Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

887 results about "Size measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematical terms, "size is a concept abstracted from the process of measuring by comparing a longer to a shorter". Size is determined by the process of comparing or measuring objects, which results in the determination of the magnitude of a quantity, such as length or mass, relative to a unit of measurement.

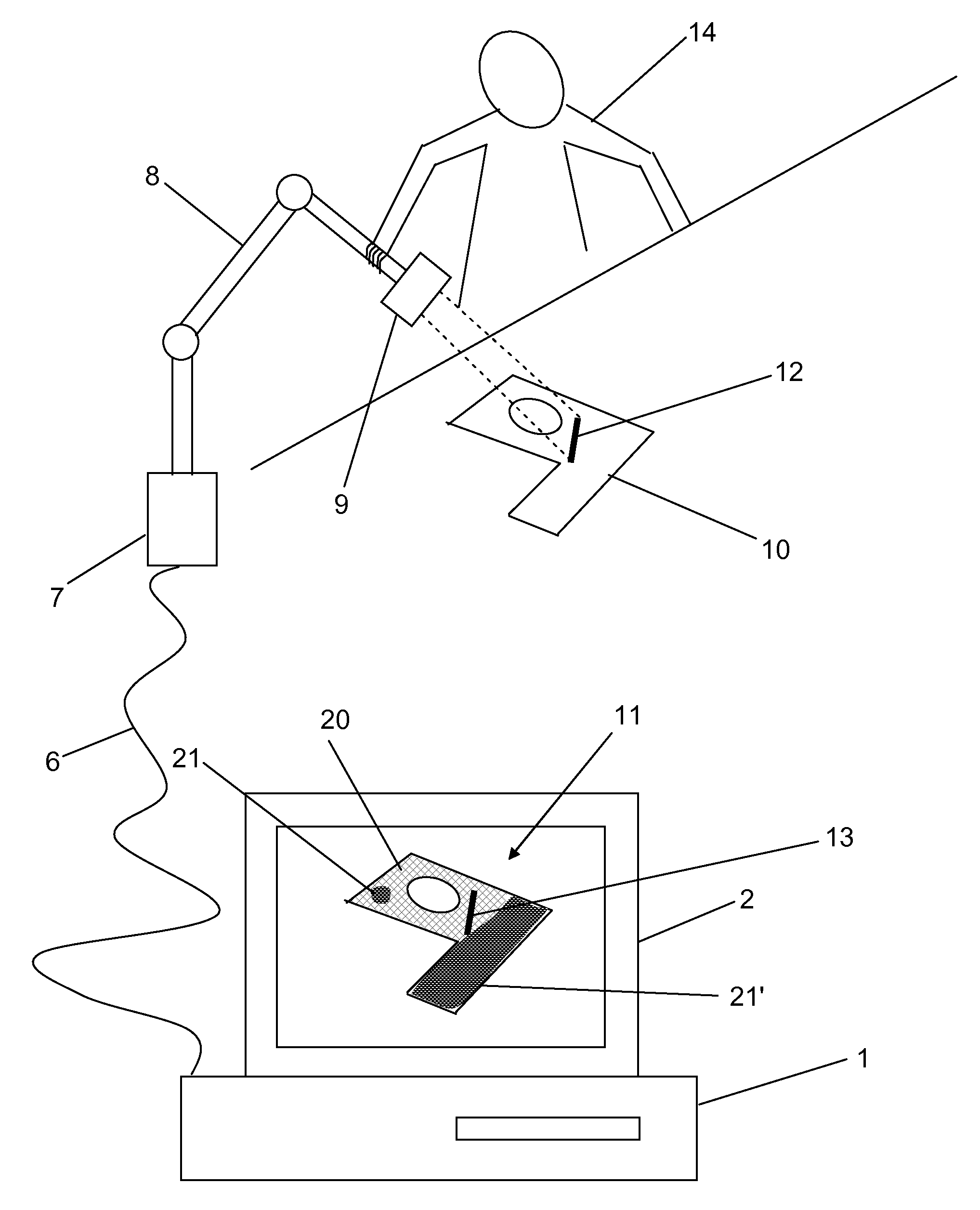

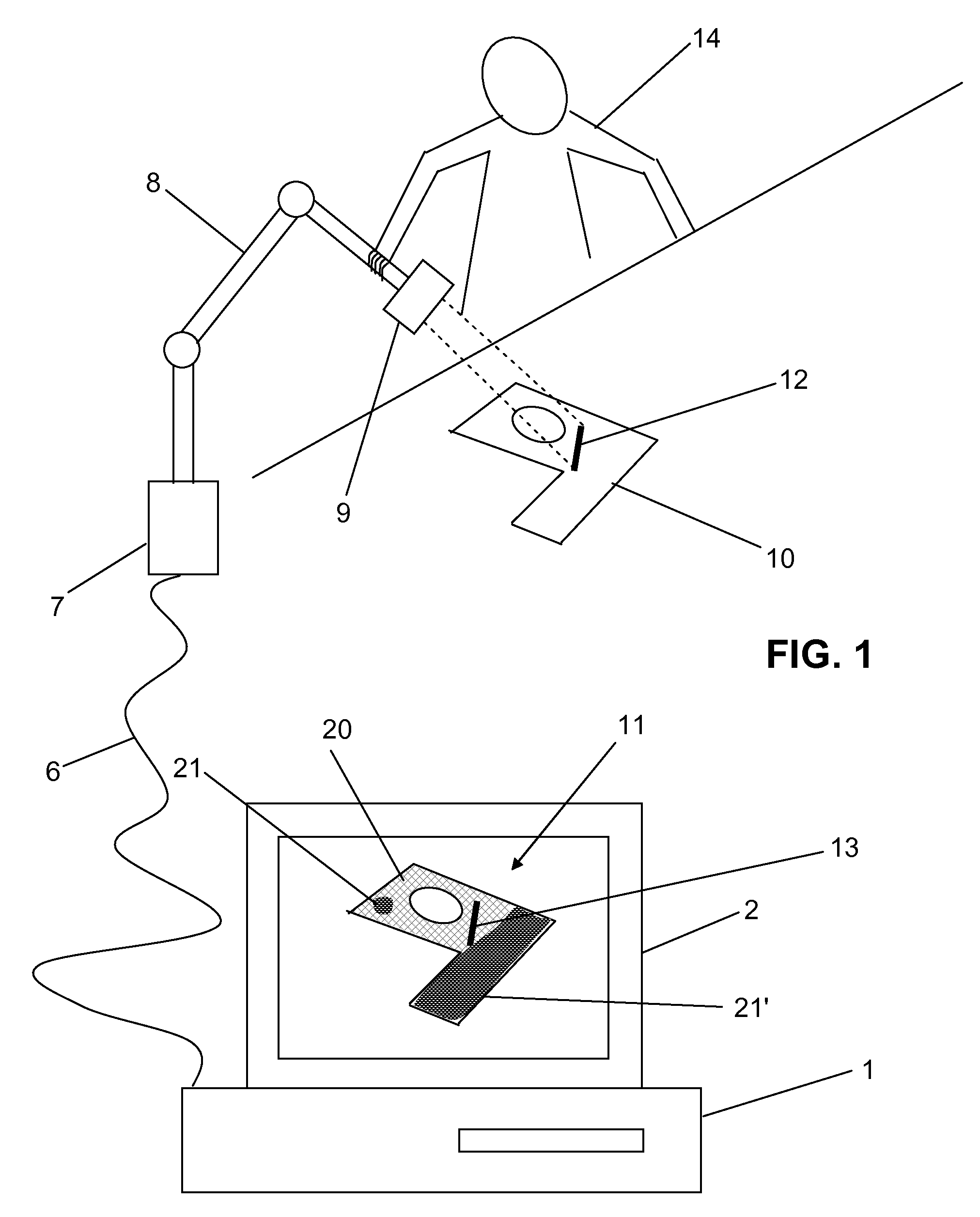

System and method for measuring irregular objects with a single camera

ActiveUS8643717B2Rapid and efficient mannerAccurate chargesCharacter and pattern recognitionColor television detailsFresnel lensSize measurement

Owner:HAND HELD PRODS

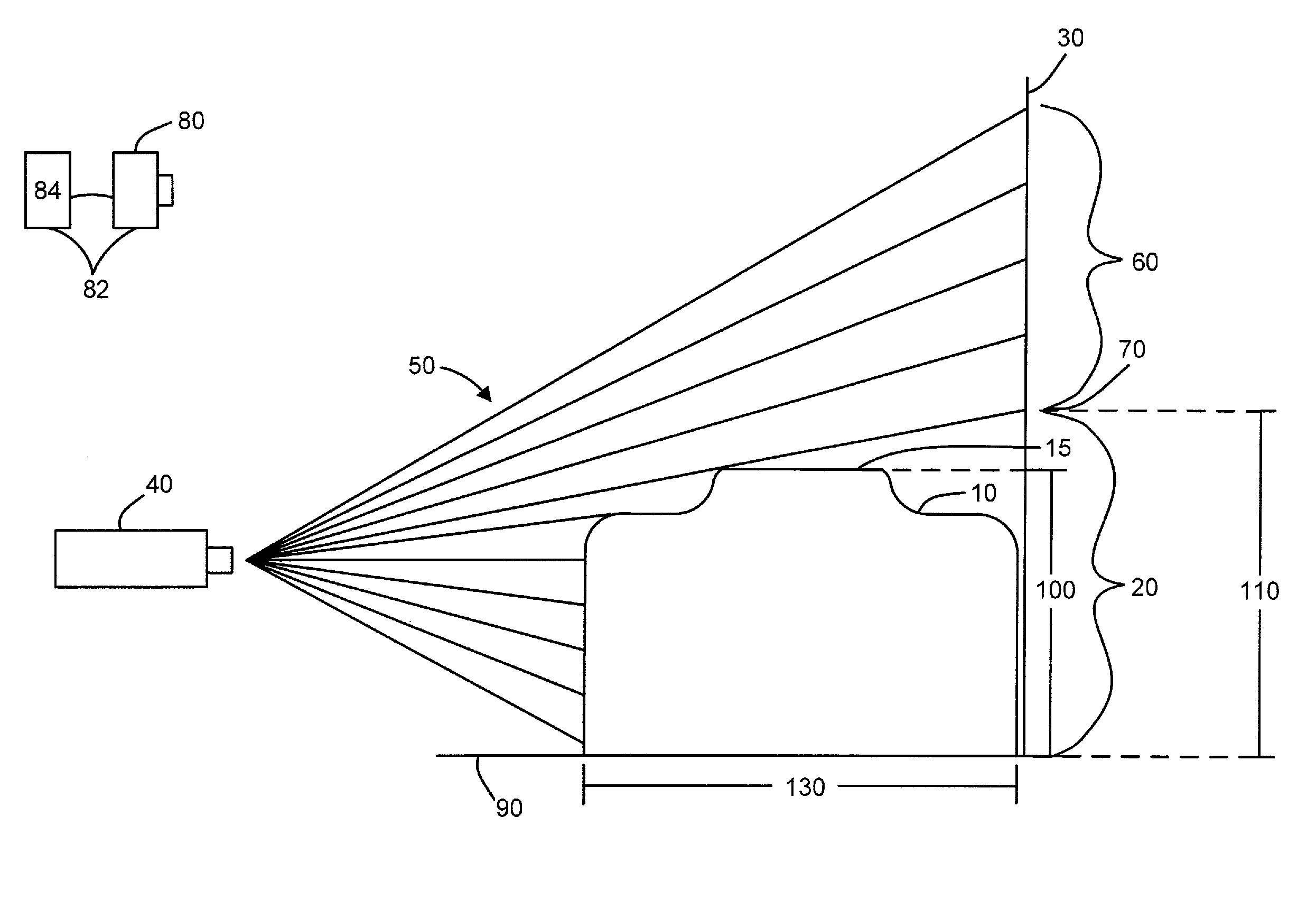

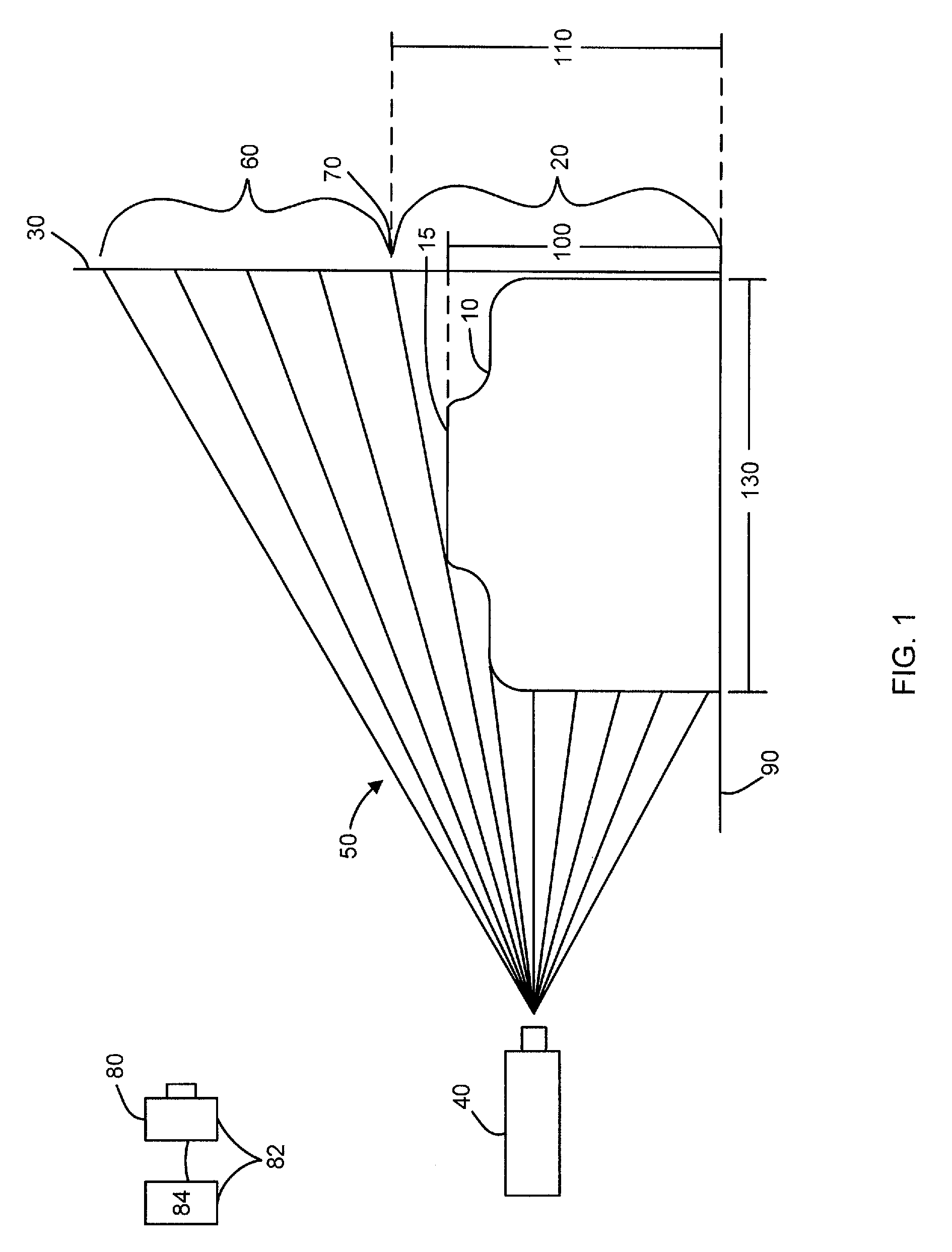

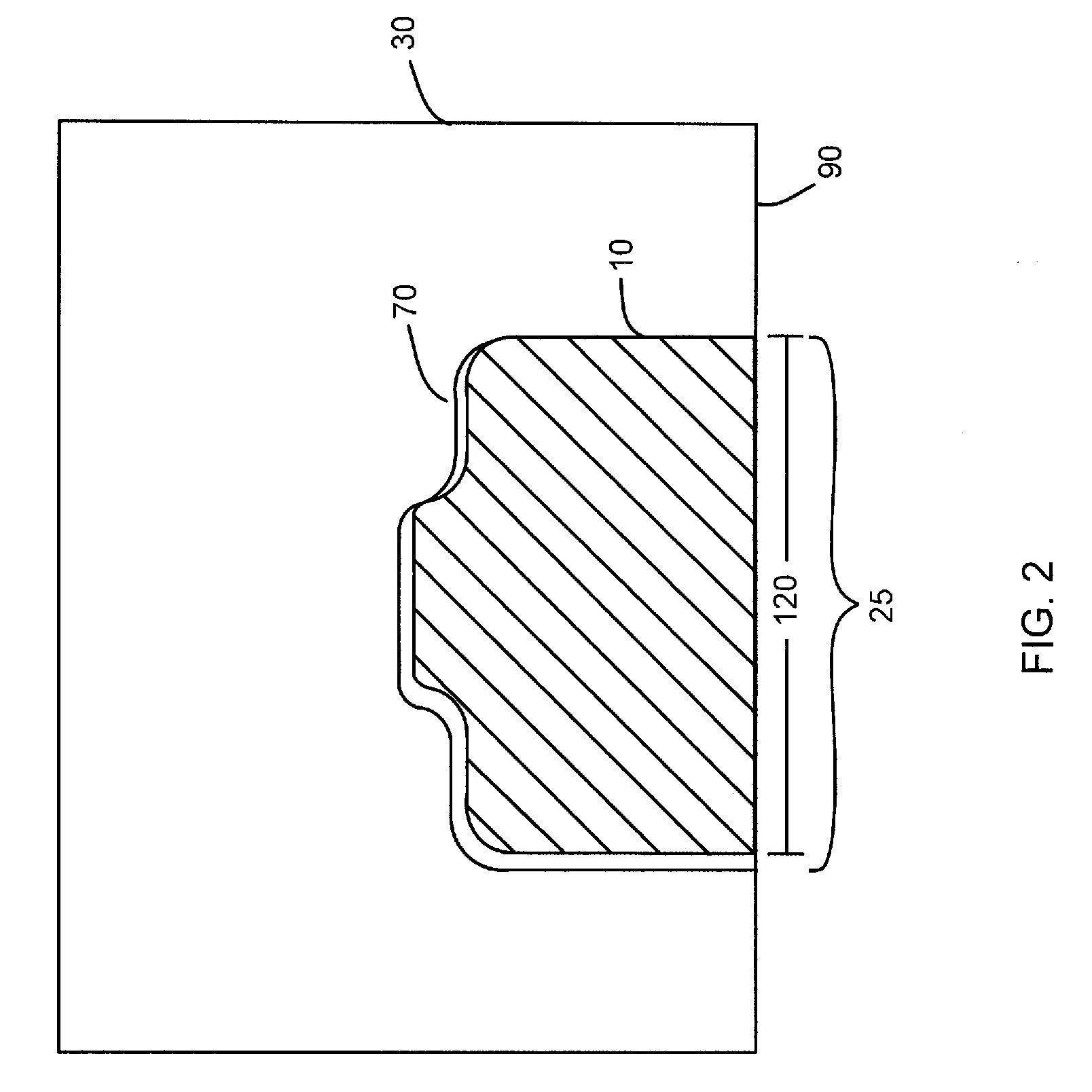

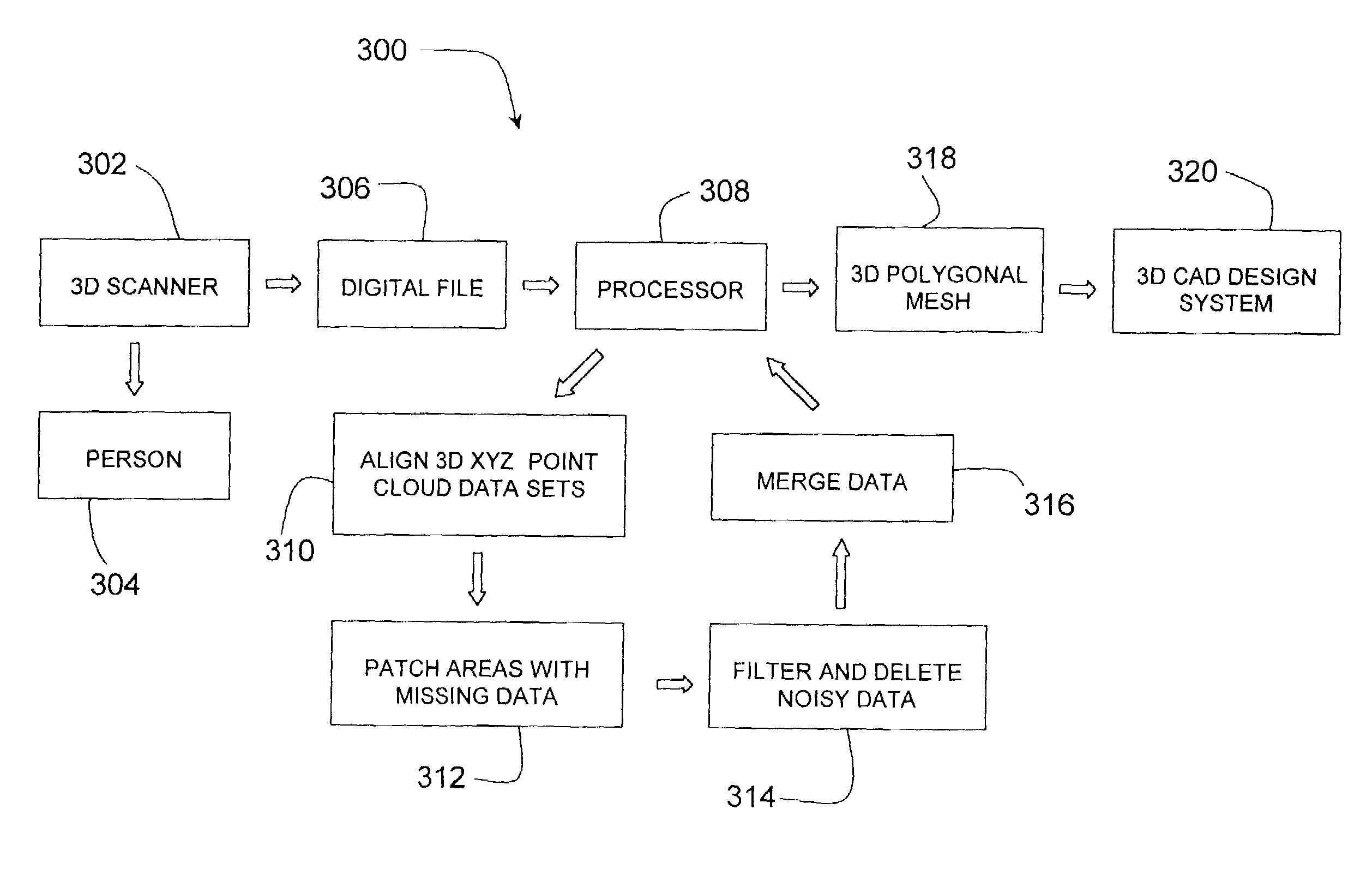

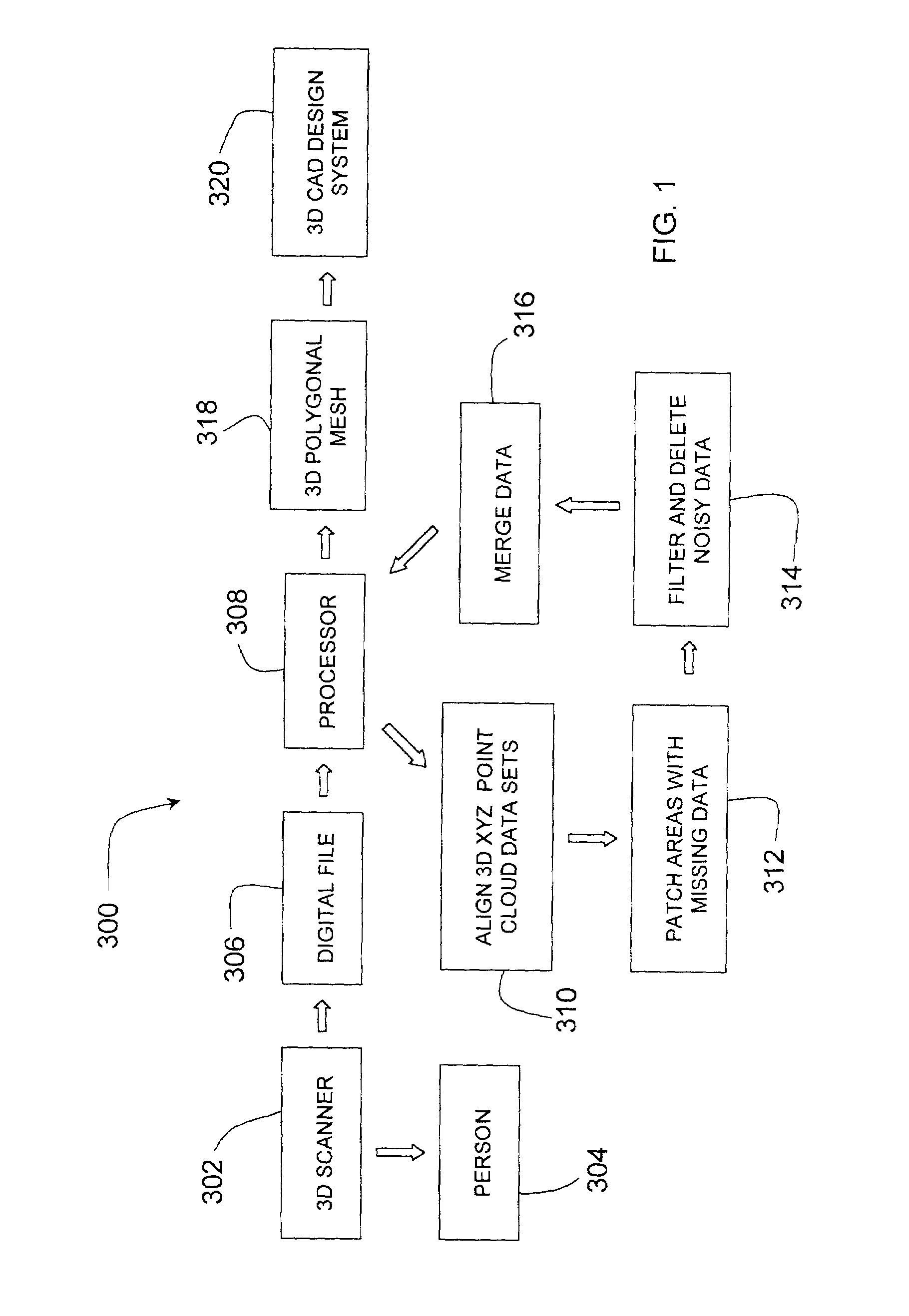

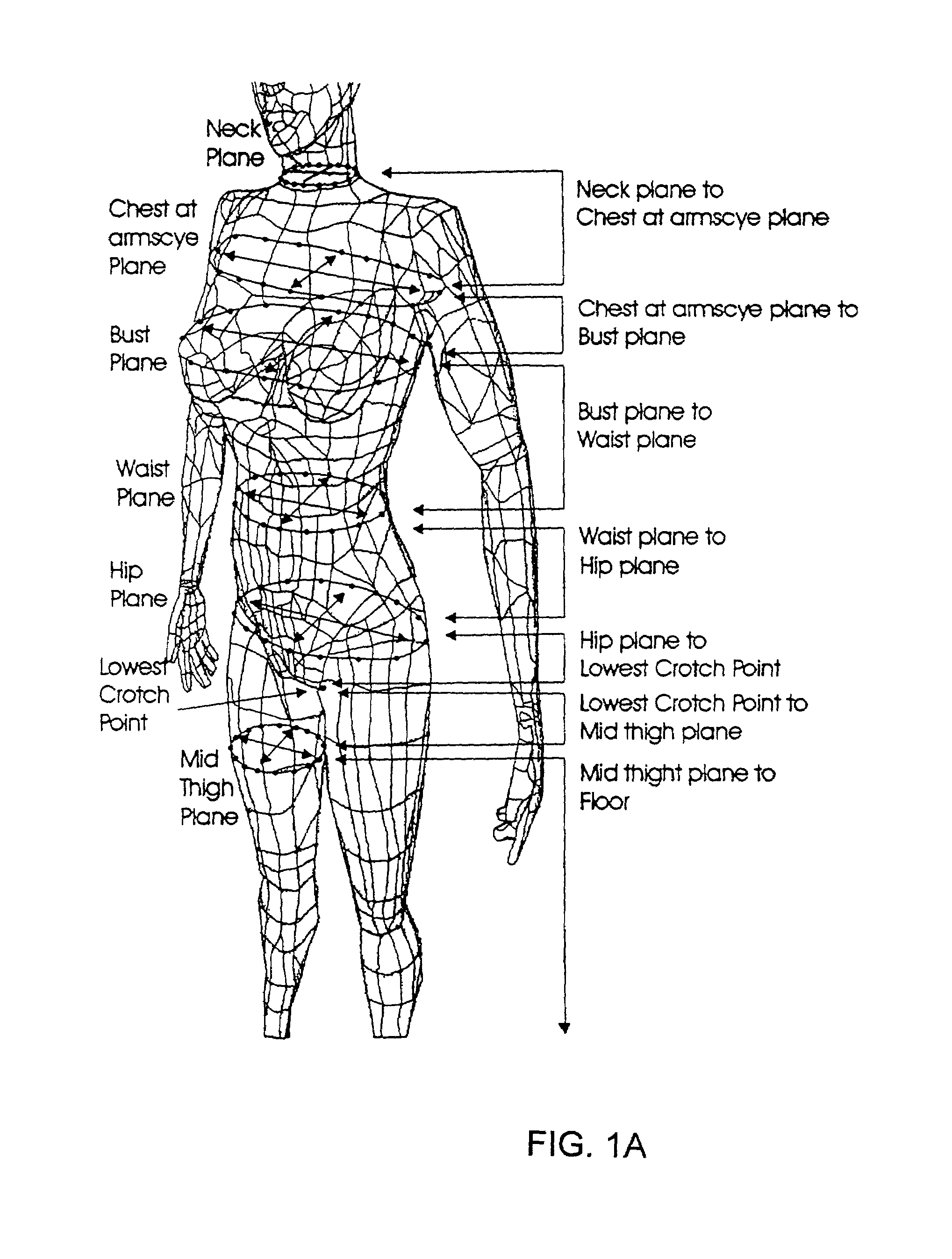

System and method for three-dimensional shape and size measurement

InactiveUS6968075B1Accurate measurementData augmentationData processing applicationsSpecial data processing applicationsComputer Aided DesignSize measurement

A method for three-dimensional shape and size measurement of a three-dimensional body surface comprising providing a three-dimensional scanner, providing a processor, providing a three-dimensional Computer Aided Design system, scanning in three dimensions with the three-dimensional scanner at least a portion of the three-dimensional body surface, creating a data file representative of the three-dimensional body surface, processing the data file with the processor, importing the data file into the three-dimensional Computer Aided Design System, employing the three-dimensional Computer Aided Design System relative to the data file to define and record three-dimensional measuring data relative to at least a portion of the three-dimensional body surface, A and employing the three-dimensional Computer Aided Design System to exploit the three-dimensional measuring data.

