Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3440 results about "Organic film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

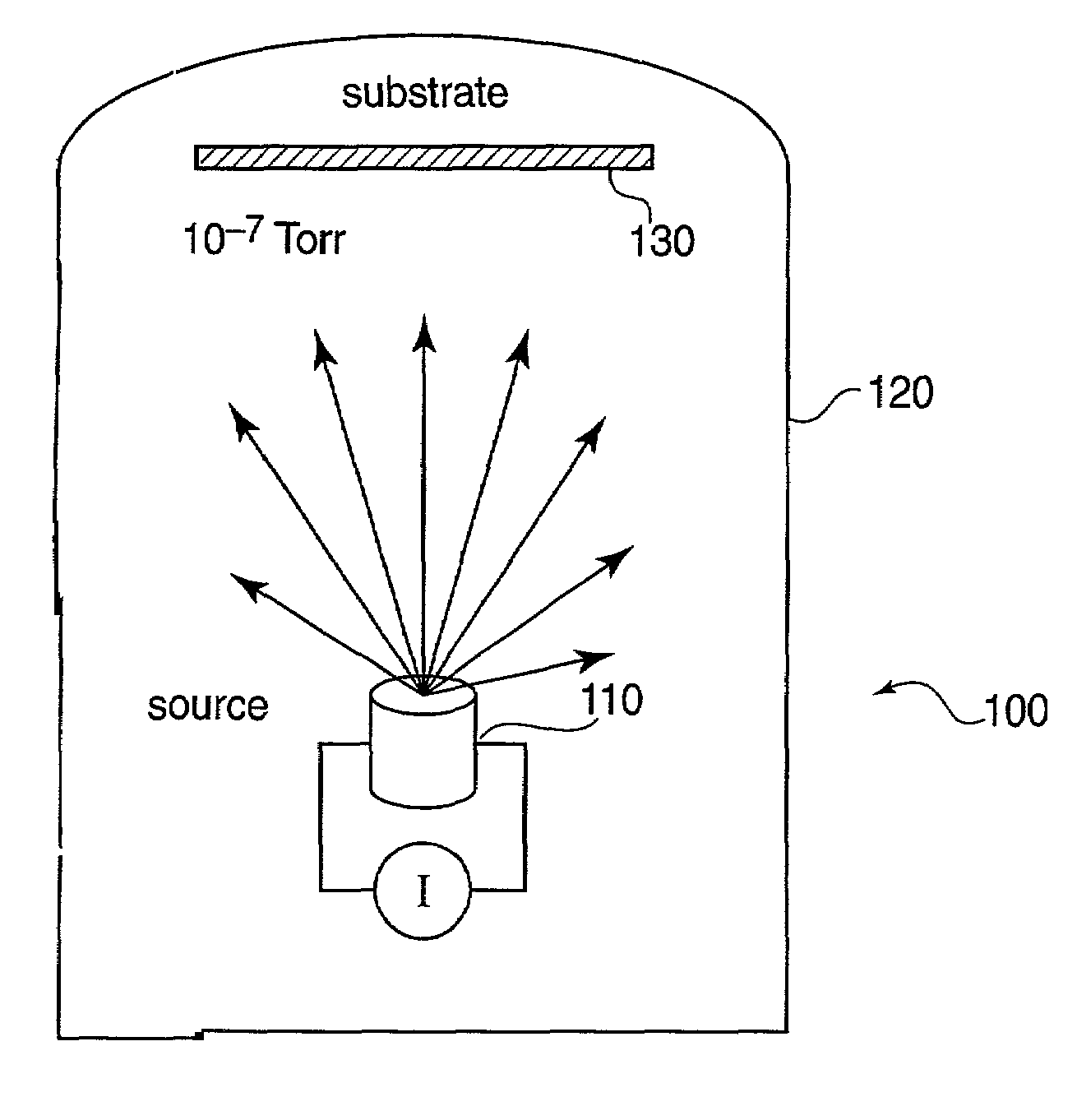

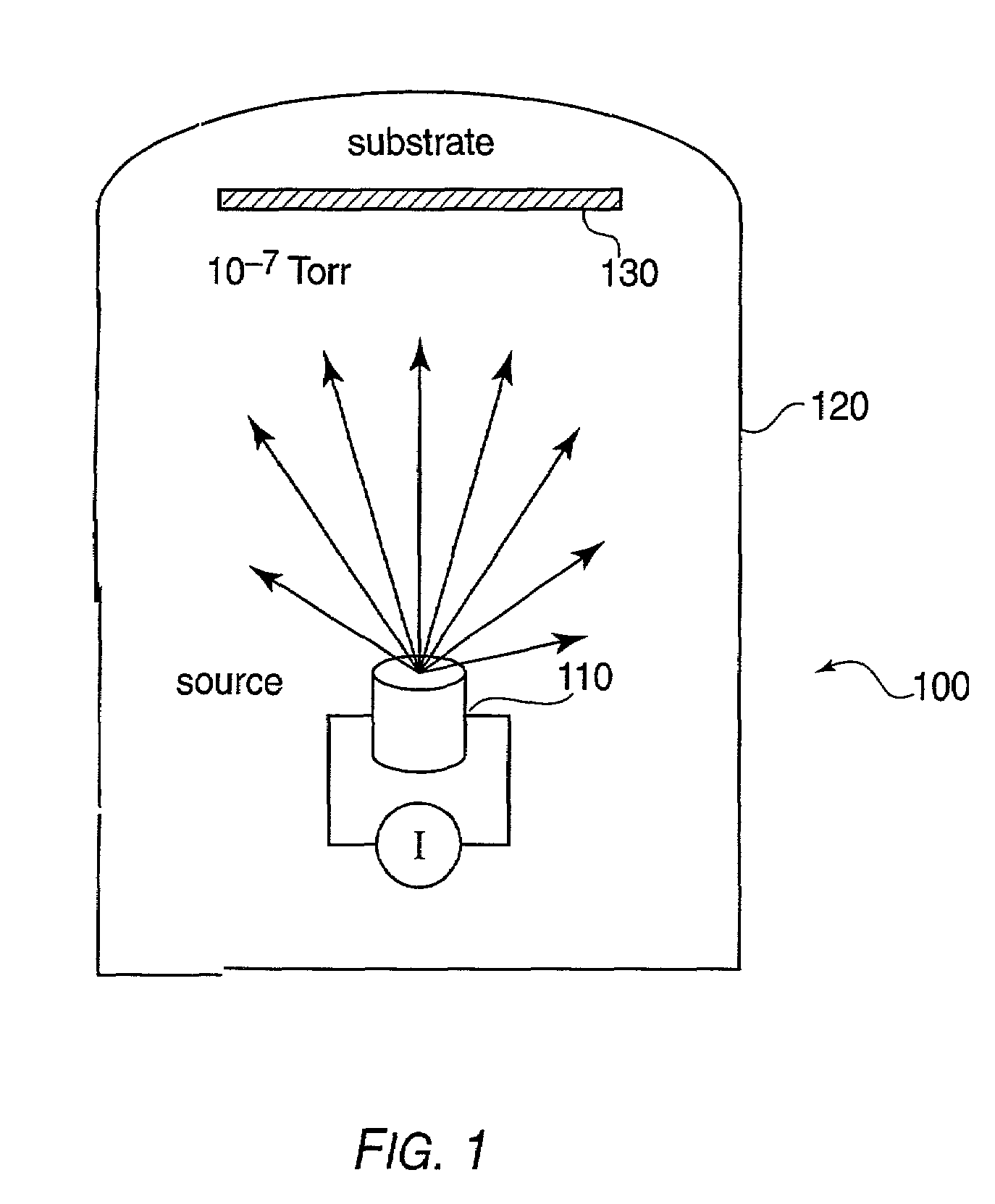

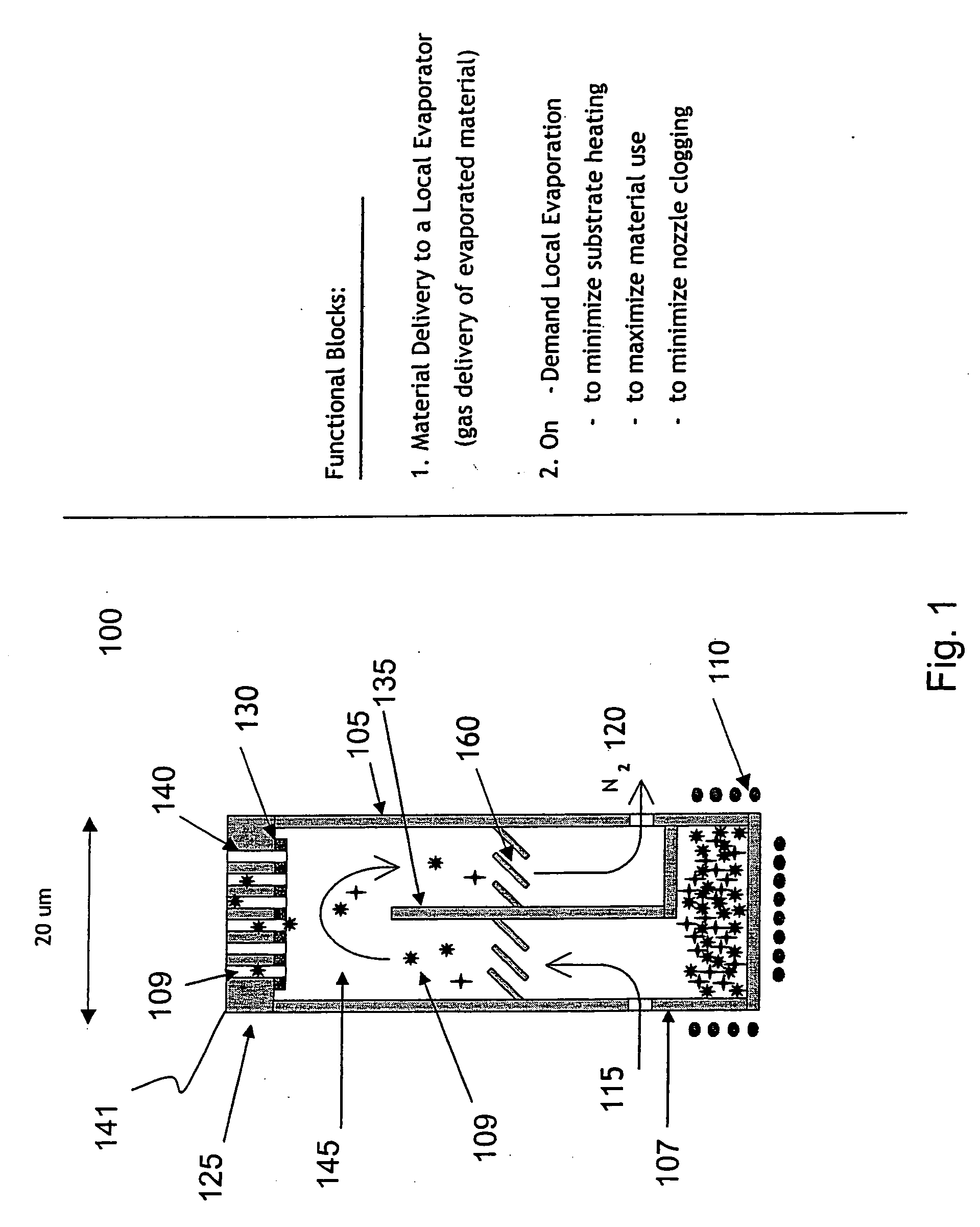

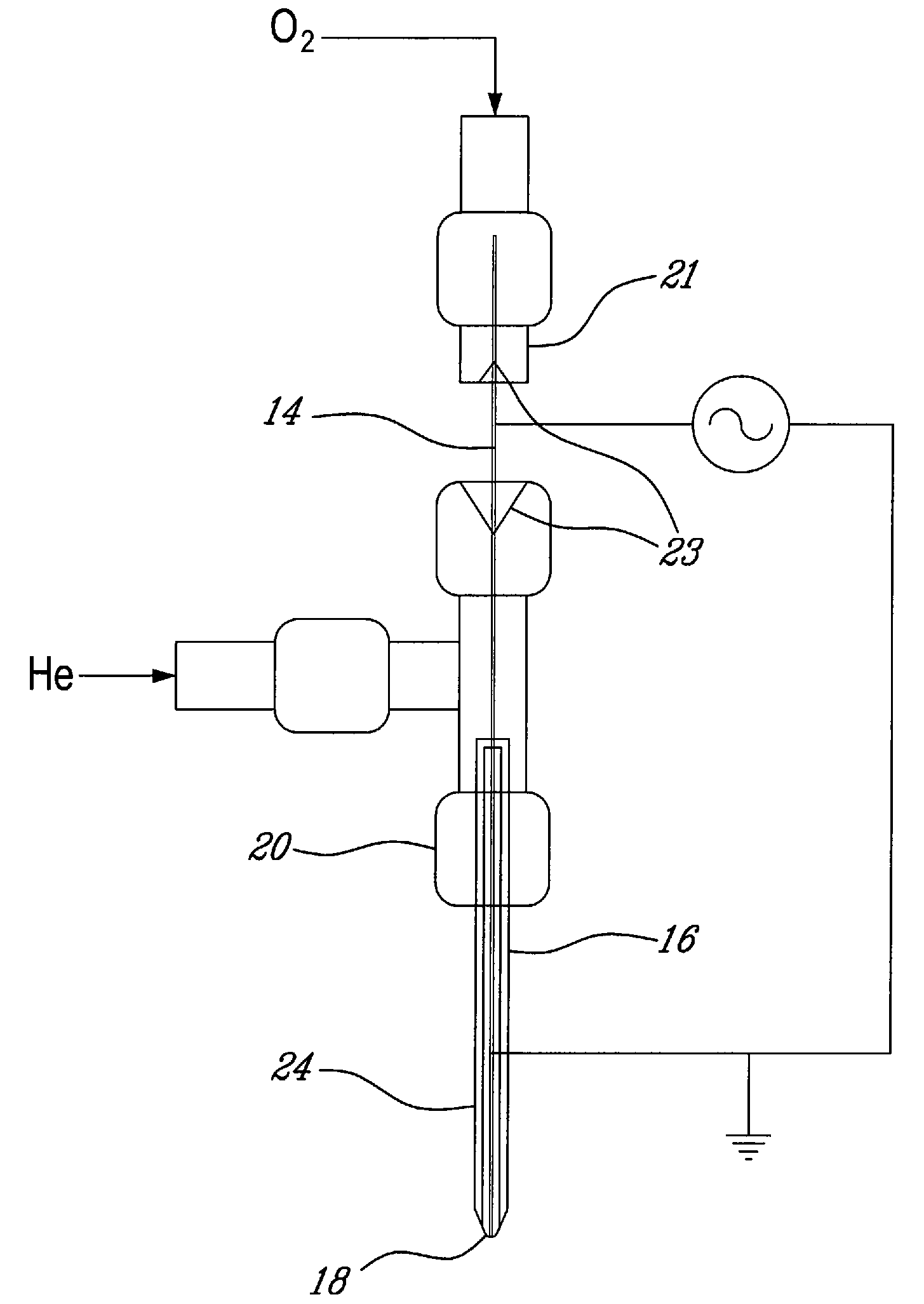

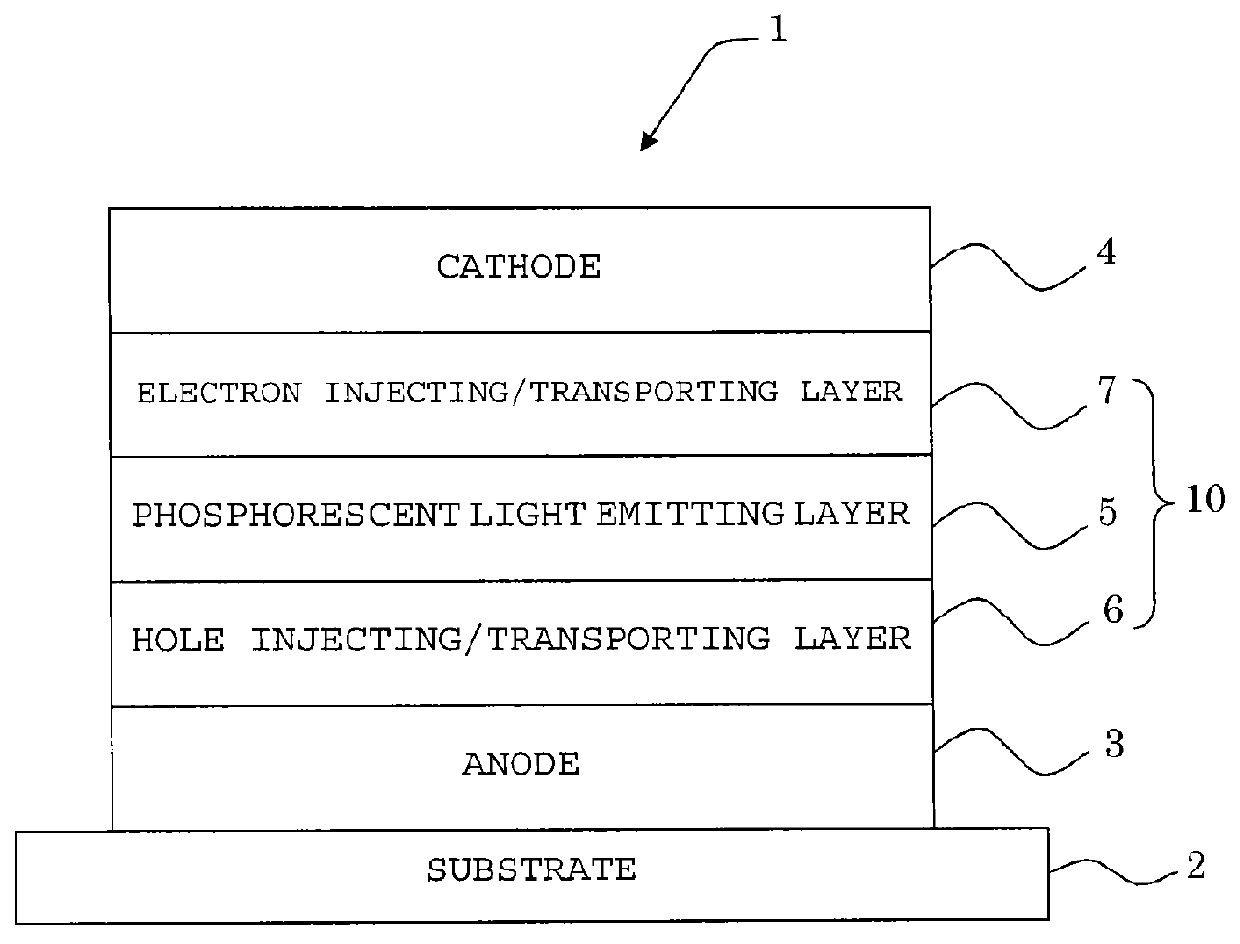

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

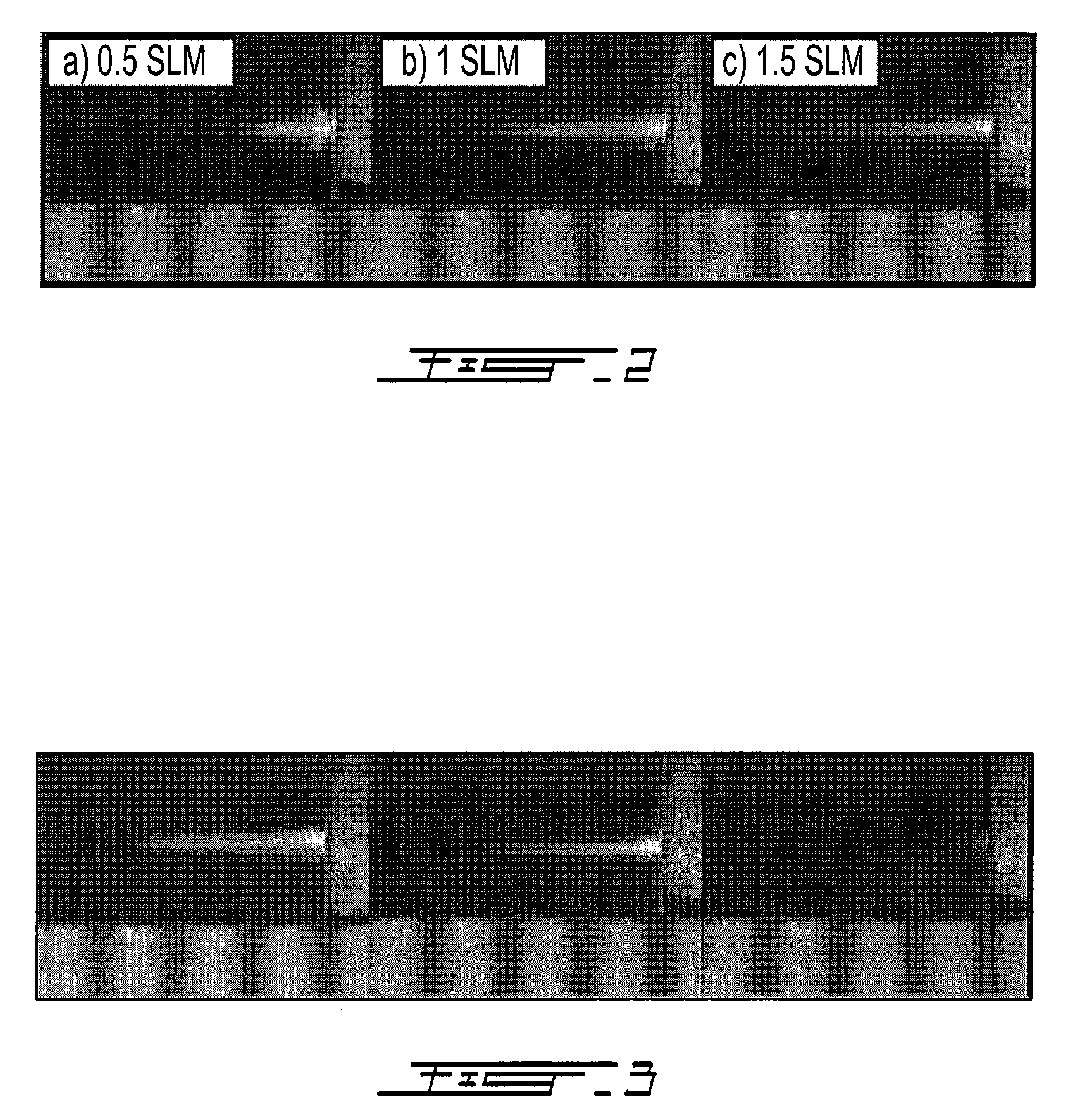

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

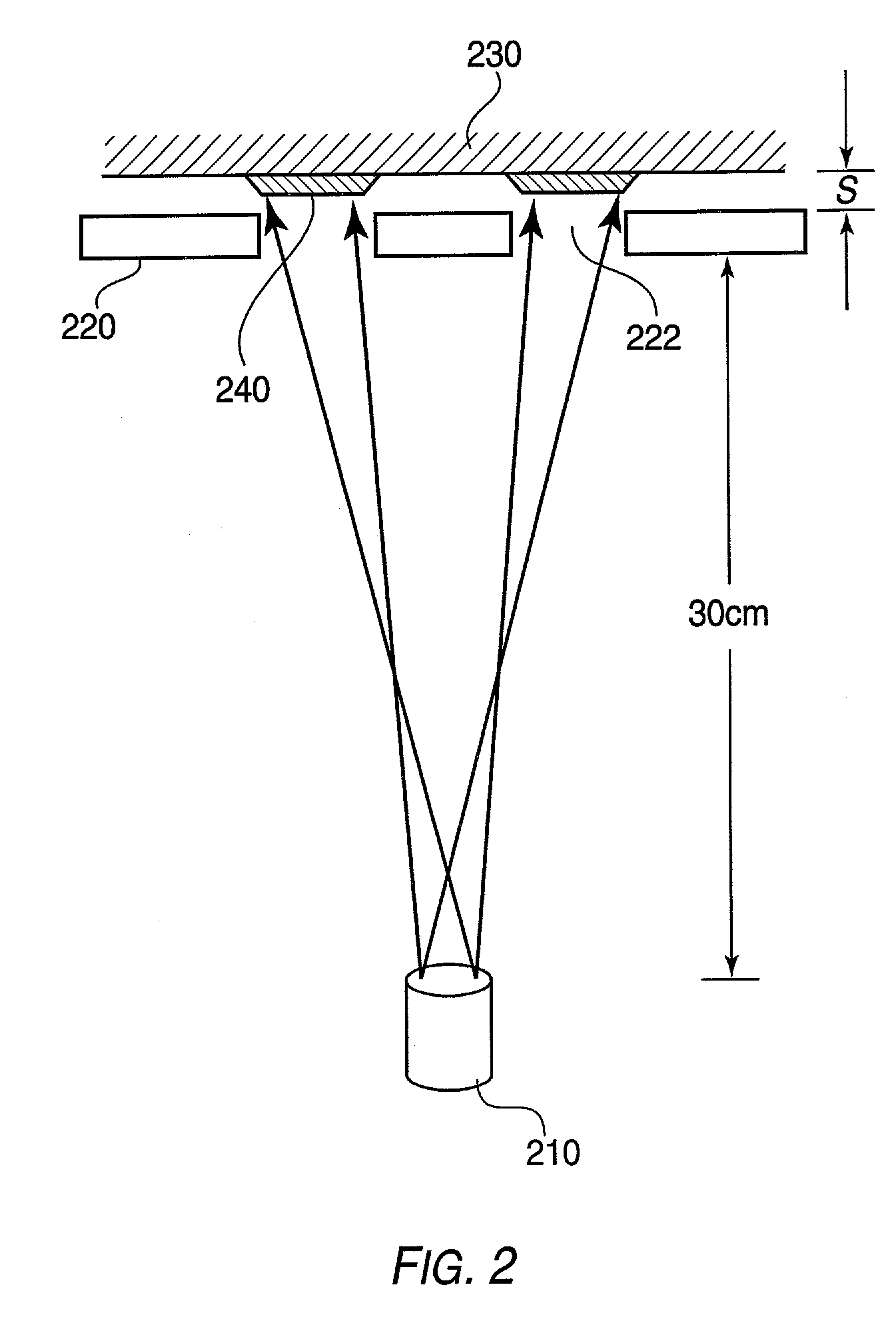

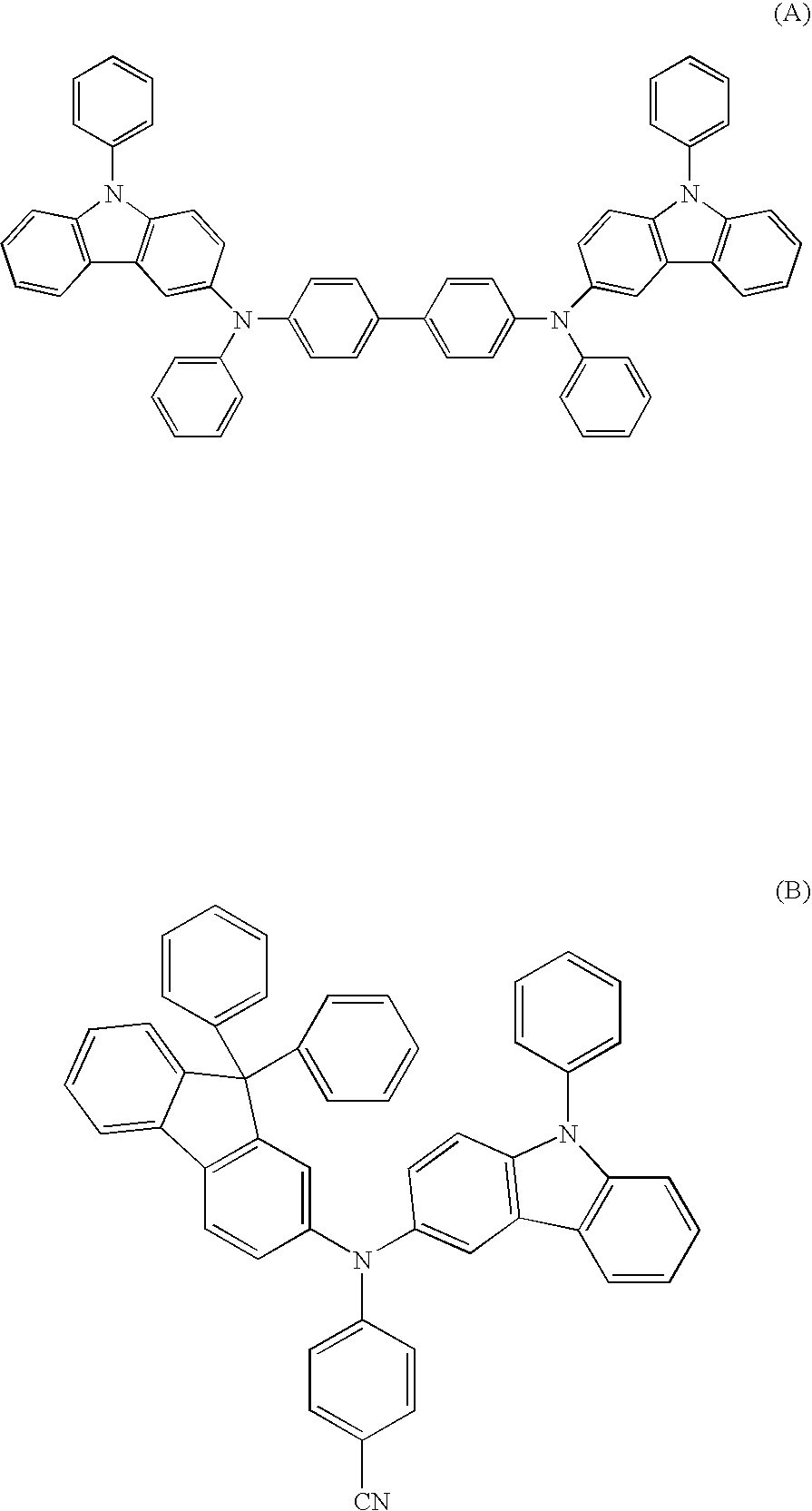

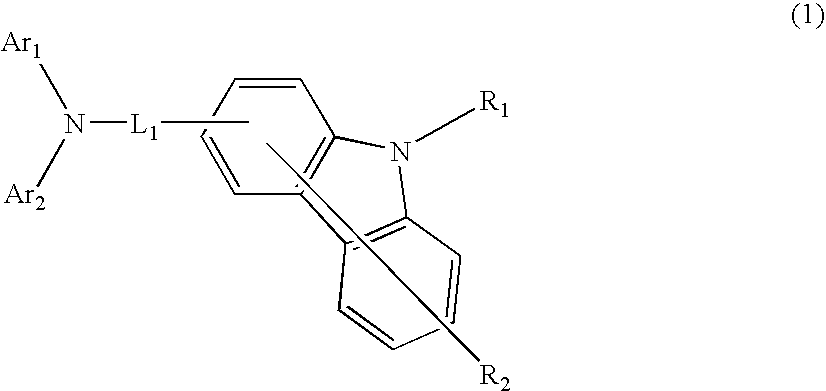

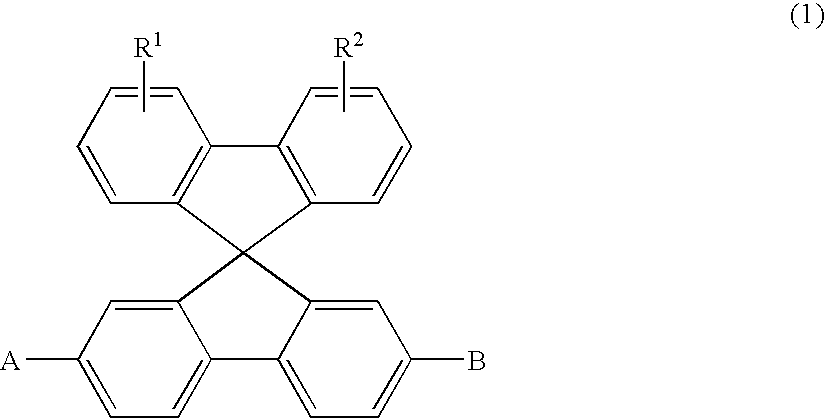

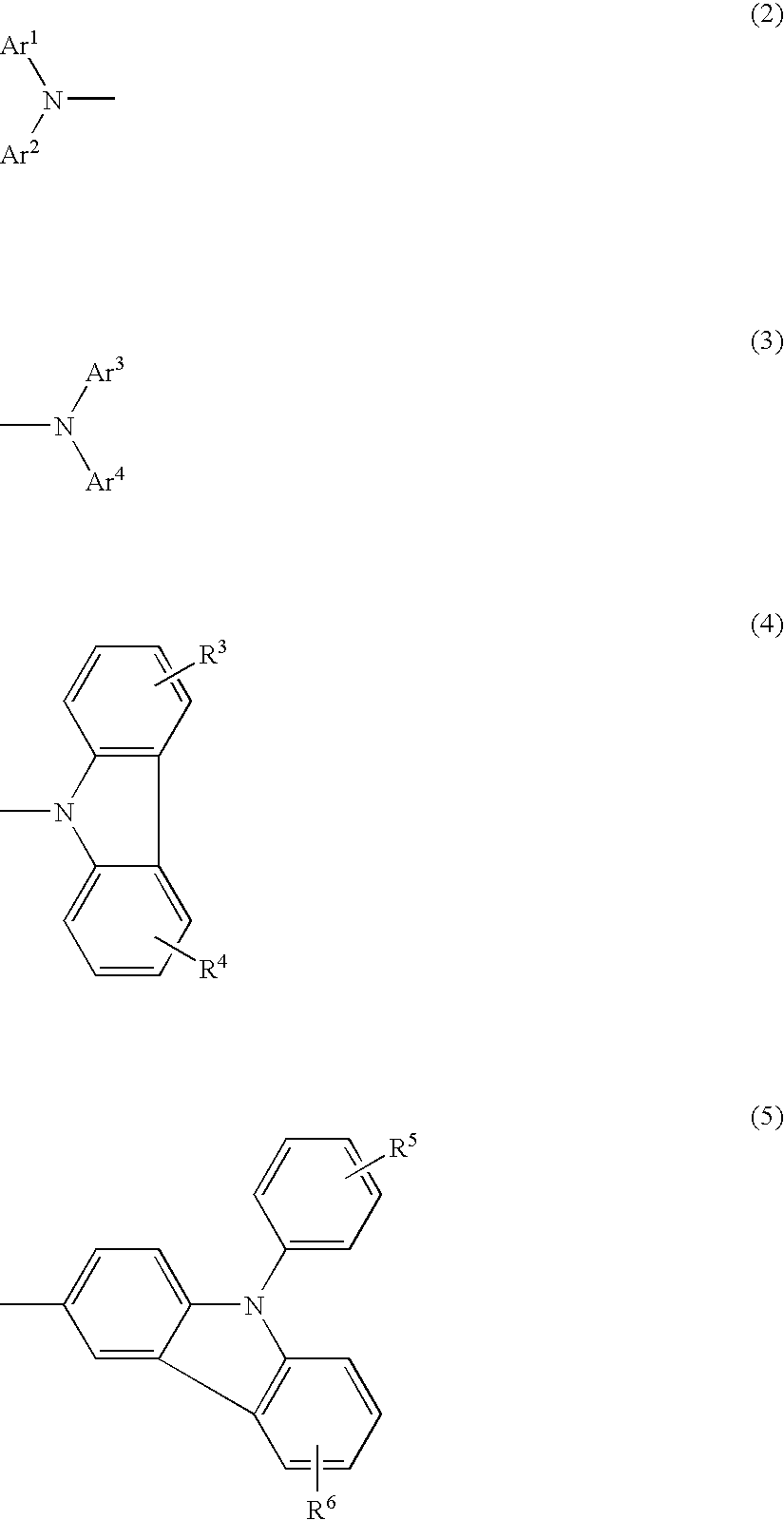

Aromatic amine derivative and organic electroluminescence device using the same

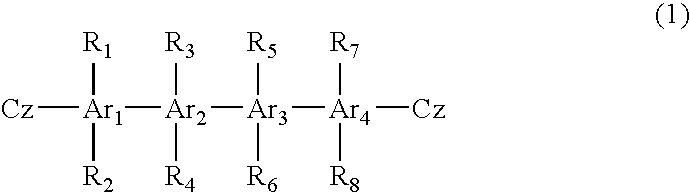

ActiveUS20080124572A1Improve efficiencyImprove recombination efficiencyOrganic chemistrySolid-state devicesArylCarbazole

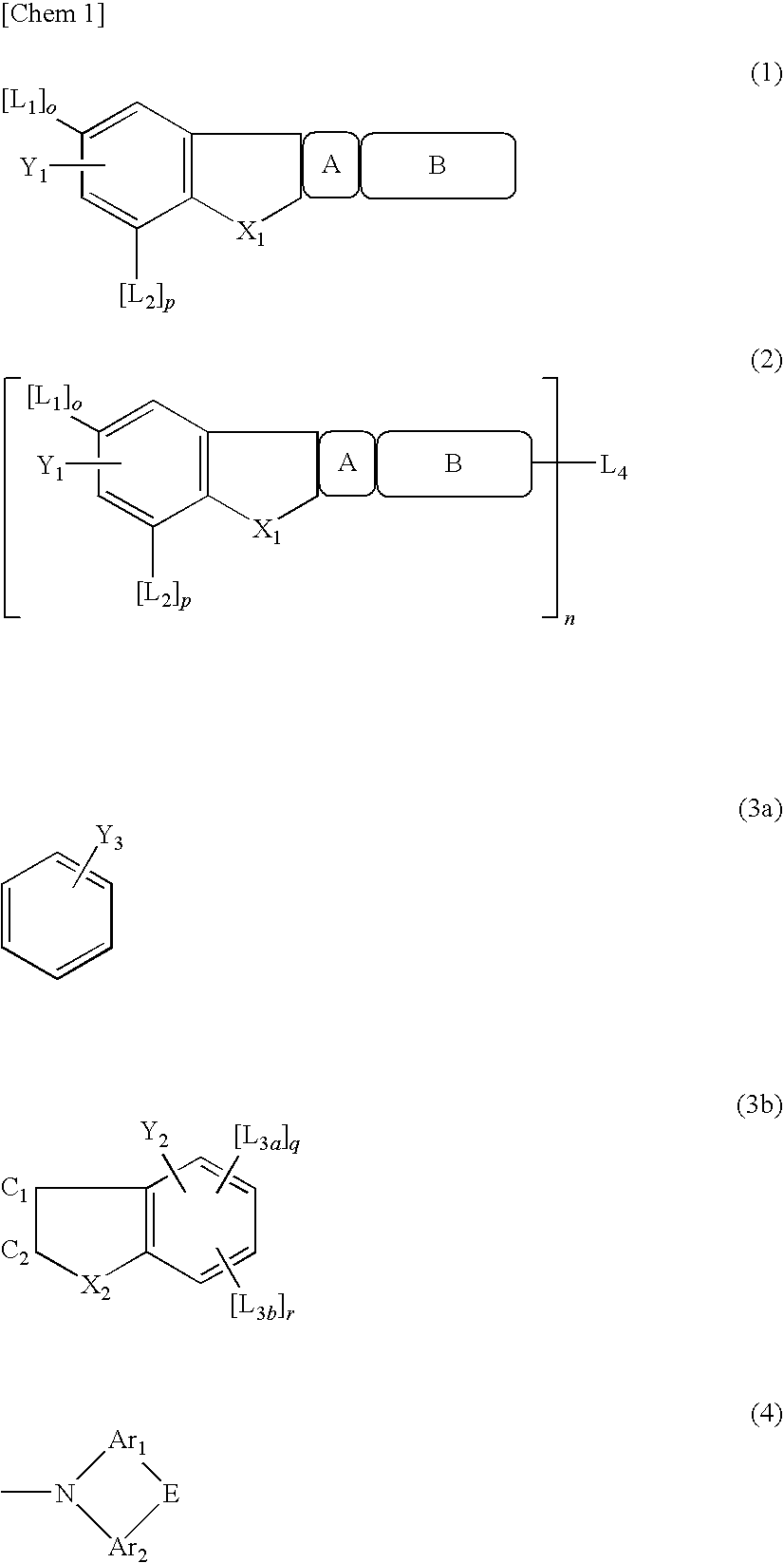

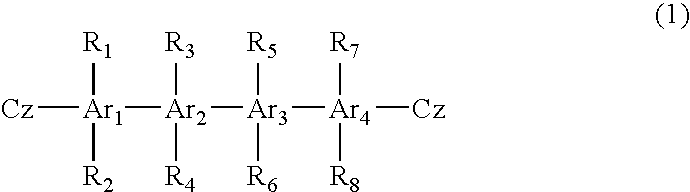

