Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7301results about "Acceleration measurement using interia forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

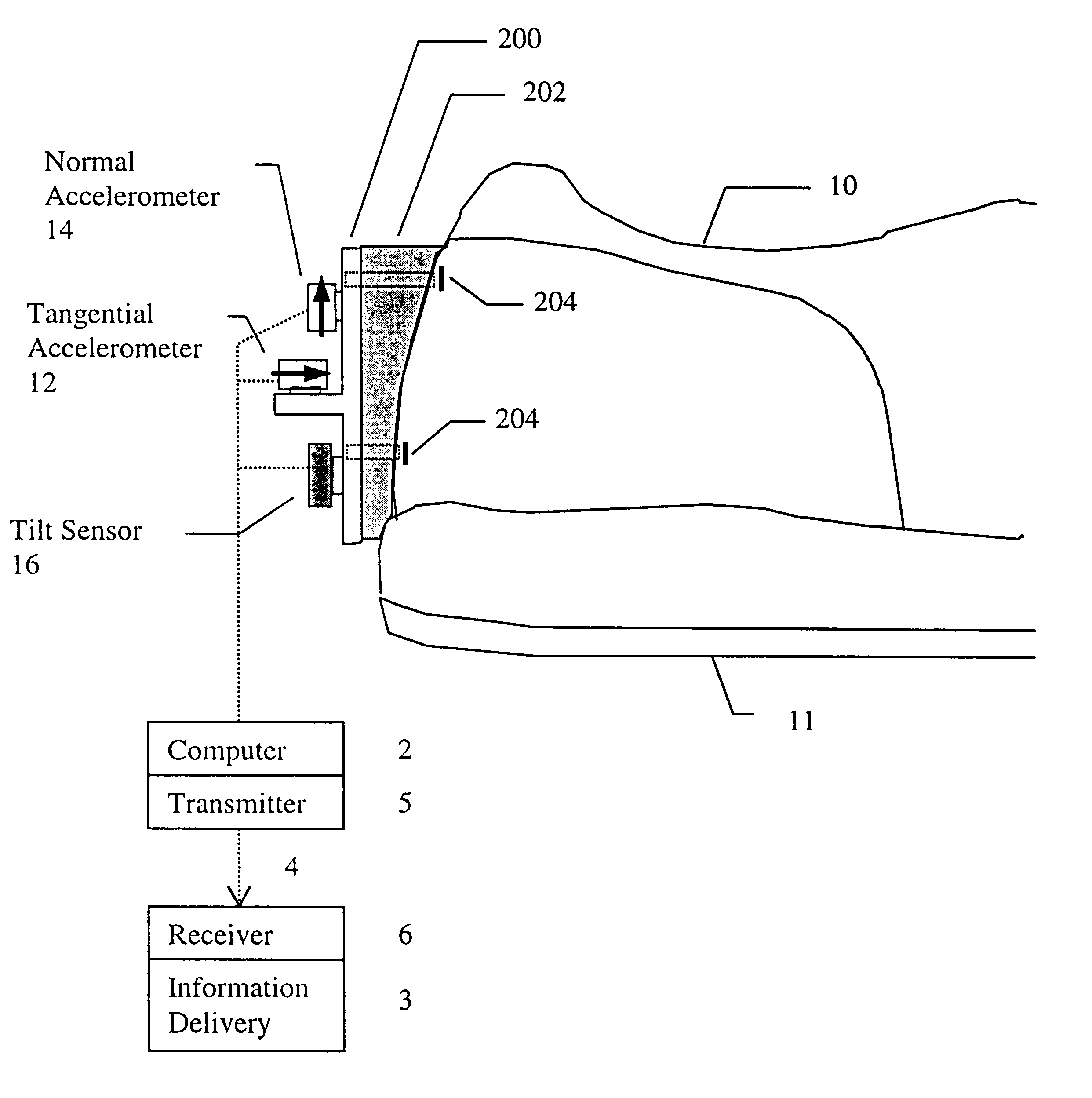

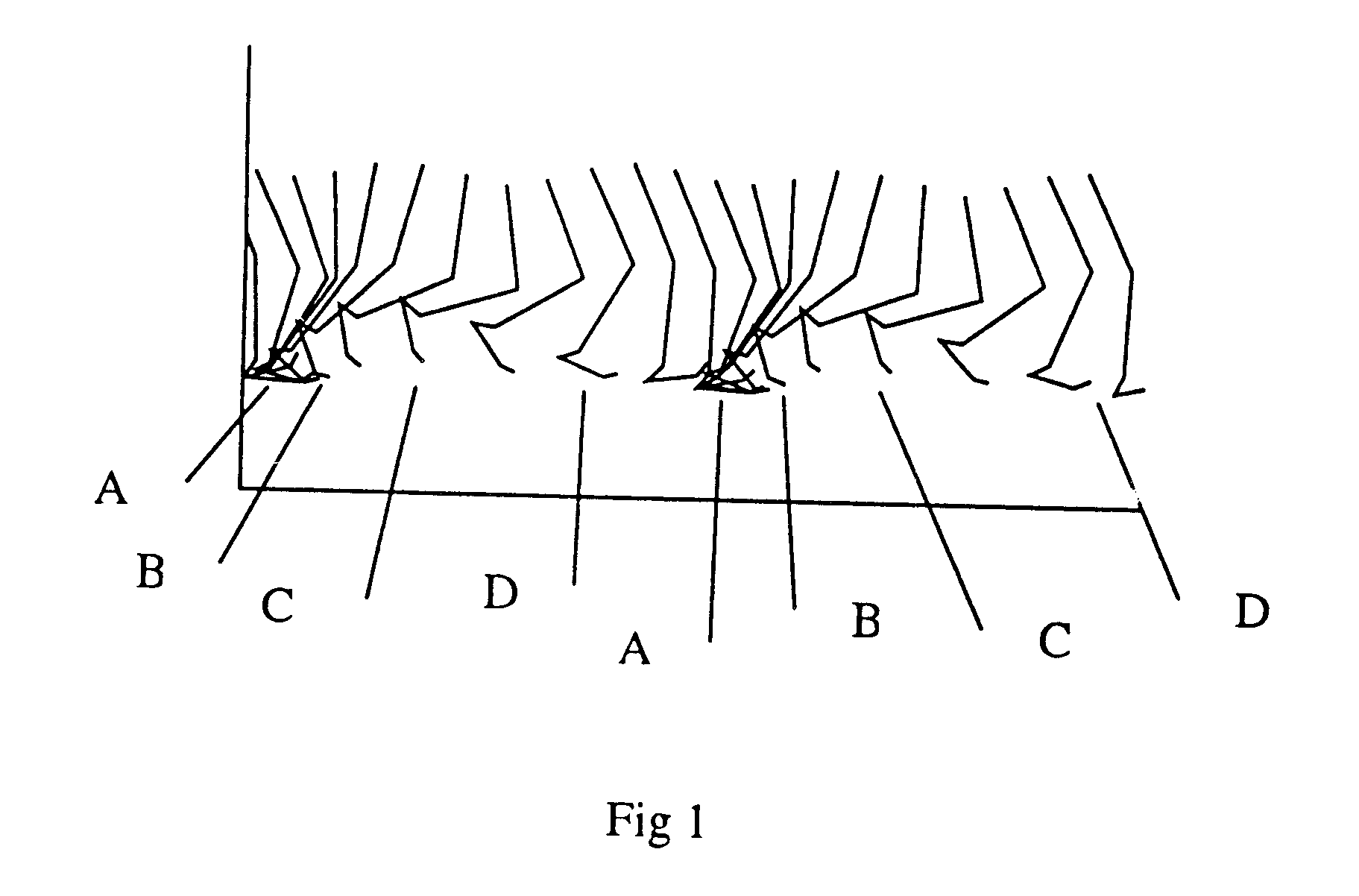

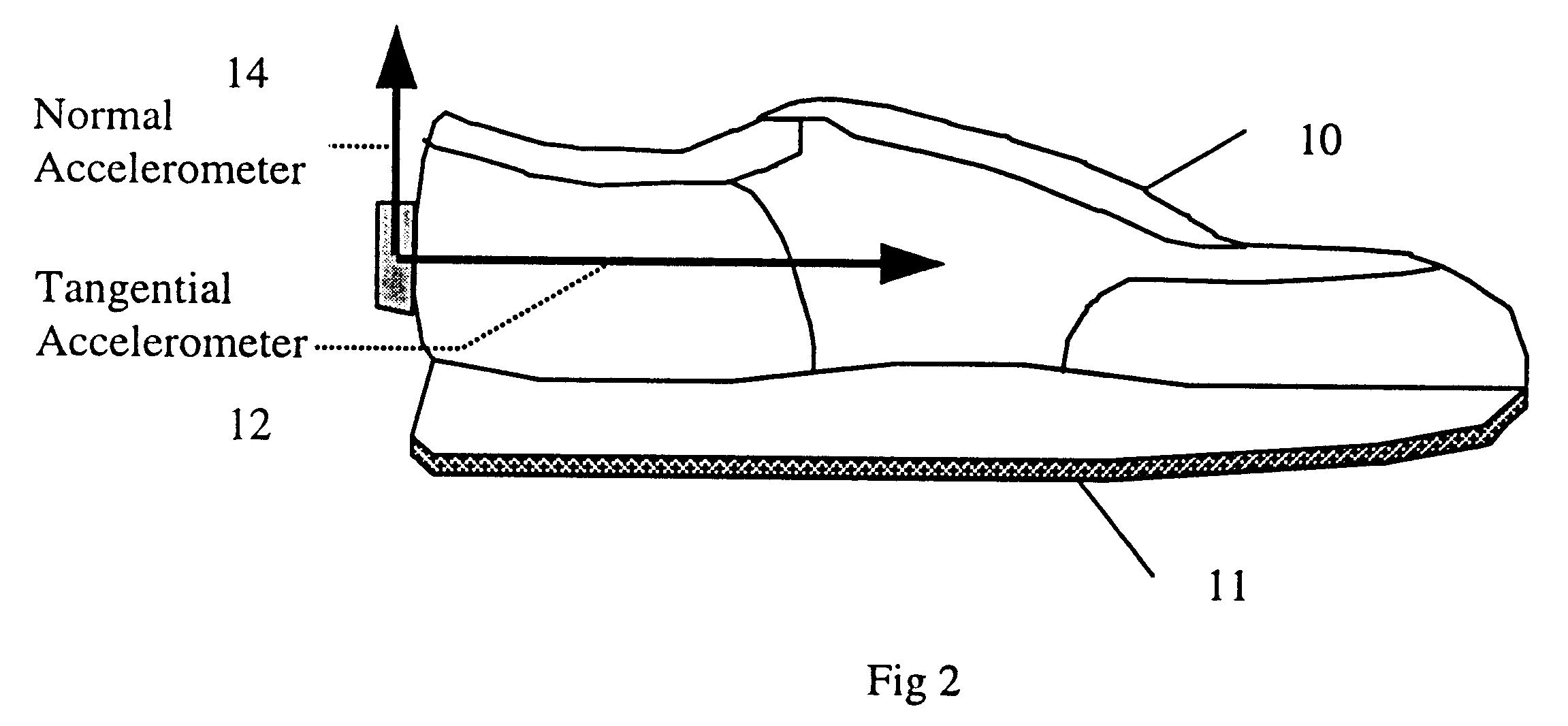

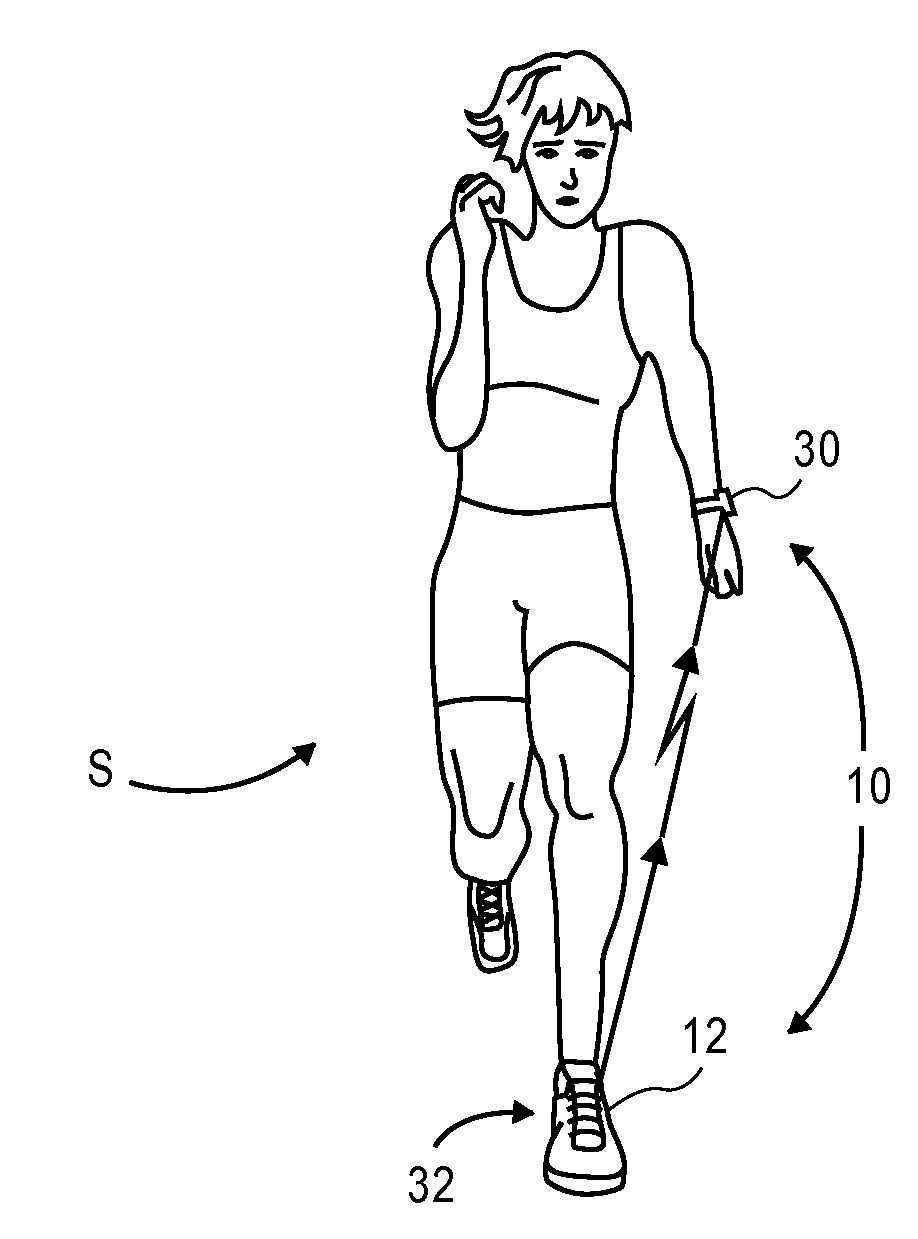

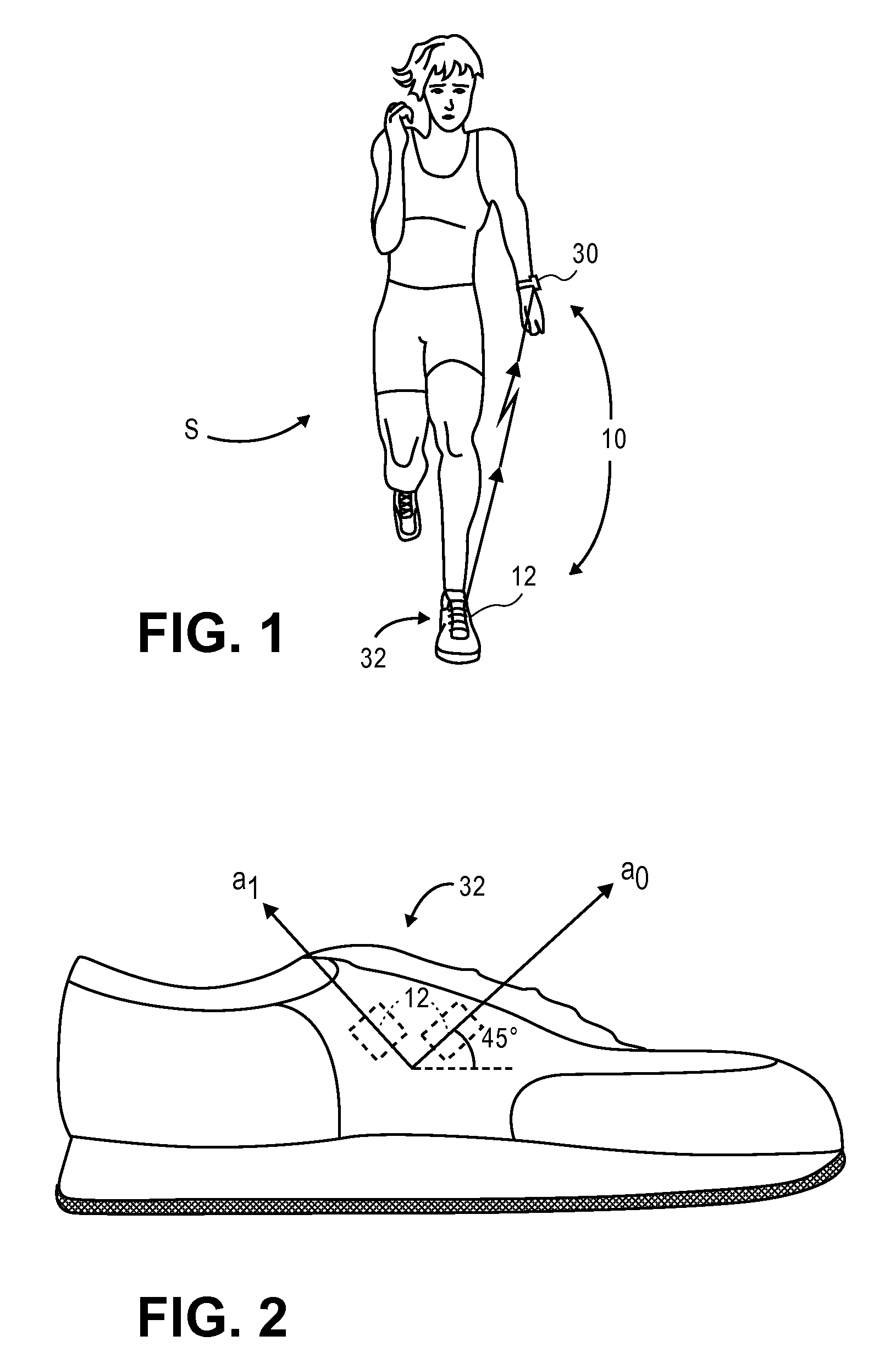

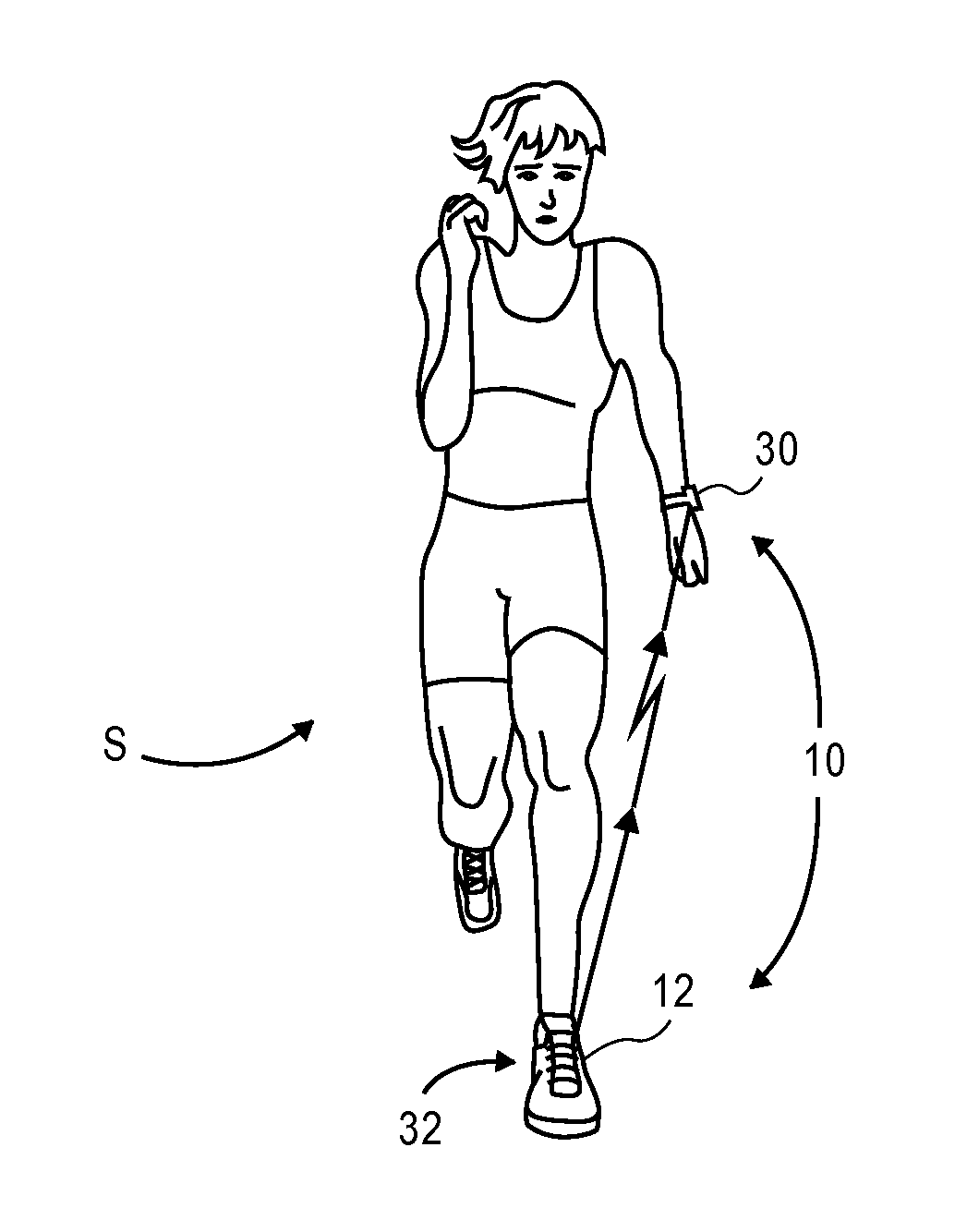

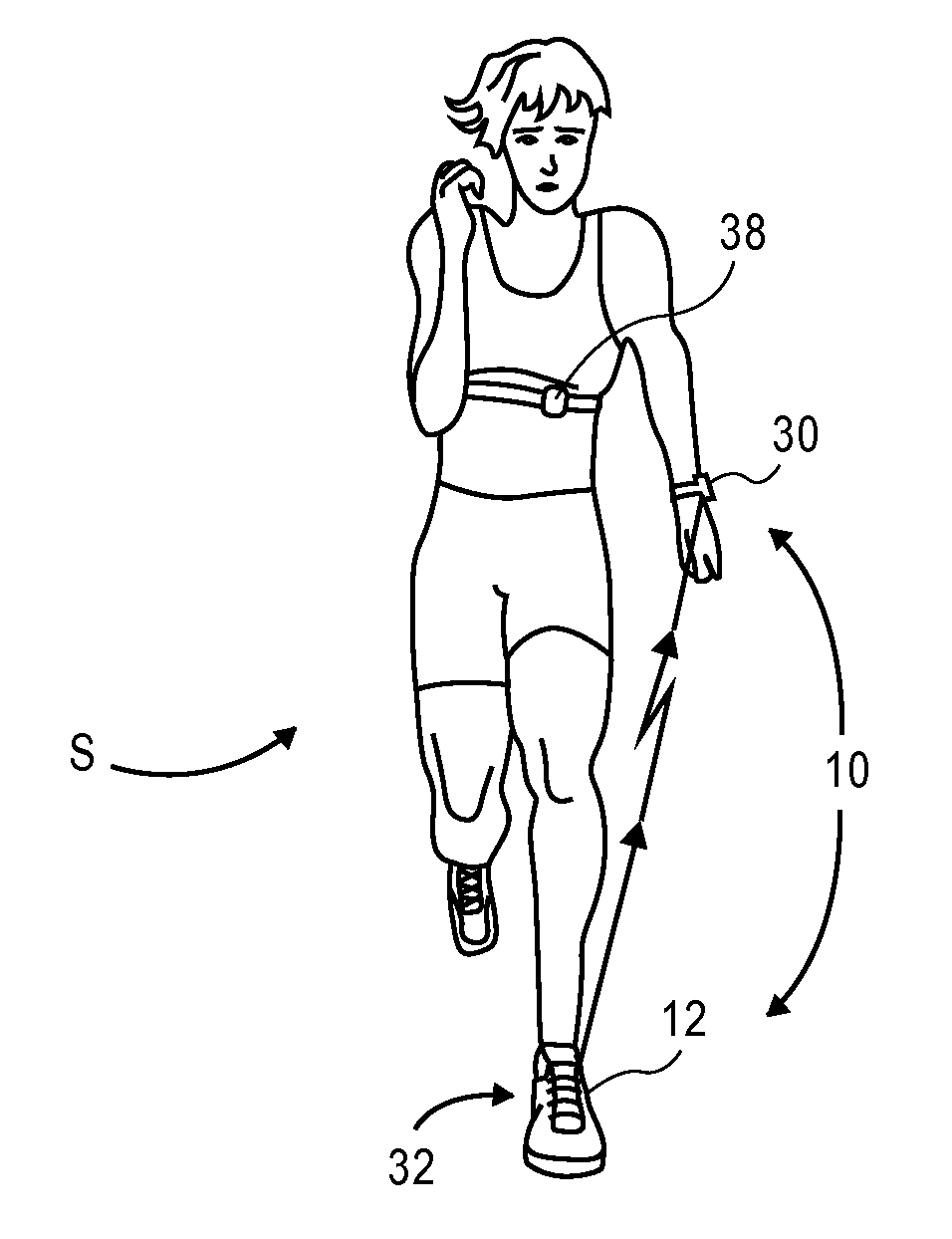

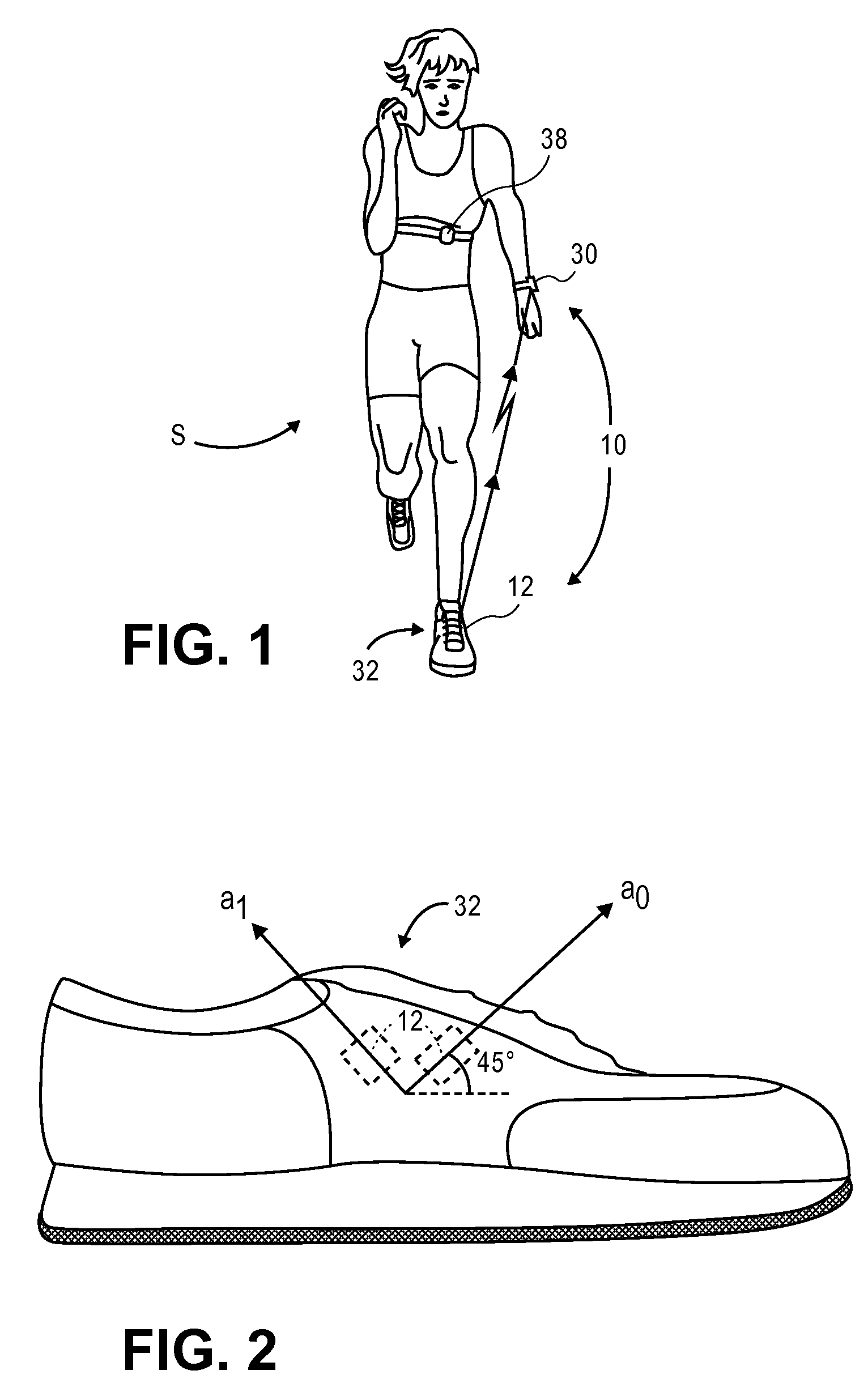

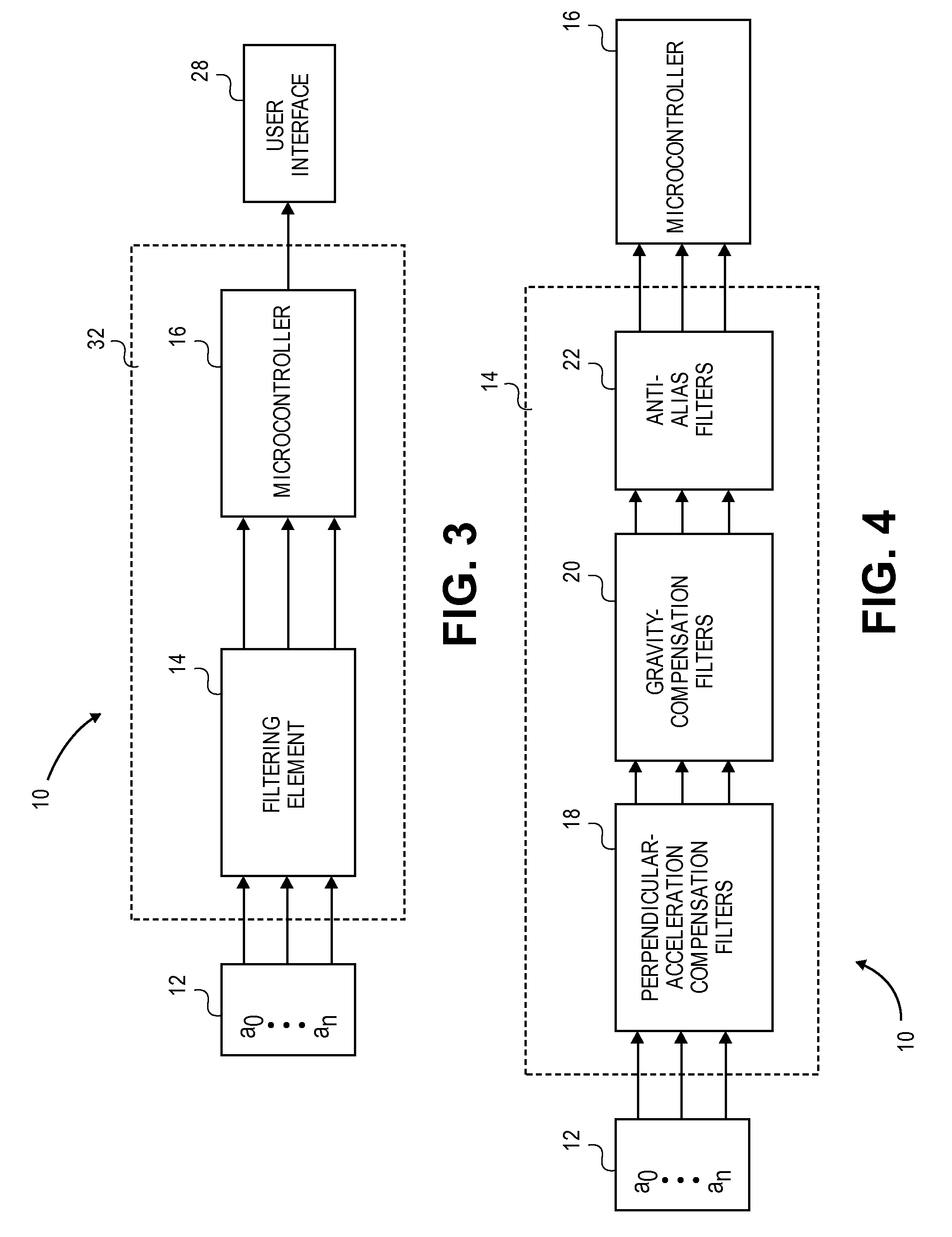

Motion analysis system

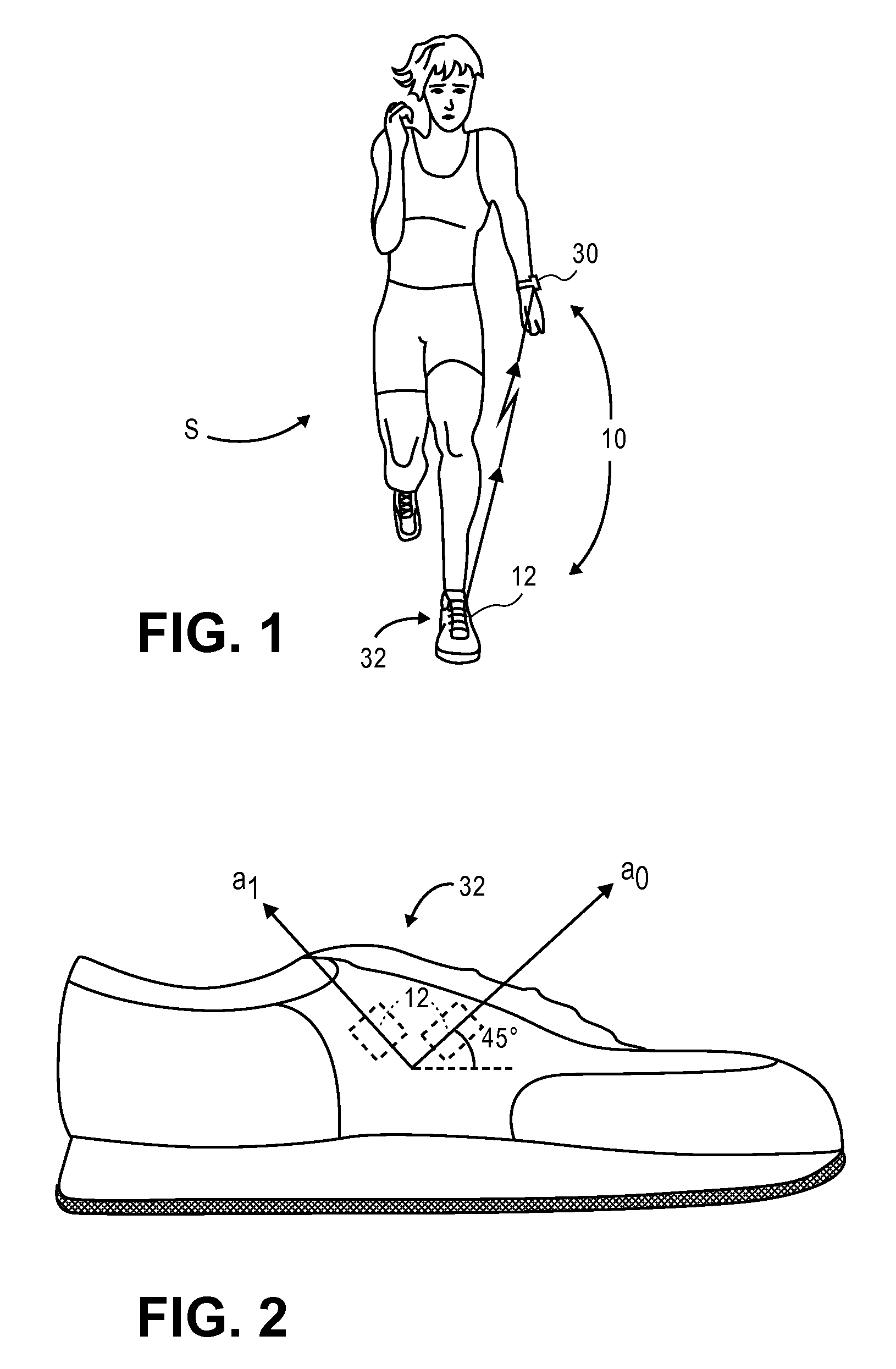

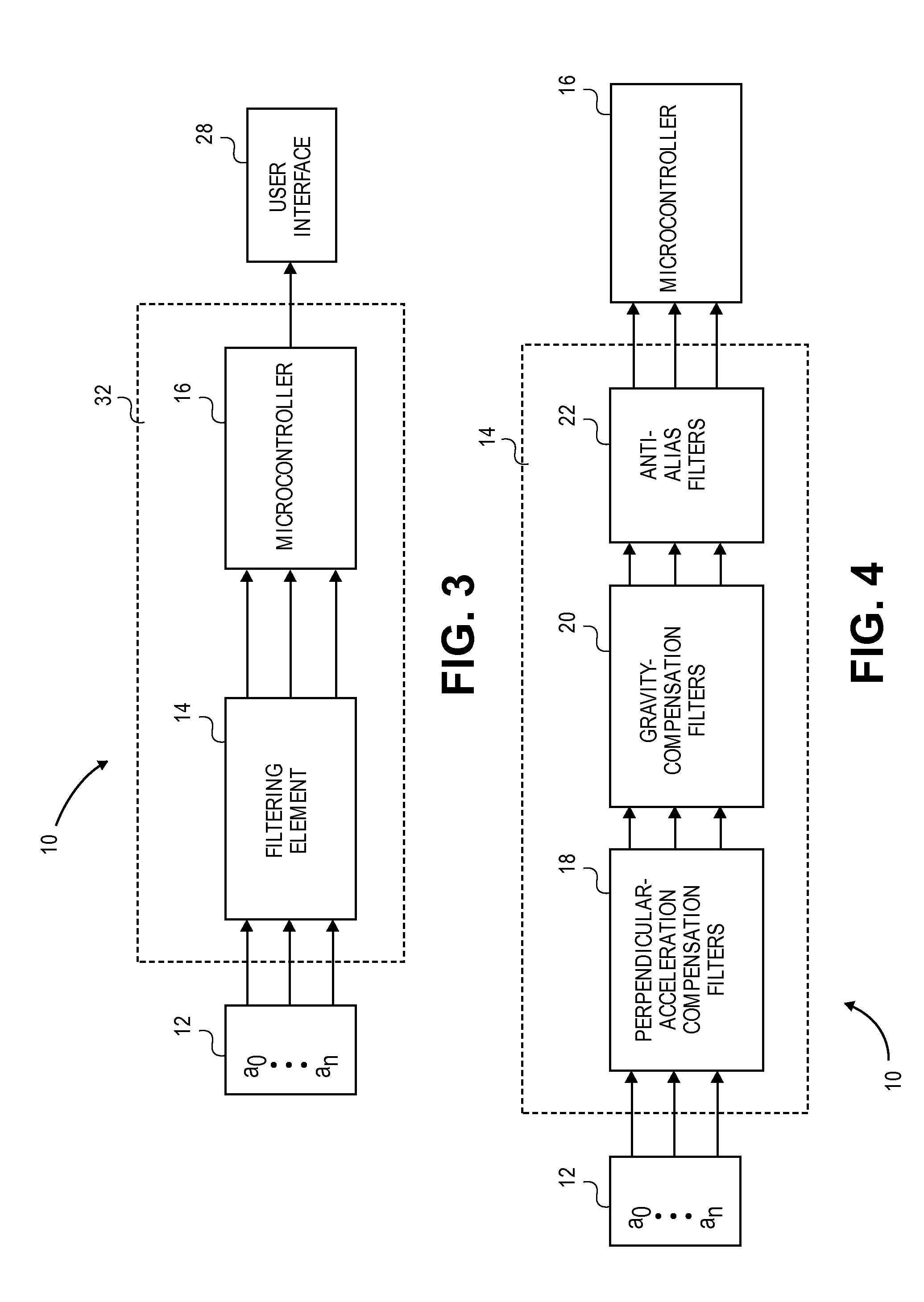

InactiveUS6301964B1Accurately determine velocity and distance traveledAcceleration measurement using interia forcesGymnastic exercisingAccelerometerTarget Motion Analysis

A device comprised of at least a pair of accelerometers and a tilt sensor mounted in fixed relation to a datum plane defining surface (sole of a shoe) may be used for extracting kinematic variables including linear and rotational acceleration, velocity and position. These variables may be resolved into a selected direction thereby permitting both relative and absolute kinematic quantities to be determined. The acceleration is determined using a small cluster of two mutually perpendicular accelerometers mounted on a shoe. Angular orientation of the foot may be determined by double integration of the foot's angular acceleration (which requires a third accelerometer substantially parallel to one of the two orthogonal accelerometers). The two orthogonal accelerations are then resolved into a net horizontal acceleration or other selected direction which may be integrated to find the foot velocity in the selected direction. The average of the foot velocity corresponds to the subject's gait speed.

