Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

837results about "Feeler-pin gauges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

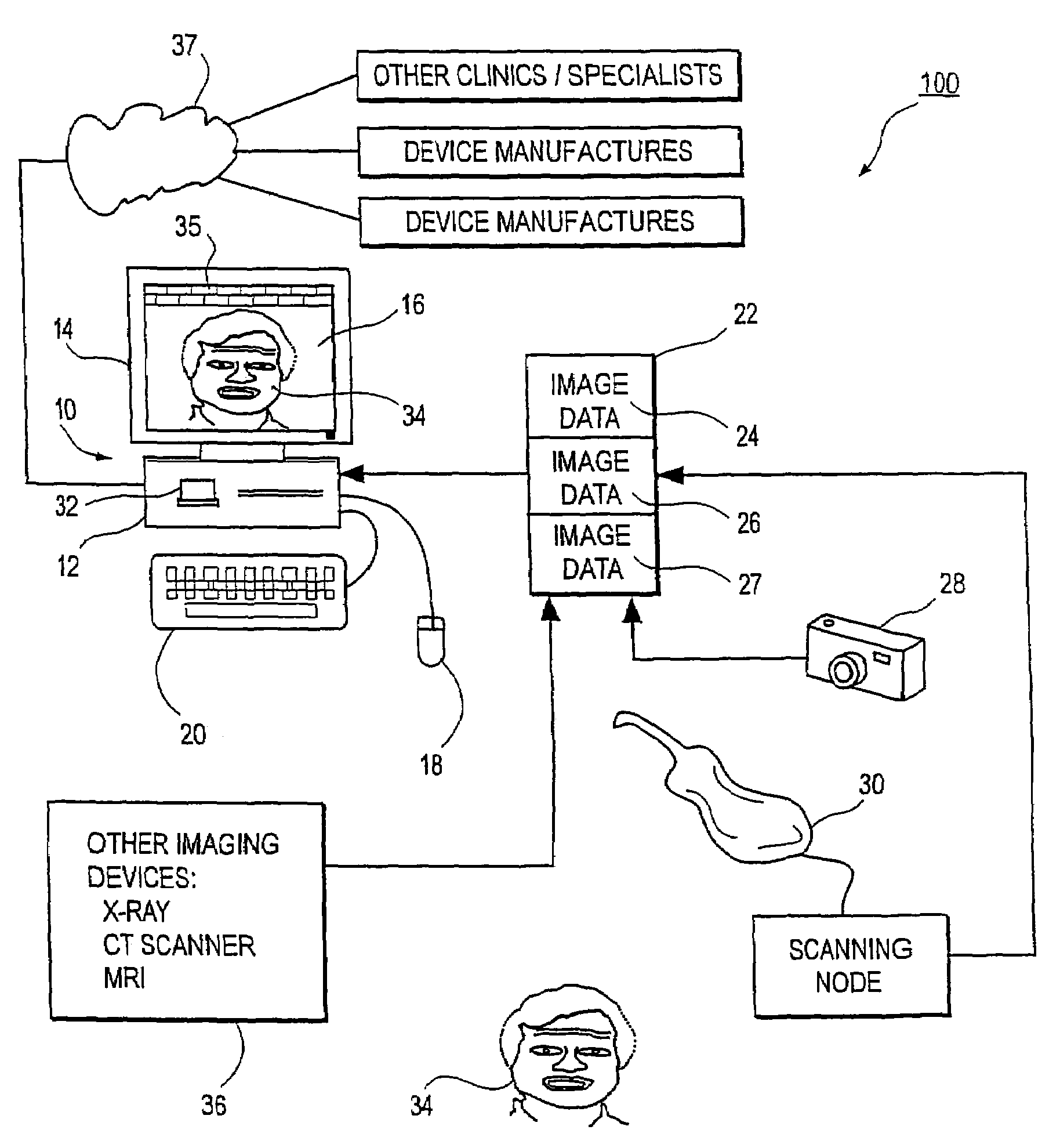

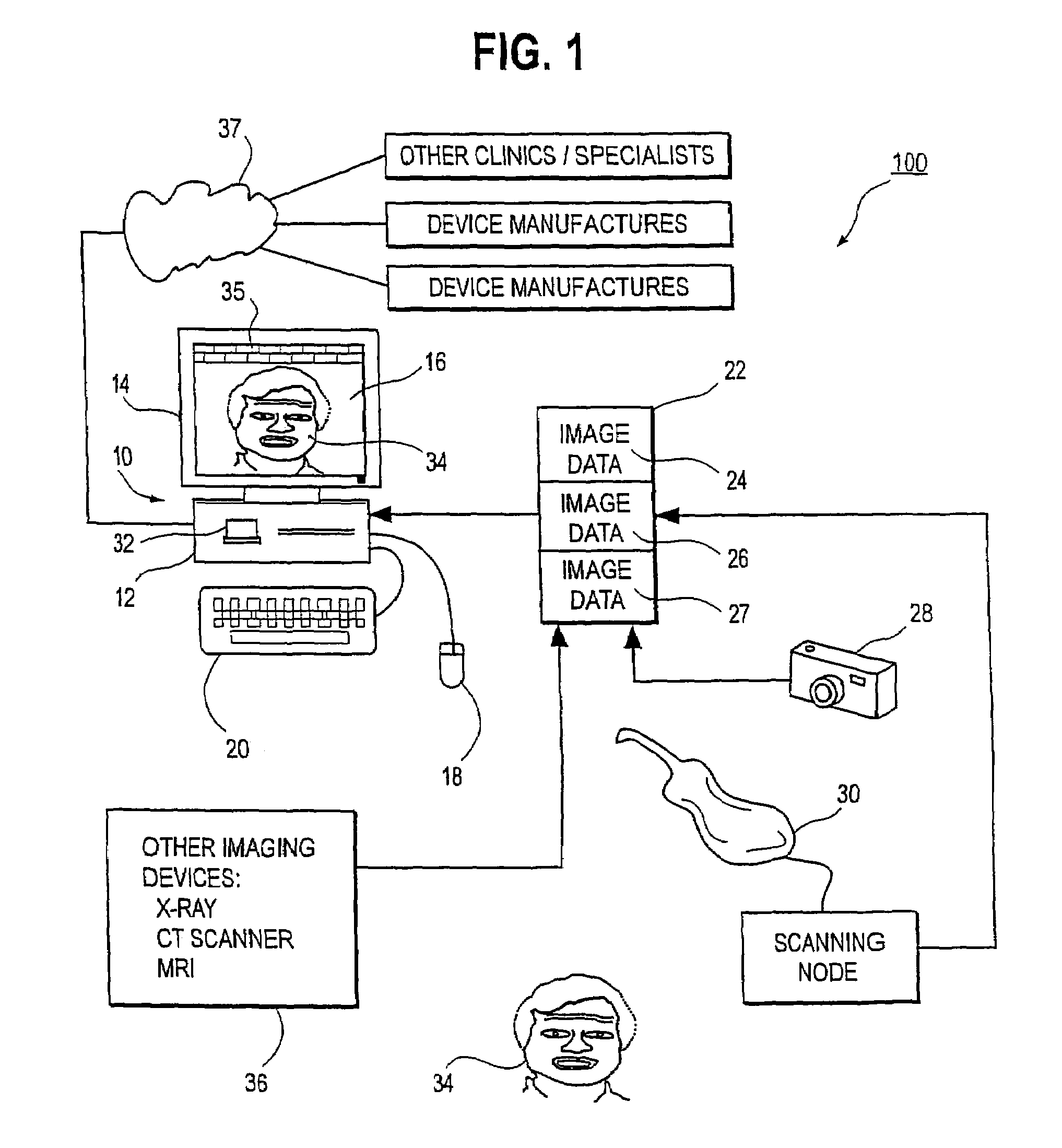

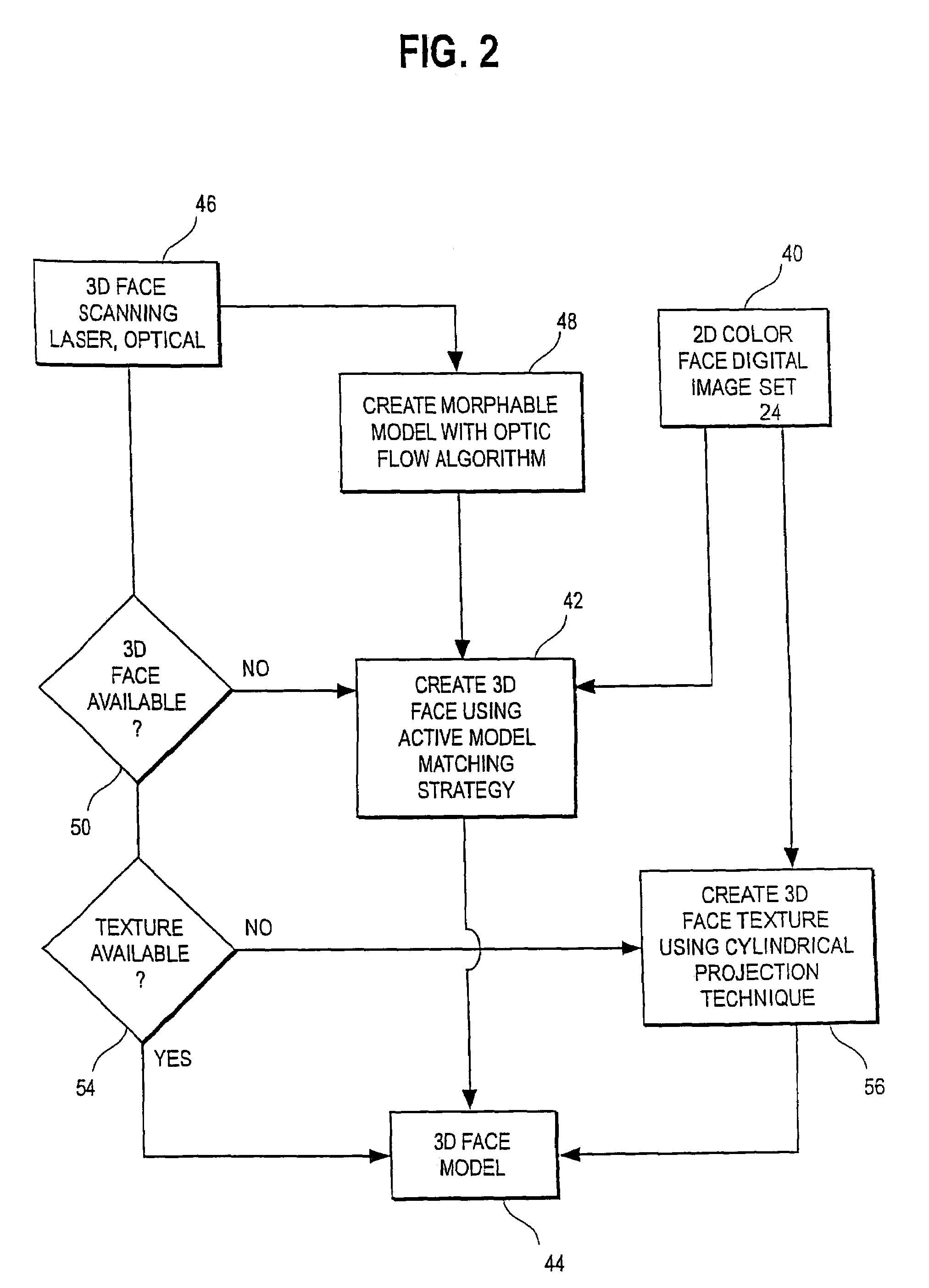

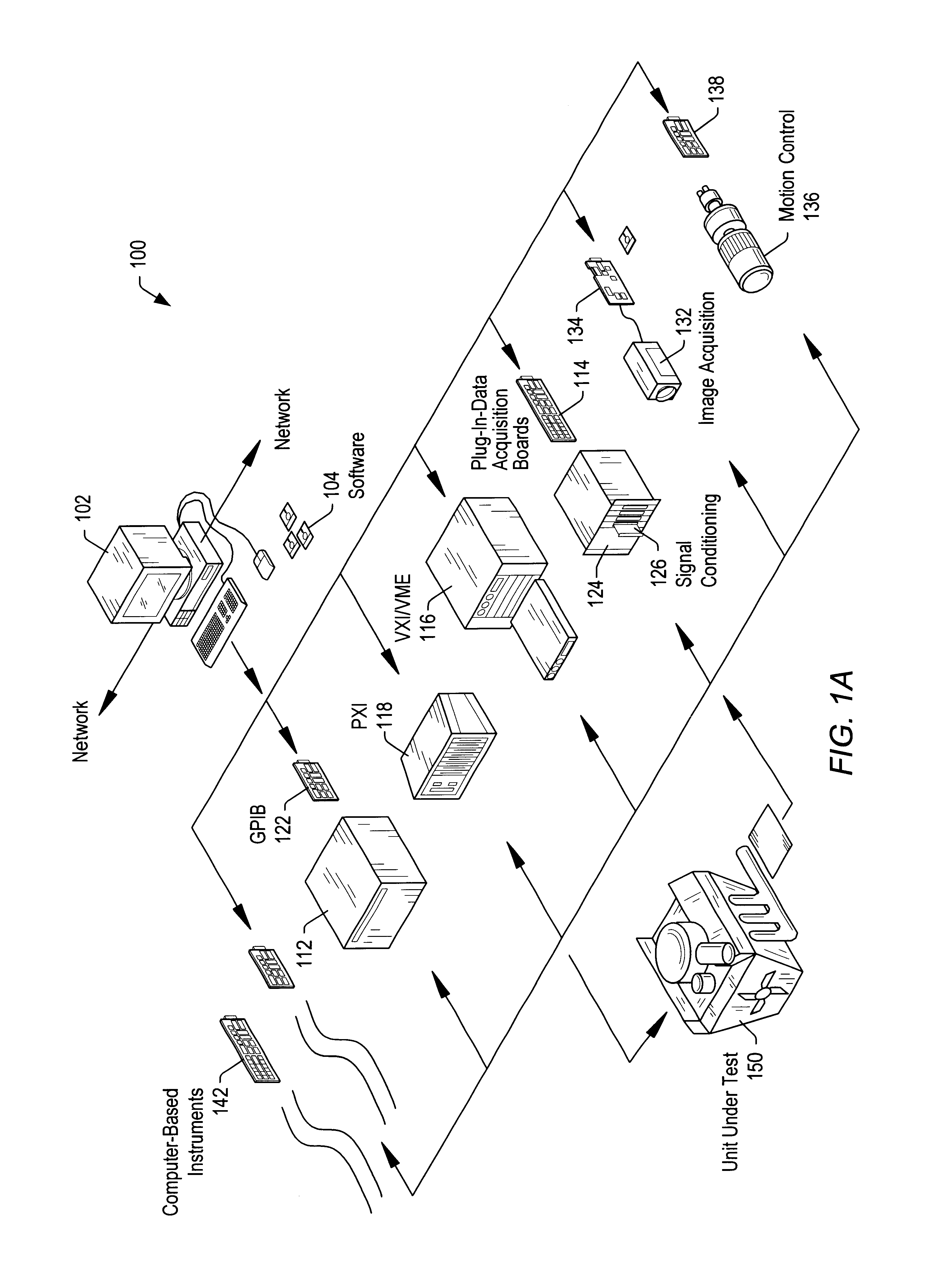

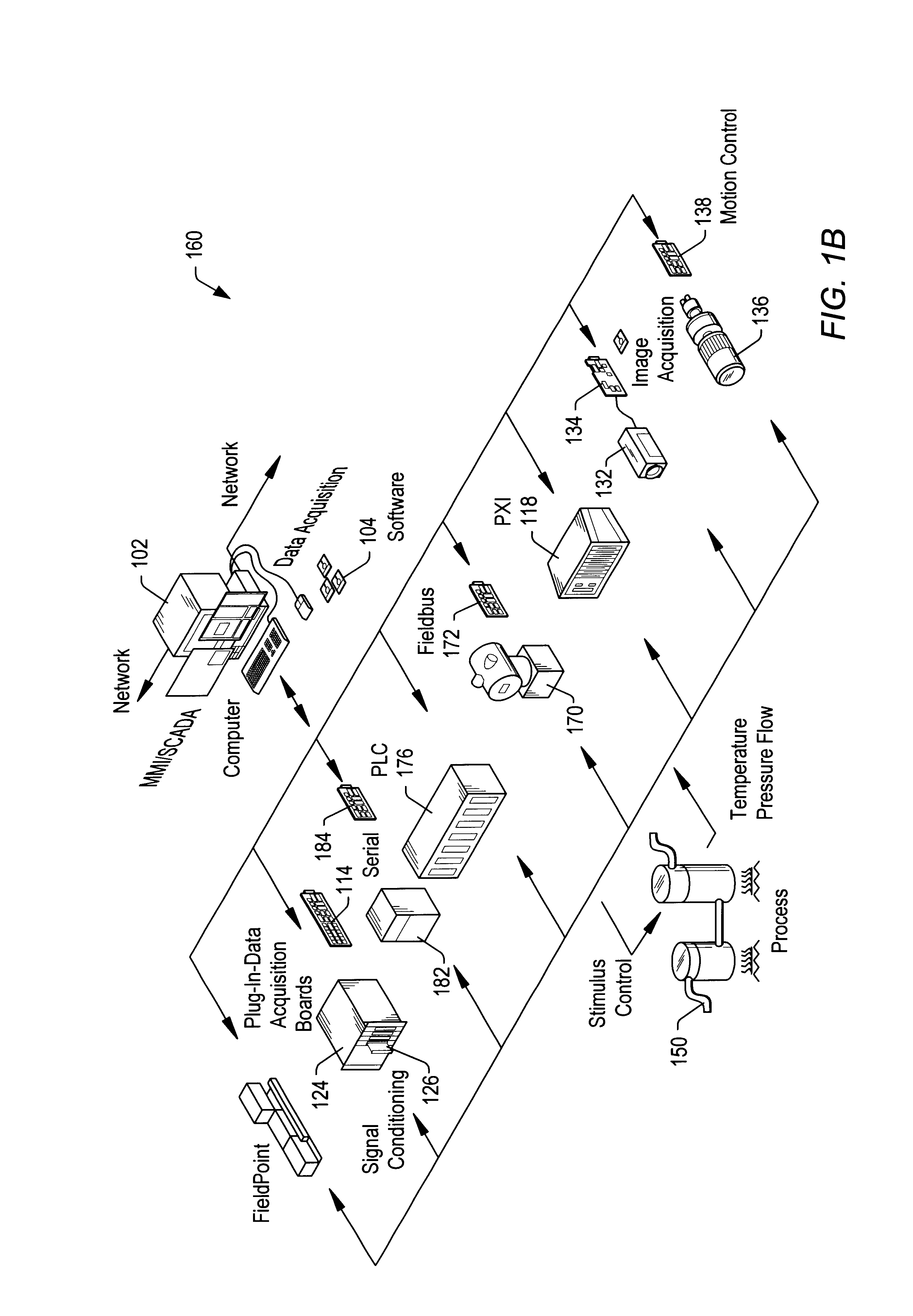

Unified workstation for virtual craniofacial diagnosis, treatment planning and therapeutics

InactiveUS7234937B2Quick analysisPowerful toolDental implantsImpression capsPlan treatmentPatient model

An integrated system is described in which digital image data of a patient, obtained from a variety of image sources, including CT scanner, X-Ray, 2D or 3D scanners and color photographs, are combined into a common coordinate system to create a virtual three-dimensional patient model. Software tools are provided for manipulating the virtual patient model to simulation changes in position or orientation of craniofacial structures (e.g., jaw or teeth) and simulate their affect on the appearance of the patient. The simulation (which may be pure simulations or may be so-called “morphing” type simulations) enables a comprehensive approach to planning treatment for the patient. In one embodiment, the treatment may encompass orthodontic treatment. Similarly, surgical treatment plans can be created. Data is extracted from the virtual patient model or simulations thereof for purposes of manufacture of customized therapeutic devices for any component of the craniofacial structures, e.g., orthodontic appliances.

Owner:ORAMETRIX

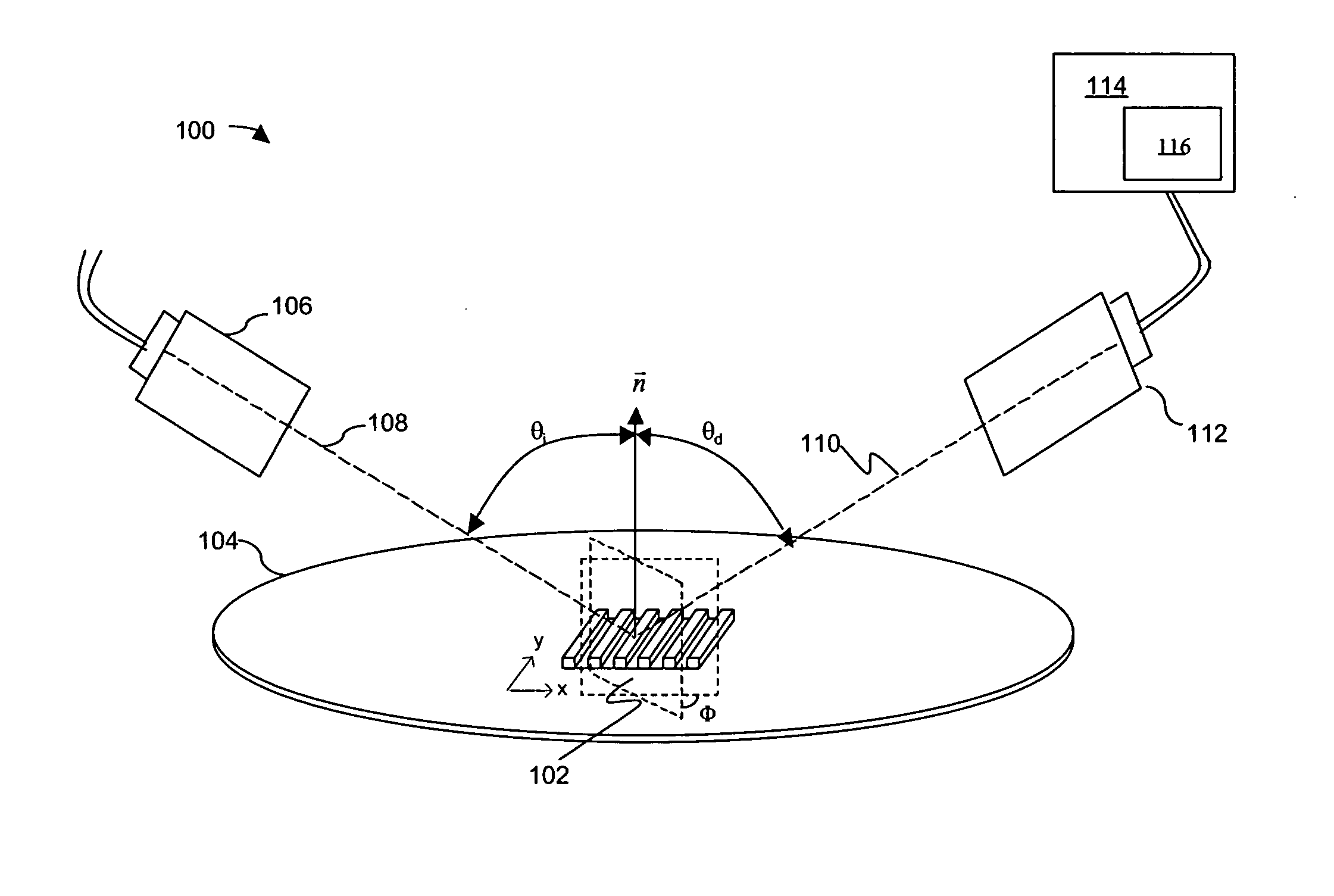

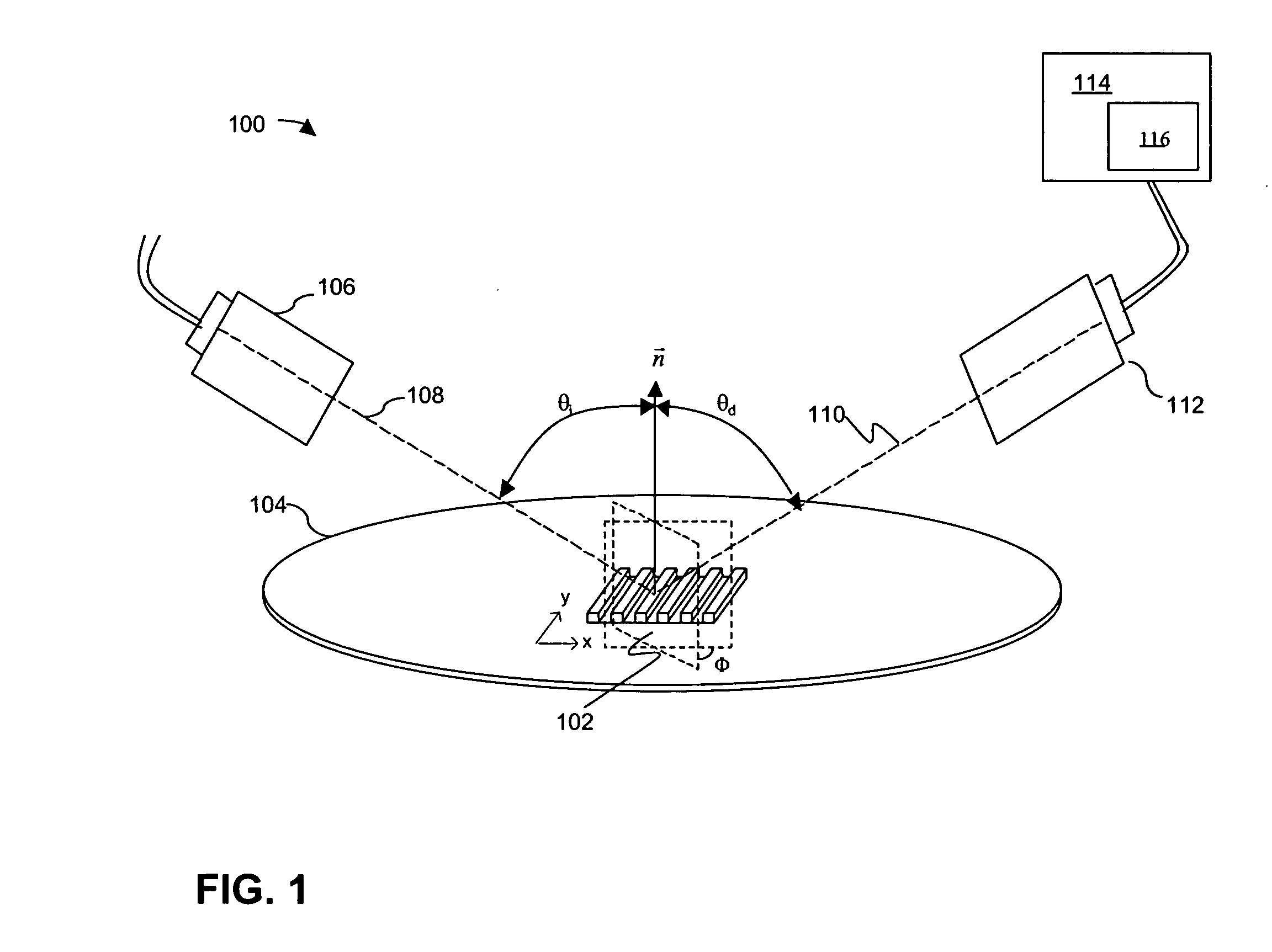

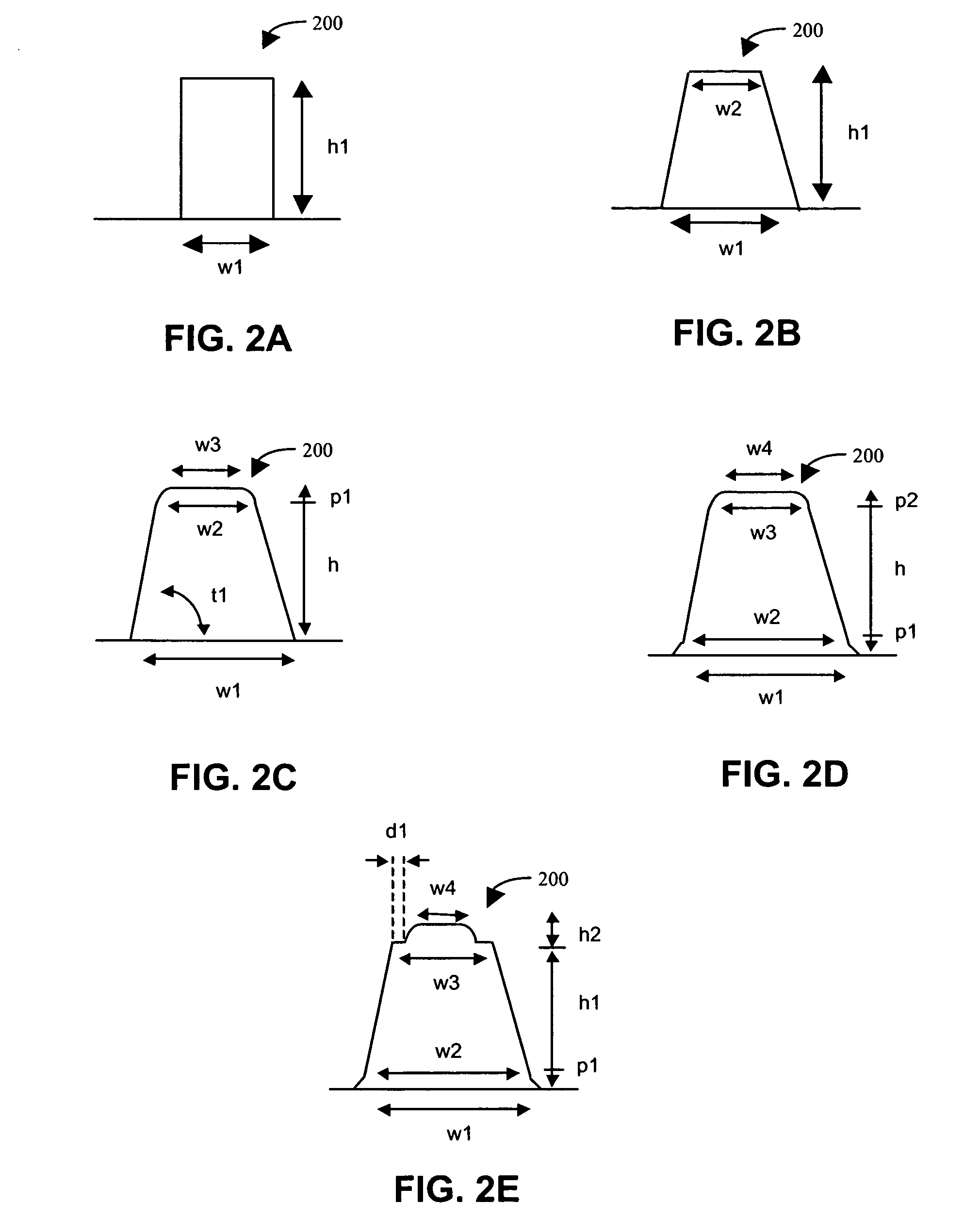

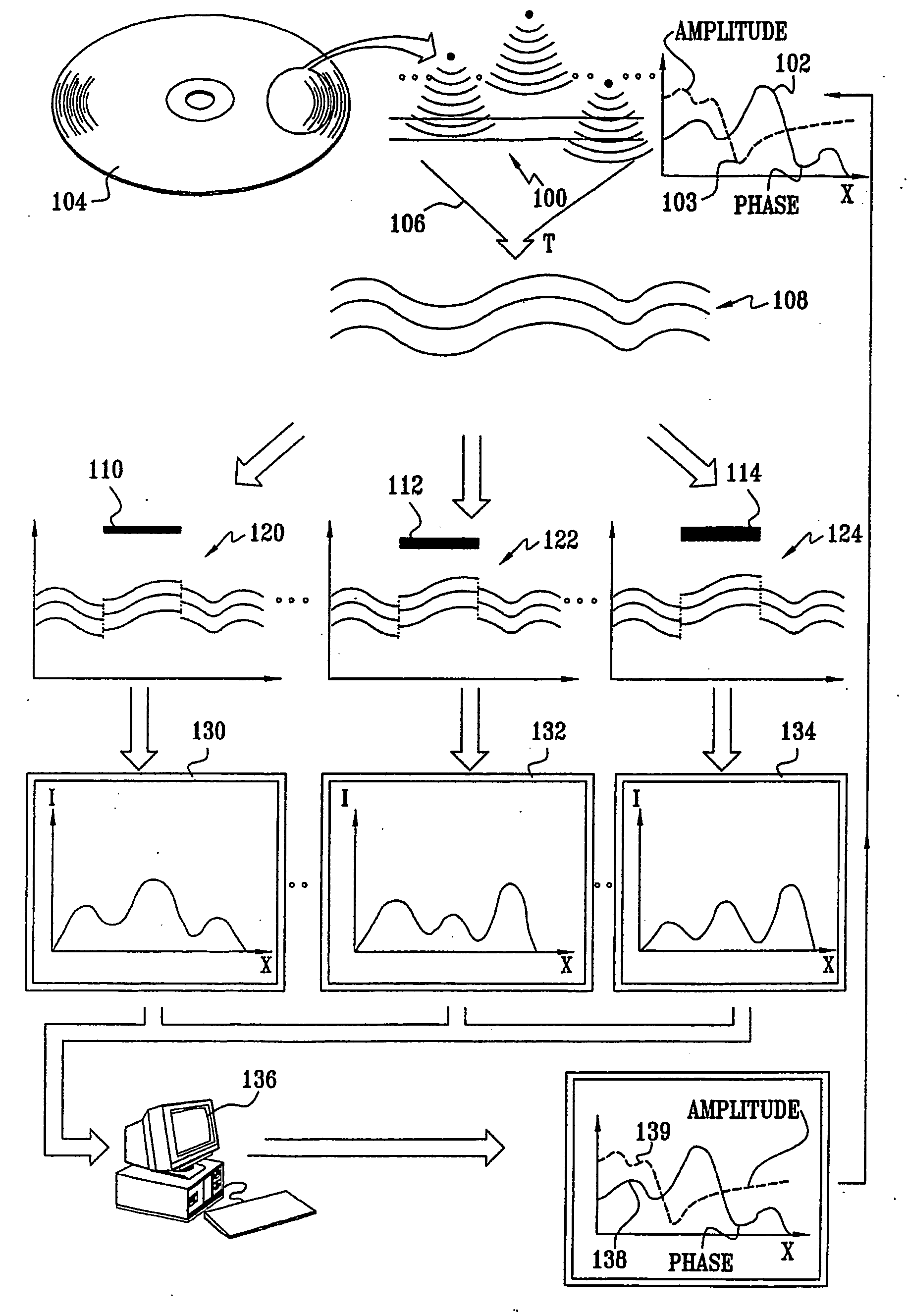

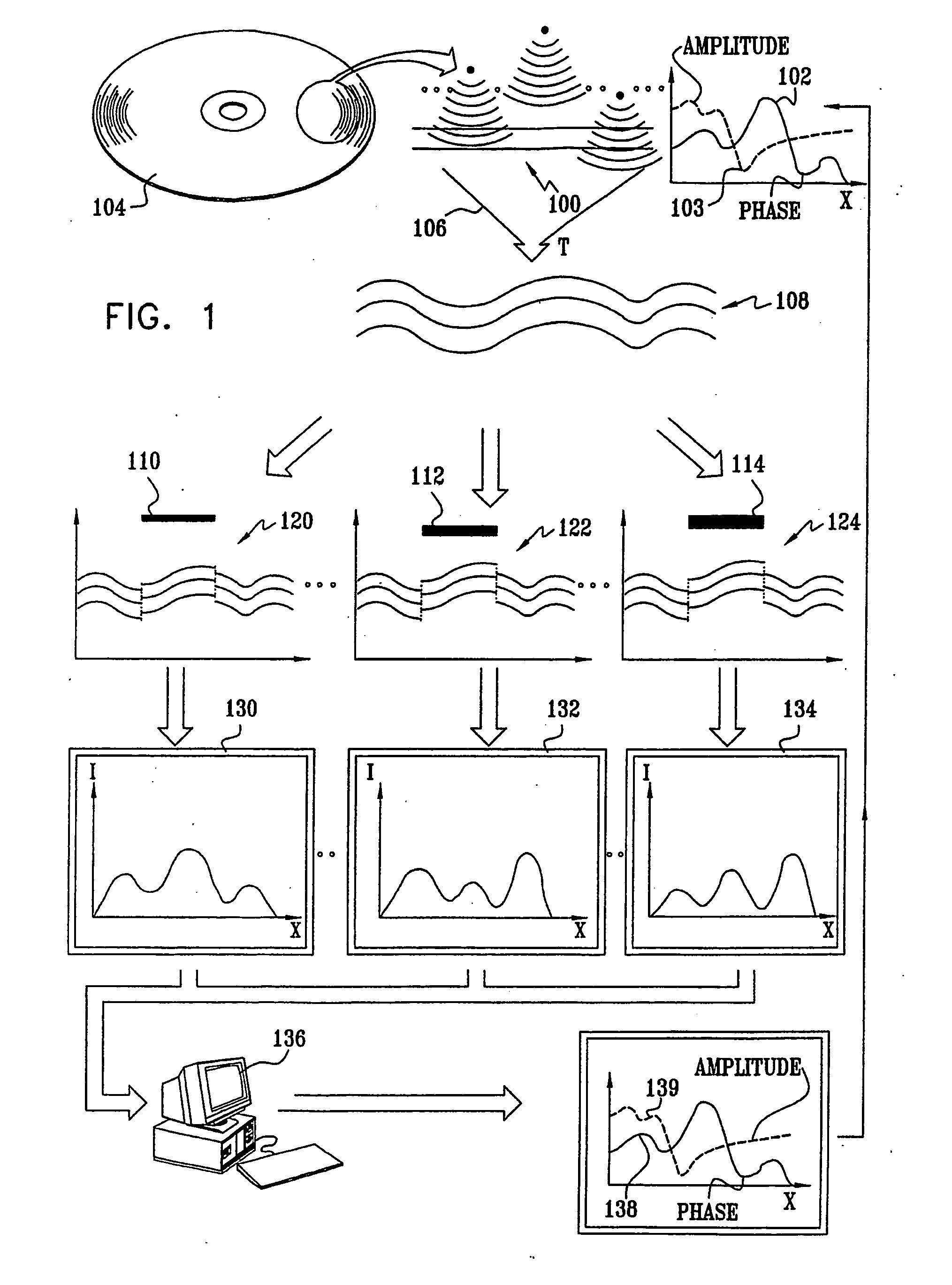

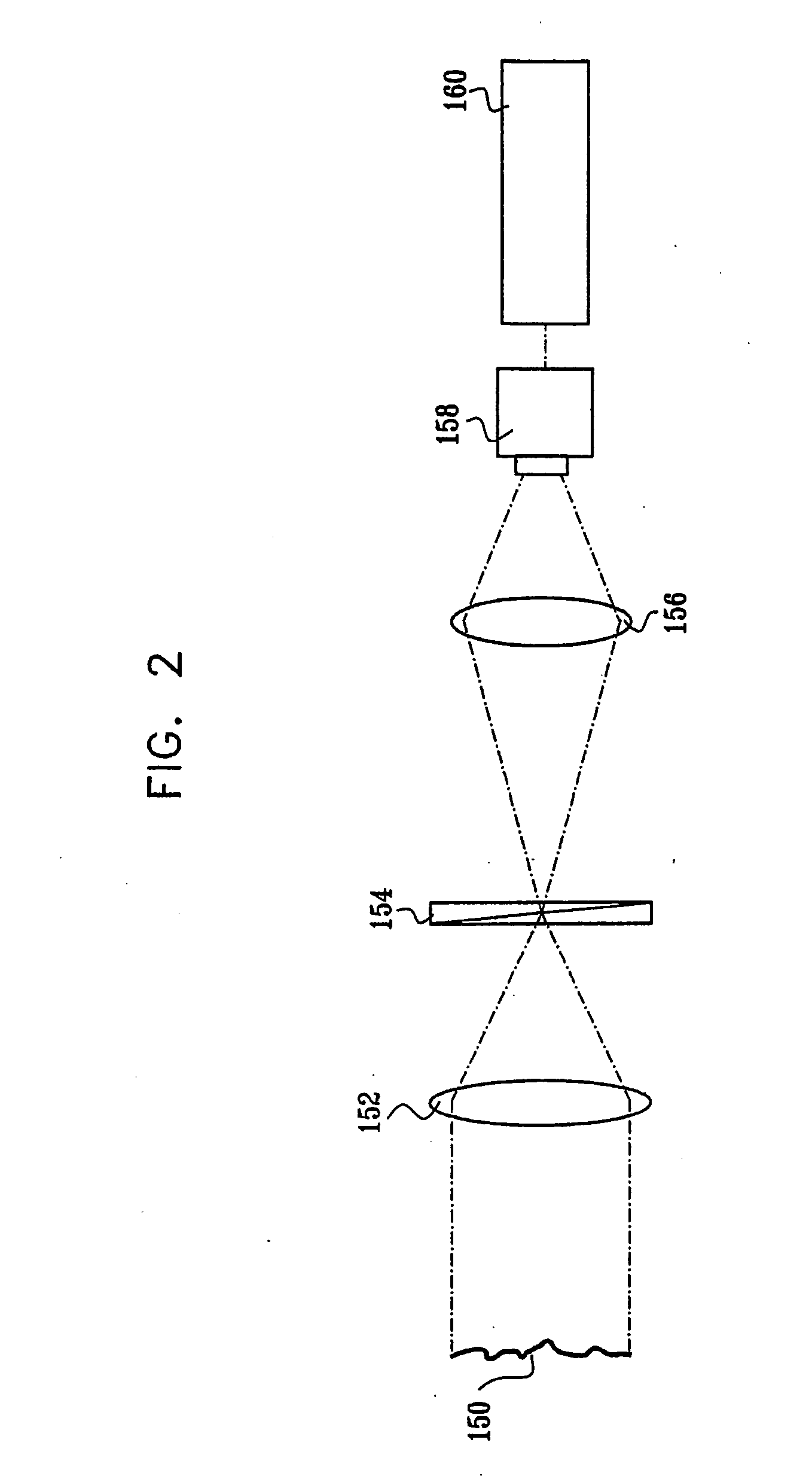

Optical metrology optimization for repetitive structures

InactiveUS20050209816A1Feeler-pin gaugesMechanical counters/curvatures measurementsComputational physicsOptical metrology

The top-view profiles of repeating structures in a wafer are characterized and parameters to represent variations in the top-view profile of the repeating structures are selected. An optical metrology model is developed that includes the selected top-view profile parameters of the repeating structures. The optimized optical metrology model is used to generate simulated diffraction signals that are compared to measured diffraction signals.