An aromatic amine derivative with a specific structure having a carbazole skeleton to which a diarylamino group bonds via a bonding group. An organic electroluminescence device which is composed of one or more organic thin film layers including at least one light emitting layer sandwiched between a cathode and an anode, wherein at least one of the organic thin film layers contains the aromatic amine derivative singly or as its mixture component. Organic electroluminescence devices with enhanced efficiency of light emission and a compound realizing the devices are provided.

Owner:IDEMITSU KOSAN CO LTD

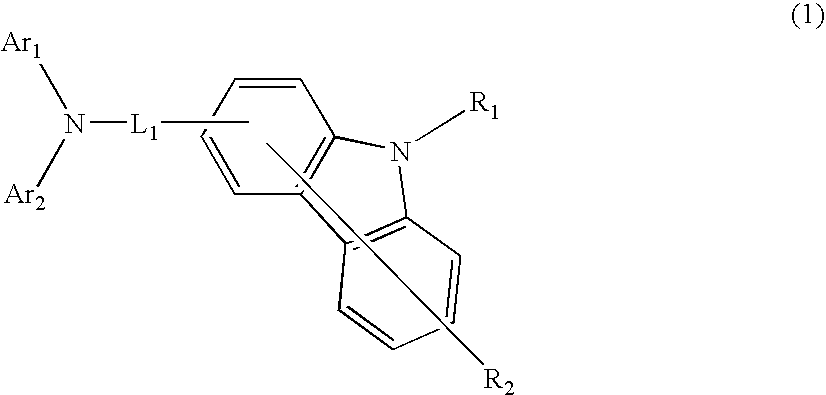

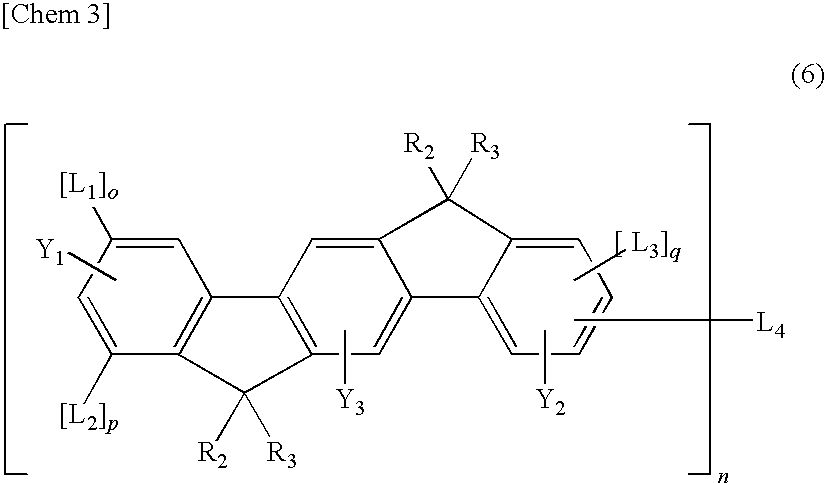

Aromatic amine derivatives and organic electroluminescent device using same

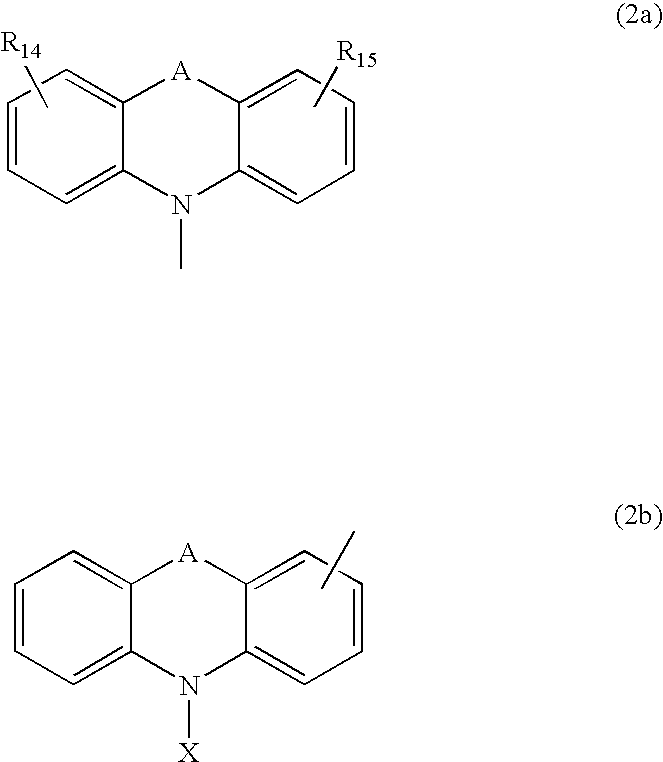

InactiveUS20080106190A1Less liableImproved in yield in producingOrganic chemistryDischarge tube luminescnet screensHole transport layerOrganic electroluminescence

The present invention provides a novel aromatic amine derivative having a specific structure and an organic electroluminescence device in which an organic thin film layer comprising a single layer or plural layers including at least a light emitting layer is interposed between a cathode and an anode, wherein at least one layer in the above organic thin film layer, particularly a hole transporting layer contains the aromatic amine derivative described above in the form of a single component or a mixed component. Use of the aromatic amine derivative described above materialize an organic electroluminescence device which reduces a driving voltage and makes molecules less liable to be crystallized and which enhances a yield in producing the organic EL device and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

Organic electroluminescence device and material for organic electroluminescence device

ActiveUS20090009065A1Improve efficiencyLong lastingSilicon organic compoundsDischarge tube luminescnet screensOrganic filmBenzo(c)phenanthrene

Owner:IDEMITSU KOSAN CO LTD

Organic electroluminescence device and material for organic electroluminescence device

