Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3123results about "Mechanical counters/curvatures measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

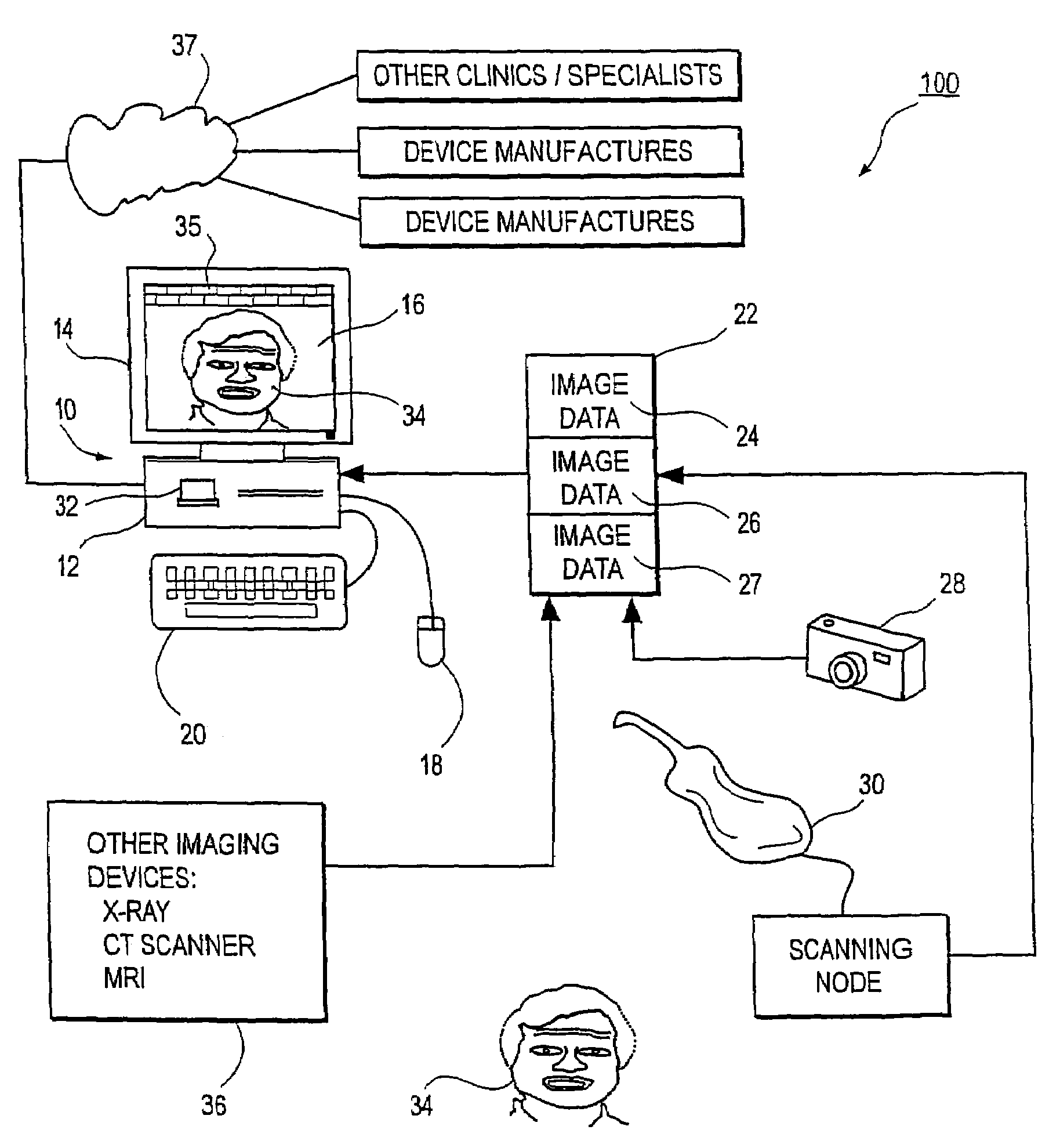

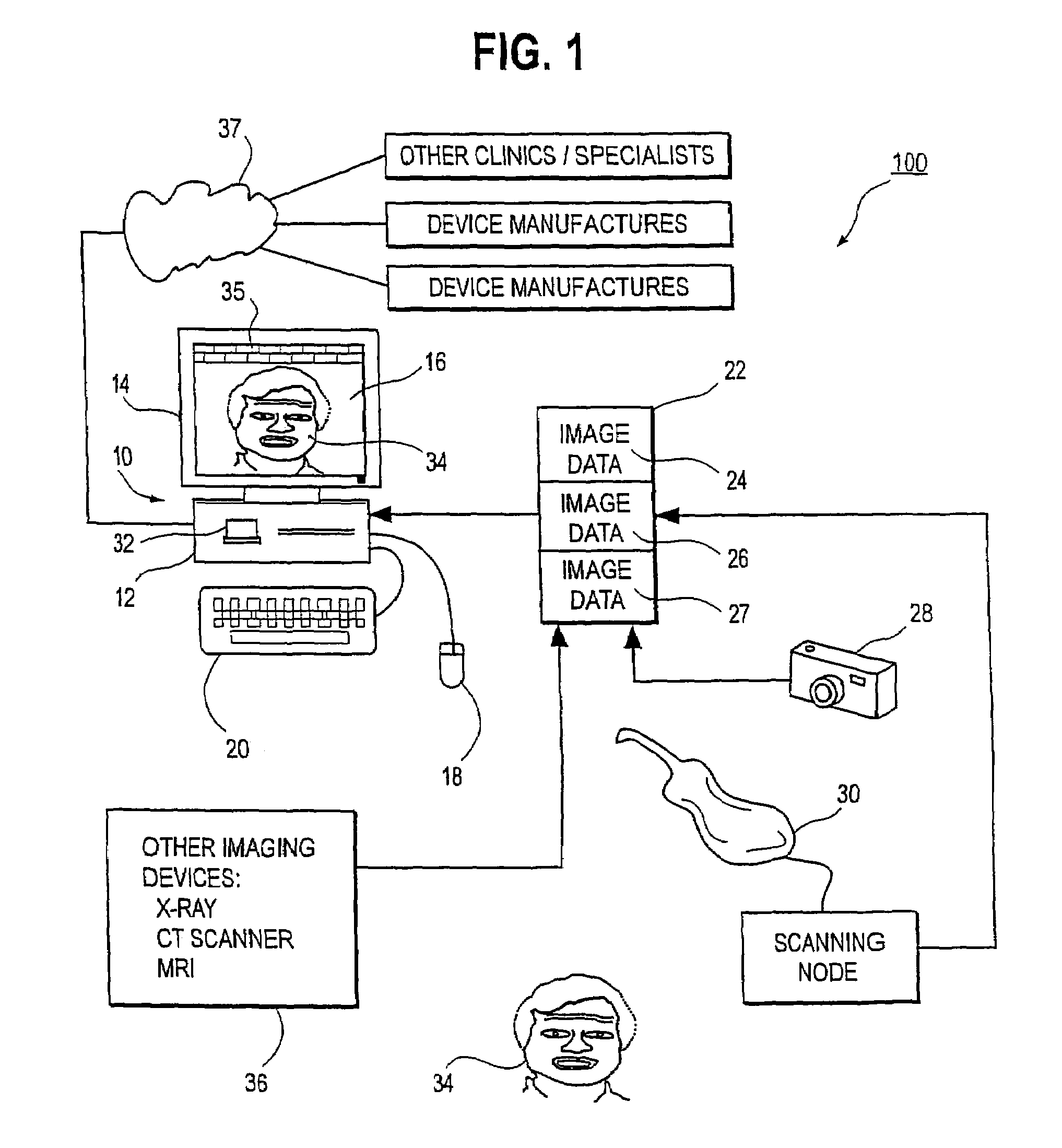

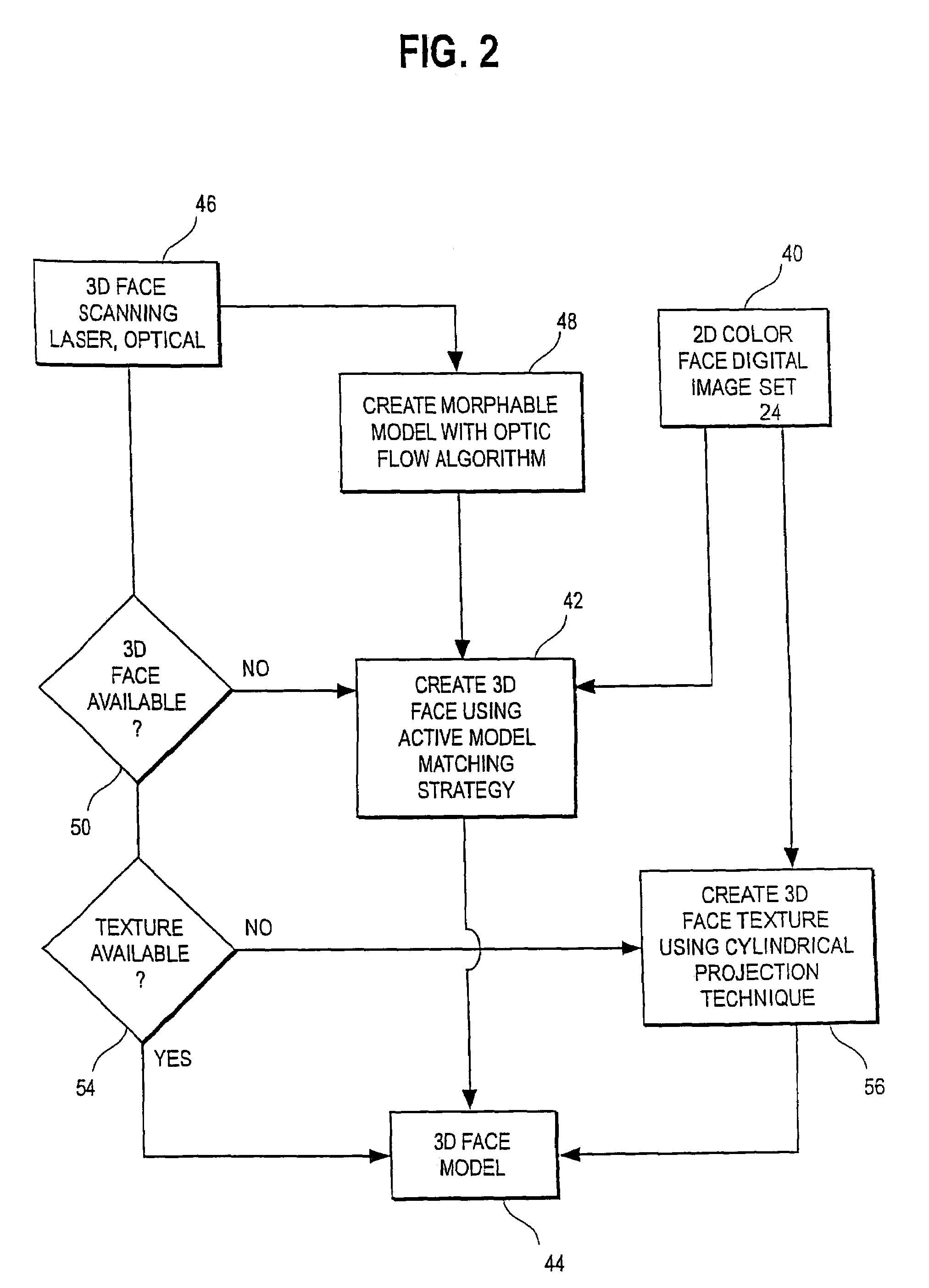

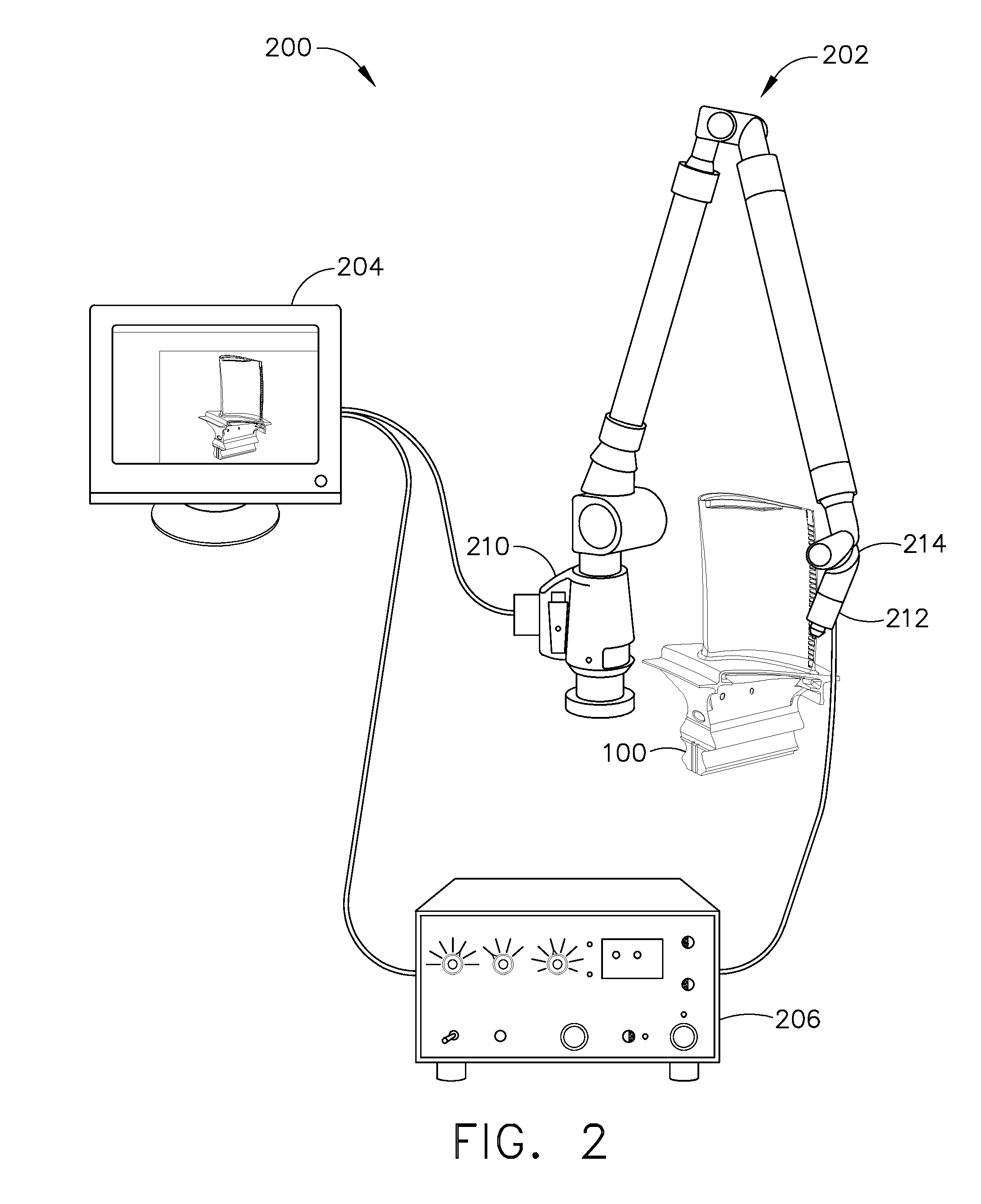

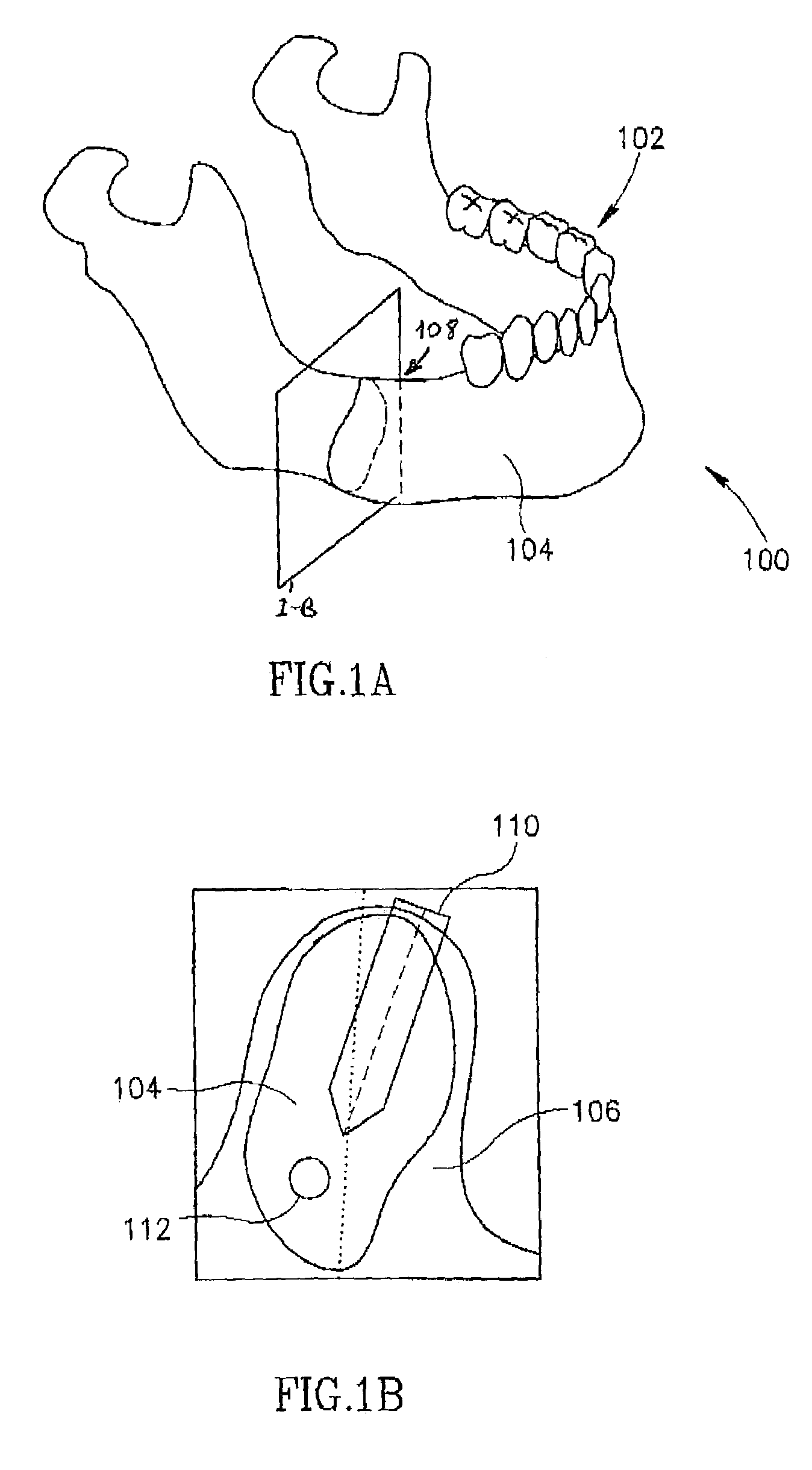

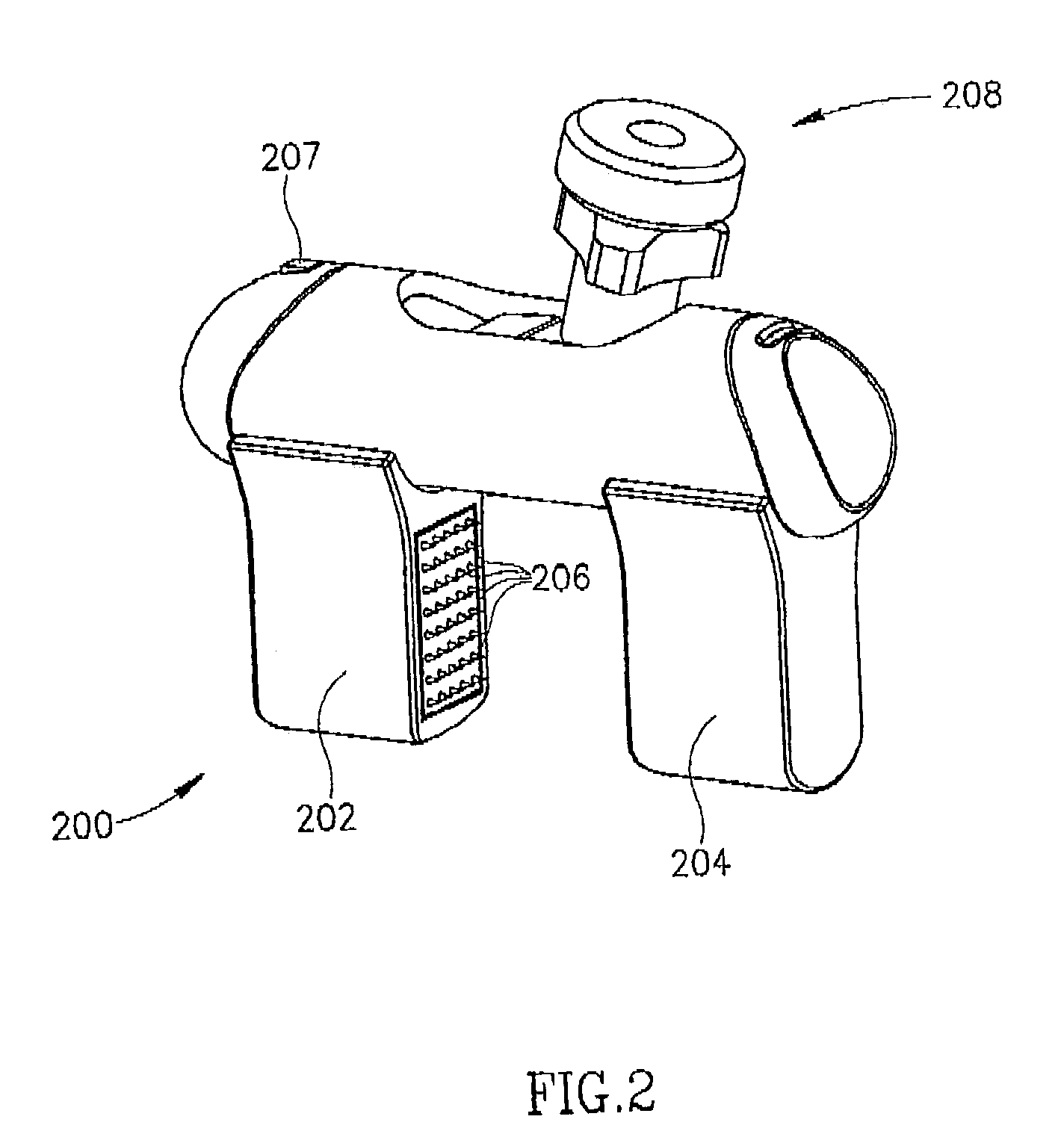

Unified workstation for virtual craniofacial diagnosis, treatment planning and therapeutics

InactiveUS7234937B2Quick analysisPowerful toolDental implantsImpression capsPlan treatmentPatient model

An integrated system is described in which digital image data of a patient, obtained from a variety of image sources, including CT scanner, X-Ray, 2D or 3D scanners and color photographs, are combined into a common coordinate system to create a virtual three-dimensional patient model. Software tools are provided for manipulating the virtual patient model to simulation changes in position or orientation of craniofacial structures (e.g., jaw or teeth) and simulate their affect on the appearance of the patient. The simulation (which may be pure simulations or may be so-called “morphing” type simulations) enables a comprehensive approach to planning treatment for the patient. In one embodiment, the treatment may encompass orthodontic treatment. Similarly, surgical treatment plans can be created. Data is extracted from the virtual patient model or simulations thereof for purposes of manufacture of customized therapeutic devices for any component of the craniofacial structures, e.g., orthodontic appliances.

Owner:ORAMETRIX

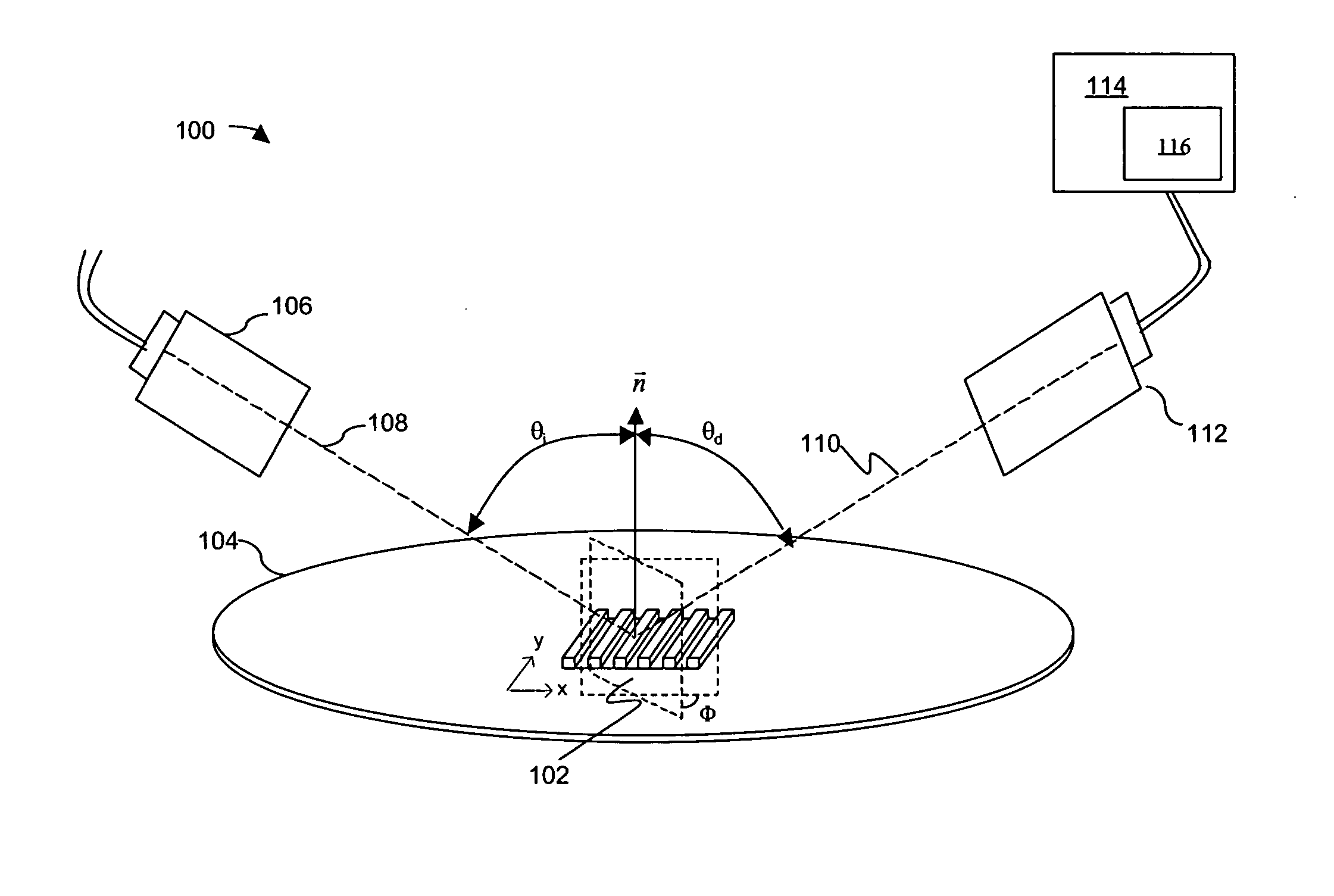

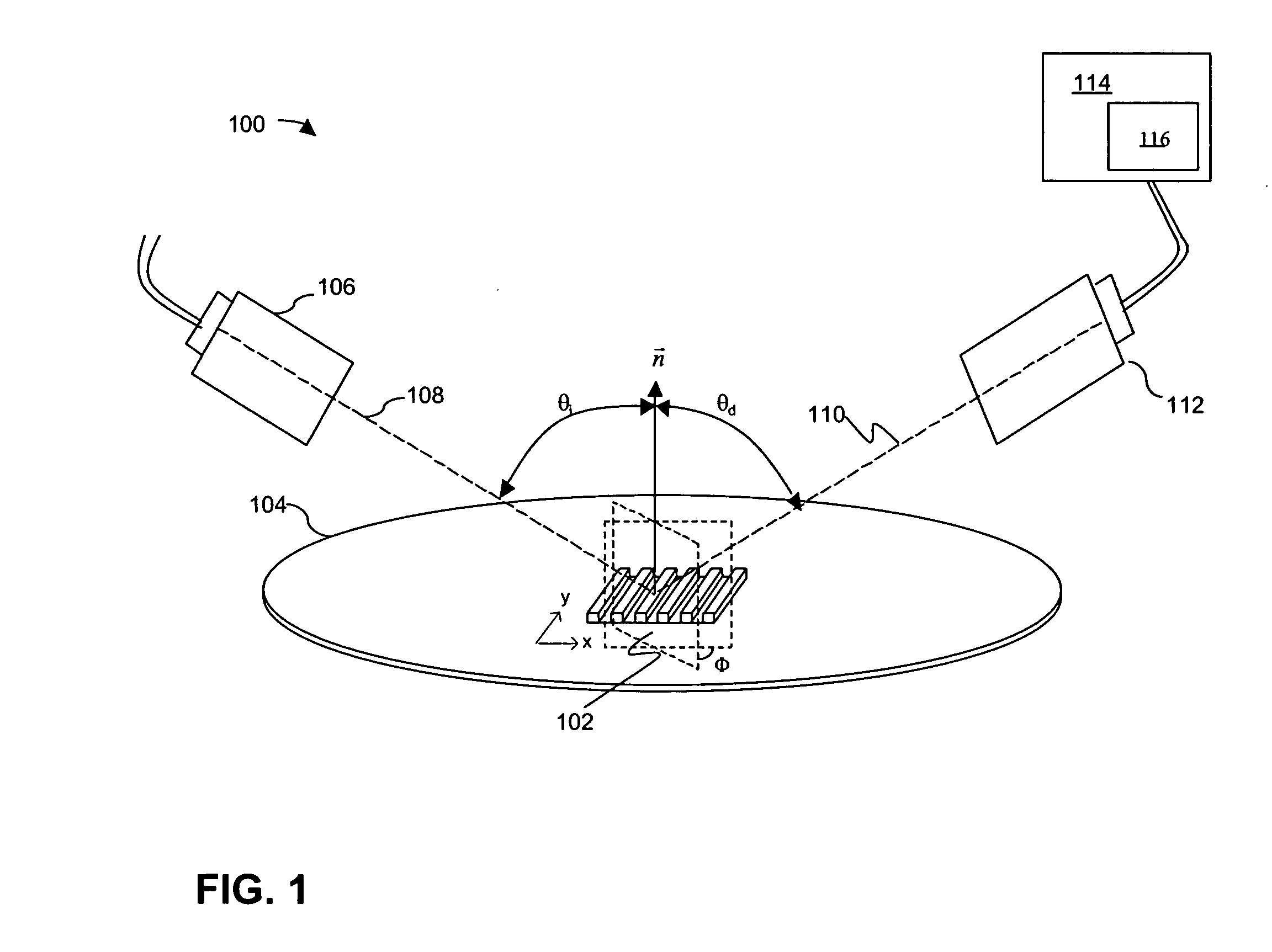

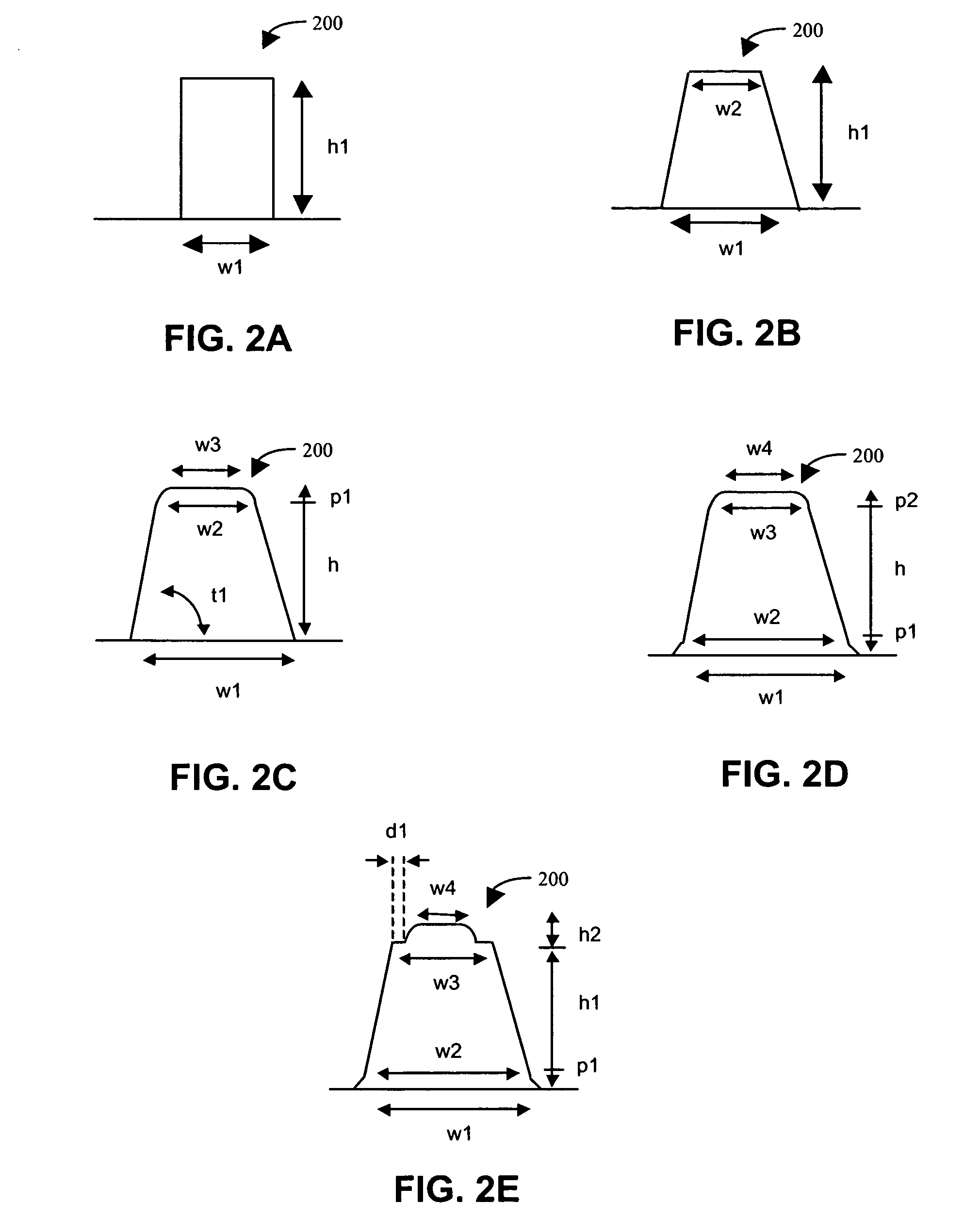

Optical metrology optimization for repetitive structures

InactiveUS20050209816A1Feeler-pin gaugesMechanical counters/curvatures measurementsComputational physicsOptical metrology

The top-view profiles of repeating structures in a wafer are characterized and parameters to represent variations in the top-view profile of the repeating structures are selected. An optical metrology model is developed that includes the selected top-view profile parameters of the repeating structures. The optimized optical metrology model is used to generate simulated diffraction signals that are compared to measured diffraction signals.

Owner:TOKYO ELECTRON LTD

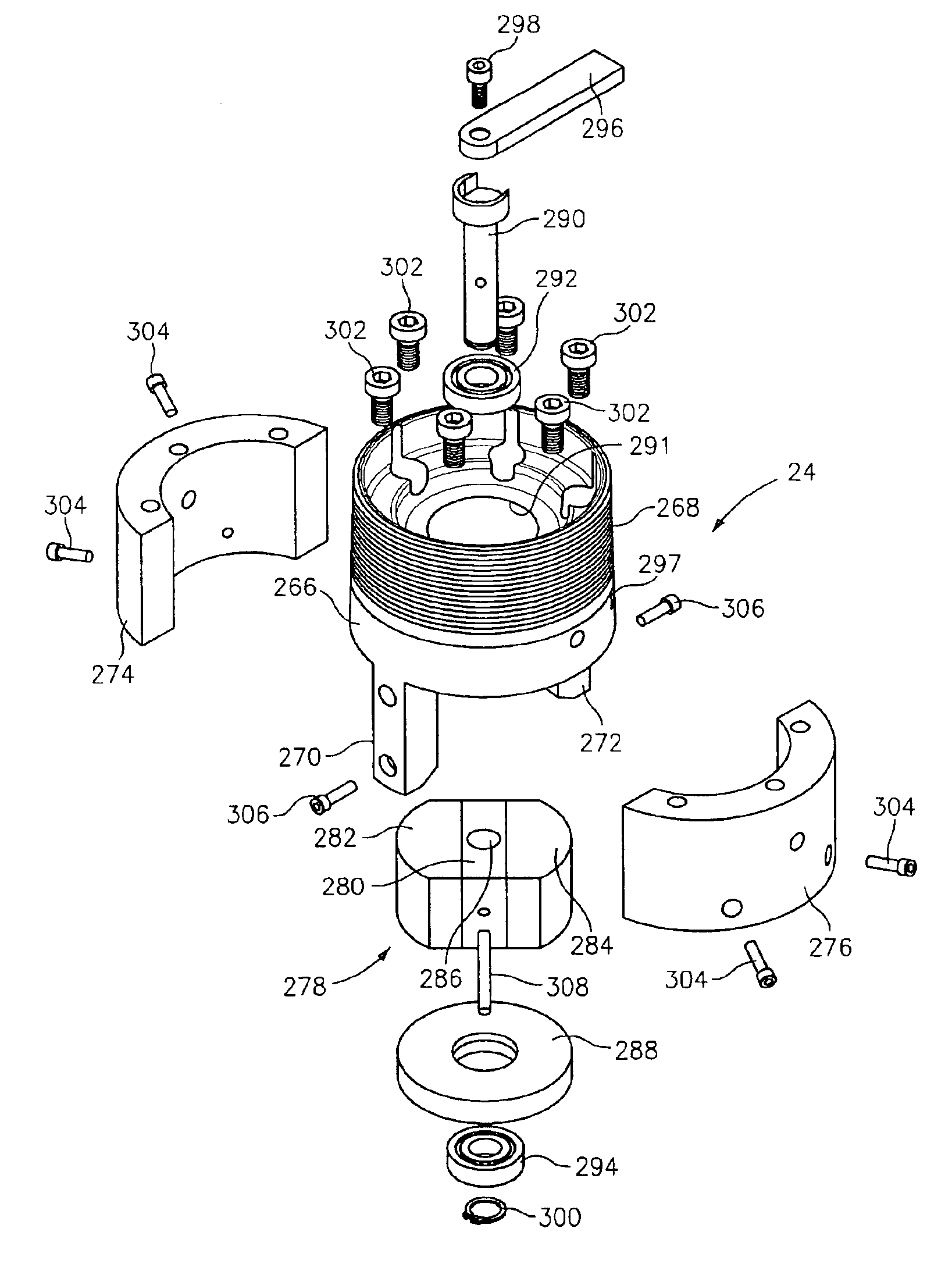

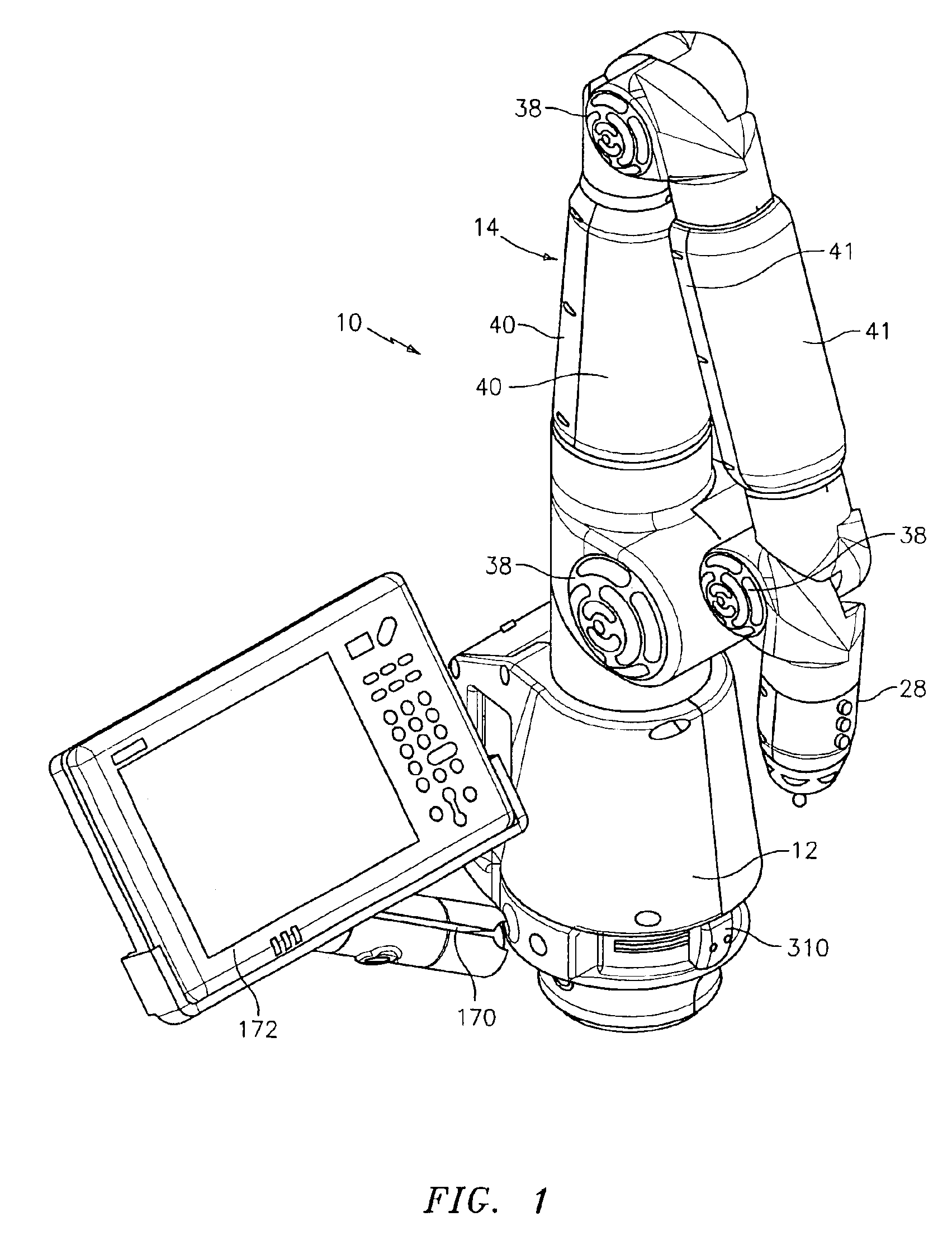

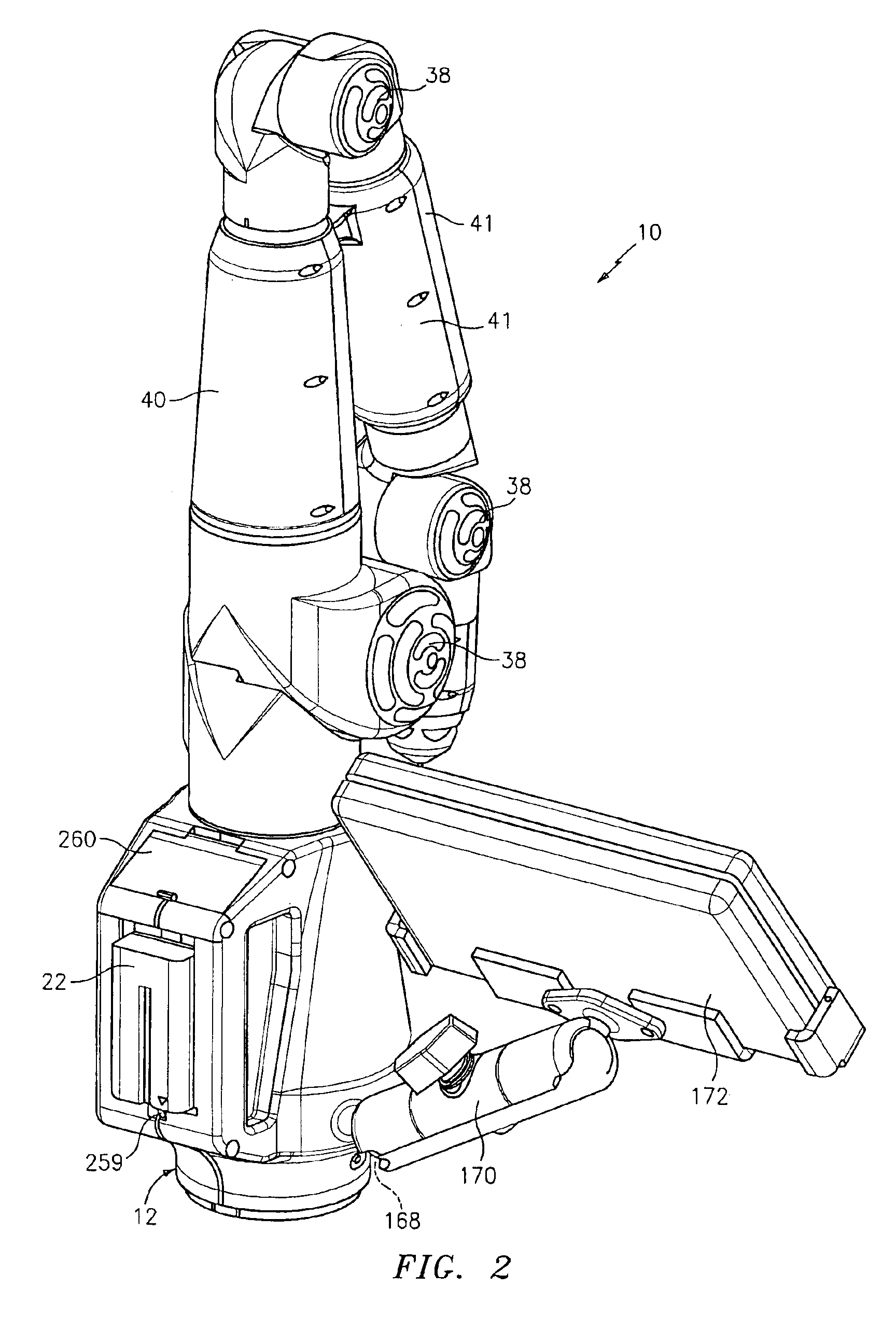

Portable coordinate measurement machine with integrated magnetic mount

InactiveUS6892465B2Easy to convertEasy to distinguishProgramme-controlled manipulatorImage analysisEngineeringMagnet

