Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

802 results about "Brown coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignite, often referred to as brown coal, is a soft, brown, combustible, sedimentary rock formed from naturally compressed peat. It is considered the lowest rank of coal due to its relatively low heat content. It has a carbon content around 60–70 percent.

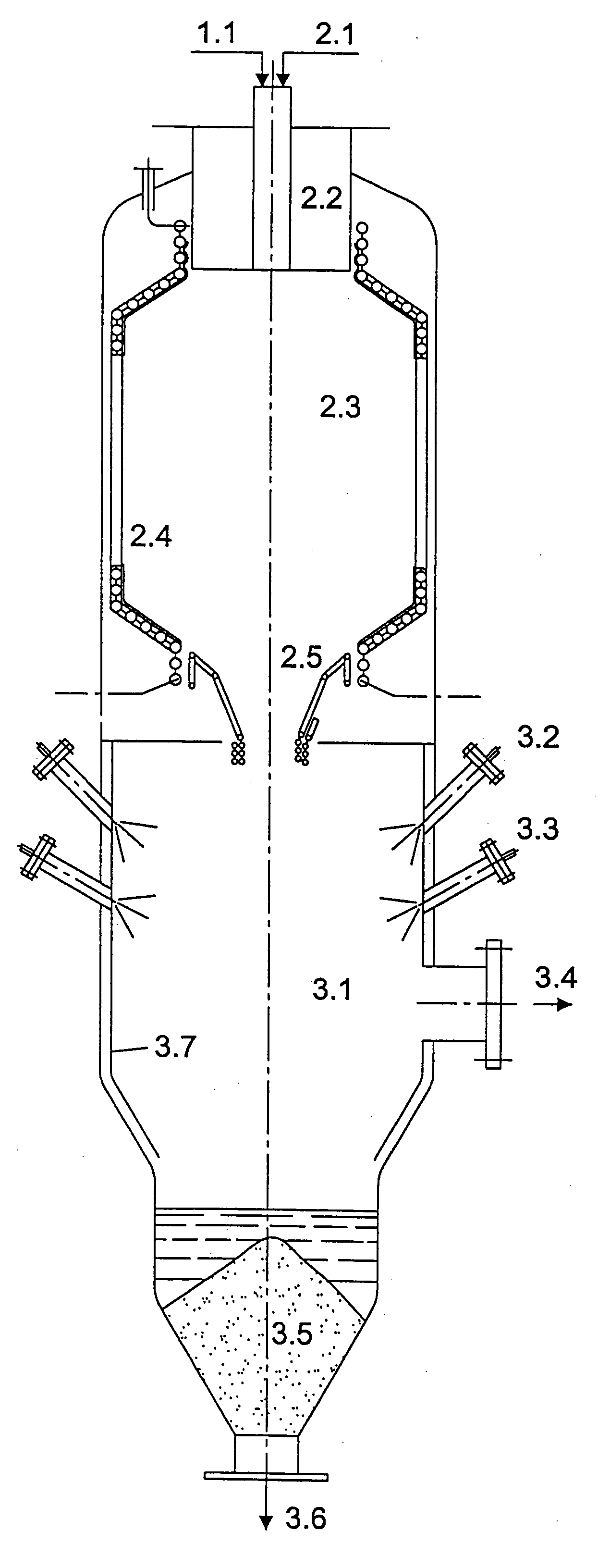

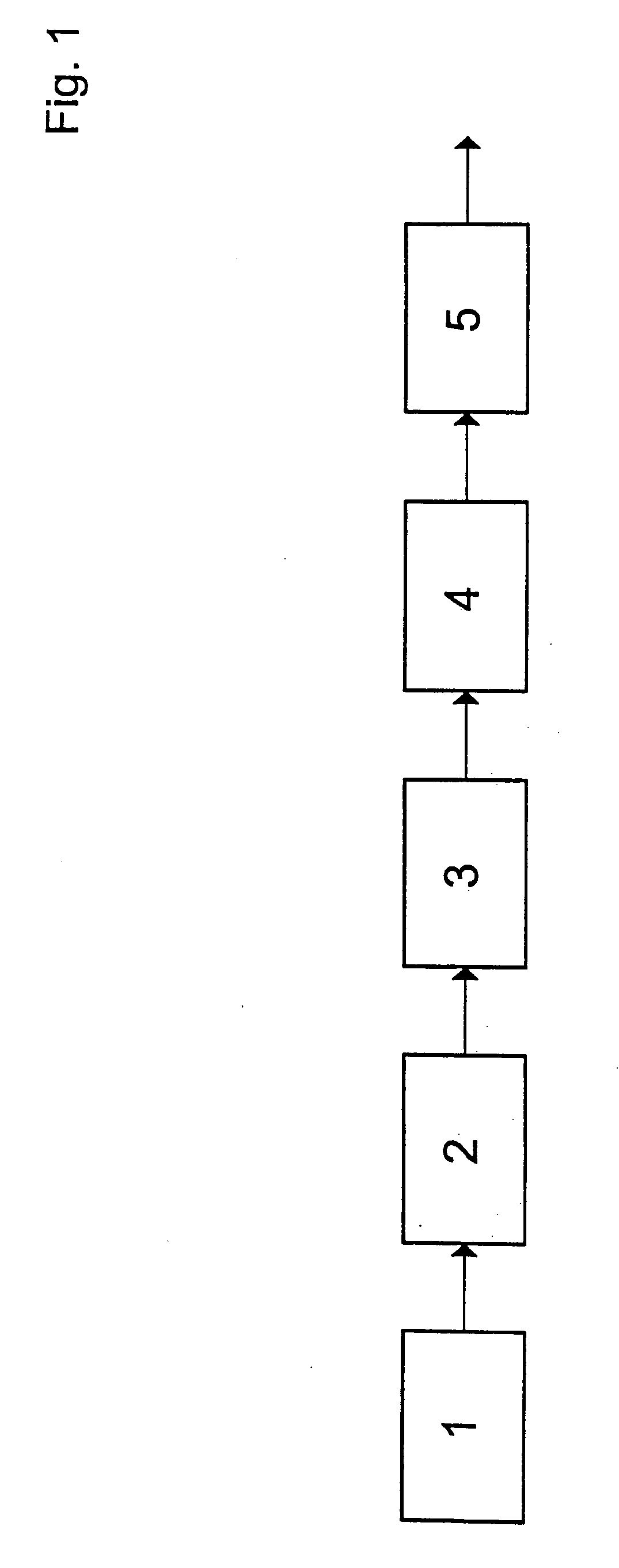

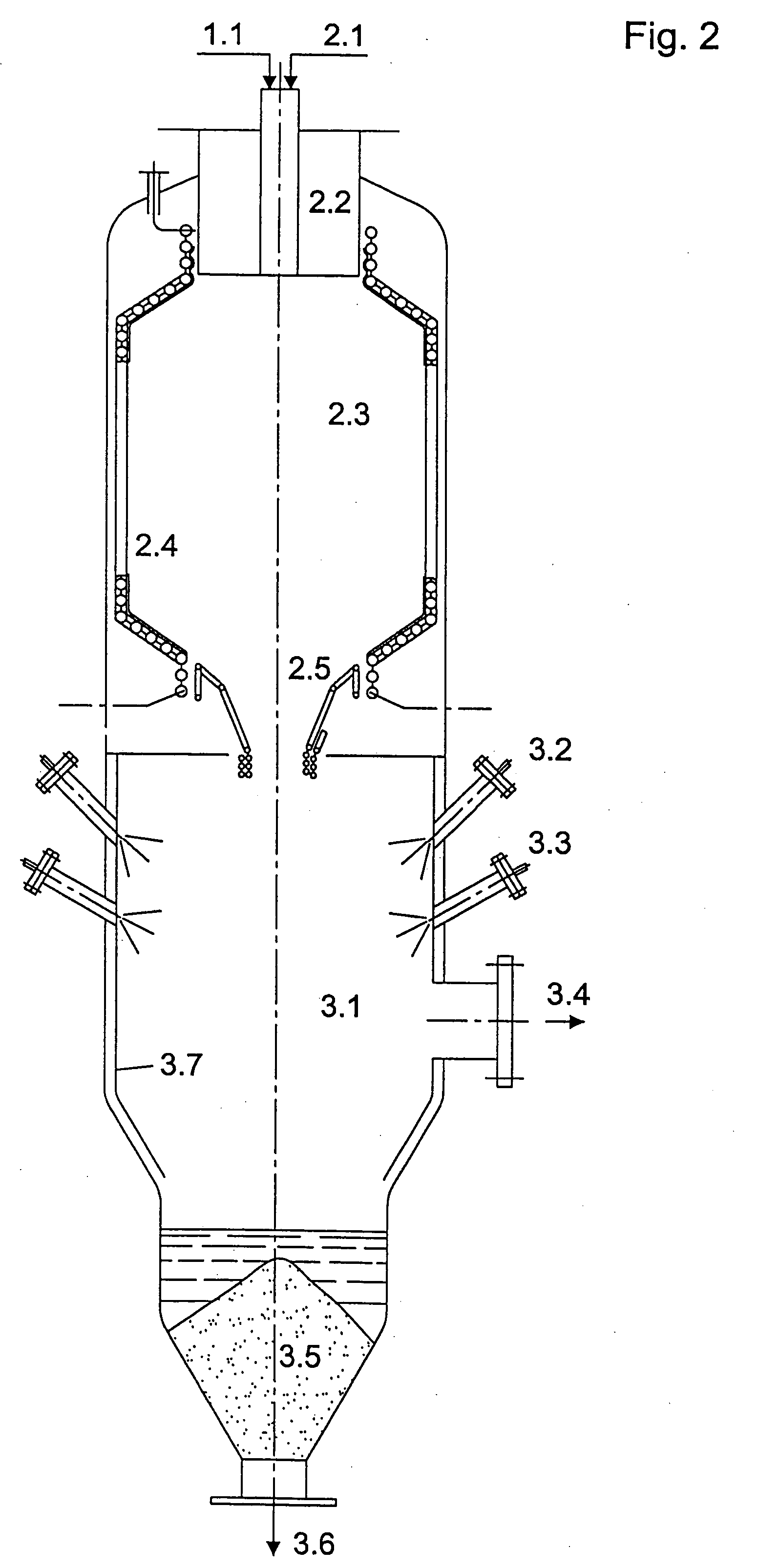

Method and device for high-capacity entrained flow gasifier

A method and device for the gasification of pulverized fuels from solid fuels such as bituminous coals, lignite coals, and their cokes, petroleum cokes, coke from peat or biomass, in entrained flow, with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 80 bar, and at temperatures between 1,200 and 1,900° C., at high reactor capacities between 1,000 and 1,500 MW. The method uses the following steps: metering of the fuel, gasification reaction in a gasification reactor with cooled reaction chamber contour, quench-cooling, crude gas scrubbing, and partial condensation.