Owner:GARMIN

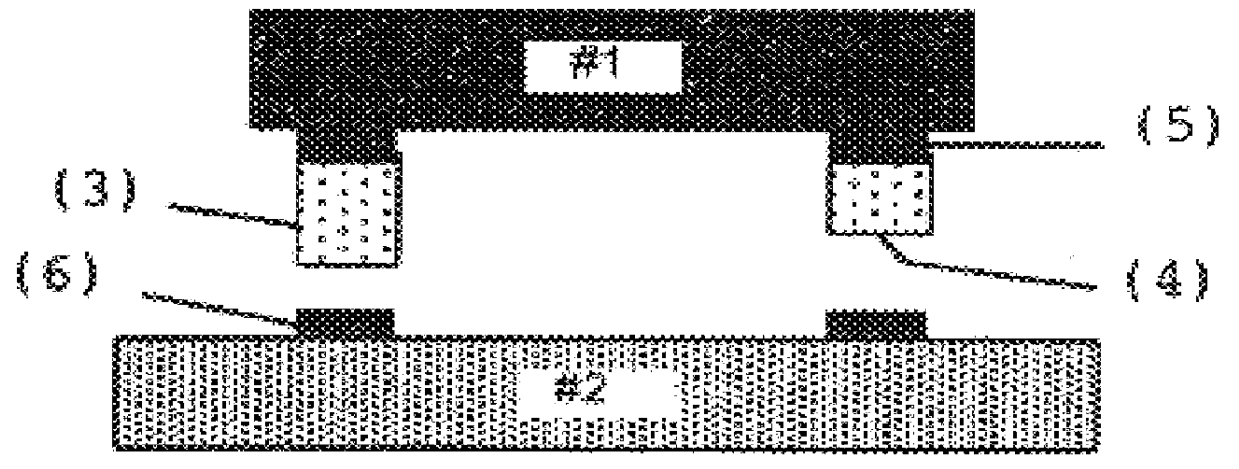

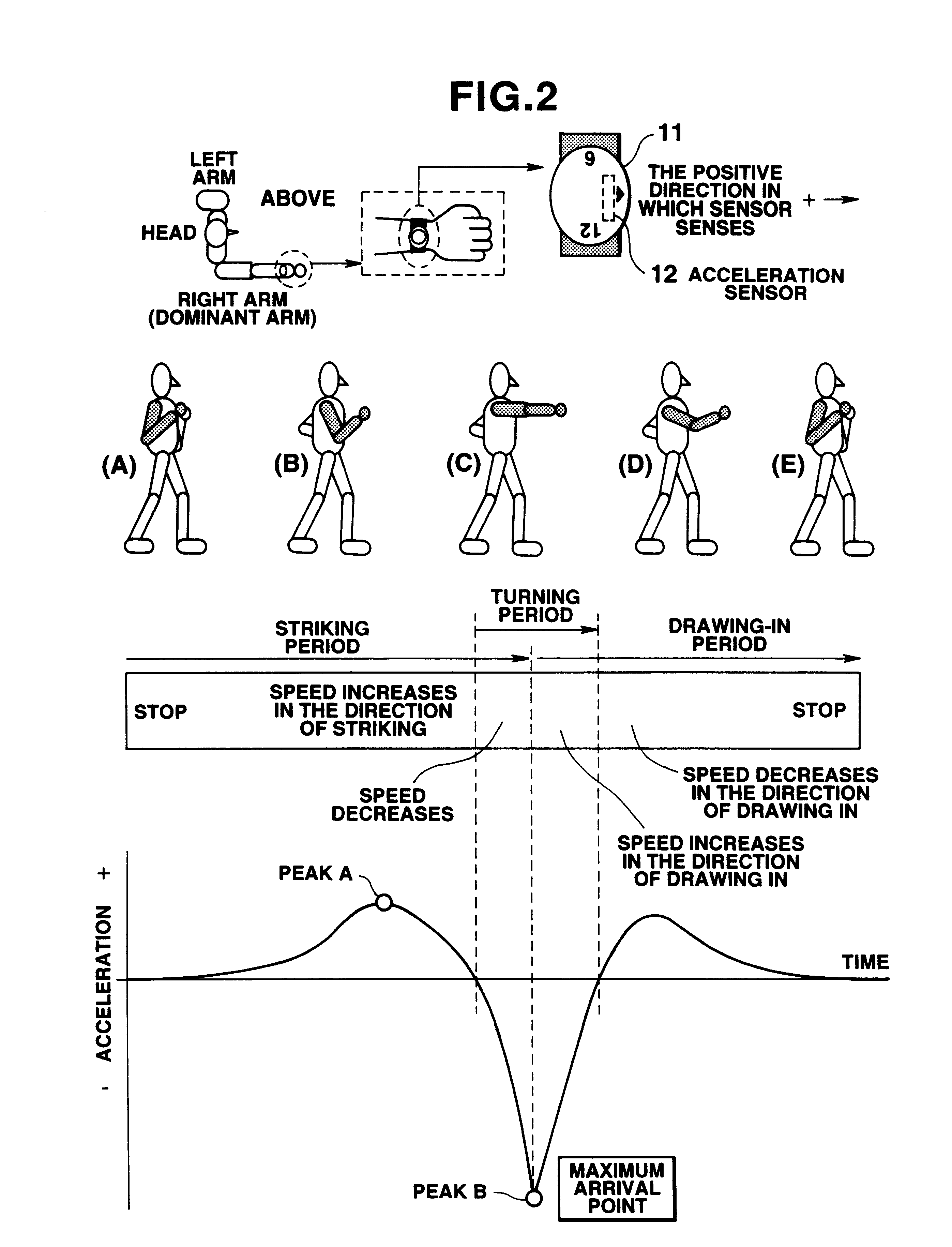

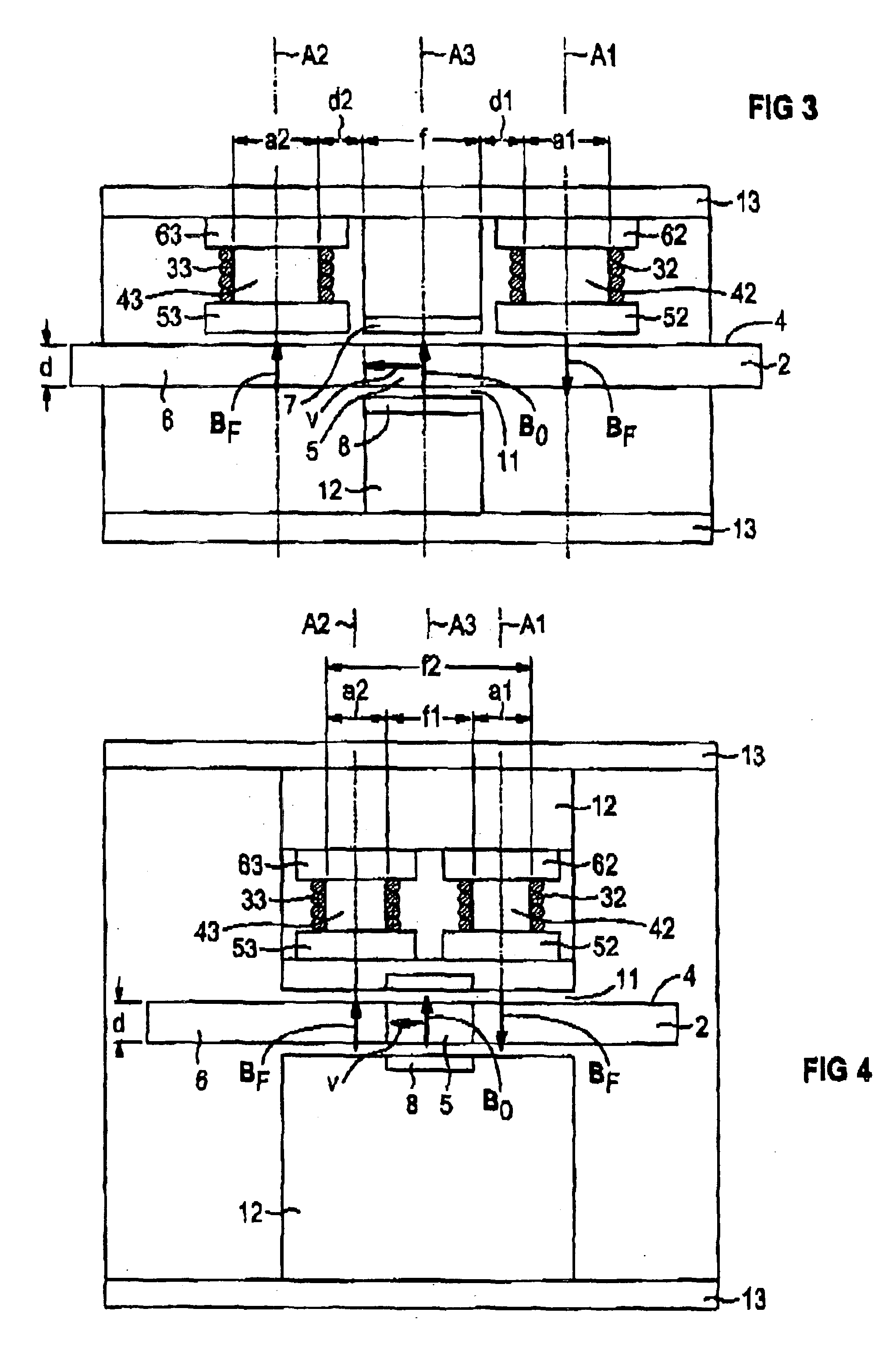

Method of fabrication of a microstructure having an internal cavity

InactiveUS6297072B1Easy to manufactureImprove air tightnessAcceleration measurement using interia forcesDecorative surface effectsInternal cavityMicrostructure

A method of fabricating a microstructure having an inside cavity. The method includes depositing a first layer or a first stack of layers in a substantially closed geometric configuration on a first substrate. Then, performing an indent on the first layer or on the top layer of said first stack of layers. Then, depositing a second layer or a second stack of layers substantially with said substantially closed geometric configuration on a second substrate. Then, aligning and bonding said first substrate on said second substrate such that a microstructure having a cavity is formed according to said closed geometry configuration.

Owner:CP CLARE +1

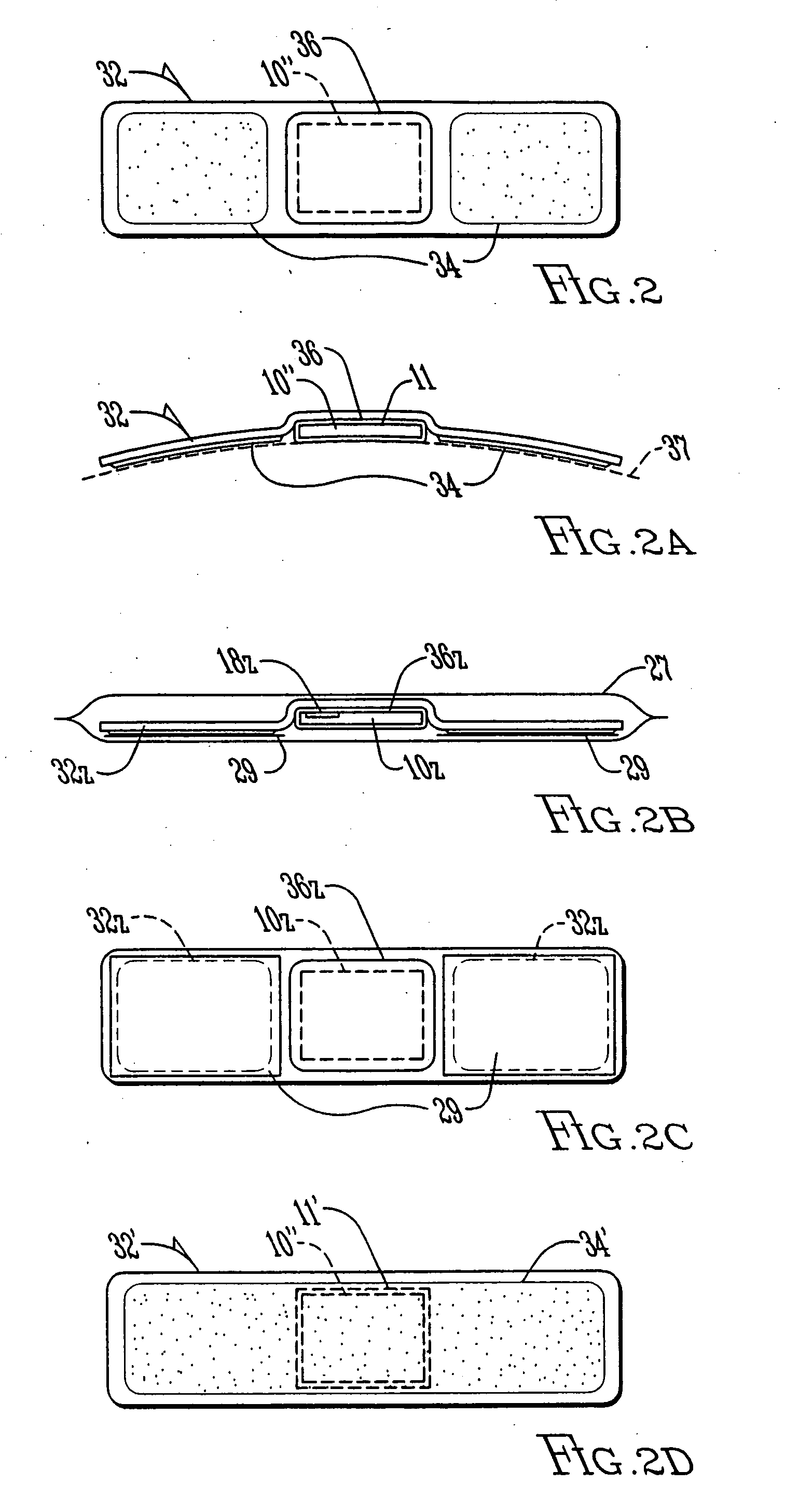

Shoes employing monitoring devices, and associated methods

InactiveUS20060143645A1Eliminate needSoften contactAcceleration measurement using interia forcesGymnastic exercisingAccelerometerEngineering

Owner:APPLE INC

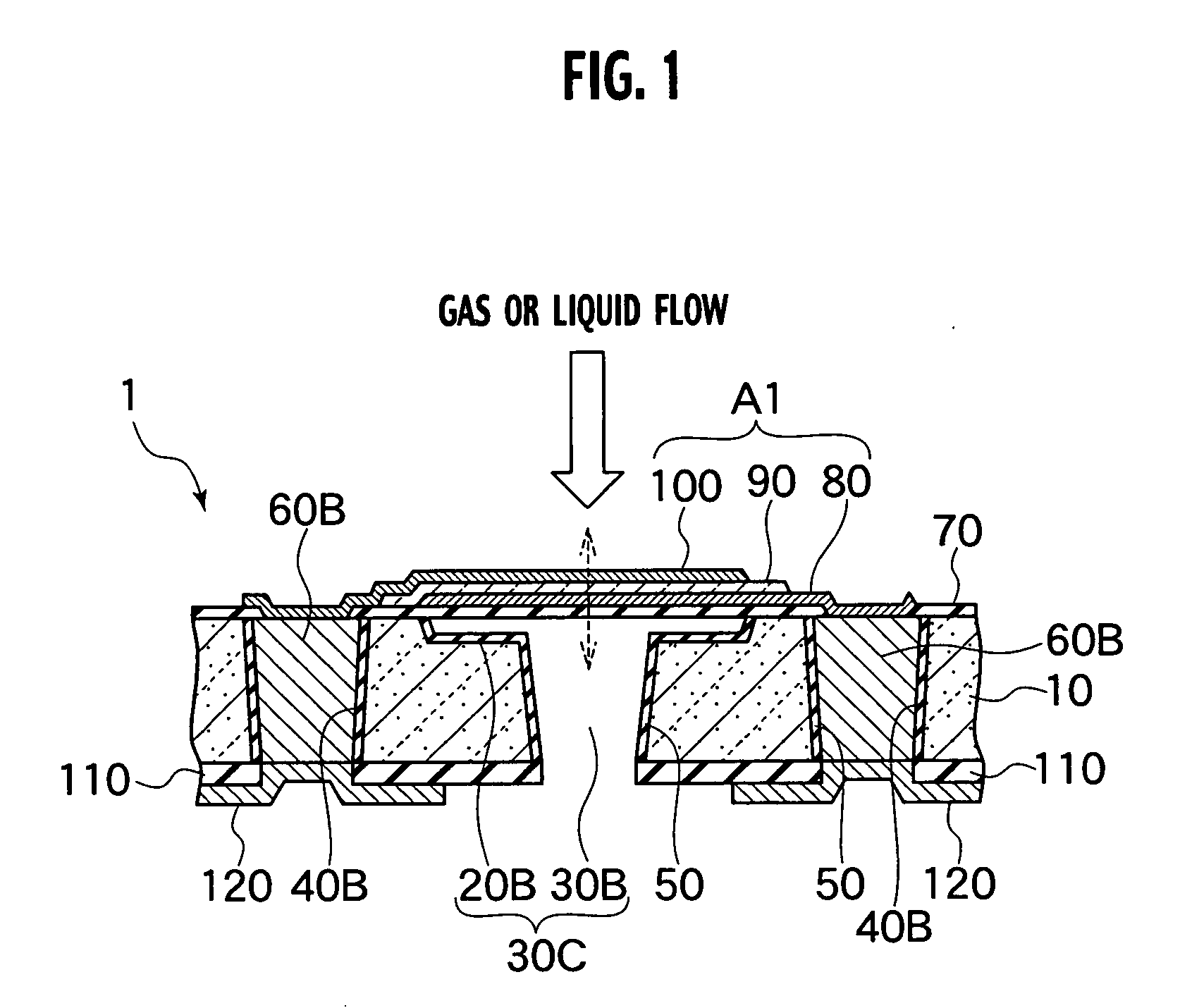

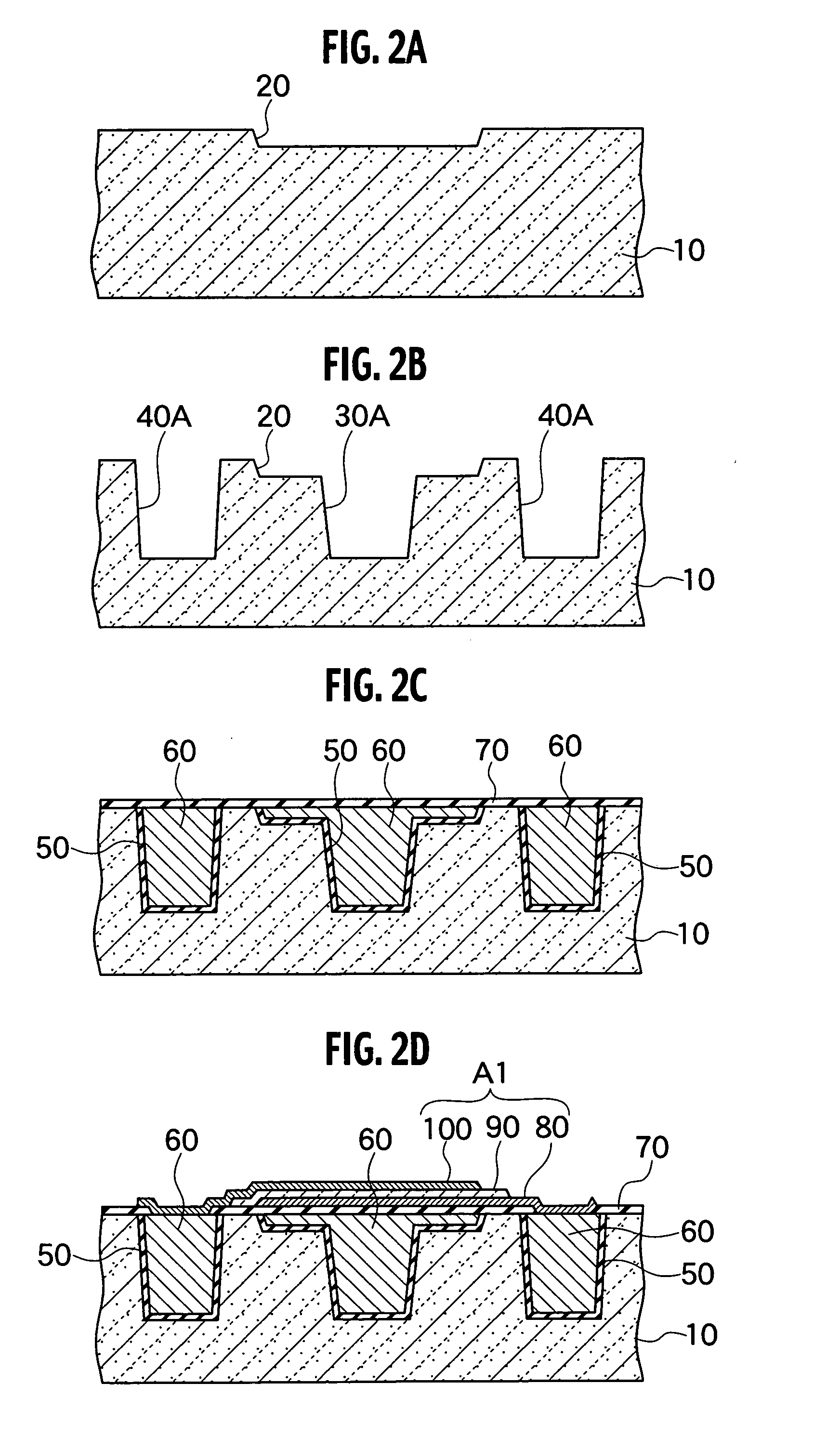

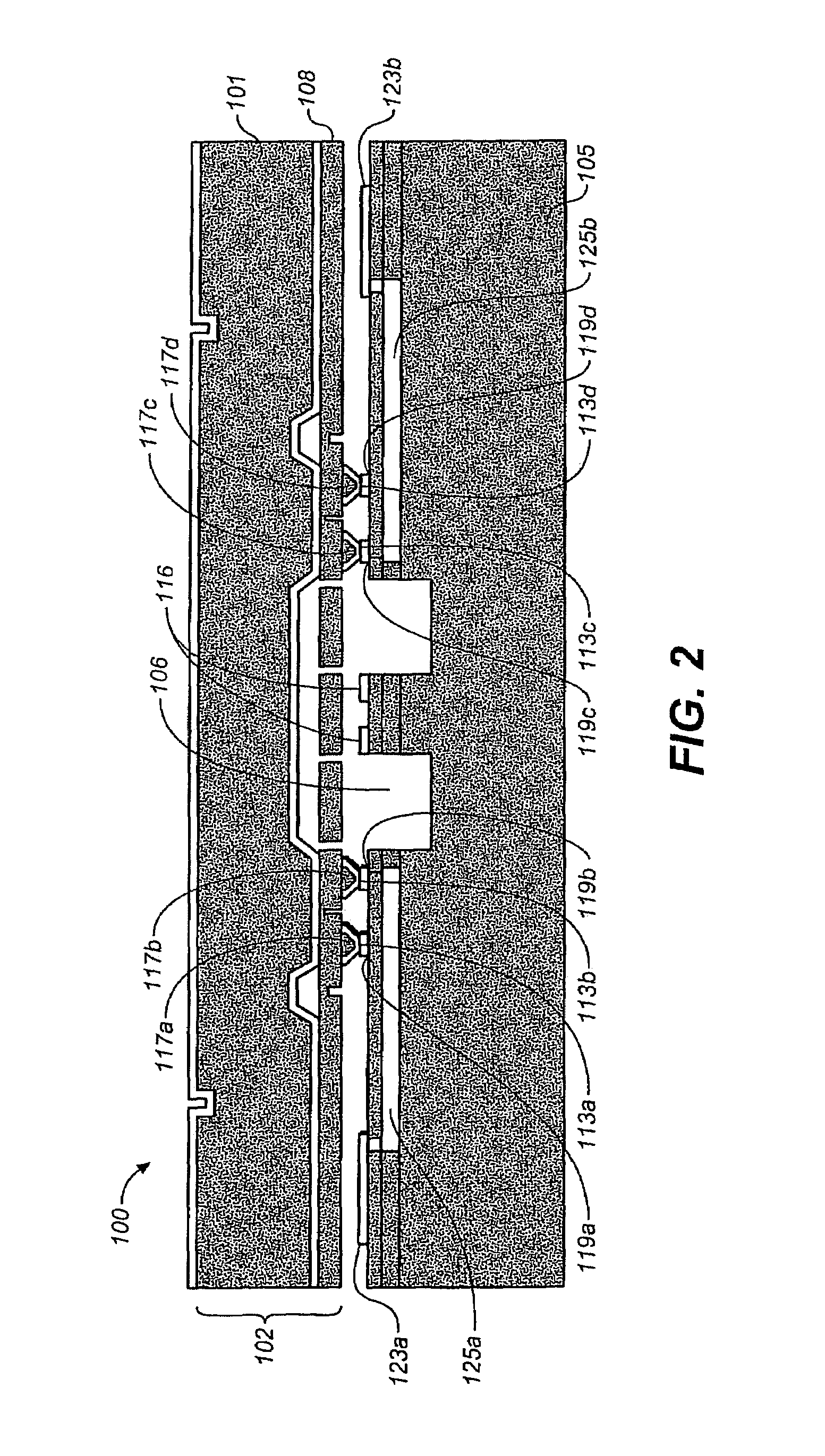

Manufacture of MEMS structures in sealed cavity using dry-release MEMS device encapsulation

InactiveUS7008812B1Eliminates undesirable liquid surface tensionIncrease etch rateAcceleration measurement using interia forcesSolid-state devicesMaterials sciencePlasma etching

The disclosed fabrication methodology addresses the problem of creating low-cost micro-electro-mechanical devices and systems, and, in particular, addresses the problem of delicate microstructures being damaged by the surface tension created as a wet etchant evaporates. This disclosure demonstrates a method for employing a dry plasma etch process to release encapsulated microelectromechanical components.

Owner:CYMATICS LAB CORP

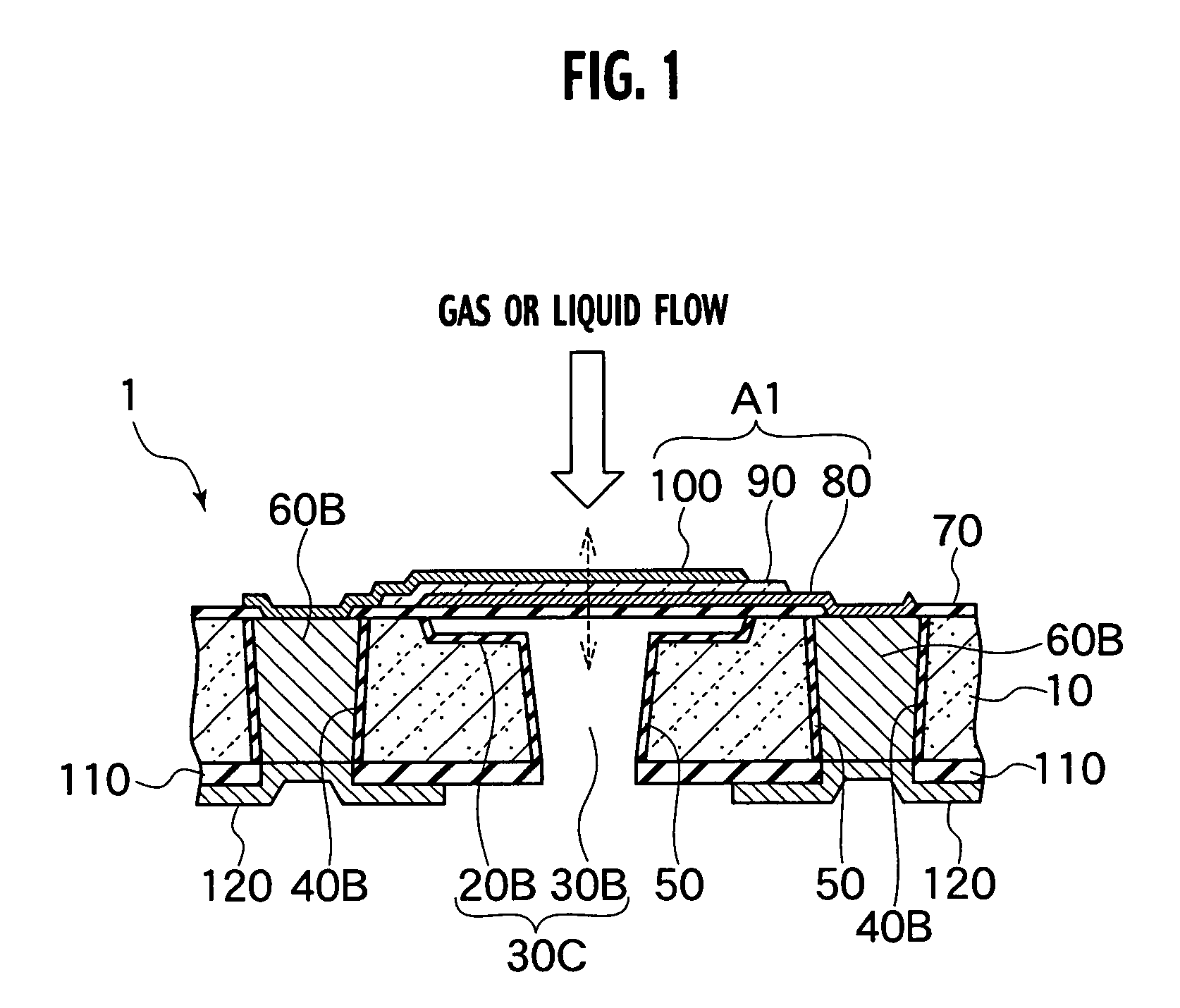

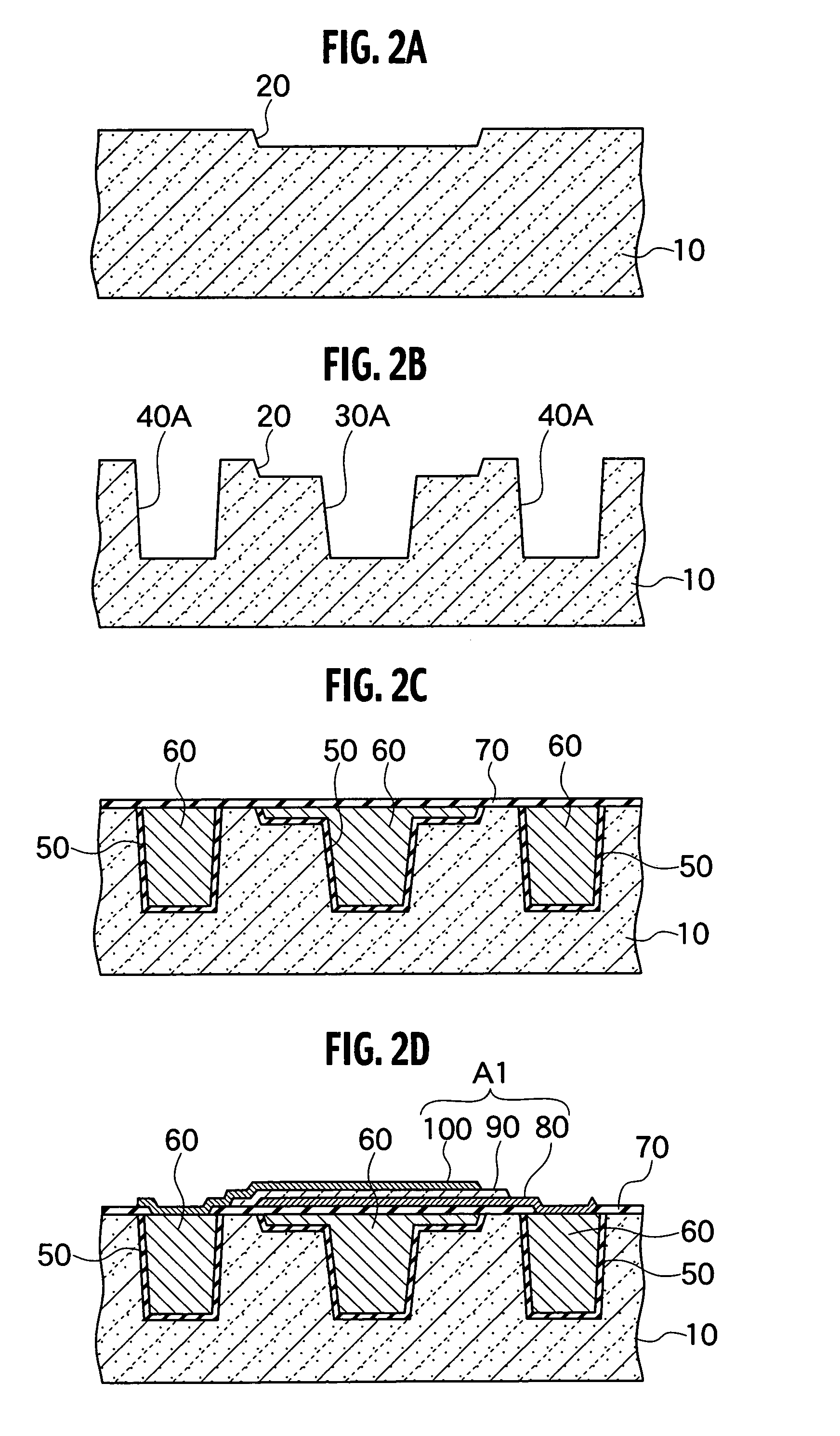

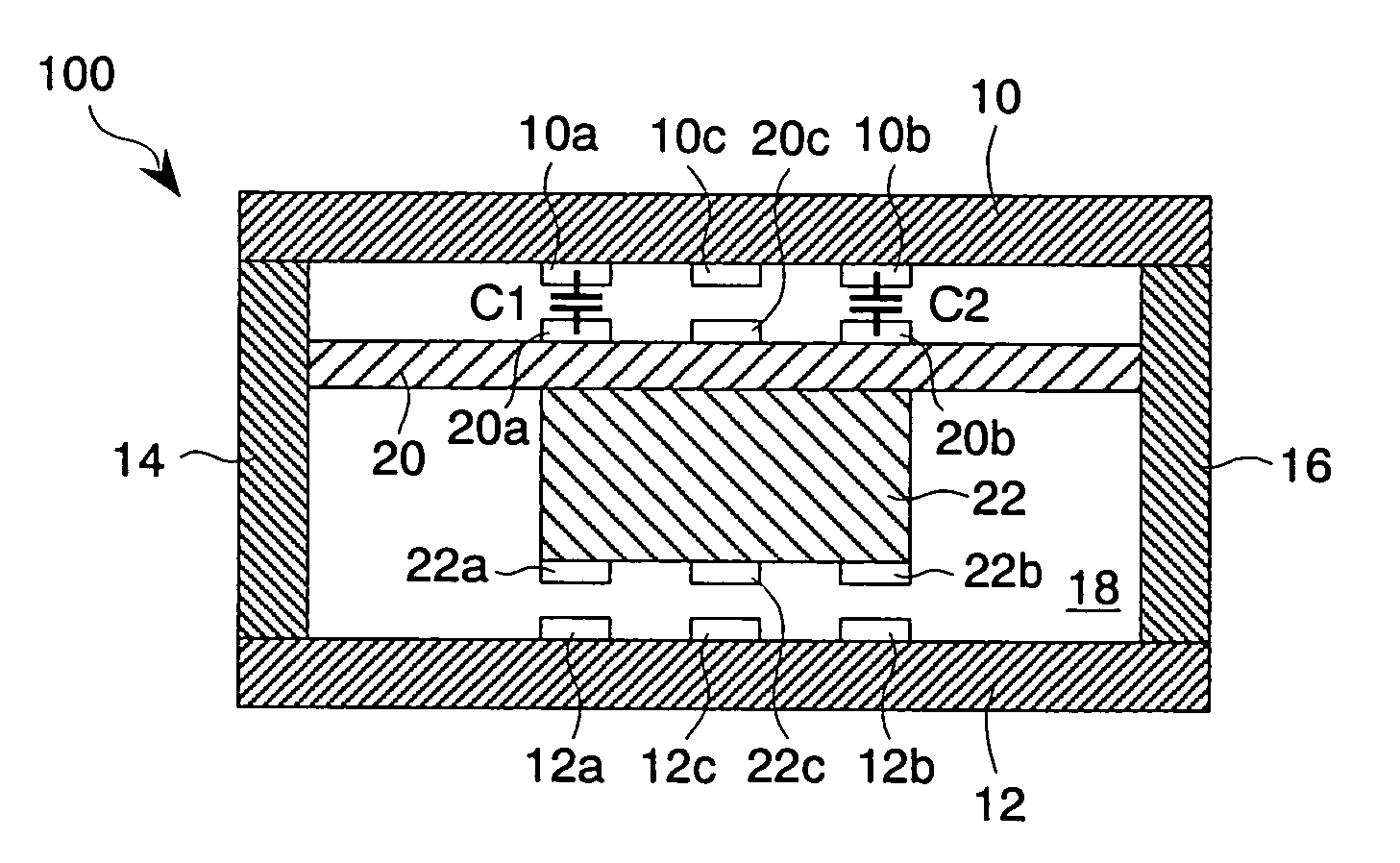

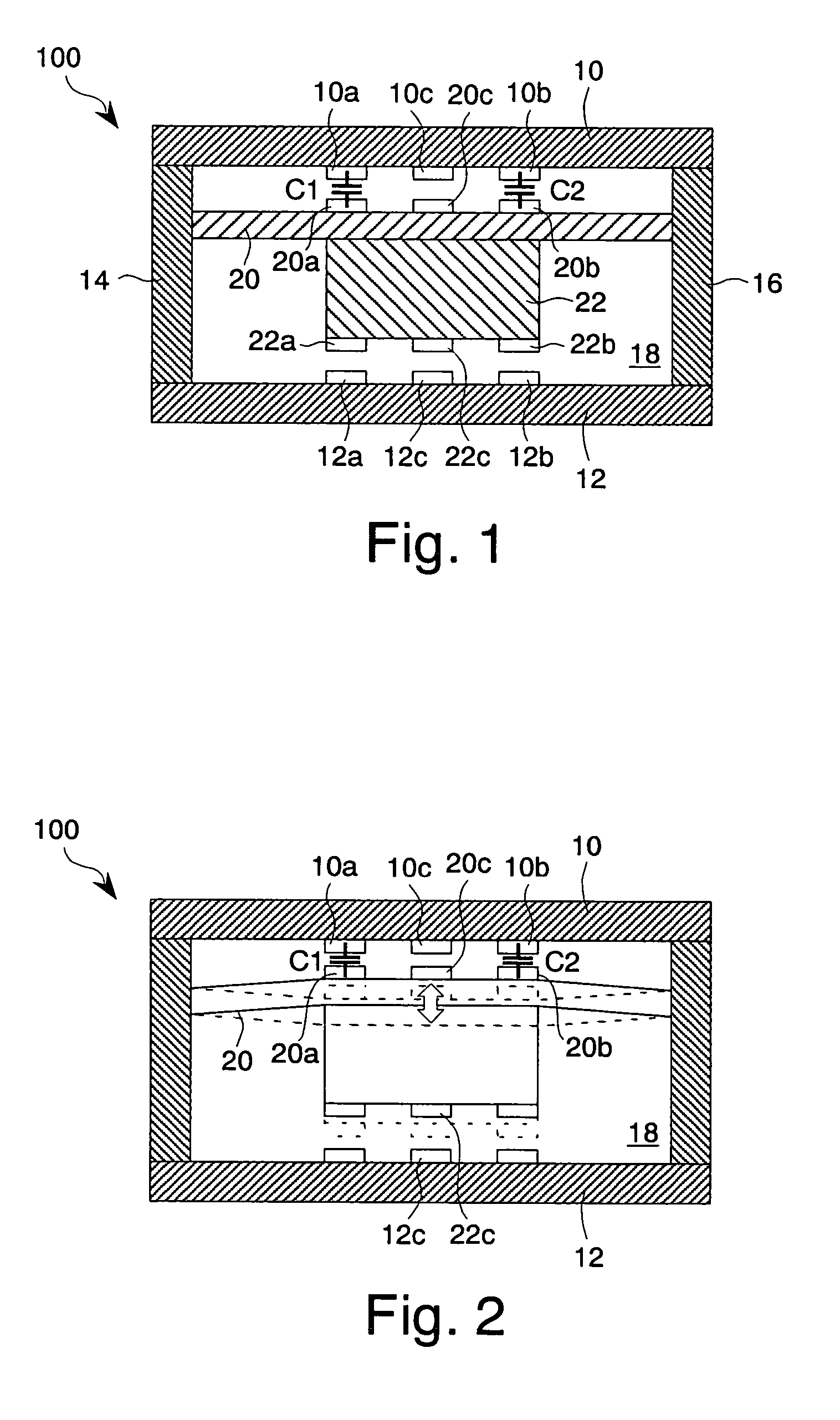

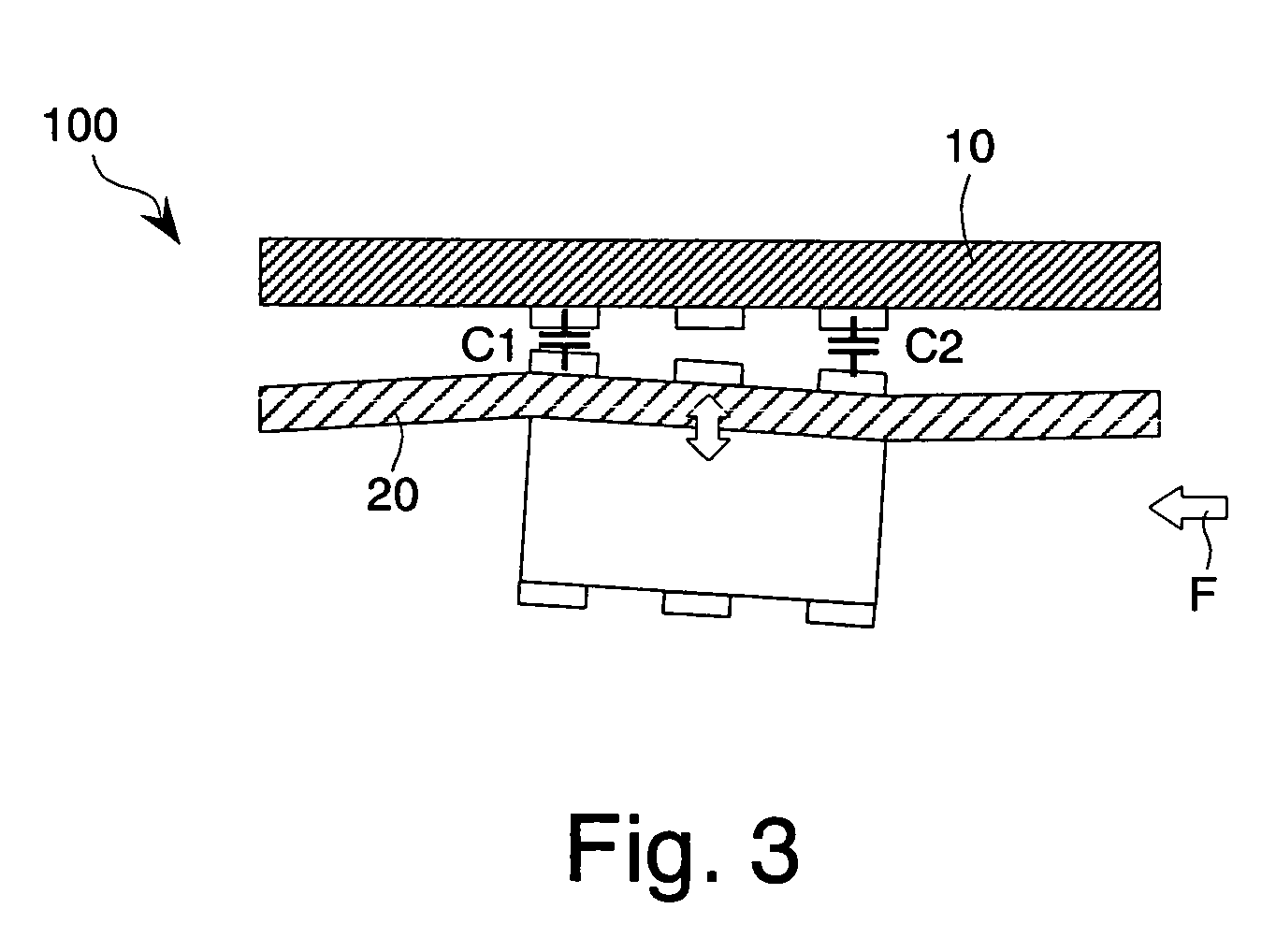

Electronic component having micro-electrical mechanical system

ActiveUS20050218488A1Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityEngineering

An electronic component includes a semiconductor substrate having a first surface and a second surface opposite to the first surface, a cavity that penetrates from the first surface to the second surface of the semiconductor substrate, and an electrical mechanical element that has a movable portion formed above the first surface of the semiconductor substrate so that the movable portion is arranged above the cavity. The electronic component further includes an electric conduction plug, which penetrates from the first surface to the second surface of the semiconductor substrate, and which is electrically connected to the electrical mechanical element.

