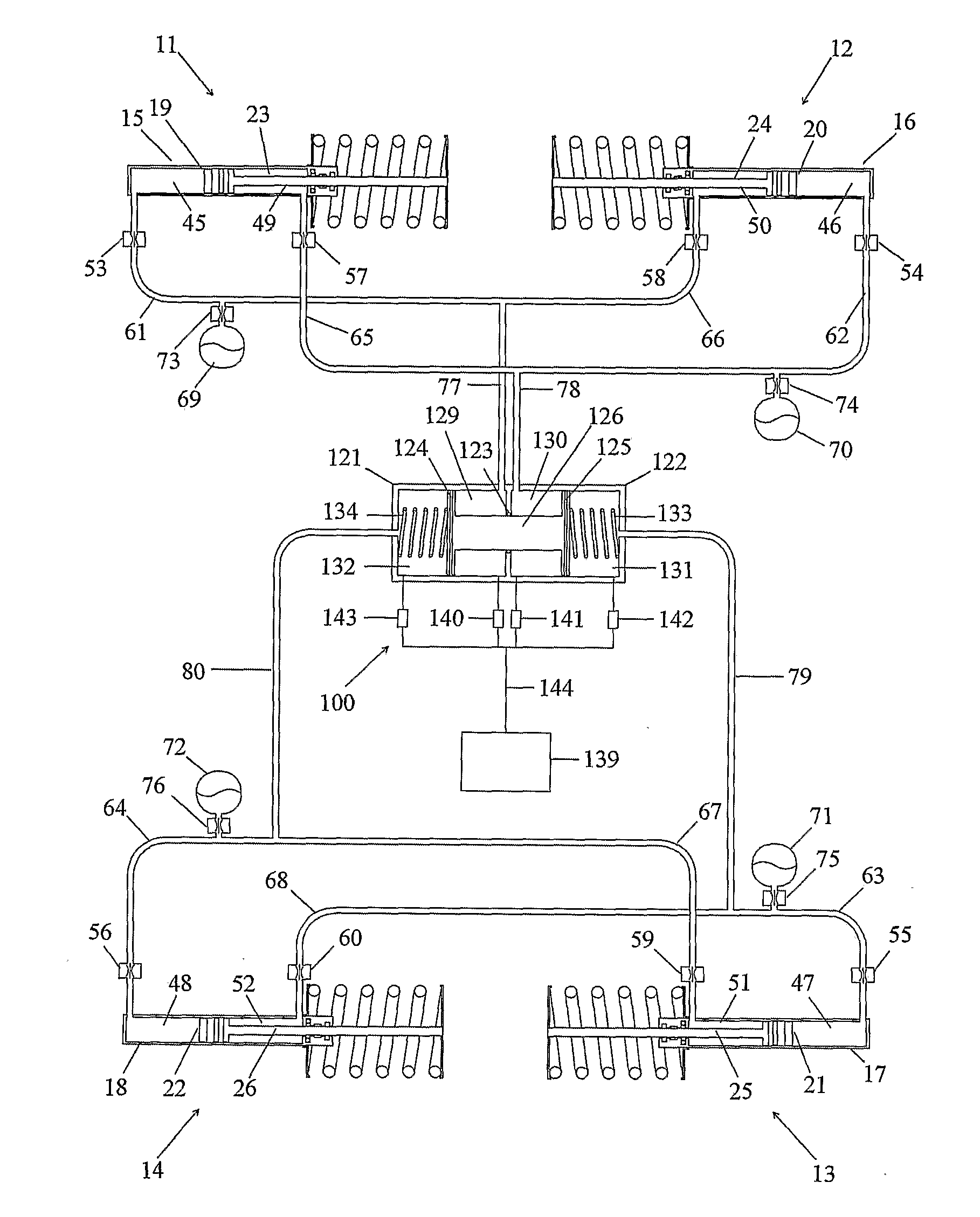

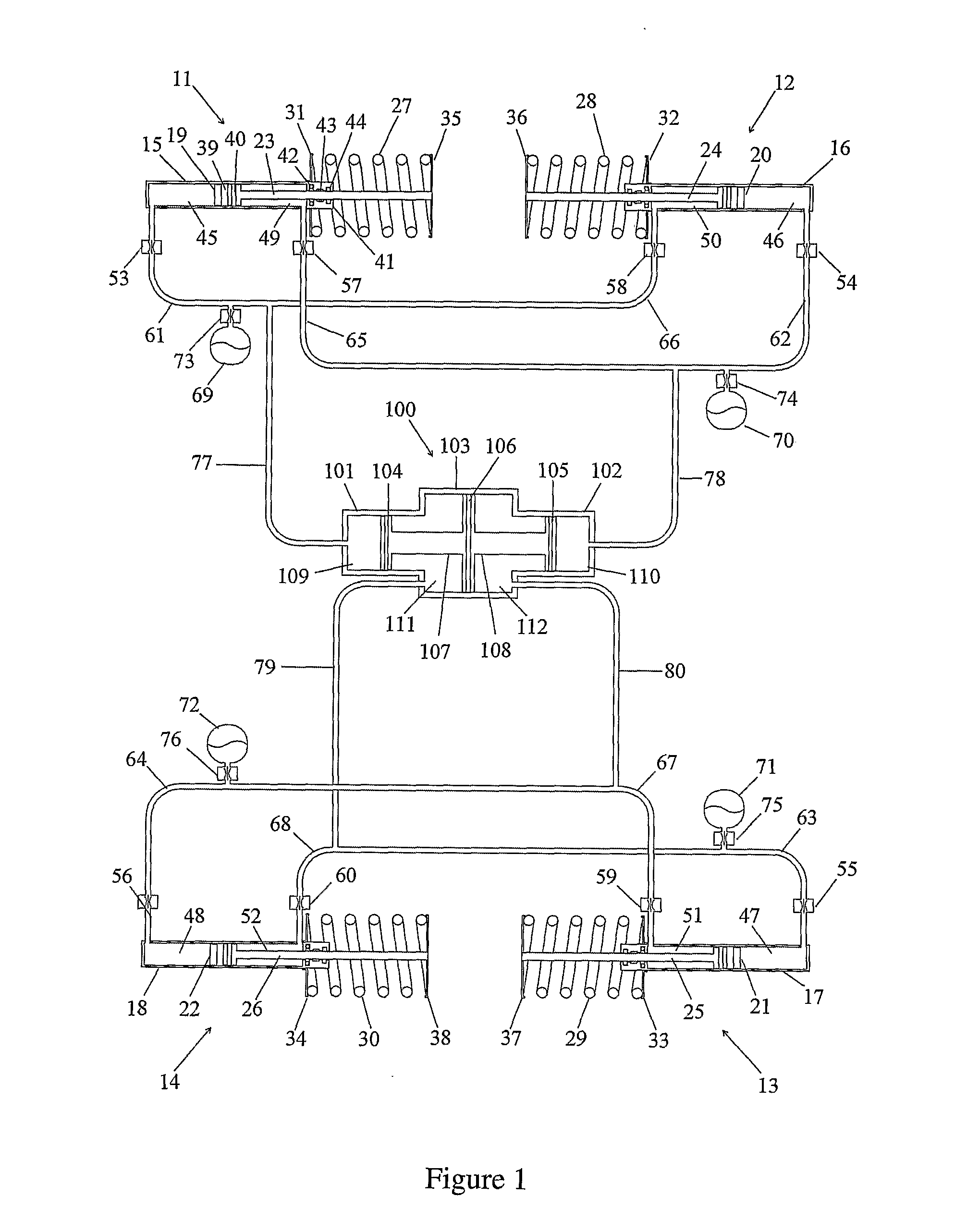

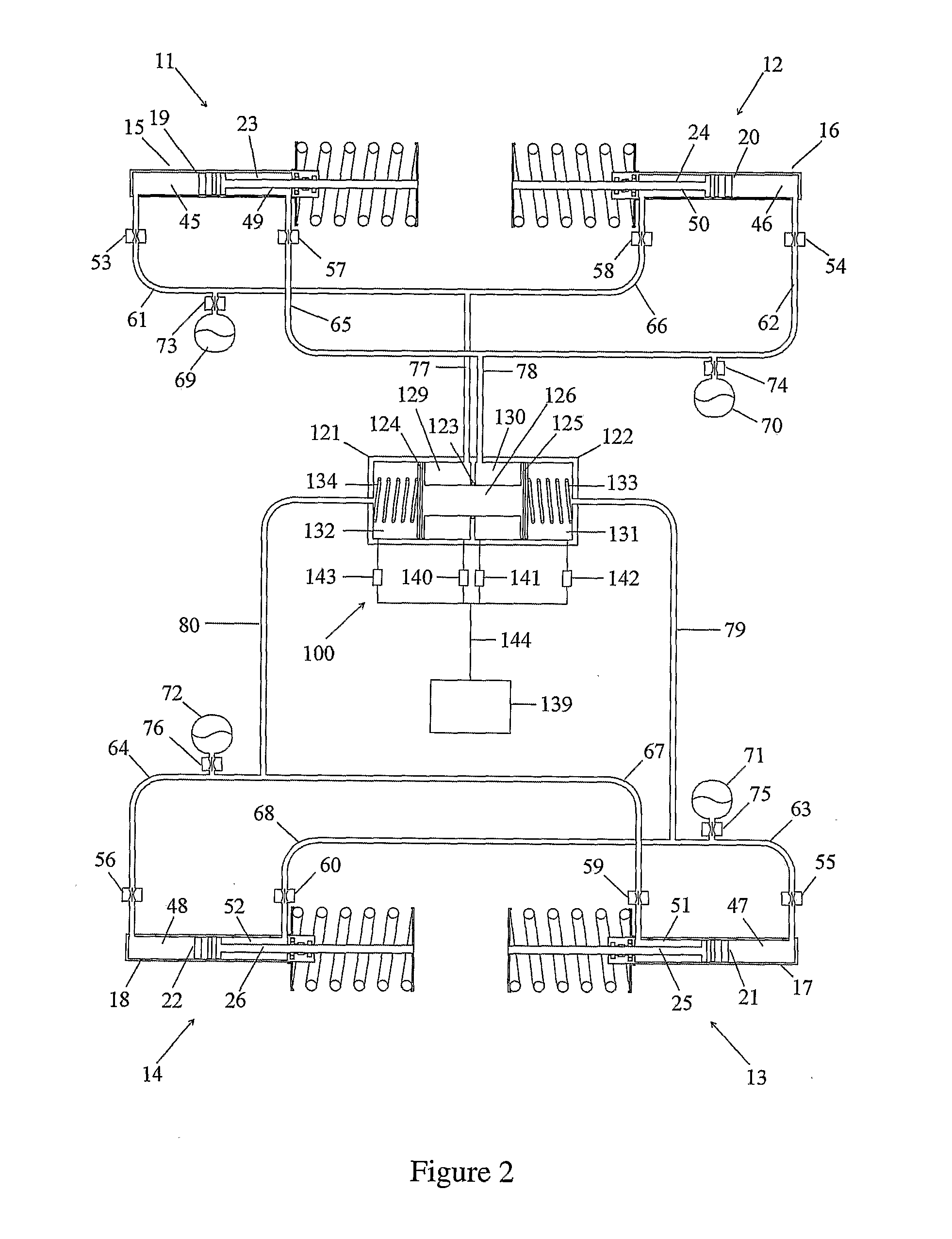

Hydraulic System for a Vehicle Suspension

ActiveUS20080272561A1Reduce system pressureReduce frictionInterconnection systemsResilient suspensionsPiston rodHydraulic pressure

A vehicle hydraulic suspension system has front left (15), front right (16), rear left (18) and rear right (17) wheel ram. There is a mode decoupling device (100) with first (129), second (130), third (132) and fourth (131) balance chambers formed by a cylinder / piston rod assembly (124,125,126). The compression chamber (45) of the front left wheel ram (15) is in fluid communication with the first balance chamber (129), the compression chamber (46) of the front right wheel ram (16) is in fluid communication with the second balance chamber (130), the compression chamber (48) of the rear left wheel ram (18) is in fluid communication with the third balance chamber (132), and the compression chamber (47) of the rear right wheel ram (17) is in fluid communication with the fourth balance chamber (131). There are also front and rear resilient vehicle support means between vehicle body and the wheel assemblies.

