Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Alkaline activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkaline activation is a chemical process where aluminosilicate materials of natural or industrial origin may be transformed into compact cementitious skeletons when mixed with a highly alkaline solution [1], [2], [3], [4], [5], [6].

Preparation method of lithium-selenium battery positive electrode

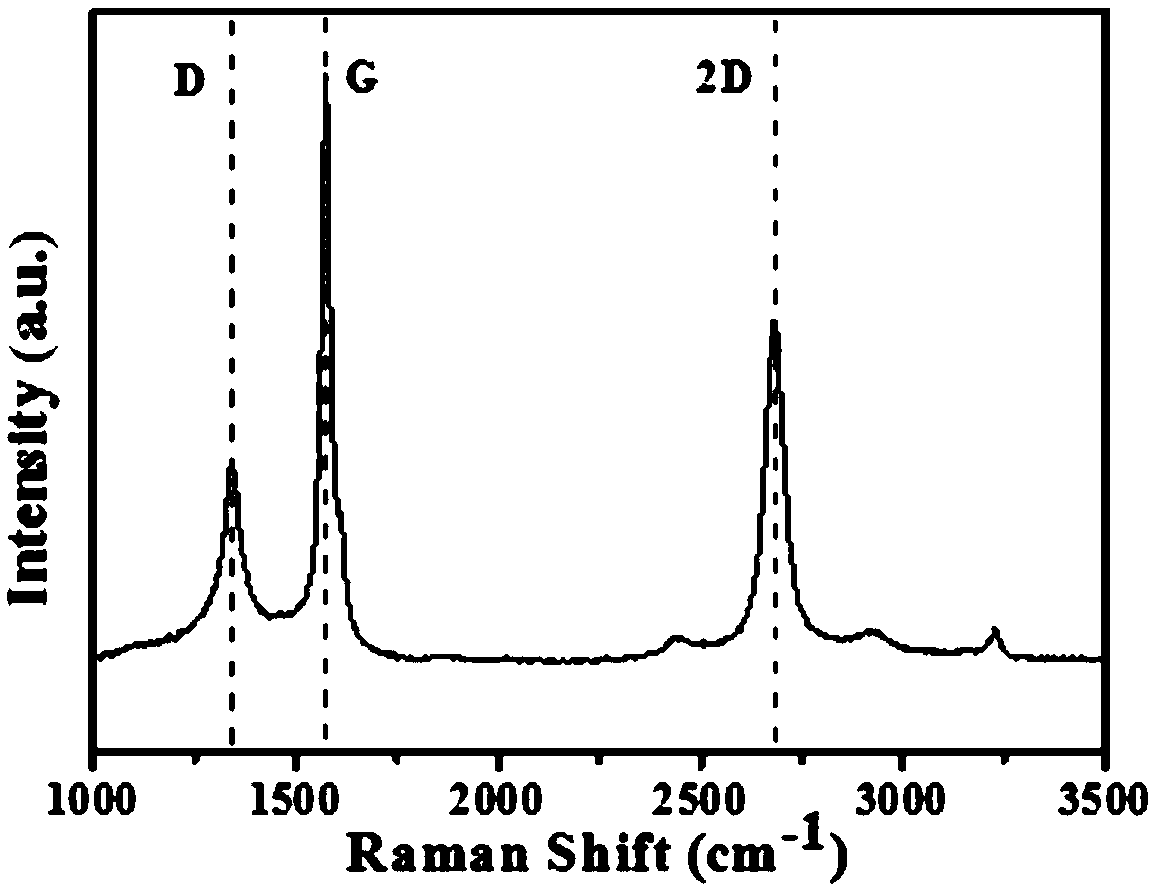

ActiveCN104201389ARich in nitrogenLarge specific surface areaCell electrodesCarbon fibersPorous carbon

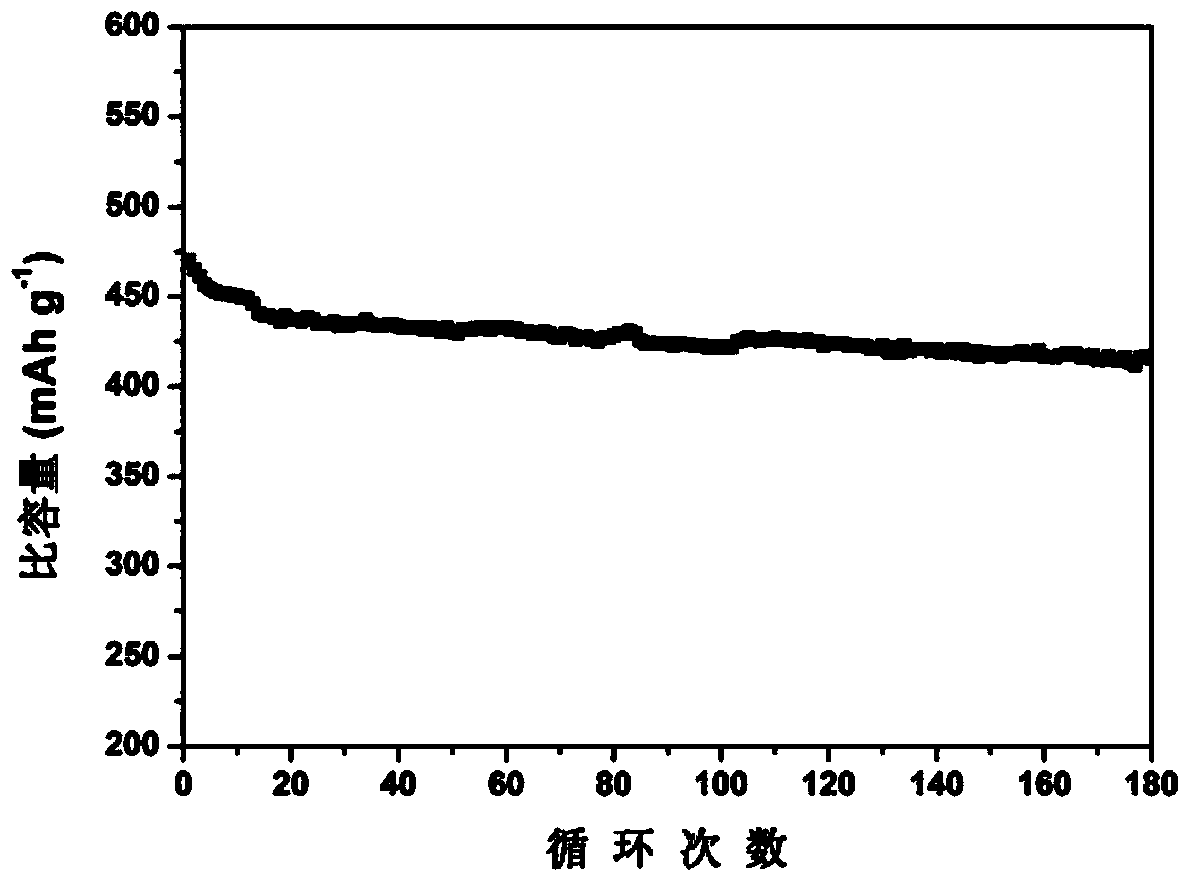

The invention discloses a preparation method of a lithium-selenium battery positive electrode. The preparation method of the lithium-selenium battery positive electrode comprises the following steps: depositing or growing a nitrogen-containing conductive polymer on the surface of a piece of paper, then carrying out alkaline activation and high-temperature carbonization to obtain a nitrogen-containing layered porous carbon compound current collector which takes a carbon fiber network structure as a self-supporting body, and further compounding the compound current collector with selenium to obtain the lithium-selenium battery positive electrode which is high in content of selenium, good in selenium fixation effect, high in mechanical performance and high in electrochemical performance. The preparation method of the lithium-selenium battery positive electrode is easy to operate, free from pollution and low in cost; the prepared lithium-selenium battery electrode is directly used for preparing a lithium-selenium battery with the high cycle performance and rate capability in the absence of an adhesive and a corresponding coating process.

Owner:CENT SOUTH UNIV

Multi-function composition for settable composite materials and methods of making the composition

InactiveUS20070131145A1Acceleration in and hardeningSmall particle sizeAlkali metal silicate coatingsInorganic adhesivesAlkaline activationSlurry

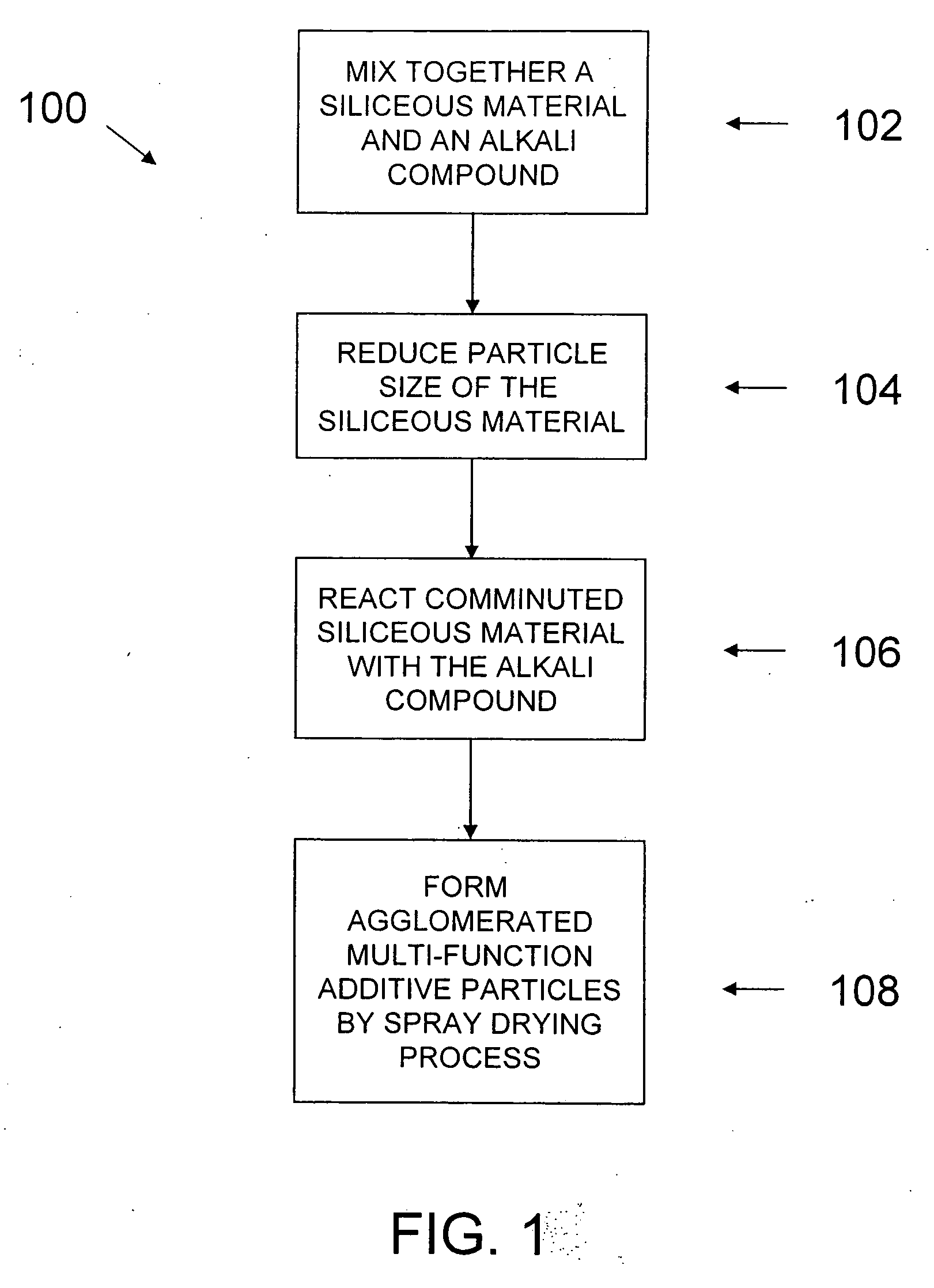

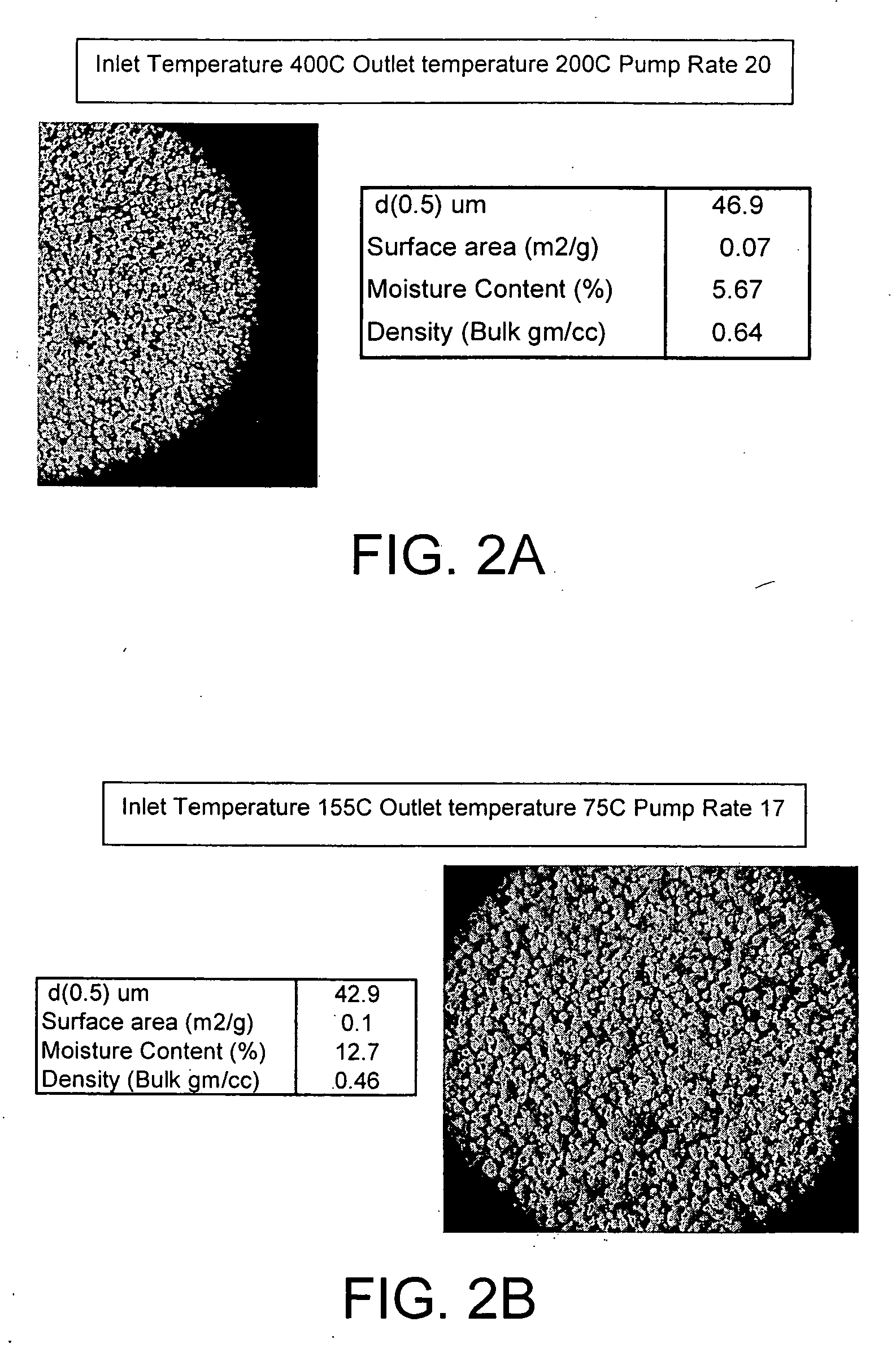

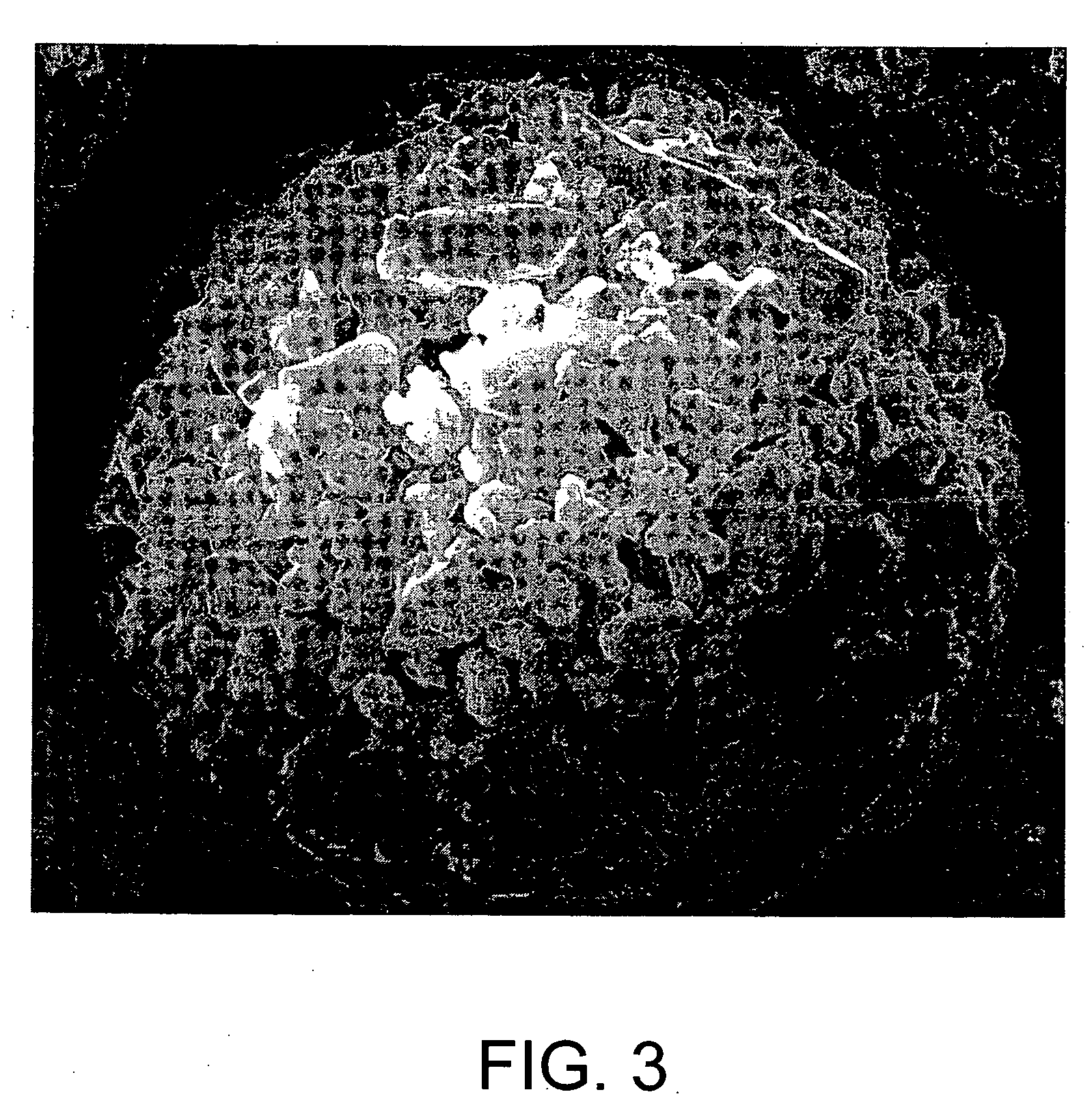

A multi-function composition for incorporation into settable composite materials is provided. The composition is formulated as an additive to modify the density of the composite material and increase the rate of hardening or strength development of the material. The composition of the additive generally includes an alkaline activation compound such as sodium silicate and a modified low density siliceous material having at least one region morphologically altered by a chemical, such as a partially digested region. The additive can be in slurry form, in powder form, or in an agglomerated particle form. The additive can be produced using a two-stage process in which a siliceous material is reduced in particle size, combined with an alkali compound in a solution and then digested in an atmospheric or pressurized vessel. In some implementations, the solution can be spray dried to form agglomerated particles containing the alkaline activation compound and the low density siliceous particle having one or more partially digested regions.

