Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8666 results about "Manufacturing cost reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

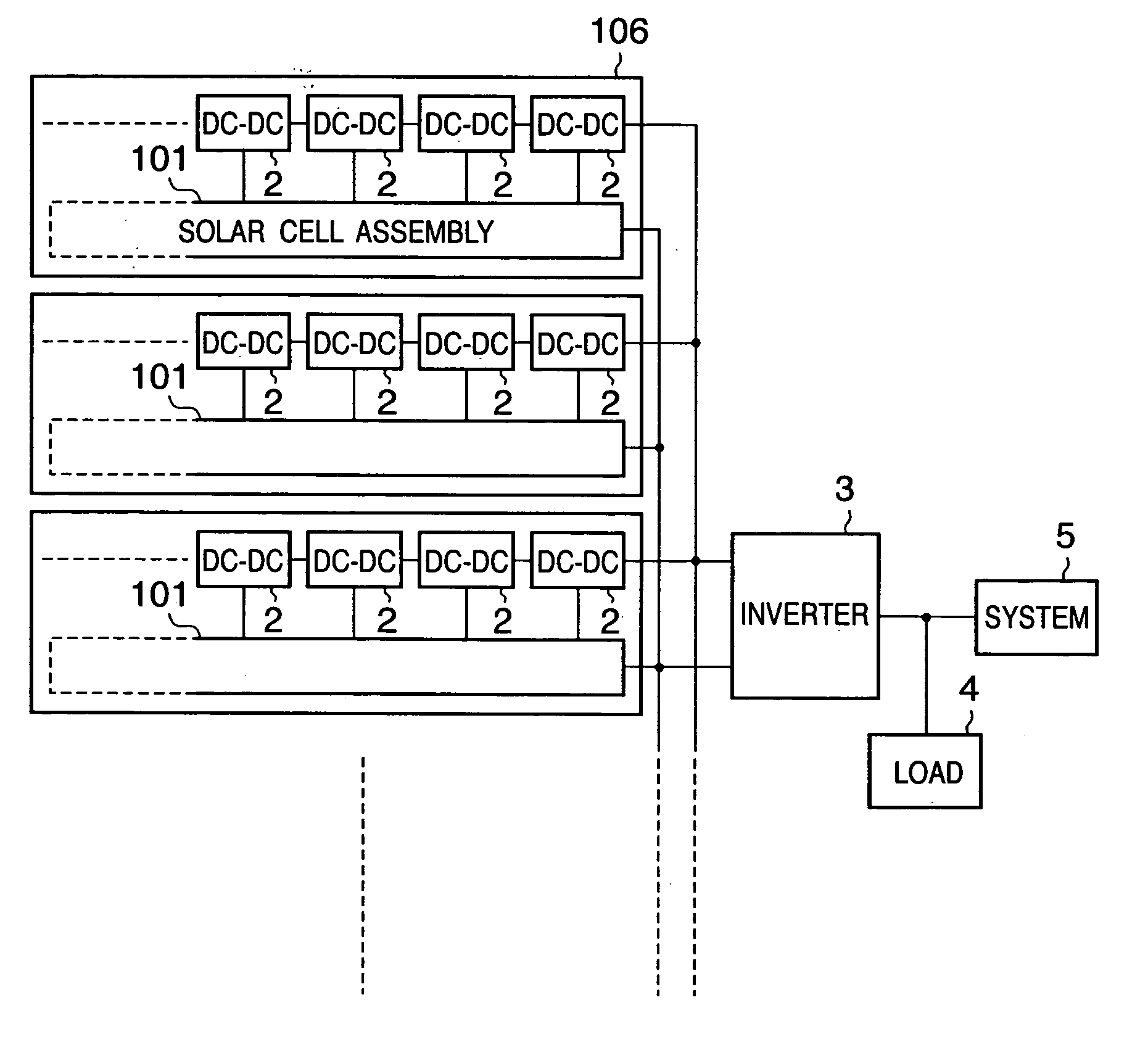

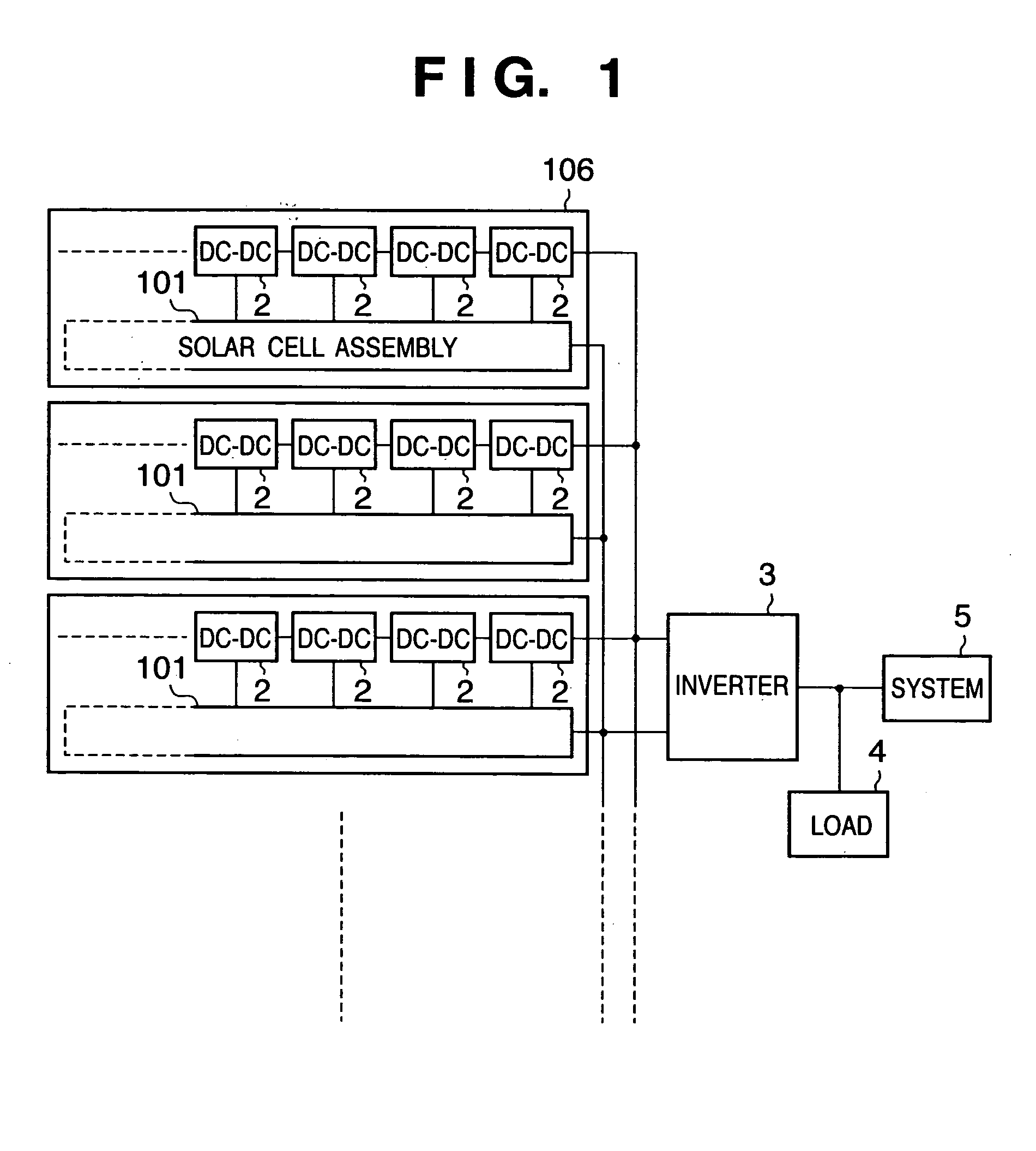

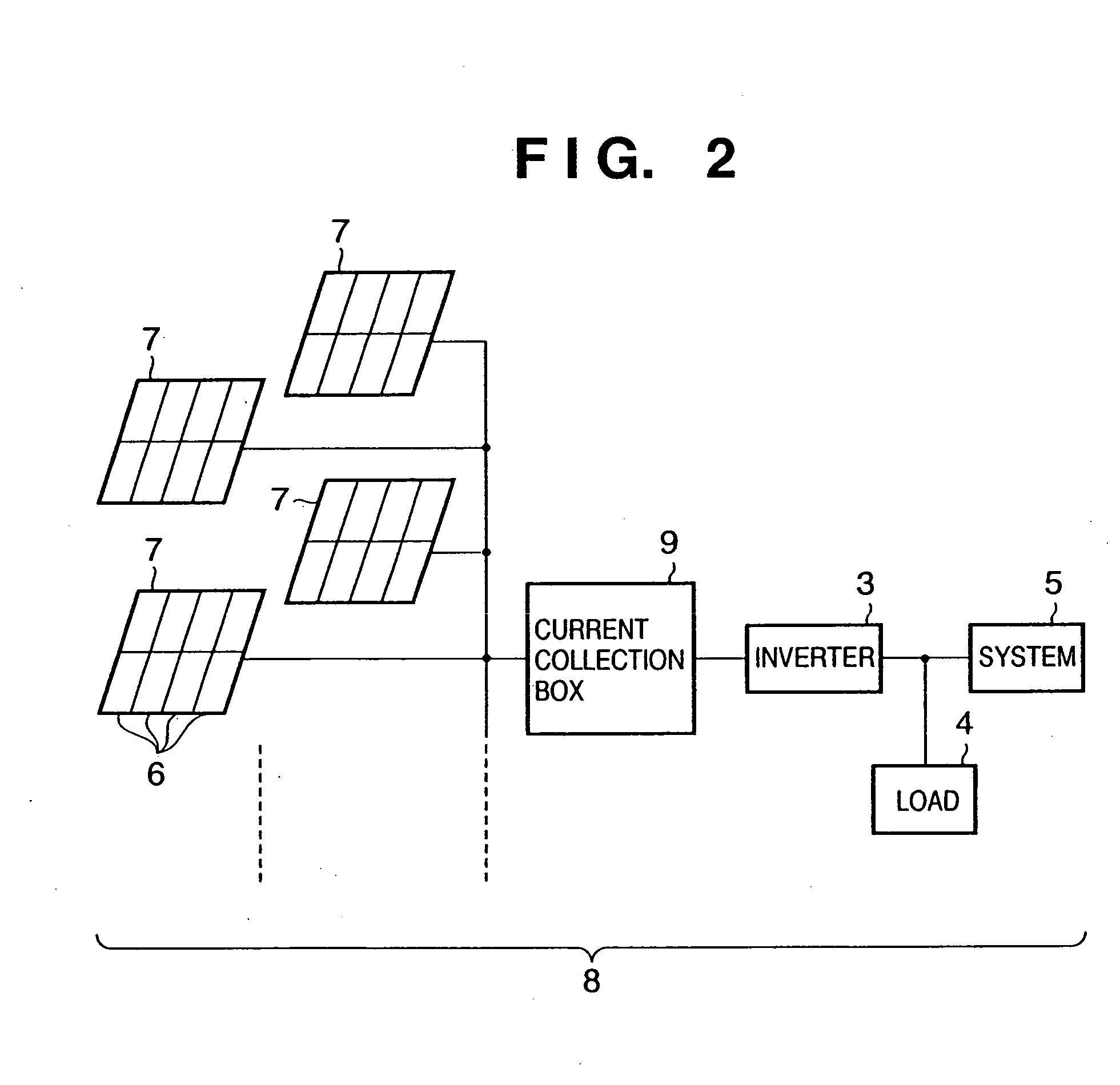

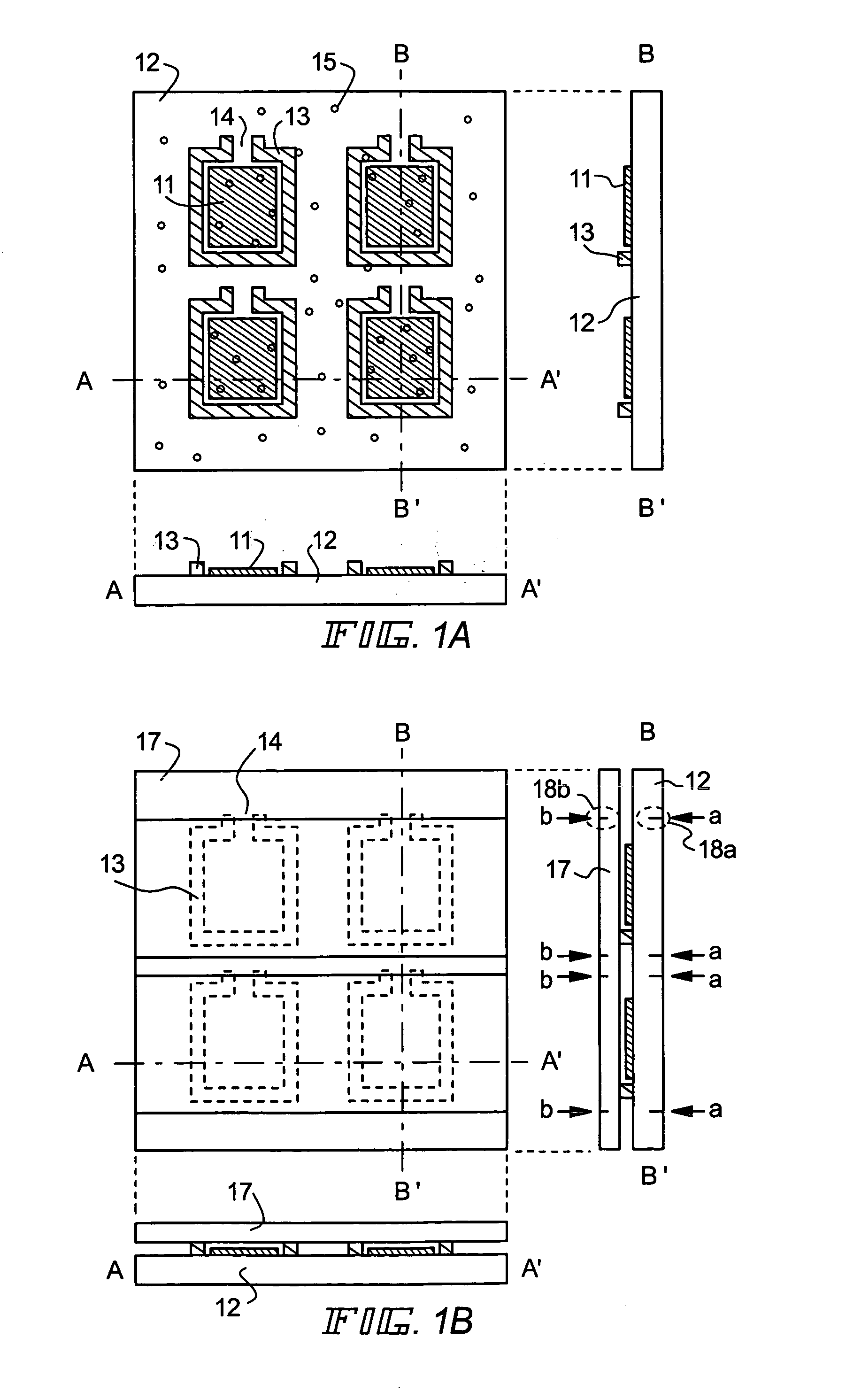

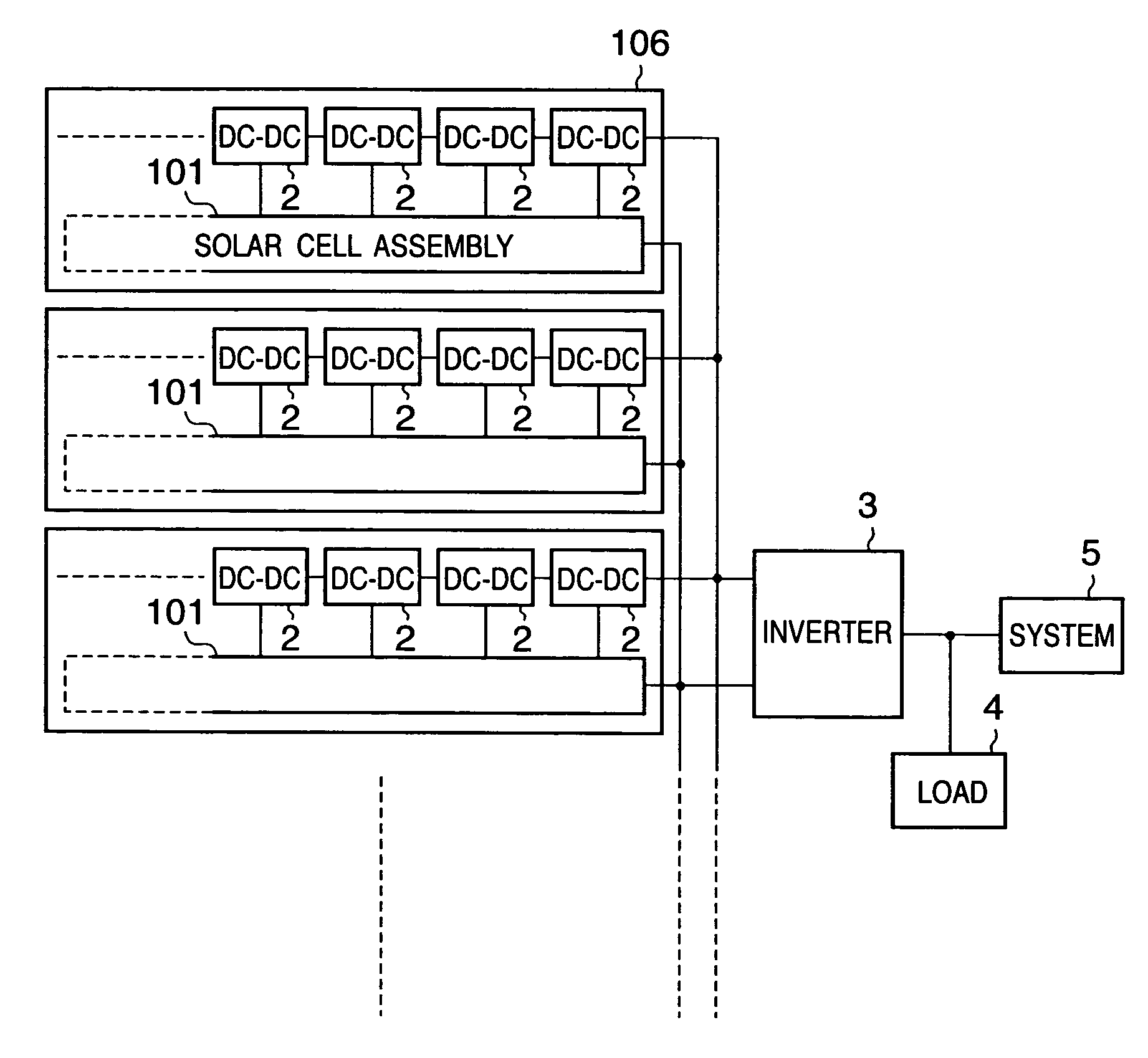

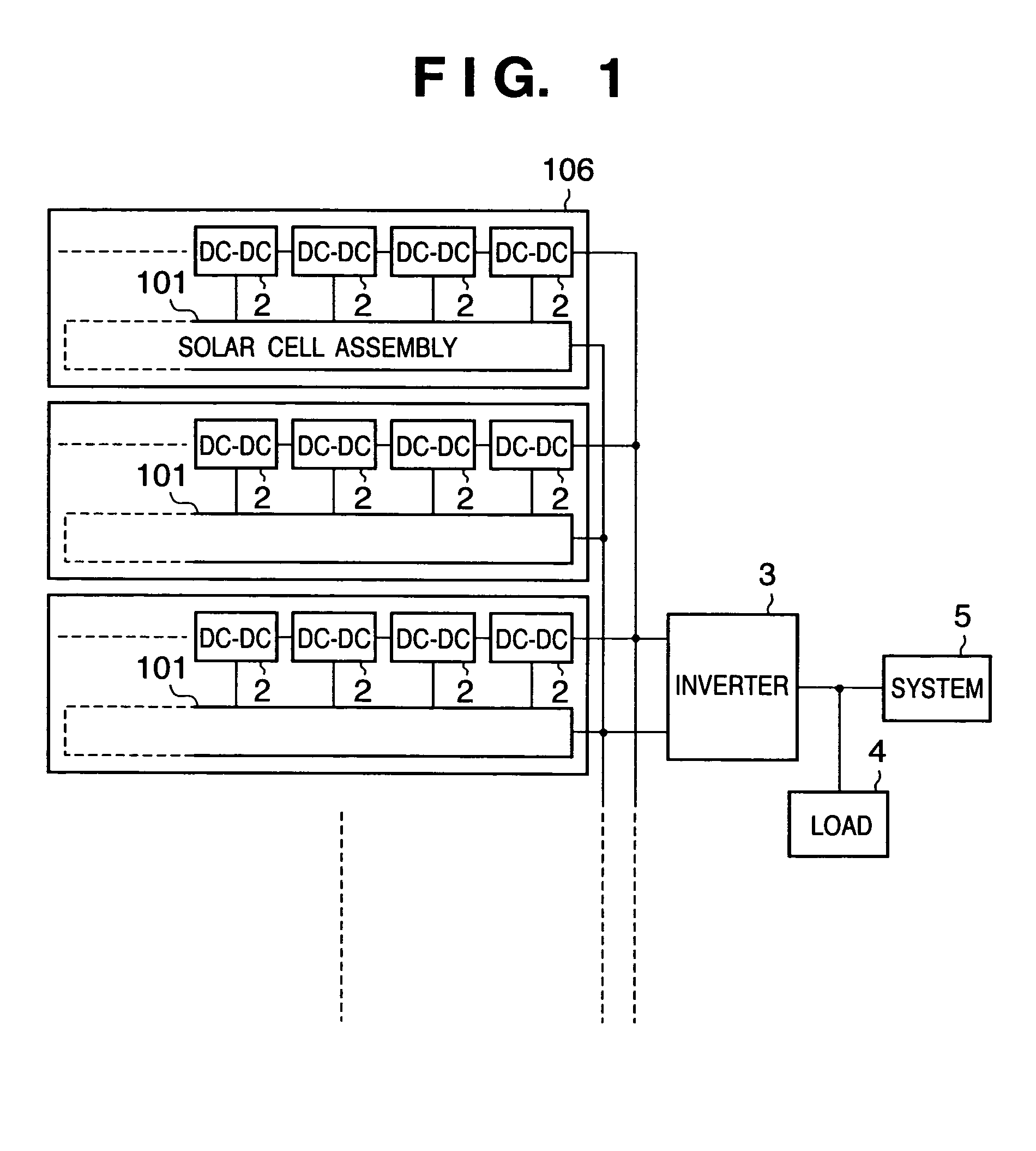

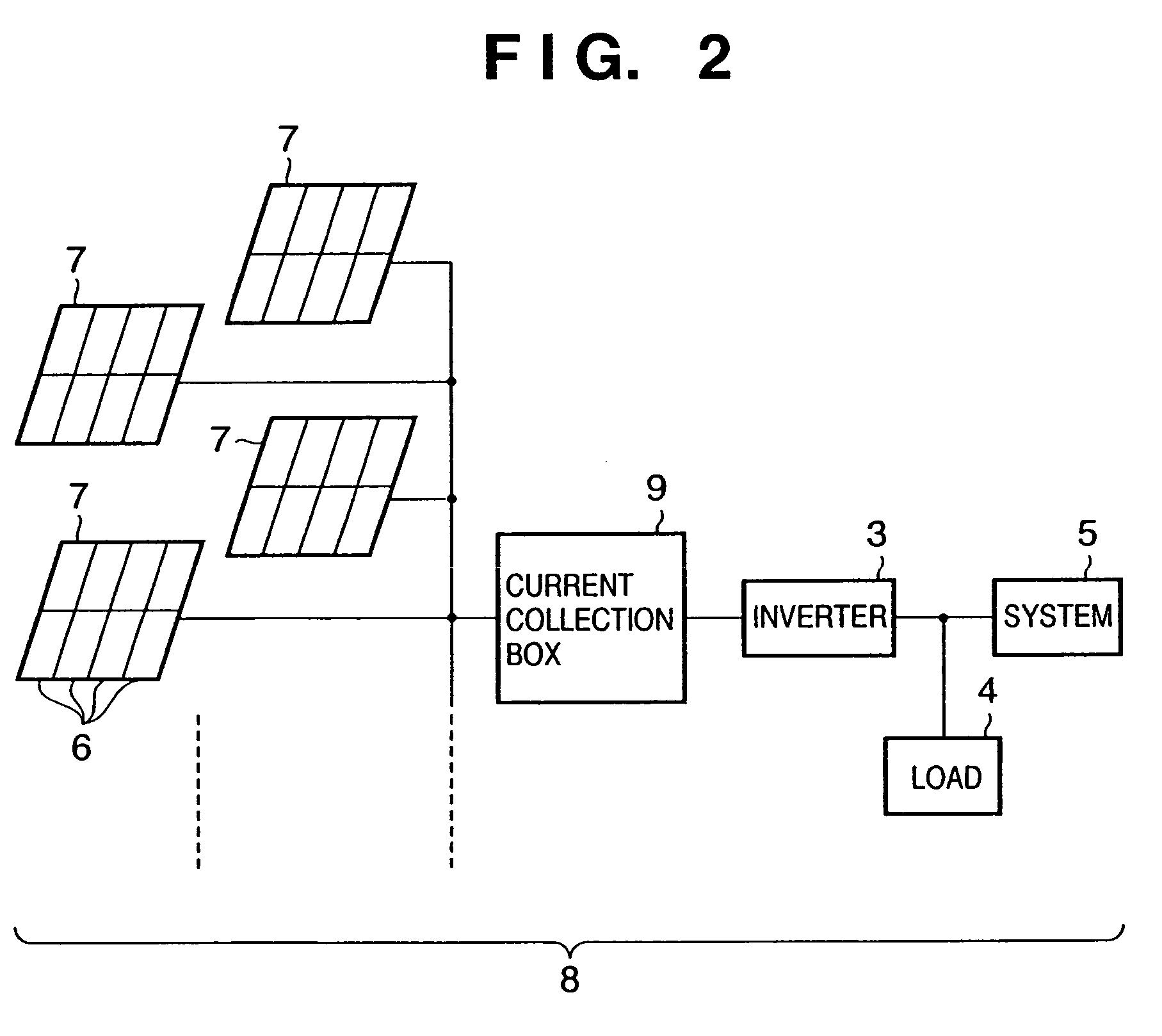

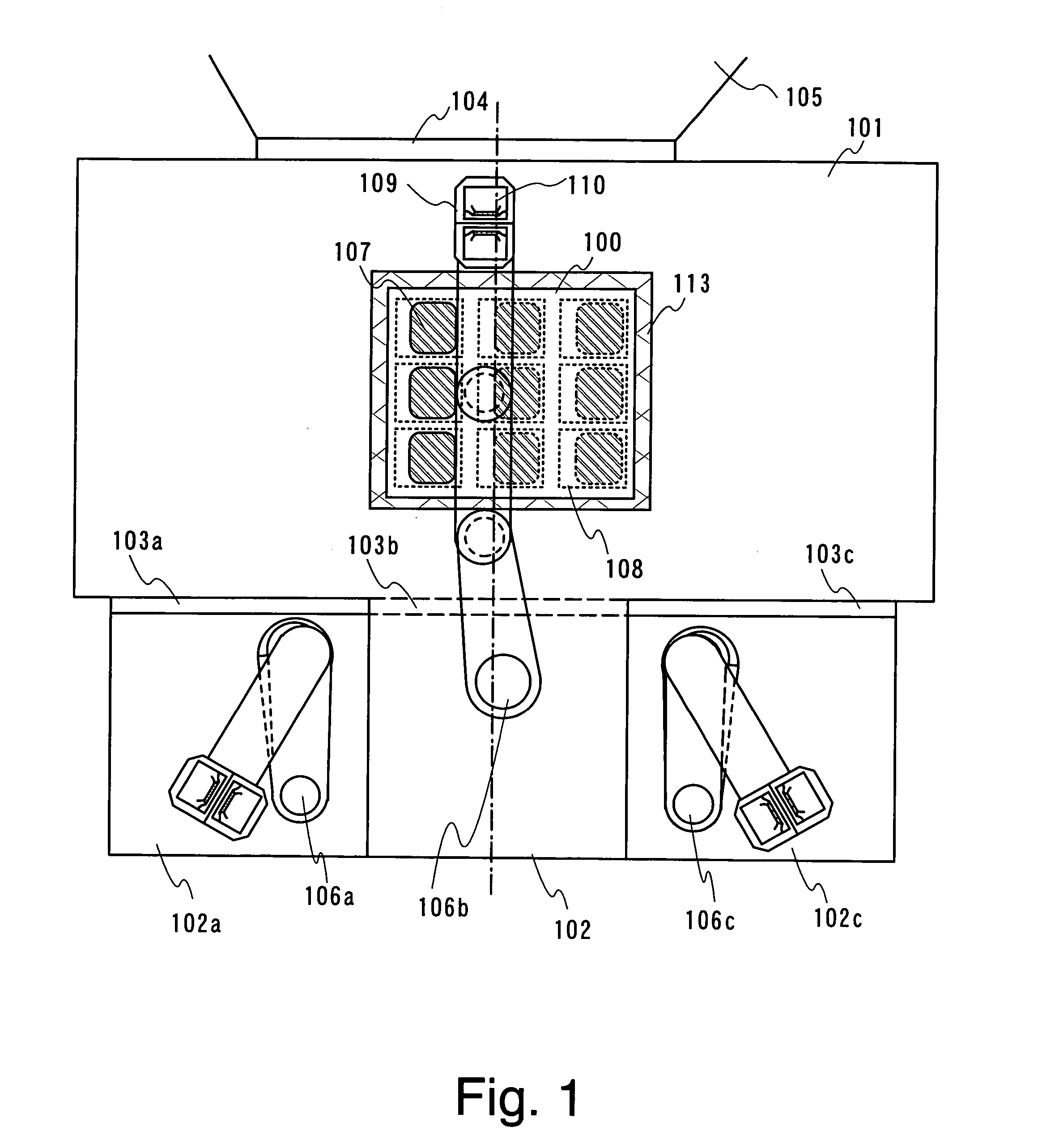

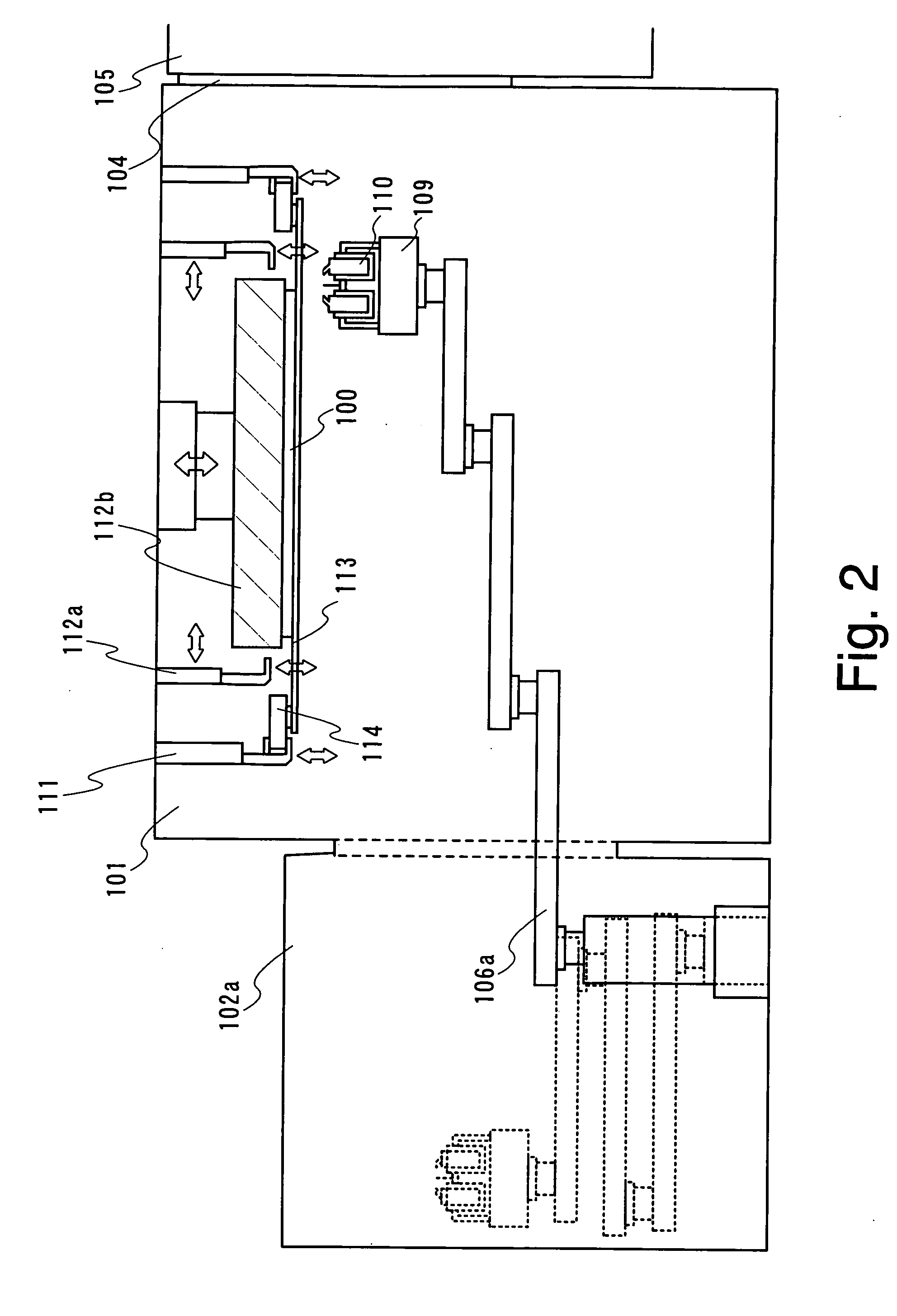

Solar power generation apparatus, solar power generation system, and method of manufacturing solar power generation apparatus

InactiveUS20050121067A1Reduce manufacturing costSimple structurePV power plantsDc-dc conversionManufacturing cost reductionAc power system

A solar cell assembly including a plurality of solar cells is formed on a common substrate, and a DC / DC converter which converts the output from the solar cell is connected to each solar cell to constitute a solar power generation apparatus. The output from the solar power generation apparatus is converted into an AC power by an inverter and supplied to a load or commercial AC power system. Since the arrangement is simplified, the manufacturing cost can be reduced, and the influence of partial shade or a variation in characteristic decreases.

