Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1227 results about "Rotation sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CMC’s shaft rotation sensor is an application specific sensor, designed to measure the shaft speed of rotating machinery. It is an Intrinsically Safe shaft rotation sensor when used as part of CMC’s single wire digital HazMon network and is ideal for monitoring shaft speed on most types of industrial machinery.

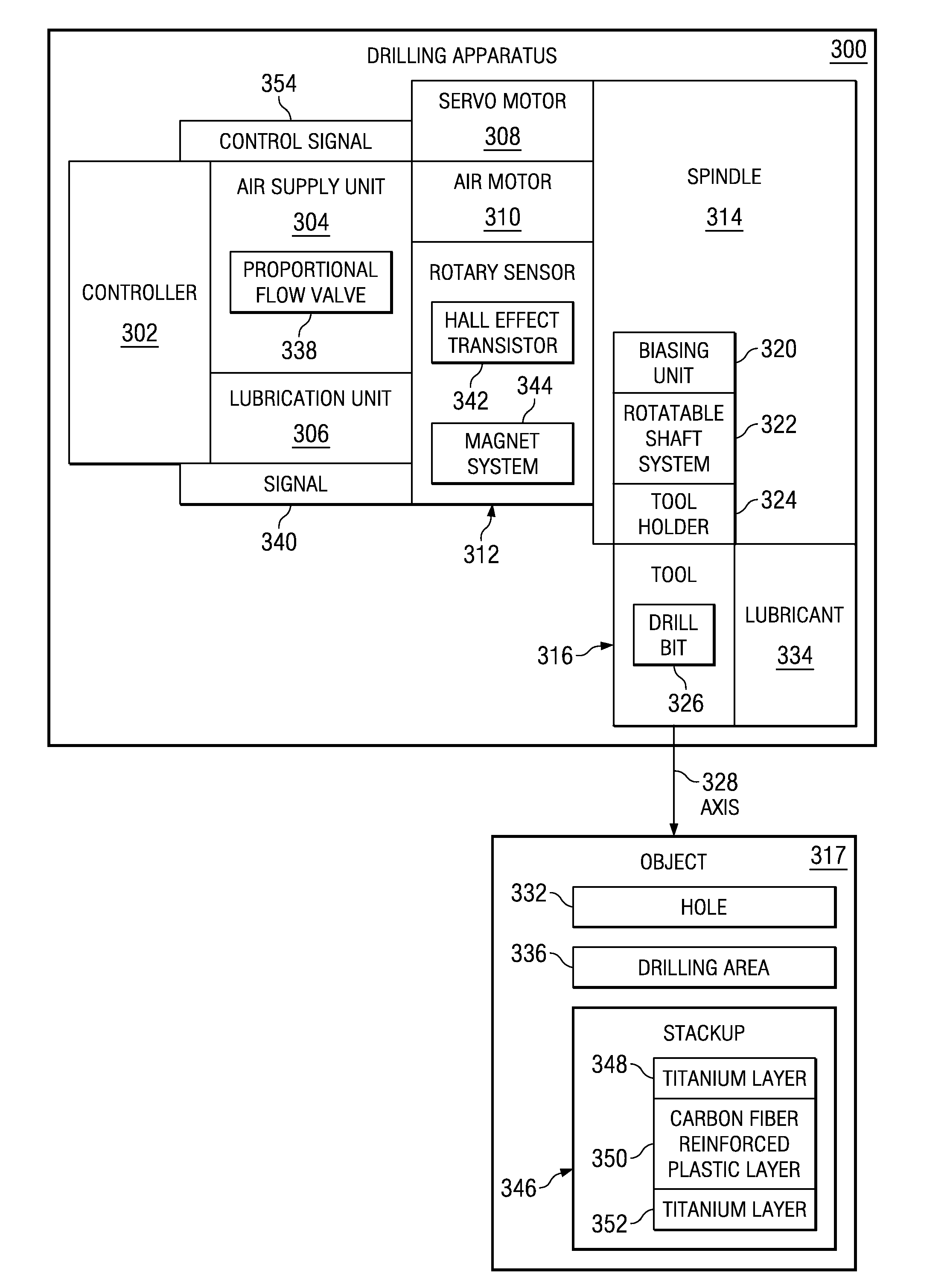

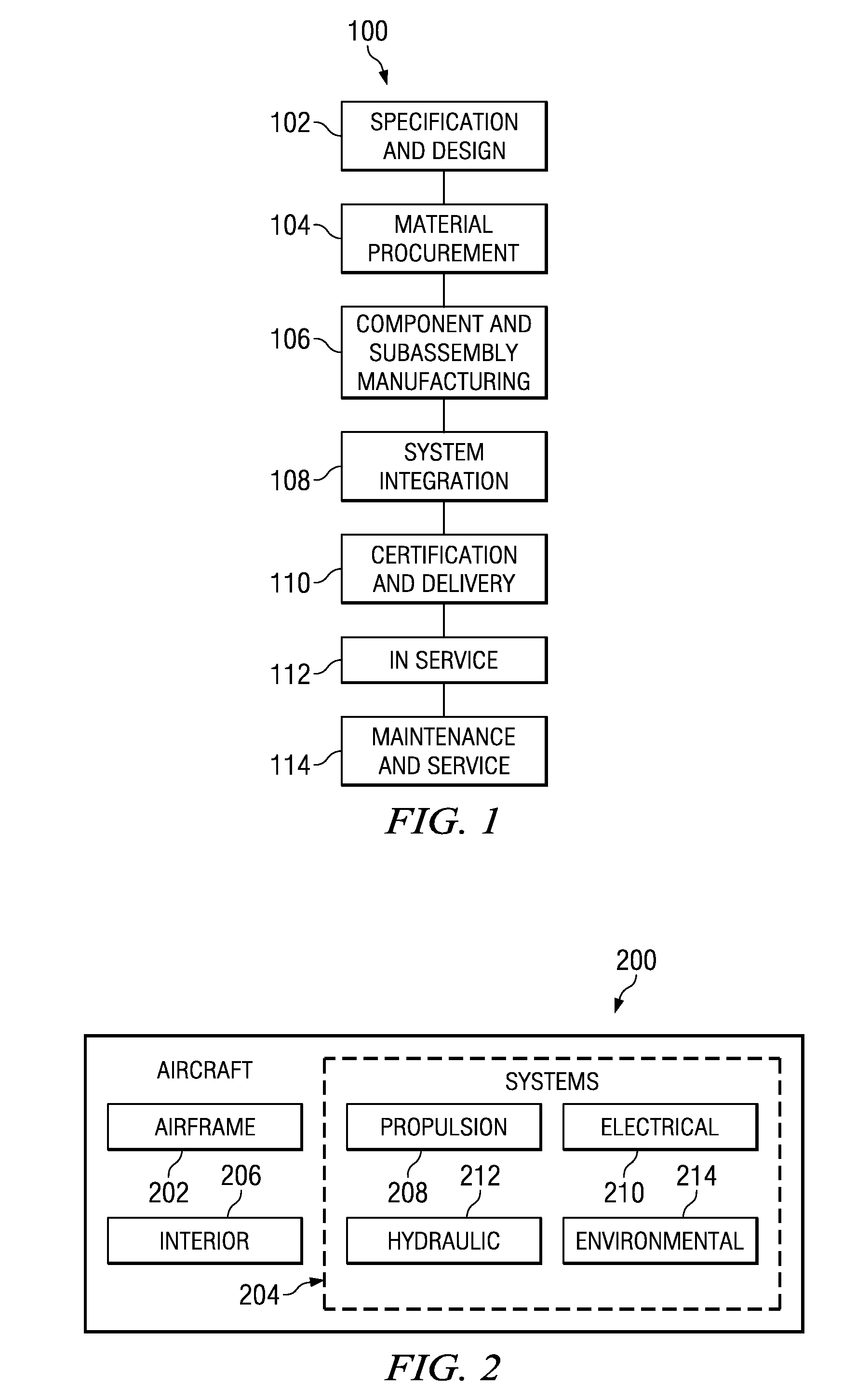

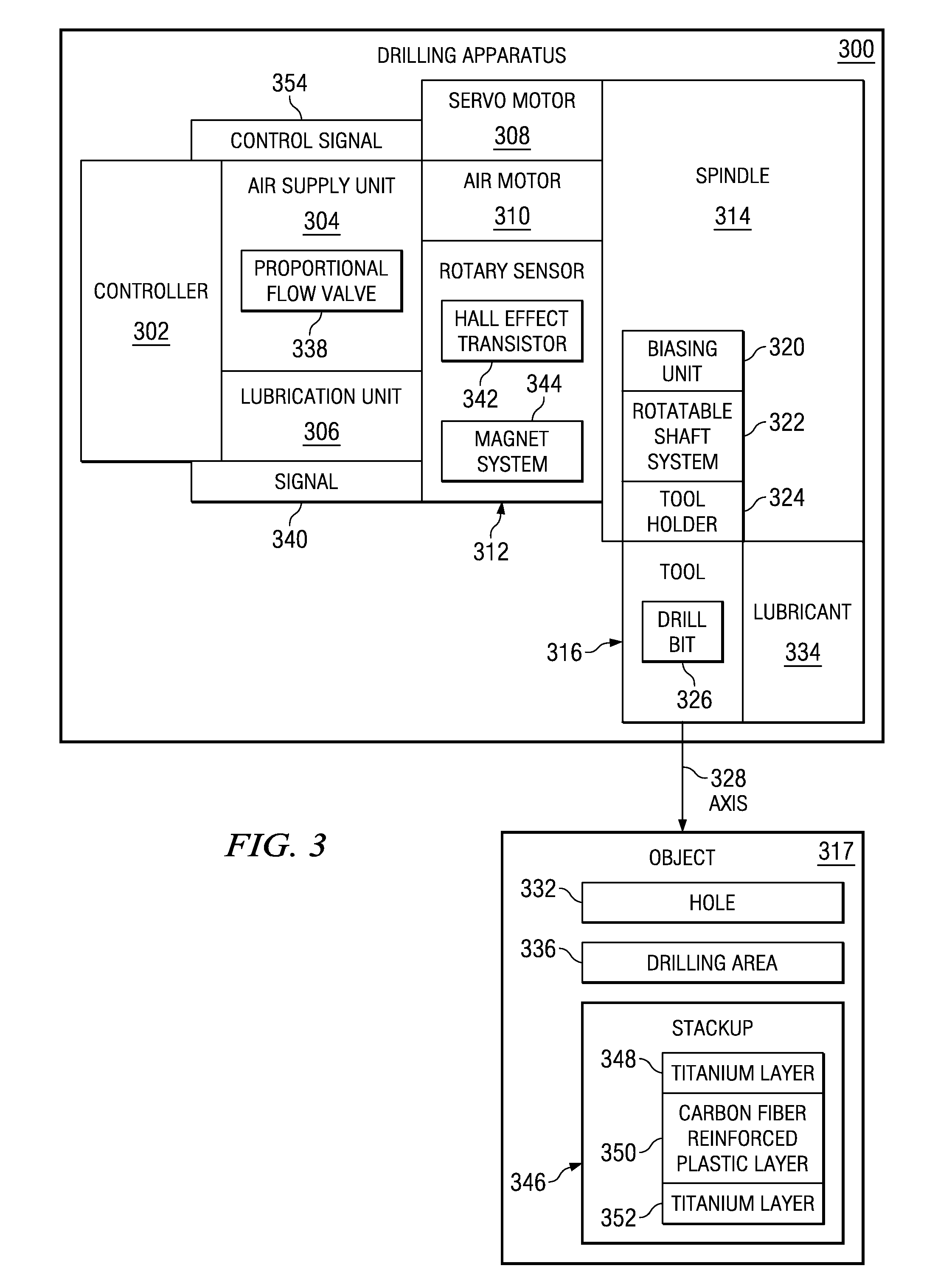

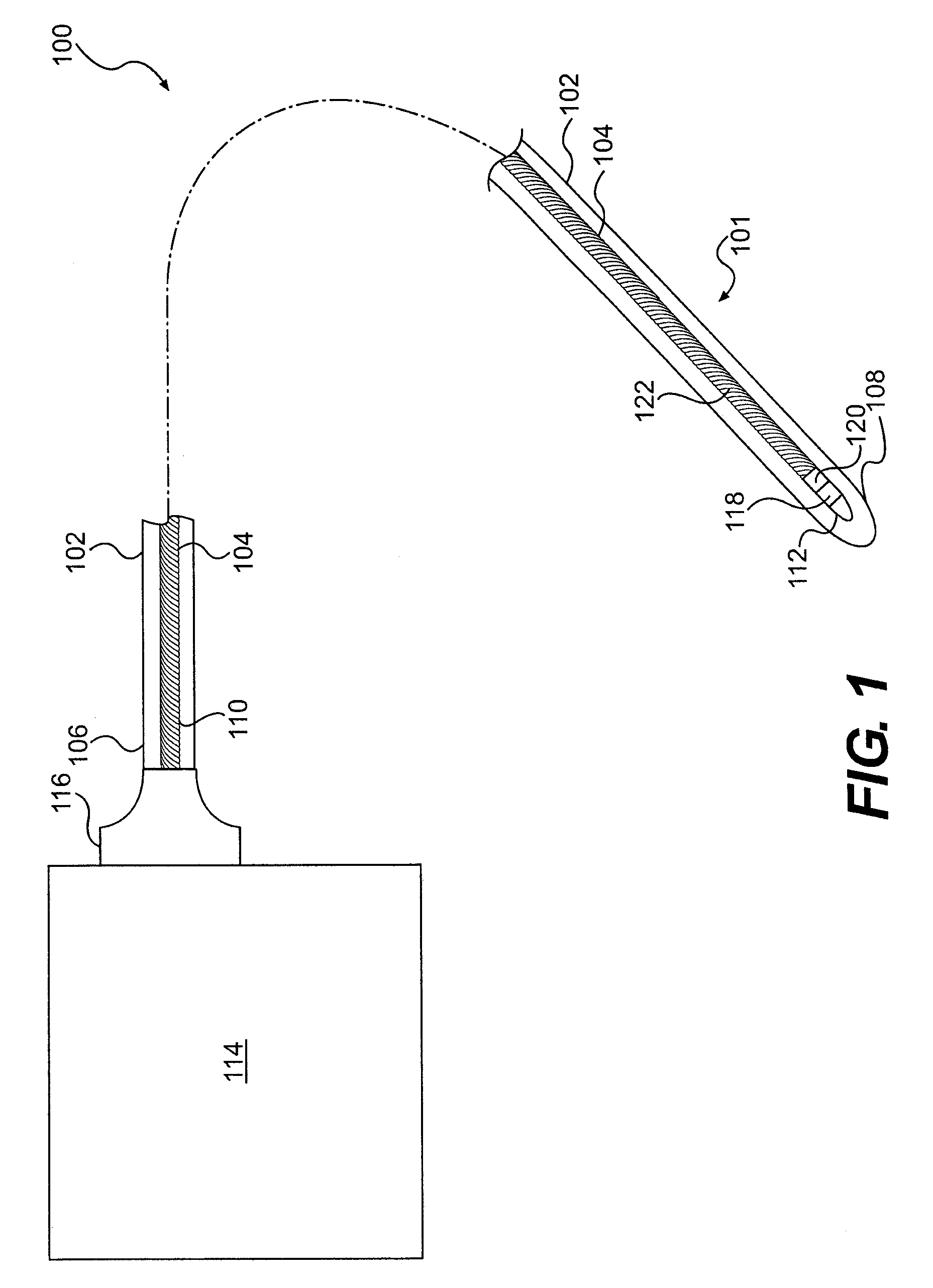

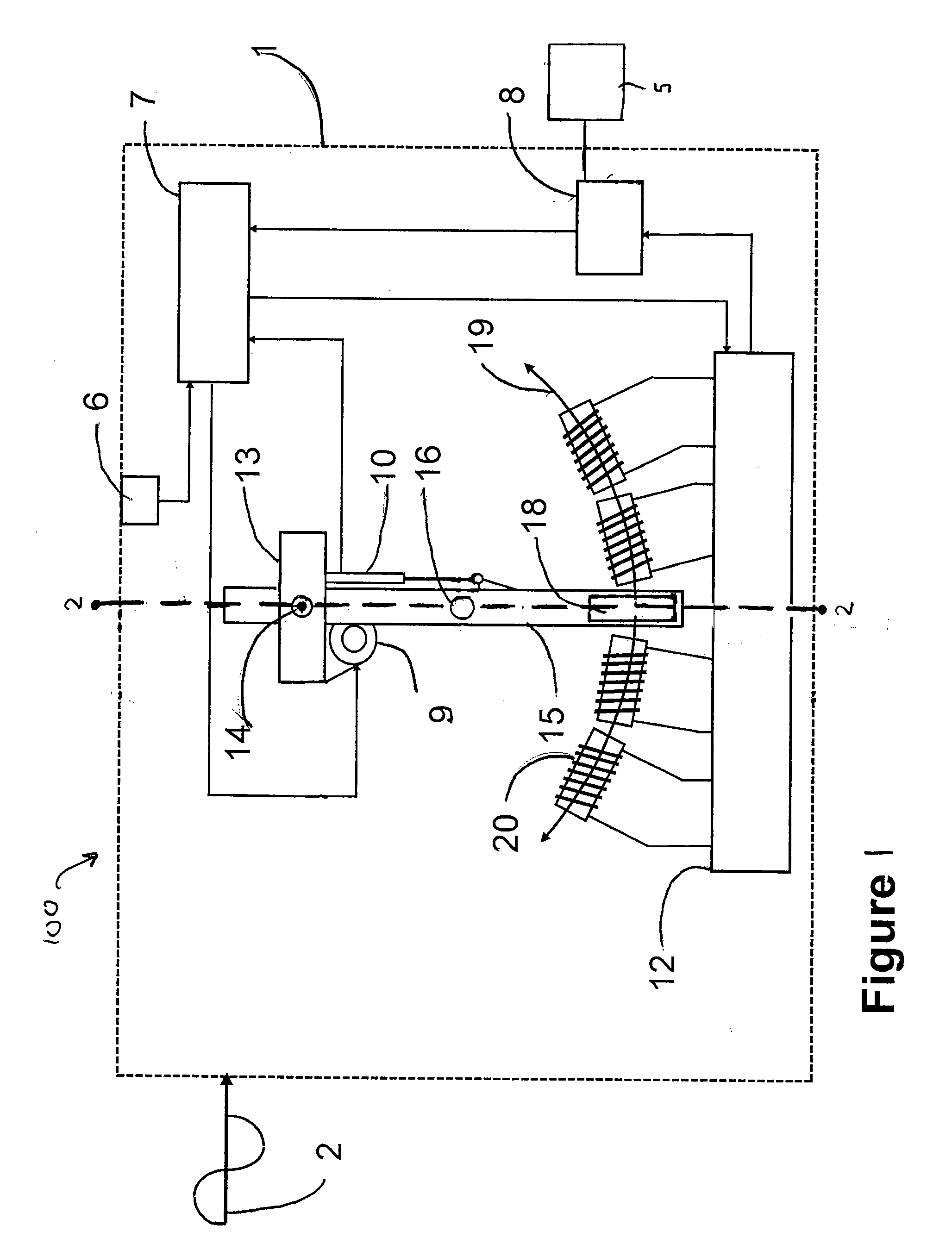

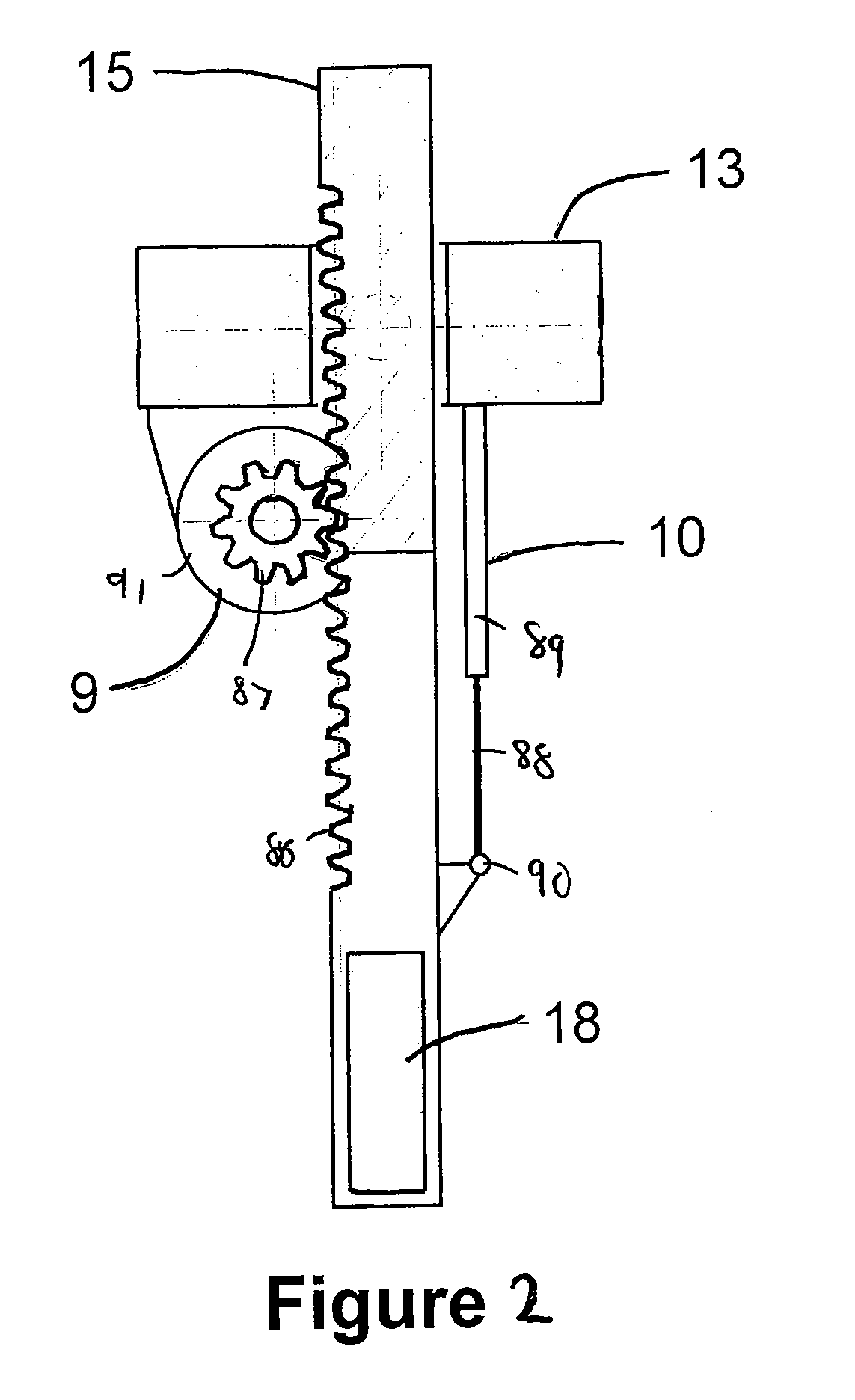

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

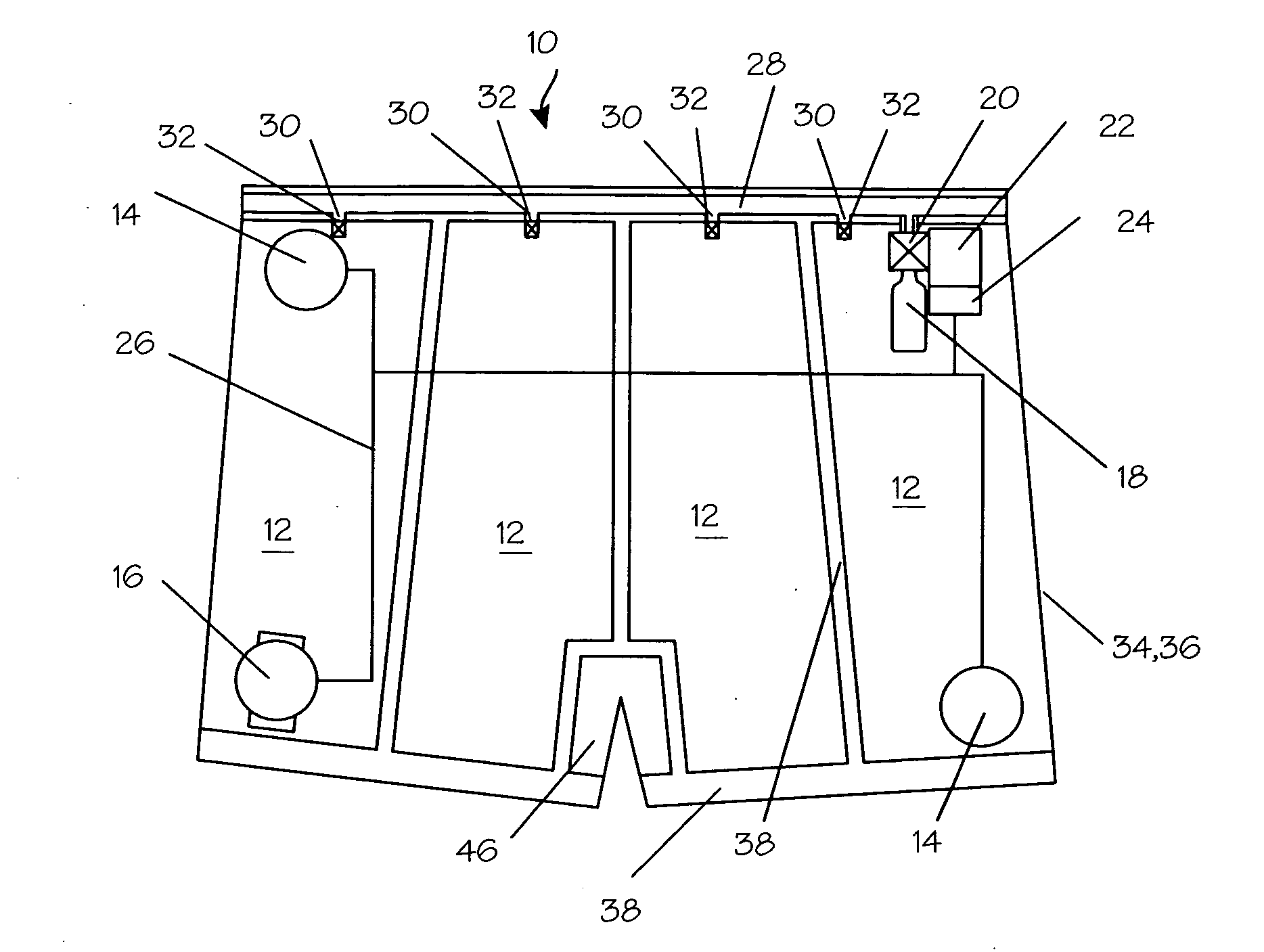

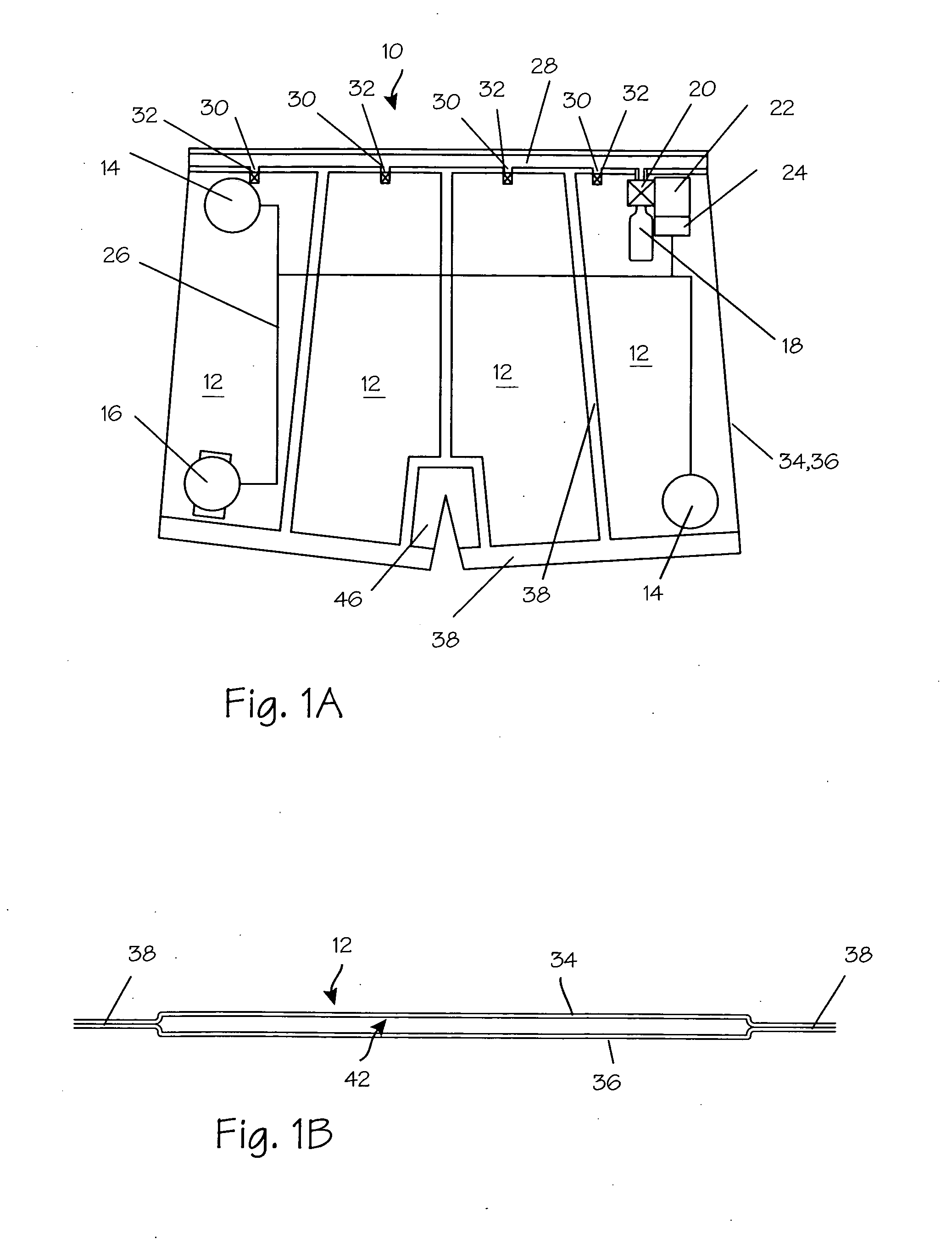

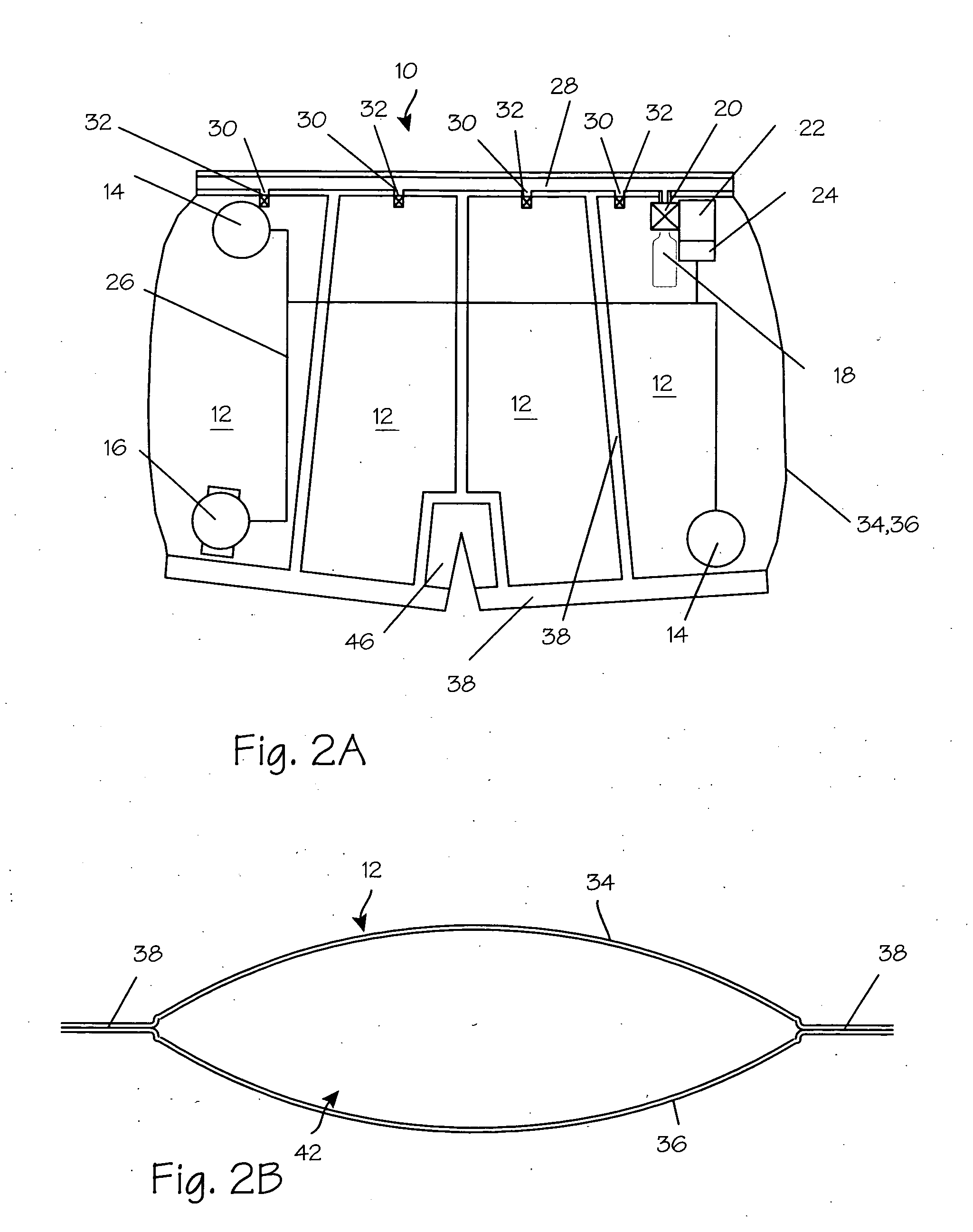

Method and apparatus for body impact protection

ActiveUS20050067816A1Risk minimizationStabilize neckSafety beltsResilient force resistorsCushioningEngineering

This invention relates to active protective garments which are inconspicuously worn by an individual and which activate upon certain conditions being met. Activation causes inflation of regions of the active protective garment to provide padding and impact cushioning for the wearer. The invention is an active protective garment such as pair of shorts or pants, a jacket, a vest, underwear, and the like. The garments comprise multiple layers of material that constrain pockets or regions that are inflatable by a source of compressed gas or foam. The garments also comprise sensors to detect ballistic parameters such as acceleration, distance, relative acceleration, and rotation. The sensor information is used to determine whether activation is required. Detection and activation are accomplished in a very short time period in order to offer maximal protection for the individual wearing the garment. The system comprises a computer or logic controller that monitors the sensor data in real time and coordinates the information from all sensors. The system calculates velocity, distance, and rotational velocity. A rule-based system is used to detect a complex fall in progress and discriminate said fall in progress from the events of every day life. The pockets or inflatable regions of the garment protect the individual against falls and other impacts that may cause bone fracture or organ damage.

