Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

818 results about "Bituminous coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bituminous coal or black coal is a relatively soft coal containing a tarlike substance called bitumen or asphalt. It is of higher quality than lignite coal but of poorer quality than anthracite. Formation is usually the result of high pressure being exerted on lignite. Its coloration can be black or sometimes dark brown; often there are well-defined bands of bright and dull material within the seams. These distinctive sequences, which are classified according to either "dull, bright-banded" or "bright, dull-banded", is how bituminous coals are stratigraphically identified.

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

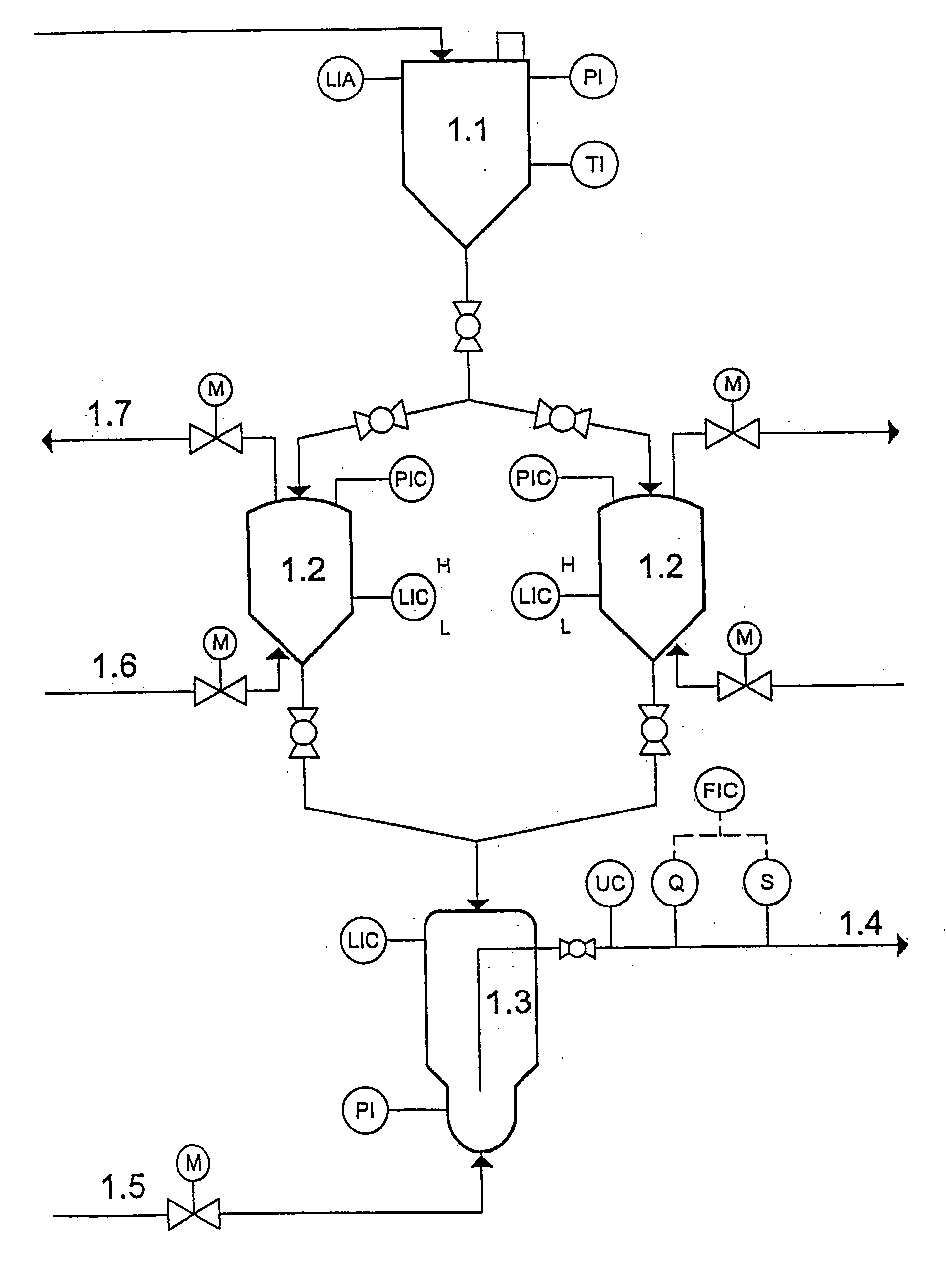

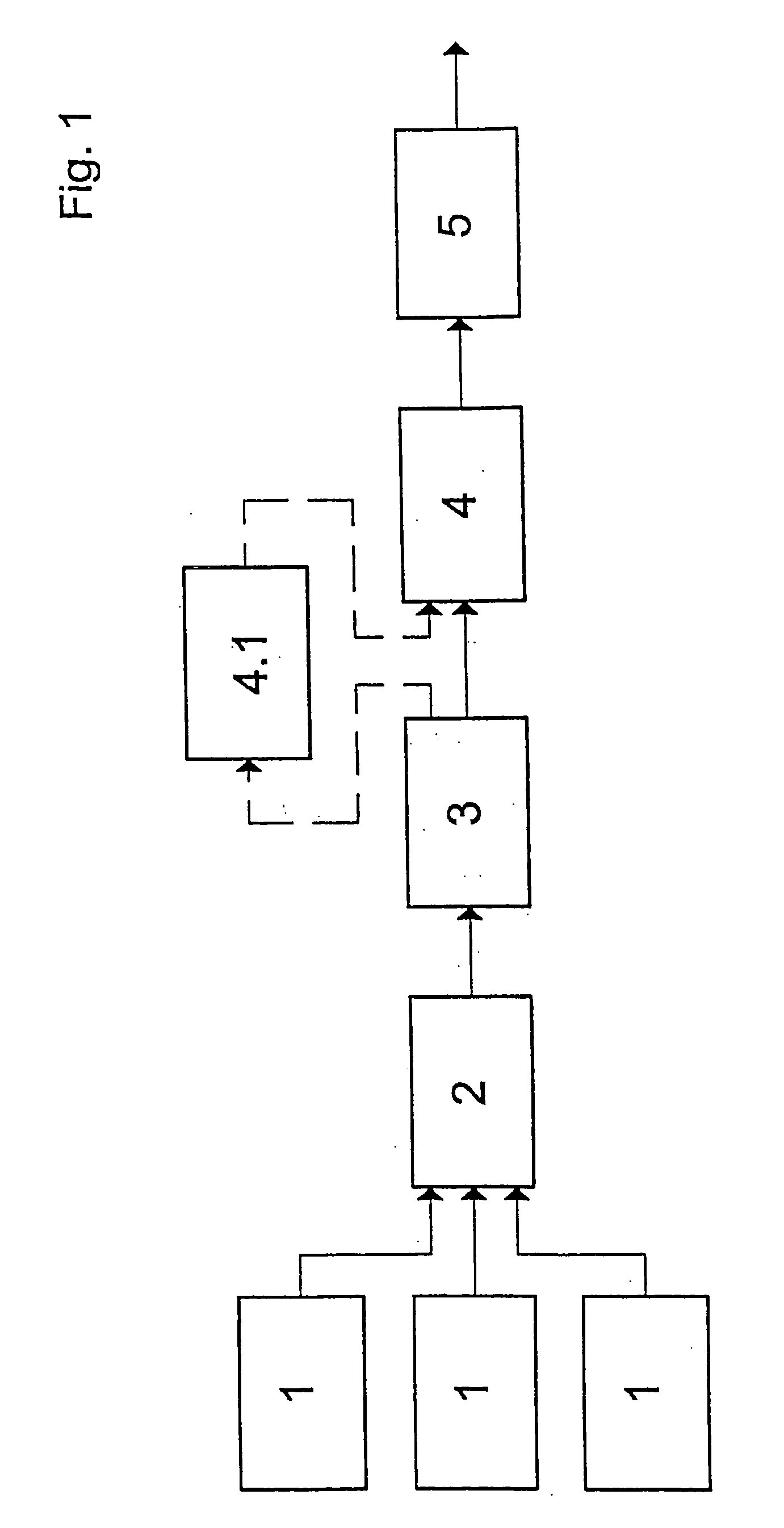

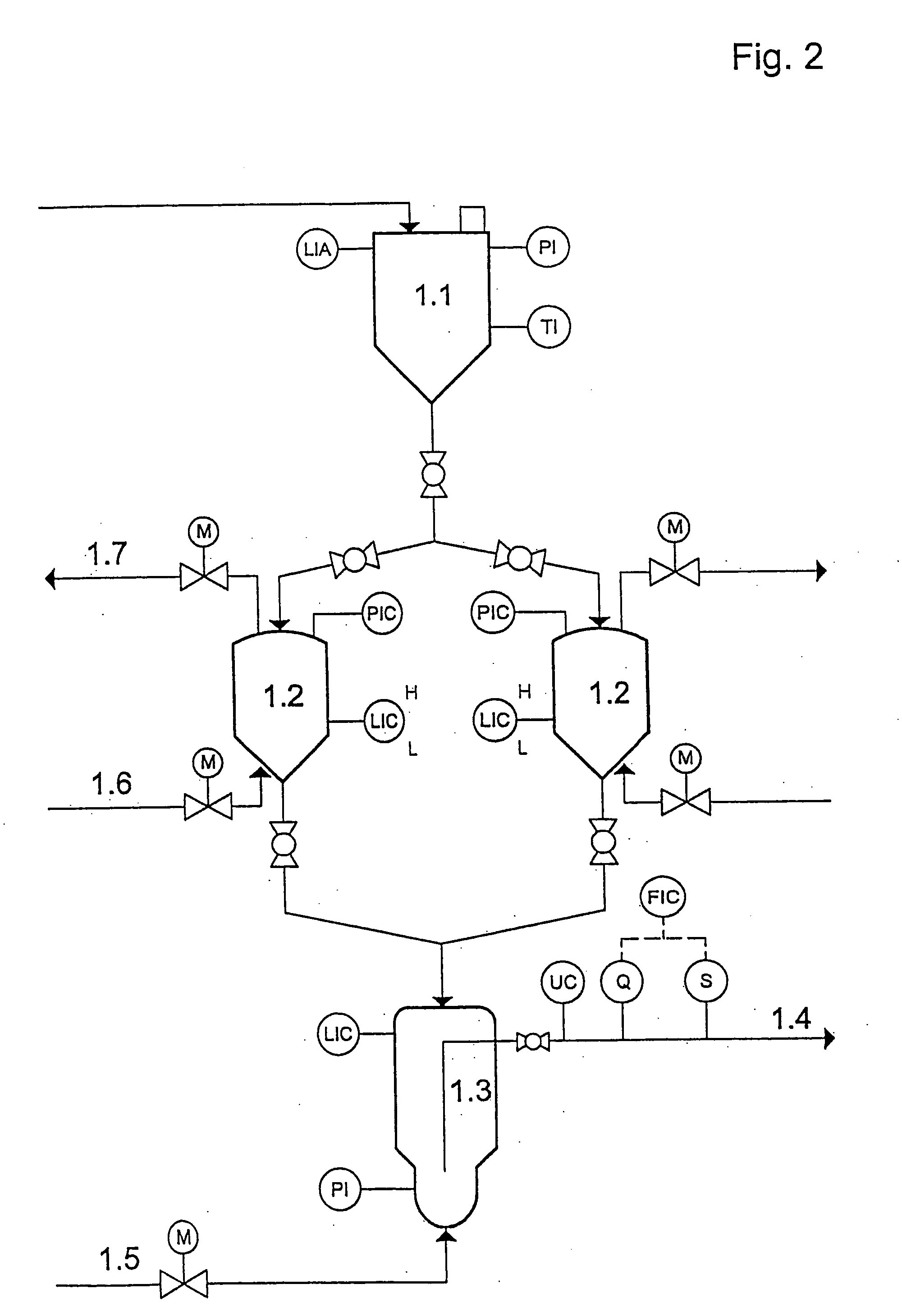

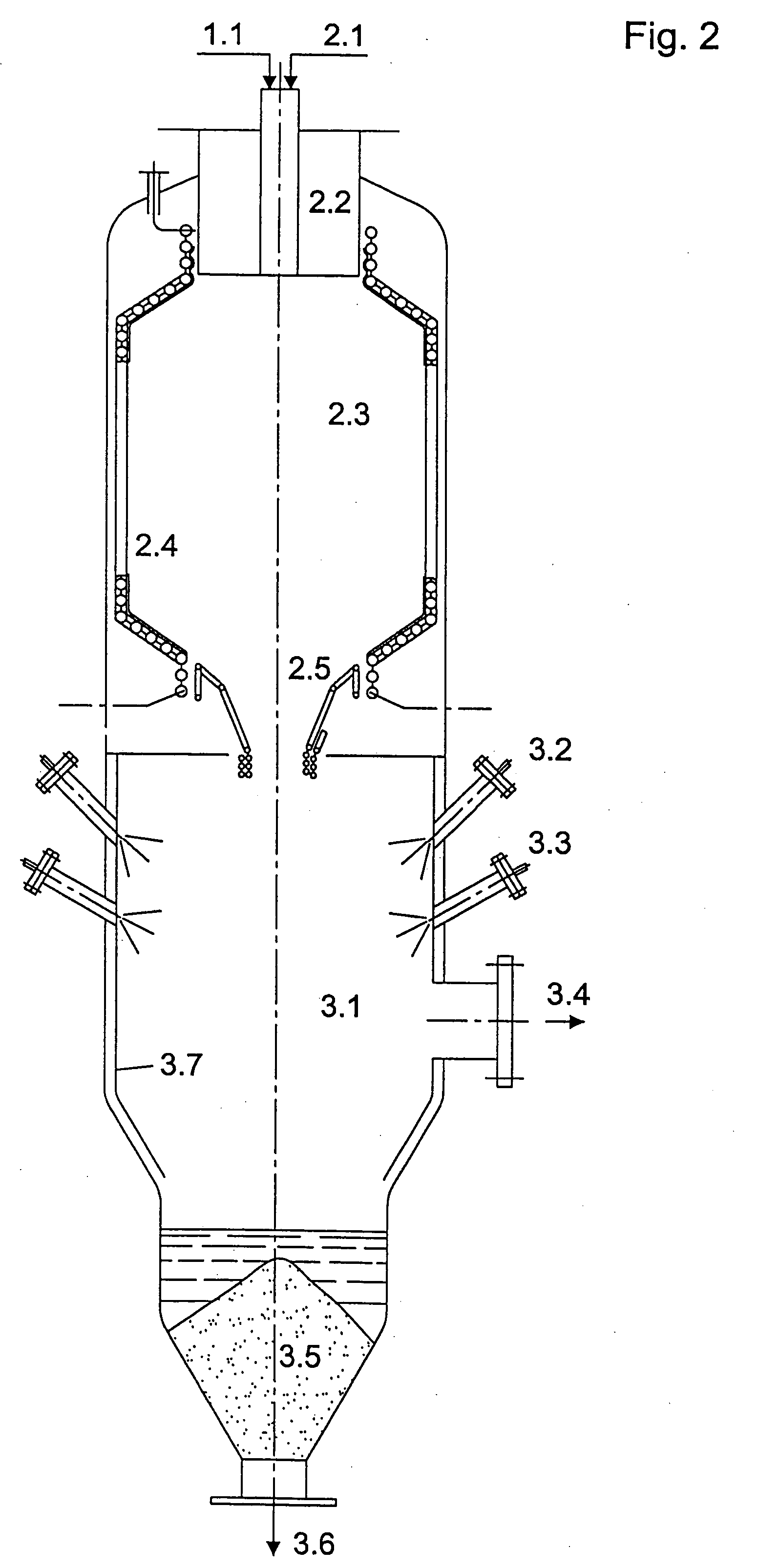

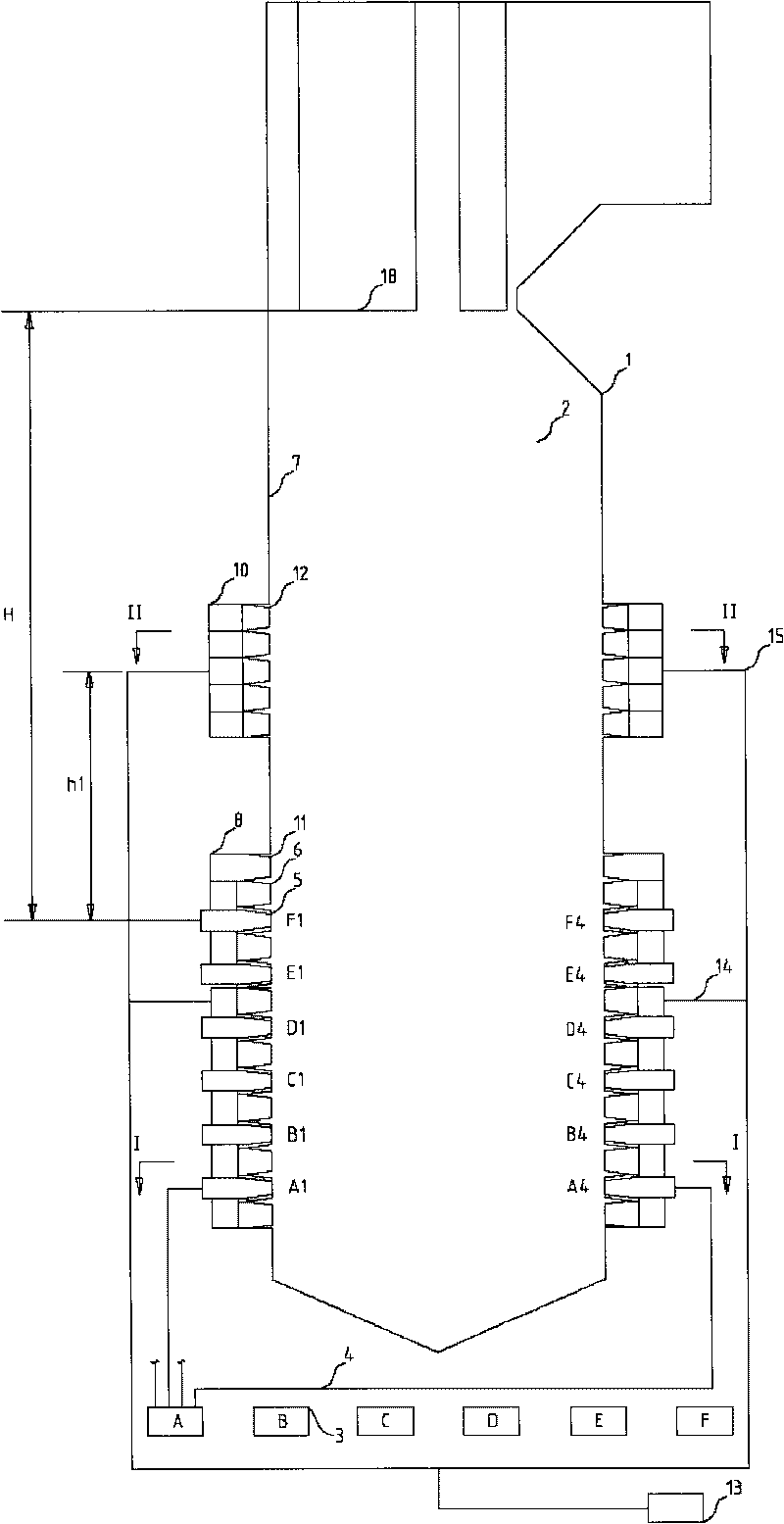

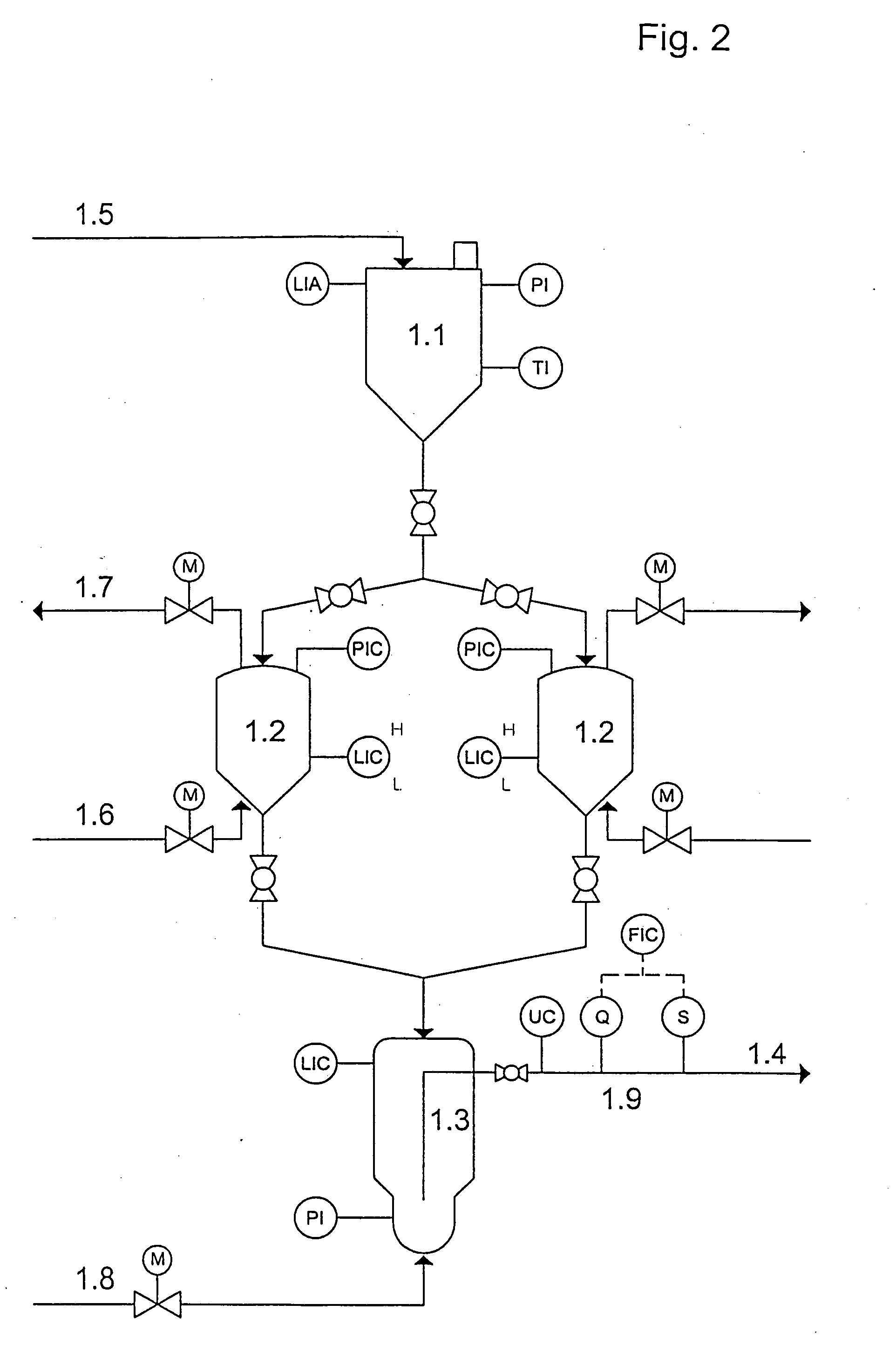

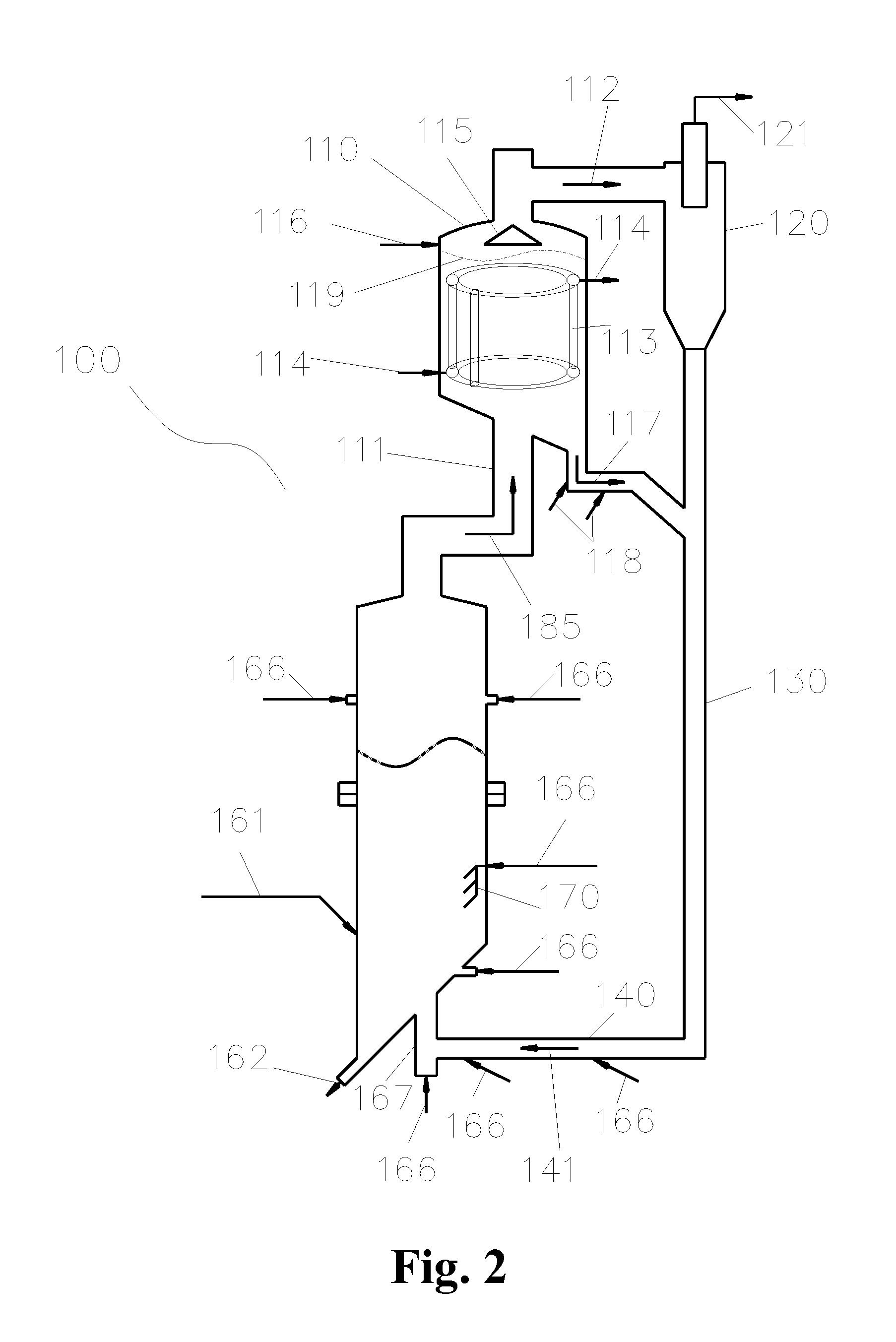

Method and device for high-capacity entrained flow gasifier

A method and device for the gasification of pulverized fuels from solid fuels such as bituminous coals, lignite coals, and their cokes, petroleum cokes, coke from peat or biomass, in entrained flow, with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 80 bar, and at temperatures between 1,200 and 1,900° C., at high reactor capacities between 1,000 and 1,500 MW. The method uses the following steps: metering of the fuel, gasification reaction in a gasification reactor with cooled reaction chamber contour, quench-cooling, crude gas scrubbing, and partial condensation.