Owner:KIOXIA CORP

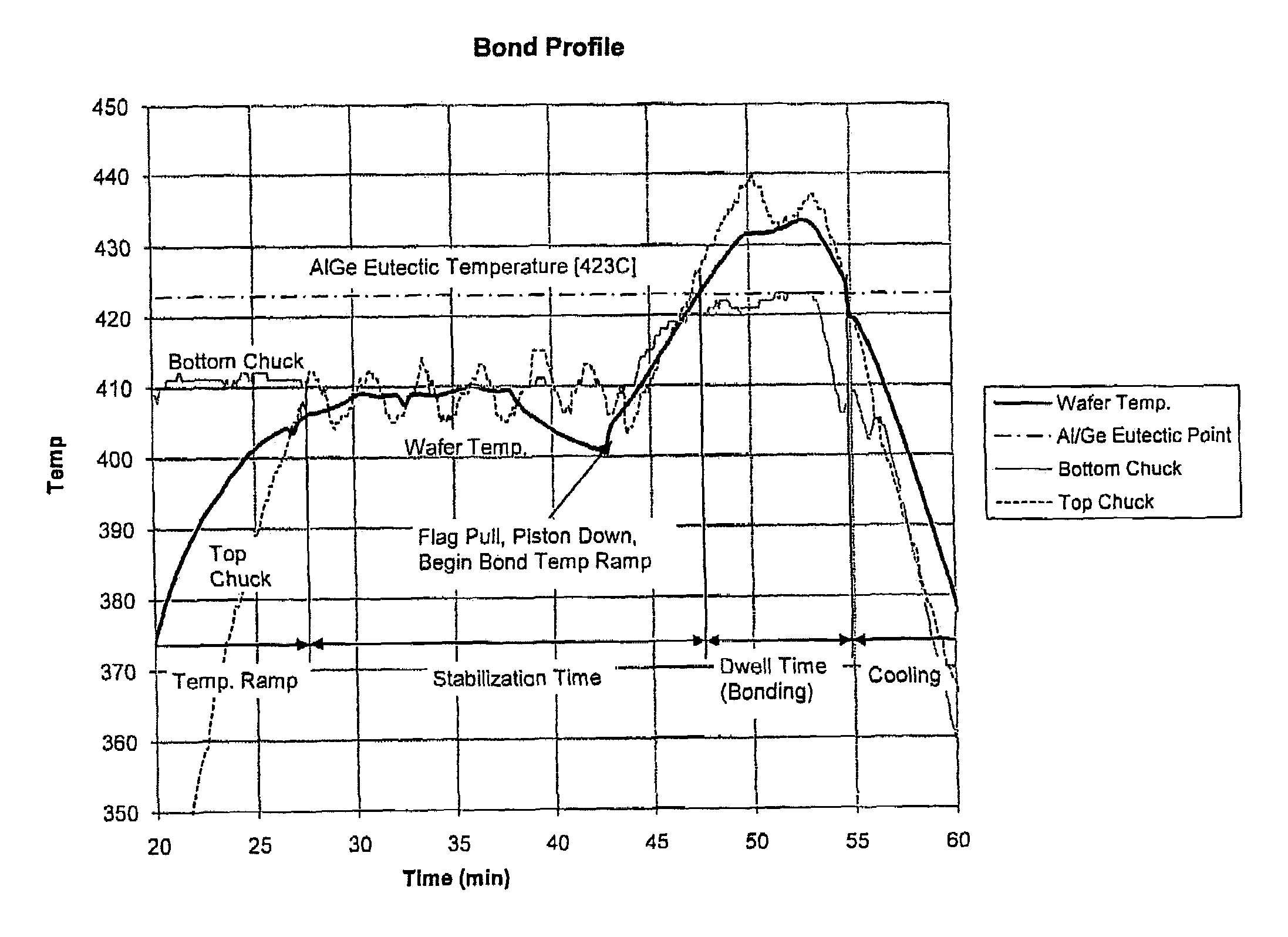

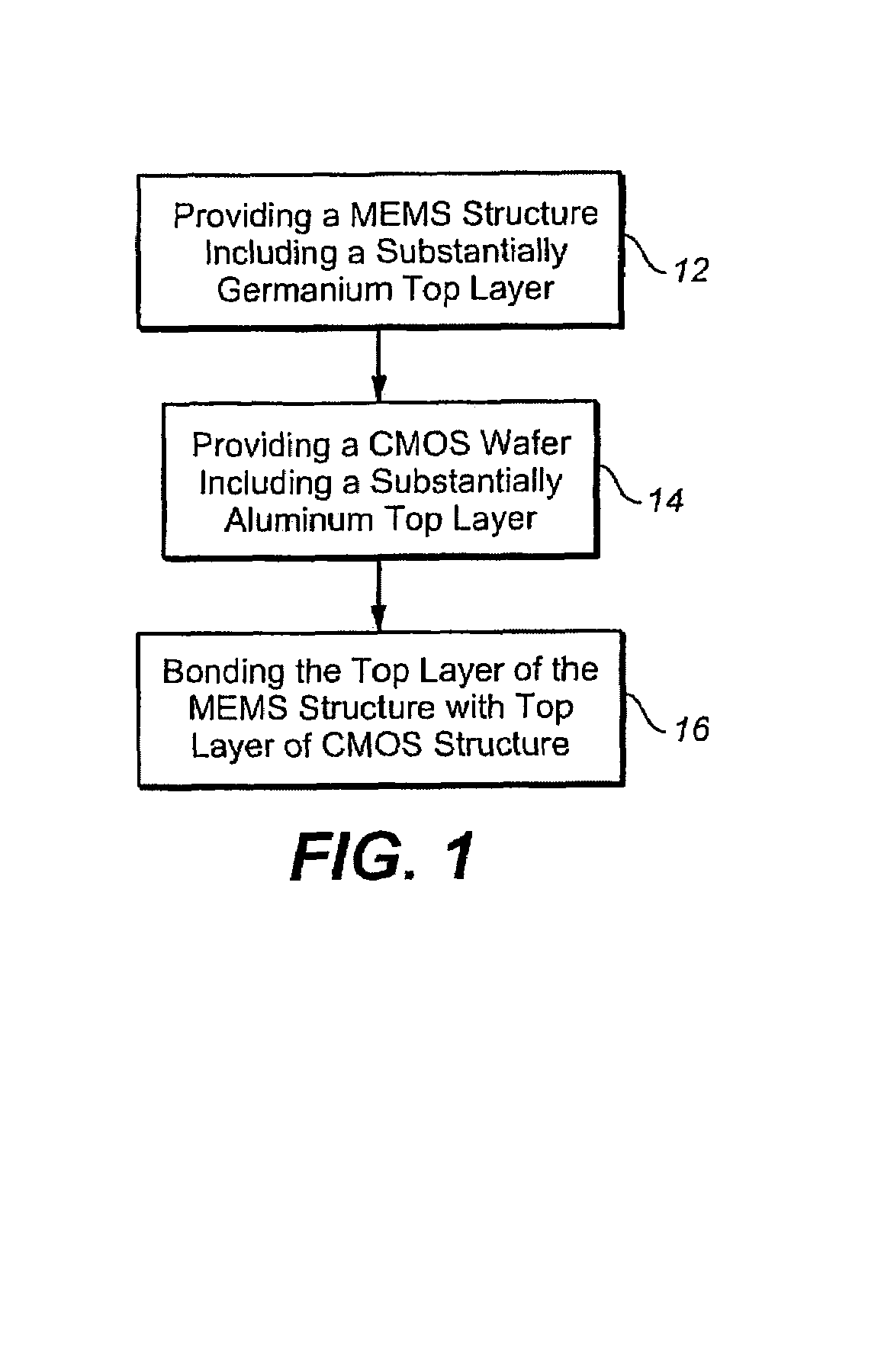

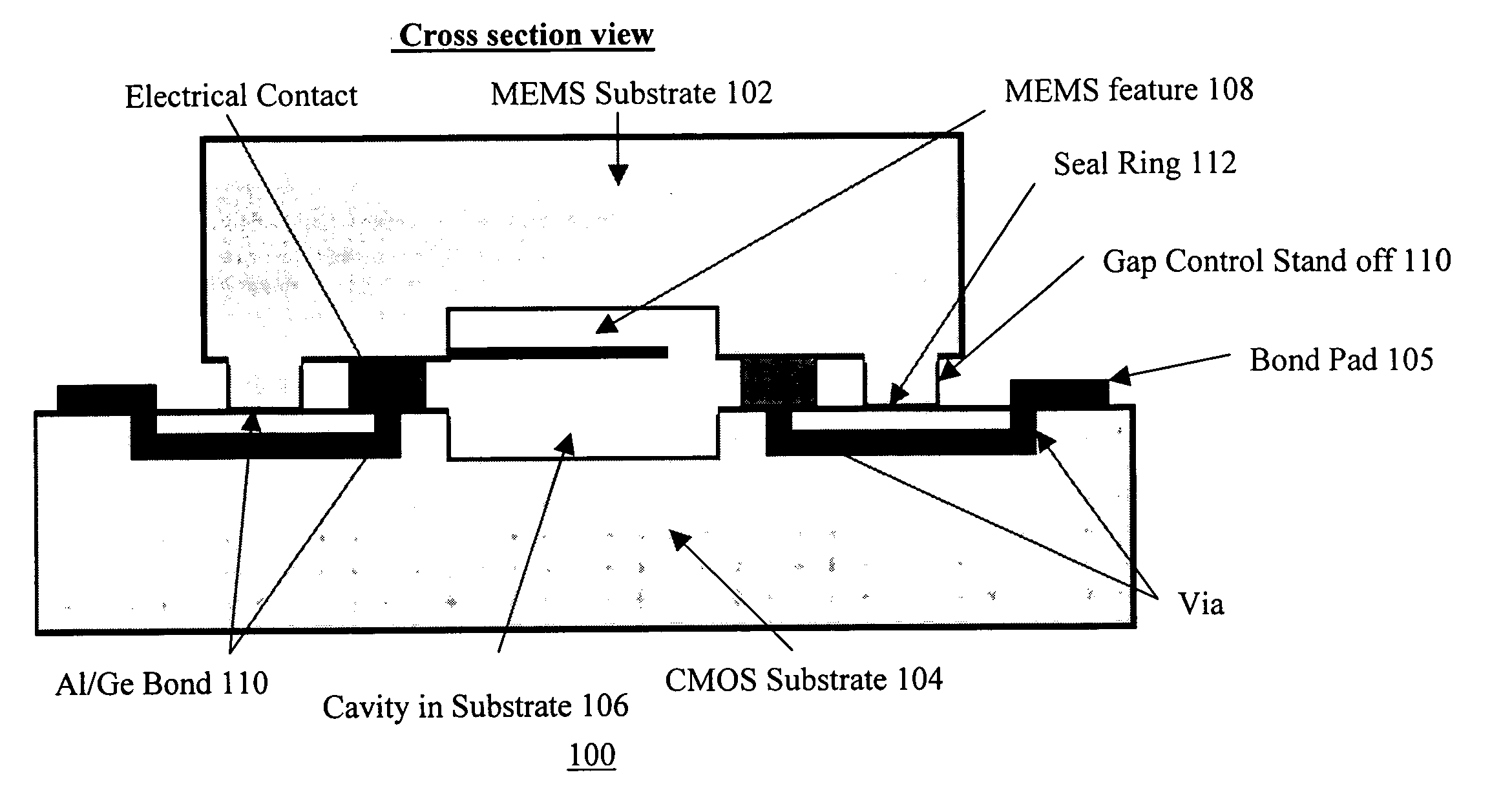

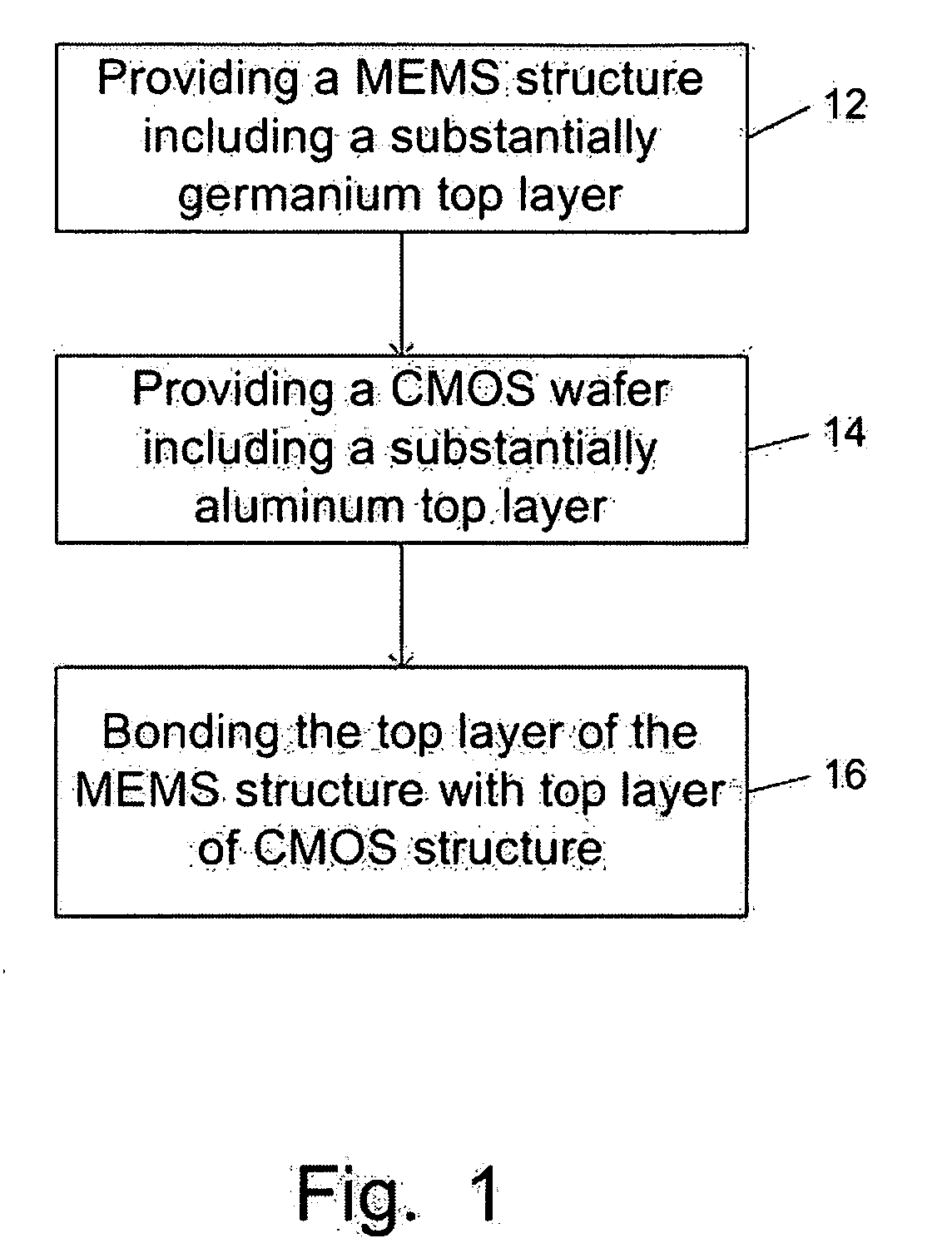

Method of fabrication of a AL/GE bonding in a wafer packaging environment and a product produced therefrom

ActiveUS7442570B2Robust and mechanical contactHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

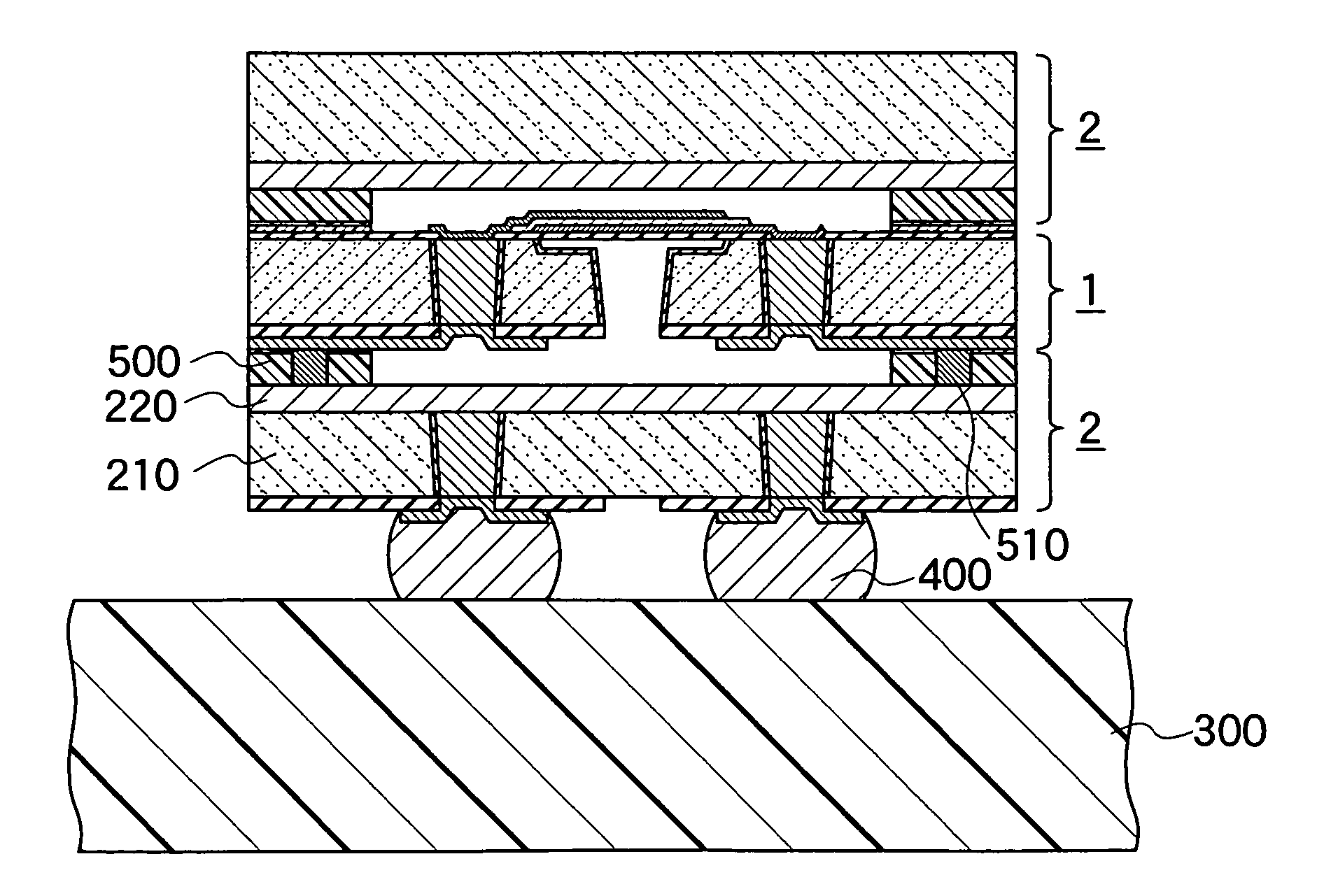

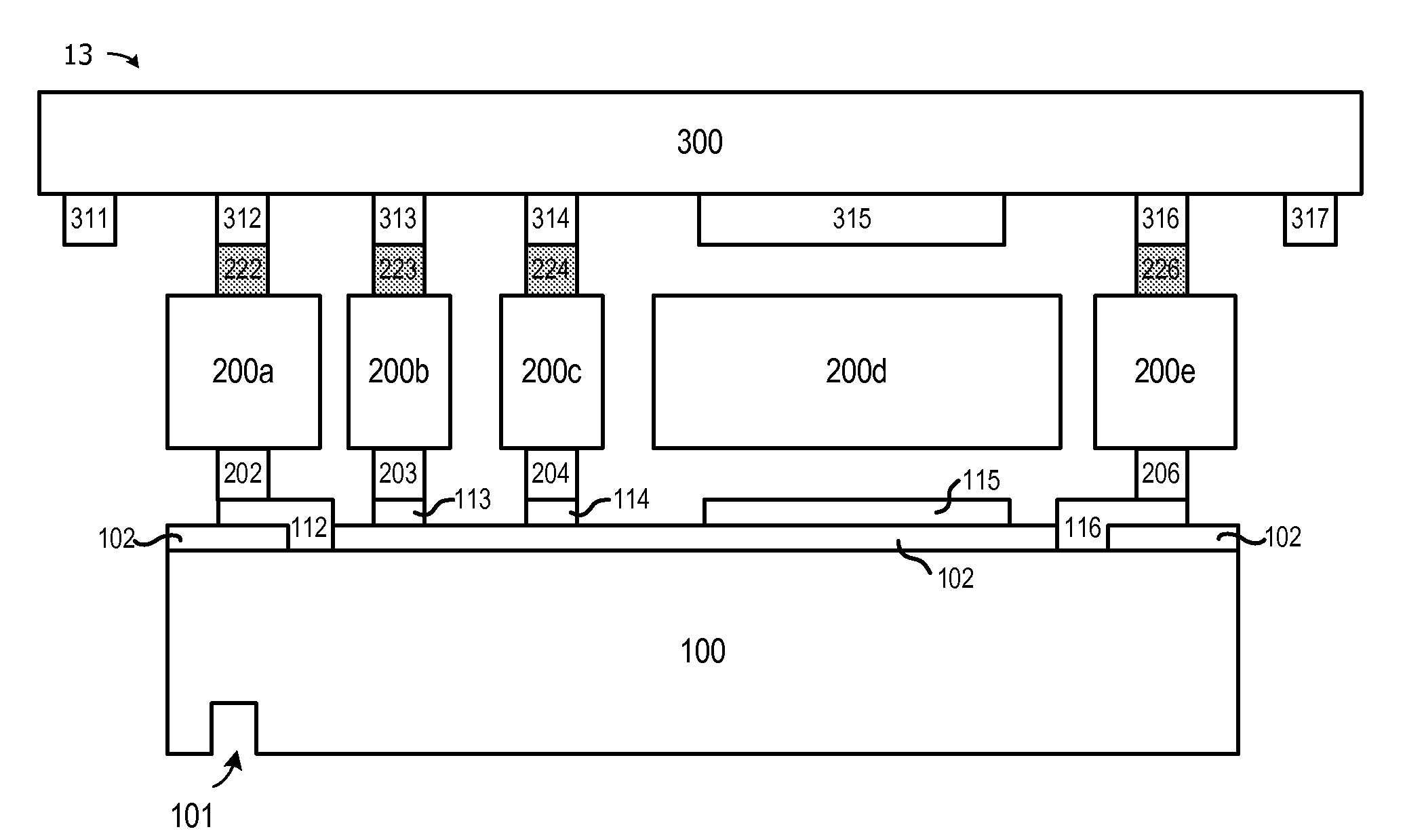

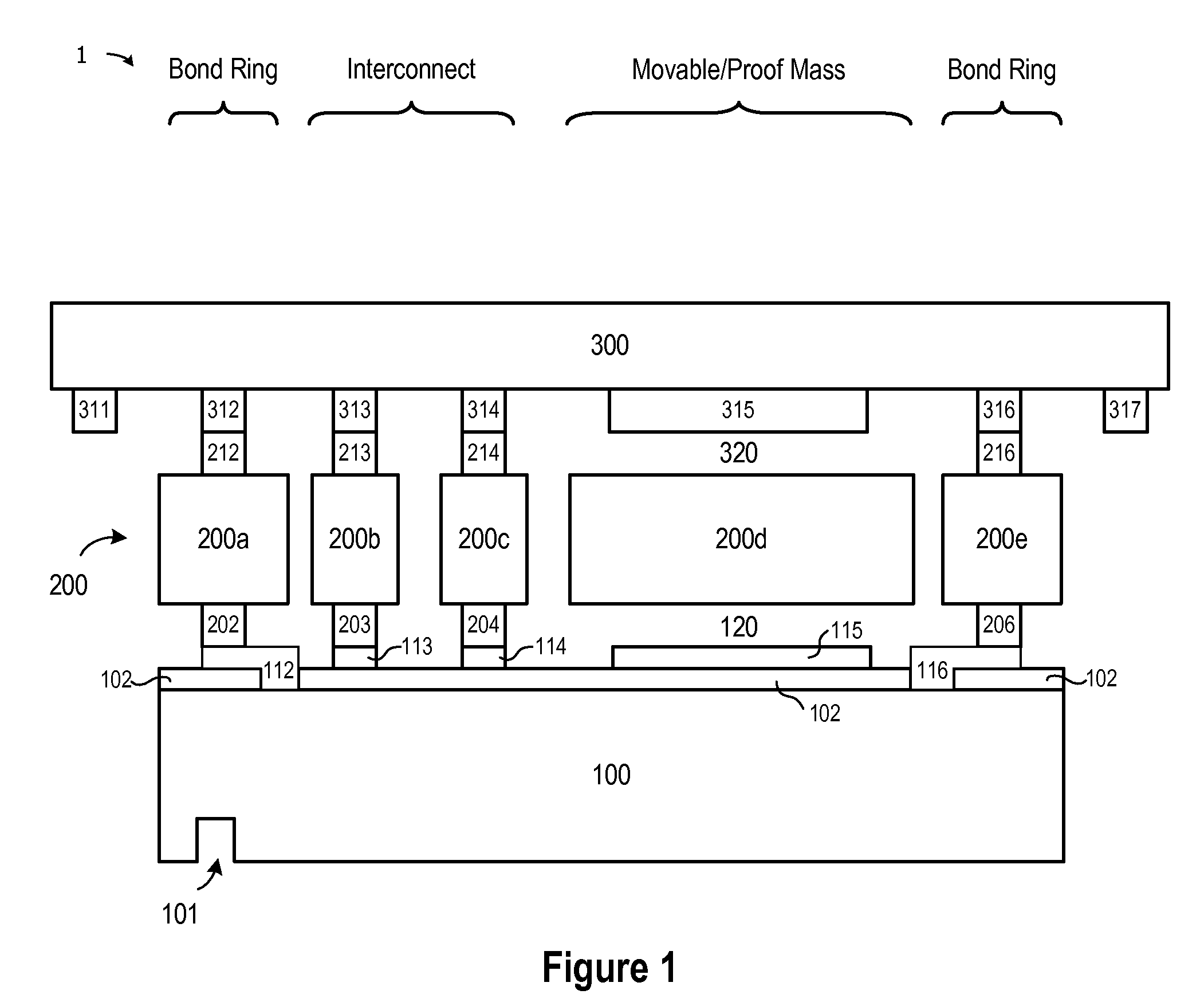

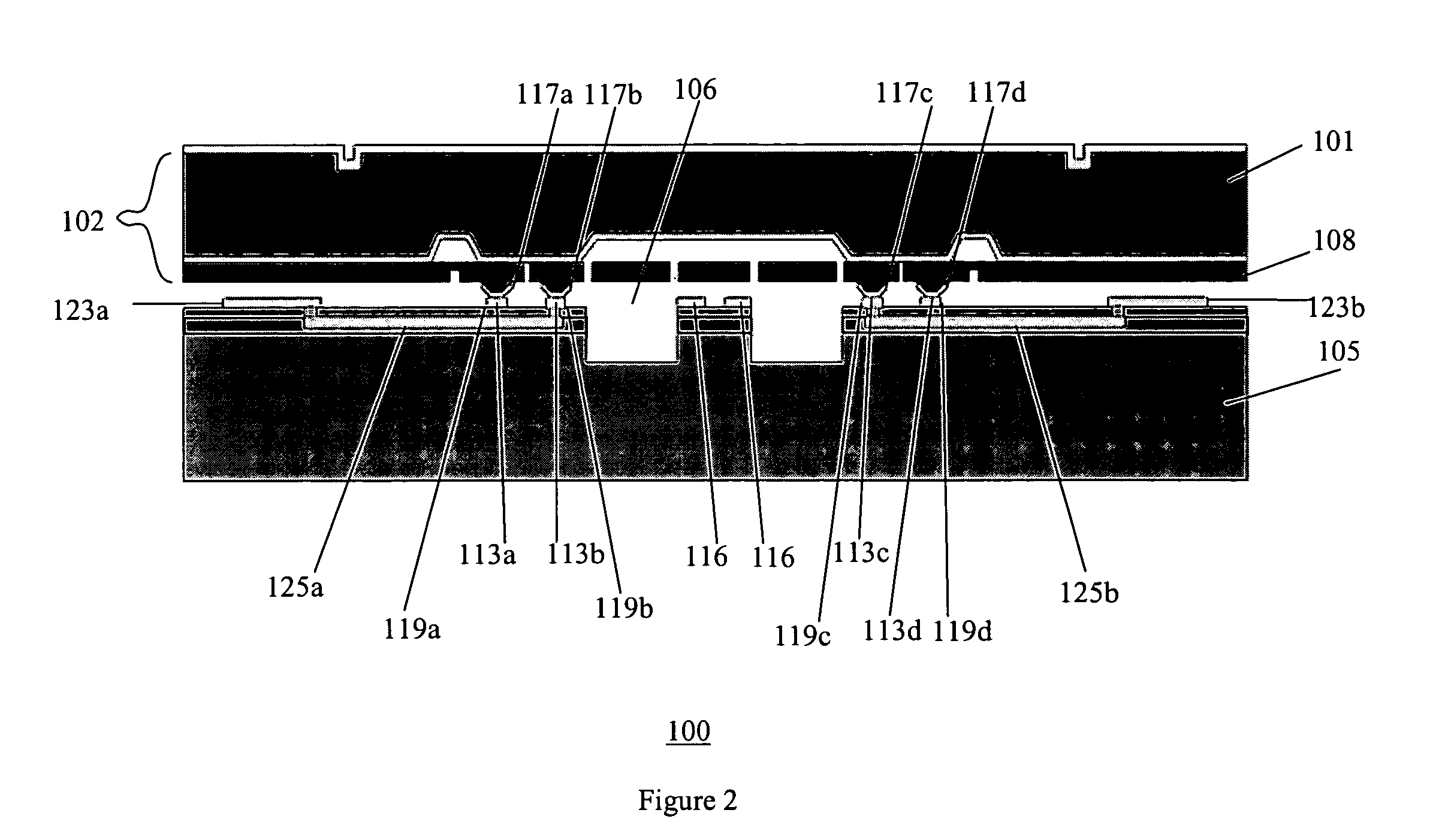

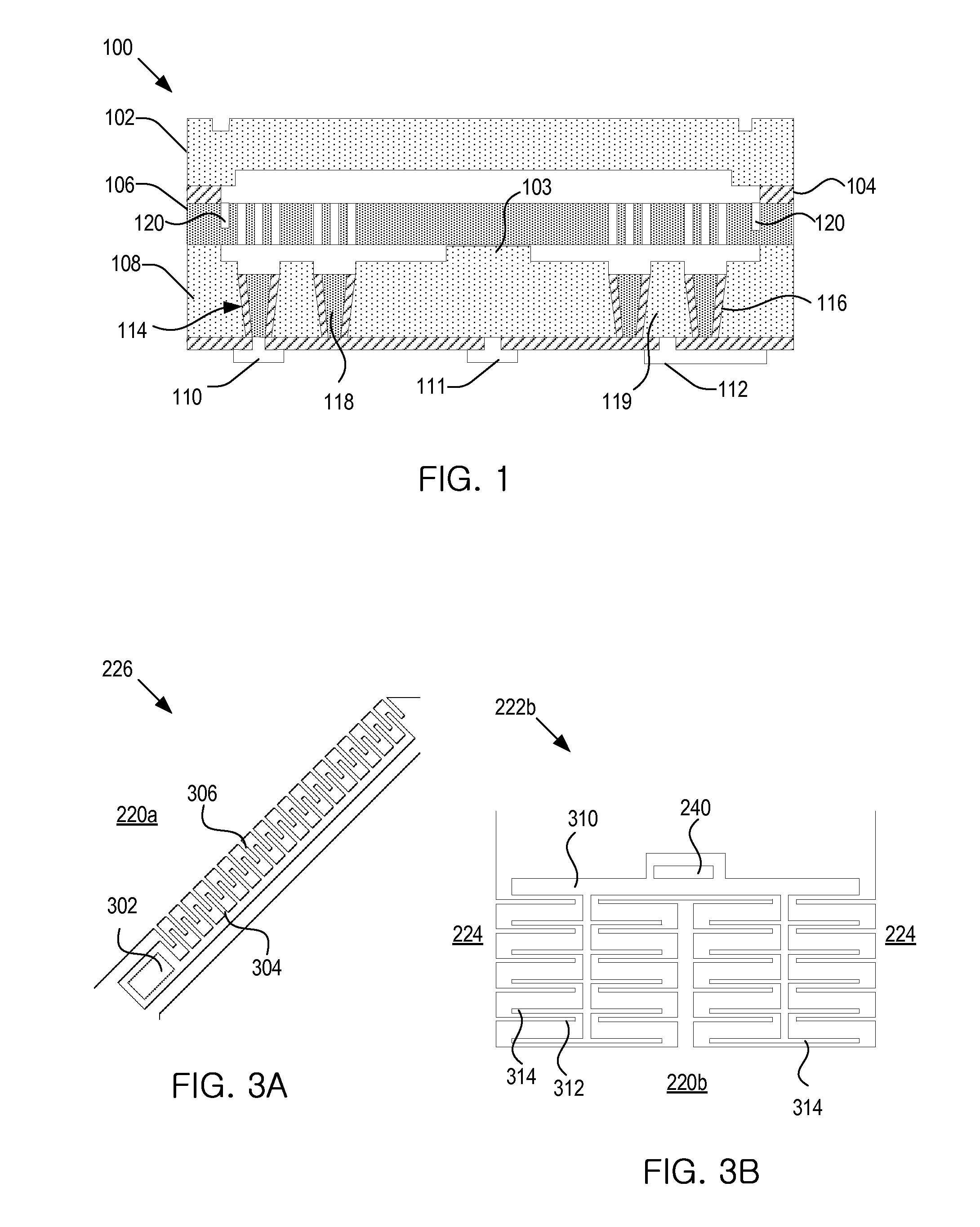

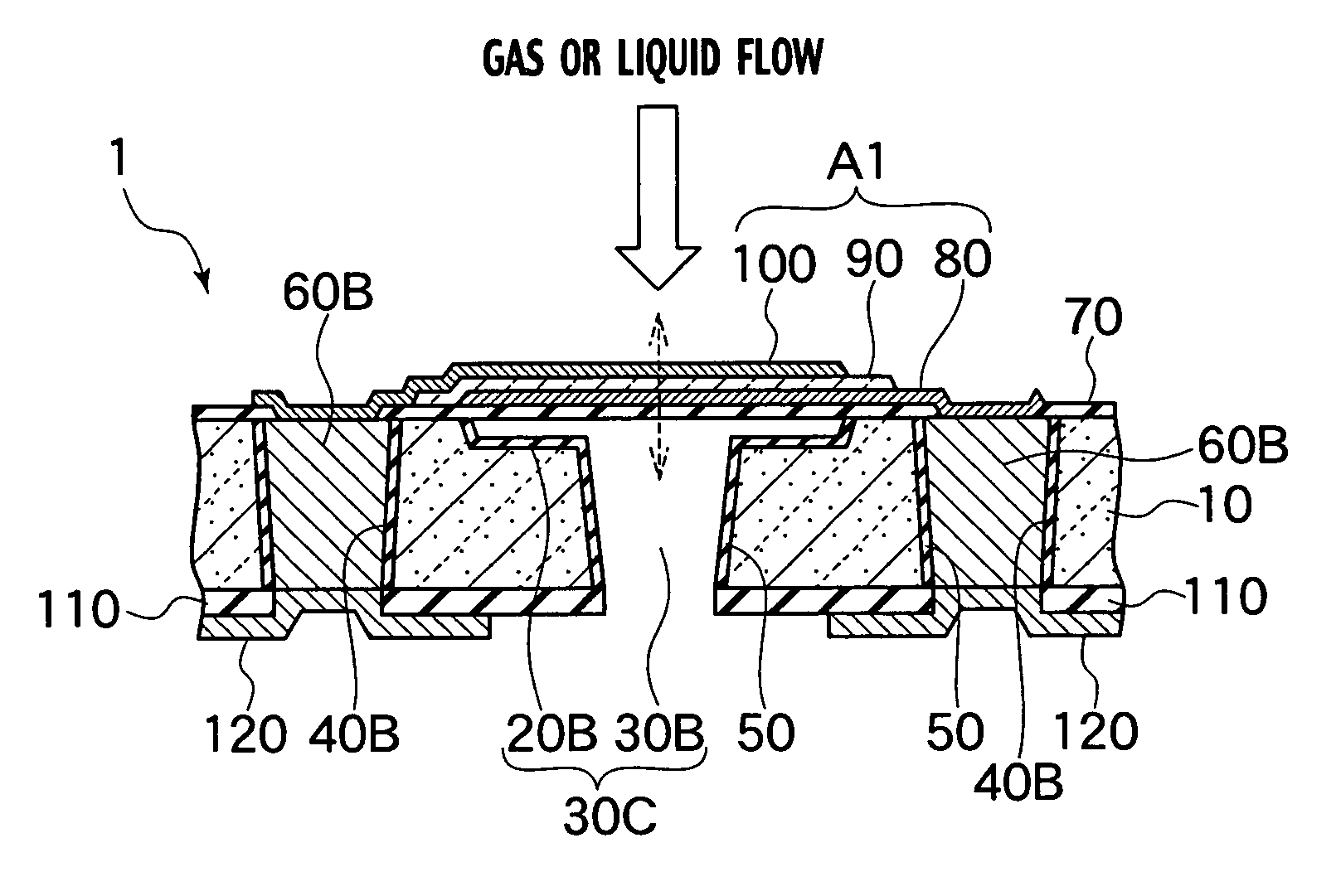

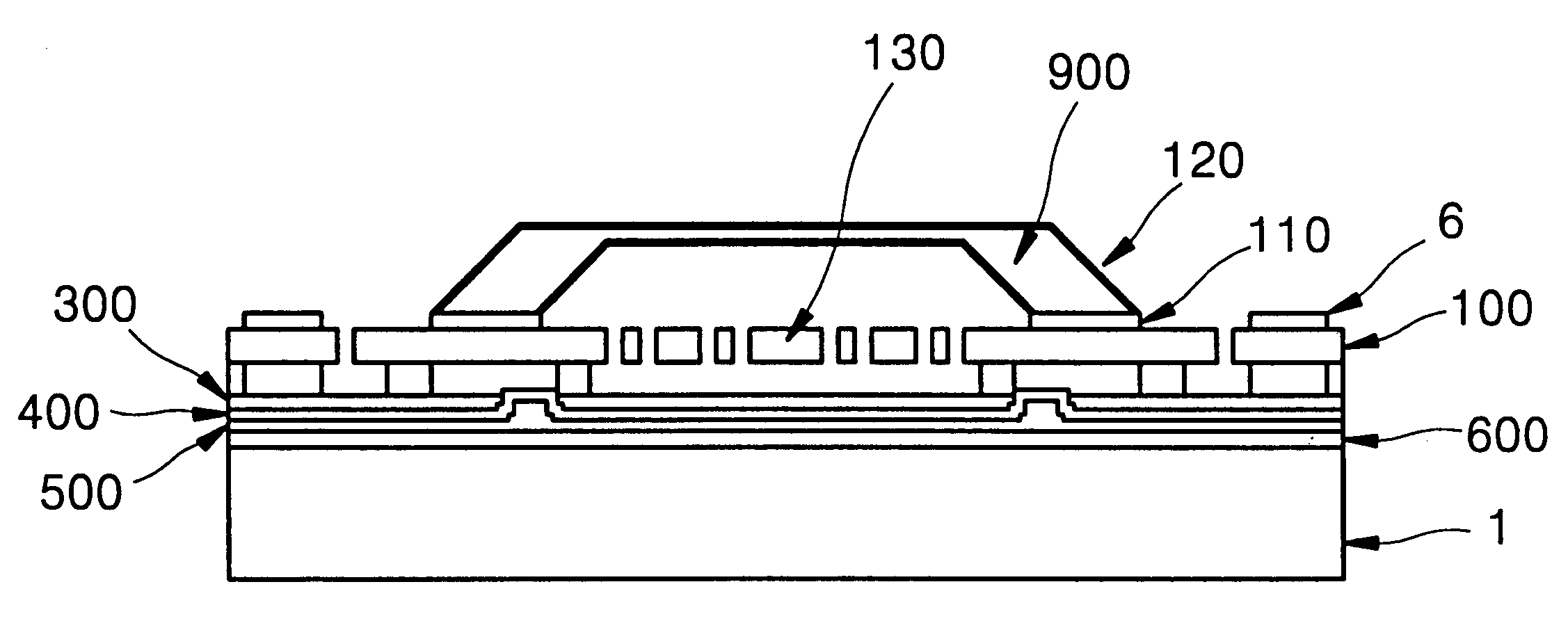

Method of Fabricating High Aspect Ratio Transducer Using Metal Compression Bonding