Owner:ACTIVE PROTECTIVE TECH

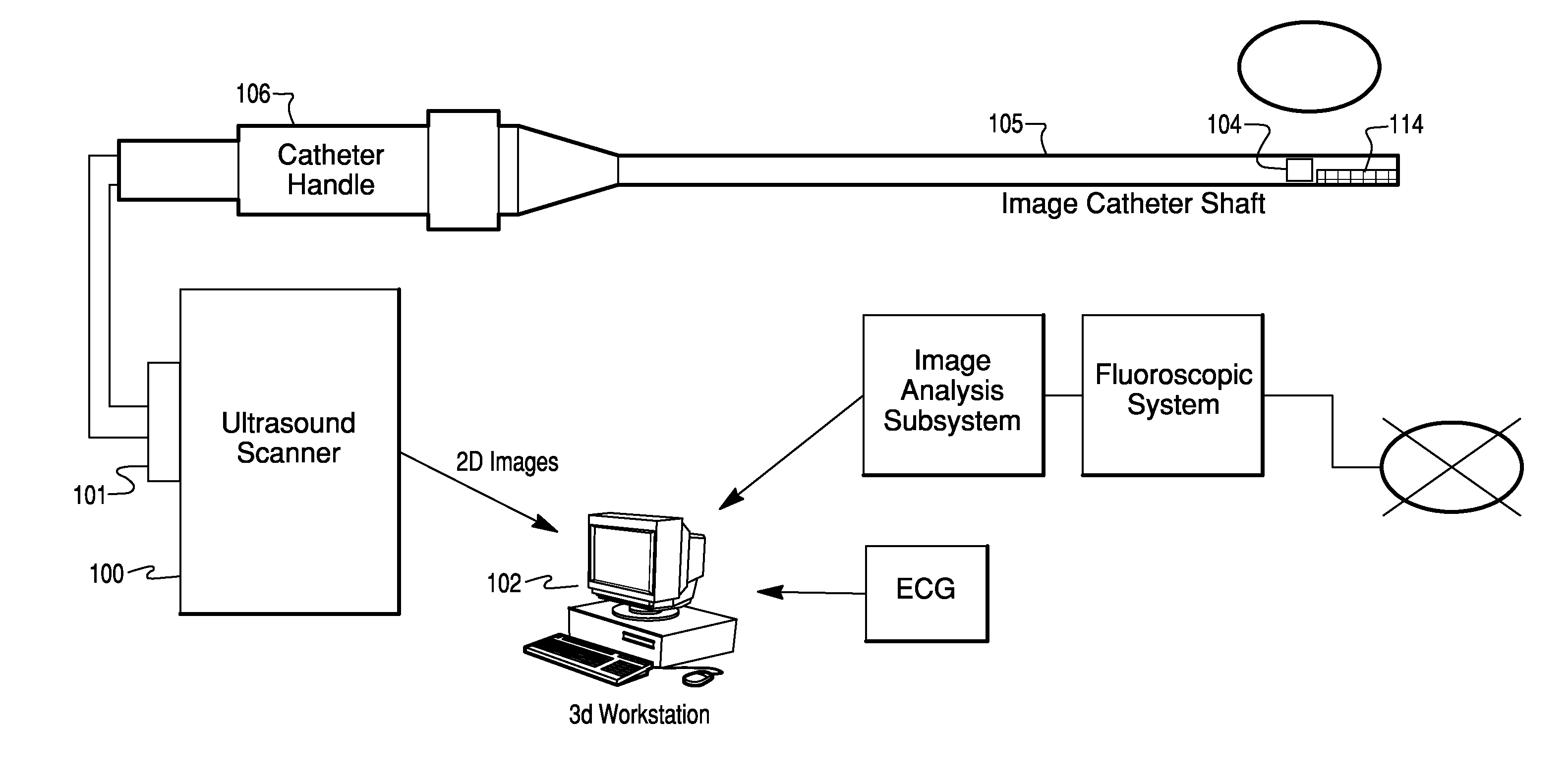

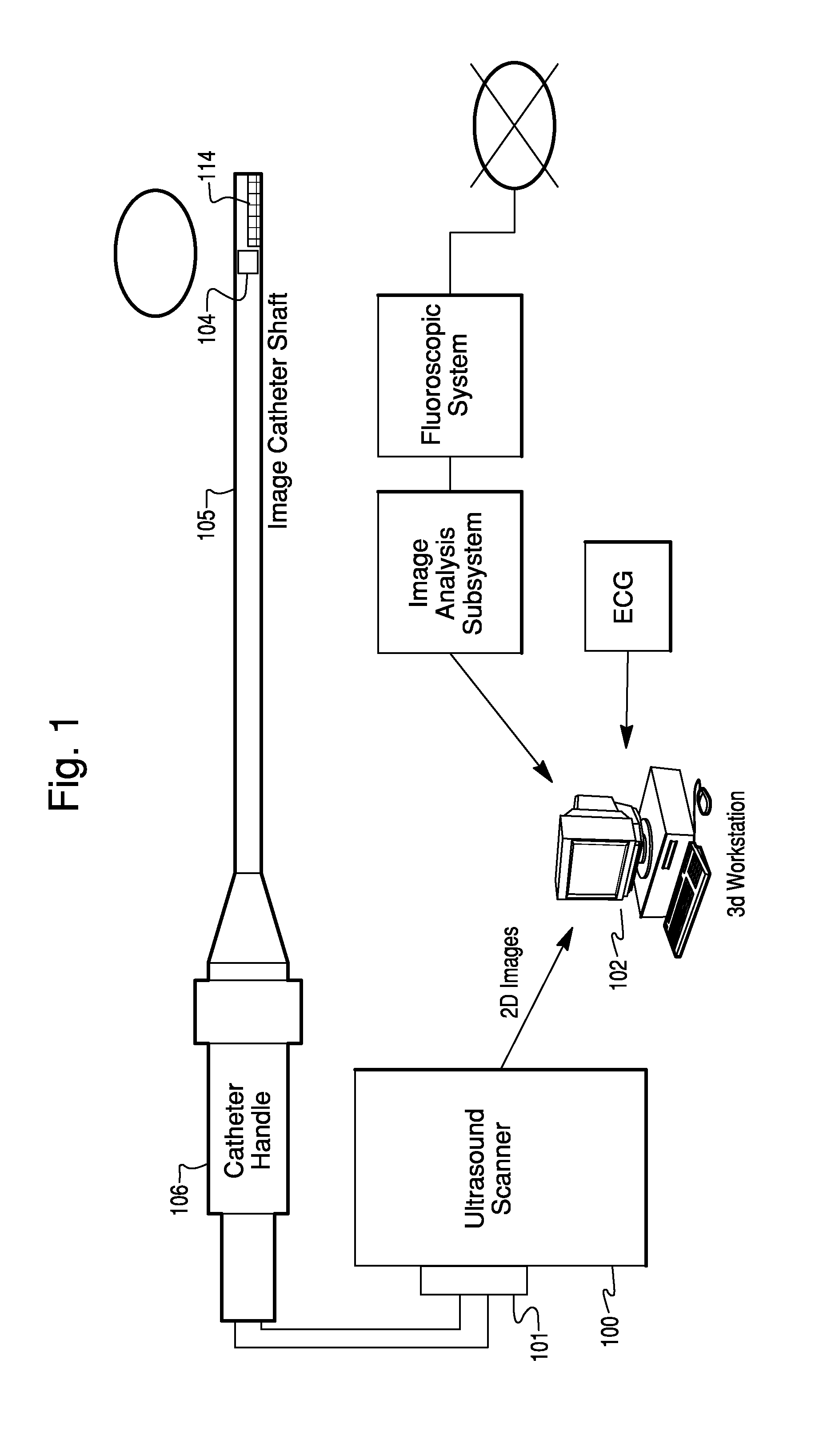

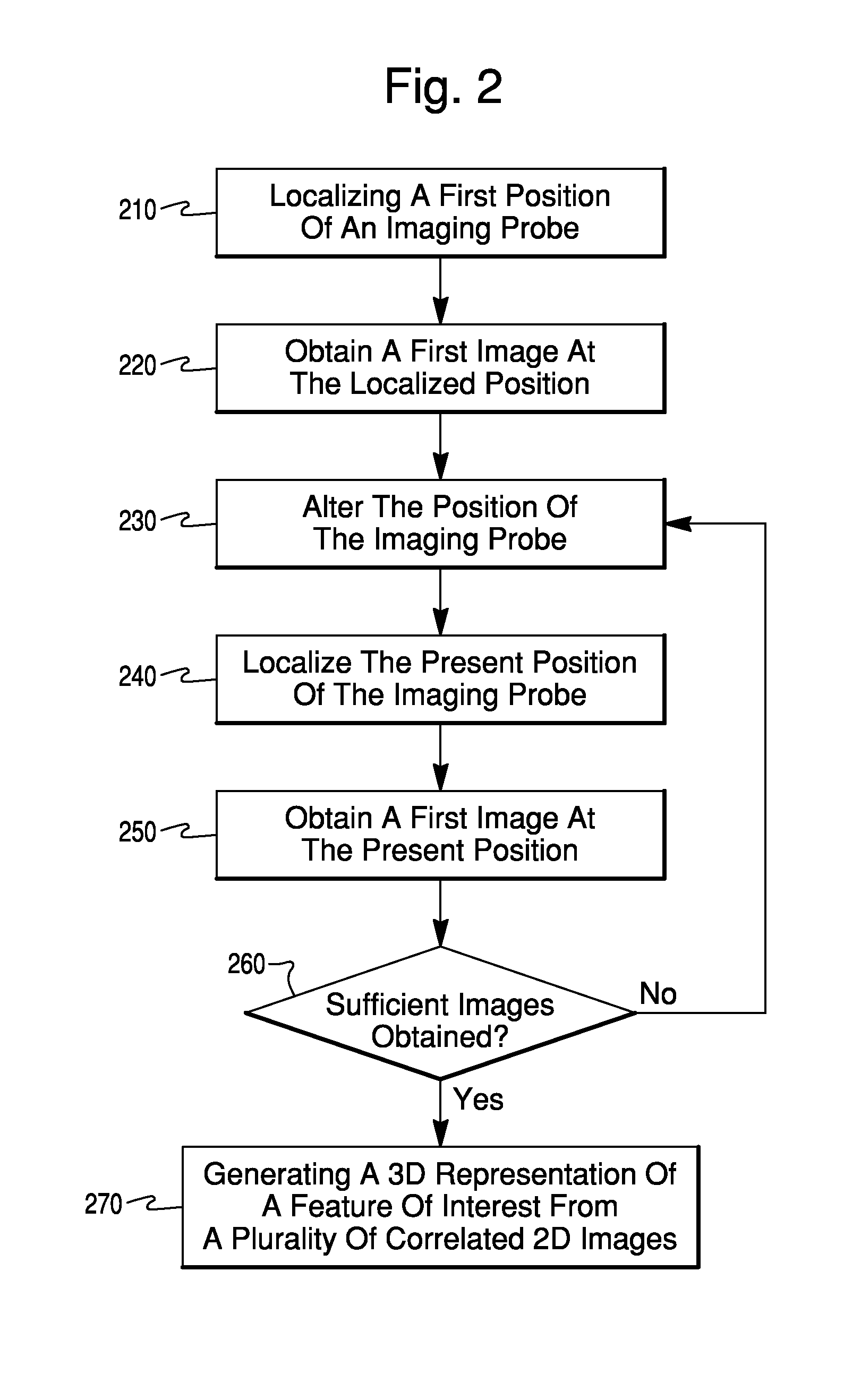

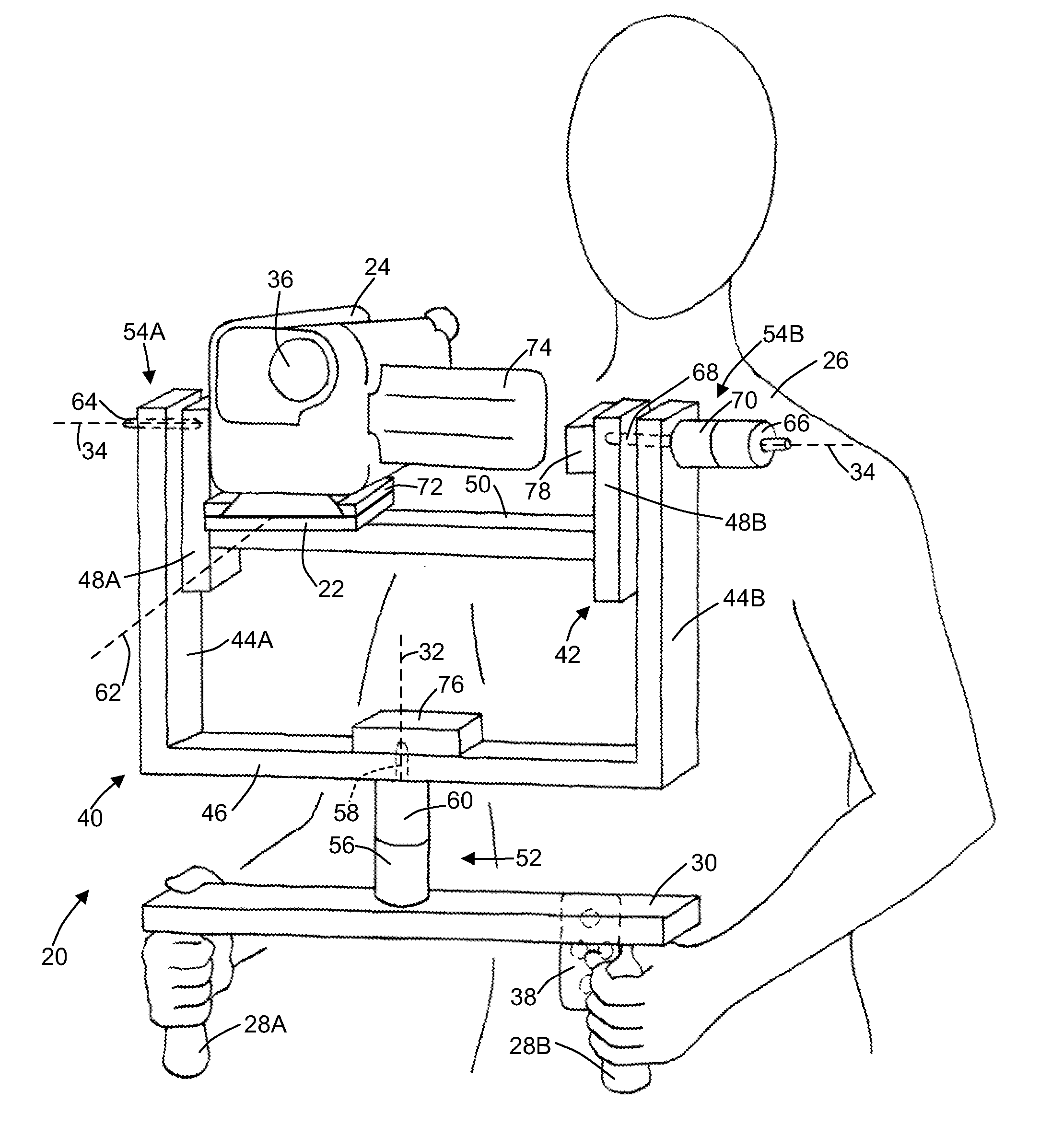

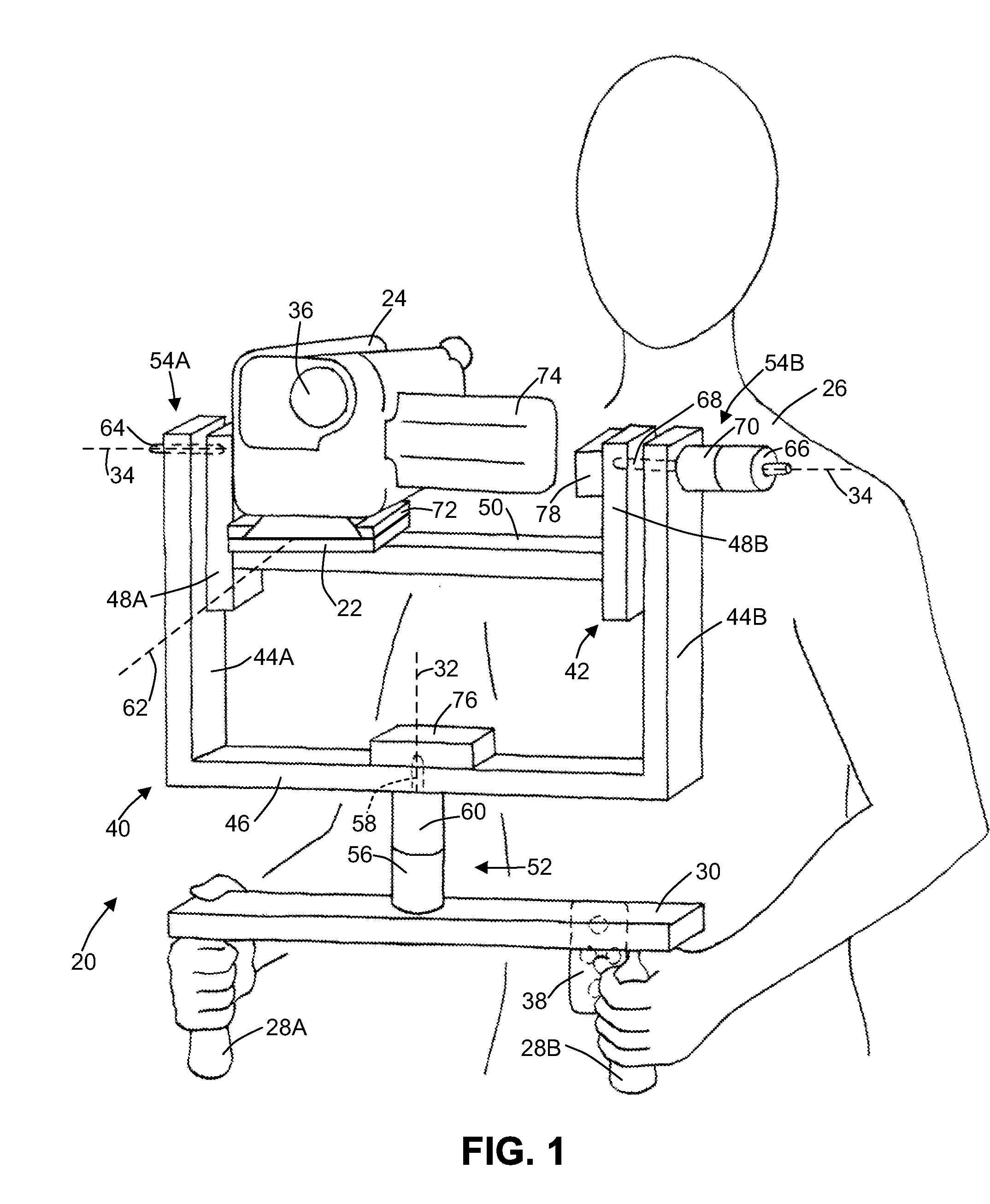

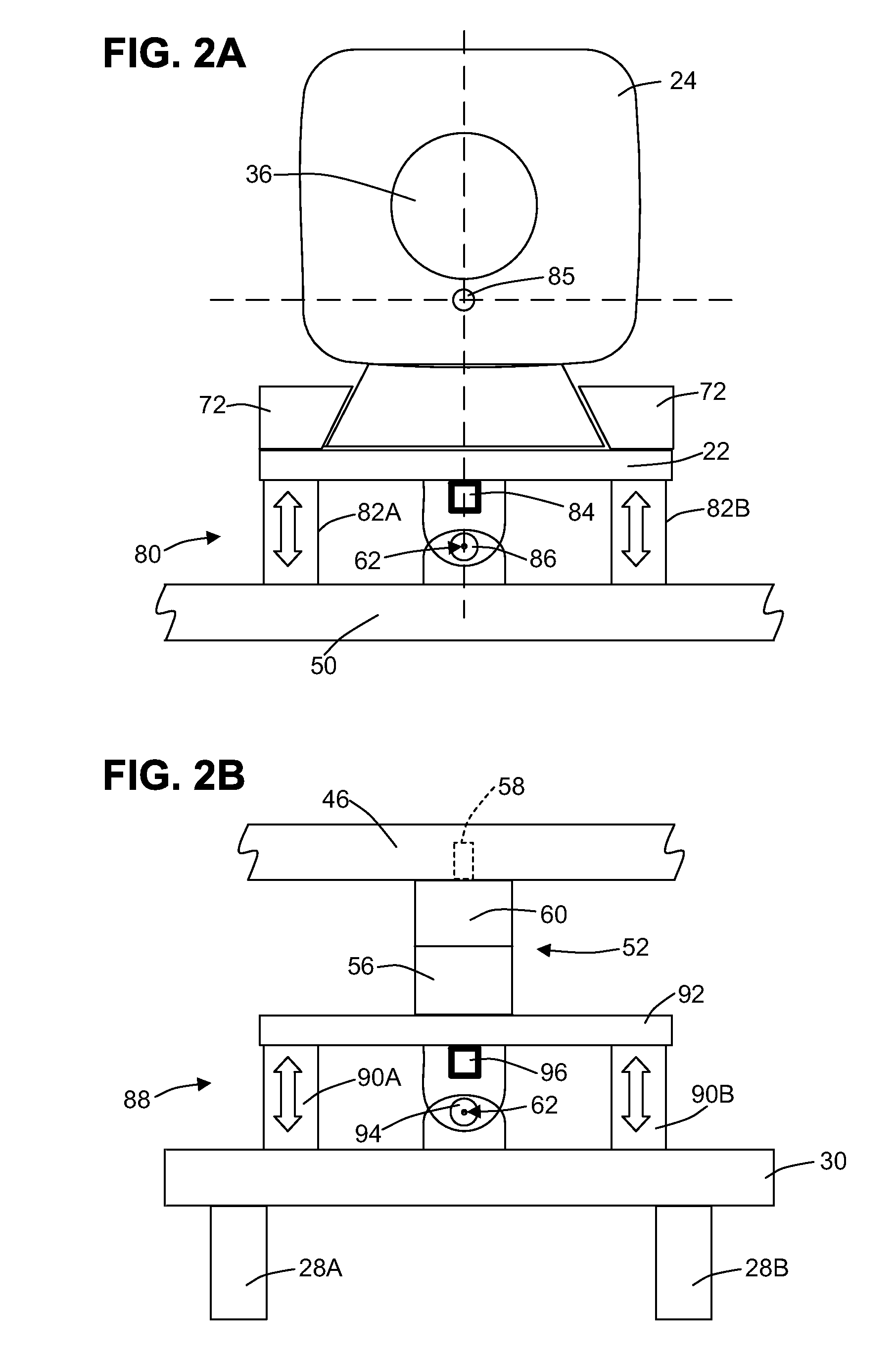

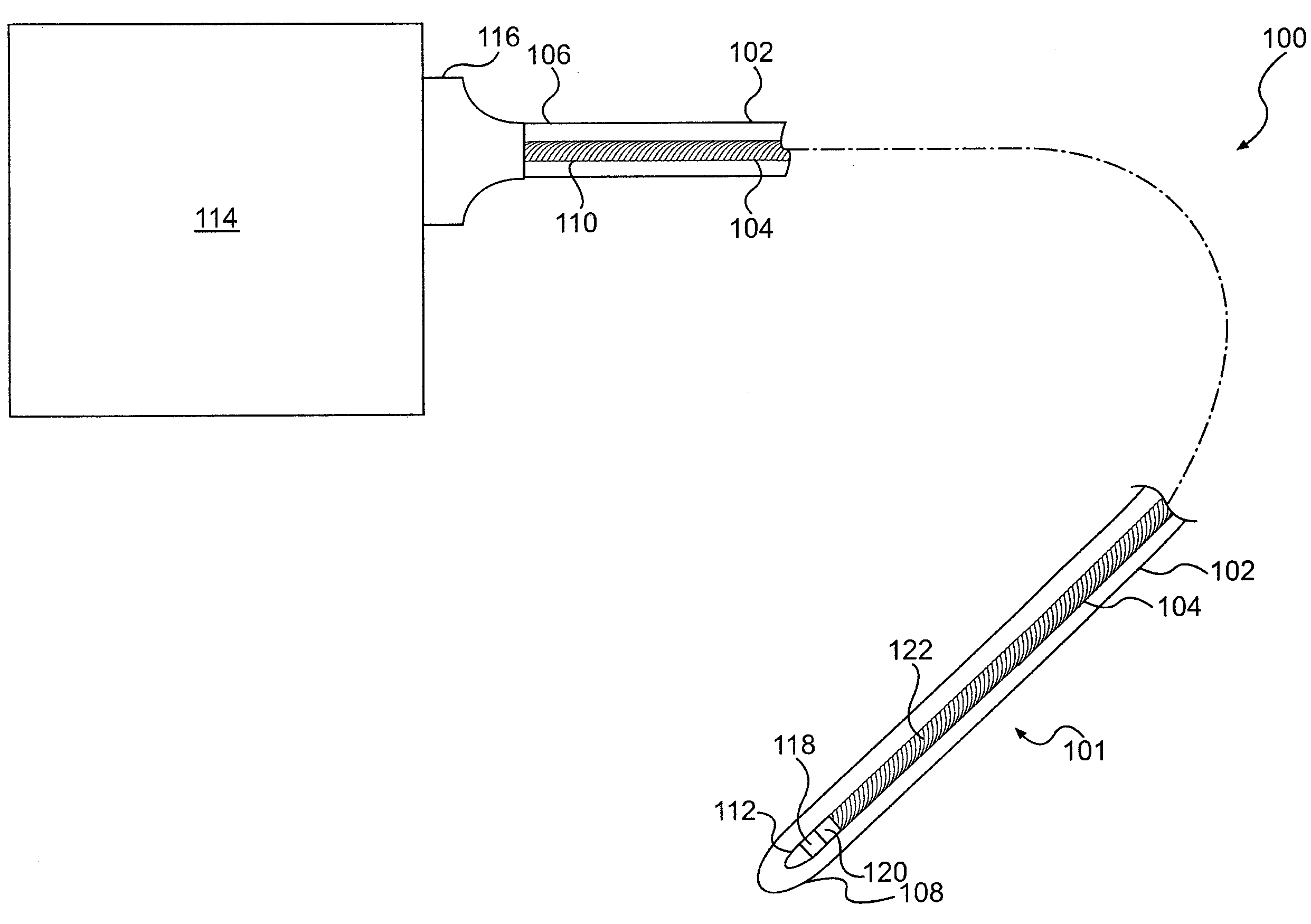

Catheter Position Tracking Methods Using Fluoroscopy and Rotational Sensors

Methods for determine the position and rotational orientation of the transducer array of an ultrasound imaging catheter within a patient include imaging the distal end of the catheter using fluoroscopy and determining the angular orientation based upon the shape and dimensions of the image of the transducer array and wire connecting harness. Additional rotational and translational information may be obtained from sensors located at the proximal end of the catheter. By combining position information obtained using fluoroscopy with information from relative rotation / translation sensors, the imaging transducer position and orientation can be determined more accurately. The resulting accurate imaging transducer position information enables combining multiple images from different positions or orientations to generate multi-dimensional images. Catheters including rotation and translation motion sensors at the proximal end, and radio-opaque materials near the distal end can be provided to enhance the methods.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

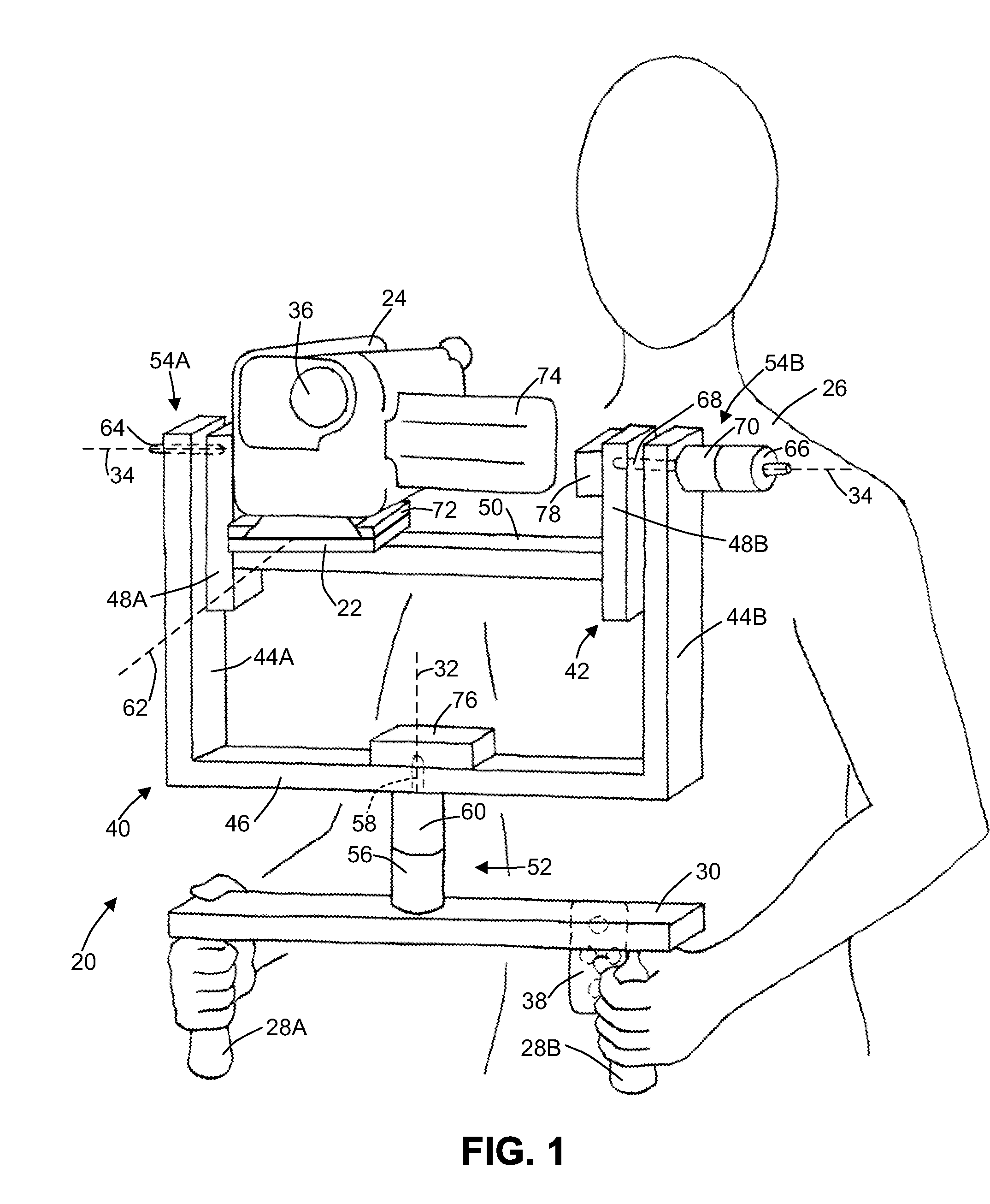

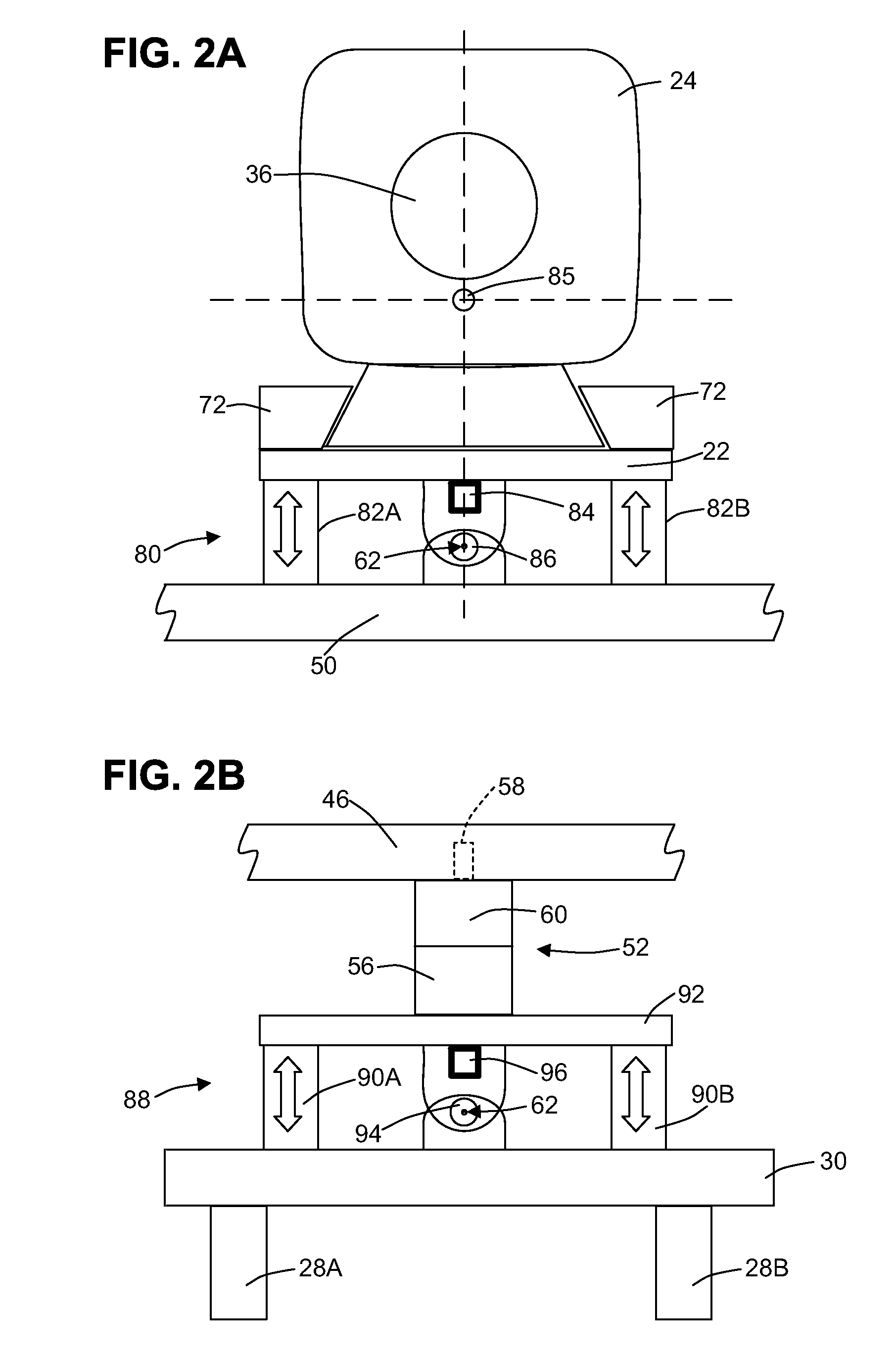

Handheld platform stabilization system employing distributed rotation sensors

ActiveUS20070050139A1Easy to liftLimit range of motionNavigation by speed/acceleration measurementsElement comparisonActuatorMotion simulator

A stabilization system including a platform supported by two or more rotatably-coupled gimbal frames each having a pivot assembly disposed at its rotation axis to couple an actuator to a rotation sensor having a rotation-sensitive sensor axis that is fixedly disposed with respect to the rotation axis, and a controller including means for accepting the sensor signals and for producing each motor signal needed to dispose the platform in a predetermined angular position with respect to each rotation axis independent of changes in the base orientation. A motion simulator embodiment includes controller means for accepting an external slew signal sequence and means for producing the motor signals needed to move the platform along a predetermined sequence of positions represented by the slew signal sequence.

Owner:SIDMAN ADAM D

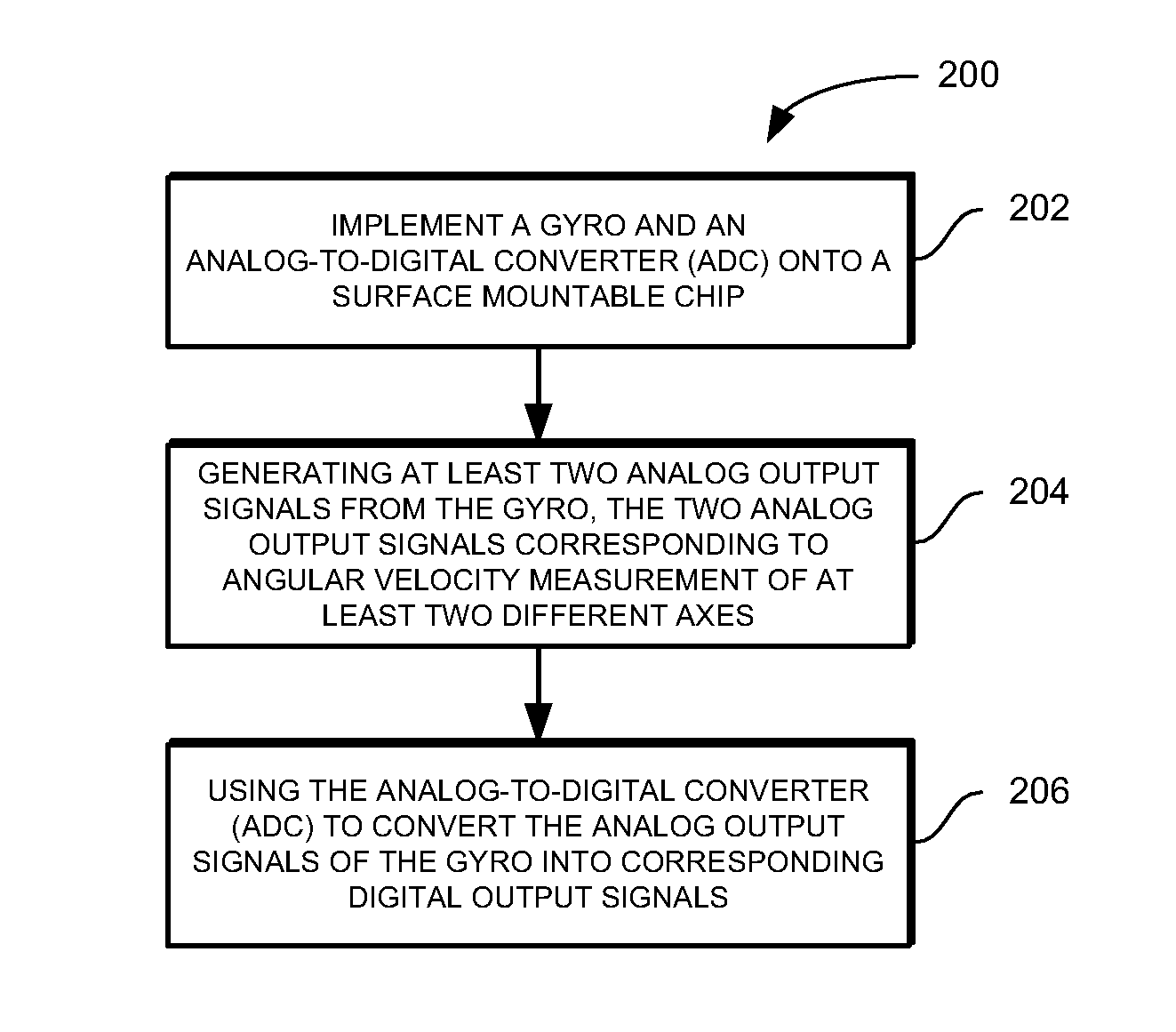

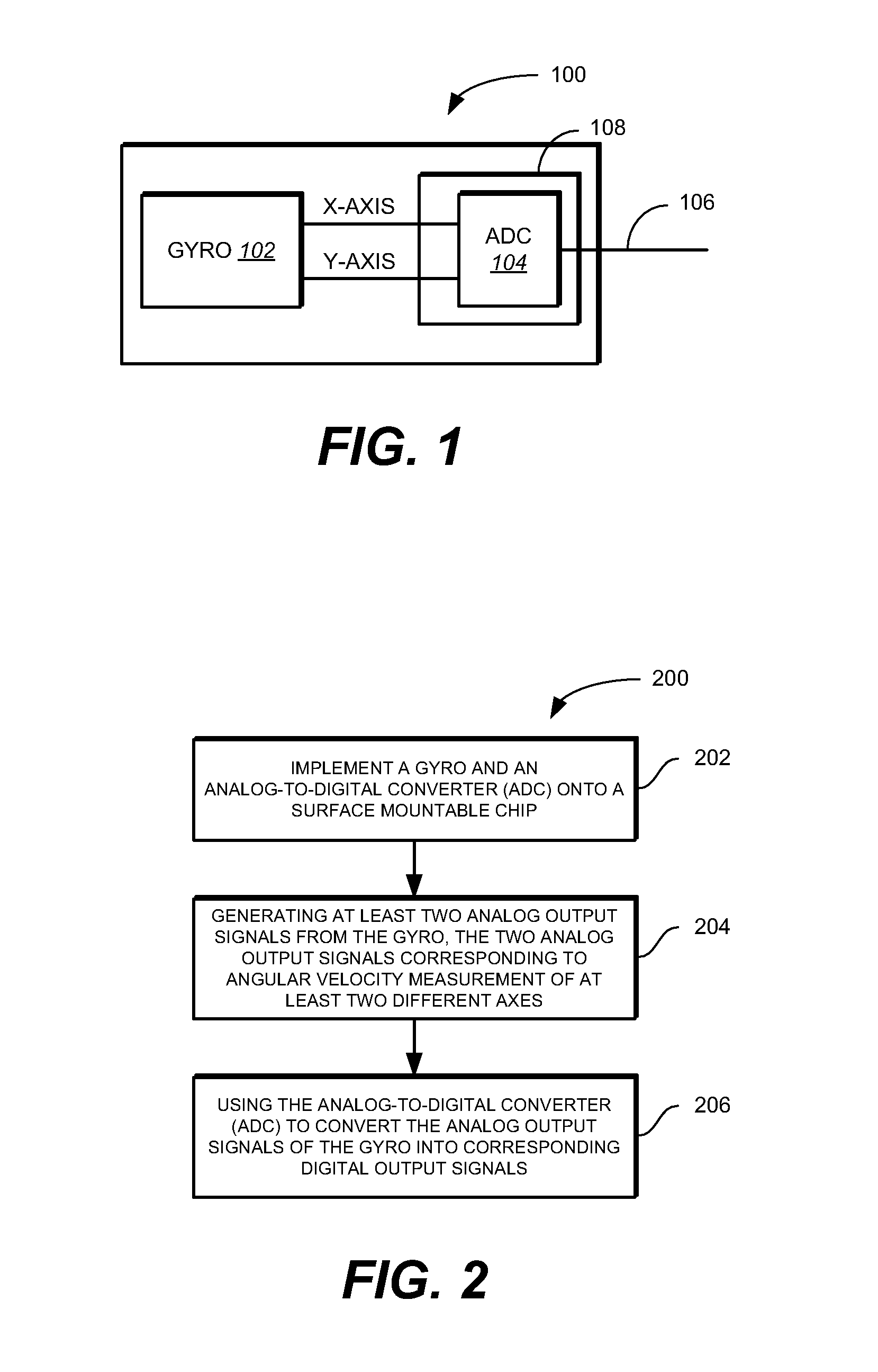

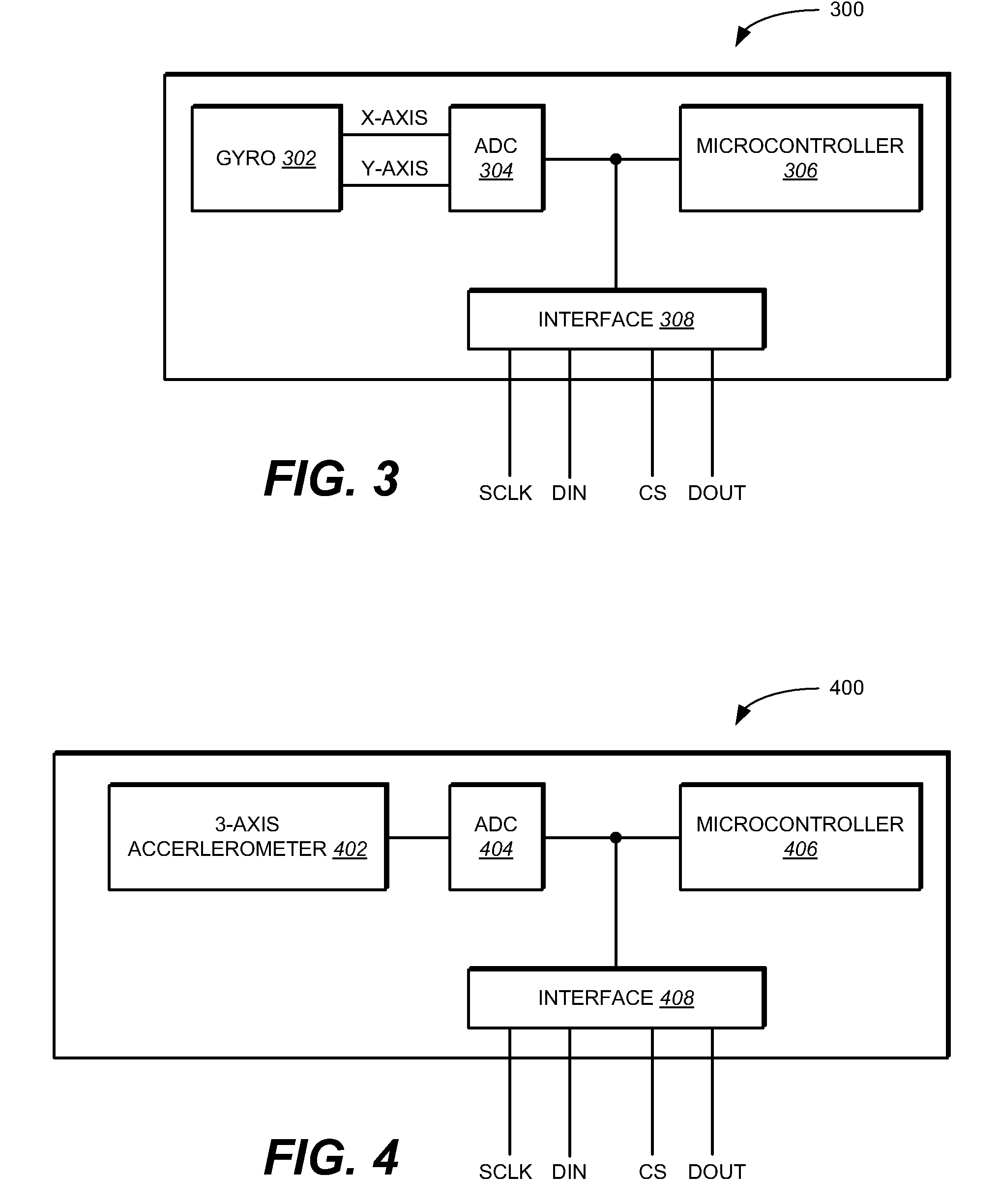

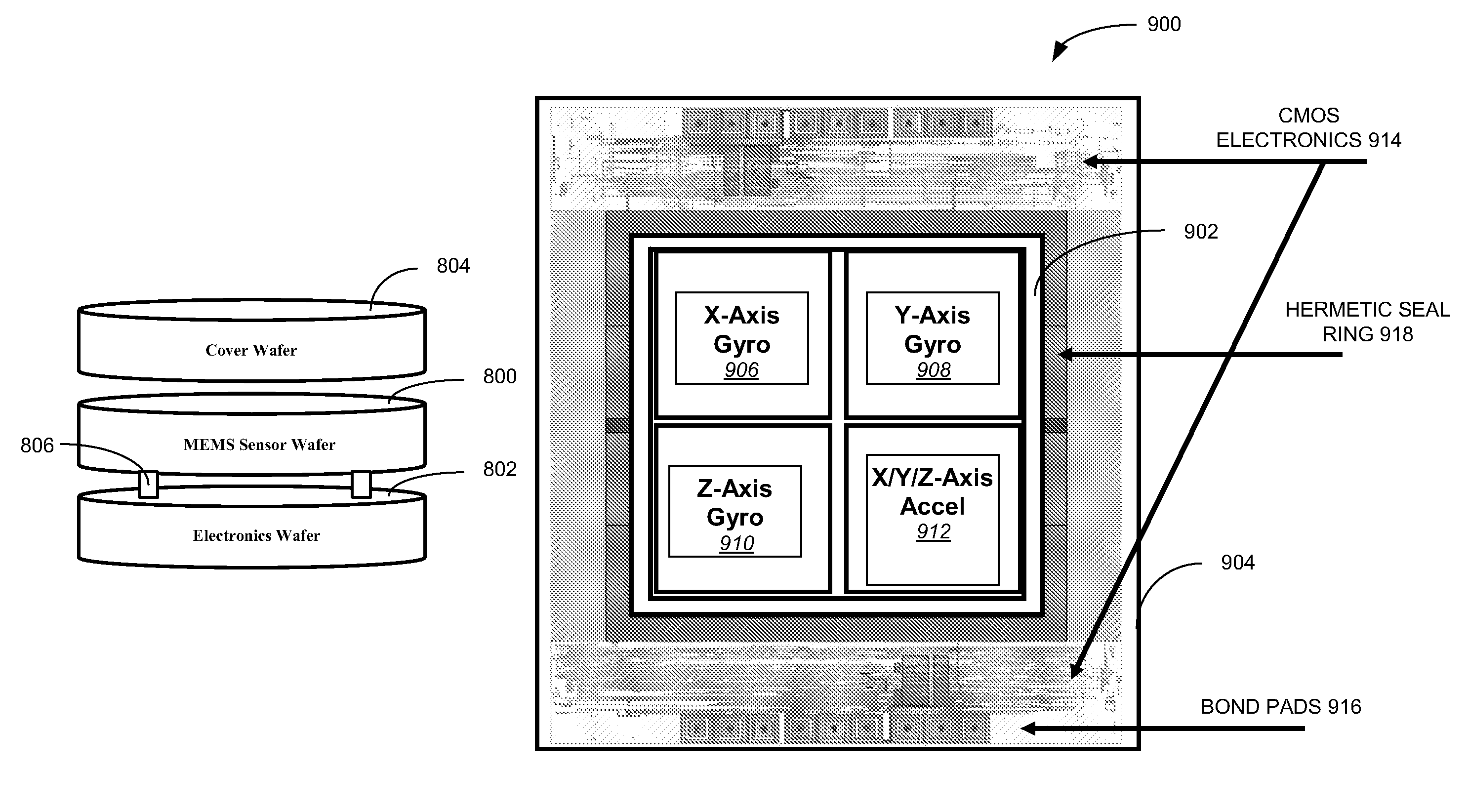

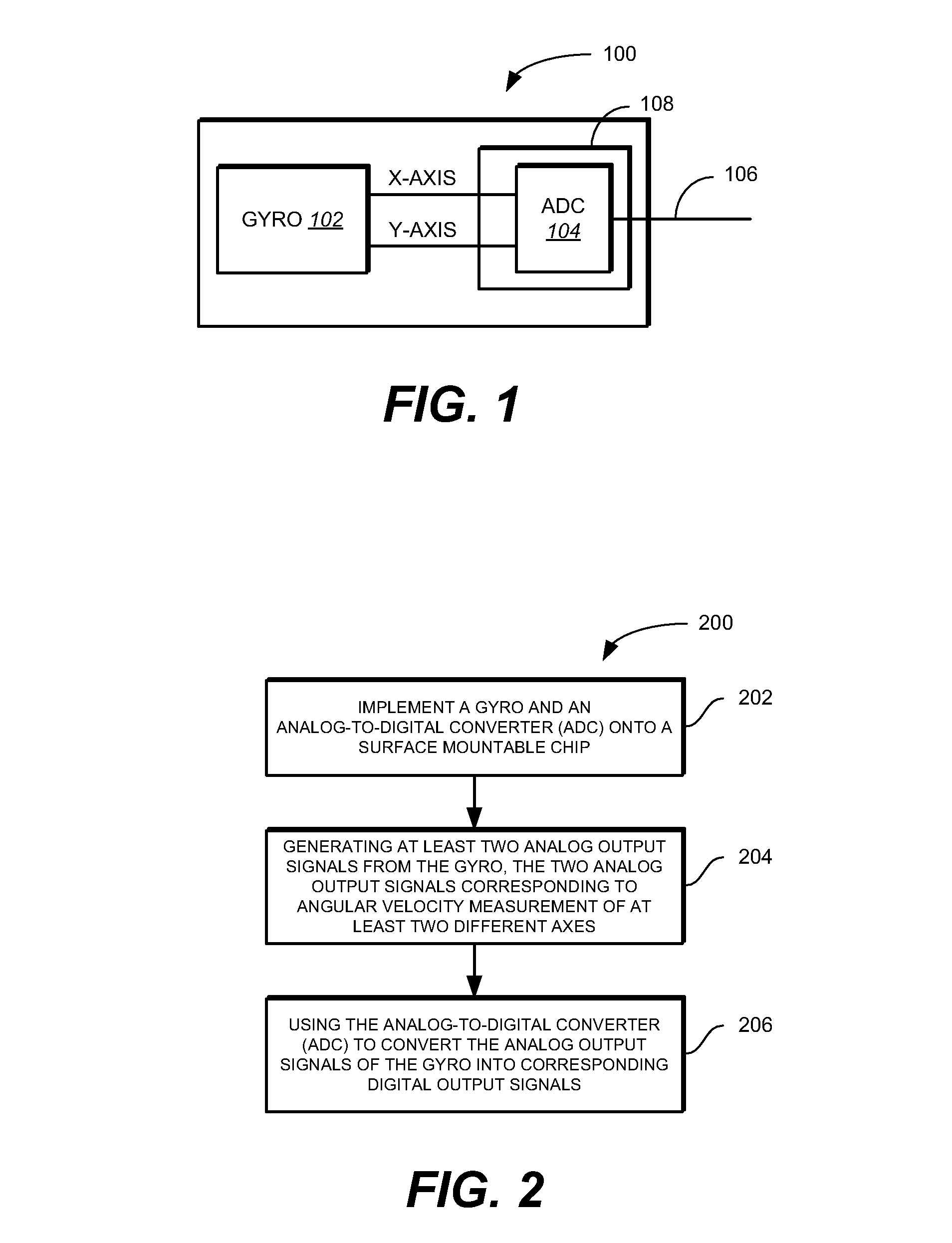

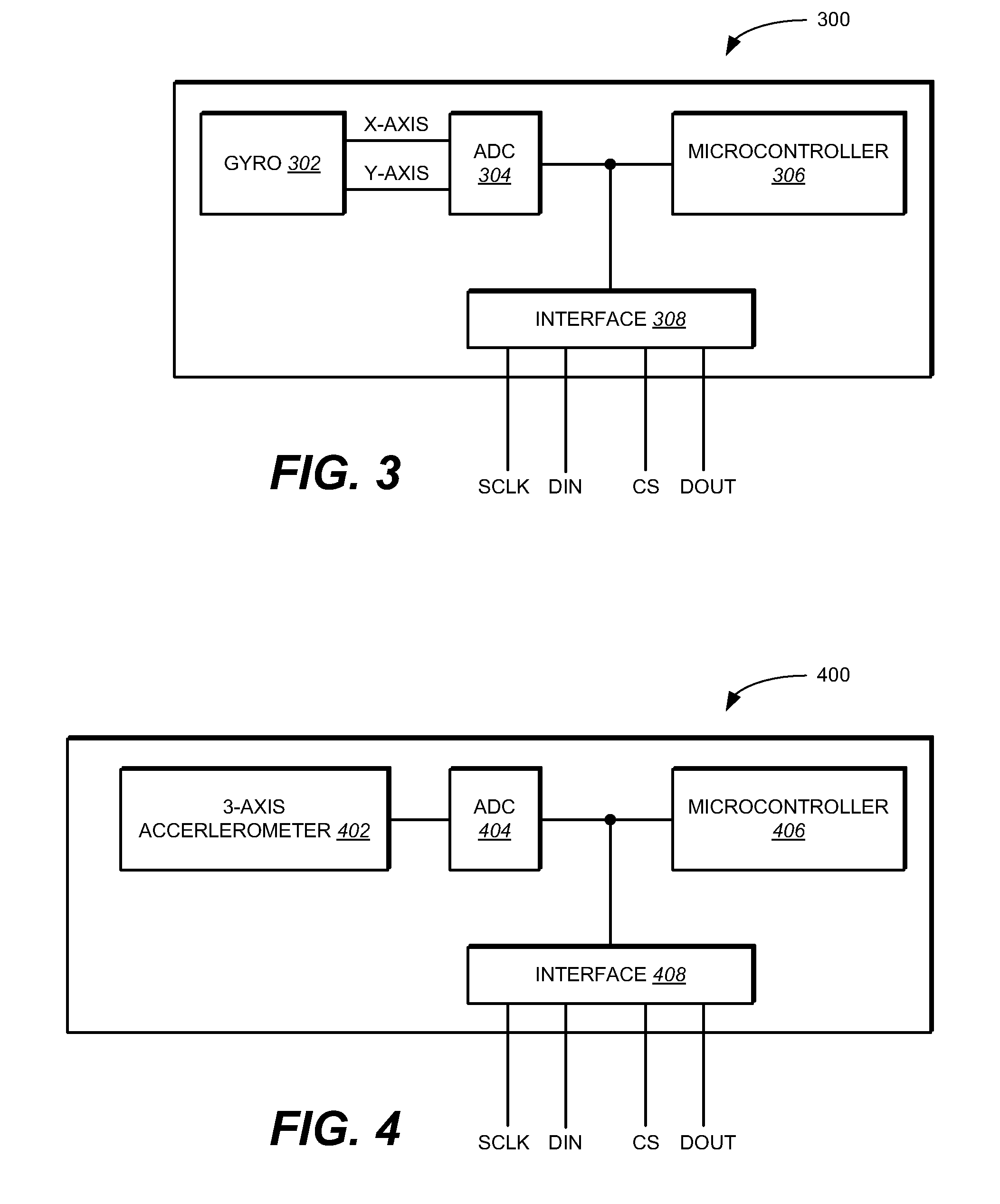

Integrated Motion Processing Unit (MPU) With MEMS Inertial Sensing And Embedded Digital Electronics

ActiveUS20090007661A1Small packageLower performance requirementsElectric signal transmission systemsAcceleration measurement using interia forcesMotion processingAccelerometer

A module operable to be mounted onto a surface of a board. The module includes a linear accelerometer to provide a first measurement output corresponding to a measurement of linear acceleration in at least one axis, and a first rotation sensor operable to provide a second measurement output corresponding to a measurement of rotation about at least one axis. The accelerometer and the first rotation sensor are formed on a first substrate. The module further includes an application specific integrated circuit (ASIC) to receive both the first measurement output from the linear accelerometer and the second measurement output from the first rotation sensor. The ASIC includes an analog-to-digital converter and is implemented on a second substrate. The first substrate is vertically bonded to the second substrate.

