Raw coal for making carbonaceous material for electricity storage or needle coke

A raw coke and activated carbon technology, which is applied in circuits, capacitors, coke ovens, etc., can solve the problems of coke quality, lower thermal expansion coefficient or suppress uplift, etc., achieve cycle characteristics improvement, thermal expansion coefficient suppression, and high industrial value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] (1) Preparation of raw material composition

[0100]In the presence of a Ni-Mo catalyst, hydrodesulfurization of atmospheric distillation residual oil from Middle East origin with a sulfur content of 2.5% by mass so that the hydrocracking rate is 25% or less, thereby producing desulfurized heavy oil (hereinafter referred to as "hydrodesulfurized oil A") ""). At a total pressure of 22MPa, a hydrogen partial pressure of 20MPa, a temperature of 380°C, a hydrogen / oil ratio of 590NL / L and a liquid hourly space velocity (LHSV) of 0.17h -1 Under the conditions of hydrodesulfurization.

[0101] Using vacuum distillation residue and desulfurized vacuum gas oil as raw materials and using platinum (Pt)-supported silica-alumina catalyst at a reaction temperature of 520 °C, a total pressure of 0.2 MPa and a catalyst / oil ratio of 7 The contact time was 3 seconds to prepare fluid catalytic cracking residual oil (hereinafter referred to as "fluid catalytic cracking residual oil ZA")....

Embodiment 2

[0113] Atmospheric distillation bottom oil having a sulfur content of 3.0% by mass was vacuum distilled under the condition that the furnace outlet temperature was 360°C and the pressure was 1.3 kPa, thereby preparing vacuum distillation bottom oil A having an initial boiling point of 410°C, 8% by mass Bitumen content, 50% by mass saturate content, 0.1% by mass sulfur content and 0.3% by mass nitrogen content.

[0114] The prepared vacuum distillation residue A was mixed with the hydrodesulfurized oil A and fluid catalytic cracking residue A prepared in Example 1 so that the content of the former was 30% by mass, thereby preparing a raw material composition B.