Owner:TOKYO ELECTRON LTD

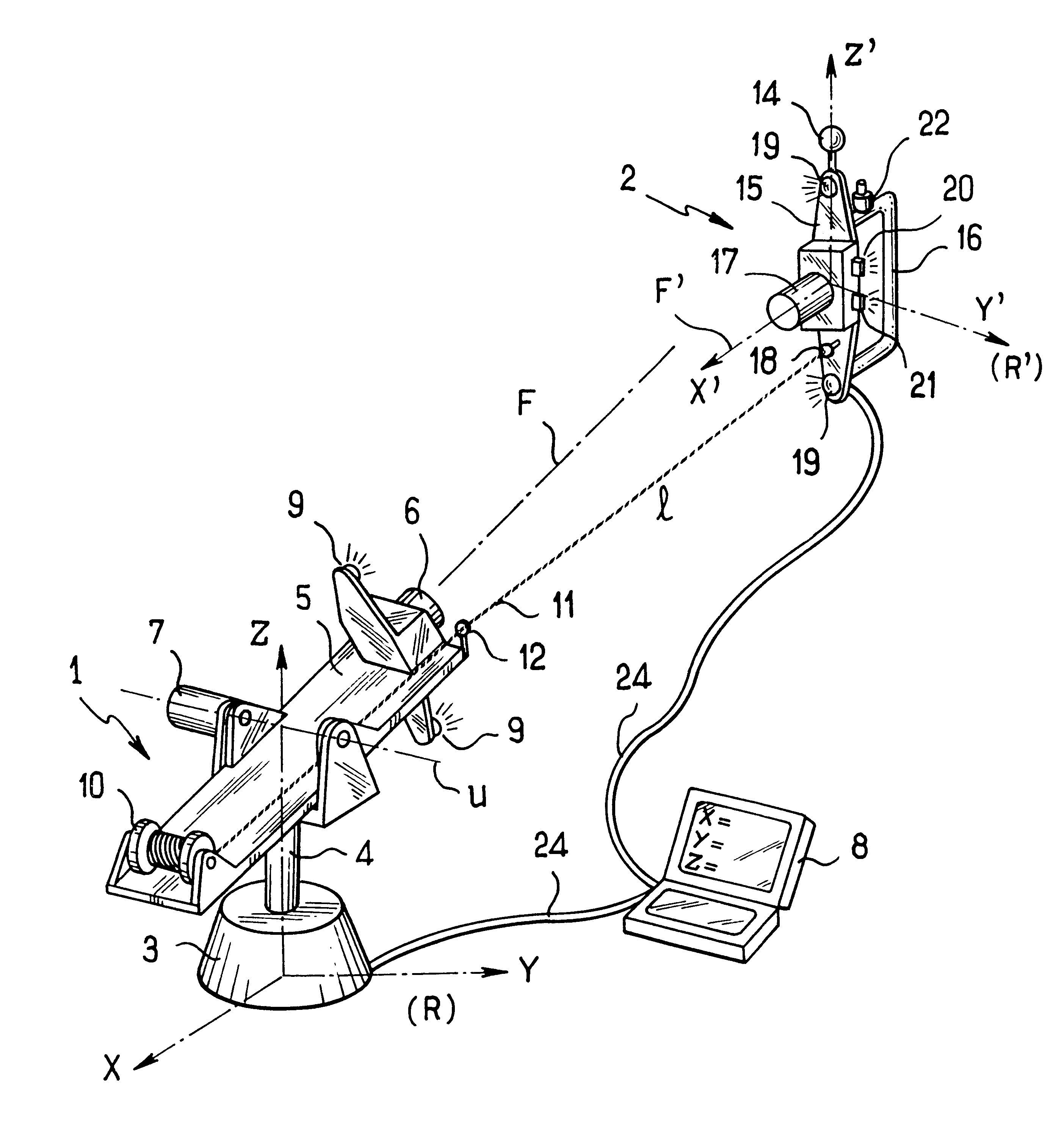

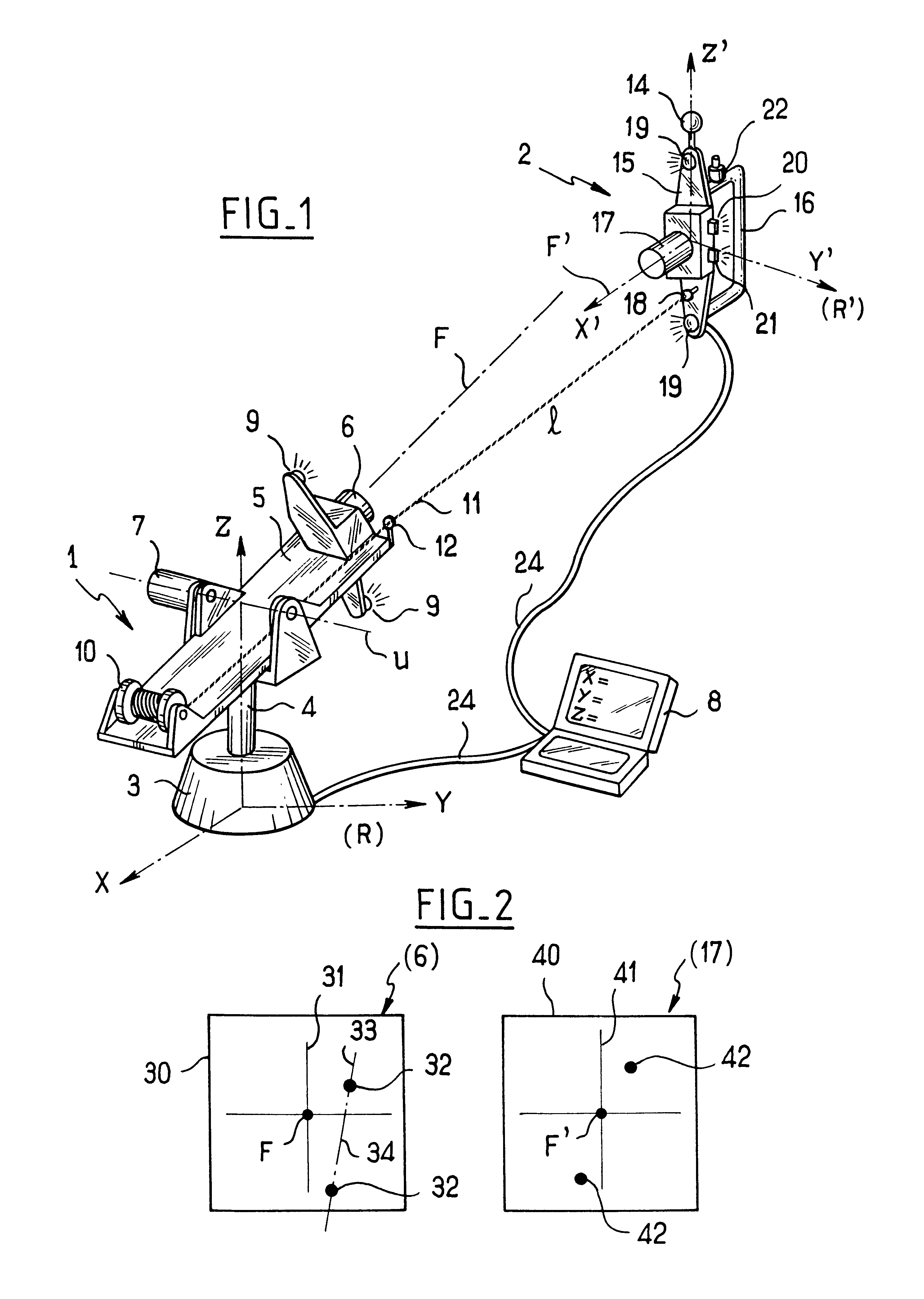

Measuring method for determining the position and the orientation of a moving assembly, and apparatus for implementing said method

InactiveUS6639659B2Easy to transportOptical rangefindersFeeler-pin gaugesMeasurement deviceFrame of reference

Owner:HEXAGON TECH CENT GMBH

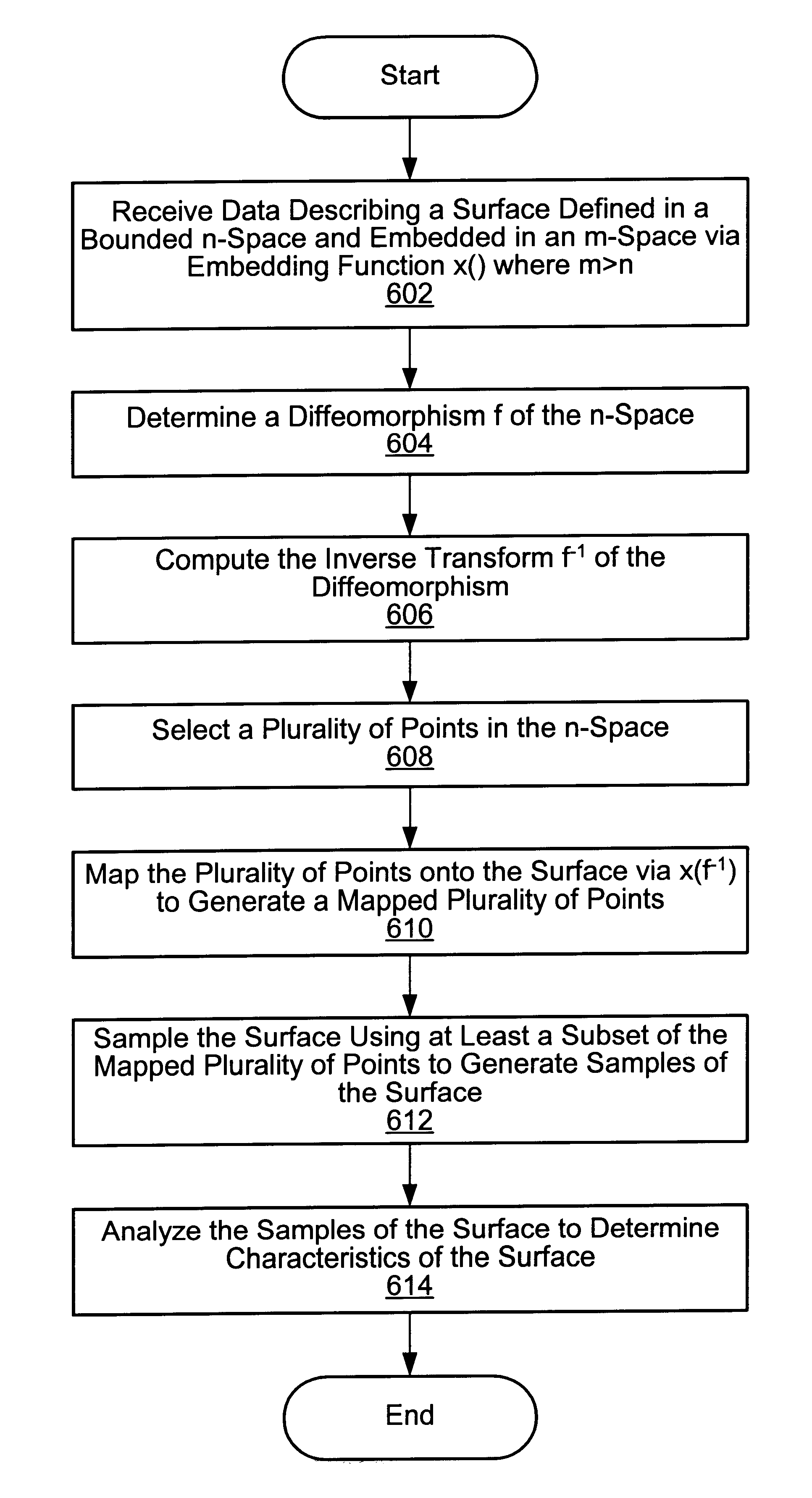

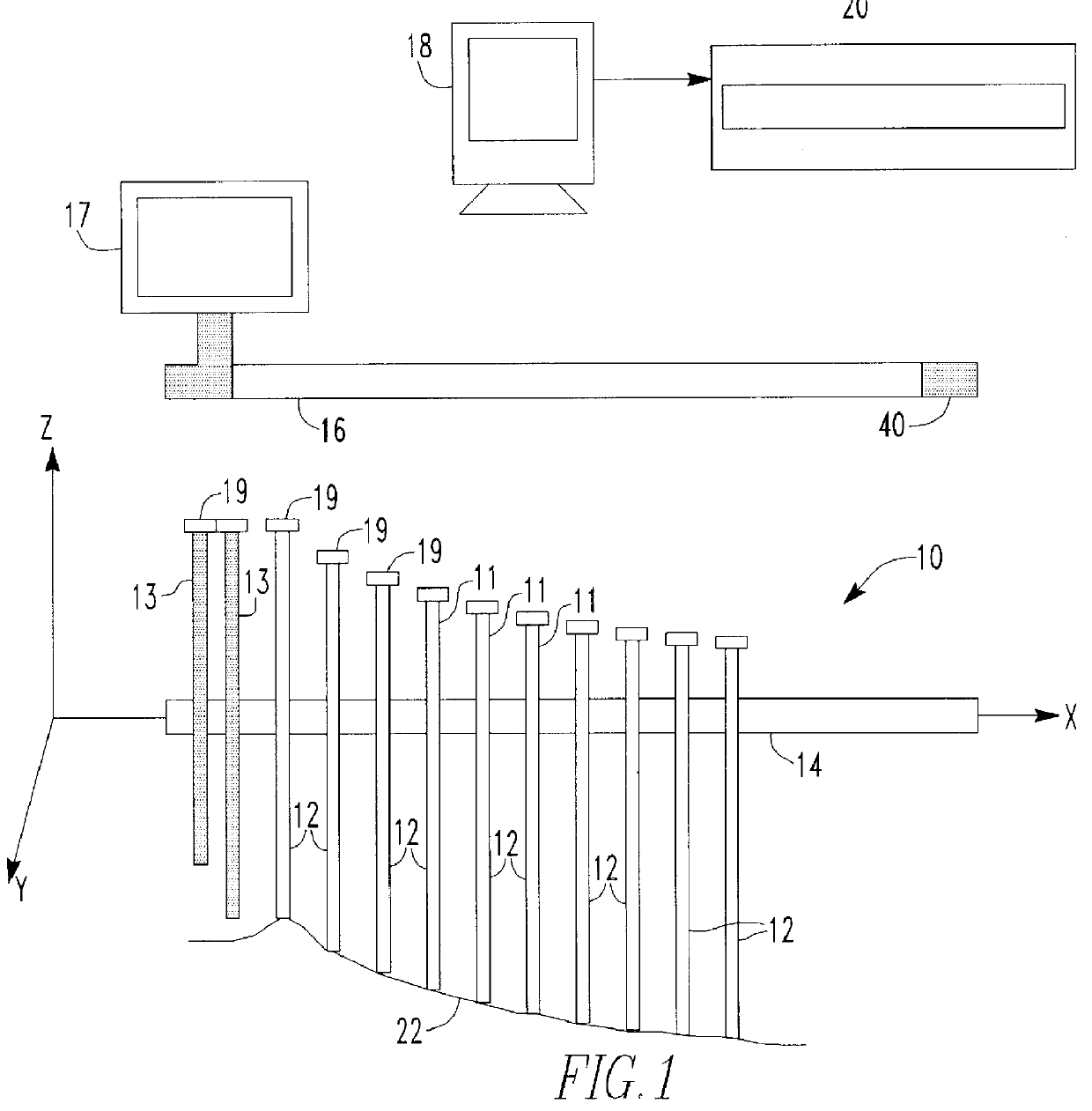

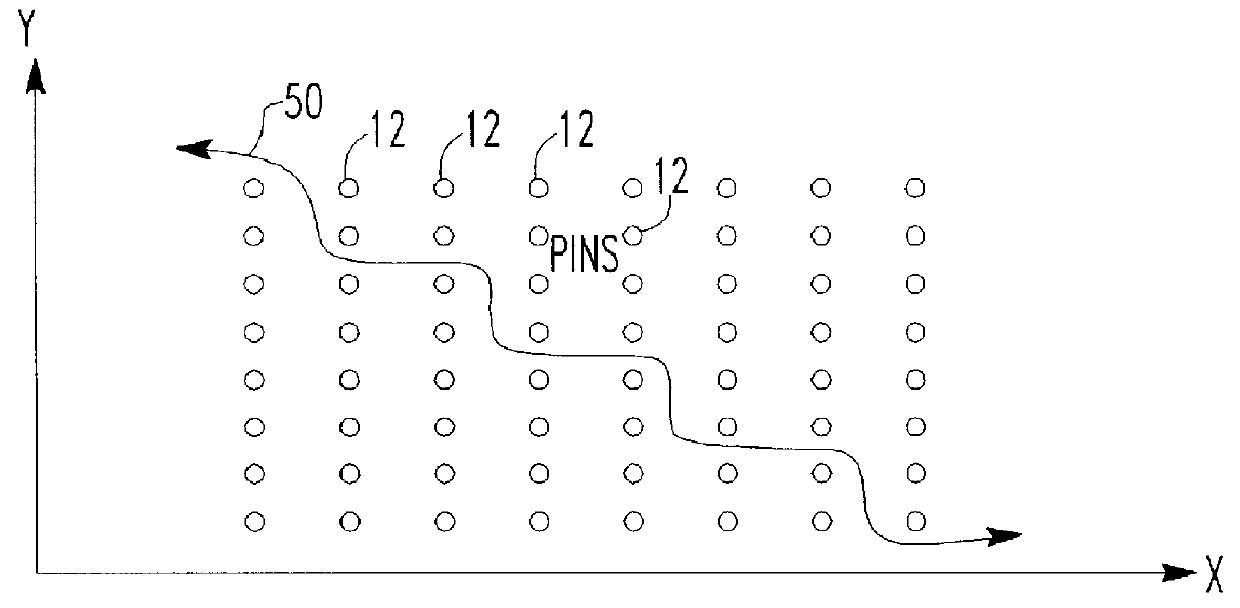

System and method for analyzing a surface by mapping sample points onto the surface and sampling the surface at the mapped points

A system and method for analyzing a surface. The system includes a computer including a CPU and a memory medium operable to store programs executable by the CPU to perform the method. The method may include: 1) receiving data describing an n-dimensional surface defined in a bounded n-dimensional space, where the surface is embedded in an m-dimensional real space via embedding function x( ), and where m>n; 2) determining a diffeomorphism f of the n-dimensional space; 3) computing the inverse transform f-1 of the diffeomorphism f; 4) selecting points, e.g., a Low Discrepancy Sequence, in the n-dimensional space; 5) mapping the points onto the surface using x(f-1), thereby generating mapped points on the surface; 6) sampling the surface using at least a subset of the mapped points to generate samples of the surface; and 7) analyzing the samples of the surface to determine characteristics of the surface.

Owner:NATIONAL INSTRUMENTS

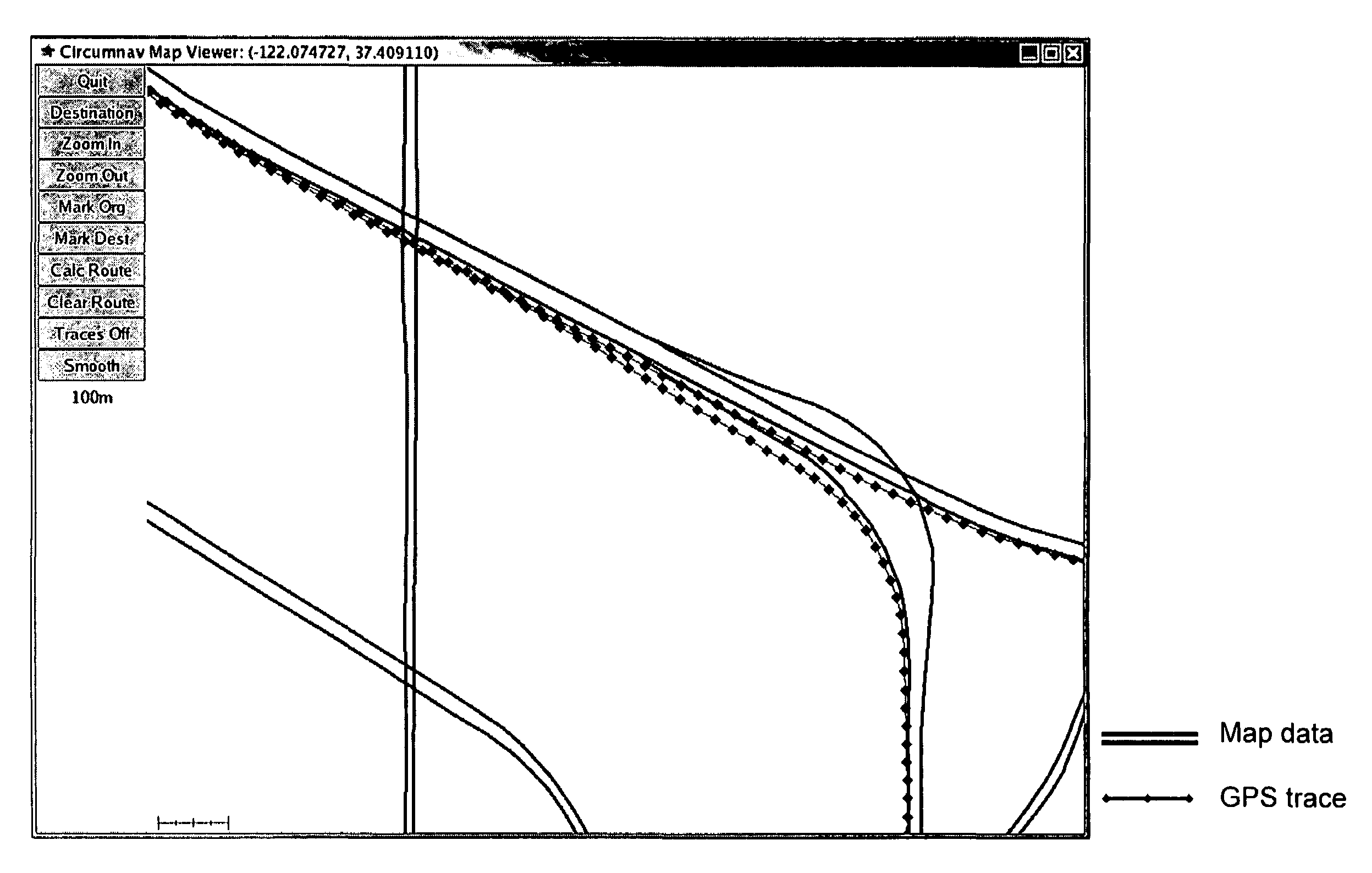

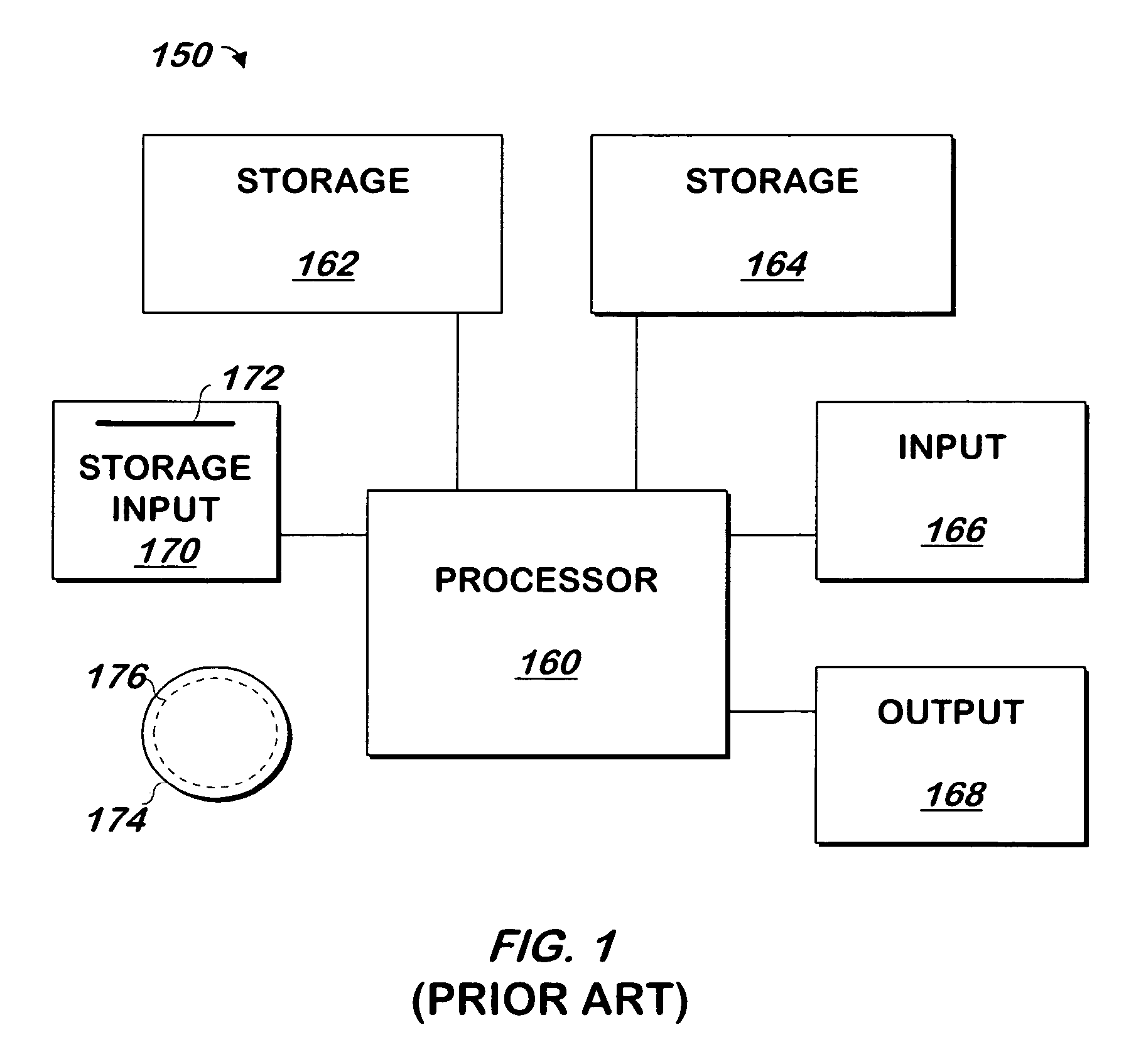

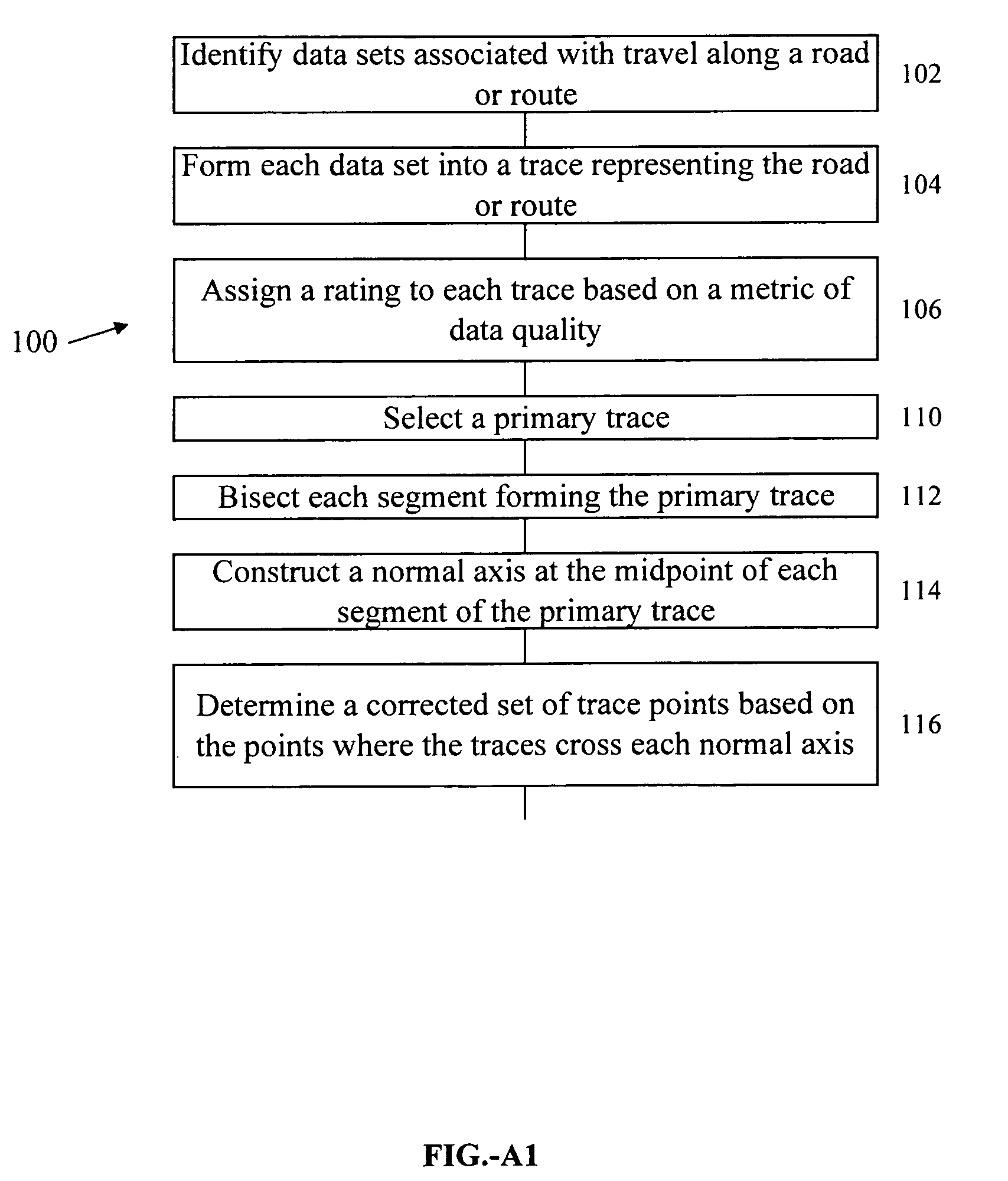

System and method for identifying road features

ActiveUS7516041B2Instruments for road network navigationFeeler-pin gaugesComputer scienceGraph database

A system and method identifies road features that may not appear on a map database, such as paths not described as roads on the map database, and whether all the roads at a crossing cross at the same grade level. The system and method may thus be used to identify points of departure from, or points of merging onto, a road described by the map database or a path identified as described herein, but not described by the map database.

Owner:MALIKIE INNOVATIONS LTD

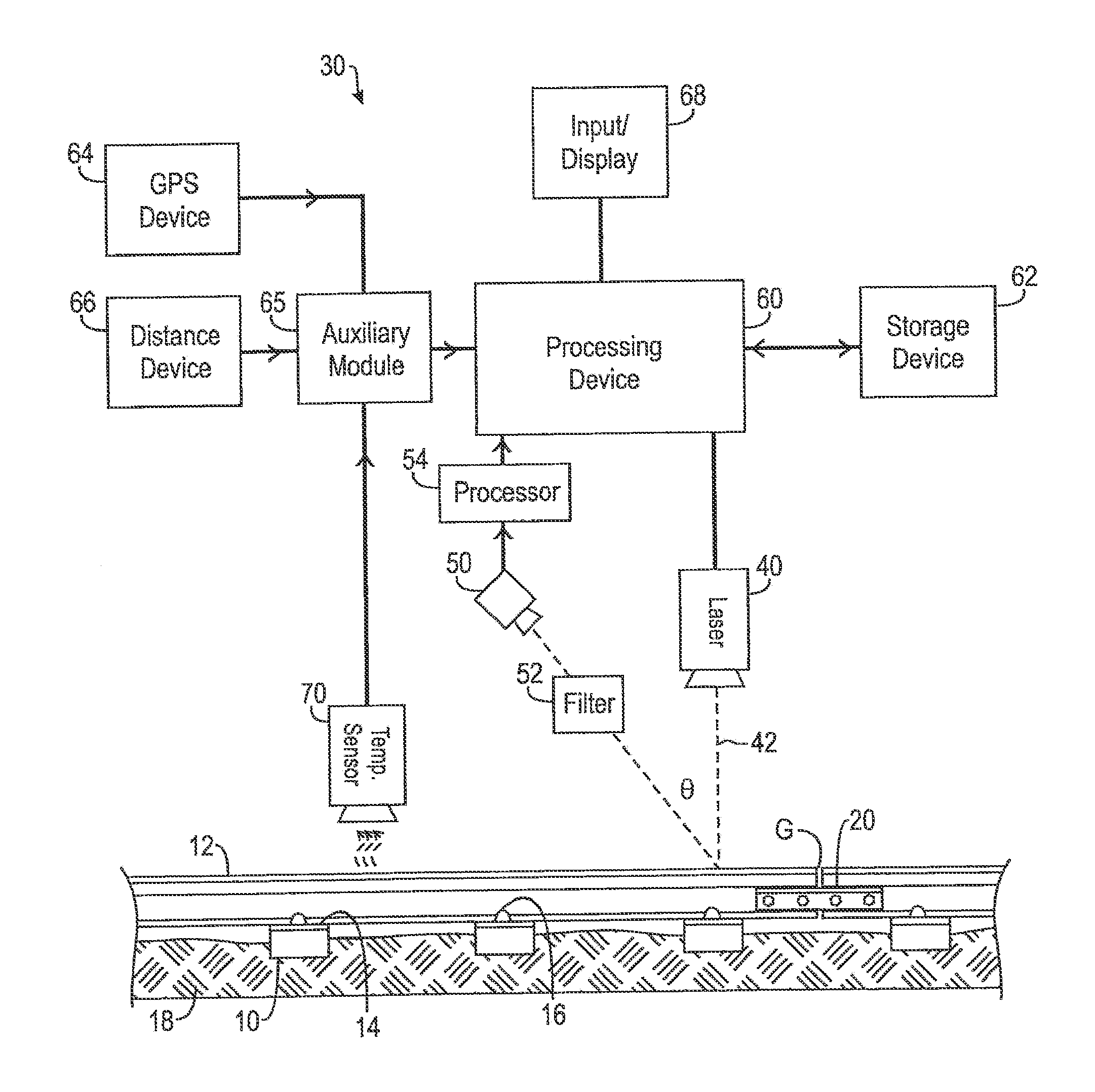

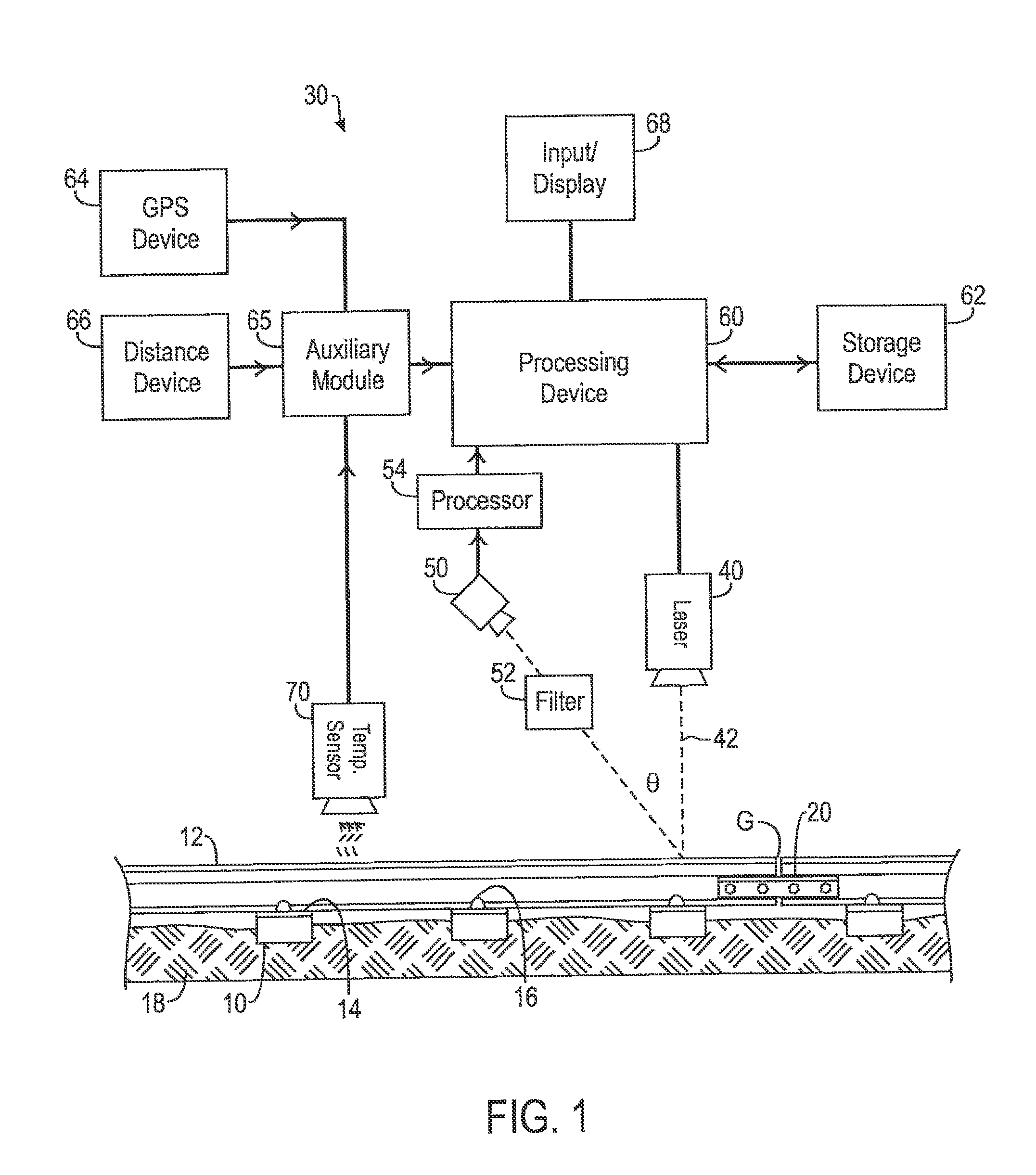

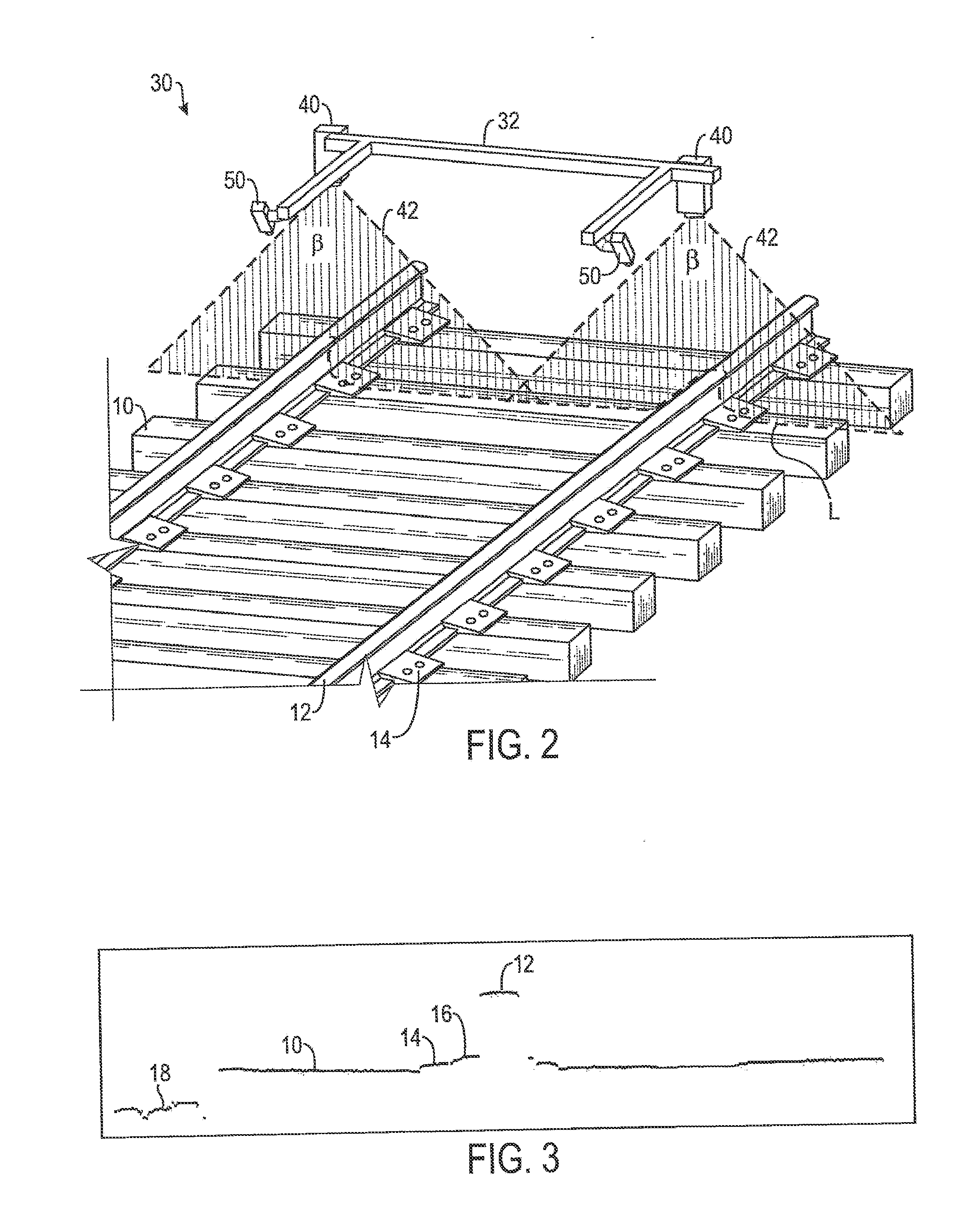

System and method for inspecting railroad ties

A system for inspecting railroad ties in a railroad track includes a light generator, an optical receiver and a processor. The light generator is oriented to project a beam of light across the railroad track while moving along the railroad track in a travel direction. The optical receiver is oriented to receive at least a portion of the beam of light reflected from the railroad track and configured to generate image data representative of a profile of at least a portion of the railroad track. The processor is configured to analyze the image data by applying one or more algorithms configured to find boundaries of a railroad tie and determine one or more condition metrics associated with the railroad tie.