Owner:CANON KK

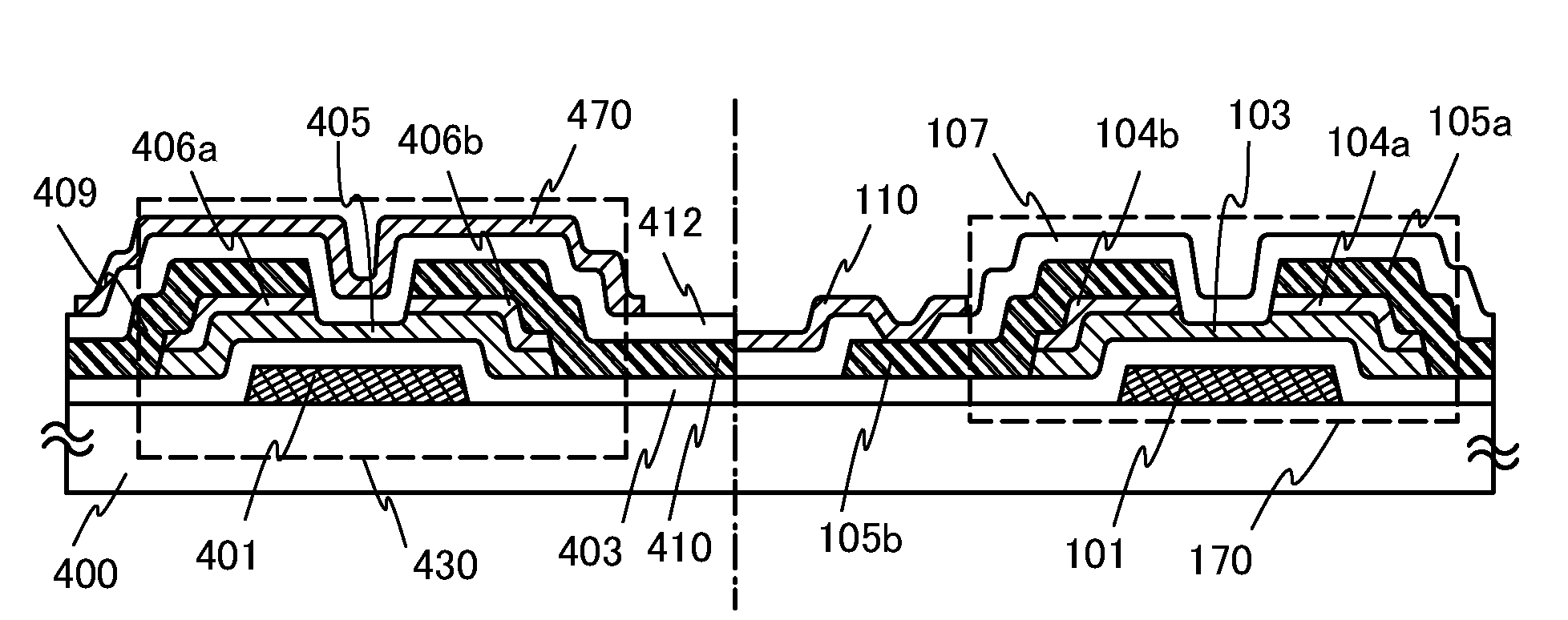

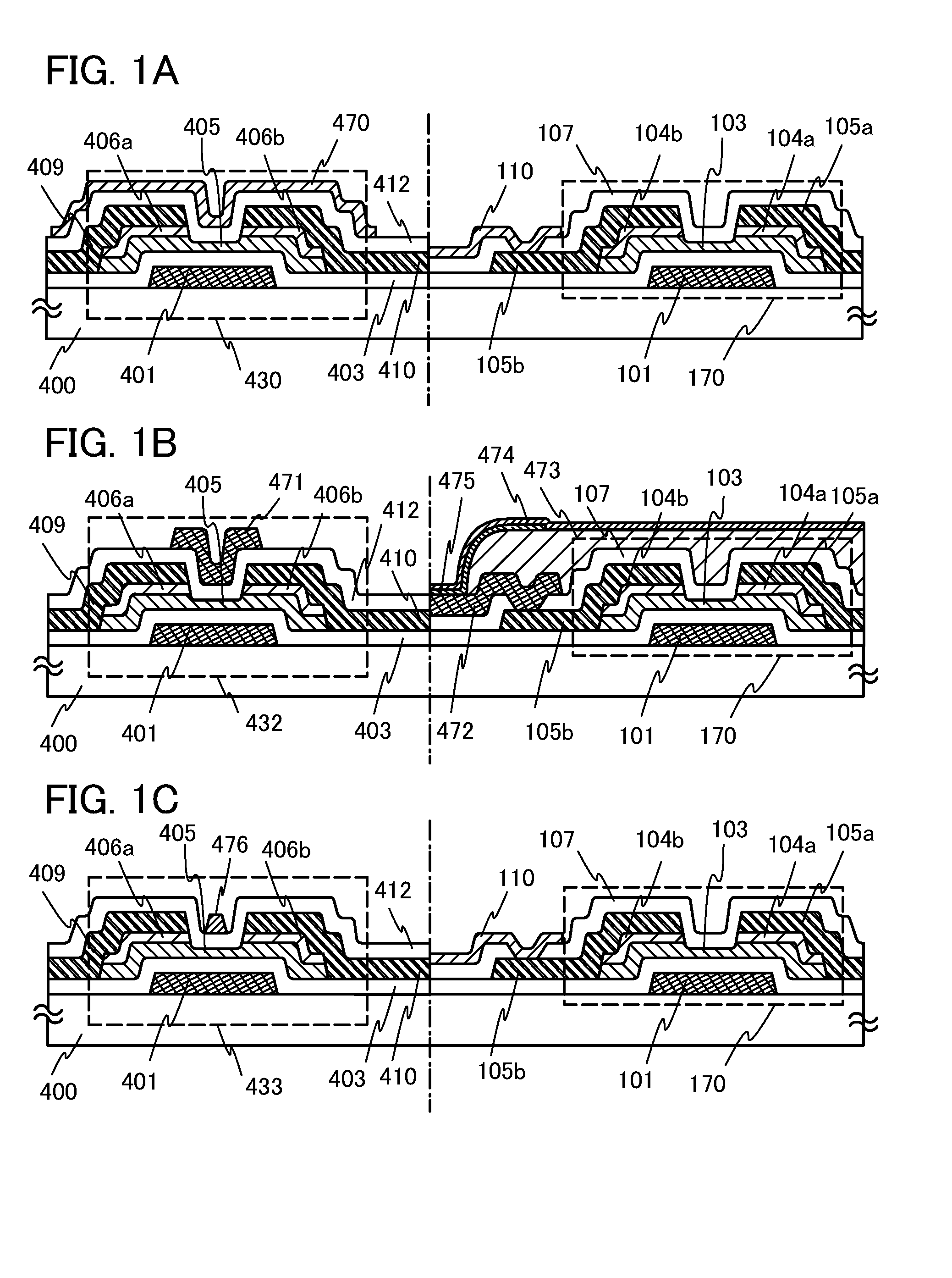

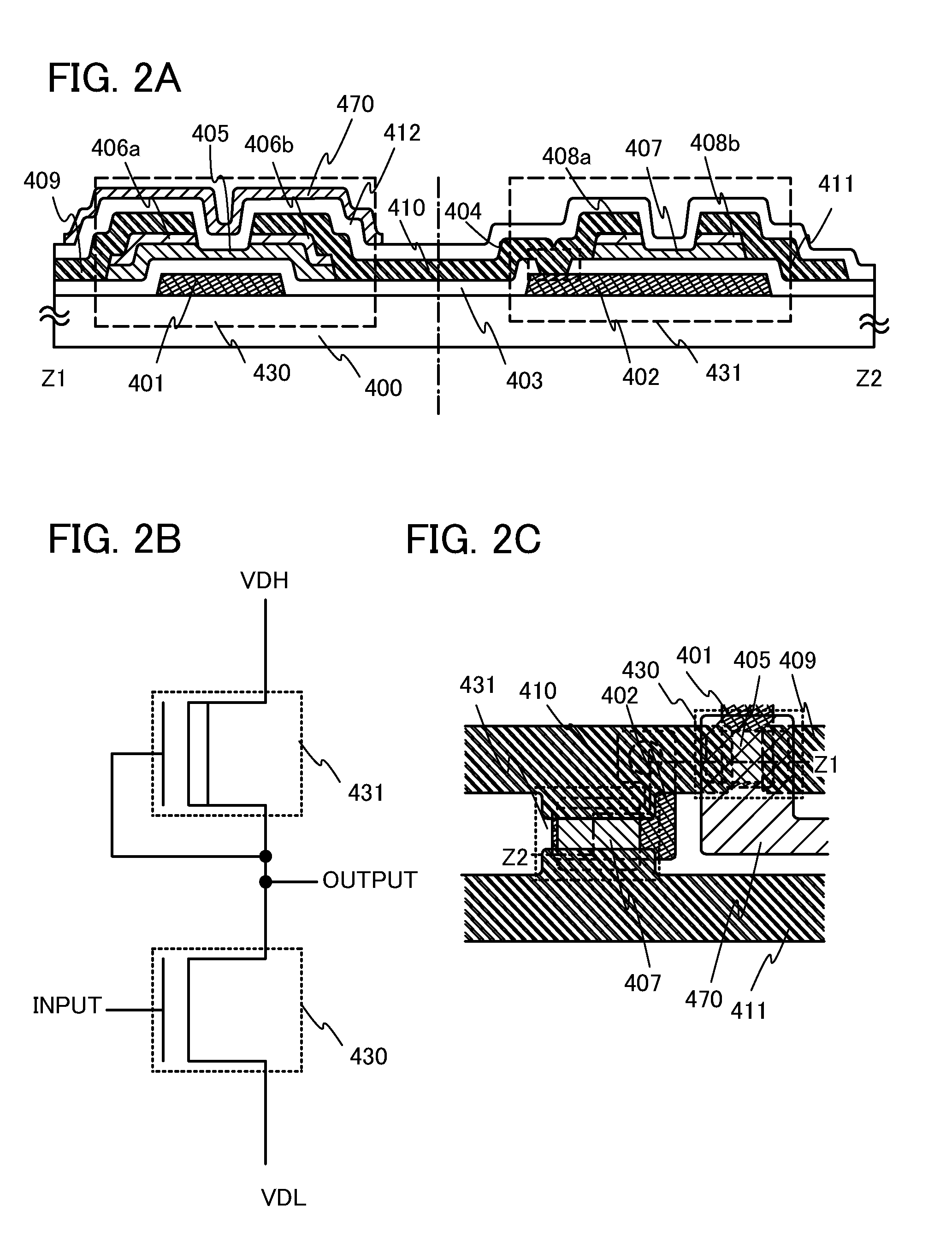

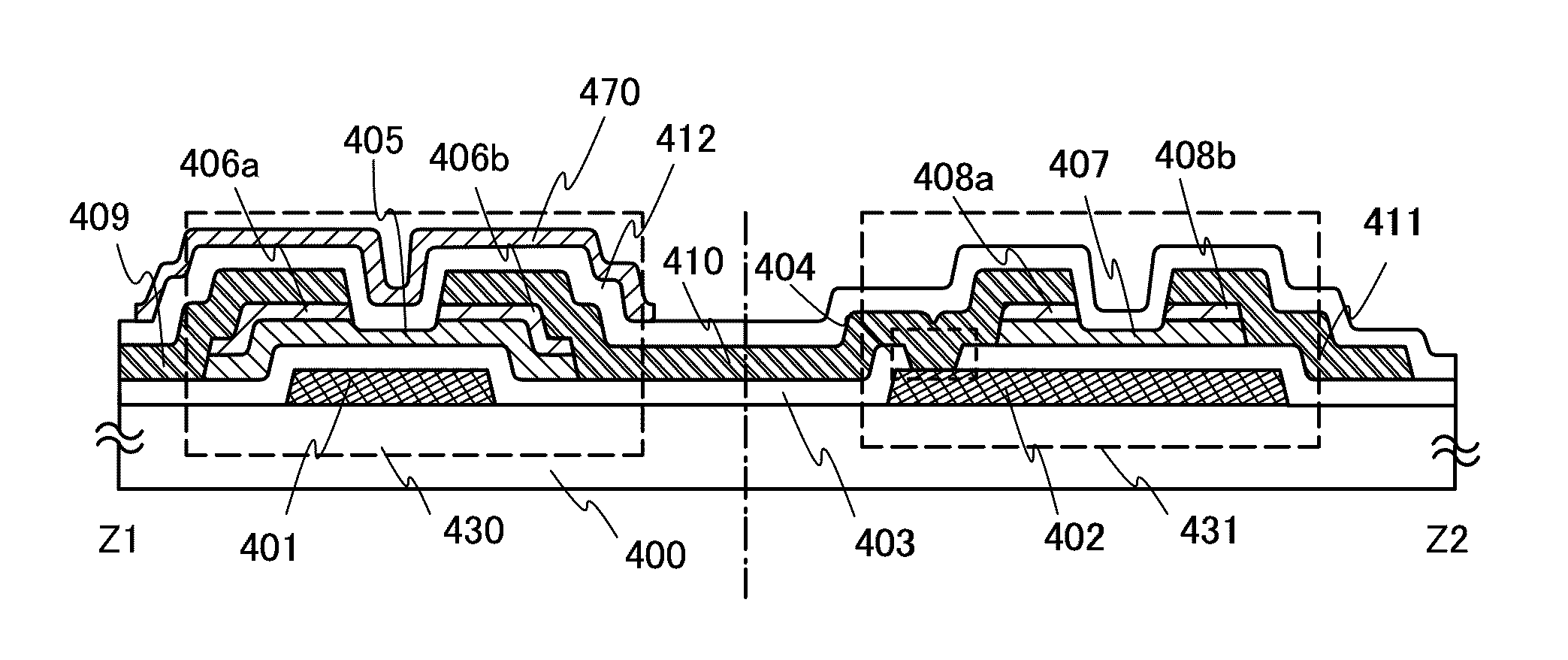

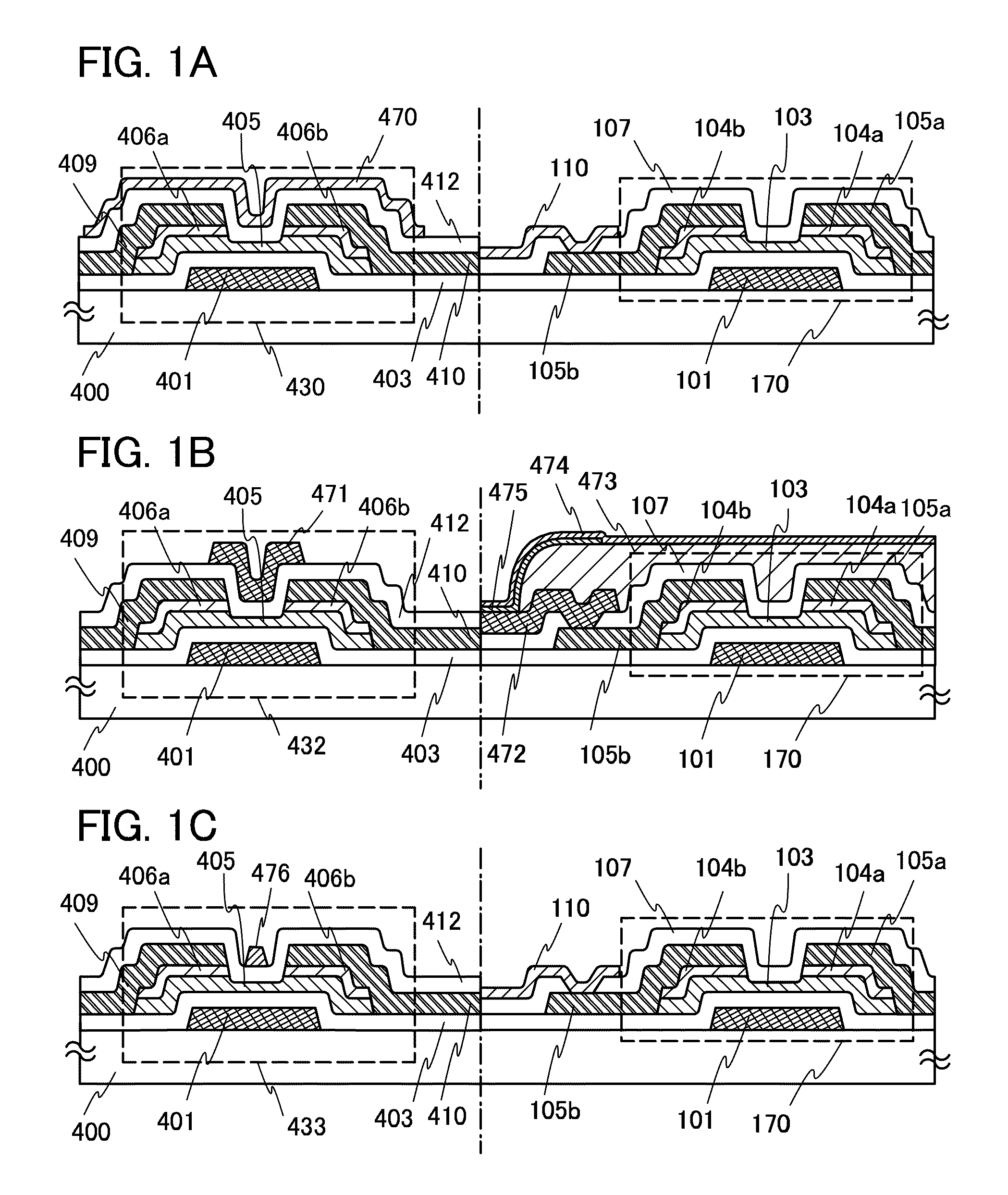

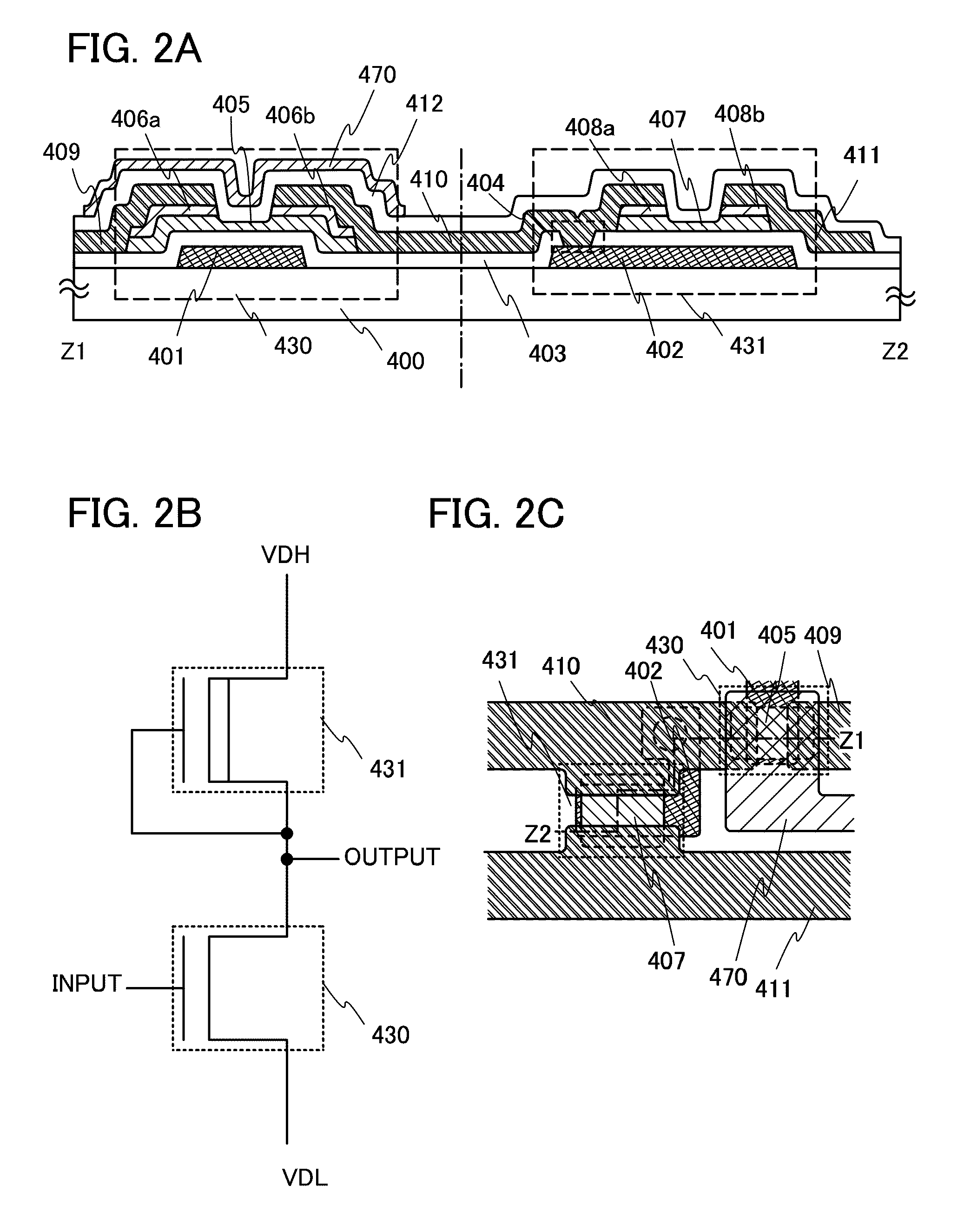

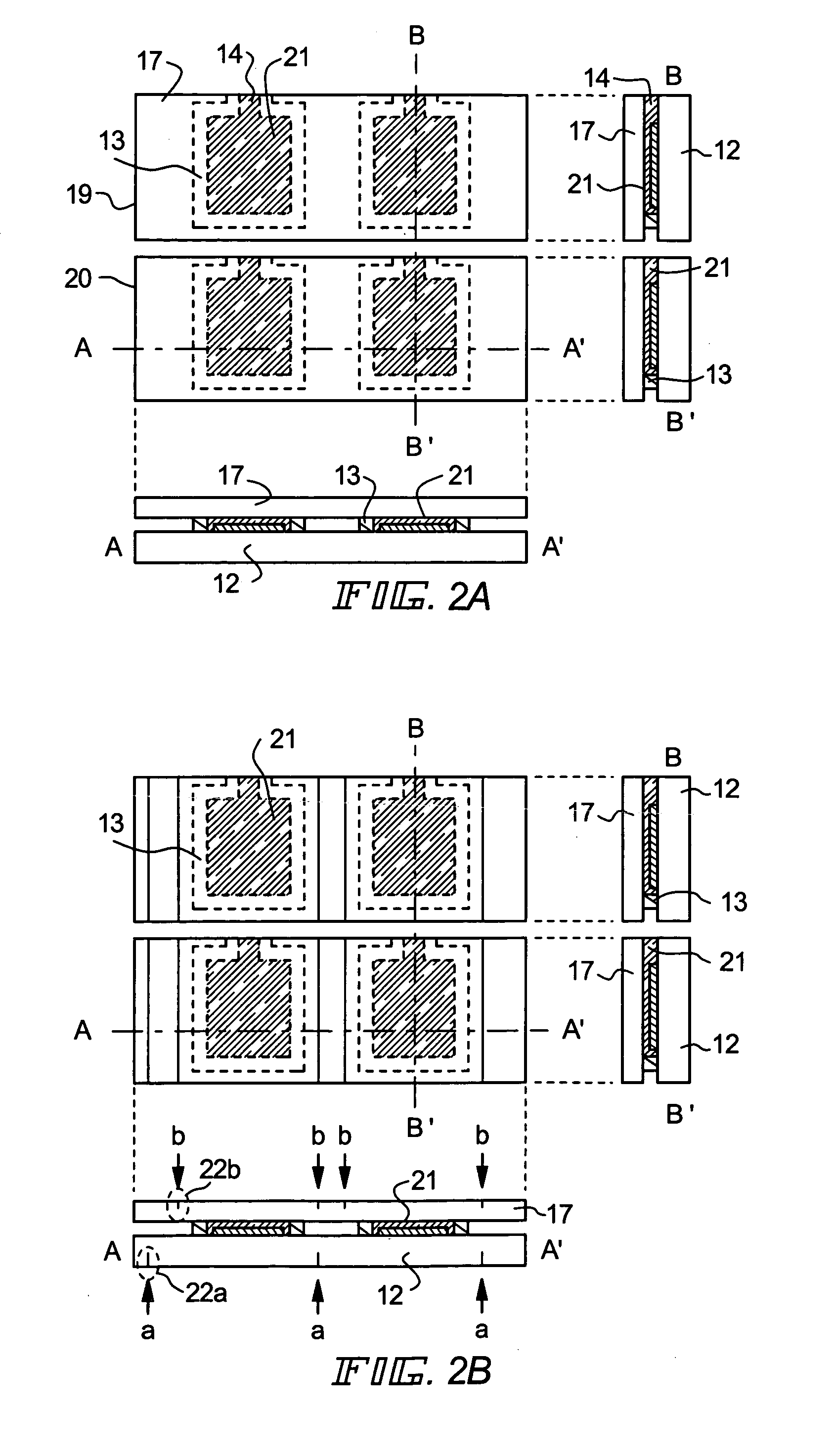

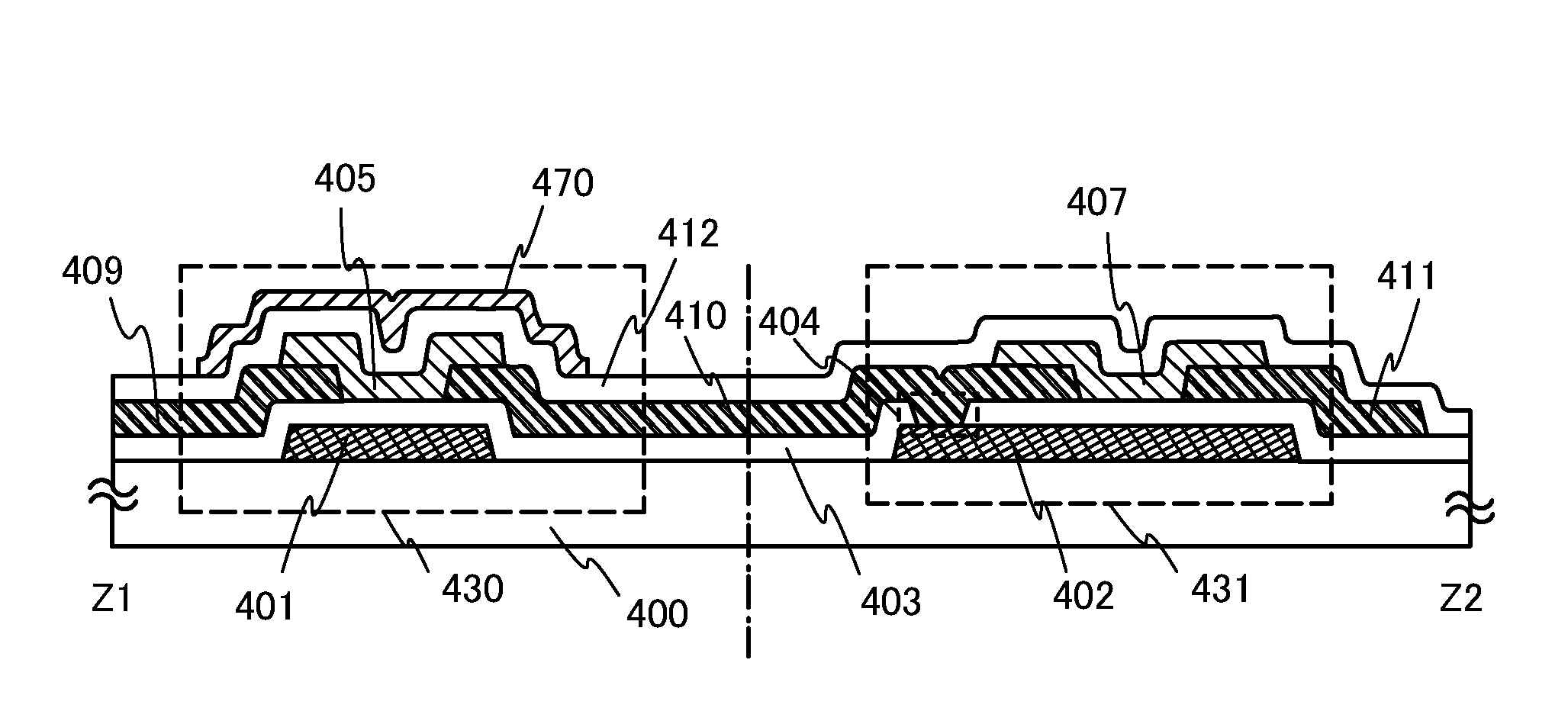

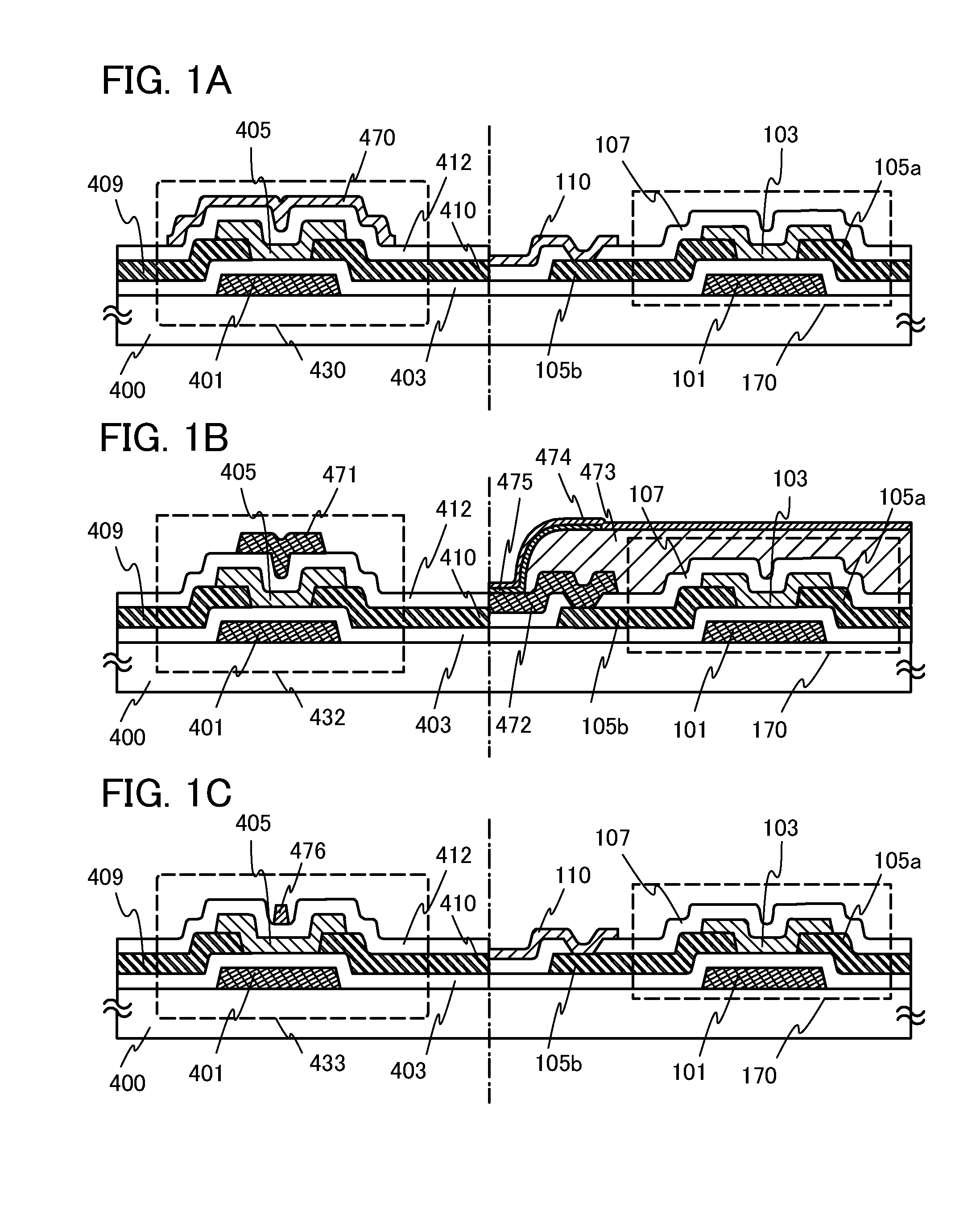

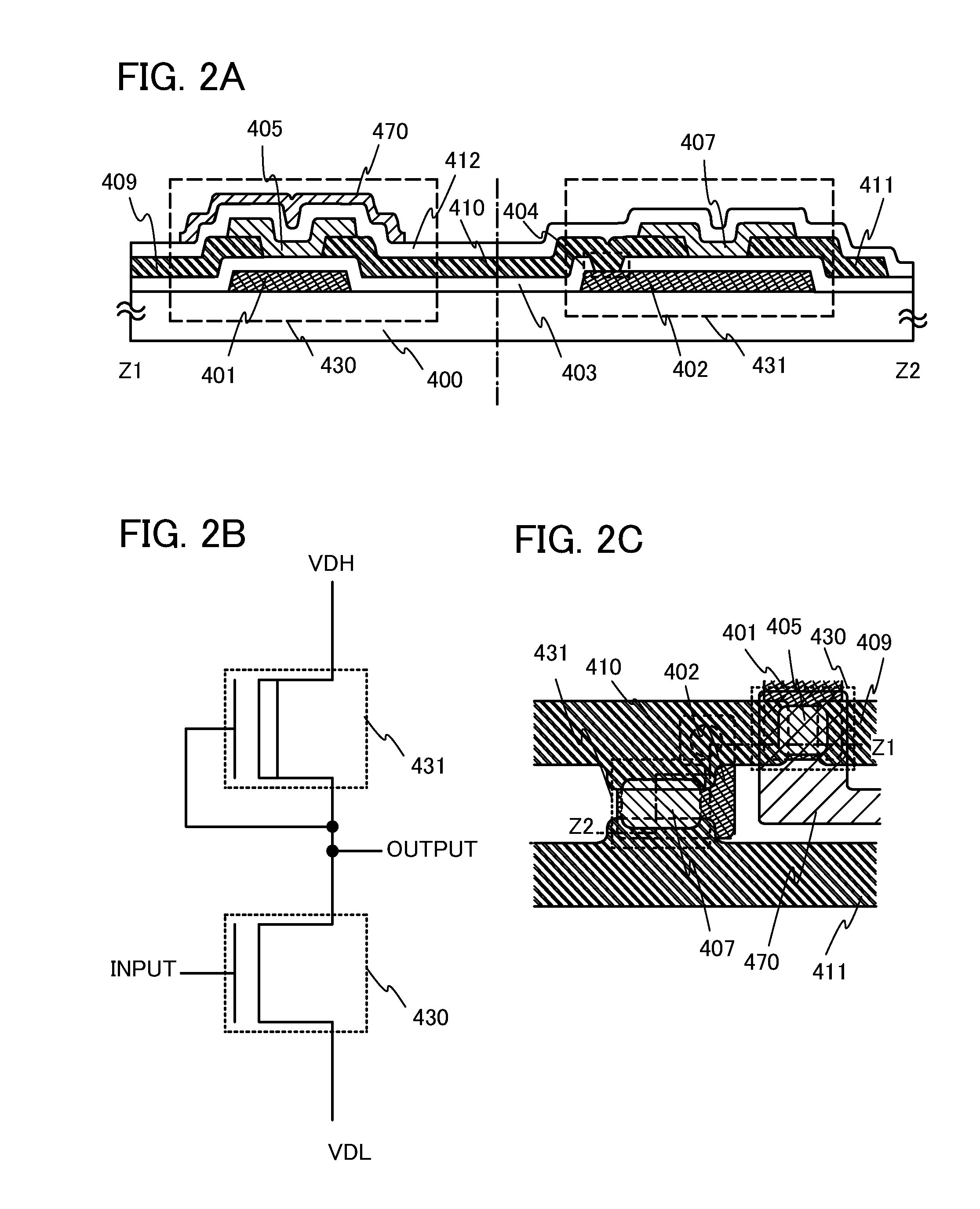

Semiconductor device and method for manufacturing the same

ActiveUS20100102313A1Reduce manufacturing costReduce the amount of variationTransistorElectroluminescent light sourcesManufacturing cost reductionDriver circuit

As a display device has a higher definition, the number of pixels, gate lines, and signal lines are increased. When the number of the gate lines and the signal lines are increased, a problem of higher manufacturing cost, because it is difficult to mount an IC chip including a driver circuit for driving of the gate and signal lines by bonding or the like. A pixel portion and a driver circuit for driving the pixel portion are provided over the same substrate, and at least part of the driver circuit includes a thin film transistor using an oxide semiconductor interposed between gate electrodes provided above and below the oxide semiconductor. Therefore, when the pixel portion and the driver portion are provided over the same substrate, manufacturing cost can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