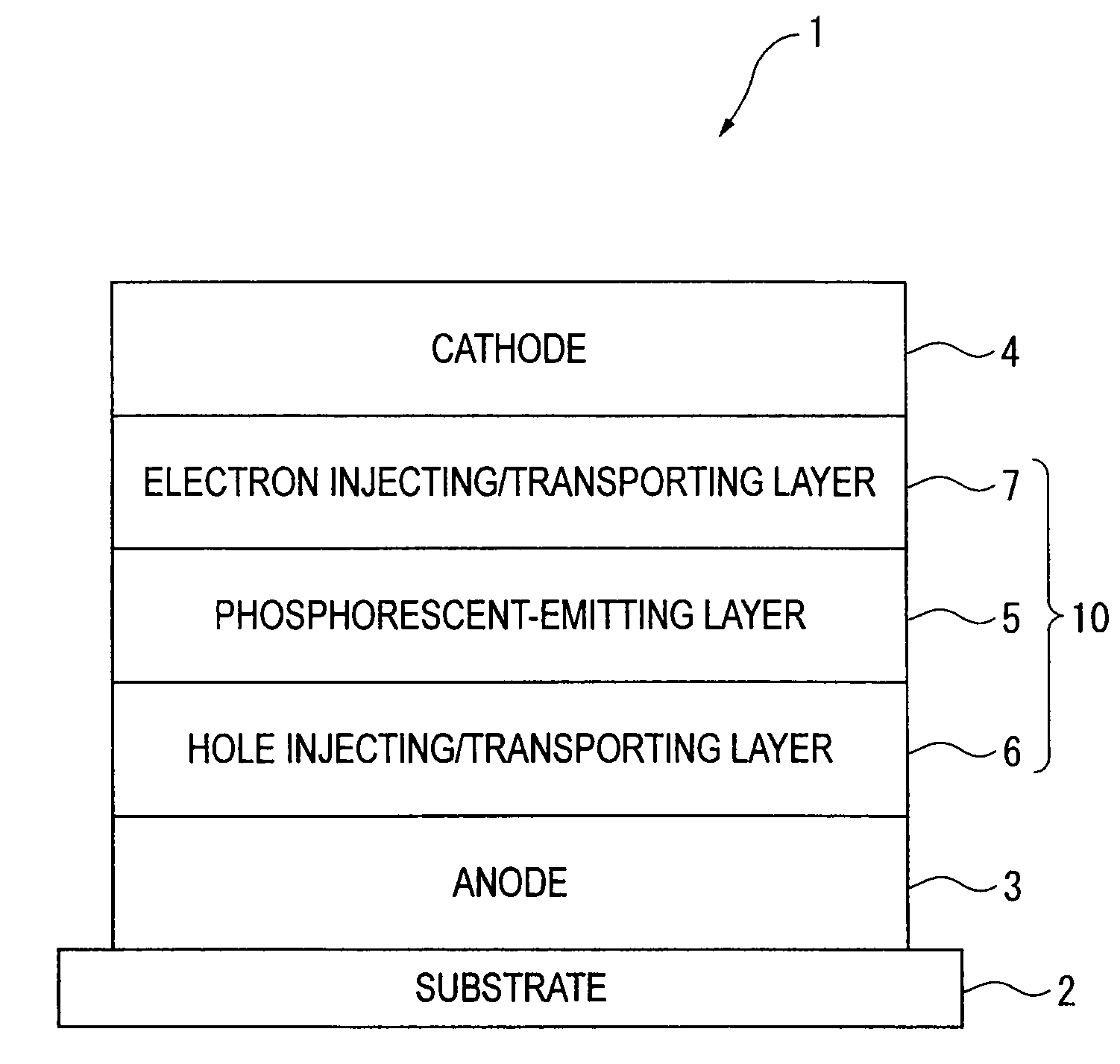

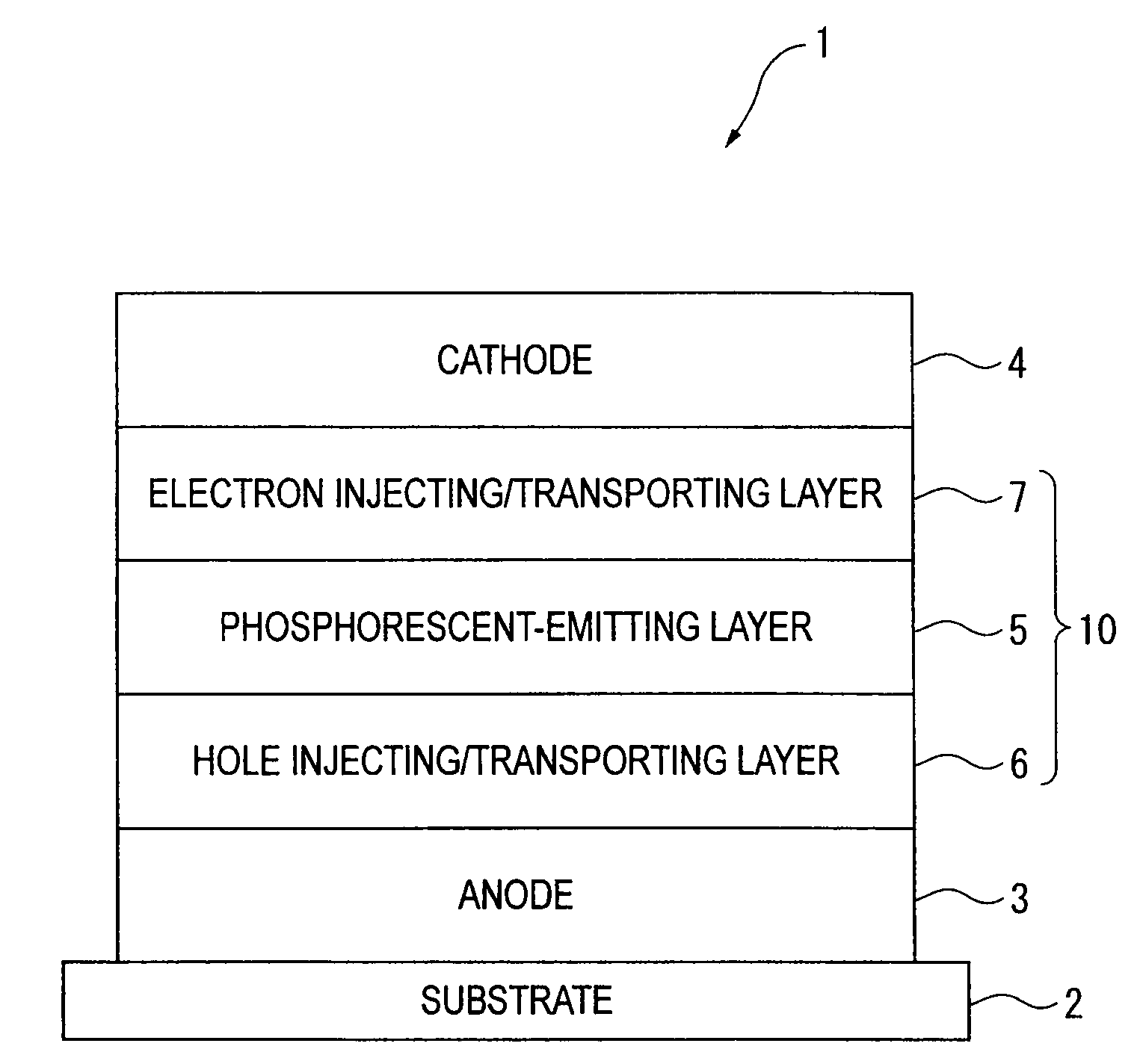

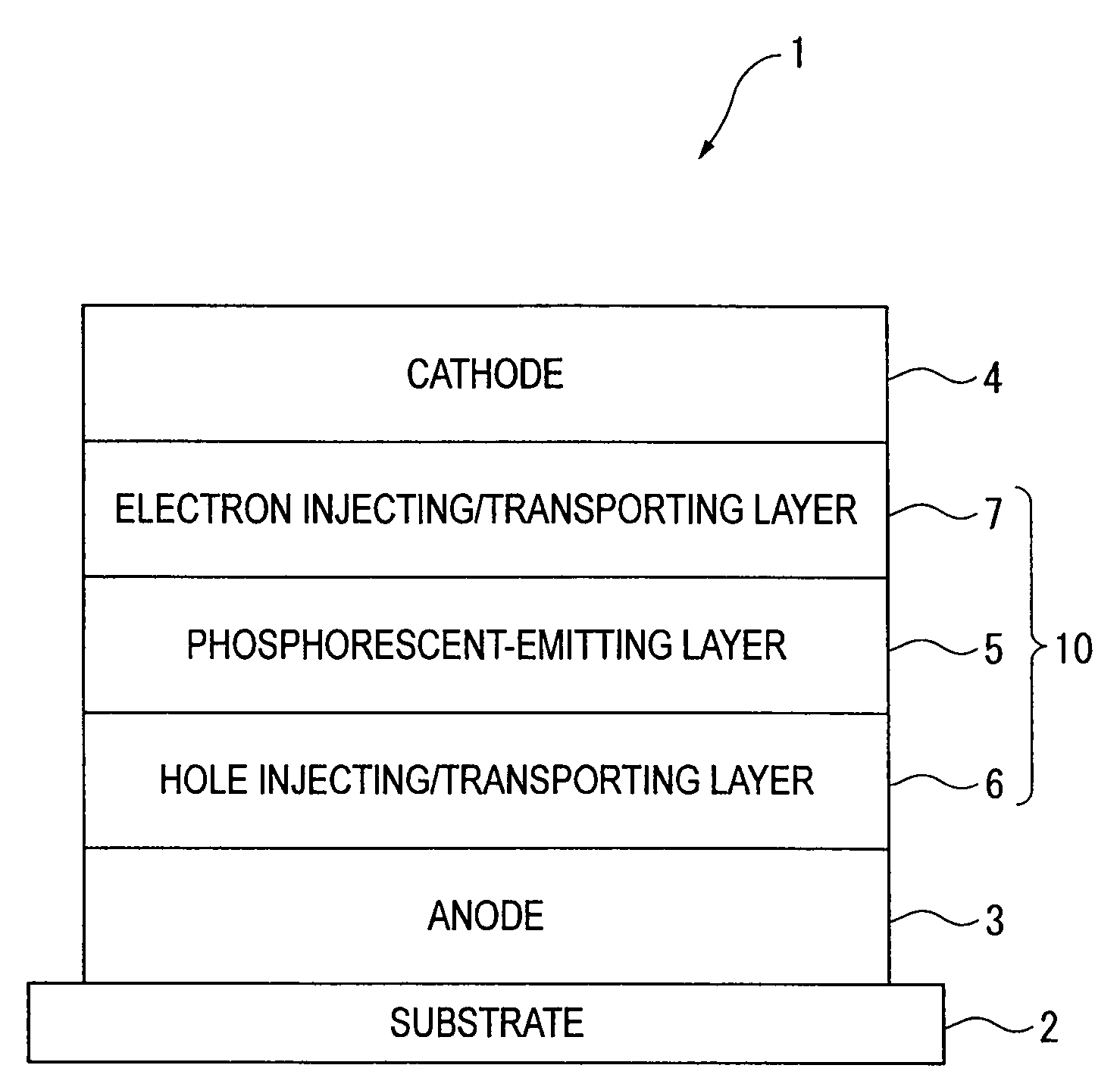

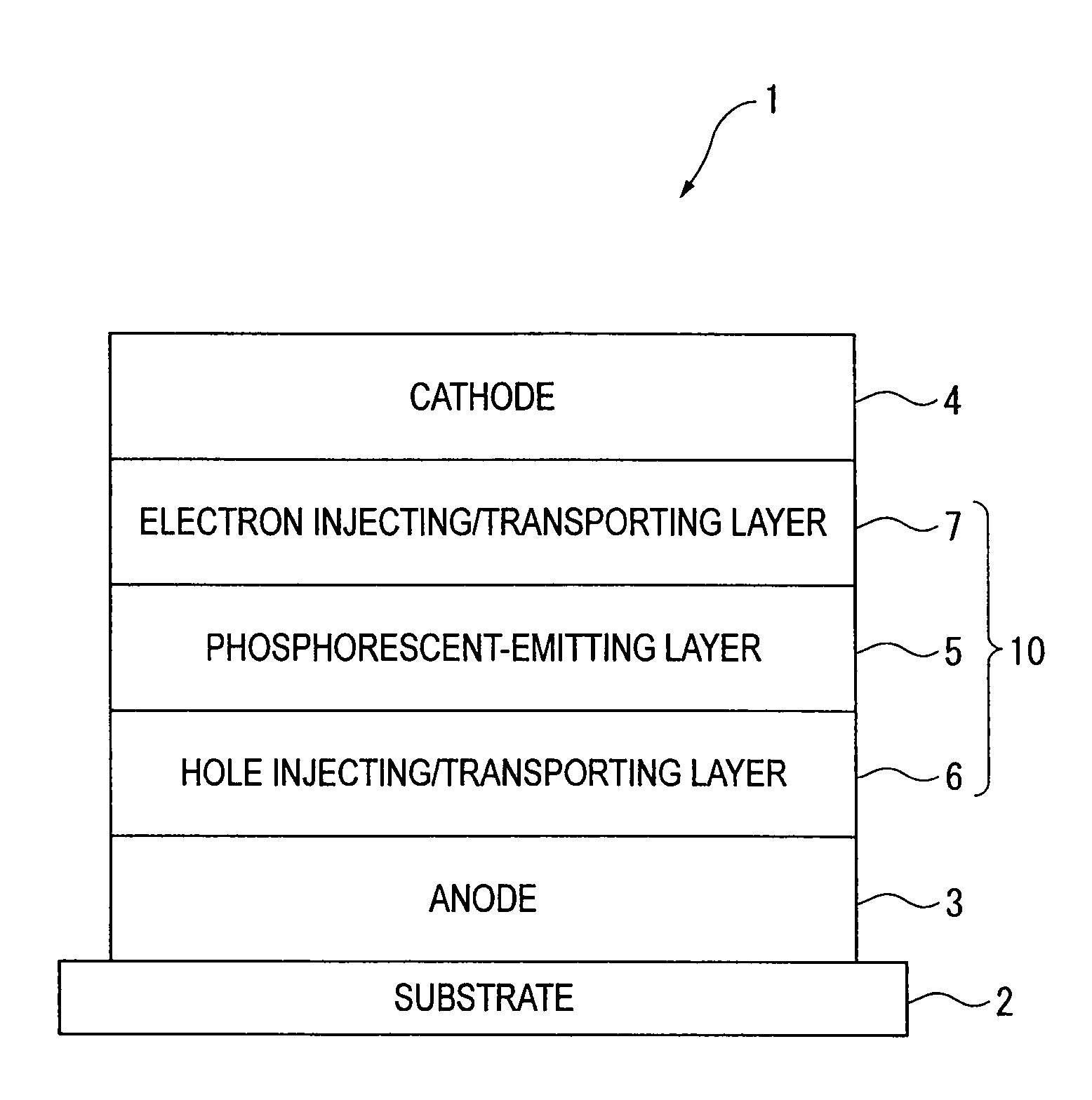

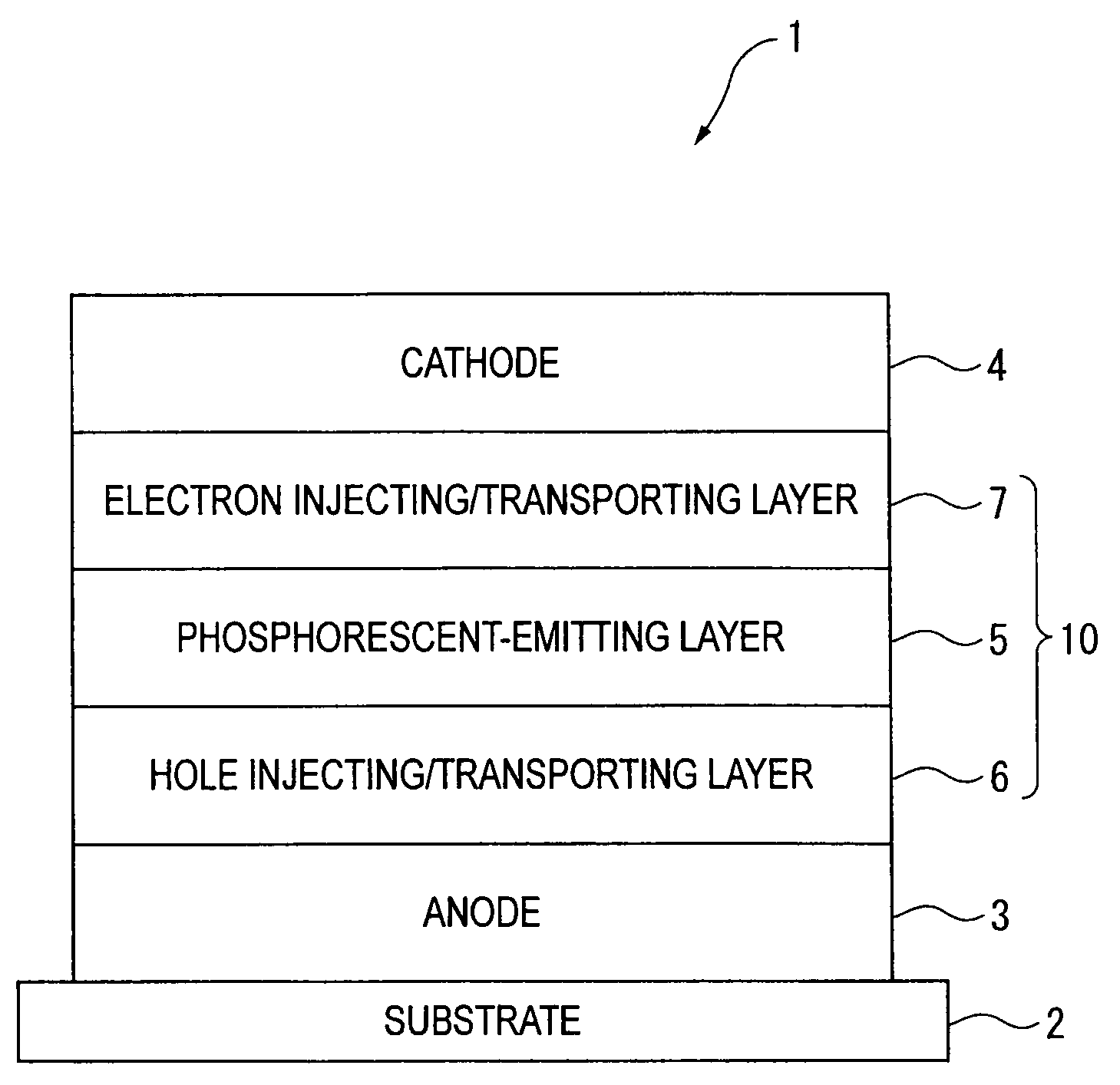

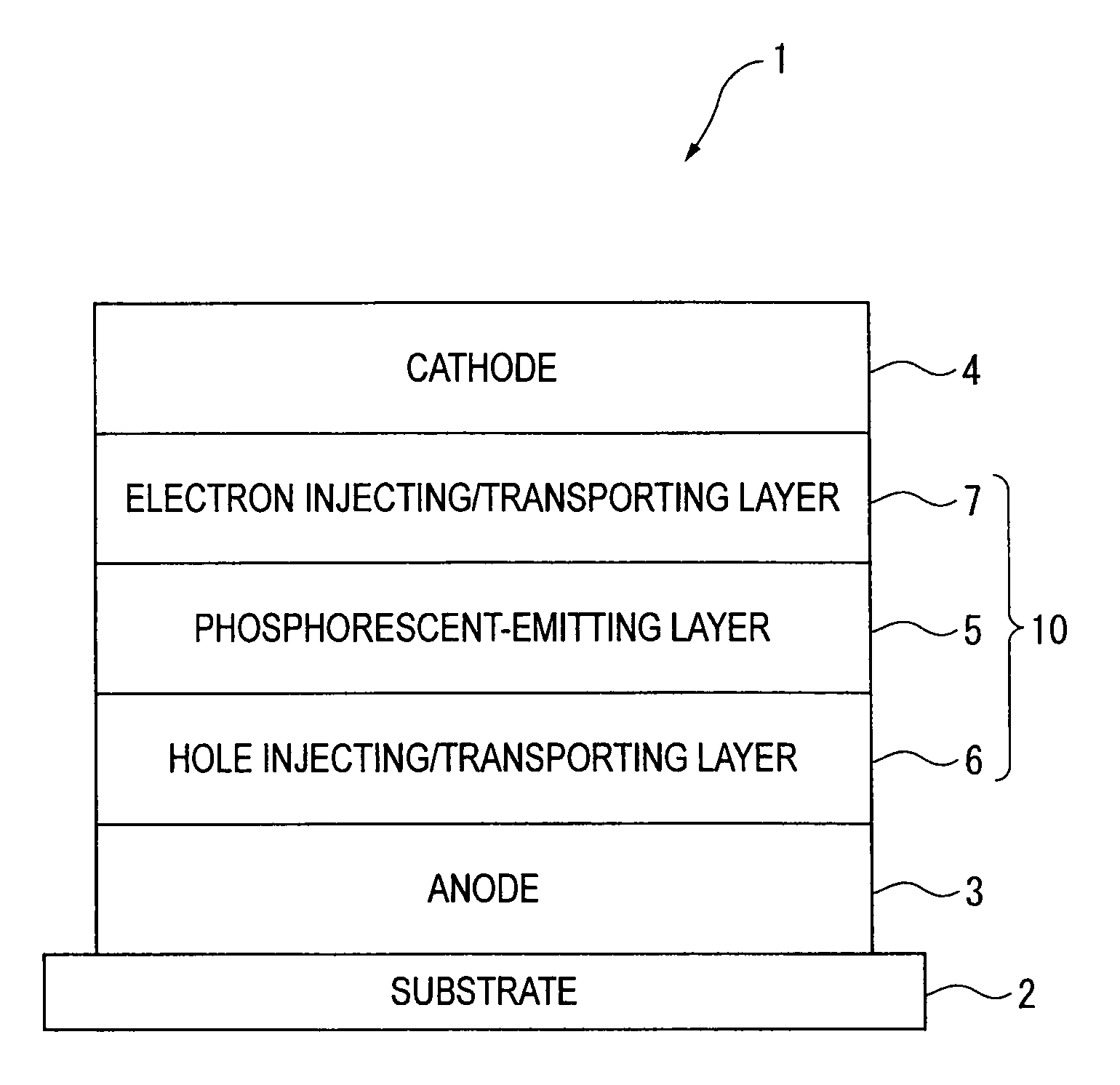

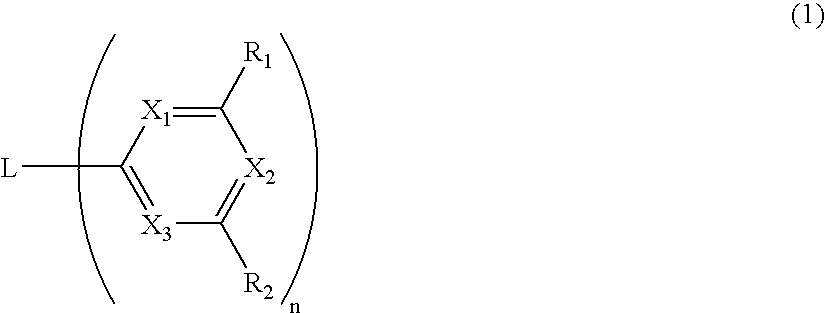

InactiveUS20090045731A1Improve efficiencyLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmFluoranthene

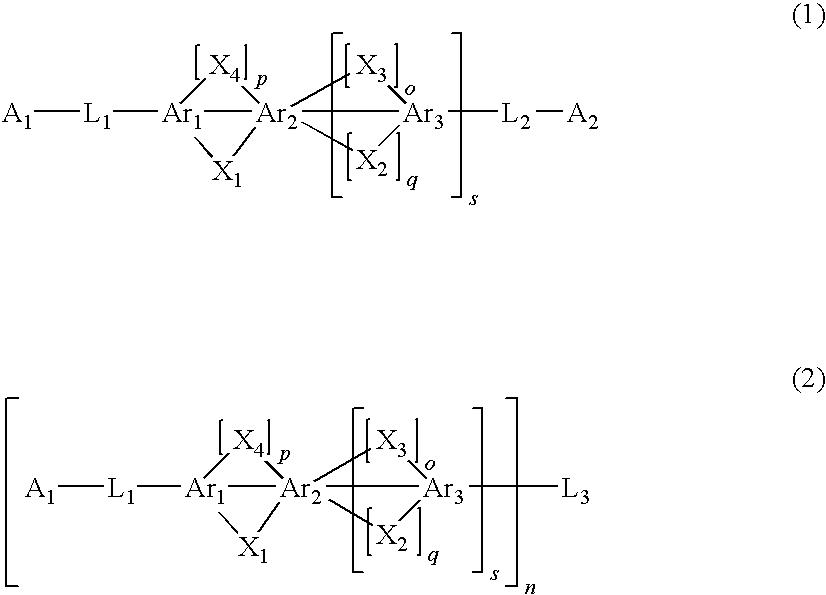

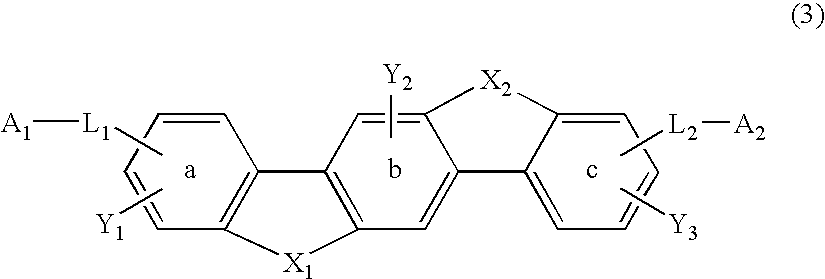

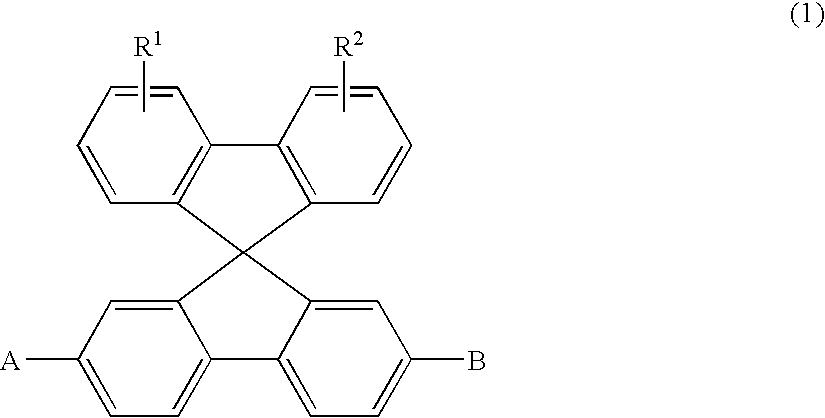

An organic electroluminescence device includes: a cathode; an anode; and a single-layered or multilayered organic thin-film layer provided between the cathode and the anode. The organic thin-film layer includes at least one emitting layer. The at least one emitting layer contains at least one phosphorescent material and a host material represented by the following formula (1).In the formula, Ar1, Ar2, Ar3, B1, B2, B3 and B4 each represent a substituted or unsubstituted benzene ring or a substituted or unsubstituted condensed aromatic hydrocarbon ring selected from a naphthalene ring, a chrysene ring, a fluoranthene ring, a phenanthrene ring, a benzophenanthrene ring, a dibenzophenanthrene ring, a triphenylene ring, a benzo[a]triphenylene ring, a benzochrysene ring, a benzo[b]fluoranthene ring and a picene ring. p is 0 or 1.

Owner:IDEMITSU KOSAN CO LTD

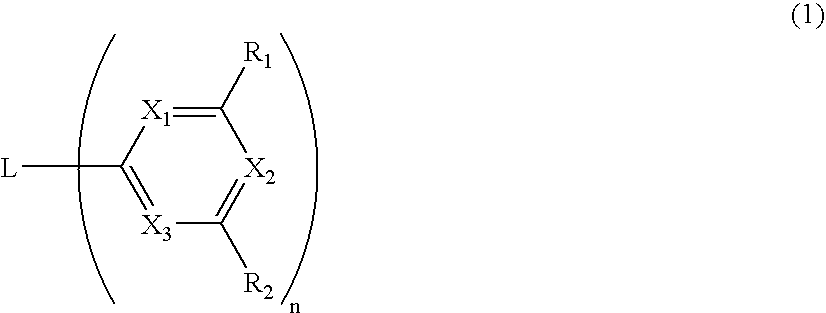

Organic electroluminescence device and material for organic electroluminescence device

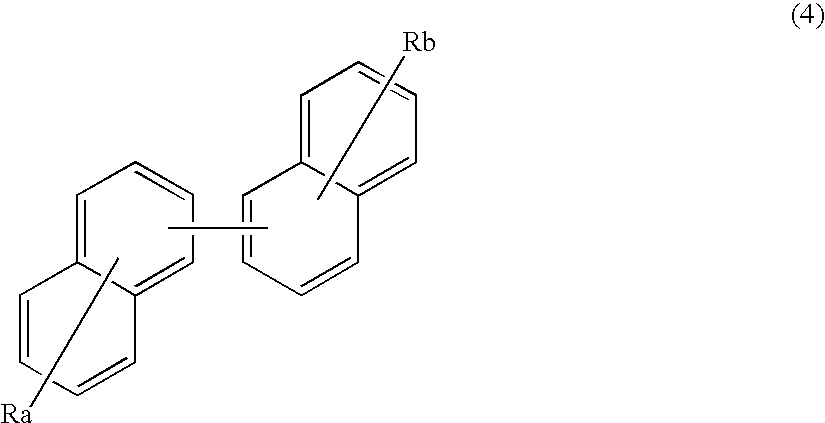

ActiveUS20090045730A1Improve efficiencyLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic filmBenzo(c)phenanthrene