Owner:INVENSENSE

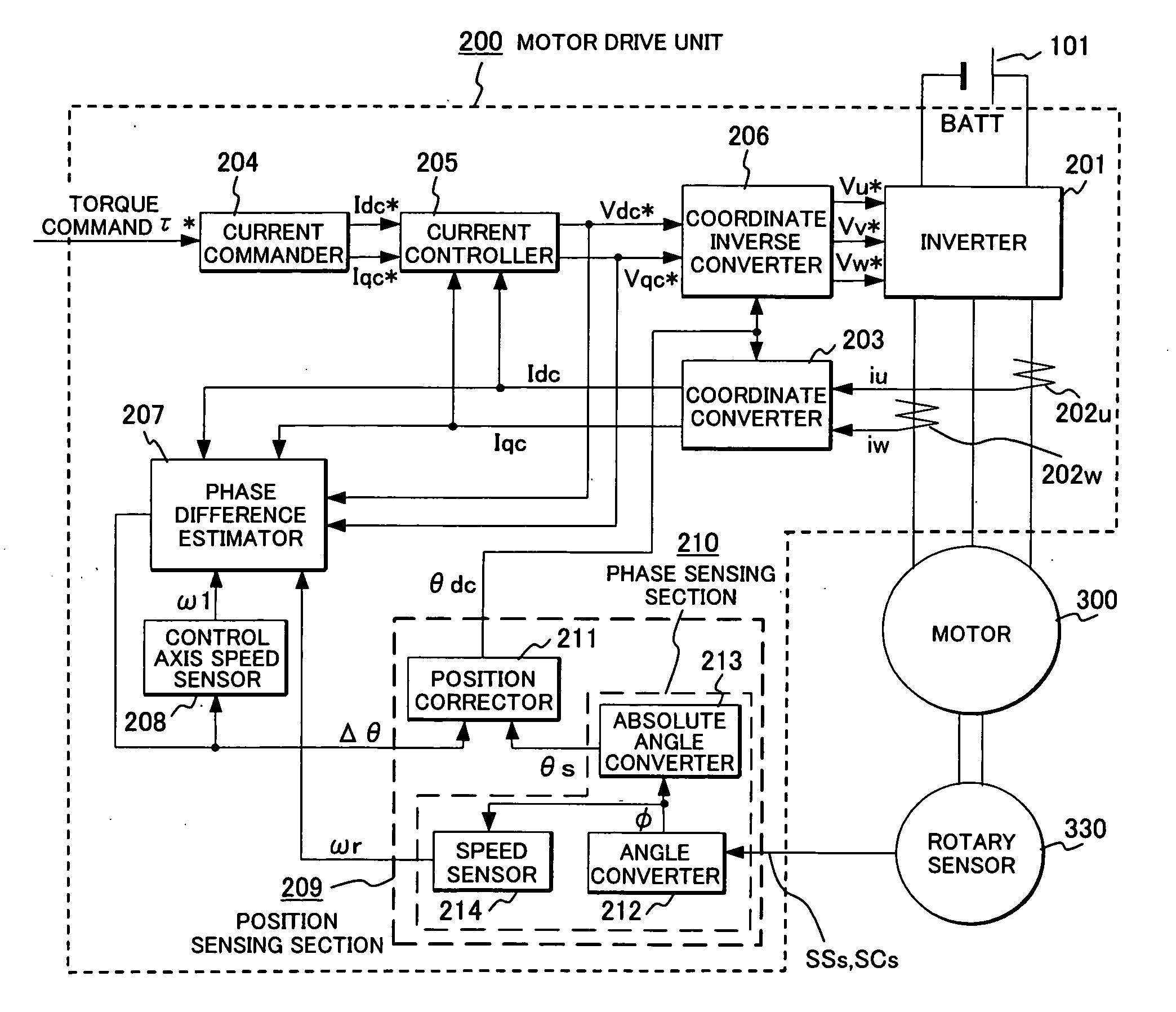

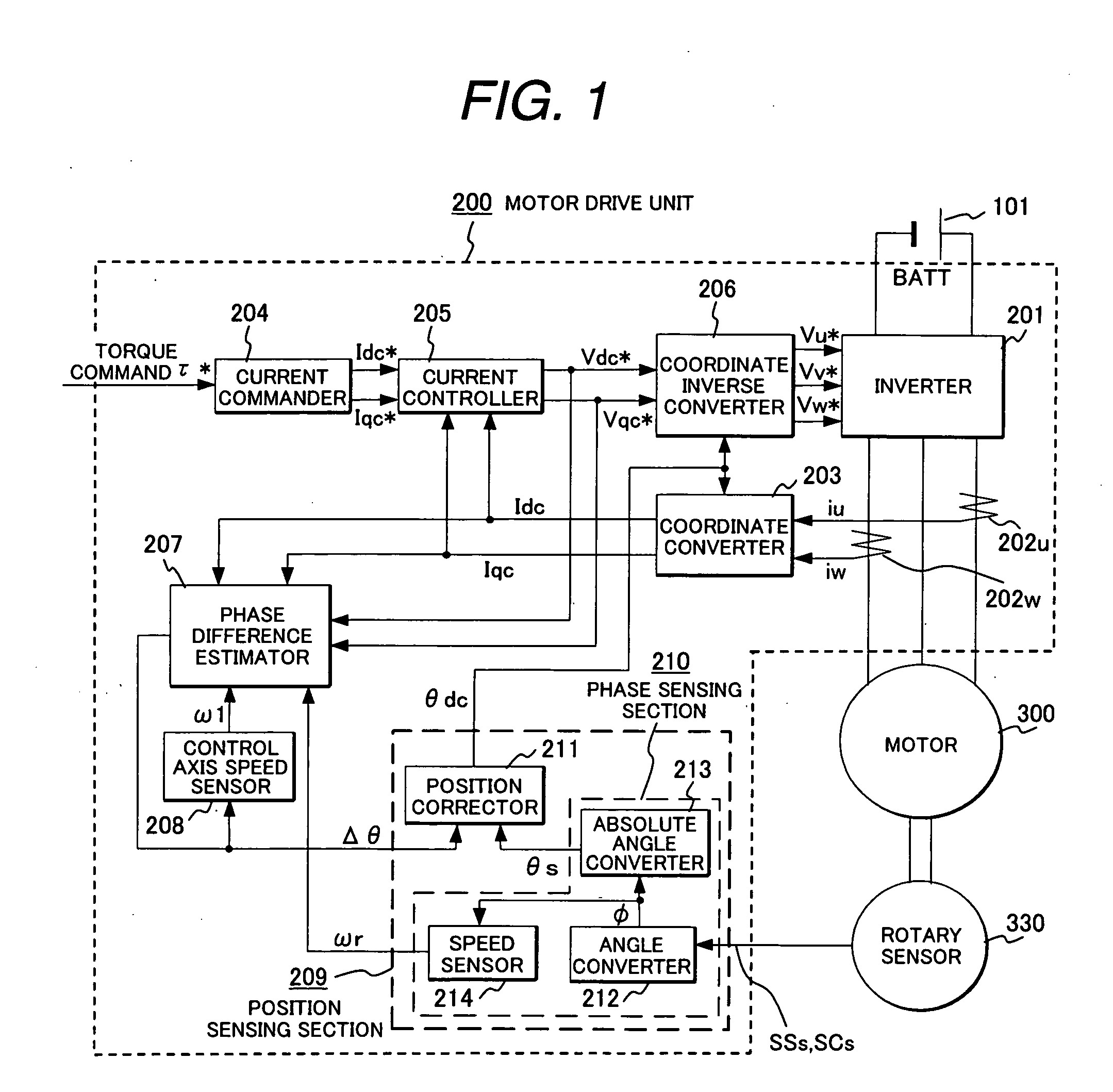

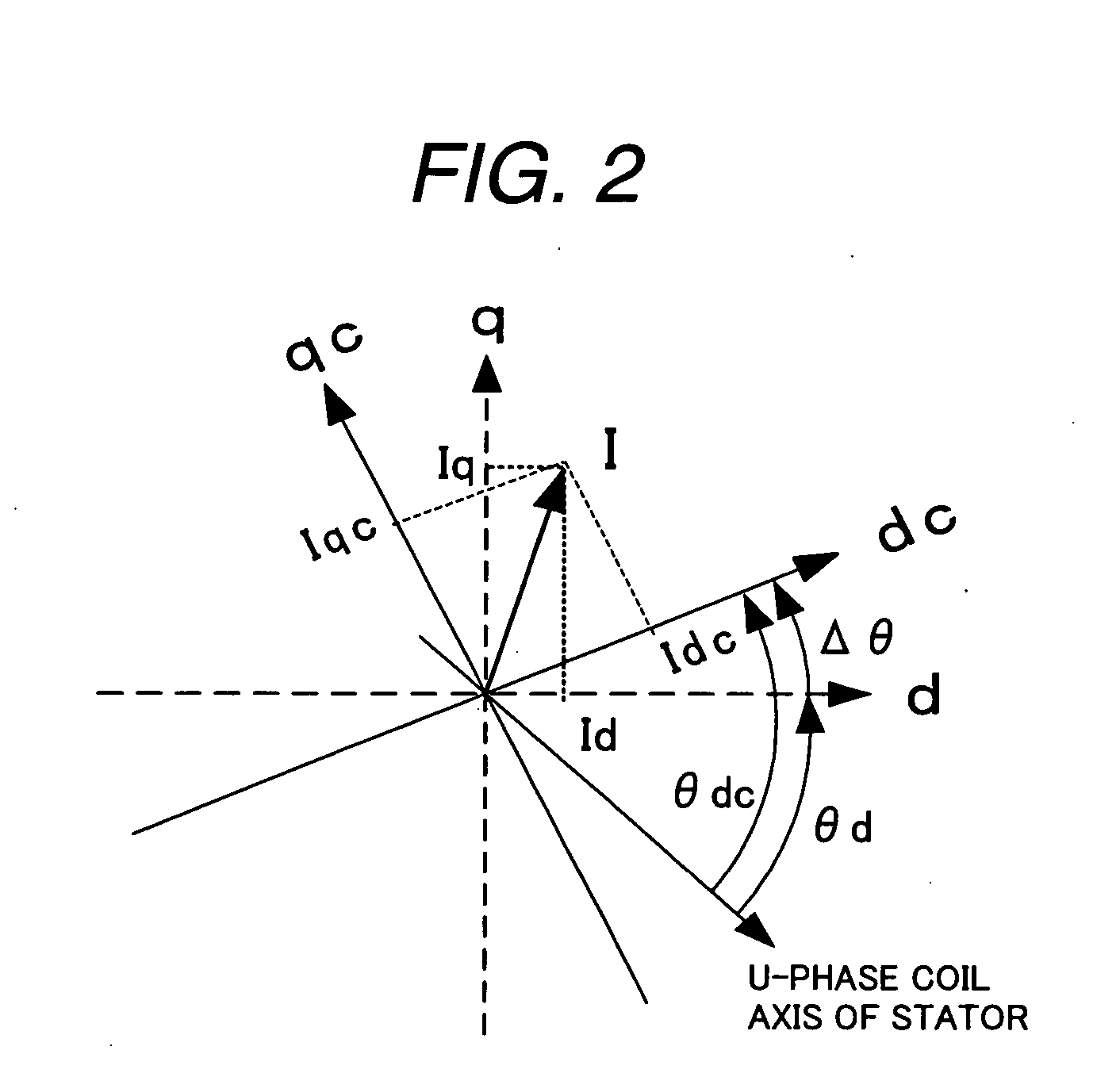

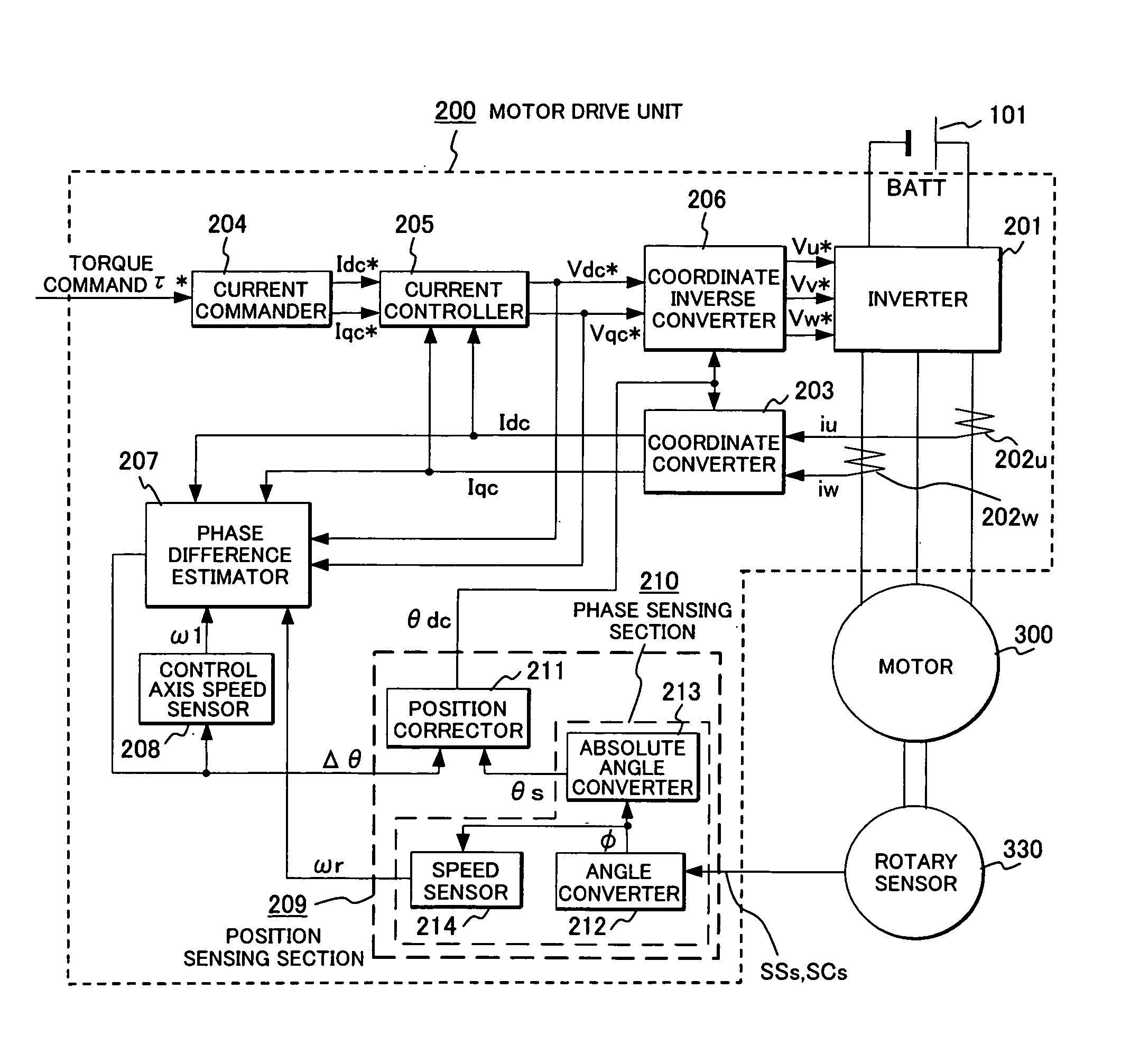

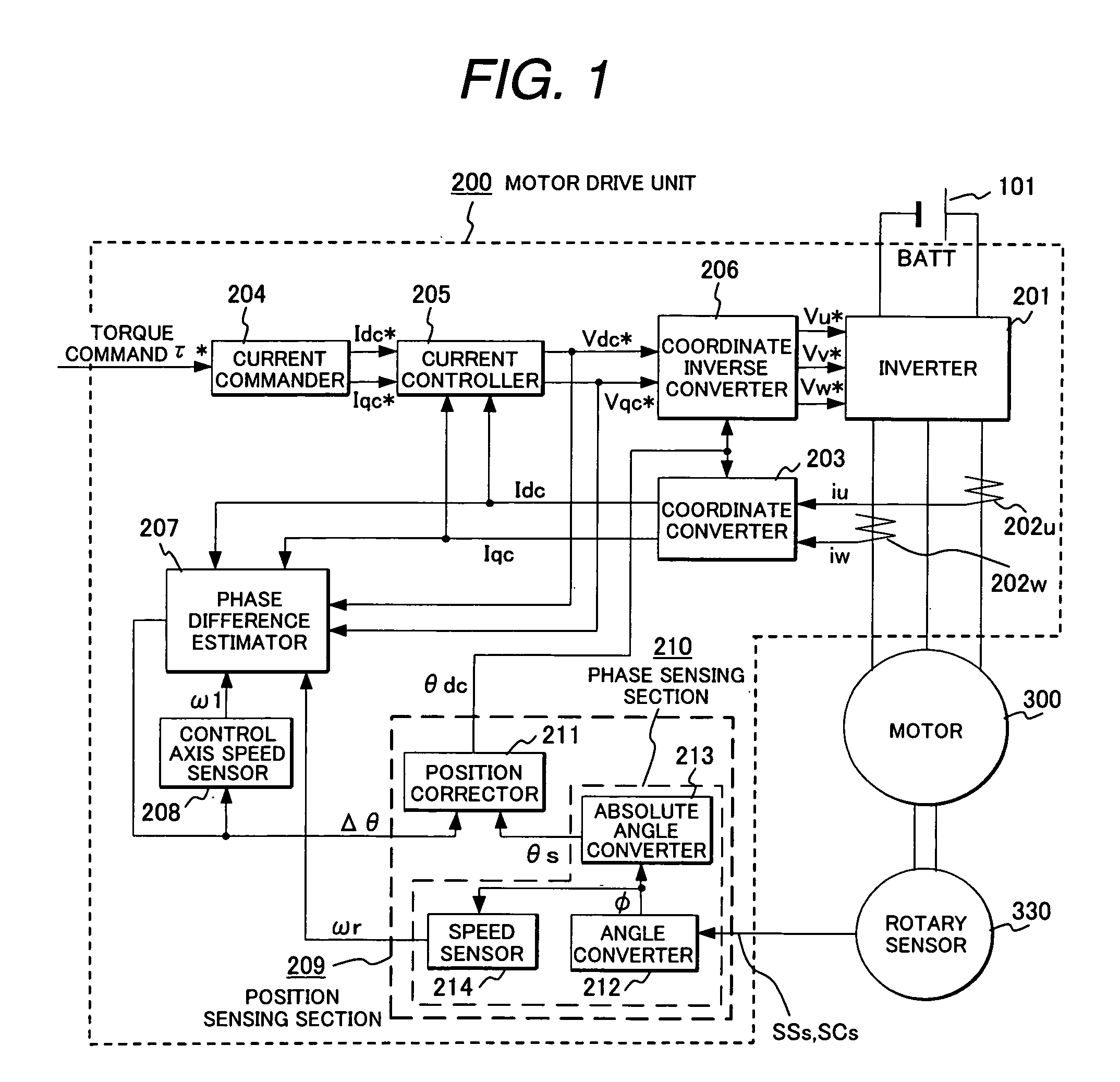

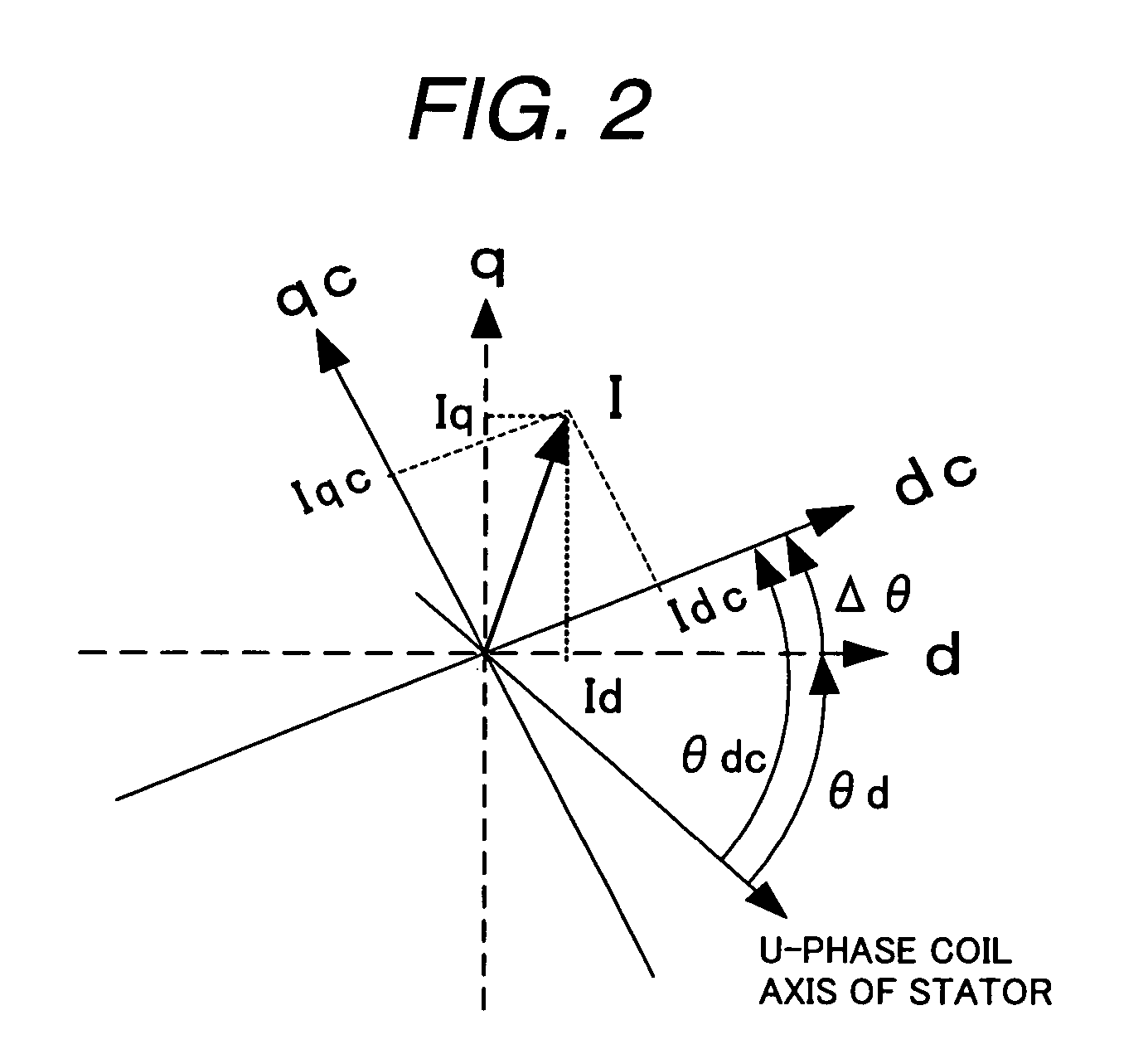

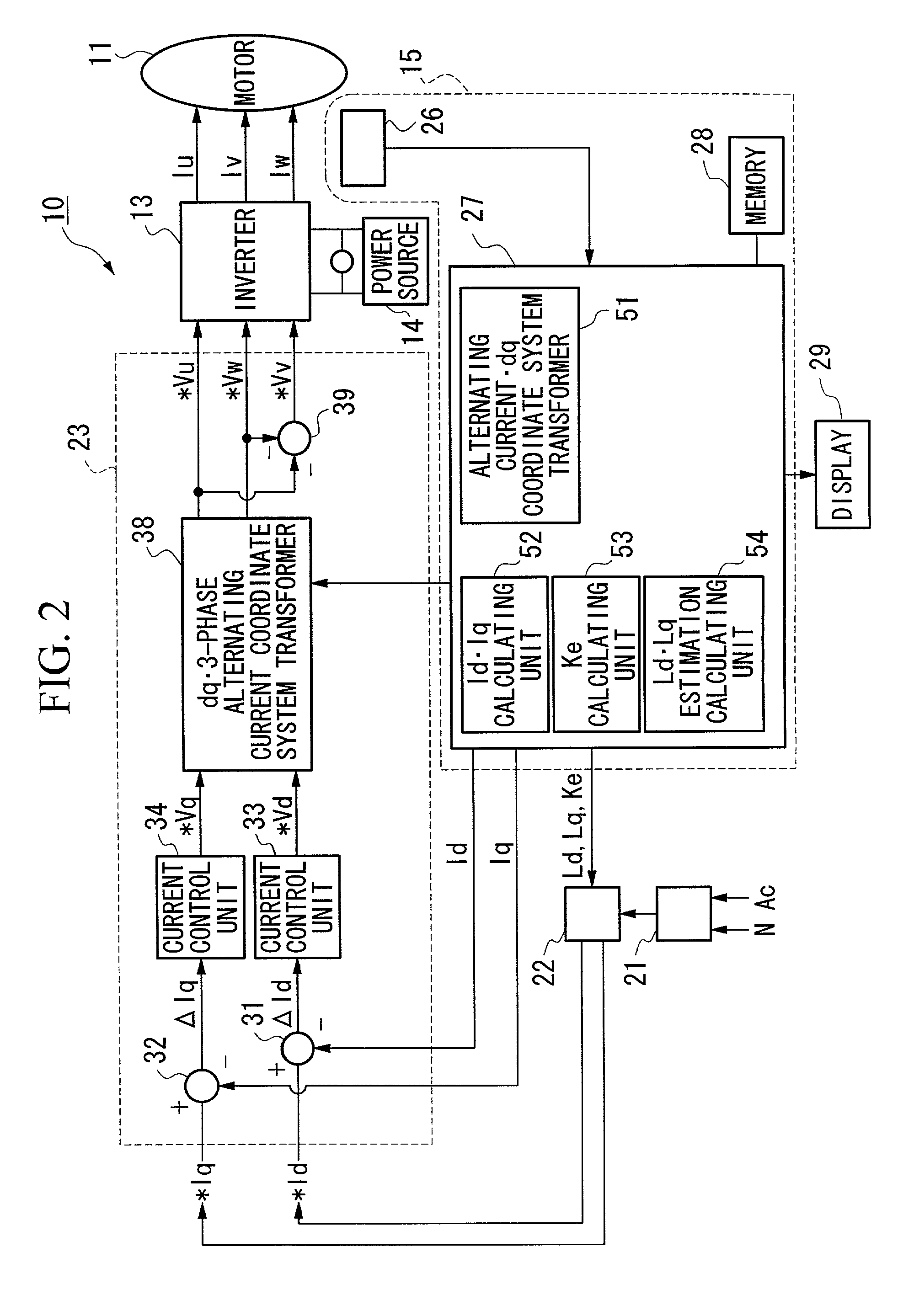

Synchronous motor drive unit and a driving method thereof

InactiveUS20060125439A1Efficient driveImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorPhase difference

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position. A high-efficiency motor drive unit with improved maintainability of rotary sensor and improved accuracy of sensing the magnet pole position of a permanent magnet synchronous motor that accelerates and decelerates very quickly in a wide range of speed is realized.

Owner:HITACHI LTD

Integrated motion processing unit (MPU) with MEMS inertial sensing and embedded digital electronics

ActiveUS8250921B2Low costSmall packageElectric signal transmission systemsSpeed/acceleration/shock instrument detailsMotion processingAccelerometer

Owner:INVENSENSE

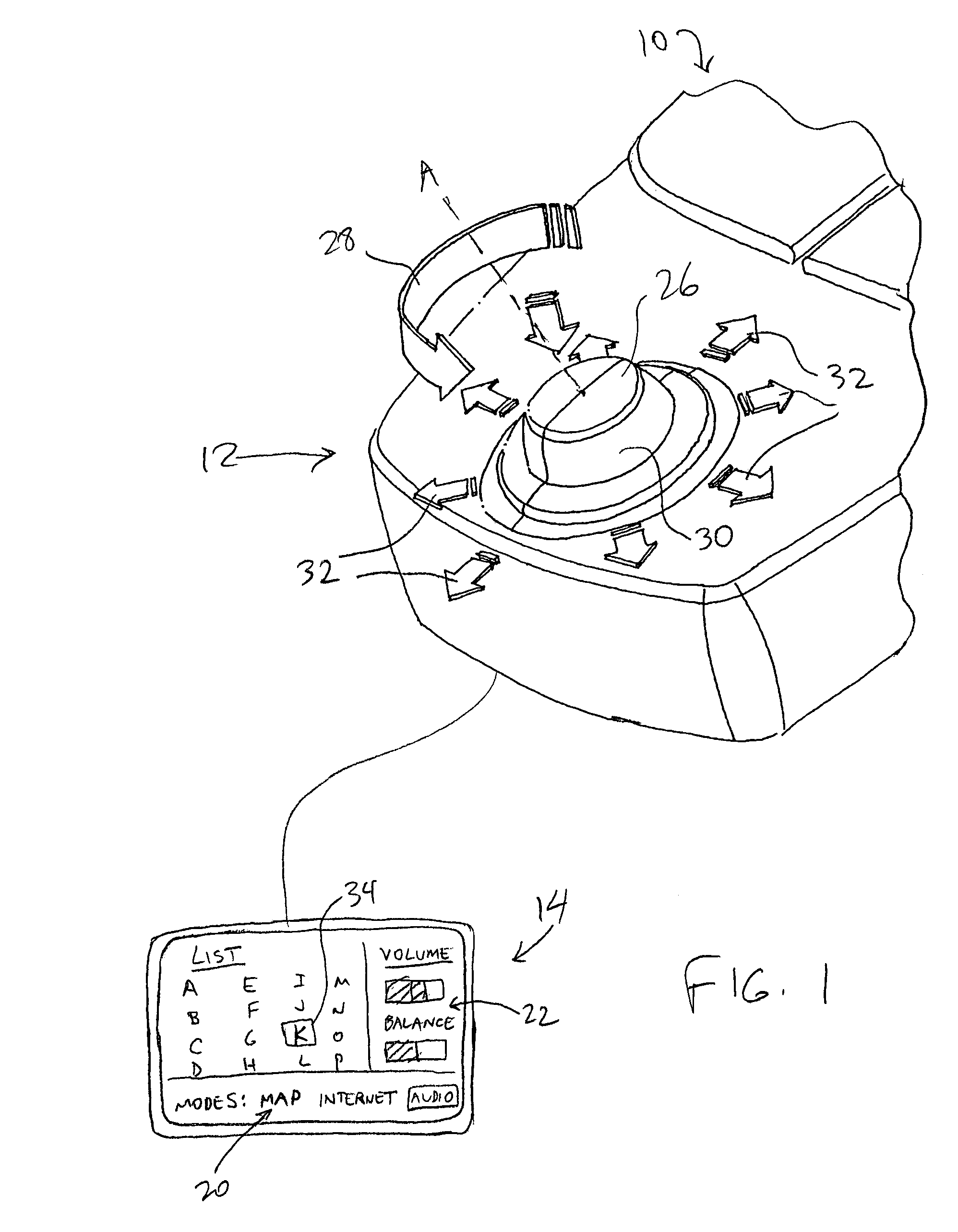

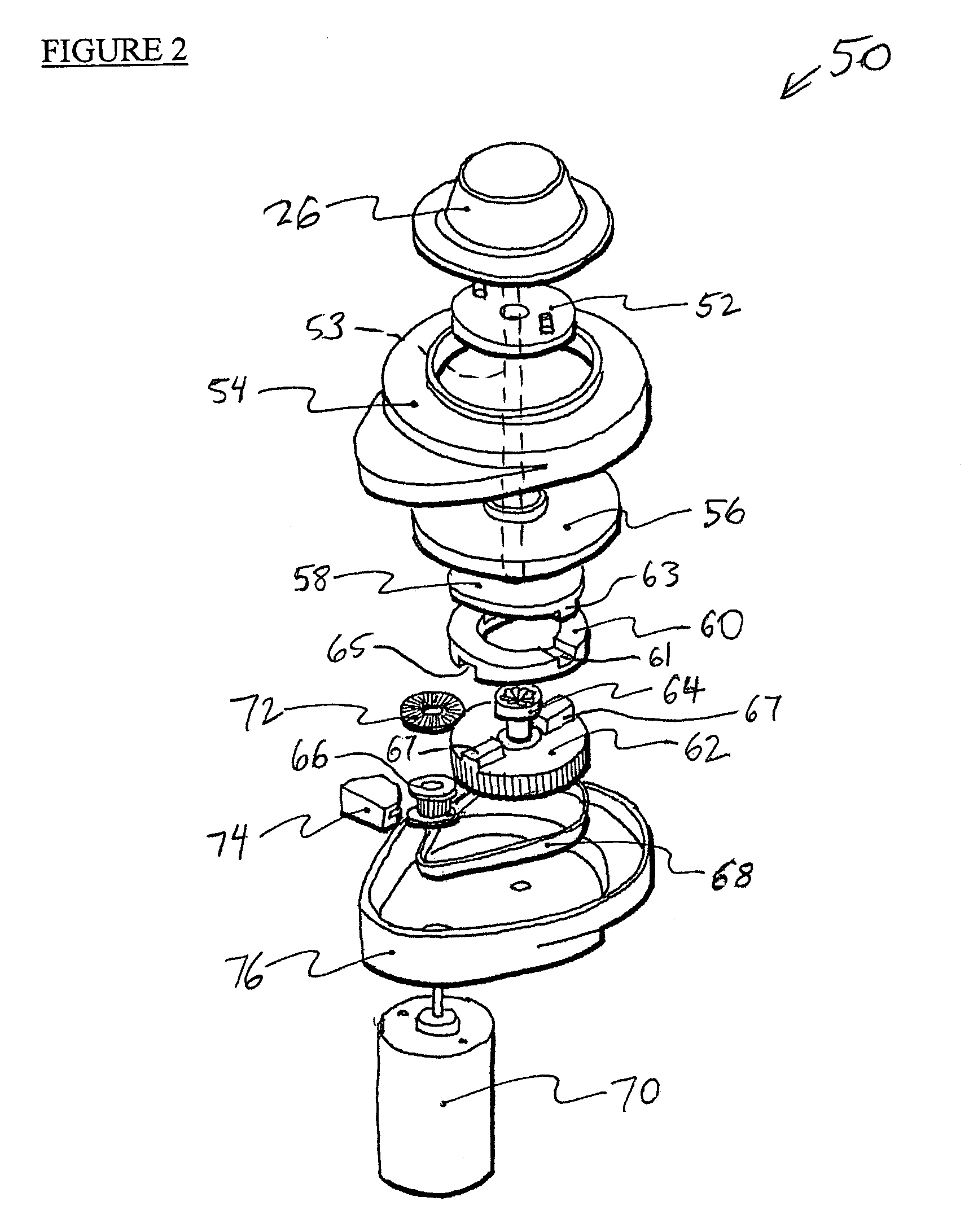

Mechanisms for control knobs and other interface devices

InactiveUS7038667B1Strong control functionGreat easeCathode-ray tube indicatorsElectrical haptic/tactile feedbackRotational axisLinear motion

Mechanisms for a control knob or other interface device providing additional degrees of freedom for the knob. One embodiment provides a rotatable knob moveable also in a lateral plane approximately perpendicular to the axis of rotation. A mechanism providing the lateral motion can include a gate member and a plunger member that engages grooves in the gate member. A rotational sensor detects a rotational position and a lateral sensor can detect a lateral position of the knob. Another embodiment provides an actuator that includes a shaft that is coaxial with the axis of rotation and which can be moved linearly along the axis of rotation with respect to actuator housing to accommodate linear motion of the knob. In another embodiment, a gear assembly including two interlocked gears is provided to transmit rotational motion from the knob to the sensor, and the interlocked gears translate with respect to each other when the knob is translated along the rotational axis.