Owner:KINEHTIK PTI LTD

Novel hydrate based systems

InactiveUS20090124520A1Low costLow operating pressureOrganic chemistryServomotor componentsForming gasWorking fluid

A method for transporting a fluid comprising a clathrate forming gas through a transportation system including a pipeline. The method involves subjecting the fluid to clathrate forming temperature and pressure conditions and introducing sufficient of a clathrate forming host to convert substantially all of the gas to clathrate and to form a flowable slurry. The flowable slurry is then conveyed through a pipeline to a destination. An alternative method involves transporting the fluid by means of a ring pipeline containing a carrier fluid, which includes clathrate inhibitors. Also provided is a heat pump whose working fluid is a clathrate forming composition.

Owner:HEROIT WATT UNIV

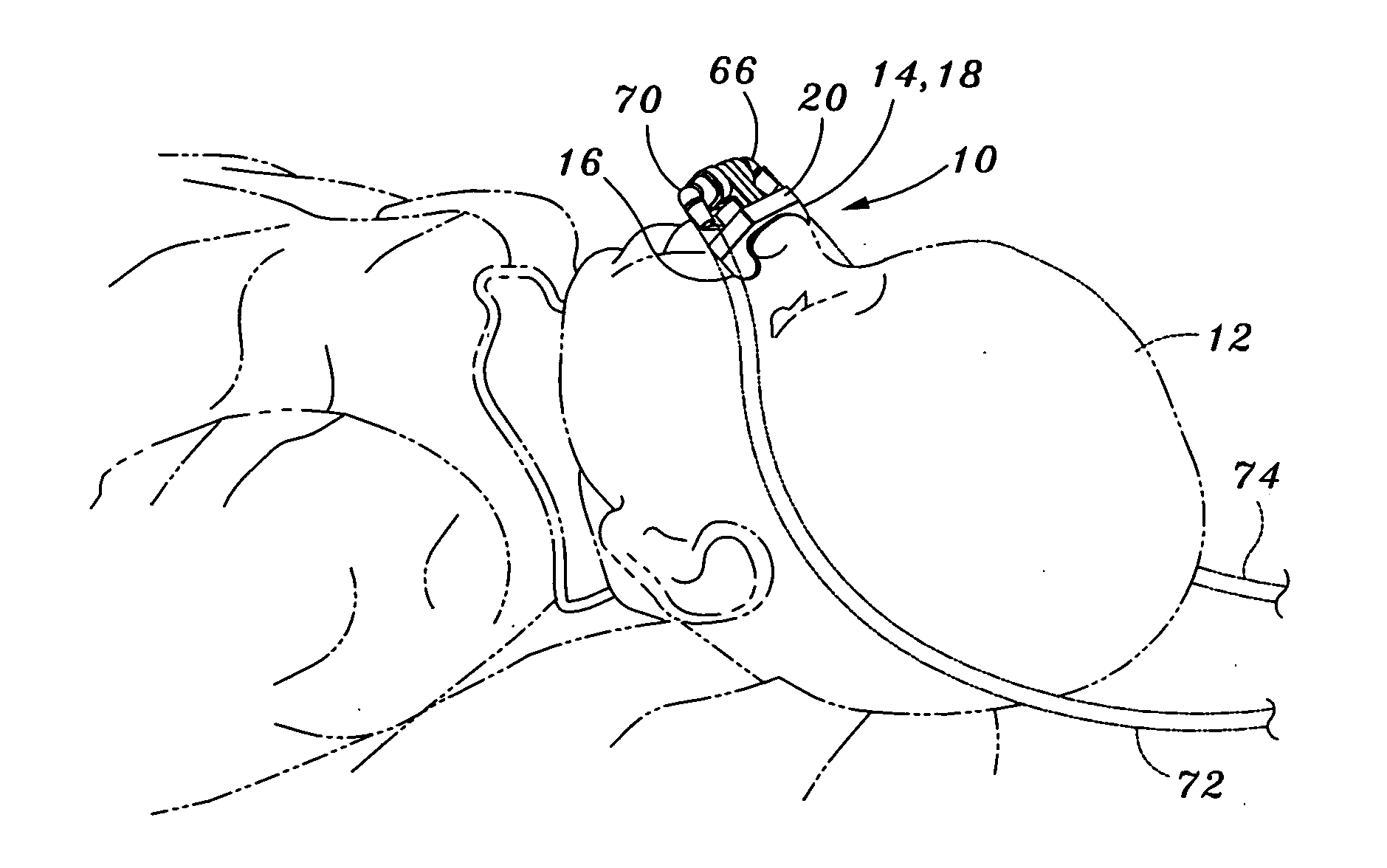

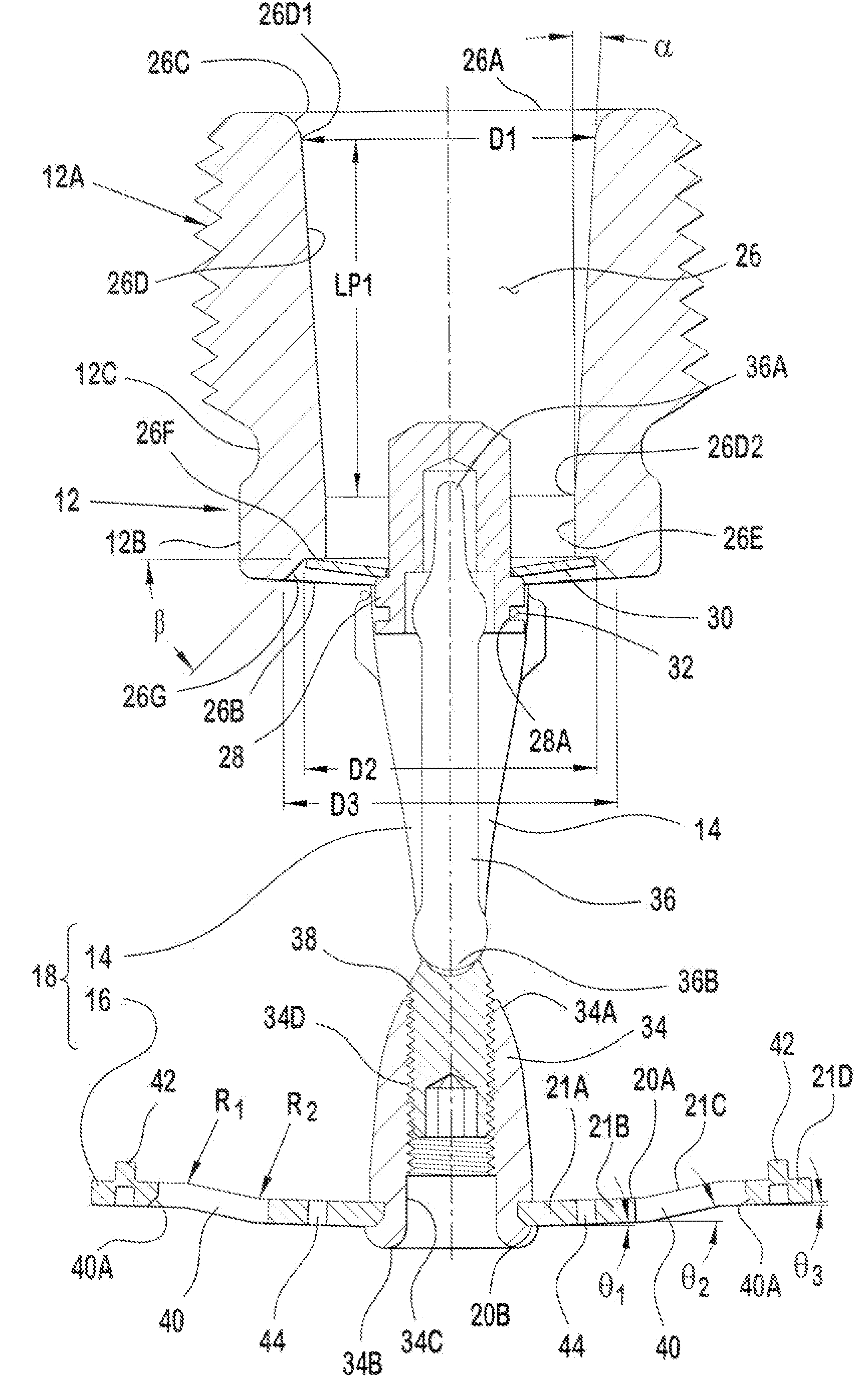

