Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1951 results about "Contact time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanotube particulates, compositions and use thereof

InactiveUS20050002851A1Suitable for useMaterial nanotechnologyNanoinformaticsParticulatesContact time

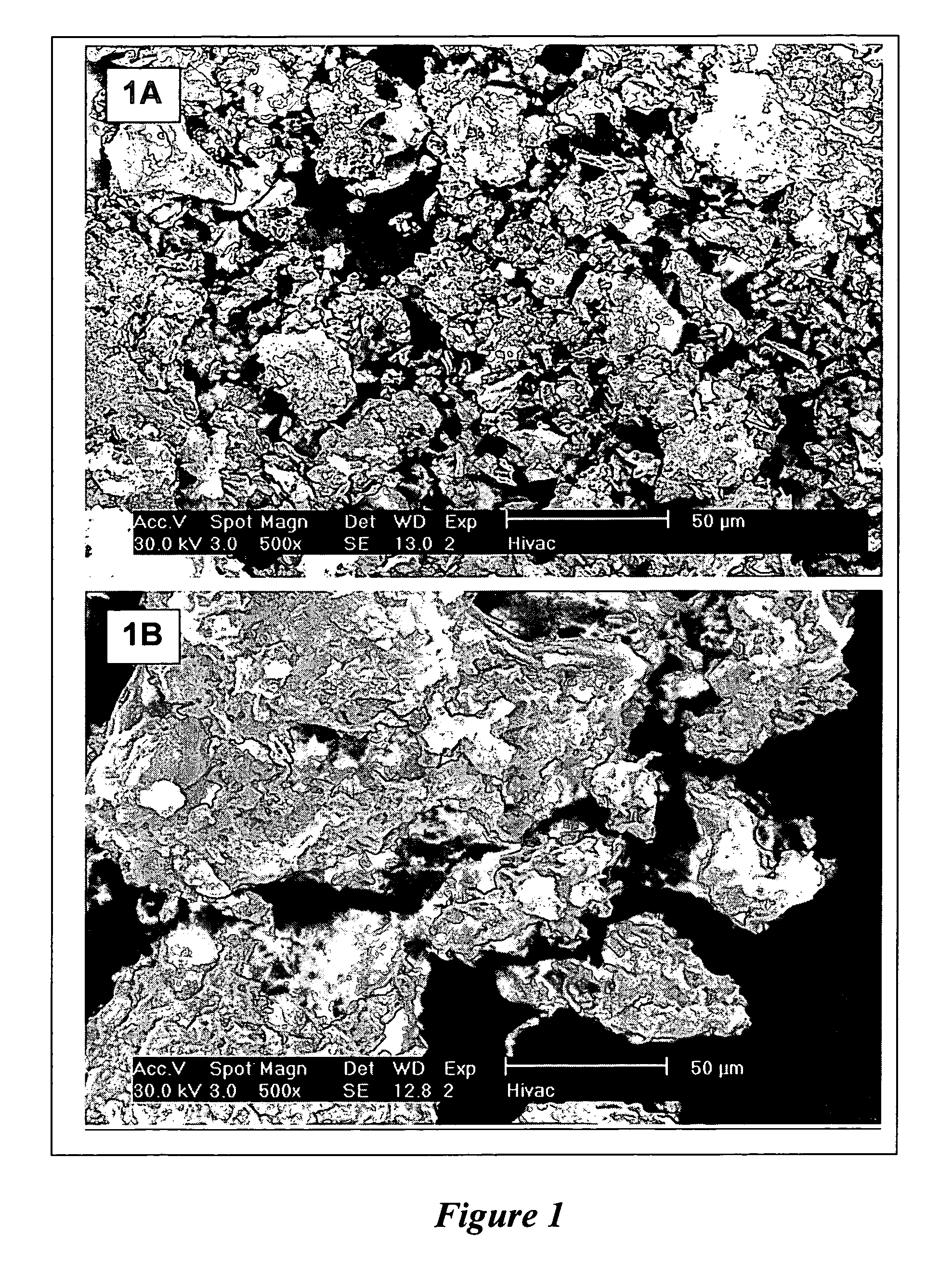

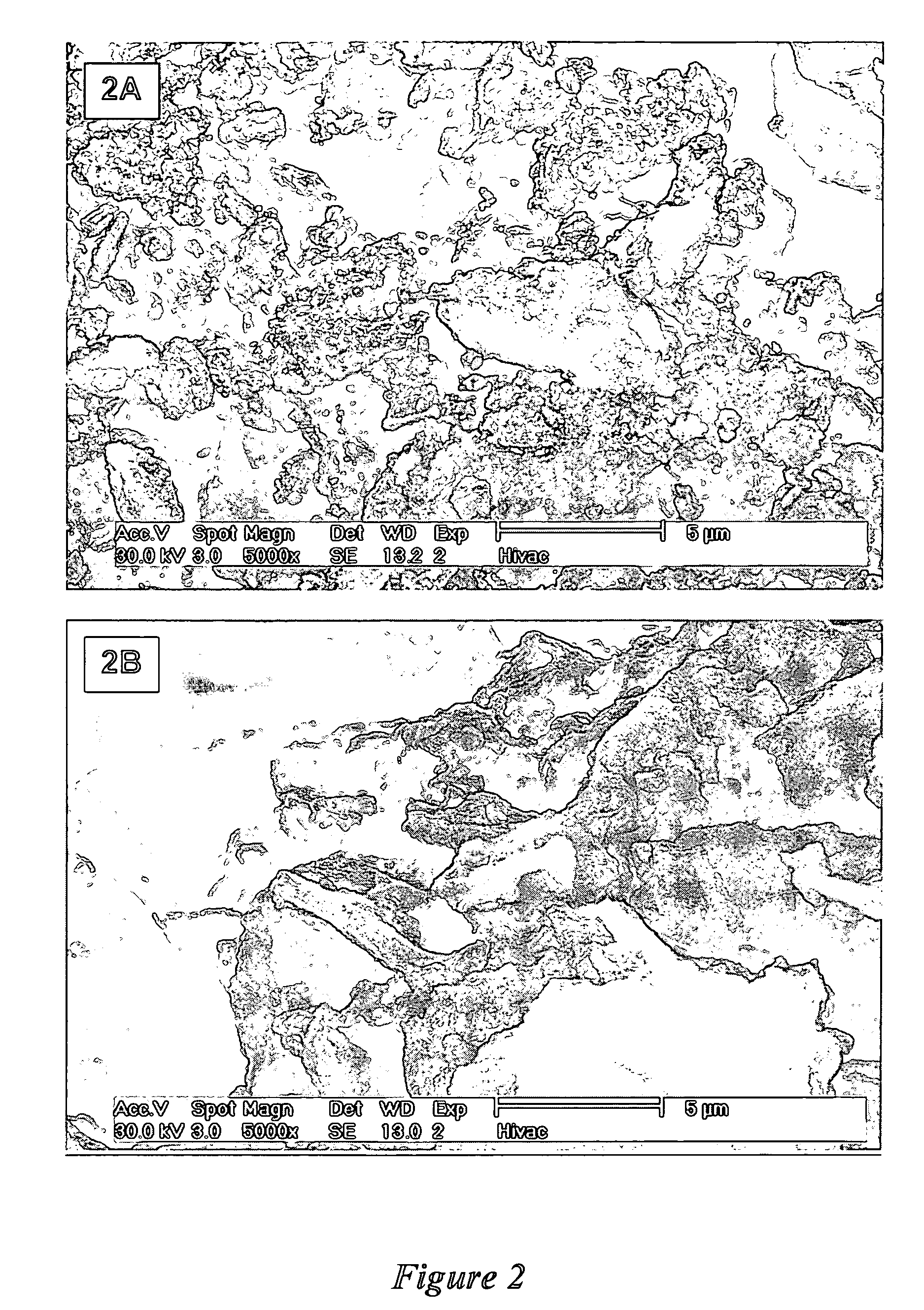

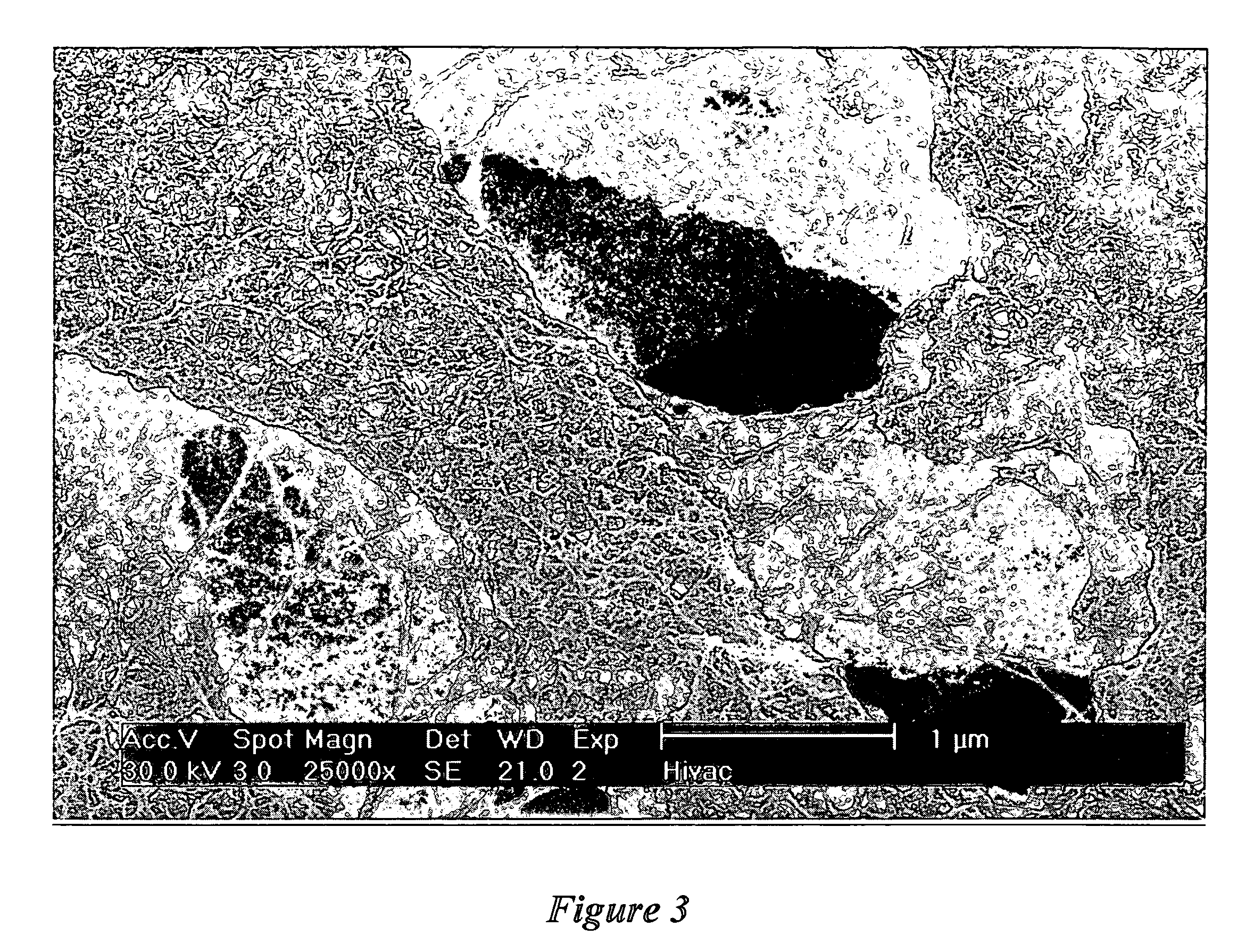

A method for making carbon nanotube particulates involves providing a catalyst comprising catalytic metals, such as iron and molybdenum or metals from Group VIB or Group VIIIB elements, on a support material, such as magnesia, and contacting the catalyst with a gaseous carbon-containing feedstock, such as methane, at a sufficient temperature and for a sufficient contact time to make small-diameter carbon nanotubes having one or more walls and outer wall diameters of less than about 3 nm. Removal of the support material from the carbon nanotubes yields particulates of enmeshed carbon nanotubes that retain an approximate three-dimensional shape and size of the particulate support that was removed. The carbon nanotube particulates can comprise ropes of carbon nanotubes. The carbon nanotube particulates disperse well in polymers and show high conductivity in polymers at low loadings. As electrical emitters, the carbon nanotube particulates exhibit very low “turn on” emission field.

Owner:UNIDYM

Method for making single-wall carbon nanotubes using supported catalysts

InactiveUS7250148B2Suitable for growthAppropriate densityMaterial nanotechnologyFibre chemical featuresCarbon nanotubeMoving bed

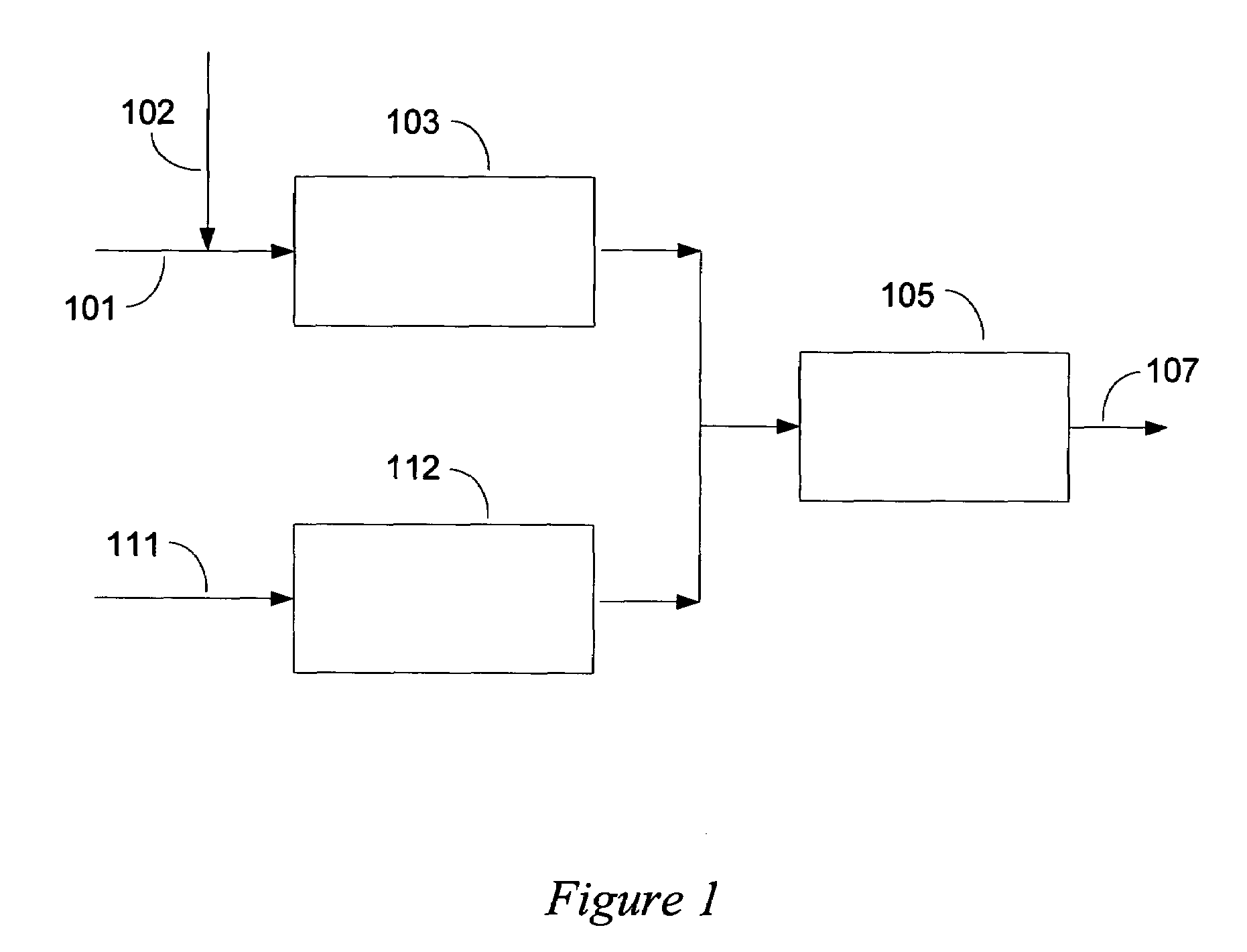

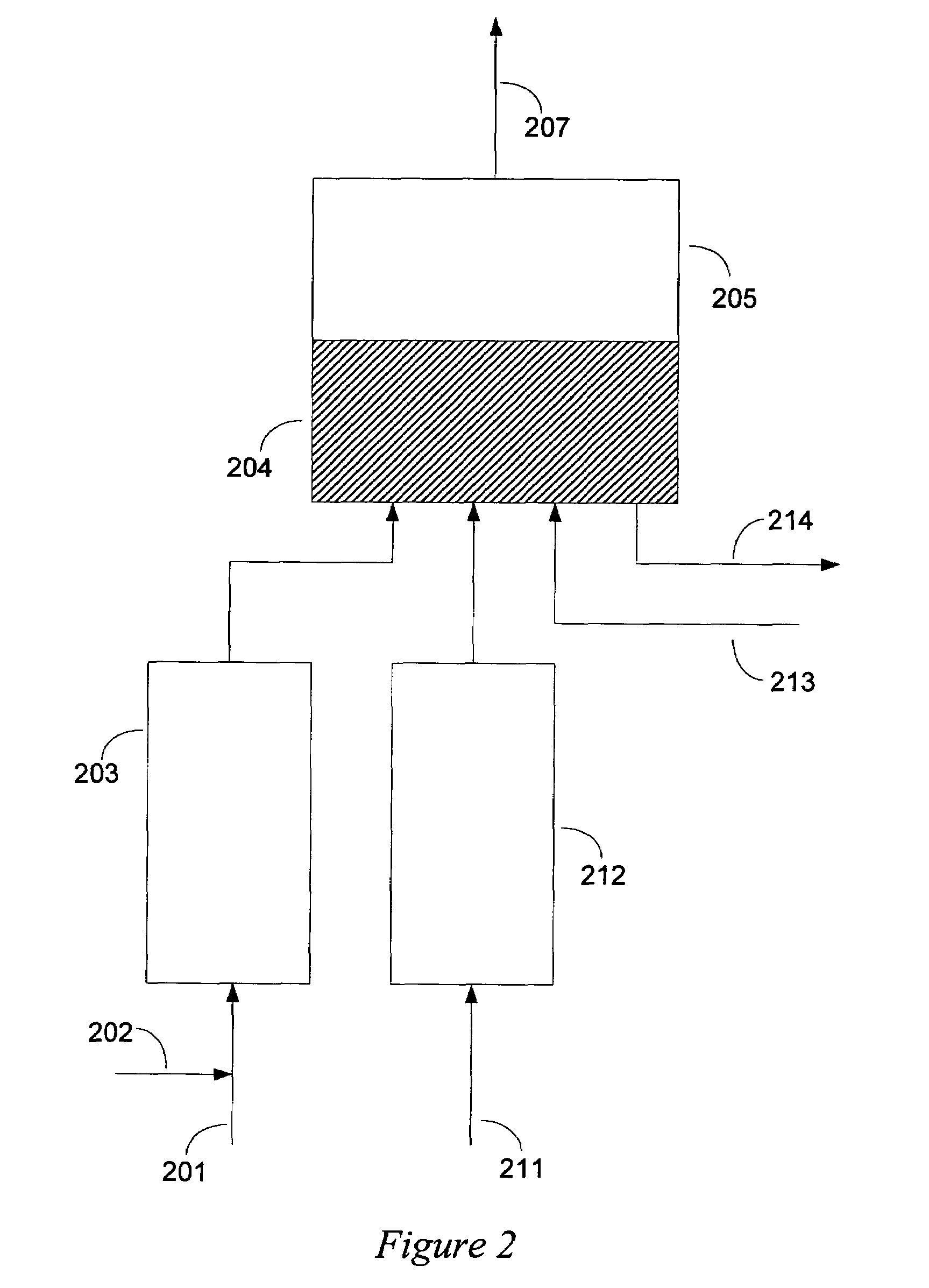

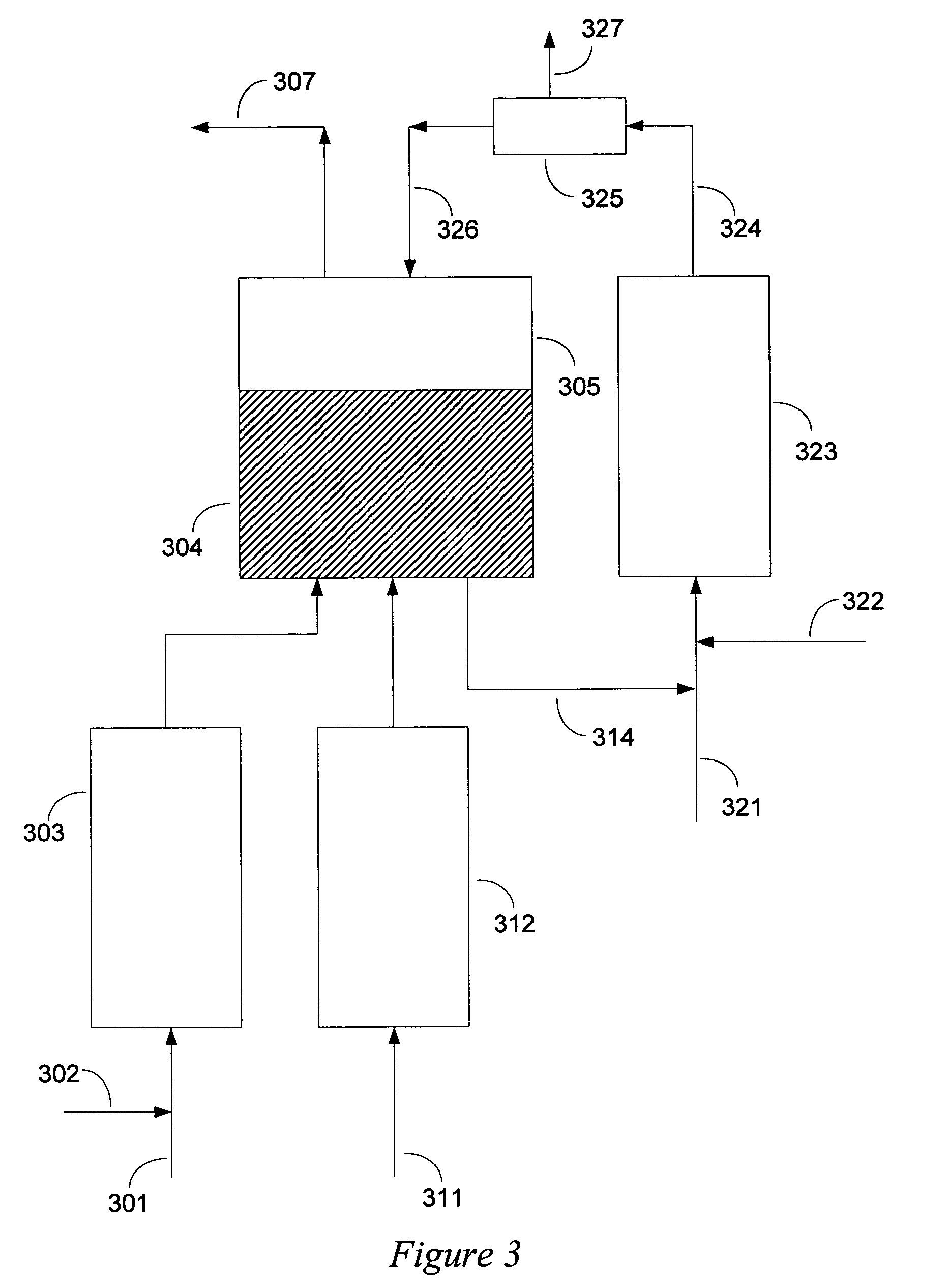

A method for growing single-wall carbon nanotubes involves preparing a catalyst comprising catalytic metals, iron and molybdenum, and magnesium oxide support material and contacting the catalyst with a gaseous carbon-containing feedstock at a sufficient temperature and for a sufficient contact time to make single-wall carbon nanotubes. The weight ratio of iron and molybdenum can range from about 2 to 1 to about 10 to 1 and the metals loading up to about 10 wt % of the MgO. The catalyst can be sulfided. Methane is a suitable carbon-containing feedstock. The process can be conducted in batch, continuous or semi-continuous modes, in reactors, such as a transport reactor, fluidized bed reactor, moving bed reactors and combinations thereof. The process also includes making single-wall carbon nanotubes with catalysts comprising at least one Group VIB or Group VIIIB metal on supports such as magnesia, zirconia, silica, and alumina, where the catalyst is sulfided.

Owner:UNIDYM

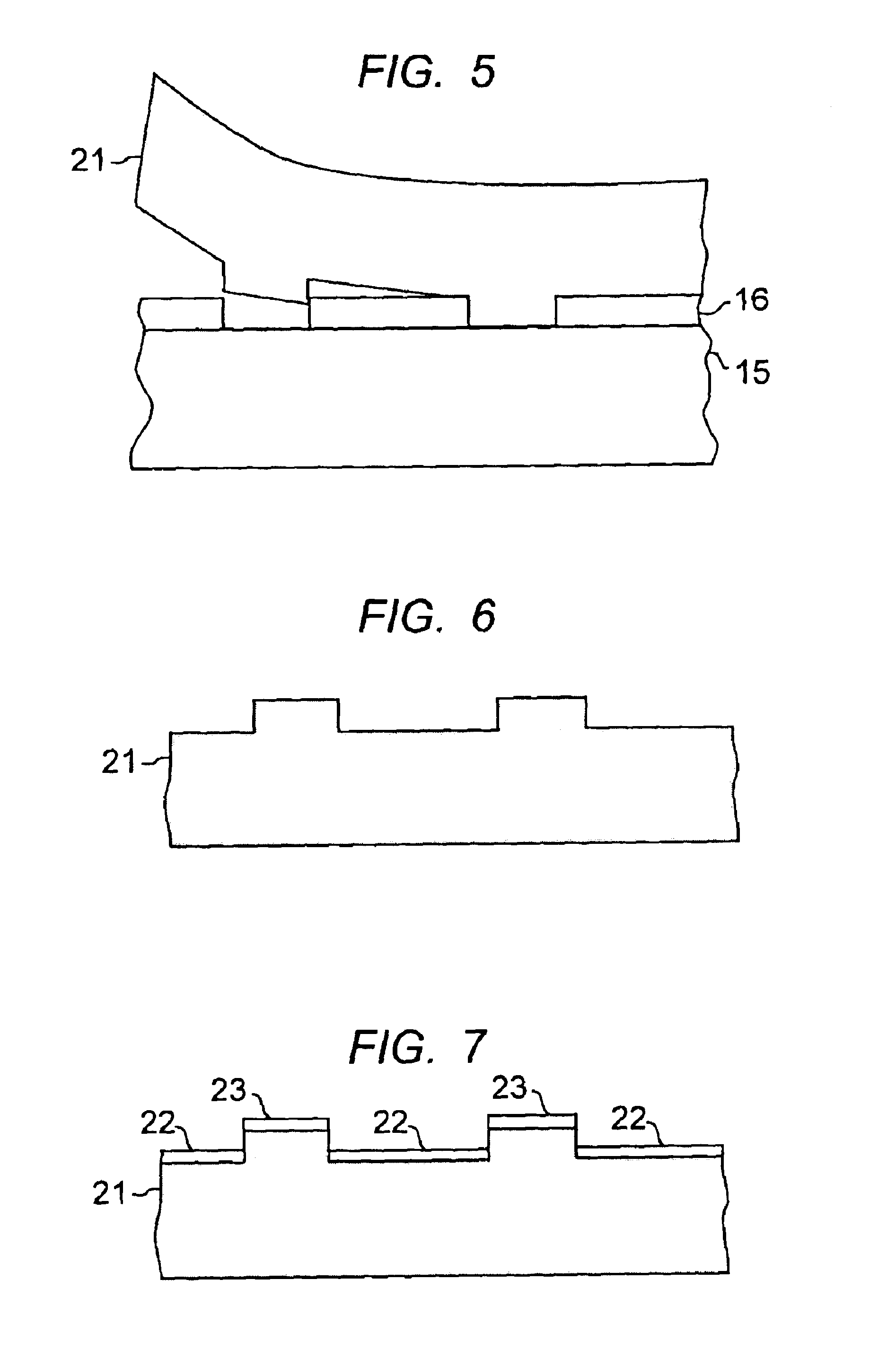

Forming nanoscale patterned thin film metal layers

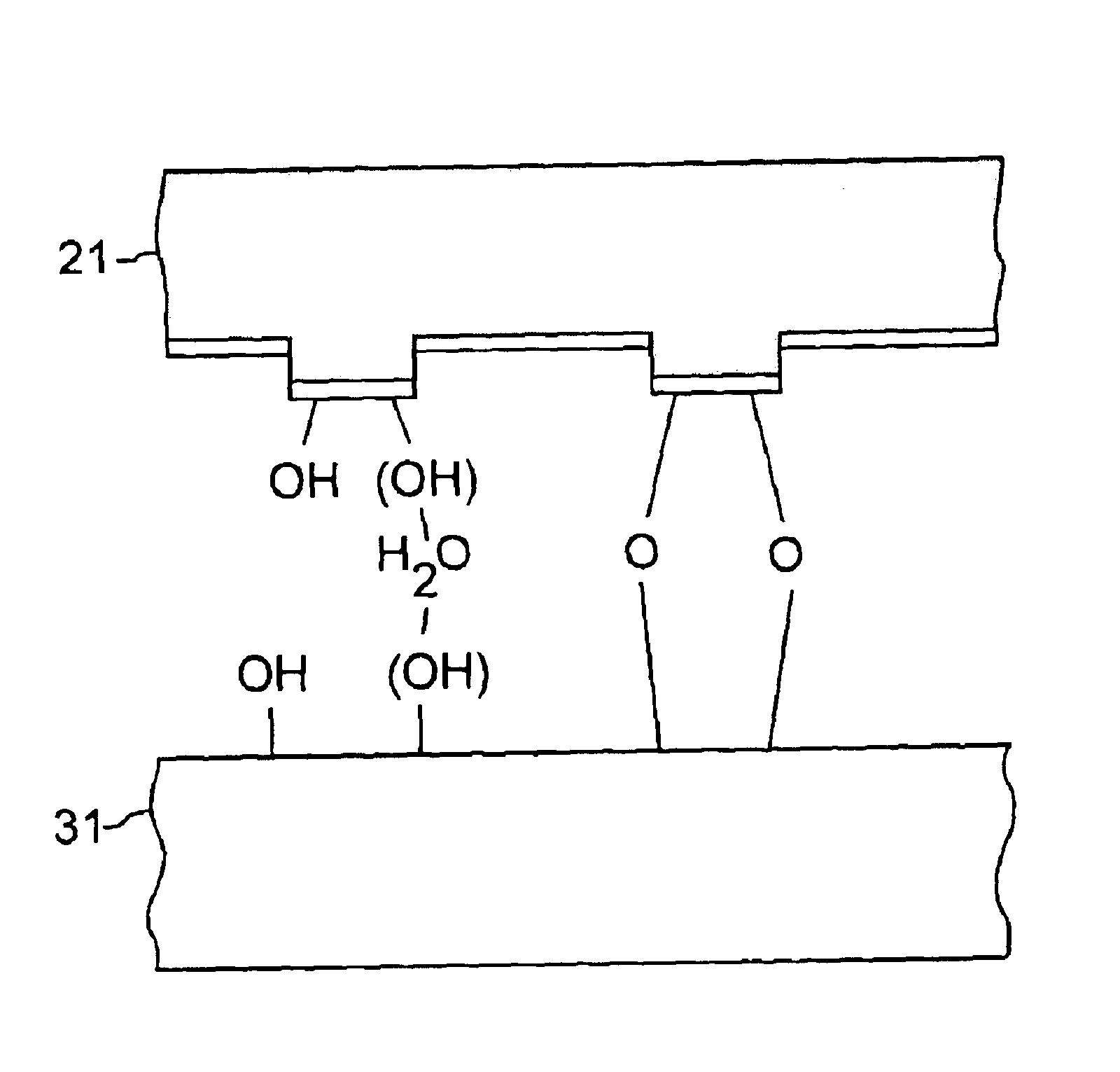

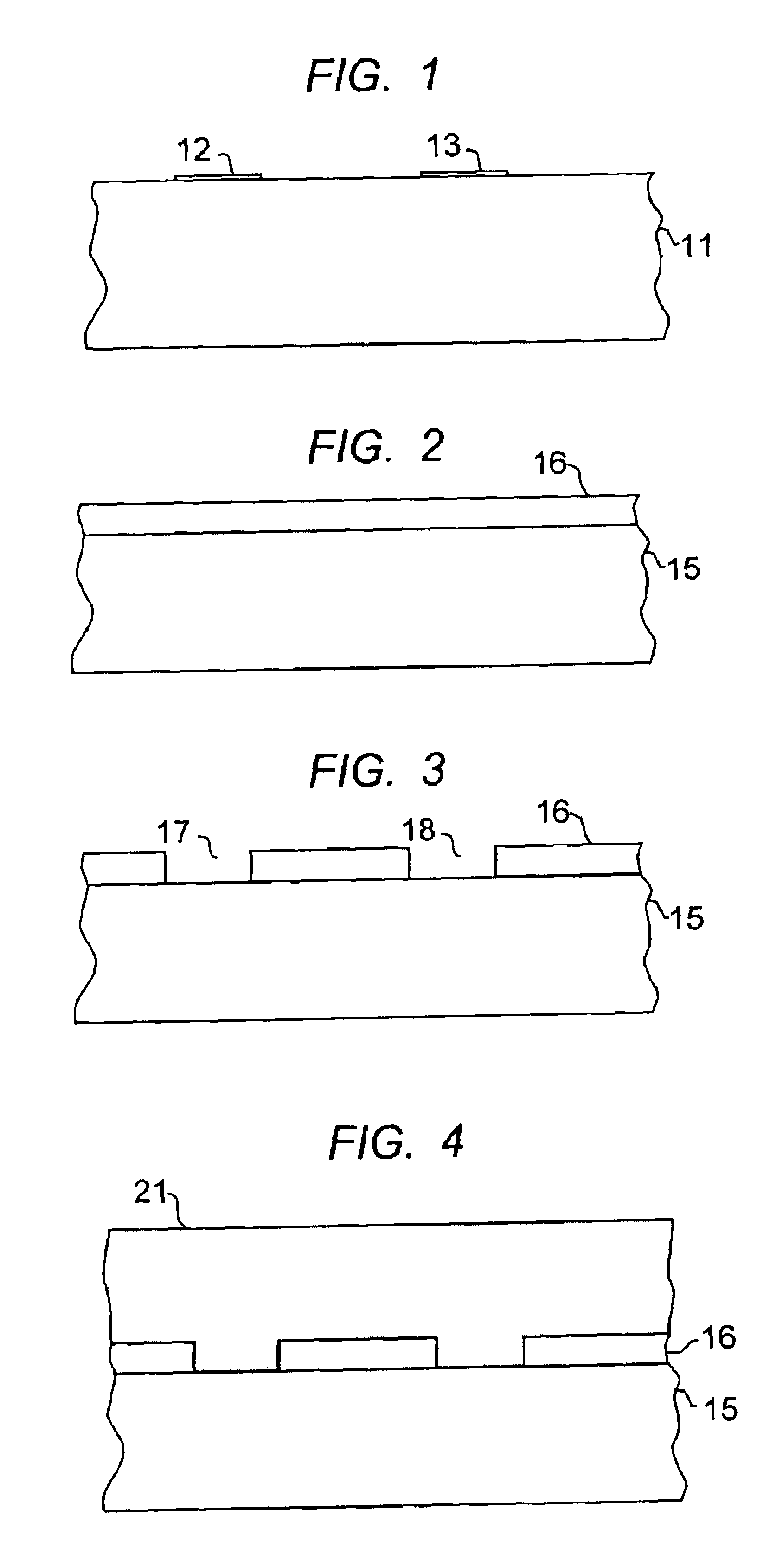

The specification describes a contact printing technique for forming patterns of thin films with nanometer resolution over large areas. The procedure, termed here “nanotransfer printing (nTP)”, relies on tailored surface chemistries for transferring thin films, typically metal films, from the raised regions of a stamp to a substrate when these two elements are brought into intimate physical contact. This technique is purely additive, it is fast (<15 s contact times), and the printing occurs in a single processing step at room temperature in open air. nTP is capable of producing patterns with a wide range of features with sizes down to ˜100 nm, and edge resolution better than 25 nm. Electrical contacts and interconnects have been fabricated for high performance organic thin film transistors (TFTs) and complementary inverter circuits, to demonstrate one of the many potential applications for nTP.