An organic electroluminescence device includes: a cathode; an anode; and a single-layered or multilayered organic thin-film layer provided between the cathode and the anode. The organic thin-film layer includes at least one emitting layer. The at least one emitting layer contains at least one phosphorescent material and a host material represented by the following formula (1).Ra-Ar1-Rb (1)In the formula, Ar1, Ra and Rb each represent a substituted or unsubstituted benzene ring or a condensed aromatic hydrocarbon ring selected from a substituted or unsubstituted naphthalene ring, a substituted or unsubstituted chrysene ring, a substituted or unsubstituted fluoranthene ring, a substituted or unsubstituted phenanthrene ring, a substituted or unsubstituted benzophenanthrene ring, a substituted or unsubstituted dibenzophenanthrene ring, a substituted or unsubstituted triphenylene ring, a substituted or unsubstituted benzo[a]triphenylene ring, a substituted or unsubstituted benzochrysene ring, a substituted or unsubstituted benzo[b]fluoranthene ring and a substituted or unsubstituted picene ring. Substituents for Ra and Rb are not aryl groups.

Owner:IDEMITSU KOSAN CO LTD

Material for organic electroluminescence device and organic electroluminescence device using the same

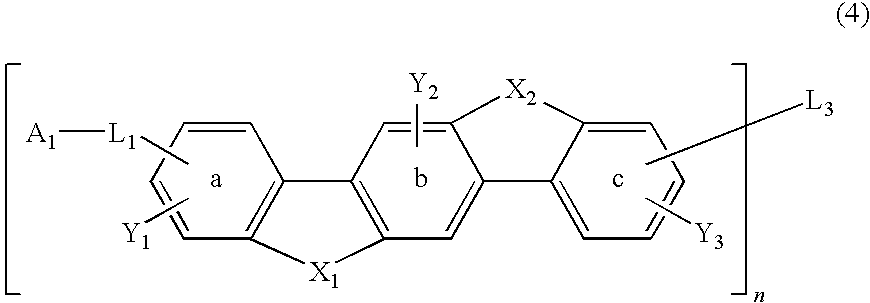

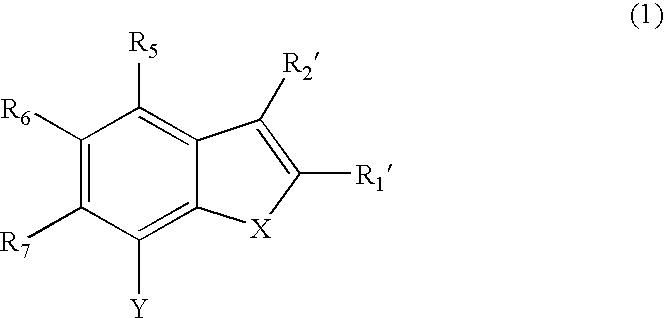

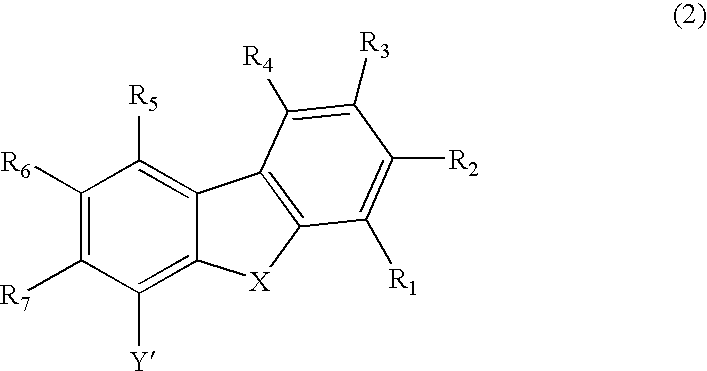

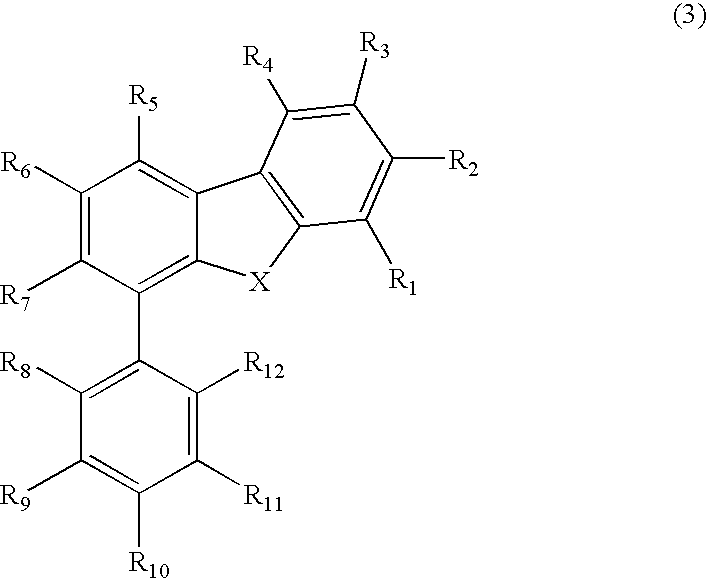

ActiveUS20090309488A1Solve low luminous efficiencyLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic filmThin membrane