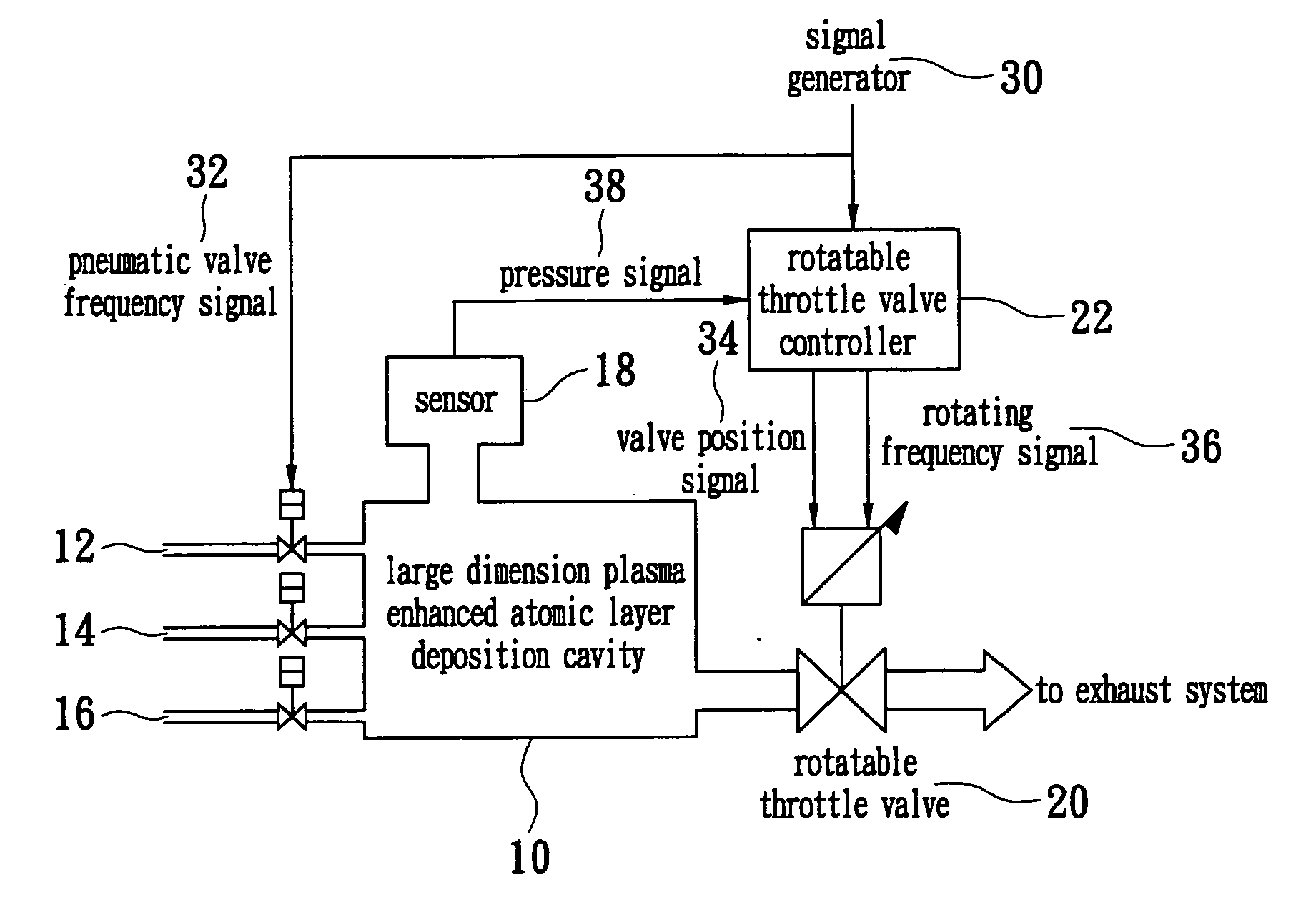

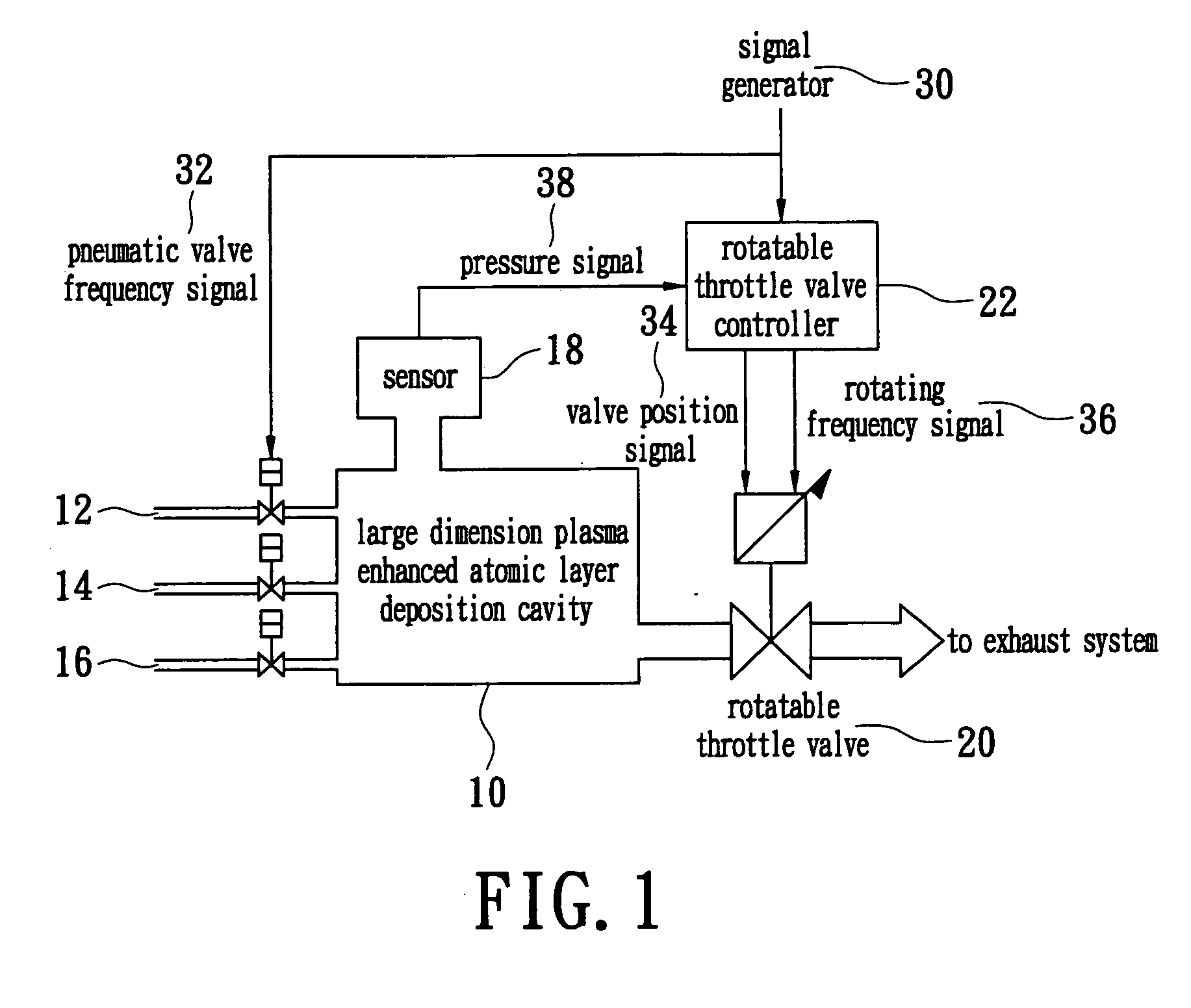

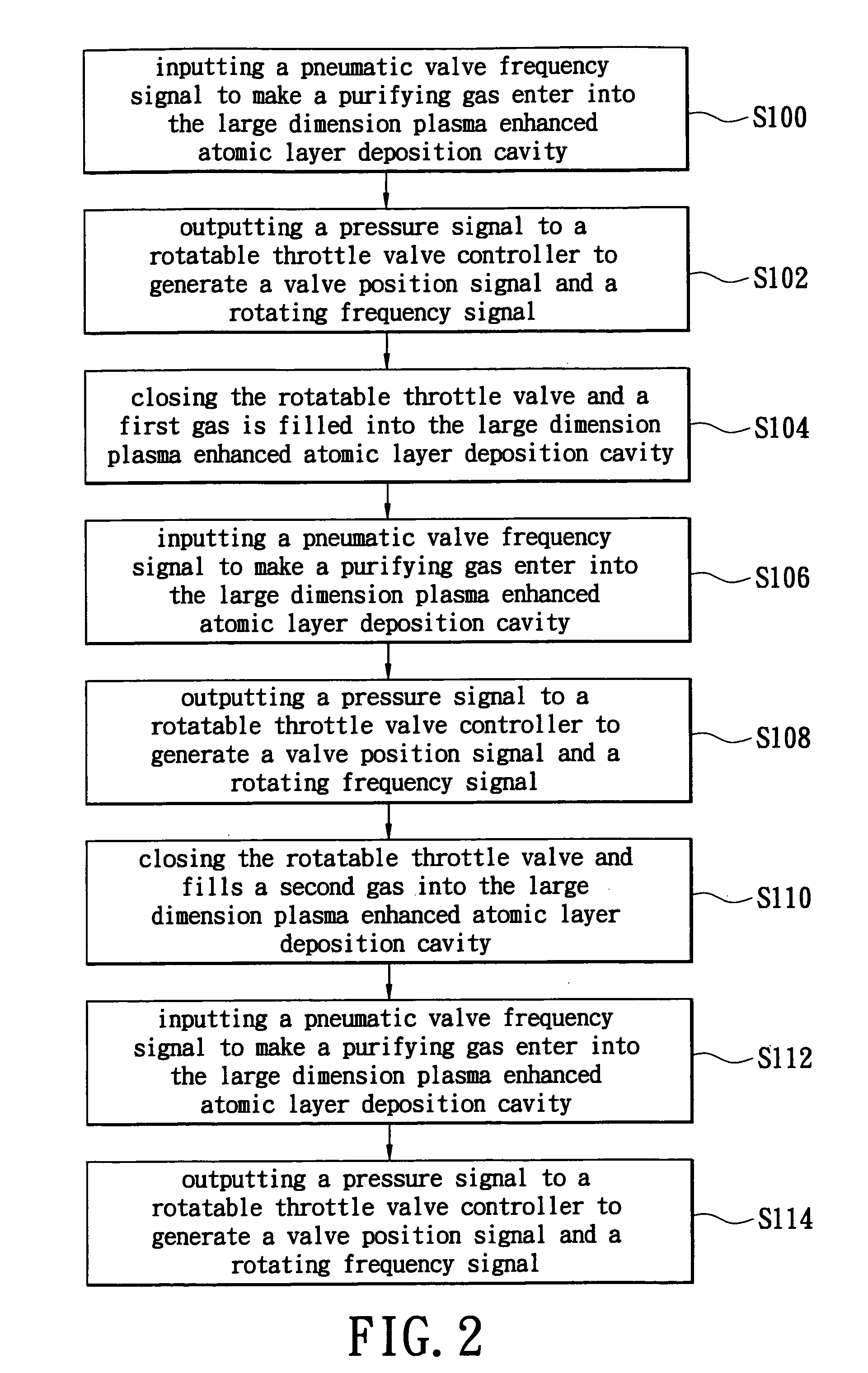

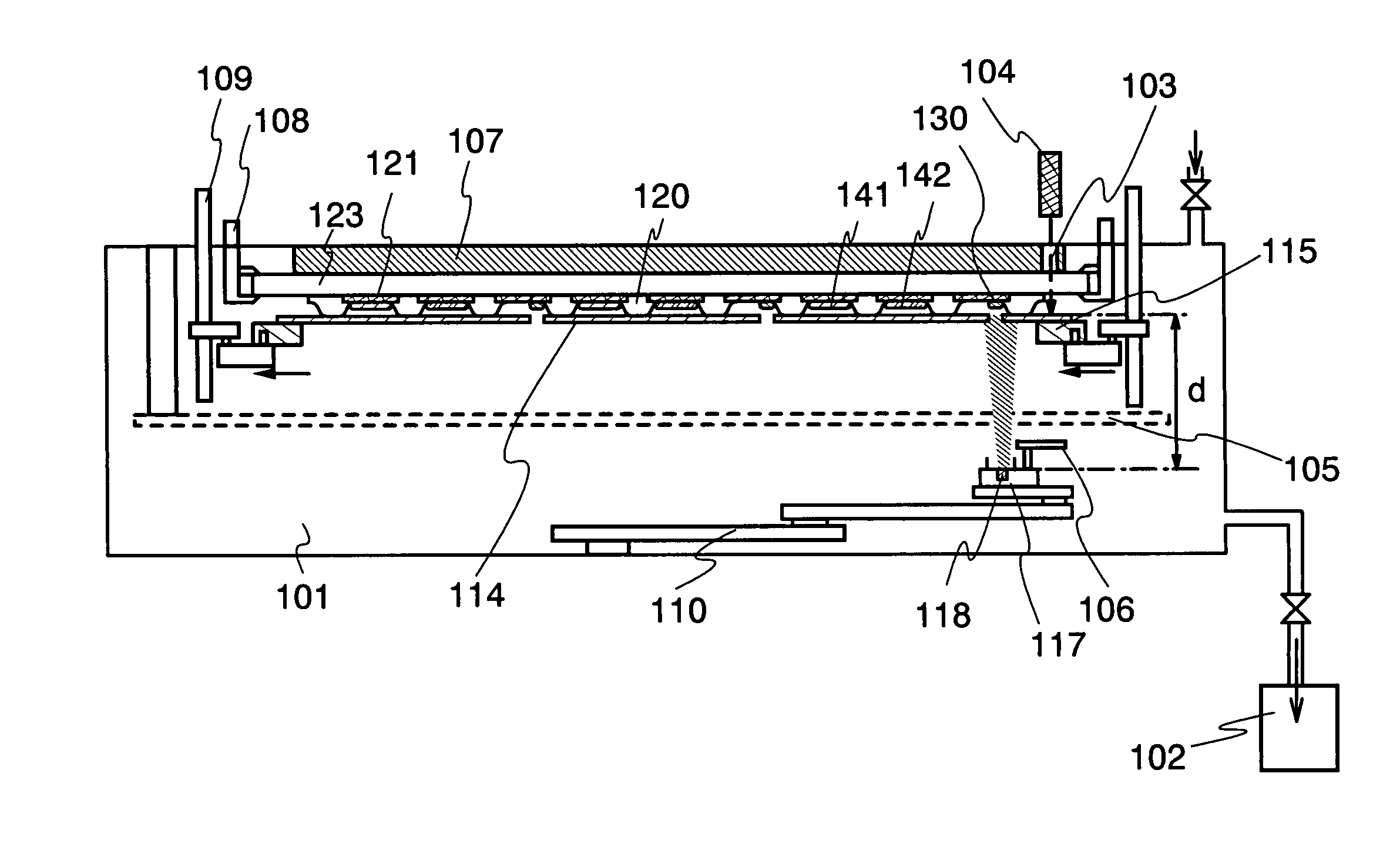

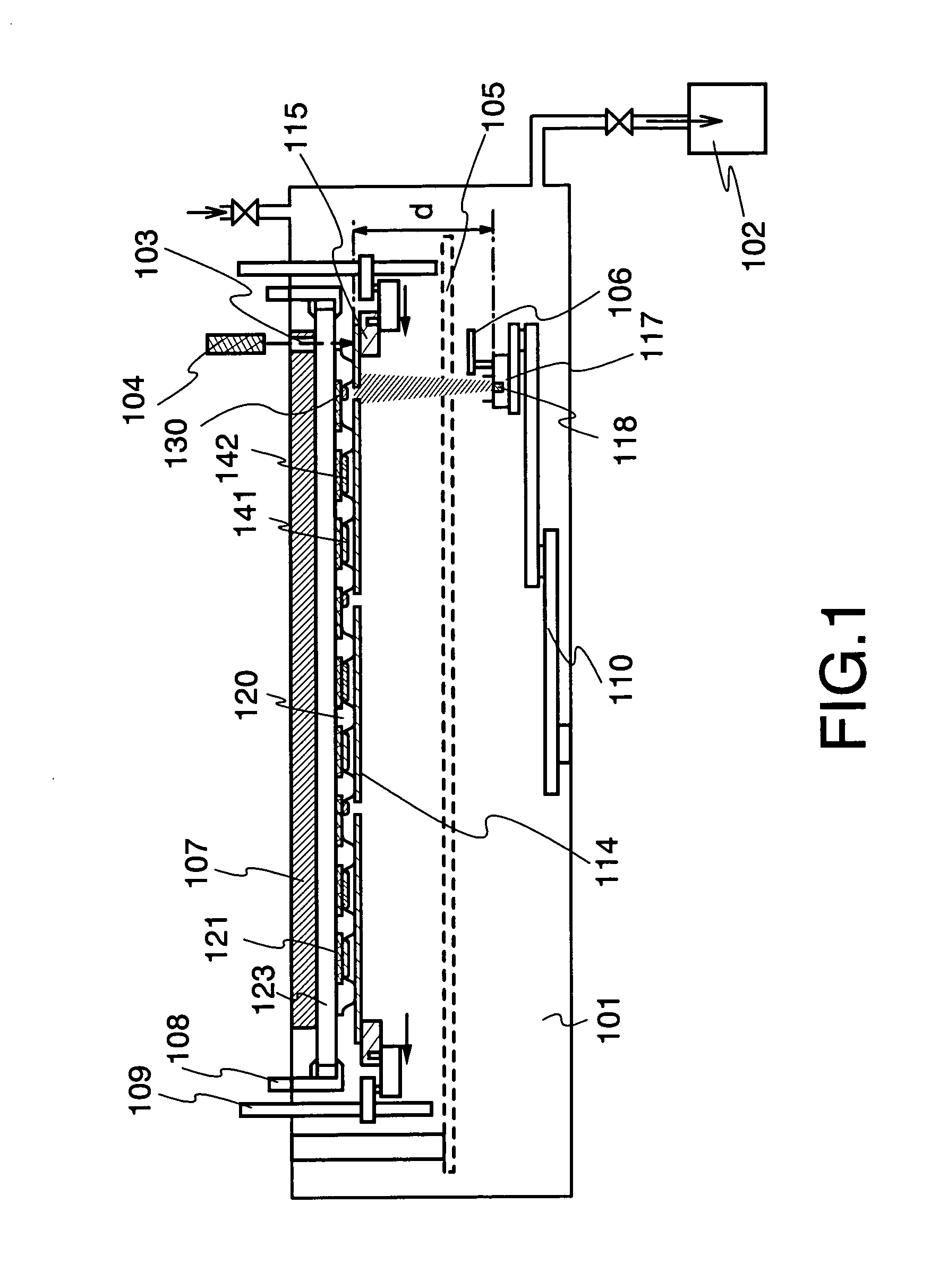

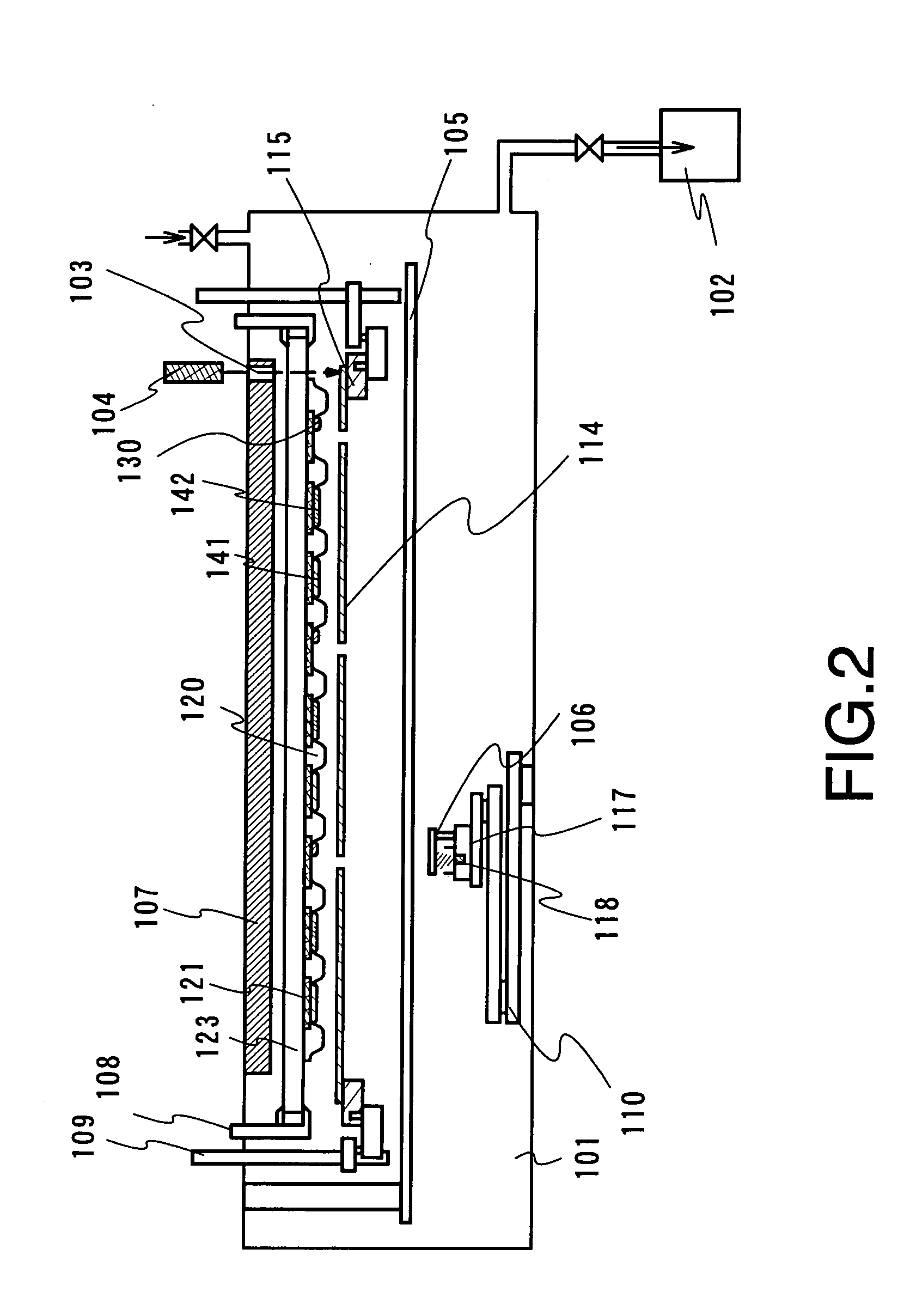

Operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof

ActiveUS20070026162A1Effectively control pressureIncrease airflowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingManufacturing cost reductionEngineering

An operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof are provided. The present invention reduces the time needed for filling the manufacturing gas into the large volume manufacturing cavity. Therefore, the plasma enhanced atomic layer deposition apparatus can switch the precursors rapidly to increase the thin film deposition rate, reduce the manufacturing gas consumption and lower the manufacturing cost.

Owner:CHINA STAR OPTOELECTRONICS INT HK

Thin film transistor with two gate electrodes

ActiveUS8067775B2Easy to makeTransistorElectroluminescent light sourcesDriver circuitManufacturing cost reduction

As a display device has a higher definition, the number of pixels, gate lines, and signal lines are increased. When the number of the gate lines and the signal lines are increased, a problem of higher manufacturing cost, because it is difficult to mount an IC chip including a driver circuit for driving of the gate and signal lines by bonding or the like. A pixel portion and a driver circuit for driving the pixel portion are provided over the same substrate, and at least part of the driver circuit includes a thin film transistor using an oxide semiconductor interposed between gate electrodes provided above and below the oxide semiconductor. Therefore, when the pixel portion and the driver portion are provided over the same substrate, manufacturing cost can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

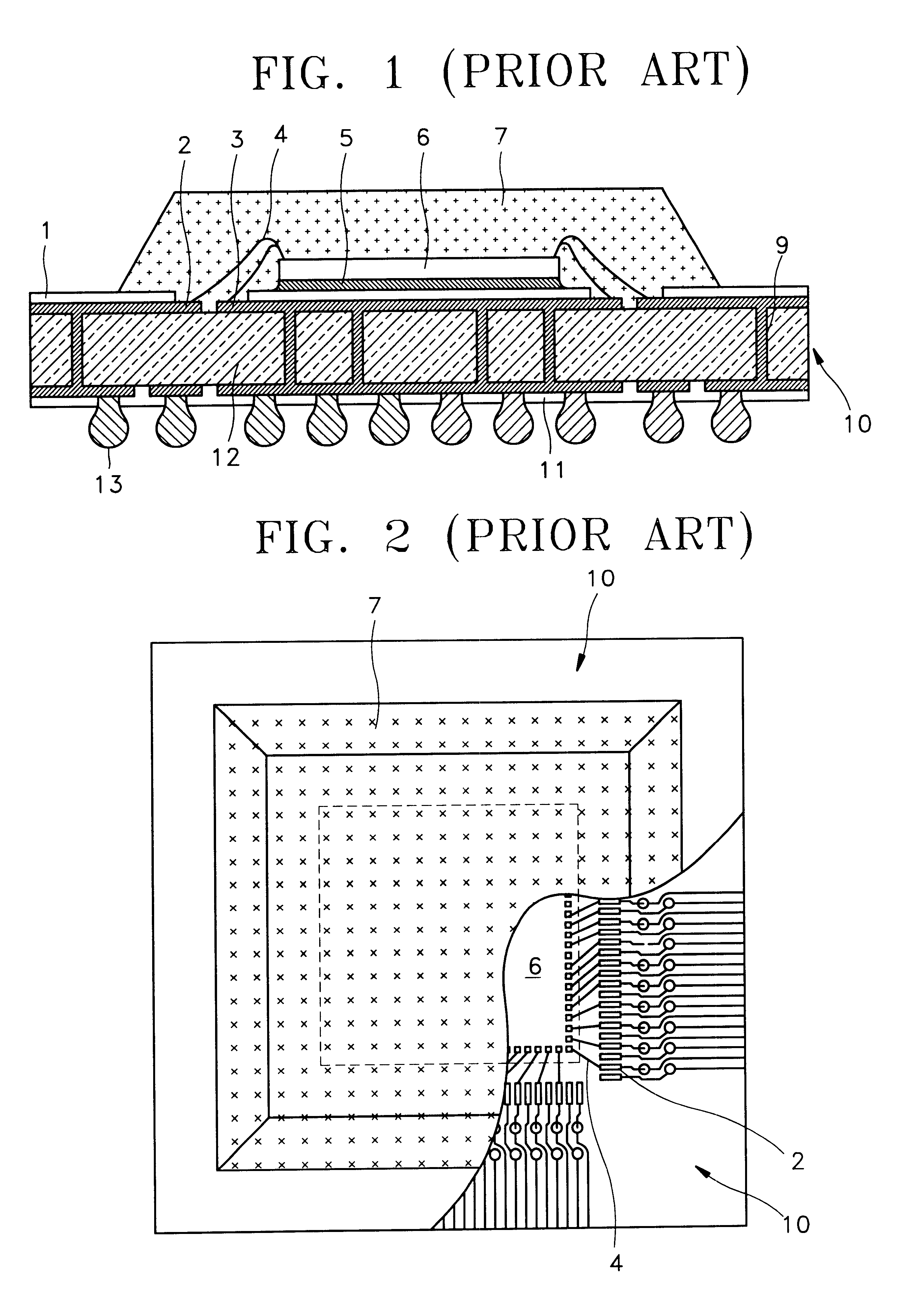

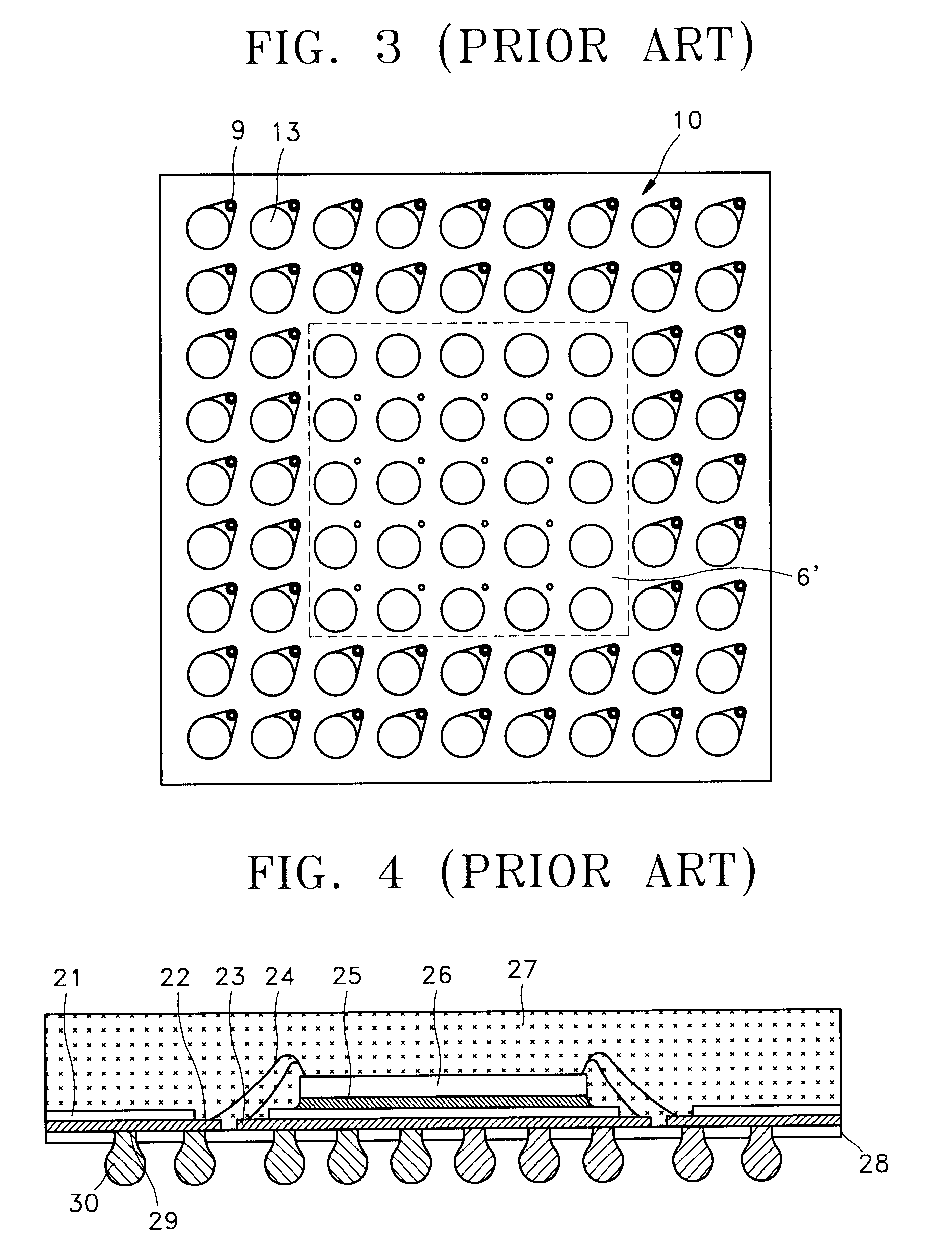

Semiconductor package having implantable conductive lands and method for manufacturing the same

InactiveUS6429508B1Semiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionSemiconductor package

Owner:KOSTAT SEMICON

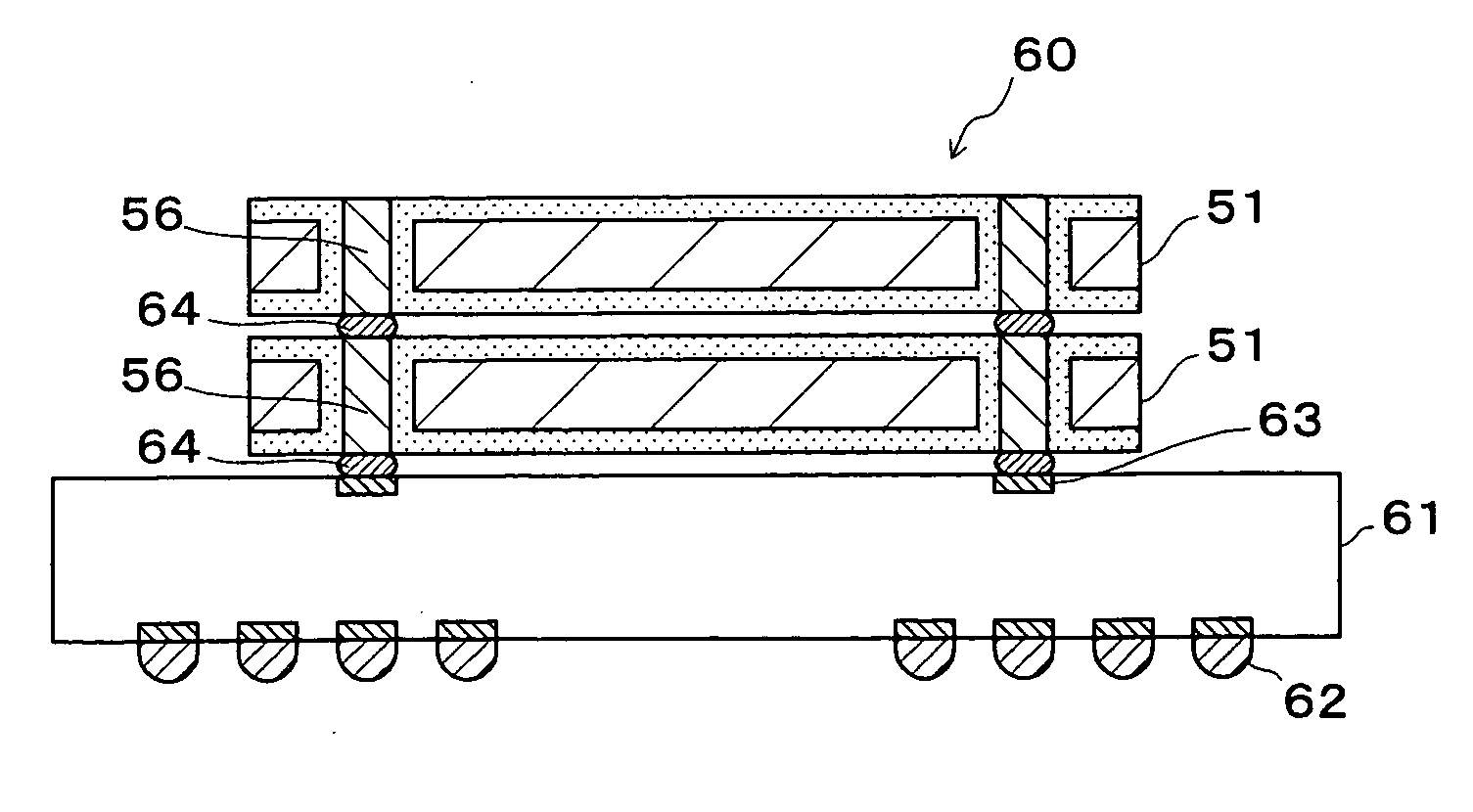

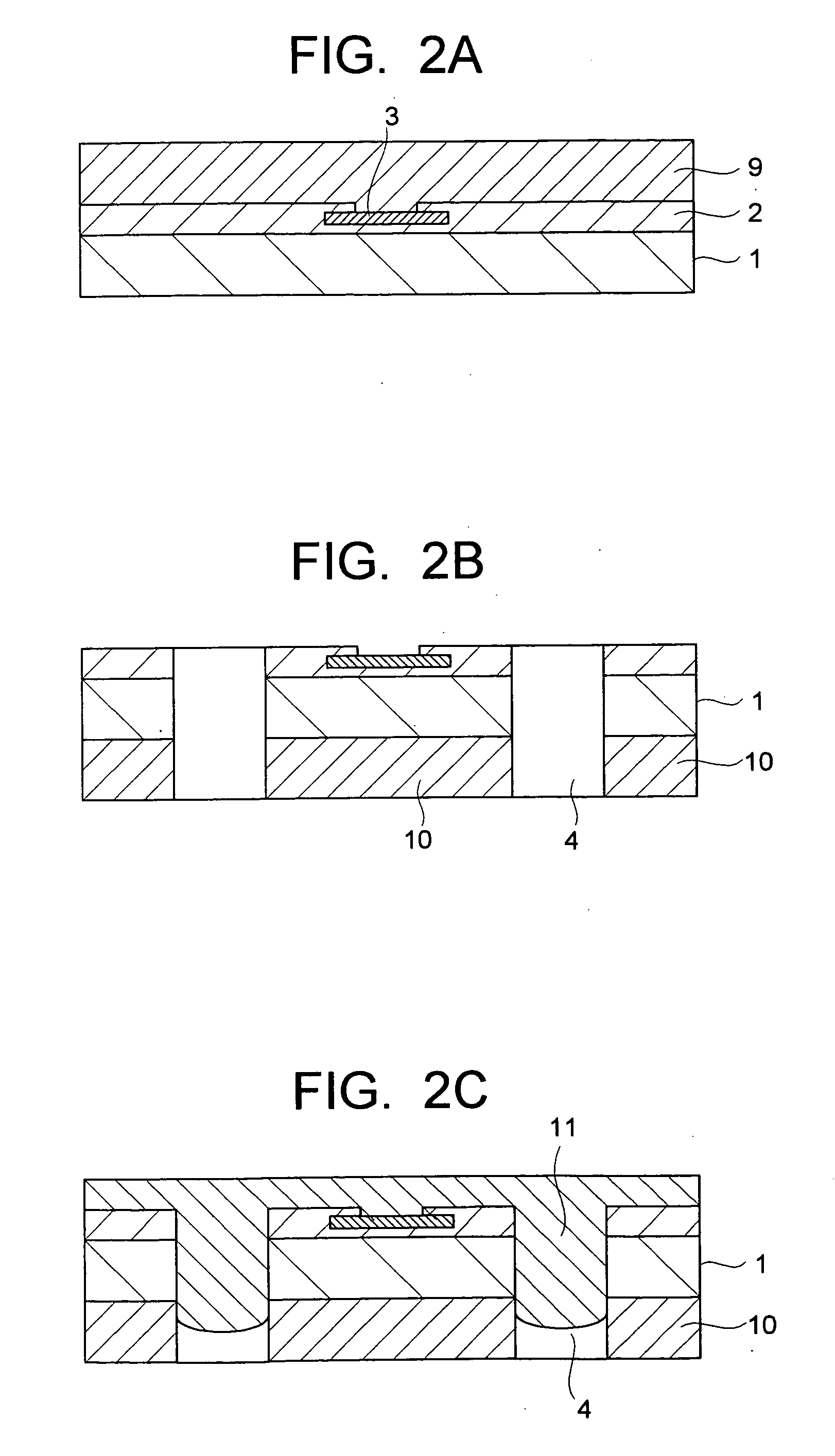

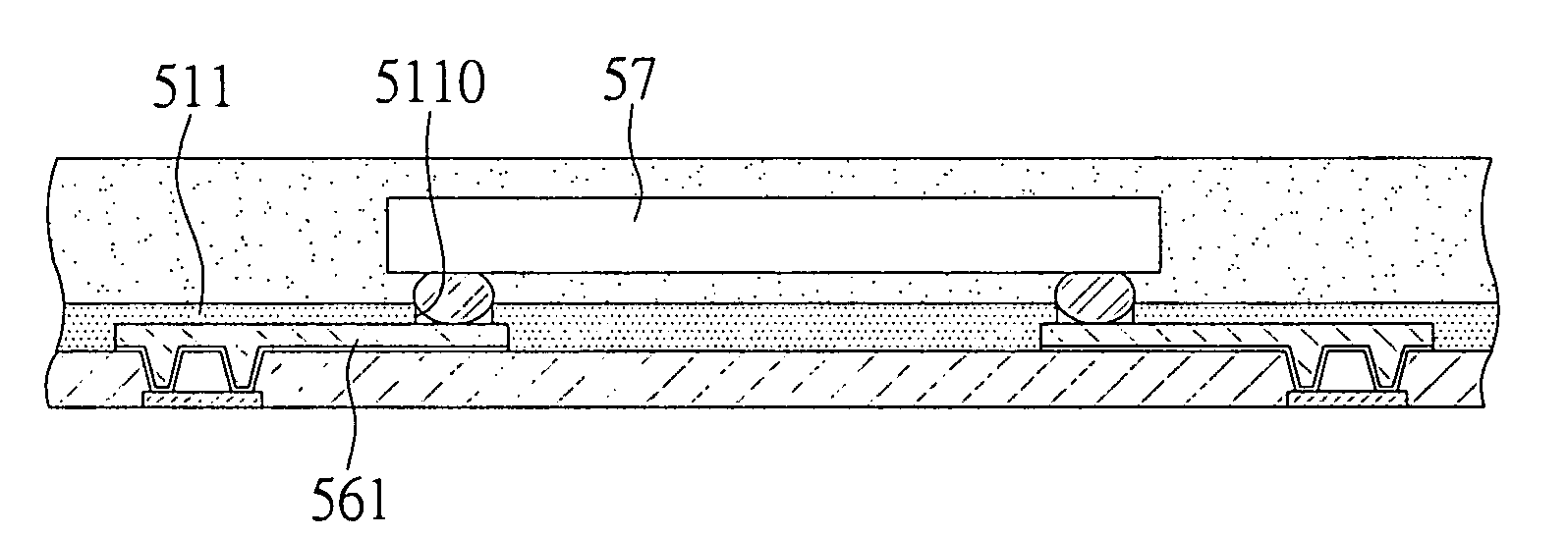

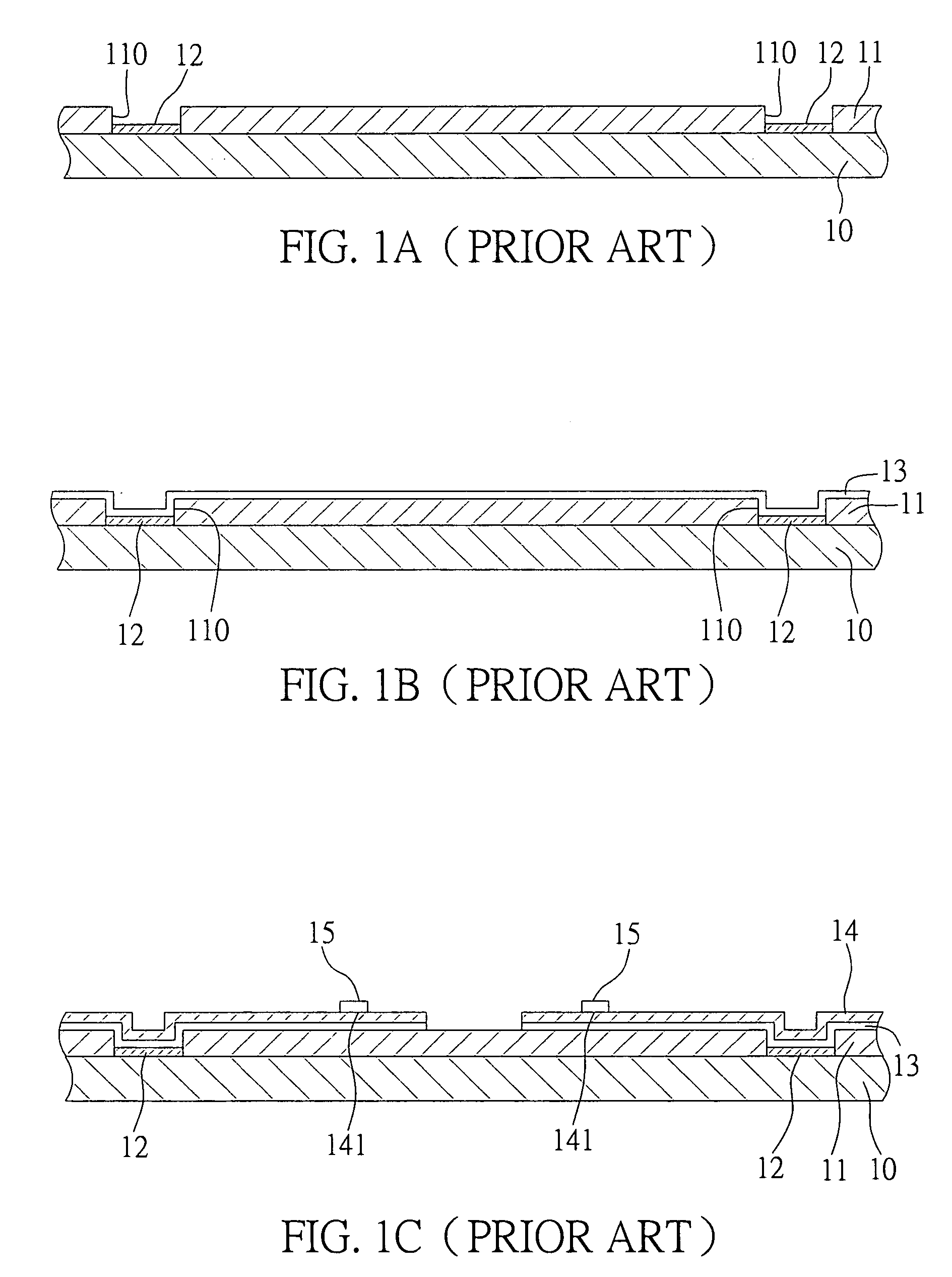

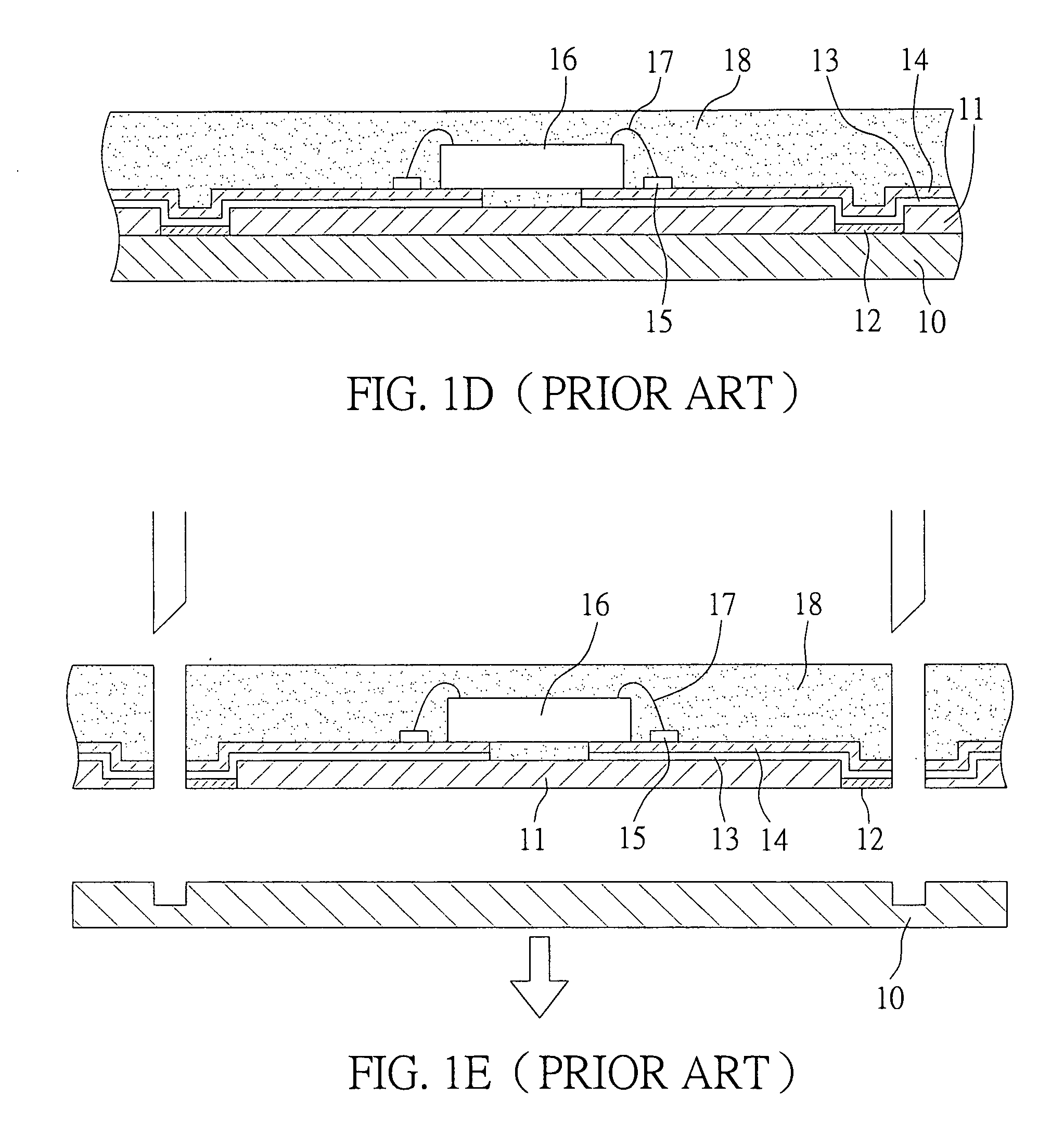

Light emitting device and method of manufacturing the same

ActiveUS7112115B1Improve throughputHigh yieldDischarge tube luminescnet screensElectroluminescent light sourcesManufacturing cost reductionEngineering

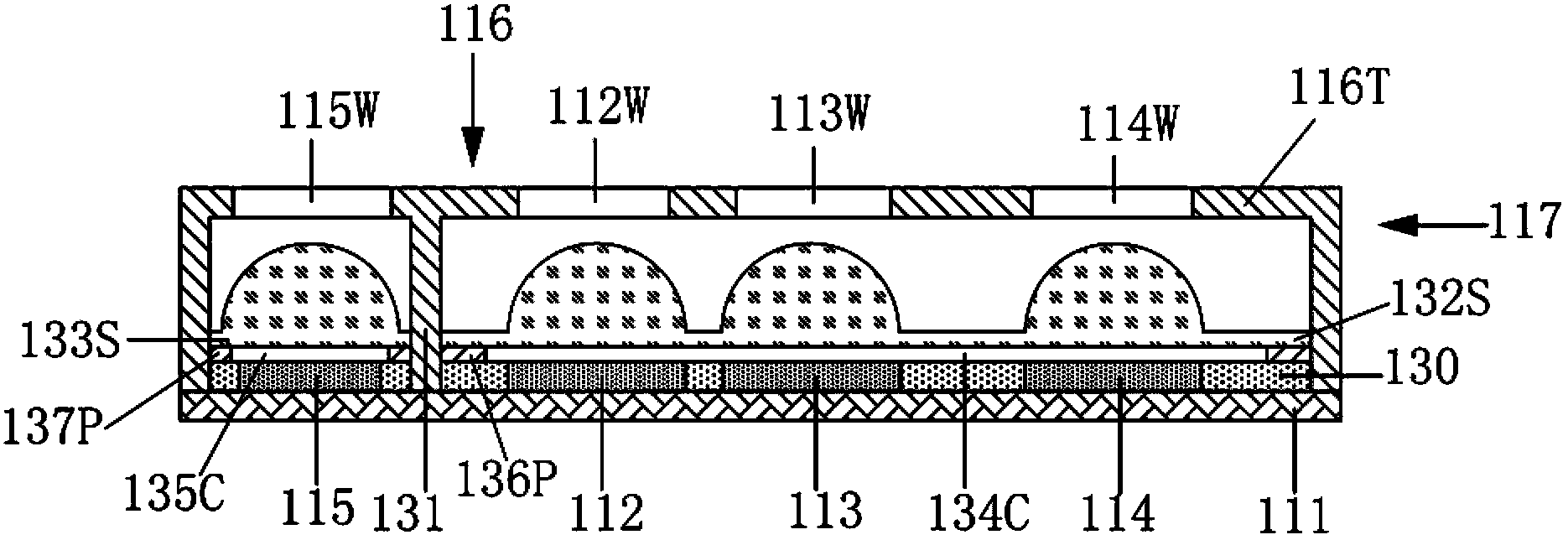

Technology to reduce the manufacturing cost of a manufacturing process of a light emitting device is provided. The manufacturing cost of a device using a light emitting element can be reduced by using a multilayout process for forming a plurality of light emitting devices from a large-sized substrate. In particular, an existing line for manufacturing liquid crystal cells can be diverted to a process of encapsulating light emitting elements, which can greatly reduce the manufacturing cost including the investment in plant and equipment.