Owner:ALCATEL-LUCENT USA INC +1

Oral Care Compositions

InactiveUS20090269287A1Prevent significant water lossGood dispersionCosmetic preparationsToilet preparationsCarrageenanRelative humidity

Disclosed are oral care compositions, particularly thickened dentifrices in liquid, paste or gel form comprising a binding / thickening system that also function effectively as humectant agent thereby replacing a significant portion or all of traditional humectant components such as glycerin, sorbitol and other polyols. The binding / thickening system comprise select carrageenans that provide a water viscosity of at least about 20 mPa·s in a 1.5% solution at 25° C. and effective water-binding capacity to prevent significant water loss from the composition when exposed to air to cause unacceptable drying out. For example, the water-binding capacity of the carrageenan must be effective such that there is no more than about 0.75% water loss from a dentifrice composition when exposed to air for 30 minutes at room temperature conditions and 50% relative humidity. The present dentifrice compositions exhibit increased dispersibility in saliva during use, which provides for increased contact time of the composition with the user's teeth and oral cavity tissues such that the active dental agents contained therein are more rapidly available to effect their beneficial activity.

Owner:THE PROCTER & GAMBLE COMPANY

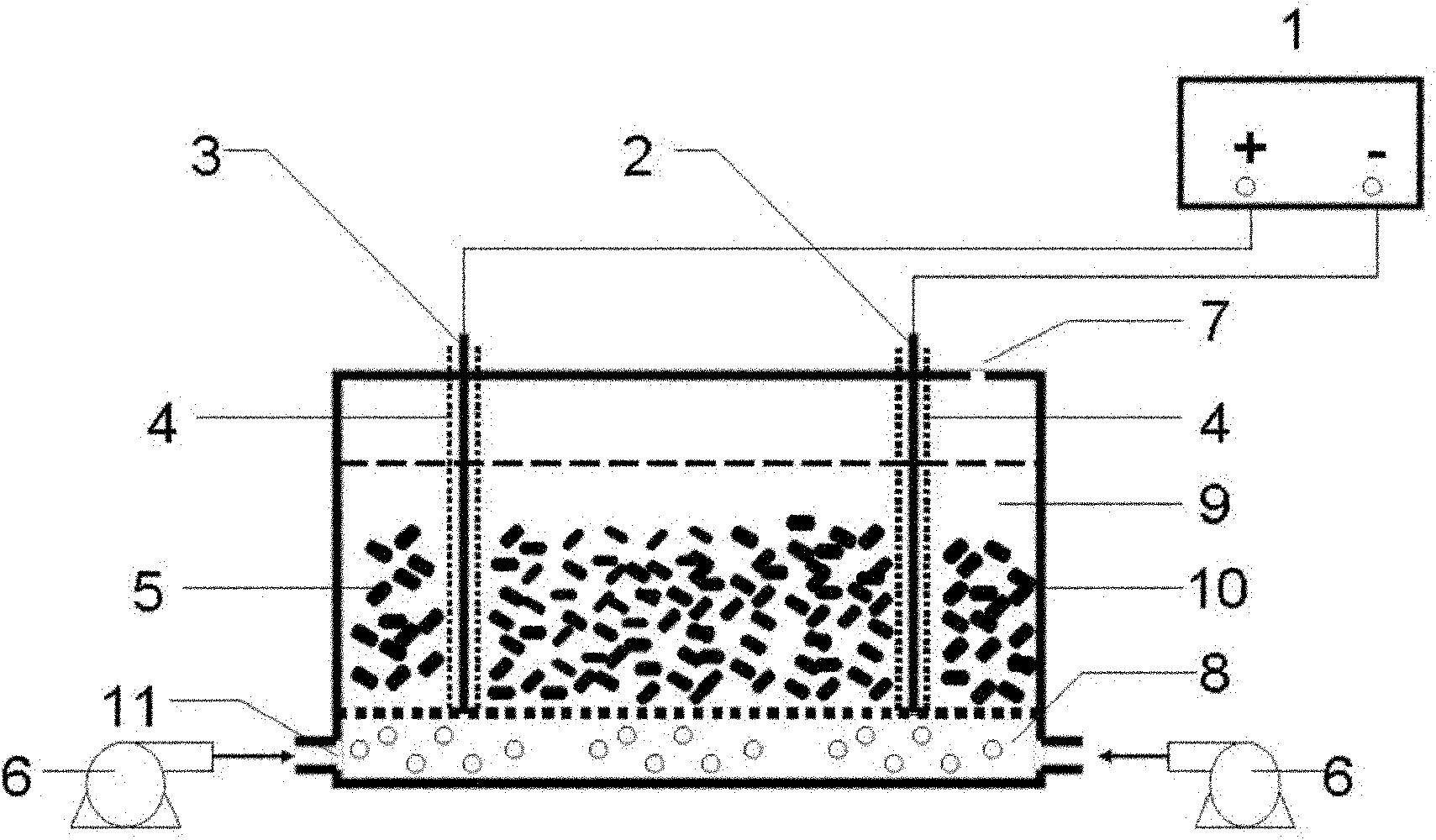

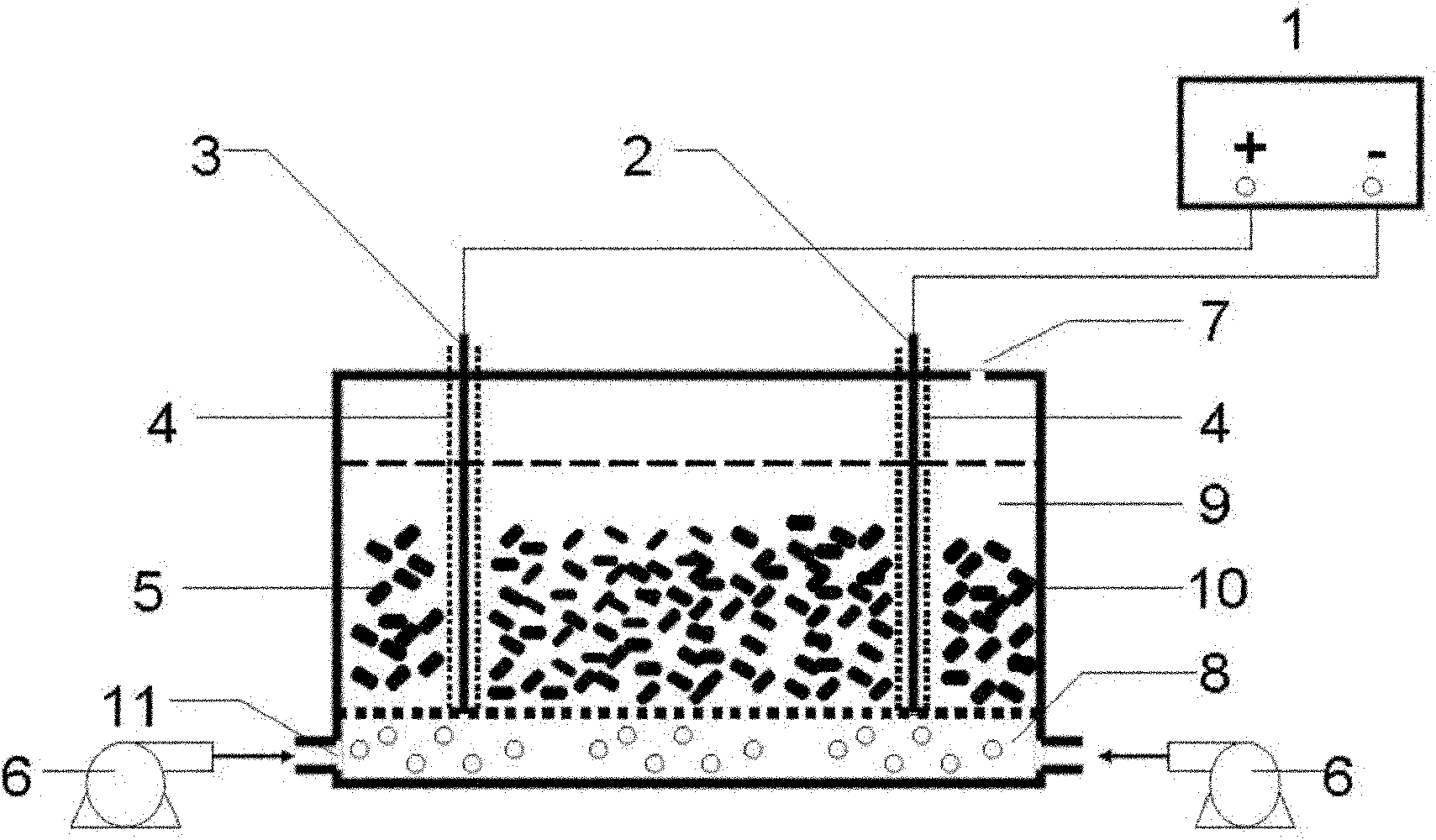

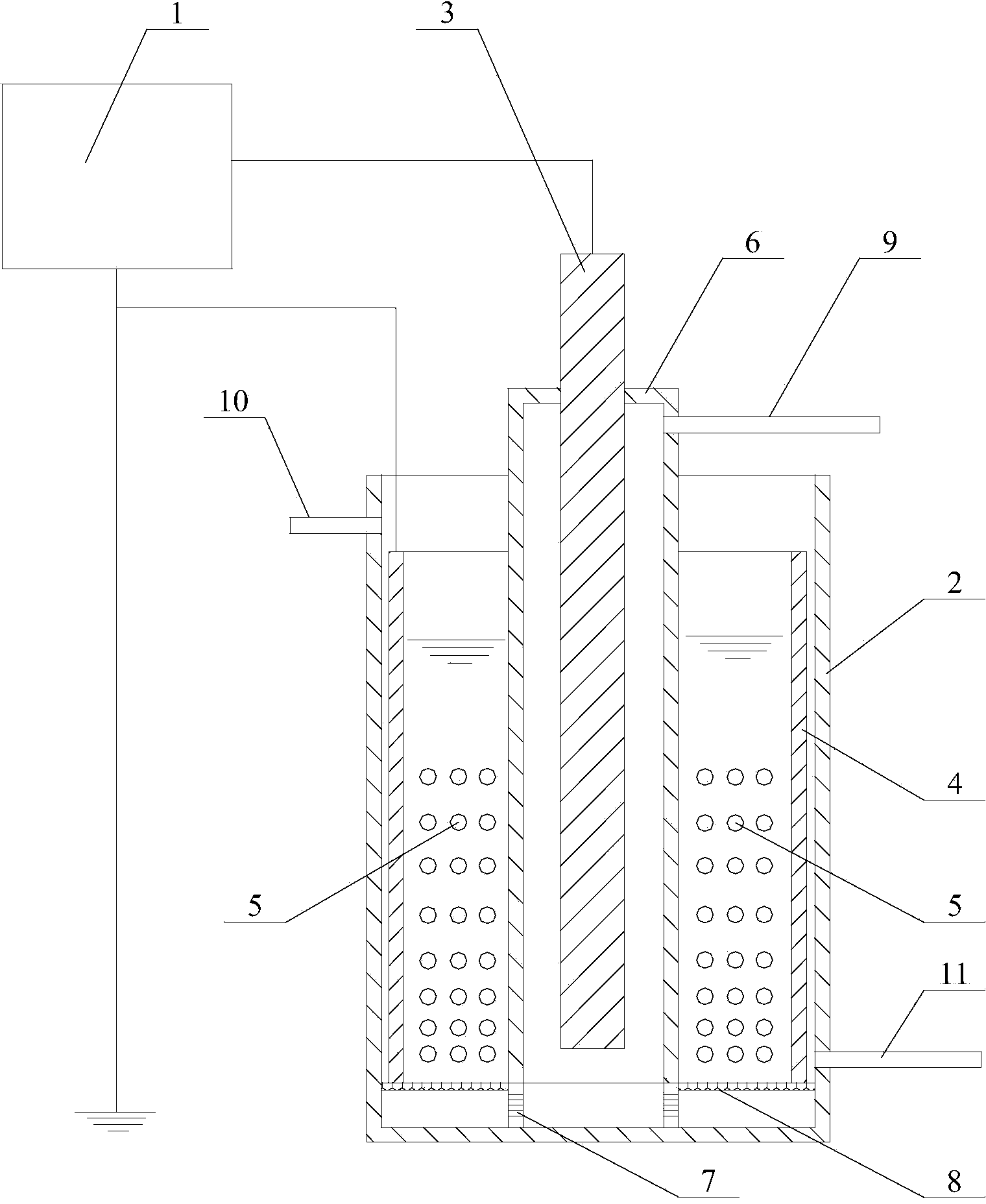

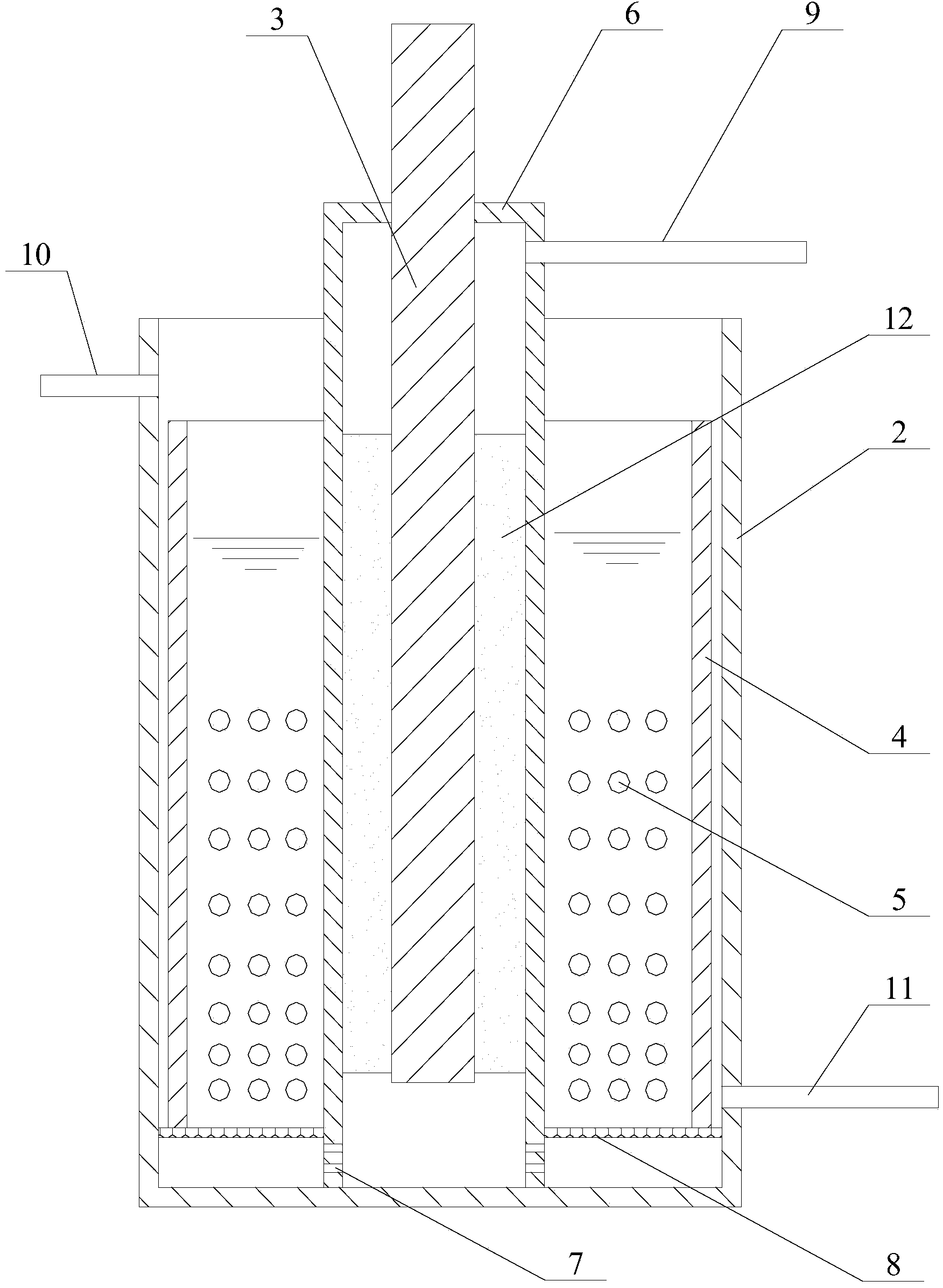

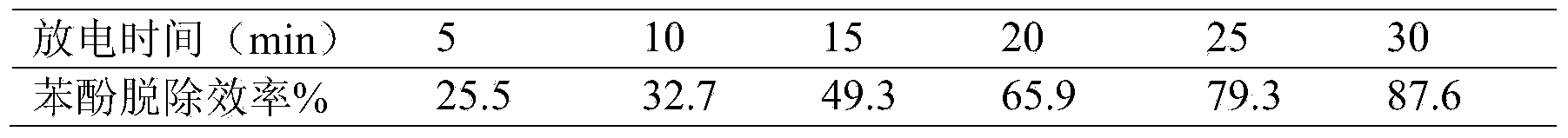

