Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15005 results about "Resist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A resist, used in many areas of manufacturing and art, is something that is added to parts of an object to create a pattern by protecting these parts from being affected by a subsequent stage in the process. Often the resist is then removed.

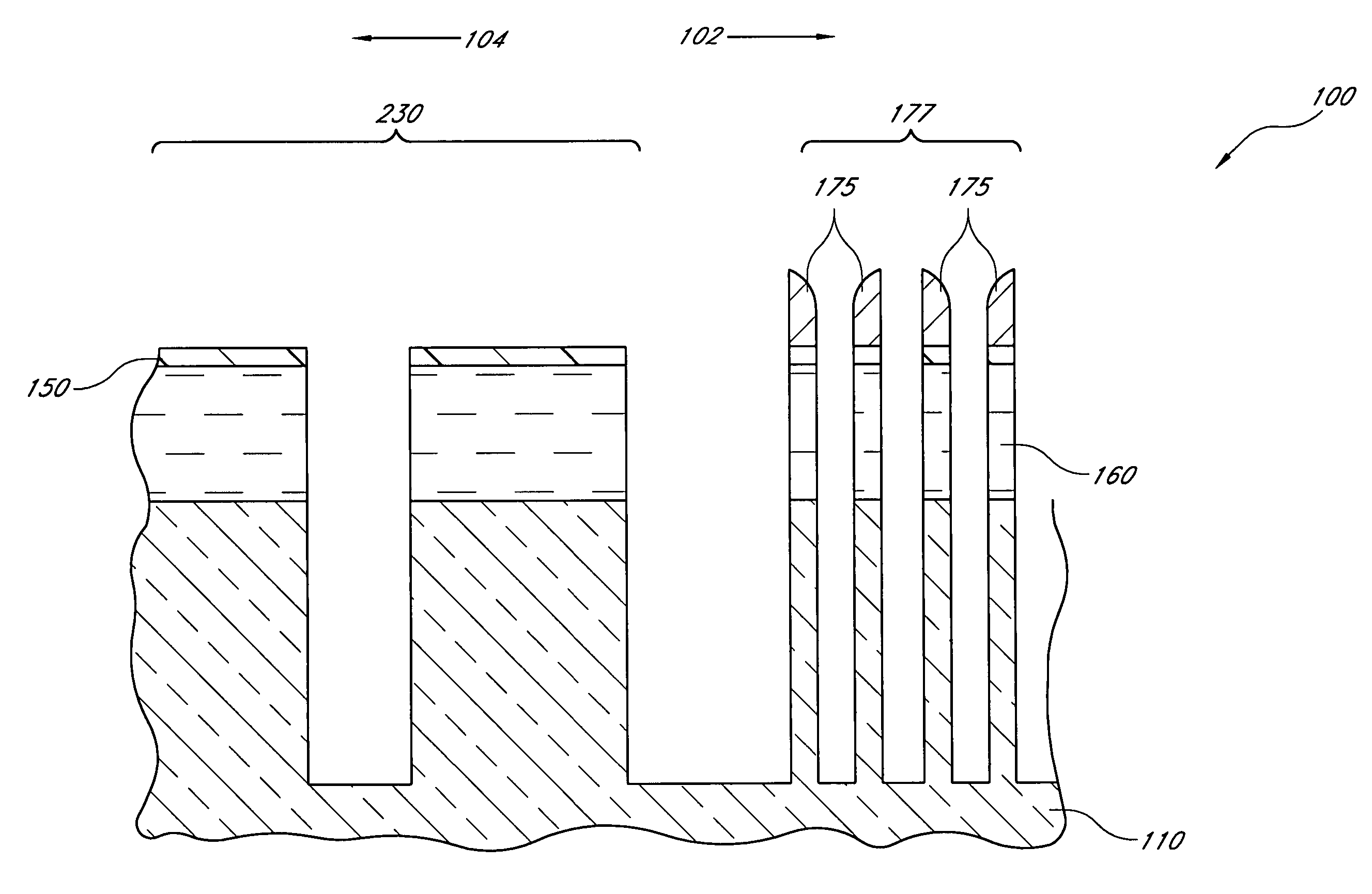

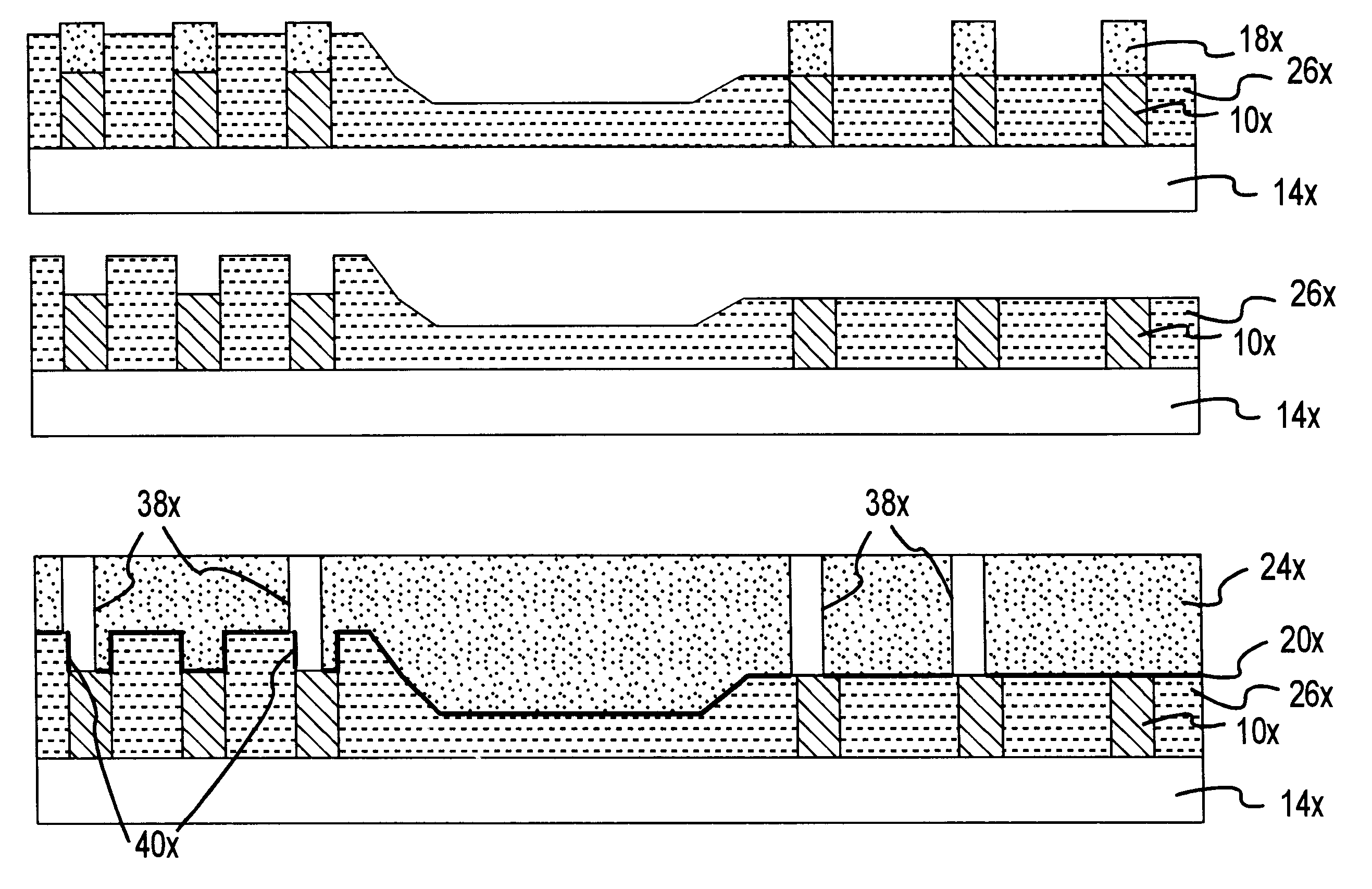

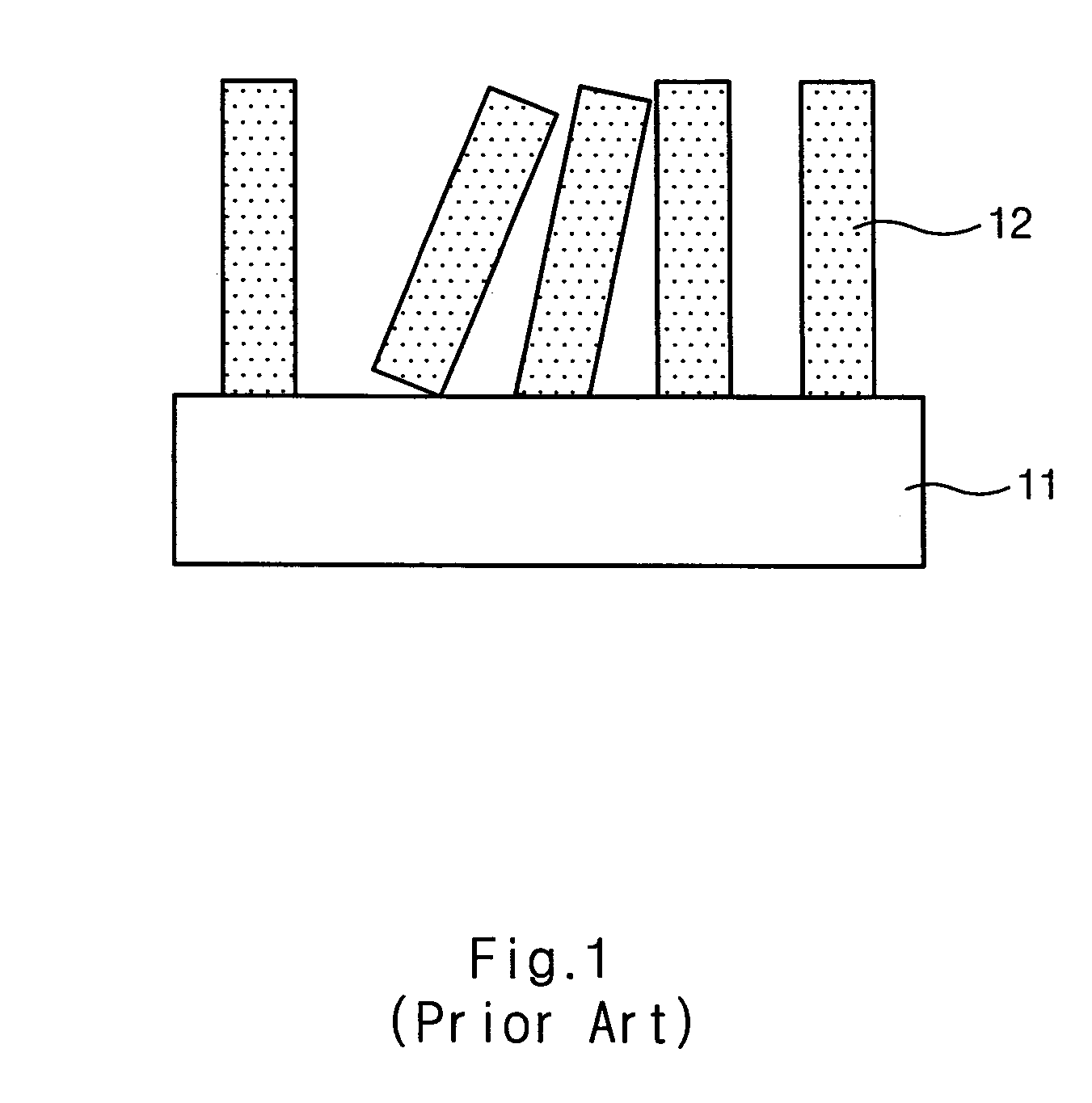

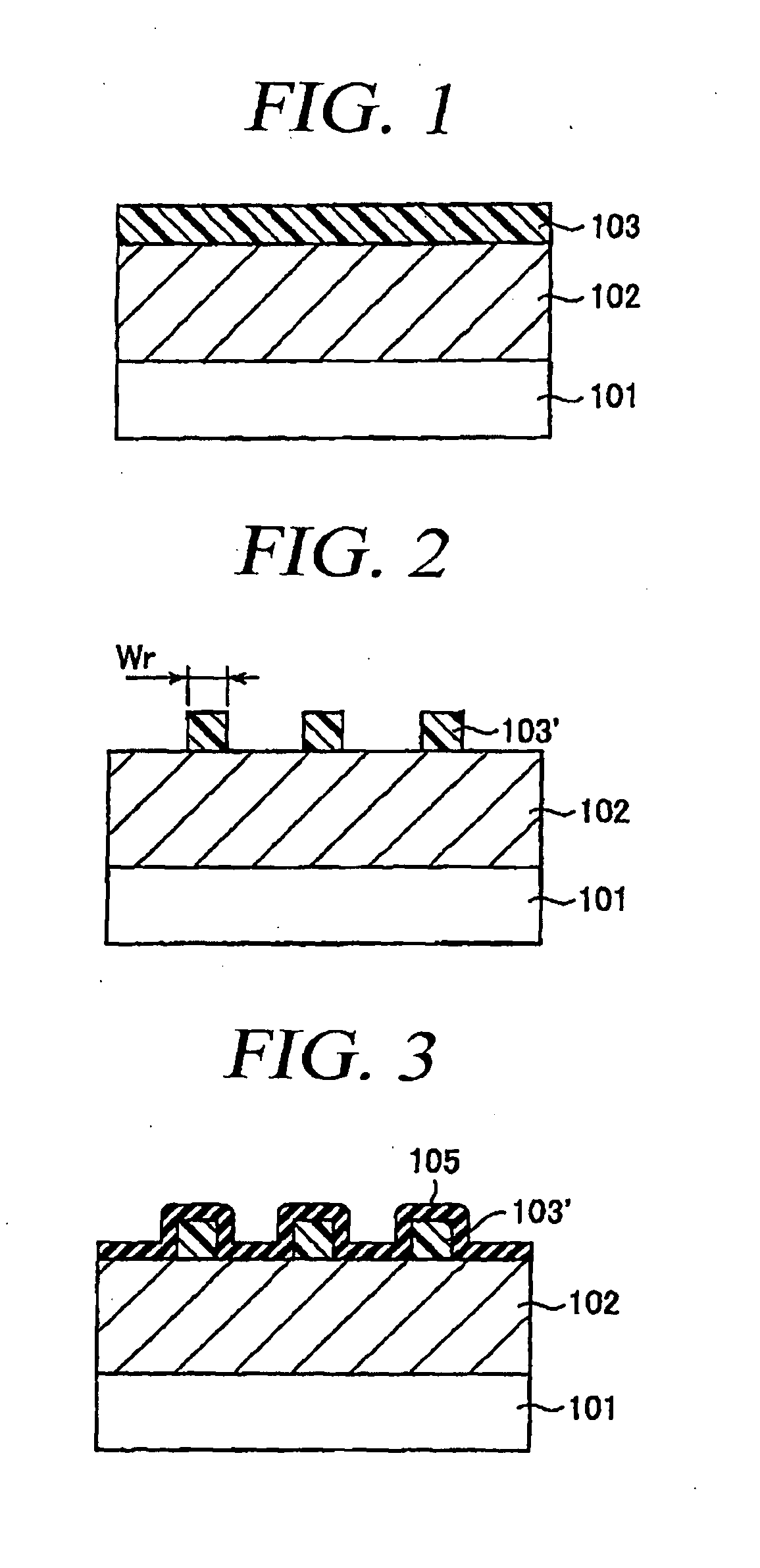

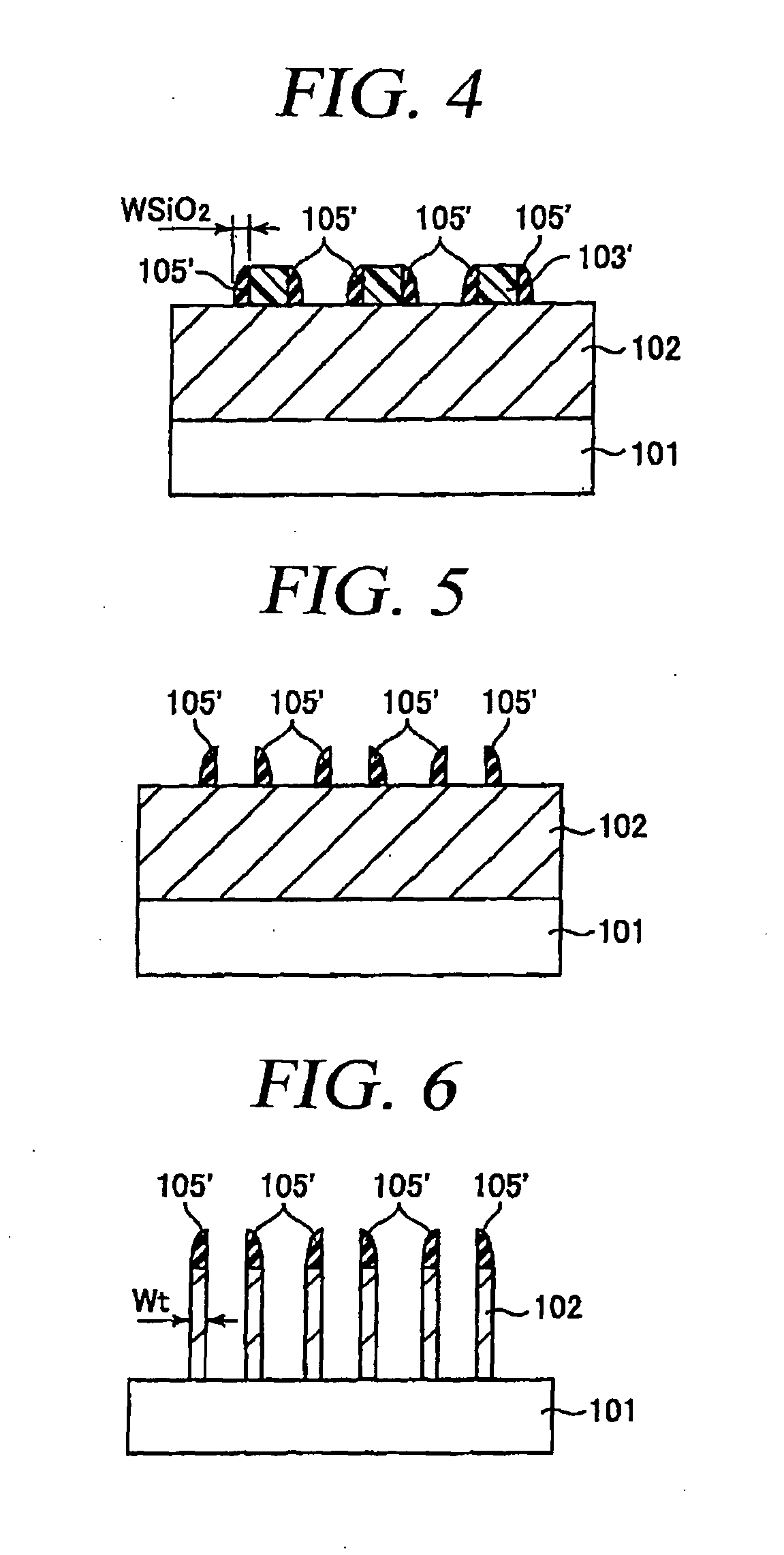

Method for integrated circuit fabrication using pitch multiplication

InactiveUS7115525B2Electric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

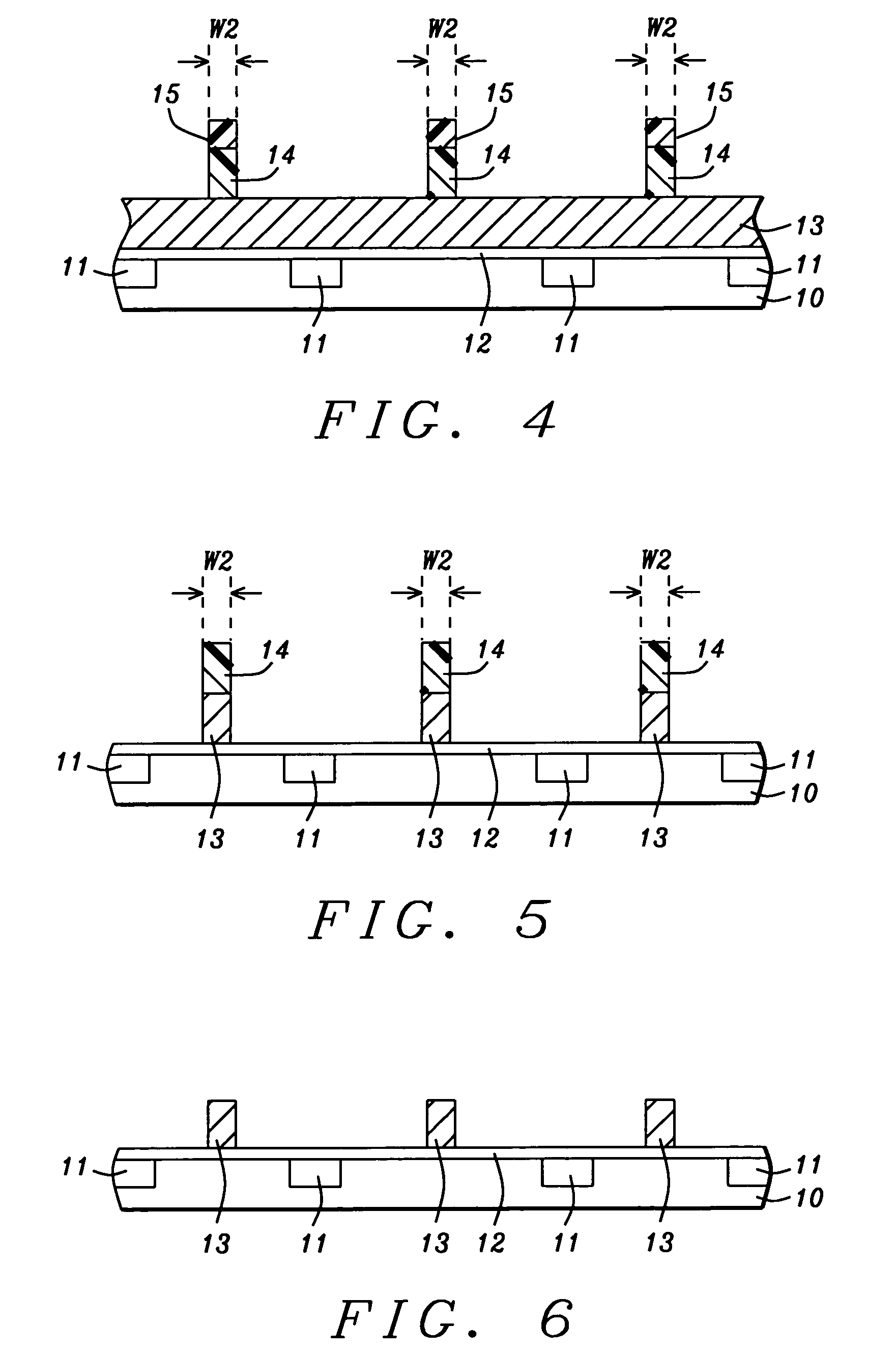

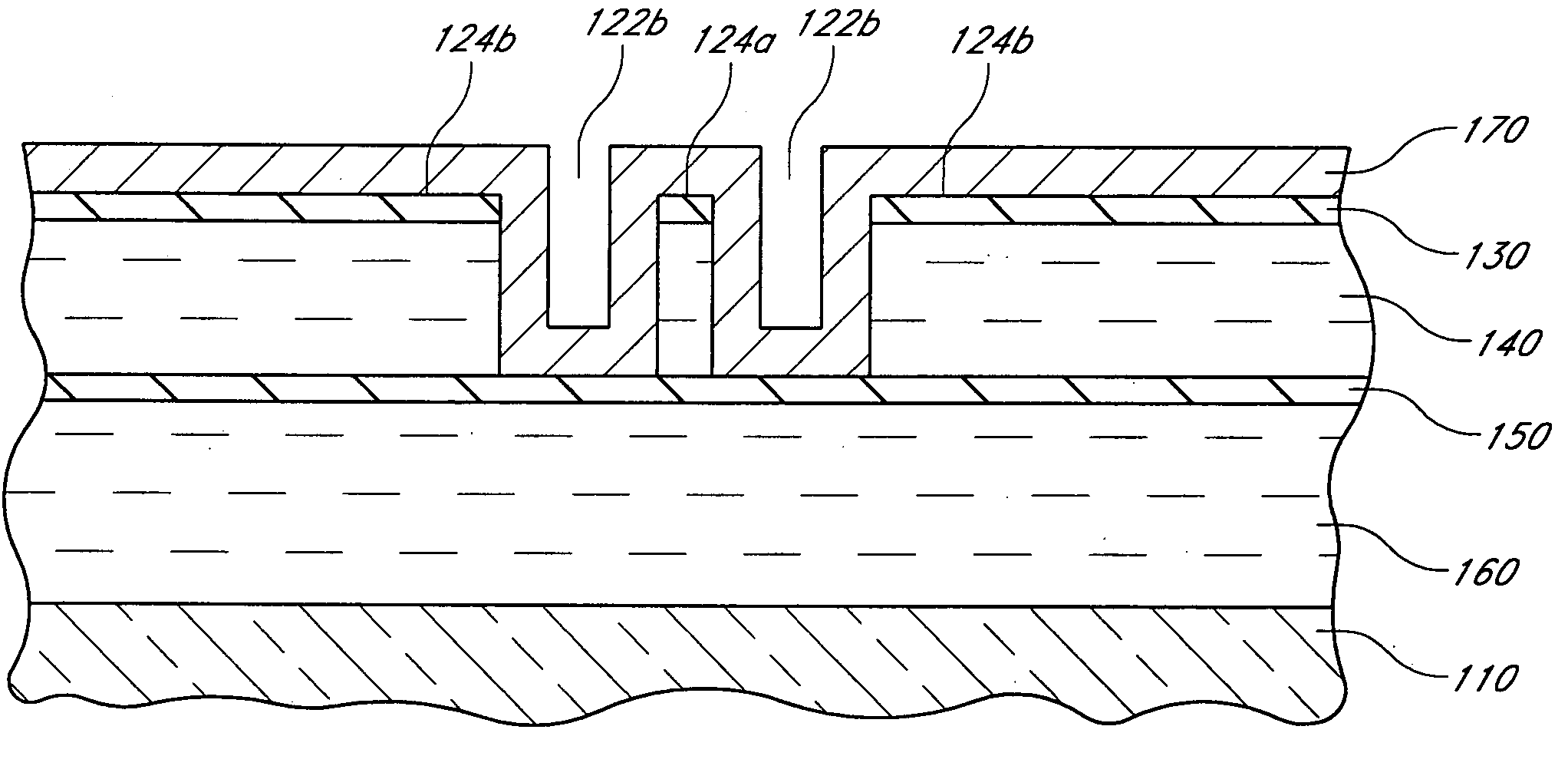

Different sized features in the array and in the periphery of an integrated circuit are patterned on a substrate in a single step. In particular, a mixed pattern, combining two separately formed patterns, is formed on a single mask layer and then transferred to the underlying substrate. The first of the separately formed patterns is formed by pitch multiplication and the second of the separately formed patterns is formed by conventional photolithography. The first of the separately formed patterns includes lines that are below the resolution of the photolithographic process used to form the second of the separately formed patterns. These lines are made by forming a pattern on photoresist and then etching that pattern into an amorphous carbon layer. Sidewall pacers having widths less than the widths of the un-etched parts of the amorphous carbon are formed on the sidewalls of the amorphous carbon. The amorphous carbon is then removed, leaving behind the sidewall spacers as a mask pattern. Thus, the spacers form a mask having feature sizes less than the resolution of the photolithography process used to form the pattern on the photoresist. A protective material is deposited around the spacers. The spacers are further protected using a hard mask and then photoresist is formed and patterned over the hard mask. The photoresist pattern is transferred through the hard mask to the protective material. The pattern made out by the spacers and the temporary material is then transferred to an underlying amorphous carbon hard mask layer. The pattern, having features of difference sizes, is then transferred to the underlying substrate.

Owner:ROUND ROCK RES LLC

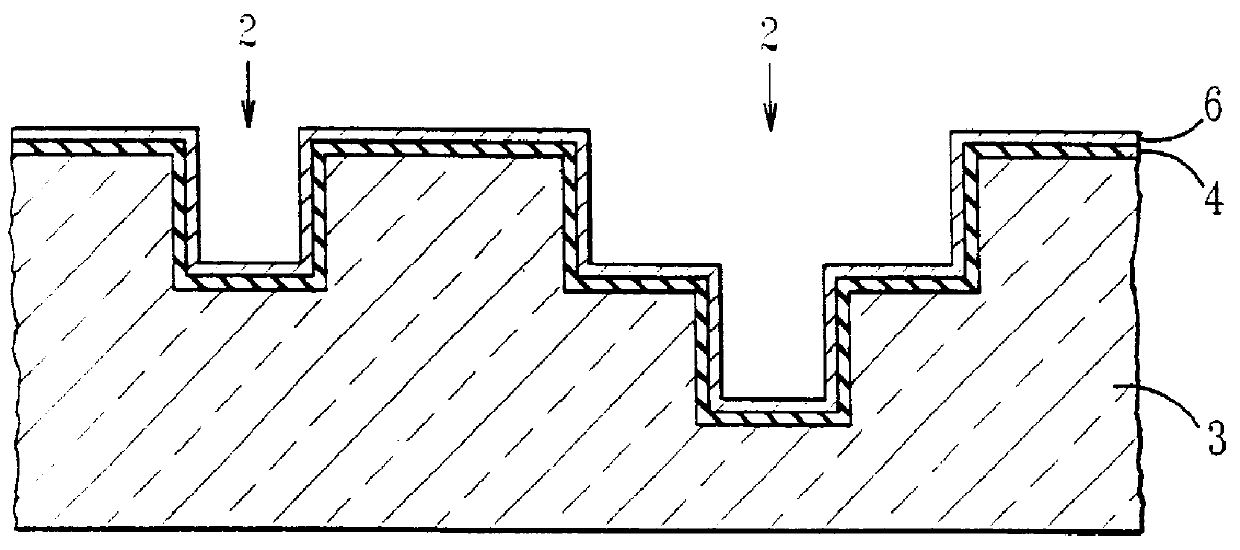

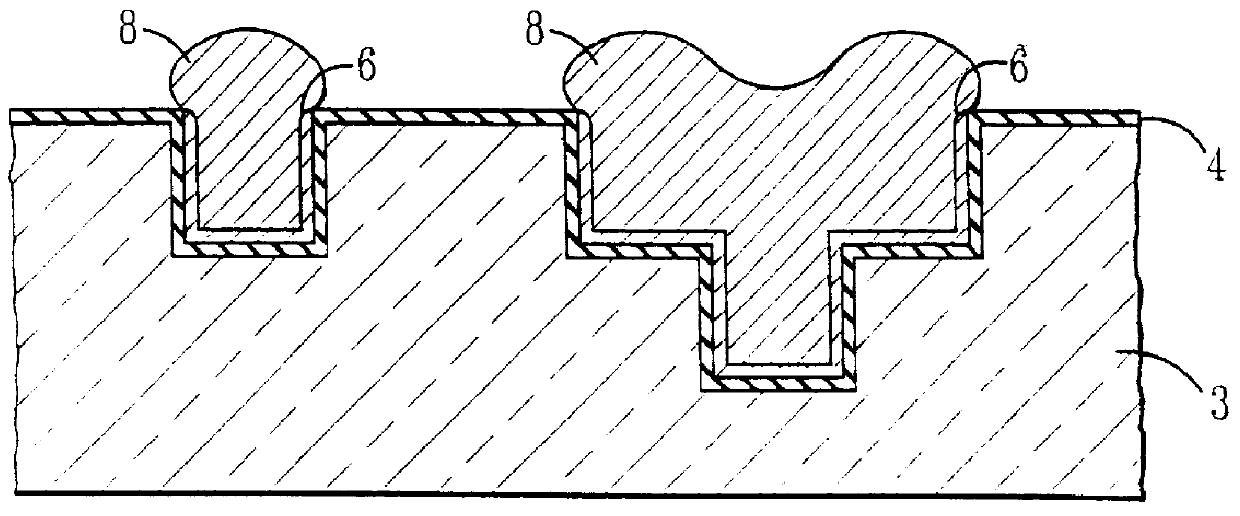

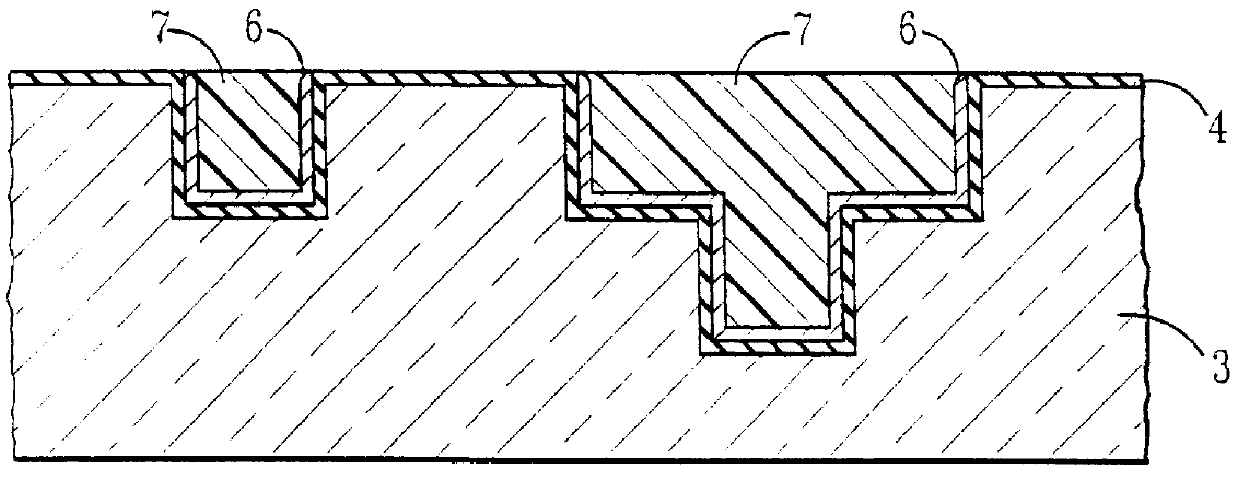

Method to selectively fill recesses with conductive metal

InactiveUS6140234AShorten the timeIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor structure

