Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3381 results about "Three dimensional shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D Shapes (Solids) The shapes like cube, cuboid, cylinder, pyramid, cone etc. which require three dimensions i.e.length, breadth and height or depth are called solid figures or 3-dimensional figures. The objects having definite shape and size are called solids.

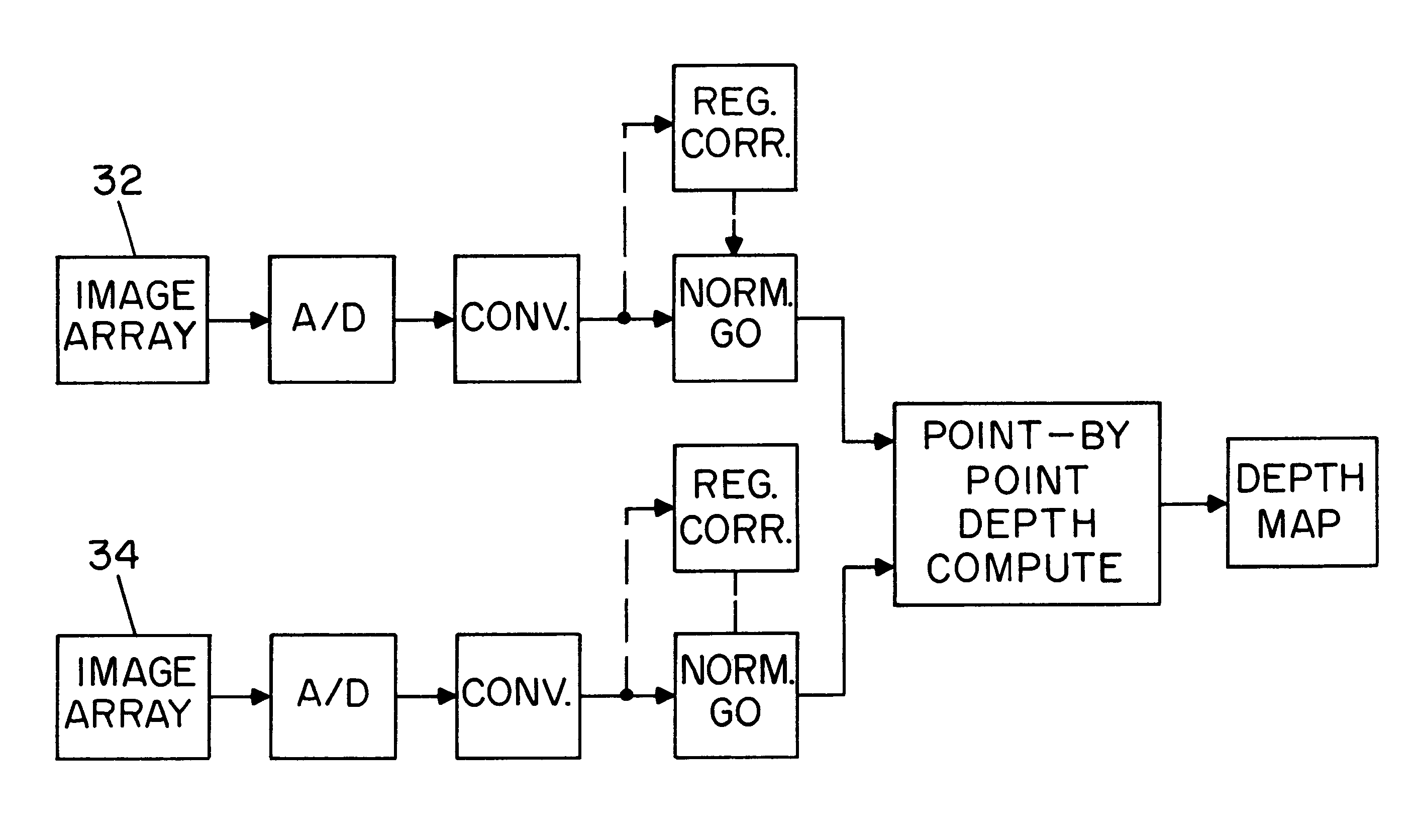

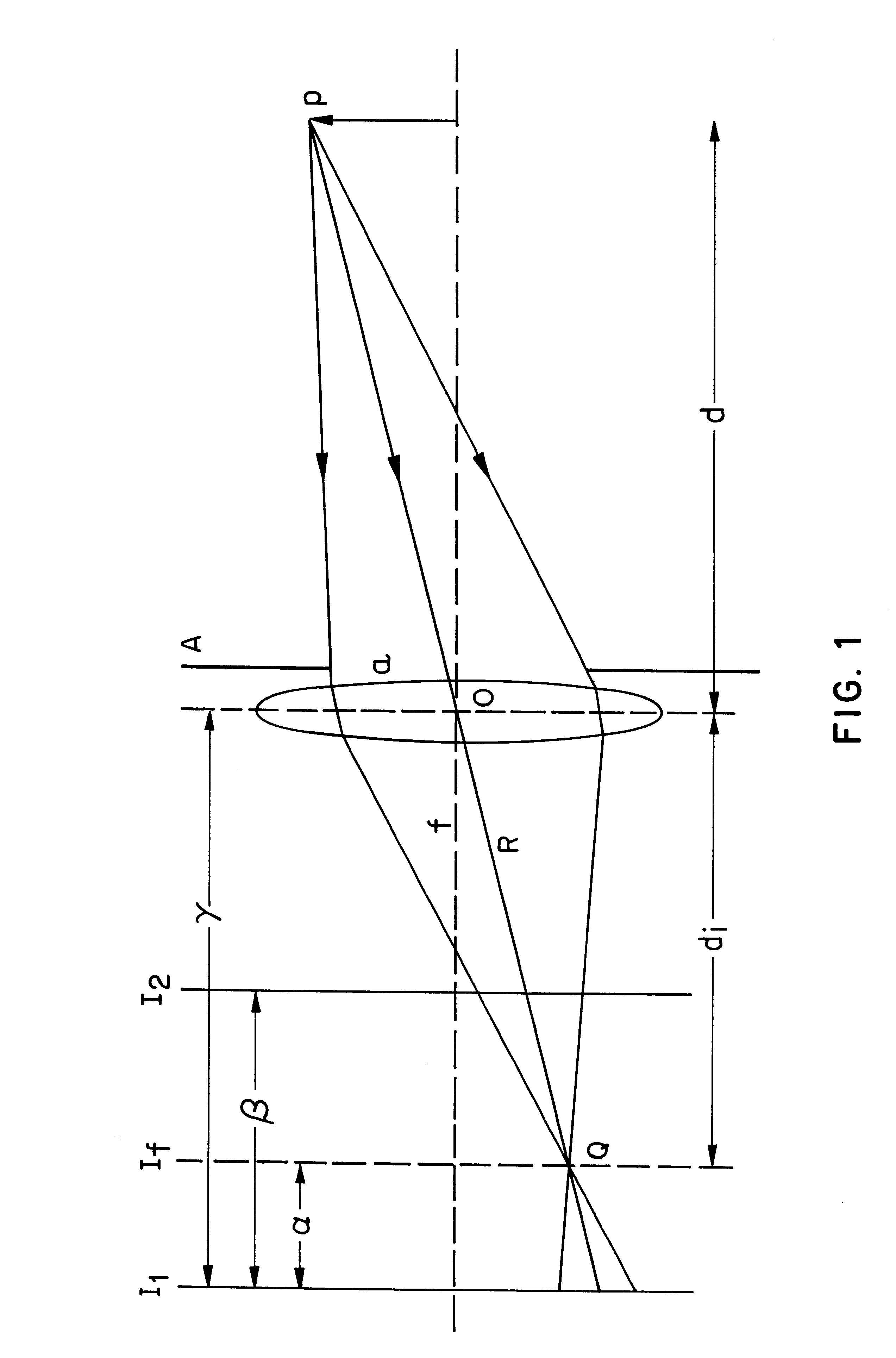

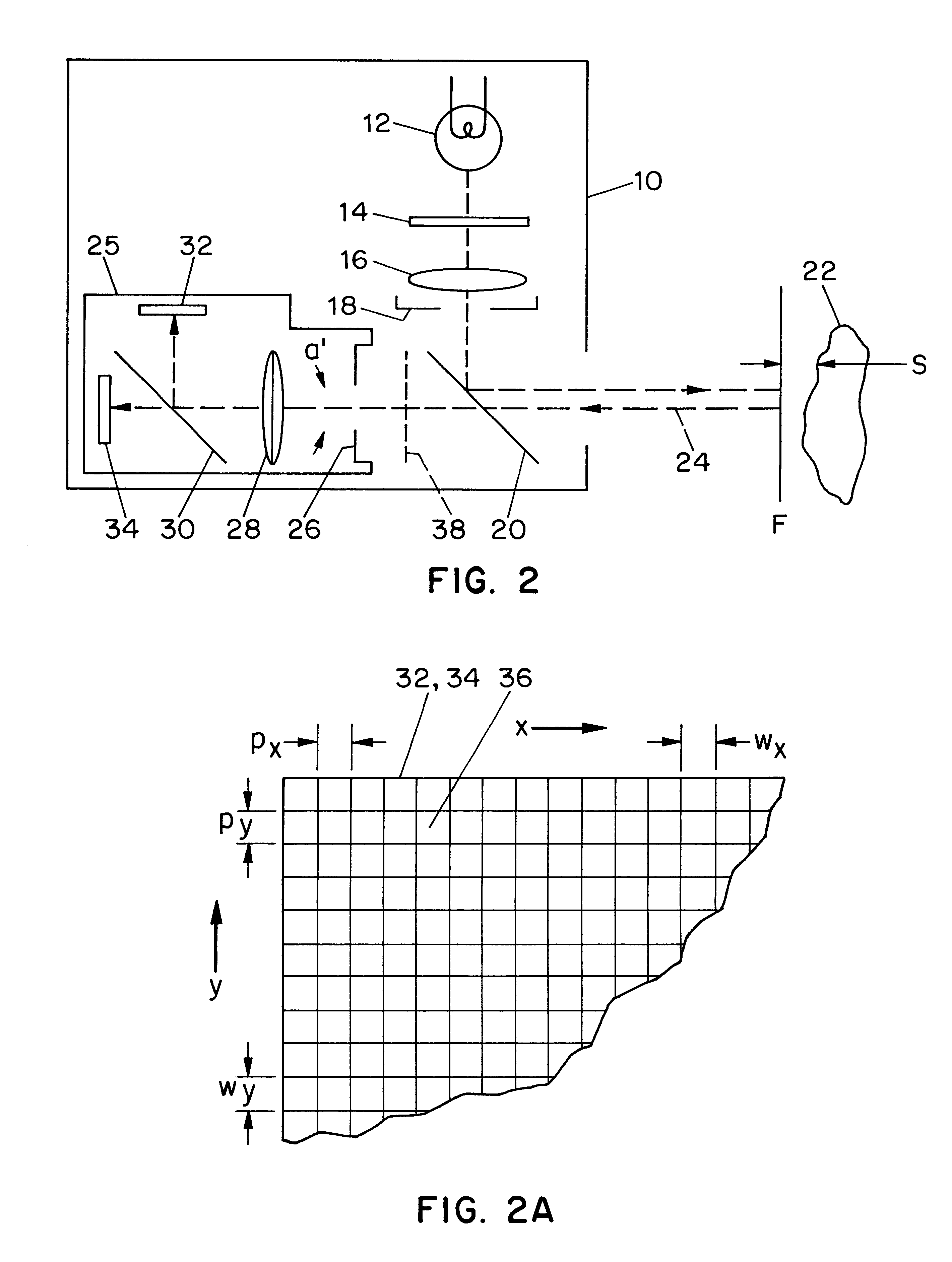

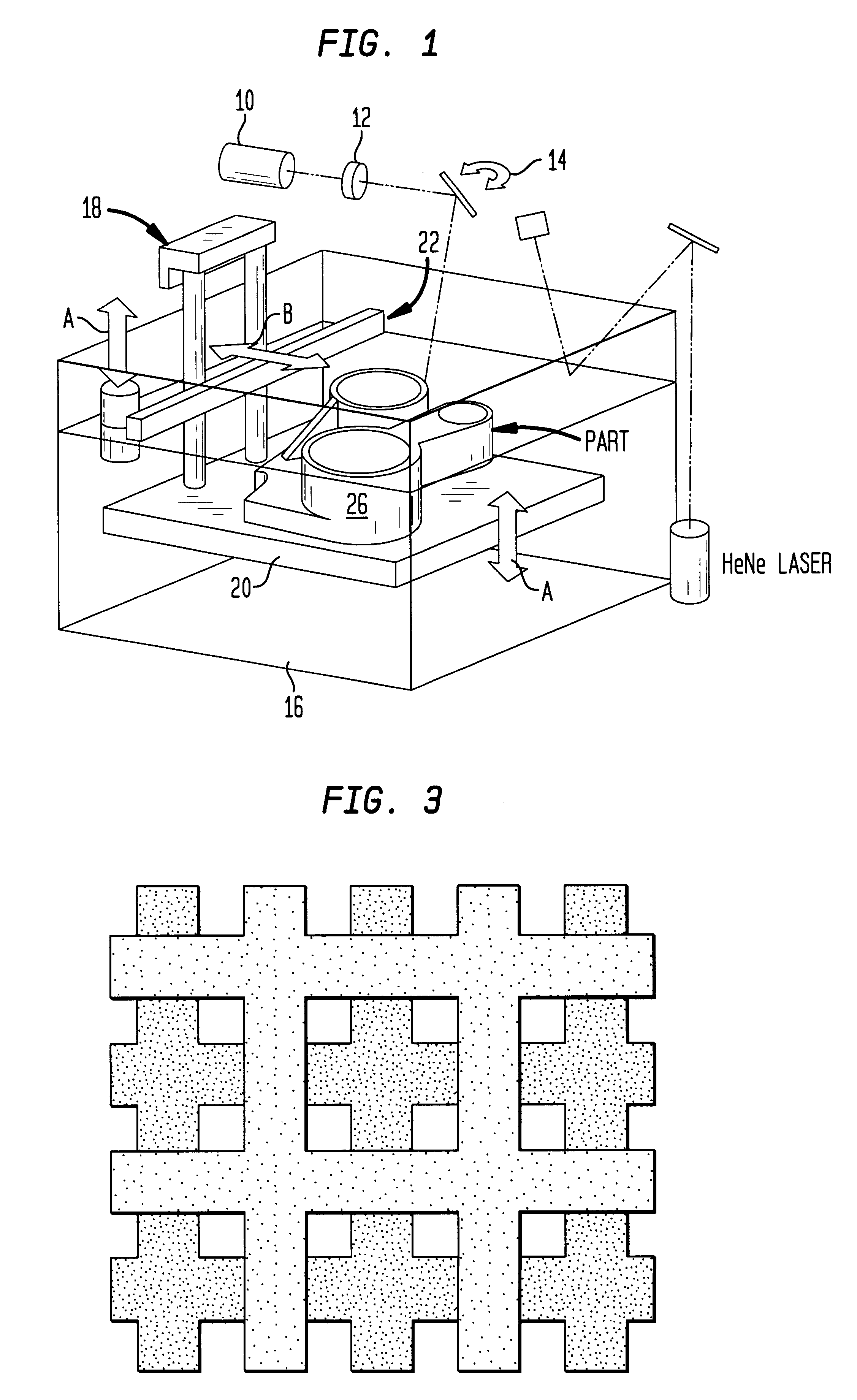

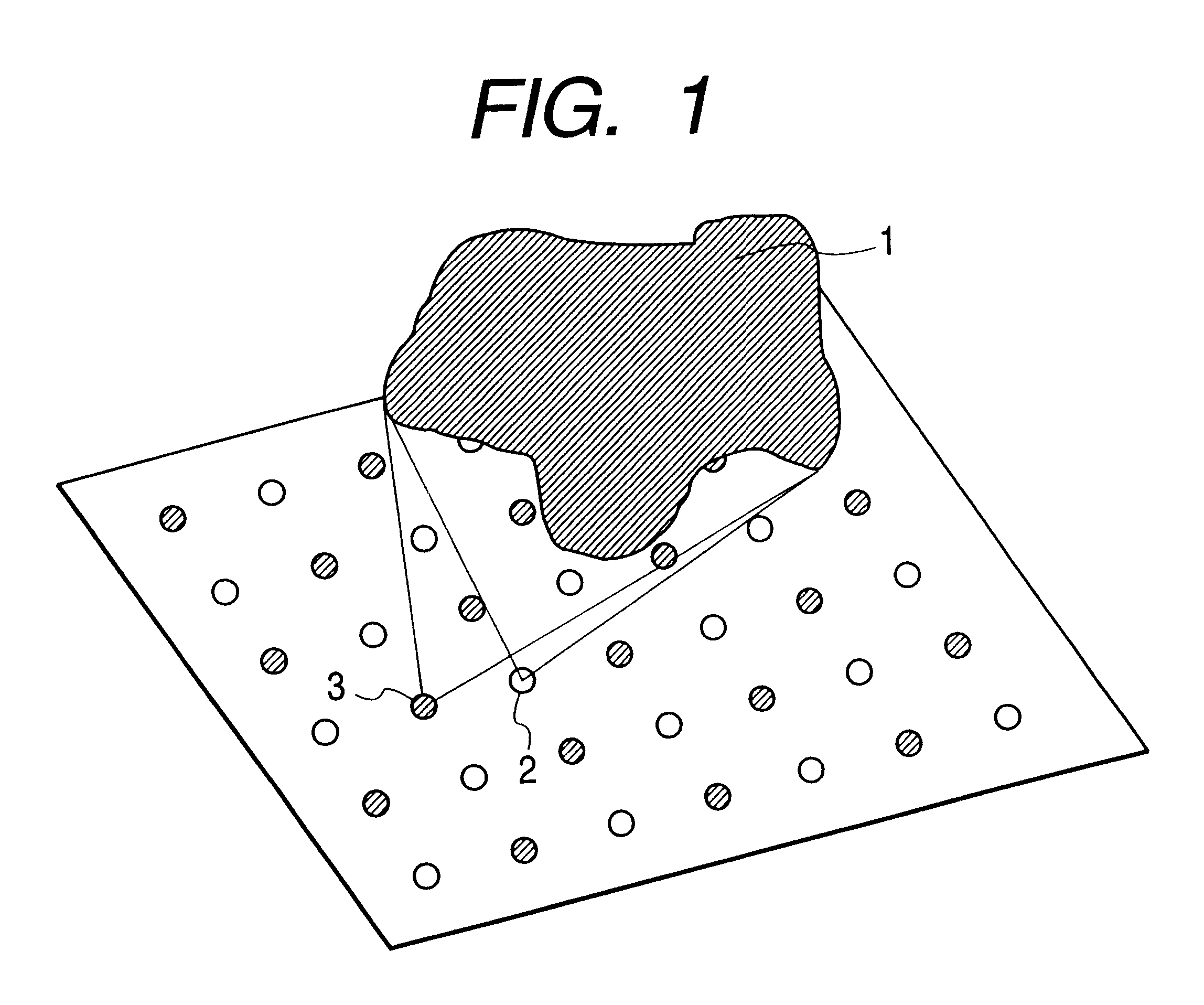

Apparatus and methods for determining the three-dimensional shape of an object using active illumination and relative blurring in two images due to defocus

A method and apparatus for mapping depth of an object (22) in a preferred arrangement uses a projected light pattern to provide a selected texture to the object (22) along the optical axis (24) of observation. An imaging system senses (32, 34) first and second images of the object (22) with the projected light pattern and compares the defocused of the projected pattern in the images to determine relative depth of elemental portions of the object (22).

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

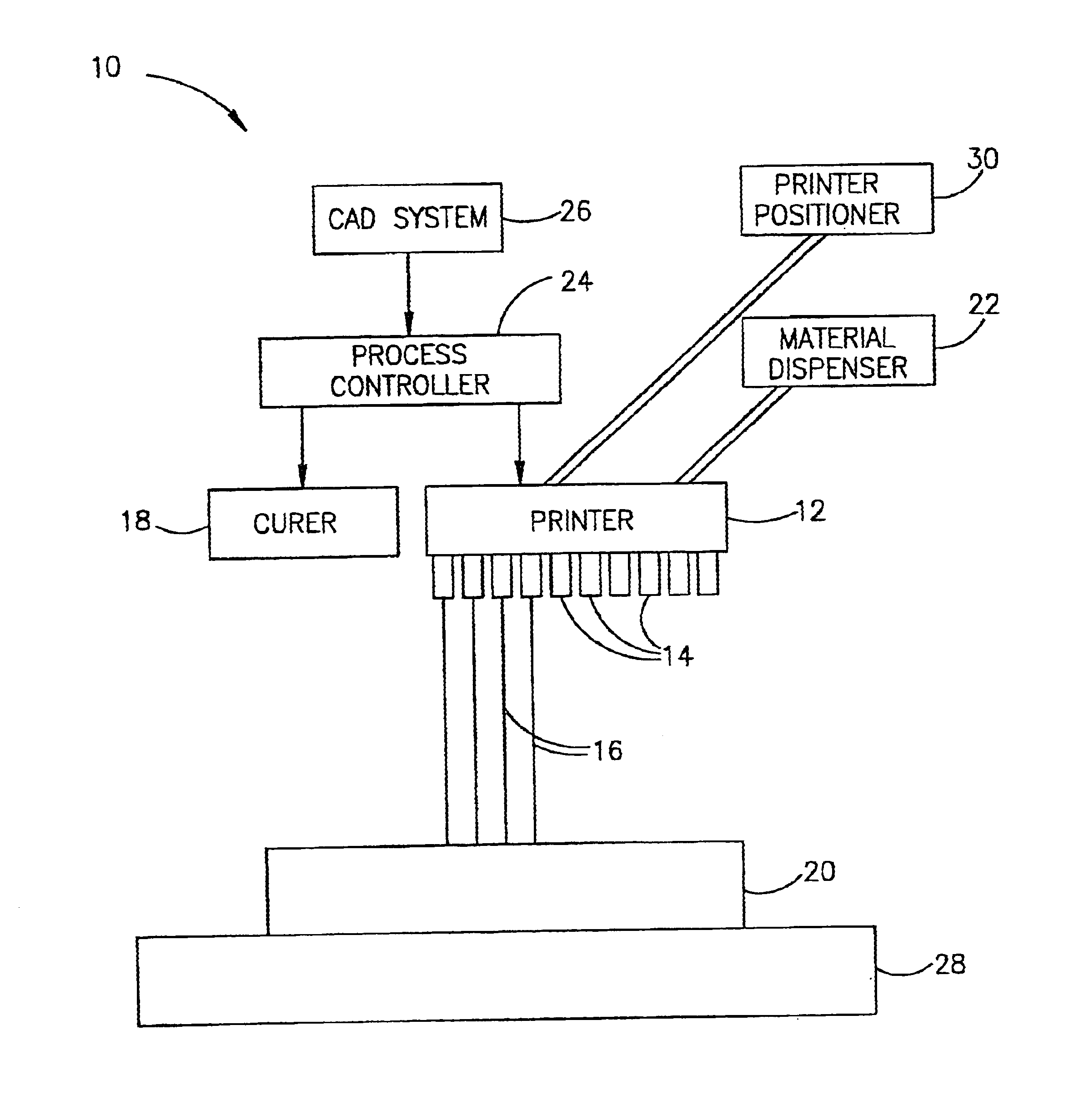

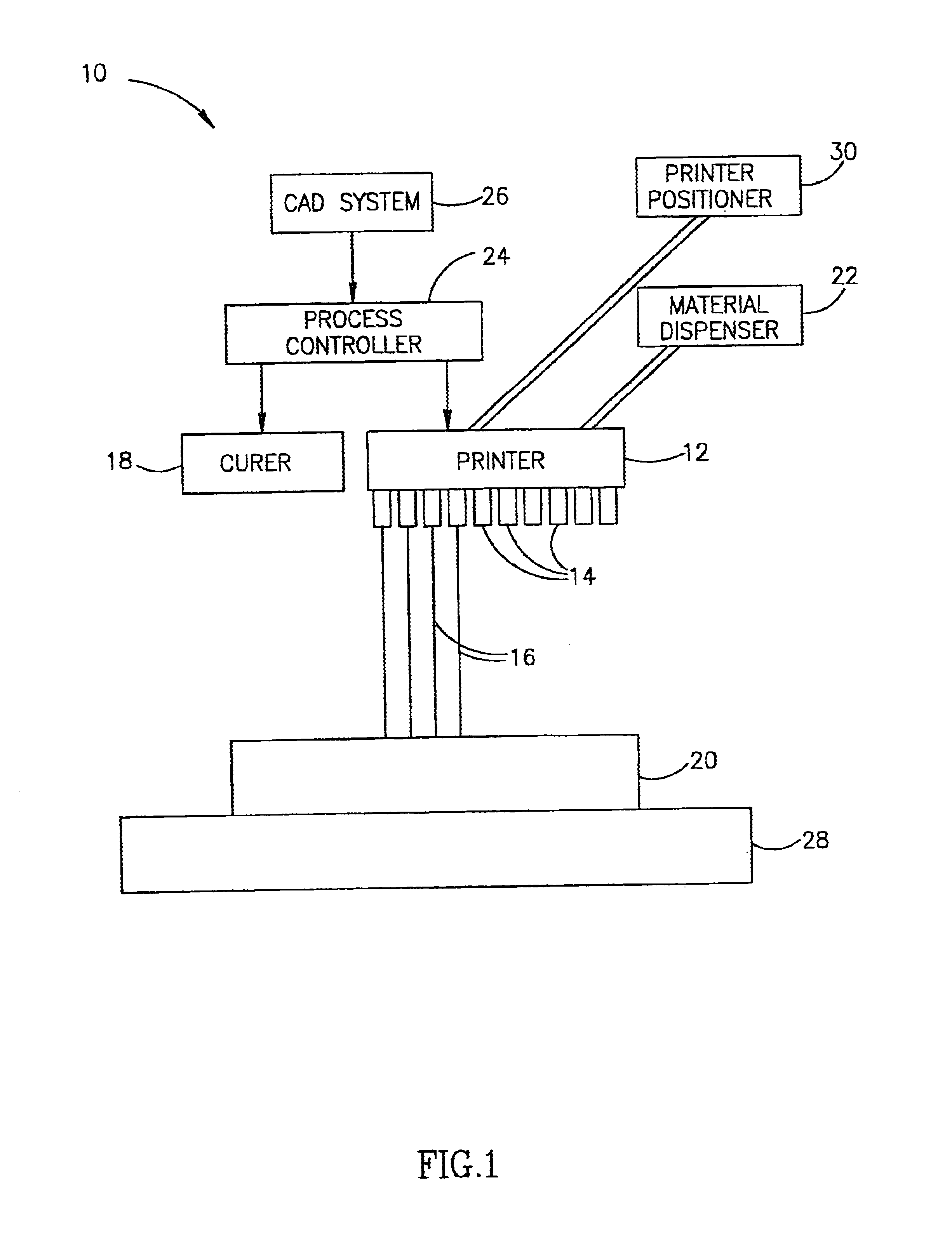

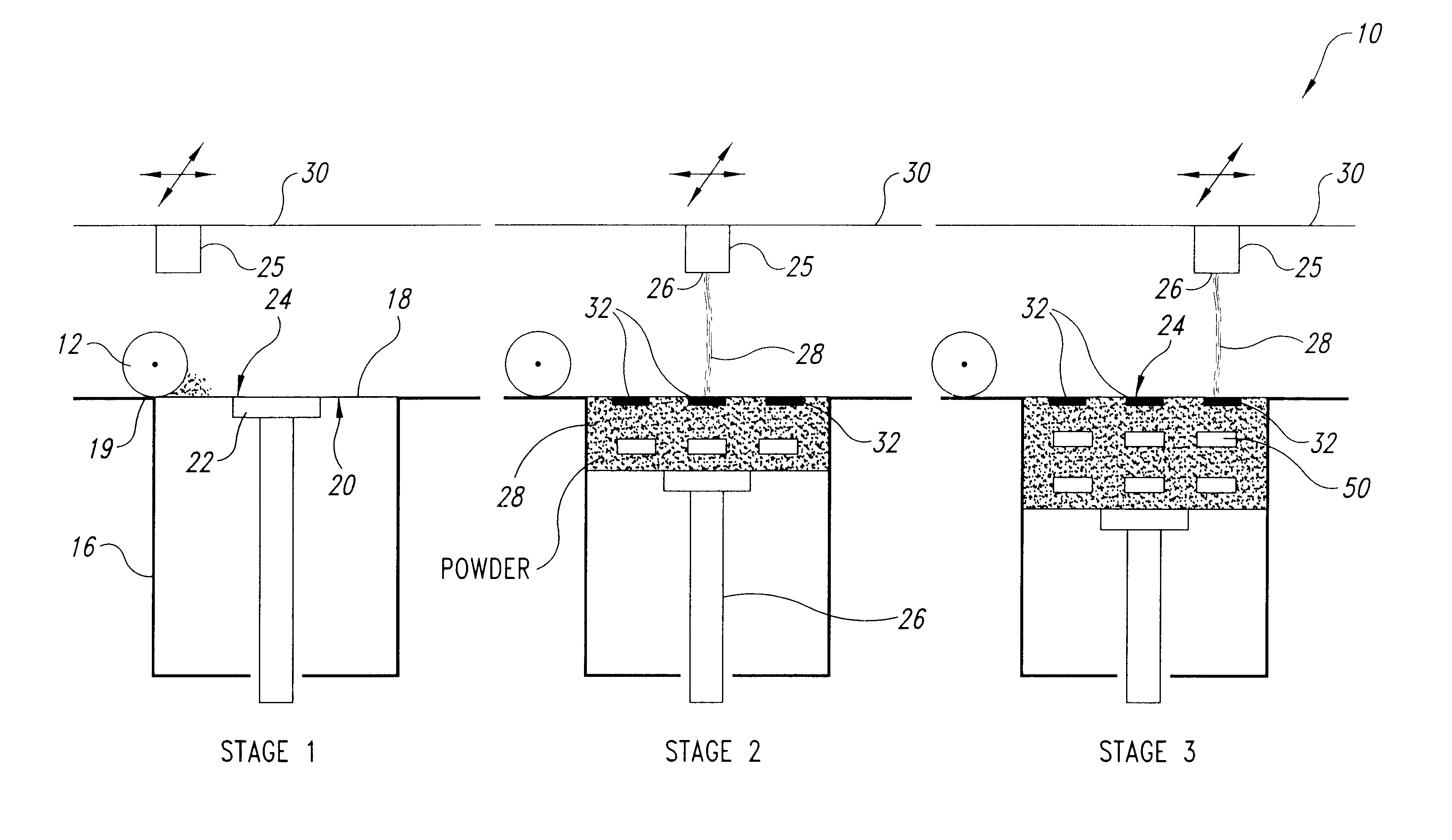

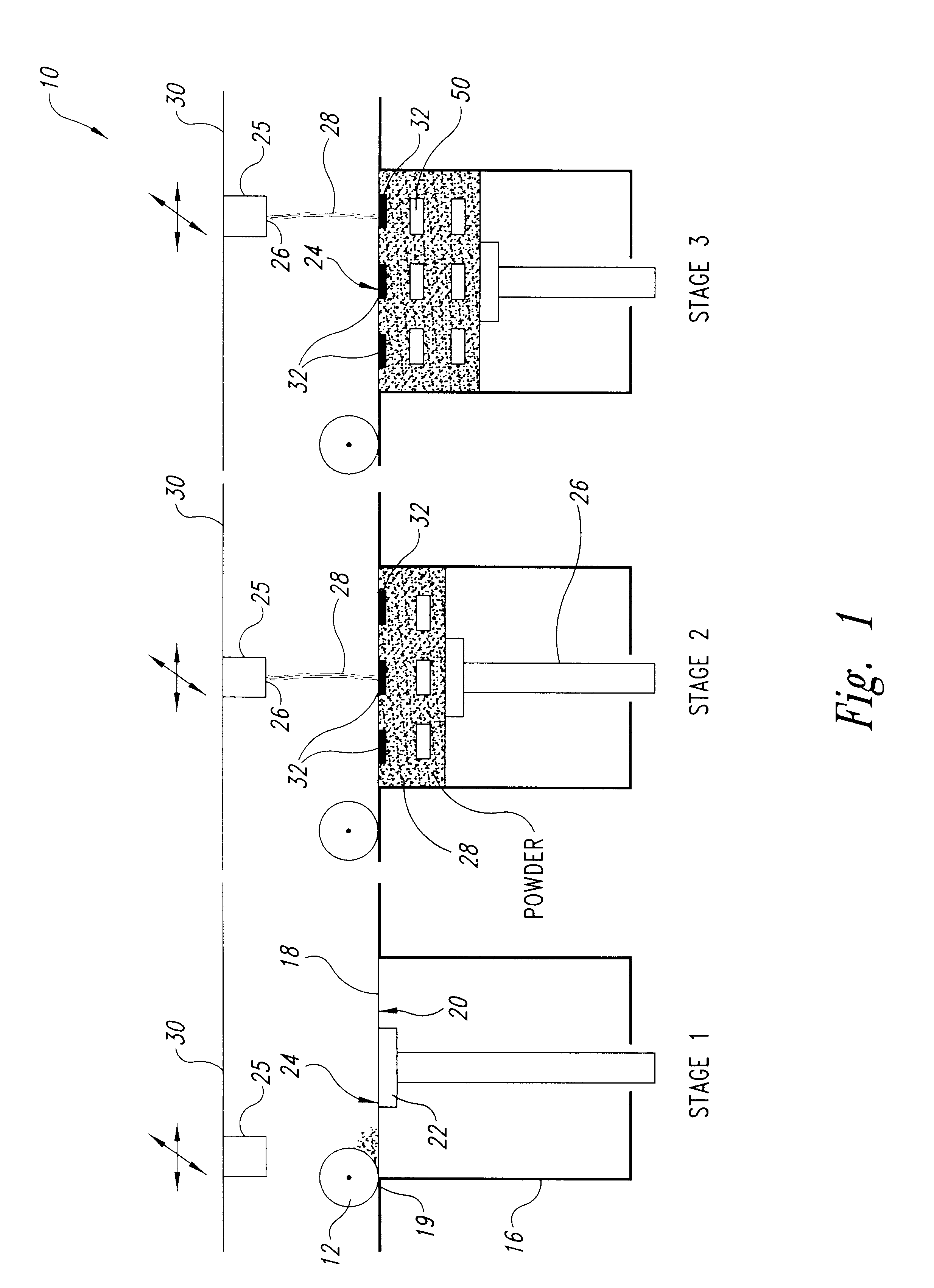

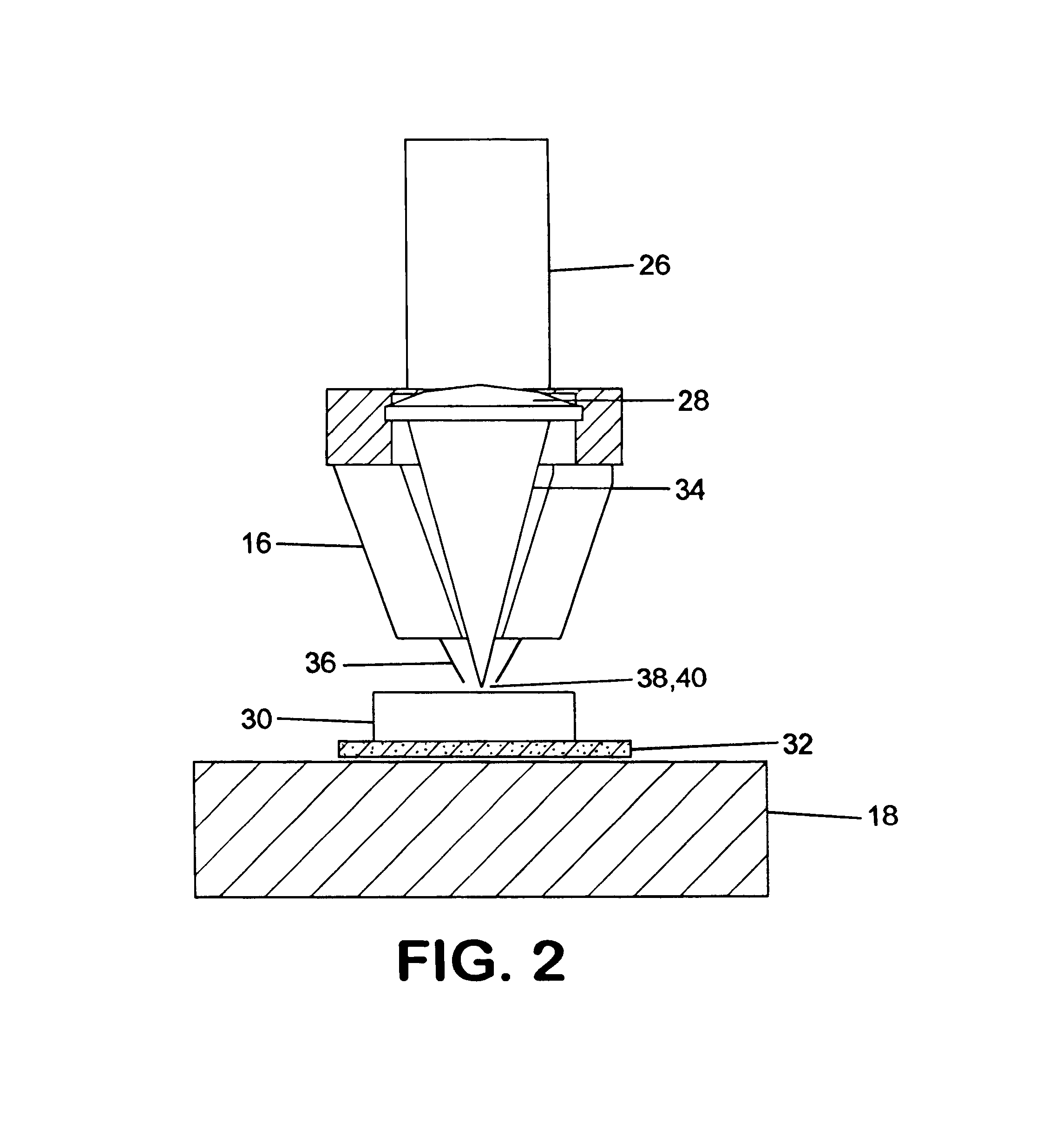

System and method for three dimensional model printing

InactiveUS6658314B1Limited hardnessAdditive manufacturing apparatusPhotomechanical treatmentThree dimensional shapeEngineering

A method and a system for three-dimensional printing of a three-dimensional model is provided. The method includes dispensing a first interface material from a printing head, dispensing at least a second interface material from the printing head and combining the first and second interface material in pre-determined proportions to produce layers for forming the three-dimensional model. In one embodiment, the layers forming the construction layers of the model are formed from interface material having a harder modulus of elasticity from the layers forming the release layers, thereby allowing for the forming complex three-dimensional shapes.