Owner:IMMERSION CORPORATION

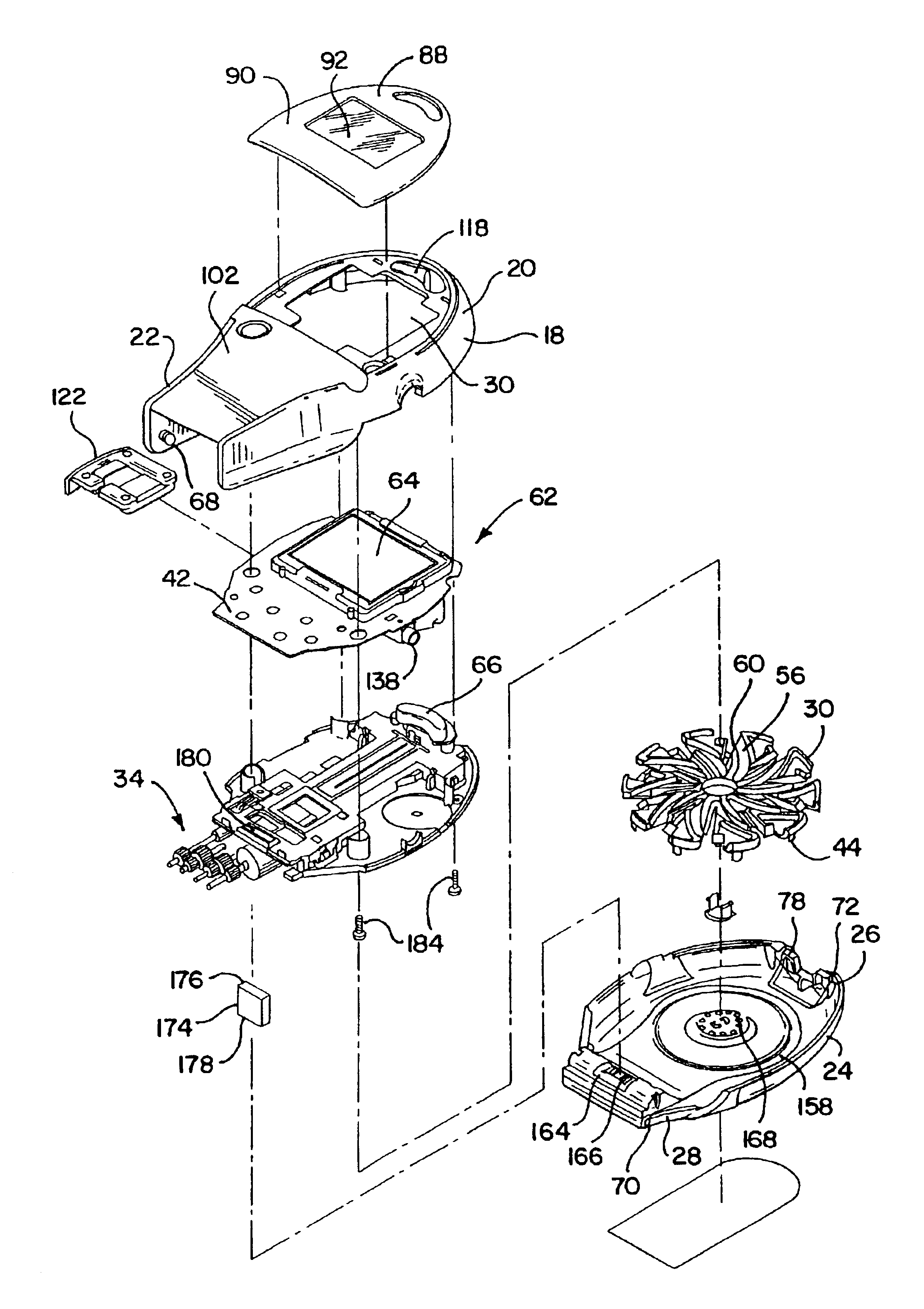

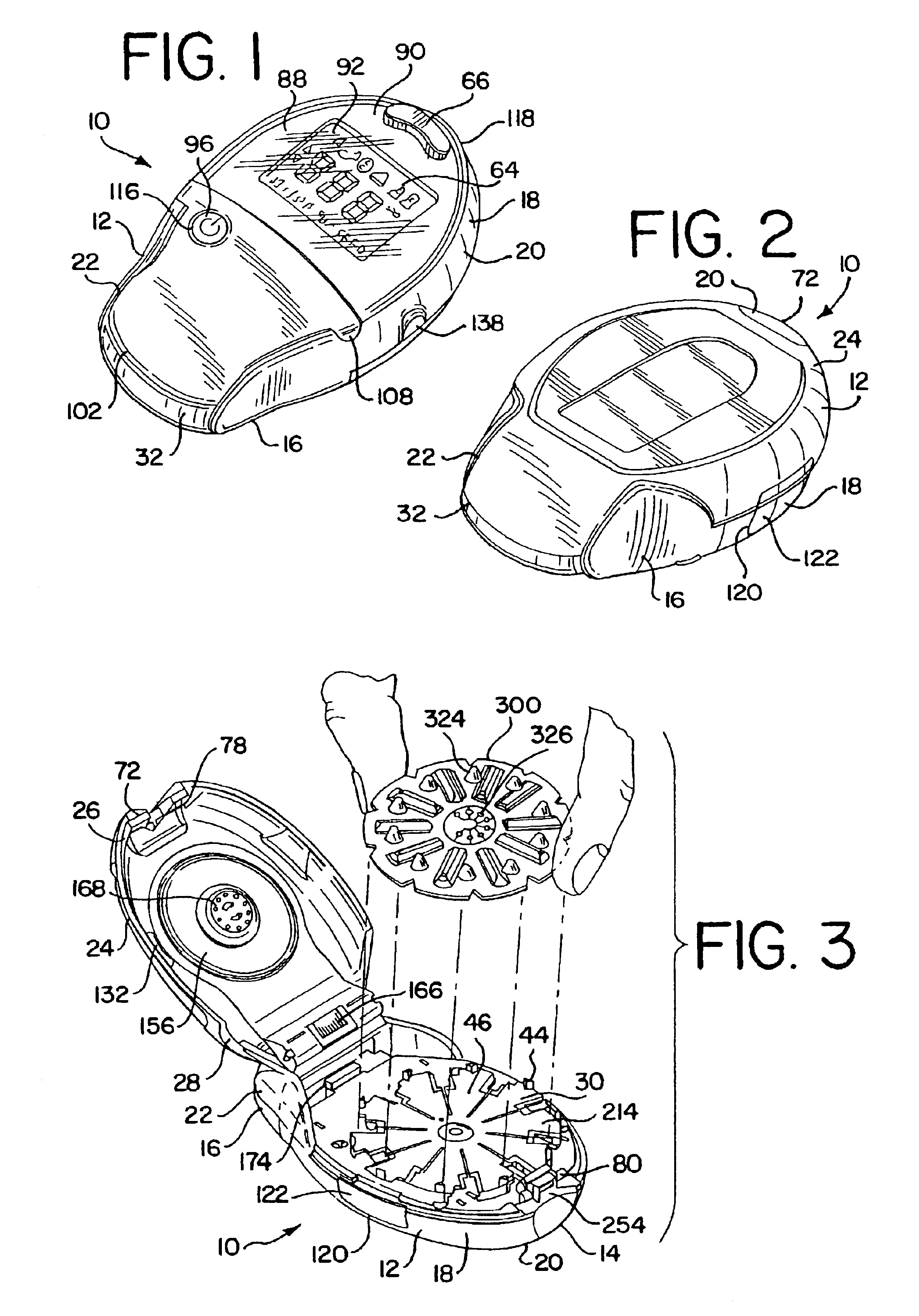

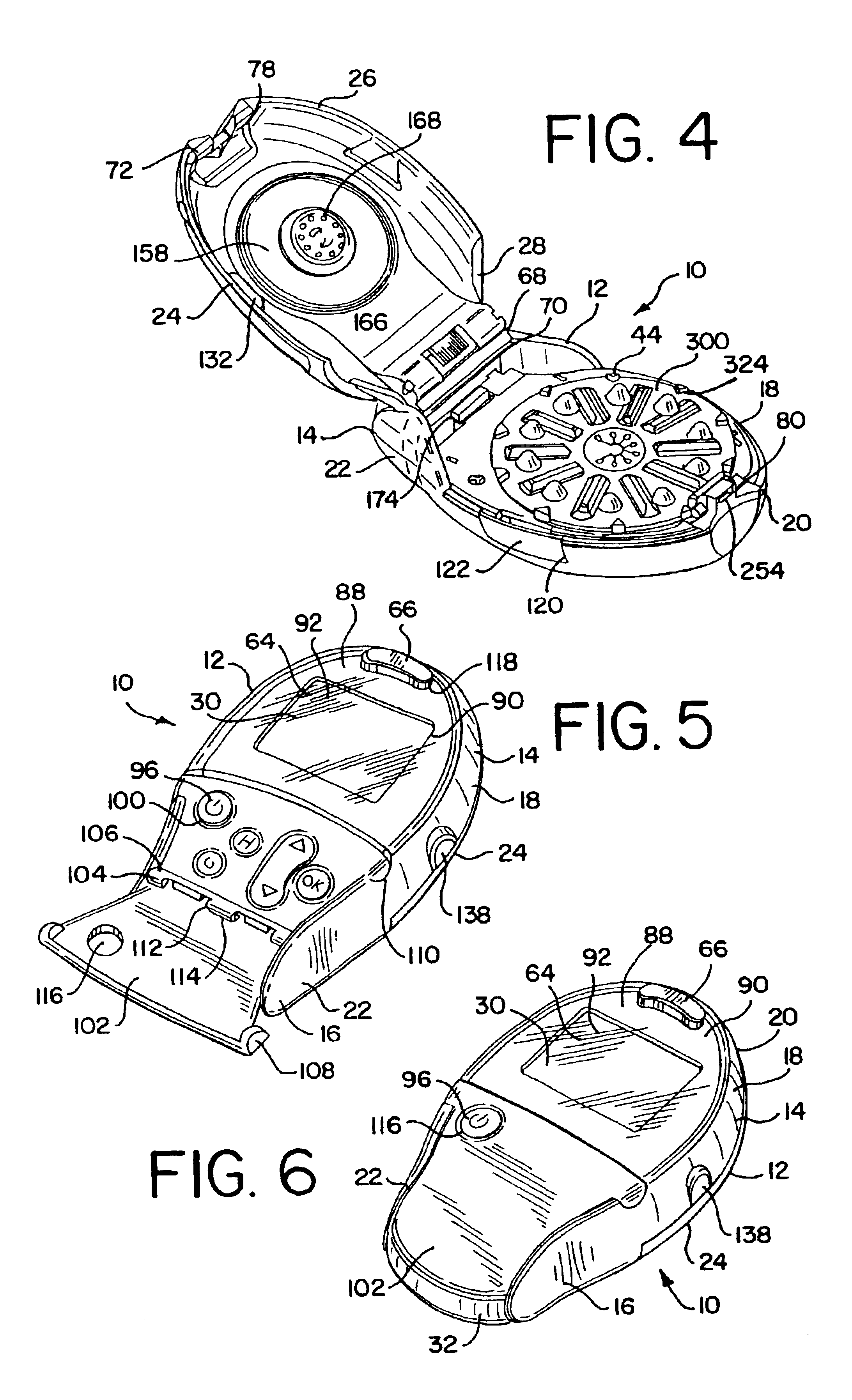

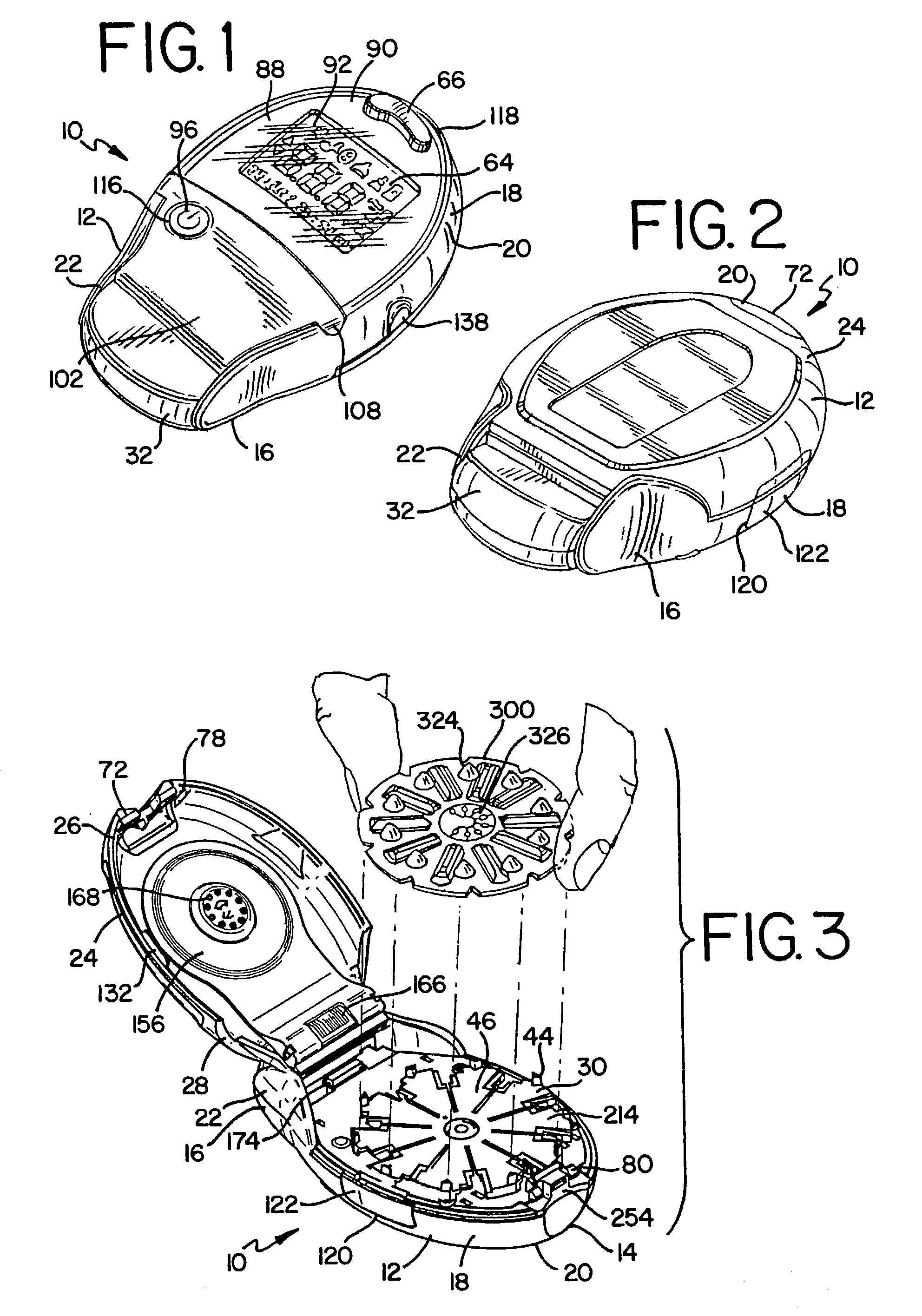

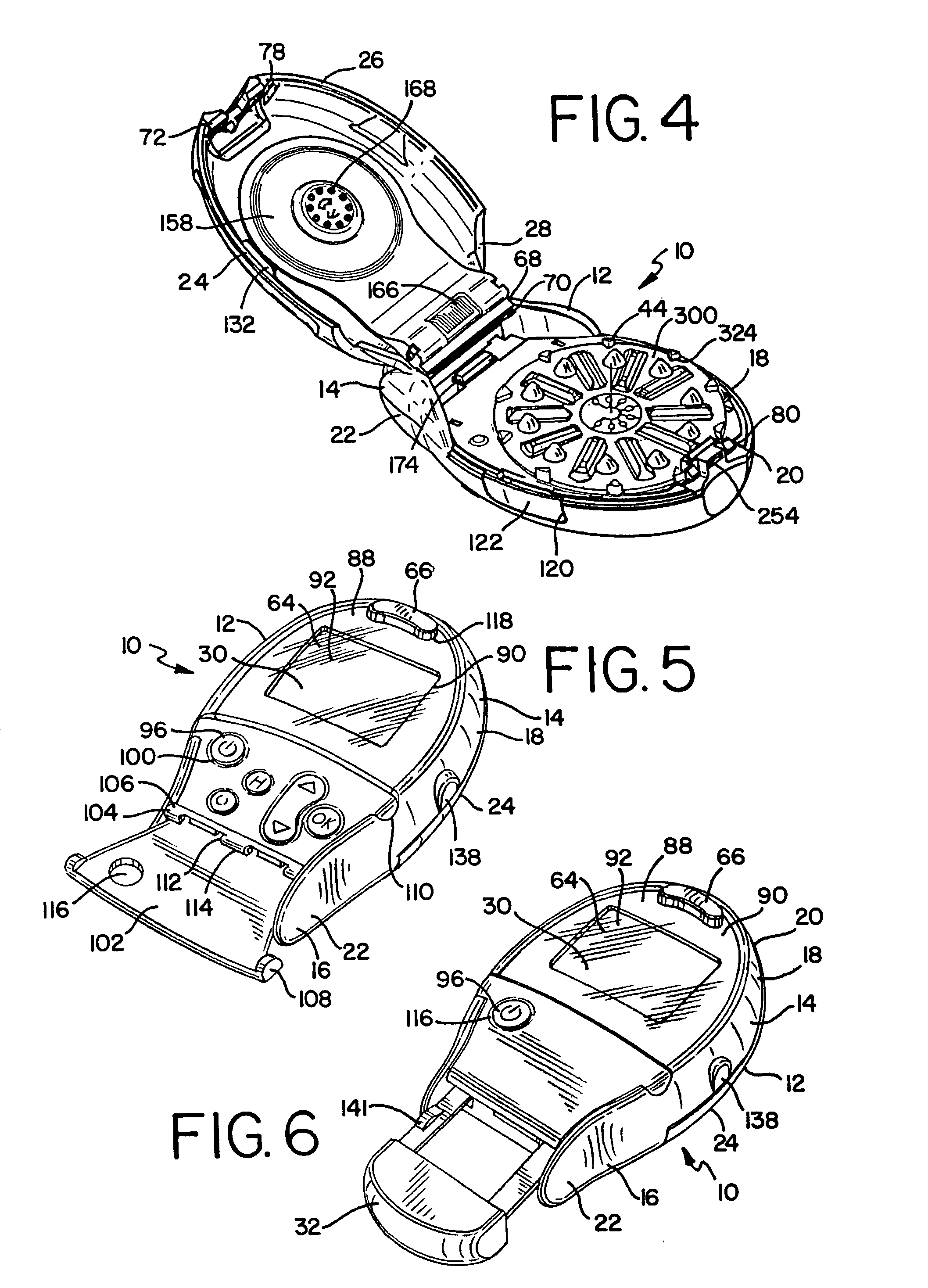

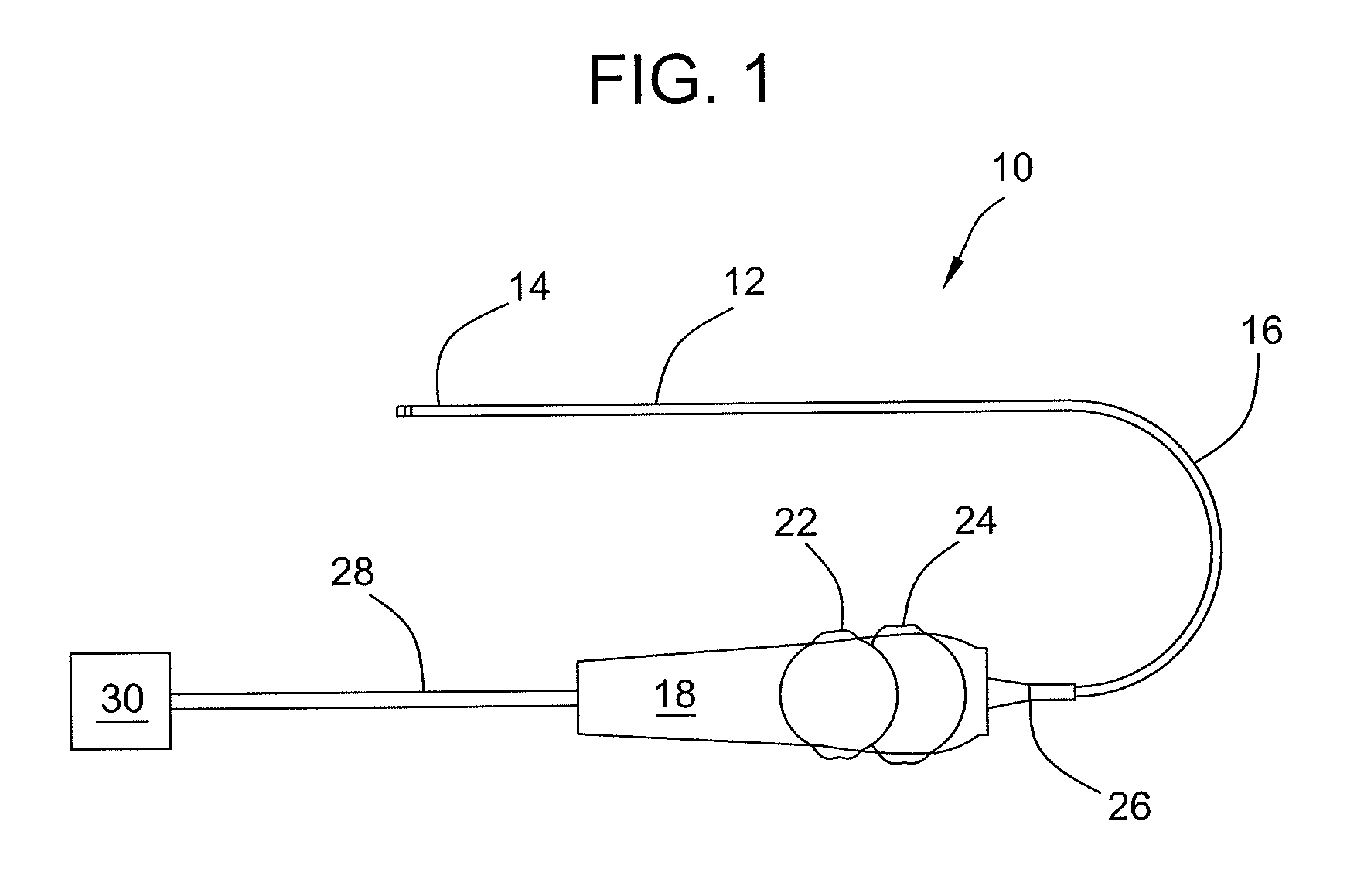

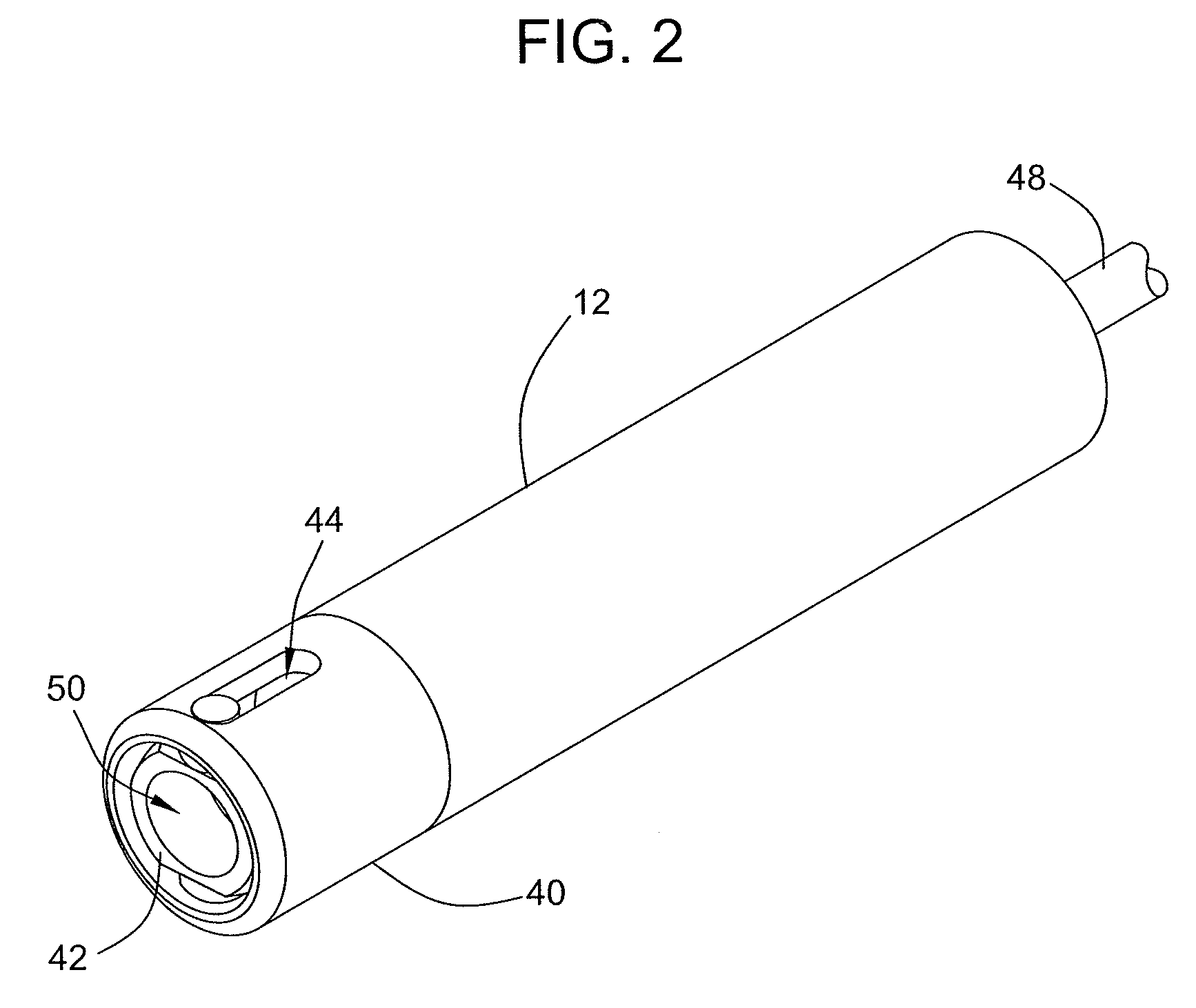

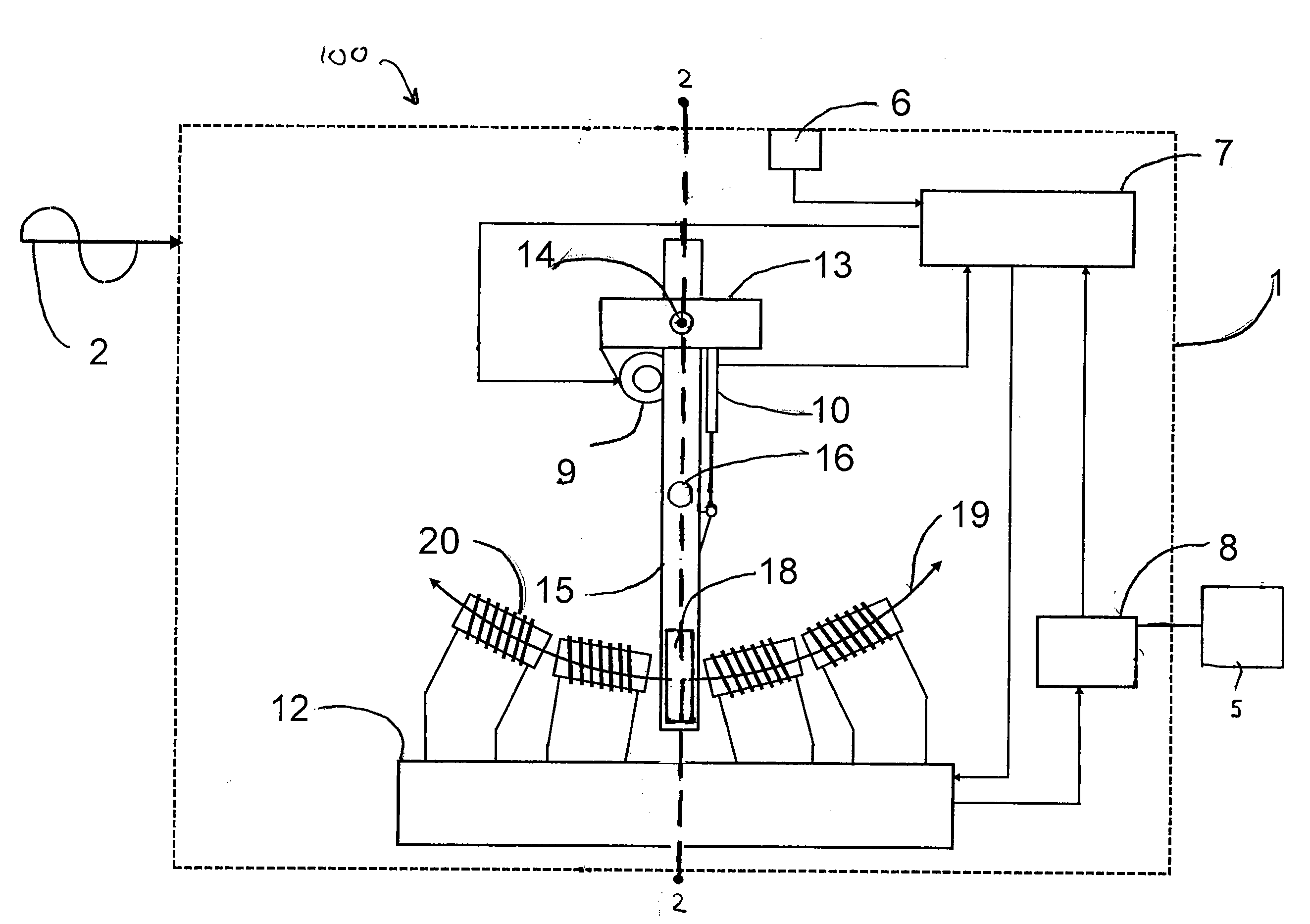

Automated mechanical mechanism for a blood glucose sensor dispensing instrument

ActiveUS6997344B2Easy to operateReduce the possibilityCoin-freed apparatus detailsBiological testingGlucose sensorsEngineering

A sensor dispensing instrument adapted to handle a sensor pack containing a plurality of sensors and to perform a test using one of the sensors. The sensor dispensing instrument includes an outer housing and a disk drive mechanism contained therein for rotating the sensor pack and ejecting one of the sensors from the sensor pack and through a sensor opening on the housing. The disk drive mechanism of the sensor dispensing instrument is operated by pressing a button which activates a motor. The motor moves a disk drive pusher in a first direction to rotate the sensor pack, and then moves the disk drive pusher in a second direction to eject a sensor from the sensor cavity and through the sensor opening.

Owner:ASCENSIA DIABETES CARE HLDG AG

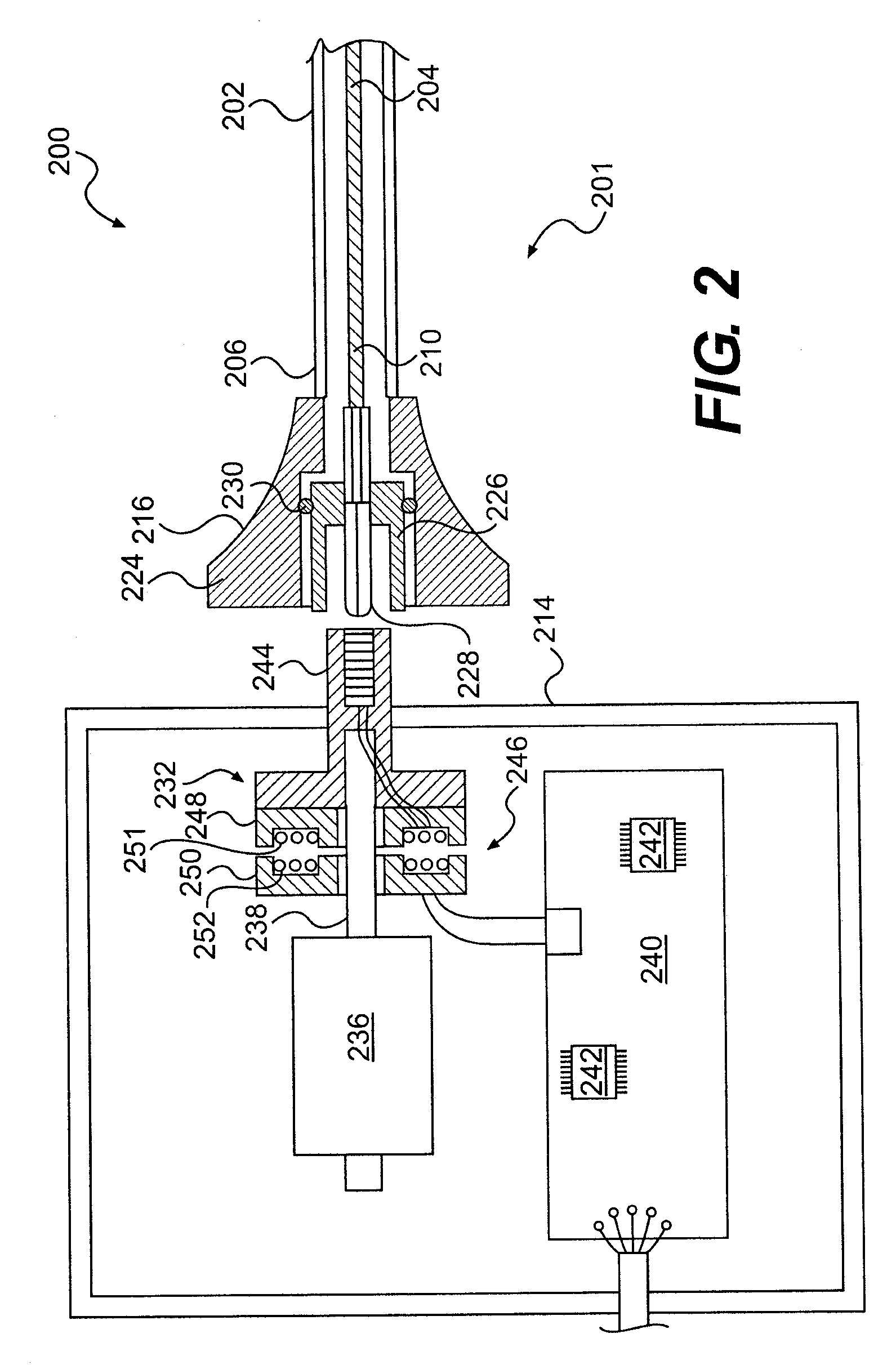

Rotational intravascular ultrasound probe with an active spinning element

ActiveUS20100234736A1Improve image qualityAccurate diagnosis of medicalCatheterInfrasonic diagnosticsManufacturing cost reductionSonification

An intravascular ultrasound probe is disclosed, incorporating features for utilizing an advanced transducer technology on a rotating transducer shaft. In particular, the probe accommodates the transmission of the multitude of signals across the boundary between the rotary and stationary components of the probe required to support an advanced transducer technology. These advanced transducer technologies offer the potential for increased bandwidth, improved beam profiles, better signal to noise ratio, reduced manufacturing costs, advanced tissue characterization algorithms, and other desirable features. Furthermore, the inclusion of electronic components on the spinning side of the probe can be highly advantageous in terms of preserving maximum signal to noise ratio and signal fidelity, along with other performance benefits.