Owner:JAMES HARDIE INT FINANCE BV

Carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent and preparation method thereof

InactiveCN103801387ANo secondary pollutionMolecular sieve catalystsOther chemical processesStreet intersectionWater vapor

The invention discloses a carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent and a preparation method thereof. The preparation method is characterized in that carbon-containing materials such as lignite carbocoal, anthracitic coal and bituminous coal carbocoal take amorphous or formed particle carbocoal, tetrabutyl titanate, absolute ethyl alcohol and the like as photo-catalyst active raw materials; firstly, the amorphous or formed particle carbocoal supports a photo-catalyst TiO2, transition metal oxide and the like through methods of ultrasonic activation of hydrogen peroxide, acid activation, alkaline activation and the like, and subsequently, the amorphous or formed particle carbocoal is activated by water vapour at a high temperature of 500-700 DEG C and then mechanically mixed with ZSM-5 or other NO adsorption molecular sieves, thereby finally obtaining the photo-catalytic desulfurization and denitration agent. The carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent has the characteristics of extensive sources and low price of active carbocoal; after TiO2 is supported, the carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent has the effect of getting twice the result with half the effort during denitration; the ZSM-5 and other NO absorption molecule sieves can play the role of capturing NO; the prepared catalyst can be used for removing NOx in fuel gas of coal-fired power plants, coal-fired boilers, coal-fired kilns and the like through a low-temperature photo-catalytic oxidation method at a temperature which is less than or equal to 110 DEG C; the prepared catalyst also can be used for removing NOx in ventilated gases generated in road tunnels, underground parking garages, street intersections and the like.

Owner:OCEAN UNIV OF CHINA

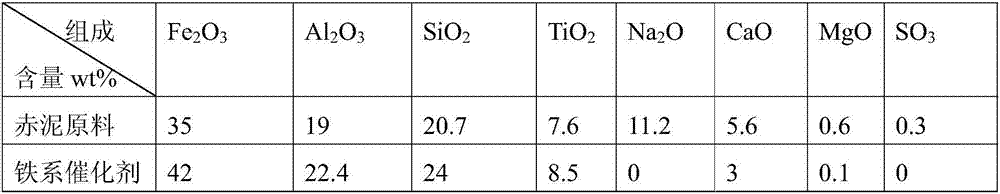

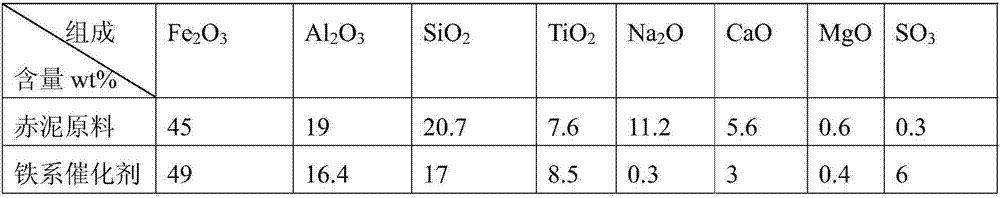

Preparation method for normal-temperature iron series hydrogen sulfide removal agent

The invention relates to a preparation method for a normal-temperature iron series hydrogen sulfide removal agent. The preparation method is characterized by including the steps of (1) alkaline activation of carrier clay and (2) homogeneous precipitation of load iron and copper. Compared with the prior art, the preparation method has the advantages that the method is high in controllability of preparation conditions and convenient to operate, the defect of poor reproducibility of grain products can be overcome, metal salt is converted completely, activity of the hydrogen sulfide removal agent is improved, and the hydrogen sulfide removal agent can be used for removal of hydrogen sulfide at the high air speed.

Owner:CHANGZHOU UNIV

Construction material based on activated fly ash

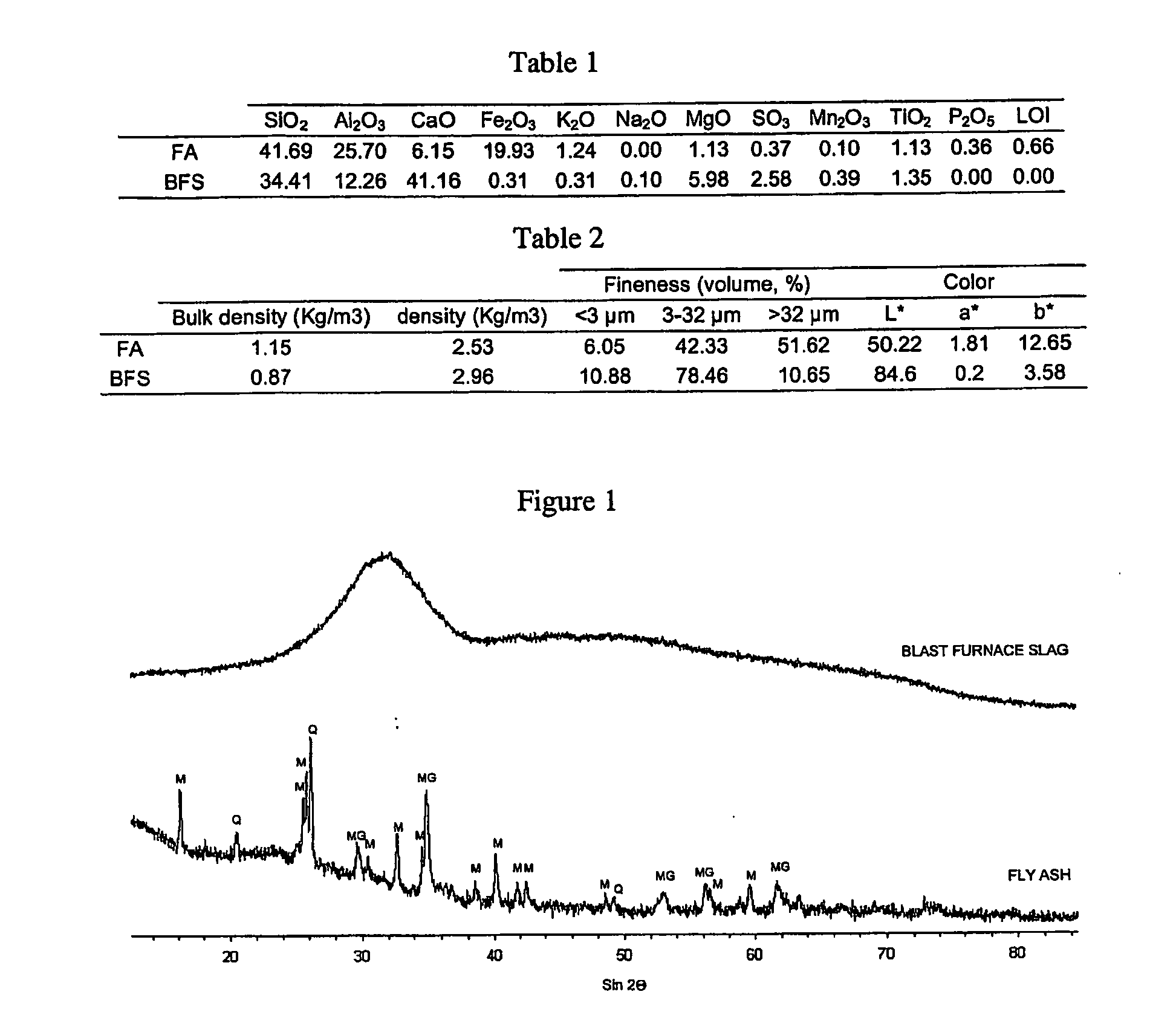

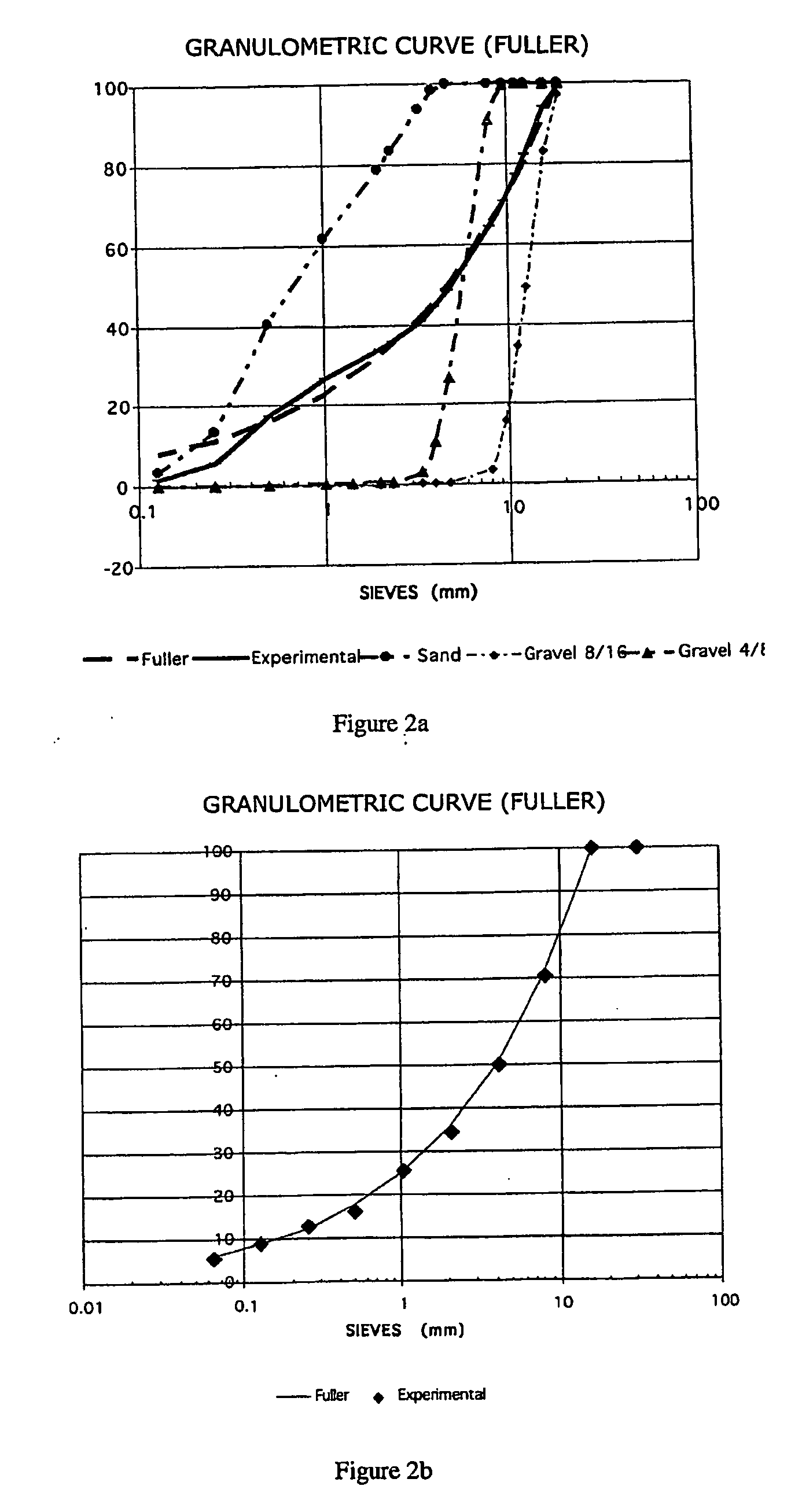

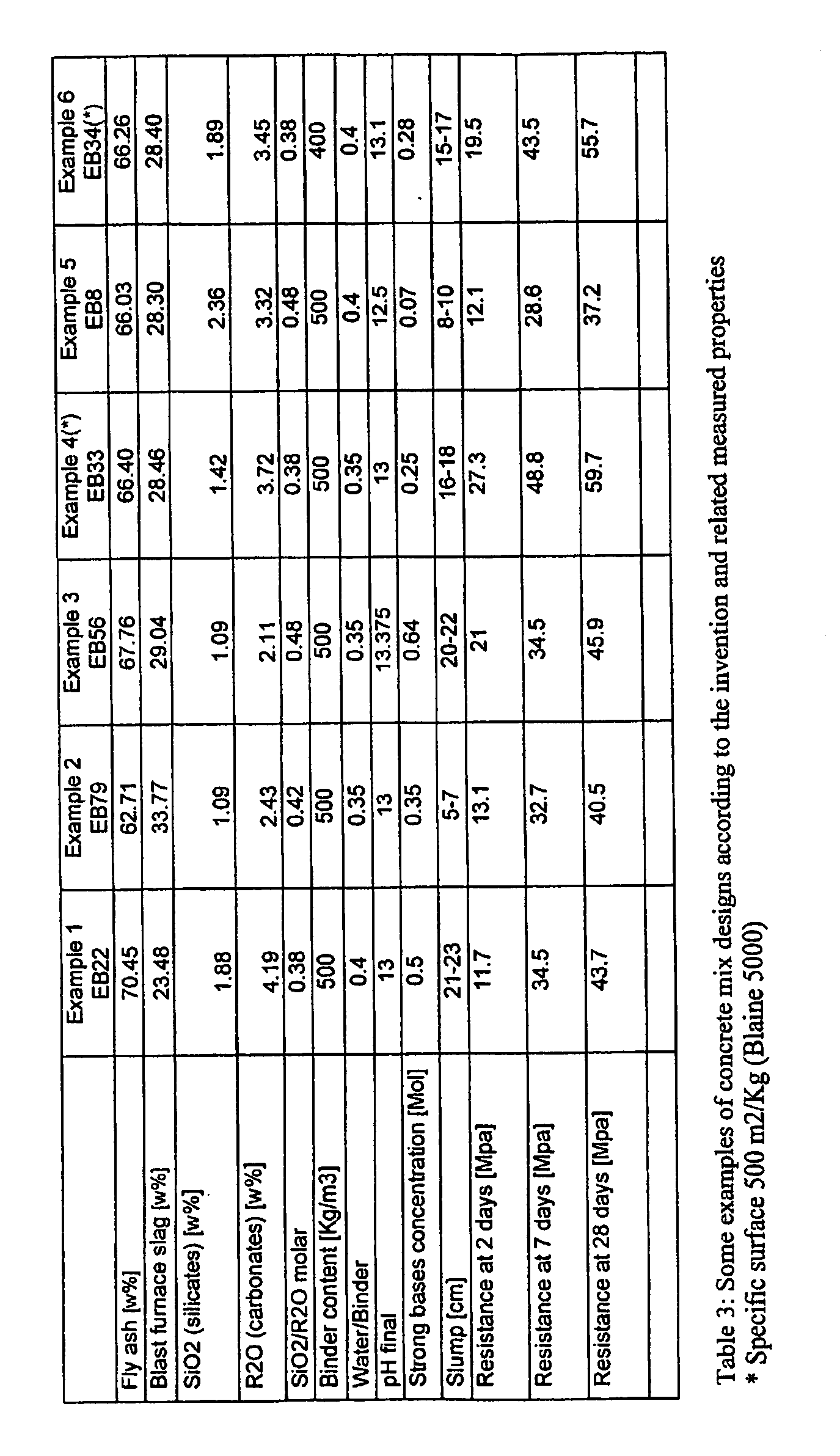

The disclosure concerns cost effective concrete formulations based on an alkali activated binder. The construction material of the concrete type, contains sand, fine aggregates, coarse aggregates, water and a binder comprising:from 55 to 80 wt. % of fly ash containing less than wt. 8% of CaO;from 15 to 40 wt. % of blast furnace slag;a chemical activator containing:from 0.8 to 4 wt. % of alkaline silicates; andfrom 1.5 to 9 wt. % of alkaline carbonates;wherein the chemical activator has an silica to alkali molar ratio from 0.1 to 0.55; anda booster comprising at least one strong base.The disclosure also concerns a method to produce such a concrete construction material.