Owner:SEMICON ENERGY LAB CO LTD

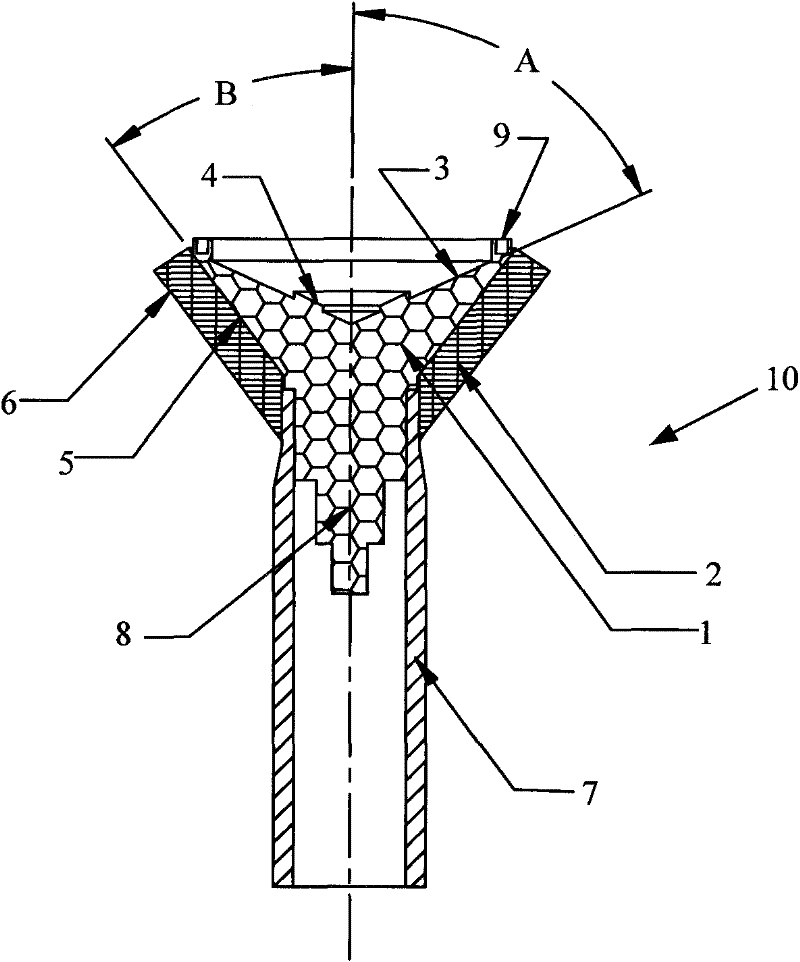

Wide-angle irradiation feed source device with parasitic matched media and microwave antenna

InactiveCN102208716AWide Feed Radiation AngleGood standing wave performanceAntennasManufacturing cost reductionMicrowave

The invention relates to a wide-angle irradiation feed source device with parasitic matched media and a microwave antenna. The wide-angle irradiation feed source device with the parasitic matched media comprises components such as guided wave media, the parasitic matched media, metal reflecting surfaces, reflective matching steps and the like. The parasitic matched media are arranged on the lateral surfaces of the guided wave media. The metal reflecting surfaces are formed on the upper surfaces of the guided wave media. The reflective matching steps are positioned at the bottom ends of the metal reflecting surfaces. Primary reflecting regions are positioned between the guided wave media and the parasitic matched media. Secondary reflecting regions are positioned outside the parasitic matched media, and are parallel to the primary reflecting regions. One end of each circular waveguide is inserted between the corresponding guided wave medium and the corresponding parasitic matched medium. The microwave antenna comprises a paraboloid and the wide-angle irradiation feed source device with the parasitic matched media. One end of the wide-angle irradiation feed source device with the parasitic matched media is fixed at the top end of the paraboloid. The feed source device provided by the invention is in fit with the short-focus paraboloid to realize the high-performance and low-profile microwave antenna, and the manufacturing cost is effectively reduced.

Owner:赵铭

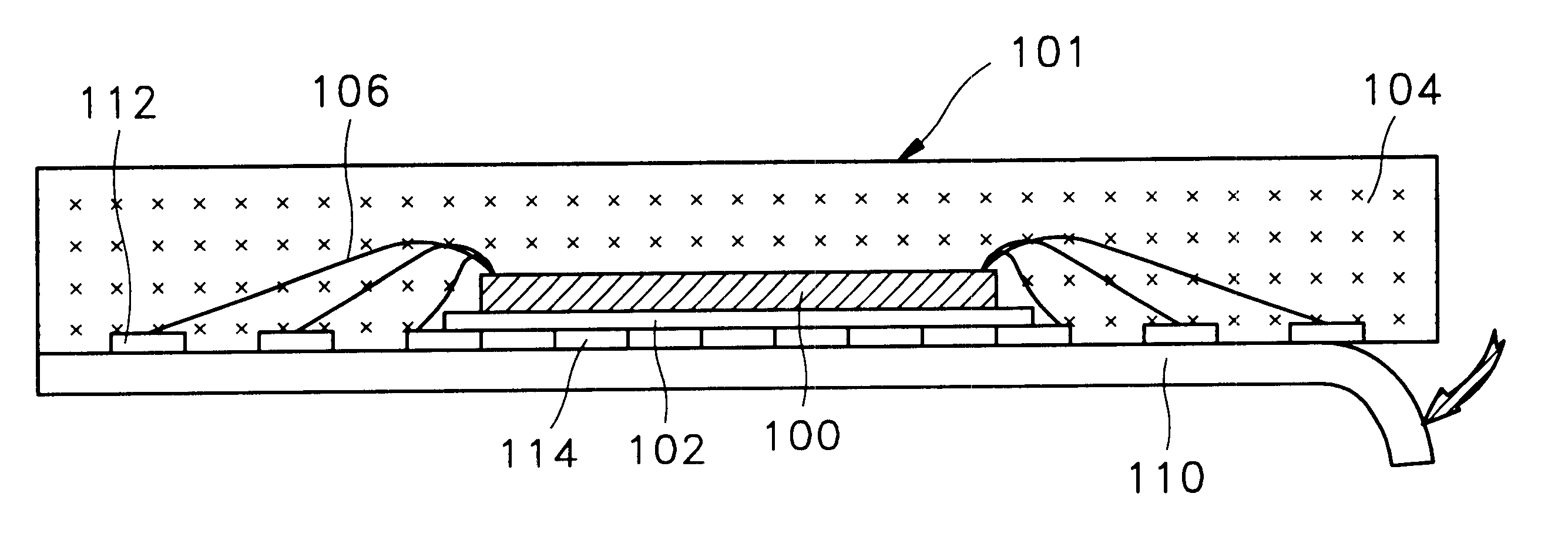

Solar power generation apparatus and its manufacturing method

InactiveUS7612283B2Reduce manufacturing costSimple structurePV power plantsDc-dc conversionManufacturing cost reductionAc power system

A solar cell assembly including a plurality of solar cells is formed on a common substrate, and a DC / DC converter which converts the output from the solar cell is connected to each solar cell to constitute a solar power generation apparatus. The output from the solar power generation apparatus is converted into an AC power by an inverter and supplied to a load or commercial AC power system. Since the arrangement is simplified, the manufacturing cost can be reduced, and the influence of partial shade or a variation in characteristic decreases.

Owner:CANON KK

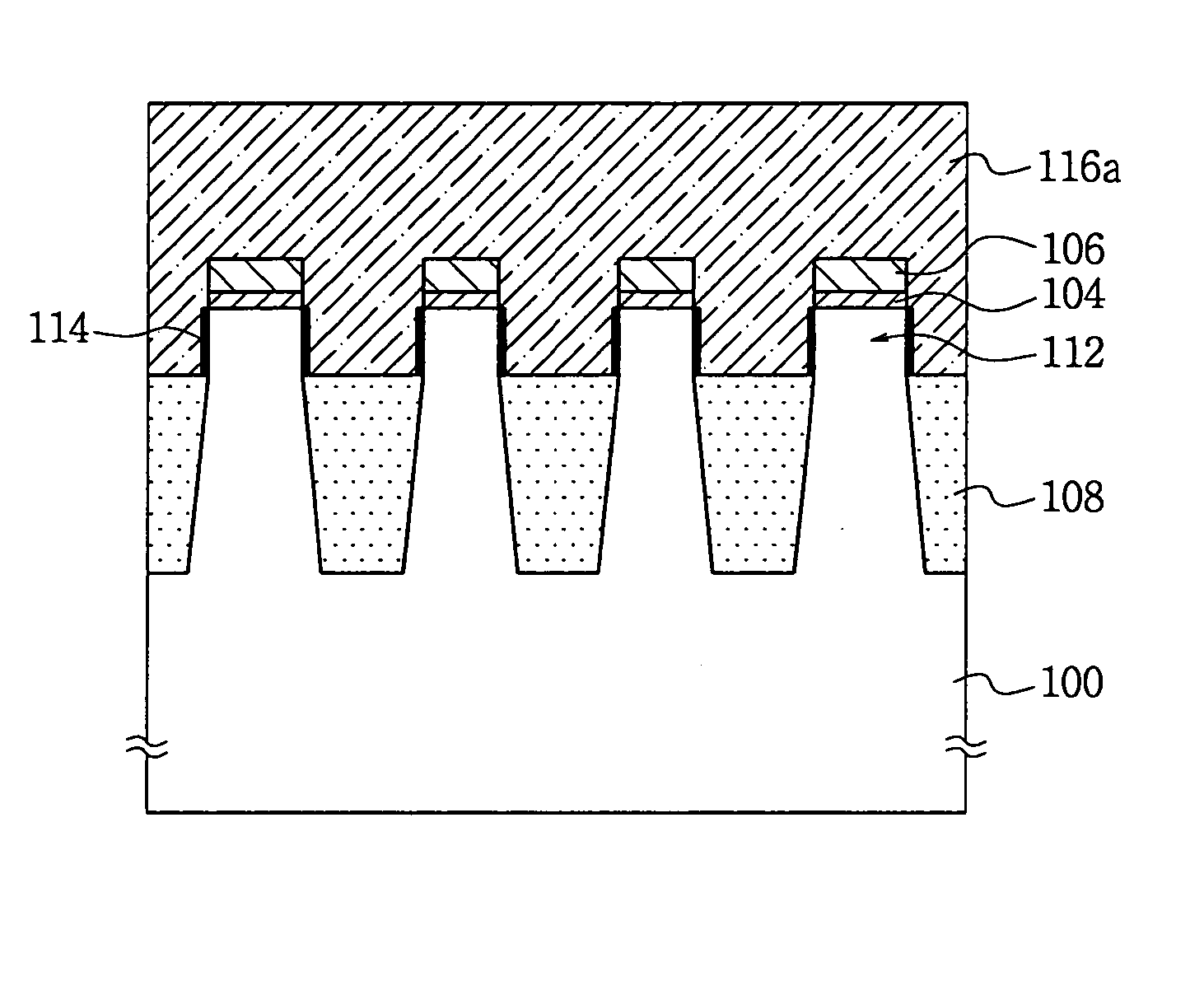

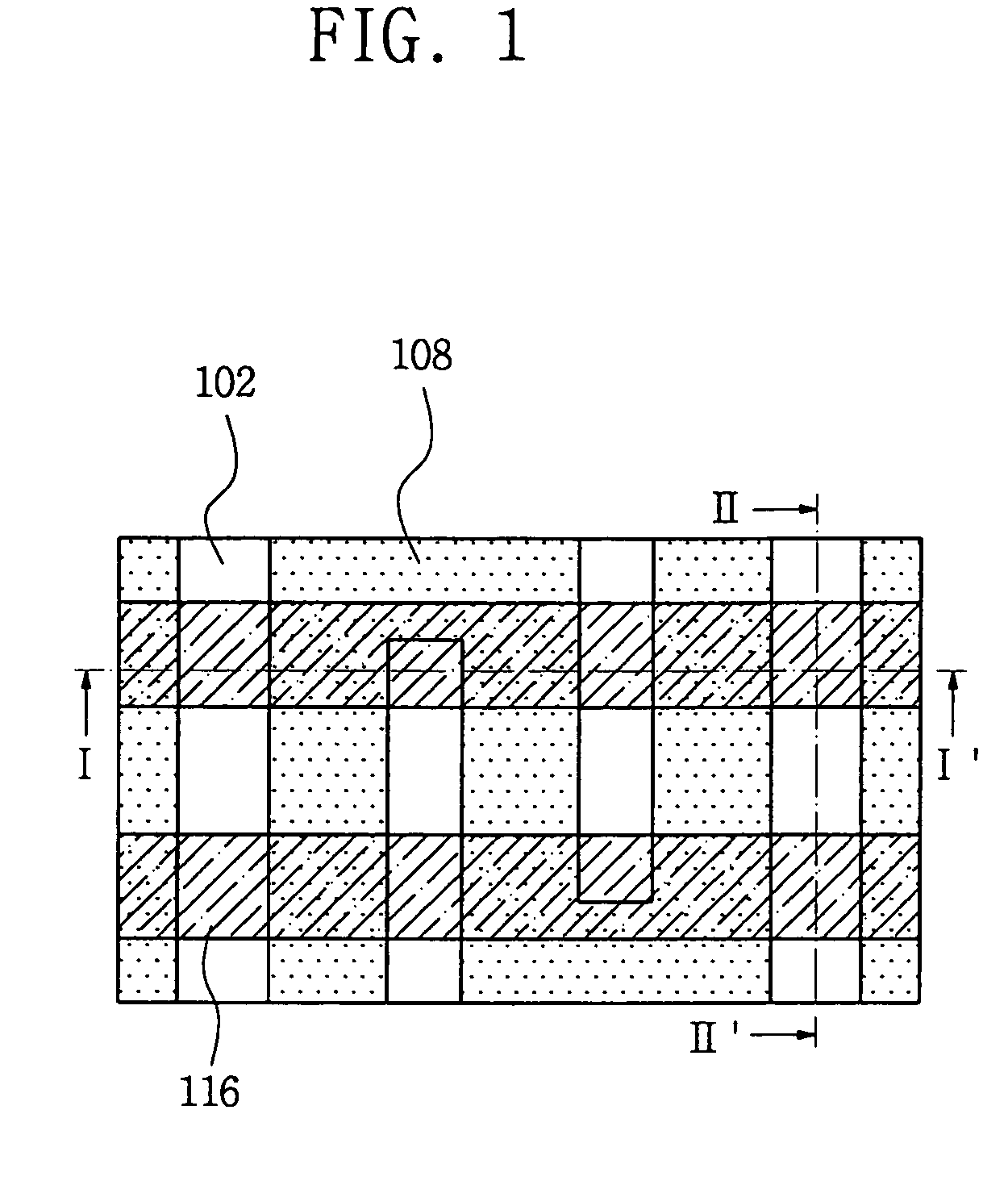

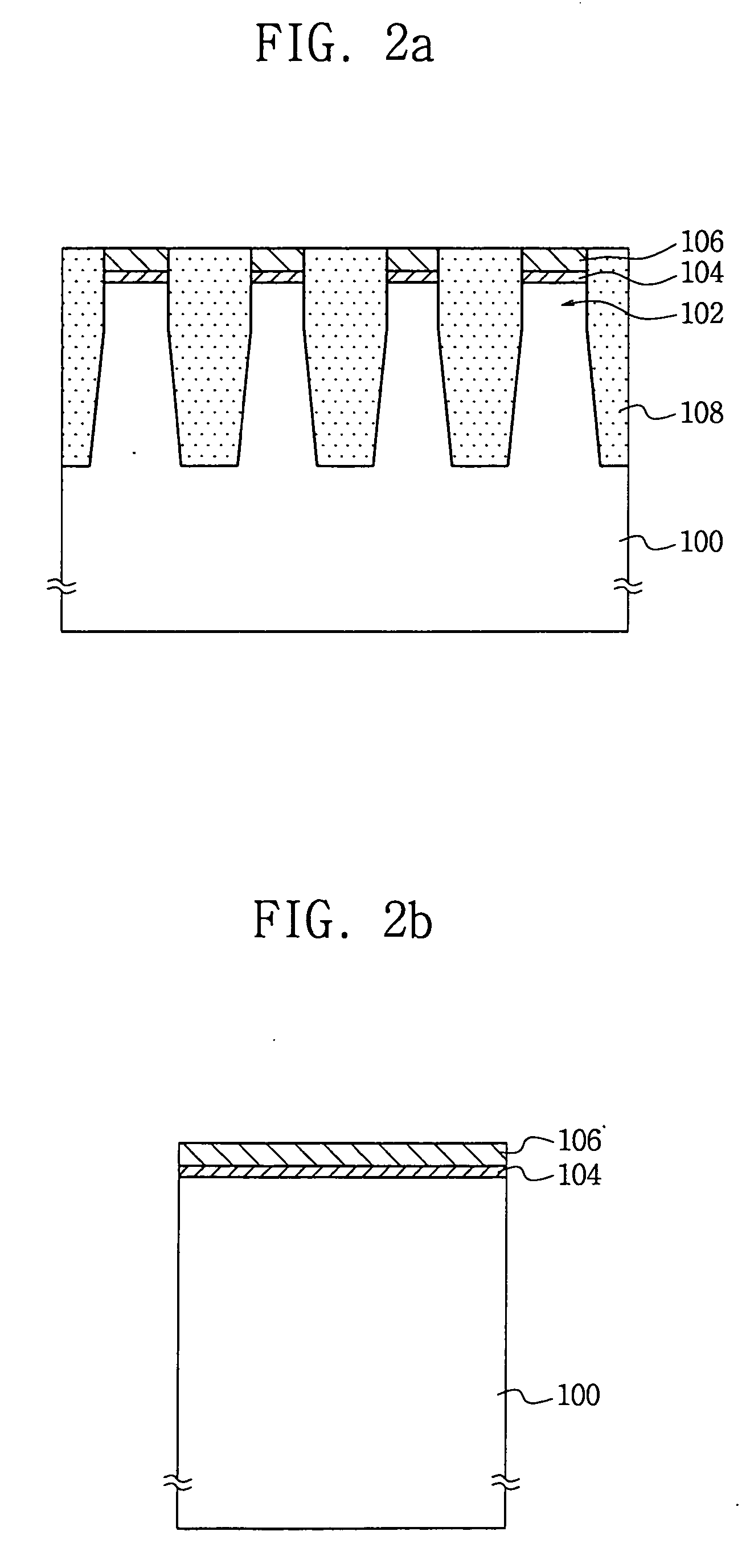

Method for forming a FinFET by a damascene process

ActiveUS20050170593A1Low costAvoid shortingTransistorBrushesManufacturing cost reductionInsulation layer

A device isolation film and an active region are formed on a semiconductor substrate, using a first mask pattern to expose only a formation region of the device isolation film. Only the device isolation film is selectively etched by using the first mask pattern and a second mask pattern as an etch mask, to form a fin only on a gate formation region, the second mask pattern to expose only a gate electrode formation region. A gate insulation layer is formed on both sidewalls of the fin and a gate electrode covering the first mask pattern and the gate insulation layer is formed. Source and drain regions are formed on the remaining portion of the active region where the gate electrode was not formed. Gate electrode separation becomes adequate and manufacturing costs can be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

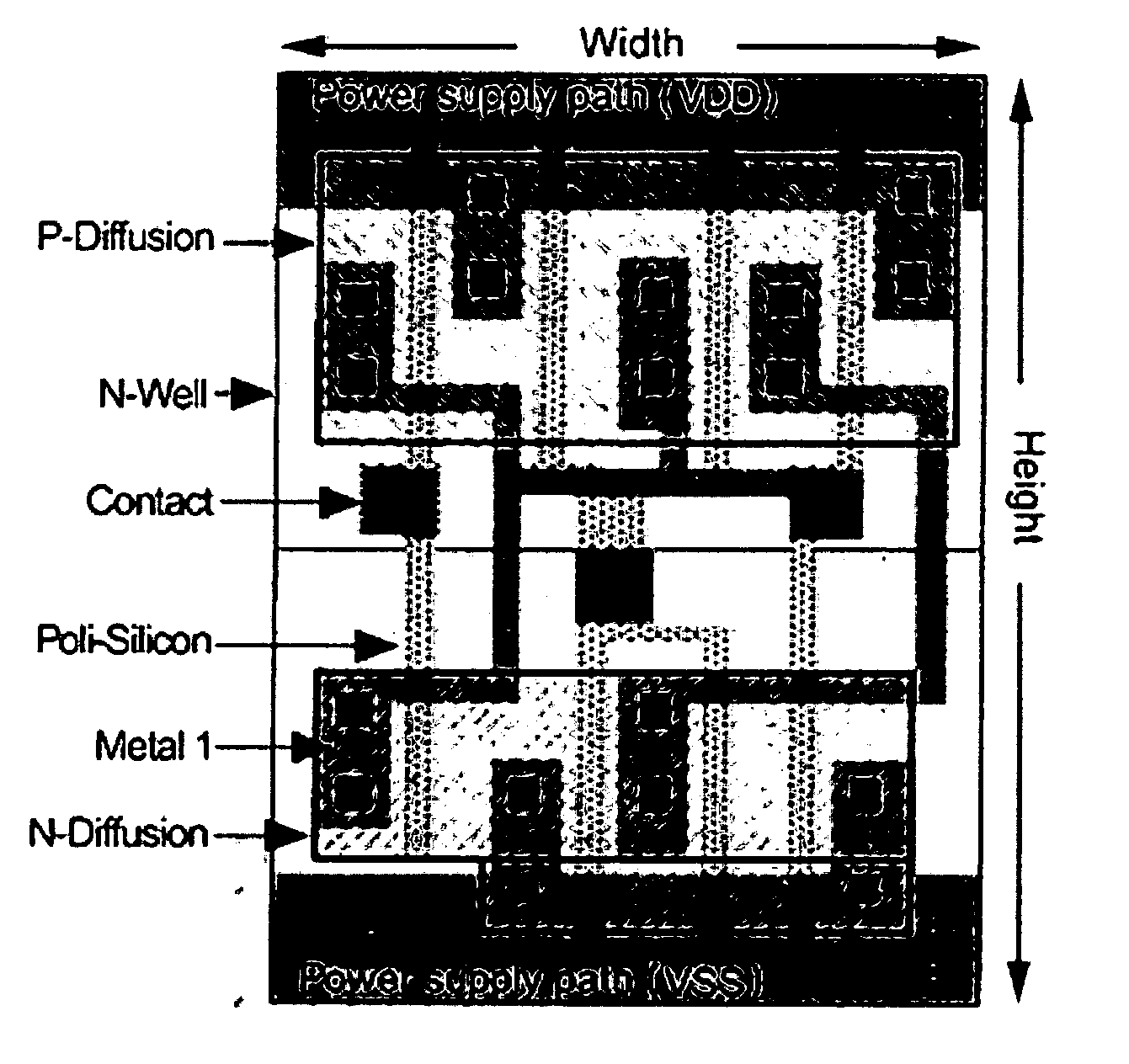

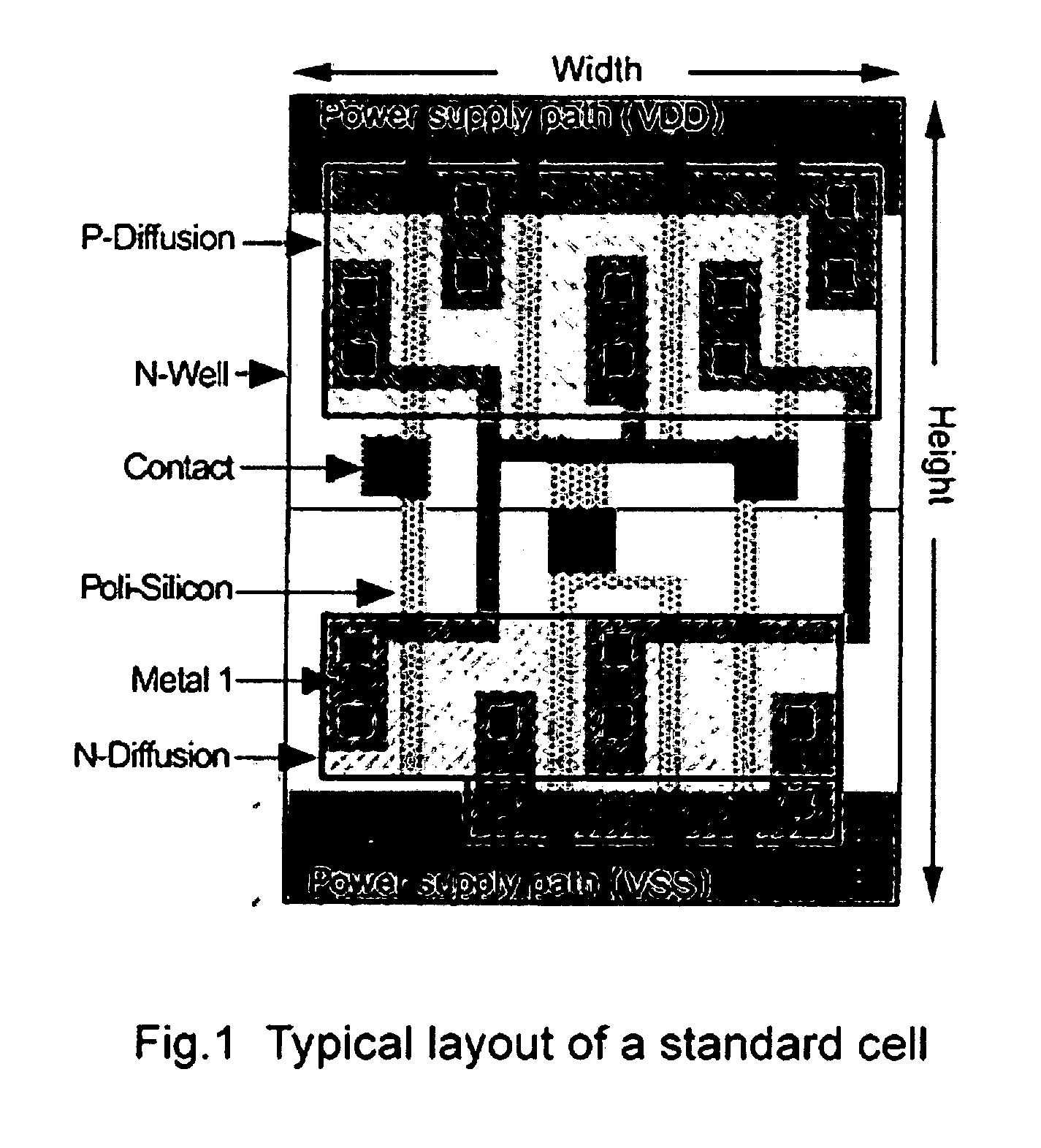

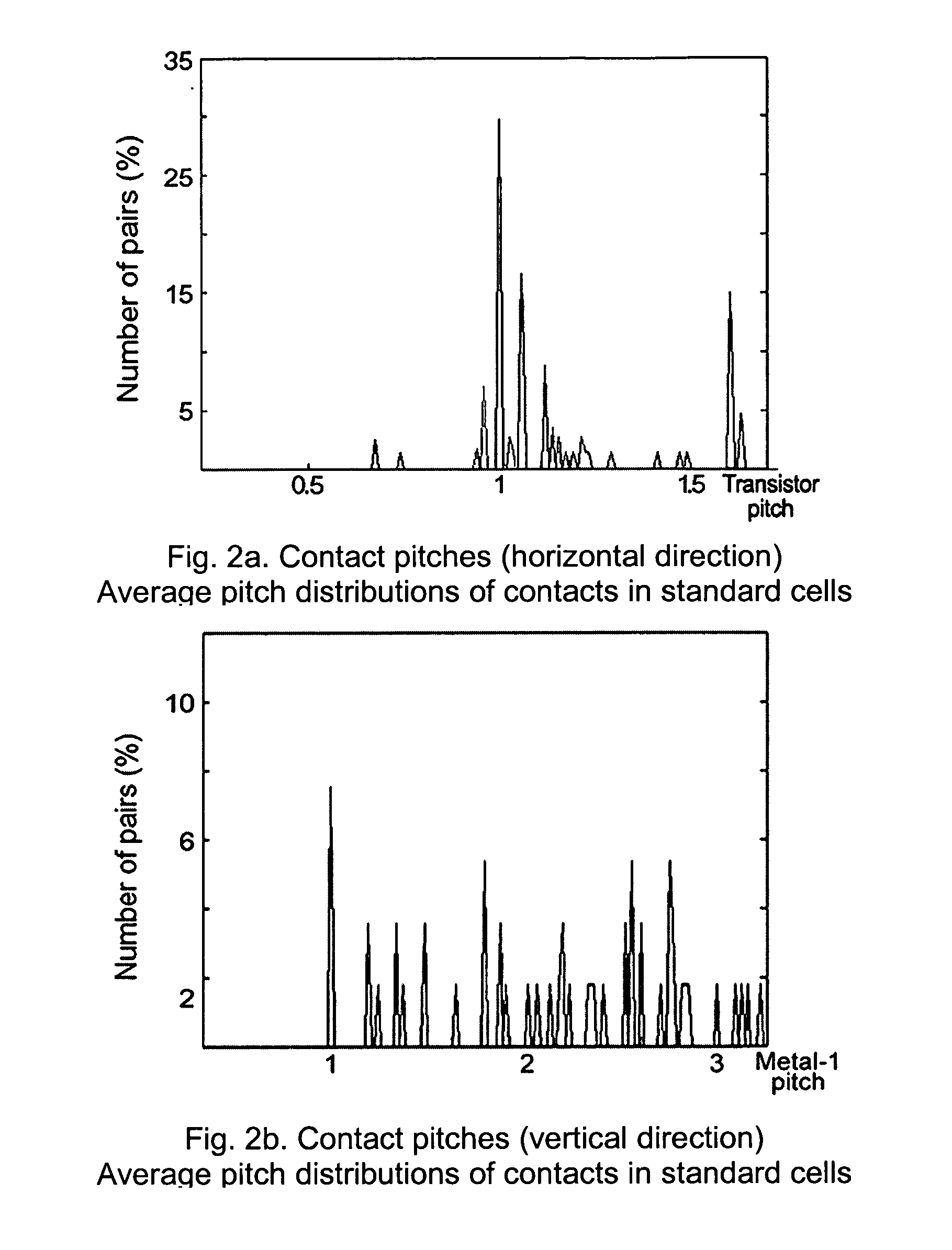

Rectangular contact lithography for circuit performance improvement and manufacture cost reduction

ActiveUS20050196685A1Reduce manufacturing costLot of restrictionPhoto-taking processesSemiconductor/solid-state device manufacturingManufacturing cost reductionEngineering

An optical lithography method is disclosed that uses double exposure of a reusable template mask and a trim mask to fabricate regularly-placed rectangular contacts in standard cells of application-specific integrated circuits (ASICs). A first exposure of the reusable template mask with periodic patterns forms periodic dark lines on a wafer and a second exposure of an application-specific trim mask remove the unwanted part of the dark lines and the small cuts of the dark lines left form the rectangular regularly-placed contacts. All contacts are placed regularly in one direction while unrestrictedly in the perpendicular direction. The regular placement of patterns on the template mask enable more effective use of resolution enhancement technologies, which in turn allows a decrease in manufacturing cost and the minimum contact size and pitch. Since there is no extra application-specific mask needed comparing with the conventional lithography method for unrestrictedly-placed contacts, the extra cost is kept to the lowest. The method of the invention can be used in the fabrication of standard cells in application-specific integrated circuits (ASICs) to improve circuit performance and decrease circuit area and manufacturing cost.