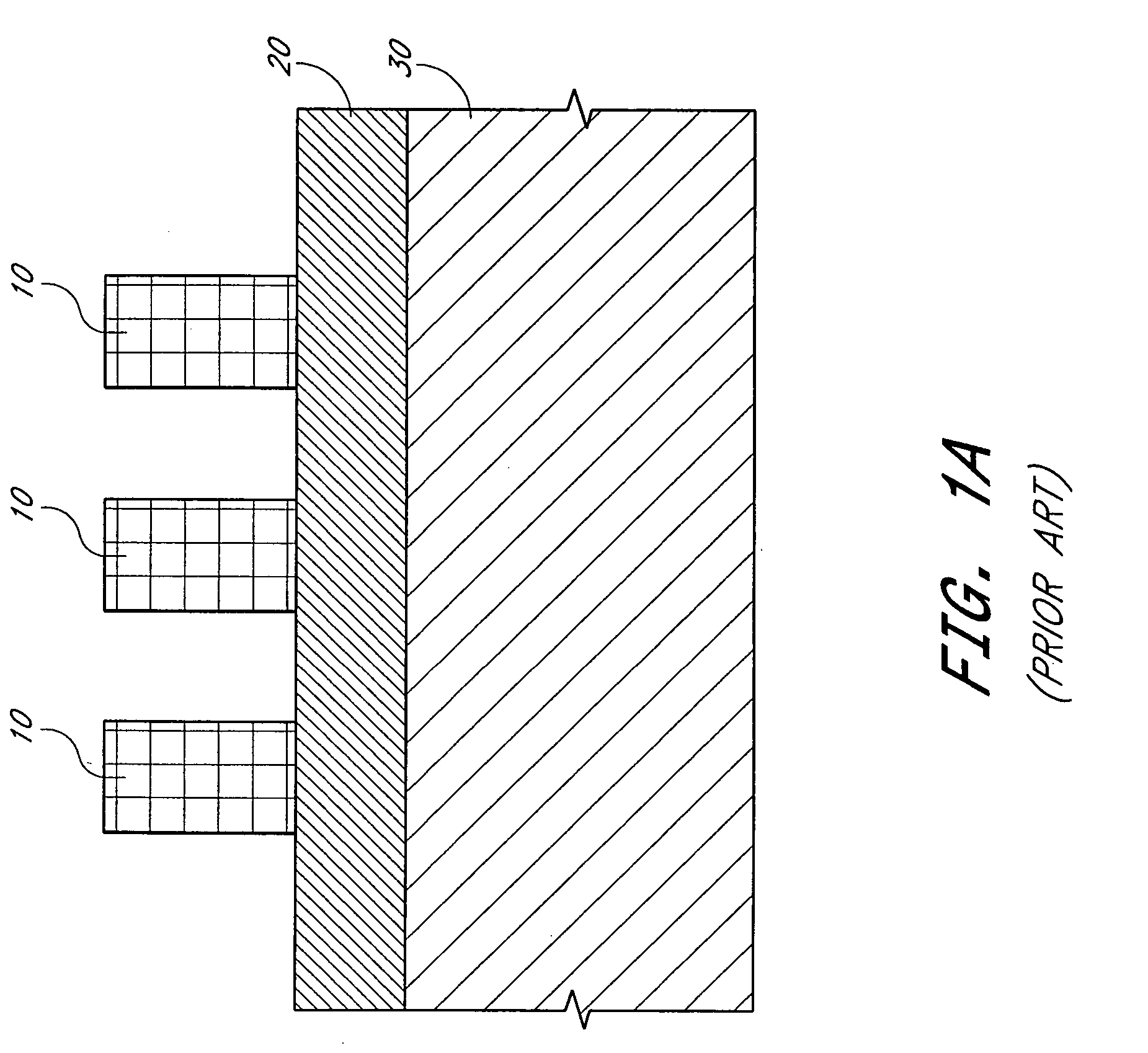

Recesses in a semiconductor structure are selectively plated by providing electrical insulating layer over the semiconductor substrate and in the recesses followed by forming a conductive barrier over the insulating layer; providing a plating seed layer over the barrier layer; depositing and patterning a photoresist layer over the plating seed layer; planarizing the insulated horizontal portions by removing the horizontal portions of the seed layer between the recesses; removing the photoresist remaining in the recesses; and then electroplating the patterned seed layer with a conductive metal using the barrier layer to carry the current during the electroplating to thereby only plate on the seed layer. In an alternative process, a barrier film is deposited over recesses in an insulator. Then, relatively thick resists are lithographically defined on the field regions, on top of the barrier film over the recesses. A plating base or seedlayer is deposited, so as to be continuous on the horizontal regions of the recesses in the insulator, but discontinuous on their surround wall. The recesses are then plated using the barrier film without seedlayers at the periphery of the substrate wafers for electrical contact. After electroplating, the resist is removed by lift-off process and exposed barrier film is etched by RIE method or by CMP. Also provided is a semiconductor structure obtained by the above processes.

Owner:GLOBALFOUNDRIES INC

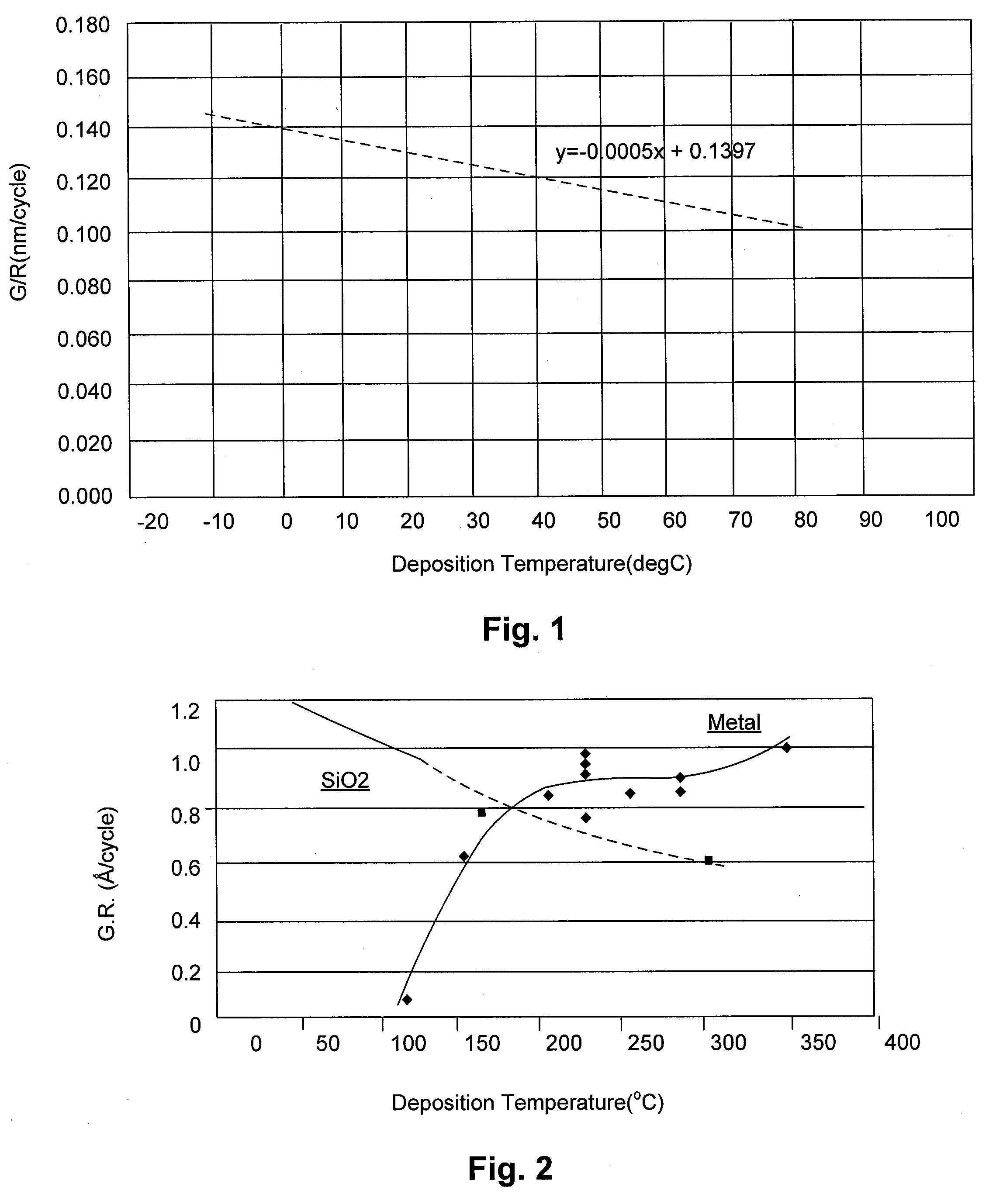

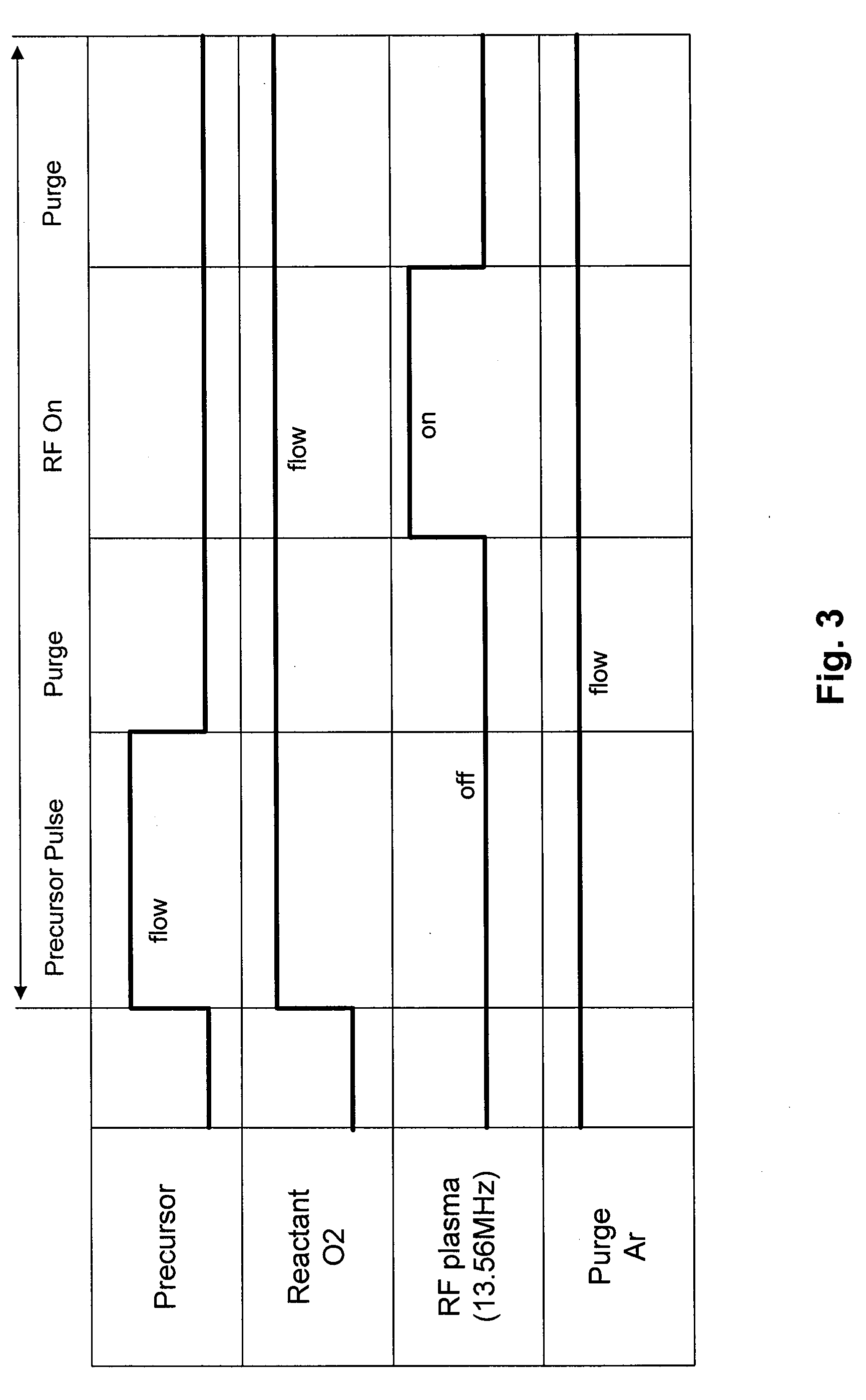

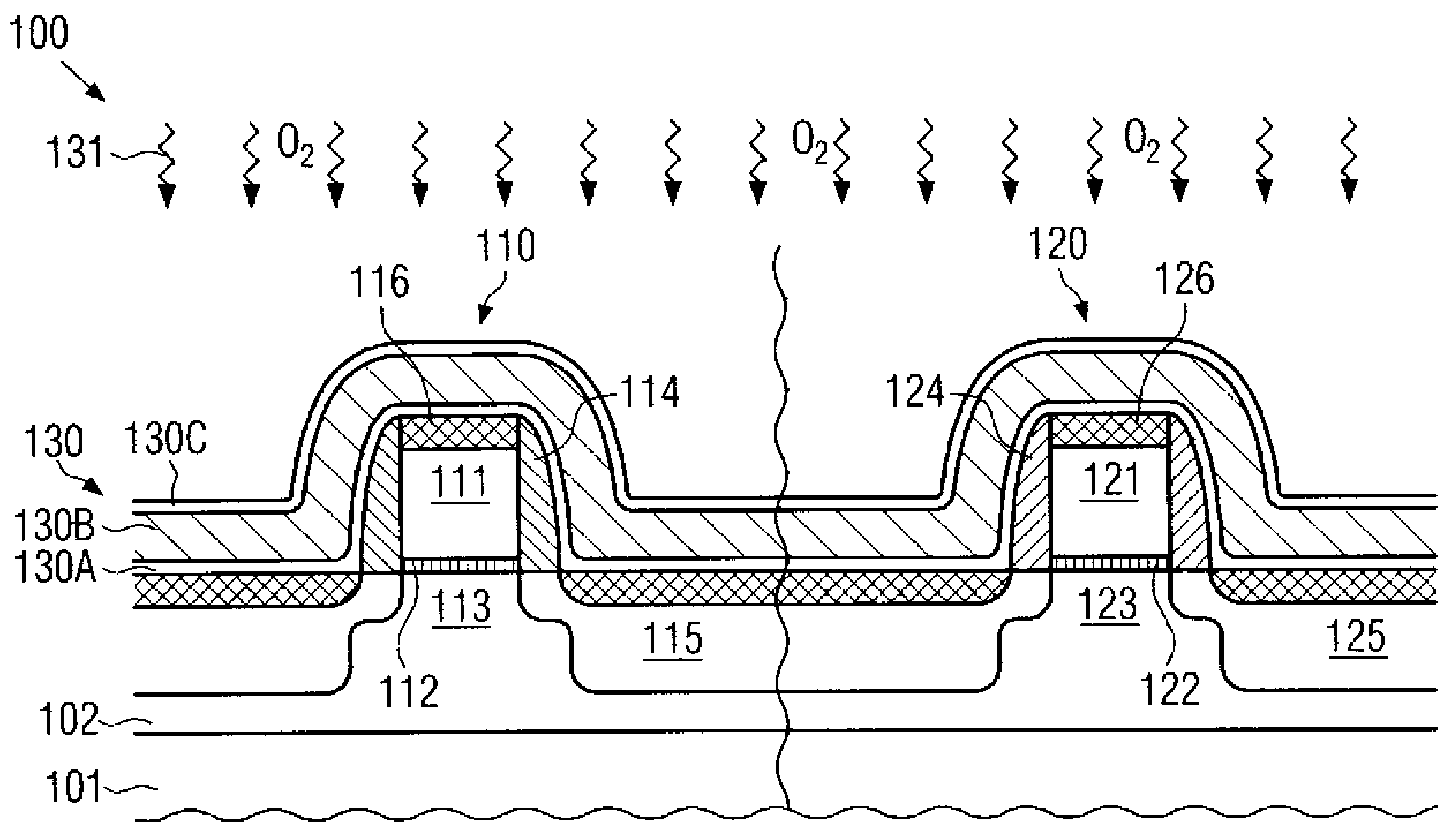

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

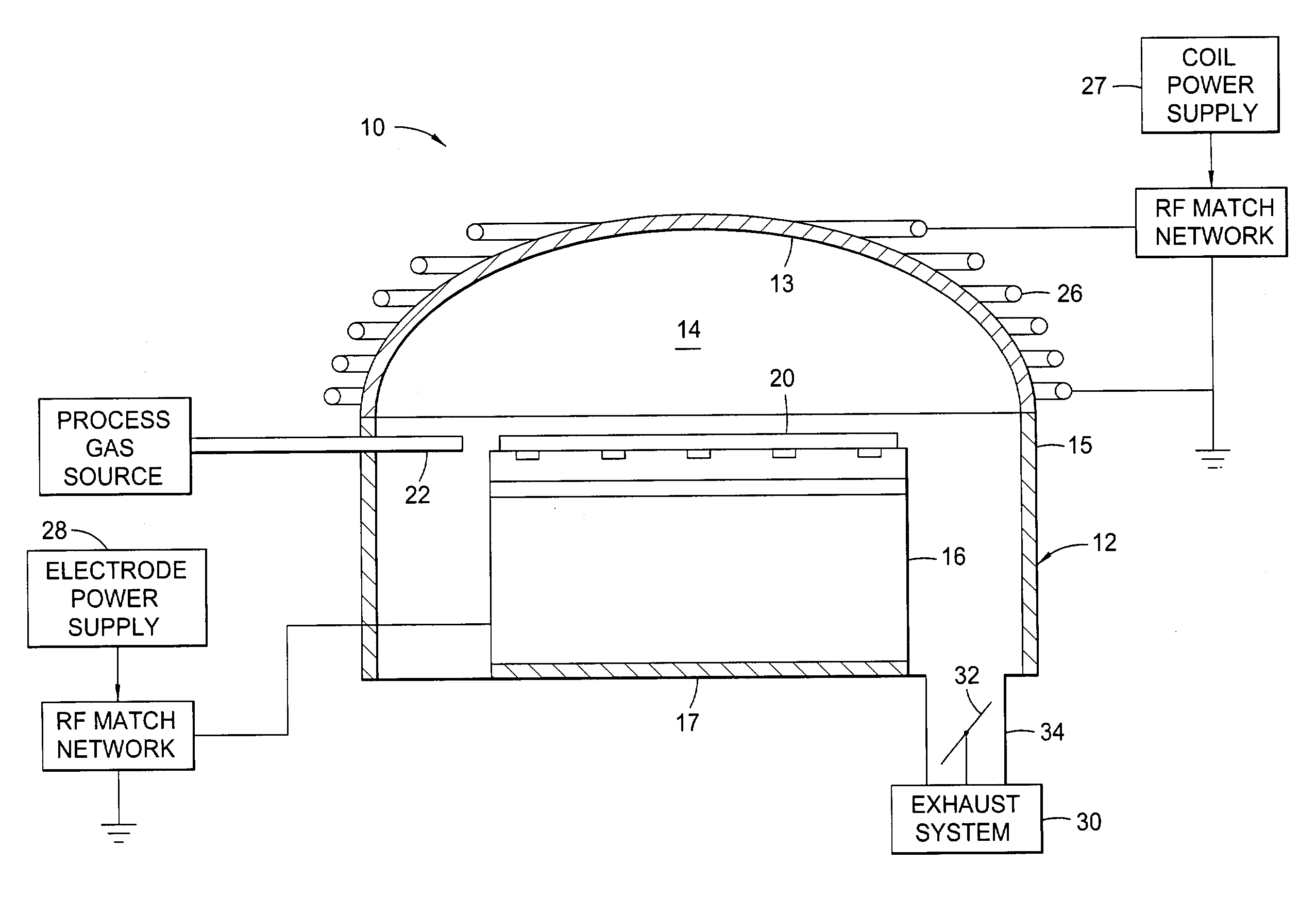

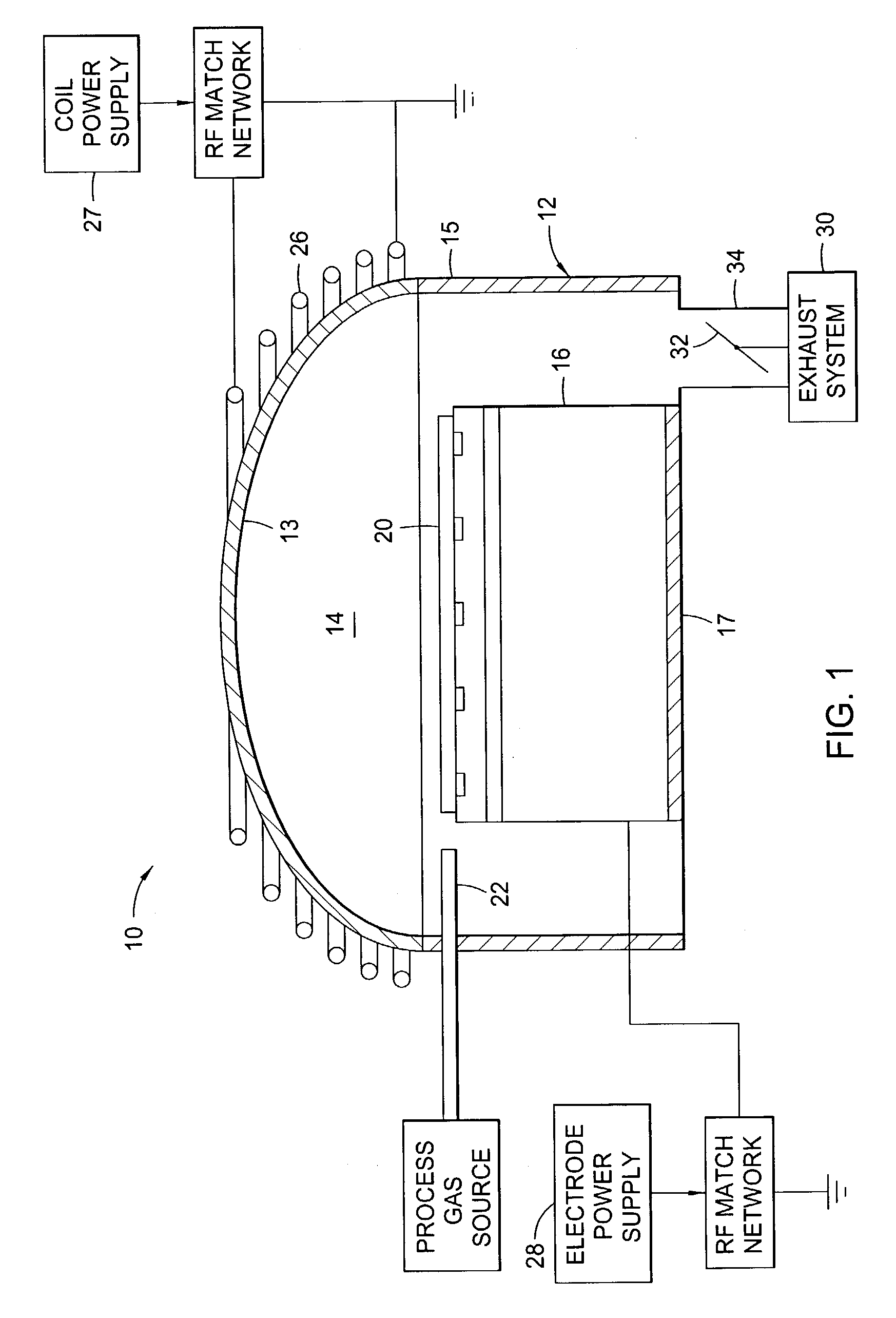

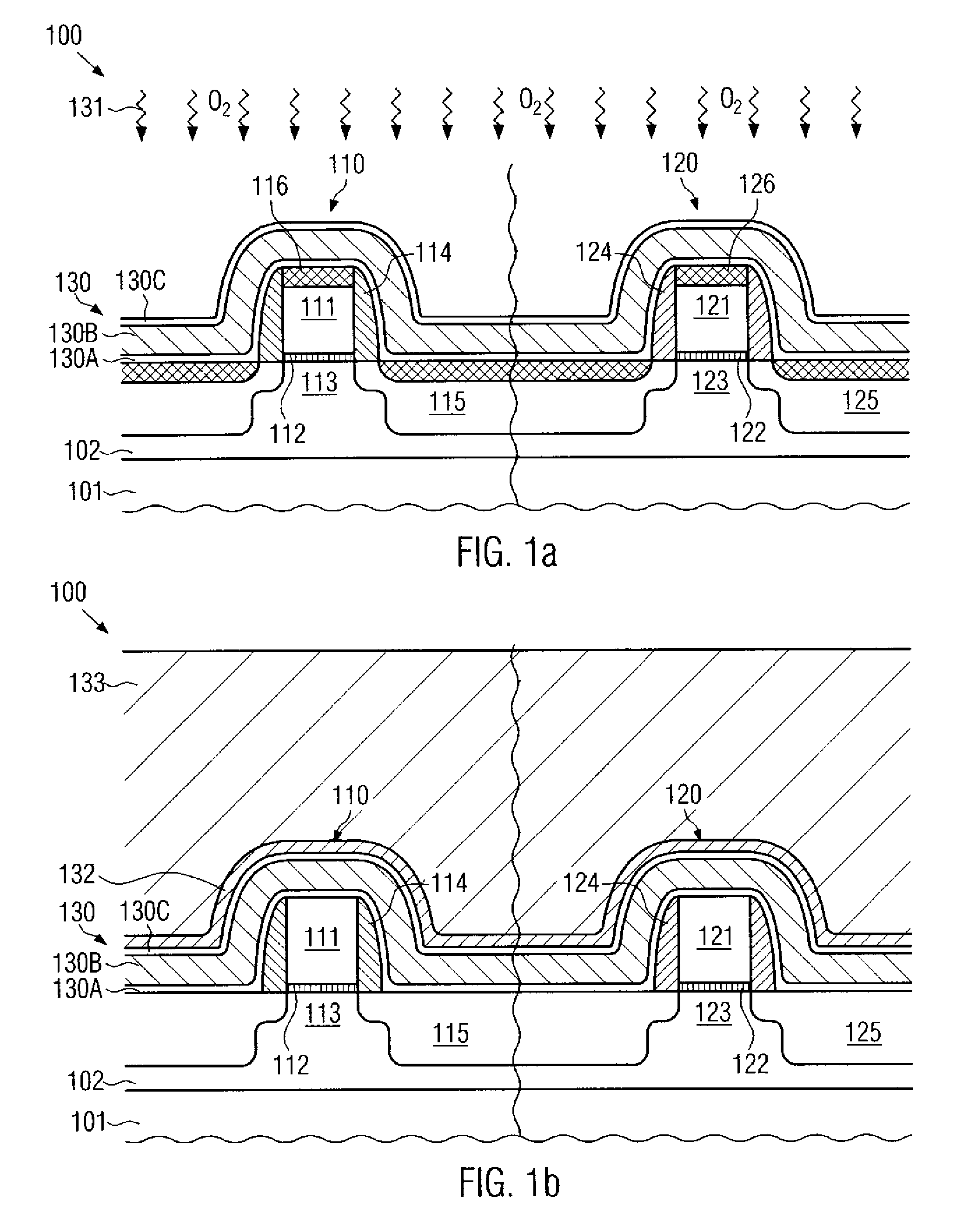

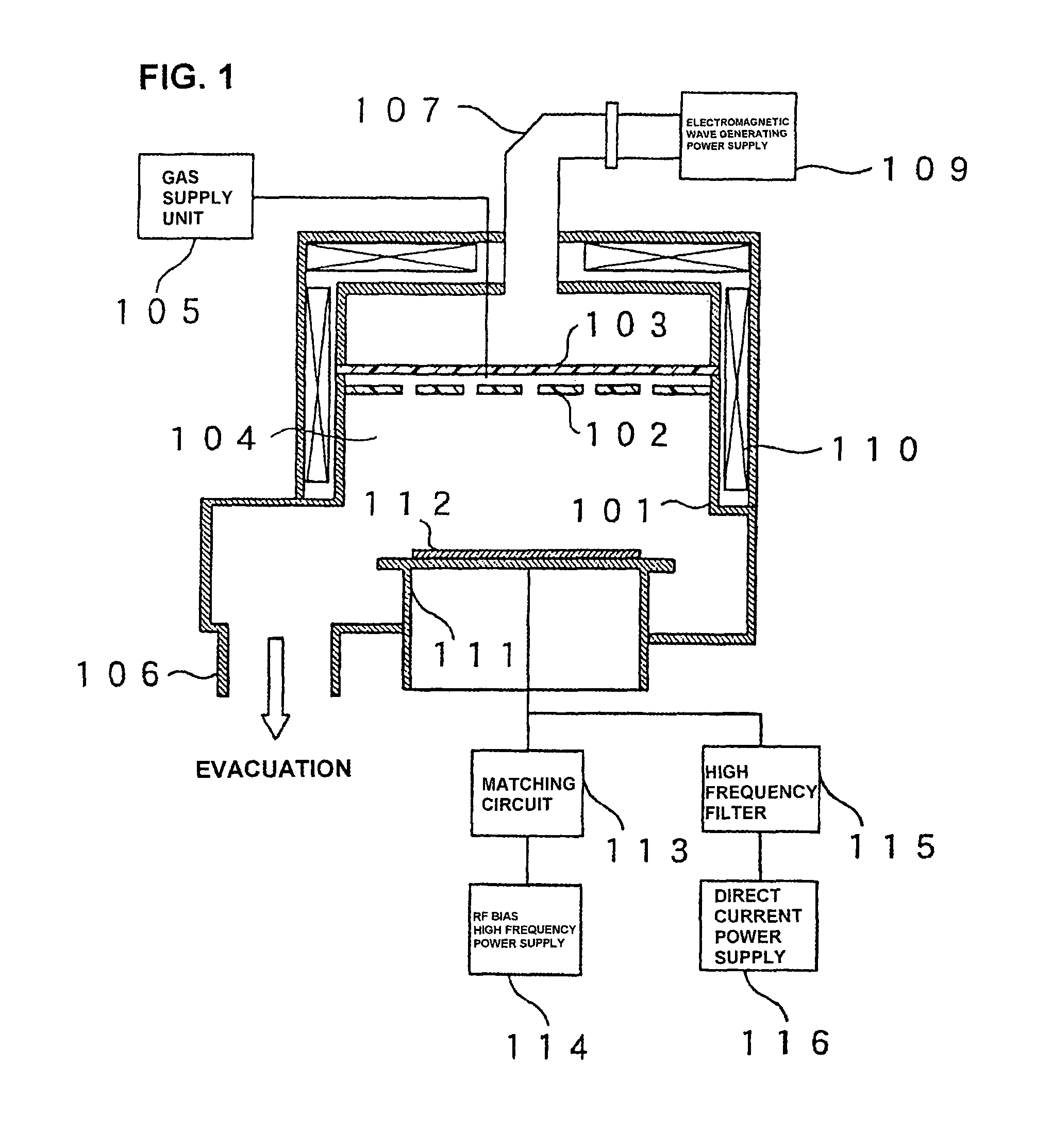

Front end of line plasma mediated ashing processes and apparatus

InactiveUS20100130017A1Increased formationElectric discharge tubesSemiconductor/solid-state device manufacturingResistFront end of line