Owner:CHANG KURT C

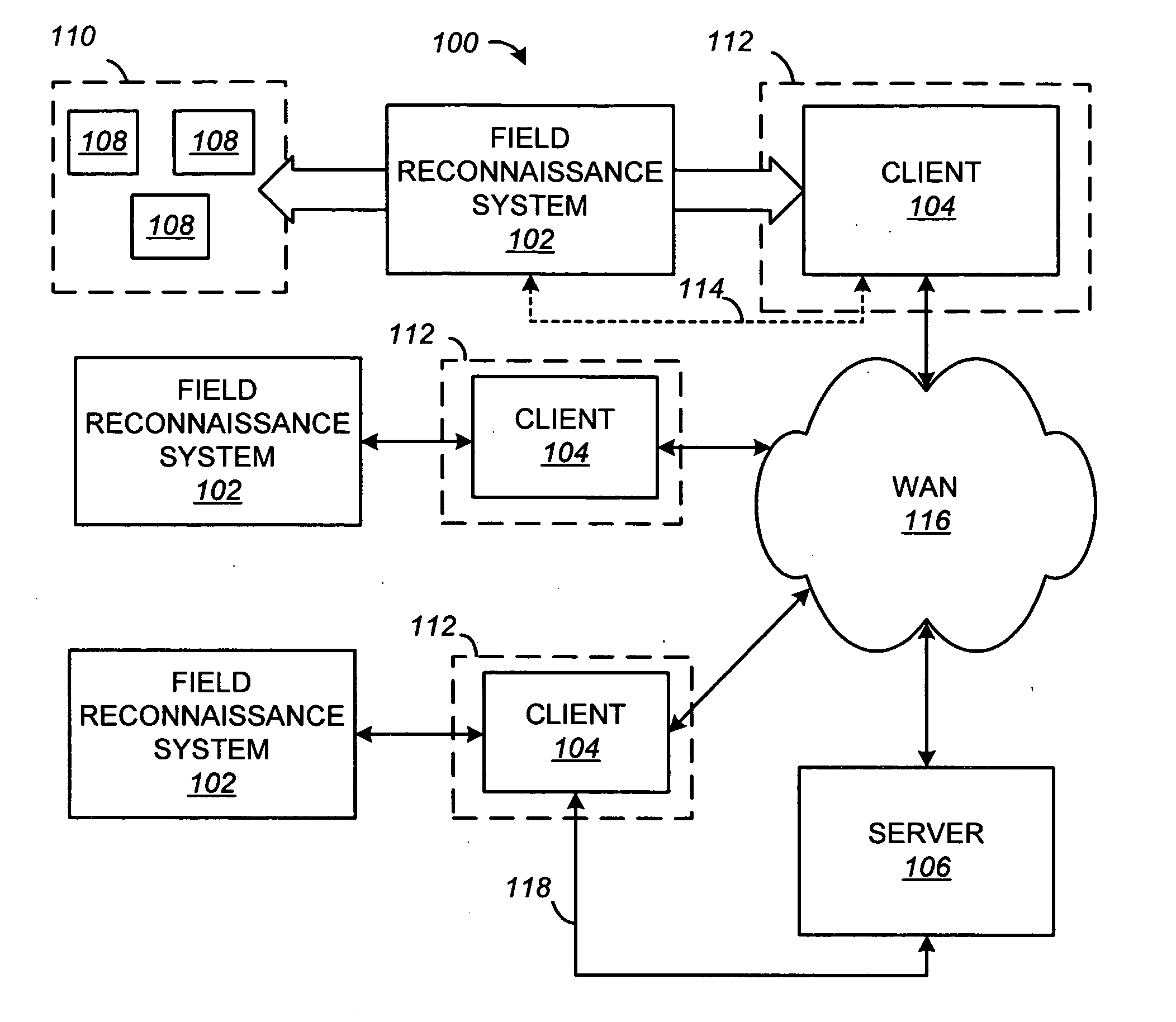

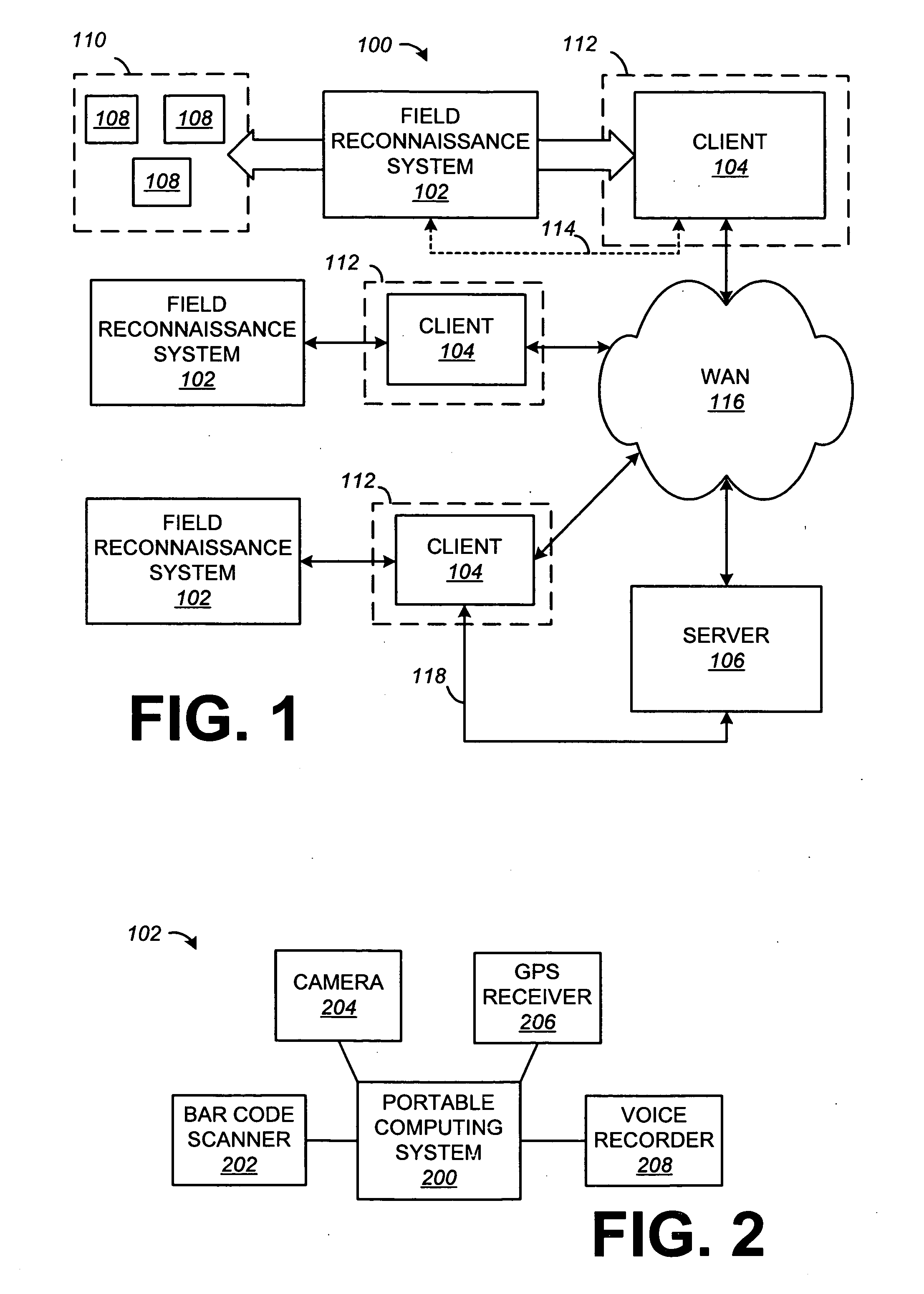

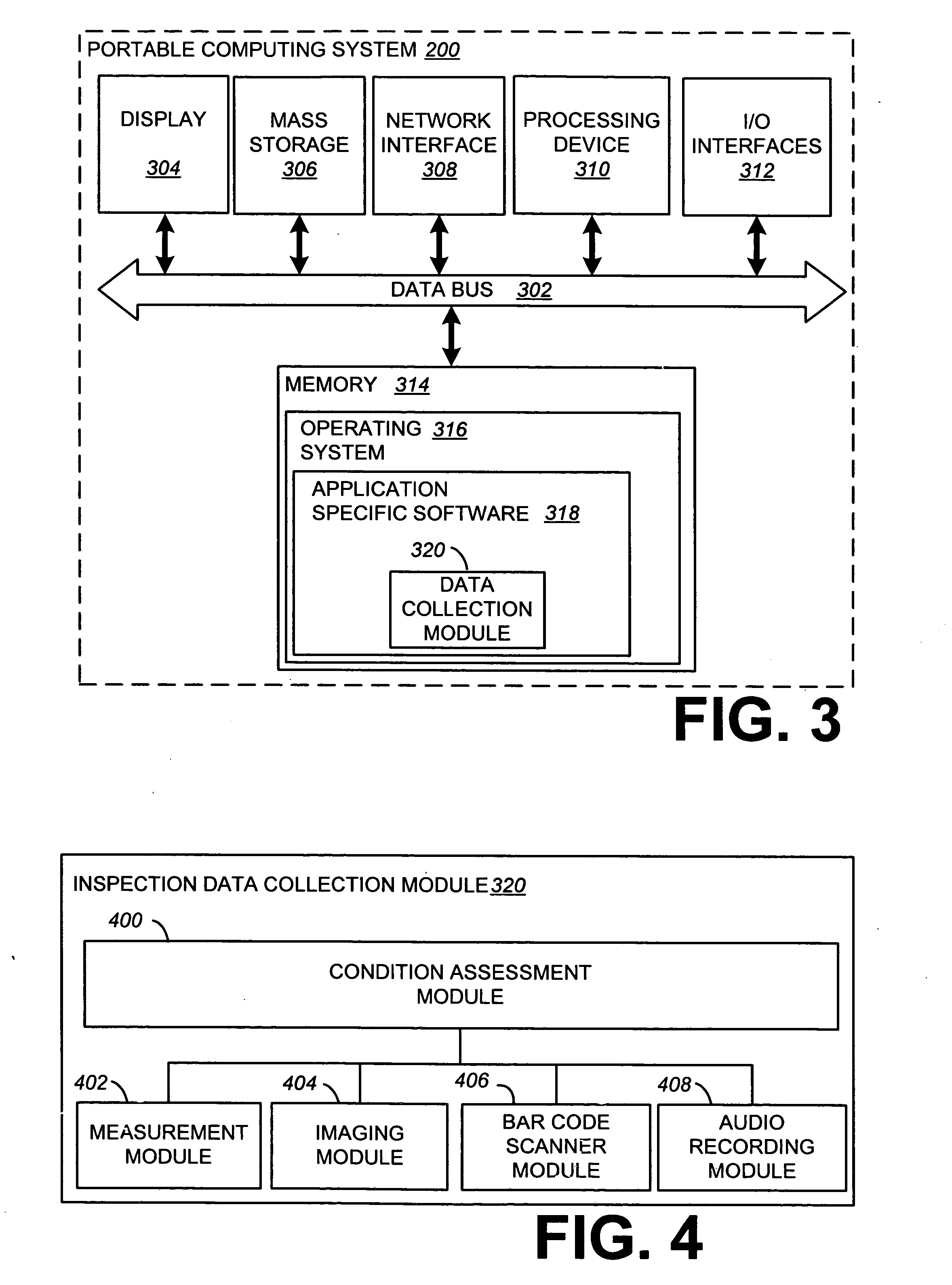

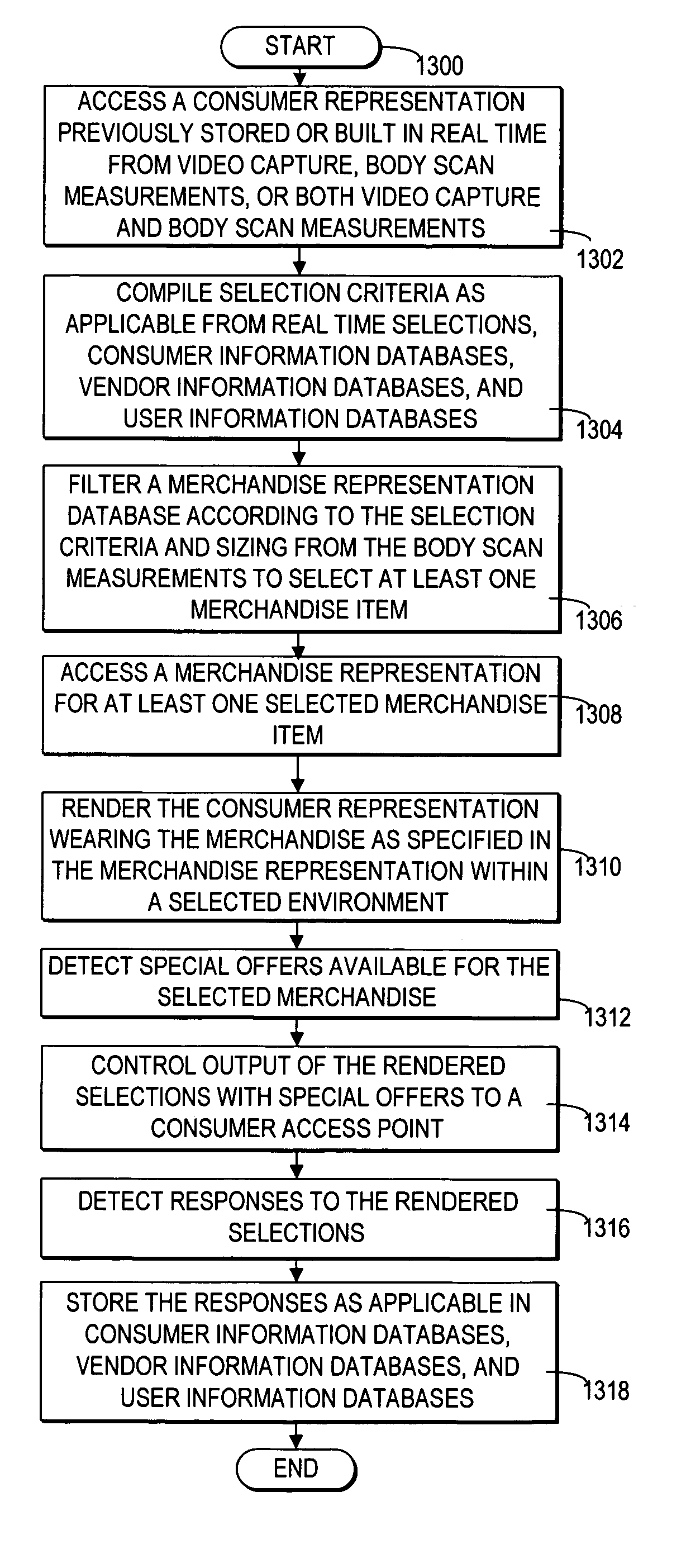

Systems and methods for recording and reporting data collected from a remote location

ActiveUS20060235611A1Position fixationSurveying instrumentsSize measurementGlobal positioning system receiver

Systems and methods for recording and reporting data collected from a remote location are disclosed. A work order, defining infrastructure to be inspected at a remote site and including an inspection plan for collecting inspection information, is generated on a first computer system and transferred to a portable computing system. Inspection data is collected pursuant to the inspection plan on the portable computing system. A global positioning system (GPS) receiver associated with the portable computing system provides location information related to inspected infrastructure during the inspection. After collection, inspection data is transferred from the portable computing system to the first and / or to a second computing system for storage and the generation of related reports. The location information obtained during the inspection can be used to determine dimensional measurements of the infrastructure and to generate visual depictions of infrastructure components and defects.

Owner:BLUEFIN LLC

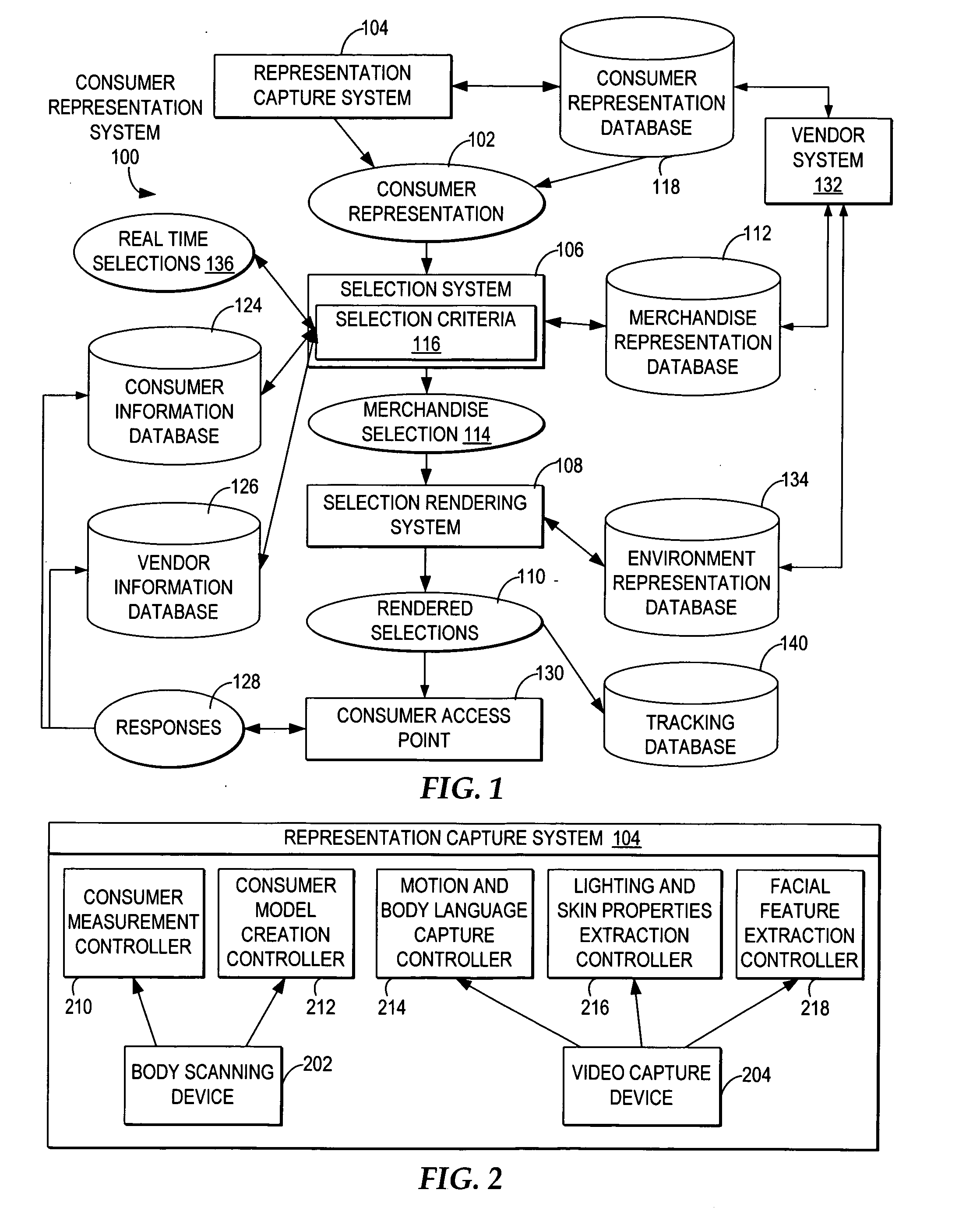

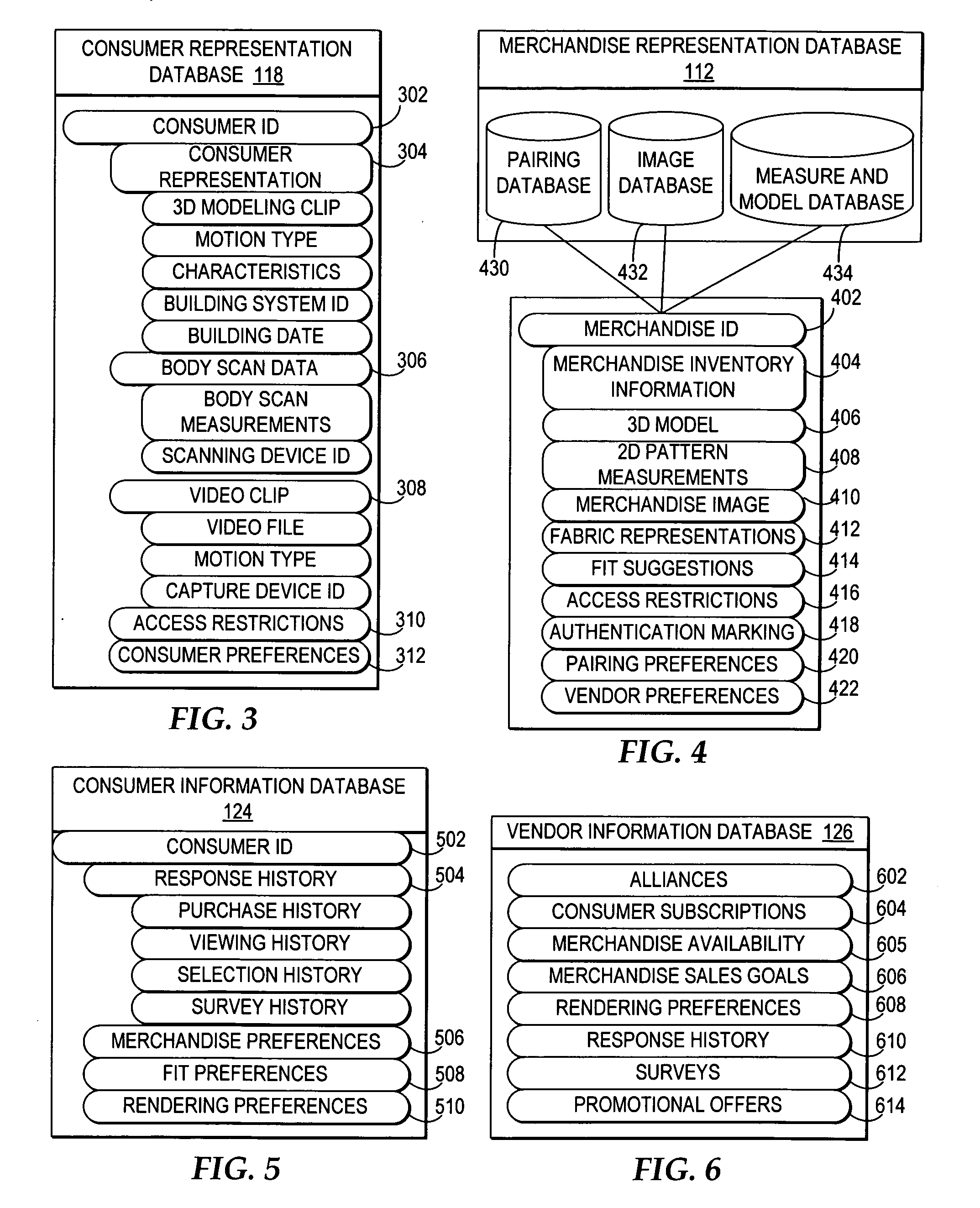

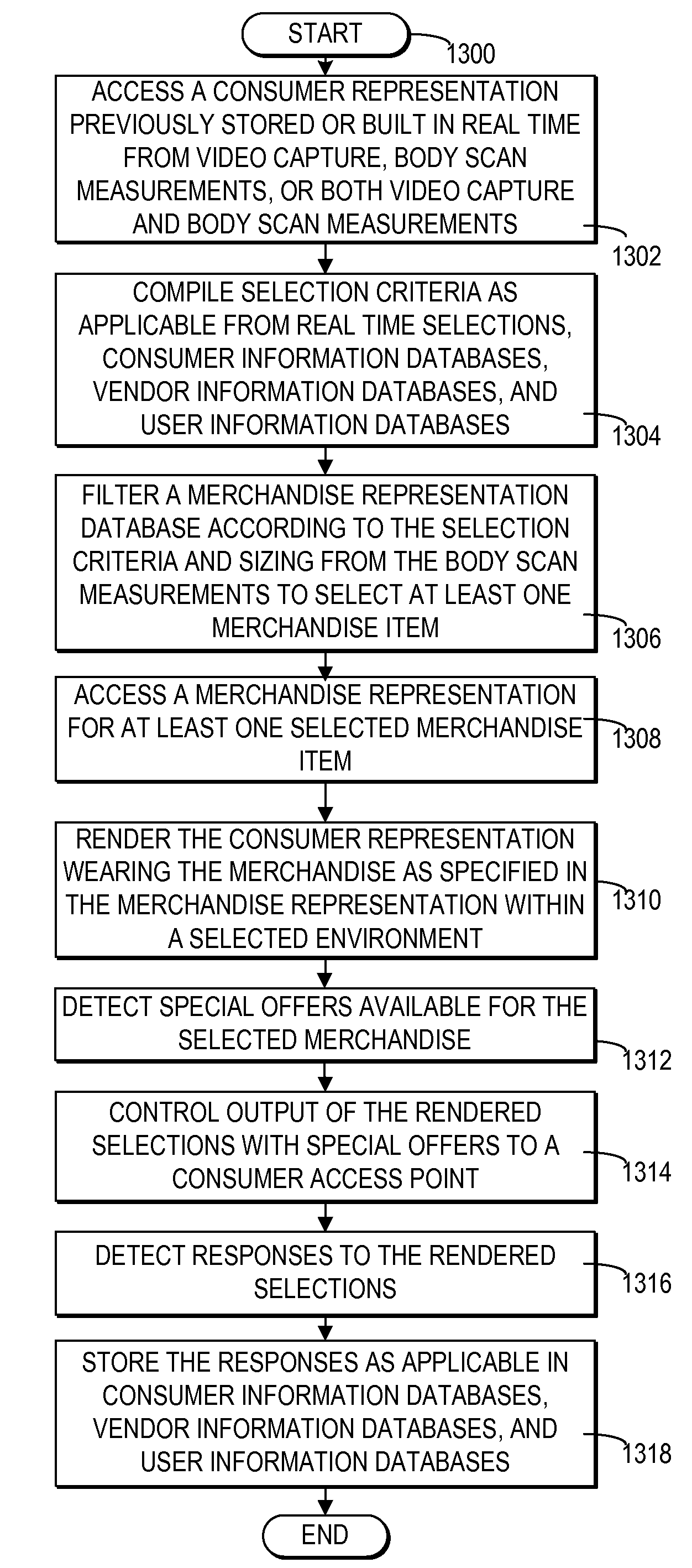

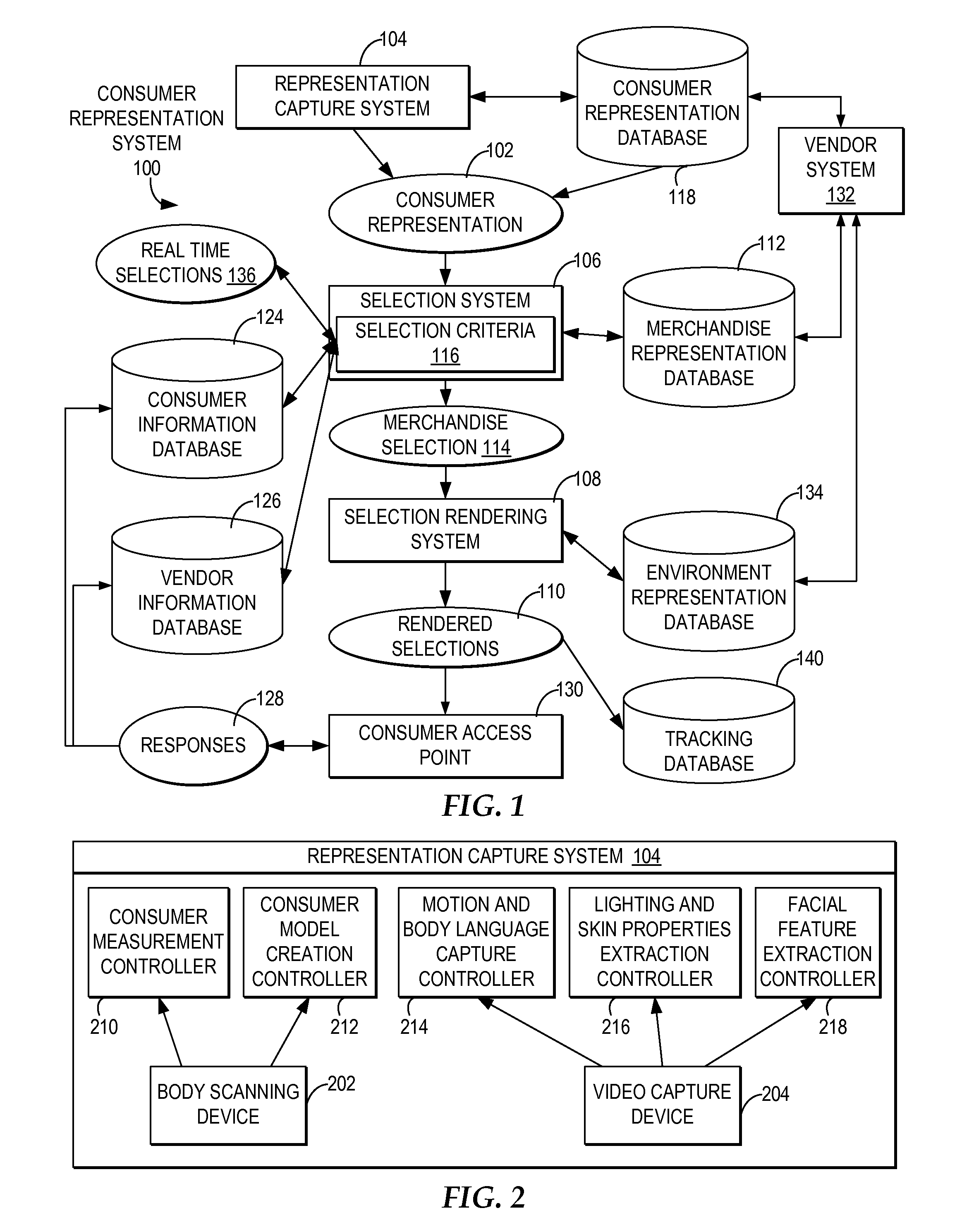

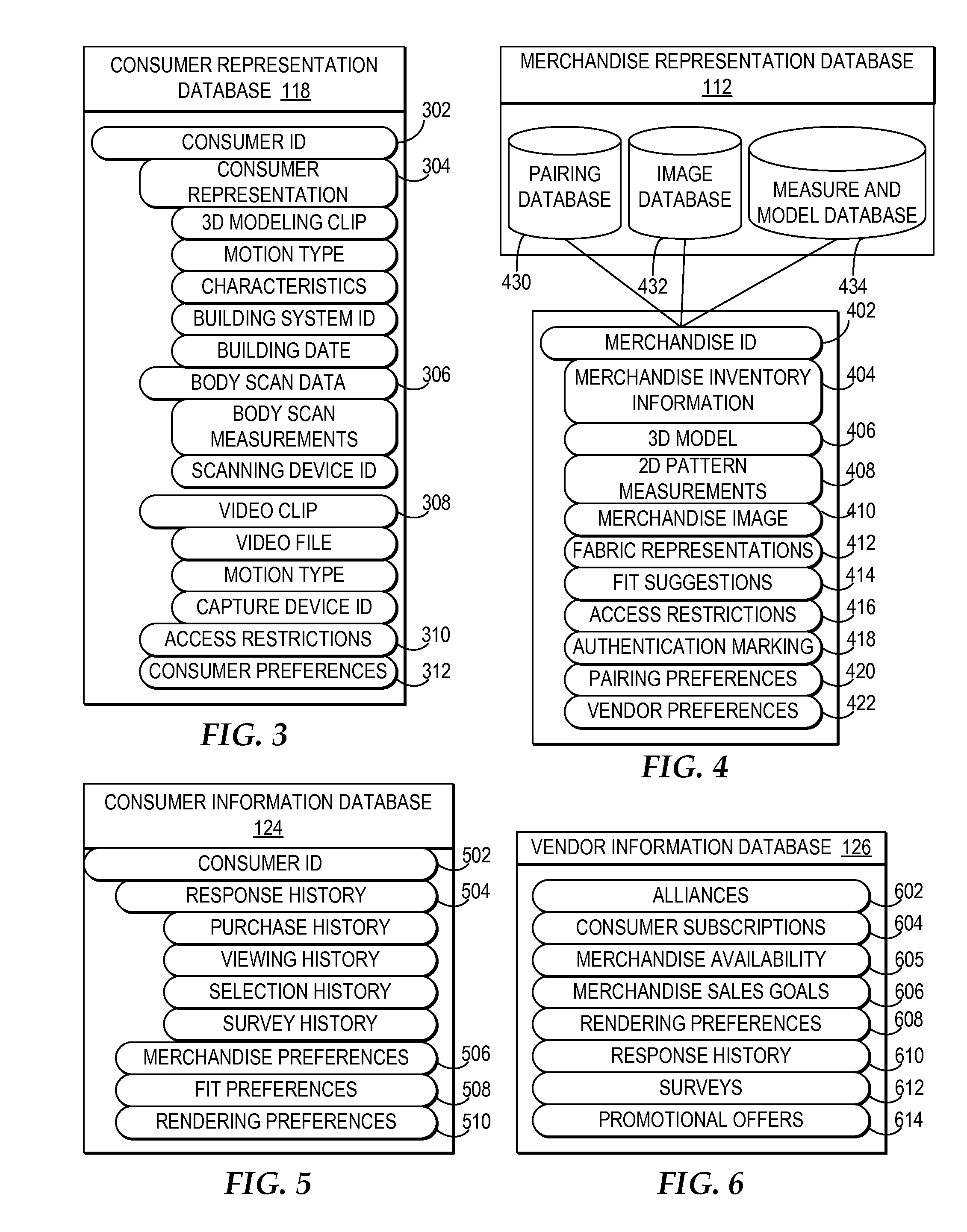

Consumer representation rendering with selected merchandise

ActiveUS20070130020A1Foot measurement devicesImage data processingSize measurementComputer graphics (images)

A method, system, and program are provided for consumer representation rendering with selected merchandise. At least one computing system, in a network or stand-alone environment, accesses a consumer representation, wherein the consumer representation comprises a three dimensional model rendered to depict a consumer appearance and movement in each frame of a captured video stream and specified by a selection of sizing measurements detected from a scan of a consumer body shape. The computing system selects at least one merchandise item from among multiple merchandise items each with separate merchandise characteristics. In particular, the computing system selects the merchandise item of a size selected to fit the selection of sizing measurements for the consumer. The computing system renders the merchandise item on each rendered frame of the three dimensional model according to the merchandise characteristics as applied to the sizing measurements, wherein a display of the rendered three dimensional model shows a realistic image of the consumer appearance and movement as captured in the video stream rendering the consumer wearing the selected merchandise item.

Owner:IBM CORP

Apparatus and method for statistical image analysis

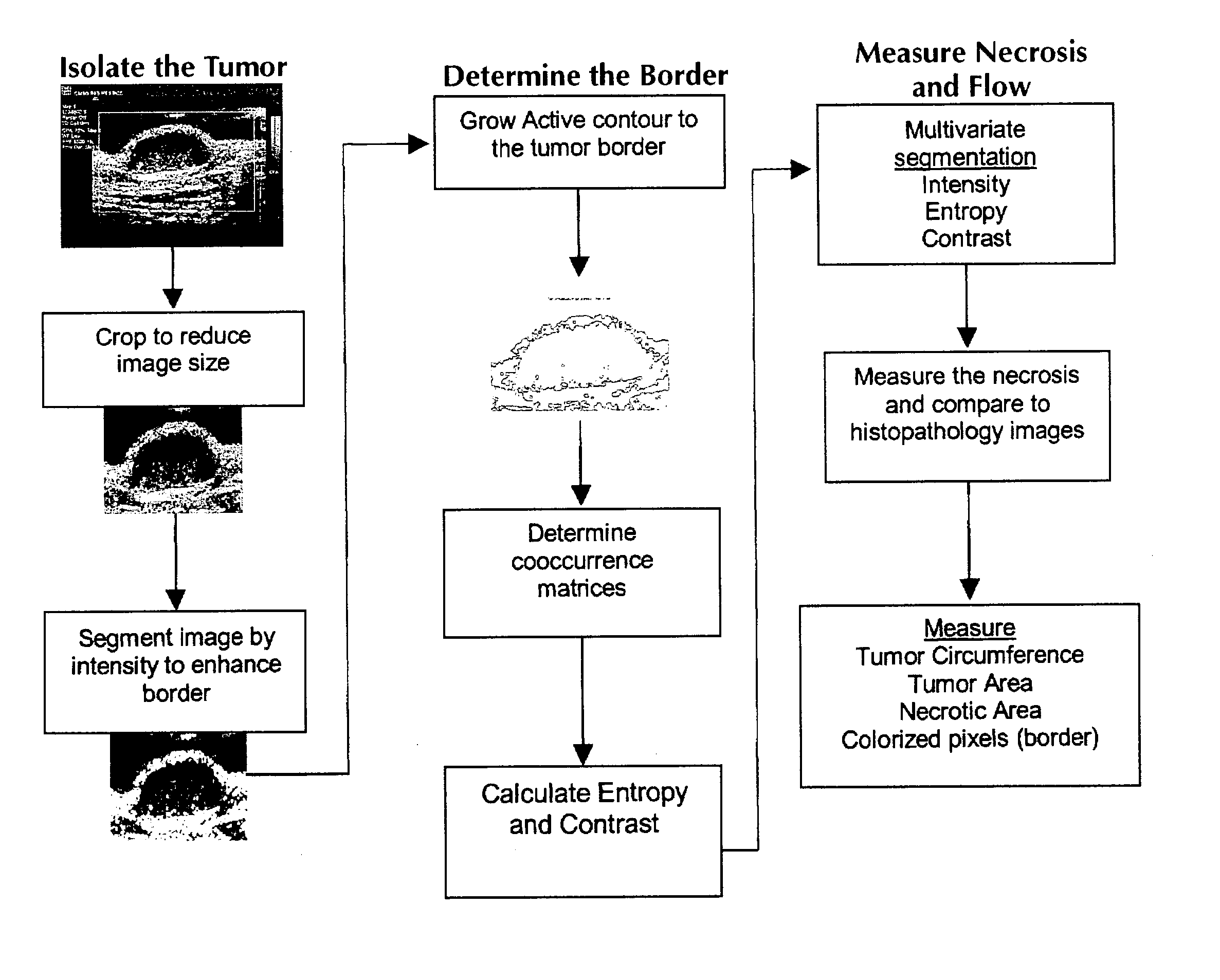

An apparatus, system, method, and computer readable medium containing computer-executable code for implementing image analysis uses multivariate statistical analysis of sample images, and allows segmentation of the image into different groups or classes, depending on a correlation to one or more sample textures, or sample surface features. In one embodiment, the invention performs multivariate statistical analysis of ultrasound images, wherein a tumor may be characterized by segmenting viable tissue from necrotic tissue, allowing for more detailed in vivo analysis of tumor growth beyond simple dimensional measurements or univariate statistical analysis. Application of the apparatus and method may also be used for characterizing other types of samples having textured features including, for example, tumor angiogenesis biomarkers from Power Doppler.