Owner:SIEMENS AG

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

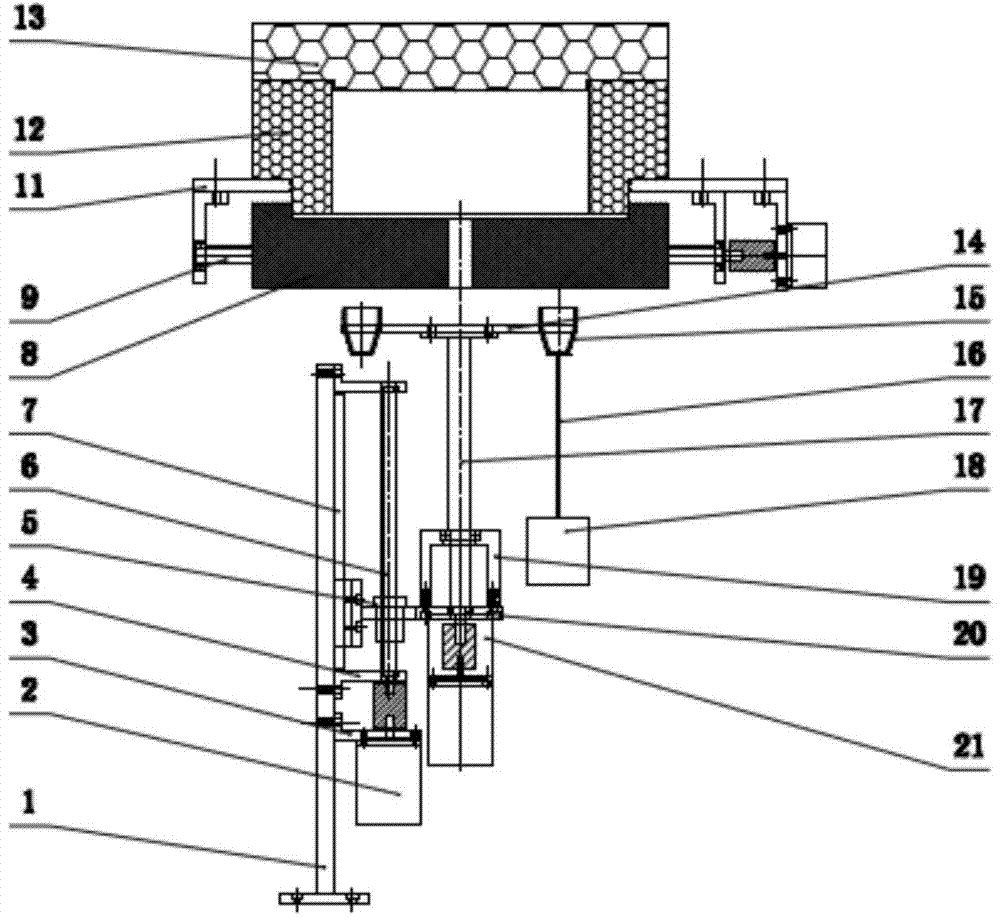

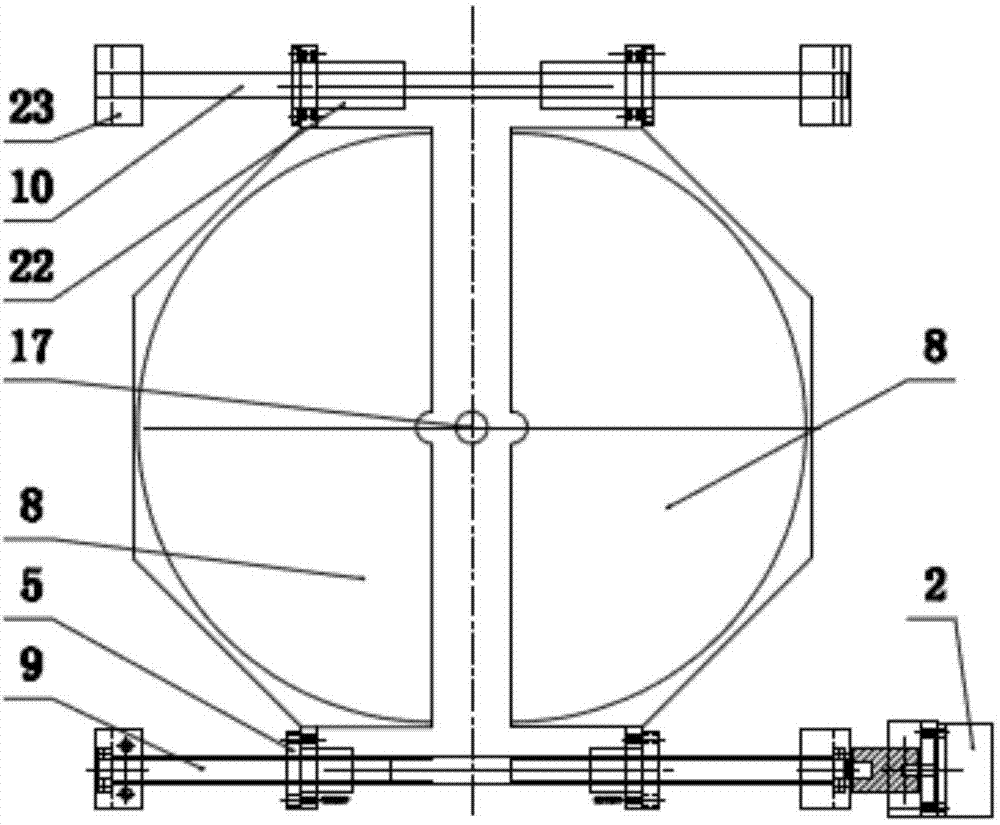

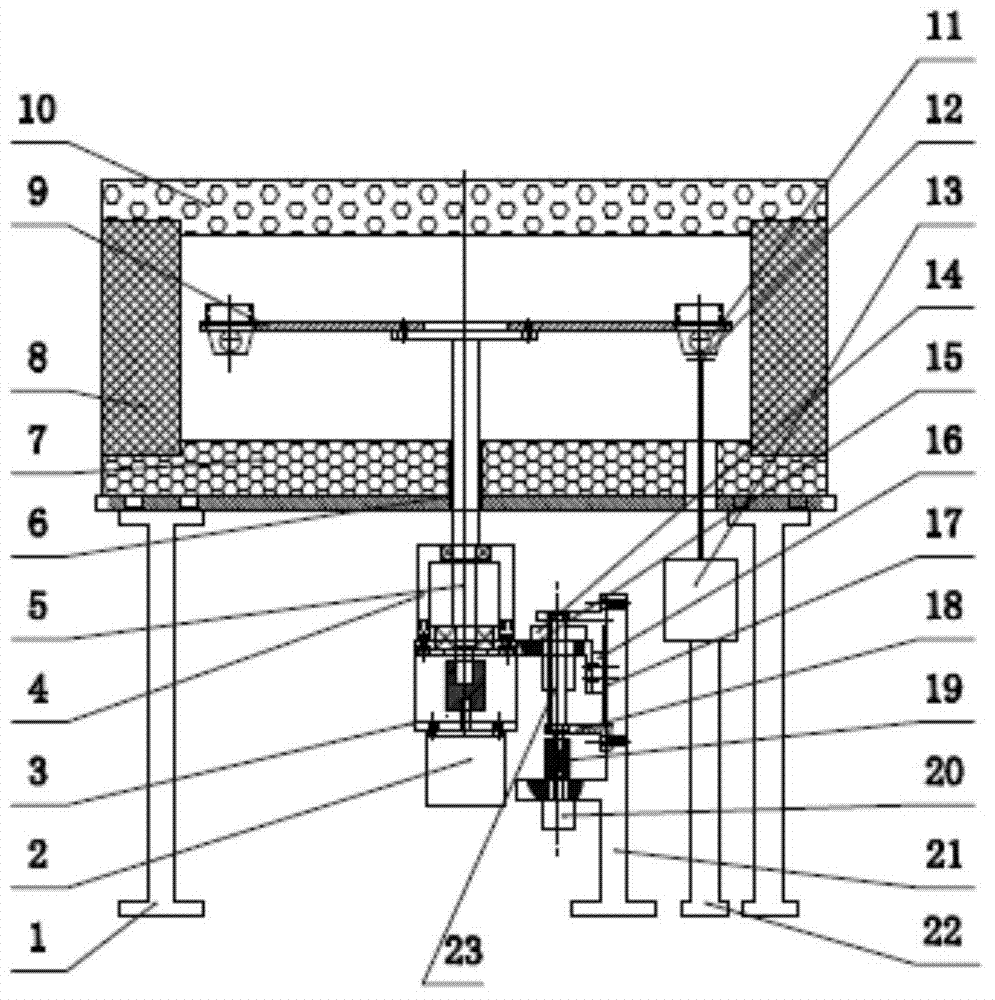

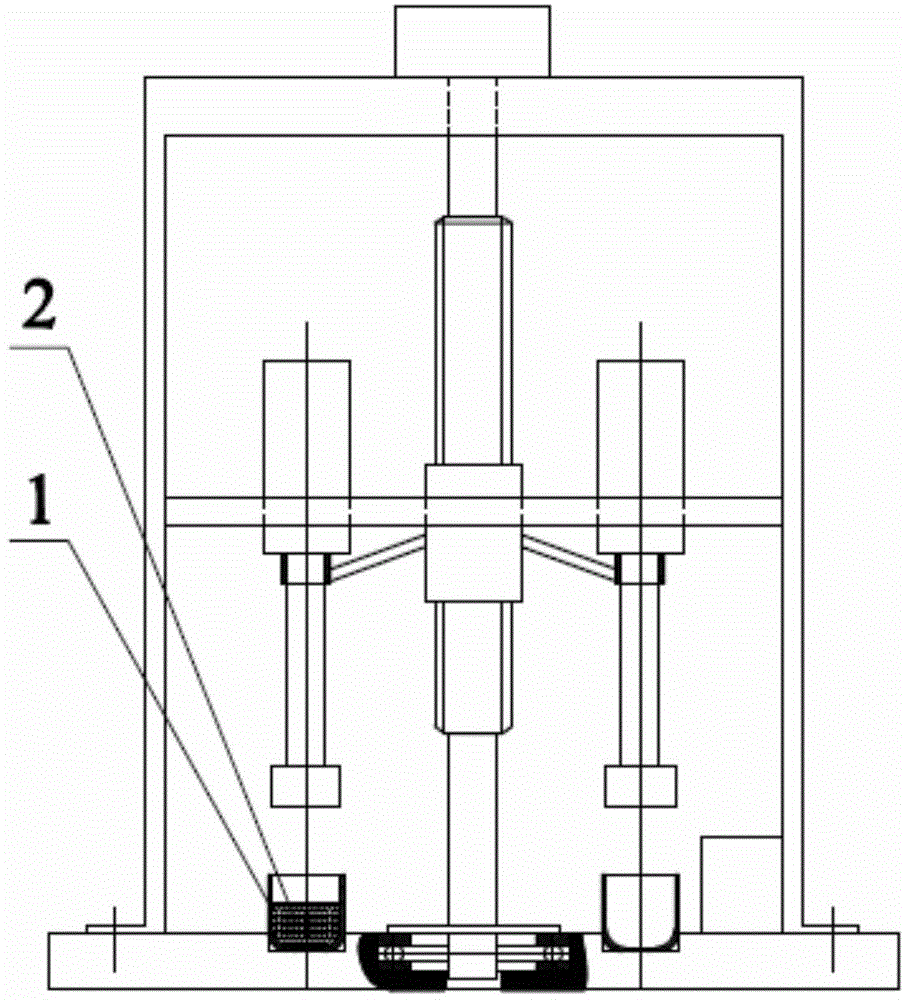

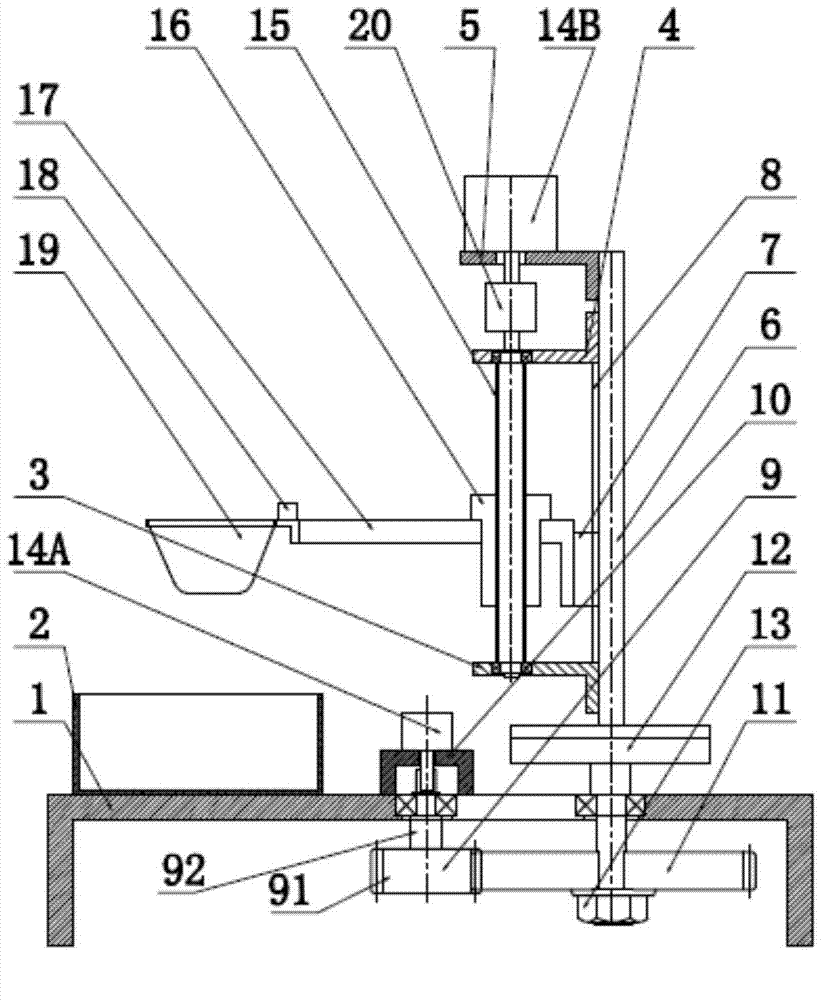

Automatic test equipment for volatiles of bituminous coal

InactiveCN104749066AImprove scienceIncrease authenticityWeighing by removing componentAutomatic test equipmentCrucible

The invention discloses automatic test equipment for the volatiles of bituminous coal. The automatic test equipment comprises a bituminous coal heating module and a bituminous coal weighing module, wherein the bituminous coal heating module has the function of automatically opening / closing a furnace door, and the bituminous coal weighing module is capable of automatically weighing the masses of each crucible containing bituminous coal before and after an experiment; experimenters only need to place the crucibles on a crucible tray and do not need to participate in the later experiment process. The invention discloses automatic test equipment which is simple and compact in structure, convenient to operate, capable of automatically weighing the masses of each crucible before and after the experiment, and capable of carrying out a volatile experiment on 20 crucibles simultaneously.

Owner:CHANGZHOU UNIV

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

Rapid hardening hydraulic cement from subbituminous fly ash and products thereof

A rapid hardening hydraulic cement is provided that is made substantially exclusively from a subbituminous fly ash with no portland cement or other strengthening aid.