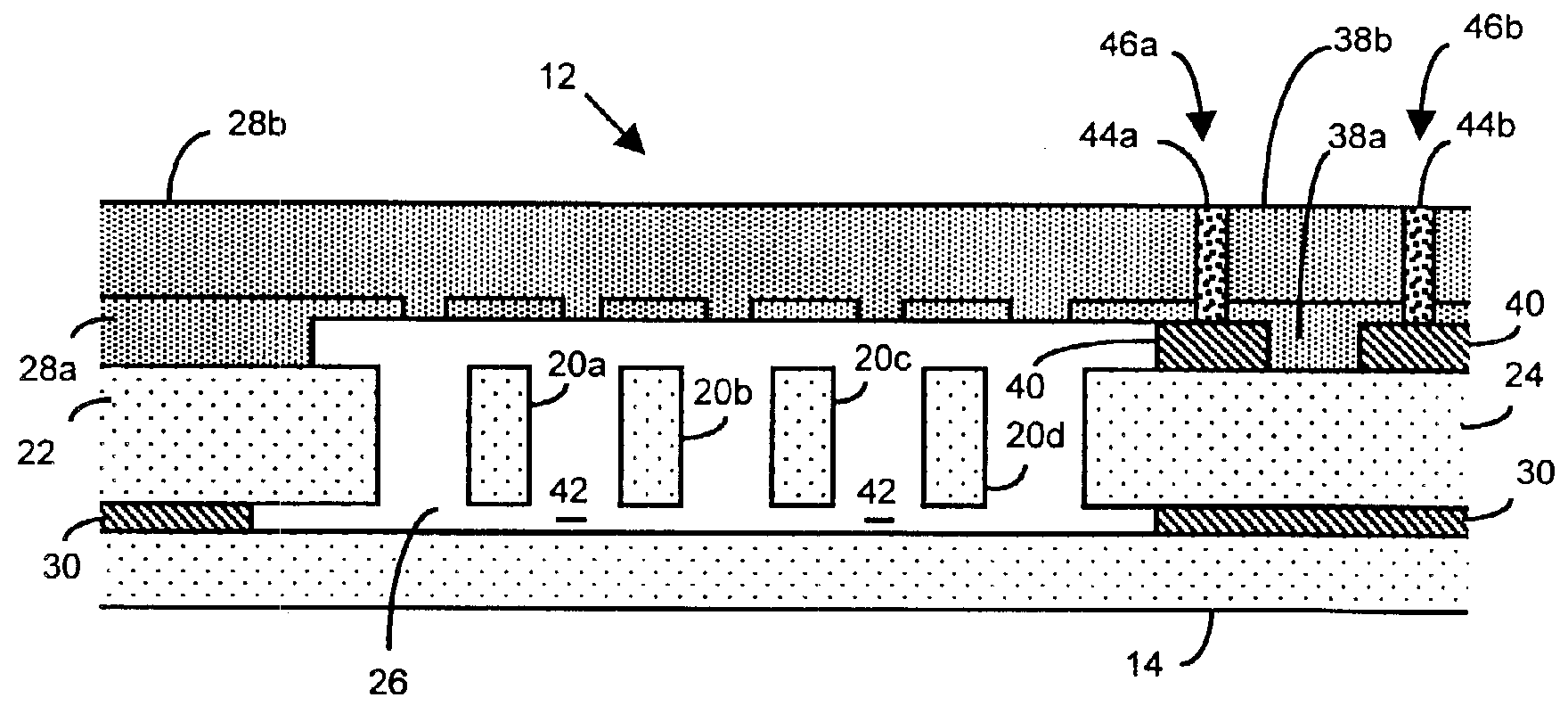

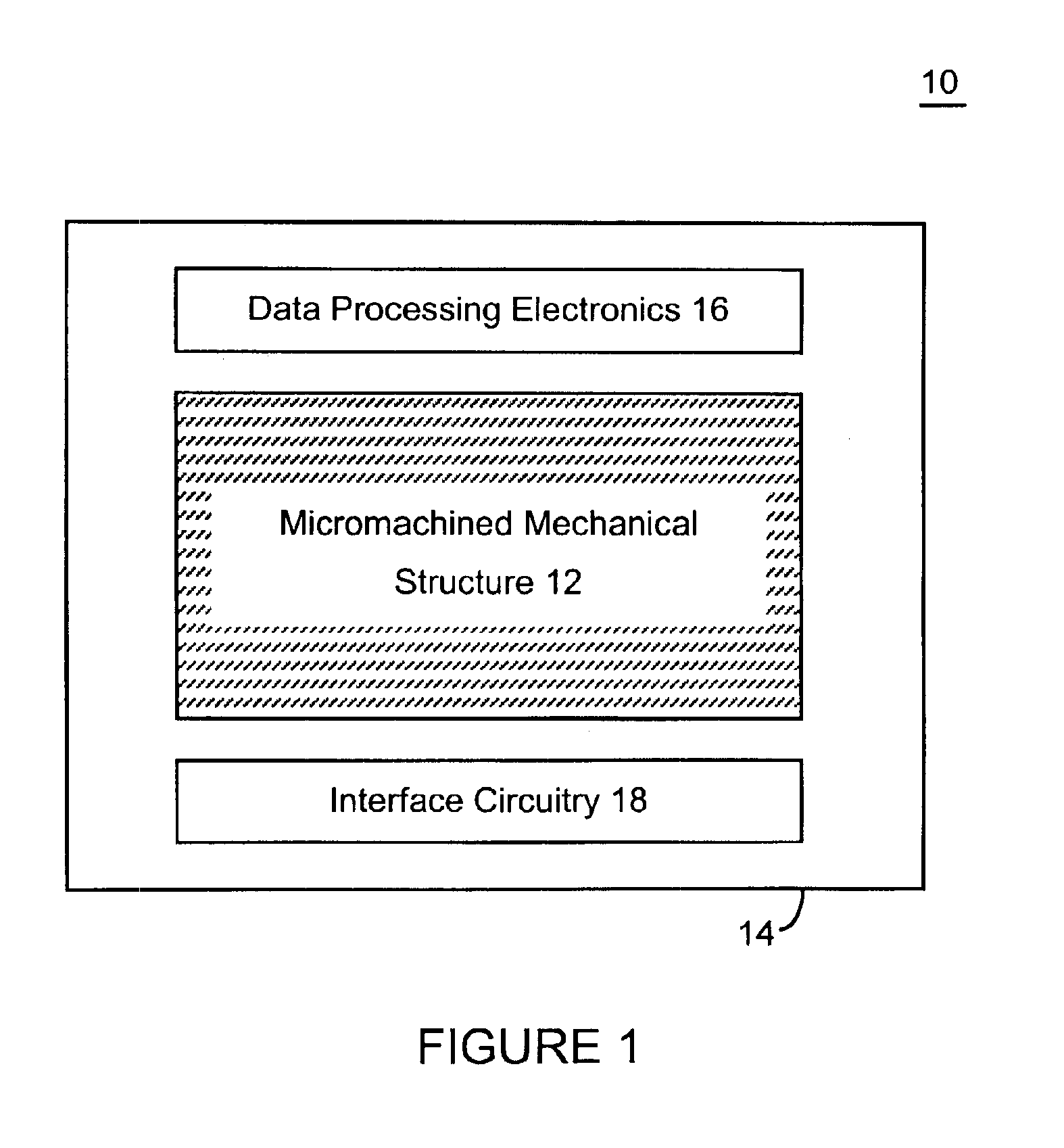

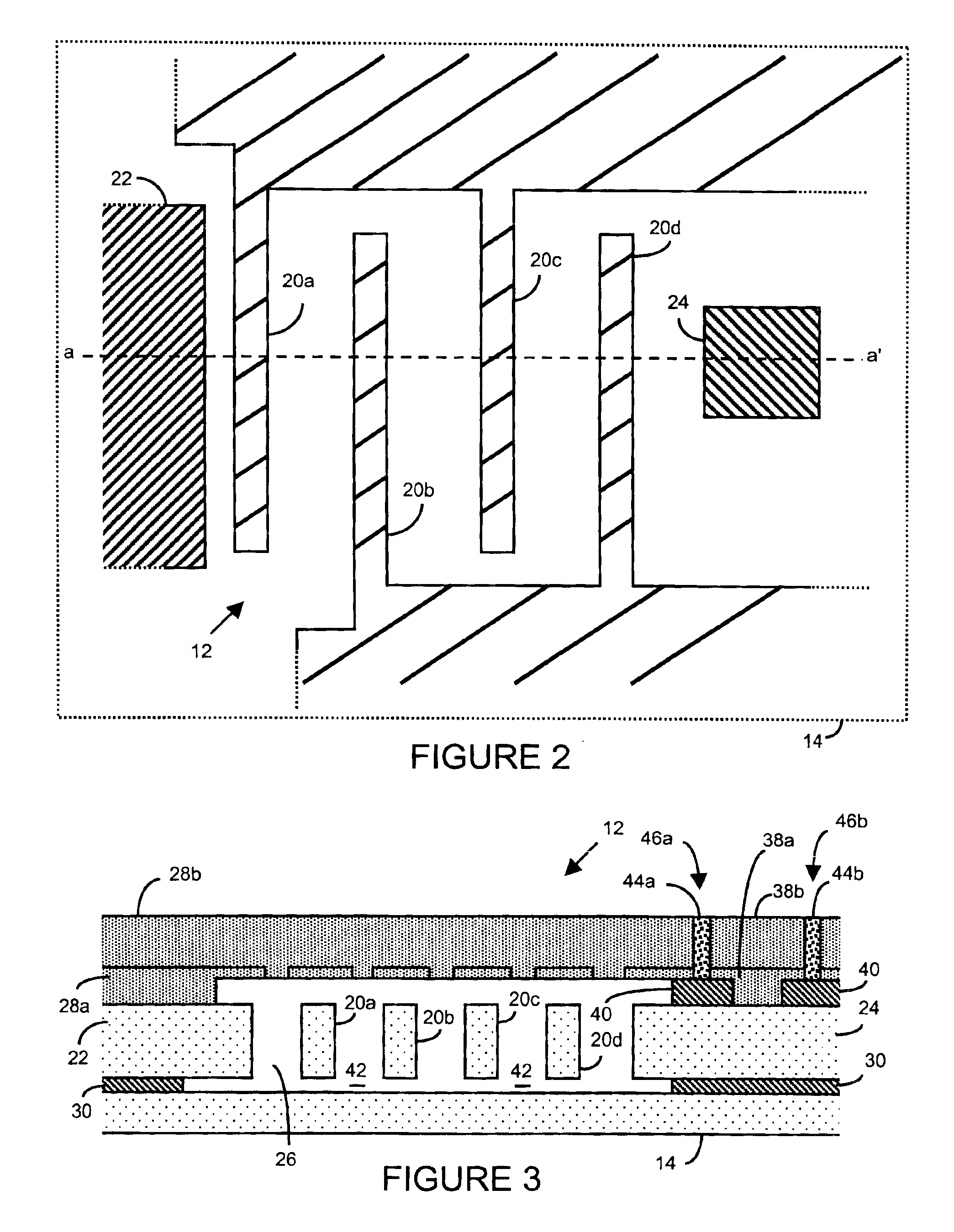

InactiveUS20100193884A1Television system detailsAcceleration measurement using interia forcesTransducerCapacitive sensing

A method and apparatus are described for fabricating a high aspect ratio MEMS device by using metal thermocompression bonding to assemble a reference wafer (100), a bulk MEMS active wafer (200), and a cap wafer (300) to provide a proof mass (200d) formed from the active wafer with bottom and top capacitive sensing electrodes (115, 315) which are hermetically sealed from the ambient environment by sealing ring structures (112 / 202 / 200a / 212 / 312 and 116 / 206 / 200e / 216 / 316).

Owner:FREESCALE SEMICON INC

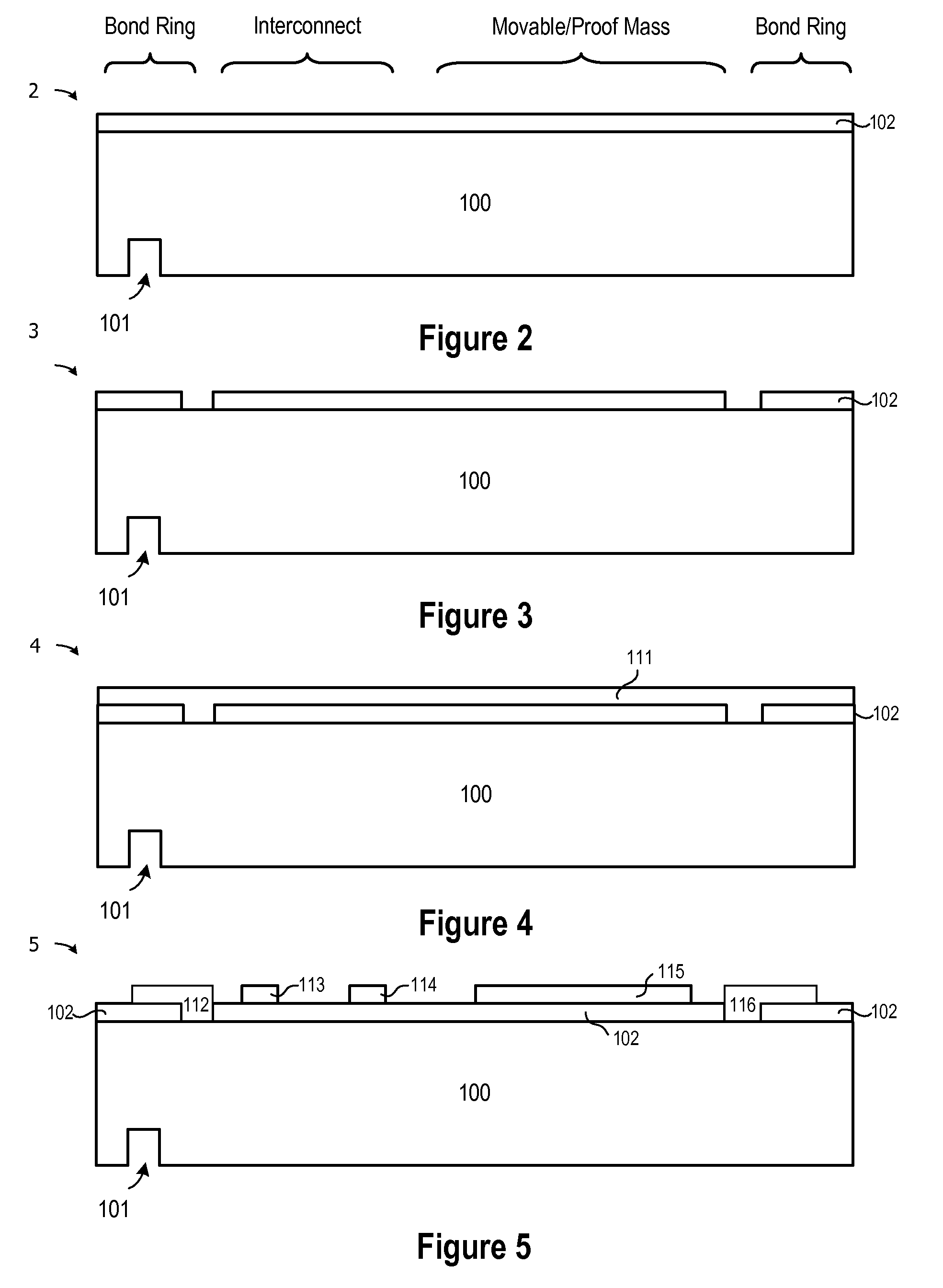

Method of fabrication of ai/ge bonding in a wafer packaging environment and a product produced therefrom

ActiveUS20060208326A1RobustHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

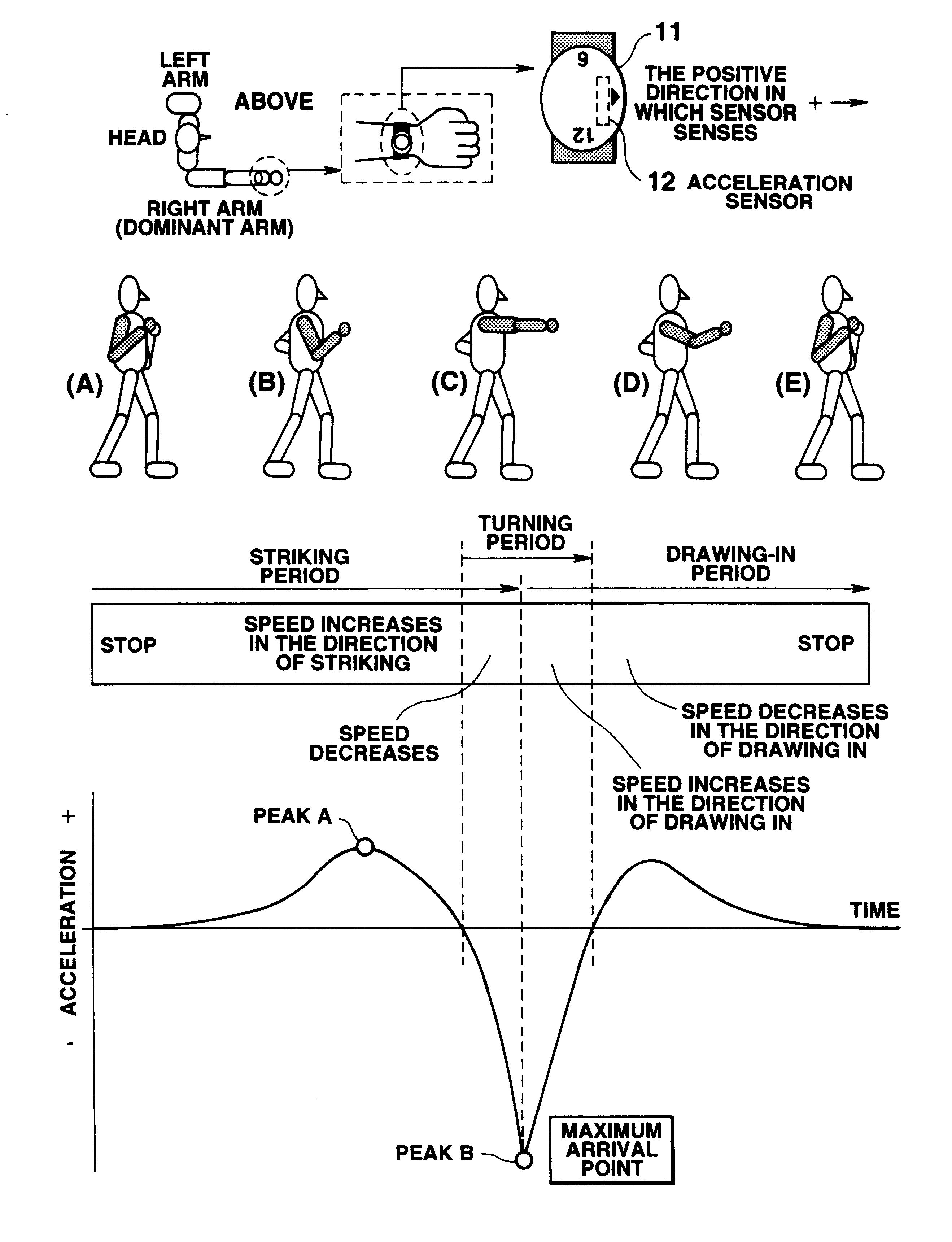

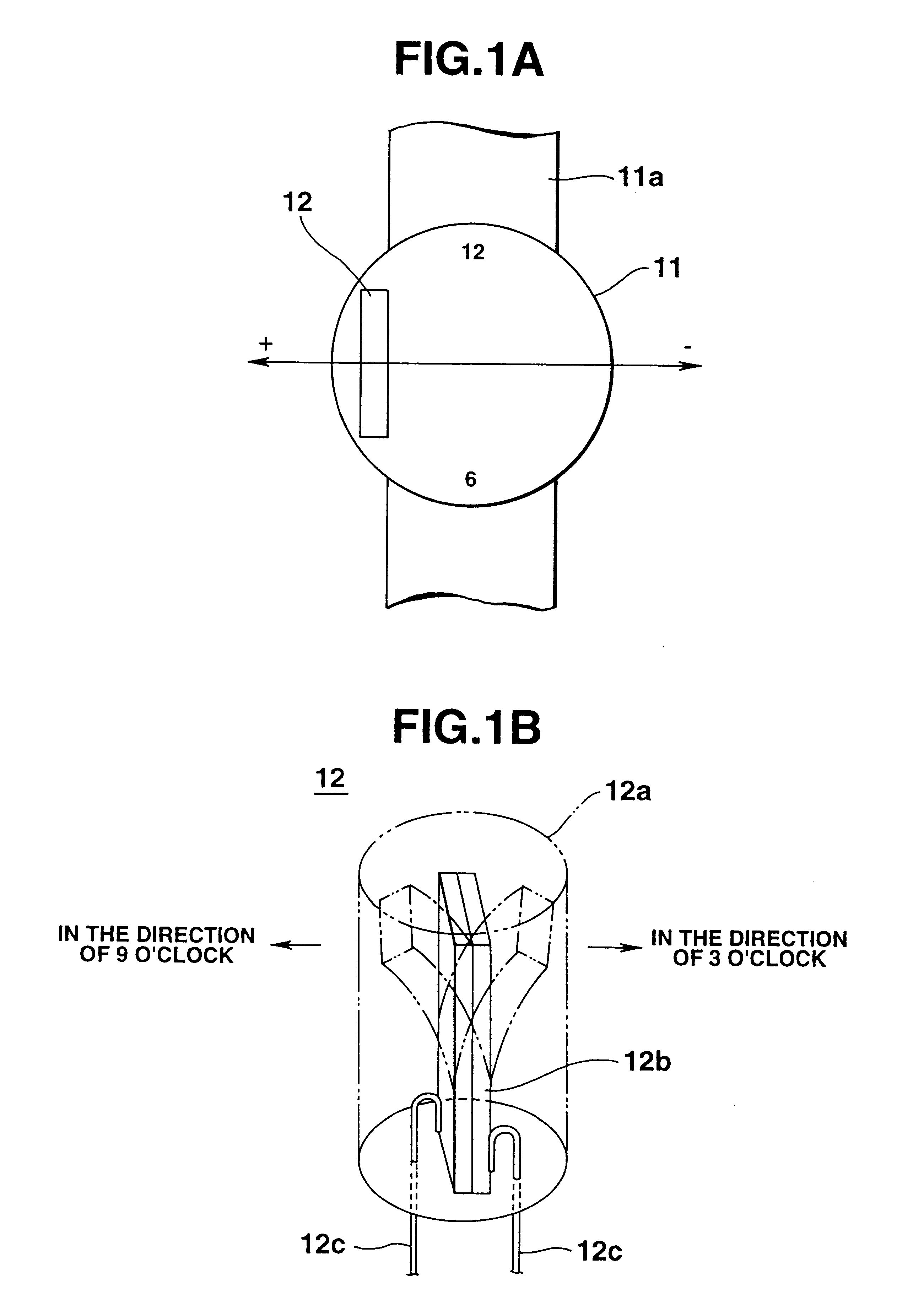

Movement measuring device, electronic game machine including movement measuring device, and method of playing game machine

InactiveUS6183365B1Easily sensing speed and impact forceCompact structureInput/output for user-computer interactionAcceleration measurement using interia forcesPunchingEngineering

A movement measuring device determines the speed of the body's specific movement on the basis of the maximum value of the acceleration sensed by an acceleration sensing unit attached to the body, when the body has made a specific movement. For example, when the player wears the device on his arm and makes a punching motion, the punching speed is found from the maximum acceleration resulting from the punching action. Furthermore, a game device obtains data indicating the magnitude of a specific movement of the body, on the basis of the acceleration sensed by an acceleration sensing unit, and then decides the outcome of the game on the basis of the strength and weakness of the punch. This enables the user to easily play a fighting sport game involving the player's actual punching motions anywhere.

Owner:CASIO COMPUTER CO LTD

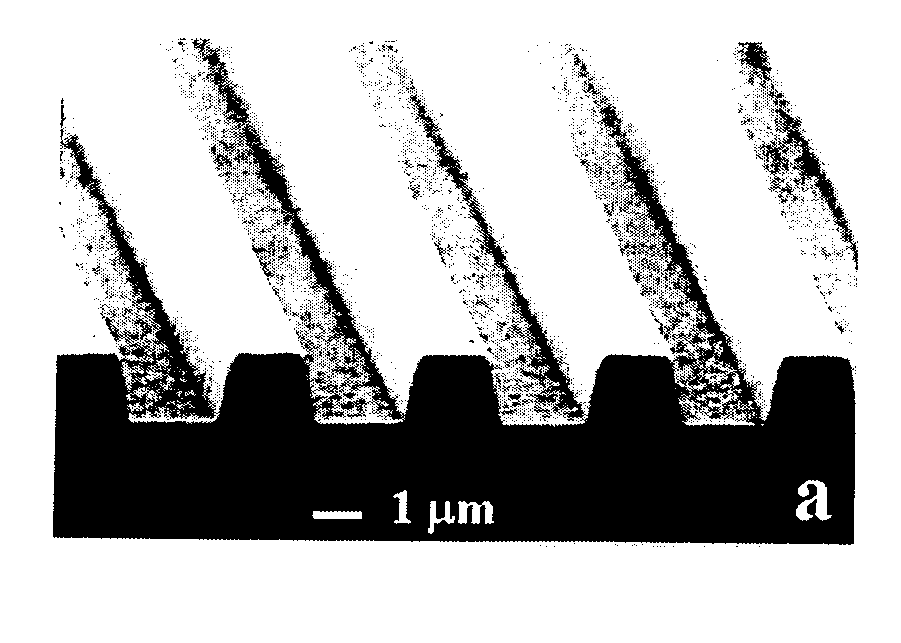

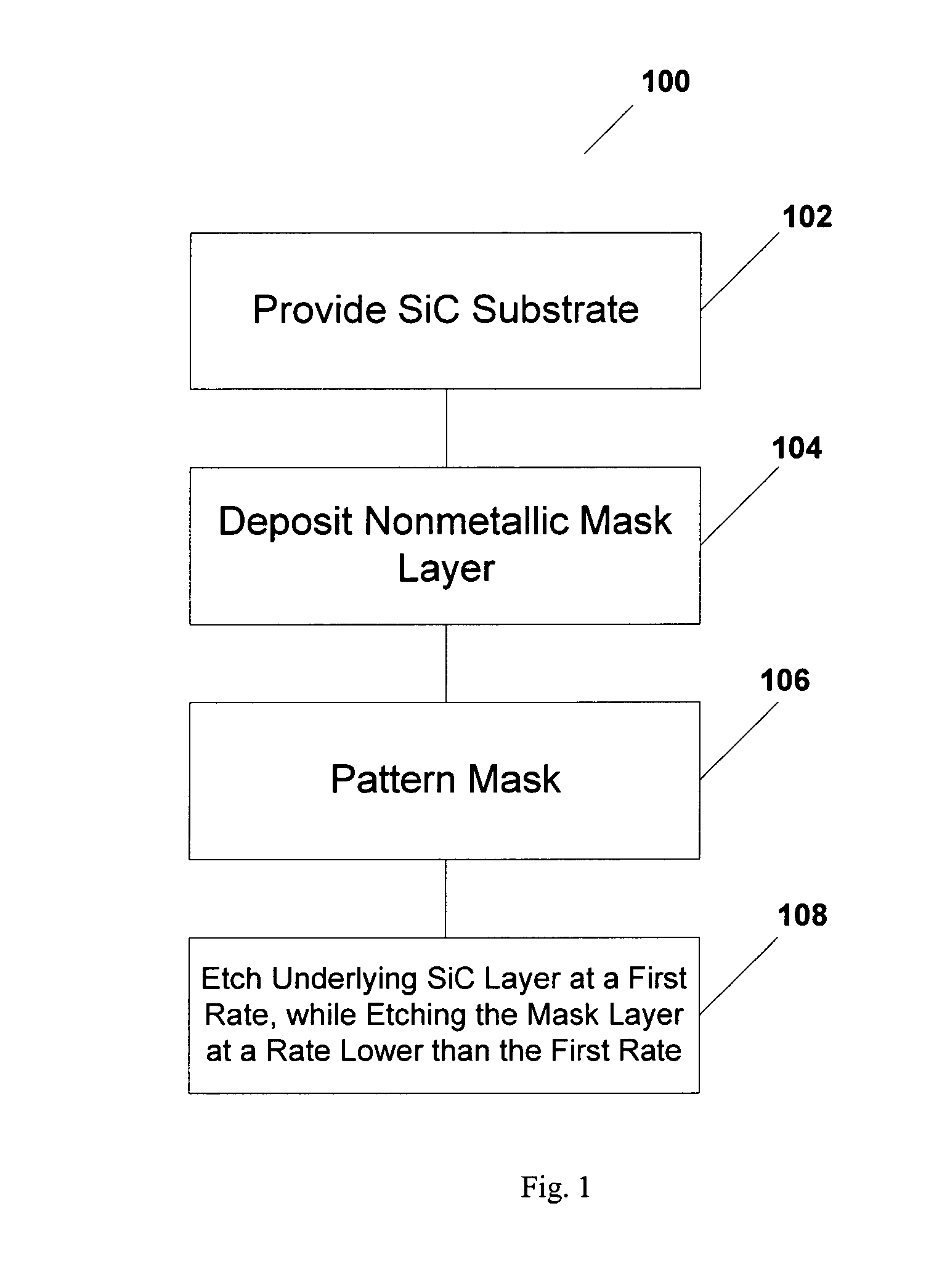

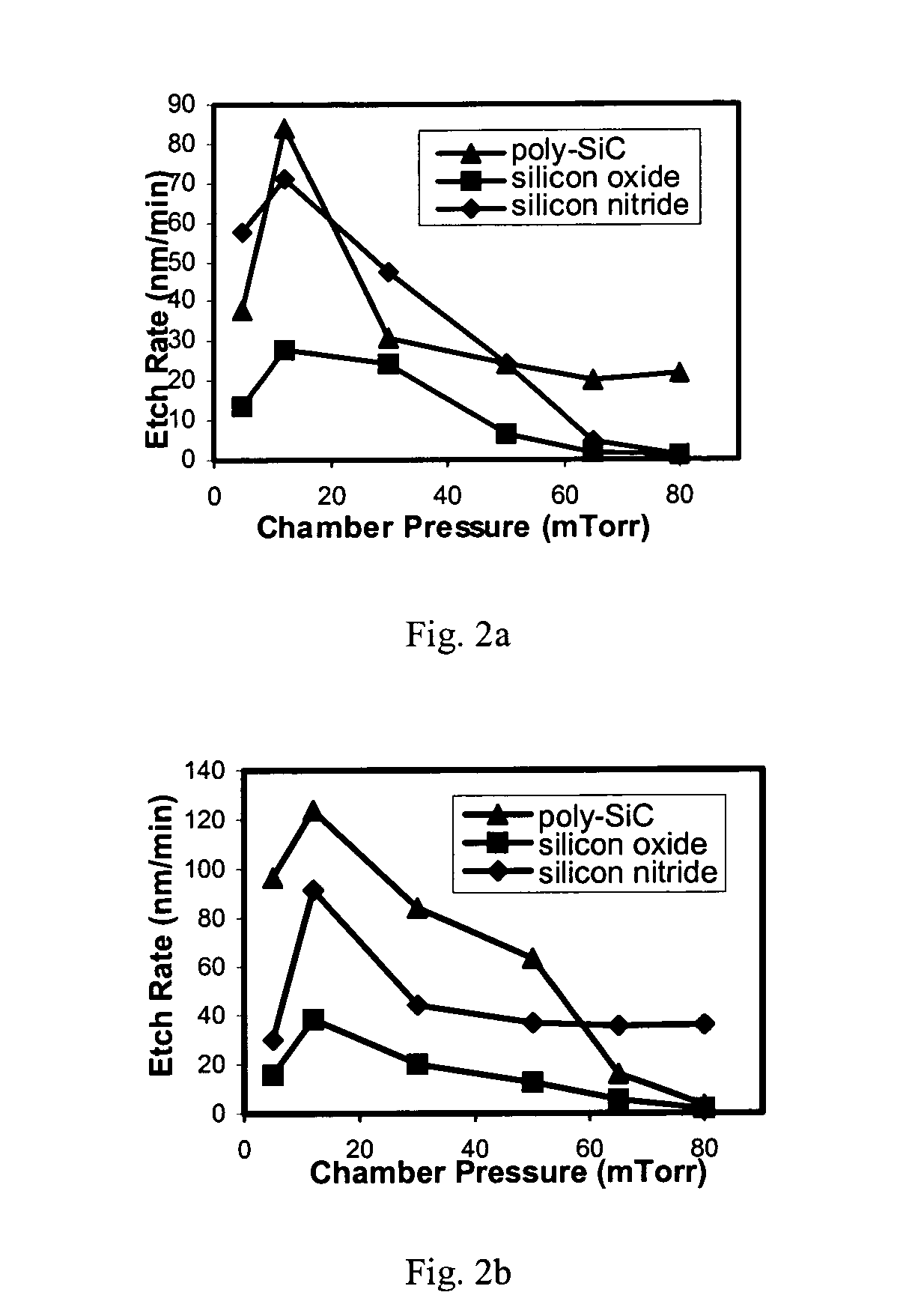

Selective etching of silicon carbide films

ActiveUS20050001276A1Acceleration measurement using interia forcesDecorative surface effectsMask layerSilicon carbide

A method of etching silicon carbide using a nonmetallic mask layer. The method includes providing a silicon carbide substrate; forming a non-metallic mask layer by applying a layer of material on the substrate; patterning the mask layer to expose underlying areas of the substrate; and etching the underlying areas of the substrate with a plasma at a first rate, while etching the mask layer at a rate lower than the first rate.

Owner:RGT UNIV OF CALIFORNIA

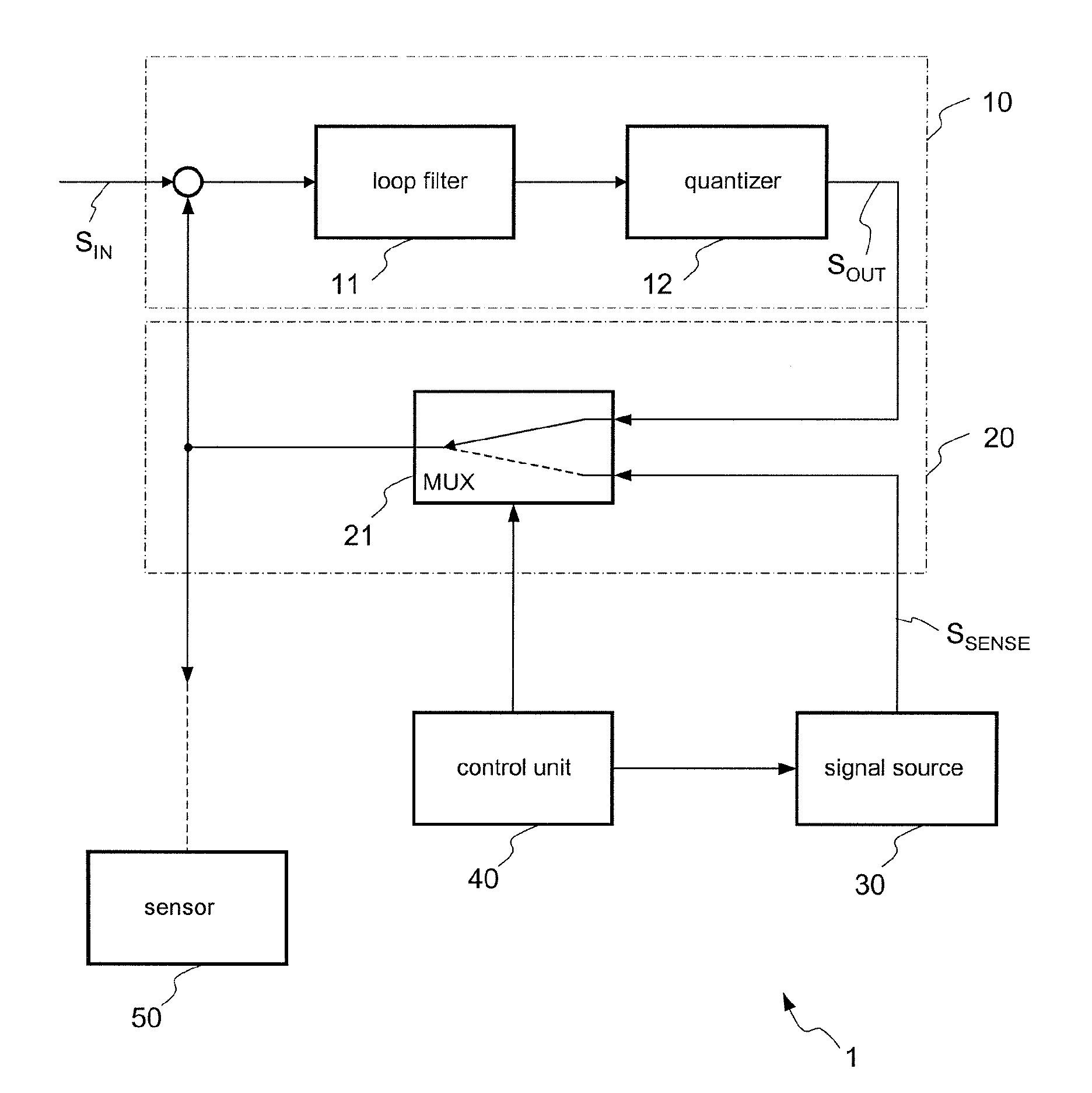

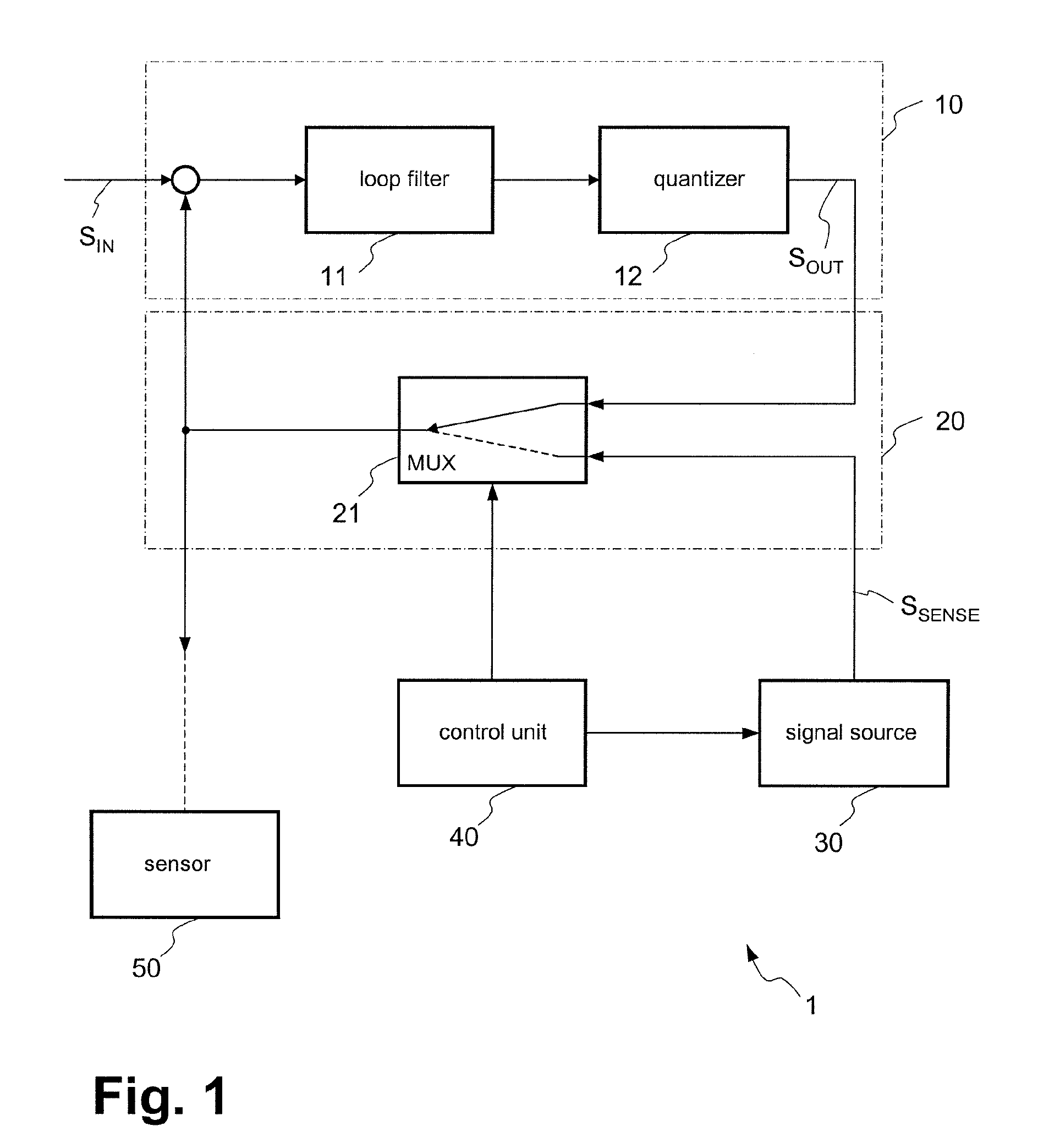

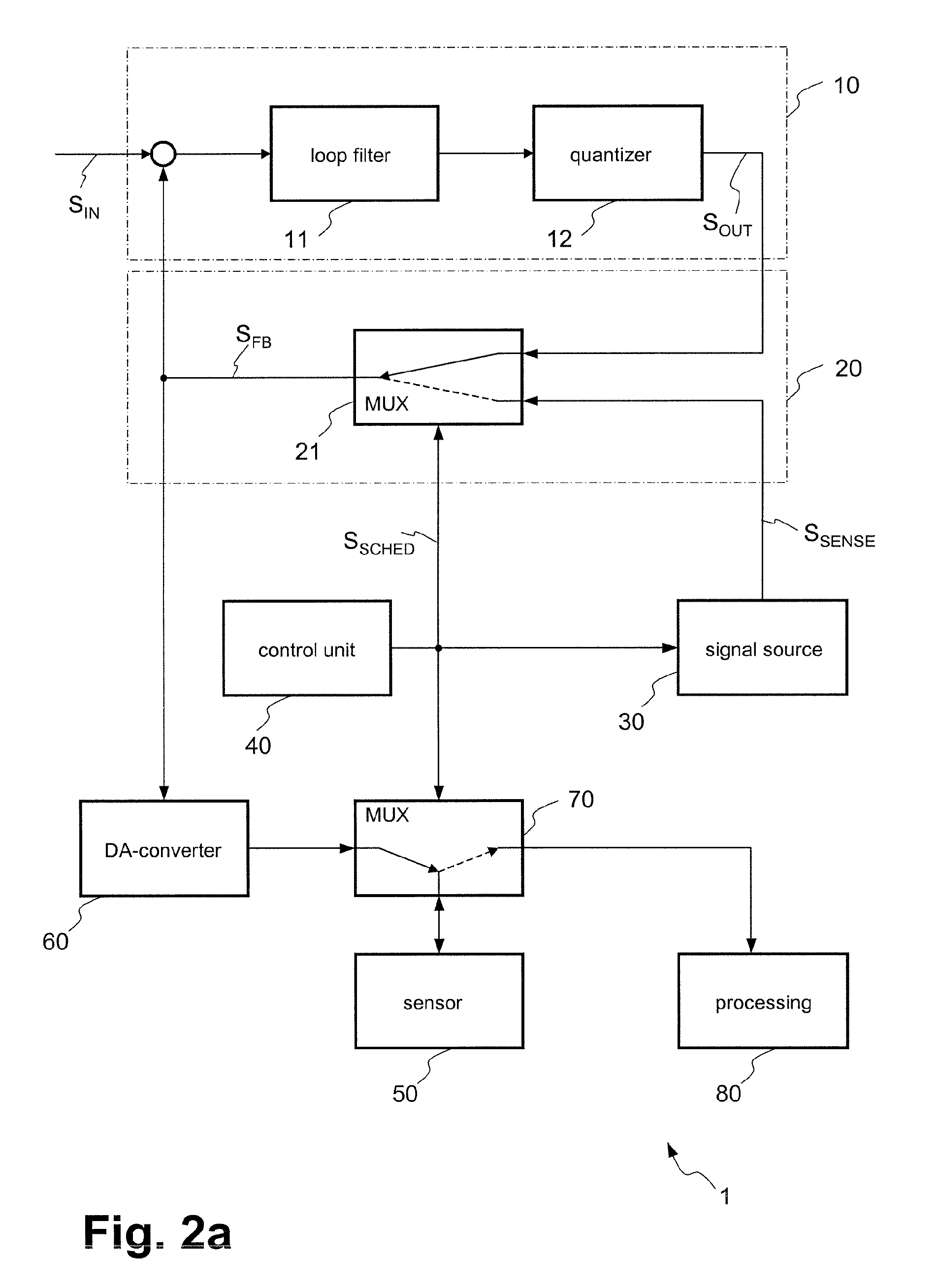

Sigma-delta modulator for operating sensors

InactiveUS7528755B2Electric signal transmission systemsAcceleration measurement using interia forcesLoop filterControl signal

A sigma-delta modulator can be used for actuating a sensor element. The sigma delta modulator includes: a forward branch to which an input signal is fed at an input and which includes a loop filter, a quantizer and an output for providing an output signal. A feedback branch is configured to feed back the output signal of the forward branch at least temporarily to the input of the forward branch. A signal source is configured to generate a readout signal which corresponds to the voltage profile at the sensor element during a measuring process. A control unit is configured to generate a control signal dependent on which either the output signal of the forward branch or the readout signal of the signal source is fed back to the input of the forward branch.