Owner:CEMEX INNOVATION HLDG LTD

Method for manufacturing binder-less environment-friendly artificial boards from steam-exploded stalks

InactiveCN103358377AImprove wettabilityAchieve glue-free gluingPressure impregnationAlkaline activationEngineering

The invention belongs to the field of manufacture for binder-less environment-friendly artificial boards, and particularly relates to a method for manufacturing binder-less environment-friendly artificial boards. The method is used for manufacturing the binder-less environment-friendly artificial boards from steam-exploded stalk raw materials by means of alkaline activation hot-pressing. The method includes steps of chopping stalk raw materials and performing steam explosion on the chopped stalk raw materials to obtain steam-exploded stalks; adding aqueous alkali into the steam-exploded stalks; uniformly mixing the aqueous alkali with the steam-exploded stalks; controlling the moisture content of a mixture of the aqueous alkali and the steam-exploded stalks; performing hot-pressing and forming on the mixture. The method has the advantages that the wettability of the stalk raw materials can be improved by means of processing the stalks by a steam explosion technology, cell wall structures are destroyed, lignin in the raw materials is easy to dissolve out under an alkaline condition, dissolved lignin and the lignin and polysaccharide in the raw materials are subjected to condensation reaction under a high-temperature condition of a hot-pressing procedure to realize a binding effect, accordingly, the stalk raw materials are bound with one another without binders by the method, the binder adding cost is saved, a process and a production line are simplified, environmental pollution due to synthetic resin binders is reduced advantageously, the production cost is lowered, and a novel and effective way for manufacturing the artificial boards is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing artificial ecological aggregate by using inland sludge and near-shore high-sand mud

The invention provides a method for preparing artificial ecological aggregate by using inland sludge and near-shore high-sand mud. The method comprises the following steps: filtering sludge and high-sand mud to remove large particles with particle diameter being greater than 2 millimeters; naturally withering the filtered sludge and high-sand mud; uniformly mixing the sludge, the high-sand mud, cement, coal ash, quicklime, steel slag, silicon ash, an activator, an early strength agent and water; pelletizing the mixture into balls in a pelletizer; naturally curing finished balls, spraying water for curing, spraying a waterproof coating or an alkaline activation curing agent, and curing naturally. The ecological aggregate which can be applied to planting concrete is mainly prepared from sludge and near-shore high-sand mud, so that natural gravels and cobbles in planting cement are replaced completely or partially, sludge is treated effectively, and environmental problems caused by sludge are solved. Moreover, sludge is turned into a usable resource to be utilized effectively, so that the method has good economical value and social value.

Owner:HOHAI UNIV

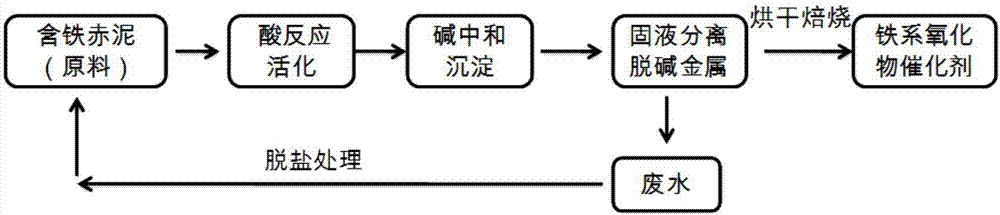

Method directly using acid and alkaline activation of red mud to prepare iron type denitrifying catalyst

InactiveCN107537492ALow costAchieving dealkalizationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline activationRed mud

The invention provides a method directly using acid and alkaline activation of red mud to prepare an iron type denitrifying catalyst. The method comprises the following steps of (1) adding acid into the red mud, and reacting at the temperature of 70 to 200 DEG C, so as to obtain first slurry, namely acid slurry; (2) adding alkaline matter into the first slurry in step (1), and adjusting the pH (potential of hydrogen) value to 5 to 10, so as to obtain second slurry; (3) separating solid and liquid of the second slurry in step (2), so as to obtain filter cake; roasting the filter cake, so as toobtain an iron, titanium, silicon and aluminum oxide catalyst with denitrifying activity. The method has the advantages that the waste of red mud can be treated in a harmless way, and the waste is changed into the valuable; when the waste of the red mud is directly applied to the denitrifying process of flue gas, the existing denitrifying cost is greatly reduced, and the wide industrial application prospect is realized; the obtained iron, titanium, silicon and aluminum oxide catalyst can be applied into the denitrifying process of the flue gas of fired coal, and be used for replacing the existing vanadium, tungsten and titanium denitrifying catalyst.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Preparation of natural nutshell carbon material and application of natural nutshell carbon material in electrochemical capacitors

InactiveCN104064369AConvenient sourceTo achieve the purpose of turning waste into treasureHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceTetrafluoroborate

The invention discloses a preparation of a natural nutshell carbon material and an application of the natural nutshell carbon material in electrochemical capacitors. The preparation of the natural nutshell carbon material refers to performing carbonization-alkali activation on a natural nutshell at high temperature to obtain a porous nano nutshell carbon material. In an alkali aqueous solution electrolyte, the specific capacitances of double electric layers respectively reach 312Fg<-1> and 224Fg<-1> under the potential scan rates of 2mV / s and 500mV / s. When organic electrolyte uses 1M tetraethylammonium tetrafluoroborate as an electrolyte, the capacitances respectively reach 209Fg<-1> and 50Fg<-1> under the potential scan rates of 10mVs(-1) and 500mVs(-1). Under a high scanning rate, the specific capacitance is relatively stable, which suggests that the natural nutshell carbon material has very broad application prospects as a high-power super capacitor active material. Moreover, as the material is natural biological material pistachio nut shell, the range of sources is wide, and the price is low. In addition, the electrode material preparation process is simple and controllable, the condition is mild, the equipment is simple, and the preparation process has practical production values.

Owner:BEIHANG UNIV

Composition for metakaolin construction material, related method for manufacturing said composition, and use for producing construction elements

Disclosed is a construction material composition including a matrix predominantly containing an aluminum silicate compound, such as a metakaolin, and an alkaline activation solution. The composition is contains less than 10 wt. % cement or clinker and in that the metakaolin is a metakaolin obtained via flash calcination. The reaction between the components is carried out at a temperature less than 30° C. The method for manufacturing the construction material includes mixing the composition with various elements such as granulates, plant fibers, unfired clay, and expanding agents. It is particularly of use in producing floor, wall, or roof coating elements, prefabricated construction elements, or insulation, adhesive, or inorganic sealant modules.

Owner:HOFFMANN JB TECH

Method of removing chlorohydrocarbon in underground water by using alkaline slow-release persulfate oxidizing agent

InactiveCN103787485AImprove transmission efficiencyOvercome adverse effects of low permeabilityWater/sewage treatment by oxidationIn situ remediationPersulfate

The invention relates to a method of removing chlorohydrocarbon in underground water by using an alkaline slow-release persulfate oxidizing agent. The alkaline slow-release persulfate oxidizing agent is prepared by mixing persulfate, sodium hydroxide, cement, sand and water according to a certain proportion; when the obtained oxidizing agent is contacted with polluted underground water, the persulfate is slowly released for a long time, the pH value of the solution can be improved, the acidification effect of the persulfate reaction process is overcome, chlorohydrocarbon pollutants are effectively degraded through a mode of alkaline activation persulfate. The method has the advantages that the provided alkaline slow-release persulfate oxidizing agent can be used for slowly releasing the persulfate for a long time, the transmission capability and use efficiency of the oxidizing agent are improved, the chlorohydrocarbon pollution underground water is remedied through the mode of alkaline activation persulfate, and the method is applicable for in-situ remediation.

Owner:EAST CHINA UNIV OF SCI & TECH

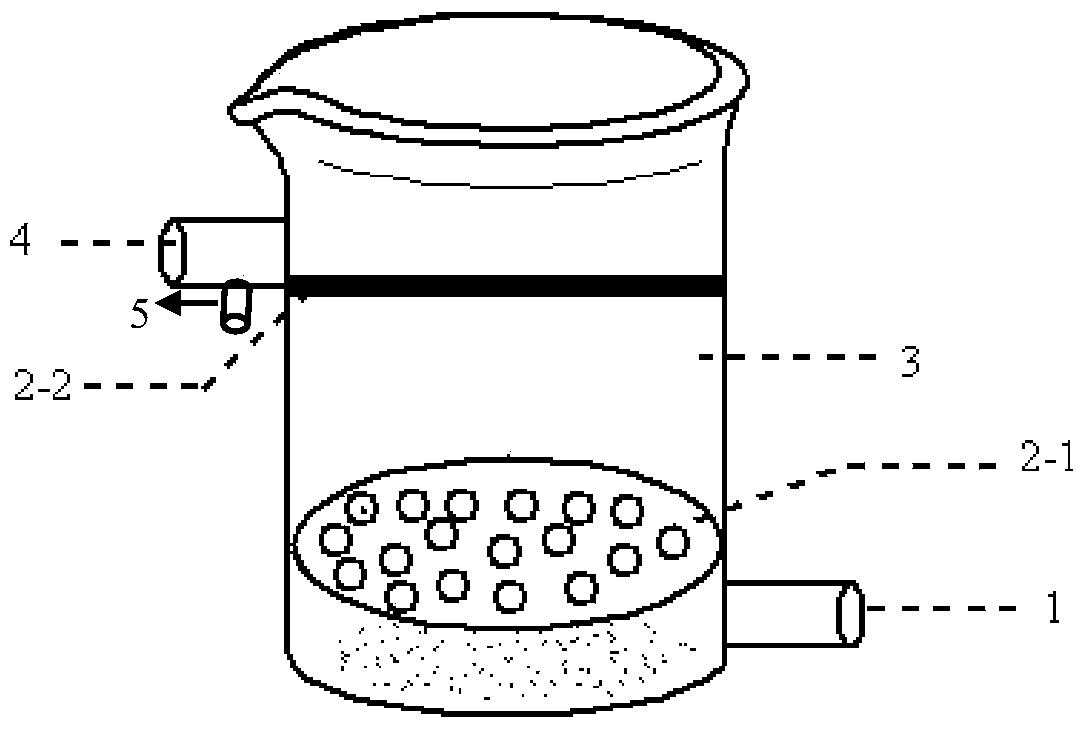

Special apparatus for removing heavy metal ions in wastewater, and method thereof

ActiveCN103523969ATo achieve the purpose of separation and recoveryImprove adsorption capacityOther chemical processesWater contaminantsIndustrial effluentIron powder

The invention discloses a special apparatus for removing heavy metal ions in wastewater, and a method thereof. The method comprises the following steps: filling pyrophillite-reduced iron powder mixed powder into a first wastewater treatment device in order to realize preliminary treatment of heavy metals; filling silane coupling agent modified pyrophillite into a second wastewater treatment device in order to adsorb heavy metal ions not subject to the preliminary treatment and iron ions generated in the first wastewater treatment device; filling a magnetite filler into a third wastewater treatment in order to remove the iron ions generated in the first wastewater treatment device and pyrophillite or modified pyrophillite powder mixed in water; and carrying out an electrochemical process to recover the heavy metals. The treatment effect of the heavy metal ions in industrial wastewater can reach above 98% in the invention. Adsorption-saturated pyrophillite and modified pyrophillite are cleaned by an acidic solution in order to desorb above 70% of the heavy metal ions, and cleaned pyrophillite and cleaned modified pyrophillite are subject to alkaline activation for recycle, so the purposes of energy saving, emission reduction and full resource utilization are realized.

Owner:ZHEJIANG UNIV OF TECH

Environment-friendly geopolymer-based foaming material

InactiveCN102910936ARealize high value utilizationSimple processCement productionCeramicwareEnvironmental resistanceSingle substance

The invention discloses an environment-friendly geopolymer-based foaming material. According to the invention, a low-density high-strength geopolymer-based foaming material is prepared by adding sodium hydroxide or potassium hydroxide in coal ash of which the main components are alumina and silicon oxide, carrying out alkaline activation on the coal ash so that geopolymerization is generated and single substance Al has chemical reaction under the alkaline condition to generate gas to foam in slurry. The high-value utilization of the coal ash is realized under the condition that solid waste pollution and air pollution are lowered, thereby reaching the purposes of energy conservation, emission reduction, environment protection. The geopolymer-based foaming material meets the requirements of first-grade heat preservation boards, and is simple in process and free from high-temperature sintering.

Owner:TIANJIN UNIV

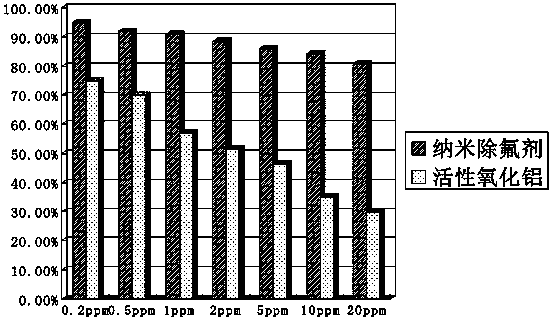

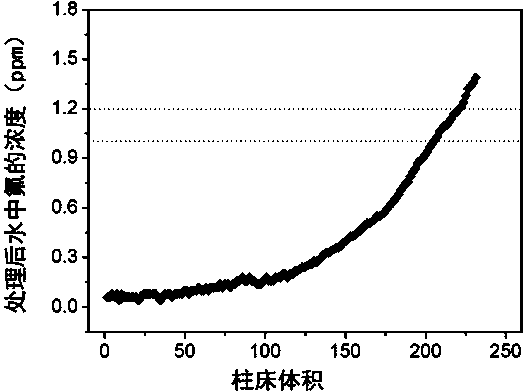

Preparation method of natural mineral-loaded nanometer fluorine removal agent

ActiveCN103706326AEffectively fixedAvoid churnOther chemical processesAluminium silicatesAlkaline activationSurface water

The invention discloses a preparation method of a natural mineral-loaded nanometer fluorine removal agent. The method comprises high-temperature activation treatment, acid activation treatment, alkali activation treatment and a metal salt reaction. Natural zeolite is high in mechanical strength and is full of fine holes and channels inside, and nanometer materials can be effectively fixed in the internal channels of the natural zeolite under a water flow condition when the natural zeolite is taken as a carrier of a nanometer fluorine removal material, so that the agglomeration and loss of the nanometer materials are avoided, and the fluorine adsorption capacity is increased. Moreover, the natural zeolite is reproducible, so that the fluorine removal cost is reduced. The fluorine removal agent with larger specific surface area can provide more active sites for realizing a high fluorine adsorption volume, and can be widely applied to the aspects of purification treatment of high-fluorine surface water and underground water, treatment of fluorine-containing sewage, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Process for preparing high adsorbing active carbon by using petroleum coke as raw material

A method for preparing activated carbon with high adsorption activity by using petroleum coke as a raw material comprises the following steps: pulverizing the petroleum coke raw material into 81-150 mesh powder, and degassing in a 220-350 DEG C vacuum dryer to obtain a product A with a certain initial pore space; preparing an alkaline medium solution with a molar concentration of 0.2-0.5N, adding the product A into the alkaline medium solution, adding a cosolvent, mixing uniformly, and allowing carbonization and alkaline activation treatment at 700-800 DEG C under inert gas atmosphere for 1-3 hours to obtain a product B; and cooling the product B, washing and drying to obtain the final product. The inventive method has the following advantages that: the activated carbon prepared by using the method has rich micro-pores and has BET specific surface area of 2,500-3,000m<2> / g; the petroleum coke has a certain initial pore space and can mix and sufficiently contact with the alkaline medium solution, so as to reduce the consumption of the alkaline medium, reduce cost, reduce pollution, and unify reaction; and the activation rate and the yield are high, and the product quality is stable.