Owner:CEMEX

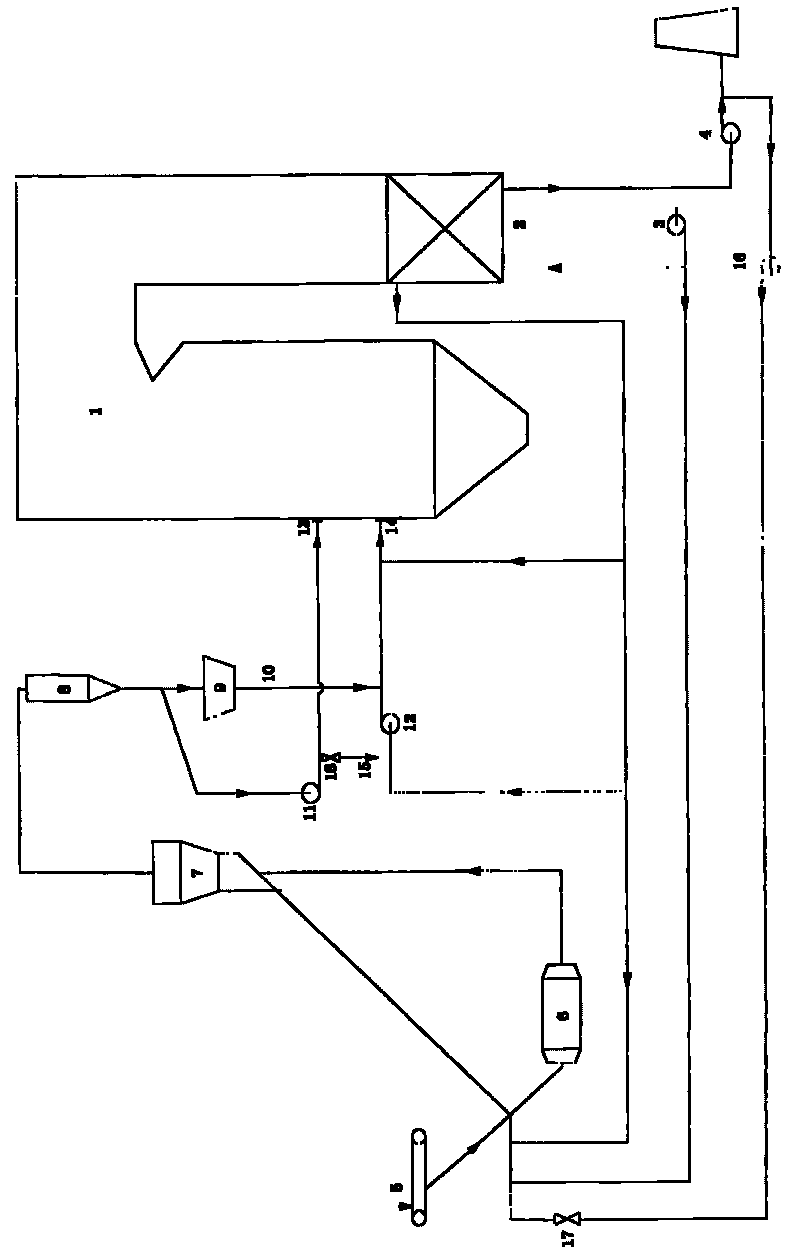

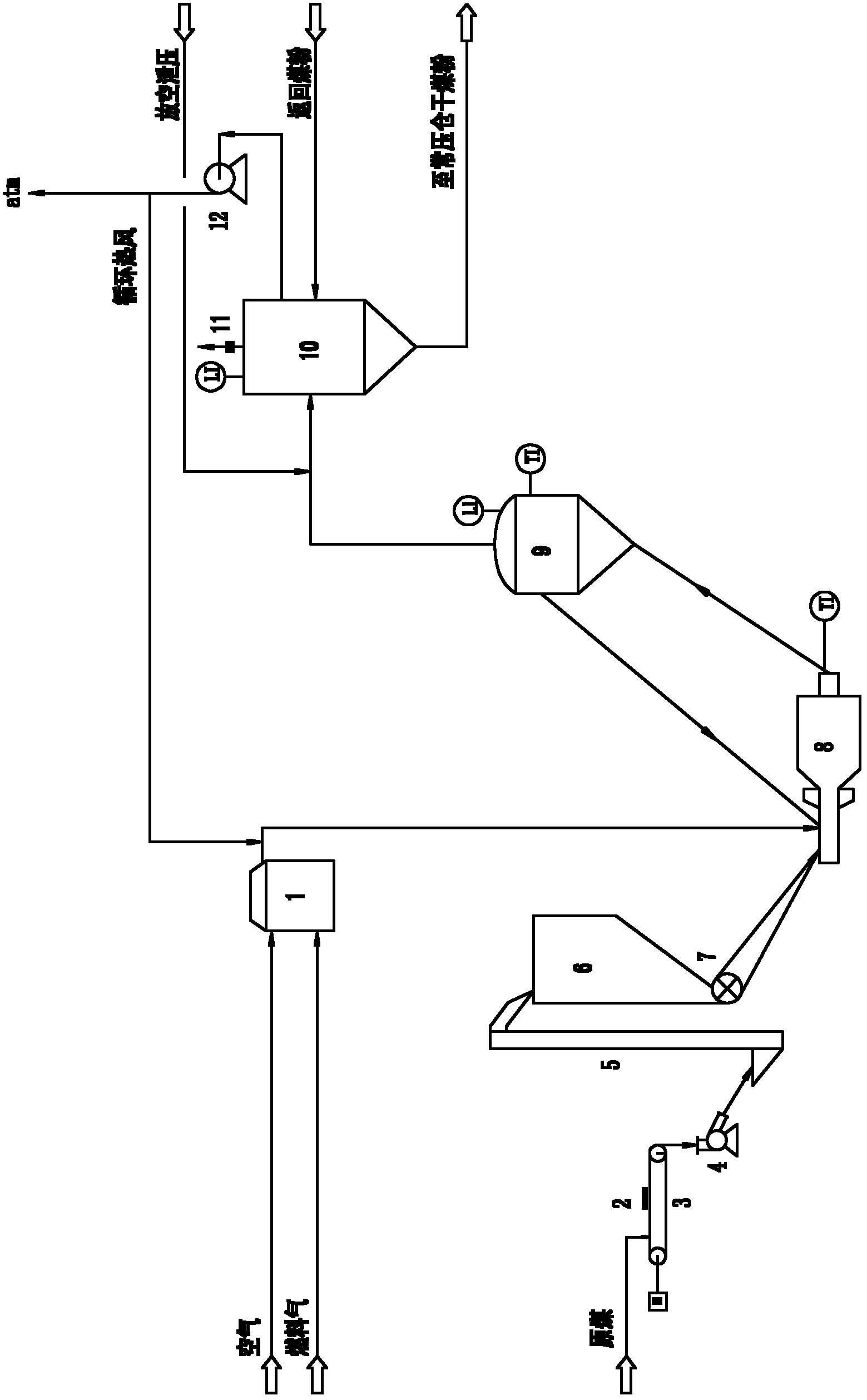

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

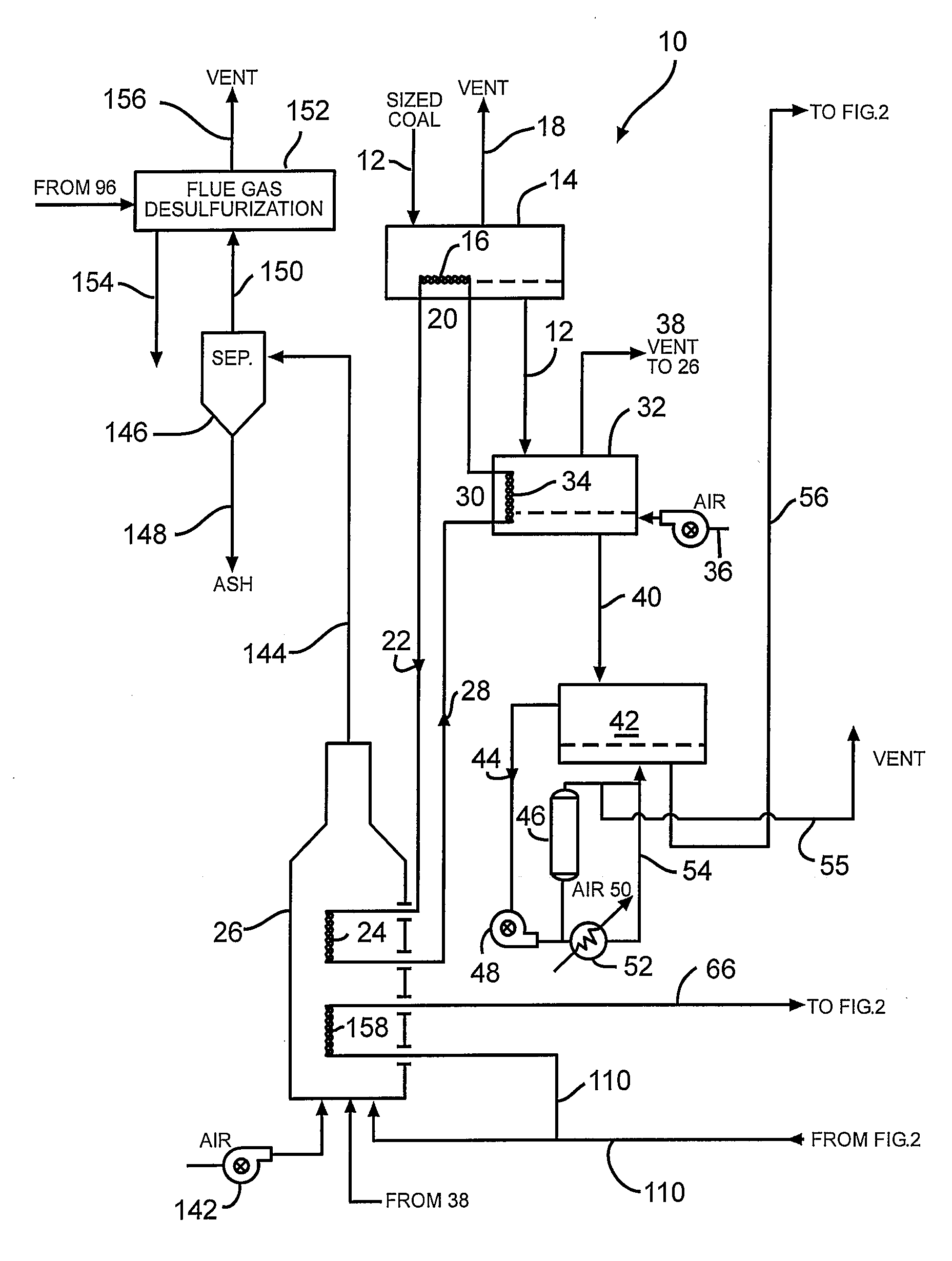

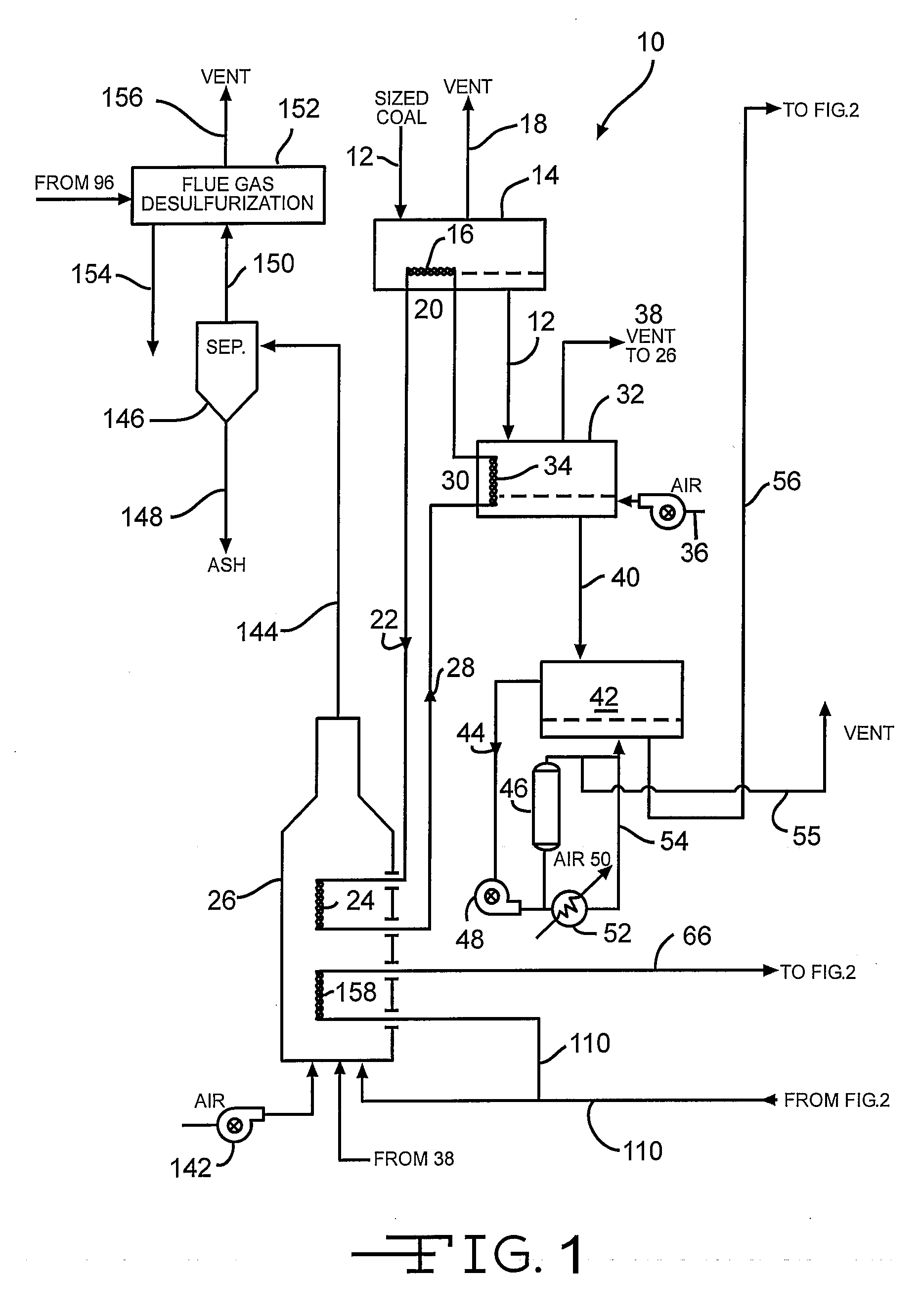

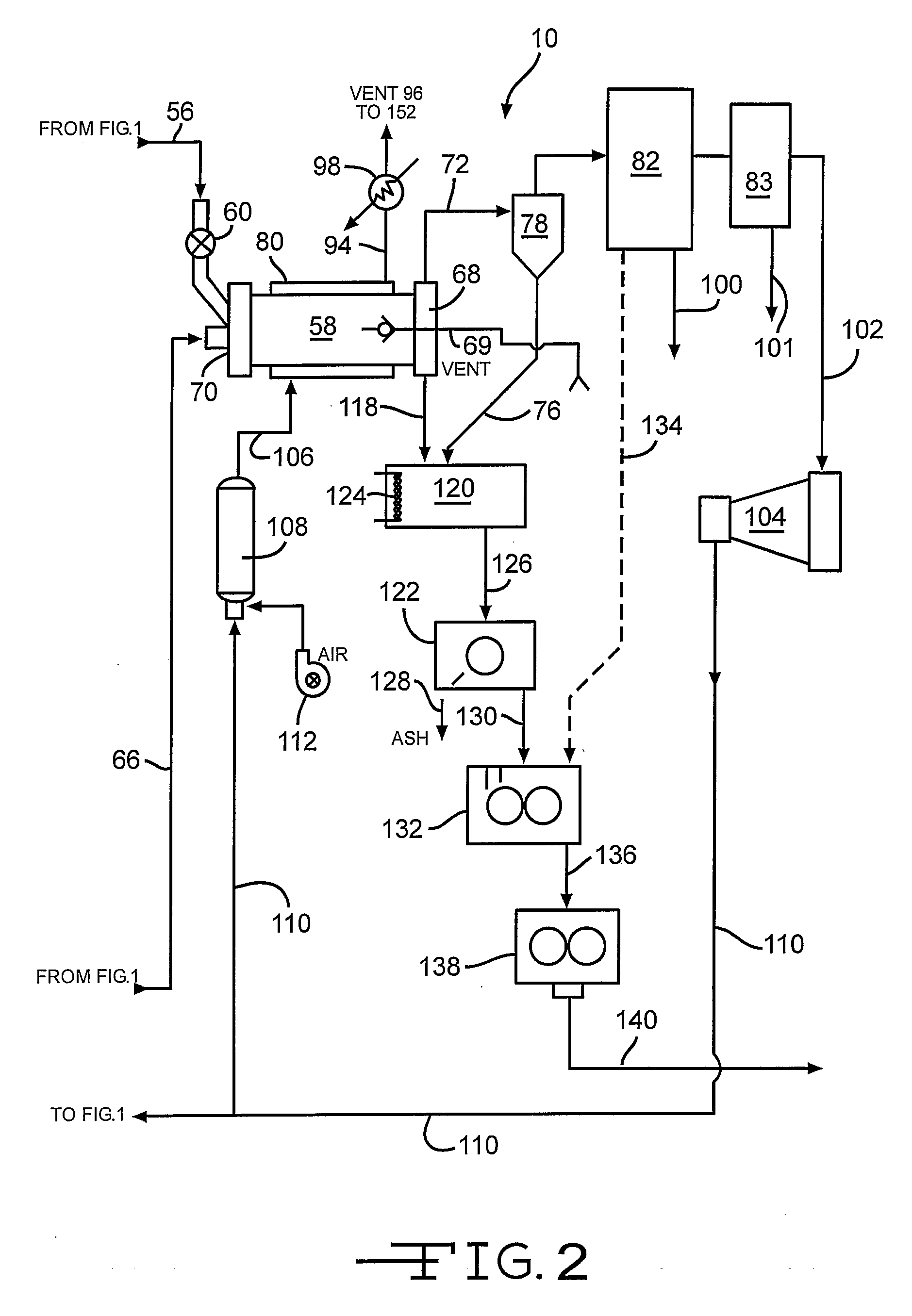

Process for treating bituminous coal by removing volatile components

InactiveUS20110011719A1Reduce ashReduce total sulfurCombustible gas coke oven heatingDirect heating destructive distillationSulfurProcess engineering

A process for treating bituminous coal includes providing dried, pulverized coal, and treating the pulverized coal in a vessel with a gas stream having an oxygen content sufficient to form oxides on surface of coal particles. The treated coal is transferred into a pyrolyzing chamber and passed into contact with an oxygen deficient sweep gas, the sweep gas being at a higher temperature than the temperature of the coal so that heat is supplied to the coal. The process further includes providing additional heat to the coal indirectly by heating the chamber, wherein the heating of coal by the sweep gas and by the indirect heating from the chamber causes condensable volatile components to be released into the sweep gas. Some of the oxides are converted into paramagnetic mineral components, which are removed from coal to form a coal char having reduced ash and sulfur.

Owner:C2O TECH

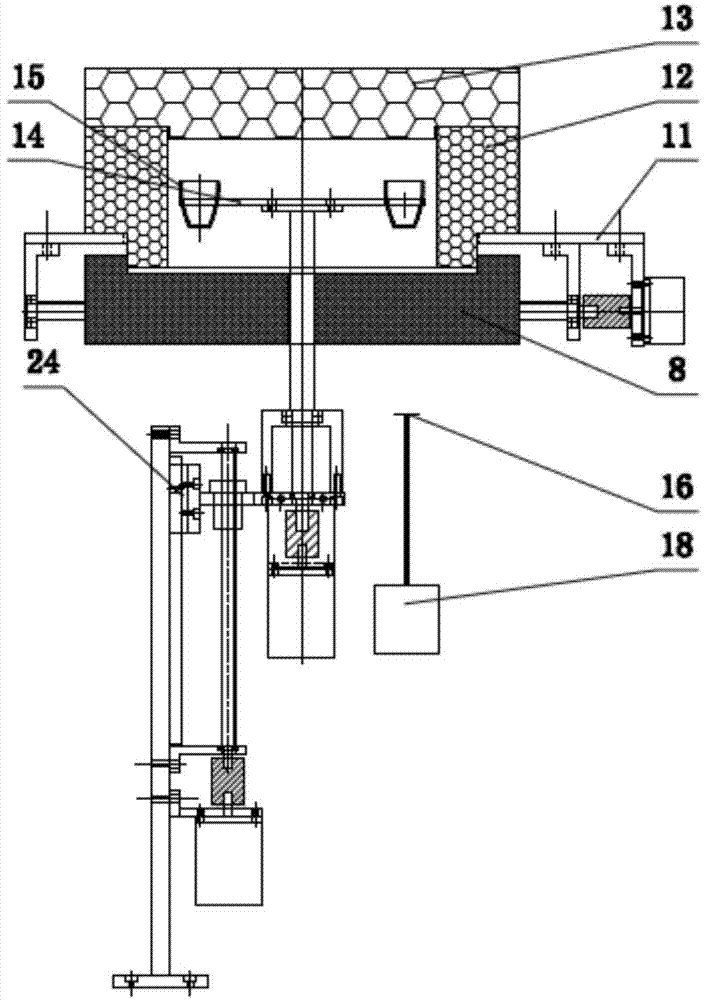

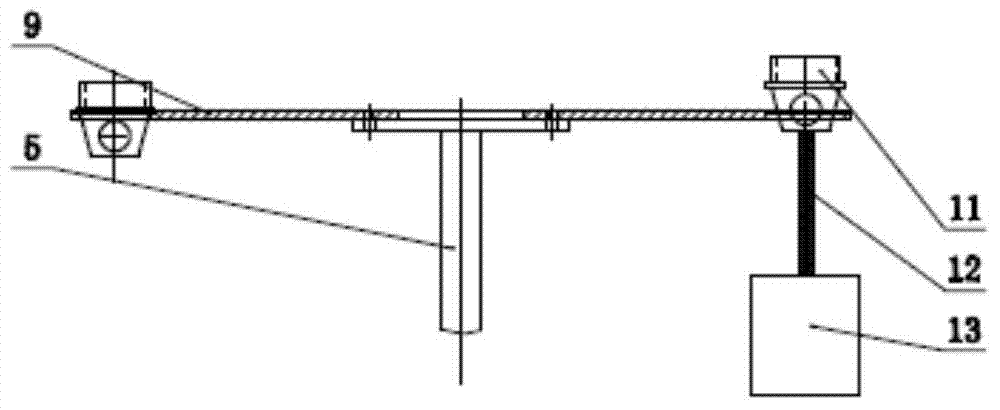

Equipment capable of automatically testing moisture of bituminous coal