Owner:PFIZER INC

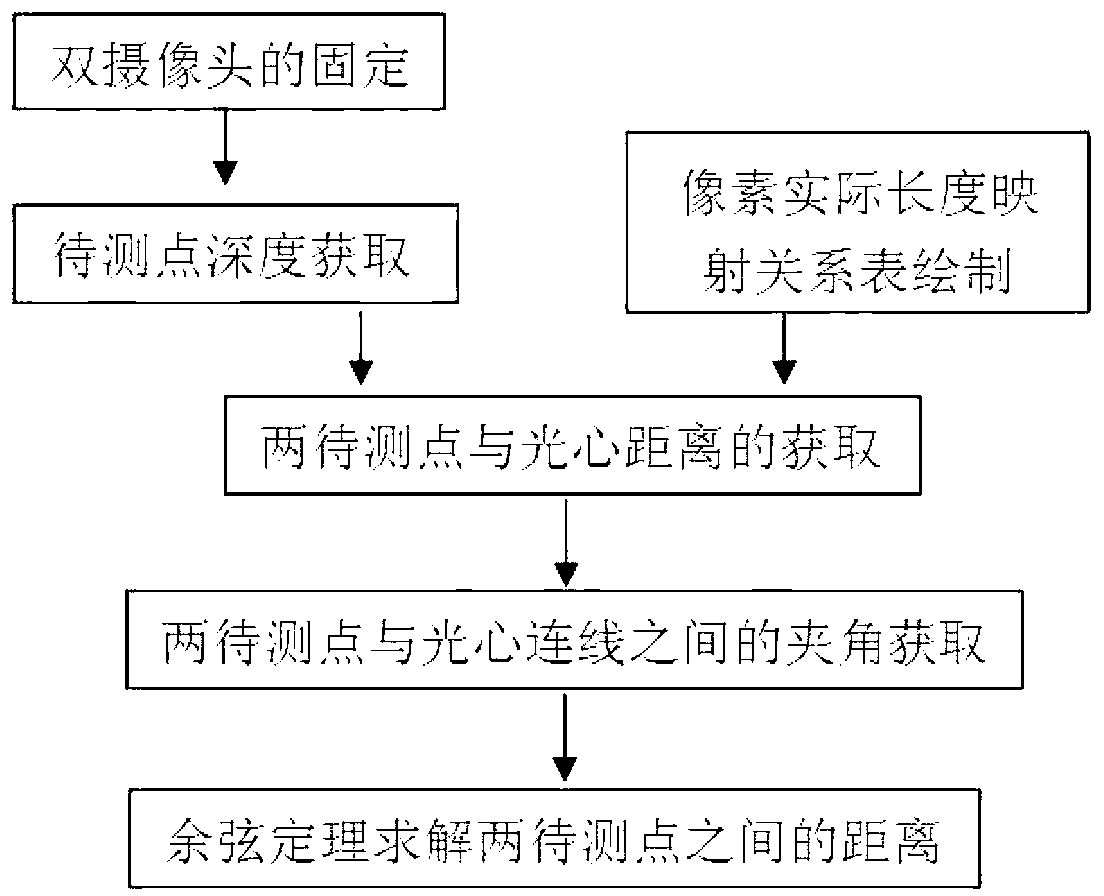

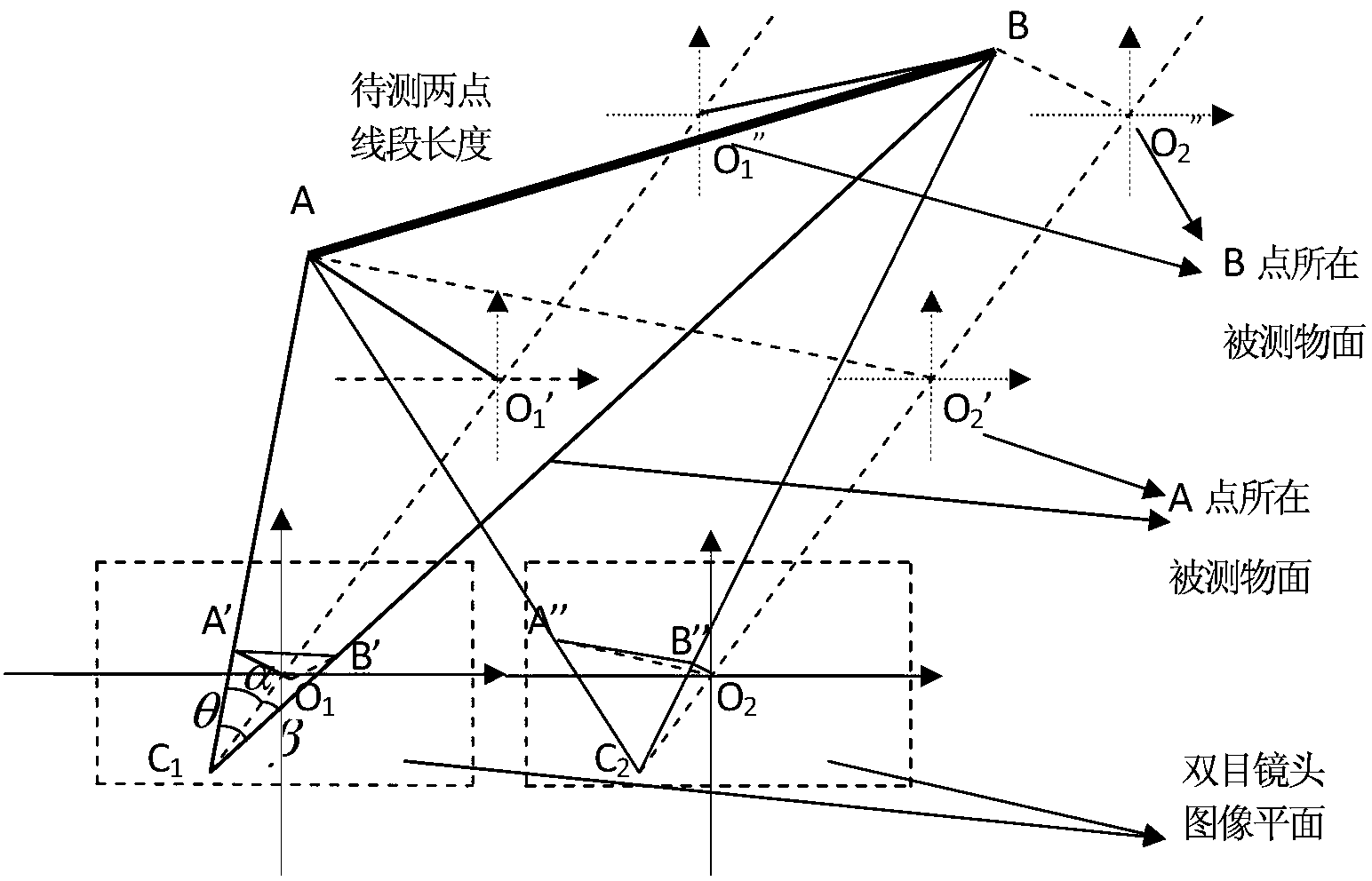

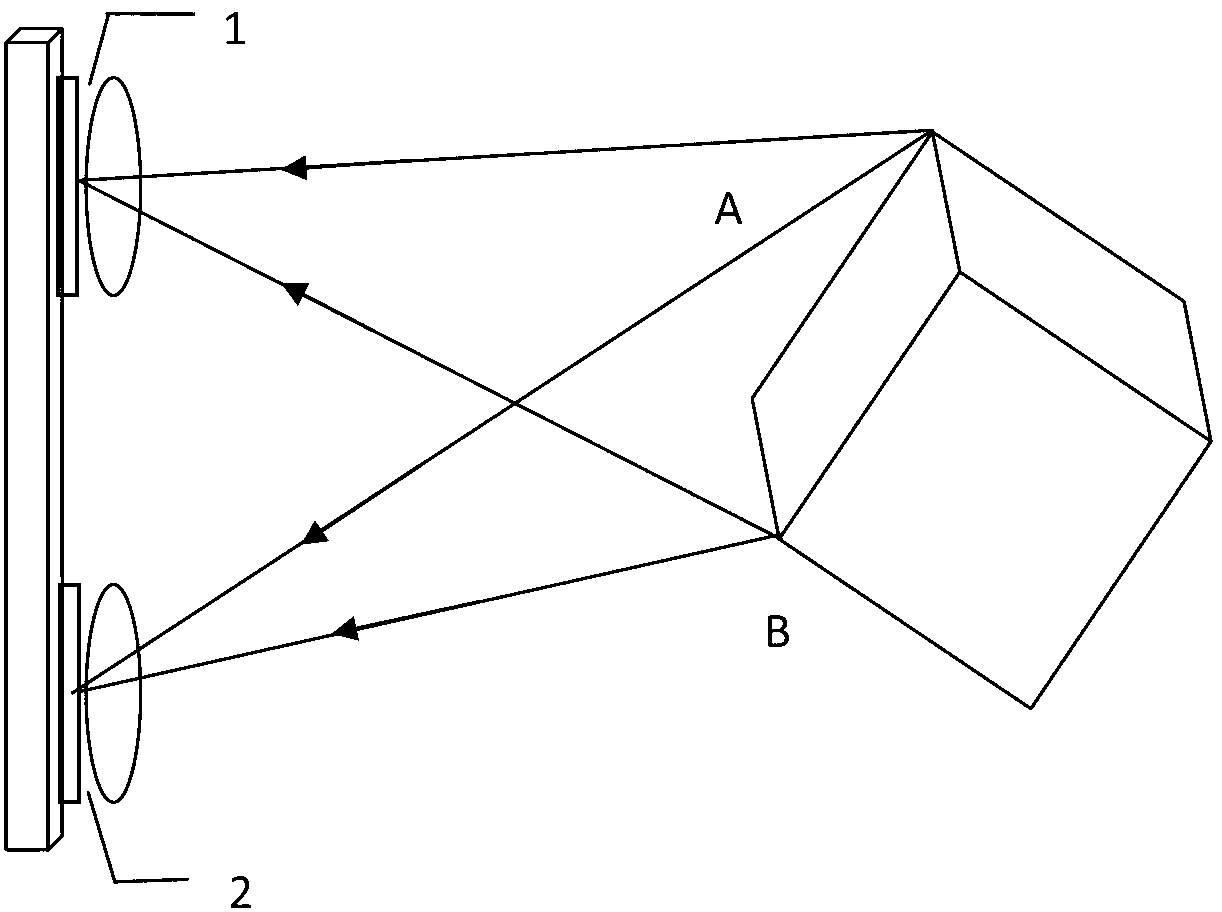

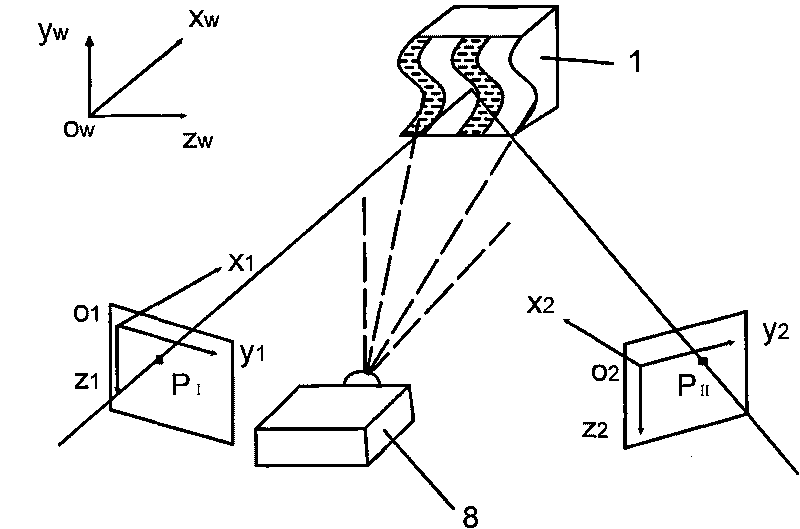

Distance measuring method applying binocular visual parallax error distance-measuring principle

InactiveCN103292710ASimple processEasy to operateUsing optical meansShortest distanceVisual perception

The invention discloses a distance measuring method applying a binocular visual parallax error distance-measuring principle. By means of adopting different base length to adapt to requirements on measurement accuracy of different distance measuring ranges, the distance measuring method is applicable to precise size measurement for short distance and small parts. On the basis of a conventional binocular measuring method, a pair of cameras which are provided with parallel optical axes and positioned side by side are adopted to make two random to-be-measured visualized points in two images into a plane vertical to the two optical axes, depth values of the two to-be-measured points are obtained via a inversely proportional relationship between binocular visual parallax error and depth, distances from the two to-be-measured points to an optic center and angles among the two to-be-measured points and an optical center connection line can be determined according to the depth value of the to-be-measured points and focal length of the cameras, and then the actual distance between the two points can be determined via the cosine law. Compared with conventional methods, the distance measuring method applying the binocular visual parallax error distance-measuring principle has the advantages of simplicity in operation, strong practicability, high precision and easiness in popularization and use.

Owner:SOUTH CHINA UNIV OF TECH

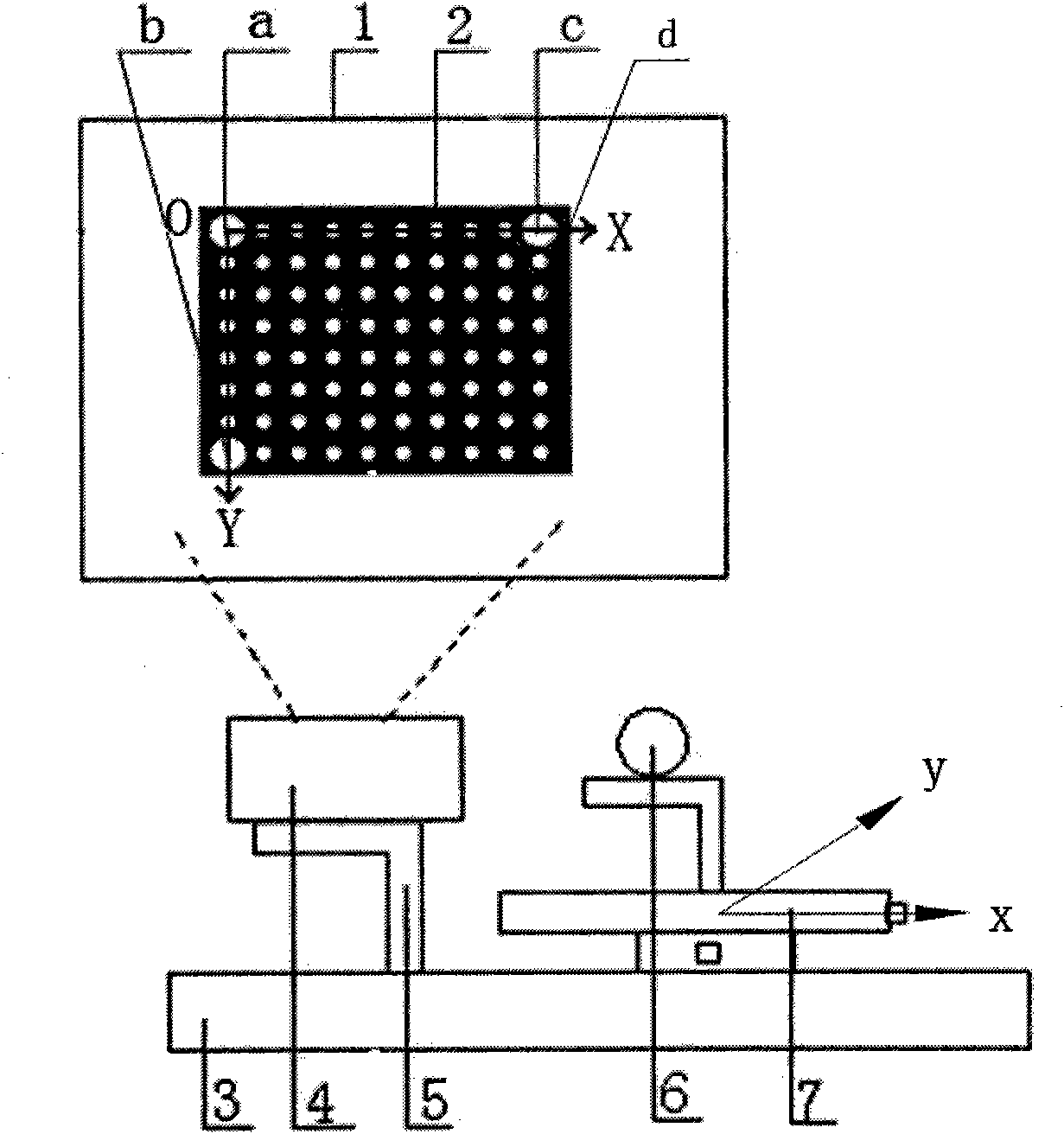

Camera on-field calibration method in measuring system

ActiveCN101876532AEasy extractionOvercome the adverse effects of opaque imagingImage analysisUsing optical meansTheodoliteSize measurement

The invention discloses a camera on-field calibration method in a measuring system, belonging to the field of computer vision detection, in particular to an on-field calibration method for solving inside and outside parameters of cameras in a large forgeable piece size measuring system. Two cameras and one projector are provided in the measuring system. The calibration method comprises the following steps of: manufacturing inside and outside parameter calibration targets of the cameras; projecting inside parameter targets and shooting images; extracting image characteristic points of the images through an image processing algorithm in Matlab; writing out an equation to solve the inside parameters of the cameras; processing the images shot simultaneously by the left camera and the right camera; and measuring the actual distance of the circle center of the target by using a left theodolite and a right theodolite, solving a scale factor and further solving the actual outside parameters. The invention has stronger on-field adaptability, overcomes the influence of impermeable and illegible images caused by the condition that a filter plate filters infrared light in a large forgeable piece binocular vision measuring system by adopting the projector to project the targets, and is suitable for occasions with large scene and complex background.

Owner:DALIAN UNIV OF TECH

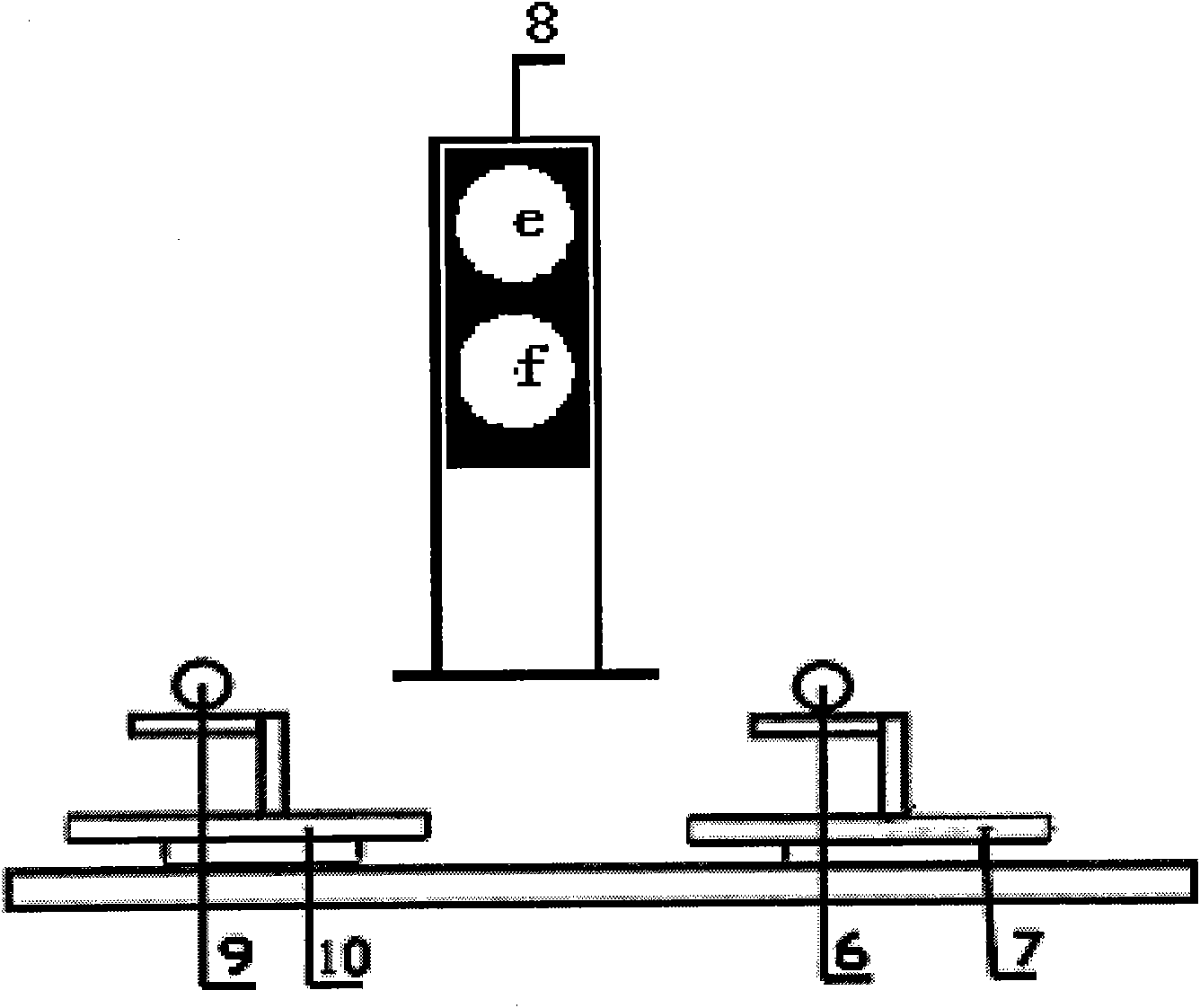

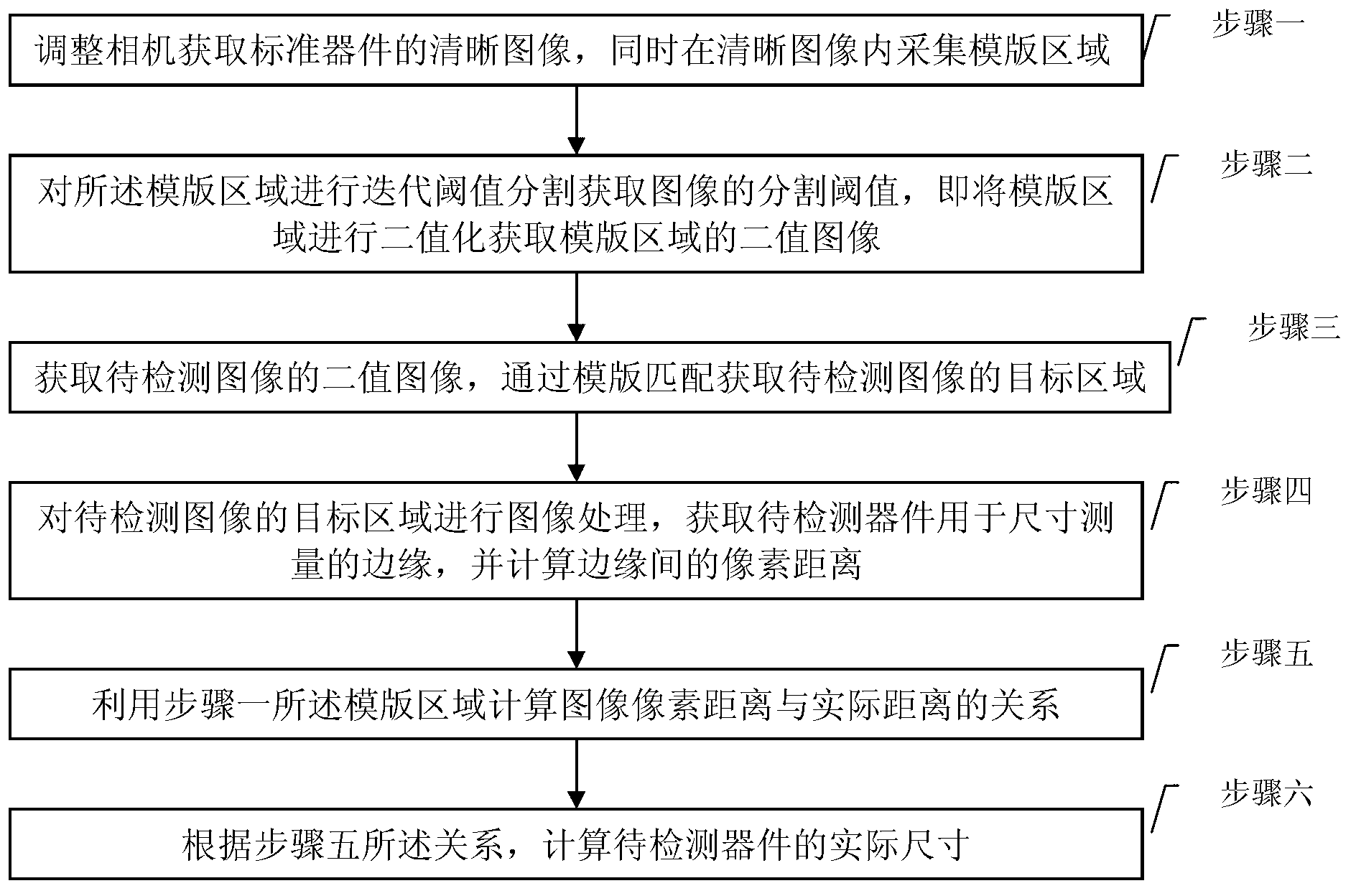

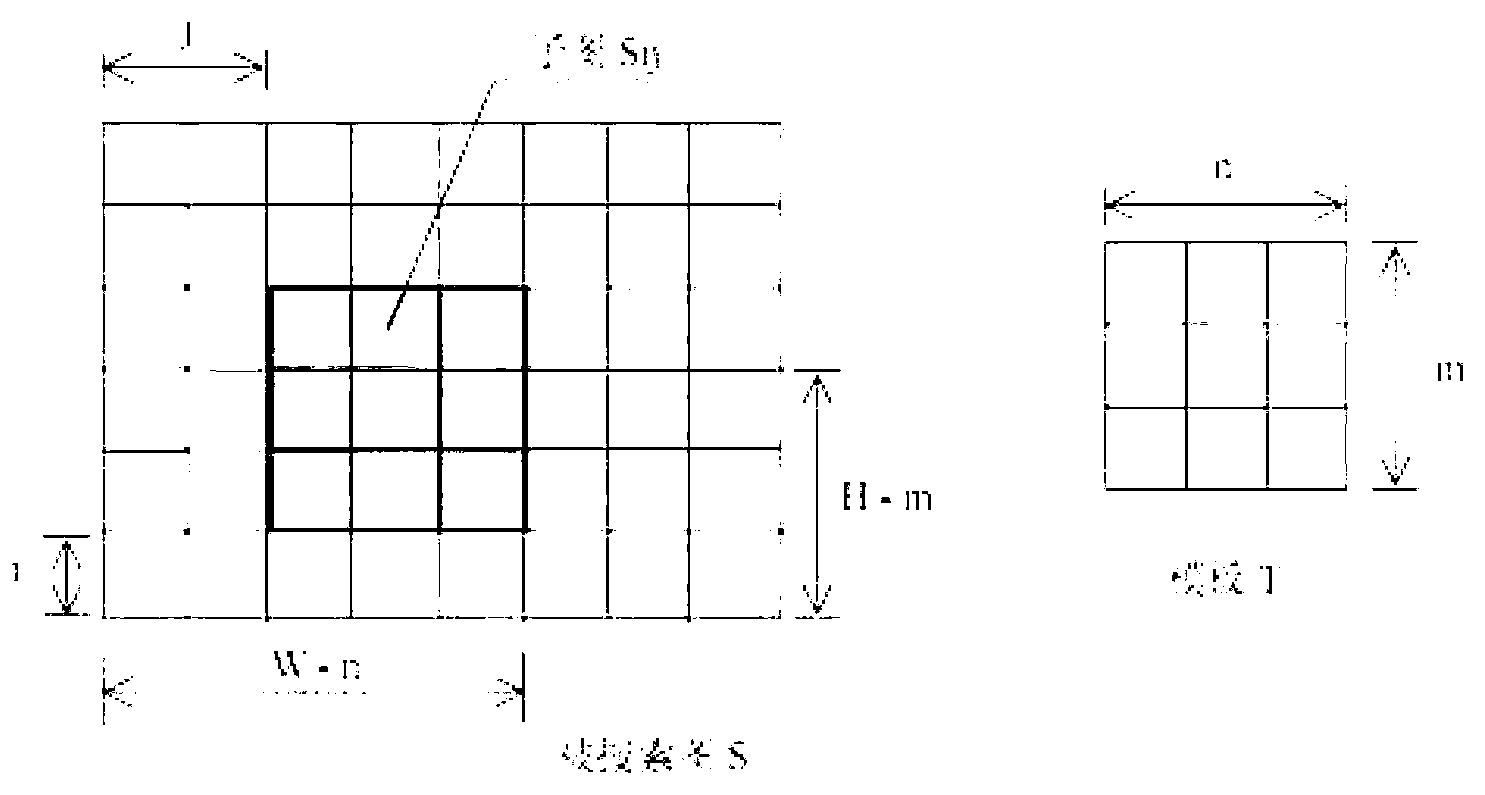

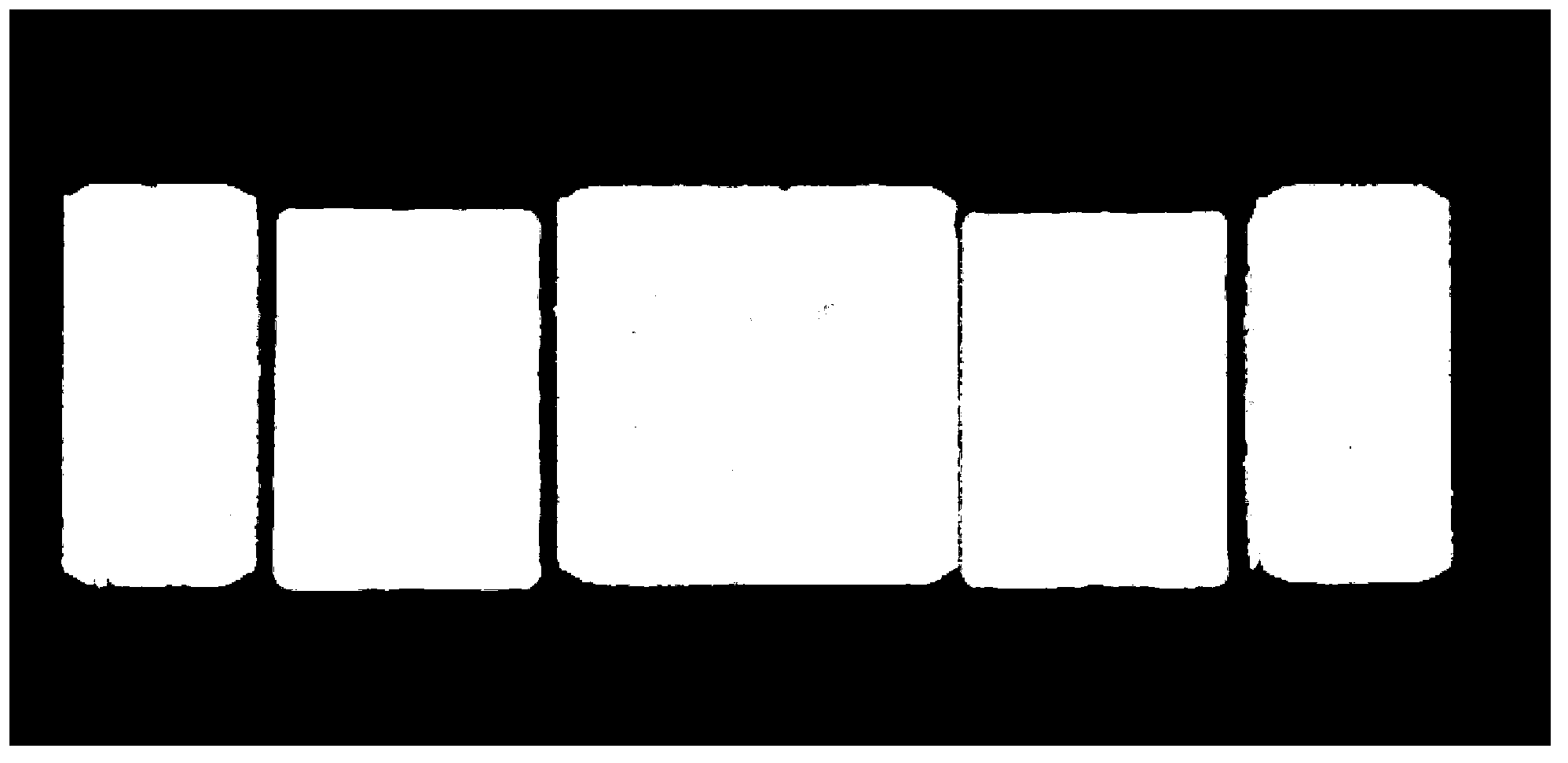

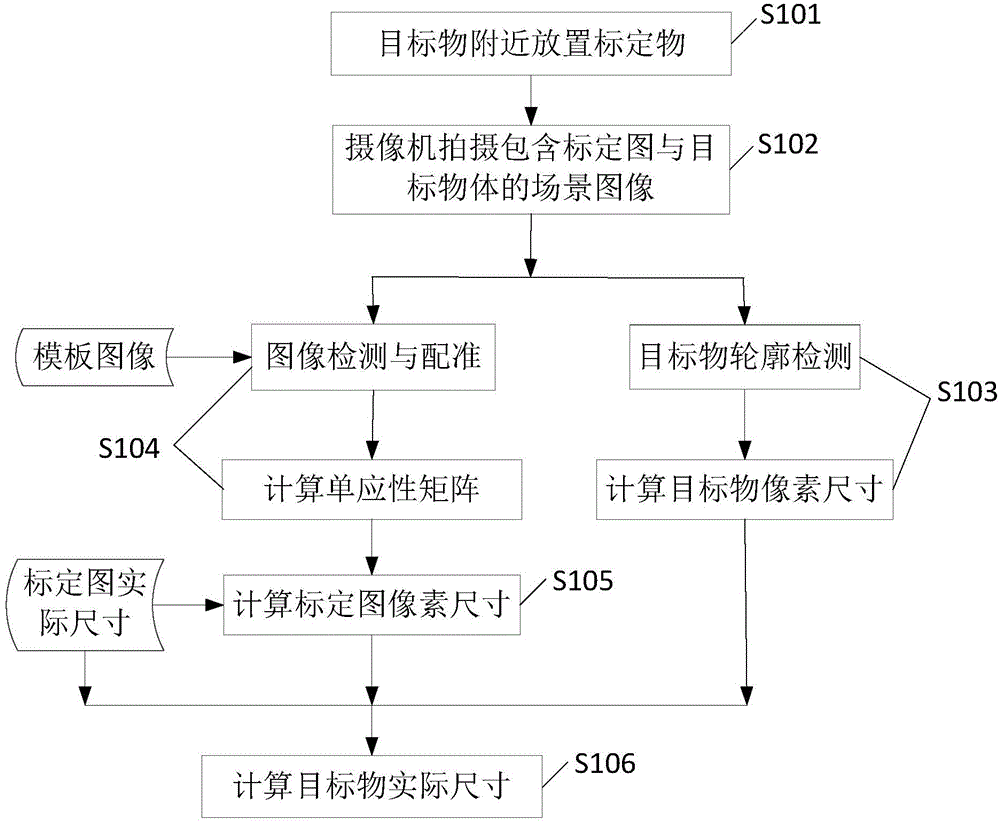

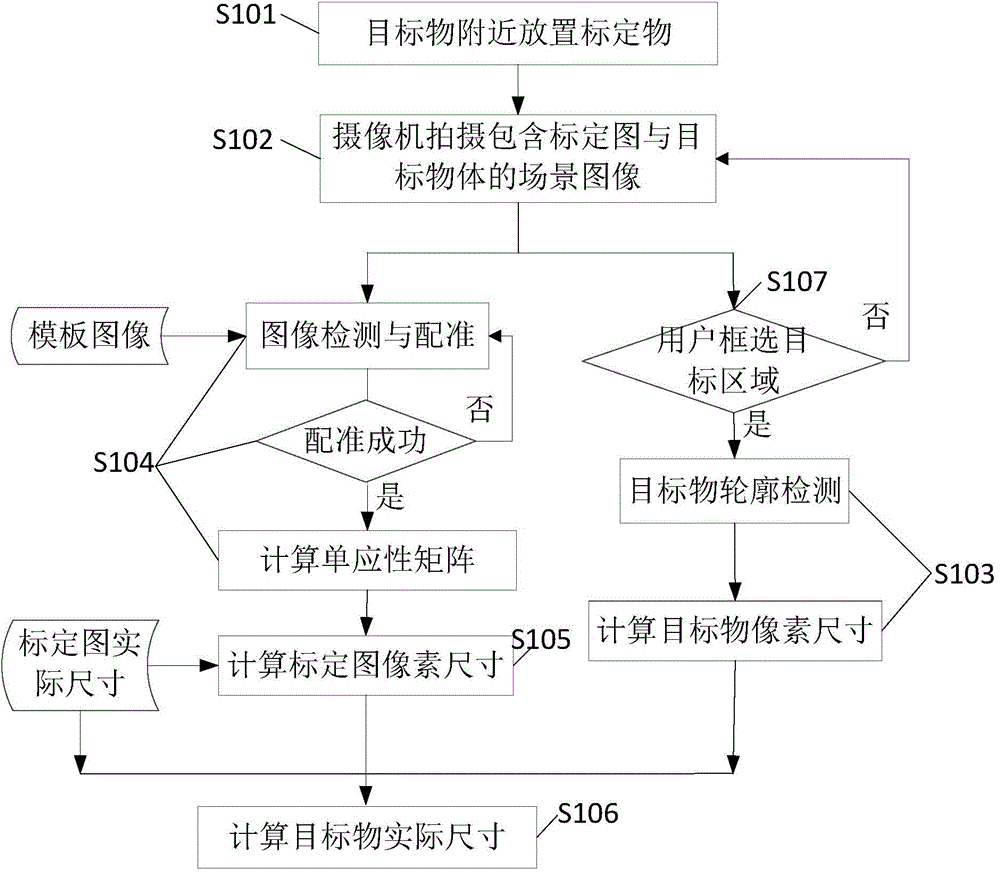

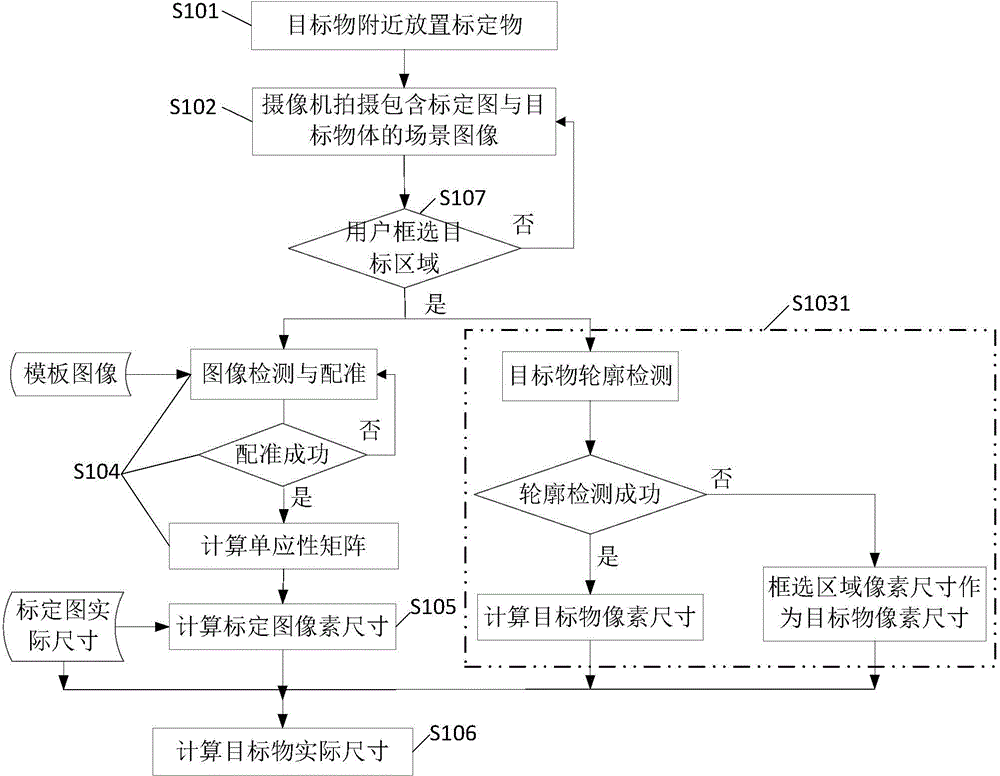

Machine-vision-based online dimensional measurement method of precise instrument

ActiveCN103292701ALower requirementImprove Pixel AccuracyUsing optical meansTemplate matchingImaging processing

A machine-vision-based online dimensional measurement method of precise instruments relates to a machine-vision-based dimensional measurement method and solves the problem of high-precision requirements on workpiece measurement in modern industry. The method comprises the steps of adjusting a camera to obtain a clear image of a standard instrument and meanwhile collecting a template area inside the clear image; performing iterative threshold segmentation on the template area to obtain the segmented threshold of the image, namely, binarizing the template area to obtain a binary image of the template area; obtaining a binary image of an image to be measured, and obtaining a target area of the image to be measured through template matching; performing image processing on the target area of the image to be measured to obtain the edges of an instrument to be measured, which is used for dimensional measurement, and calculating the pixel distances among the edges; calculating the relation between the pixel distances and the actual distances of the image; and calculating out the actual dimension of the instrument to be measured. The machine-vision-based online dimensional measurement method of precise instruments can be widely applied to the machine vision dimensional measurement of the precise instruments.