Owner:THE UNIVERSITY OF HONG KONG

Semiconductor device and method for manufacturing the same

ActiveUS20100102314A1Easy to makeTransistorSolid-state devicesManufacturing cost reductionDriver circuit

As a display device has a higher definition, the number of pixels, gate lines, and signal lines are increased. When the number of the gate lines and the signal lines are increased, there occurs a problem that it is difficult to mount an IC chip including a driver circuit for driving the gate and signal lines by bonding or the like, whereby manufacturing cost is increased. A pixel portion and a driver circuit for driving the pixel portion are provided over the same substrate, and at least part of the driver circuit includes a thin film transistor using an oxide semiconductor interposed between gate electrodes provided above and below the oxide semiconductor. The pixel portion and the driver portion are provided over the same substrate, whereby manufacturing cost can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

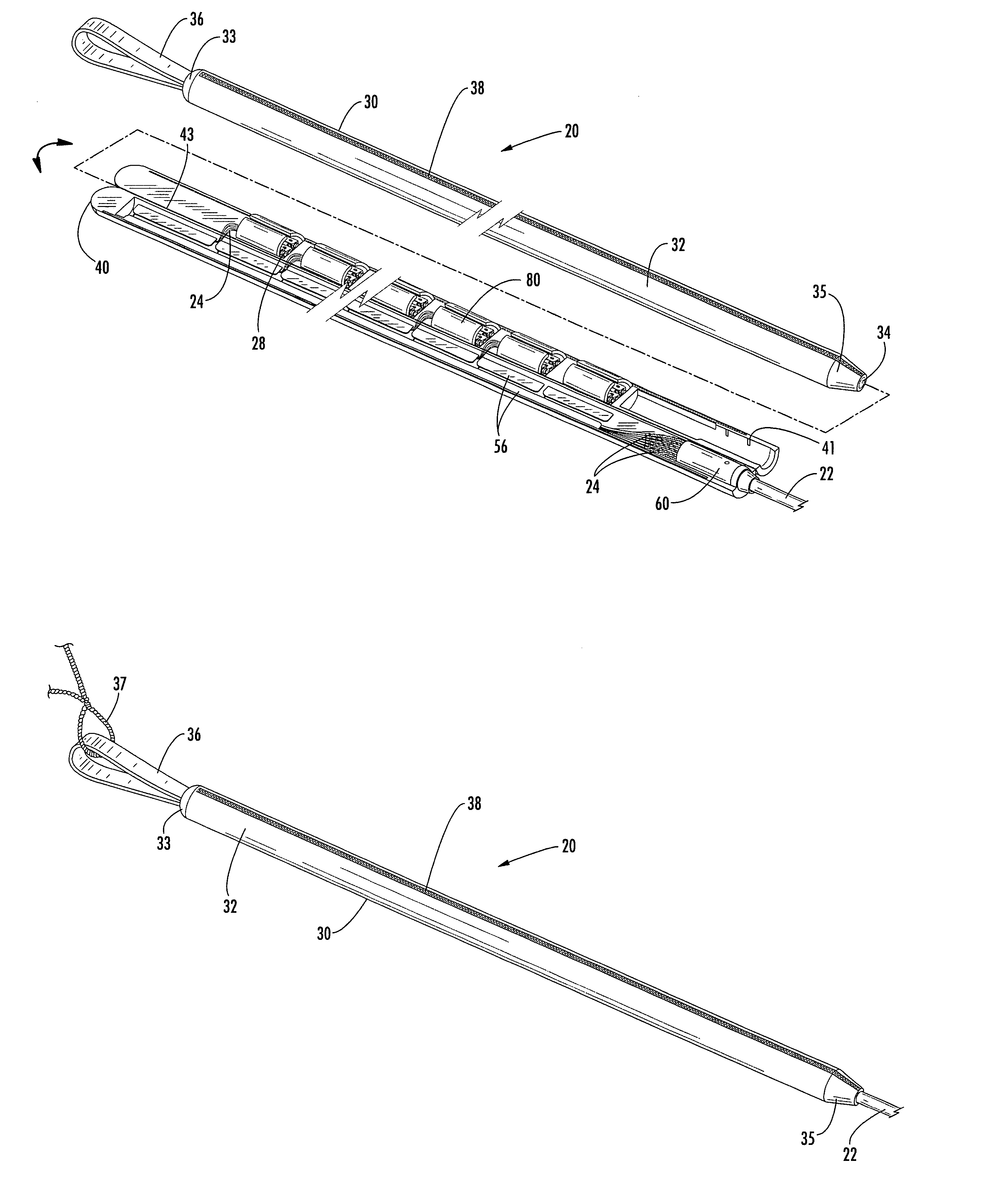

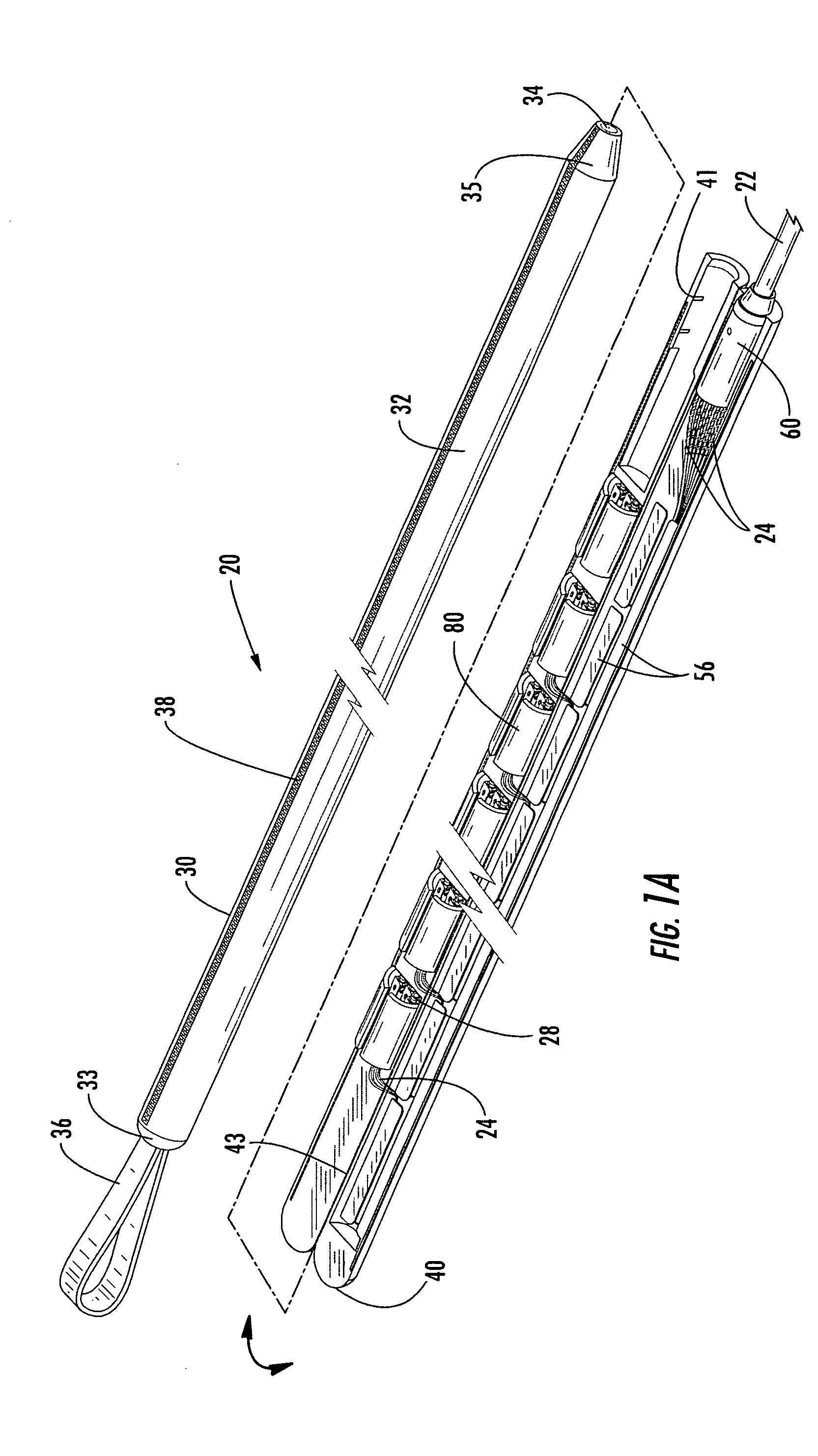

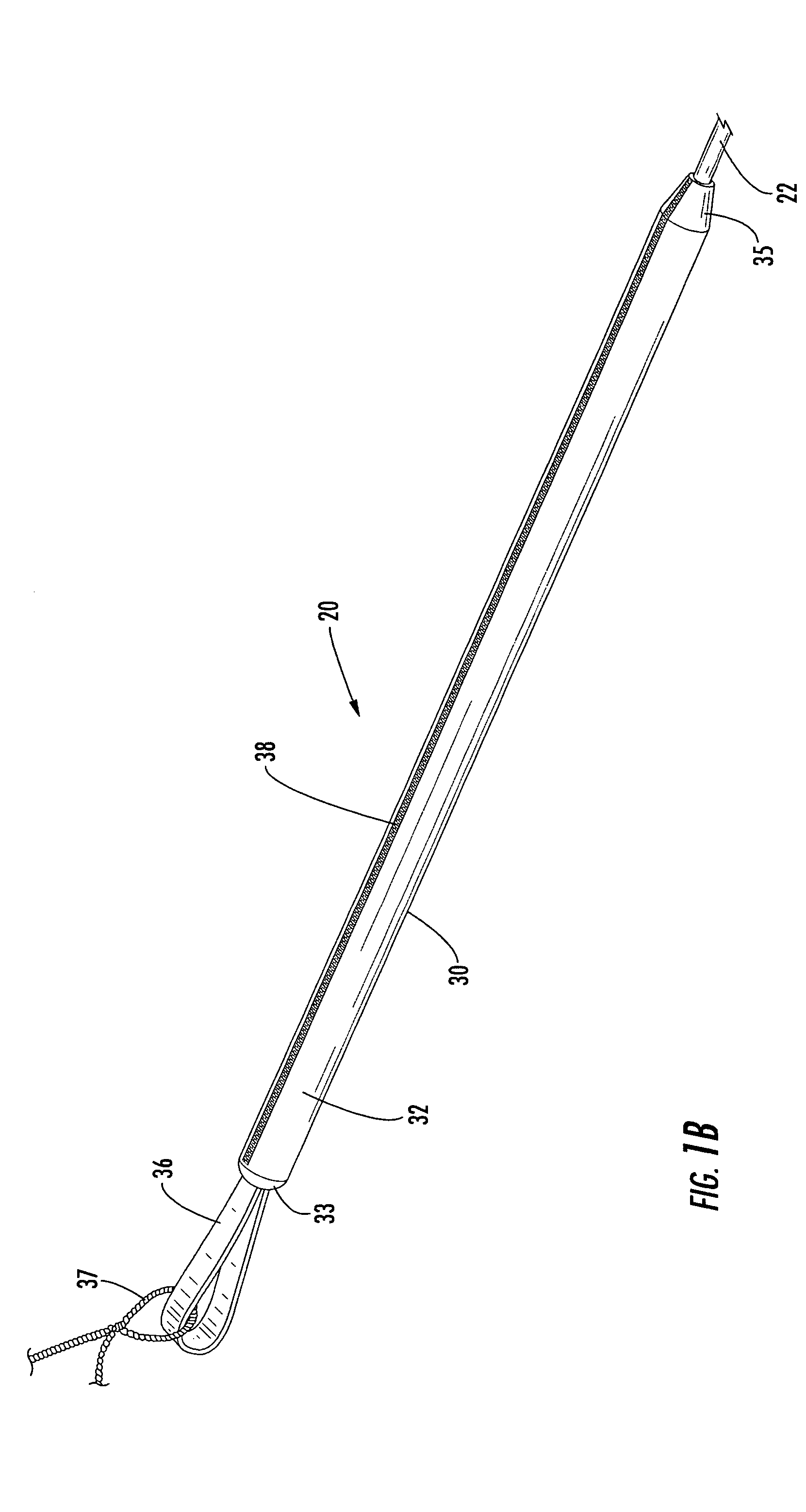

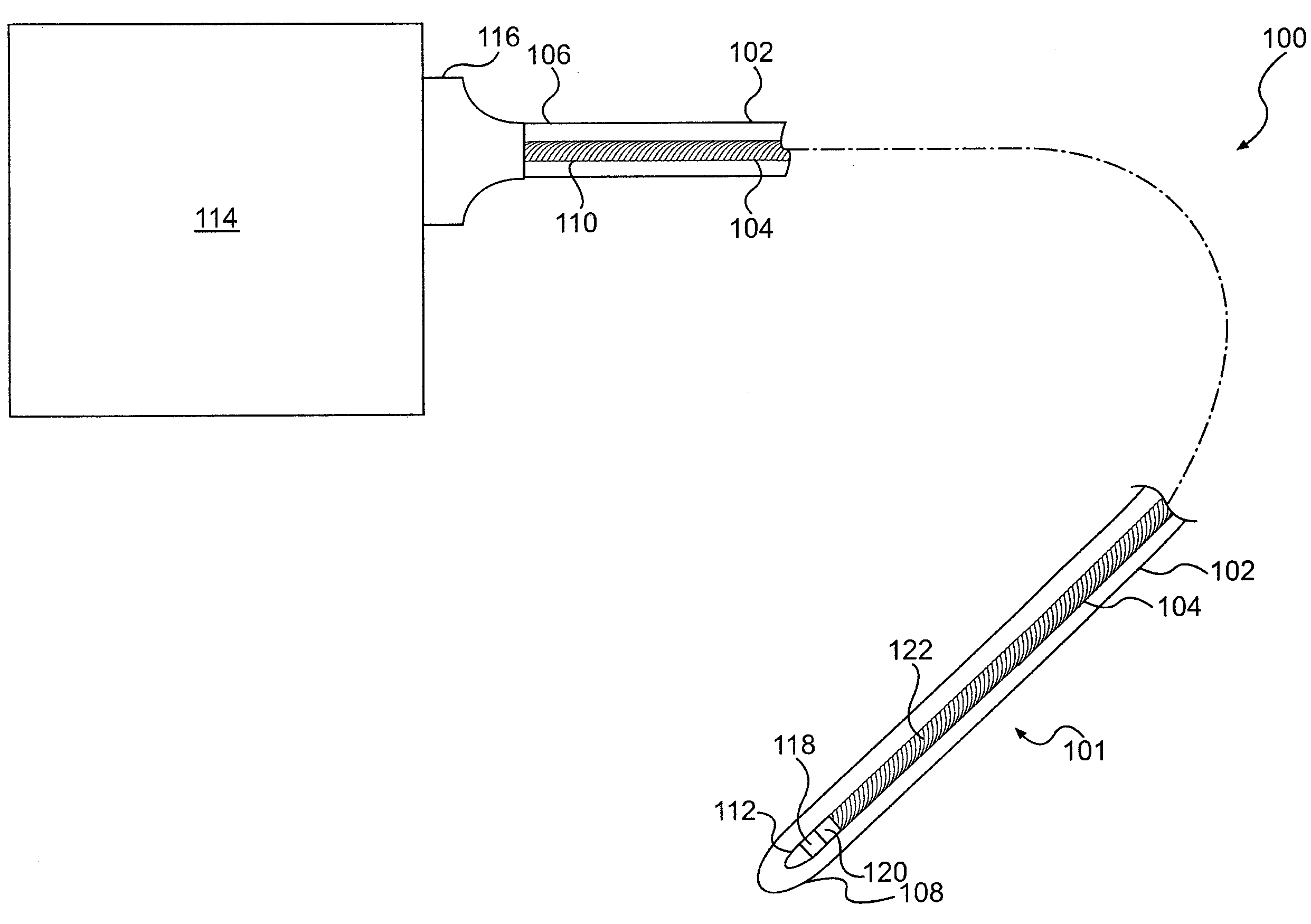

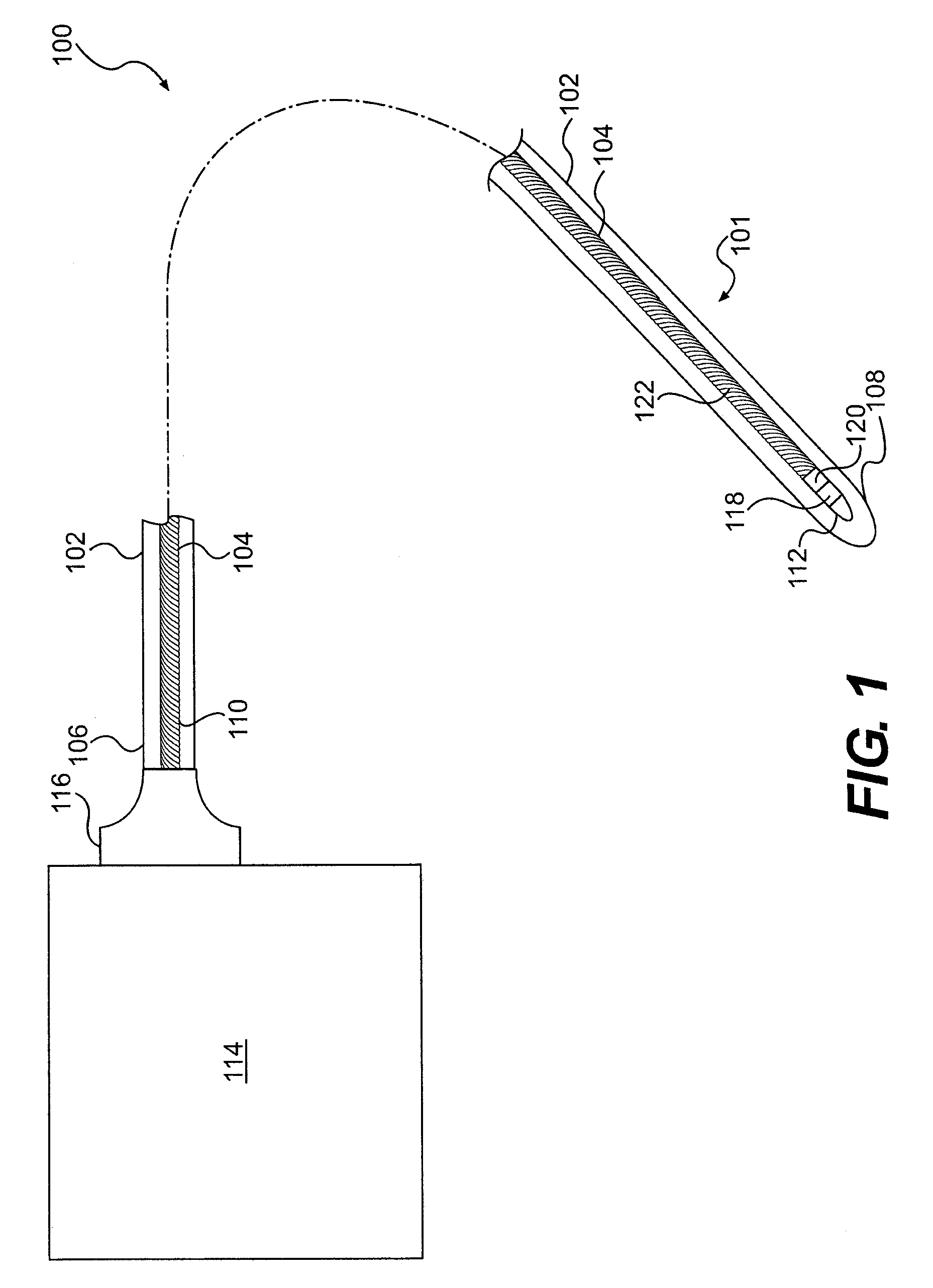

Pulling grip for installing pre-connectorized fiber optic cable

InactiveUS6993237B2Not time-consume and labor intensive to loadInexpensively moldedCoupling light guidesFibre mechanical structuresFiberManufacturing cost reduction

A pulling grip includes a pulling grip sleeve, a pulling grip housing and a furcation plug attached to the terminated end of a fiber optic cable. The pulling sleeve includes a bag adapted to be positioned over the pulling grip housing and the furcation plug and to be opened and closed by a lengthwise extending zipper. The pulling grip housing has a first compartment defining an elongate channel for routing optical fibers of the fiber optic cable and a second compartment defining a plurality of pockets that each store a plurality of fiber optic connectors mounted upon the ends of the optical fibers. The pulling grip housing may be formed as a plurality of injection molded modules to increase rigidity and to reduce manufacturing cost. The furcation plug includes means for readily integrating the furcation plug with a conventional distribution frame or rack, or with a cross-connect housing.

Owner:CORNING OPTICAL COMM LLC

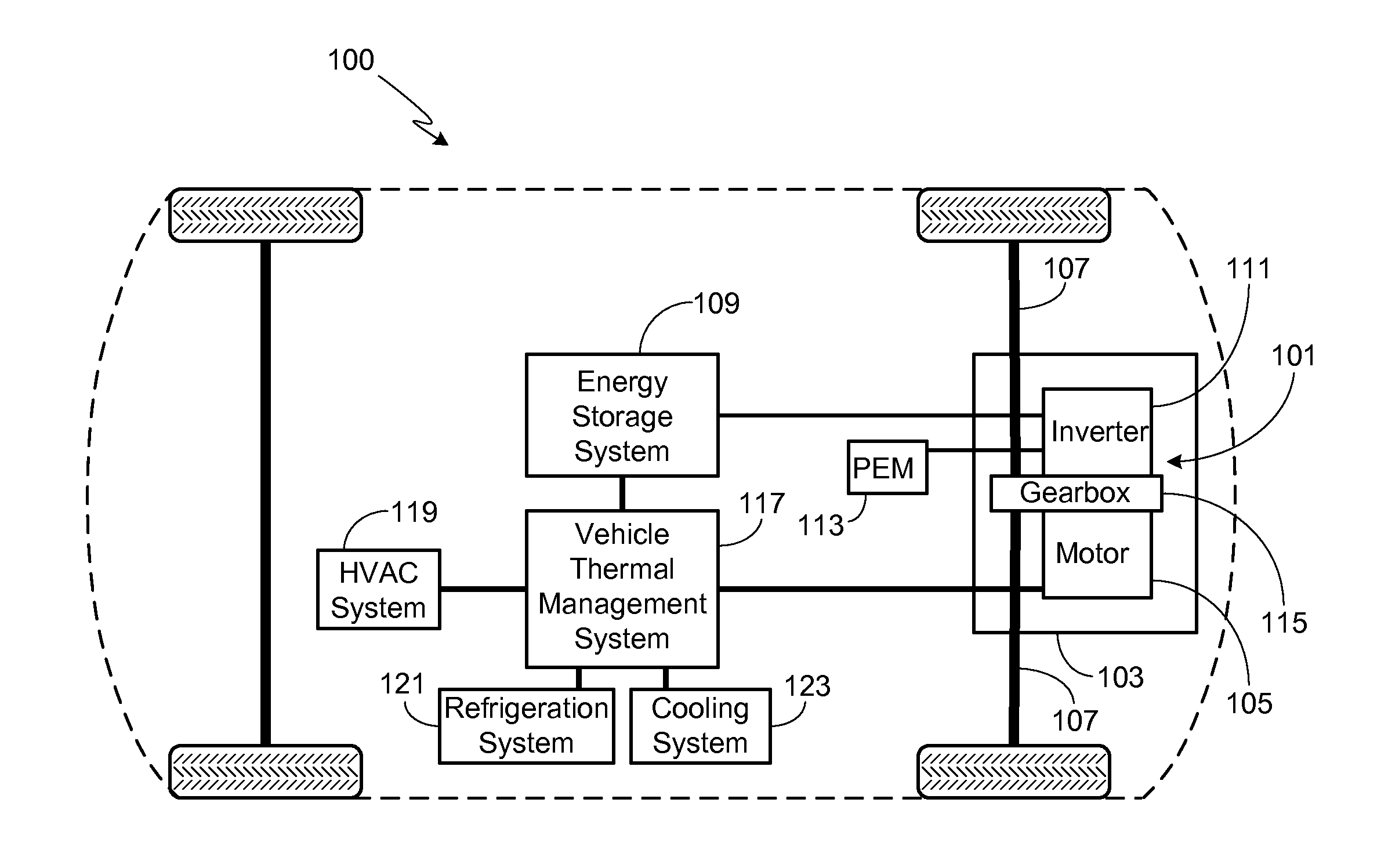

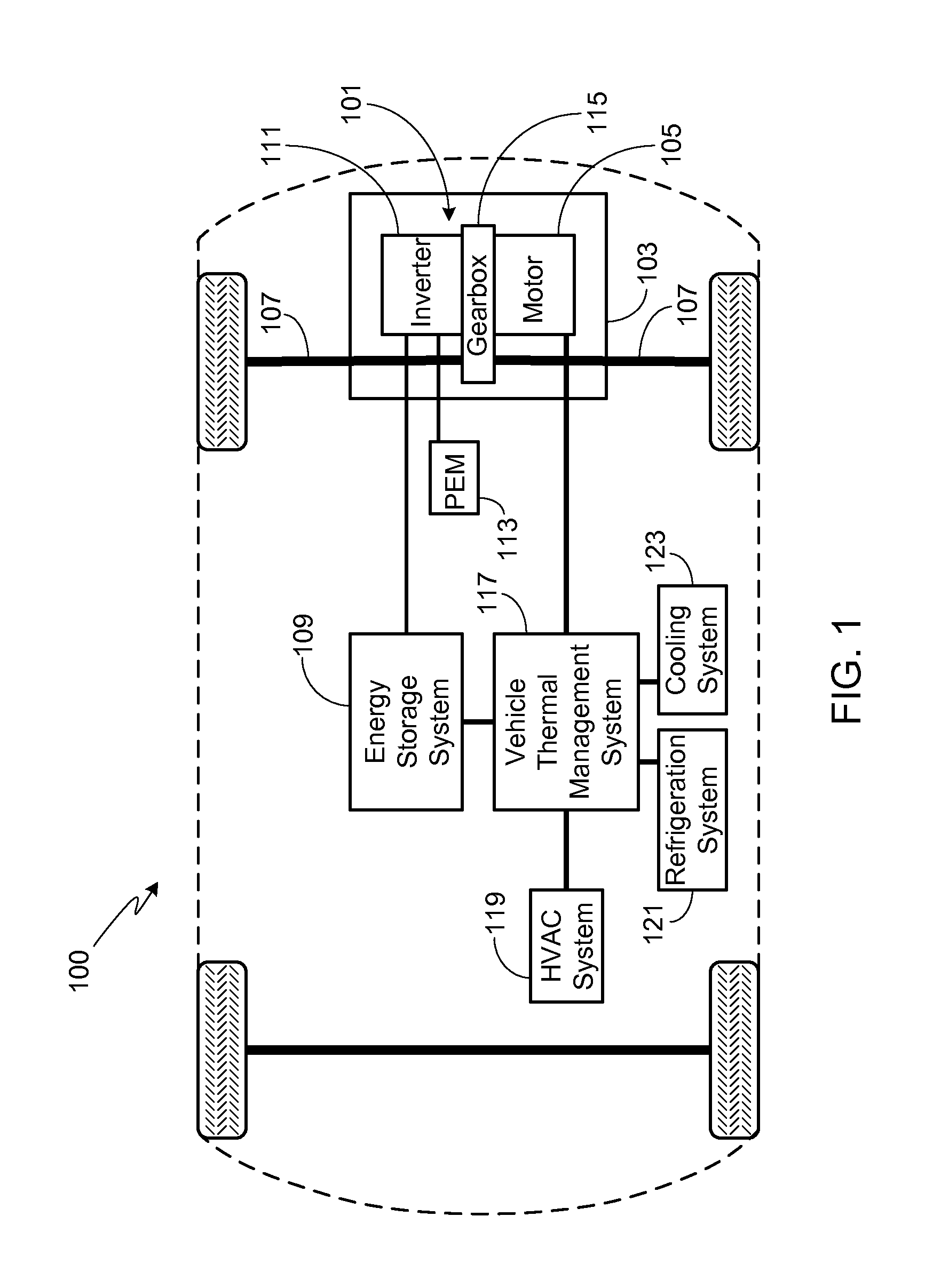

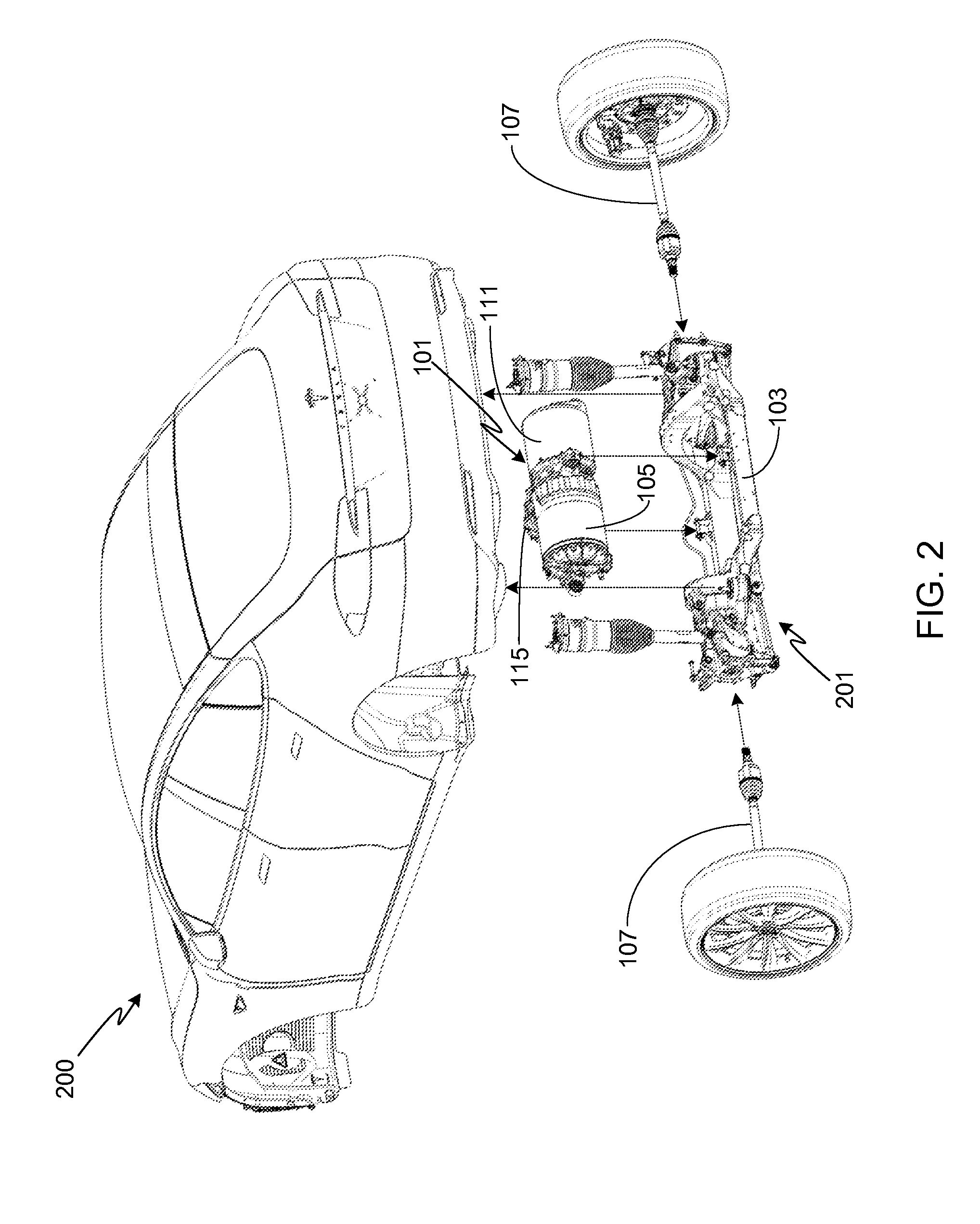

Thermal Management System for Use with an Integrated Motor Assembly

ActiveUS20120153718A1Reduce weightEasy to assembleHybrid vehiclesGearboxesManufacturing cost reductionPower inverter

An integrated drive system assembly is provided that combines an electric motor, a power inverter assembly and a gearbox into a single, multi-piece enclosure. Combining these components into a single enclosure reduces weight, reduces drive system complexity, reduces system volume, simplifies assembly integration into an electric vehicle, reduces manufacturing cost, allows the flexible and lengthy electrical cables between the power inverter and the electric motor to be replaced with short, low loss, rigid bus bars, and simplifies component cooling by allowing the use of a common thermal management system. The common thermal management system includes a liquid coolant loop that is thermally coupled to the electric motor, the power inverter assembly and the gearbox.

Owner:TESLA INC

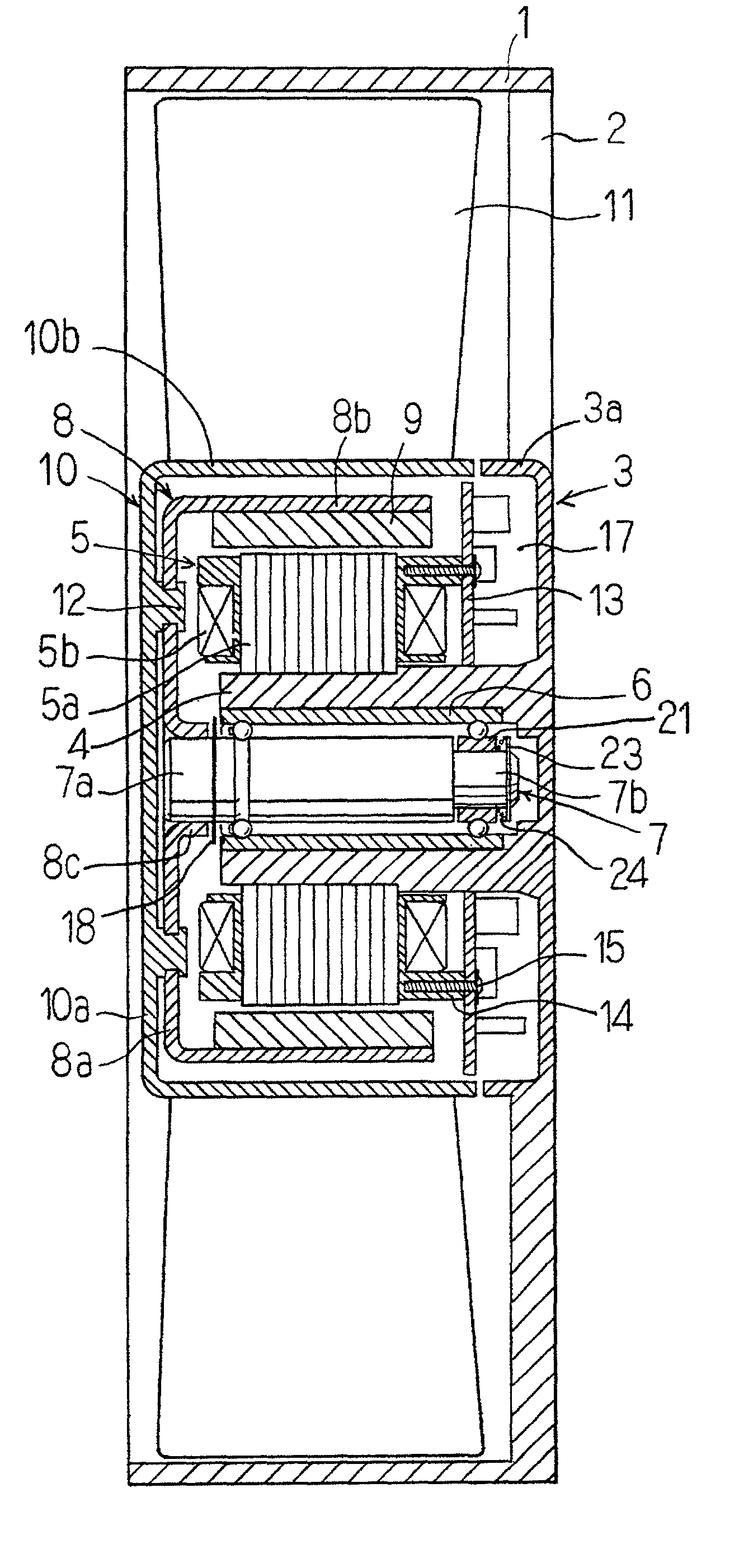

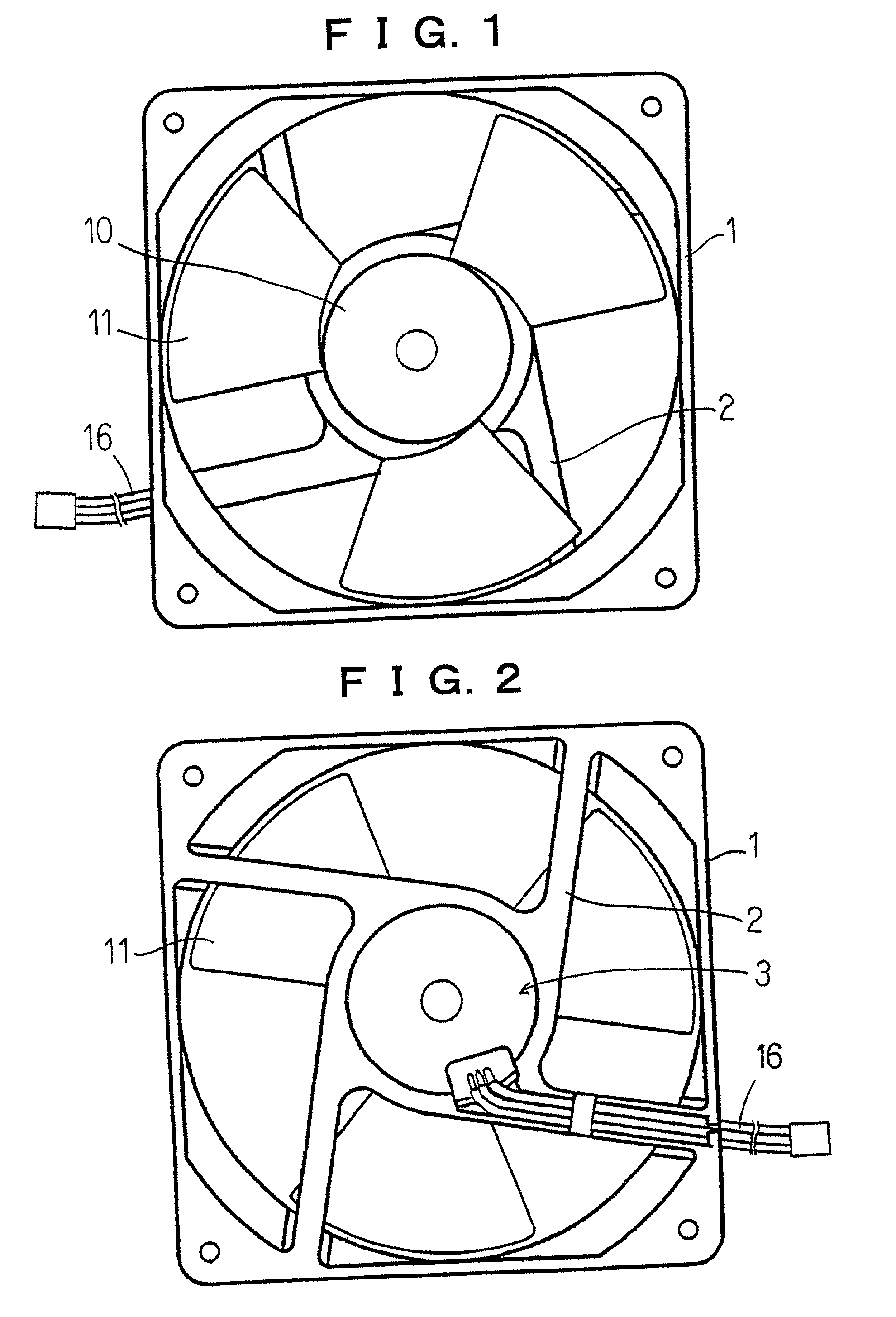

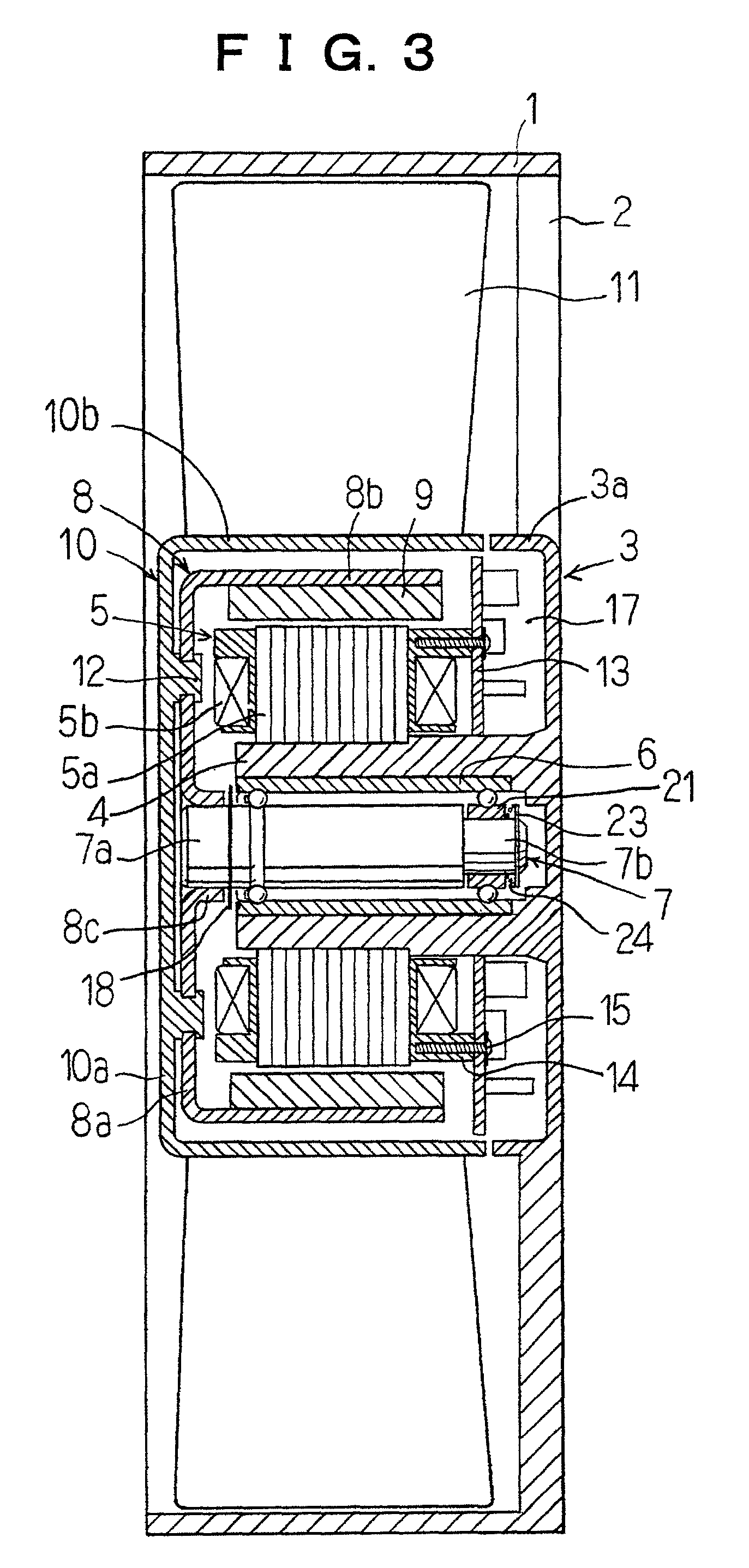

Blower

The object of the present invention is to provide a blower including a bearing structure wherein the number of components is reduced, the cost for manufacturing can be reduced, and the diameter of the shaft can be increased. The bearing structure is good at its durability, eliminates or reduces the rotational run out, and provides superior quietness. The blower of the present invention having an impeller adapted to be rotated upon energizing the blower comprising; a bearing device for supporting a rotational center portion of the impeller, the bearing device including; a sleeve, a stepped shaft including a larger diameter portion and a reduced diameter portion provided at one end thereof, the first inner raceway groove formed at an appropriate position around the outer peripheral surface of the larger diameter portion, the first outer raceway groove formed on an inner peripheral surface of the sleeve so as to correspond with the first inner raceway groove, balls of the first row interposed between the first and second grooves, an inner ring slidably fit over the reduced diameter portion, the second inner raceway groove formed around an outer peripheral surface of the inner ring, the second outer raceway groove formed on the inner peripheral surface of the sleeve so as to correspond with the second inner raceway groove, balls of the second row interposed between the second inner and outer raceway grooves, a stop ring provided around the inner periphery of the distal end of the reduced diameter portion, and a pre-loading spring interposed between the stop ring and an end surface of the inner ring to provide a suitable amount of pre-loading force to the inner ring.