The invention discloses equipment capable of automatically testing moisture of bituminous coal. The equipment comprises two main brackets, a bottom plate, a lower fiber plate, a hearth, an upper fiber plate, a turn plate, a rotating shaft, a secondary bracket, an elevating rack, a U-shaped rack, a motor rack, a rotating motor, two bearing brackets, a ball screw, a balance, a weighing lever, a guide block and a slide block, wherein the lower fiber plate is assembled on the bottom plate; the weighing lever is assembled on the balance. The equipment capable of automatically testing moisture of bituminous coal is high in automatic degree, high in work efficiency and convenient to operate.

Owner:CHANGZHOU UNIV

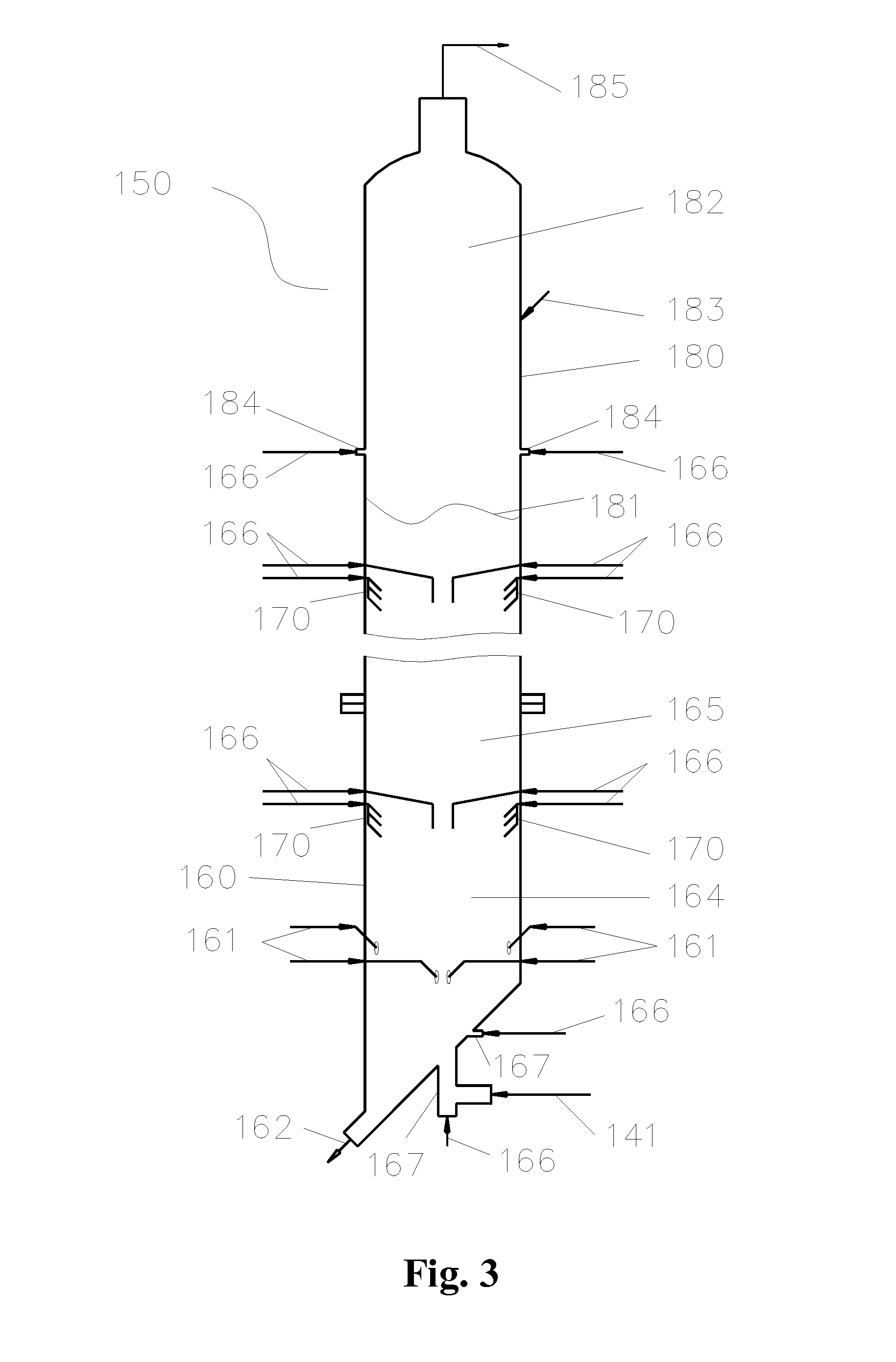

Method and device for producing synthesis gases by partial oxidation of slurries prepared from fuels containing ash and full quenching of the crude gas

ActiveUS20070062117A1Improve usabilityGuaranteed uptimeMuffle furnacesGasifier mechanical detailsPartial oxidationSlurry

A method and device for the gasification of solid fuels such as bituminous coals, and cokes such as those from bituminous coals, lignite coals, and biomasses, as well as petroleum cokes, that are ground fine and mixed with water or oil to obtain fuel-in-liquid suspensions, so-called slurries, and their gasification together with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 100 bar, and at temperatures between 1200 and 1900° C. in an entrained flow reactor. The method includes slurry preparation and infeed to the reactor, gasification in an entrained flow reactor with cooled reaction chamber contour, full quenching of the crude gas to saturation temperature that may be 180-260° C. depending on the gasification pressure, and wet or dry dust separation. The crude gas is pretreated so that it can be fed to further technological steps such as crude gas conversion, H2S and CO2 removal, and synthesis.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