Owner:FARO TECH INC

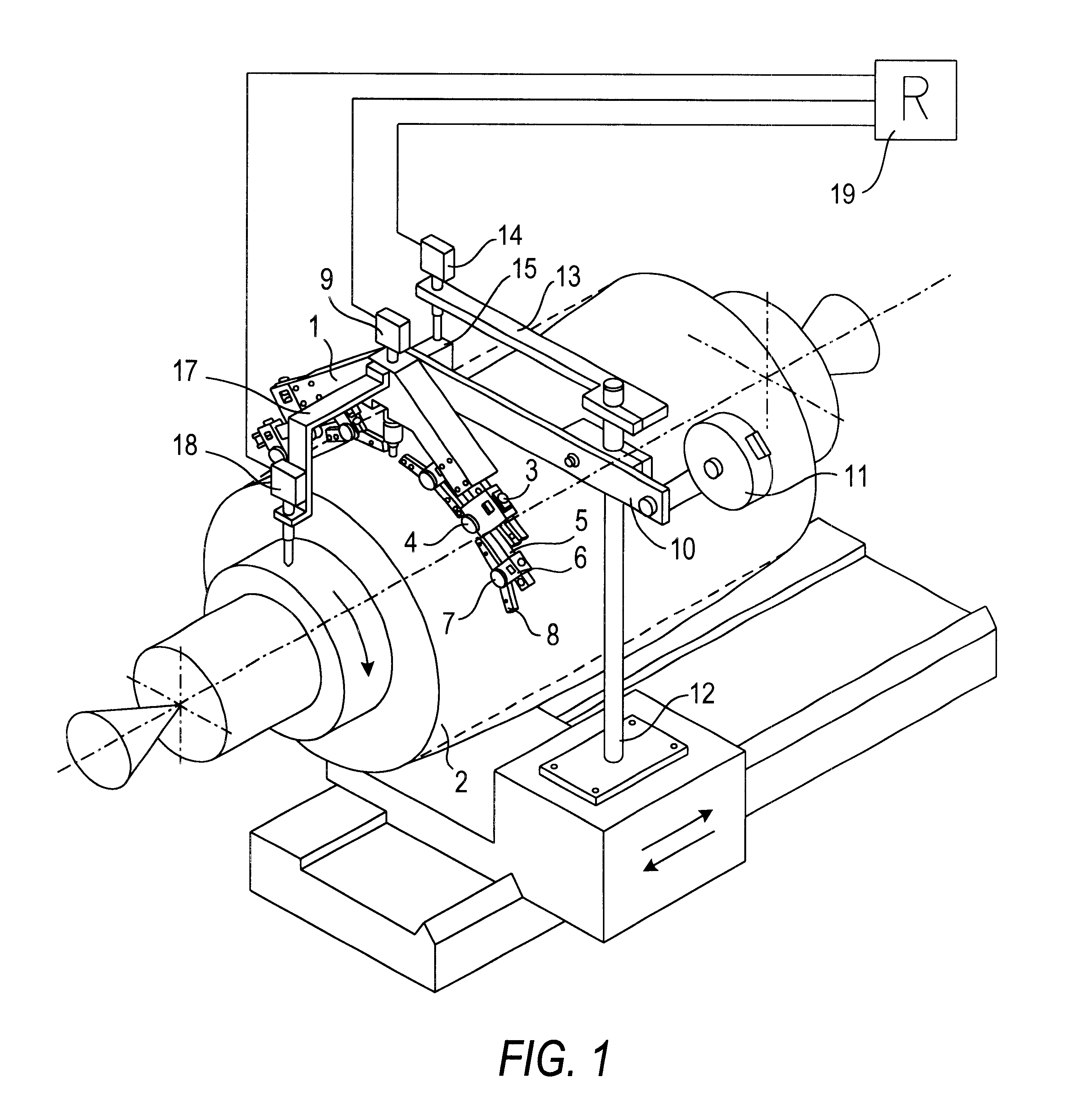

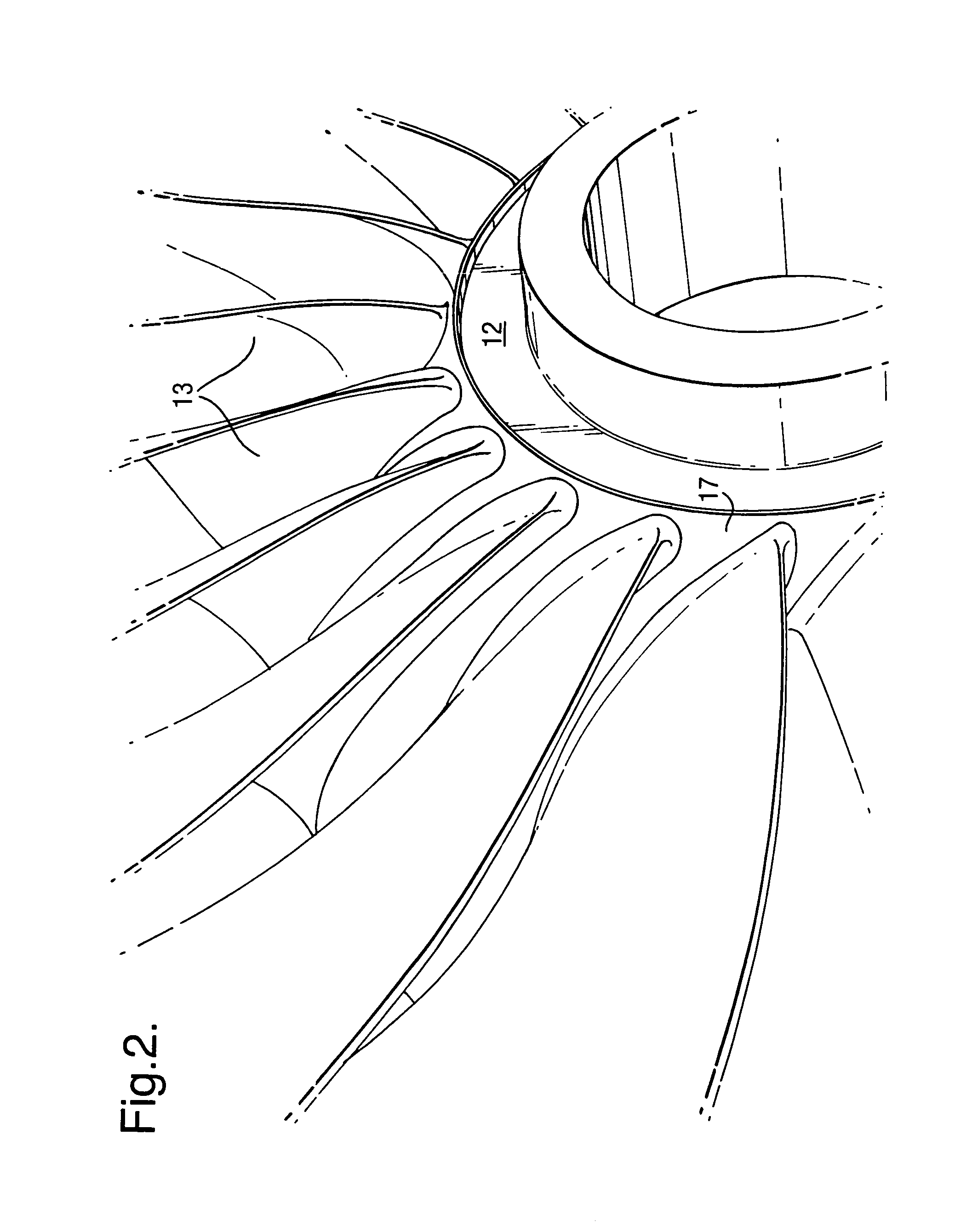

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

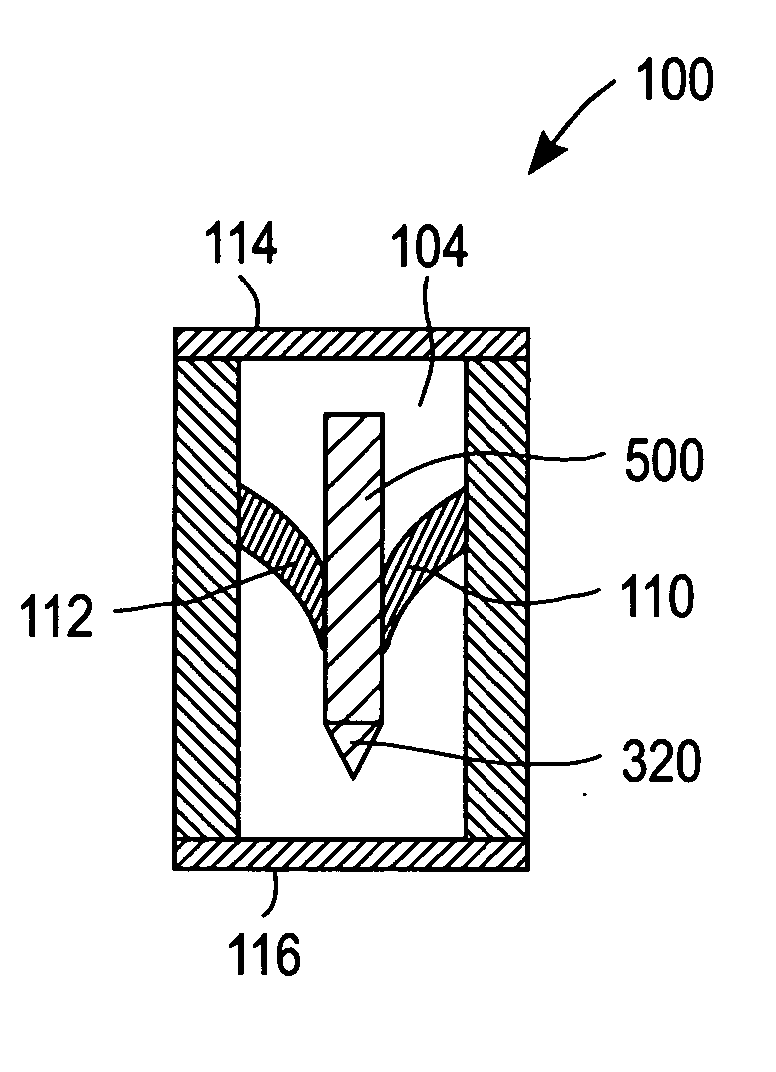

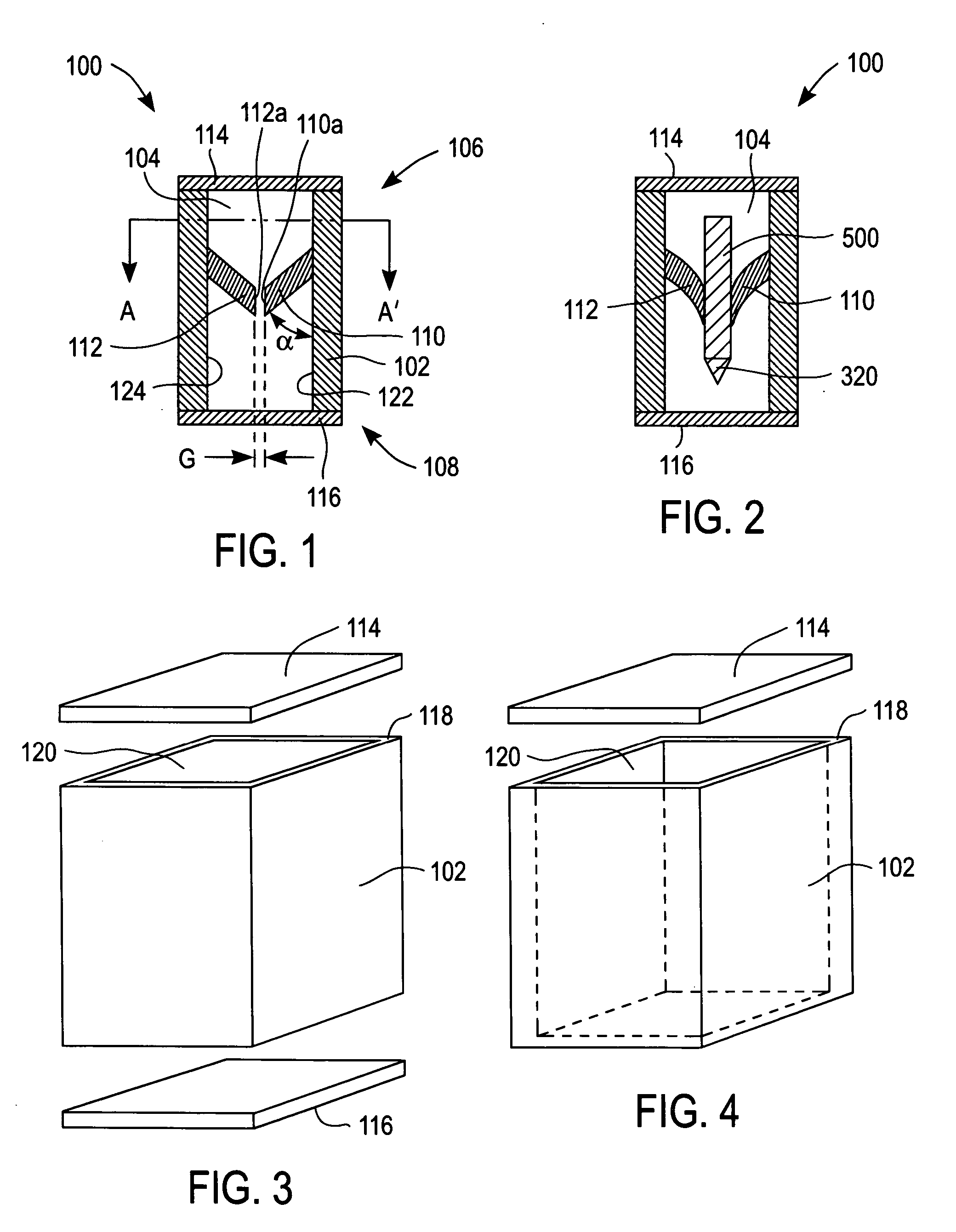

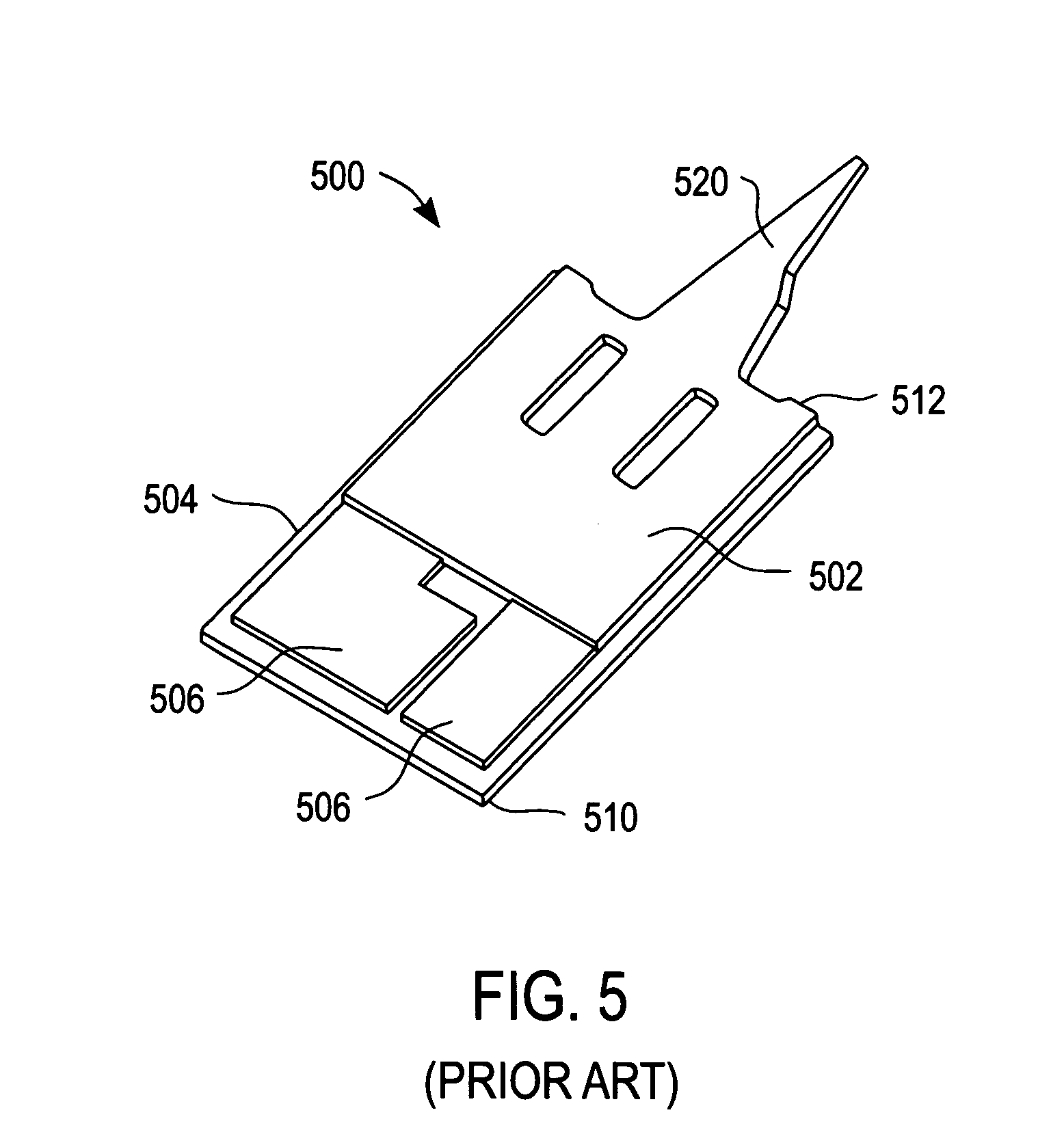

Medical device package with deformable projections

ActiveUS20050218024A1Disabling useEasy to deploySurgical furnitureDispensing apparatusMedical deviceBiomedical engineering

A medical device package includes a body with at least one chamber therein, a proximal end and a distal end. The medical device package also includes at least one deformable projection within the chamber(s). Furthermore, the deformable projection is configured to deform resiliently upon contact with a medical device during insertion of the medical device into the chamber and, thereby, removably retain the medical device within the chamber.

Owner:LIFESCAN IP HLDG LLC

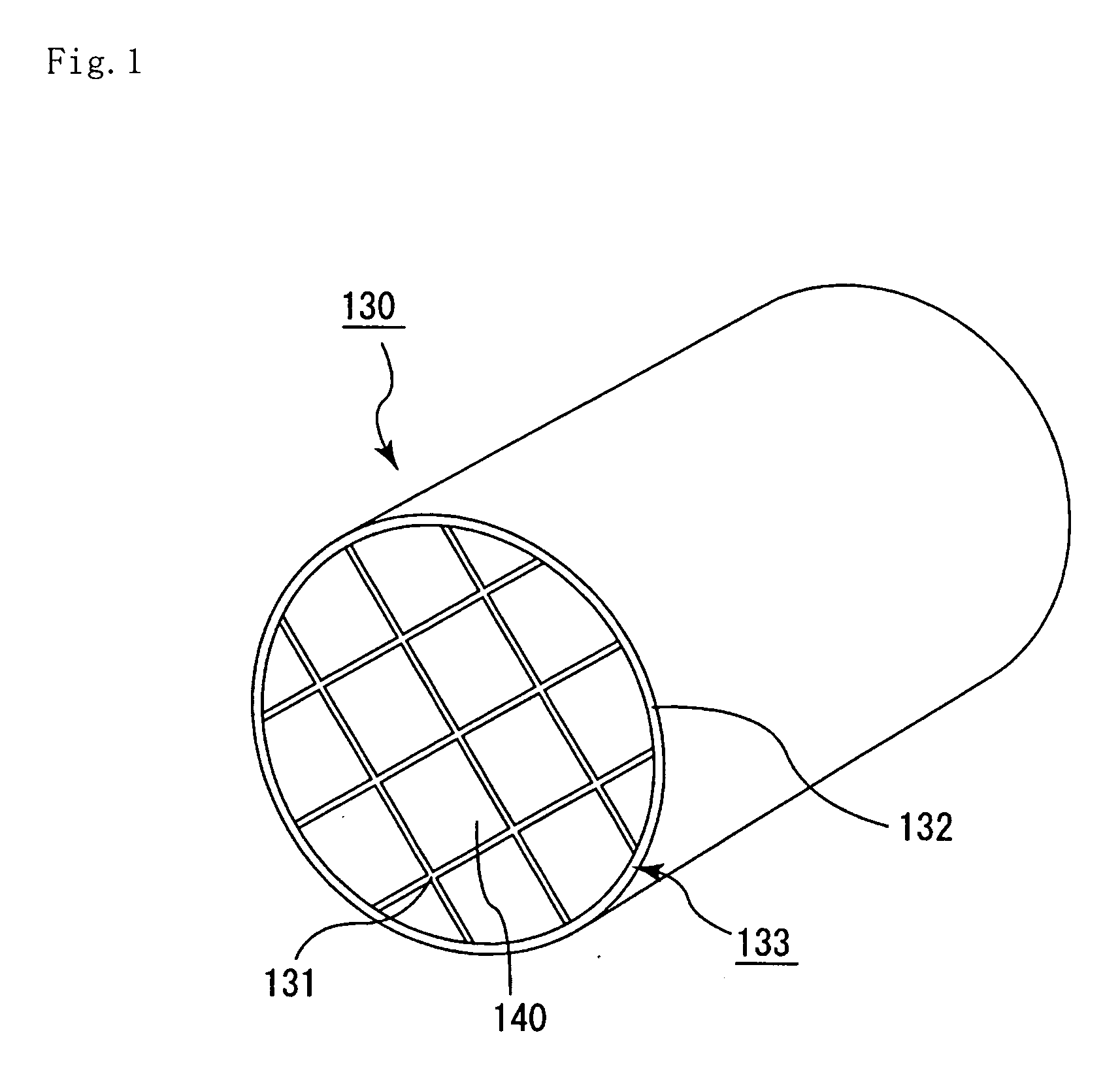

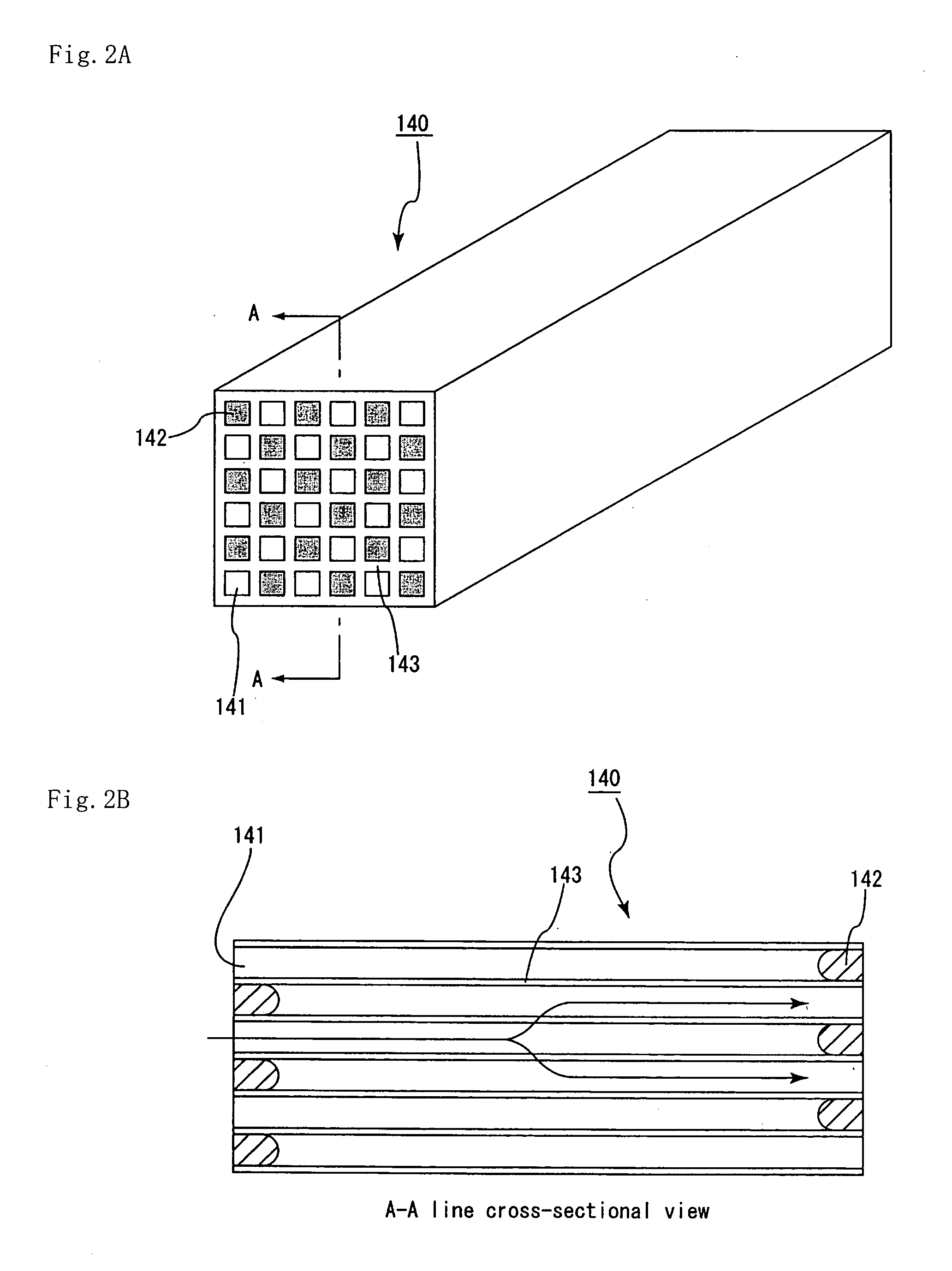

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

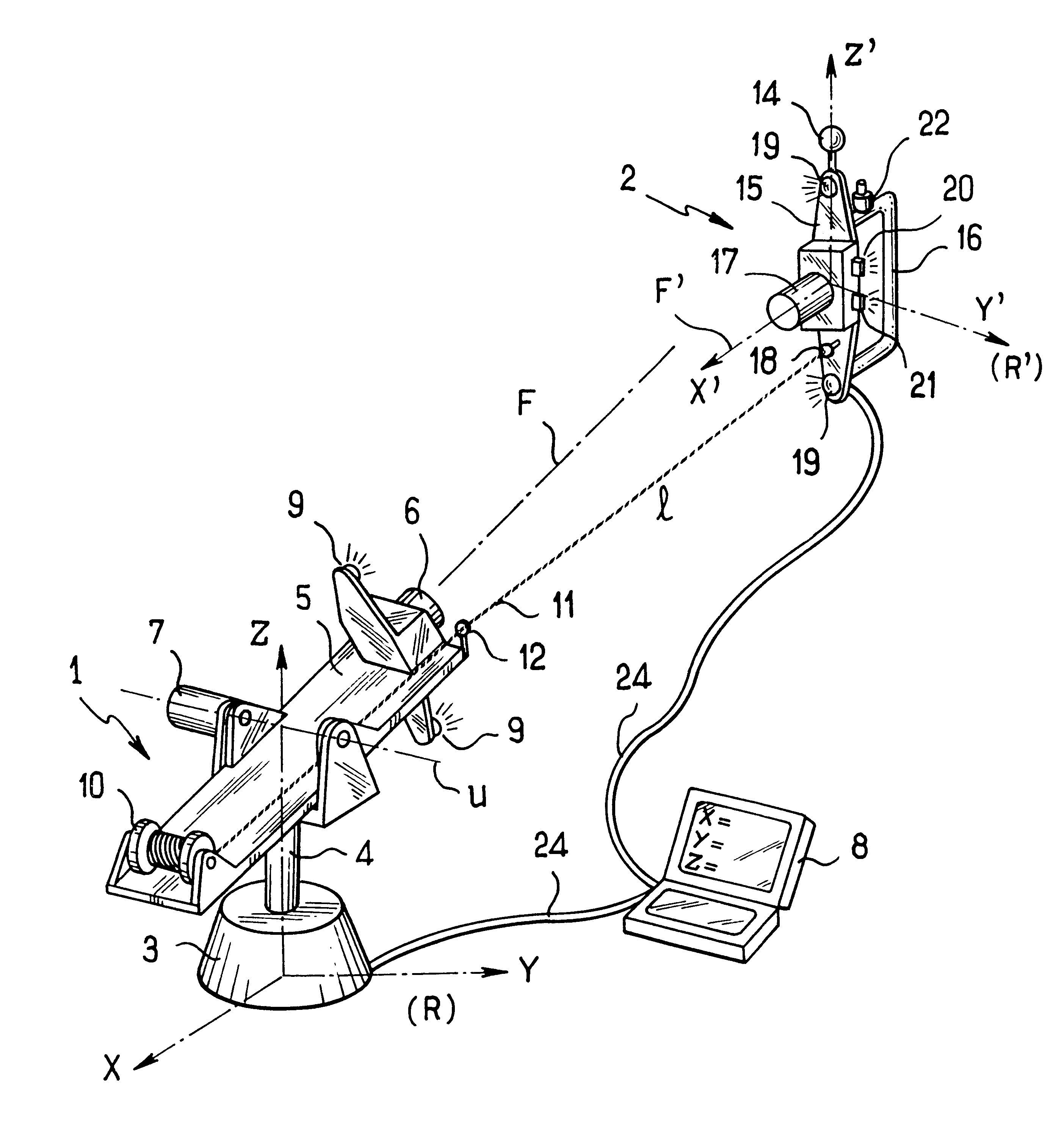

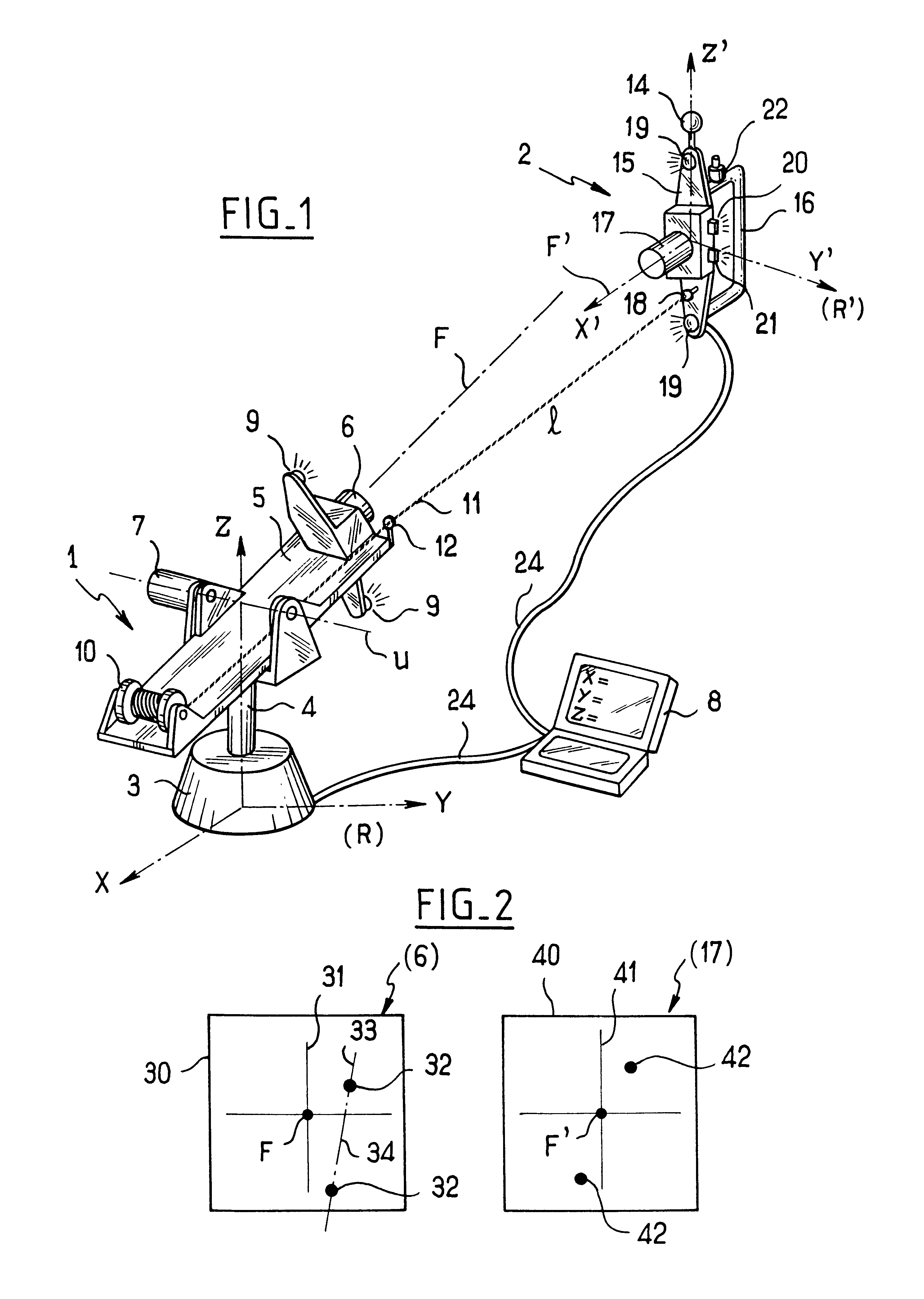

Measuring method for determining the position and the orientation of a moving assembly, and apparatus for implementing said method

InactiveUS6639659B2Easy to transportOptical rangefindersFeeler-pin gaugesMeasurement deviceFrame of reference