Owner:MINEBEA CO LTD

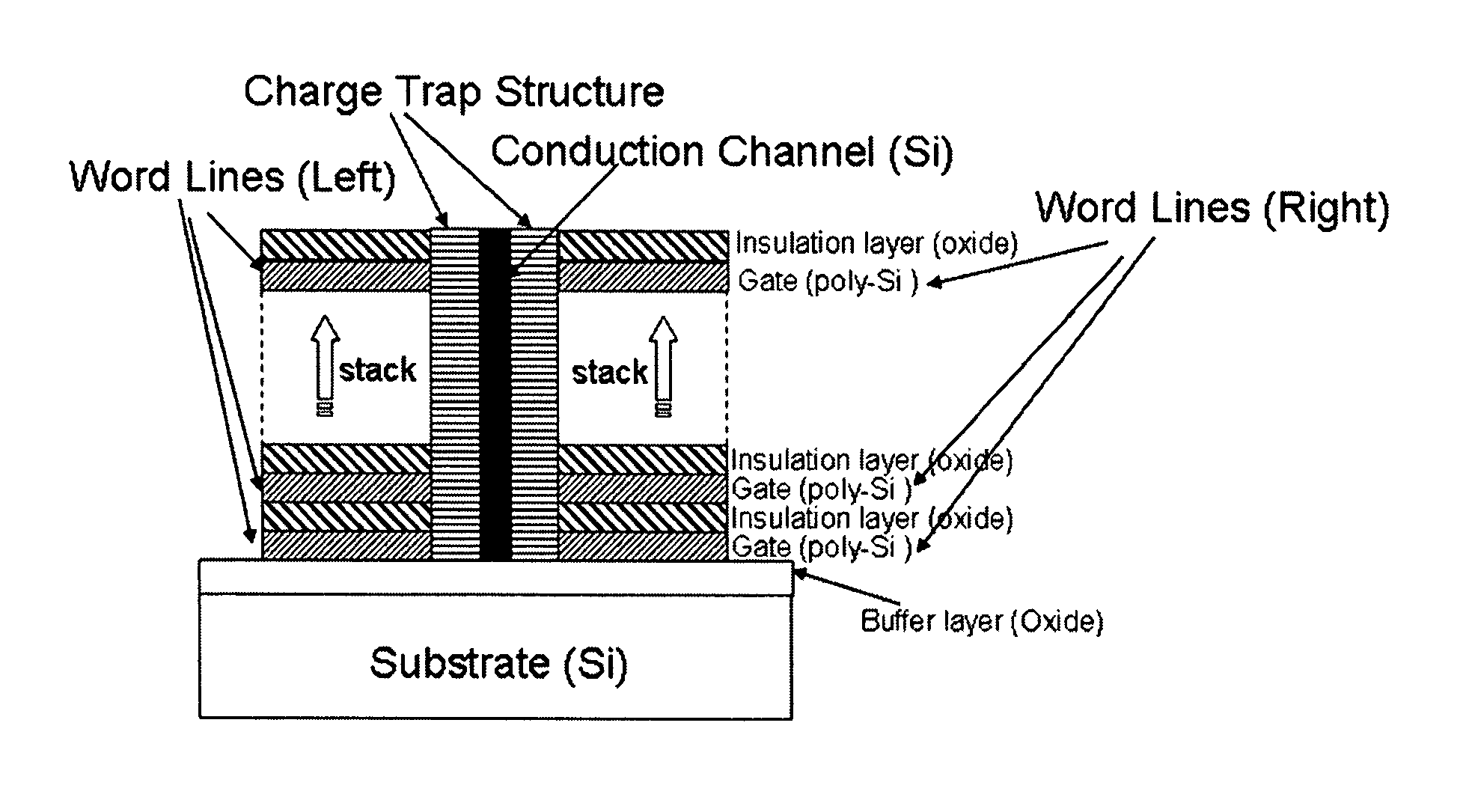

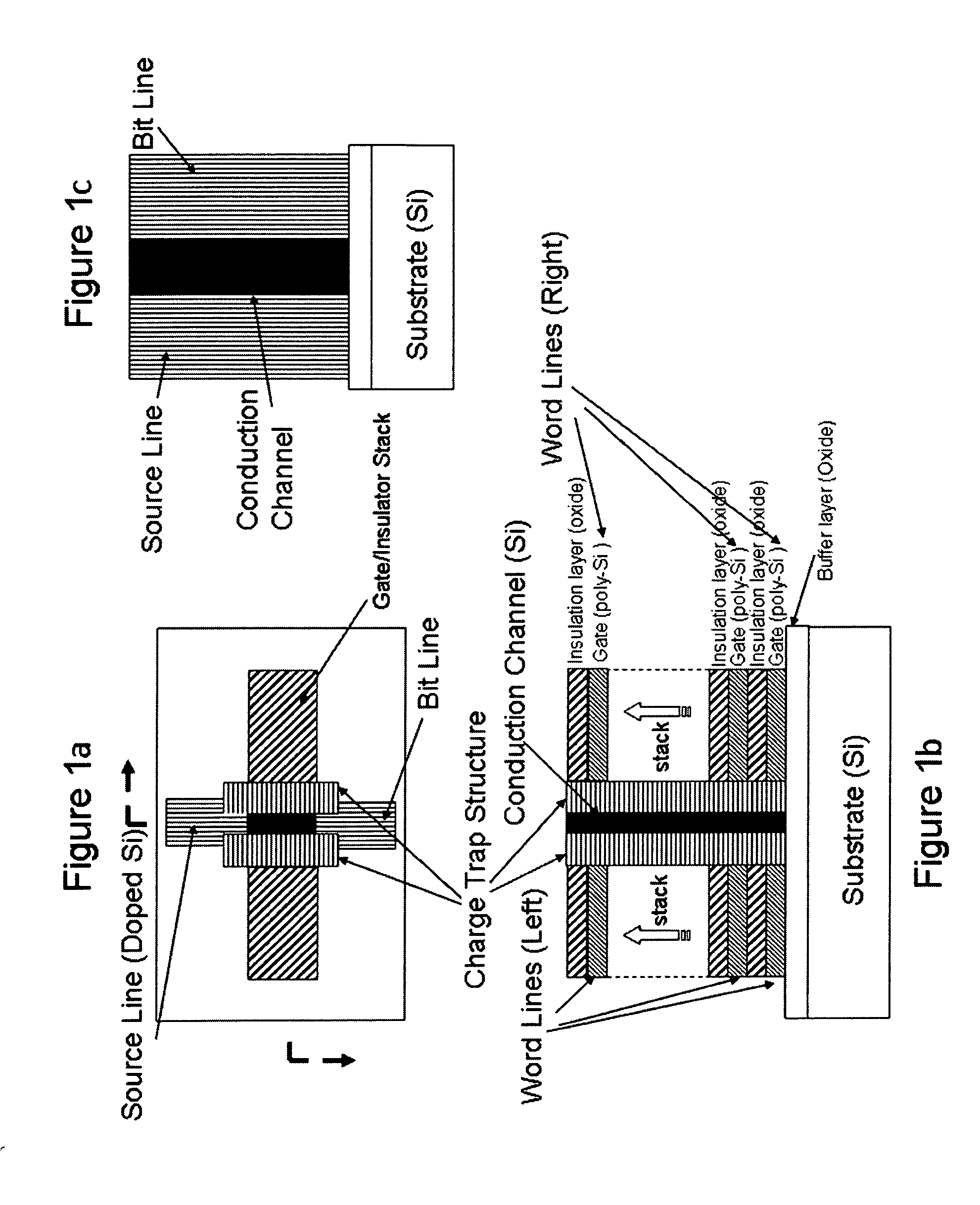

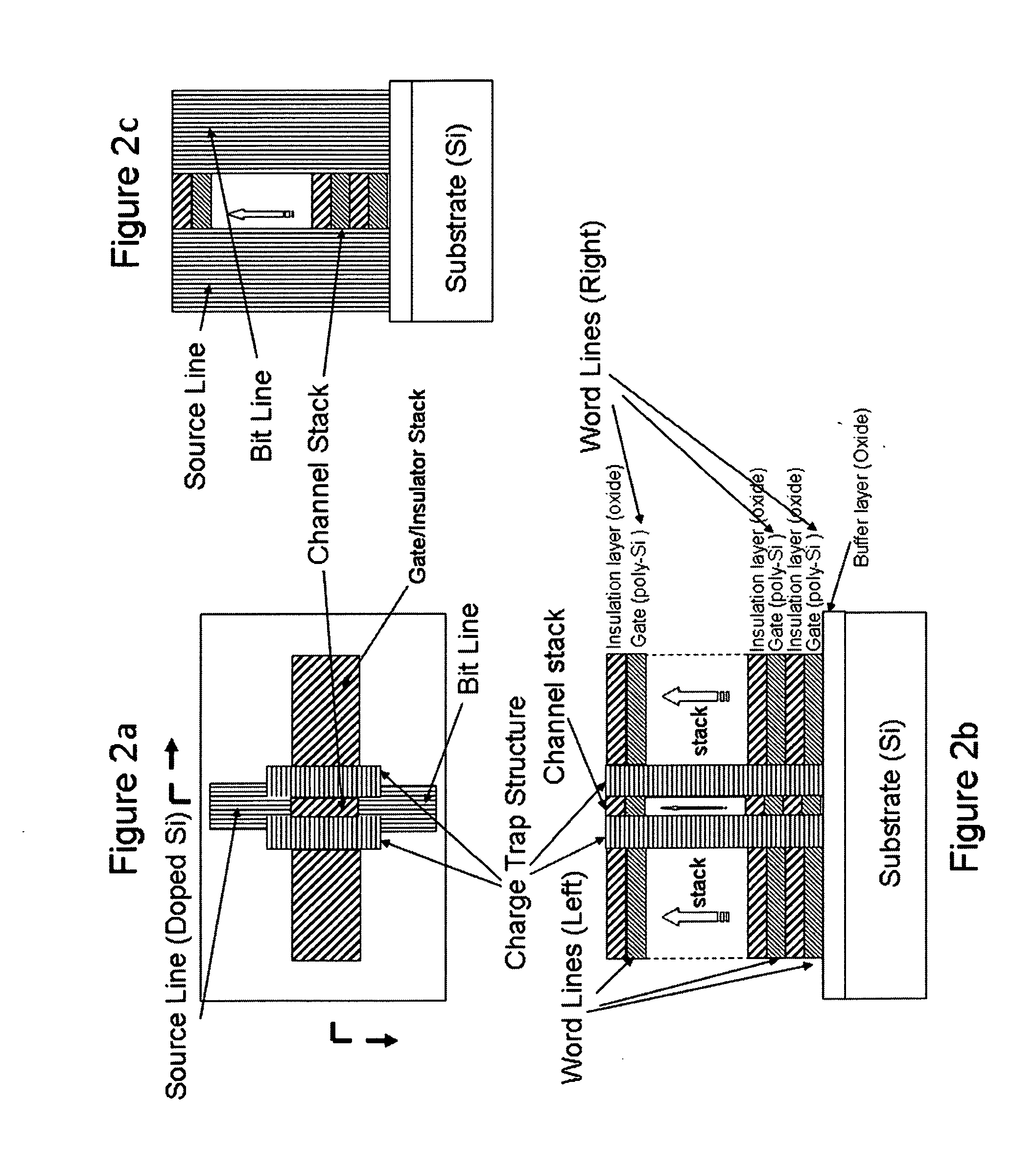

Three-dimensional non-volatile nor-type flash memory

ActiveUS20160086970A1High storage densitySolid-state devicesSemiconductor devicesElectricityEngineering

The present invention provides a design of three-dimensional non-volatile NOR flash memory devices consisting of arrays of basic NOR memory group in which individual memory cells (field-effect-transistors) are stacked along a direction (or directions) either out of or parallel to the plane of the substrate and electrically connected in parallel to achieve high storage densities approaching 1 TB with lower manufacturing cost. Offering full random access to every individual memory cells and also capability of parallel programming / erasing in blocks of memory cells, such three-dimensional non-volatile NOR flash memory can be widely used for both executable-code storage and mass data storage applications.

Owner:PENG HAIBING

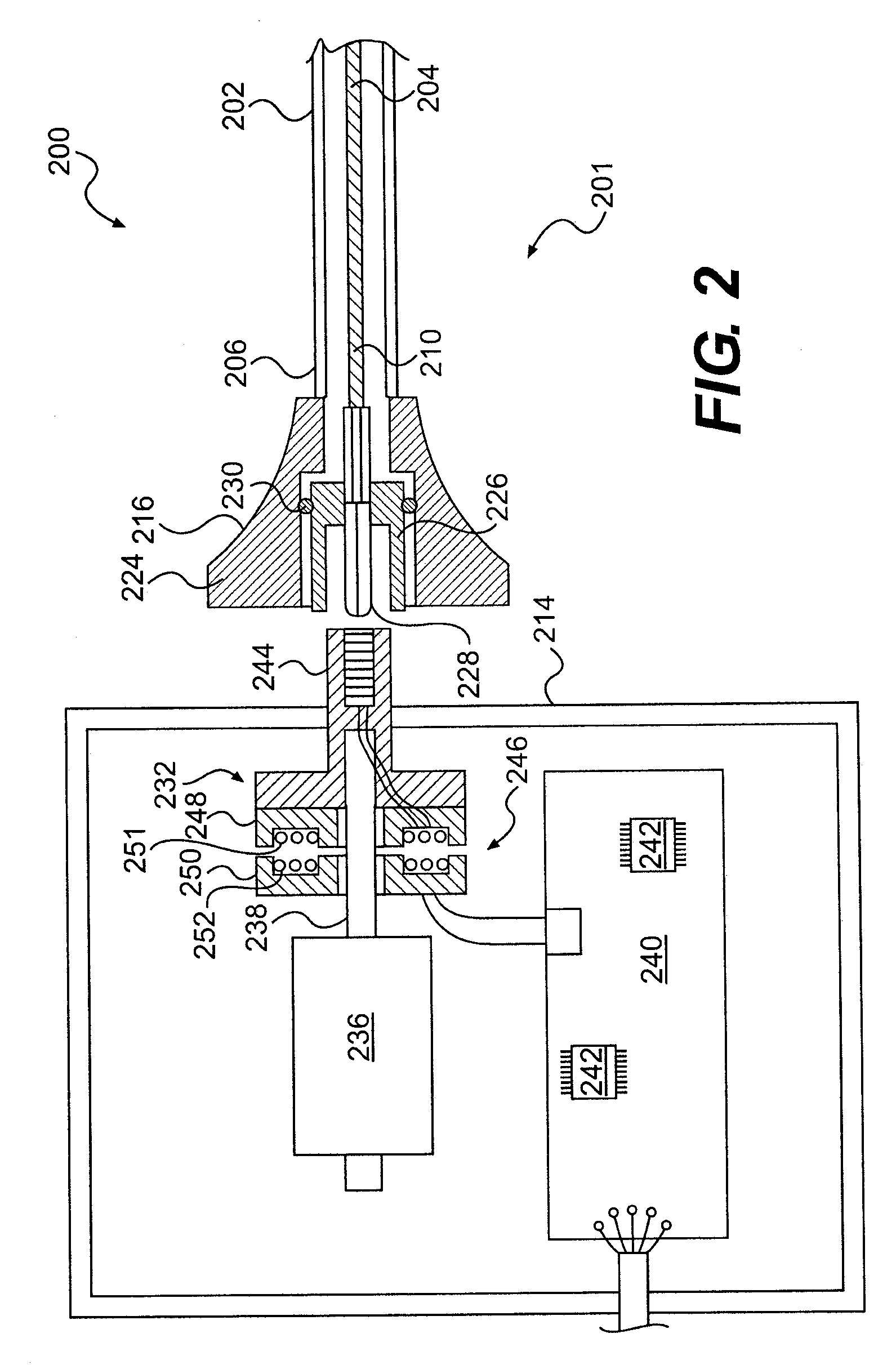

Rotational intravascular ultrasound probe with an active spinning element

ActiveUS20100234736A1Improve image qualityAccurate diagnosis of medicalCatheterInfrasonic diagnosticsManufacturing cost reductionSonification

An intravascular ultrasound probe is disclosed, incorporating features for utilizing an advanced transducer technology on a rotating transducer shaft. In particular, the probe accommodates the transmission of the multitude of signals across the boundary between the rotary and stationary components of the probe required to support an advanced transducer technology. These advanced transducer technologies offer the potential for increased bandwidth, improved beam profiles, better signal to noise ratio, reduced manufacturing costs, advanced tissue characterization algorithms, and other desirable features. Furthermore, the inclusion of electronic components on the spinning side of the probe can be highly advantageous in terms of preserving maximum signal to noise ratio and signal fidelity, along with other performance benefits.

Owner:VOLCANO CORP

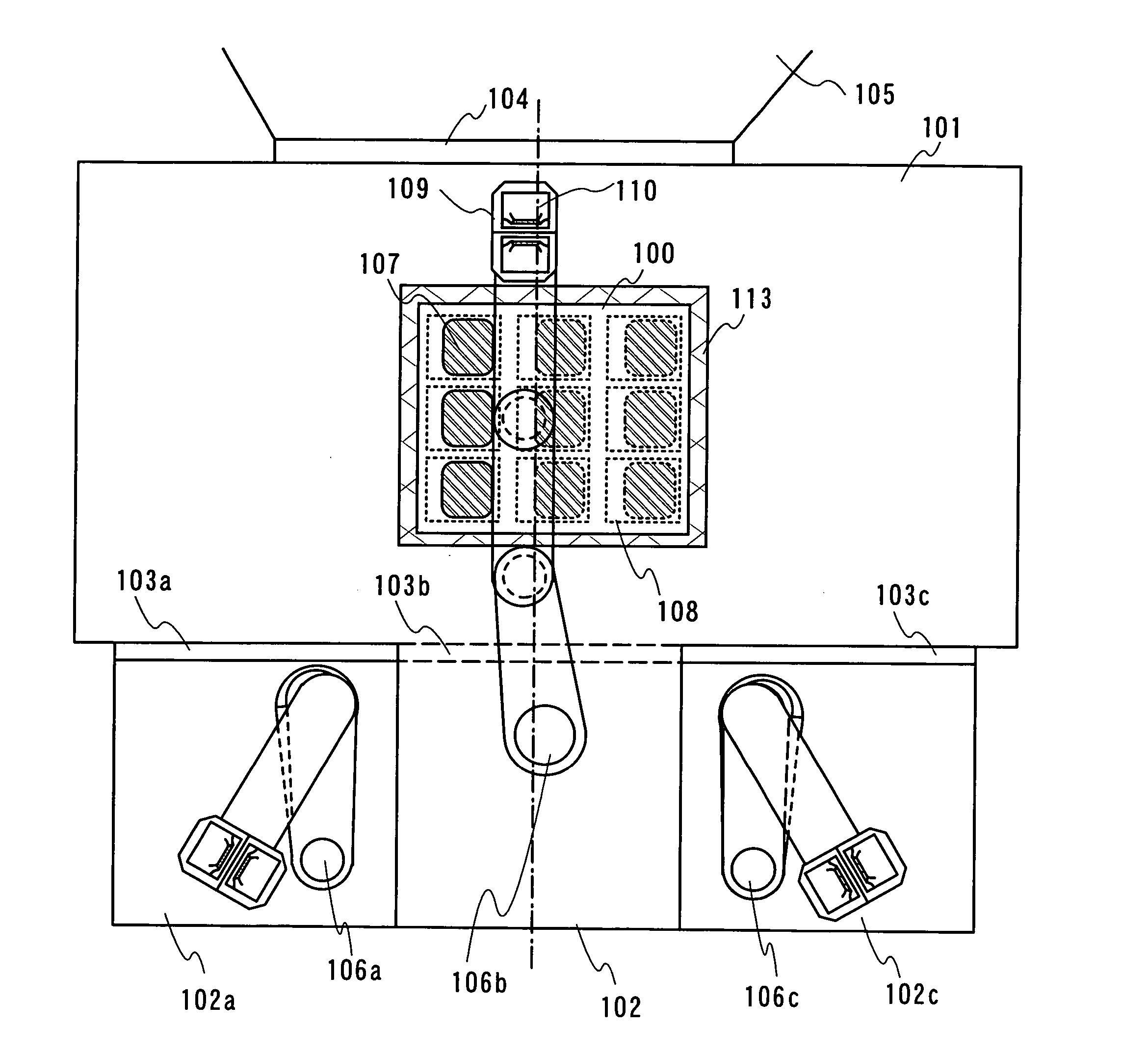

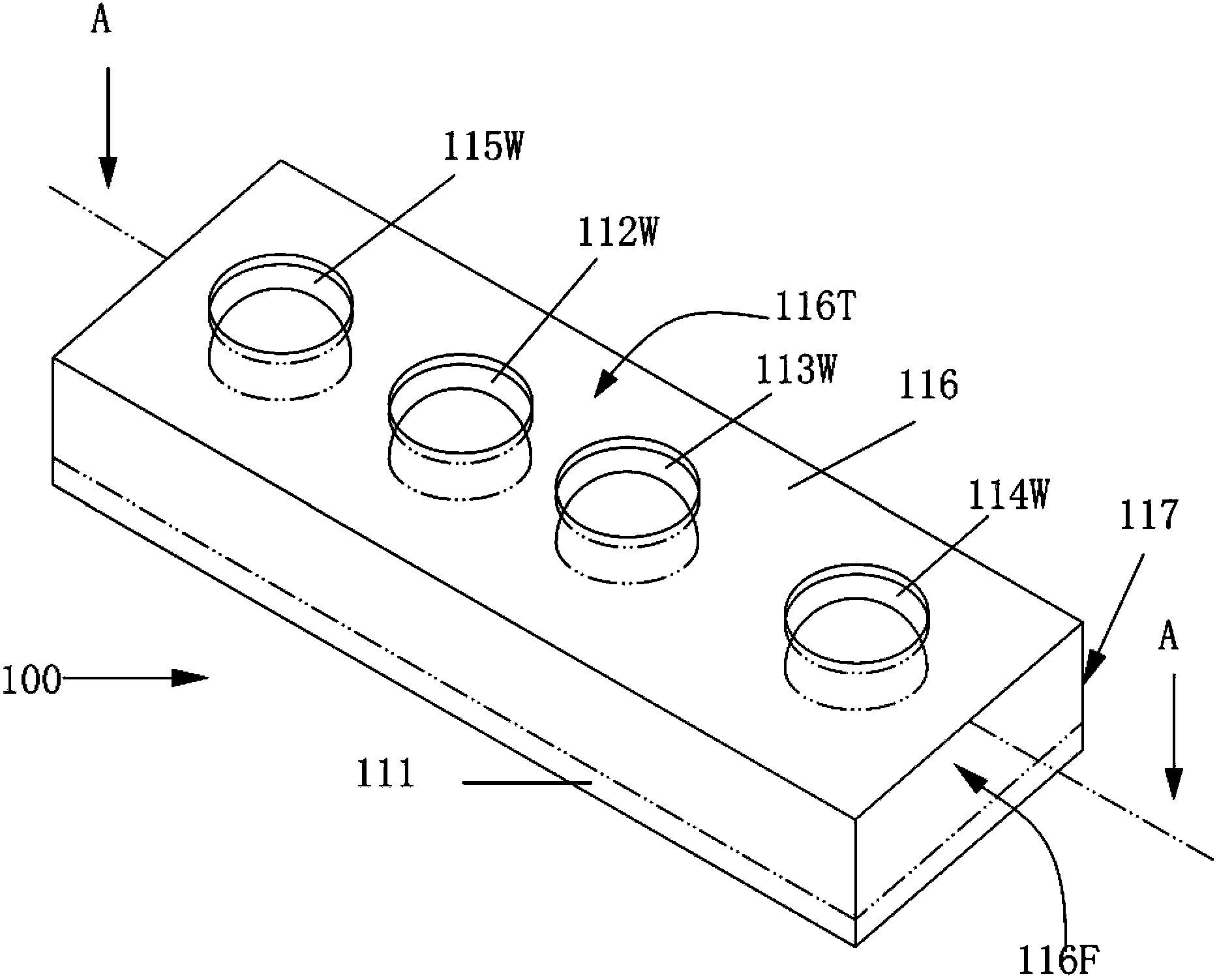

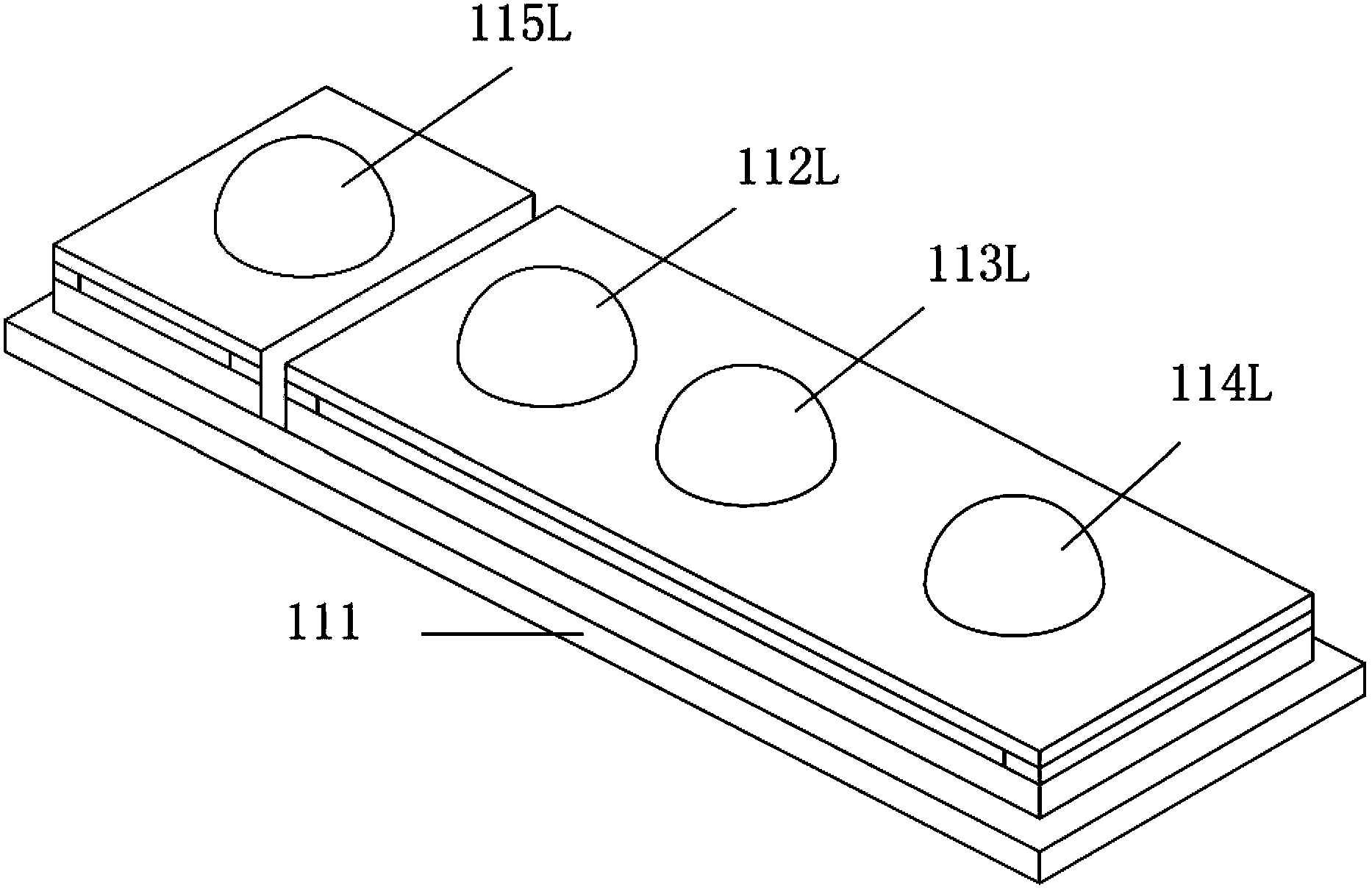

Manufacturing apparatus

InactiveUS20060011136A1High definitionIncrease opening ratioVacuum evaporation coatingSputtering coatingManufacturing cost reductionGas phase

It is an object of the present invention to provide a manufacturing apparatus that reduces a manufacturing cost by enhancing efficiency in the use of an EL material and that is provided with a vapor deposition apparatus which is one of manufacturing apparatuses superior in uniformity in forming an EL layer and in throughput in the case of manufacturing a full-color flat panel display using emission colors of red, green, and blue. According to one feature of the invention, a mask having a small opening with respect to a desired vapor deposition region is used, and the mask is moved accurately. Accordingly, a desired vapor deposition region is vapor deposited entirely. In addition, a vapor deposition method is not limited to movement of a mask, and it is preferable that a mask and a substrate move relatively, for example, the substrate may be moved at a μm level with the mask fixed.