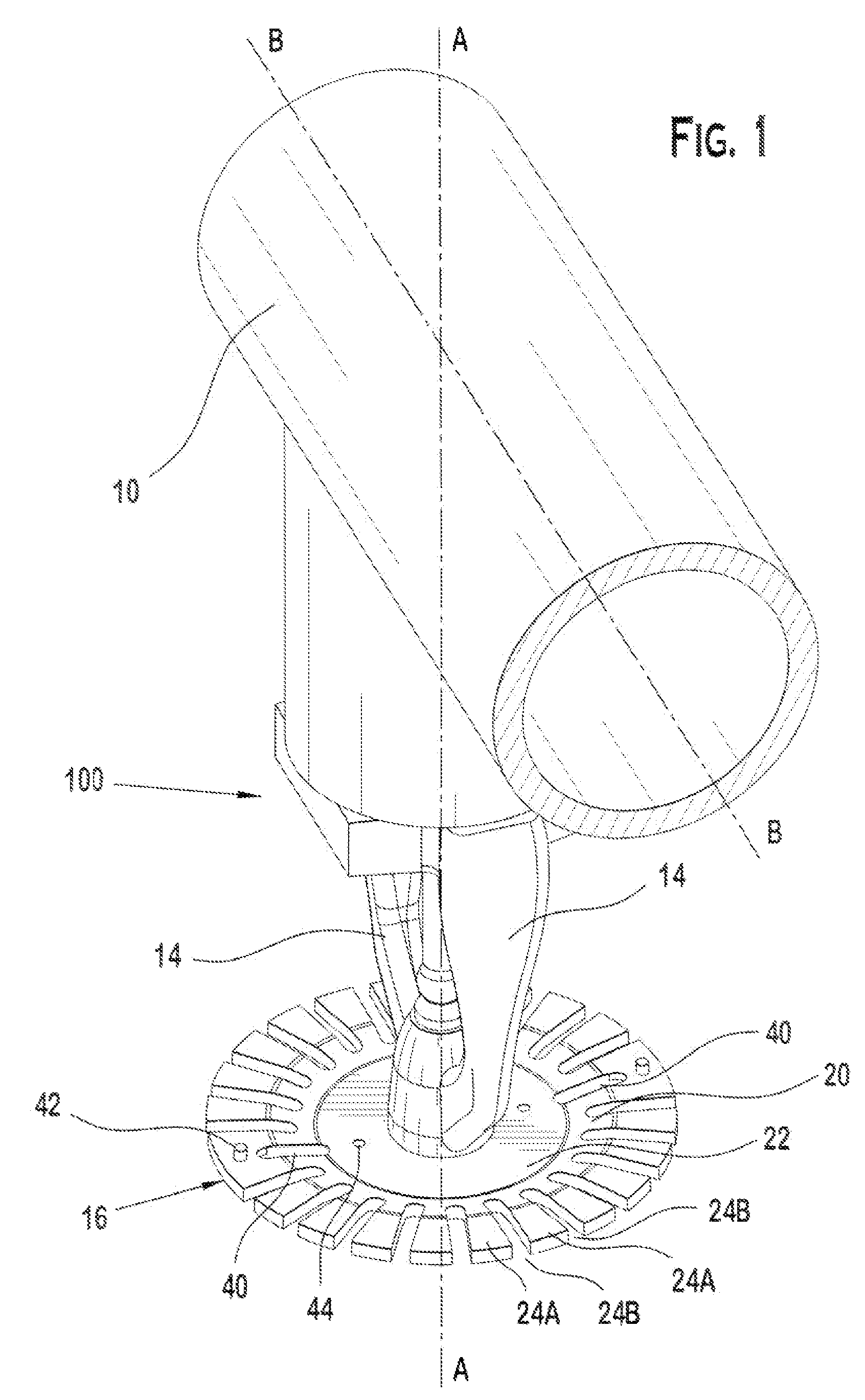

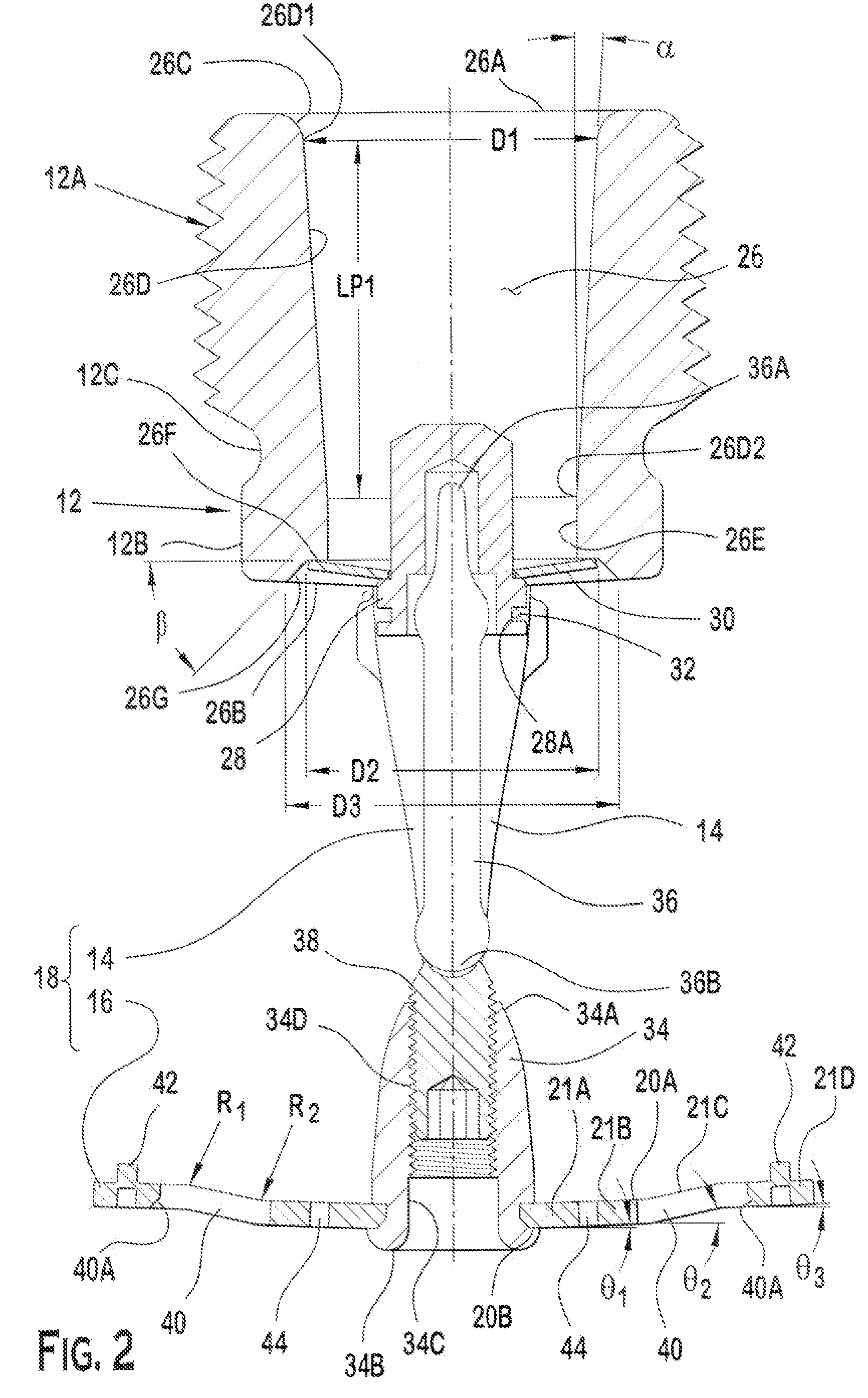

Residential fire sprinkler

ActiveUS7201234B2Reduce design pressureLow operating pressureSpray nozzlesFire rescueFire protectionEngineering

A pendent type residential fire sprinkler is described. The residential fire sprinkler has a body with a K-factor of at least 6 passage coupled to a deflector assembly that distributes fluid flowing through the passage over a coverage area to perform in accordance with Underwriters Laboratory Standard 1626 (October 2003) for listing by Underwriters Laboratory Incorporated so that the body and a heat responsive trigger disposed between the passage and the deflector assembly of the sprinkler can be installed in accordance with the 2002 Edition of National Fire Protection Association Standards 13, 13D, and 13R. Various aspects of the residential fire sprinkler, including a method of protecting a residential dwelling unit are described.