Owner:HEXAGON TECH CENT GMBH

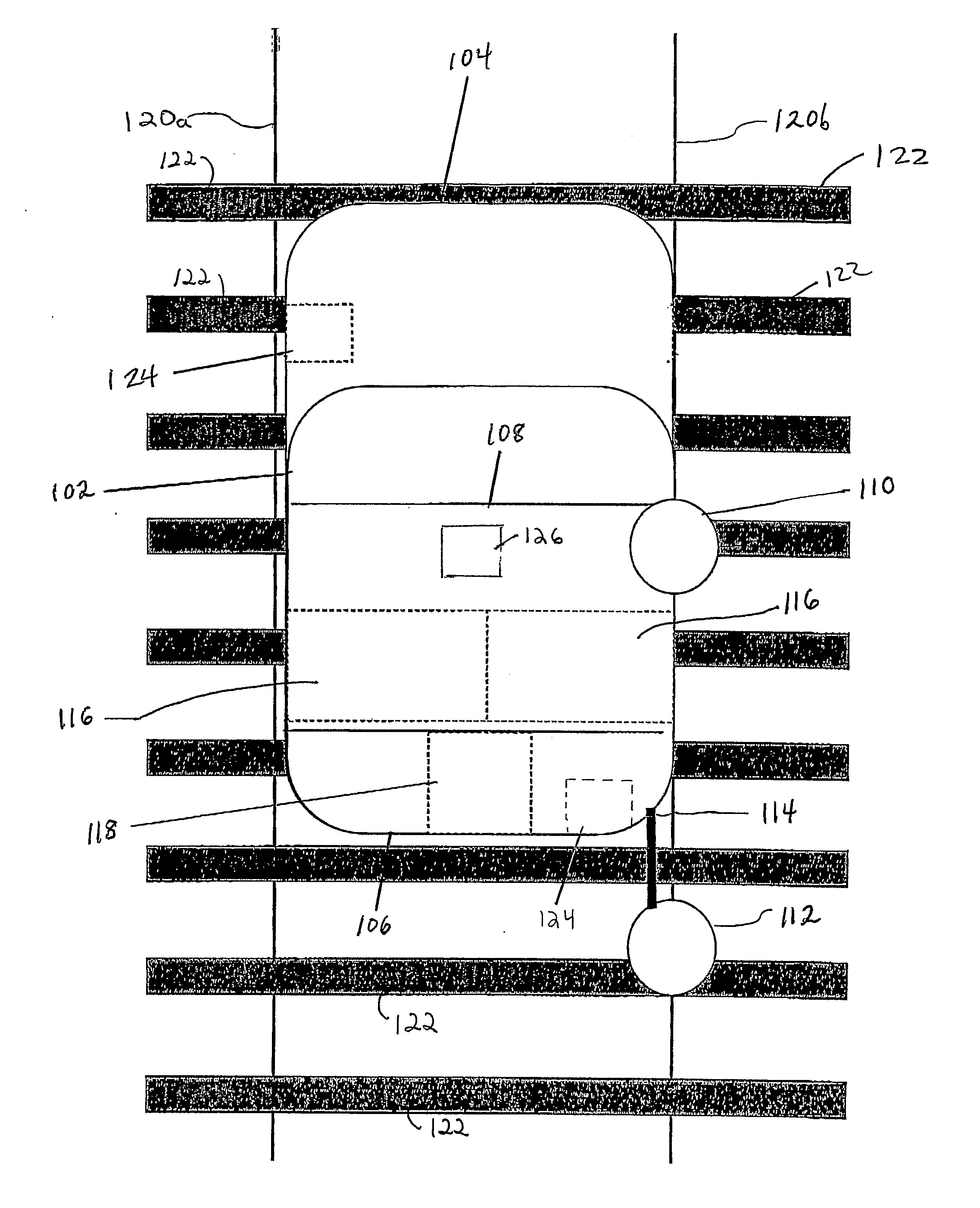

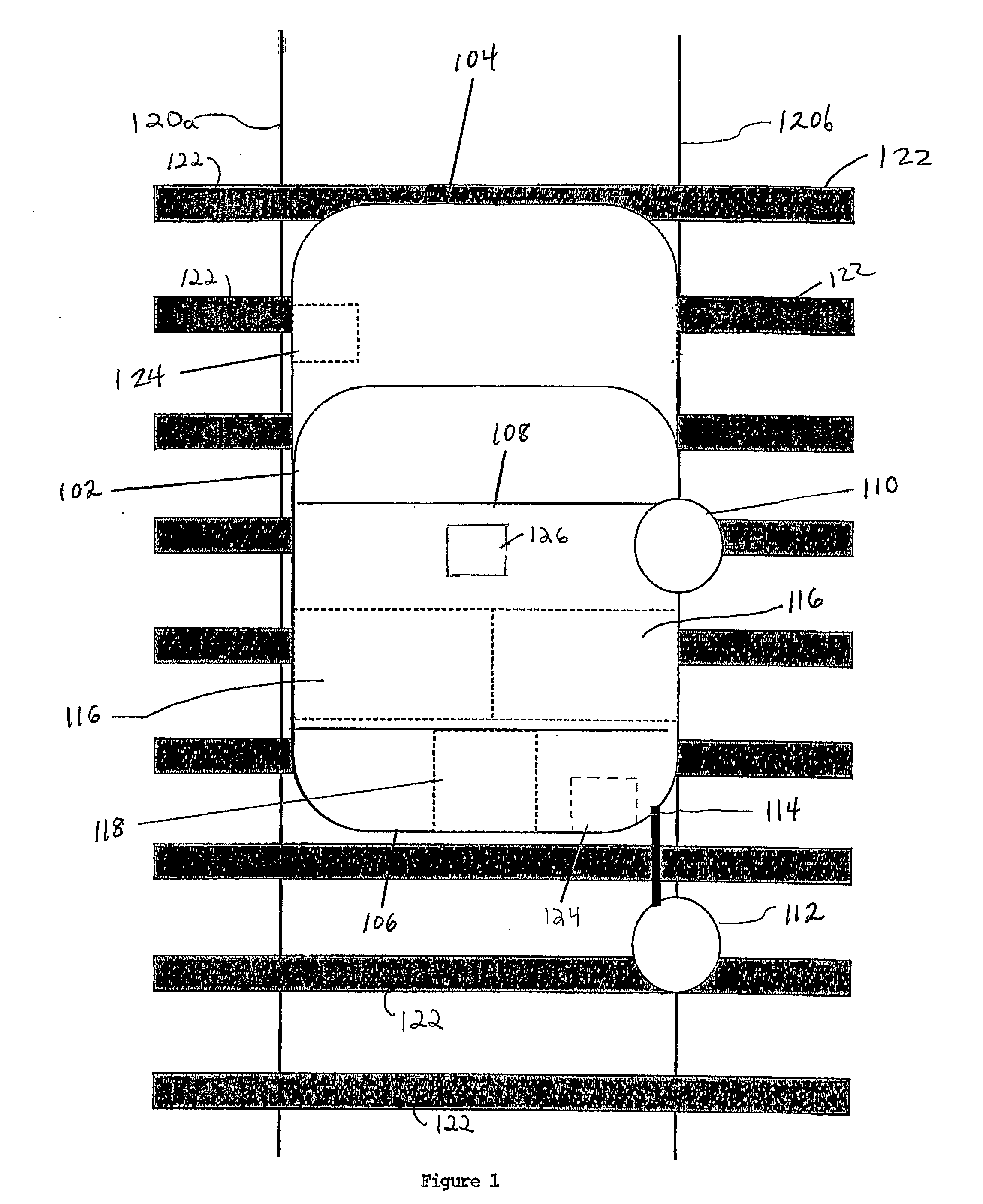

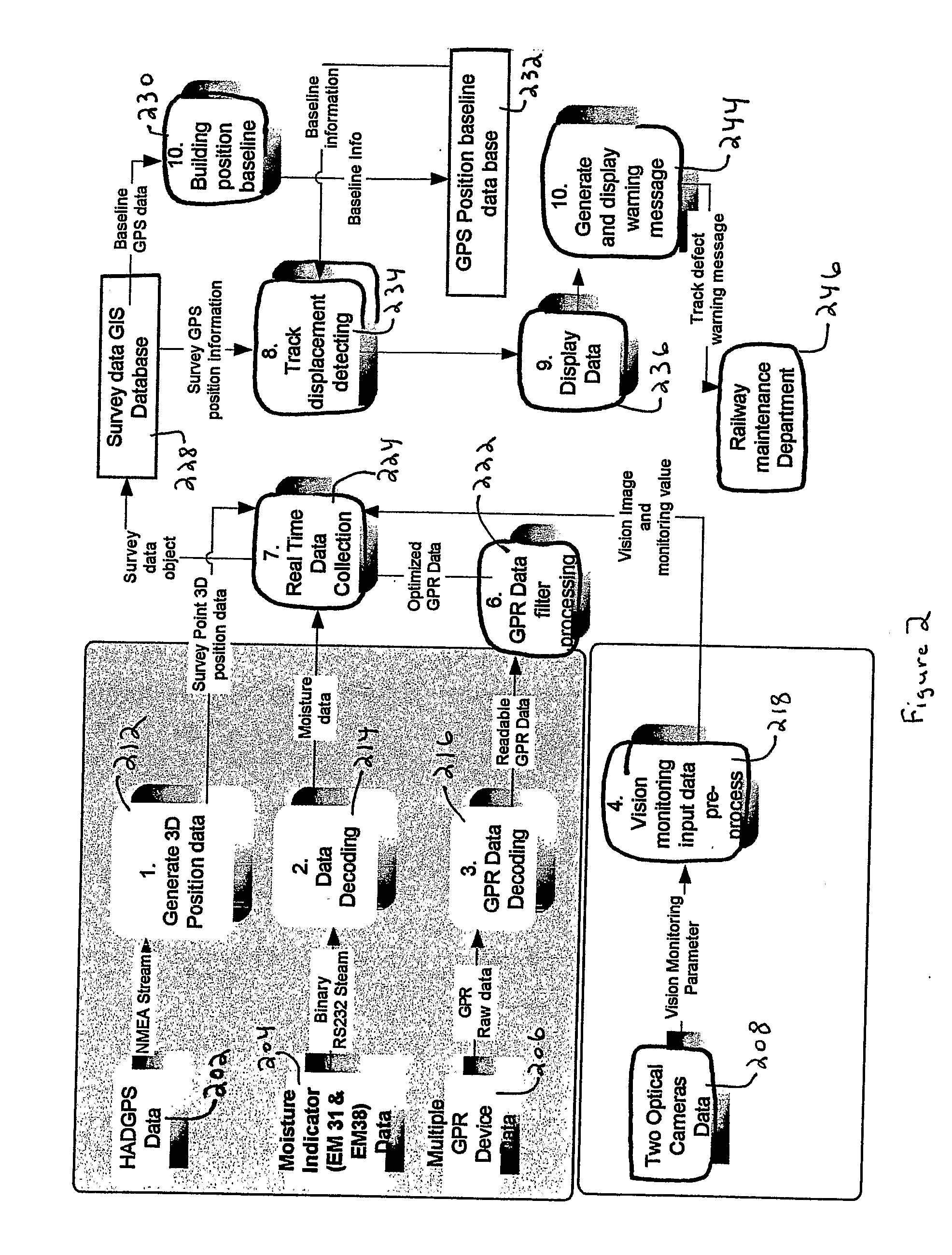

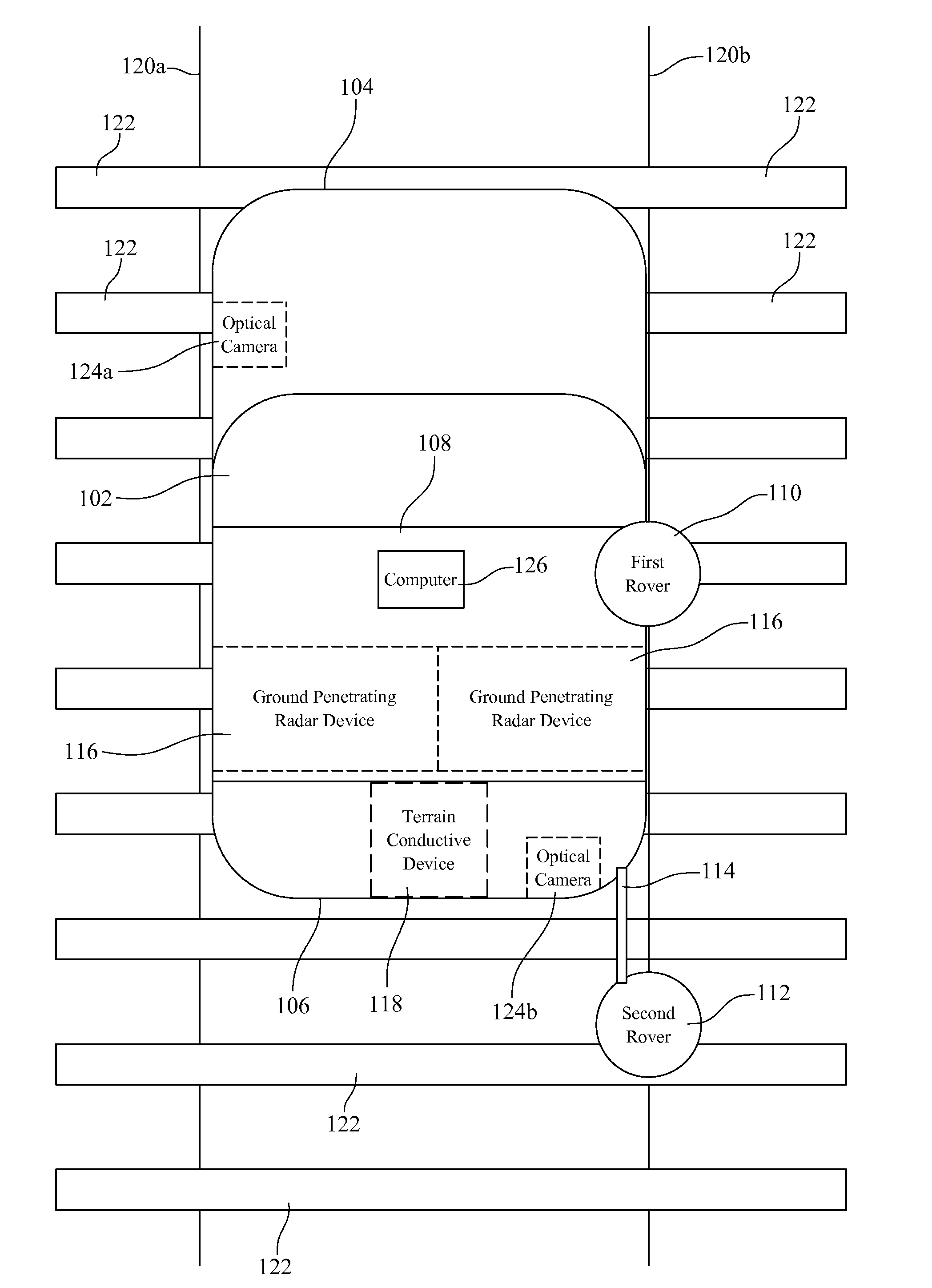

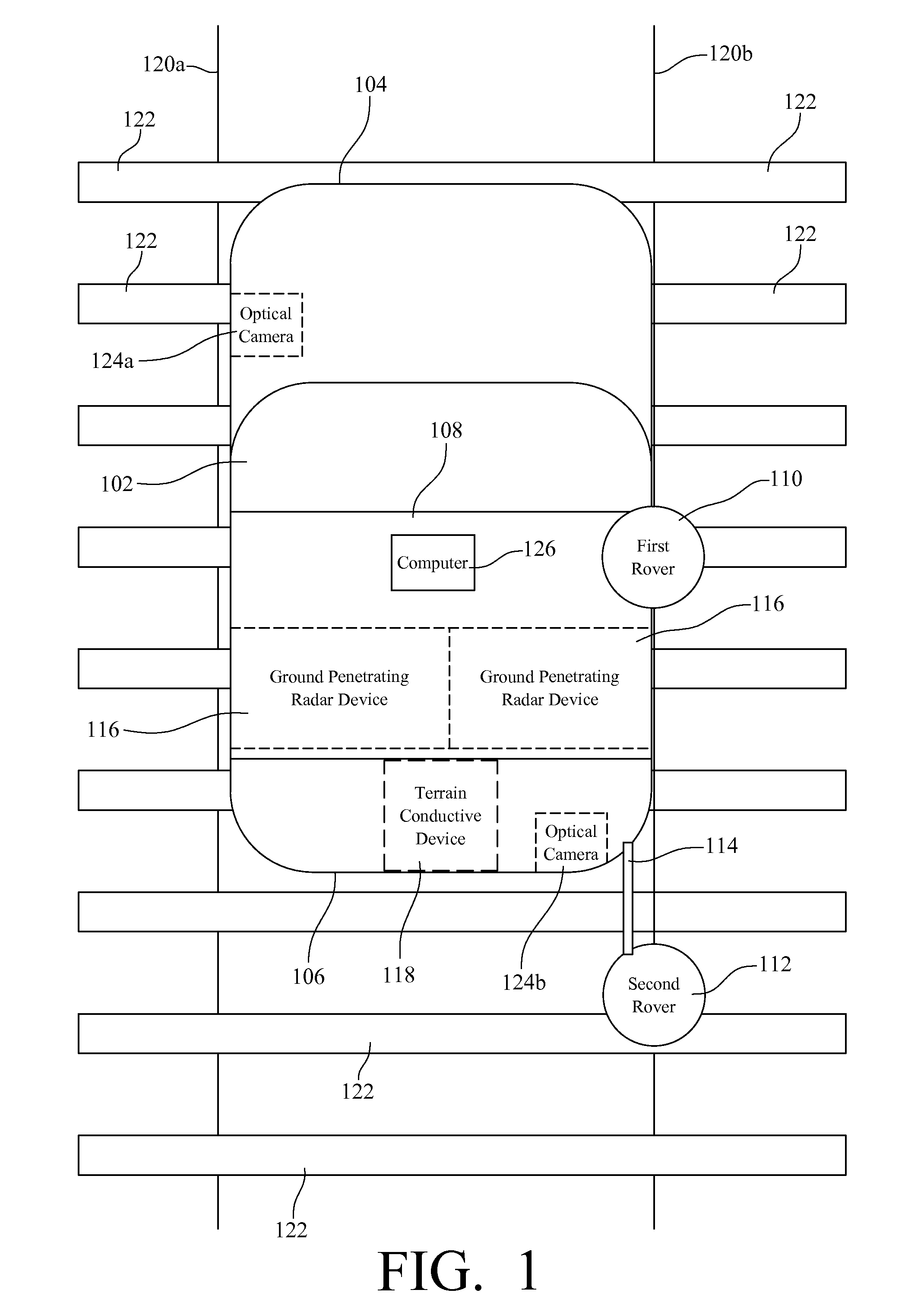

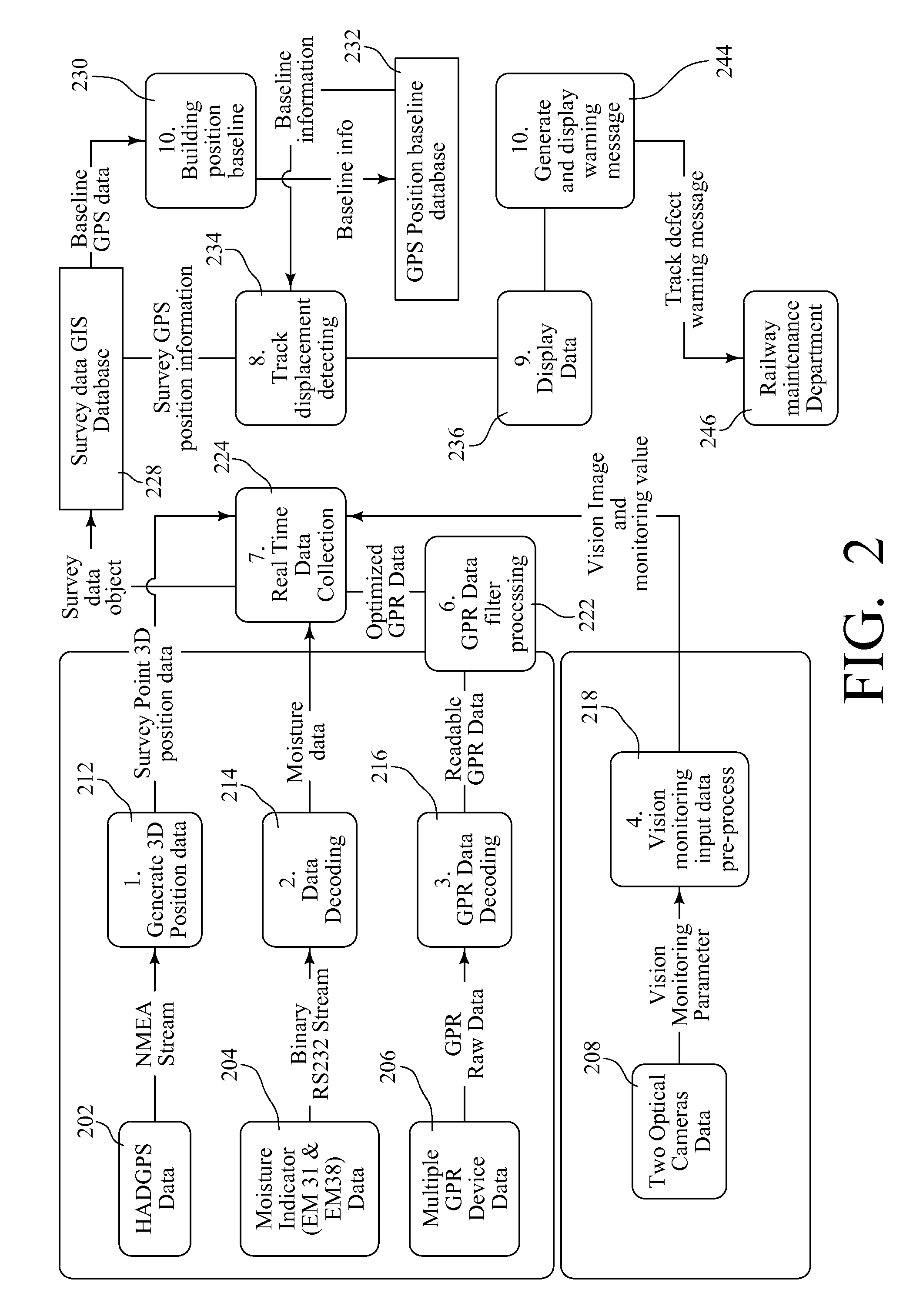

Railroad surveying and monitoring system

InactiveUS20100026551A1Easy to adaptOptimizationPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTerrainLandform

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

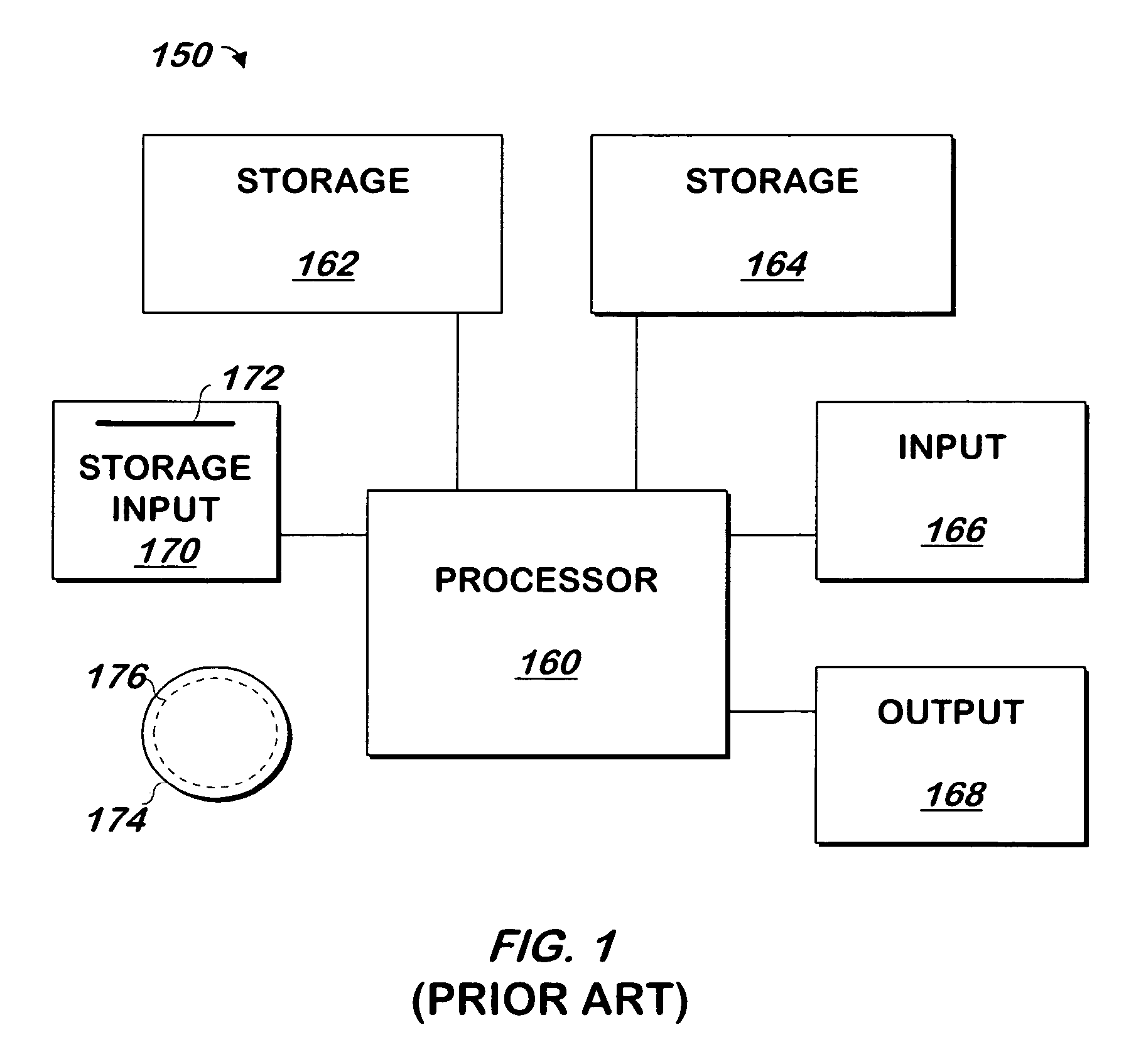

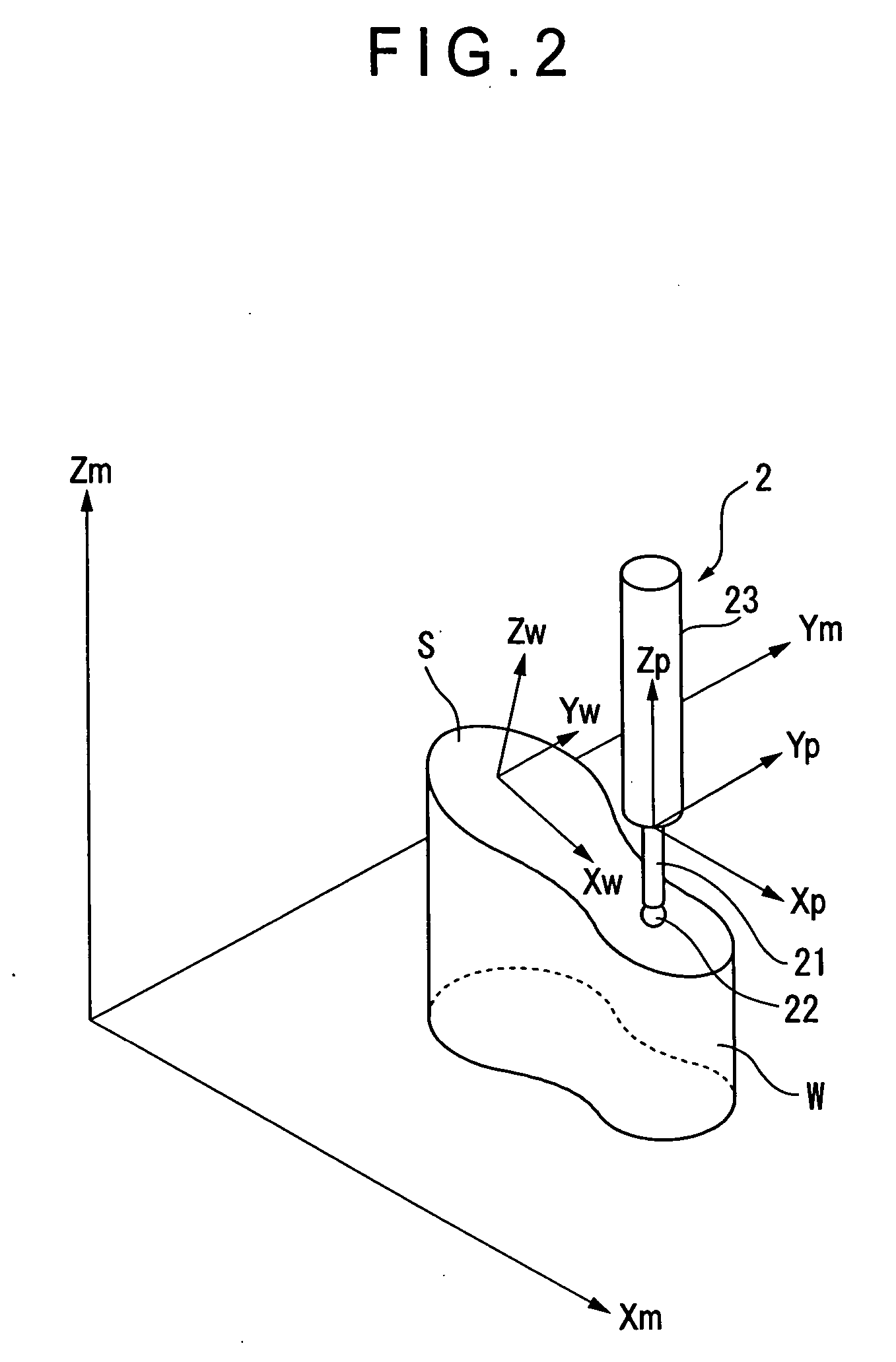

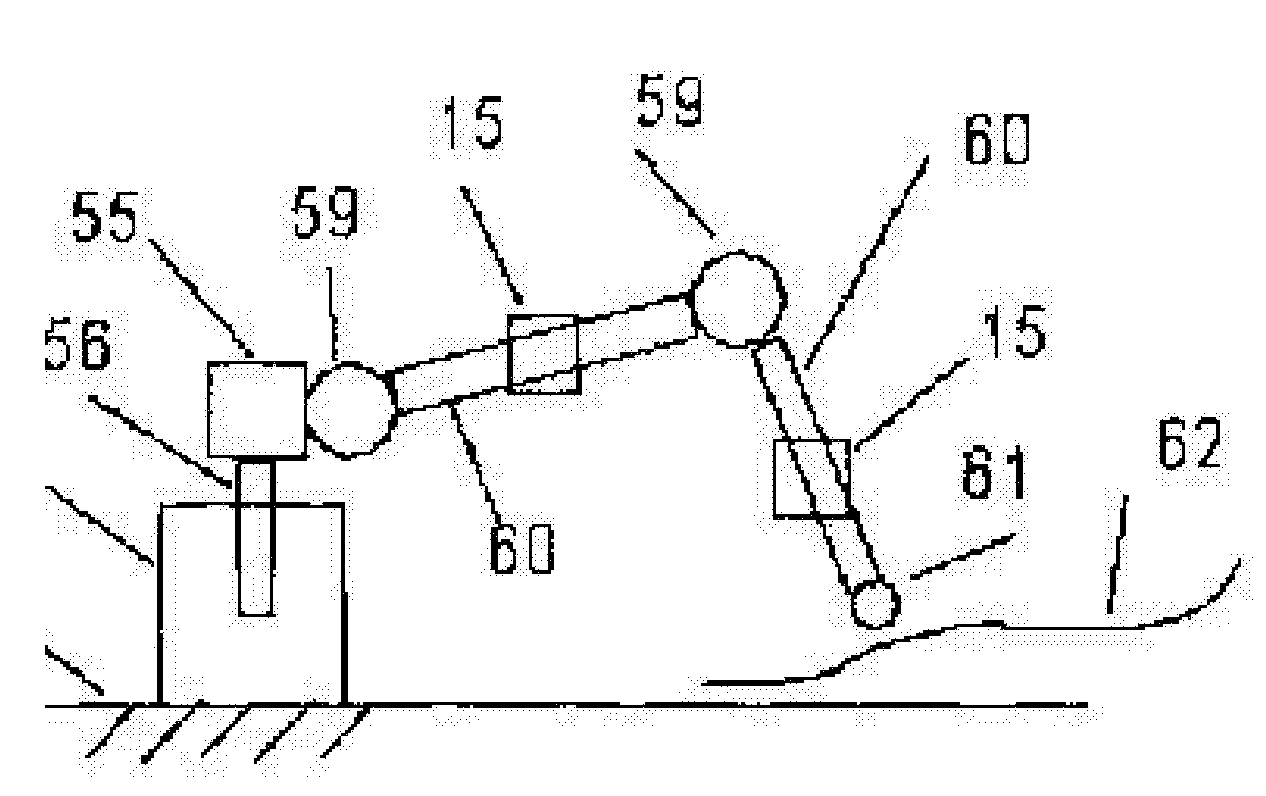

Coordinate measuring method and device

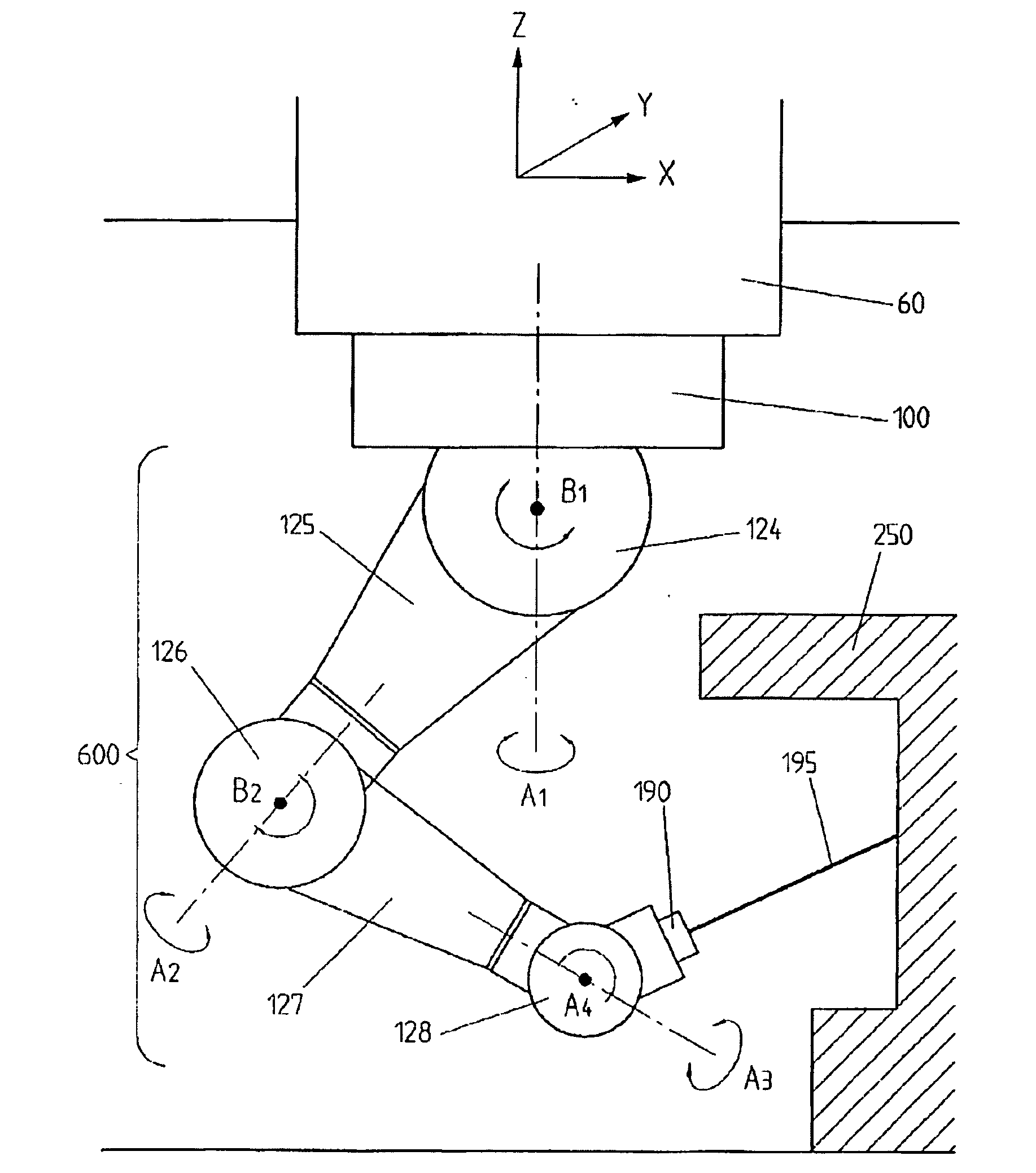

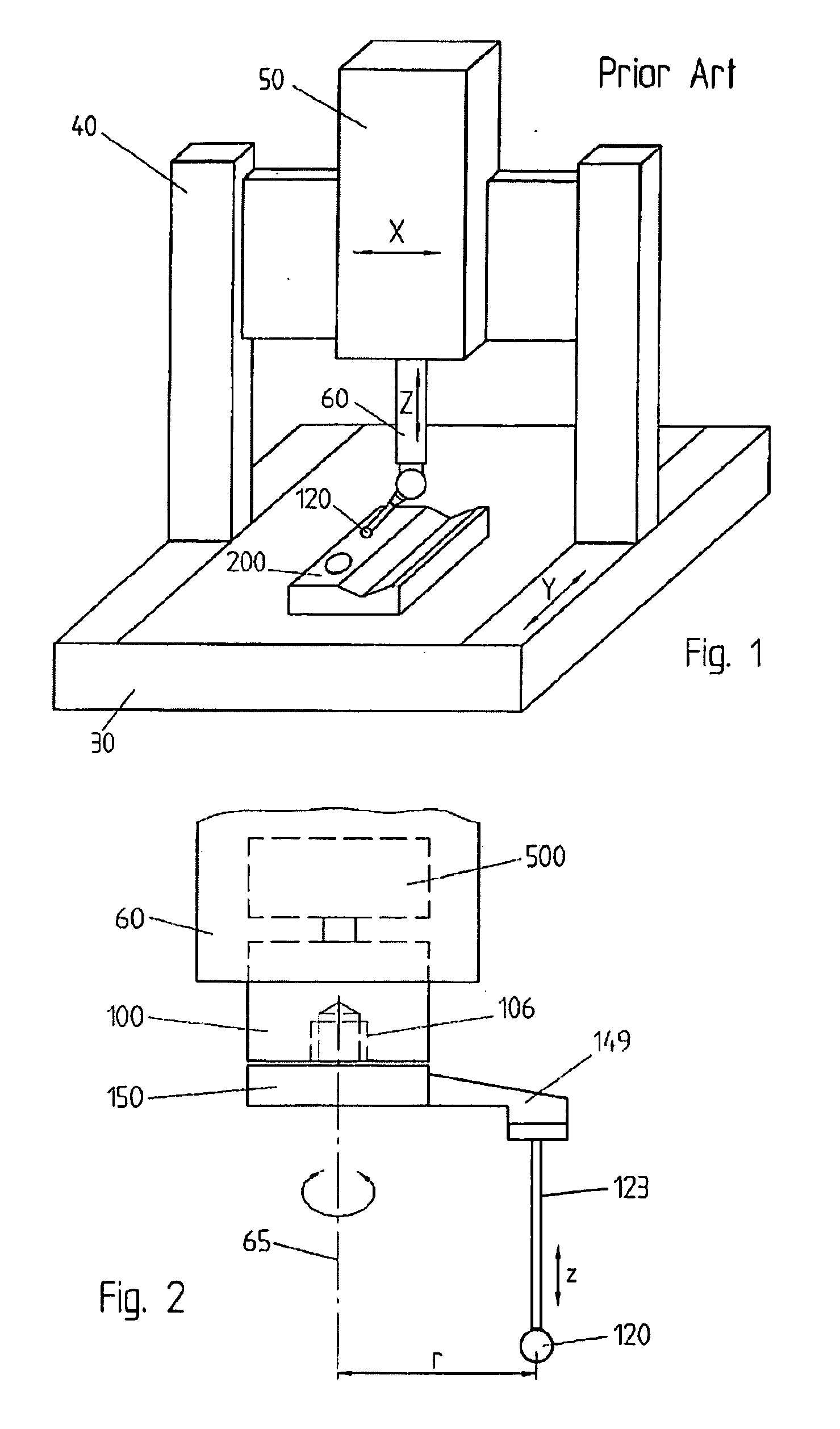

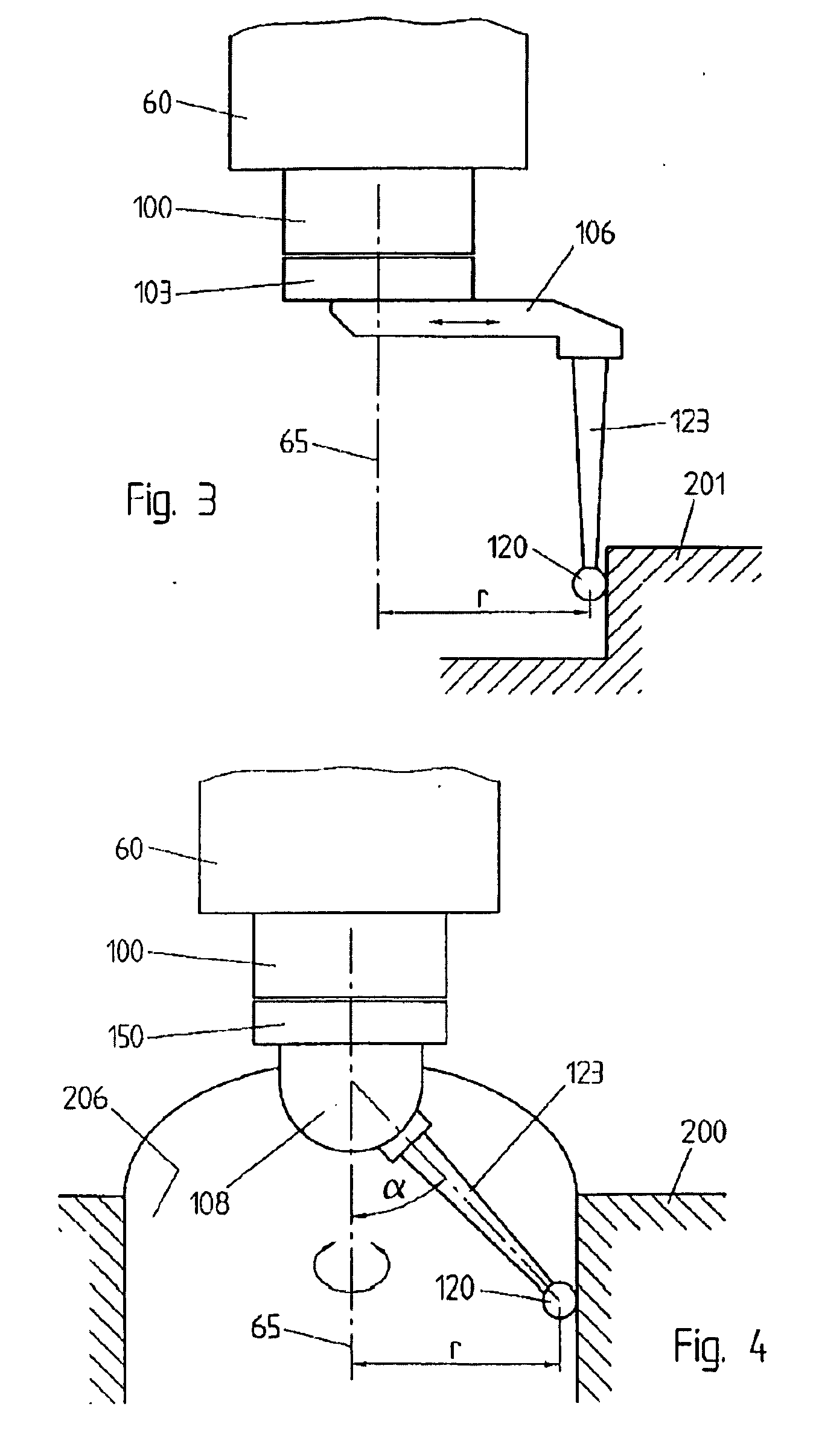

A measuring method and system involving a measuring coordinate probe, which can be moved precisely, by appropriate actuators, with respect to a positioning platform (60) on which the probe is mounted; and whose position relative capable to said positioning platform (60) can be measured, by suitable encoders (780). The invention can be carried out with probes, actuators and encoders of different nature. The actuators (730) preferably allow the motion of the probe according to two or more independent degrees of freedom, so that the probe itself can be moved in a plane, or in a three-dimensional region of space, and its orientation can be chosen, within some suitable limits. The method and system of the invention provide very exact local measurement, even if the platform (60) does not deliver the very best precision