Owner:LORAM TECH INC

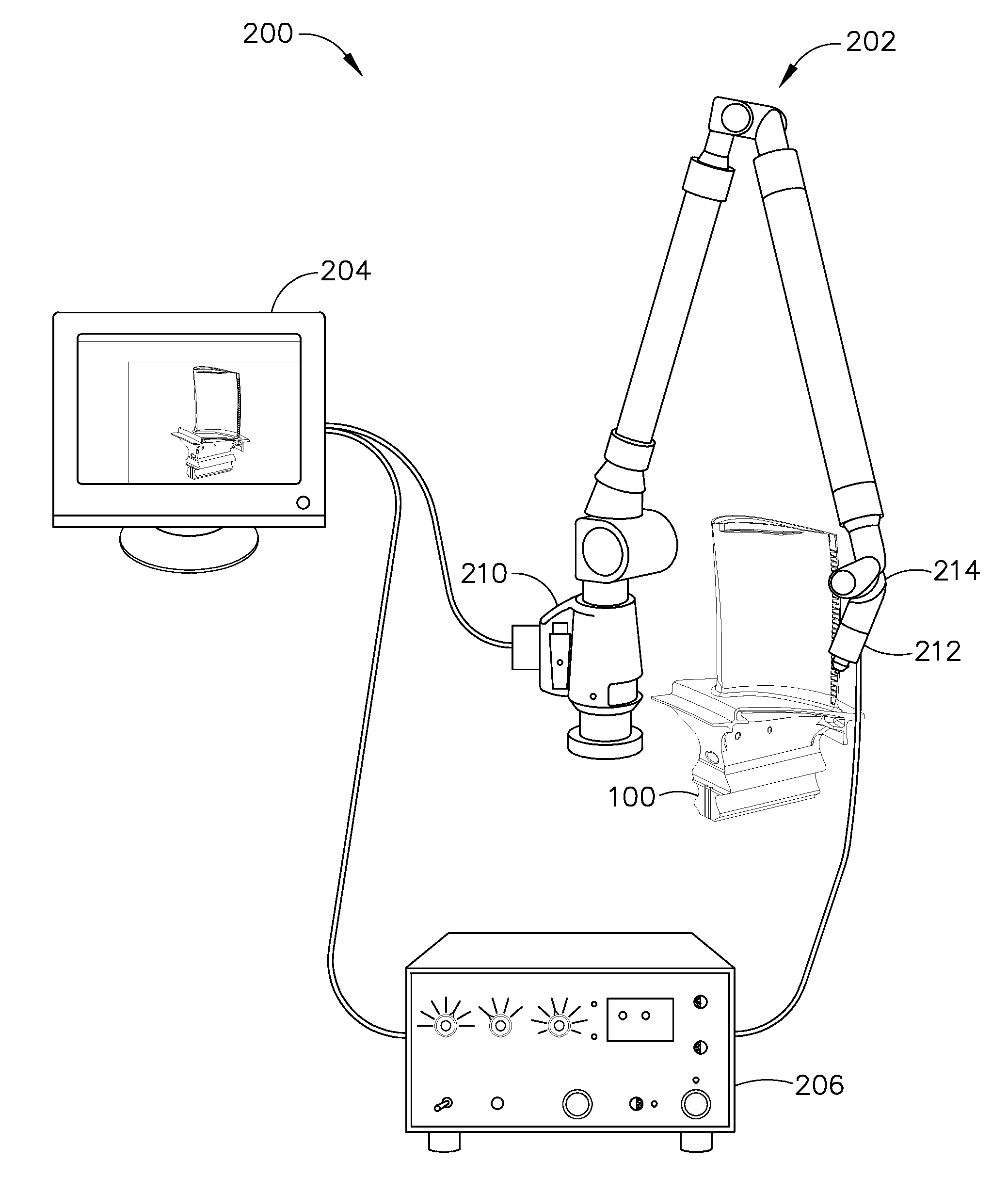

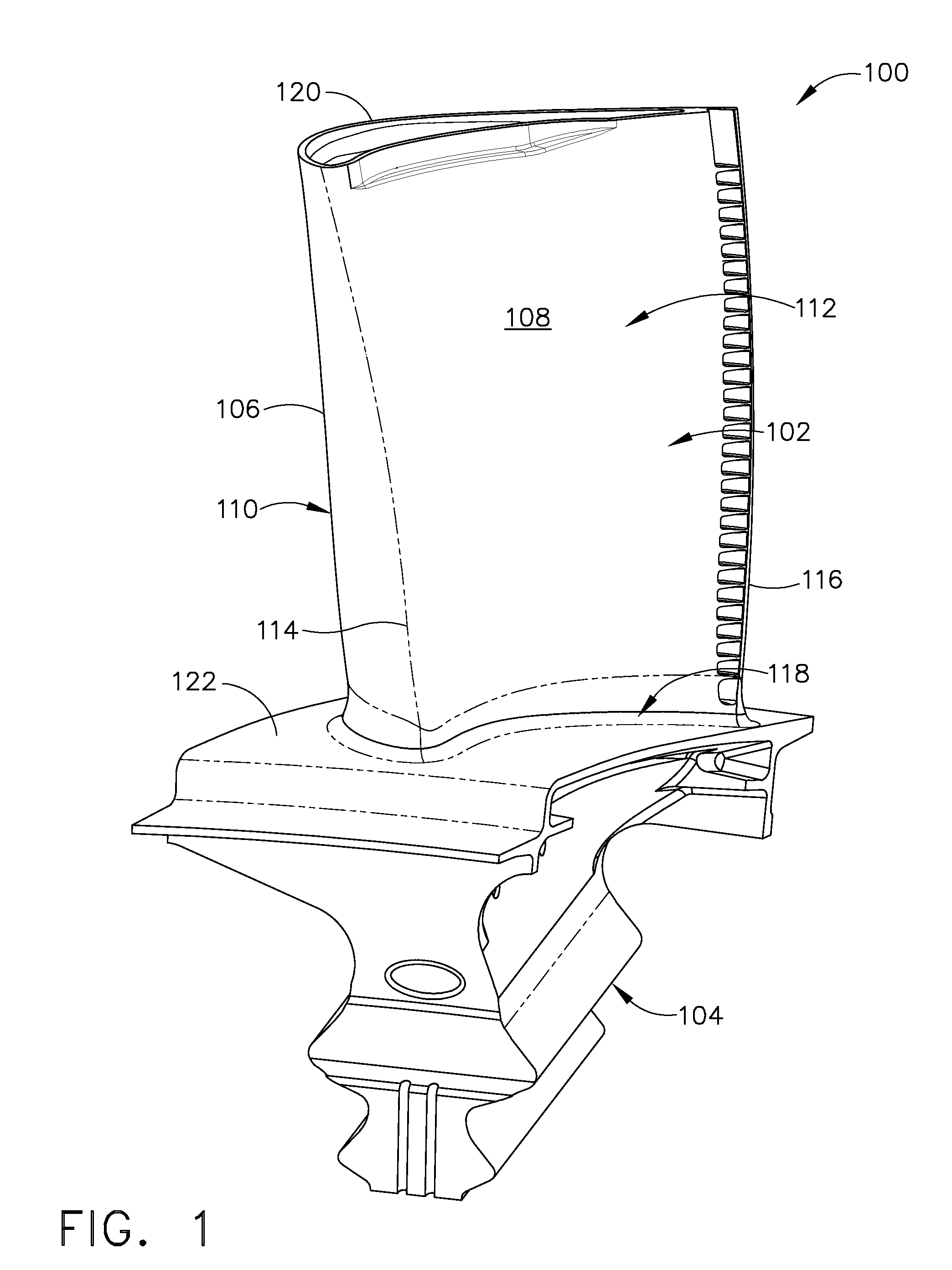

Method and system for integrating ultrasound inspection (UT) with a coordinate measuring machine (CMM)

InactiveUS20090165317A1Easy to measureAnalysing solids using sonic/ultrasonic/infrasonic wavesFeeler-pin gaugesMeasurement deviceCoordinate-measuring machine

A method is provided for assembling a measurement device for use in measuring a machine component. The method includes providing a coordinate measuring machine (CMM). The method also includes combining ultrasonic inspection (UT) capabilities and CMM capabilities to form an inspection probe. The inspection probe is installed on the CMM so that the inspection probe measures external boundaries of the machine component with the CMM capabilities and substantially simultaneously measures internal boundaries of the machine component with the UT capabilities.

Owner:GENERAL ELECTRIC CO

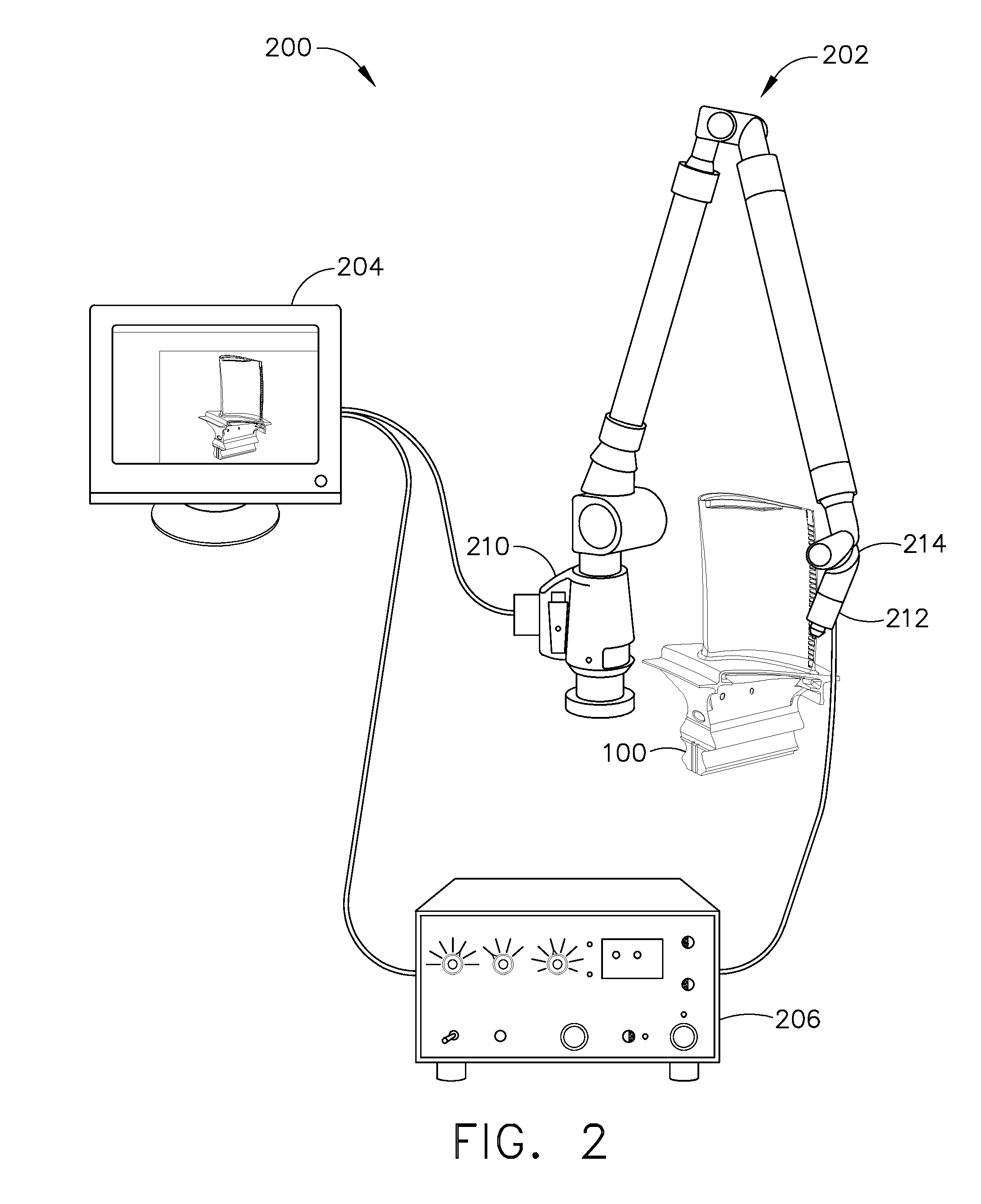

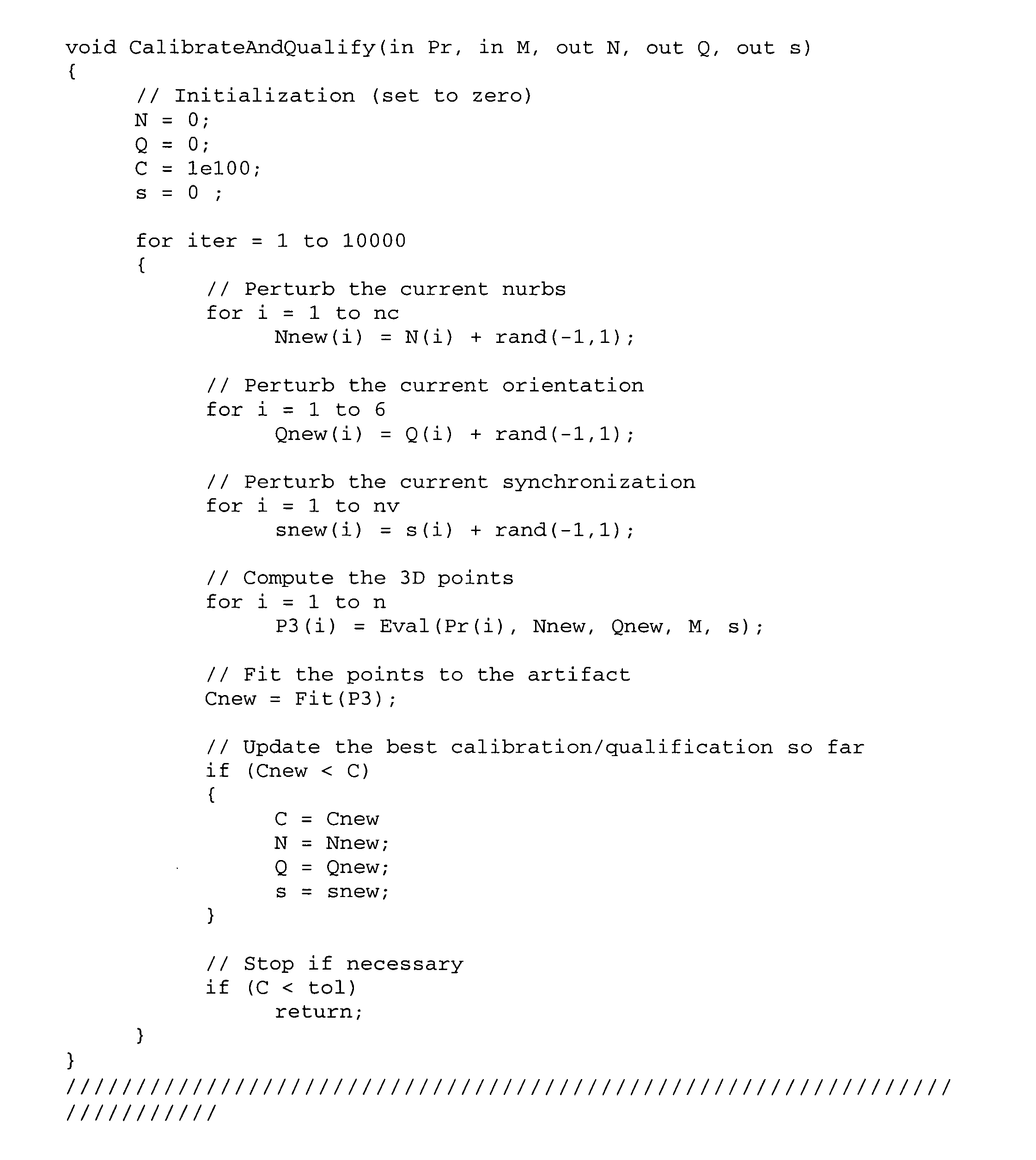

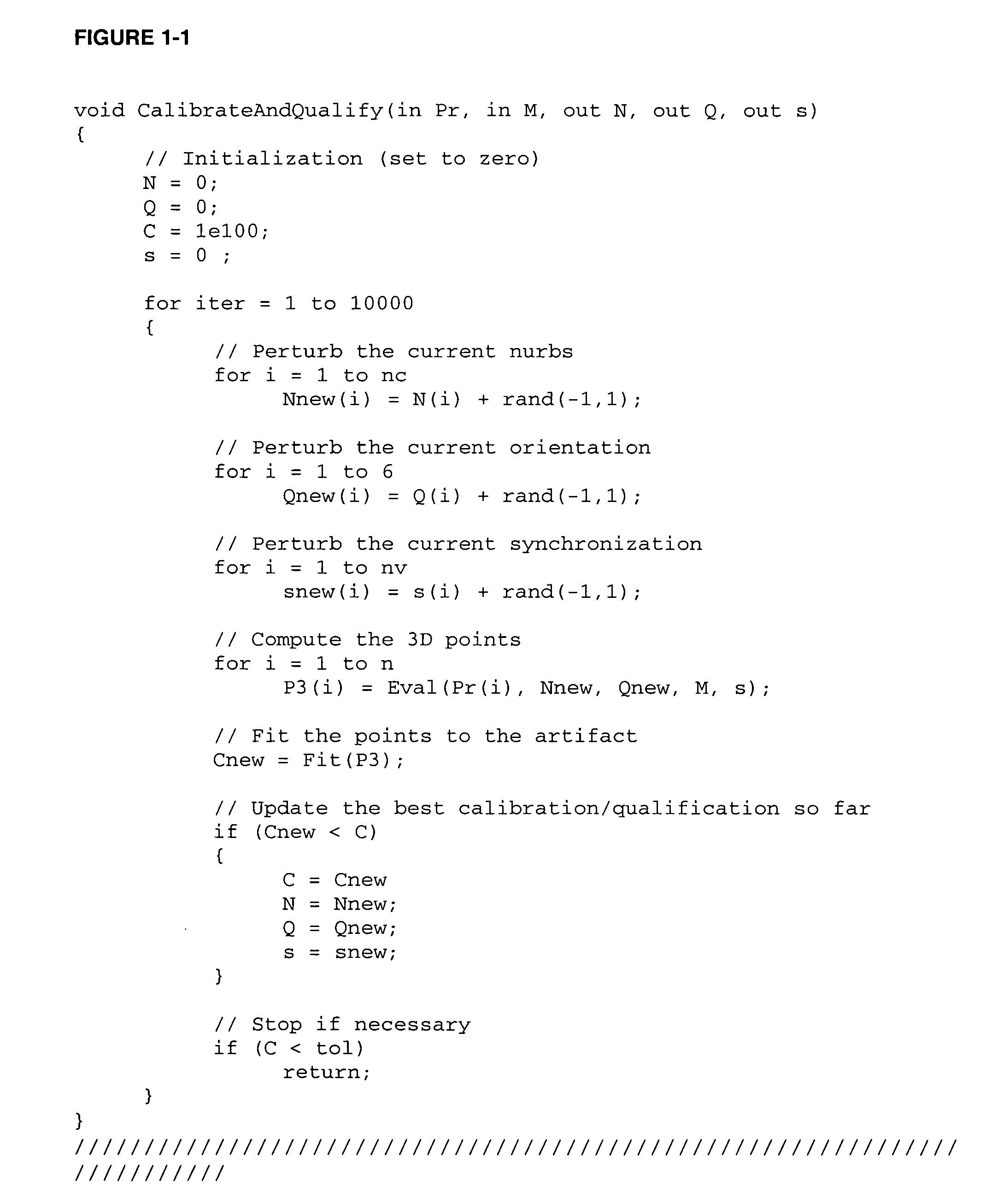

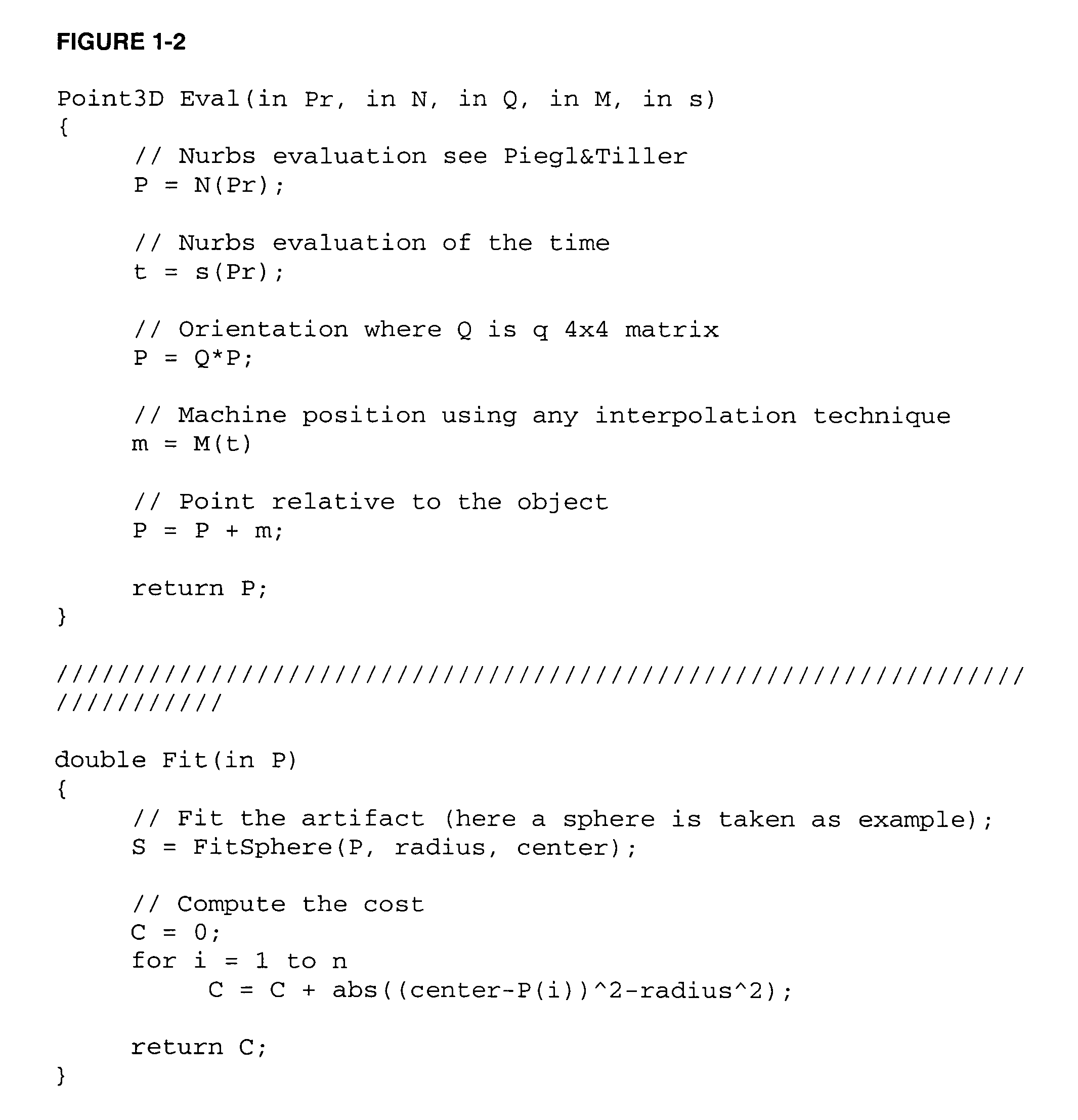

Method for the automatic simultaneous synchronization, calibration and qualification of a non-contact probe

The present invention relates to an improved method for the simultaneous calibration and qualification of a non-contact probe on a localizer using a single artifact, in which non-contact probe readings and localizer readings are synchronised using parameters determined simultaneously with calibration and qualification. The invention also relates to a non-contact probe and other devices, and a computer program for performing the invention.

Owner:METRIS +1

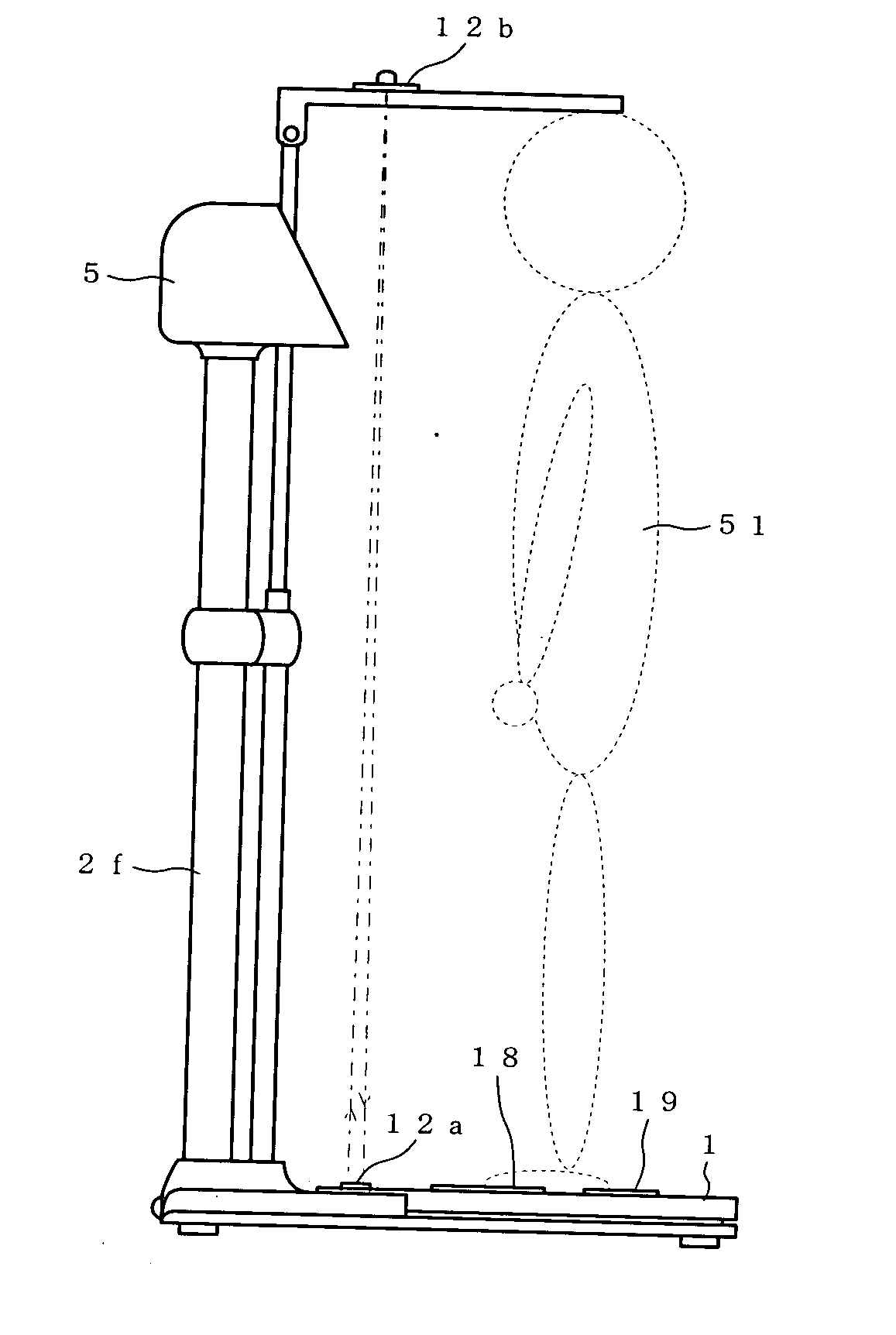

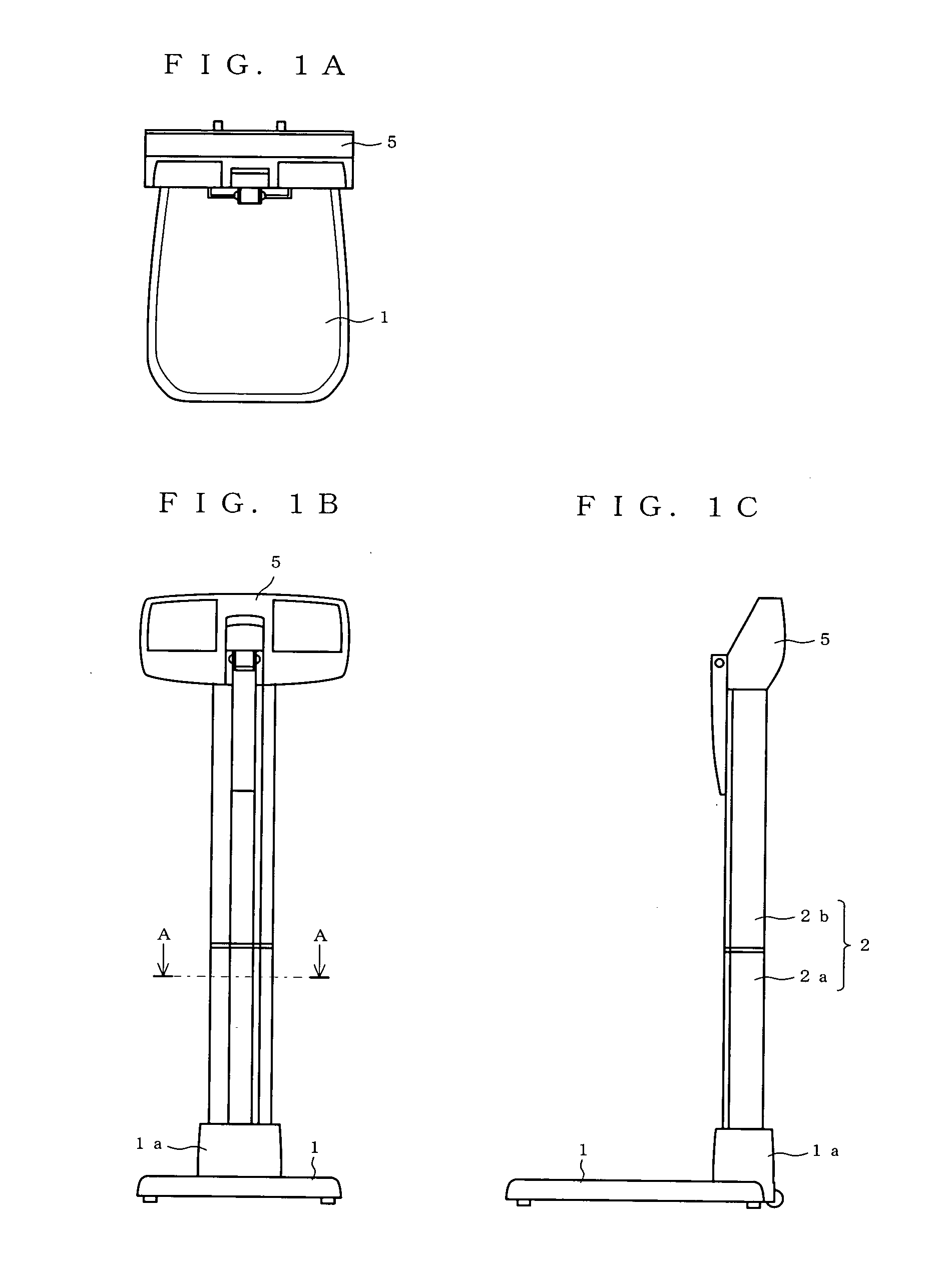

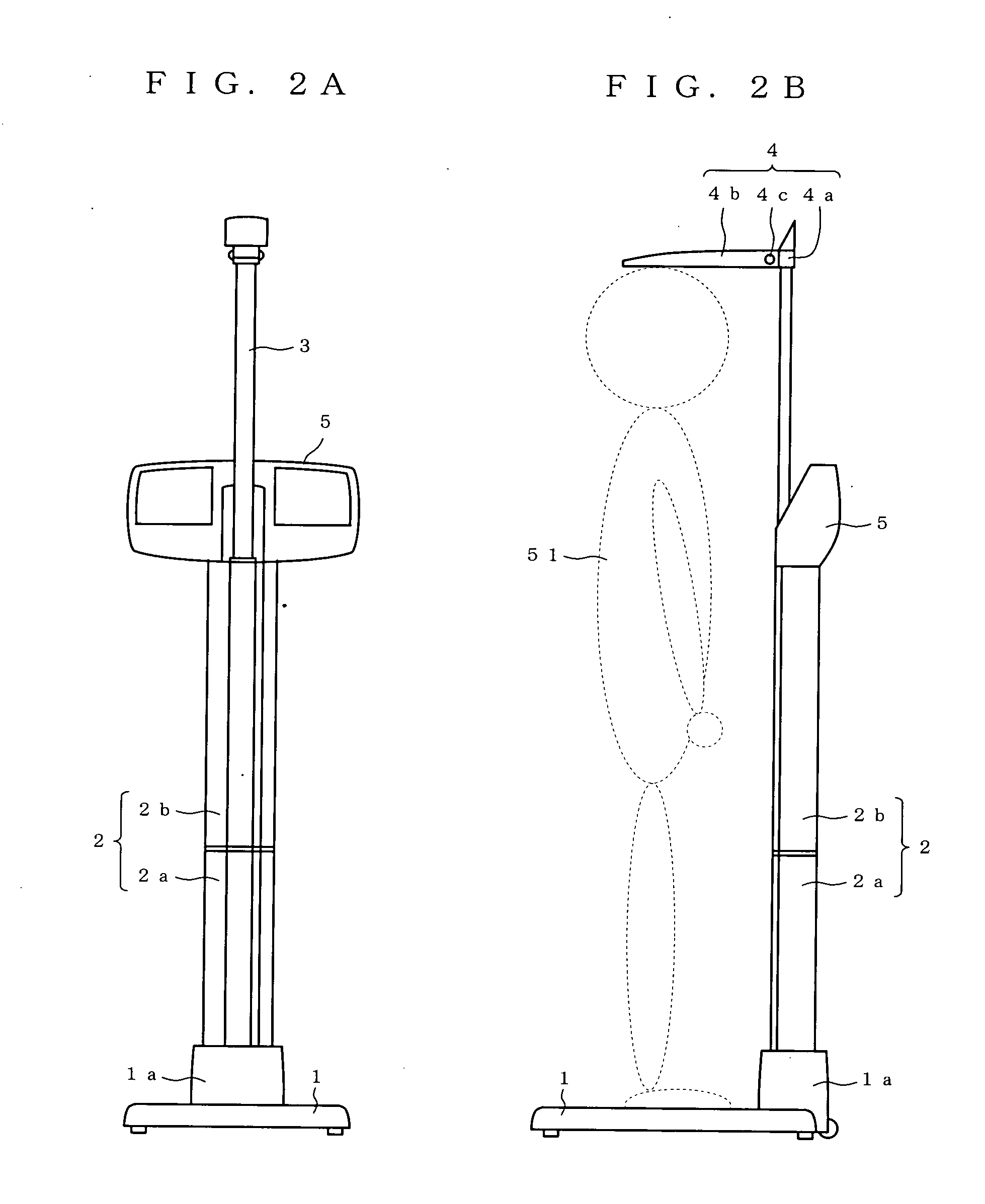

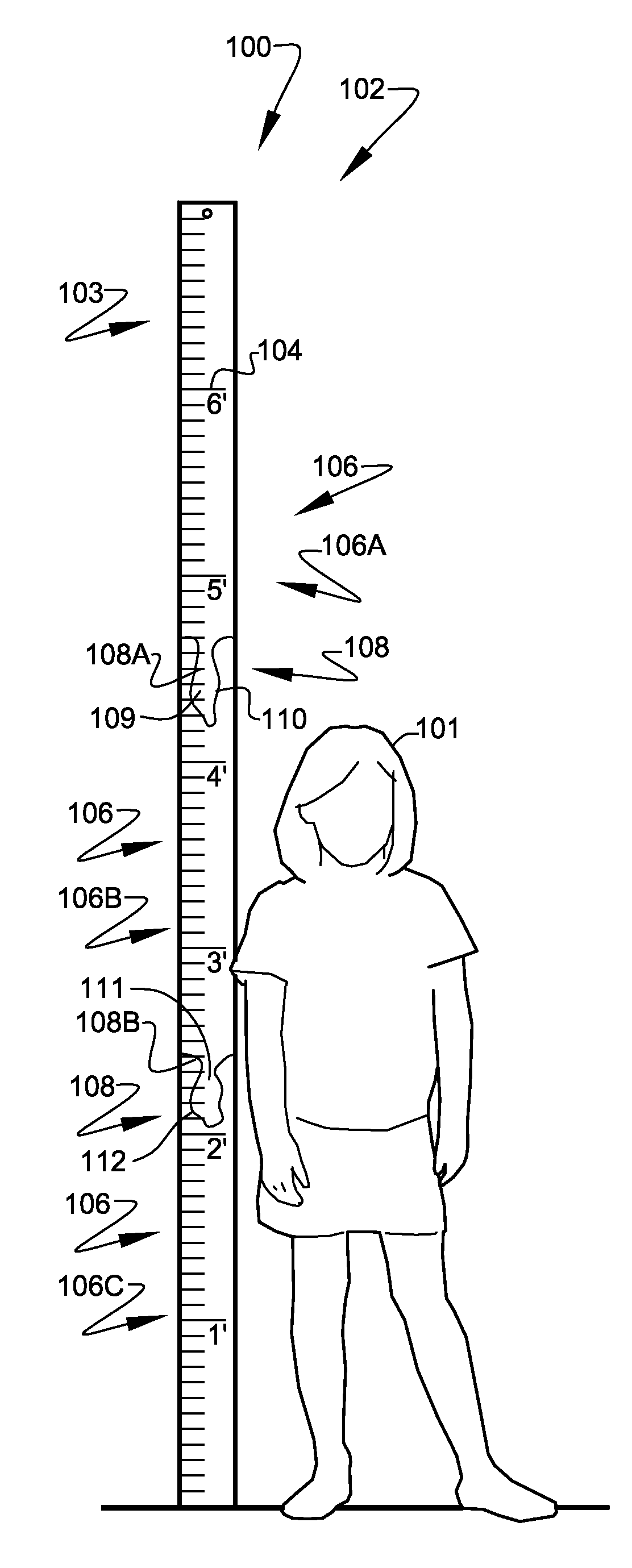

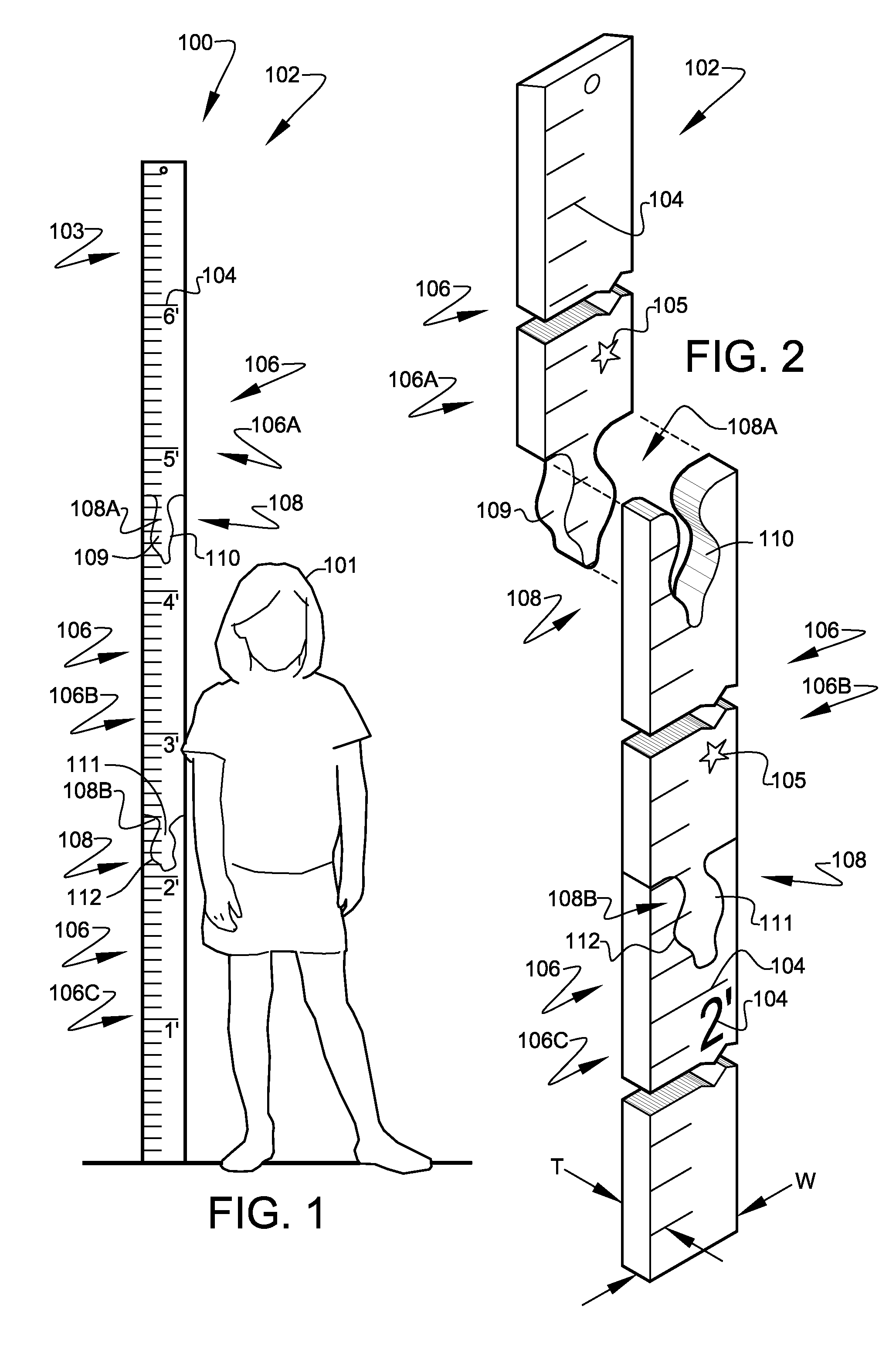

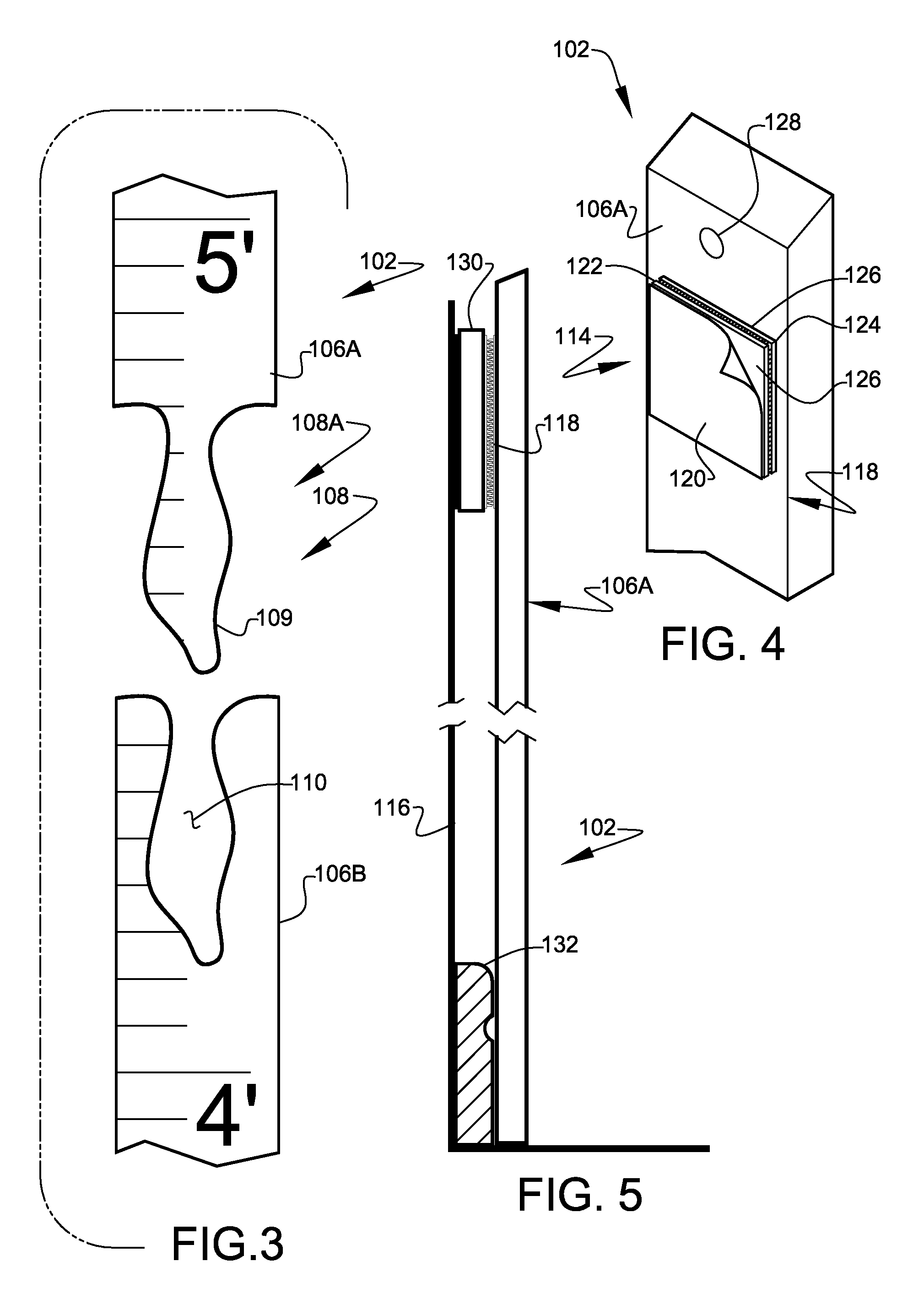

Height measuring apparatus and bioinstrumentation apparatus with height measuring device

InactiveUS20050155246A1Improve convenienceIncrease awarenessFeeler-pin gaugesSurgeryTransceiverMeasurement device

A height measuring apparatus and a bioinstrumentation apparatus with a height measuring device are provided capable of precise measurement accuracy without being affected by an examinee and being highly convenient to assemble, handle and operate. A height detector (a transceiver and a reflector or a transmitter and a receiver having a communication conformation with a laser or ultra sonic beam) has components arranged in a movable part (a head-contact arm or a movable bar) and in a stationary part (a height measurement unit (base platform) or a fixed bar) of a telescoping height measurement bar such that a communication signal route between the parts is not blocked when an examinee is standing thereon, to obtain a height measurement by detecting the distance between the movable and stationary parts.