Owner:宁波智能装备研究院有限公司

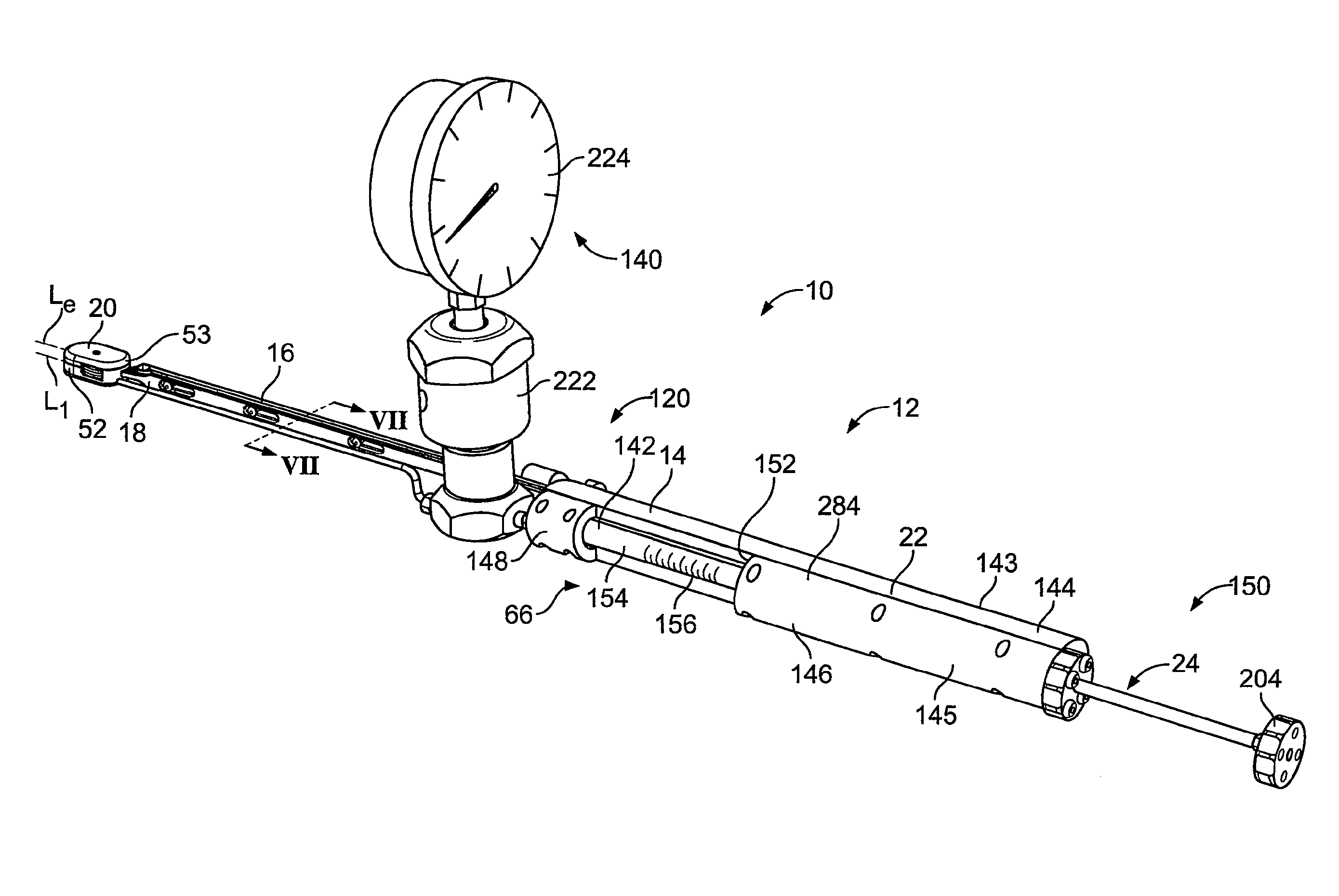

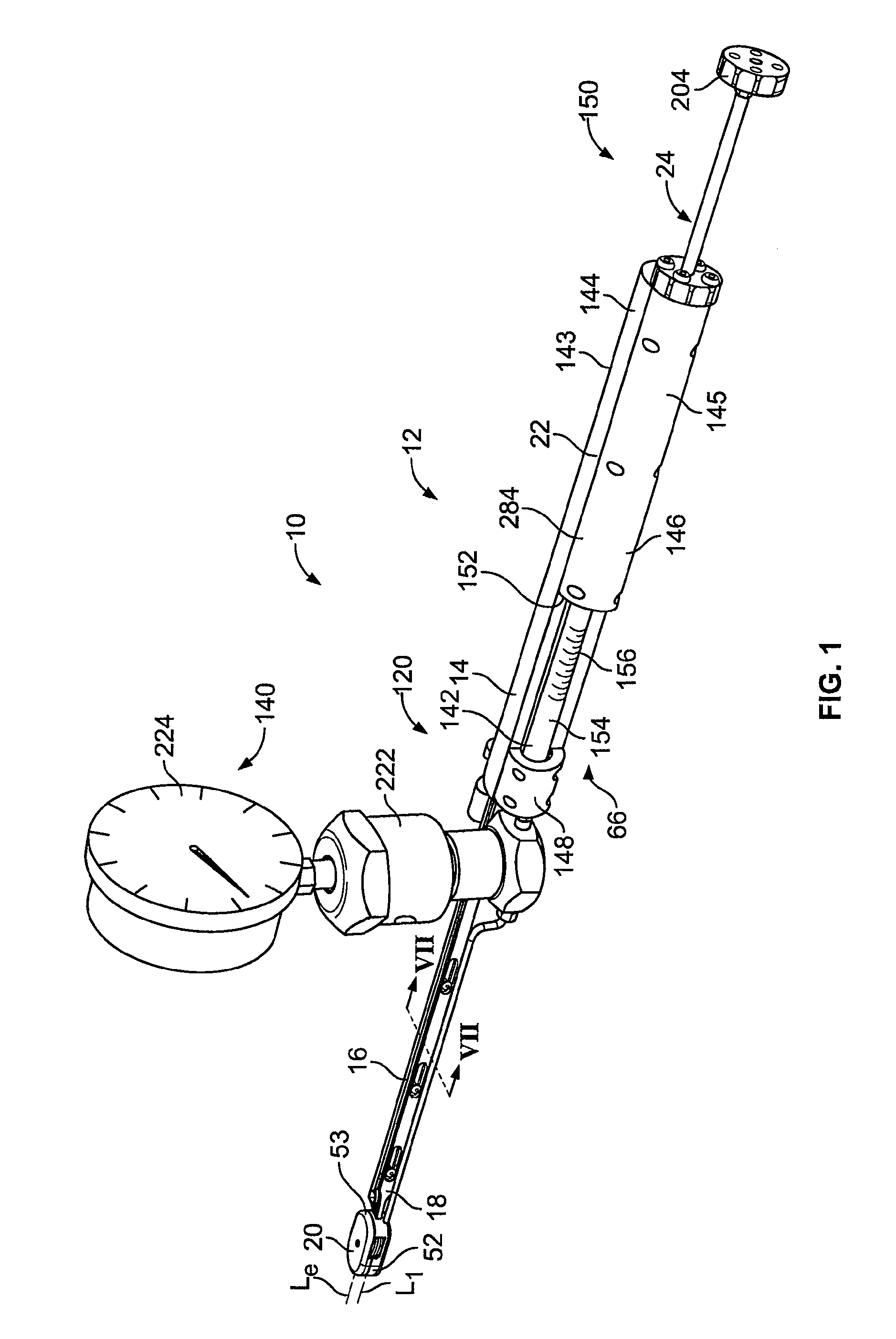

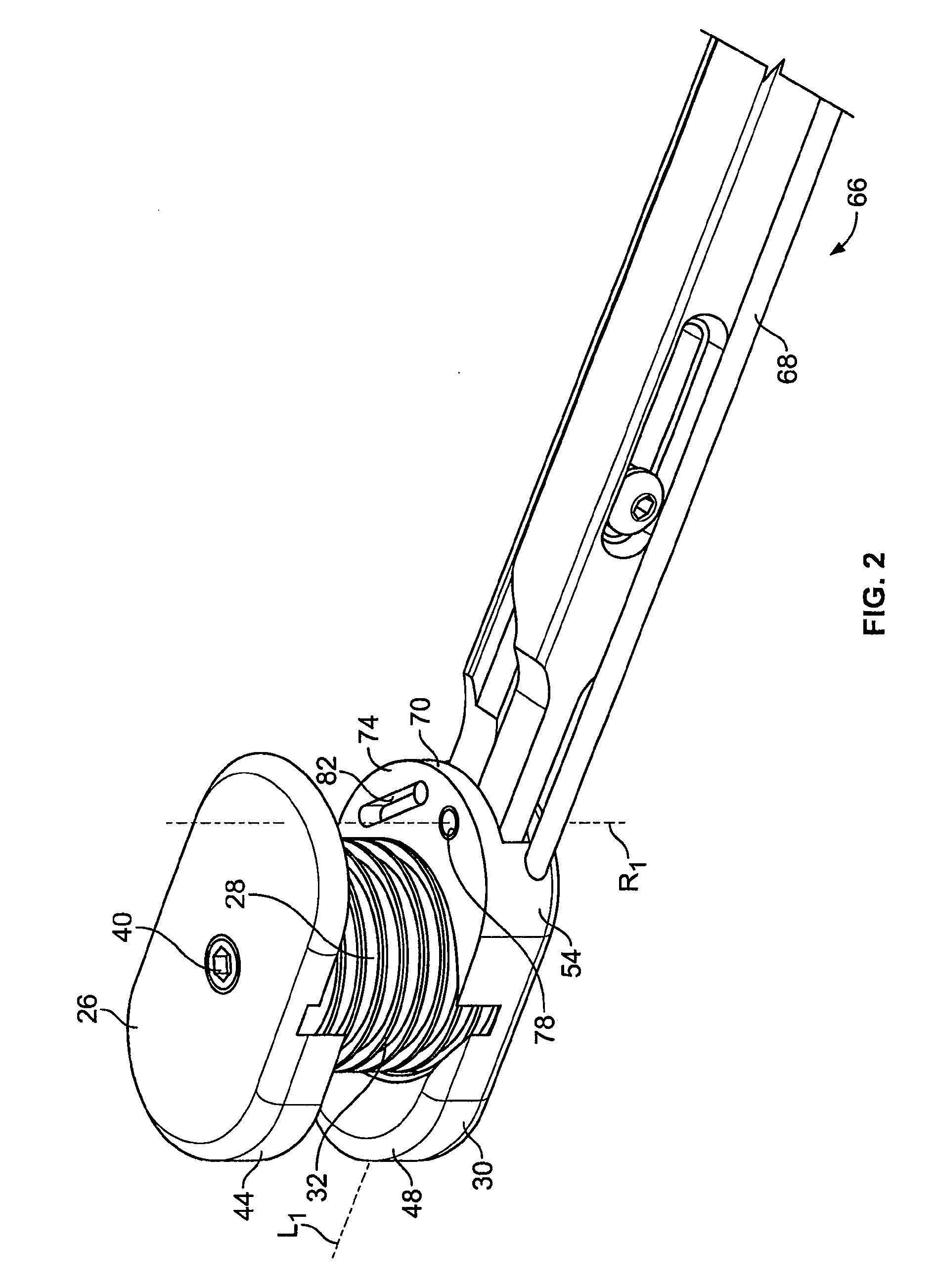

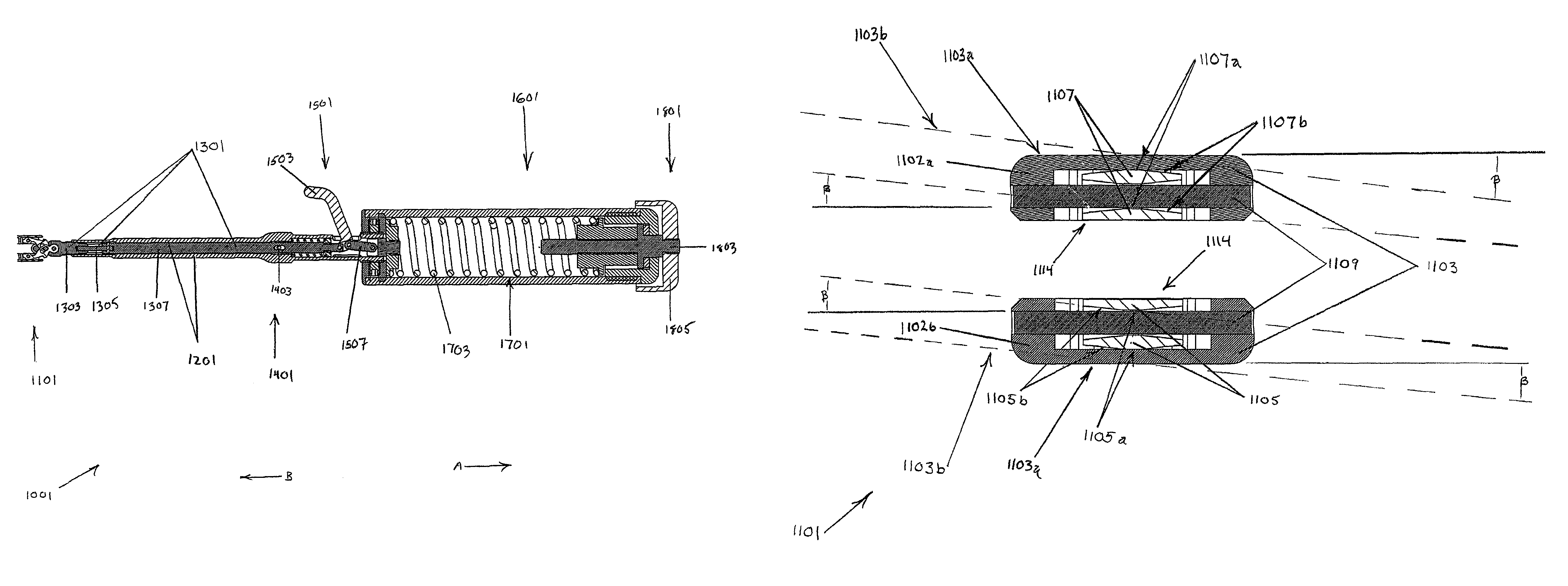

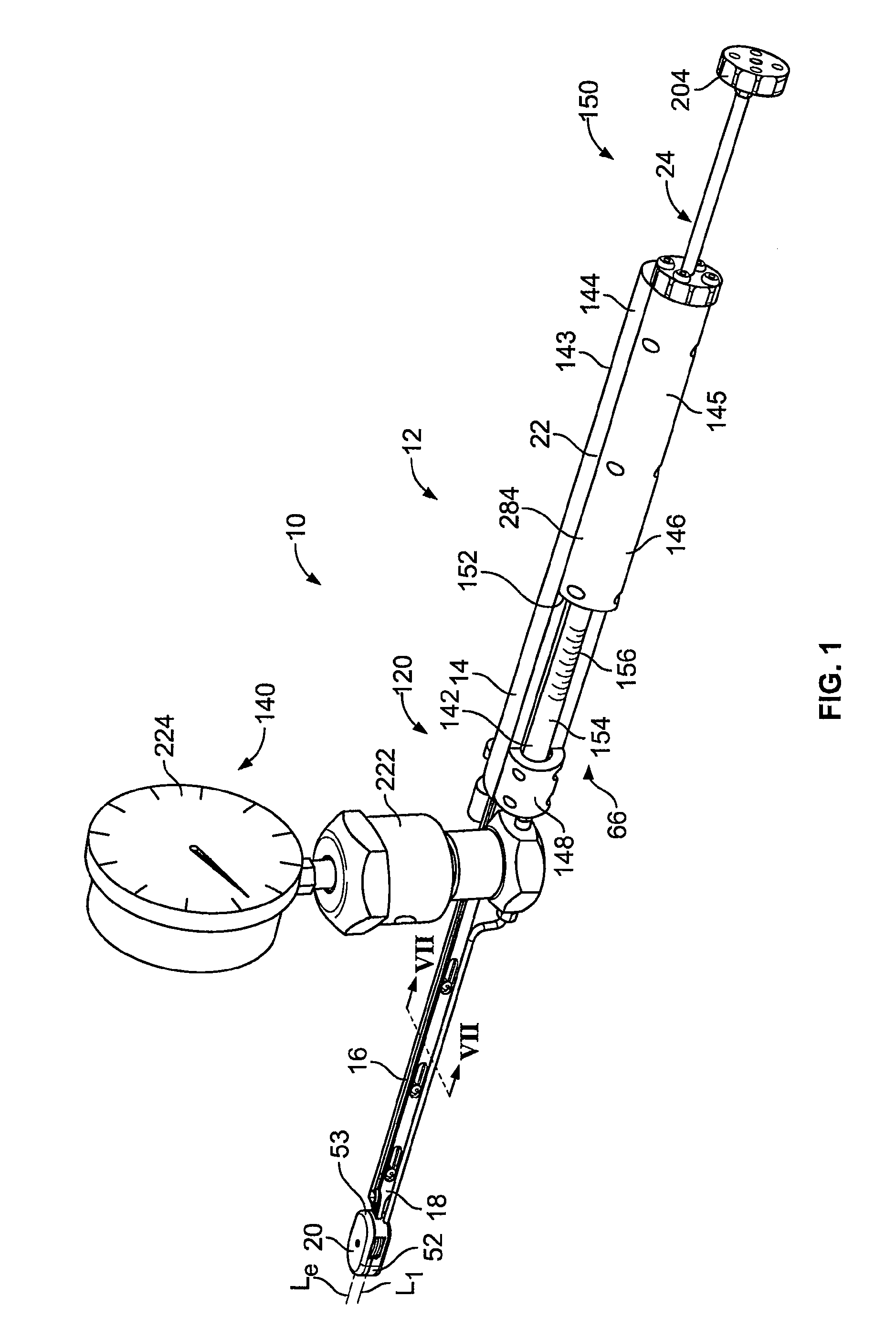

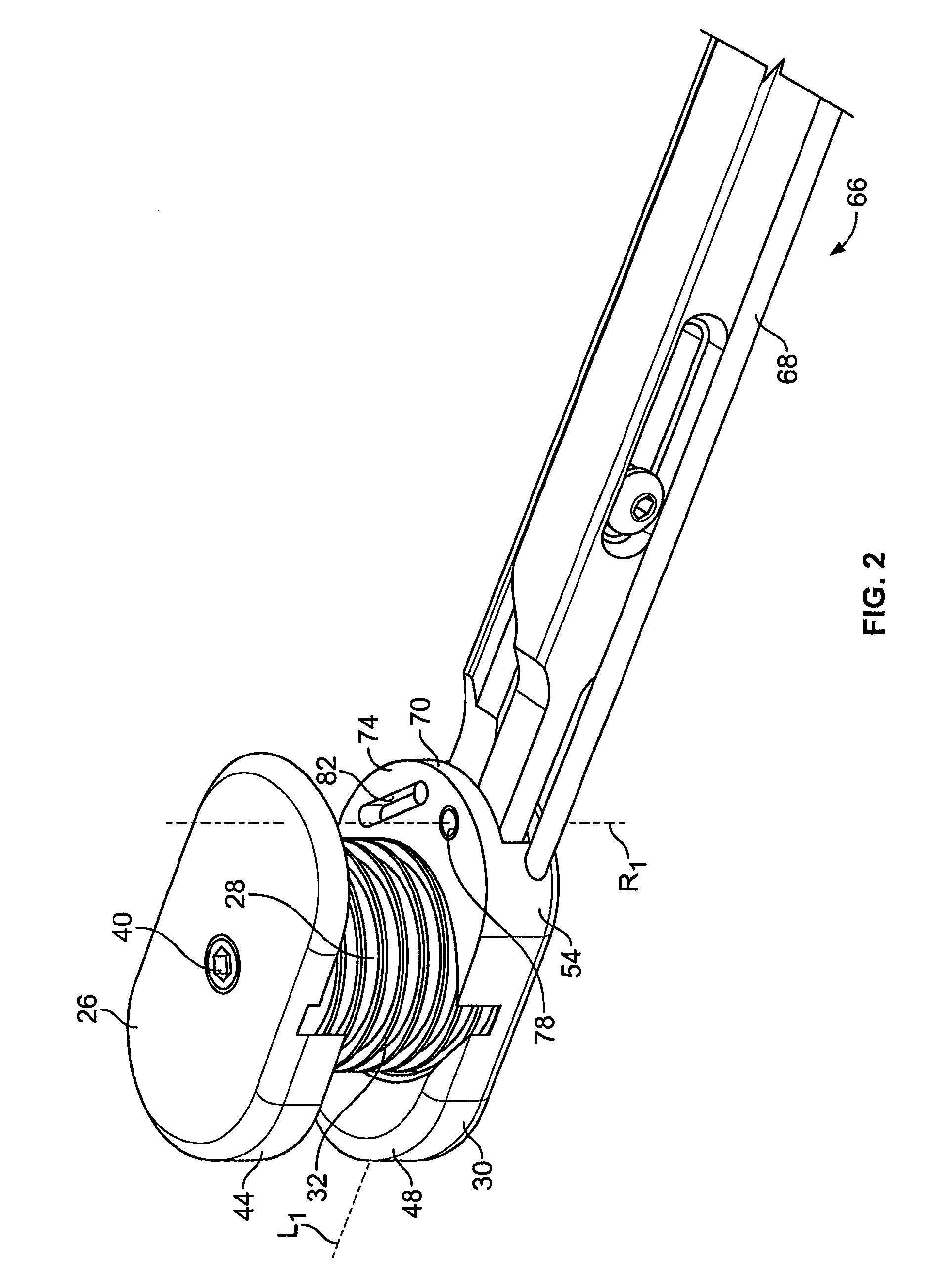

Intervertebral disc space sizing tools and methods

ActiveUS20090182343A1Reduces time amount of timeShorten surgery timeSpinal implantsOsteosynthesis devicesDistractionSize measurement

A method and apparatus for making a size measurement within an intervertebral space by placing an expandable and contractible device into the intervertebral space, expanding the device, measuring a size characteristic of the space, contracting the device and then removing it. The measurement may be accomplished by an external x-ray or other imaging device imaging the expanded device in situ or by mechanically operated devices. An expansion and contraction mechanism such as fluid containing bladder or mechanically shifted members expands the device which later contracts in a controlled manner to the contracted size. An apparatus and method is provided for the measuring of the intervertebral space at a controlled distraction force. The apparatus includes an expandable device for providing a measurement within the intervertebral space and facilitating the measurement of the angulations of the lordotic curve of the intervertebral space.

Owner:PIONEER SURGICAL TECH INC

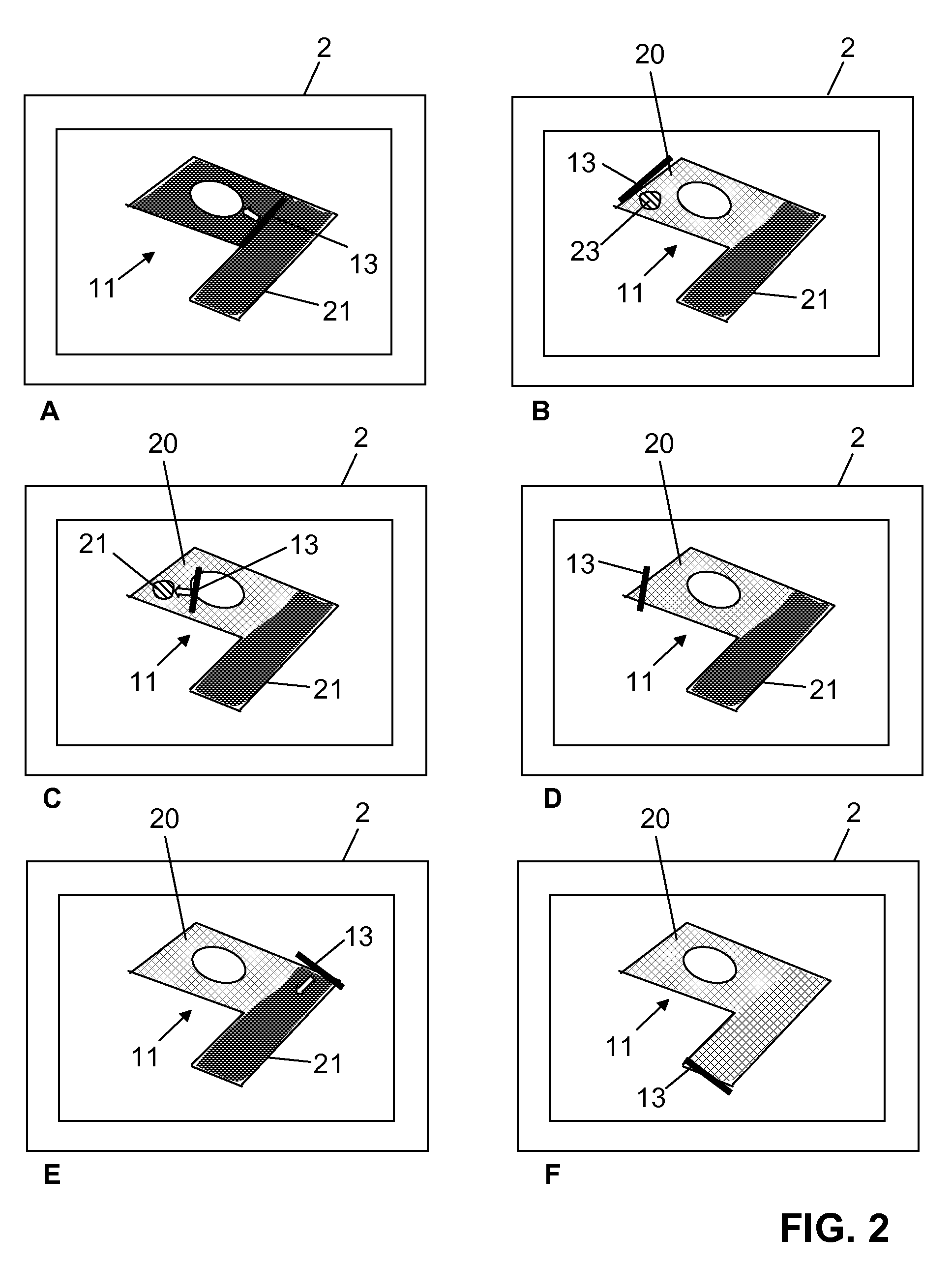

Method and computer program for improving the dimensional acquisition of an object

ActiveUS20110123097A1Improve accuracyIncrease speedMeasurement devicesCharacter and pattern recognitionSize measurementMeasurement device

The present invention relates to a method for improving the efficiency of dimensional acquisition of an object by a dimensional measurement device directed over the object, comprising the steps: a) directing the measurement device over the object to acquire its dimensions, b) providing an indication of the resolution of the acquired regions, c) re-directing the measurement device over at least part of the acquired regions indicating insufficient resolution according to predetermined criteria, d) updating the indication of the resolution of the acquired regions, and e) repeating steps c) and d) until sufficient resolution is indicated according to the predetermined criteria, thereby efficiently acquiring the dimensions of the object at sufficient resolution. It also relates to a computer program therefor.

Owner:3D SCANNERS LTD

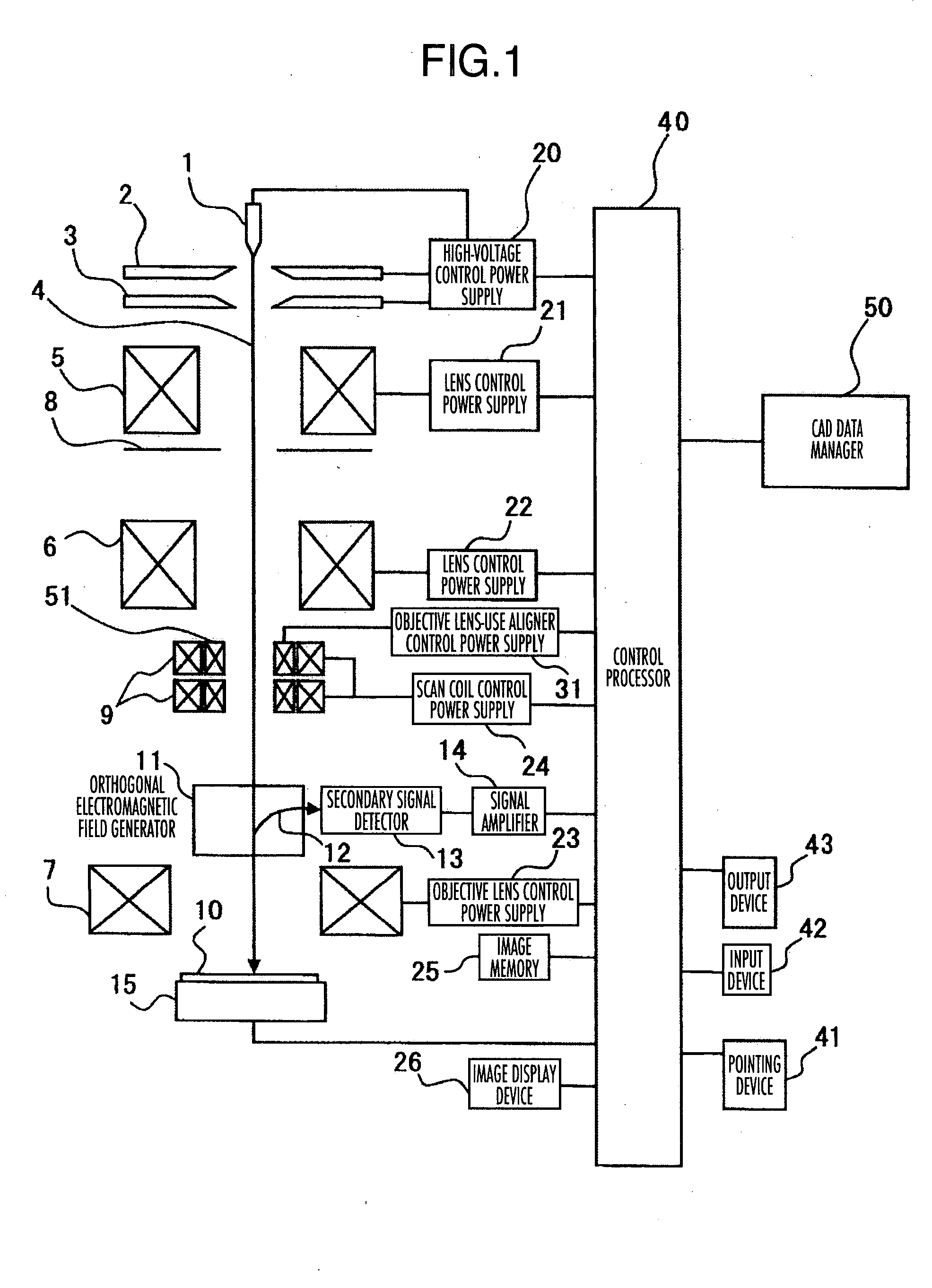

Workpiece size measurement method and apparatus

ActiveUS20070221842A1Increased complexityImprove measurement efficiencyMaterial analysis using wave/particle radiationCharacter and pattern recognitionSize measurementEngineering

A workpiece size measurement method suitable for length measurement of multilayered circuit elements with increased complexities is disclosed. This method employs a technique for changing measurement conditions in a way pursuant to either an image of workpiece or the situation of a target semiconductor circuit element to be measured when measuring pattern sizes on the workpiece image using design data of the semiconductor circuit element. With such an arrangement, adequate measurement conditions are selectable in accordance with the state of workpiece image and / or the state of a circuit element formed on the workpiece, thereby making it possible to improve the measurement efficiency. A workpiece size measurement apparatus using the technique is also disclosed.

Owner:HITACHI HIGH-TECH CORP

Consumer representation rendering with selected merchandise

At least one computing system, in a network or stand-alone environment, accesses a consumer representation, wherein the consumer representation comprises a three dimensional model rendered to depict a consumer appearance and movement in each frame of a captured video stream and specified by a selection of sizing measurements detected from a scan of a consumer body shape. The computing system selects at least one merchandise item from among multiple merchandise items each with separate merchandise characteristics. In particular, the computing system selects the merchandise item of a size selected to fit the selection of sizing measurements for the consumer. The computing system renders the merchandise item on each rendered frame of the three dimensional model according to the merchandise characteristics as applied to the sizing measurements, wherein a display of the rendered three dimensional model shows a realistic image of the consumer appearance and movement as captured in the video stream rendering the consumer wearing the selected merchandise item.