Owner:HEXAGON TECH CENT GMBH

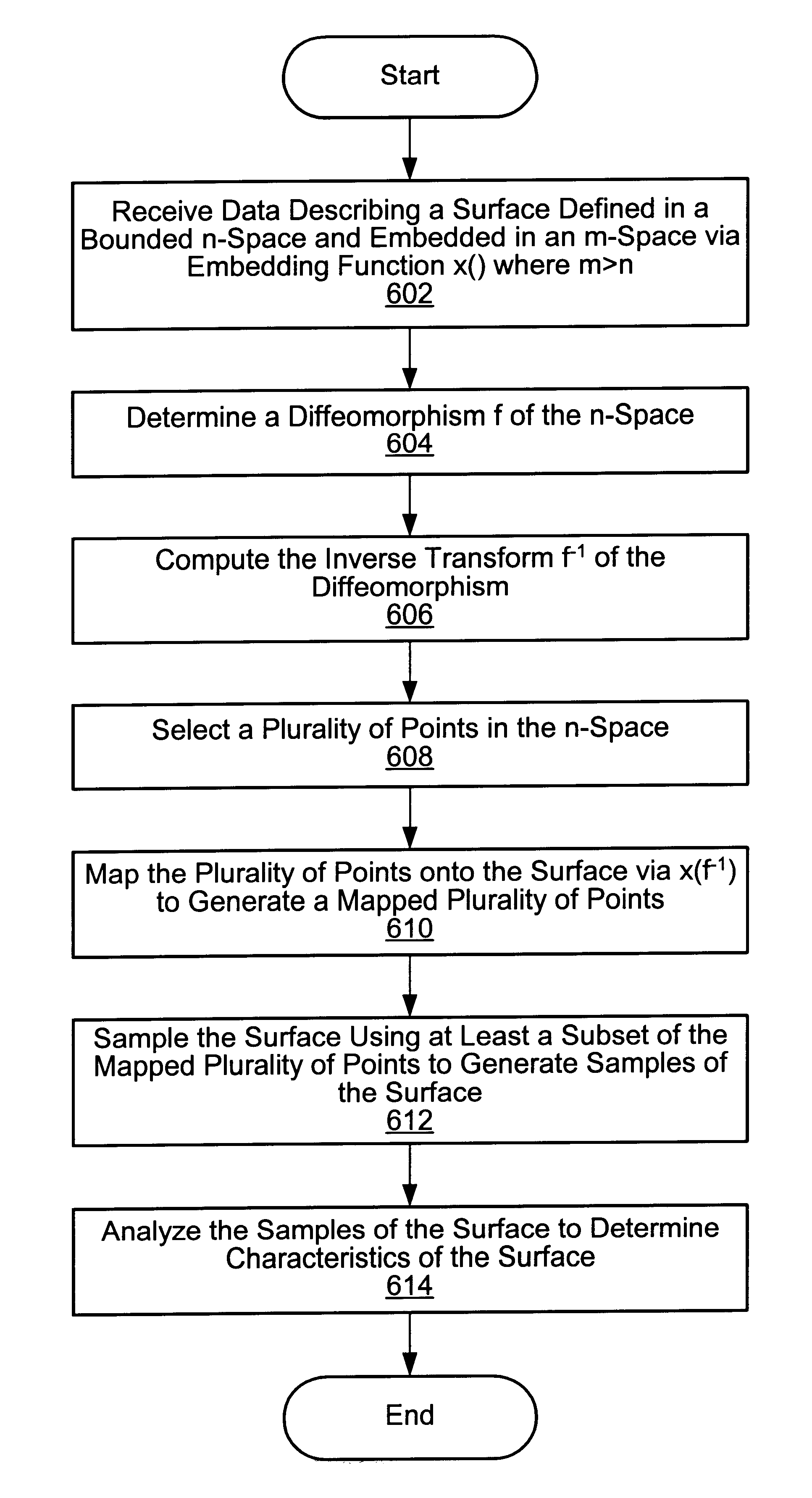

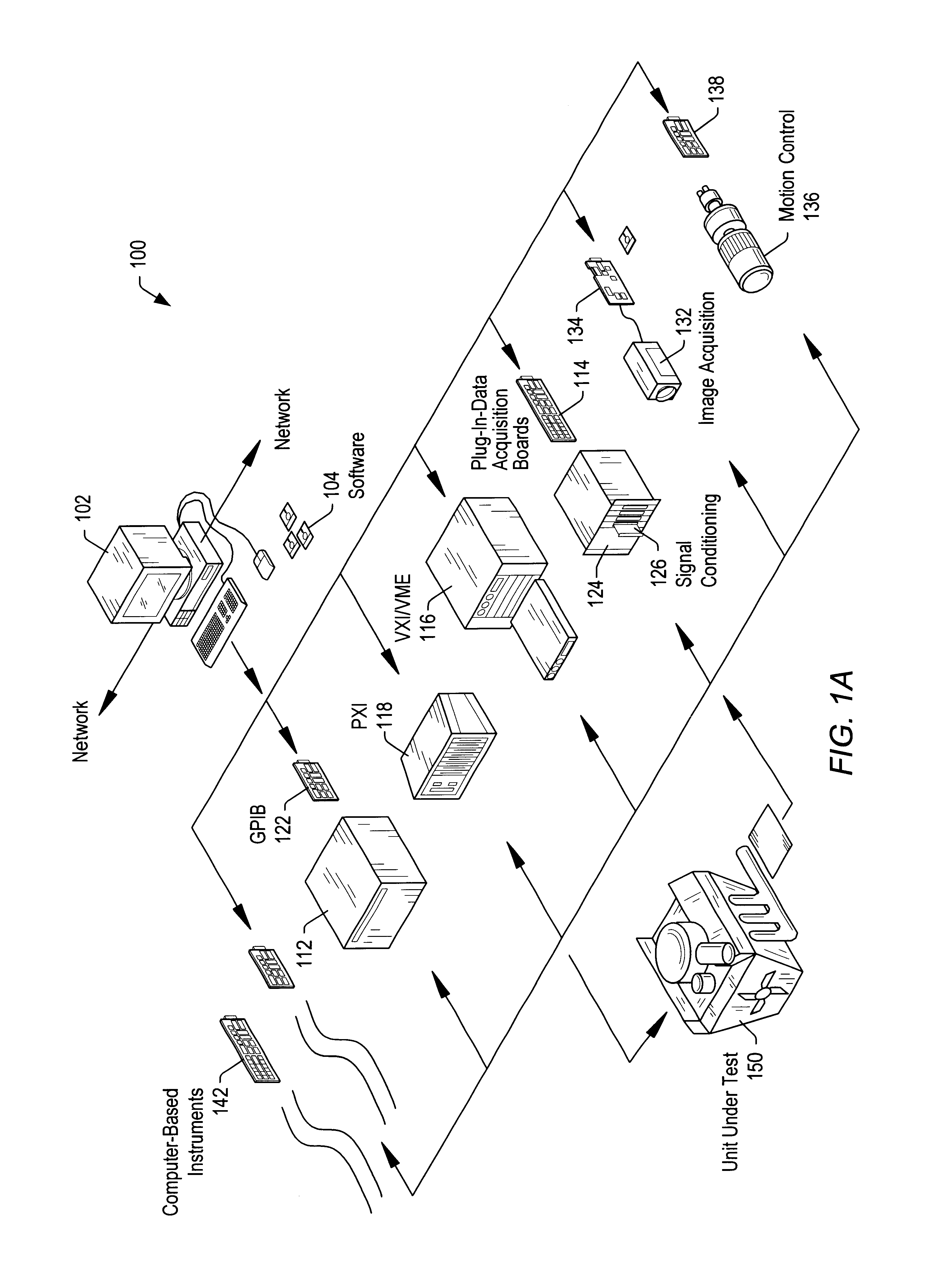

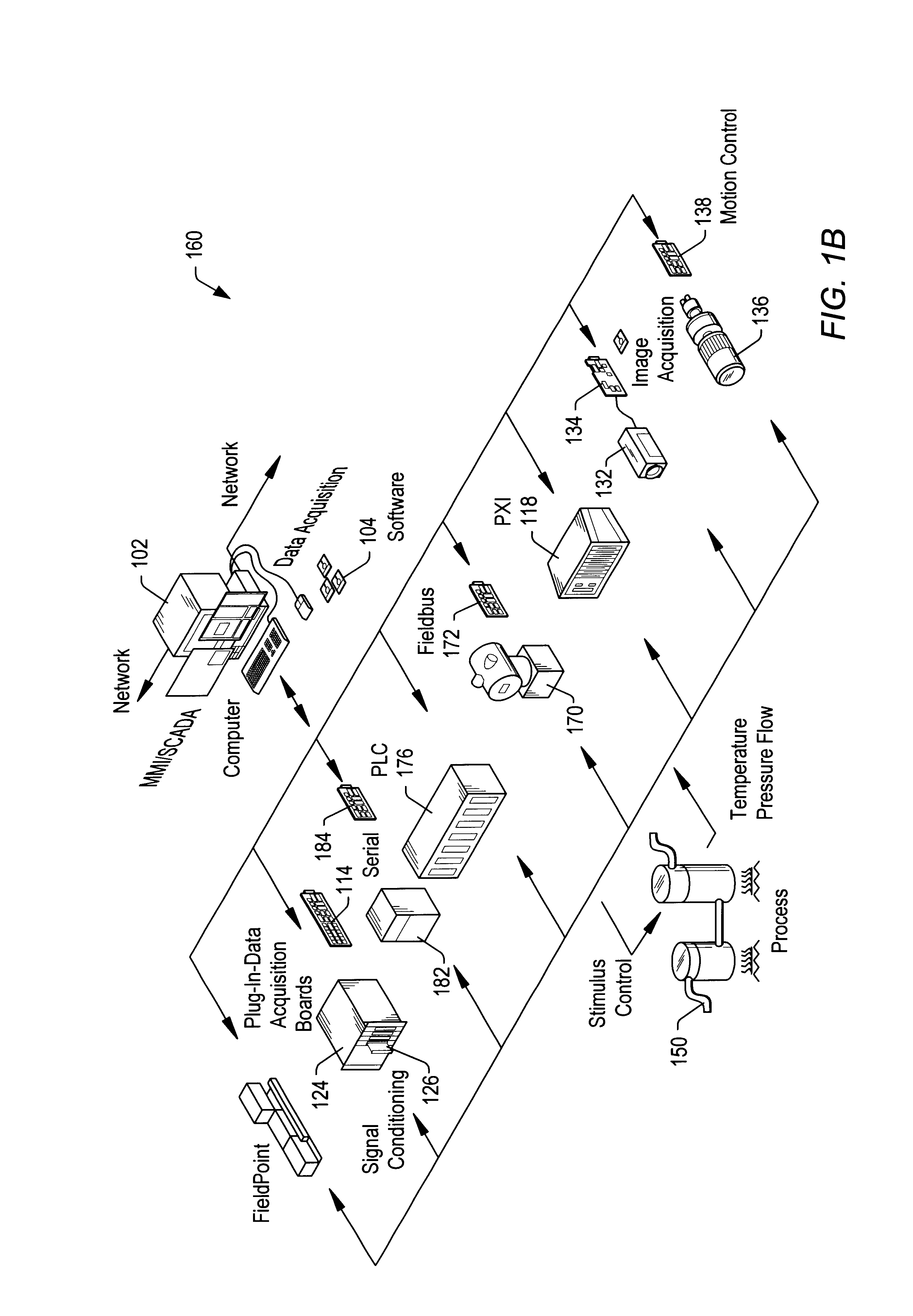

System and method for analyzing a surface by mapping sample points onto the surface and sampling the surface at the mapped points

A system and method for analyzing a surface. The system includes a computer including a CPU and a memory medium operable to store programs executable by the CPU to perform the method. The method may include: 1) receiving data describing an n-dimensional surface defined in a bounded n-dimensional space, where the surface is embedded in an m-dimensional real space via embedding function x( ), and where m>n; 2) determining a diffeomorphism f of the n-dimensional space; 3) computing the inverse transform f-1 of the diffeomorphism f; 4) selecting points, e.g., a Low Discrepancy Sequence, in the n-dimensional space; 5) mapping the points onto the surface using x(f-1), thereby generating mapped points on the surface; 6) sampling the surface using at least a subset of the mapped points to generate samples of the surface; and 7) analyzing the samples of the surface to determine characteristics of the surface.

Owner:NATIONAL INSTRUMENTS

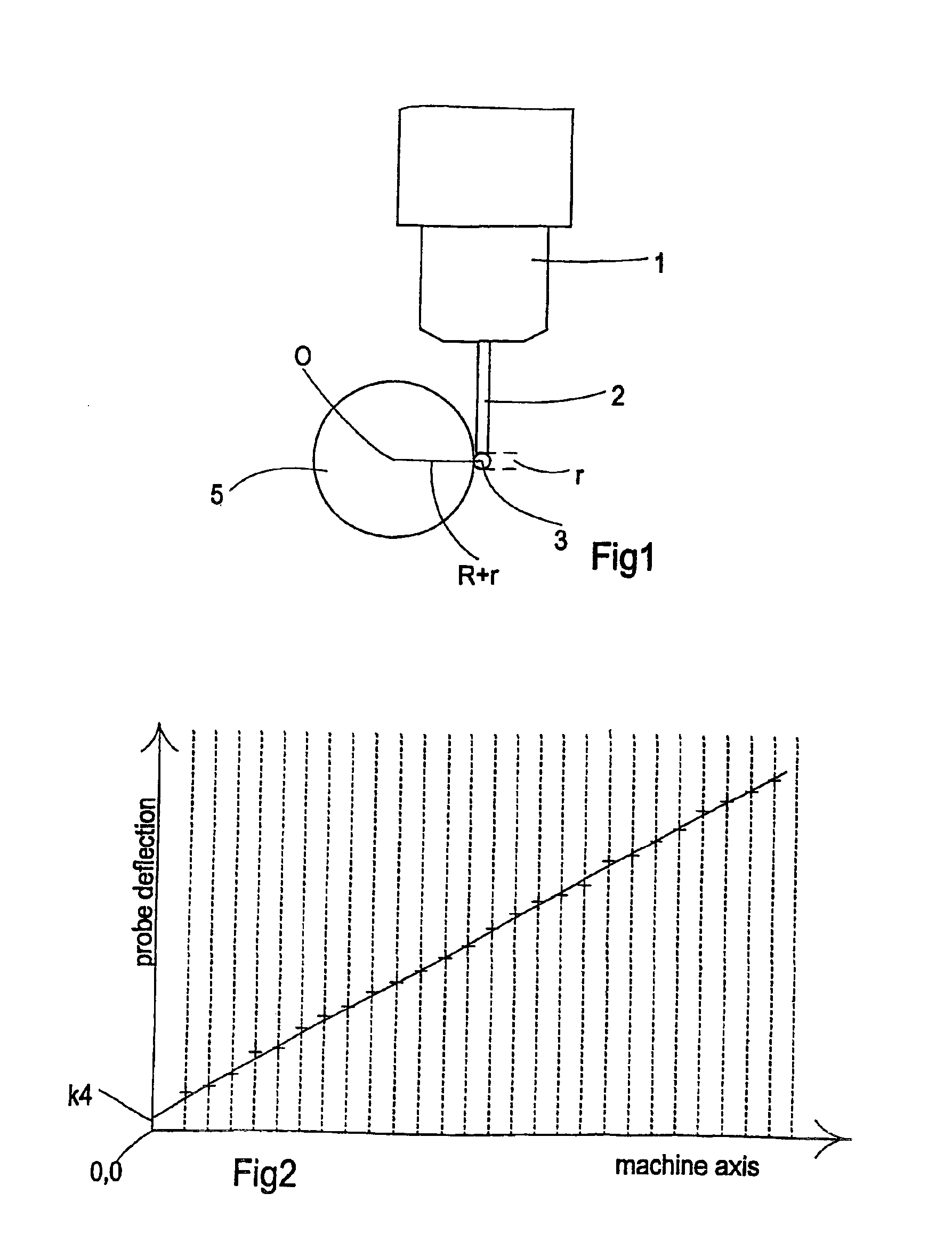

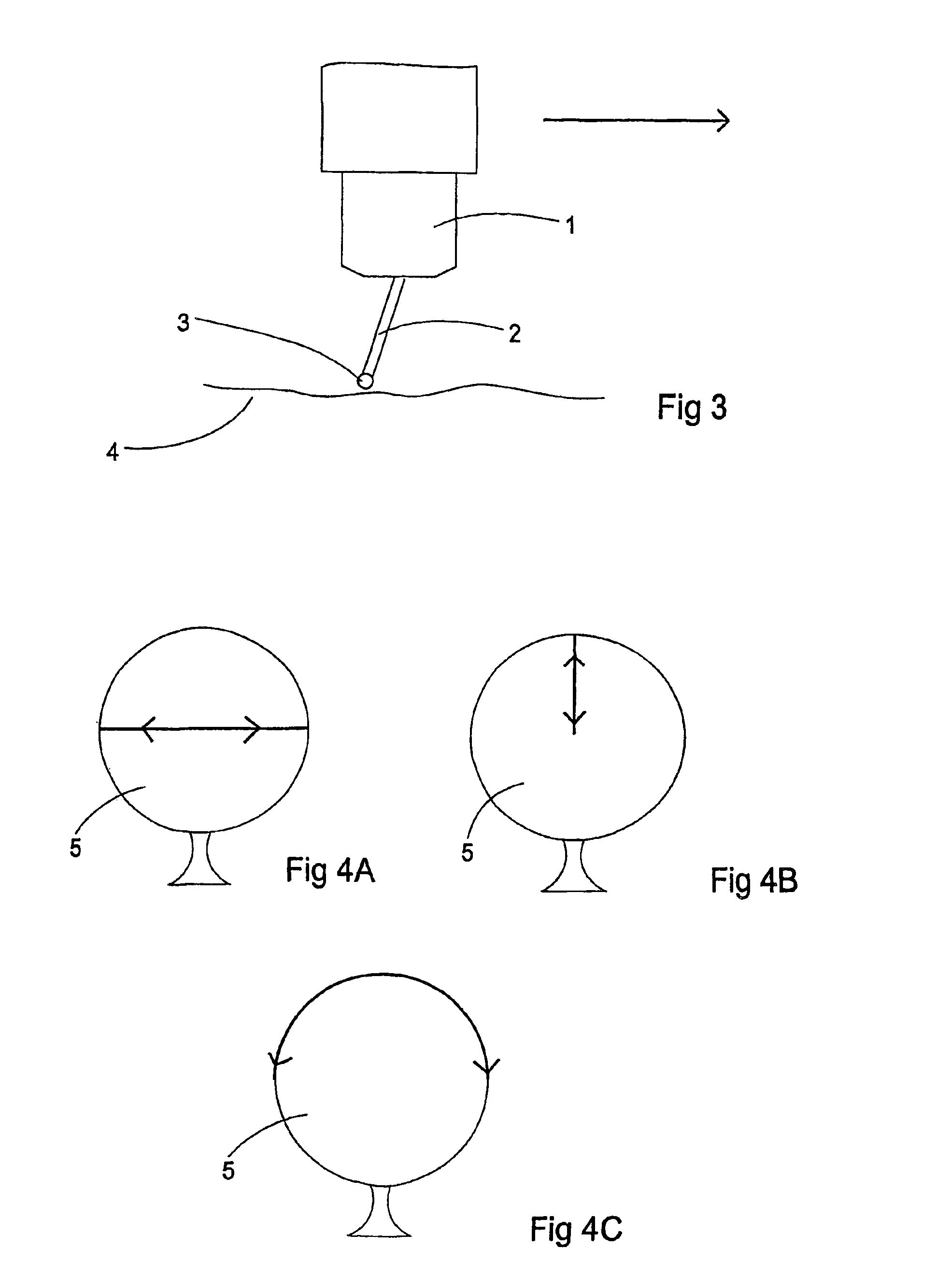

Calibration of an analogue probe

InactiveUS6909983B2Testing/calibration apparatusMechanical counters/curvatures measurementsClassical mechanicsZ-Coordinate

A method of calibrating a probe mounted on a machine in which the probe has a probe calibration matrix which relates the probe outputs in three orthogonal axes to the machine's X, Y and Z coordinate system. A datum ball mounted on the machine is bi-directionally scanned by the probe in one or more planes. For each plane, the mean direction of two approximate probe vectors in the plane is rotated about an axis orthogonal to that plane until the apparent material condition from the scan in each direction is the same. This process may be iterative. The mean values of the directions of the probe vectors for each plane are rotated, thus forming a corrected probe calibration matrix. The datum ball is preferably bi-directionally scanned in three orthogonal planes.

Owner:RENISHAW PLC

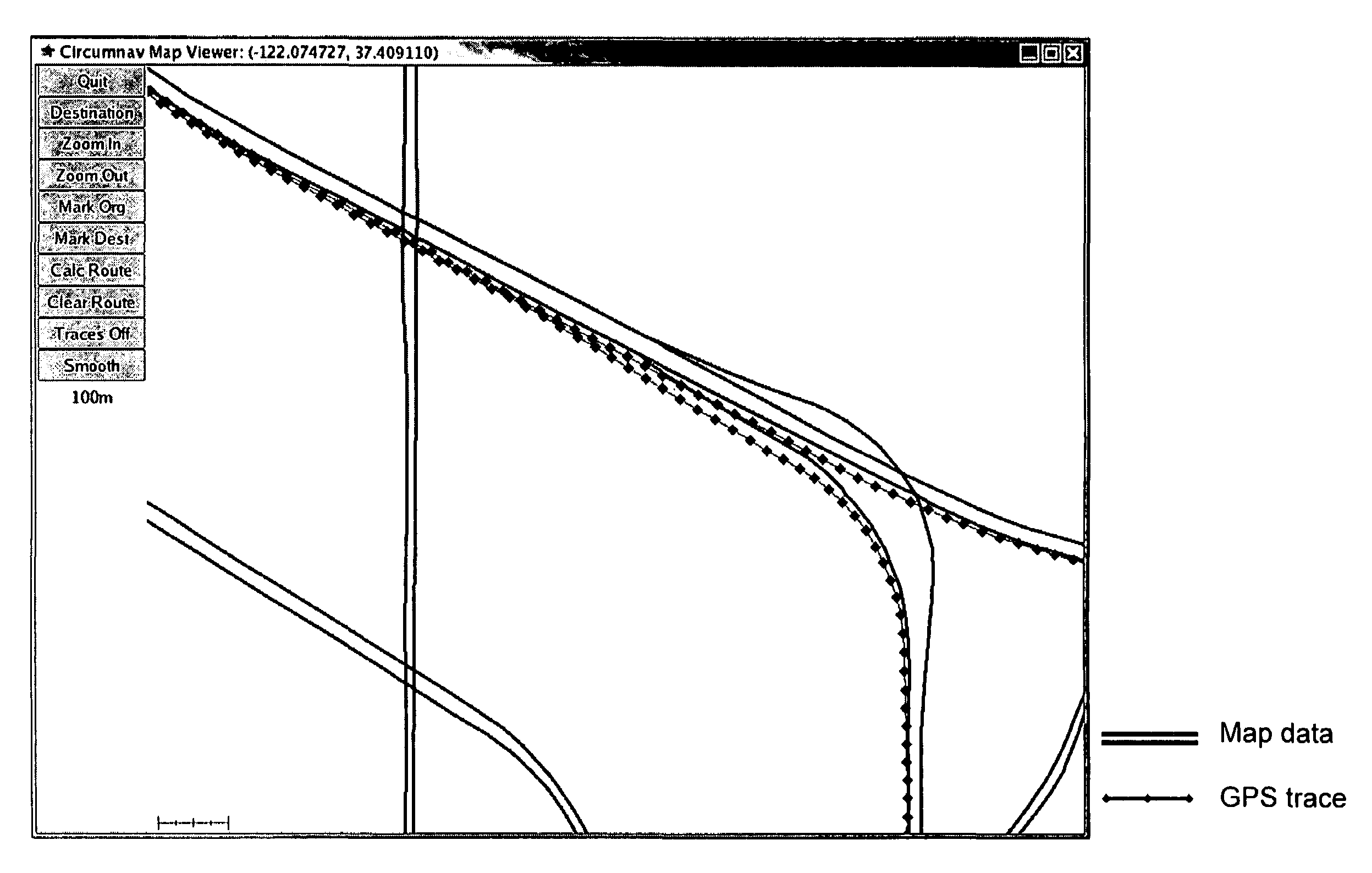

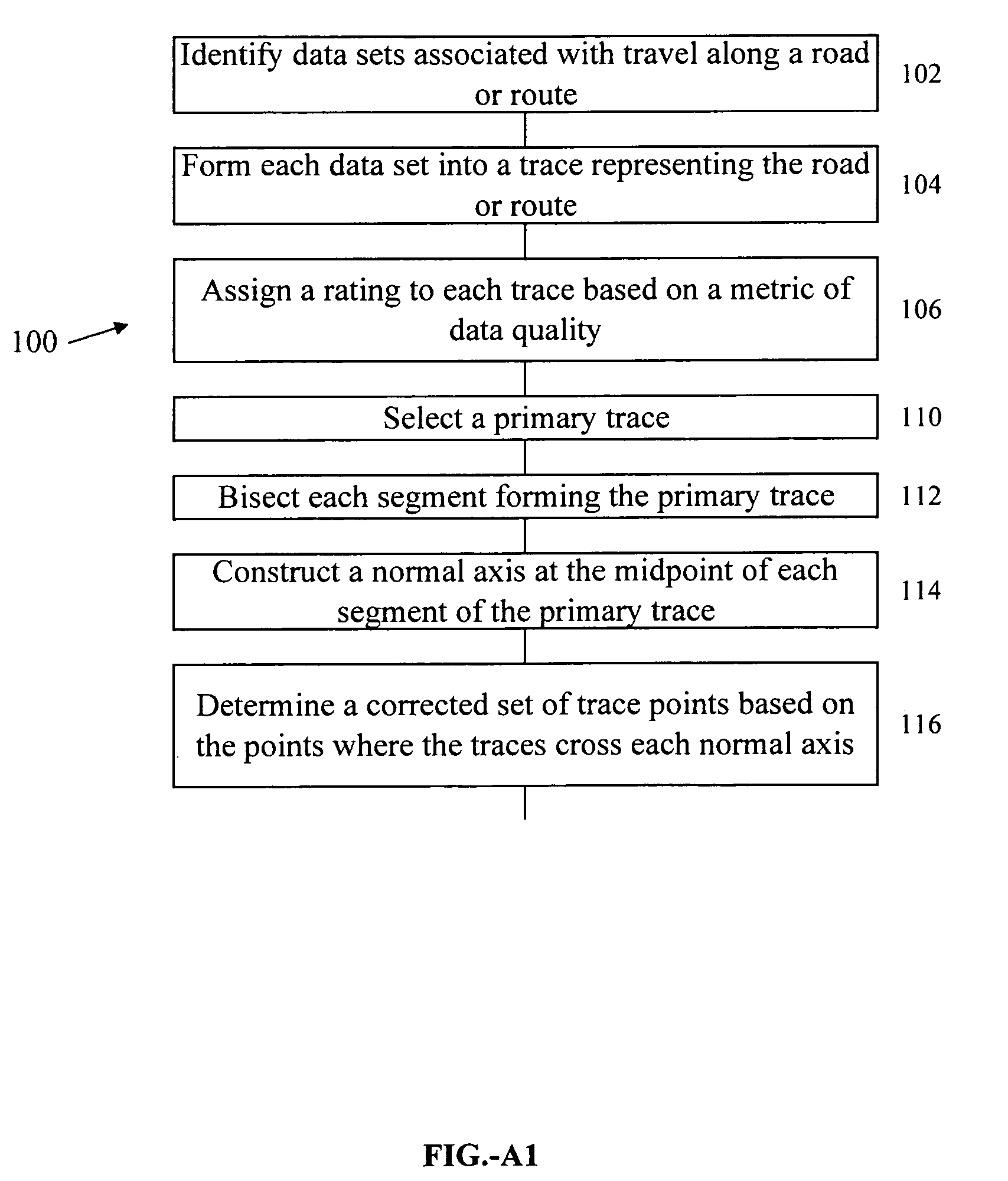

System and method for identifying road features

ActiveUS7516041B2Instruments for road network navigationFeeler-pin gaugesComputer scienceGraph database

A system and method identifies road features that may not appear on a map database, such as paths not described as roads on the map database, and whether all the roads at a crossing cross at the same grade level. The system and method may thus be used to identify points of departure from, or points of merging onto, a road described by the map database or a path identified as described herein, but not described by the map database.

Owner:MALIKIE INNOVATIONS LTD

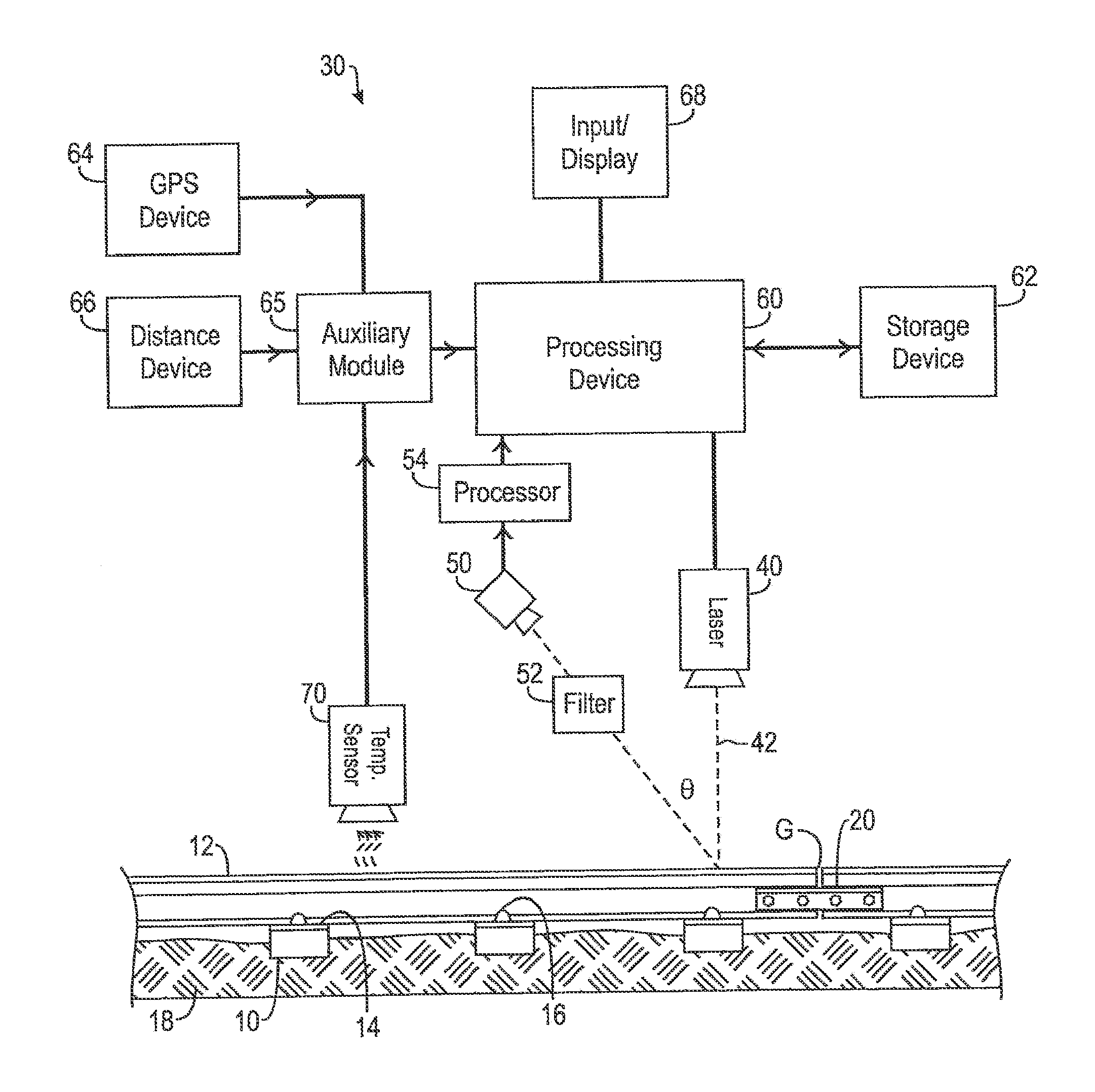

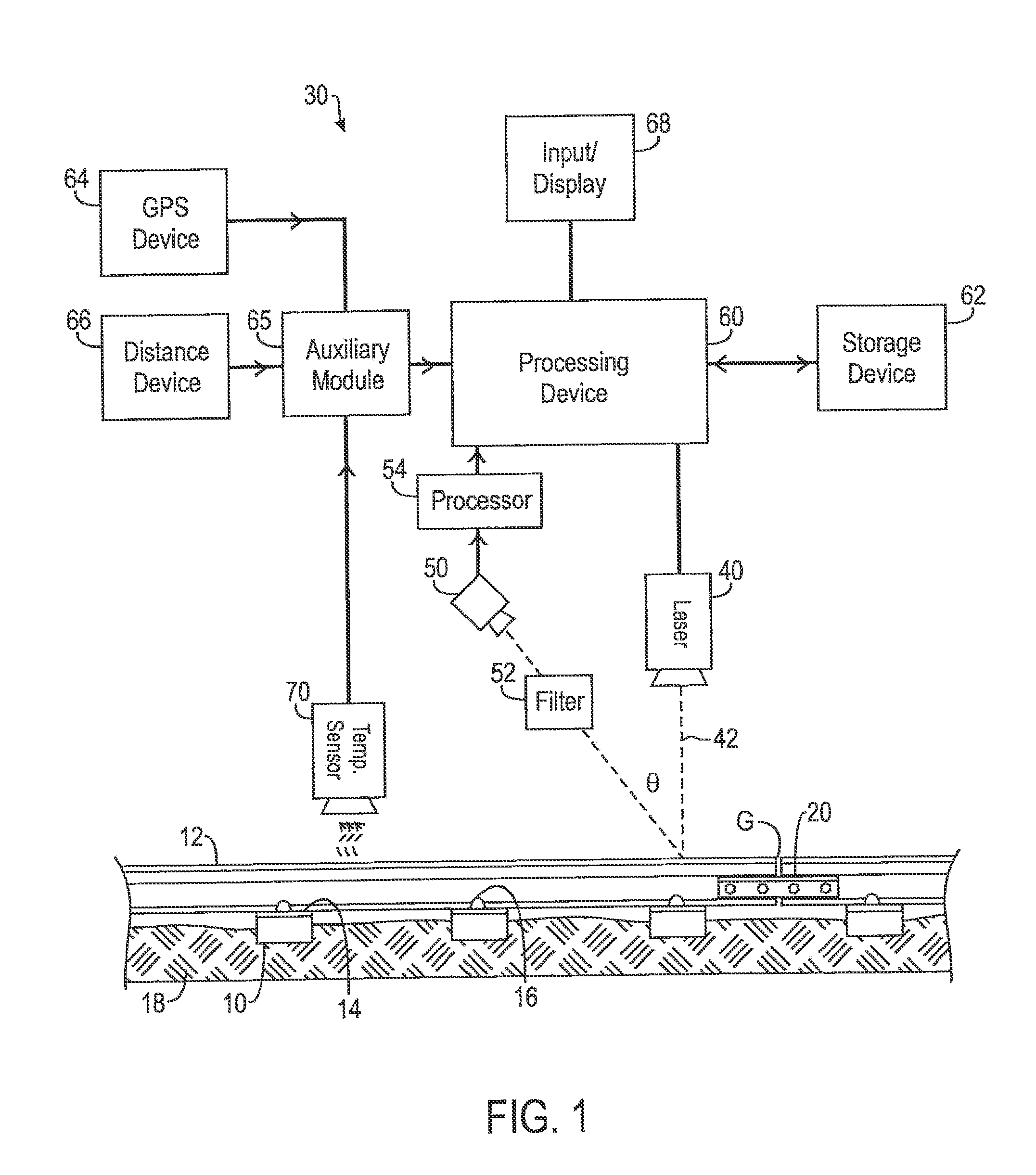

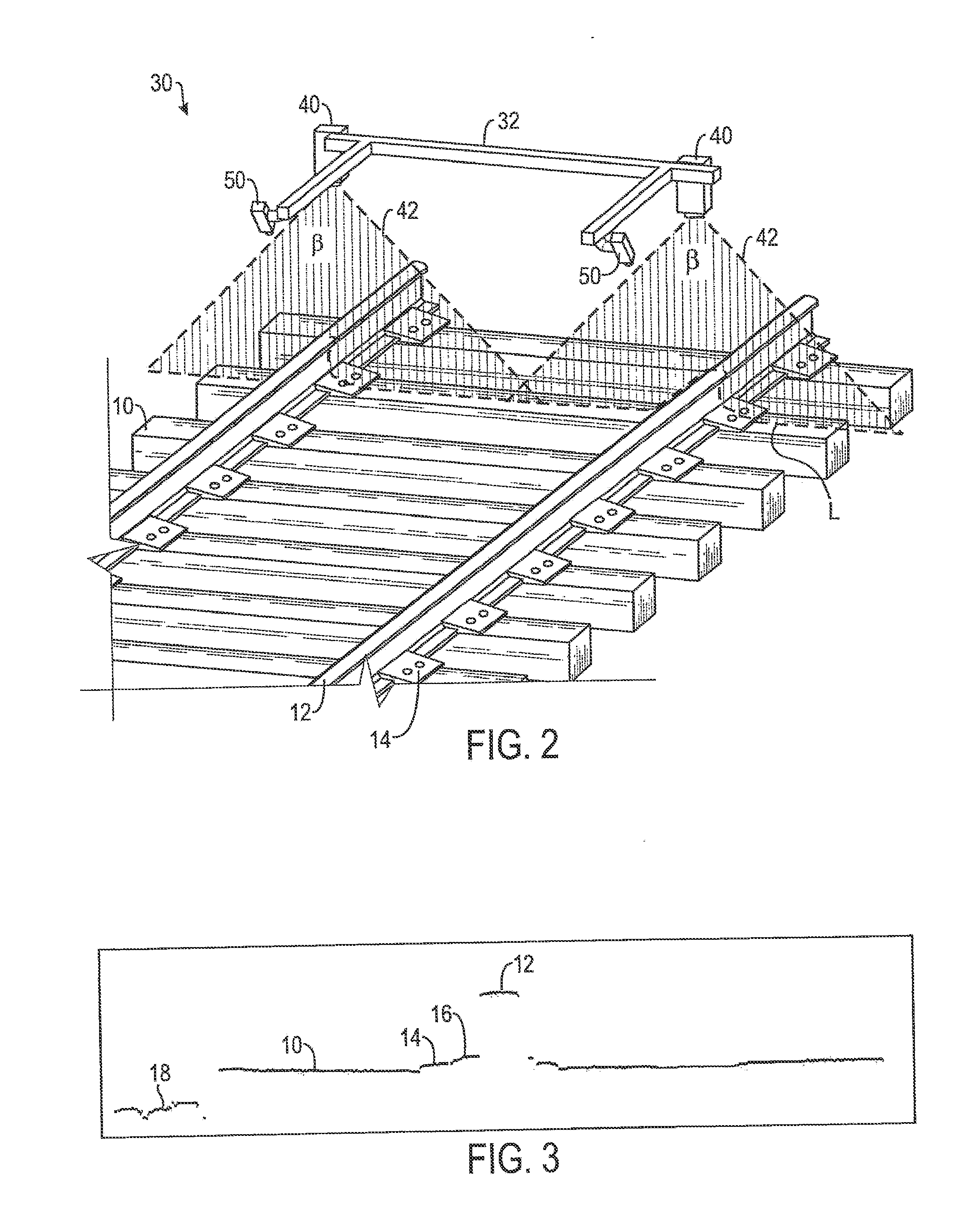

System and method for inspecting railroad ties

A system for inspecting railroad ties in a railroad track includes a light generator, an optical receiver and a processor. The light generator is oriented to project a beam of light across the railroad track while moving along the railroad track in a travel direction. The optical receiver is oriented to receive at least a portion of the beam of light reflected from the railroad track and configured to generate image data representative of a profile of at least a portion of the railroad track. The processor is configured to analyze the image data by applying one or more algorithms configured to find boundaries of a railroad tie and determine one or more condition metrics associated with the railroad tie.