Owner:TANITA CORP

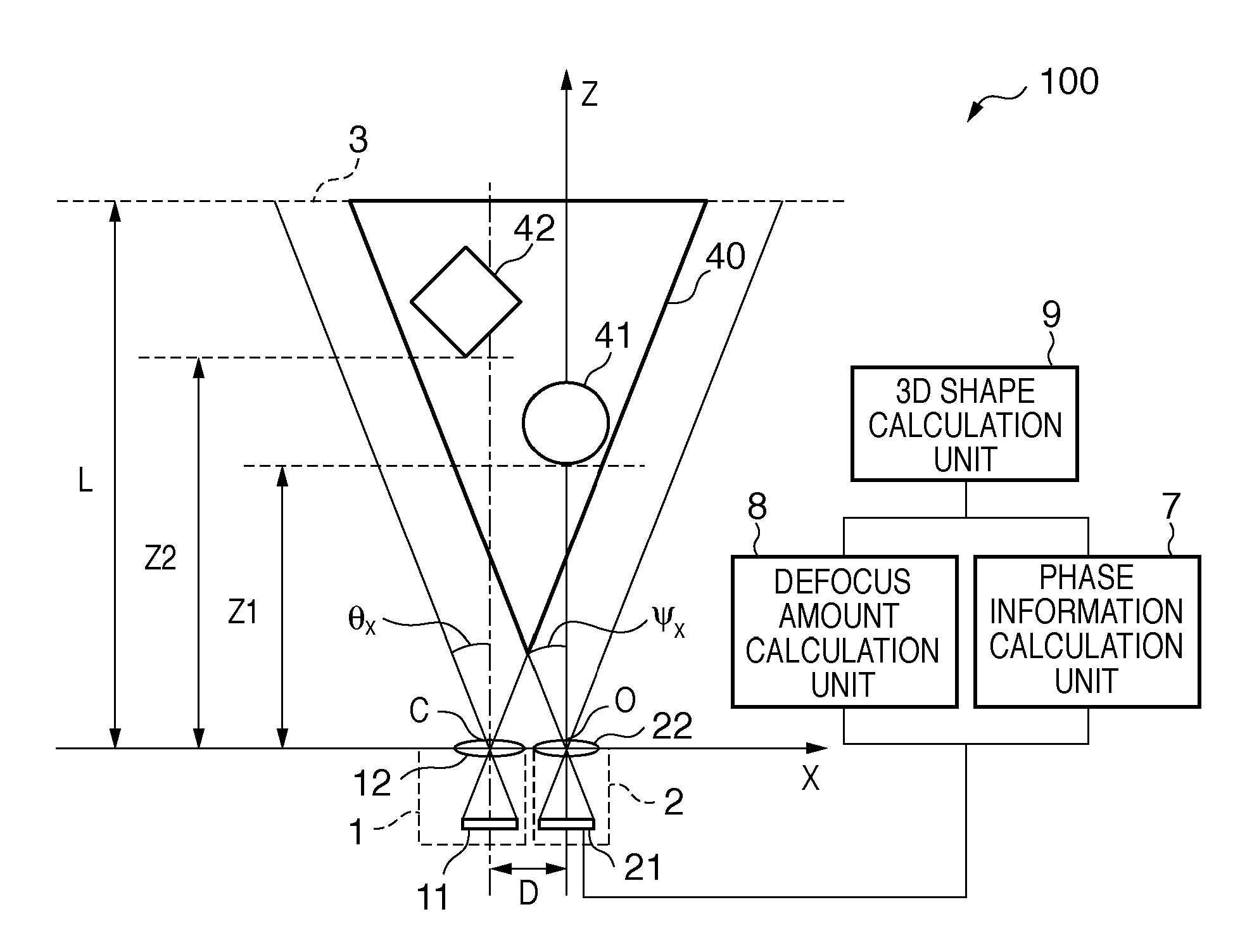

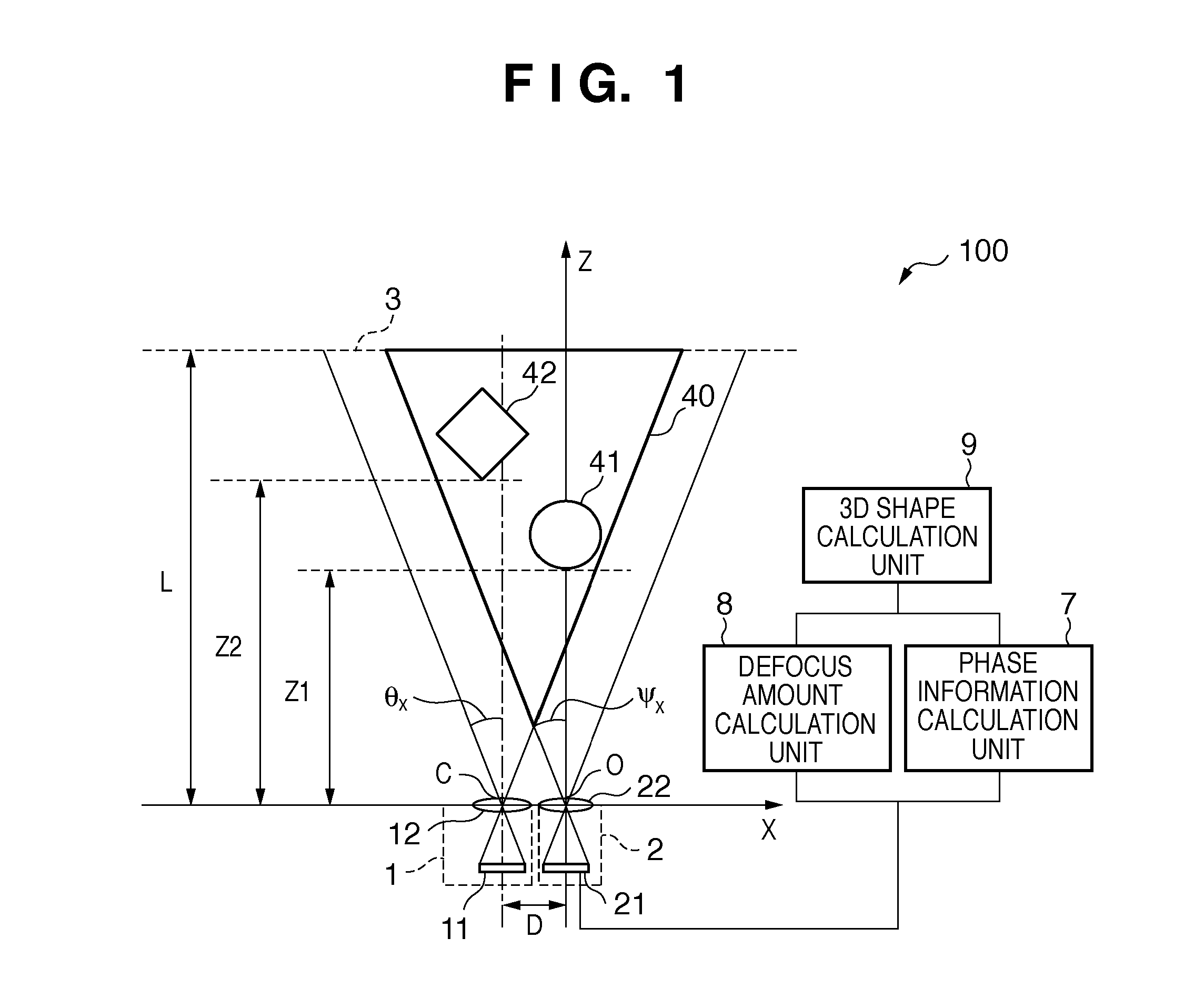

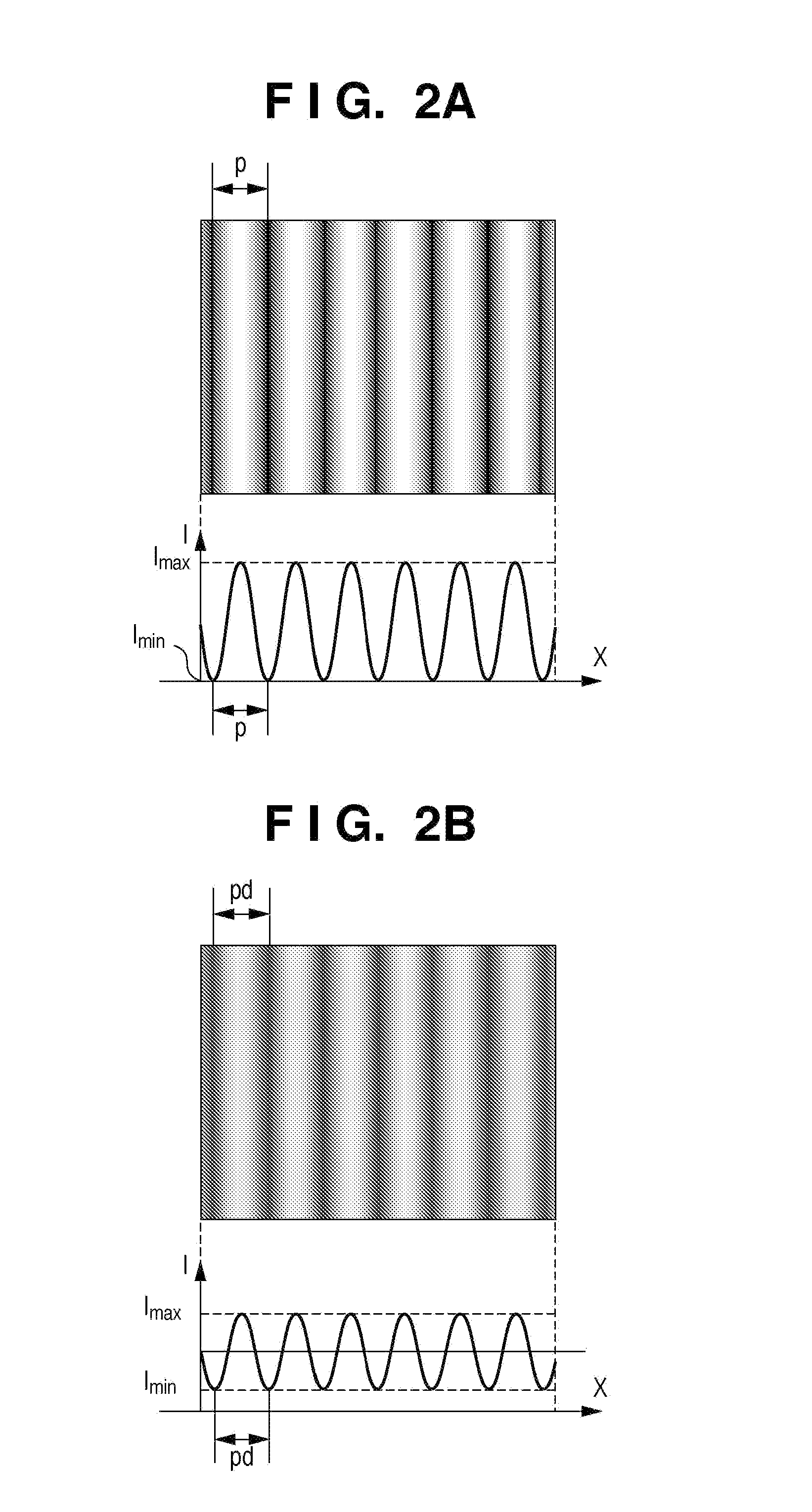

Three dimensional shape measurement apparatus, three dimensional shape measurement method, and computer program

A 3D shape measurement apparatus for measuring a 3D shape of an object existing on a measurement area, comprising, a pattern projection unit for projecting a pattern having a periodicity onto the measurement area, and a capturing unit for capturing an image of the area where the pattern is projected, wherein the measurement area is specified by a reference plane, a projection area of the pattern projection unit, and a capturing area of the capturing unit, and the pattern projection unit projects the pattern to be focused on the reference plane. The apparatus further comprises a first calculation unit for calculating phase information of a pattern of the captured image, a second calculation unit for calculating defocus amounts of the pattern in the captured image, and a third calculation unit for calculating a 3D shape of the object based on the phase information and the defocus amounts.

Owner:CANON KK

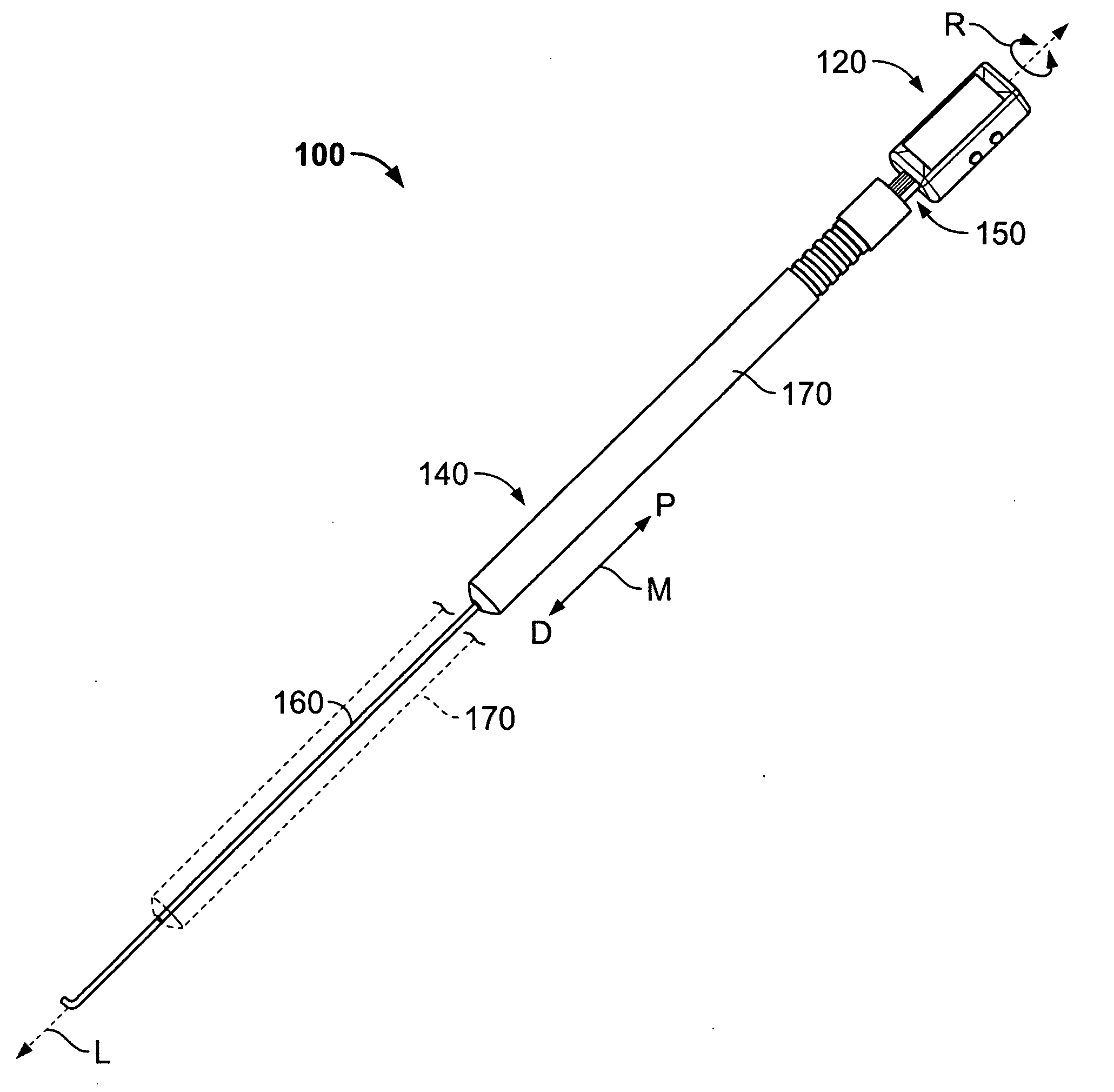

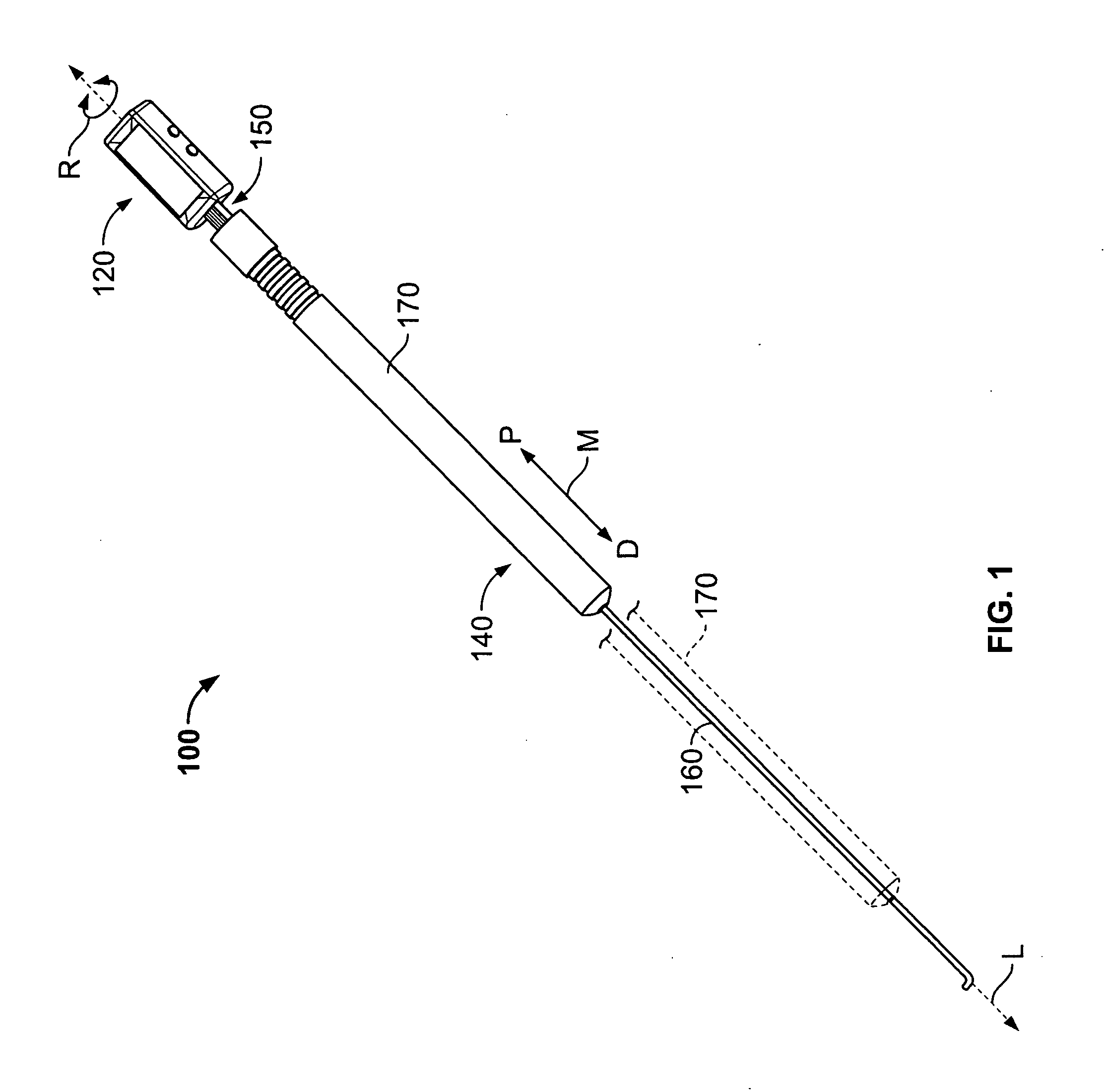

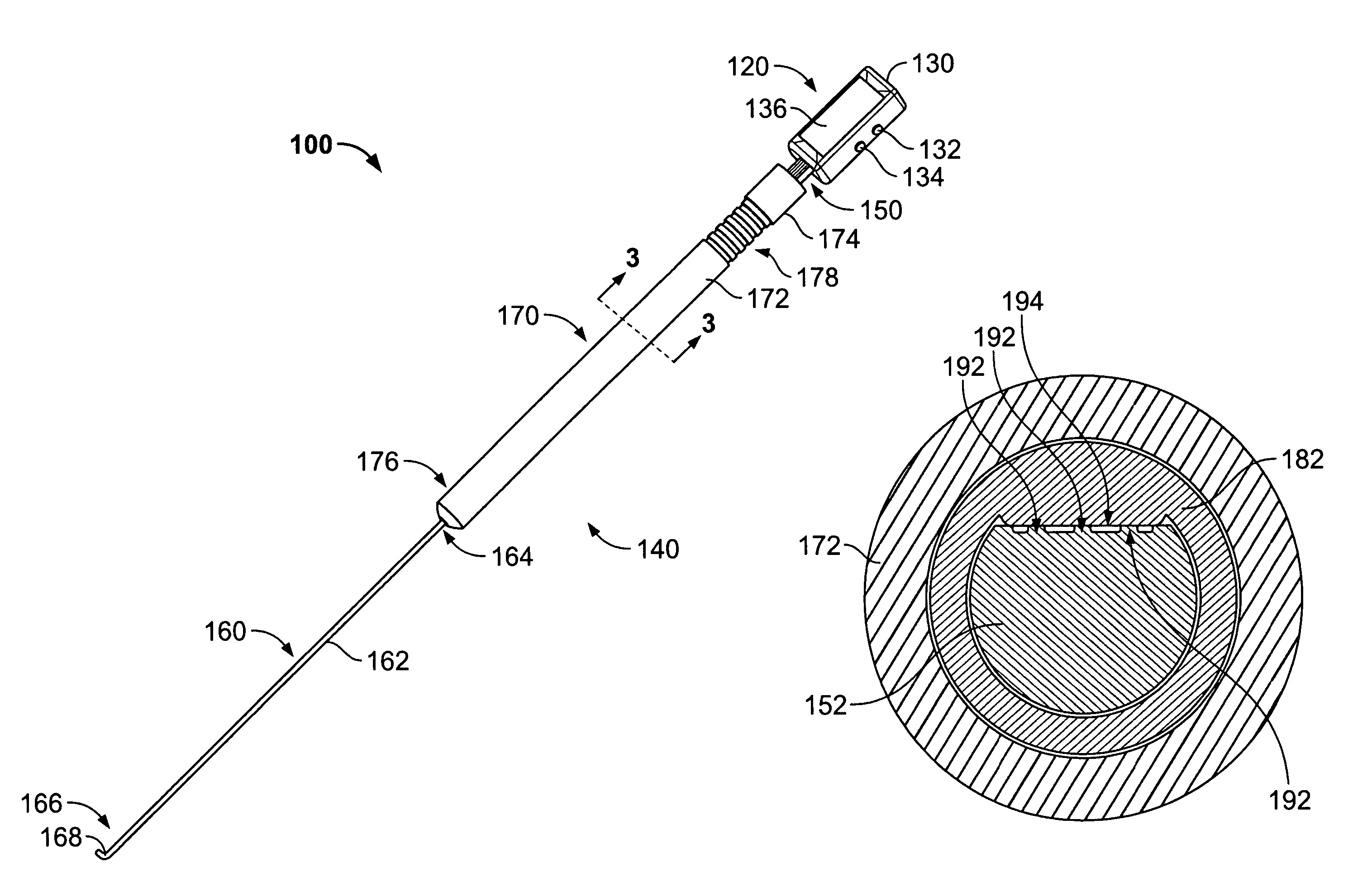

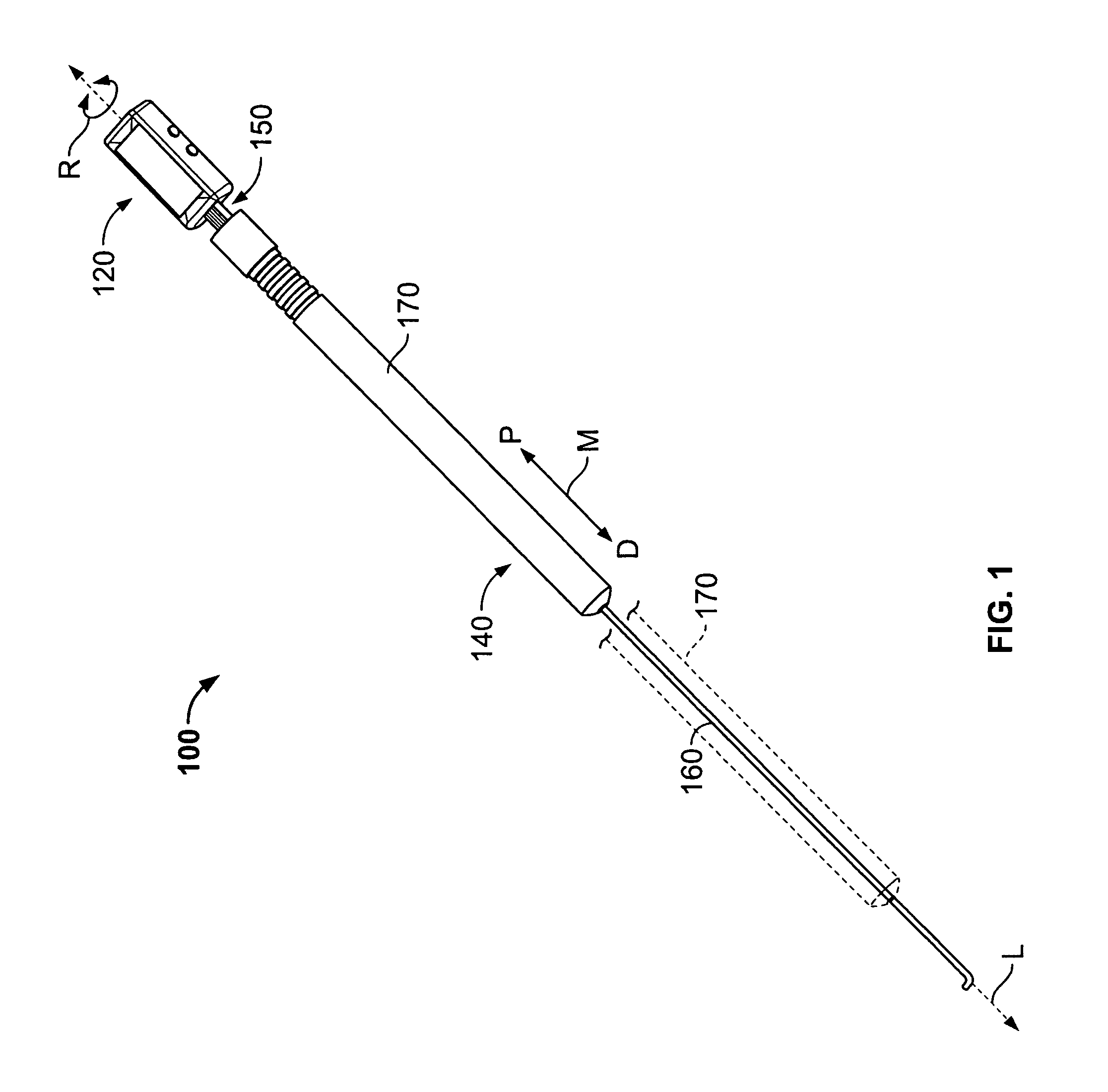

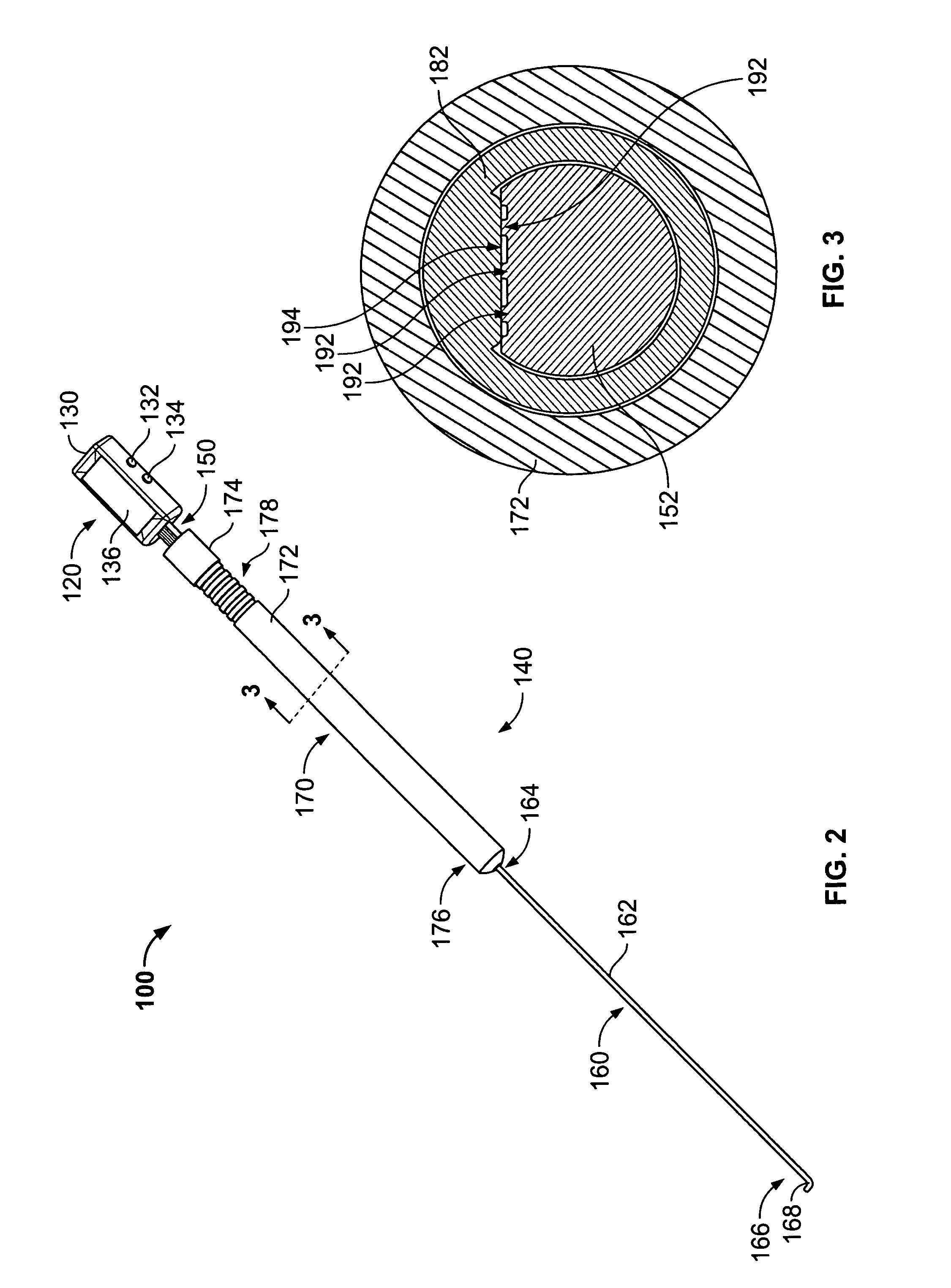

Digital depth gauge

A digital depth gauge is provided for measuring a depth of a hole in an object. In one embodiment the gauge includes: a user interface with a display and at least one actuator; a reader shaft with a distal end and a proximal end connected to the user interface; a probe that extends from the distal end of the reader shaft and which includes a tip configured to locate a distal surface of the hole; a sleeve member with a distal end configured to abut a proximal surface of the hole, the sleeve member being coupled with the reader shaft for relative translational and rotational movement; and a sensor interposed between the reader shaft and the sleeve member for measuring relative translational movement between the reader shaft and the sleeve member. In some embodiments, the gauge may include a means for aligning elements of the sensor.