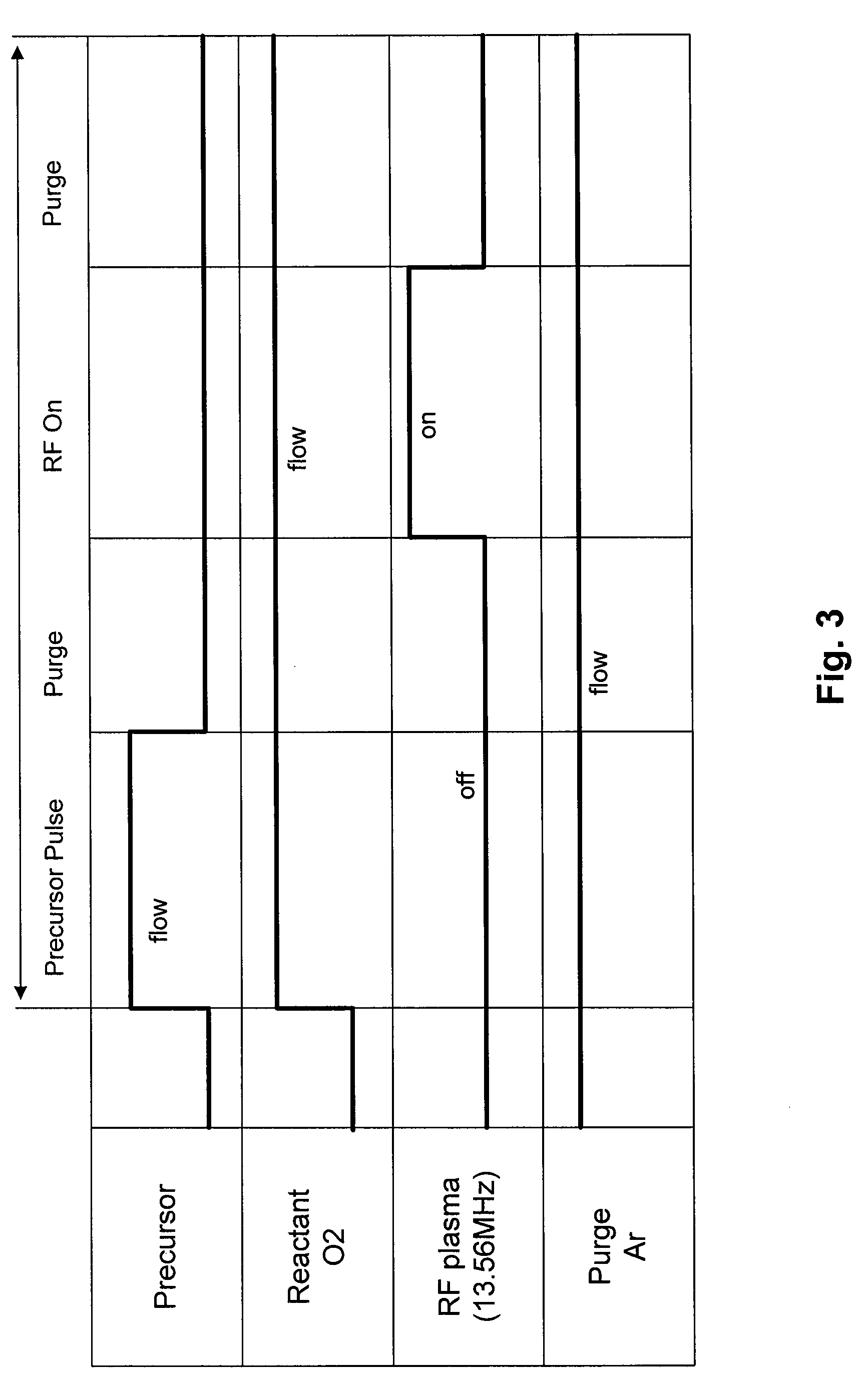

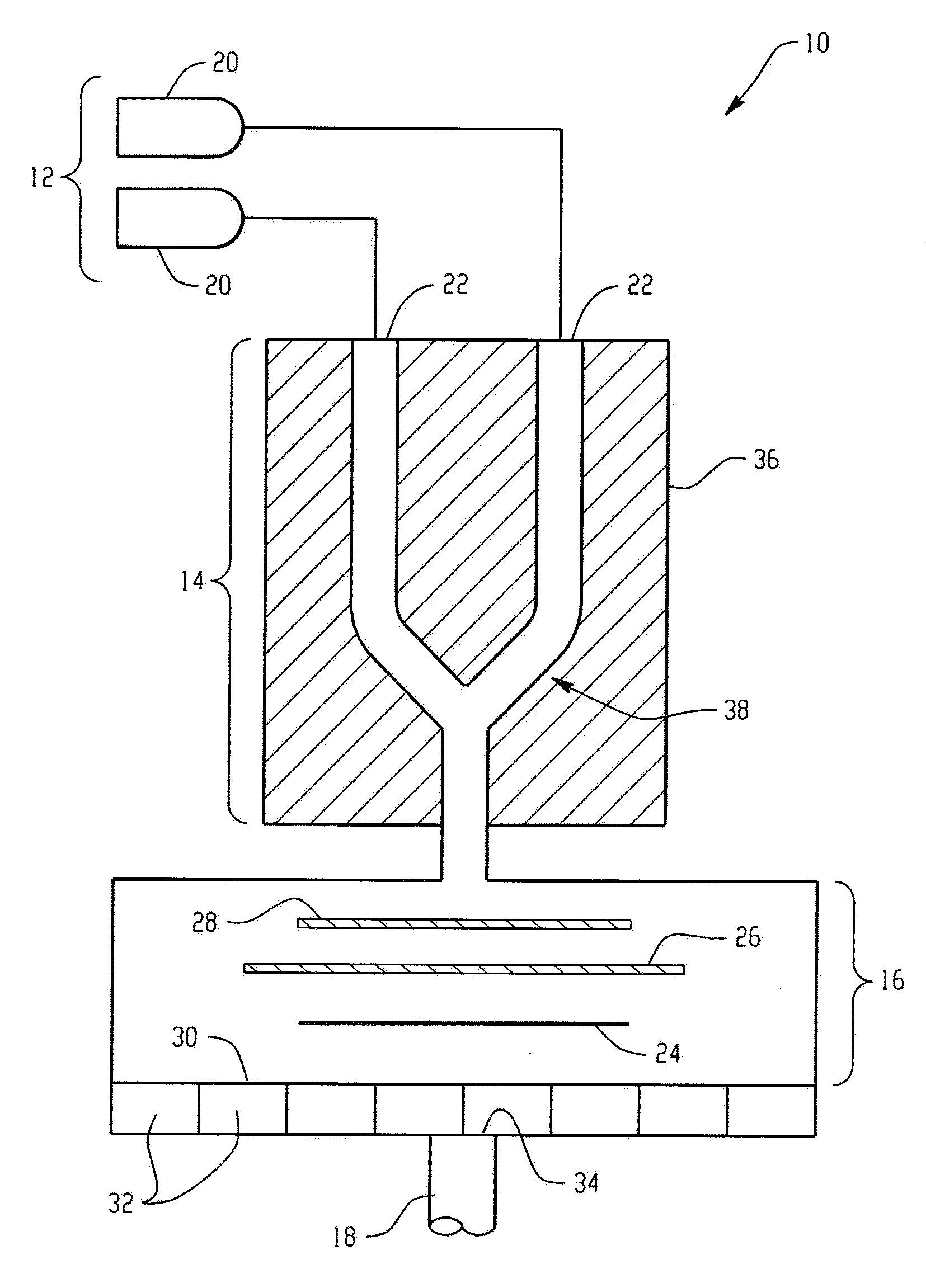

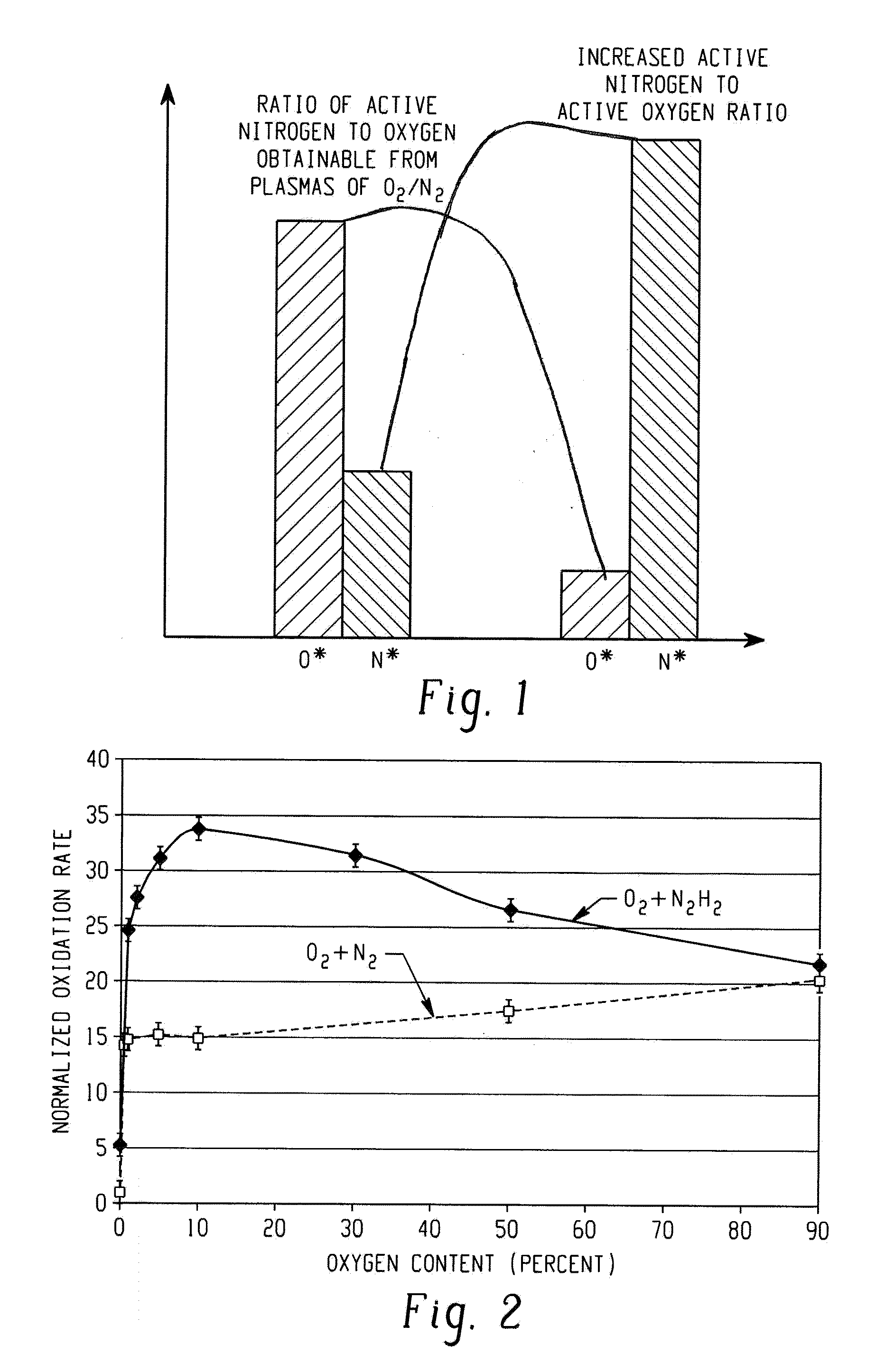

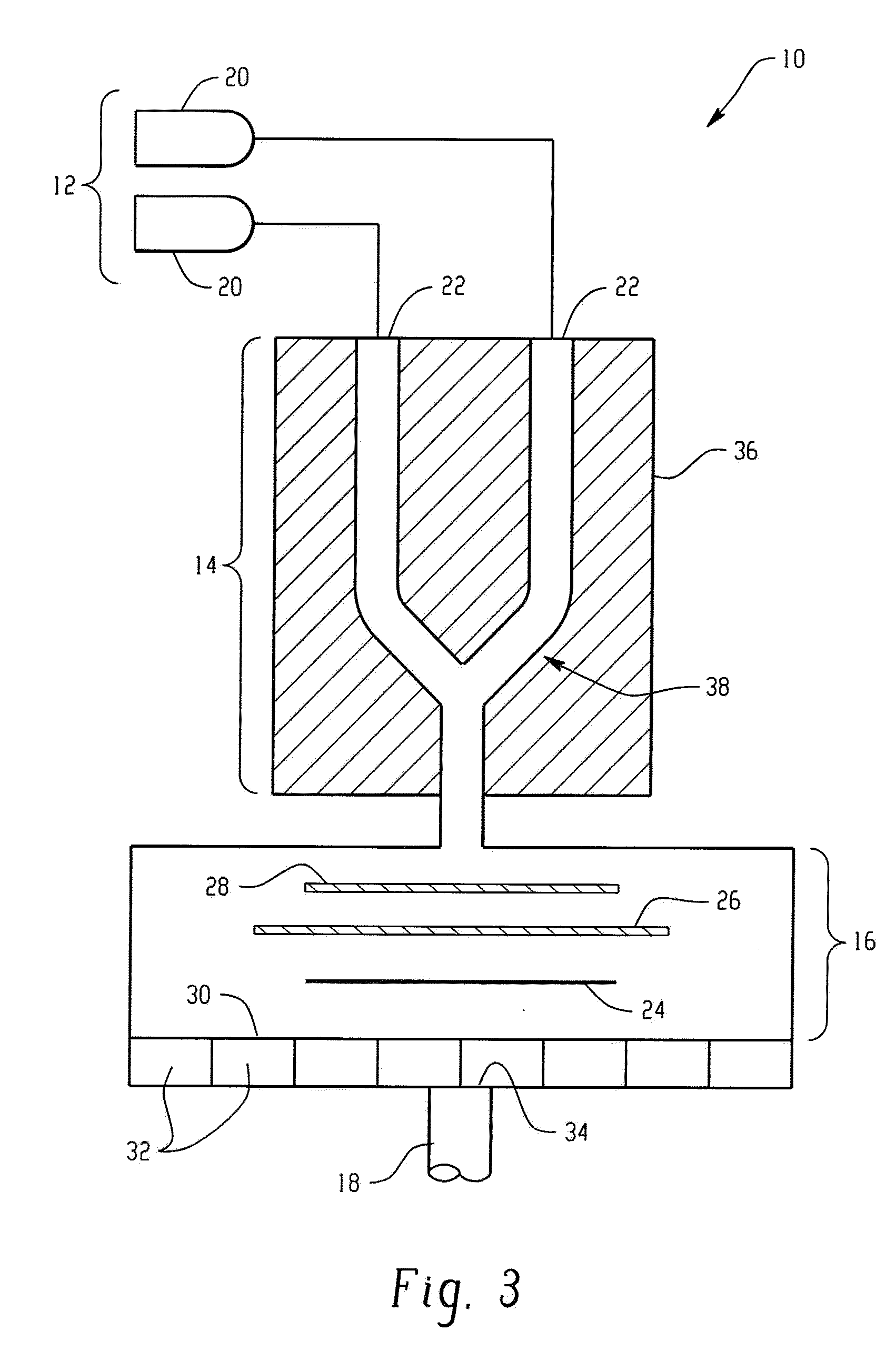

Front end of line (FEOL) plasma mediated ashing processes for removing organic material from a substrate generally includes exposing the substrate to the plasma to selectively remove photoresist, implanted photoresist, polymers and / or residues from the substrate, wherein the plasma contains a ratio of active nitrogen and active oxygen that is larger than a ratio of active nitrogen and active oxygen obtainable from plasmas of gas mixtures comprising oxygen gas and nitrogen gas. The plasma exhibits high throughput while minimizing and / or preventing substrate oxidation and dopant bleaching. Plasma apparatuses are also described.

Owner:LAM RES CORP

Method of trimming technology

ActiveUS7354847B2Easy to controlAvoid insufficient thicknessSolid-state devicesSemiconductor/solid-state device manufacturingResistMOSFET

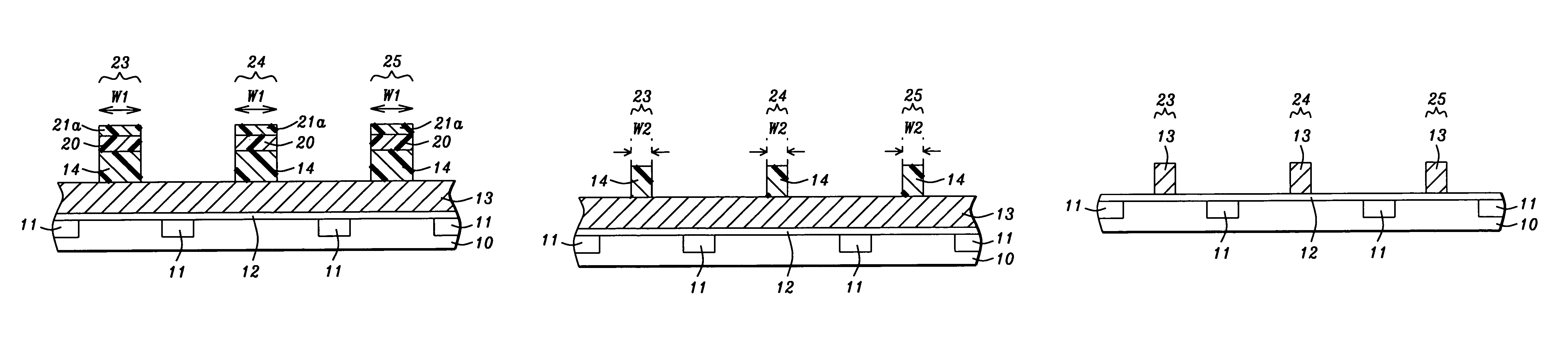

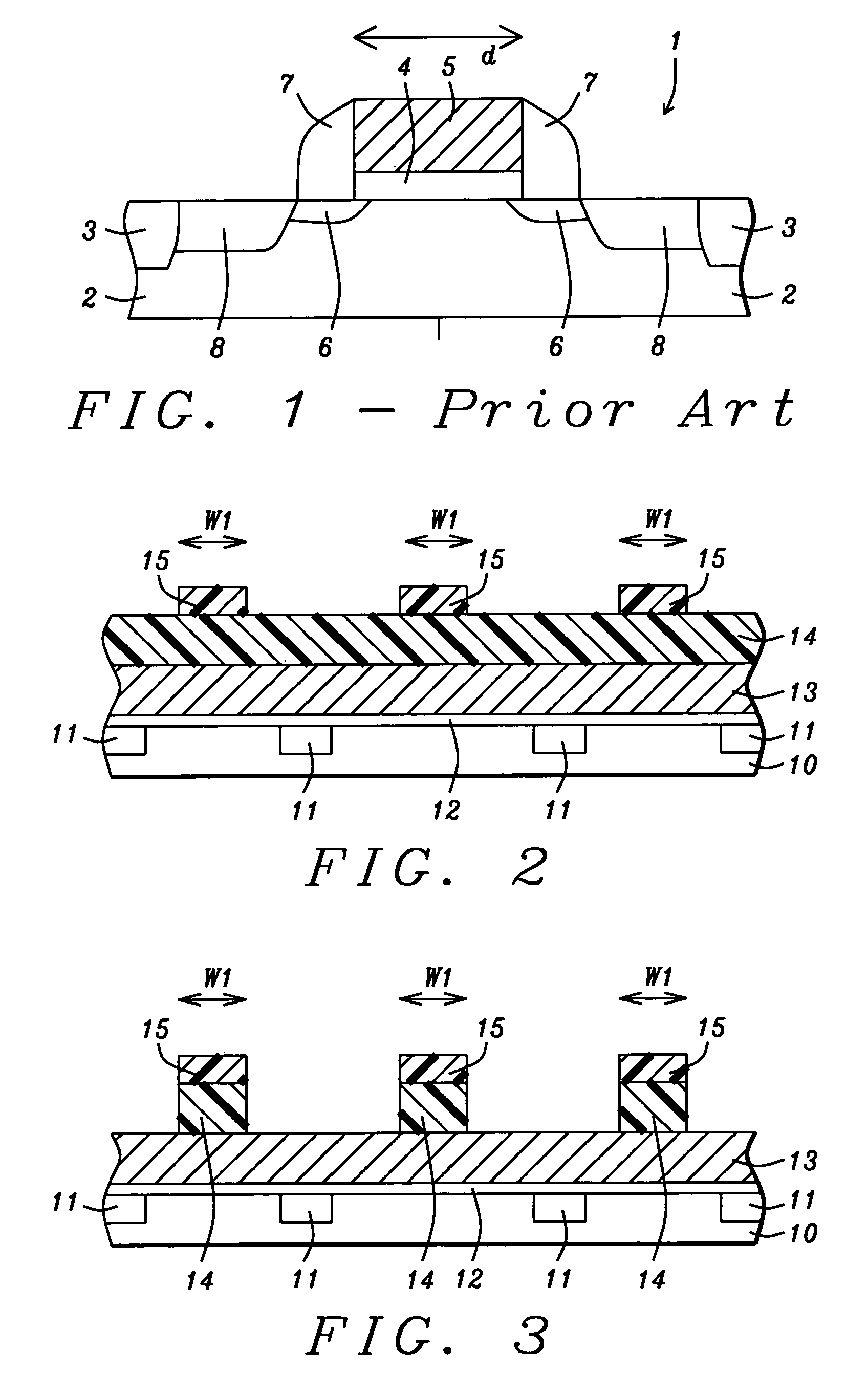

A process for trimming a photoresist layer during the fabrication of a gate electrode in a MOSFET is described. A bilayer stack with a top photoresist layer on a thicker organic underlayer is patternwise exposed with 193 nm or 157 nm radiation to form a feature having a width w1 in the top layer. A pattern transfer through the underlayer is performed with an anisotropic etch based on H2 / N2 and SO2 chemistry. The feature formed in the bilayer stack is trimmed by 10 nm or more to a width w2 by a HBr / O2 / Cl2 plasma etch. The pattern transfer through an underlying gate layer is performed with a third etch based on HBr / O2 / Cl2 chemistry. The underlayer is stripped by an O2 ashing with no damage to the gate electrode. Excellent profile control of the gate electrode is achieved and a larger (w1−w2) is possible than in prior art methods.

Owner:TAIWAN SEMICON MFG CO LTD

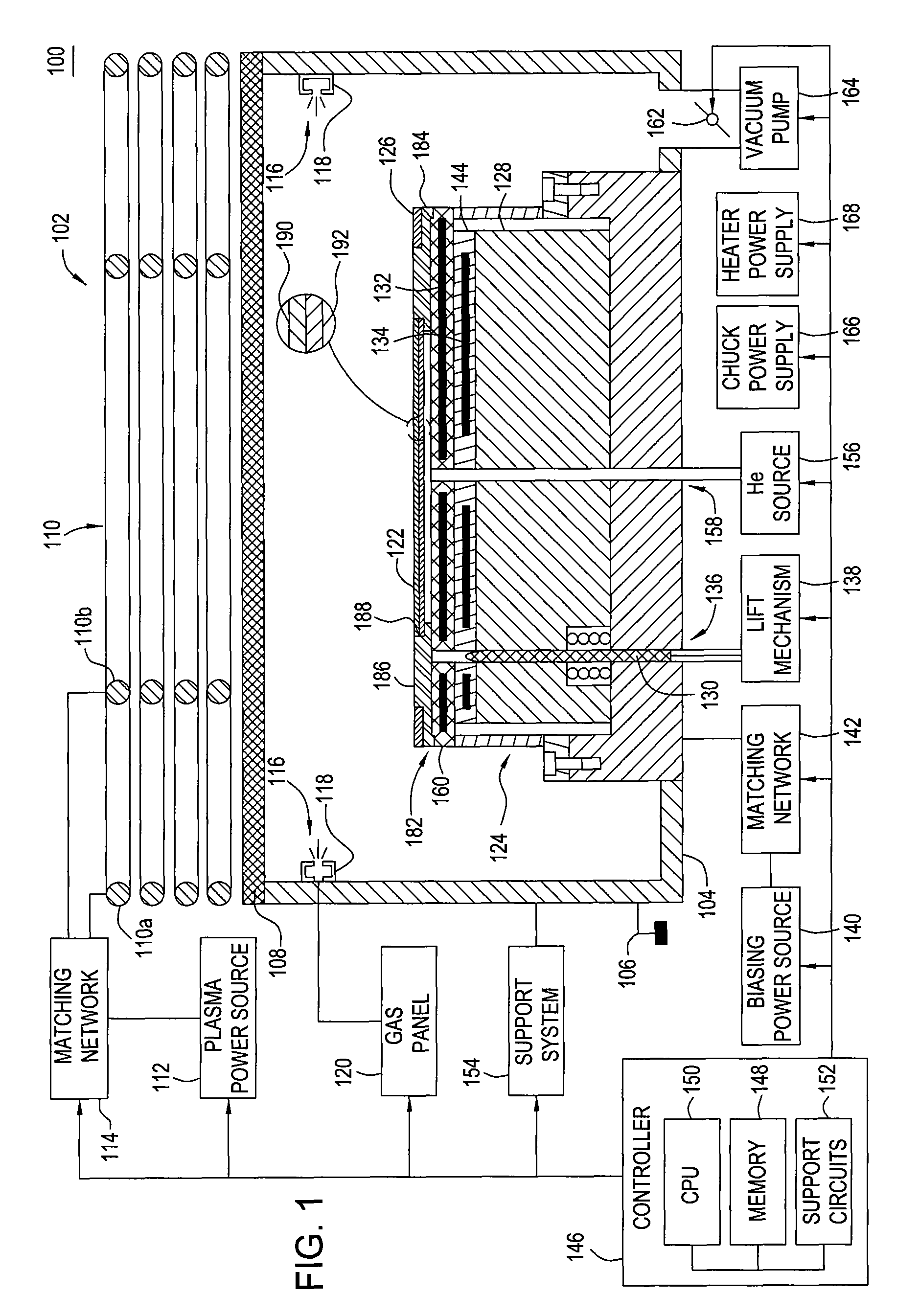

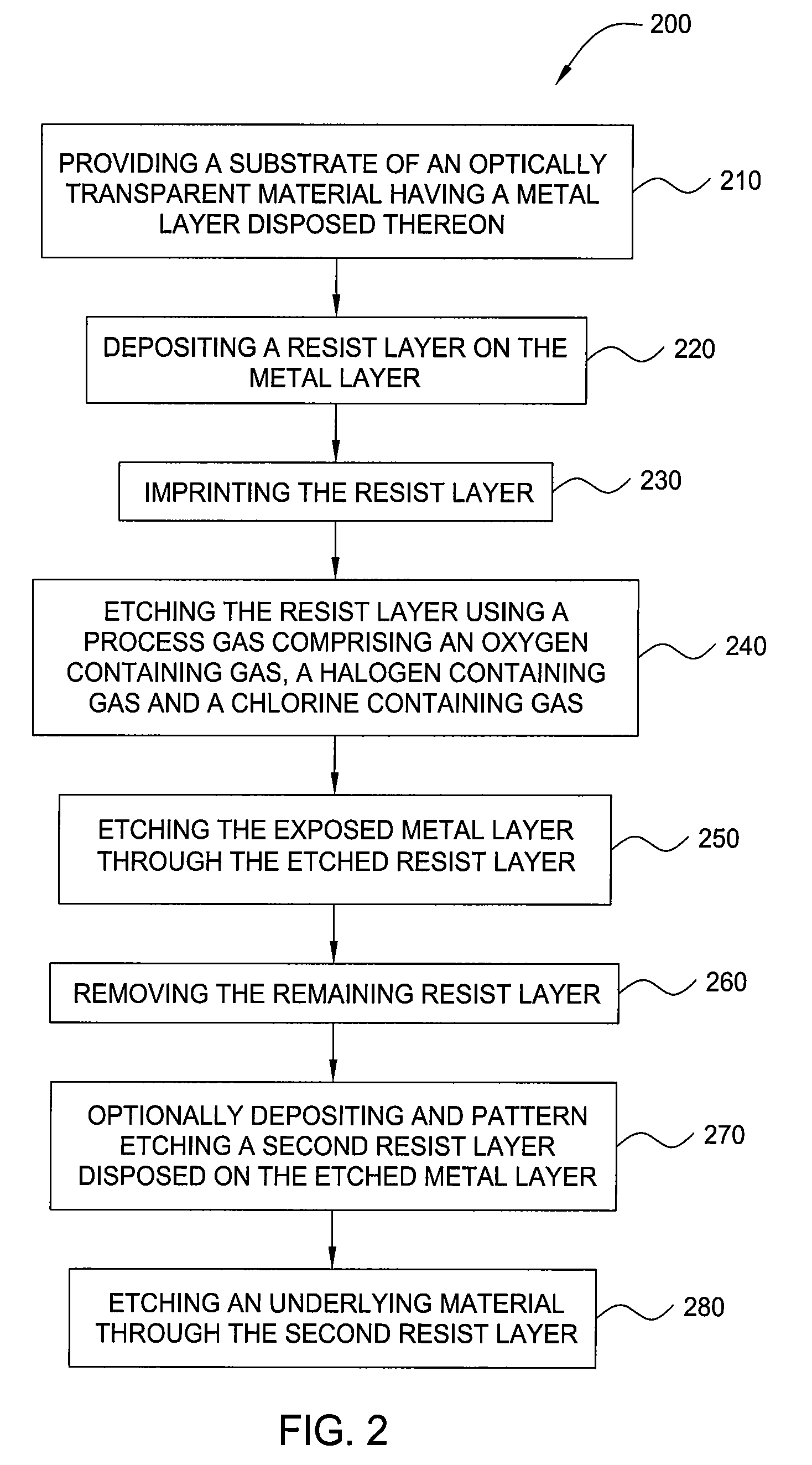

Etching of nano-imprint templates using an etch reactor

Owner:APPLIED MATERIALS INC

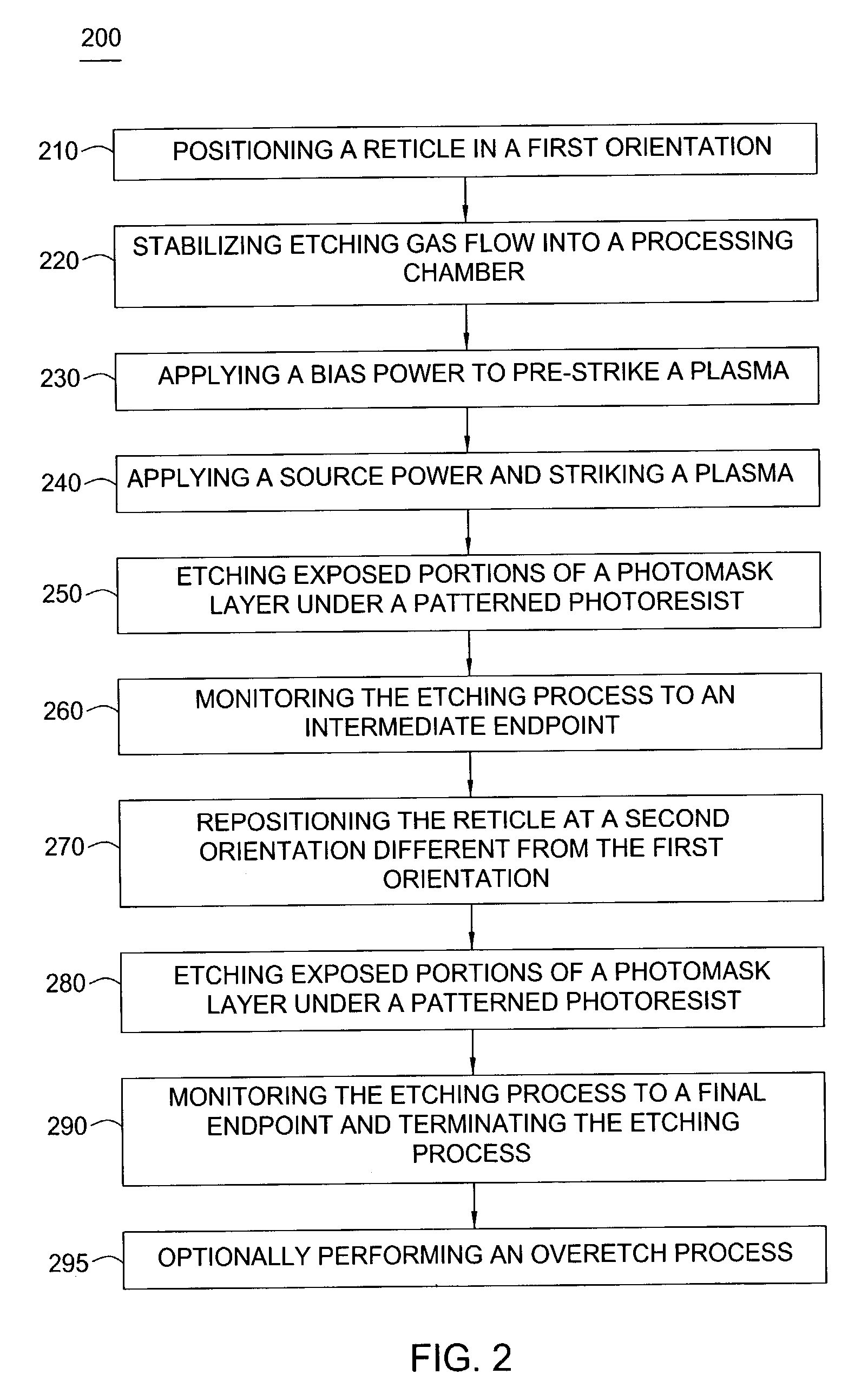

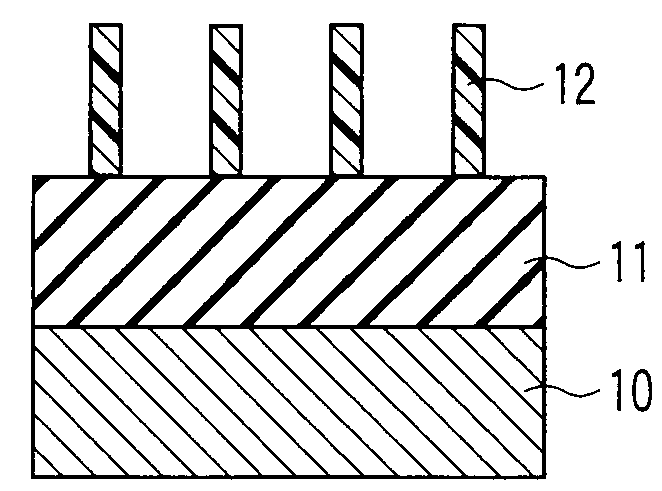

Methods for substrate orientation

Method and apparatus for etching a metal layer disposed on a substrate, such as a photolithographic reticle, are provided. In one aspect, a method is provided for processing a photolithographic reticle including positioning the reticle in a first orientation on a reticle support in a processing chamber, wherein the reticle comprises a metal photomask layer formed on an optically transparent substrate, and a patterned resist material deposited on the metal photomask layer, etching the metal photomask layer in the first orientation, positioning the reticle in at least a second orientation, and etching the metal photomask layer in the at least second orientation.