Owner:林建屏

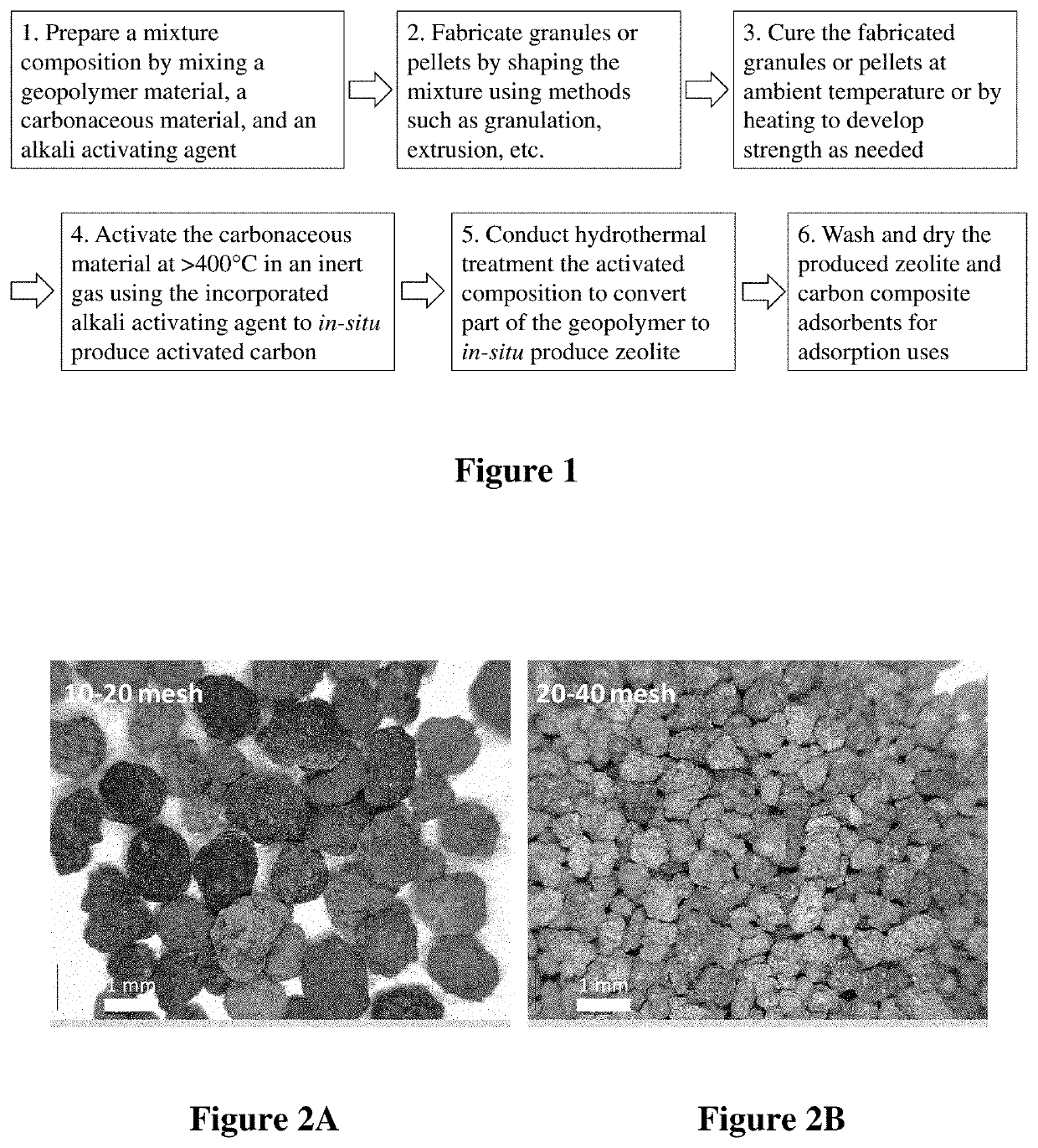

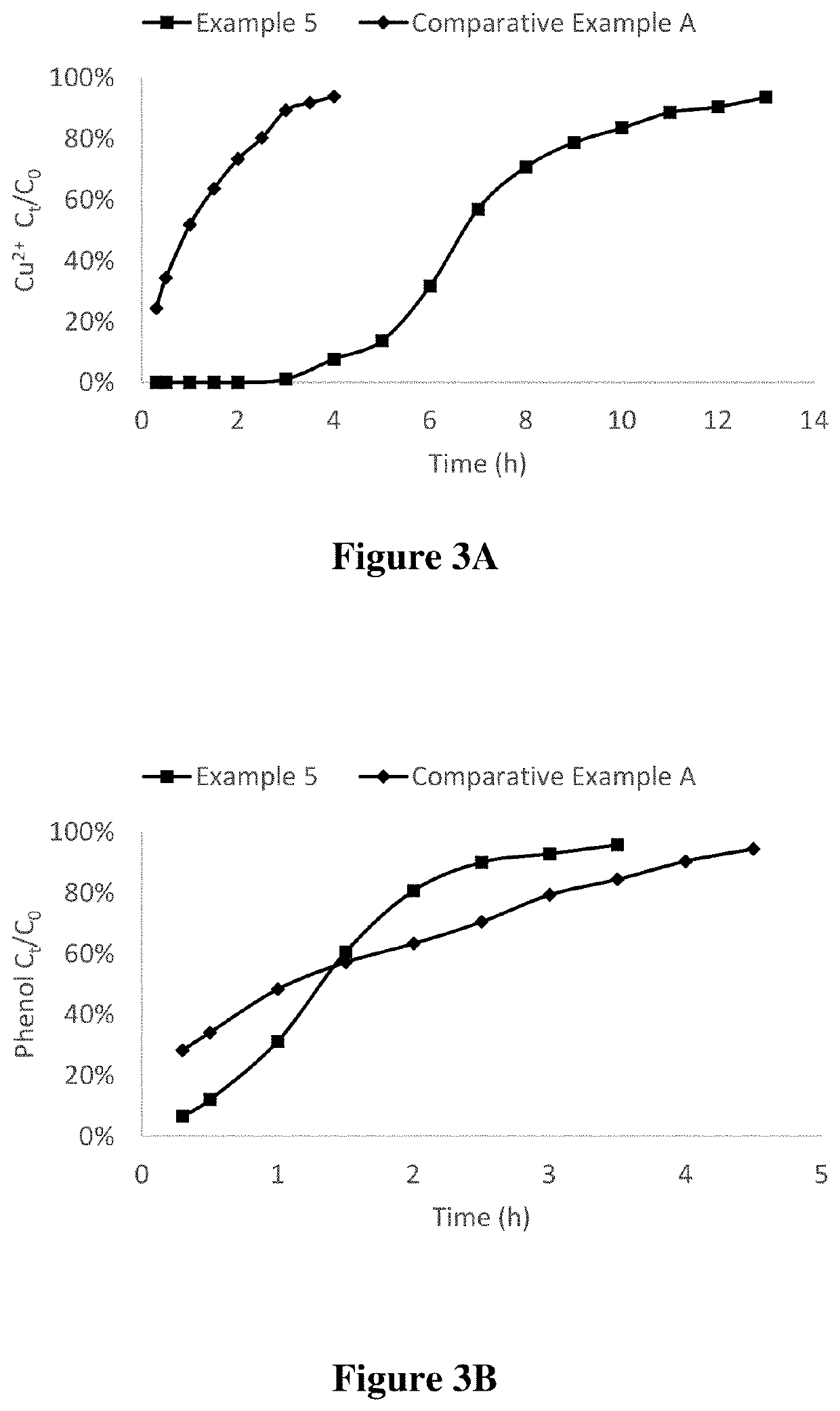

Composite adsorbents and method of making them

ActiveUS20200276556A1Efficient removalVersatile and effective adsorptionOther chemical processesWater/sewage treatmentActivated carbonAlkaline activation

A composition for making composite adsorbents from a mixture of geopolymer, zeolite and activated carbon wherein a geopolymer material, a carbonaceous material, and an alkali activating agent are the components of the mixture. The alkali activating agent to carbonaceous material solid mass ratio is at least 0.25:1, respectively. A process for producing shaped composite adsorbents from the composition is done using conventional means such as mixing, shaping, extrusion and other methods. Alkali activation is used to convert the carbonaceous material to activated carbon, followed by hydrothermal treatment to convert the geopolymer material to zeolites. Shaped composite adsorbents fabricated from the composition of the instant invention are used for adsorption, purification, or other separation applications of liquids and gases.

Owner:NOVOREACH TECH LLC

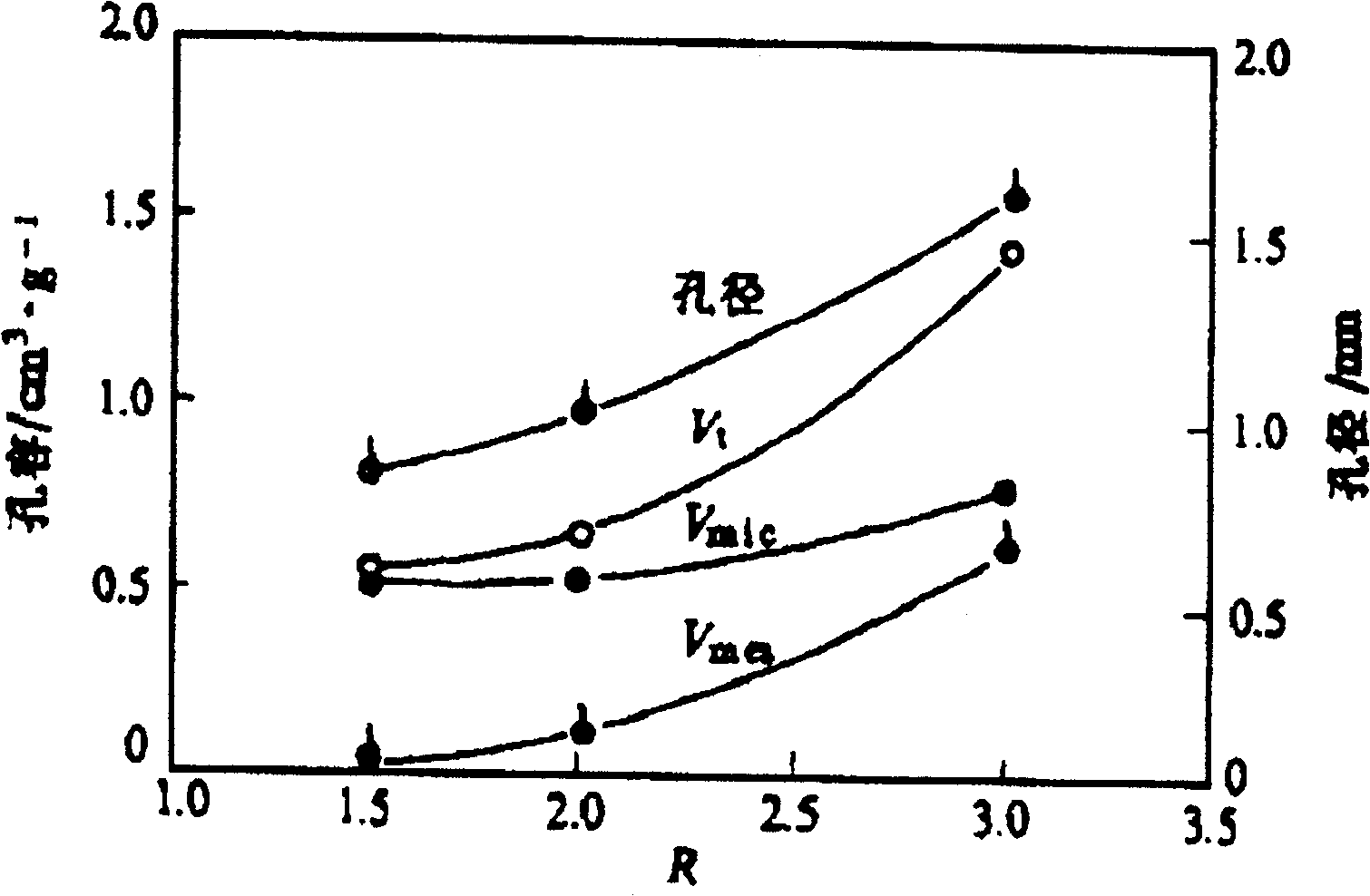

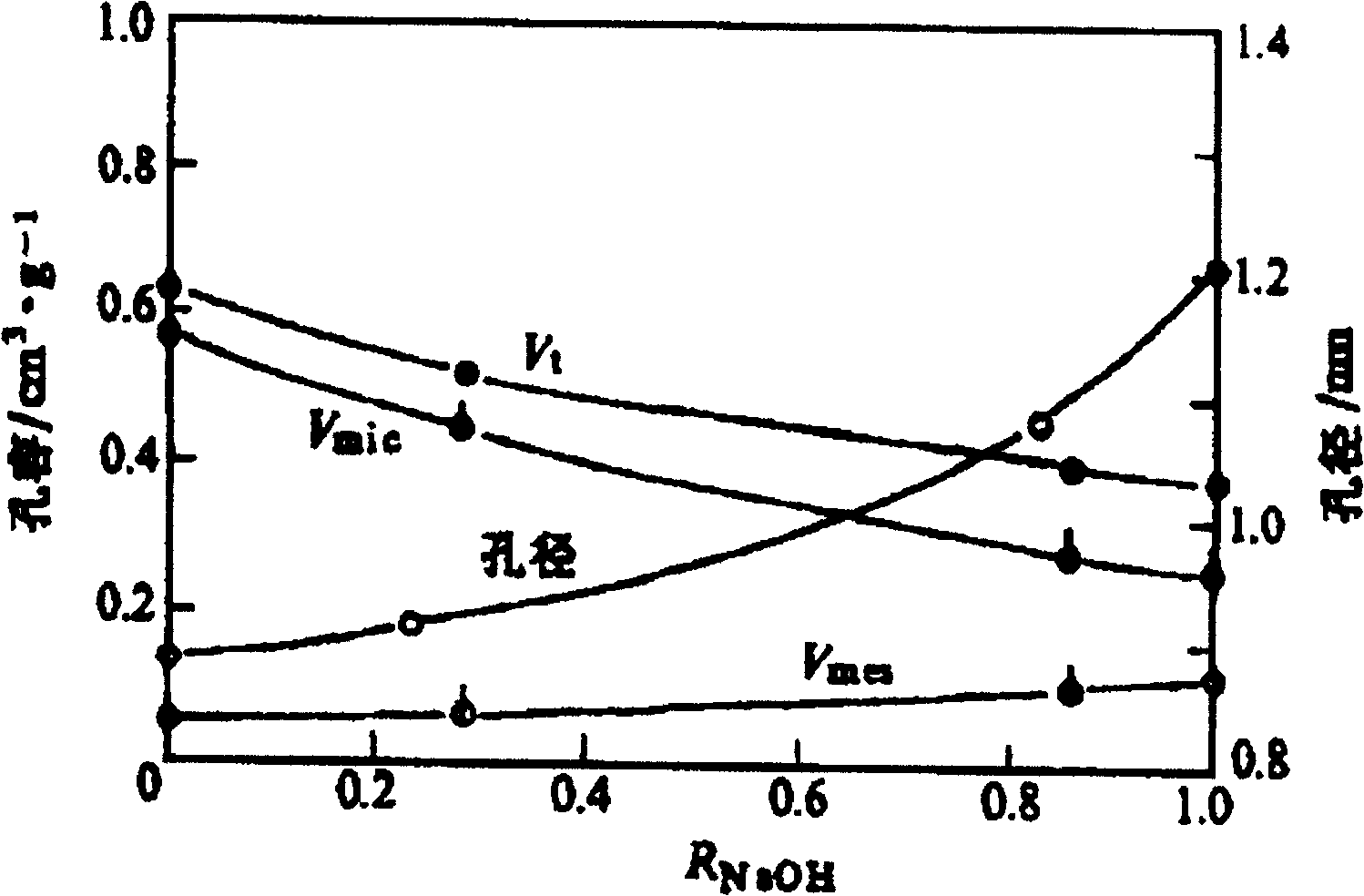

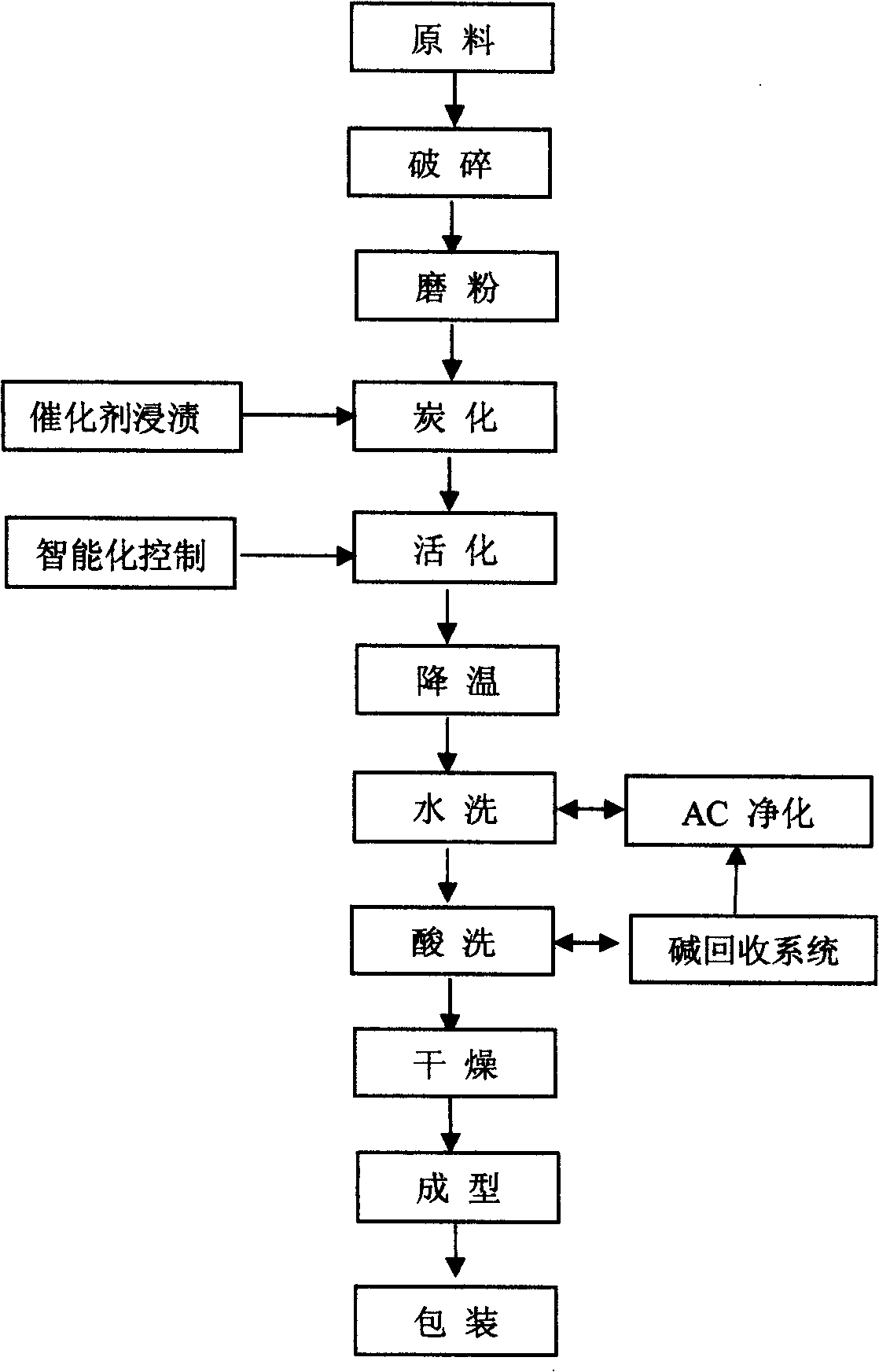

Preparation technique of carbon-based material having energy-storage property

InactiveCN101249956ALarge specific surface areaCarbon compoundsOther chemical processesBiological activationPetroleum

A process for preparing carbon material with the property of energy storage is a method of high-temperature strong base activation, which takes petroleum pitch coke as raw material and is composed of processes of crushing and grinding, screening, charring, catalyzing and activating, washing, drying and alkali recovery. The energy storage carbon material can be mass-produced and has specific surface area of 2500-4000m2g, iodine sorption value 2500-3500mg / g, methylene blue value of 600-1200mg / g, ash less than 1%, nano microporous aperture of 0.75-1.5mm and micro volume rate larger than 90-95%. The process particularly meets the absorption and storage requirements, thereby facilitating the wide and safe application of natural gas.