Owner:SEMICON ENERGY LAB CO LTD

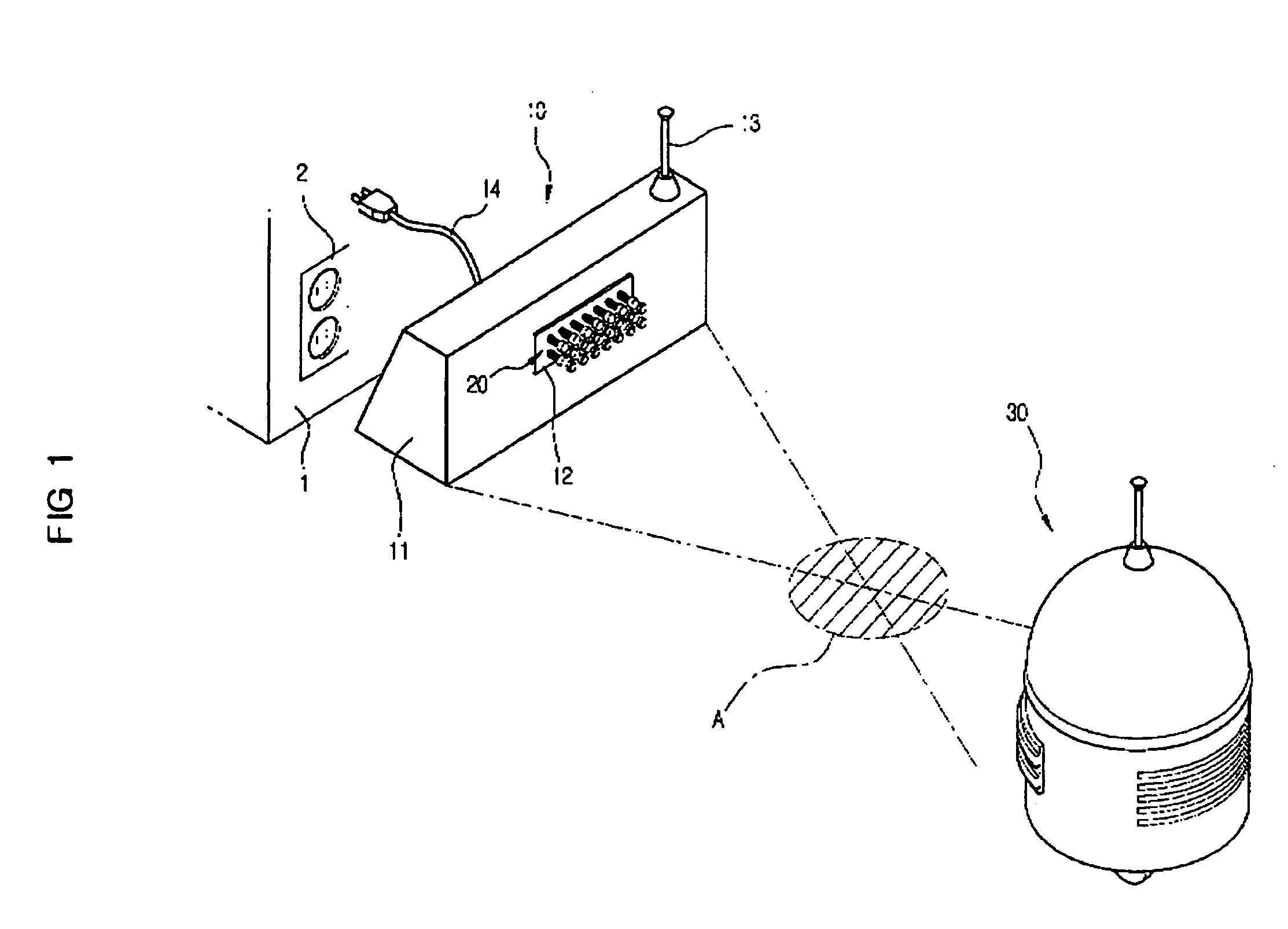

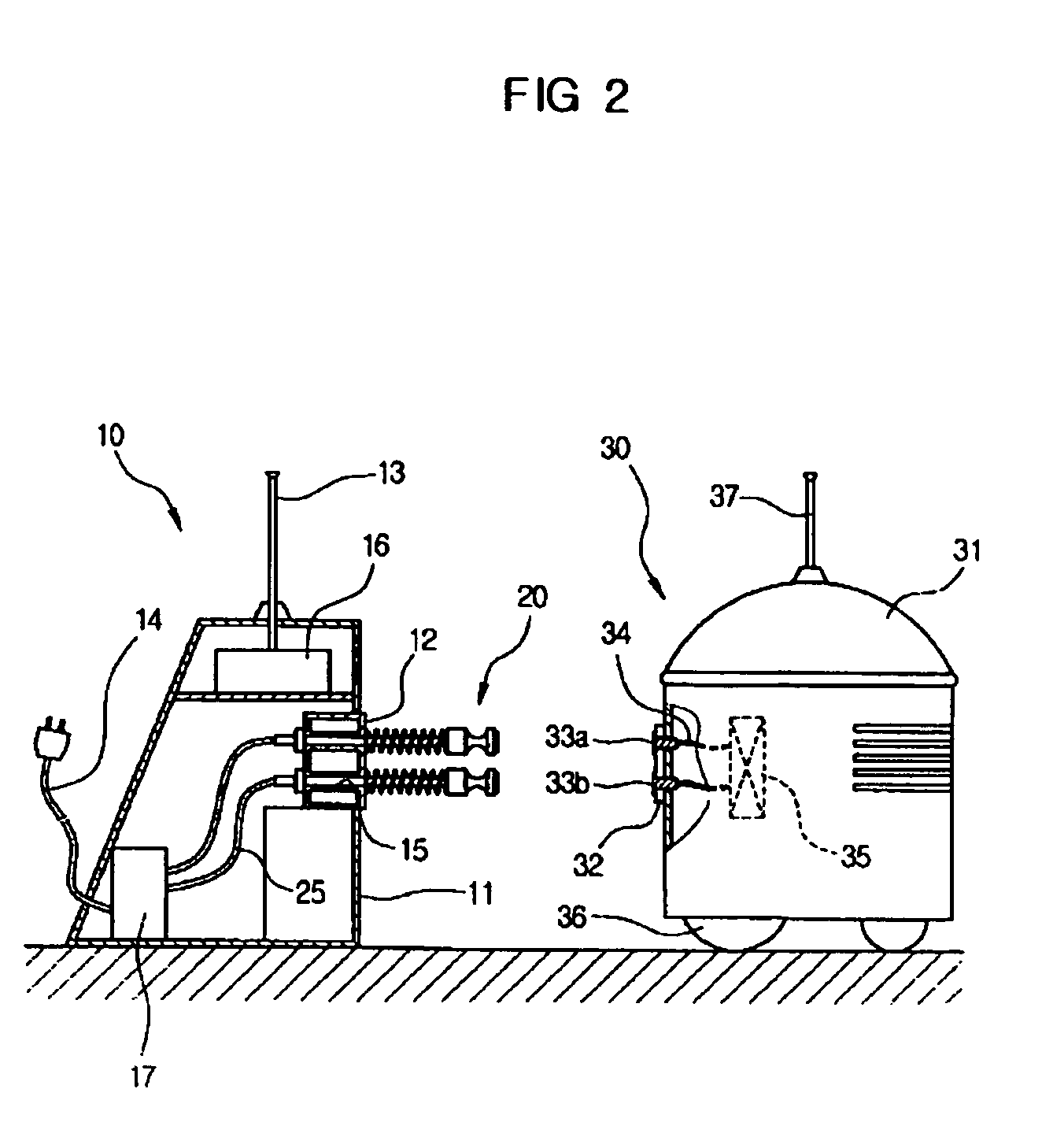

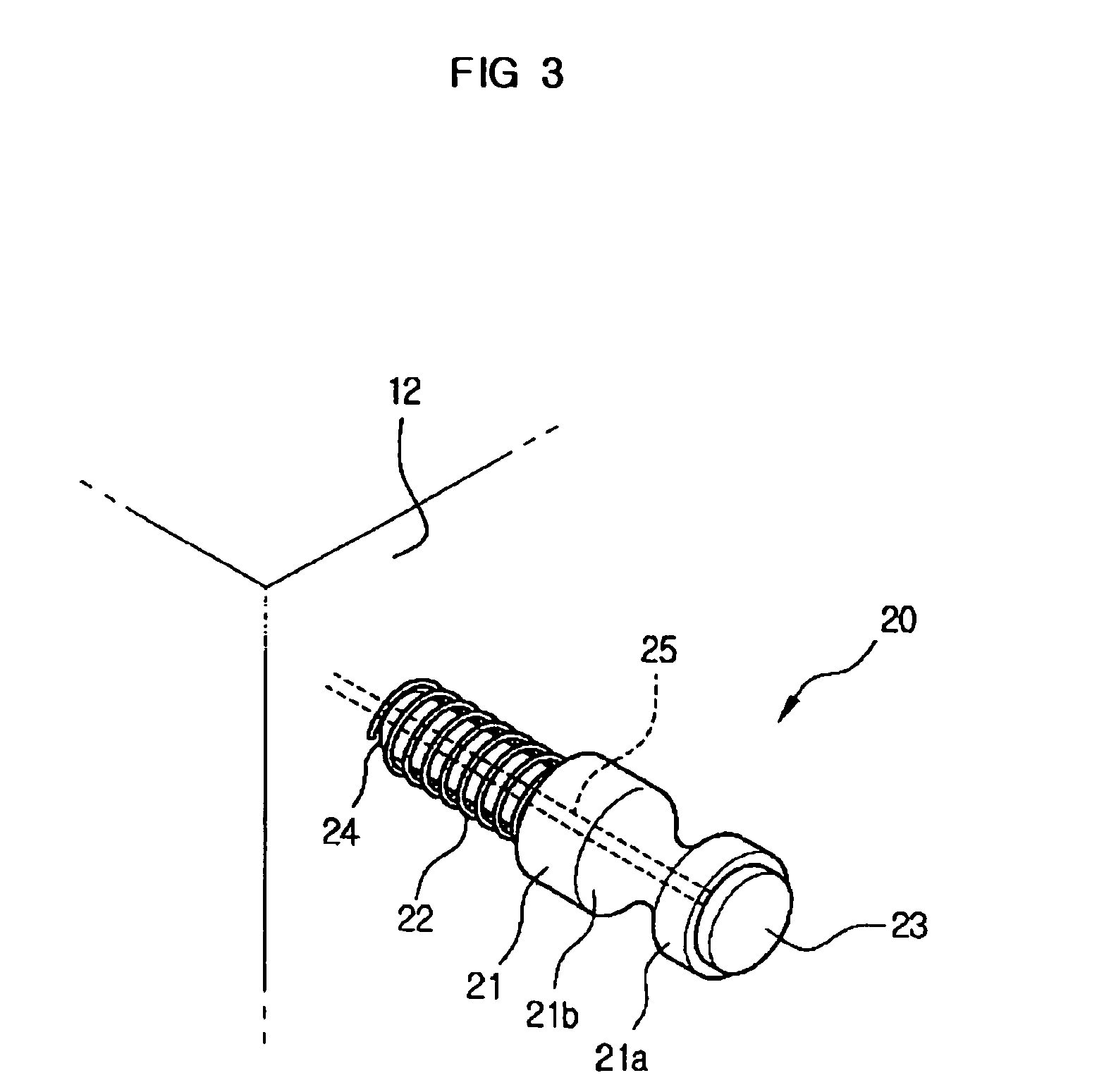

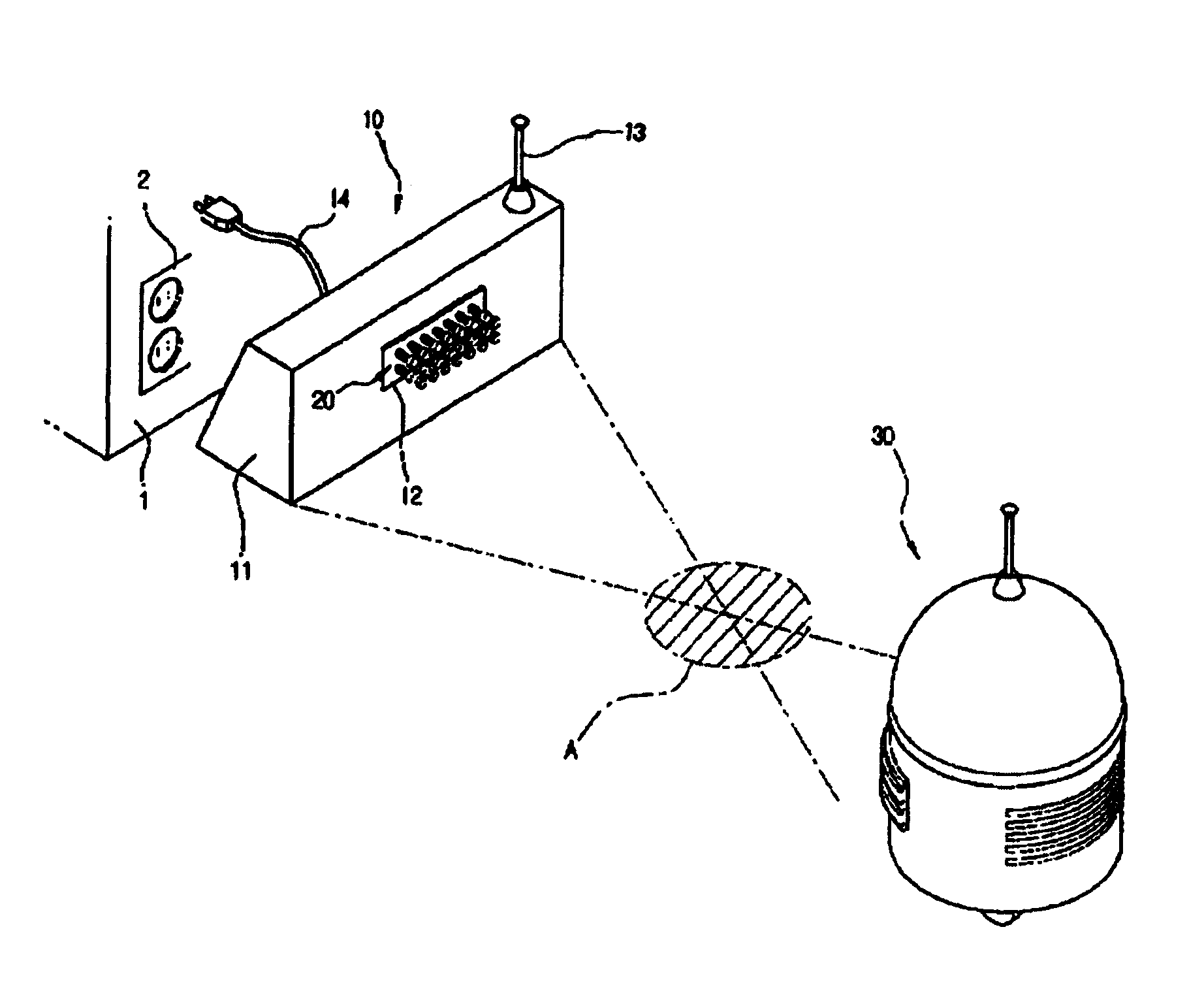

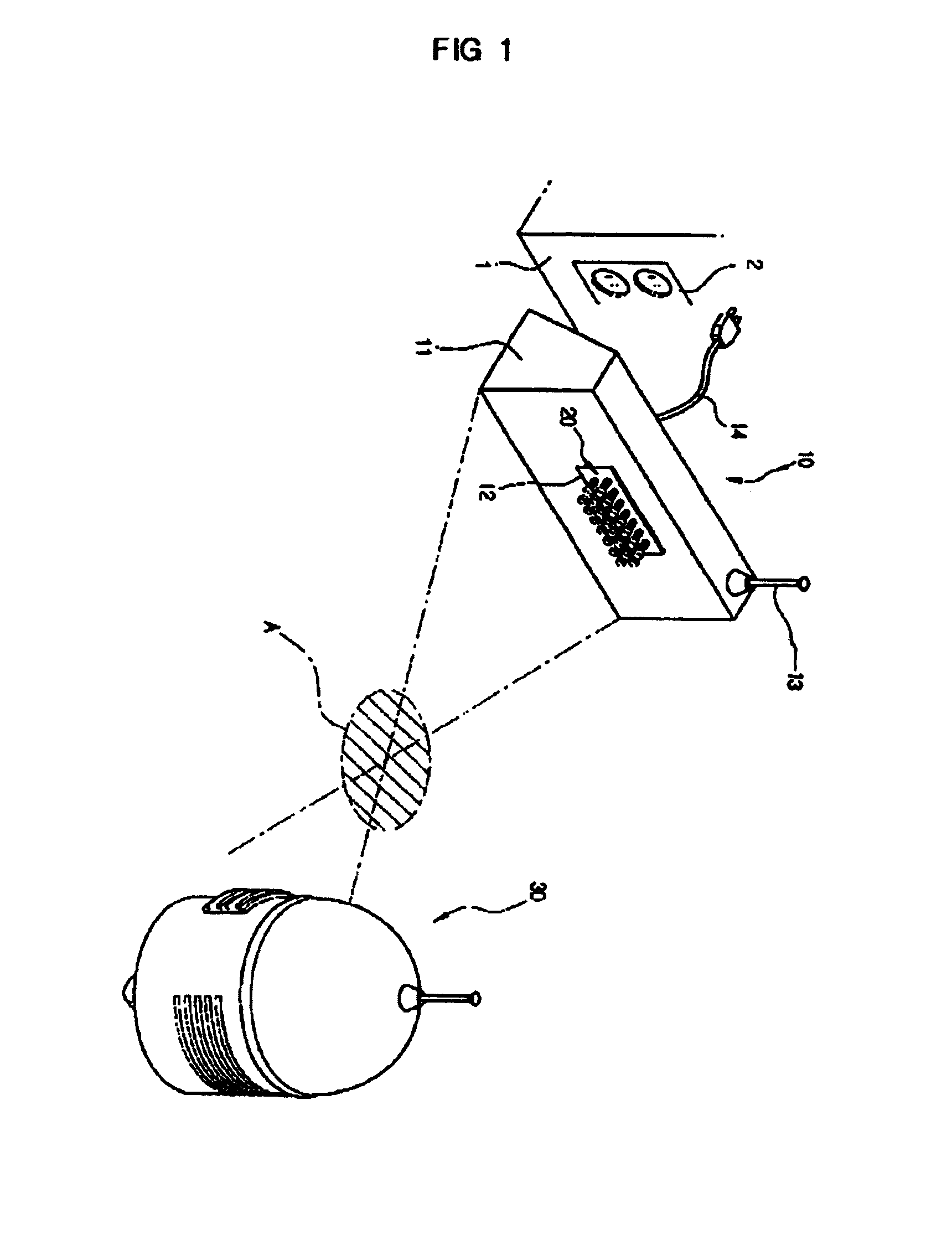

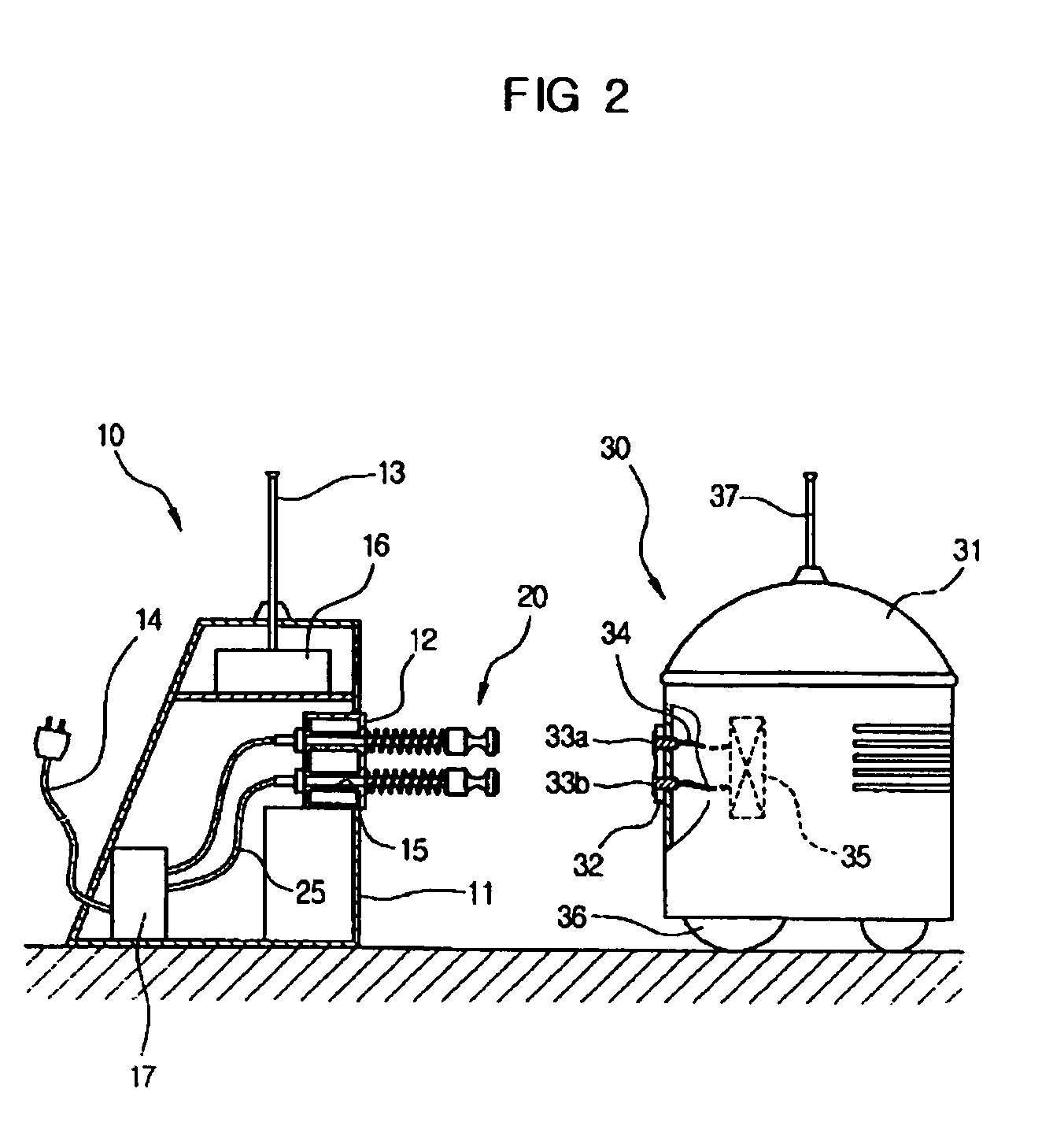

Charging apparatus used with a mobile robot

InactiveUS20050083011A1Simple structureReduce manufacturing costBatteries circuit arrangementsIncorrect coupling preventionElectricityManufacturing cost reduction

A charging apparatus used with a mobile robot has an improved charging structure so that a mobile robot is easily brought into electrical contact with a charging unit, thereby reducing manufacturing costs and preventing a charging failure. The charging unit is provided with a plurality of charging terminals which are brought into electrical contact with corresponding ones of contact terminals of the mobile robot. Each of the charging terminals includes a body and a head. A contact plate is mounted to a predetermined portion of the head to be brought into electrical contact with a corresponding one of the contact terminals.

Owner:SAMSUNG ELECTRONICS CO LTD

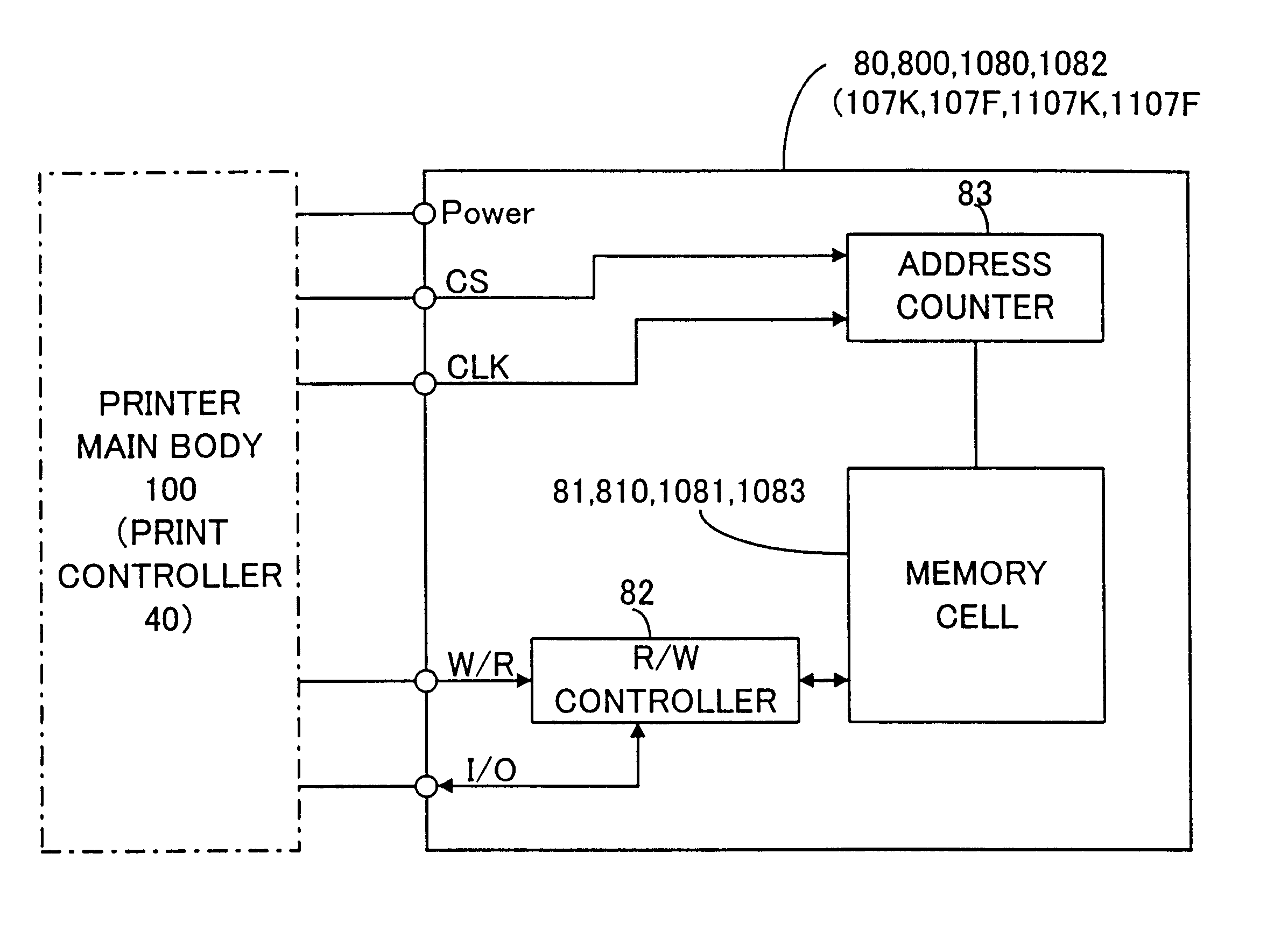

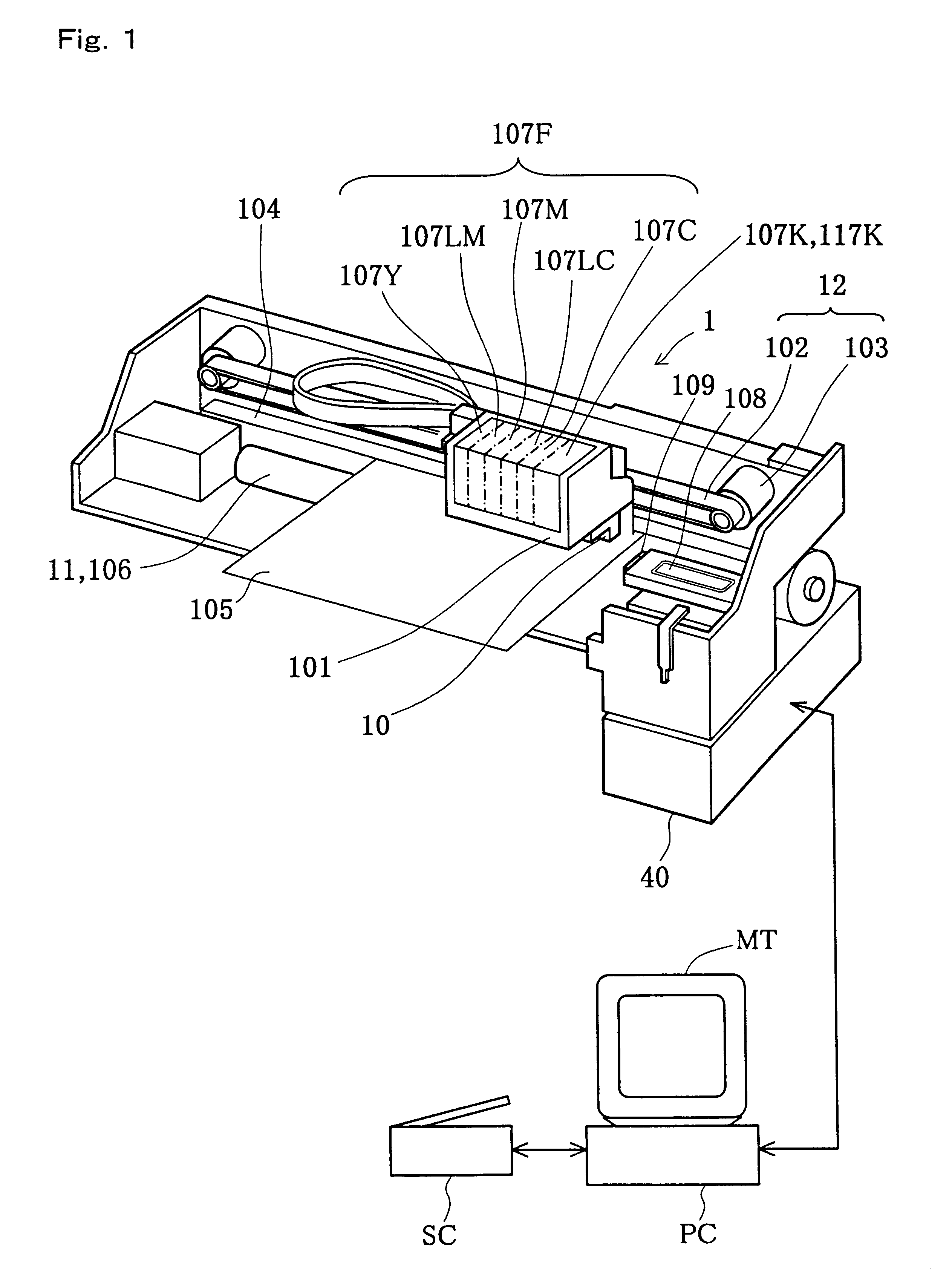

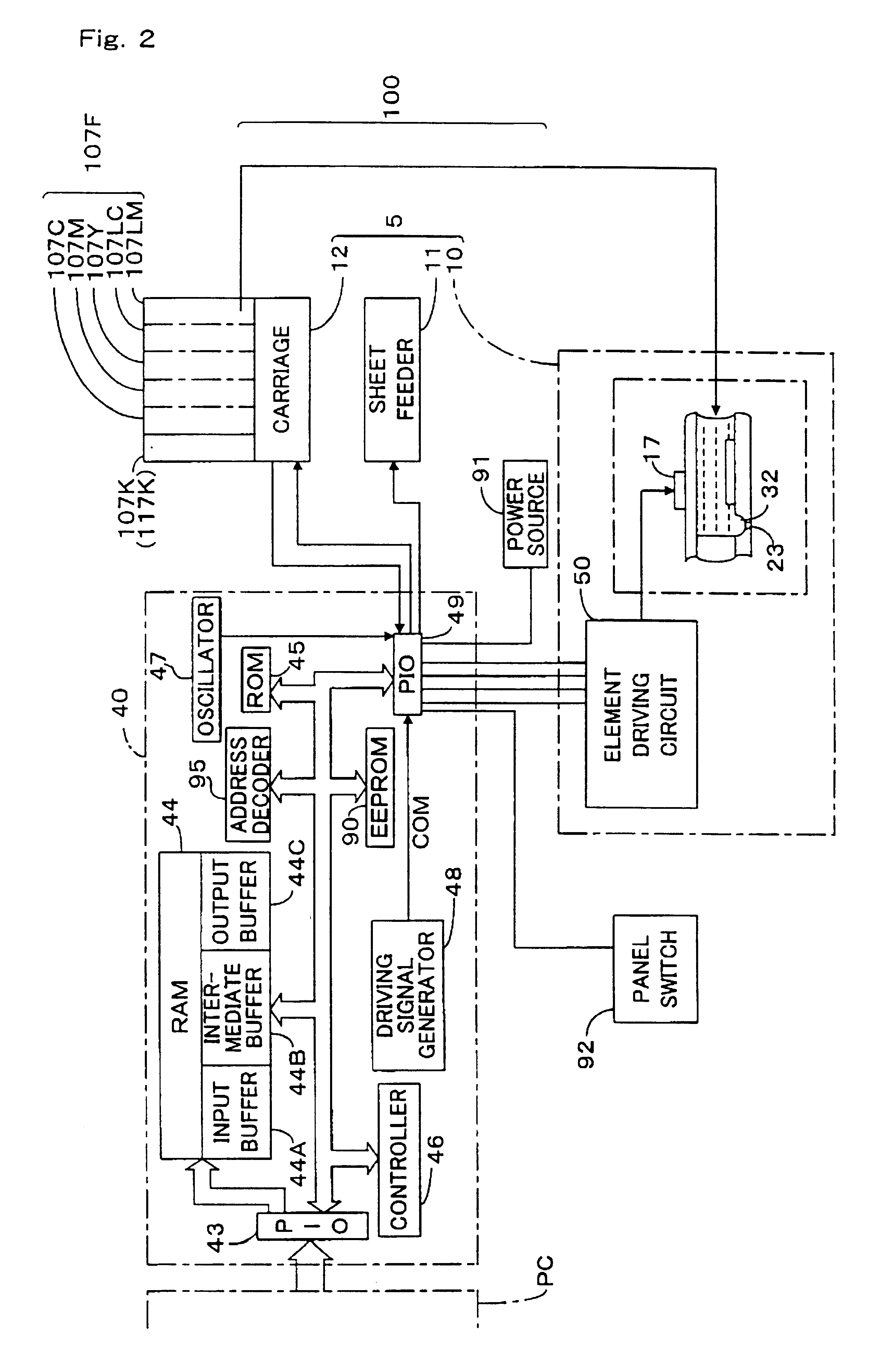

Ink cartridge and printer using the same

InactiveUS6565198B2Low costStored quickly and securelyOther printing apparatusManufacturing cost reductionInk printer

In an ink jet printer of the present invention, in order to reduce the manufacturing cost, an inexpensive EEPROM enabling only sequential accesses is applied for storage elements incorporated in a black ink cartridge and a color ink cartridge. The data array of a memory cell included in each of the storage elements mounted on the ink cartridges is determined in such a manner that a second storage area, in which rewritable data, for example, data on remaining quantities of inks in the ink cartridge, are stored, is accessed prior to a first storage area, in which read only data are stored. This configuration enables the rewritable data to be securely written into the second storage area even after a power-off operation. The second storage area has two memory divisions allocated to each ink, that is, a first ink remaining quantity memory division and a second ink remaining quantity memory division. Latest data on the remaining quantity of each ink is alternately written into these two memory divisions. Alternatively, the latest data on the remaining quantity of each ink is written into these two memory divisions in a duplicated manner. Each ink remaining quantity memory division has a write complete flag to determine whether or not a writing operation has been completed normally in the ink remaining quantity memory division. This arrangement enables the remaining quantities of the respective inks to be monitored accurately and continuously.

Owner:SEIKO EPSON CORP

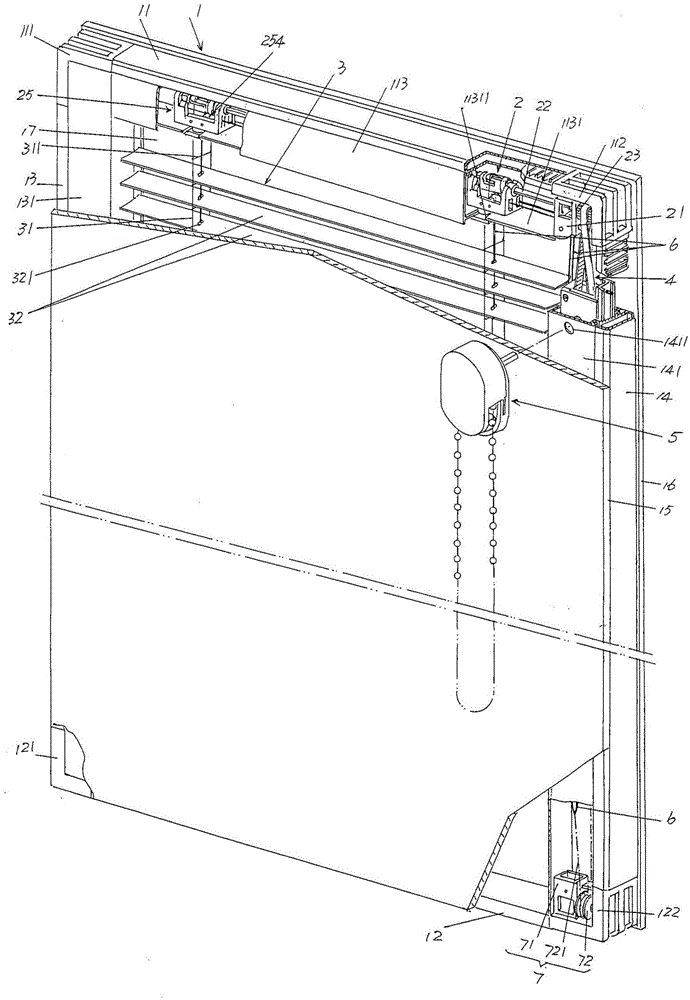

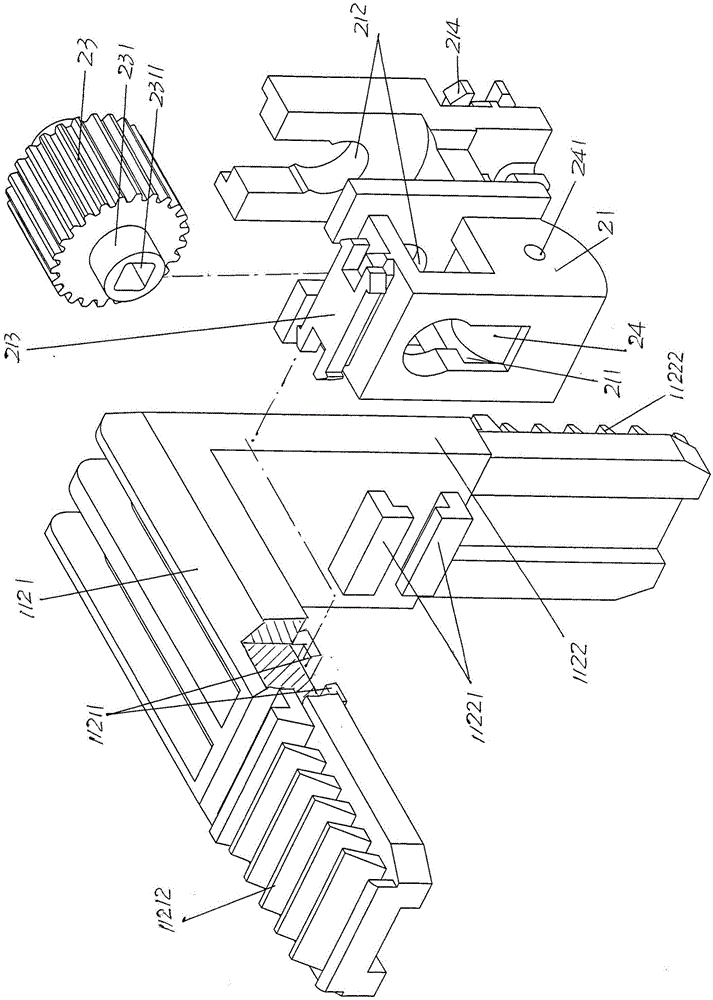

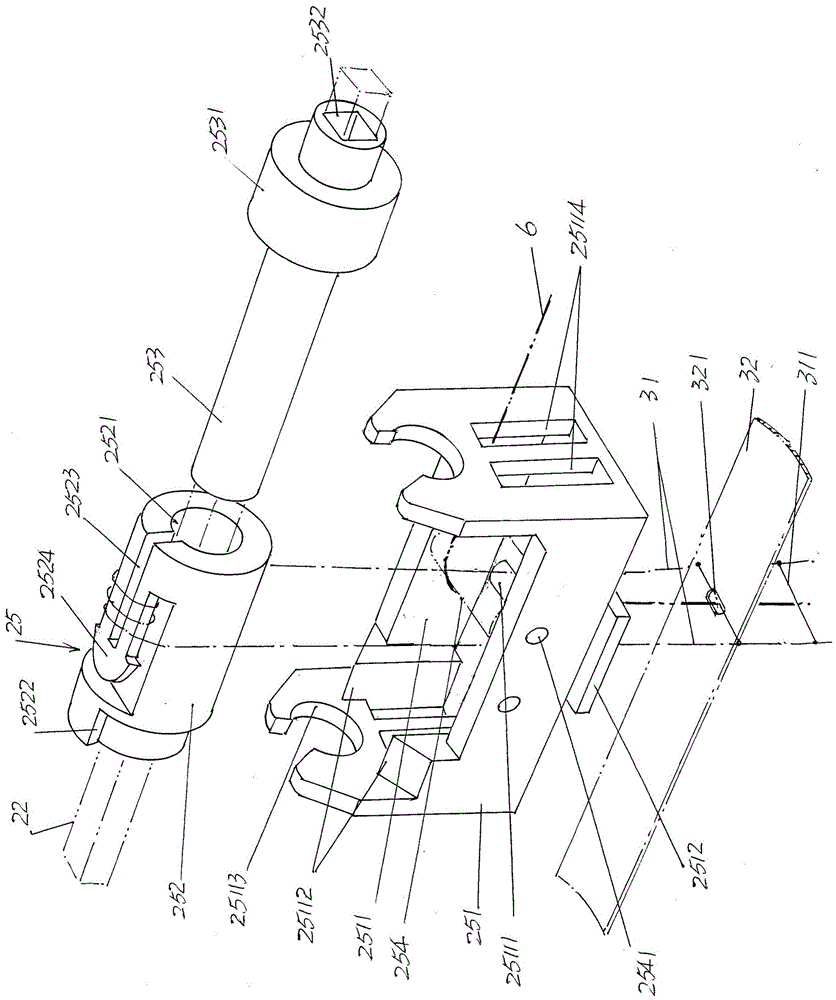

Bead-chain driven double-glazed built-in shutters

ActiveCN105041172BMeet the use requirementsReduce manufacturing costLight protection screensManufacturing cost reductionWindow shutter

The invention discloses a bead chain driving type double-layer hollow glass built-in louver and belongs to the technical field of sunshade hollow glass products. The louver comprises a window body, a curtain piece turning mechanism, a venetian blind, an inner control mechanism, an outer control mechanism and a venetian blind lifting traction rope. The window body comprises an upper window body transverse tube, a lower window body transverse tube, a left window body longitudinal tube, a right window body longitudinal tube, inner glass and outer glass. The louver is characterized in that the inner control mechanism comprises a box body, a box cover, a synchronous belt pulley, a synchronous belt and a lifting traction rope driving wheel. The outer control mechanism comprises a protective cover, a friction plate, a bead chain wheel shaft, a bead chain wheel shaft hub, a bead chain and a bead chain wheel shaft base. The protective cover forms a protective cover cavity. The friction plate is arranged in the protective cover cavity. The bead chain wheel shaft hub is supported by a shaft hub cavity. The bead chain wheel shaft is arranged in the middle of the bead chain wheel shaft hub. One end of the bead chain is arranged on the bead chain wheel shaft hub in a sleeving mode. The other end of the bead chain forms a suspending end. The bead chain wheel shaft base is matched with the protective cover. One end of the venetian blind lifting traction rope is in driving connection with a lifting traction rope driving wheel. Manufacturing cost is reduced; labor is saved during operation; service life is long, and the using effect is good; resource-saving economy is reflected.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

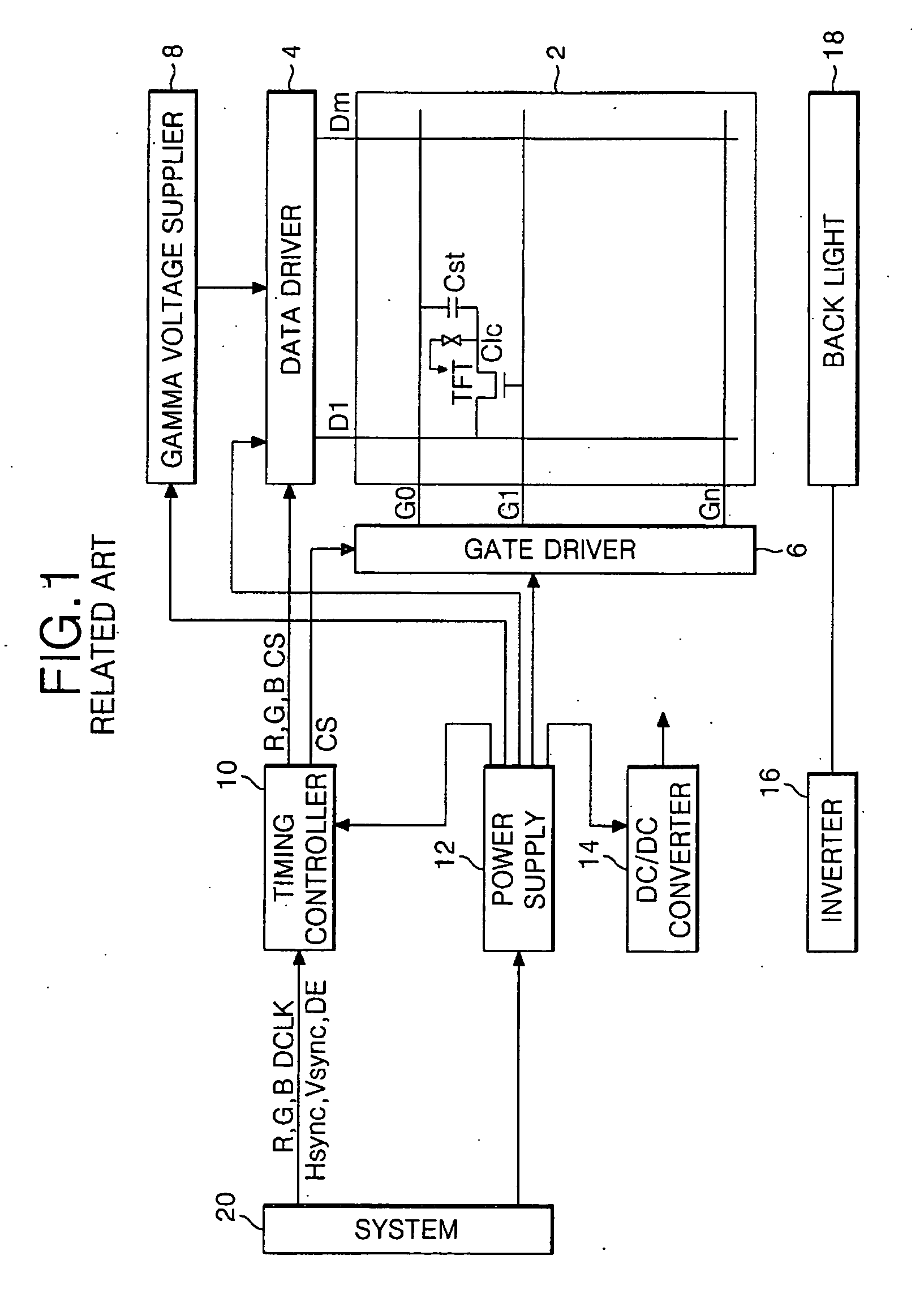

Method and apparatus for driving liquid crystal display

InactiveUS20050104837A1Increase contrastReduce manufacturing costStatic indicating devicesManufacturing cost reductionLiquid-crystal display

A driving method and apparatus for a liquid crystal display uses a comparison between the previous frame and the current frame to expand the contrast ratio and reduce the manufacturing cost. A limited amount of data from the current image may be used: either using a limited area of the image or merely the amount of green in the overall image or the limited area. In the apparatus, an image signal modulator expands the contrast of the input data when the previous image is analogous to the current image to thereby generate output data. A timing controller re-arranges the output data to apply the output data to a data driver.