Owner:INFINEON TECH AG

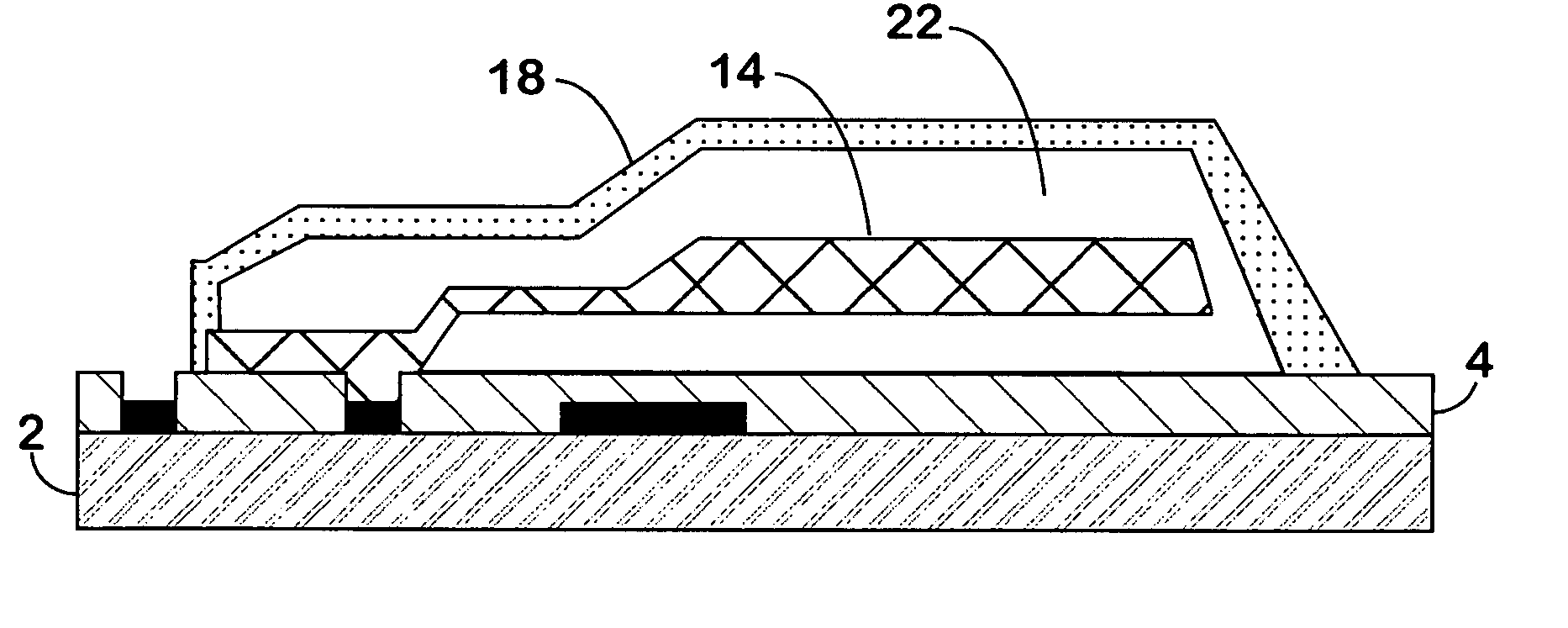

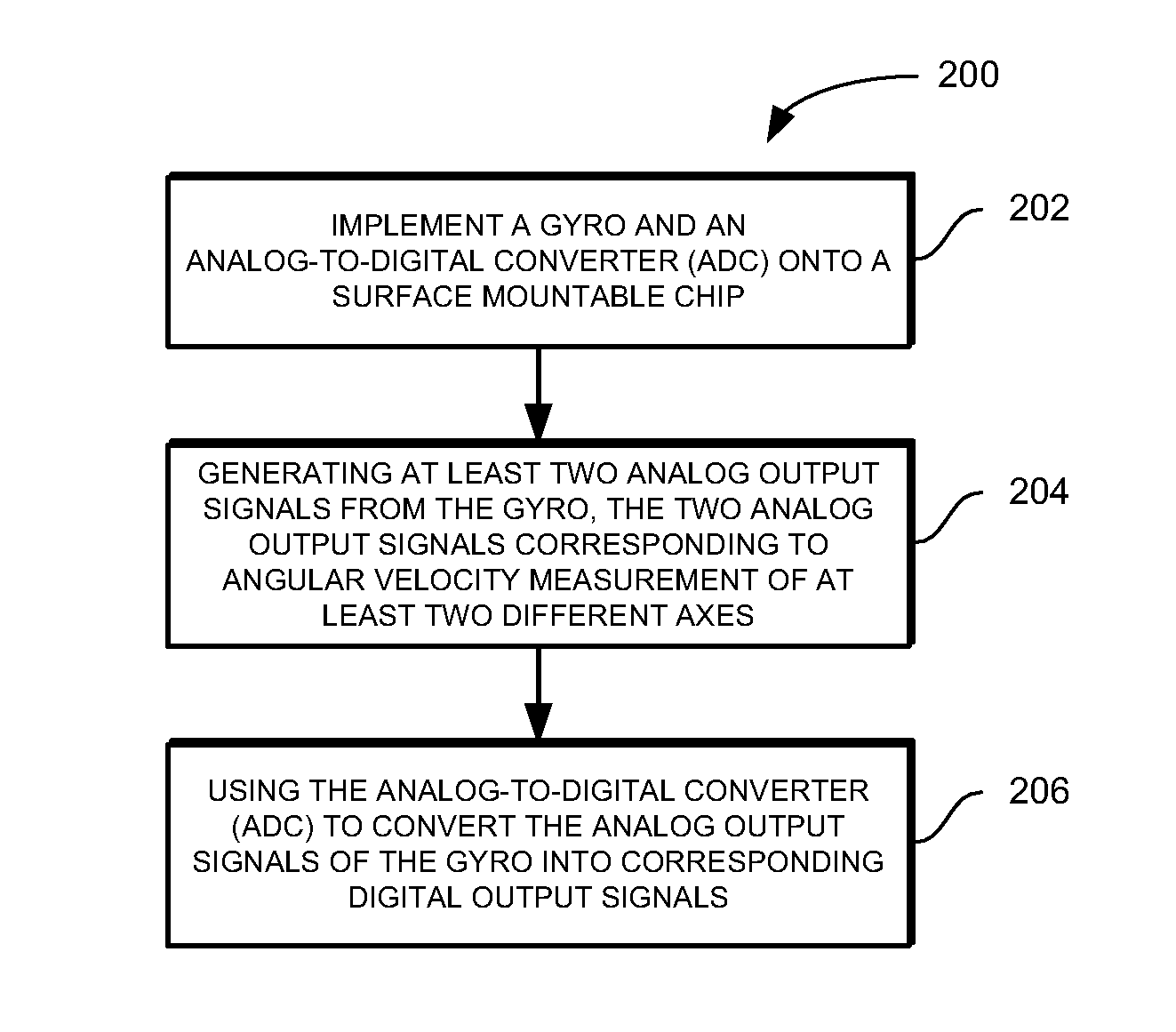

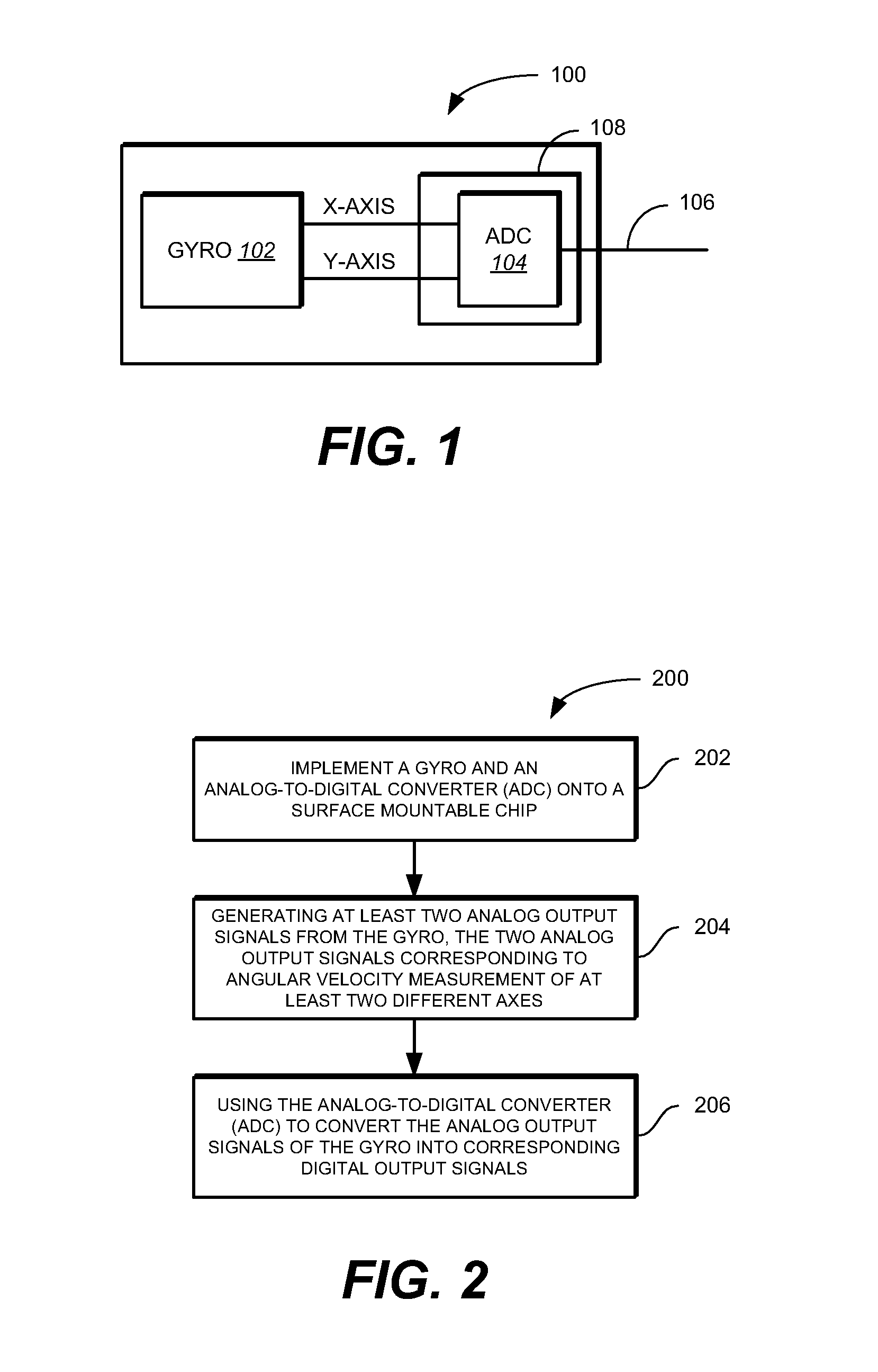

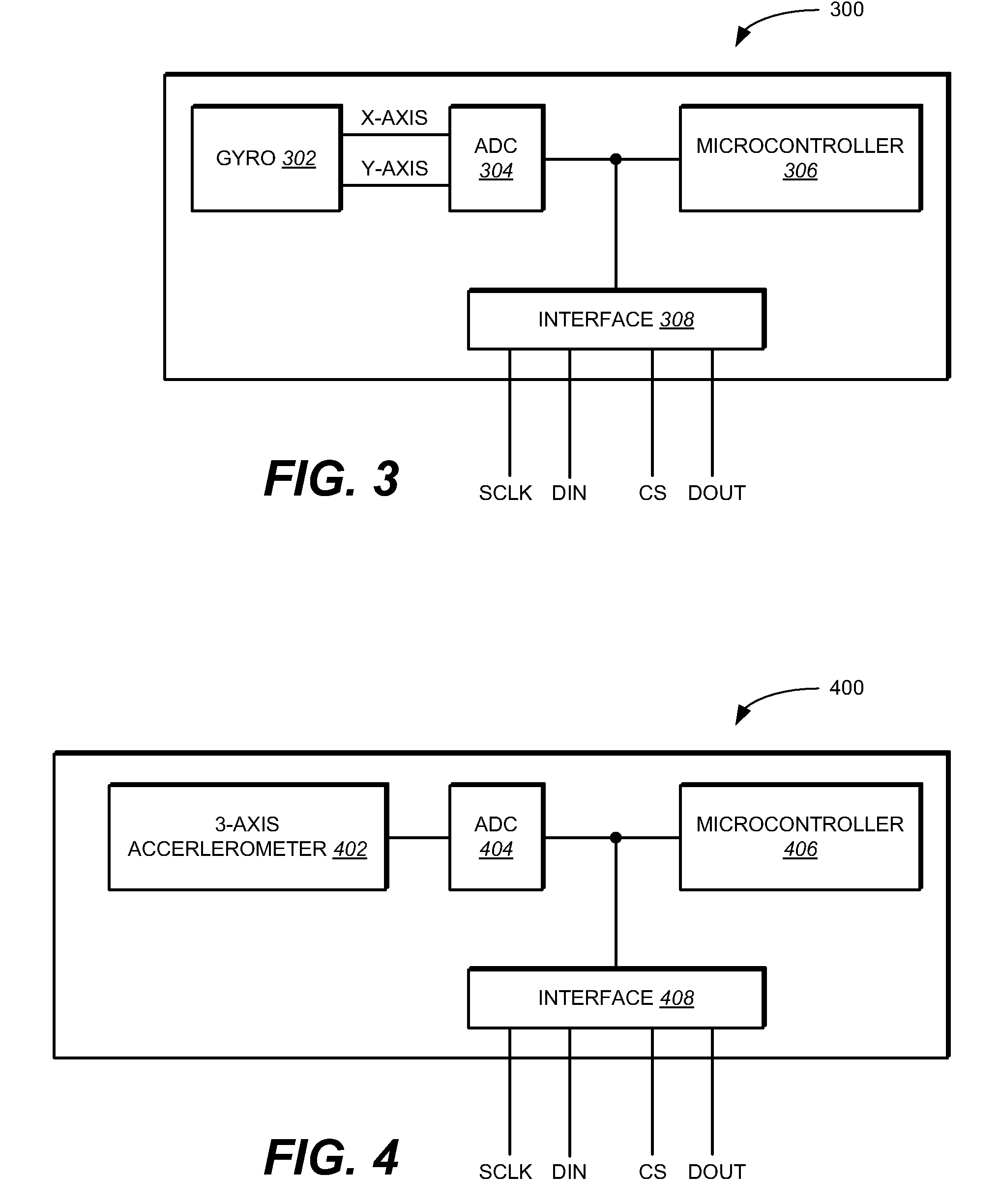

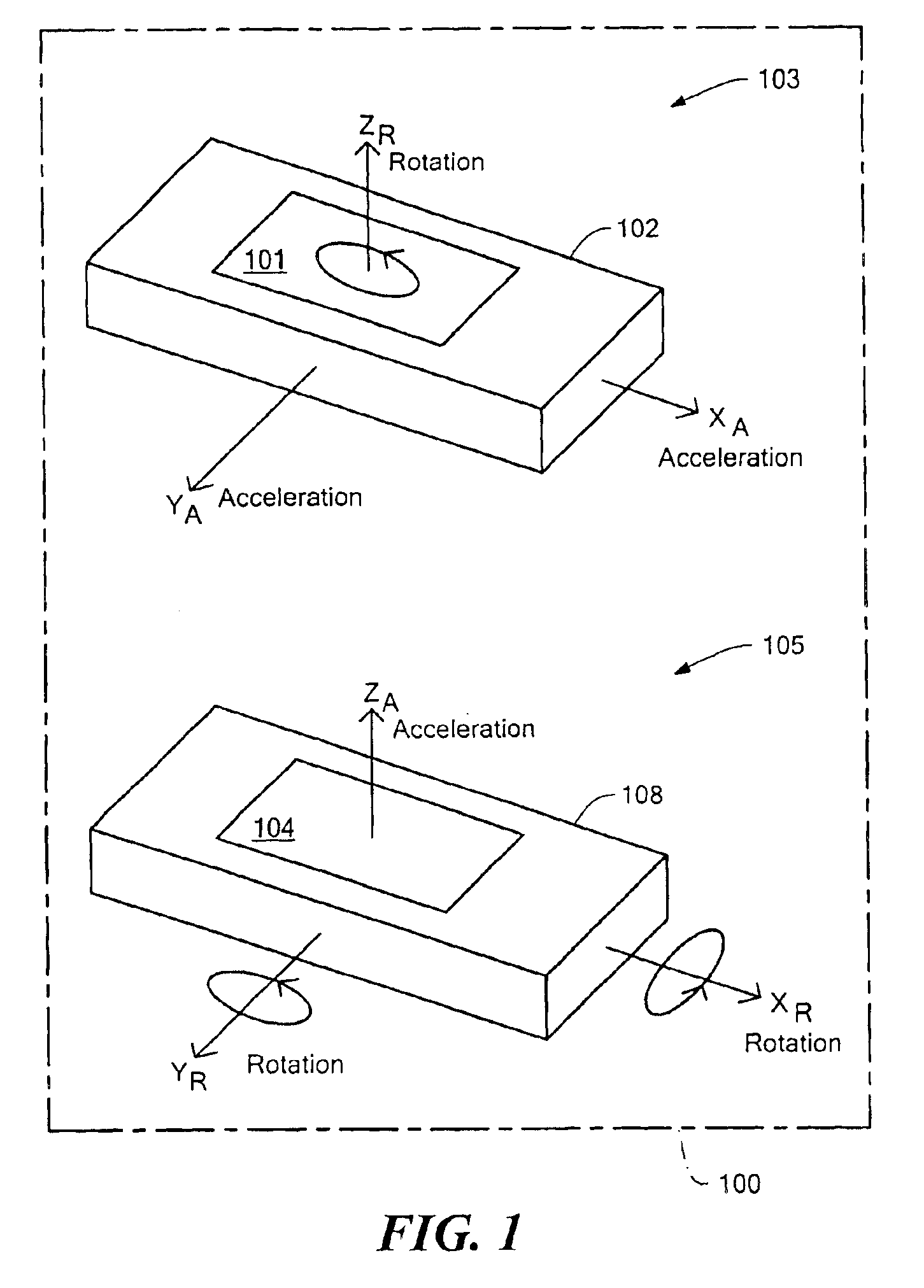

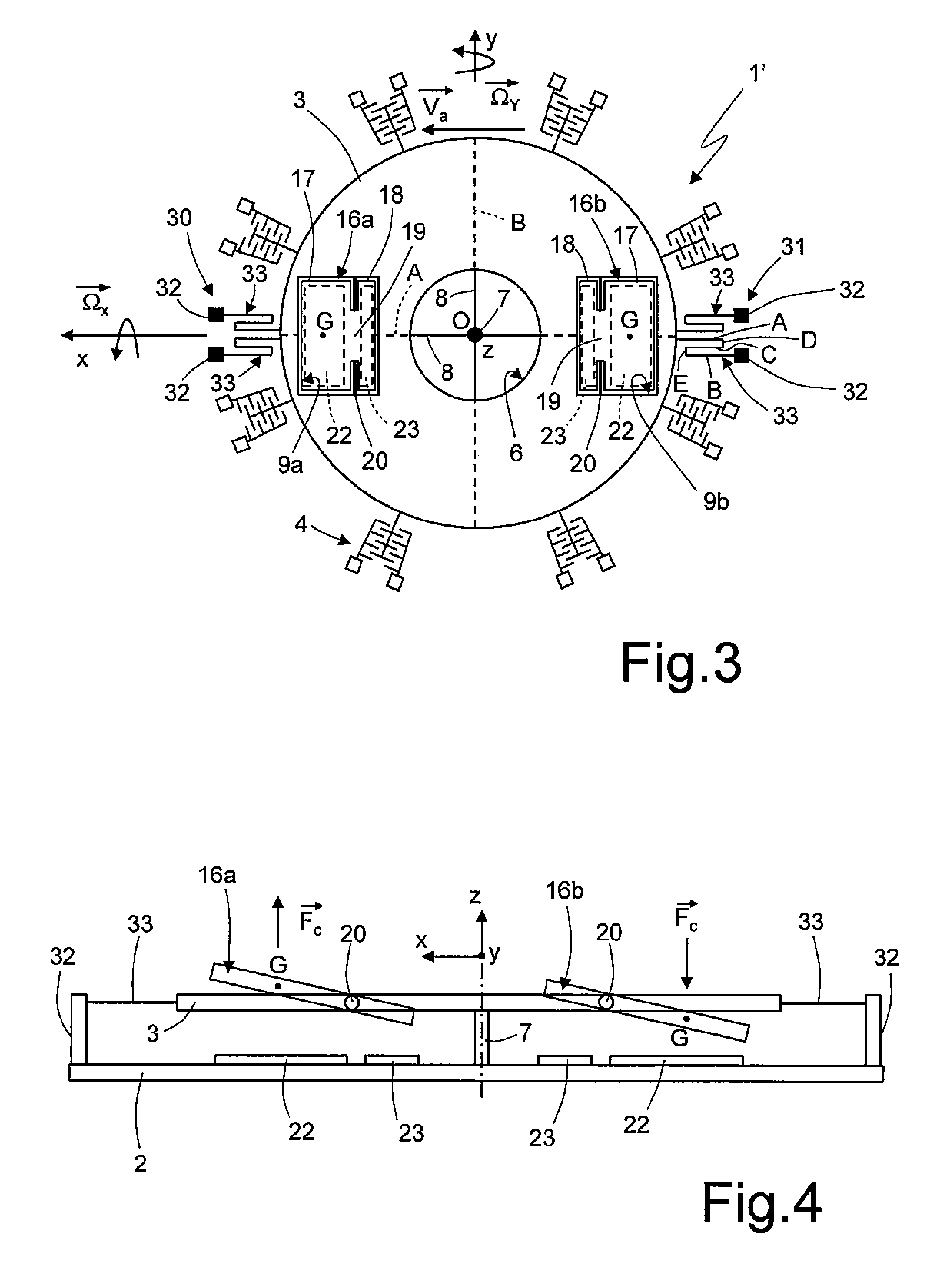

Integrated Motion Processing Unit (MPU) With MEMS Inertial Sensing And Embedded Digital Electronics

ActiveUS20090007661A1Small packageLower performance requirementsElectric signal transmission systemsAcceleration measurement using interia forcesMotion processingAccelerometer

A module operable to be mounted onto a surface of a board. The module includes a linear accelerometer to provide a first measurement output corresponding to a measurement of linear acceleration in at least one axis, and a first rotation sensor operable to provide a second measurement output corresponding to a measurement of rotation about at least one axis. The accelerometer and the first rotation sensor are formed on a first substrate. The module further includes an application specific integrated circuit (ASIC) to receive both the first measurement output from the linear accelerometer and the second measurement output from the first rotation sensor. The ASIC includes an analog-to-digital converter and is implemented on a second substrate. The first substrate is vertically bonded to the second substrate.

Owner:INVENSENSE

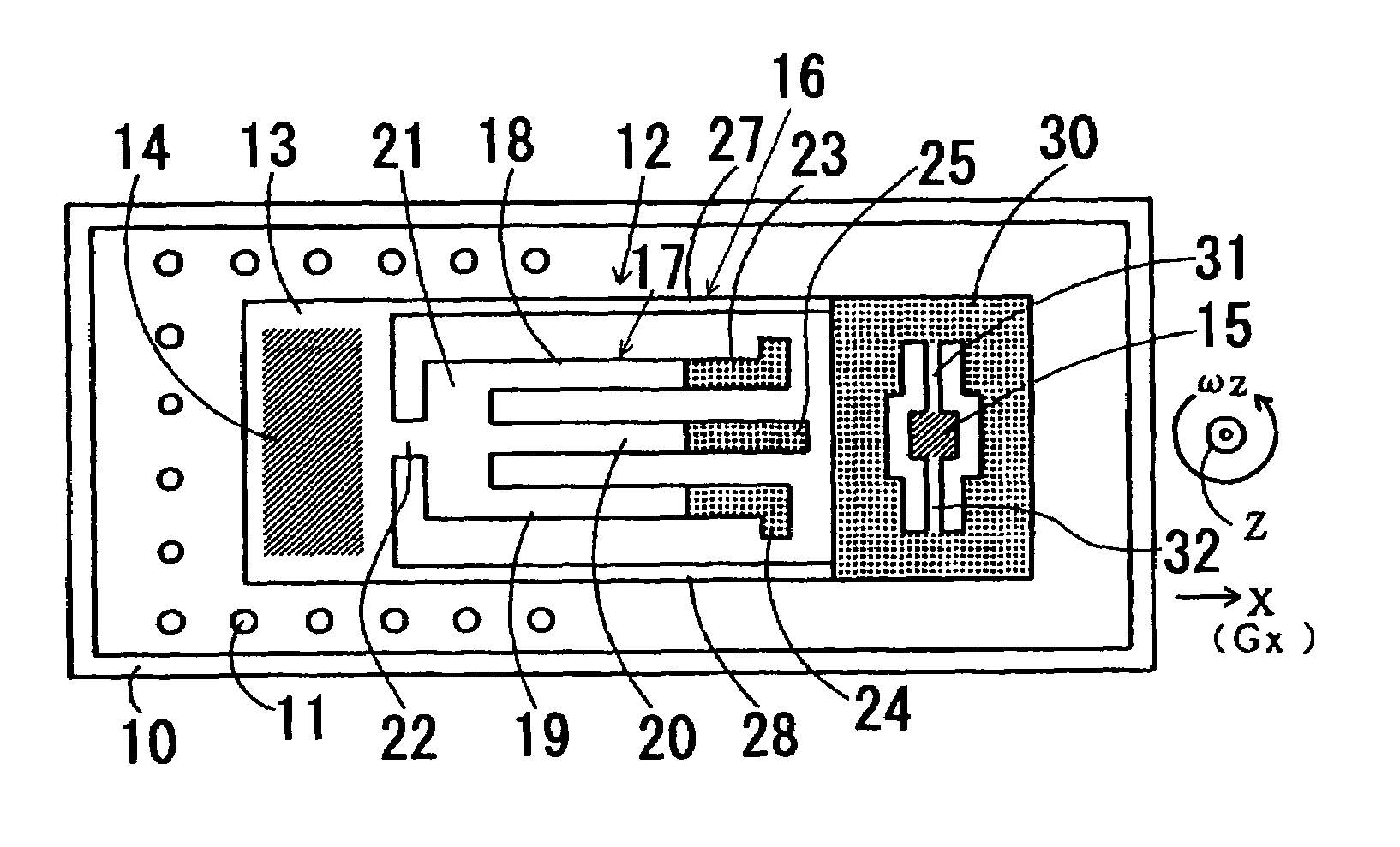

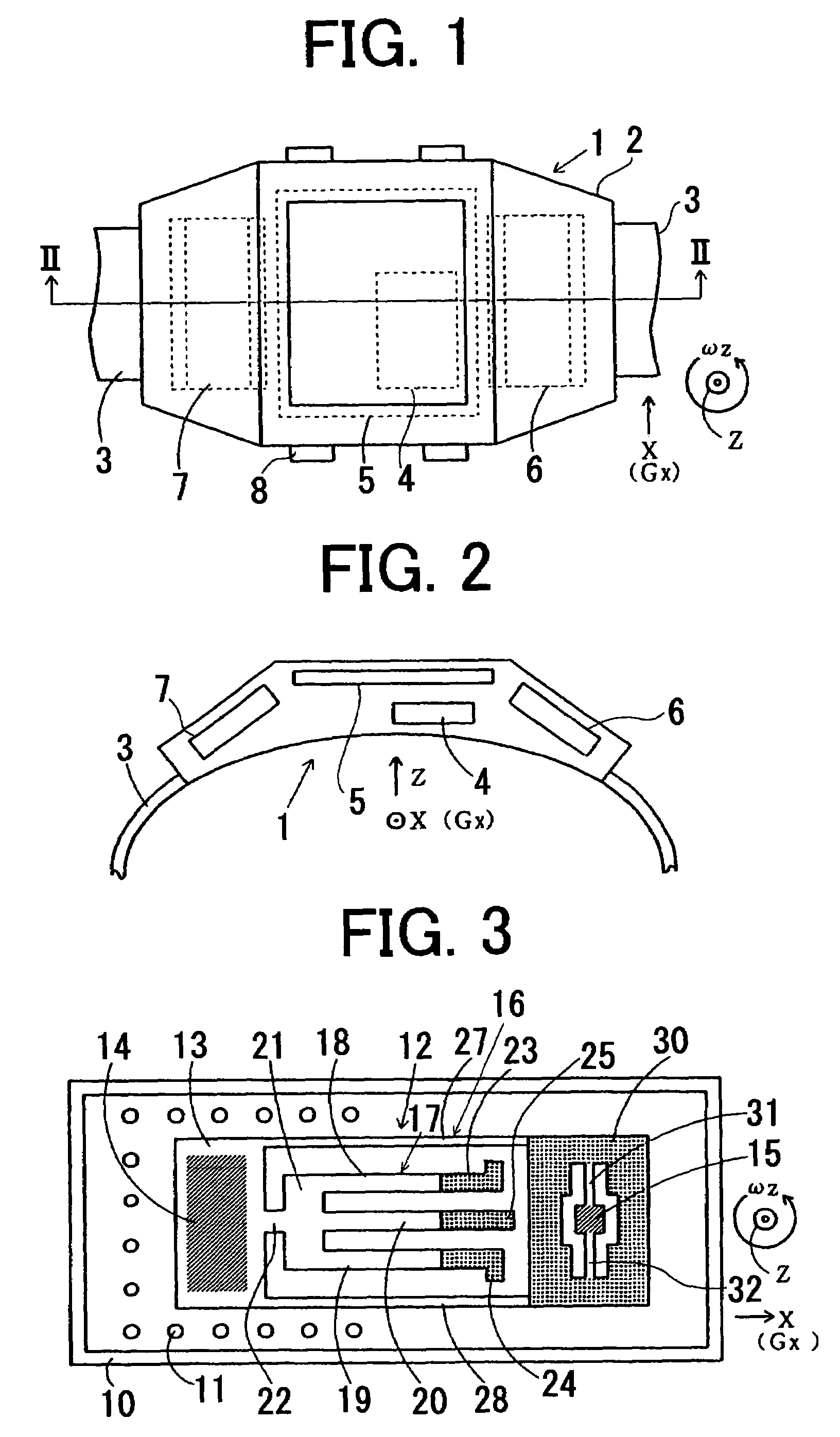

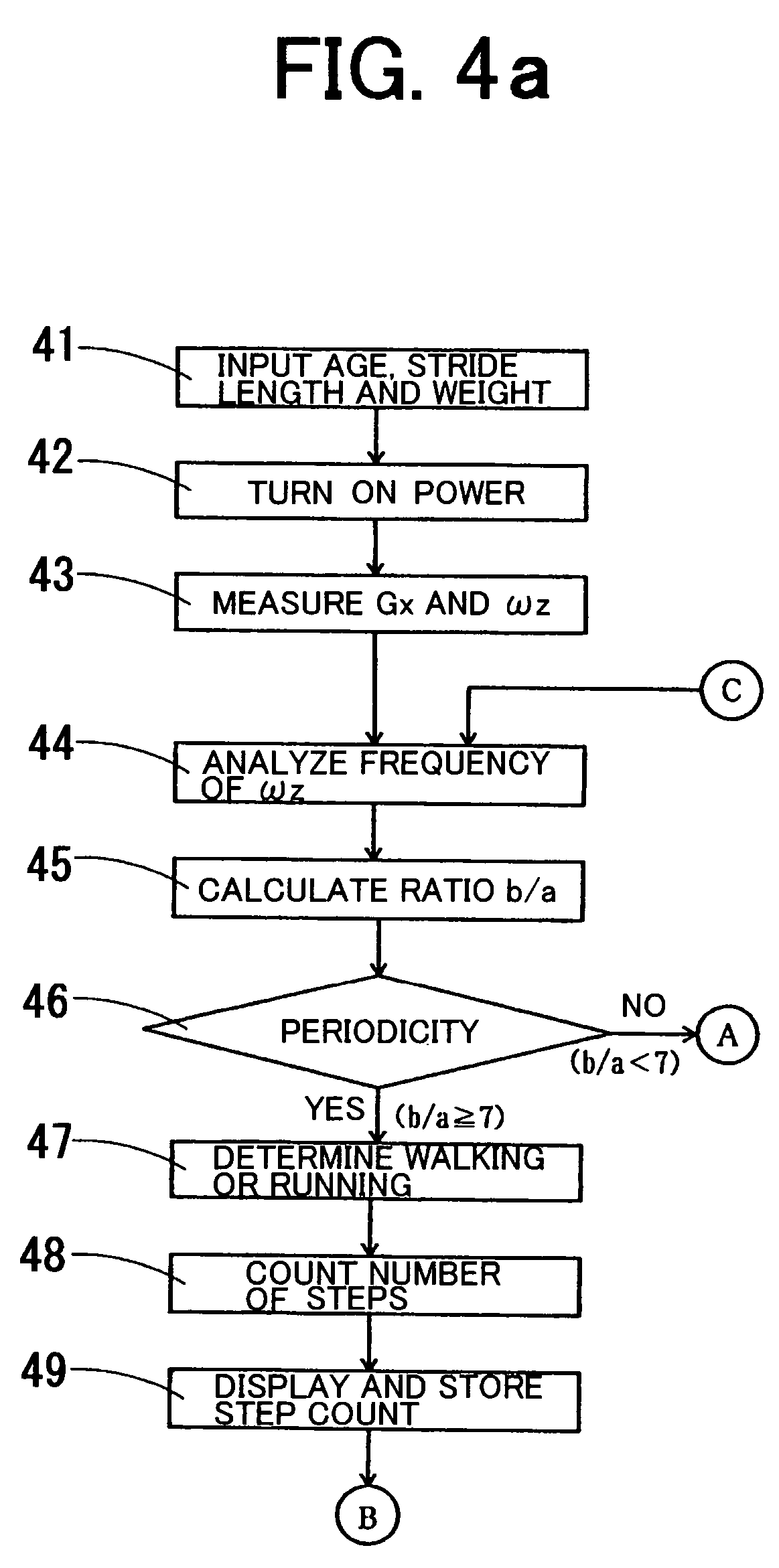

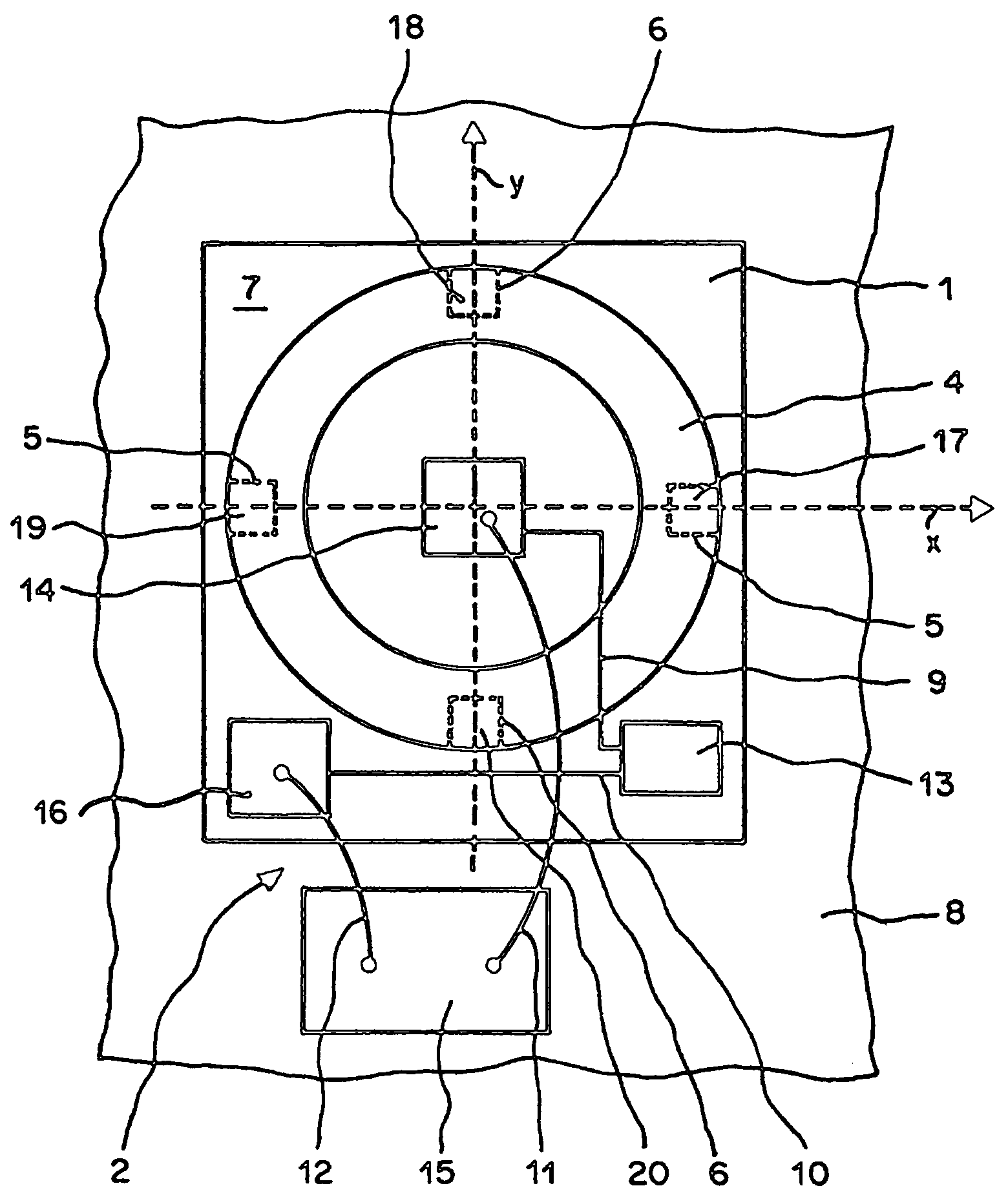

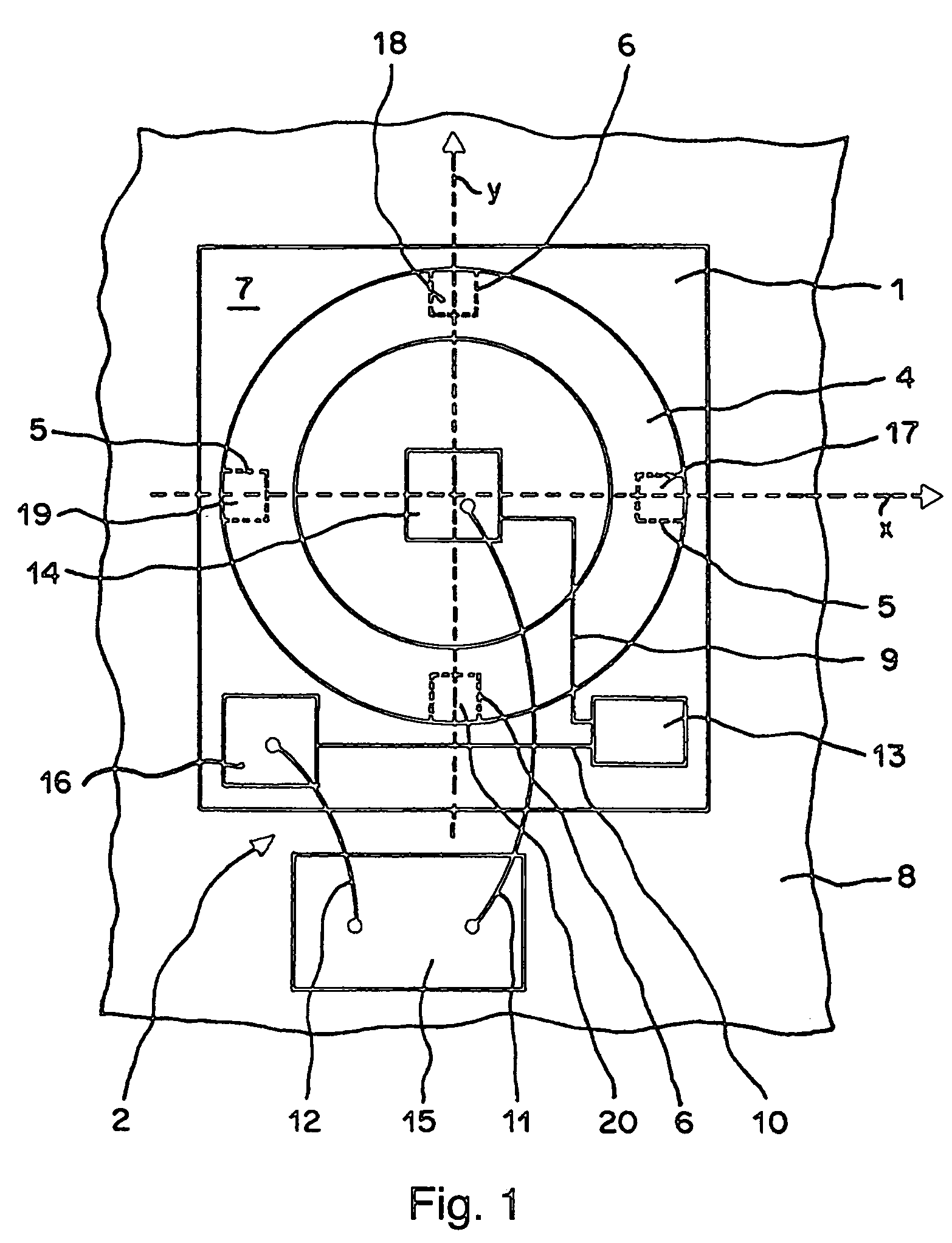

Body motion detector

InactiveUS7028547B2Not burdenImprove usabilityAcceleration measurement using interia forcesInertial sensorsMotion detectorElectricity

A movement detecting device comprises a container (10), at least a first vibrator (16) which vibrates in accordance with a physical movement in a first direction (X), and a second vibrator (17) which vibrates about a second direction (Z), the first and second vibrators mounted in the container. The vibrations of the first and second vibrators are converted into an electric signal, and a value of the converted signal is shown on a display.