Owner:SIEMENS AG

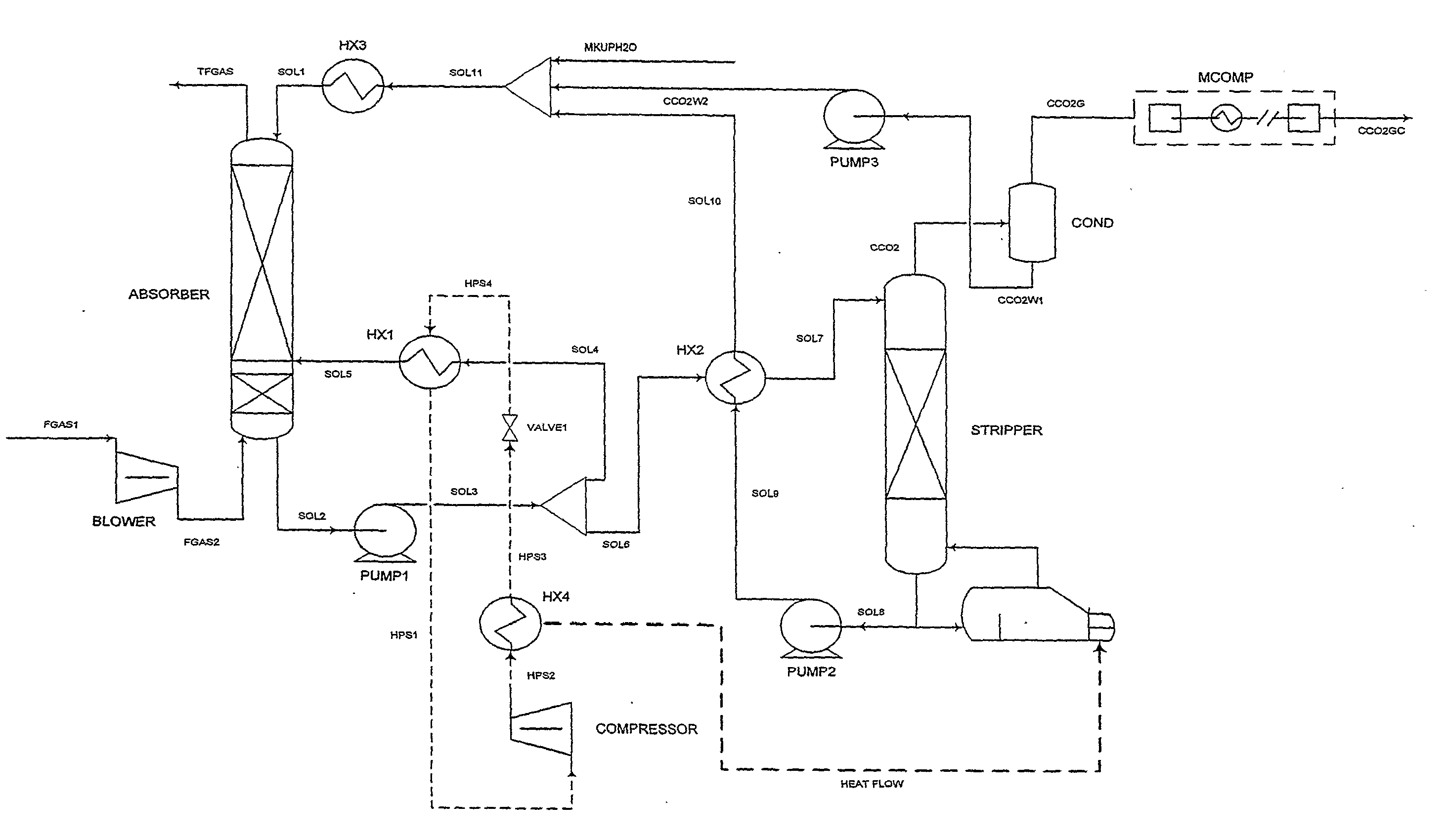

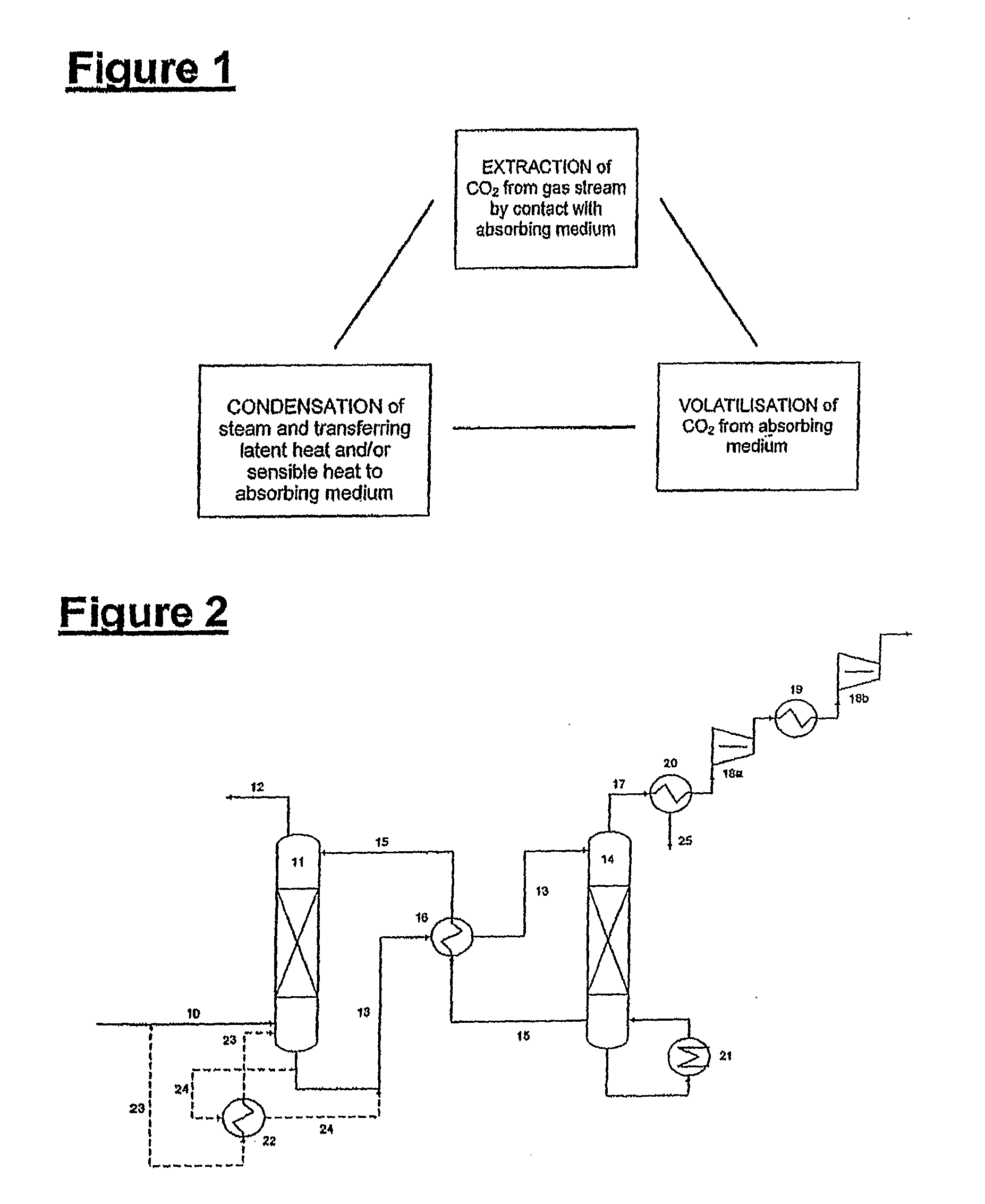

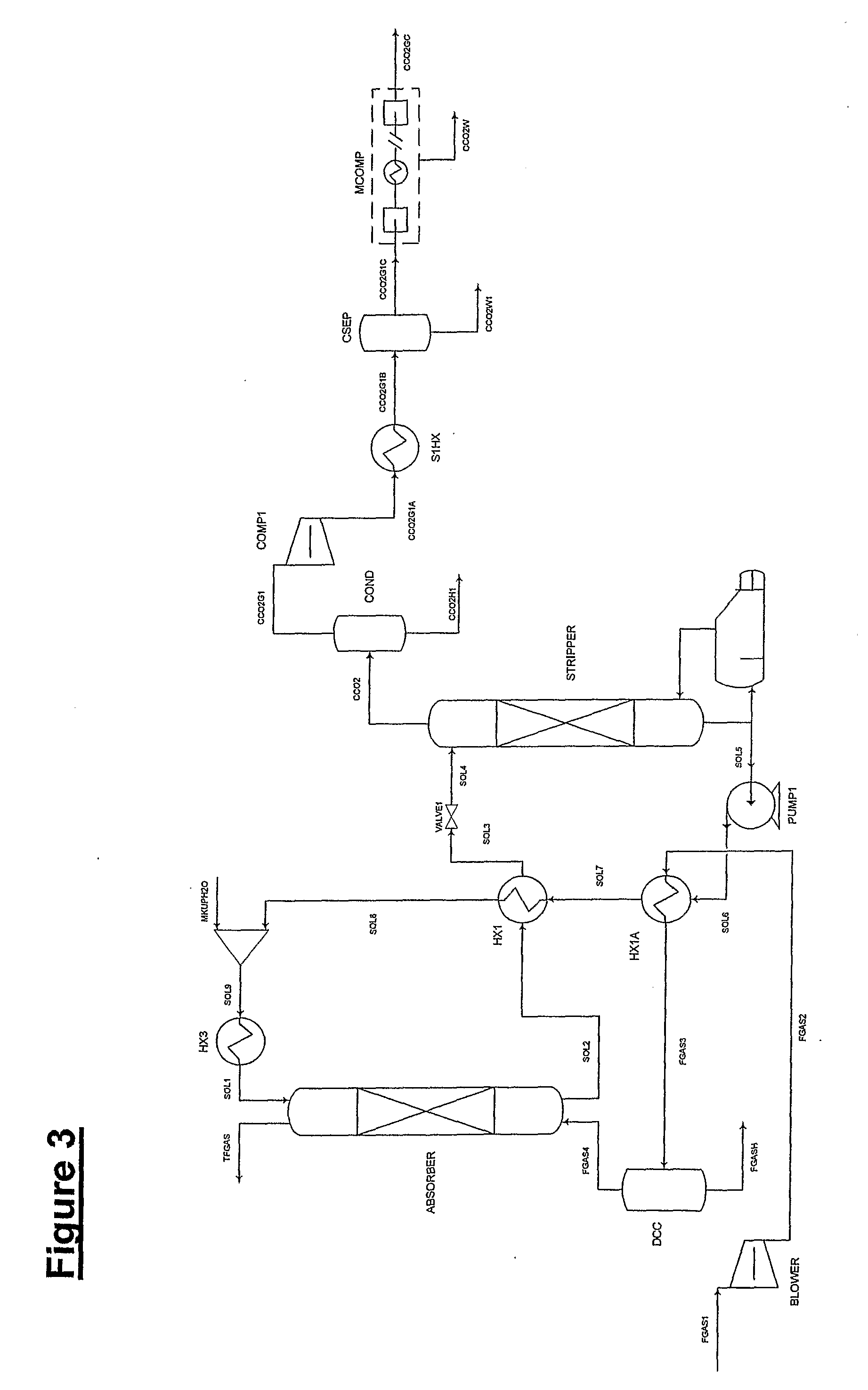

Plant And Process For Removing Carbon Dioxide From Gas Streams

ActiveUS20080317651A1Minimizing overall energy requiredAssist in volatilizationExhaust apparatusDispersed particle separationBy-productChemistry

The present invention is based on the realization that the carbon dioxide component of industrial gas streams also containing steam can be processed so to utilize either as latent and / or sensible heat the heat available from the steam component to assist in separating carbon dioxide from the remainder of the gas stream. For example, flue gases produced by power stations burning brown coal, black coal or natural gas inherently contain a useful amount of energy that can be harnessed according to the present invention. According to particular preferred forms of the invention, nitrogen and sulphur constituent such as SOx and NOx, H2S and other nitrogen containing compounds may also be removed from the gas stream through direct contact with the absorbing medium and used to produce by-products such as fertiliser material.

Owner:KC8 CAPTURE TECH LTD

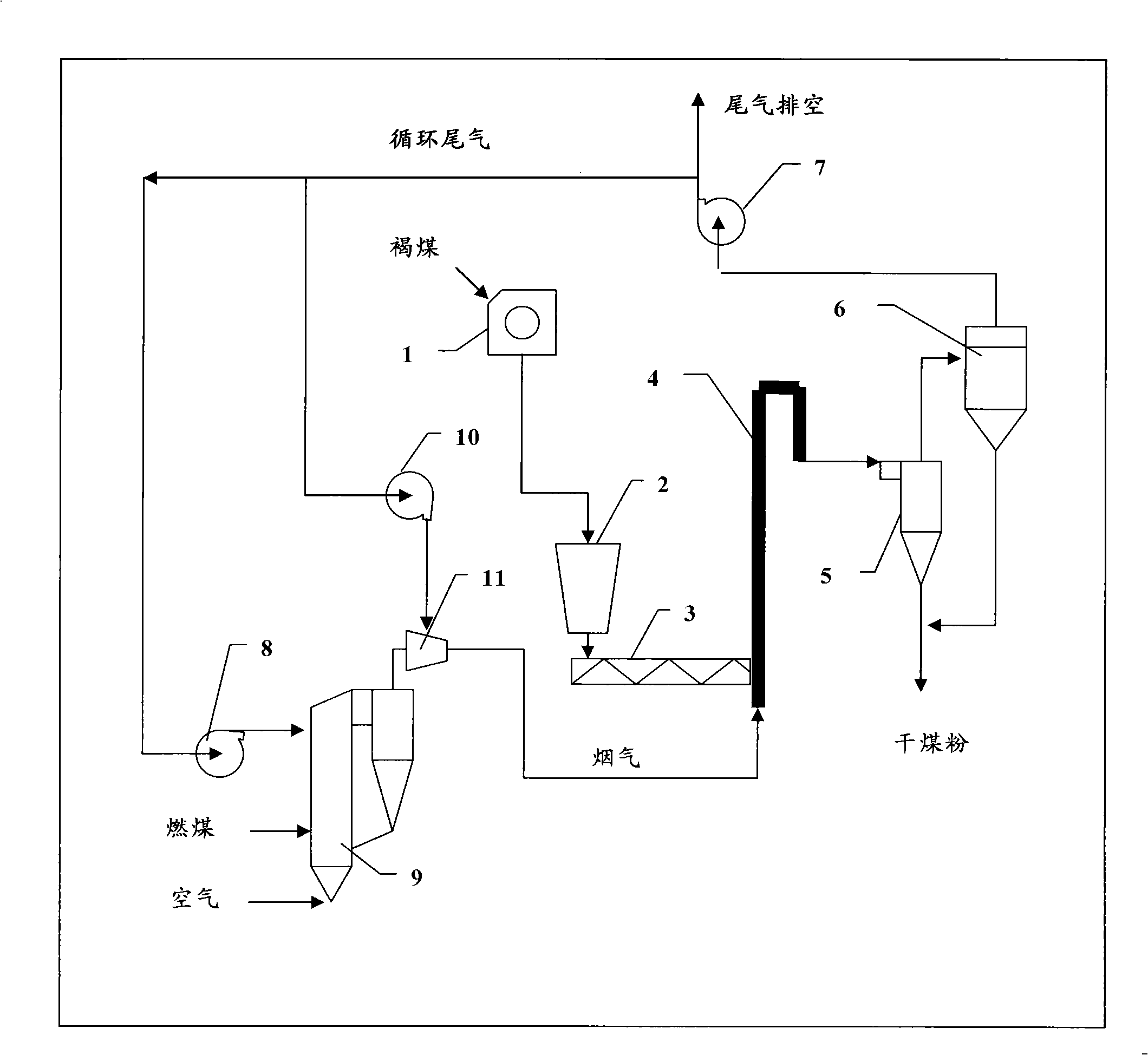

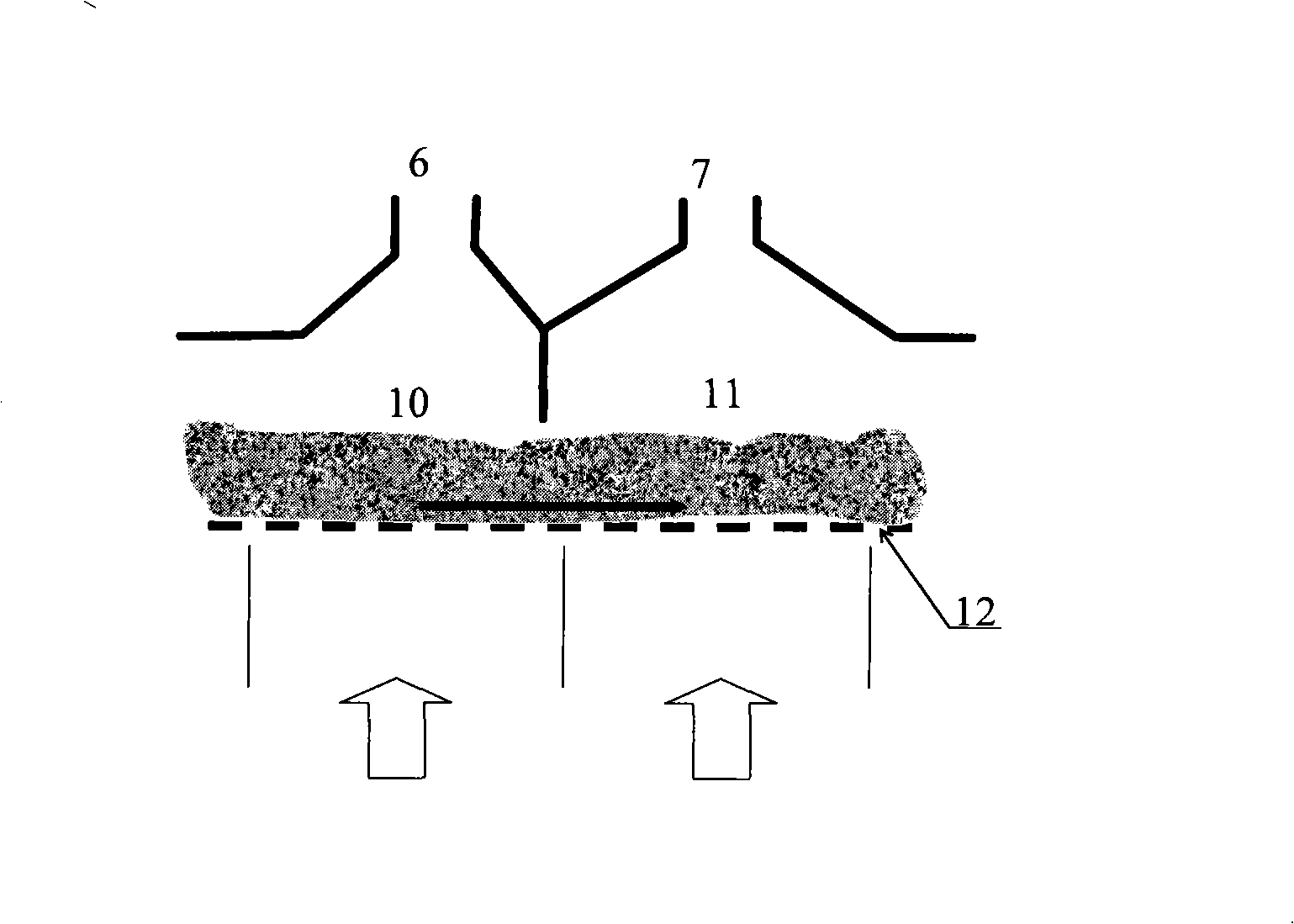

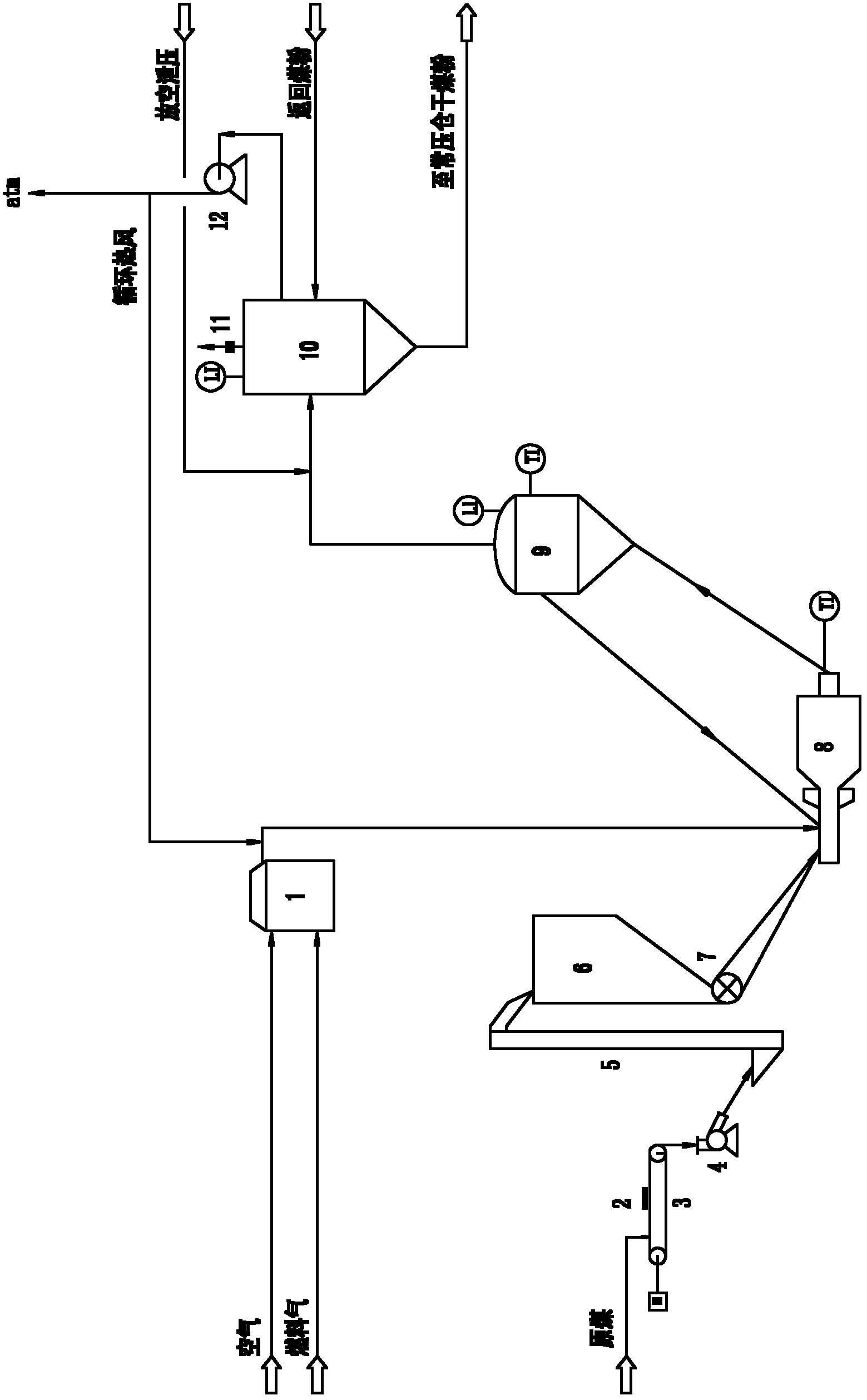

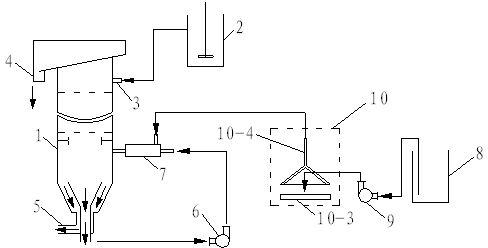

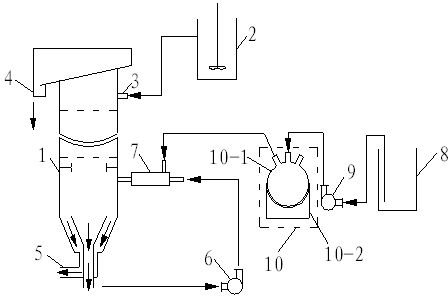

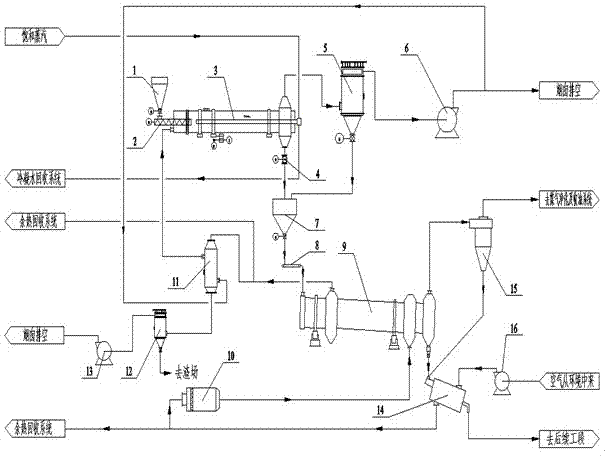

Low rank coal high temperature flue gas drying method and device

The invention relates to a method of high-temperature flue gas drying, which is particularly suitable for drying long flame coal, brown coal or other low rank coal. The coal-fired high-temperature flue gas is used to dry flammable and explosive coal types, such as brown coal in the direct contact method; therefore, the method has less gas exhaust, high thermal efficiency and high drying speed. The internal water content of the dried coal is obviously reduced, and the heating power of the dried coal is greatly increased. The invention also relates to the device using the method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

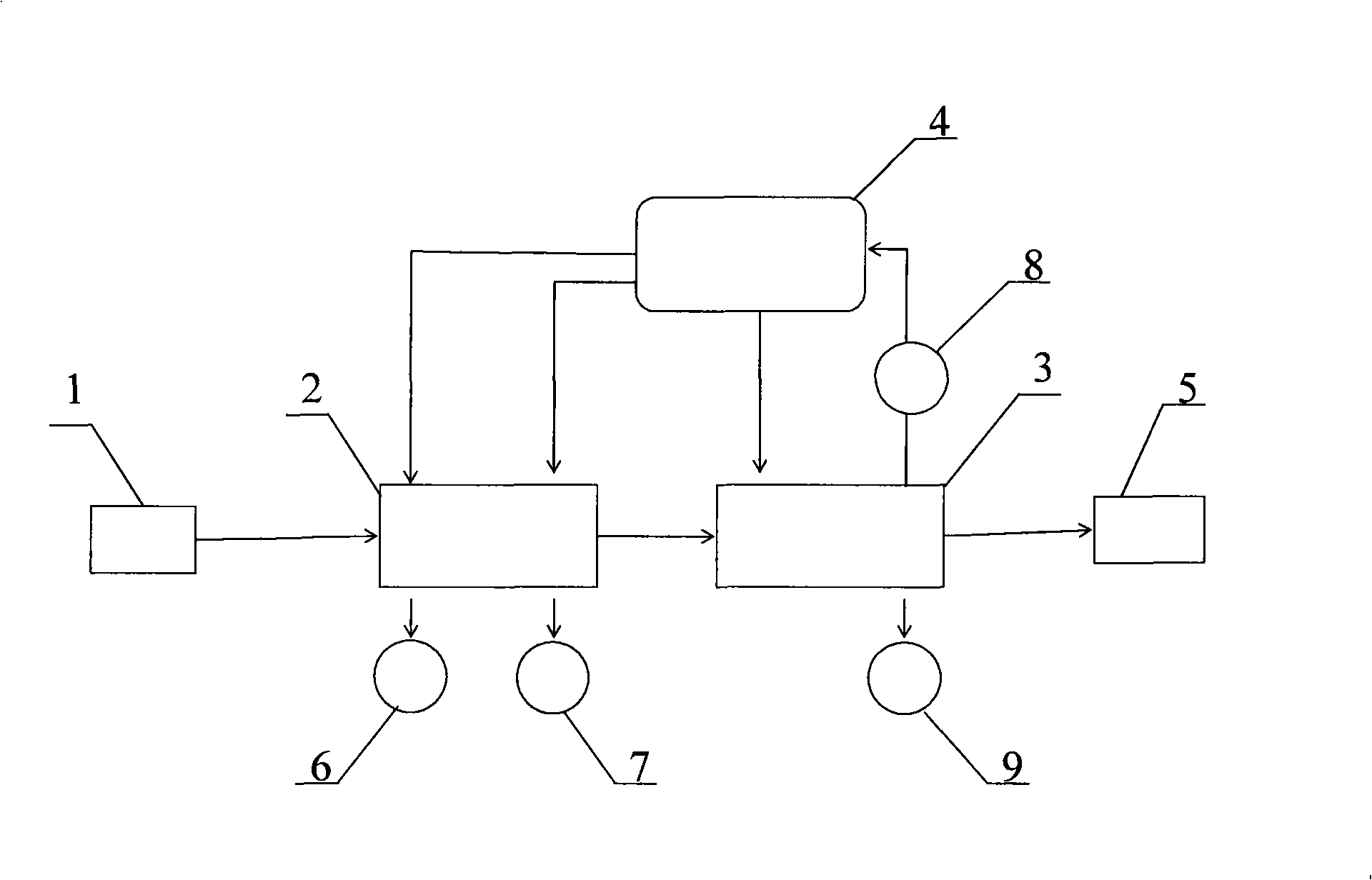

Brown coal drying quality-increasing device and technique

InactiveCN101260307AAvoid burnsGuaranteed classificationDrying solid materials with heatCoke ovensBrown coalLiquid product

A drying and upgrading device for lignite and a technological method thereof, relating to the lignite efficient utilization field. The invention comprises a chamber dryer for the lignite, a fluidized-bed pyrolysis device, a combustion device for the pyrolysed gas, and other adjuvant devices. The dried lignite is fed into the pyrolysis device, volatiles and liquid products are extracted, the volatiles are sent into the combustion device to be burnt to generate fume and steam, the fume and a part of the steam are sent into the drying device to serve as the drying media. The rest steam is sent into the pyrolysis device to provide the heat source for the pyrolysis. A chain conveying method and a method of chamber drying / discharge of the fume and the steam are adopted for the drying device. Two different steams with different temperatures are generated in the combustion device and used for drying and pyrolysis of the lignite respectively. Compared with the prior technology, the device and the method provided by the invention have the advantages of safe and reliable operation, reasonable design, steady running in the large-scale application, and capability of improving the comprehensive utilization rate of the lignite.