Owner:EDGE SURGICAL INC

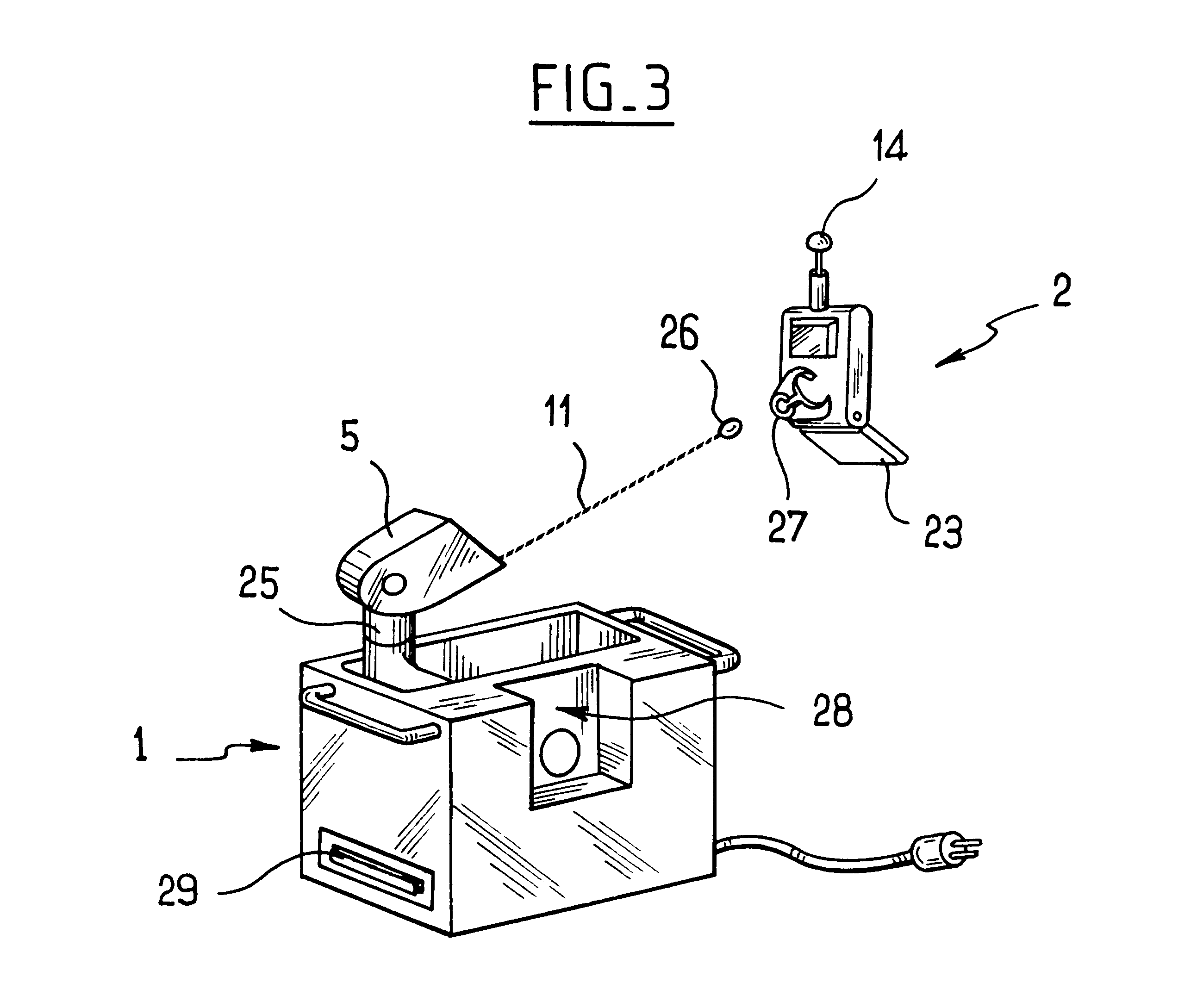

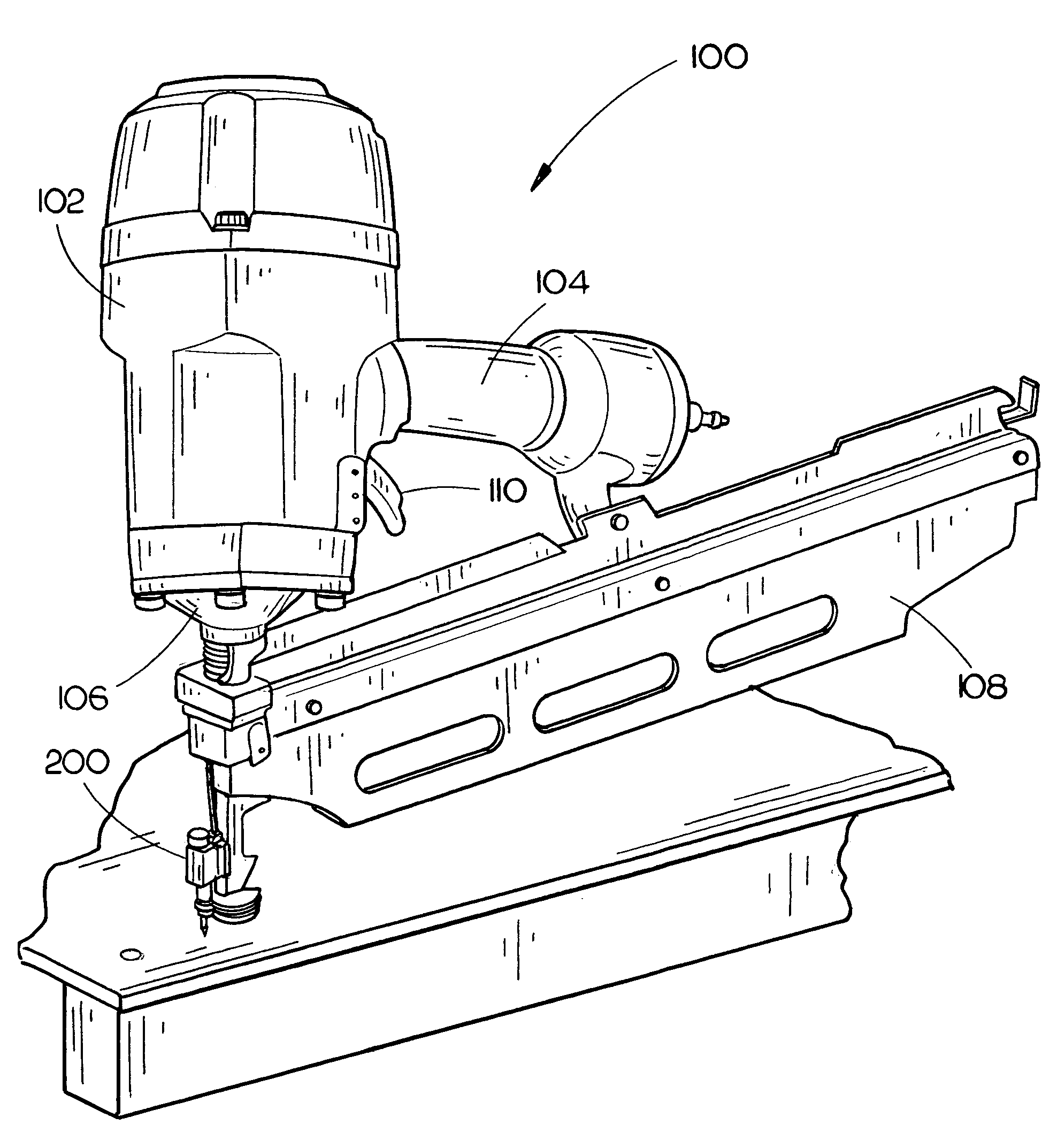

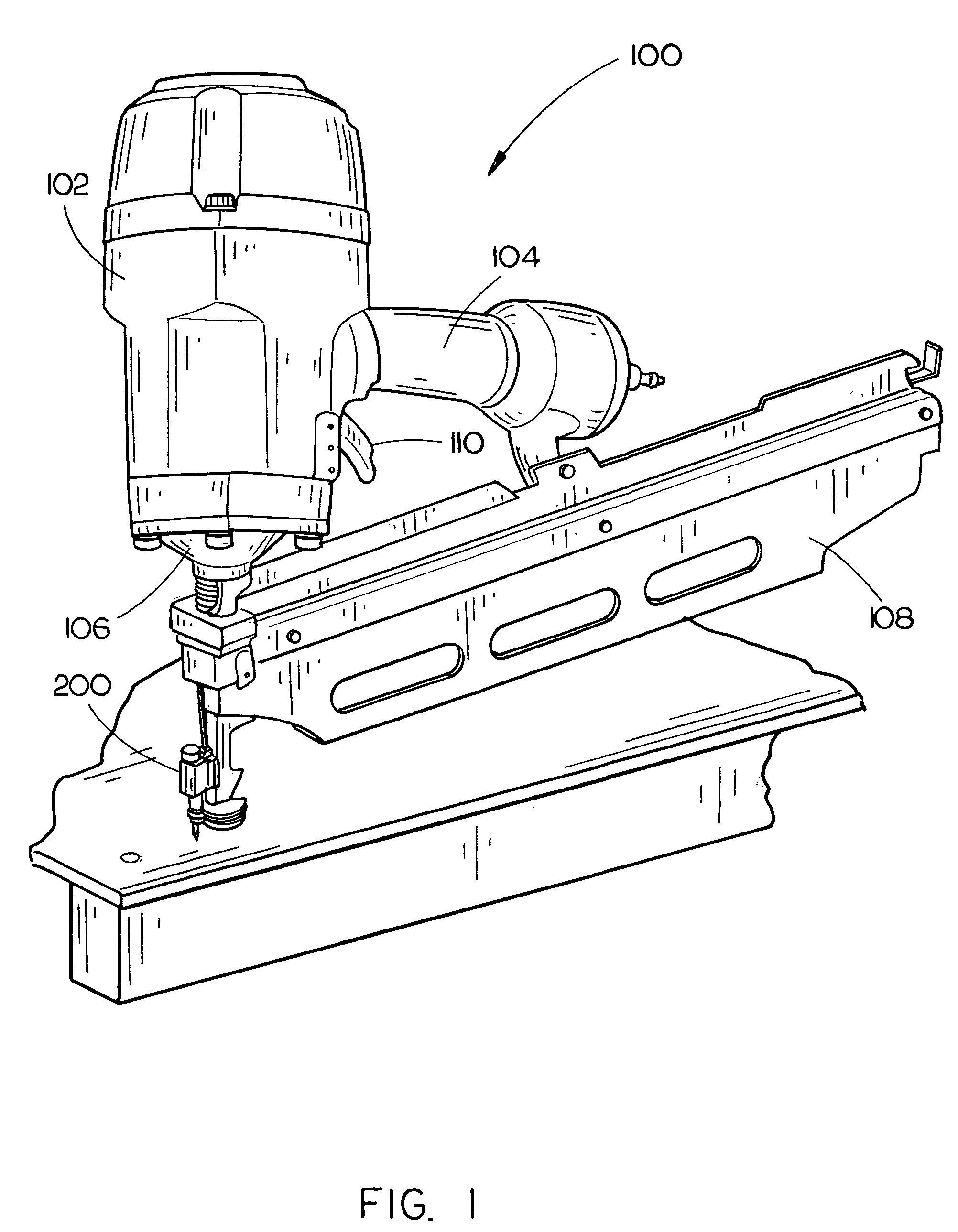

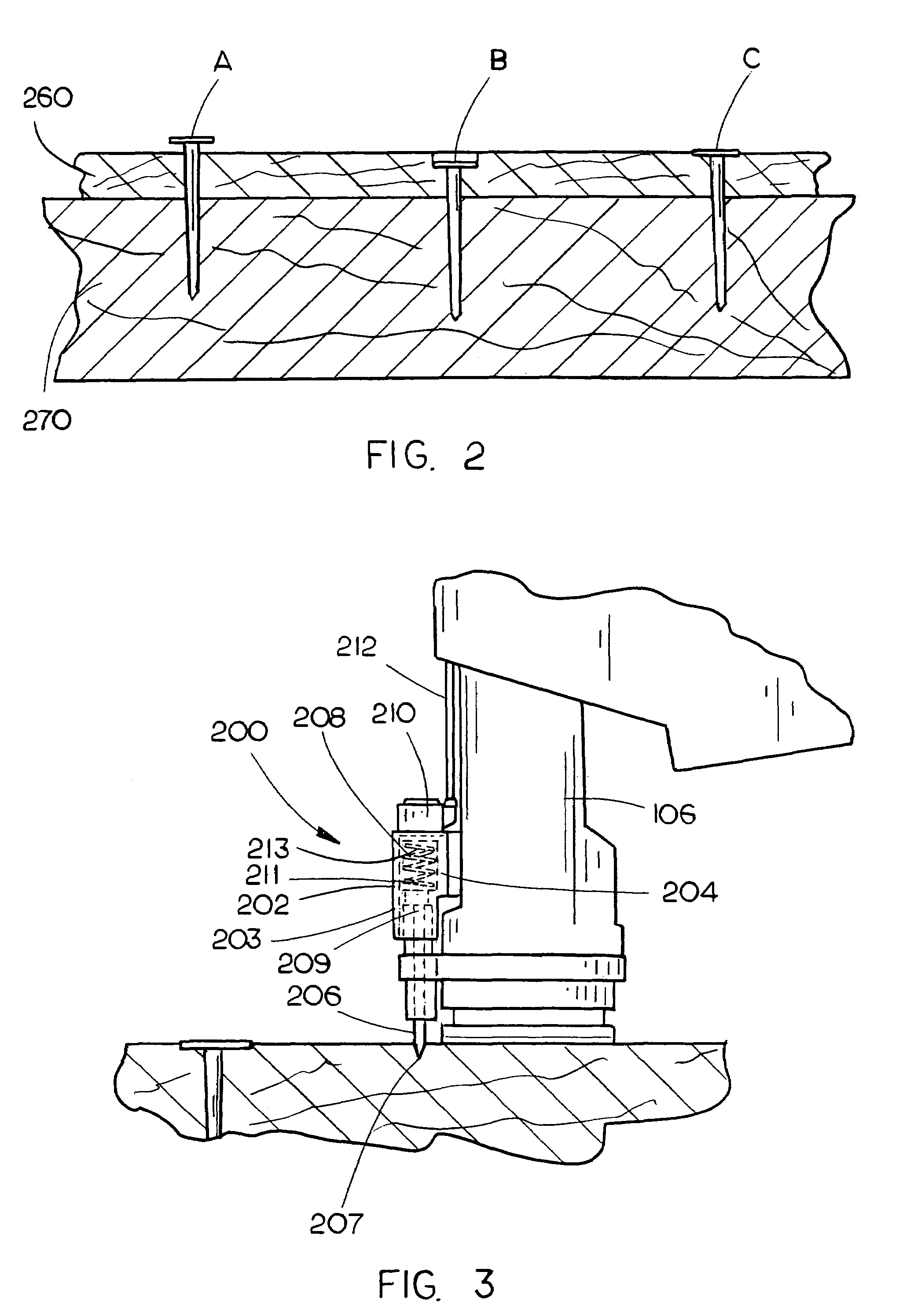

Gauge for use with power tools

InactiveUS7243440B2Improve efficiencyEasy to operateStapling toolsDrilling/boring measurement devicesEngineeringPower tool

Owner:BLACK & DECKER INC

Method for custom fitting of apparel

InactiveUS6711455B1Quickly and easily and conveniently orderFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansHuman bodyMathematical model

The present invention is directed to a method for custom fitting an article to a human being having the steps of defining a first set of human body dimensions to be reported by the human being, defining a second set of human body dimensions to be inferred from said first set of human body dimensions, providing a first mathematical model relating said second set of human body dimensions to said first set of human body dimensions, wherein said mathematical model has been generated by statistical analysis of a human anthropometric database, obtaining a first set of values of said first set of body dimensions by report of the human being, computing a second set of values of said second set of human body dimensions from said first set of values of said first set of human body dimensions by using said first mathematical model, defining a set of article dimensions, providing a second mathematical model relating said article dimensions to said first set of human body dimensions and said second set of human body dimensions, computing a third set of values of said set of article dimensions from said first set of values of said first set of human body dimensions and said second set of values of said second set of human body dimensions by using said second mathematical model.

Owner:THIRDLOVE INC

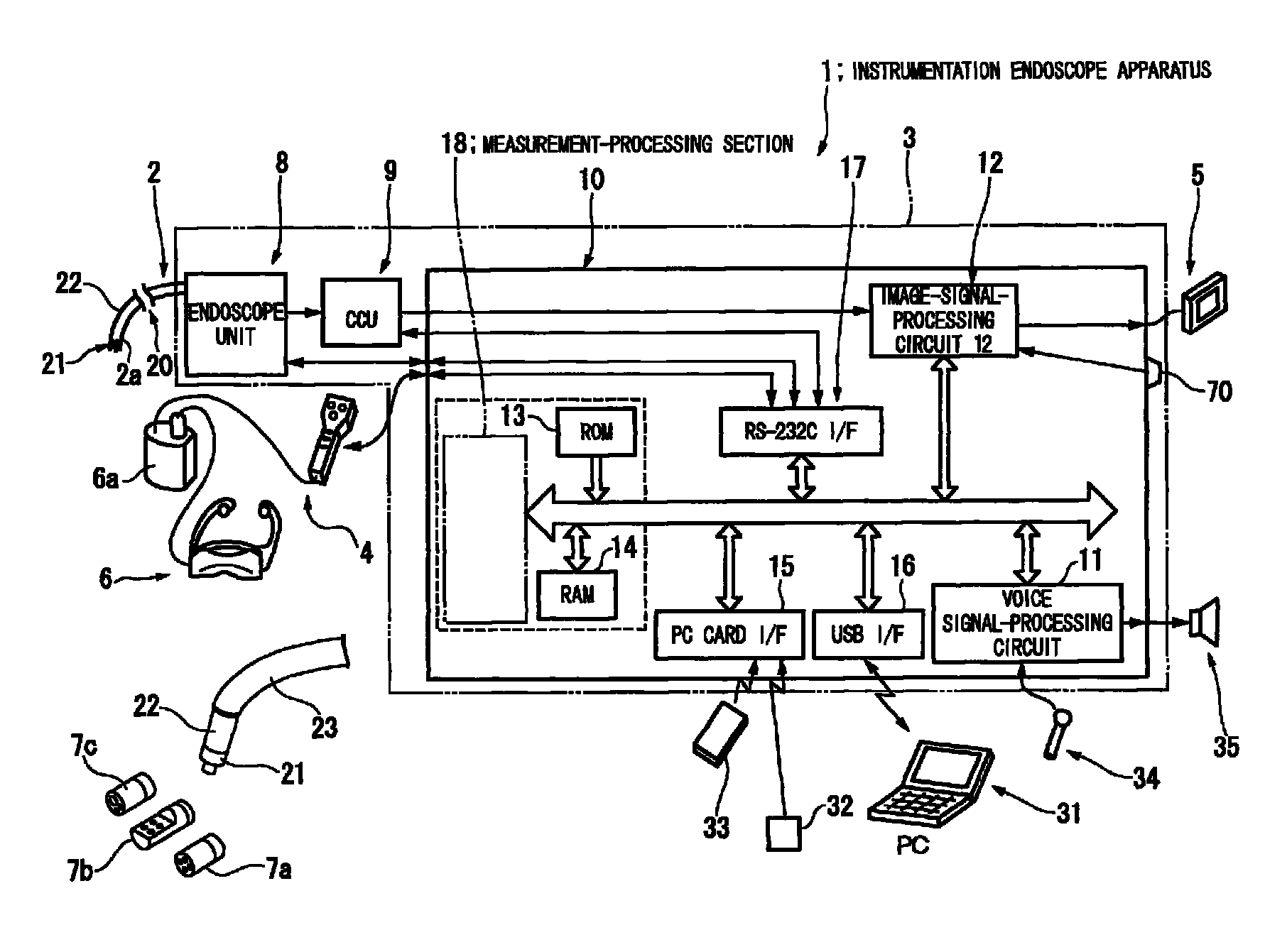

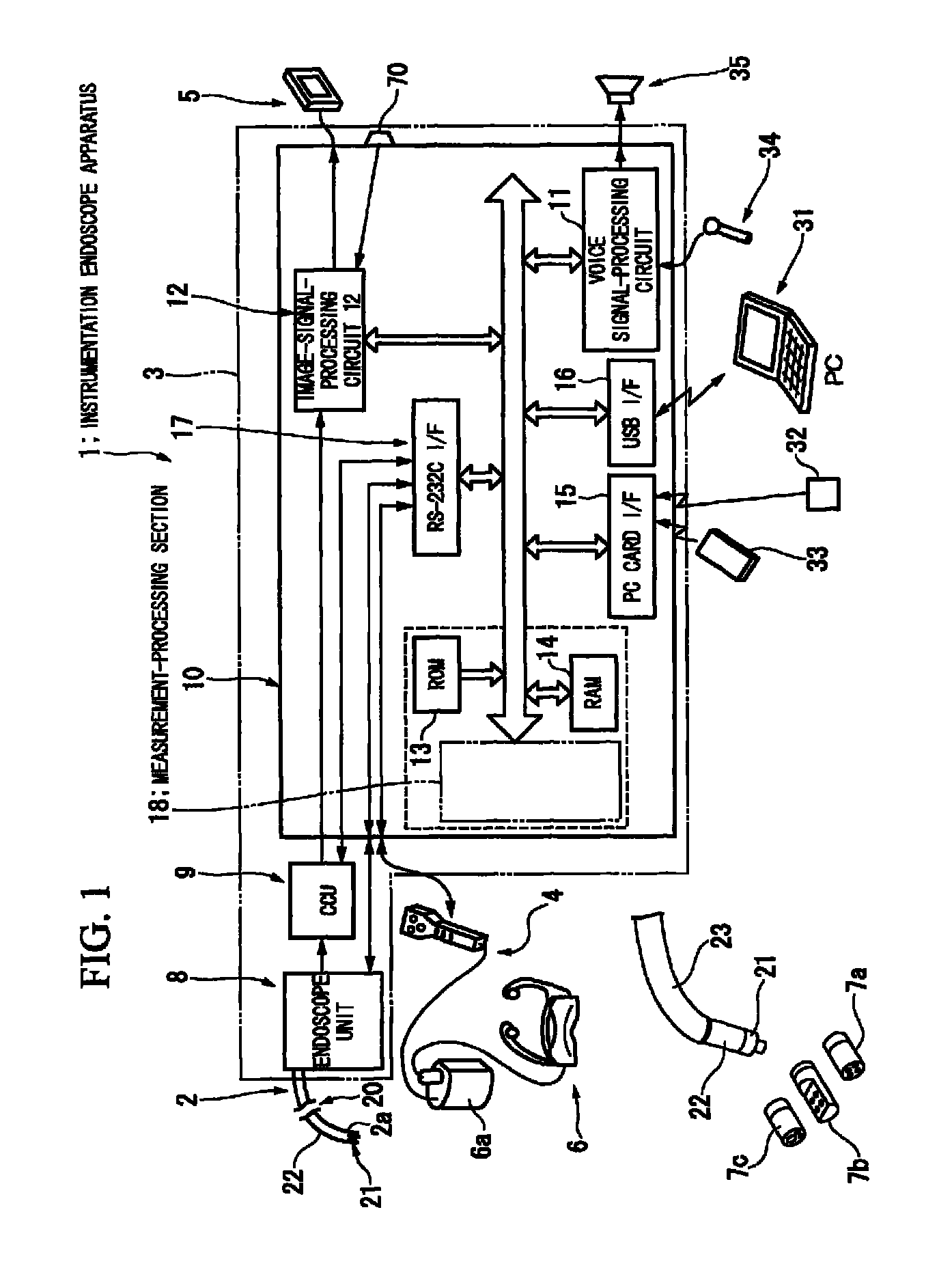

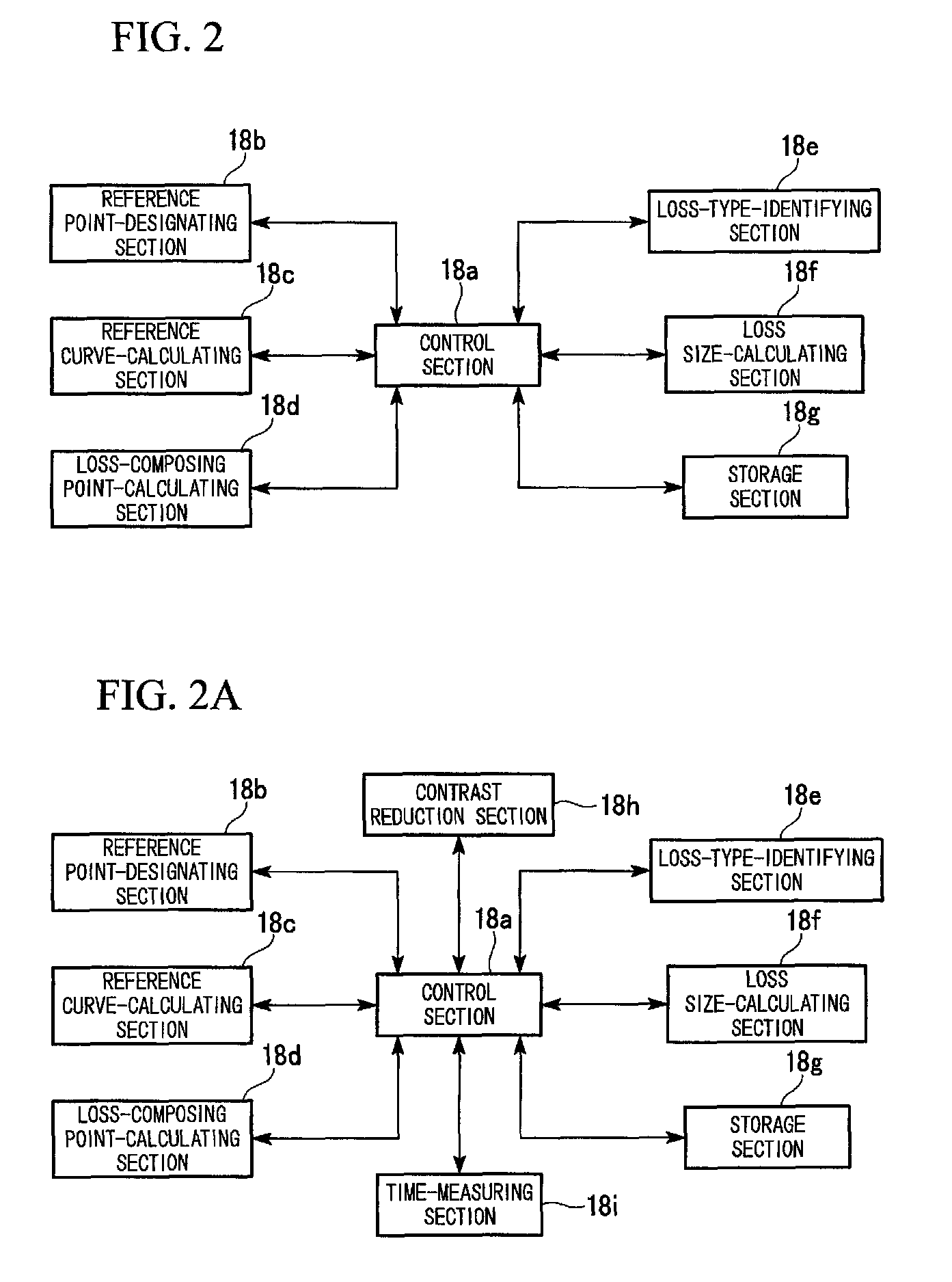

Endoscope apparatus and program

An endoscope apparatus includes an electronic endoscope that picks up a measurement object and produces a picked-up-image signal; an image-processing unit that produces a image signal based on the picked-up-image signal; and an measurement processing unit that undertakes measurement processing to the measurement object based on the image signal. The measurement processing unit includes: a reference point-designating unit that designates two reference points on the measurement object; an approximate-outline—calculating unit that calculates an approximate outline by approximating the outline of the measurement object based on the reference points; and a loss-composing points-calculating unit that calculates loss-composing points that constitute a loss outline formed on the measurement object based on the reference points and the approximate outline. This enables loss size measurement upon designating two reference points, thereby reducing complex operations and improving operability.

Owner:EVIDENT CORP

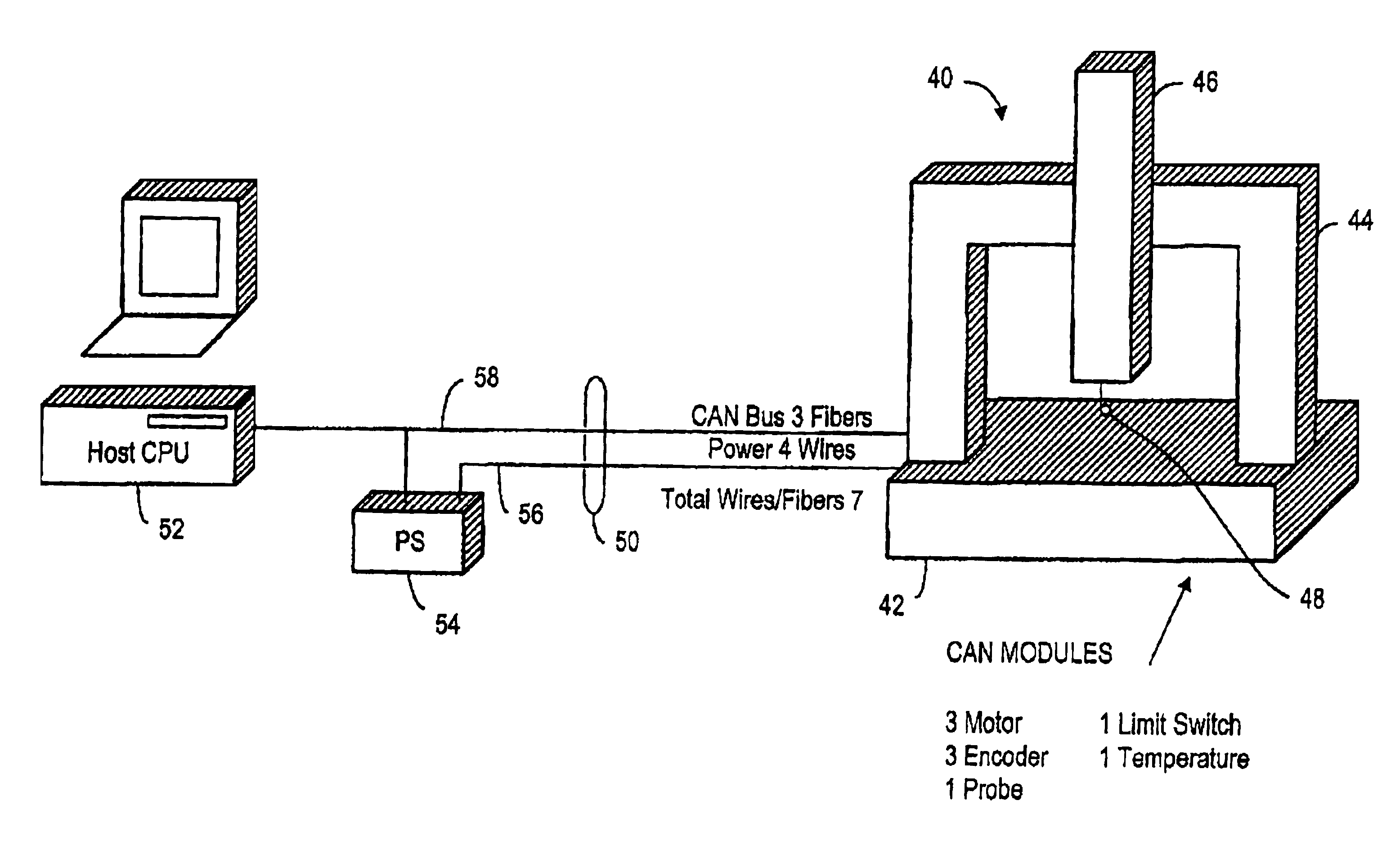

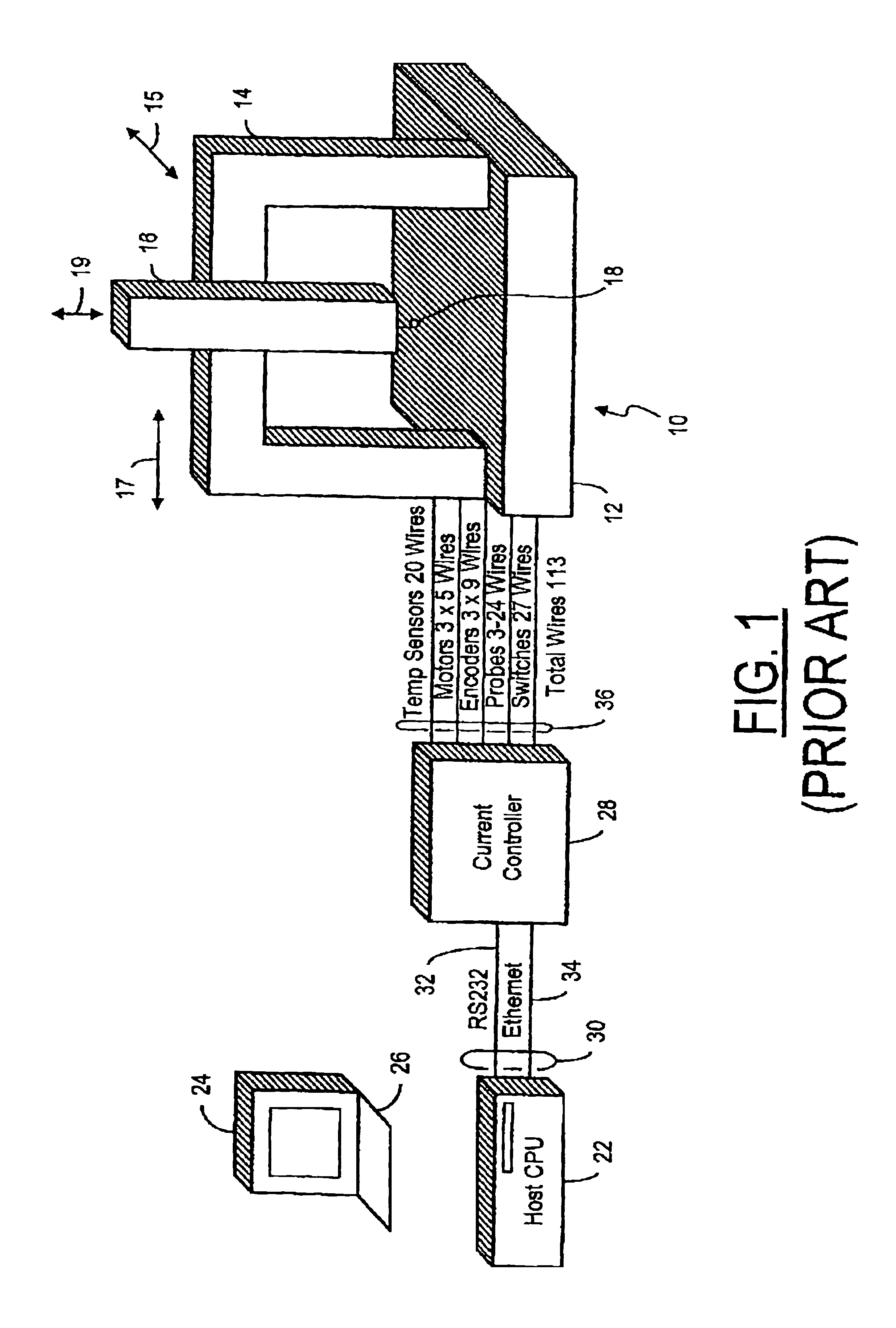

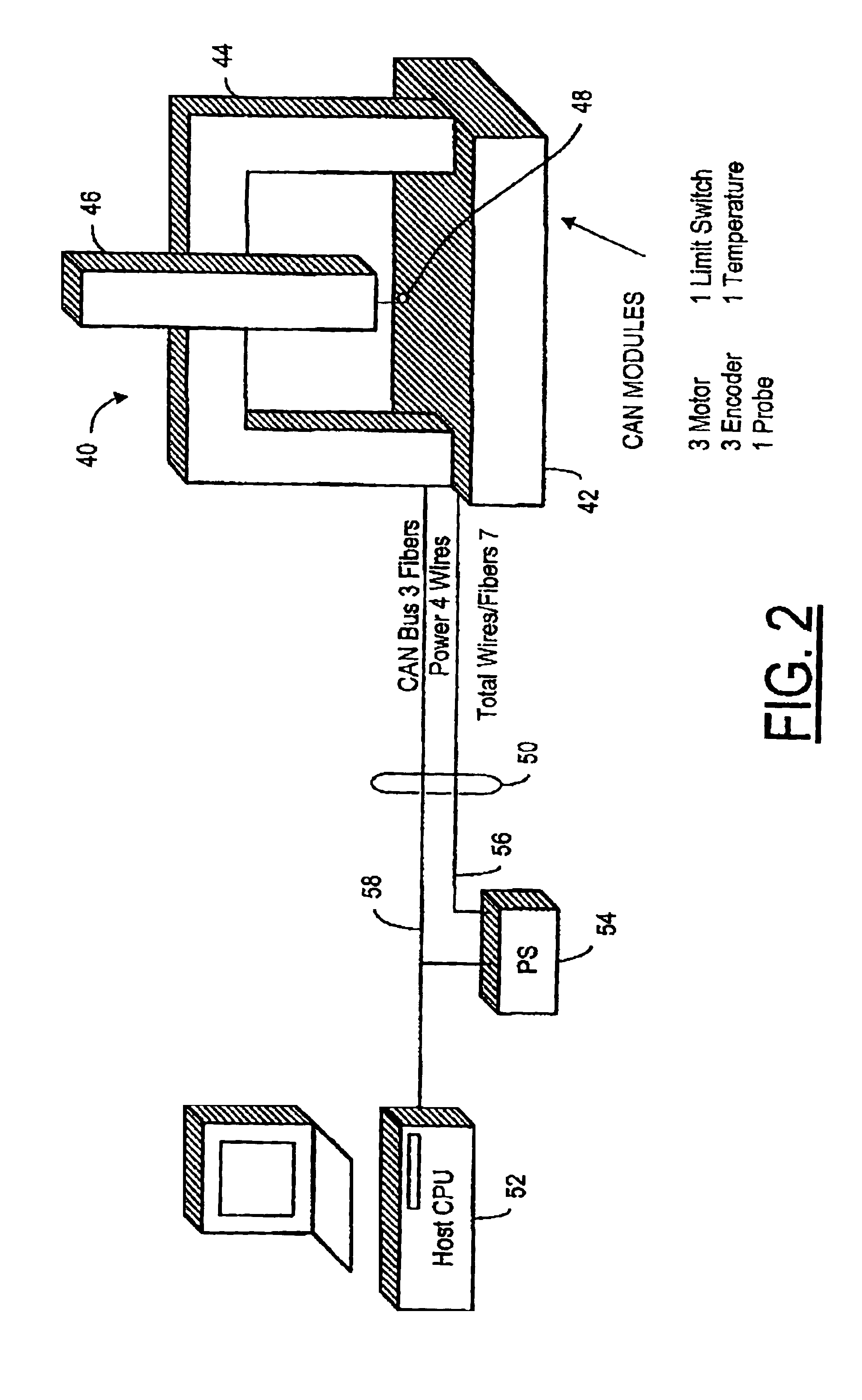

Communication method and common control bus interconnecting a controller and a precision measurement assembly

InactiveUS6948255B2Reduce cable dragImprove servo performanceFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansControl busEmbedded system

The number and weight of wires interconnecting a host and / or controller with a precision measurement assembly is reduced using a common or shared bus. The bus may be entirely electrical or may include optical fibers to reduce EMI susceptibillty. A custom bus or a known serial network bus such as CAN or SIRCOS may be used.

Owner:HEXAGON TECH CENT GMBH

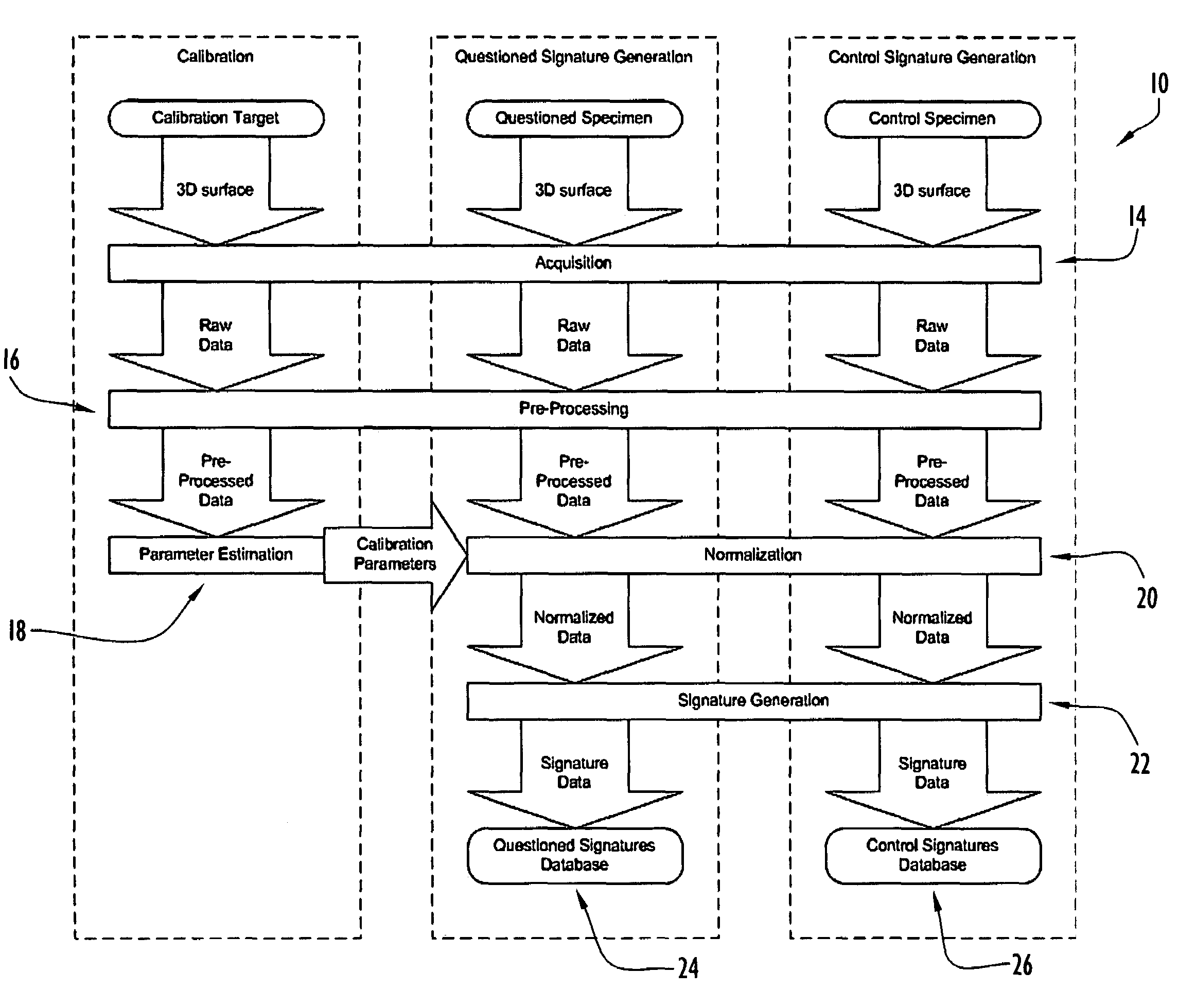

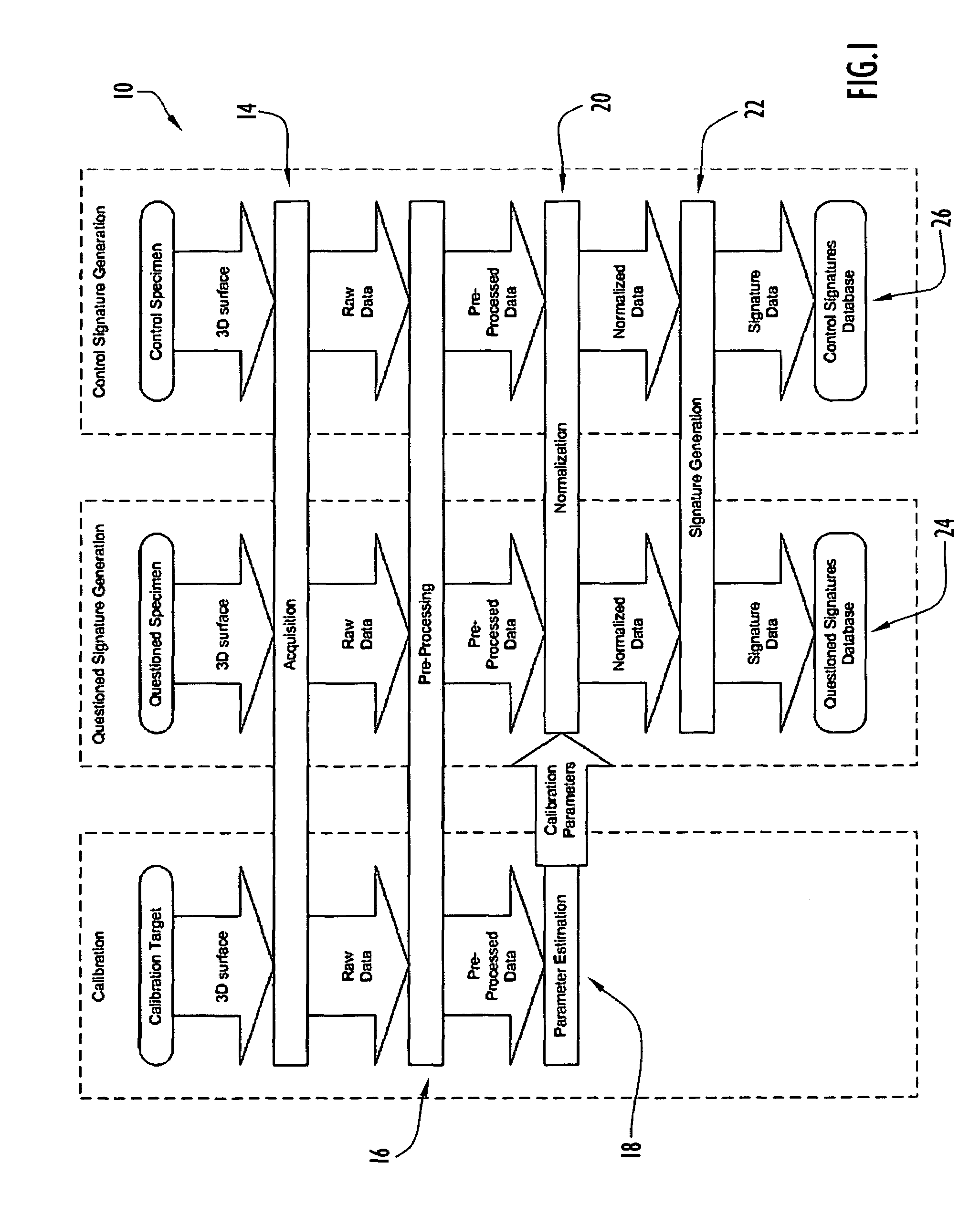

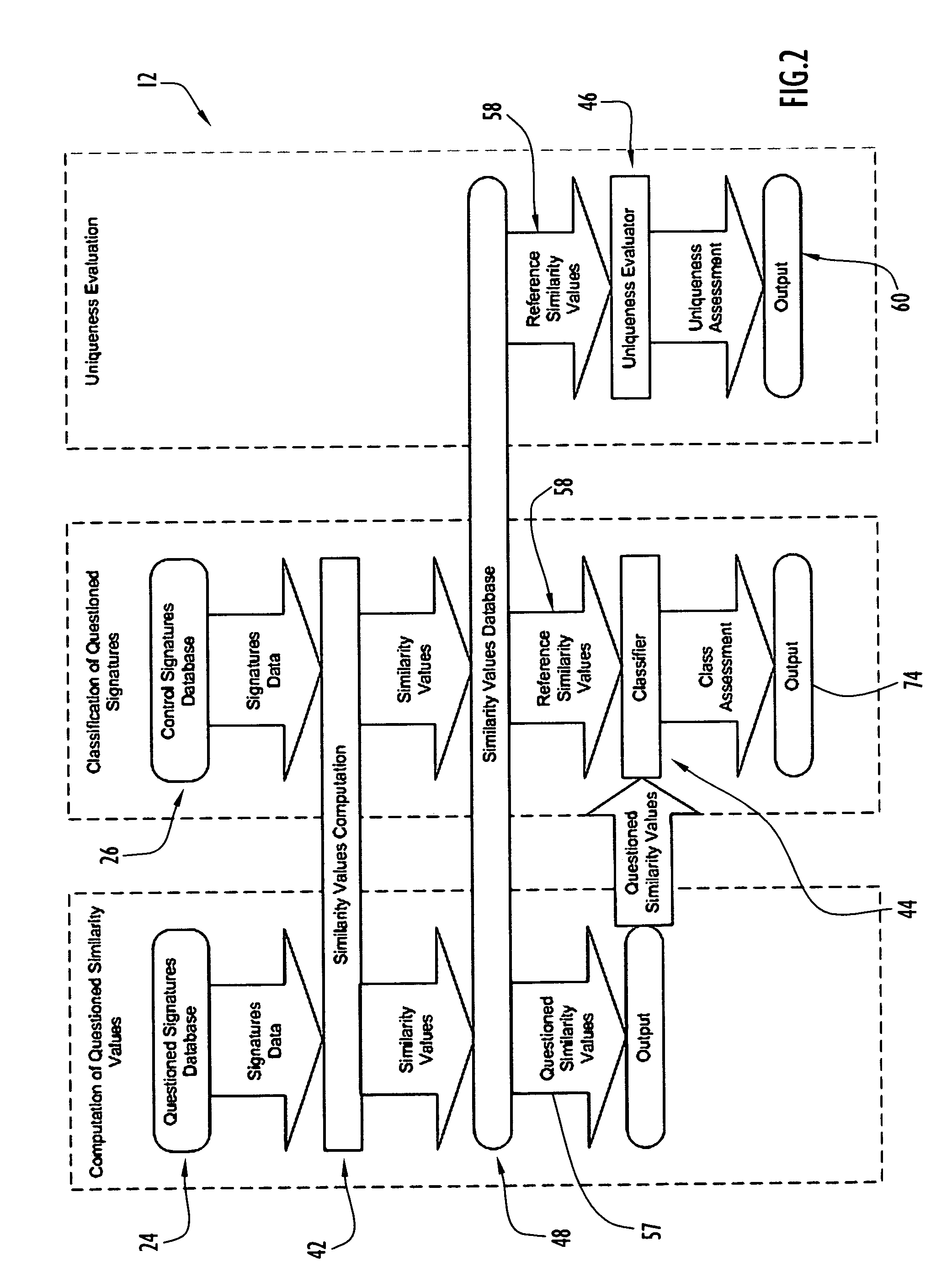

Automated system and method for tool mark analysis

An automated system for tool mark analysis includes an acquisition mechanism for acquiring 3D data of tool marks left on the surfaces of specimens by tools, a signature generation module for generating tool mark signatures from the acquired data, an analysis unit for comparing pairs of the tool mark signatures to obtain a numerical similarity value reflective of their similarity, and a database in which the similarity values are stored. An automated method for tool mark analysis involves the steps of acquiring the 3D data of tool marks, generating the tool mark signature, statistically evaluating pairs of the tool mark signatures, and providing a numerical similarity value for each pair of tool mark signatures reflecting the degree of similarity between the tool mark signatures of each pair. The method is carried out with automated assistance of a computer.