Owner:INT BUSINESS MASCH CORP

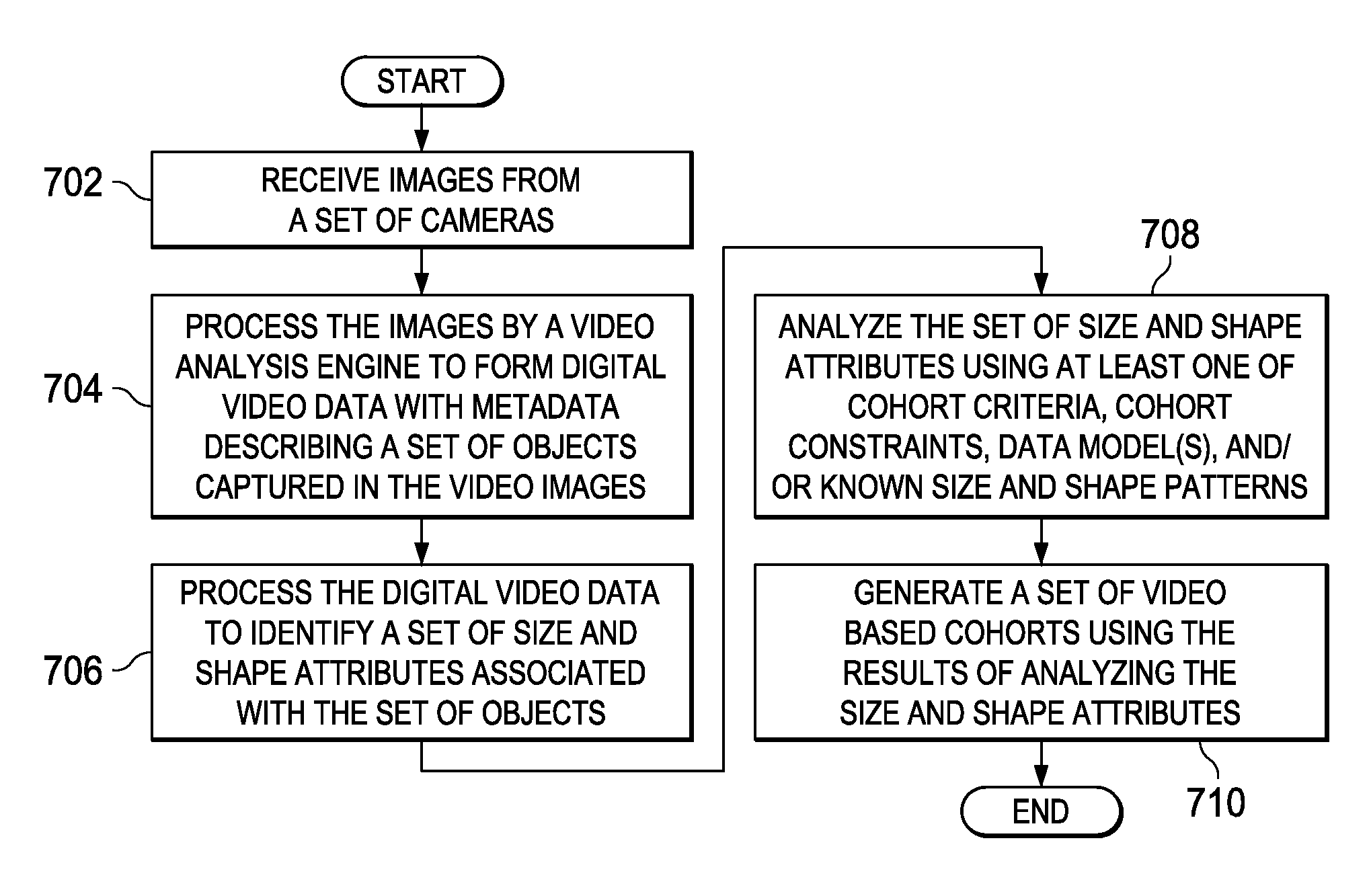

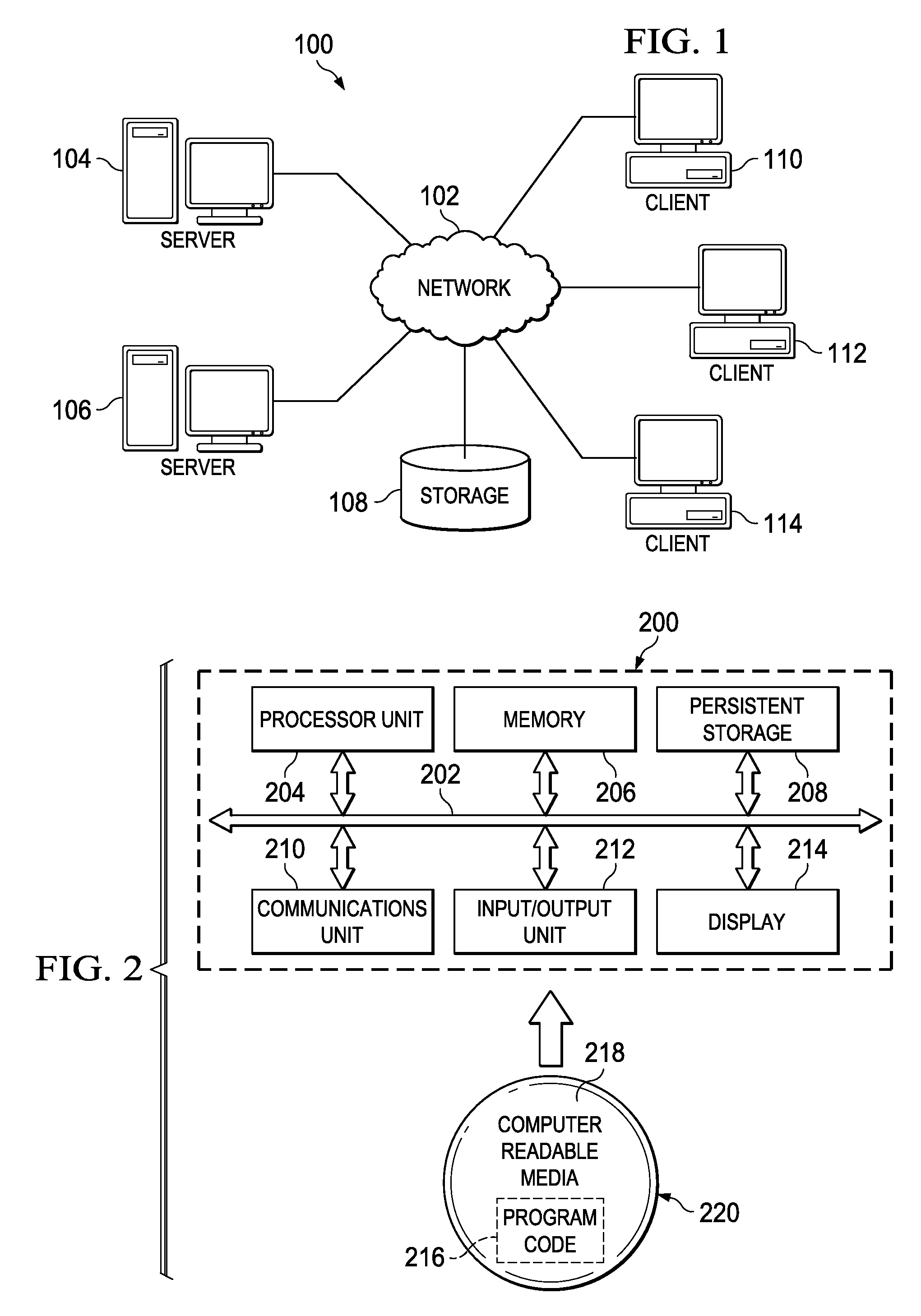

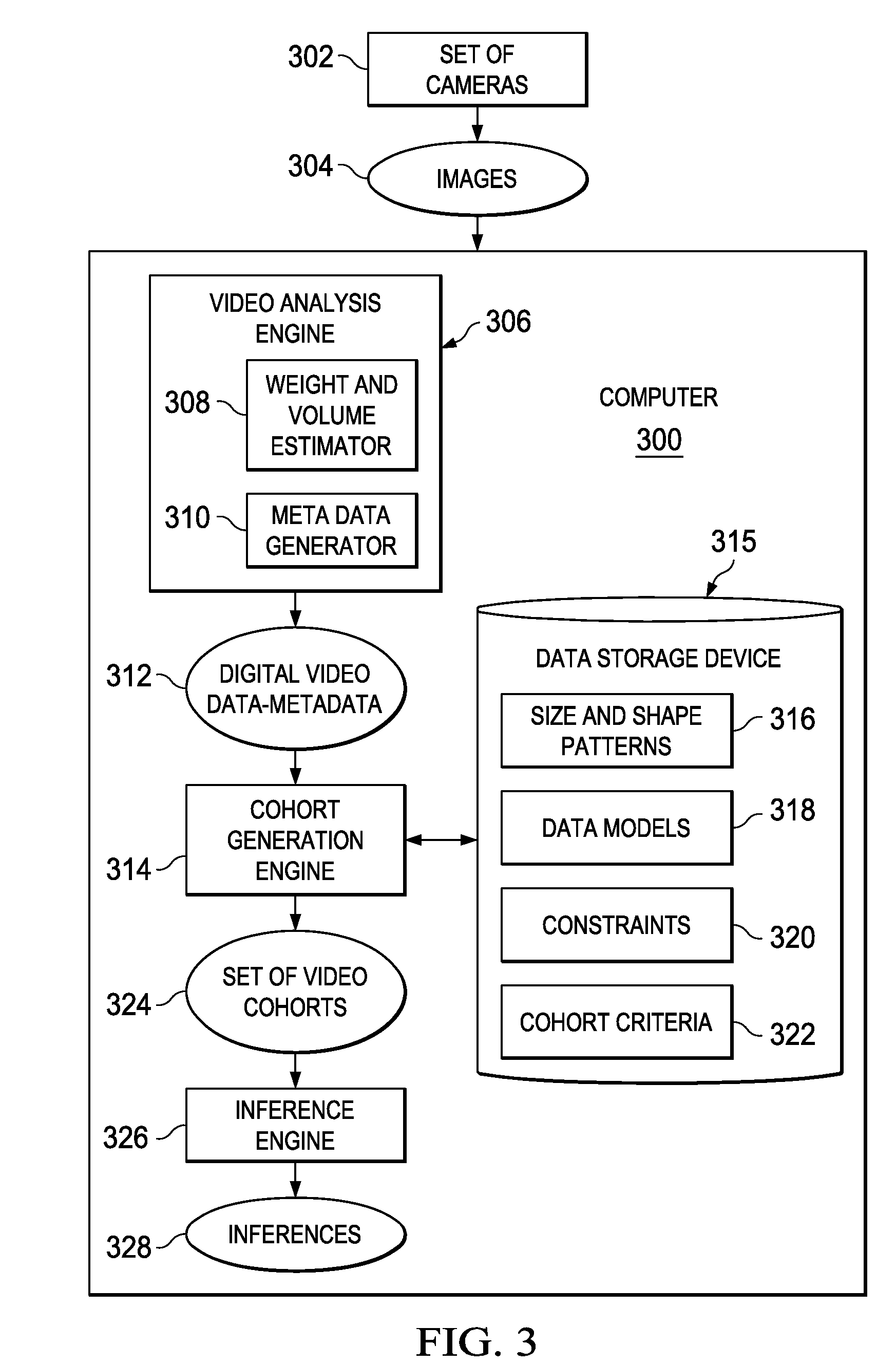

Generating Cohorts Based on Attributes of Objects Identified Using Video Input

InactiveUS20100150458A1Character and pattern recognitionColor television detailsDigital videoSize measurement

A computer implemented method, apparatus, and computer program product for generating video based cohorts. Digital video data is processed to identify a set of size and shape based attributes associated with the set of objects. The digital video data comprises metadata describing the set of objects. A size and shape attribute comprises an attribute describing a shape associated with a portion of an object or a size measurement of the portion of the object. The set of size and shape based attributes are analyzed using cohort criteria to form a result. The cohort criteria specify attributes that are associated with members of a given cohort. A set of cohorts is generated based on the result. Each cohort in the set of cohorts comprises a subset of objects from the set of objects that share at least one size and shape based attribute in common.

Owner:IBM CORP

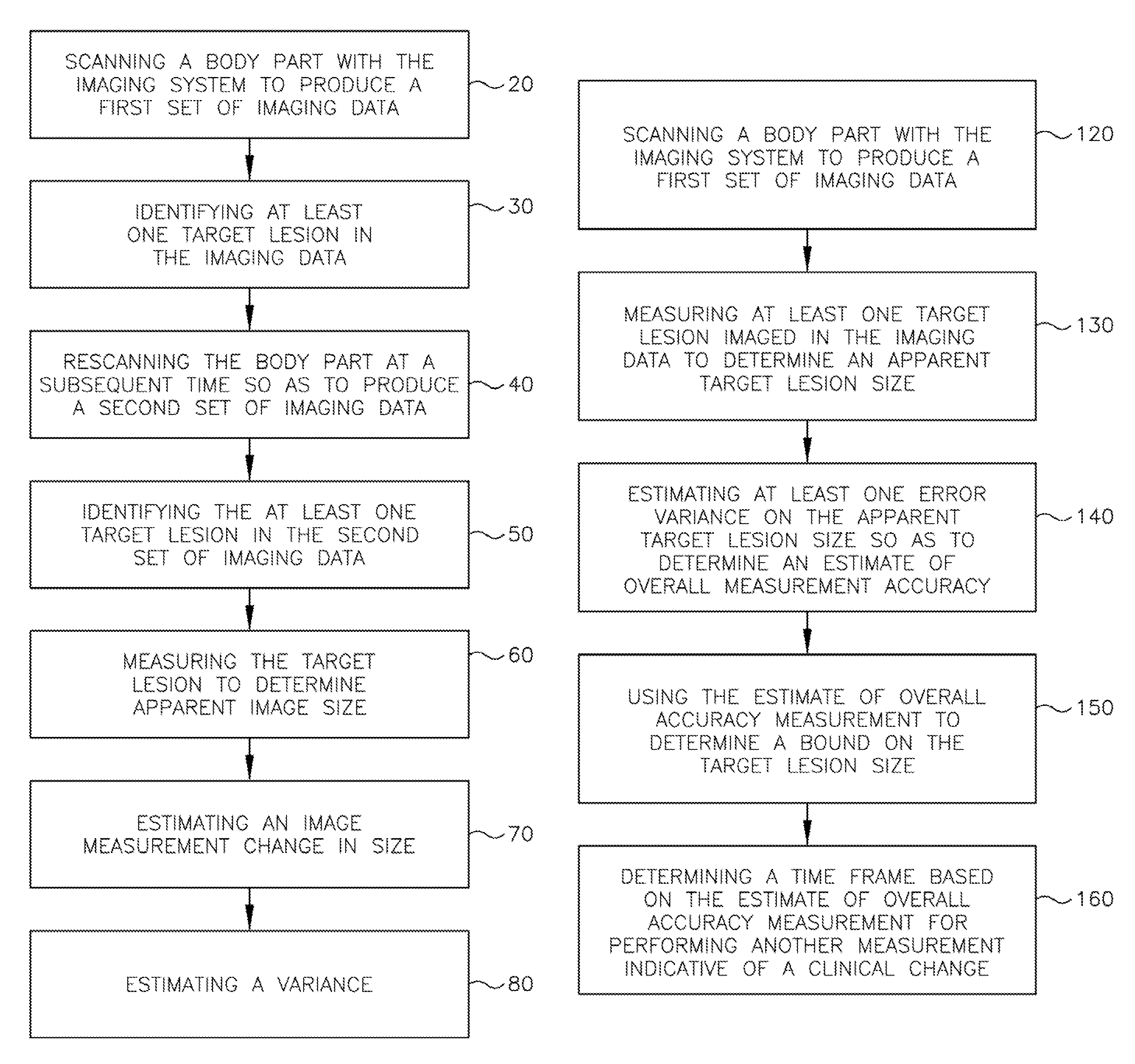

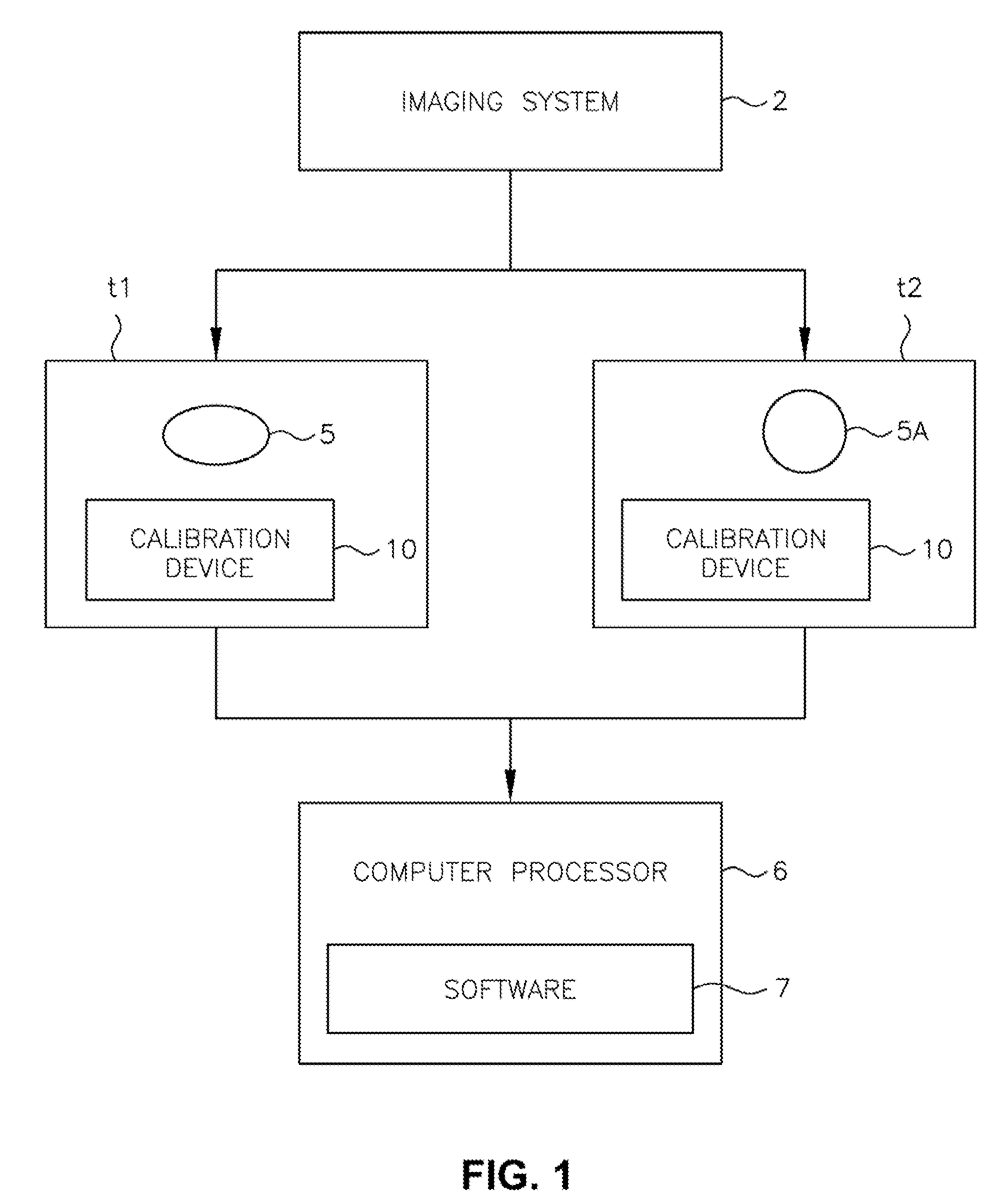

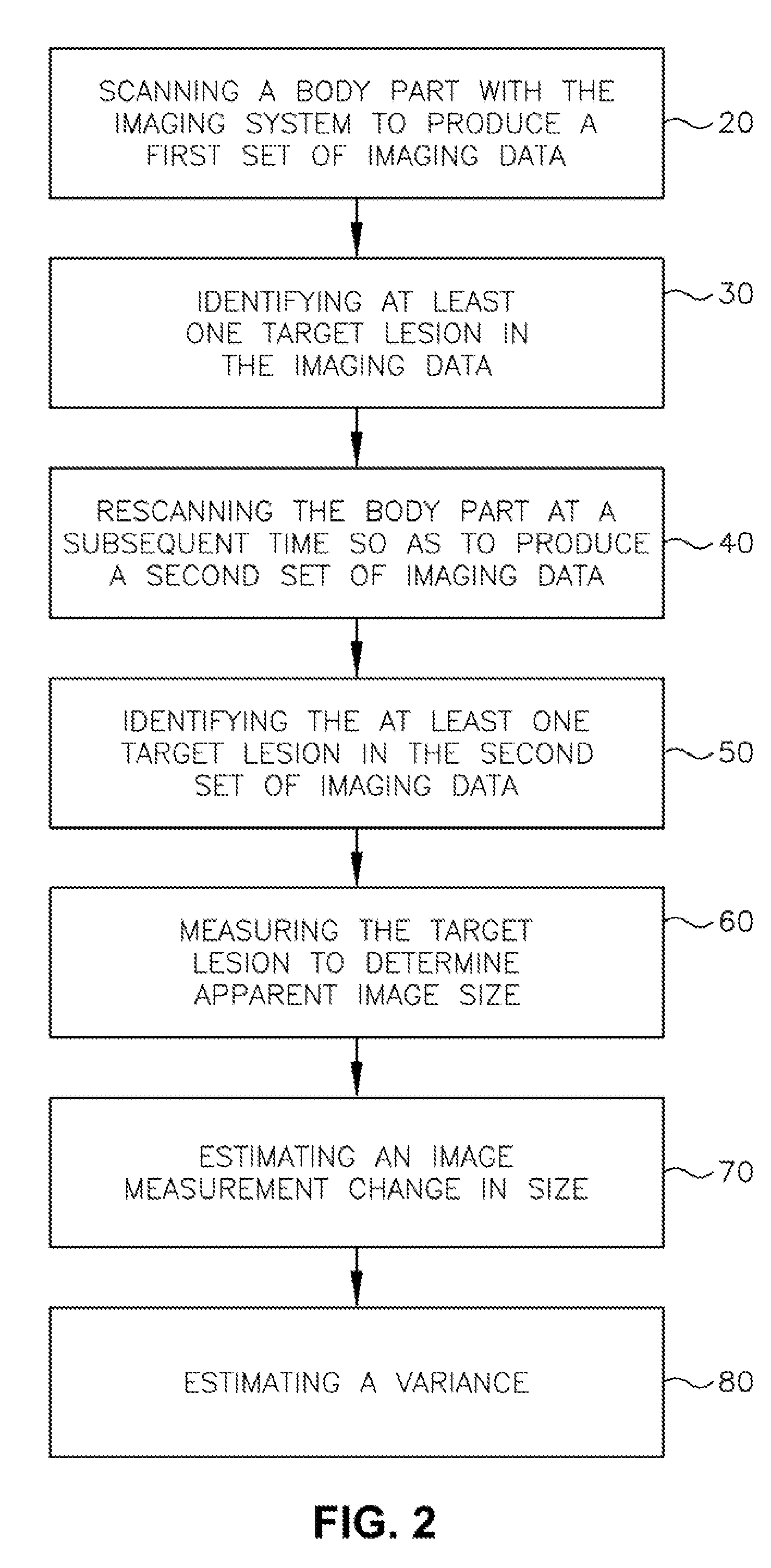

Medical imaging system for accurate measurement evaluation of changes in a target lesion

ActiveUS7876939B2Shorten the lengthShort time intervalImage enhancementImage analysisSize measurementMeasurement evaluation

A body part is scanned to produce a first set of imaging data. A target lesion in the imaging data is identified. The body part is rescanned at a subsequent time so as to produce a second set of imaging data. The target lesion is identified in the second set of imaging data and the size of the target lesion is measured in the first and second sets of imaging data to determine two apparent image volumes corresponding to the first and second sets of imaging data. A change in size is estimated by comparing the first and second apparent lesion sizes. A variance on the change in size is estimated so as to determine a bound on the change in size measurement.