Owner:STRATASYS LTD

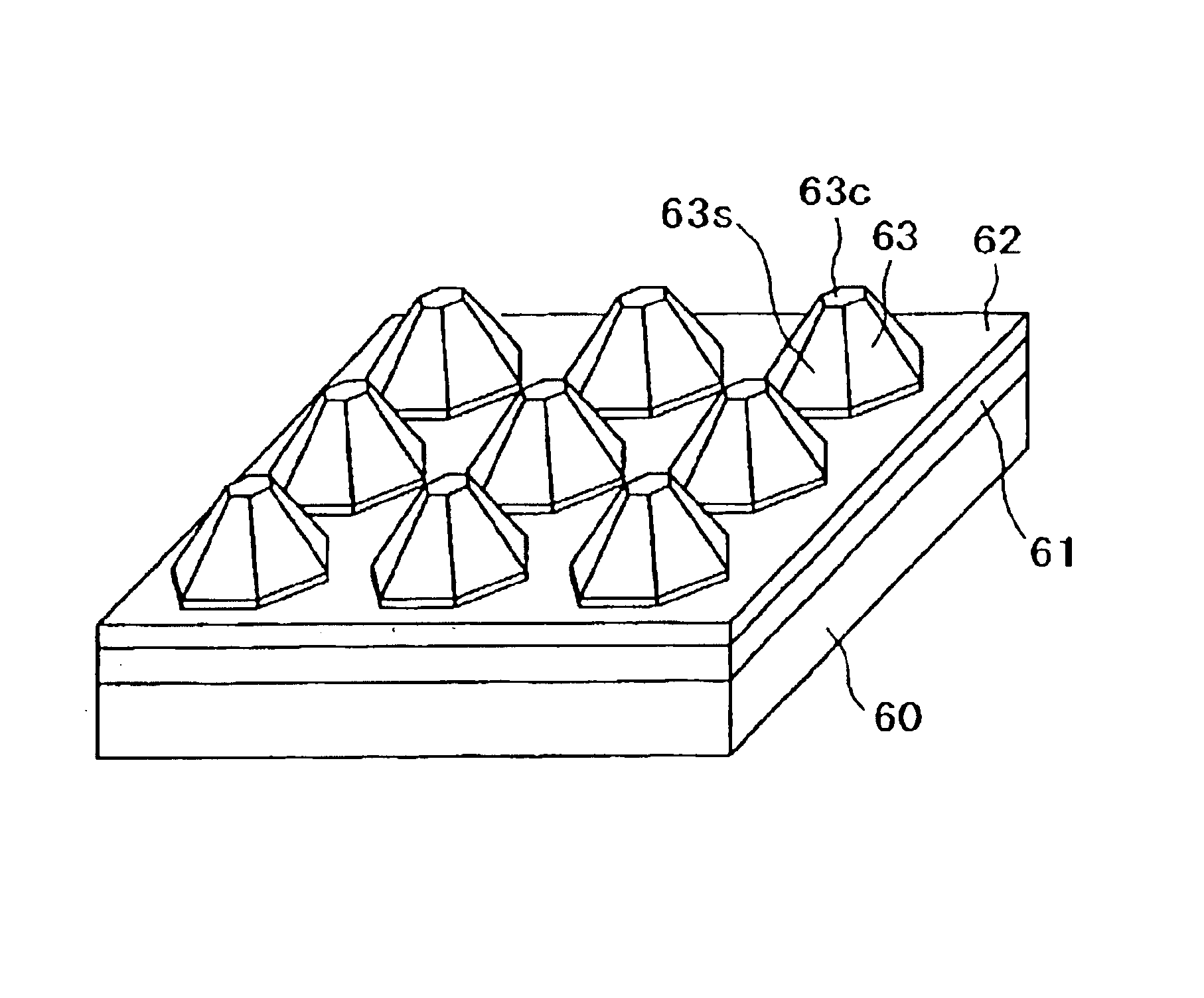

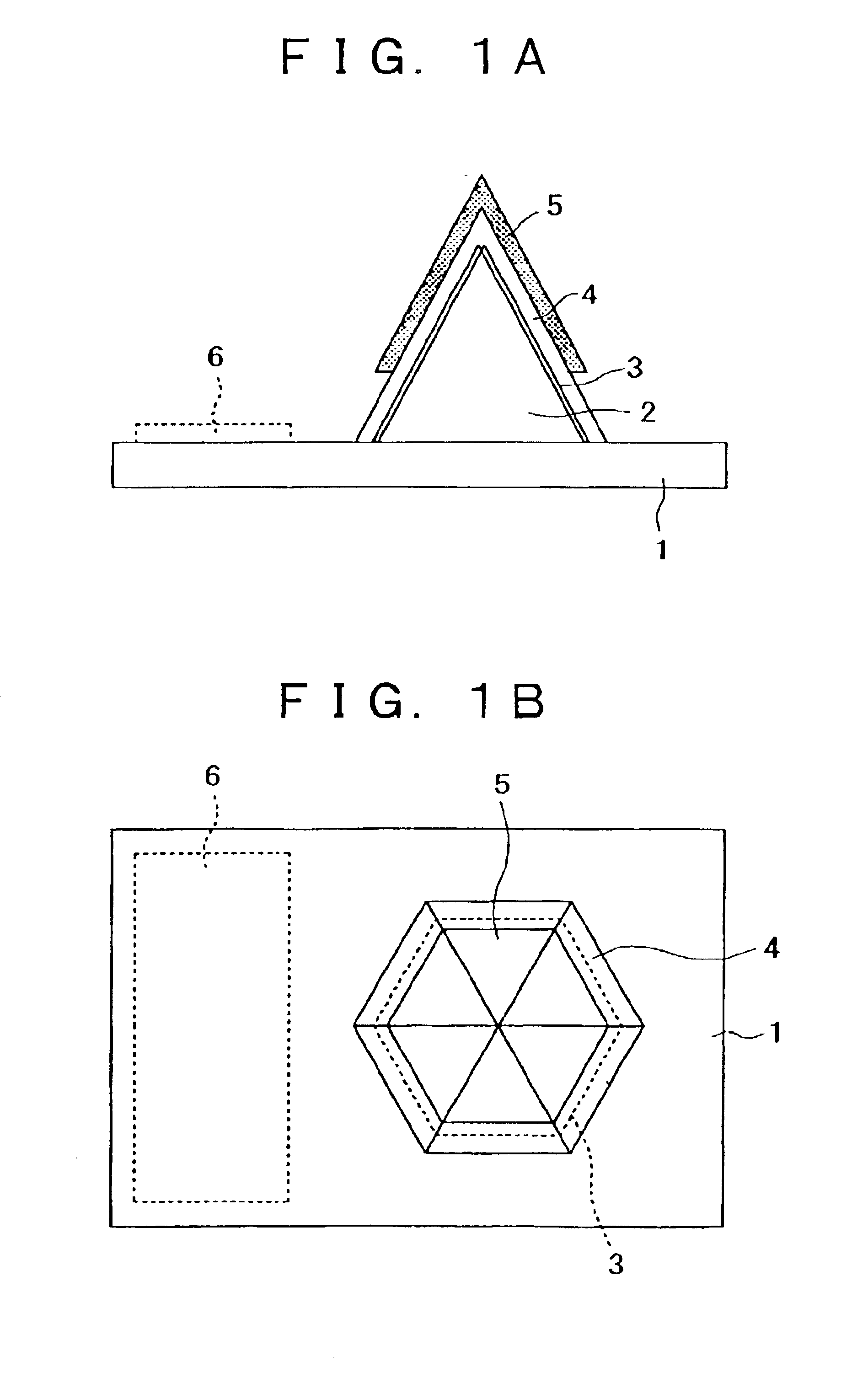

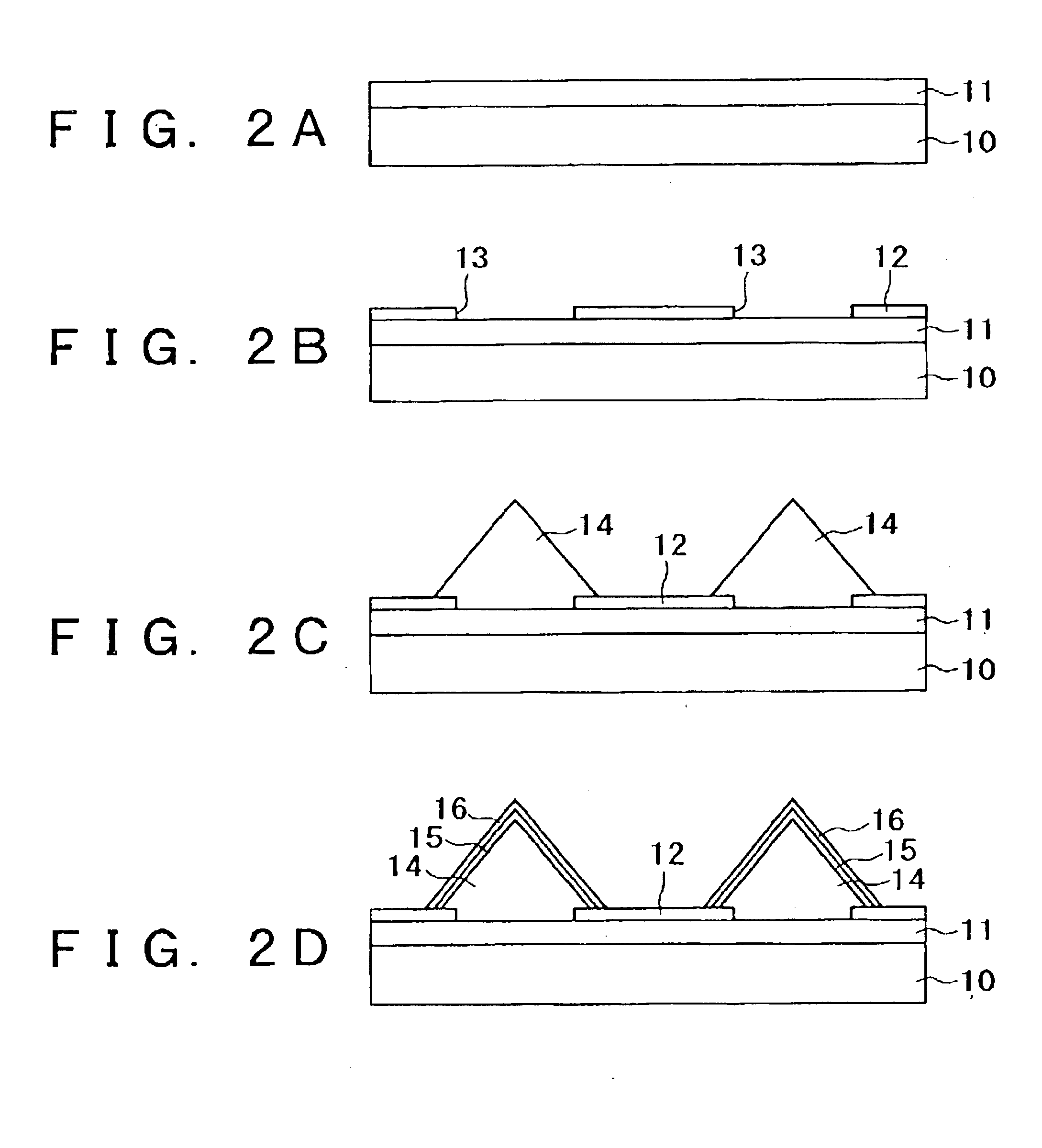

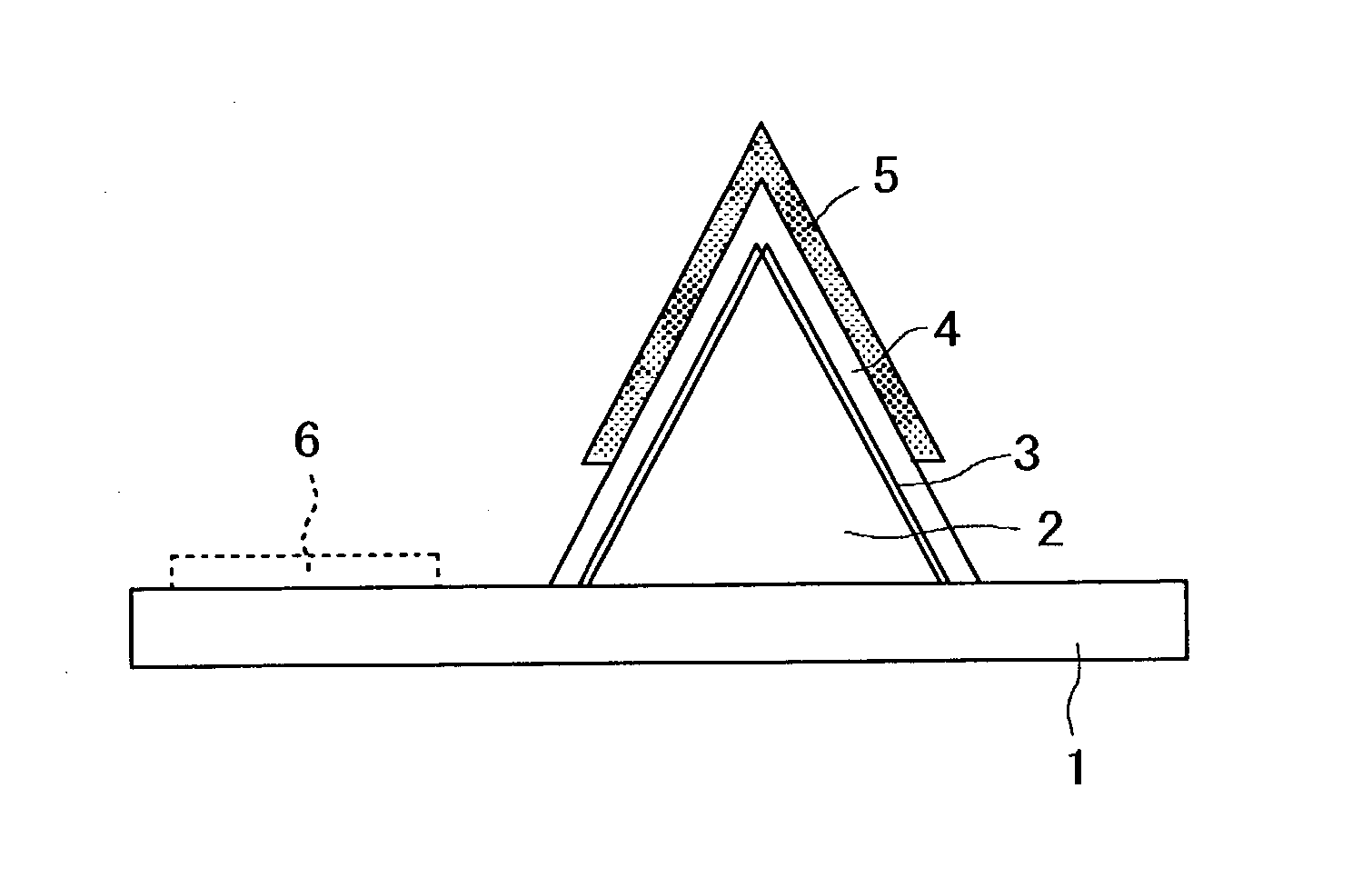

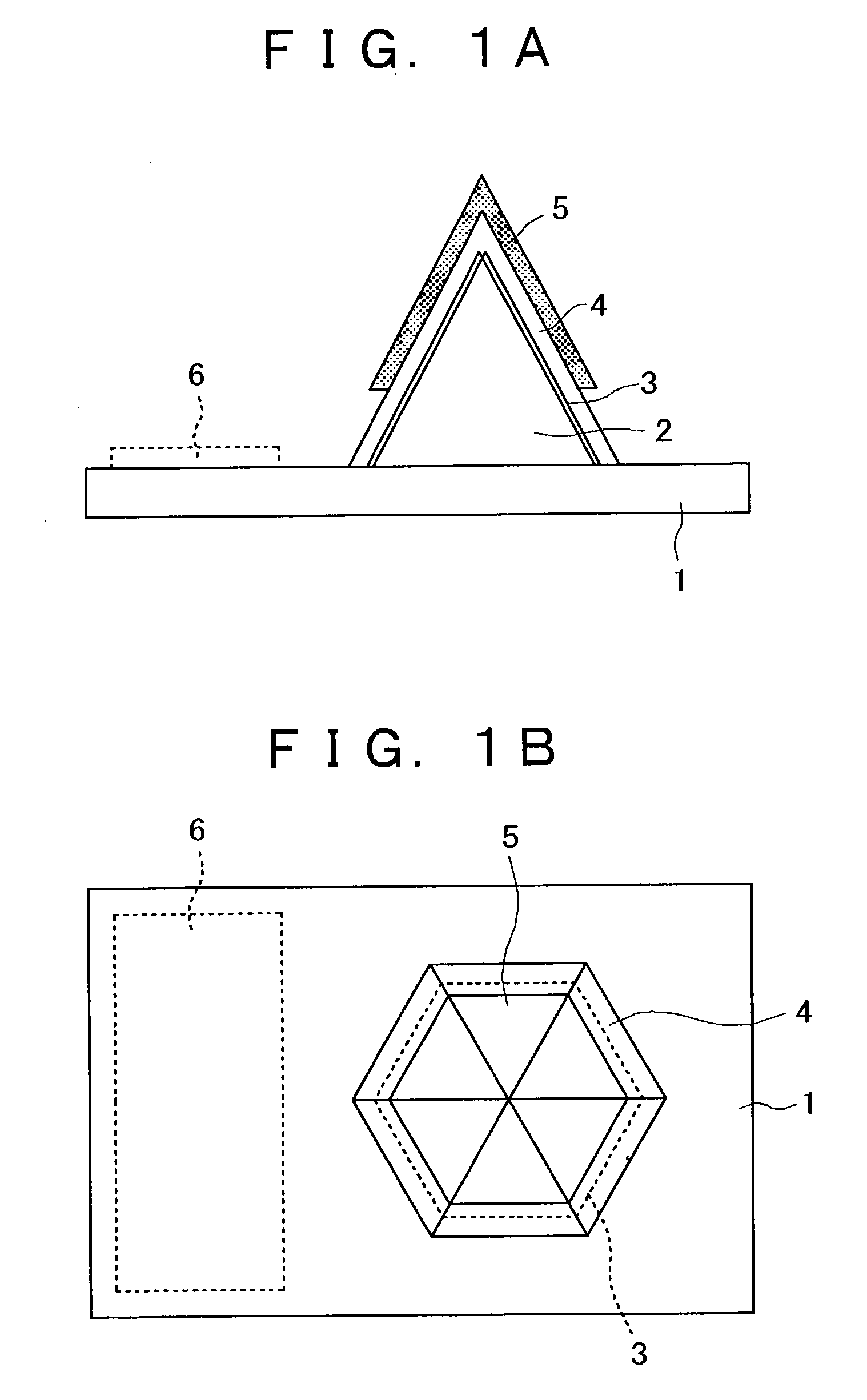

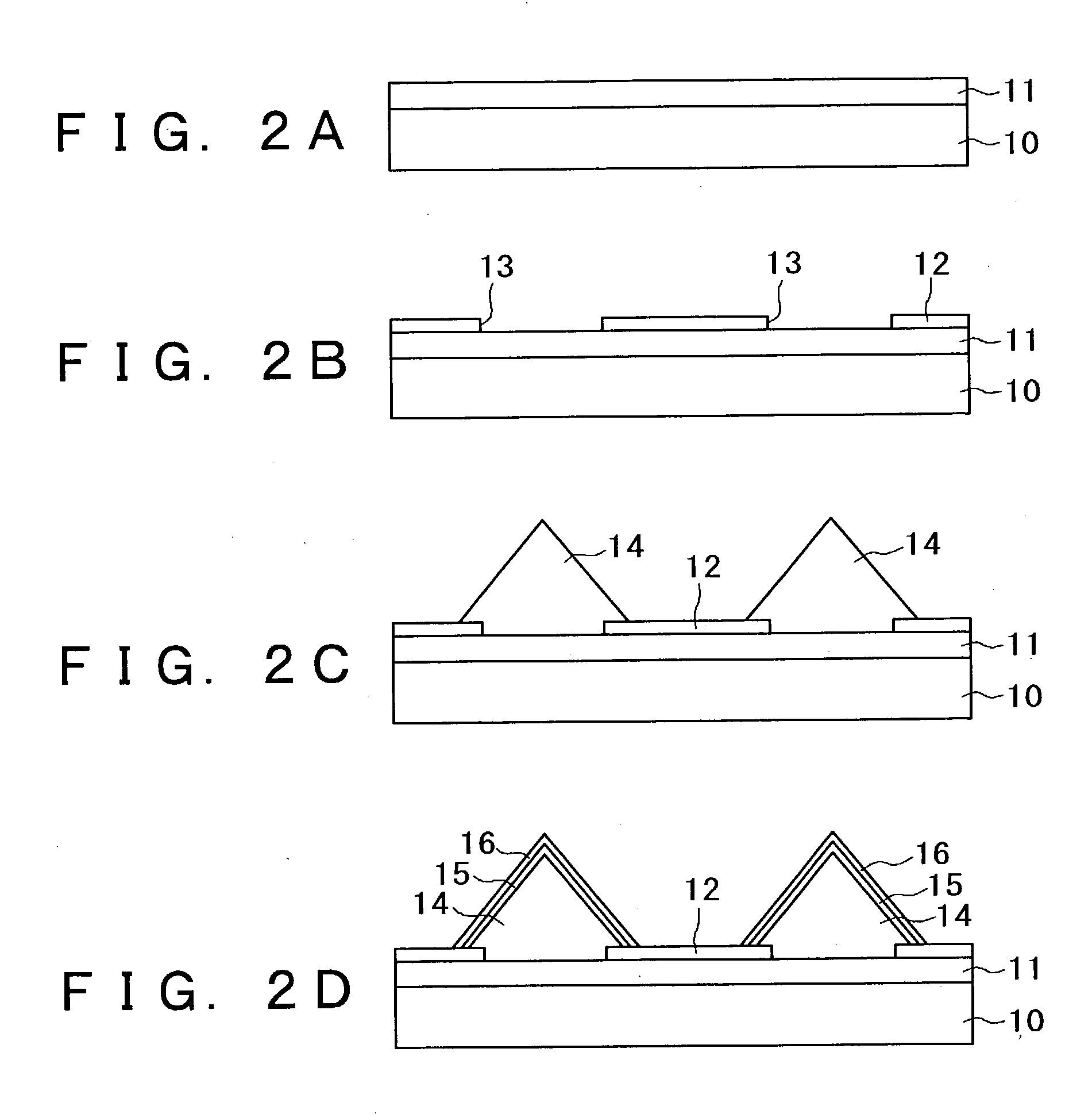

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

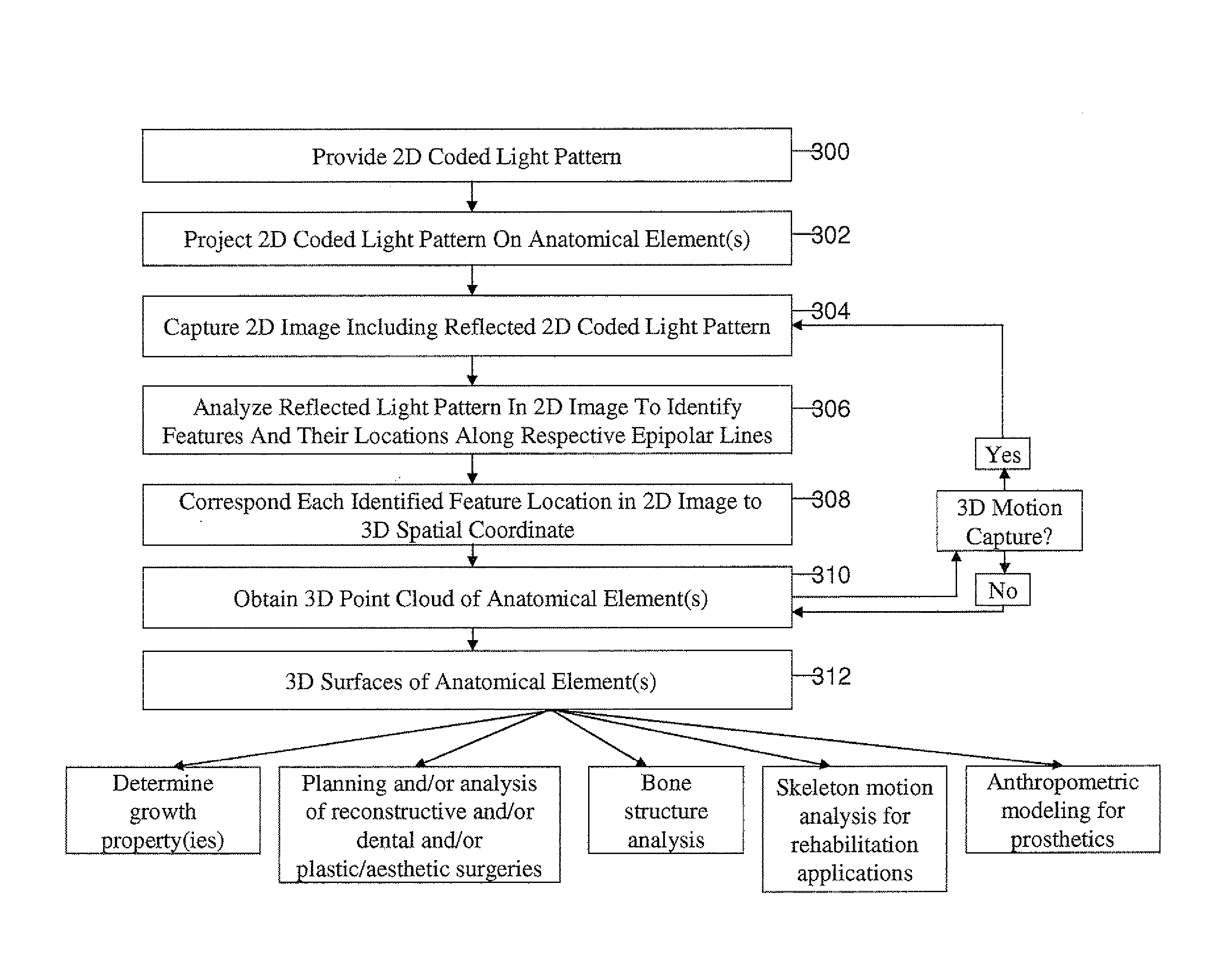

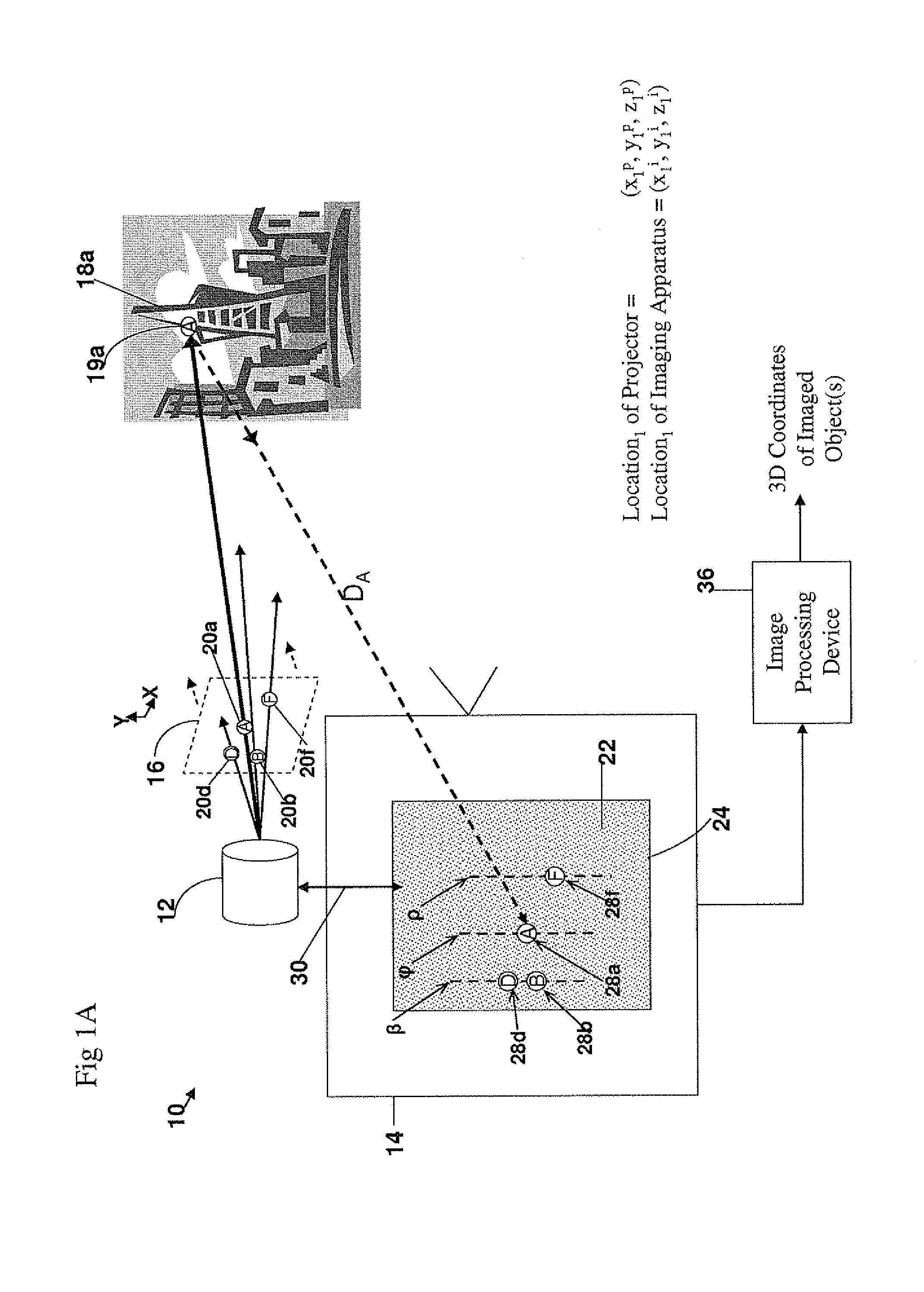

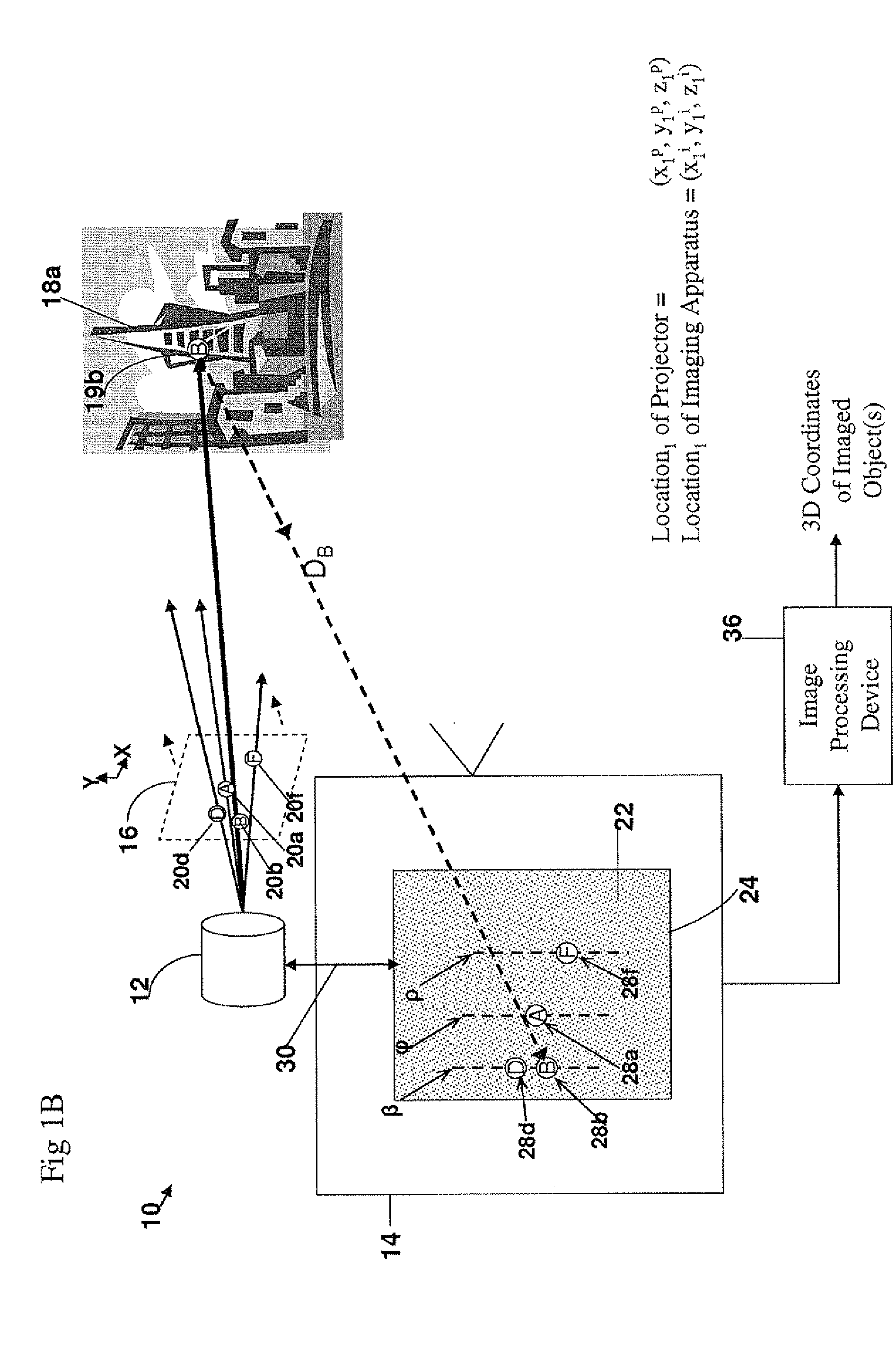

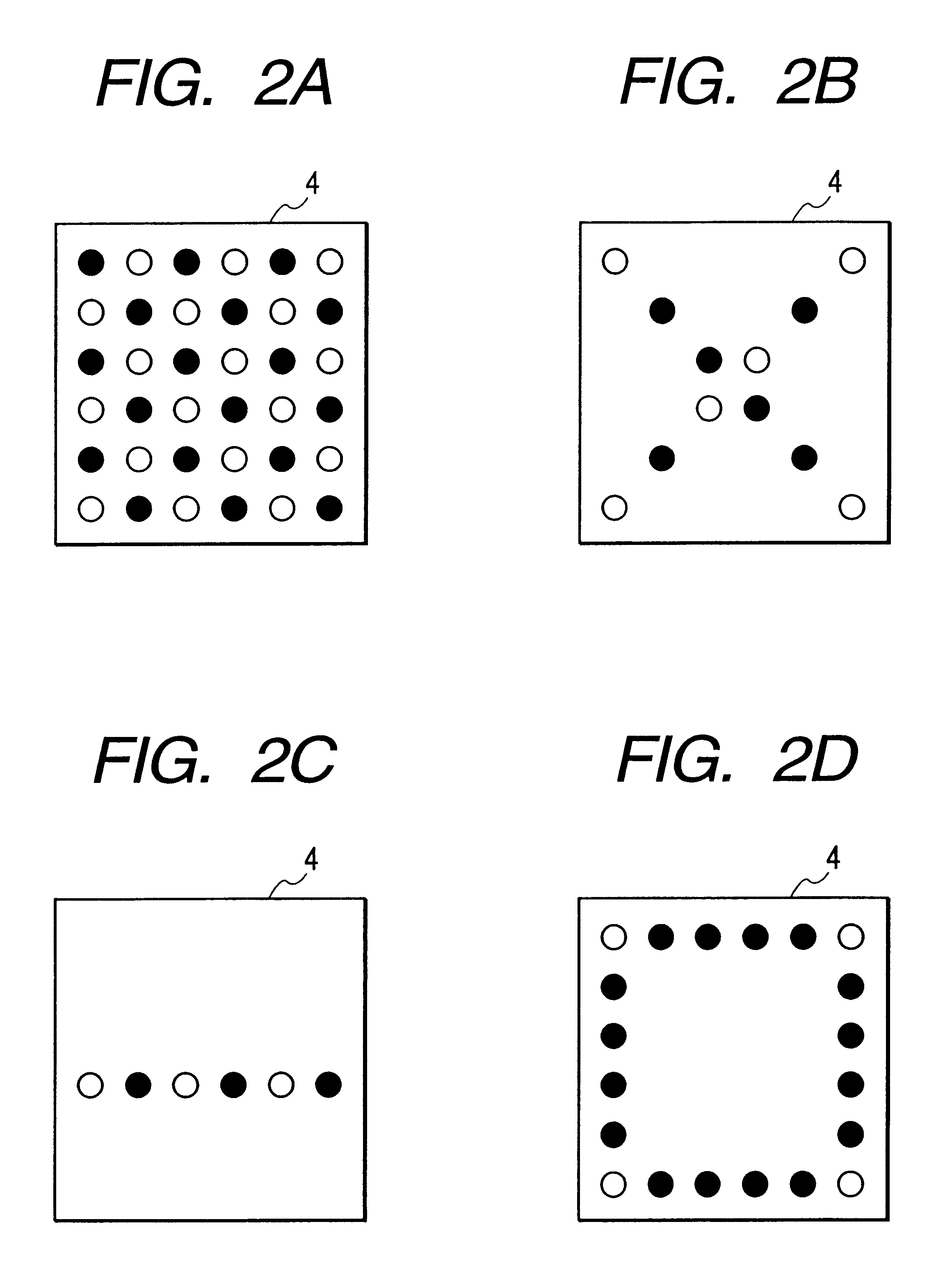

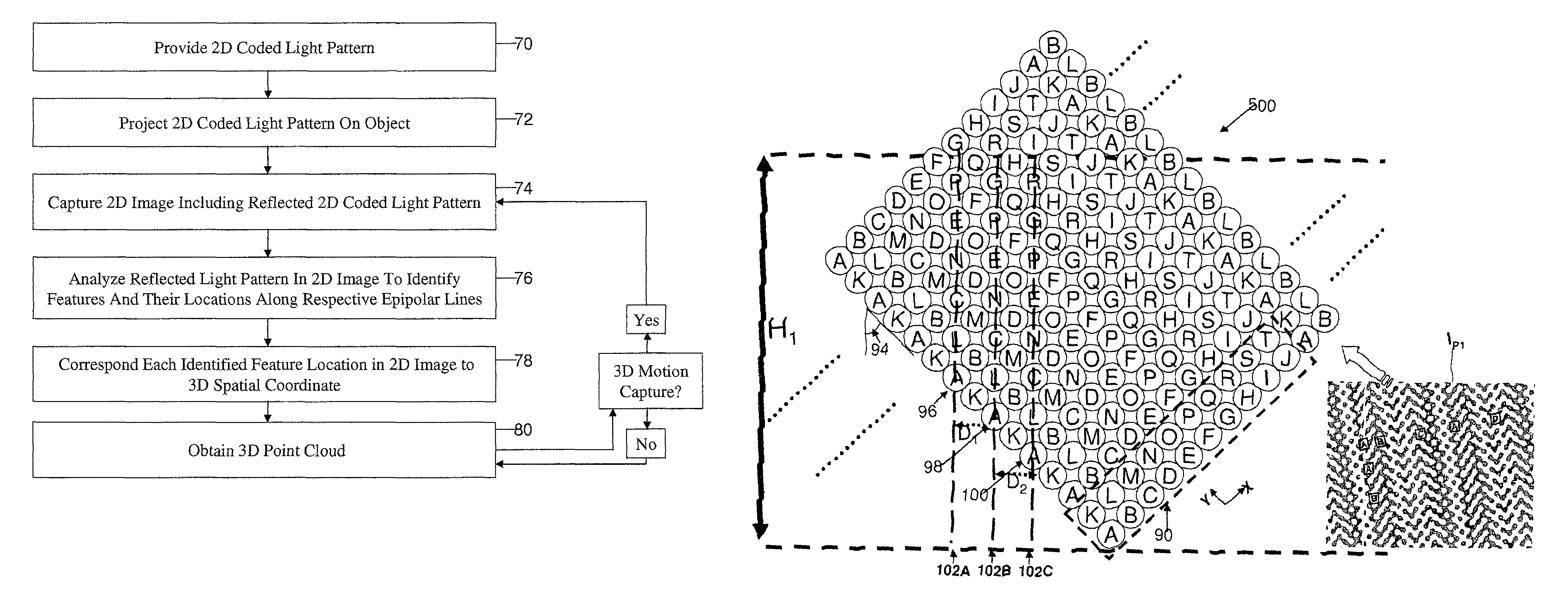

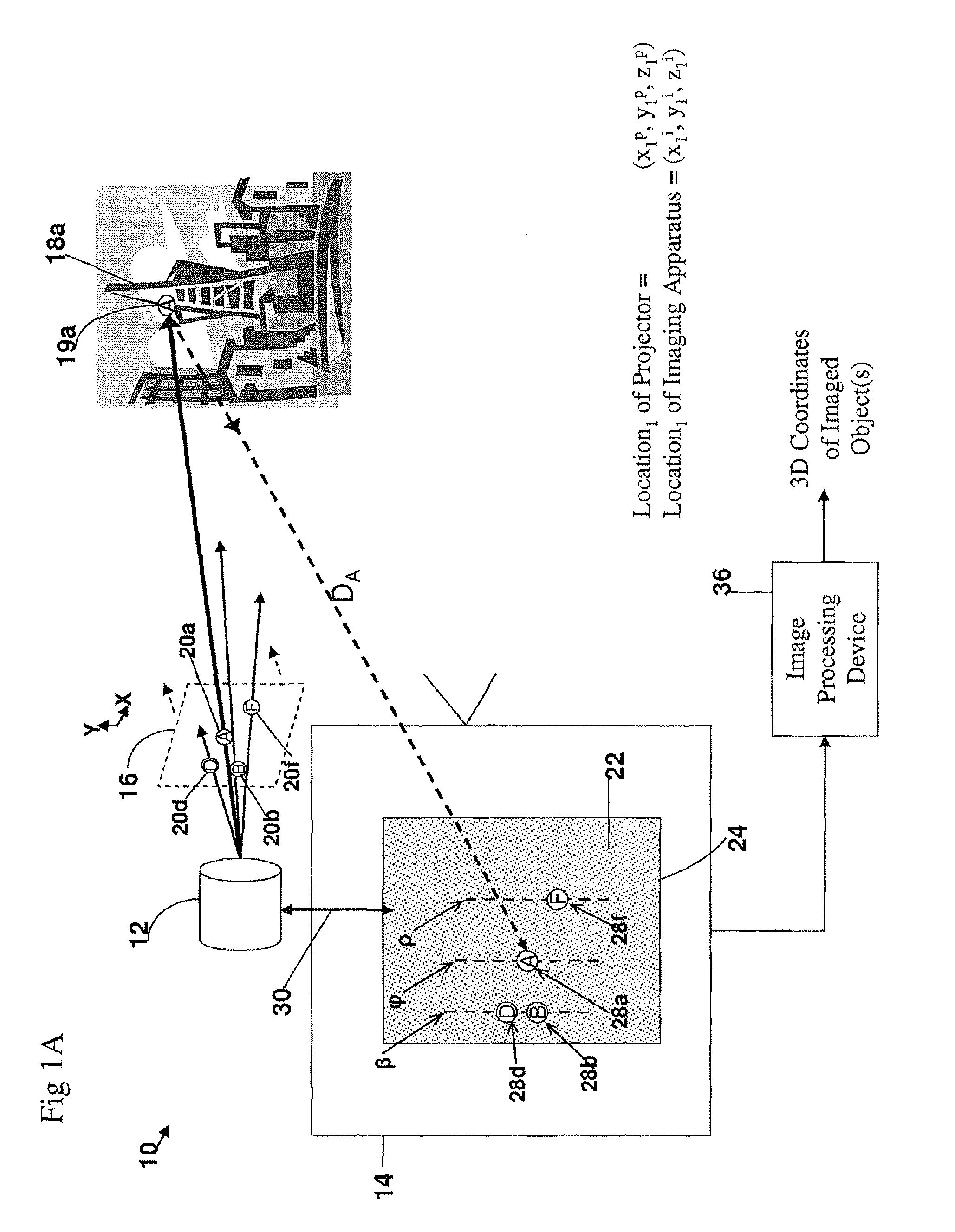

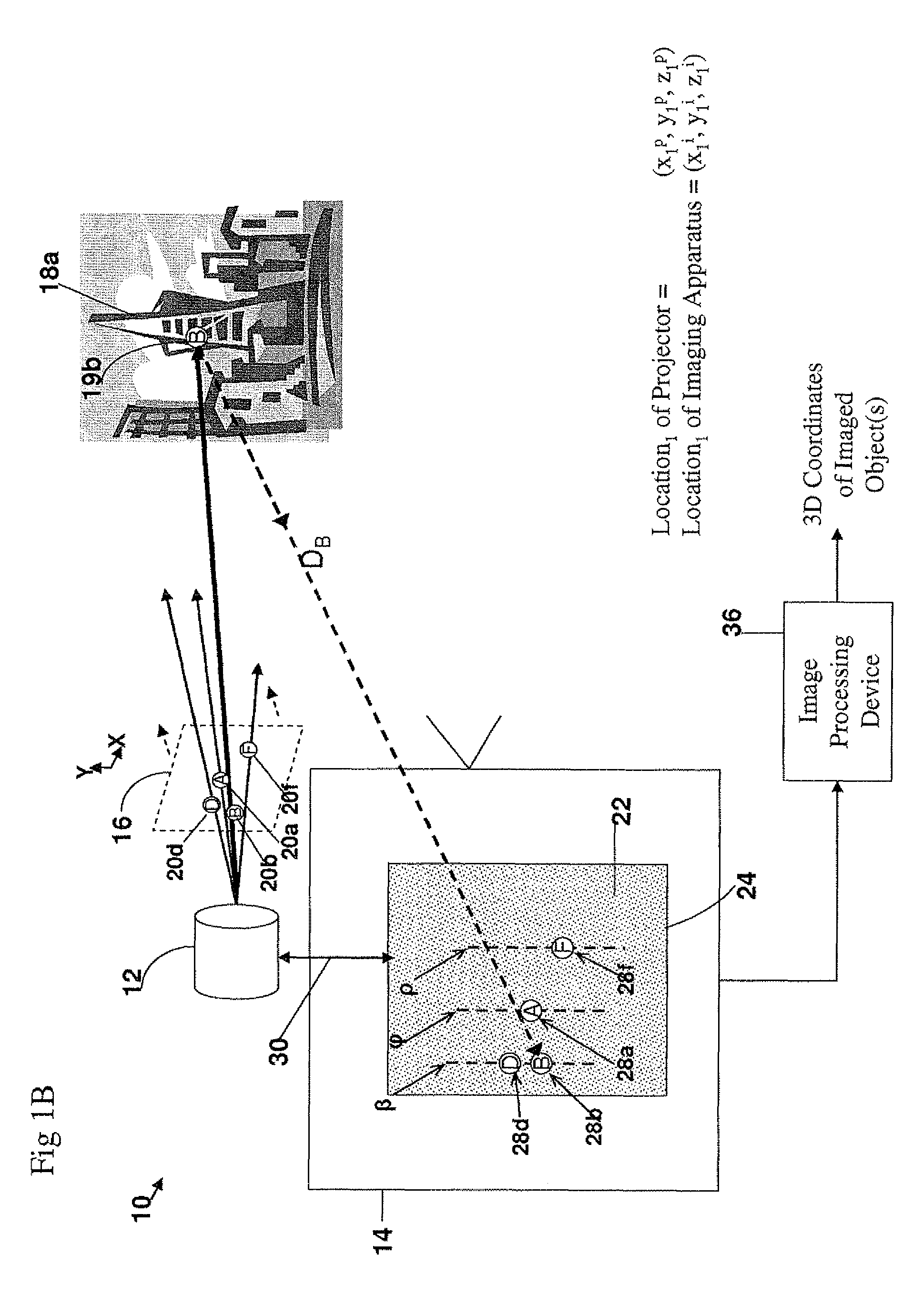

3D Geometric Modeling And Motion Capture Using Both Single And Dual Imaging

A method and apparatus for obtaining an image to determine a three dimensional shape of a stationary or moving object using a bi dimensional coded light pattern having a plurality of distinct identifiable feature types. The coded light pattern is projected on the object such that each of the identifiable feature types appears at most once on predefined sections of distinguishable epipolar lines. An image of the object is captured and the reflected feature types are extracted along with their location on known