Owner:TYCO FIRE PRODS LP

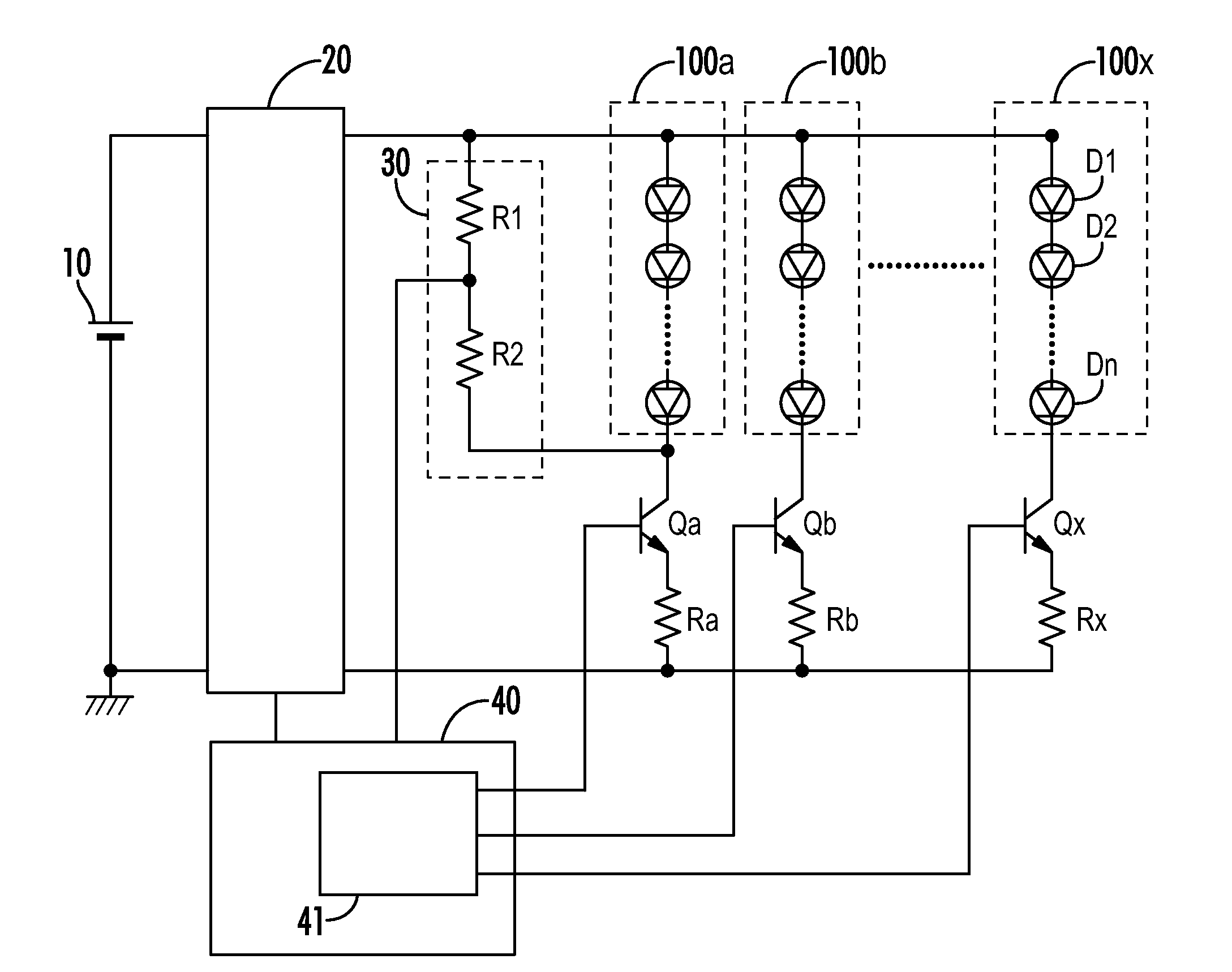

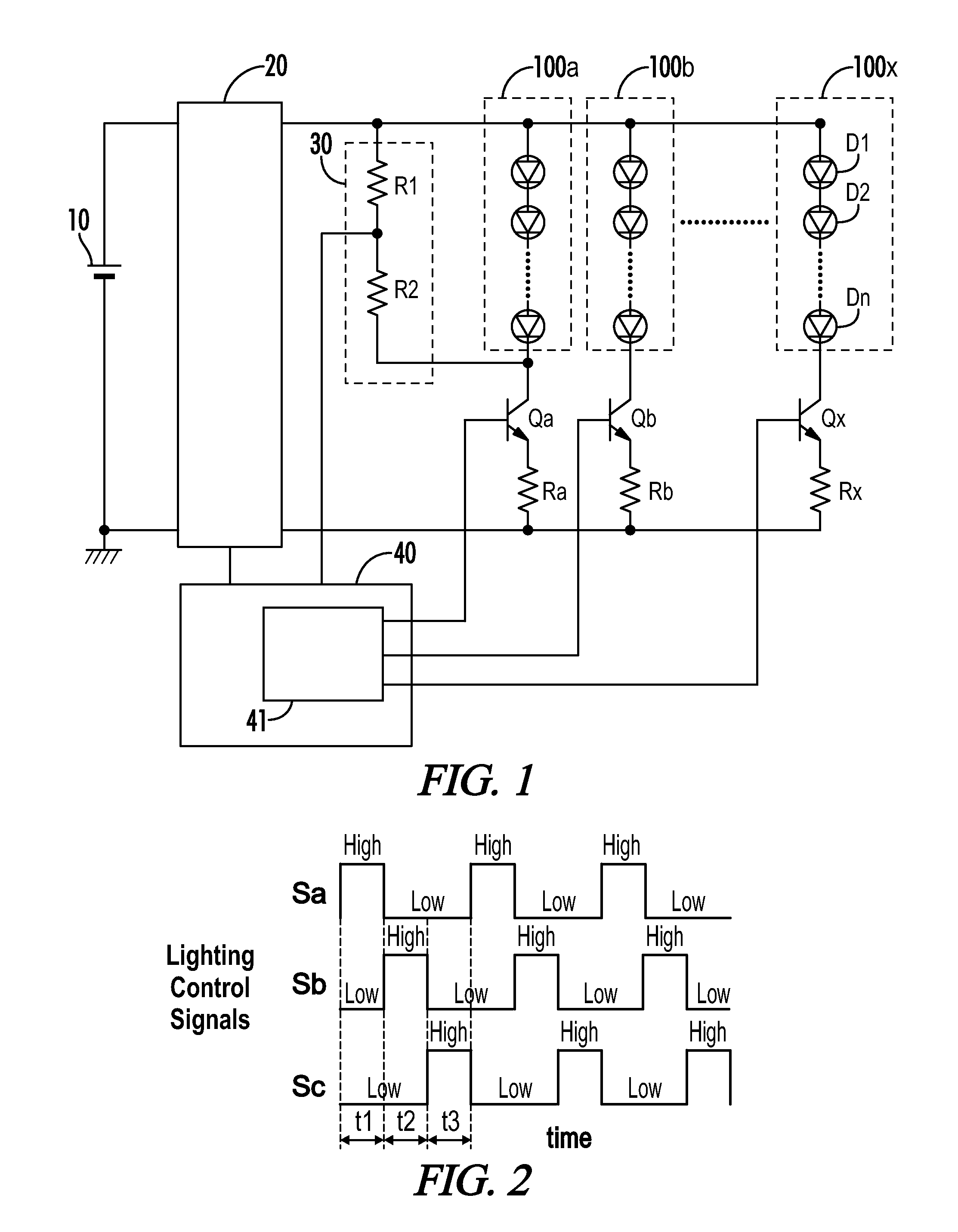

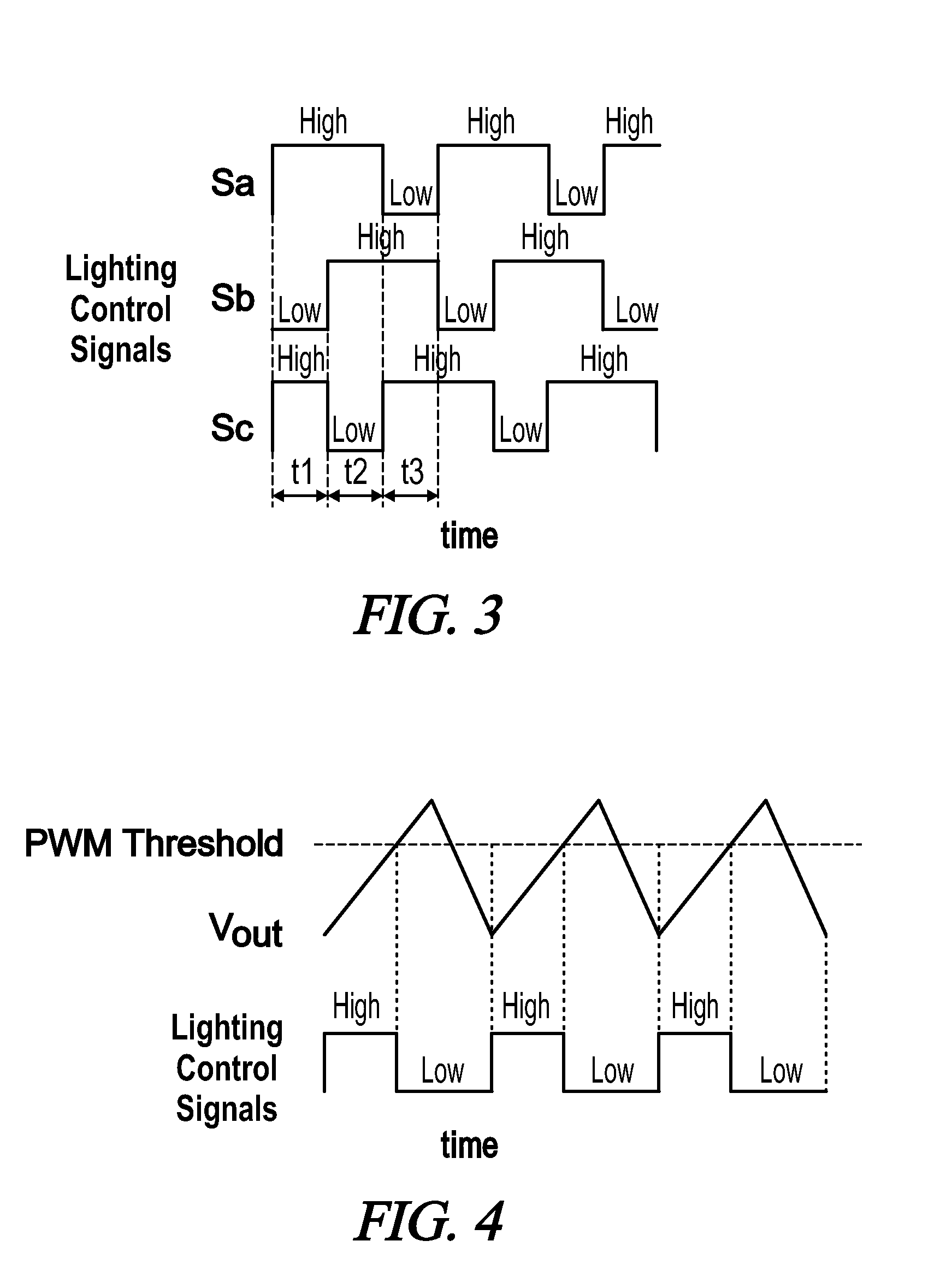

LED driver circuit with sequential LED lighting control

InactiveUS20100141162A1Extend lifeReduce operational stressElectrical apparatusElectroluminescent light sourcesLed driverLED circuit

An LED driver circuit powers a plurality of LED arrays coupled in parallel, each LED array having one or more LEDs coupled in series. A power converter converts an input signal from a power source into an output signal across the LED arrays. A switching element is coupled in series with each of the LED arrays and alternates between first and second switch states in response to lighting control signals. A control circuit generates the lighting control signals and supplies them to the switching elements to sequentially operate one or more of the switching elements in the first switch state during each of a plurality of predetermined time periods in a light emitting state for the LED driver circuit.

Owner:PANASONIC CORP

Method for producing low-sulfur methyl tertiary butyl ether

ActiveCN102491882ASatisfy to reconcileFulfil requirementsEther separation/purificationSulfur contentRaw material

The invention provides a method for producing low-sulfur methyl tertiary butyl ether (MTBE), which is used for producing low-sulfur MTBE products by re-rectifying MTBE containing sulfur. The method can use the MTBE with 10-150 ppm of sulfur content as a raw material to produce the MTBE products with containing sulfur content less than 10 ppm or even less than 5 ppm, and can use the MTBE with sulfur content more than150 ppm to produce the MTBE products with sulfur content less than 150 ppm. Especially, produced MTBE with the sulfur content less than 10 ppm or even less than 5 ppm can not only meet blend requirements of state V clean gasoline, but also requirements of industrial chemical raw materials can be met.