Owner:LG DISPLAY CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20060055050A1Semiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionElectrical conductor

A semiconductor device comprises a semiconductor substrate having an through hole, a first insulation resin layer formed on an inner surface of the through hole, a second insulation resin layer formed on at least one of front and rear surfaces of the semiconductor substrate, and a first conductor layer formed in the through hole to connect at least both front and rear surfaces of the semiconductor substrate and insulated from the inner surface of the through hole with the first insulation resin layer. A second conductor layer (wiring pattern) which is electrically connected to the first conductor layer in the through hole is further provided on the second insulation resin layer. The conductor layer formed in the through hole and constituting a connecting plug has a high insulation reliability. Therefore, a semiconductor device suitable for a multi-chip package and the like can be obtained. Further, since the forming ability of the conductor layer connecting the front and rear surfaces and the insulation layer is high, the manufacturing cost can be reduced.

Owner:KK TOSHIBA

Apparatus for forming a film and an electroluminescence device

InactiveUS20050005848A1Improve utilization efficiencyExcellent uniformity and throughputElectroluminescent light sourcesSolid-state devicesManufacturing cost reductionEvaporation

A device having three evaporation sources and a unit for moving the respective evaporation sources in one chamber is used, whereby it becomes possible to increase efficiency of use of an evaporation material. Consequently, manufacturing cost can be reduced, and a uniform thickness can be obtained over an entire surface of a substrate even in the case in which a large area substrate is used.

Owner:SEMICON ENERGY LAB CO LTD

Integrated optical sensor package

ActiveCN103515371AReduce volumeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionOptoelectronics

The invention relates to an integrated optical sensor package. The integrated optical sensor package comprises a package substrate, an ambient light sensor, a proximity optical sensor, an image sensor and a package cover, wherein the package substrate is positioned at the bottom; the ambient light sensor, the proximity optical sensor and the image sensor are arranged on the package substrate; and the package cover is mutually sealed with the package substrate so that a package housing is formed. The integrated optical sensor package provided by the invention can reduce the package volume and reduce the manufacturing cost.

Owner:GALAXYCORE SHANGHAI

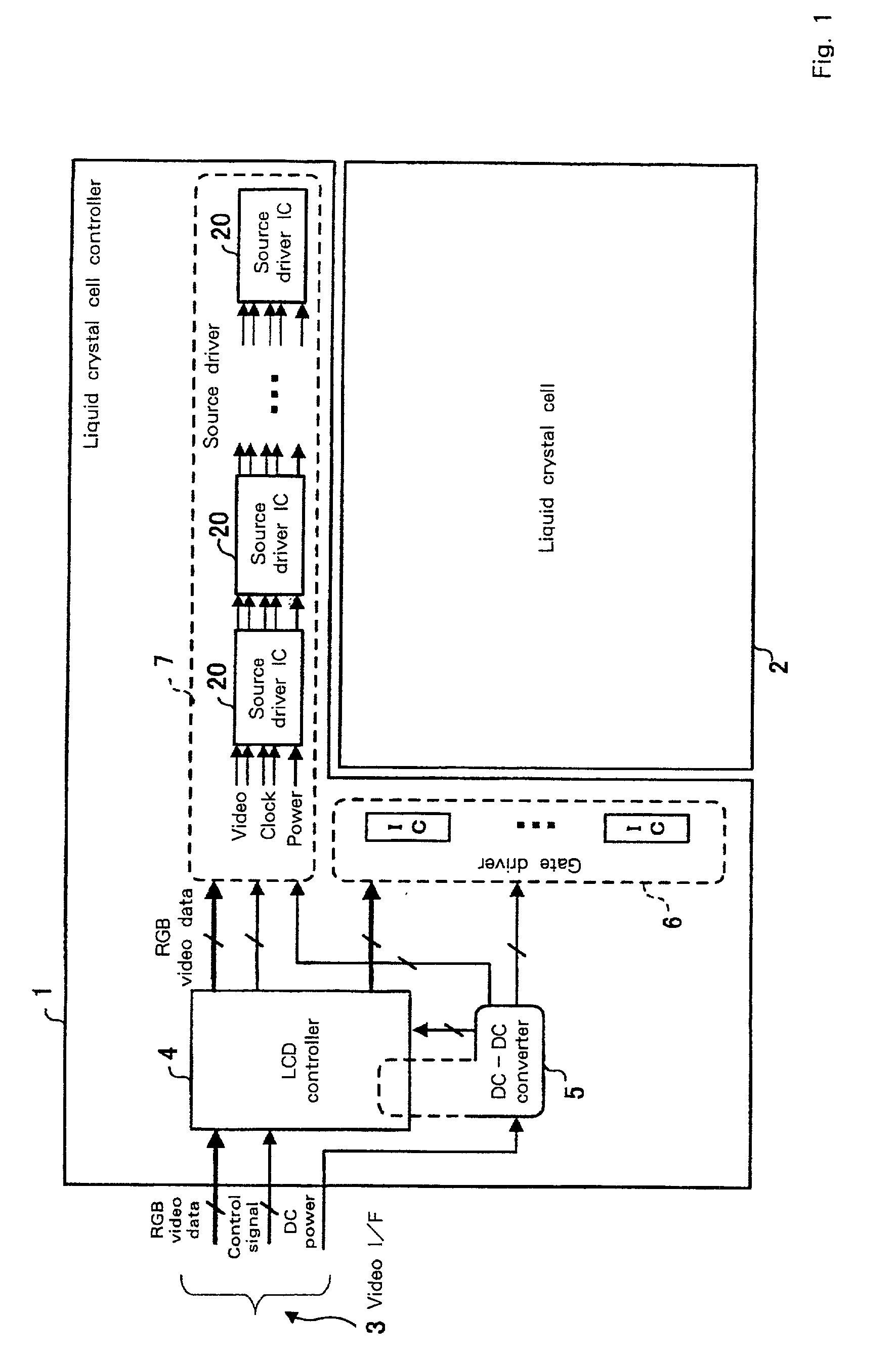

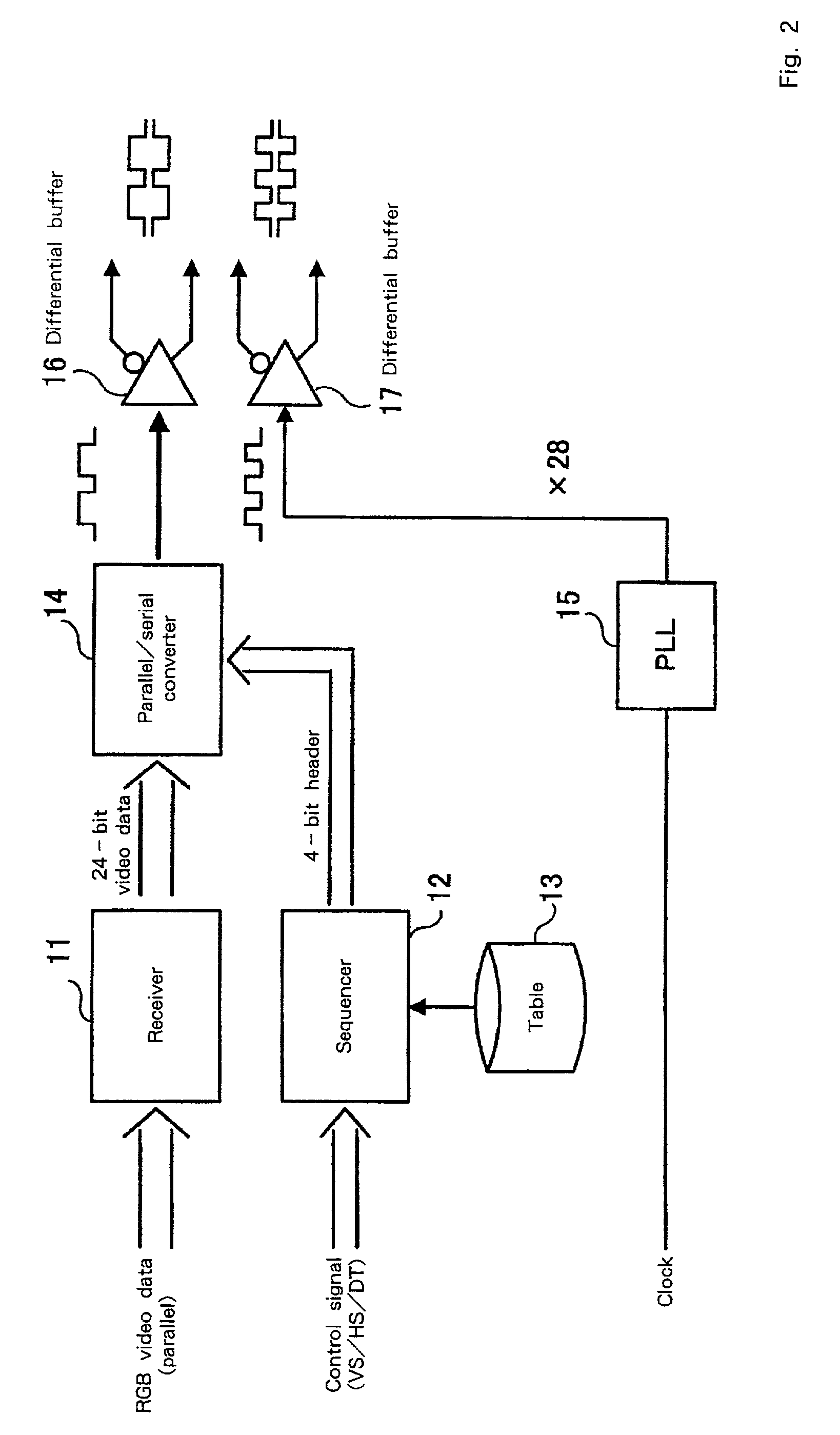

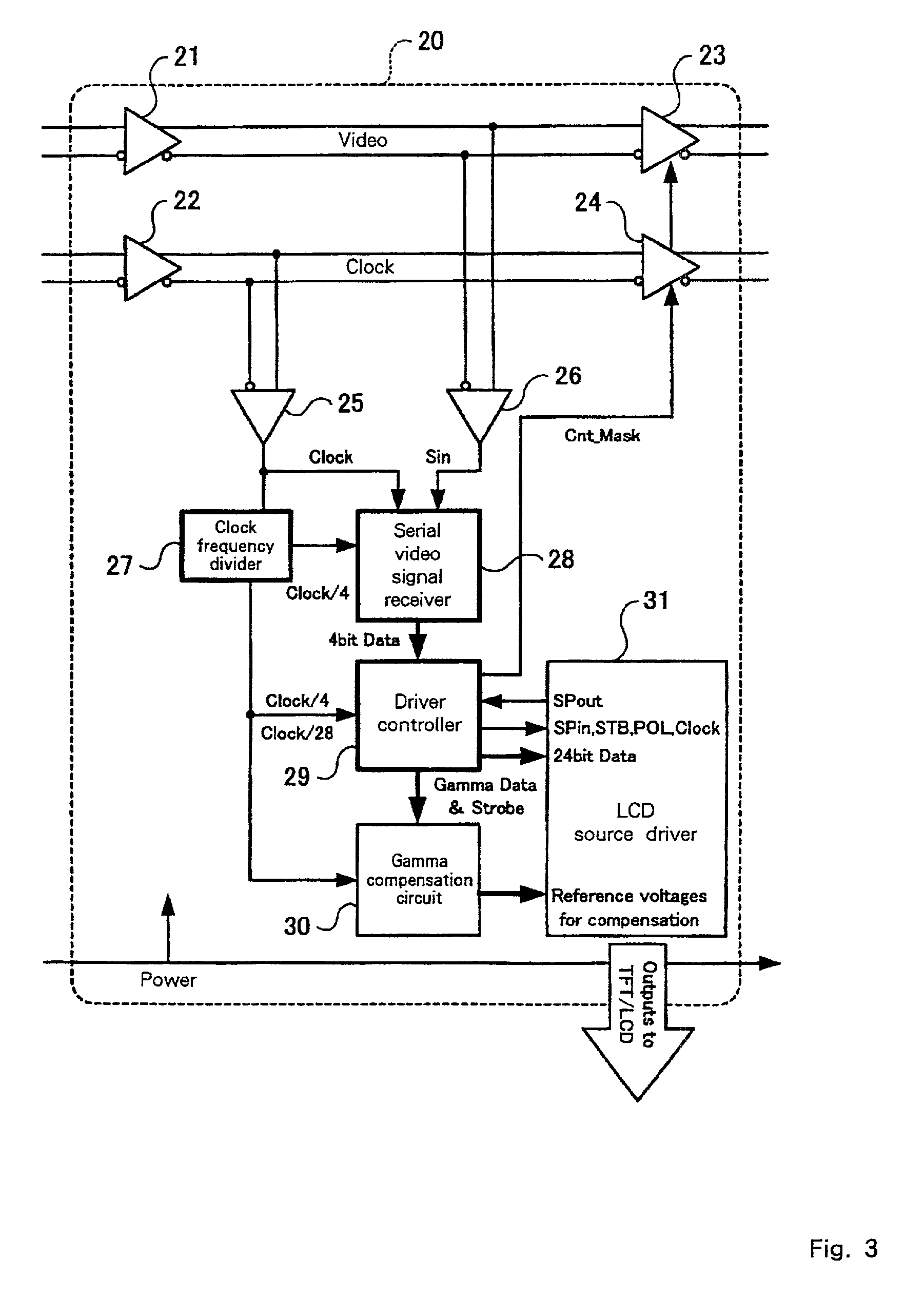

Liquid crystal display device, liquid crystal controller and video signal transmission method

InactiveUS20010013850A1Television system detailsCathode-ray tube indicatorsManufacturing cost reductionEngineering

It is one object of the present invention to reduce the number of inputs to an LCD driver and to reduce manufacturing costs by employing the COG&WOA technique. For a liquid crystal display device, source driver ICs 20, among which video signals are transmitted and distributed via a video I / F 3, are cascade-connected, and the connection lines to the source driver ICs 20 are reduced as much as possible to employ the COG&WOA technique. That is, a liquid crystal display device comprises: a liquid crystal cell 2, which forms an image display area on a substrate, and a source driver 7, which applies a voltage to the liquid crystal cell 2 based on a video signal input via a video I / F 3. The source driver 7 includes a plurality of source driver ICs 20 that are mounted on the same substrate as the liquid crystal cell 2 and that are cascade-connected by signal lines.

Owner:AU OPTRONICS CORP

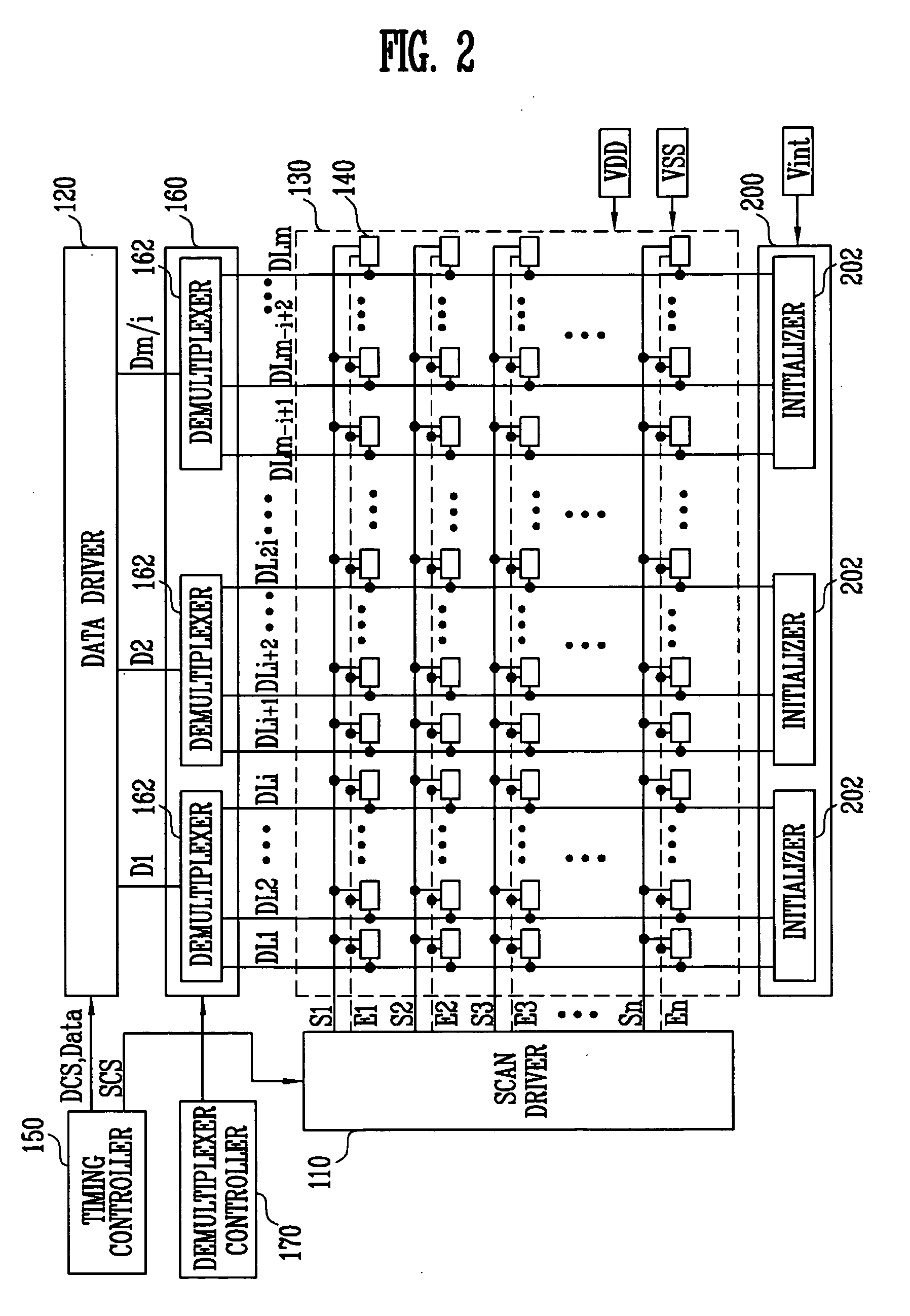

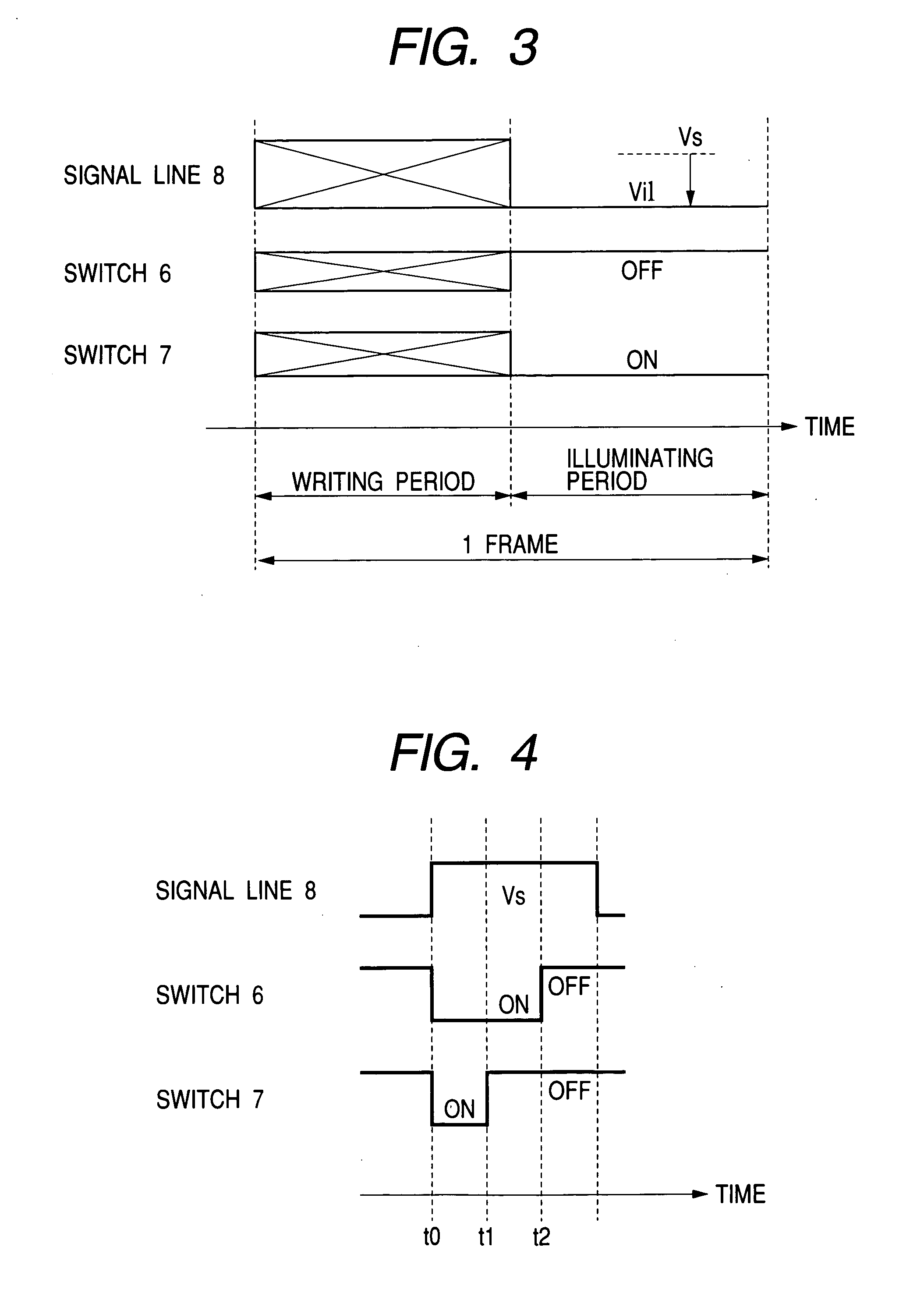

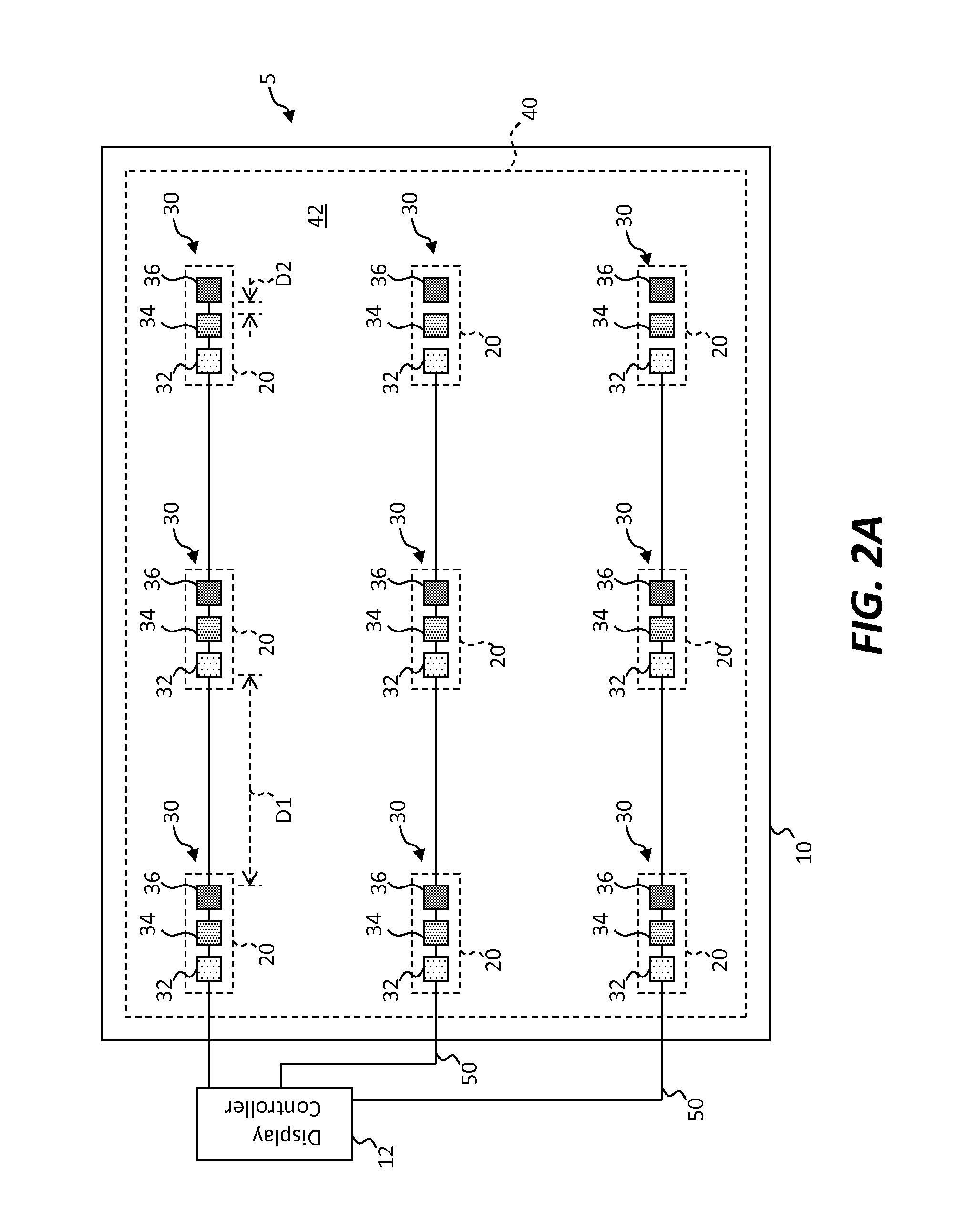

Organic light emitting display

ActiveUS20060071884A1Reduce manufacturing costUniform brightnessTime-division multiplexCathode-ray tube indicatorsManufacturing cost reductionScan line

An organic light emitting display capable of reducing the manufacturing cost and displaying images with uniform brightness. The organic light emitting display includes: a data driver for supplying a plurality of data signals to a plurality of first data lines, respectively; an image display portion having a plurality of second data lines, a plurality of scan lines, and a plurality of pixels; and a demultiplexer having a plurality of data transistors arranged in the respective first data lines to supply the plurality of data signals supplied to the first data lines to the plurality of second data lines, and a plurality of capacitors connected between respective gate terminals of the plurality of data transistors and the second data lines.

Owner:SAMSUNG DISPLAY CO LTD

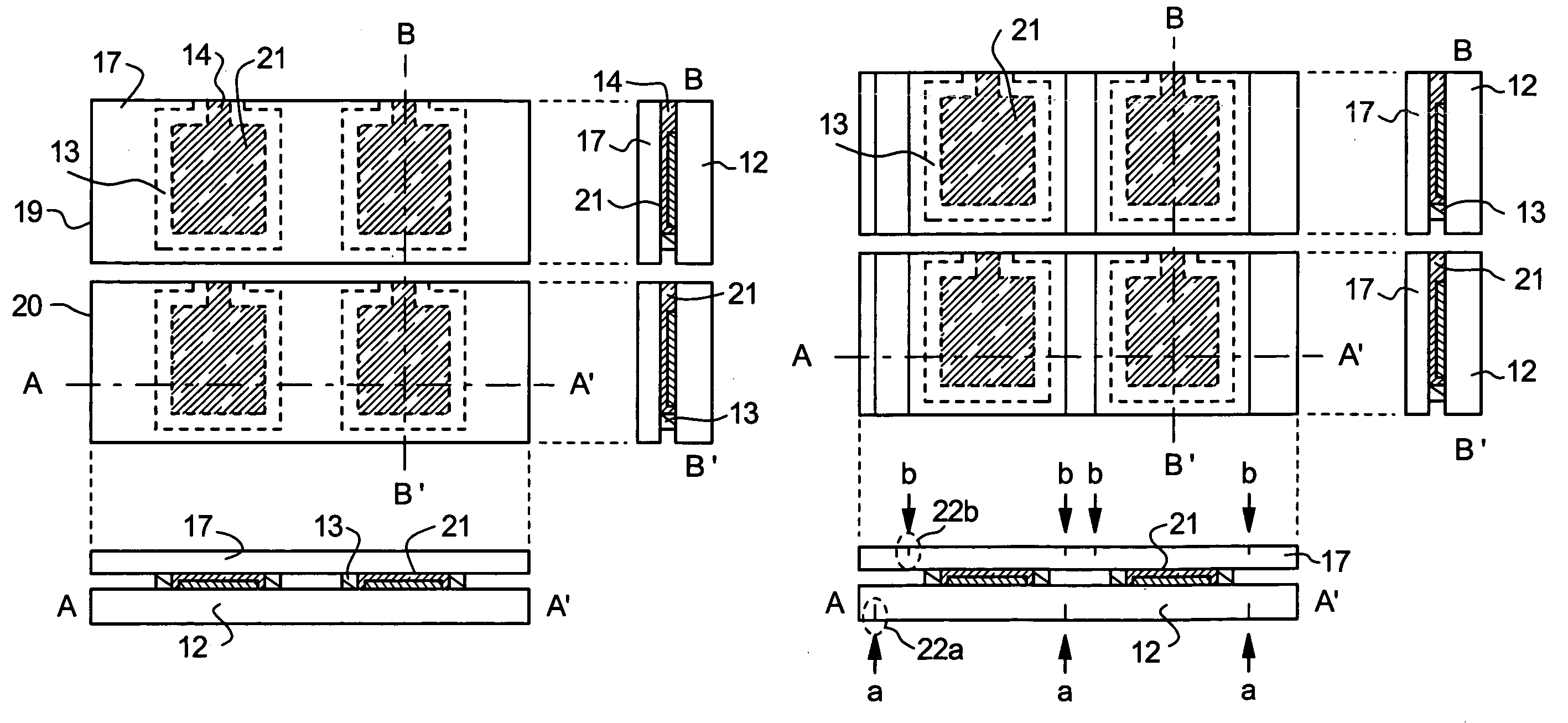

Semiconductor package and method for fabricating the same

InactiveUS20090102063A1Effective installationSmall sizeSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionResist

This invention provides a semiconductor package and a method for fabricating the same. The method includes: forming a first resist layer on a metal carrier; forming a plurality of openings penetrating the first resist layer; forming a conductive metal layer in the openings; removing the first resist layer; covering the metal carrier having the conductive metal layer with a dielectric layer; forming blind vias in the dielectric layer to expose a portion of the conductive metal layer; forming conductive circuit on the dielectric layer and conductive posts in the blind vias, such that the conductive circuit is electrically connected to the conductive metal layer via the conductive posts; electrically connecting at least one chip to the conductive circuit; forming an encapsulant for encapsulating the chip and the conductive circuit; and removing the metal carrier, thereby allowing a semiconductor package to be formed without a chip carrier. Given the conductive posts, both the conductive circuit and conductive metal layer are efficiently coupled to the dielectric layer to prevent delamination. Further, downsizing the blind vias facilitates the fabrication process and cuts the fabrication cost.

Owner:SILICONWARE PRECISION IND CO LTD

Image display device

InactiveUS20050007316A1Increase manufacturing costReduce yieldStatic indicating devicesElectroluminescent light sourcesManufacturing cost reductionEngineering

Disclosed herewith an image display device capable of displaying high quality images and preferred for reducing the manufacturing cost. The image display device is provided with illuminating state controlling state for controlling the illuminating state or non-illuminating state and constant voltage supply for supplying a constant voltage to each pixel through a signal line when the illuminating state is selected for the pixel.

Owner:HITACHI DISPLAYS

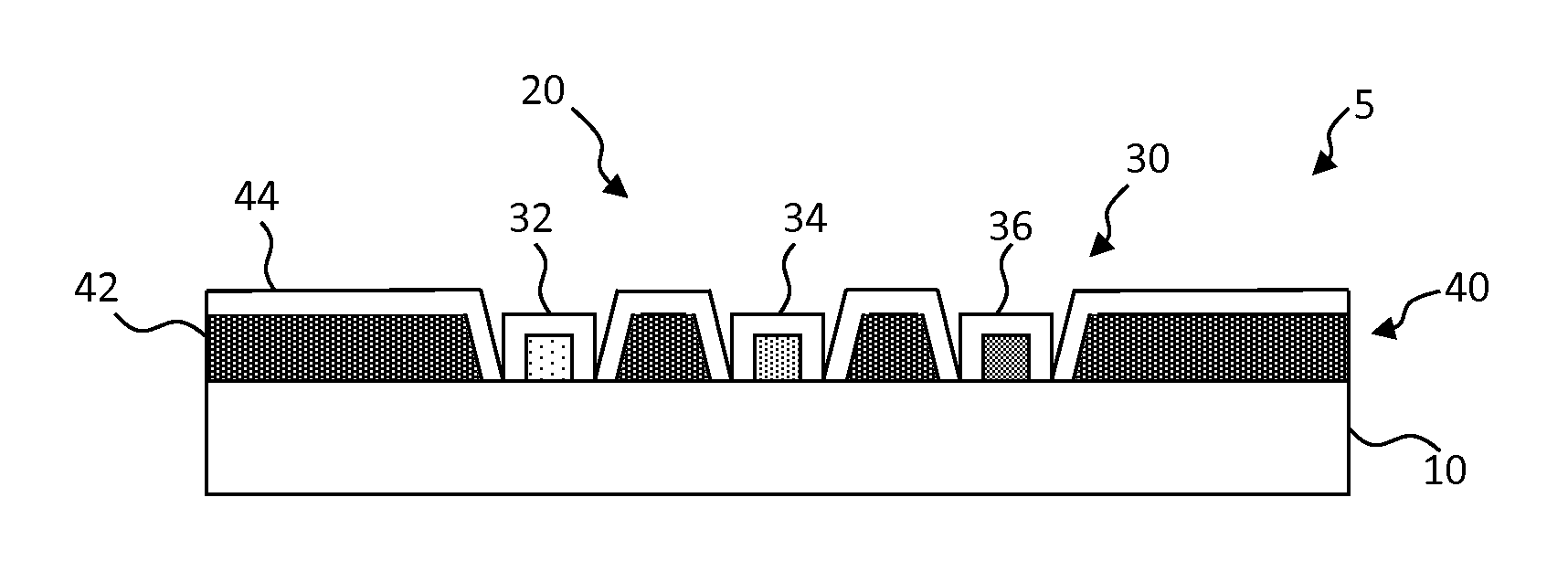

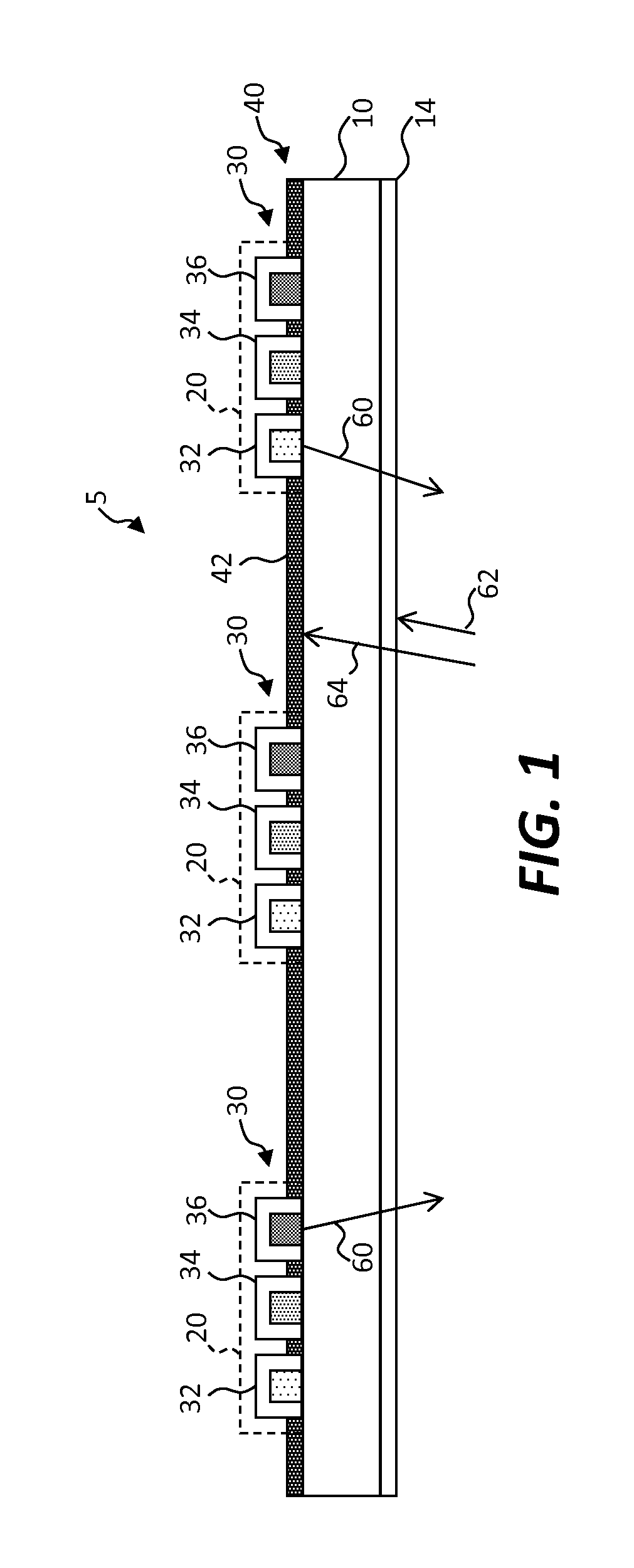

Inorganic-light-emitter display with integrated black matrix

ActiveUS20160351539A1Improve light output efficiencyImprove image qualitySolid-state devicesSemiconductor devicesParallaxManufacturing cost reduction

An inorganic-light-emitter display includes a display substrate and a plurality of spatially separated inorganic light emitters distributed on the display substrate in a light-emitter layer. A light-absorbing layer located on the display substrate in the light-emitter layer is in contact with the inorganic light emitters. Among other things, the disclosed technology provides improved angular image quality by avoiding parallax between the light emitters and the light-absorbing material, increased light-output efficiency by removing the light-absorbing material from the optical path, improved contrast by increasing the light-absorbing area of the display substrate, and a reduced manufacturing cost in a mechanically and environmentally robust structure using micro transfer printing.

Owner:X DISPLAY CO TECH LTD

Charging apparatus used with a mobile robot

InactiveUS7227334B2Simple structureReduce manufacturing costBatteries circuit arrangementsCoupling device engaging/disengagingElectricityManufacturing cost reduction

A charging apparatus used with a mobile robot has an improved charging structure so that a mobile robot is easily brought into electrical contact with a charging unit, thereby reducing manufacturing costs and preventing a charging failure. The charging unit is provided with a plurality of charging terminals which are brought into electrical contact with corresponding ones of contact terminals of the mobile robot. Each of the charging terminals includes a body and a head. A contact plate is mounted to a predetermined portion of the head to be brought into electrical contact with a corresponding one of the contact terminals.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com