Owner:LORAM TECH INC

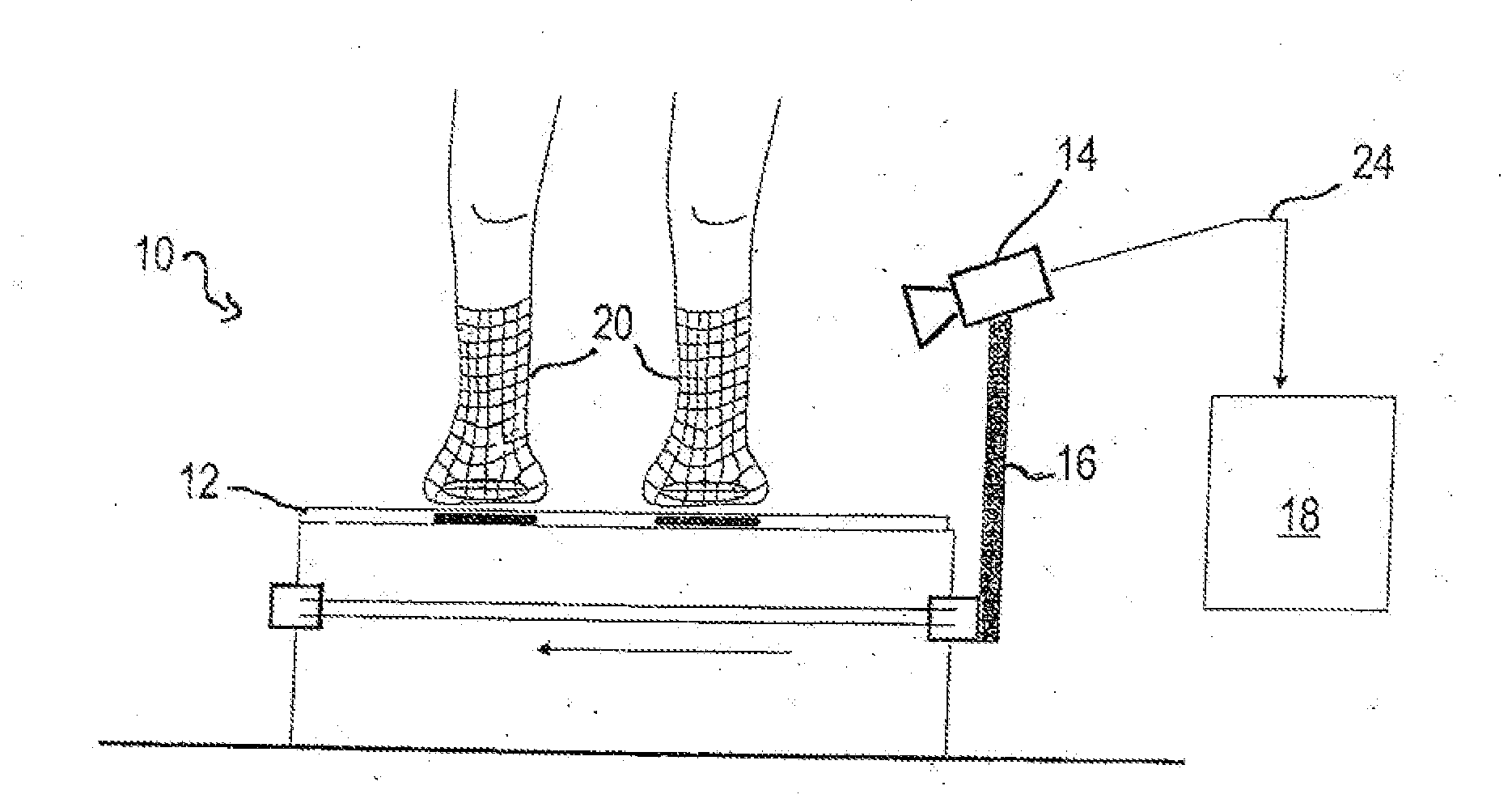

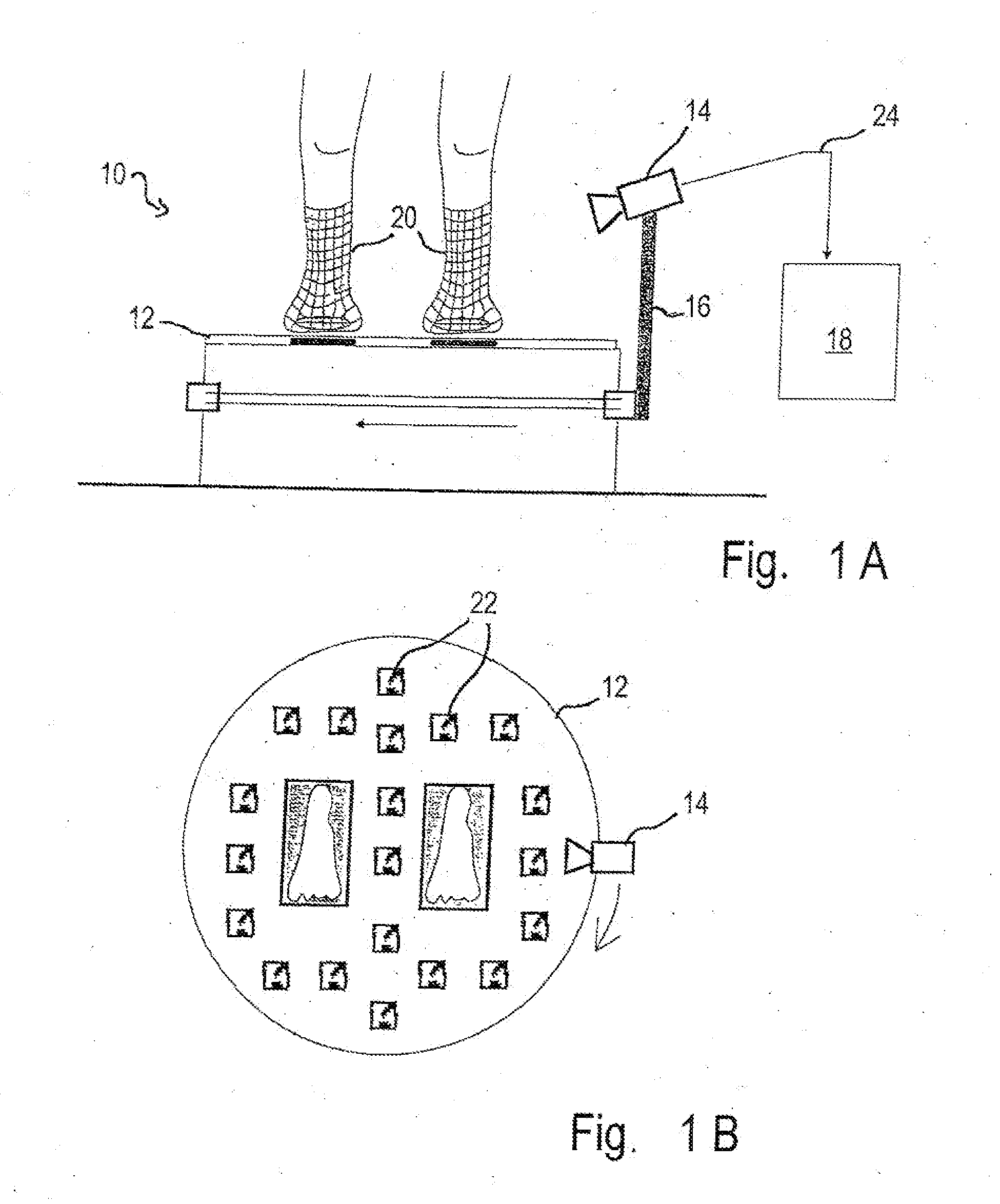

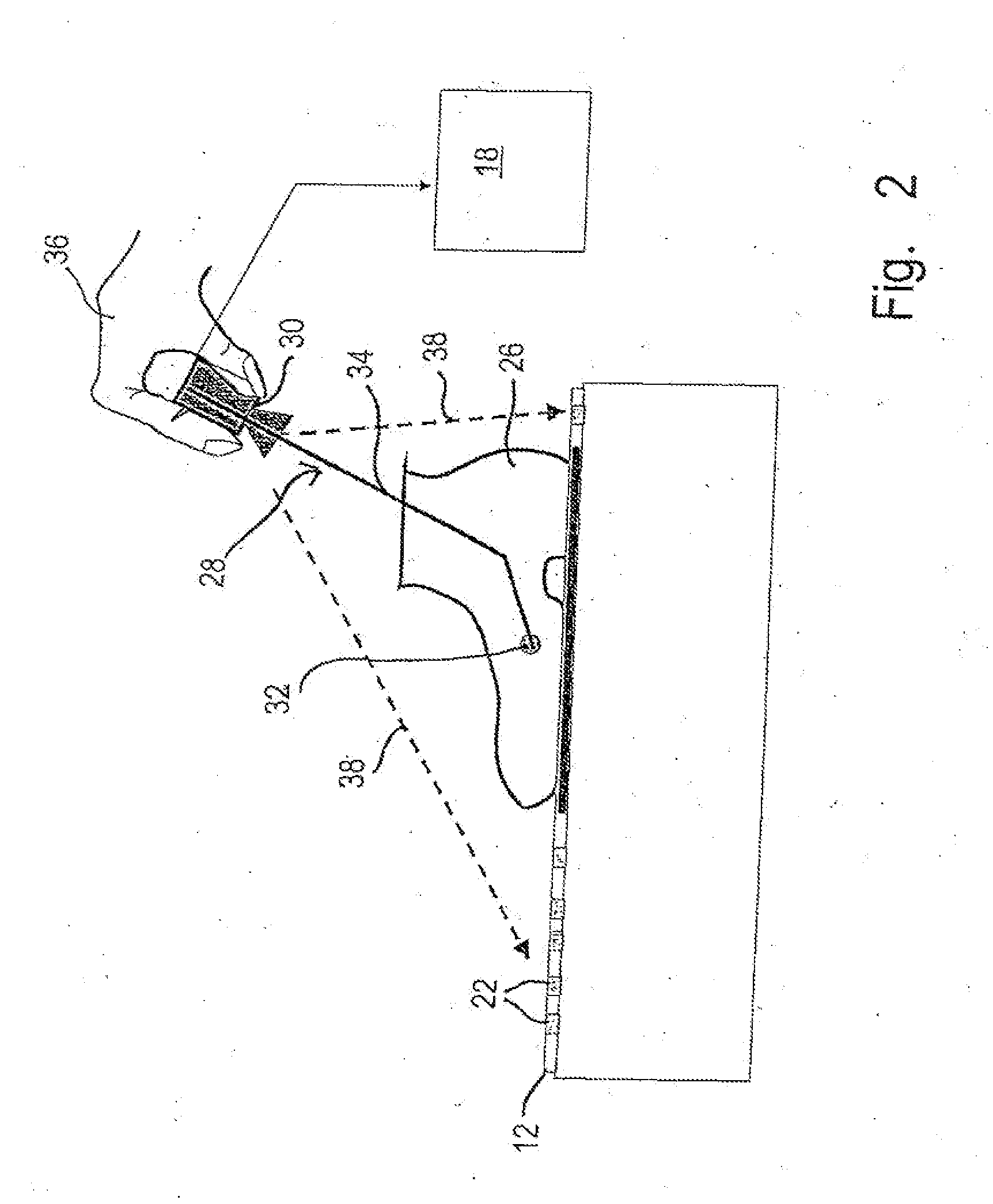

Sensing Apparatus and Method for Detecting a Three-Dimensional Physical Shape of a Body

ActiveUS20100238271A1Simple designImprove accuracyFoot measurement devicesMechanical counters/curvatures measurementsThree-dimensional spacePhysical shape

Owner:CORPUS E

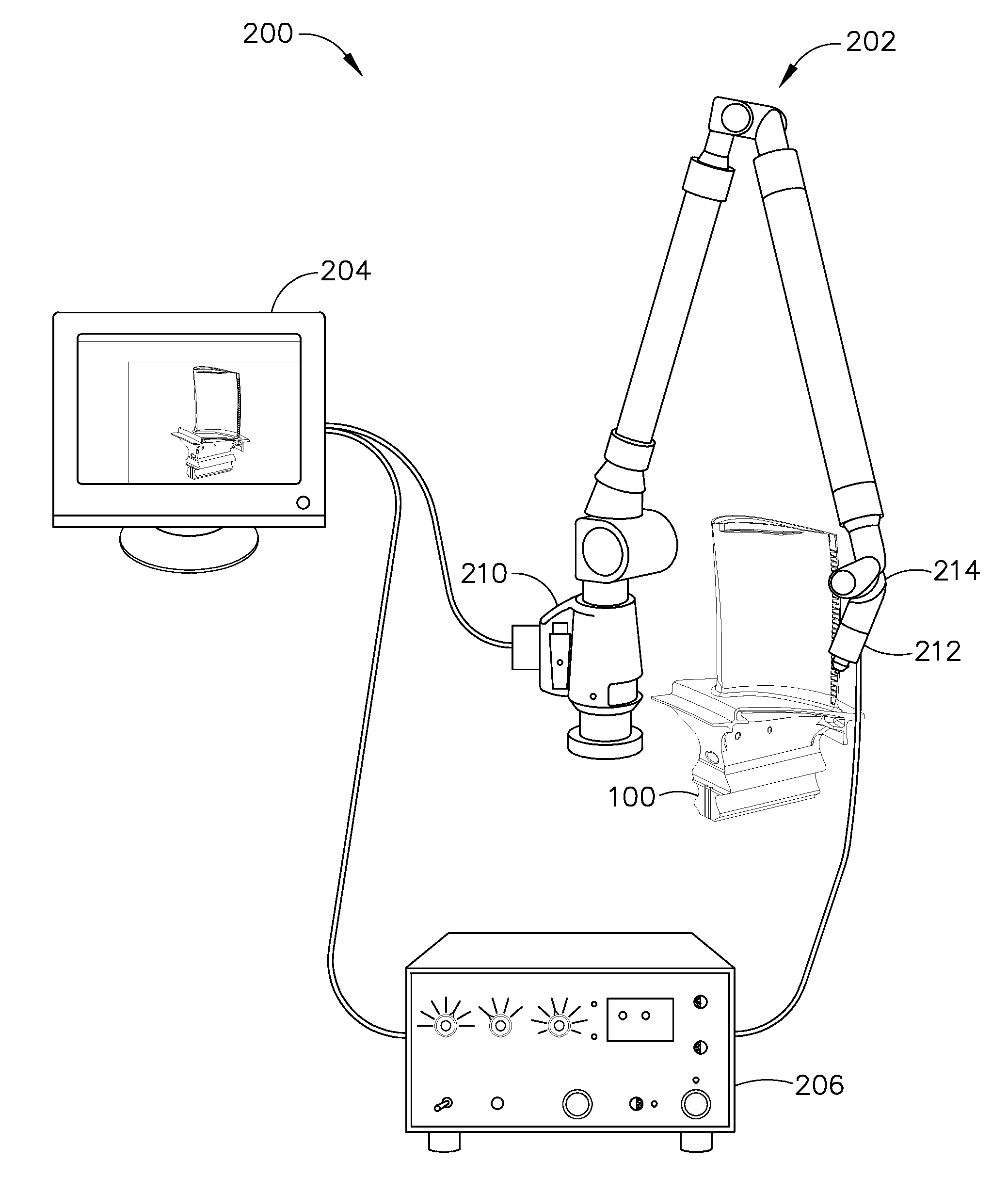

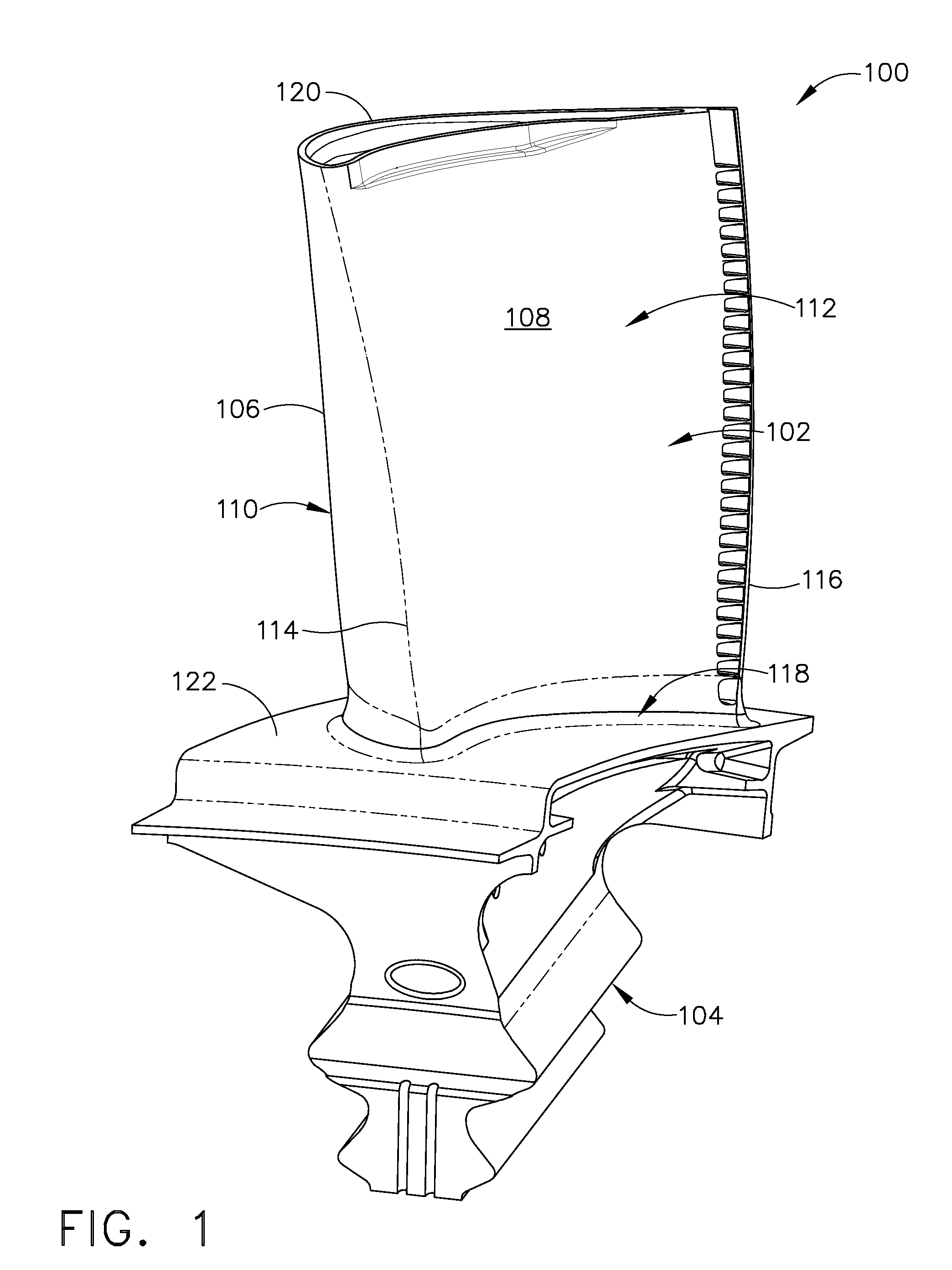

Method and system for integrating ultrasound inspection (UT) with a coordinate measuring machine (CMM)

InactiveUS20090165317A1Easy to measureAnalysing solids using sonic/ultrasonic/infrasonic wavesFeeler-pin gaugesMeasurement deviceCoordinate-measuring machine

A method is provided for assembling a measurement device for use in measuring a machine component. The method includes providing a coordinate measuring machine (CMM). The method also includes combining ultrasonic inspection (UT) capabilities and CMM capabilities to form an inspection probe. The inspection probe is installed on the CMM so that the inspection probe measures external boundaries of the machine component with the CMM capabilities and substantially simultaneously measures internal boundaries of the machine component with the UT capabilities.

Owner:GENERAL ELECTRIC CO

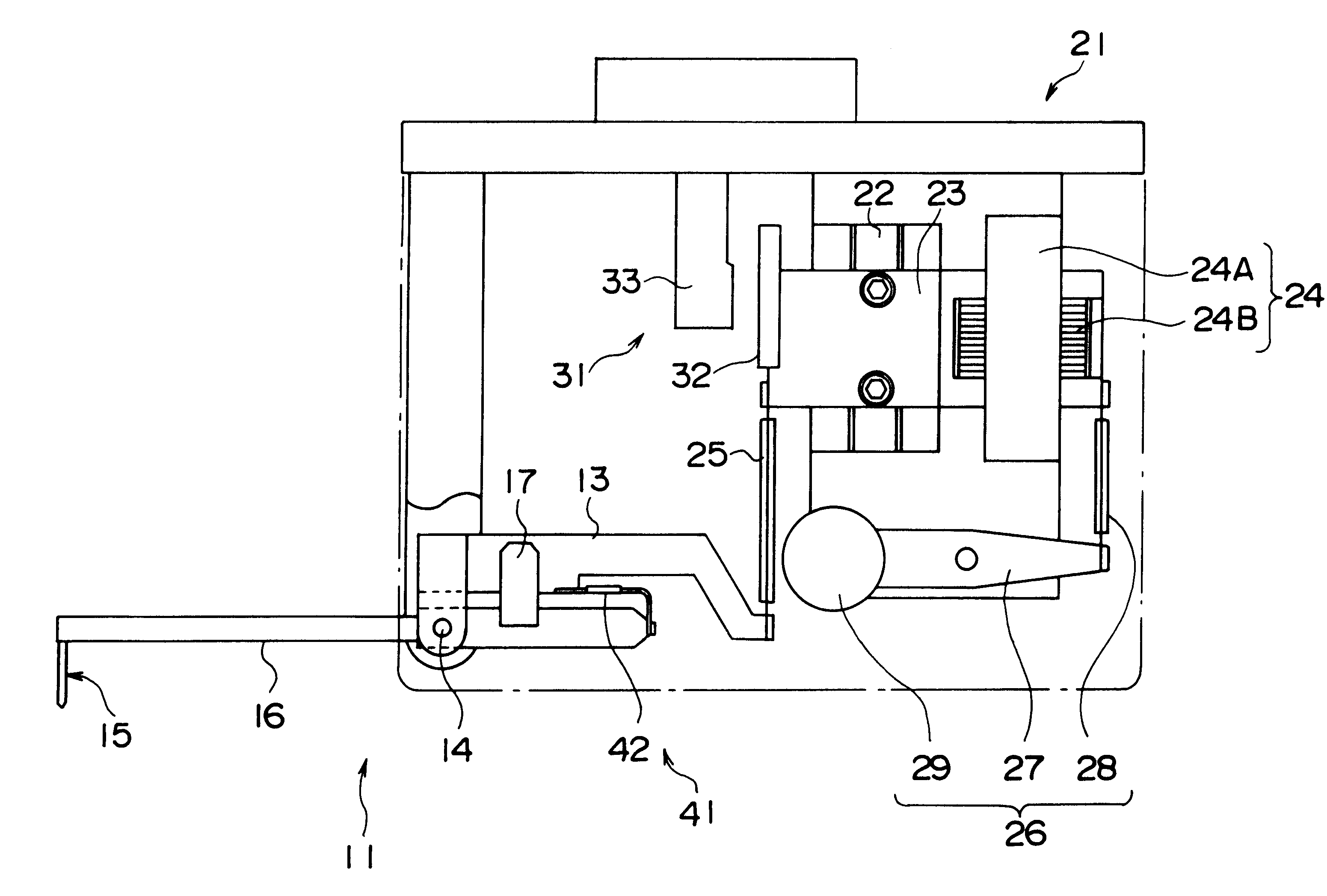

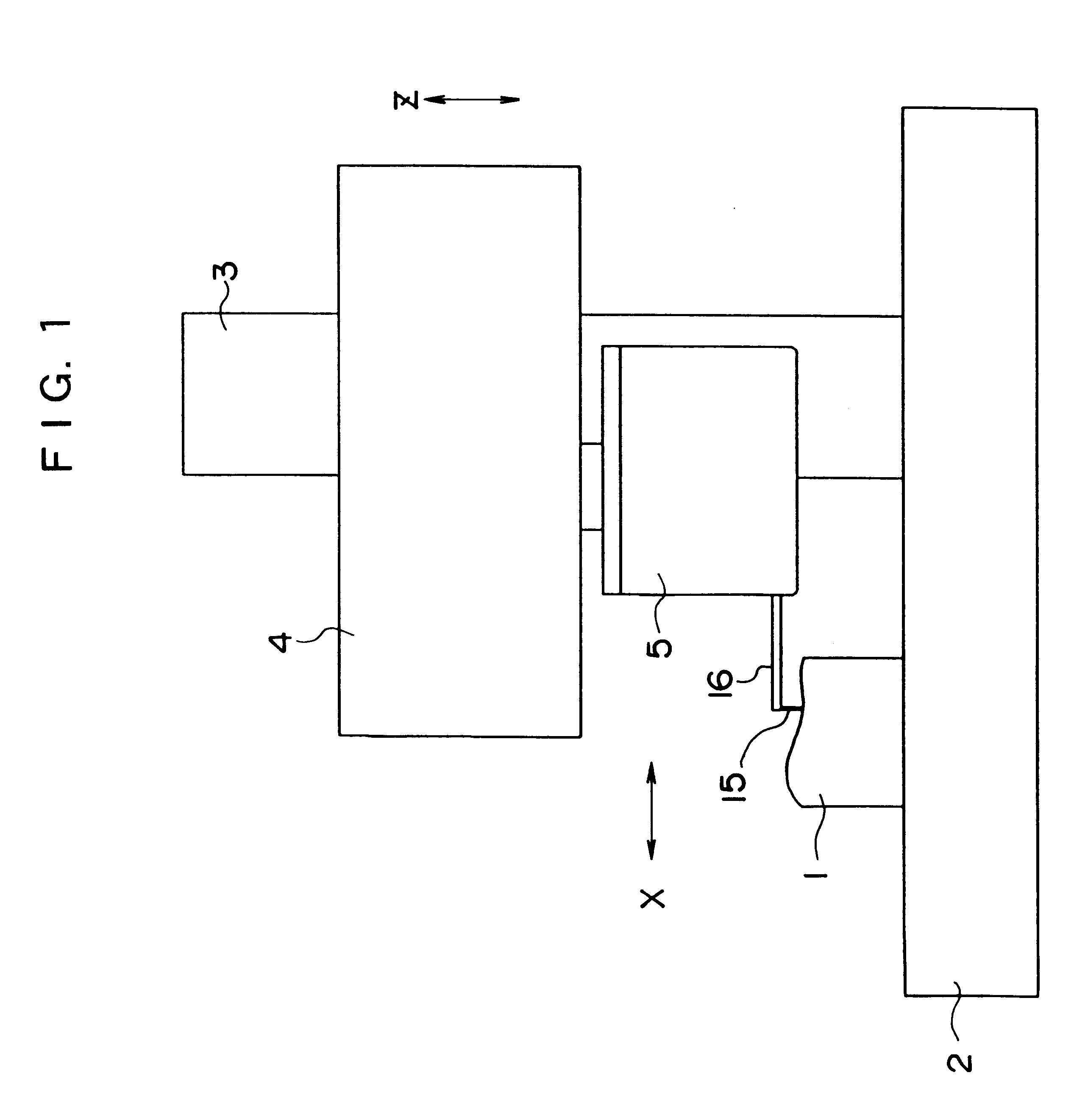

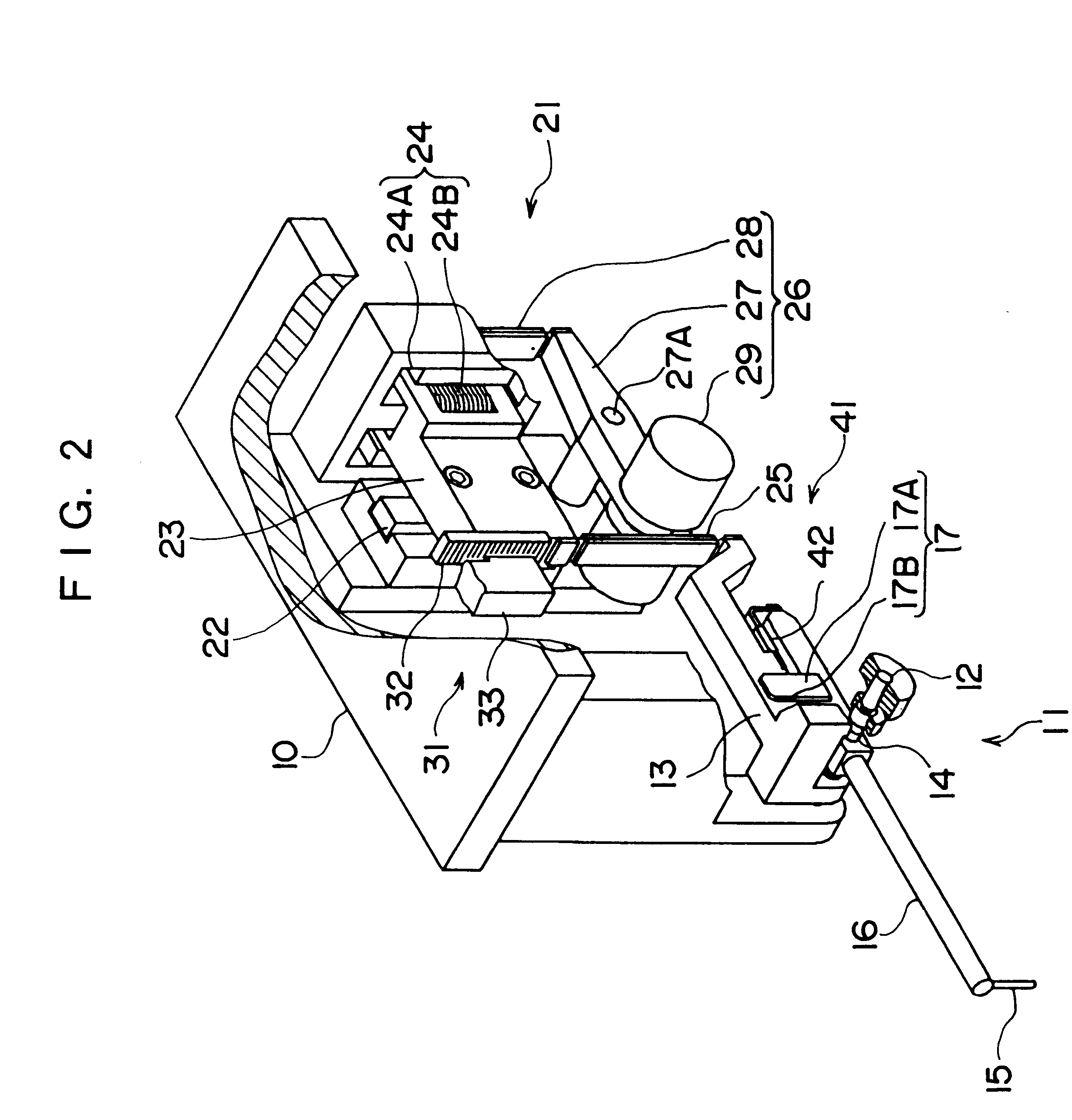

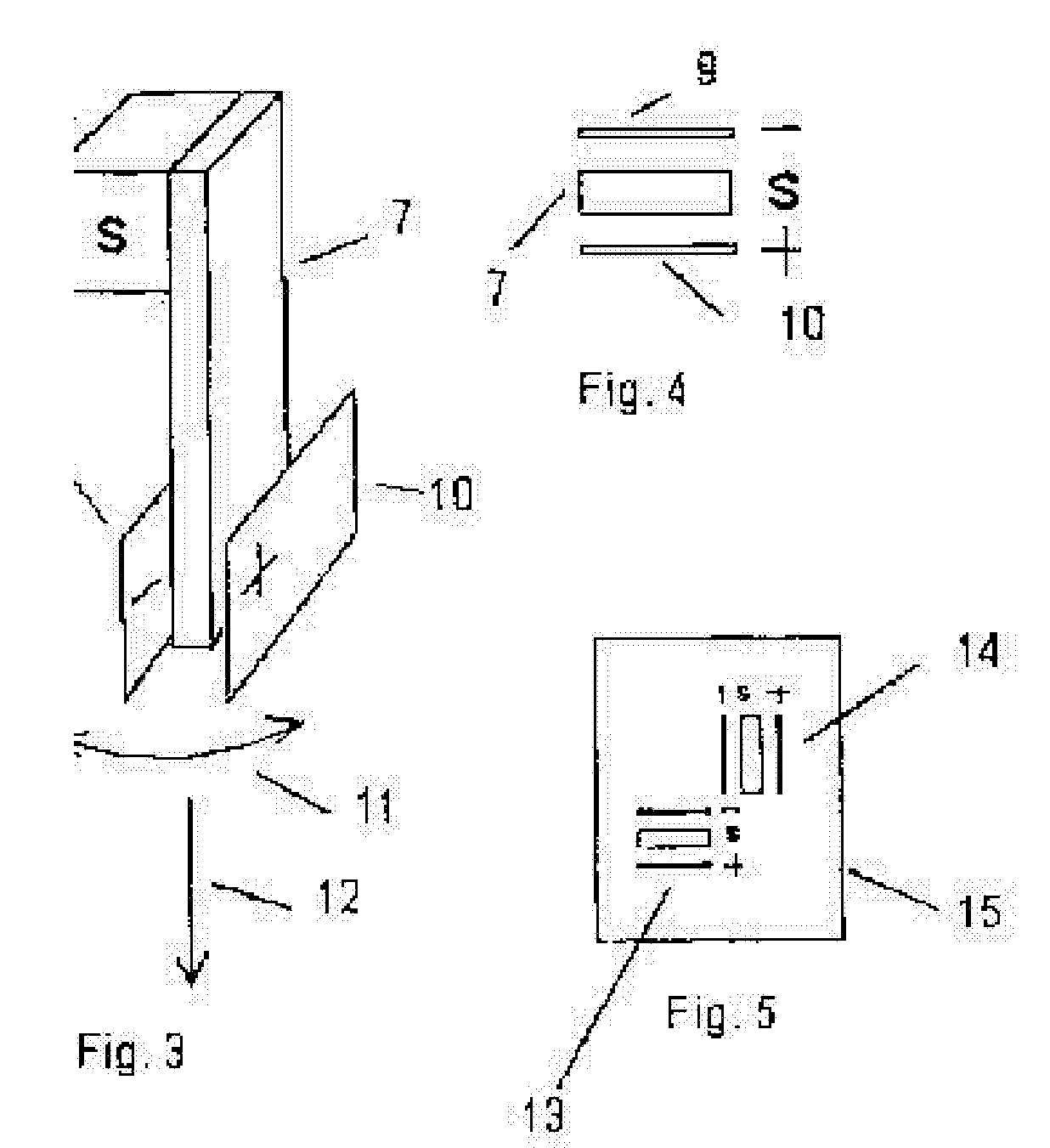

Surface-tracking measuring machine

InactiveUS6295866B1Accurate detectionReduce sensitivityCompasses with pivoted armsMechanical counters/curvatures measurementsResponsivityClassical mechanics

A surface-tracking measuring machine is provided, in which measurement range is enlarged while keeping a measuring force, responsivity, resolution thereof. For the object, the surface-tracking measuring machine has a frame (10), a probe (11) swingably supported by the frame (10) and having a tracer (15) at an end thereof, a measuring force controller (21) for controlling the measuring force applied to the probe, a displacement detector (31) for detecting a displacement of the probe, a measuring force detector (41) for detecting the measuring force applied to the probe, and a controller (51) for comparing a measuring force detected value detected by the measuring force detector and a previously commanded measuring force command value and to control the measuring force controller so that the measuring force detected value is equal to the measuring force command value.

Owner:MITUTOYO CORP

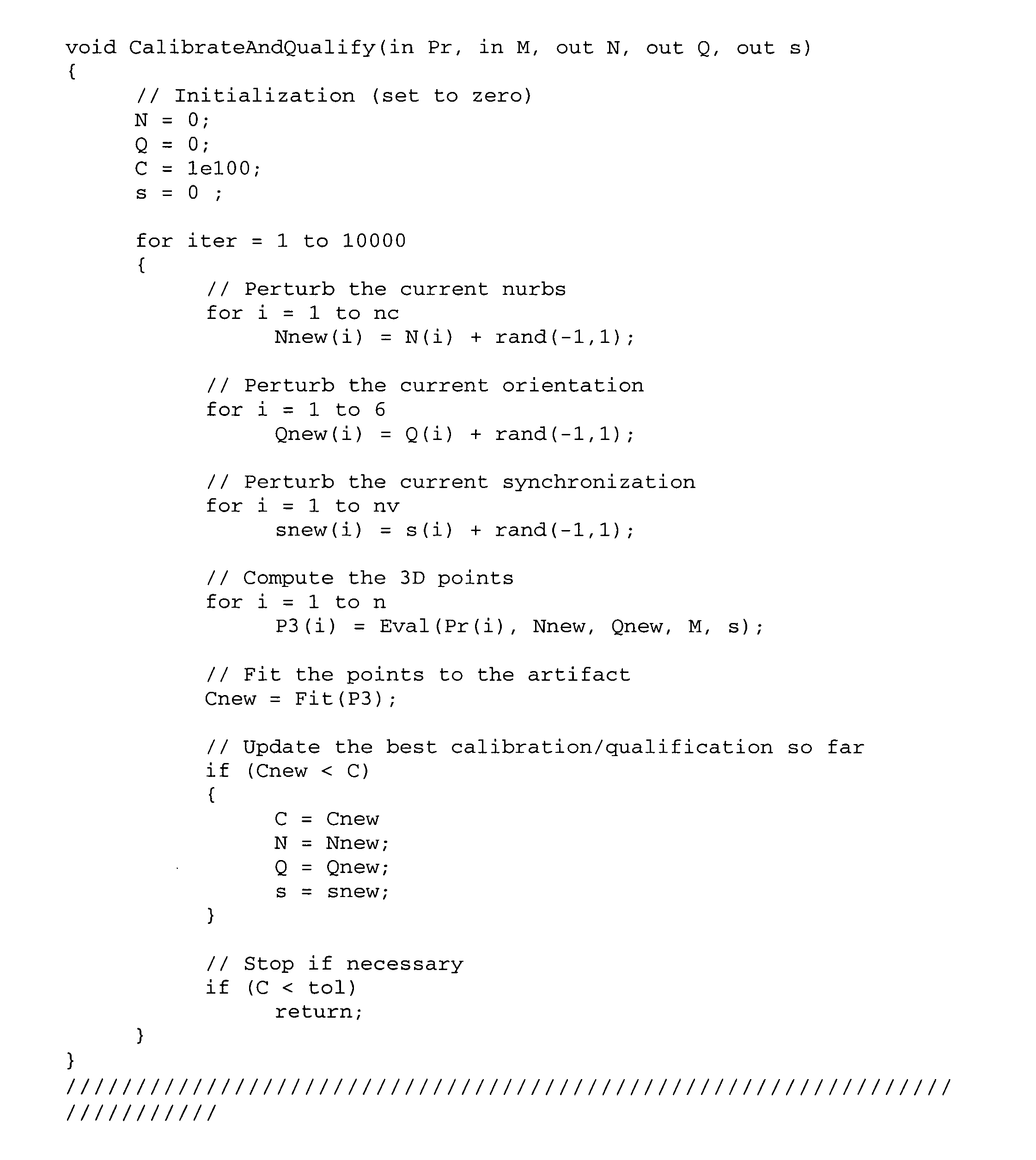

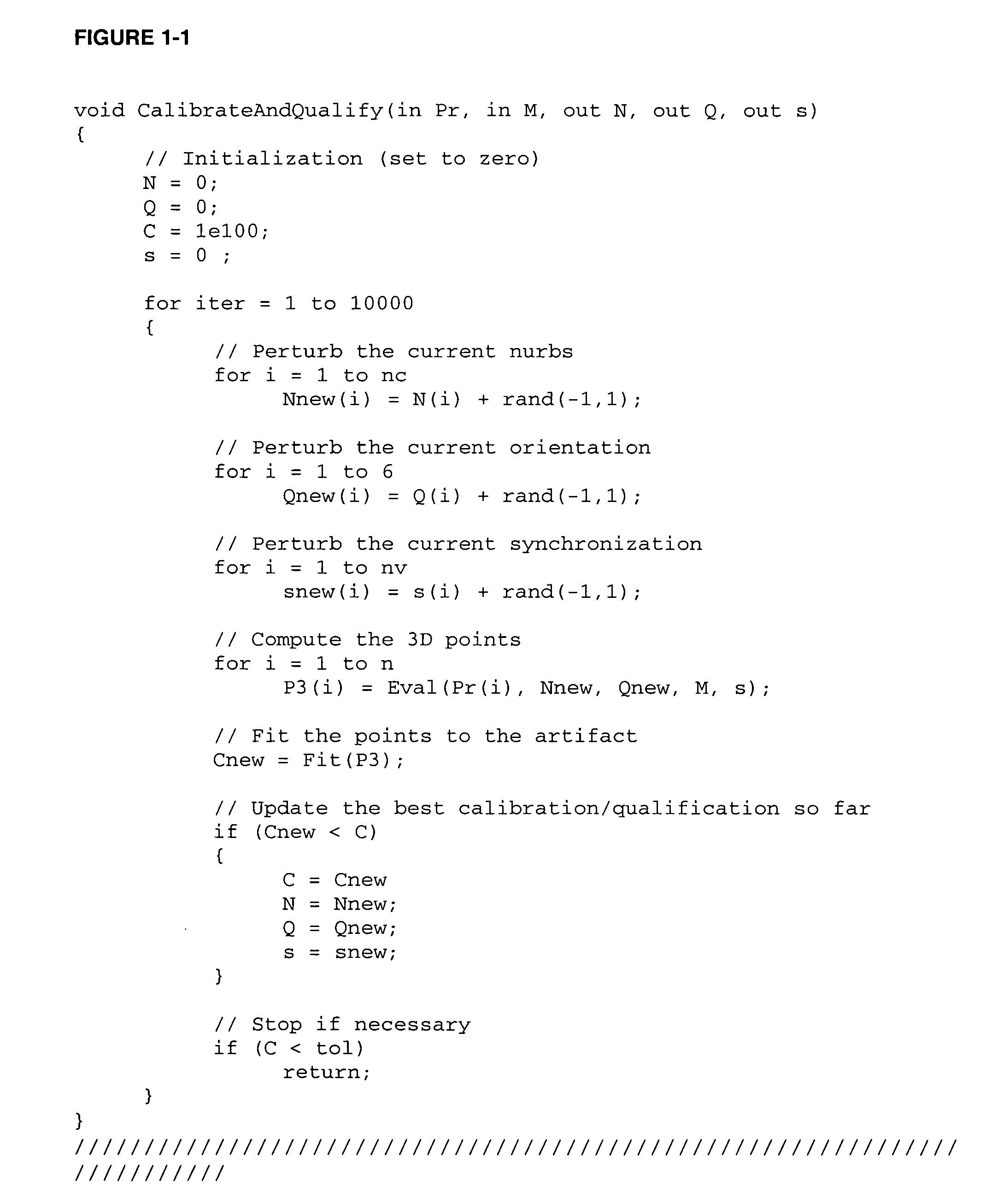

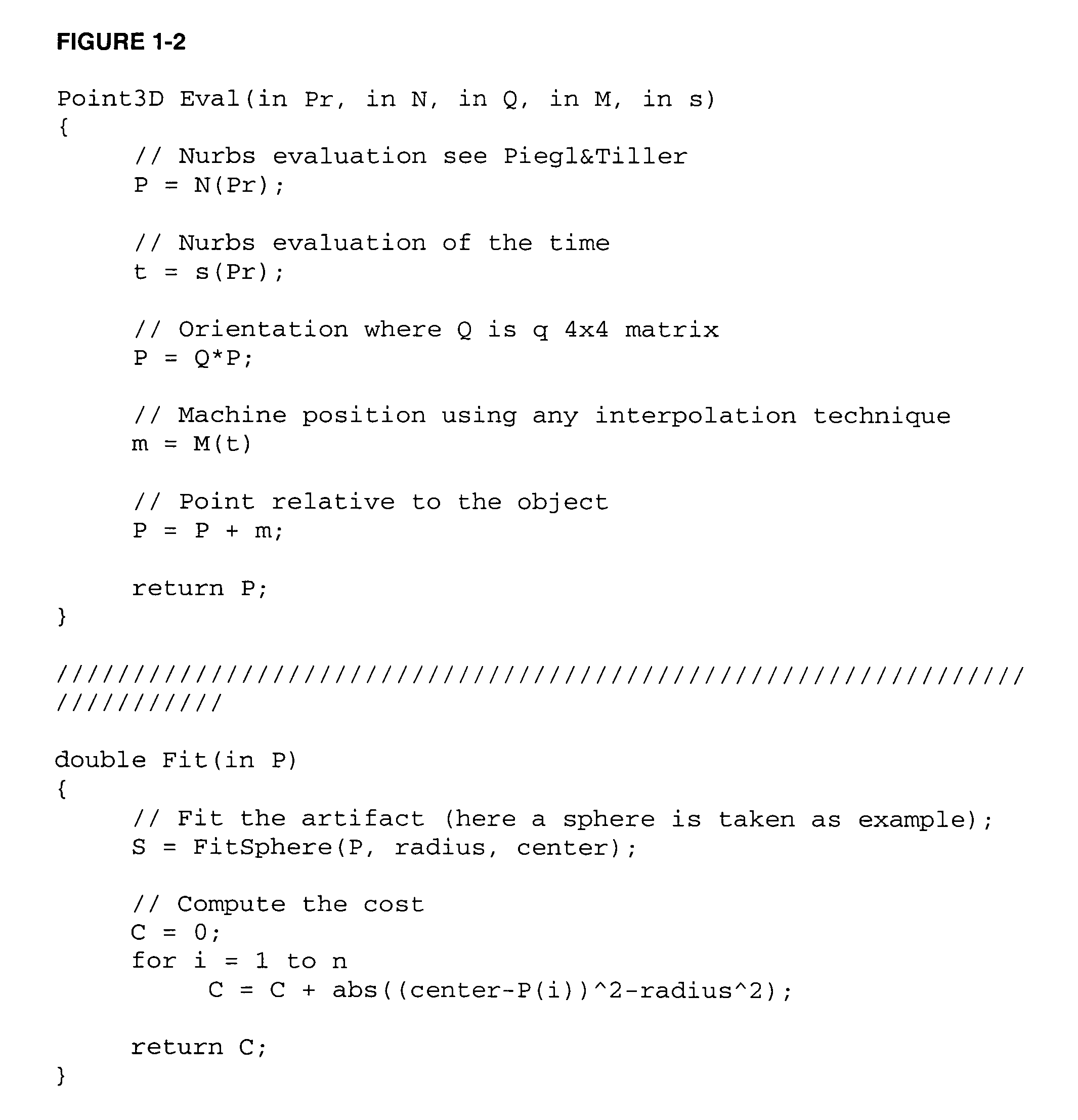

Method for the automatic simultaneous synchronization, calibration and qualification of a non-contact probe

The present invention relates to an improved method for the simultaneous calibration and qualification of a non-contact probe on a localizer using a single artifact, in which non-contact probe readings and localizer readings are synchronised using parameters determined simultaneously with calibration and qualification. The invention also relates to a non-contact probe and other devices, and a computer program for performing the invention.