Owner:HEBEI REFINING TECH CO LTD

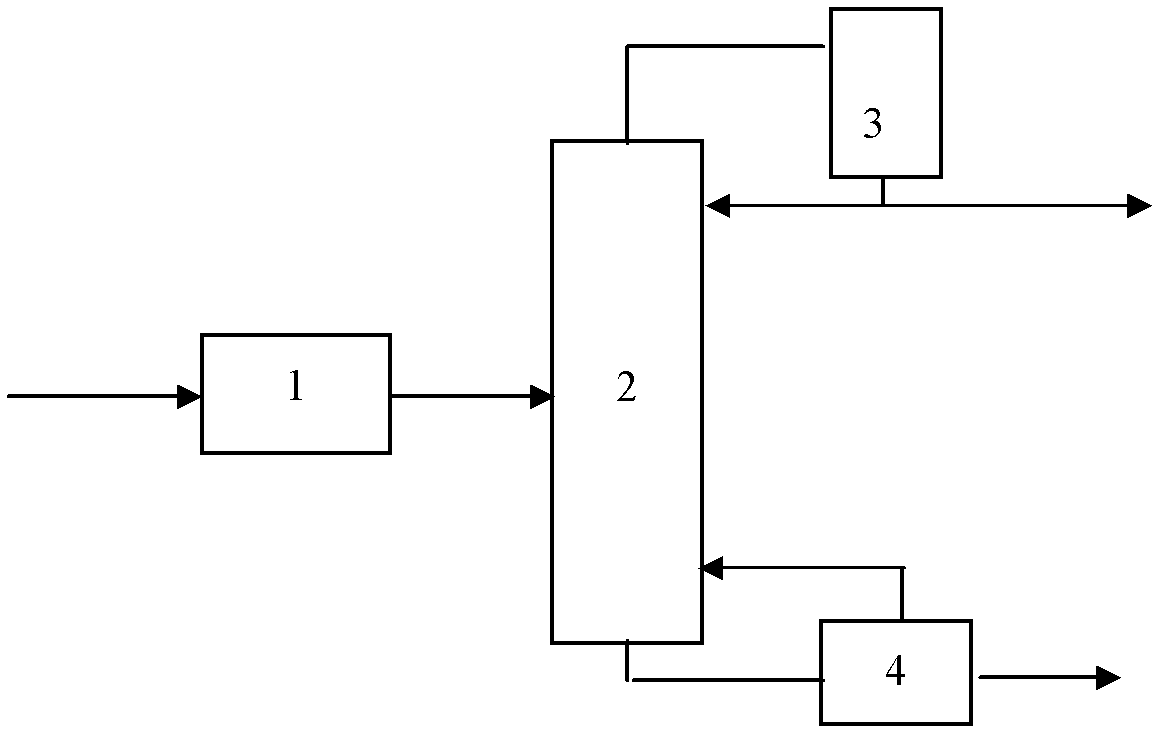

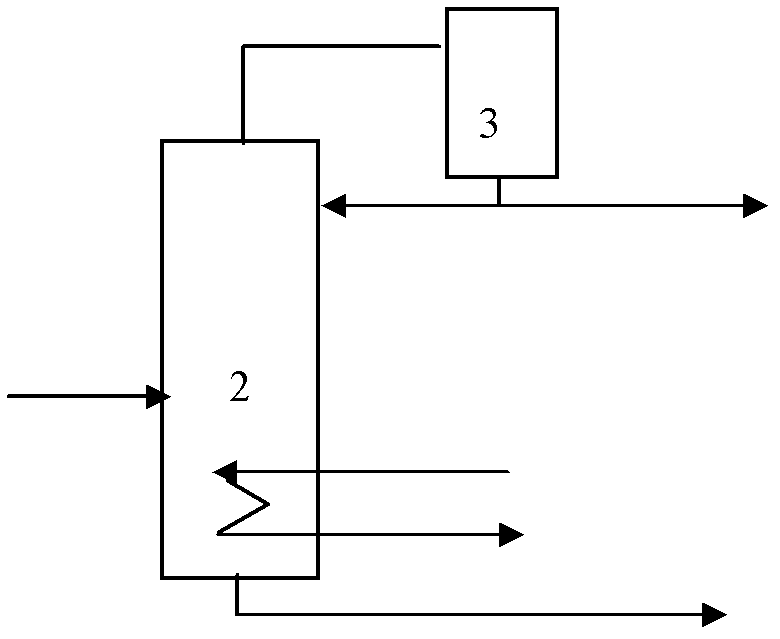

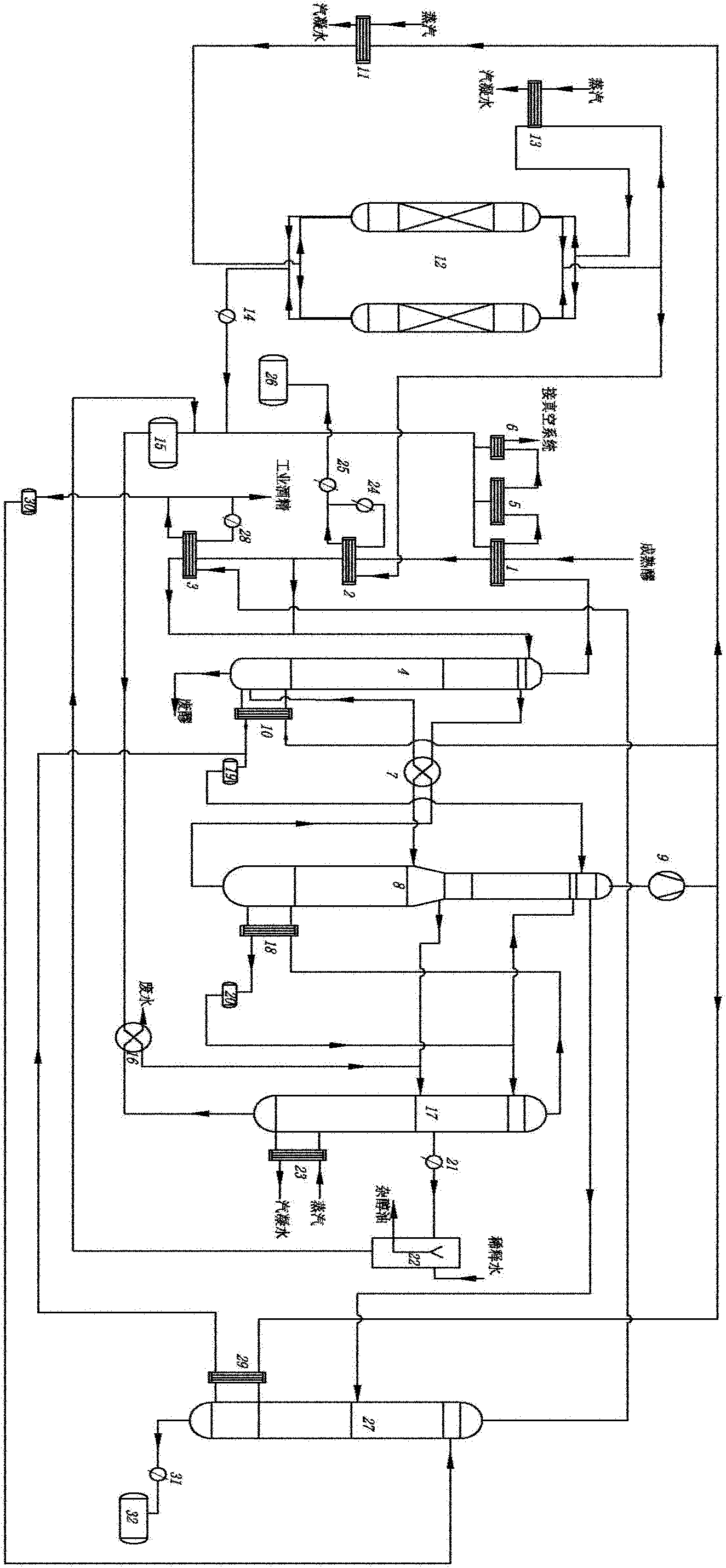

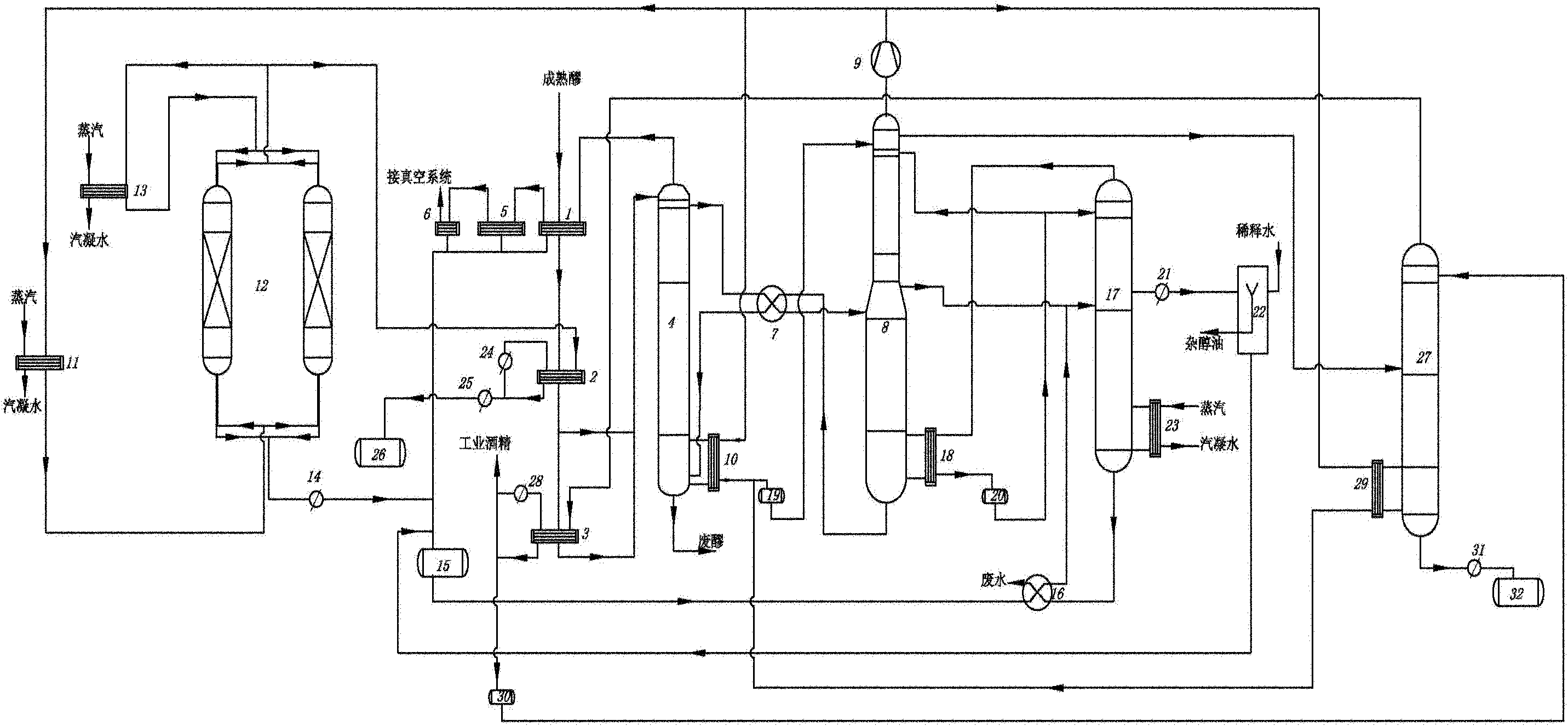

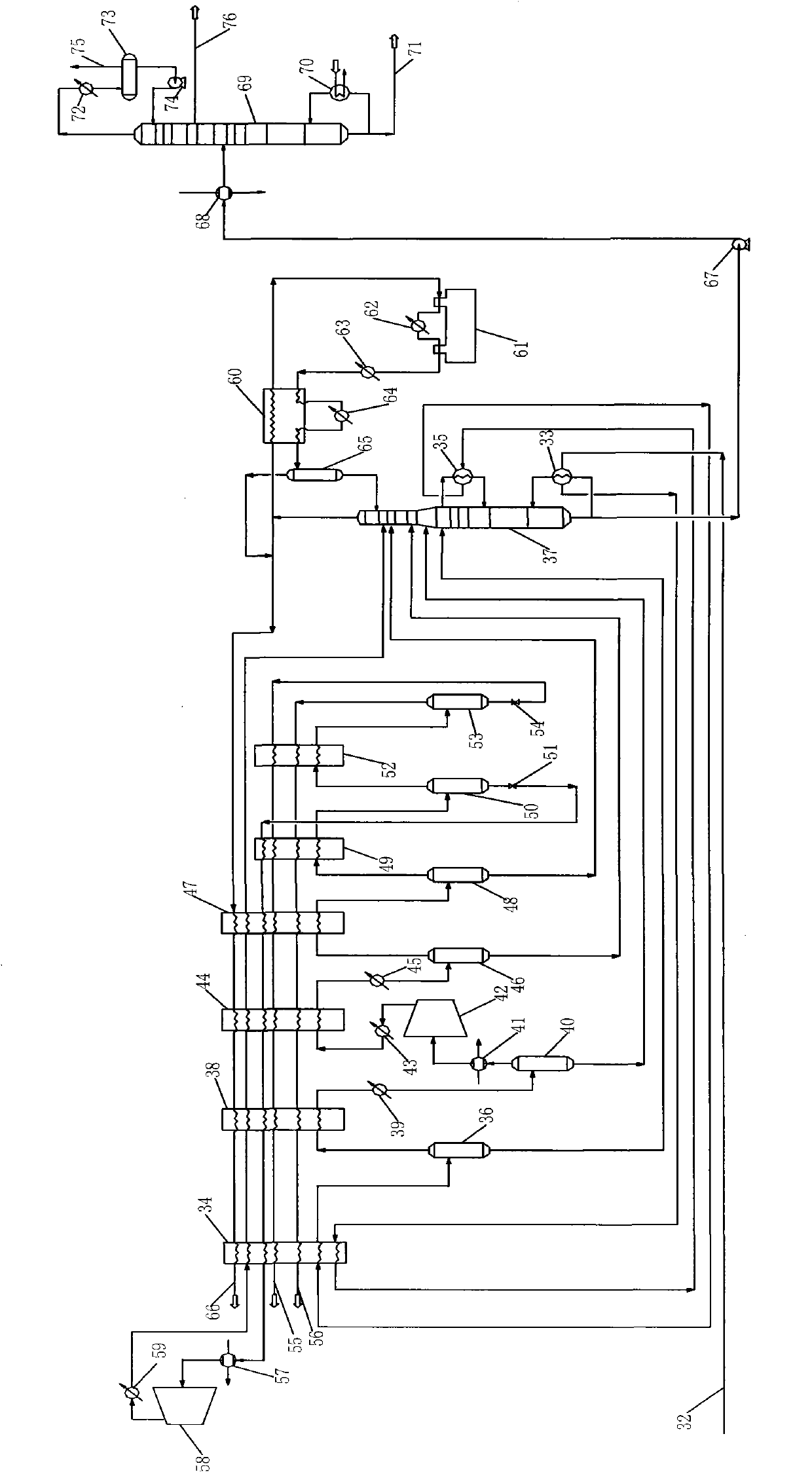

Distillation dehydration device and process for co-producing ethanol fuels and custom grade edible alcohols

ActiveCN102040471ALow operating pressureLess investmentOrganic compound preparationHydroxy compound separation/purificationDesorptionDistillation

The invention discloses a distillation dehydration device and a distillation dehydration process for co-producing ethanol fuels and custom grade edible alcohols. The device comprises a molecular sieve adsorption / desorption tower, a coarse fractionating tower, an assembled tower, a rectifying tower, a methanol tower and mash pre-heaters, wherein the wine steam of the assembled tower, after compressed by an ethanol steam compressor, is used as the heat sources and raw material wine steams of the coarse fractionating tower and the methanol tower; the wine steam of the rectifying tower is used asthe heat source of the assembled tower; and the wine steam of the coarse fractionating tower, the anhydrous alcohol steam and the wine steam of the methanol tower are respectively used as the heat sources of the first, second and third mash pre-heaters. The device can simultaneously produce ethanol fuels and custom gradeedible alcohols, and can separately produce ethanol fuels or custom grade edible alcohols. The device and the process of the invention have the advantages that, because a multi-effect energy coupling mode is adopted, compared with an original process, the energy consumption ofthe process of the invention is greatly reduced, and the steam consumption of the ethanol fuel per metric ton is