Owner:VOLCANO CORP

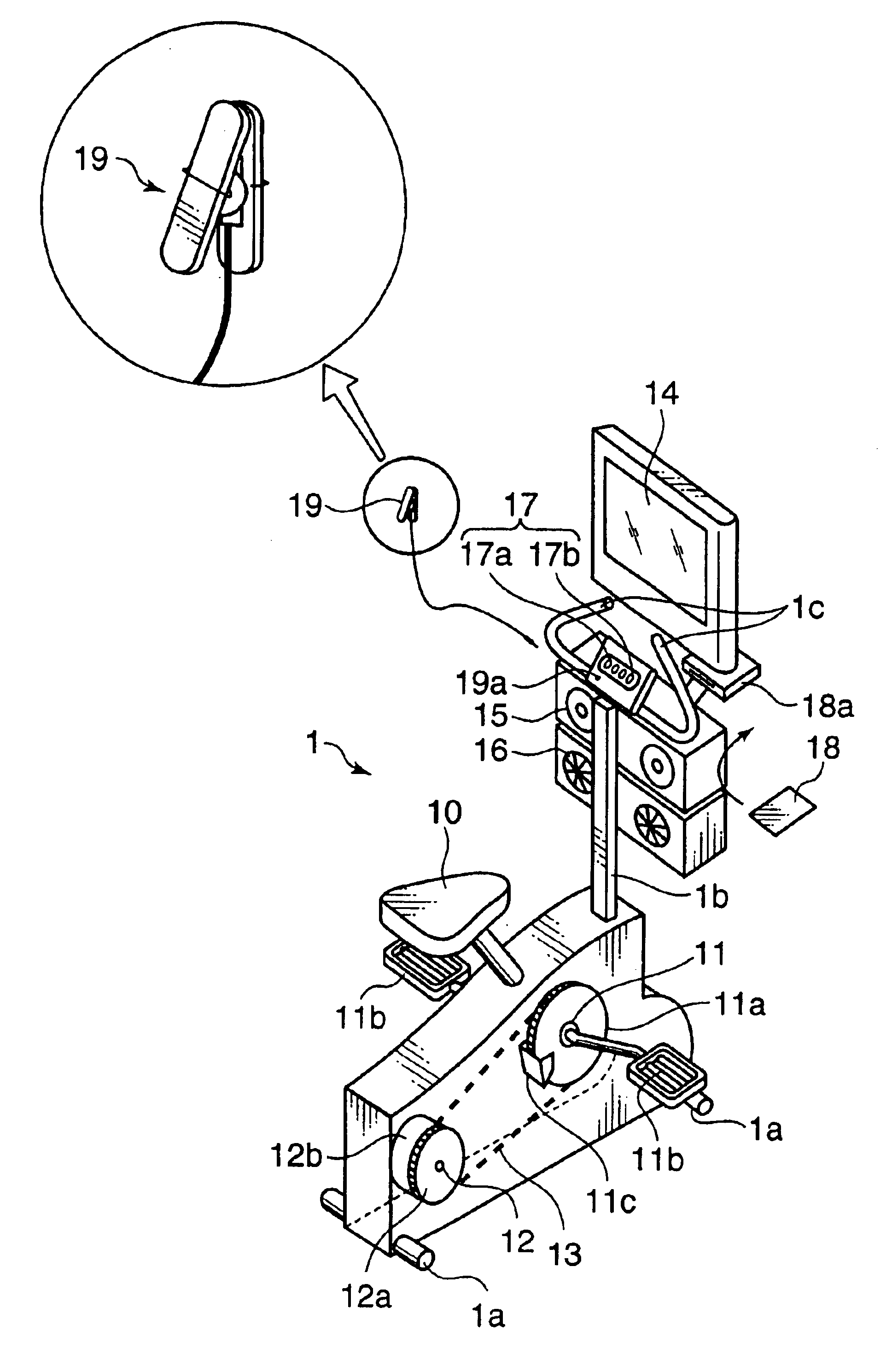

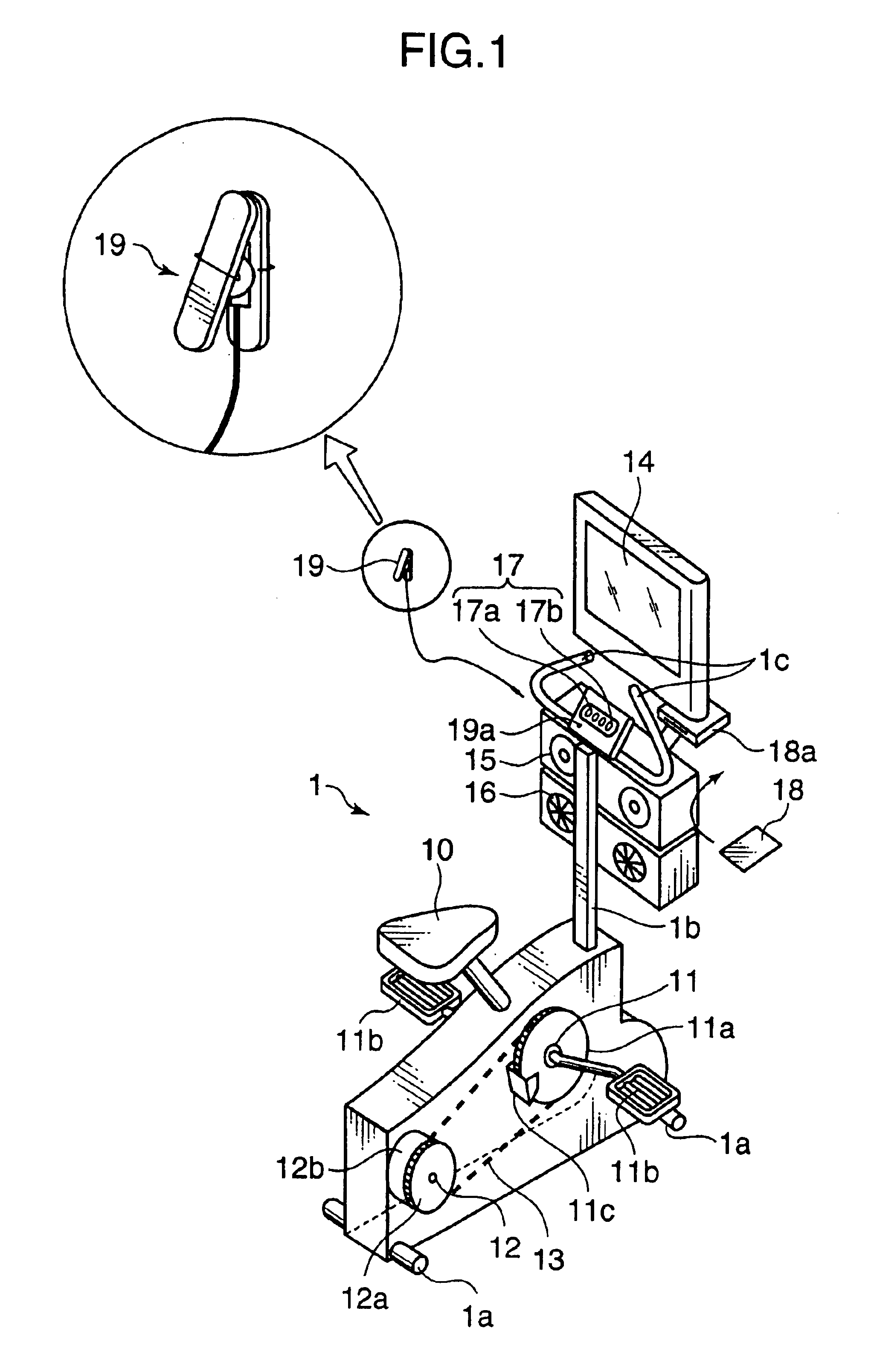

Exercise assisting method and apparatus implementing such method

Owner:KONAMI SPORTS & LIFE

Exercise assistance apparatus

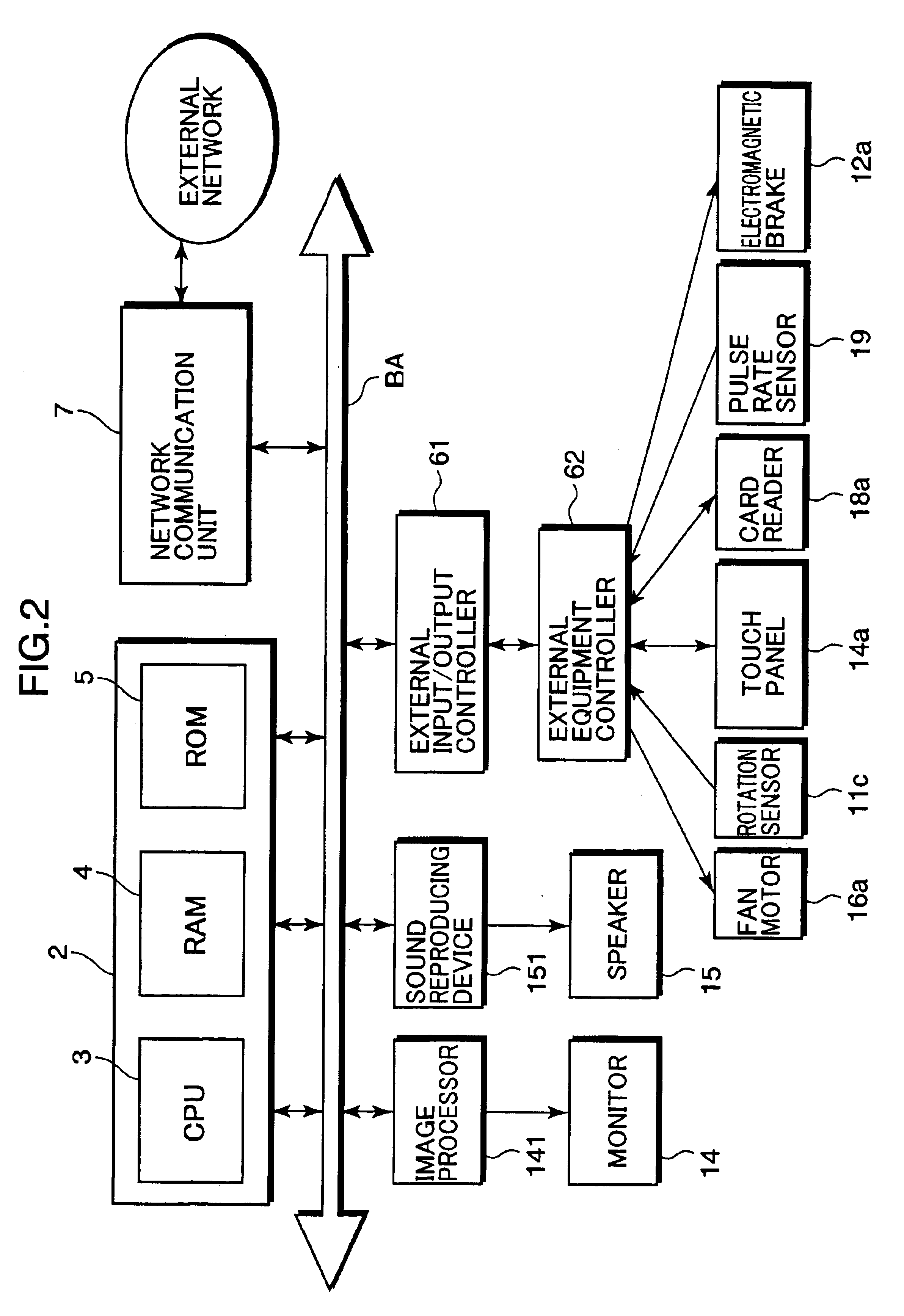

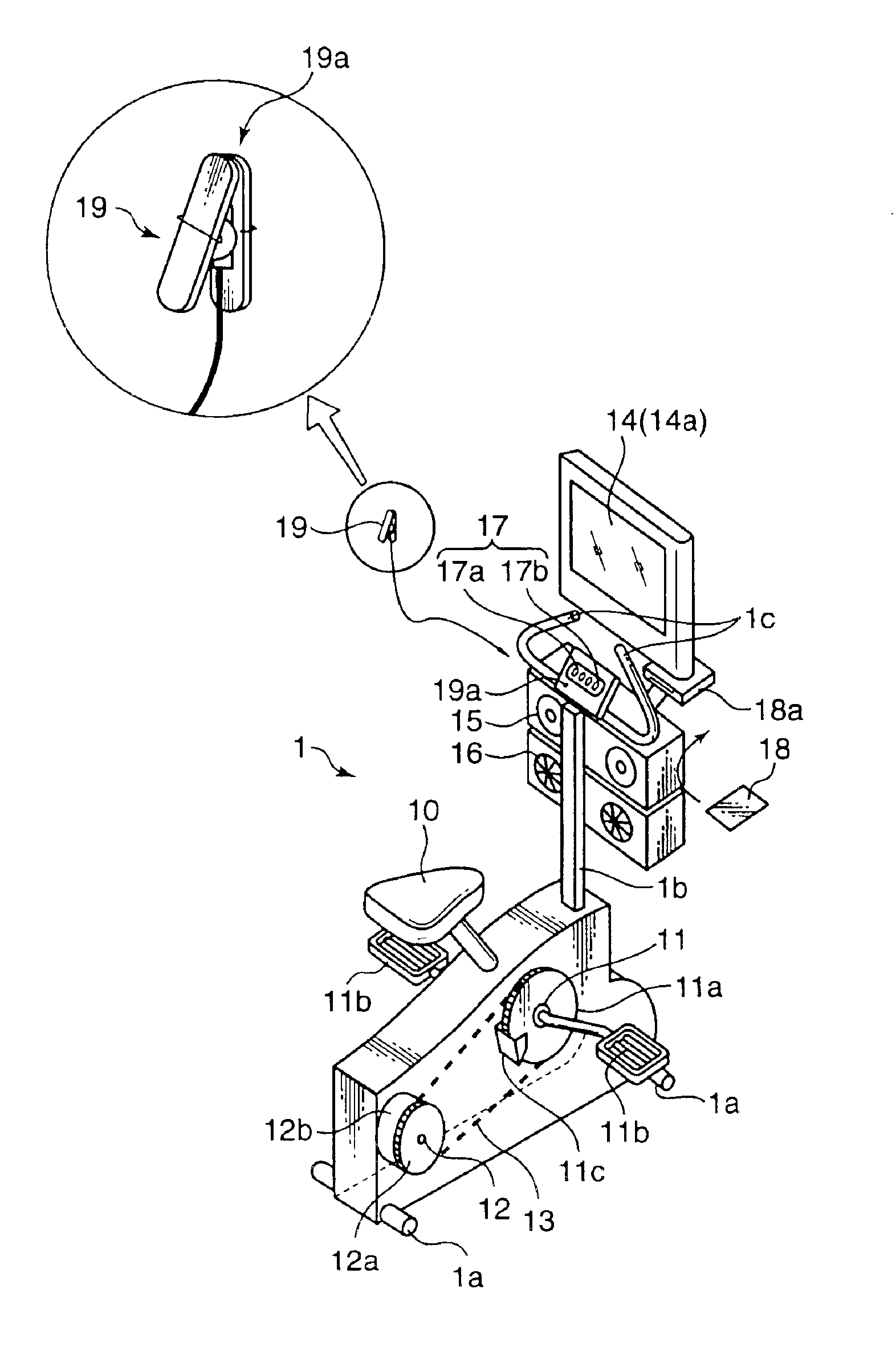

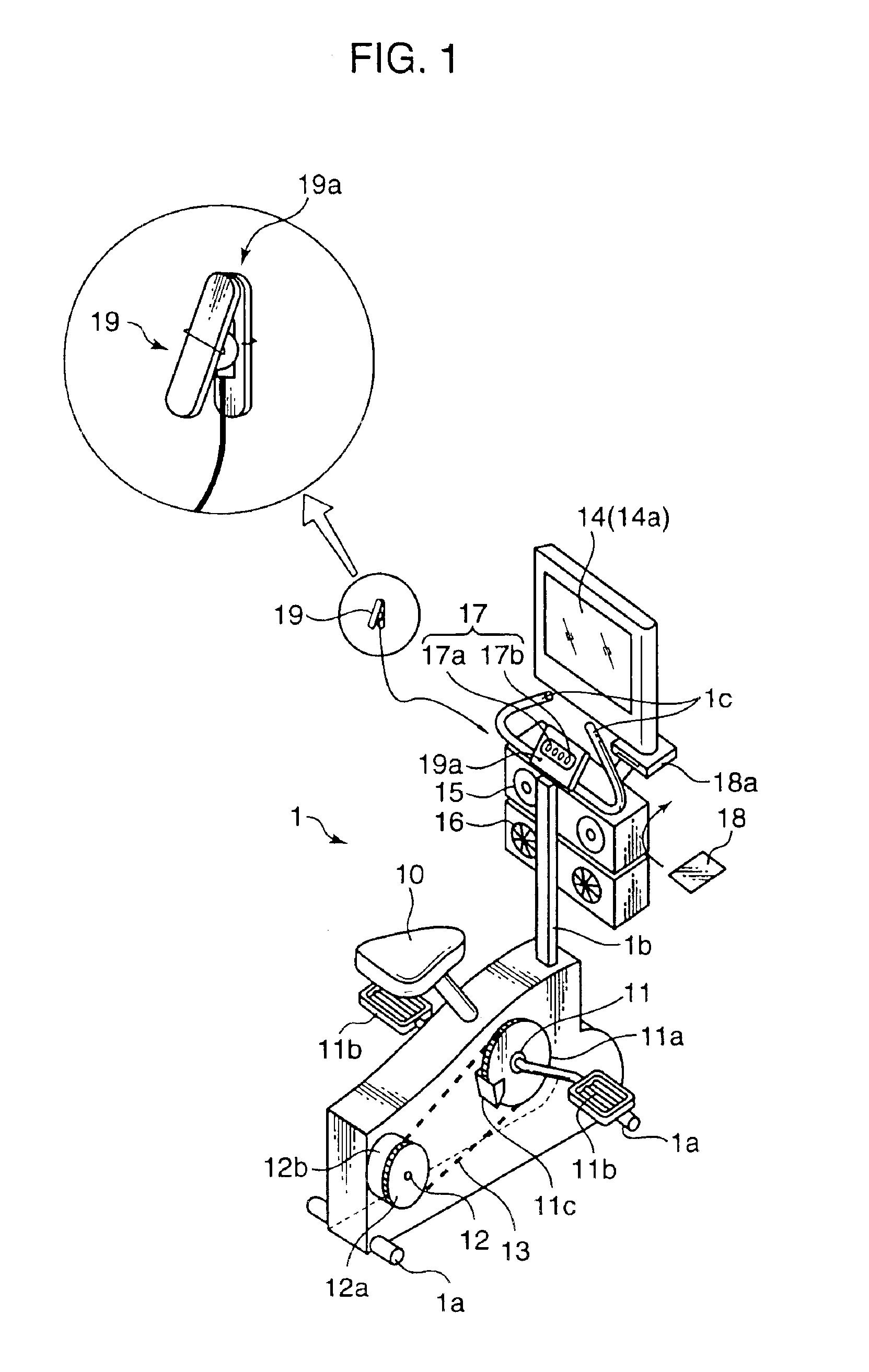

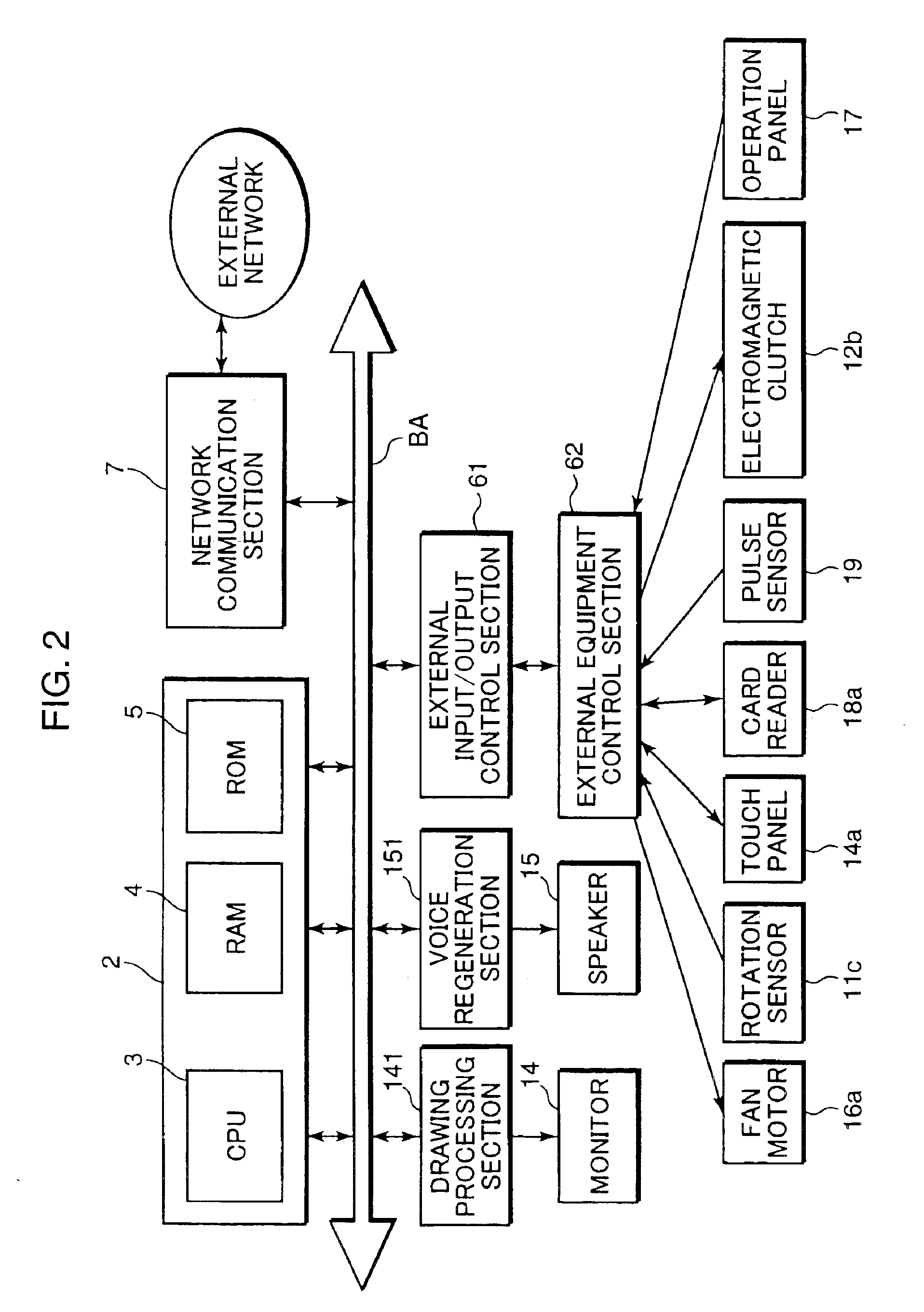

InactiveUS6881176B2Arouses senseHighly motivatedChiropractic devicesTherapy exerciseElectromagnetic clutchRotation sensor

The present invention is for arousing a sense of rivalry to the user so that the user can exhibit an active will to exercise. The present invention relates to an exercise assistance apparatus which has a cycling machine 1 provided with pedals 11b and a rotation sensor 11c for detecting the movement of the pedals 11b, comprising a monitor 14 for displaying images, means for storing image data to express a traveling path and opponent characters, exercise equipment control means for performing variable control for the load status of the electromagnetic clutch 12b of the machine 1, means for sequentially updating and controlling the traveling position of the opponent characters on the traveling path, means for calculating a virtual self position of the user on the traveling path from the detection content of the rotation sensor 11c and the load status controlled by the exercise equipment control means, and image display means for displaying the traveling path and opponent characters on the monitor 14, and displaying the degree of difficulty to pass an opponent character.

Owner:KONAMI SPORTS & LIFE

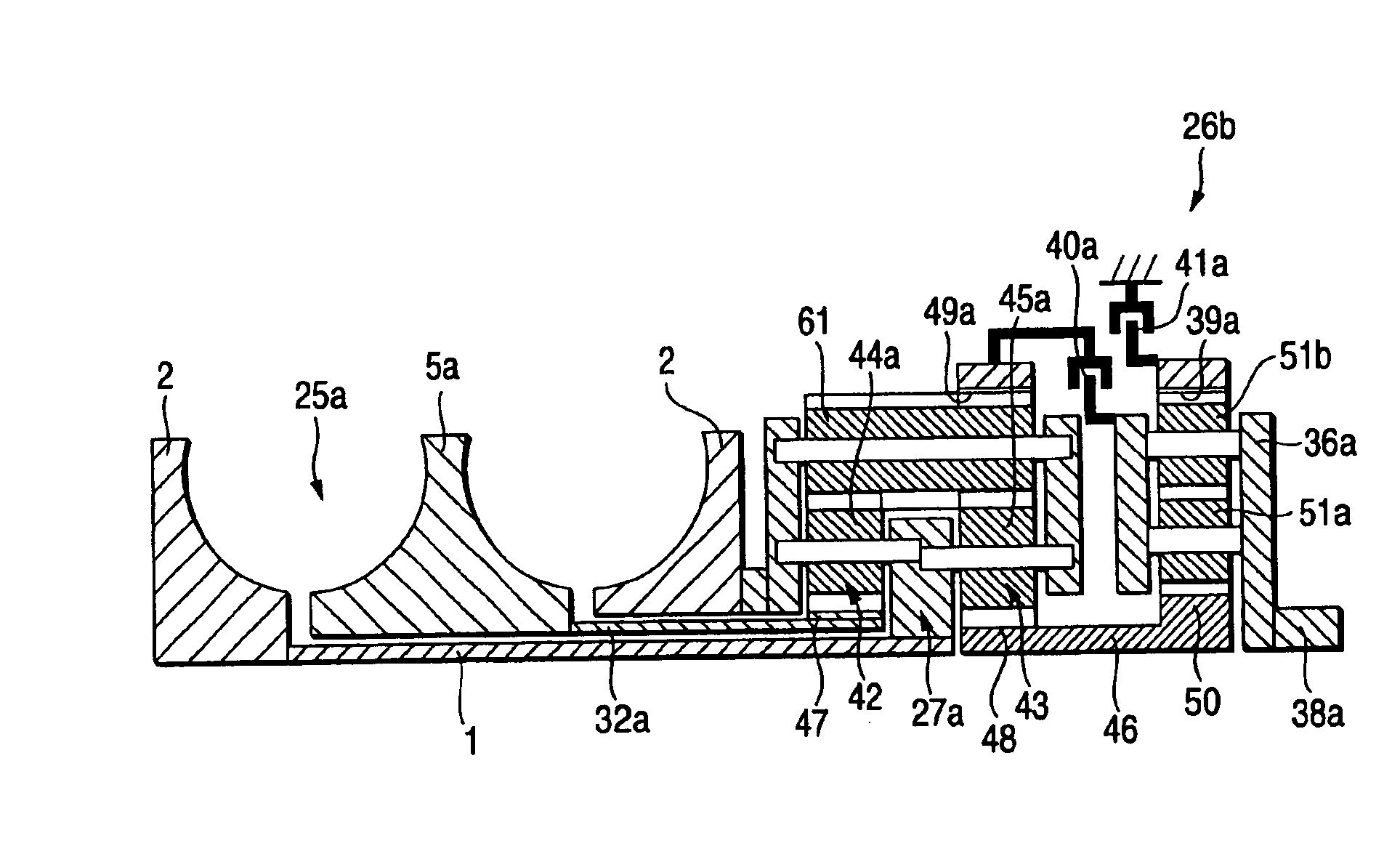

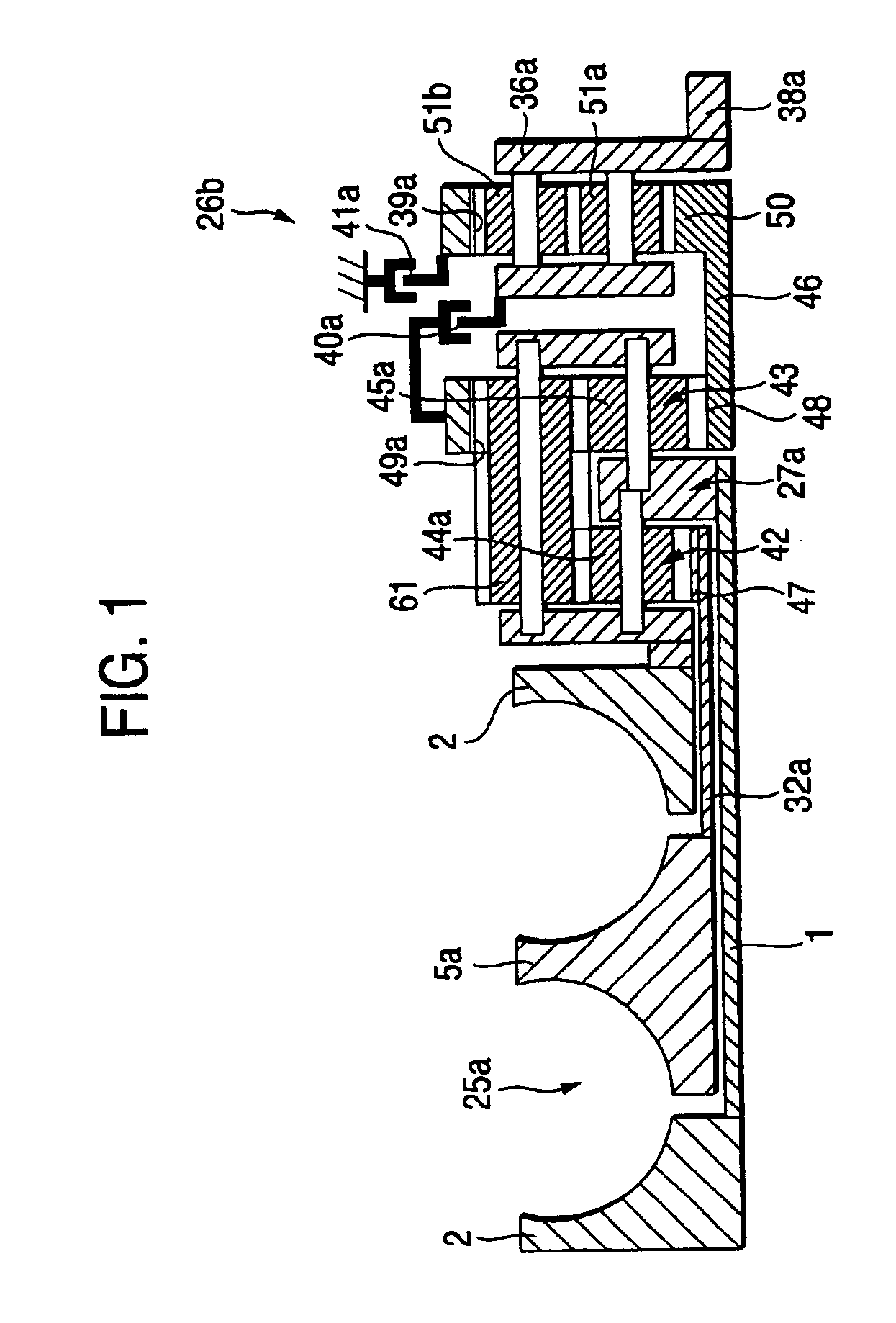

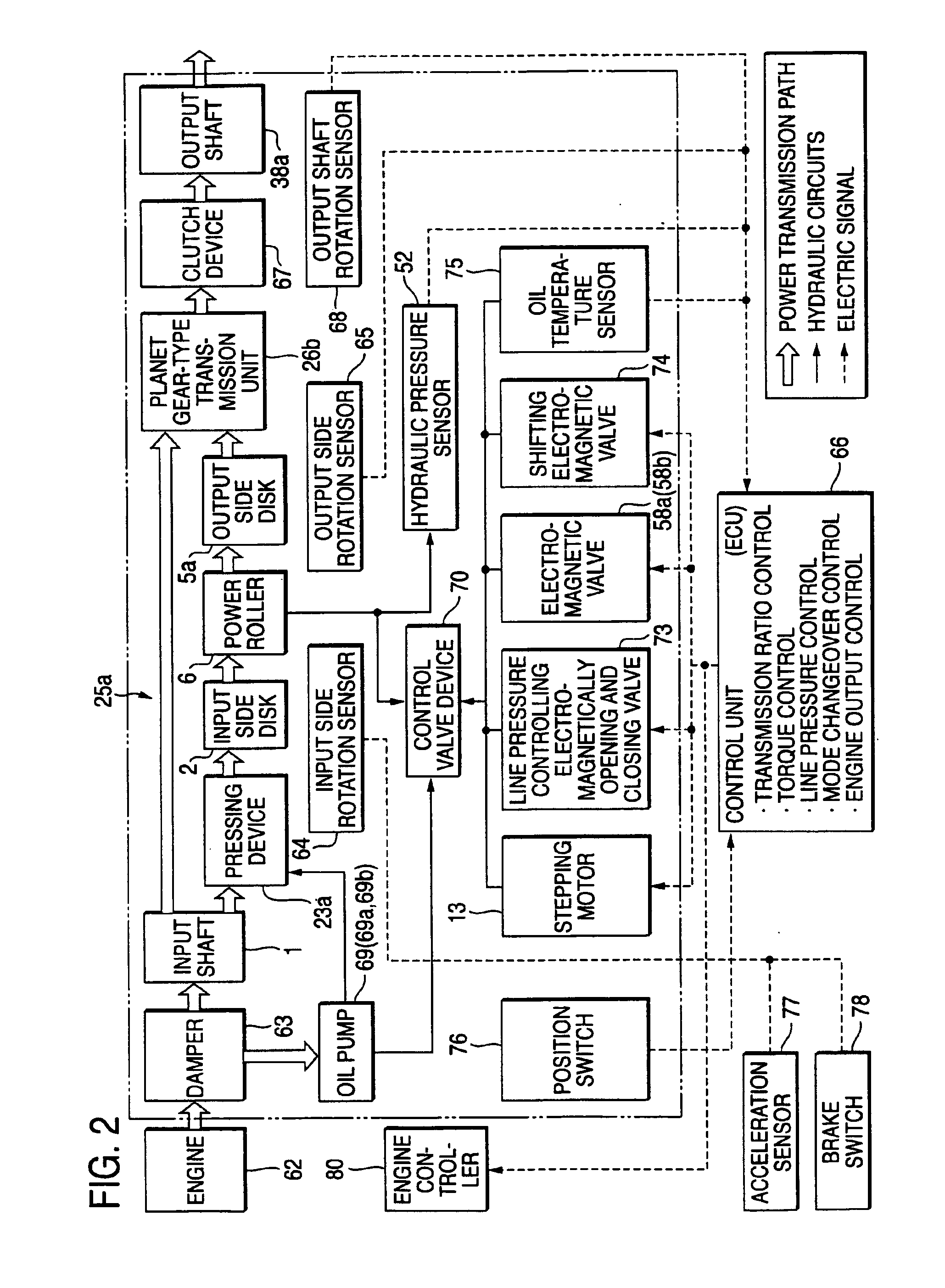

Continuously variable transmission apparatus

A continuously variable transmission apparatus having input and output shafts, a toroidal-type continuously variable transmission unit (CVT unit), a gear-type differential unit with gears, and a control unit, the CVT unit has; input and output side disks, power rollers, input and output side rotation sensors, wherein the differential unit has; a first input portion and a second input portion, and wherein the control unit regulates the transmission ratio of the CVT unit so as to change relative displacement speeds of the gears of the differential unit to thereby convert the rotational state of the output shaft to forward and backward rotations with a stationary state being interposed therebetween, with the input shaft being kept rotating in one direction, and to calculate a rotational speed of the output shaft based on rotational speeds of the input and output side disks and a gear ratio of the differential unit.

Owner:NSK LTD

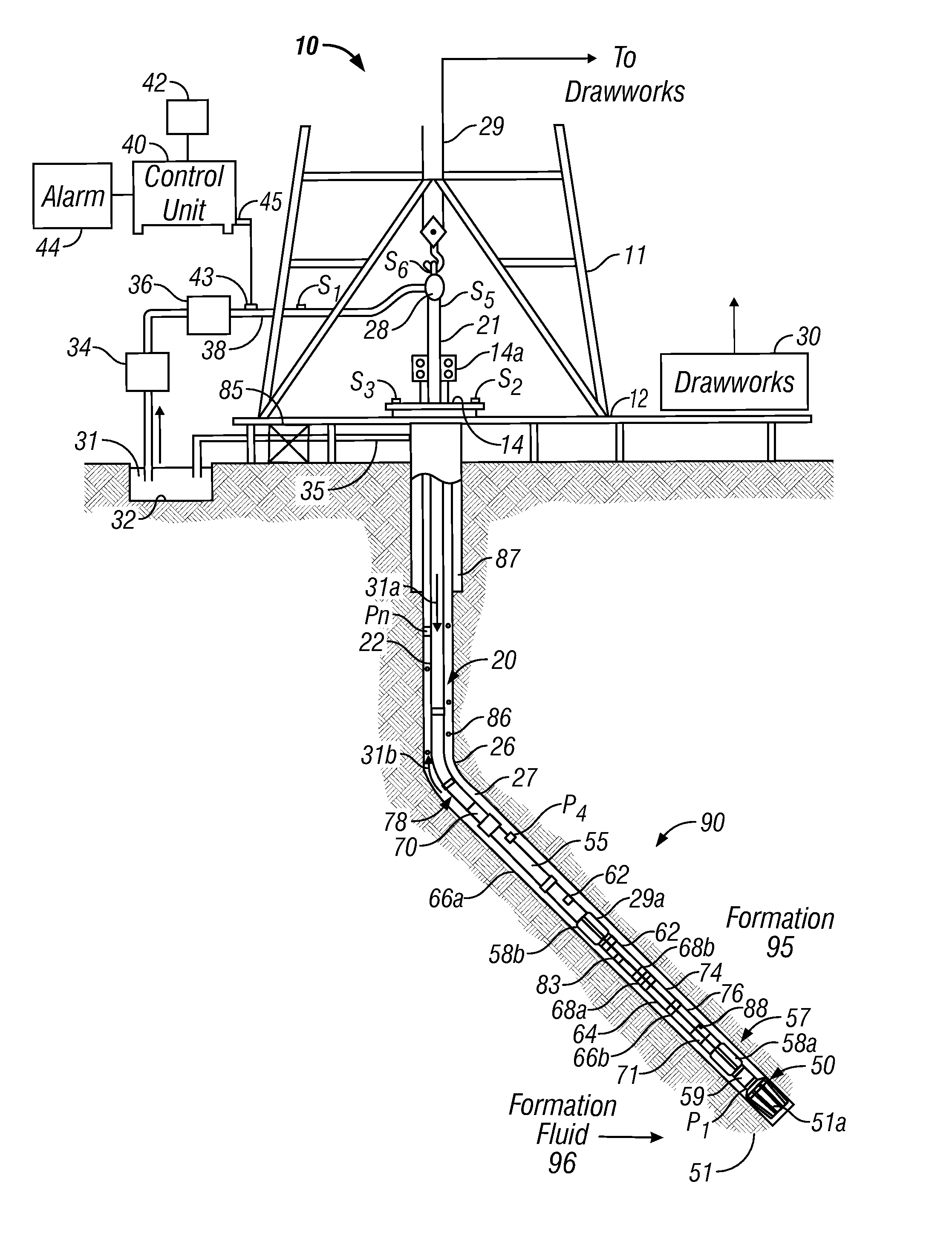

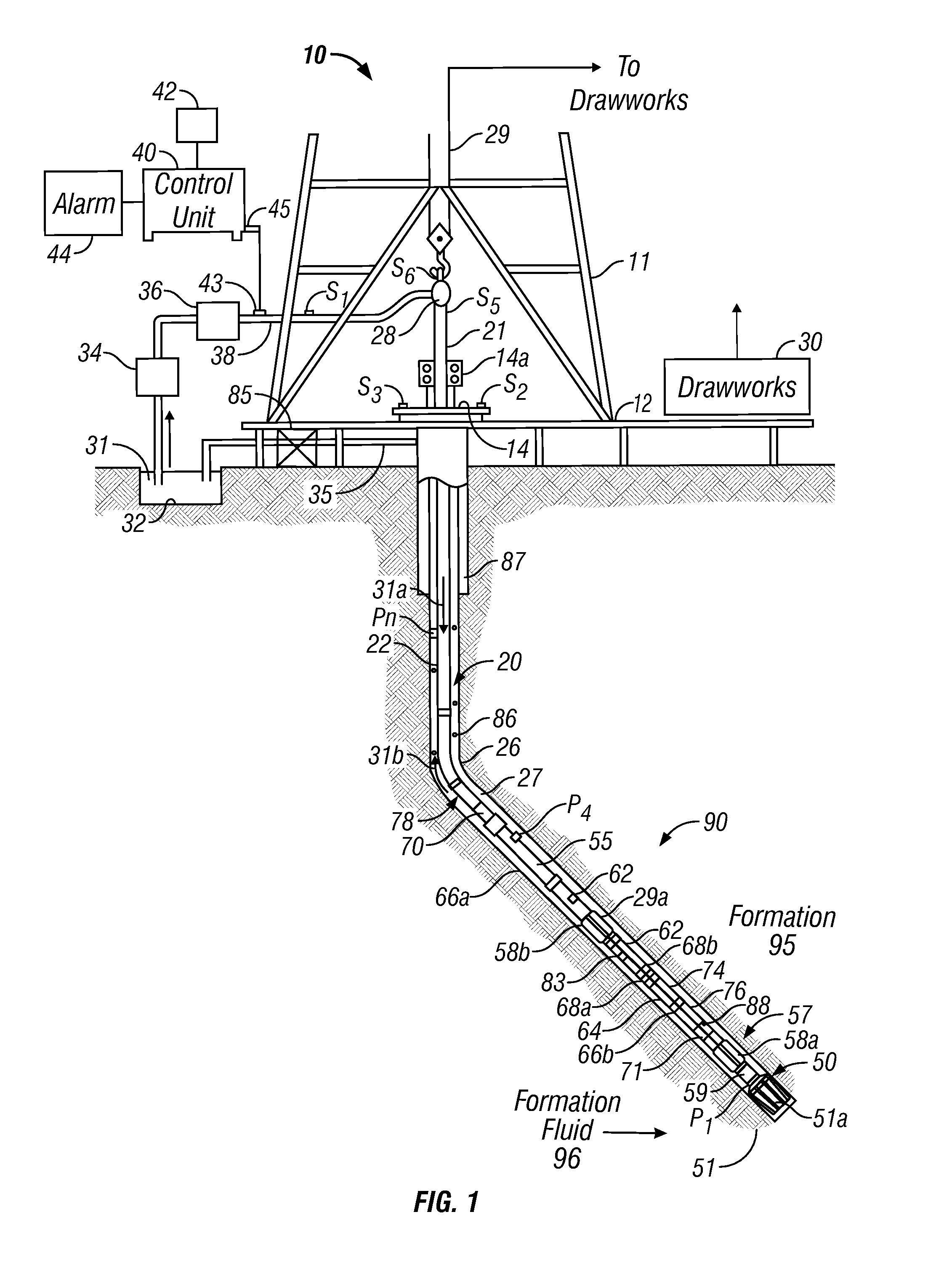

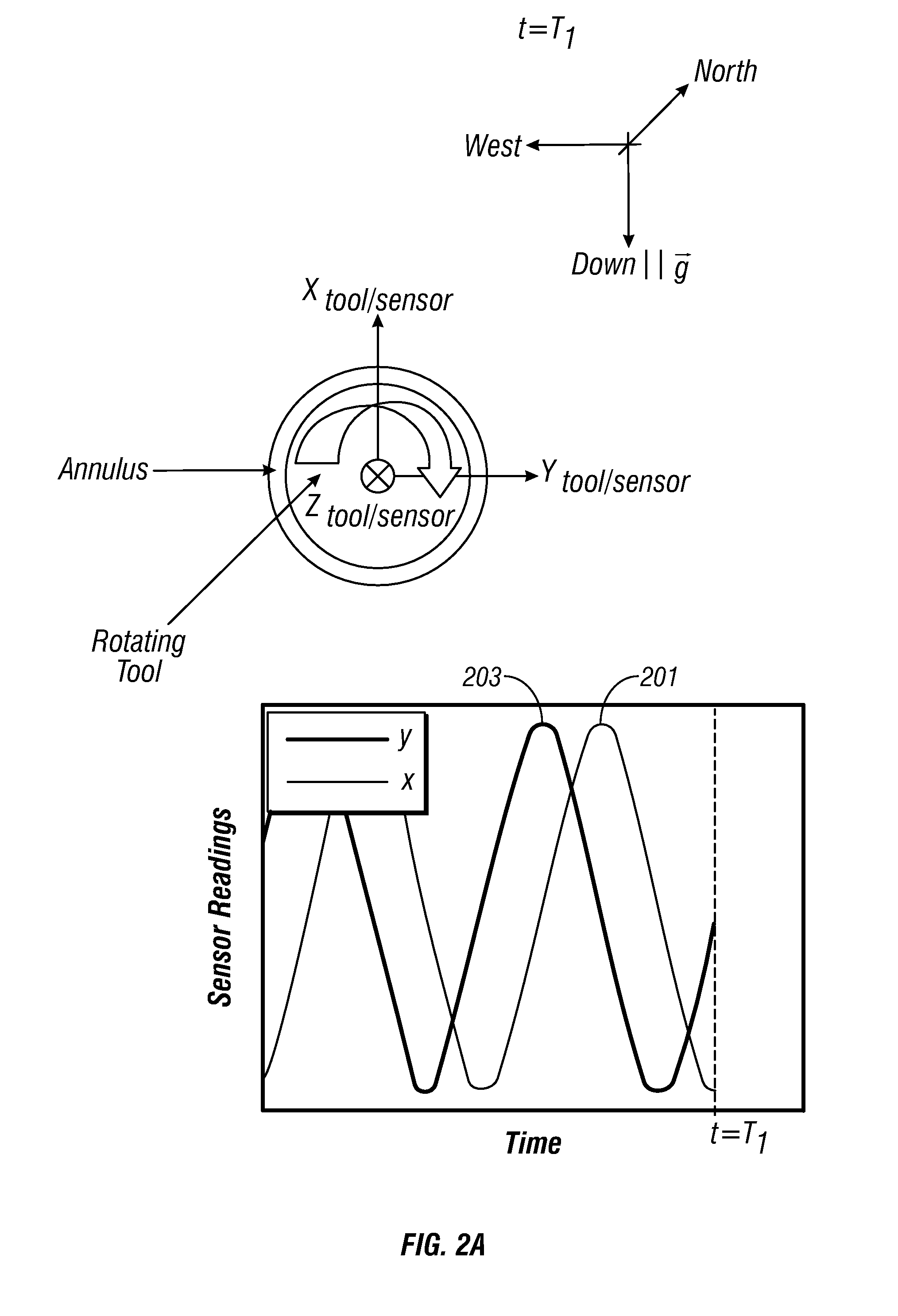

Phase Estimation From Rotating Sensors To Get a Toolface

Measurements made by a rotating sensor on a bottomhole assembly are used to determine the toolface angle of the BHA. The method includes using a phase locked loop (PLL) to determine a phase difference between the sensor output and a reference signal.

Owner:BAKER HUGHES INC

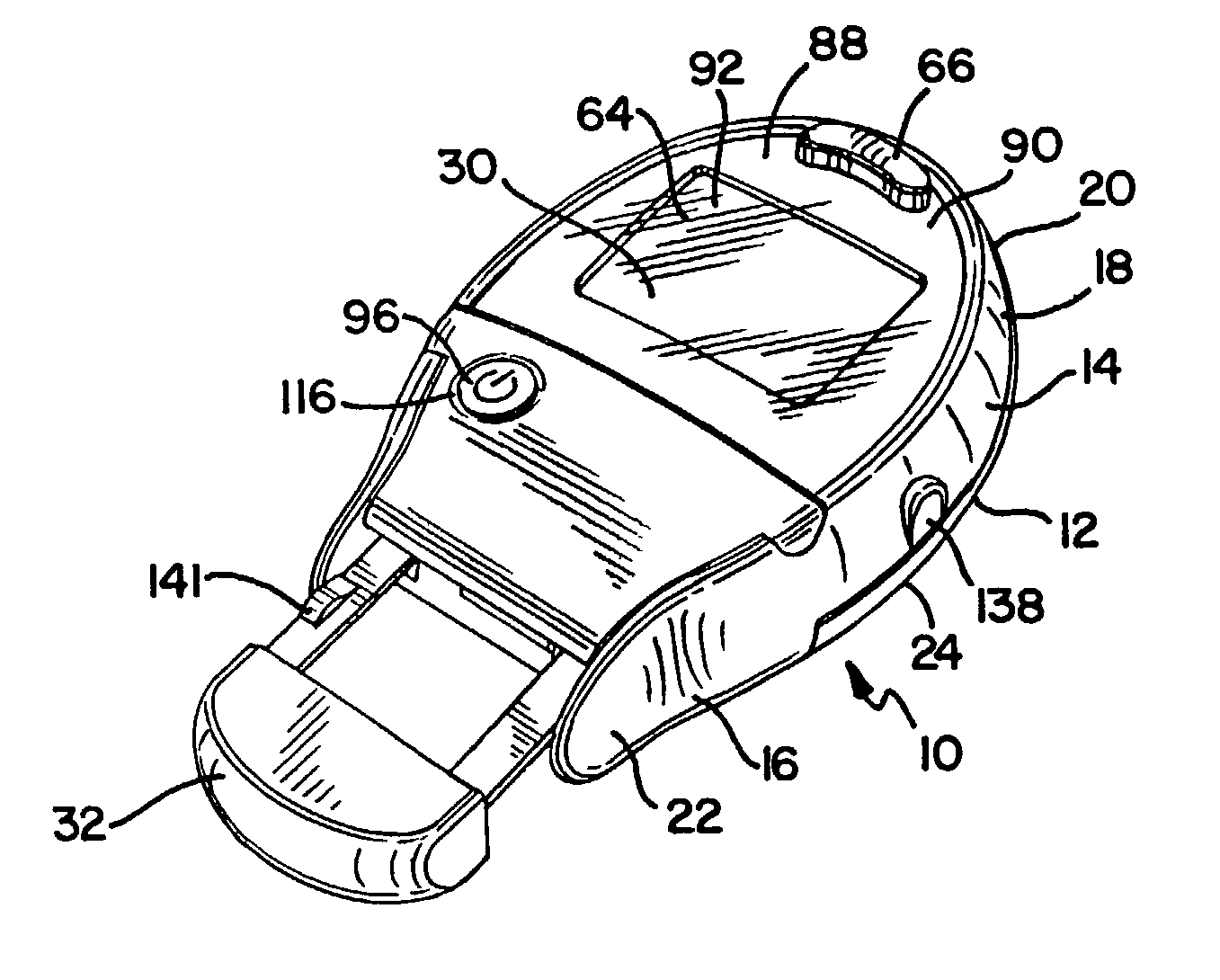

Sensor dispensing instrument having an activation mechanism and methods of using the same

ActiveUS7279130B2Easy to operateSimplified and intuitive mode of operationAnalysis using chemical indicatorsSamplingEngineeringRotation sensor

A sensor dispensing instrument adapted to handle a sensor pack containing a plurality of sensors and to perform a test using one of the sensors. The sensor dispensing instrument includes an outer housing and a mechanical mechanism contained therein for rotating the sensor pack and ejecting one of the sensors from the sensor pack and through a sensor slot on the housing. The sensor dispensing instrument also includes a puller handle for operating the mechanical mechanism. The puller handle is adapted to be grasped between the thumb and finger of a user's hand, and is moveable between a testing position adjacent to the rear end of the outer housing and an extended position spaced outwardly from the rear end of the outer housing.