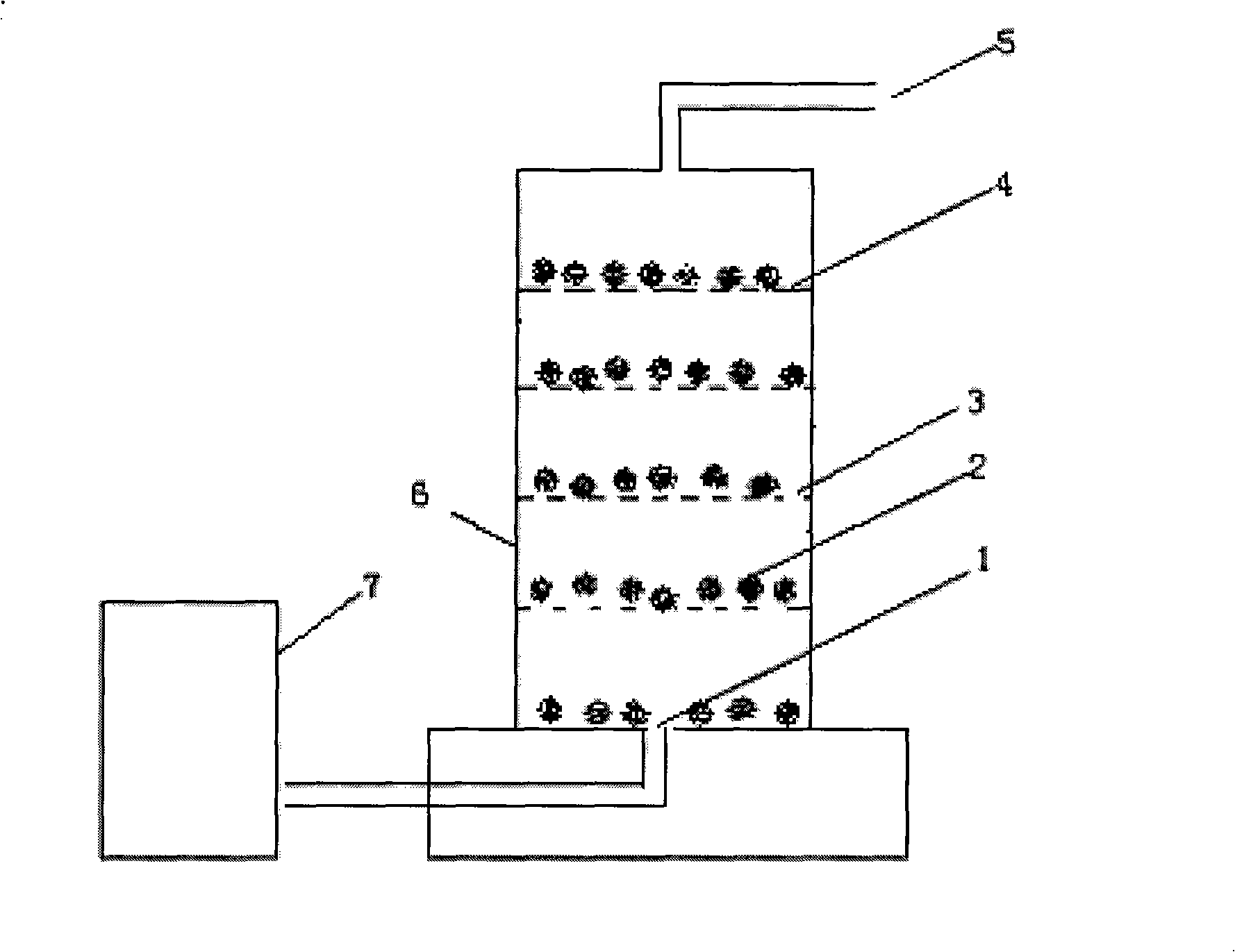

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

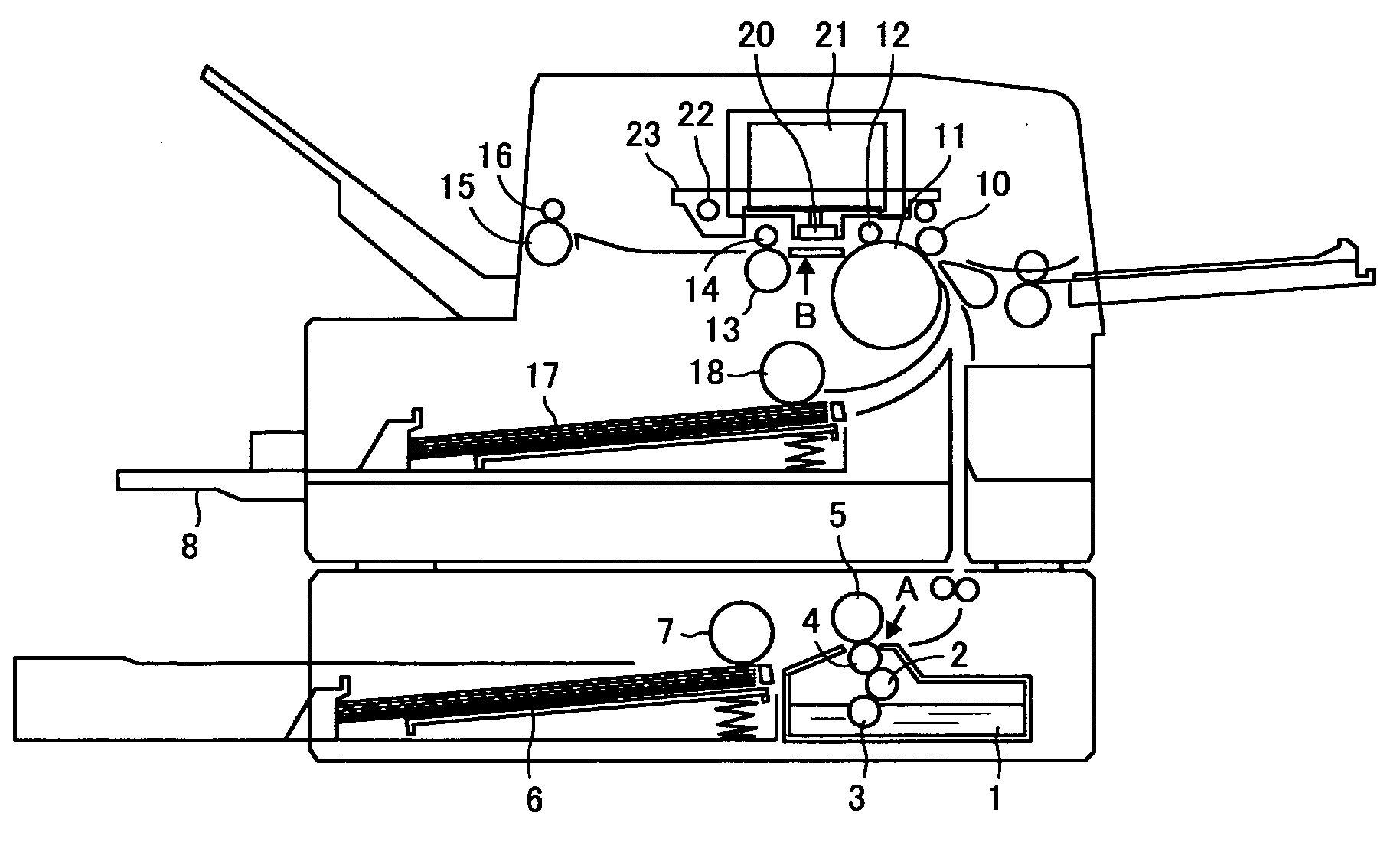

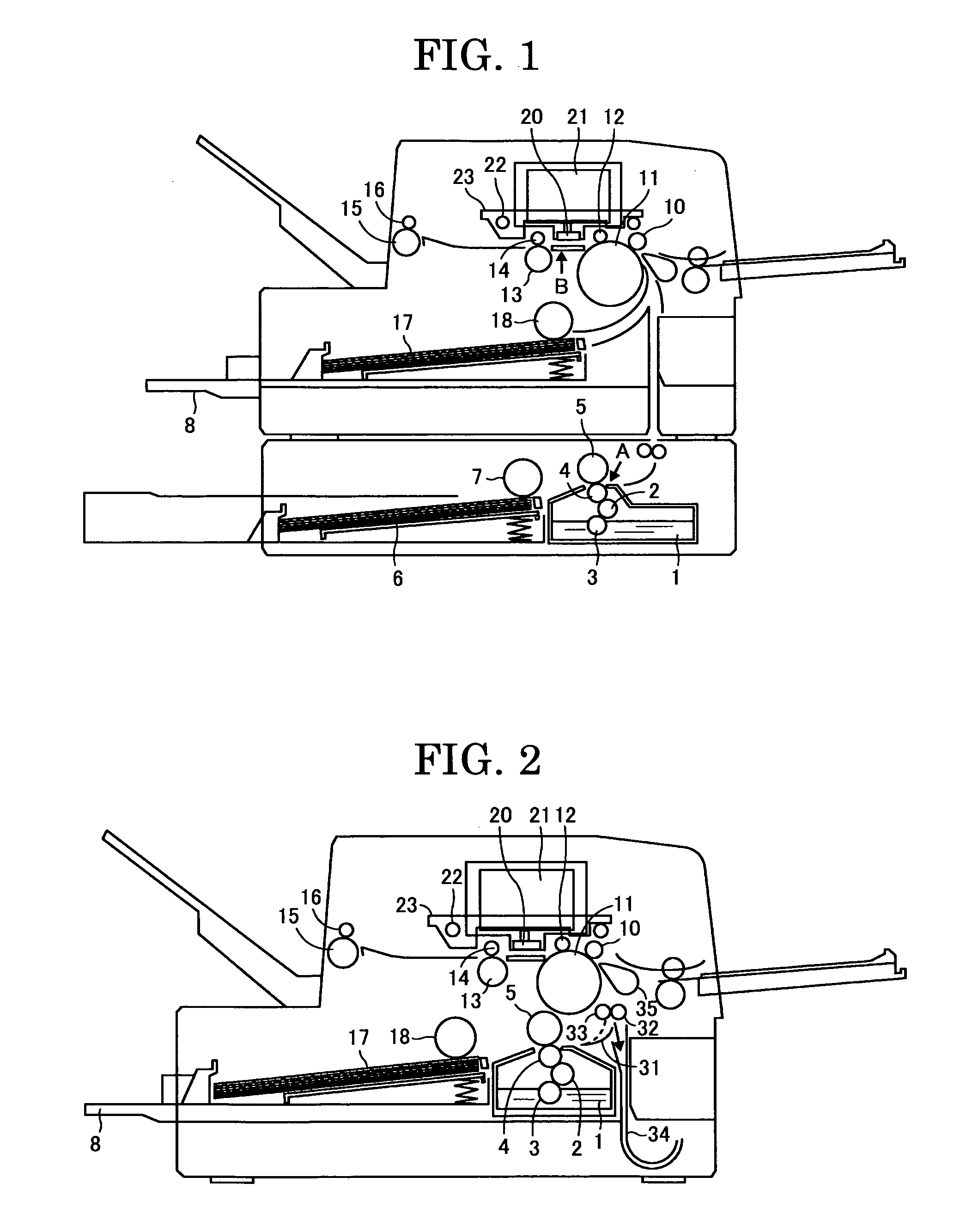

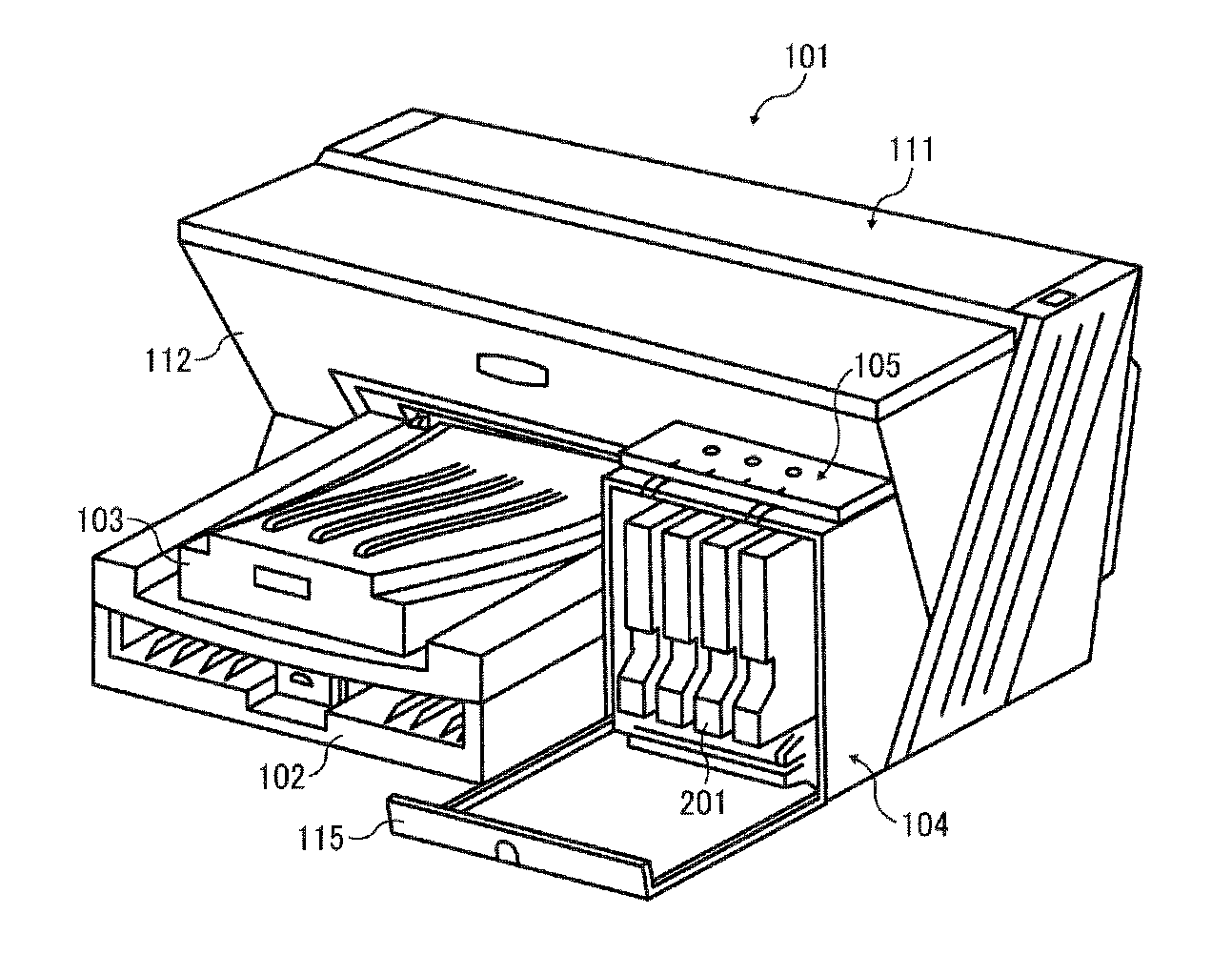

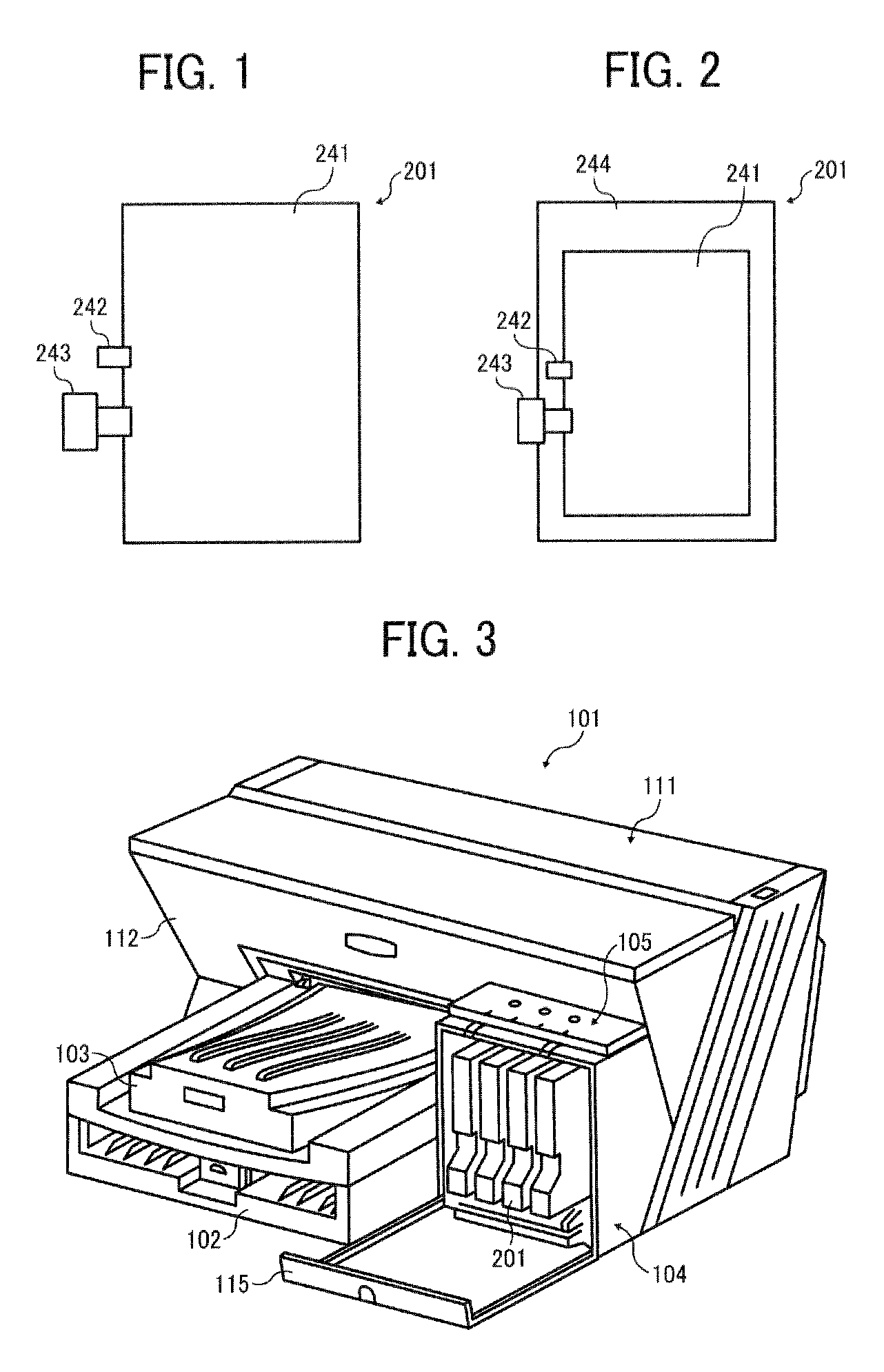

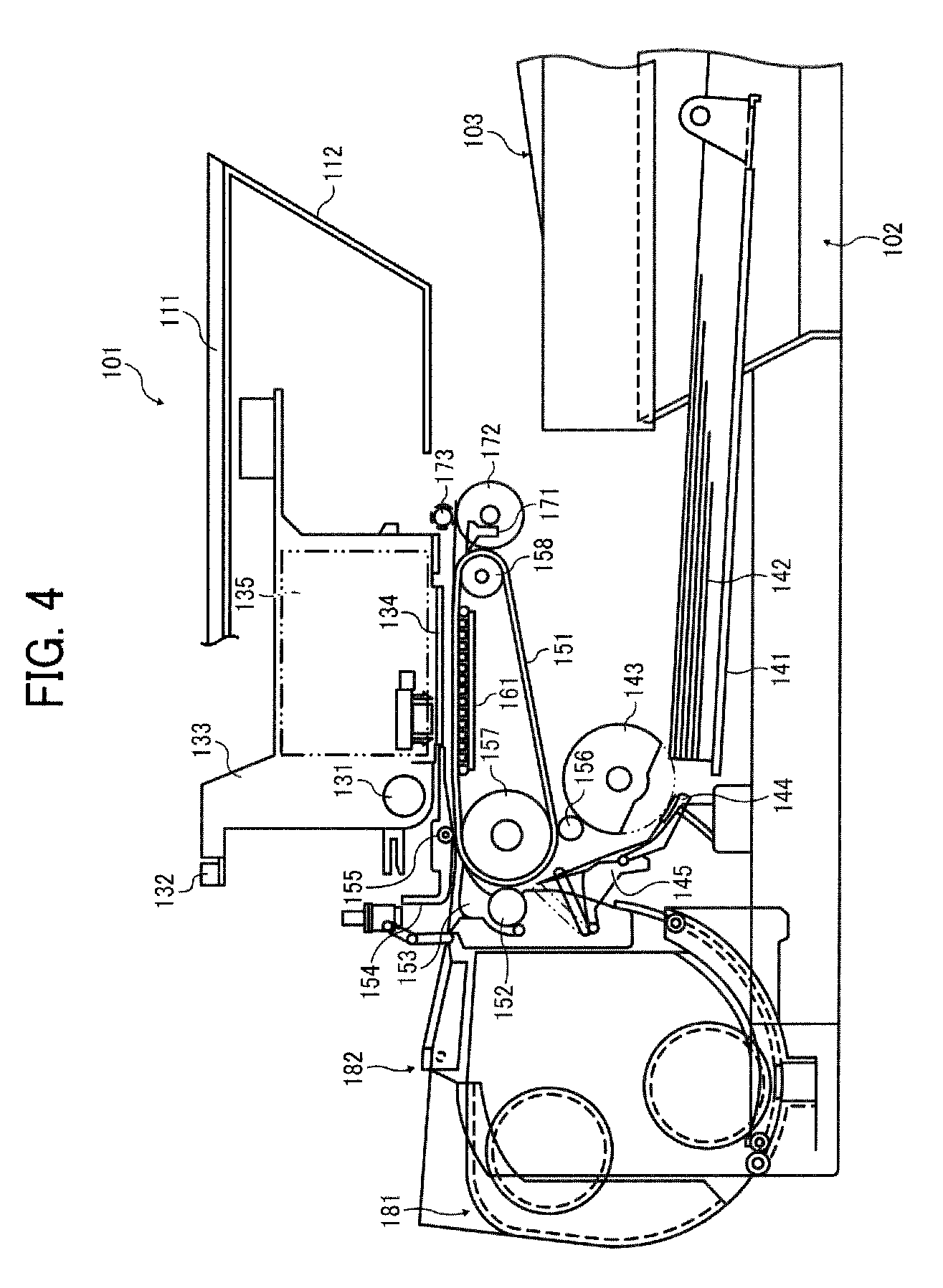

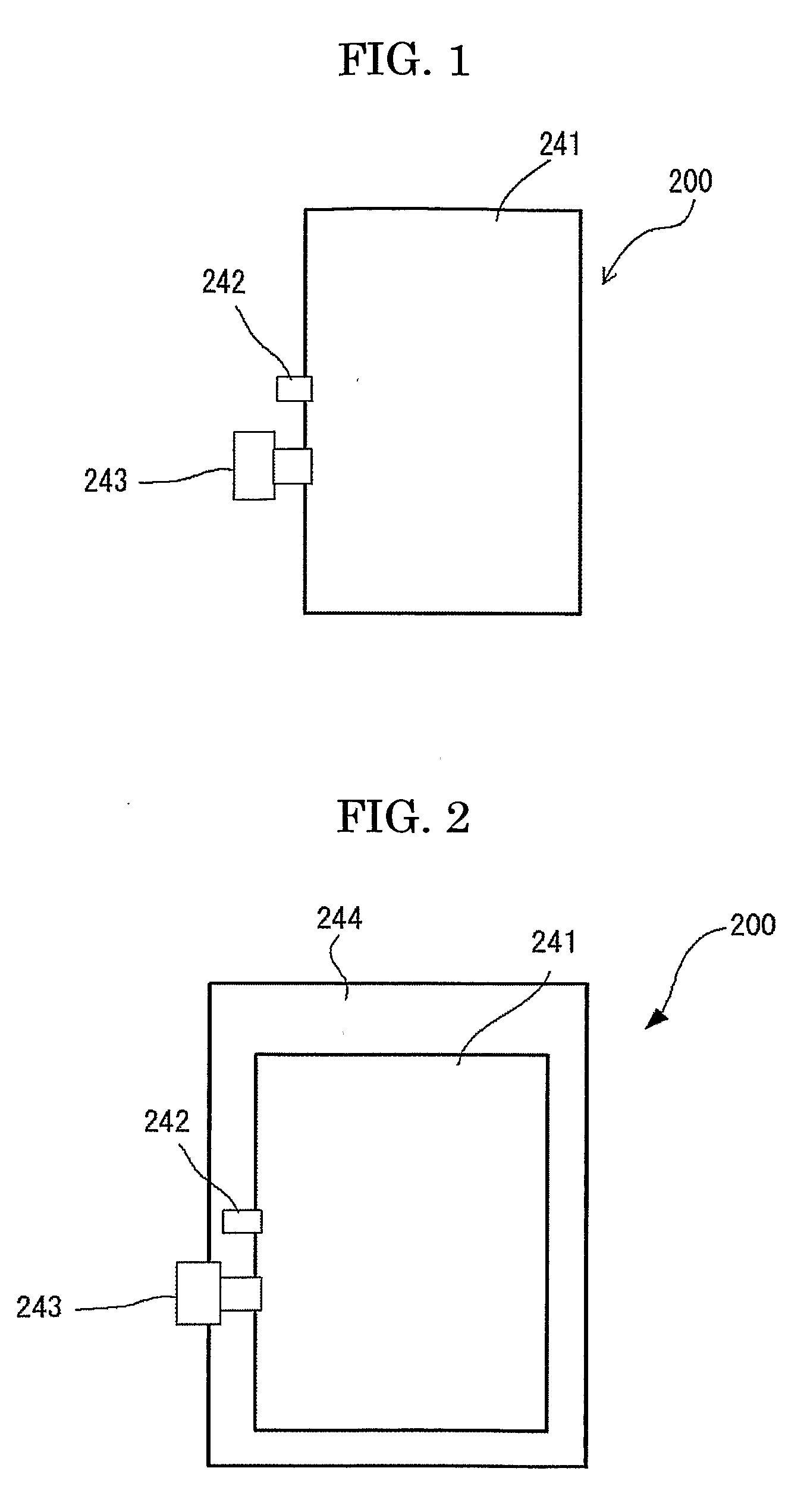

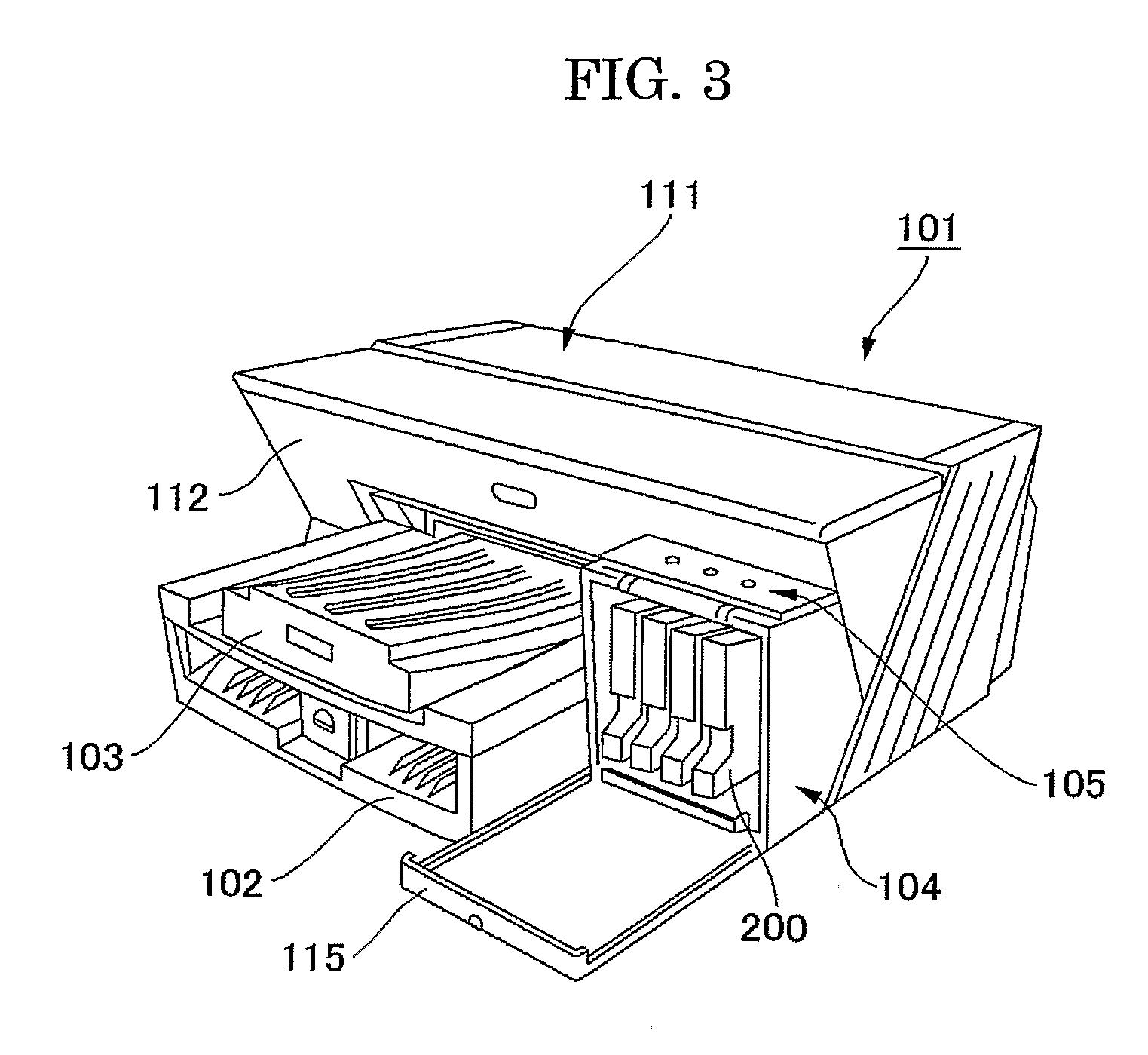

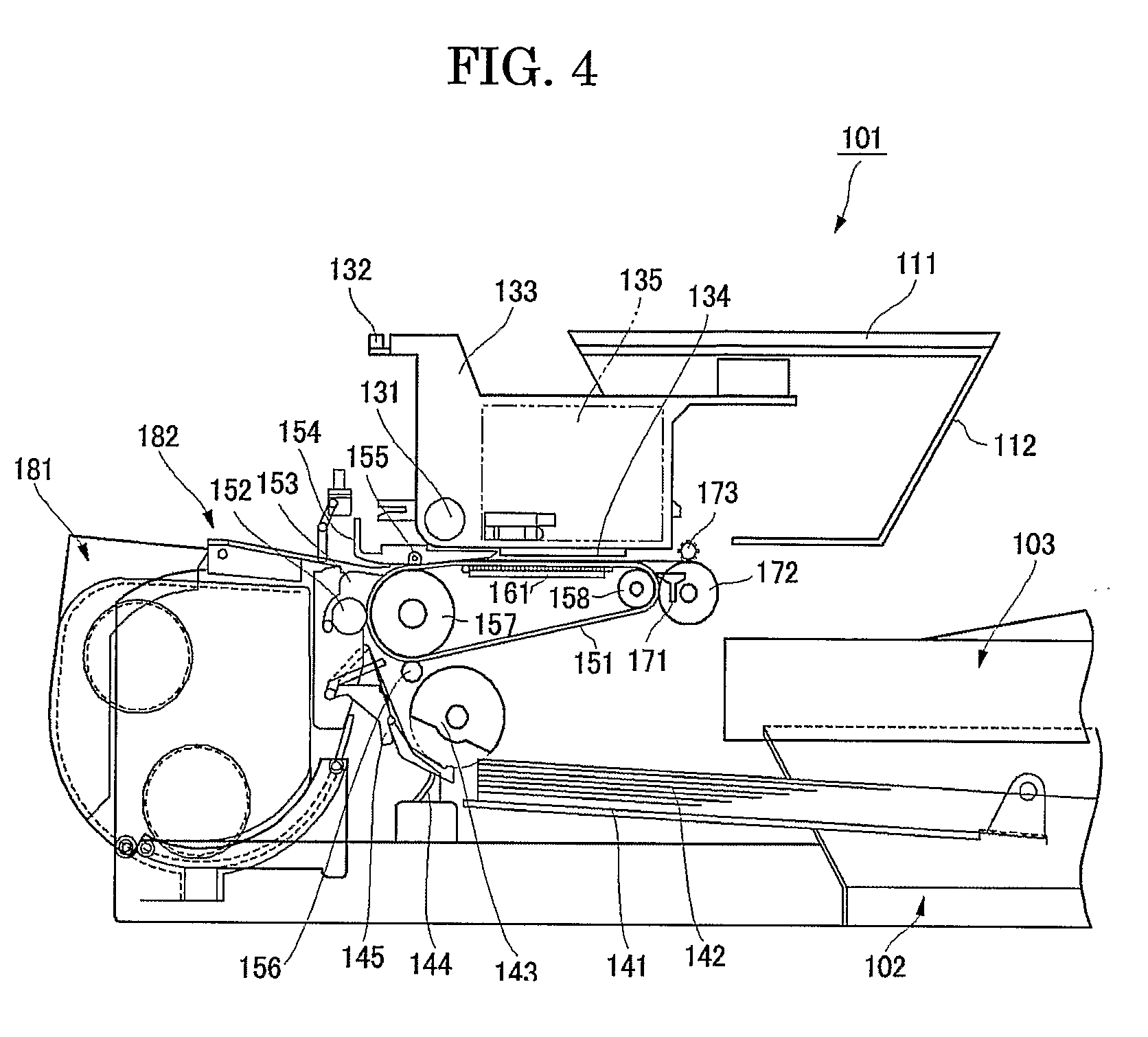

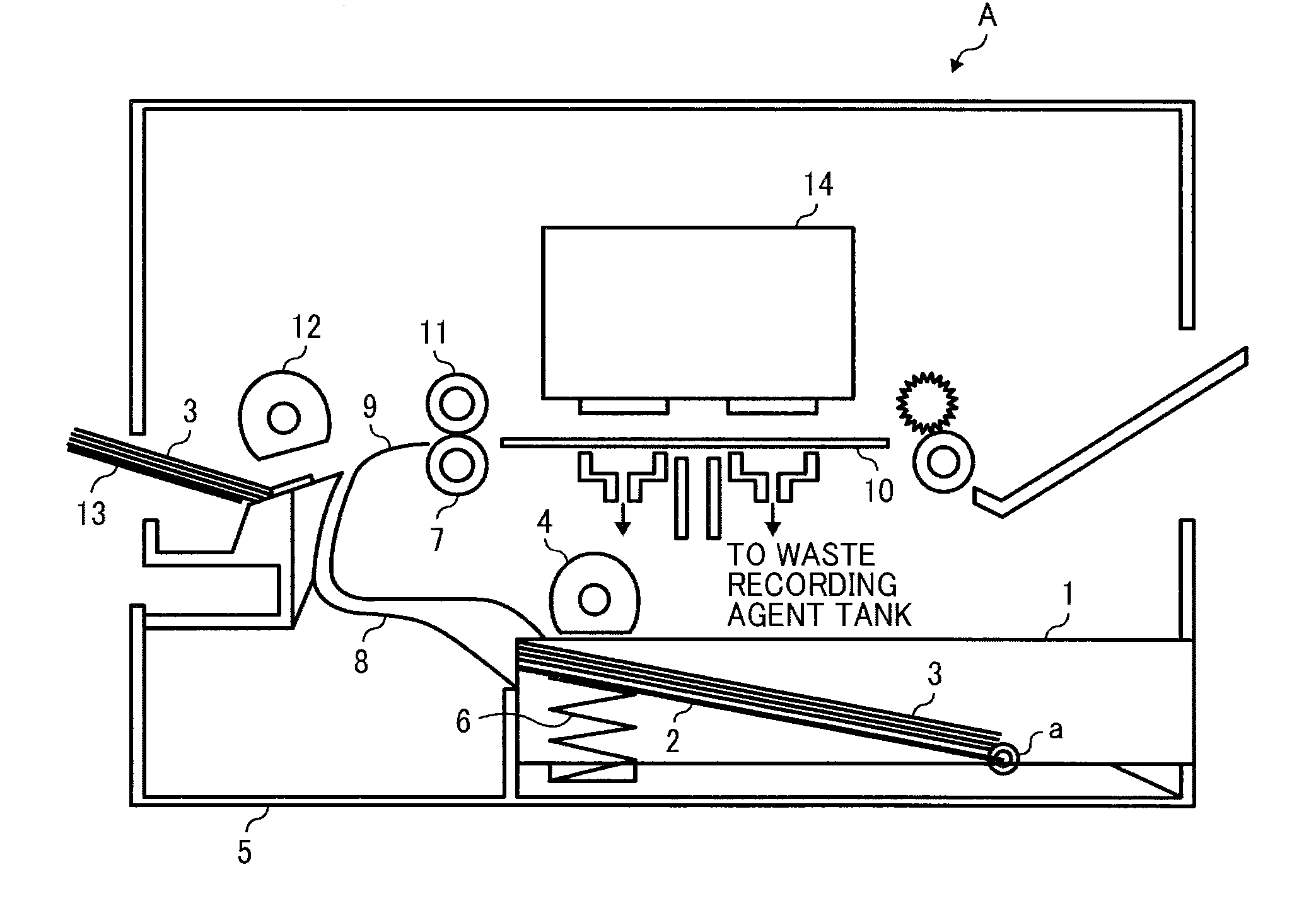

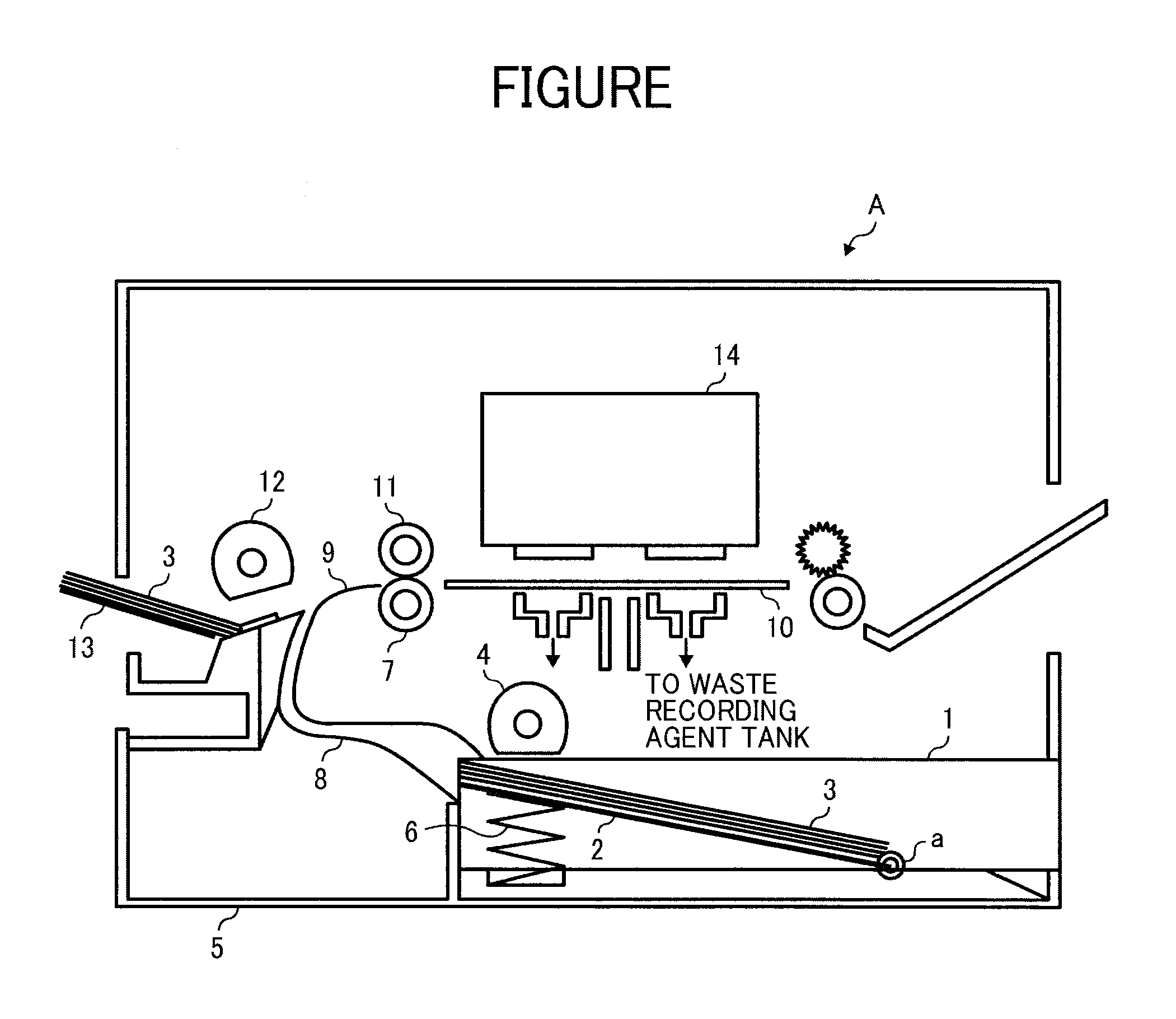

Image forming method, and image formed matter

InactiveUS20120128949A1Improve wear resistanceIncrease speedLayered productsDuplicating/marking methodsWater dispersibleEngineering

An image forming method including: applying a pre-treatment liquid onto a coating layer provided on at least one surface of a support of a recording medium, jetting an inkjet ink onto the coating layer, onto which the pre-treatment liquid has been applied, so as to form an image, and applying or jetting a post-treatment liquid onto the coating layer, onto which the inkjet ink has been jetted, so as to form a transparent protective layer on the coating layer, wherein the inkjet ink contains the water-dispersible colorant, a water-soluble organic solvent, a surfactant, a penetrant and water, and wherein an amount of pure water transferred into the recording medium, provided with the coating layer, measured at a contact time of 100 ms with a dynamic scanning liquid absorptometer is 1 ml / m2 to 10 ml / m2, and the pre-treatment liquid contains a water-soluble aliphatic organic acid.