Provided are an organic electroluminescence device, which shows high luminous efficiency, is free of any pixel defect, and has a long lifetime, and a material for an organic electroluminescence device for realizing the device. The material for an organic electroluminescence device is a compound having a n-conjugated heteroacene skeleton crosslinked with a carbon atom, nitrogen atom, oxygen atom, or sulfur atom. The organic electroluminescence device has one or more organic thin film layers including a light emitting layer between a cathode and an anode, and at least one layer of the organic thin film layers contains the material for an organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

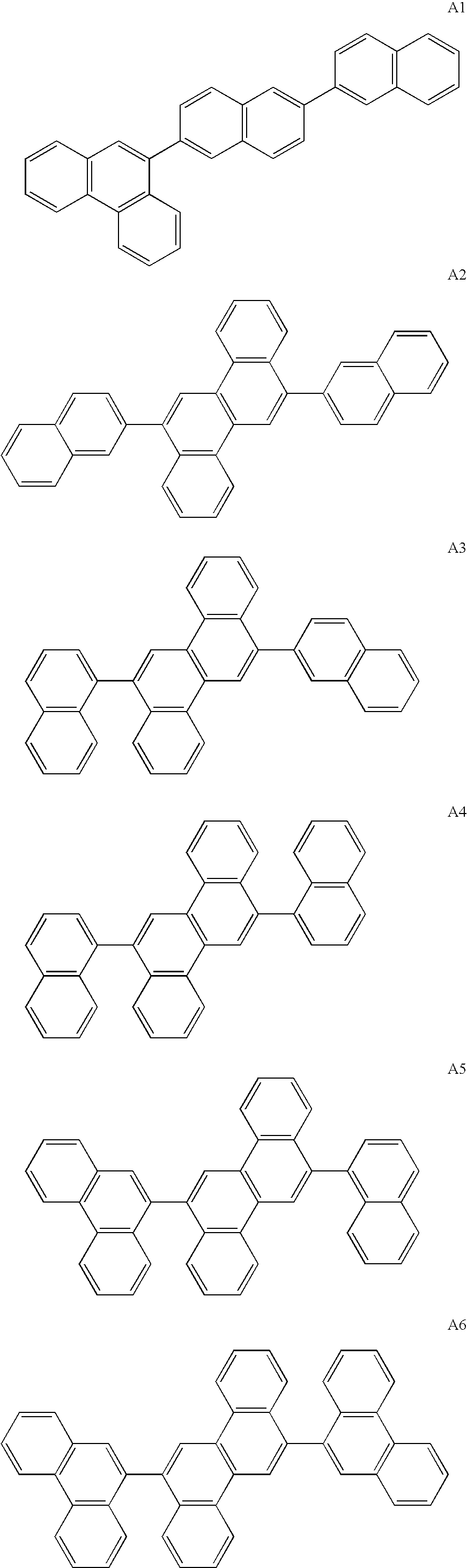

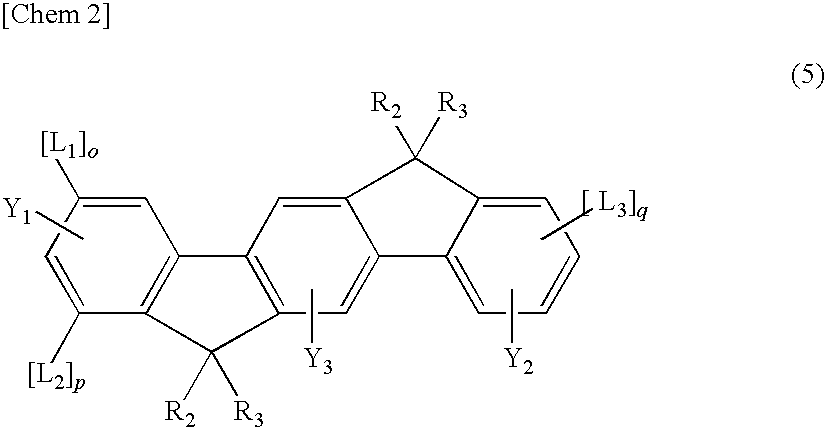

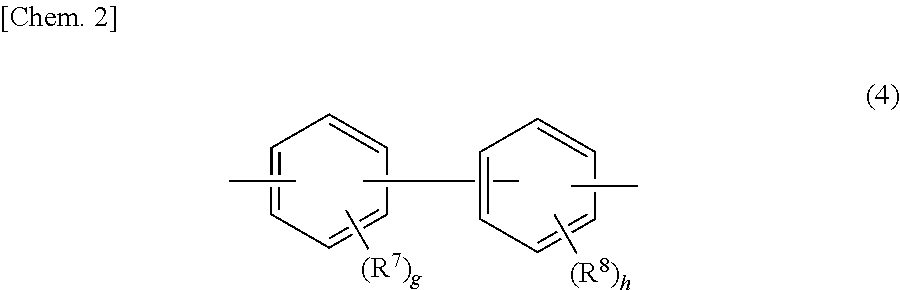

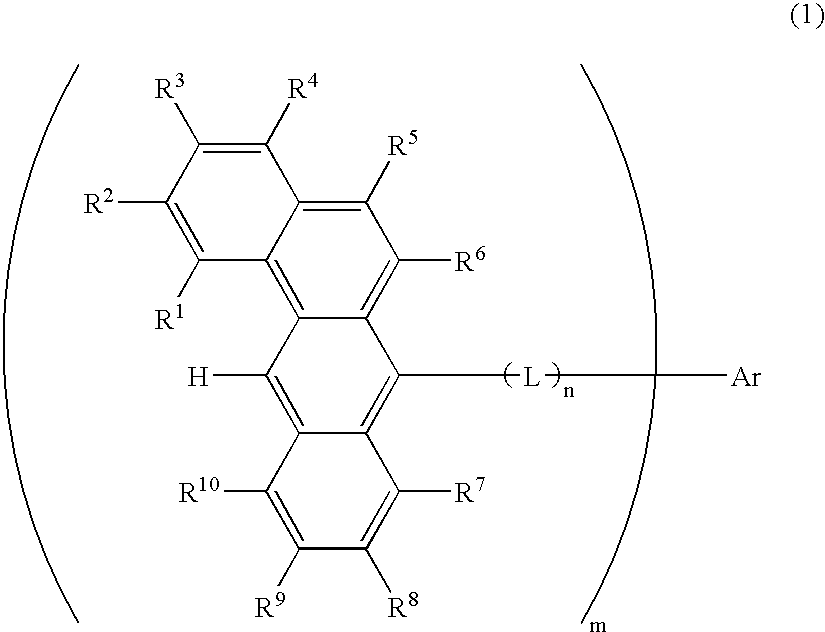

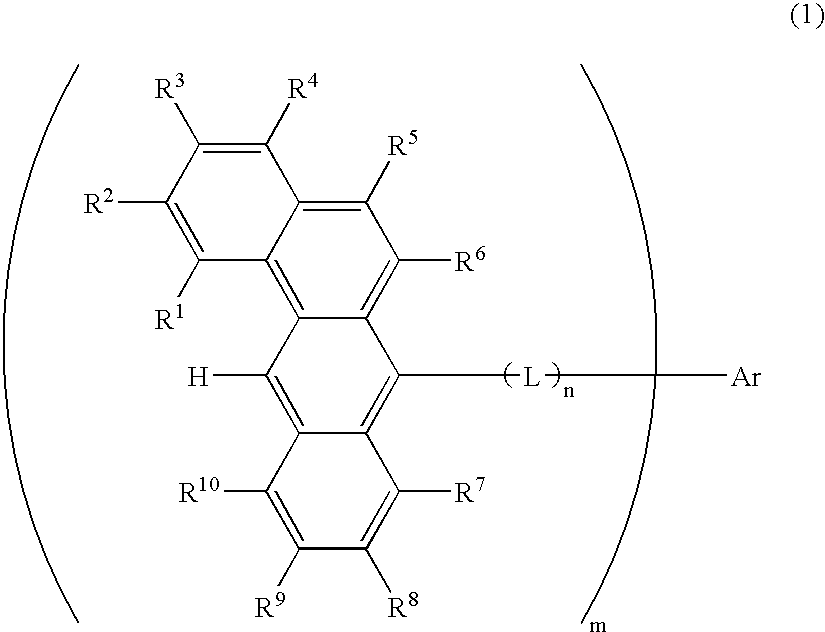

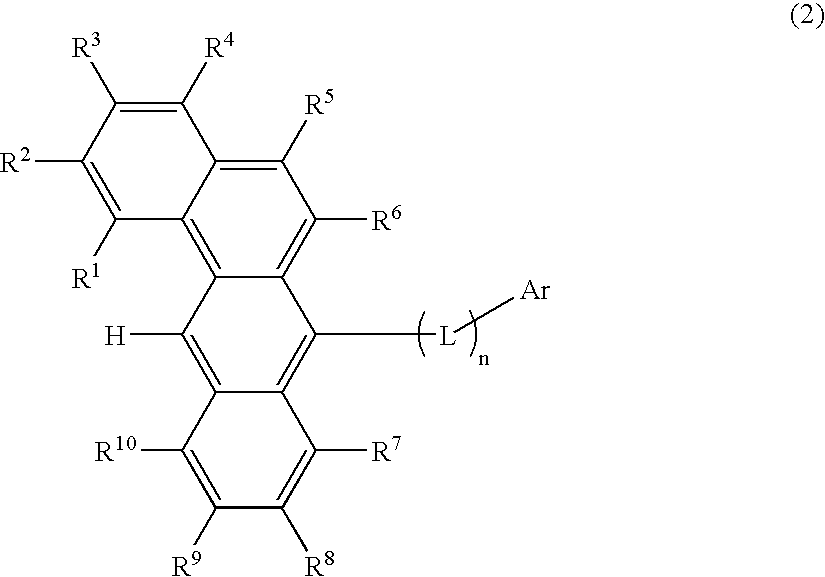

Polycyclic compounds and organic electroluminescence device employing the same

ActiveUS20100012931A1Solve low luminous efficiencyLong life-timeOrganic chemistryDischarge tube luminescnet screensPolycyclic compoundBenzene

Provided are a polycyclic compound of a compound having such a structure that two benzene rings bond to a central benzene ring each other to form a fused ring and another fused ring bonds to a terminal thereof, and an organic electroluminescence device including one or more organic thin film layers containing a light emitting layer between a cathode and an anode, in which at least one of the organic thin film layers includes the polycyclic compound of the present invention. The organic electroluminescence device has high luminous efficiency, no defect in pixels, and long lifetime. In addition, provided is a polycyclic compound realizing the organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

Aromatic amine derivatives and organic electroluminescence device using the same

InactiveUS20090167161A1Increase productionLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceHole transport layer

Provided are an organic electroluminescence device and an aromatic amine derivative for realizing the device. The aromatic amine derivative improves the luminous efficiency of an organic electroluminescence device using the derivative, and its molecules hardly crystallize. The organic electroluminescence device has an organic thin film layer composed of one or a plurality of layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode, and at least one layer of the organic thin film layer, especially a hole transporting layer contains the aromatic amine derivative alone or as a component of a mixture, so the organic electroluminescence device can be produced in improved yield, and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

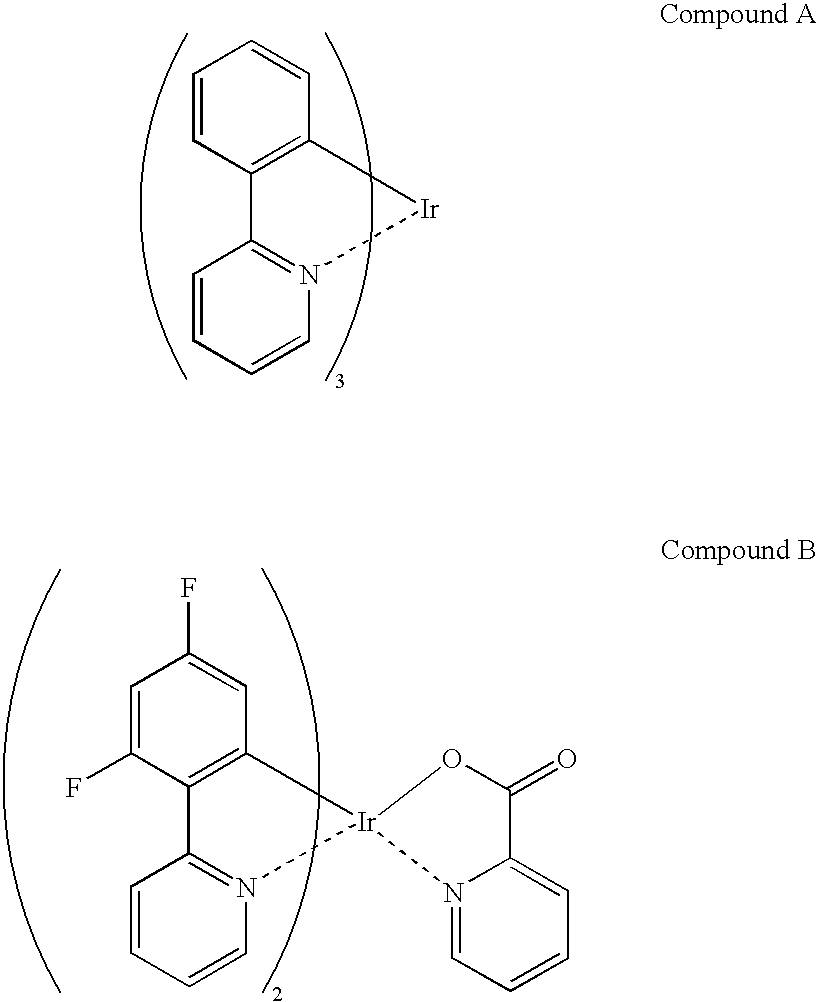

Metal complex compound and organic electroluminescence device using the compound

InactiveUS20070138437A1Improve efficiencyLong life-timeIndium organic compoundsElectroluminescent light sourcesOrganic filmLength wave

Provided are an organic electroluminescence device whose wavelength of light emission is short and which can emit blue light having a high color purity, and a metal complex compound for realizing the device. The metal complex compound is of a specific structure having a partial structure including two tridentate ligands. The organic electroluminescence device includes: a pair of electrodes; and an organic thin film layer which has one layer or a plurality of layers including at least a light emitting layer and is disposed between the pair of electrodes. In the organic electroluminescence device, at least one layer of the organic thin film layer contains the metal complex compound. The organic electroluminescence device emits light by applying a voltage between both the electrodes.