Owner:ASCENSIA DIABETES CARE HLDG AG +1

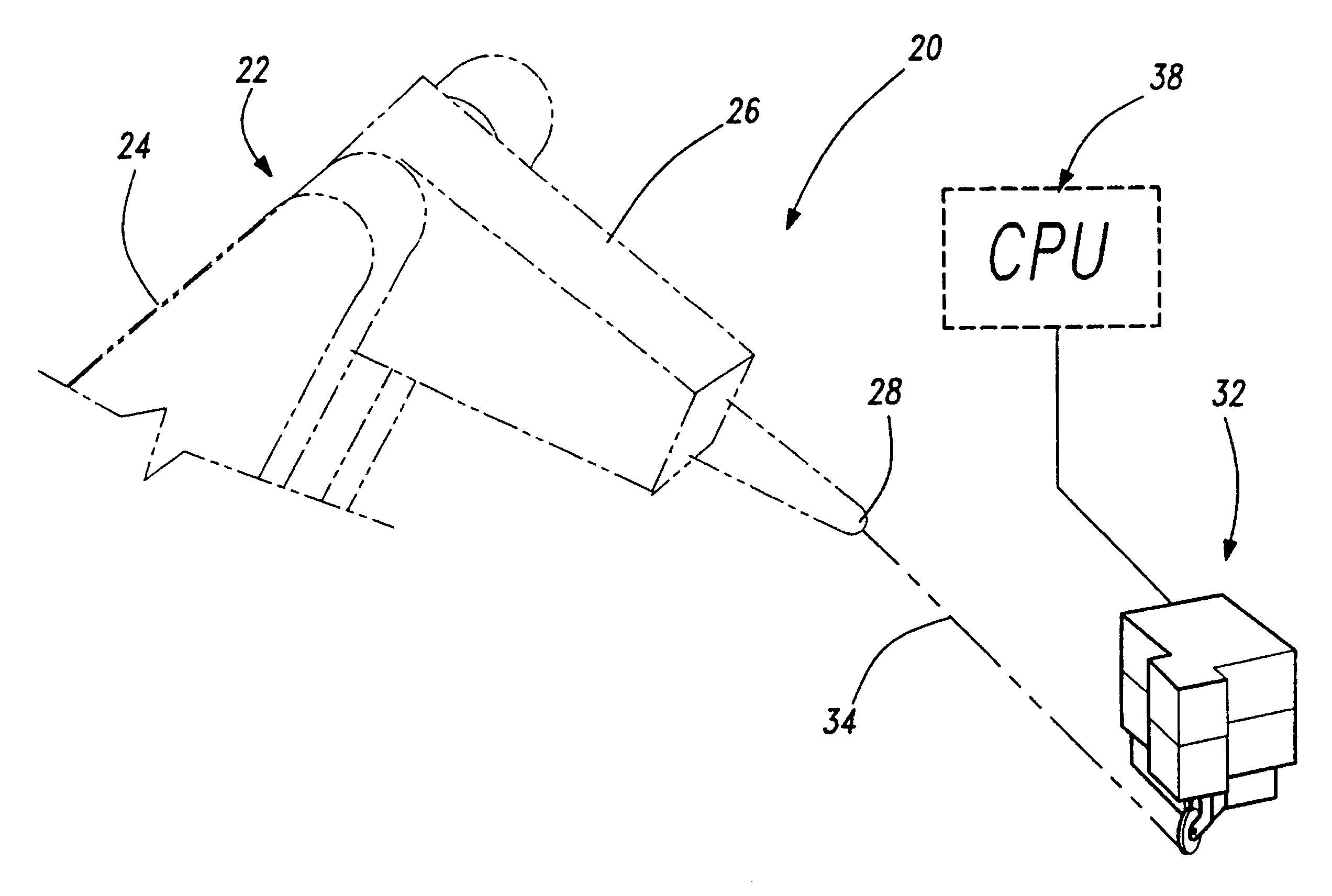

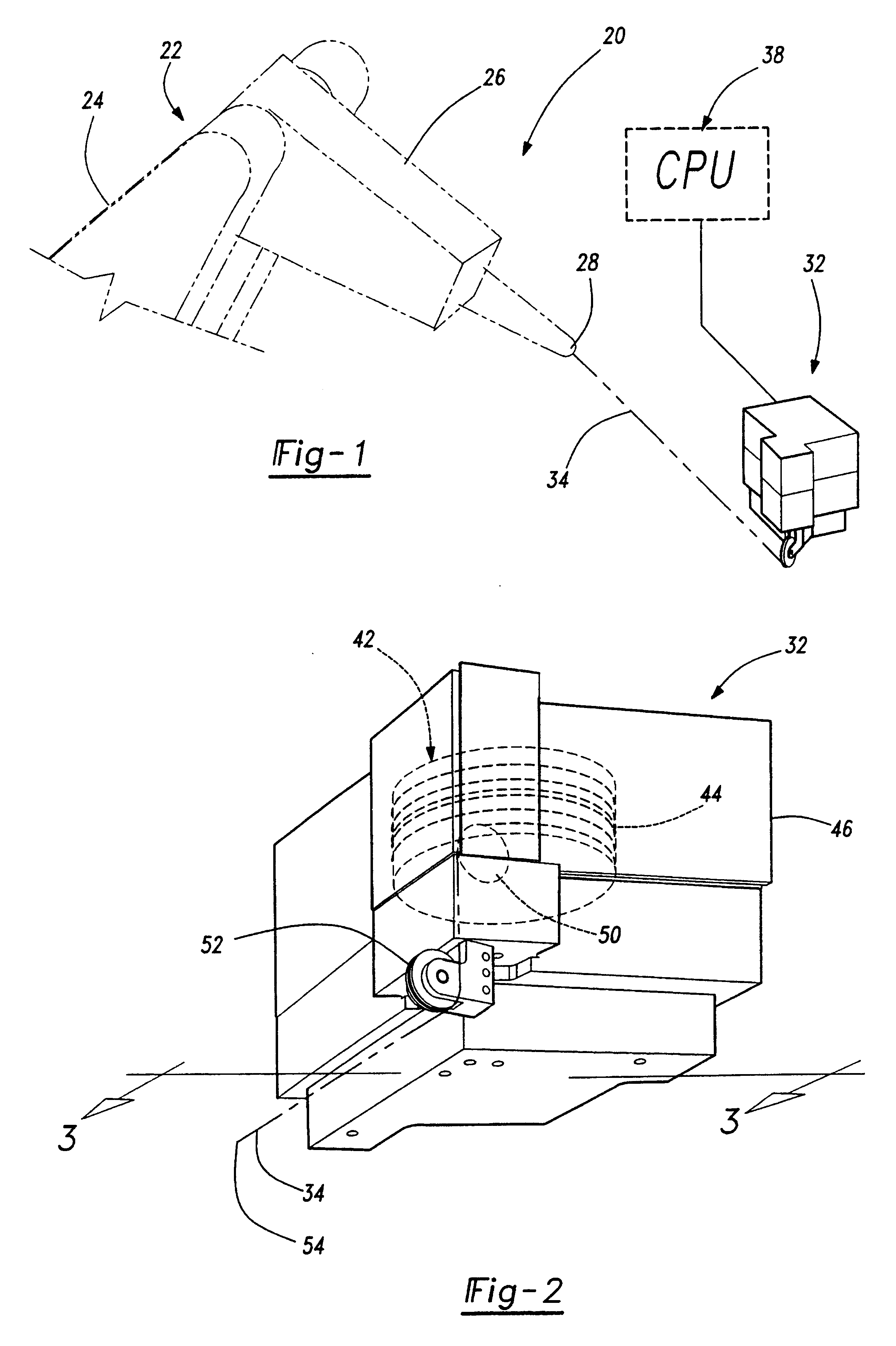

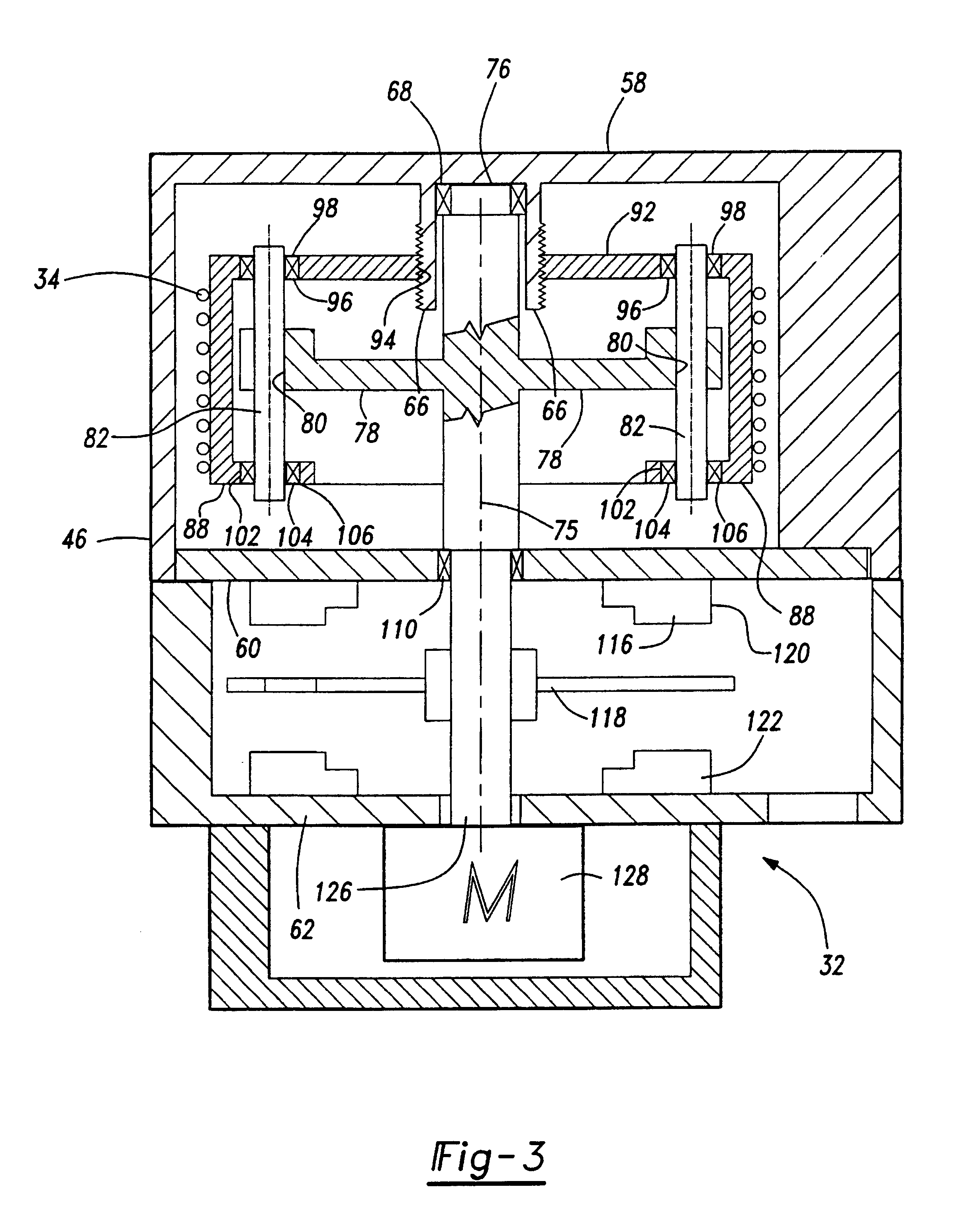

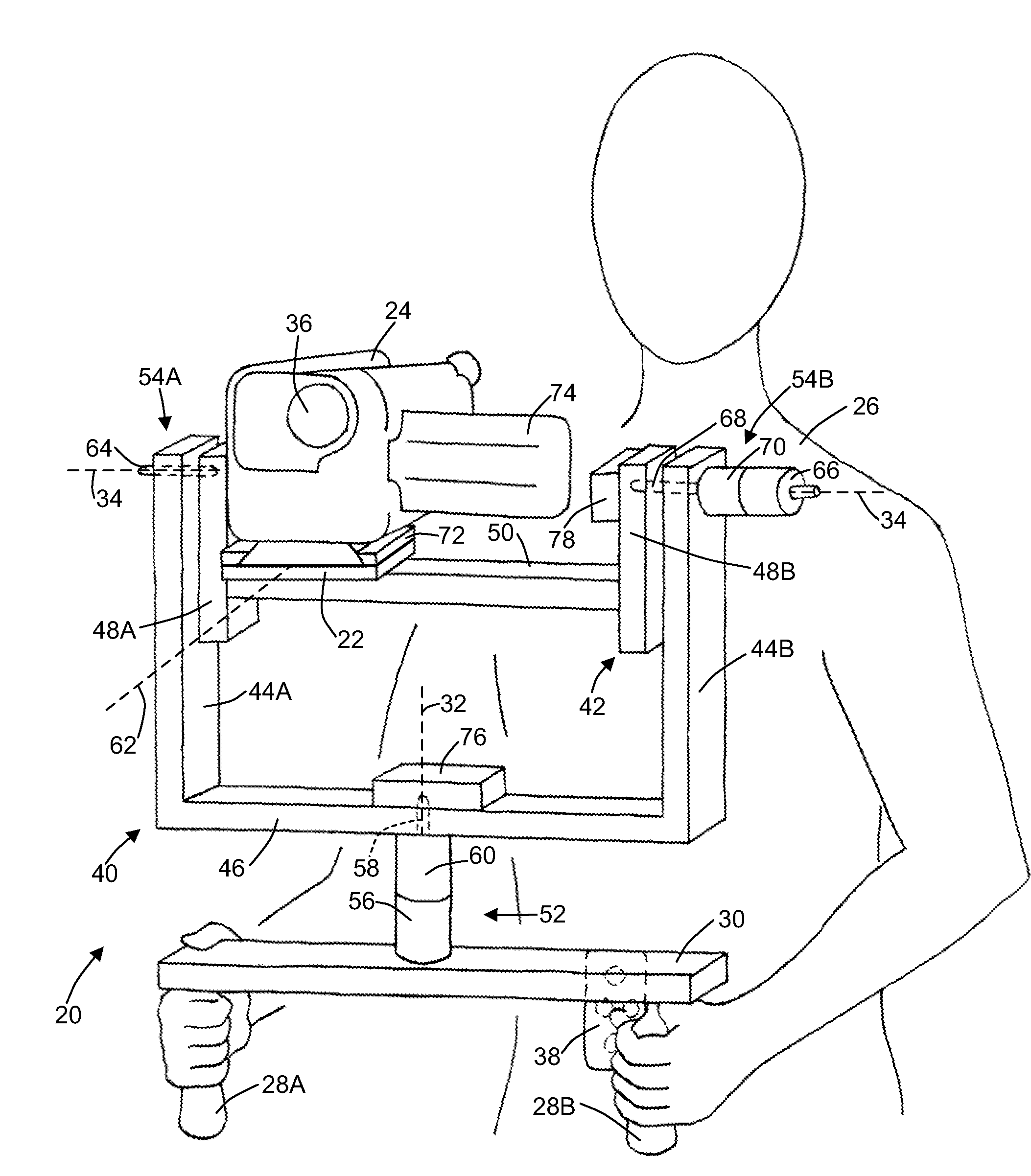

Calibration system and displacement measurement device

An improved system (20) for the calibration of a robot system. The system (20) comprising a linear displacement measurement device (32) in conjunction with a robot calibration system. The linear displacement measurement device (32) comprising an elongated member (34), a drum, a shaft, a drum displacement mechanism and a drum rotation sensor. The drum is displaced axially upon the shaft as the drum rotates when the elongated member (34) is moved. The drum rotation sensor provides accurate information regarding the distance the elongated member (34) travels. The displacement measuring device (32) is used in an iterative manner with the calibration system (20) for the purpose of the calibration of a robotic device (22).

Owner:DYNALOG

Synchronous motor drive unit and a driving method thereof

InactiveUS7294988B2Improve sensing accuracyImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorEngineering

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position.

Owner:HITACHI LTD

Handheld platform stabilization system employing distributed rotation sensors

ActiveUS7642741B2Facilitates constant control loop gainAvoid less flexibilityNavigation by speed/acceleration measurementsElement comparisonRotational axisActuator

A stabilization system including a platform supported by two or more rotatably-coupled gimbal frames each having a pivot assembly disposed at its rotation axis to couple an actuator to a rotation sensor having a rotation-sensitive sensor axis that is fixedly disposed with respect to the rotation axis, and a controller including means for accepting the sensor signals and for producing each motor signal needed to dispose the platform in a predetermined angular position with respect to each rotation axis independent of changes in the base orientation. A motion simulator embodiment includes controller means for accepting an external slew signal sequence and means for producing the motor signals needed to move the platform along a predetermined sequence of positions represented by the slew signal sequence.

Owner:SIDMAN ADAM D

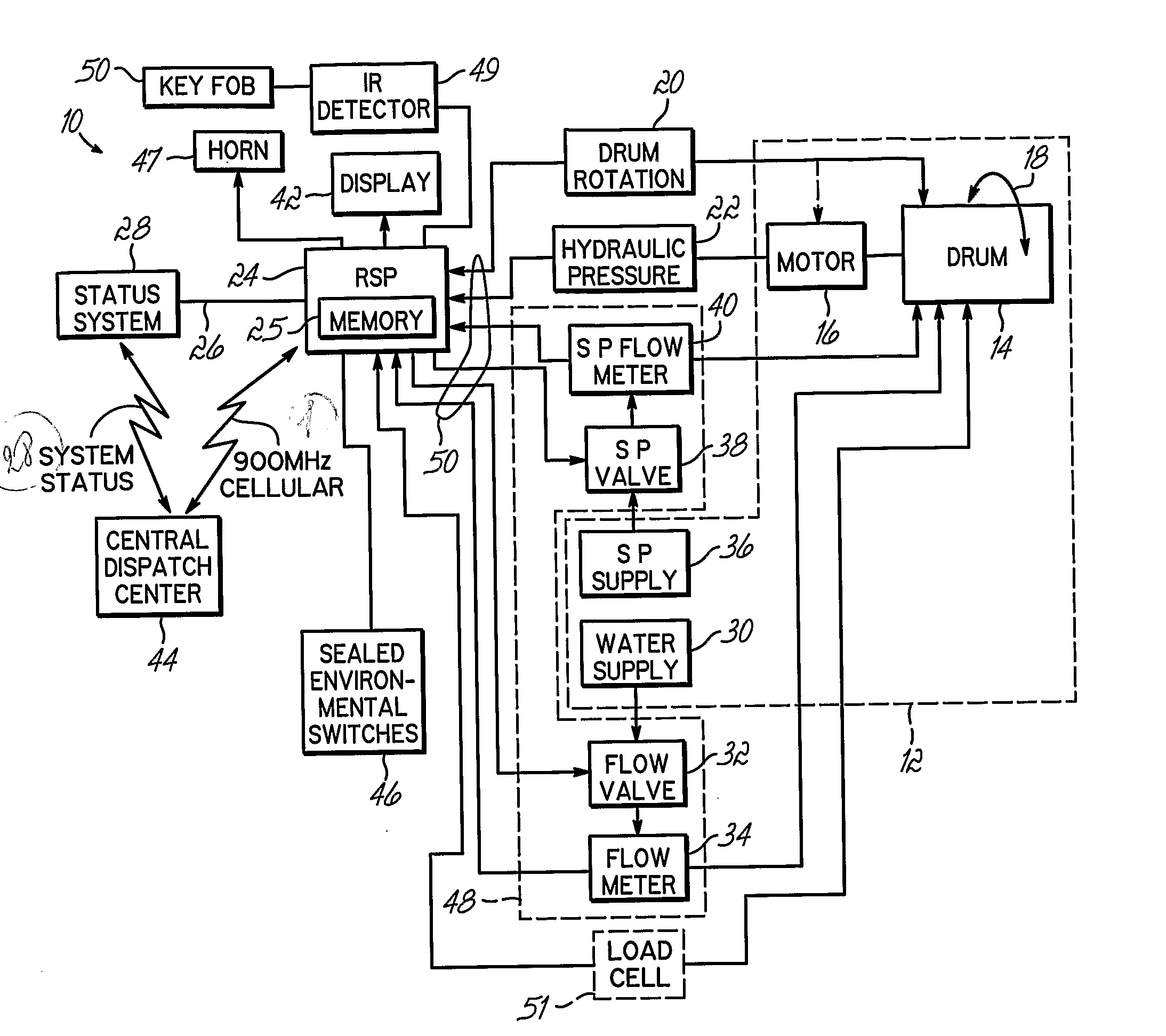

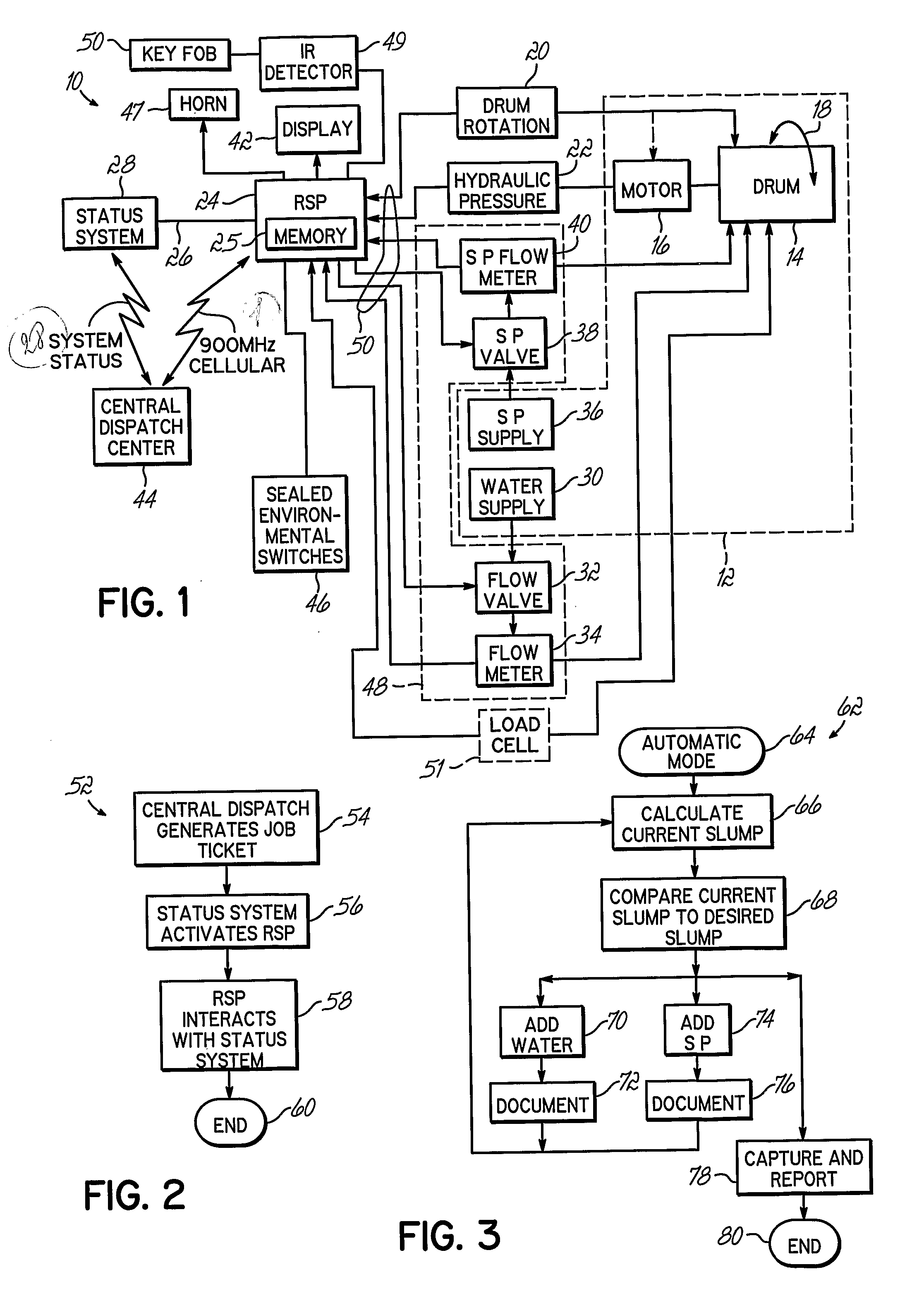

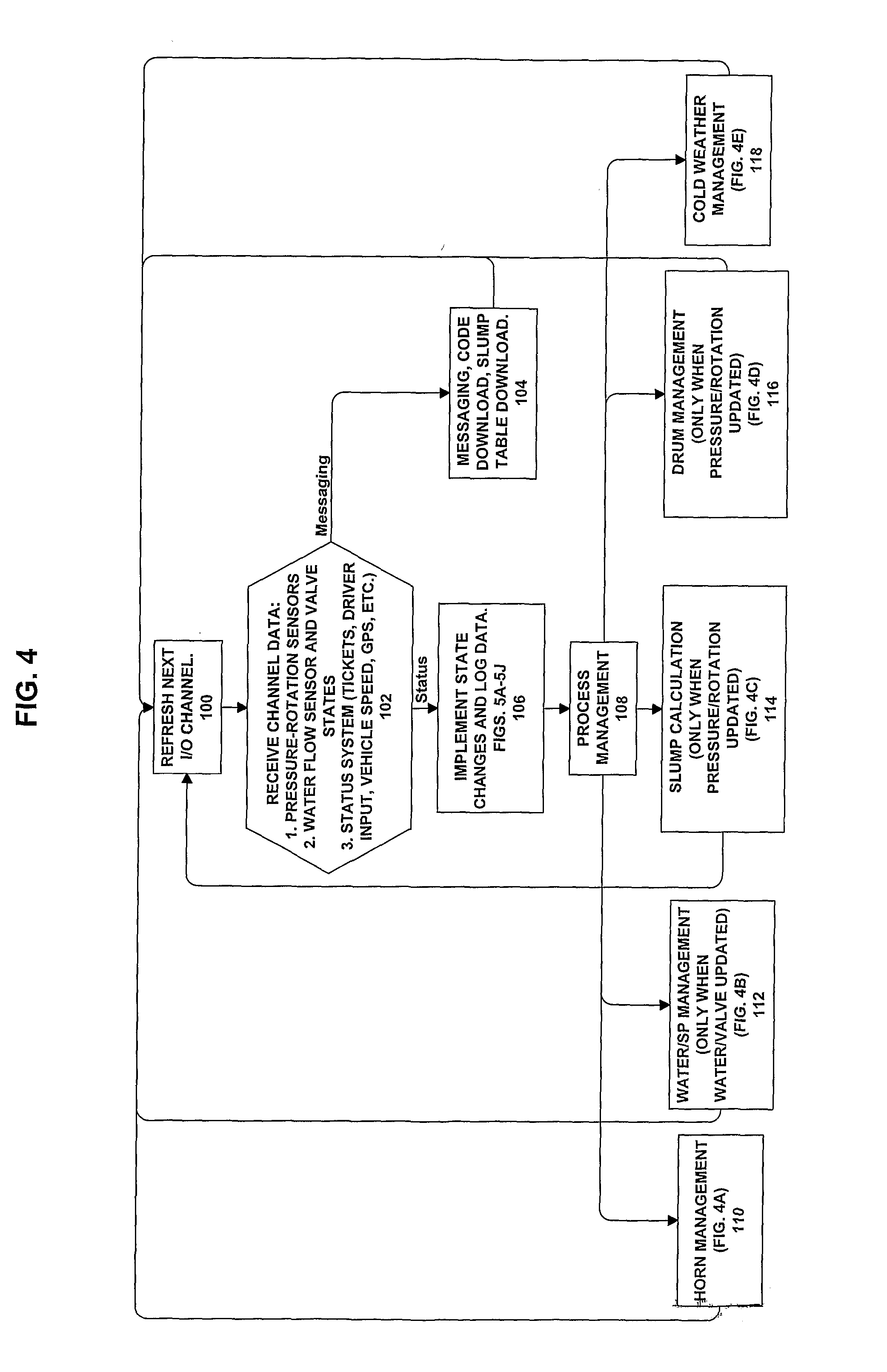

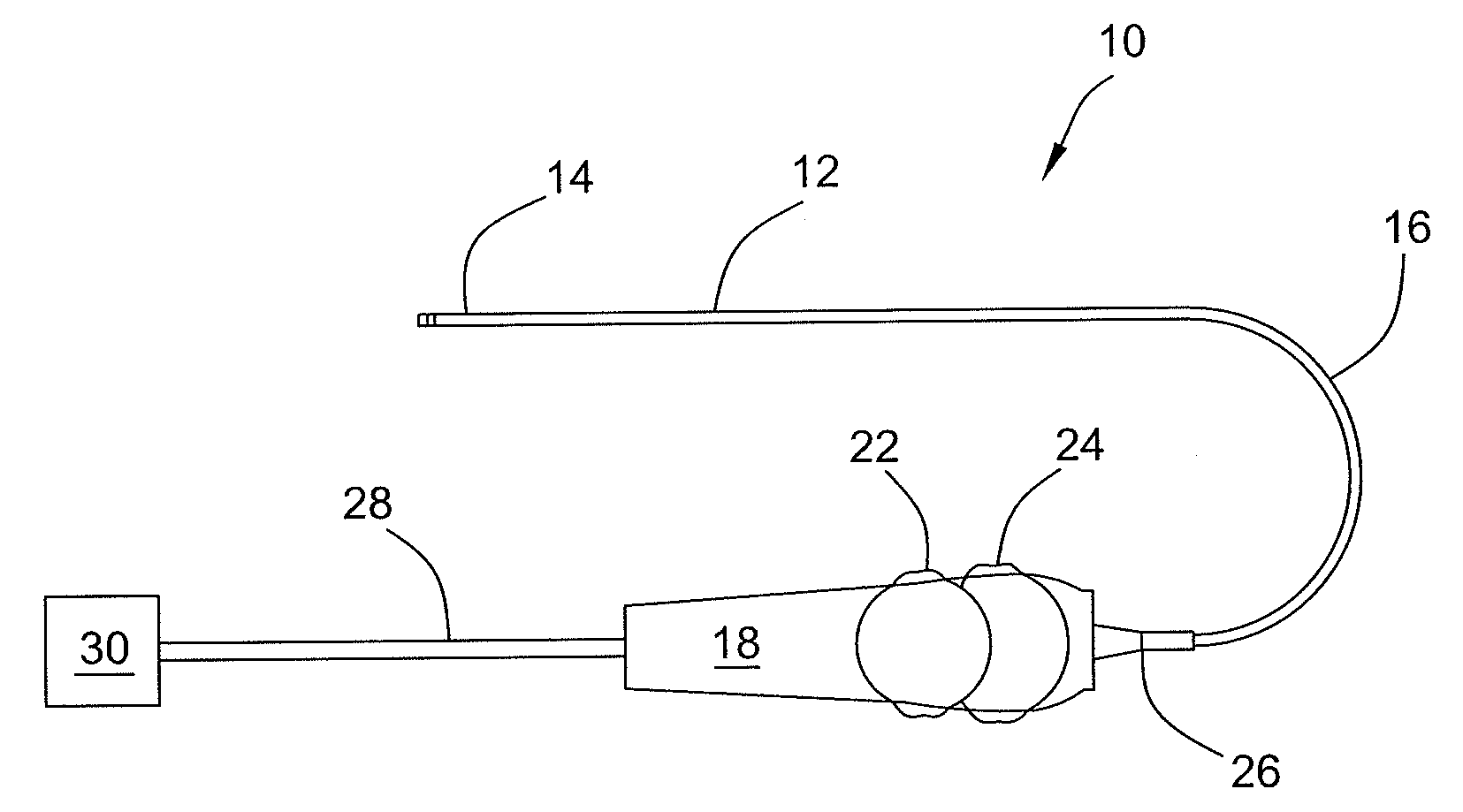

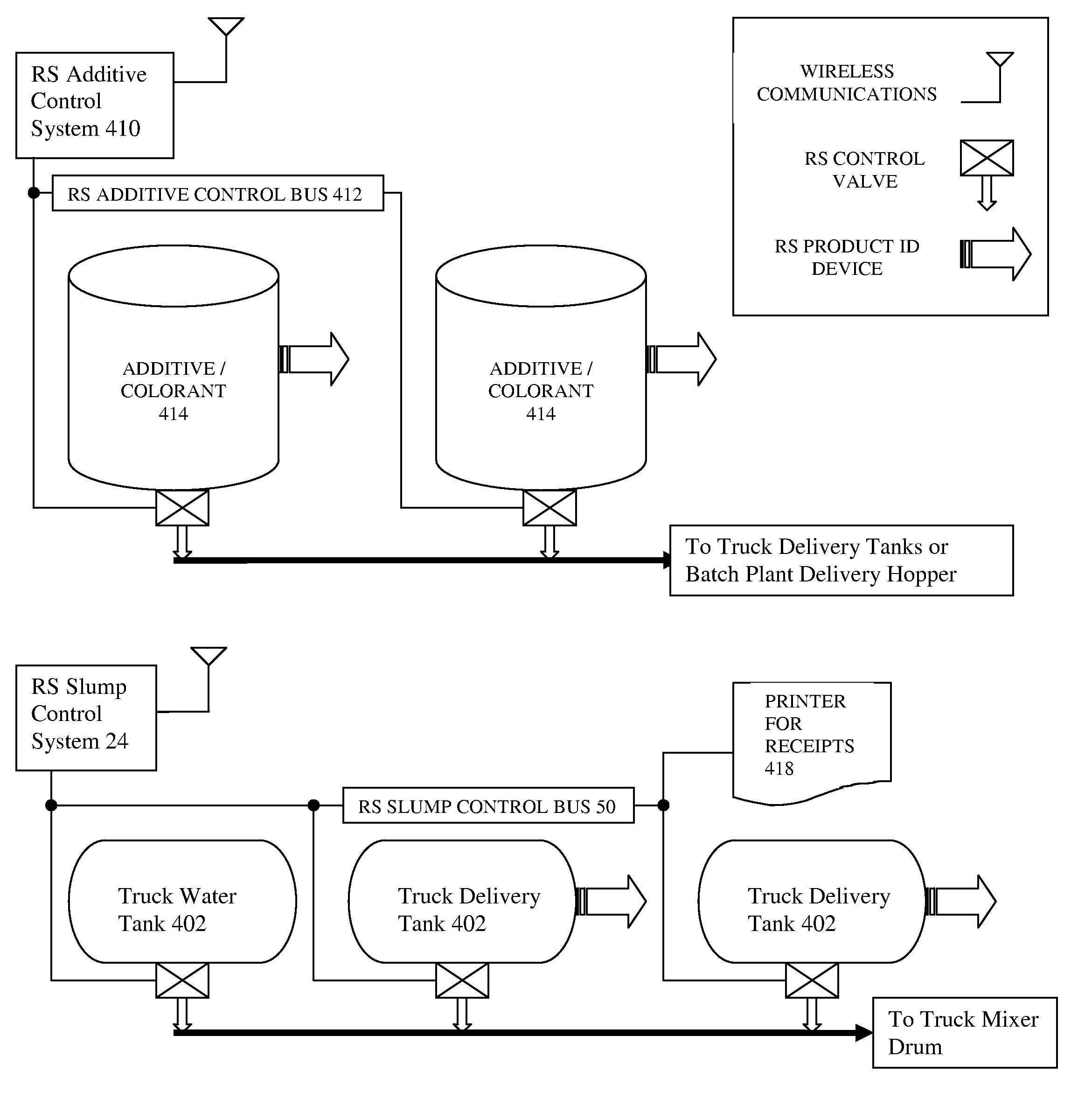

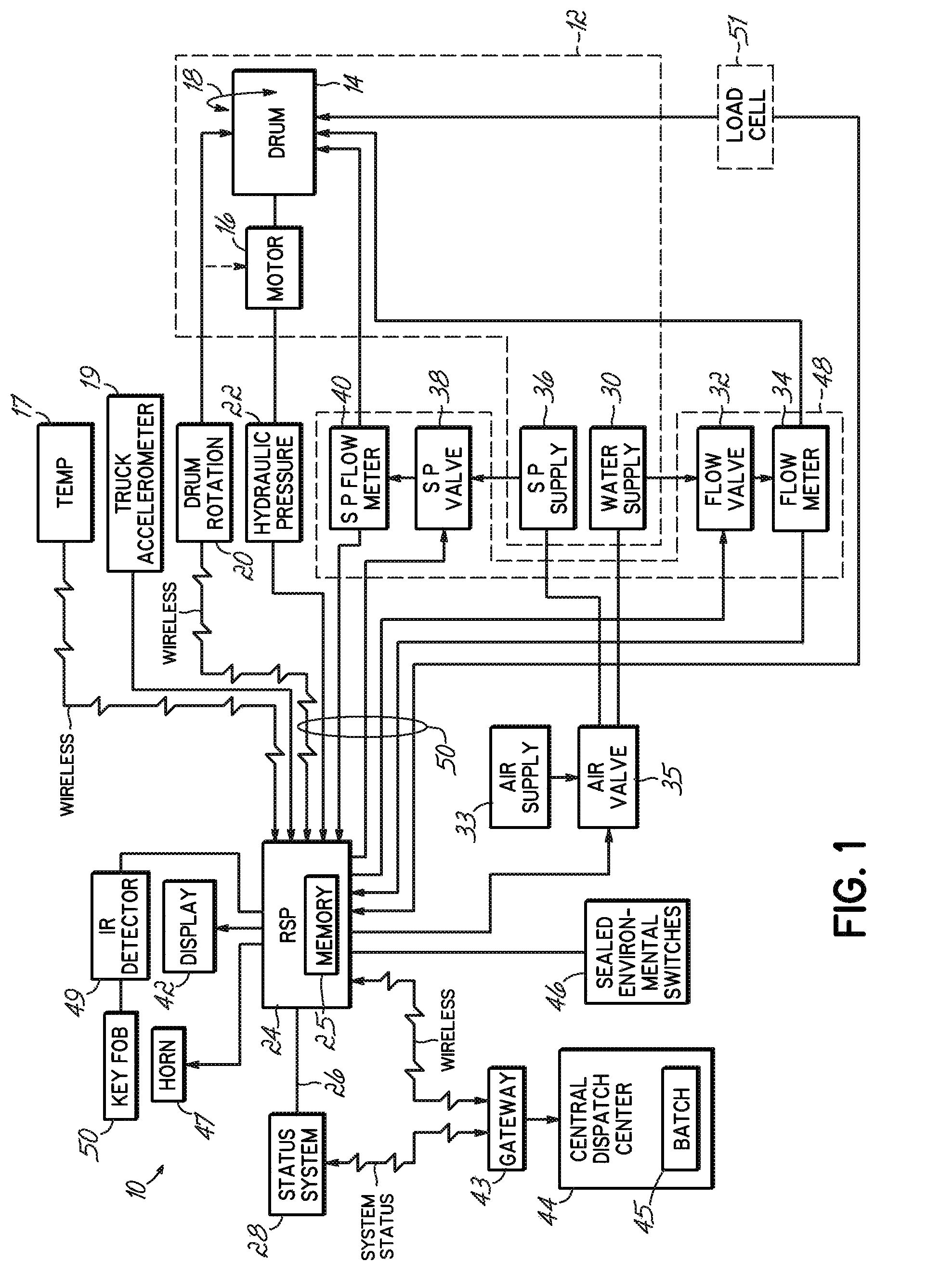

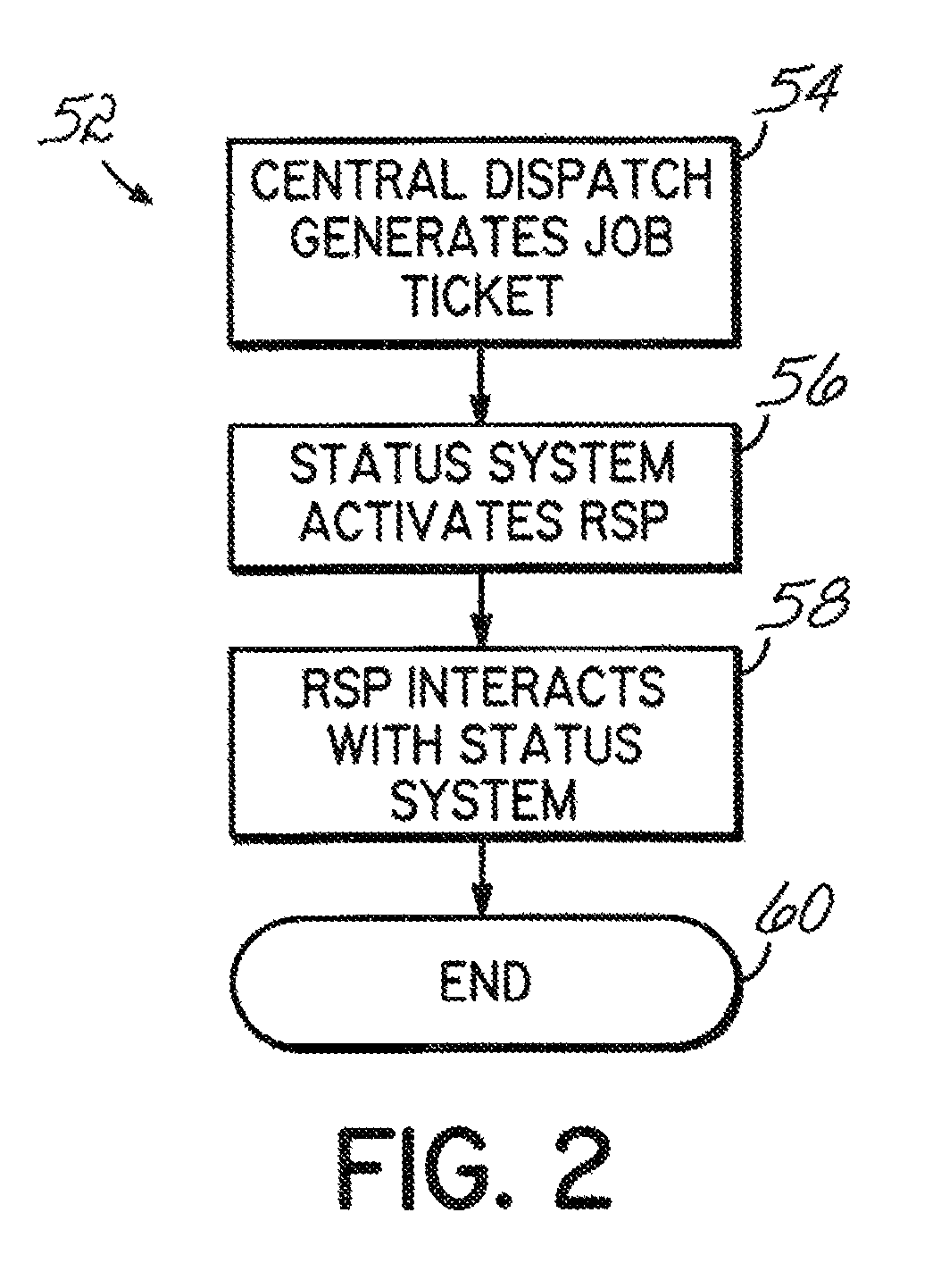

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS20070185636A1Amount be controlSampled-variable control systemsAnalogue computers for trafficDelivery vehicleControl theory

A system for calculating and reporting slump in a delivery vehicle having a mixing drum (14) and hydraulic drive (16) for rotating the mixing drum, including a rotational sensor (20) configured to sense a rotational speed of the mixing drum, a hydraulic sensor (22) coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, and a communications port (26) configured to communicate a slump calculation to a status system (28) commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum.

Owner:VERIFI

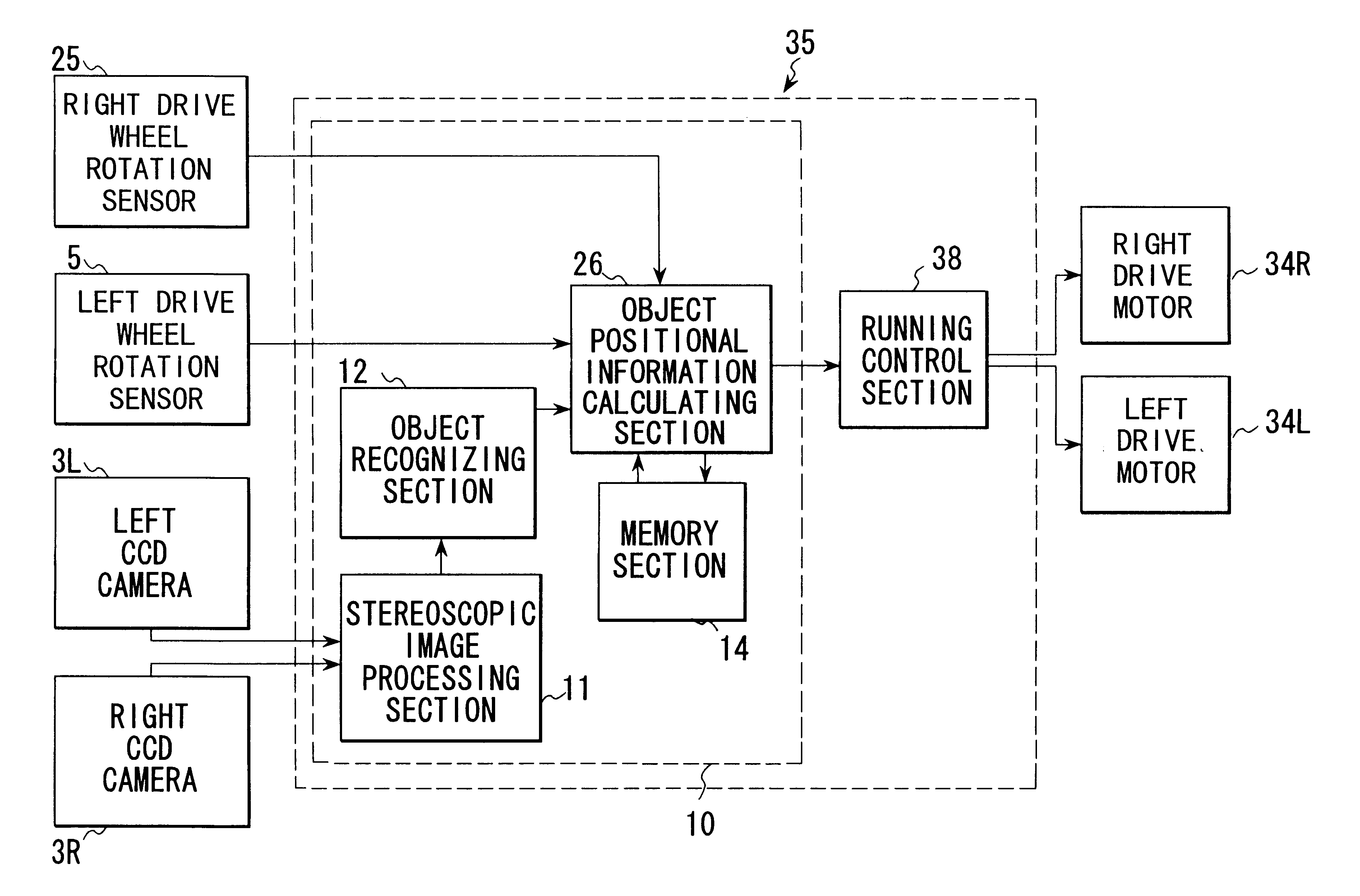

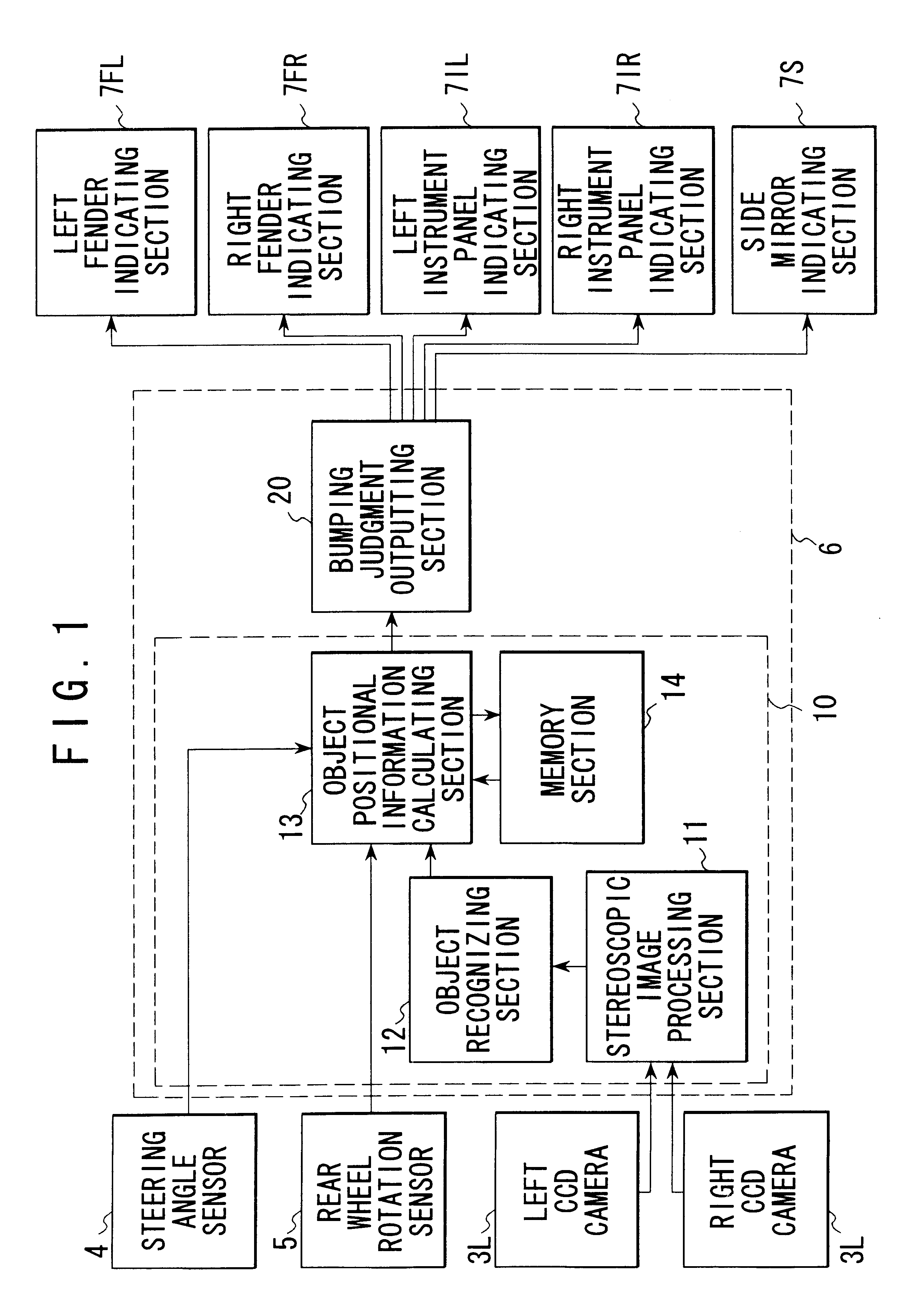

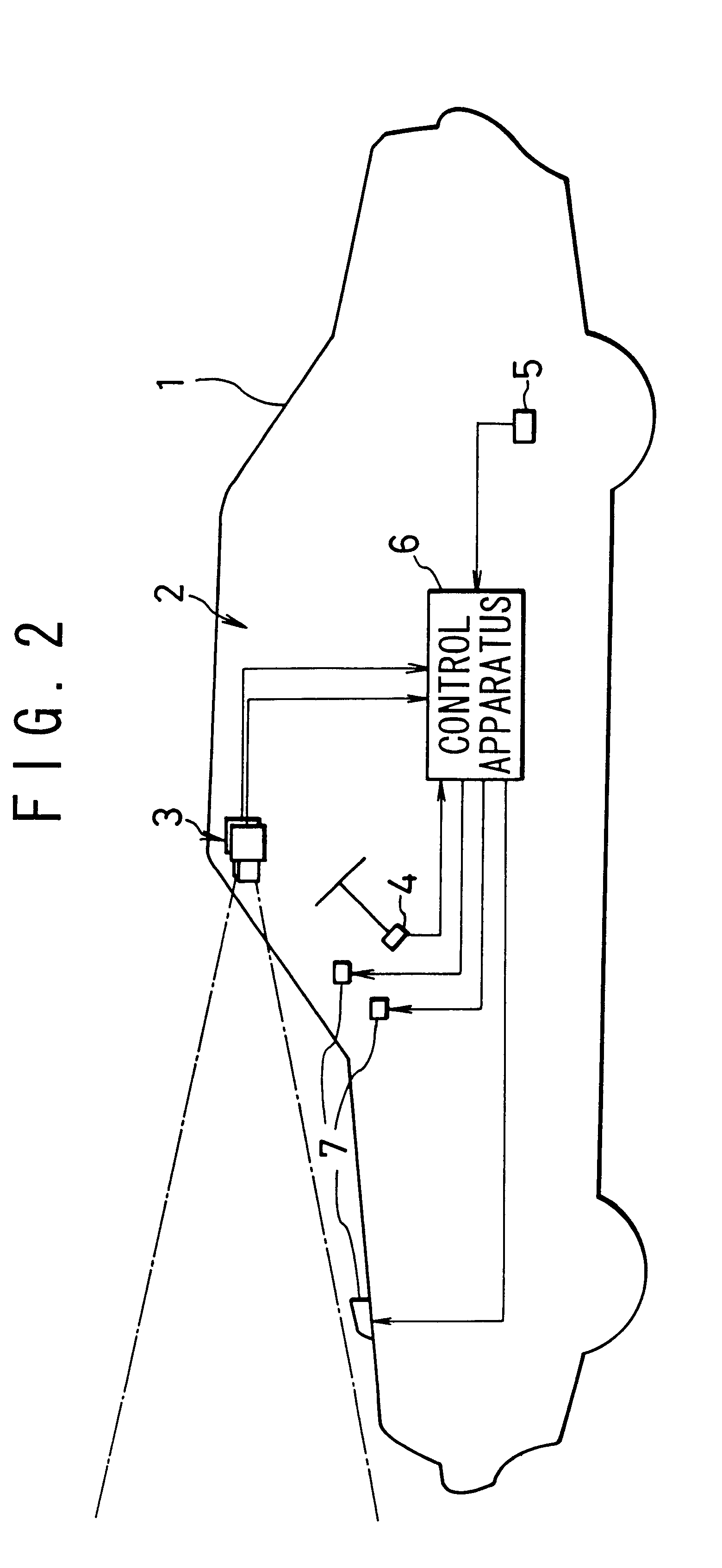

Object recognizing apparatus for vehicle and the method thereof

A stereoscopic optical system images a stereoscopic picture image, a stereoscopic image processing section calculates a three-dimensional distance distribution from the stereoscopic picture image, and an object recognizing section recognizes objects from the distance distribution information to calculate a relative position of the objects with respect to the vehicle. On the other hand, a travelling amount of the vehicle is detected by a steering sensor and a rear wheel rotation sensor. Then, an object positional information calculating section calcuLates a new relative position of the objects based on the relative position information memorized in a memory section and the calculated travelling amount of the vehicle and the memory section memorizes the new positional information. And, a bumping judgment outputting section judges the possibility of bumping against the objects based on the new relative position of the objects with reference to memorized information about the external shape of the vehicle. If it is judged therein that there is a possibility of bumping, the bumping judgment outputting section outputs a warning signal to an indicating section.