Owner:YANKELEVITZ DAVID DR

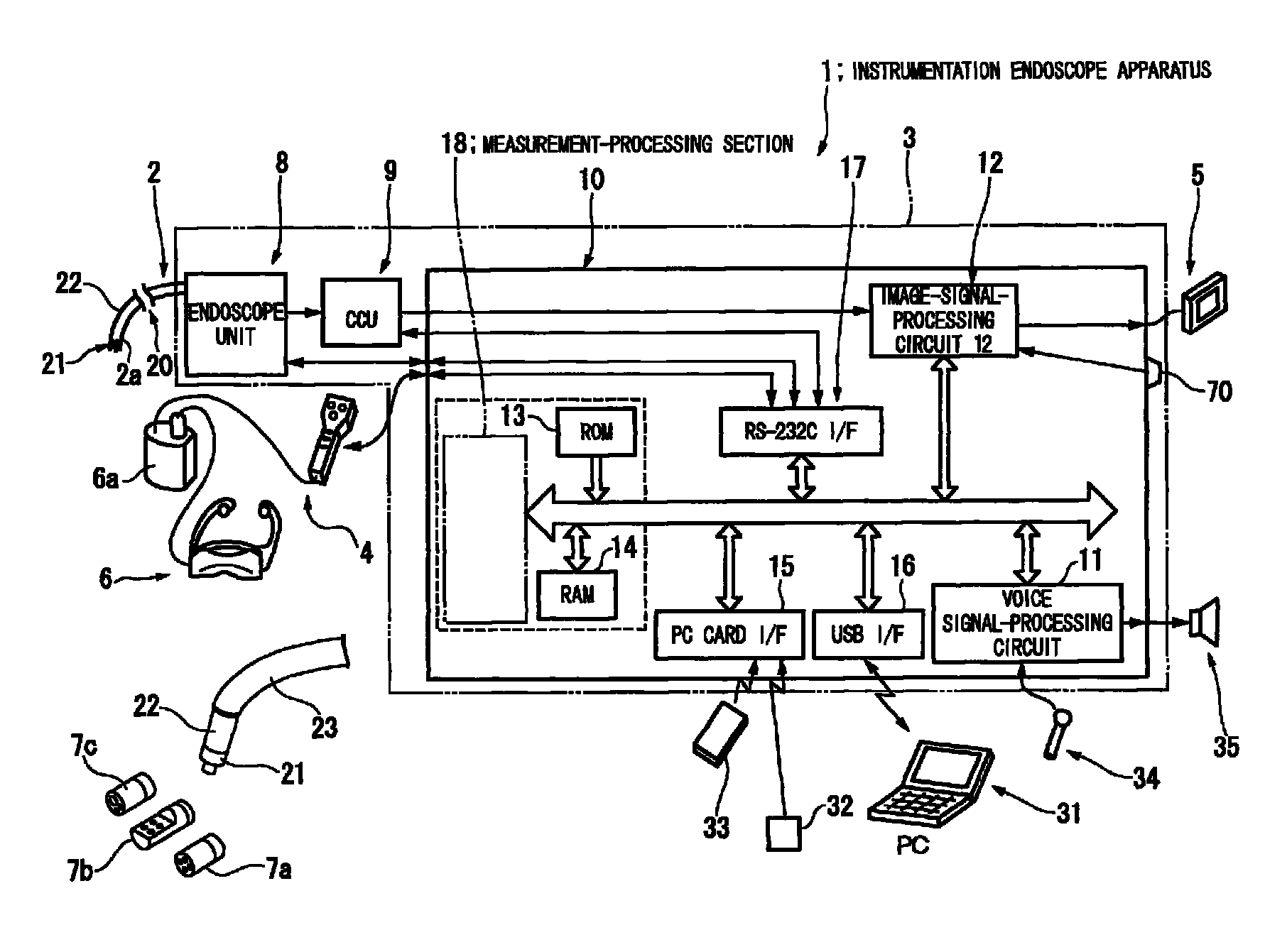

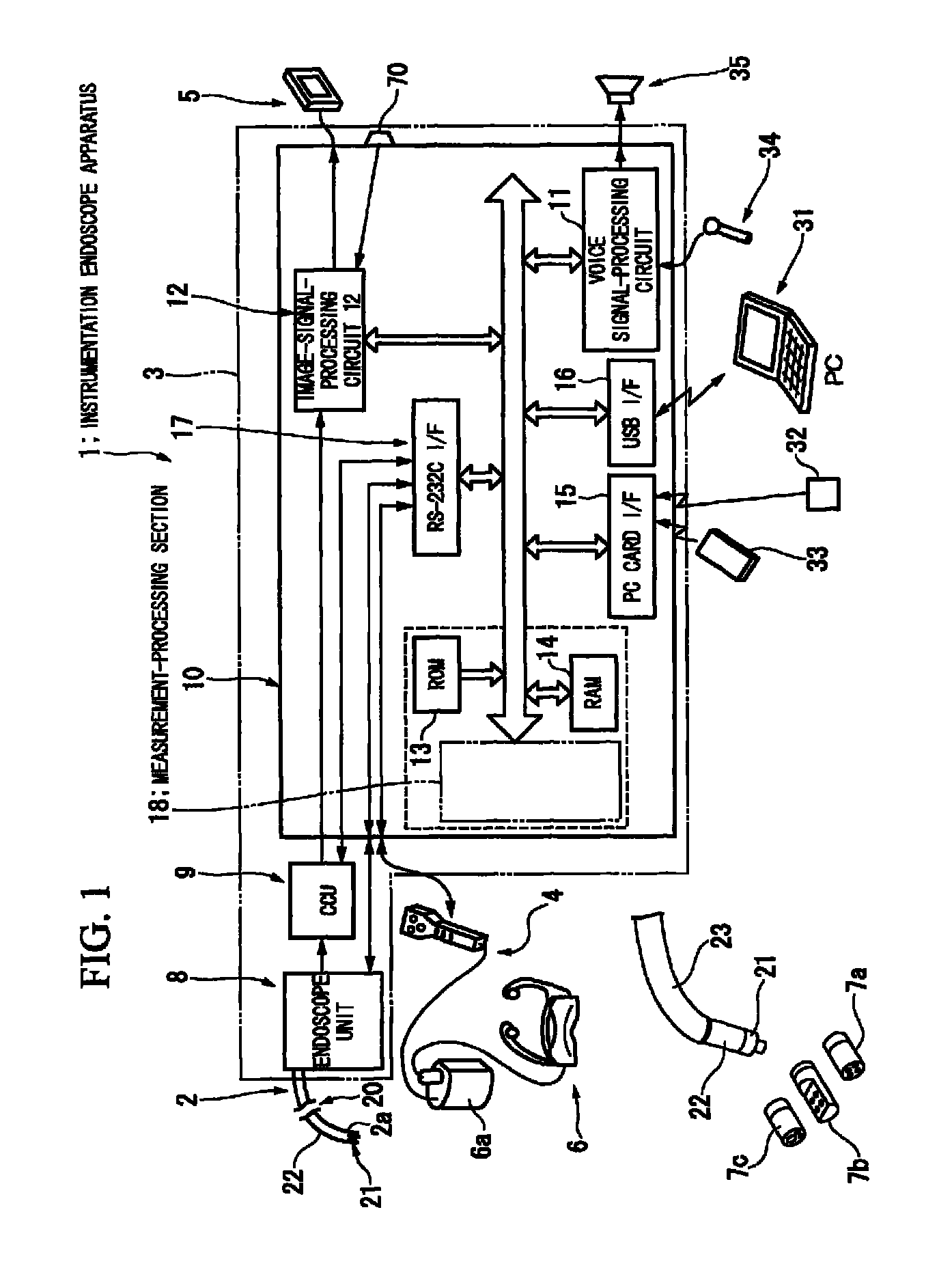

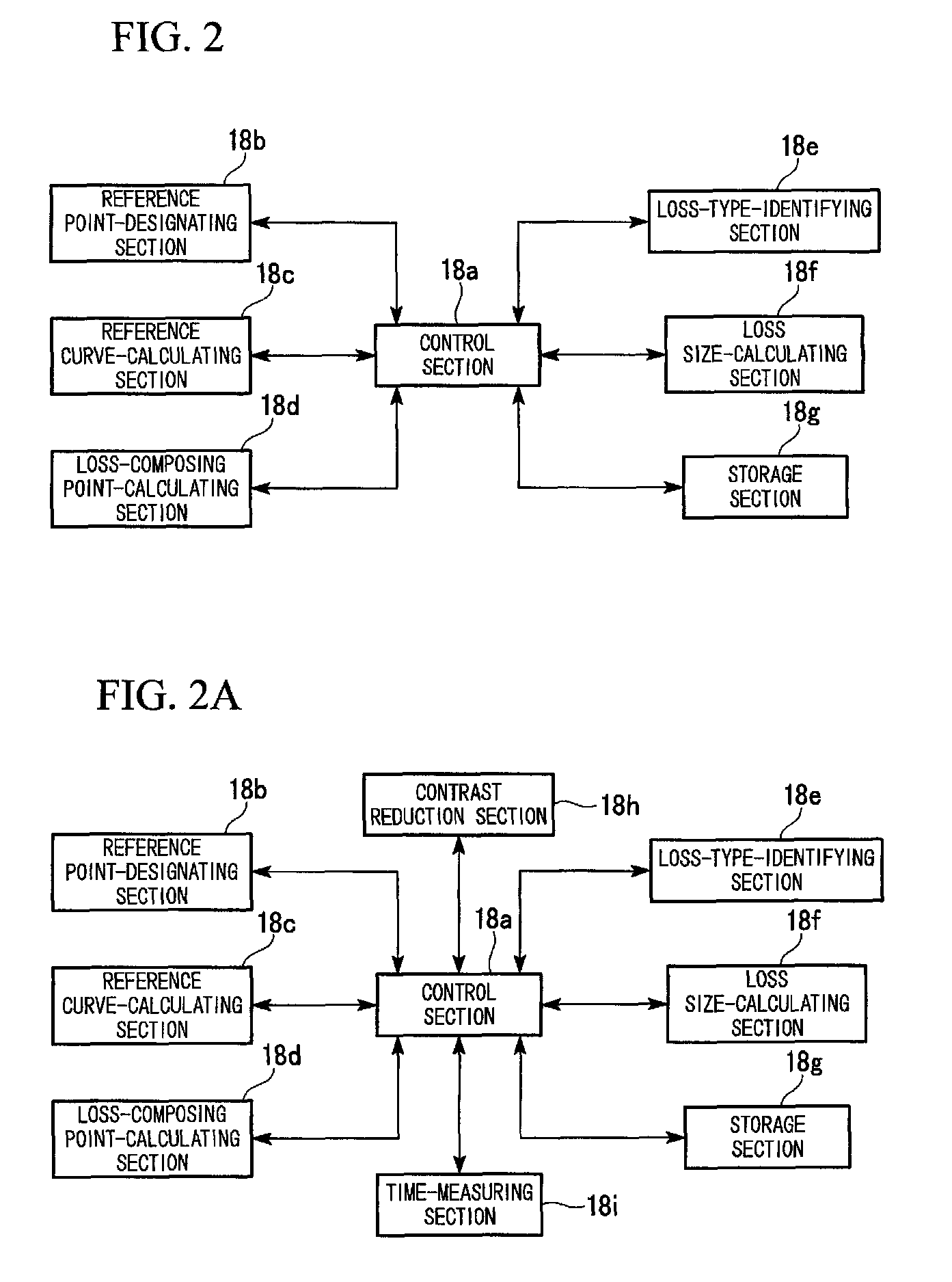

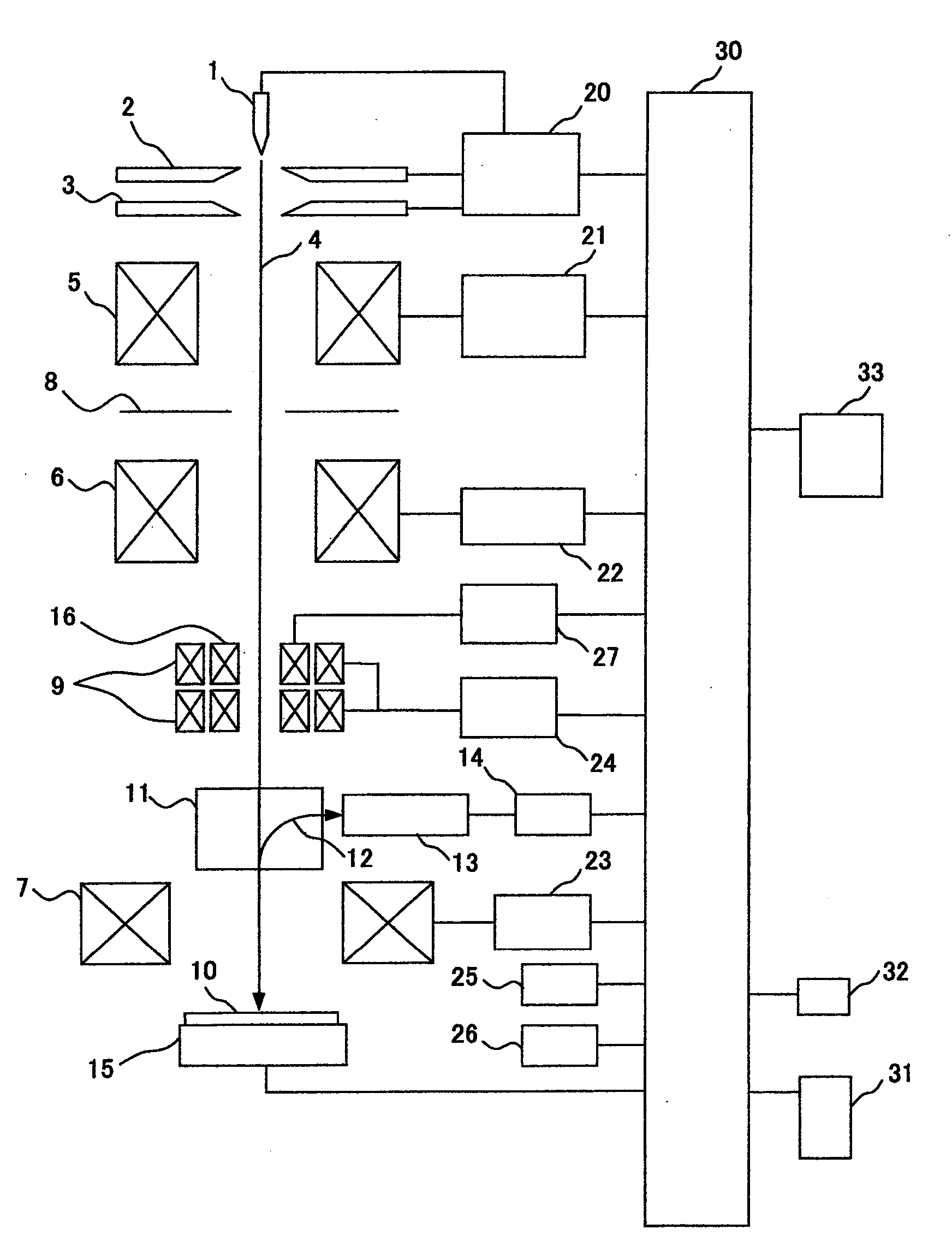

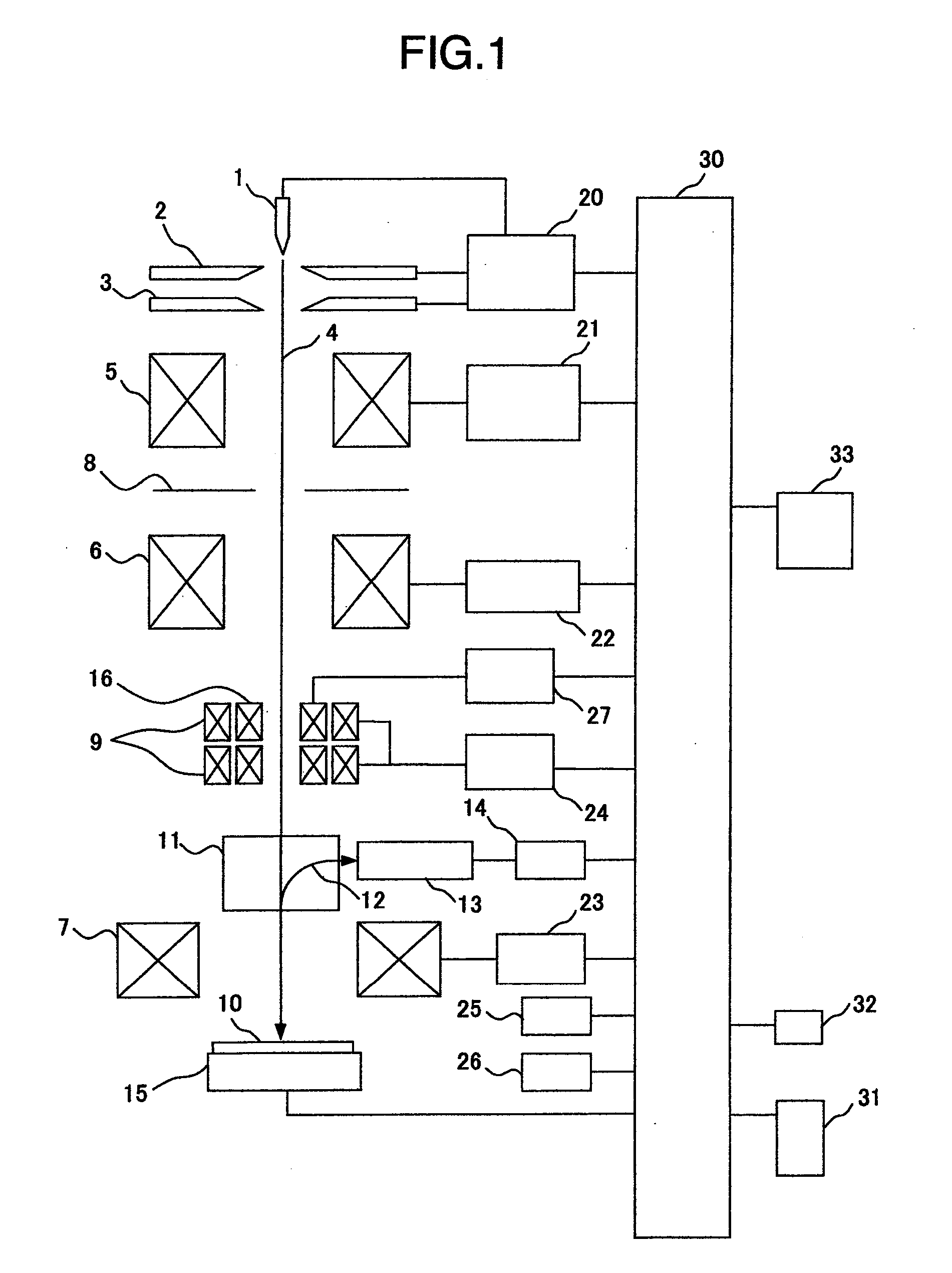

Endoscope apparatus and program

An endoscope apparatus includes an electronic endoscope that picks up a measurement object and produces a picked-up-image signal; an image-processing unit that produces a image signal based on the picked-up-image signal; and an measurement processing unit that undertakes measurement processing to the measurement object based on the image signal. The measurement processing unit includes: a reference point-designating unit that designates two reference points on the measurement object; an approximate-outline—calculating unit that calculates an approximate outline by approximating the outline of the measurement object based on the reference points; and a loss-composing points-calculating unit that calculates loss-composing points that constitute a loss outline formed on the measurement object based on the reference points and the approximate outline. This enables loss size measurement upon designating two reference points, thereby reducing complex operations and improving operability.

Owner:EVIDENT CORP

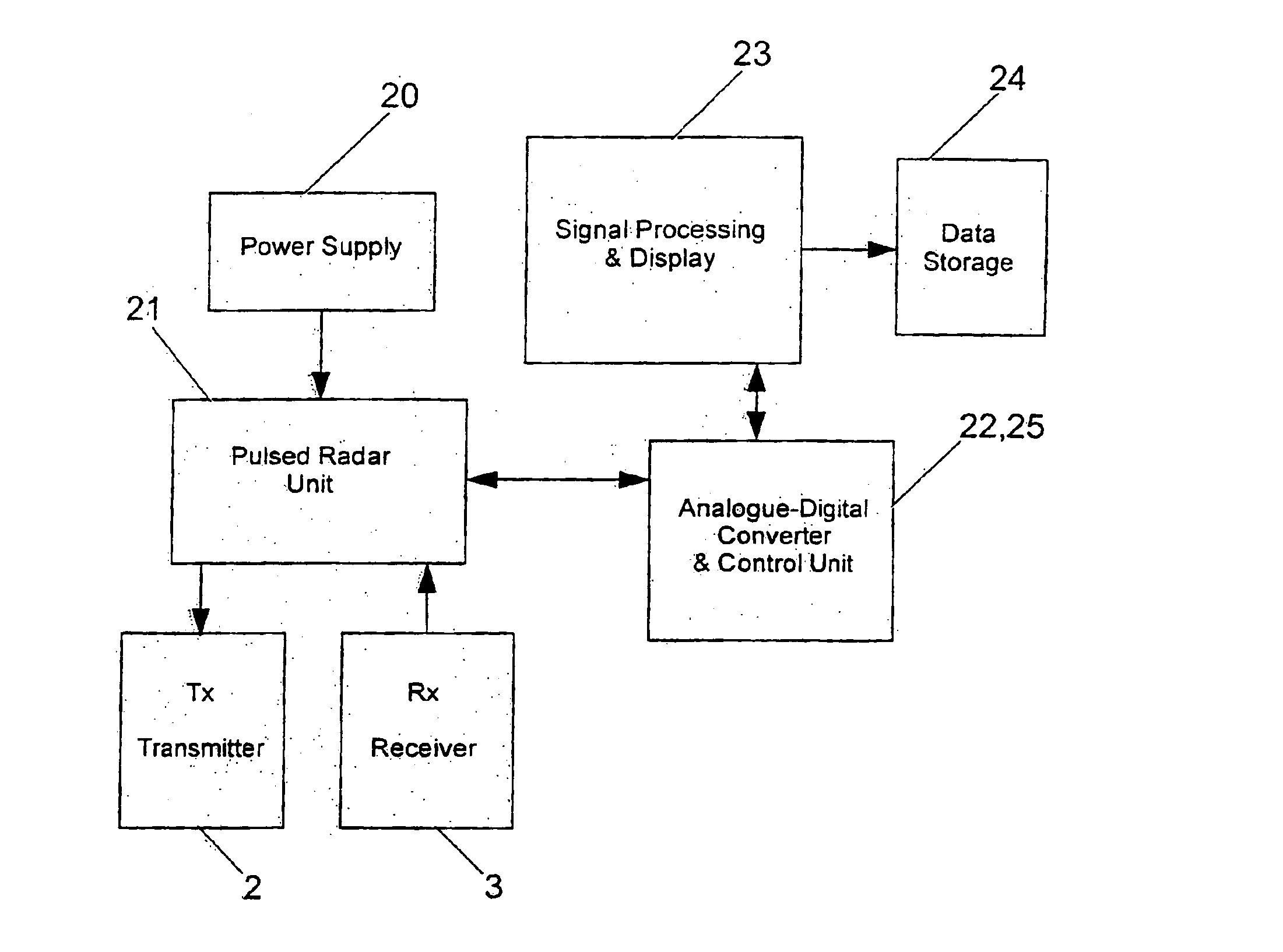

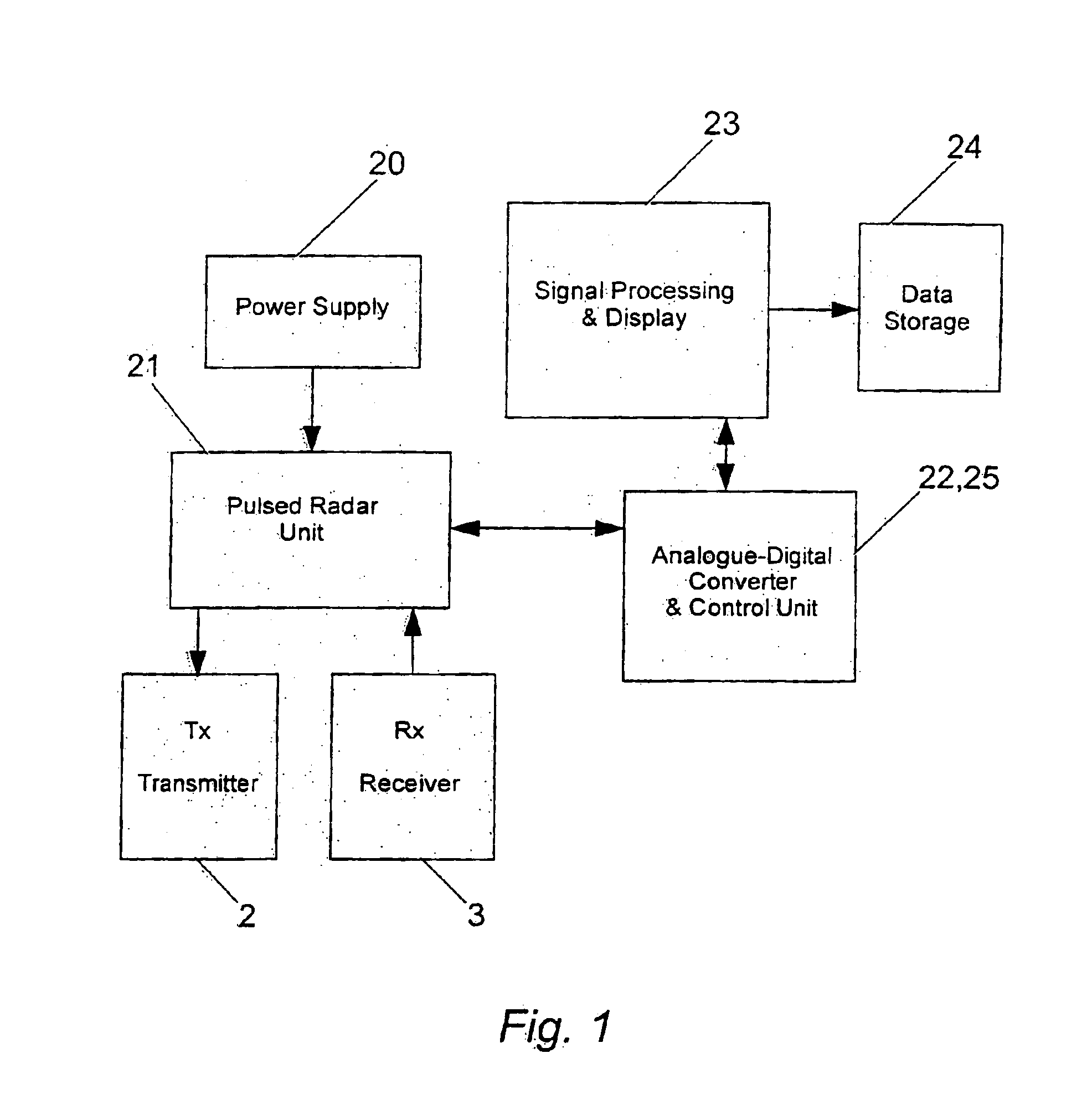

Radar apparatus for imaging and/or spectrometric analysis and methods of performing imaging and/or spectrometric analysis of a substance for dimensional measurement, identification and precision radar mapping

InactiveUS6864826B1Material analysis using microwave meansRadio wave reradiation/reflectionFrequency spectrumStatistical analysis

Radar apparatus and methods of use thereof for imaging and / or spectrometric analysis. The invention employs pulsed radar signals for magnifying, imaging, scale measuring, identifying and / or typecasting the composition of substances by radargrammetric imaging and / or statistical analysis of energy / frequency spectrums. The invention may be used to locate and / or distinguish a substance from other substances, to image a substance / feature and to monitor the movement of an imaged substance / feature. The systems and methods can be adapted for a variety of applications at a wide range of scales and distances, from large scale, long range applications such as geophysical imaging / analysis, to the small scale such as material typecasting applications and small scale (including microscopic) imaging / analysis, including biological and medical imaging and diagnostic applications. The invention includes novel antenna assemblies and novel data processing techniques.

Owner:STOVE GEORGE COLIN

Intervertebral disc space sizing tools and methods

ActiveUS9216098B2Minimize damageImprove Consistency and ReliabilityJoint implantsSpinal implantsDistractionSize measurement

A method and apparatus for making a size measurement within an intervertebral space by placing an expandable and contractible device into the intervertebral space, expanding the device, measuring a size characteristic of the space, contracting the device and then removing it. The measurement may be accomplished by an external x-ray or other imaging device imaging the expanded device in situ or by mechanically operated devices. An expansion and contraction mechanism such as fluid containing bladder or mechanically shifted members expands the device which later contracts in a controlled manner to the contracted size. An apparatus and method is provided for the measuring of the intervertebral space at a controlled distraction force. The apparatus includes an expandable device for providing a measurement within the intervertebral space and facilitating the measurement of the angulations of the lordotic curve of the intervertebral space.

Owner:XTANT MEDICAL HLDG INC

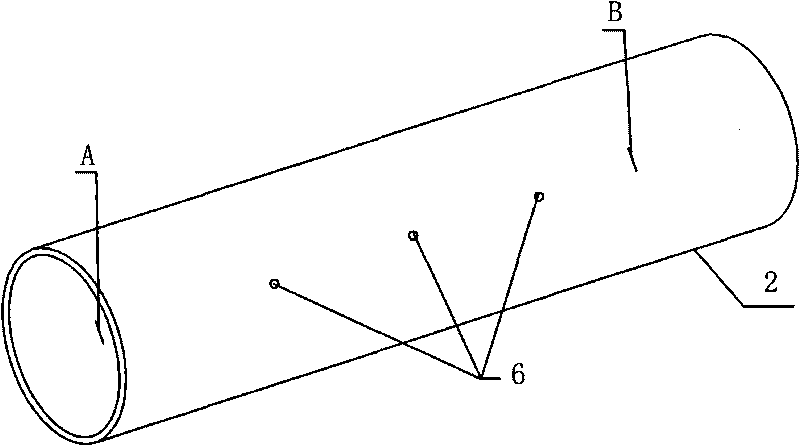

Power station thick-walled pipeline ultrasonic guided wave detecting method

ActiveCN101726541AQuick checkReliable detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSize measurementPower station

The invention belongs to the field of nondestructive detection, and particularly relates to a power station thick-walled pipeline ultrasonic guided wave detecting method, wherein the method comprises the following steps of: selecting an ultrasonic guided wave detecting probe; selecting an ultrasonic guided wave detecting instrument; manufacturing a sensitivity test block; making a distance-amplitude curve; scanning; carrying out flaw size measurement; and verifying and grading detecting results. The detecting method is suitable for comprehensively detecting the flaws of pipelines with different pipe diameters and thicknesses, and is particularly suitable for comprehensively detecting power station thick-walled pipelines. The detecting method has the characteristics of rapidness, simpleness, safety and reliability, can overcome some limitations of a conventional nondestructive detection method, lowers the manual detection intensity and saves human and material resources.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

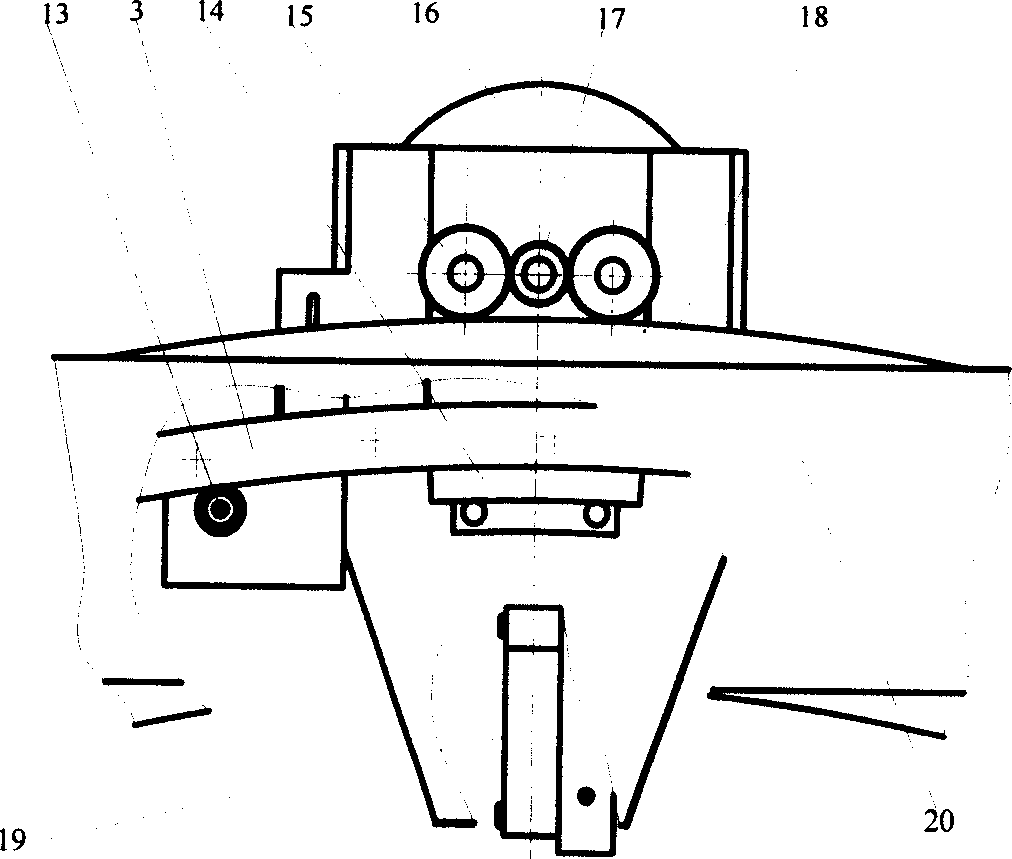

Vehicle size measurement method and device

ActiveCN102679889ASolve the problem that the size cannot be measured quickly and accuratelyAccurate measurementUsing optical meansSize measurementRadar

The invention discloses a vehicle size measurement method and a device. The vehicle size measurement method comprises scanning a plane vertical to the running direction of a vehicle by a laser radar to measure the width and the height of the vehicle; and scanning a plane parallel to running direction of the vehicle and vertical to the horizontal plane by the laser radar to measure the length of the vehicle. According to the vehicle size measurement method and device provided by the invention, the critical positions in the three dimensions of length, width and height of the vehicle can be measured by the laser radar, and the vehicle size can be calculated by reducing the critical positions on both ends in each dimension. Accordingly, the problem in quickly and accurately measuring the vehicle size is solved, thereby realizing quick and accurate measurement.

Owner:恒华数元科技(天津)有限公司

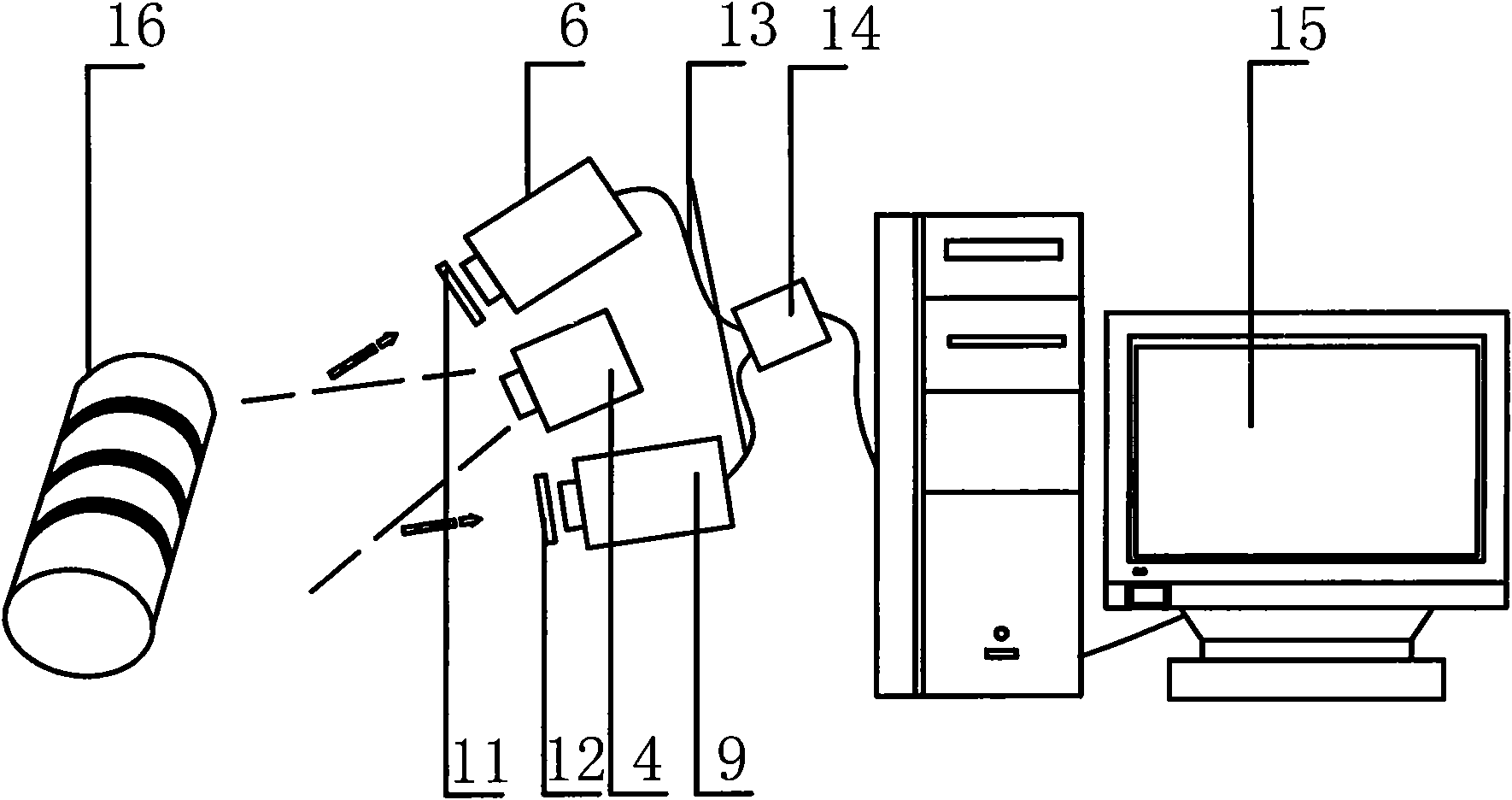

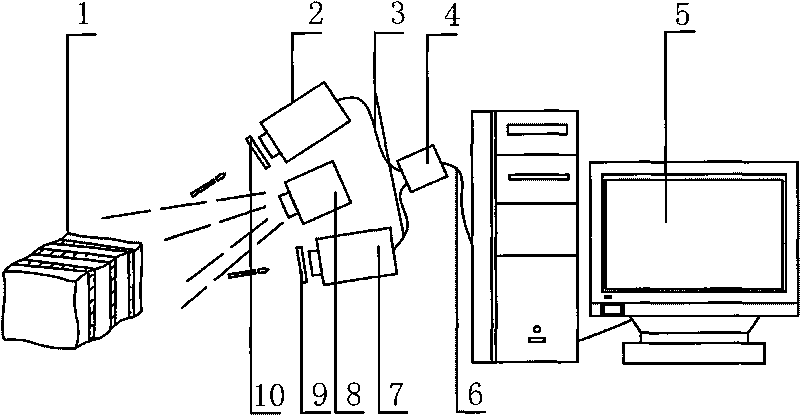

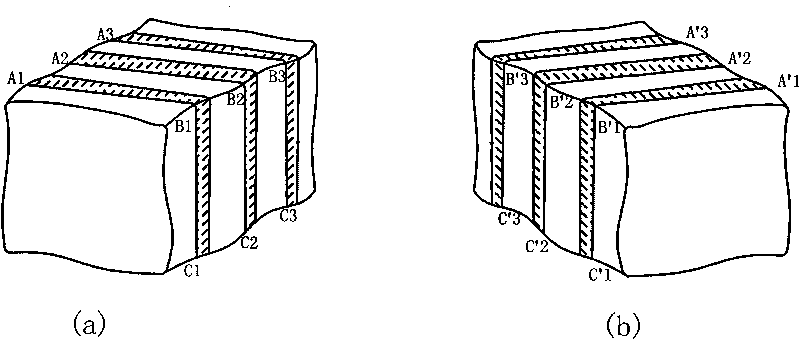

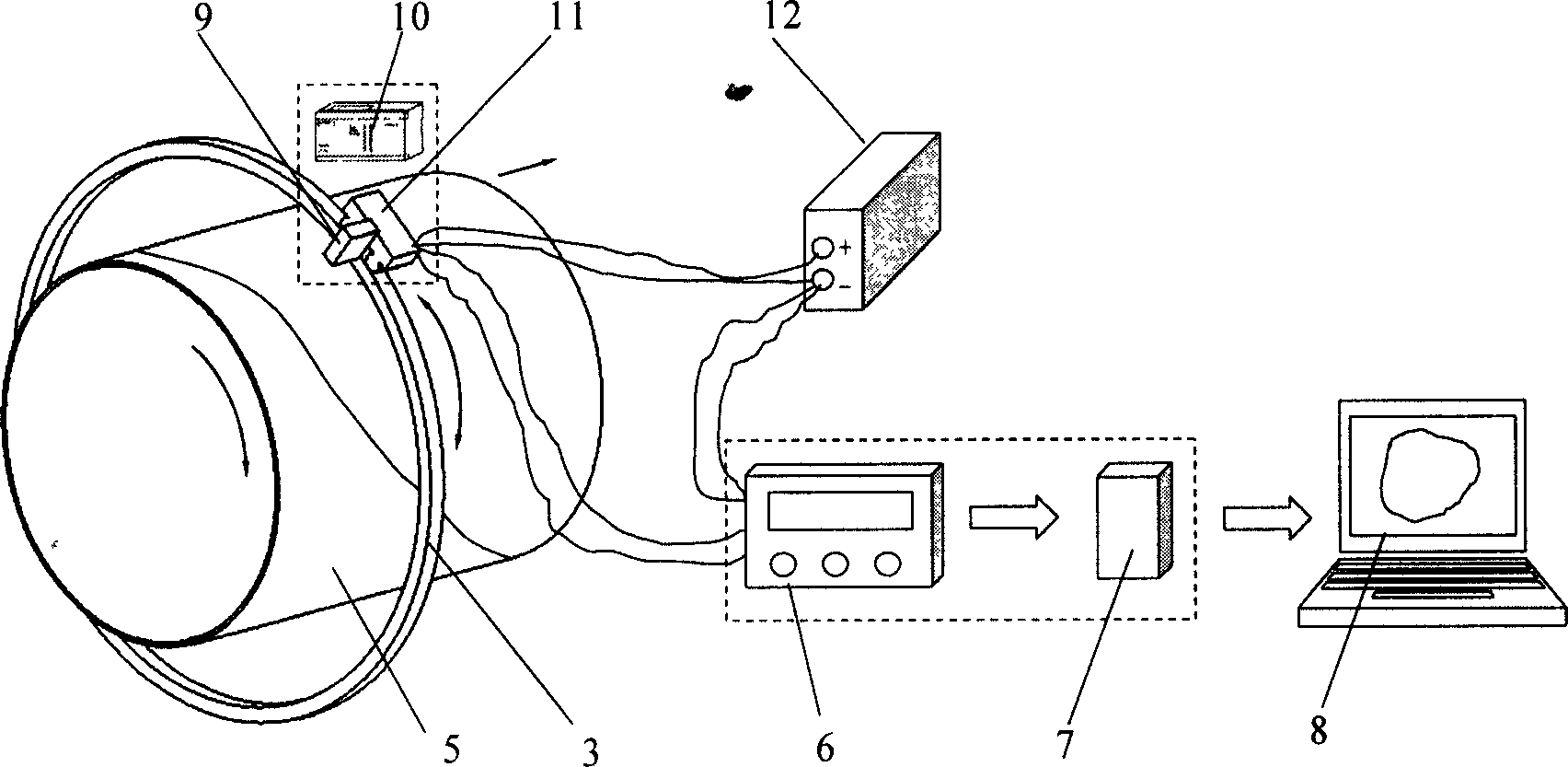

Non-contact measurement method for thermal state sizes of forgings

ActiveCN101713640ARealize real-time non-contact measurementGuaranteed real-time effectivenessImage analysisMetal-working apparatusThermal stateCalibration result

The invention relates to a non-contact measurement method for thermal state sizes of forgings, in particular to a method for measuring the sizes of the forgings by using strip structured light, and belongs to the field of high-temperature forging size measurement,. The method comprises the following steps of: dividing the forgings into a square class and a cylindrical class, then calibrating internal and external parameters of a first CCD camera and a second CCD camera, and building a coordinate relation of the cameras and an external viewing field; projecting the strip structured light to the high-temperature forgings; acquiring images of the high-temperature forgings projected by the strip structured light by an image acquisition system; processing the acquired images; quickly extracting feature points of the associated forging size by analyzing shape characteristics of the edge of the structured light on the cylindrical and the square forgings; combining calibration results of the first CCD camera and the second CCD camera to carry out three-dimensional modeling on the feature points of the forgings; and calculating the forging size and partial form and position errors of the forgings. The method adopts the binocular vision technology to shoot the images of the high-temperature forgings in real time, is quick and accurate in measurement, and can meet the requirements of industrial forging and stamping production.