Owner:TSINGHUA UNIV

Method and device for producing synthesis gases by partial oxidation of slurries prepared from fuels containing ash and full quenching of the crude gas

ActiveUS20070062117A1Improve usabilityGuaranteed uptimeMuffle furnacesGasifier mechanical detailsPartial oxidationSlurry

A method and device for the gasification of solid fuels such as bituminous coals, and cokes such as those from bituminous coals, lignite coals, and biomasses, as well as petroleum cokes, that are ground fine and mixed with water or oil to obtain fuel-in-liquid suspensions, so-called slurries, and their gasification together with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 100 bar, and at temperatures between 1200 and 1900° C. in an entrained flow reactor. The method includes slurry preparation and infeed to the reactor, gasification in an entrained flow reactor with cooled reaction chamber contour, full quenching of the crude gas to saturation temperature that may be 180-260° C. depending on the gasification pressure, and wet or dry dust separation. The crude gas is pretreated so that it can be fed to further technological steps such as crude gas conversion, H2S and CO2 removal, and synthesis.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

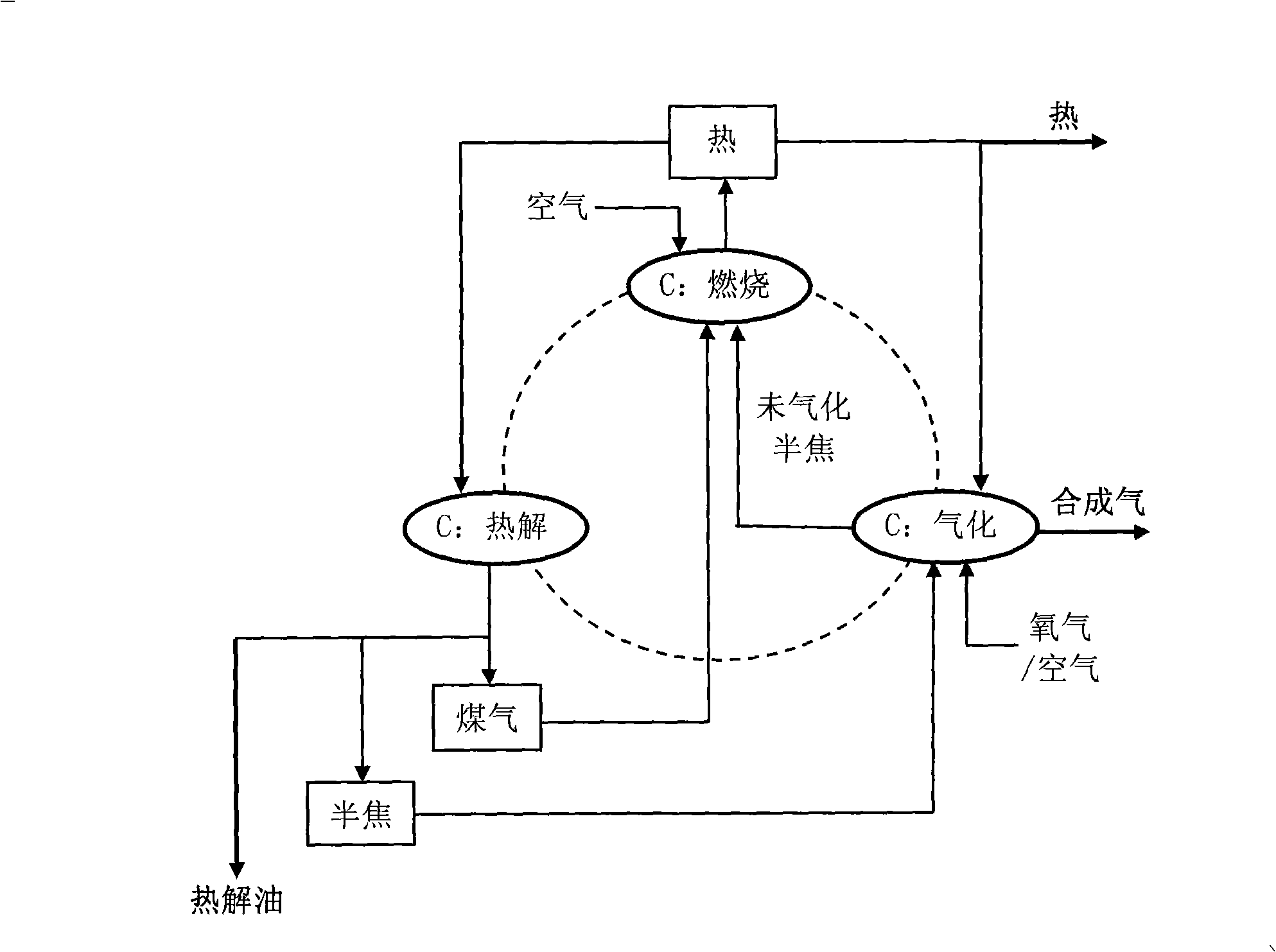

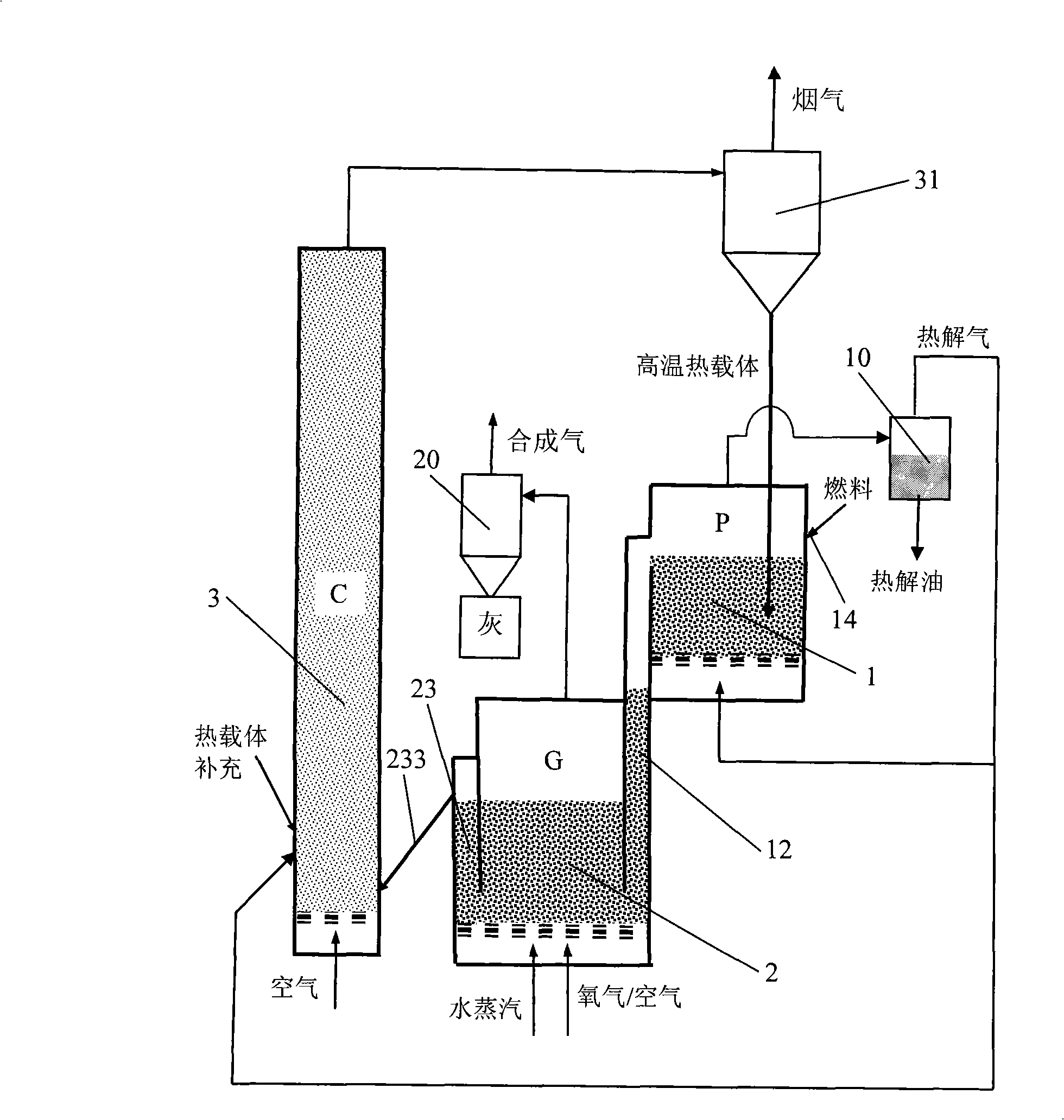

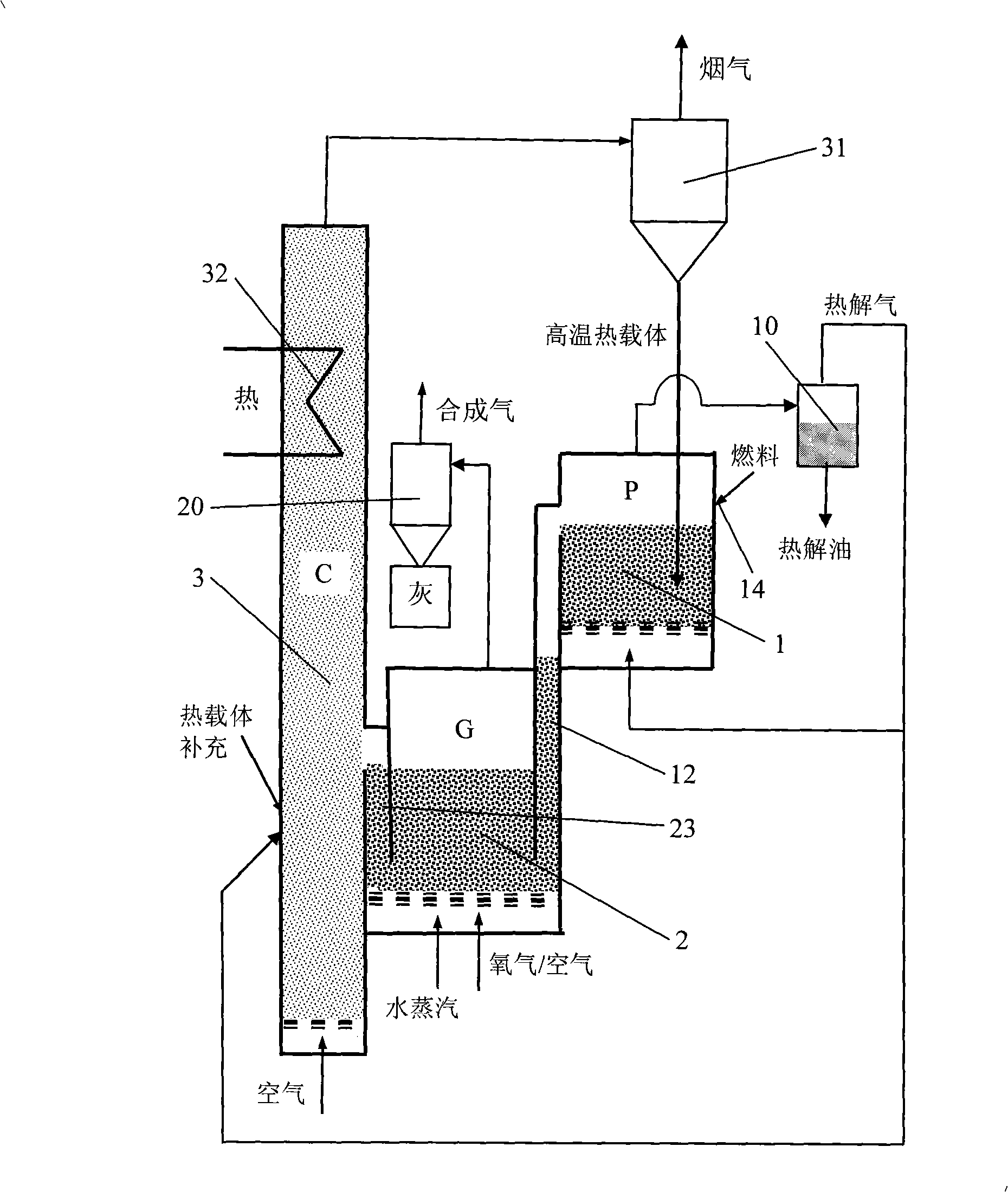

Combined thermal transition method and apparatus for solid fuel

InactiveCN101294092ARealize the value of "resources"Efficient productionLiquid hydrocarbon mixture productionCombined combustion mitigationBrown coalThermal transition

The invention relates to a thermal conversion method and a thermal conversion device of solid fuel, wherein the thermal conversion of the solid fuel is composed of three independent and association-controllable sub-processes of pyrolysis, gasification and burning by decoupling the integrated pyrolysis, gasification and burning reactions in the conventional thermal conversion process. A hot carrier substance is circulated among the sub-processes, so that the burning sub-process provides reactive heat to the pyrolysis and the gasification sub-processes and simultaneously provides oxygen to the gasification process to initiate internal burning so as to compensate for the gasification reaction heat that the hot carrier substance is unlikely to supply. Accordingly, the thermal conversion method can control the three thermochemical reactions of pyrolysis, gasification and burning by decoupling, recombination and association to achieve combined production of pyrolysis oil, synthesis gas and heat. Different from conventional single conversion devices for burning, gasification and pyrolysis, the thermal conversion method of the invention has the advantages of compact structure, high heat utilization efficiency and greatly reduced oxygen consumption for synthesis gas production, thus achieving high-value comprehensive conversion and utilization of solid fuels such as brown coal, bituminous coal and biomass.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

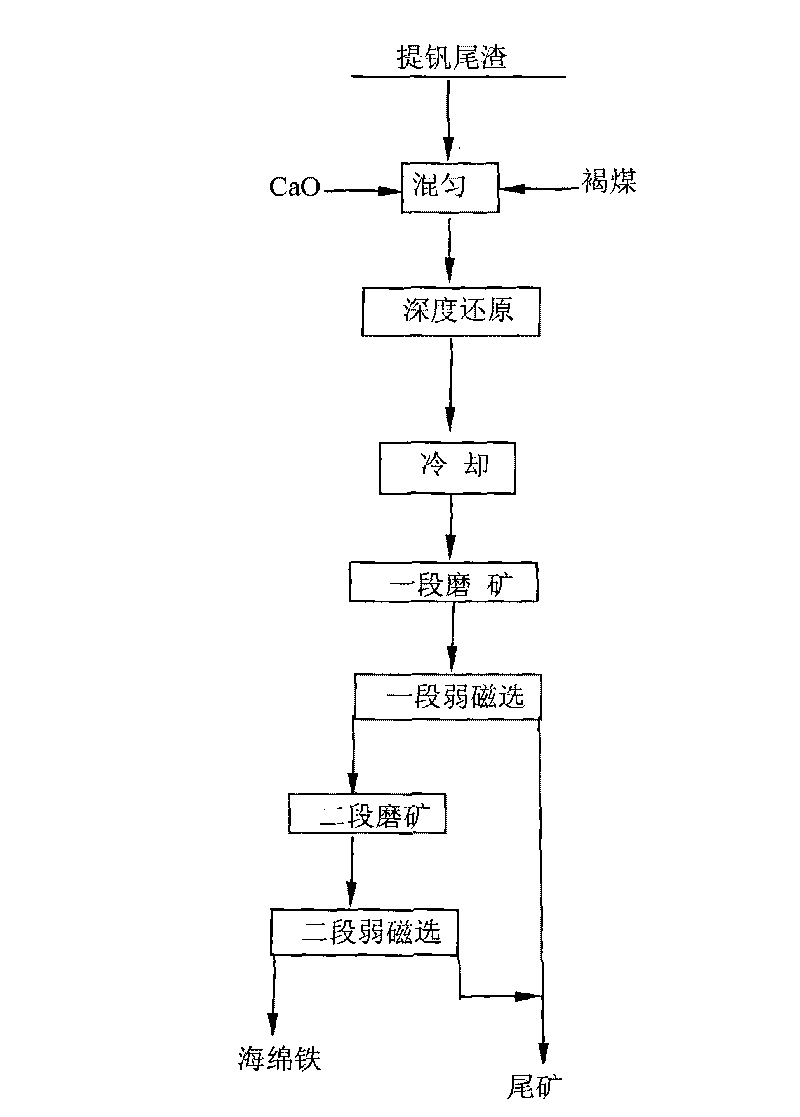

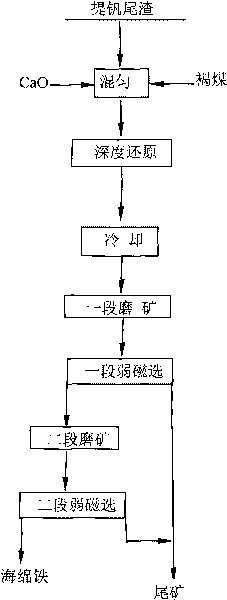

Technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings

The invention relates to a technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings, belonging to the field of iron making. The method adopts brown coal as the reducing agent, and simultaneously CaO is added as slag former and used for increasing alkalinity to synergize with Na2O and K2O in the tailings to react with SiO2 and Al2O3 to generate zeolite-like stable mineral so as to boost extraction and separation of sponge iron in products of deep reduction. The products of deep reduction are subject to two-section ore grinding-two-section low intensity magnetic separation technique to obtain sponge iron with iron grade larger than 90% and TiO2 smaller than 0.20%. The invention is simple in technique and easy to control, and has large reserves of raw materials and low price; the product can be used as raw material for steel making; other impurities meet steel making requirements, the technique flow of processing iron ore into rolled steel is shortened, the environment pollution caused by sintering, pelletizing and blast furnace iron making of iron ore concentrate obtained by other methods can be avoided, and the invention has obvious environment benefit and energy conservation and consumption reduction effects.