Owner:CHUO UNIVERSITY +1

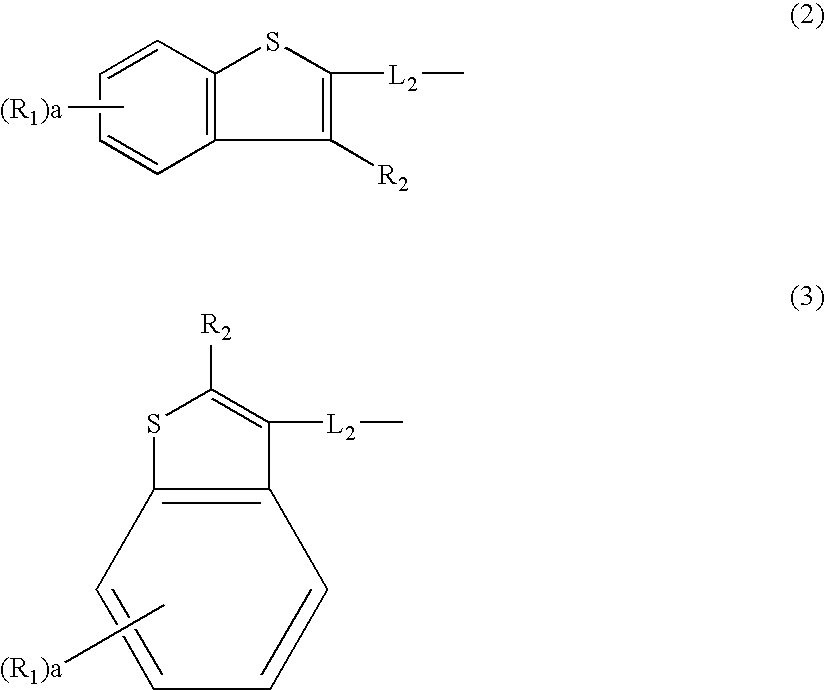

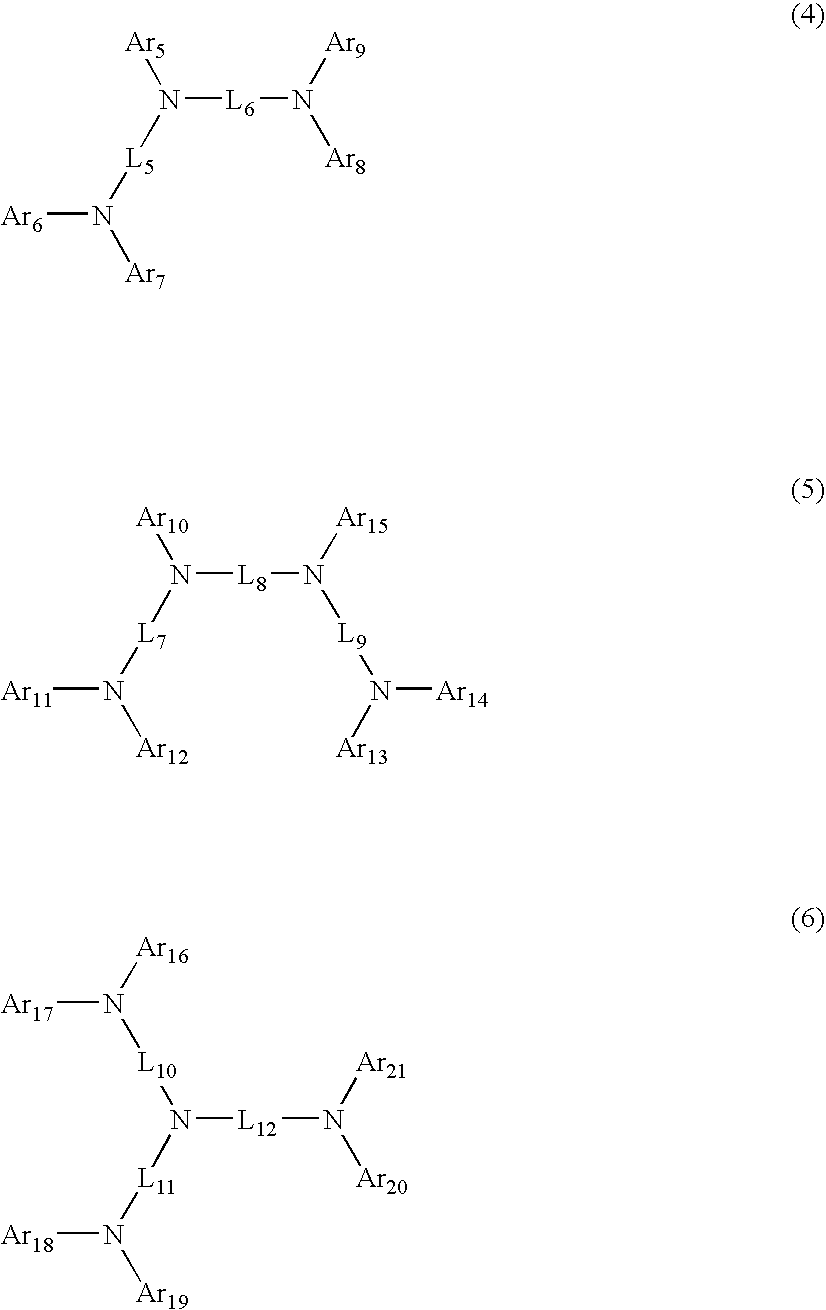

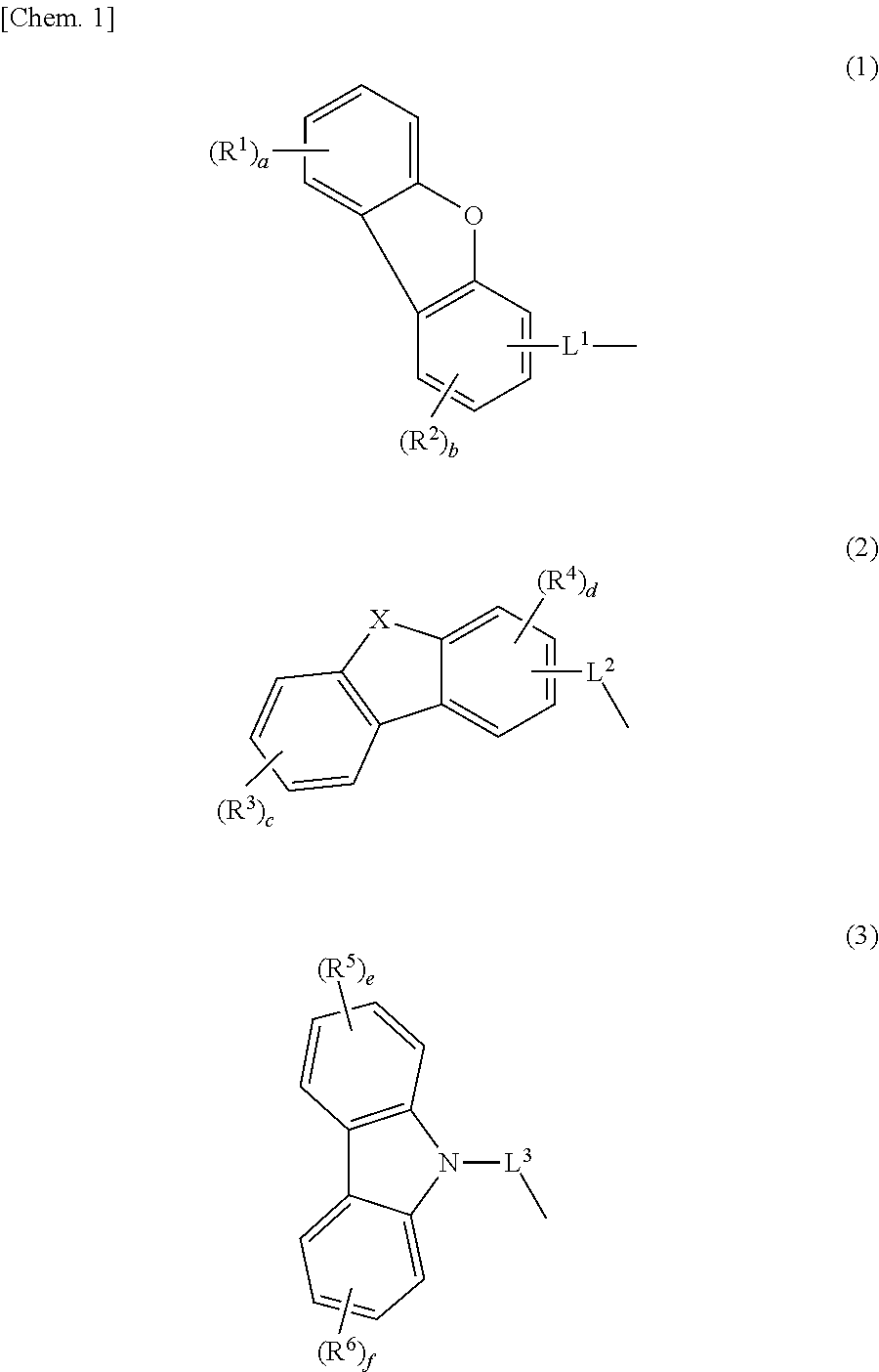

Aromatic amine derivative, and organic electroluminescent element

ActiveUS20110278551A1Improve efficiencyLong life-timeOrganic chemistryElectroluminescent light sourcesOrganic filmHole transport layer

Provided are an organic electroluminescence device that not only provides high efficiency but also has a long lifetime, and an aromatic amine derivative that realizes the device. The organic electroluminescence device includes an aromatic amine derivative, including at least one substituent A having dibenzofuran and at least one substituent B selected from groups each having dibenzofuran or carbazole, in a molecule thereof, in which the substituent A and the substituent B include groups different from each other, and the substituent A and the substituent B are bonded to the same nitrogen atom, or different nitrogen atoms, in the molecule. The molecules of the aromatic amine derivative hardly crystallize, which improves a yield in the production of the organic electroluminescence device. In the organic electroluminescence device, including an organic thin film layer formed of one or more layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode, the aromatic amine derivative is contained in at least one layer, particularly a hole transport layer, in the organic thin film layer.