Owner:APPLIED MATERIALS INC

Pattern forming method using relacs process

InactiveUS20080305443A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistOrganic film

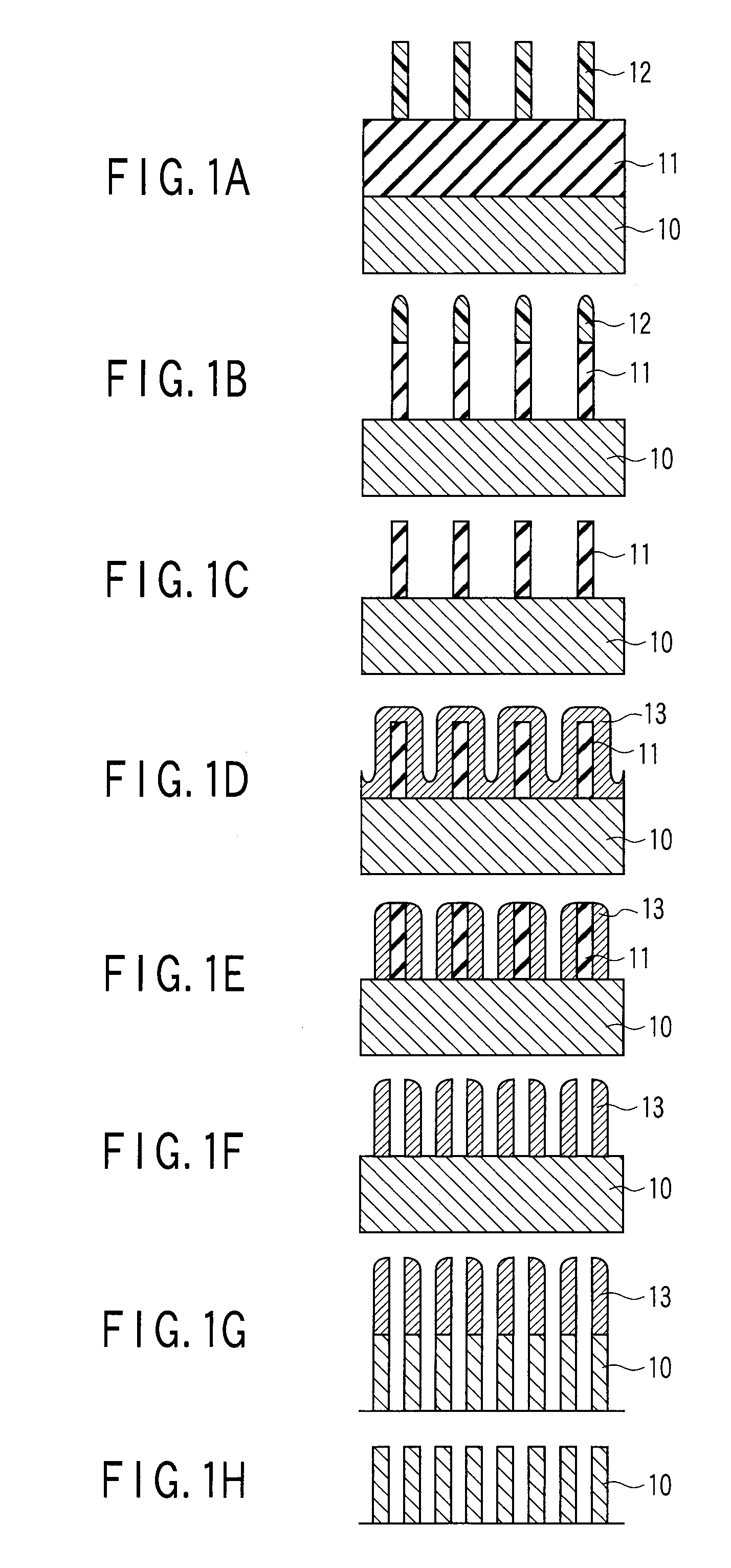

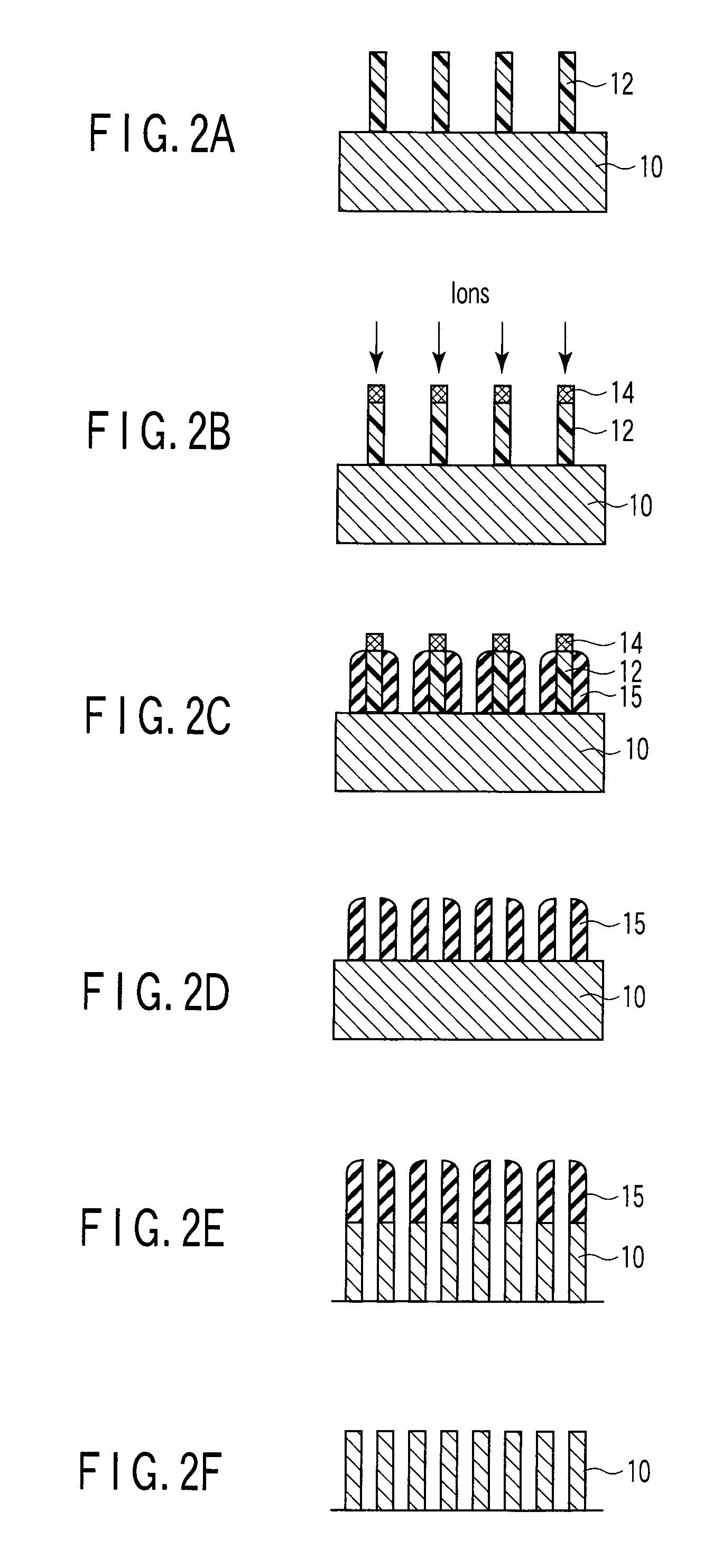

A resist pattern is formed on a to-be-processed film. Ions are implanted in the upper surface of the resist pattern. After ion implantation, an organic film is formed to cover the resist pattern and heated. A crosslinked resin film made of the organic film which has crosslinked is formed on the sidewall of the resist pattern by developing the organic film after heating. After formation of the crosslinked resin film, the resist pattern is removed. The to-be-processed film is processed using the crosslinked resin film as a mask.

Owner:KK TOSHIBA

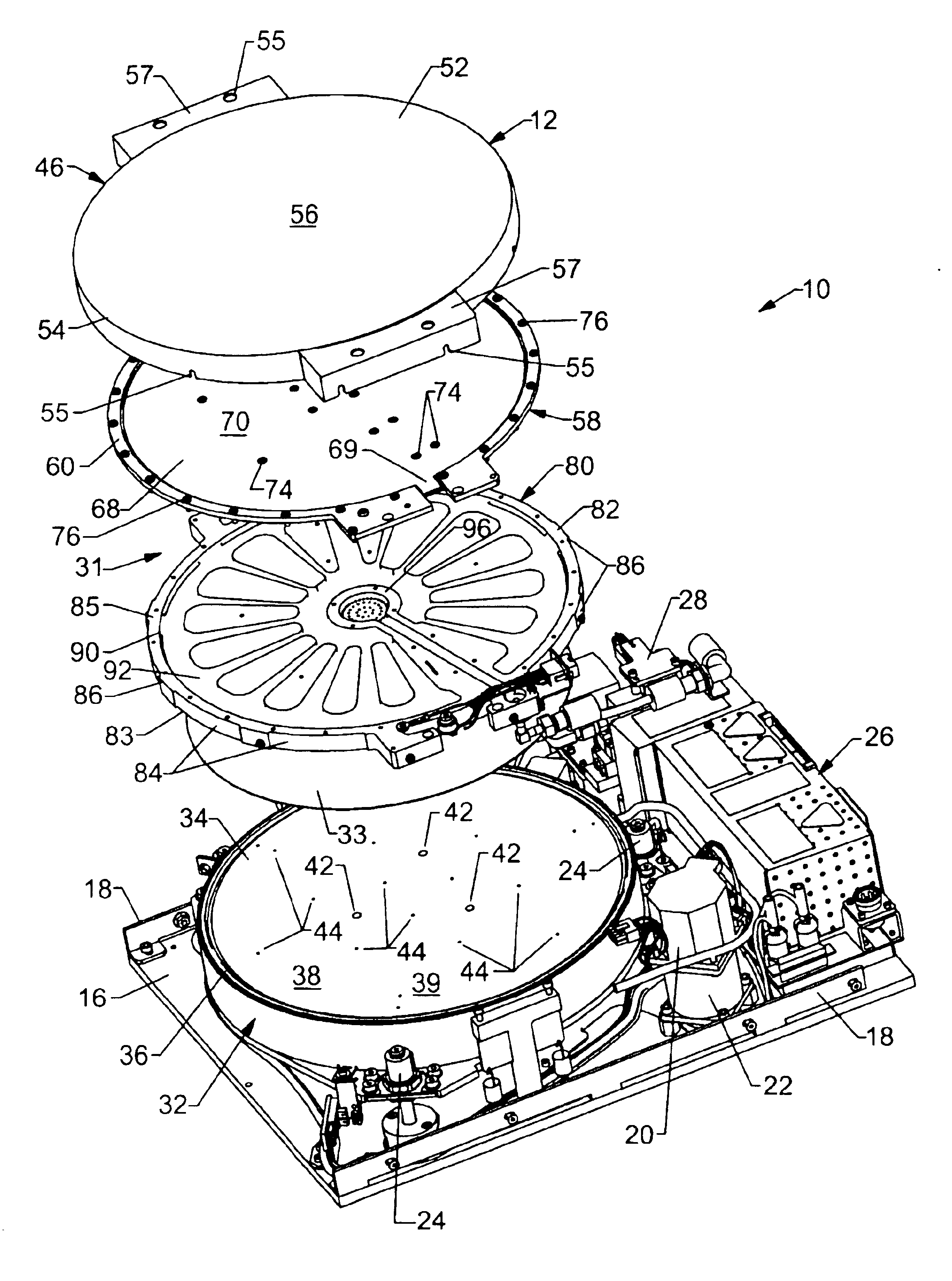

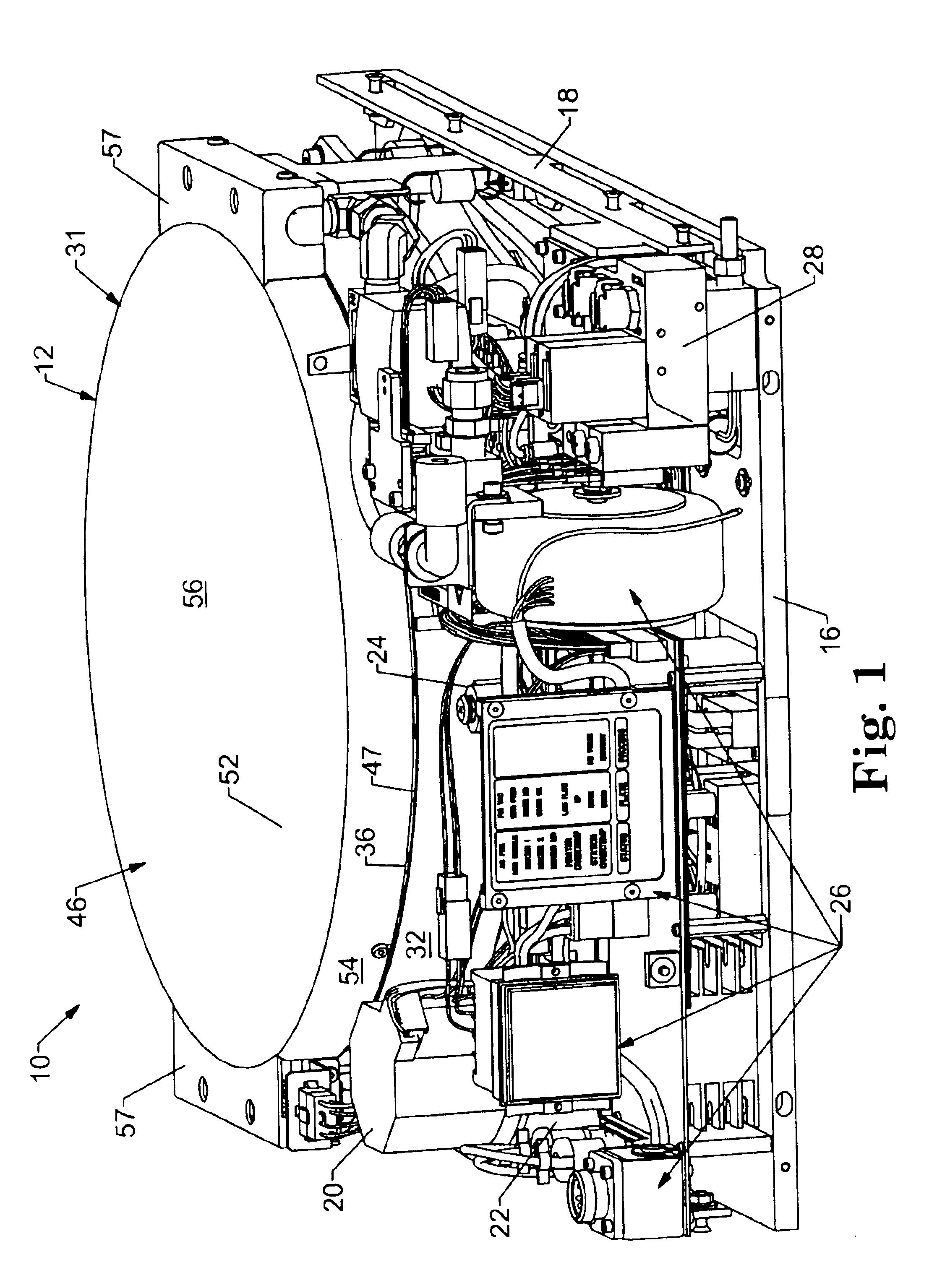

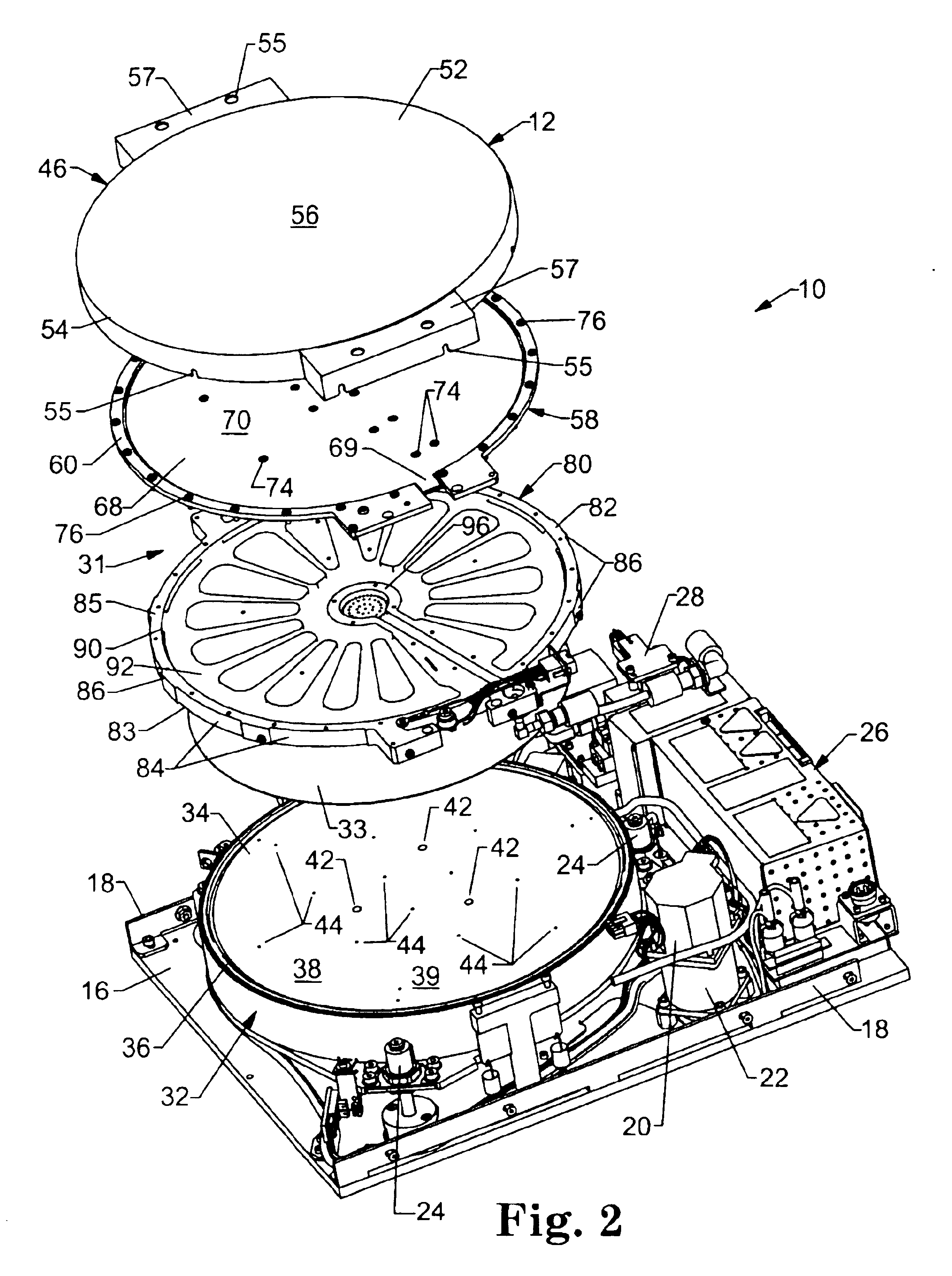

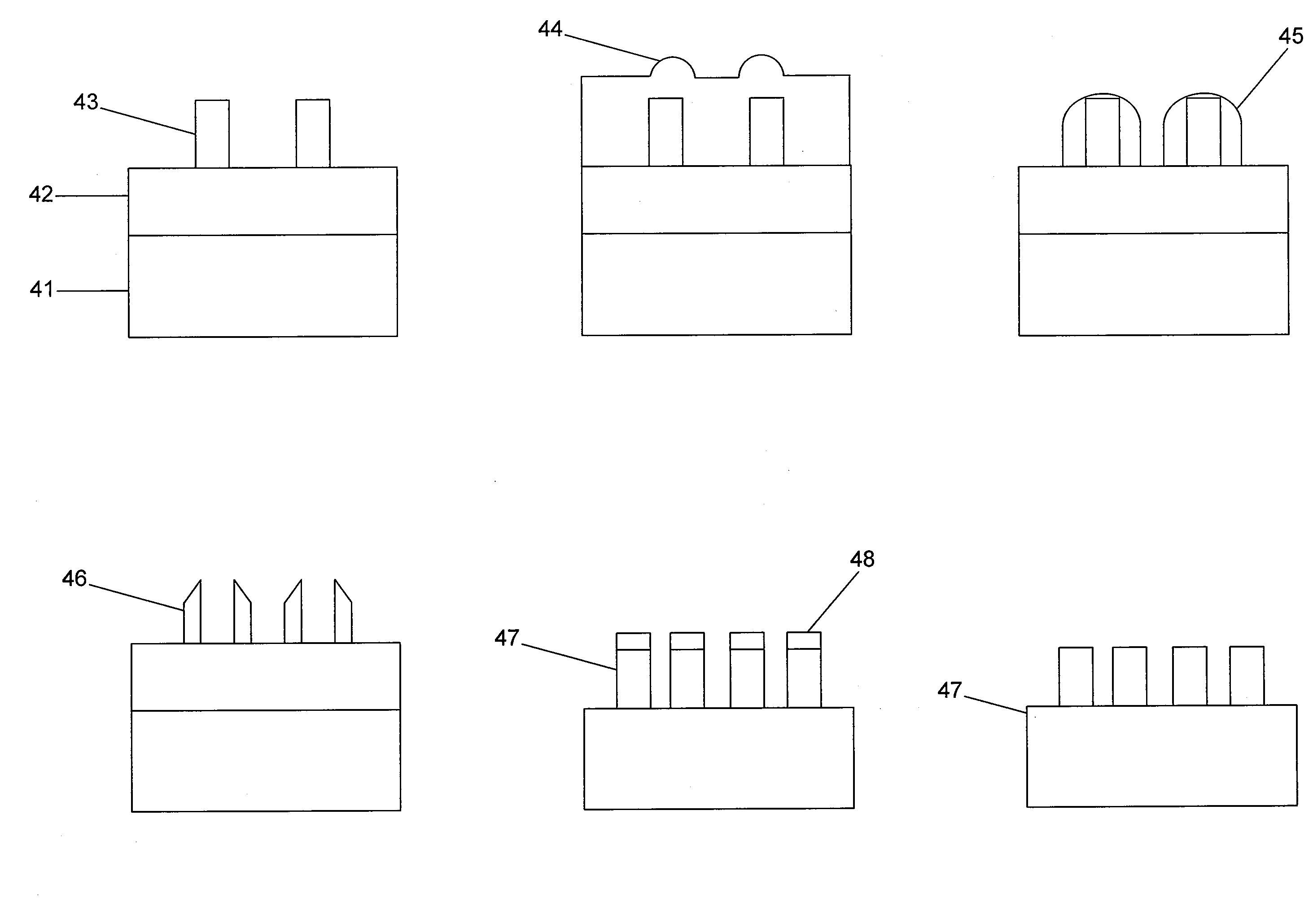

Thermal process station with heated lid

ActiveUS6884066B2Improve thermal uniformityImprove temperature uniformityCharge supportsSemiconductor/solid-state device manufacturingResistThermal energy

Methods and apparatuses to improve the temperature uniformity of a workpiece being processed on a heated platen of a thermal processing station. A heated platen is enclosed in a housing incorporating an additional heat source that uniformly outputs thermal energy into the process chamber in which the heated platen is positioned. In preferred embodiments, this heat source is positioned in the lid of the housing. It is additionally preferred that the heated lid includes features that provide a gas flow path to introduce to and / or purge gas from the process chamber. In terms of photoresist performance, the improved thermal uniformity provided by using such an additional heat source in the housing, e.g., in the lid, offers improved line width control and line uniformity across a wafer.

Owner:TEL EPION

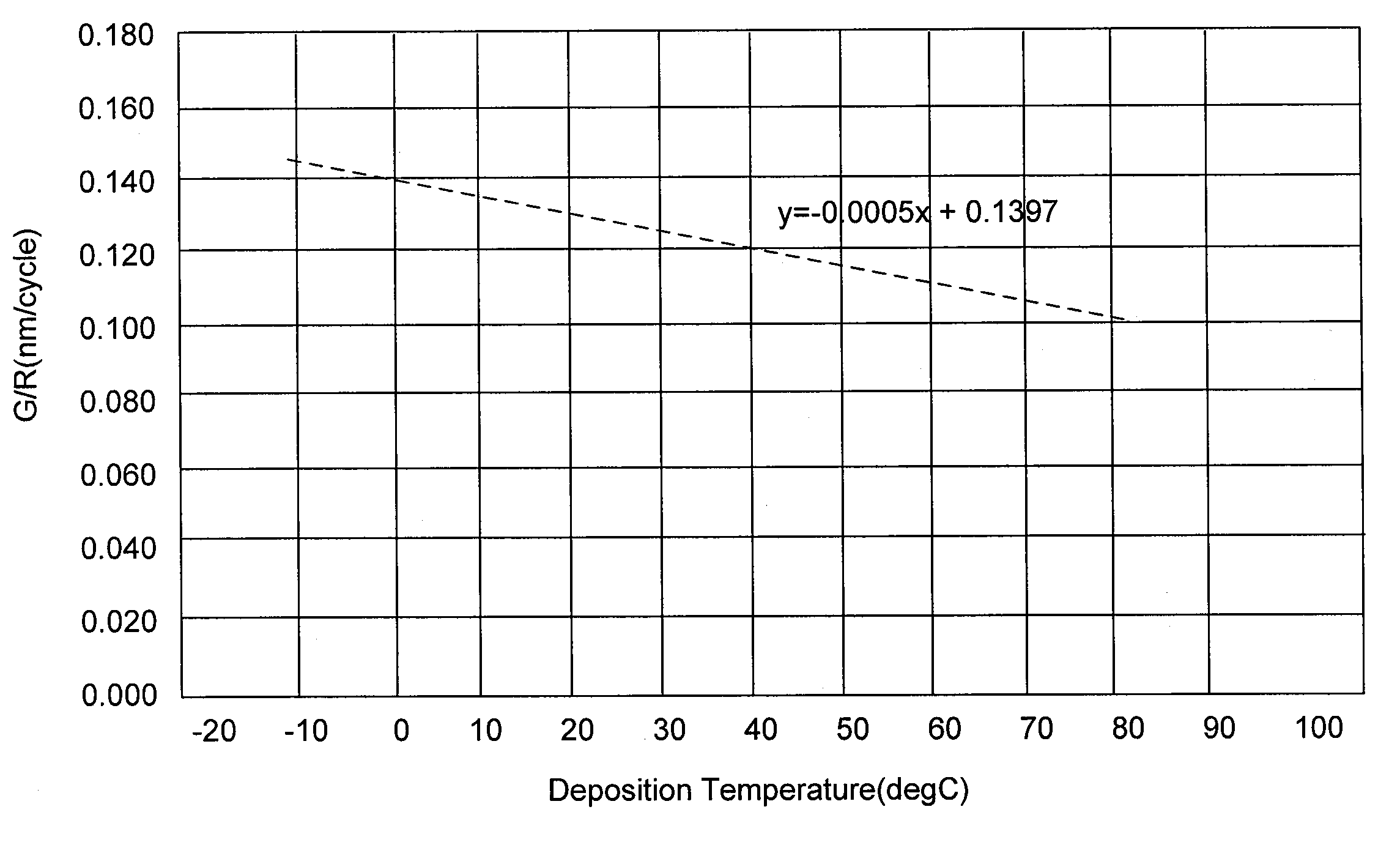

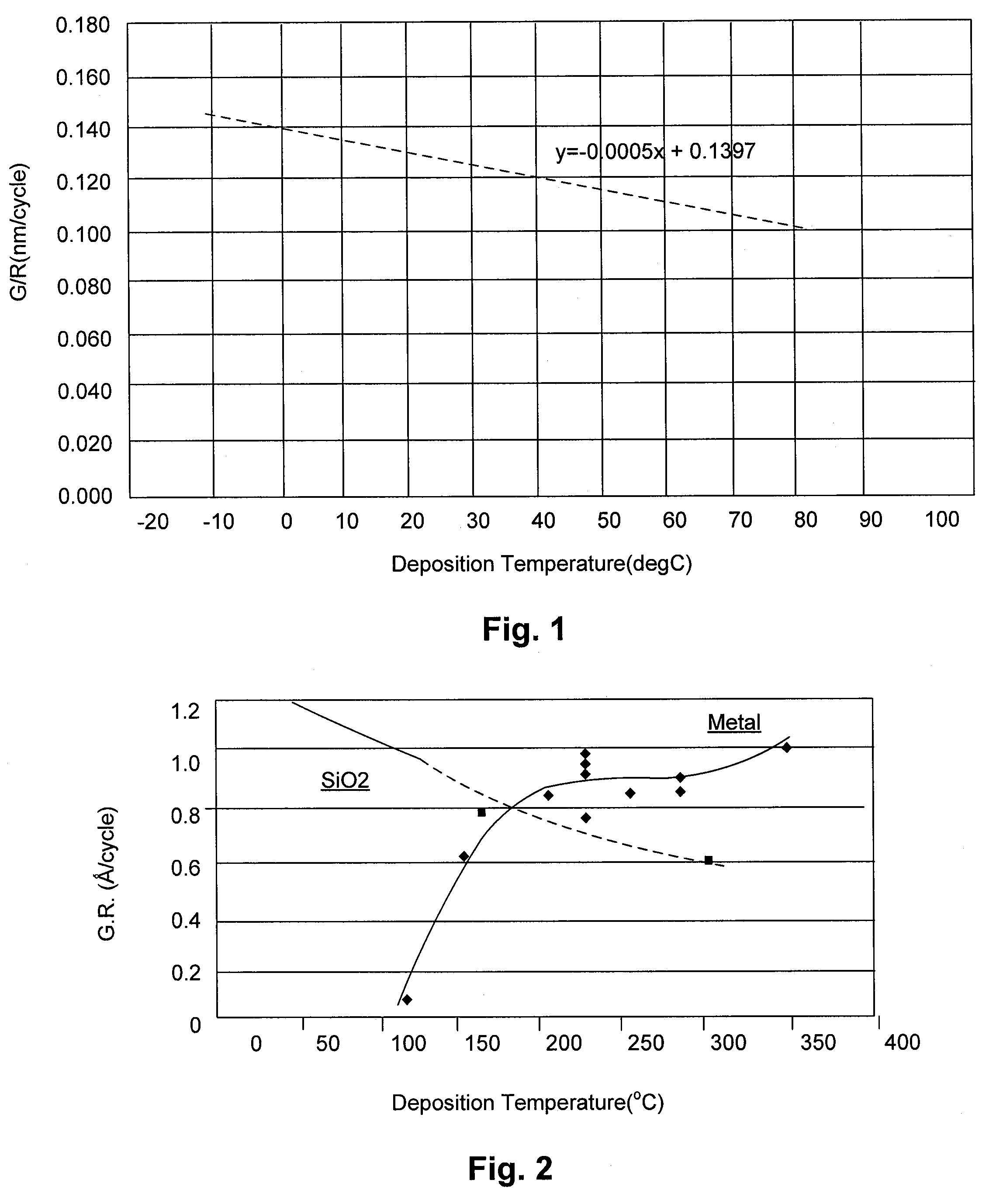

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

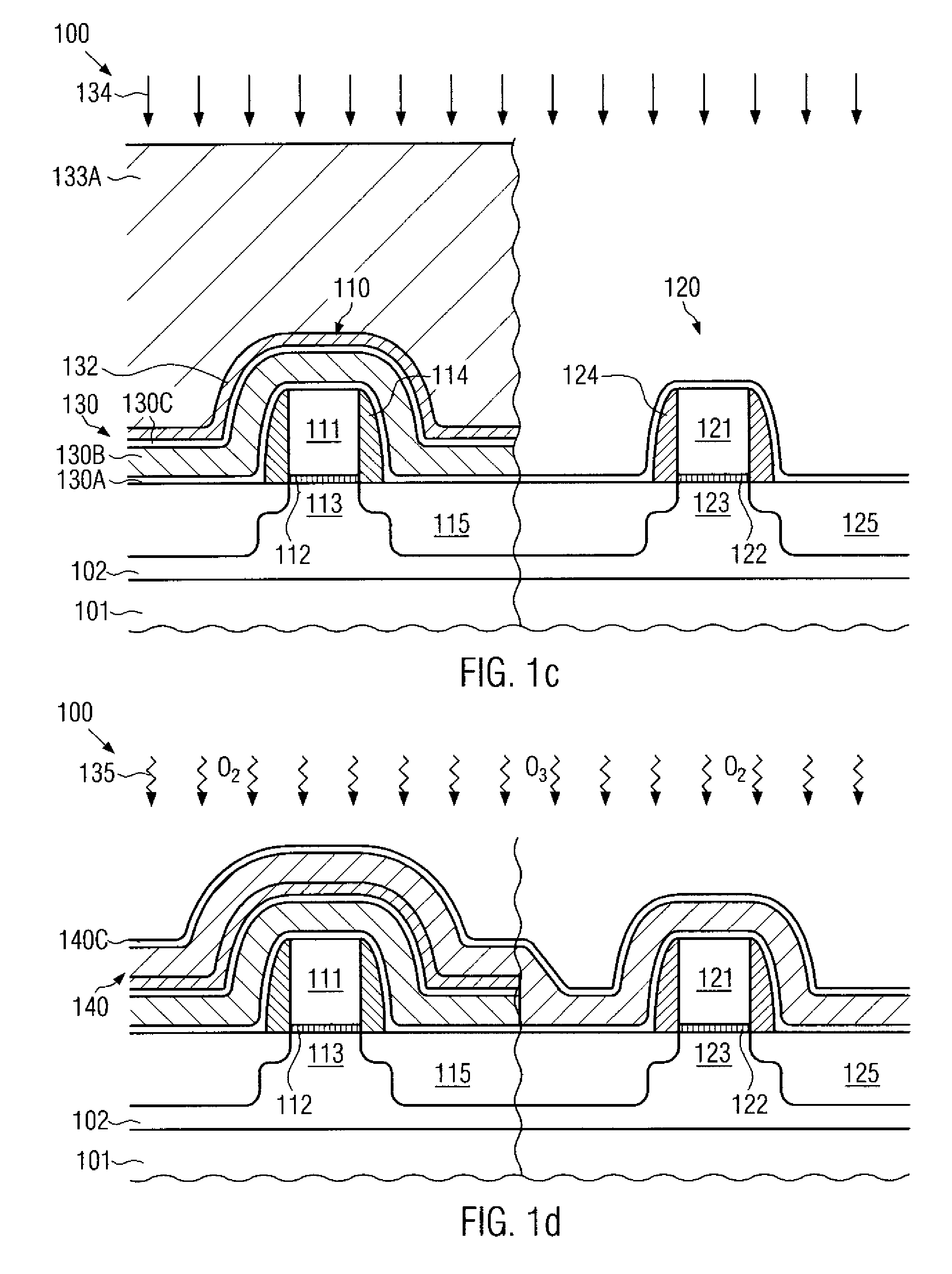

Method for reducing resist poisoning during patterning of silicon nitride layers in a semiconductor device

ActiveUS7550396B2Improve performanceReduce diffuseSemiconductor/solid-state device manufacturingSemiconductor devicesResistNitrogen

By performing a plasma treatment for efficiently sealing the surface of a stressed dielectric layer containing silicon nitride, an enhanced performance during the patterning of contact openings may be achieved, since nitrogen-induced resist poisoning may be significantly reduced during the selective patterning of stressed layers of different types of intrinsic stress.