Owner:RICOH KK

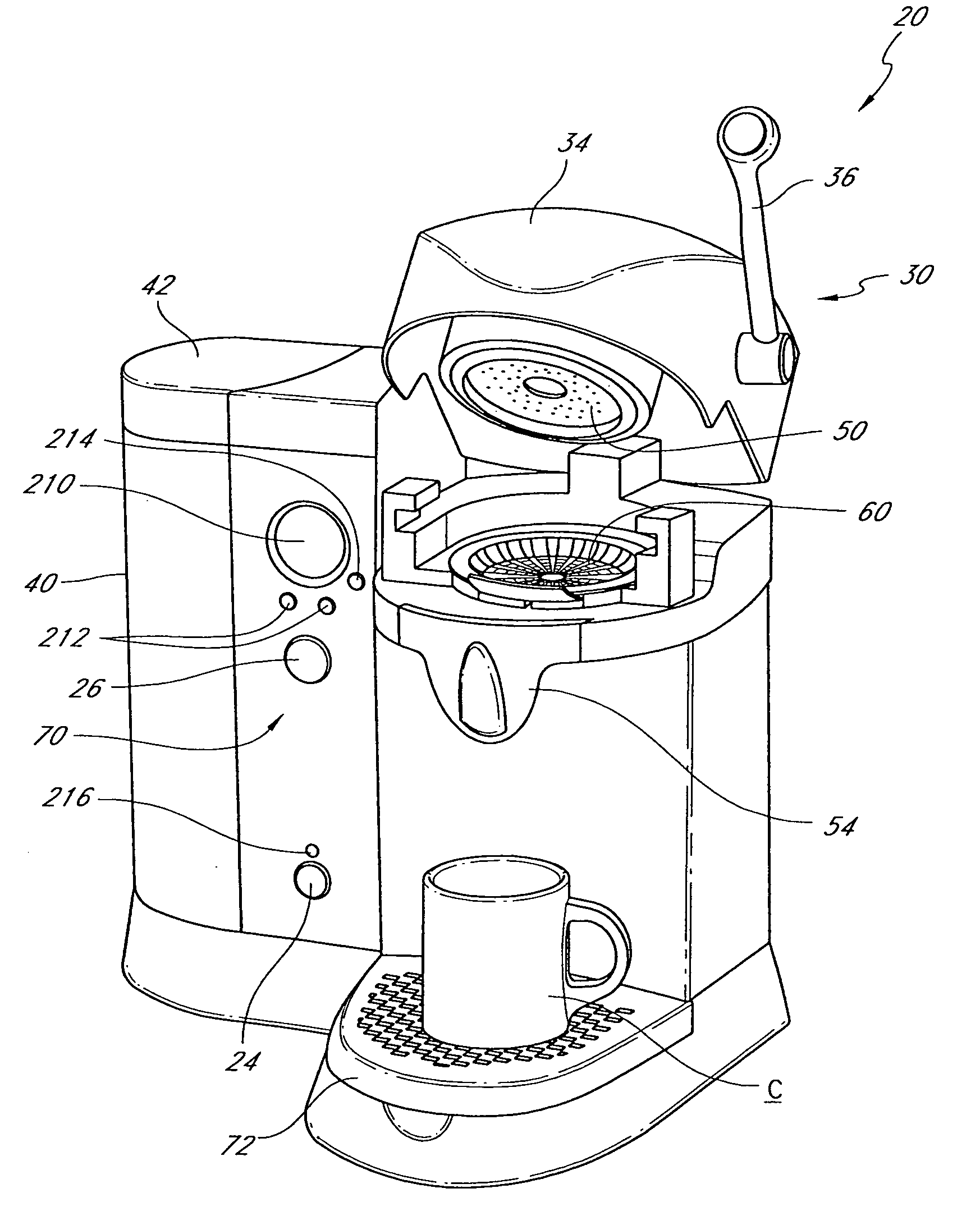

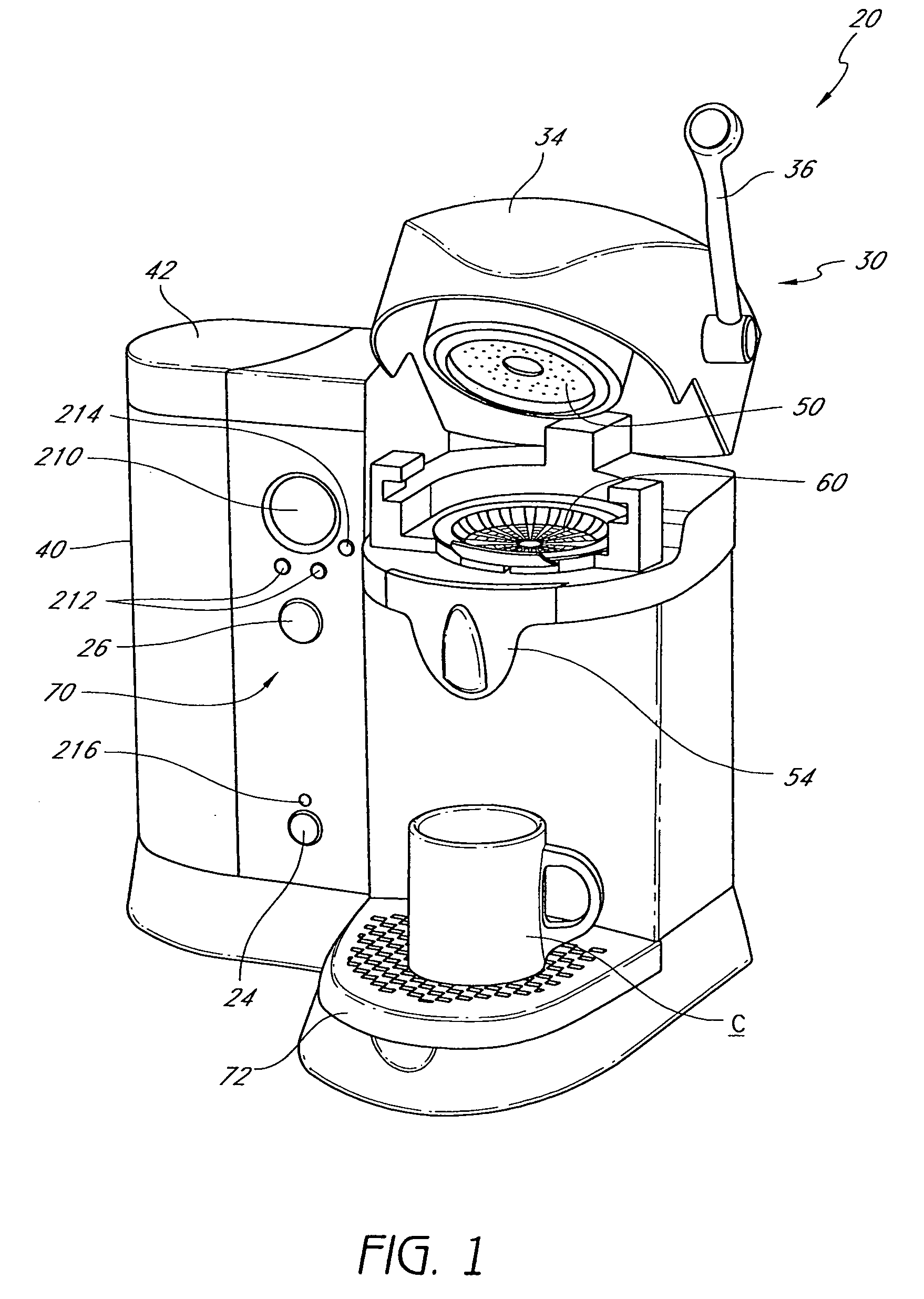

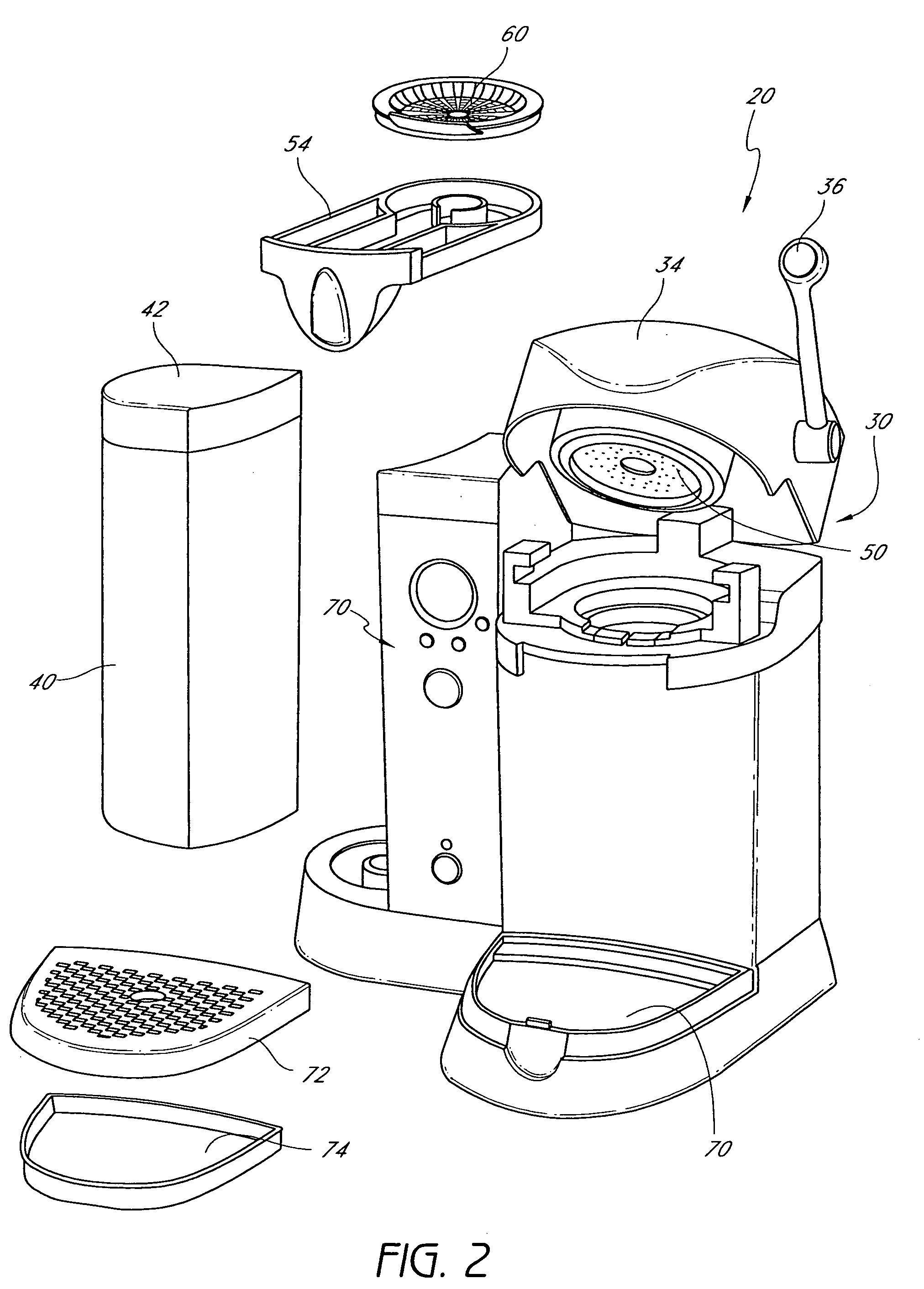

Hot beverage brewing device

A brewing device can include a pump and a heater configured to deliver heated water to a beverage ingredient receiving assembly. The brewing device can include a controller to regulate the operation of the various components and to interface with the user. The beverage ingredient receiving assembly can have a lid portion secured to a corresponding lower portion using a latching mechanism. A shower head can be used to distribute the heated water over the beverage ingredient and can be configured to maintain the filter or other brewed item within the filter tray after a beverage has been brewed. A handle positioned on the lid portion can be used to control the latch mechanism and position of the shower head relative to the adjacent filter tray. The filter tray has a plurality of diversion members configured to optimize the contact time between the heated liquid and the beverage ingredient.

Owner:SIMPLEHUMAN

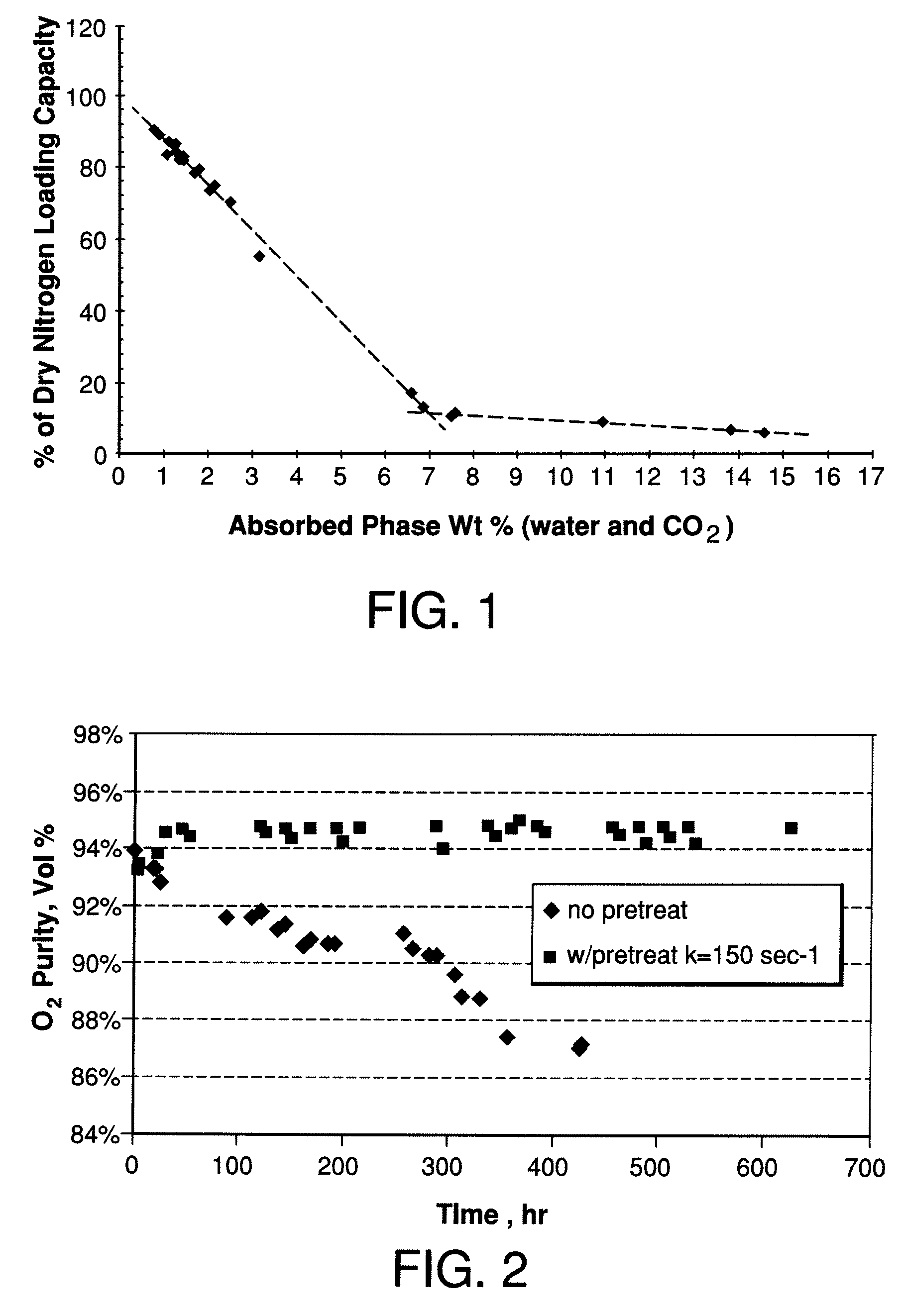

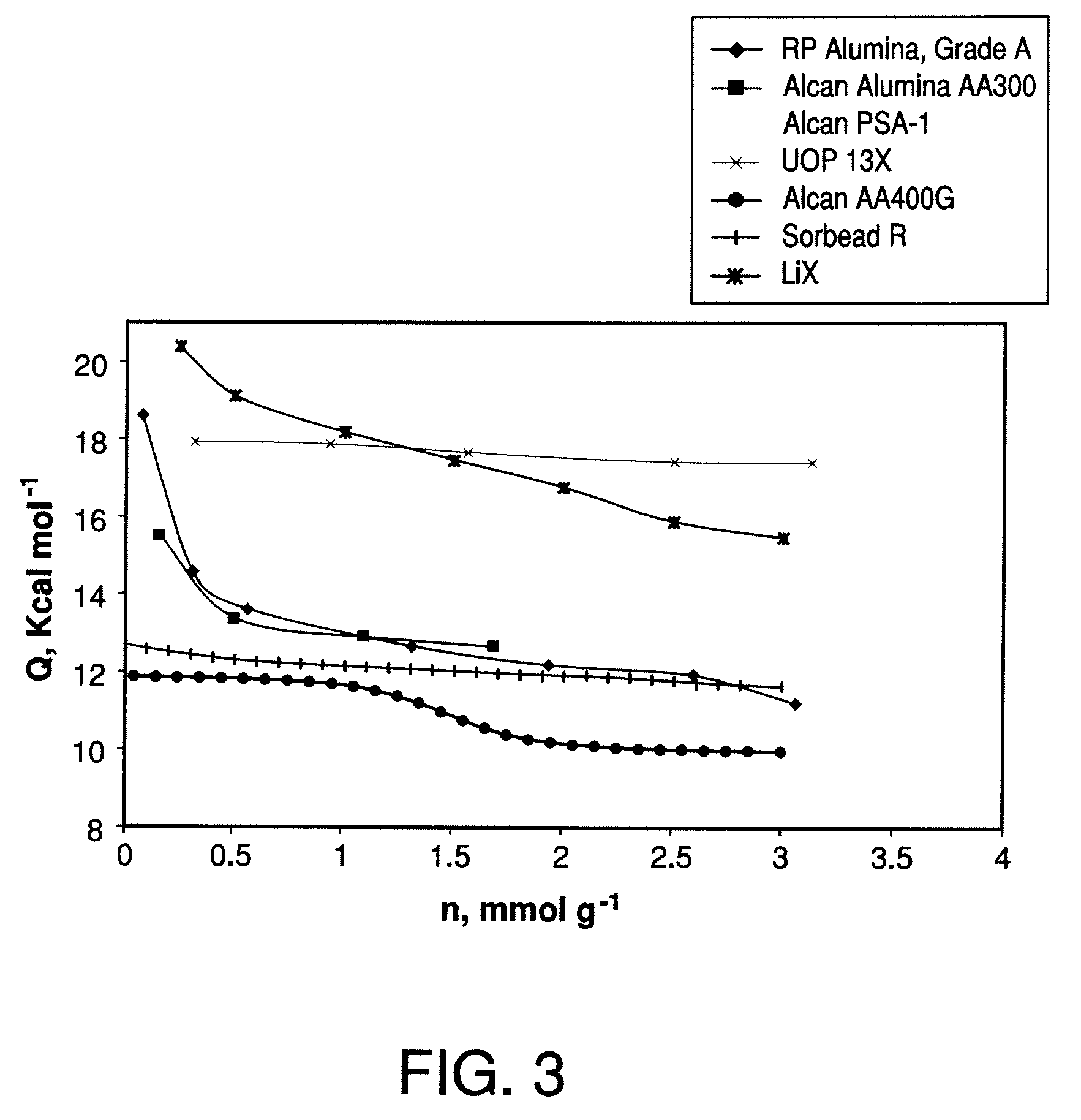

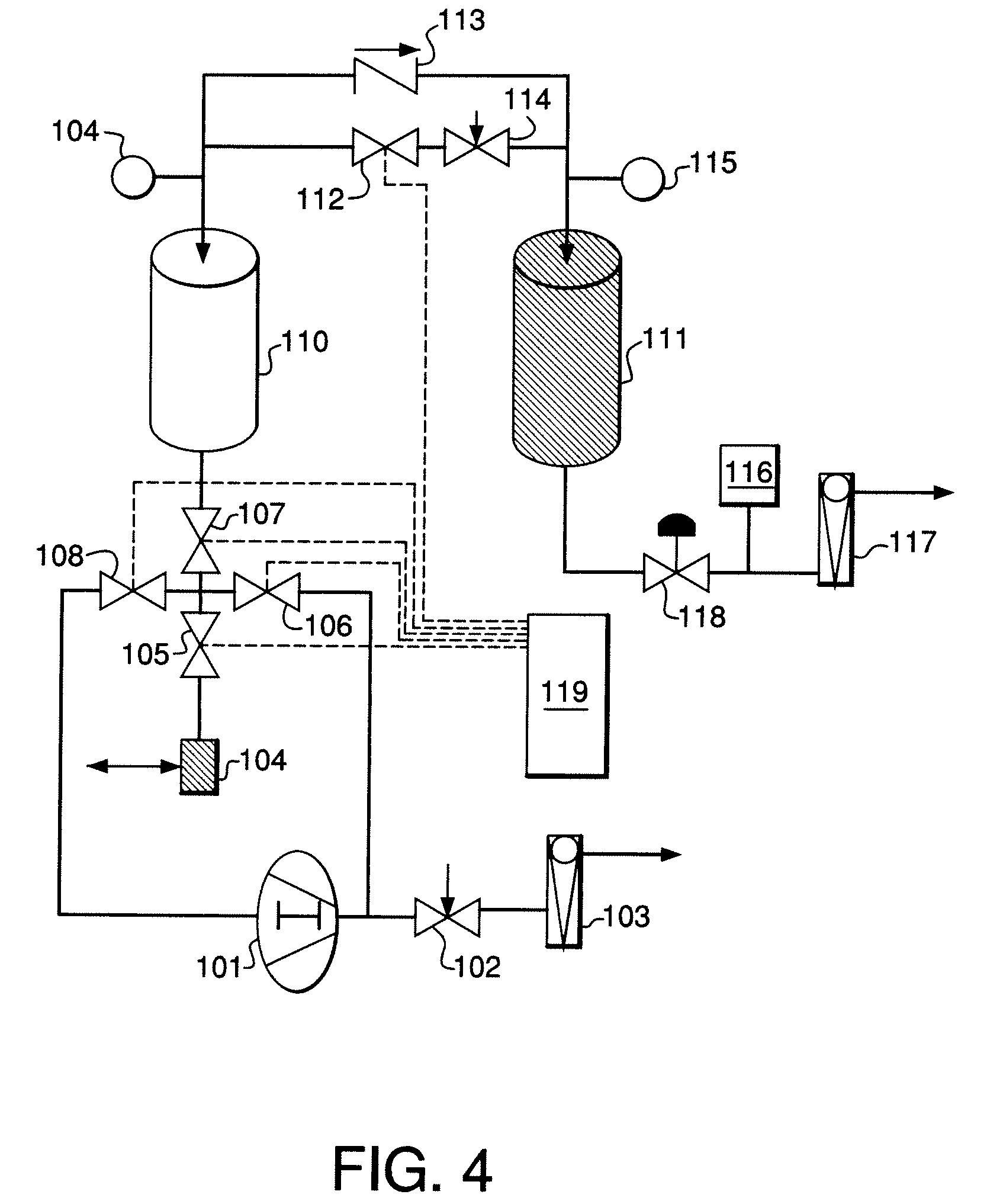

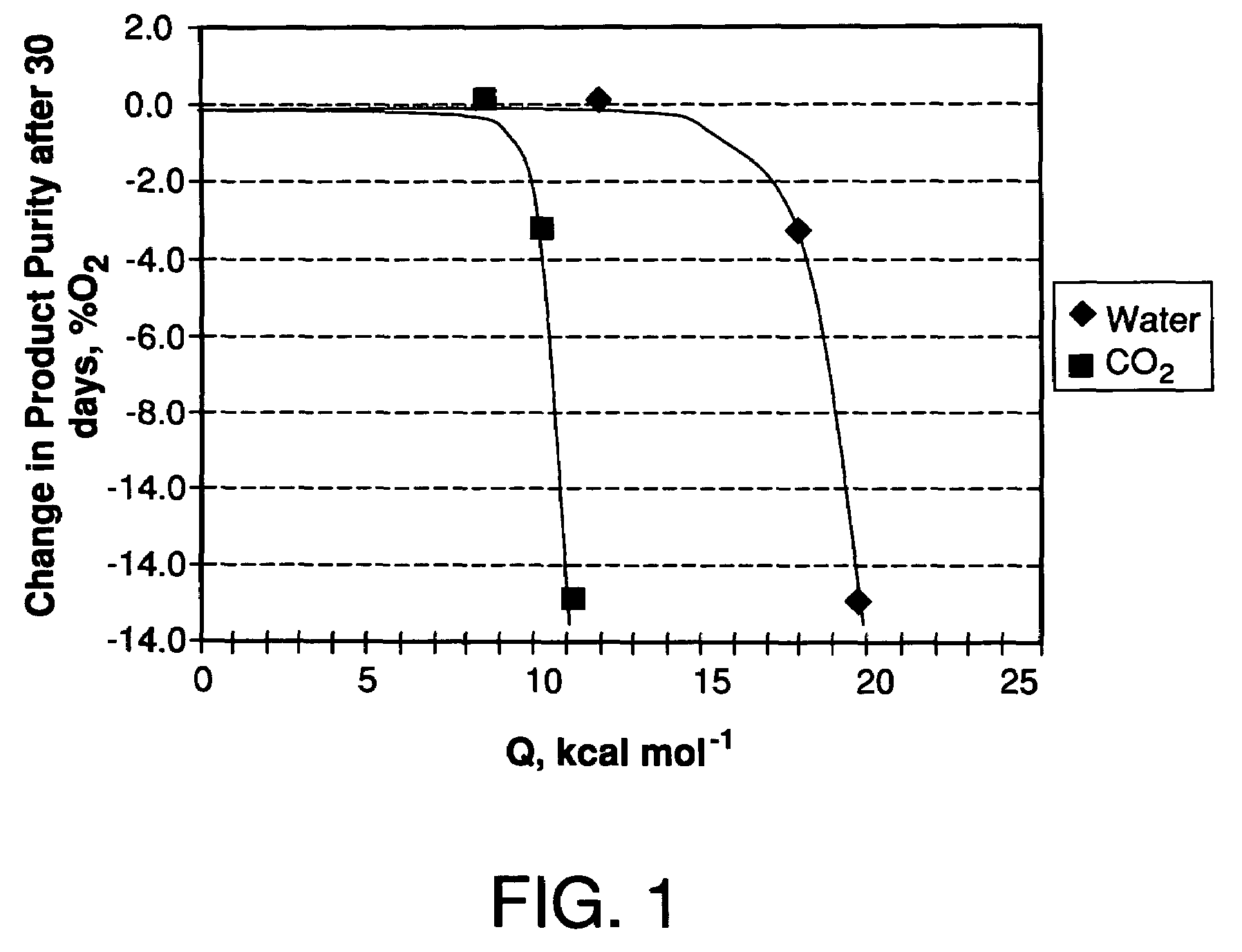

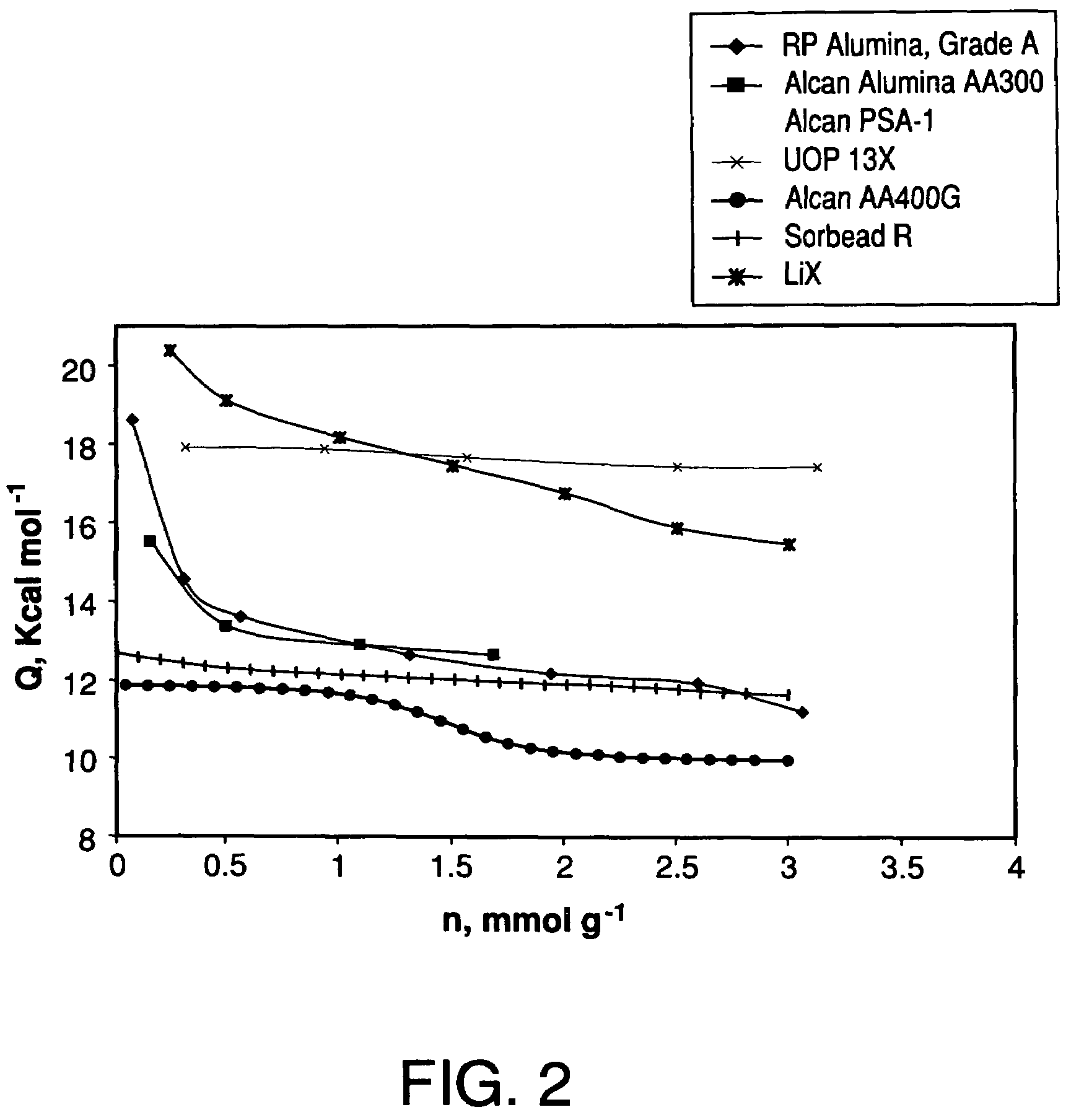

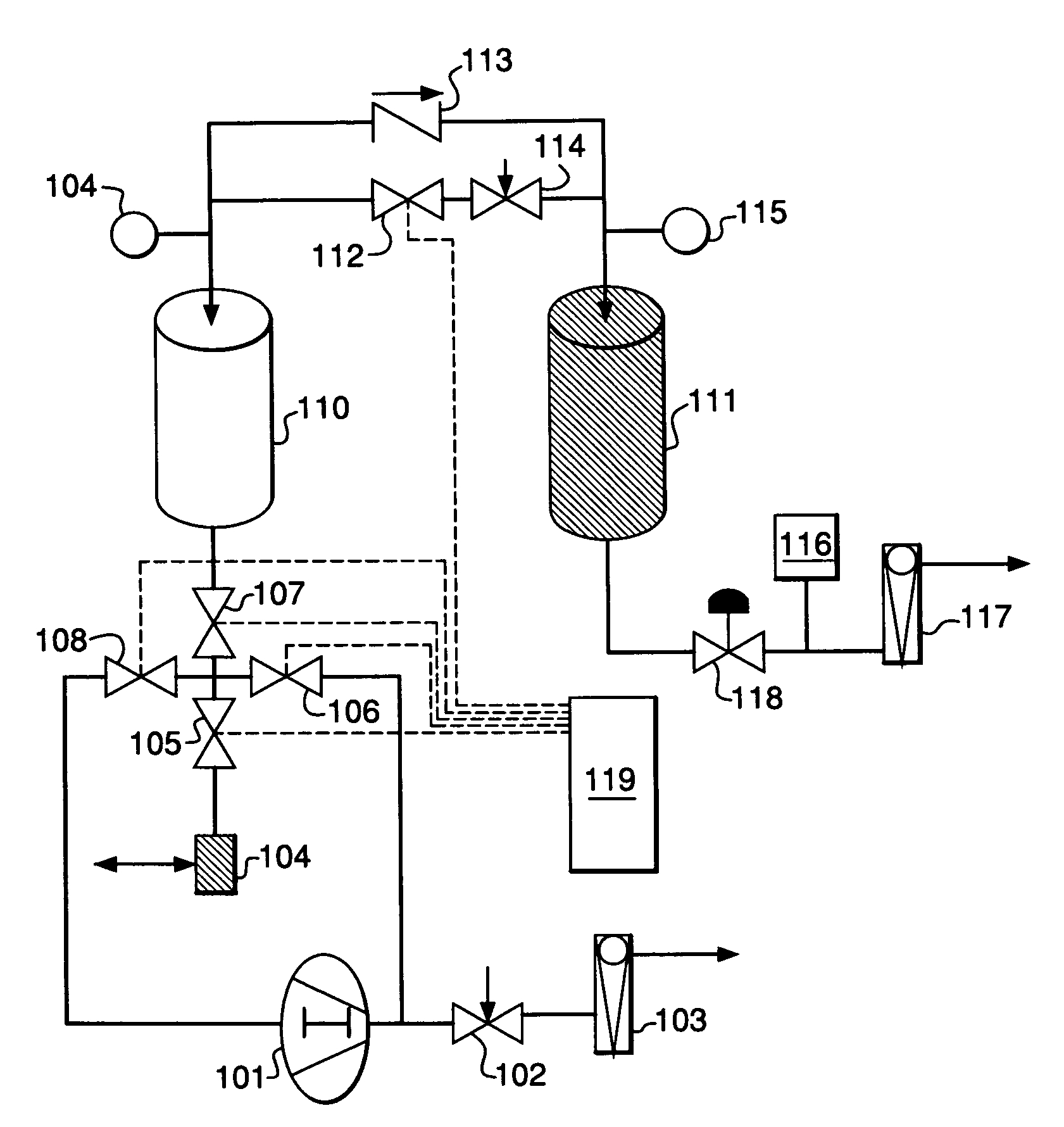

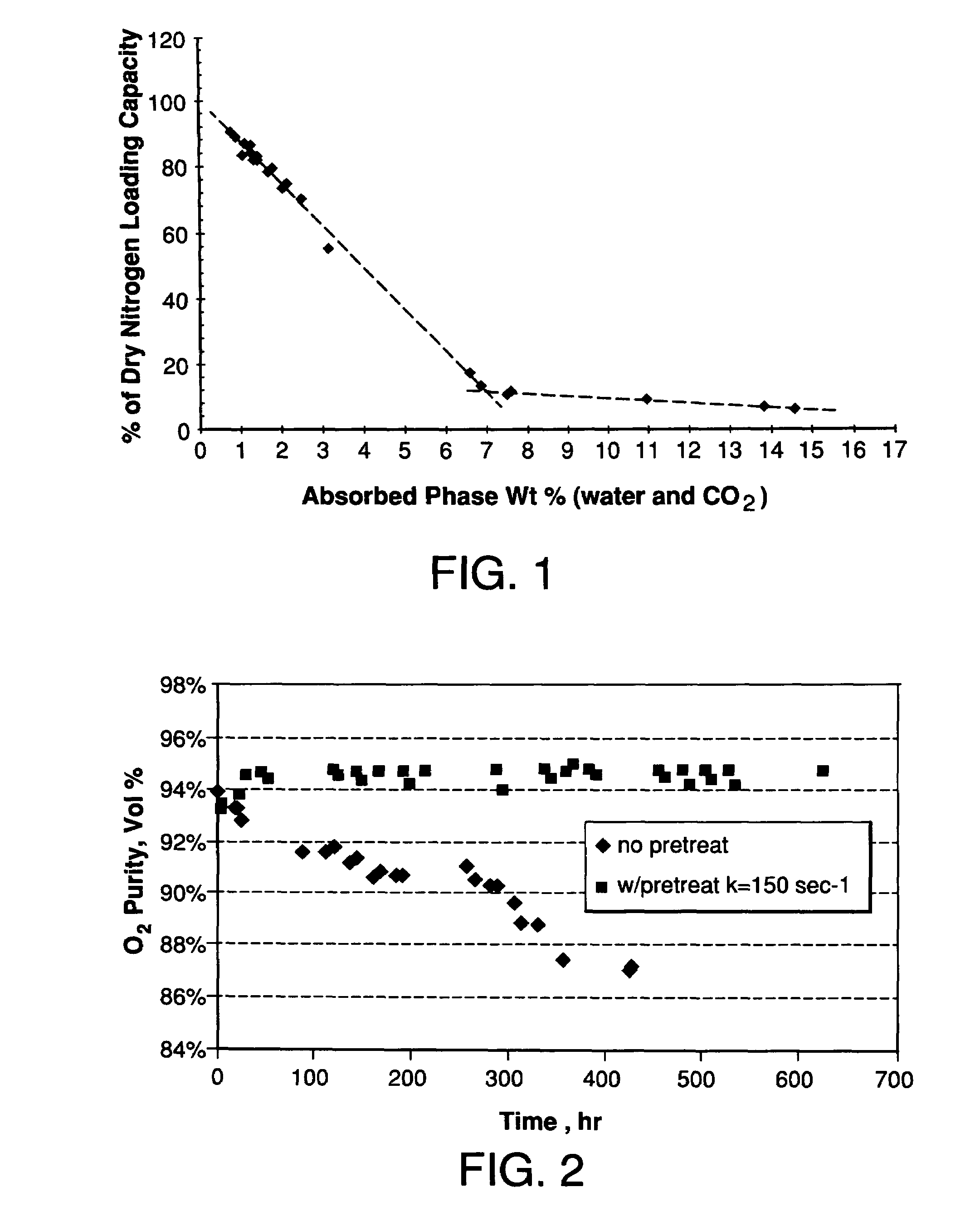

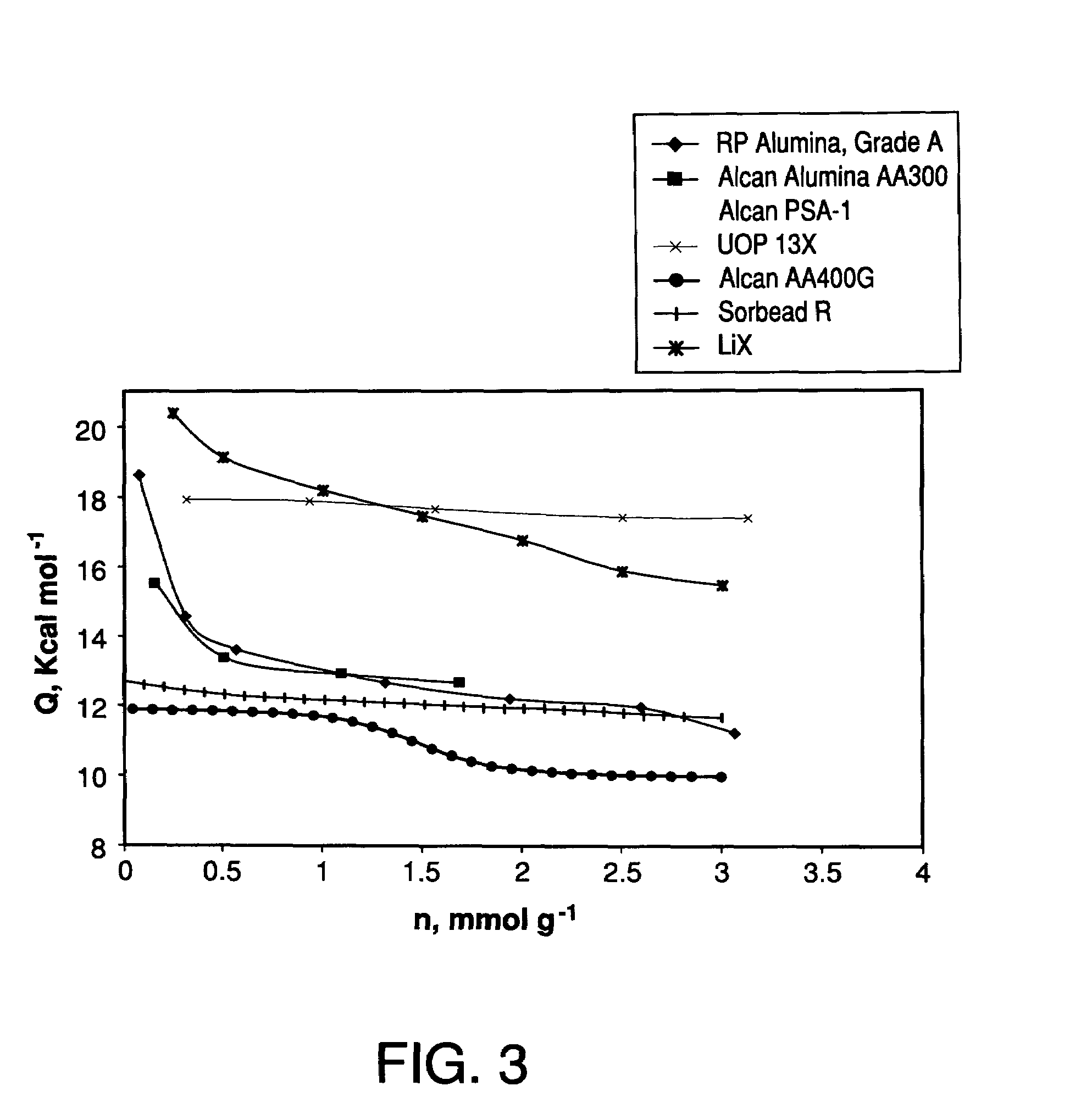

Performance Stability in Shallow Beds in Pressure Swing Adsorption Systems

PSA process for oxygen production comprising (a) providing an adsorber having a first layer of adsorbent selective for water and a second layer of adsorbent selective for nitrogen, wherein the heat of adsorption of water on the adsorbent in the first layer is equal to or less than about 14 kcal / mole at water loadings less than about 0.05 mmol per gram; (b) passing a feed gas comprising at least oxygen, nitrogen, and water successively through the first and second layers, adsorbing water in the first layer of adsorbent, and adsorbing nitrogen in the second layer of adsorbent, wherein the mass transfer coefficient of water in the first layer is in the range of about 125 to about 400 sec−1 and the superficial contact time of the feed gas in the first layer is between about 0.08 and about 0.50 sec; and (c) withdrawing a product enriched in oxygen from the adsorber.