Owner:MICROSTONE

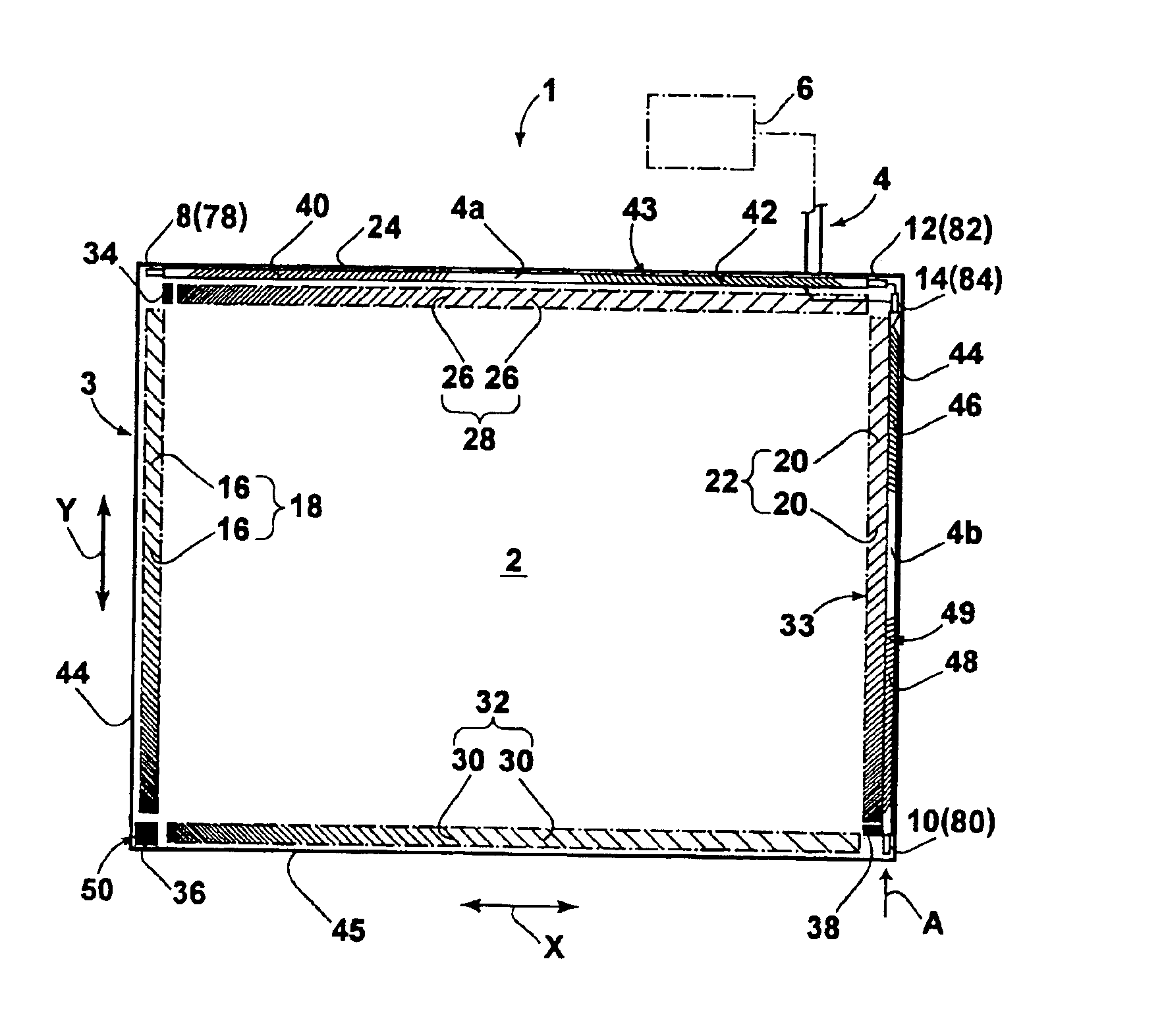

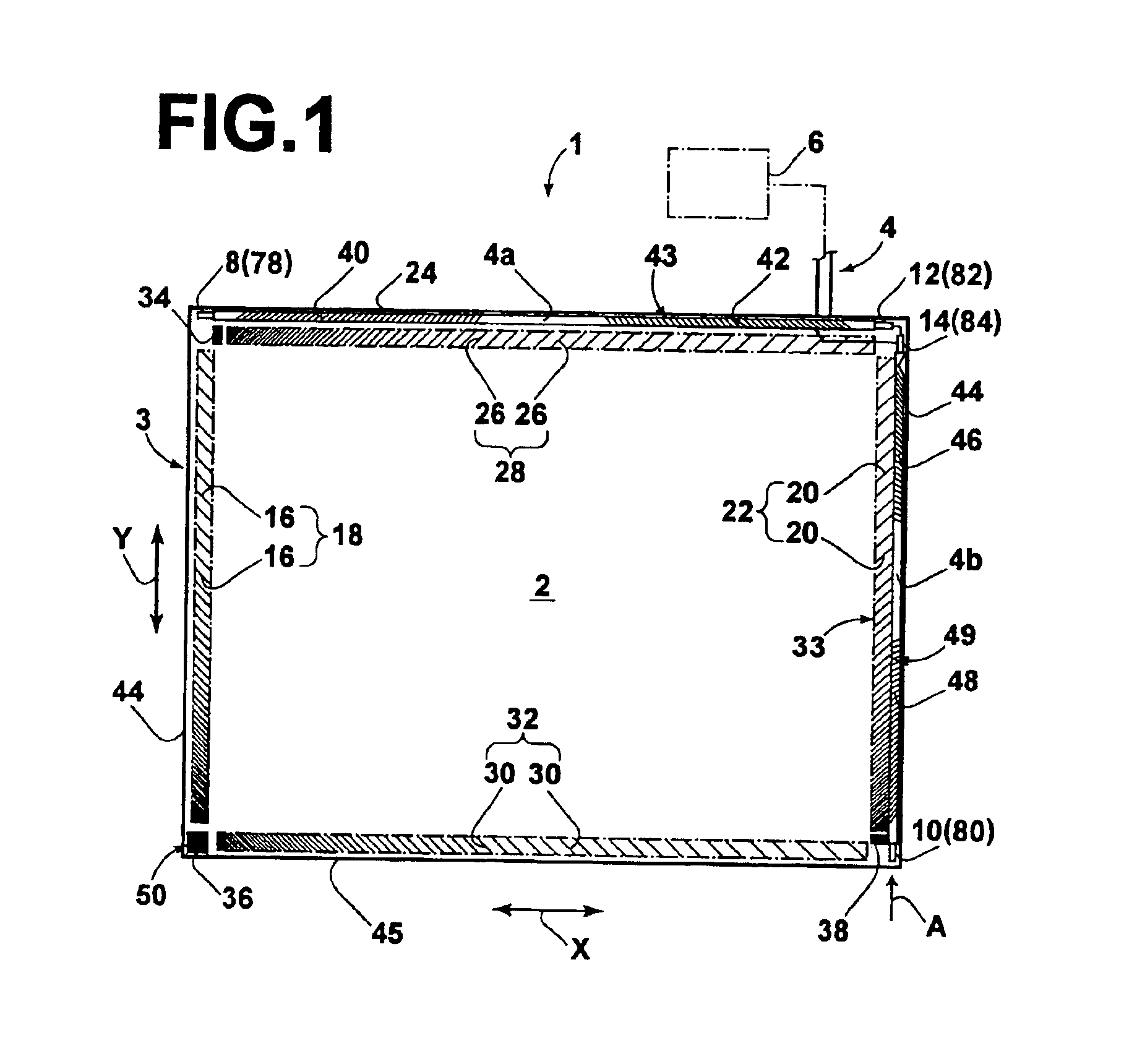

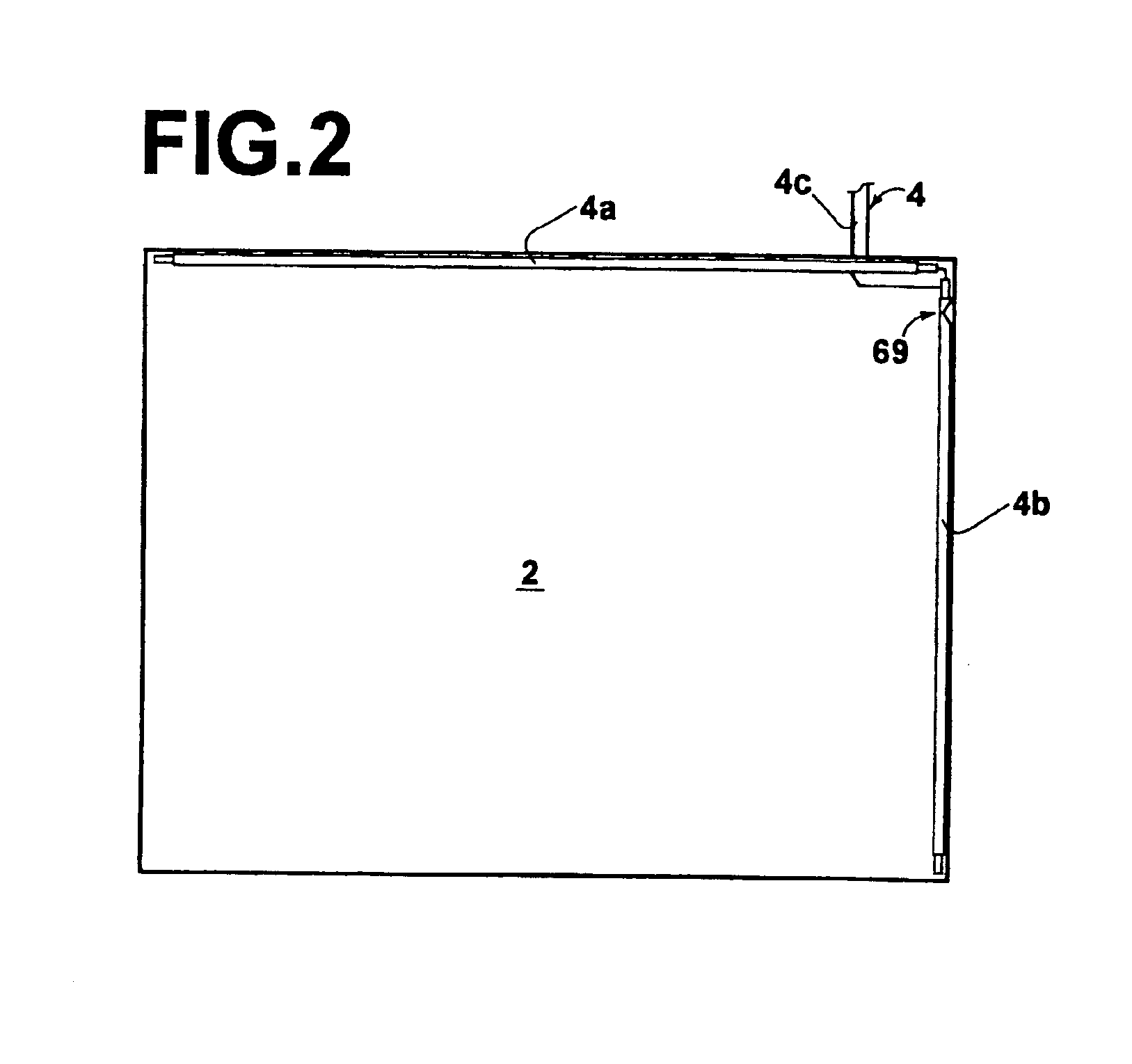

Acoustic wave touch detecting apparatus

InactiveUS6948371B2Superior in anti-Electromagnetic Interference (EMI) propertiesLow costInput/output for user-computer interactionAcceleration measurement using interia forcesEngineeringAcoustic wave

An FPC is constructed of two FPC branches, and a connection line that connects to a controller. Printed wiring of the connection line includes ten printed wires. The central four printed wires are signal reception wires, which are connected to two converters (sensors). Grounding wires are provided on both sides of the four signal reception wires. Two outer signal wires are provided adjacent to the grounding wires, respectively toward the outsides thereof. Further, two more grounding wires are provided adjacent to the outer signal wires, respectively on the outsides thereof. This construction results in shielding of all of the signal wires. This relationship is maintained in the FPC branches as well.

Owner:ELO TOUCH SOLUTIONS INC

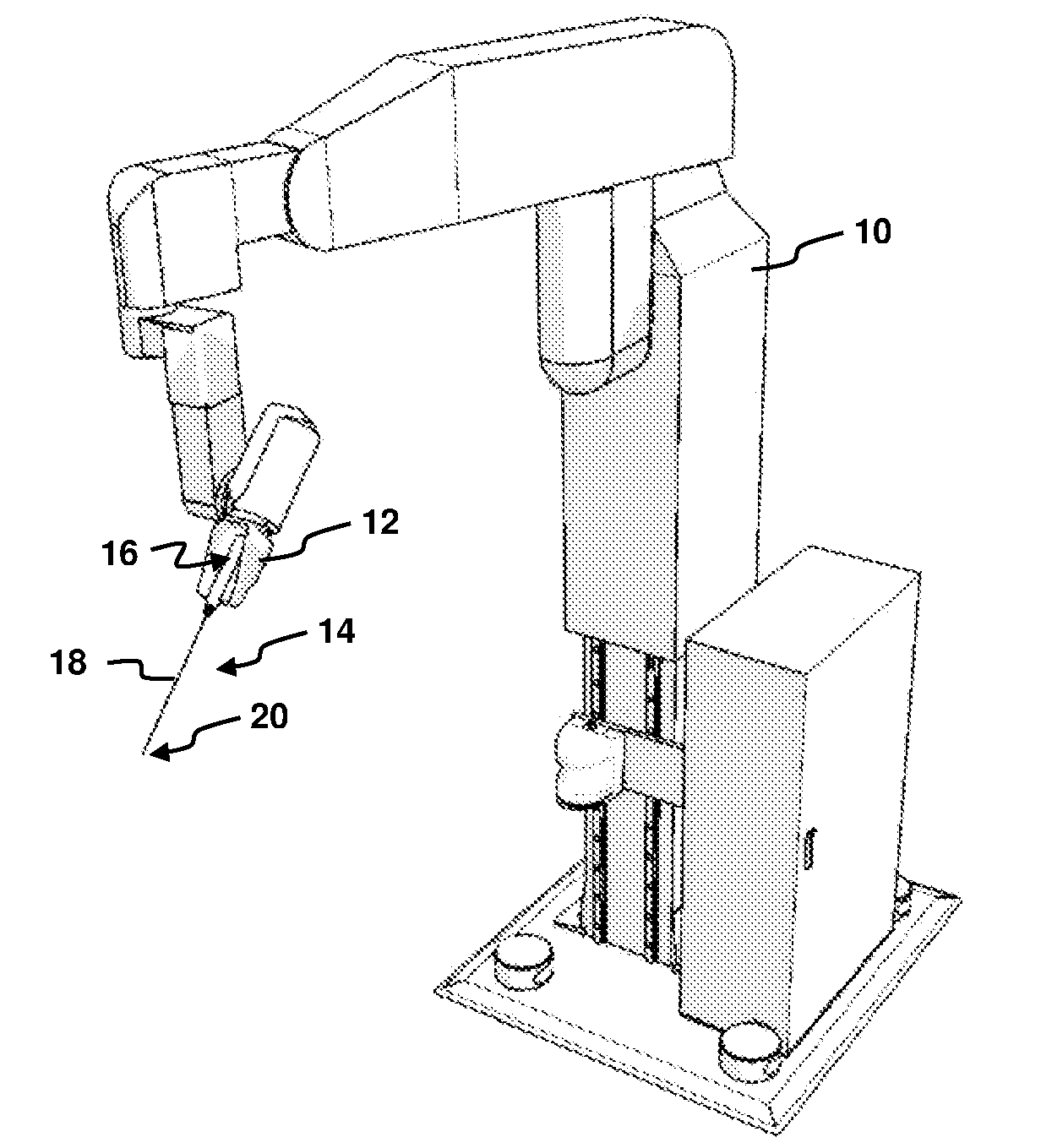

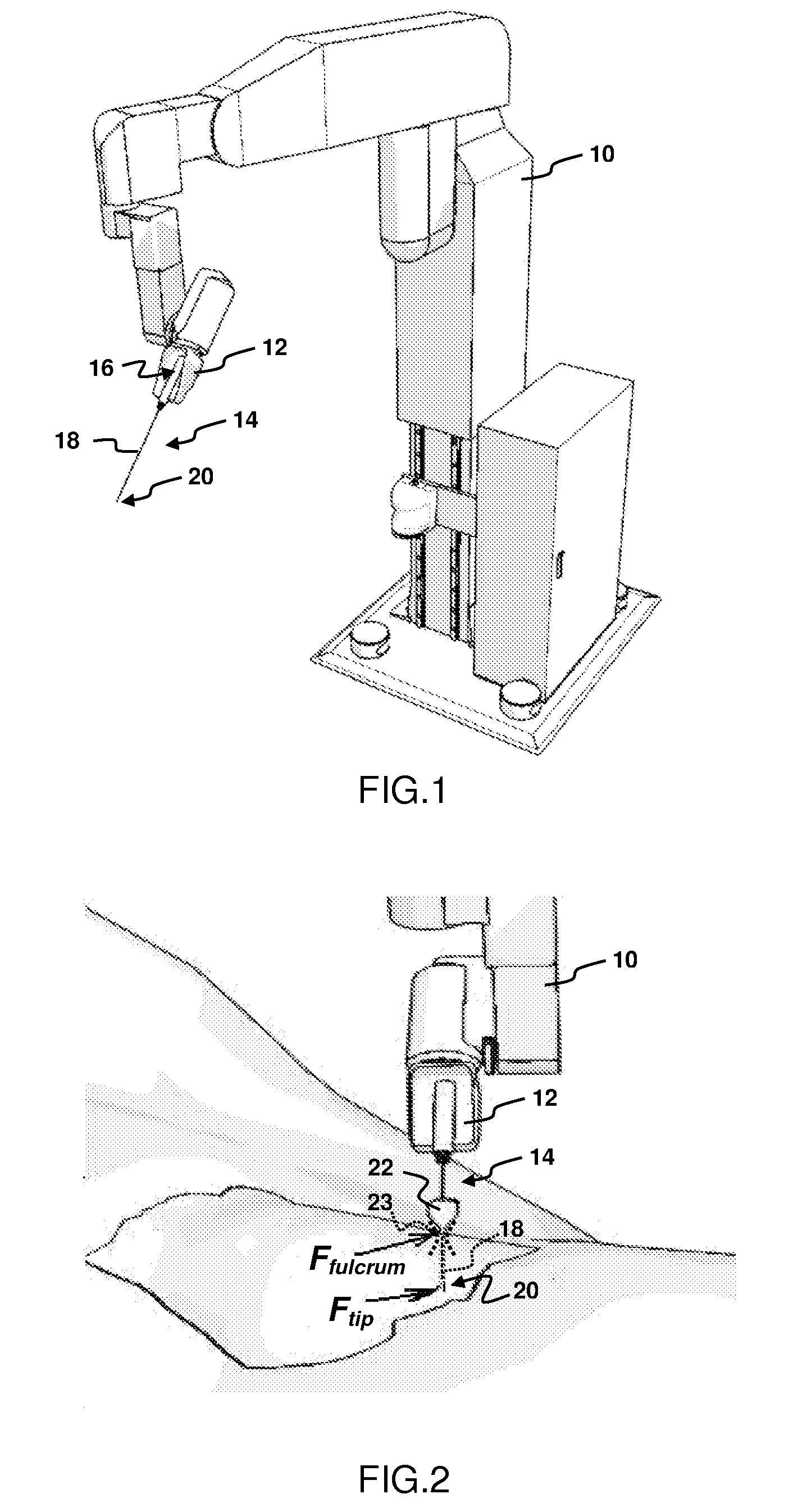

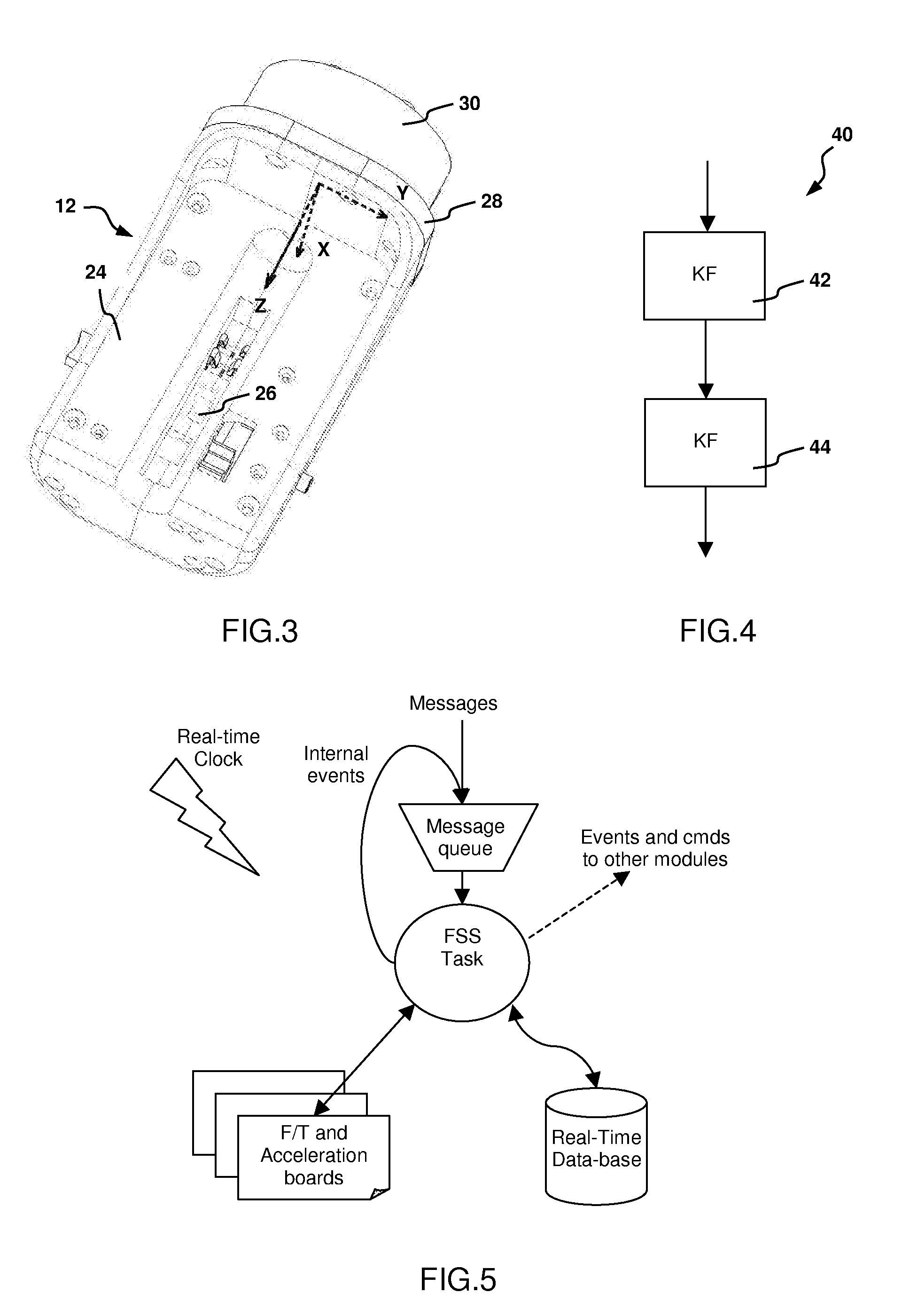

Force estimation for a minimally invasive robotic surgery system

ActiveUS20100094312A1Efficient and cost-effectiveAvoid the needProgramme-controlled manipulatorAcceleration measurement using interia forcesDegrees of freedomEngineering

A method of force estimation for a minimally invasive medical system comprising a robot manipulator (10). The manipulator has an effector unit (12) equipped with a 6-degrees-of-freedom (DOF) force / torque sensor and is configured to hold a minimally invasive instrument (14) having a first end (16) mounted to the effector unit and a second end (20) located beyond an external fulcrum (23) that limits the instrument in motion, usually to 4 DOF. The method comprising the steps: —determining a position of the instrument relative to the fulcrum; —measuring by means of the 6-DOF force / torque sensor a force and a torque exerted onto the effector unit by the first end of the instrument; and —calculating by means of the principle of superposition an estimate of a force exerted onto the second end of the instrument based on the determined position, the measured force and the measured torque.

Owner:EURATOM

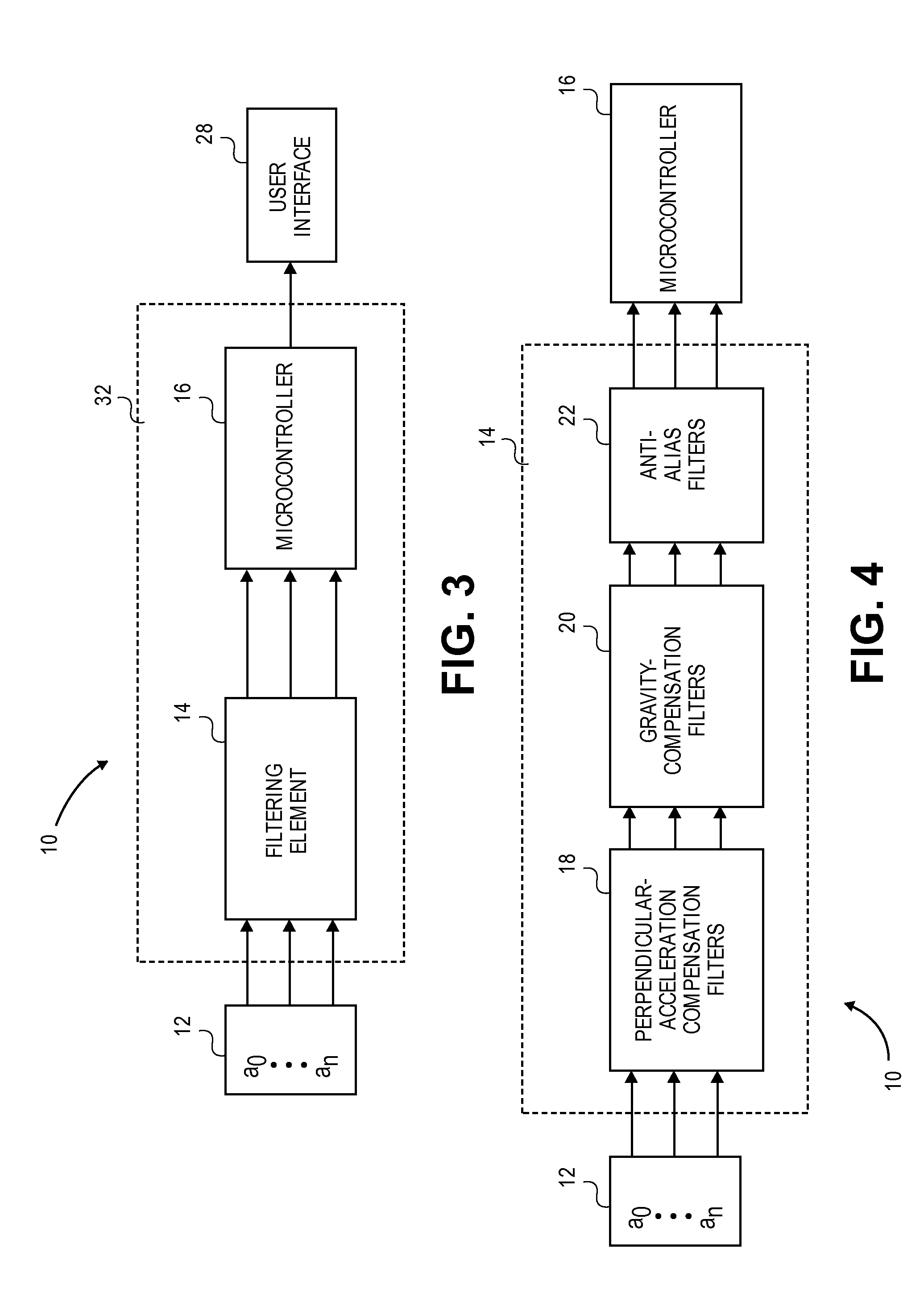

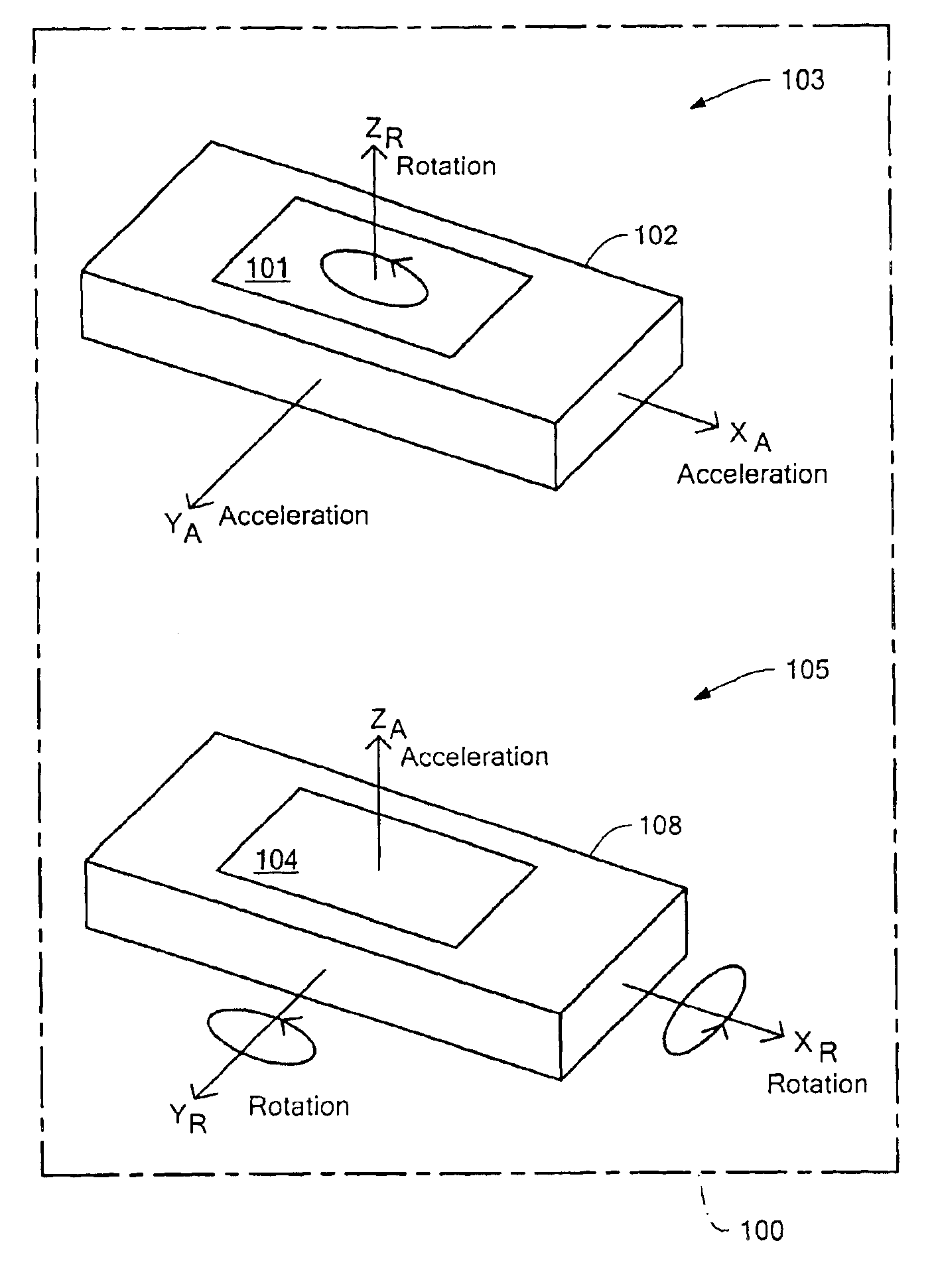

Method and apparatus for determining the attachment position of a motion sensing apparatus

ActiveUS20080190202A1Sacrificing all of its material advantageAcceleration measurement using interia forcesGymnastic exercisingAccelerometerMotion sensing

A motion sensing apparatus generally comprising a housing unit operable to be attached to an object at an attachment position, an accelerometer operable to provide a signal corresponding to an acceleration measurement; and a processing system. The processing system is operable to acquire the signal corresponding to the acceleration measurement and analyze the acquired acceleration measurement to identify the attachment position of the housing unit.

Owner:GARMIN

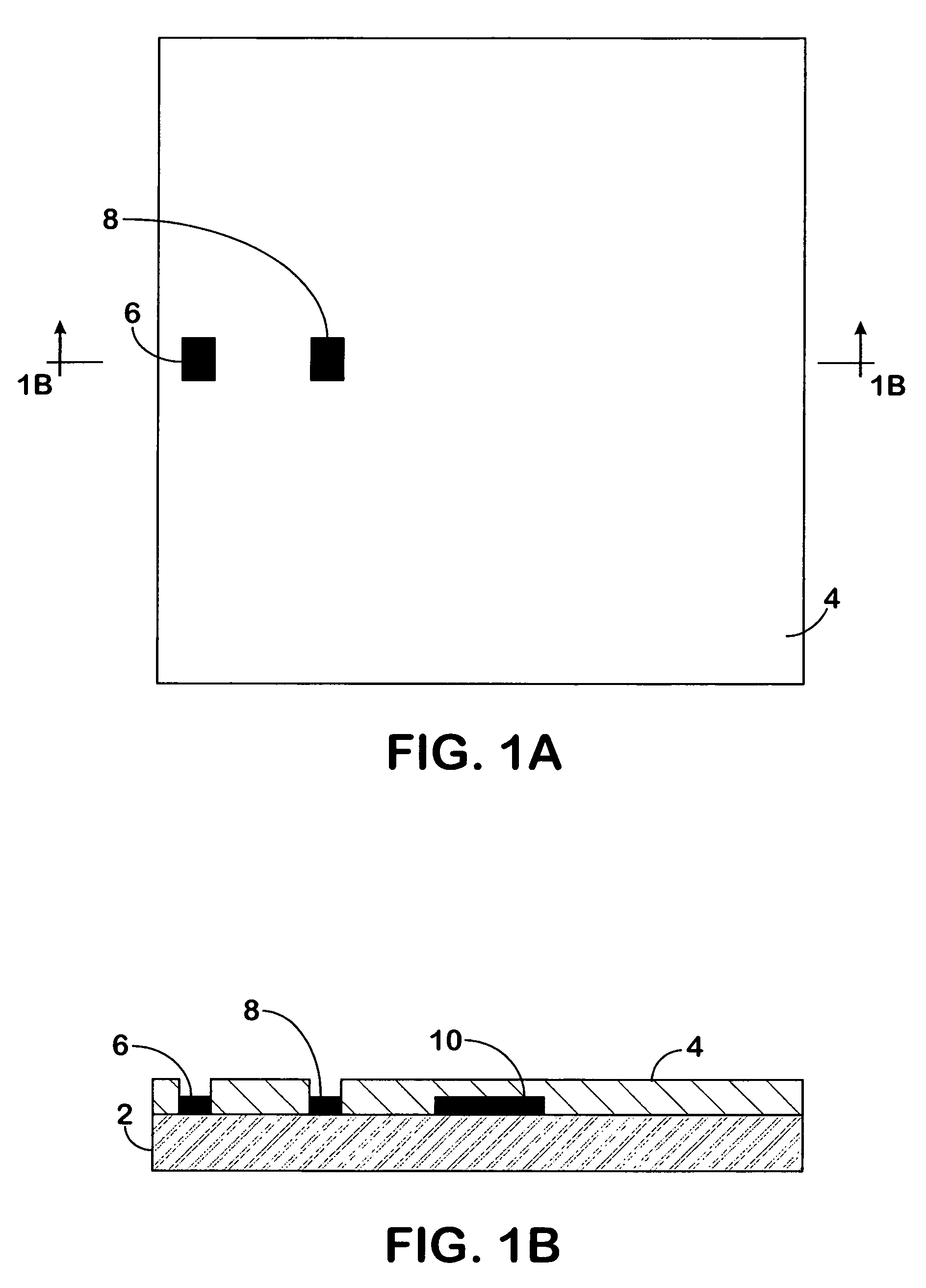

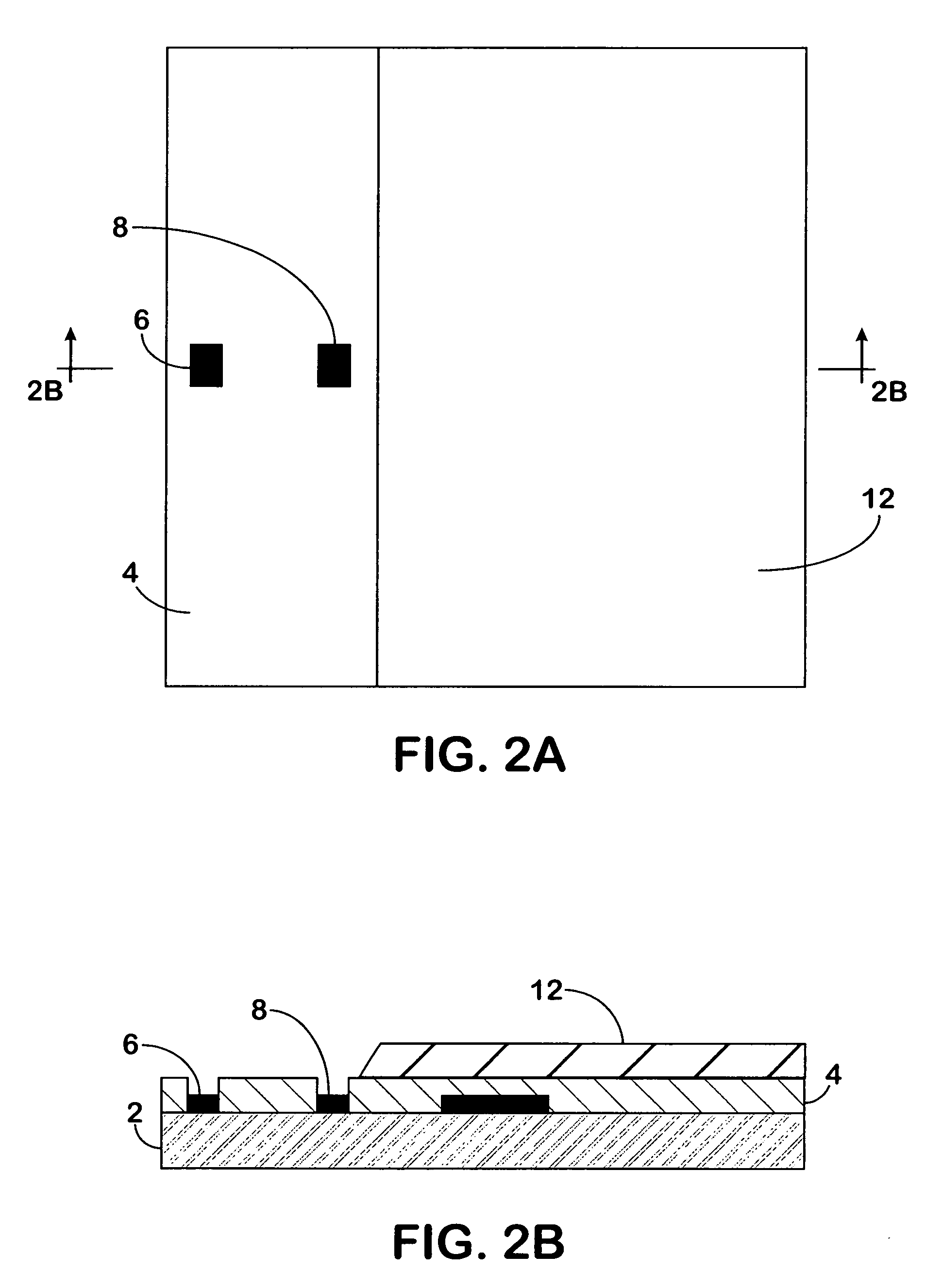

Method of fabricating microelectromechanical systems and devices having trench isolated contacts

InactiveUS6936491B2Acceleration measurement using interia forcesSolid-state devicesEngineeringMicroelectromechanical systems

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a MEMS device, and technique of fabricating or manufacturing a MEMS device, having mechanical structures encapsulated in a chamber prior to final packaging and a contact area disposed at least partially outside the chamber. The contact area is electrically isolated from nearby electrically conducting regions by way of dielectric isolation trench that is disposed around the contact area. The material that encapsulates the mechanical structures, when deposited, includes one or more of the following attributes: low tensile stress, good step coverage, maintains its integrity when subjected to subsequent processing, does not significantly and / or adversely impact the performance characteristics of the mechanical structures in the chamber (if coated with the material during deposition), and / or facilitates integration with high-performance integrated circuits. In one embodiment, the material that encapsulates the mechanical structures is, for example, silicon (polycrystalline, amorphous or porous, whether doped or undoped), silicon carbide, silicon-germanium, germanium, or gallium-arsenide.