Owner:INTELLIGENT AUTOMATION LLC

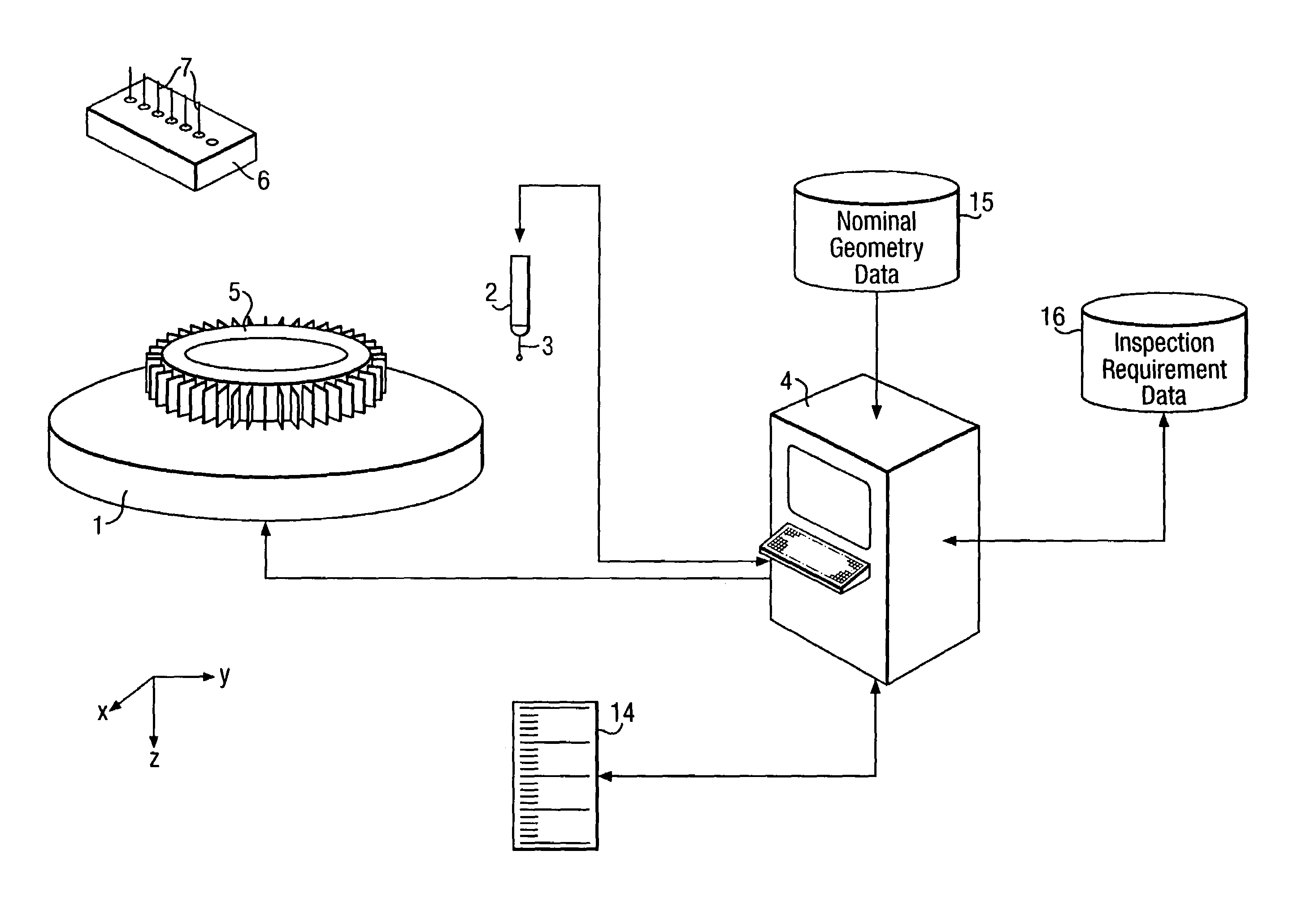

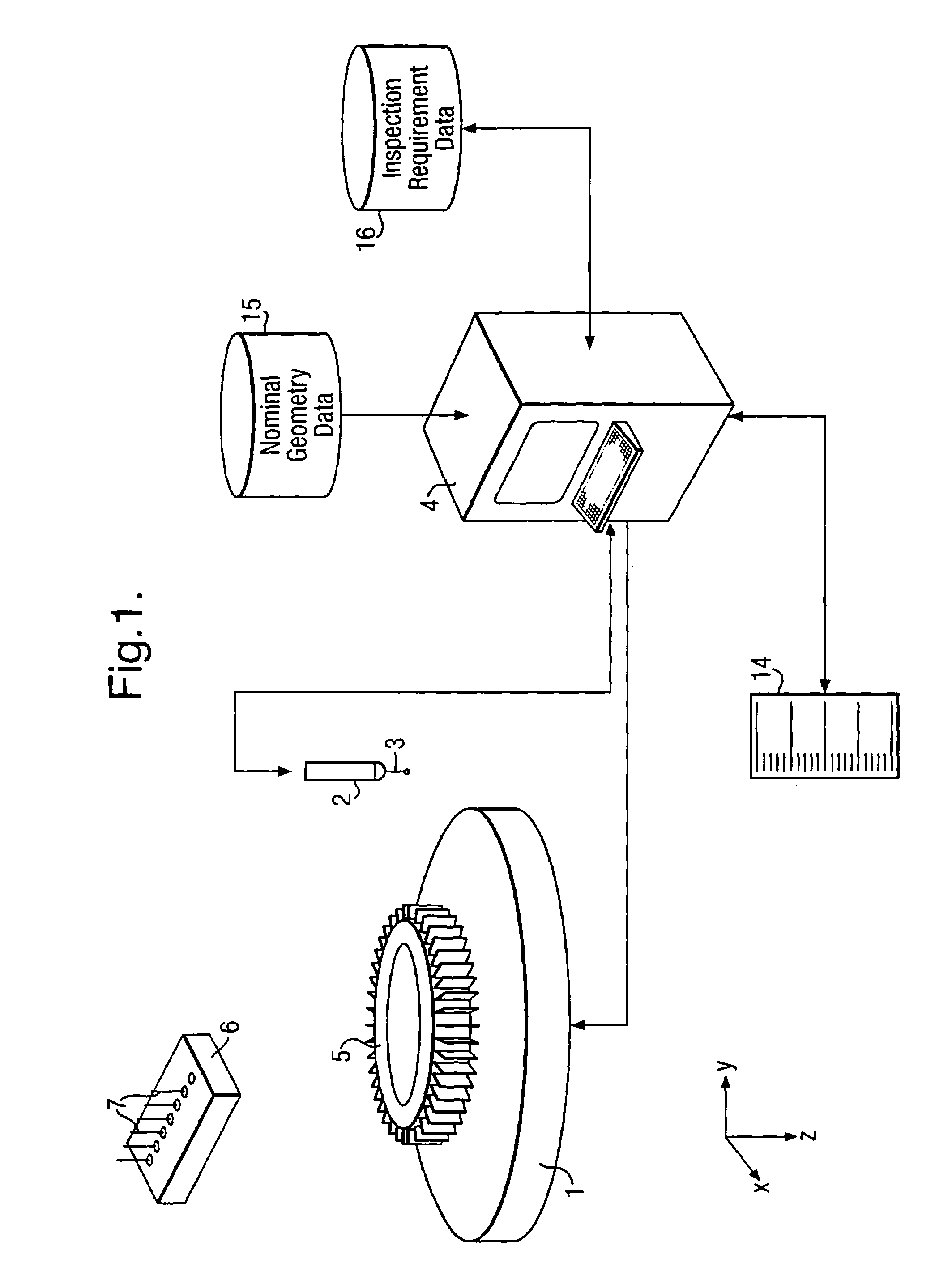

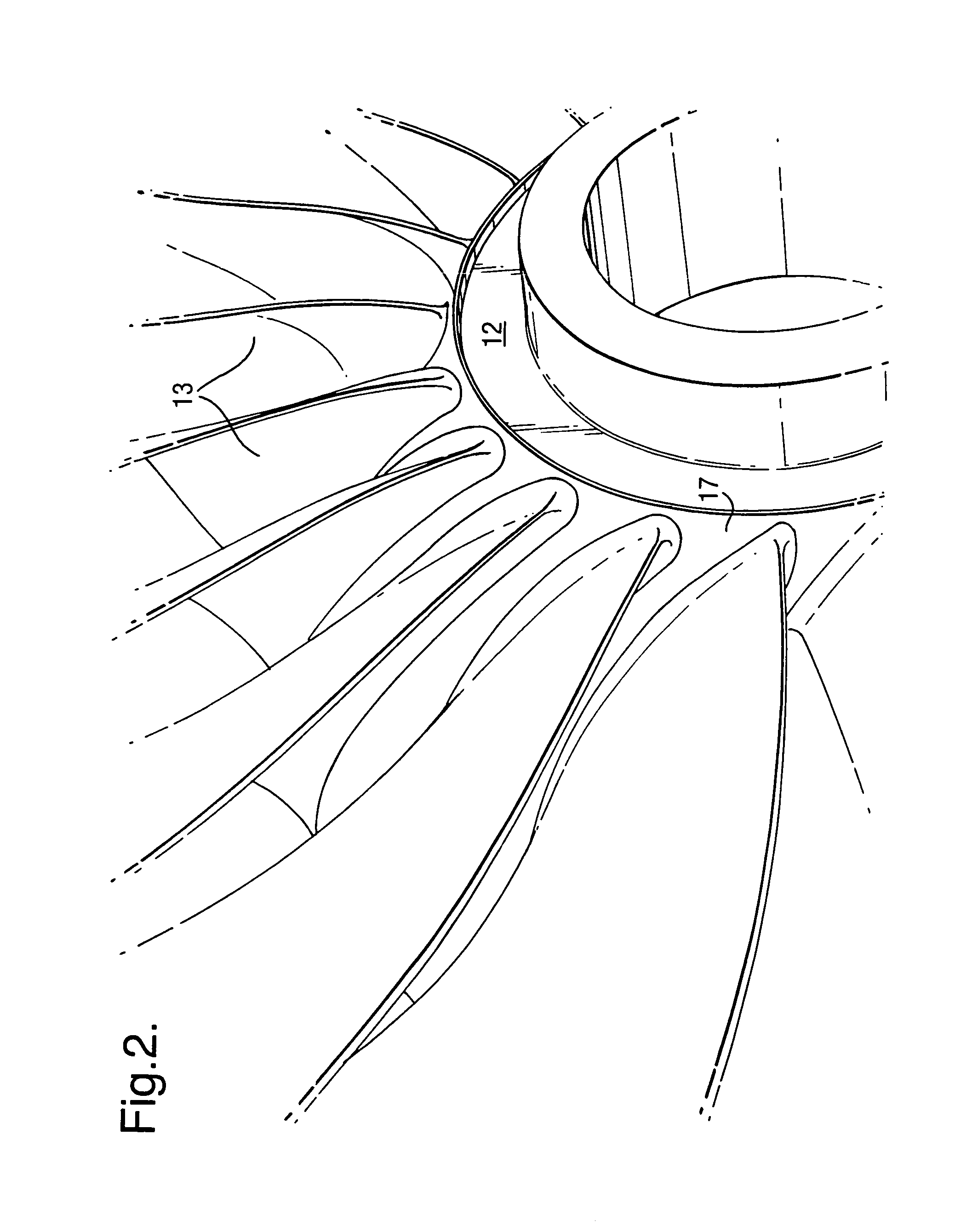

Method of generating an inspection program and method of generating a visual display

InactiveUS7146291B2Amount of timeChange in numberFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansAlgorithmData mining

Owner:ROLLS ROYCE PLC

Adaptive 3D Scanning

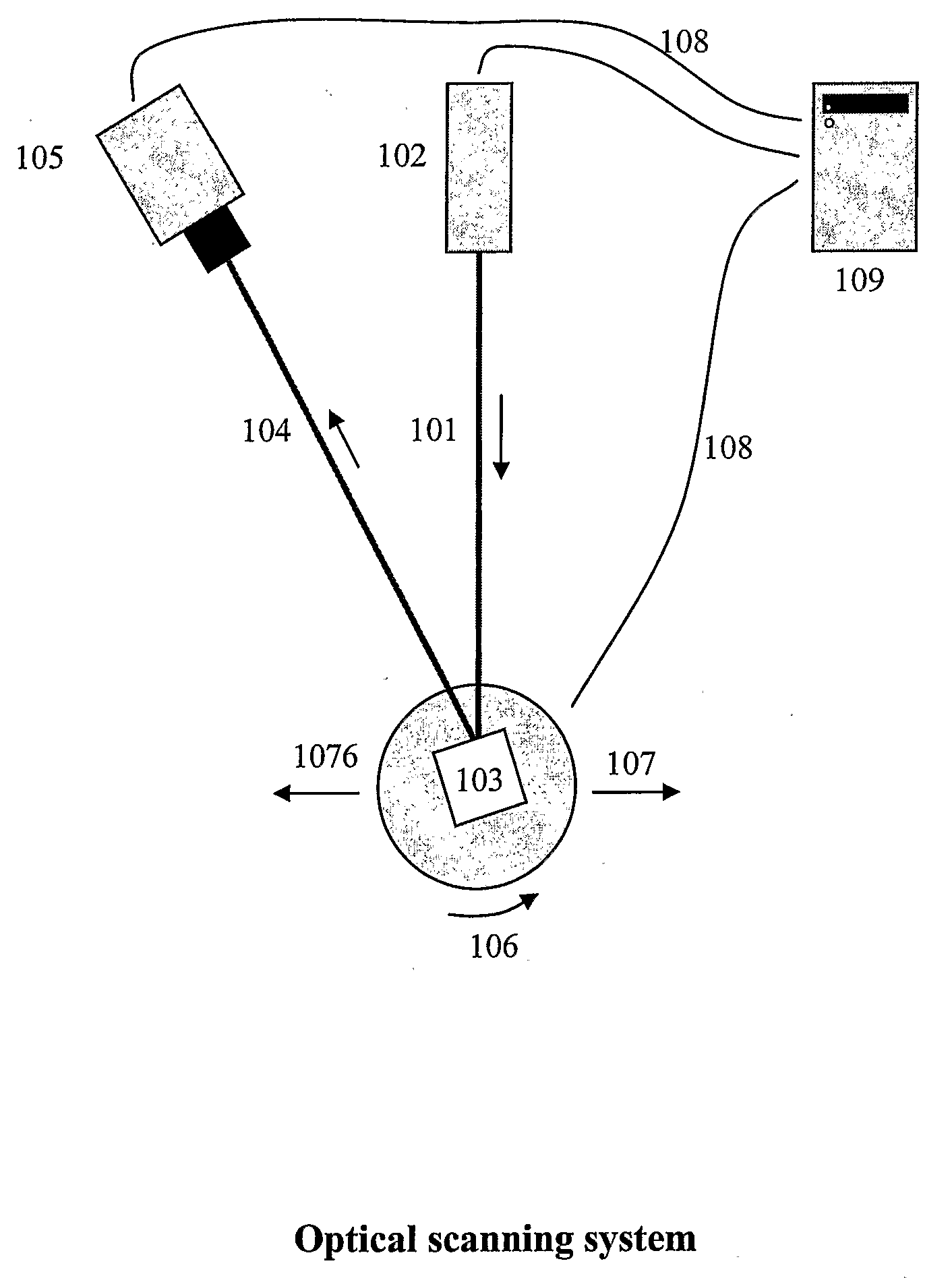

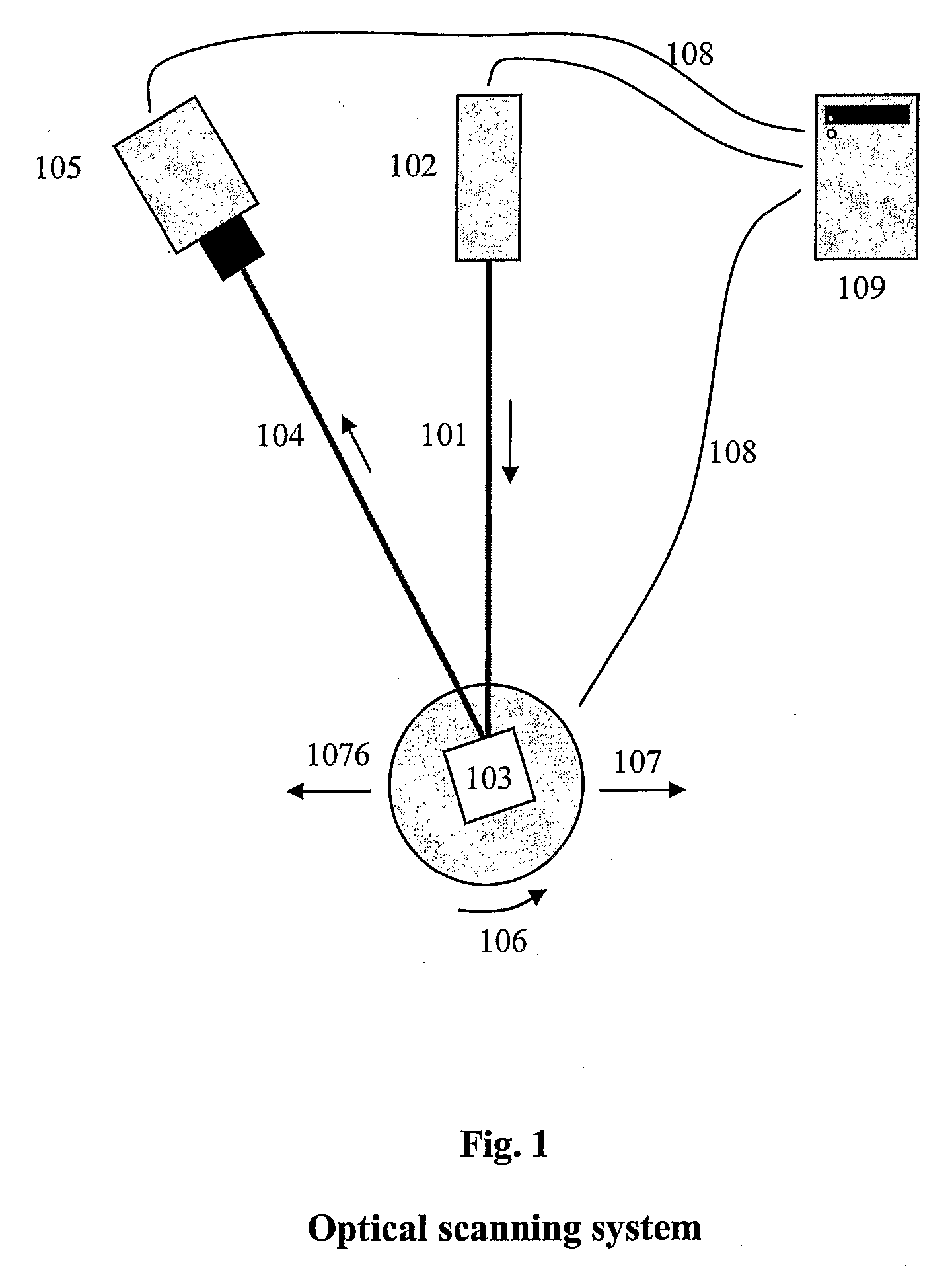

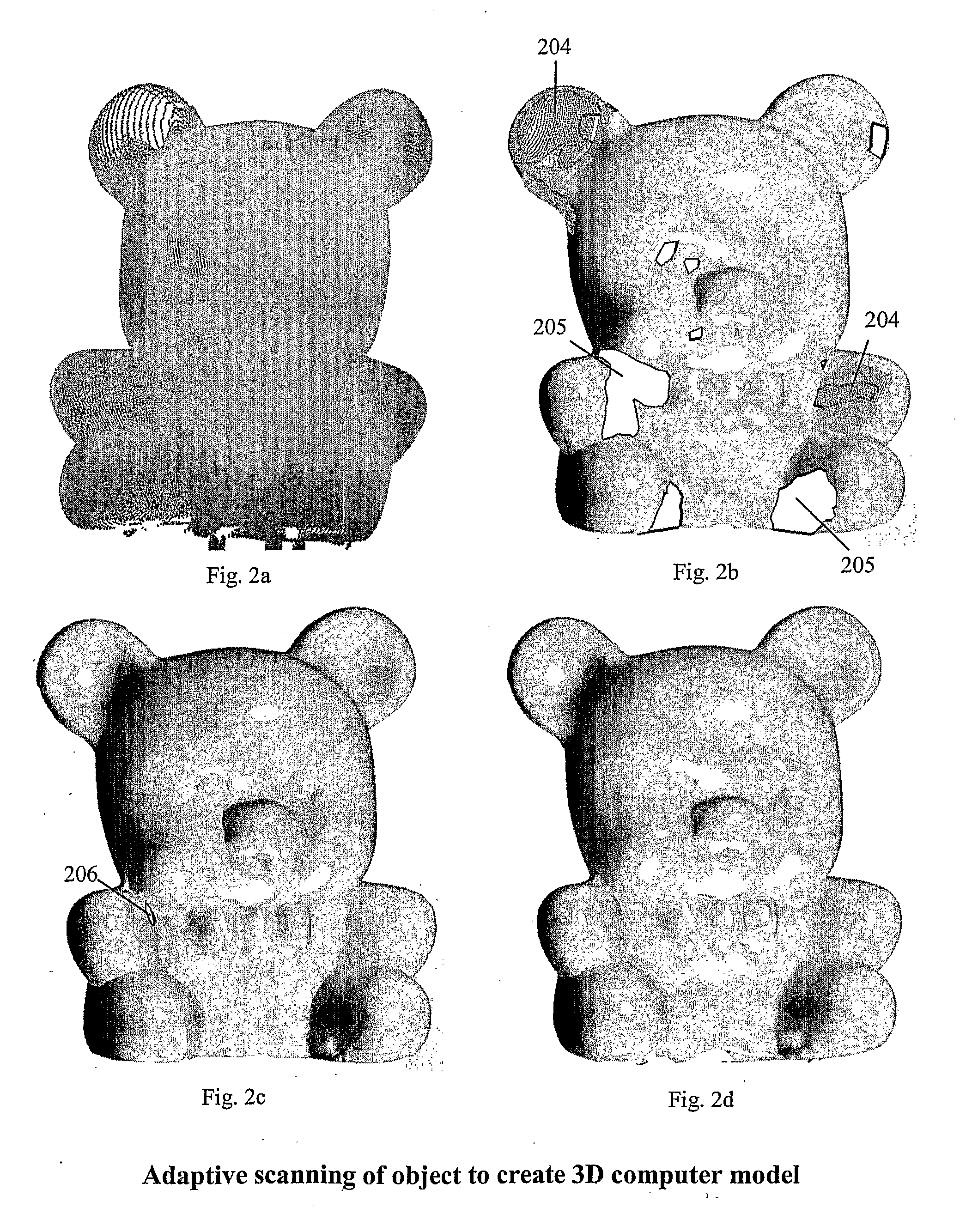

ActiveUS20080306709A1Feeler-pin gaugesMechanical counters/curvatures measurementsComputer graphics (images)3d scanning

The present invention relates to adaptive 3D scanning wherein a scan sequence for obtaining full geometrical coverage of a physical object are created automatically and specifically for the physical object, by using a method and a system for producing a 3D computer model of a physical object, wherein the method comprises the following steps providing a scanner system, said scanner system comprising a scanner, and a computer connectable to and / or integrated in said scanner, said computer comprising a virtual model of said scanner, entering shape information of the physical object into the computer, creating in said computer a visibility function based on said virtual model and the shape information, said visibility function being capable of evaluating the coverage of areas of interest of the physical object by at least one predetermined scan sequence, establishing at least one scan sequence based on the evaluation of the visibility function, performing a scan of the physical object using said at least one scan sequence, and obtaining a 3D computer model of the physical object.

Owner:3SHAPE AS

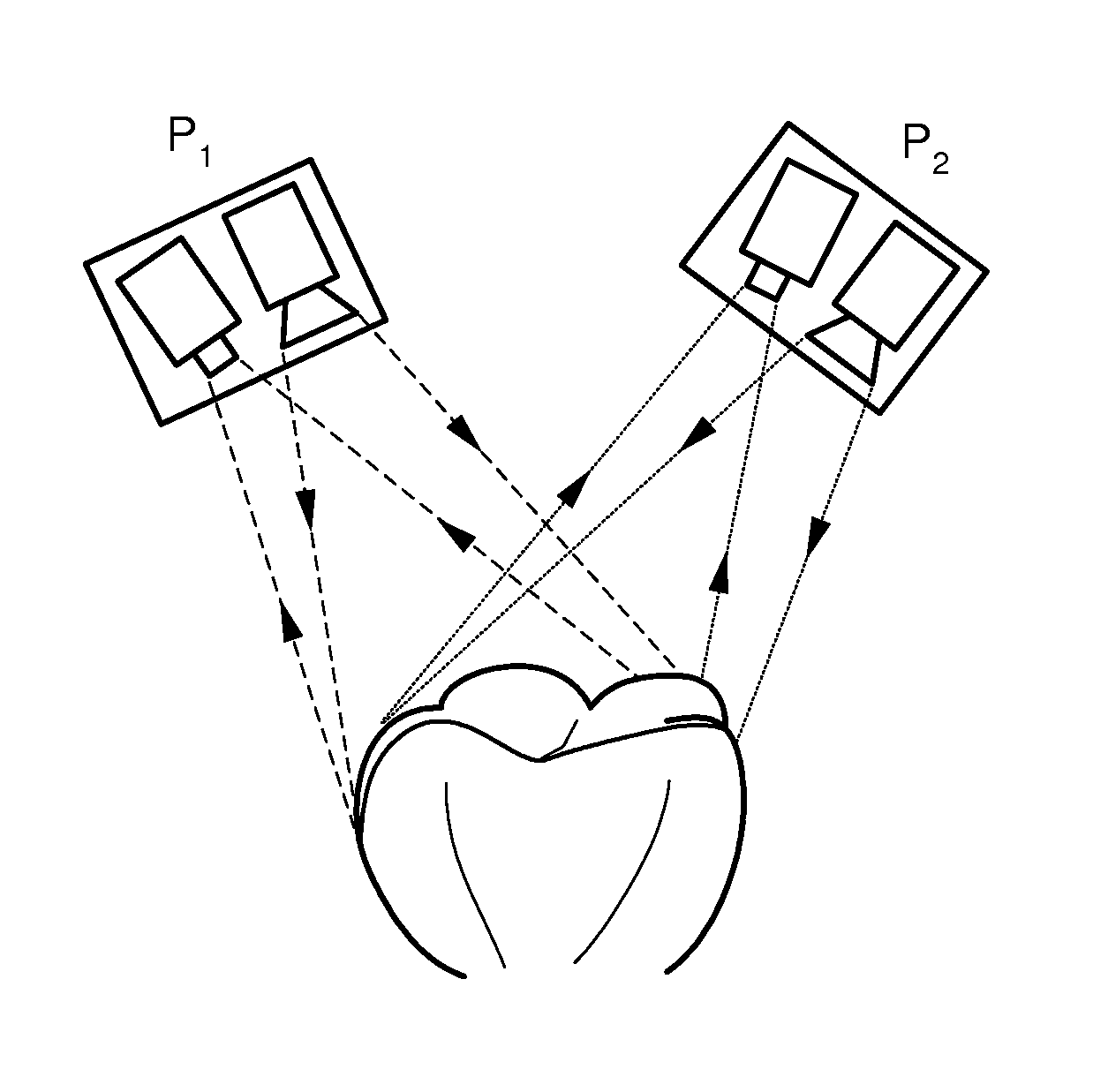

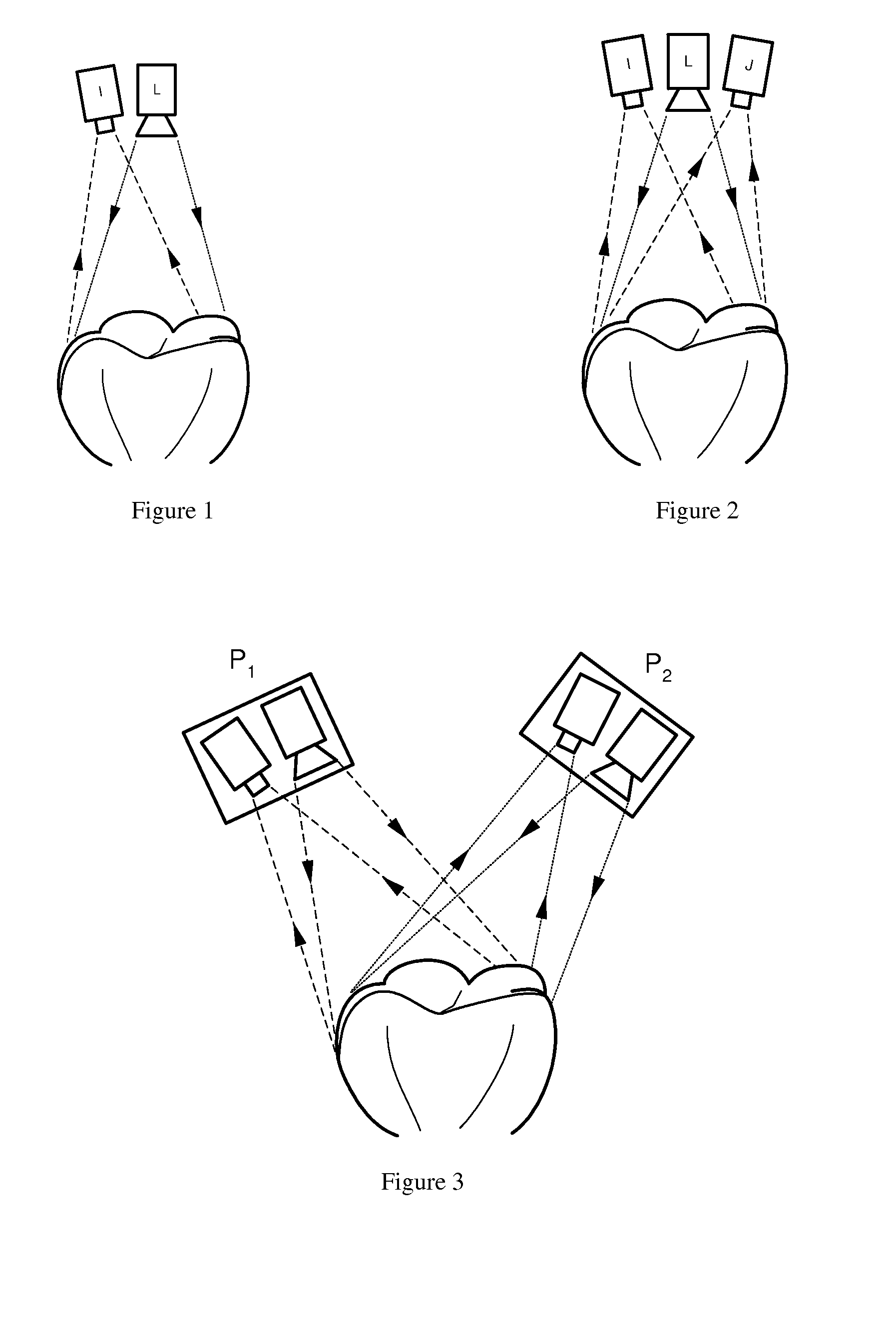

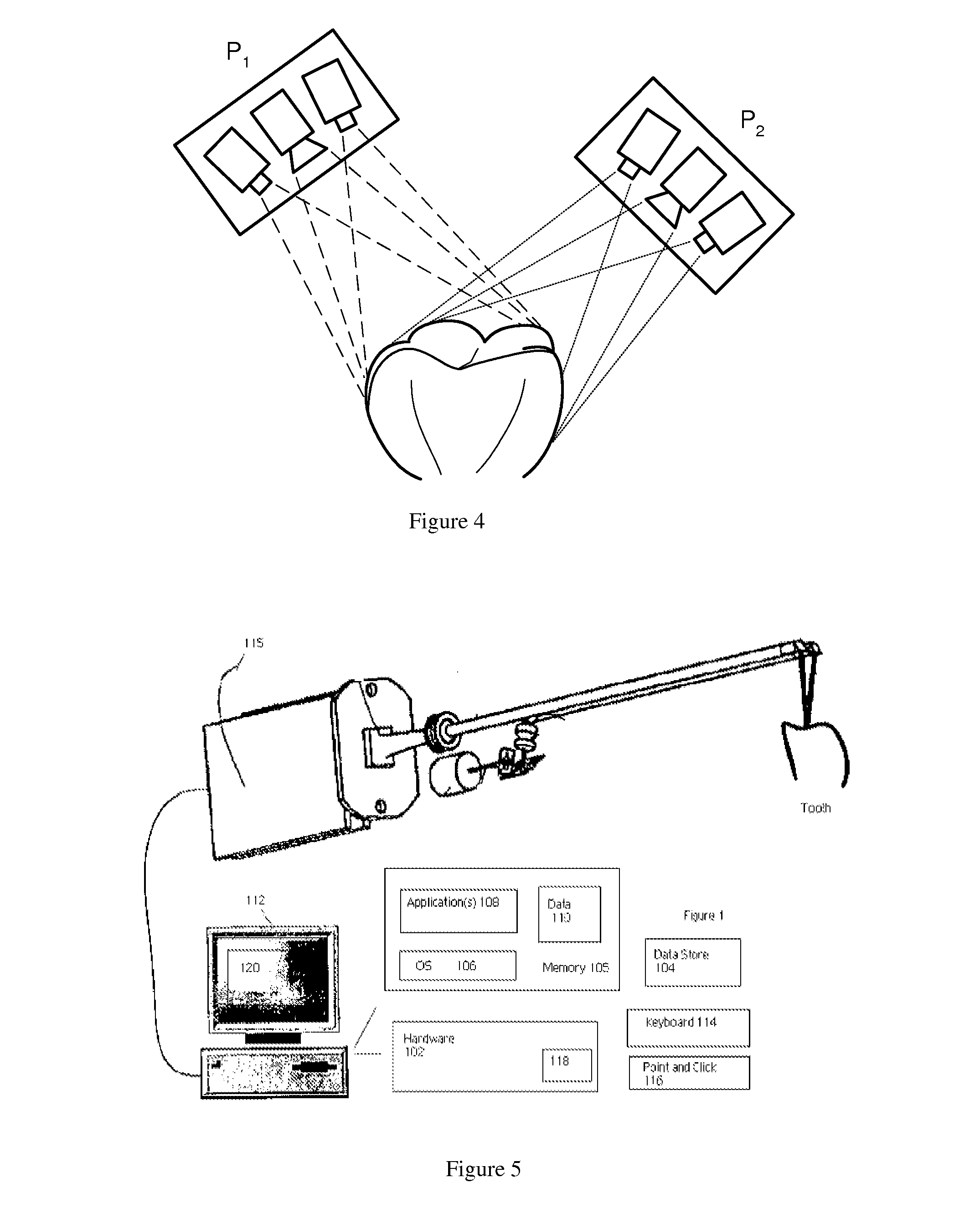

3D photogrammetry using projected patterns

A structured light pattern digitizing method is combined with photogrammetry to determine a 3D model of an object. The structured light digitizing operation generates a 3D model of the object being scanned, and this model is then used to compute a higher accuracy model using photogrammetry.