Owner:AIR PROD & CHEM INC

Performance stability in rapid cycle pressure swing adsorption systems

Pressure swing adsorption process for producing oxygen comprising (a) providing at least one adsorber vessel having a first layer of adsorbent adjacent the feed end of the vessel and a second layer of adsorbent adjacent the first layer, wherein the surface area to volume ratio of the first layer is in the range of about 0.75 to about 1.8 cm−1; (b) introducing a pressurized feed gas comprising at least oxygen, nitrogen, and water into the feed end, adsorbing at least a portion of the water in the adsorbent in the first layer, and adsorbing at least a portion of the nitrogen in the adsorbent in the second layer, wherein the superficial contact time of the pressurized feed gas in the first layer is between about 0.08 and about 0.50 sec; and (c) withdrawing a product gas enriched in oxygen from the product end of the adsorber vessel.

Owner:AIR PROD & CHEM INC

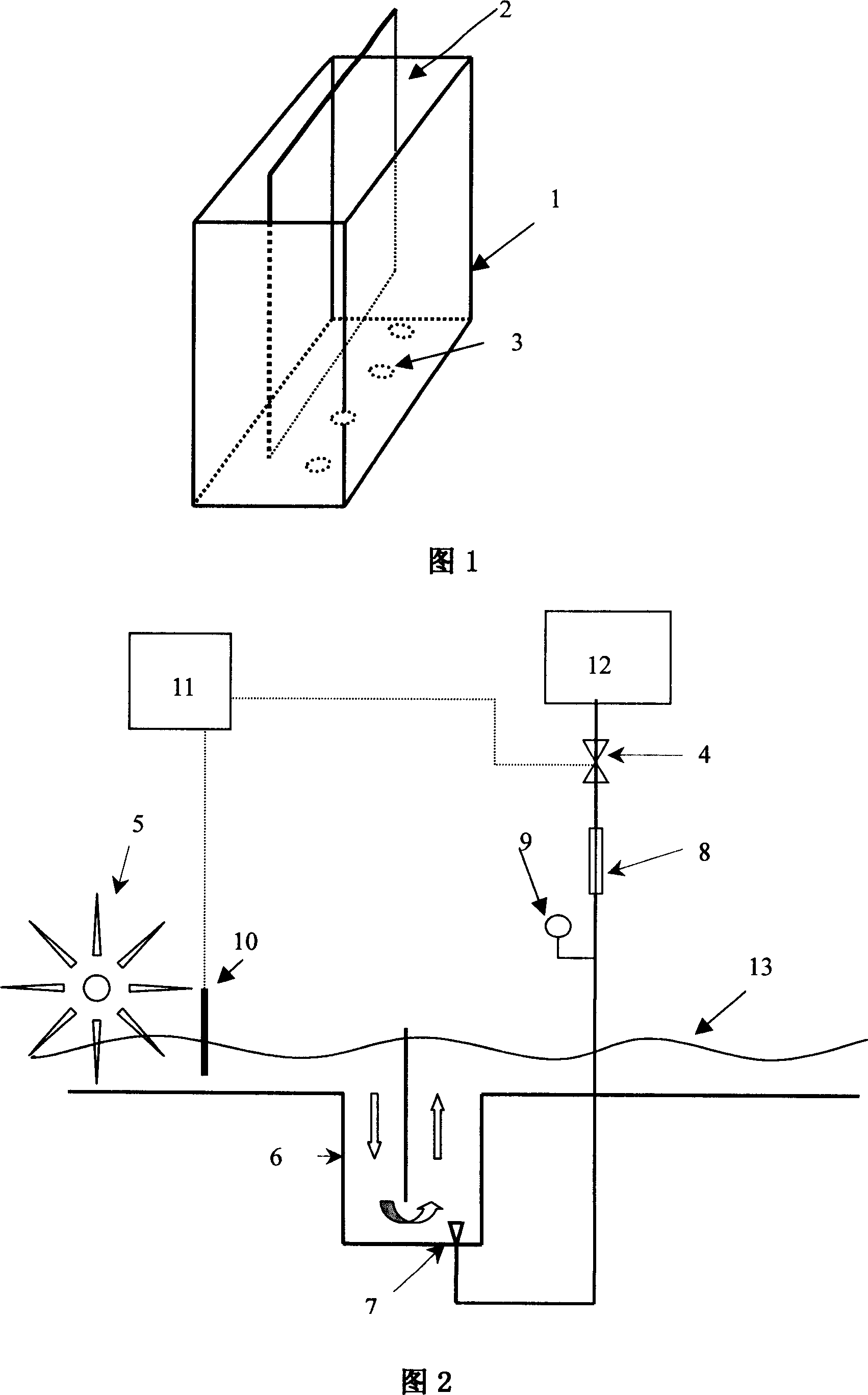

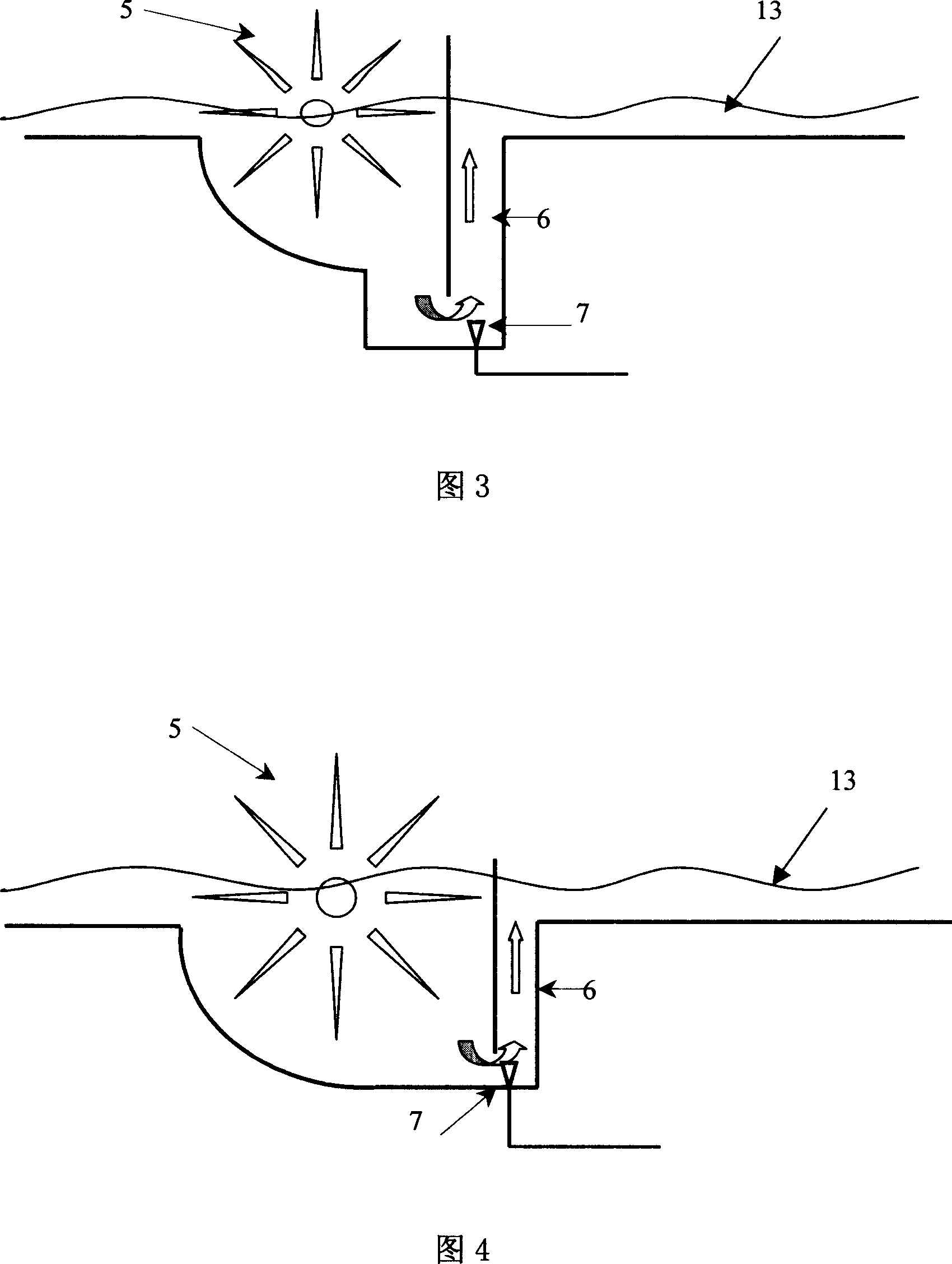

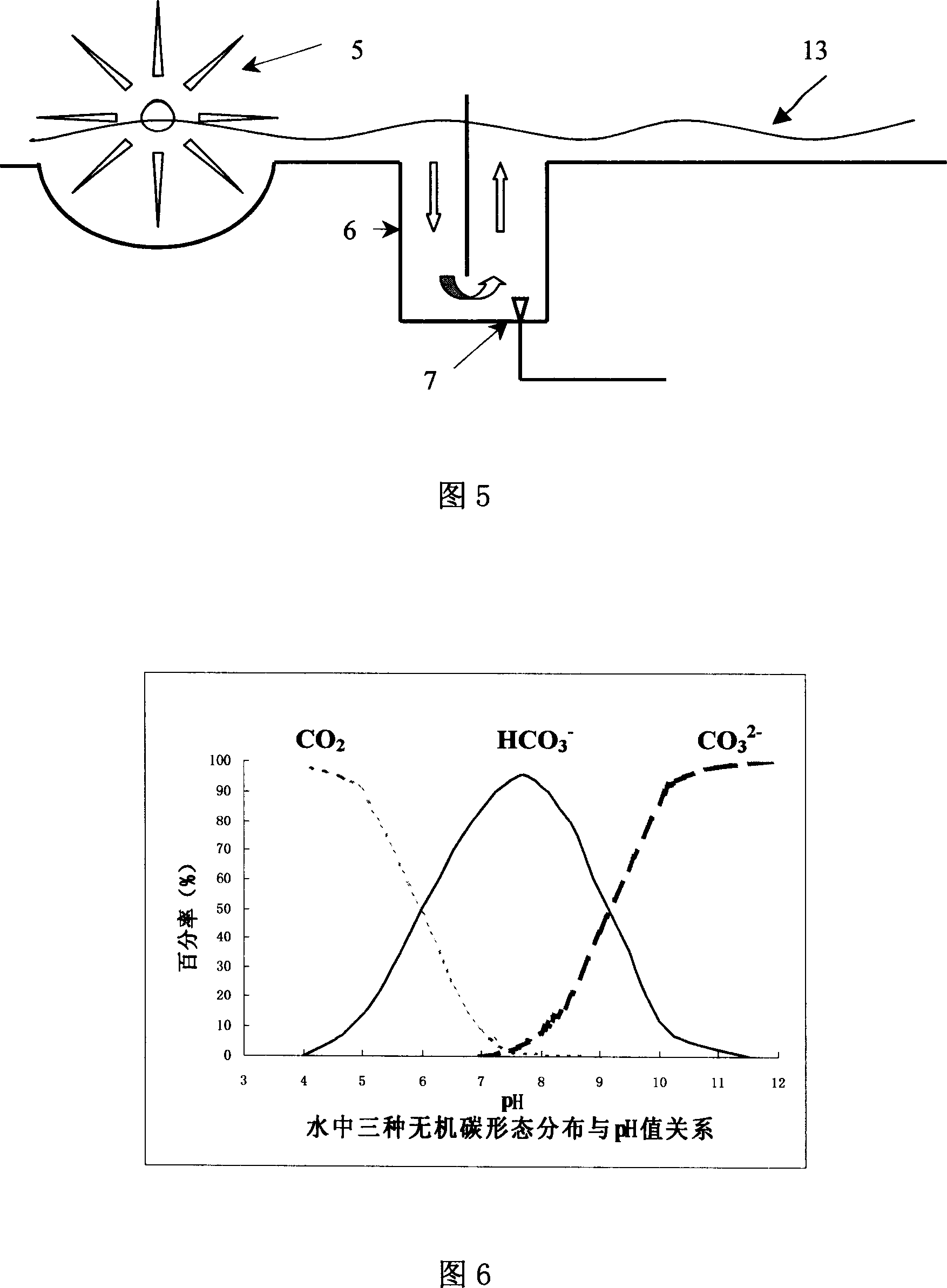

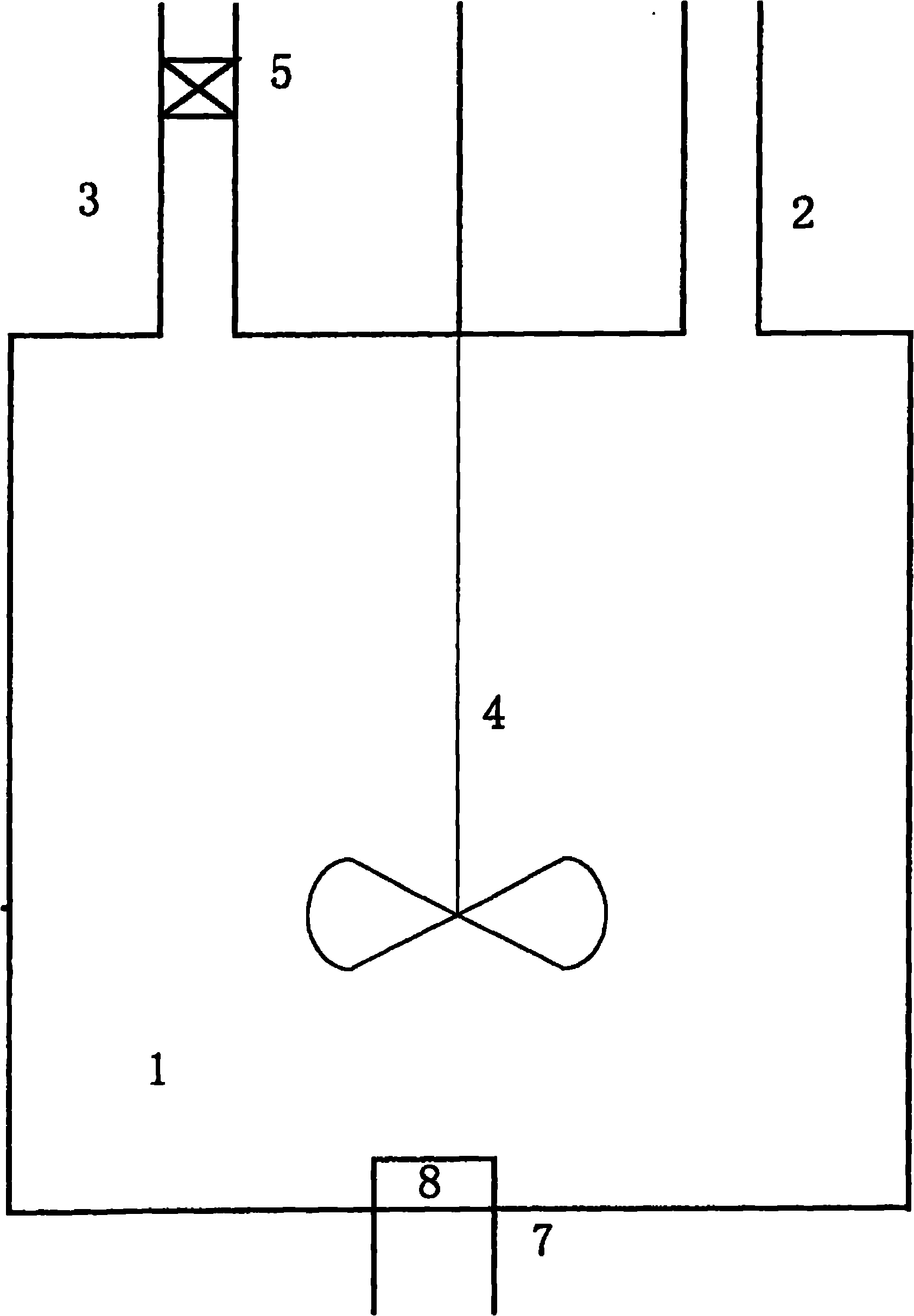

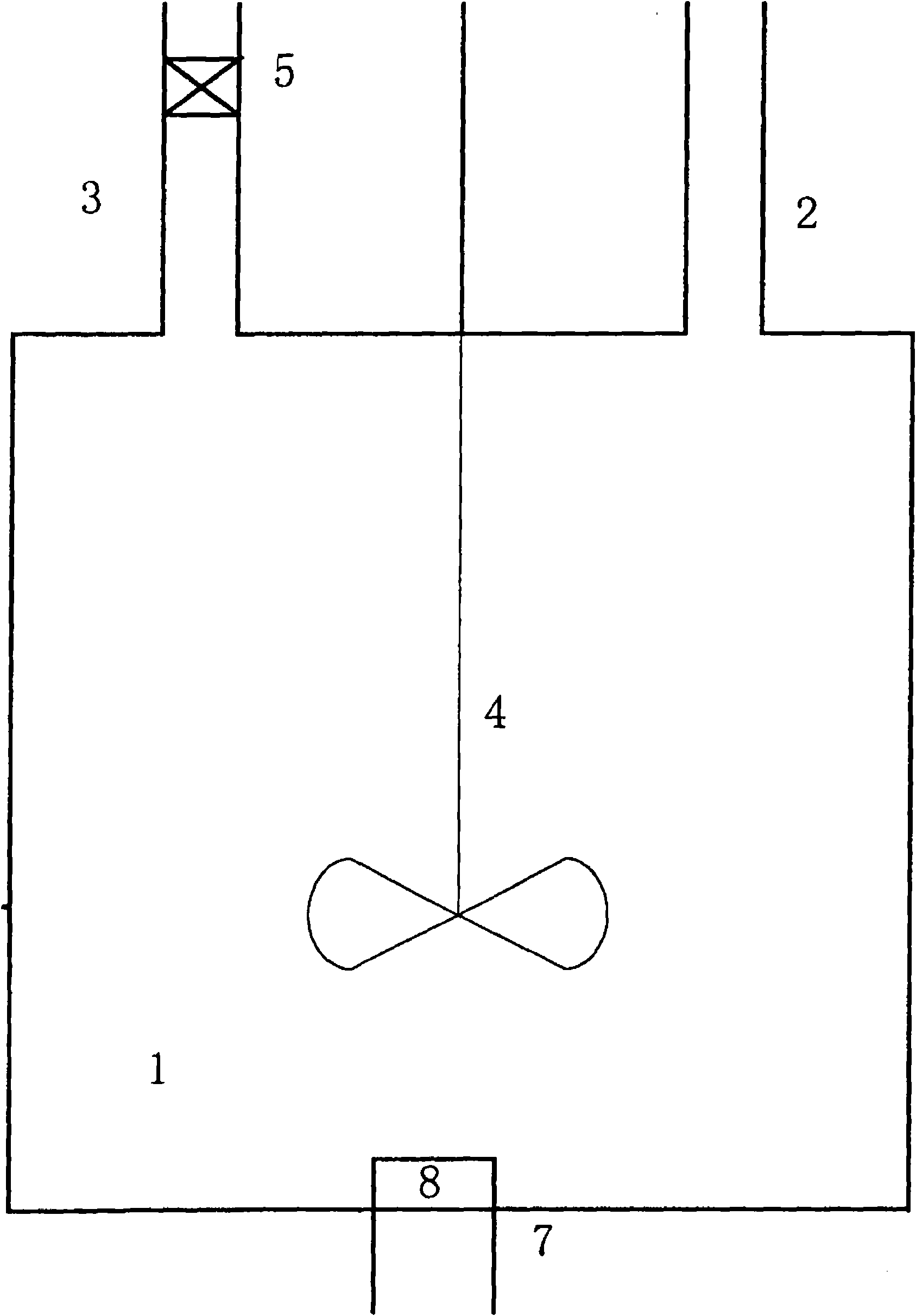

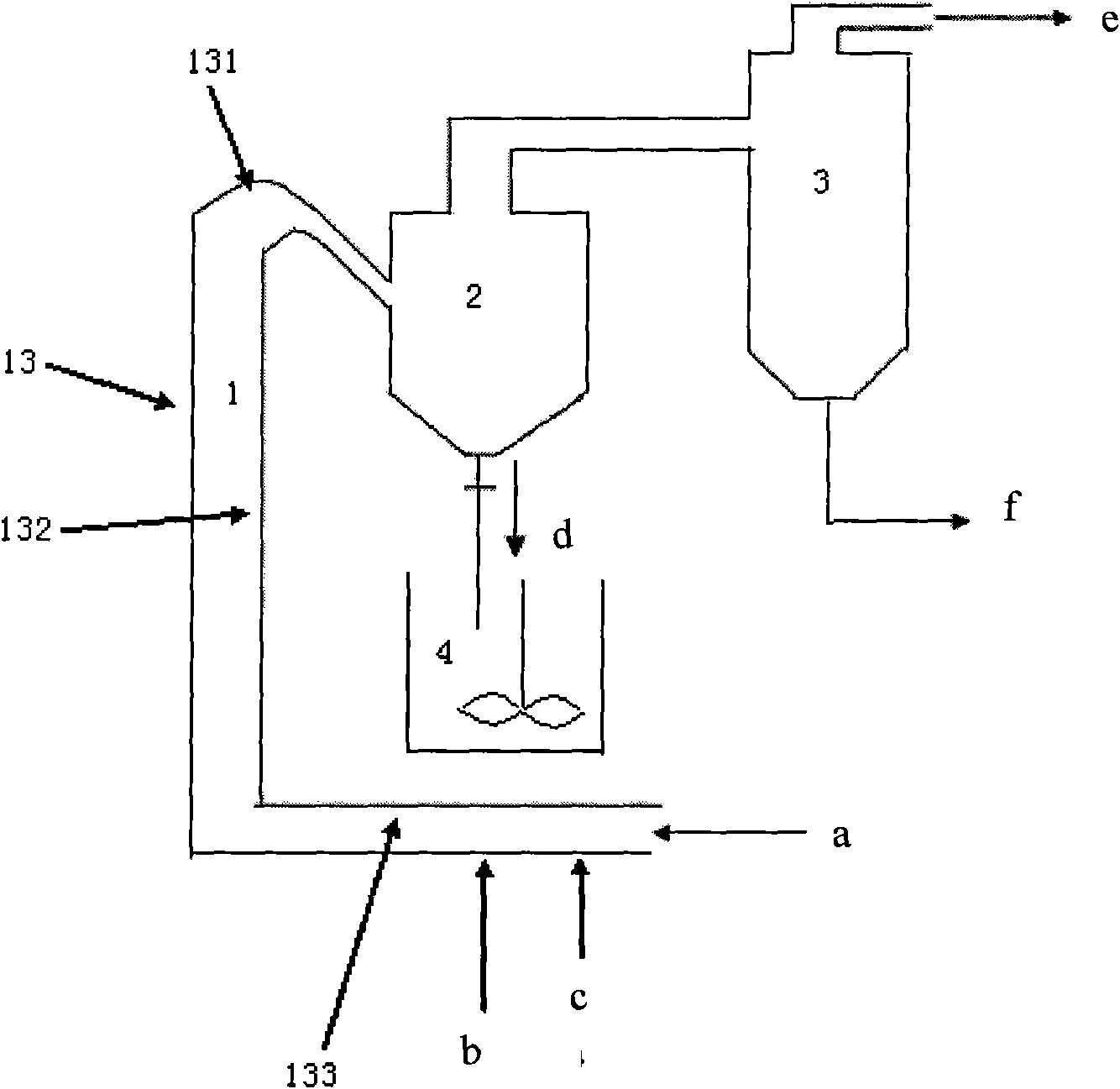

Carbon compensator for large-scale culturing micro-algae, its utilization and use

InactiveCN1982432AIncrease profitReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsVapor liquidContact time

A carbon supplementing apparatus for supplying carbon dioxide efficiently in micro-algae culturing tank, its usage and use are disclosed. A vertical baffle plate is installed above in the container with 10-50 cm gap, gas distributor is arrange at bottom of tank, the apparatus is built-in the bottom of tank, whose upper edge is aligned with the tank bottom, baffler plate is above culturing level of tank so as to pass culturing fluid to the apparatus with agitator driven. It has longer vapor-liquid contact time, more vapor-liquid contact area and higher carbon dioxide efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Performance stability in shallow beds in pressure swing adsorption systems