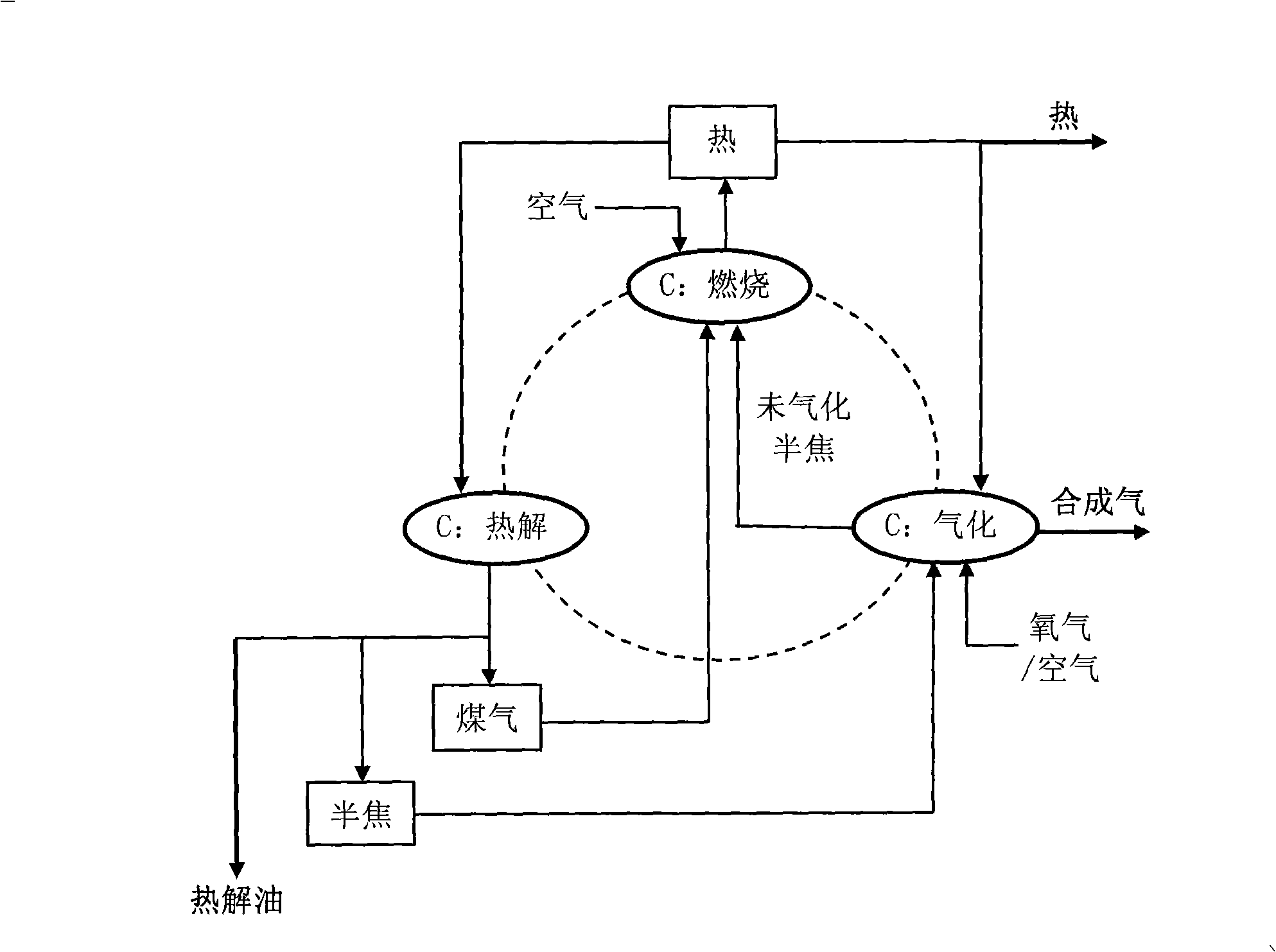

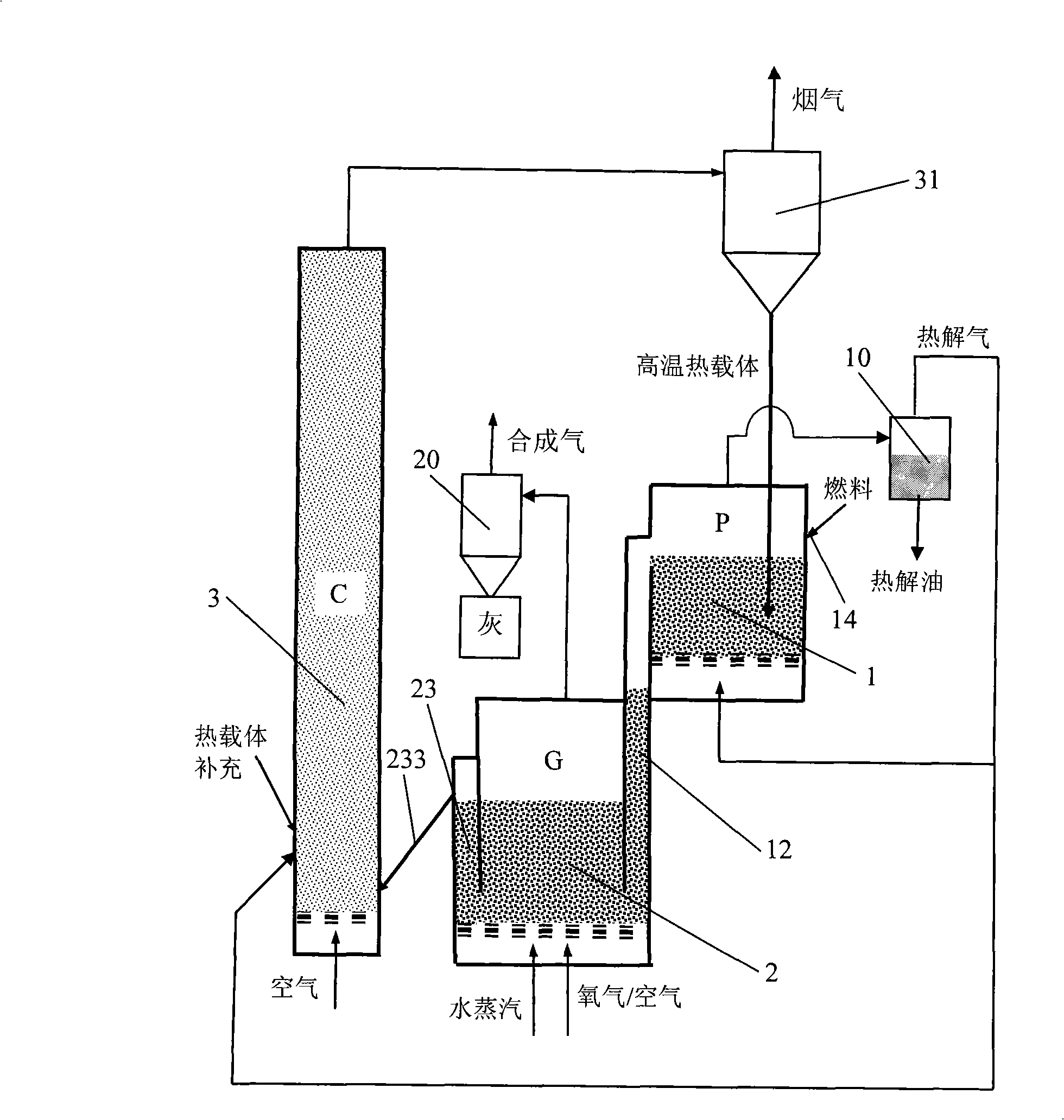

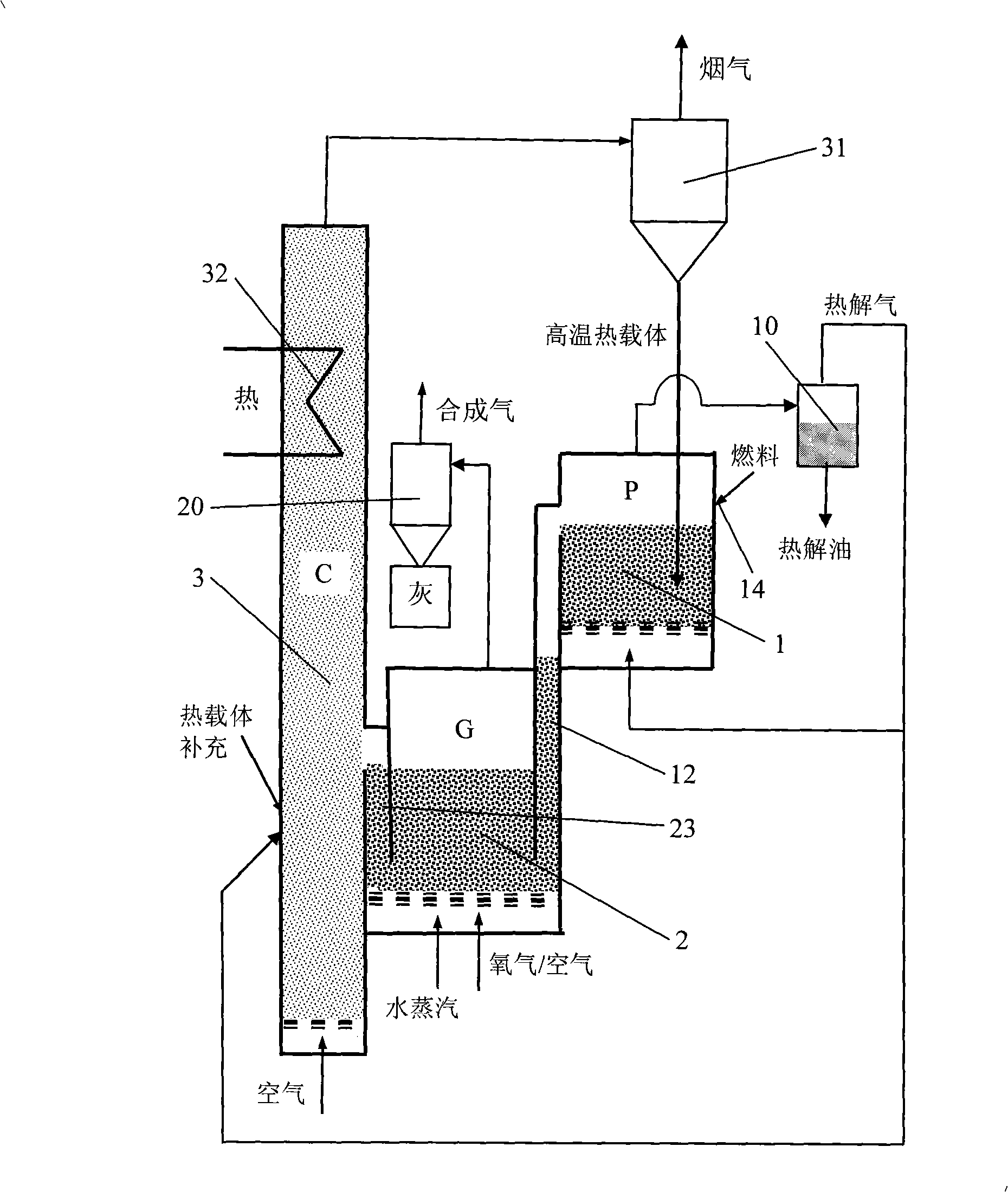

Combined thermal transition method and apparatus for solid fuel

InactiveCN101294092ARealize the value of "resources"Efficient productionLiquid hydrocarbon mixture productionCombined combustion mitigationBrown coalThermal transition

The invention relates to a thermal conversion method and a thermal conversion device of solid fuel, wherein the thermal conversion of the solid fuel is composed of three independent and association-controllable sub-processes of pyrolysis, gasification and burning by decoupling the integrated pyrolysis, gasification and burning reactions in the conventional thermal conversion process. A hot carrier substance is circulated among the sub-processes, so that the burning sub-process provides reactive heat to the pyrolysis and the gasification sub-processes and simultaneously provides oxygen to the gasification process to initiate internal burning so as to compensate for the gasification reaction heat that the hot carrier substance is unlikely to supply. Accordingly, the thermal conversion method can control the three thermochemical reactions of pyrolysis, gasification and burning by decoupling, recombination and association to achieve combined production of pyrolysis oil, synthesis gas and heat. Different from conventional single conversion devices for burning, gasification and pyrolysis, the thermal conversion method of the invention has the advantages of compact structure, high heat utilization efficiency and greatly reduced oxygen consumption for synthesis gas production, thus achieving high-value comprehensive conversion and utilization of solid fuels such as brown coal, bituminous coal and biomass.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

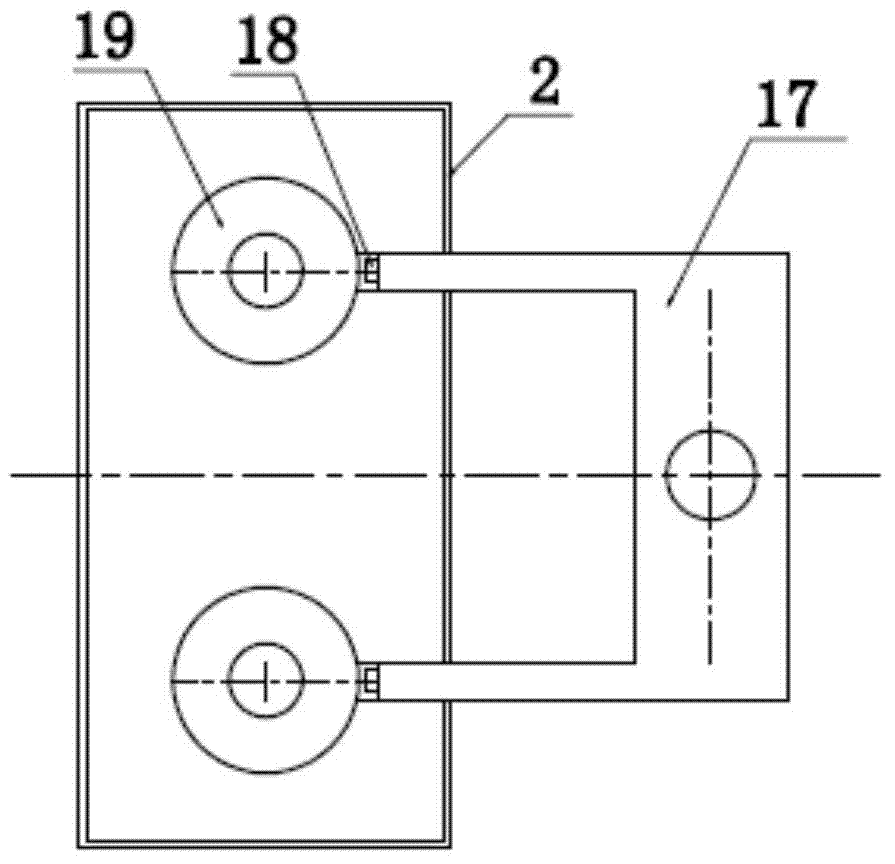

Simple production equipment for bituminous coal sample block

ActiveCN104792590AIncrease or decrease stressSimple structurePreparing sample for investigationCrucibleBituminous coal

The invention discloses simple production equipment for a bituminous coal sample block, and relates to the field of automatic equipment for manufacture of bituminous coal samples. The simple production equipment comprises a T-shaped frame, a motor rack, a lower bearing bracket, an upper bearing bracket, guide rails, two sliders, a T-shaped crucible holder, a T-shaped pressure plate frame, a two-way screw, a pressure applying plate and a spring, wherein the two-way screw is used for changing the distance between a crucible and the pressure applying plate for pressure applying; the spring is sued for controlling the pressure accurately. The equipment for automatically producing the bituminous coal sample block is simple and compact in structure and convenient to operate, and the pressure is controllable.

Owner:上海屹苒自动化设备有限公司

Reducing environmental pollution and fouling when burning coal

InactiveUS20140299028A1Lower Level RequirementsEmission reductionEmission preventionSolid fuel pretreatmentAlkalinityHalogen

Powder components containing calcium, alumina, silica, iron, magnesium, and a halogen sorbent are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame. The alkalinity and chlorine of the powder is minimized in order to mitigate unwanted fouling, especially when used with sub-bituminous and lignite coals.

Owner:NOX II LTD

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1698931ALittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

This invention relates to a catalytic oxidation smoke gas mercury removing method, which is used for controlling and reclaiming the gas mercury, especially for the brown coal and subbituminous coal smoke gas. The method uses the mercury oxidative catalyst and the adsorbent to oxygenize and absorb mercury in the smoke gas, then dissociate and elution the mercuric oxide in high temperature to regenerate it. The heat of the elution gas can be reclaimed by residual heat utilization device, and the high concentration mercury will be reclaimed through cold-trap or processed by the agent in the mercury reactor. The reclaimed mercury and other by-product can be sold to reduce the cost. Said invention uses the thermal instability of the mercuric oxide, and reclaims in the relative lower temperature; the recovery ratio can reach to 98%, meanwhile, it processes post-treatment with the mercury and has no secondary pollution.

Owner:SHANGHAI JIAO TONG UNIV

Multistage over fire air distributing mode

ActiveCN101737771AReduce generationIncrease flexibilityNon-combustible gases/liquids supplyCombustorEngineering

The invention provides a multistage over fire air distributing mode. The mode comprises a primary air pulverized coal nozzle, a secondary air nozzle, main burners, low separating over fire air bellows and high separating over fire air bellows, wherein a group of the main burners is arranged at each corner of a hearth; the separating over fire air is divided into low separating over fire air and high separating over fire air; the low separating over fire air bellows are arranged at four corners of the hearth or on four walls; and the high separating over fire air bellows are arranged at the four corners of the hearth or on the four walls. The distributing mode can realize NOx low emission based on NOx effect of between 250 and 650mg / m3 controlled by integral air classification technology in the current combustion bituminous coal and meager coal furnace (oxygen concentration in smoke is 6 percent.) so as to reduce the generation amount of NOx by about 15 percent. The equipment solves the problems of high combustibles in fly ash caused by the integral air classification technology in the furnace, large difference between speed and temperature of smoke at the outlet of the hearth and the like, and improves the operation regulating performance on different coal varieties and load changes.