Owner:TAIWAN SEMICON MFG CO LTD

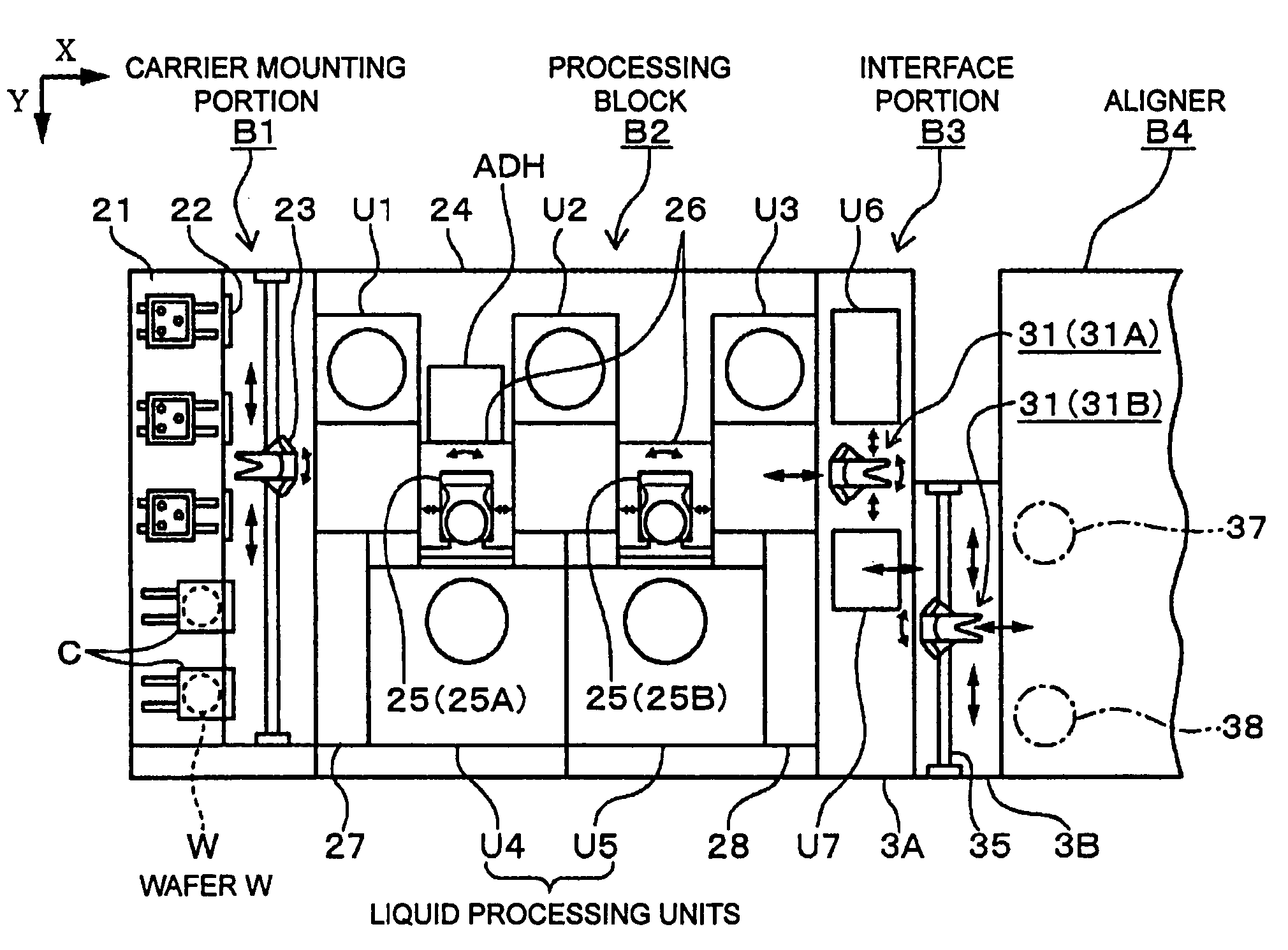

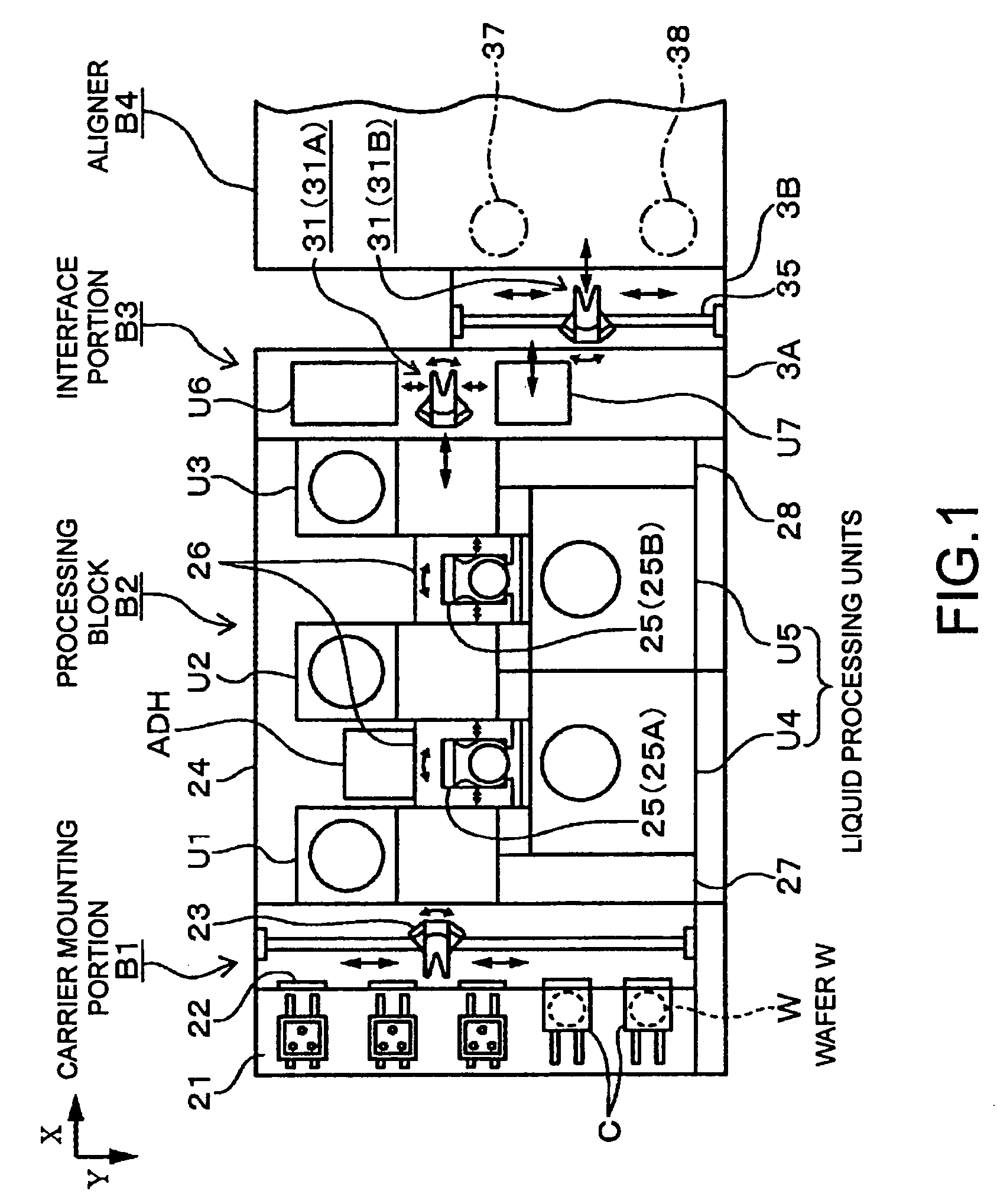

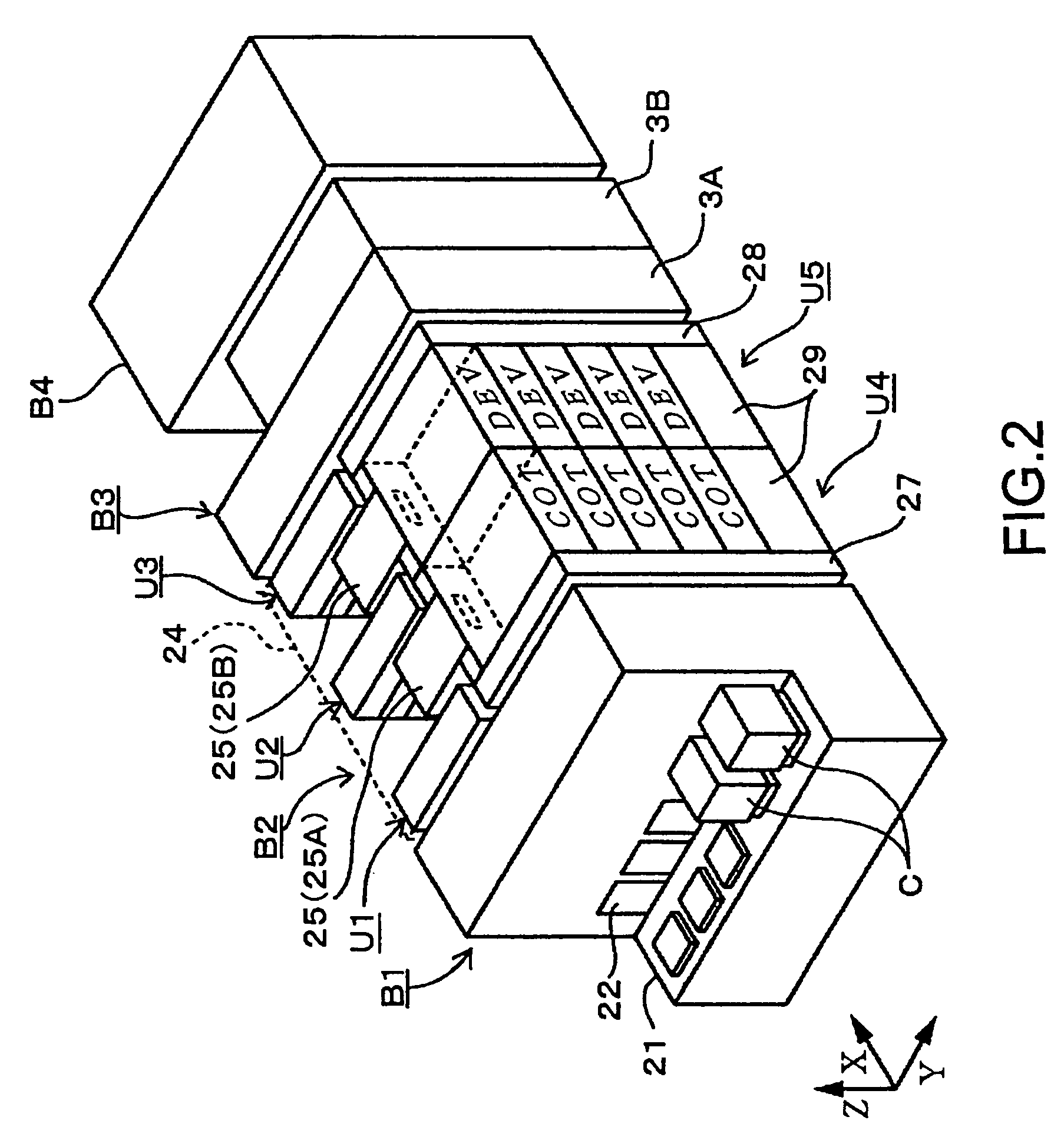

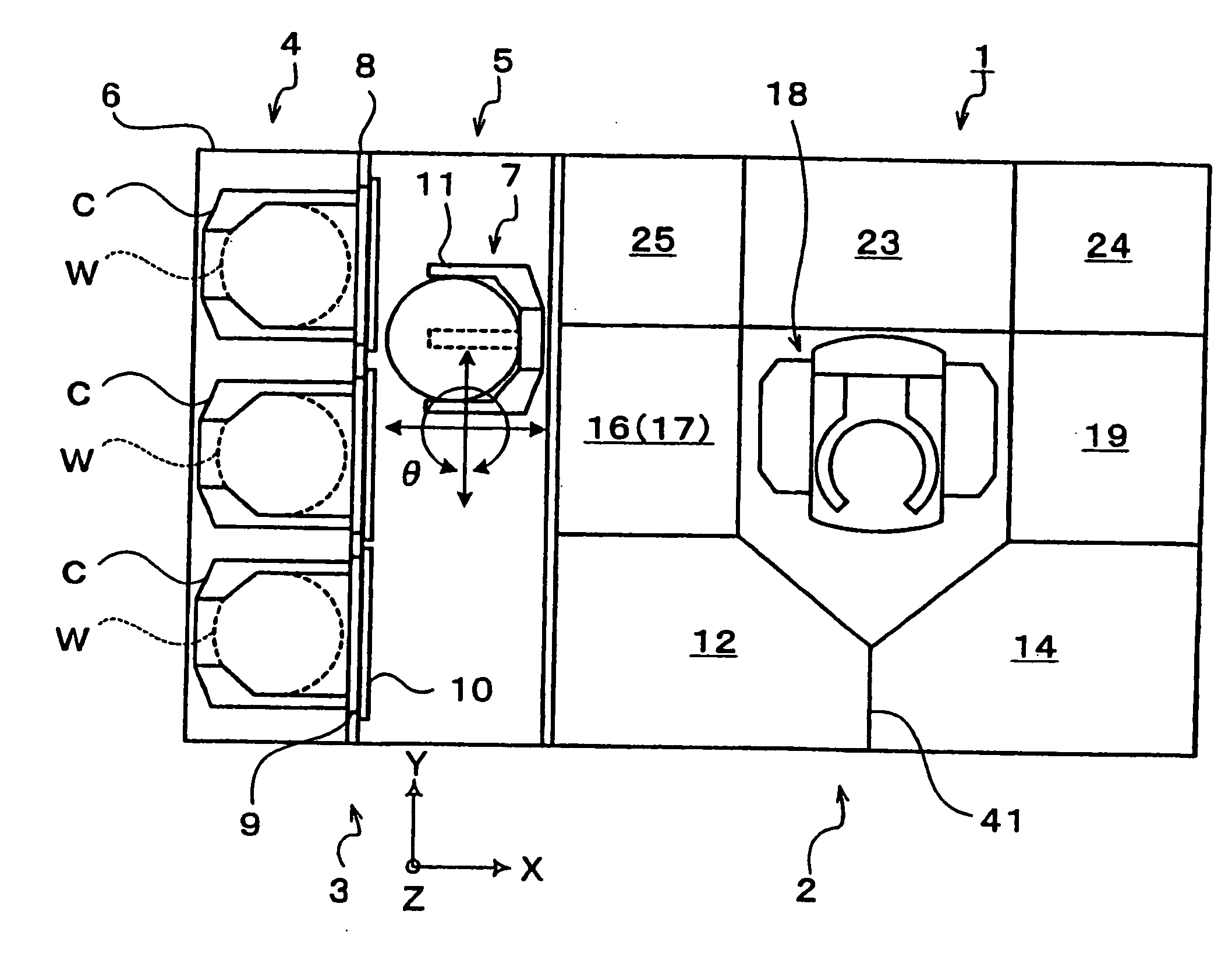

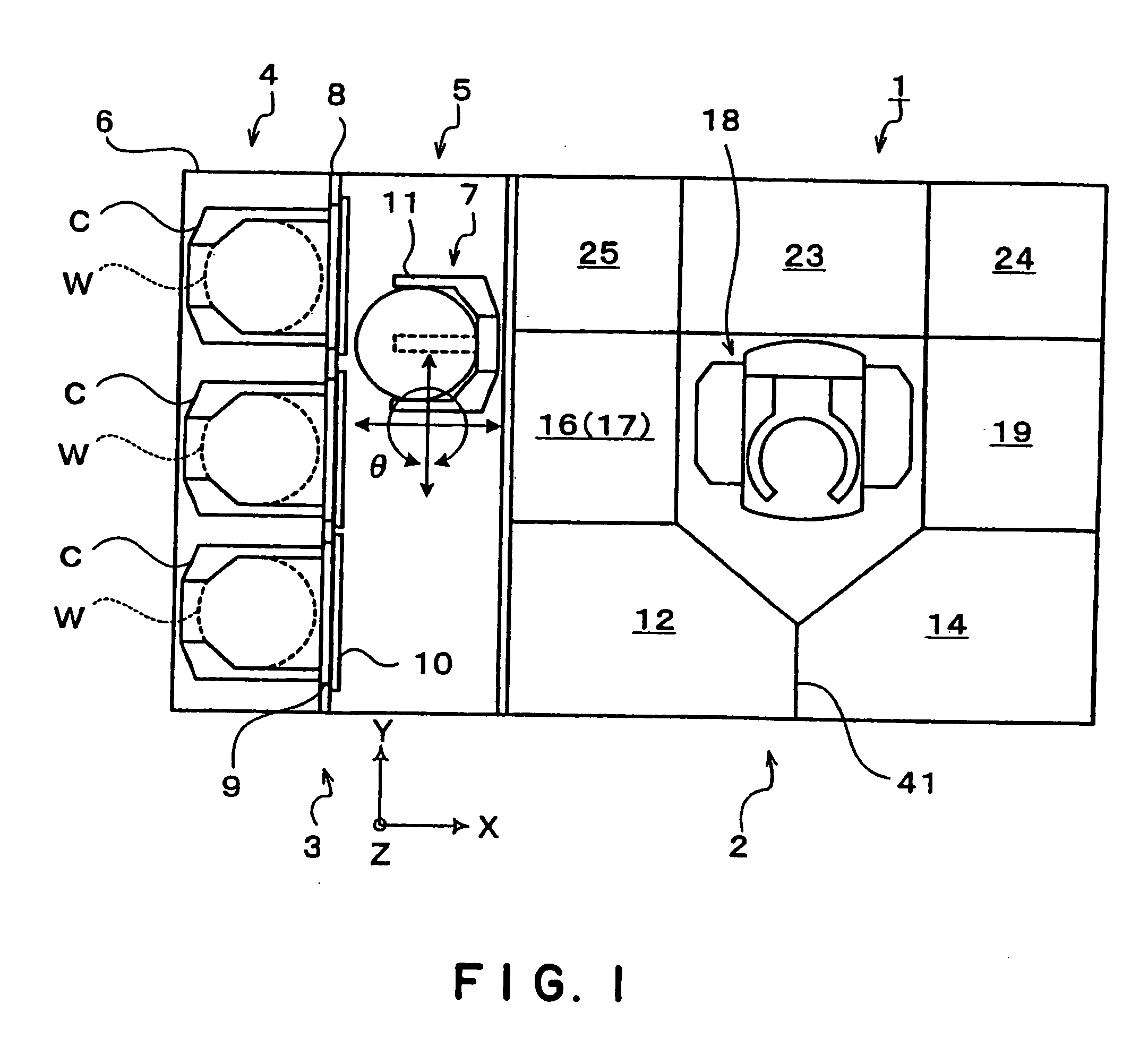

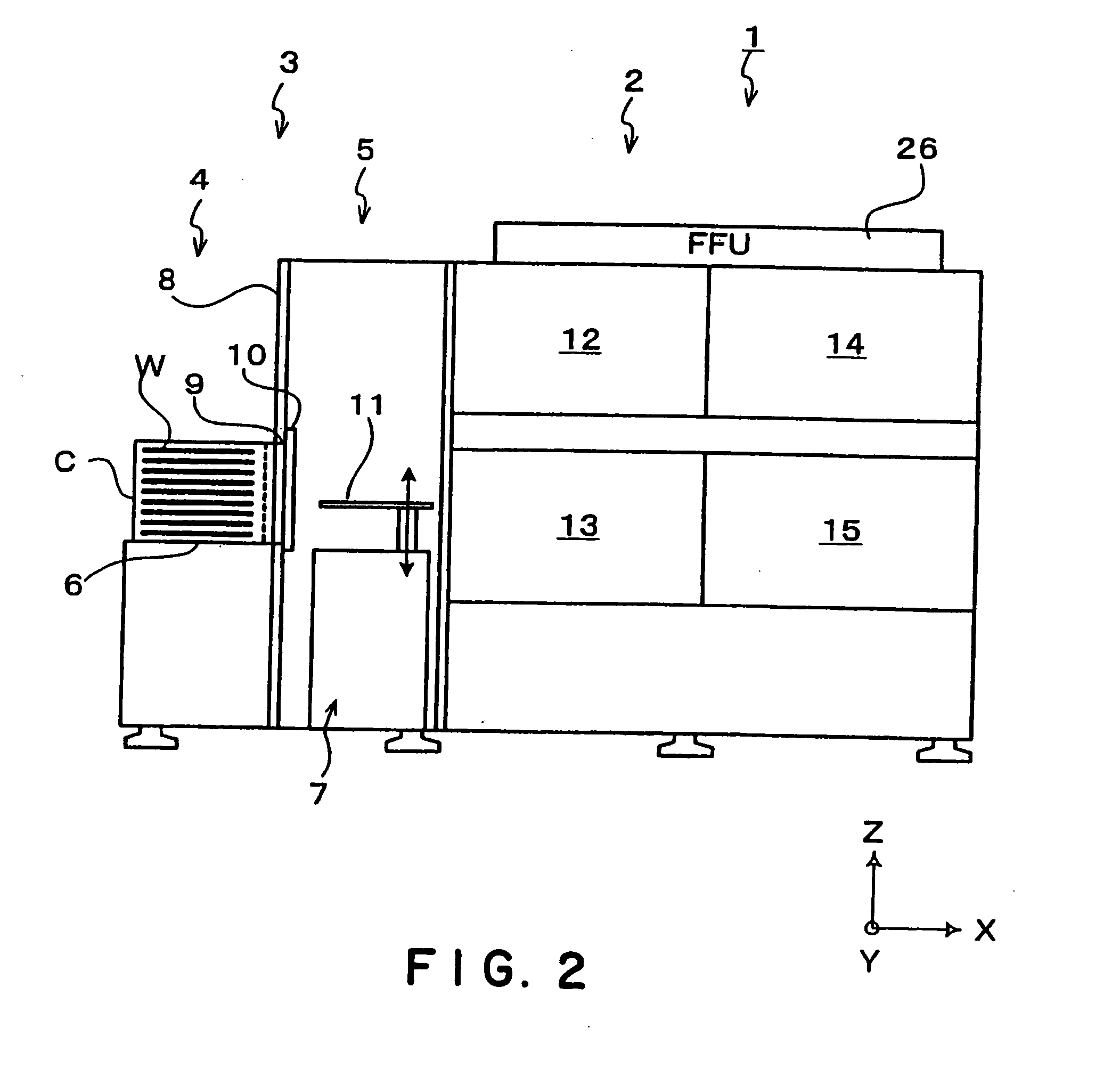

Substrate processing system, coating/developing apparatus, and substrate processing apparatus

InactiveUS7379785B2Substrates can be prevented from beingQuick uninstallSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistComputer module

In a coating and developing apparatus that forms a resist film on substrates such as semiconductor wafers, and develops substrates exposed by an aligner, times after the aligner unloads substrates until heating units (PEB) start heating the substrates are kept uniform. Exposed wafers are prevented from being left stagnant in an interface portion disposed between a region in which resist is coated and developed and the aligner. In the region in which resist is coated and developed, a first transferring means that successively executes transportation cycles to transfer substrates from upstream side modules to downstream side modules in a flow of processes of substrates. N heating units (PEB) are disposed (n is for example 5). Exposed wafers loaded into the heating units (PEB) are unloaded by the first transferring means after (n−1) cycles including the transferring cycle of the first transferring means have elapsed.