Owner:AIR PROD & CHEM INC

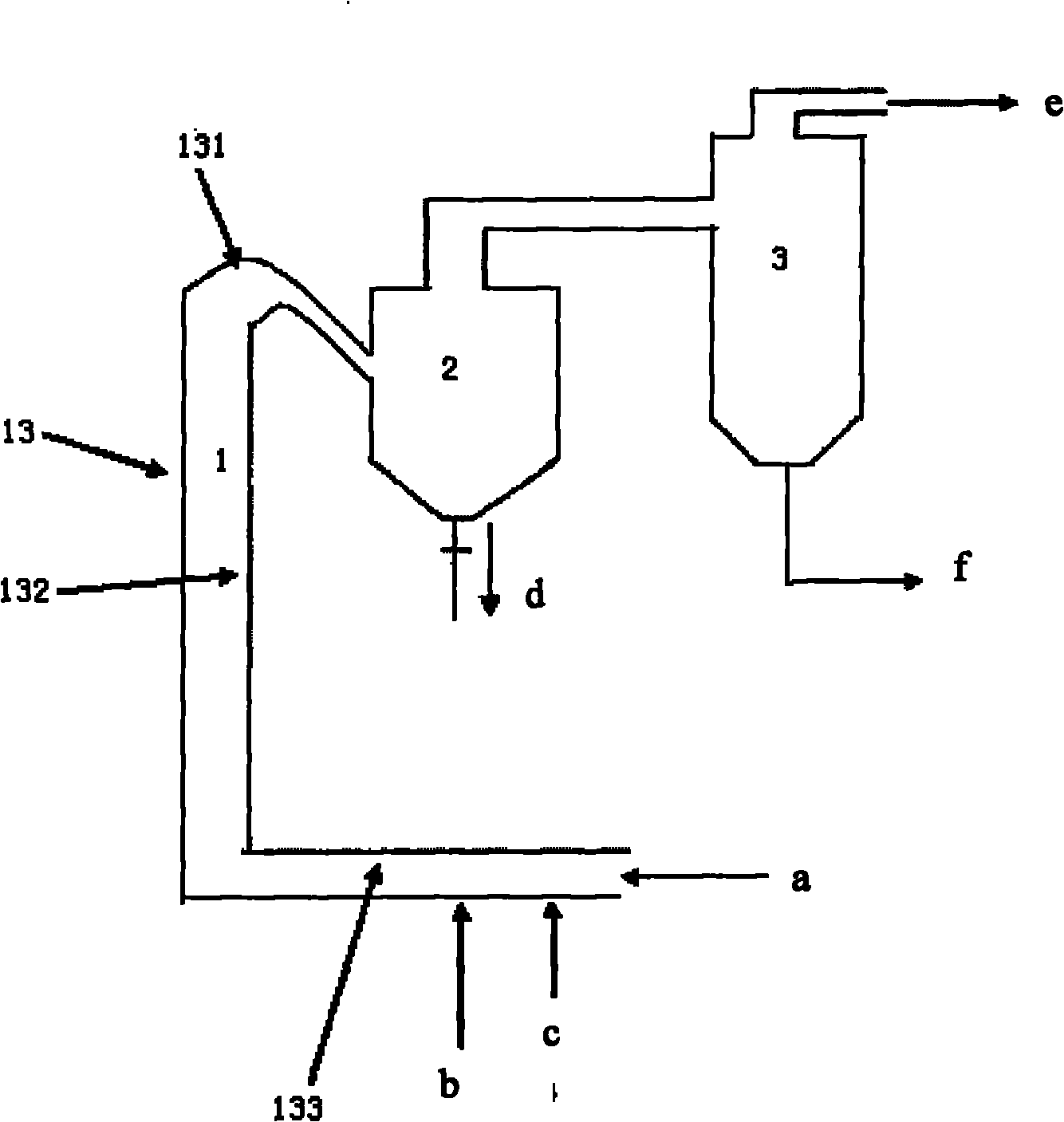

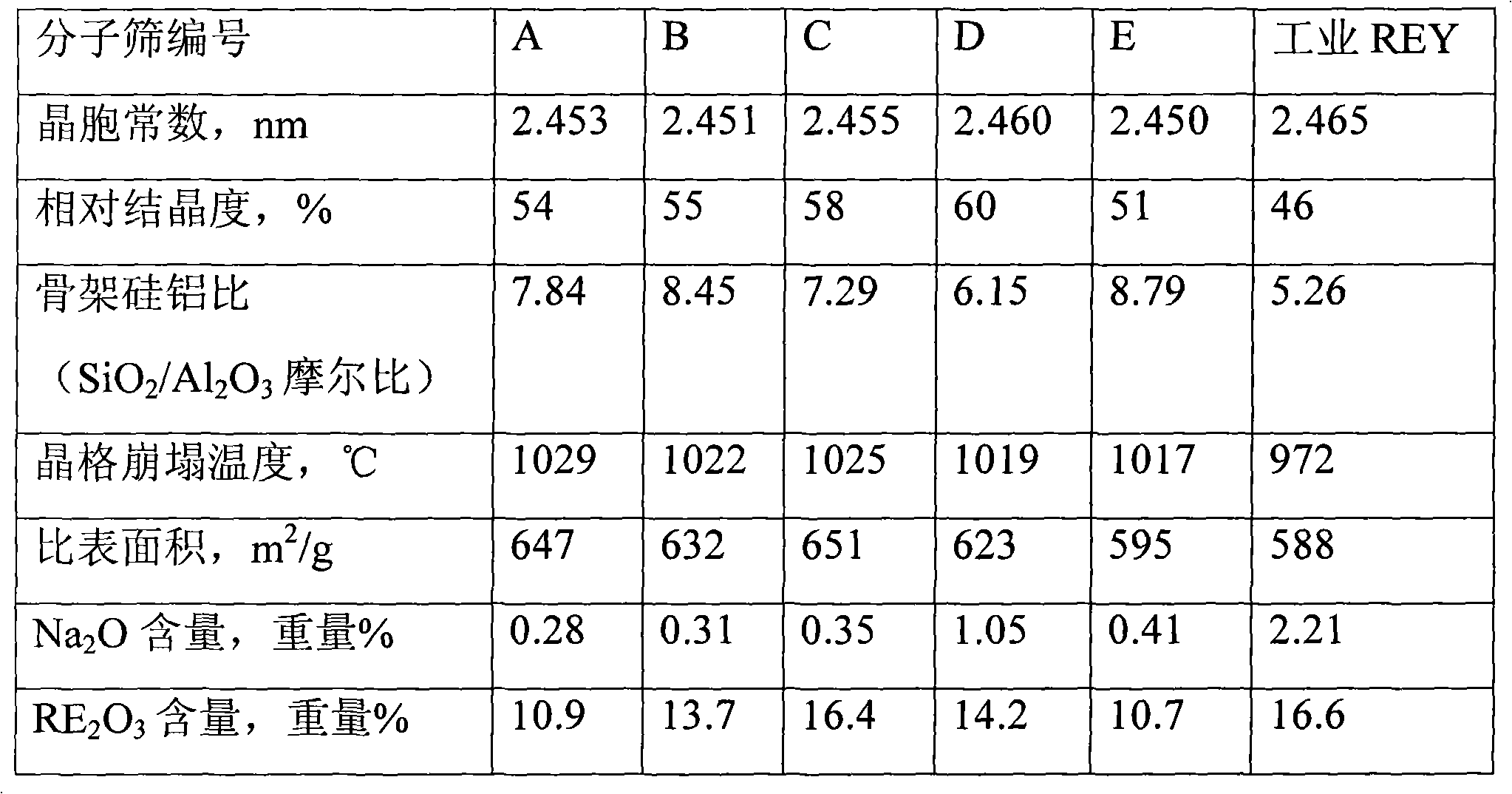

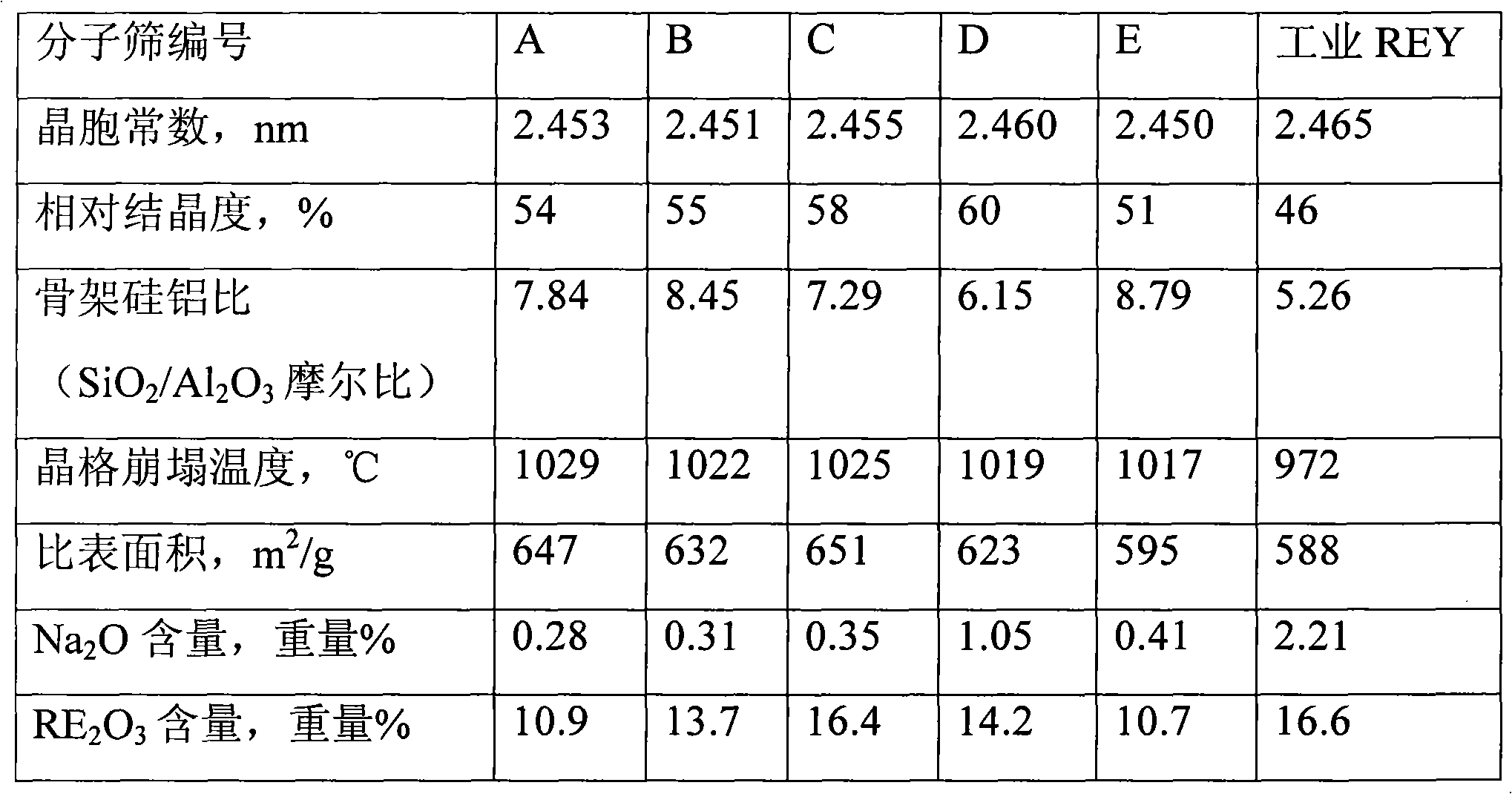

Method for preparing high silicon molecular sieve

ActiveCN102050459AAdequate contact responseContinuous contact reactionFaujasite aluminosilicate zeoliteMolecular-sieve compoundsMolecular sieveGas phase

The invention relates to a method for preparing a high silicon molecular sieve. The method comprises the following steps: circulating a molecular sieve along with inert carrier air under the carrying of inert carrier air flow and contacting the molecular sieve with gas-phase SiCl4 in a flowing sate, wherein the contact time of the molecular sieve and the gas-phase SiCl4 is from 10 seconds to 100 minutes. By using the method for preparing the high silicon molecular sieve in the invention, the continuous contact reaction of the molecular sieve and the SiCl4 can be achieved, and the contact time of the molecular sieve and the SiCl4 can be controlled through controlling the flow speed of the carrier air and the length of a tubular reactor, thus the contact reaction of the molecular sieve and the SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP

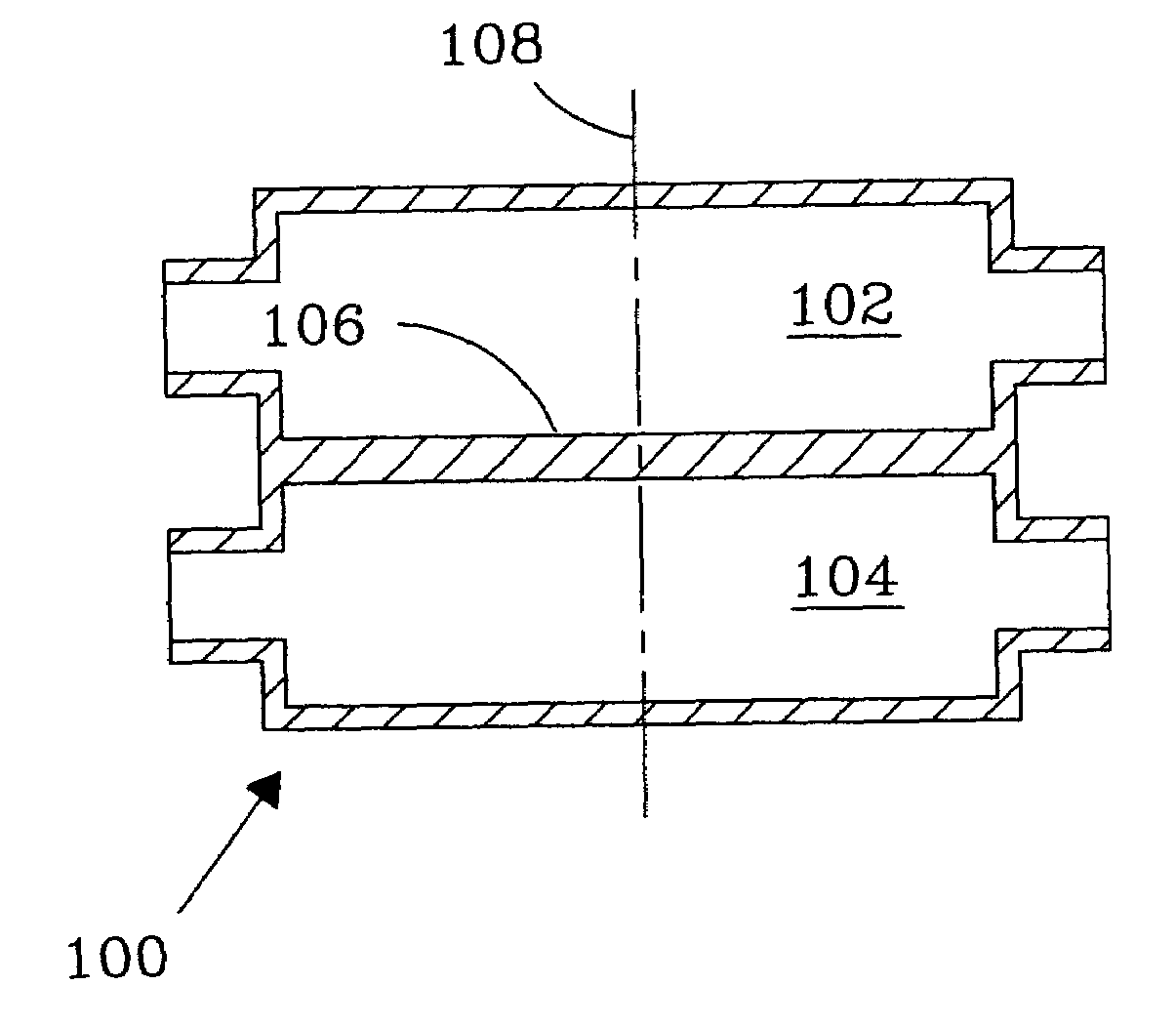

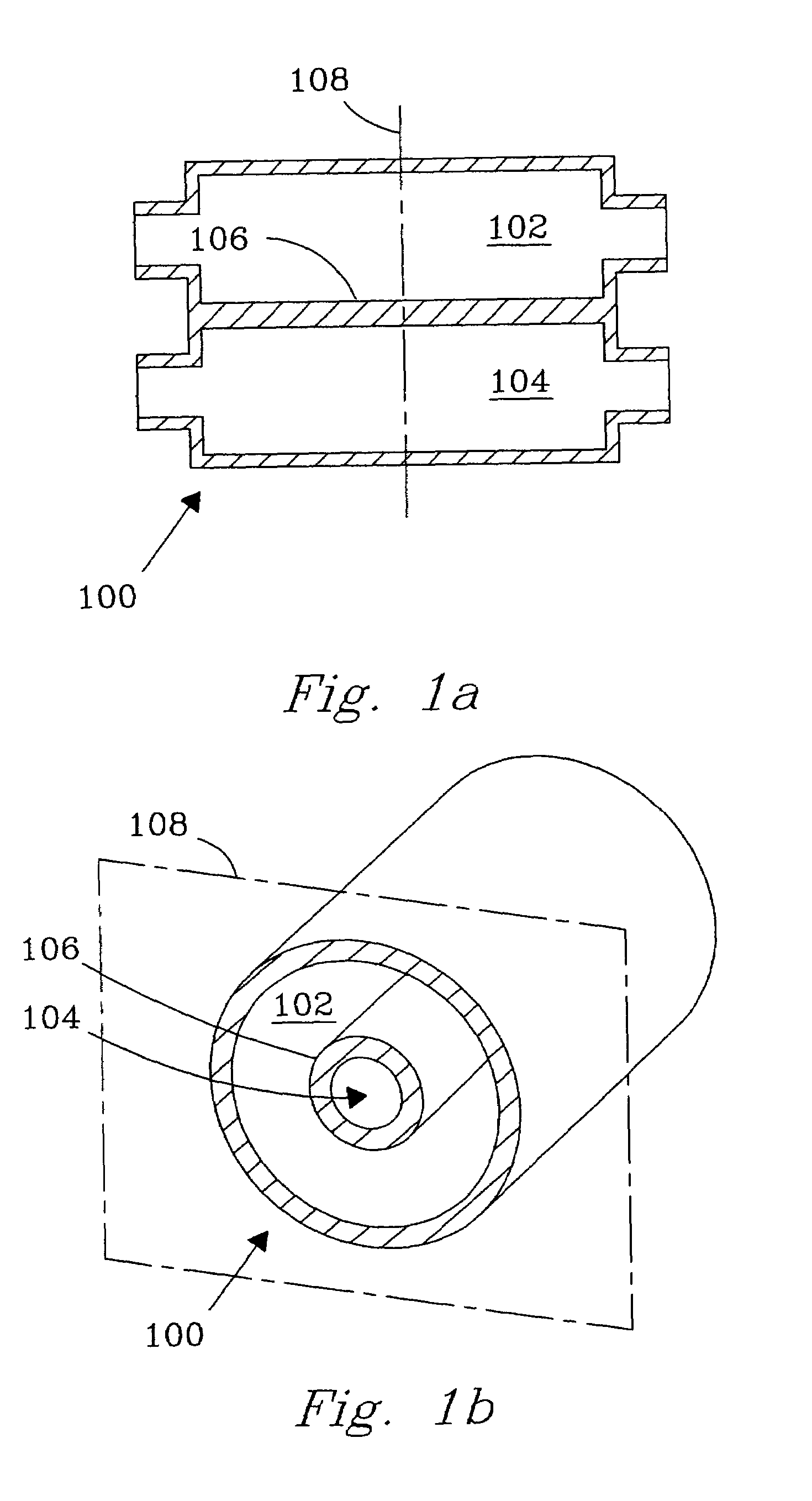

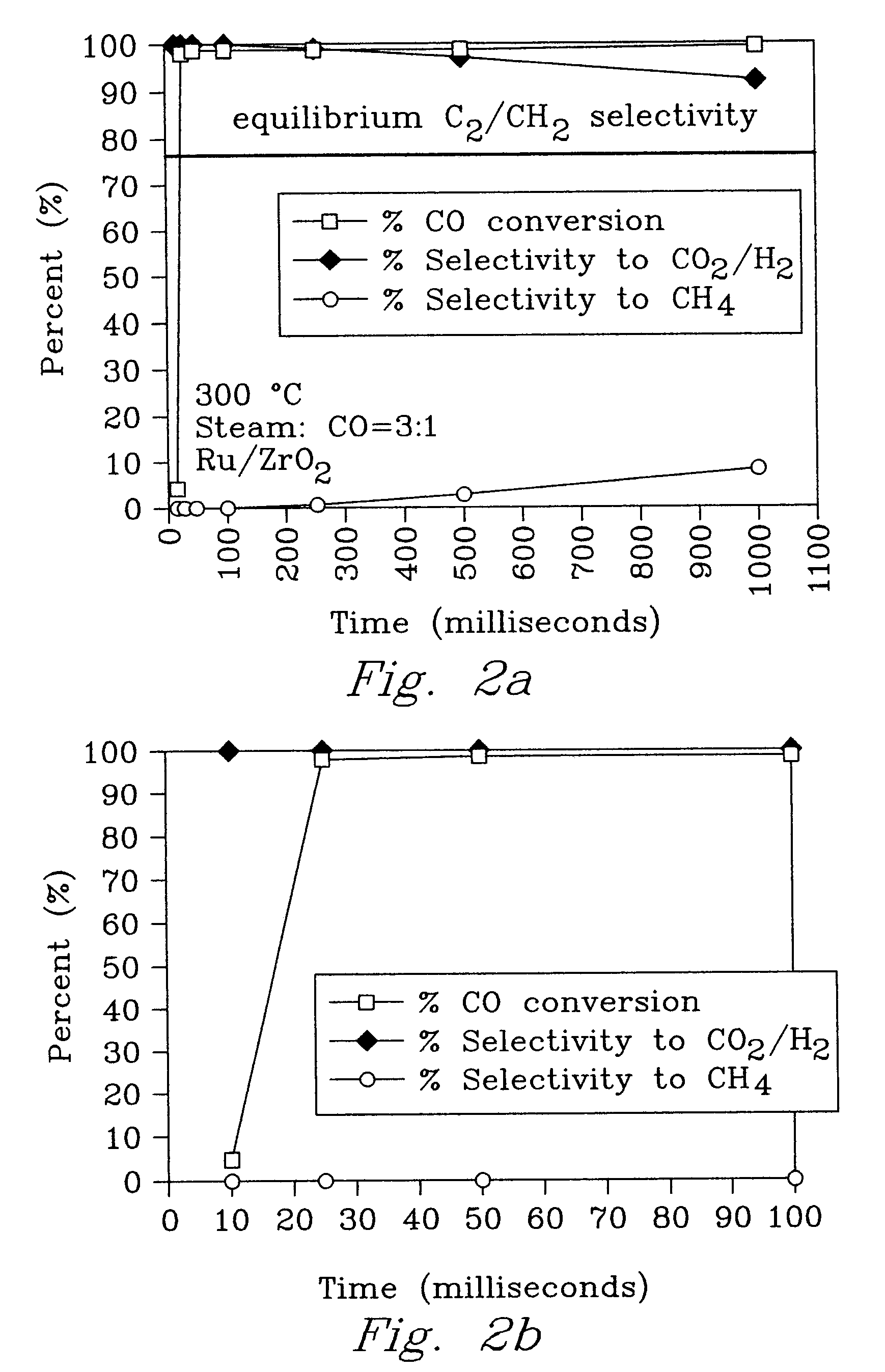

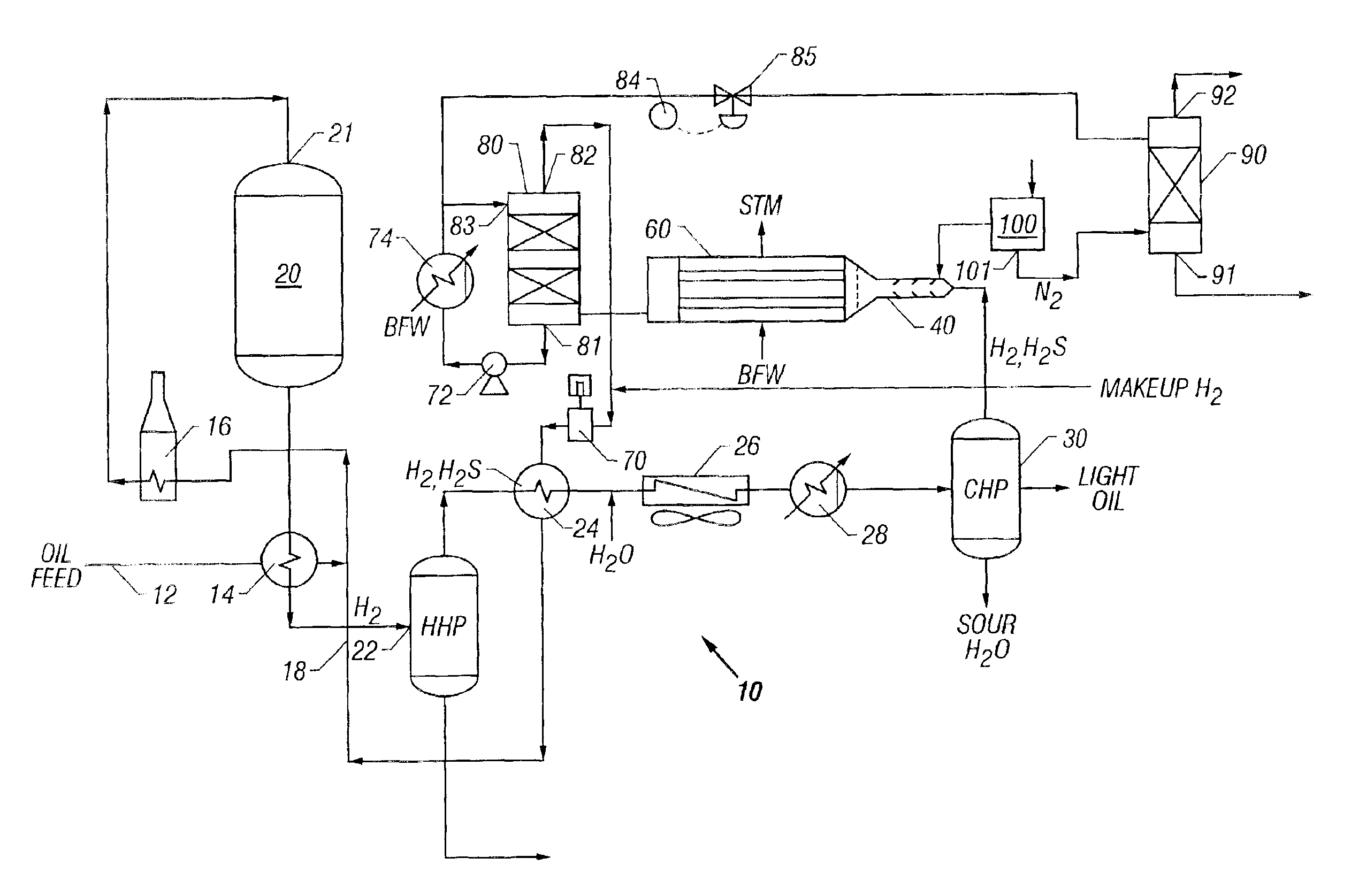

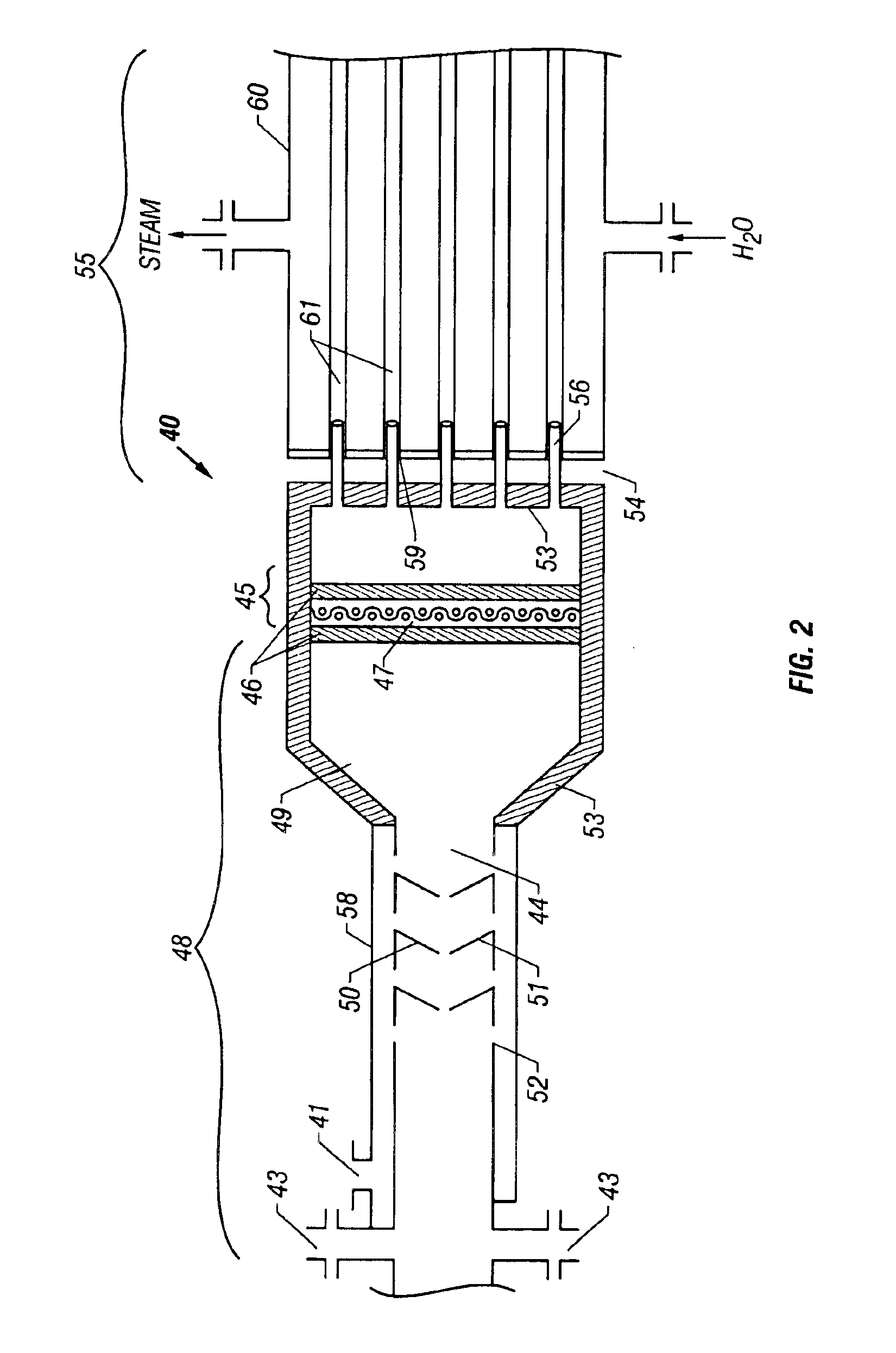

Method and apparatus for obtaining enhanced production rate of thermal chemical reactions

InactiveUS7045114B2Reduce formationReaction is slowOrganic chemistry methodsChemical/physical/physico-chemical microreactorsSteam reformingChemical reaction

Reactors and processes are disclosed that can utilize high heat fluxes to obtain fast, steady-state reaction rates. Porous catalysts used in conjunction with microchannel reactors to obtain high rates of heat transfer are also disclosed. Reactors and processes that utilize short contact times, high heat flux and low pressure drop are described. Improved methods of steam reforming are also provided.