reduced to 1.1 to 1.5 t / t, compared with the steam consumption of 1.5 to 2.0 t / t in the original process, the steam consumption is down by 25 to 35 percent without consuming high-grade steams (more than 0.7 MPag); and the steam consumption of the custom grade edible alcohol per metric ton is reduced to 1.2 to 1.4 t / t, compared with the steam consumption of 1.9 to 2.5 t / t in the original process, the steam consumption is down by 35 to 50 percent.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

A dicyclopentadiene hydrogenation special-purpose catalyzer and its preparing method

InactiveCN101157029AGood dispersionHigh activityMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveUnsaturated hydrocarbon

The invention relates to dicyclopentadiene hydrogenation special catalyst and the preparation method thereof; a catalyst active component is abstracted from Pd or Pt, the percentage content of the weight can be Pd 0.3 to 1.3 percent or Pt 0.5 to 1.2 percent, carriers can be porous inorganic materials of aluminum oxide, silicon oxide, molecular sieves, kaolin, etc. By adopting the novel noble metal colloid method process, the prepared catalyst has the advantages that the grain size of active component particles is concentrated, the dispersion degree is high, the surface area is large, etc., thus the catalyst activity is higher, and the operating pressure of a hydrogenation device can be notably reduced. The preparation method provided by the invention effectively reduces the quantity of noble metals, the catalyst is used for the dicyclopentadiene petroleum resin hydrogenation device with poor color phase in the carbon five fraction, the content of unsaturated hydrocarbon key can be obviously reduced, and the color phase of the resin is improved to be of a water white color.