Owner:TOKYO ELECTRON LTD

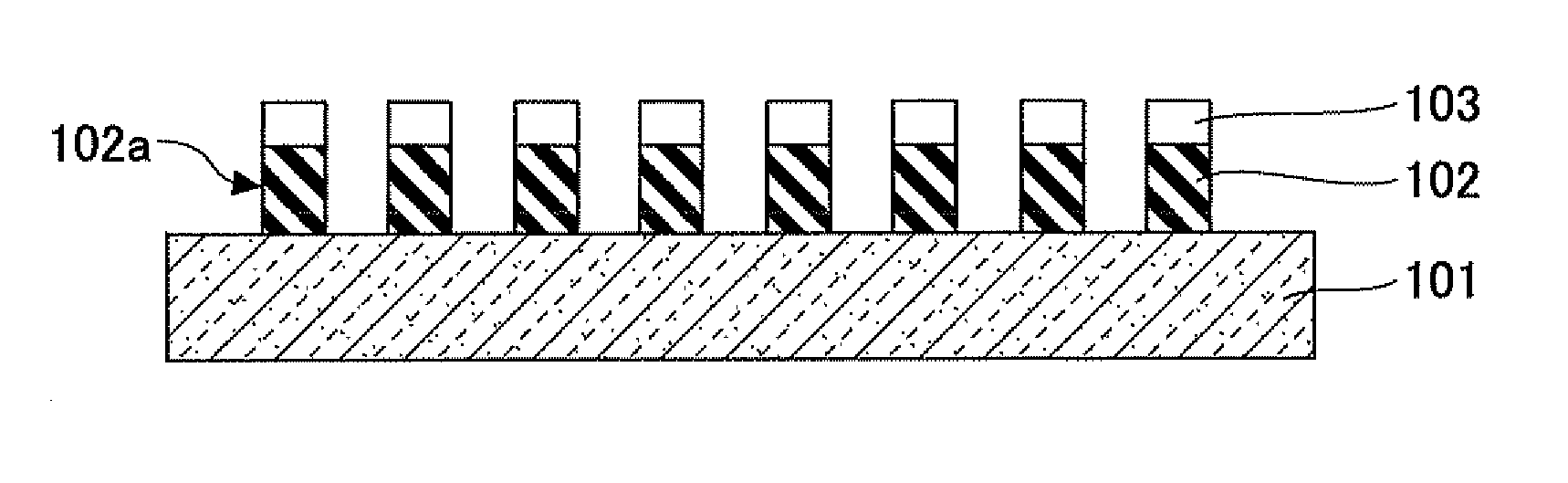

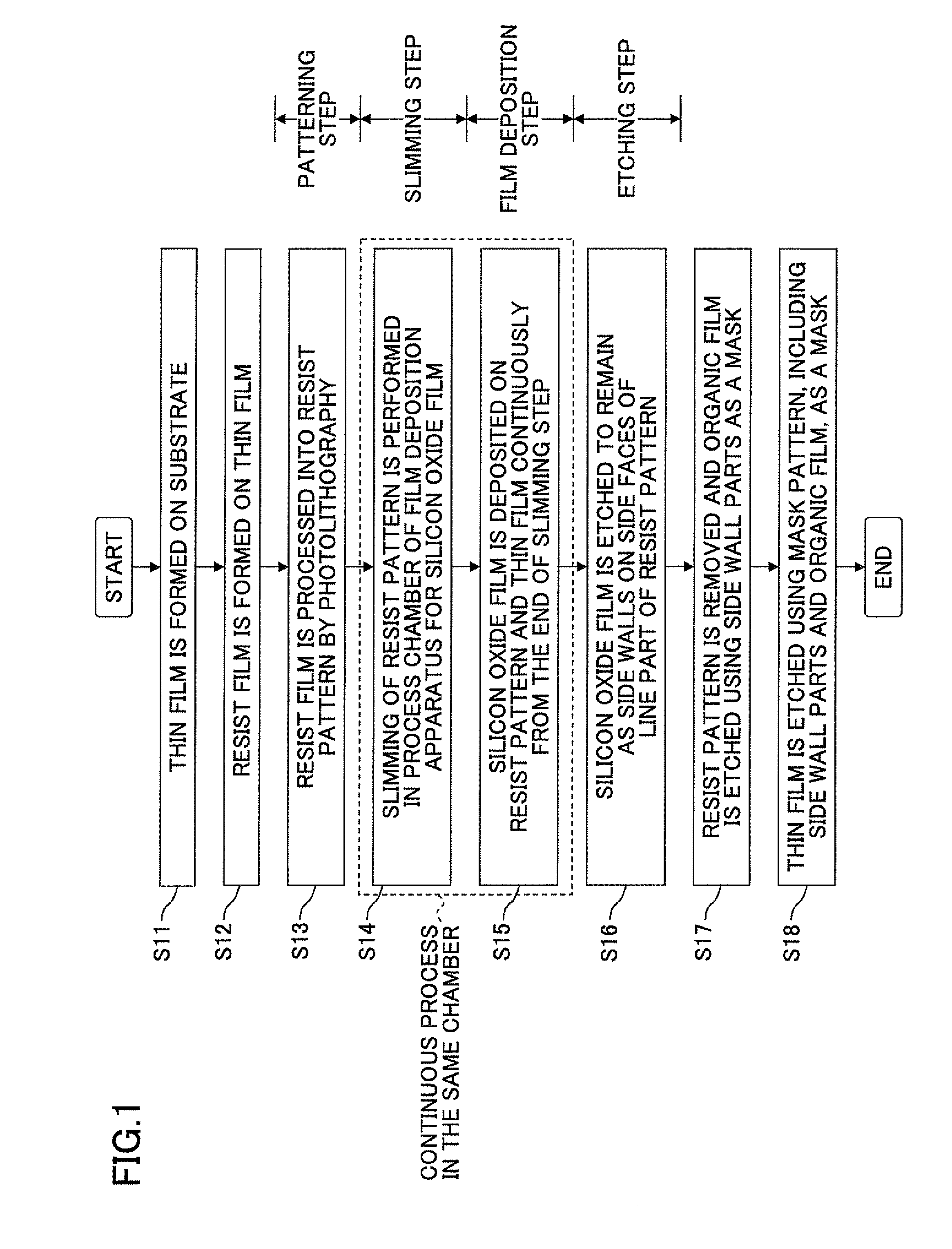

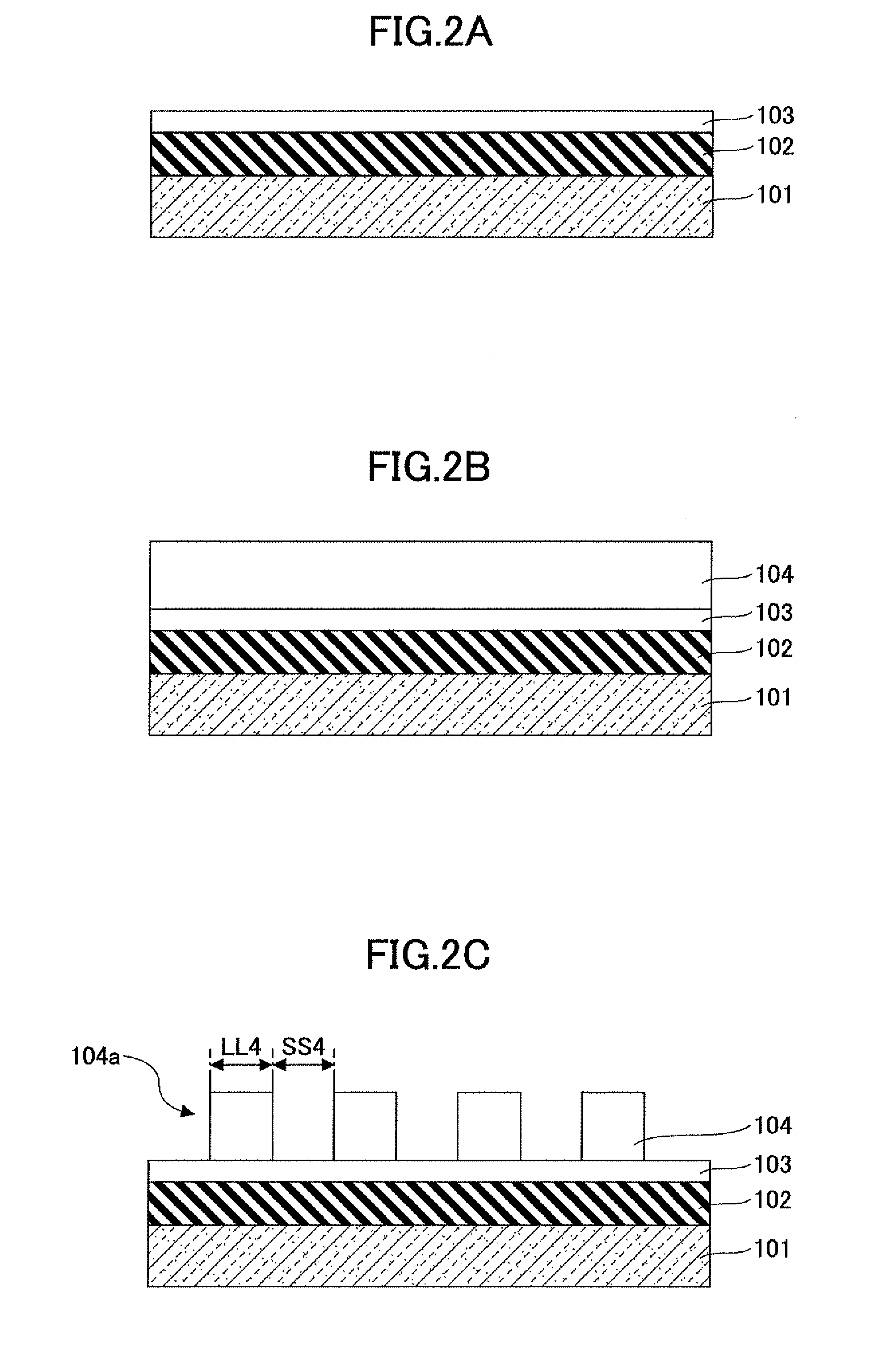

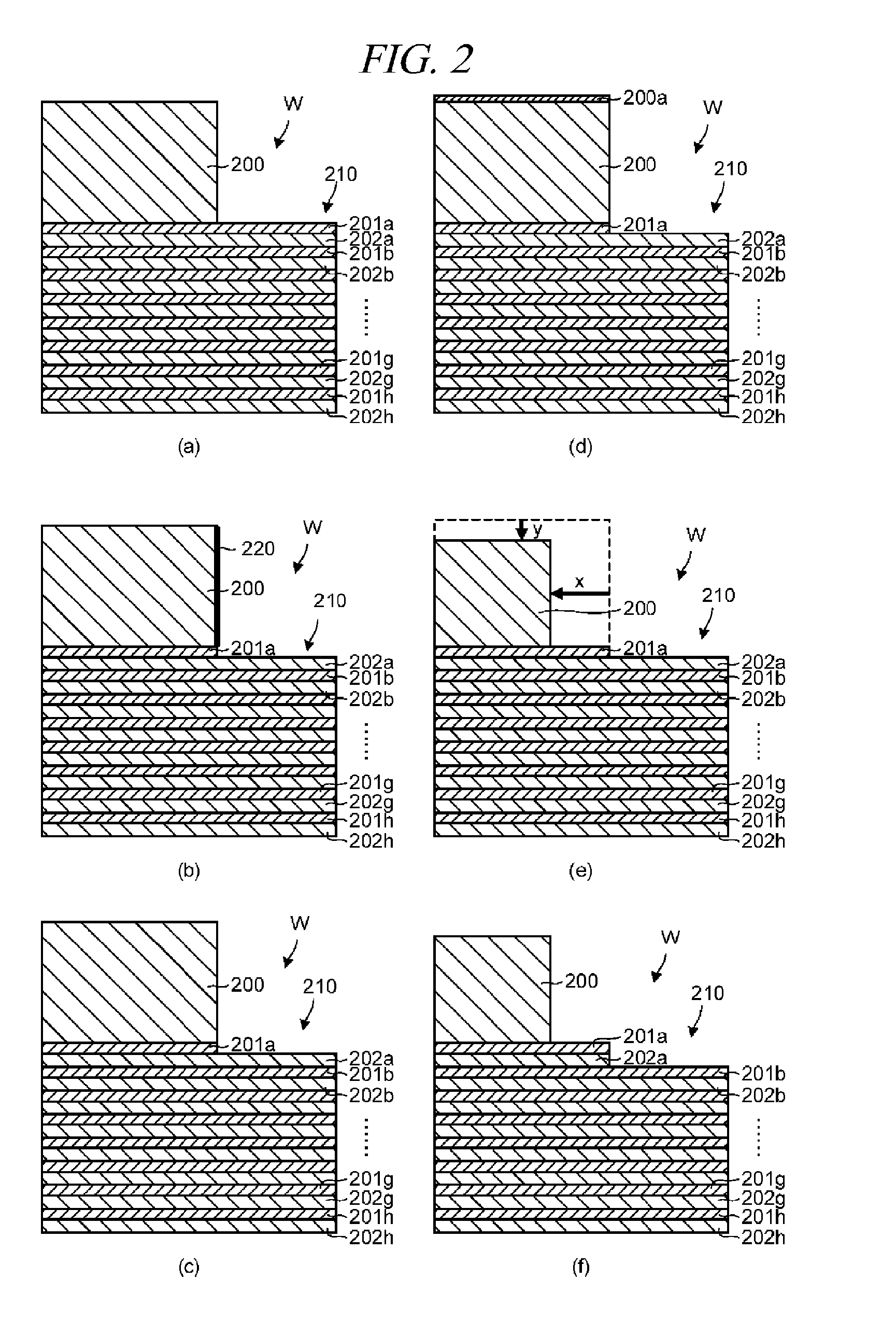

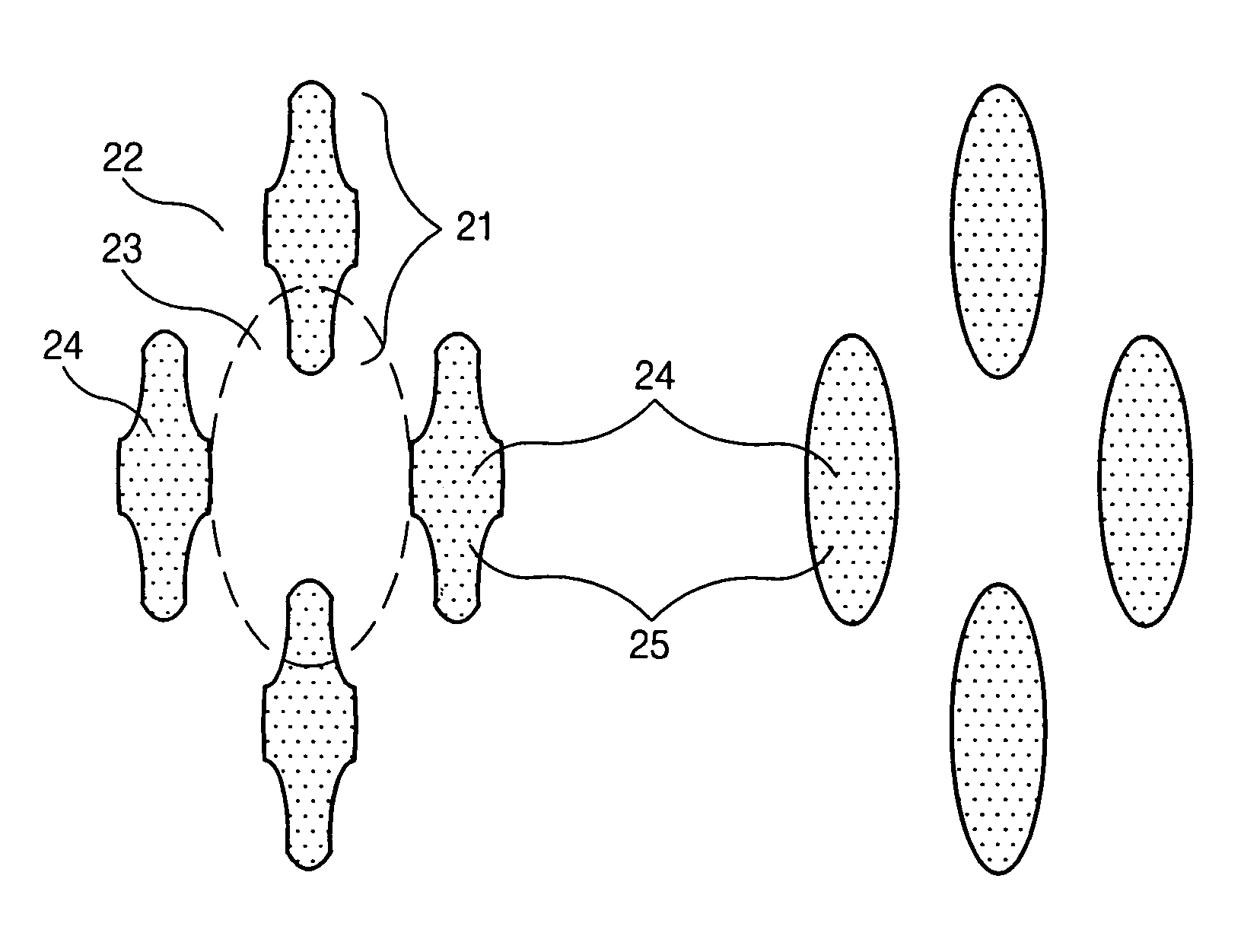

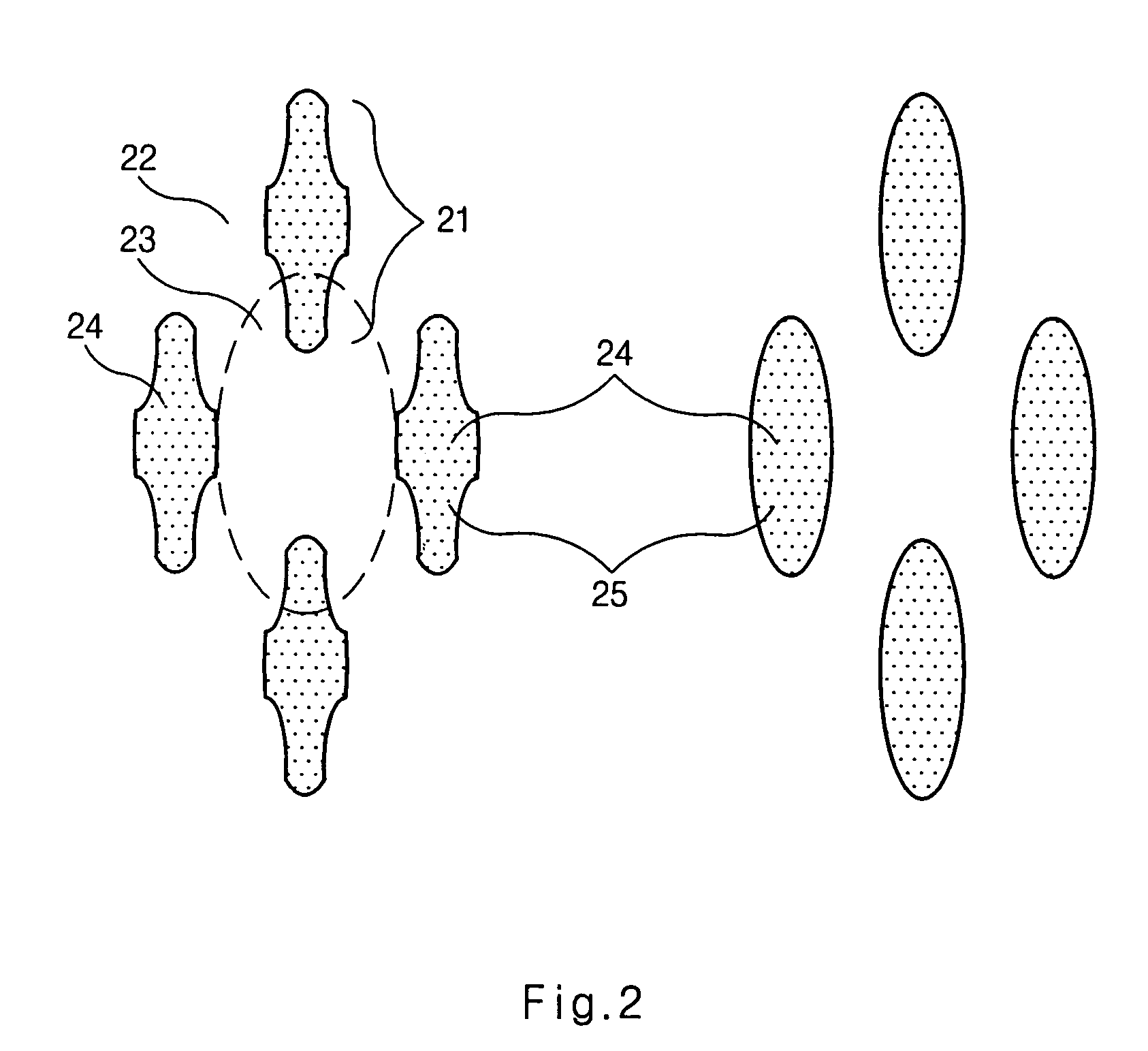

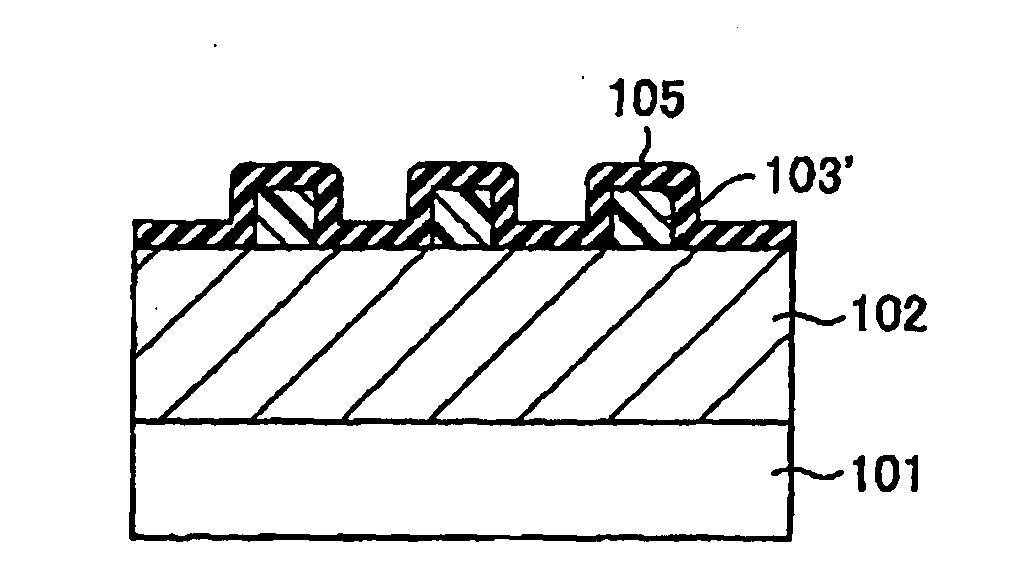

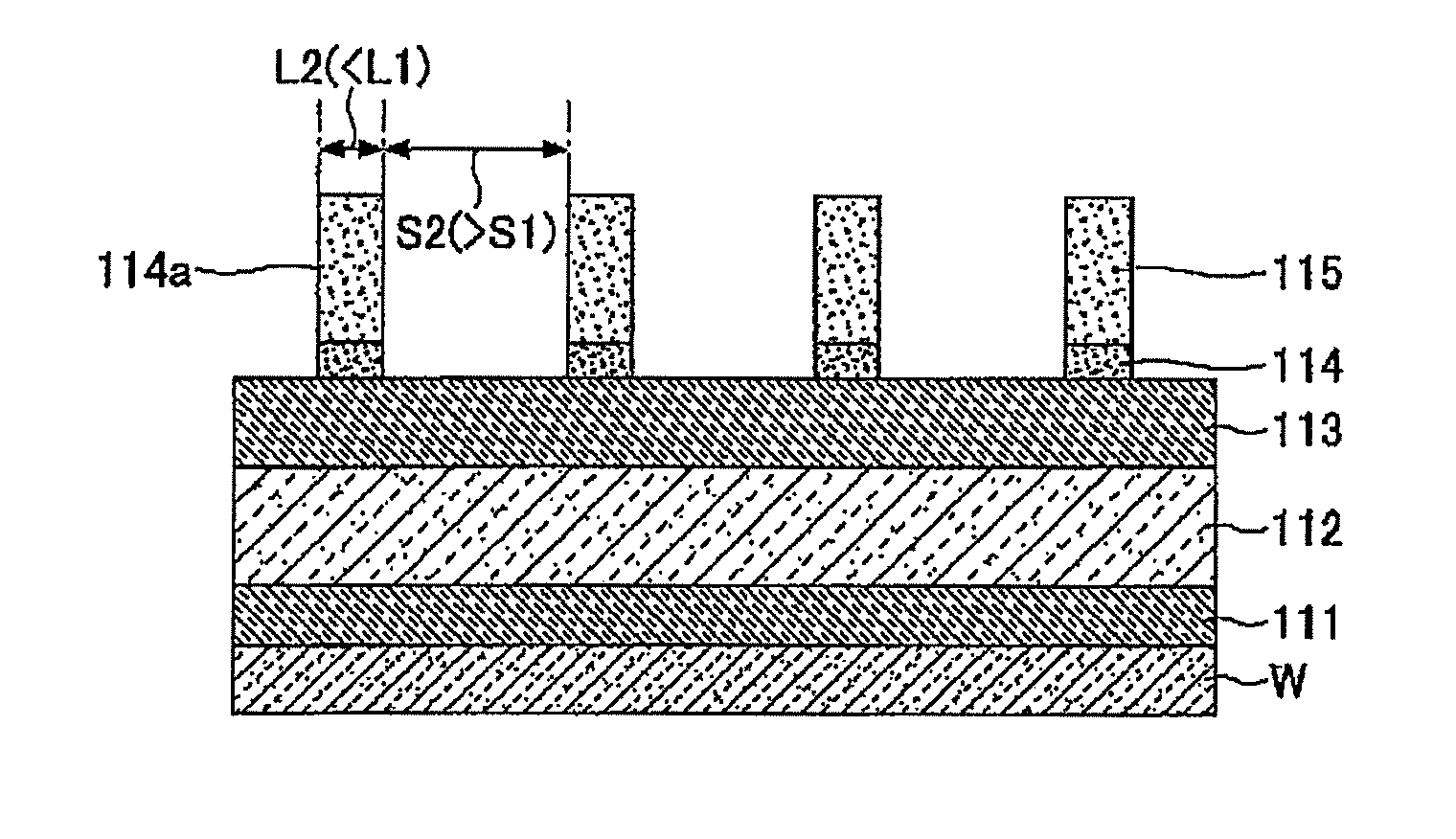

Mask pattern forming method, fine pattern forming method, and film deposition apparatus

ActiveUS20100081094A1Low costOptimizationElectric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

In a mask pattern forming method, a resist film is formed over a thin film, the resist film is processed into resist patterns having a predetermined pitch by photolithography, slimming of the resist patterns is performed, and an oxide film is formed on the thin film and the resist patterns after an end of the slimming step in a film deposition apparatus by supplying a source gas and an oxygen radical or an oxygen-containing gas. In the mask pattern forming method, the slimming and the oxide film forming are continuously performed in the film deposition apparatus.

Owner:TOKYO ELECTRON LTD

Interconnect with low dielectric constant insulators for semiconductor integrated circuit manufacturing

InactiveUS6187672B1Semiconductor/solid-state device manufacturingResistIntegrated circuit manufacturing

A method is provided for forming an improved interconnect structure on a semiconductor body. A first metal layer is deposited on the semiconductor body. A sacrificial layer having a height is deposited on the first metal layer. The sacrificial layer and the metal layer are patterned to form separate metal lines with the sacrificial layer remaining on said metal lines. A low-k material is then deposited to fill the gaps between metal lines and to cover the sacrificial layer. The low-k material is then removed to a level within the height of the sacrificial layer. The sacrificial layer is then removed. A protective layer is deposited on top of the metal lines and the low-k material. A dielectric layer is deposited over the protective layer. The protective layer protects the low-k material from attack by chemicals utilized by subsequent process steps to etch vias in the dielectric layer, to strip photo-resist, and to clean the vias. The protective layer is then selectively etched away to make contact between a via plug and the metal lines.

Owner:NEWPORT FAB

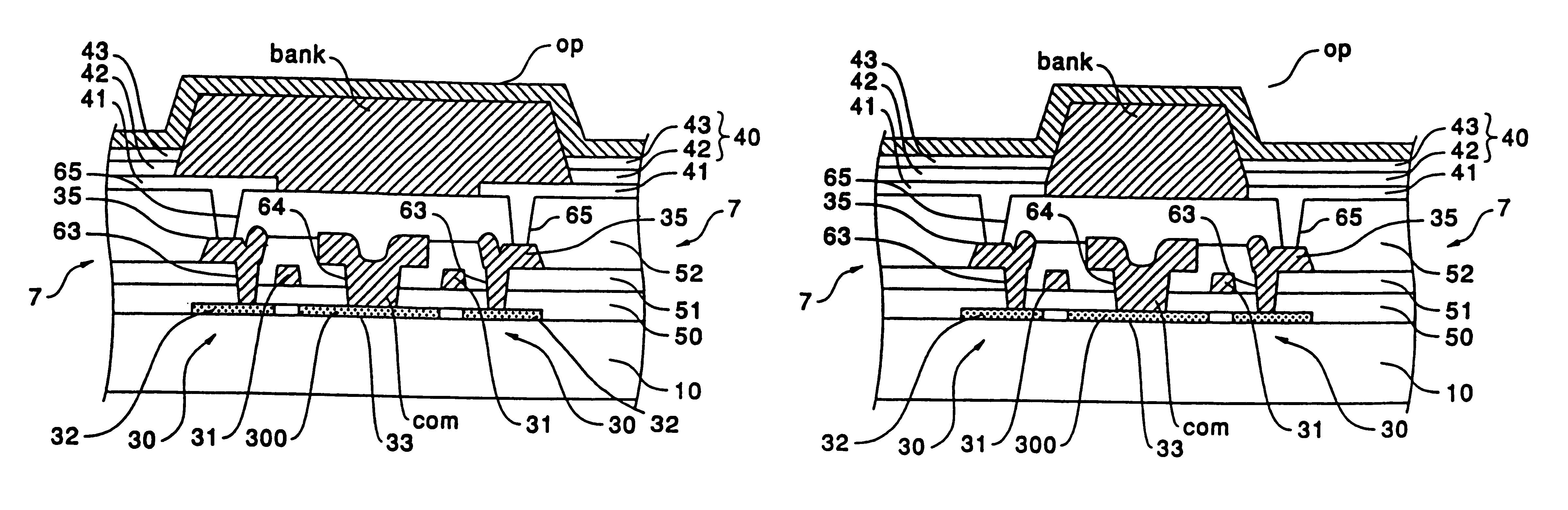

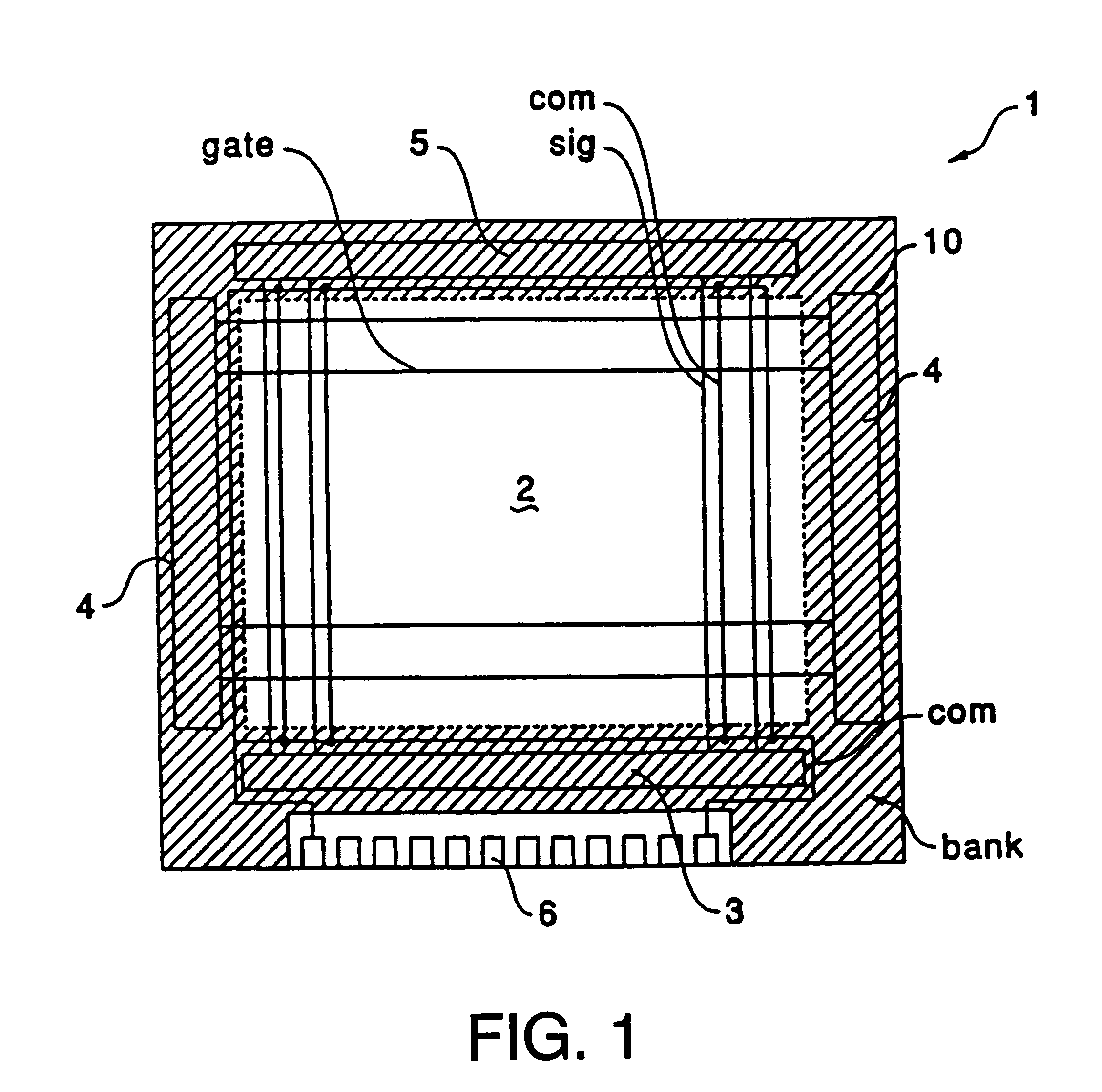

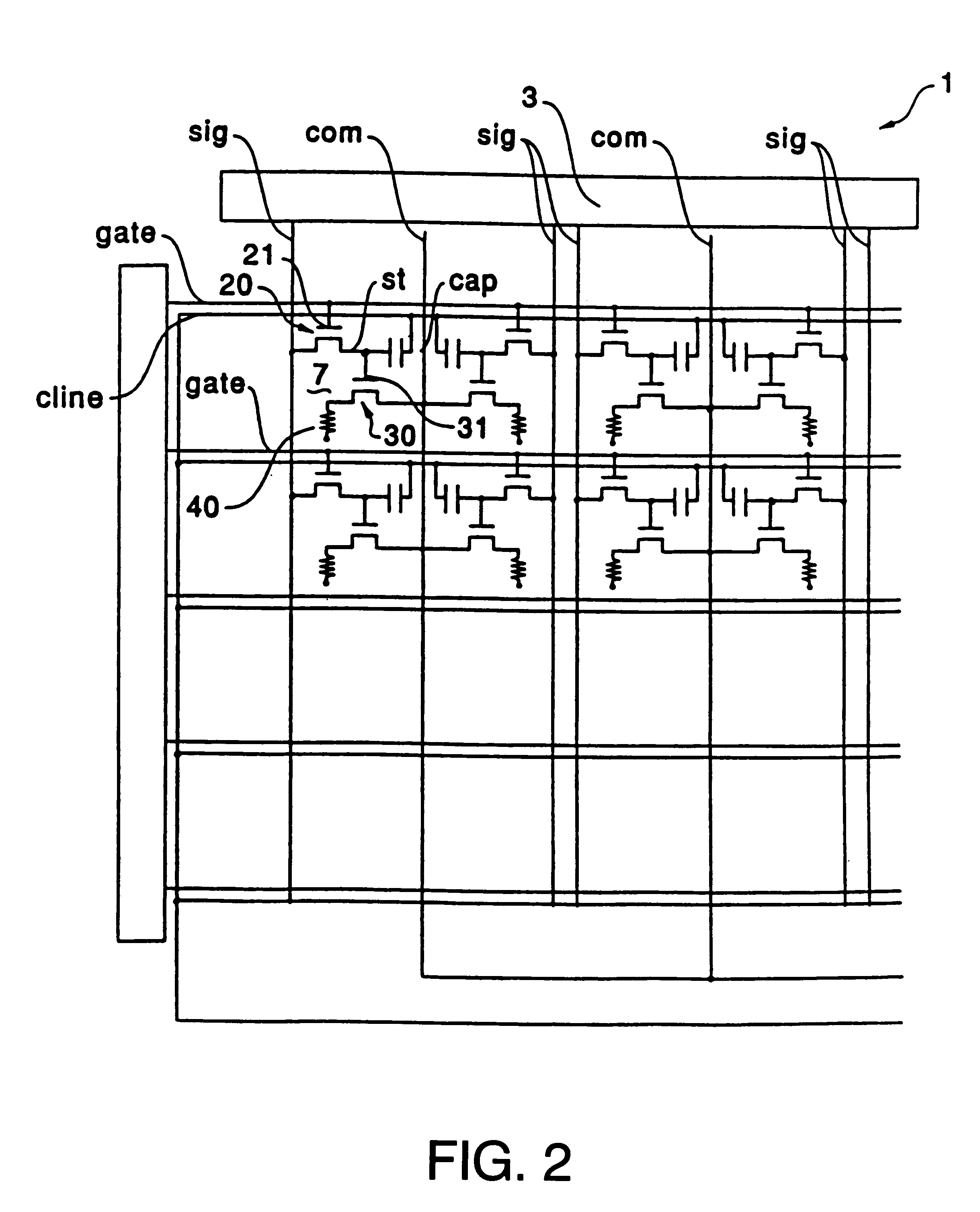

Display device

The invention provides a display device in which parasitic capacitance associated with data lines and driving circuits is prevented using a bank layer whose primary purpose is to define areas on a substrate in which an organic semiconductor film is formed. When the organic semiconductor film for forming a luminescent element such as an electroluminescent element or an LED is formed is formed in pixel regions (7), the organic semiconductor film is formed in the areas surrounded by the bank layer (bank) formed of a black resist. The bank layer (bank) is also formed between an opposite electrode (op) and data lines (sig) for supplying an image signal to first TFTs (20) and holding capacitors (cap) in the pixel regions (7) thereby preventing parasitic capacitance associated with the data lines (sig).