Owner:SHANGHAI BOILER WORKS

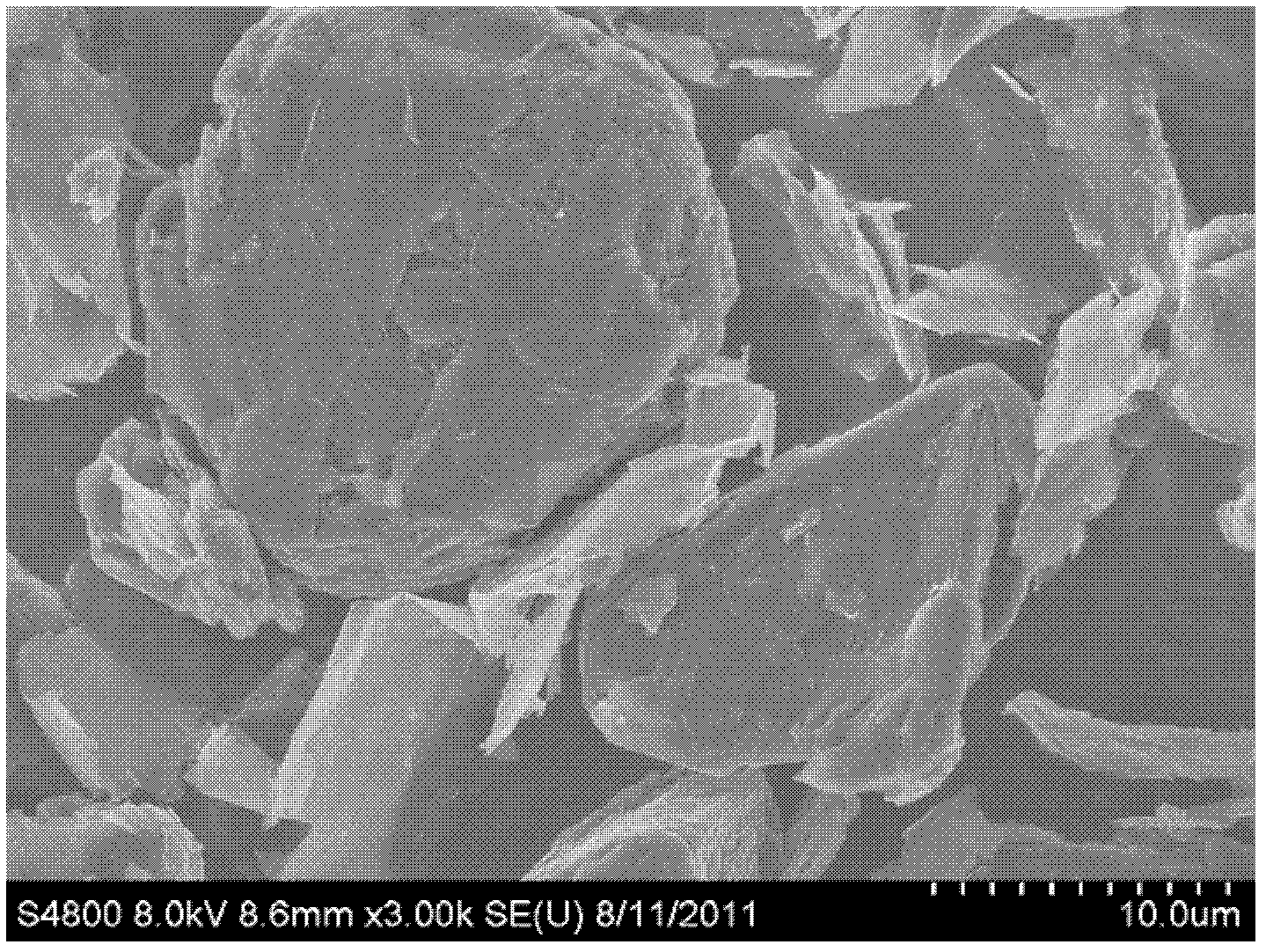

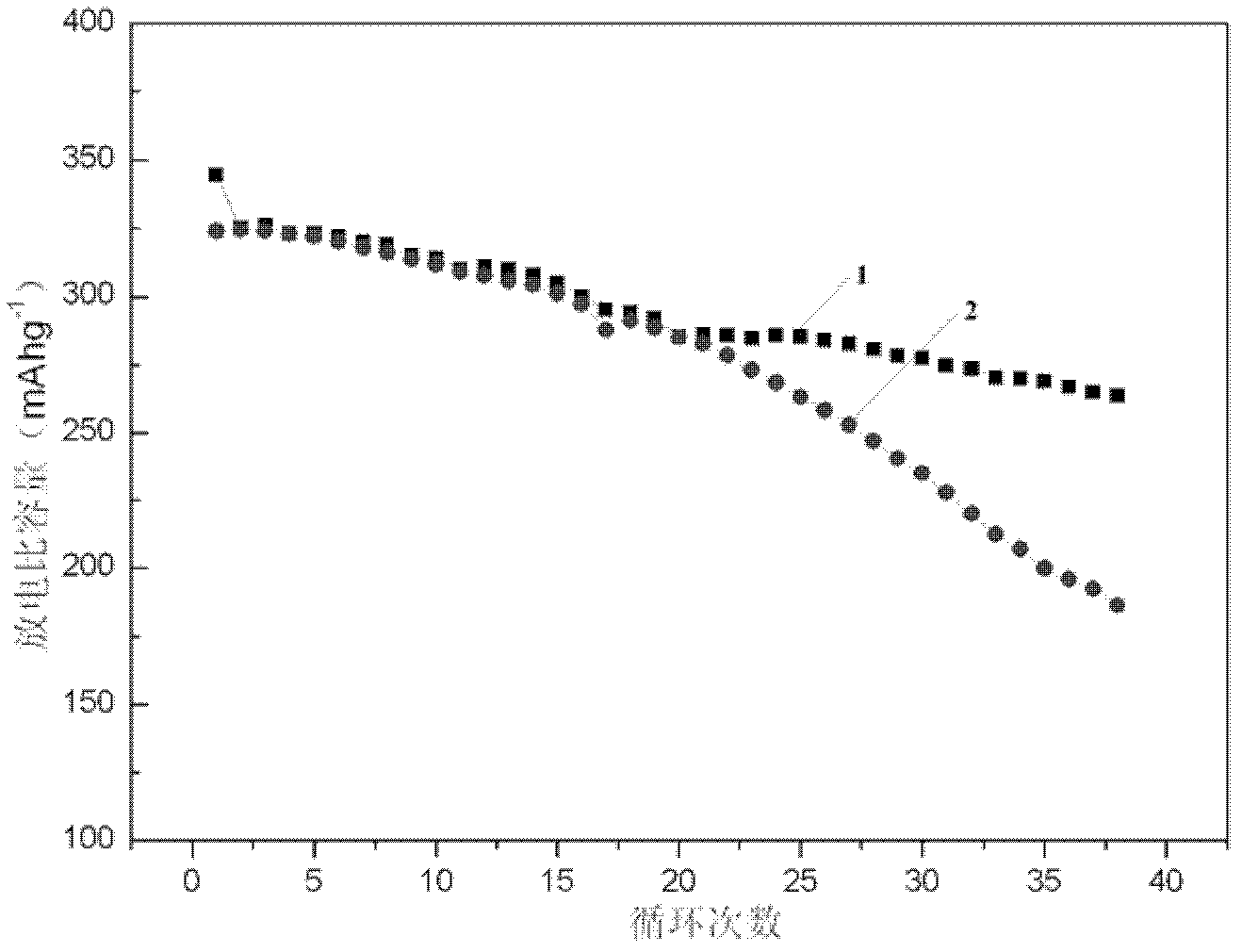

Cathode composite material of lithium ion battery and preparation method thereof

InactiveCN102569750AEasy to prepareRaw materials are easy to getCell electrodesTin dioxideMicrosphere

The invention provides a cathode composite material of a lithium ion battery. The cathode composite material comprises graphene and an electrode active material, wherein the electrode active material is one or more of intermediate-phase bituminous coal microspheres, silicon, lithium titanate, titanium dioxide, tin dioxide and graphite. According to the invention, the graphene and the electrode active material are mixed with water to obtain a mixed solution, which is dried to obtain the cathode composite material of the lithium ion battery. According to the invention, the graphene is adopted as an electroconductive additive, has favorable electroconductive performance, mechanical strength and huge specific surface area, can be favorably attached to the surface of the electrode active material, and is beneficial for shortening the diffusion path of lithium ions, so that the ionic conductivity of the cathode composite material of the lithium ion battery is increased; in addition, the addition of the graphene is beneficial to the enhancement of the full contact between the cathode material of the battery and a current collector, so that the cyclic performance and the multiplying power of the lithium ion battery can be improved in a better way; and the cathode composite material of the lithium ion battery, provided by the invention, has better electric properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

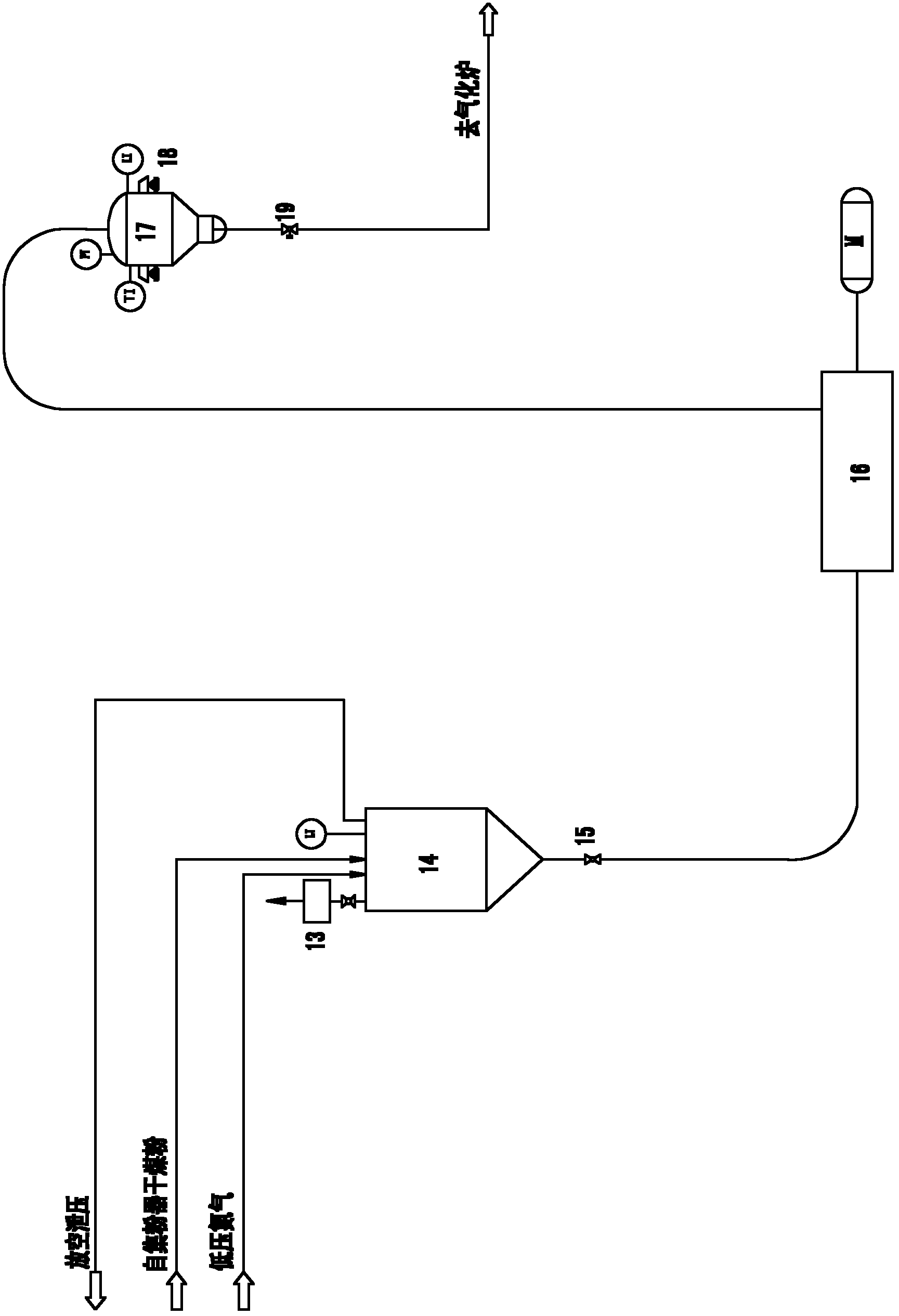

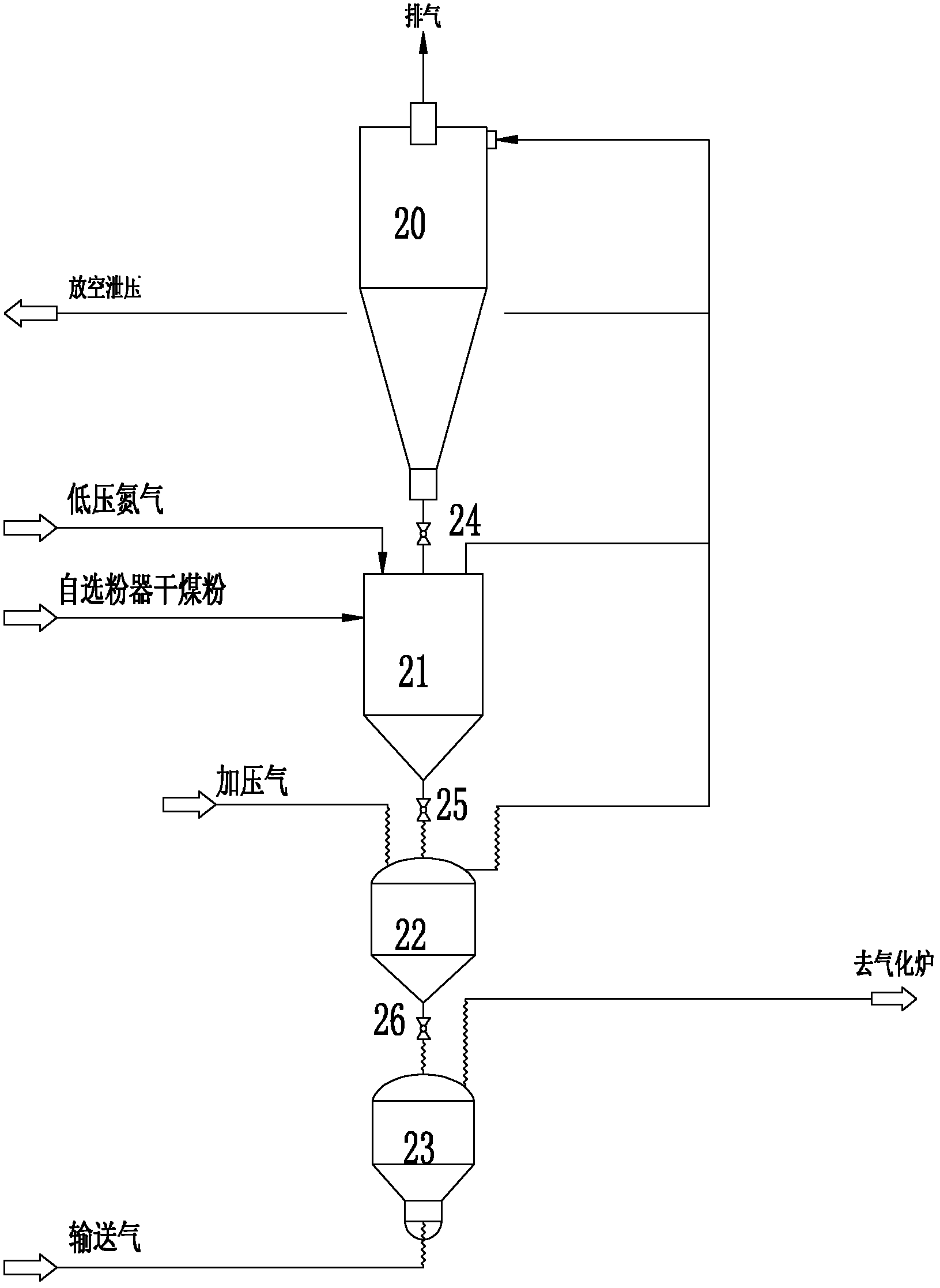

Method for producing synthesis gas by using coal powder as raw material

ActiveCN102352268AImprove utilization efficiencyWon't happenMultistage water/sewage treatmentCombined combustion mitigationProcess configurationAnthracite

The invention discloses a pressurization high temperature gasification method of dry coal powder. The method comprises the following five steps: the preparation of dry coal powder, the pressurization delivery of the dry coal powder, the pressurization and high temperature gasification of the dry coal powder, the cooling of high temperature crude synthesis gas and molten ash and the washing and purifying of the crude synthesis gas, and the treatment of water containing fine ash. The method is suitable for not only the bituminous coal with low ash content and low ash fusion point, but also other types of coal, which widely exist at home and abroad, have different metamorphic degrees and qualities and contain the coal with low ash content and high ash fusion point, the coal with high ash content and low ash fusion point and the anthracite, bituminous coal and lignite with high ash content and high ash fusion point. The method has good gasification index, simple equipment, flexible process configuration, low investment and operation convenience, the large-scale product is easy to realize, and the method has the beneficial effects of wide raw material application range, environmental friendliness and the like.

Owner:THE NORTHWEST RES INST OF CHEM IND

Automatic bituminous coal screening device

ActiveCN104741313AChanging the method of manually screening bituminous coalImprove screening effectSievingScreeningEngineeringTwo step

The invention discloses an automatic bituminous coal screening device. The automatic bituminous coal screening device comprises a waste box, a U-shaped motor rack, a composite gear shaft, a transmission shaft, a driven gear, a T-shaped elevator, a lower bearing bracket, a guide rail, an upper bearing bracket, an L-shaped motor rack, a sieve rack, two fine-mesh sieves symmetrically mounted on the sieve rack, two eccentric motors, two stepping motors and a rolling lead screw. The lifting motor is used for lifting the fine-mesh sieves; a vibrating motor rotates to drive the fine-mesh sieves to vibrate left and right; the two eccentric motors are capable of driving the fine-mesh sieves to vibrate up and down. The automatic bituminous coal screening device is an automatic instrument reasonable in structure, simple to operate, and capable of screening two parts of bituminous coal particles in a vibrating manner.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Small-sized coal gasification hydrogen making method

ActiveCN101391746AReduce consumptionReduce production energy consumptionHydrogen separationChemical industryImpurityFine chemical

The invention discloses a mini-type coal-gasifying hydrogen preparation method which comprises the following steps: blind coals are burnt and introduced with steam to prepare water gas; the water gas is processed by electricity to remove tar and then is processed by wet desulphurization so as to lead the content of H<2>S to be less than 200ppm; the water gas is converted to obtain a converted gas mixed by CO<2> and H<2>; VPSA decarbonization is carried out to remove the impurity of H<2>O and CO<2> from the converted gas; PSA purification is carried out to remove all the impurity except hydrogen so as to obtain the hydrogen product. Compared with the mini-type natural-gas hydrogen preparation method, the method has simple process, easily-supplied materials and low energy consumption; the cost of preparing hydrogen can be reduced by 30 to 50 percent and then the investment can be saved by 20 percent. The method can be applicable to industries of petrifaction, metallurgy, food production, electronic, non-ferrous metals processing, steel, fine chemicals and the like, with the hydrogen consumption of 2000 to 50000m<3>n / h.

Owner:SHANGHAI HANXING ENERGY TECH

Active carbon used for adsorbing and removing sulfides in gasoline, and preparation method thereof

ActiveCN102188954AHighly selective adsorptionLow ashOther chemical processesHydrocarbon oils refiningHydration reactionAdhesive

The invention relates to active carbon used for absorbing and removing sulfides in gasoline, and a preparation method thereof. The active carbon is composed of the following components in percentage by weight: 40-70% of petroleum coke, 10-50% of coal, 10-30% of adhesive, 0.1-10% of pore forming agent and 0.1-10% of amodifier, wherein the ash content of the petroleum coke is less than 1%; the coalis anthracite or bituminous coal with volatile content less than 35%; the adhesive is one of or the mixture of coal pitch, coal tar, vacuum residue, coked condensed oil, ethylene cracked residue, catalytic slurry, petroleum pitch and petroleum pitch oxide; the pore forming agent is one of or the mixture of carbon black containing active functional groups and active elements, furfural residue, ferrocene, furfuryl alcohol and potassium; and the modifier is a hydrate nitrate of Cr, Fe, Co, Ni, Mo, Ti, Cu or Zn. The active carbon has the characteristics of low ash content, high strength, high selectivity, excellent adsorption performance and the like.