Owner:UNIV OF SCI & TECH BEIJING

Tobacco powder biological organic fertilizer formula and production method thereof

InactiveCN101734962APrevent compactionIncrease air permeabilityBio-organic fraction processingOrganic fertiliser preparationBrown coalInsect pest

The invention relates to the organic fertilizer field, in particular to tobacco powder biological organic fertilizer formula and production method thereof. The invention is characterized in that the formula includes the following components by parts by weight: 5-6 parts of tobacco powder, 0.5-1.5 parts of brown coal, 1.5-2.5 parts of live stock excrement and 1-2 parts of straw powder. The tobacco powder biological organic fertilizer is complete in nutrient elements and can regulate soil, activate micro organism liveness in soil, overcome soil hardening and improve soil air permeability; insect pest in soil can be effectively killed; stress resistance of crop is improved, stress reaction of crop is improved, and deformity is reduced; the organic fertilizer is safe and notoxic to human, live stock and environment; the organic fertilizer uses tobacco powder of cigarette factory and redrying factory and straw powder as main raw materials, solves the problems that tobacco powder of the cigarette factory and redrying factory is difficult to treat and secondary pollution is caused by direct burning of the tobacco powder and straw and is environmentally friendly.

Owner:云南澄江立杉生物工程有限公司

Coking method of lignite addition and coal charge

InactiveCN101787296AEfficient use ofThe scope of coal use is expandedCoke ovensBrown coalEnvironmental engineering

The invention discloses a coking method of lignite addition and coal charge. The method of the invention comprises: mixing evenly 5 percent to 20 percent of mixture of lignite and asphalt to be made into coal charge, and then performing coking to produce lignite coke. The coke produced by the coking method and the coal charge has greatly improved quality and reaches the goal of coking lignite addition and reducing the coking cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

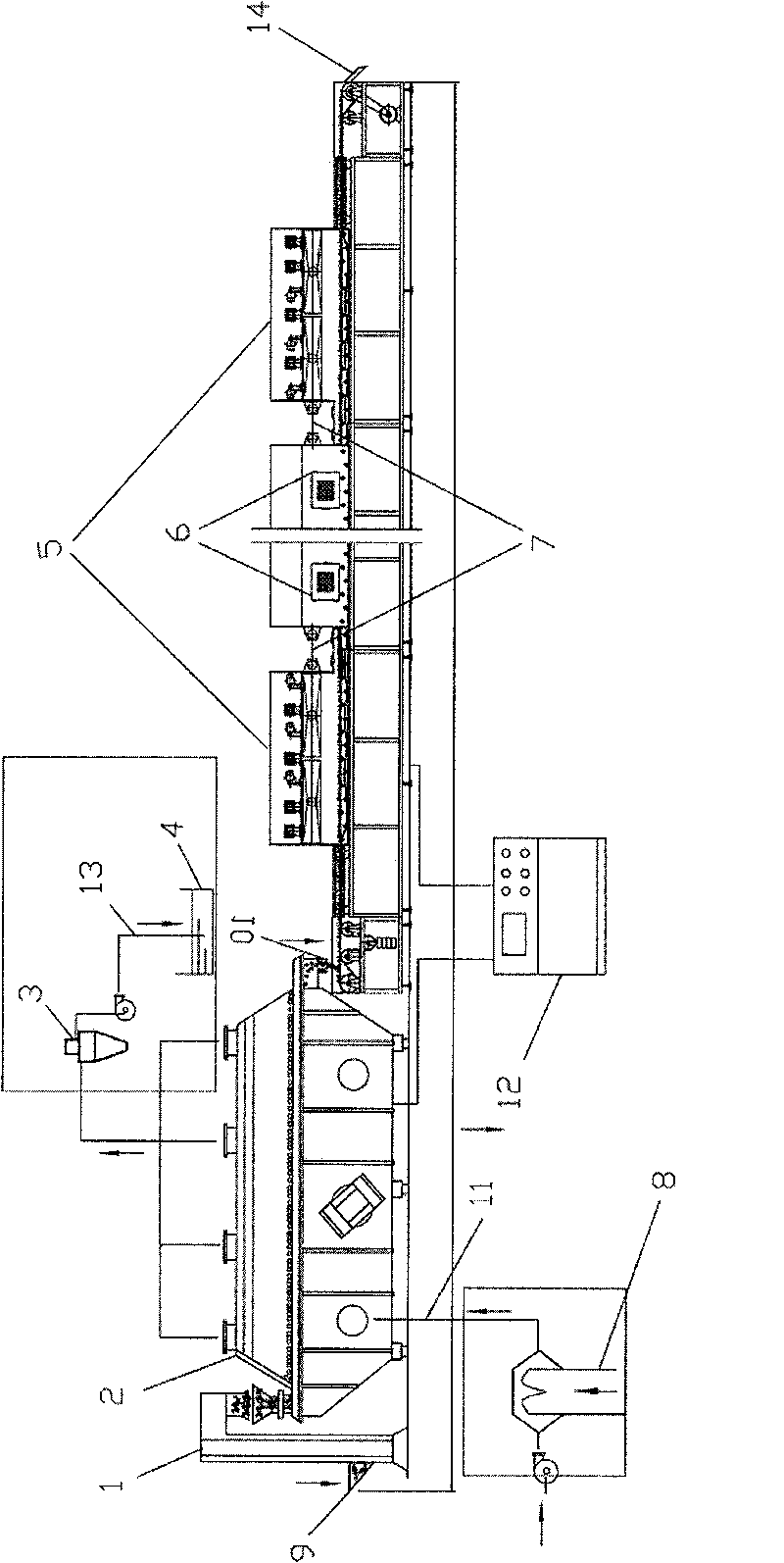

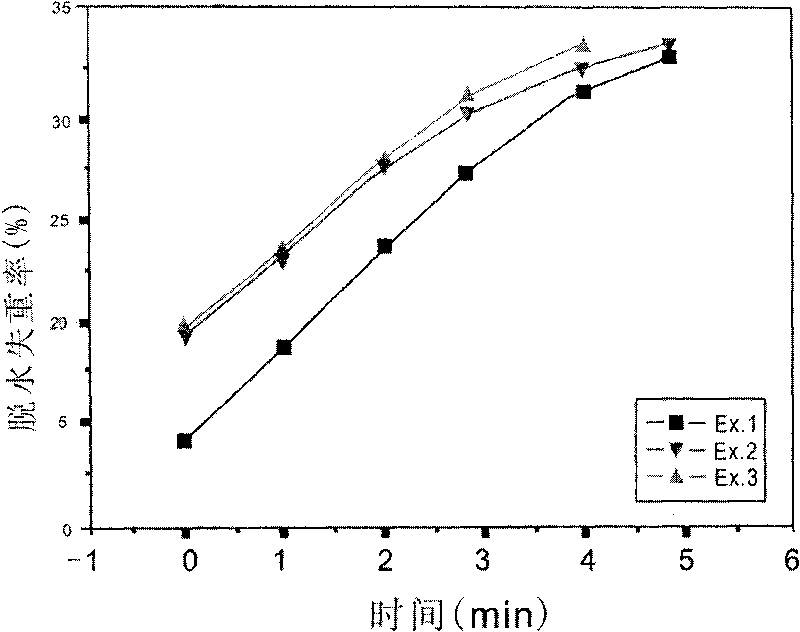

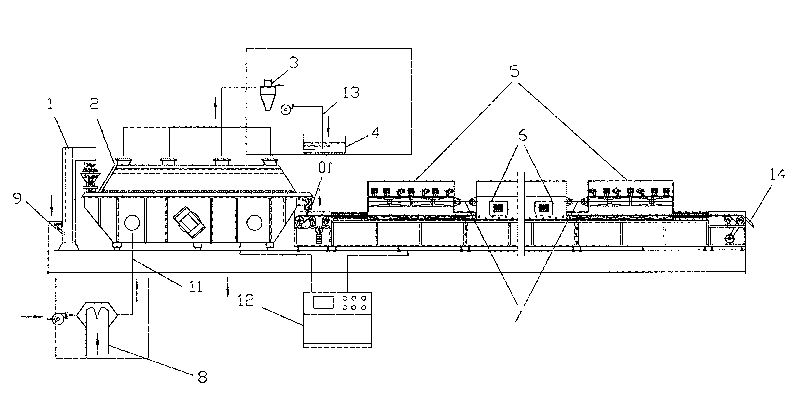

Brown coal drying and dehydrating device

InactiveCN101738077AAchieve dryingImprove coal qualityDrying solid materials with heatDrying machine combinationsComing outBrown coal

The invention relates to a brown coal drying and dehydrating device and an application method. The hot-air drying and dehydrating device dries and dehydrates brown coal at high speed and low energy consumption by main means of high-power microwaves and infrared. The application method for the device comprises the steps of: crushing raw coal; pretreating the coal through a hot-air drying system to remove external water; and then drying and dehydrating the coal further by microwaves, wherein an infrared scanning system is adopted in the drying and dehydrating process in order to prevent the brown coal from backwater. By applying the device, the water in the brown coal can be removed by over 98 percent in short time. The brown coal drying and dehydrating device has the advantages of simpleness and easy operation of process flow, quick dehydration and low energy consumption. The device and the method have no negative effect on the environment, the water coming out through drying can also be recycled, and the device and the method are economic and effective.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH +1

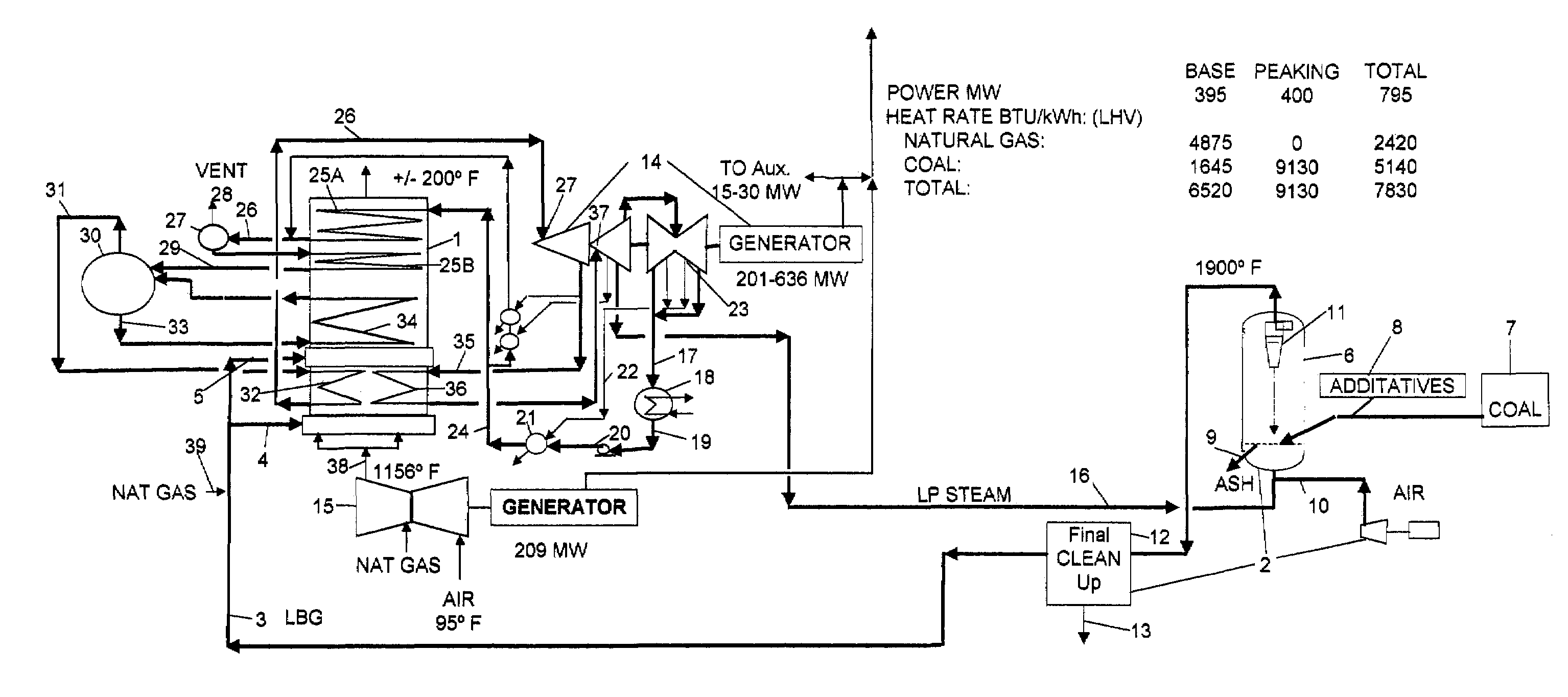

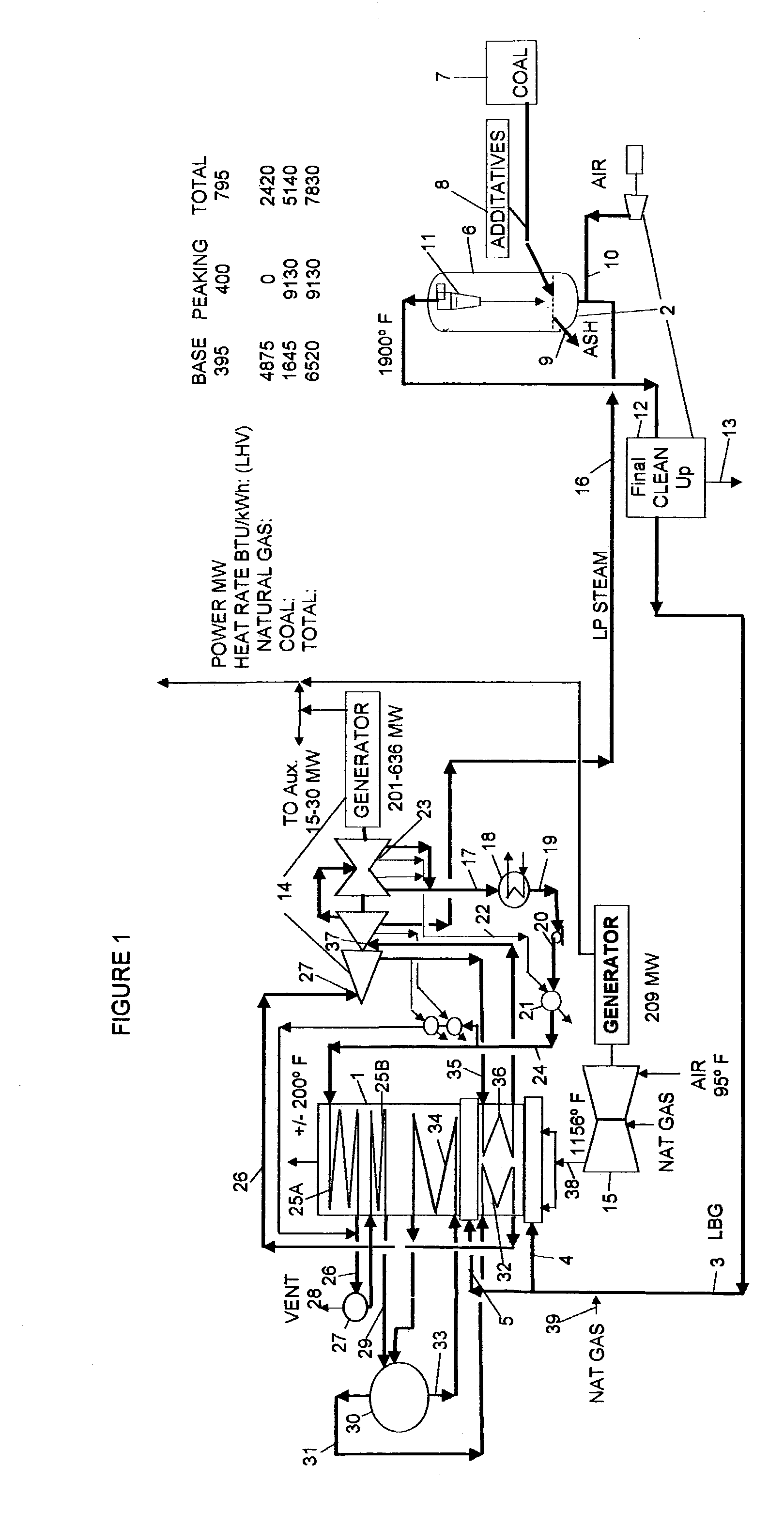

Combined cycle for generating electric power

InactiveUS6966190B2Low costImprove fuel efficiencyBiofuelsCombustion enginesBrown coalHydrocotyle bowlesioides

A combined cycle process that includes gas turbines, a steam turbine train, a heat recovery unit, and a gasification unit that produces low or mid BTU fuel gas from coal, lignite, coke, biomass, or other suitable hydrocarbon containing material wherein the fuel gas is burned in the heat recovery unit at one or more points to increase steam rate to the steam turbine train.The fuel gas injection flow rates into the heat recovery unit are controlled to avoid exceeding peak temperatures in the heat recovery unit of about 2500 F.Optionally, the fuel gas from the gasification unit is cooled by transferring sensible heat to condensate from the steam turbine train to convert the condensate to high pressure steam for driving the steam turbine train.Optionally, a steam boiler unit is integrated into the combined cycle process to raise additional high pressure steam for the steam turbine train. The steam boiler feed water is condensate from the steam turbine train. The steam boiler produces saturated high pressure steam that is superheated in the heat recovery unit.

Owner:WYLIE INVENTIONS

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1698931ALittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

This invention relates to a catalytic oxidation smoke gas mercury removing method, which is used for controlling and reclaiming the gas mercury, especially for the brown coal and subbituminous coal smoke gas. The method uses the mercury oxidative catalyst and the adsorbent to oxygenize and absorb mercury in the smoke gas, then dissociate and elution the mercuric oxide in high temperature to regenerate it. The heat of the elution gas can be reclaimed by residual heat utilization device, and the high concentration mercury will be reclaimed through cold-trap or processed by the agent in the mercury reactor. The reclaimed mercury and other by-product can be sold to reduce the cost. Said invention uses the thermal instability of the mercuric oxide, and reclaims in the relative lower temperature; the recovery ratio can reach to 98%, meanwhile, it processes post-treatment with the mercury and has no secondary pollution.