Owner:METRIS +1

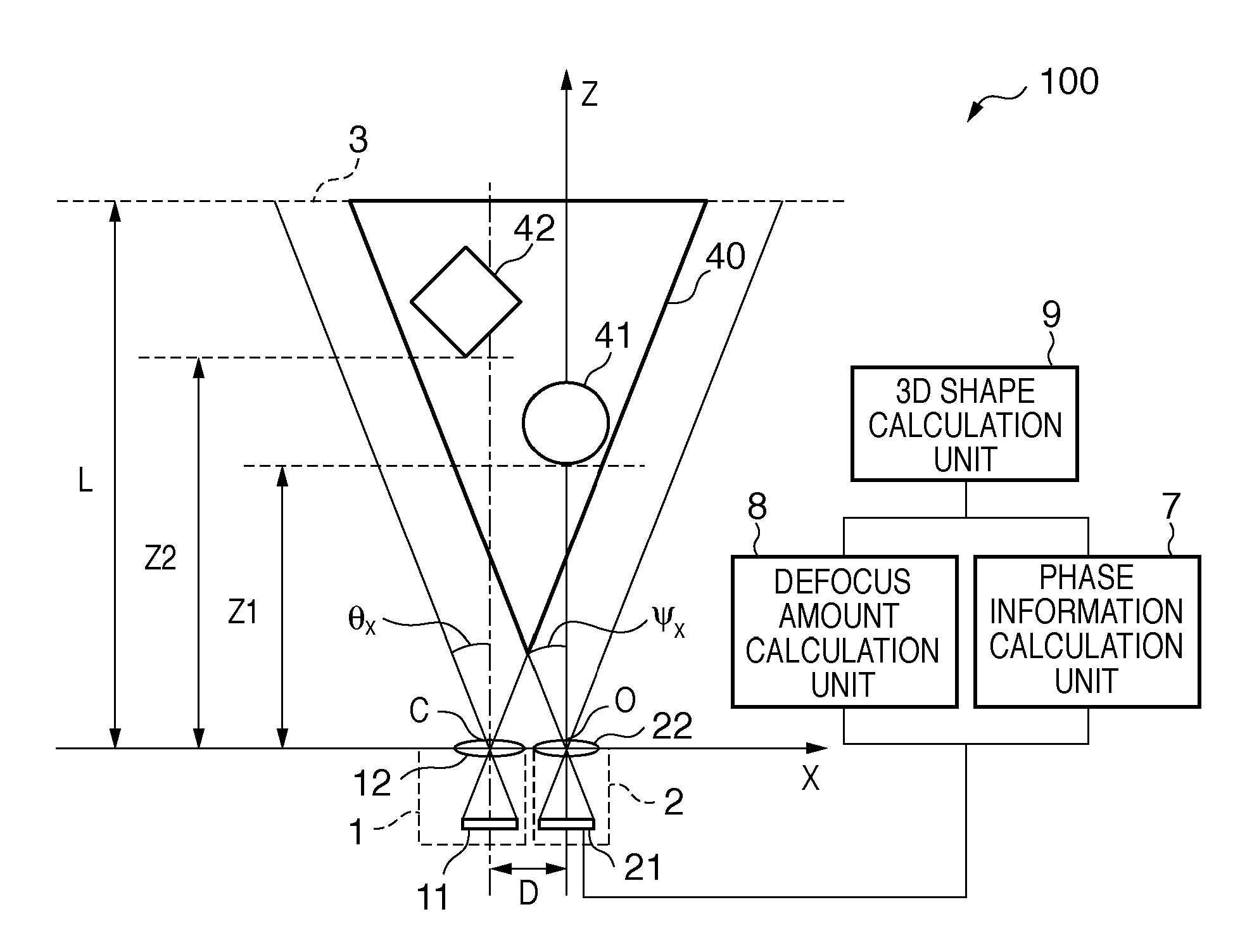

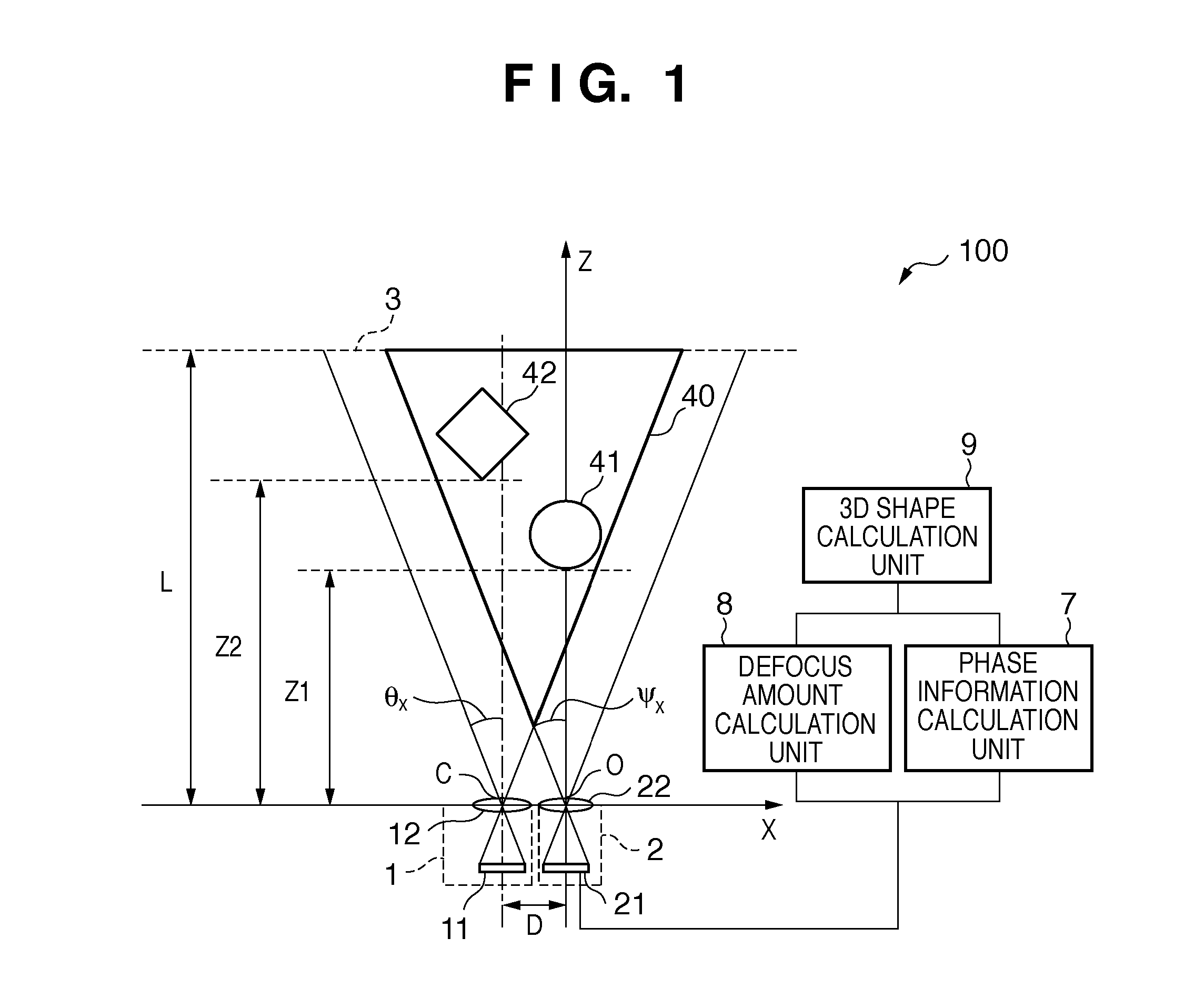

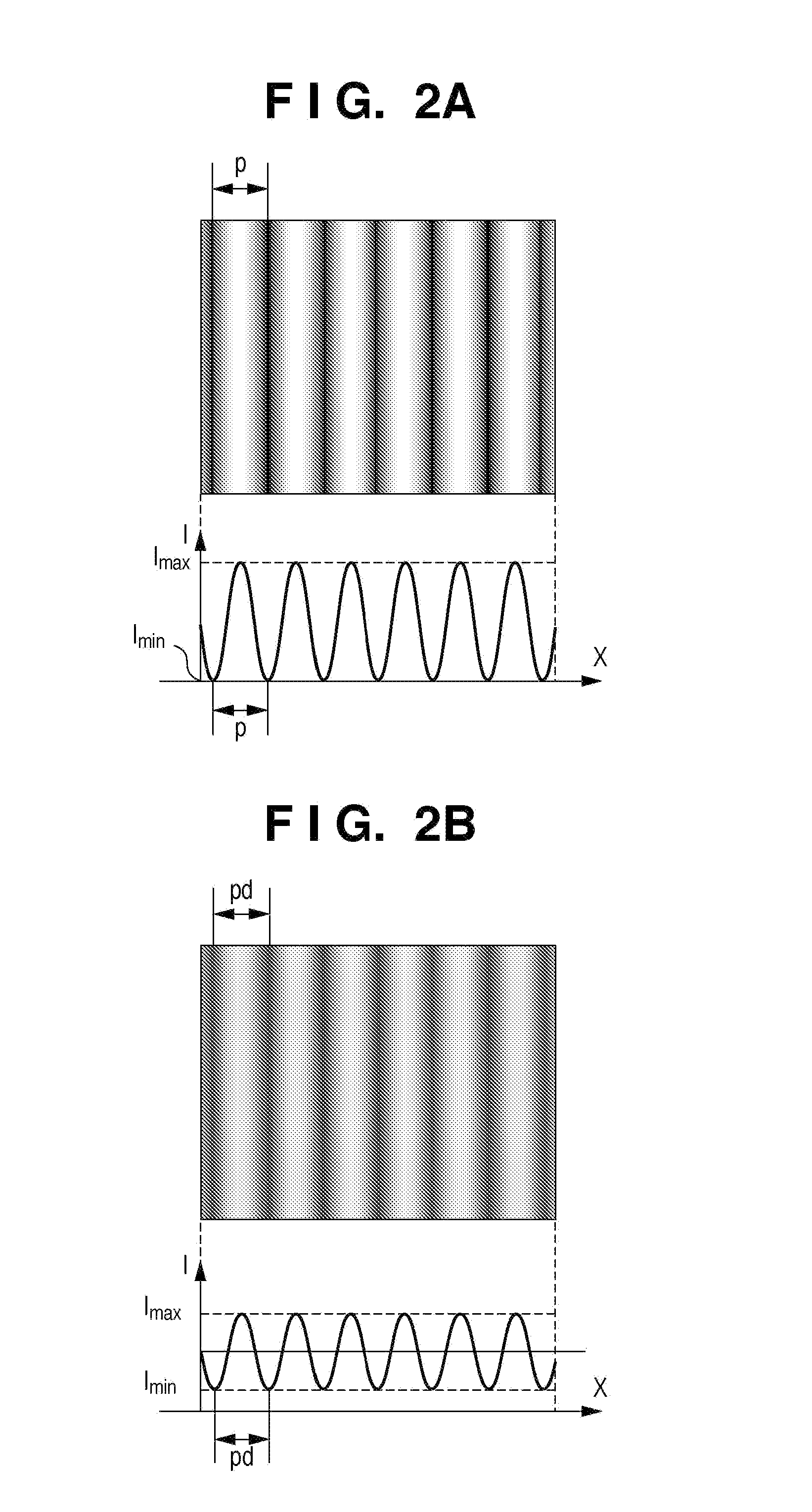

Three dimensional shape measurement apparatus, three dimensional shape measurement method, and computer program

A 3D shape measurement apparatus for measuring a 3D shape of an object existing on a measurement area, comprising, a pattern projection unit for projecting a pattern having a periodicity onto the measurement area, and a capturing unit for capturing an image of the area where the pattern is projected, wherein the measurement area is specified by a reference plane, a projection area of the pattern projection unit, and a capturing area of the capturing unit, and the pattern projection unit projects the pattern to be focused on the reference plane. The apparatus further comprises a first calculation unit for calculating phase information of a pattern of the captured image, a second calculation unit for calculating defocus amounts of the pattern in the captured image, and a third calculation unit for calculating a 3D shape of the object based on the phase information and the defocus amounts.

Owner:CANON KK

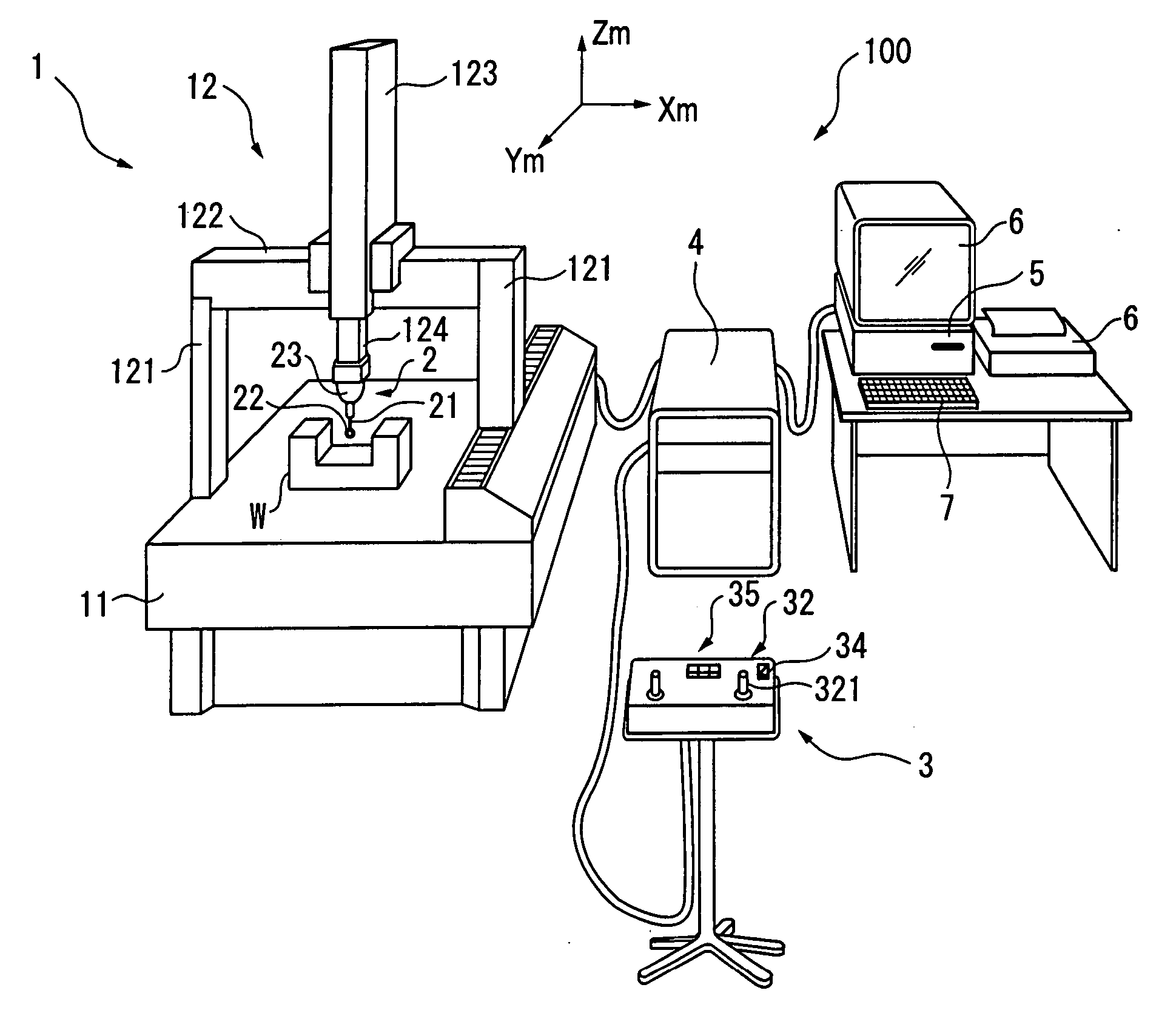

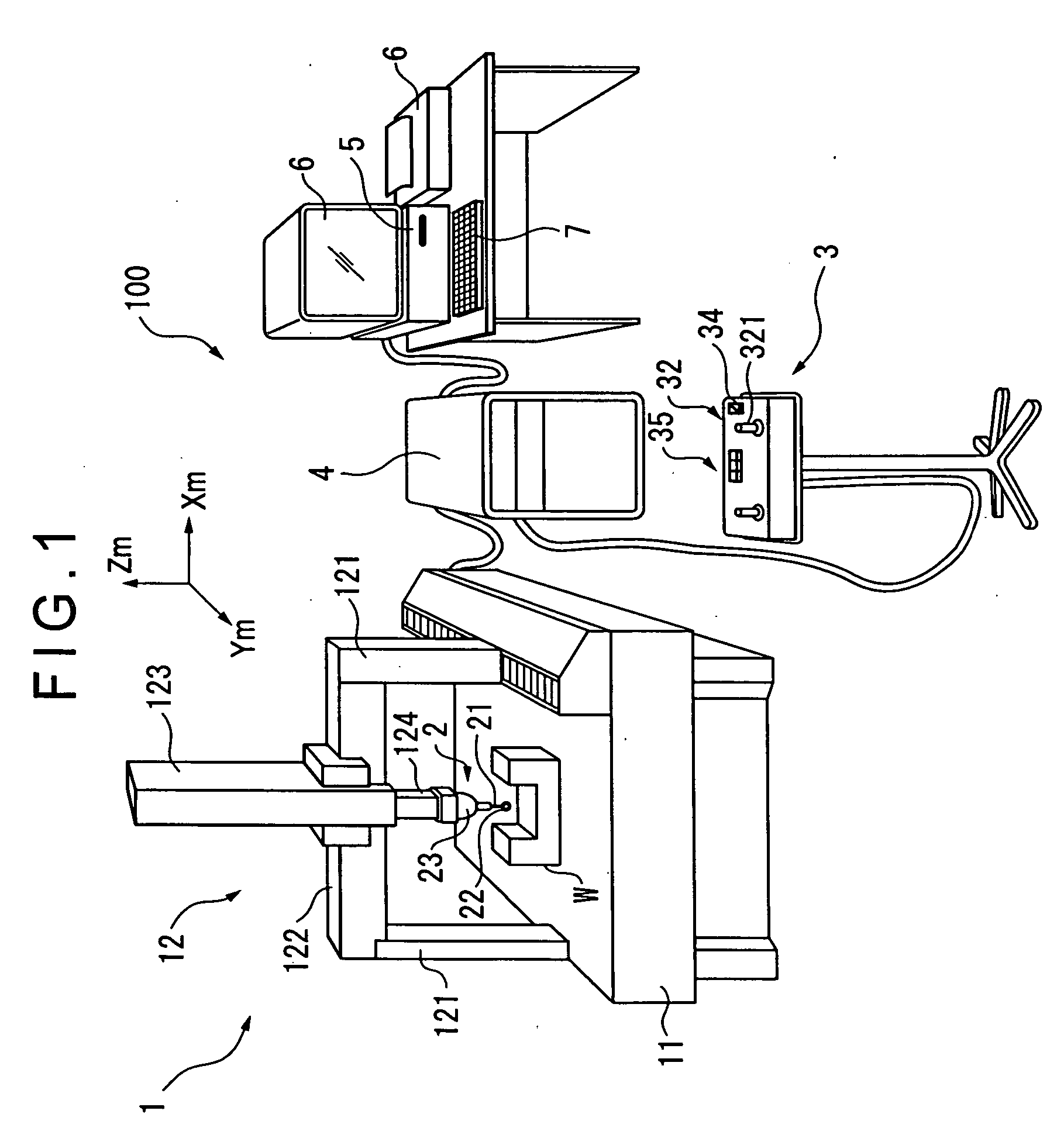

Surface scan measuring device, surface scan measuring method, surface scan measuring program and recording medium

ActiveUS20050263727A1Reduce necessary measuring timeImprove accuracyMechanical counters/curvatures measurementsInvestigating moving sheetsMeasurement deviceSurface conditions

A surface scan measuring device, a surface scan measuring method, a surface scan measuring program and a recording medium storing such a program which can appropriately adjust the scanning speed, the sampling pitch and other measurement parameters according to the surface condition of a workpiece are provided. The surface scan measuring device includes a radius of curvature computing section (543) for computing the radius of curvature of the scanning point from the measurement data acquired during the ongoing scanning operation, a moving speed deciding section (544) for deciding the moving speed of the scanning probe according to the computed radius of curvature and a sampling pitch deciding section (546) for deciding the sampling pitch according to the computed radius of curvature.

Owner:MITUTOYO CORP

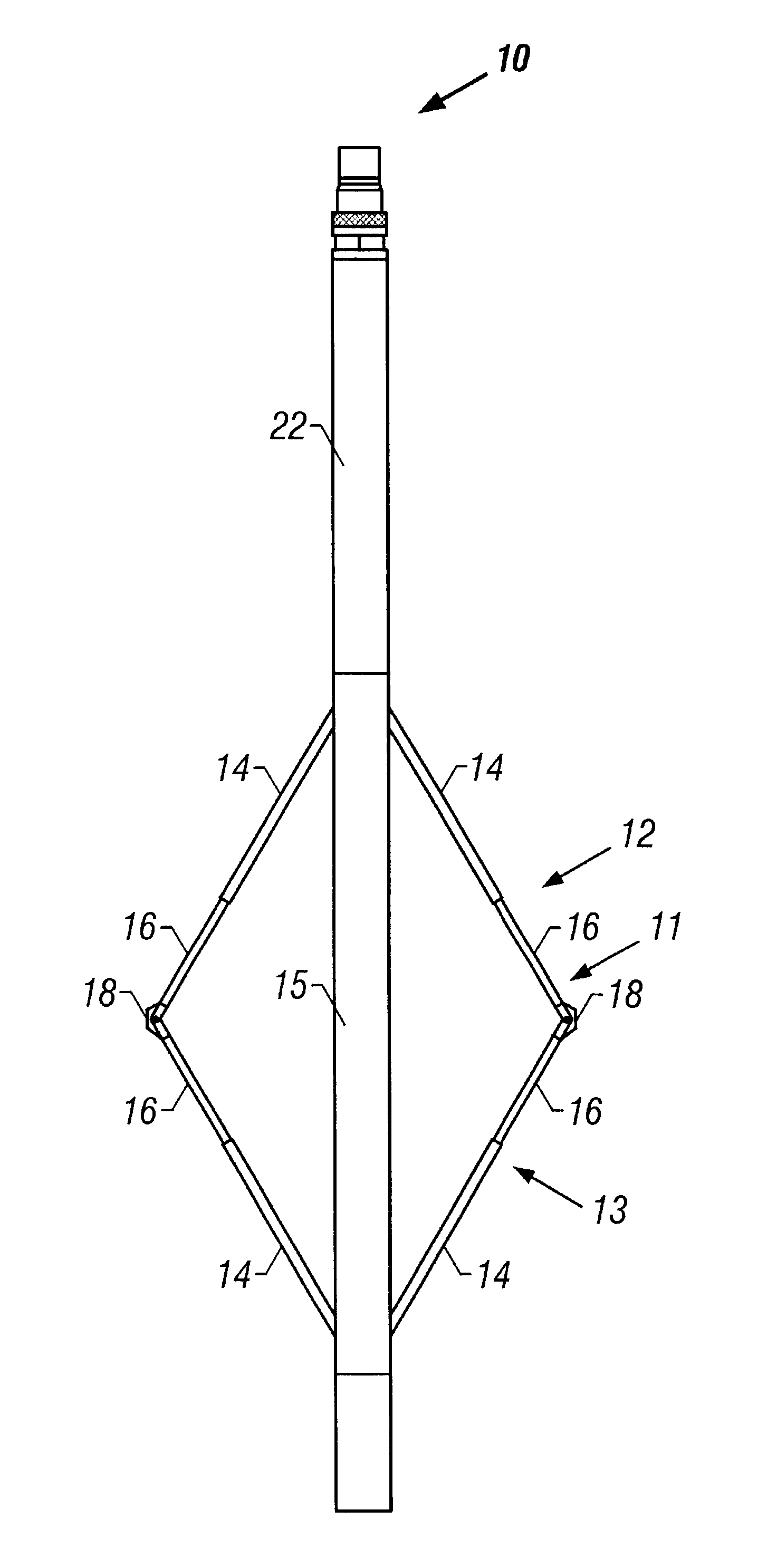

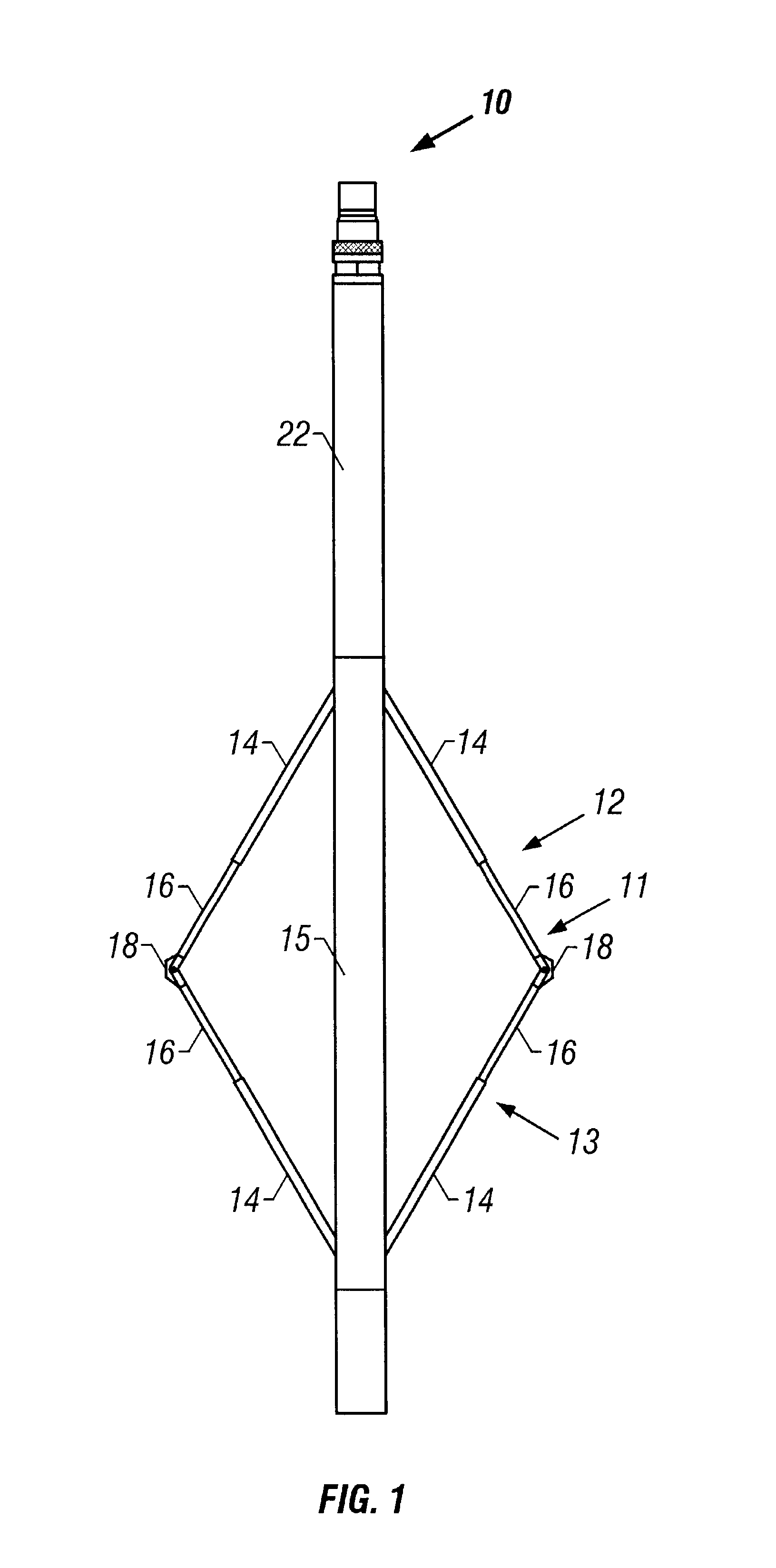

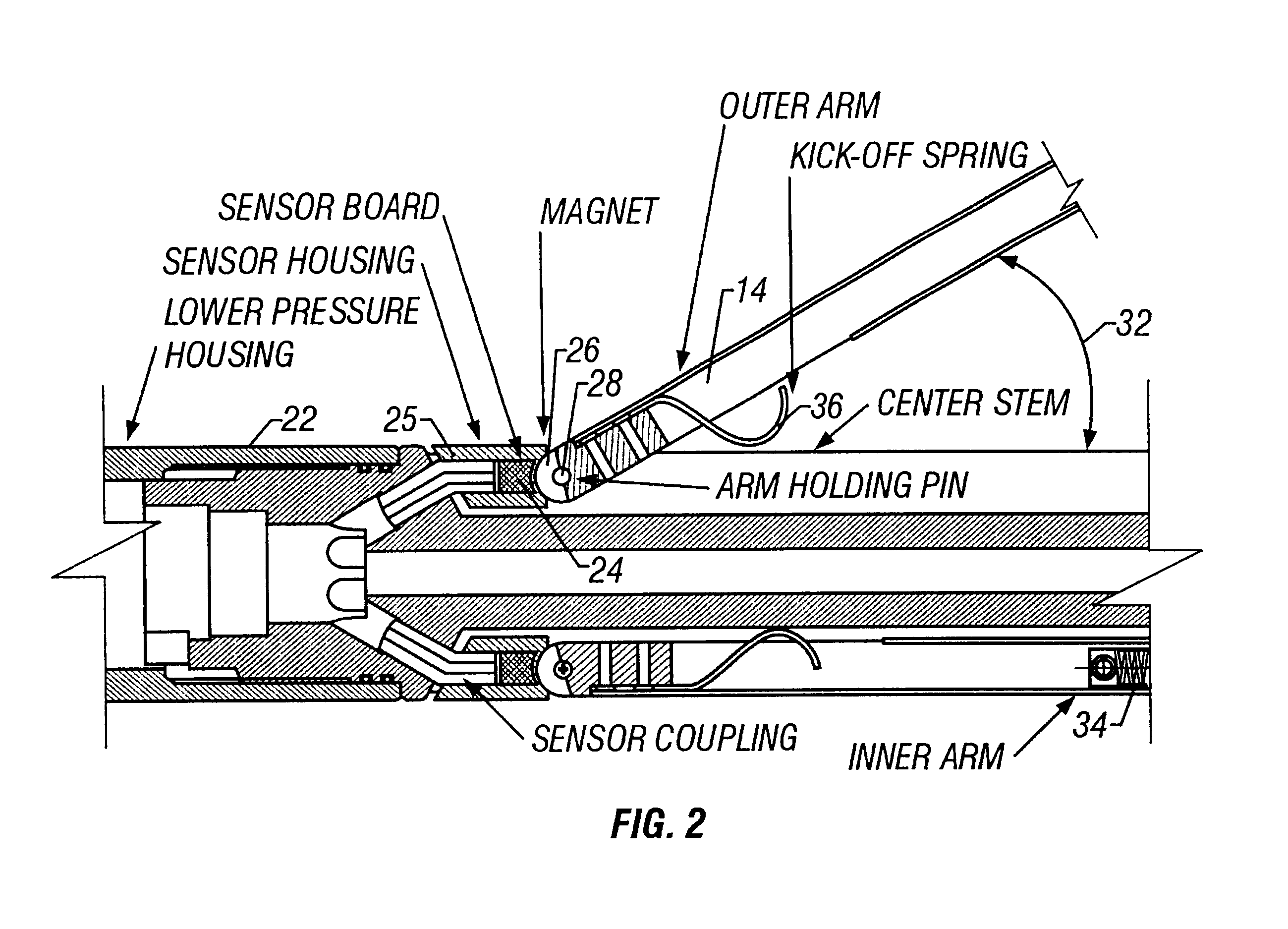

Use of magneto-resistive sensors for borehole logging

Owner:BAKER HUGHES INC

Method for custom fitting of apparel

InactiveUS6711455B1Quickly and easily and conveniently orderFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansHuman bodyMathematical model

The present invention is directed to a method for custom fitting an article to a human being having the steps of defining a first set of human body dimensions to be reported by the human being, defining a second set of human body dimensions to be inferred from said first set of human body dimensions, providing a first mathematical model relating said second set of human body dimensions to said first set of human body dimensions, wherein said mathematical model has been generated by statistical analysis of a human anthropometric database, obtaining a first set of values of said first set of body dimensions by report of the human being, computing a second set of values of said second set of human body dimensions from said first set of values of said first set of human body dimensions by using said first mathematical model, defining a set of article dimensions, providing a second mathematical model relating said article dimensions to said first set of human body dimensions and said second set of human body dimensions, computing a third set of values of said set of article dimensions from said first set of values of said first set of human body dimensions and said second set of values of said second set of human body dimensions by using said second mathematical model.

Owner:THIRDLOVE INC

Shape-acceleration measurement device and method

ActiveUS7296363B2Accurate measurementImprove accuracyAcceleration measurement using interia forcesSurveySensor arrayBiological body

The present invention provides for a sensor array having at least one field-measuring sensor and at least one curvature-measuring sensor within a flexible substrate, the field-measuring sensors capable of providing orientation data of the flexible substrate relative to a field and the curvature-measuring sensors capable of providing relative orientation data within the substrate, for measuring dynamic and static shapes and vibration of geotechnical, structural and biological bodies.

Owner:MEASURAND INSTR INC

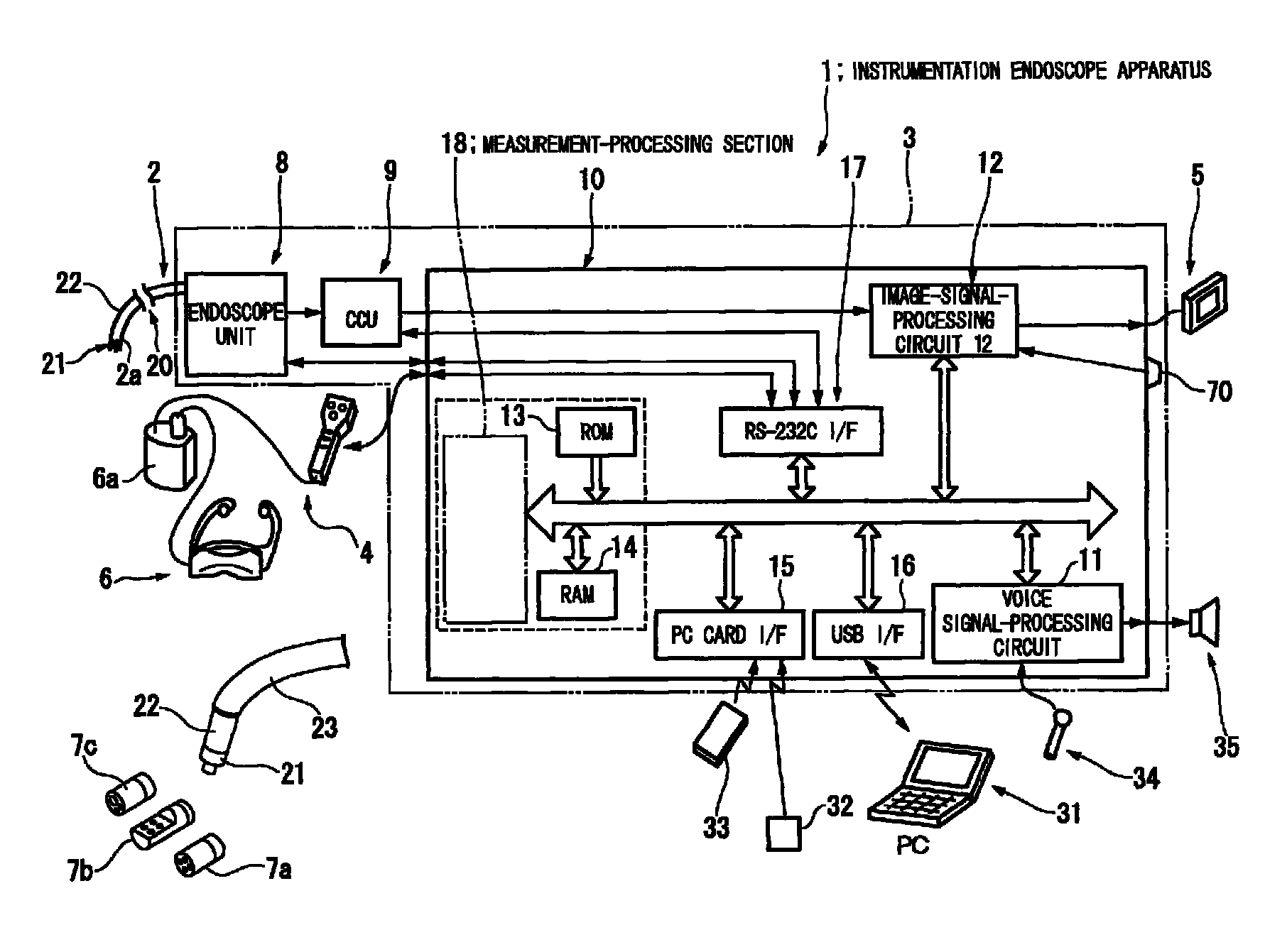

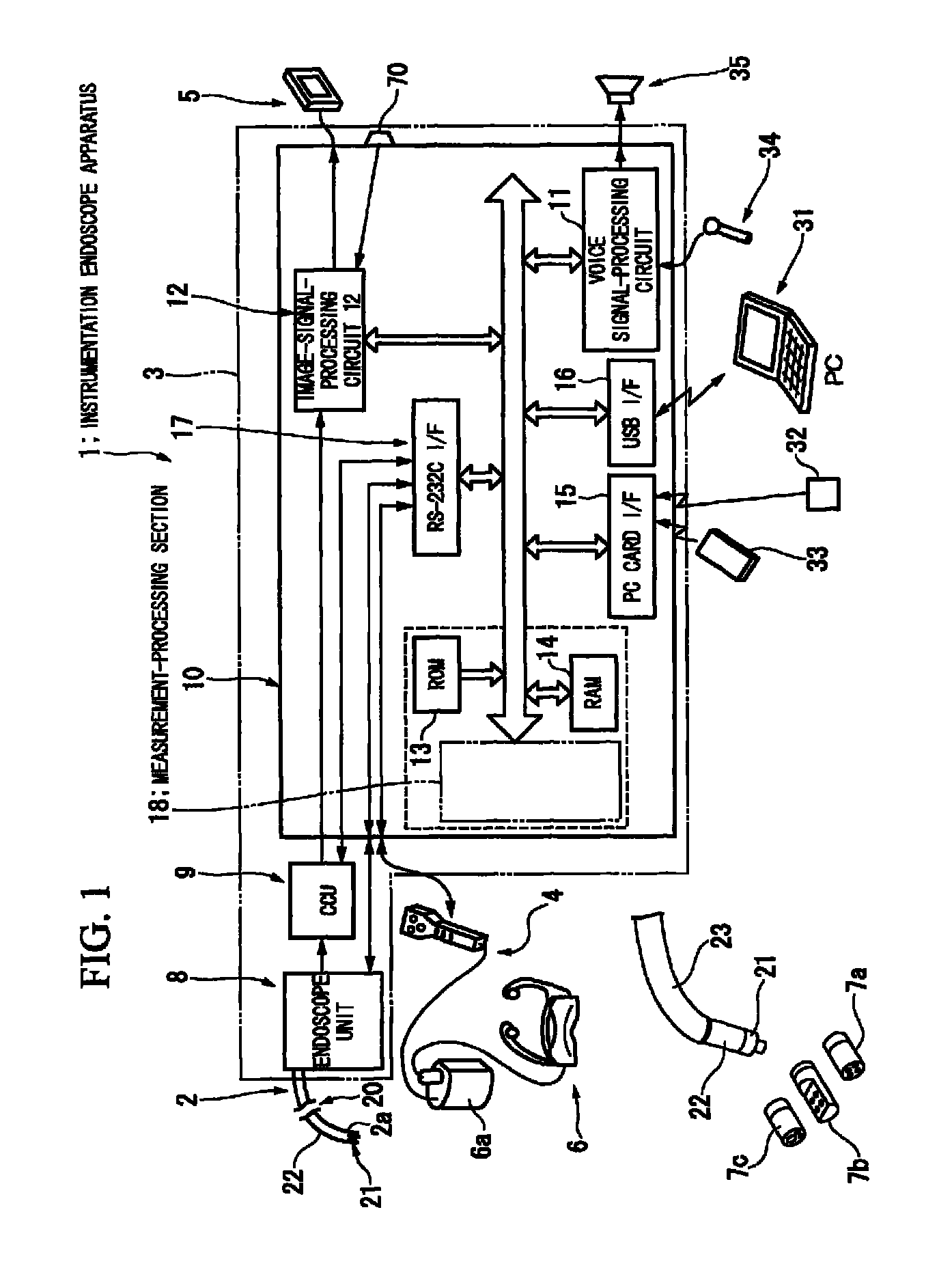

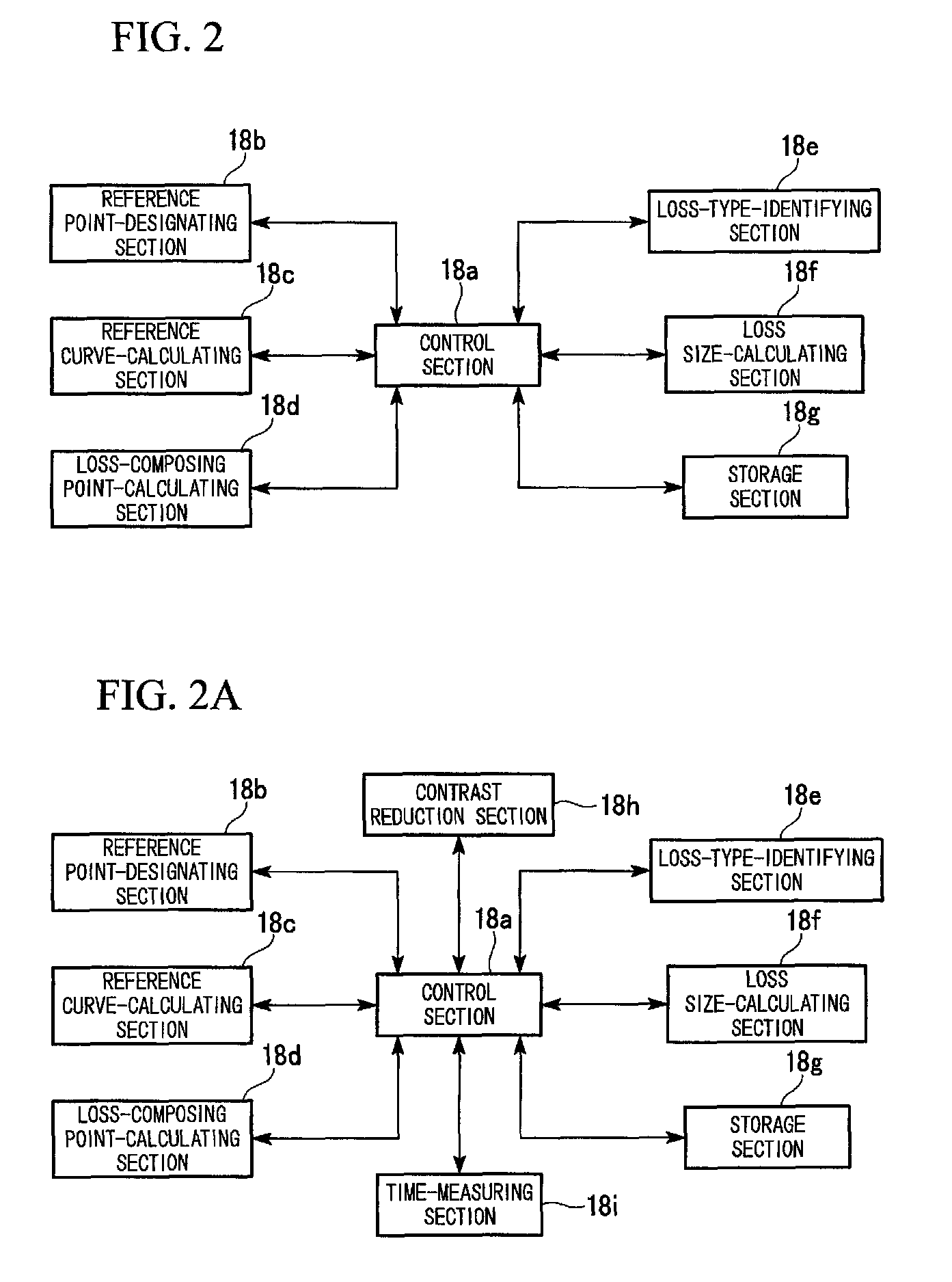

Endoscope apparatus and program

An endoscope apparatus includes an electronic endoscope that picks up a measurement object and produces a picked-up-image signal; an image-processing unit that produces a image signal based on the picked-up-image signal; and an measurement processing unit that undertakes measurement processing to the measurement object based on the image signal. The measurement processing unit includes: a reference point-designating unit that designates two reference points on the measurement object; an approximate-outline—calculating unit that calculates an approximate outline by approximating the outline of the measurement object based on the reference points; and a loss-composing points-calculating unit that calculates loss-composing points that constitute a loss outline formed on the measurement object based on the reference points and the approximate outline. This enables loss size measurement upon designating two reference points, thereby reducing complex operations and improving operability.