Owner:DALIAN UNIV OF TECH

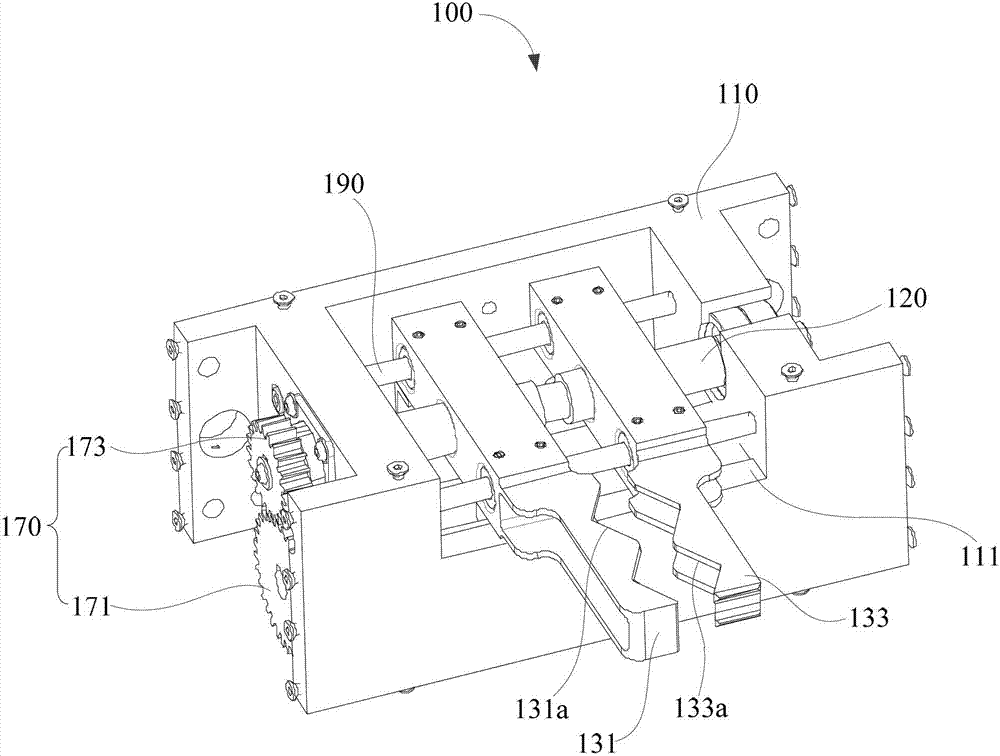

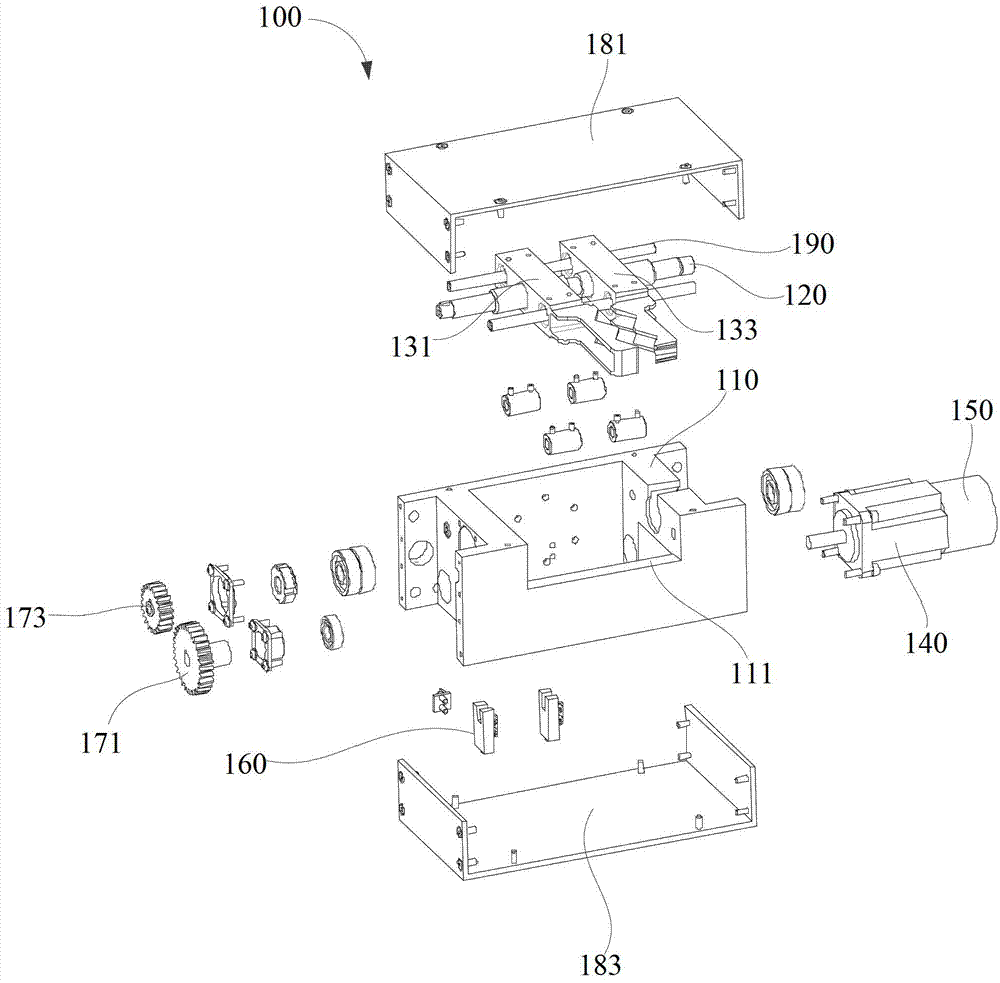

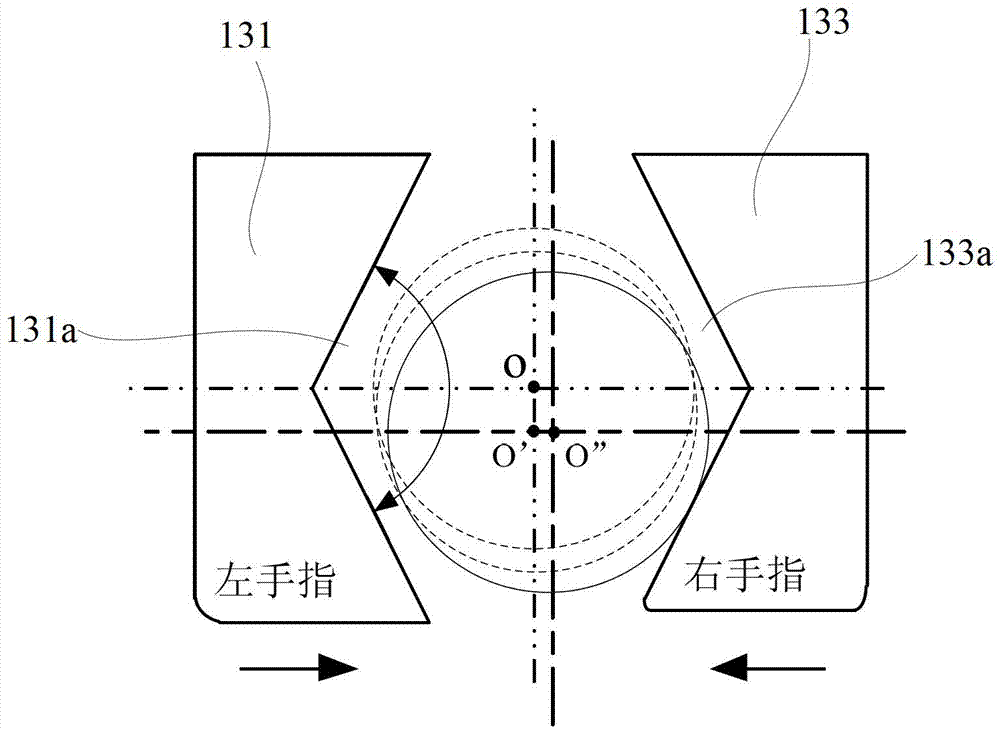

Mechanical gripper of dispensing robot

ActiveCN102785251AAchieve adaptiveRealize automatic centeringGripping headsSize measurementMotor drive

The invention relates to a mechanical gripper of a dispensing robot. The mechanical gripper of the dispensing robot comprises a rack, a double-threaded screw, a left finger and a right finger, a motor, an encoder and a gripper controller, wherein the double-threaded screw is rotatably arranged on the rack, and the two ends of the double-threaded screw are respectively provided with threaded parts; the rotating directions of the threaded parts are opposite, and the left finger and the right finger are respectively matched with the two threaded parts of the double-threaded screw; the double-threaded screw rotates to drive the left finger and the right finger to move closely or oppositely, and the rotating shaft of the motor drives the double-threaded screw to rotate; the encoder is used for detecting the rotating position of the rotating shaft of the motor, and the gripper controller is connected with the motor and the encoder, and is used for controlling the rotation of the motor and processing signals fed back by the encoder; and the left finger and the right finger are provided with wedge-shaped grooves, and the wedge-shaped groove of the left finger is corresponding to the wedge-shaped groove of the right finger, so that a drug bottle is clamped in a clamping space formed by the wedge-shaped groove of the left finger and the wedge-shaped groove of the right finger. The mechanical gripper has the functions of size measurement, self-adaptability, self-centering and controllable gripping force.

Owner:深圳市博为医疗机器人有限公司

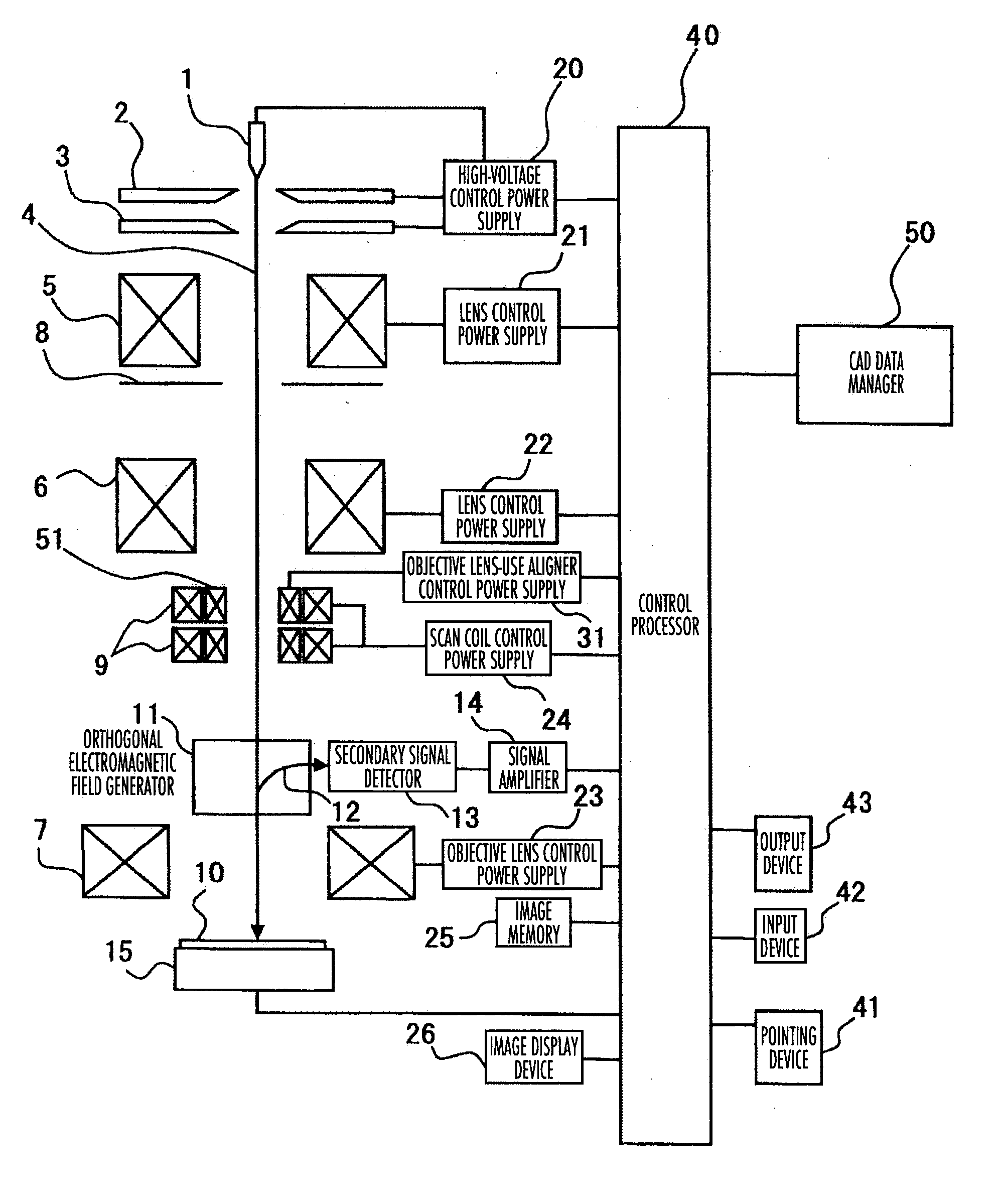

Sample dimension inspecting/measuring method and sample dimension inspecting/measuring apparatus

ActiveUS20090218491A1Improve accuracyReduce measurement errorImage enhancementMaterial analysis using wave/particle radiationMeasurement deviceSize measurement

One of principal objects of the present invention is to provide a sample dimension measuring method for detecting the position of an edge of a two-dimensional pattern constantly with the same accuracy irrespective of the direction of the edge and a sample dimension measuring apparatus. According to this invention, to accomplish the above object, it is proposed to correct the change of a signal waveform of secondary electrons which depends on the direction of scanning of an electron beam relative to the direction of a pattern edge of an inspection objective pattern. It is proposed that when changing the scanning direction of the electron beam in compliance with the direction of a pattern to be measured, errors in the scanning direction and the scanning position are corrected. In this configuration, a sufficient accuracy of edge detection can be obtained irrespective of the scanning direction of the electron beam.

Owner:HITACHI HIGH-TECH CORP

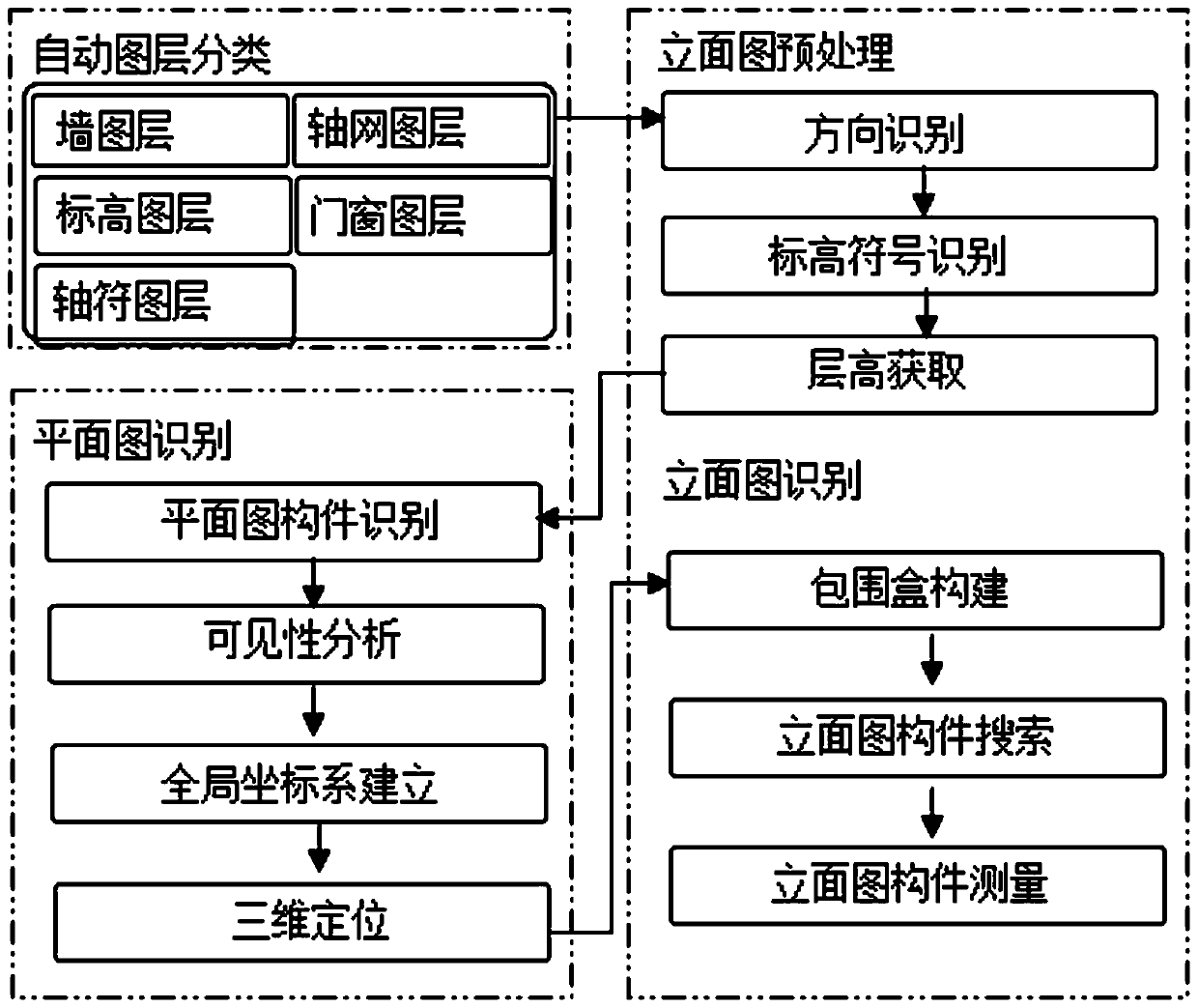

Vertical graph identification method for converting architectural drawing into three-dimensional BIM model

ActiveCN109993827AImprove integrityImprove accuracyGeometric CADSpecial data processing applicationsVisibilitySize measurement

The invention discloses a vertical graph recognition method for converting a building drawing into a three-dimensional BIM model, and the method comprises the following steps: a, obtaining a target graph layer of the CAD building drawing, and obtaining a wall graph layer, a door and window graph layer, an elevation graph layer, an axis symbol graph layer, and an axis network graph layer; b, performing direction identification, elevation symbol identification and story height acquisition on each vertical drawing of the CAD building drawings; c, performing building component recognition, visibility analysis and three-dimensional positioning on each layer of plane drawing of the CAD building drawing; d, carrying out bounding box construction on the elevation drawing paper in each direction ofthe CAD building drawing paper, and carrying out search and size measurement on the elevation drawing component; according to the method, when the CAD building drawing is converted into the three-dimensional BIM model, the components of the elevation map of the CAD building drawing are recognized, the size numerical value of the components is obtained, and the CAD building drawing recognition andthree-dimensional BIM model reconstruction efficiency is improved.

Owner:宁波睿峰信息科技有限公司

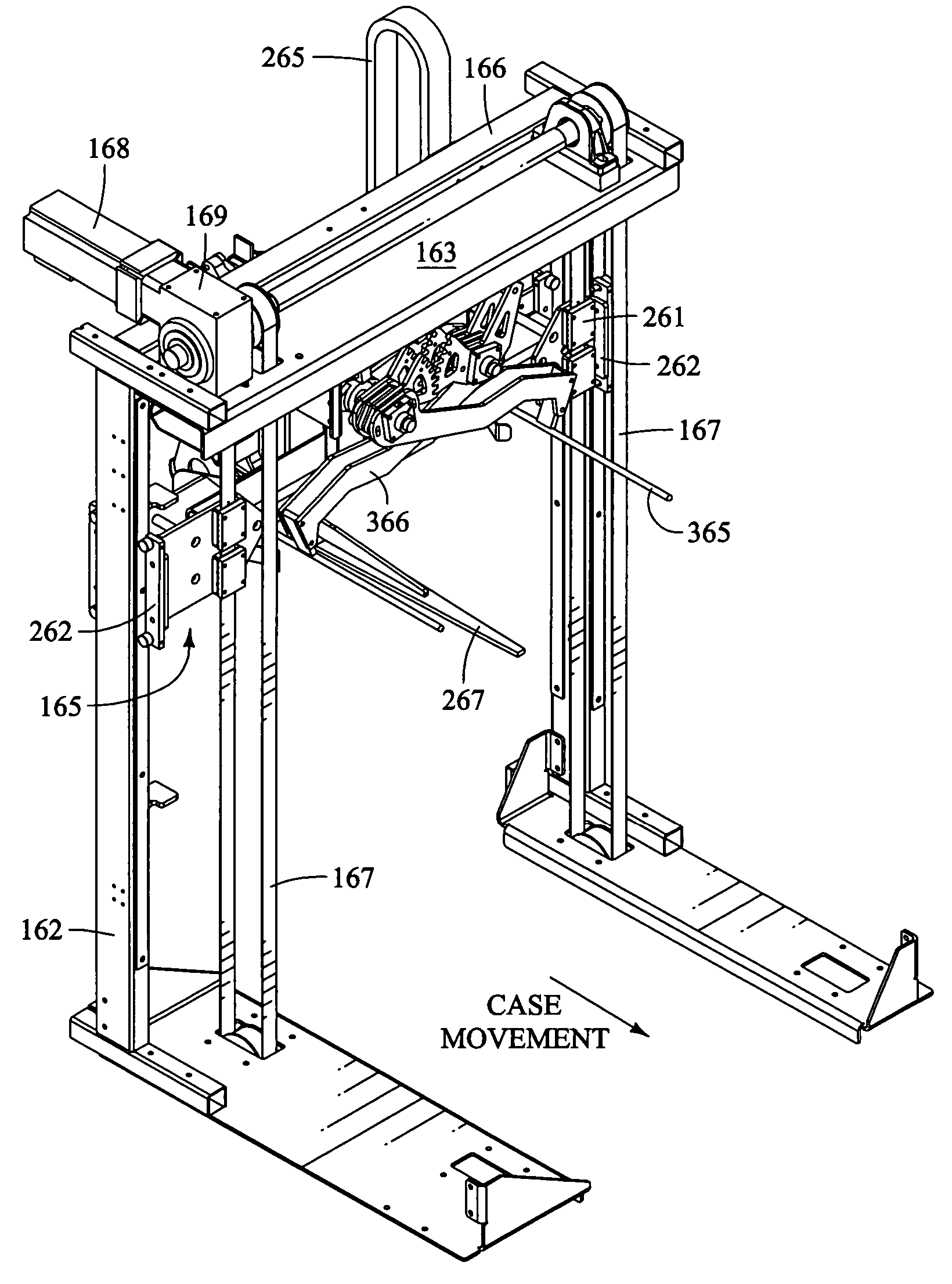

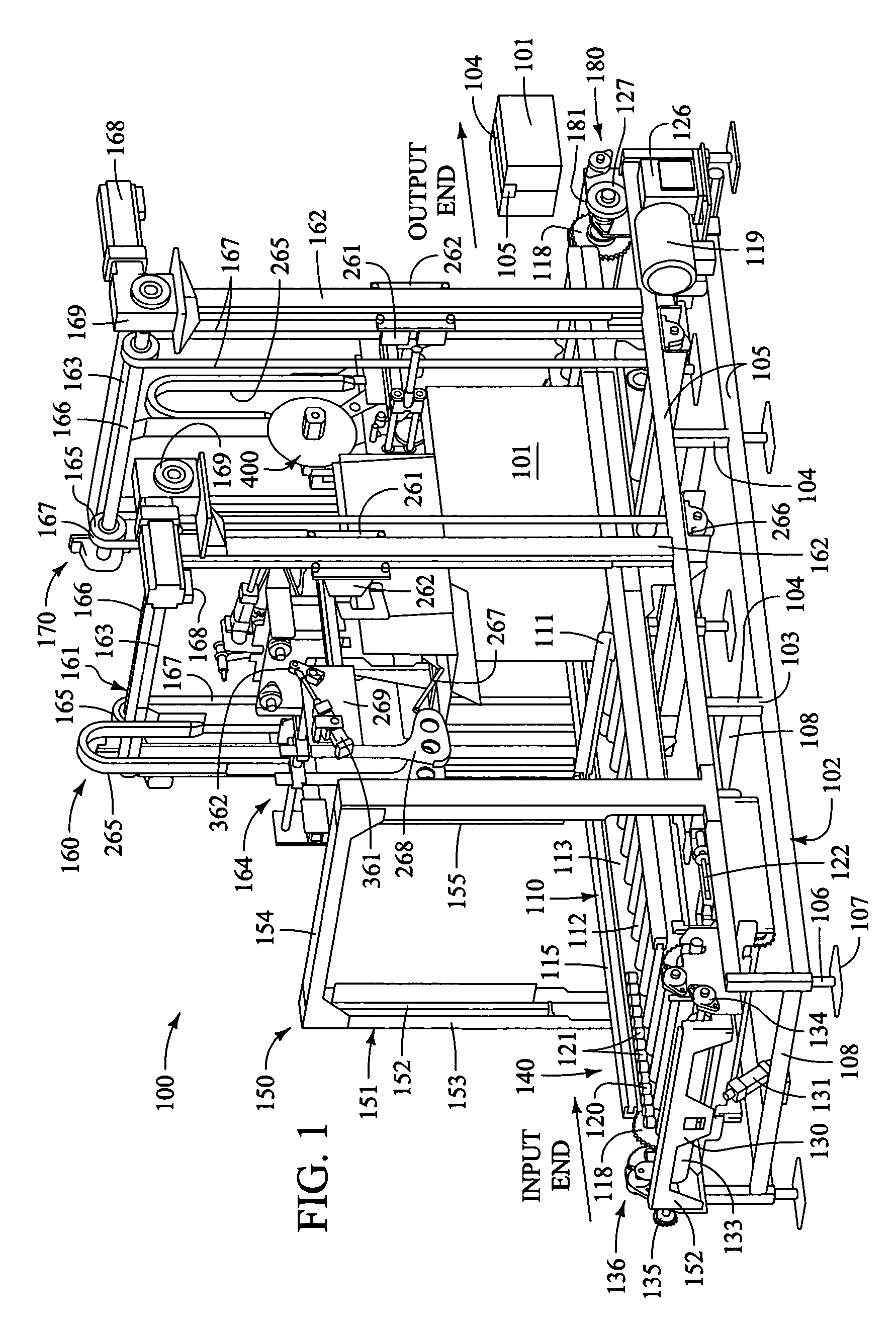

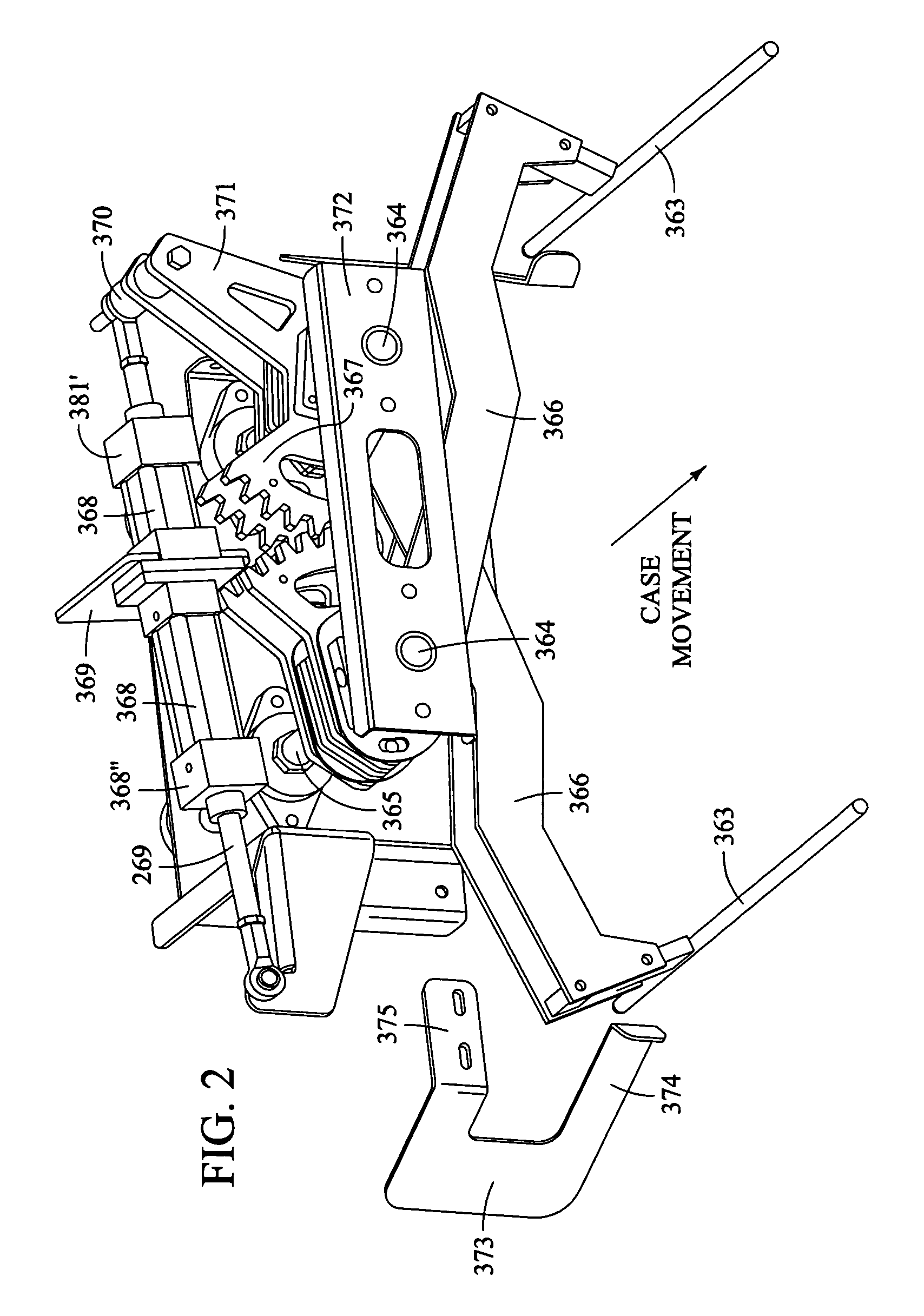

Packaging case closing and tape sealing machine and processes

A machine for closing and sealing cardboard boxes or other packaging cases with random sizes of cases presented. An input gate controls passage of cases onto at least one conveyor that moves the cases through the machine. An input positioning stage centers and squares the case. A measuring station performs a primary measurement of the width and height of the open case. A closing station and tape sealing station are adjusted to the primary case size measurement. The case closing station then closes the case. The side major flaps are closed using a major flap closer with crossed arms pivoted at separated pivot axes. The sealing station has a secondary or closed case measurement detector which more accurately adjusts the tape applicator height. Lateral support heads engage the sides of the case to prevent distortion while tape is applied.

Owner:R A PEARSON

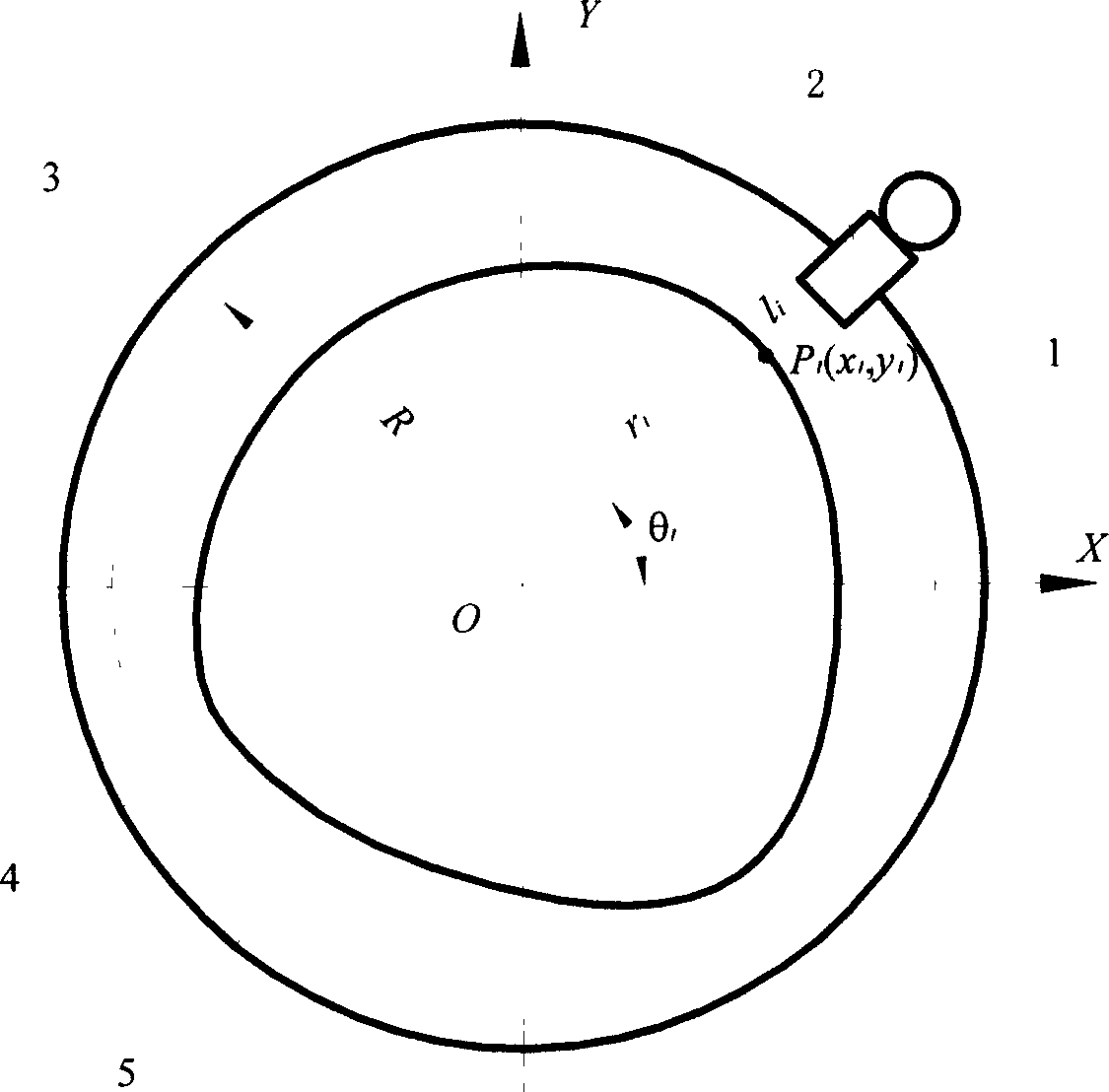

System and method for measuring section shape and size of heavy caliber steel pipe

InactiveCN1734233ATrue reflection of geometric featuresReflect geometric featuresMeasurement devicesInformation processingSize measurement

This invention discloses such a measurement and method of a large caliber steel tube cross-section shape, which belongs to the domain of geometric measurement technique. The measurement system of information processing mode and measurement mode is located in the small moving car, with the small car moving on the datum circular orbit. The input and output mode connect the information processing mode through the serial port. The measurement method is like this: testing a series of the steel tube surface and the radial distance of a certain known datum circular orbit radius in order to get a configuration point coordinates of the steel tube cross-section. When the amount of sampling points is abundant enough, we can get the accurate outline of steel tube. Then the information-processing mode counts the steel tube cross-section shape and dimension parameter.