Owner:BATTELLE MEMORIAL INST

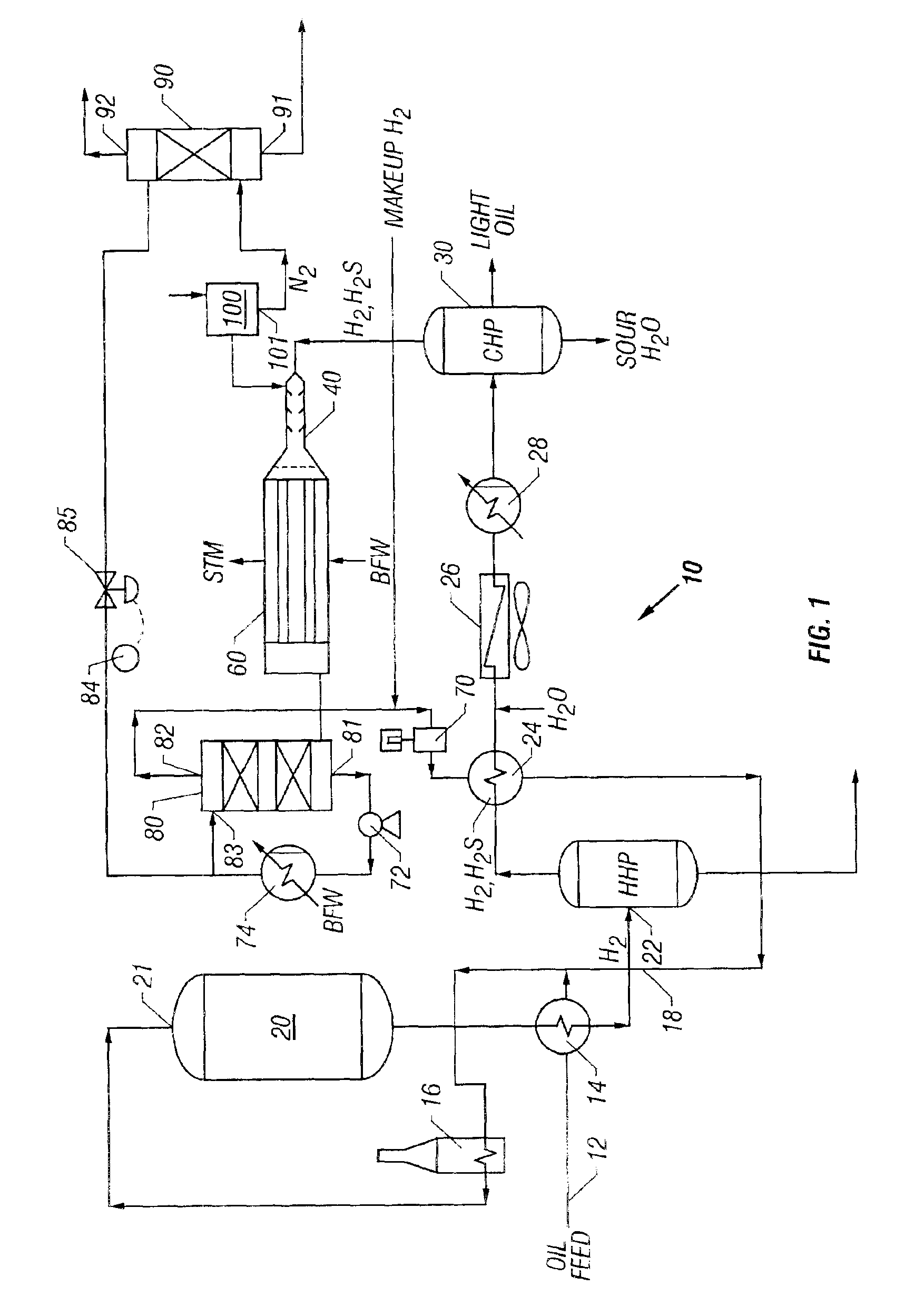

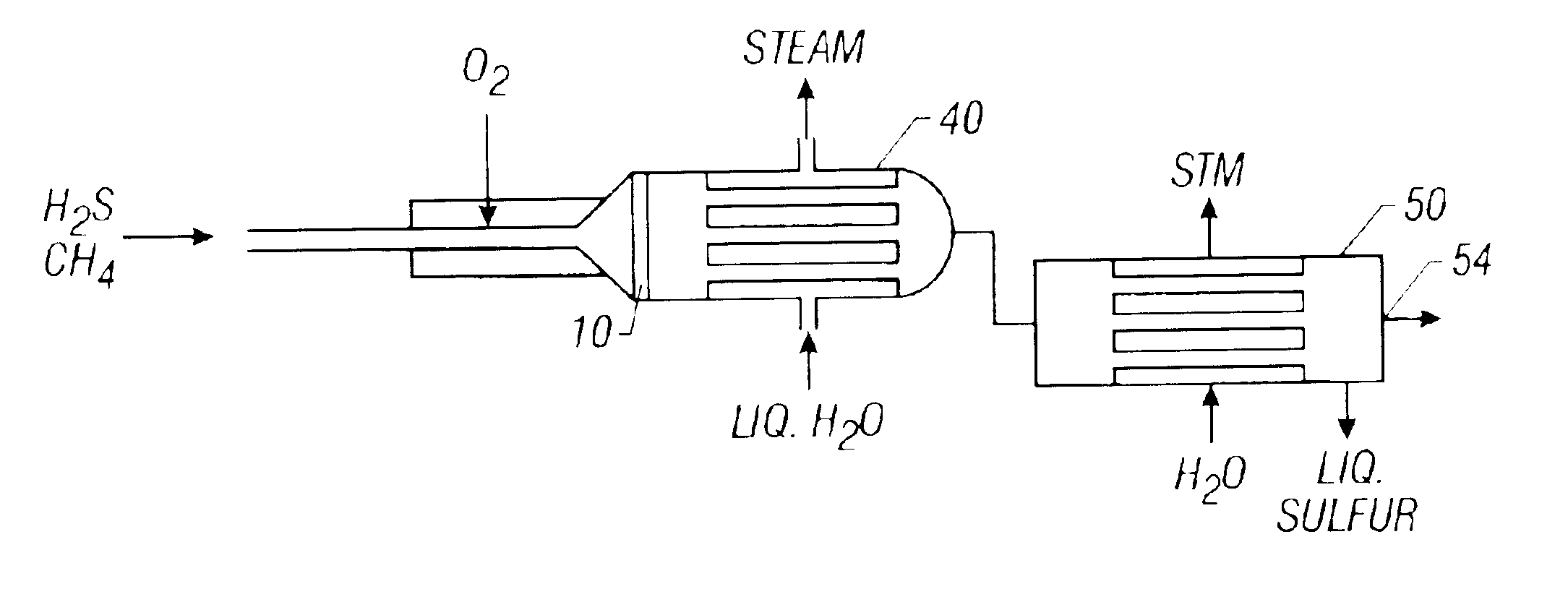

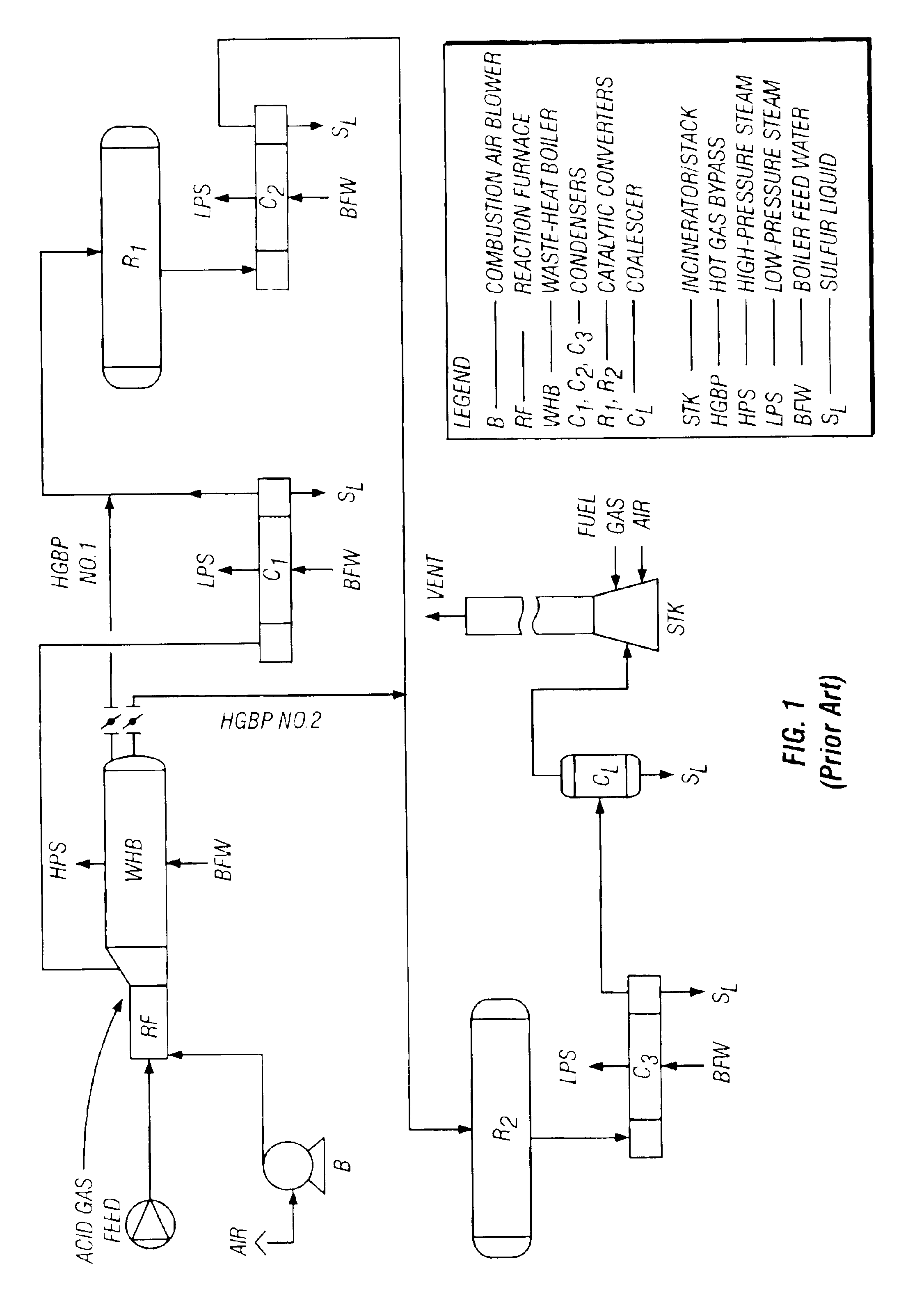

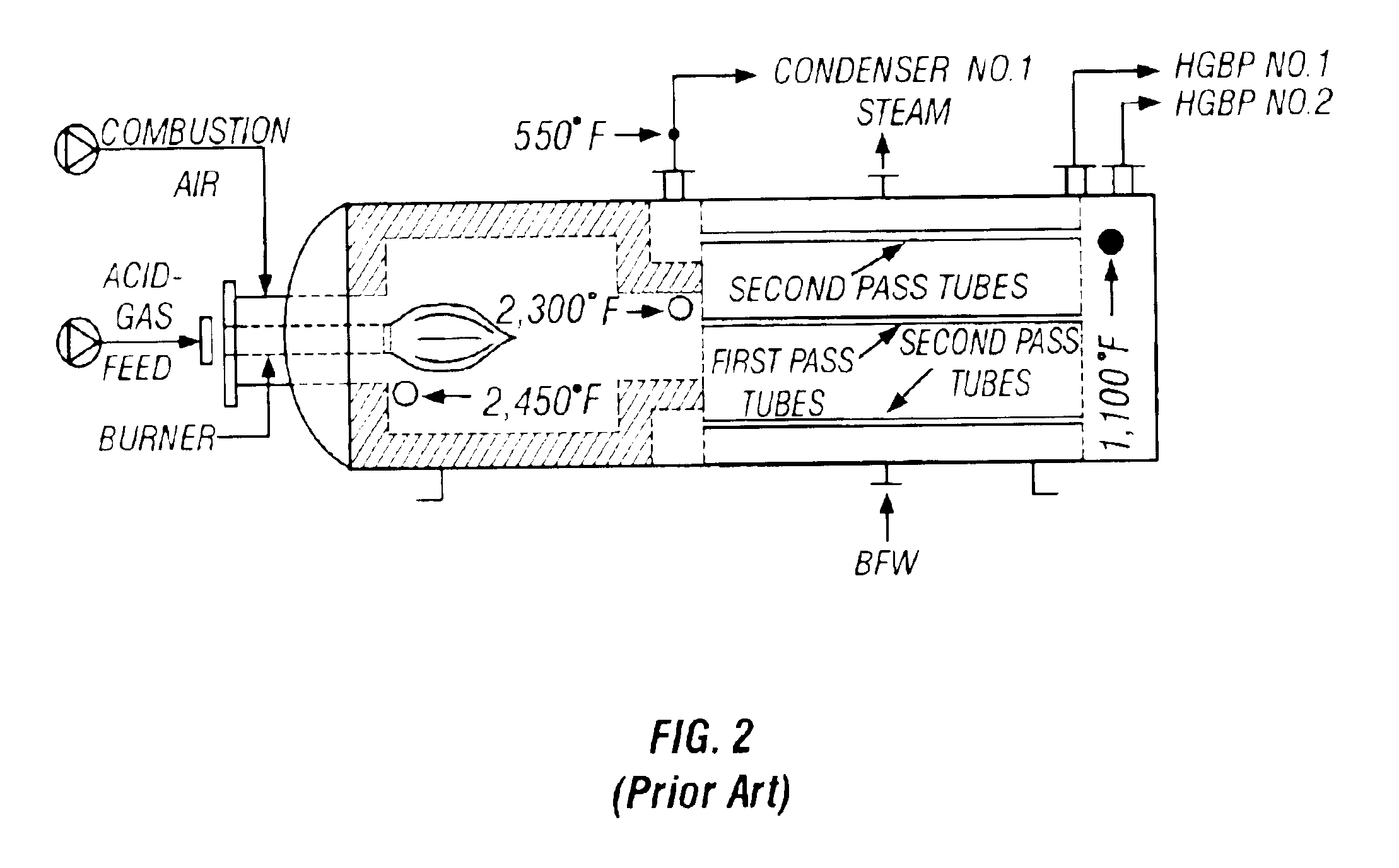

Short contact time catalytic partial oxidation process for recovering sulfur from an H2S containing gas stream

InactiveUS6946111B2Avoid contactExcess buildupHydrogenDispersed particle separationPartial oxidationSulfur

A process for removing sulfur from a H2S-containing gas stream is disclosed. A preferred embodiment of the process comprises incorporating a short contact time catalytic partial oxidation reactor, a cooling zone, and a condenser into a conventional refinery or gas plant process, such as a natural gas desulfurizer, a hydrotreater, coker or fluid catalytic cracker, in which sulfur removal is needed in order to produce a more desirable product. An H2S-containing gas stream is fed into a short contact time reactor where the H2S is partially oxidized over a suitable catalyst in the presence of O2 to elemental sulfur and water.

Owner:PHILLIPS 66 CO

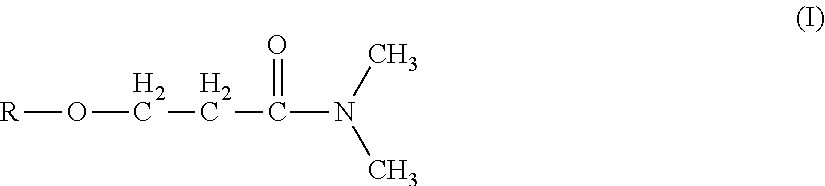

Inkjet recording medium and ink set, and inkjet recording method

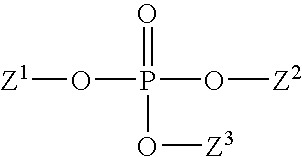

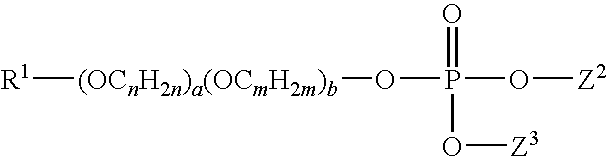

ActiveUS20130002776A1Measurement apparatus componentsDuplicating/marking methodsChemical structureOrganic solvent

A inkjet recording medium and ink set including ink containing water, a hydrosoluble organic solvent comprising an amide compound represented by the following Chemical Structure 1, a surface active agent; and a coloring agent, and a recording medium containing a substrate; and a coated layer on at least one side of the substrate, wherein the transfer amount of pure water to the recording medium having the coated layer is 2 ml / m2 to 35 ml / m2 during a contact time of 100 ms and 3 ml / m2 to 40 ml / m2 during a contact time of 400 ms when measured by a liquid dynamic absorption tester at 23° C. and 50% RH:

Owner:RICOH KK

Compositions for water-based and solvent-based sprayable gels and methods for making same

InactiveUS6838426B1Efficient removalCationic surface-active compoundsOrganic detergent compounding agentsWater basedBrick

The present invention is a sprayable gel cleaning composition and a method of making said sprayable gel cleaning composition. The gel stays on the stained surface until it is wiped off, unlike non-gelatinous compositions that have a very short surface contact time. The active agents of the sprayable gel cleaning composition are in contact with the stain for a longer period of time than other cleaners. The sprayable gel cleaning composition can be used to remove household and industrial spots and stains that are present on walls, cabinets, stove tops, doors, and trim. In addition, this invention can be used to clean concrete and brick, and remove caulk and paint from surfaces, as well as remove bug and tar stains present on automobiles, trucks, and other machinery and surfaces. The gelatinous composition may be water-based or solvent-based.

Owner:WEIMAN PROD

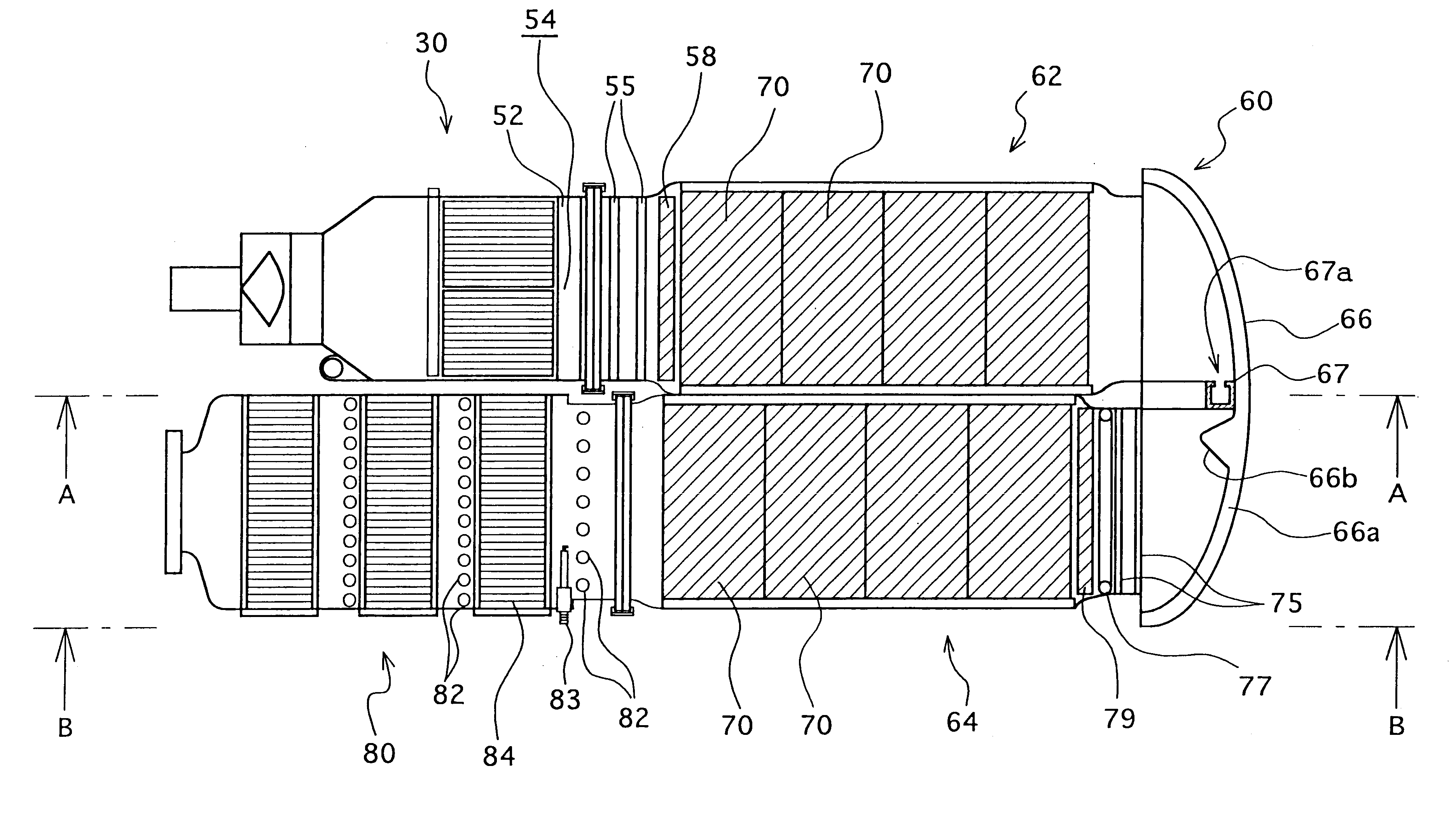

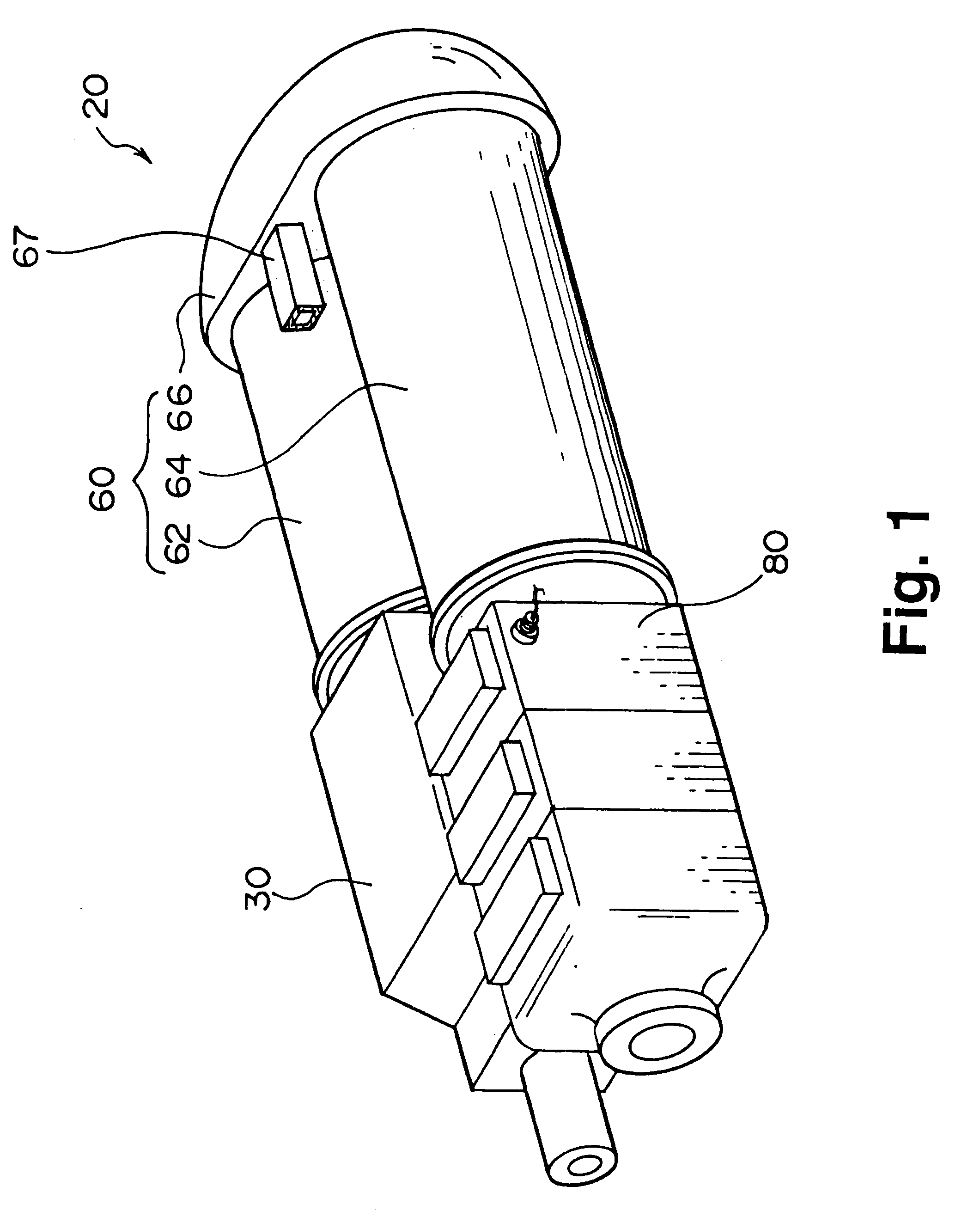

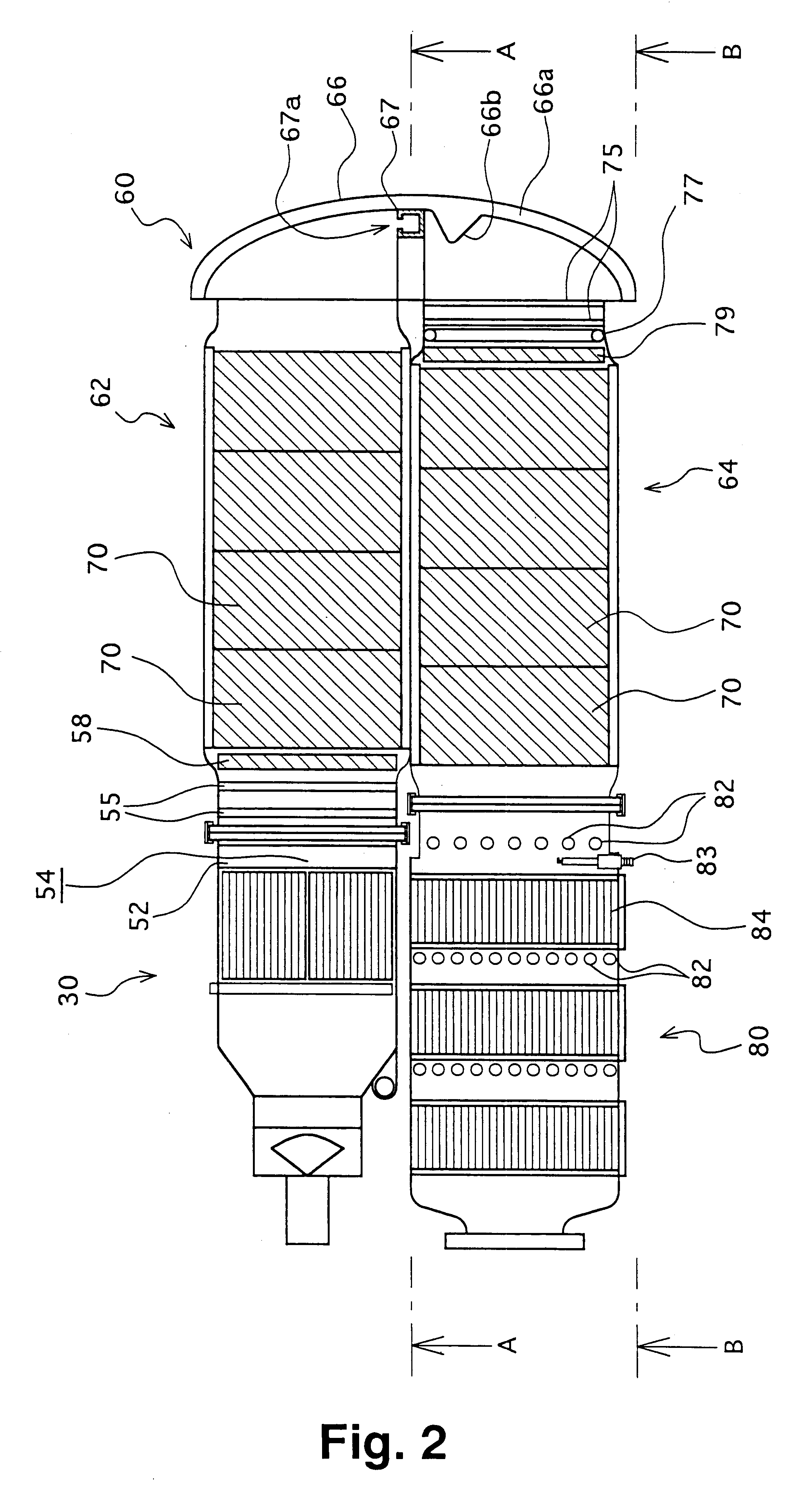

Fuel reformer for mounting on a vehicle

InactiveUS6390030B1Keep for a long timeImprove fuel performanceHydrogen separation using solid contactChemical industryContact timeVaporization

A fuel reformer suited for mounting on a vehicle is provided. A raw material gas containing methanol and water is vaporized at a vaporization section 30. The vaporized gas flows horizontally to a reforming section 60 with monolithic catalyst 70. The reforming section is divided into two sides, a front side 62 and a rear side 64, with an interconnecting pipe 66 bent at 180 degrees, for connecting the front and rear sides. By making the material gas flow horizontally, even when the reformer is mounted to a vehicle which has a larger space in its horizontal direction than in its vertical direction, especially a small passenger car, the contact time period between gas and catalyst can be extended. By bending the reforming section by 180 degrees, the size of the reformer can be reduced so that the reformer is suited for mounting on a vehicle having limited space. Because the vaporization section 30 and the CO reducing section 80 can be placed adjacent to each other, by using heat generated at the CO reducing section, the heat loss during pre-heating of the methanol and water can be reduced.

Owner:TOYOTA JIDOSHA KK

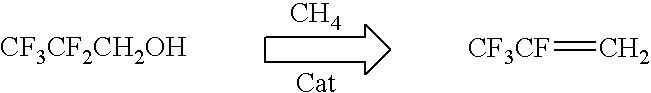

Catalytic conversion of hydrofluoroalkanol to hydrofluoroalkene

ActiveUS7026520B1High-yieldPreparation by hydrogen halide split-offPreparation by halogen halide addition1-PropanolHigh pressure

Methane is used as the selective dehydrating agent for the production of 2,3,3,3-tetrafluoro-1-propene (R1234yf) from 2,2,3,3,3-pentafluoro-1-propanol. Supported transition metal catalysts are prepared and used for this reaction with high activity. Almost 58% selectivity to R1234yf is obtained at an alcohol conversion level of 60% using unsupported Ni-mesh as the catalyst. Pd and Pt show almost similar level of conversion; however, the selectivity to the desired product is low. The activity of the metal catalyst was found to be a function of the type of support material, activated carbon showing better activity than alumina. Different important process parameters such as temperature, pressure, and contact time are studied to optimize the process. High pressure and temperature are deleterious to the rate of 1234yf formation; yet, the highest yield to 1234yf is obtained while performing a reaction at 494° C. with a contact time of 23 sec.

Owner:HONEYWELL INT INC

Method of treating biomass, fuel for fuel cell, gasoline, diesel fuel, liquefied petroleum gas, and synthetic resin

ActiveUS20110113675A1Reduce amountStable processing efficiencyCatalytic crackingBiofuelsFuel cellsContact time

In processing of biomass by catalytic cracking in a fluidized catalytic cracker having a reaction zone, a separation zone, a stripping zone, and a regeneration zone, the feedstock oil containing the biomass is processed in the reaction zone using a catalyst containing 10 to 50 mass % of ultrastable Y-type zeolite under the conditions: outlet temperature of the reaction zone 580 to 680° C., catalyst / oil ratio 10 to 40 wt / wt, reaction pressure 1 to 3 kg / cm2 G, and contact time of the feedstock oil with the catalyst in the reaction zone 0.1 to 1.0 sec, and the catalyst is then treated in the regeneration zone under the conditions: regeneration zone temperature 640 to 720° C., regeneration zone pressure 1 to 3 kg / cm2 G, and exhaust gas oxygen concentration at the regeneration zone outlet 0 to 3 mol %.

Owner:NIPPON OIL CORP

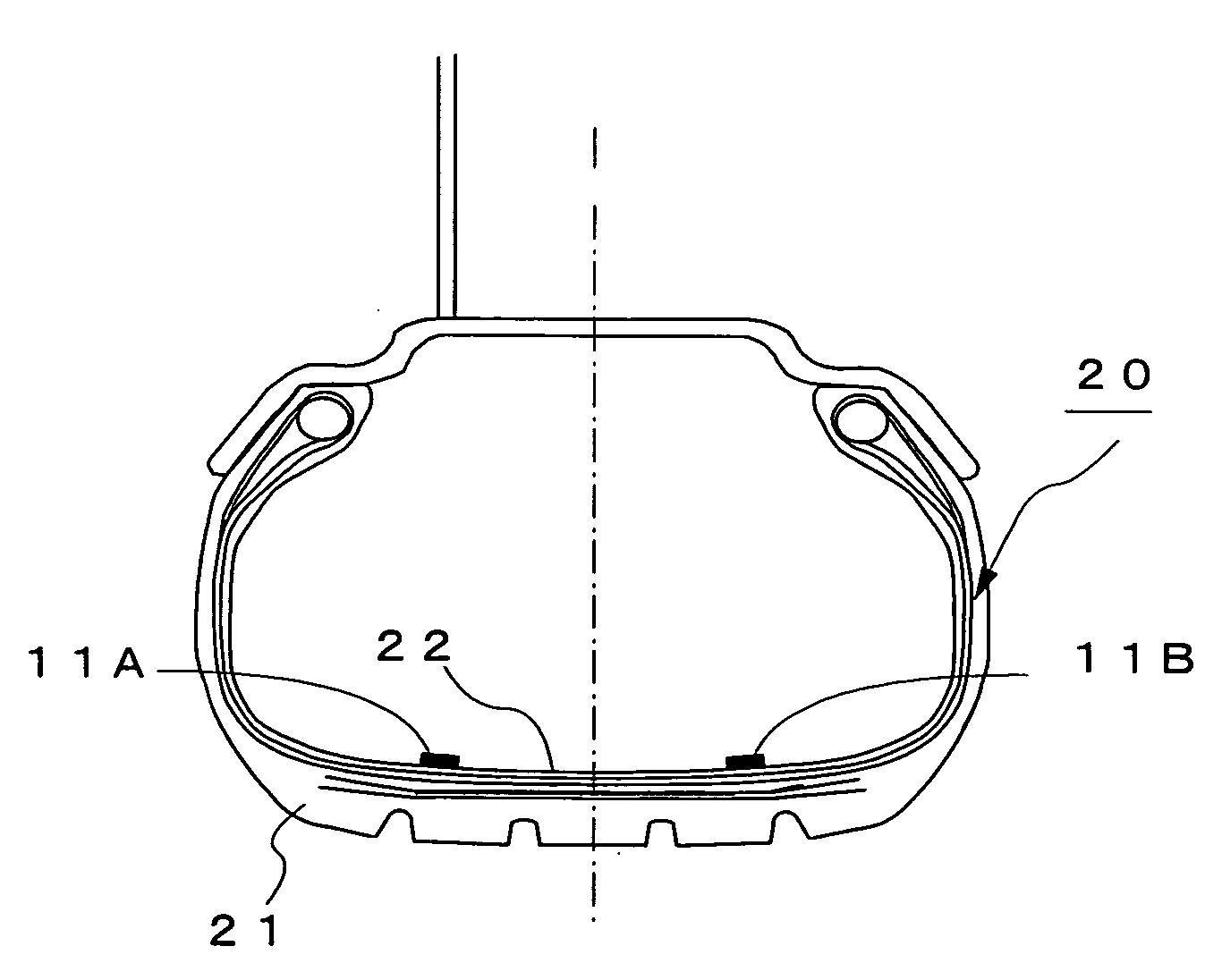

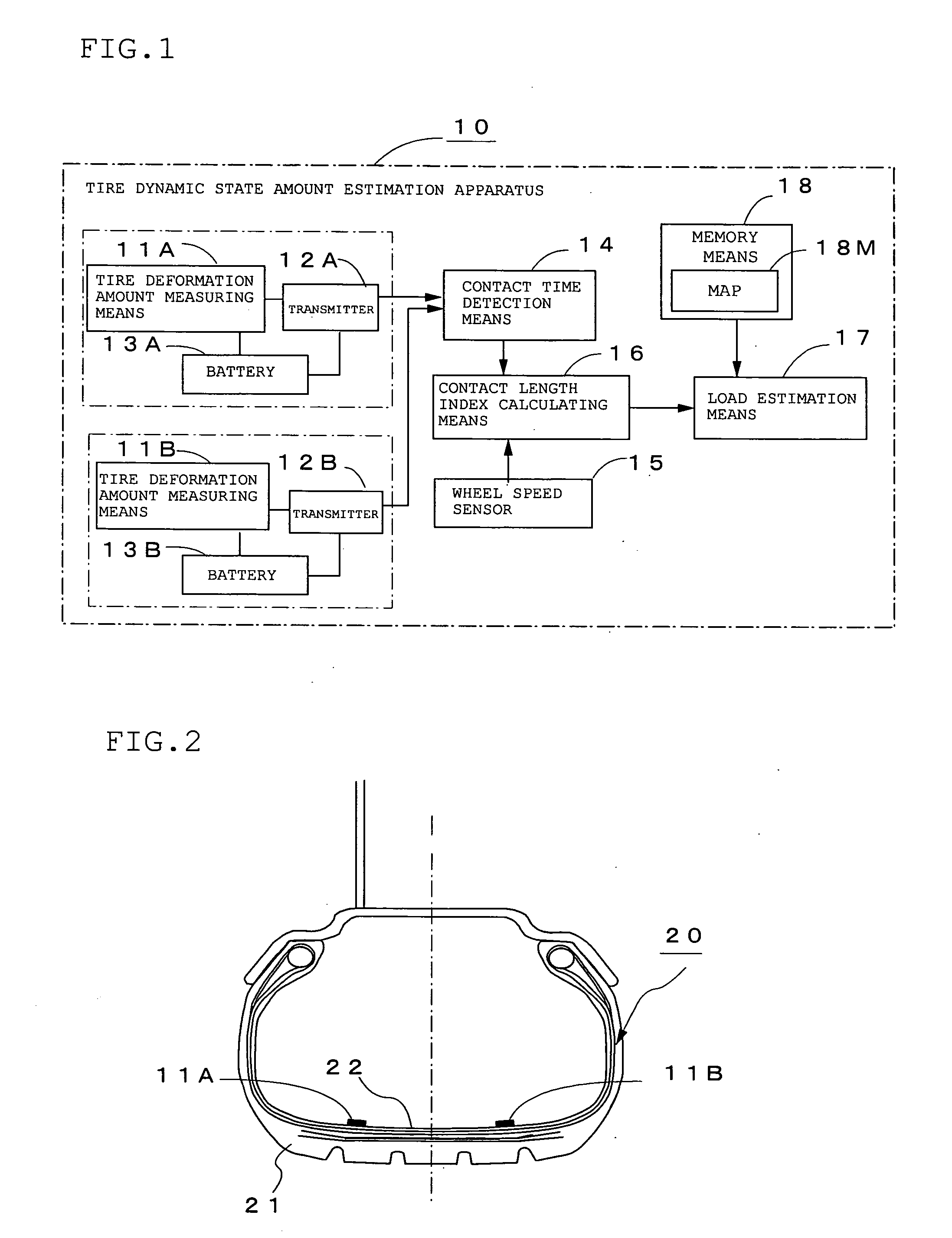

Estimation method and apparatus of tire dynamic state amount and tire with sensors

Owner:BRIDGESTONE CORP

Patches for teeth whitening

InactiveUS20050031554A1Poor flavorEnough timeCosmetic preparationsGum massageContact timeWhitening Agents

The present invention relates to a dry type tooth whitening patch comprising peroxide as a tooth whitening agent. In particular, disclosed is a dry type tooth whitening patch in which a peroxide is contained, as a teeth whitening agent, in a matrix type adhesive layer. The adhesive layer includes, as a base polymer thereof, a hydrophilic glass polymer which provides a strong adhesion to teeth while releasing the tooth whitening agent when hydrated on the enamel layers of teeth in the moist oral cavity. The dry type patch according to the present invention is convenient in use, as compared to wet type patches. Further, it exhibits a superior adhesion while being maintained in a state attached to the teeth for a lengthened period of time so as to assure an enough contact time between the whitening agent in the patch and stains on the teeth, thereby giving a sufficient whitening effect.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

Inkjet recording ink and recording media set, inkjet recording method, recorded matter and recording apparatus

ActiveUS20090258196A1Superior glossinessHigh image densityMaterial nanotechnologyDecorative surface effectsOrganic solventContact time

There is provided an inkjet recording ink and recording media set, which contains: an inkjet recording ink; and a recording medium, wherein the inkjet recording ink comprises at least: water; a water-soluble organic solvent; and a colorant containing carbon black, and having a volume average particle diameter of 40 nm to 100 nm, wherein the recording medium contains: a substrate; and a coating layer on at least one side of the substrate, and wherein an amount of pure water transferred to the recording medium, as measured with a dynamic scanning absorptometer at 23 C and 50% RH, at a contact time of 100 ms is 2 ml / m2 to 35 ml / m2 while an amount of pure water transferred to the recording medium at a contact time of 400 ms is 3 ml / m2 to 40 ml / m2.