Owner:SHANGHAI JIAO TONG UNIV

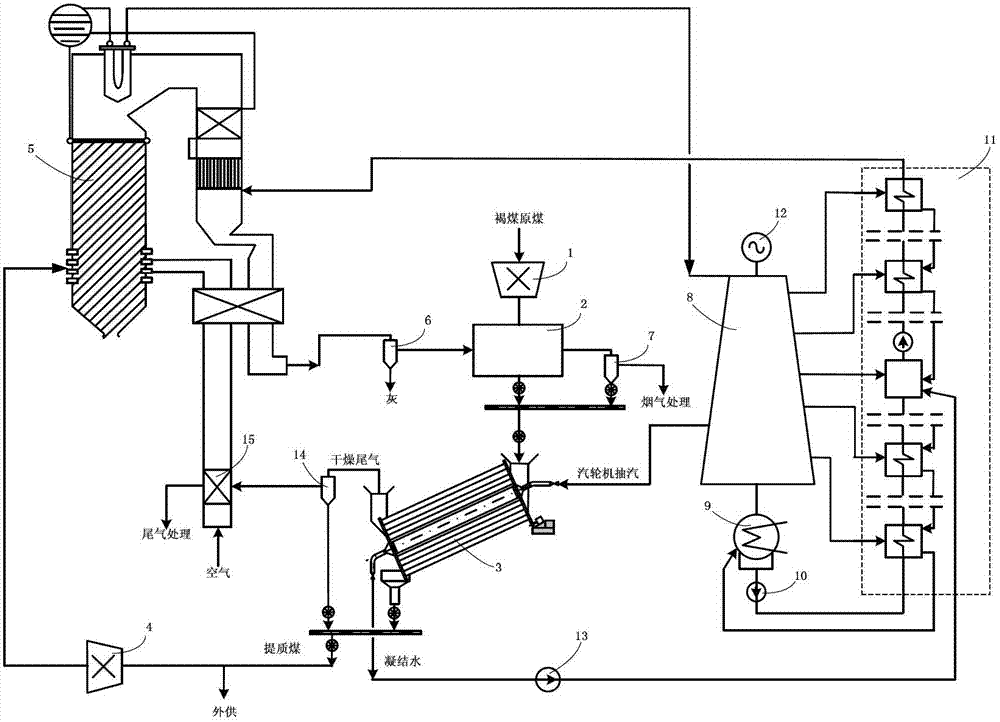

Brown coal upgrading-power generation co-production system

ActiveCN102759259AIncrease drynessImprove utilization efficiencyCombustion processSteam useBrown coalFlue gas

The invention relates to a brown coal upgrading-power generation co-production system. The brown coal upgrading-power generation co-production system is characterized in that the system comprises a raw coal crusher and a flue gas drier which is connected with the raw coal crusher, a coal outlet of the flue gas drier is connected with a coal inlet of an intermediate wall type roller dryer, a gas inlet of the flue gas drier is connected with a flue gas outlet of a boiler through a pipeline, a gas outlet of the flue gas drier is connected with a flue gas treatment system, a heating unit pipe bundle of the intermediate wall type roller dryer is connected with a steam turbine through the pipeline, extracted steam from the steam turbine flows through the heating unit pipe bundle of the intermediate wall type roller dryer, dries raw coal in the intermediate wall type roller dryer and then is input to a heat regenerative system through the pipeline, the dried upgrading coal is output through a conveyer device, and tail gases output by the intermediate wall type roller dryer are used for preheating air supplied by a boiler in a tail gas air boiler through the pipeline. For the brown coal upgrading-power generation co-production system, flue gas discharged by the boiler is used for carrying out first-stage drying on the brown coal in the flue gas drier, and then extracted steam from the steam turbine is used for carrying out second-stage drying on the brown coal, thereby enabling the brown coal to be at a higher drying degree.