Owner:TSINGHUA UNIV

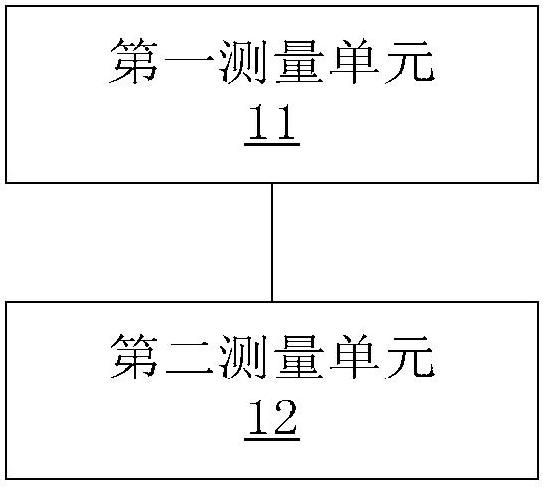

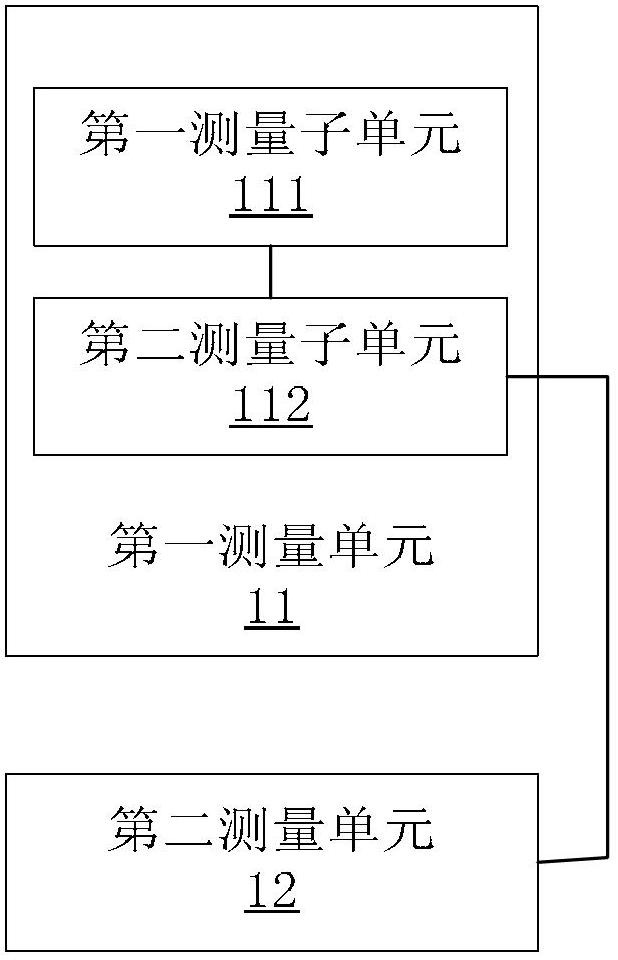

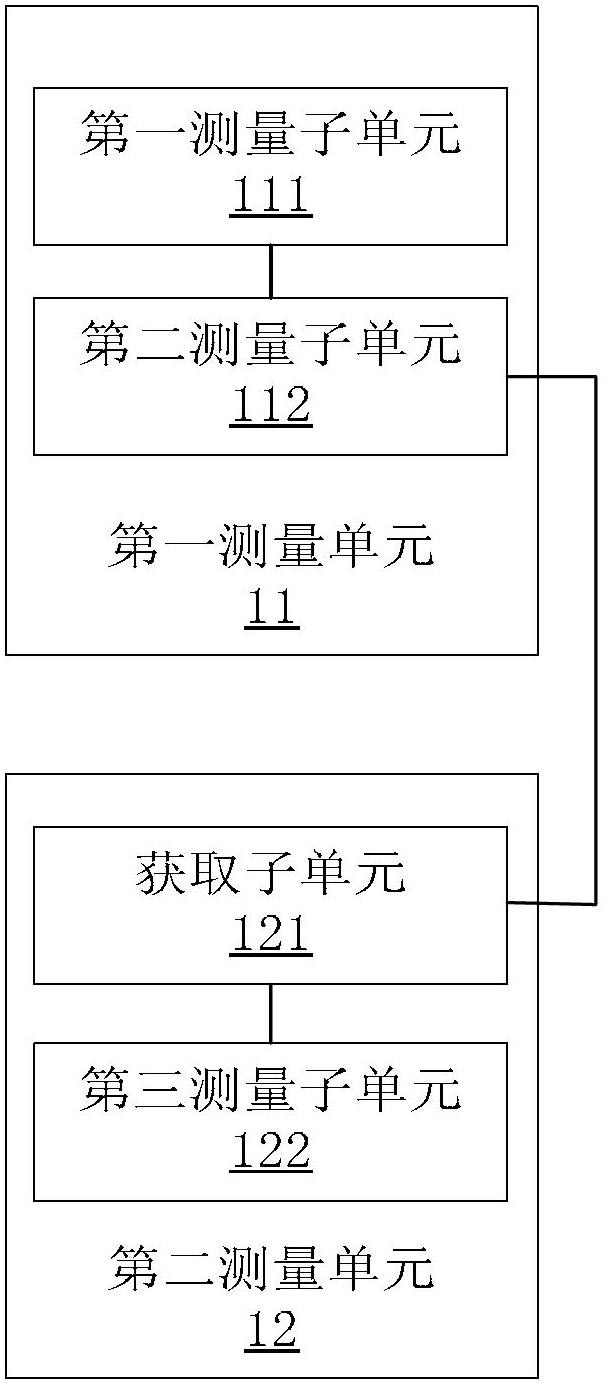

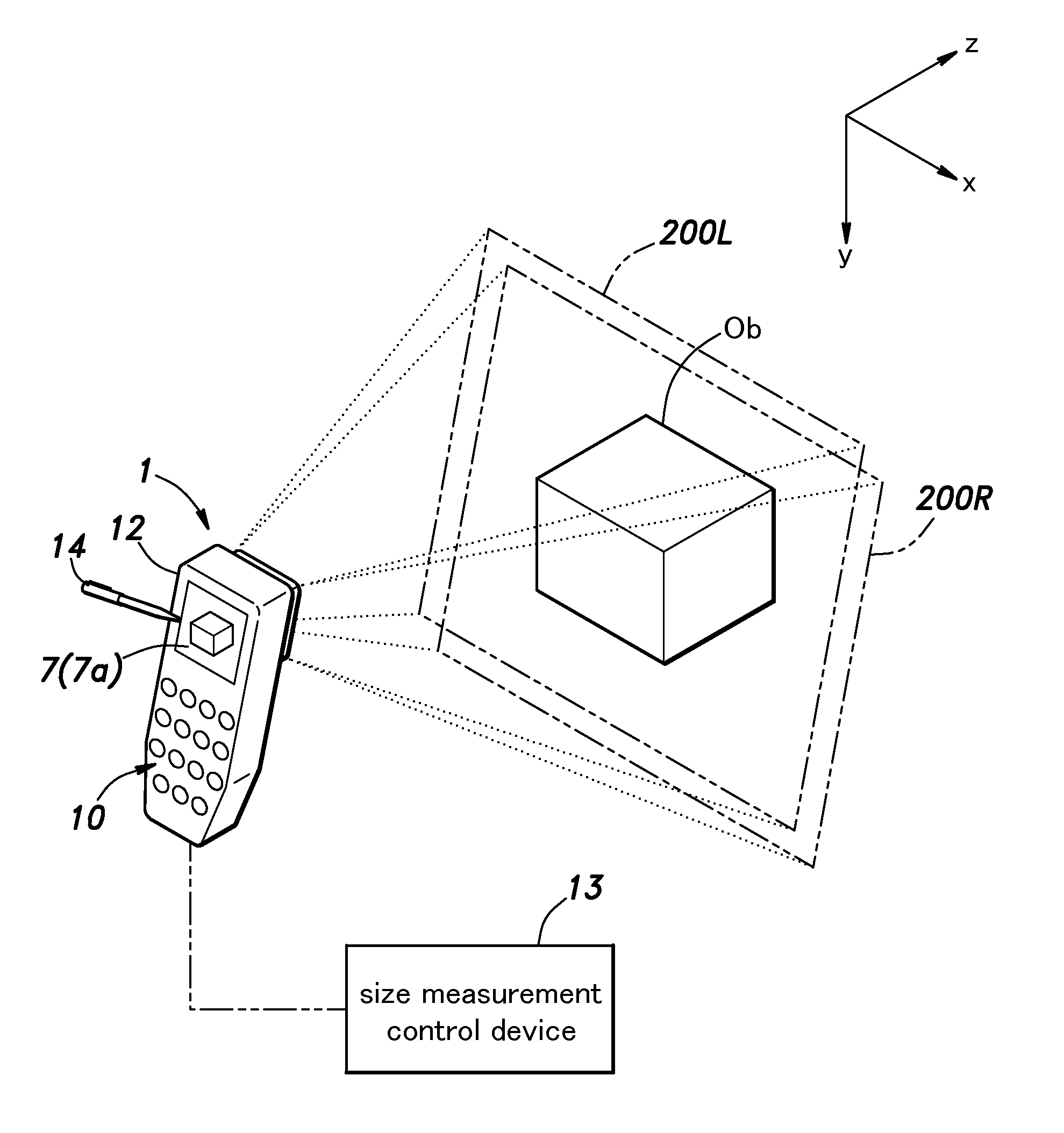

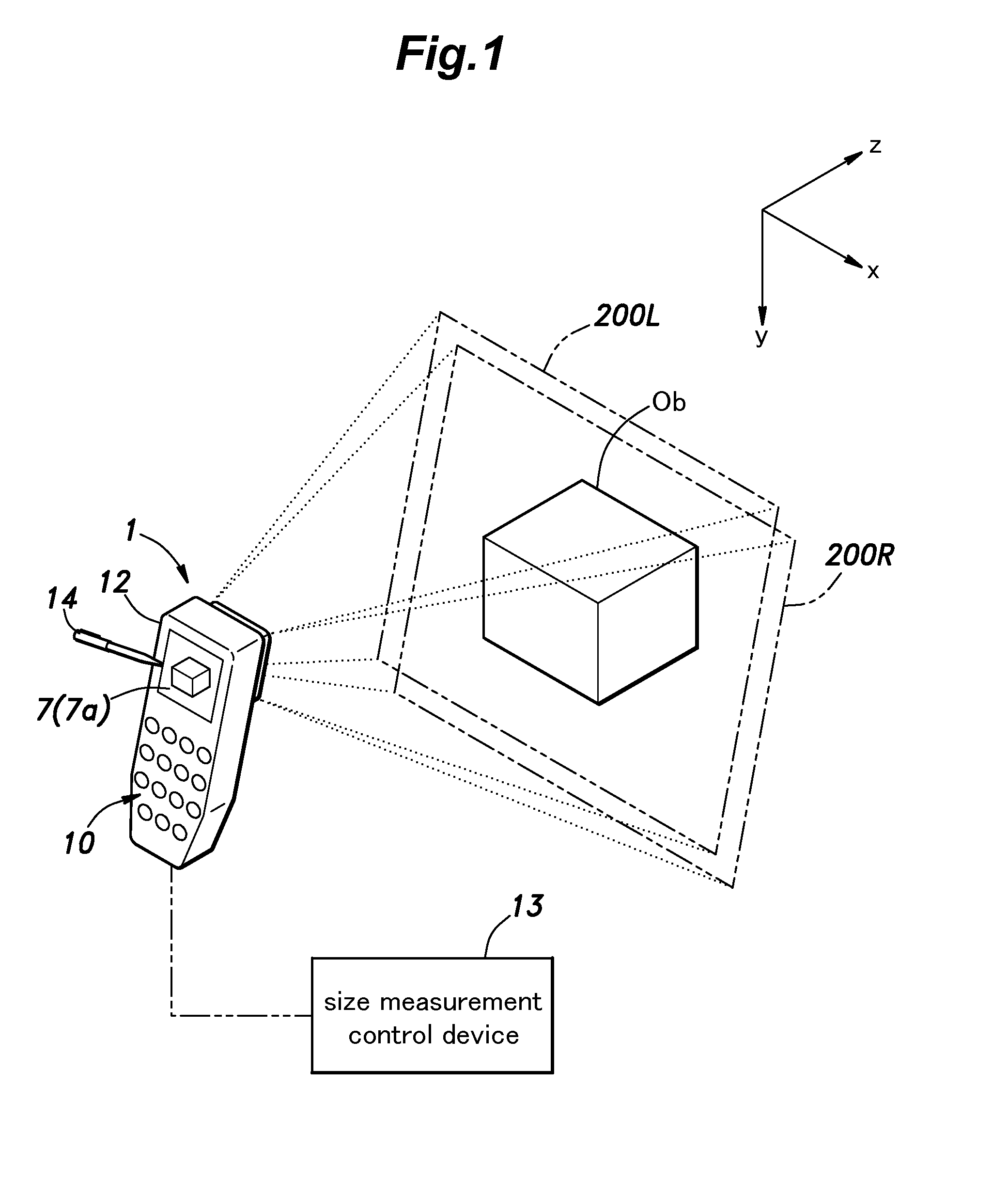

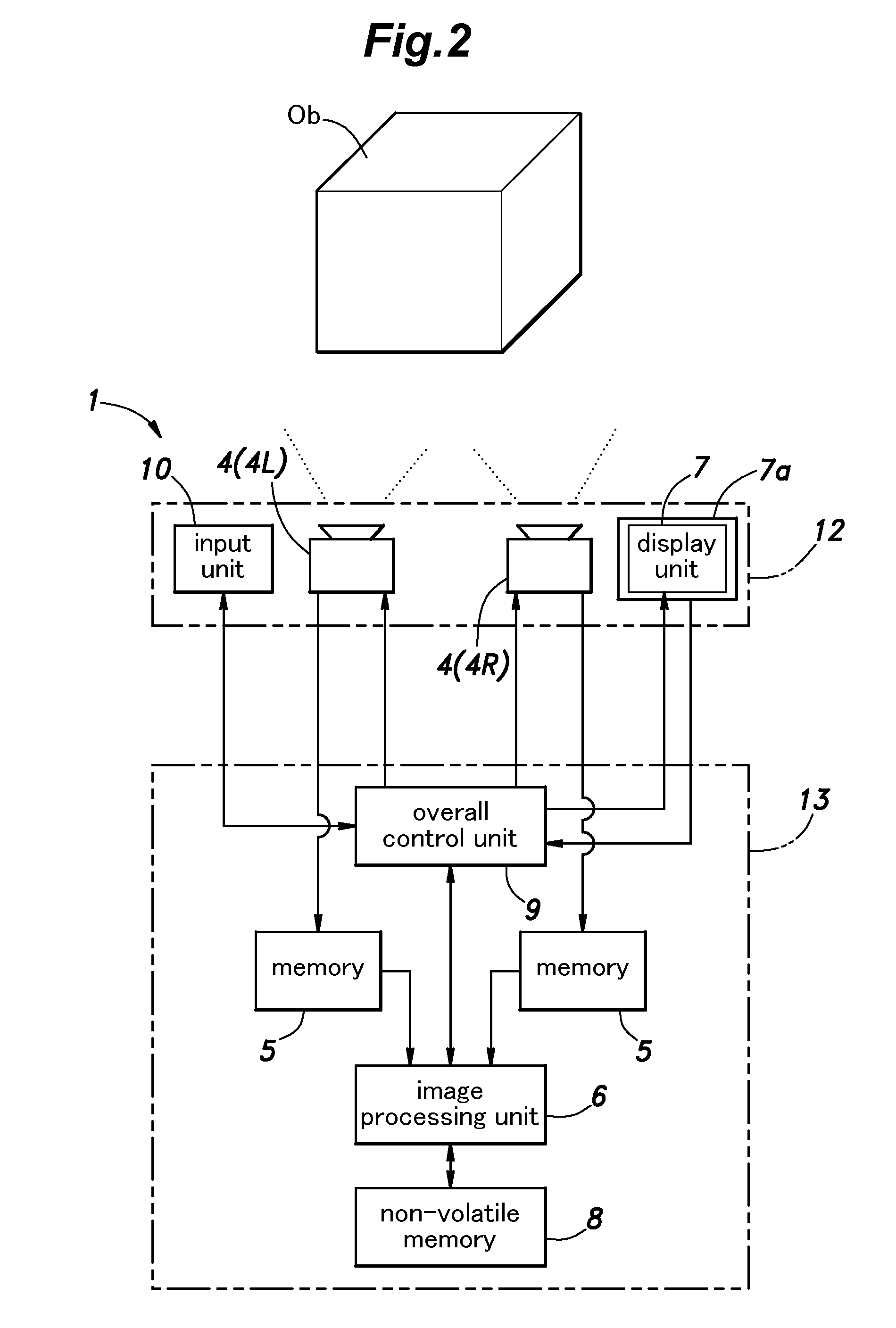

Size measurement device and size measurement method

InactiveUS20150187091A1Reduce processing loadImage enhancementImage analysisSize measurementImaging data

A size measurement device for measuring a size of an object from a captured image of the object includes: an imaging unit that captures an image of an object; a display unit that displays image data captured by the imaging unit; an input unit for inputting instructions of a user; a region setting unit that, when positions are designated with the input unit in the image data displayed on the display unit, sets surrounding regions including therein respective designated positions; and a feature point determination unit that determines, in the surrounding regions set by the region setting unit, feature points providing coordinates of the object to be measured.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

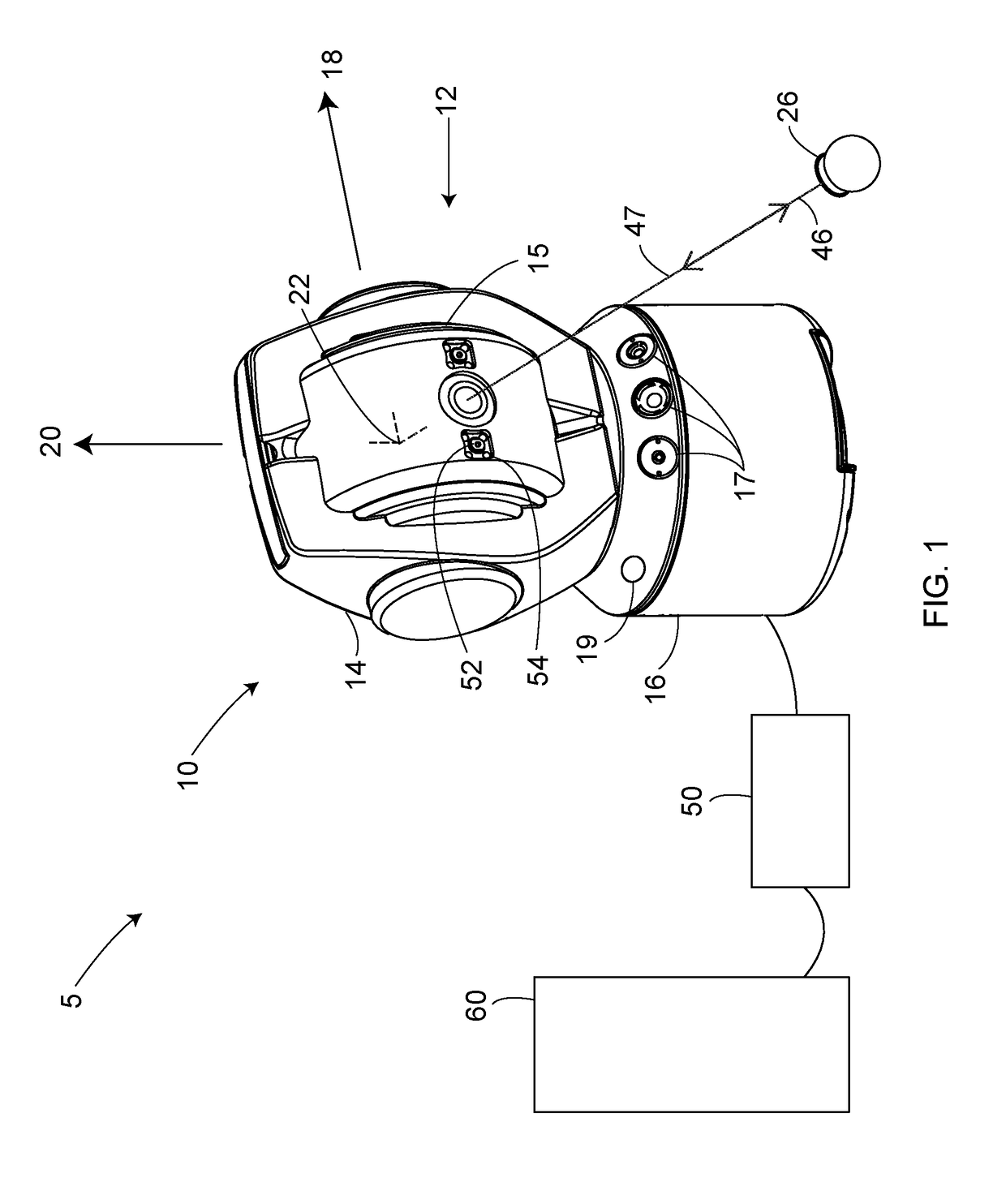

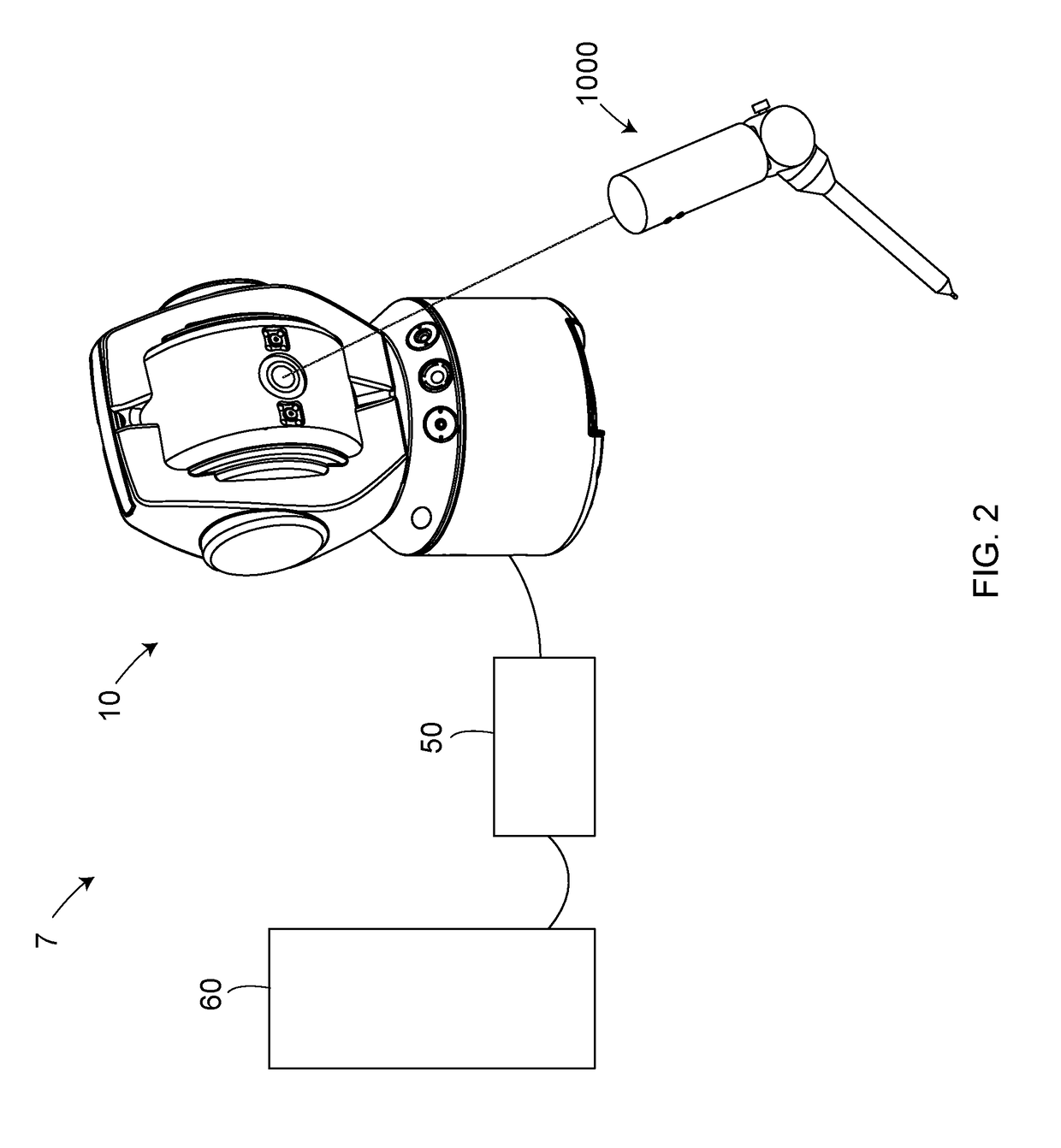

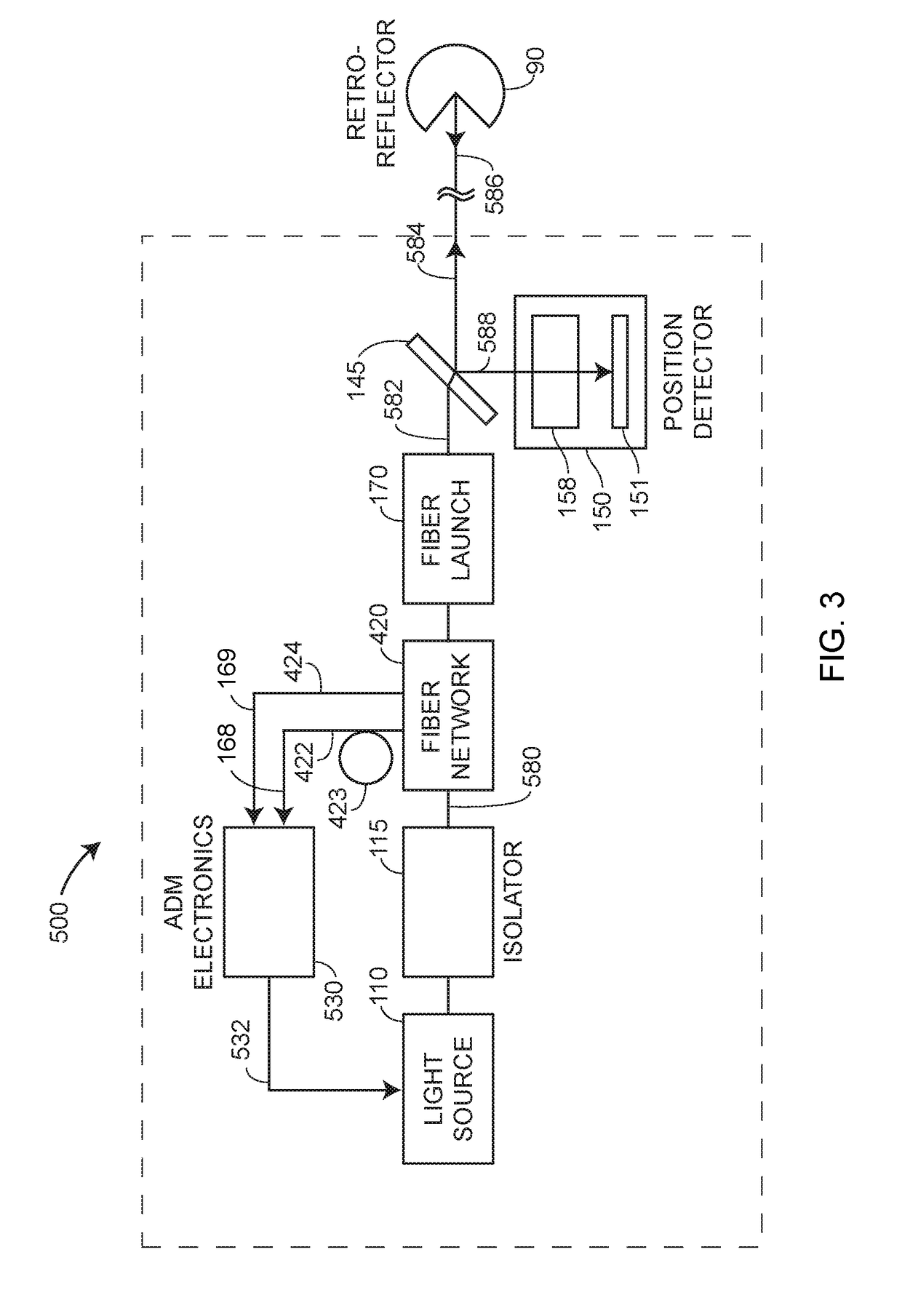

System for measuring six degrees of freedom

InactiveUS20170108528A1Position fixationDirection/deviation determining electromagnetic systemsSize measurementDegrees of freedom

A system that measures six degrees-of-freedom of a remote target, the system including a dimensional measuring device having a camera, the remote target including a retroreflector, at least three light markers, and a pitch-yaw sensor, the six degrees-of-freedom determined based at least in part on measured 3D coordinates of the retroreflector by the dimensional measuring device, on a captured image of the at least three light markers by the camera, and on readings of the pitch-yaw sensor.

Owner:FARO TECH INC

Part size measurement method based on charge coupled device (CCD)

ActiveCN103063159AHigh speed measurementLow costCharacter and pattern recognitionUsing optical meansSize measurementHardware implementations

Owner:邳州市景鹏创业投资有限公司

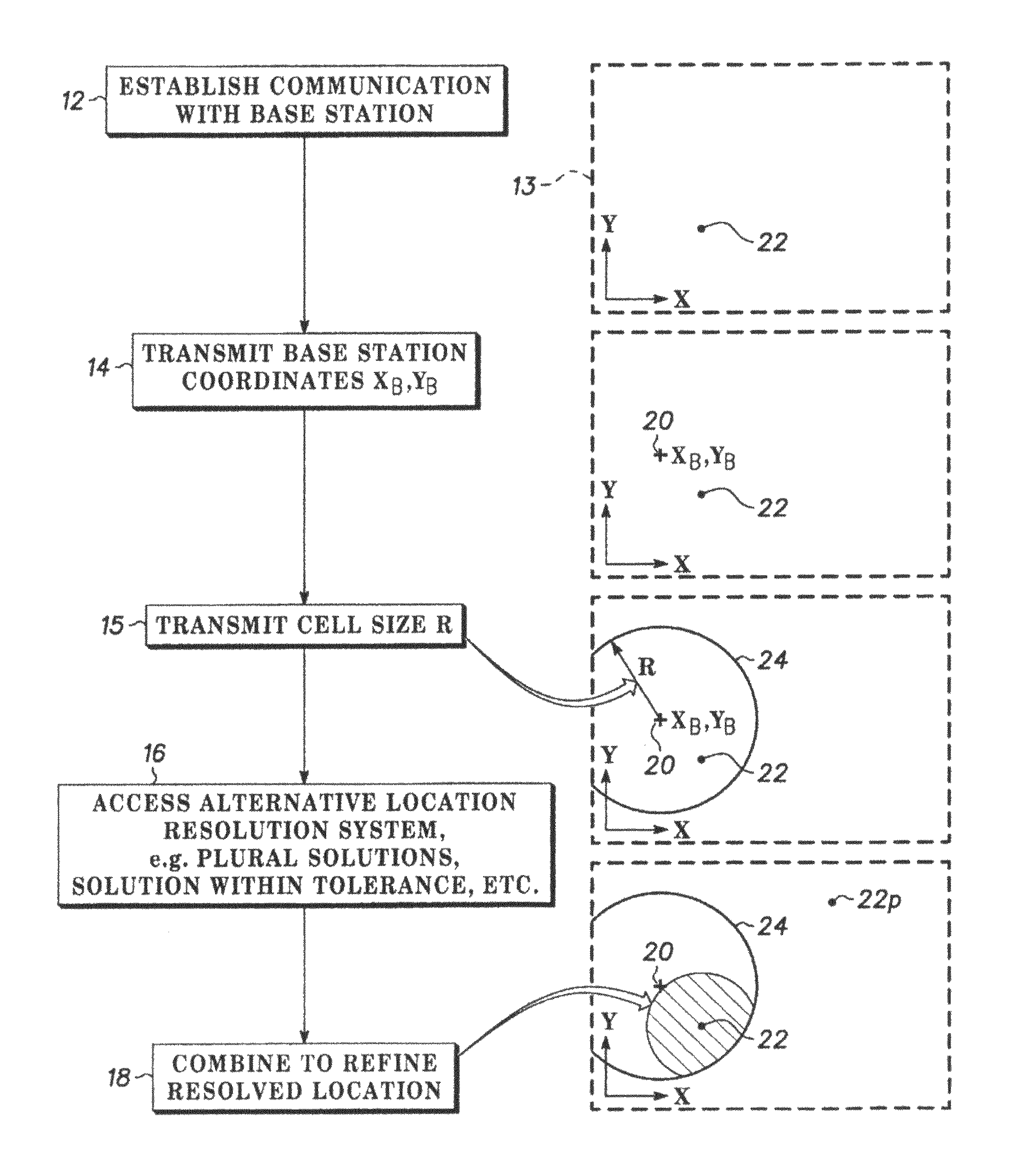

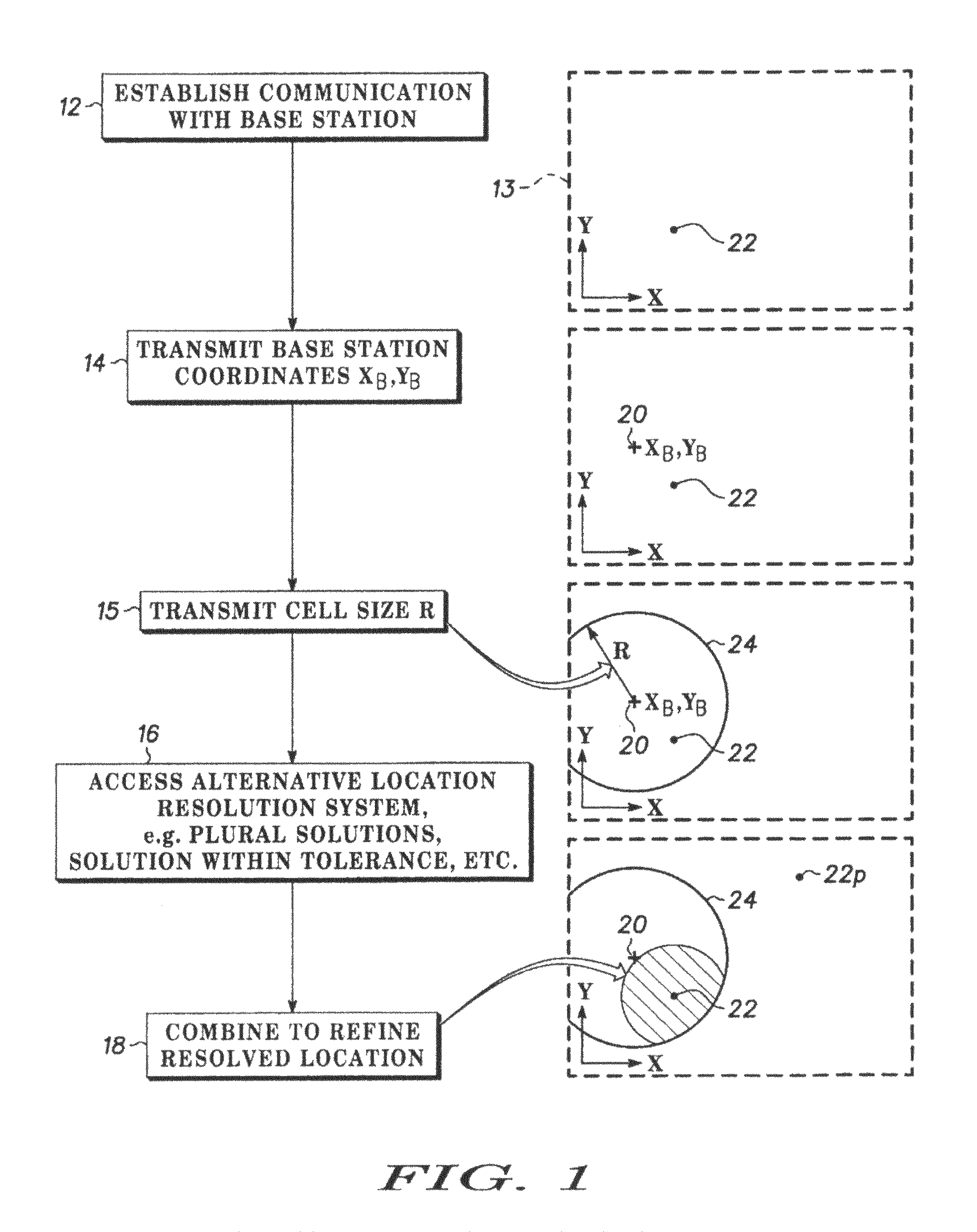

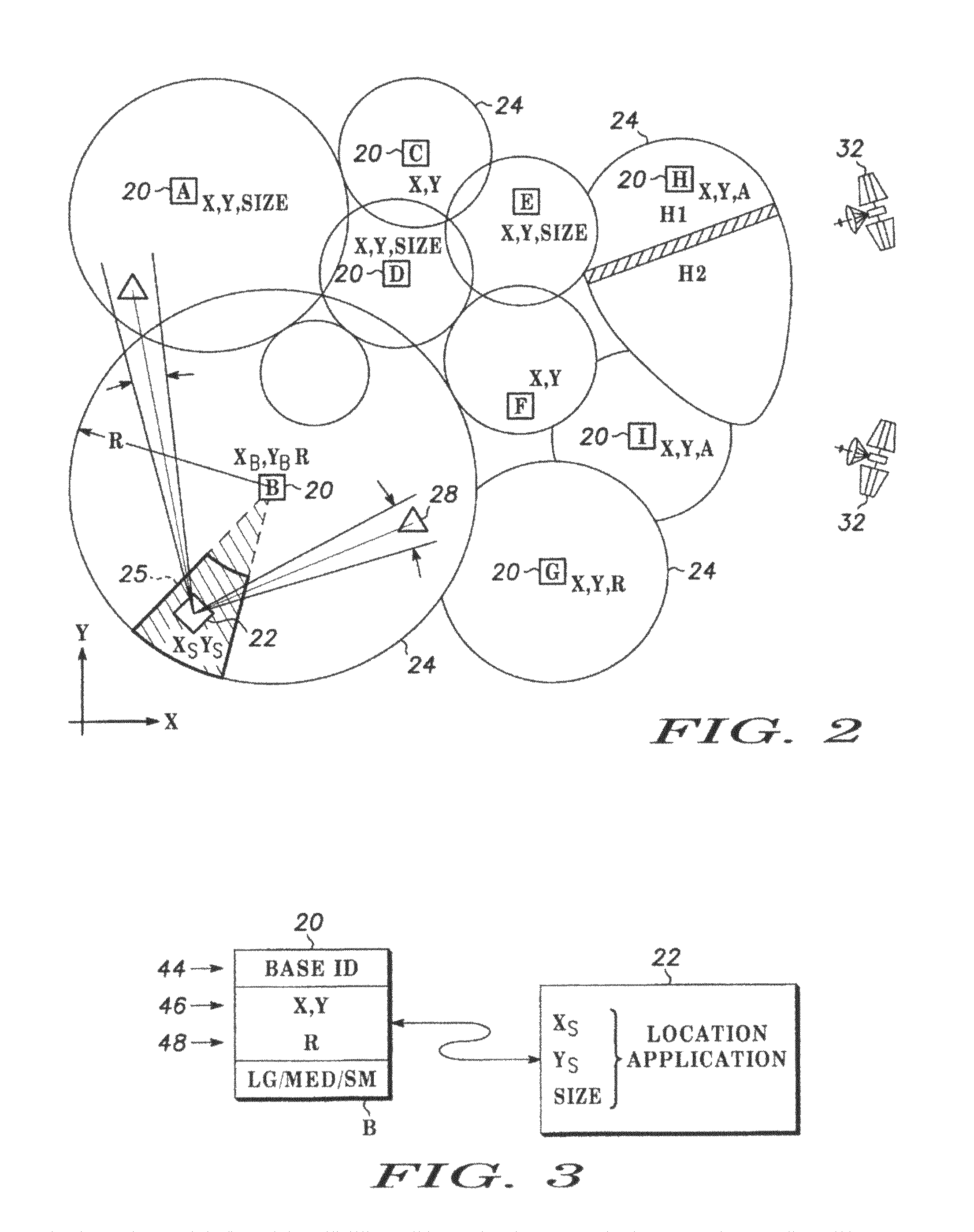

Method of enabling low tier location applications

ActiveUS8050686B1Reduce dependenceImprove performancePosition fixationTransmission monitoringSize measurementImage resolution

In a wireless communication network having remote receivers (subscriber units) communicating through base units in a service area, each of the base units servicing a cell area encompasses one or more identifiable zones which can be occupied by receivers. According to the invention, at least one measure of the spatial size of the cell is reported to a receiver communicating with a base station, for use in location specific applications. The measure can be a size category, an average diameter or another measure, such as a shape and orientation of the cell, a boundary apex, and a boundary line of the cell. The base station coordinates are conventionally available to the receiver. By providing a measure of size, the receiver can resolve its zone or location to a coarse or low level of resolution. The zone occupied by the receiver is at least within the cell and the size of the cell and location of the base station are now known. According to additional embodiments, the resolved zone known to be occupied by the receiver is refined to an area within the defined cell area. The size of the cell or service area of the location transmitter can be appended to the identification code of the base station. Reporting the cell size and location is sufficient to facilitate some location applications in the receiver, and can reduce or eliminate reliance on satellite and other positioning systems, particularly if the zone initially defined as the cell size is resolved further, for example using time-of-arrival, power level, angular bearing and similar techniques.

Owner:GOOGLE TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com