Owner:ROBERT BOSCH GMBH

Method and apparatus for determining the attachment position of a motion sensing apparatus

ActiveUS8055469B2Sacrificing all of its material advantageAcceleration measurement using interia forcesGymnastic exercisingAccelerometerMotion sensing

A motion sensing apparatus generally comprising a housing unit operable to be attached to an object at an attachment position, an accelerometer operable to provide a signal corresponding to an acceleration measurement; and a processing system. The processing system is operable to acquire the signal corresponding to the acceleration measurement and analyze the acquired acceleration measurement to identify the attachment position of the housing unit.

Owner:GARMIN

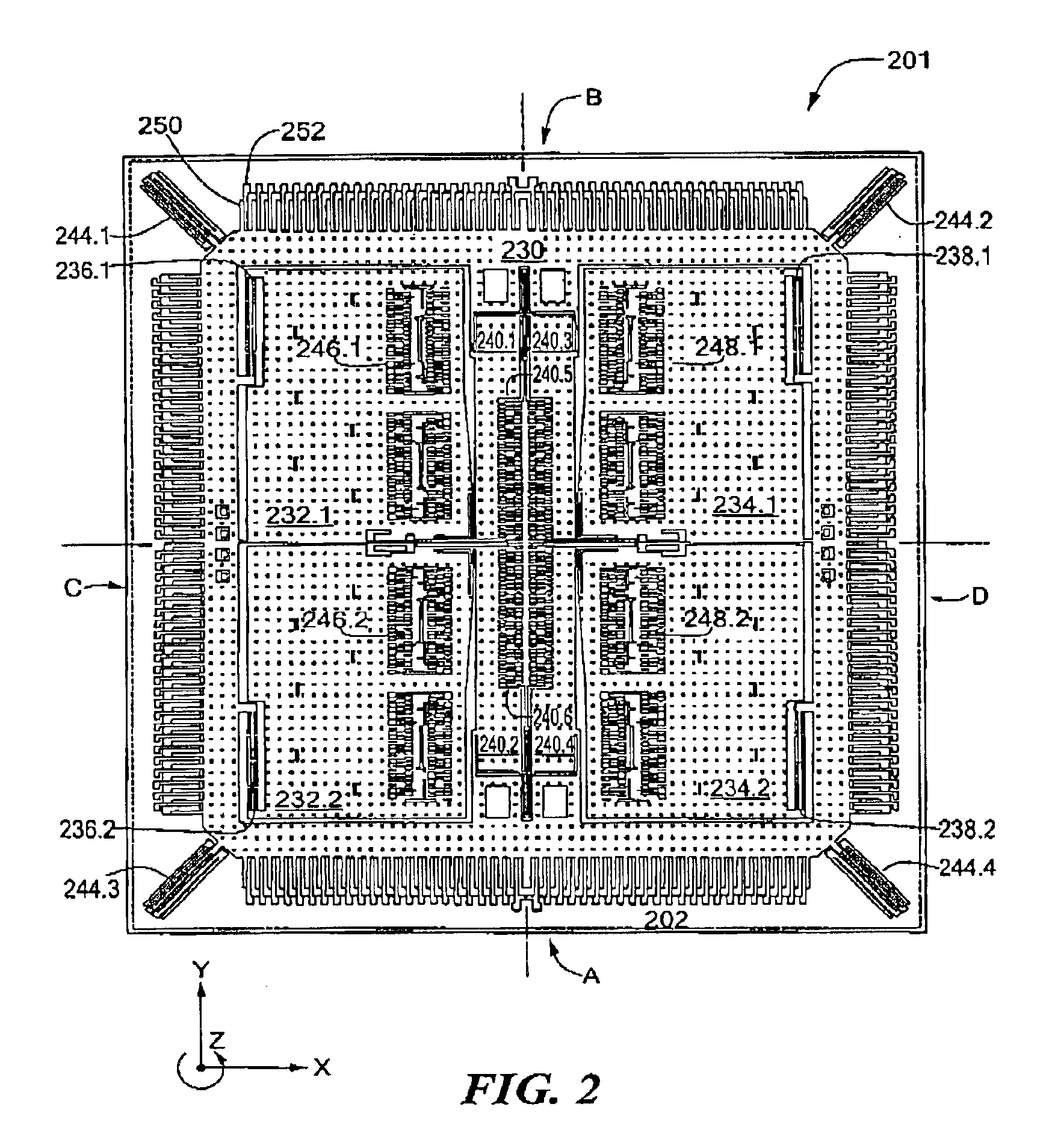

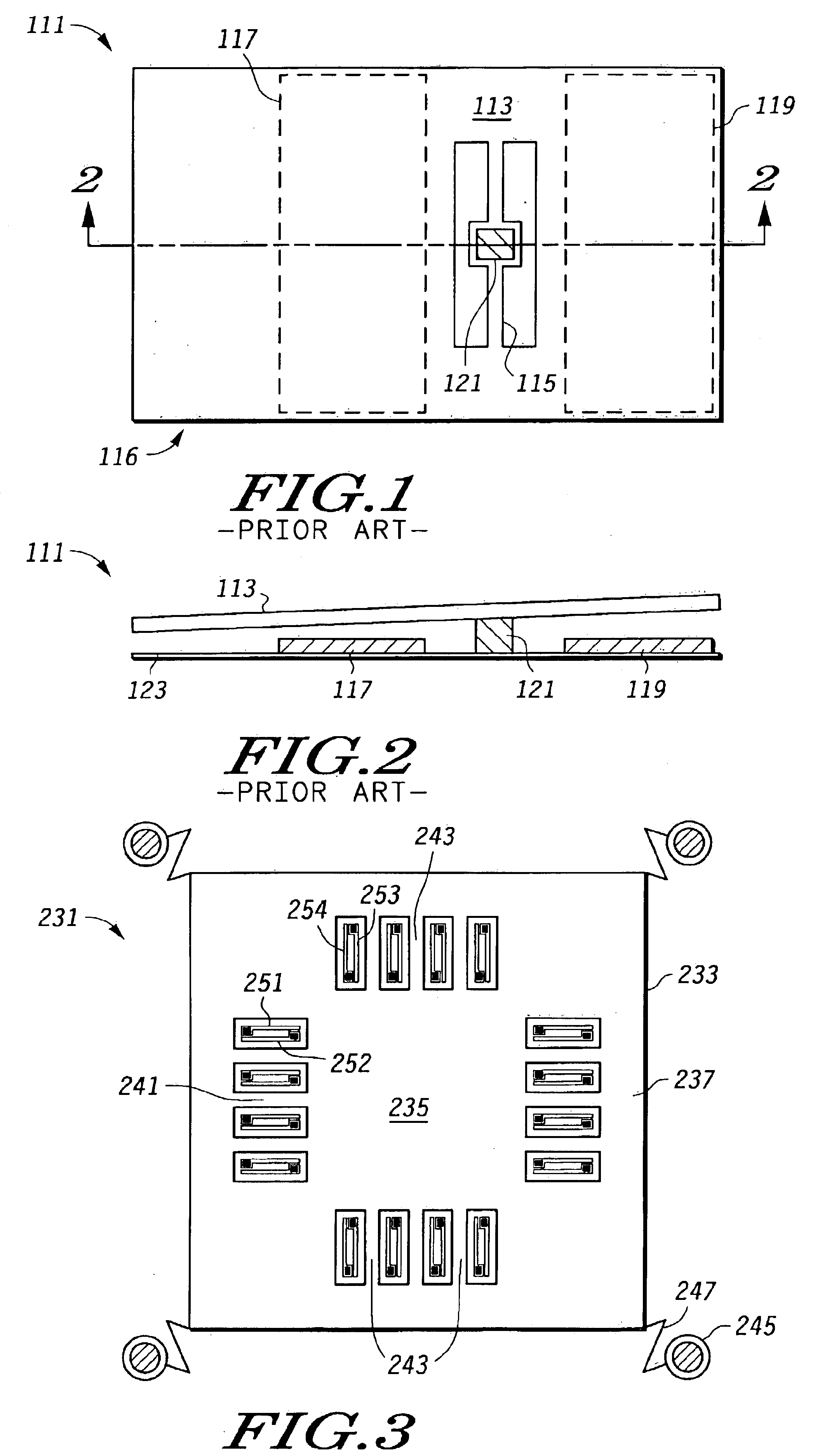

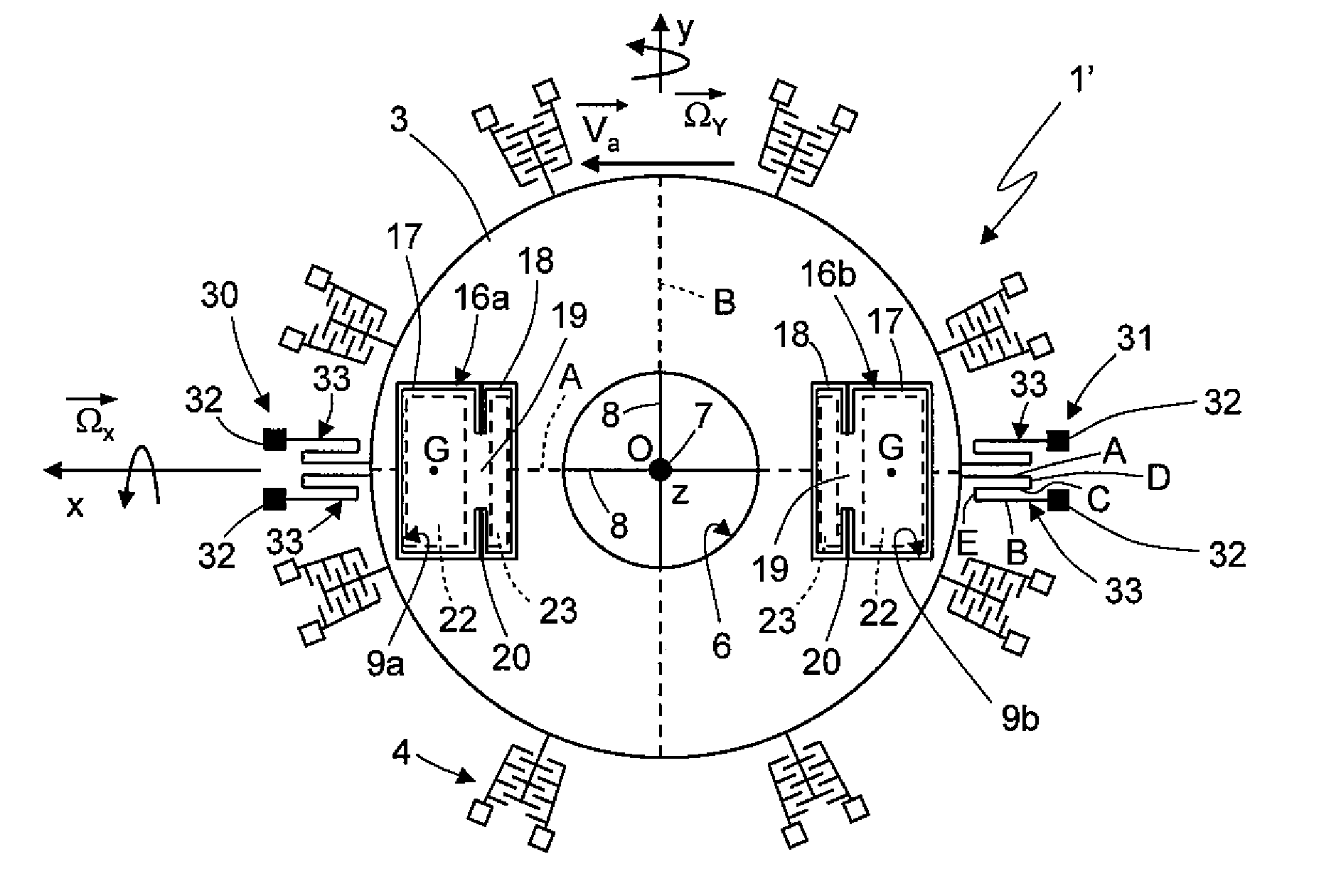

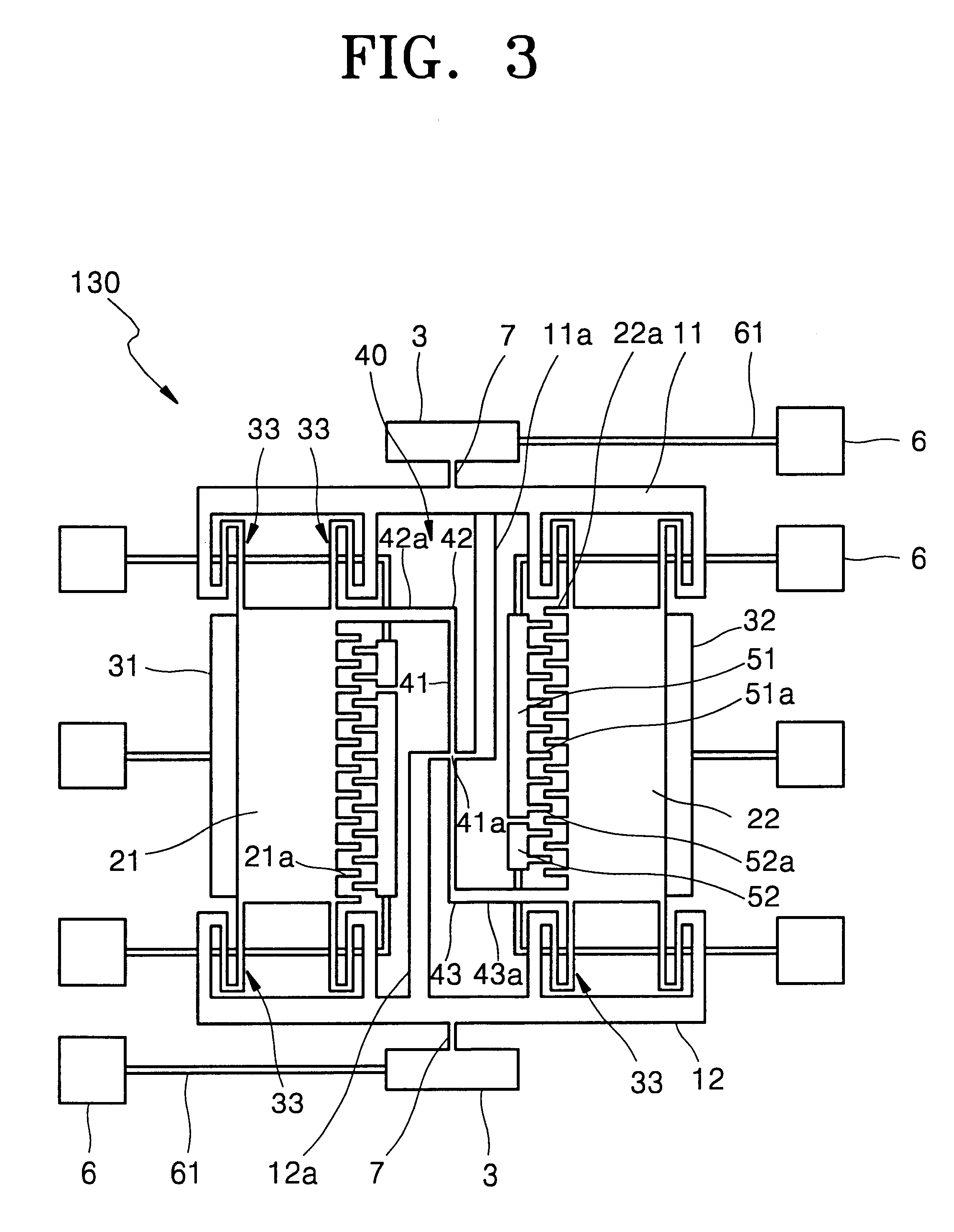

Six degree-of-freedom micro-machined multi-sensor

InactiveUS6848304B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDegrees of freedomSubstructure

A six degree-of-freedom micro-machined multi-sensor that provides 3-axes of acceleration sensing, and 3-axes of angular rate sensing, in a single multi-sensor device. The six degree-of-freedom multi-sensor device includes a first multi-sensor substructure providing 2-axes of acceleration sensing and 1-axis of angular rate sensing, and a second multi-sensor substructure providing a third axis of acceleration sensing, and second and third axes of angular rate sensing. The first and second multi-sensor substructures are implemented on respective substrates within the six degree-of-freedom multi-sensor device.

Owner:ANALOG DEVICES INC

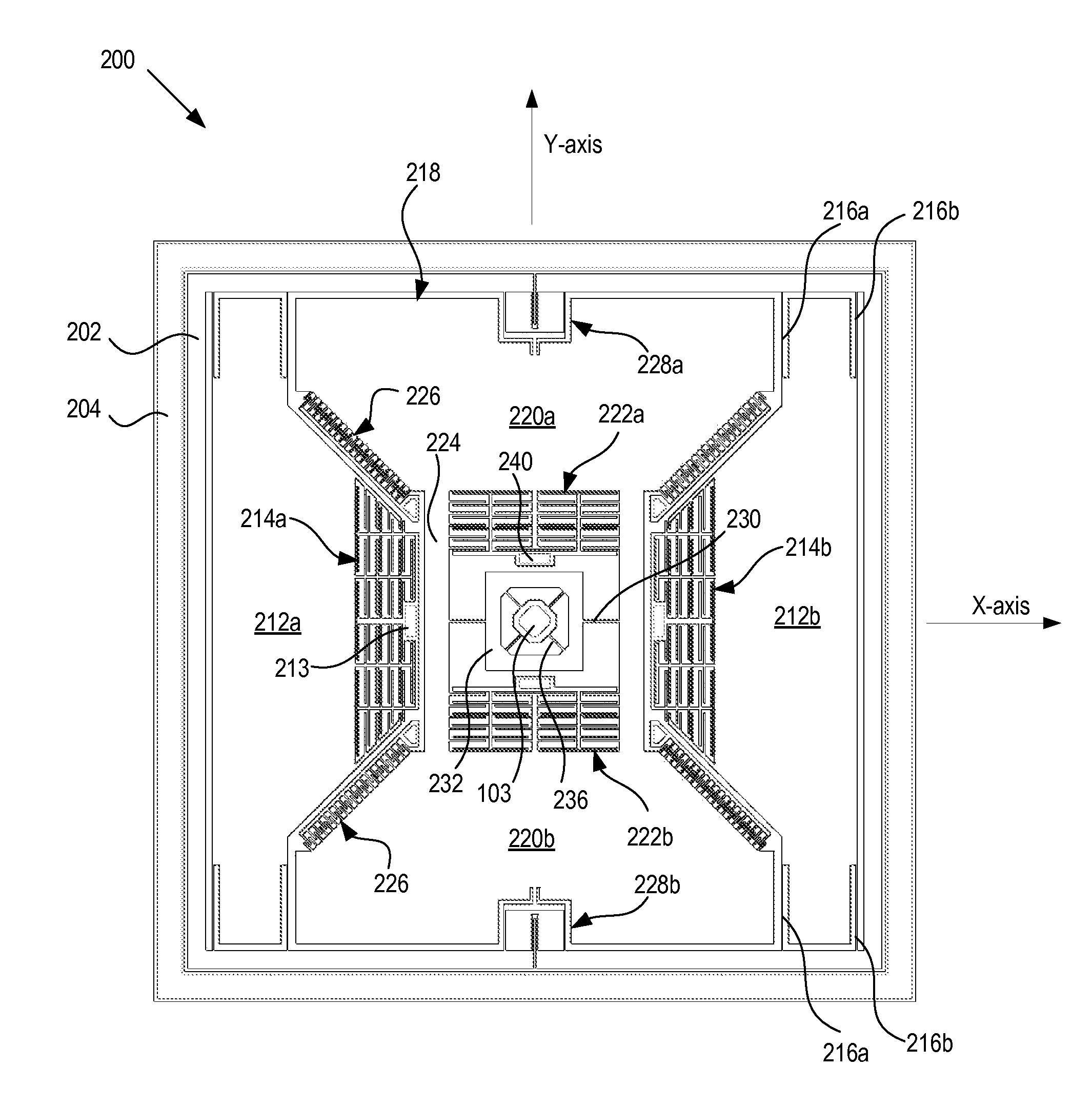

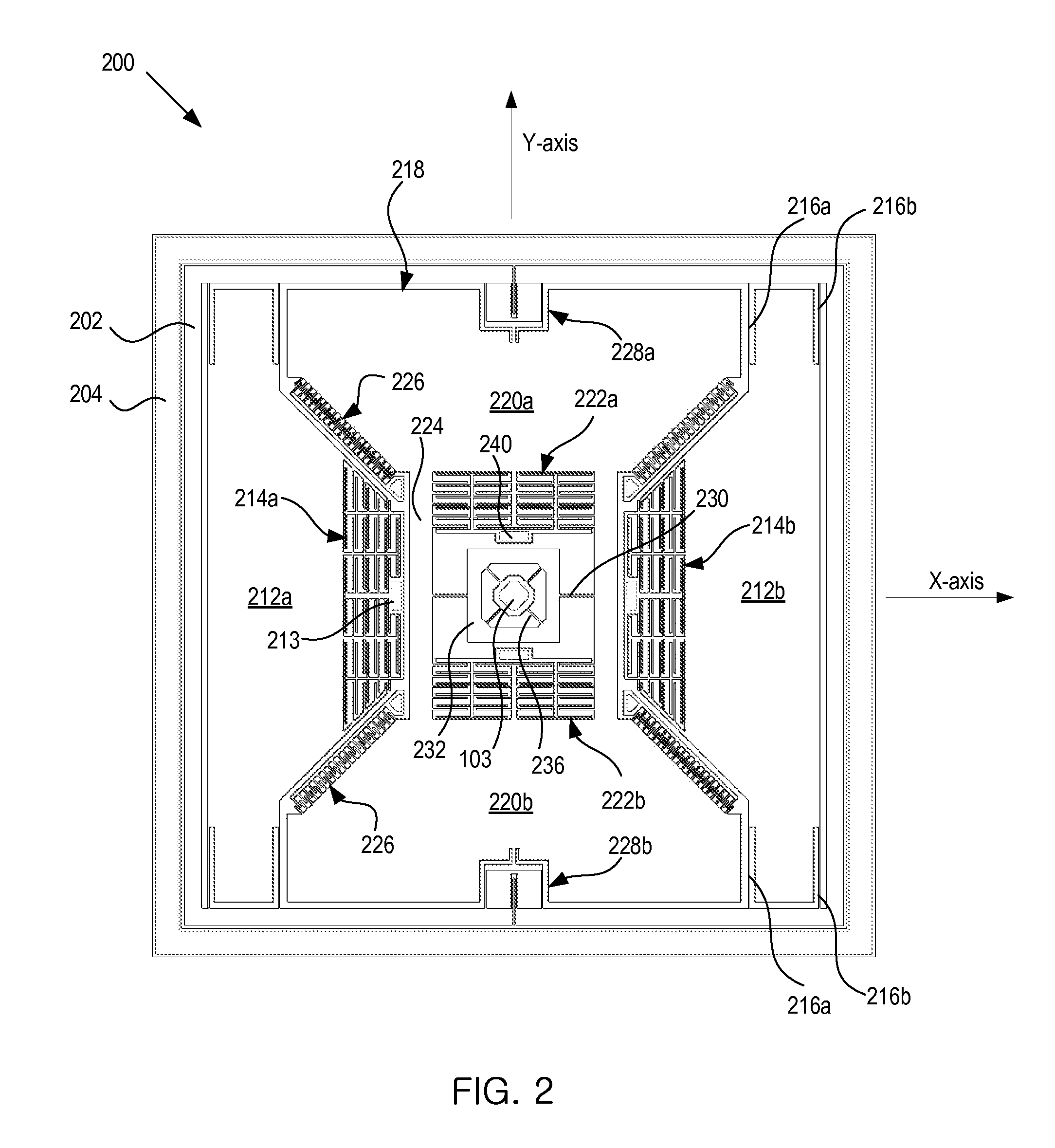

Micromachined inertial sensor devices

ActiveUS20110030473A1Acceleration measurement using interia forcesSolid-state devicesProof massLinear acceleration

A micromachined inertial sensor with a single proof-mass for measuring 6-degree-of-motions. The single proof-mass includes a frame, an x-axis proof mass section attached to the frame by a first flexure, and a y-axis proof mass section attached to the frame by a second flexure. The single proof-mass is formed in a micromachined structural layer and is adapted to measure angular rates about three axes with a single drive motion and linear accelerations about the three axes.

Owner:SEMICON COMPONENTS IND LLC

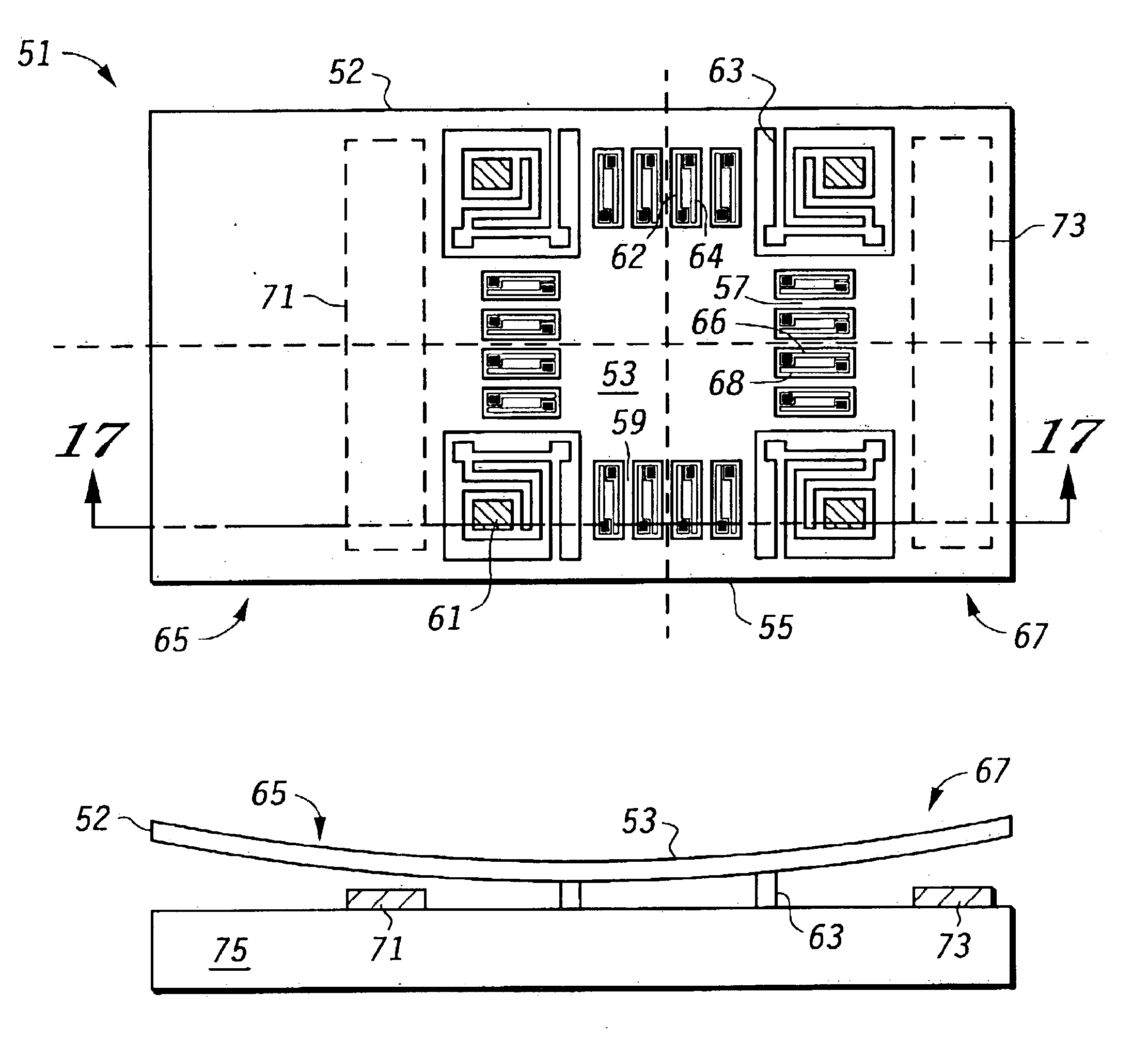

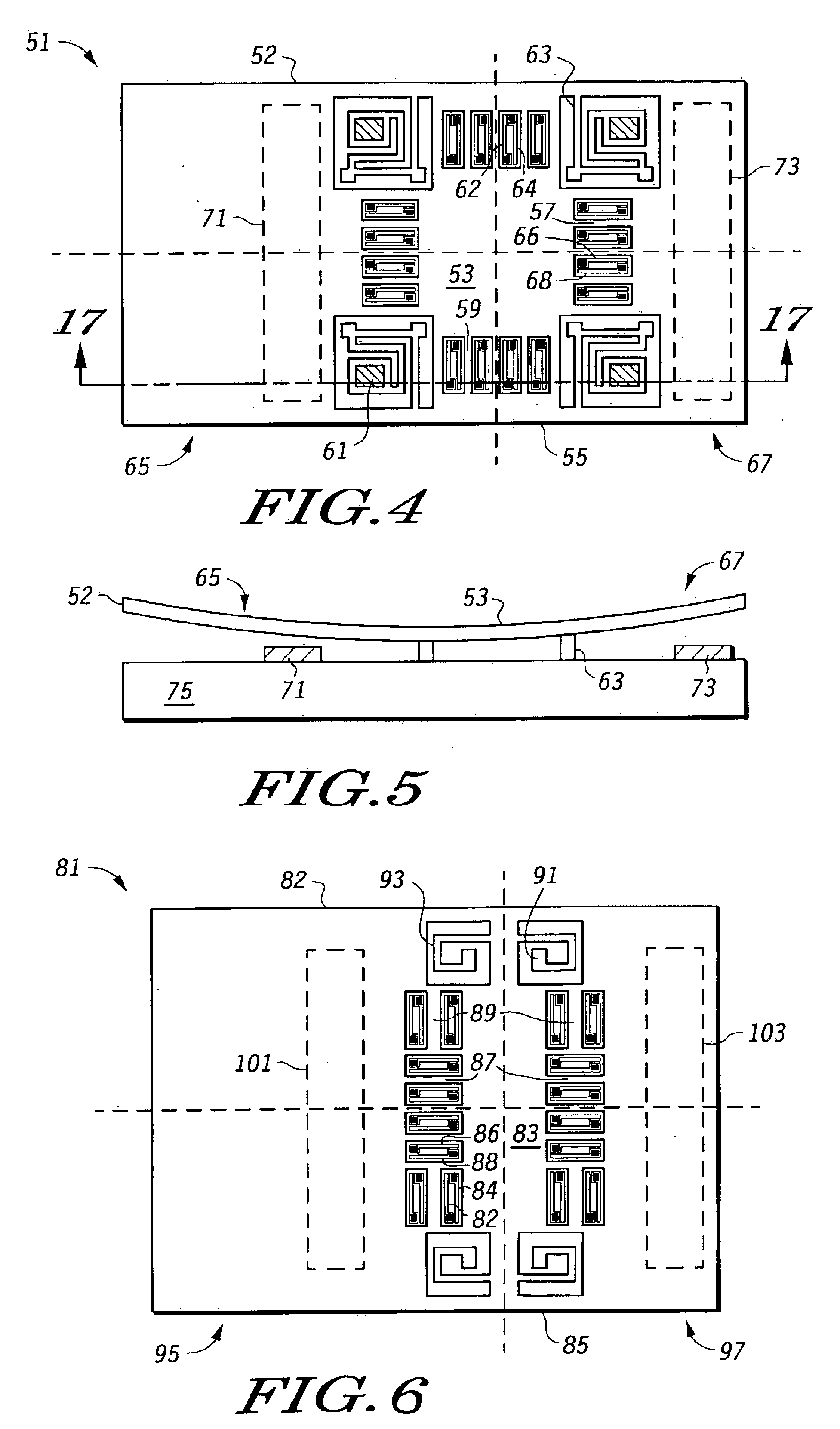

Single proof mass, 3 axis MEMS transducer

InactiveUS6845670B1Acceleration measurement using interia forcesDevices characerised by mechanical meansTransducerClassical mechanics

A transducer is provided herein which comprises an unbalanced proof mass (51), and which is adapted to sense acceleration in at least two mutually orthogonal directions. The proof mass (51) has first (65) and second (67) opposing sides that are of unequal mass.

Owner:NORTH STAR INNOVATIONS

Electronic component having micro-electrical mechanical system

ActiveUS7053456B2Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityElectronic component

Owner:KIOXIA CORP

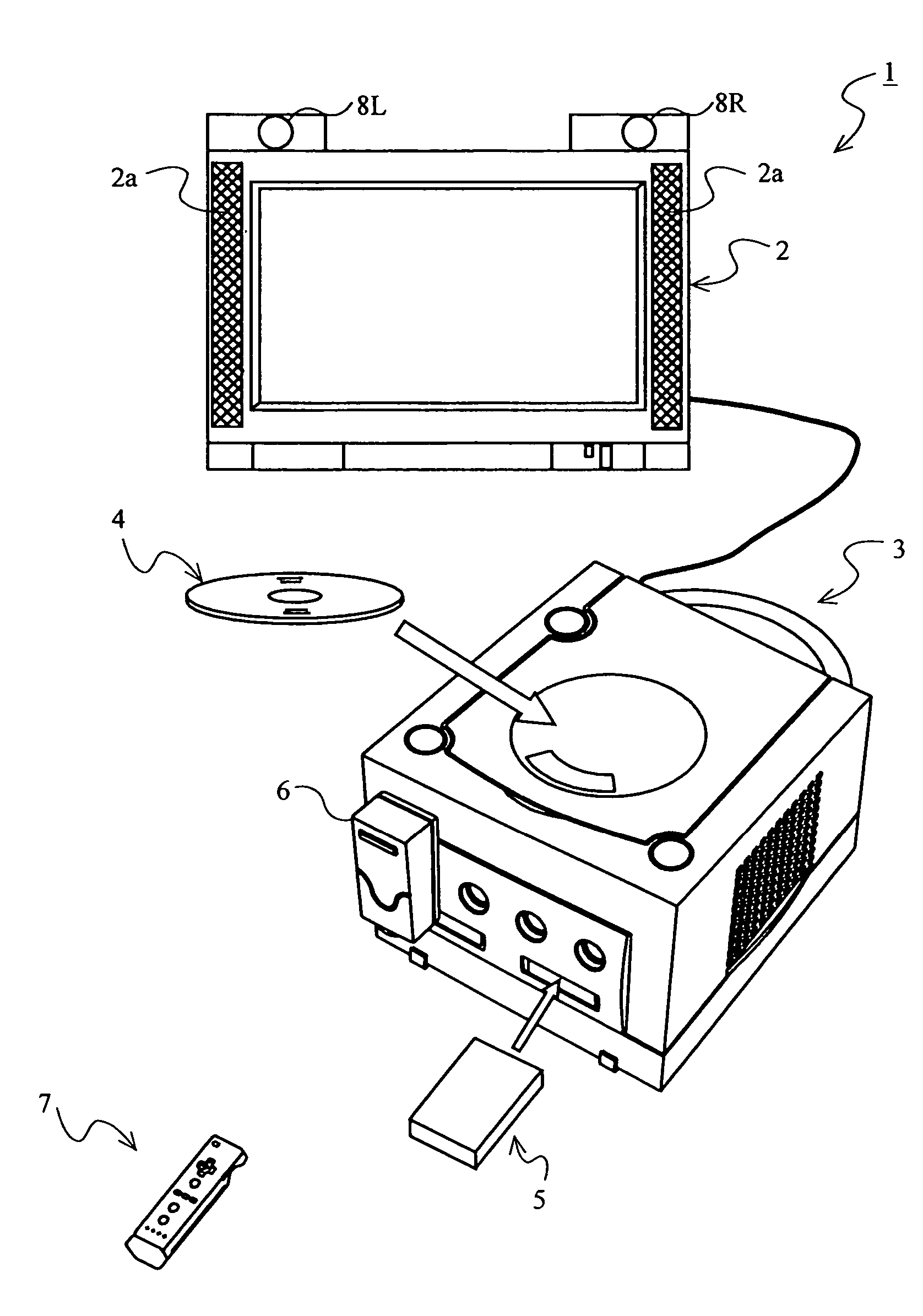

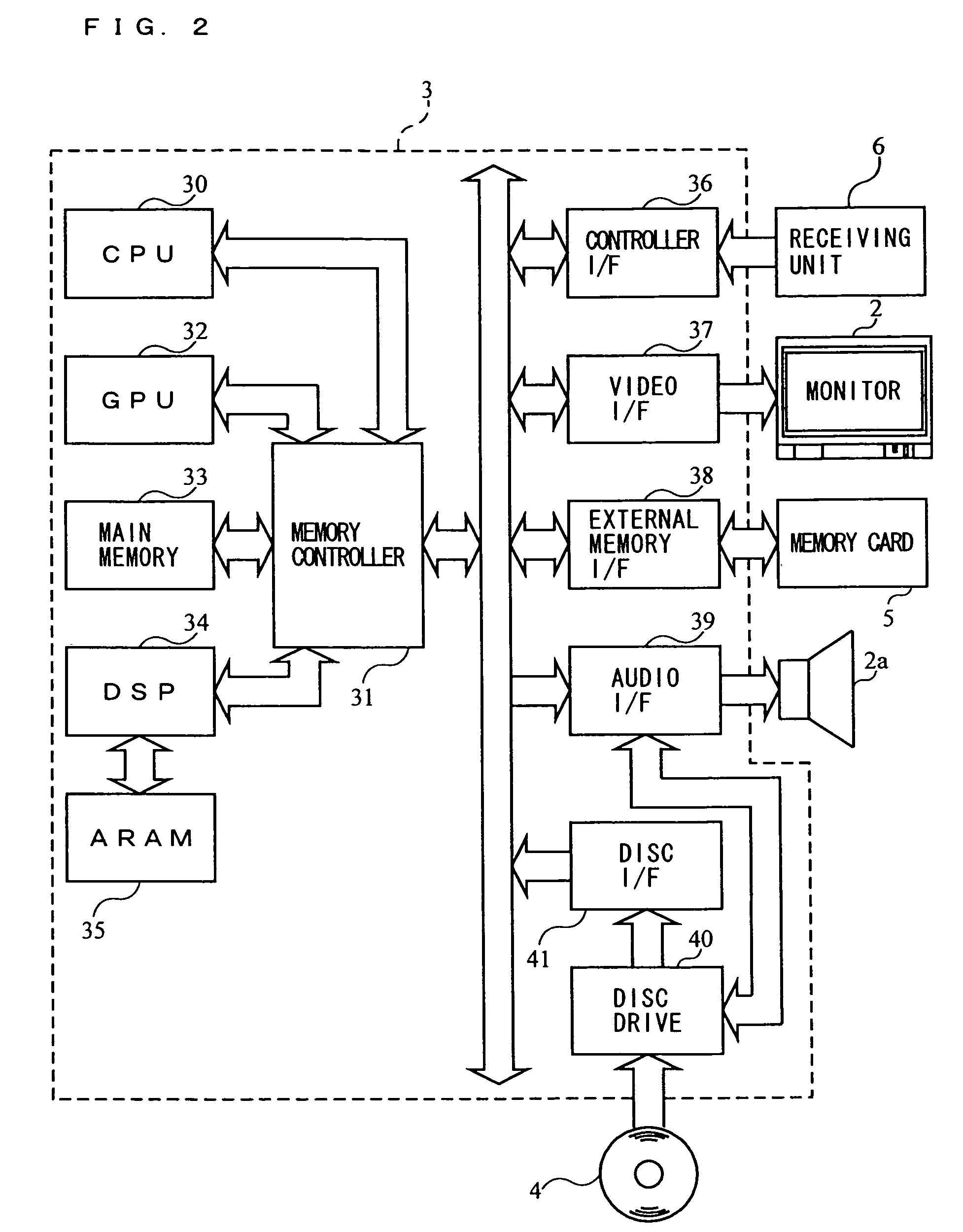

Motion determining apparatus and storage medium having motion determining program stored thereon

ActiveUS7424388B2Rotation motionAccurately determineInput/output for user-computer interactionAcceleration measurement using interia forcesComputer scienceGravitation