Owner:FUJI JUKOGYO KK

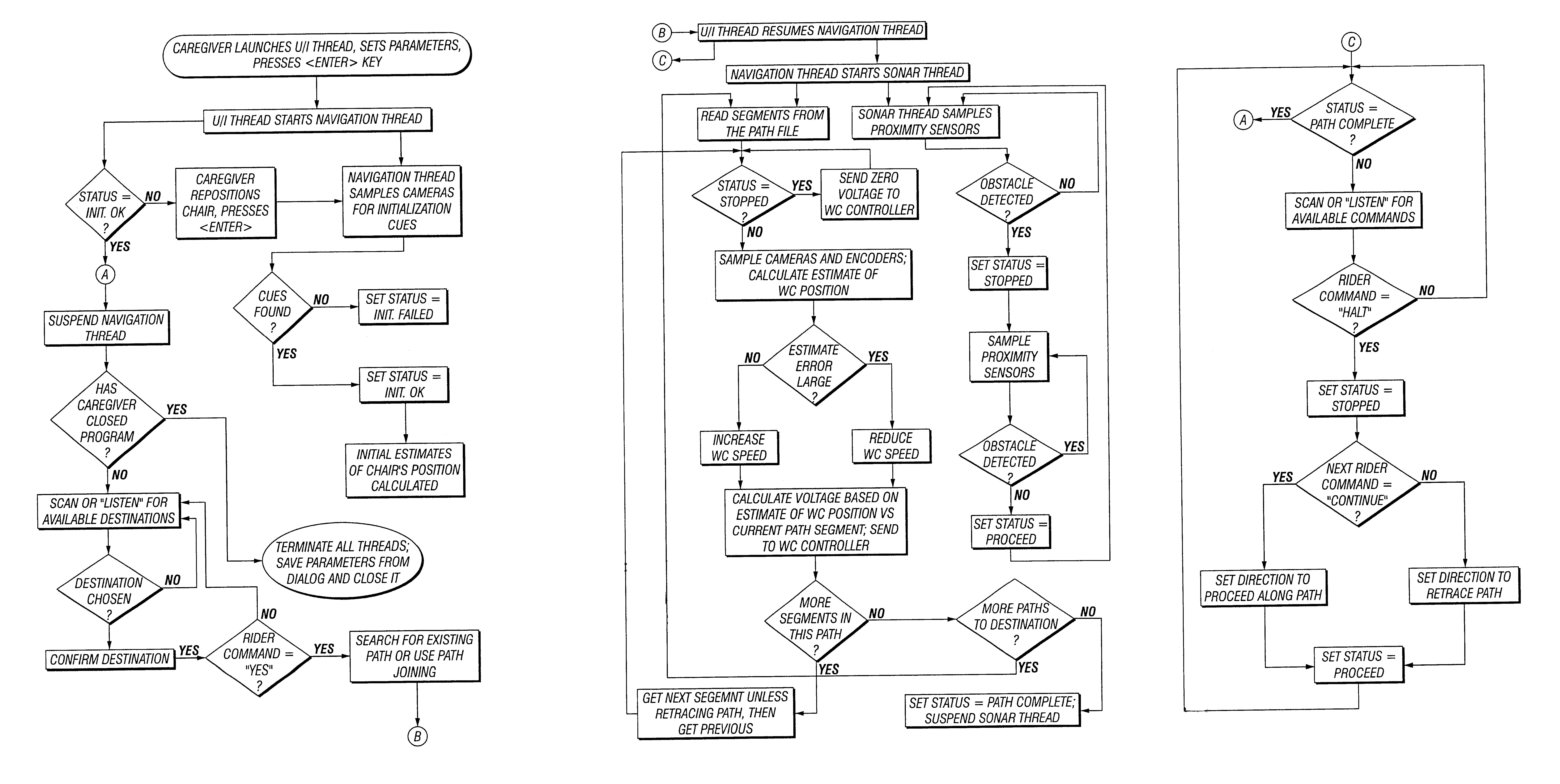

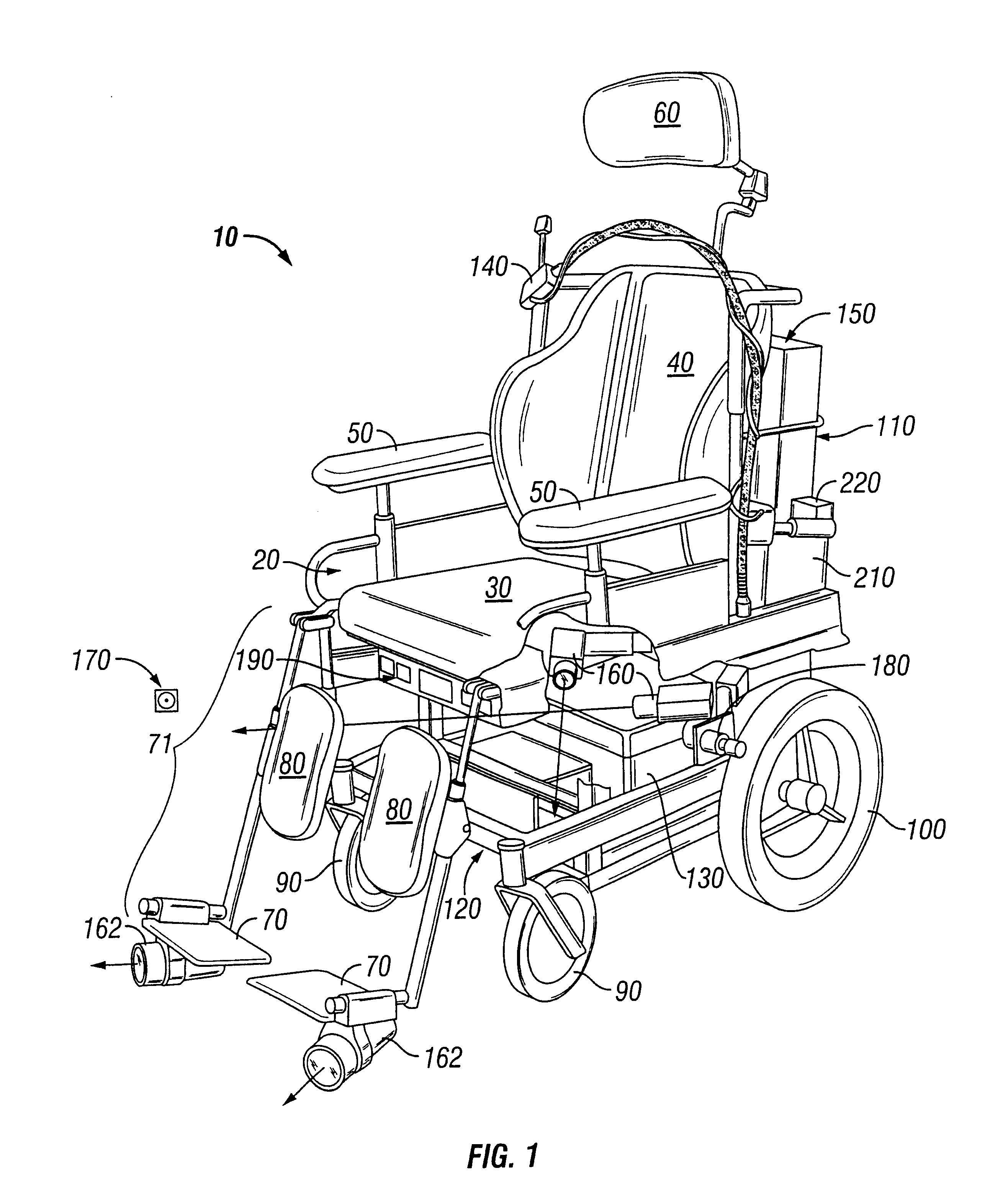

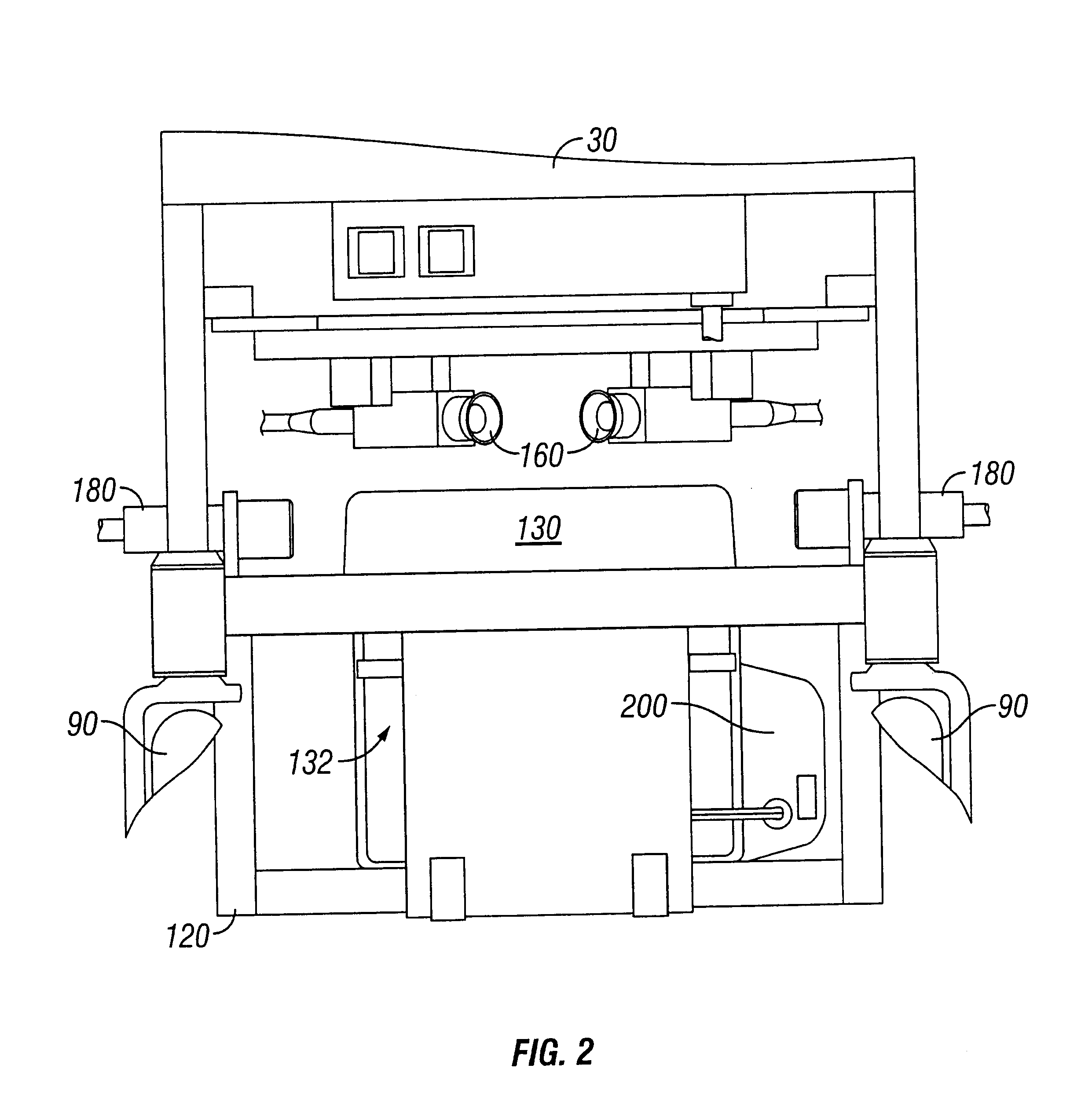

Computer-controlled power wheelchair navigation system

InactiveUS6842692B2Enable independent mobilityEasily and accurately maneuvering through doorwayInstruments for road network navigationNavigational calculation instrumentsProximity sensorWheelchair

A wheelchair navigation system having motorized wheelchair which is powered by at least one onboard battery, and a battery charger. The navigation system also has a filter-based estimator with interface software running that is operated on an onboard laptop computer. Dual cameras, proximity sensors, microphones, and rotation sensors for the wheels are mounted to the wheelchair. Small markers are placed on the walls of a location or room. The navigation system uses the proximity sensors, rotation sensors and cameras in conjunction with the specialized software to determine where objects or impediments are located in the room and thereby redirect the path of the wheelchair so as to avoid such objects. The wheelchair is walked through the marked location thereby ‘teaching’ various paths which are recorded in the computer and recalled later when the wheelchair is in use.

Owner:VETERANS AFFAIRS U S DEPT OF +1

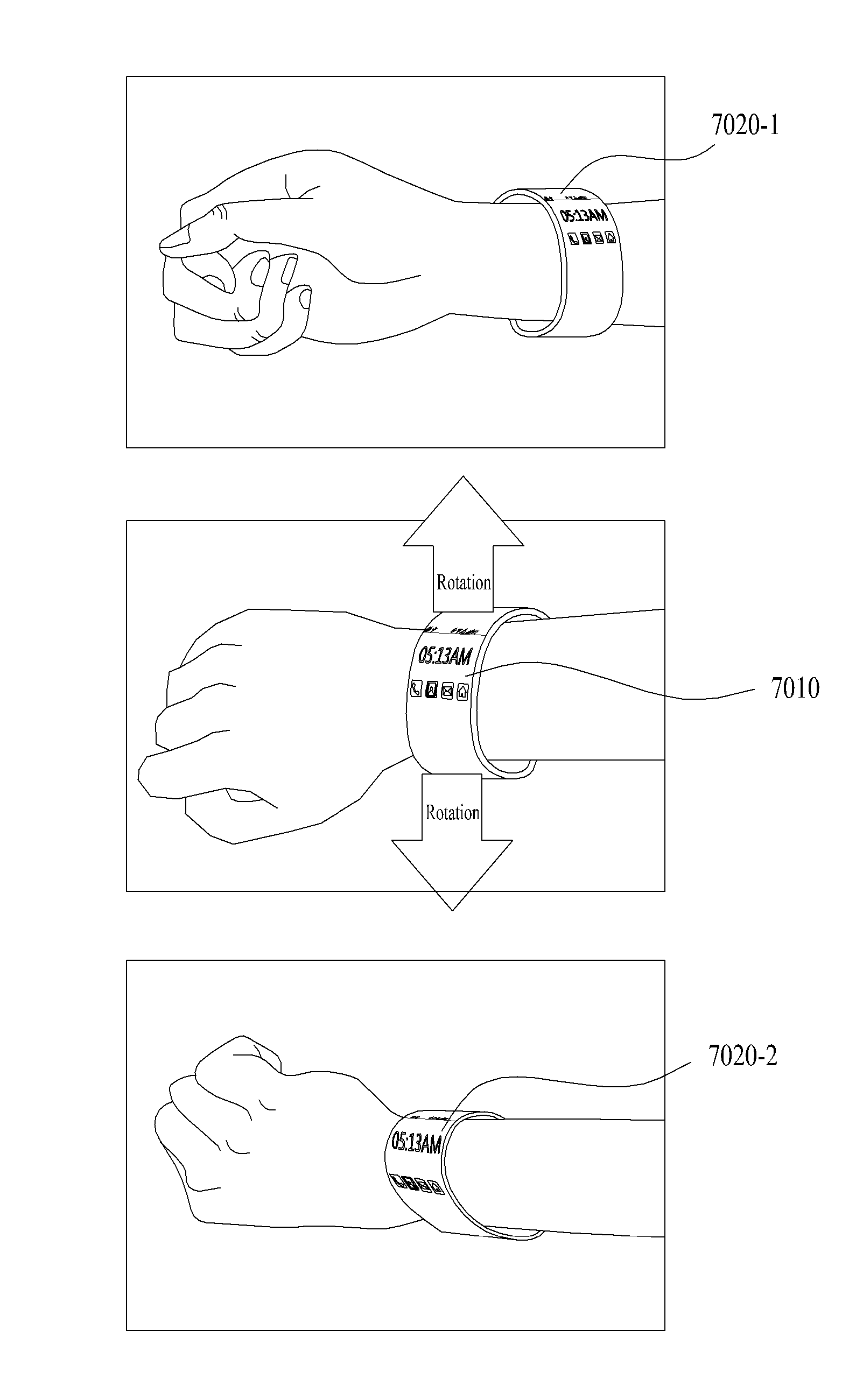

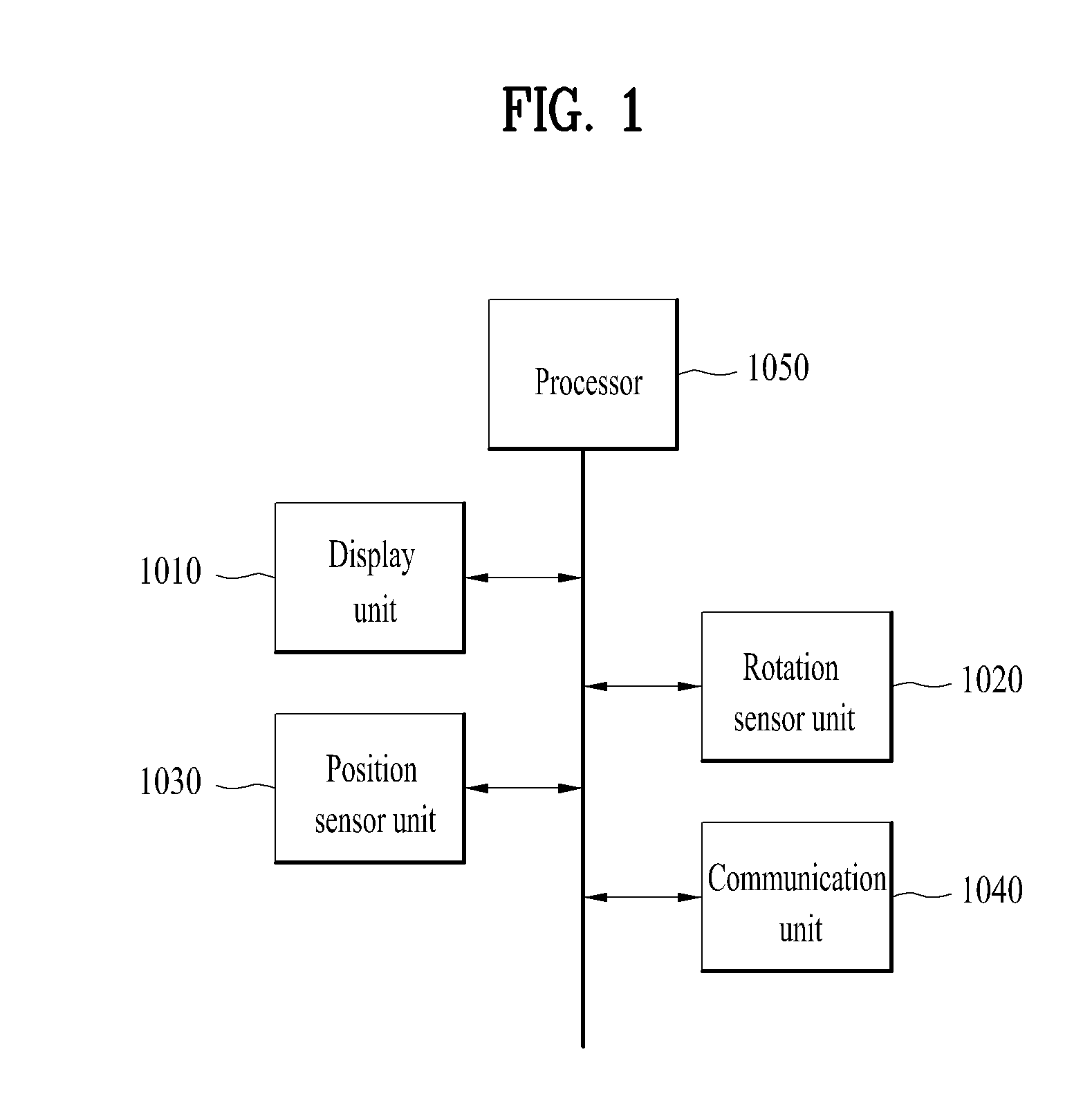

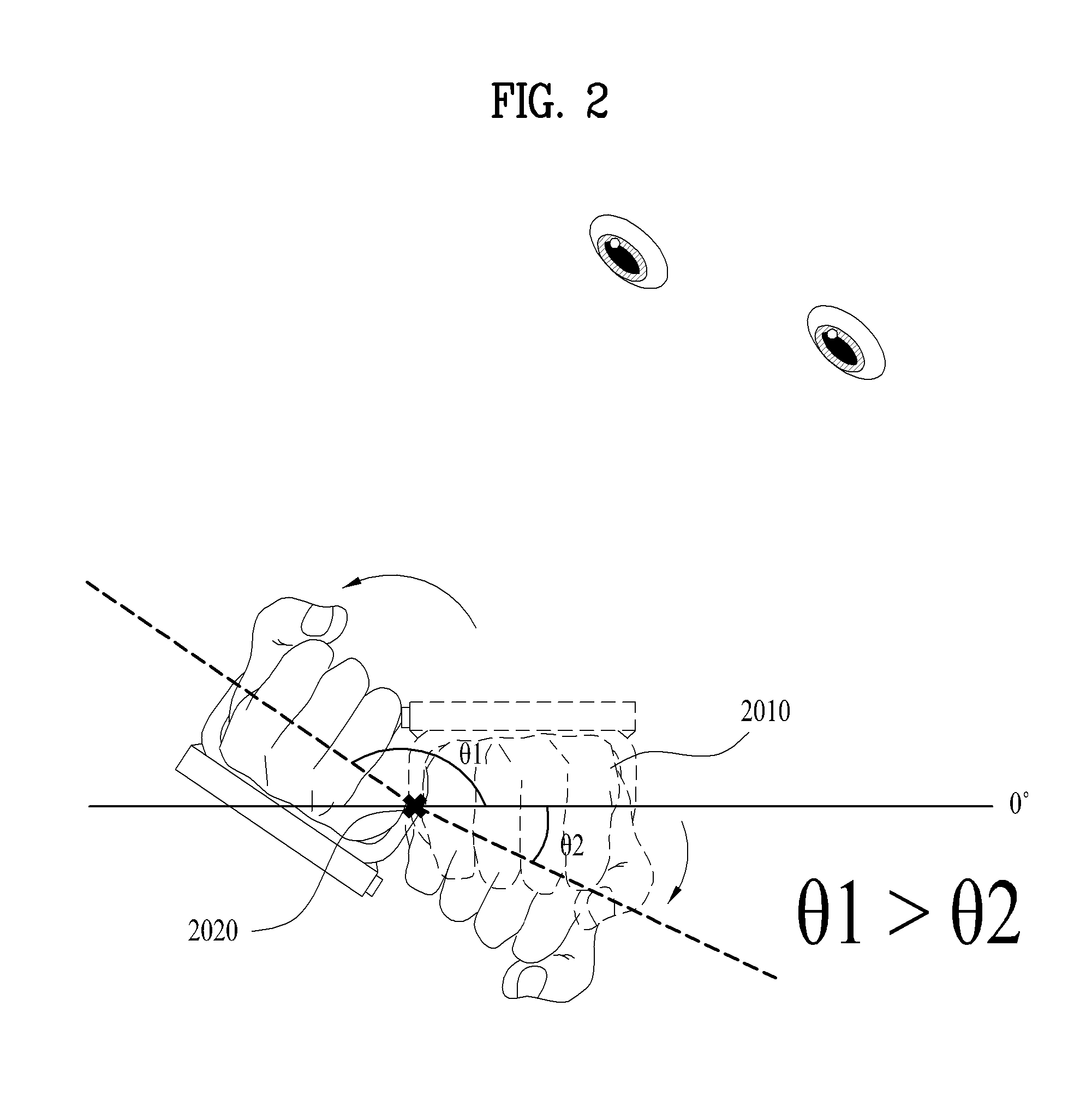

Smart watch and control method thereof

Discussed are a smart watch and a control method thereof. The smart watch includes a rotation sensor unit configured to sense a rotation direction and a rotation speed of the smart watch; a display unit configured to display visual information; and a processor configured to control the rotation sensor unit and the display unit and detect a first snap motion and a second snap motion of the smart watch. The first snap motion is detected when the smart watch rotates on an axis of rotation of the smart watch in a first direction at a first threshold speed or more, and the second snap motion is detected when the smart watch rotates on the axis of rotation in the first direction at less than the first threshold speed and then rotates in a second direction at a second threshold speed or more within a predetermined time.

Owner:LG ELECTRONICS INC

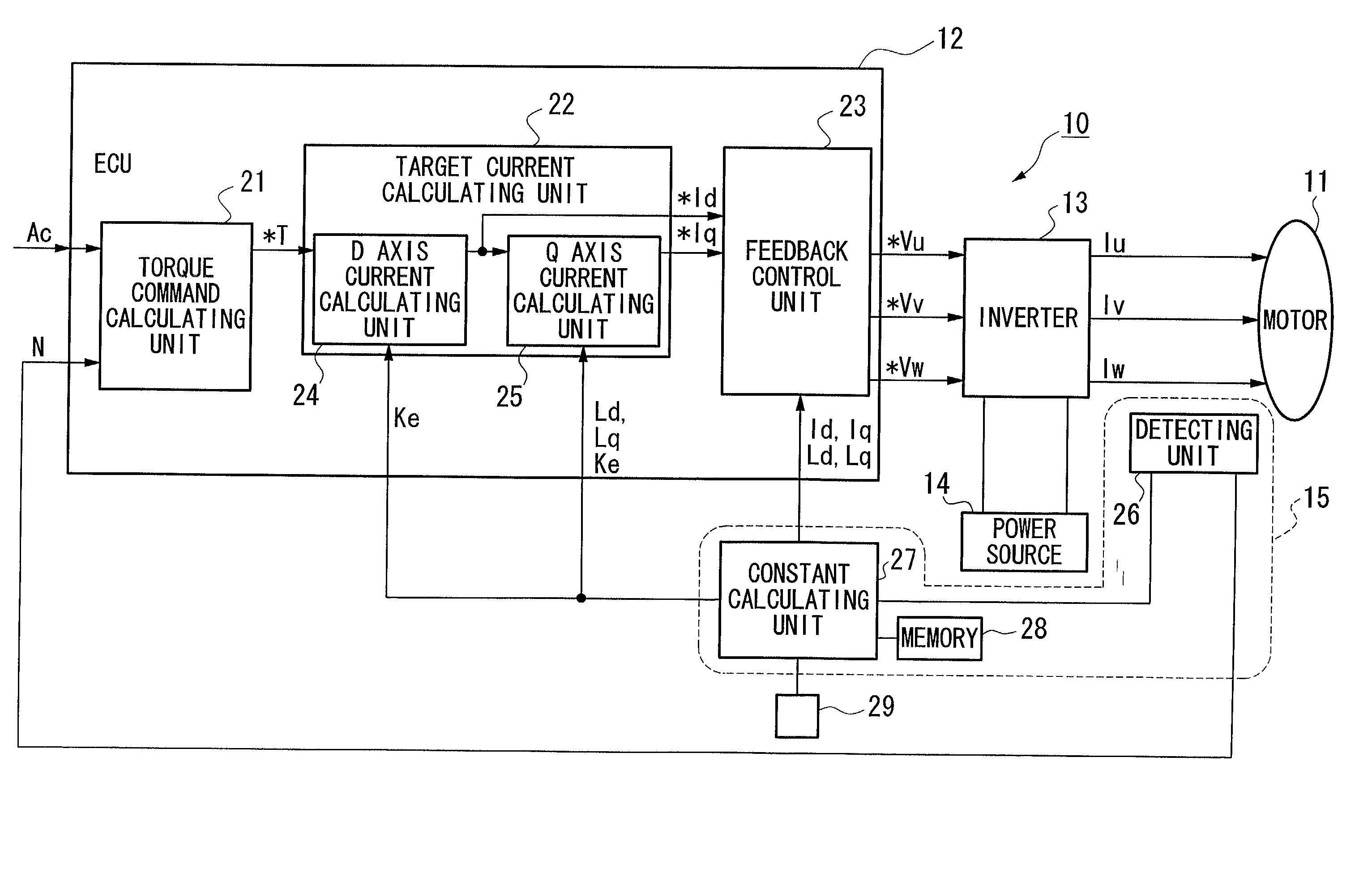

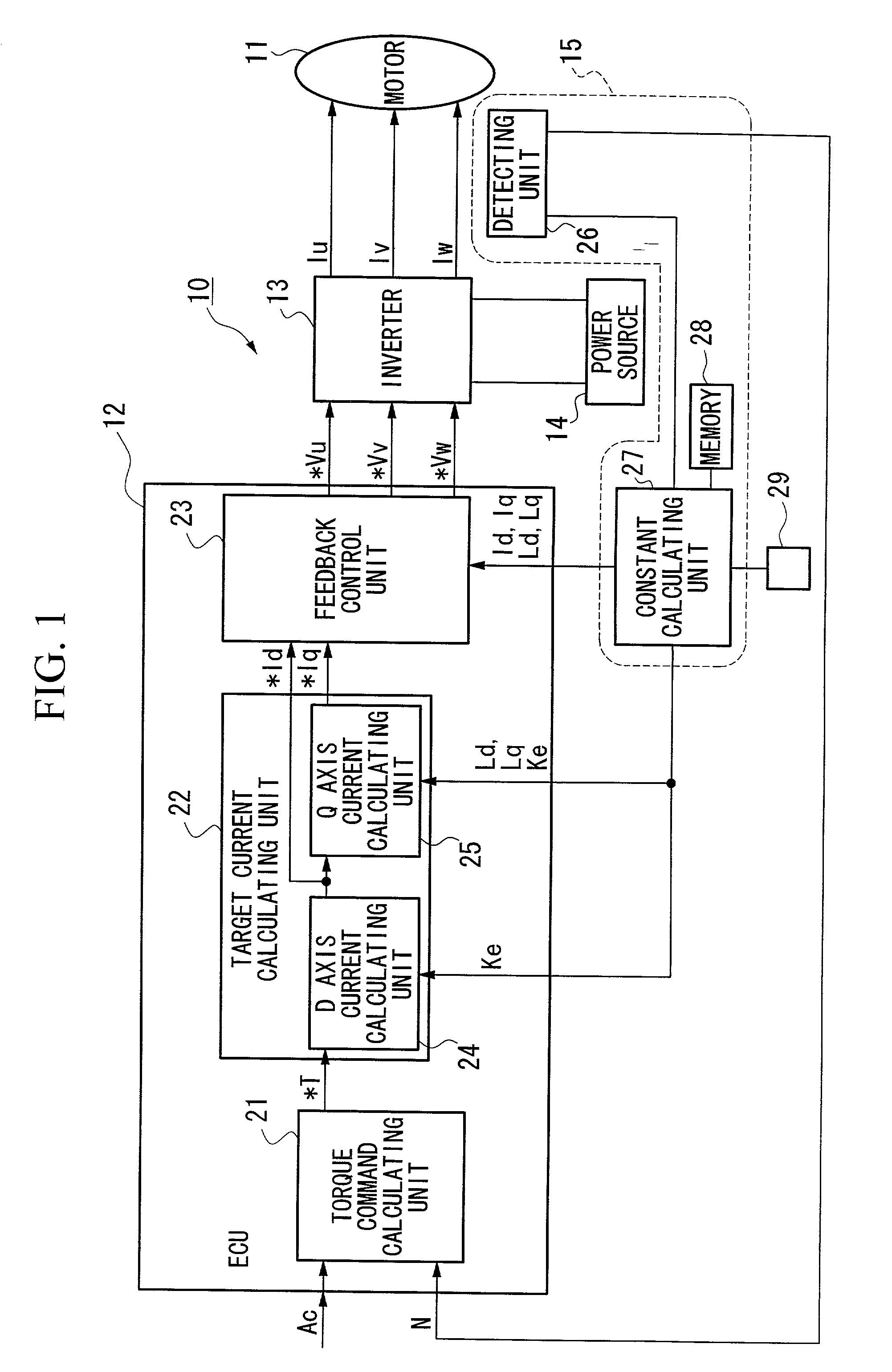

Constant detecting apparatus for brushless DC motor, control apparatus for brushless DC motor, and program for detecting constant of brushless DC motor

InactiveUS20020113615A1Easy to calculateImprove errorAnalogue computers for vehiclesSynchronous motors startersPhase currentsConductor Coil

A constant detecting apparatus 15 comprising a detecting unit 26 and a calculating unit 27. The detecting unit 26 is structured comprising a rotation sensor 41, a torque sensor 42, a position sensor 43, a rotor temperature sensor 44, a winding temperature sensor 45, a phase voltage detector 46, and phase current detectors 47 and 47. The calculating unit 27 calculates the induced voltage constant Ke that changes depending on the motor temperature Tmag while the motor 11 is being driven based on each of the detected signals from the detecting unit 26, and at the same time, the d axis current Id and the q axis current Iq are calculated after elimination of the iron loss, and the d axis inductance Ld and the q axis inductance Lq in the actual operating state of the motor 11 are calculated.

Owner:HONDA MOTOR CO LTD

Ultrasound catheter with rotatable transducer

An ultrasound catheter assembly having a rotatable transducer assembly is disclosed. The ultrasound catheter assembly includes an elongate flexible shaft having a lumen and a proximal end and a distal end. The catheter assembly further includes a drive member that engages the transducer assembly at a distal end of the catheter. Rotation of the drive member in a first direction causes the transducer assembly to rotate in an oscillatory fashion in a second direction.

Owner:VOLCANO CORP

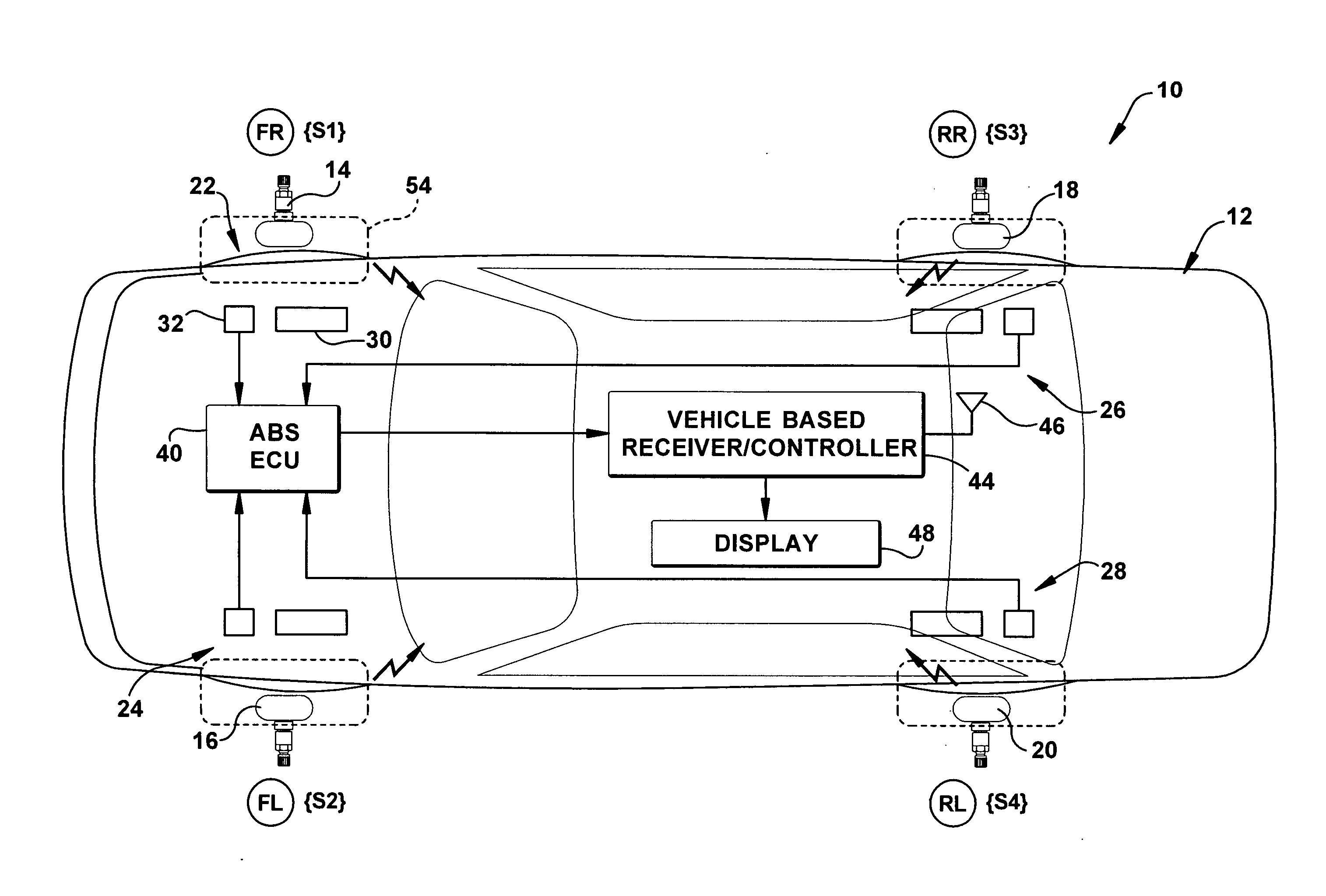

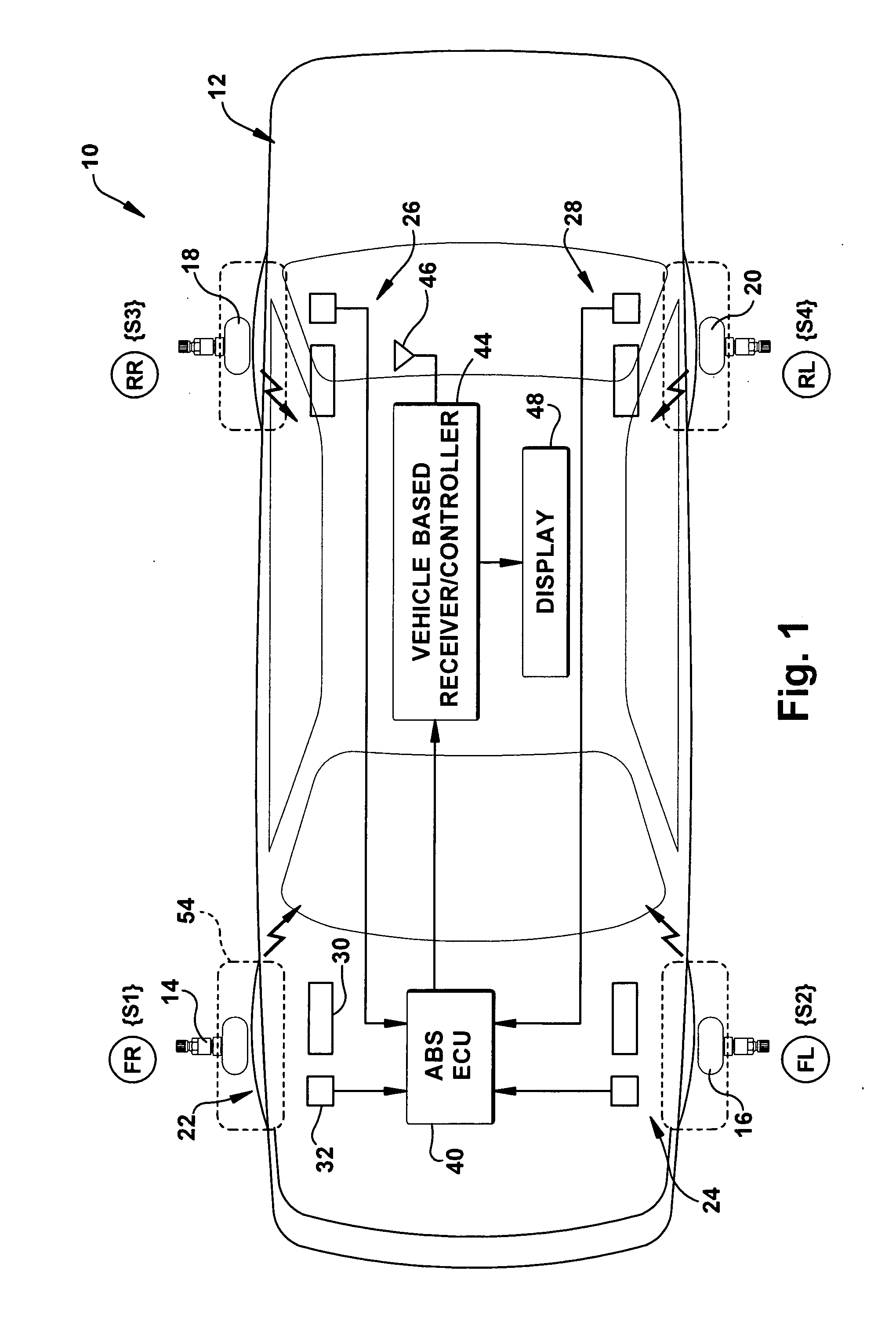

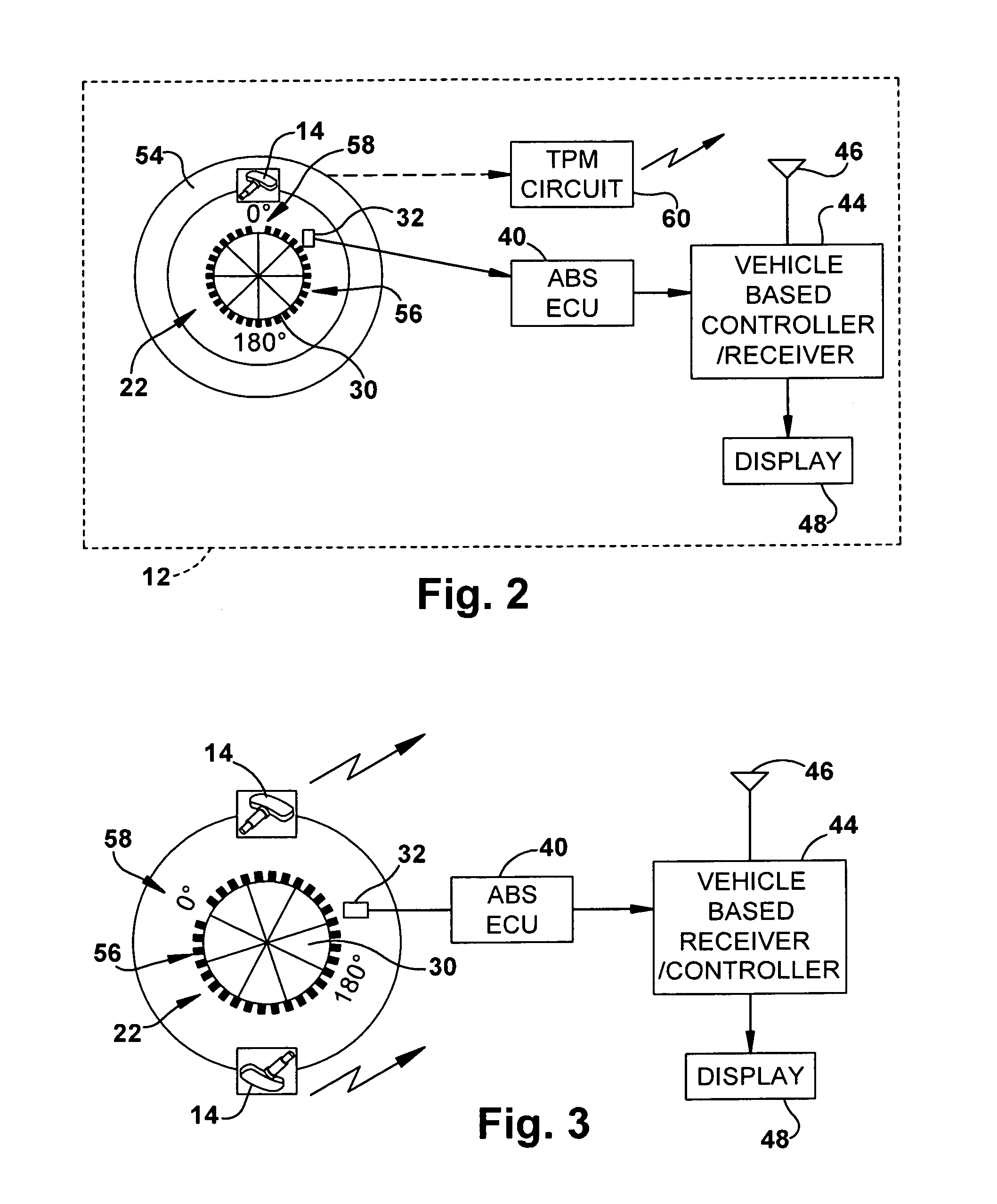

Method and apparatus for determining tire condition and location

An apparatus (10) determines a tire condition and location on a vehicle (12) including a tire-based sensing unit (14), a plurality of tires (54) on the vehicle having an associated tire-based sensing unit, each tire-based sensing unit (14) including, a first tire rotation sensor (66) mounted for rotation with the tire (54) and for providing a first tire rotation signal (80) each time the tire passes one of at least two predetermined rotational positions during tire rotation, a tire condition sensor (82) for sensing a tire condition and for providing a tire condition signal indicative thereof and an unique tire identification indicator, a transmitter (86) for transmitting the tire condition signal and the unique tire identification indicator, and a controller for controlling the transmitter so that the transmission of the tire condition signal and the unique tire identification indicator occurs when the first tire rotation signal indicates the tire has reached one of the at least two predetermined rotational positions during tire rotation. The apparatus further includes a second tire rotation sensor (22) mounted external of the tire for sensing tire rotation and for providing a second tire rotation signal indicative of incremental angular position of the tire relative to a reference. A vehicle-based receiver (44) receives the transmitted tire condition signal, the unique tire identification indicator, and the second tire rotation signal and correlates reception of the tire condition signal with the second tire rotation signal so as to associate the unique tire identification indicator with a particular tire location on the vehicle.