Owner:RICOH KK

Short contact time catalytic sulfur recovery system for removing H2S from a waste gas stream

Owner:PHILLIPS 66 CO

Method for preparing catalytic cracking catalyst

ActiveCN102049315AAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for preparing a catalytic cracking catalyst. The method comprises the following steps: a molecular sieve flows along with inert carrier gas under the condition of being carried by the inert carrier gas flow, and is in contact with gas phase SiCl4 under the flow state; the contact time between the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes; and then the molecular sieve in contact with the gas phase SiCl4 is mixed with a binding agent, clay and water for pulping and pelleting to obtain the catalytic cracking catalyst. The provided preparation method for the catalytic cracking catalyst can realize the continuous contact reaction between the molecular sieve and the gas phase SiCl4 and can control the contact time between the molecular sieve and the gas phase SiCl4 by controlling the flow velocity of the carrier gas and the length of the tubular reactor, so that the contact reaction between the molecular sieve and the gas phase SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

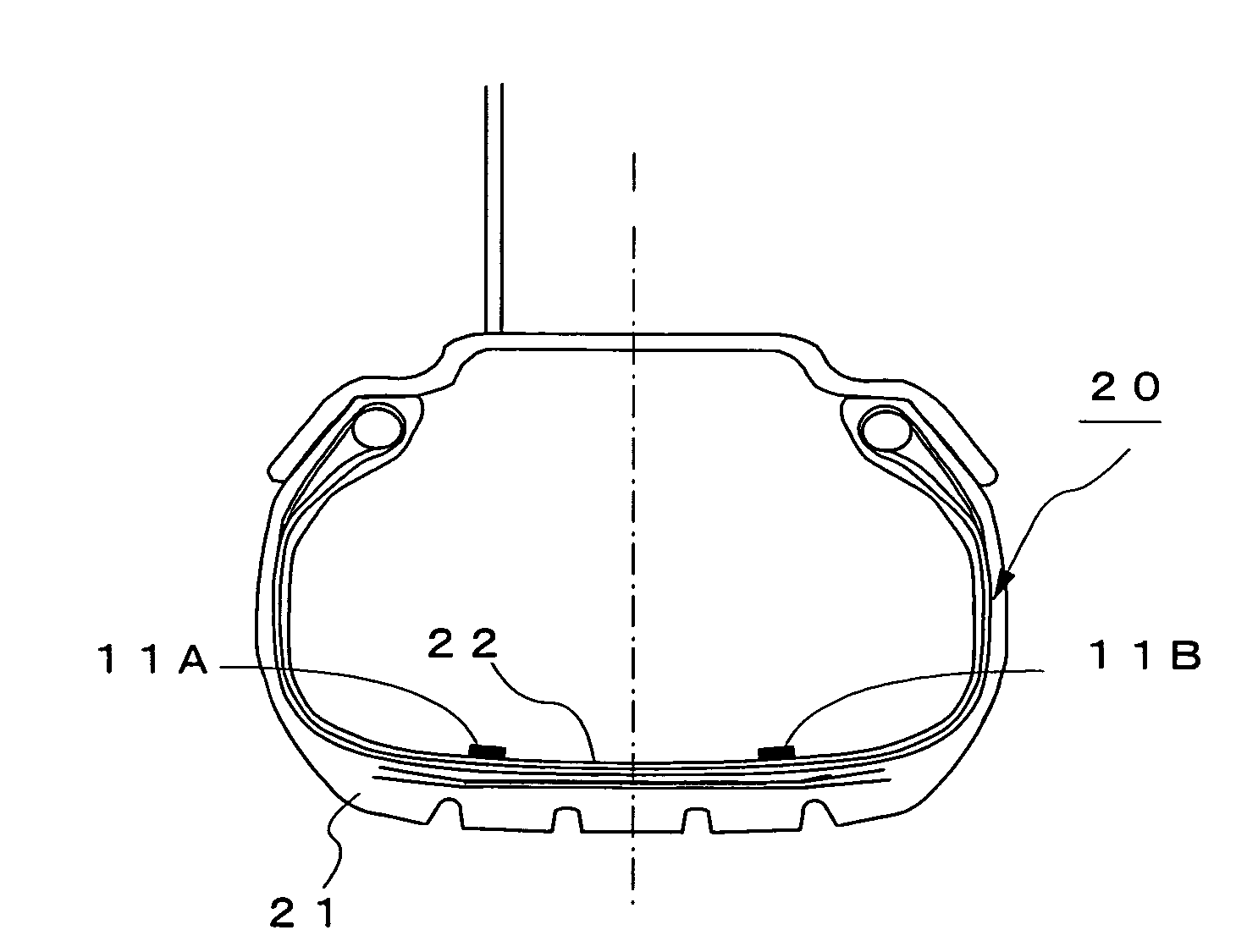

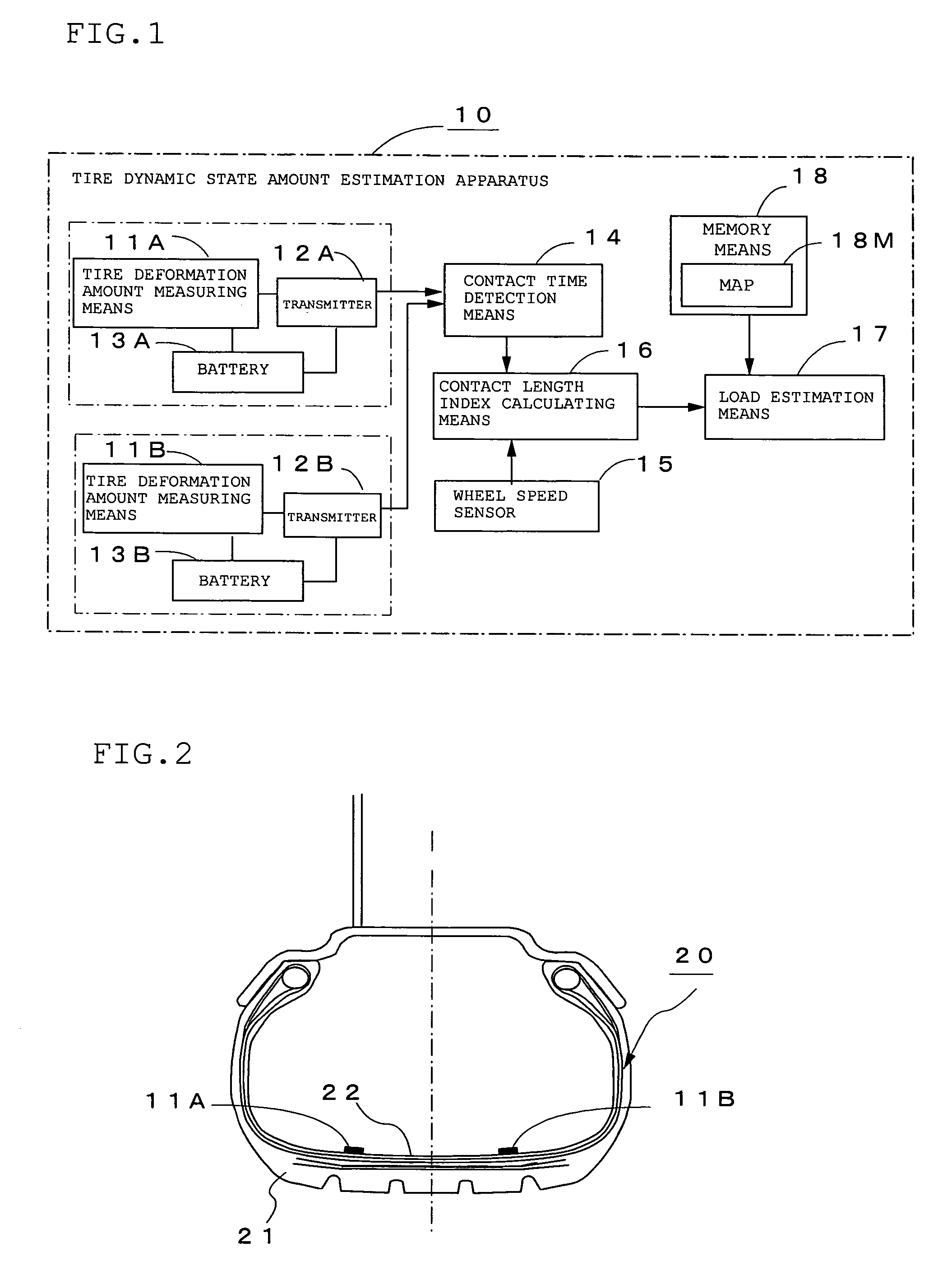

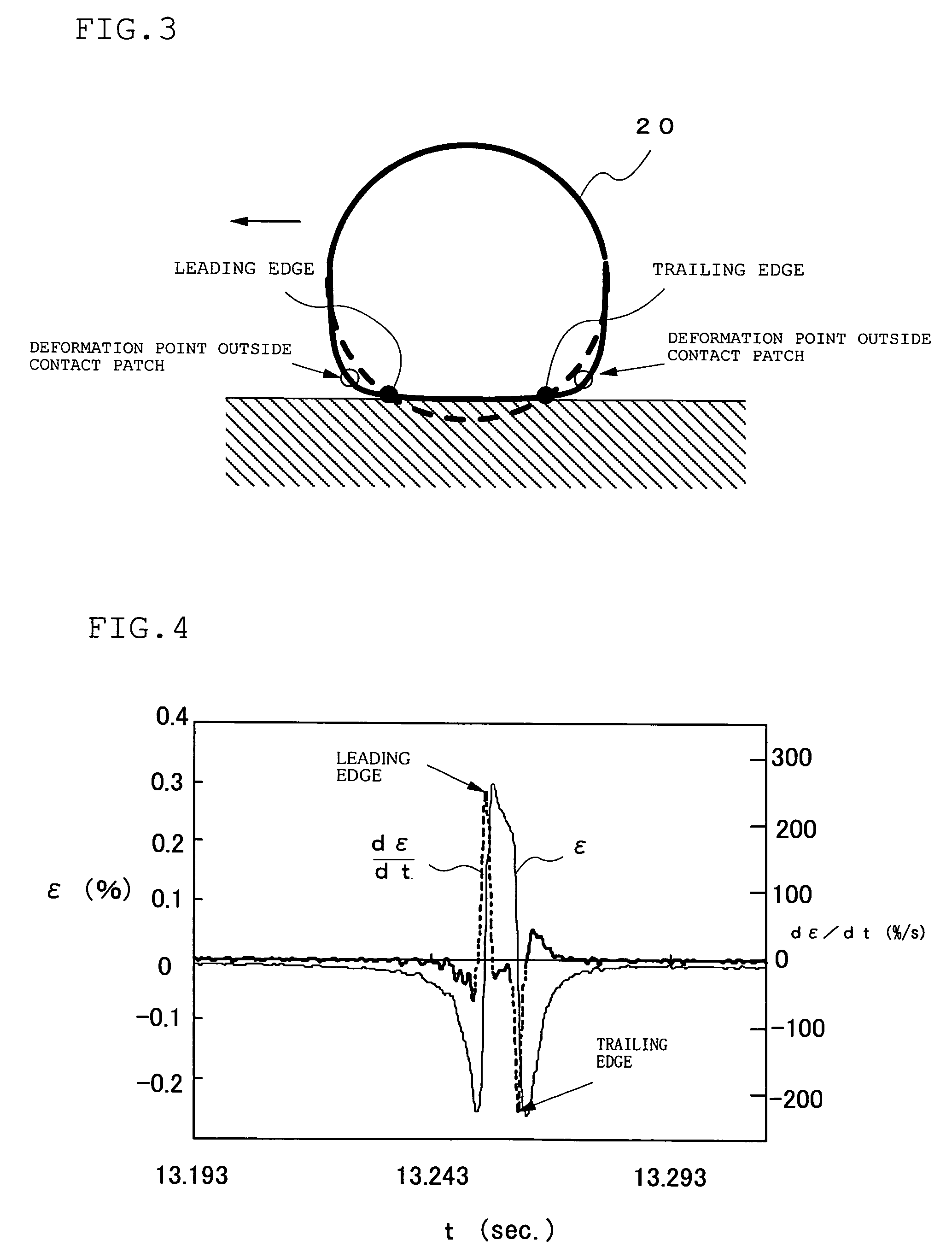

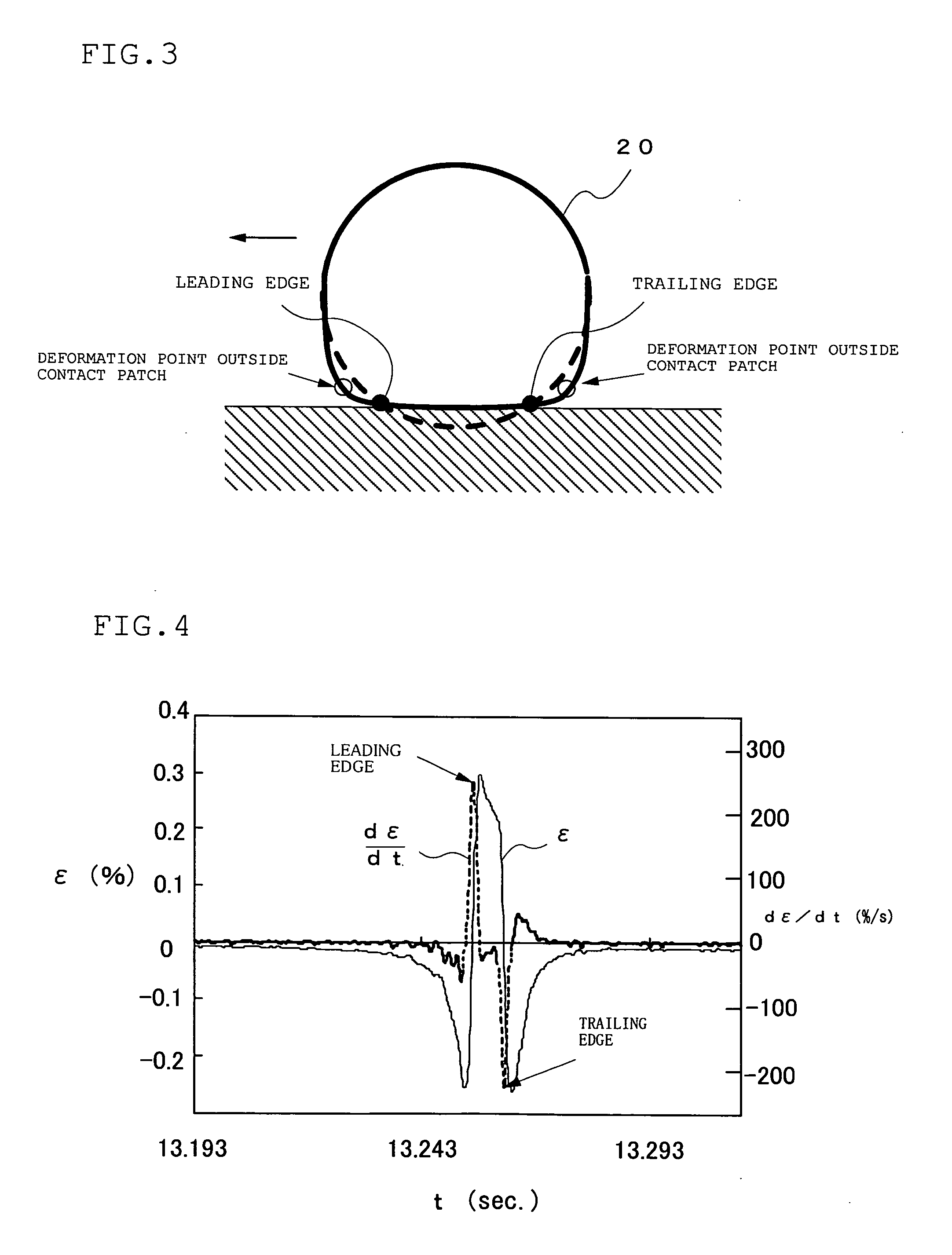

Estimation Method and Apparatus of Tire Dynamic State Amount and Tire with Sensors

ActiveUS20070240502A1Tyre measurementsApparatus for force/torque/work measurementContact timeWheel speed sensor

The dynamic state amount of a tire when a load is applied to the tire while running can be estimated accurately and stably by installing tire deformation amount measuring means 11A and 11B at axisymmetrical positions which are equally distant in the axial direction from the center in the axial direction of the tire on the cross-section in the radial direction of the tire on the inner side of the belt portion of a tire tread in the radial direction, such as at the inner surface of the tread, between an inner liner and a ply, between plies or between a ply and a belt to measure the waveforms of deformation of the tire, detecting the contact time which is the time difference between contact edges from the waveforms of deformation, calculating contact length indices kA and kB from the contact time and the wheel speed detected by a wheel speed sensor 15, calculating the average value k of the above indices kA and kB, and obtaining a load applied to the tire by using the calculated average value k of the indices of contact length and a map 18M showing the relationship between the average value of the indices of contact length and load pre-stored in memory means 18.

Owner:BRIDGESTONE CORP

Dielectric barrier discharge water treatment device and method

InactiveCN103482720AIncrease chance of contactImprove mass transfer efficiencyWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsLow voltageHigh pressure

Owner:TAIYUAN UNIV OF TECH

Image forming method

ActiveUS20130155145A1High quality imagingIncrease speedDuplicating/marking methodsInksPolyolOrganic solvent

An image forming method applying a pretreatment liquid on the surface of a recording medium; and applying an inkjet ink including a colorant, a hydrosoluble organic solvent, a surfactant and water on the surface applied with the pretreatment liquid, wherein the hydrosoluble organic solvent includes at least one polyol including an equilibrium water content in an amount not less than 30% by weight at 23° C. and 80% RH; an amide compound having the following formula (I); and at least one of compounds having the following formulae (II) to (IV), and wherein a pure water transfers to the recording medium in an amount of from 1 to 15 mL / m2 when measured by a dynamic scanning liquid absorptometer at a contact time of 100 ms.

Owner:RICOH KK

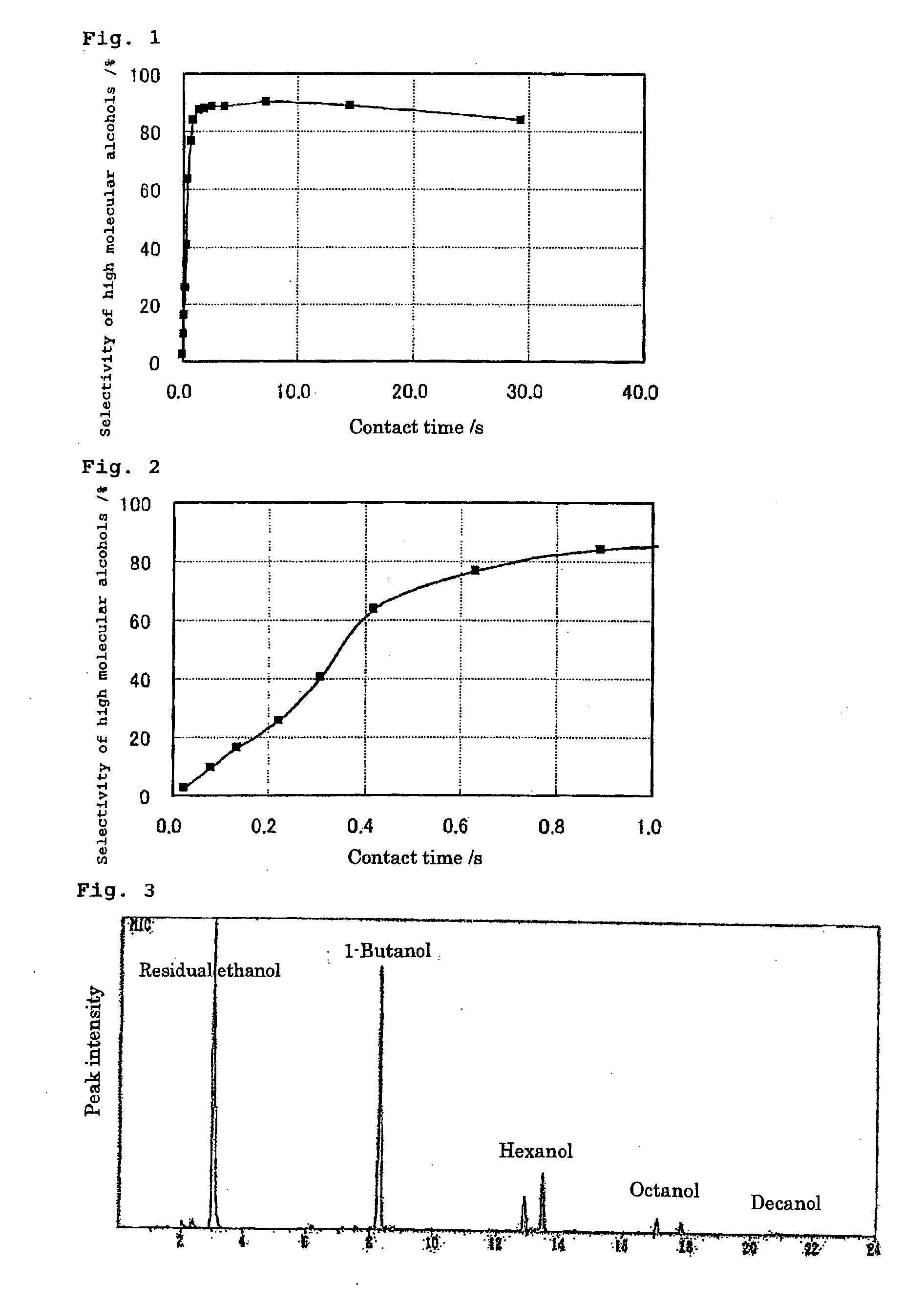

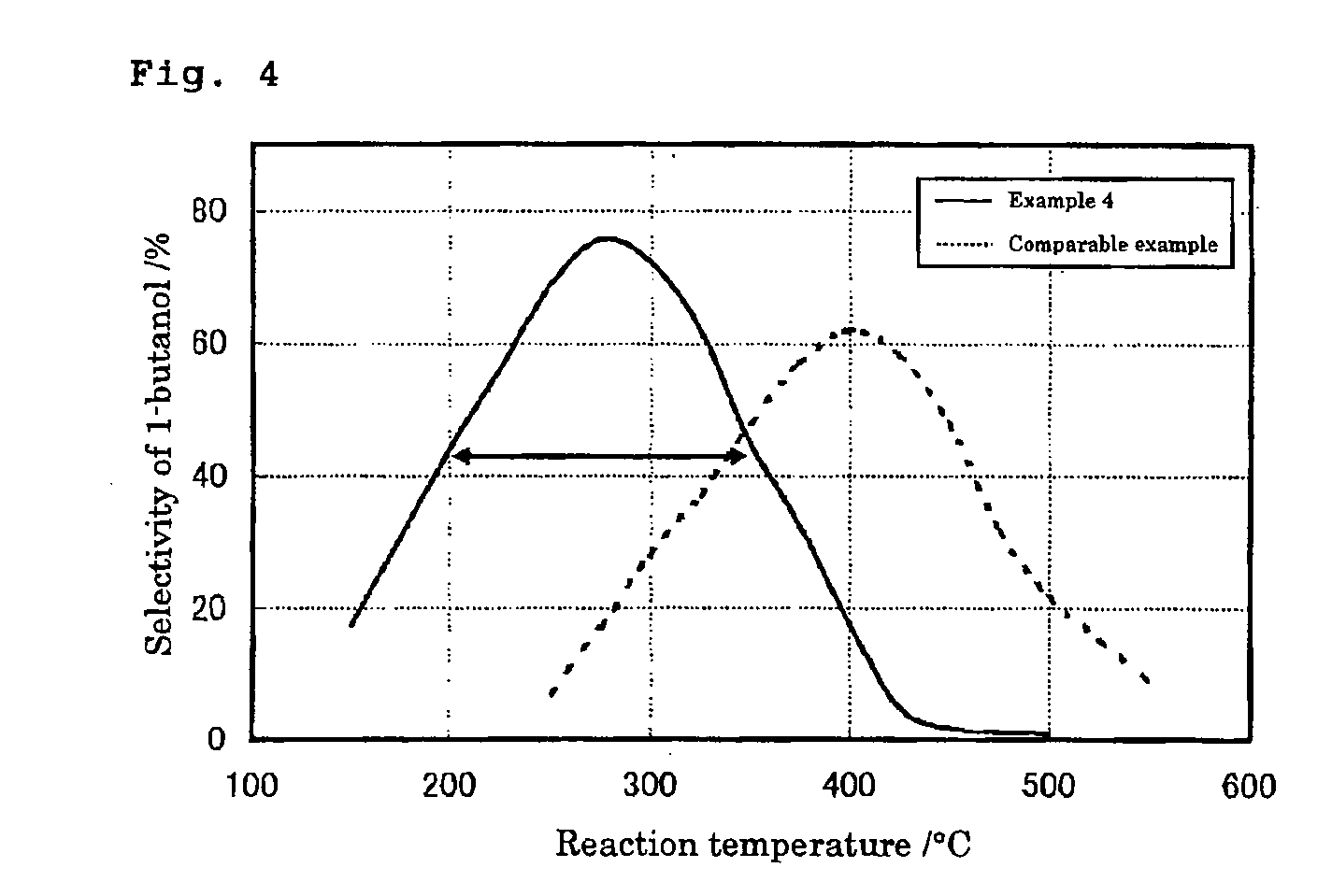

Method of Synthesizing Higher-Molecular Alcohol

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

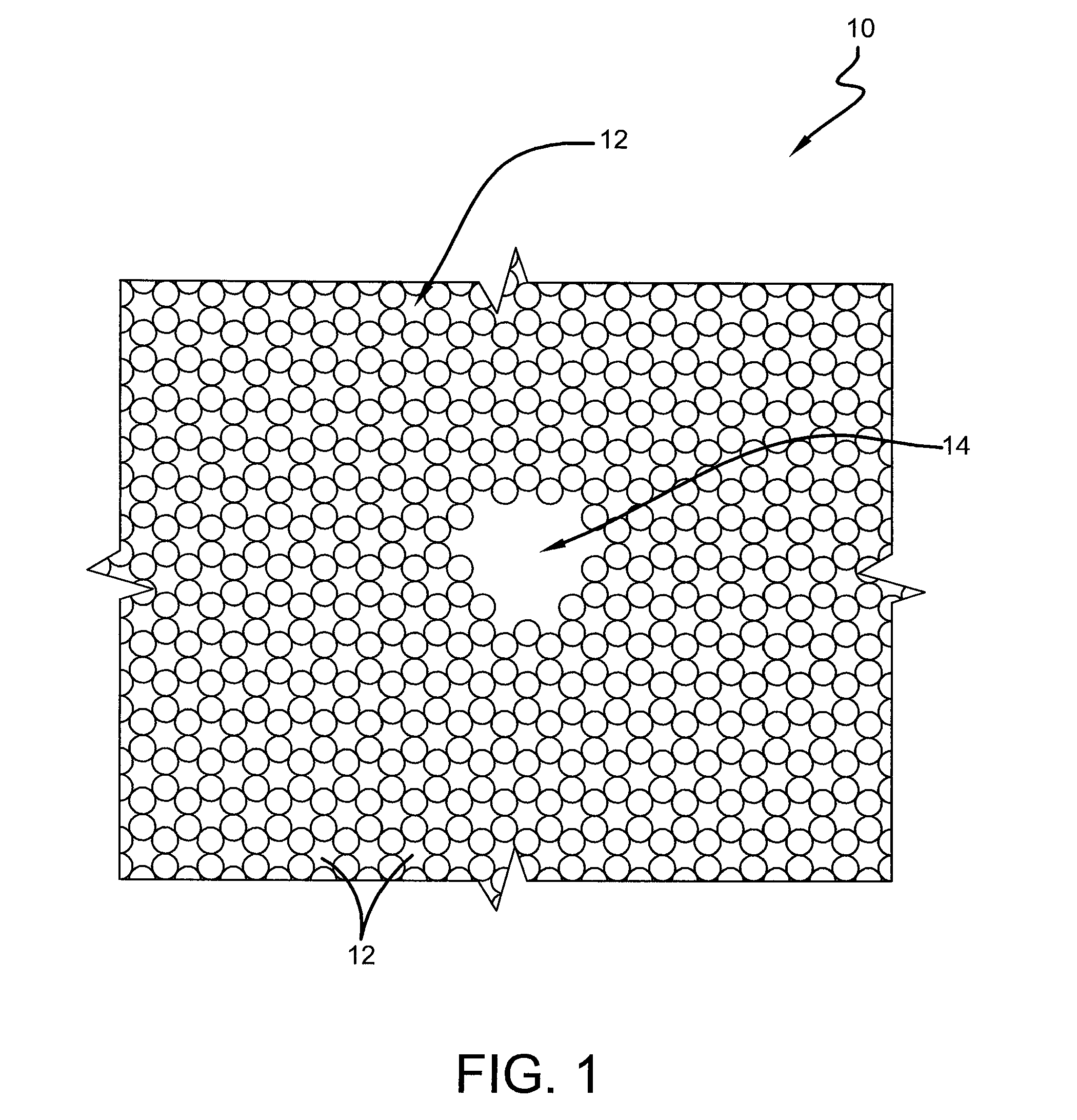

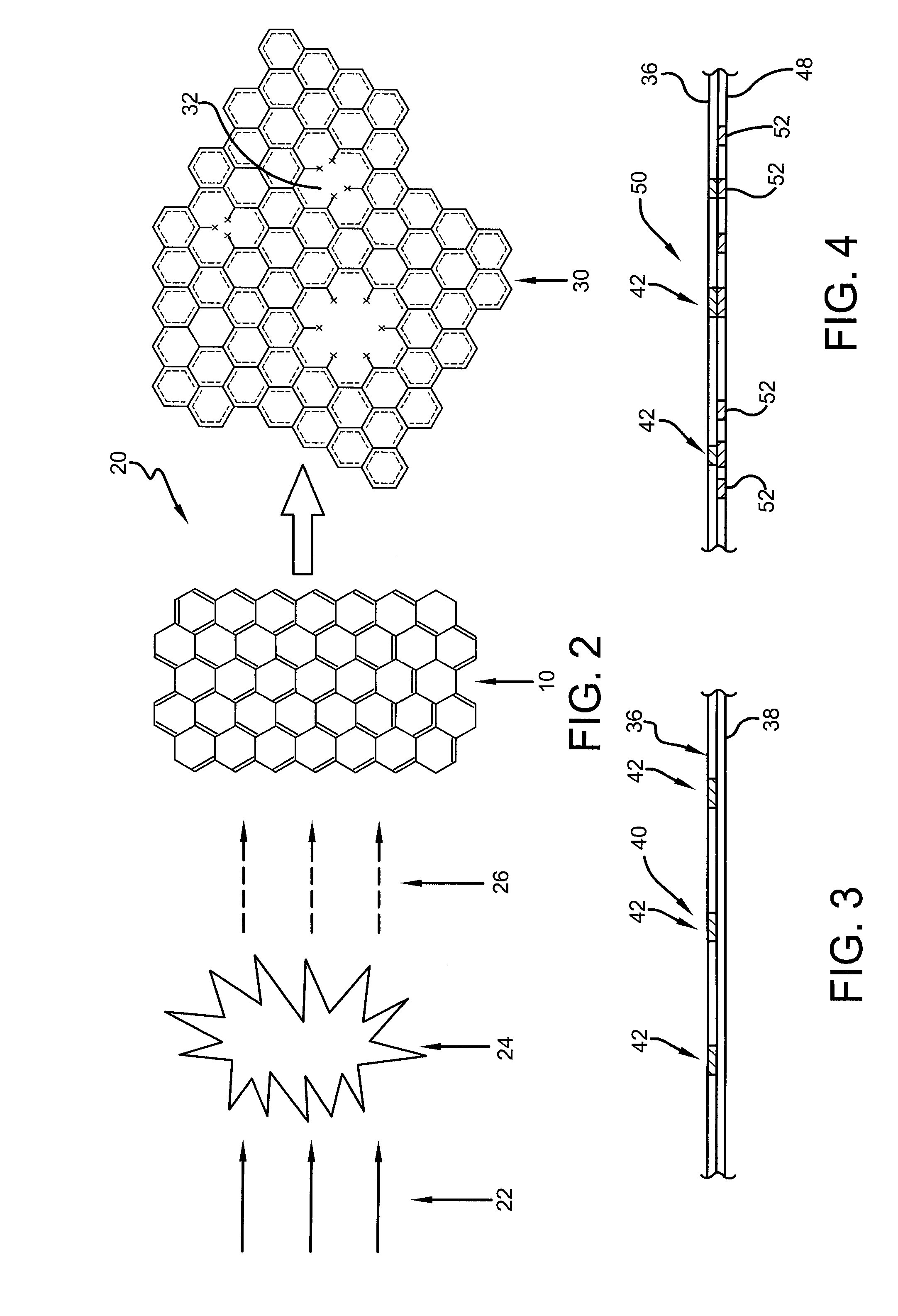

Methods for perforating graphene using an activated gas stream and perforated graphene produced therefrom

InactiveUS20130249147A1Reliably allow passage of certain nano-sized componentMaterial nanotechnologyGrapheneContact timeProduct gas

Graphene sheets having a plurality of holes in their basal planes are described herein. Methods for making the graphene sheets can involve contacting graphene sheets with an activated gas that has contacted a helium or argon atmospheric pressure plasma. The size and / or number of holes introduced can be altered by changing the contact time, the stand-off distance, the activated gas concentration, and / or the plasma power. Polymer composites containing the perforated graphene sheets are also described.

Owner:LOCKHEED MARTIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com