Owner:盐城市炭化工业有限公司

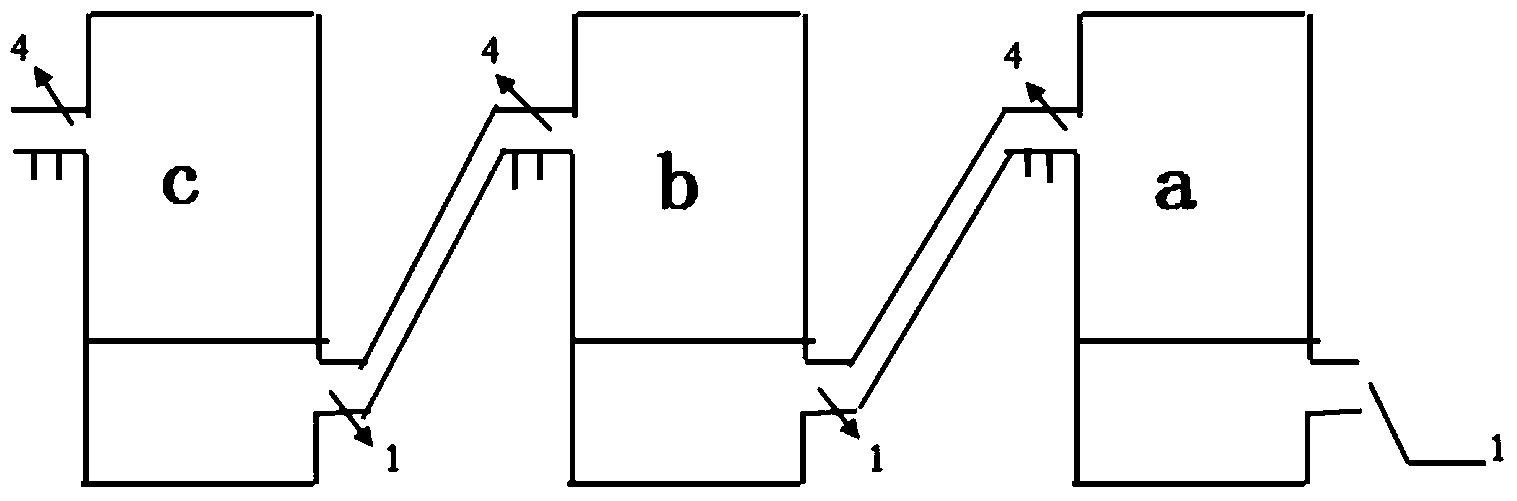

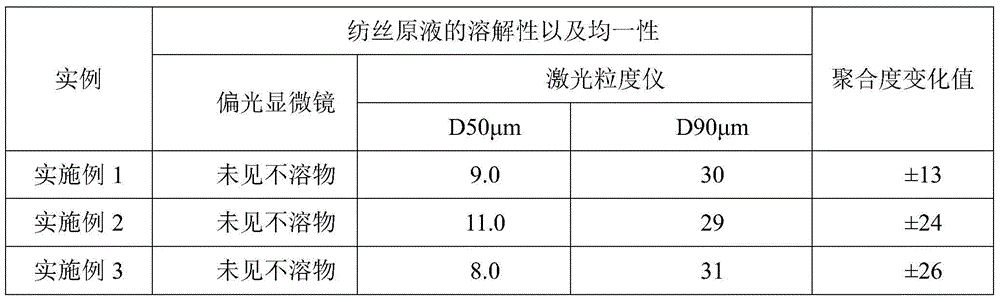

Activating method of cellulose pulp

ActiveCN106283242AIncrease profitReduce manufacturing costArtificial filaments from viscoseFibre treatment to obtain bast fibrePretreatment methodChemical reaction

The invention relates to a preparation method of solvent-spun cellulose fiber (Lyocell), and more specifically relates to an activating method of cellulose pulp. The activating method comprises following three cellulose pretreatment methods: a, acid activation; b, alkaline activation; and c, water activation. The activating method comprises following steps: firstly, an activating reagent is delivered into a pulper for acid activation, alkaline activation, and water activation of cellulose, wherein the activating reagent is selected from water, water containing an acid, or water containing an alkaline, and the temperature of the activating reagent is controlled to be 25 to 60 DEG C; an obtained pulp is delivered into the pulper for 15 to 60min of pulping activating, and then is subjected to pressing and smashing so as to obtain a pretreated pulp, wherein the cellulose content of the pretreated pulp ranges from 45 to 80%. According to the activating method, a trace acid is used for activating cellulose, only physical swelling of cellulose crystalline regions is caused, and no chemical reaction is carried out, so that raw material utilization ratio is increased, and production cost is reduced.

Owner:CHINESE TEXTILE ACAD

Method for making alkali activated carbon

ActiveUS20130078179A1Quantity minimizationImprove securityPigmenting treatmentCarbon compoundsActivated carbonWater vapor

A method for activating carbon via alkali activation processes includes the introduction of water vapor during the activation phase to control the formation of highly reactive by-products. The method includes heating the mixture of a carbon-containing first material and a alkali-containing second material, introducing water vapor at a first threshold temperature and stopping water vapor introduction at a second threshold temperature. The activated carbon material is suitable for carbon-based electrodes and for use in high energy density devices.

Owner:CORNING INC

Preparation method for load type iron-based sulfureted hydrogen removal agent under room temperature

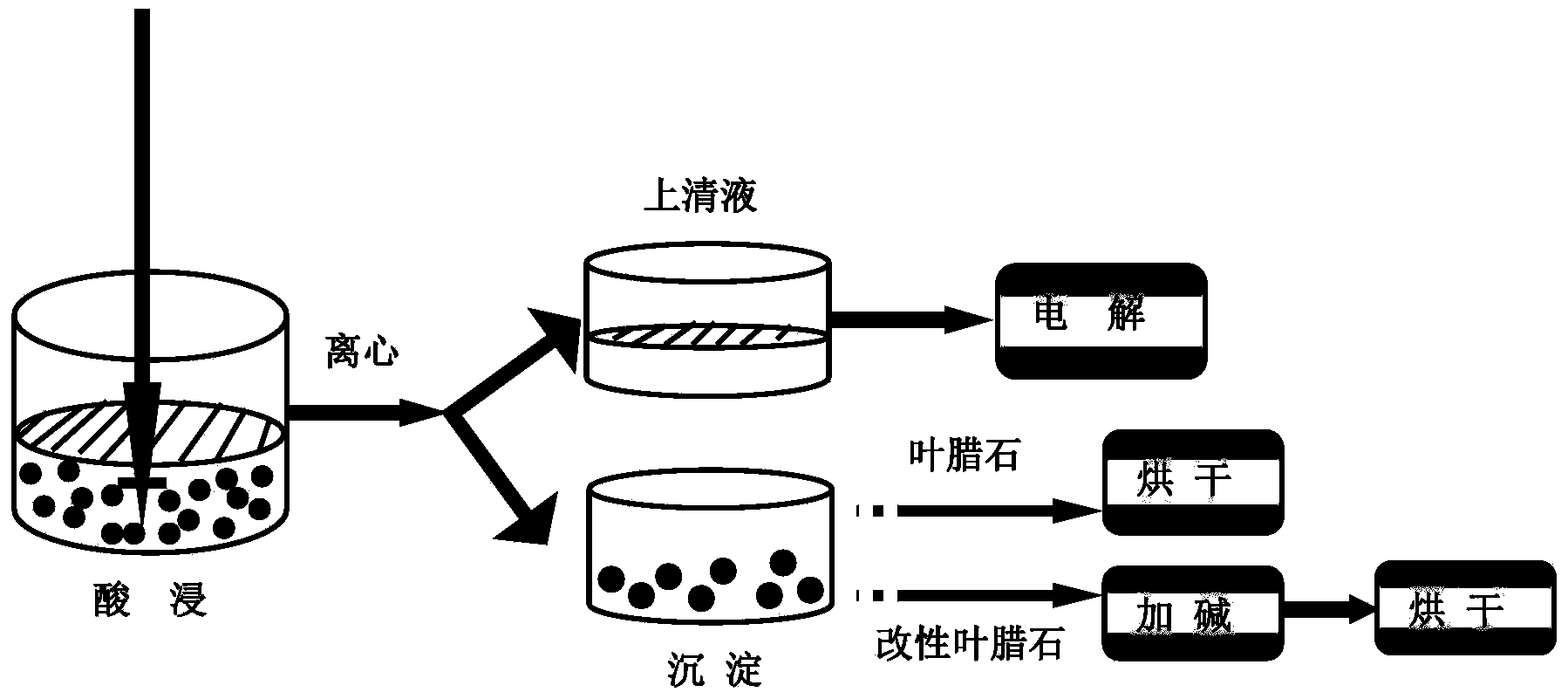

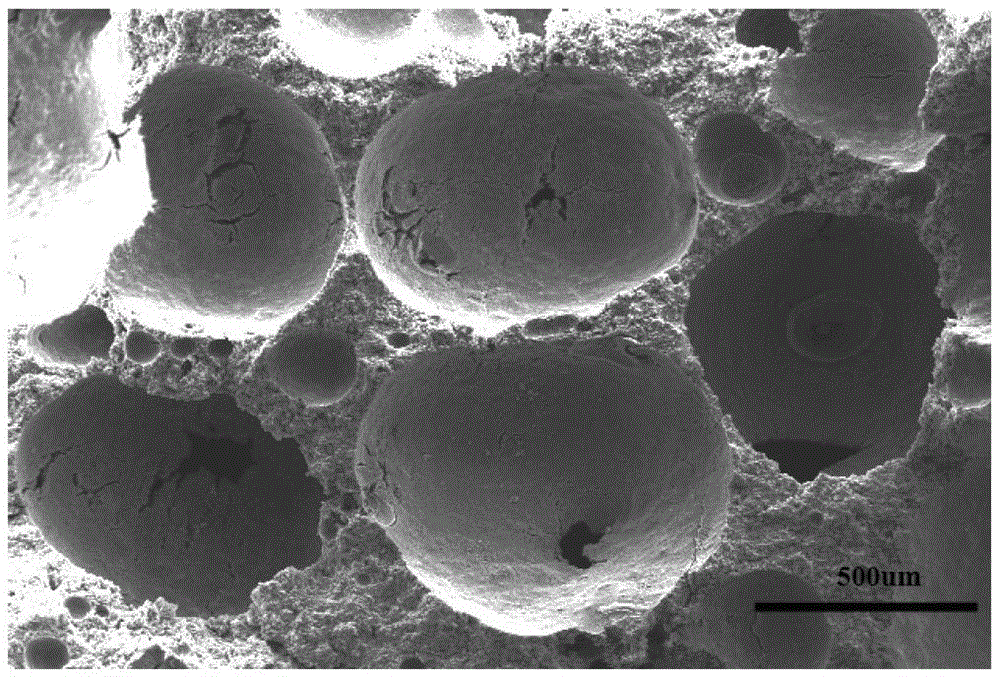

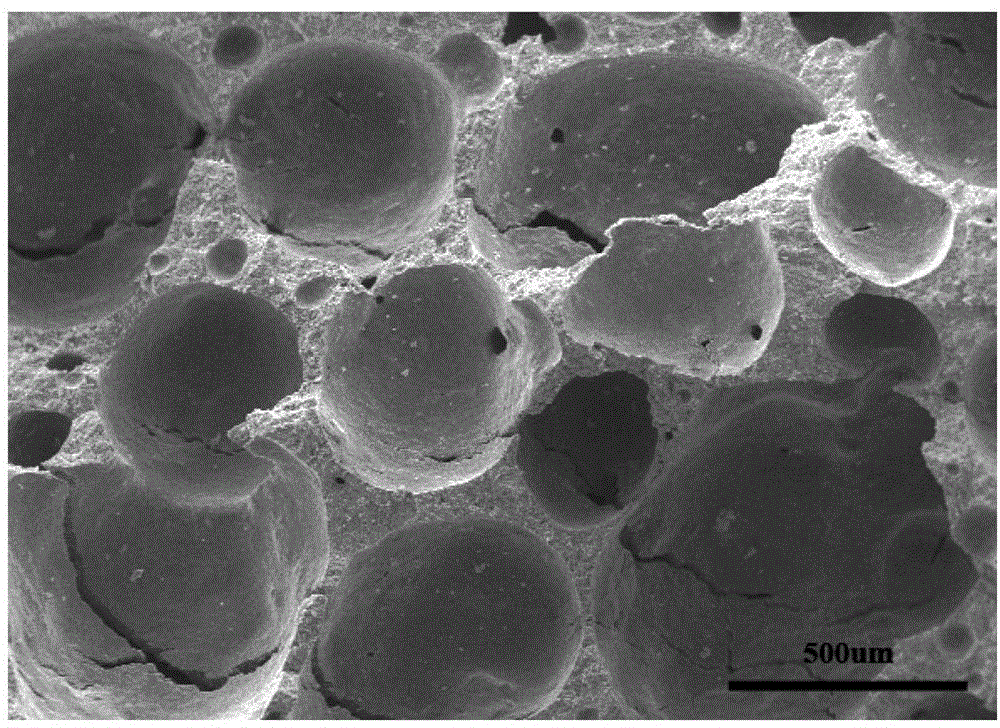

ActiveCN102489150AGood dispersionHigh activityOther chemical processesDispersed particle separationAlkaline activationFixed bed

The invention discloses a preparation method for a load type iron-based sulfureted hydrogen removal agent under room temperature. The preparation method comprises first preparing alkali activation carrier clay, preparing slurry by utilizing the clay and water, adding NaOH to adjust the potential hydrogen (pH) value of solution, then performing dipping and activation to obtain the clay by means of centrifugal separation, cleaning the clay with distilled water and obtaining centrifugal objects by means of the centrifugal separation, and drying the centrifugal objects to obtain the alkali activation carrier clay; then depositing iron by means of homogeneous precipitation, adding the alkali activation carrier clay into molysite solution, adding urea and stirring the solution, reflowing the solution, controlling reaction temperature and reaction time, then obtaining a product by means of the centrifugal separation, cleaning the product till the product has no counter ion, then drying the product, burning the product to obtain an iron-based carrier object; and finally performing sulfuration and activation, placing the iron-based load object into a fixed bed reactor of a bed layer, and feeding mixed gas under the room temperature to obtain a final sulfureted hydrogen removal agent. The preparation method for the load type iron-based sulfureted hydrogen removal agent under the room temperature effectively controls load quantity and improves conversion rate of metal salt and utilization efficiency of urea; active maters are dispersed well in a carrier, and the preparation method can improve mass transfer rate and has a good function of sulfureted hydrogen removal under the room temperature.

Owner:CHANGZHOU UNIV

Tail gas continuous processing device utilizing alkaline activation to prepare activated carbon and tail gas continuous processing method thereof

InactiveCN103599681AAvoid security issuesEliminate potential safety hazardsCarbon compoundsDispersed particle separationActivated carbonAlkaline activation

The invention provides a tail gas continuous processing device utilizing alkaline activation to prepare activated carbon. The tail gas continuous processing device comprises a heating exhaust pipe, an oxidizing tower and a recycling chamber, wherein an air outlet of the heating exhaust pipe is connected to the upper part of the oxidizing tower; the top of the oxidizing tower is provided with a ventilation opening, the bottom of the oxidizing tower is provided with an inclined plane structure and is provided with an outlet which is connected with the recycling chamber, the recycling chamber is provided with a spraying device and an exhaust fan, and the upper part of the recycling chamber is provided with a discharge outlet. The invention also provides a tail gas continuous processing method for utilizing alkaline activation to prepare the activated carbon. The airflow direction of the tail gas can enter from the upper part of the oxidizing tower and can downward move so as to discharge the oxidizing tower from the lower part of the oxidizing tower, and the tail gas enters from the lower part of the recycling chamber and can discharge from the upper part of the recycling chamber. The tail gas continuous processing device and the tail gas continuous processing method provided by the invention have the advantages that the exhaust gas generated through preparation of activated carbon by using the continuous processing alkaline activation and can fully solve the safe problem of an alkali metal, the industrialization continuous production of the high specific-surface-area activated carbon prepared through alkaline activation becomes the possibility, harmful organic matter constituents in the activated gas can be burned to remove and absorbed through spraying in a processing process, and the alkali metal after processing is recycled.

Owner:浙江阿佩克斯能源科技有限公司

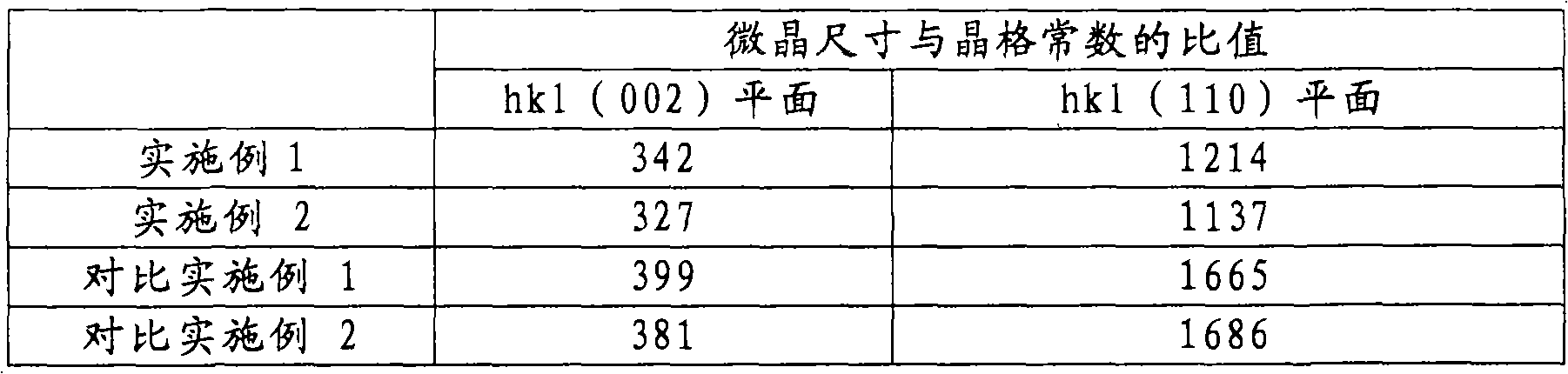

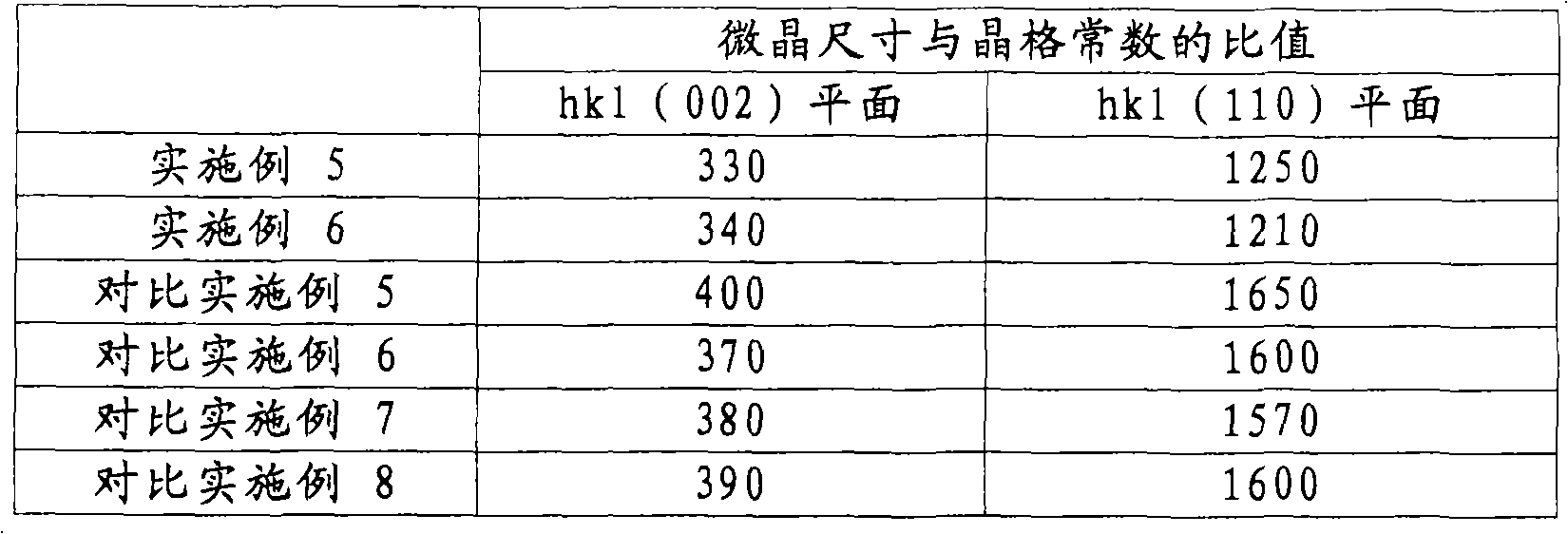

Raw coal for making carbonaceous material for electricity storage or needle coke

ActiveCN101346307AHigh industrial valueSmall coefficient of thermal expansionElectrolytic capacitorsSpecial form destructive distillationElectricityActivated carbon

A raw coal having such a structure that the product obtained by graphitizing the raw coal in an inert gas atmosphere at 2800 DEG C has crystallite size / lattice constant ratios of 360 or below in (002) plane and 1500 or below in (110) plane is provided either as a raw coal capable of giving, through alkali activation followed by washing, active carbon which is reduced in residual alkali content and permits simplified operation in the washing since washing fluid in the washing can go in and out of active carbon easily, or as a raw coal for making needle coke.