Owner:CHINA NAT OFFSHORE OIL CORP +1

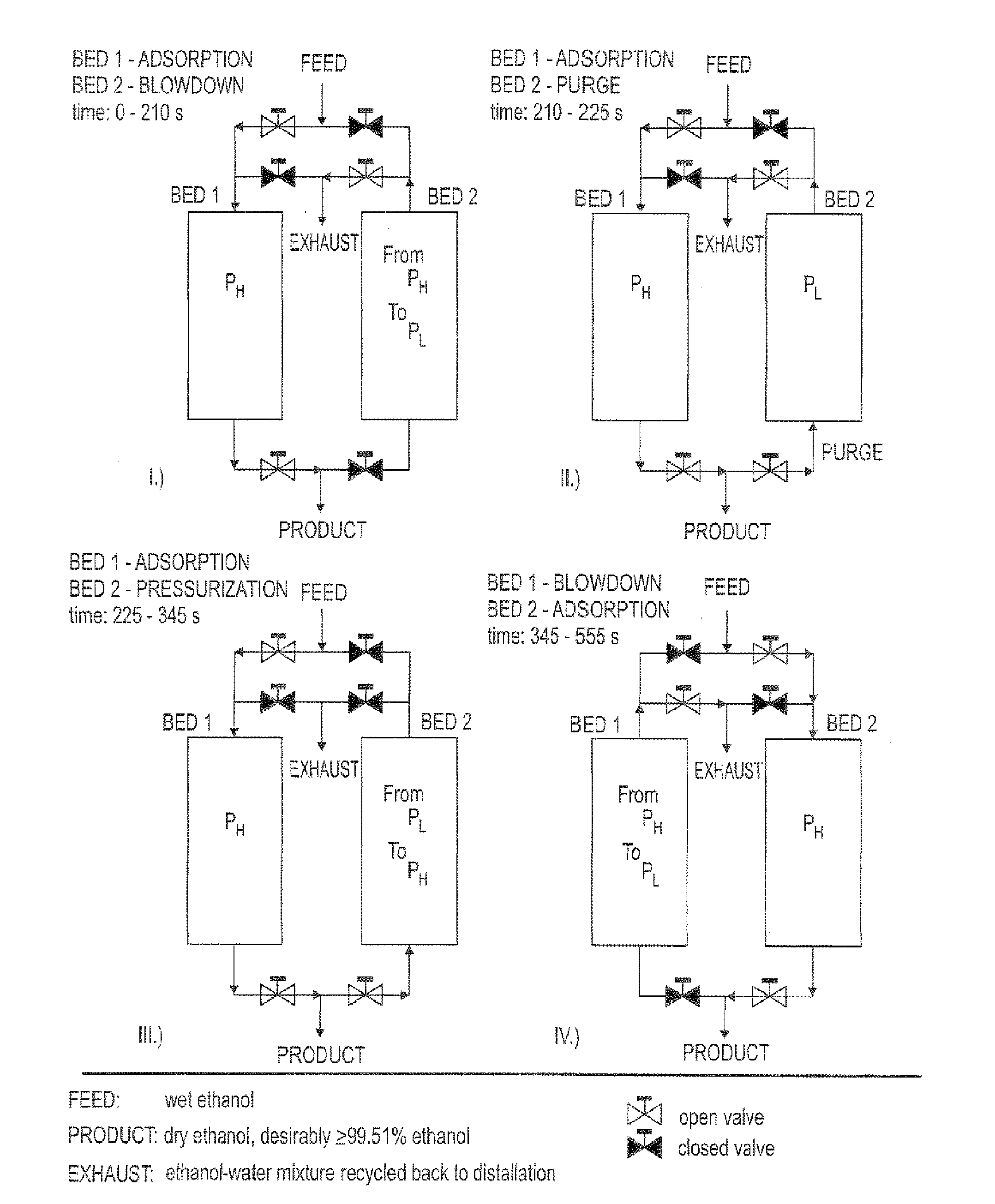

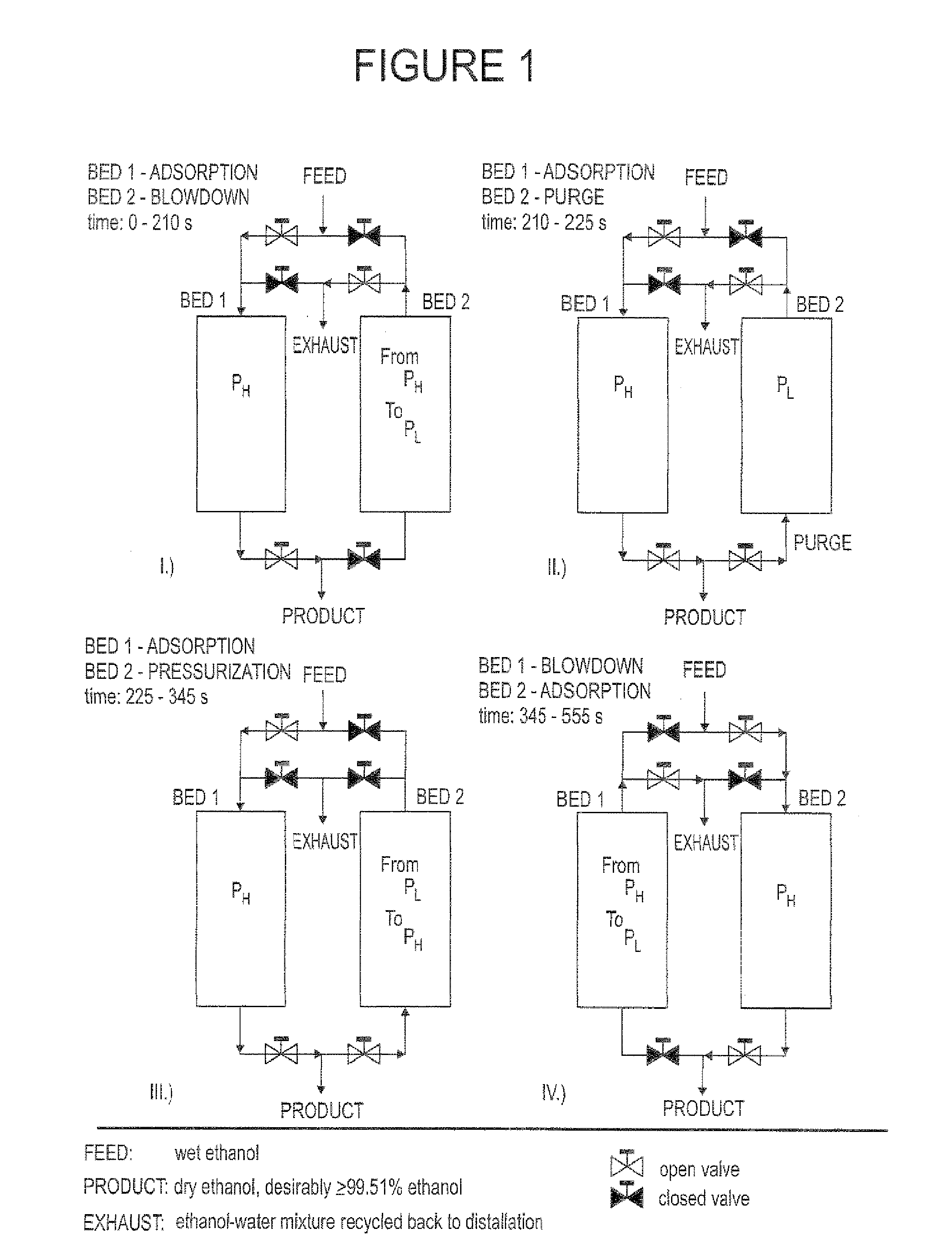

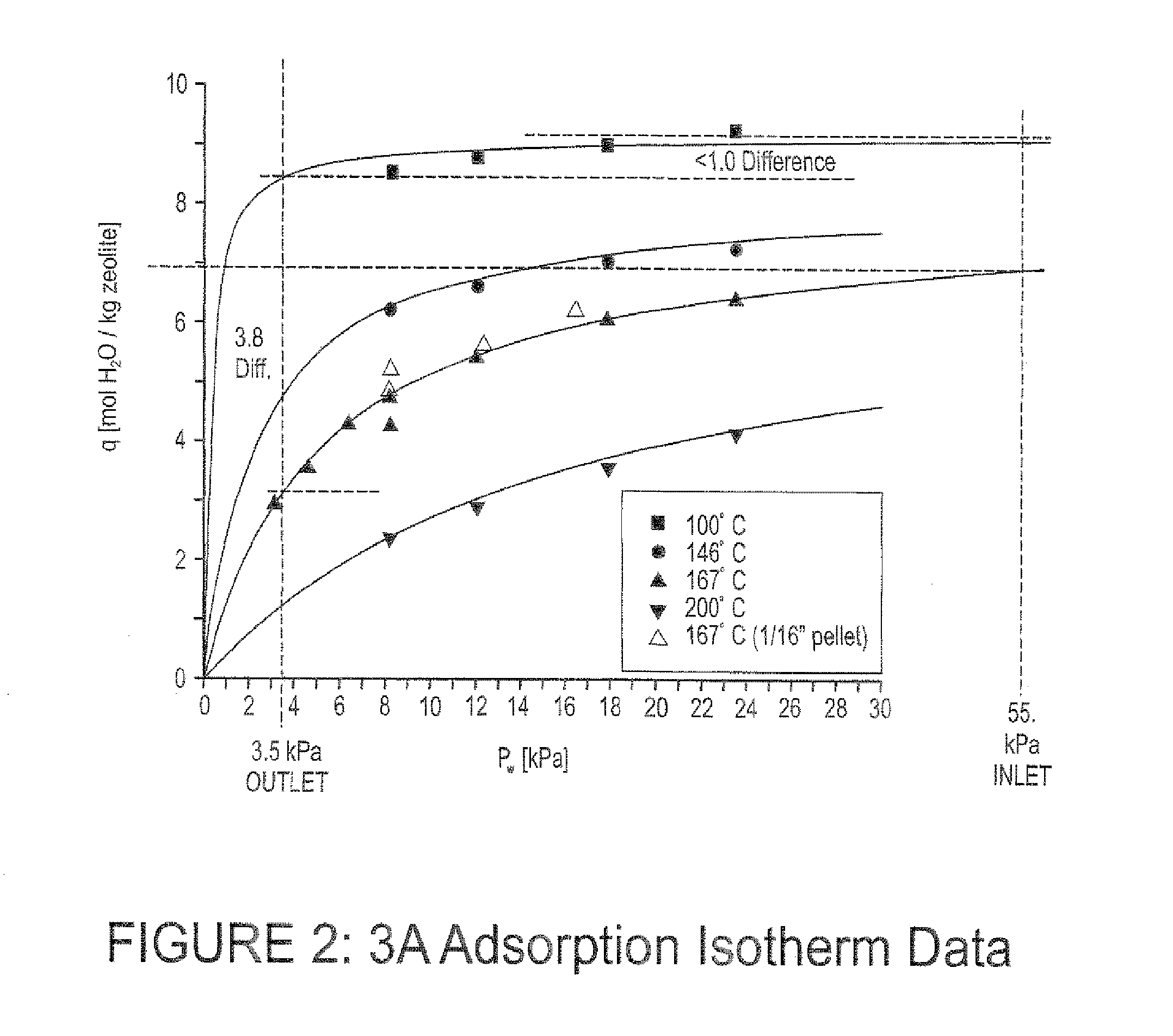

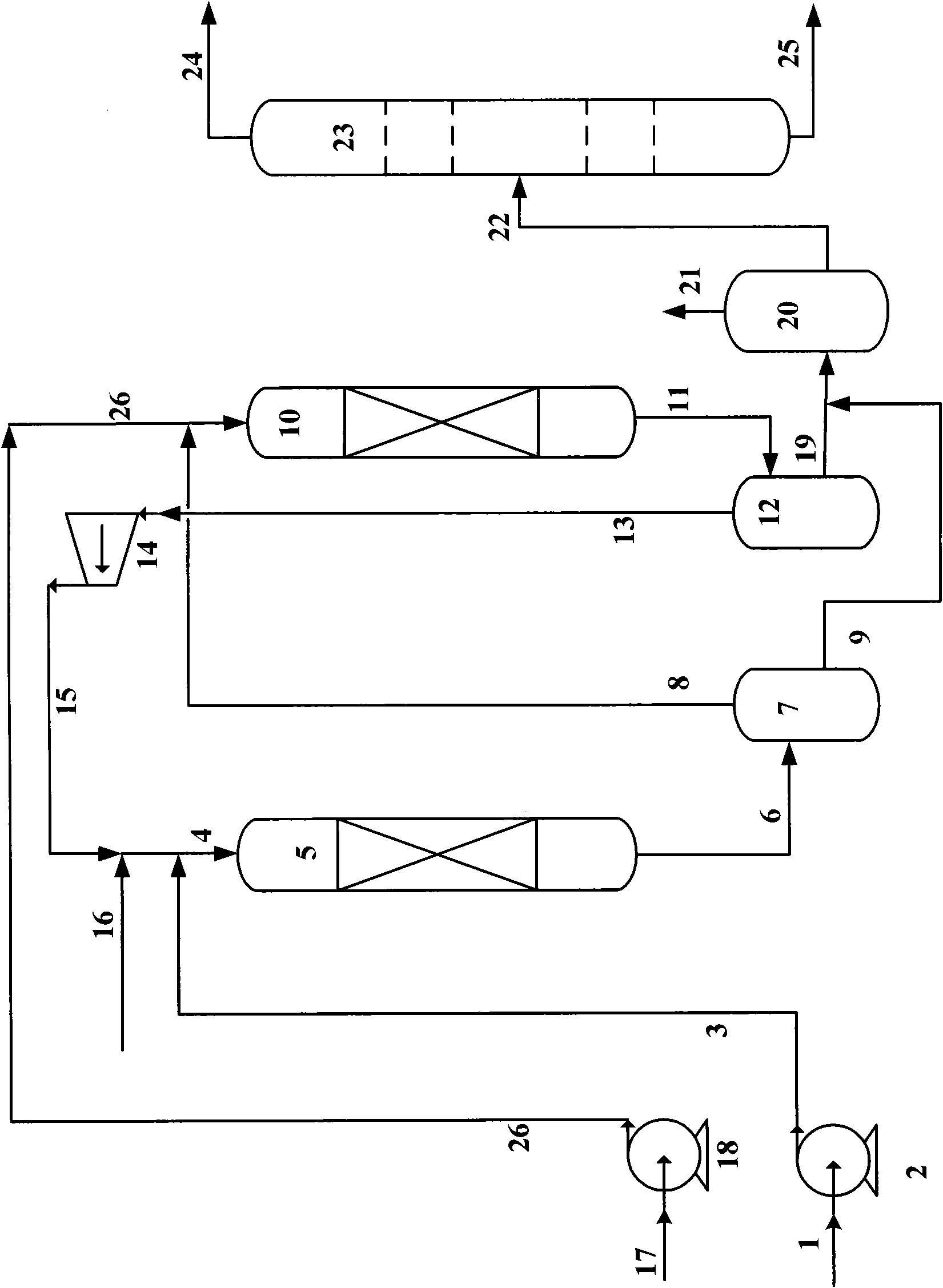

Adsorption process for the dehydration of alcohol

ActiveUS20130225880A1Increase productivityImprove performanceGas treatmentOrganic compound preparationAqueous alcoholHigh pressure

The present invention includes a process for the dehydration of ethanol by adsorption of water at elevated pressure and for the regeneration (purging) of adsorbent at a lower pressure than the pressure used for the adsorption of water where the ratio of the duration of the regeneration (purge) step to the duration of the water adsorption step is higher than 0.1 and the temperature of adsorption is greater than 260 degree Fahrenheit.