epipolar lines in the captured image. Displacements of the reflected feature types along their epipolar lines from reference coordinates thereupon determine corresponding three dimensional coordinates in space and thus a 3D mapping or model of the shape of the object at any point in time.

Owner:MANTIS VISION LTD

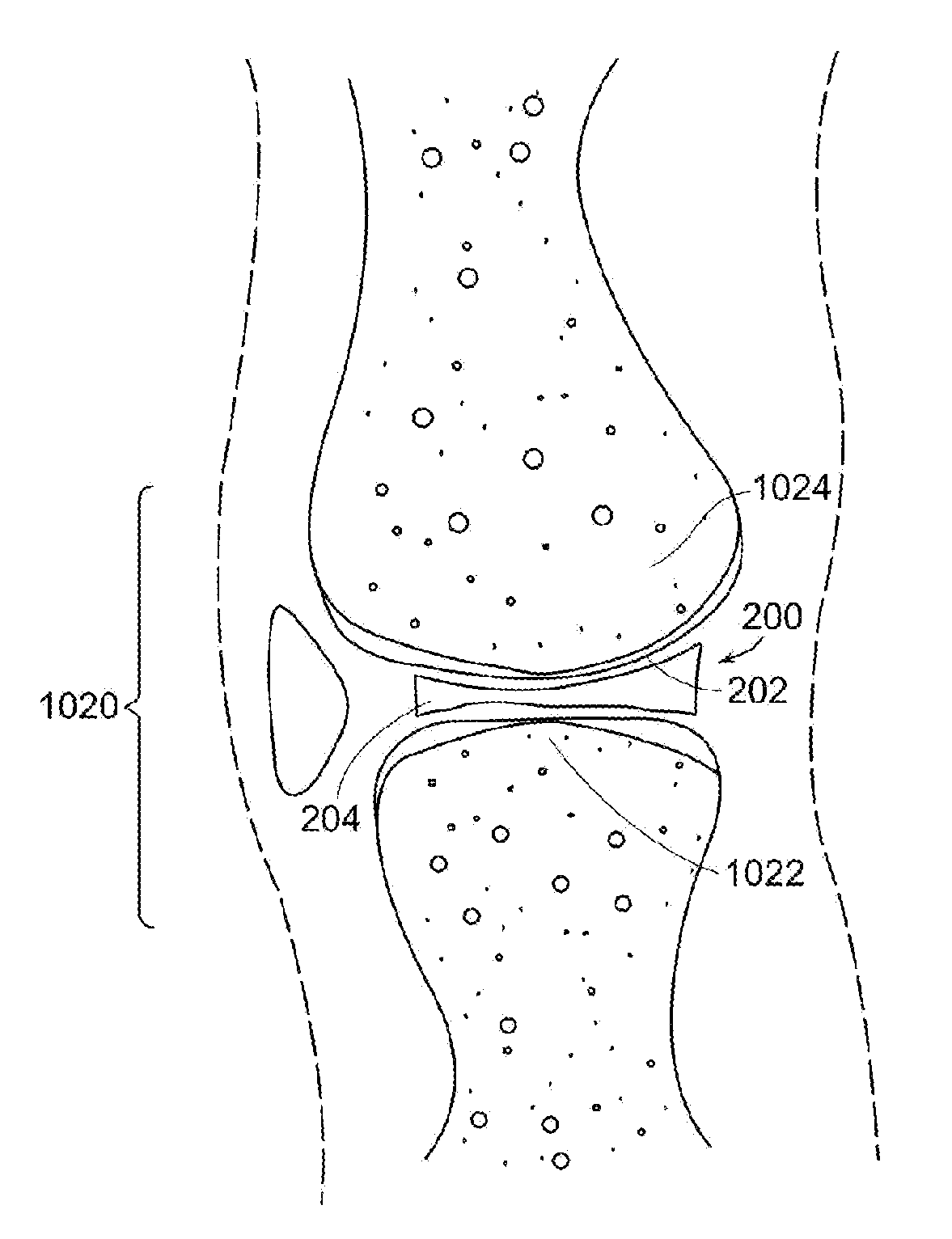

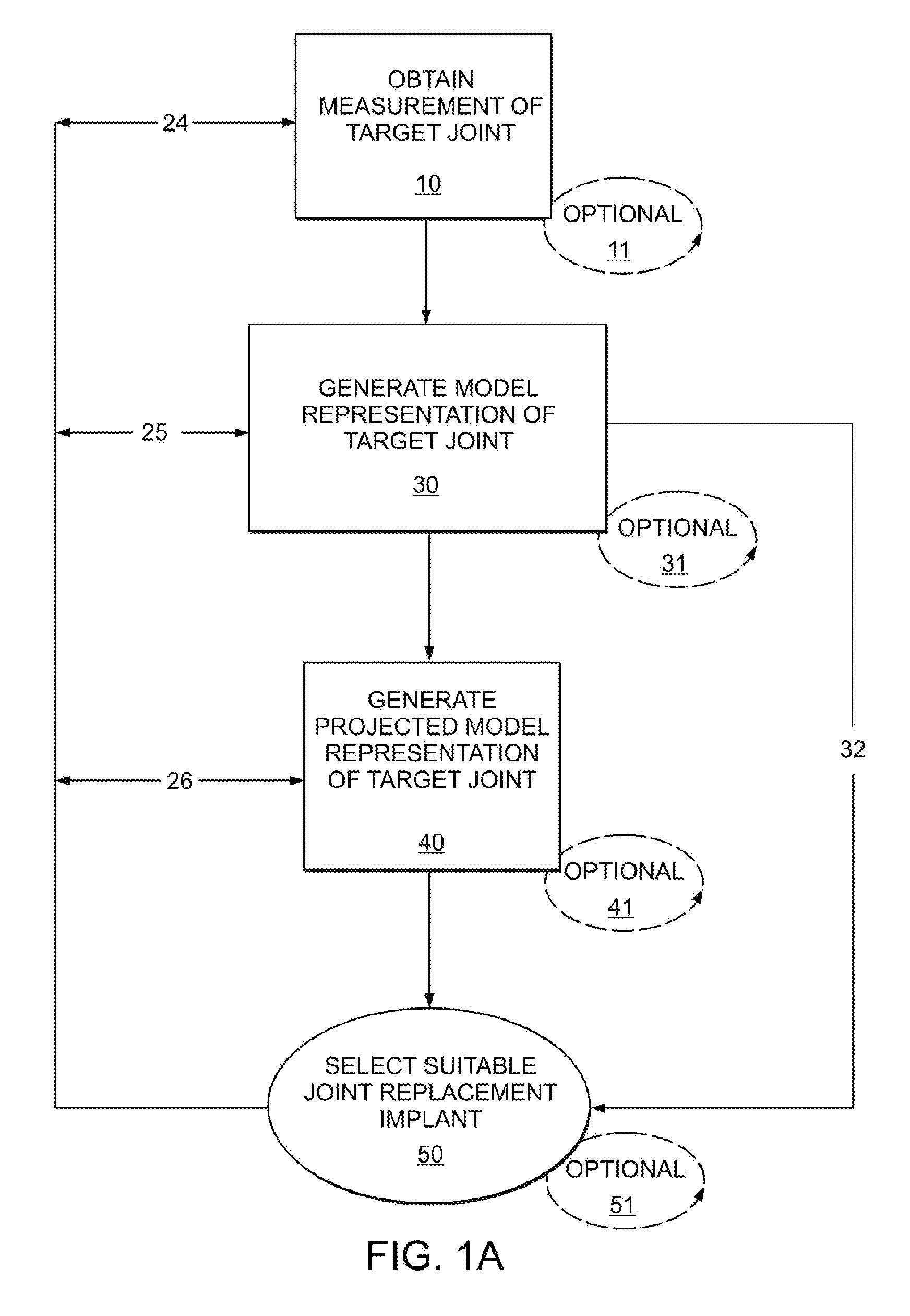

Interpositional Joint Implant

InactiveUS20070233269A1Improve anatomic functionalityPromote resultsJoint implantsDiagnostic recording/measuringTibiaTibial surface

A method of preparing an interpositional implant suitable for a knee. The method includes determining a three-dimensional shape of a tibial surface of the knee. An implant is produced having a superior surface and an inferior surface, with the superior surface adapted to be positioned against a femoral condyle of the knee, and the inferior surface adapted to be positioned upon the tibial surface of the knee, The inferior surface conforms to the three-dimensional shape of the tibial surface. The implant may be inserted into the knee without making surgical cuts on the tibial surface. The tibial surface may include cartilage, or cartilage and bone.