Owner:D4D TECH LP

Contour replicating and measuring device

InactiveUS6125338AAccurately and inexpensively and quickly measureSimple designFeeler-pin gaugesMechanical counters/curvatures measurementsPin arrayComputer science

Owner:PITTSBURGH UNIV OF

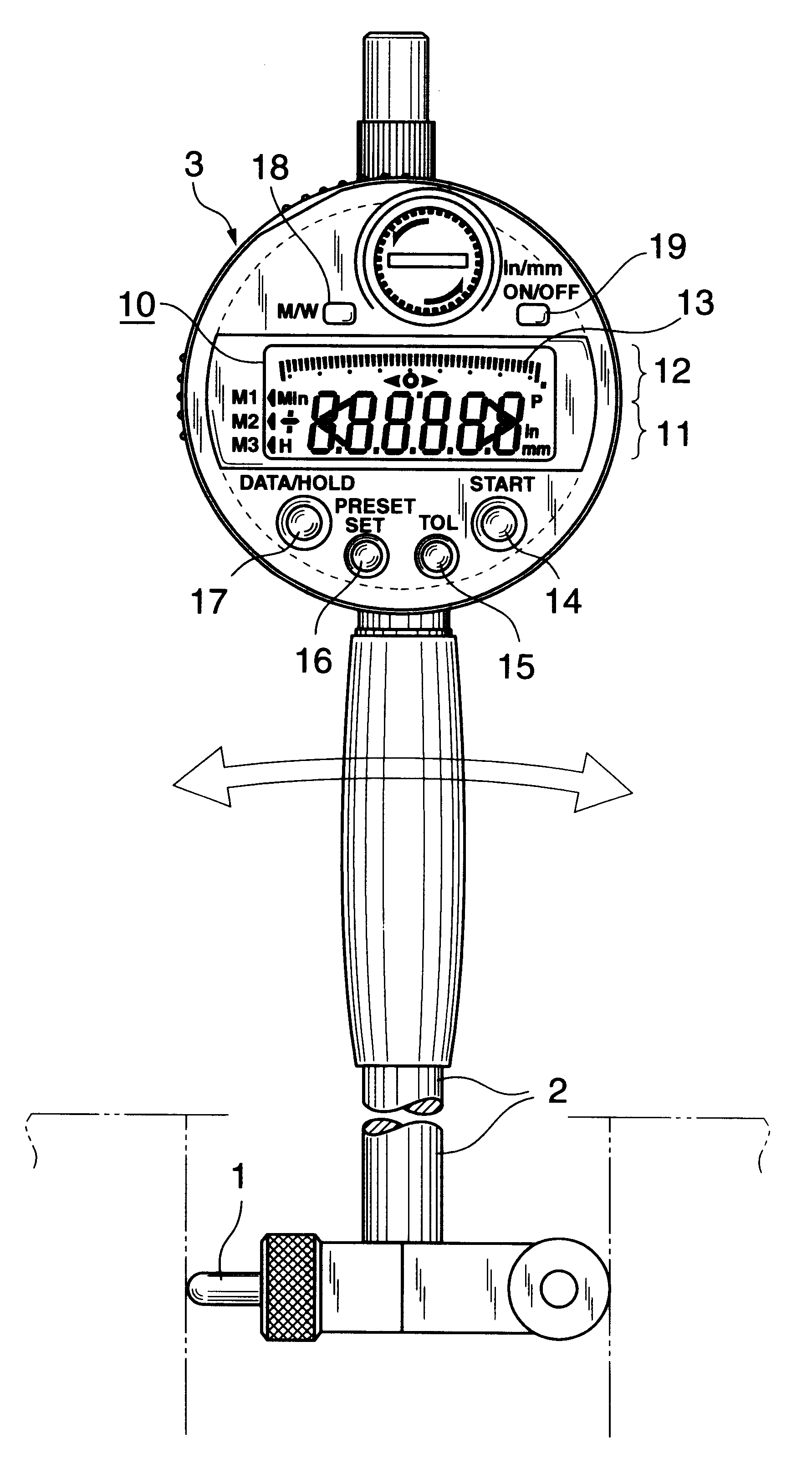

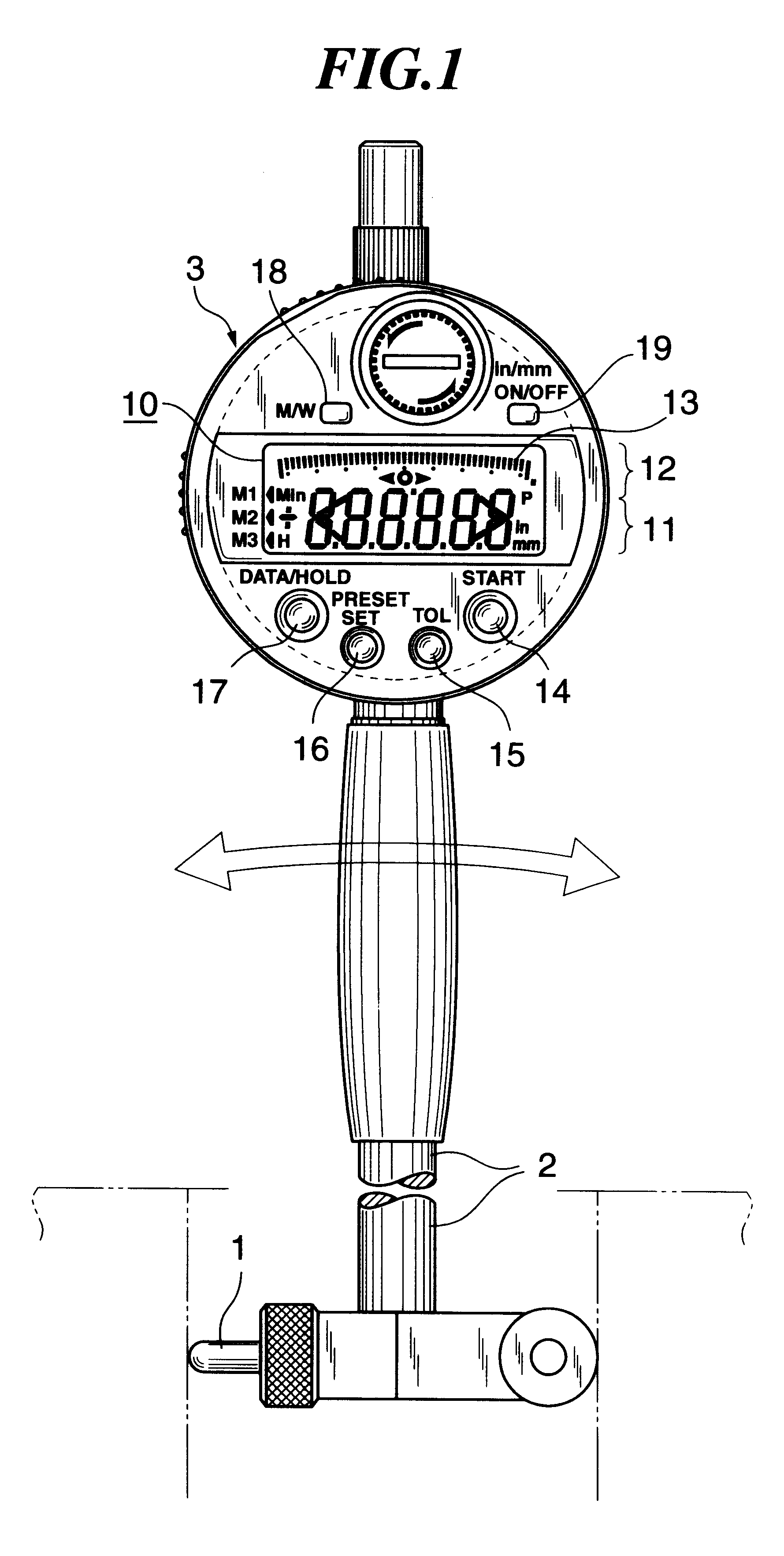

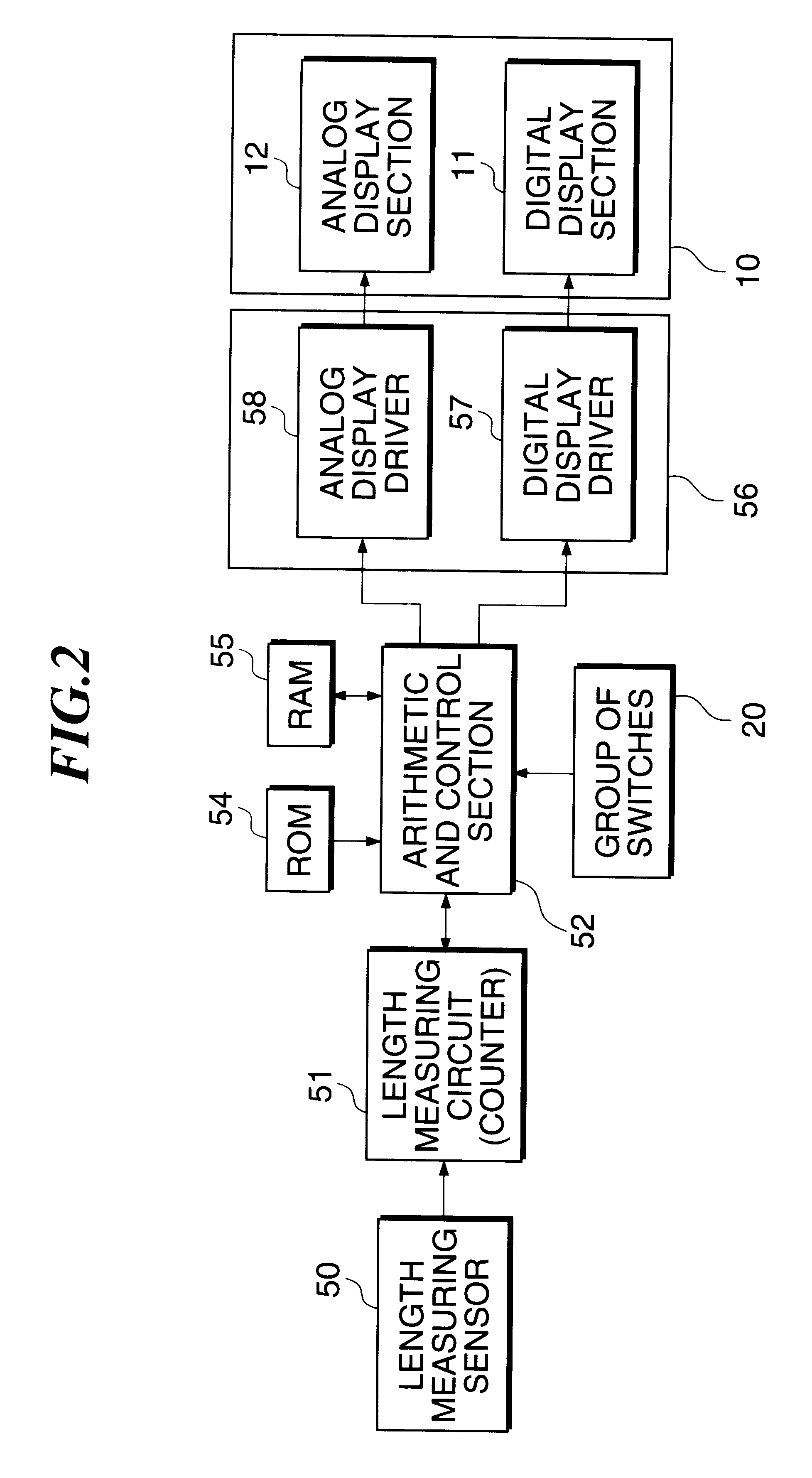

Analog quantity display method, analog quantity measuring method, and digital/analog display type measuring instrument

InactiveUS6412187B1Easy CalibrationImprove measurement reliabilityAnalog and numerical indicationBallastwayMeasuring instrumentEngineering

The present invention provides an analog quantity display method of counting displacement of a probe disposed in contact with an object to be measured and analog-displaying the obtained count value by an analog display section as an analog quantity. If a peak value of the count value exceeds a possible analog-display range of the analog display section, an offset provided for the analog-displayed count value is updated in such a manner that the peak value is displayed within the possible analog-display range. Further, an analog quantity measuring method is provided, which comprises counting displacement of the probe, compares the obtained count value with a peak value of the count value, holds the count value as a new peak value depending upon a result of the comparison, and executes the comparison and the holding of the peak value again if the difference between the present peak value and the present count value exceeds a predetermined value. The analog quantity display and measuring methods are applicable to a digital / analog display type measuring instrument comprising a counter for counting the displacement of the probe in contact with the measured object, a digital display section for digitally displaying the count value, and an analog display section located adjacent to the digital display section, for displaying the count value as the bar graph comprising the large number of analog bars arranged in juxtaposition in one direction.

Owner:MITUTOYO CORP

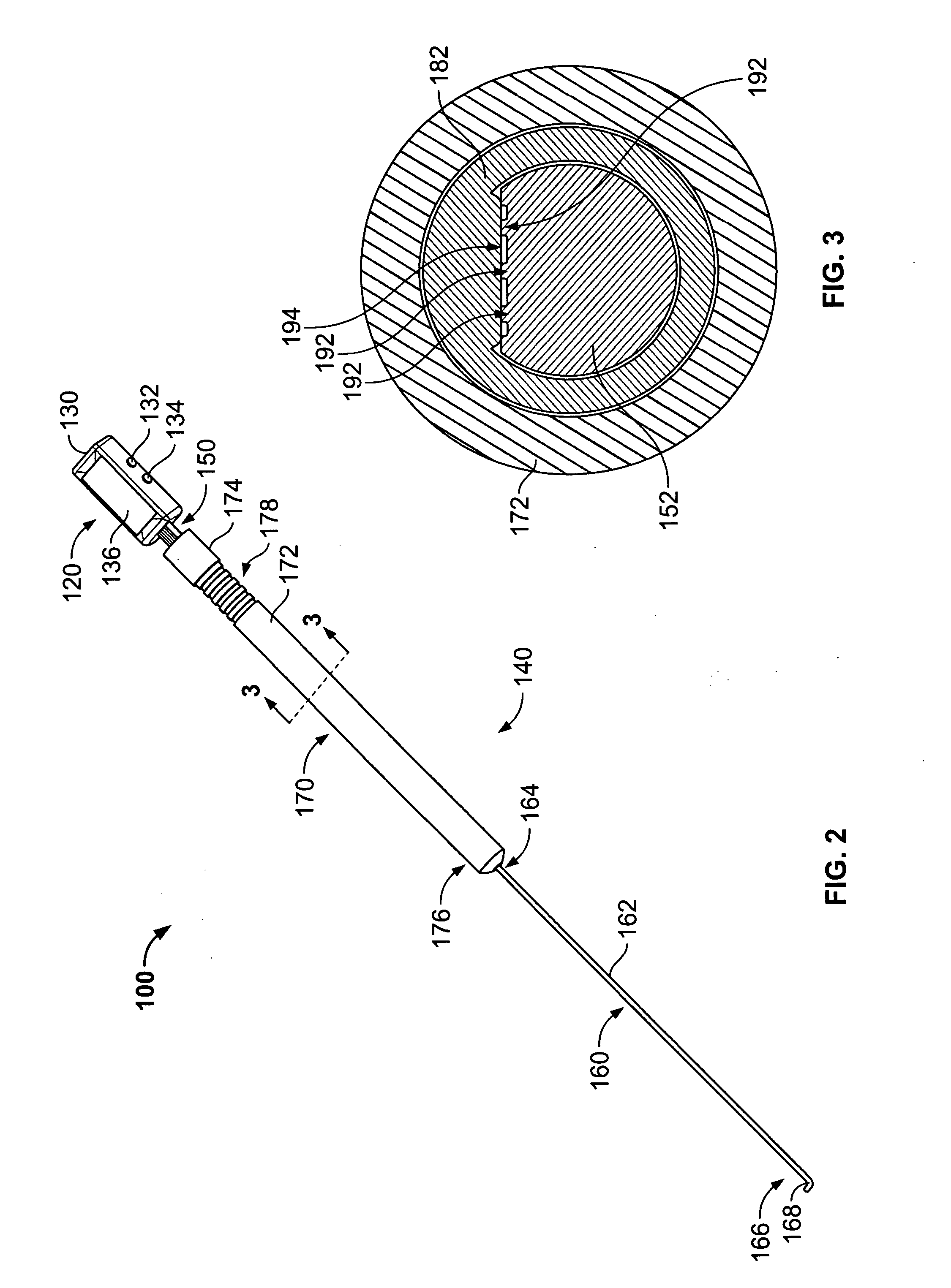

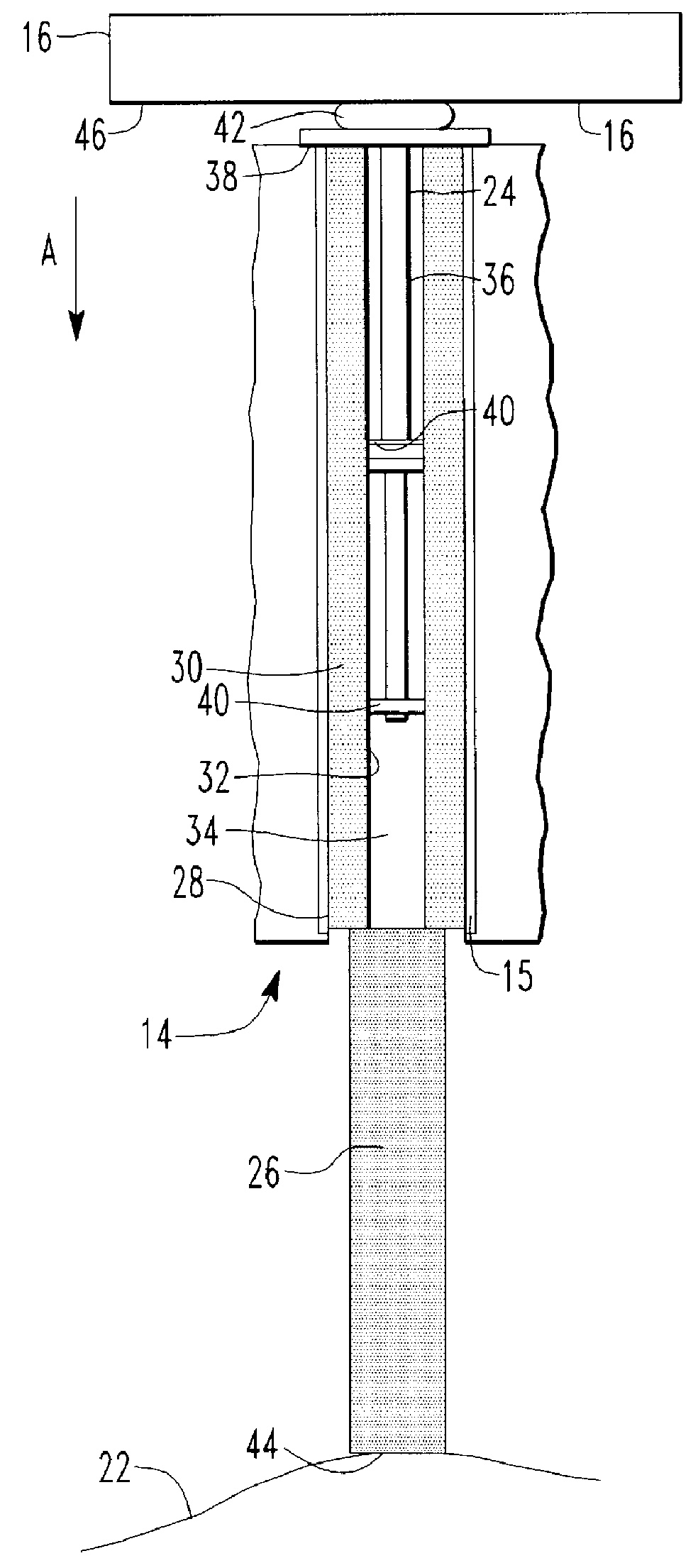

Digital depth gauge

A digital depth gauge is provided for measuring a depth of a hole in an object. In one embodiment the gauge includes: a user interface with a display and at least one actuator; a reader shaft with a distal end and a proximal end connected to the user interface; a probe that extends from the distal end of the reader shaft and which includes a tip configured to locate a distal surface of the hole; a sleeve member with a distal end configured to abut a proximal surface of the hole, the sleeve member being coupled with the reader shaft for relative translational and rotational movement; and a sensor interposed between the reader shaft and the sleeve member for measuring relative translational movement between the reader shaft and the sleeve member. In some embodiments, the gauge may include a means for aligning elements of the sensor.

Owner:EDGE SURGICAL INC

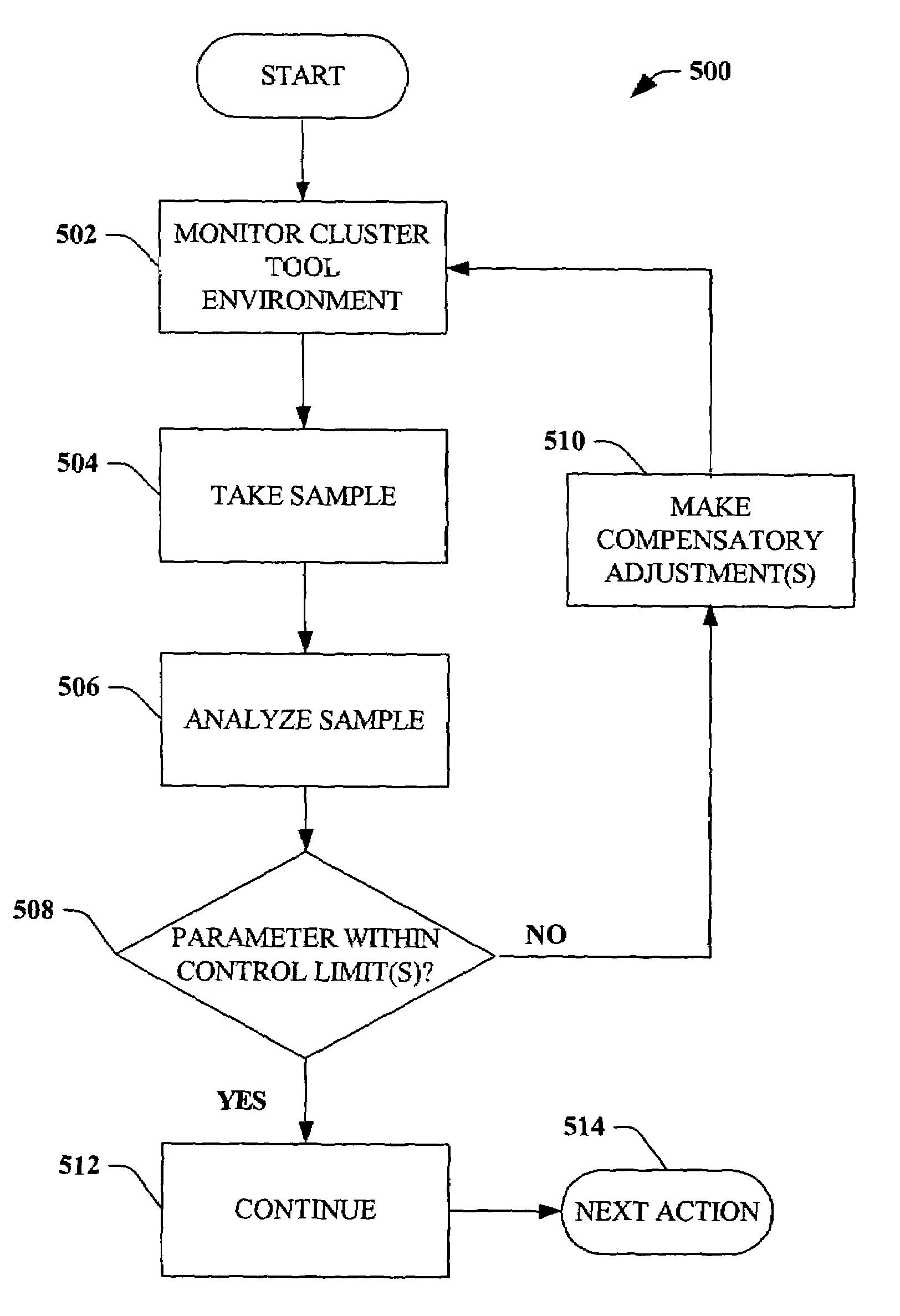

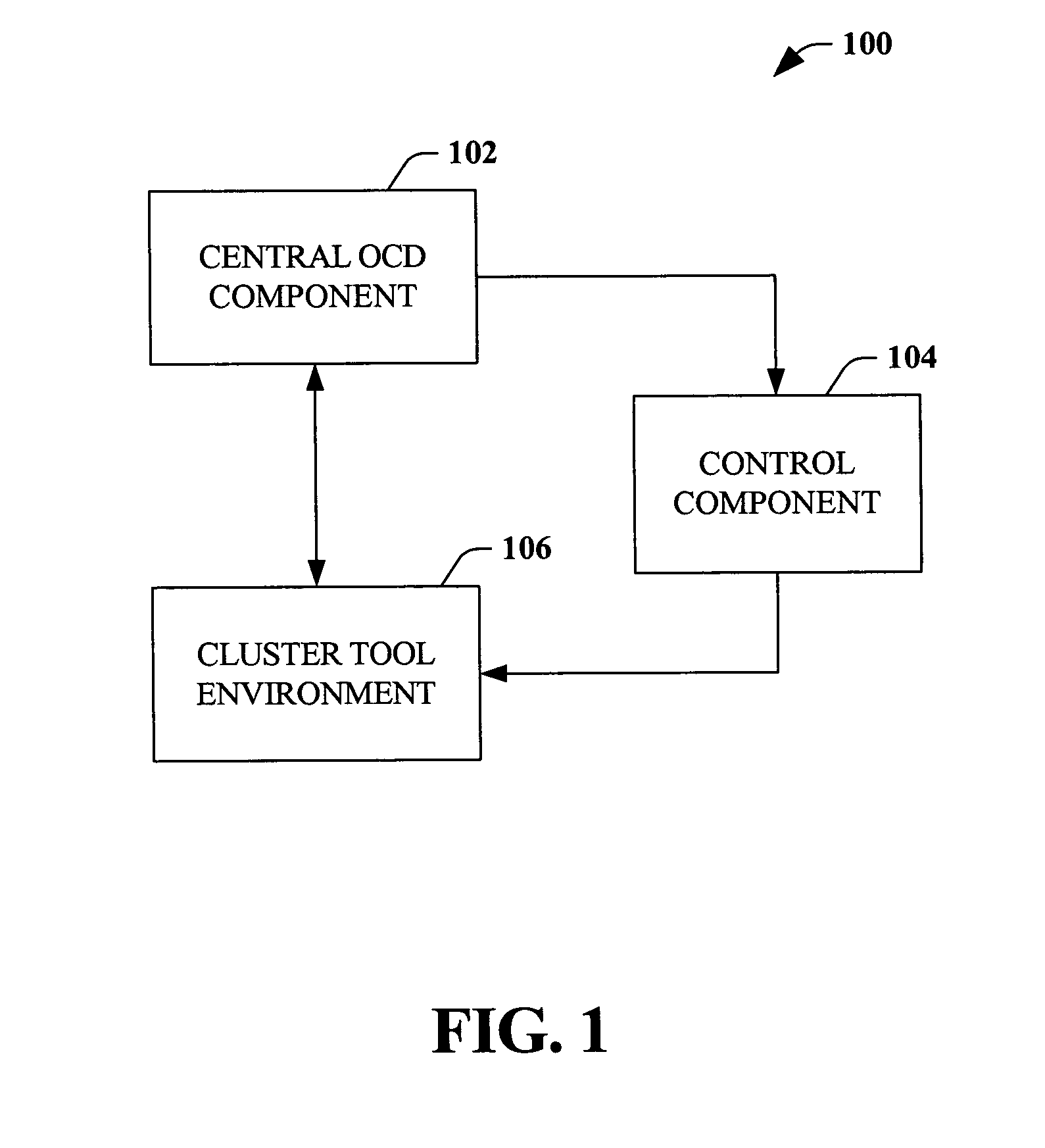

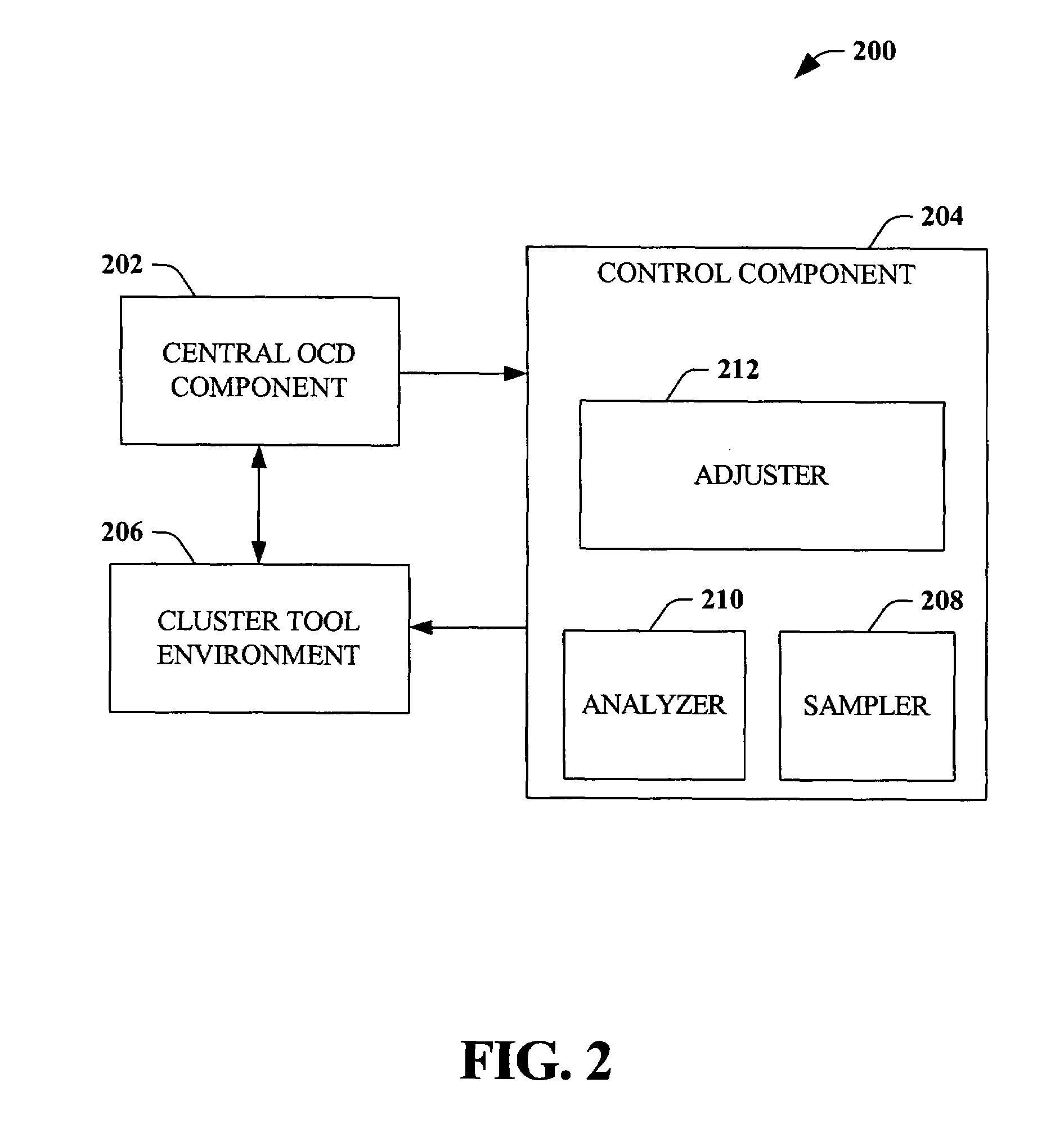

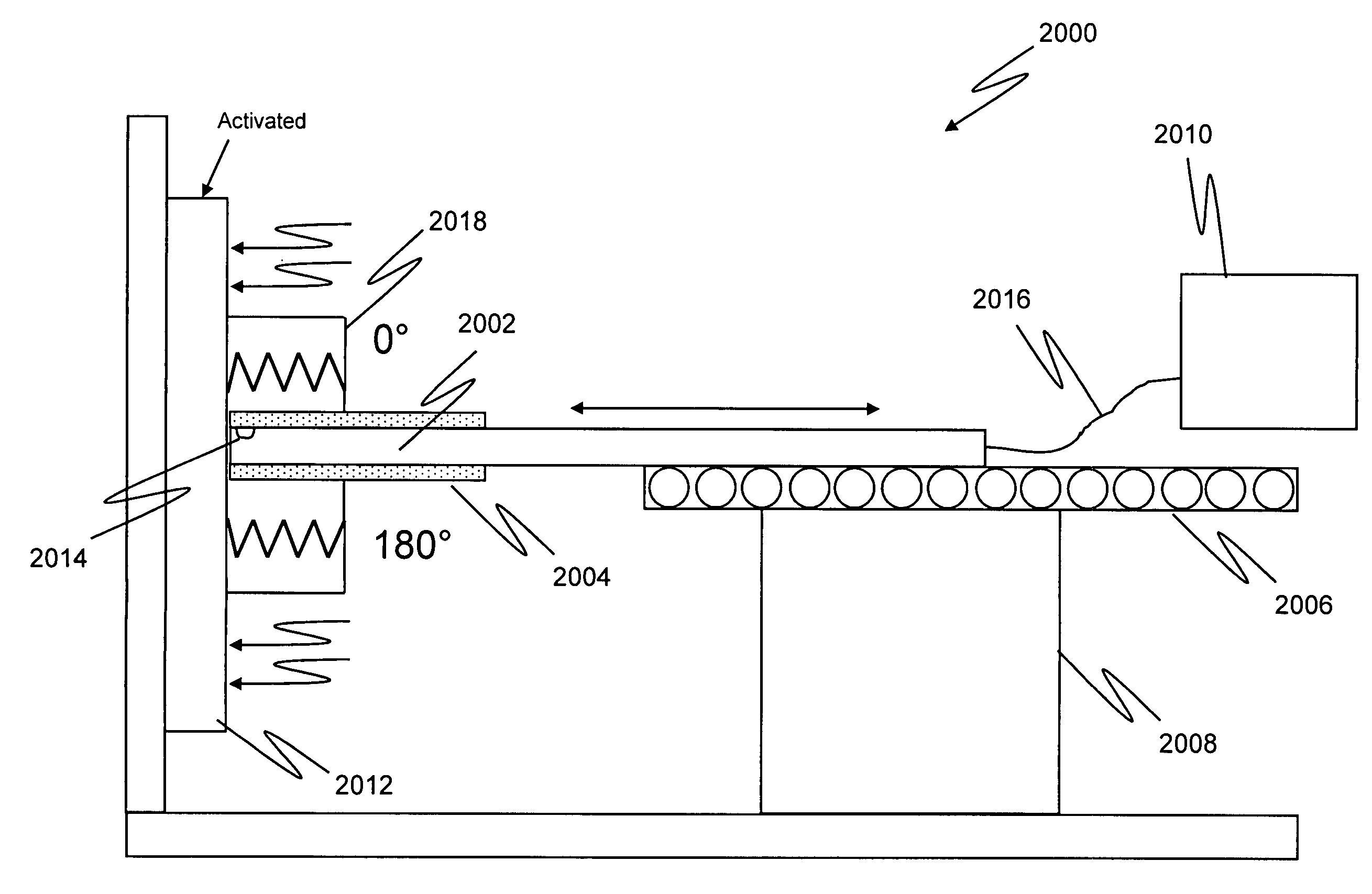

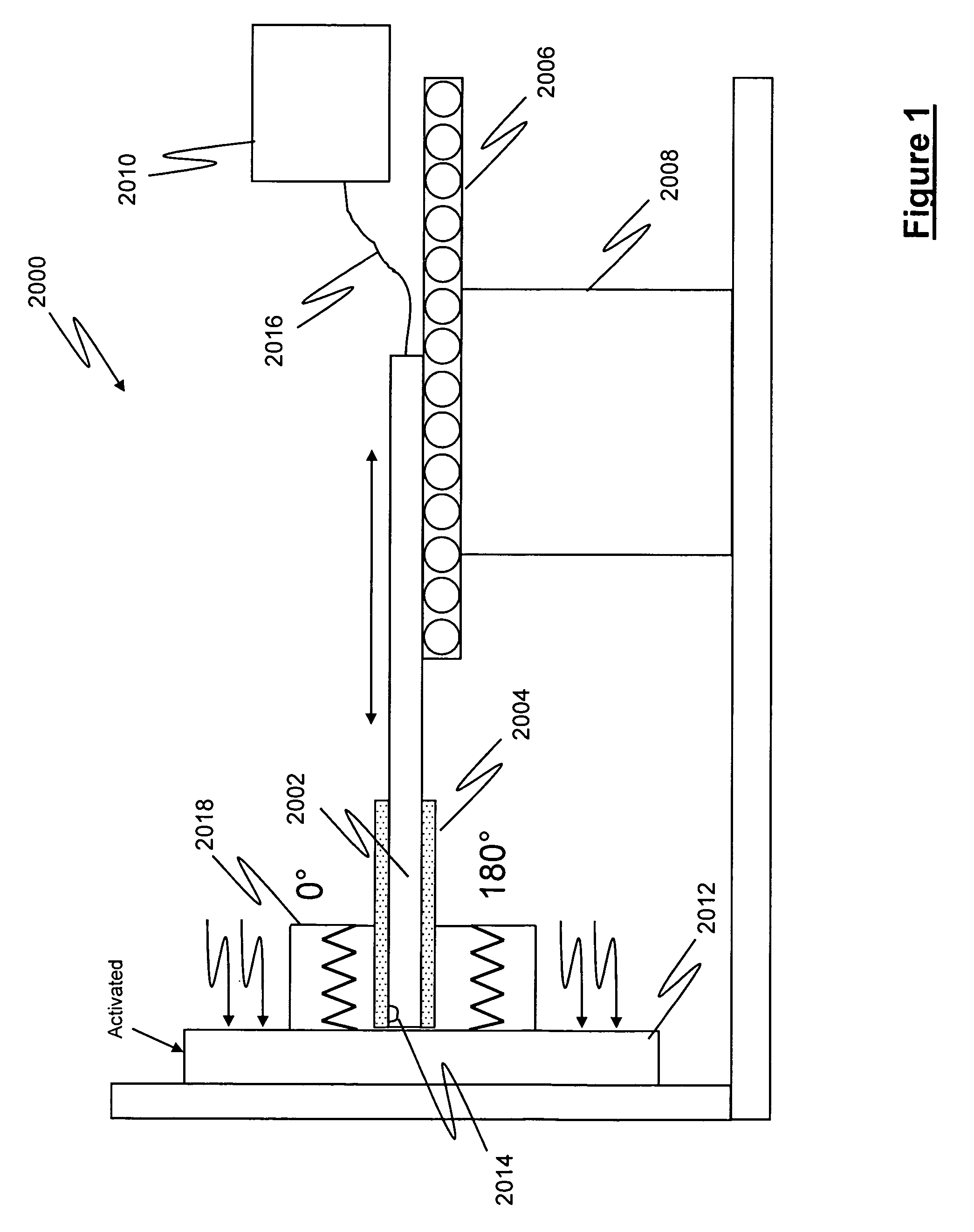

Scatterometry monitor in cluster process tool environment for advanced process control (APC)

ActiveUS7076320B1Strengthen process controlIncrease productivityFeeler-pin gaugesPhotomechanical apparatusControl limitsPlasma etcher

Systems and methods that improve process control in semiconductor manufacturing are disclosed. According to an aspect of the invention, conditions in a cluster tool environment and / or a wafer therein can be monitored in-situ via, for example, a scatterometry system, to determine whether parameters associated with wafer production are within control limits. A cluster tool environment can include, for example, a lithography track, a stepper, a plasma etcher, a cleaning tool, a chemical bath, etc. If an out-of-control condition is detected, either associated with a tool in the cluster tool environment or with the wafer itself, compensatory measures can be taken to correct the out-of-control condition. The invention can further employ feedback / feed-forward loop(s) to facilitate compensatory action in order to improve process control.

Owner:ADVANCED MICRO DEVICES INC

Internal inspection system and method

ActiveUS20100110448A1Feeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansOffset distanceEngineering

A system and method for measuring the threaded surface of an internally threaded component is provided, where the inspection system includes at least one measuring probe, wherein the at least one measuring probe includes an emitter and a receiver and is sized and shaped to be positionable adjacent at least a portion of the threaded surface at an offset distance, wherein the emitter is configured to emit electromagnetic energy that is incident upon the threaded surface to generate reflected electromagnetic energy responsive to the threaded surface and wherein the receiver is configured to receive at least a portion of the reflected electromagnetic energy and generate threaded surface data. A processing device is also provided, wherein the processing device is in signal communication with the measuring probe to receive the threaded surface data and process the threaded surface data to determine physical characteristics of the threaded surface.