Owner:INTELLECTUAL KEYSTONE TECH LLC

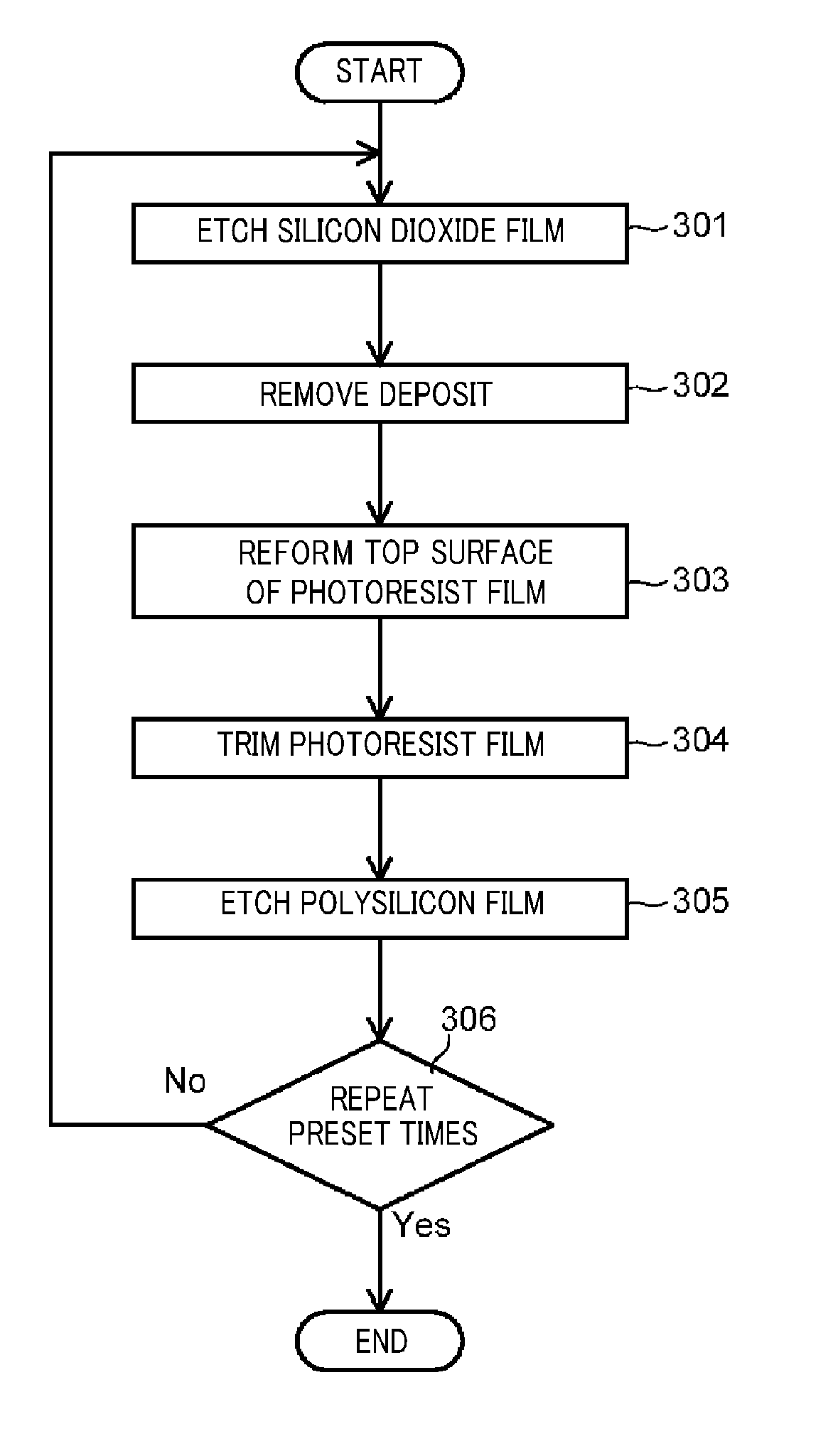

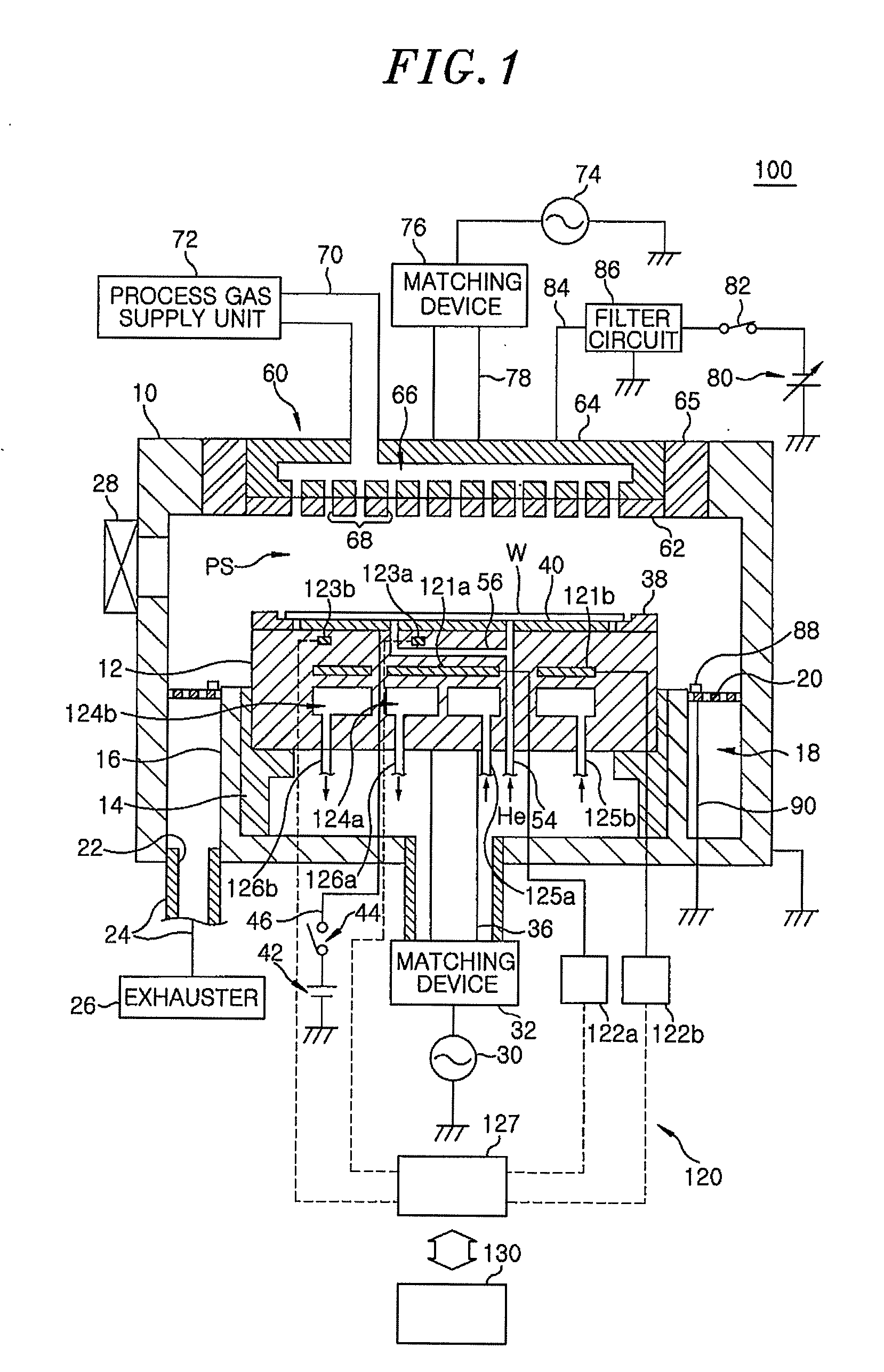

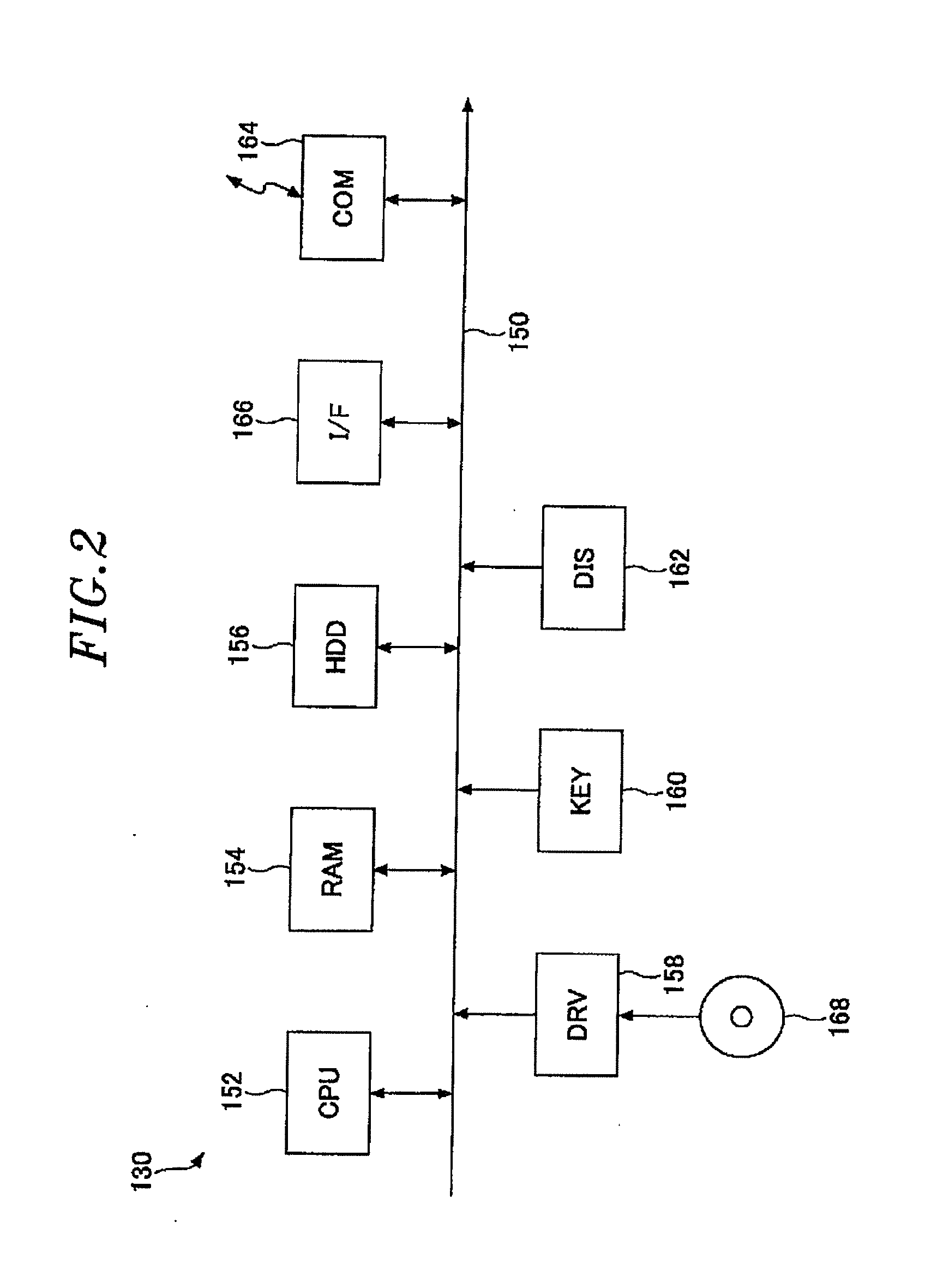

Semiconductor device manufacturing method and computer-readable storage medium

ActiveUS20120225561A1Efficiently formedLiquid surface applicatorsElectric discharge tubesResistHydrogen

There is provided a semiconductor device manufacturing method for forming a step-shaped structure in a substrate by etching the substrate having thereon a multilayer film and a photoresist film on the multilayer film and serving as an etching mask. The multilayer film is formed by alternately layering a first film having a first permittivity and a second film having a second permittivity different from the first permittivity. The method includes a first process for plasma-etching the first film by using the photoresist film as a mask; a second process for exposing the photoresist film to hydrogen-containing plasma; a third process for trimming the photoresist film; and a fourth process for etching the second film by using the trimmed photoresist film and the plasma-etched first film as a mask. The step-shaped structure is formed in the multilayer film by repeatedly performing the first process to the fourth process in this sequence.

Owner:TOKYO ELECTRON LTD

Cleaning solution for photoresist and method for forming pattern using the same

ActiveUS7238653B2Use cleanOrganic detergent compounding agentsTransportation and packagingResistAlcohol

Cleaning solutions for photoresist are disclosed which are useful for cleaning a semiconductor substrate in the last step of development when photoresist patterns are formed. Also, methods for forming photoresist patterns using the same are disclosed. The disclosed cleaning solution comprises H2O as a solution, a surfactant which is phosphate-alcoholamine salt represented by Formula 1, and an alcohol compound. The disclosed cleaning solution has lower surface tension than that of distilled water which has been used for conventional cleaning solutions, thereby improving resistance to photoresist pattern collapse and stabilizing the photoresist pattern formation.wherein R, x, y, z, a and b are as defined in the specification.

Owner:SK HYNIX INC

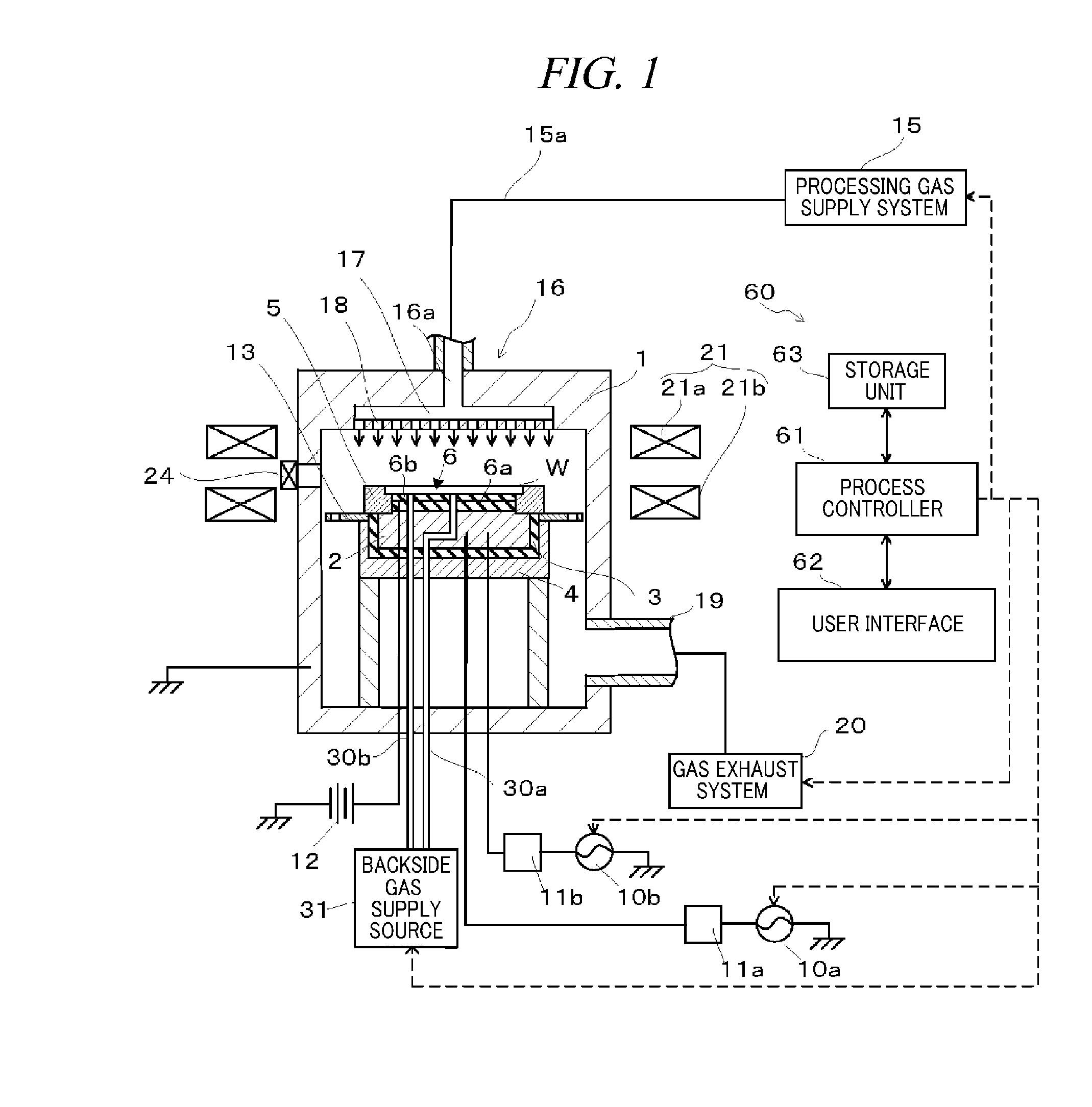

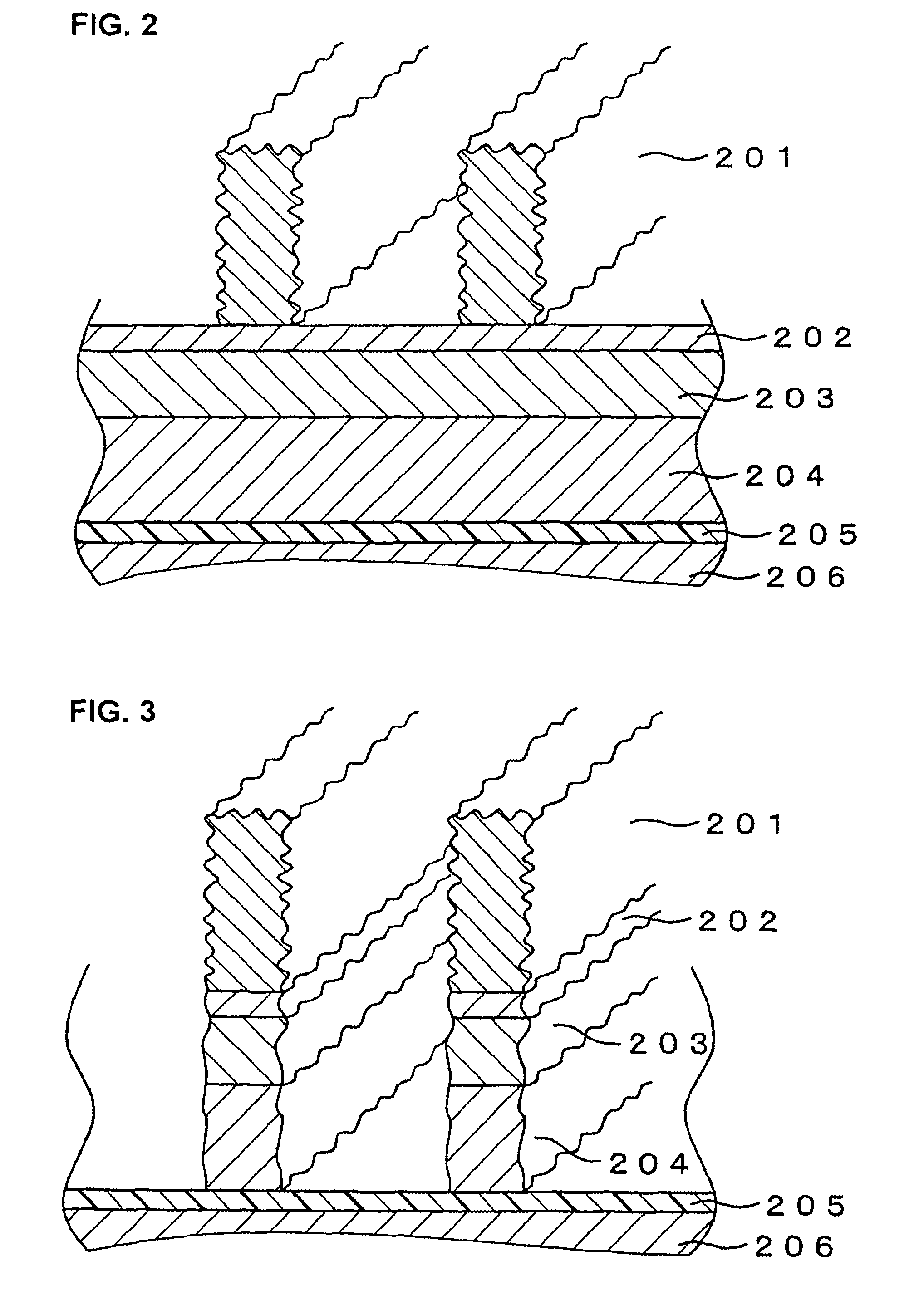

Plasma processing method

ActiveUS8497213B2Preventing deterioration of semiconductor device performanceReduce roughnessDecorative surface effectsSemiconductor/solid-state device manufacturingResistNitrogen gas

The invention provides a method for subjecting laminated thin films disposed below a photoresist mask pattern to plasma processing, wherein the roughness on the side walls of the formed pattern is reduced, and the LER and LWR are reduced. When etching a material to be processed to form a gate electrode including thin films such as a gate insulating film 205, a conducting layer 204, a mask layer 203 and an antireflection film 202 laminated on a semiconductor substrate 206 and a photoresist mask pattern 201 disposed on the antireflection film, prior to etching the mask pattern 201, plasma is generated from nitrogen gas or a mixed gas including nitrogen gas and deposition gas to subject the mask pattern 201 to a plasma curing process so as to reduce the roughness on the surface and side walls of the mask pattern 201, and then the laminated thin films 202, 203 and 204 disposed below the mask pattern 201 are subjected to a plasma etching process.

Owner:HITACHI HIGH-TECH CORP

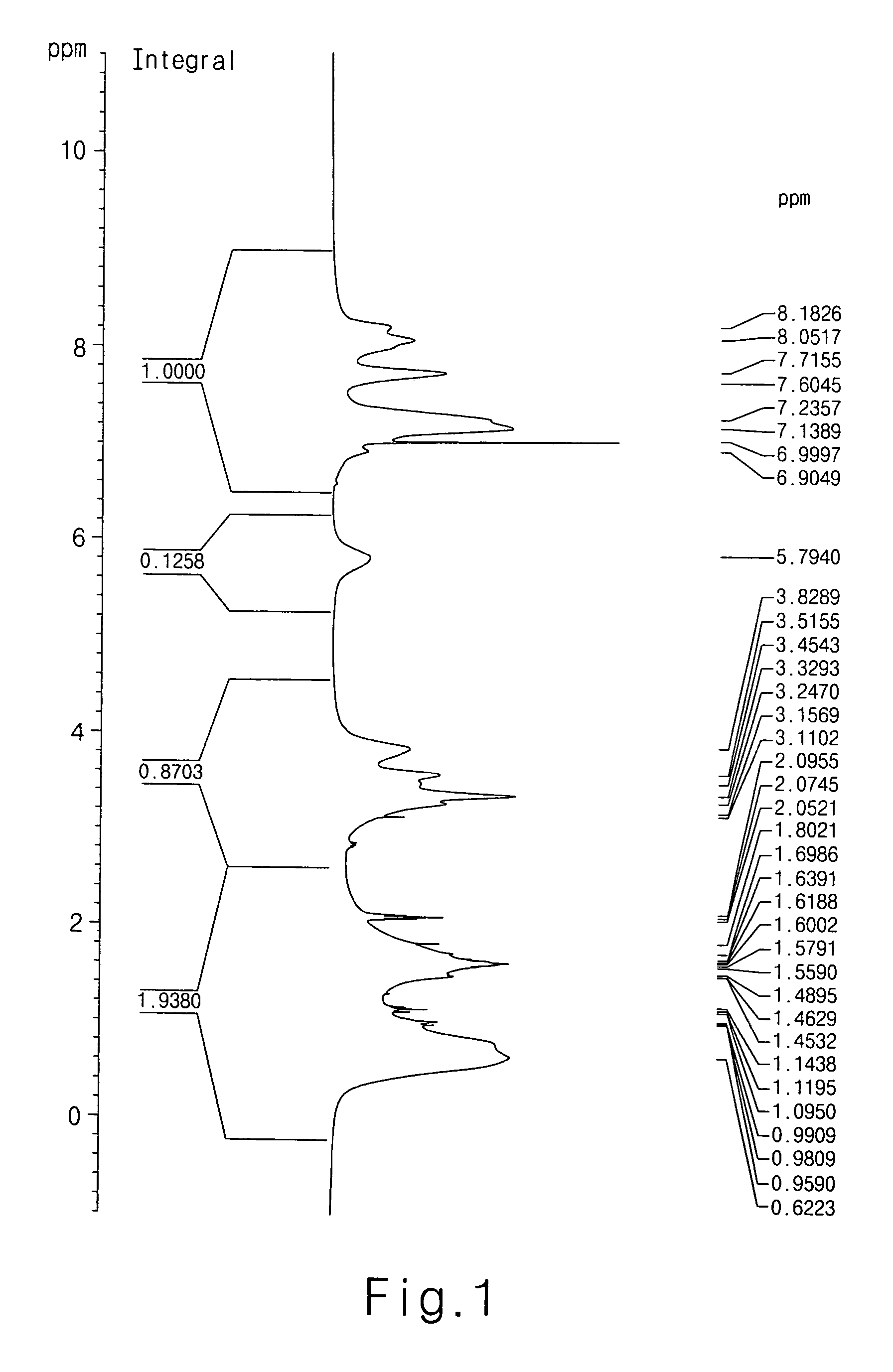

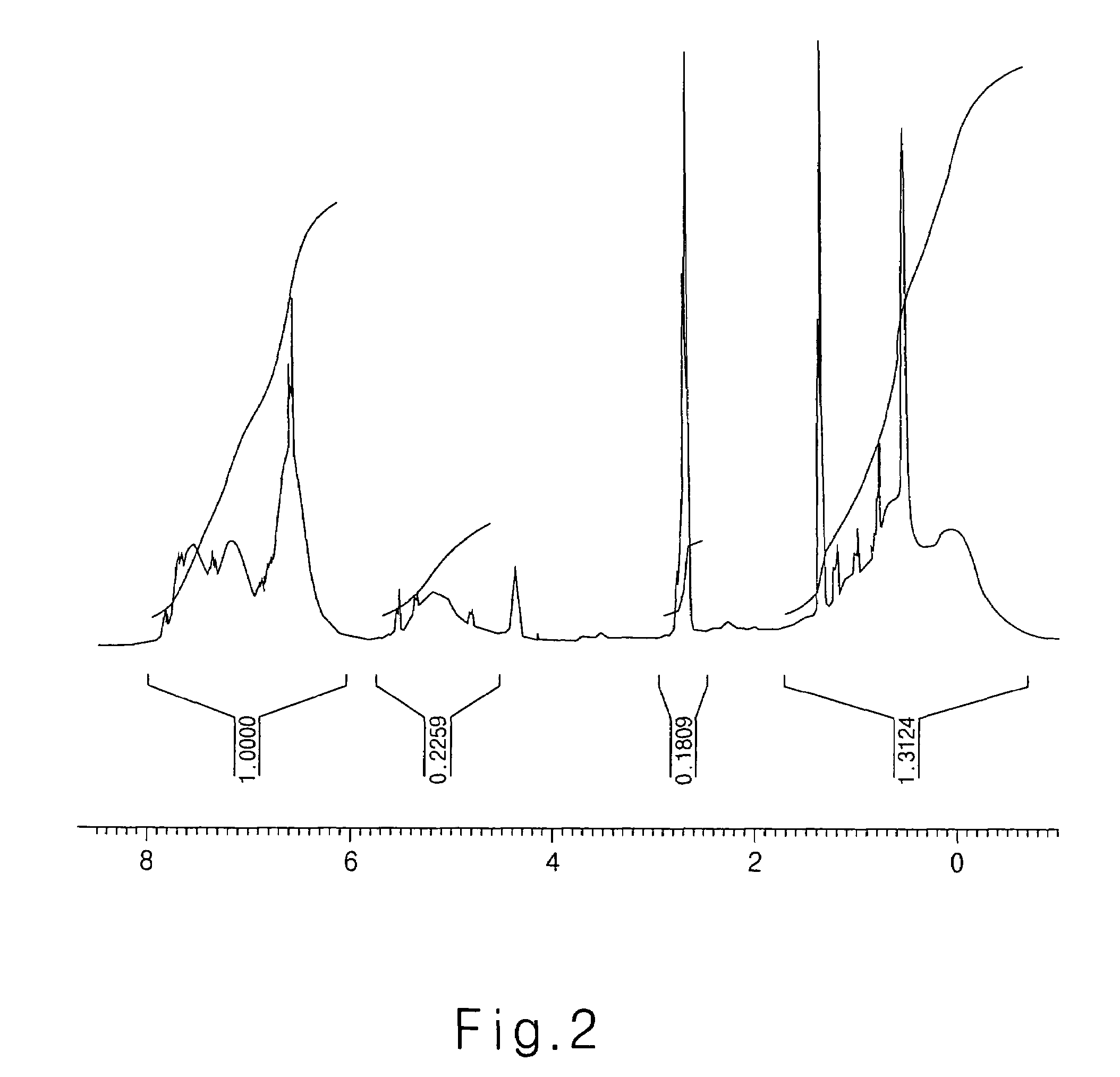

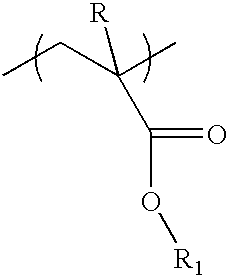

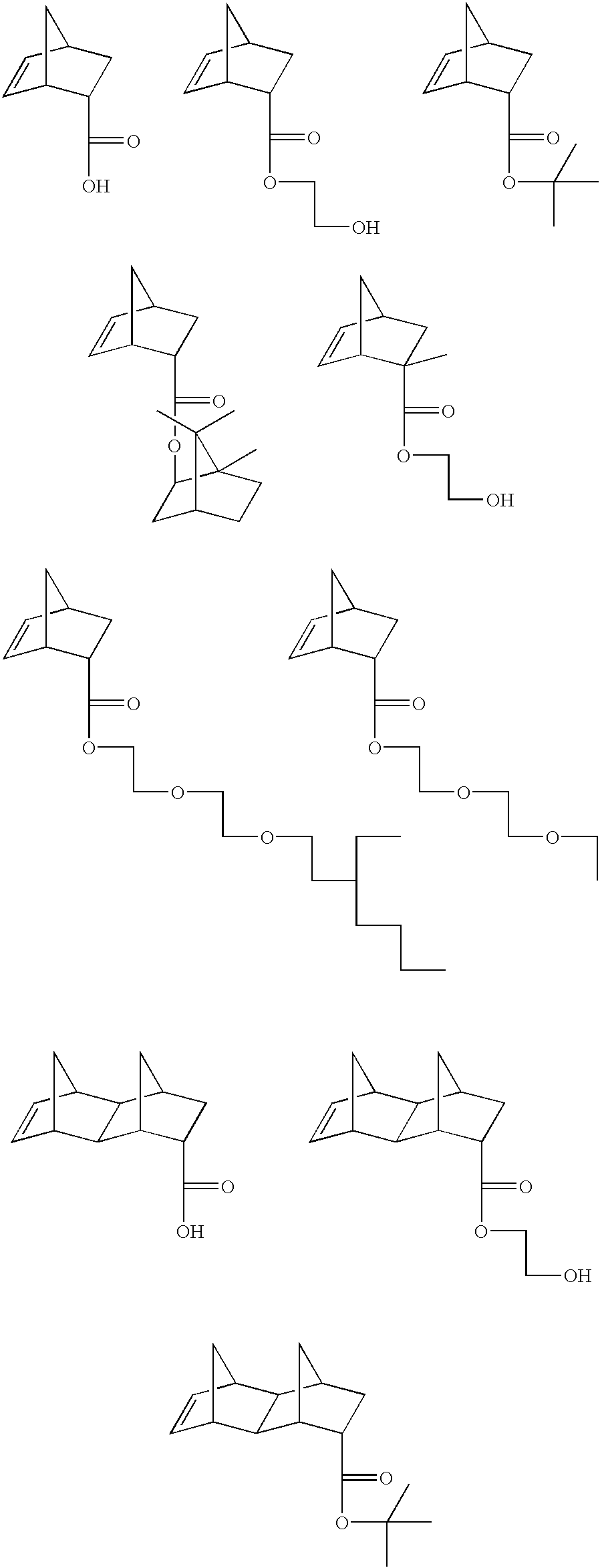

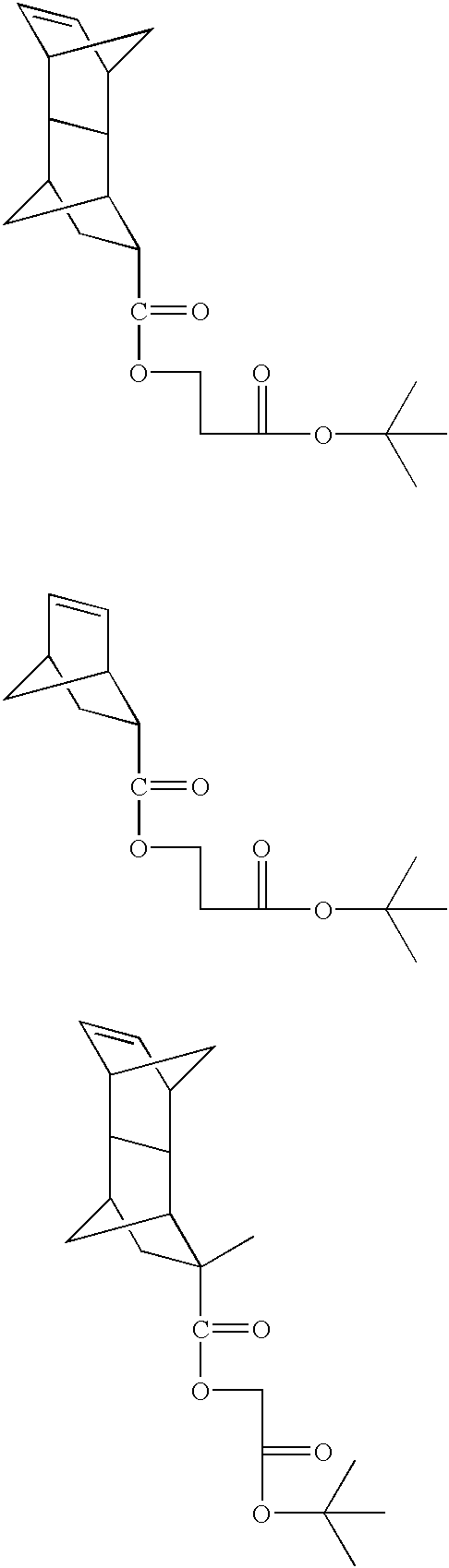

Photoresist polymer and photoresist composition containing the same

InactiveUS7361447B2Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersResistPolymer science

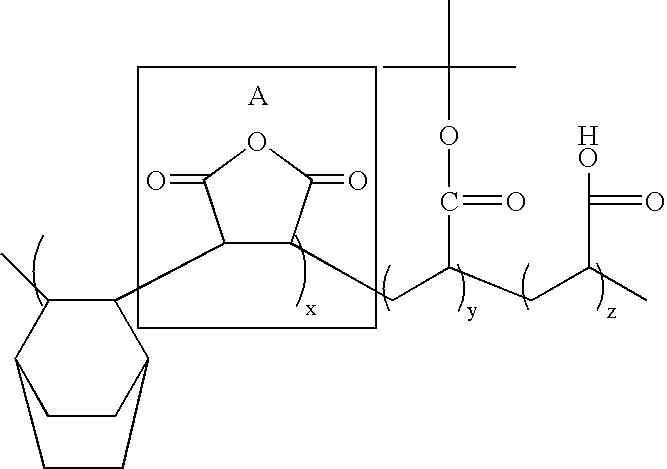

Photoresist polymers and photoresist compositions containing the same. Photoresist patterns of less than 50 nm are achieved with EUV (Extreme Ultraviolet) as an exposure light source with photoresist compositions comprising (i) a photoresist polymer comprising a polymerization repeating unit of Formula 2 or (ii) a photoresist polymer comprising a polymerization repeating unit of Formula 3 with polyvinylphenol. As a result, excellent etching resistance can be secured although the photoresist patterns have a very small thickness.wherein R1, R2, R3, R4, R5, R6, R7, R8, R9, R10, R11, R12, a, b, c, d, e, f and g are as defined in the specification.

Owner:SK HYNIX INC

Photoresist polymer and photoresist composition containing the same

InactiveUS7279256B2Enhance the imageImprove the immunityPhotosensitive materialsRadiation applicationsResistEnergy variation

Photoresist polymers and photoresist compositions are disclosed. A photoresist polymer comprising a polymerization repeating unit represented by Formula I is less sensitive to change in the amount of energy due to its higher active energy than that of a conventional photoresist polymer. As a result, a phenomenon where the portion of the pattern for the storage electrode contact region that receives relatively large amount of light becomes too thin is avoided when the device isolation film pattern is formed, and wherein pattern collapse caused by a high aspect ratio due to high etching resistance is prevented or avoided.whereinR1–R10, a, b, c and d are as defined in the description.

Owner:SK HYNIX INC

Substrate processing apparatus

InactiveUS20080210278A1Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

A substrate processing apparatus is provided. The apparatus includes a plurality of fluid suppliers 61, 61, 63 for supplying different processing fluids. In processing a wafer W, the substrate processing apparatus moves the fluid suppliers 61, 62, 63 along the peripheral part of the wafer W relatively. The fluid suppliers 61, 62, 63 are arranged in a direction extending from the circumference of the wafer W to its inside. With the arrangement, the apparatus is capable of stable processing of the wafer W in spite of rotating the wafer W at a low speed. Further, it is possible to improve a throughput of the apparatus in resist processing.

Owner:TOKYO ELECTRON LTD

Patterning method

ActiveUS20100112496A1Photosensitive materialsSemiconductor/solid-state device manufacturingResistSilicon oxide

Owner:TOKYO ELECTRON LTD

Photoresist composition for deep UV and process thereof

InactiveUS6447980B1Radiation applicationsSemiconductor/solid-state device manufacturingResistSide chain

The present invention relates to a chemically amplified system, which is, sensitive to wavelengths between 300 nm and 100 nm, and comprises a) a polymer that is insoluble an aqueous alkaline solution and comprises at least one acid labile group, b) a compound capable of producing an acid upon radiation. The present invention comprises a polymer that is made from a alicyclic hydrocarbon olefin, an acrylate with a pendant cyclic moeity, and a cyclic anhydride. The present invention also relates to a process for imaging such a photoresist.

Owner:AZ ELECTRONICS MATERIALS USA CORP

Method for forming a photoresist pattern

InactiveUS20070163625A1Inhibition formationSurface-active detergent compositionsNon-surface-active detergent compositionsResistPhotoresist

A photoresist cleaning solution and method for forming photoresist patterns using the same. More specifically, disclosed are a photoresist cleaning solution comprising H2o and an ionic surfactant represented by Formula 1, and a method for forming a photoresist pattern using the same. By spraying the cleaning solution of the present invention over photoresist film before and / or after exposing step, pattern formation in an undesired region caused by ghost images can be removed.