Owner:NINTENDO CO LTD

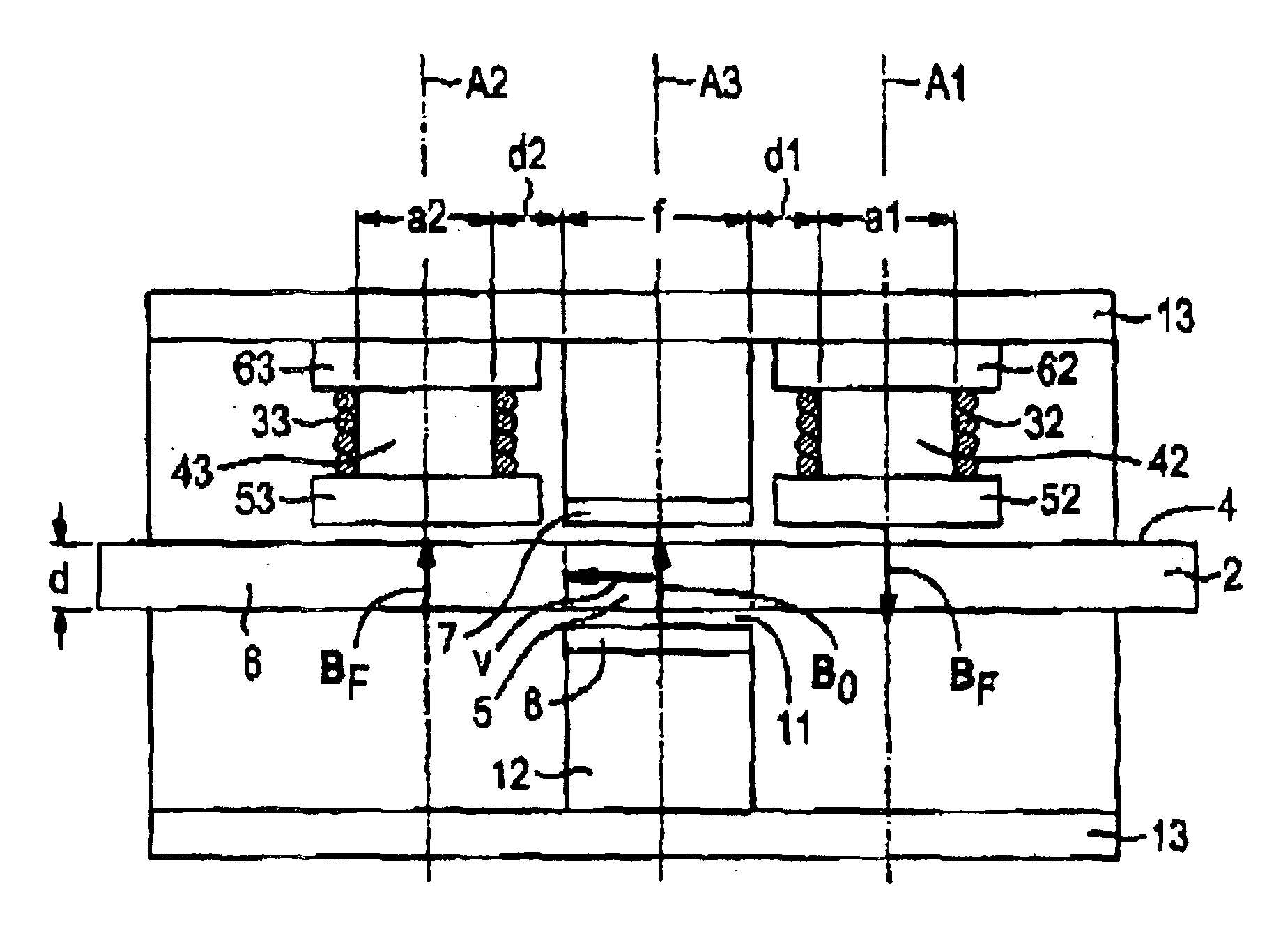

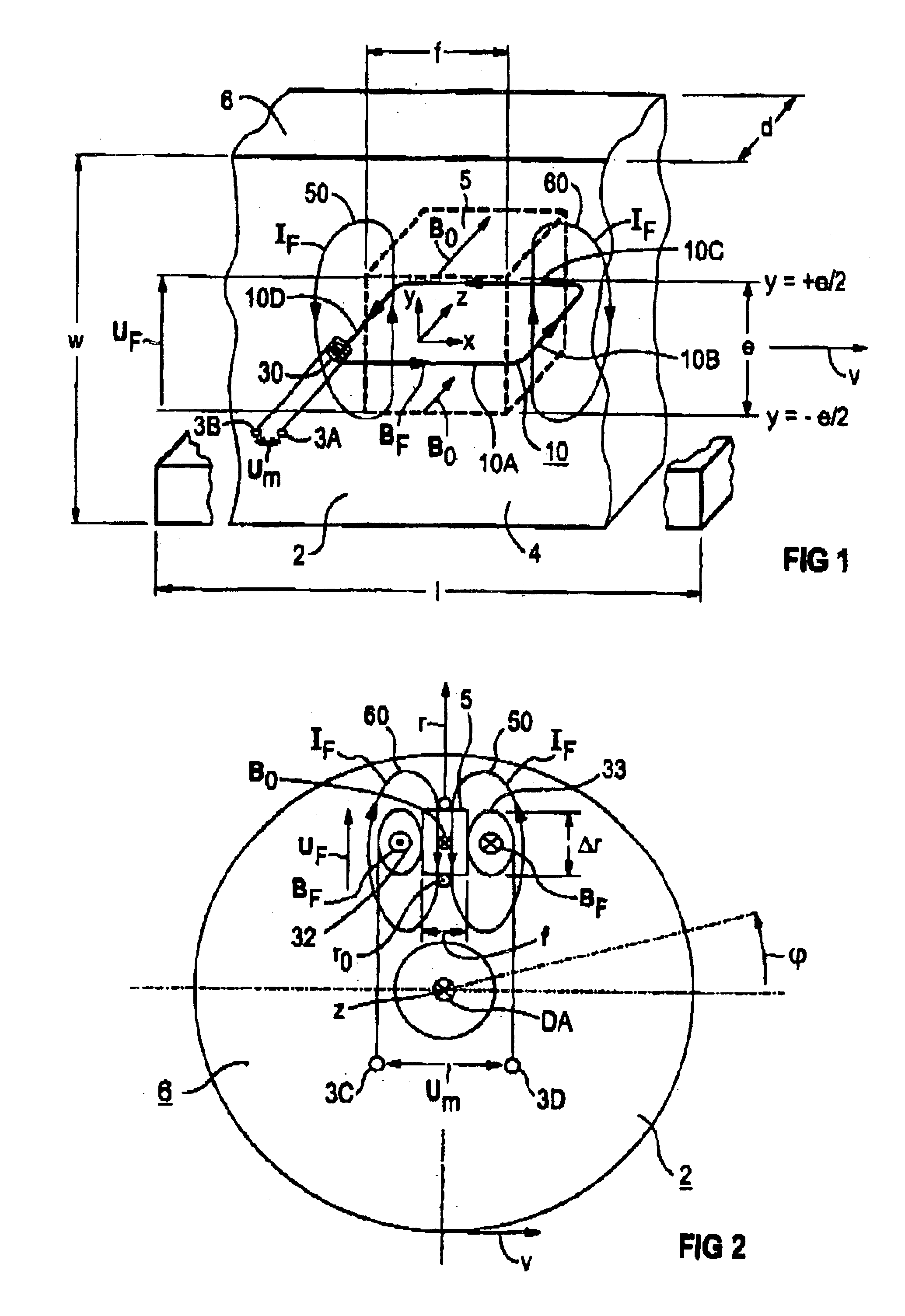

Magnetic field sensor

InactiveUS7038448B2Without loss in sensitivitySmall sizeAcceleration measurement using interia forcesMagnetic field measurement using flux-gate principleElectrical conductorSemiconductor chip

A magnetic field sensor for measuring at least two components of a magnetic field comprises a ferromagnetic core mounted on a semiconductor chip, an exciter coil to which a current can be applied and two read-out sensors. The ferromagnetic core is ring-shaped. The exciter coil is preferably formed from conductor tracks of the semiconductor chip and from bonding wires.

Owner:MELEXIS TECH NV

Capacitance difference detecting circuit and MEMS sensor

ActiveUS7119550B2Improve accuracyAcceleration measurement using interia forcesResistance/reactance/impedenceCapacitanceMems sensors

Oscillators have capacitors, respectively, whose capacitances change according to an external force and generate first oscillating signals according to the capacitances. Each of the capacitors is disposed, for example, between a substrate and a mass body that is movably disposed to face the substrate and oscillates in a direction perpendicular to the substrate. A detecting unit detects a relative difference between the capacitances of the capacitors as a difference between frequencies of the first oscillating signals. An angular speed or acceleration applied in a horizontal direction of the substrate is calculated according to the frequency change detected by the detecting unit. Therefore, a capacitance difference detecting circuit and a MEMS sensor that detect a minute change in the capacitances of the two capacitors caused by the external force are formed.

Owner:MONTEREY RES LLC

Method and apparatus for estimating a motion parameter

ActiveUS7827000B2Acceleration measurement using interia forcesInertial sensorsMotion parameterComputer science

Owner:GARMIN

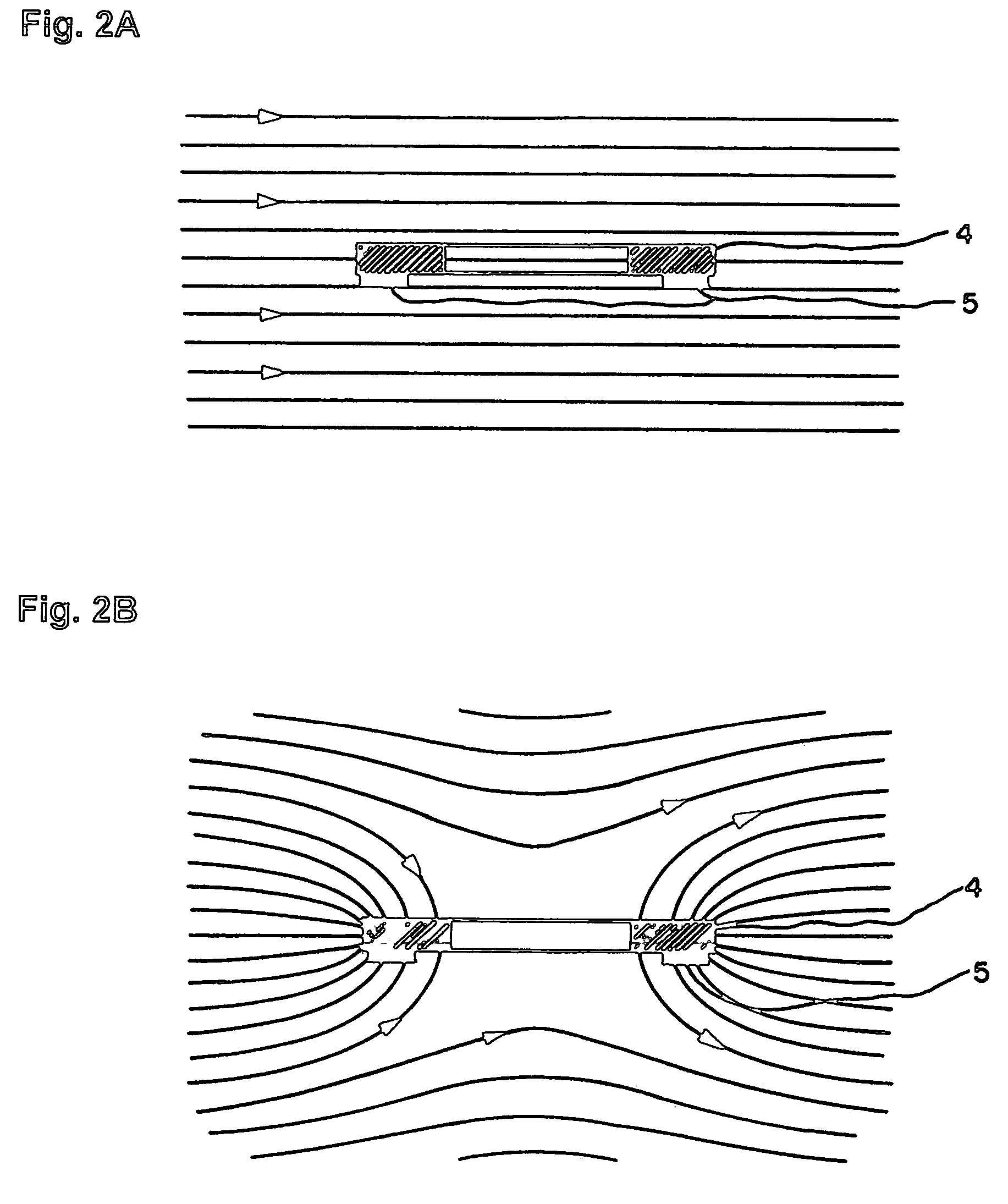

Device for measuring the motion of a conducting body through magnetic induction

InactiveUS6850053B2Improve cooling effectReduce thermal noiseAcceleration measurement using interia forcesMagnetic-field-controlled resistorsMeasurement deviceClassical mechanics

A device for measuring a motion of a moving electrically conducting body is disclosed. A magnetic field generated by, for example, electromagnets or permanent magnets, penetrates at least a partial area of the moving body. Two or more measuring devices are arranged outside the magnetic field to measure a measurement magnetic field that is induced by electrical currents in the moving body. The measuring devices are arranged essentially symmetrically with respect to the magnetic field generating means or the moving body. The measurement magnetic field represents at least one motion variable of the moving body. The measuring device is thereby no longer subjected to the temperature-dependent variations of the exciting field.

Owner:SIEMENS AG

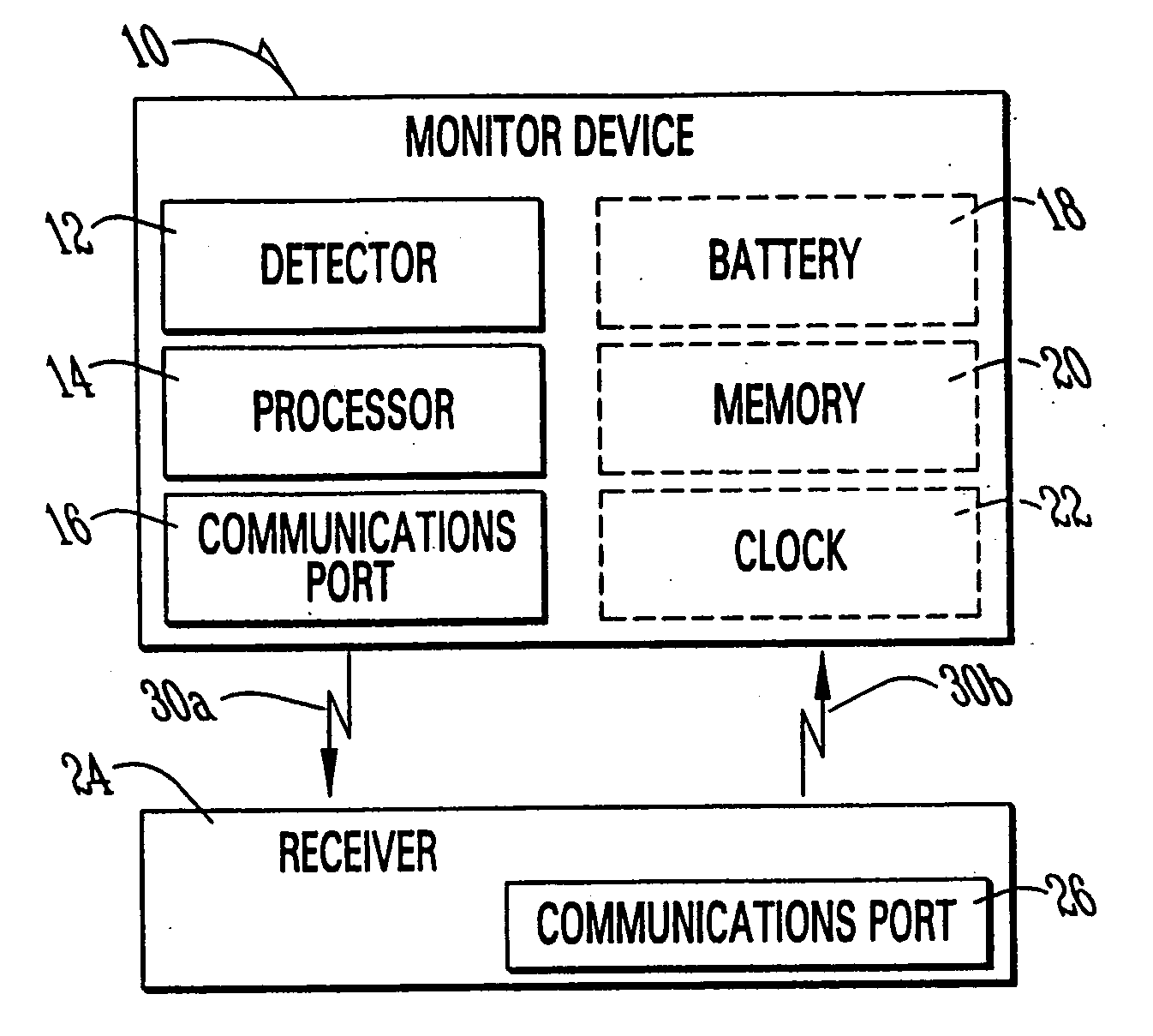

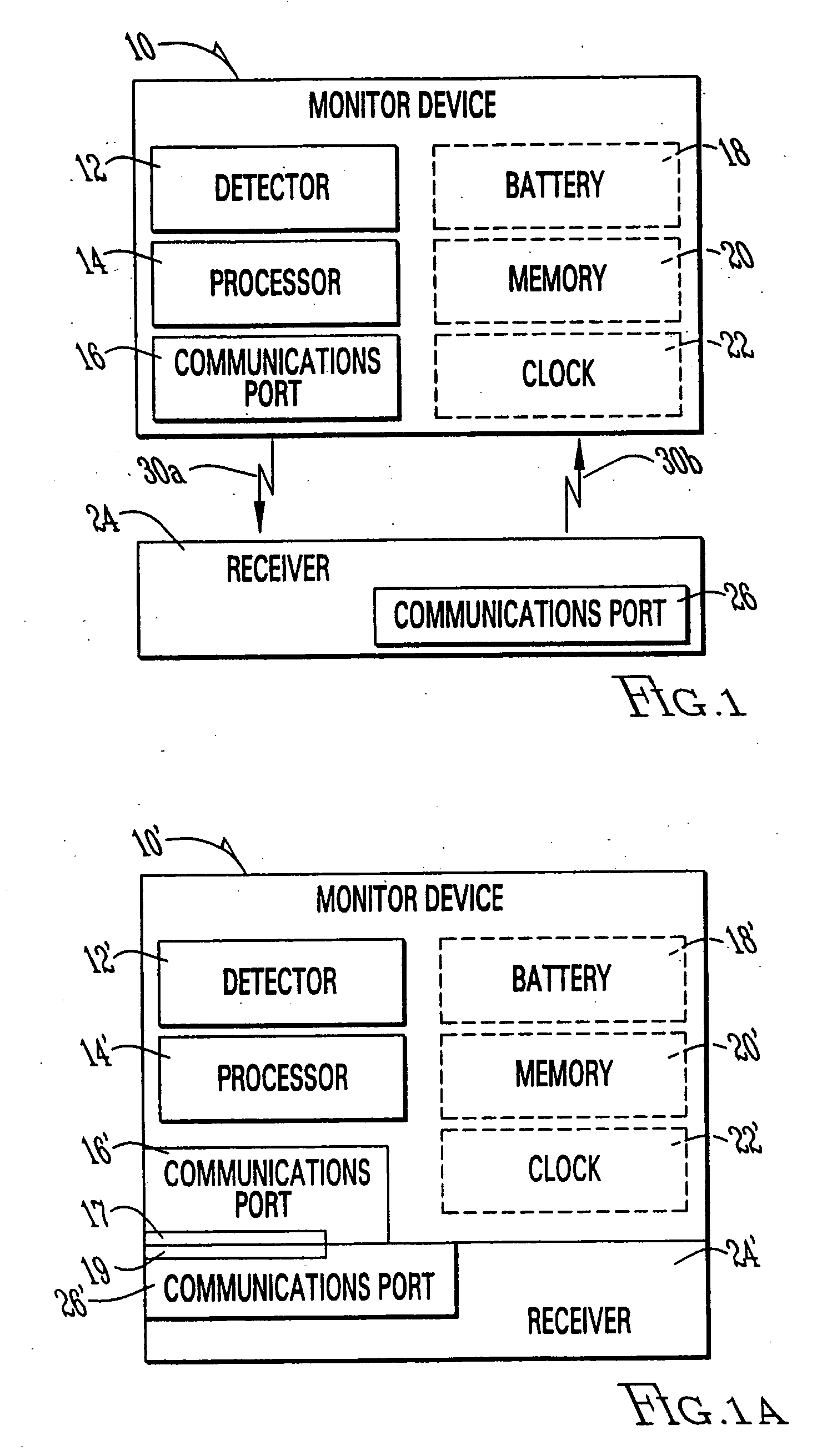

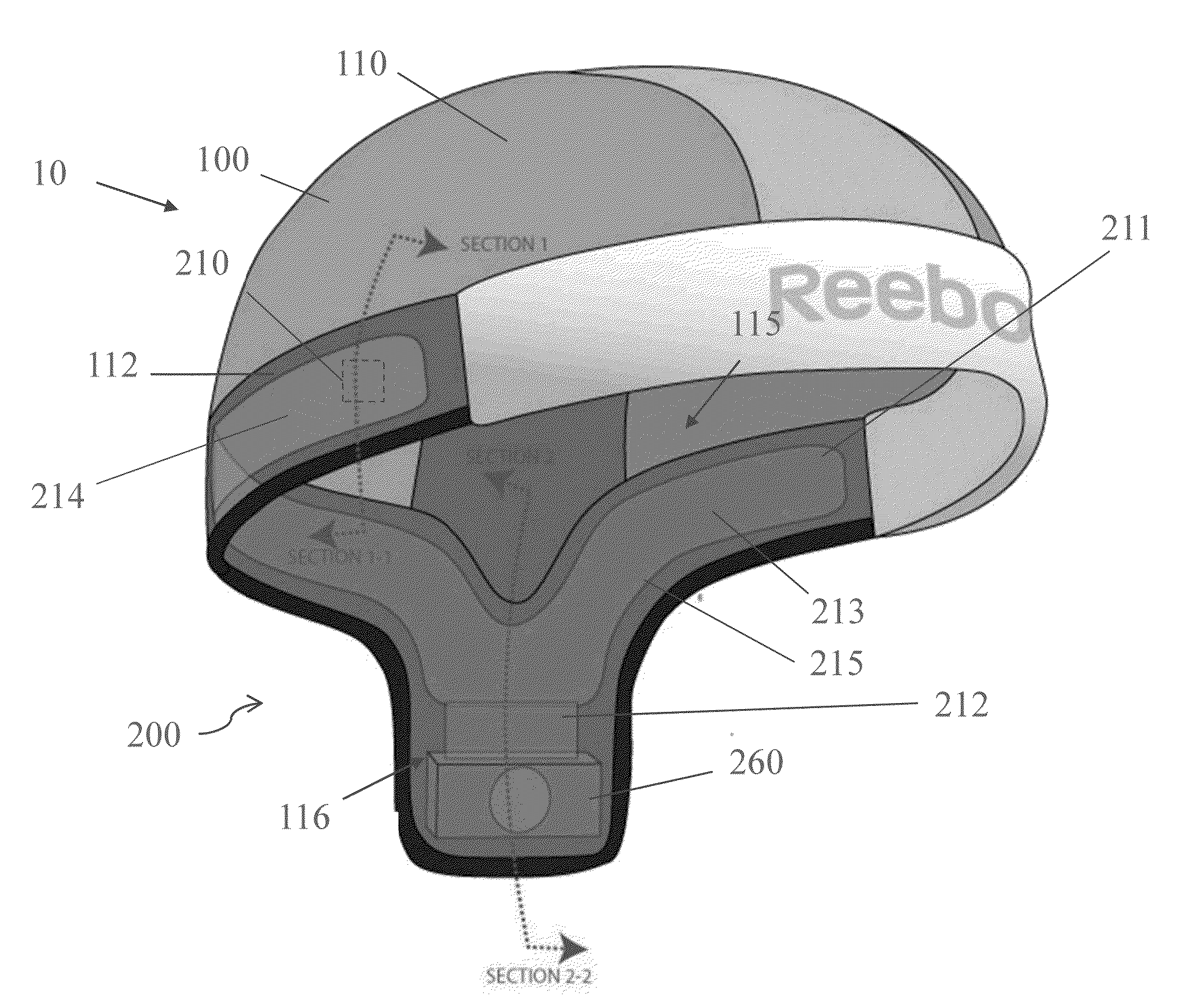

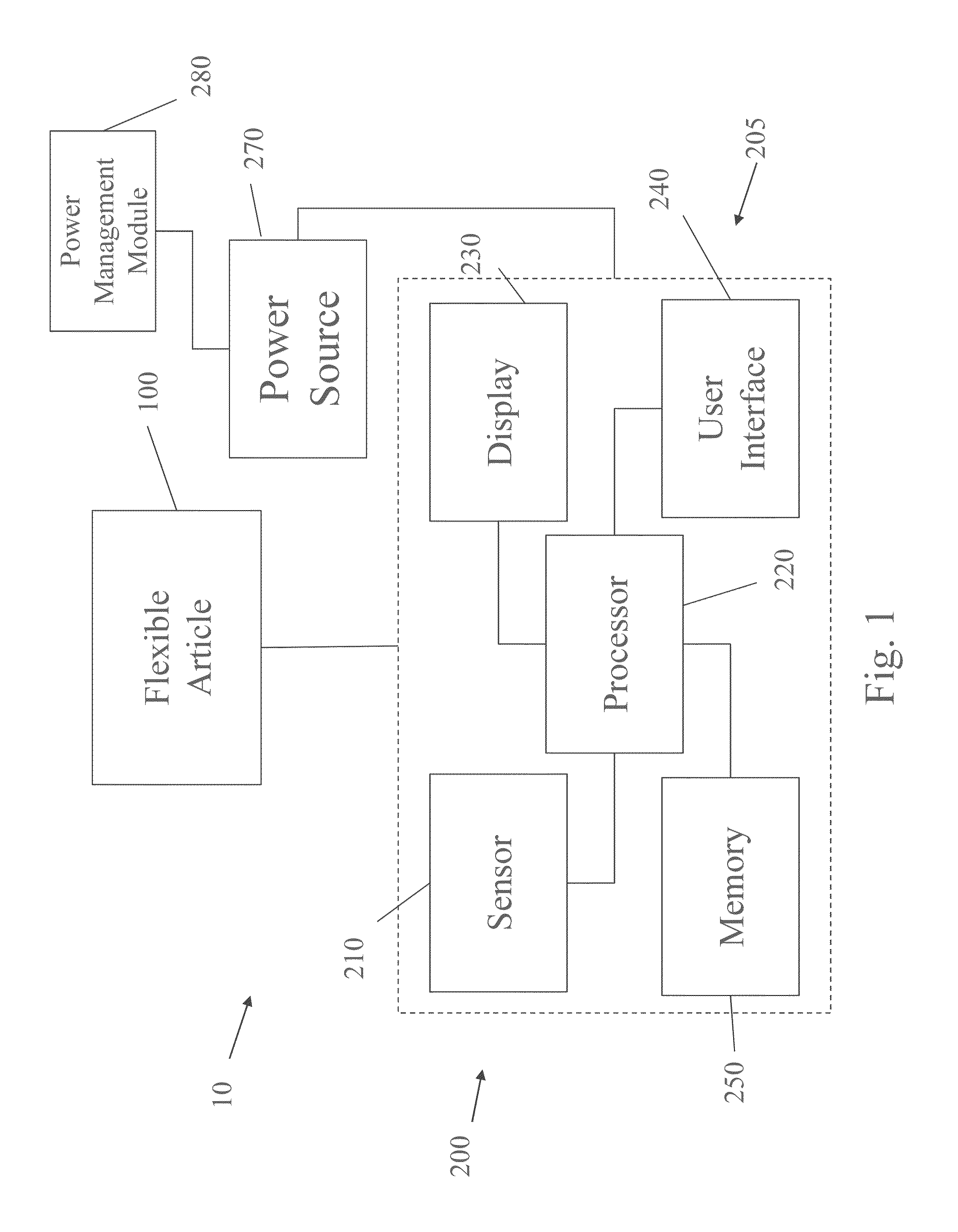

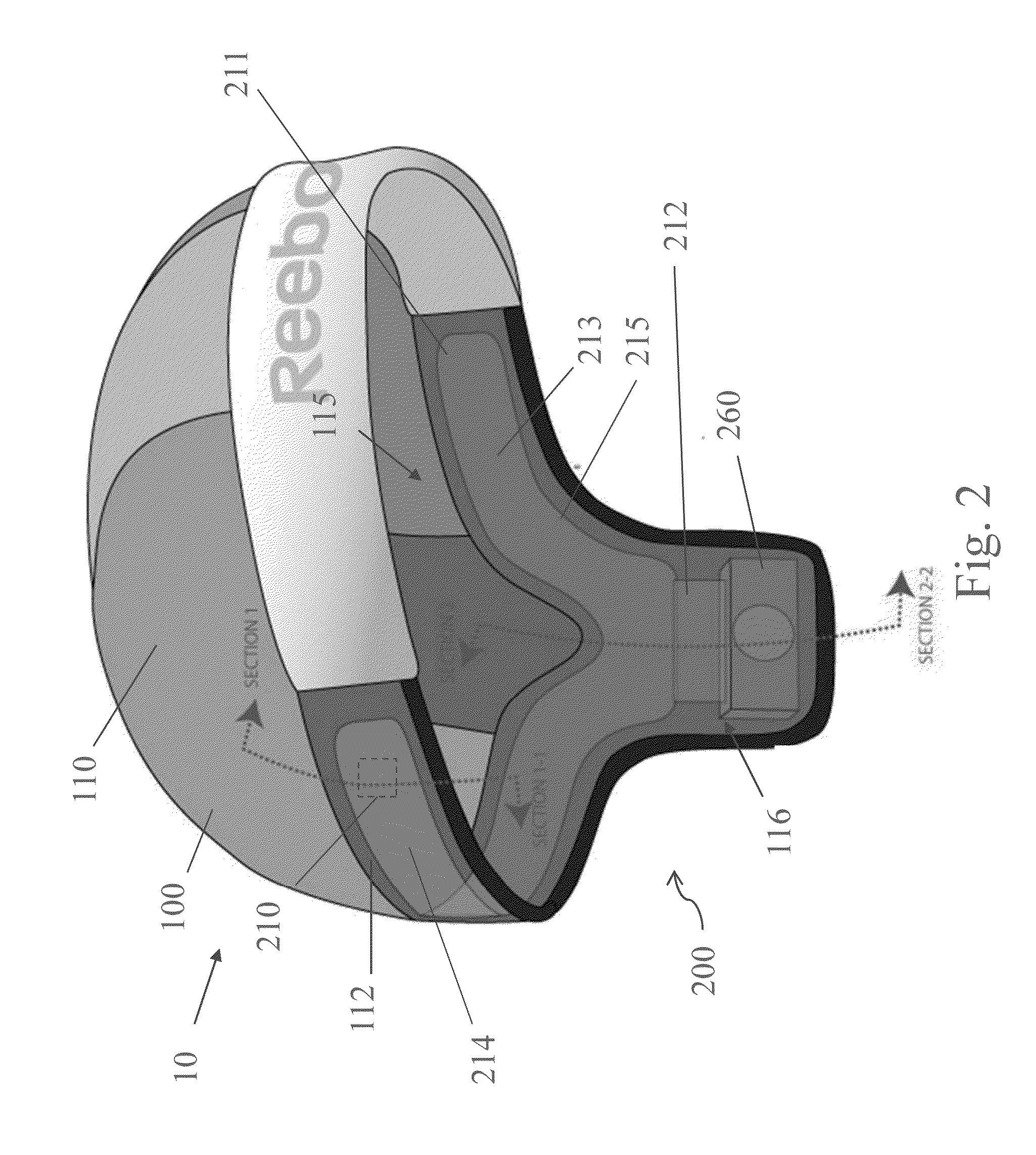

Body Mounted Monitoring System And Method

ActiveUS20130110415A1Acceleration measurement using interia forcesForce measurementMonitoring systemEngineering

Apparatus, systems, and methods for monitoring head acceleration and / or forces acting thereon are disclosed. A device for monitoring an acceleration or a force acting on the head of a user includes a flexible article adapted to be worn on the head of the user; and a monitoring assembly coupled to the flexible article. The monitoring assembly includes a sensor for measuring a force on the head and transmitting data relating to the force, the sensor disposed proximate to the head, a processor adapted to receive the force data from the sensor, and a flexible strip operatively connecting the sensor and the processor.

Owner:MEDIDATA SOLUTIONS +1

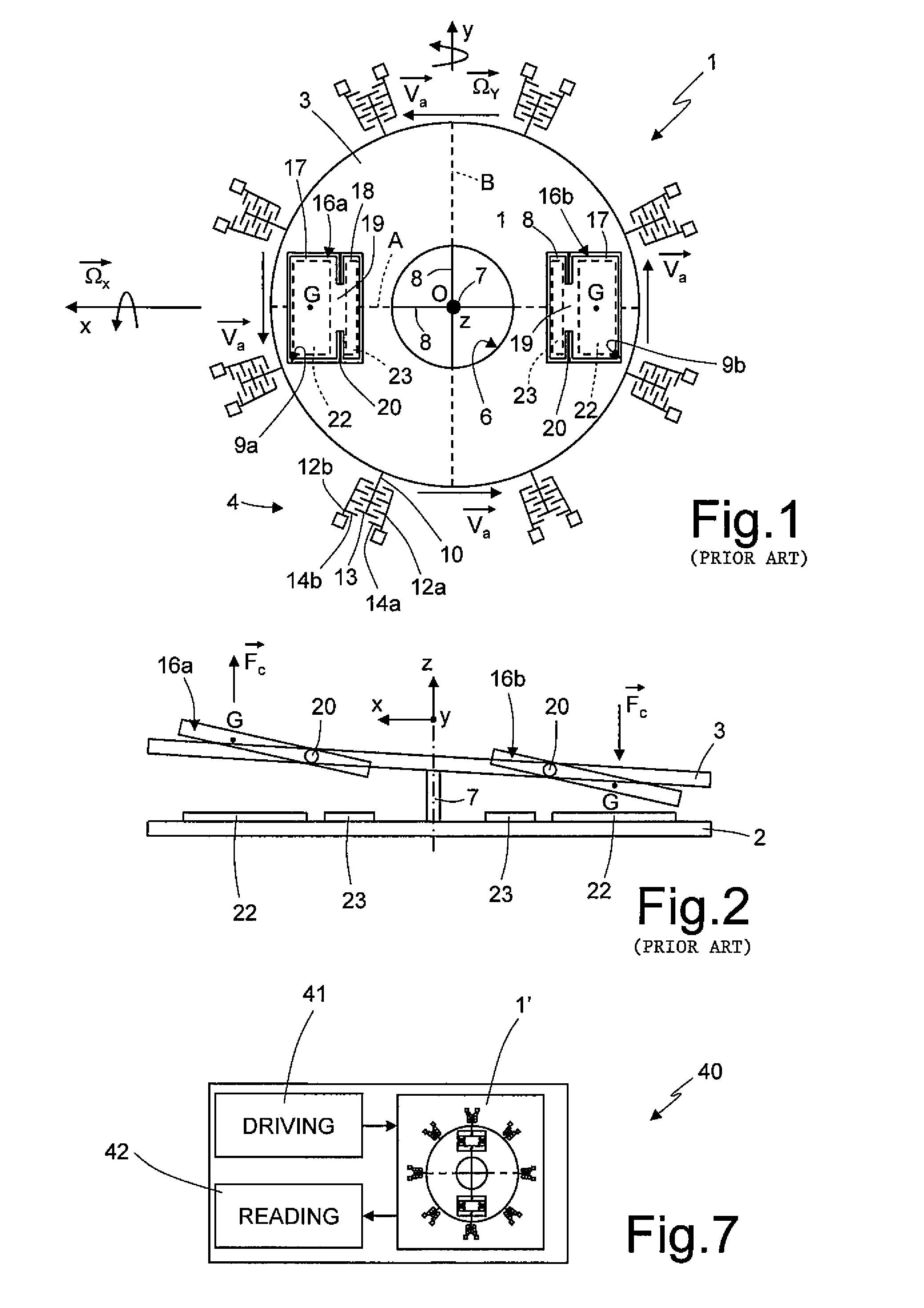

Microelectromechanical sensor with improved mechanical decoupling of sensing and driving modes

ActiveUS20090064780A1Improved mechanical decouplingAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsEngineeringDriving mode

A driving mass of an integrated microelectromechanical structure is moved with a rotary motion about an axis of rotation, and a sensing mass is connected to the driving mass via elastic supporting elements so as to perform a detection movement in the presence of an external stress. The driving mass is anchored to a first anchorage arranged along the axis of rotation by first elastic anchorage elements. The driving mass is also coupled to a pair of further anchorages positioned externally thereof and coupled to opposite sides with respect to the first anchorage by further elastic anchorage elements; the elastic supporting elements and the first and further elastic anchorage elements render the driving mass fixed to the first sensing mass in the rotary motion, and substantially decoupled from the sensing mass in the detection movement, the detection movement being a rotation about an axis lying in a plane.

Owner:STMICROELECTRONICS SRL

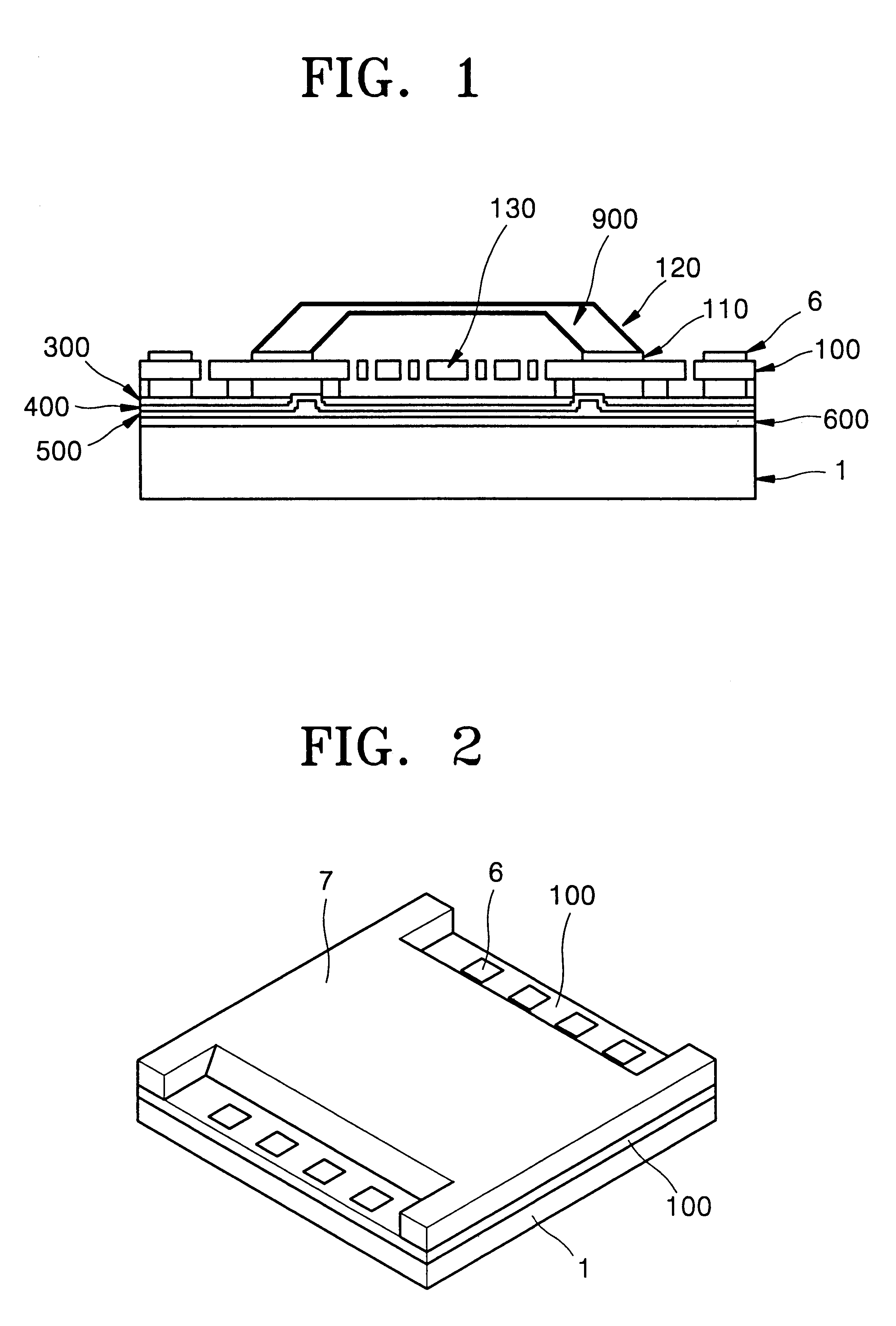

Method of fabricating micro electro mechanical system structure which can be vacuum-packed at wafer level

InactiveUS6391673B1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsVacuum packVacuum level

A method of fabricating a micro electromechanical system (MEMS) structure which can be vacuum-packaged at the wafer level is provided. The method includes the steps of forming a multilayered stack including a signal line on a first wafer; bonding a second wafer to the multilayered stack; polishing the first wafer to a predetermined thickness; forming a MEMS structure in a vacuum area of the first wafer and a pad outside the vacuum area, the MEMS structure and the pad being connected to the signal line; forming a structure in a third wafer to have space corresponding to the vacuum area of the MEMS structure; and bonding the third wafer to the polished surface of the first wafer in a vacuum state. For protection of the structure and maintaining a vacuum level required for operation, the fabricated structure is vacuum-packaged at the wafer level, thereby improving the yield of fabrication. In addition, since a special vacuum packaging process is not necessary, the fabrication can be simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com