Owner:NIPPON OIL CO LTD +1

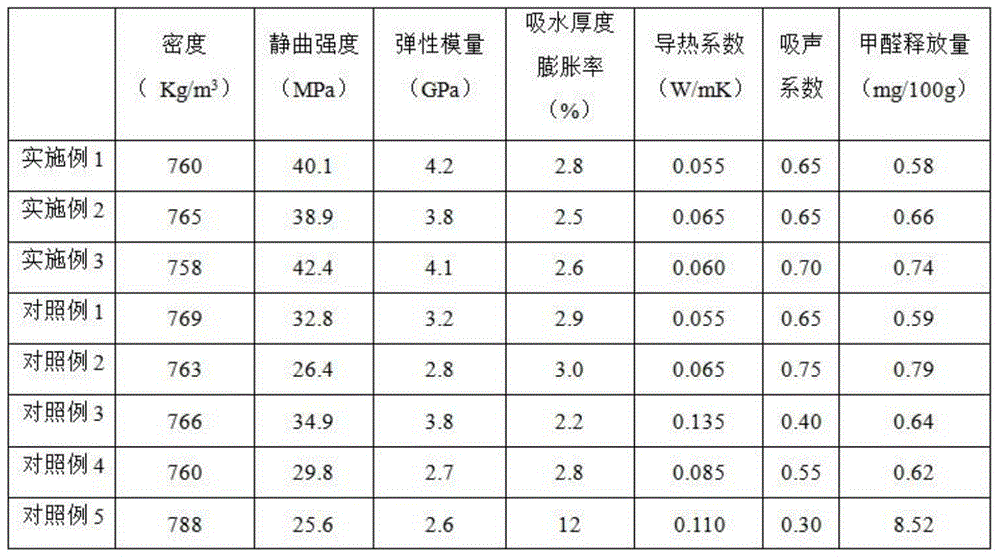

Lightweight wood-plastic composite fiberboard and preparation method thereof

The invention discloses a lightweight wood-plastic composite fiberboard and a preparation method thereof. The lightweight wood-plastic composite fiberboard is composed of hot-ground wooden fiber, high-density polyethylene, a foaming agent and other additives. The prepared composite fiberboard has wooden fiber content of 60 to 70%, average density of 800 to 900 kg / m<3>, an average pore size of 50 [mu]m and porosity of 20 to 30%. The preparation method comprises the following steps: subjecting the wooden fiber to alkaline activation and isocyanate grafting; and then subjecting the modified wooden fiber, polyethylene, the foaming agent and other auxiliary agents to high-speed mixing, granulation, mould pressing, foaming and rapid cooling. The lightweight wood-plastic composite fiberboard has same advantages as a fiberboard and a wood-plastic composite and has the advantages of good dimensional stability, high strength-to-weight ratio, good shock resistance, anticorrosion performance, pest damage resistance, sound insulation performance, heat insulation performance, etc. The lightweight wood-plastic composite fiberboard has a wide application scope and is applicable to fields like decoration, buildings, floors, municipal projects, packaging and automotive interior decorative parts.

Owner:BEIJING FORESTRY UNIVERSITY

Method of preparing dual-function catalyst having oxygen reduction and oxygen separation activities by using biomass tar

The invention discloses a method of preparing a dual-function catalyst having oxygen reduction and oxygen separation activities by using biomass tar, wherein with the biomass tar being a carbon source, high-temperature carbonization is coupled with ammonia reduction by using KOH and a soft template, and specific surface area and degree of graphitization of the material are increased by means of high temperature alkaline activation and soft template pore forming. In addition, nitrogen is doped to improve the catalytic activity, selectivity and stability of the material. The catalyst is low in raw material cost and wide in raw material source, has great catalytic activity and is good in stability.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

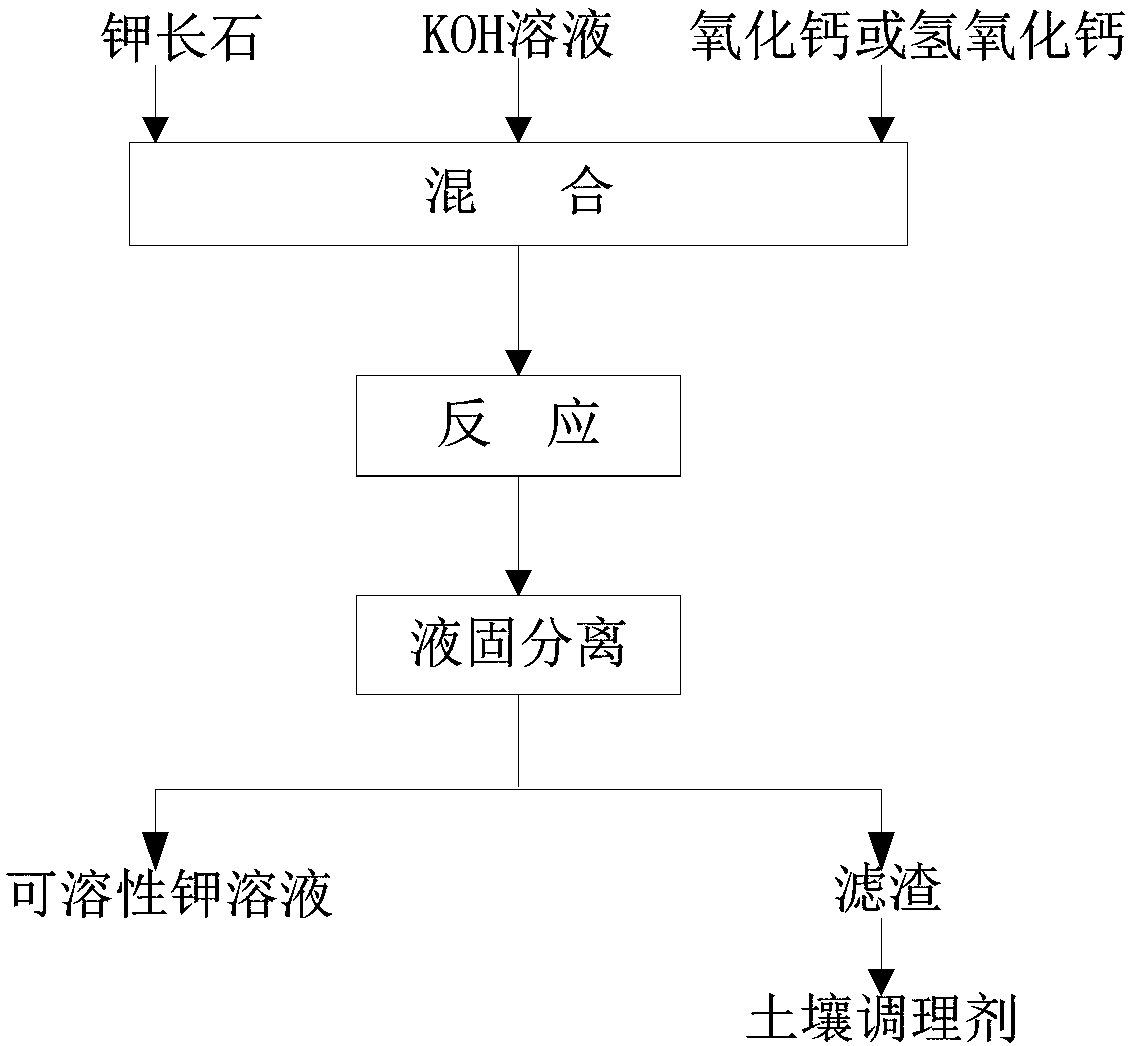

Method for preparing soluble potassium and calcium silicate soil conditioner through alkaline activation of potassium feldspar

ActiveCN108238832AReduce dosageEffective destructionCalcareous fertilisersAlkali metal oxidesCalcium silicateReaction rate

The invention belongs to the field of comprehensive utilization of resources such as chemical engineering metallurgy and environmental protection and particularly relates to a method for preparing a soluble potassium and calcium silicate soil conditioner through alkaline activation of potassium feldspar. The method comprises the following steps; (1) mixing raw materials, namely mixing an alkalineactivating agent, potassium feldspar and a calcium preparation; (2) carrying out pressurization reaction, namely putting the mixture into a pressurization reaction kettle for reaction; (3) carrying out liquid-solid separation, namely cooling a reactant in the step (2), and carrying out liquid-solid separation, so as to obtain filtrate to prepare a soluble potassium solution; and (4) drying, namelywashing filter residues filtered in the step (3), washing, and drying, so as to obtain a calcium silicate soil conditioner. According to the method, the reaction rate is high, and the reaction residue has the characteristics of lightness and high water absorption rate, is rich in high-activity silicon and calcium, contains a small amount of potassium and is suitable for being used as the soil conditioner. The process has the advantages of simplicity in operation, low reaction temperature, environmental pollution and equipment requirements and the like and further has relatively good industrial prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

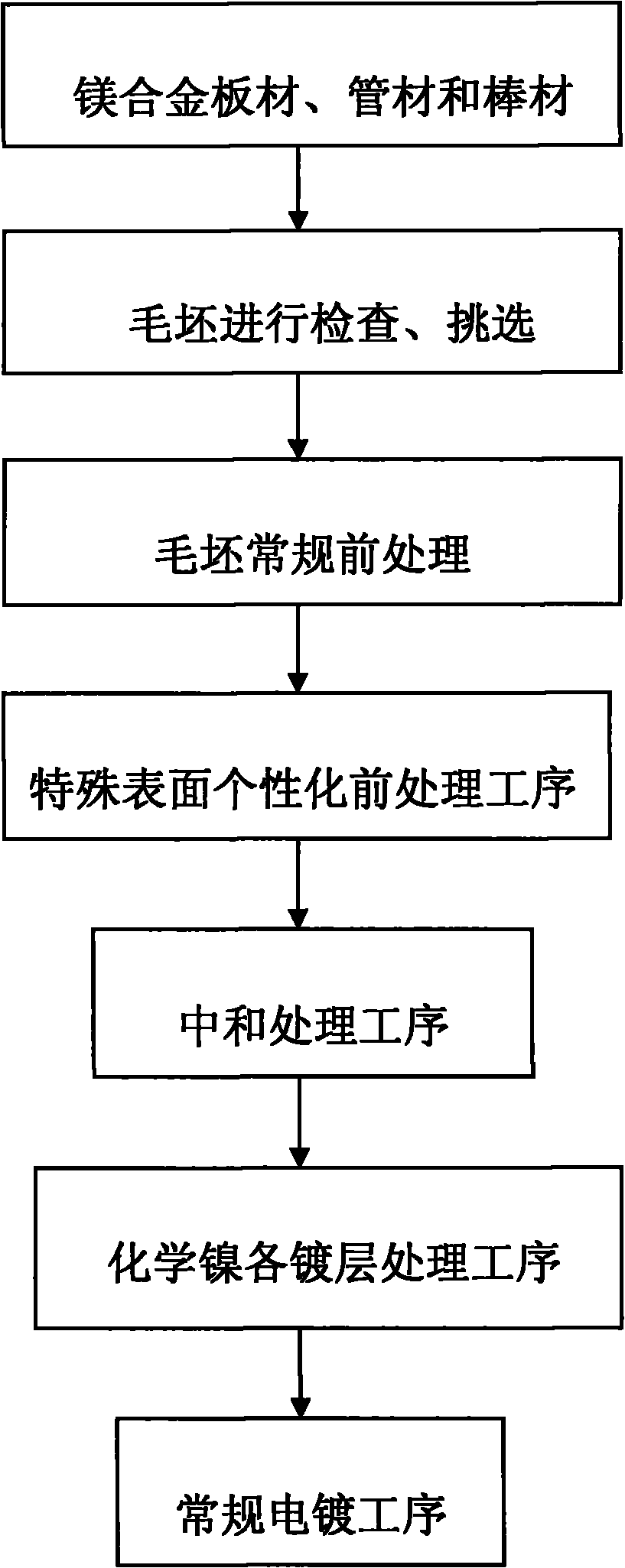

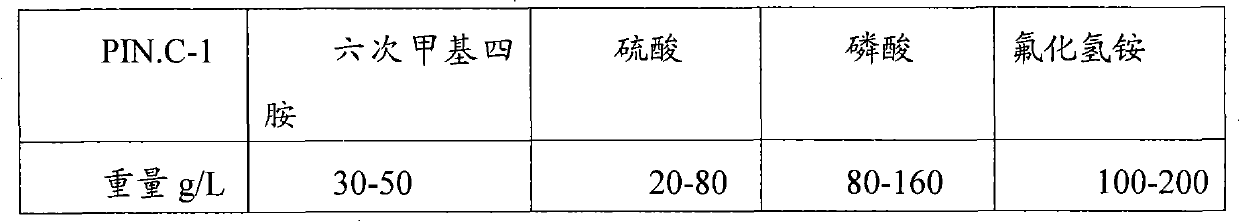

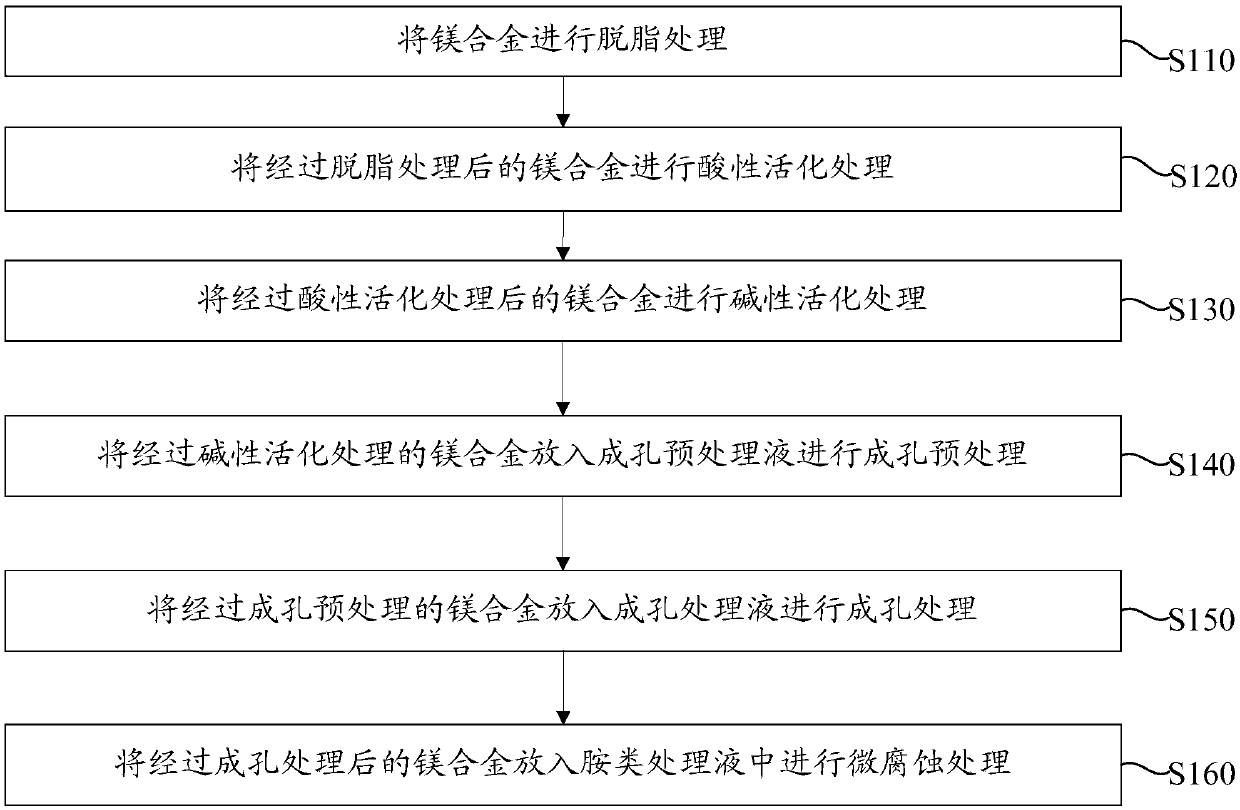

Electroplating blank surface treatment method of magnesium alloy rolling product

InactiveCN101906623AImprove bindingLow costLiquid/solution decomposition chemical coatingAlkaline activationPhosphoric acid

The invention discloses an electroplating blank surface treatment method of a magnesium alloy rolling product, comprising the following steps of: carrying out oil wax removal on the magnesium alloy rolling product; carrying out acidic activation treatment on the magnesium alloy rolling product subjected to oil wax removal by using an acid solution of ammonium bifluoride or acid solutions of sodium salts; carrying out alkaline activation treatment on the magnesium alloy rolling product by using alkaline activators of potassium pyrophosphate, sodium hydroxide and sodium citrate; carrying out acidic activation treatment on the magnesium alloy rolling product by using acid solutions of ammonium bifluoride, hydrofluoric acid and phosphoric acid; and carrying out neutralization treatment on the magnesium alloy rolling product by using neutralizing solutions of ammonium bifluoride and sodium hypophosphite. By adopting the method, bottom layer nickel or copper which has sufficient binding force and is even and compact can be covered on magnesium alloy rolling plates, bar materials and pipes. The method has low cost and is easy to popularize and apply.