Owner:CONFORMIS

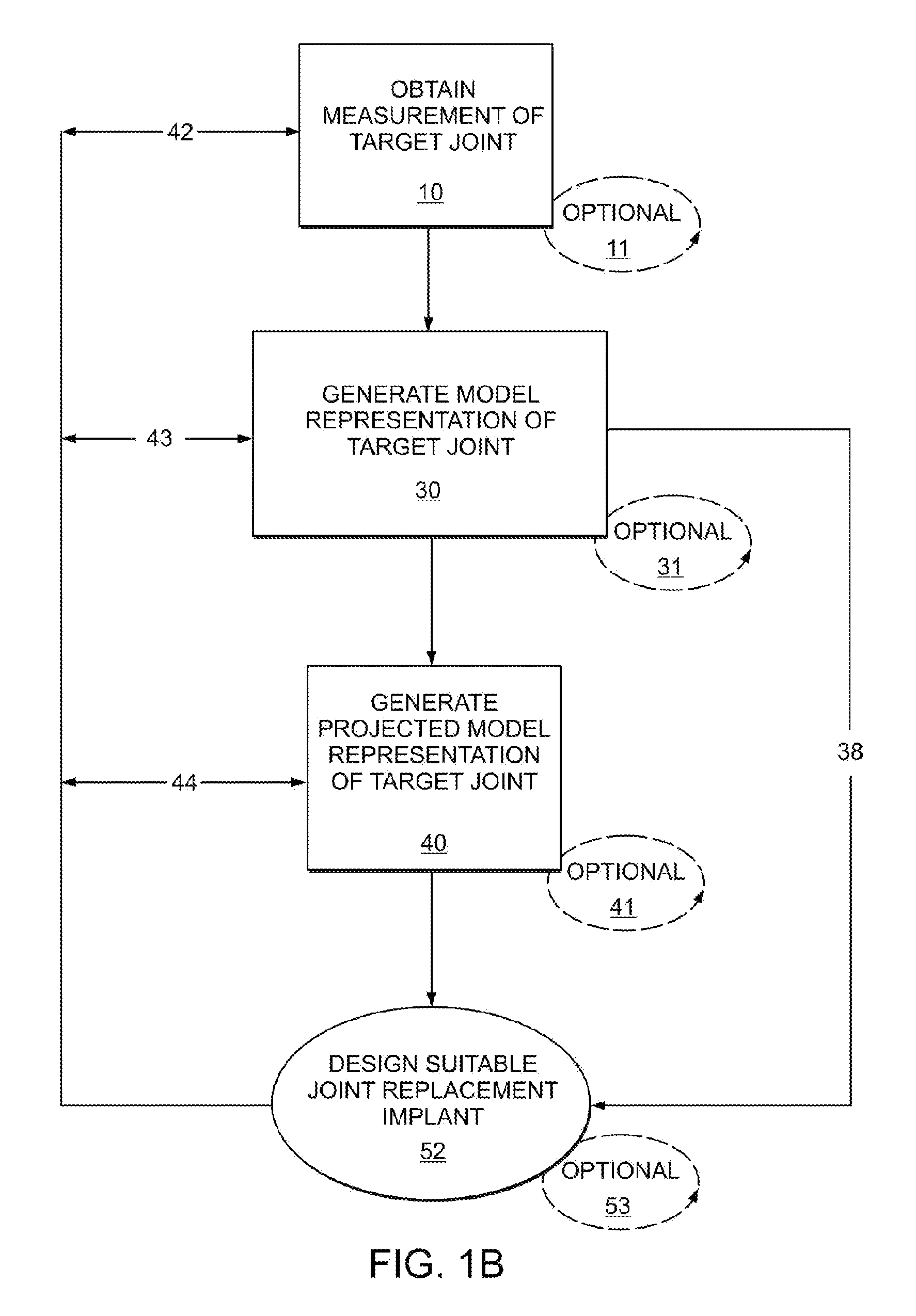

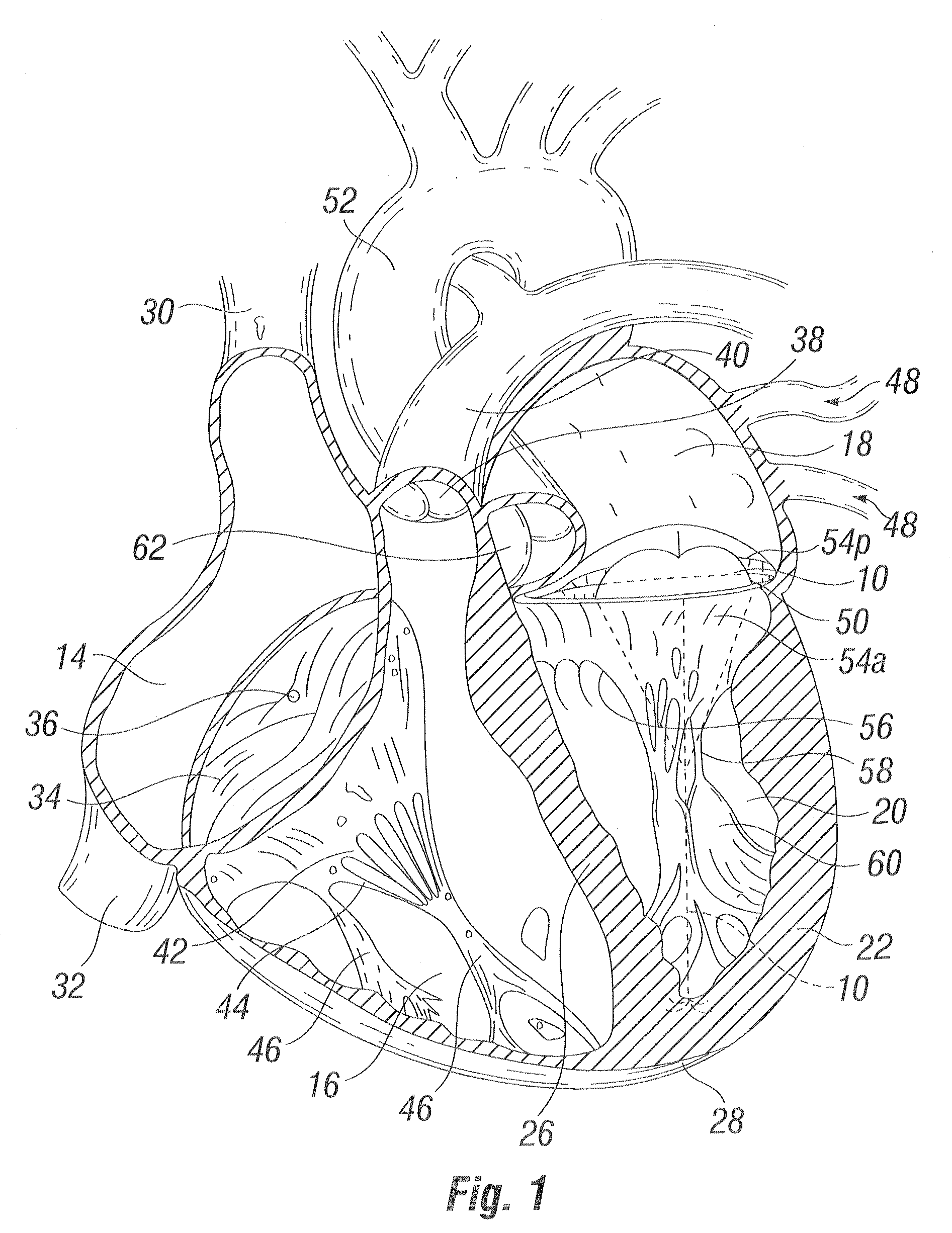

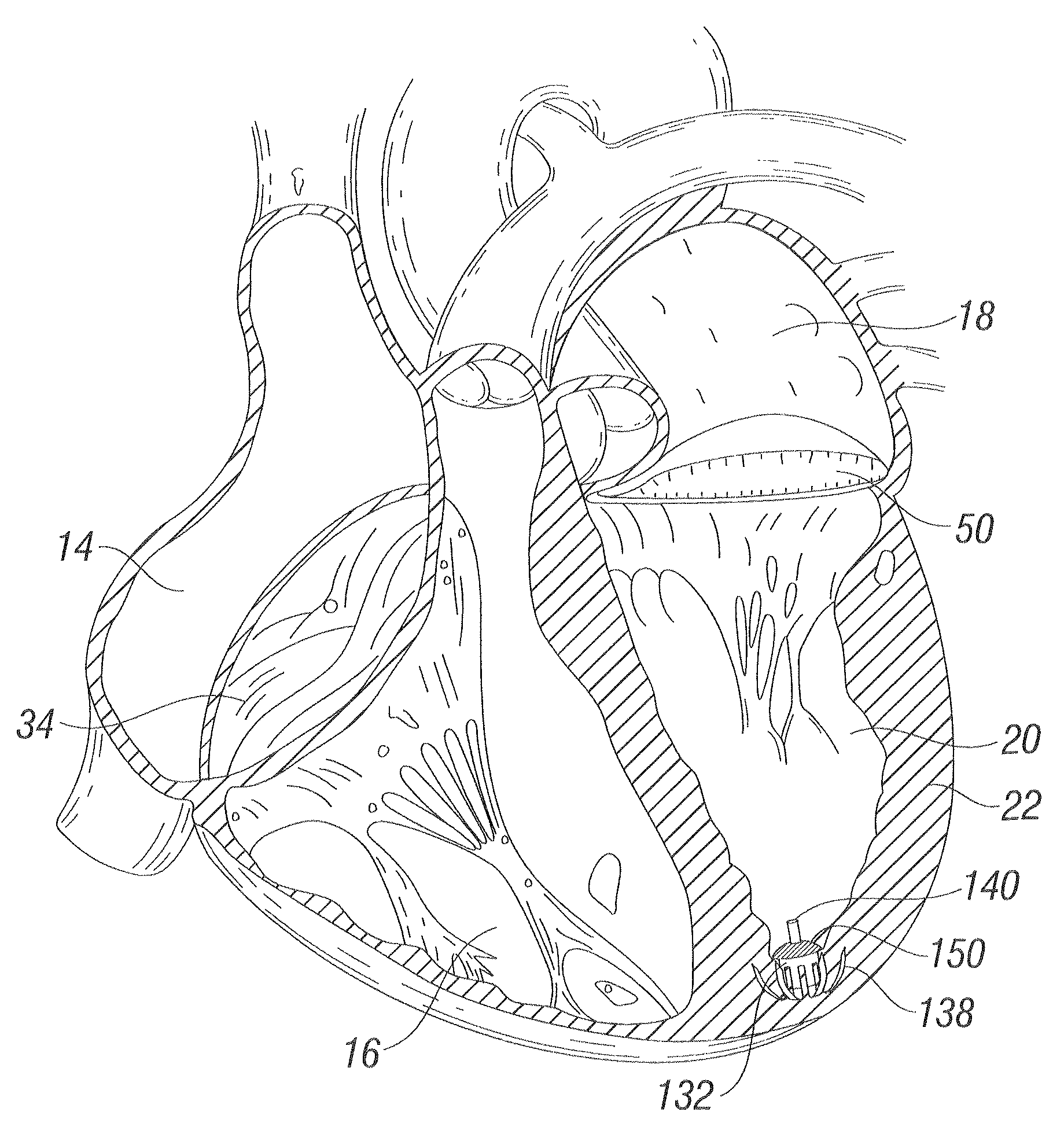

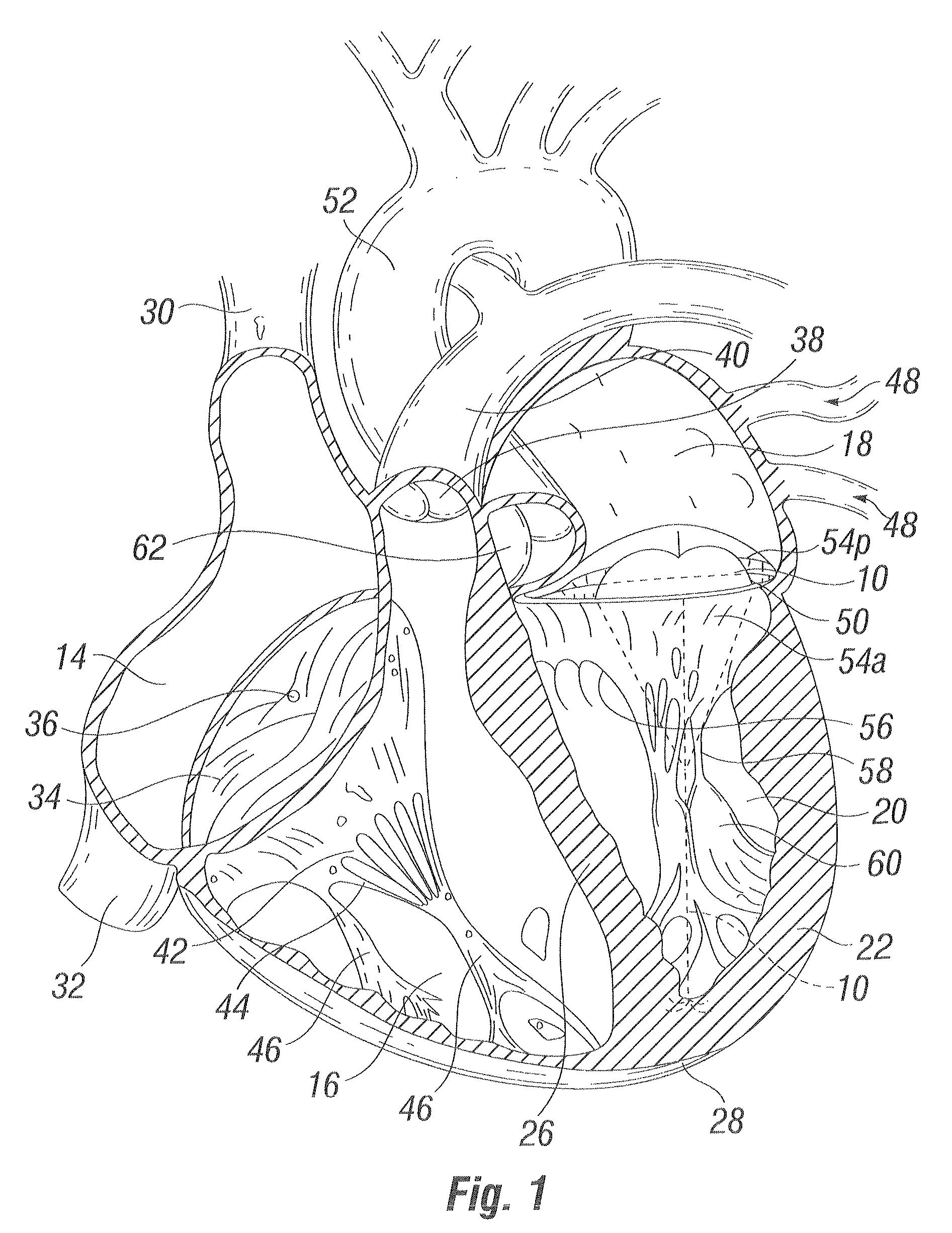

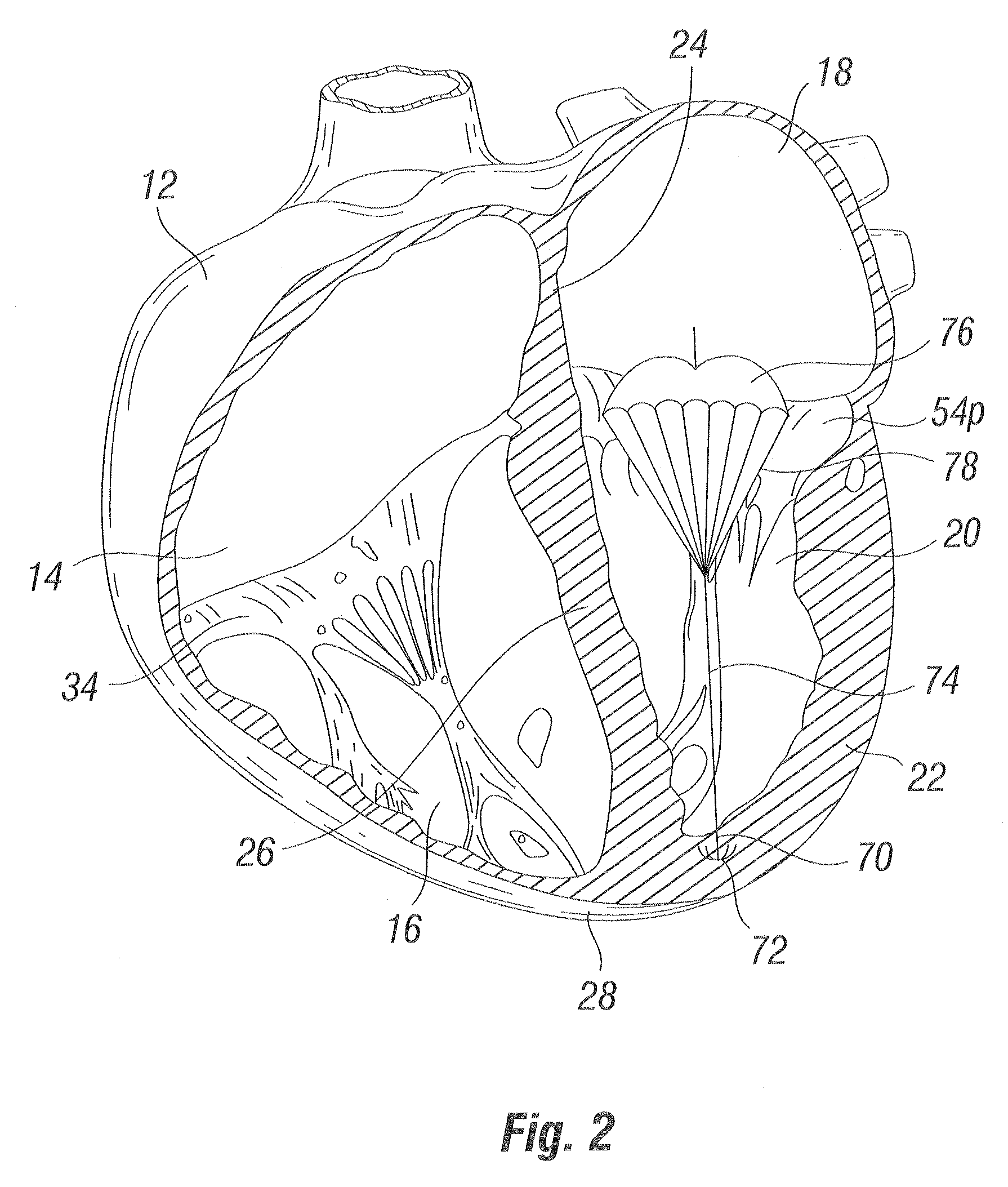

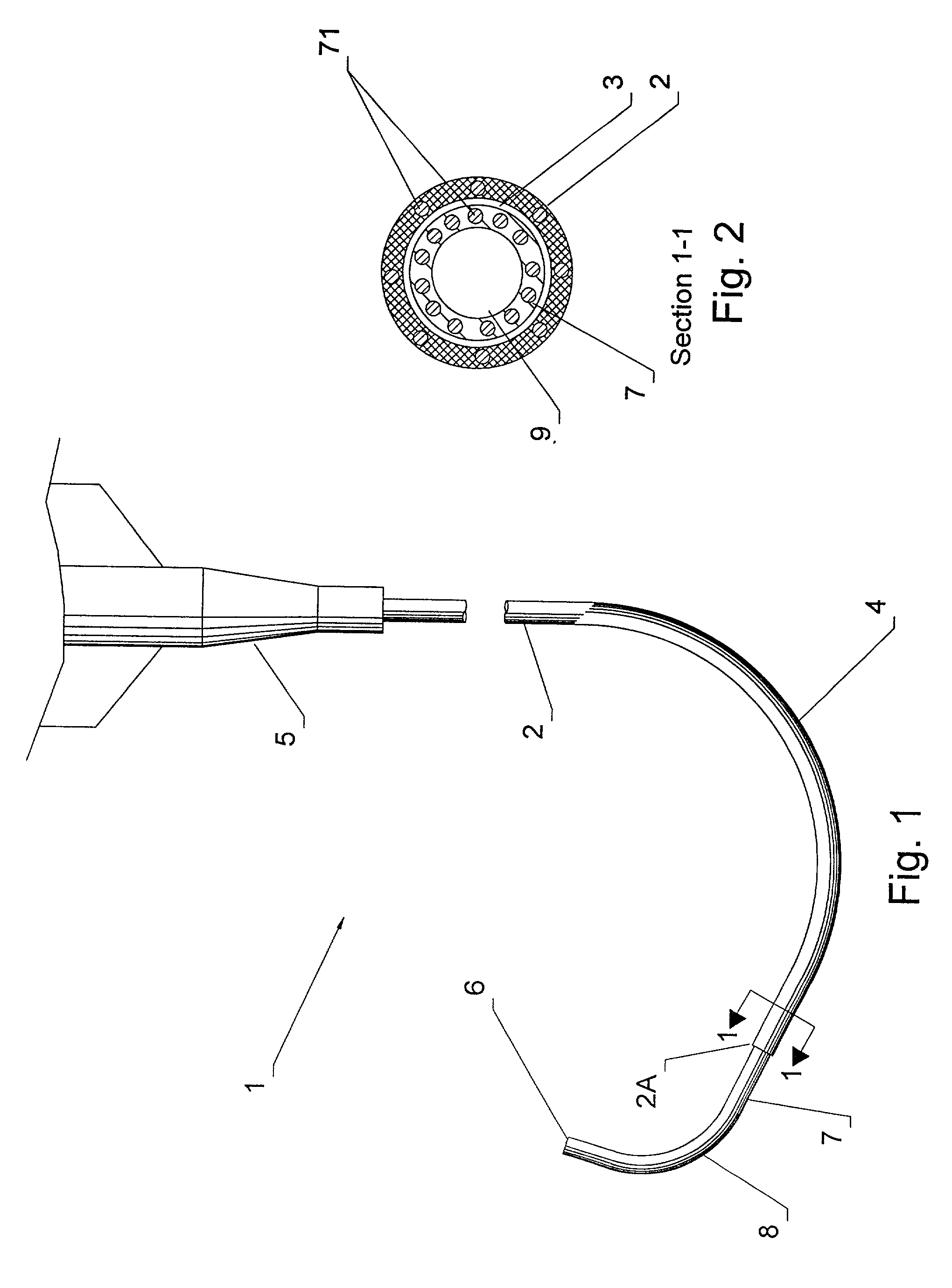

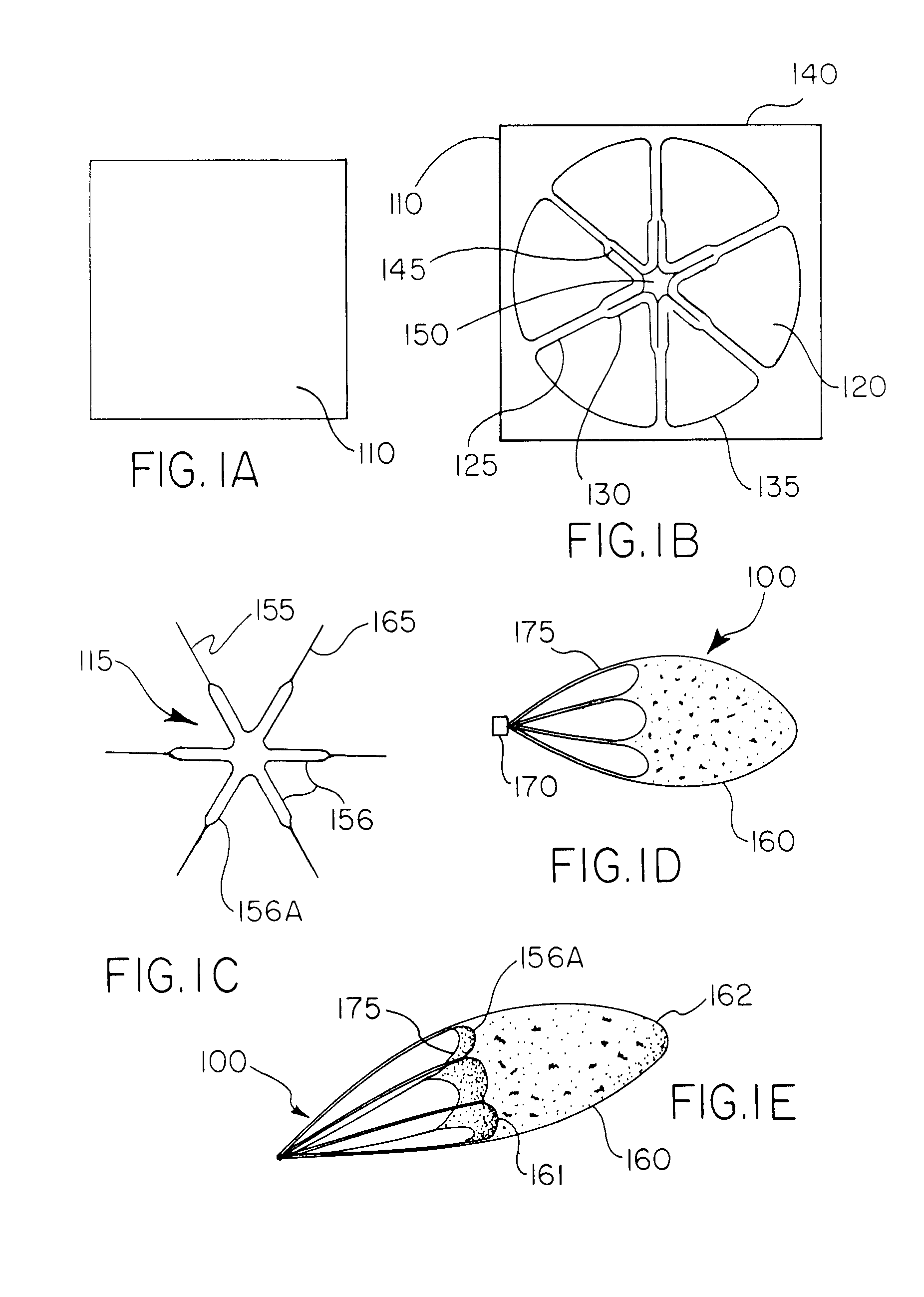

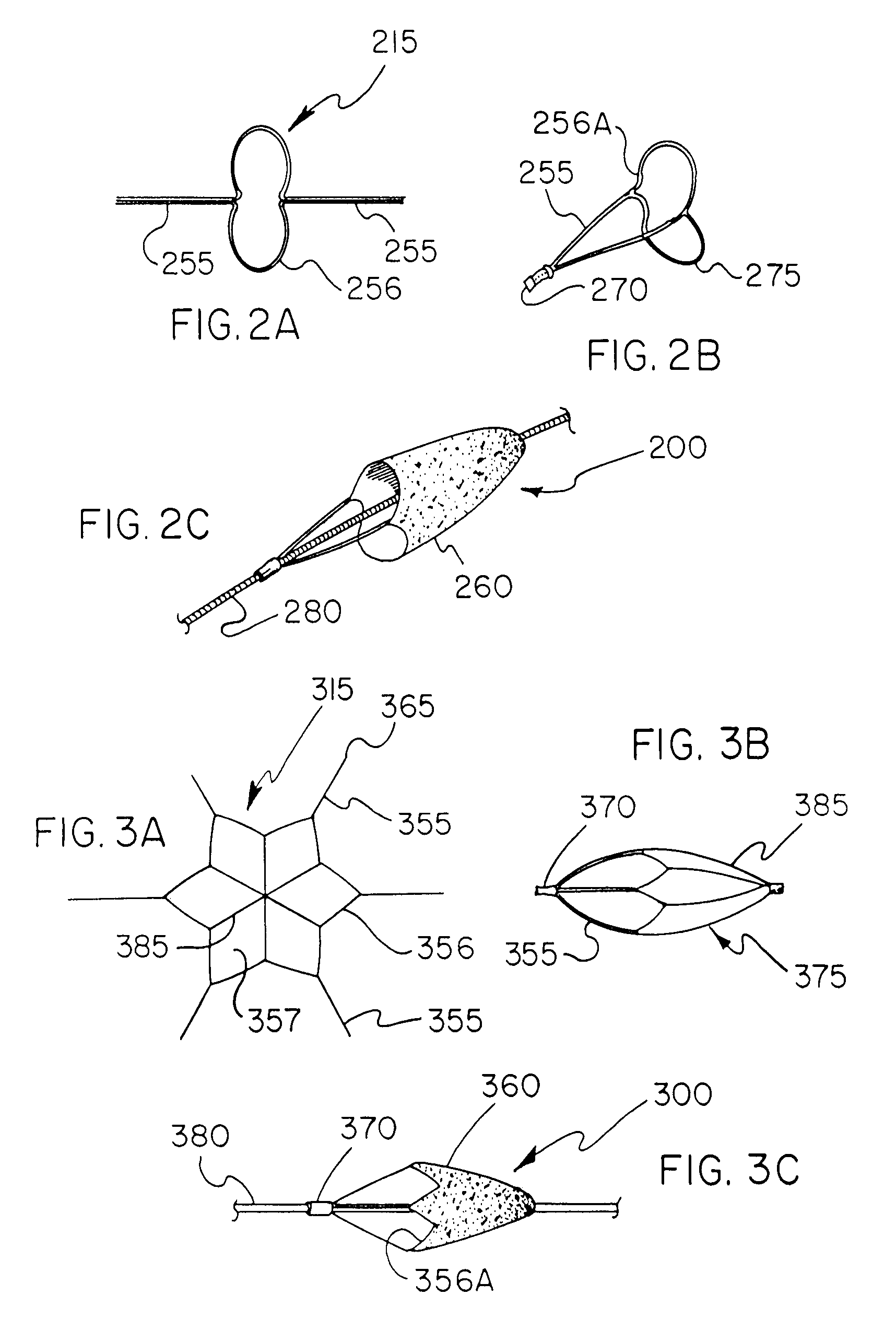

Device and method for improving heart valve function

ActiveUS20070270943A1Function increaseInhibit refluxSuture equipmentsHeart valvesCardiac wallHeart chamber

The invention is device and method for reducing regurgitation through a mitral valve. The device and method is directed to an anchor portion for engagement with the heart wall and an expandable valve portion configured for deployment between the mitral valve leaflets. The valve portion is expandable for preventing regurgitation through the mitral valve while allowing blood to circulate through the heart. The expandable valve portion may include apertures for reducing the stagnation of blood. In a preferred configuration, the device is configured to be delivered in two-stages wherein an anchor portion is first delivered and the valve structure is then coupled to the anchor portion. In yet another embodiment, the present invention provides a method of forming an anchor portion wherein a disposable jig is used to mold the anchor portion into a three-dimensional shape for conforming to a heart chamber.

Owner:EDWARDS LIFESCIENCES CORP +1

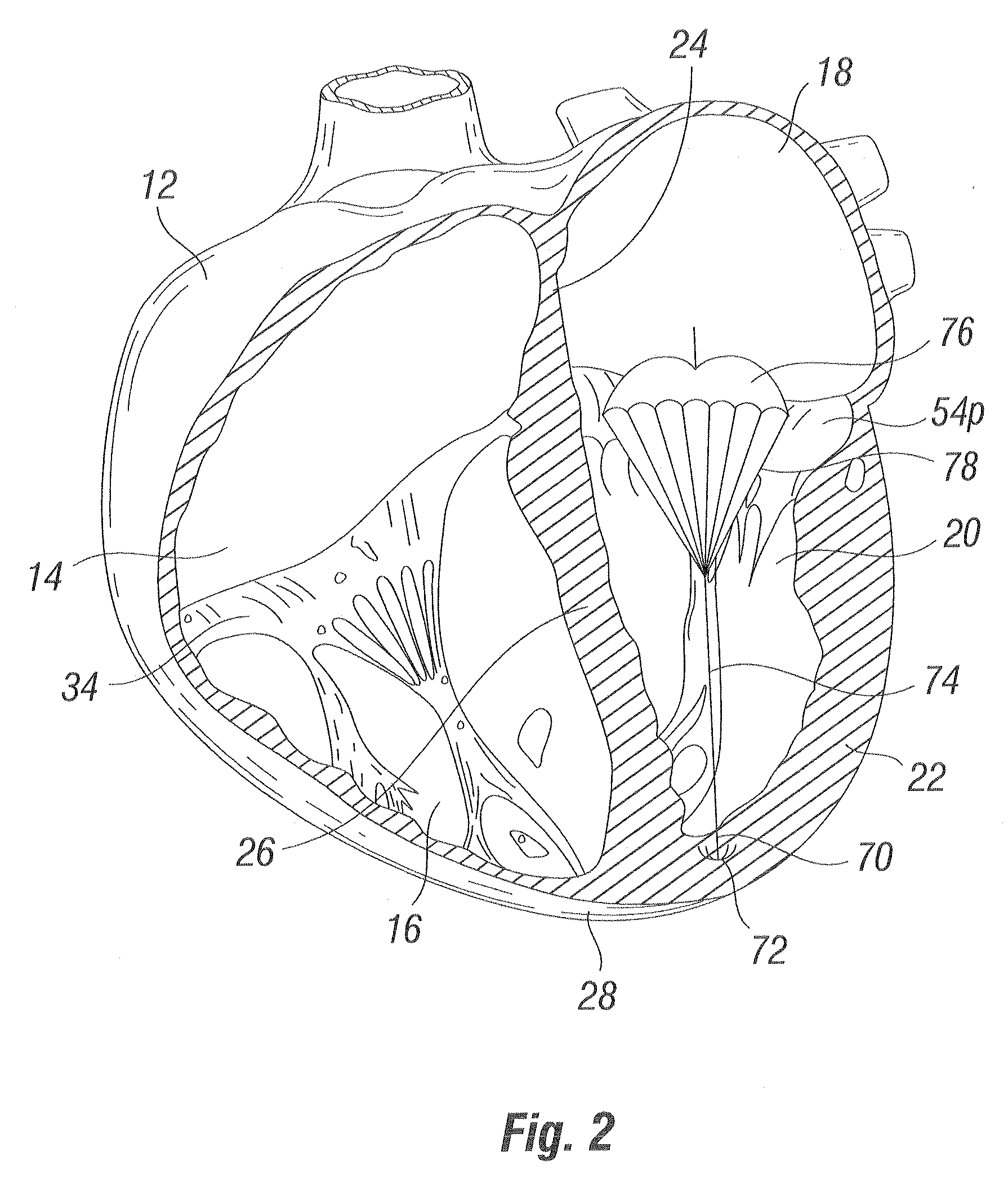

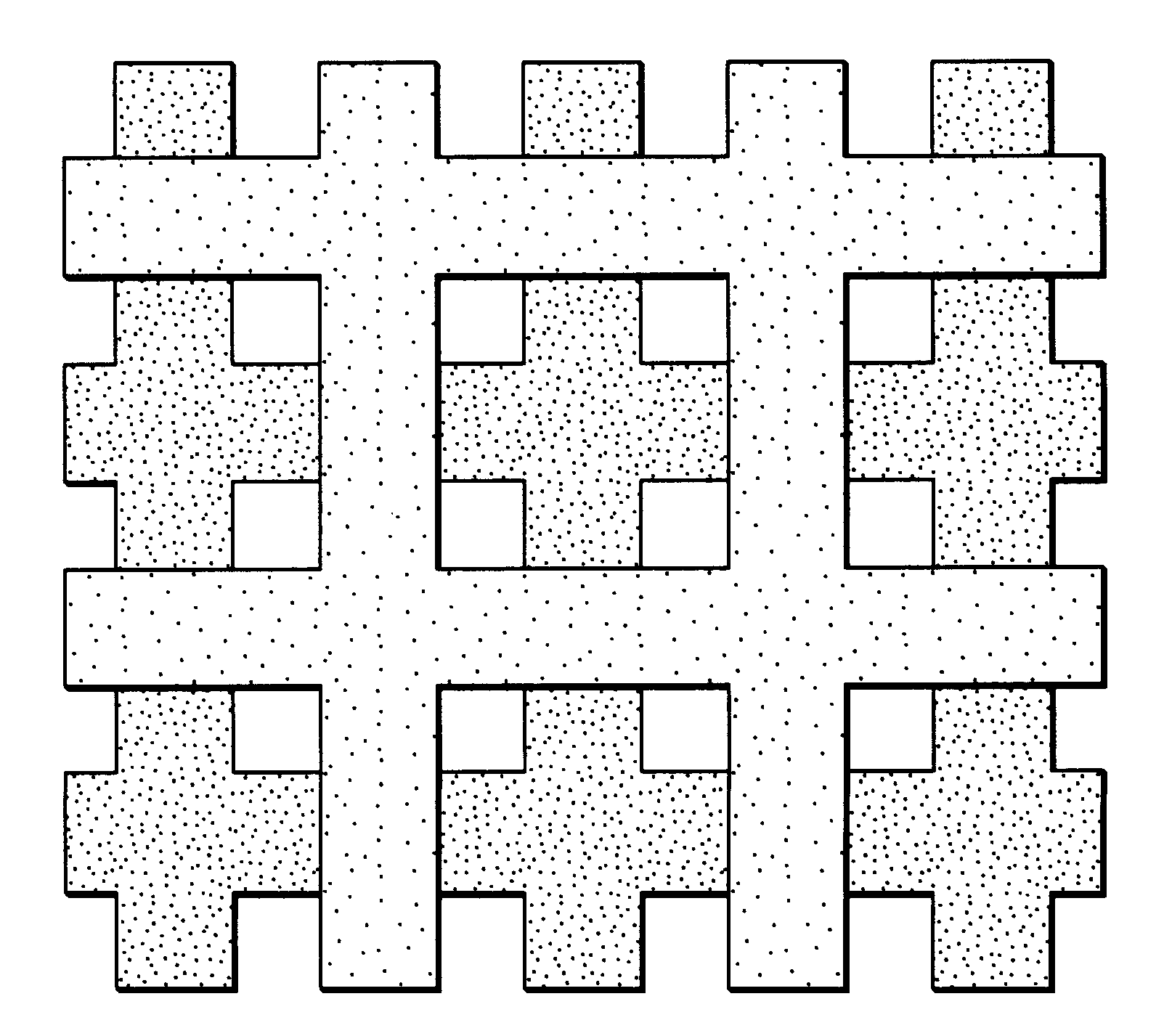

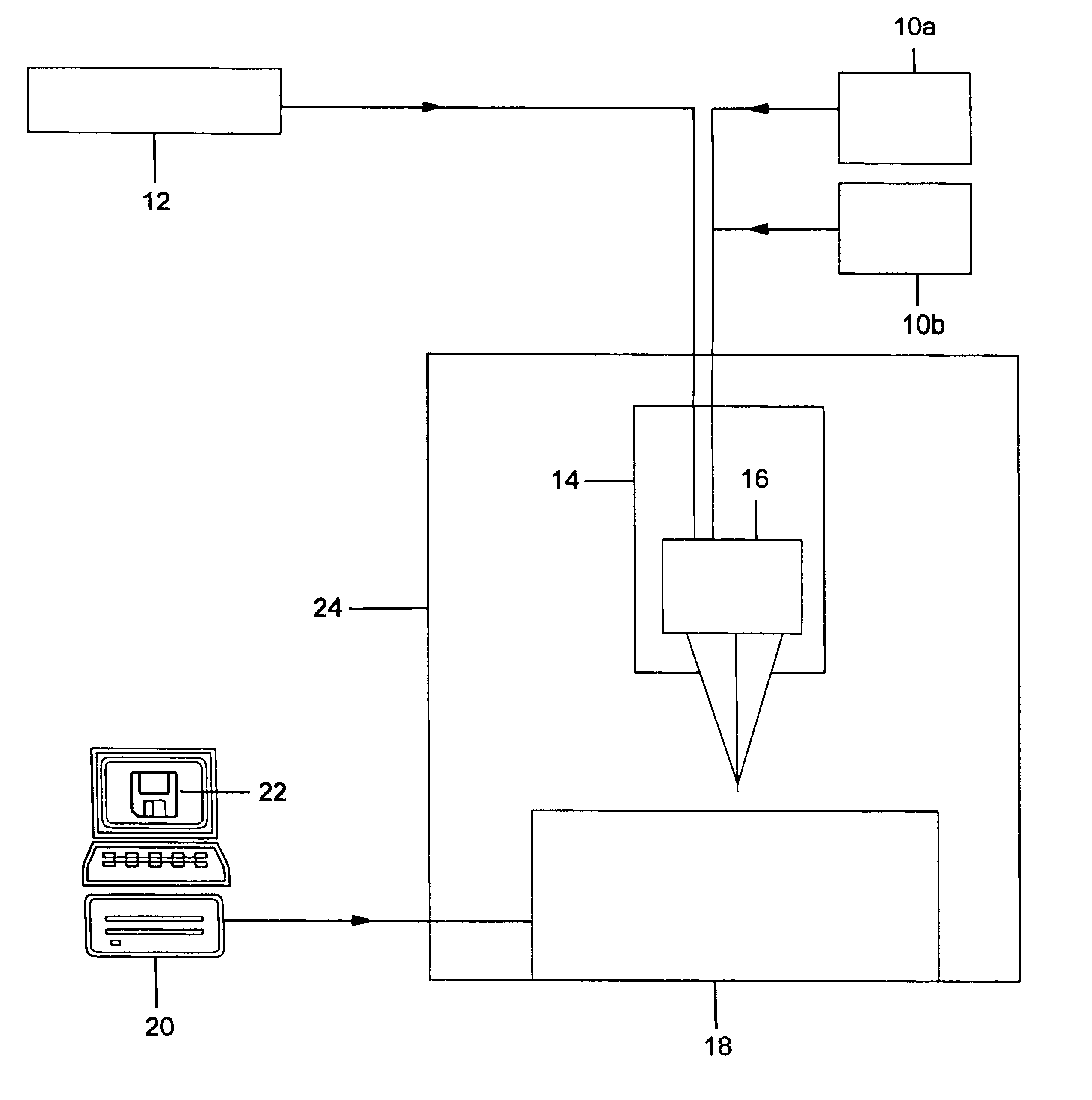

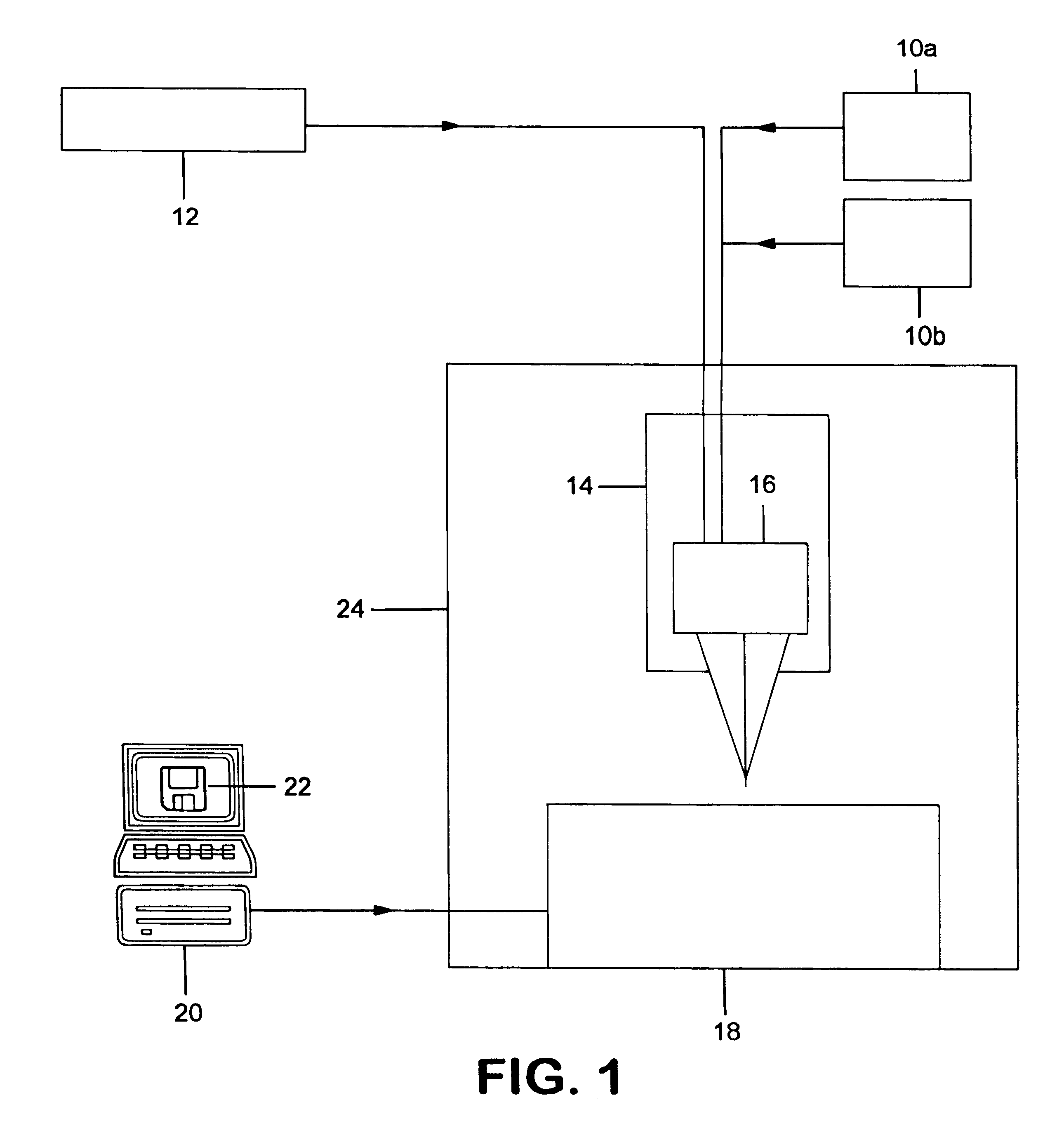

Controlled architecture ceramic composites by stereolithography

InactiveUS6283997B1Quality improvementFast preparationProgramme controlAdditive manufacturing apparatusCeramic compositeMetallurgy

A process for producing a ceramic composite having a porous network. The process includes providing a photocurable ceramic dispersion. The dispersion consists of a photocurable polymer and a ceramic composition. The surface of the dispersion is scanned with a laser to cure the photocurable polymer to produce a photocured polymer / ceramic composition. The photocured composition useful as a polymer / ceramic composite, or the polymer phase can be removed by heating to a first temperature that is sufficient to burn out the photocured polymer. It is then heated to a second temperature that is higher than the first temperature and is sufficient to sinter the ceramic composition to produce a purely ceramic composition having a porous network.Preferably and more specifically, the process uses a stereolithographic technique for laser scanning. The process can form a high quality orthopedic implant that dimensionally matches the bone structure of a patient. The technique relies upon laser photocuring a dense colloidal dispersion into a desired complex three-dimensional shape. The shape is obtained from a CAT scan file of a bone and is rendered into a CAD file that is readable by the stereolithography instrument. Or the shape is obtained directly from a CAD file that is readable by the stereolithography instrument.

Owner:UNITED STATES SURGICAL CORP +2

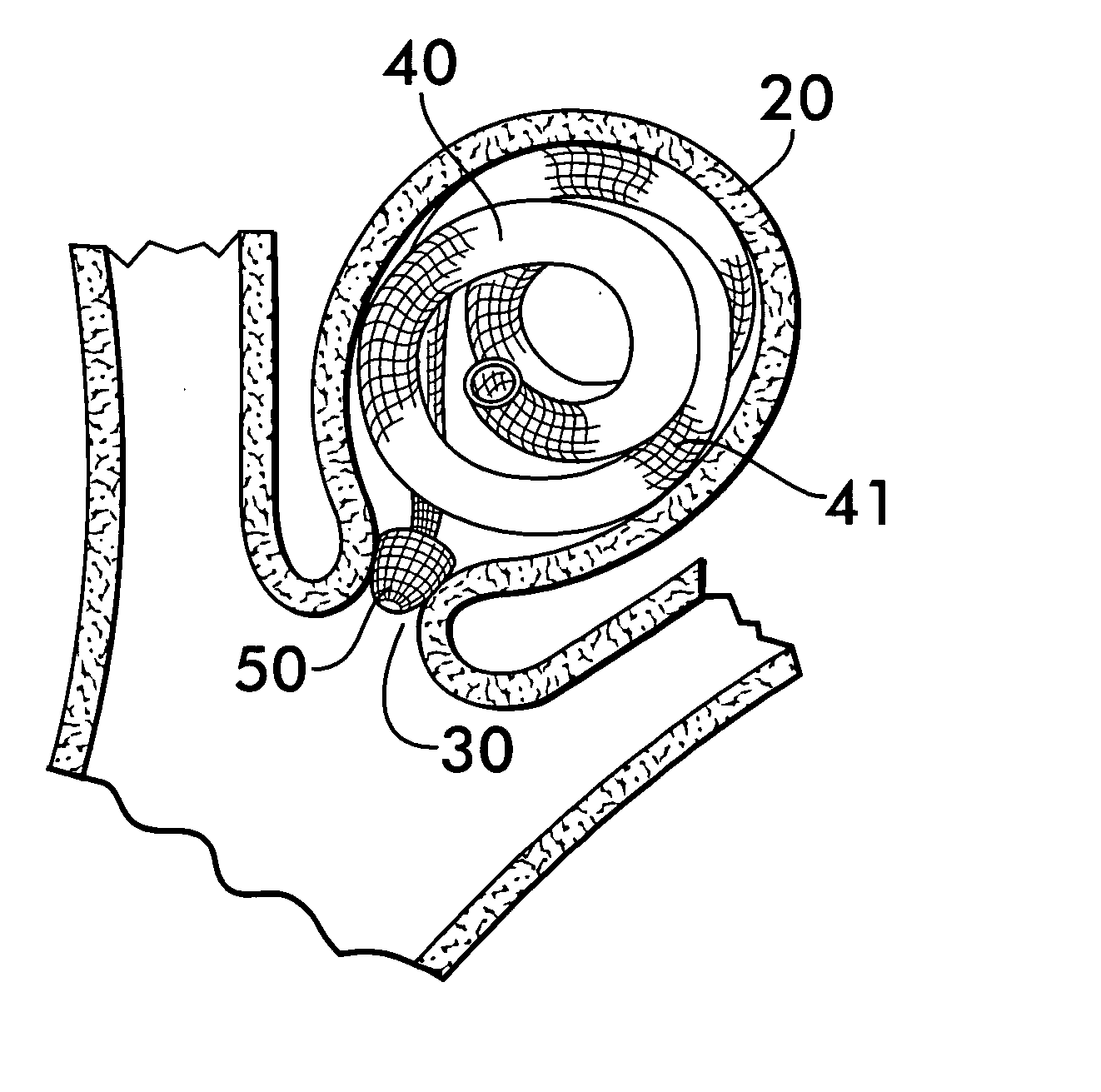

Device and method for improving heart valve function

ActiveUS8932348B2Function increaseInhibit refluxSuture equipmentsHeart valvesHeart chamberThree dimensional shape

The invention is device and method for reducing regurgitation through a mitral valve. The device and method is directed to an anchor portion for engagement with the heart wall and an expandable valve portion configured for deployment between the mitral valve leaflets. The valve portion is expandable for preventing regurgitation through the mitral valve while allowing blood to circulate through the heart. The expandable valve portion may include apertures for reducing the stagnation of blood. In a preferred configuration, the device is configured to be delivered in two-stages wherein an anchor portion is first delivered and the valve structure is then coupled to the anchor portion. In yet another embodiment, the present invention provides a method of forming an anchor portion wherein a disposable jig is used to mold the anchor portion into a three-dimensional shape for conforming to a heart chamber.

Owner:EDWARDS LIFESCIENCES CORP +1

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

Dosage form exhibiting rapid disperse properties, methods of use and process for the manufacture of same

InactiveUS6471992B1Disperse fastHigh hardnessPowder deliveryAdditive manufacturing apparatusThree dimensional shapeBULK ACTIVE INGREDIENT

A rapidly dispersing dosage form is described, which releases its active ingredients within a period of less than about ninety seconds. These dosage forms exhibit a three-dimensional shape that is retained for adequate storage but is readily dispersed in the presence of excess moisture. Also disclosed are methods of administration of a medicament and a process for the preparation of rapidly dispersing dosage forms.