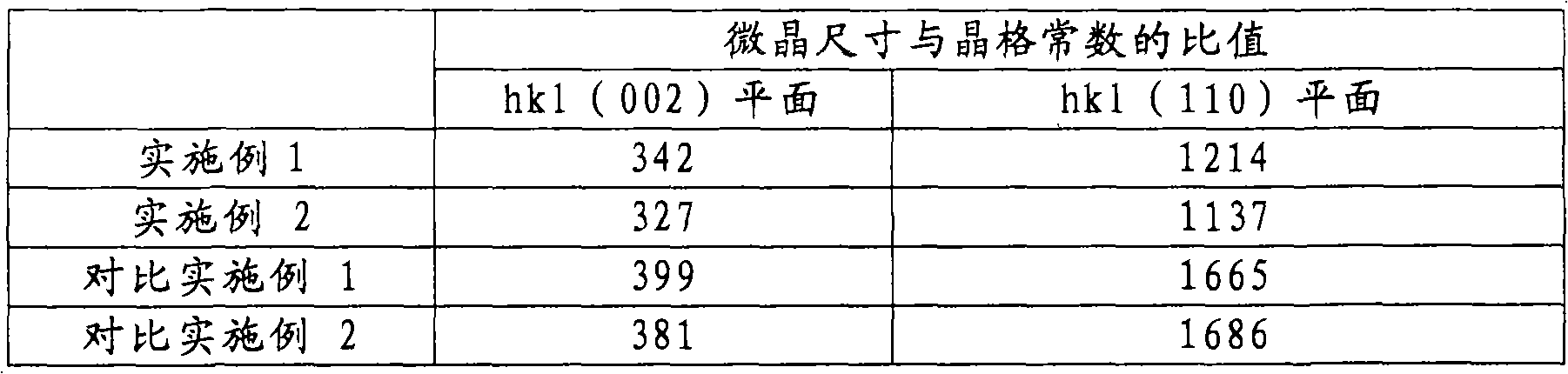

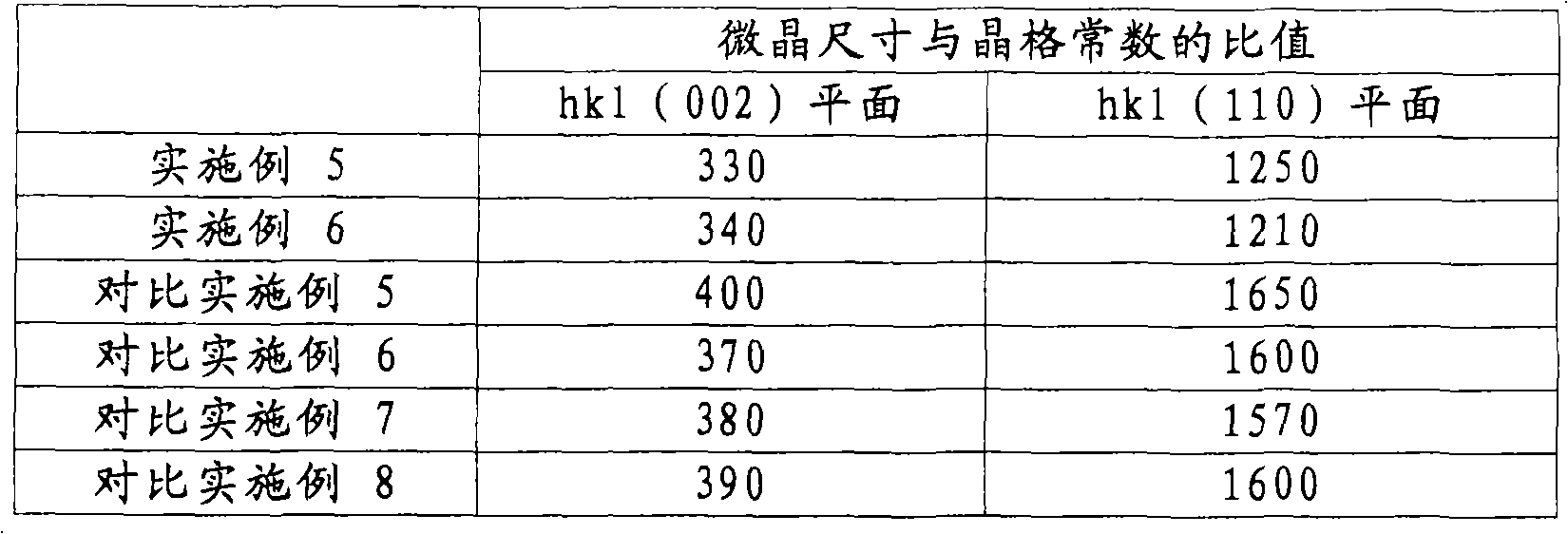

[0115] The prepared raw material composition B was coked under nitrogen at a pressure of 400 kPa and a temperature of 500° C. for 40 hours, thereby producing a coke (raw coke B). The prepared raw coke B was heated under nitrogen at a temperature of 2800° C., thereby preparing a graphitized product. The graphitized pro...

Embodiment 3

[0128] (1) Preparation of raw material composition

[0129] Atmospheric distillation bottom oil having a sulfur content of 3.5% by mass was hydrodesulfurized in the presence of a Ni-Mo catalyst so that the hydrocracking rate was 30% or less, thereby producing desulfurized heavy oil (hereinafter referred to as "hydrodesulfurized oil B") . At a total pressure of 18.5MPa, a hydrogen partial pressure of 16.5MPa, a temperature of 370°C, a hydrogen / oil ratio of 590NL / L and a liquid hourly space velocity (LHSV) of 0.17h -1 Under the conditions of hydrodesulfurization. The prepared hydrodesulfurized oil B had an initial boiling point of 260°C, a sulfur content of 0.3% by mass, a nitrogen content of 0.1% by mass, a bitumen content of 2% by mass and a saturate content of 70% by mass.

[0130] This hydrodesulfurized oil B was put into a test tube and heated at a temperature of 500° C. for 3 hours under atmospheric pressure to coke it. The prepared focal was embedded in a commercially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com