Owner:PETROCHINA CO LTD

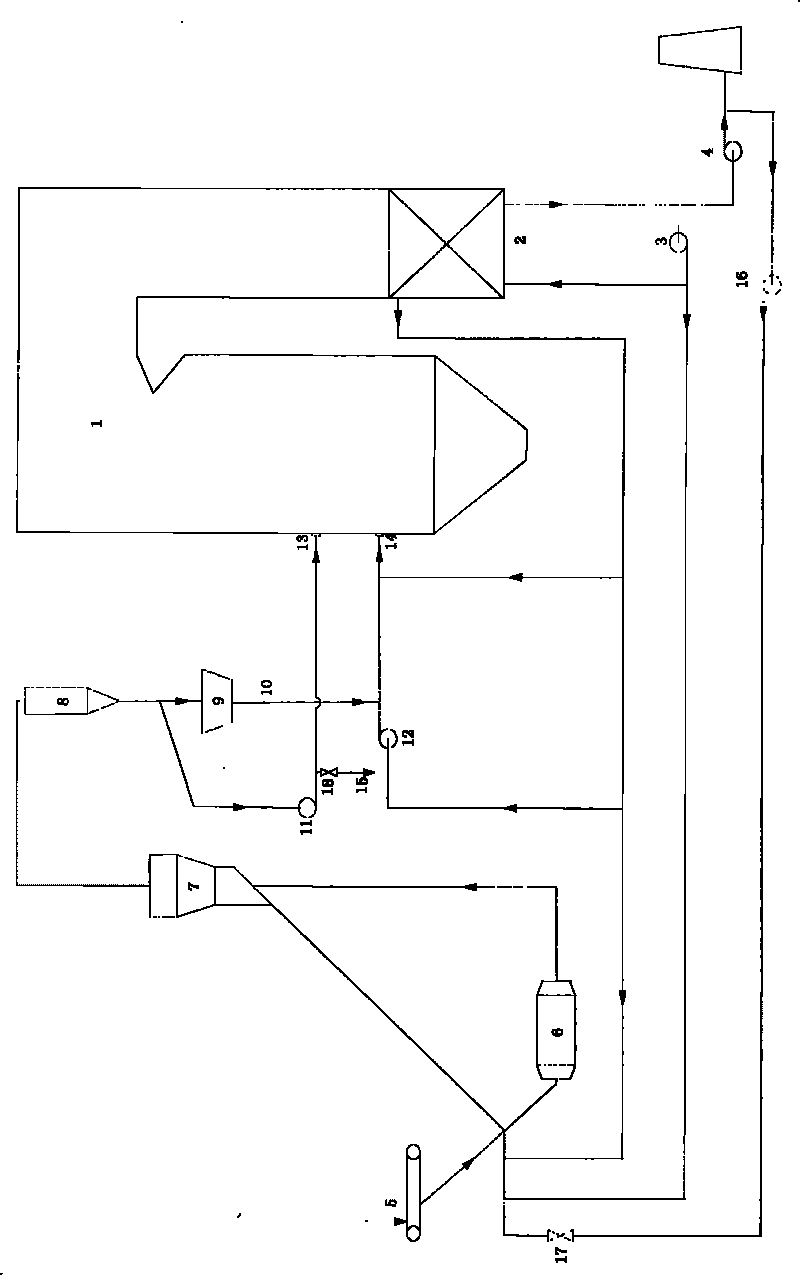

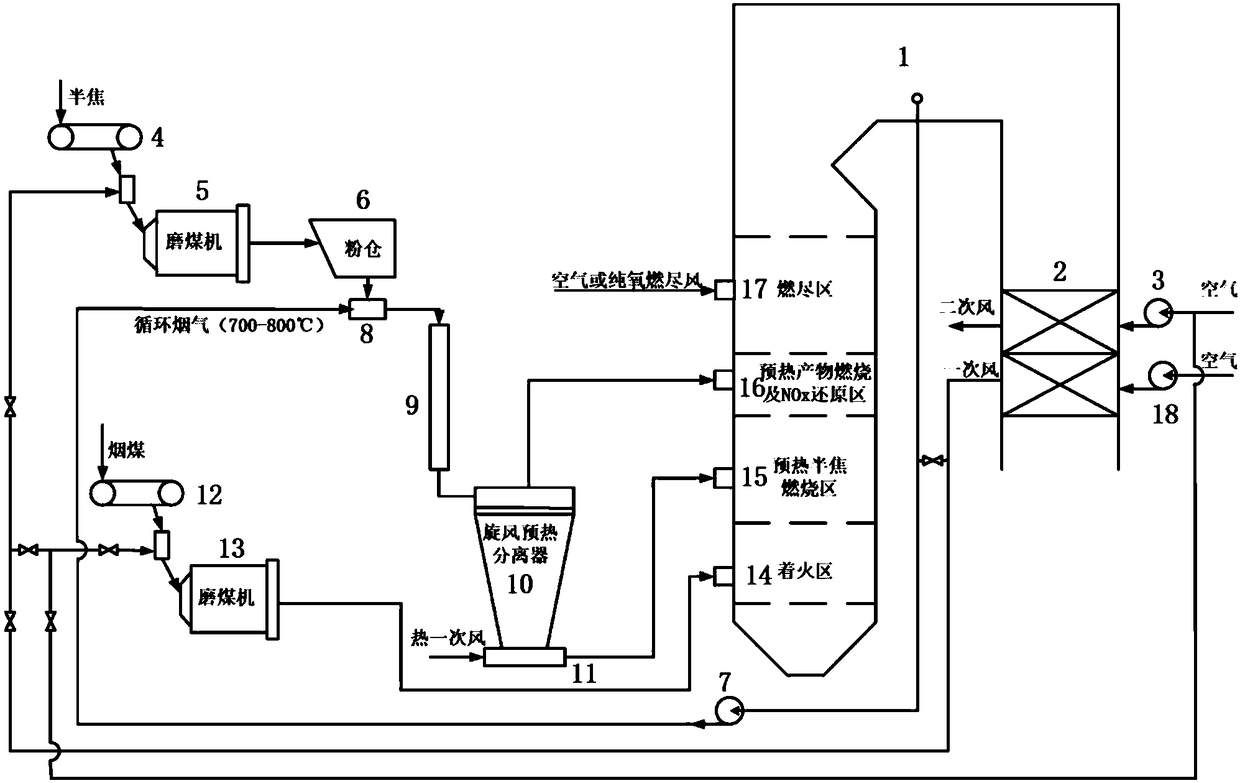

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

Method for preparing active semicoking H2S desulphurizer

InactiveCN1621498AWide variety of sourcesLow pricePhysical/chemical process catalystsOther chemical processesSorbentCoking plant

The present invention discloses the preparation process of active semi-coke H2S desulfurizer. The active semi-coke H2S desulfurizer is prepared with lignite semi-coke, anthracite or soft coal semi-coke and other carbon containing material and through first pressurized hydrothermal chemical modification, subsequent soaking with cuprammonia, CuSO4 solution or K2CO3 solution, drying and high temperature calcining. The present invention has the features of wide material source, low cost, repeated use of the adsorbent product, final use in waste water treatment and as fuel and no secondary pollution. The present invention may be used widely in purifying gas in various plants and environment protecting industry.

Owner:OCEAN UNIV OF CHINA

Sewage sludge harmlessness disposing technique

InactiveCN101139158ALow powerEasy to combineSludge treatment by de-watering/drying/thickeningIncinerator apparatusWater bathsSludge

The present invention discloses a harmless treatment process for sewage sludge. The dewater treatment is applied to the sewage sludge and then the treated sewage sludge is delivered into a dryer so as to be dried; when the water content of the dried sewage sludge is controlled to range from 40 percent to 50 percent, 40 percent to 60 percent of anhydrated sewage sludge is taken to be mixed with the bituminous coal and then treated sewage sludge is delivered into a hot blast stove to go into incineration. The mix proportion between the bituminous coal against the sewage sludge ranges from 0.25 to 1 and the heat generated from the incineration is supplied to the dryer in the form of hot air. The tail gas delivered out from the dryer enters a cyclone separator to go into the solid separation and the fine particles after the separation are recycled, and the discharged gas enters a water bath tower and is exhausted after going through the cooling and deodorization treatment. The sewage sludge is mixed with the coal and then the incineration is implemented and the heat generated from the incineration is recycled so as to be supplied to the dryer for the present invention, thus avoiding the moisture content of the sewage sludge from being lowered to be less than 10 percent, simplifying the combination of the equipments, saving the initial investment and lowering the operating cost and enhancing the throughput.

Owner:SHAOXING WATER TREATMENT DEV

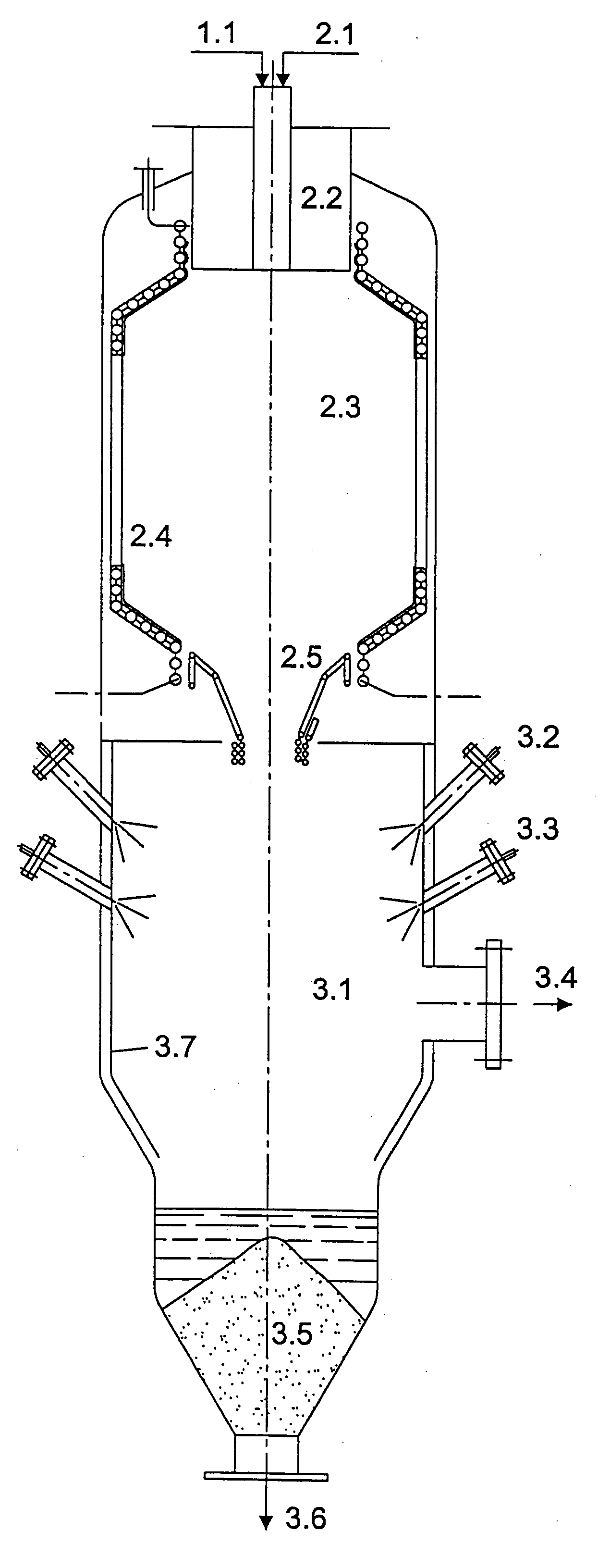

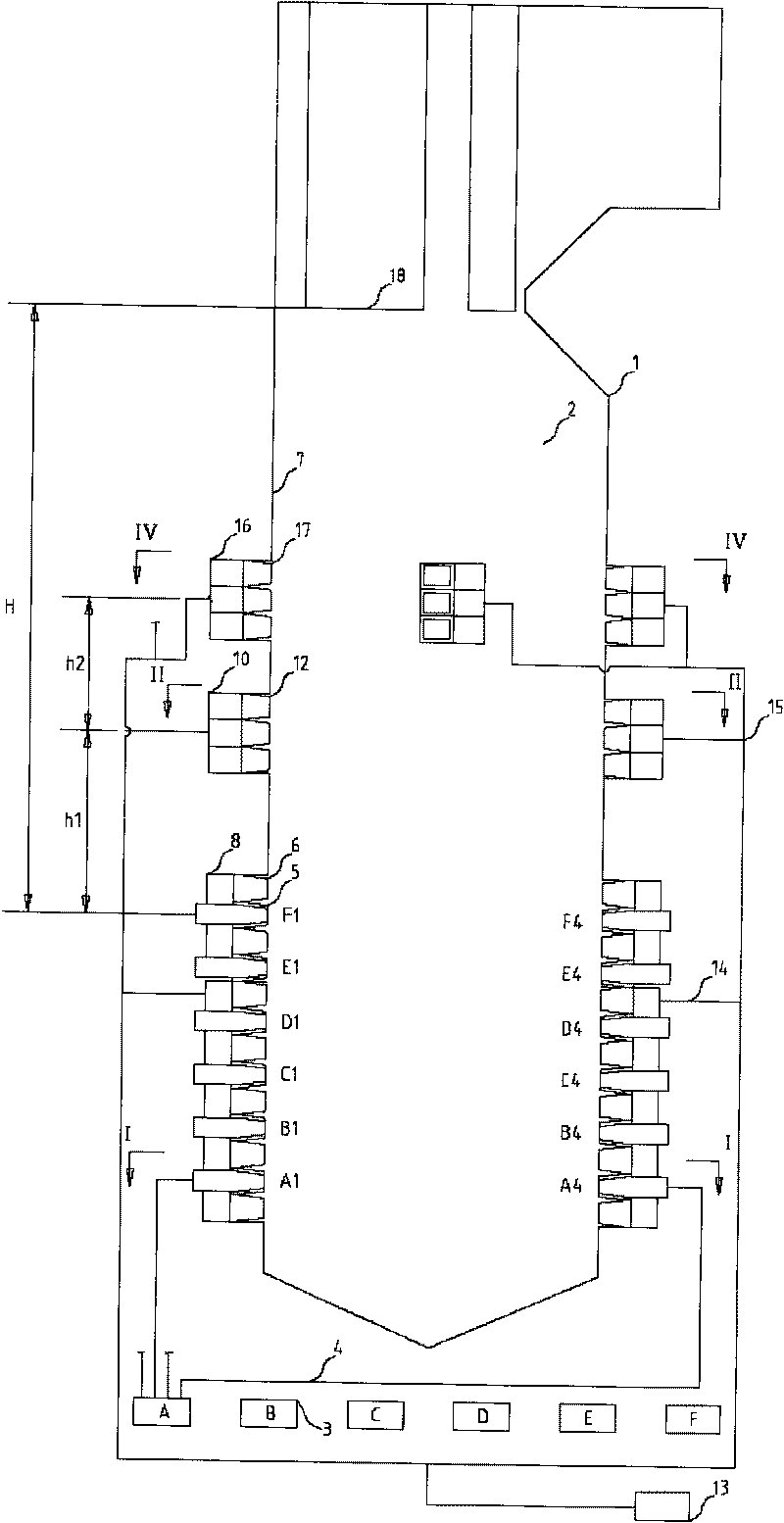

Gasification method and device for producing synthesis gases by partial oxidation of fuels containing ash at elevated pressure with partial quenching of the crude gas and waste heat recovery

InactiveUS20070051044A1Improve usabilityGuaranteed uptimeGasifier mechanical detailsEnergy inputBrown coalPartial oxidation

A method and device for the gasification of solid fuels such as bituminous coal, lignite coal, and petroleum coke in the flue stream, with an oxidizing medium containing free oxygen by partial oxidation at pressures between atmospheric pressure and 80 bar, and at temperatures between 1200 and 1900° C., consisting of the process steps of pneumatic metering for pulverized fuel, gasification in a flue stream reactor with cooled reaction chamber contour, partial quenching, cooling, crude gas scrubbing, and partial condensation.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method for producing moulded coal by oil-rich coal with low-ash low-sulfur low-phosphor and high-heat productivity

InactiveCN101445756AIncrease added valueLow ash low sulfurSolid fuelsChemical industrySodium Bentonite

The invention relates to a method for producing environmental protective smokeless moulded coal by oil-rich coal with low-ash low-sulfur low-phosphor and high-heat productivity. Soft coal powder is used as a raw material to produce tar, coal gas and semi coke powder by low-temperature carbonization. The semi coke powder is powdered and added with caking agent and additive to be mixed, extruded to be formed and then dried, and the environmental protective clean smoke less molded coal is produced, wherein, the caking agent is compound caking agent, including organic caking agent, inorganic caking agent; the organic caking agent is polyvinyl alcohol and starch; the polyvinyl alcohol and the starch are made into 5 percent to 10 percent of latex; every ton of moulded coal is added with 1-2kg of the polyvinyl alcohol and 6-15kg of the starch; the inorganic caking agent is bentonite; and every ton of the moulded coal is added with 20-40kg of the bentonite. The production method can relieve the status that smokeless coal has insufficient resource and is in short supply and increases a novel raw material supply variety for the coal used for Chinese chemical industry and synthetic ammonia gas-making industry, and at the same time the technical processing can improve the added value of Shenfu raw coal powder and the semi coke powder and changes waste into valuable.

Owner:杨兴平

Carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent and preparation method thereof

InactiveCN103801387ANo secondary pollutionMolecular sieve catalystsOther chemical processesStreet intersectionWater vapor

The invention discloses a carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent and a preparation method thereof. The preparation method is characterized in that carbon-containing materials such as lignite carbocoal, anthracitic coal and bituminous coal carbocoal take amorphous or formed particle carbocoal, tetrabutyl titanate, absolute ethyl alcohol and the like as photo-catalyst active raw materials; firstly, the amorphous or formed particle carbocoal supports a photo-catalyst TiO2, transition metal oxide and the like through methods of ultrasonic activation of hydrogen peroxide, acid activation, alkaline activation and the like, and subsequently, the amorphous or formed particle carbocoal is activated by water vapour at a high temperature of 500-700 DEG C and then mechanically mixed with ZSM-5 or other NO adsorption molecular sieves, thereby finally obtaining the photo-catalytic desulfurization and denitration agent. The carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent has the characteristics of extensive sources and low price of active carbocoal; after TiO2 is supported, the carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent has the effect of getting twice the result with half the effort during denitration; the ZSM-5 and other NO absorption molecule sieves can play the role of capturing NO; the prepared catalyst can be used for removing NOx in fuel gas of coal-fired power plants, coal-fired boilers, coal-fired kilns and the like through a low-temperature photo-catalytic oxidation method at a temperature which is less than or equal to 110 DEG C; the prepared catalyst also can be used for removing NOx in ventilated gases generated in road tunnels, underground parking garages, street intersections and the like.