Owner:EVIDENT CORP

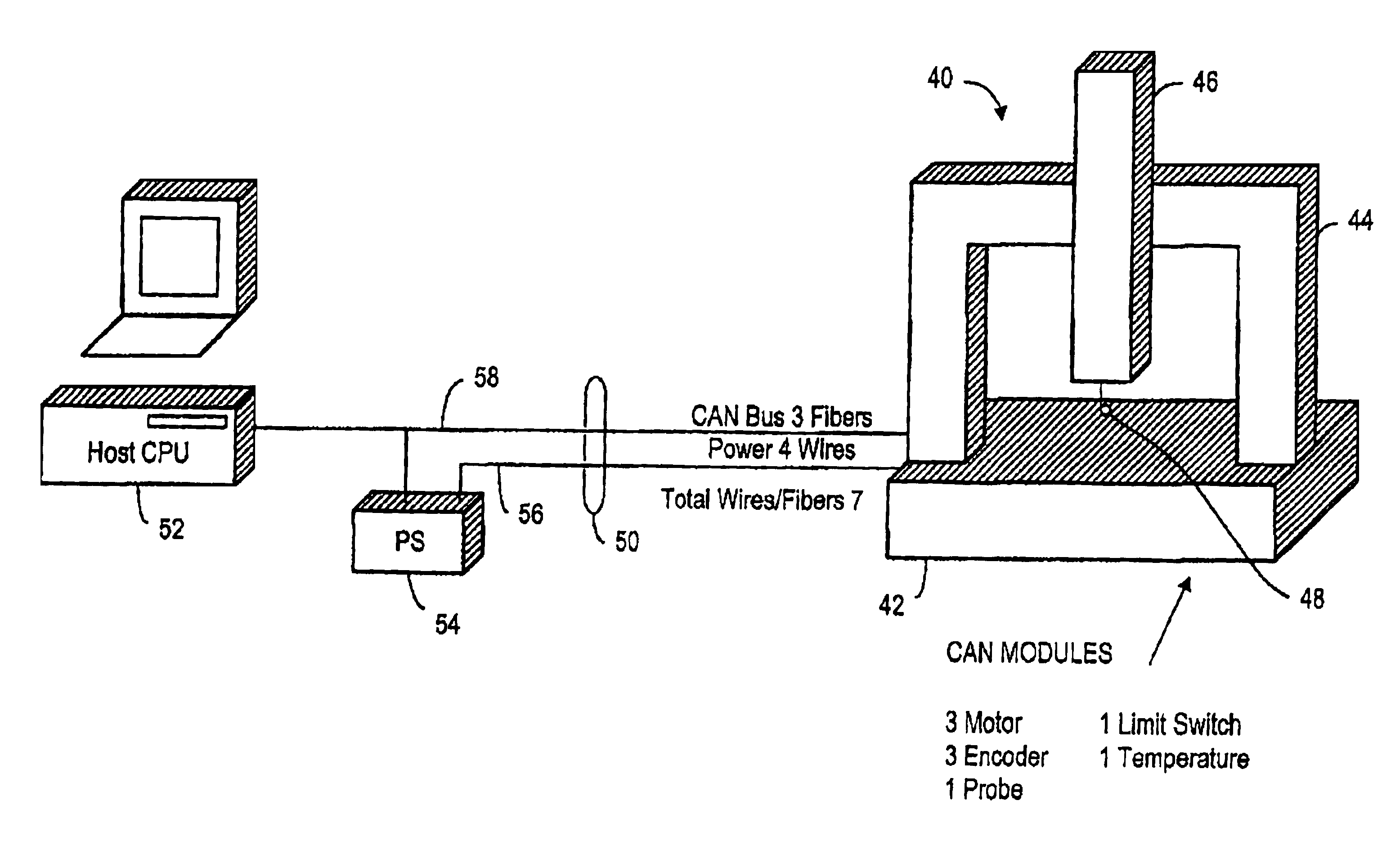

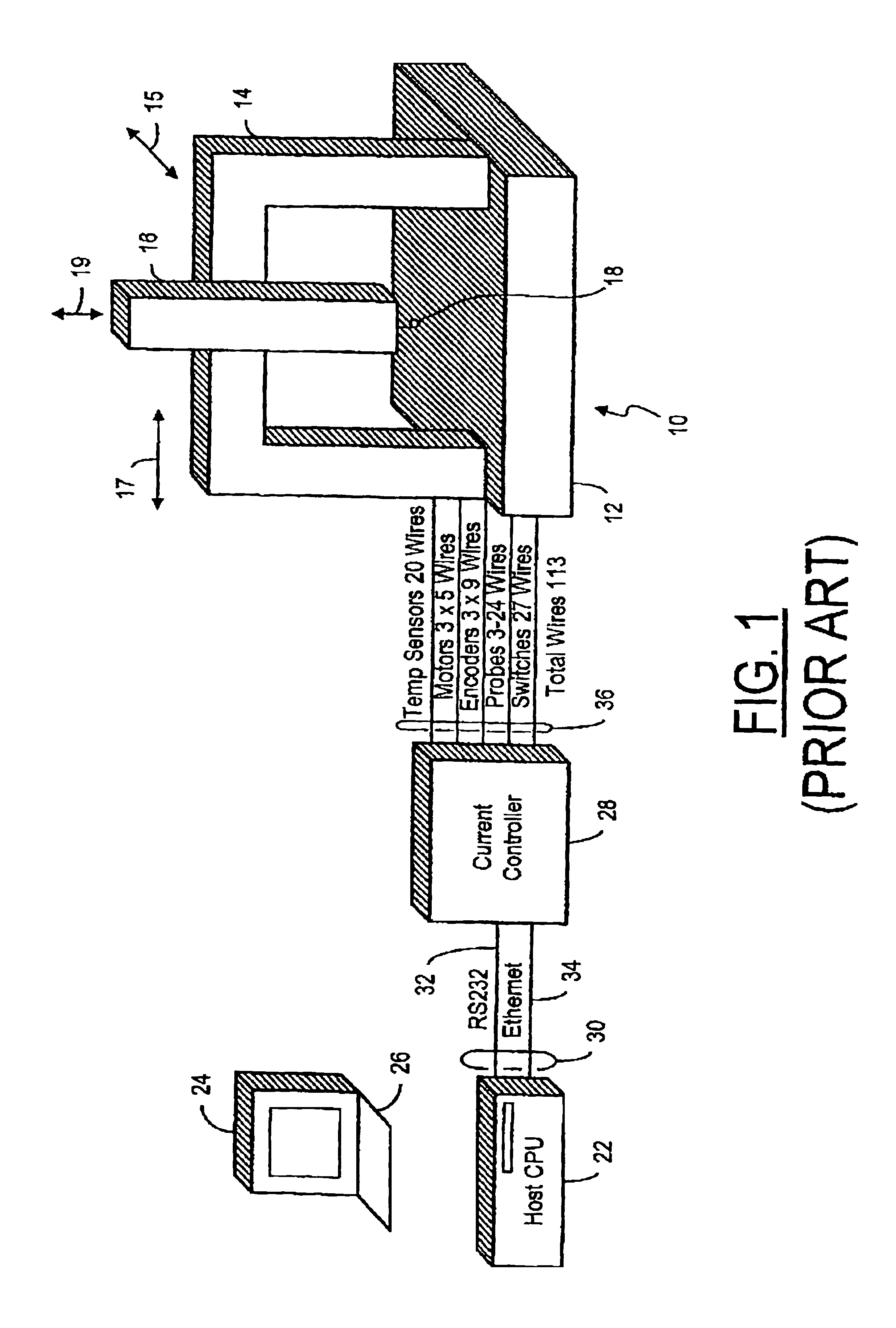

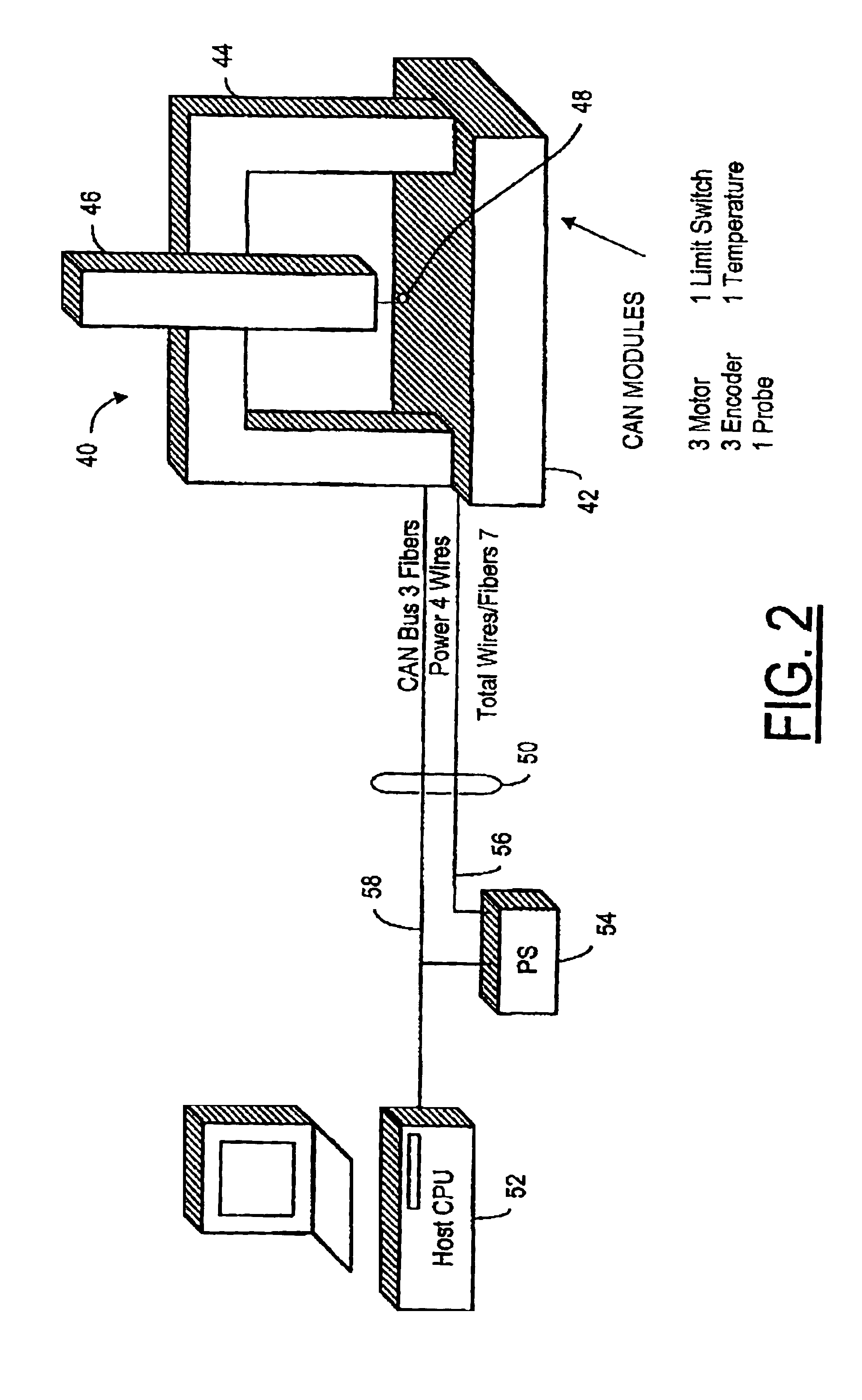

Communication method and common control bus interconnecting a controller and a precision measurement assembly

InactiveUS6948255B2Reduce cable dragImprove servo performanceFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansControl busEmbedded system

The number and weight of wires interconnecting a host and / or controller with a precision measurement assembly is reduced using a common or shared bus. The bus may be entirely electrical or may include optical fibers to reduce EMI susceptibillty. A custom bus or a known serial network bus such as CAN or SIRCOS may be used.

Owner:HEXAGON TECH CENT GMBH

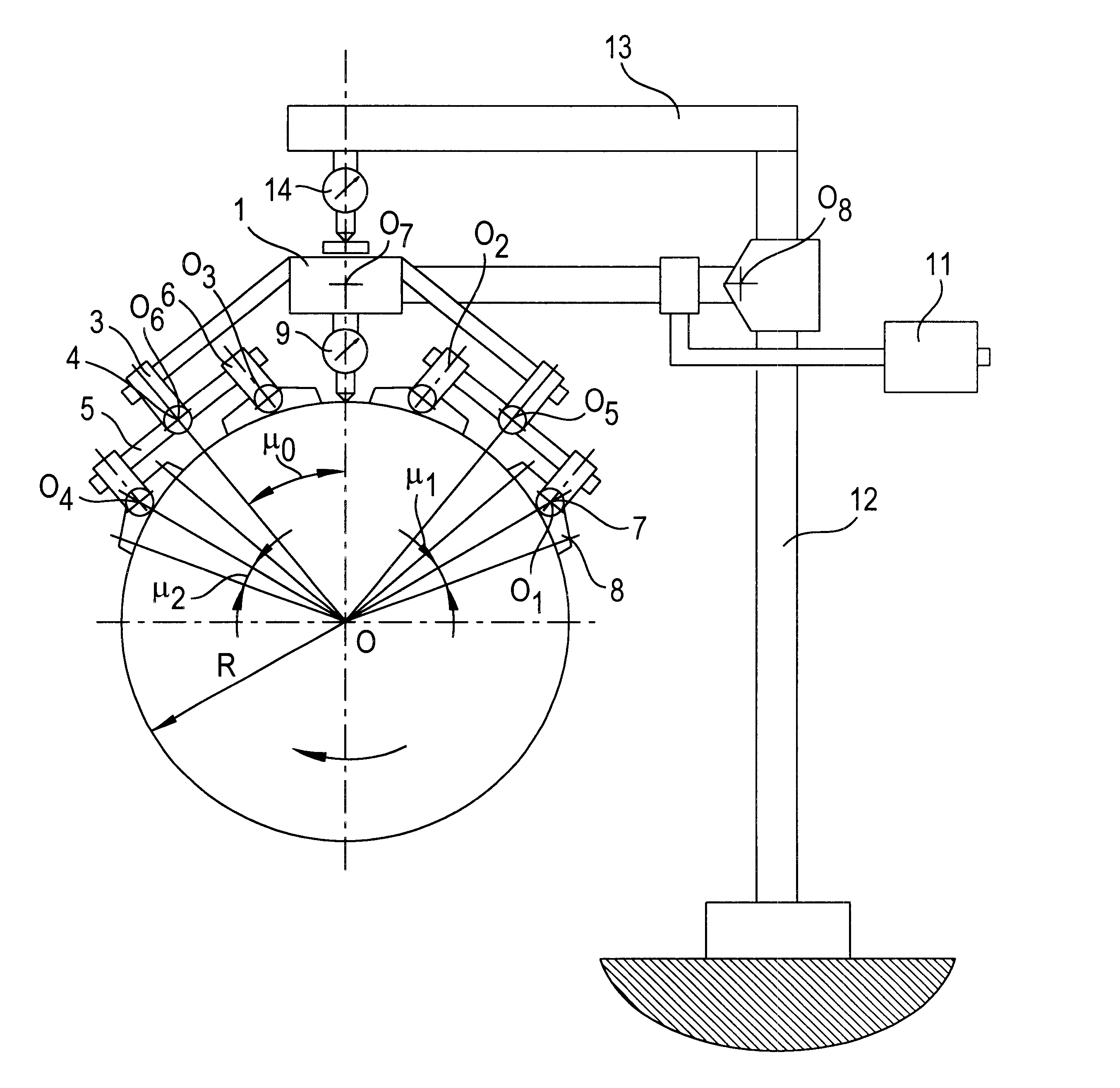

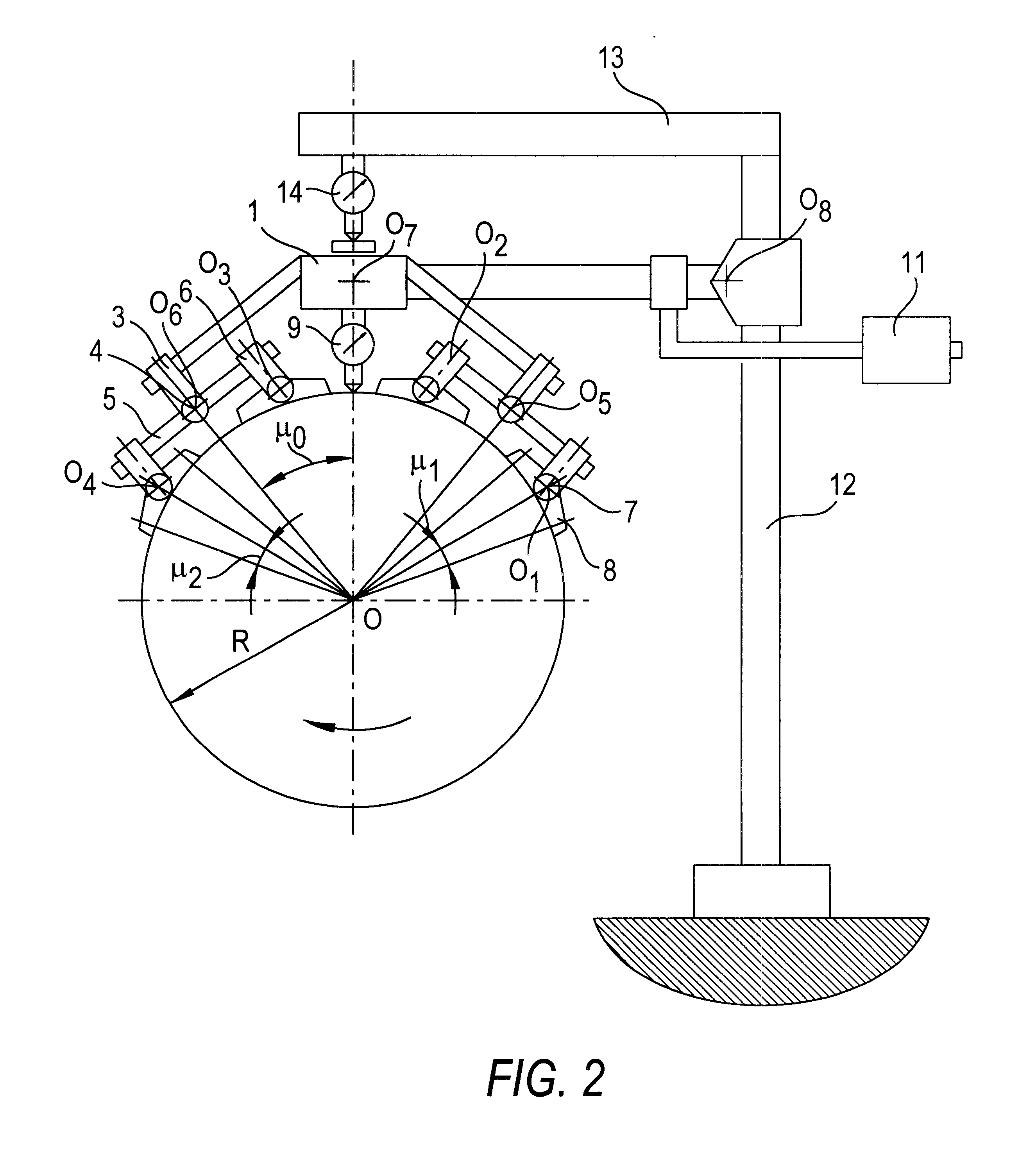

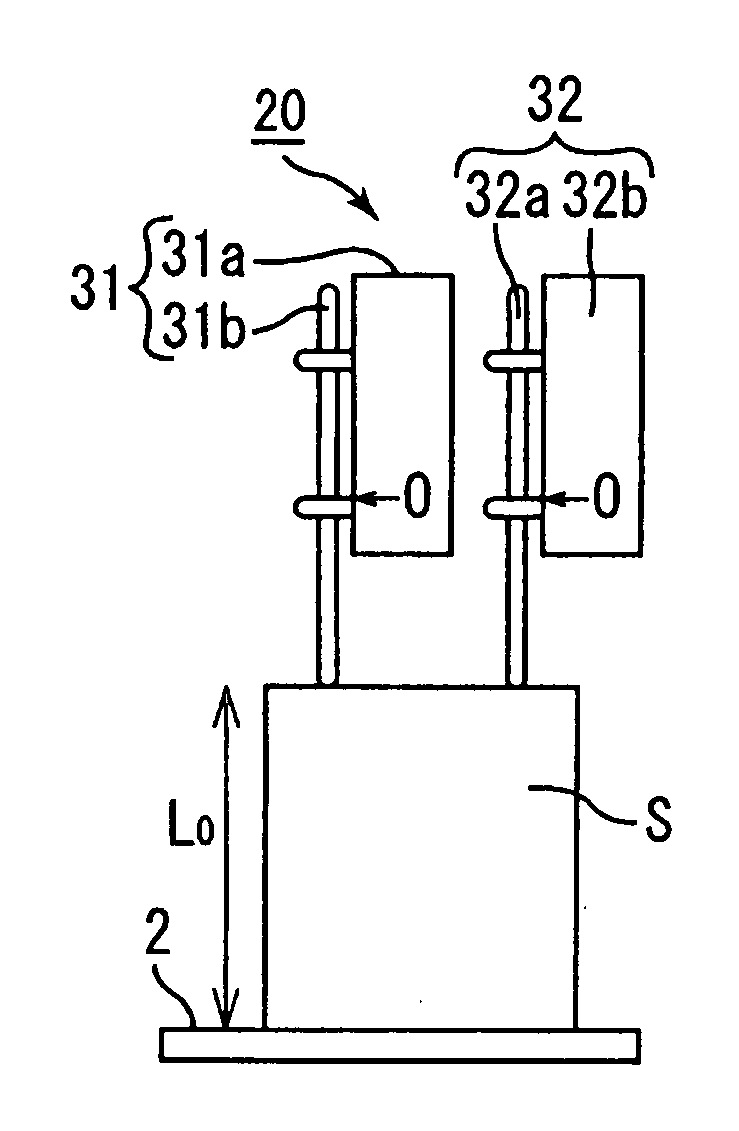

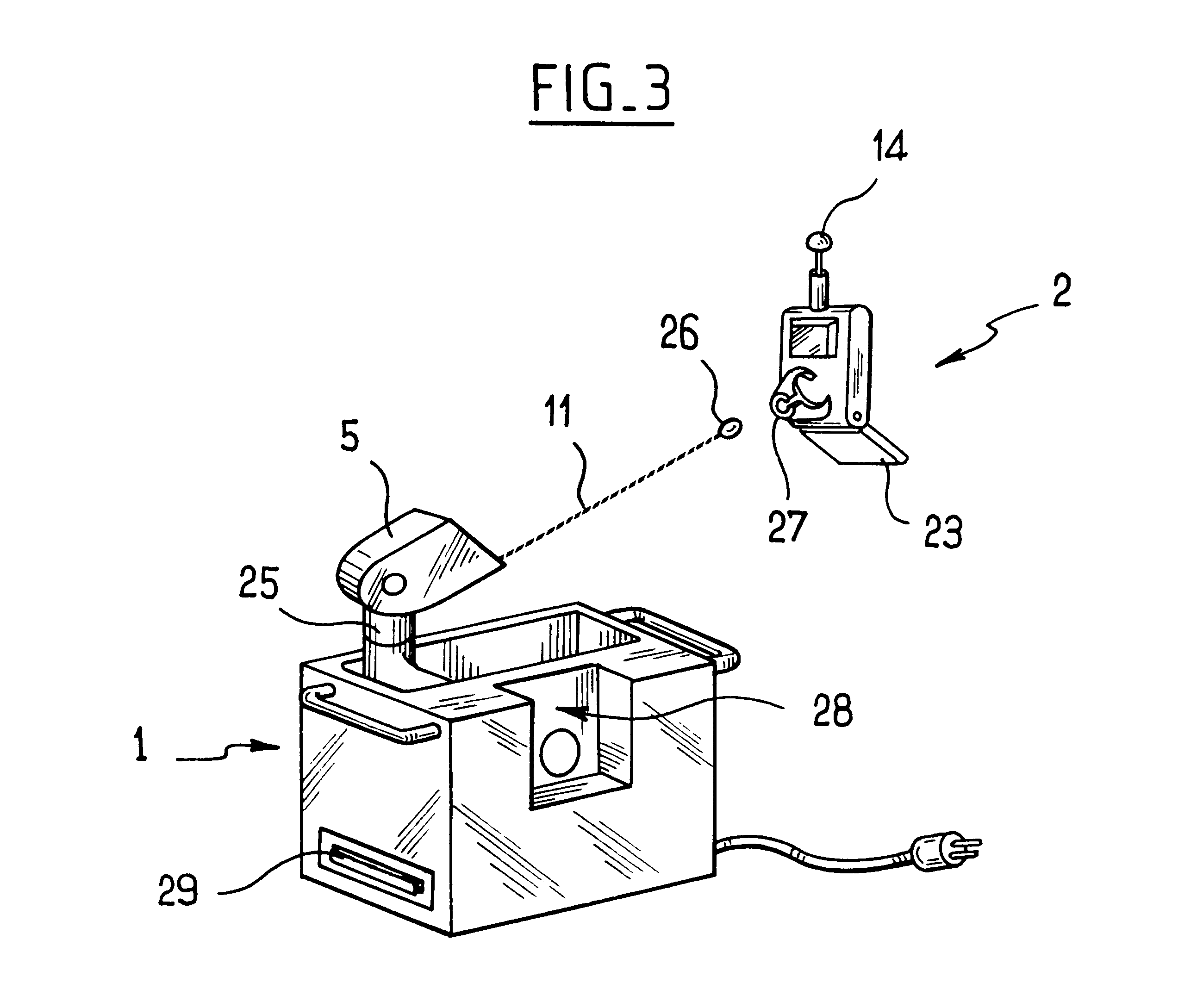

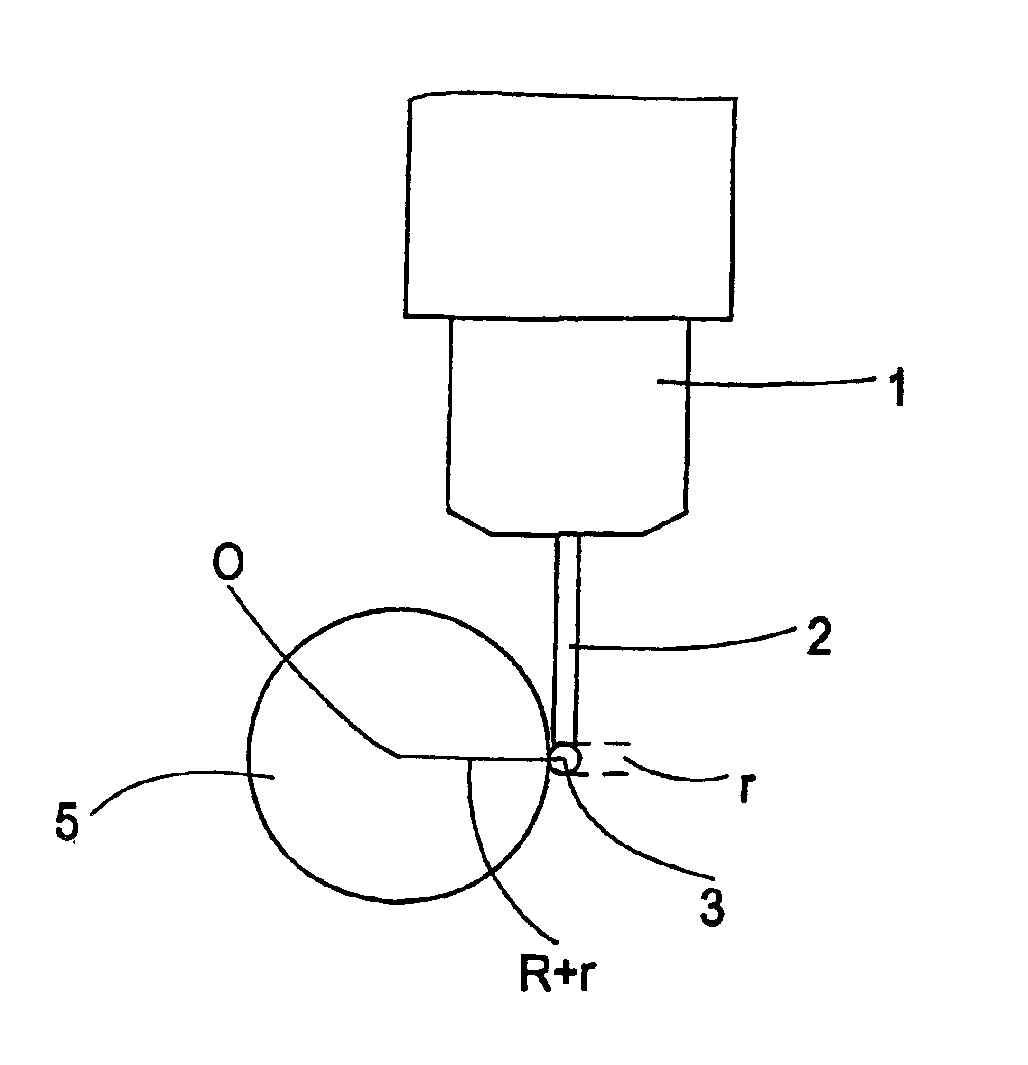

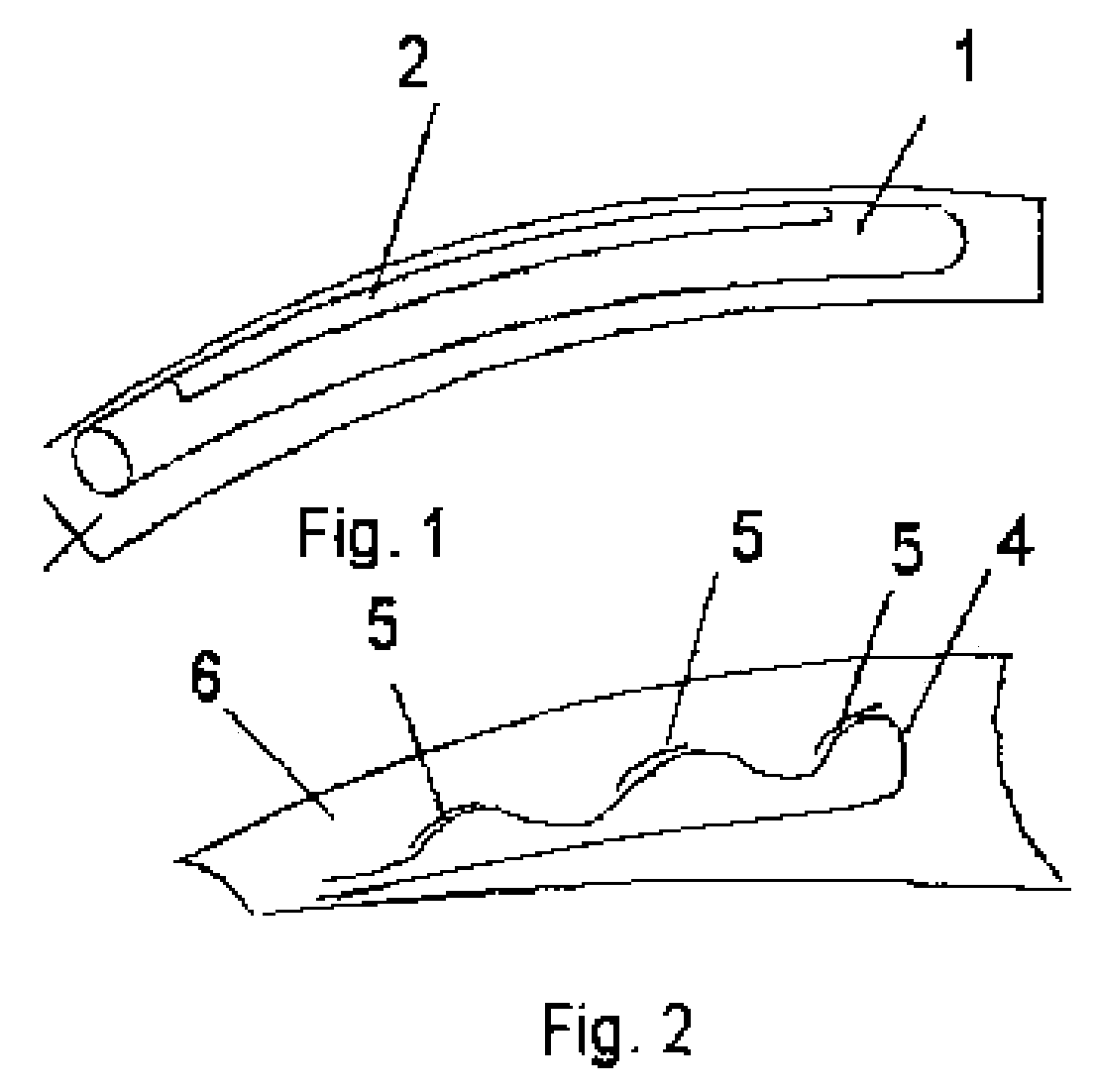

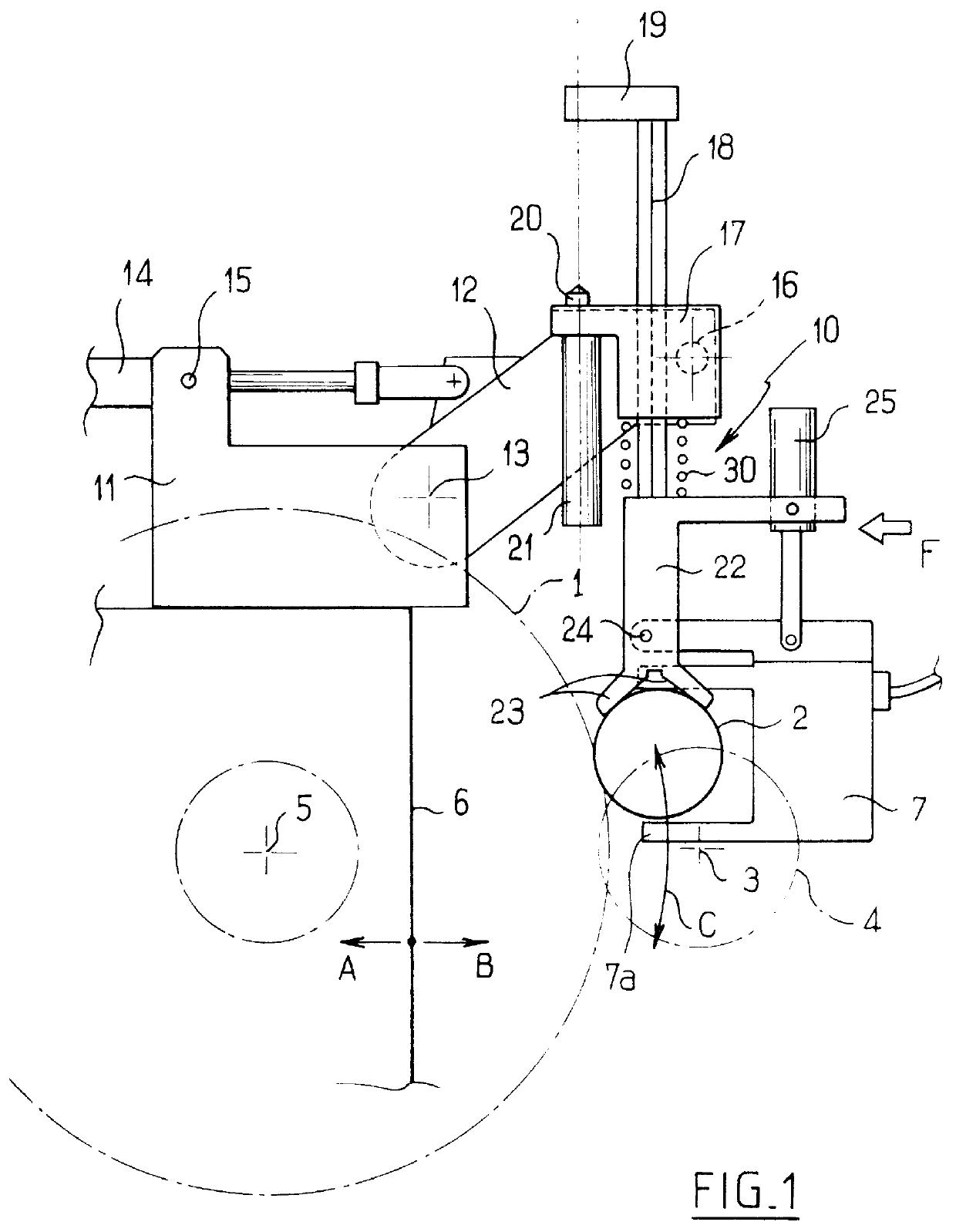

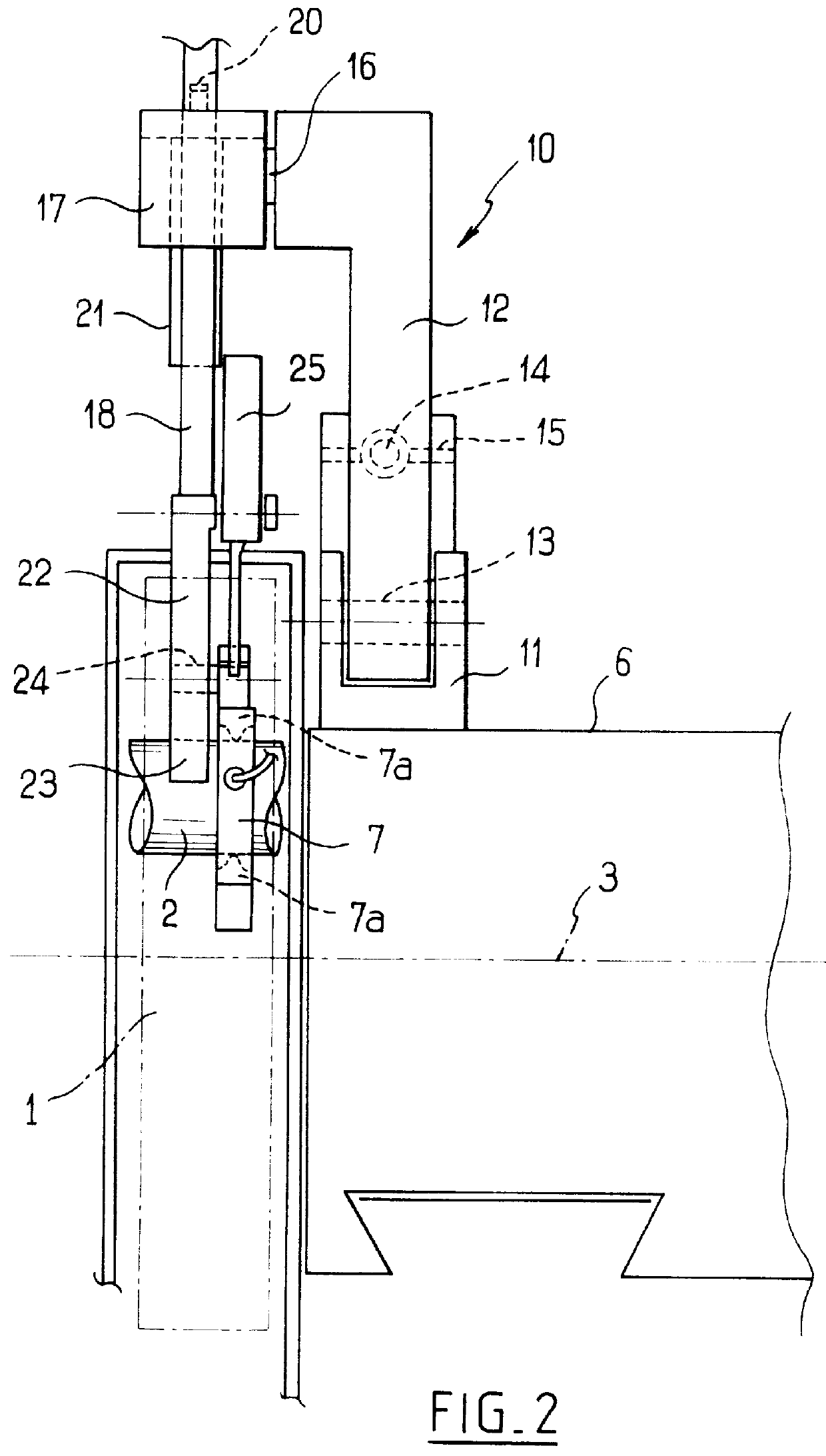

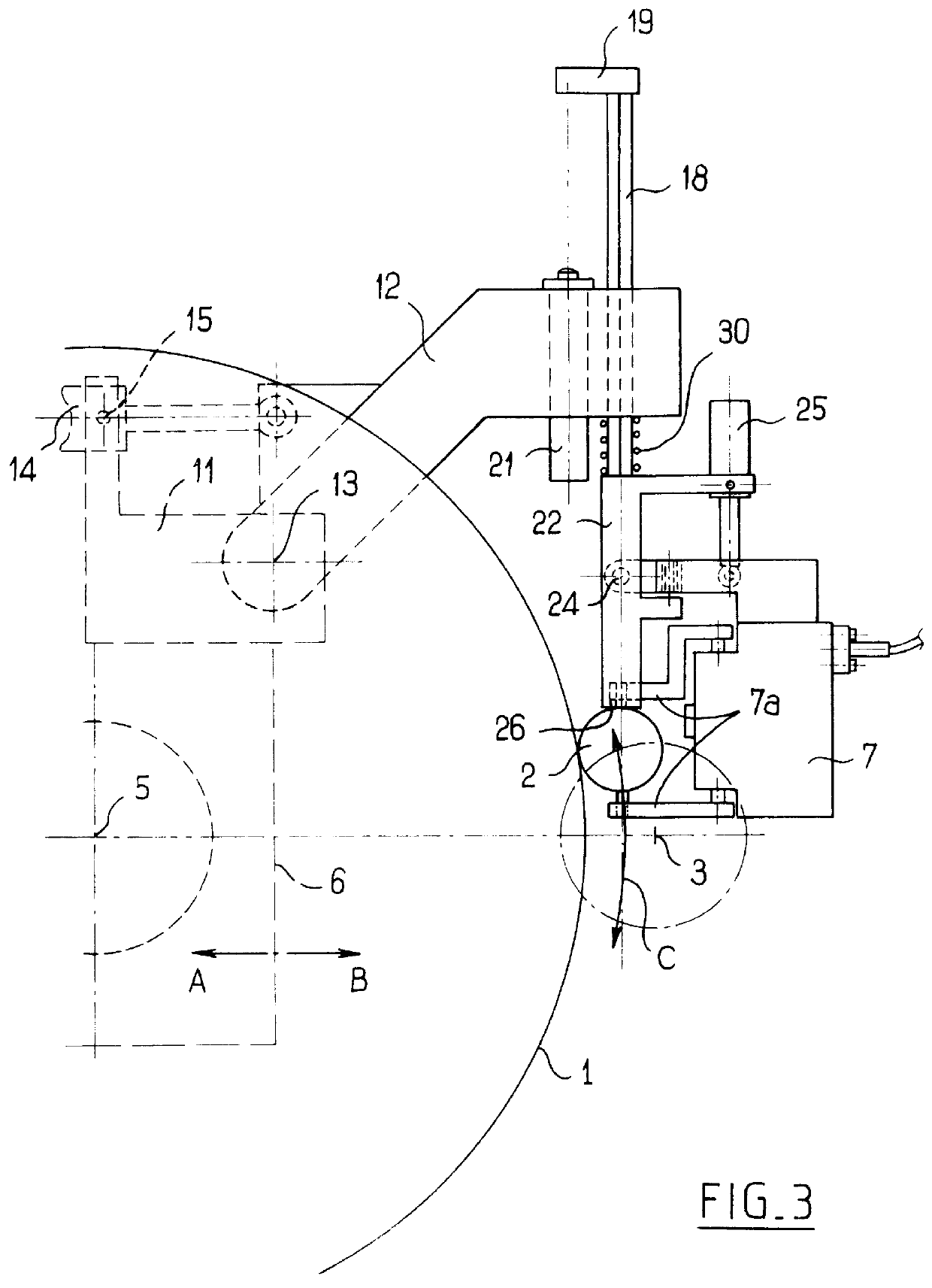

Device for monitoring the diameter of an orbitally mobile cylindrical piece during machining thereof

InactiveUS6088924ARevolution surface grinding machinesMechanical counters/curvatures measurementsEngineeringMachining process

PCT No. PCT / FR96 / 01545 Sec. 371 Date Mar. 31, 1998 Sec. 102(e) Date Mar. 31, 1998 PCT Filed Oct. 6, 1996 PCT Pub. No. WO97 / 13614 PCT Pub. Date Apr. 17, 1997A device for measuring and / or checking the diameter of a cylindrical part (2) moving orbitally about an axis (3) during a grinding process. The device comprises a measuring head (7) coupled to a holder (18, 22) which is provided with a member (26) for engaging the circumference of the part (2), and is movably mounted in a direction parallel to itself on a frame (31) so that it can follow the orbital motion of the part (2). Grinding is performed by means of a tool (1) moving transversely to said axis (3), and the frame (31) is moved transversely to said axis and synchronised with the motion of the tool (1).