Owner:RCM TECH USA INC

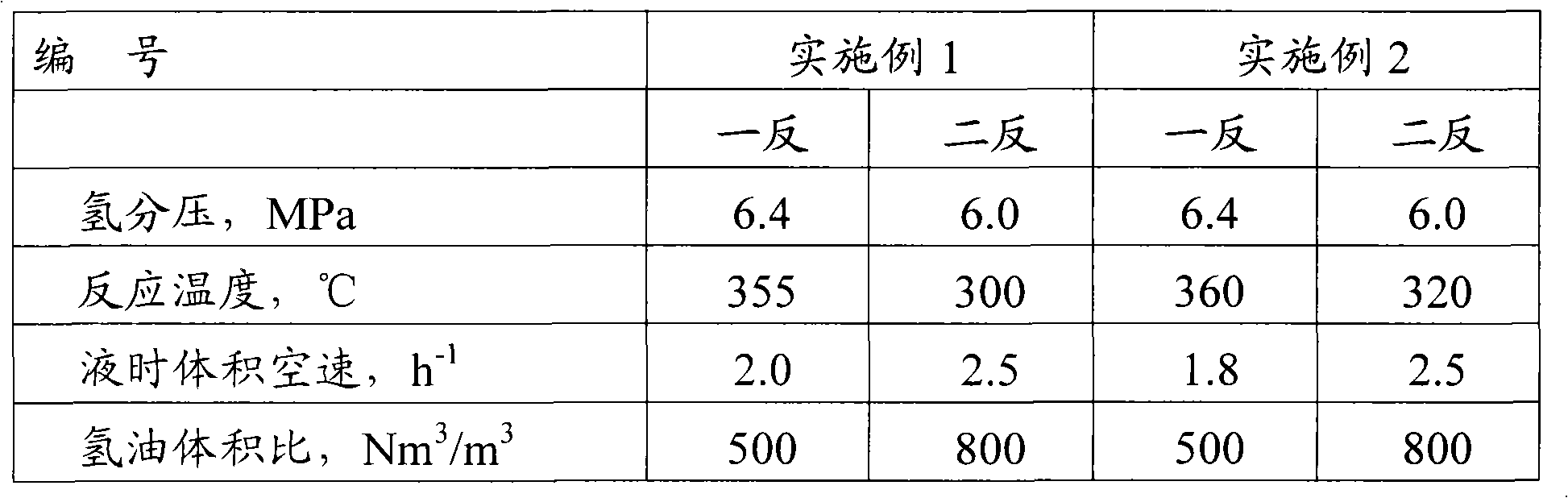

Combined hydrogenation method for mineral oil and animal and vegetable oil

ActiveCN101768469AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonVegetable oil

The invention relates to a combined hydrogenation method for mineral oil and animal and vegetable oil. In two hydrogenation reaction zones, high-sulfur mineral diesel oil distillate and animal and vegetable oil are respectively used as the raw materials and hydrogenated under different conditions, and the products are mixed to obtain a low-surfur or an even ultralow-surfur diesel oil product, wherein the gas-phase compound flow obtained in the first hydrogenation reaction zone is cycled to the second hydrogenation reaction zone, and the gas-phase compound flow obtained in the second hydrogenation reaction zone is cycled to the first hydrogenation reaction zone. The method can process high-sulfur mineral diesel oil distillate and vegetable oil. The method can be used for obtaining a clean diesel oil product with low sulfur content and high content of polycyclic aromatic hydrocarbon and cetane number under mild operating conditions. The invention saves the equipment and the operating procedure for regular sulfur supplement for hydrogenation of the vegetable oil, reduces the effect of water generated by the vegetable oil hydrogenation reaction on the activity of the hydrogenation catalyst, and prolongs the device operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

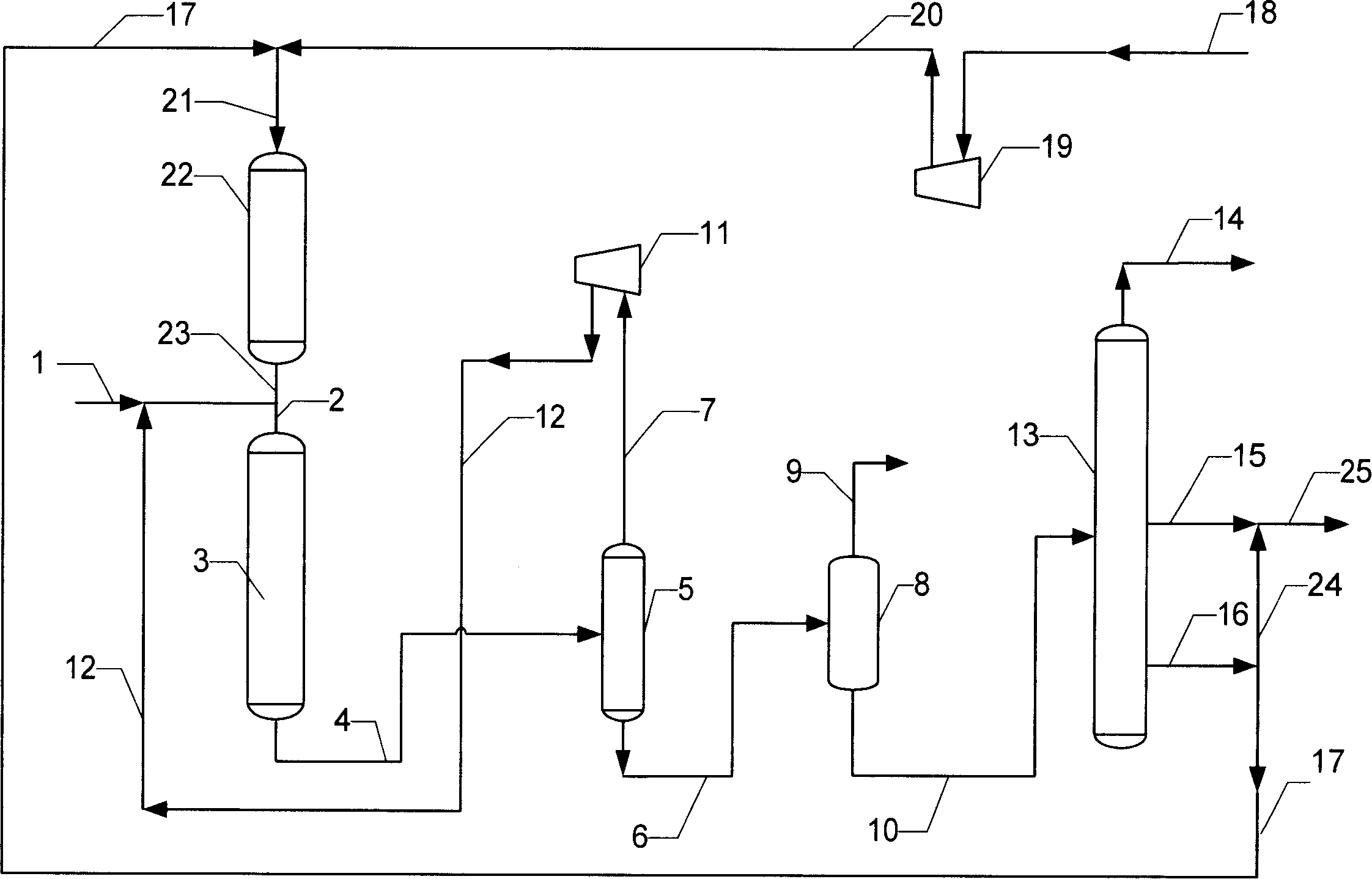

Hydrogenation method for producing clean diesel oil

The present invention relates to a hydrogenation method for producing clean diesel oil, after the raw material oil is mixed with circulating hydrogen, the mixture enters into a second hydrogenating reactor area, under the action of hydrogenation refining catalyst, the reaction is performed, after the reaction effusion is cooled, separated and fractionated, naphtha distillate, light diesel oil distillate and heavy diesel oil distillate are got, after a part or whole heavy diesel oil distillate is mixed with new hydrogen, the mixture enters into a first hydrogenating reactor area, and contacts with the hydrogenating reforming catalyst to perform reaction, the reactant enters into the second hydrogenating reactor area directly without separation, the left heavy diesel oil distillate and the light diesel oil distillate are mixed to get the diesel oil product. The adoption method of the present invention can treat high sulpher, high nitrogen and high drying point diesel oil distillate, under the relaxer operation condition, 2 type and 3 type of standard clean diesel oil which meet the requirement of the World Fuel Oil Code can be got. The present invention has simple flow and low operation pressure, the investment for equipments and the operation cost are all comparatively lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for making higher value products from sulfur containing crude oil

ActiveUS7790018B2High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

Trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and operating method

ActiveCN101786630ASave heating and energy saving lossReduce cooling loadChemical industryHalogenated silanesDifferential pressureProcess engineering

The invention relates to a trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and an operating method. The trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system comprises a primary tower, a secondary tower and a tertiary tower; the three towers are connected in series from low pressure to highpressure or from high pressure to low pressure, and a condensation re-boiler is arranged between the primary tower and the secondary tower and between the secondary tower and the tertiary tower respectively; and the three towers can be used for light removal, heavy removal and light removal in turn, and also can be used for combining light removal, heavy removal and light removal. According to the characteristics of approach full tower composition and approach temperature in the process of rectifying the trichlorosilane, the invention provides a trichlorosilane differential pressure coupling rectifying process which is expected to greatly reduce the production cost and energy consumption and theoretically rectify and save energy by nearly 70 percent. The technology remarkably improves themarket competitiveness of polycrystal silicon materials and promotes the development of a photovoltaic and information material industry chain.

Owner:TIANJIN UNIV

Technology for separating low carbon olefin gases

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com