Owner:MASSACHUSETTS INST OF TECH +2

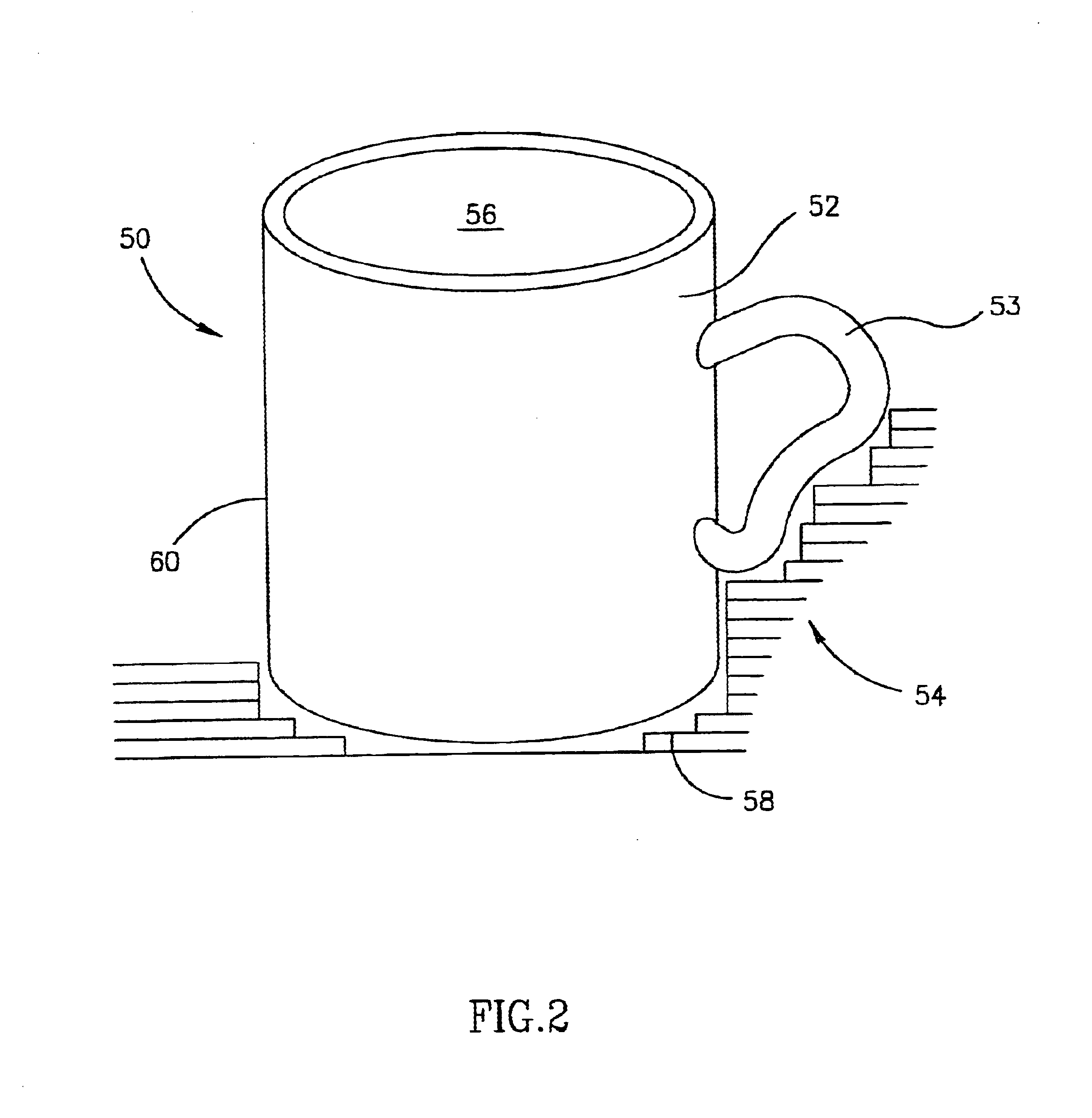

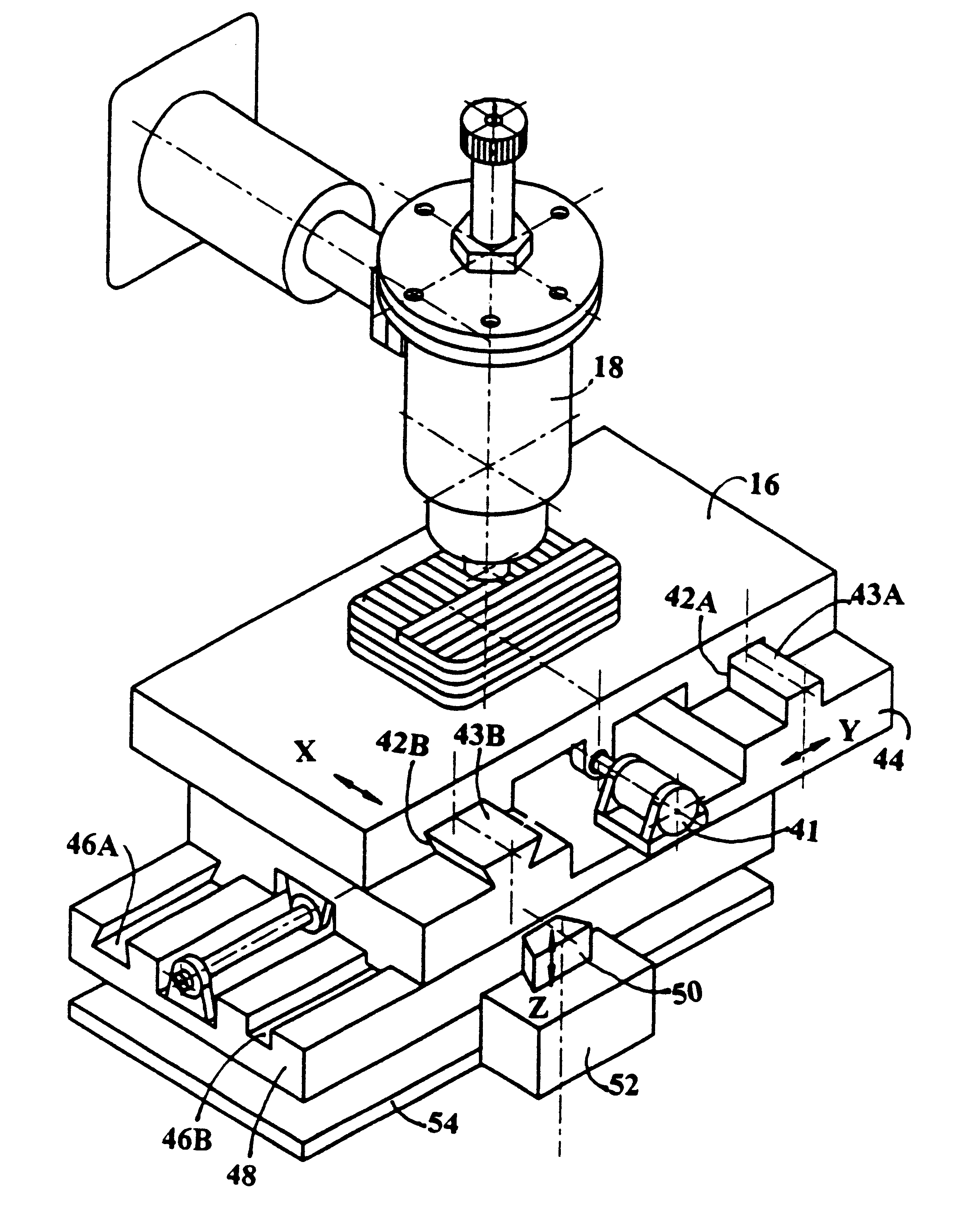

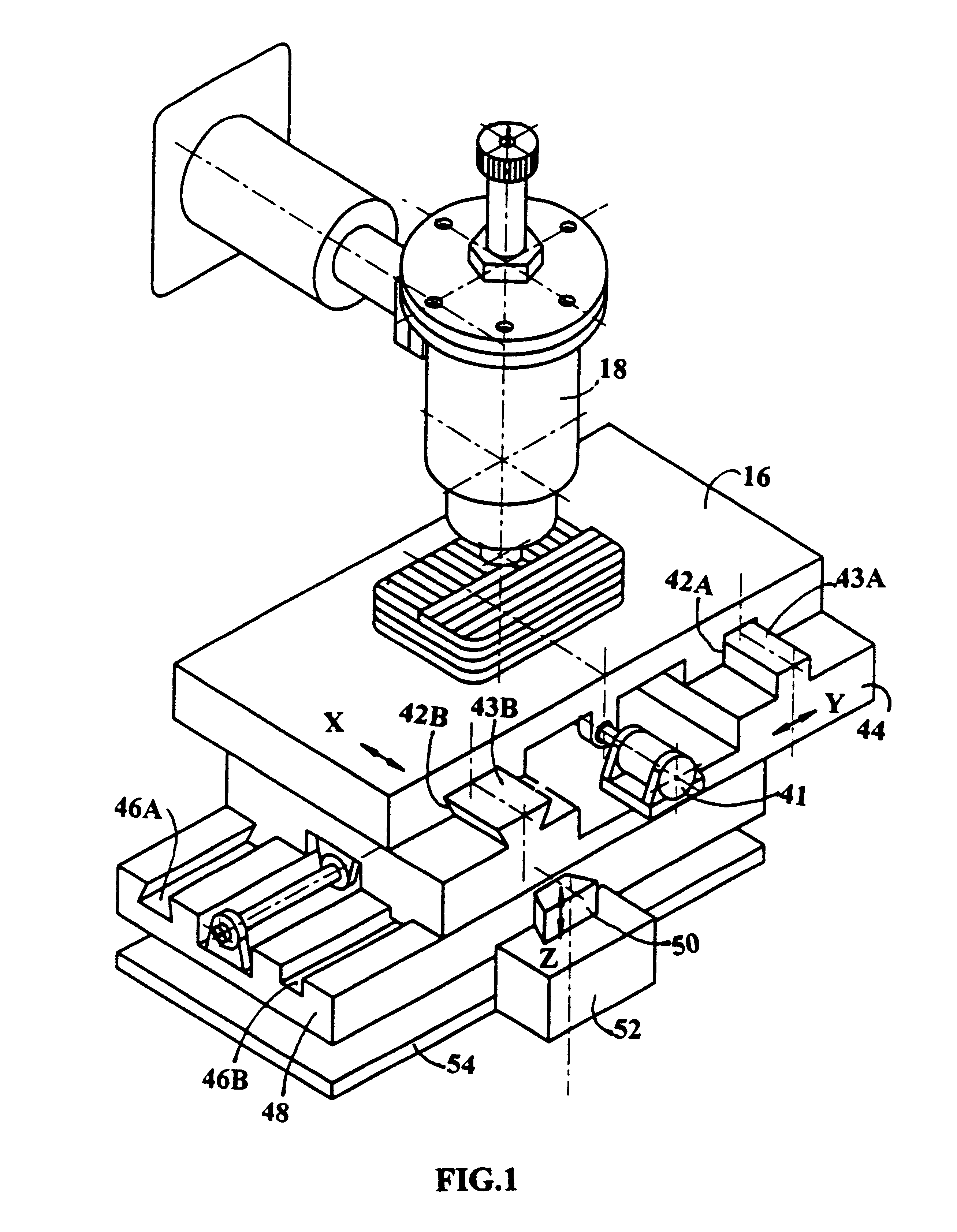

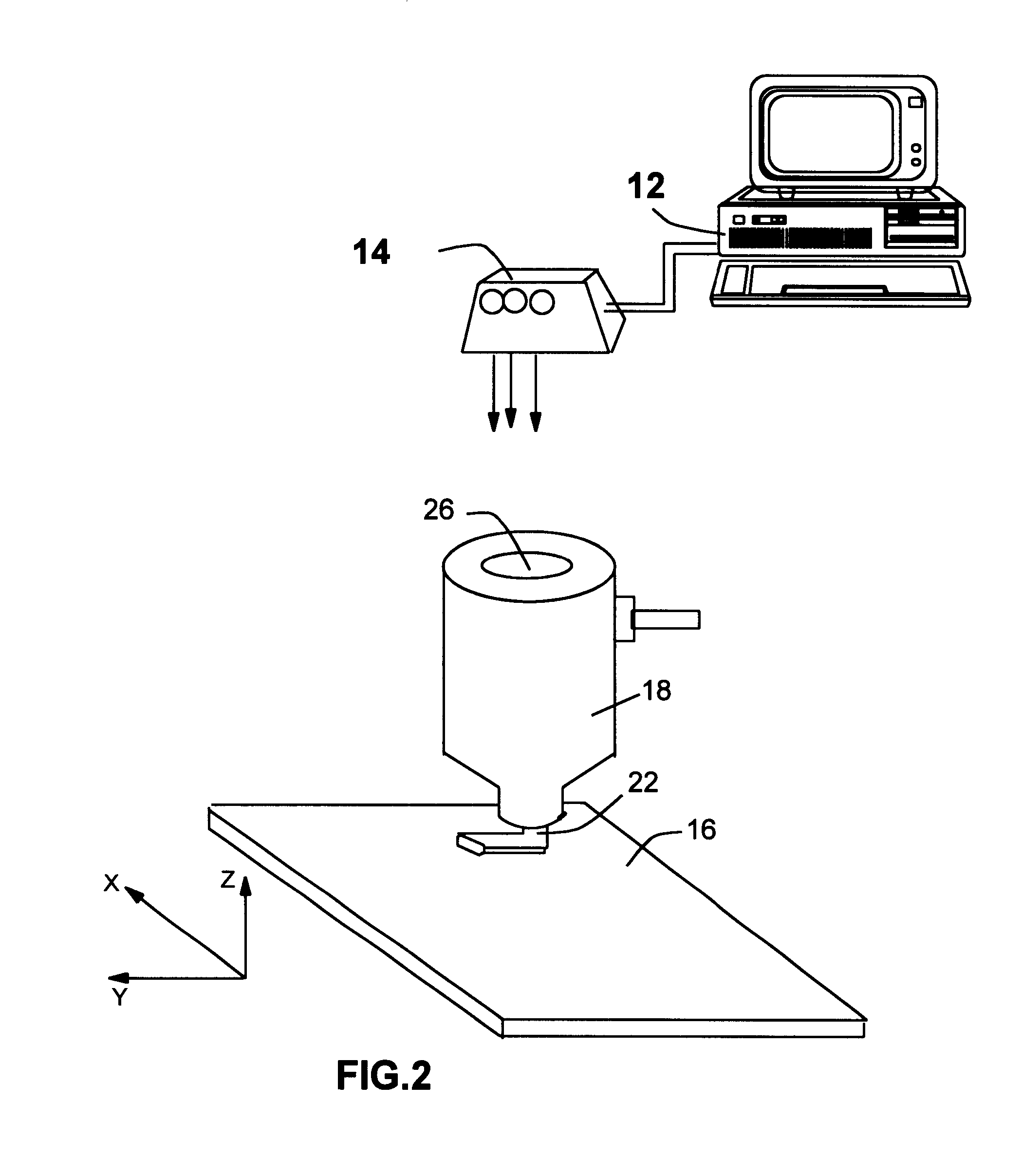

Rapid prototyping and fabrication method for 3-D food objects

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

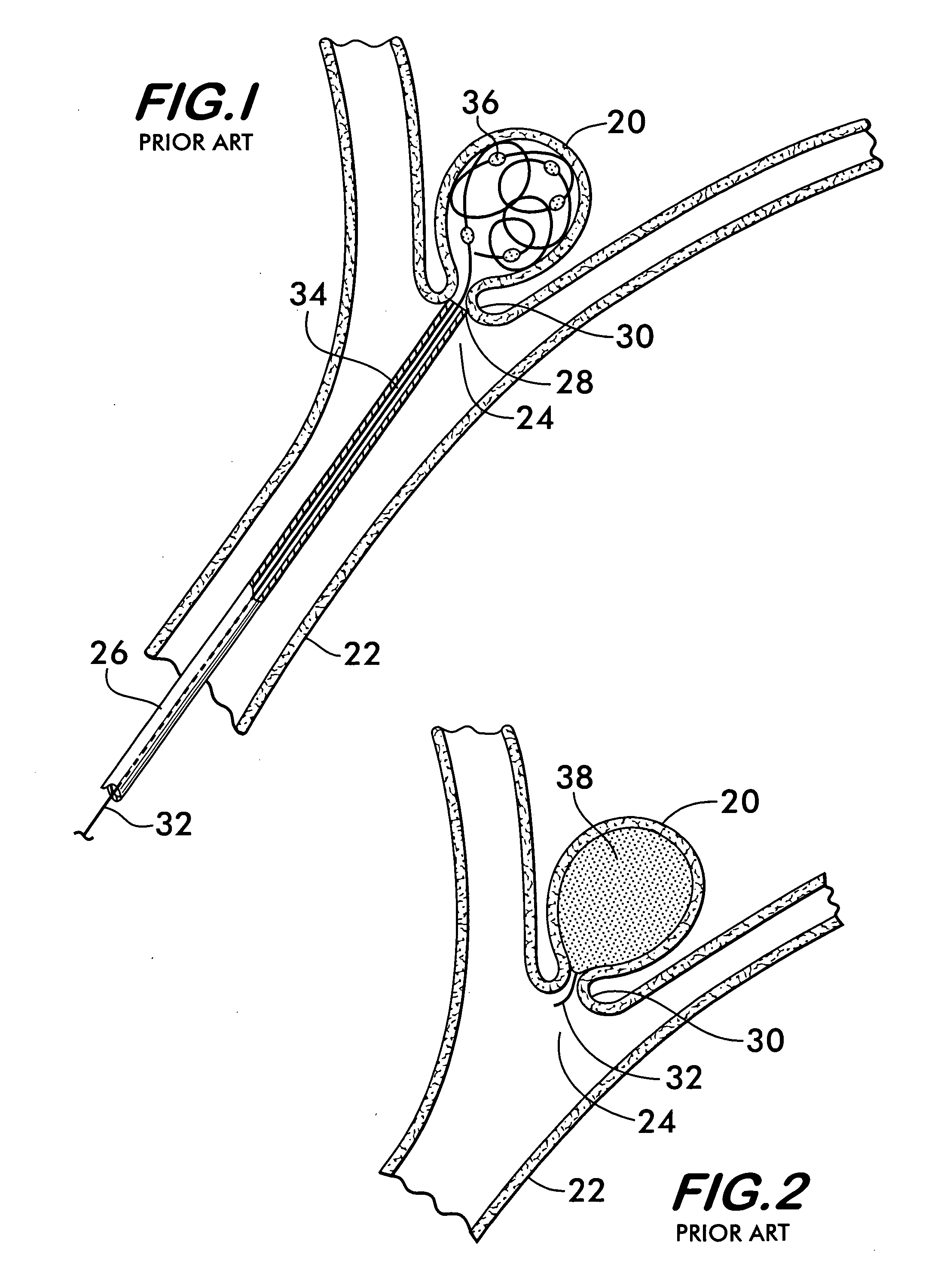

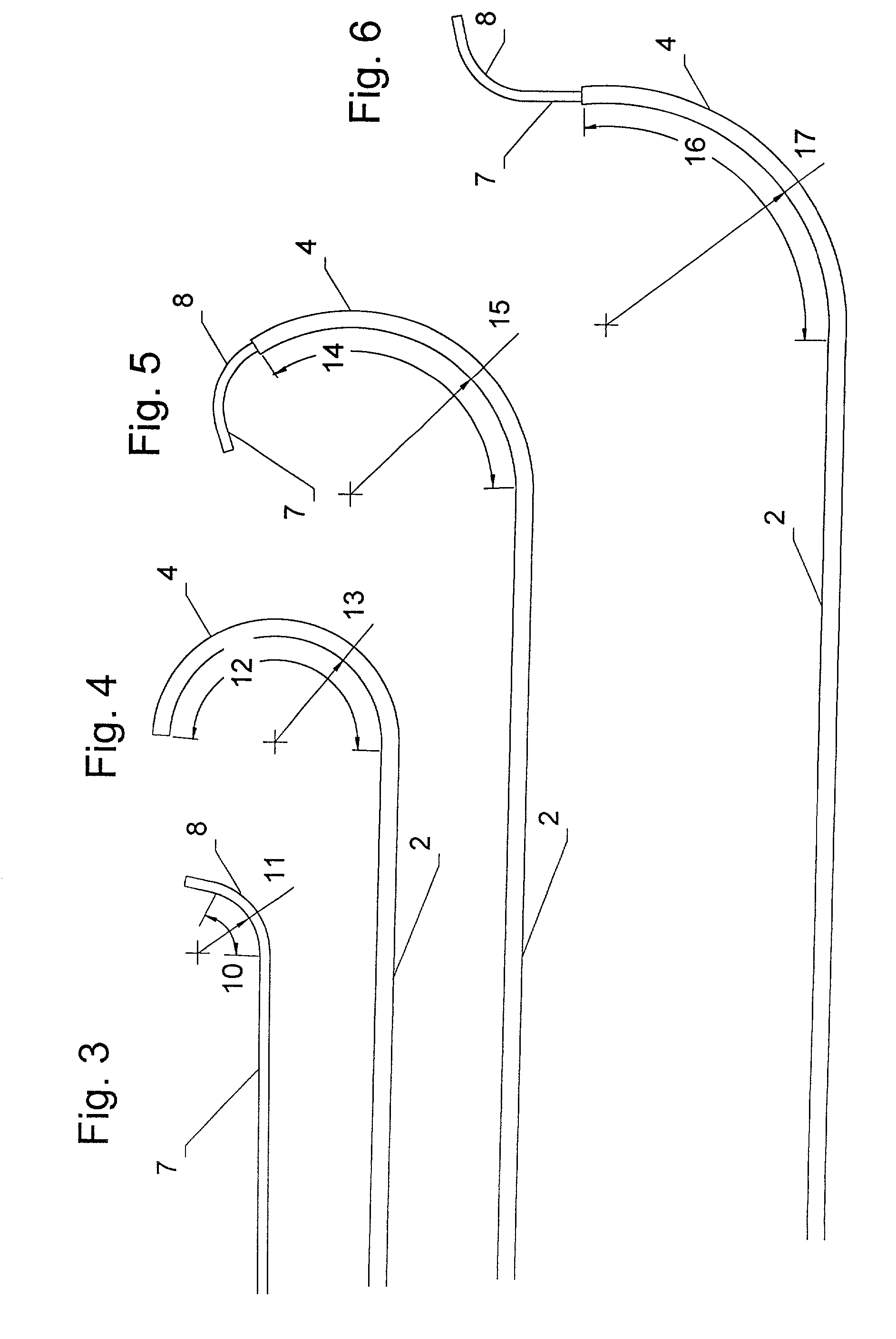

Three-dimensional coils for treatment of vascular aneurysms

InactiveUS20050277978A1High elastic modulusImprove biological activityDilatorsOcculdersThree dimensional shapeBiomedical engineering

A coil for the treatment of vascular aneurysms is disclosed. The coil is formed from filamentary members interlaced to form a three-dimensional substrate. The substrate is deformable between a collapsed state wherein it fits within a catheter, and an expanded state, which it assumes once deployed from the catheter into the vascular aneurysm. The three-dimensional shapes of the substrate include flat sheets biased into a helix or a tubular forms biased into figure eight loops, helical loops or a sinusoid. Bioactive characteristics may be imparted to the coil through the use of coatings or materials that provoke a healing response in living tissue.

Owner:STOUT MEDICAL GROUP

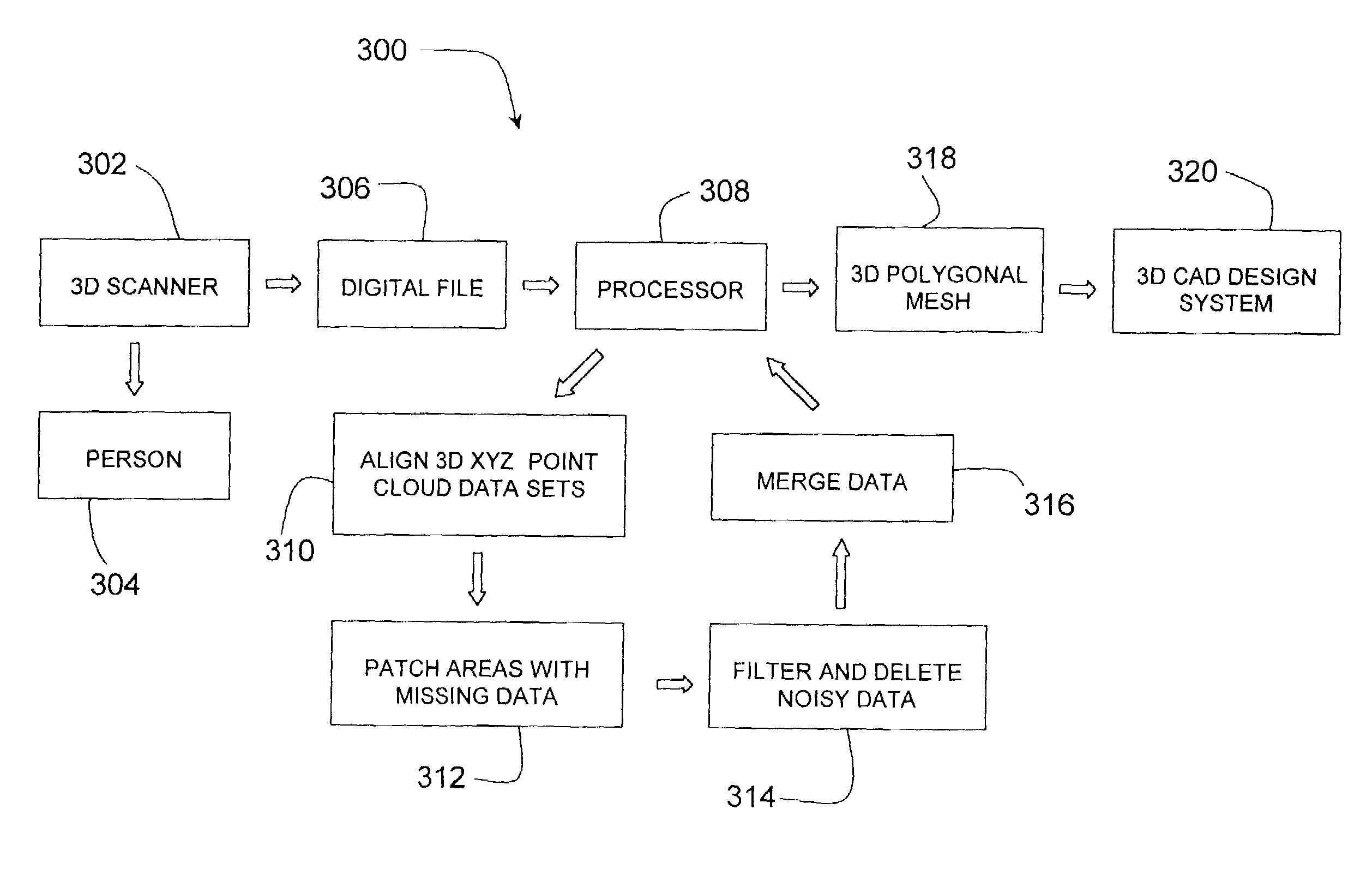

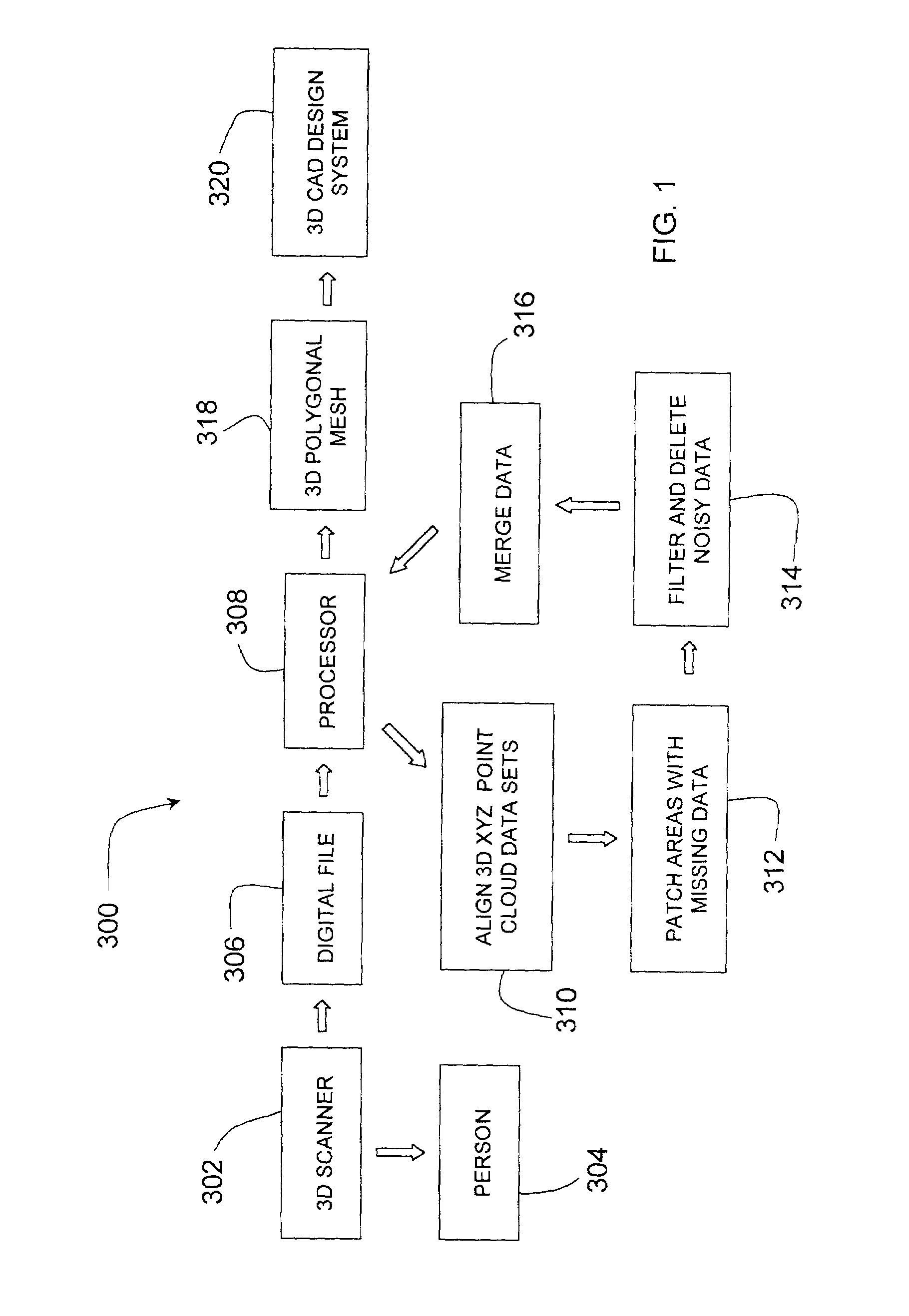

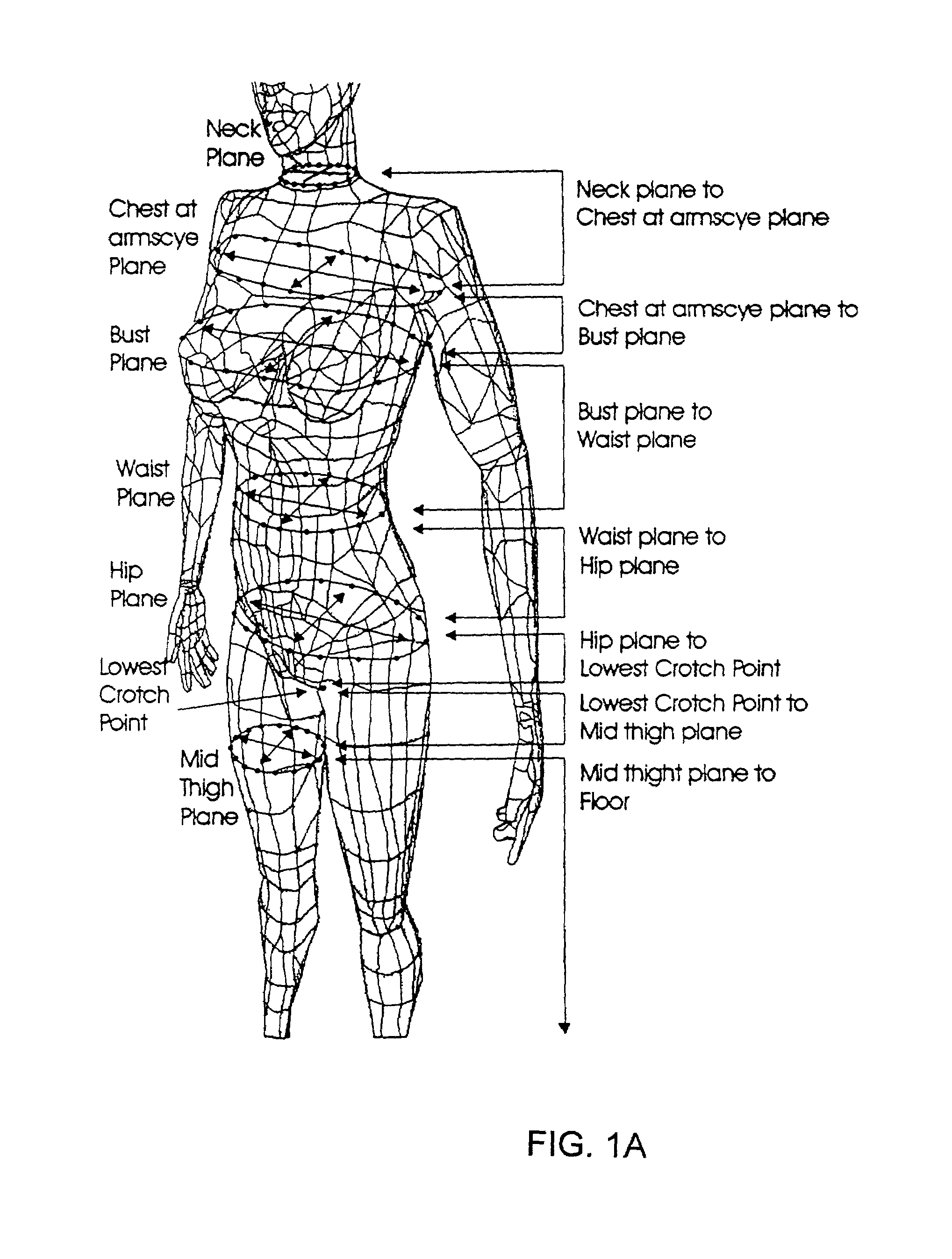

System and method for three-dimensional shape and size measurement

InactiveUS6968075B1Accurate measurementData augmentationData processing applicationsSpecial data processing applicationsComputer Aided DesignSize measurement

A method for three-dimensional shape and size measurement of a three-dimensional body surface comprising providing a three-dimensional scanner, providing a processor, providing a three-dimensional Computer Aided Design system, scanning in three dimensions with the three-dimensional scanner at least a portion of the three-dimensional body surface, creating a data file representative of the three-dimensional body surface, processing the data file with the processor, importing the data file into the three-dimensional Computer Aided Design System, employing the three-dimensional Computer Aided Design System relative to the data file to define and record three-dimensional measuring data relative to at least a portion of the three-dimensional body surface, A and employing the three-dimensional Computer Aided Design System to exploit the three-dimensional measuring data.

Owner:CHANG KURT C

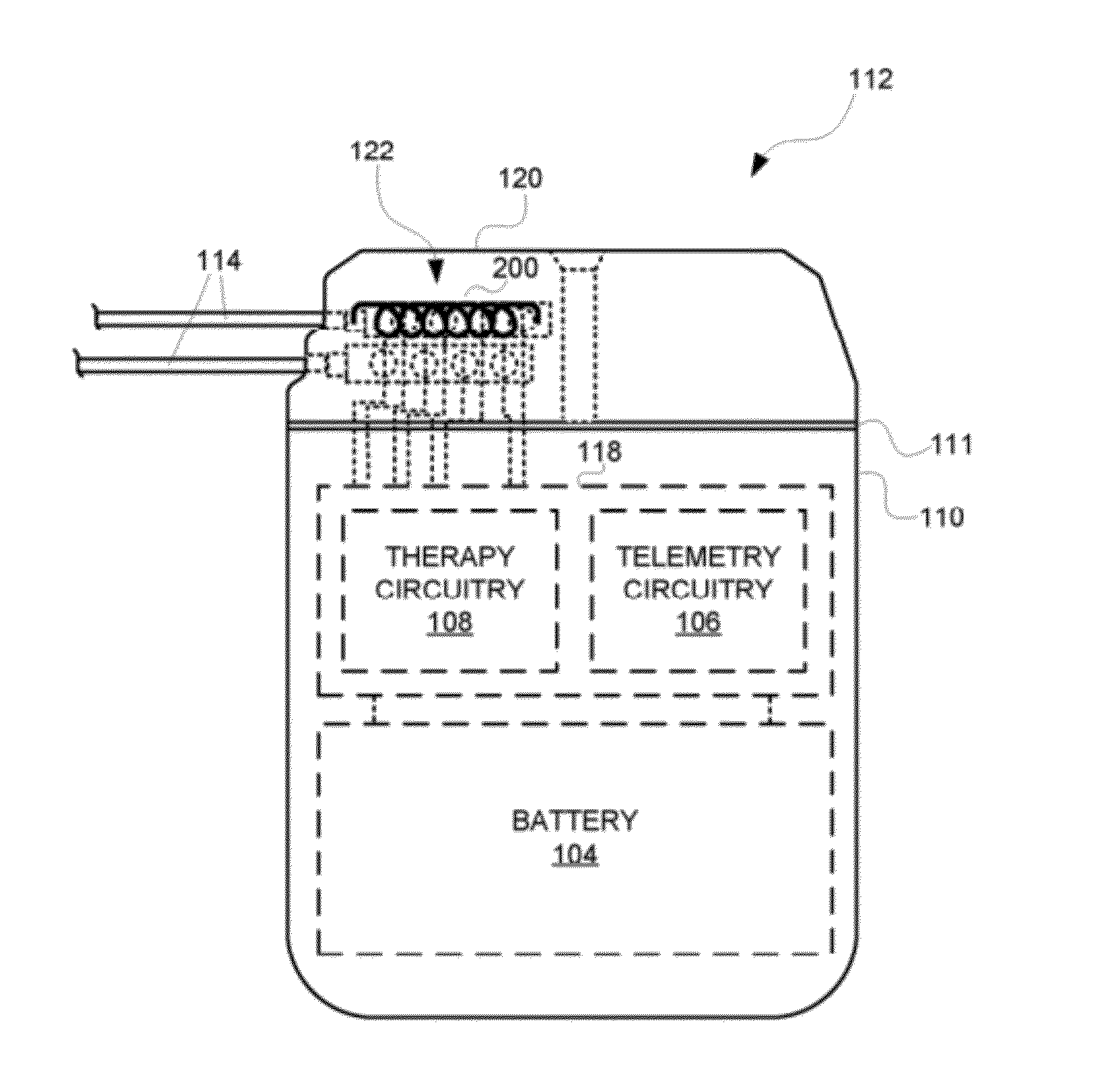

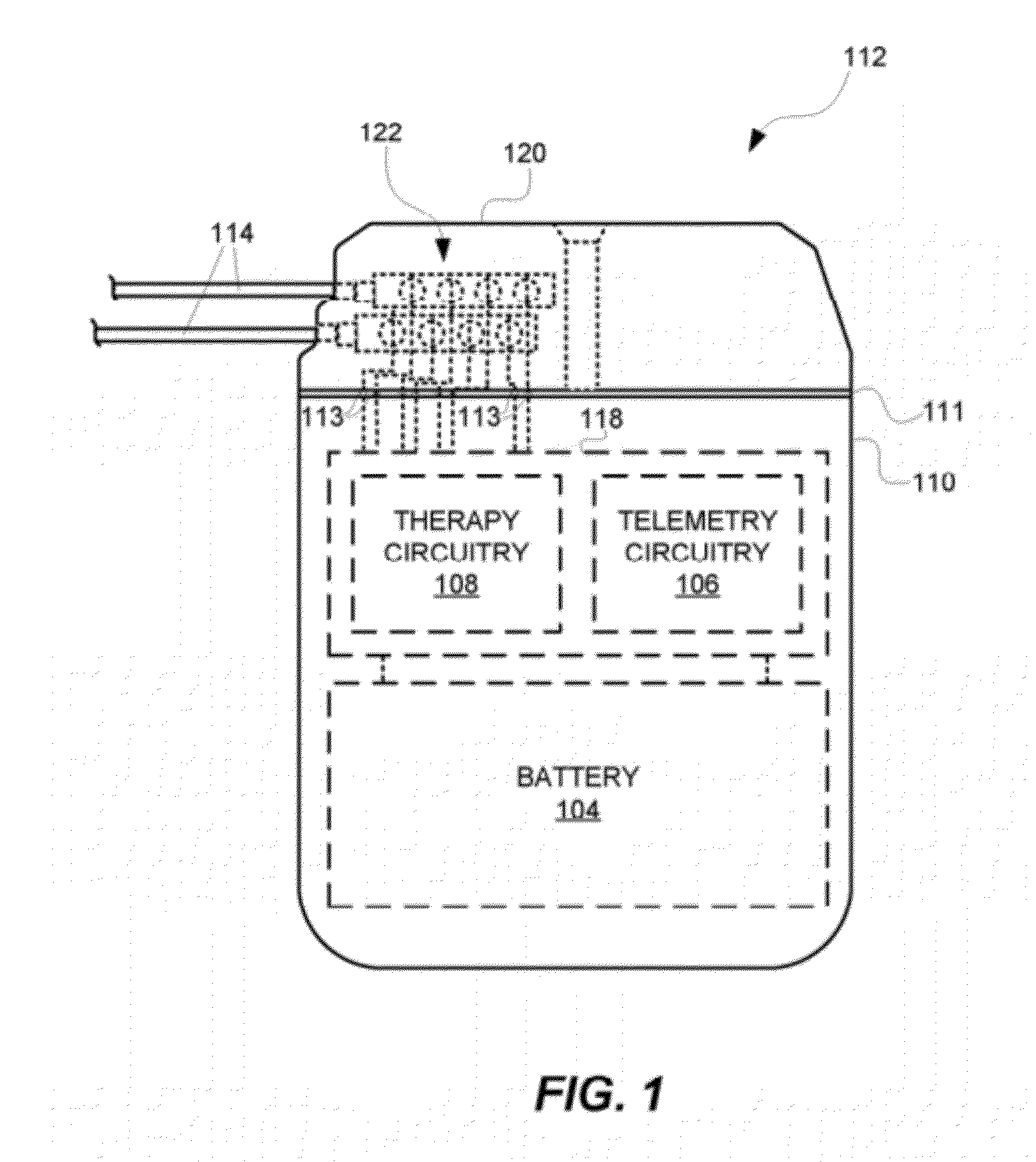

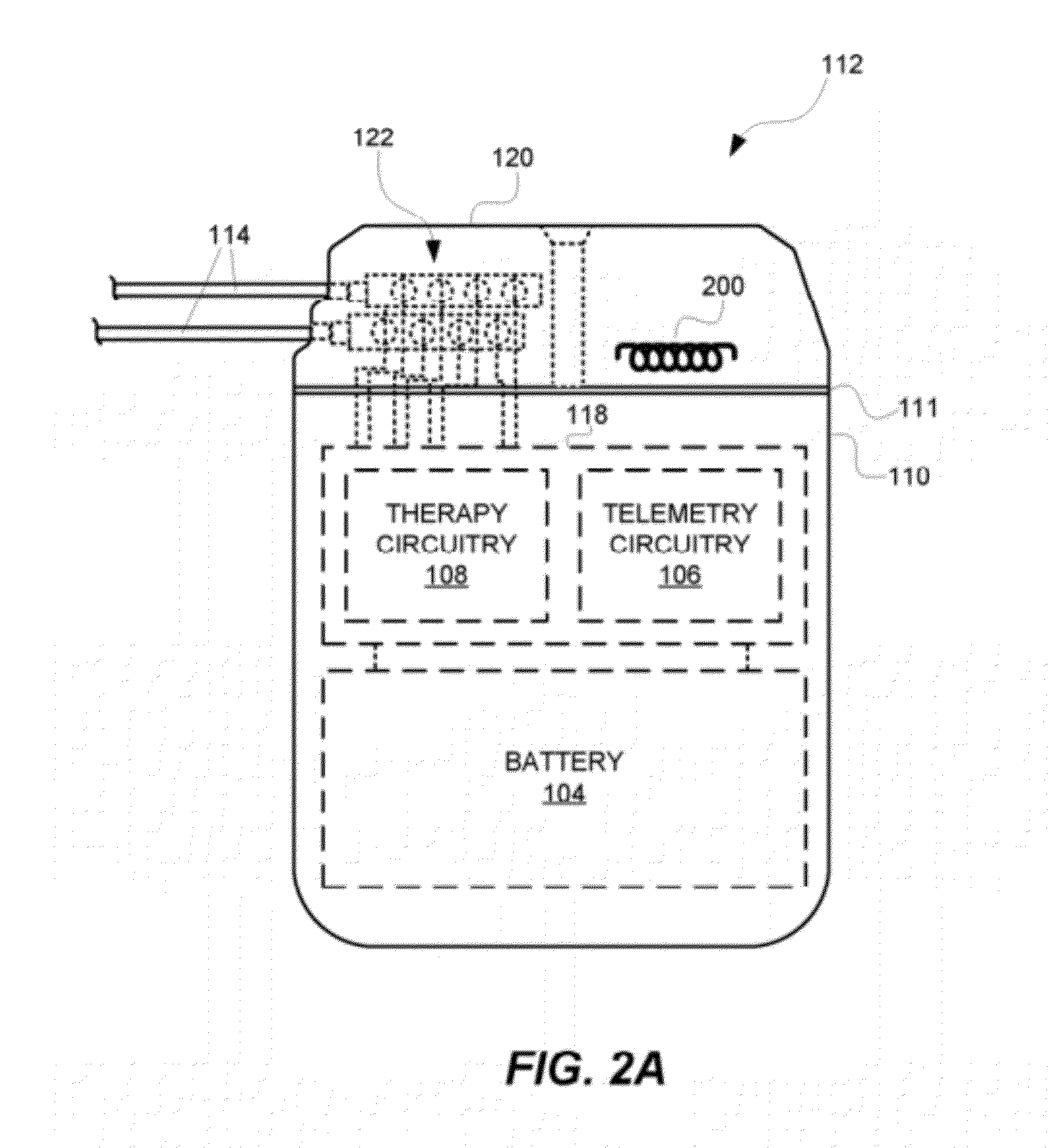

Telemetry antennas for medical devices and medical devices including telemetry antennas