Owner:QUEST INTEGRATED LLC

Portable measuring systems

ActiveUS7770301B1Easy to transportEasy to install and disassembleOptical rangefindersFeeler-pin gaugesEngineering

Owner:GRANDBERRY LEE A +1

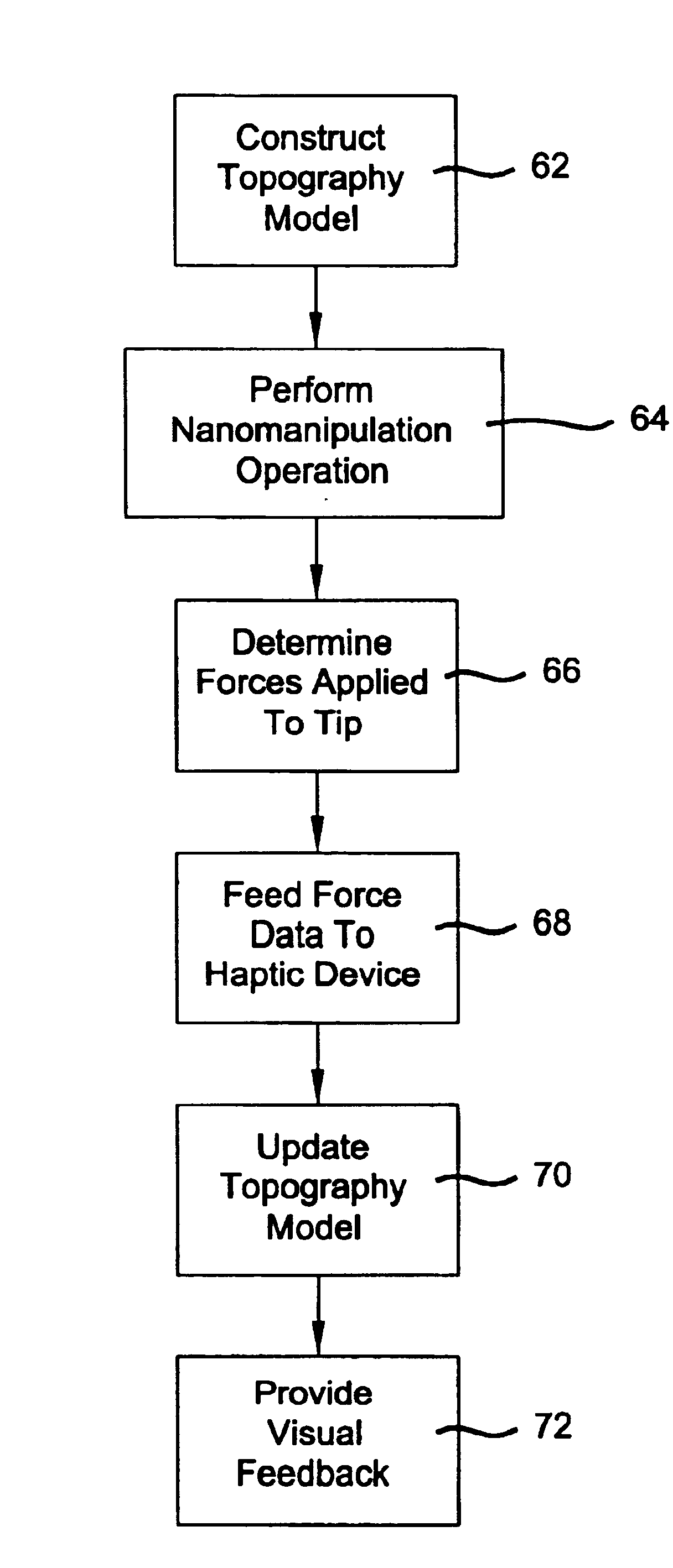

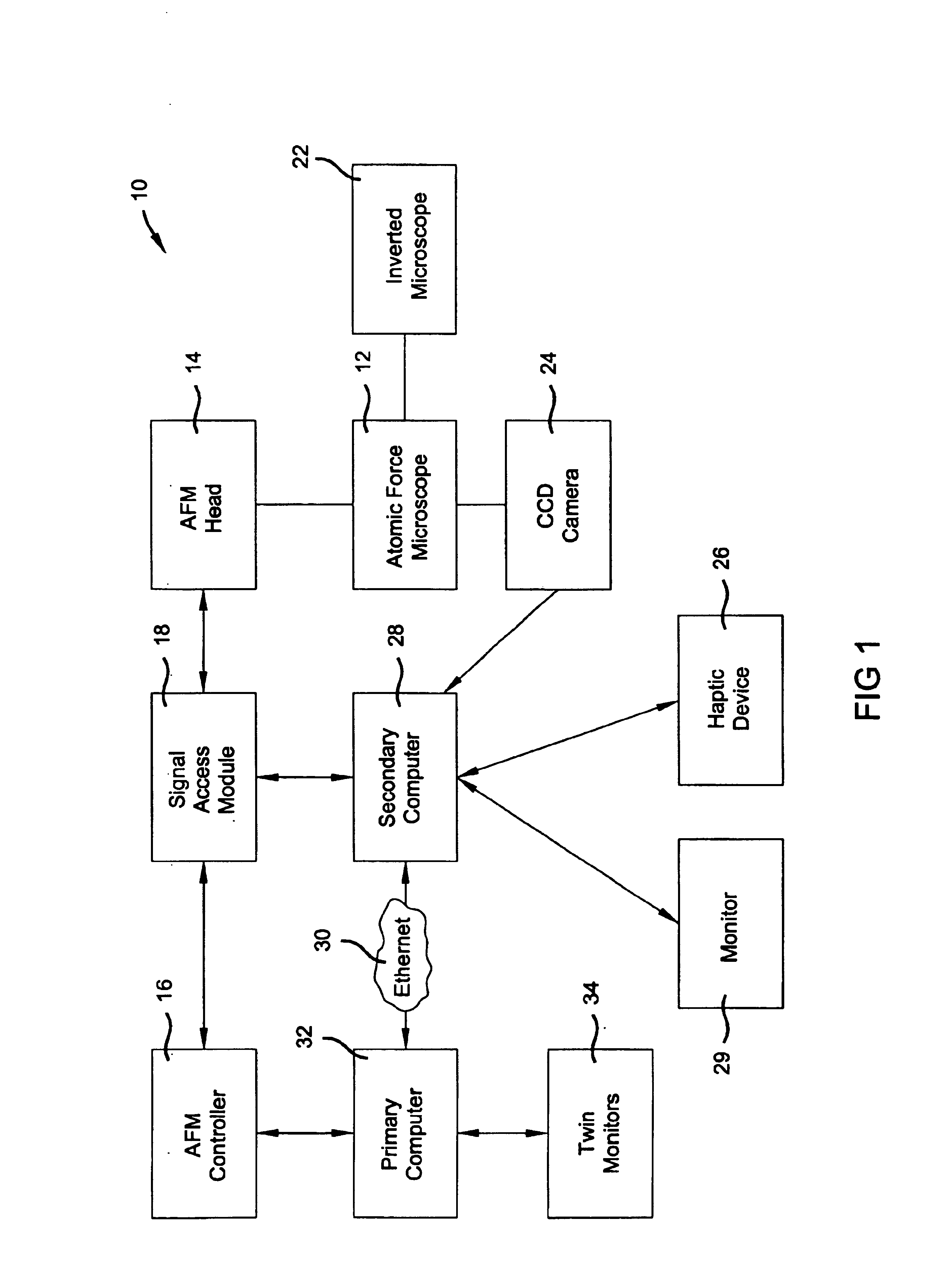

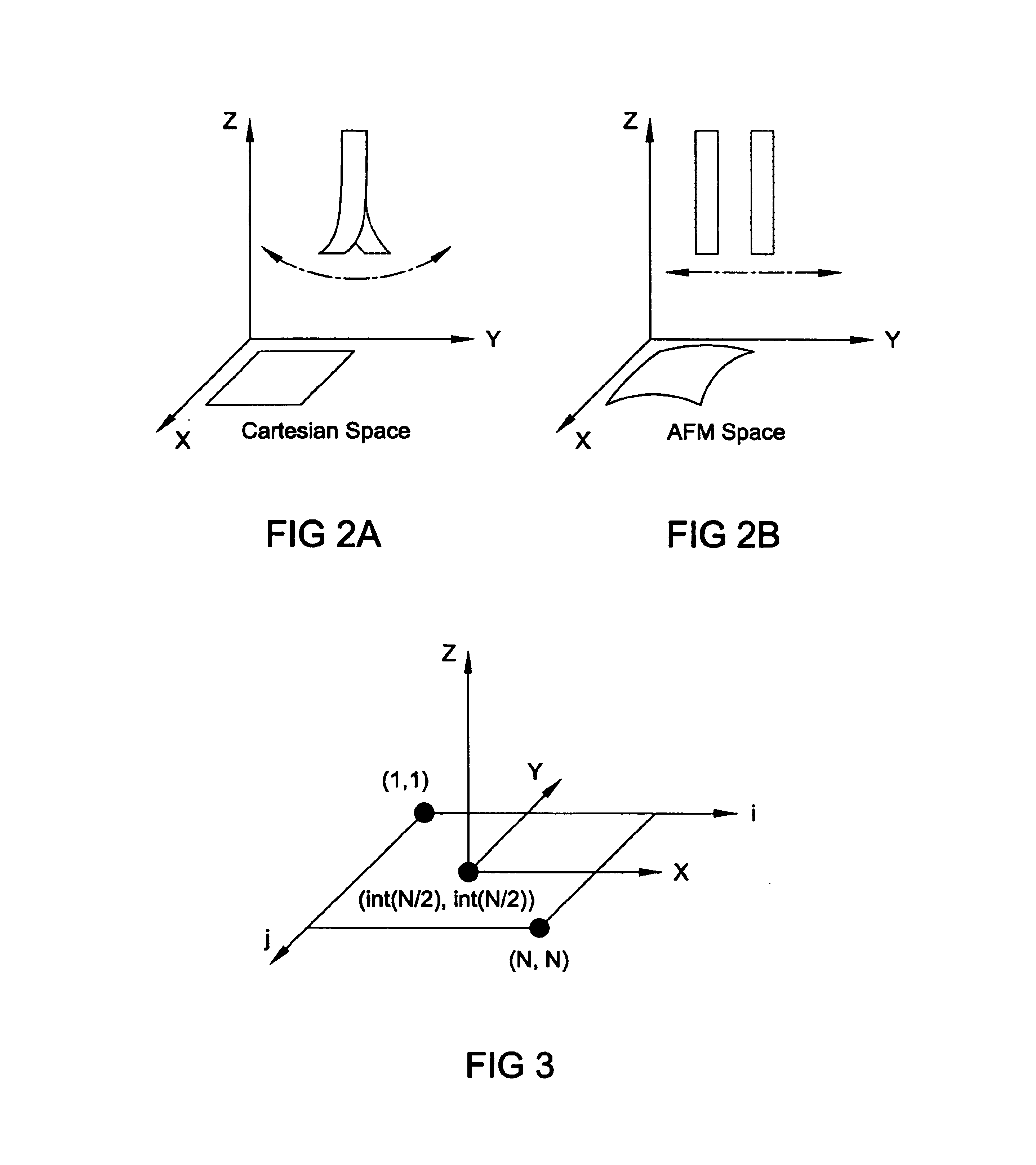

Augmenting reality system for real-time nanomanipulation using atomic force microscopy

An improved method is provided for performing nanomanipulations using an atomic force microscope. The method includes: performing a nanomanipulation operation on a sample surface using an atomic force microscope; determining force data for forces that are being applied to the tip of the cantilever during the nanomanipulation operation, where the force data is derived along at least two perpendicularly arranged axis; and updating a model which represents the topography of the sample surface using the force data.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

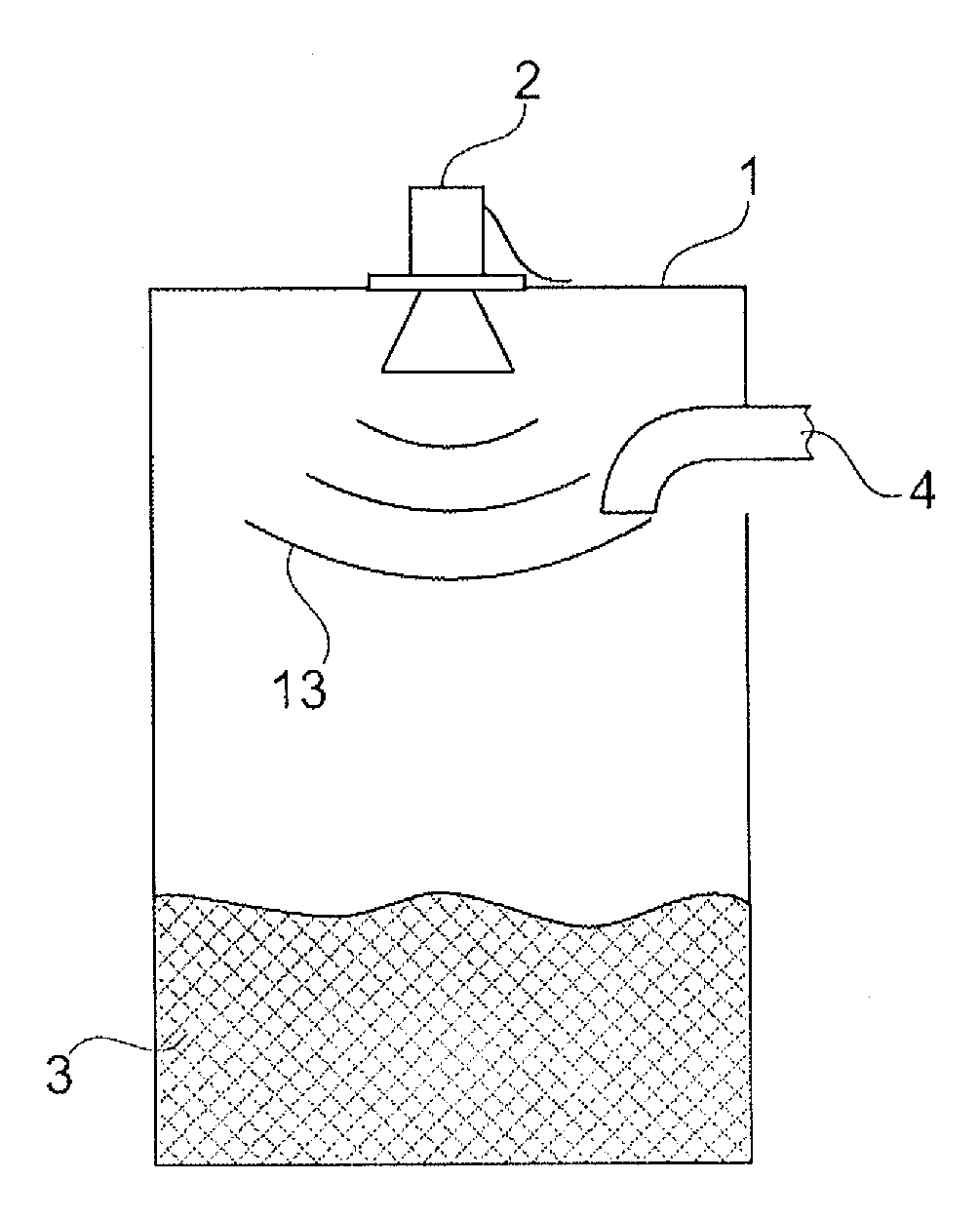

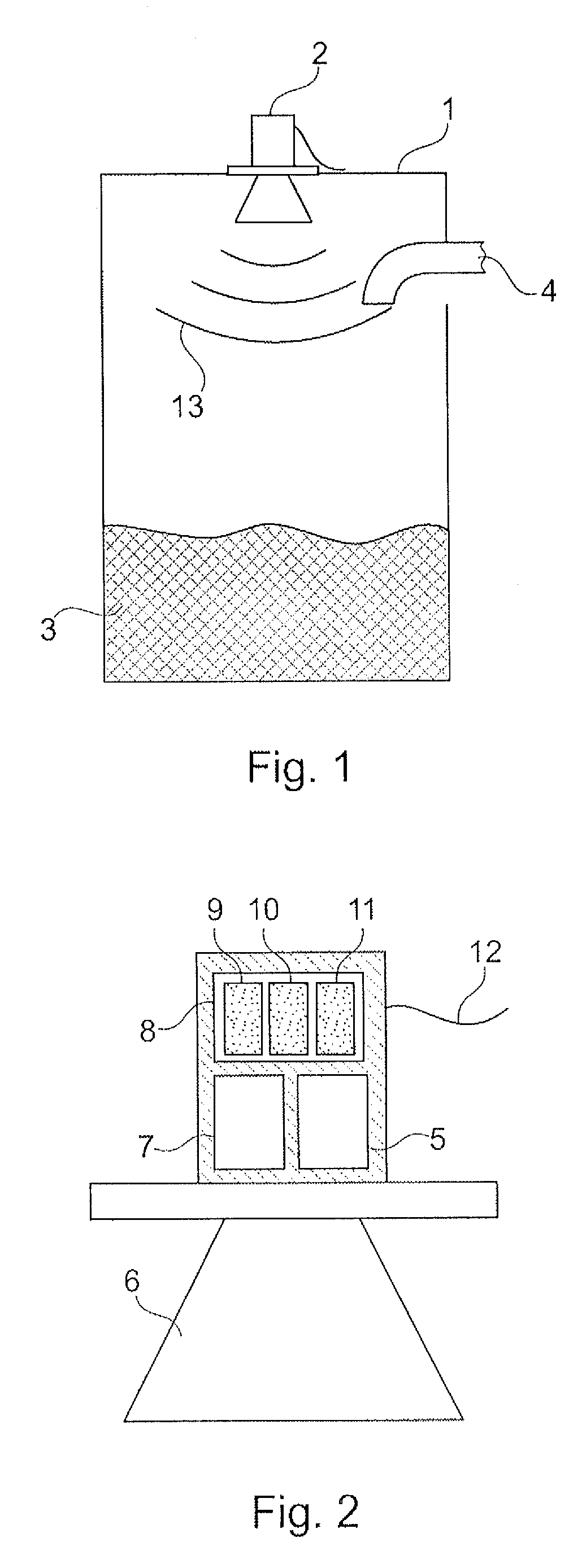

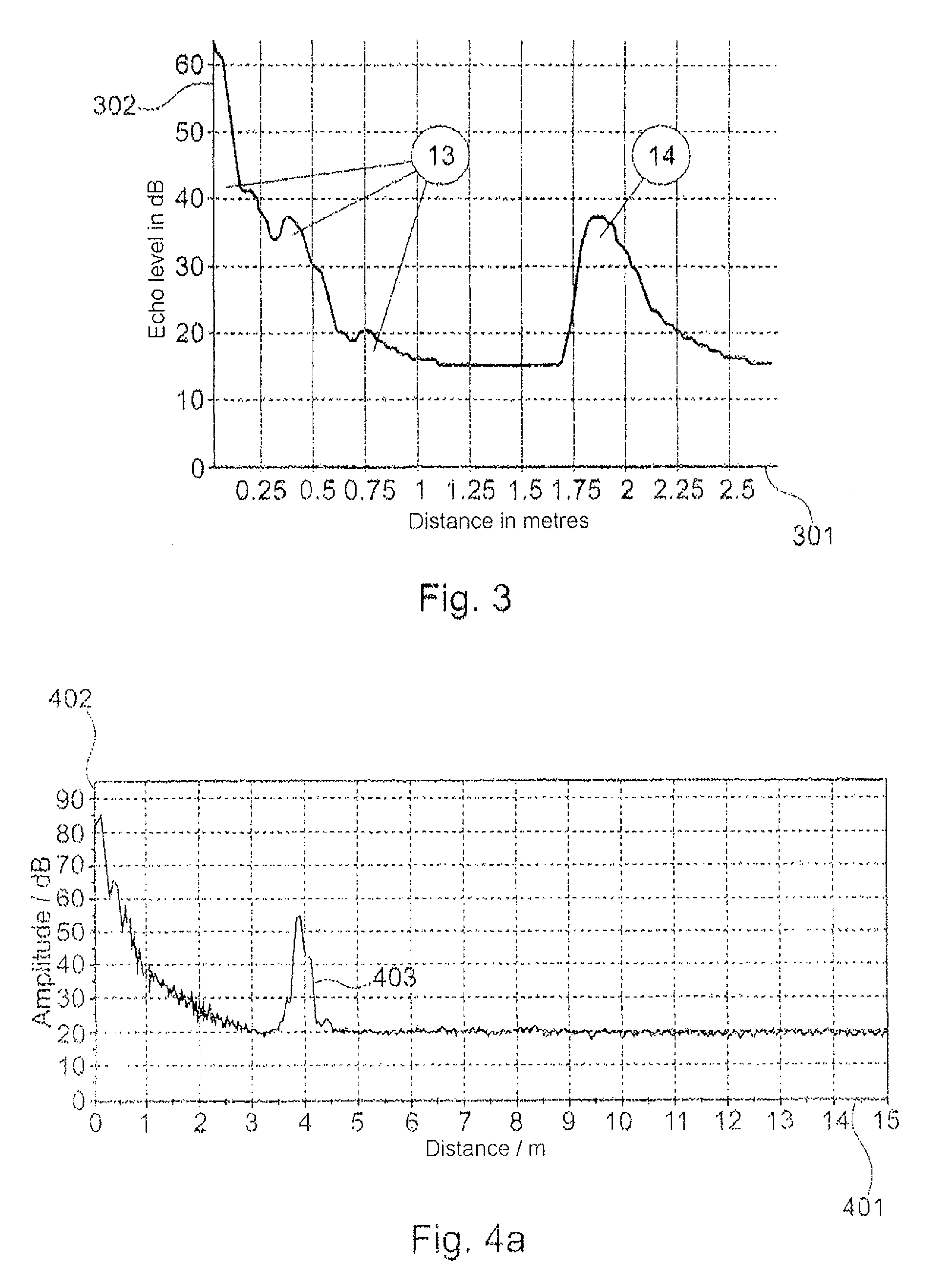

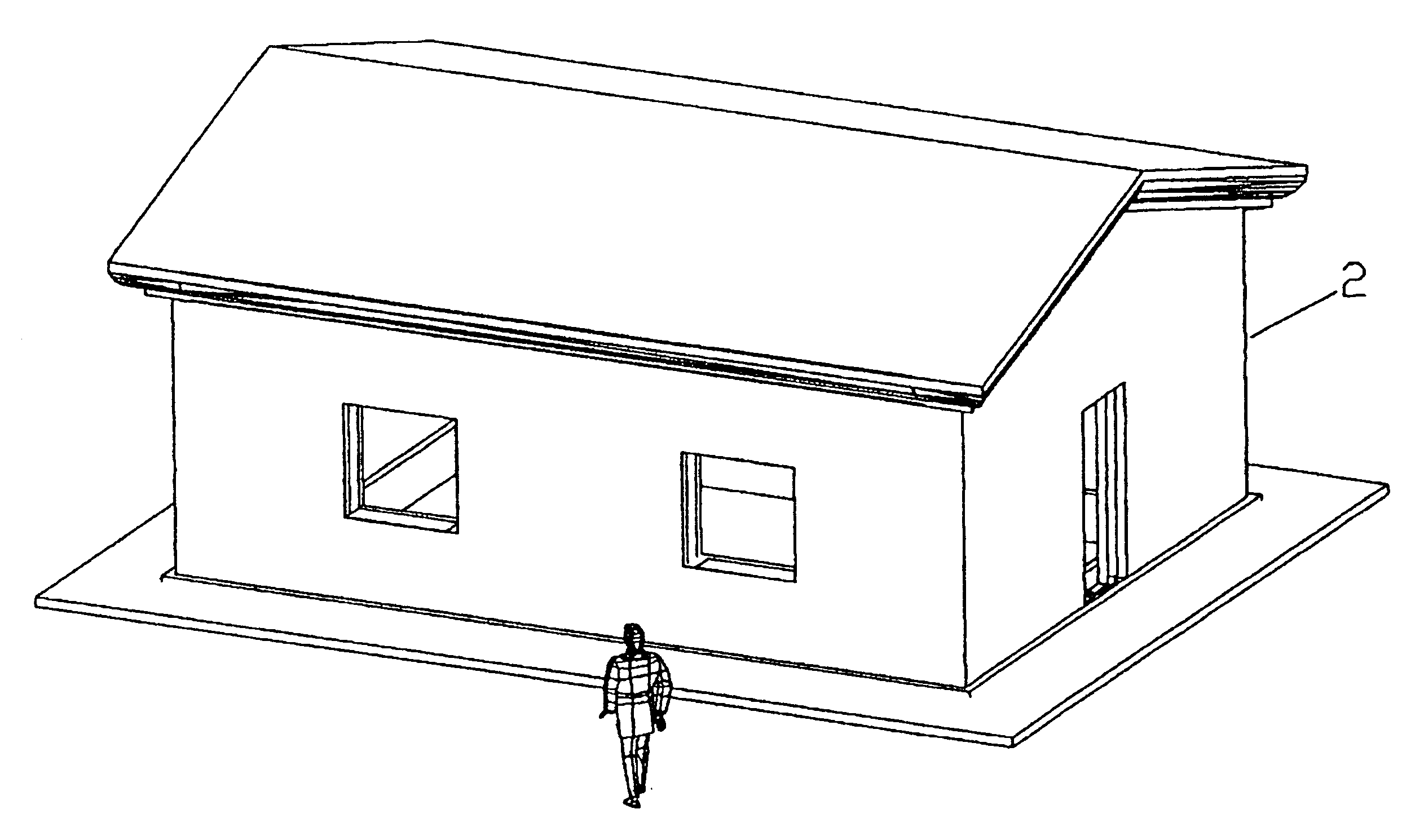

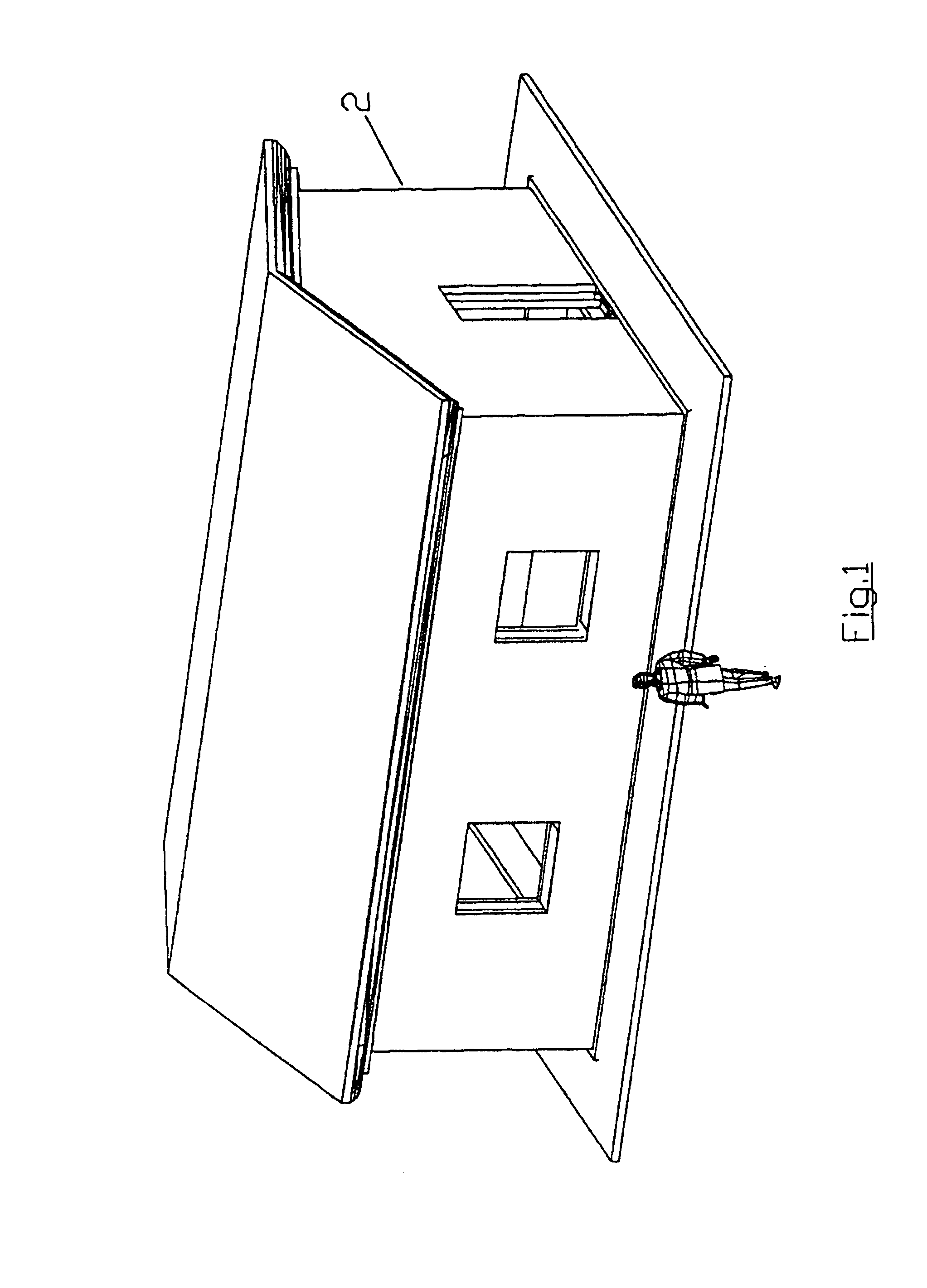

Evaluation of an Echo Shape of Filling Level Sensors

ActiveUS20090299662A1High resolutionEasy to fillFlow propertiesFeeler-pin gaugesMeasurement deviceFilling materials

A transit-time fill-level measuring device for measuring the fill level of a filling material in a container is stated, in which transit-time fill-level measuring device information about the topography of the filling material surface is determined on the basis of the shape of a single echo curve of the receiving signal. From this the fill volume can then be derived.

Owner:VEGA GRIESHABER GMBH & CO

Method of manufacturing and analyzing a composite building

InactiveUS6985832B2Easily assembled materialReduce energy consumptionGeometric CADWallsGlass fiberReinforced concrete

The invention provides a method of manufacturing and analyzing a building made from Expanded PolyStyrene (EPS) which is coated on the inside and outside with Glass Fiber Reinforced Concrete (GFRC). The building is designed in a CAD program. Then, the building is divided up into small volumes in the CAD program or in a Finite Element Analysis program. Plates are added to the inner and outer surfaces of the volumes. Appropriate characteristics of the EPS and GFRC are assigned to the volumes and plates. A FEA analysis can then be run.

Owner:SAEBI NASSER

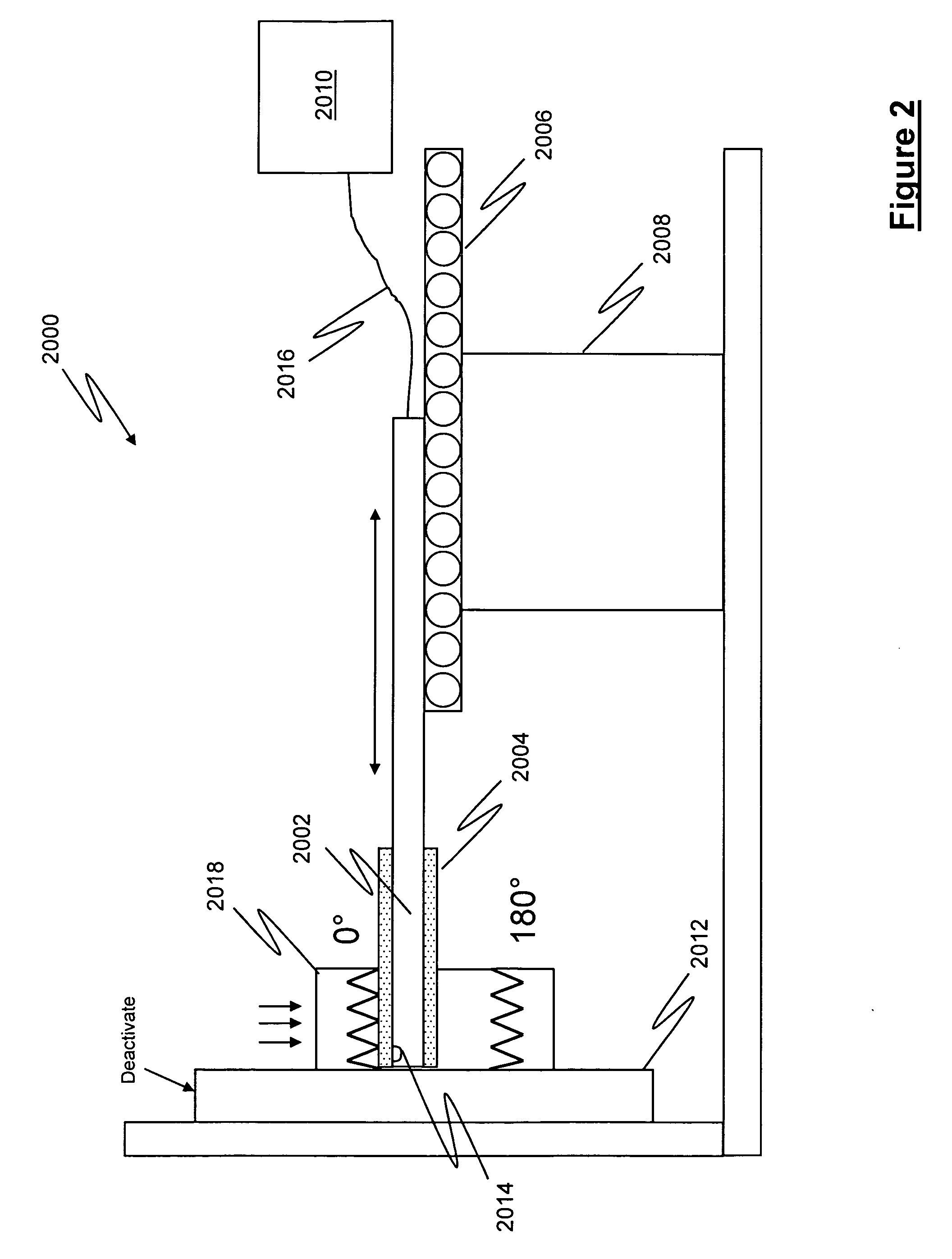

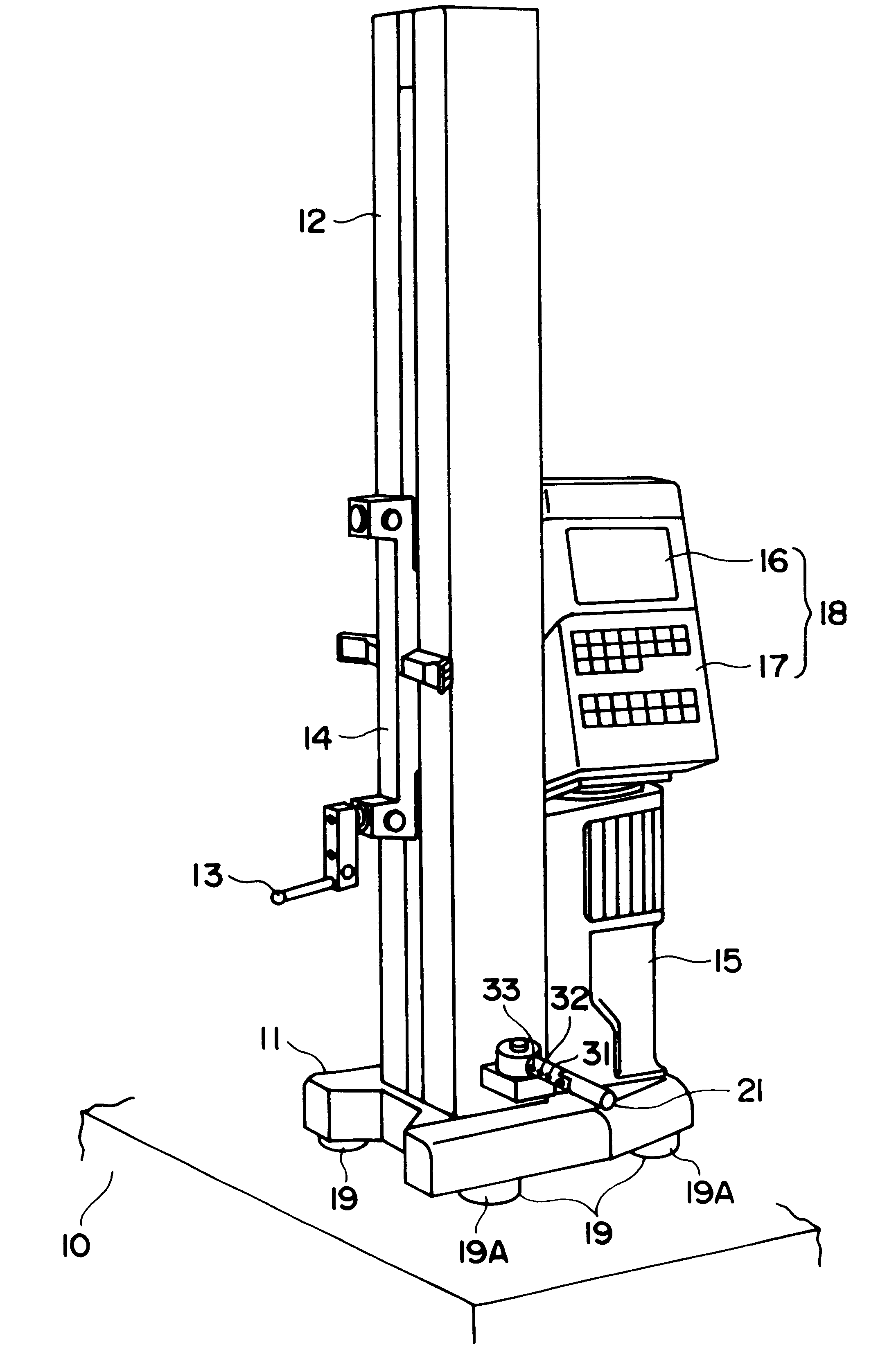

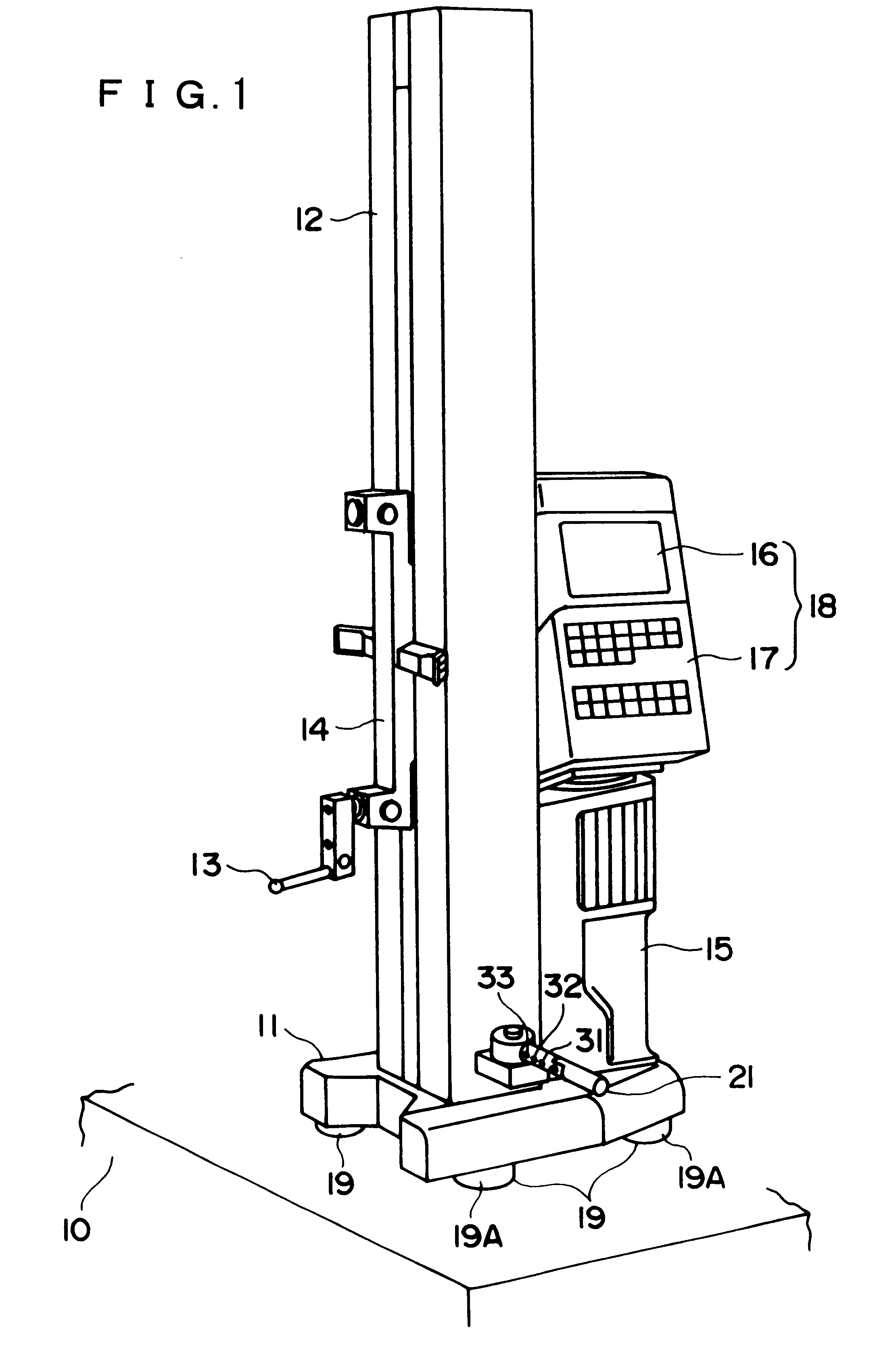

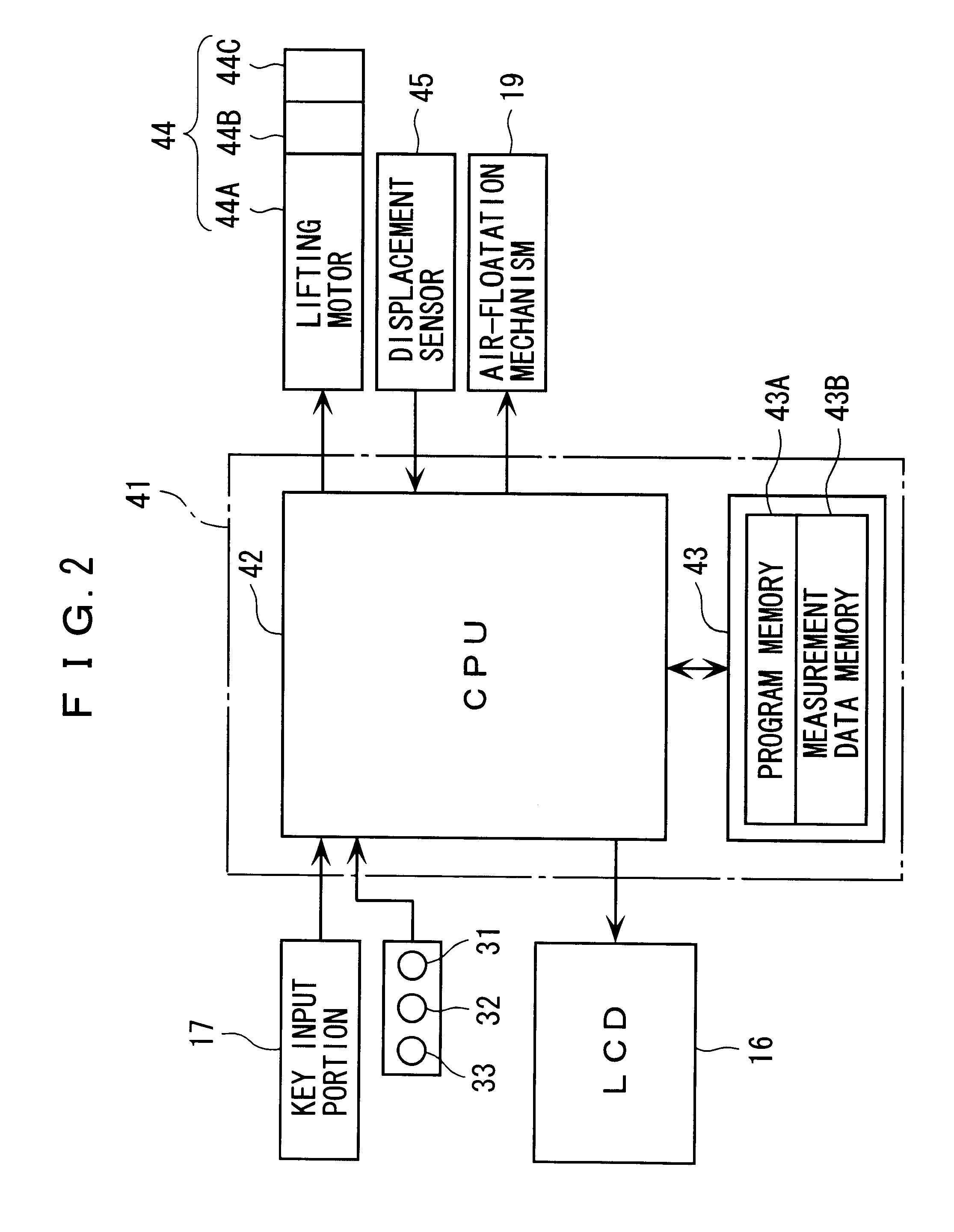

Linear measuring machine

InactiveUS6446351B1Not scarredImprove measurement efficiencyMechanical depth measurementsFeeler-pin gaugesElectric machineEngineering

A linear measuring machine is provided, the linear measuring machine having a base (11), a column (12) disposed on the base, a slider (14) elevatable along the column and an elevation driving mechanism (44) including a motor for lifting and lowering the slider. The linear measuring machine further includes a touch-and-back mechanism for driving the elevation driving mechanism in a direction for a probe (13) to move away from a measurement surface of the workpiece after fetching a detection value of a displacement sensor (45) when the probe touches the measurement surface of the workpiece and for stopping the elevation driving mechanism.

Owner:MITUTOYO CORP

Methods and apparatus for wavefront manipulations and improved 3-D measurements

InactiveUS20100002950A1Accurate calculationPoor spatial resolutionFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansMaxwell's equations3d measurement

Methods and apparatus to perform wavefront analysis, including phase and amplitude information, and 3D measurements in optical systems, and in particular those based on analyzing the output of an intermediate plane, such as an image plane, of an optical system. Measurement of surface topography in the presence of thin film coatings, or of the individual layers of a multilayered structure is described. Multi-wavelength analysis in combination with phase and amplitude mapping is utilized. Methods of improving phase and surface topography measurements by wavefront propagation and refocusing, using virtual wavefront propagation based on solutions of Maxwell's equations are described. Reduction of coherence noise in optical imaging systems is achieved by such phase manipulation methods, or by methods utilizing a combination of wideband and coherent sources. The methods are applied to Integrated Circuit inspection, to improve overlay measurement techniques, by improving contrast or by 3-D imaging, in single shot imaging. Data supplied from the esp@cenet database—Worldwide

Owner:ICOS VISION SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com