Owner:SK HYNIX INC

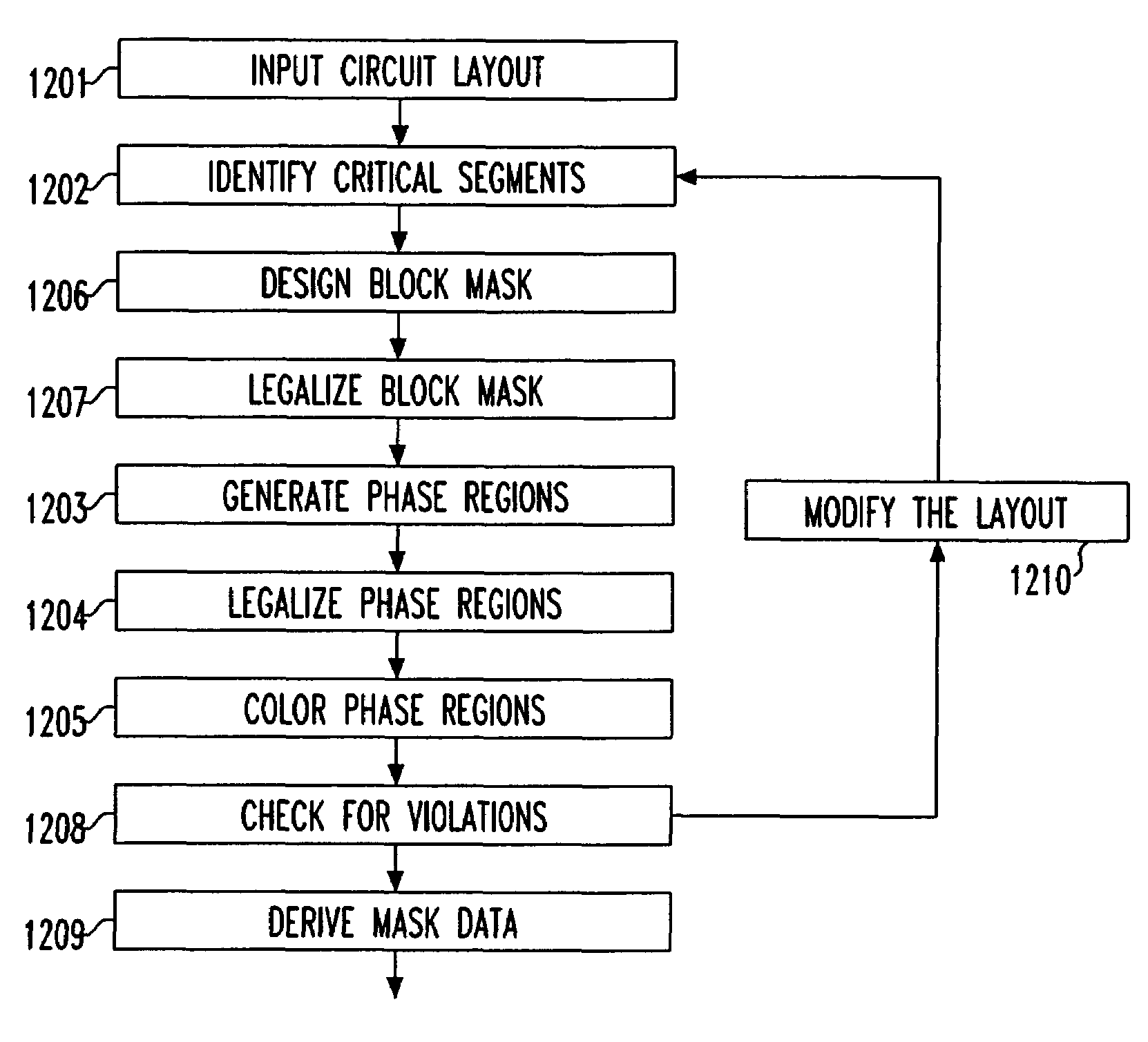

Generating mask patterns for alternating phase-shift mask lithography

InactiveUS6993741B2Photosensitive materialsSemiconductor/solid-state device manufacturingResistEngineering

A method of generating patterns of a pair of photomasks from a data set defining a circuit layout to be provided on a substrate includes identifying critical segments of the circuit layout to be provided on the substrate. Block mask patterns are generated and then legalized based on the identified critical segments. Thereafter, phase mask patterns are generated, legalized and colored. The legalized block mask patterns and the legalized phase mask patterns that have been colored define features of a block mask and an alternating phase shift mask, respectively, for use in a dual exposure method for patterning features in a resist layer of a substrate.

Owner:GLOBALFOUNDRIES INC

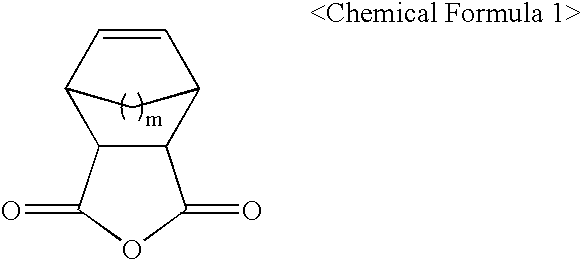

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

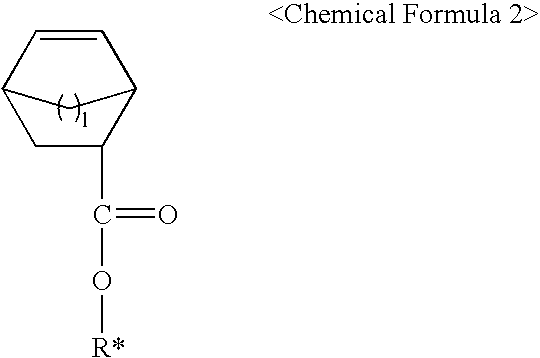

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

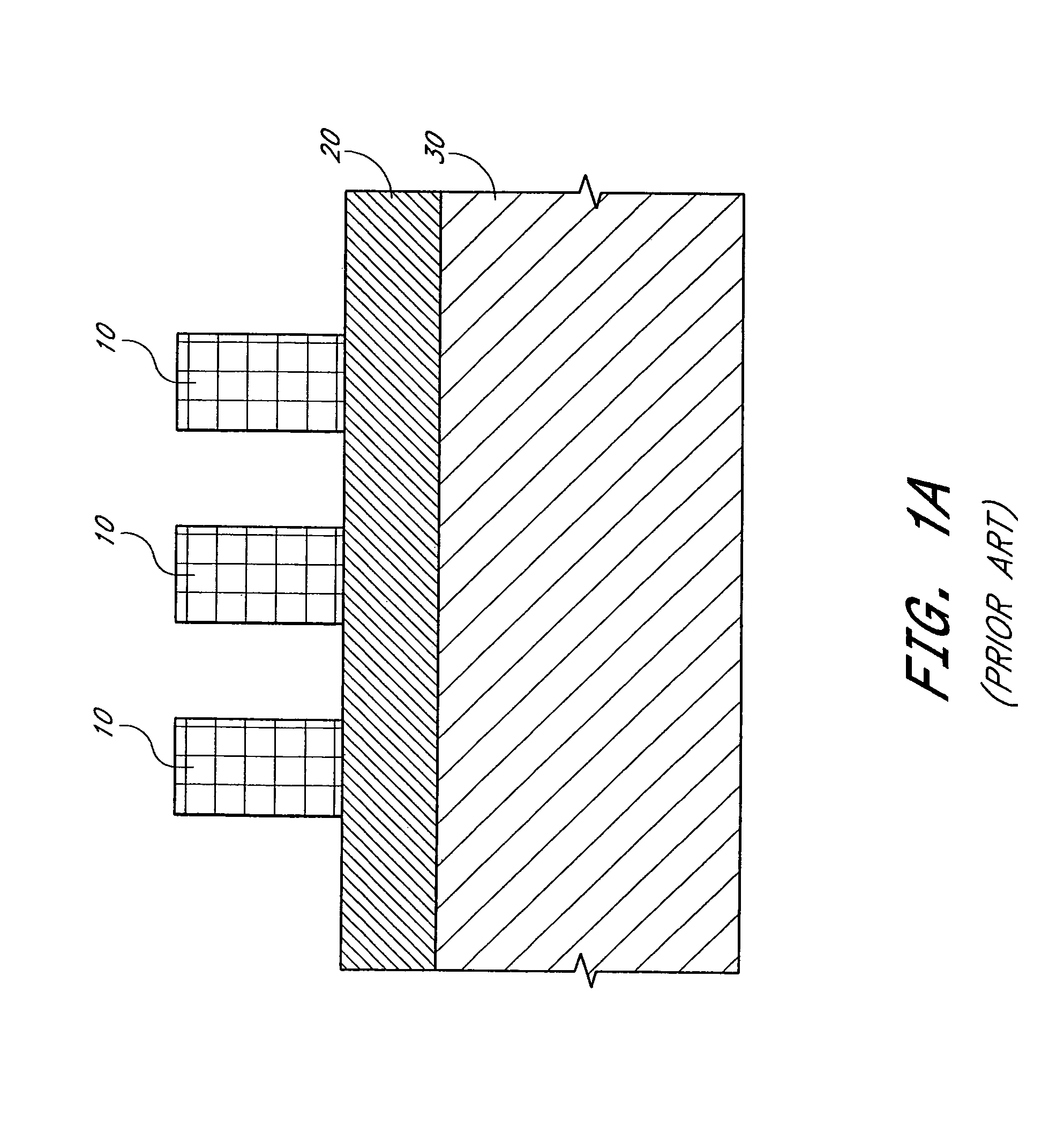

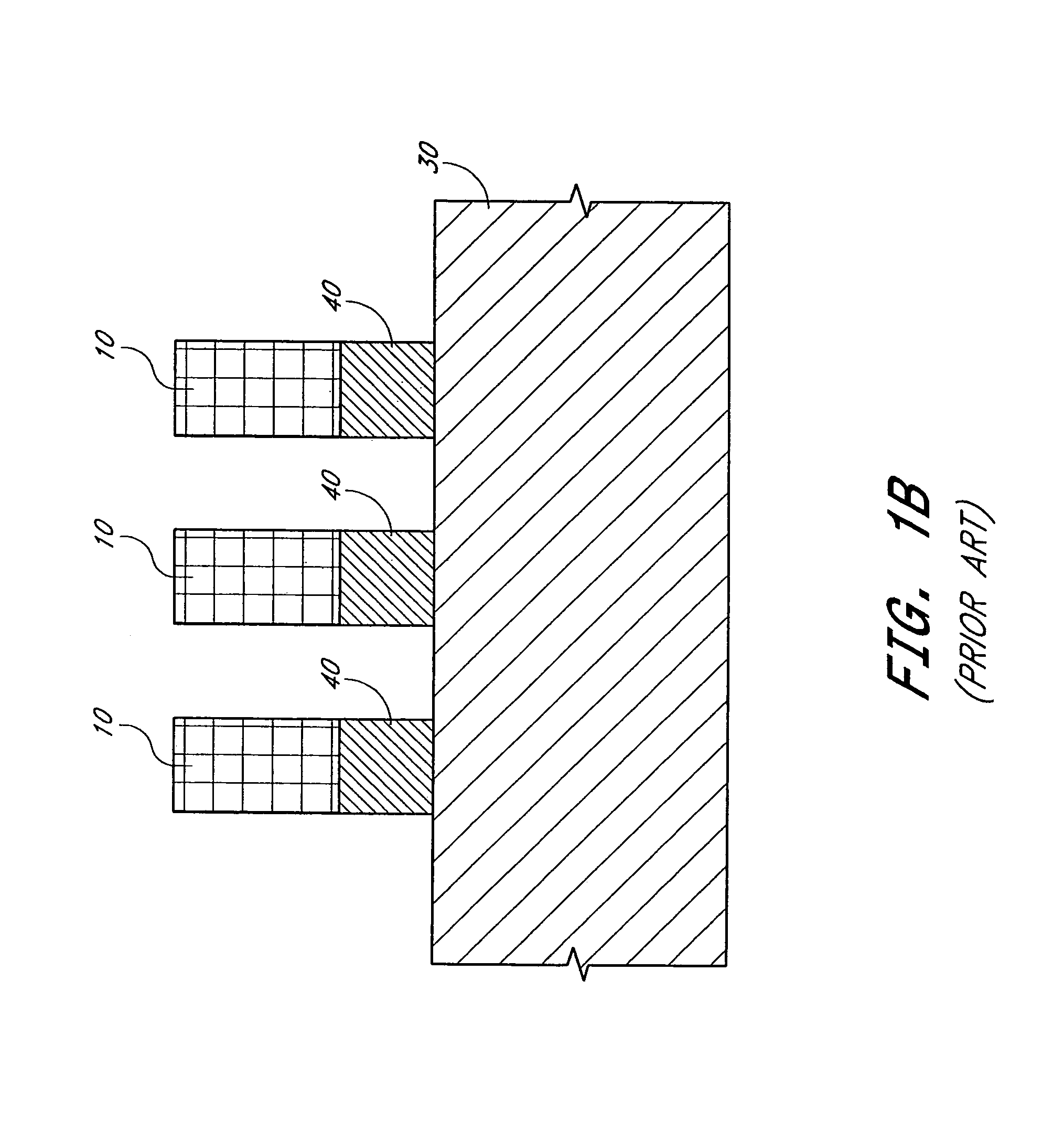

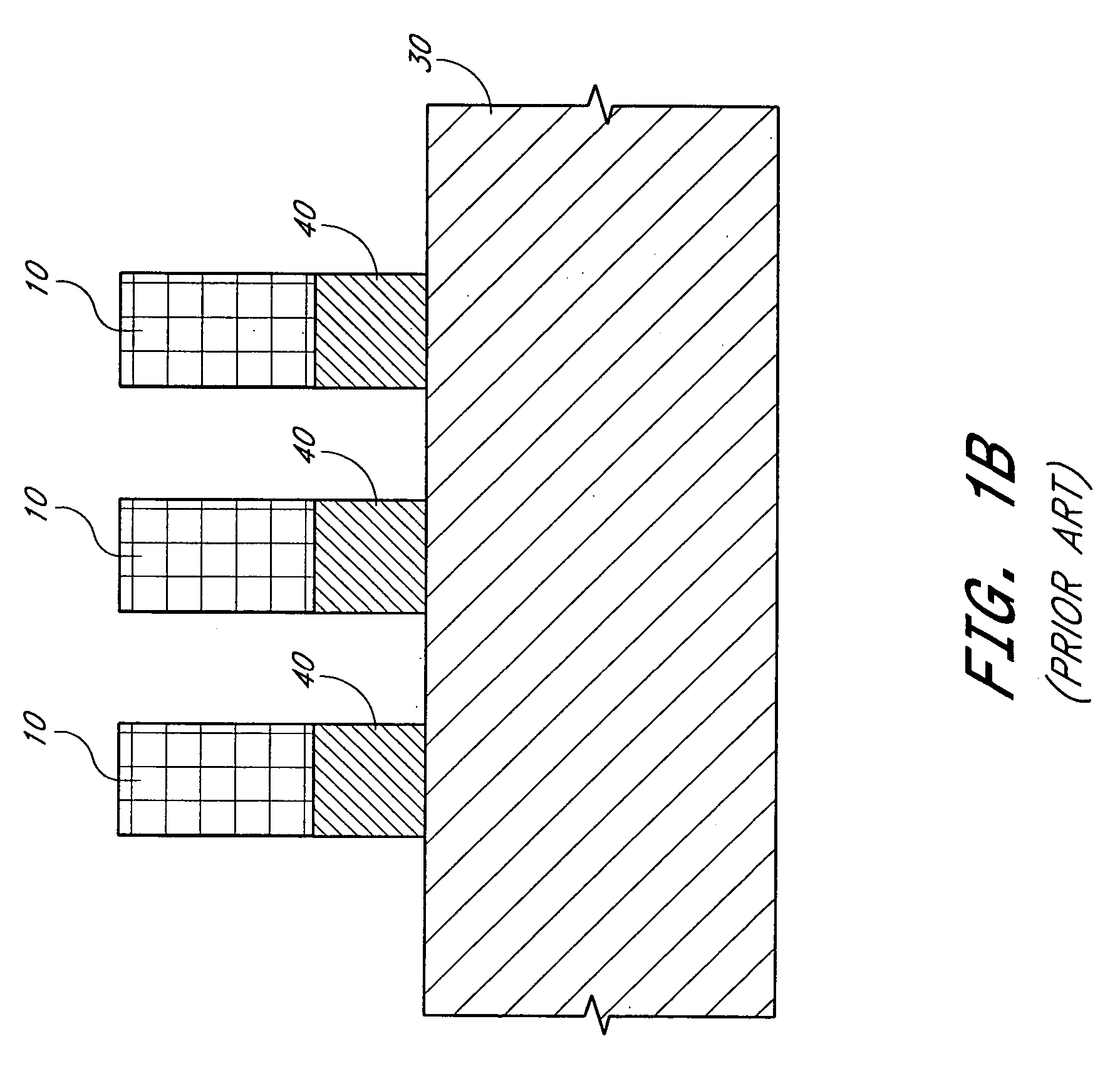

Method to align mask patterns

Alignment tolerances between narrow mask lines, for forming interconnects in the array region of an integrated circuit, and wider mask lines, for forming interconnects in the periphery of the integrated circuit, are increased. The narrow mask lines are formed by pitch multiplication and the wider mask lines are formed by photolithography. The wider mask lines and are aligned so that one side of those lines is flush with or inset from a corresponding side of the narrow lines. Being wider, the opposite sides of the wider mask lines protrude beyond the corresponding opposite sides of the narrow mask lines. The wider mask lines are formed in negative photoresist having a height less than the height of the narrow mask lines. Advantageously, the narrow mask lines can prevent expansion of the mask lines in one direction, thus increasing alignment tolerances in that direction. In the other direction, use of photolithography and a shadowing effect caused by the relative heights of the photoresist and the narrow mask lines causes the wider mask lines to be formed with a rounded corner, thus increasing alignment tolerances in that direction by increasing the distance to a neighboring narrow mask line.

Owner:MICRON TECH INC

Method of forming mask pattern and method of manufacturing semiconductor device

InactiveUS20130023120A1Avoid deformationElectric discharge tubesSemiconductor/solid-state device manufacturingResistSilicon oxide

A method of forming a mask pattern includes a first pattern forming step of etching an anti-reflection coating film by using as a mask a first line portion made up of a photo resist film formed on the anti-reflection film to form a pattern including a second line portion made up of the photo resist film and the anti-reflection film; an irradiation step of irradiating the photo resist film with electrons; a silicon oxide film forming step to cover the second line portion isotropically; and an etch back step of etching back the silicon oxide film such that the silicon oxide film is removed from the top of the second line portion as sidewalls of the second line portion. The method further includes a second pattern forming step of ashing the second line portion to form a mask pattern including a third line portion made up of the silicon oxide film and remains.

Owner:TOKYO ELECTRON LTD

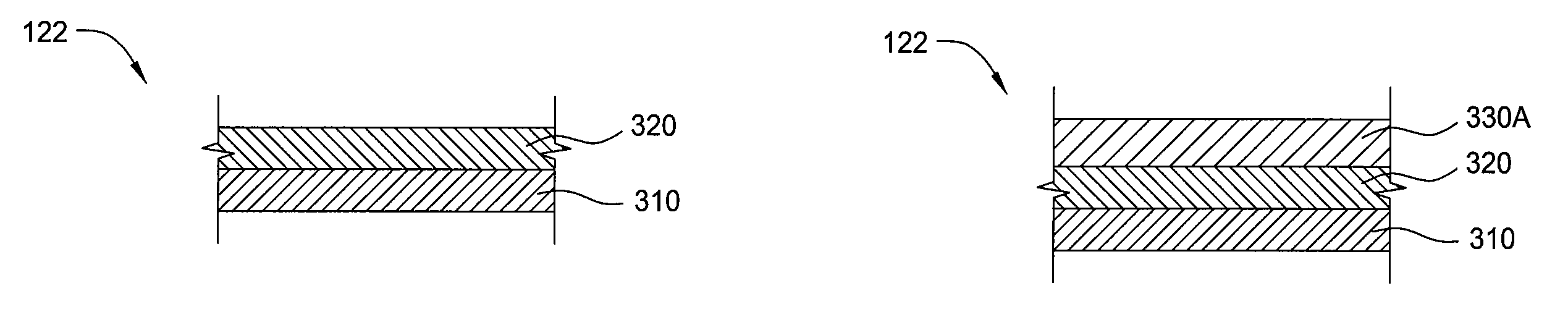

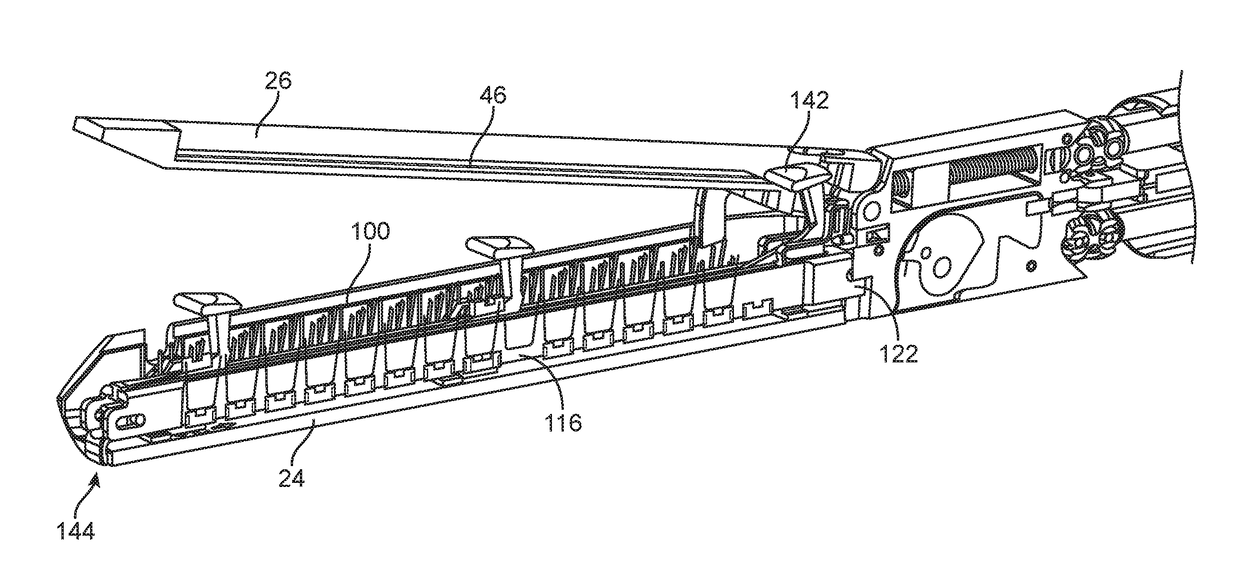

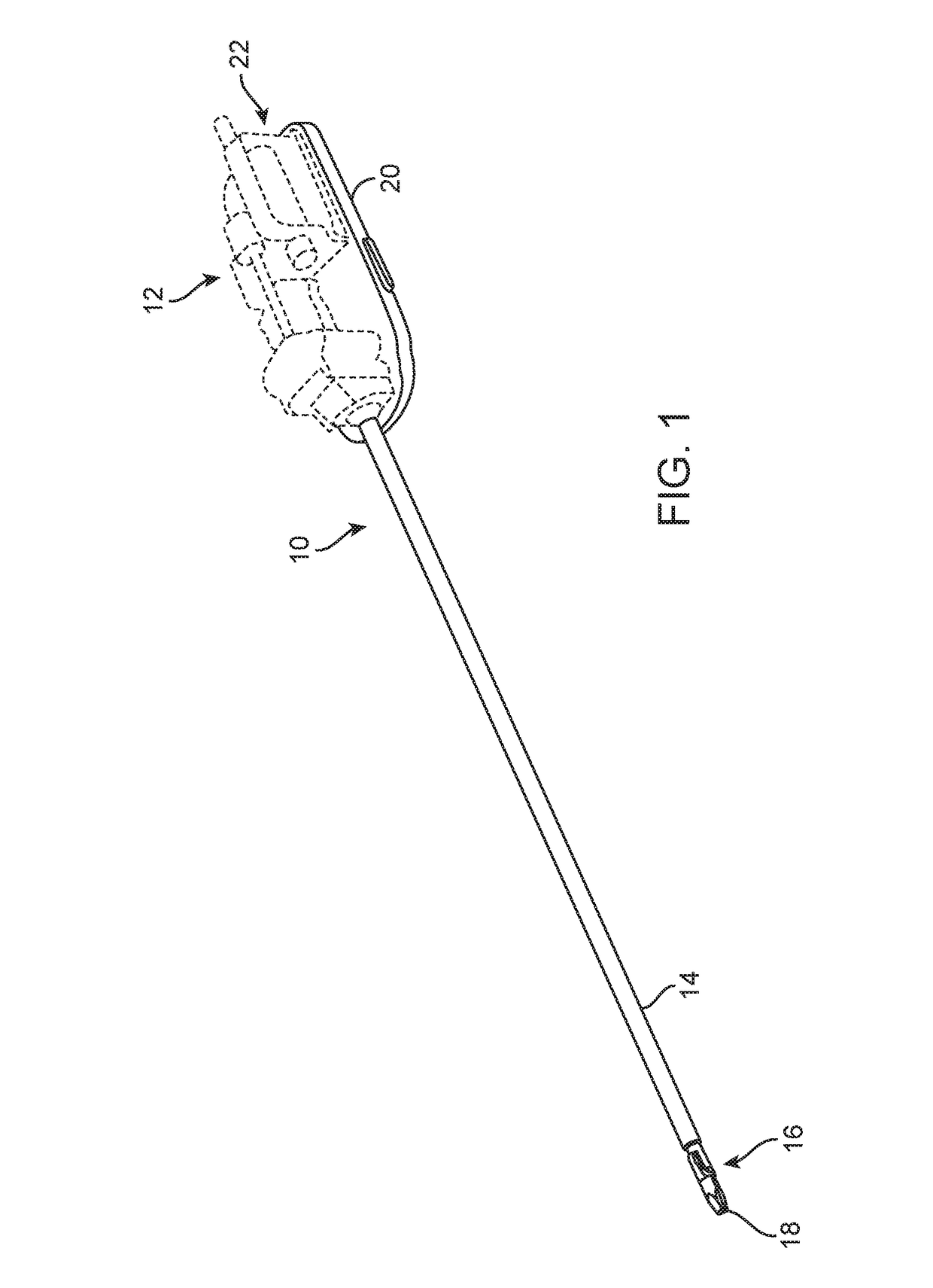

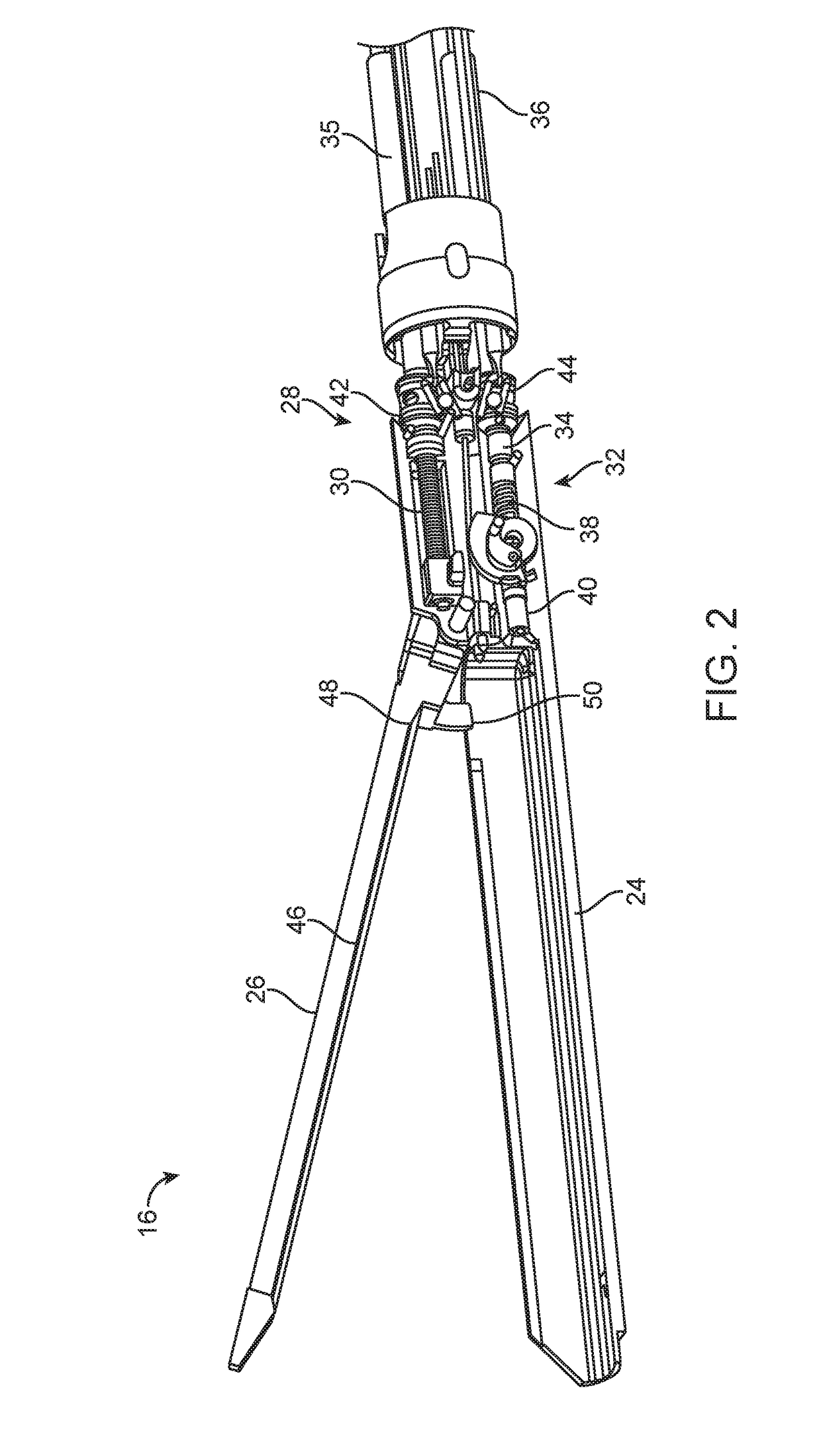

Stapling cartridge

A stapling cartridge having an elongated rail that provides support to a moveable clamping element and resists pulling or spreading forces caused by compressing and cutting tissue. The elongated rail can directly connect the stapling cartridge to the lower jaw and completely carry the moveable clamping element, which can couple and decouple to an anvil of an upper jaw.

Owner:INTUITIVE SURGICAL OPERATIONS INC

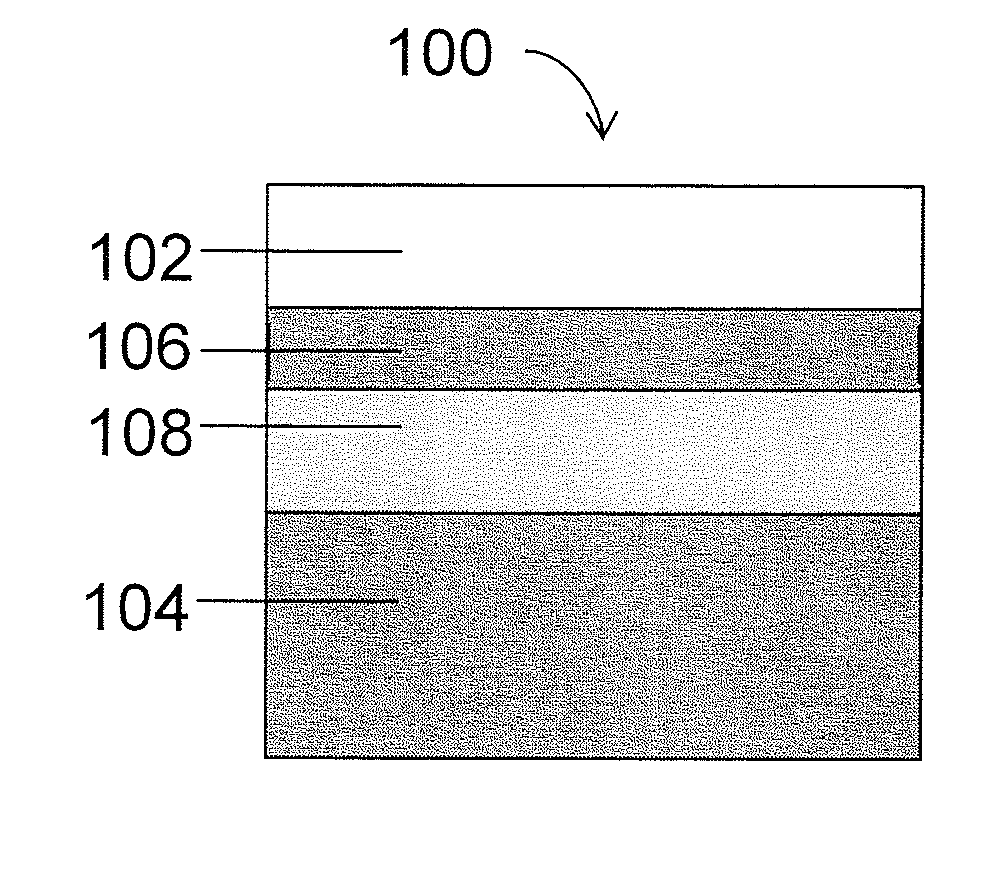

Solution processible hardmasks for high resolution lithography

Solution processible hardmasks are described that can be formed from aqueous precursor solutions comprising polyoxometal clusters and anions, such as polyatomic anions. The solution processible metal oxide layers are generally placed under relatively thin etch resist layers to provide desired etch contrast with underlying substrates and / or antireflective properties. In some embodiments, the metal oxide hardmasks can be used along with an additional hardmask and / or antireflective layers. The metal oxide hardmasks can be etched with wet or dry etching. Desirable processing improvements can be obtained with the solution processible hardmasks.

Owner:INPRIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com