ActiveUS20120265272A1Increase in sizeGreat antenna gain antennaElectrotherapyHelical antennasAntenna bandwidthAntenna gain

In an embodiment, an antenna for a medical device, e.g., an implantable medical device (IMD), comprises an electrically conductive wire that spirals to form a three-dimensional shape of a rectangular cuboid. In another embodiment, the antenna comprises an electrically conductive wire that spirals to form a three-dimensional shape of an elliptical cylinder, an oval cylinder, an elongated pentagonal prism, an elongated hexagonal prism, or some other shape where the longitudinal diameter of the antenna is greater than the lateral diameter of the antenna. The antennas are sized to fit within a portion of a header of the medical device. Such antennas are designed to provide increased antenna gain and antenna bandwidth.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

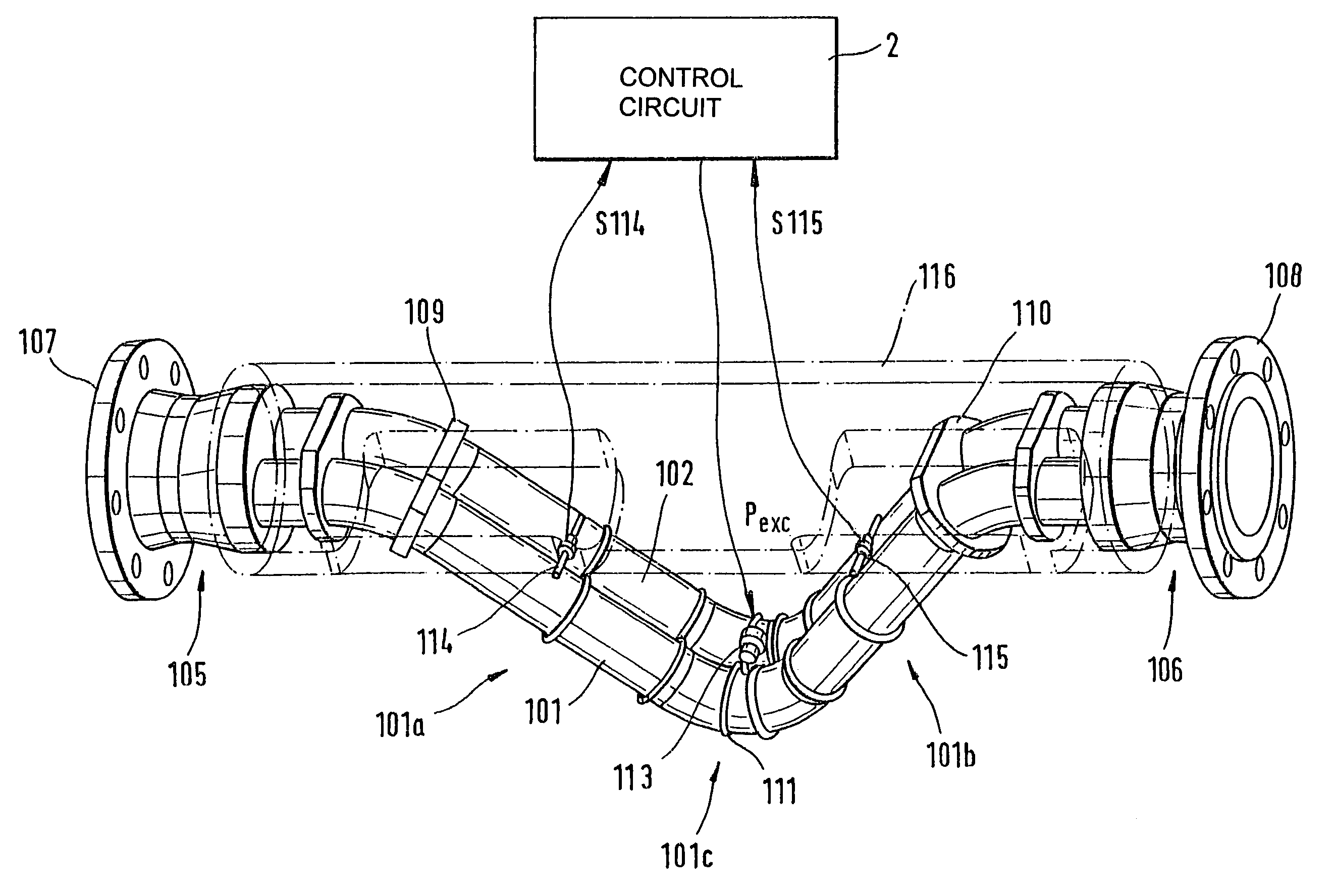

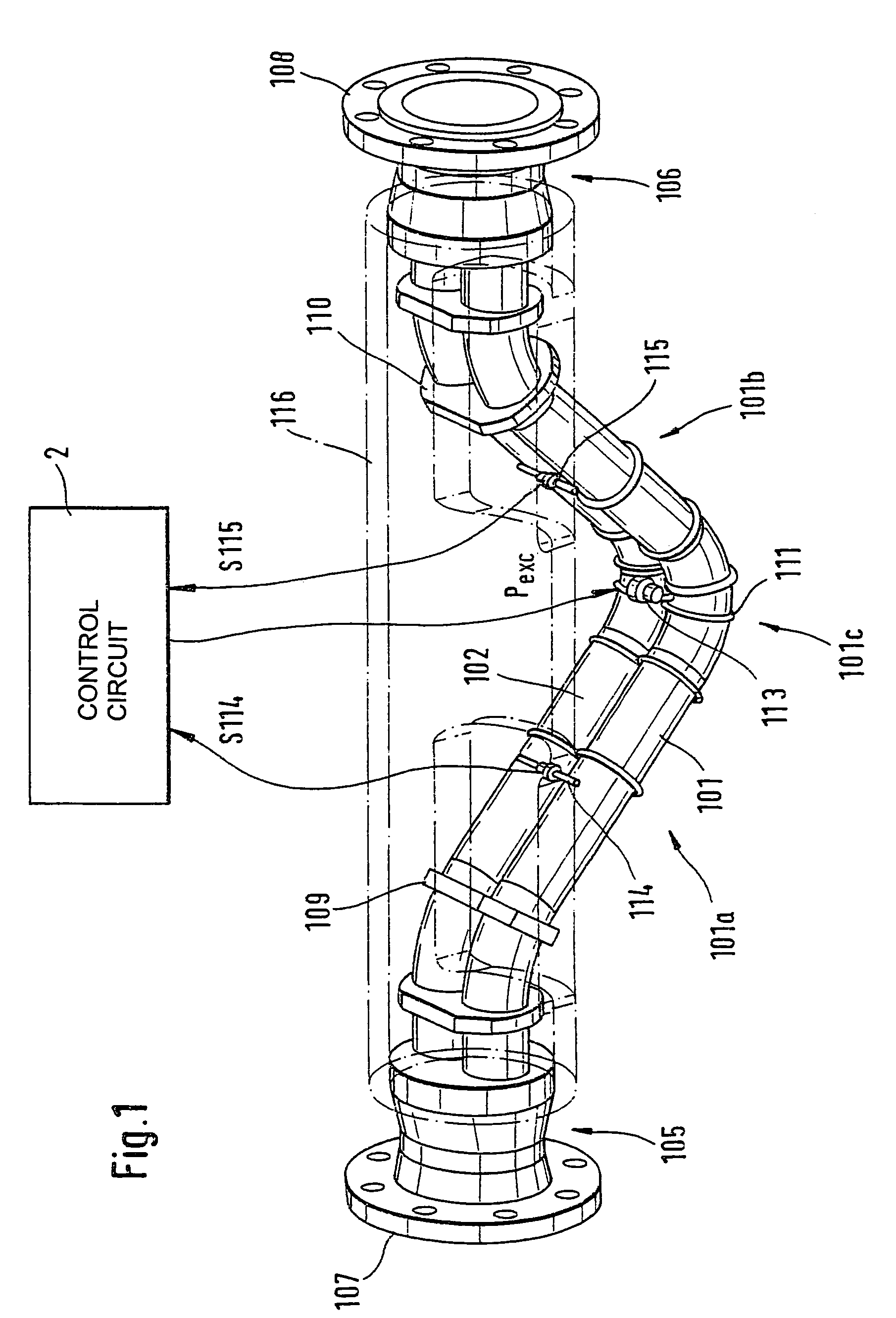

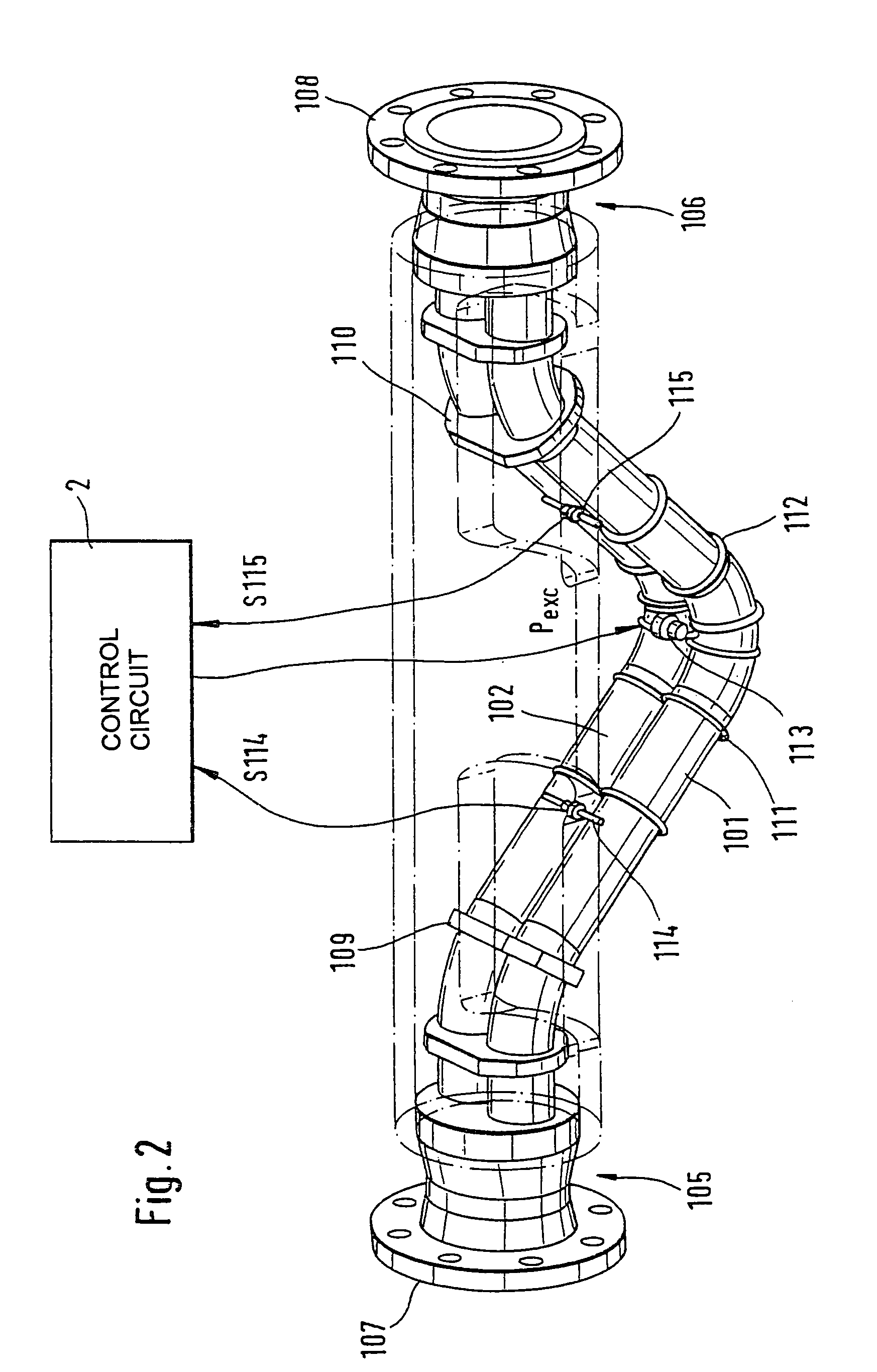

Vibratory transducer

InactiveUS6920798B2Easy to manufactureEasy to bendMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceCross sensitivityStraight tube

The transducer (1) has at least one at least temporarily vibrating flow tube (101) of predeterminable lumen for conducting a fluid. The flow tube (101) communicates with a connected pipe via an inlet tube section (103), ending in an inlet end, and an outlet tube section (104), ending in an outlet end, and in operation performs flexural vibrations about an axis of vibration joining the inlet and outlet ends. The flow tube (101) has at least one arcuate tube section (101c) of predeterminable three-dimensional shape which adjoins a straight tube segment (101a) on the inlet side and a straight tube segment (101b) on the outlet side. At least one stiffening element (111, 112) is fixed directly on or in close proximity to the arcuate tube segment (101c) to stabilize the three-dimensional shape. By means of the at least one stiffening element (111, 112), the cross sensitivity of the transducer (1) is greatly reduced, so that cross talks from pressure to mass flow signals are minimized and the accuracy of the transducer is improved.

Owner:ENDRESS HAUSER FLOWTEC AG

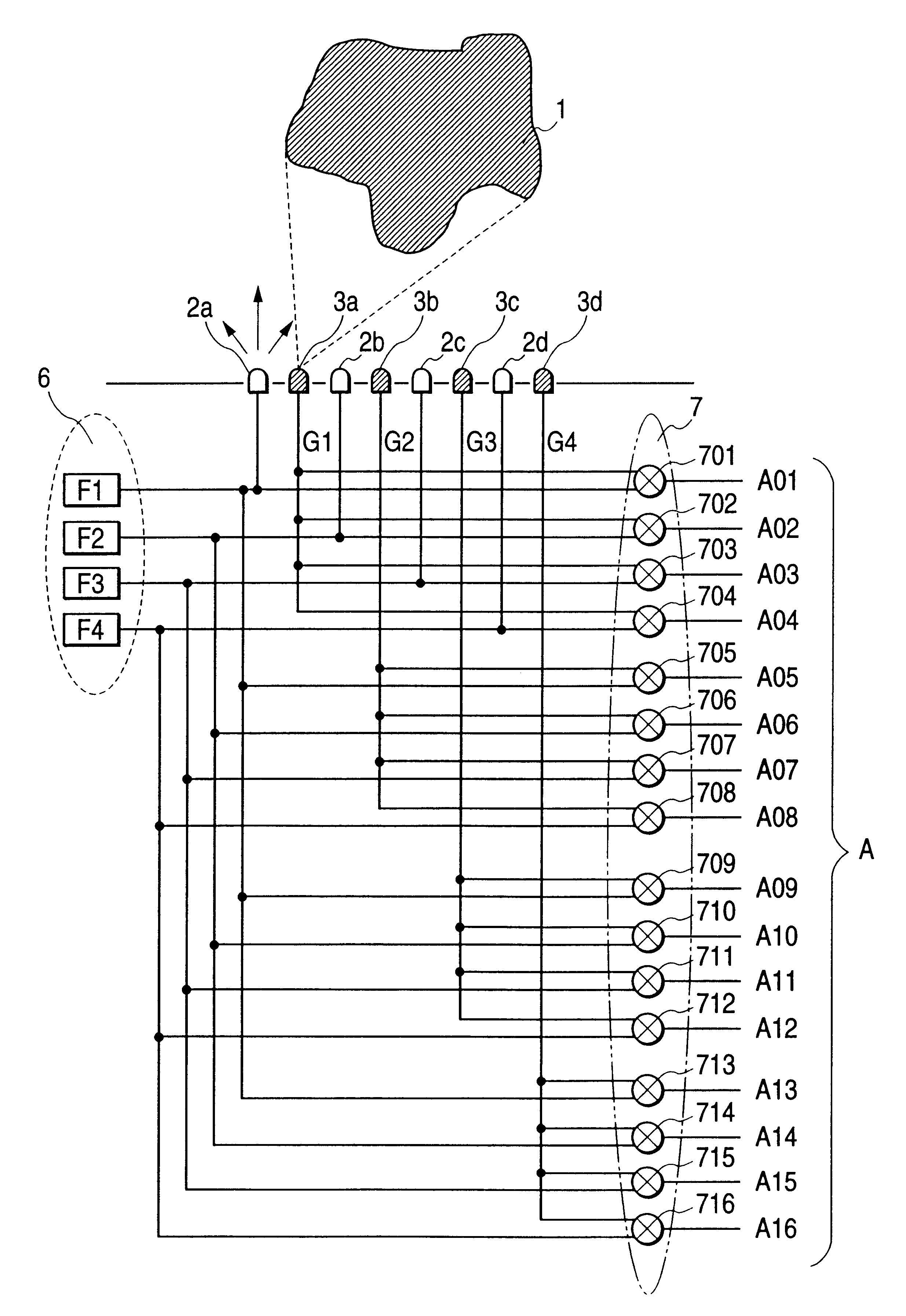

Three-dimensional object identifying system

InactiveUS6603867B1Programme controlElectric signal transmission systemsThree dimensional shapeInformation device

A three-dimensional object identifying system is disclosed which identifies a three-dimensional shape object optically such as a part of a human body for preventing an information apparatus such as a personal computer from being used by any other illegitimate user than a legitimate user. The three-dimensional object identifying system has a function generating unit which generates modulation signals, light emitting elements which emit lights based on the modulation signals to a three-dimensional object, light receiving elements which receive reflected lights from the three-dimensional object and which produce detection signals, a correlation detecting unit which detects correlation information between each detection signal and modulation signal, and an identifying unit which performs identifying processing for the three-dimensional object on the basis of both pre-cataloged correlation information and the detected correlation information.

Owner:FUJIFILM BUSINESS INNOVATION CORP

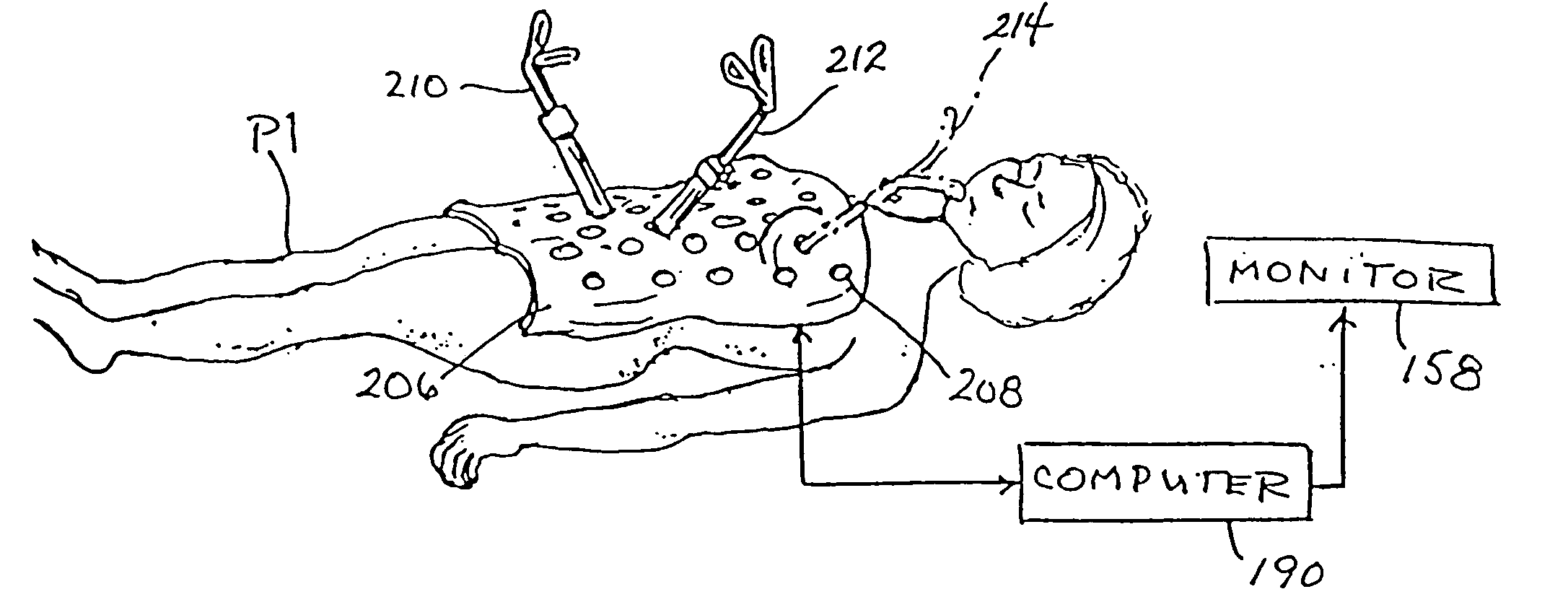

Ultrasonic medical device and associated method

InactiveUS20050020918A1Inexpensive and easy to transportOrgan movement/changes detectionSurgical needlesSignal processing circuitsSonification

A medical system includes a carrier and a multiplicity of electromechanical transducers mounted to the carrier, the transducers being disposable in effective pressure-wave-transmitting contact with a patient. Energization componentry is operatively connected to a first plurality of the transducers for supplying the same with electrical signals of at least one pre-established ultrasonic frequency to produce first pressure waves in the patient. A control unit is operatively connected to the energization componentry and includes an electronic analyzer operatively connected to a second plurality of the transducers for performing electronic 3D volumetric data acquisition and imaging (which includes determining three-dimensional shapes) of internal tissue structures of the patient by analyzing signals generated by the second plurality of the transducers in response to second pressure waves produced at the internal tissue structures in response to the first pressure waves. The control unit includes phased-array signal processing circuitry for effectuating an electronic scanning of the internal tissue structures which facilitates one-dimensional (vector), 2D (planar), and 3D (volume) data acquisition. The control unit further includes circuitry for defining multiple data gathering apertures and for coherently combining structural data from the respective apertures to increase spatial resolution. When the data gathering apertures are contained in a flexible web or carrier so that the instantaneous positions of the data gathering apertures are unknown, a self-cohering algorithm is used to determine their positions so that coherent aperture combining can be performed.