Owner:TRW AUTOMOTIVE US LLC

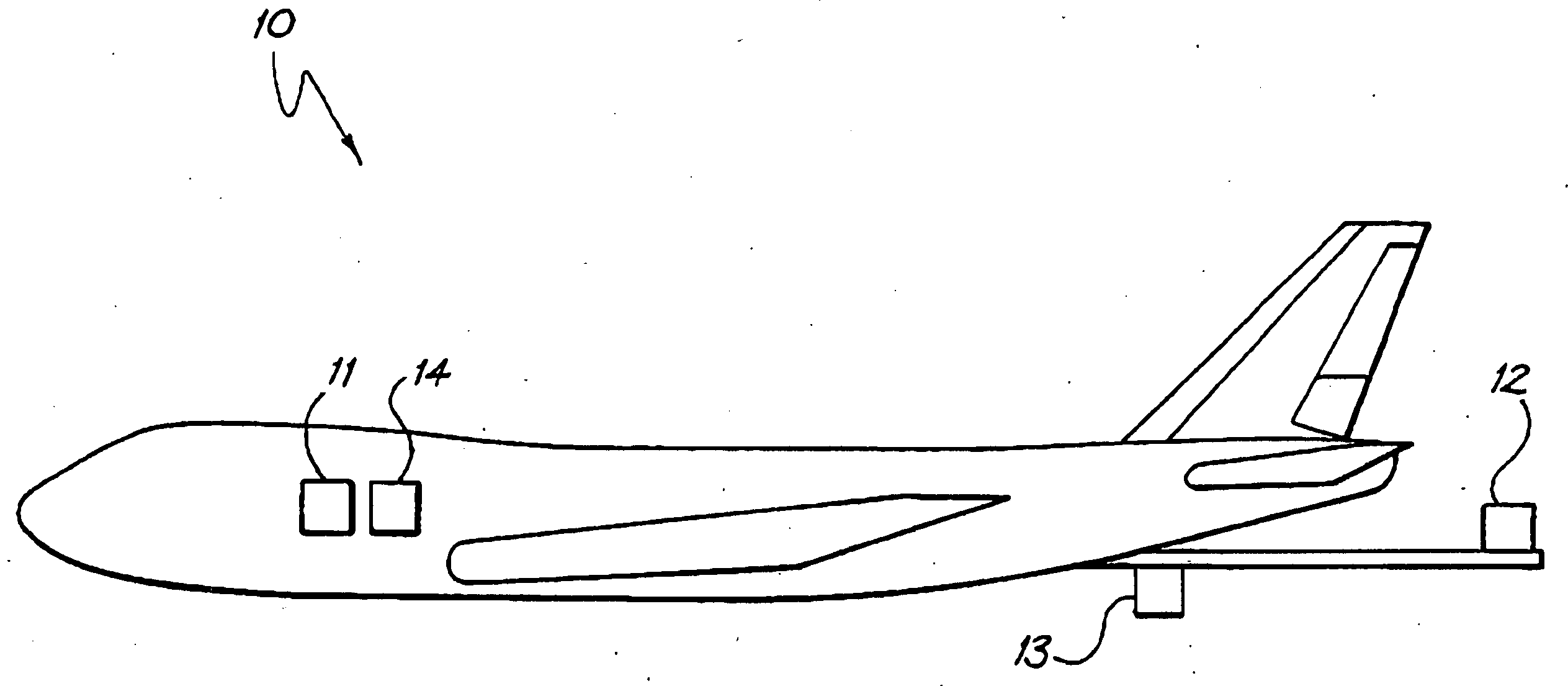

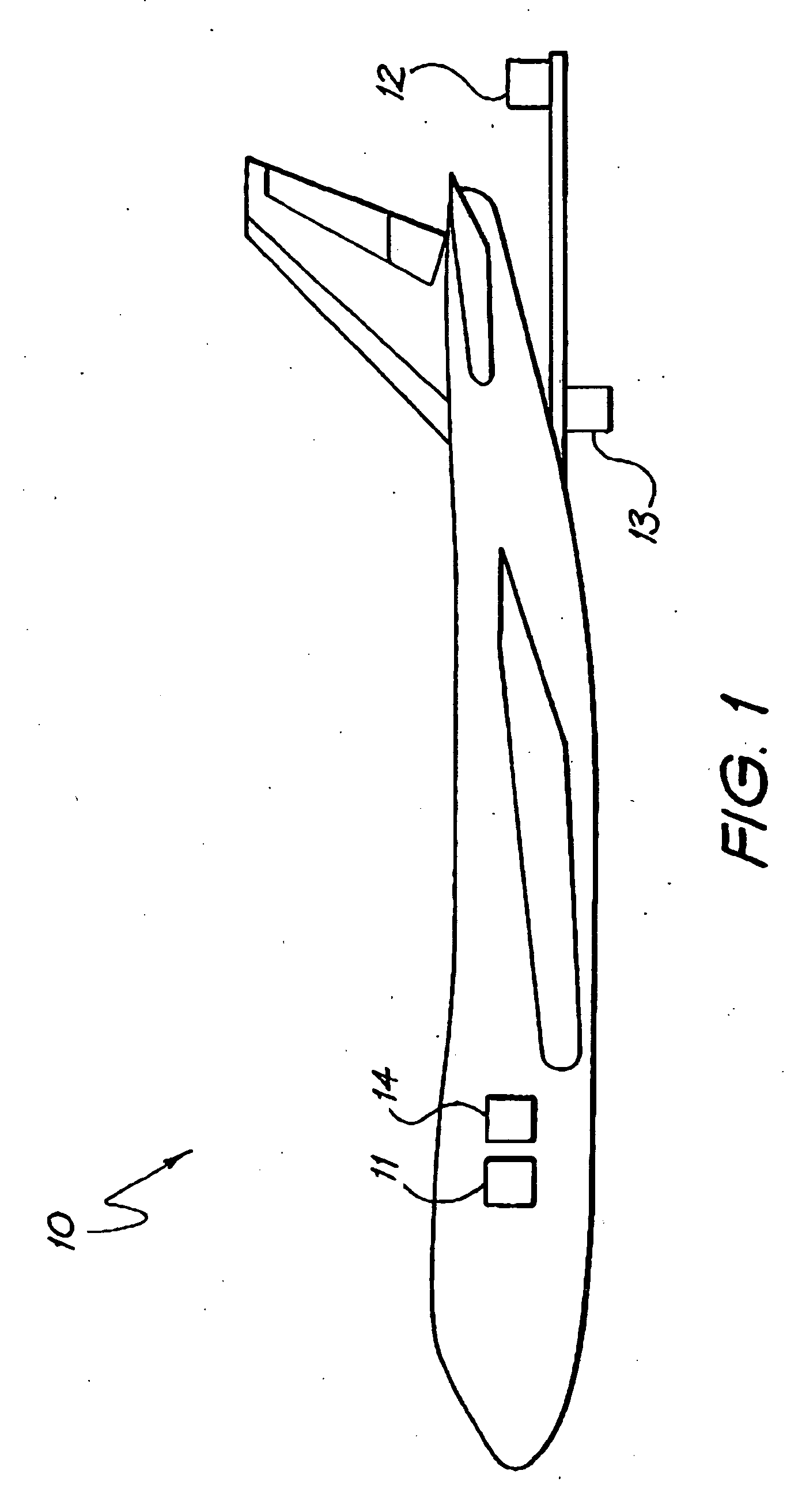

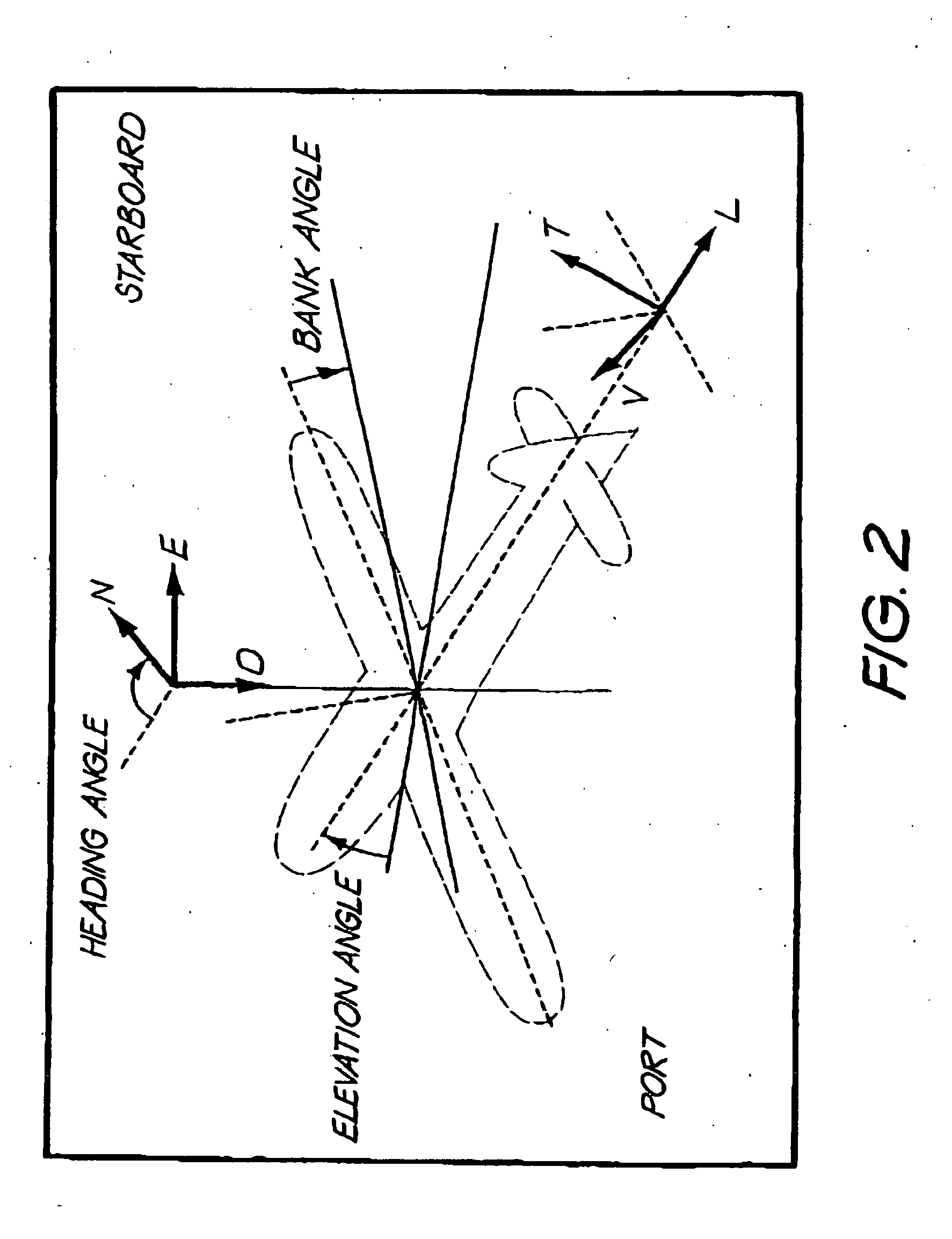

Airborne vector magnetic surveys

InactiveUS20050116717A1Reduce noiseImprove performanceStray field compensationAcoustic wave reradiationMagnetic tension forceMagnetic effect

An aircraft equipped for airborne vector magnetic exploration surveys comprising three magnetometers orthogonally mounted to measure the components of the earth's vector magnetic field; two rotation sensors mounted to measure the angular orientation of the aircraft; and a recording system to record the measurements of the magnetometers, and rotation sensors. The measured angular orientation is used to orientate the measured components of the earth's vector magnetic field to derive true vector acro-magnetic (VAM) data from airborne surveys. Also disclosed is a method for processing magnetic data by removing the permanent, induced, and eddy-current magnetic effects of the aircraft from the magnetic data.

Owner:FUGRO FINANCE

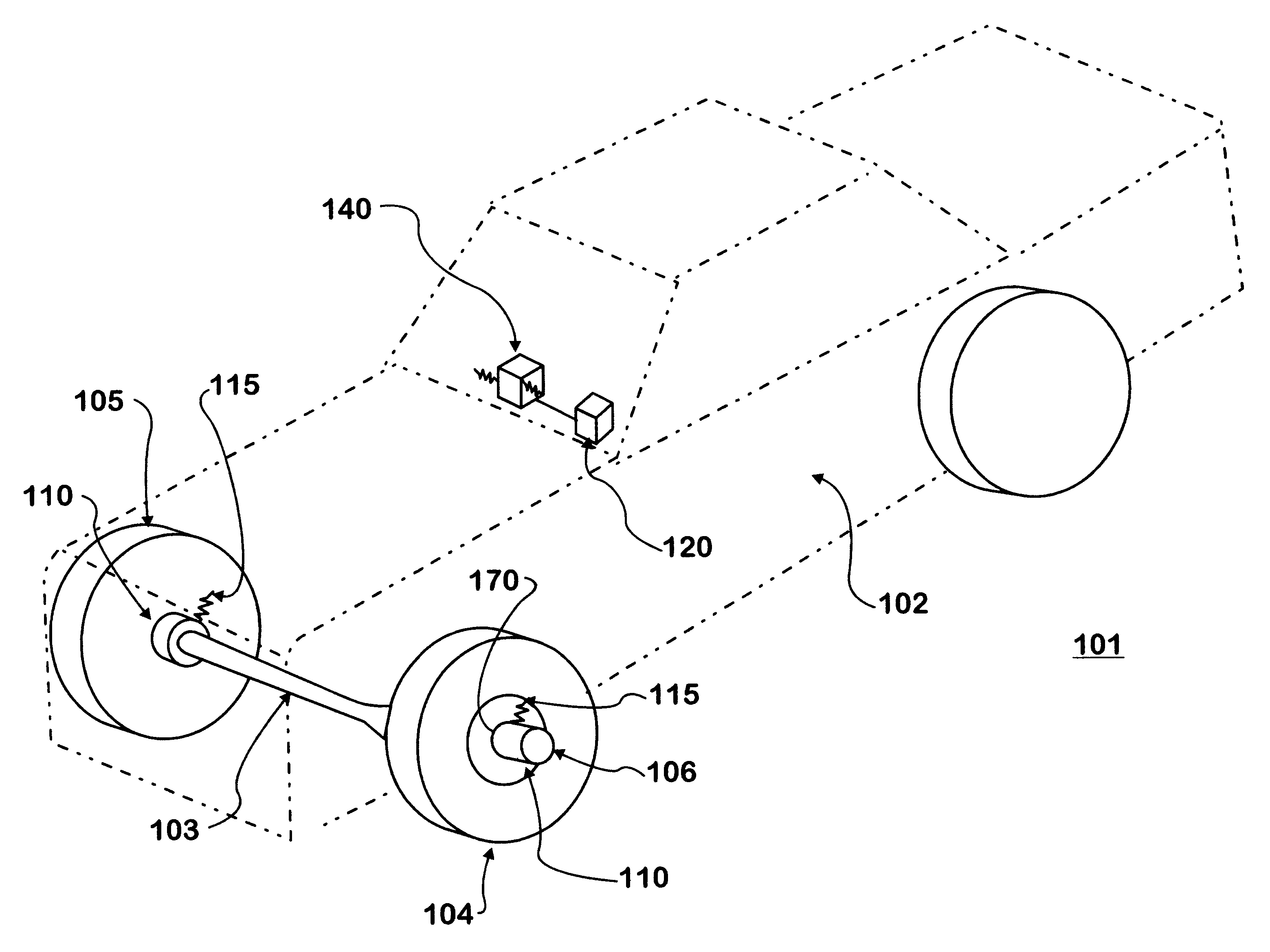

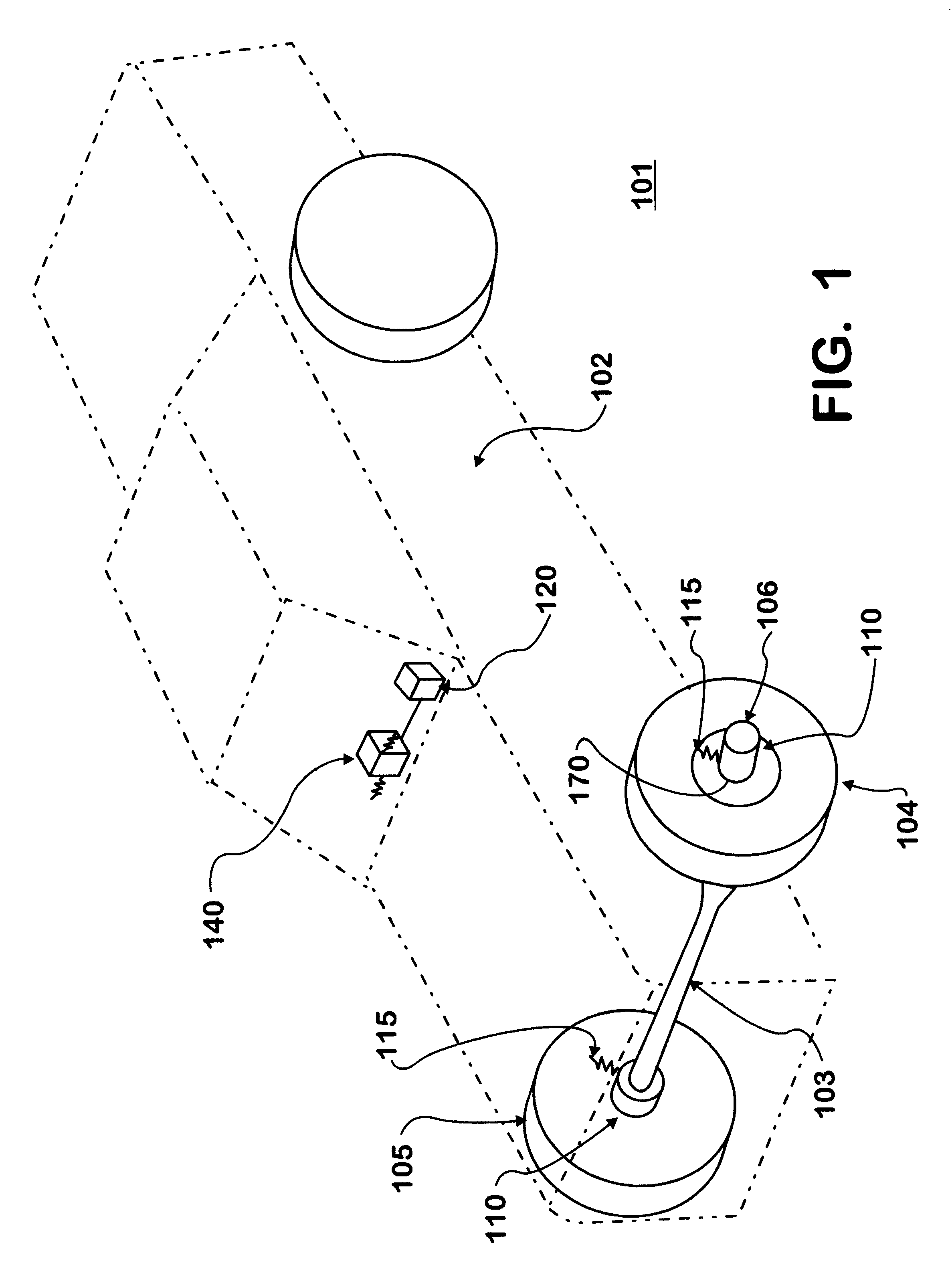

Gravimetric rotation sensors: dead reckoning, velocity, and heading sensor system for vehicle navigation systems

InactiveUS6466887B1Less importantHigh precisionInstruments for road network navigationAcceleration measurement using interia forcesAccelerometerIn vehicle

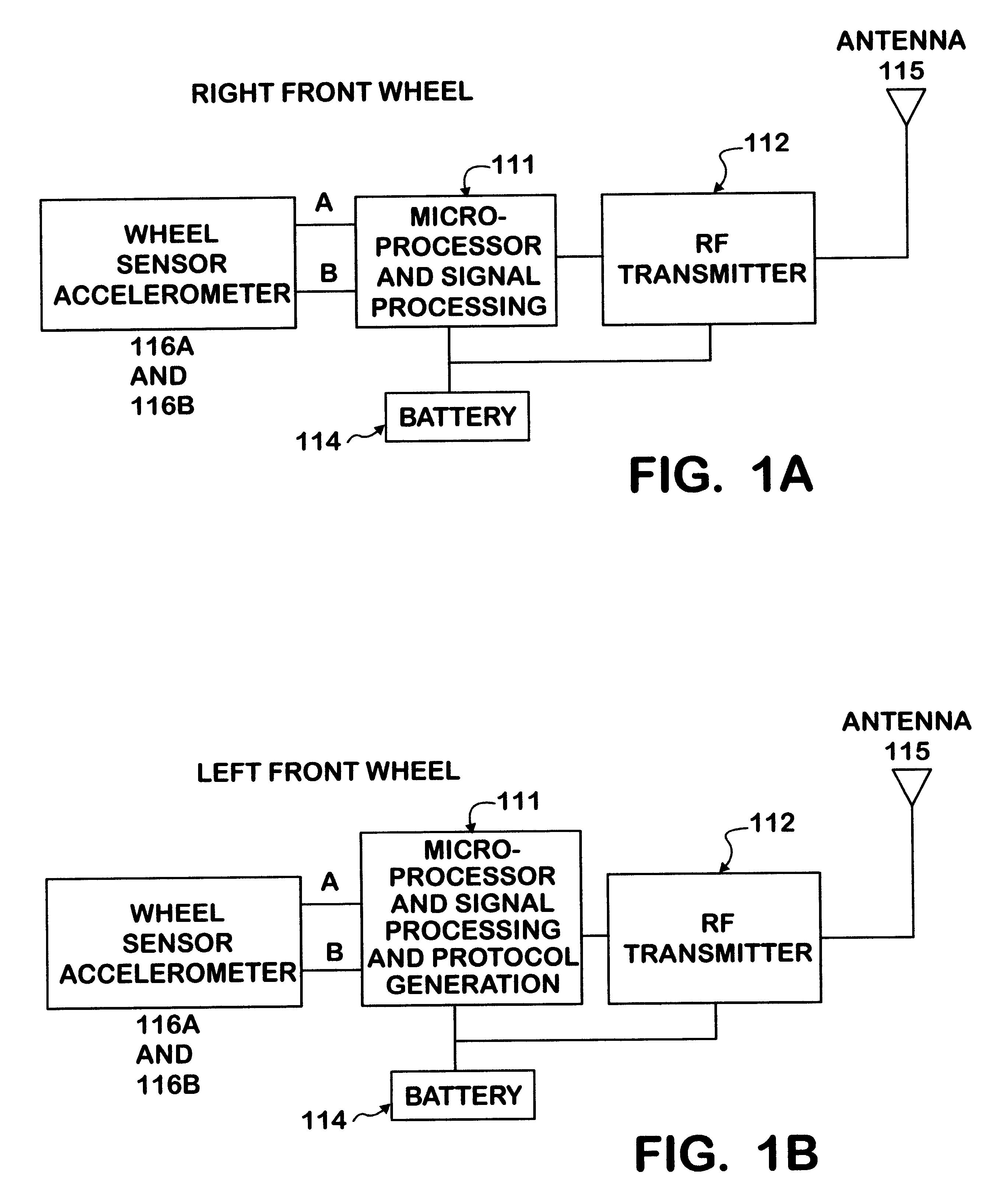

A rotational sensor for use with an in-vehicle navigation system , a navigation system that uses the sensor, and a vehicle with the sensor installed. The rotational sensor is created by placing two gravitational accelerometers configured at 90 degrees with respect to one another and mounted at the center of a vehicle wheel. As this resulting sensor is rotated, sine and cosine signals with a quadrature relationship are generated with respect to the earth's gravity vector, from which both rotation and direction of rotation can be determined. These signals may then allow the counting of the turns of the wheel, thus estimating the distance and the rate at which the vehicle has moved. A self-contained version of this device including a transmitter can relay this information to a receiving unit located within the vehicle. When one of these devices is located on each of the steerable wheels of the vehicle, the relative heading-direction of the vehicle may also be estimated.

Owner:WEINBRENNER RICHARD L

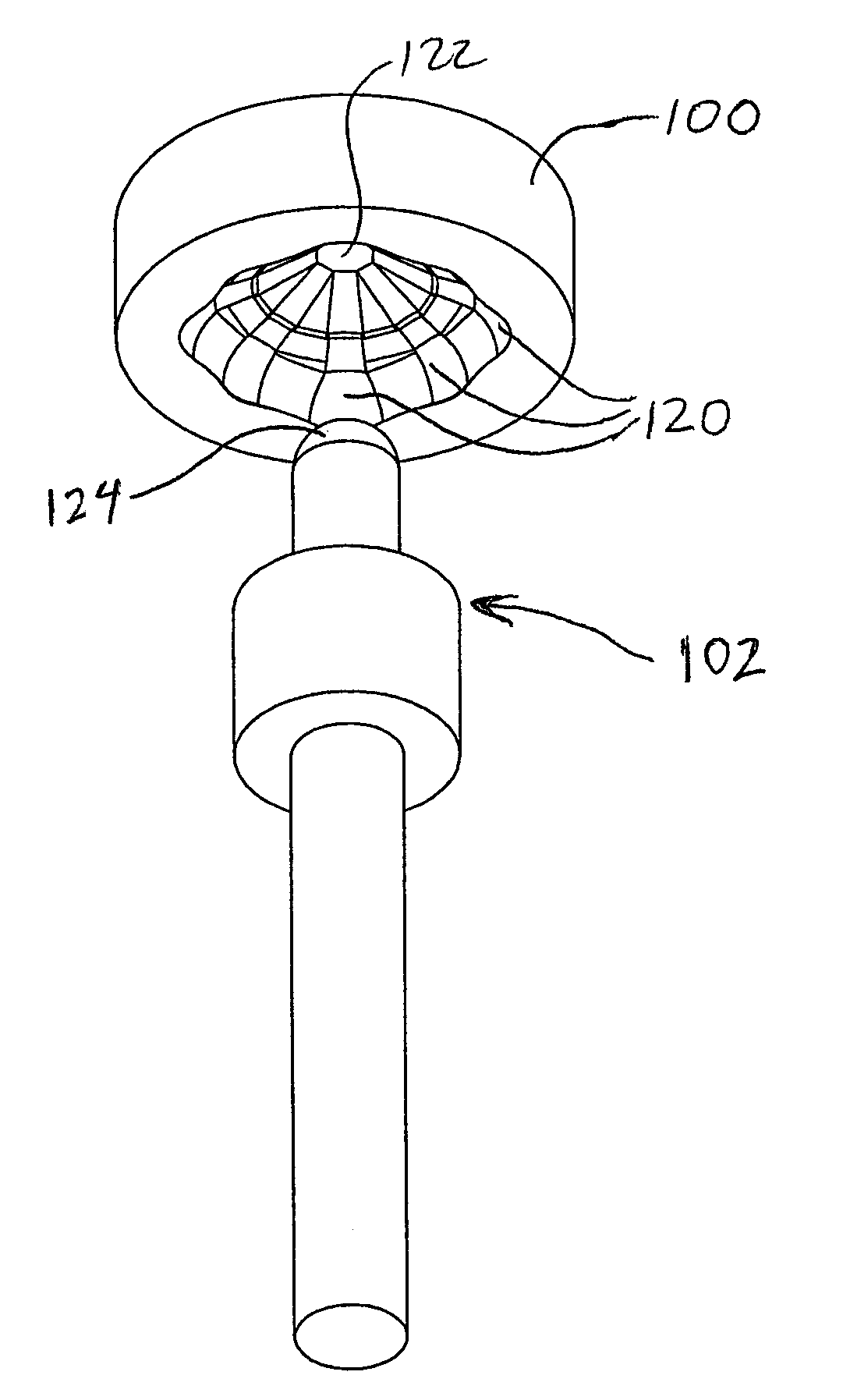

Combine header height control

InactiveUS6202395B1Accurate height positioningReduce combine ingestionAgricultural machinesMowersCoil springEngineering

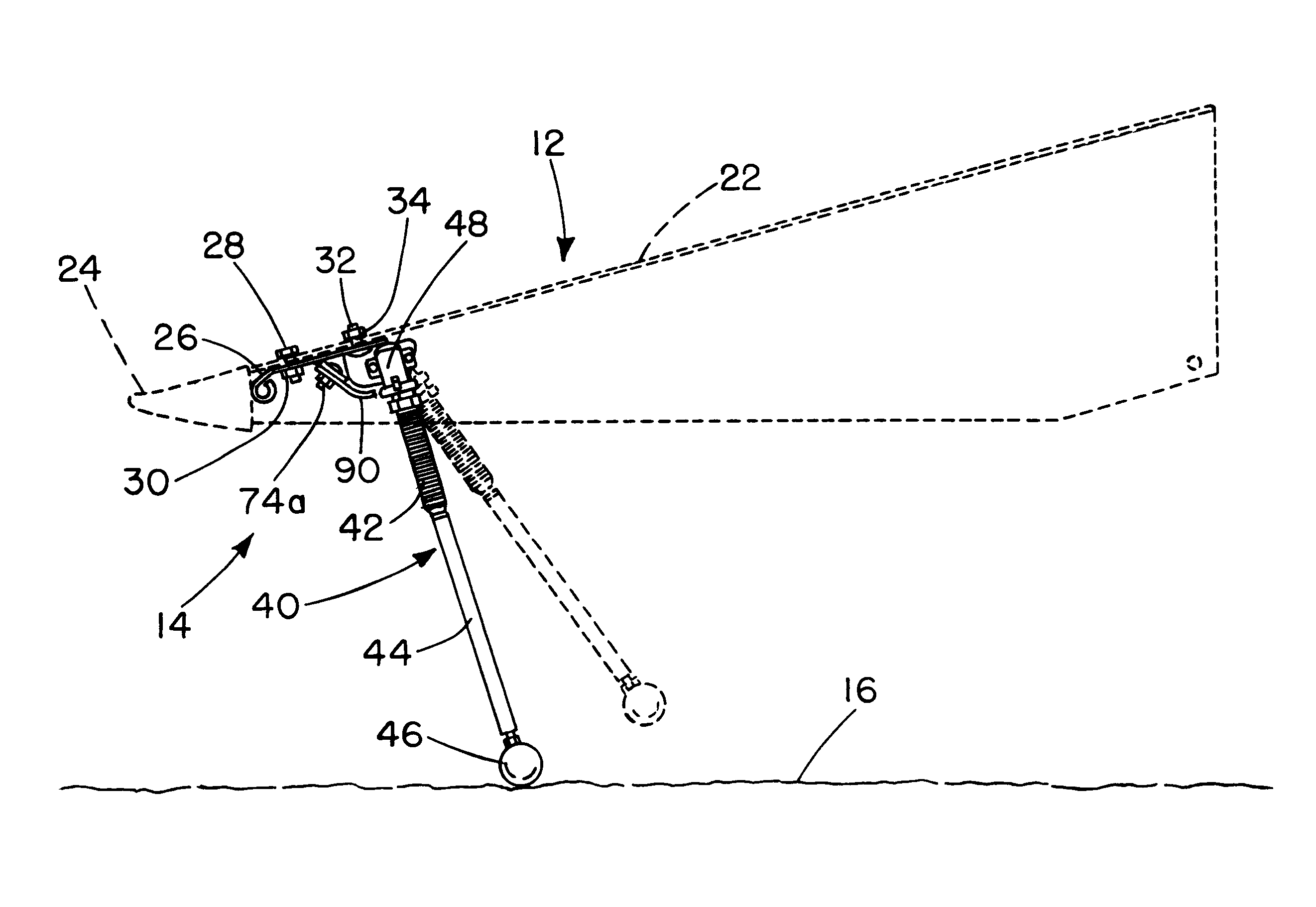

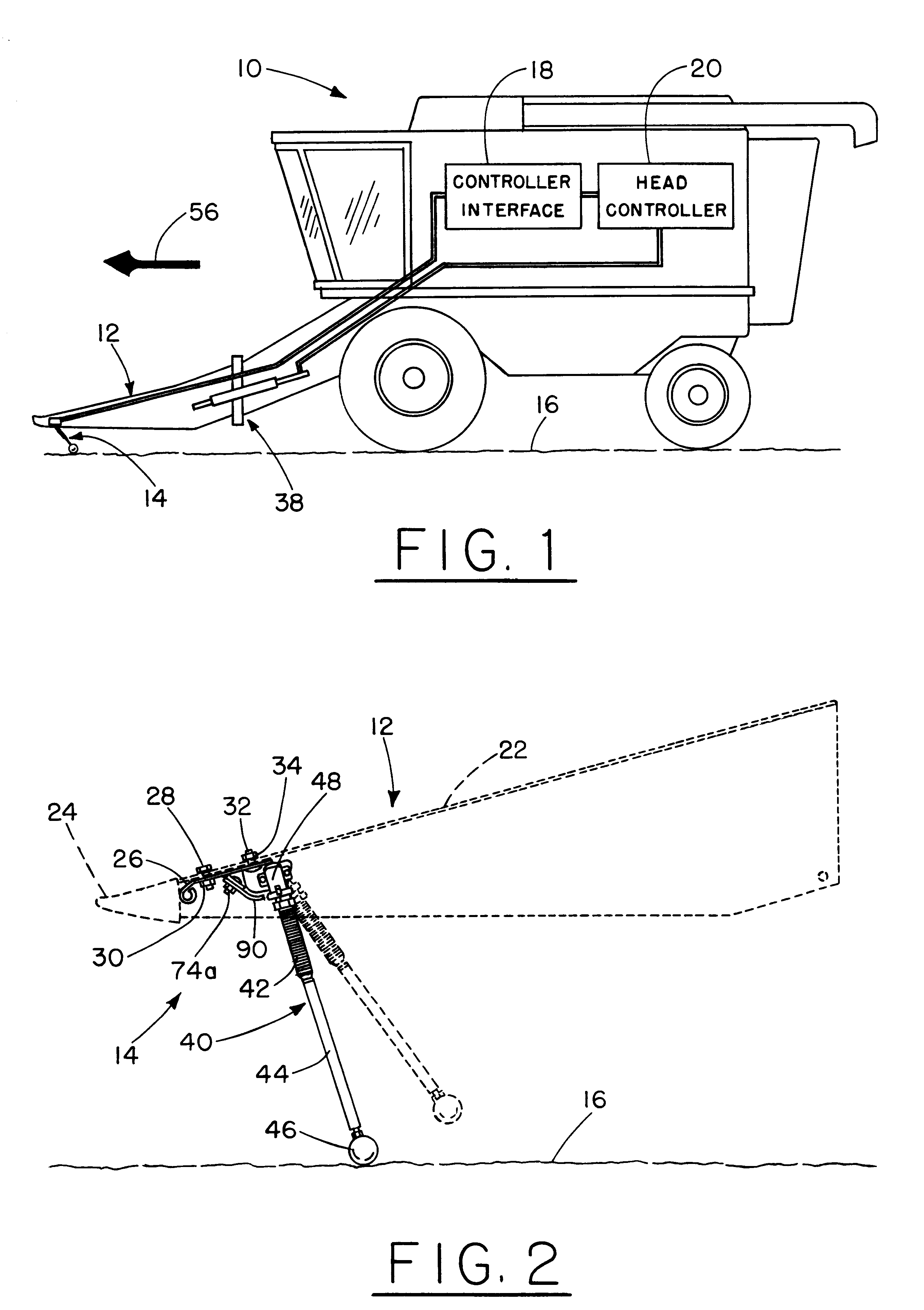

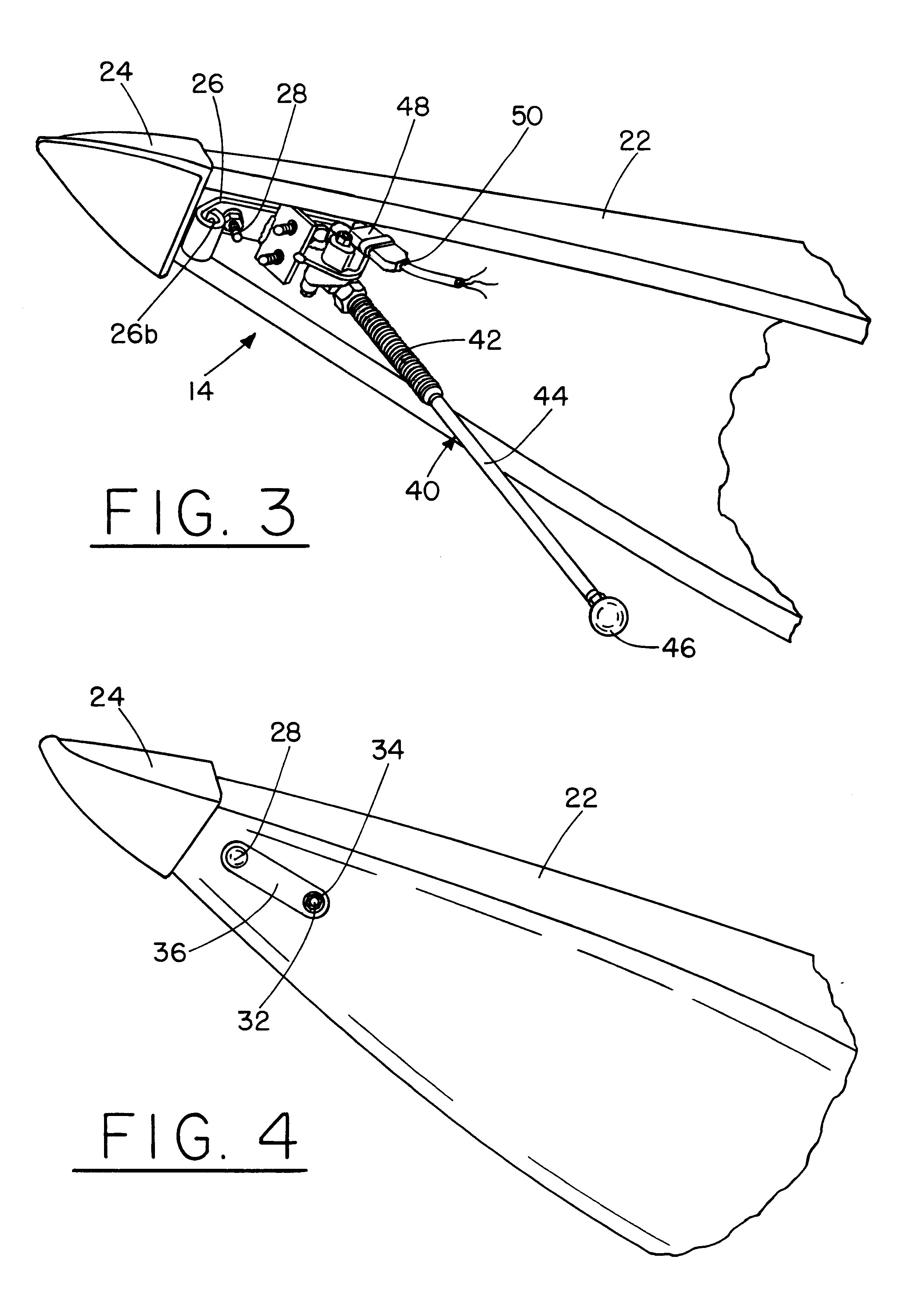

An arrangement for controlling the height above or depth below an irregular surface of a body moving over or below the surface includes a rotation sensor coupled to a controller responsive to an angular deflection signal output by the rotation sensor. The rotation sensor and controller are mounted to a vehicle moving over the surface such as an agricultural vehicle traversing a field. A semi-rigid, flexible arm has a first end coupled to the rotation sensor with a ground engaging member attached to a second opposed end of the arm. In one embodiment, the flexible arm includes an elongated coil spring attached to a rigid shaft and the ground engaging member is a spherical ball attached to the shaft's distal end. The coil spring is pre-loaded to a selected bending or flexure force and permits the ground engaging member to impact obstructions in the field without damage to the rotation sensor. The coil spring also prevents damage to the rotation sensor when the vehicle is reversed in direction. The flexible arm may be urged downwardly to ensure that the ground engaging member contacts the soil and upward and downward rotation stops may be provided to limit rotation of the rotation sensor and flexible arm combination. When a plurality of rotation sensors and flexible arms are employed such as along the length of a combine header, each rotation sensor may be individually calibrated by rotating the sensor relative to the head unit to which it is mounted to permit all sensors to uniformly measure the height above or depth below the soil surface.

Owner:GRAMM RICHARD

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS8989905B2Easy to useThermometer detailsTransportation and packagingDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

Wave energy converter

A wave energy converter has a shell, a pendulum pivotally positioned in the shell, a magnet thereon, a variable inductor positioned in the shell, a pendulum adjustor for changing a center of gravity of the pendulum, a motion sensor positioned in the shell, a position sensor connected to the pendulum, a rotation sensor connected to the pendulum, and a controller connected to the motion sensor and the position sensor and the rotation sensor. The pendulum has a magnet thereon. The magnet of the pendulum oscillates adjacent the variable inductor. The variable inductor can adjust the inductive capacity.

Owner:HOBDY MILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com