Owner:XI AN JIAOTONG UNIV

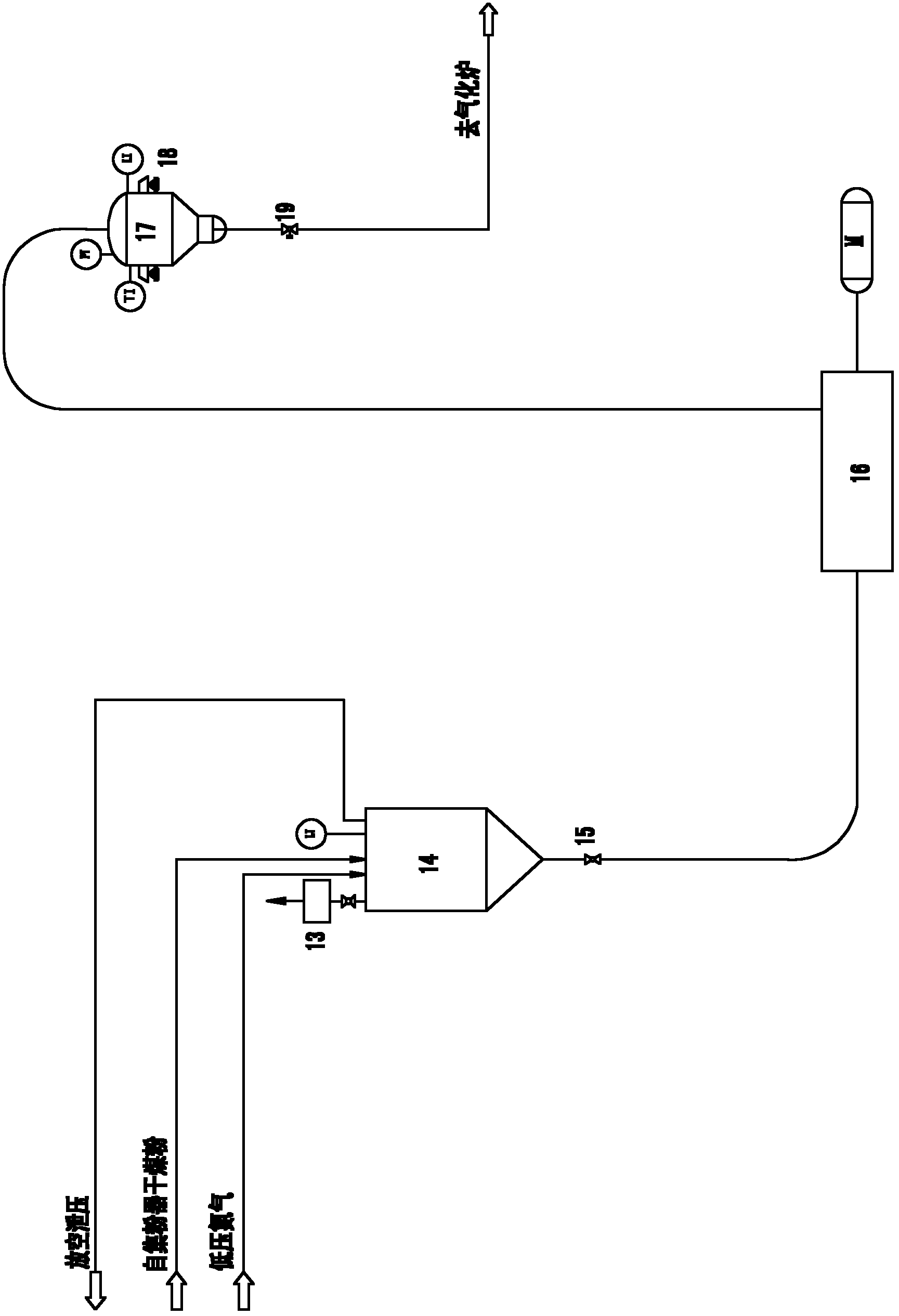

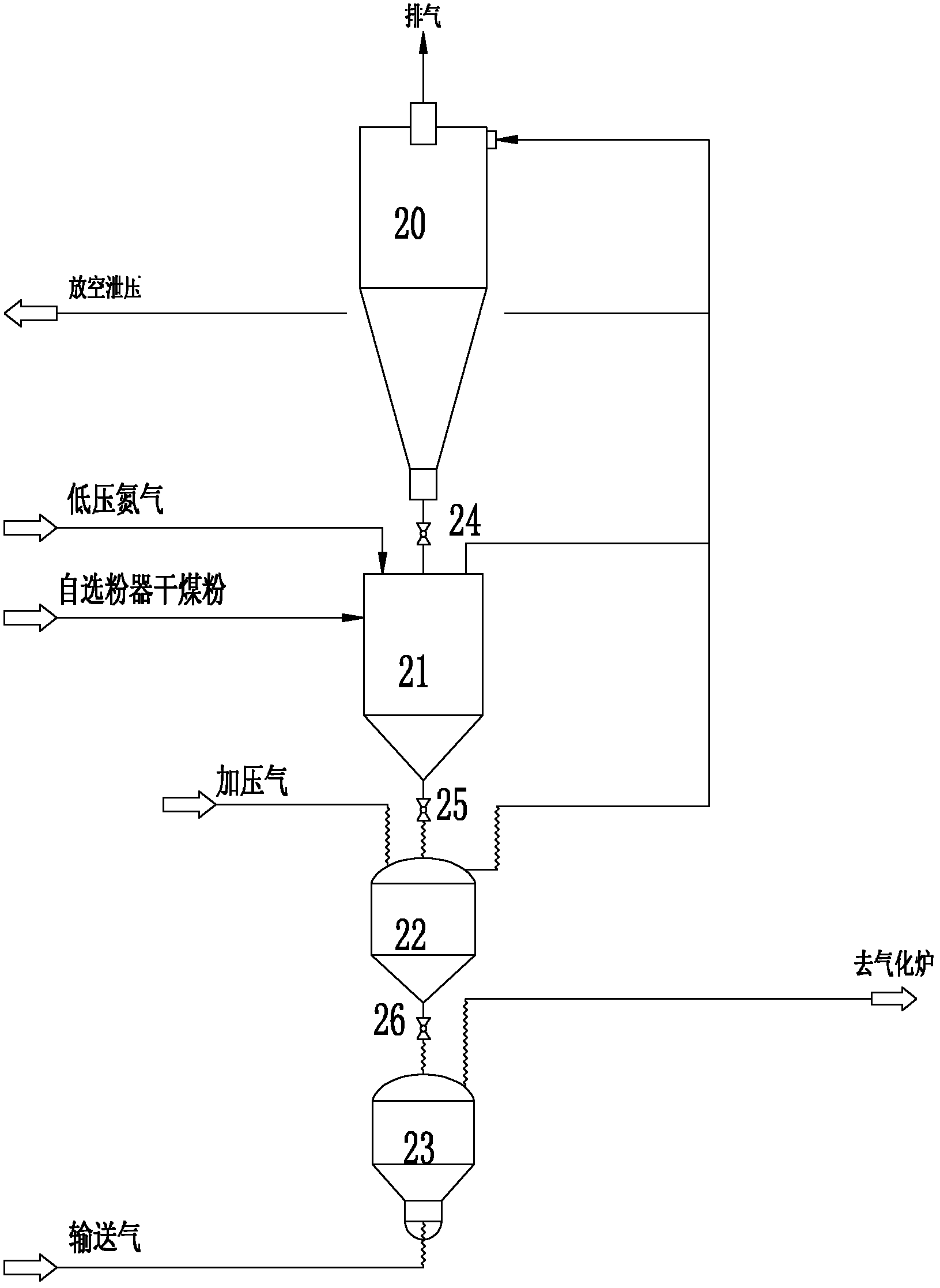

Method for producing synthesis gas by using coal powder as raw material

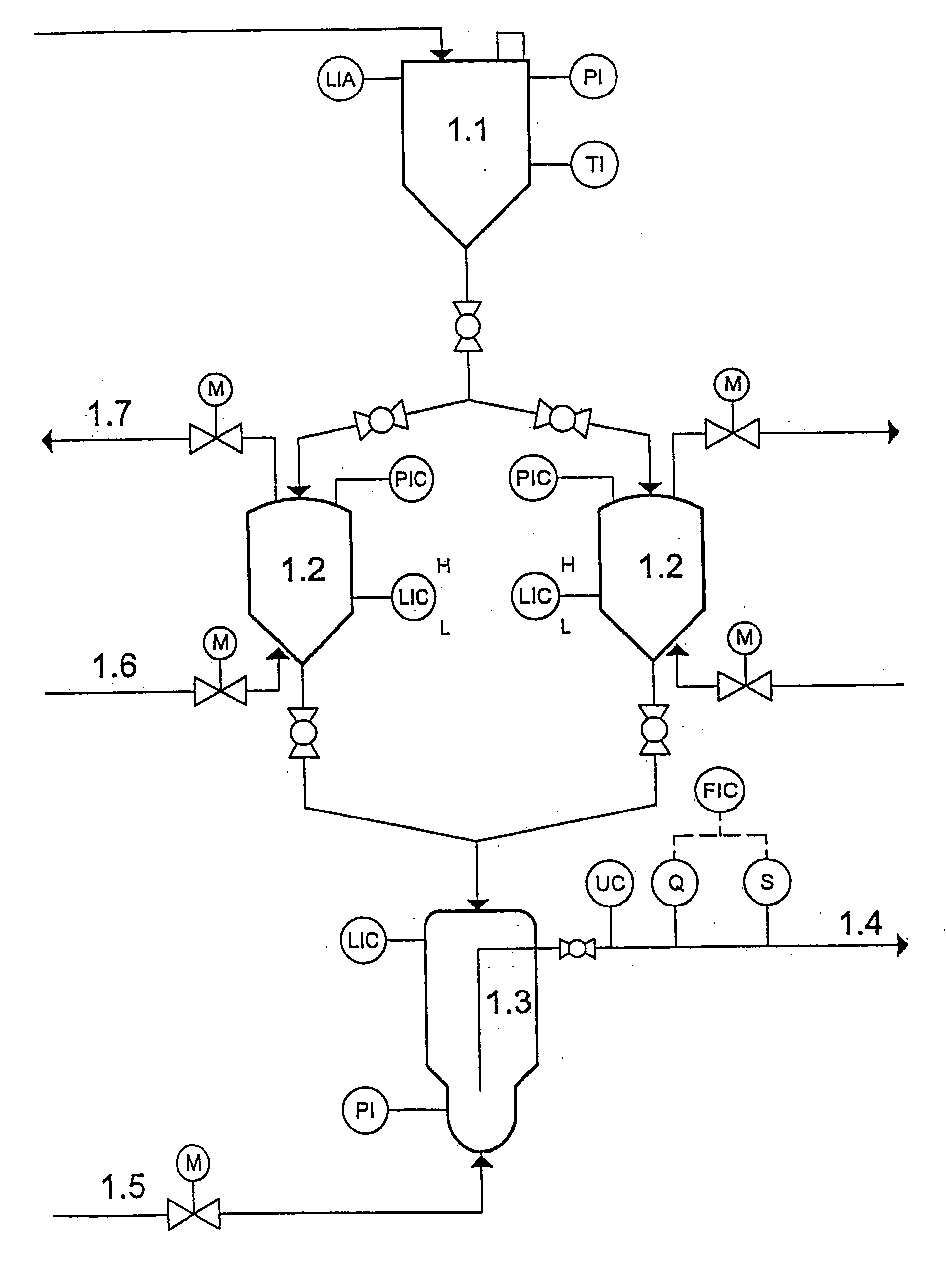

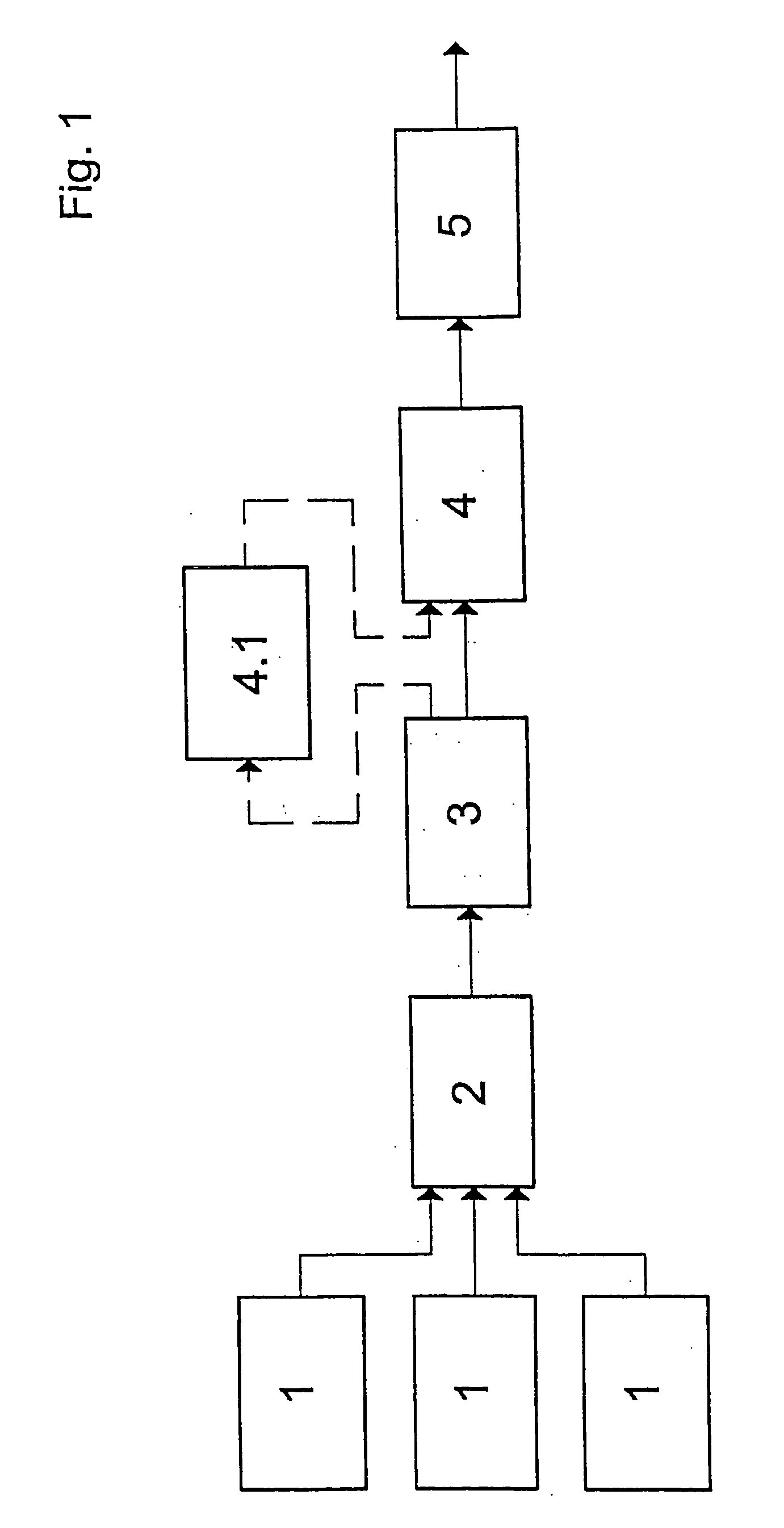

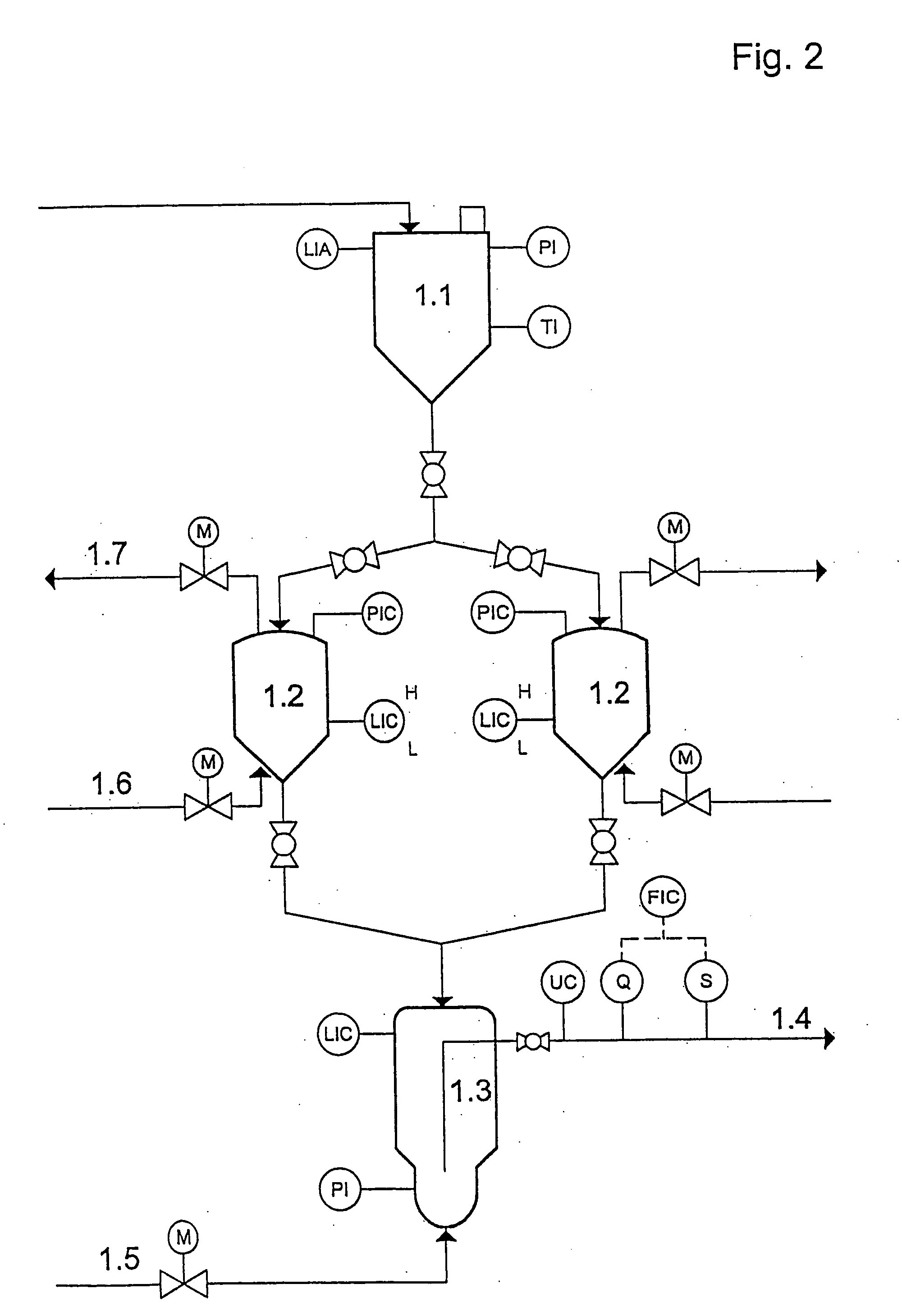

ActiveCN102352268AImprove utilization efficiencyWon't happenMultistage water/sewage treatmentCombined combustion mitigationProcess configurationAnthracite

The invention discloses a pressurization high temperature gasification method of dry coal powder. The method comprises the following five steps: the preparation of dry coal powder, the pressurization delivery of the dry coal powder, the pressurization and high temperature gasification of the dry coal powder, the cooling of high temperature crude synthesis gas and molten ash and the washing and purifying of the crude synthesis gas, and the treatment of water containing fine ash. The method is suitable for not only the bituminous coal with low ash content and low ash fusion point, but also other types of coal, which widely exist at home and abroad, have different metamorphic degrees and qualities and contain the coal with low ash content and high ash fusion point, the coal with high ash content and low ash fusion point and the anthracite, bituminous coal and lignite with high ash content and high ash fusion point. The method has good gasification index, simple equipment, flexible process configuration, low investment and operation convenience, the large-scale product is easy to realize, and the method has the beneficial effects of wide raw material application range, environmental friendliness and the like.

Owner:THE NORTHWEST RES INST OF CHEM IND

A coal deep purification system and method

The invention relates to a system and a method for deeply purifying coal. The system is composed of a flotation column, a mixing tank, a circulating pump, a bubble generator, an oil storage barrel, a gasoline pump and an oil gas generator. The method comprises the following steps: adding kerosene or diesel oil into the oil gas generator and then heating and evaporating the kerosene or diesel oil,thereby generating kerosene or diesel oil steam; introducing the kerosene or diesel oil steam together with air into a floatation device, thereby generating oil bubbles; and promoting the wetting property of the bubbles under the condition of maintaining the floatation of a mineral main body, thereby achieving the purpose of promoting the floatability of the mineral. The problem of difficulty in flotation of low-rank coals can be solved, the rate of multipurpose utilization of the coal can be increased and the economic value can be promoted. The system and method provided by the invention aresuitable for deeply purifying the low-rank coals with low metamorphic grade, such as brown coal, long flame coal, non-caking coal, weakly caking coal, gas coal, and the like, can be used for greatly promoting the yield of clean coal and can be used for obviously reducing the dosage of the kerosene or diesel oil used as a collecting agent. The system has the advantages that the structure is simple, the operation is convenient, the floatation index of the low-rank coals is excellent and the dosage is small.

Owner:CHINA UNIV OF MINING & TECH

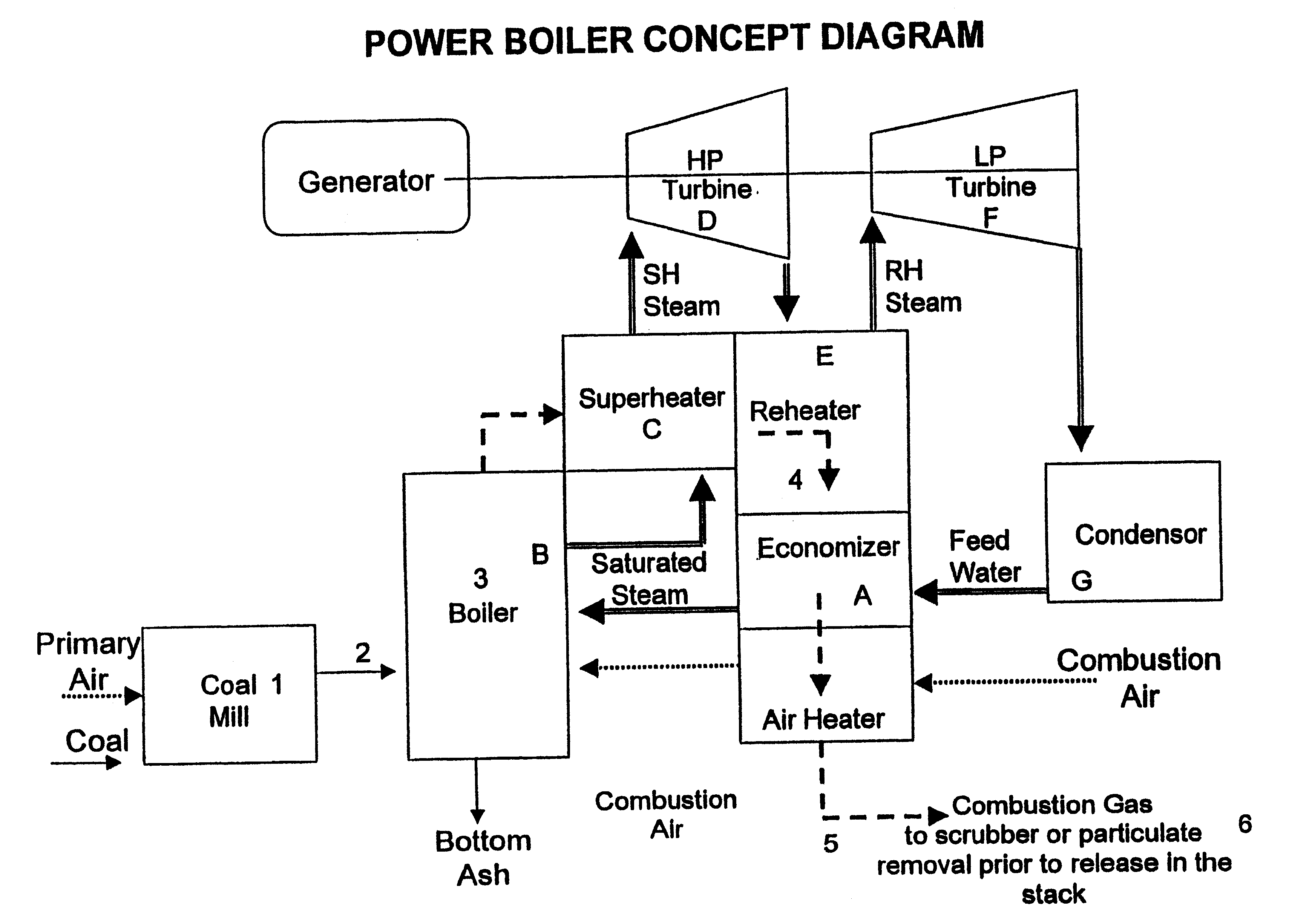

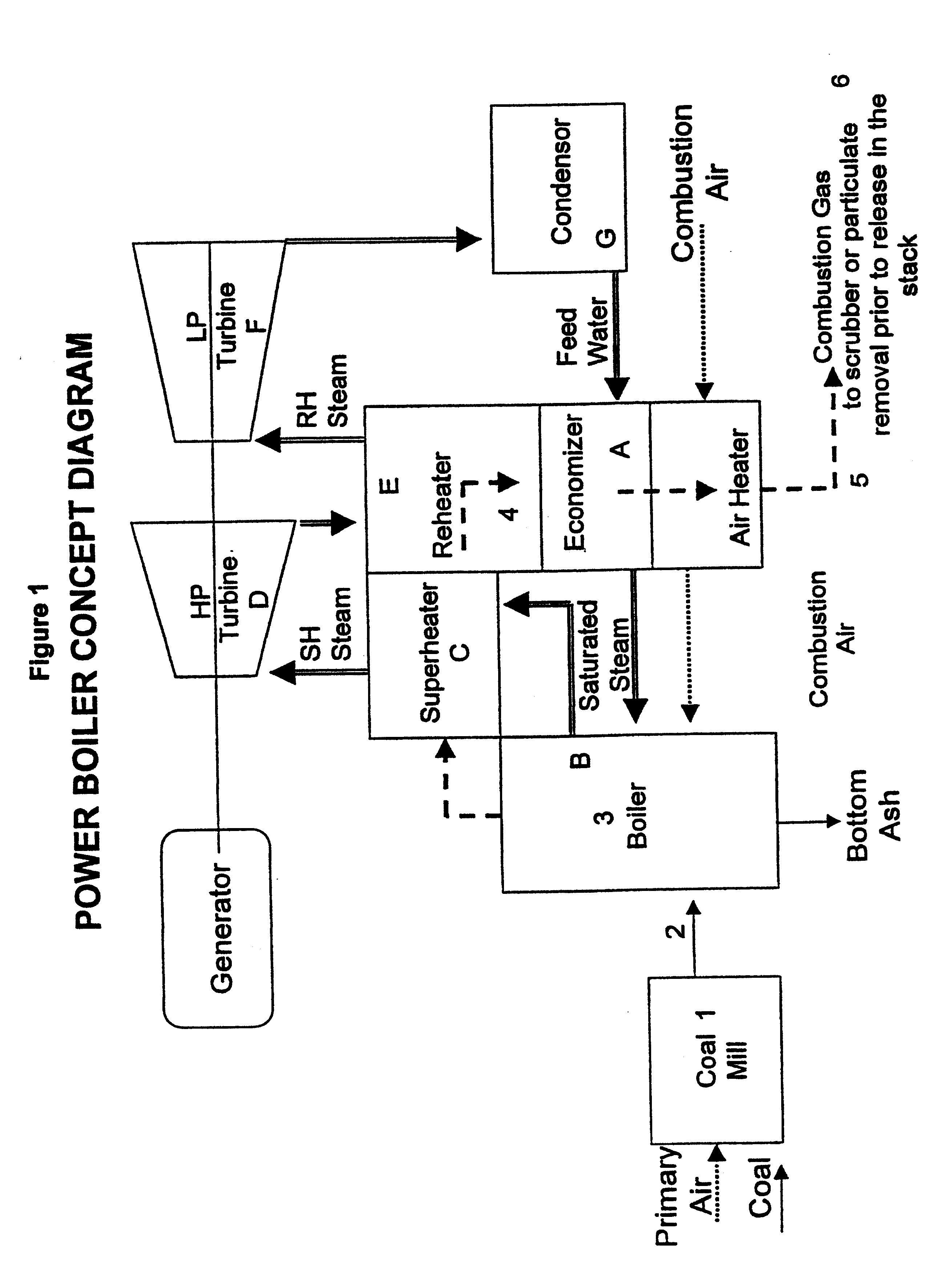

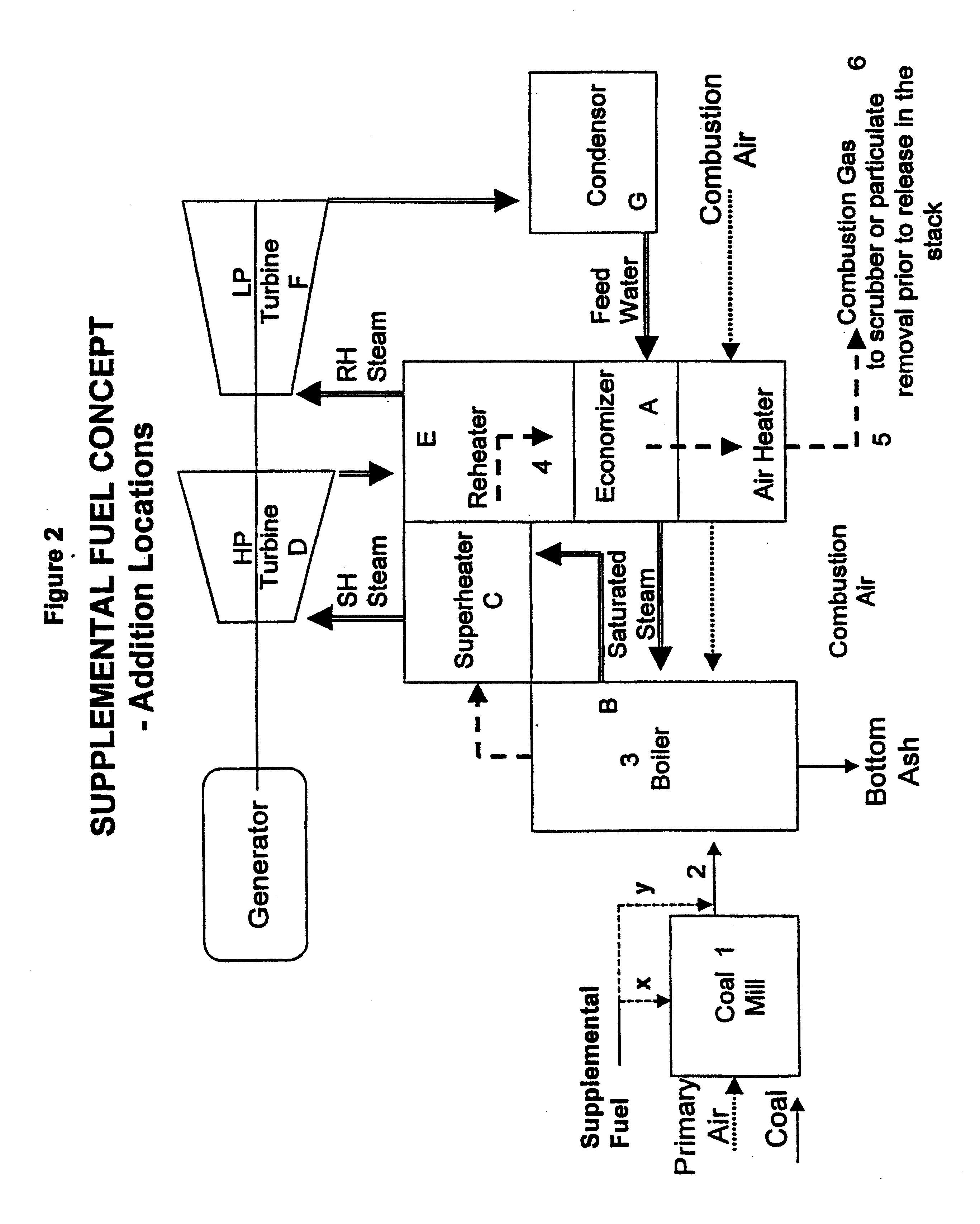

Process to improve boiler operation by supplemental firing with thermally beneficiated low rank coal

InactiveUS6325001B1Improve combustion characteristicsImprove combustion performanceSolid fuel pretreatmentSolid fuelsDevice typeBrown coal

The invention described is a process for improving the performance of a commercial coal or lignite fired boiler system by supplementing its normal coal supply with a controlled quantity of thermally beneficiated low rank coal, (TBLRC). This supplemental TBLRC can be delivered either to the solid fuel mill (pulverizer) or directly to the coal burner feed pipe. Specific benefits are supplied based on knowledge of equipment types that may be employed on a commercial scale to complete the process. The thermally beneficiated low rank coal can be delivered along with regular coal or intermittently with regular coal as the needs require.