Owner:李克清 +1

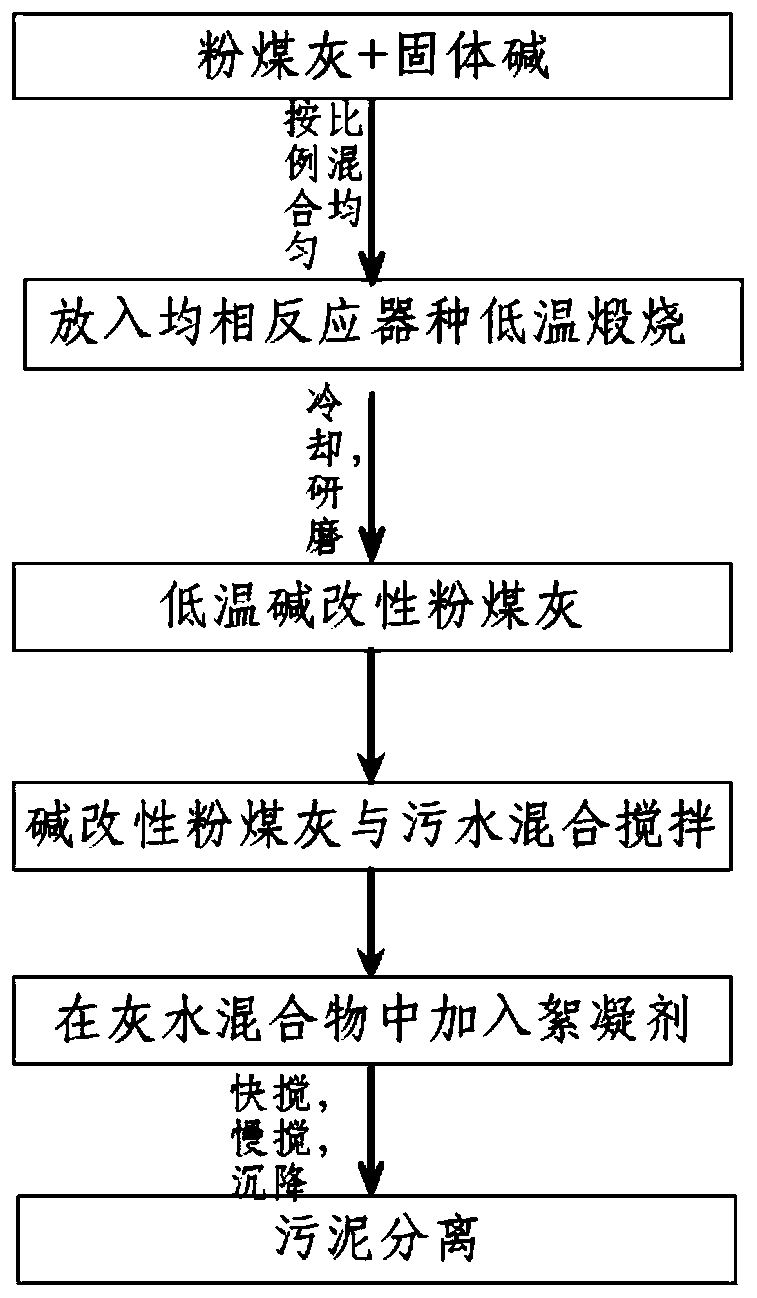

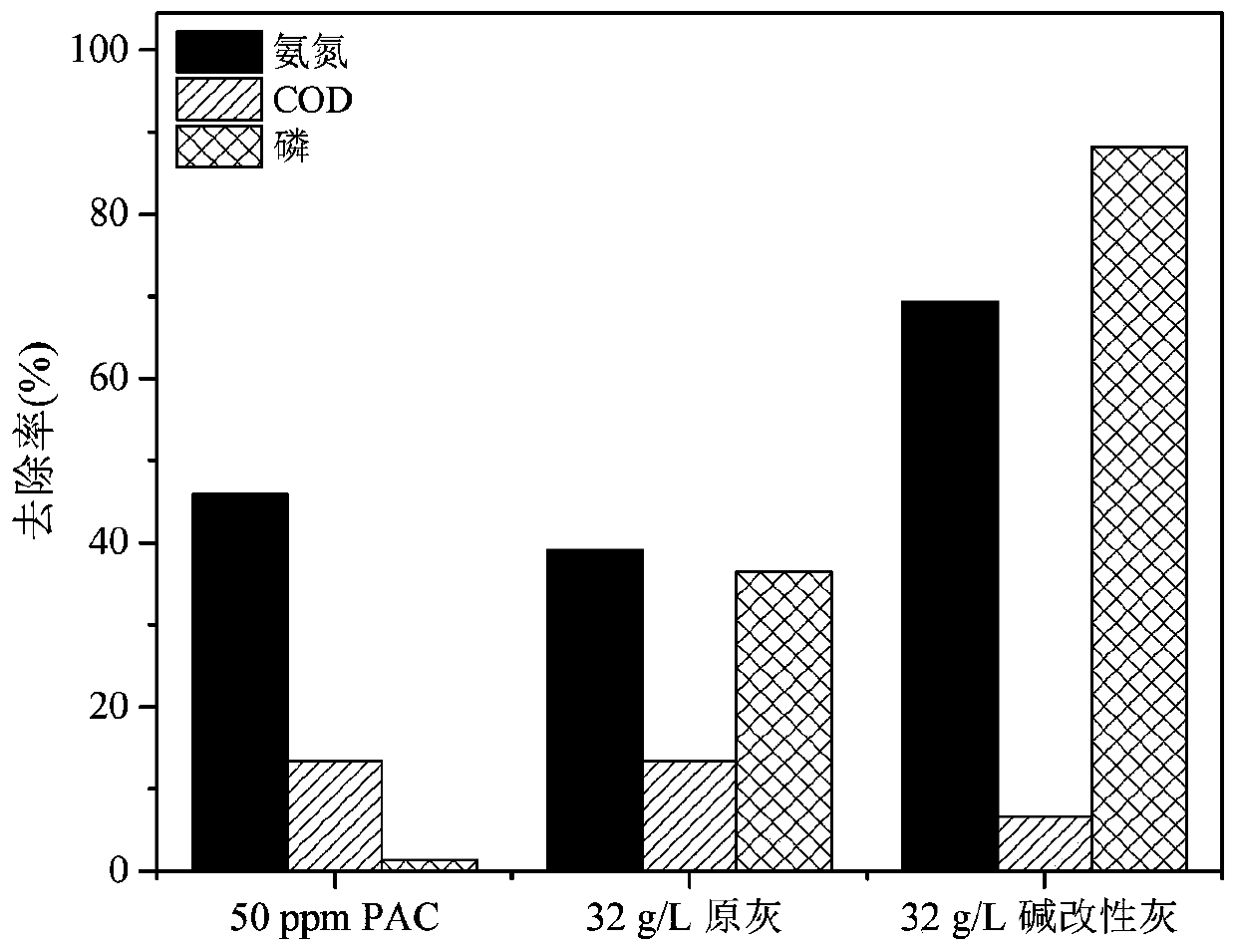

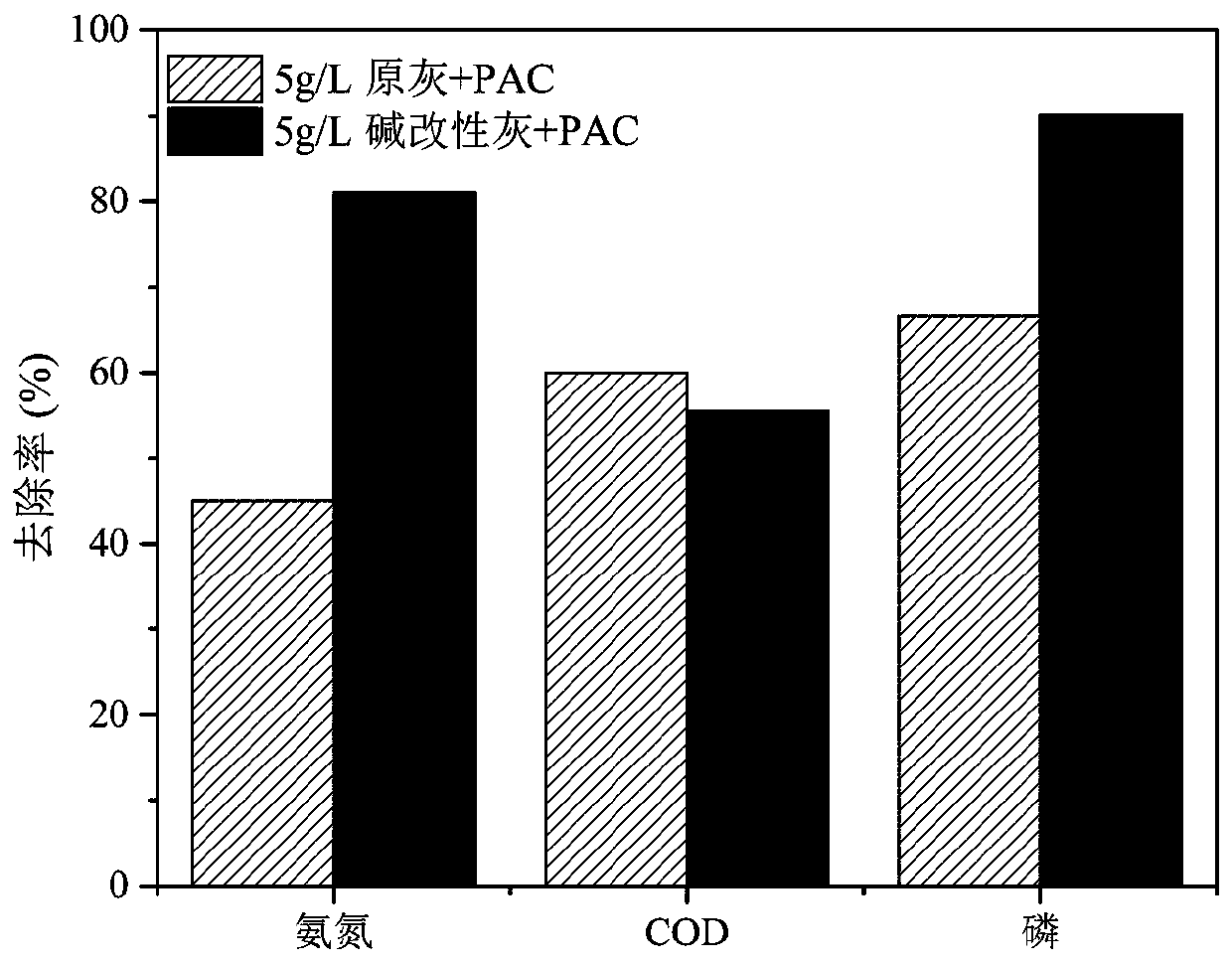

Fly ash water purification method

InactiveCN111392804AReduce processing costsSettling time is shortOther chemical processesWater contaminantsAmmoniacal nitrogenPurification methods

The invention provides a fly ash water purification method which comprises the following steps: uniformly mixing fly ash with solid alkali in proportion, putting the mixture into a homogeneous reactor, and performing calcining, drying and grinding to obtain low-temperature alkali-modified fly ash; and adding the low-temperature alkali-modified fly ash into sewage, performing mixing and stirring onthe low-temperature alkali-modified fly ash and the sewage, adding a flocculant, quickly stirring, slowly stirring, standing for settling, and finally carrying out sludge separation. The fly ash is comprehensively utilized, environmental pollution can be reduced, the additional value is high, and the dosage of an adsorbent is effectively reduced after alkali modification. The sludge adsorbing ammonia nitrogen, phosphorus and COD can be subjected to alkali activation and cyclic utilization again, so that the resource utilization of the solid waste fly ash is realized. The method is simple in process, low in cost and easy to operate, and can be applied to treatment of heavy metals, ammonia nitrogen, phosphorus and COD in surface water pollution, town sewage and industrial sewage.