Owner:WILK ULTRASOUND OF CANADA

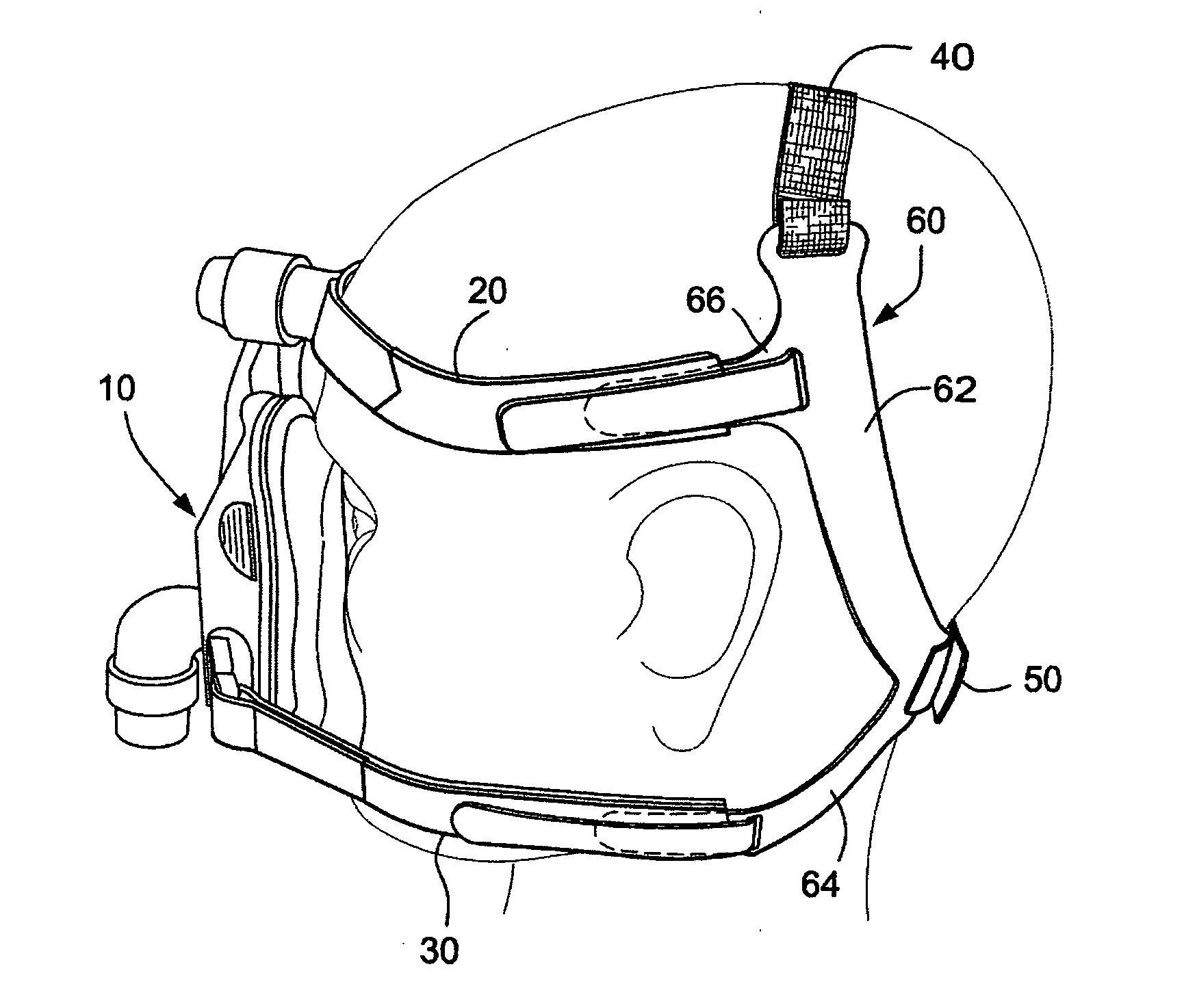

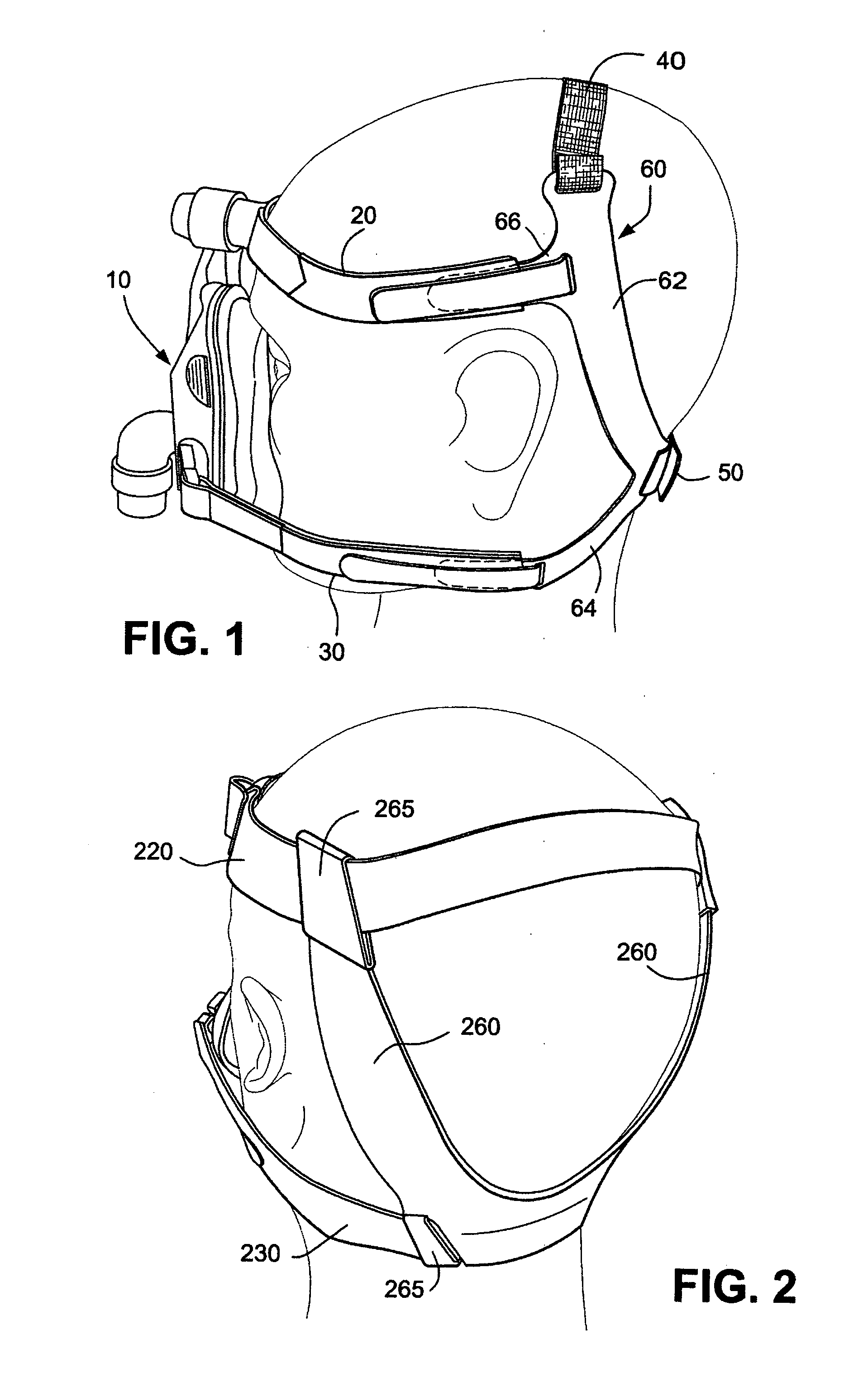

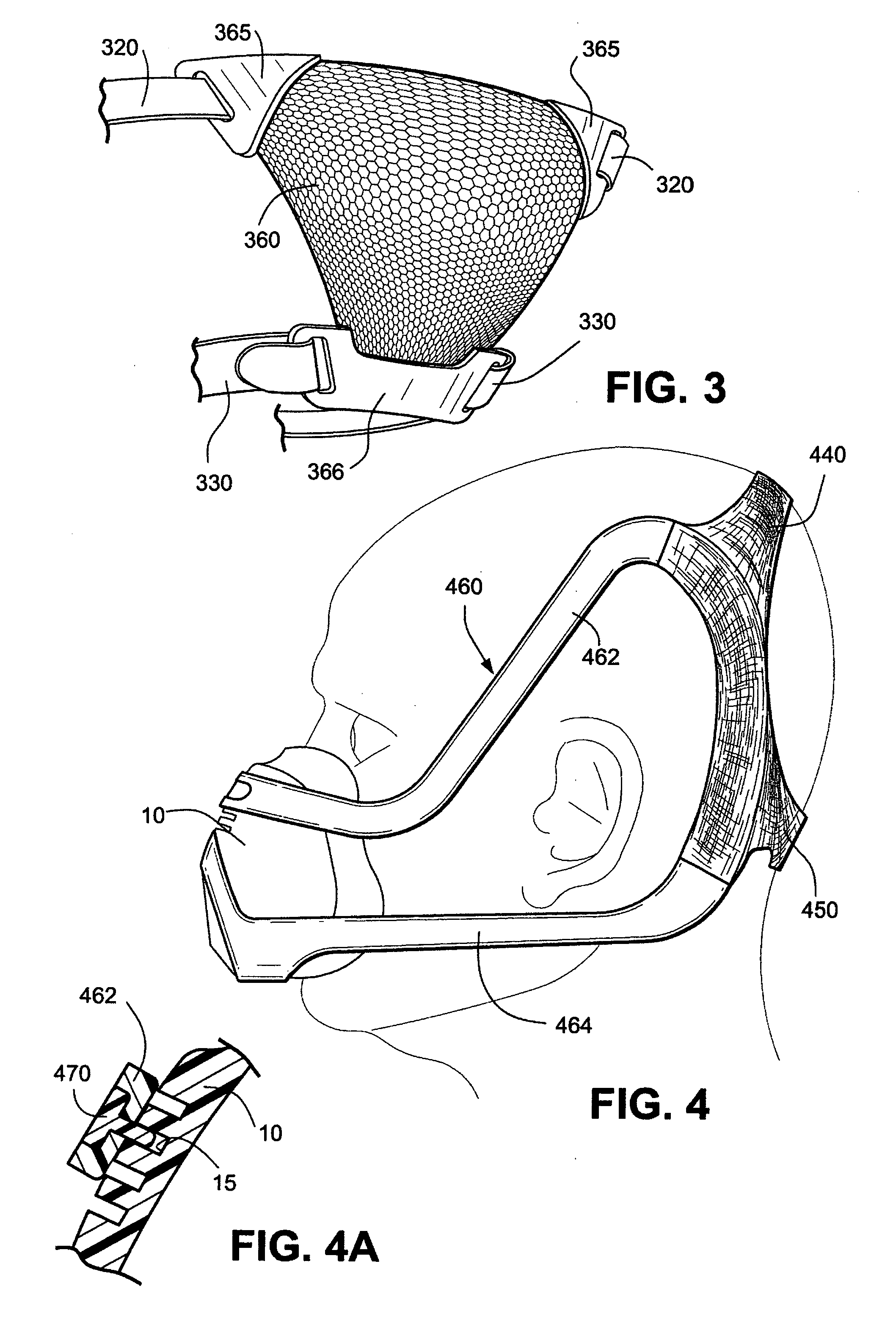

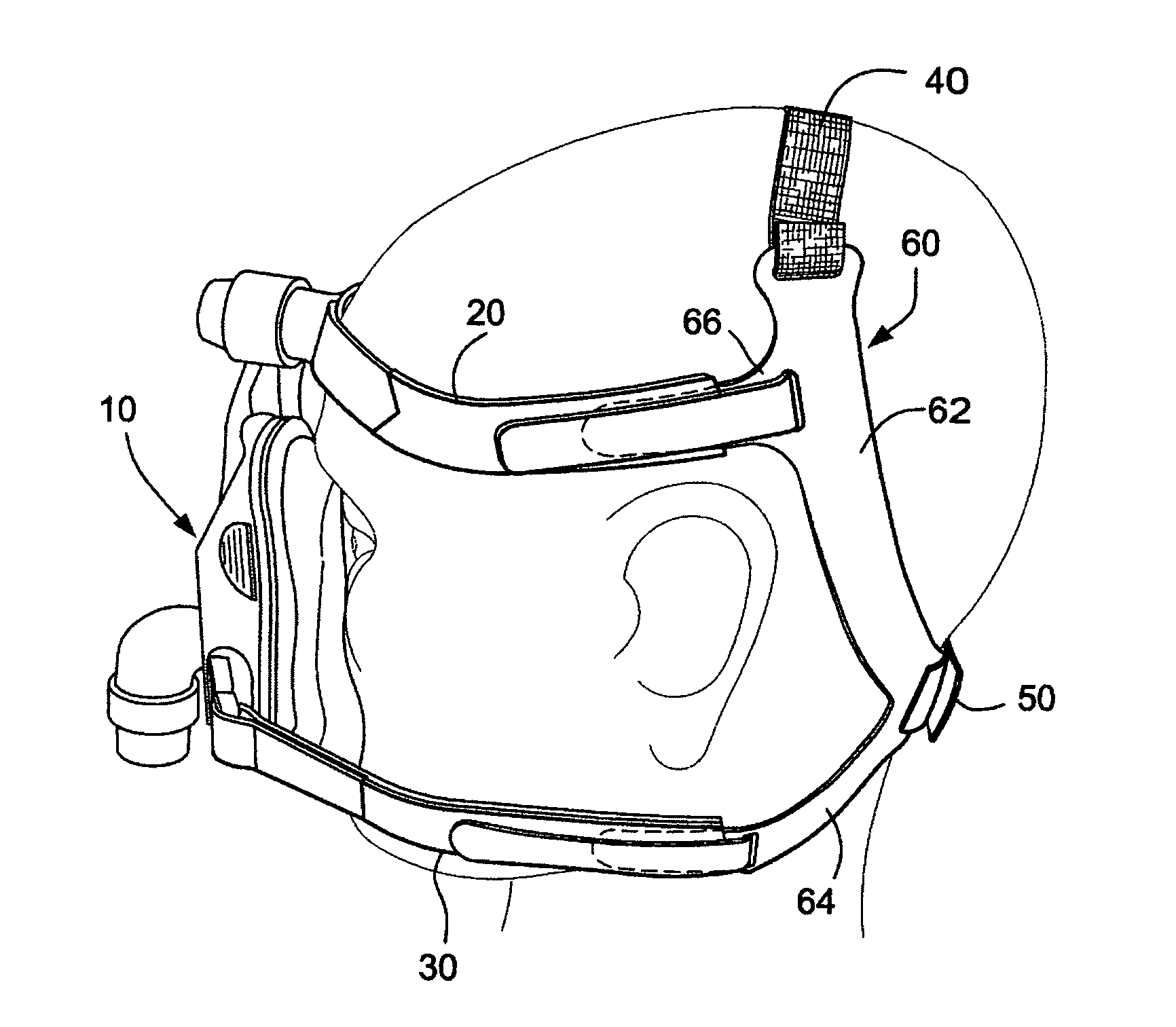

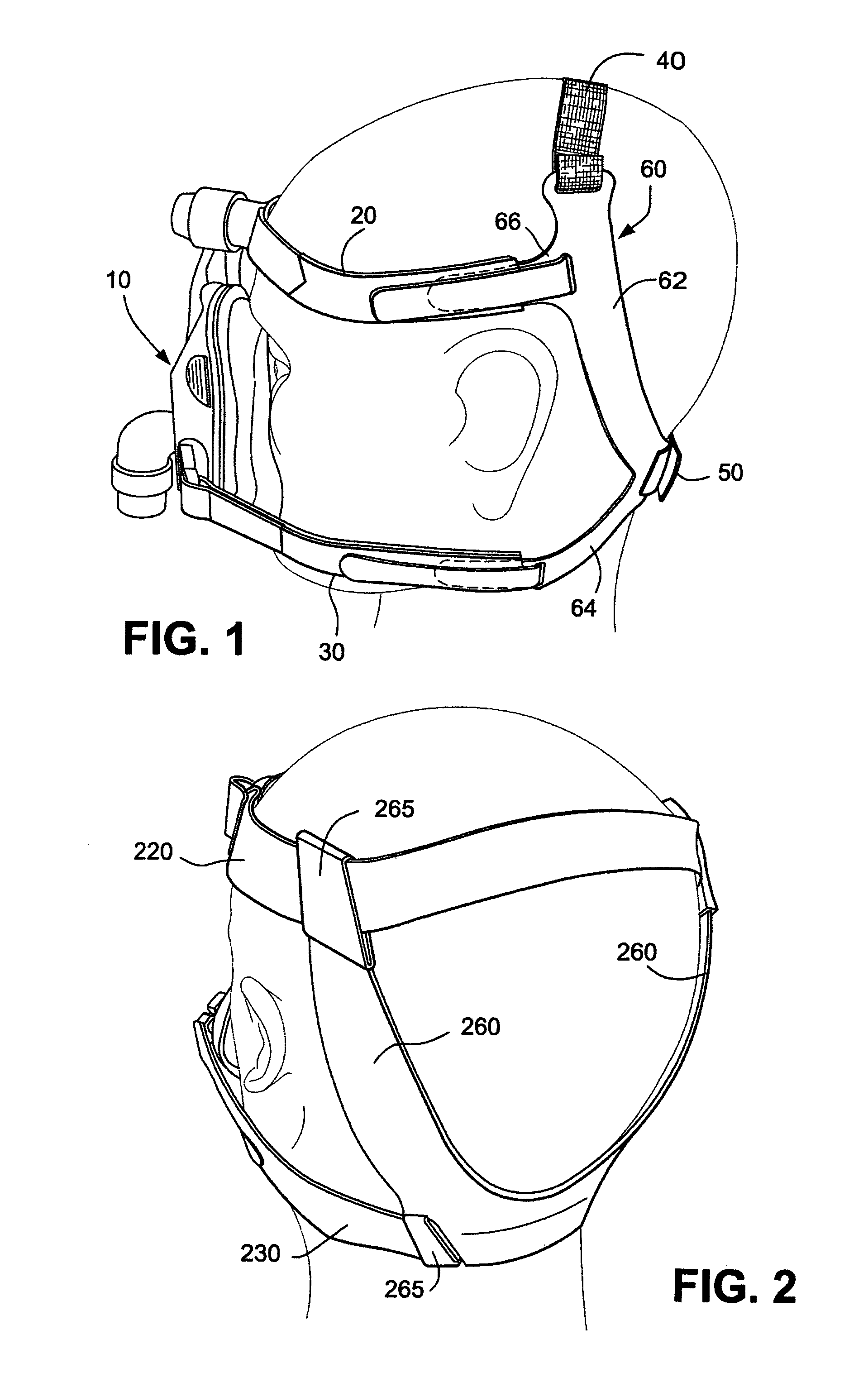

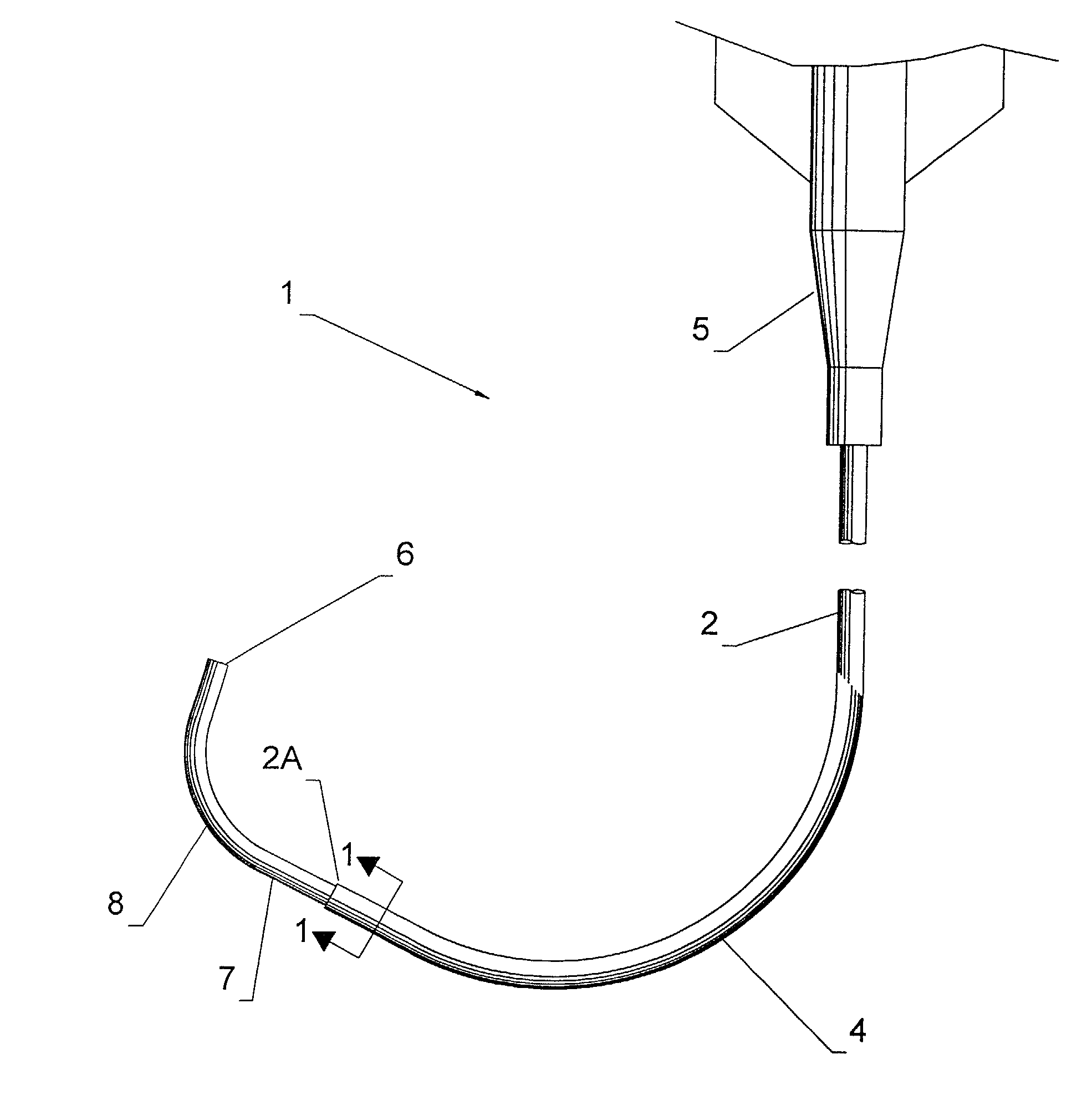

Headgear for masks

ActiveUS20110197341A1Low costEasy to useBreathing masksMedical devicesPhysical medicine and rehabilitationEngineering

A headgear for use with a mask includes a first strap (660) being configured to engage a back of a patient's head and extend on either side of the patient's parietal bone behind the patient's ears and assume, in use, a substantially circular or oval shape. At least a portion of the first strap is substantially inextensible. The headgear also includes at least one second strap (620, 630) configured to removably connect the first strap to the mask. The second strap may be more extensible than the first strap. At least a portion of the first strap is self-supporting such that the headgear maintains a three dimensional shape when not in use. The substantially inextensible portion of the first strap is constructed to resiliently return to a predetermined shape when not in use. The arcuate region includes a first portion that may be arranged to align substantially parallel with a top of the patient's head and a second portion being arranged to align substantially to a rear surface of the patient's head.

Owner:RESMED LTD

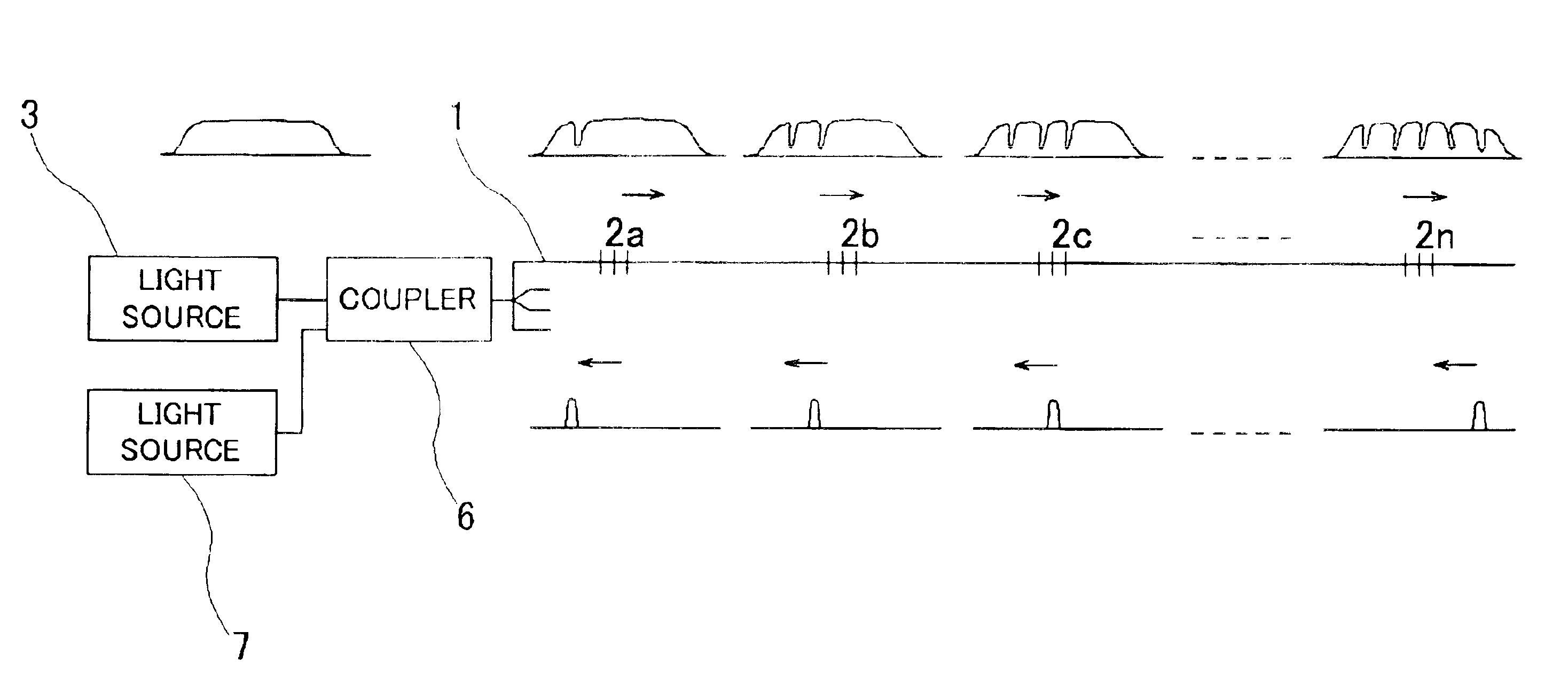

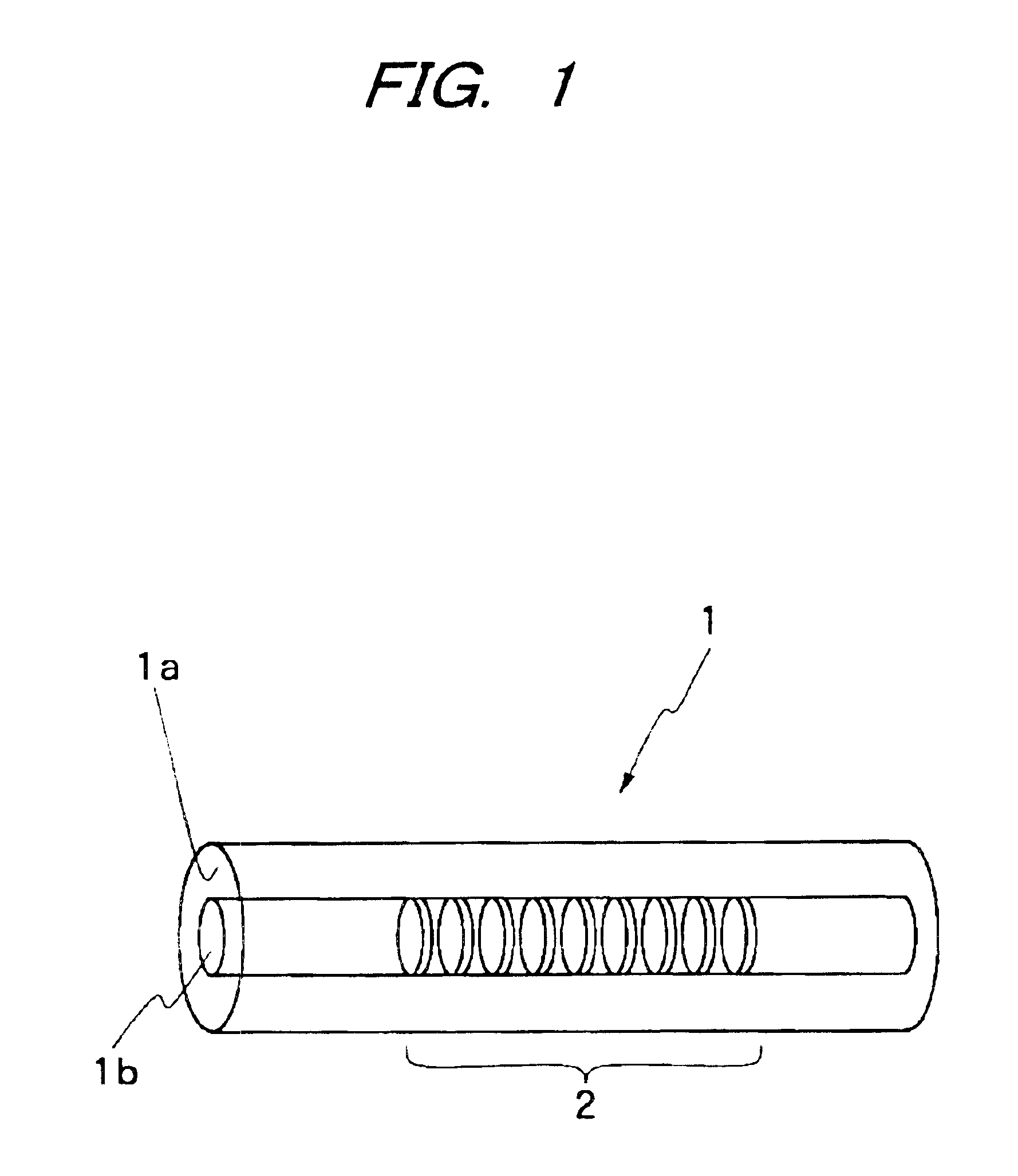

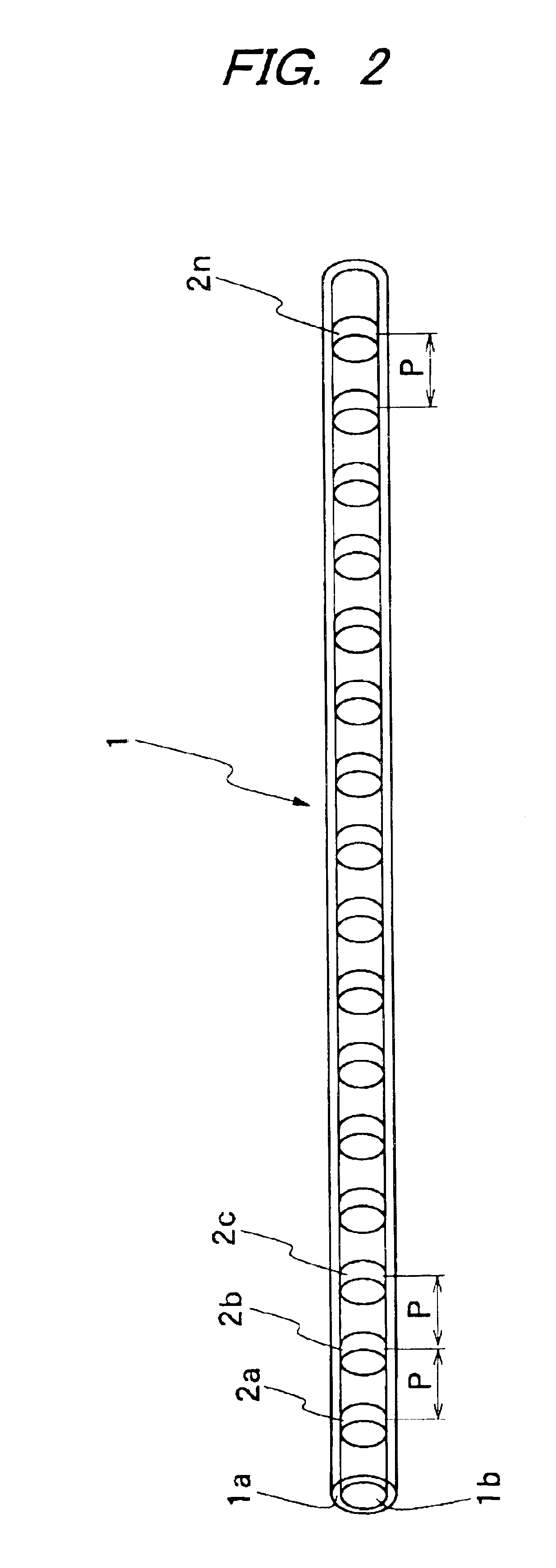

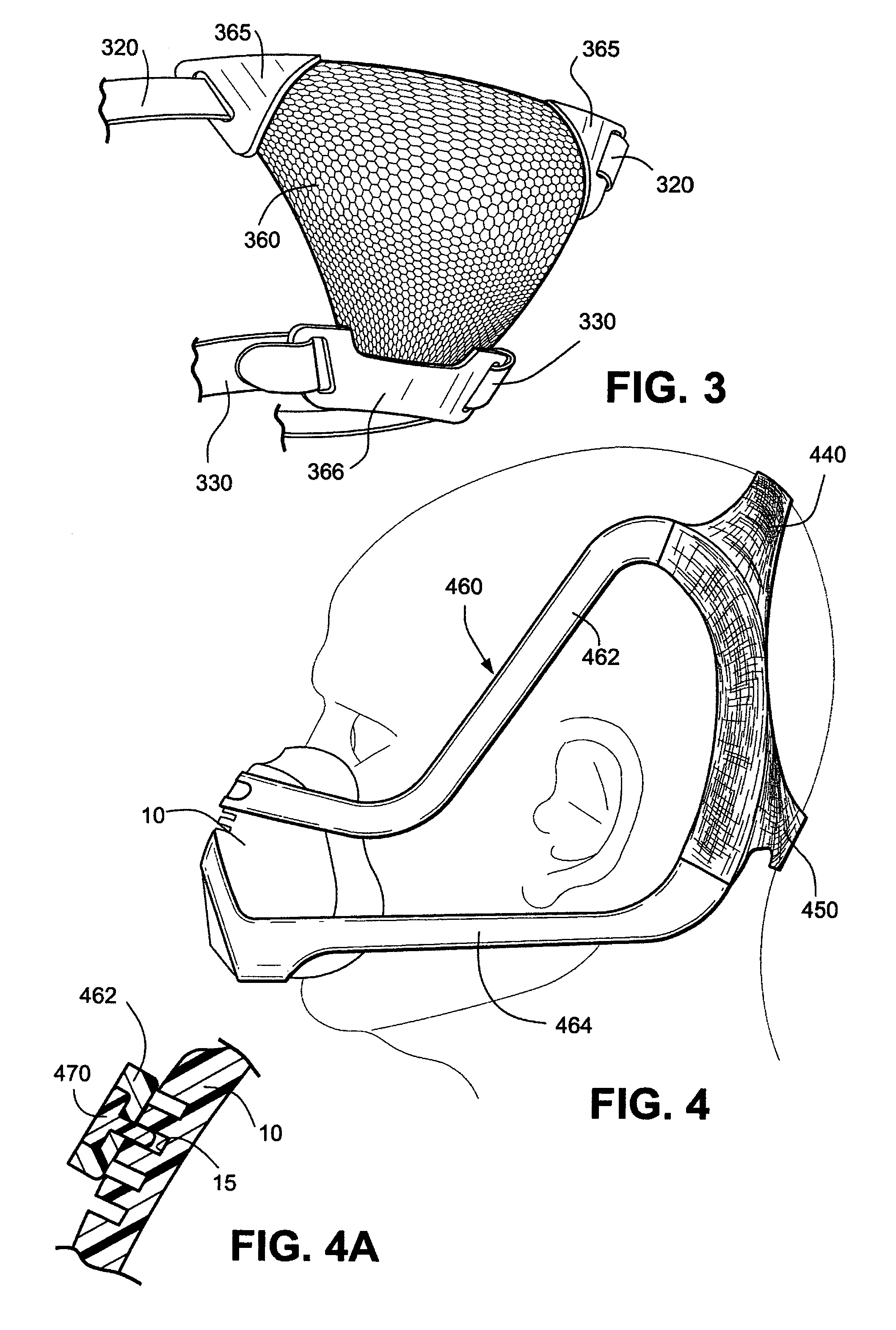

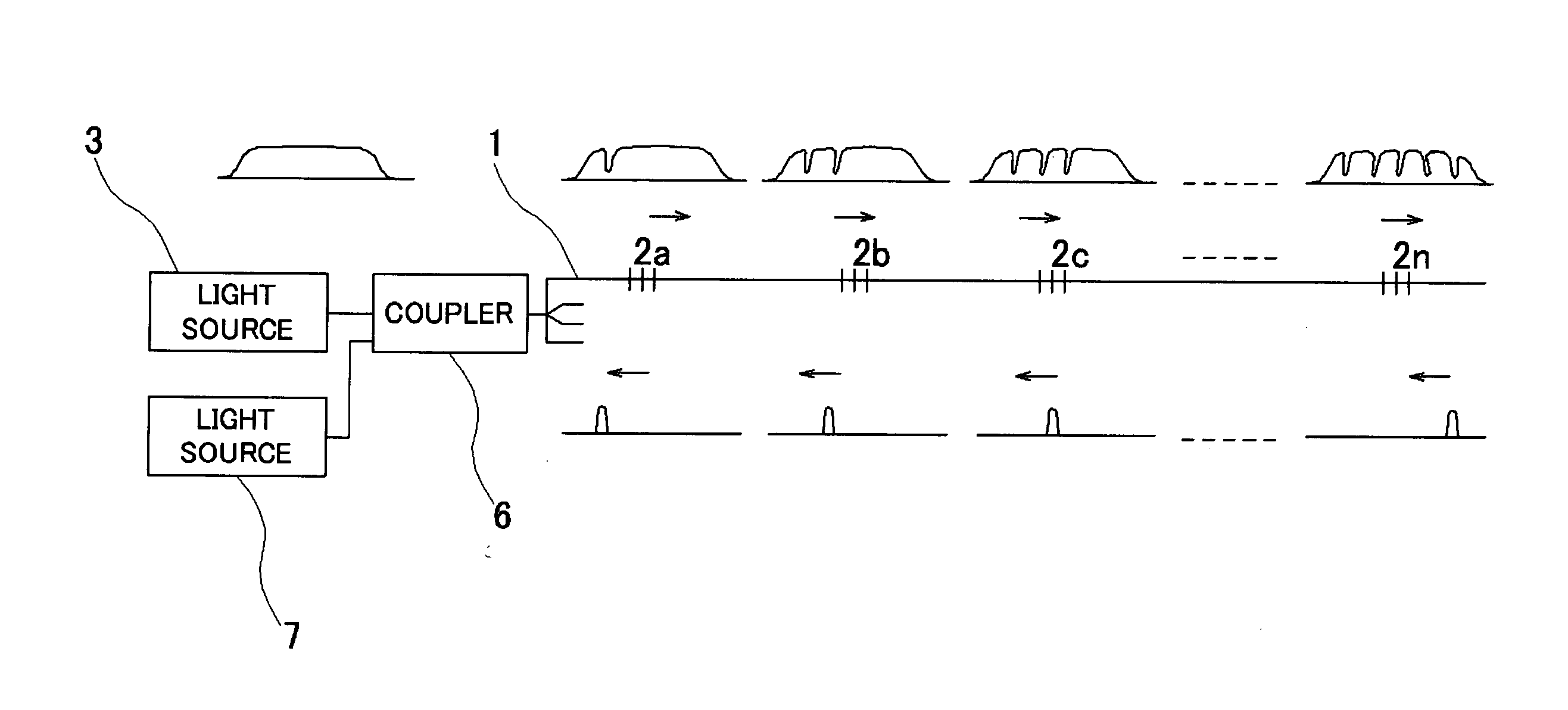

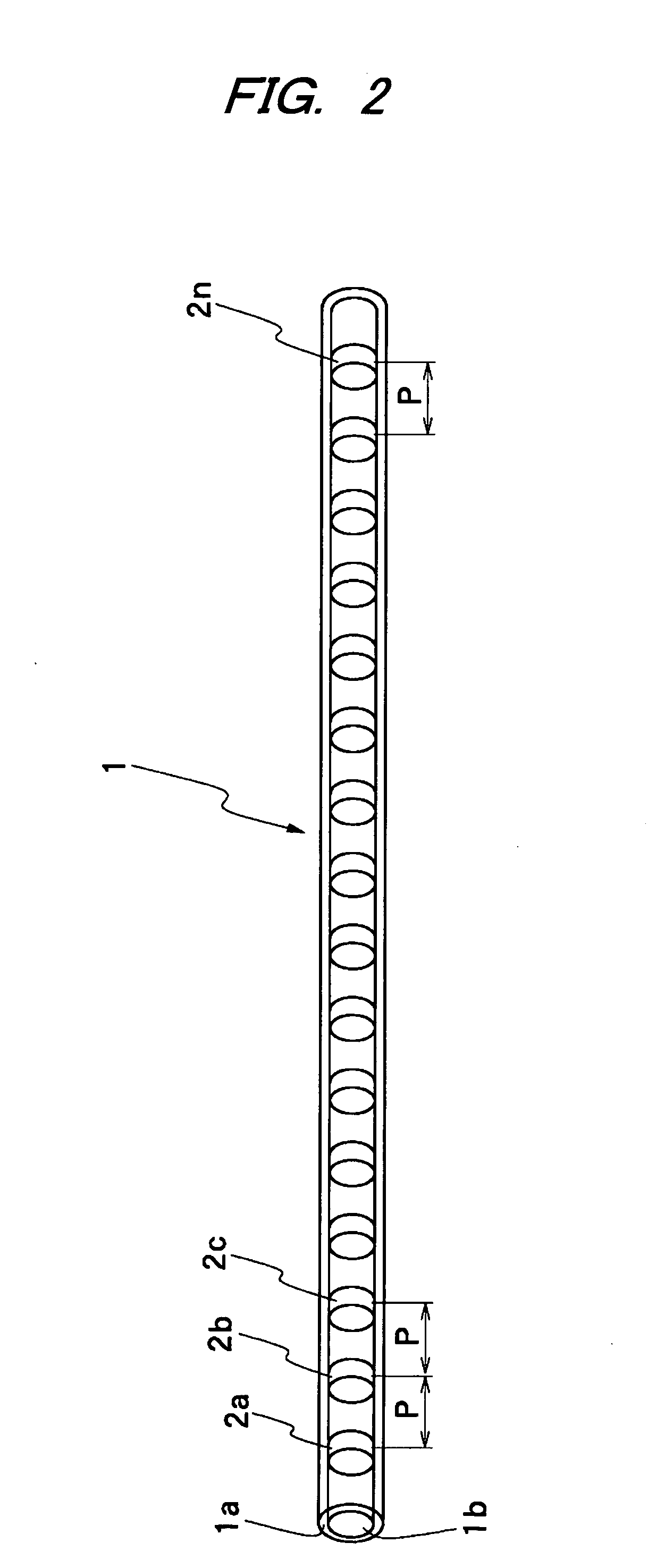

Device for detecting three-dimensional shapes of elongated flexible body

InactiveUS6868195B2Simple and compact structureEndoscopesMaterial analysis by optical meansFiberRefractive index

For detecting three-dimensional shapes of an elongated flexible body, a sensor cable to be placed in a passage or channel which is formed axially and coextensively within the elongated flexible body. The sensor cable has two pairs of fiber Bragg grating strands within a tubular carrier casing. A signal light beam containing Bragg wavelength bands is projected from a light source to input same to refractive index change portions in the fiber Bragg grating strands. Reflection diffraction light signals from the refractive index change portions are received by a signal processor to measure the degree of strain at each one of the respective refractive index change portions by comparing wavelengths of the reflection diffraction light signals with reference wavelength.

Owner:FUJI PHOTO OPTICAL CO LTD

Headgear for masks

ActiveUS8950404B2Low costEasy to useProtective equipmentRespiratory masksMedicineThree dimensional shape

A headgear for use with a mask includes a first strap (660) being configured to engage a back of a patient's head and extend on either side of the patient's parietal bone behind the patient's ears and assume, in use, a substantially circular or oval shape. At least a portion of the first strap is substantially inextensible. The headgear also includes at least one second strap (620, 630) configured to removably connect the first strap to the mask. The second strap may be more extensible than the first strap. At least a portion of the first strap is self-supporting such that the headgear maintains a three dimensional shape when not in use. The substantially inextensible portion of the first strap is constructed to resiliently return to a predetermined shape when not in use. The arcuate region includes a first portion that may be arranged to align substantially parallel with a top of the patient's head and a second portion being arranged to align substantially to a rear surface of the patient's head.

Owner:RESMED LTD

Device for detecting three-dimensional shapes of elongated flexible body

For detecting three-dimensional shapes of an elongated flexible body, a sensor cable to be placed in a passage or channel which is formed axially and coextensively within the elongated flexible body. The sensor cable has two pairs of fiber Bragg grating strands within a tubular carrier casing. A signal light beam containing Bragg wavelength bands is projected from a light source to input same to refractive index change portions in the fiber Bragg grating strands. Reflection diffraction light signals from the refractive index change portions are received by a signal processor to measure the degree of strain at each one of the respective refractive index change portions by comparing wavelengths of the reflection diffraction light signals with reference wavelength.

Owner:FUJI PHOTO OPTICAL CO LTD

Ultrasonic medical device and associated method

InactiveUS20080228077A1Inexpensive and easy to transportOrgan movement/changes detectionSurgical needlesSignal processing circuitsControl cell

A medical system includes a carrier and a multiplicity of electromechanical transducers mounted to the carrier, the transducers being disposable in effective pressure-wave-transmitting contact with a patient. Energization componentry is operatively connected to a first plurality of the transducers for supplying the same with electrical signals of at least one pre-established ultrasonic frequency to produce first pressure waves in the patient. A control unit is operatively connected to the energization componentry and includes an electronic analyzer operatively connected to a second plurality of the transducers for performing electronic 3D volumetric data acquisition and imaging (which includes determining three-dimensional shapes) of internal tissue structures of the patient by analyzing signals generated by the second plurality of the transducers in response to second pressure waves produced at the internal tissue structures in response to the first pressure waves. The control unit includes phased-array signal processing circuitry for effectuating an electronic scanning of the internal tissue structures which facilitates one-dimensional (vector), 2D (planar), and 3D (volume) data acquisition. The control unit further includes circuitry for defining multiple data gathering apertures and for coherently combining structural data from the respective apertures to increase spatial resolution. When the data gathering apertures are contained in a flexible web or carrier so that the instantaneous positions of the data gathering apertures are unknown, a self-cohering algorithm is used to determine their positions so that coherent aperture combining can be performed.