Owner:SYNCOAL SOLUTIONS

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

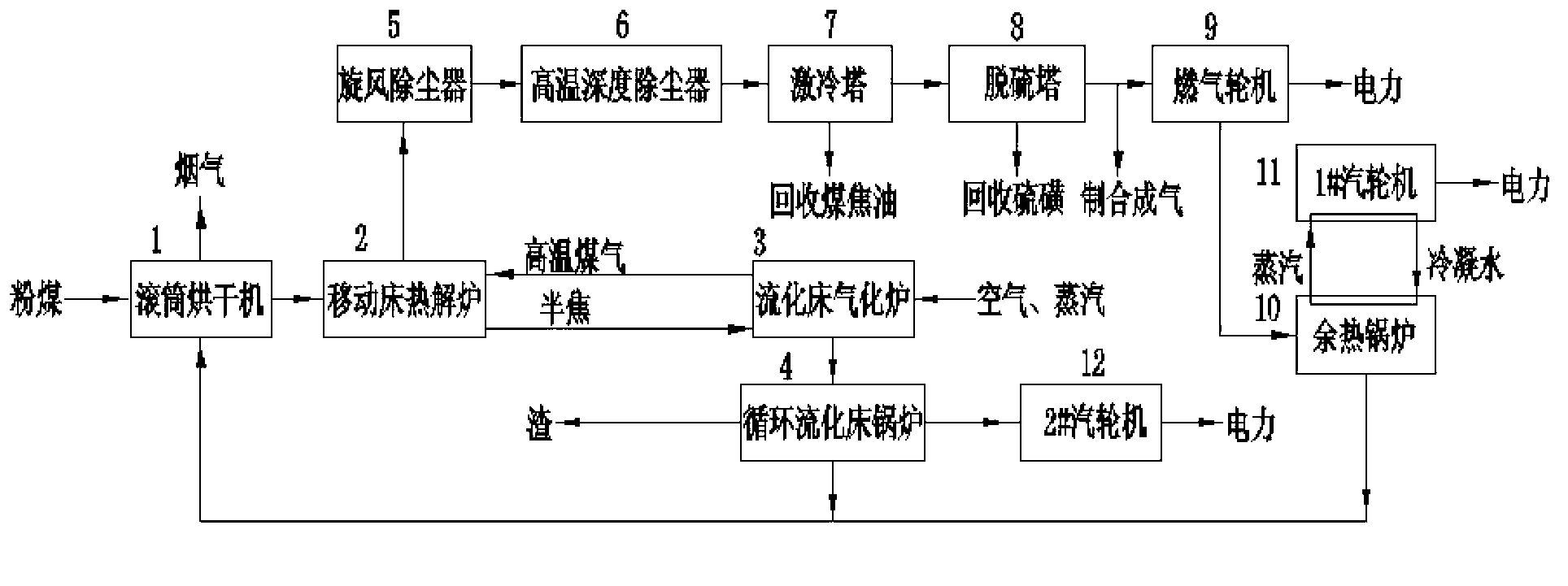

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

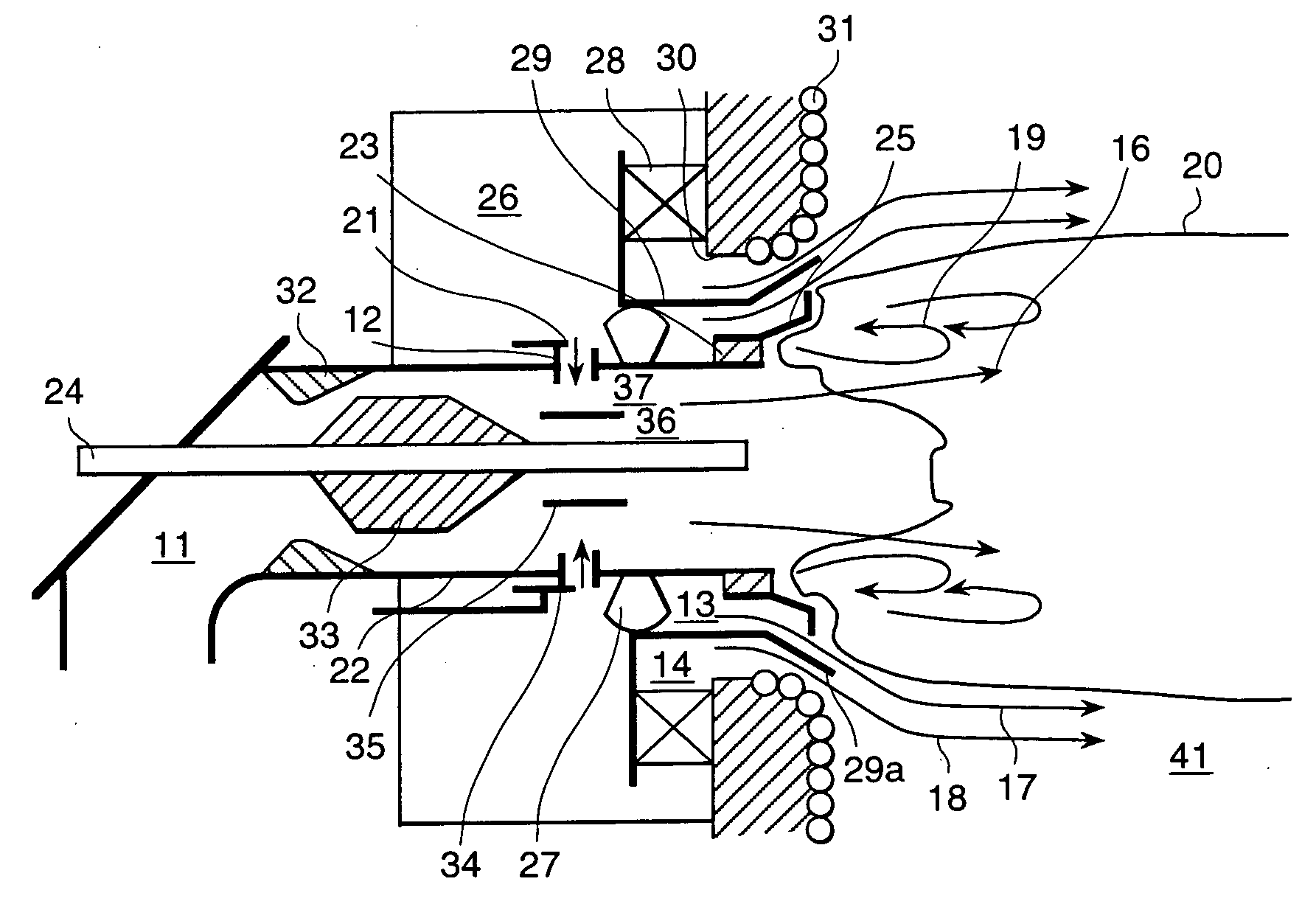

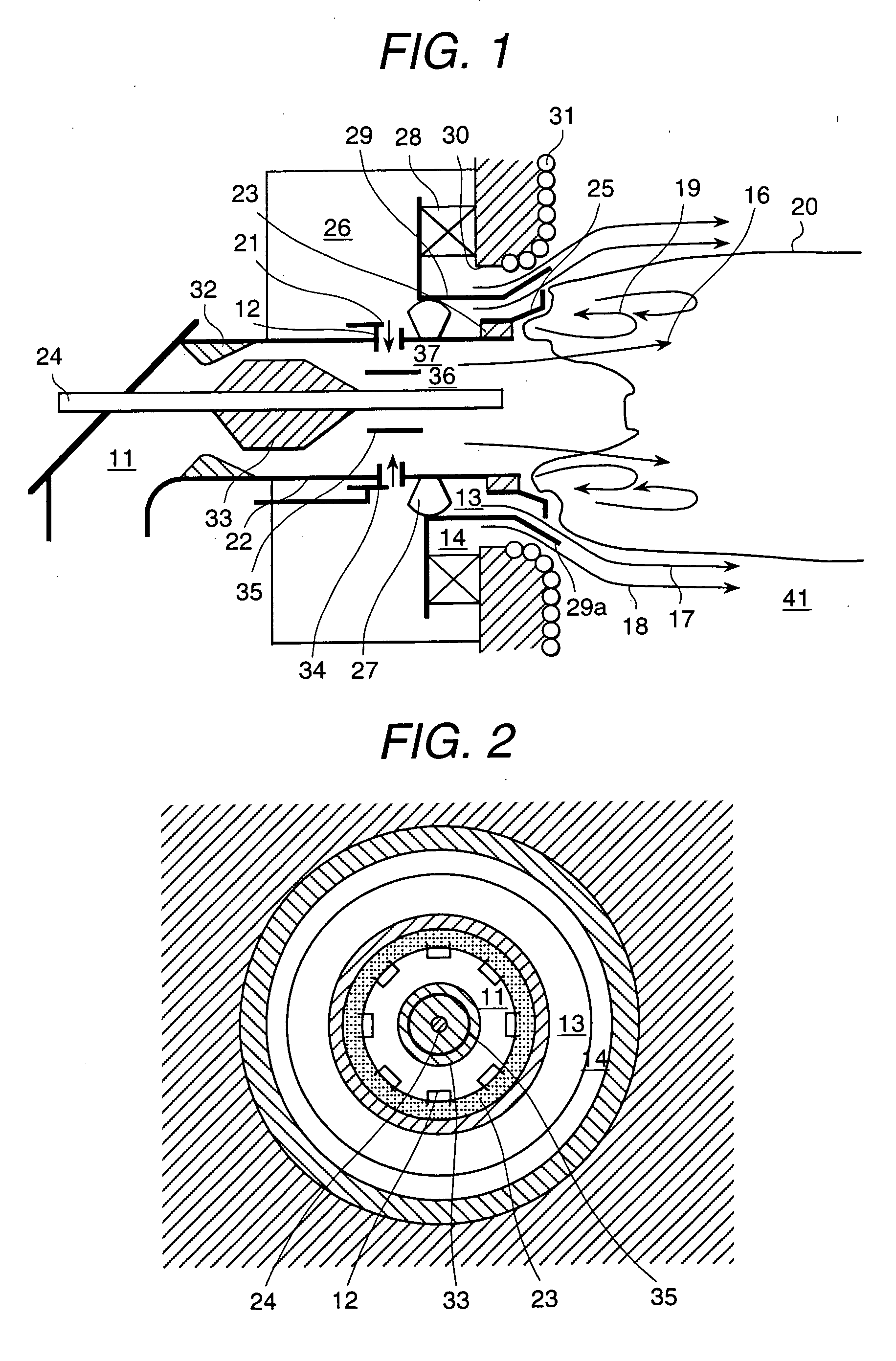

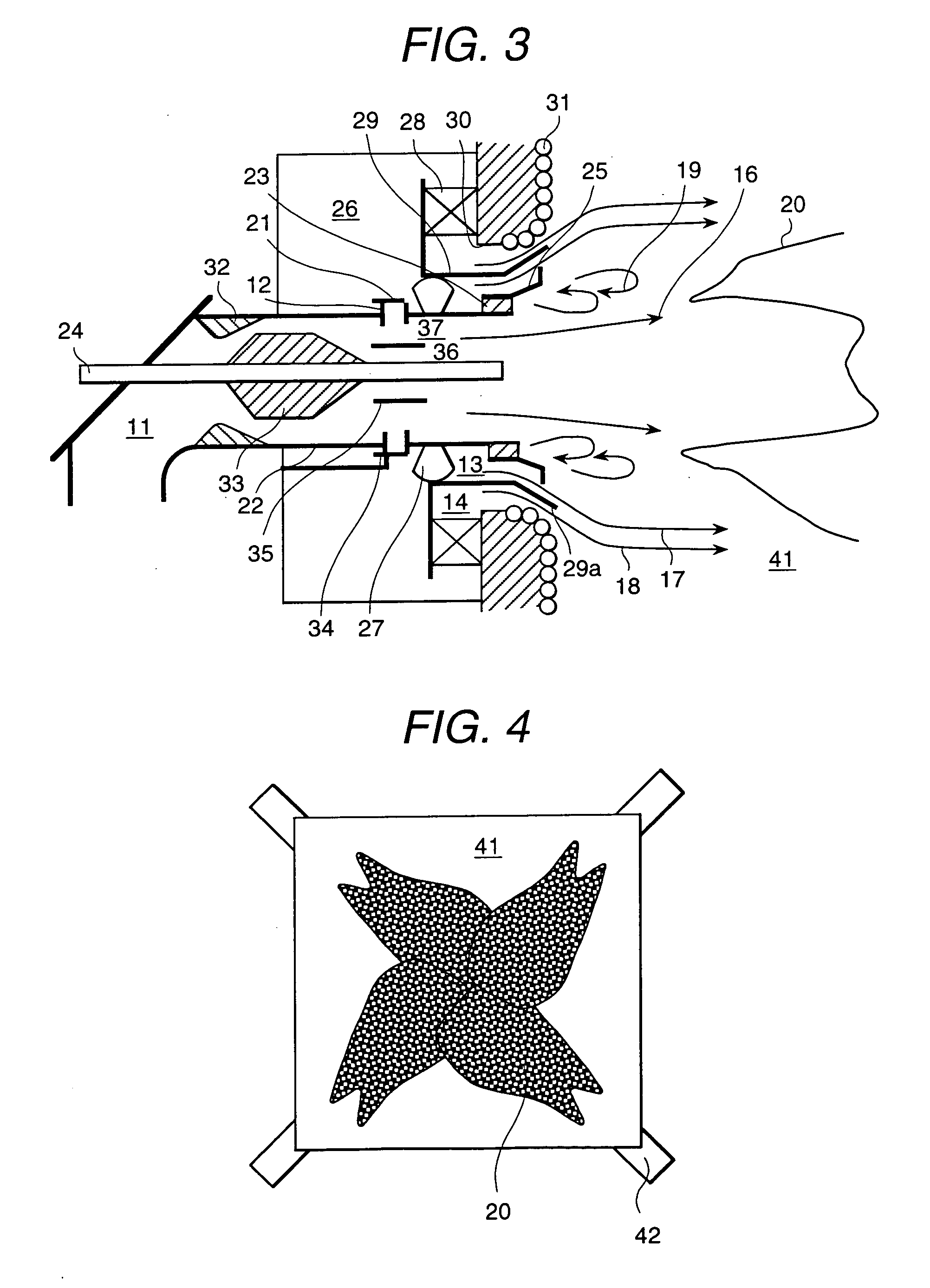

Solid fuel burner, burning method using the same, combustion apparatus and method of operating the combustion apparatus

InactiveUS20040211345A1Swirling intensityInhibitionCombustion using gaseous and pulverulent fuelBurner safety arrangementsBrown coalJet flow

A solid fuel burner using a low oxygen concentration gas as a transporting gas of a low grade solid fuel such as brown coal or the like and a combustion method using the solid fuel burner are provided. The solid fuel burner comprises a means for accelerating ignition of the fuel and a means for preventing slugging caused by combustion ash from occurring. Mixing of fuel and air inside a fuel nozzle 11 is accelerated by that an additional air nozzle 12 and a separator 35 for separating a flow passage are arranged in the fuel nozzle 11, and the exit of the additional air nozzle 12 is set at a position so as to overlap with the separator 35 when seeing from a direction perpendicular to a burner axis, and additional air is ejected in a direction nearly perpendicular to a flow direction of a fuel jet flowing through the fuel nozzle 11. An amount of air from the additional air nozzle 12 is varied corresponding to a combustion load. By increasing the amount of air from the additional air nozzle 12 at a low load operation, an oxygen concentration of a circulation flow 19 formed in a downstream portion outside the exit of the fuel nozzle 11 is increased to stably burn the fuel. By decreasing the amount of air from the additional air nozzle 12 at a high load operation, a flame is formed at a position distant from the fuel nozzle 11 to suppress radiant heat received by structures of the solid fuel burner and walls of the furnace.

Owner:HITACHI LTD +1

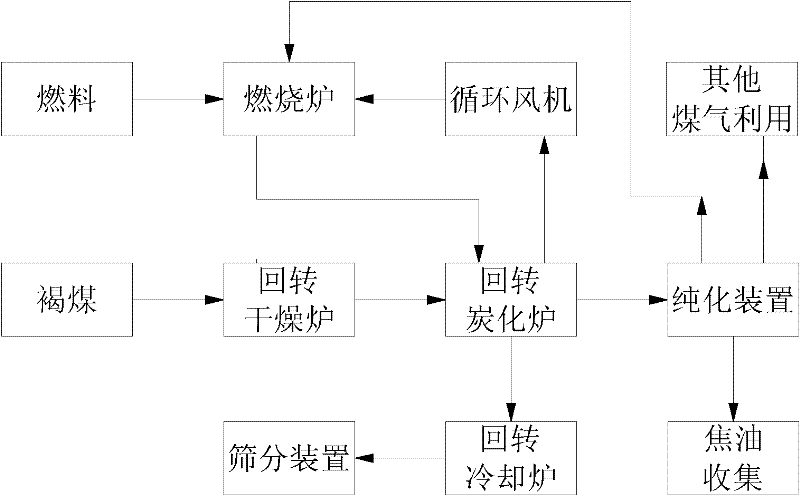

Method for improving quality of brown coal with externally heated rotary furnace

InactiveCN102250633AIncrease profitHigh value availableCoke quenchingChemical industryBrown coalCombustion

Owner:西安三瑞实业有限公司

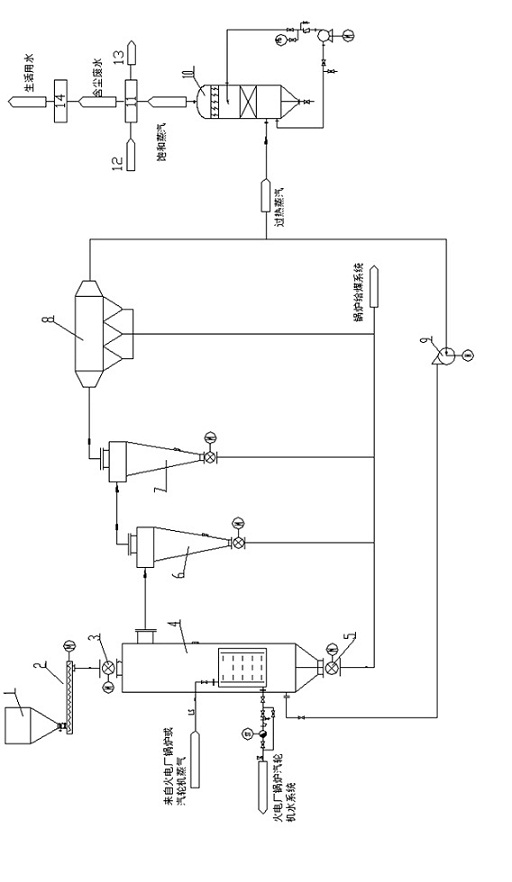

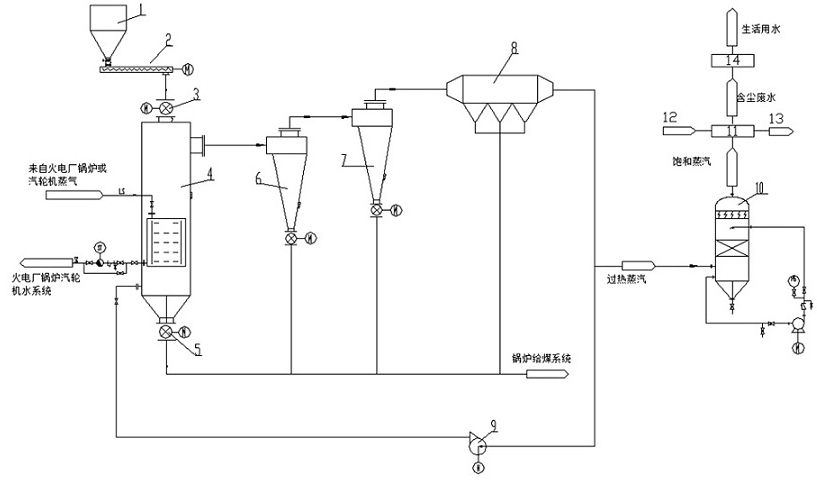

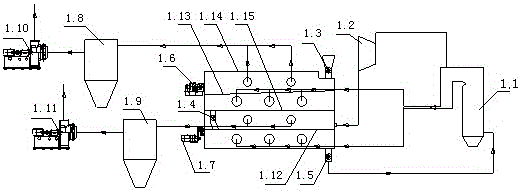

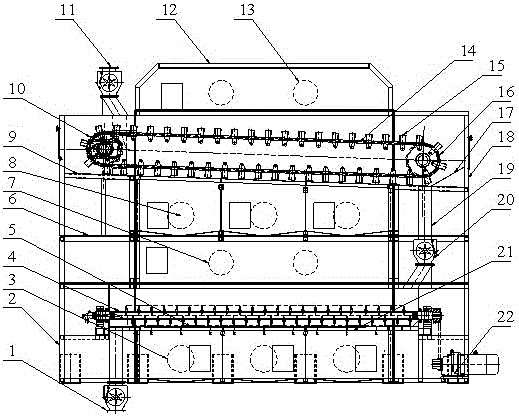

Comprehensive utilization system for drying low-order coal of thermal power plant in steam pumping and indirect heat exchanging way and process thereof