Owner:GUODIAN NEW ENERGY TECH INST

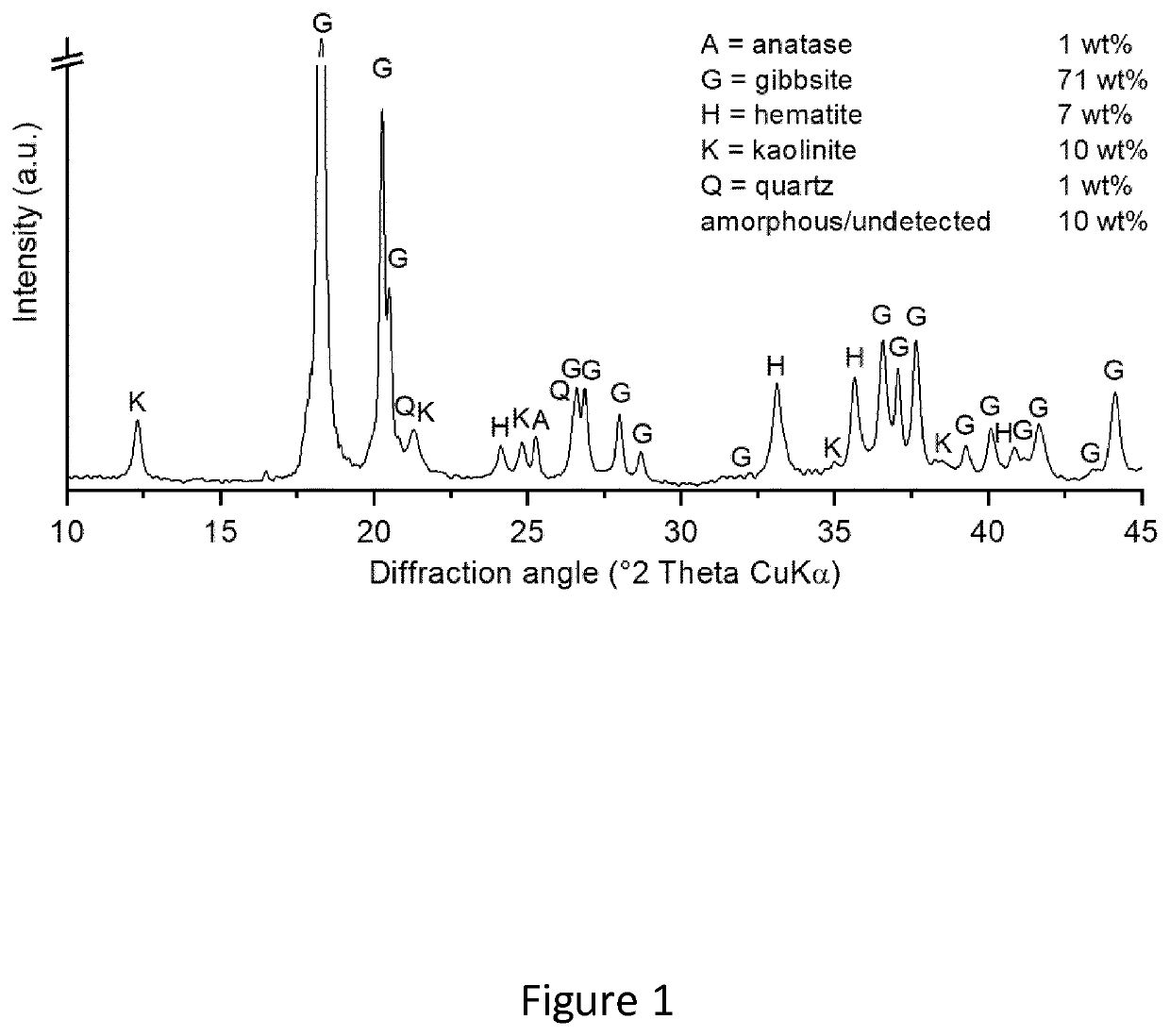

Non-fired monoliths

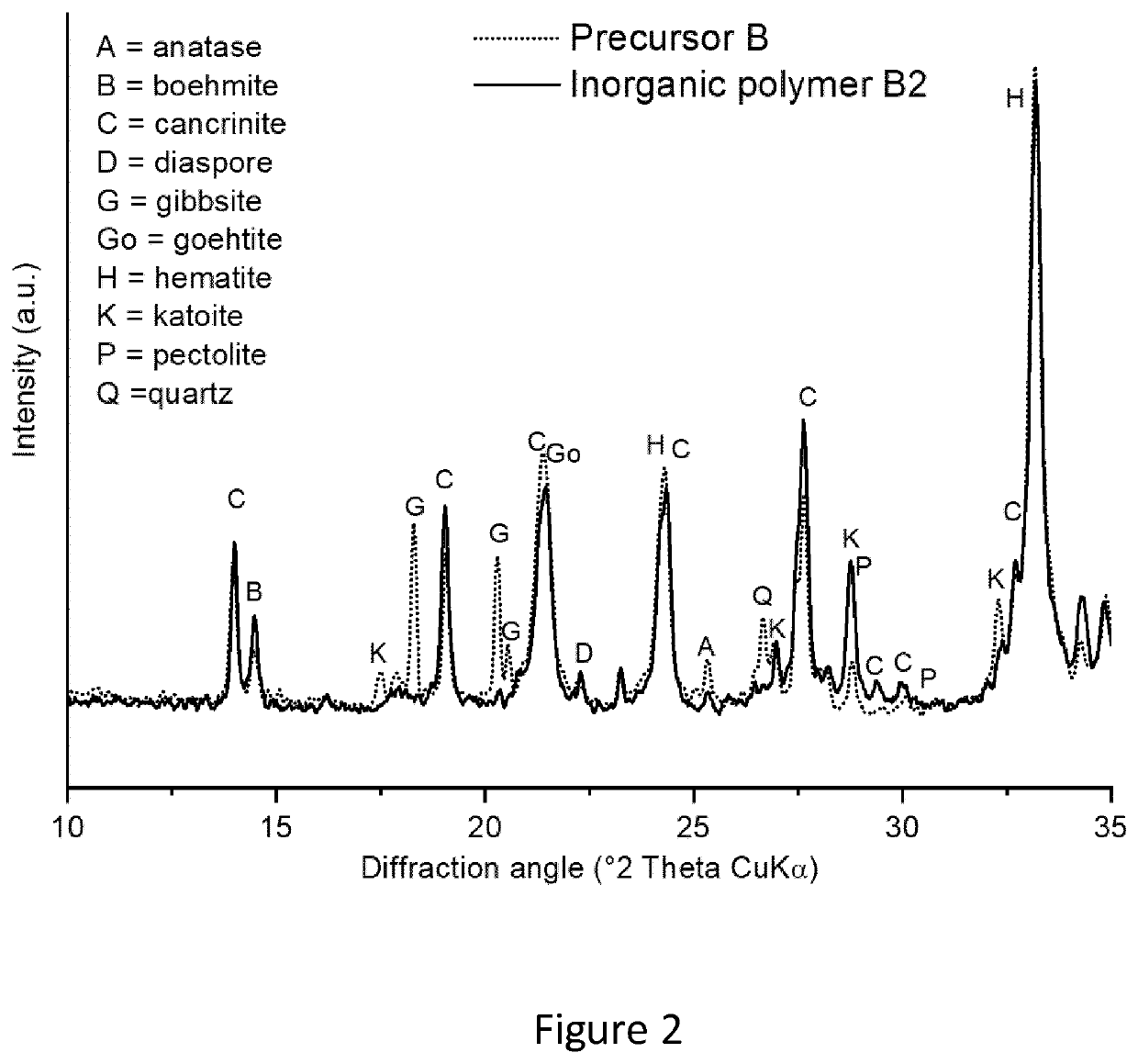

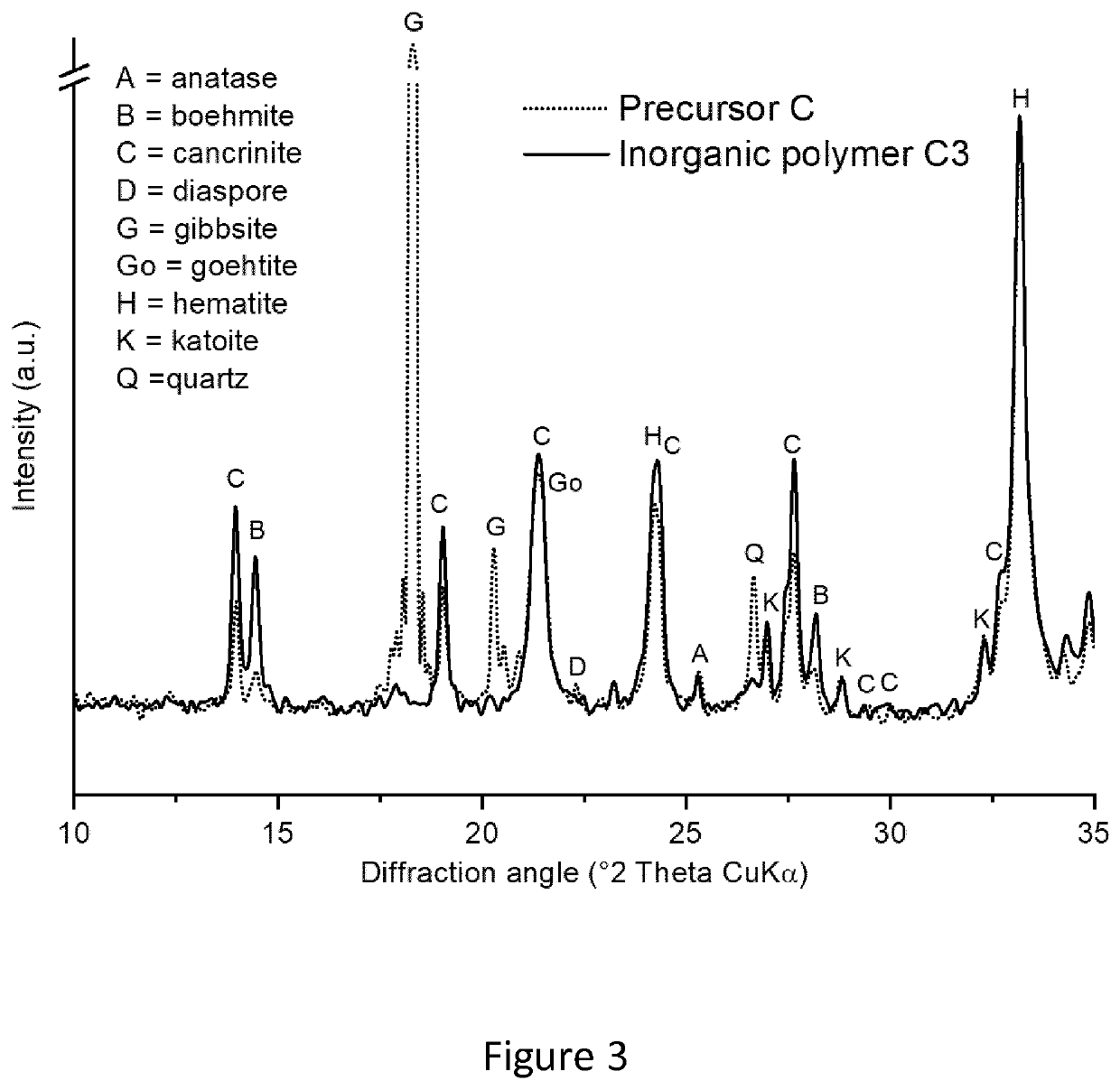

The invention relates to methods for manufacturing an inorganic polymer object from a precursor wherein the precursor consists of one or more or comprises one or more selected from the group consisting of gibbsite-containing bauxite, gibbsite containing residue of the Bayer process, thermally processed gibbsite-containing bauxite, and thermally processed gibbsite-containing residue of the Bayer process, the method comprising the steps of alkaline-activating said precursor, mixing the precursor, shaping the mixed precursor and hydrothermally curing the shaped precursor at a temperature between 70° C. and 350° C.

Owner:KATHOLIEKE UNIV LEUVEN

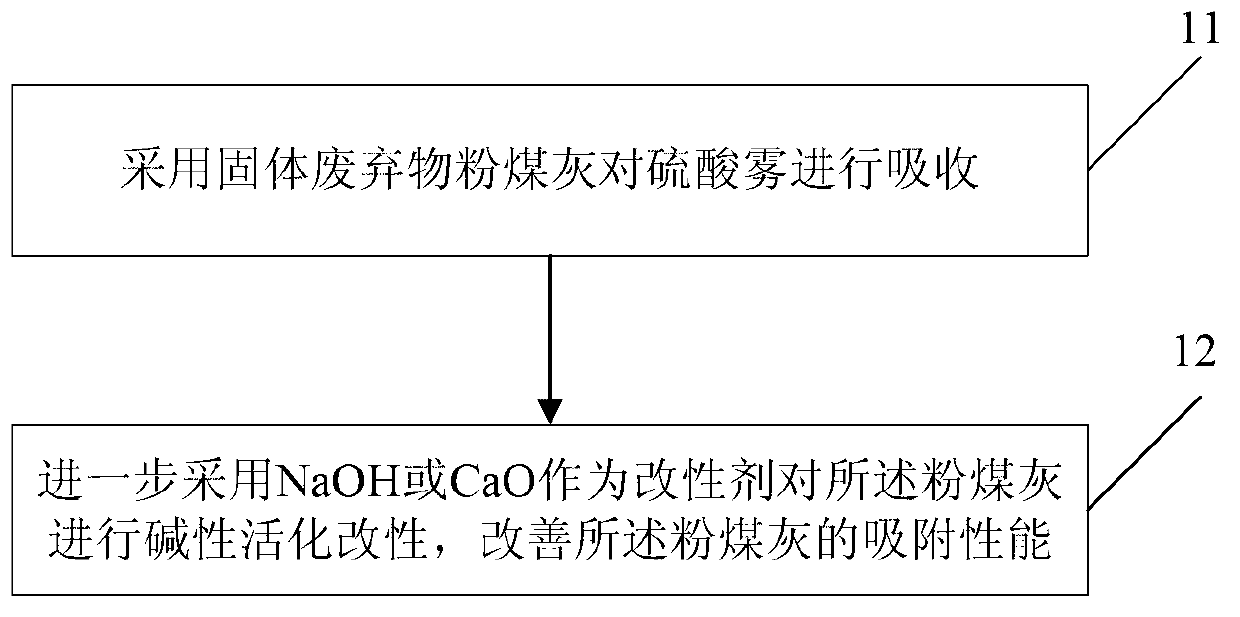

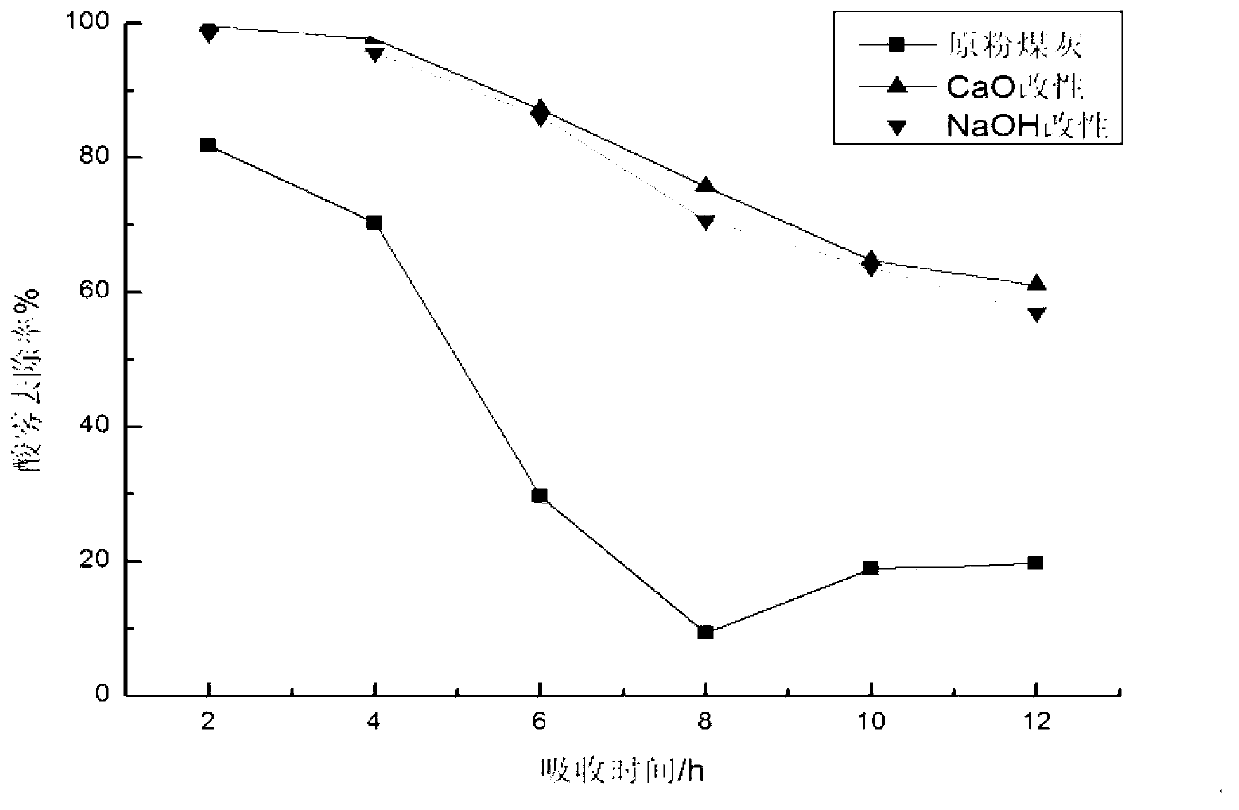

Sulfuric acid mist elimination method

InactiveCN102989260AImprove adsorption capacityAddress governance issuesOther chemical processesDispersed particle separationAlkaline activationToxic industrial waste

The embodiment of the invention discloses a sulfuric acid mist elimination method. The method comprises the following steps of absorbing the sulfuric acid mist by adopting solid waste coal ash; and further carrying out alkaline activation and modification on the coal ash by adopting NaOH or CaO as a modifying agent so as to improve the adsorption performance of the coal ash. According to the sulfuric acid mist elimination method, not only is the cost low, but also the adsorptive property is good, an the secondary pollution can be avoided, so that the management problem of the sulfuric acid mist in a lead-acid storage battery plant is solved, and the treatment problem of industrial waste material coal ash is also solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

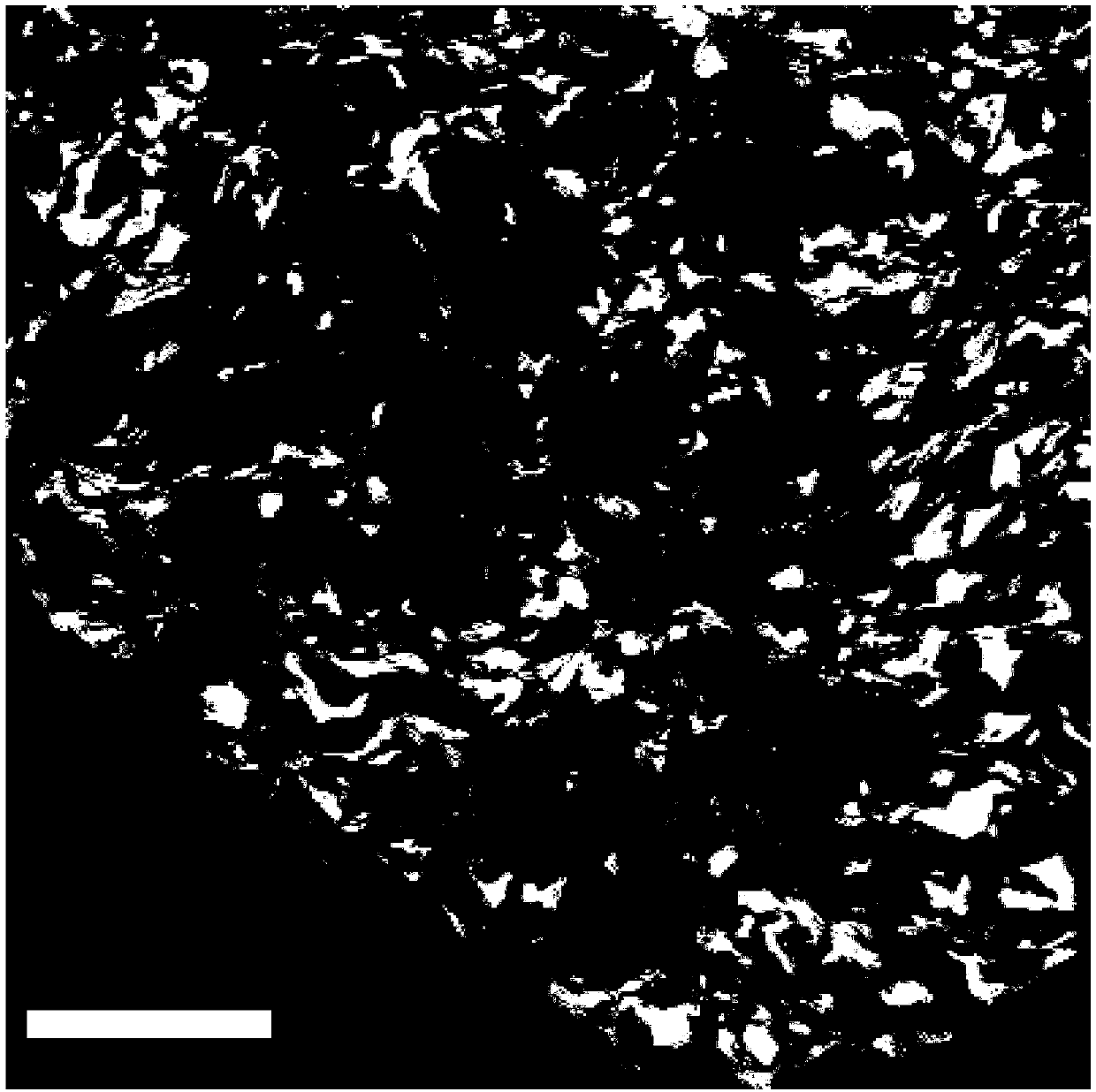

Magnesium alloy surface treatment method and preparation method of magnesium alloy and resin complex

ActiveCN108034983AEvenly distributedStrong binding strengthAnodisationAlkaline activationPorous membrane

The invention relates to a magnesium alloy surface treatment method and a preparation method of a magnesium alloy and resin complex. The magnesium alloy surface treatment method comprises the following steps: performing degreasing treatment on magnesium alloy; performing acid activation treatment on the magnesium alloy after degreasing treatment; performing alkaline activation treatment on the magnesium alloy after acid activation treatment; putting the magnesium alloy after alkaline activation treatment in a hole-forming pretreatment solution for hole-forming pretreatment; putting the magnesium alloy after hole-forming pretreatment in a hole-forming treatment solution for hole-forming treatment; putting the magnesium alloy after hole-forming treatment in an amine treatment solution for micro-corrosion treatment. The magnesium alloy surface treatment method provided by the invention has the benefits that a nano-scale porous membrane can be formed on the magnesium alloy surface, and theaverage diameter of a nano-porous structure is 10-50 nm, so that when the magnesium alloy is subjected to subsequent injection molding treatment, resin can enter nano-scale holes and gullies during injection molding, and the magnesium alloy and the resin have stronger bonding strength.

Owner:广东东明新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com