Owner:WILK ULTRASOUND OF CANADA

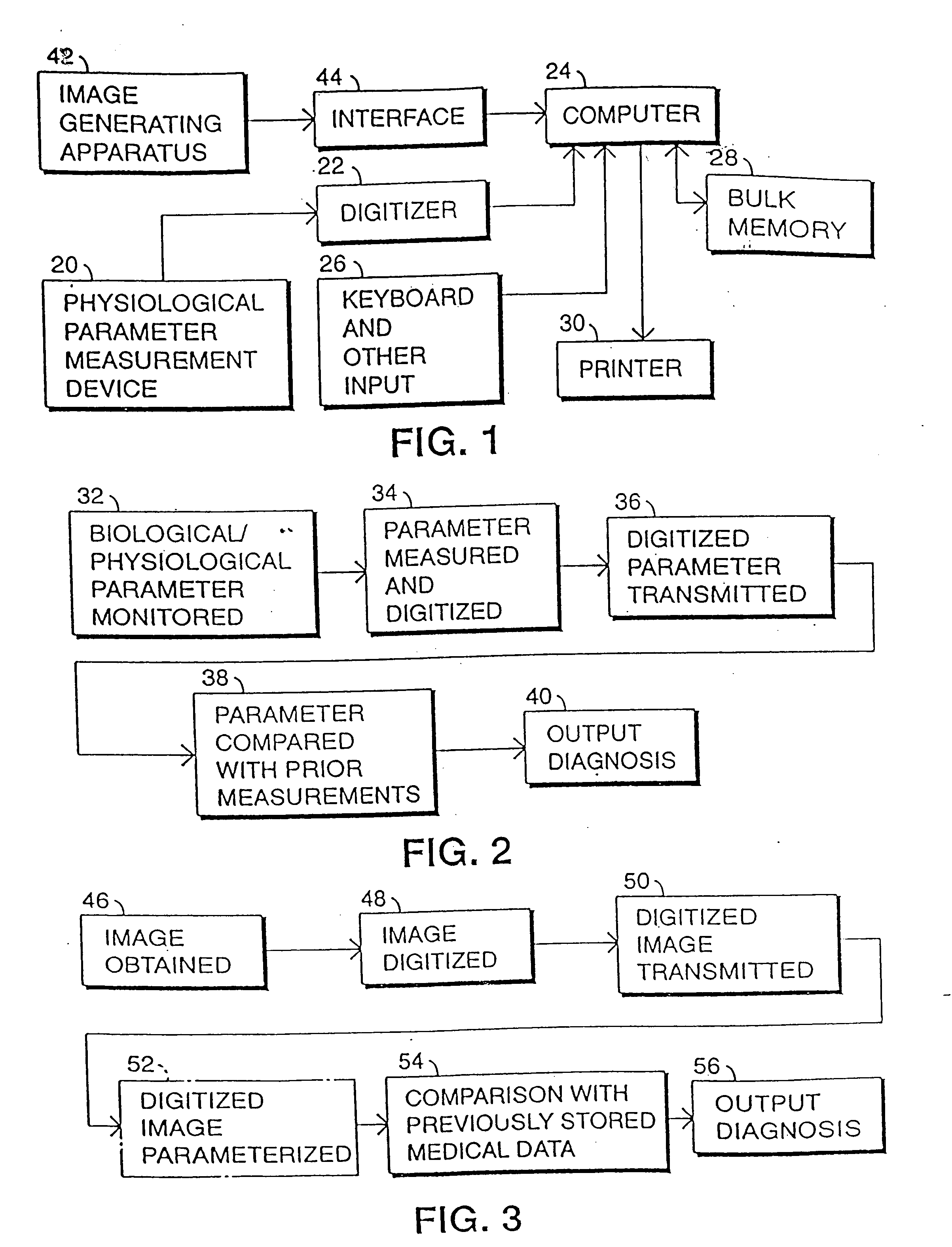

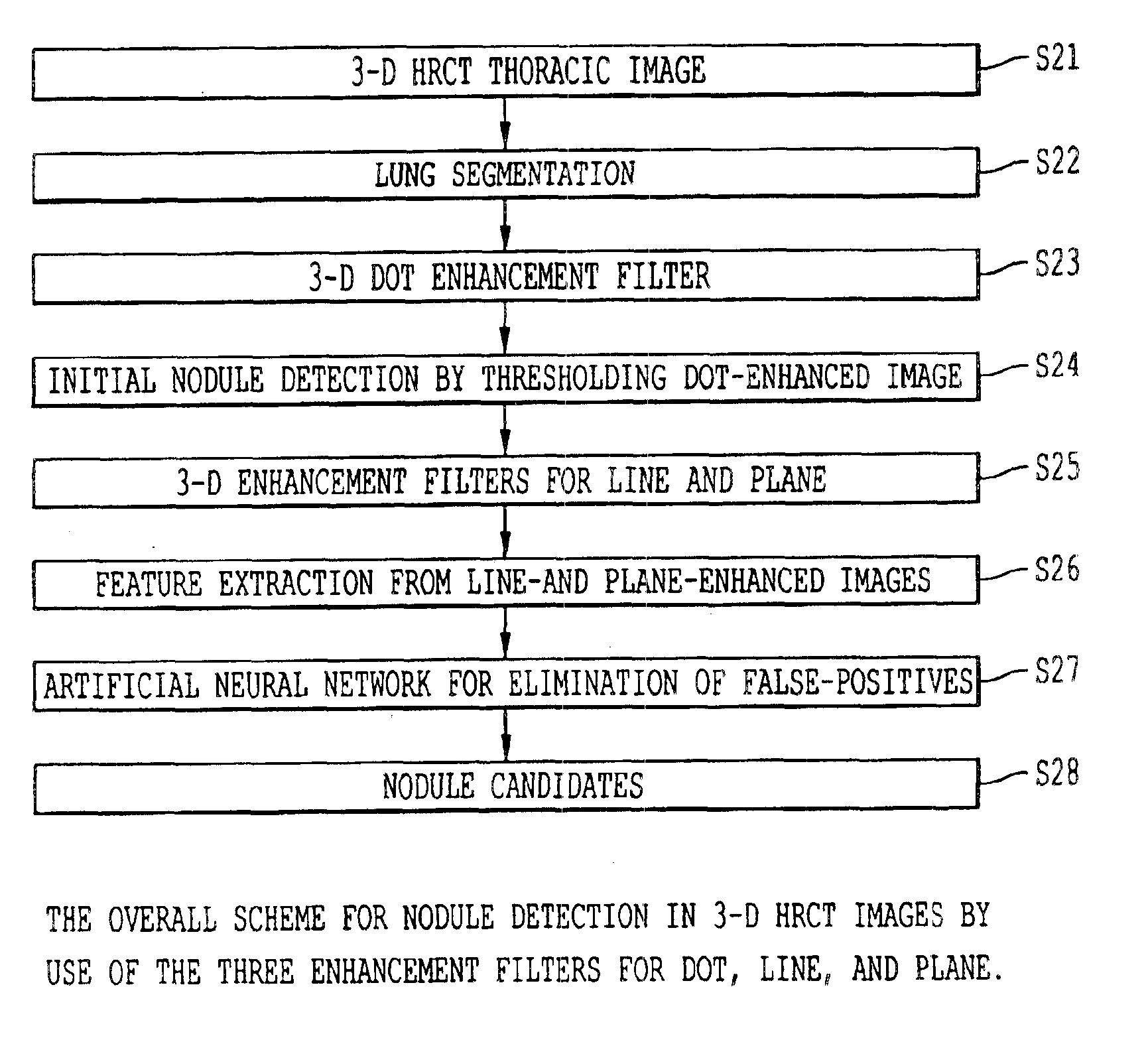

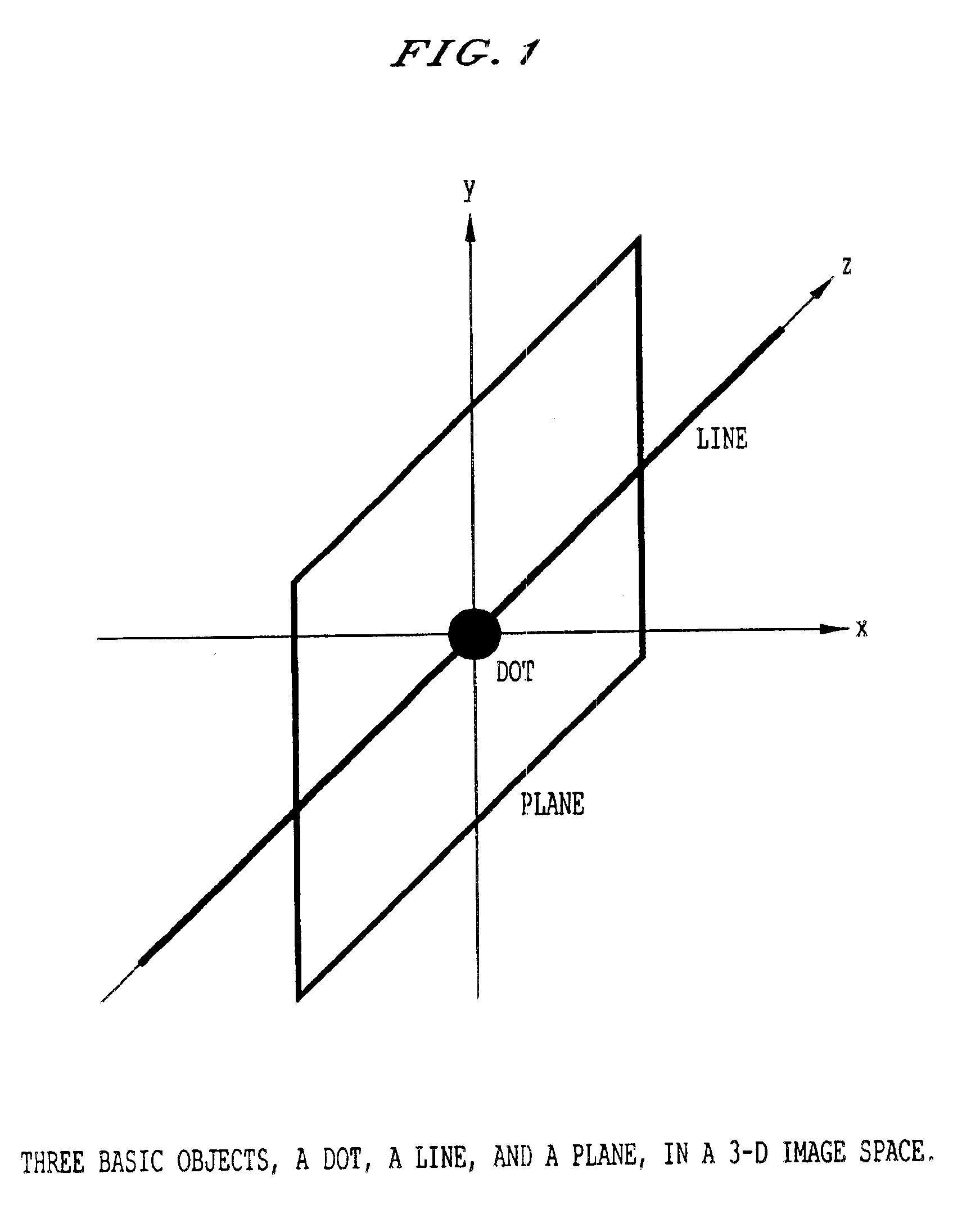

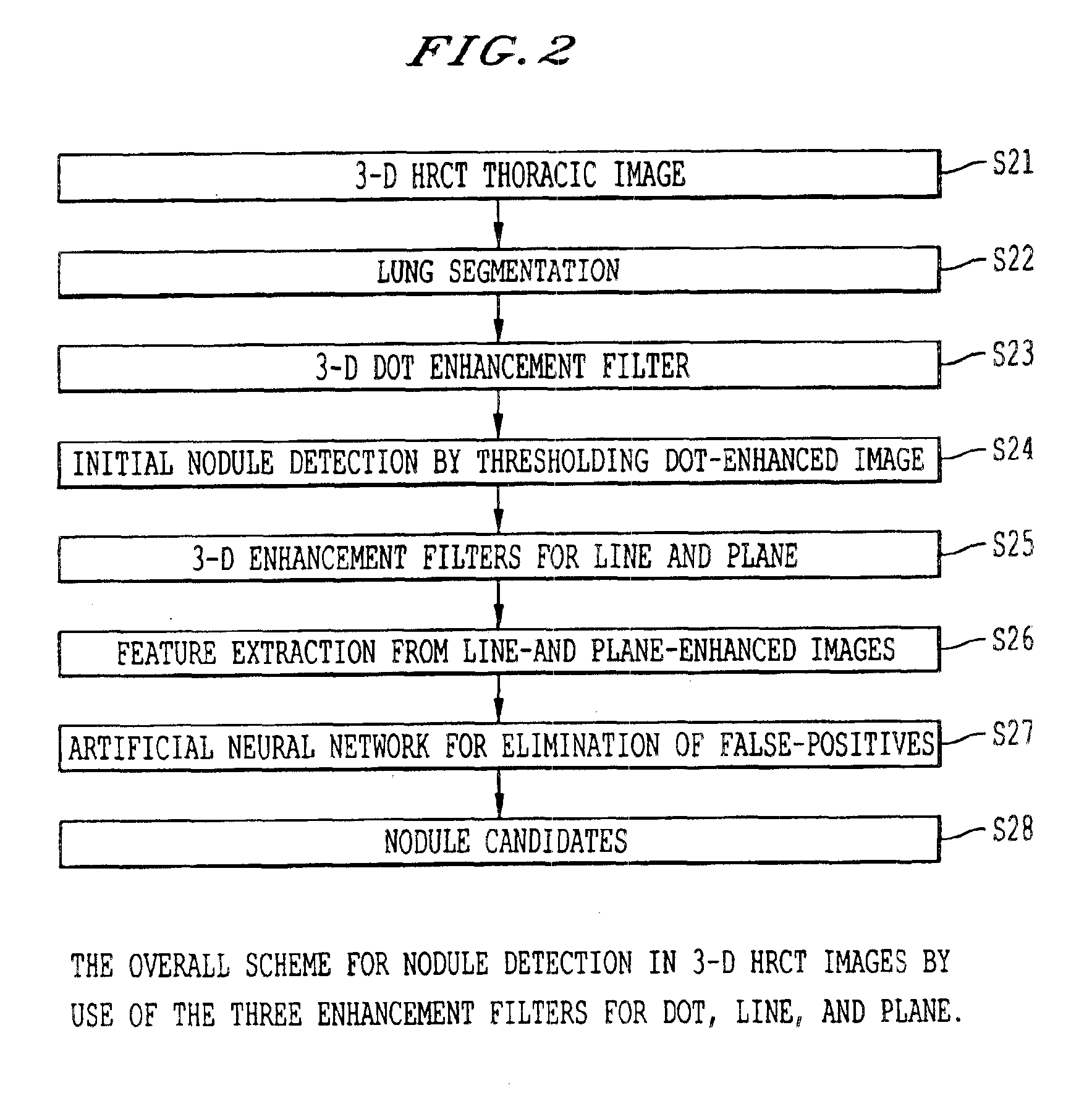

Method, system, and computer program product for computer-aided detection of nodules with three dimensional shape enhancement filters

InactiveUS6937776B2High sensitivityStrong specificityImage enhancementImage analysisThree dimensional shapeComputer science

A method, system, and computer program product for evaluating an image including an object, including filtering image data derived from the image with a first geometric enhancement filter having magnitude and likelihood filter components so as to produce first filtered image data in which a first geometric pattern is enhanced. Thereafter the filtered image data can be subjected to processing to derive a measure indicative of the presence of the object in the image, including determining a region of interest in the image, extracting at least one feature from the first filtered image data from within the region of interest, and applying the at least one extracted feature to a classifier configured to output the measure indicative of the presence of the object in the image. The image data can also be subjected to filtering with second and / or third geometric filters which enhance different geometric patterns, and which produce respective filtered data which are also processed to derive the measure indicative of the presence of the object.

Owner:UNIVERSITY OF CHICAGO

Inner and outer telescoping catheter delivery system

A catheter assembly employs an outer catheter with a pre-formed distal end and an open lumen. An inner catheter having an open lumen and a pre-formed distal end is movably disposed within the outer catheter. Relative rotation and extension of the inner and outer catheters provides the distal end of the catheter assembly with an adjustable range of two- and three-dimensional shapes. The inner catheter can include sections of varying stiffness, such that extension of the inner catheter within the outer catheter modifies the shape of the outer catheter's pre-formed distal end. The adjustable shaping of the catheter assembly's distal tip provides an improved system for locating and cannulating cardiac venous structures, particularly the coronary sinus via the right atrium.

Owner:CARDIAC PACEMAKERS INC

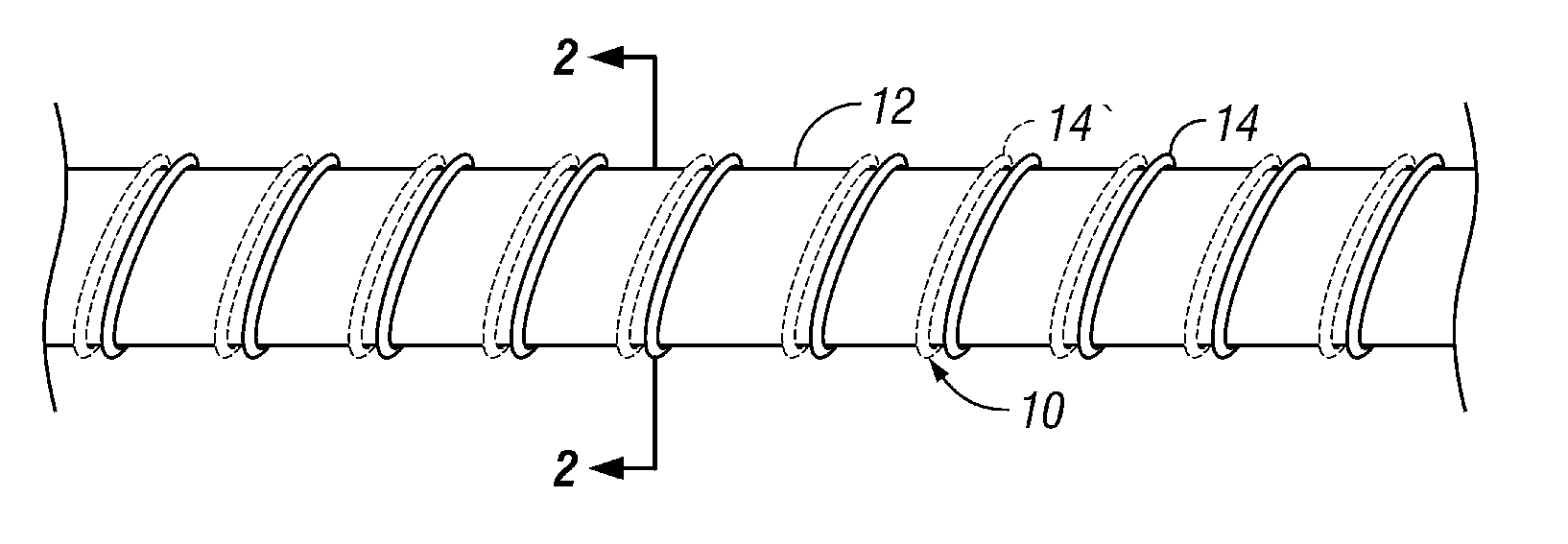

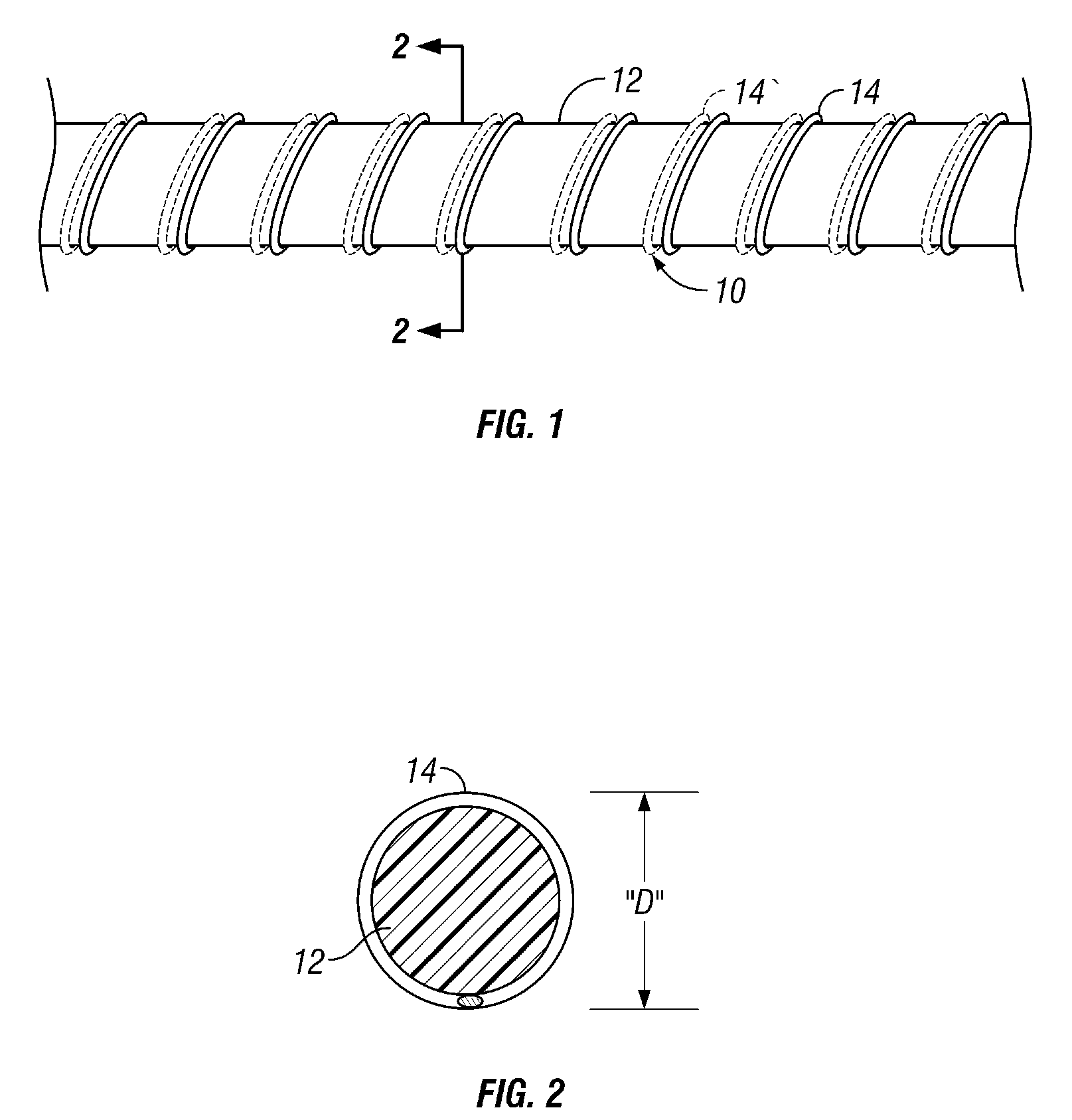

Micro-helix antenna and methods for making same

InactiveUS7183998B2Loop antennas with ferromagnetic coreLogperiodic antennasElectrical conductorThree dimensional shape

A micro-helix antenna. The antenna comprises a helically-shaped conductive element disposed on a dielectric core. The diameter of the helix formed by the conductive element is very small relative to the wavelength of the antenna, preferably no more than about 1 / 100th of the wavelength. Having such a small diameter, this micro-helix antenna can be further compressed into two- and three-dimensional shapes, such as spirals, helices and meandering or stochastic patterns. The micro-helix antenna can be created by pressing a fine wire into a helical shape. Alternately, the helical conductor can be formed by a laser ablation process or laying down the helical shape using a direct-write process.

Owner:SCIPERIO

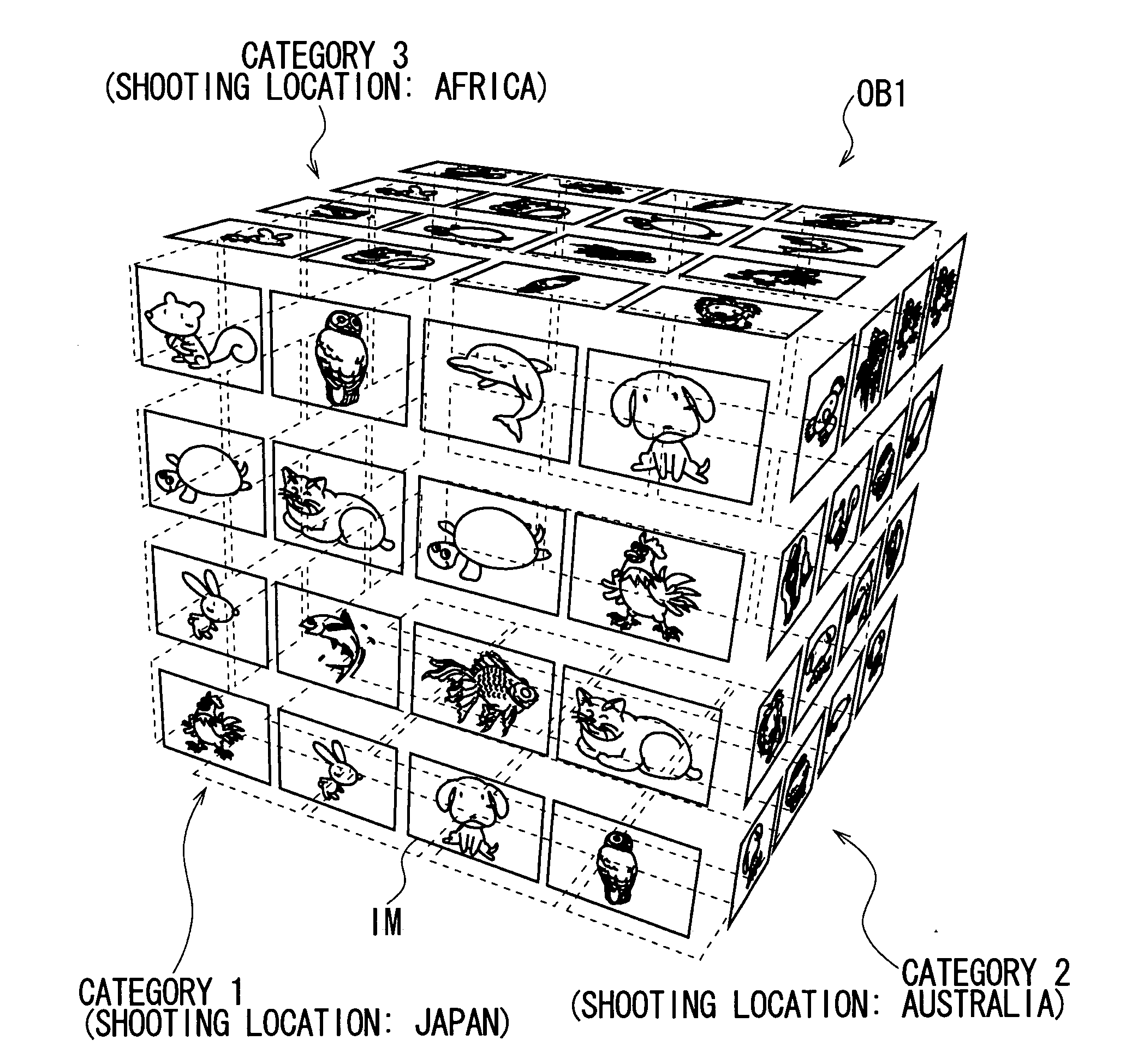

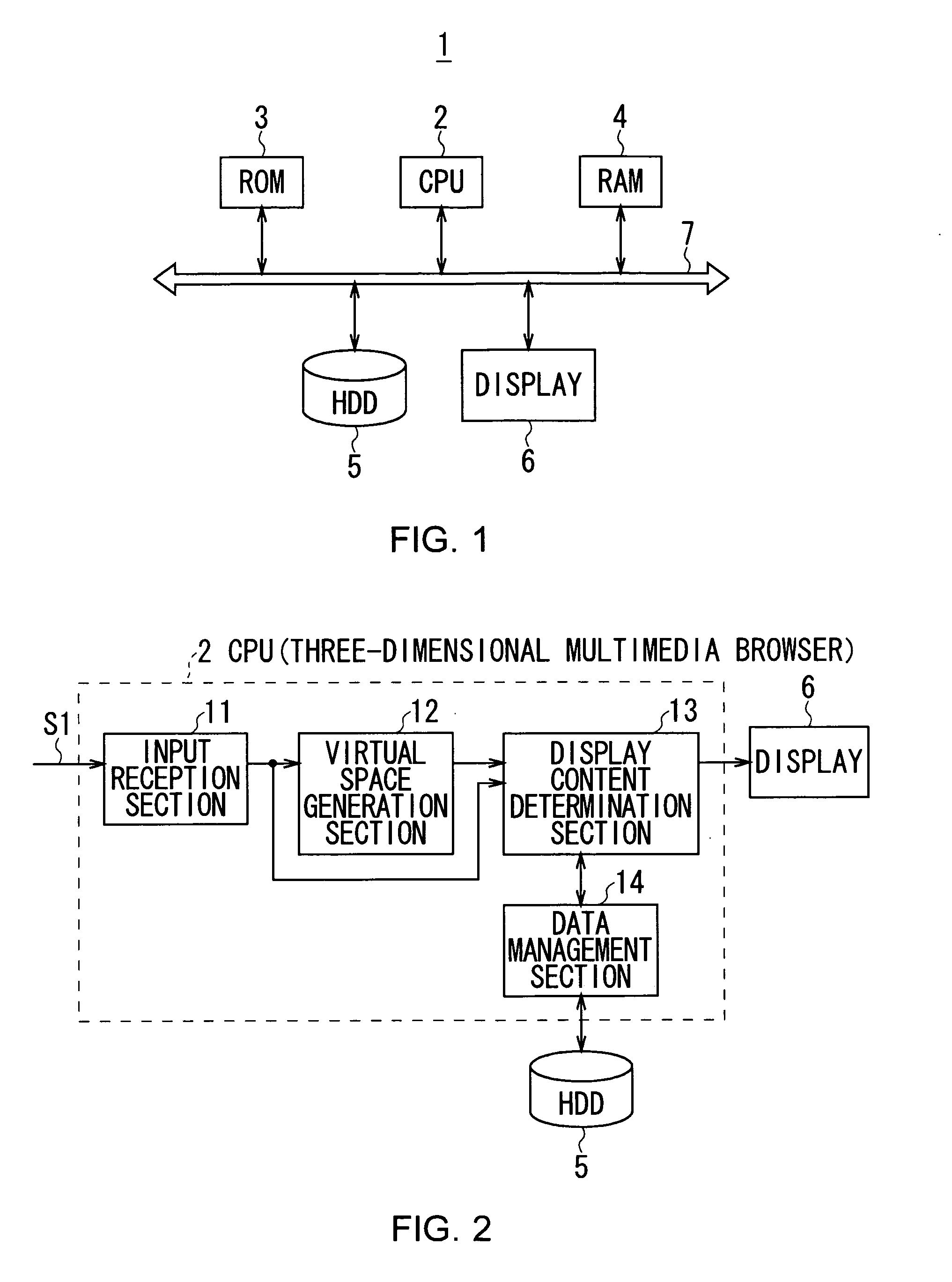

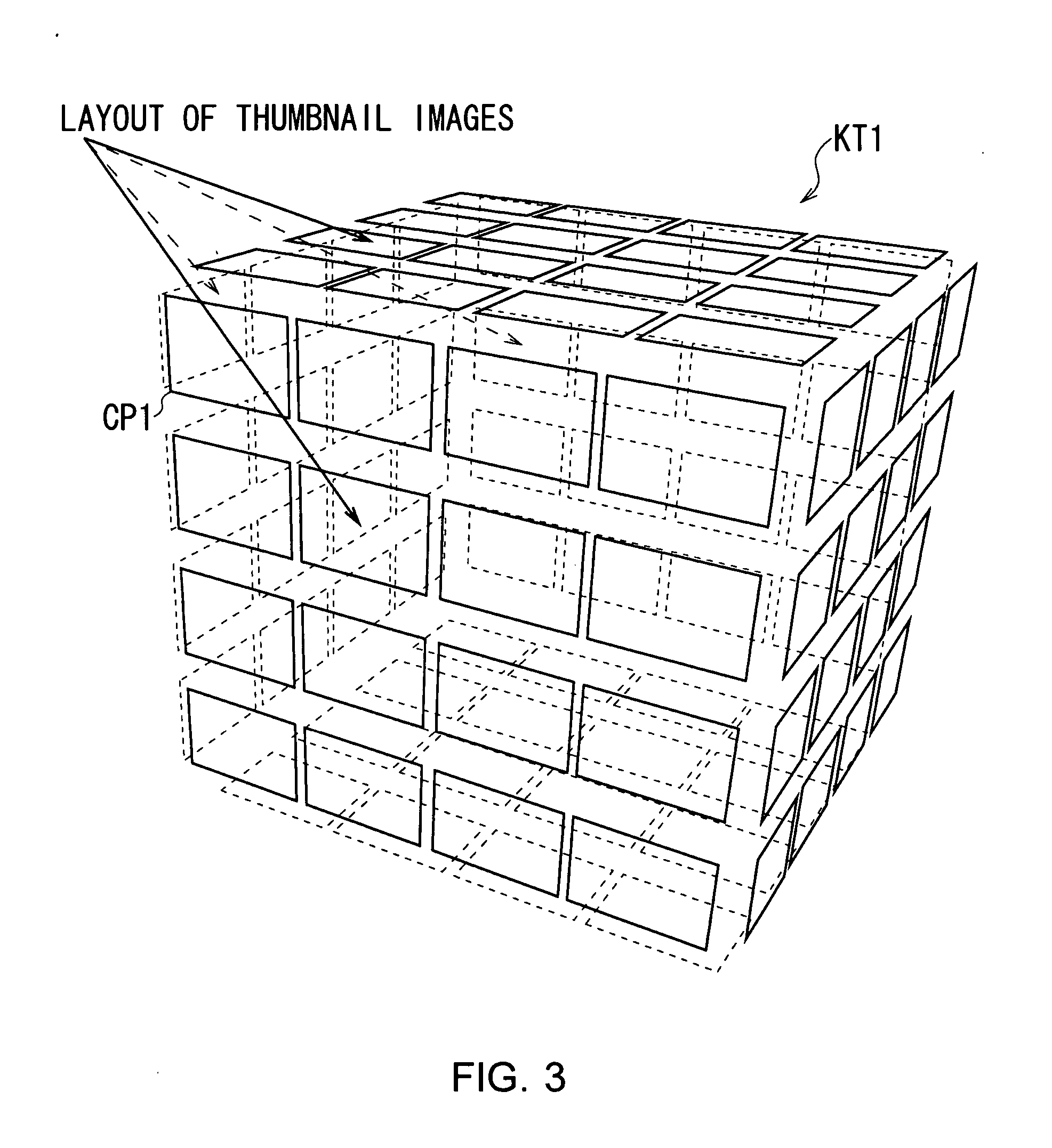

Three-dimensional object display apparatus, three-dimensional object switching display method, three-dimensional object display program and graphical user interface

ActiveUS20060274060A1Easy to displayEasily visuallyInput/output processes for data processing3D-image renderingGraphicsGraphical user interface

The present invention allows a device to display image data in a visually easy-to-see manner to users. The device generates a cubic object OB1 or a cylindrical object OB2, which is a three-dimensional shape to be displayed on a display 6, by laying out a plurality of thumbnail images IM to surfaces of a virtual polyhedron KT1. The device subsequently allows a user to select through a “Classification by Category” button BT1 or an “Order of Time” button BT2 a manner of presenting the plurality of thumbnail images IM to the user. The device then switches its display format between the cubic object OB1 and the cylindrical object OB2 in response to the selected manner. Therefore, the device can display the thumbnail images IM in a visually easy-to-see manner to the user.

Owner:SONY CORP

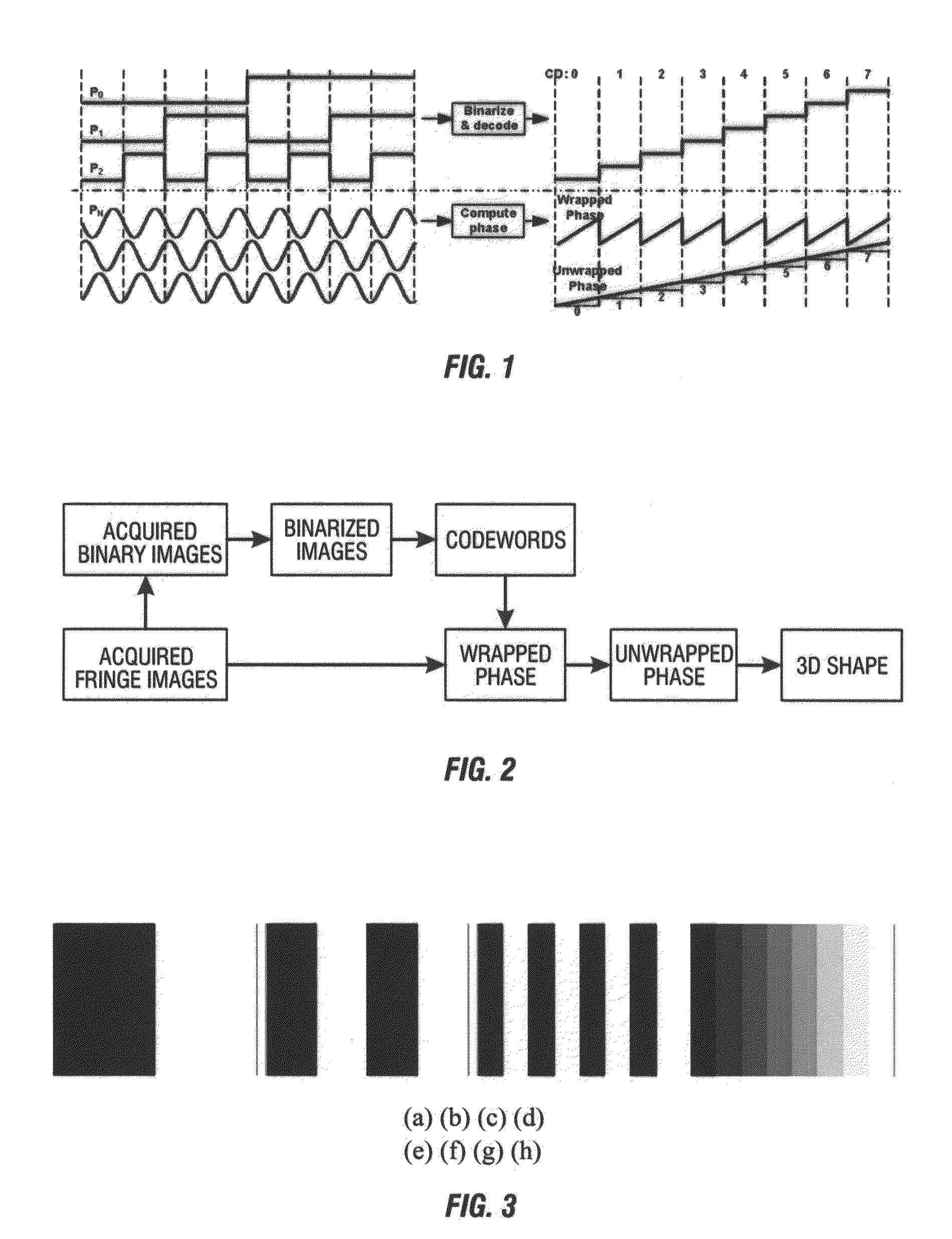

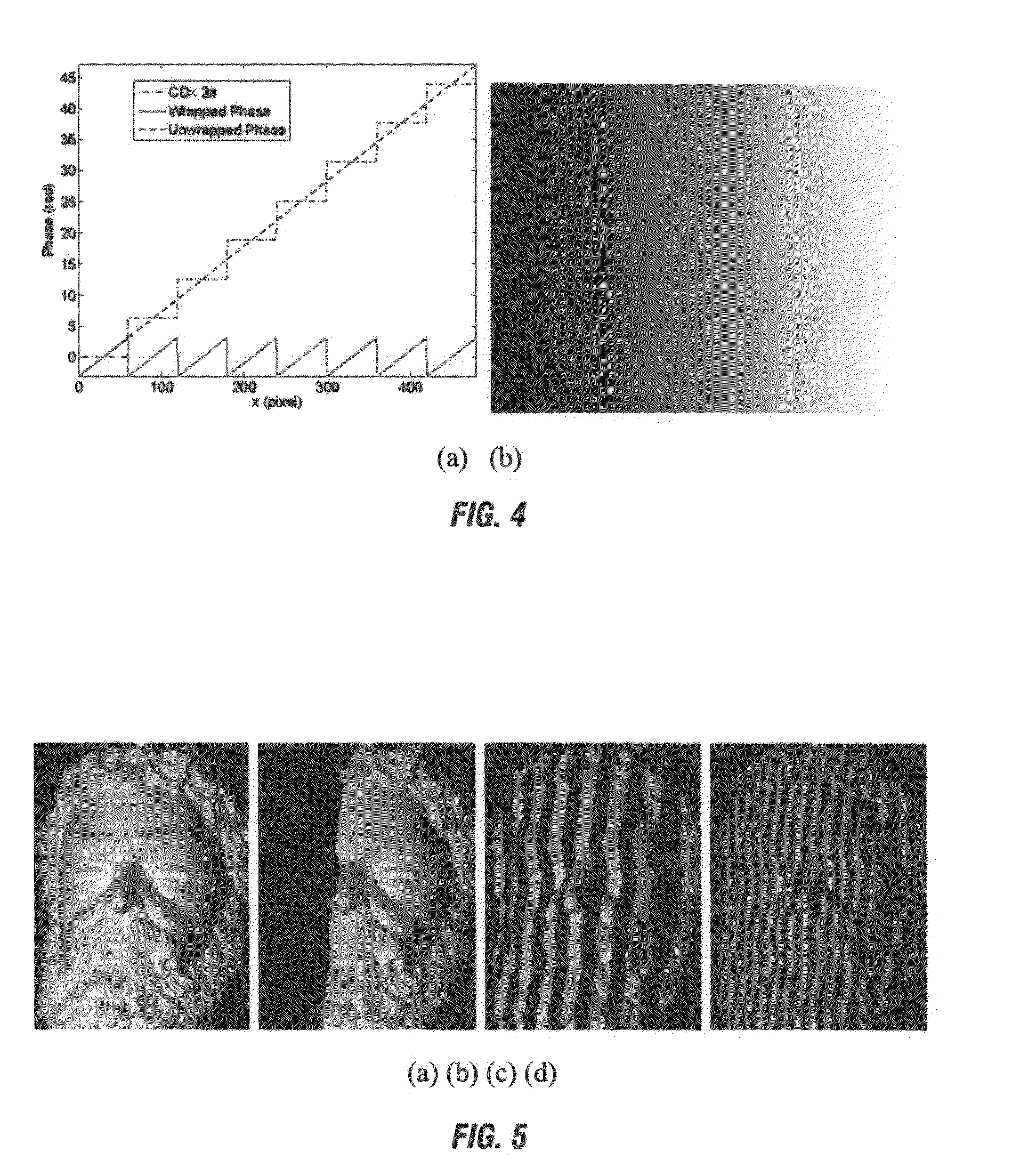

Hybrid method for 3D shape measurement

InactiveUS20110080471A1Provide imageMeasurement speedImage enhancementImage analysis3d shapesHybrid approach

A method for three-dimensional shape measurement provides for generating sinusoidal fringe patterns by defocusing binary patterns. A method for three-dimensional shape measurement may include (a) projecting a plurality of binary patterns onto at least one object; (b) projecting three phase-shifted fringe patterns onto the at least one object; (c) capturing images of the at least one object with the binary patterns and the phase-shifted fringe patterns; (d) obtaining codewords from the binary patterns; (e) calculating a wrapped phase map from the phase-shifted fringe patterns; (f) applying the codewords to the wrapped phase map to produce an unwrapped phase map; and (g) computing coordinates using the unwrapped phase map for use in the three-dimensional shape measurement of the at least one object. A system for performing the method is also provided. The high-speed real-time 3D shape measurement may be used in numerous applications including medical science, biometrics, and entertainment.

Owner:IOWA STATE UNIV RES FOUND

Methods of manufacture and use of endoluminal devices

Owner:WL GORE & ASSOC INC

Manufacturable geometries for thermal management of complex three-dimensional shapes

Uniform cooling of complex surface shapes in injection mold tooling can be accomplished with cooling channels that conform to the shapes of the mold cavity or mold cone. By conventional methods this can be very difficult to accomplish. By applying methods of material deposition or material sintering, which include but are not limited to, laser metal deposition, where material is deposited on a layer by layer basis, certain cooling or heating passages could be integrated into the manufactured component that follow the contours and profiles of the mold's complex surfaces. These passages would act as internal heat sinks with a much higher surface area for heat transfer than traditional drilled and plugged straight passages. These geometries could also be incorporated into complex geometries such as, but not limited to, turbine blades where the cooling passages can follow the contour of the outer shape, provide a more uniform or controlled heat transfer from the component. Multiple loops of cooling or heating channels could be designed and manufactured into solid objects for small-scale heat exchanger technologies.

Owner:OPTOMEC DESIGN CO

3D geometric modeling and motion capture using both single and dual imaging

Owner:MANTIS VISION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com