Owner:ETAMIC

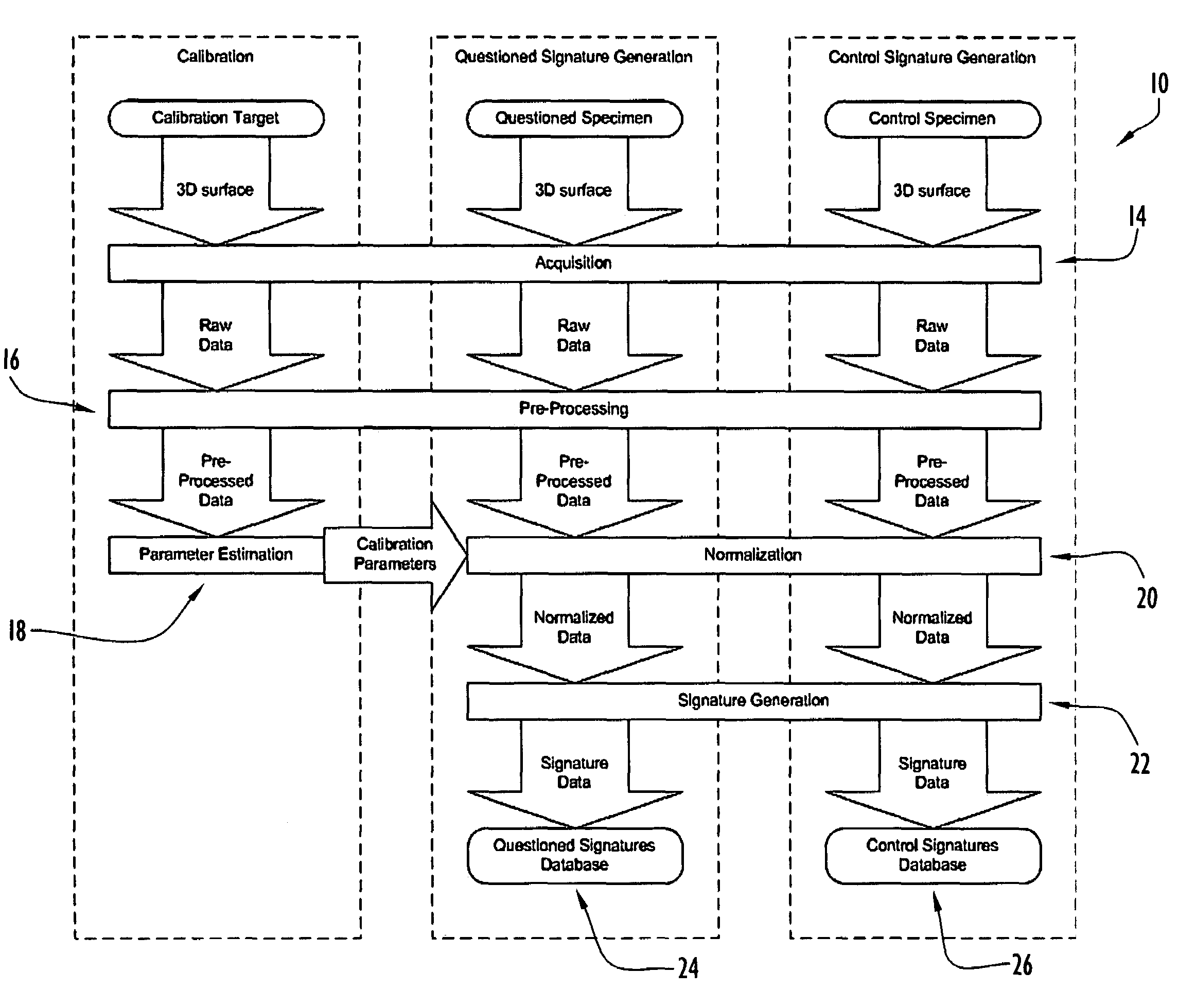

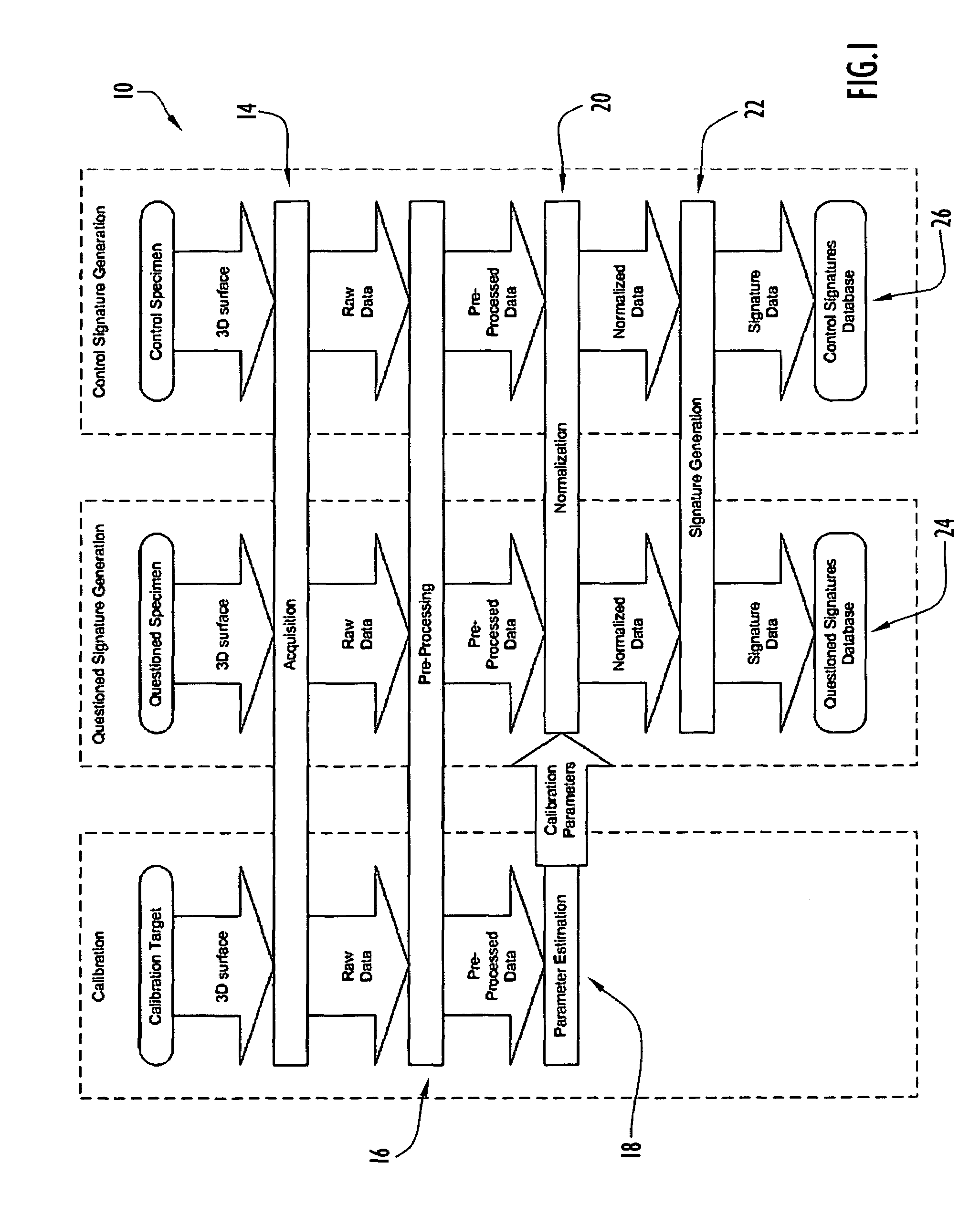

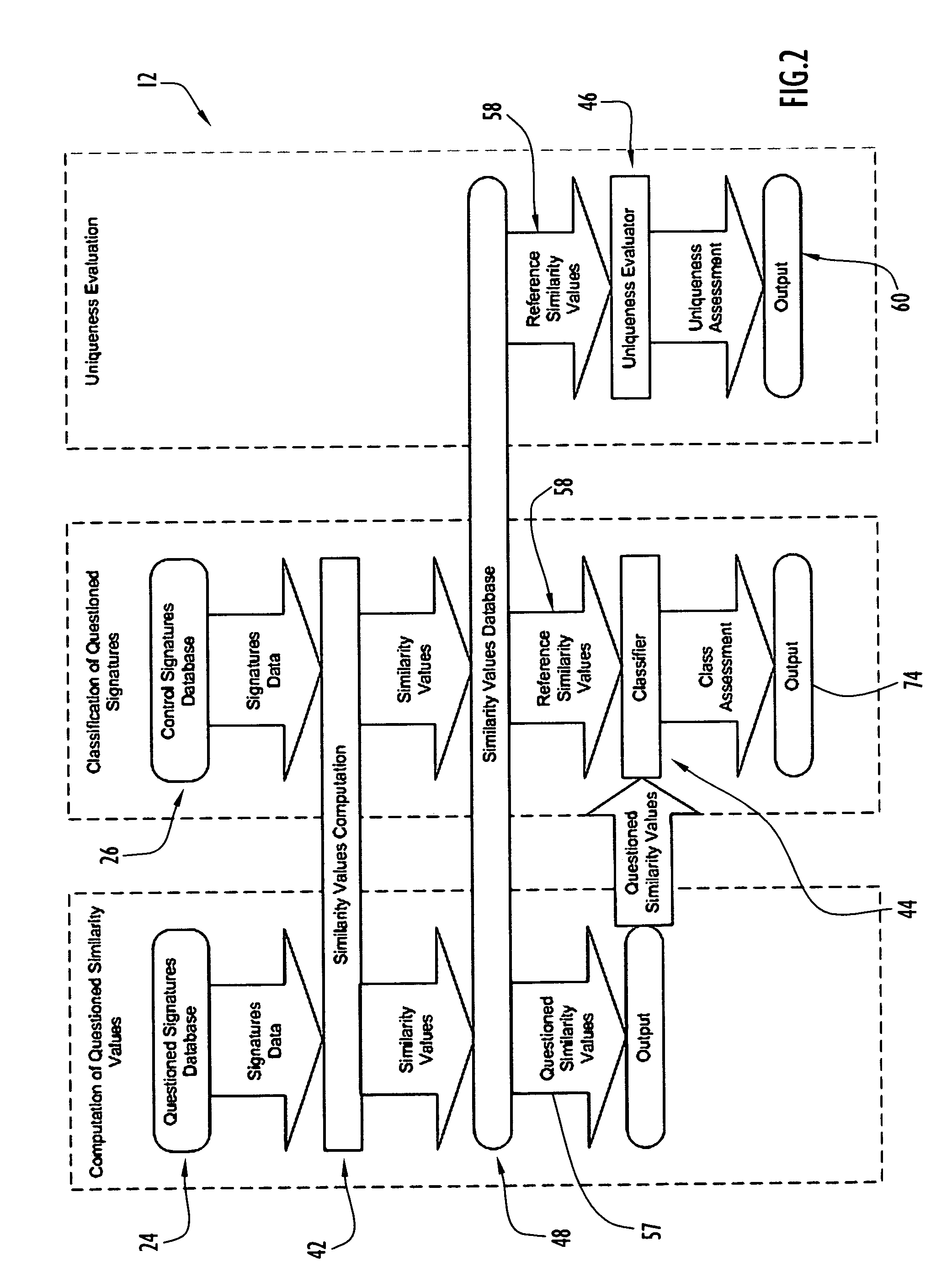

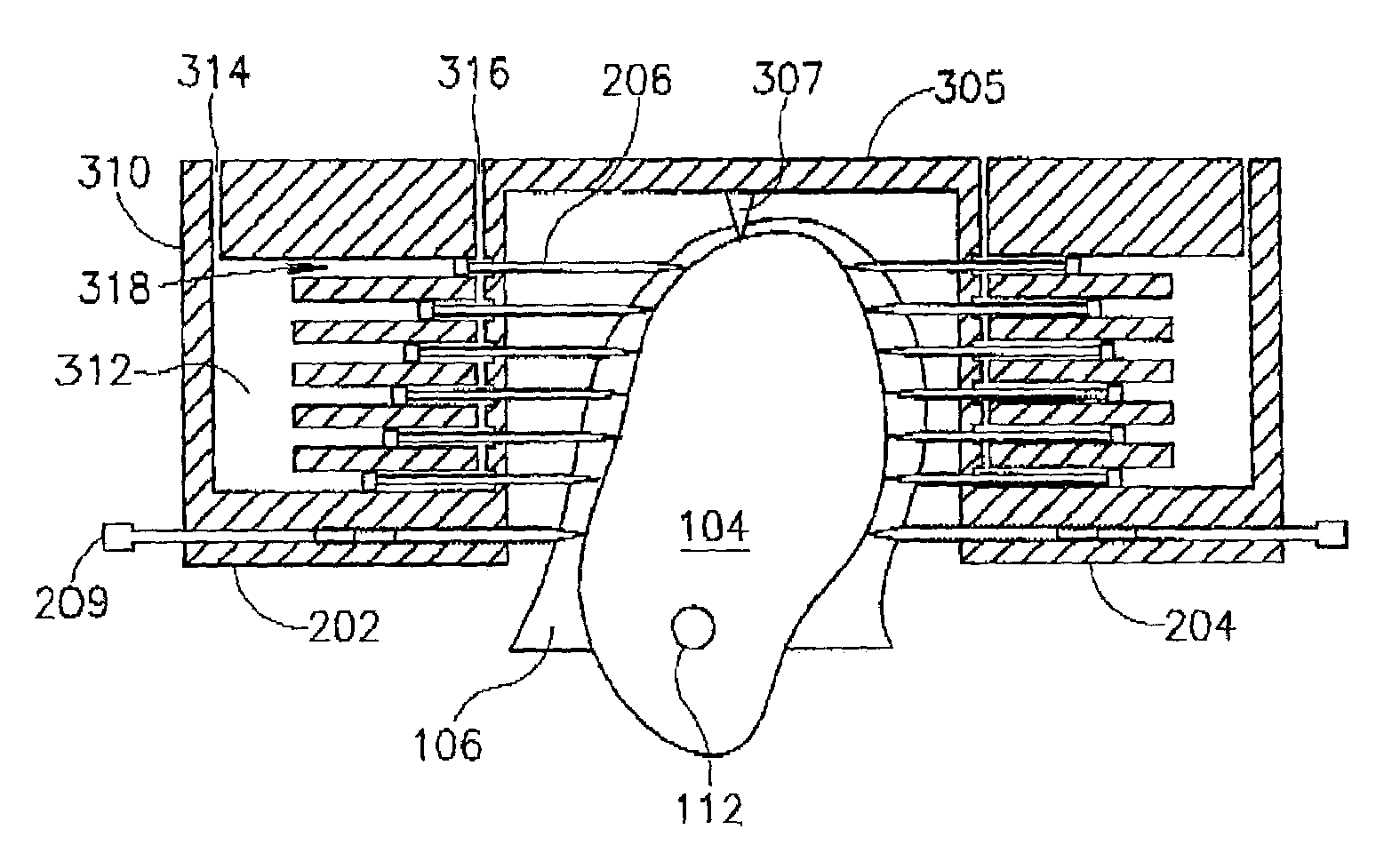

Automated system and method for tool mark analysis

An automated system for tool mark analysis includes an acquisition mechanism for acquiring 3D data of tool marks left on the surfaces of specimens by tools, a signature generation module for generating tool mark signatures from the acquired data, an analysis unit for comparing pairs of the tool mark signatures to obtain a numerical similarity value reflective of their similarity, and a database in which the similarity values are stored. An automated method for tool mark analysis involves the steps of acquiring the 3D data of tool marks, generating the tool mark signature, statistically evaluating pairs of the tool mark signatures, and providing a numerical similarity value for each pair of tool mark signatures reflecting the degree of similarity between the tool mark signatures of each pair. The method is carried out with automated assistance of a computer.

Owner:INTELLIGENT AUTOMATION LLC

Hard tissue surface geometry determination

Apparatus for measuring a surface geometry of hard tissue covered by a layer of soft tissue, including a plurality of elements each having a tip adapted to penetrate said soft tissue and not substantially penetrate said hard tissue; a frame supporting movement of said elements, each along a path, such that a plurality of said tips, when positioned along the paths, define a surface; and at least one position sensor which generates a signal indicative of a tip position of at least one of said elements.

Owner:TACTILE TECH

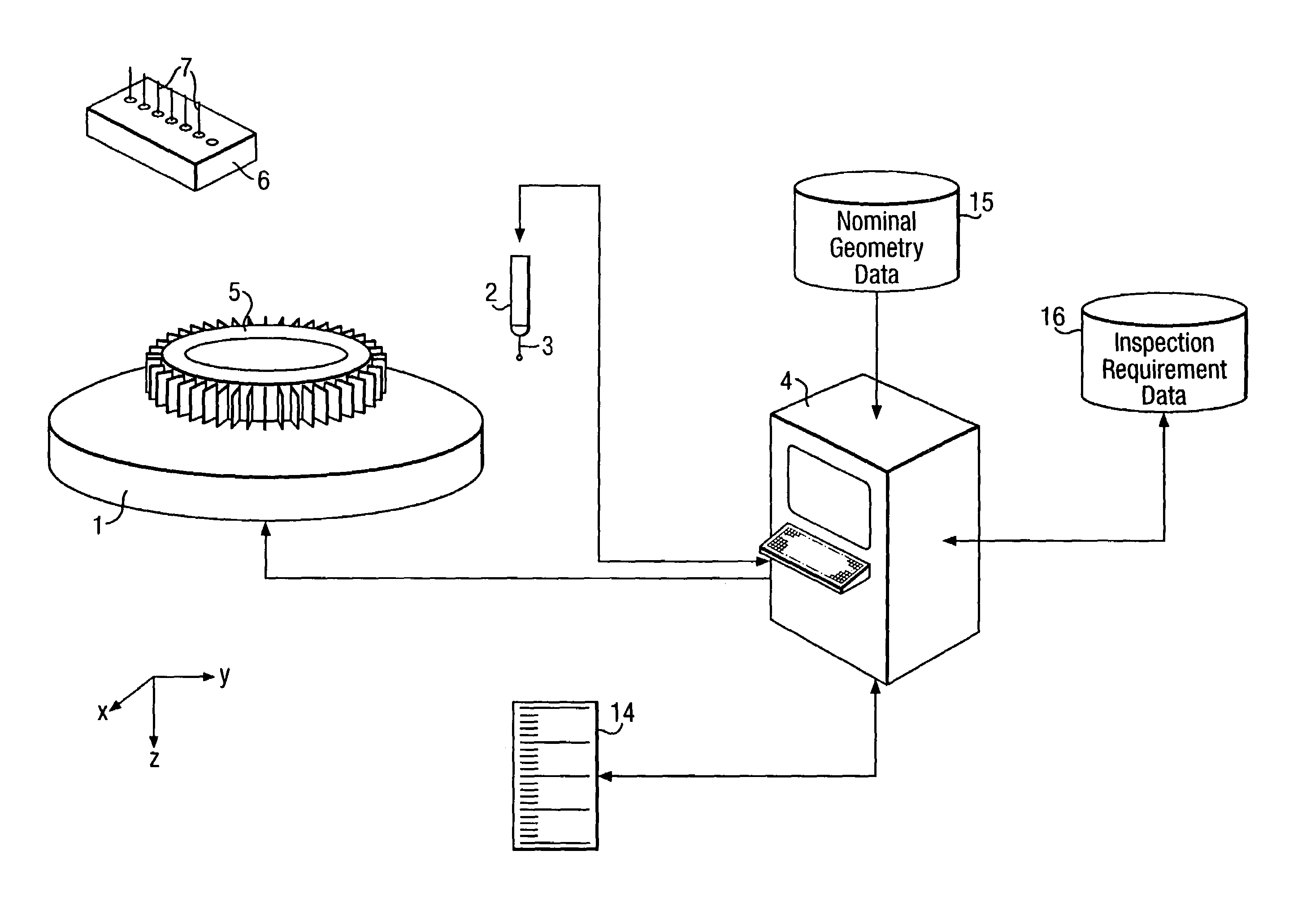

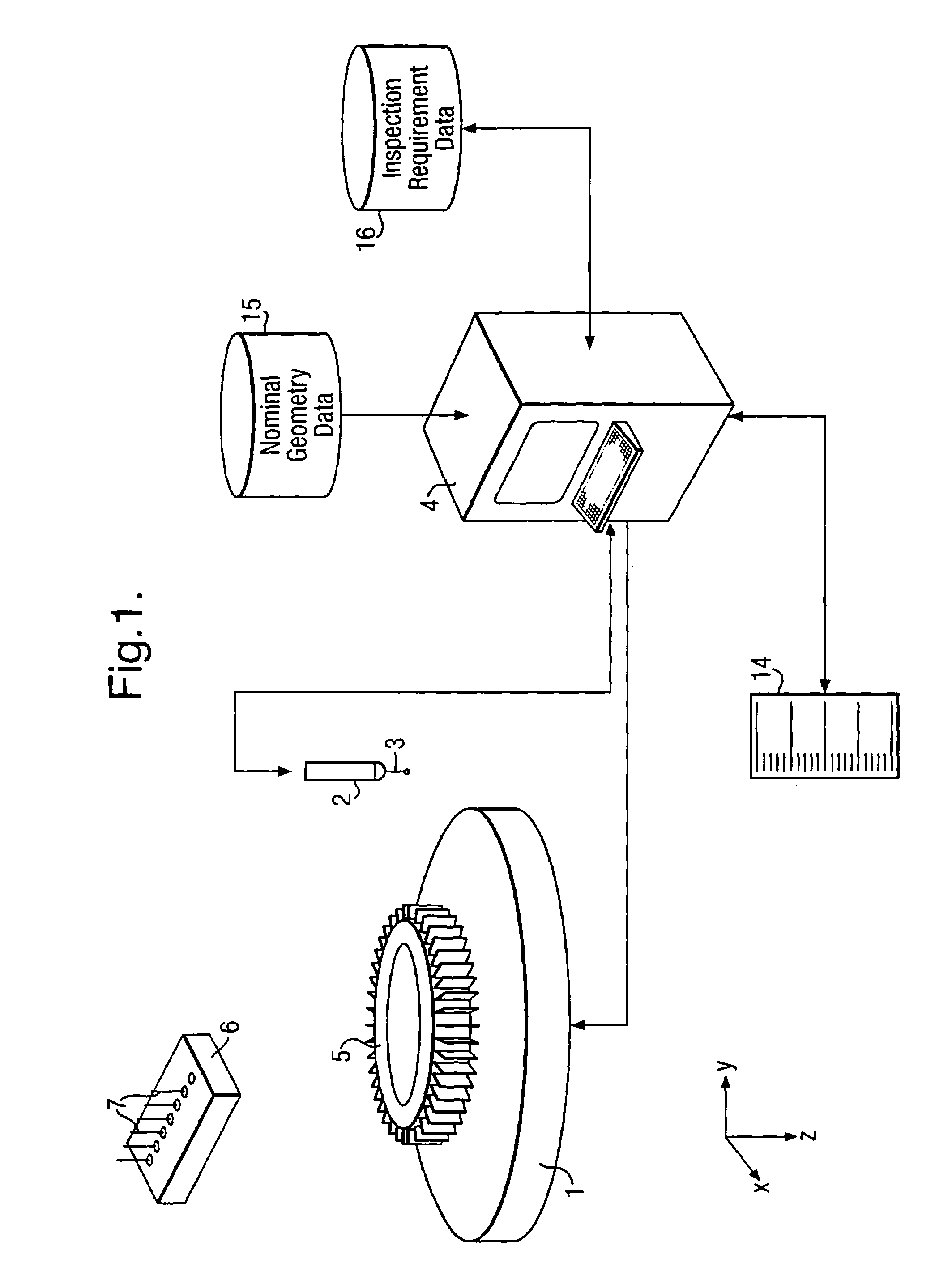

Method of generating an inspection program and method of generating a visual display

InactiveUS7146291B2Amount of timeChange in numberFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansAlgorithmData mining

Owner:ROLLS ROYCE PLC

Railroad surveying and monitoring system

InactiveUS8180590B2Avoid large vibrationsPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTrackwayMonitoring system

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

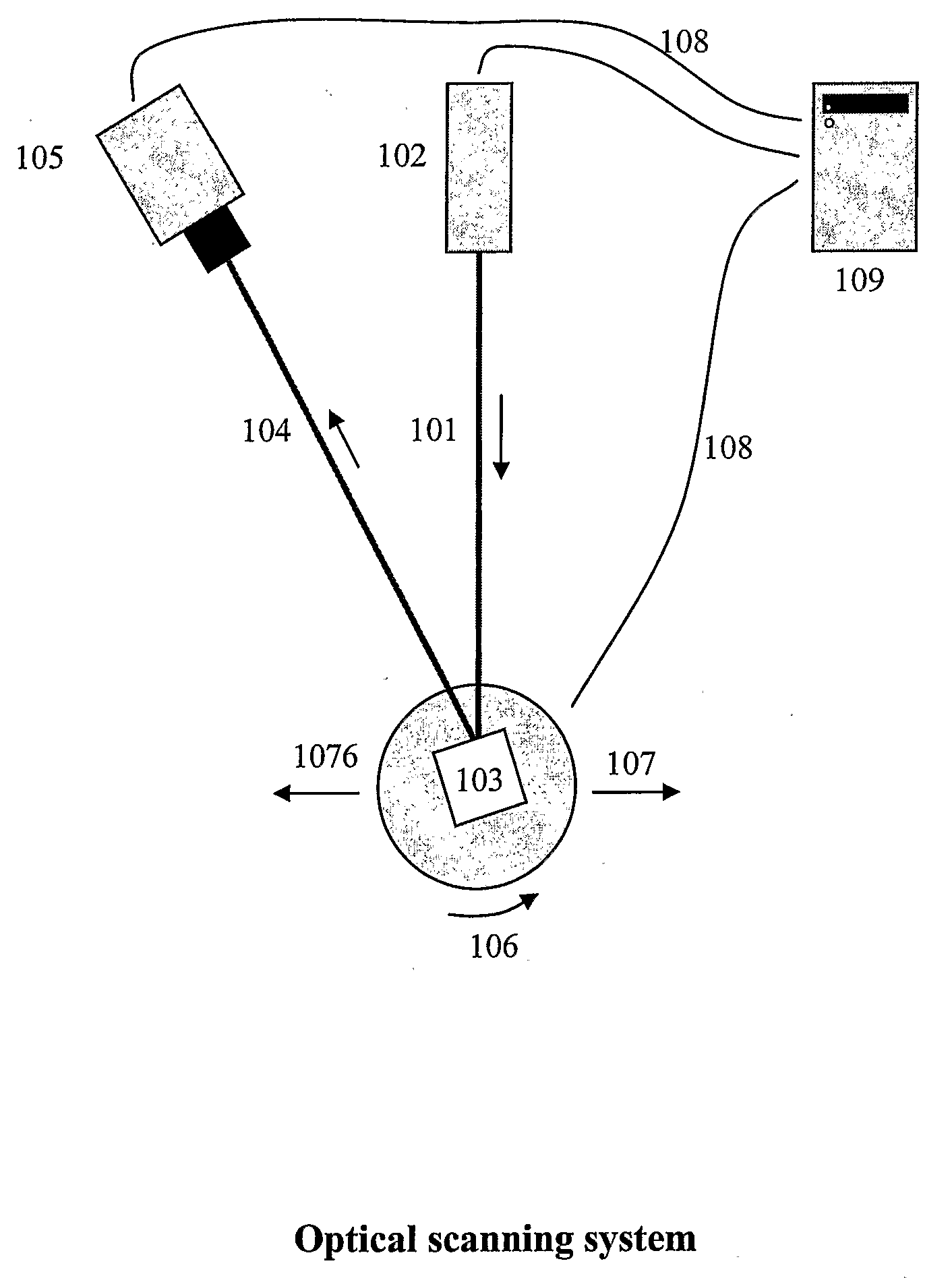

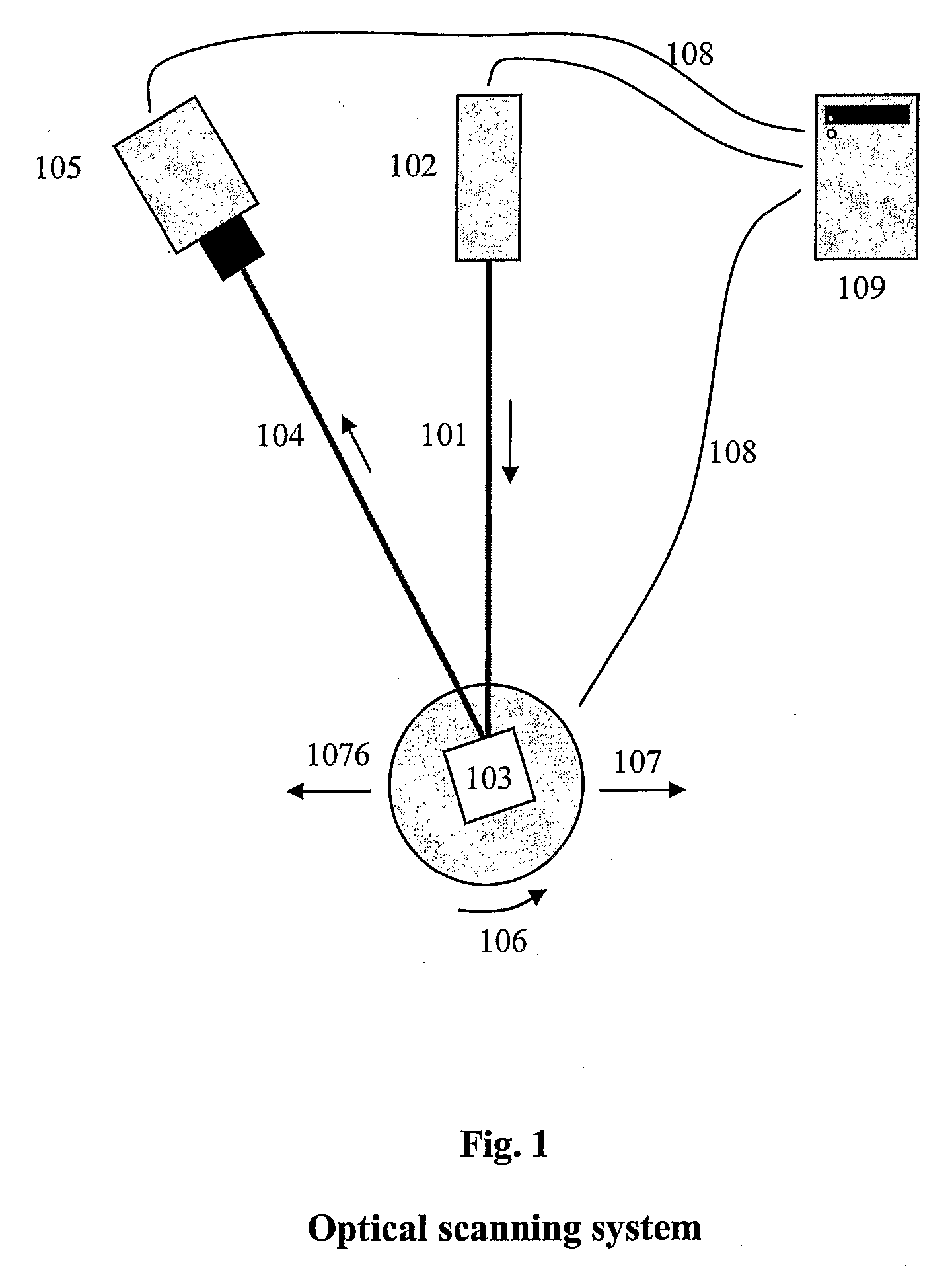

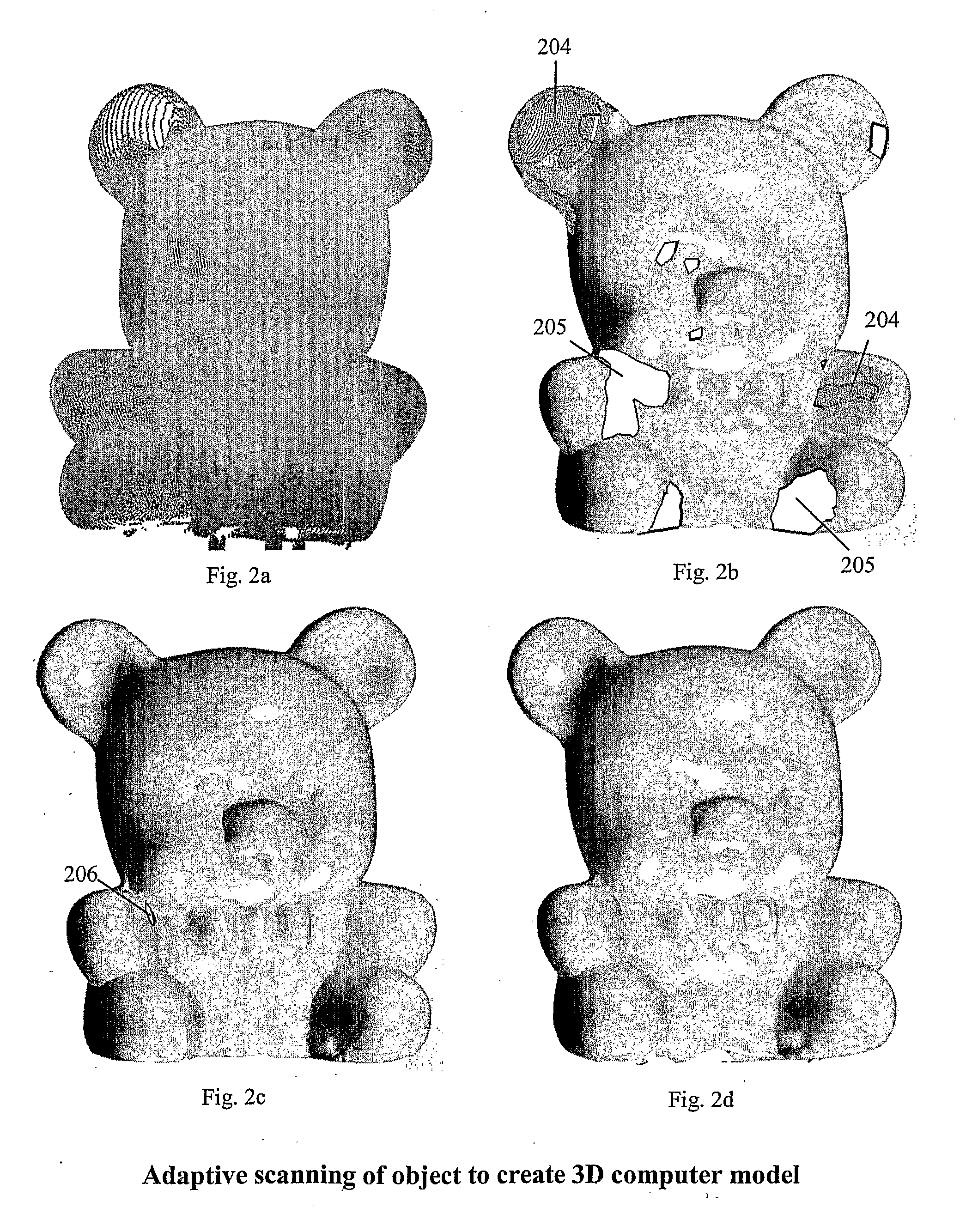

Adaptive 3D Scanning

ActiveUS20080306709A1Feeler-pin gaugesMechanical counters/curvatures measurementsComputer graphics (images)3d scanning

The present invention relates to adaptive 3D scanning wherein a scan sequence for obtaining full geometrical coverage of a physical object are created automatically and specifically for the physical object, by using a method and a system for producing a 3D computer model of a physical object, wherein the method comprises the following steps providing a scanner system, said scanner system comprising a scanner, and a computer connectable to and / or integrated in said scanner, said computer comprising a virtual model of said scanner, entering shape information of the physical object into the computer, creating in said computer a visibility function based on said virtual model and the shape information, said visibility function being capable of evaluating the coverage of areas of interest of the physical object by at least one predetermined scan sequence, establishing at least one scan sequence based on the evaluation of the visibility function, performing a scan of the physical object using said at least one scan sequence, and obtaining a 3D computer model of the physical object.

Owner:3SHAPE AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com