Owner:OCEAN UNIV OF CHINA

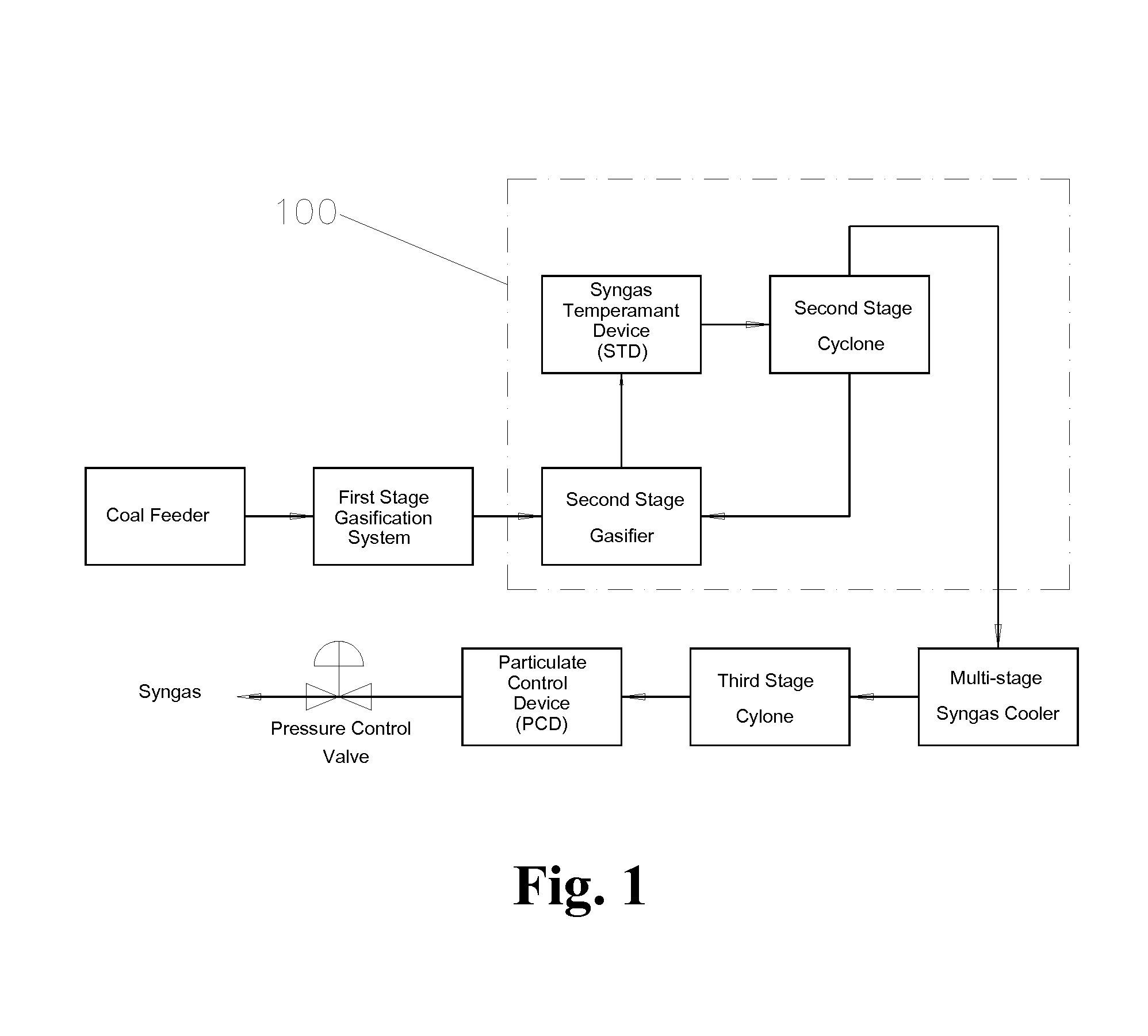

Second Stage Gasifier In Staged Gasification And Integrated Process

ActiveUS20140158941A1Energy efficient and cost-effectiveHydrogenHydrocarbon from carbon oxidesFluidized bed gasifierFluidized bed

A second stage gasification unit in a staged gasification integrated process flow scheme and operating methods are disclosed to gasify a wide range of low reactivity fuels. The inclusion of second stage gasification unit operating at high temperatures closer to ash fusion temperatures in the bed provides sufficient flexibility in unit configurations, operating conditions and methods to achieve an overall carbon conversion of over 95% for low reactivity materials such as bituminous and anthracite coals, petroleum residues and coke. The second stage gasification unit includes a stationary fluidized bed gasifier operating with a sufficiently turbulent bed of predefined inert bed material with lean char carbon content. The second stage gasifier fluidized bed is operated at relatively high temperatures up to 1400° C. Steam and oxidant mixture can be injected to further increase the freeboard region operating temperature in the range of approximately from 50 to 100° C. above the bed temperature.

Owner:THE SOUTHERN CO

Blast furnace spray-blow coal technology using semi-coke of iron works

InactiveCN102827972ABroaden the scope of industrial applicationsPromote industrial developmentBlast furnace detailsCarbonizationEconomic benefits

The invention provides a blast furnace spray-blow coal technology using semi-coke of iron works. The technology comprises the following steps of: mixing semi-coke, anthracitic coal and bituminous coal based on a ratio; powdering the mixture in a mill, and carrying out spraying and blowing to a blast furnace for one time or multiple times through a blast furnace coal spraying system under a wind temperature of 1200 DEG C. With adoption of the technology, the semi-coke industrial application field can be further expanded; the industrial development can be sped up; the supply situation that the supply of the coking coal and the bituminous coal become tighter can be released through the semi-coke blast furnace spray-blow coal technology; and a benefit is provided to achieve the application and popularization of the coal carbonization technology; the bituminous coal can be replaced via the semi-coke, and the national current requirement on energy conservation and emission reduction can be met; and moreover, the economic benefit of the downstream enterprises can be obviously improved due to the low cost of the semi-coke.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

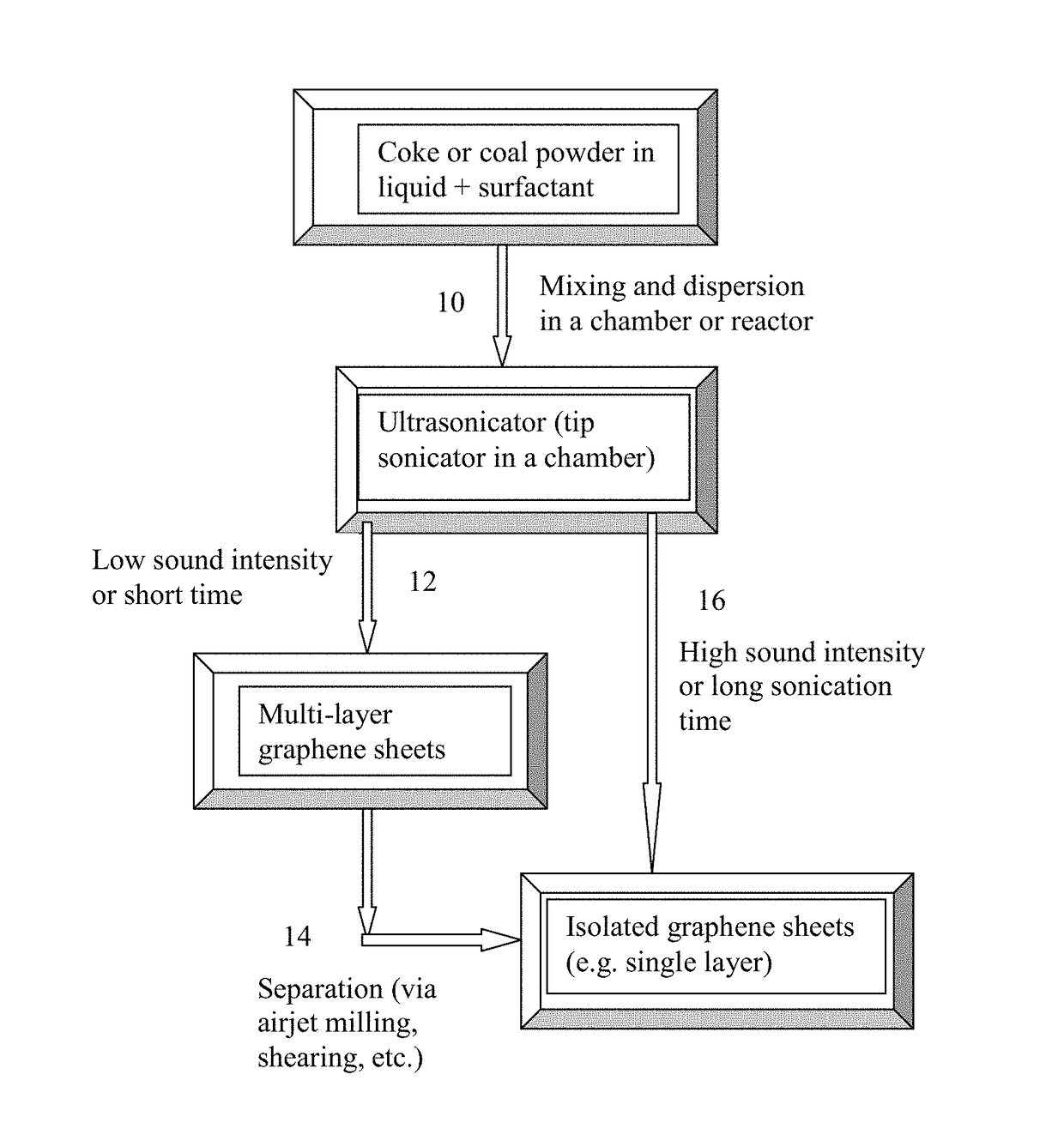

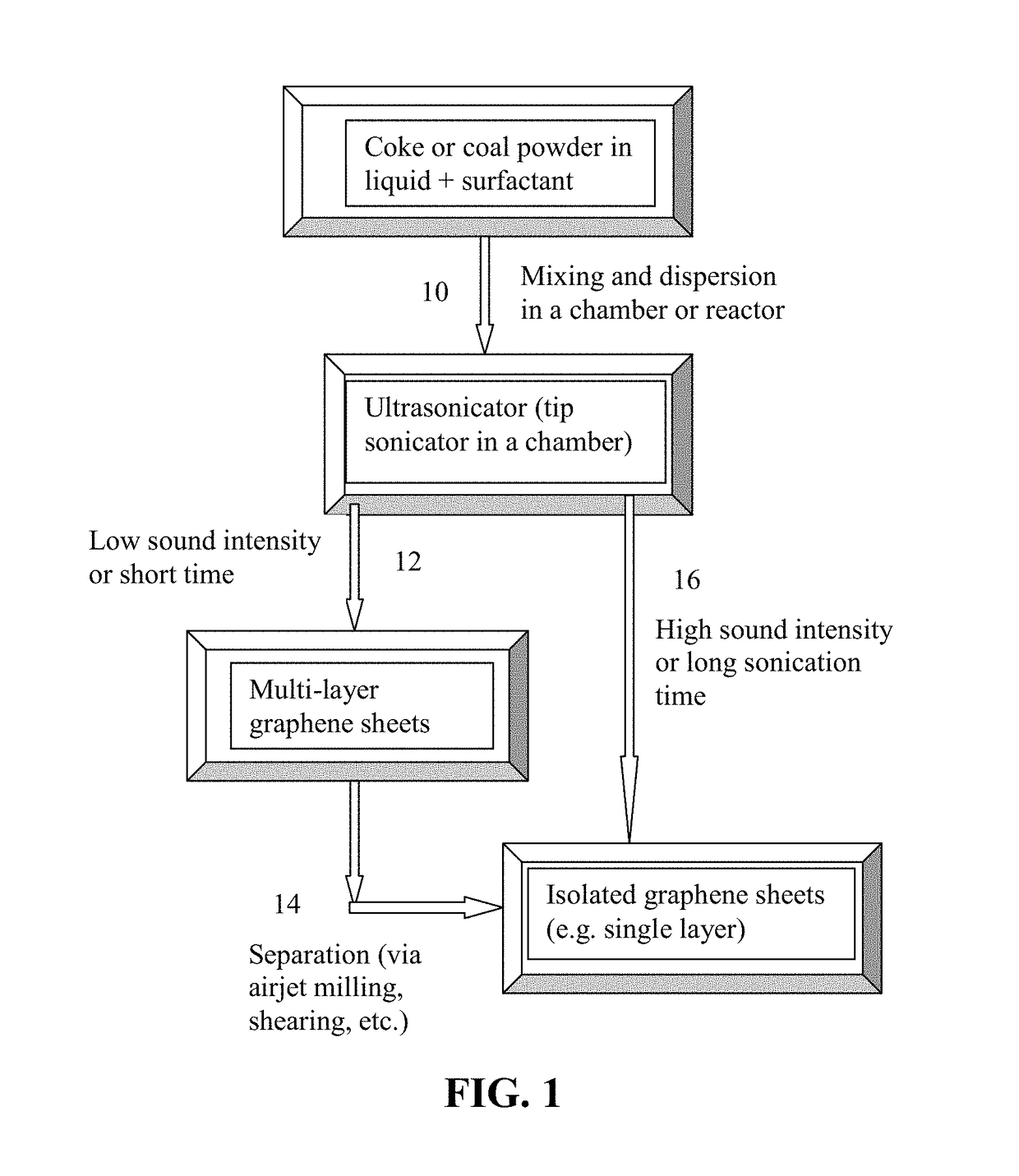

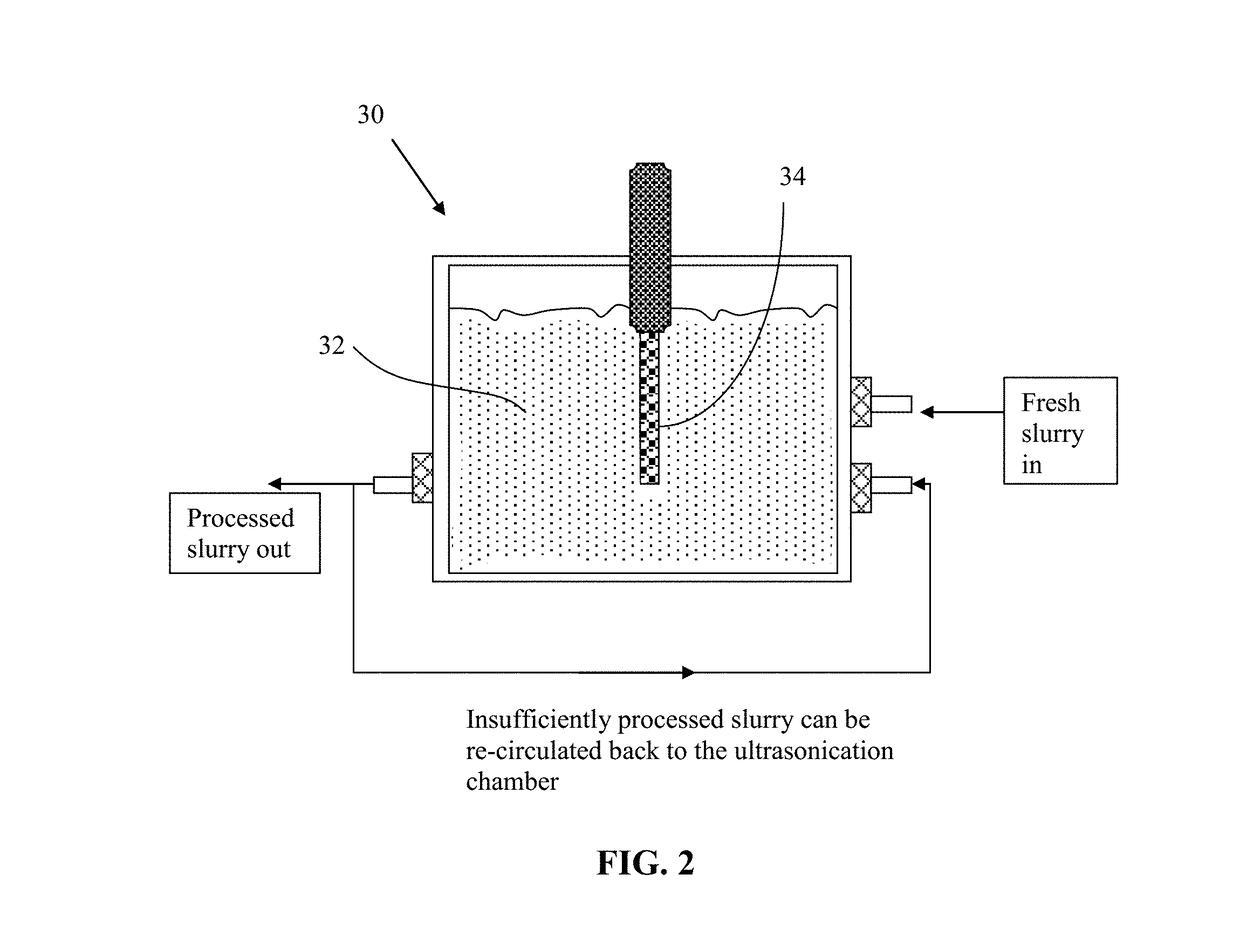

Direct Ultrasonication Production of Graphene Sheets from Coke or Coal

ActiveUS20170369320A1Prevent restackingGuaranteed normal transmissionGrapheneInksLiquid mediumAnthracite

Provided is a method of producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; and (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce the isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Method for producing clay coal water slurry

InactiveCN101831330ATake advantage of stabilityGood pulpingLiquid carbonaceous fuelsLump/pulverulent fuel preparationResource utilizationOil sludge

The invention relates to a resource utilization technology for combining clay and clean coal and discloses a method for producing clay coal water slurry. The clay coal water slurry comprises the raw material components in percentage by weight: 15-35 percent of clay, 42-58 percent of pulverized bituminous coal over 80 percent of which passes through a 200-mesh sieve, 18-28 percent of water and 0.5-1.5 percent of viscosity-reducing dispersant. The invention has the advantages of simple operation, low energy consumption, low cost and no secondary pollution. The produced clay coal water slurry has favorable flowability, strong stability and high combustion efficiency, thereby meeting the requirement of a boiler for fuel combustion or gas making, not only relieving the problem that the current coal is in shortage, but also effectively using clay, achieving the requirements of reduction, reclamation and harmlessness on clay treatment and having favorable market and popularization value.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com