The invention relates to a comprehensive utilization system for drying low-order coal of a thermal power plant in a steam pumping and indirect heat exchanging way and a process thereof. The system comprises an indirect-heat-exchange low-order coal predrying device using a steam pipeline of a boiler or a steam turbine of the thermal power plant as a heat source, wherein tail steam obtained by the drying low-order coal of the device is connected with a secondary steam heat insulating and washing device; the secondary steam heat insulating and washing device is connected with a secondary steam recycling device; and the secondary steam recycling device is connected with a dust-containing waste water purifying and utilizing device. In the invention, the steam pumped by the boiler or the steam turbine is used as the drying heat source, high-moisture low-order coal (brown coal) is dewatered and dried through an indirect-heat-exchange drier, and secondary steam generated by dewatering the low-order coal (brown coal) is butt jointed with a steam-water system of the power plant, thereby the operating condition of the boiler is improved, the CO2 emission and fuel consumption are obviously reduced, the loss of a coal mill and matched systems is reduced, the generating efficiency of the power plant is improved, and the blank of the drying and the comprehensive utilization of the low-order coal (brown coal) of the thermal power plant in China is filled.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

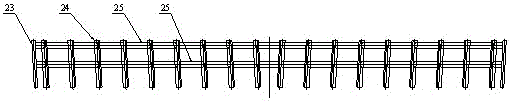

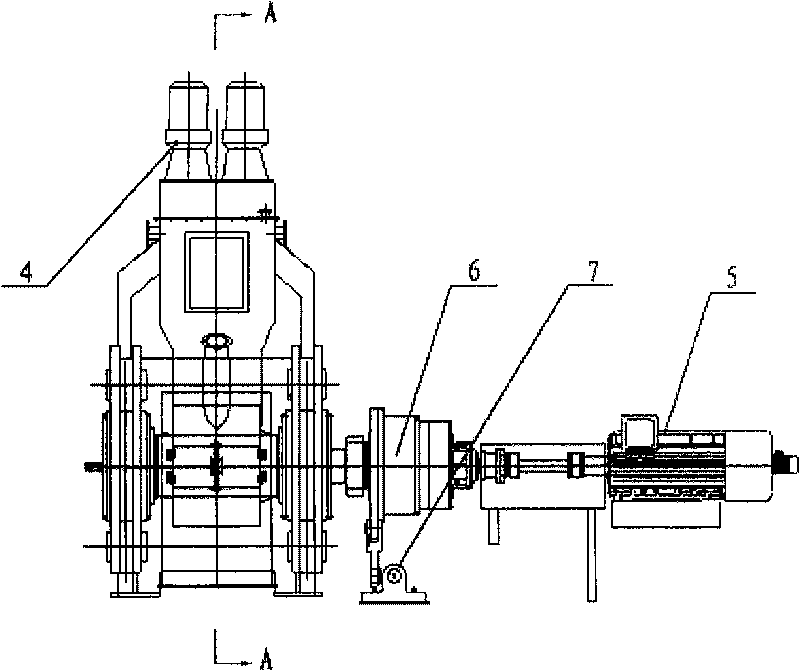

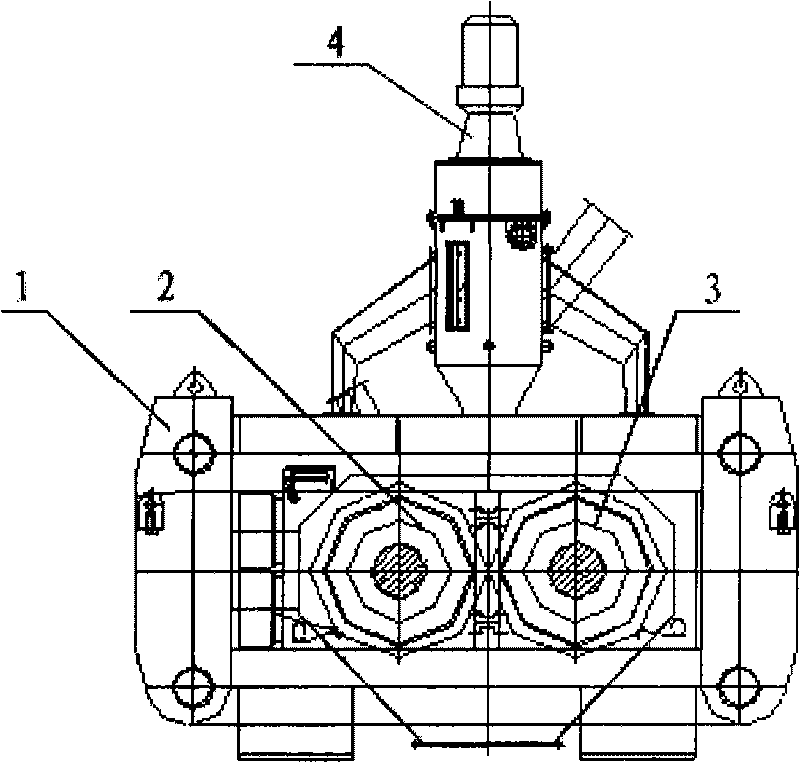

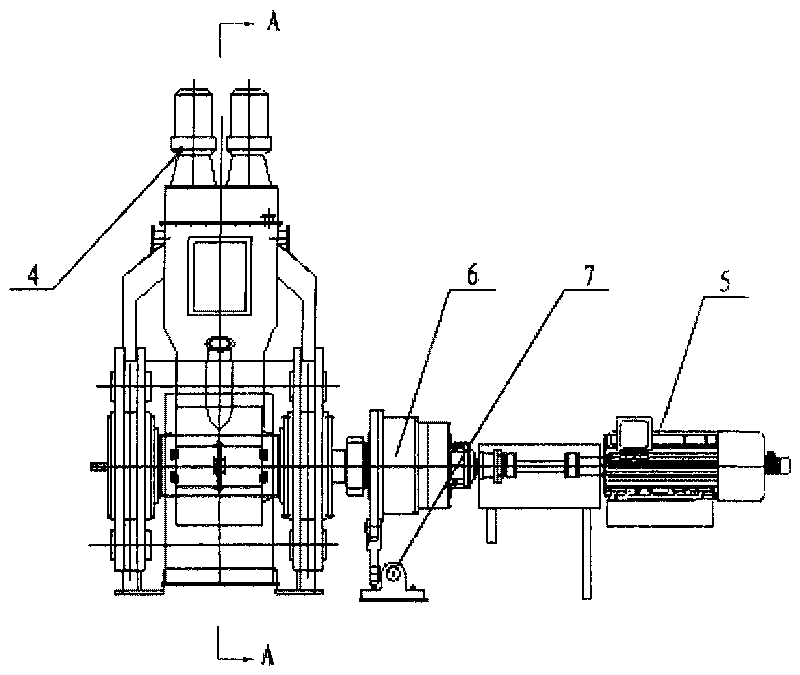

Pulverized coal molding method without binding agent and double-roller molding machine suitable for method

InactiveCN101722669AMeet shipping requirementsMeet industrial application requirementsShaping pressWater contentCircular surface

The invention provides a pulverized coal molding method without binding agent, which comprises the following steps of: 1. screening pulverized coal with the granularity of not more than 6mm by a screening device, carrying out drying dehydration processing on the pulverized coal and controlling the water content to be 2-15 percent; 2. forcibly compressing and feeding the pulverized coal obtained in the step 1 into a seam between double rollers of a double-roller molding machine by a feeding machine; and 3. running the double-roller molding machine, continuously rotating the double rollers of which at least one roller circular surface is distributed with pits and compacting and molding molded coal by the pits. The invention also provides the double-roller molding machine which is suitable for the method. The invention solves the problem of pulverized coal molding without binding agent of weak caking coal and non-caking coal, such as low-order bituminous coal, middle and old aged lignite, and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +4

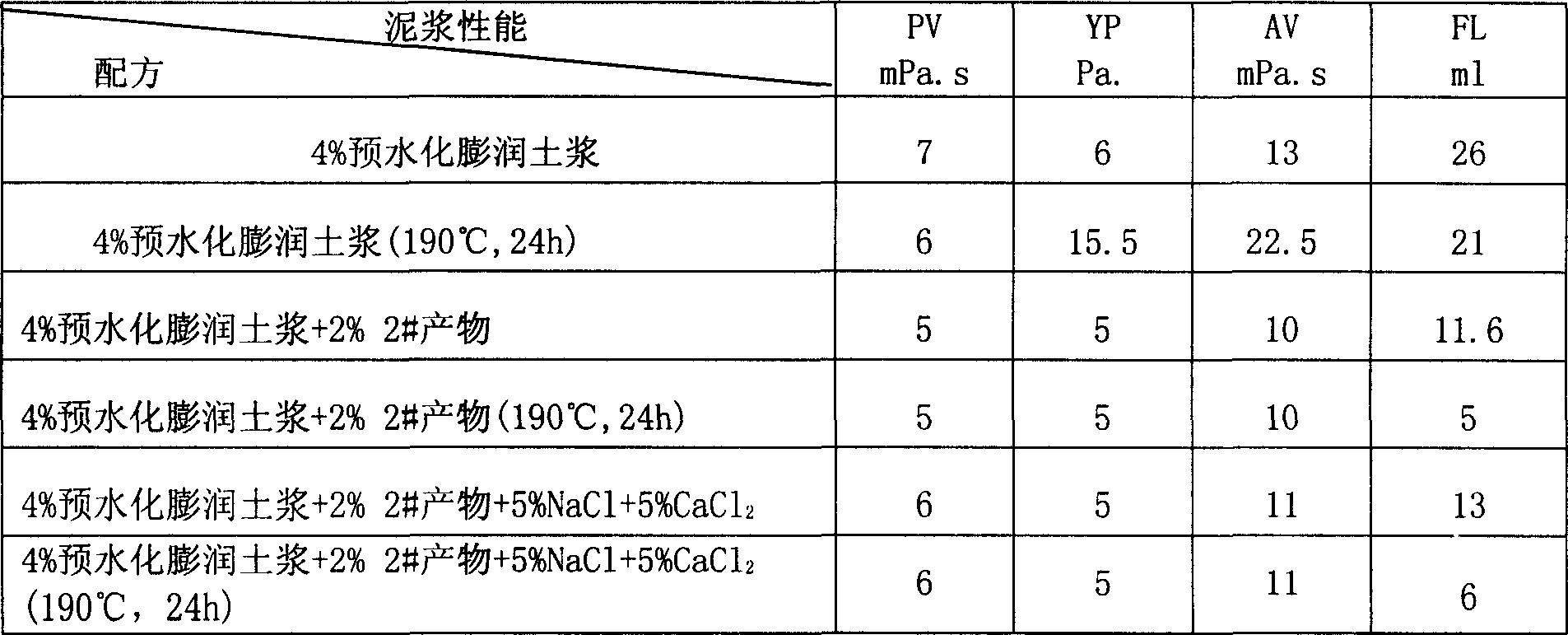

Filtrate reducer for oil field well drilling fluid

ActiveCN101054512AImprove anti-slump inhibitionImprove collapse resistanceDrilling compositionFragilityMonomer

The invention relates to an oil field fluid loss additive for drilling liquid and its producing method and the application of the treating agent in the process of producing drilling liquid system. The treating agent utilizes the cation monomer dimethyl diallyl ammonium chloride can make the sodium lignin sulfonate and the sulfonated-methyl brown coal graft induced by FeCl3 so as to produce a new fluid loss agent with the resistance to salt and collapse at high temperature. The composed product integrates the brown coal and lignin. The cation introduction improves the resistance to collapse. The weak crosslinking function of the Fe3+ makes the heat resistance improved further based on the brown coal. Therefore, the product can be widely applied in different complicated conditions such as high temperature deep well, gypsum / slat bed, stratum with a bad water sensitivity, fragility stratum and etc. and has a good prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refined biological organic fertilizer and its preparing process

ActiveCN101209933ASufficient and easily available raw materialsLow costBio-organic fraction processingClimate change adaptationBrown coalMicroorganism

The invention relates to a crop fertilizer, in particular to a refined biological organic fertilizer made by using poultry and livestock excrements and monosodium residues and the preparation method. The refined biological organic fertilizer comprises 30 to 50 percent of poultry and livestock excrements, 20 to 30 percent of monosodium residues, 10 to 30 brown coal, 2 to 8 percent of soybean powder, 2 to 5 percent bone powder, and 1 to 2 percent of rice bran; these components are made into biological organic fertilizers containing the essential nutrients of crops through the functions of a plurality of beneficial microorganism floras. The invention has the advantages of simple preparation method, low cost, no pollution, and can improve the quality of crops, therefore, the invention is an environmental friendly organic fertilizer and suitable for wide popularization.

Owner:沈阳中科新型肥料有限公司

Drying and dry distillation combined quality improving process and system for low rank coal

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Plant and process for removing carbon dioxide from gas streams

The present invention is based on the realization that the carbon dioxide component of industrial gas streams also containing steam can be processed so to utilize either as latent and / or sensible heat the heat available from the steam component to assist in separating carbon dioxide from the remainder of the gas stream. For example, flue gases produced by power stations burning brown coal, black coal or natural gas inherently contain a useful amount of energy that can be harnessed according to the present invention. According to particular preferred forms of the invention, nitrogen and sulphur constituent such as SOx and NOx, H2S and other nitrogen containing compounds may also be removed from the gas stream through direct contact with the absorbing medium and used to produce by-products such as fertiliser material.

Owner:CO2CRC TECH PTY LTD

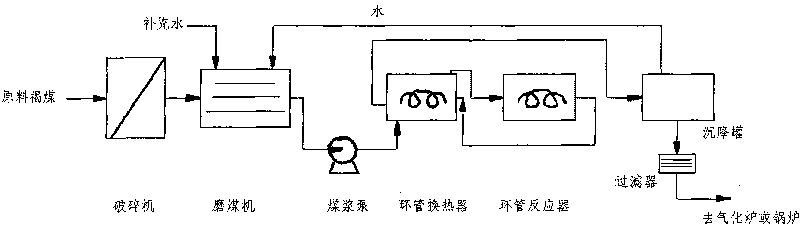

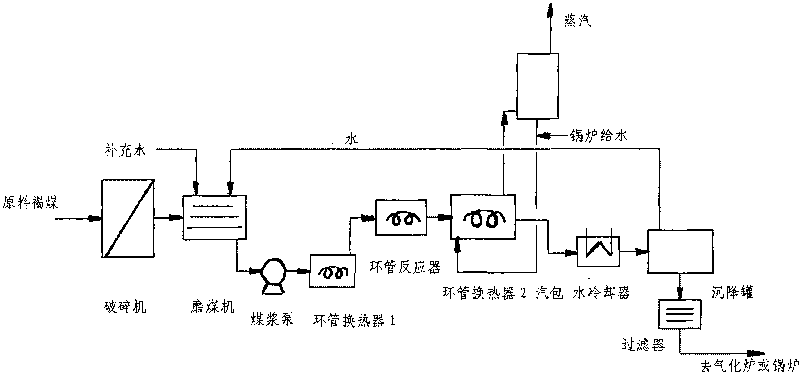

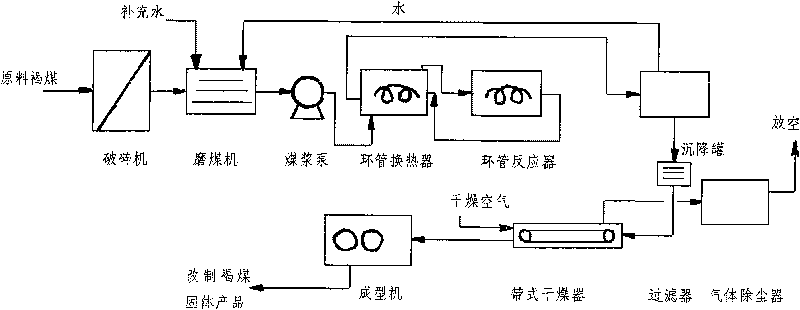

Method for modifying lignite

The invention relates to a method for modifying lignite, belonging to the technical field of coal processing. In the method, the lignite is broken, sent into a coal mill, and is ground into coal pulp after water is added. Due to high content of internal water of the lignite, the concentration of the water-coal-slurry is relatively low, generally 30-55%. Modified water-coal-slurry is obtained after treatment under high temperature and pressure, wherein the internal water of lignite particles in the modified water-coal-slurry is reduced, and the water used for lubrication among the particles is more than needed water content of the water-coal-slurry. Measure of settlement or / and other specific measure, is / are needed to separate the excess water, and the concentration of the water-coal-slurry is increased from 30-50% to 50-70%, thereby increasing the calorific value of the lignite.

Owner:TSINGHUA UNIV +1

Soil improving synergistic saline-alkali resistant water soluble fertilizer and preparation method thereof

The invention discloses a soil improving synergistic saline-alkali resistant water soluble fertilizer and a preparation method thereof. The waste liquid generated in the amino acid fermentation production process is taken as a carrier, and added with active humic acid prepared from decomposed coal or brown coal or peat rich in humic acid, and then the mixture is thoroughly and proportionally mixed with water soluble nitrogen fertilizer, water soluble phosphatic fertilizer, water soluble potassic fertilizer, and macroelements and microelements such as copper sulfate, borax, zinc sulfate and ferrous sulfate; and then the final mixture is subjected to spray drying, separation and collection treatment, so that a powdery material is obtained; and as a result, the soil improving synergistic saline-alkali resistant water soluble fertilizer is formed. The soil improving synergistic saline-alkali resistant water soluble fertilizer provided by the invention is low in cost, low in investment, low in energy consumption, small in floor area, energy-saving, environment-friendly and free of pollution; zero emission of amino acid waste liquid and deep processing of the decomposed coal, the brown coal and the peat are realized and pollution on the environment is reduced; the waste is well utilized and changed into things of value; besides, the soil improving synergistic saline-alkali resistant water soluble fertilizer is good in water solubility, free of residue, rich in nutrition, high in active organic matter content and high in safety; and furthermore, the soil improving synergistic saline-alkali resistant water soluble fertilizer achieves the effects or improving the soil and resisting saline and alkali, and is obvious in synergia and wide in uses.

Owner:XINJIANG FENGTIAN AGRI MATERIALS CO LTD

Process for preparing super-strong anti-hard-water sodium (potassium) humate

InactiveCN1594338AAchieve preparationRaw materials are easy to getOrganic chemistryBrown coalPotassium

The invent relates to a process for preparing super-strong anti-hard-water sodium (potassium) humate by using brown coal or decomposed coal as principal raw material, H2SO4 as acidating agent, H2O2 as oxidizing agent, and a two step synthesis is employed which consists of, subjecting the raw material containing rich humic acid (brown coal or decomposed coal) to acid-treatment under acidic conditions, then charging oxidation agent (hydrogen peroxide) under alkality condition, thus improving the product capability for resisting hard water.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com