Owner:IDEMITSU KOSAN CO LTD

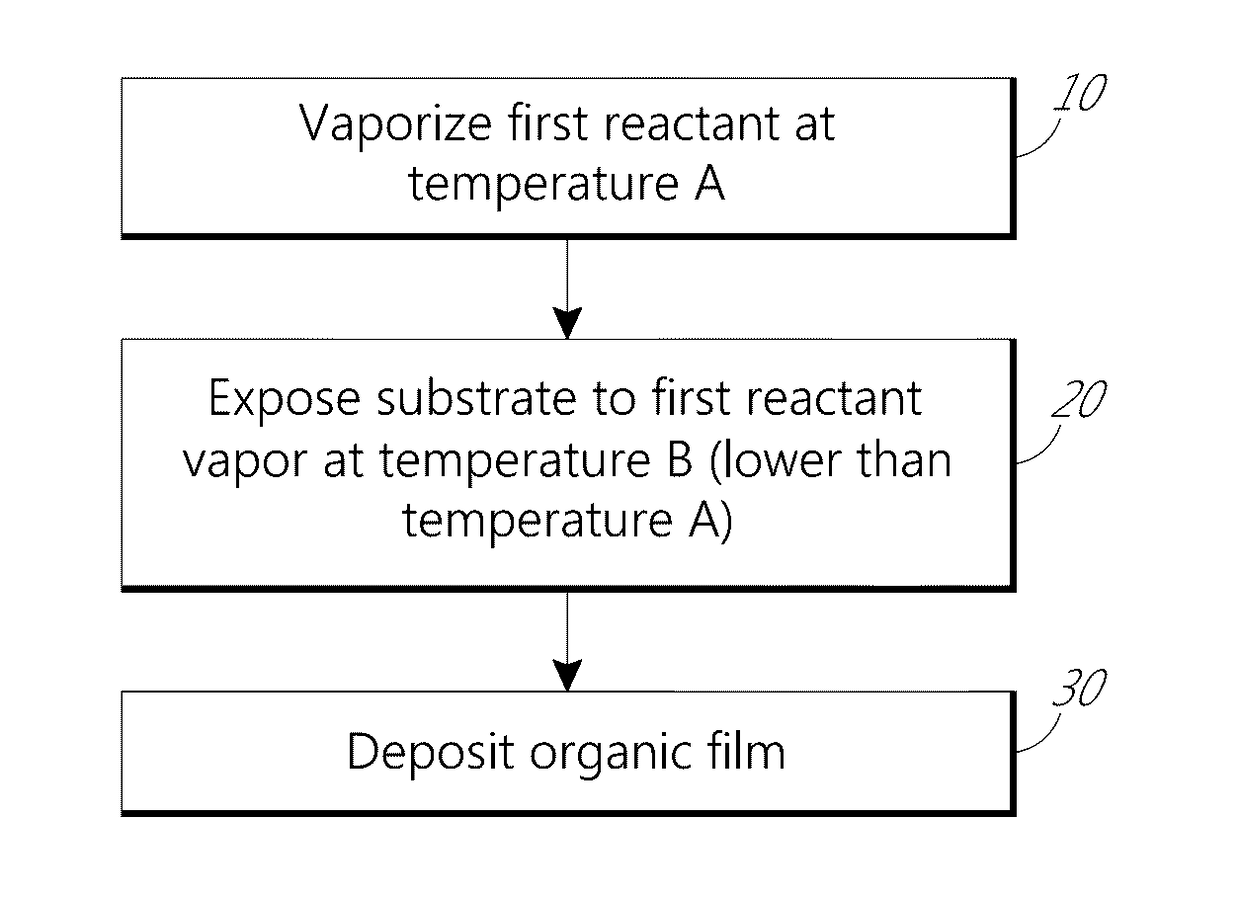

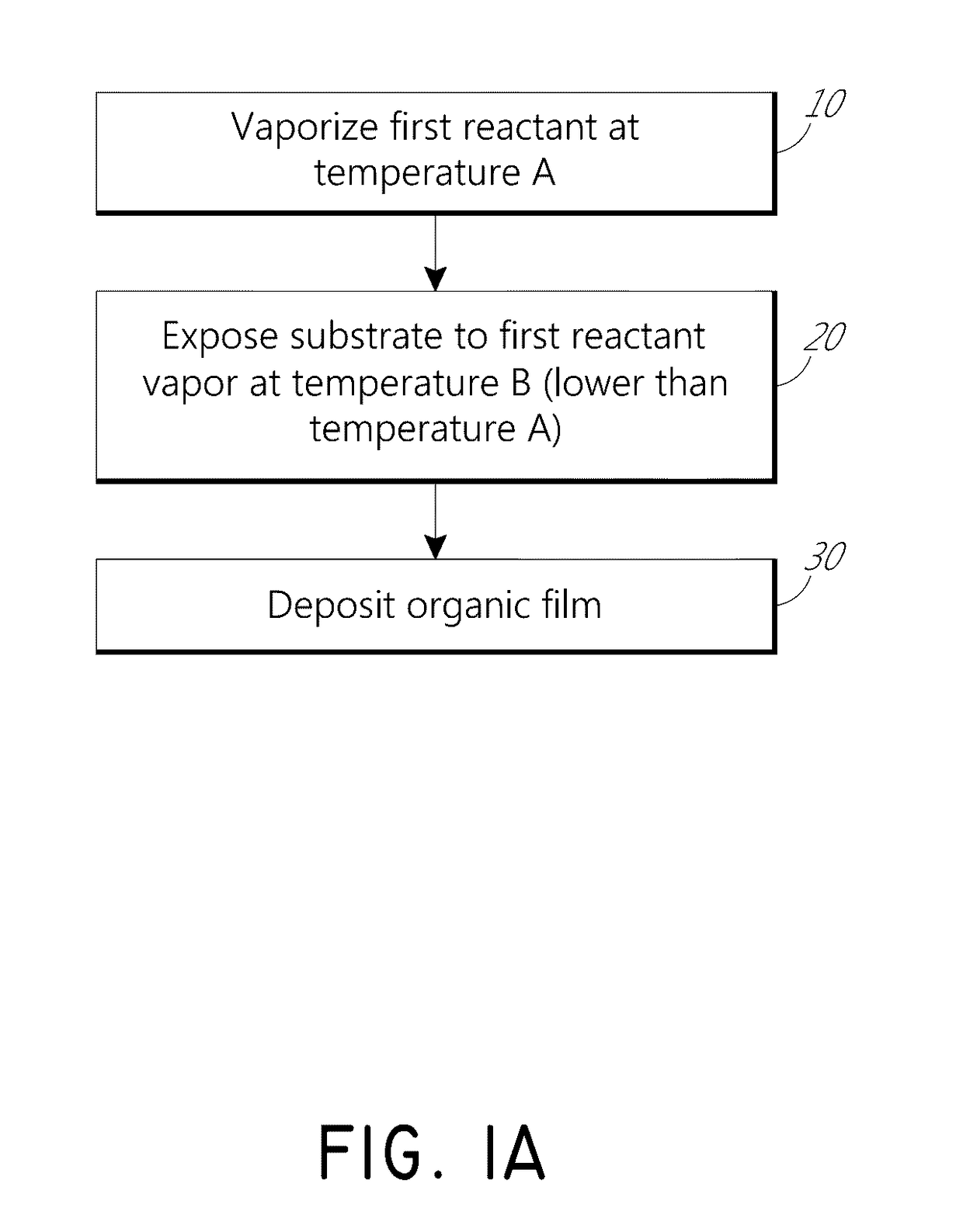

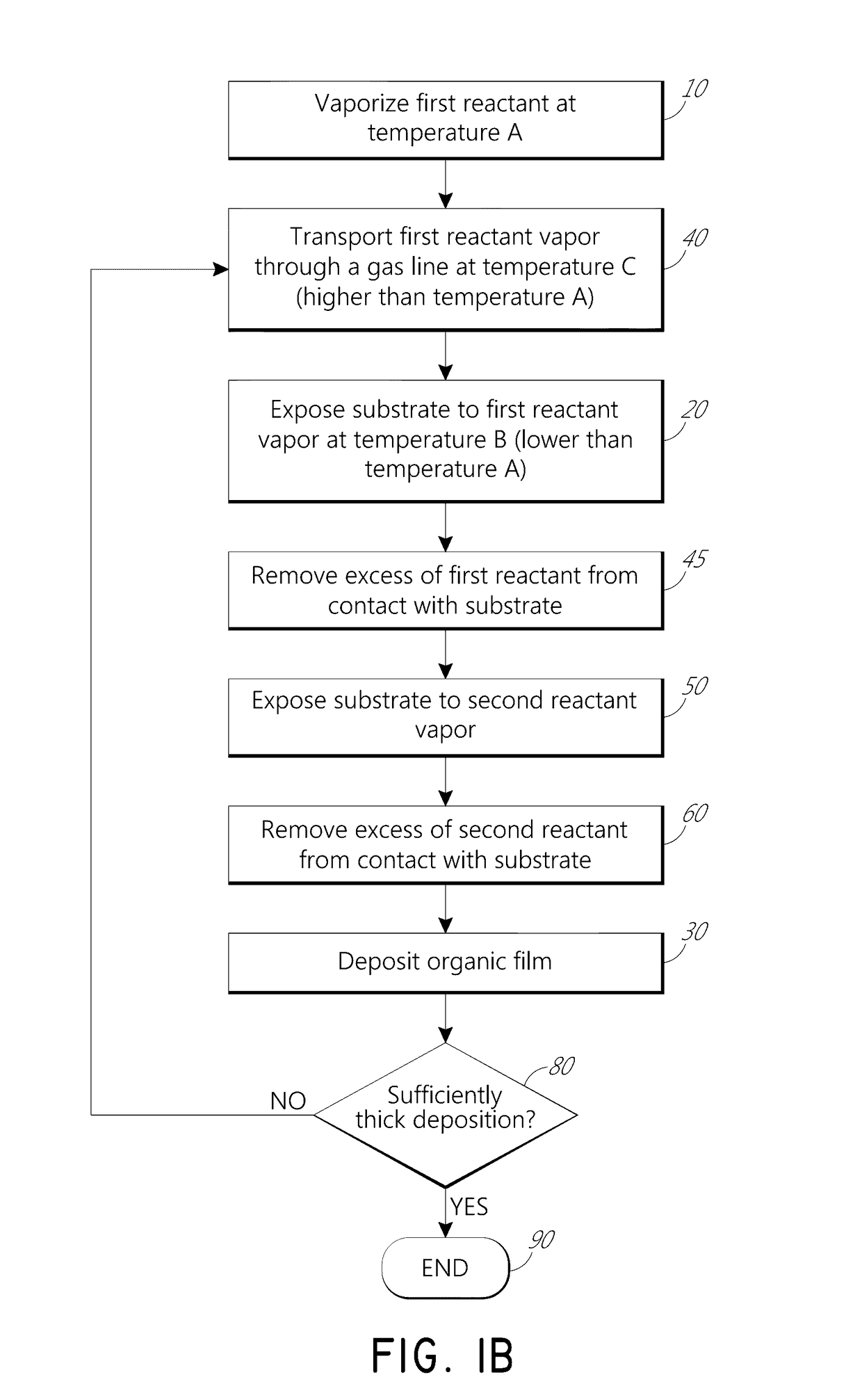

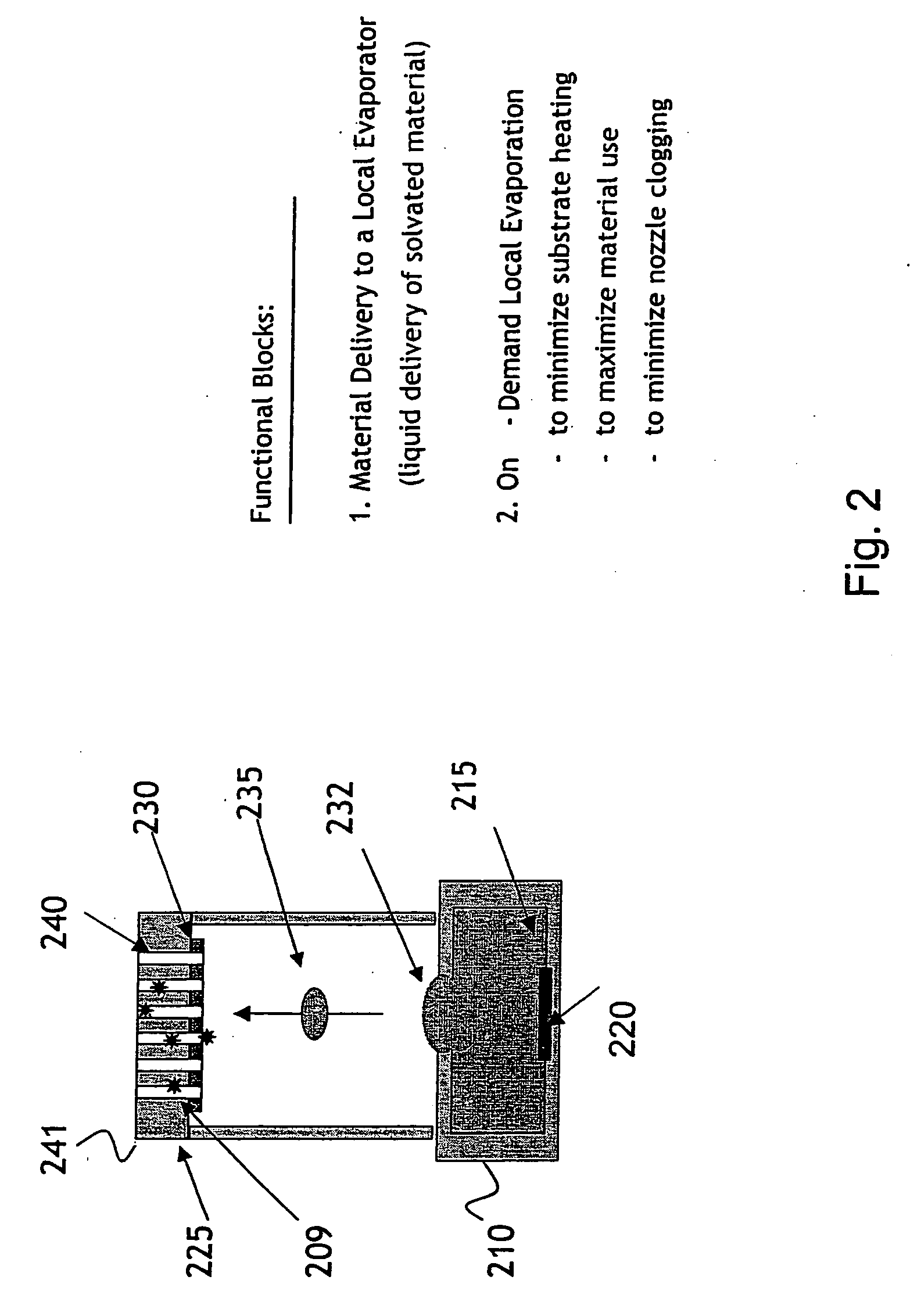

Vapor phase deposition of organic films

ActiveUS20170100742A1Reduce aspect ratioLiquid surface applicatorsChemical vapor deposition coatingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve.

Owner:ASM IP HLDG BV

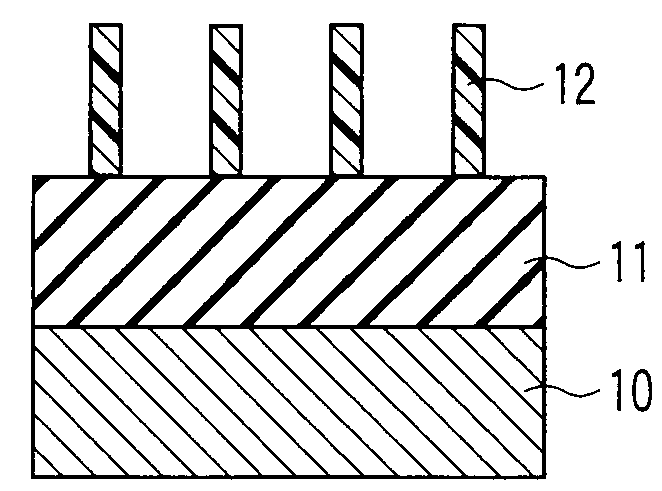

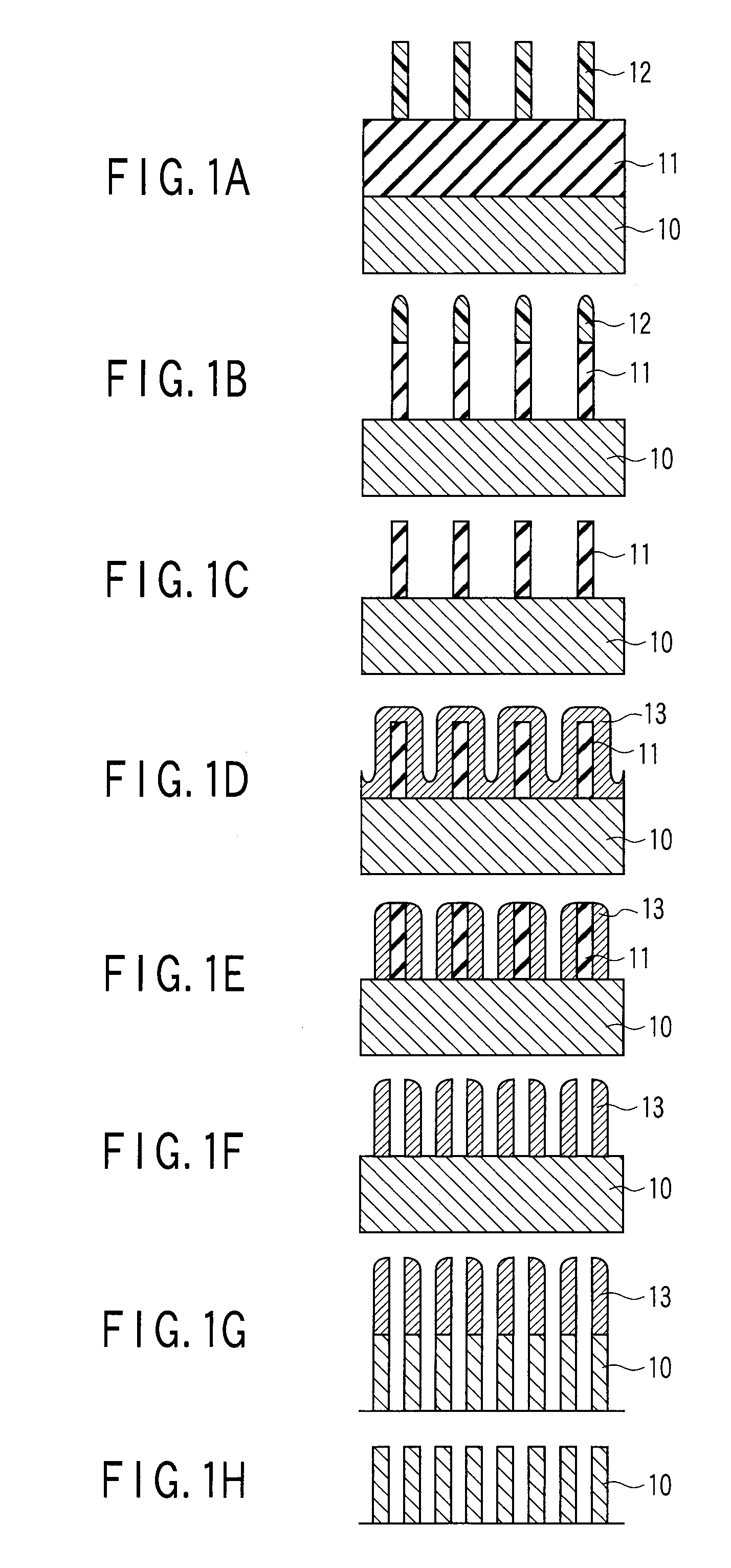

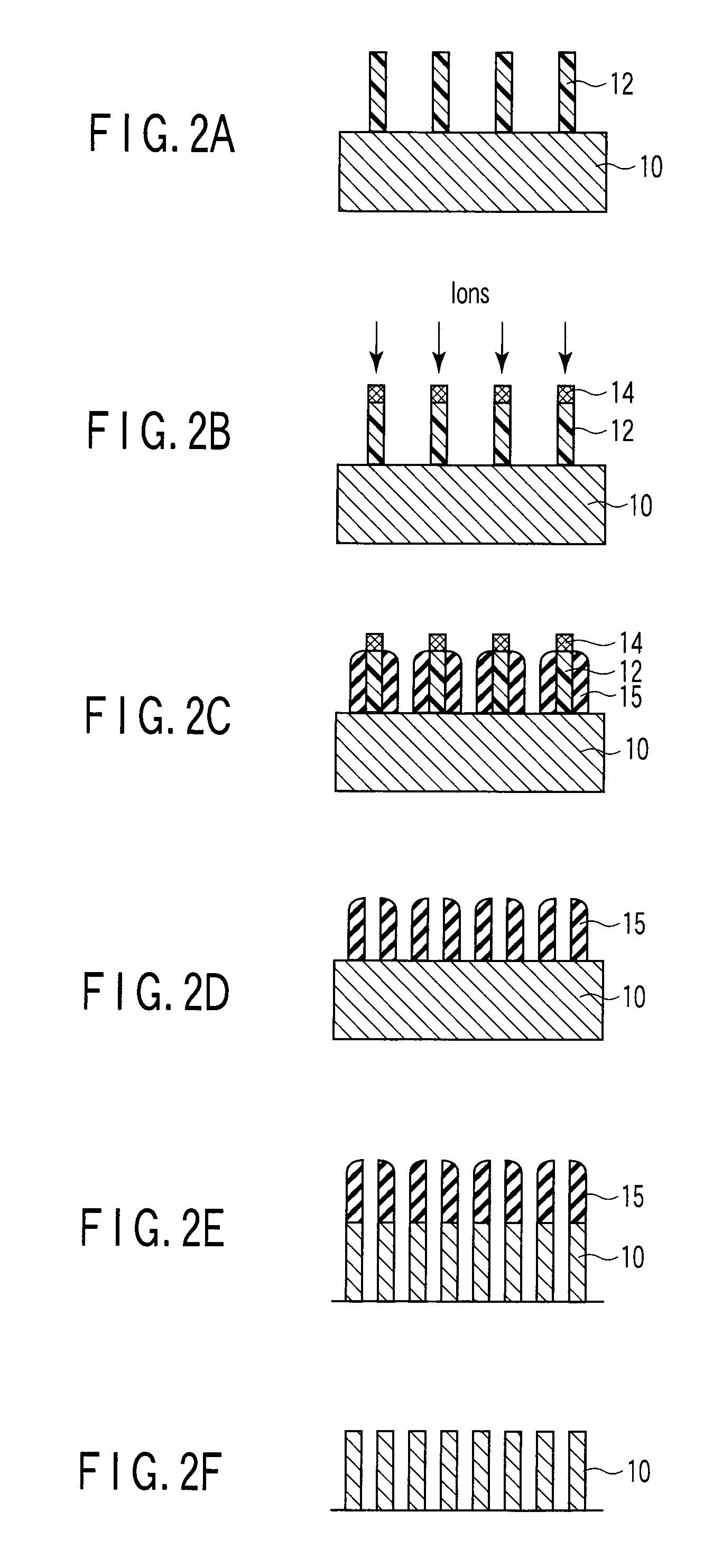

Pattern forming method using relacs process

InactiveUS20080305443A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistOrganic film

A resist pattern is formed on a to-be-processed film. Ions are implanted in the upper surface of the resist pattern. After ion implantation, an organic film is formed to cover the resist pattern and heated. A crosslinked resin film made of the organic film which has crosslinked is formed on the sidewall of the resist pattern by developing the organic film after heating. After formation of the crosslinked resin film, the resist pattern is removed. The to-be-processed film is processed using the crosslinked resin film as a mask.

Owner:KK TOSHIBA

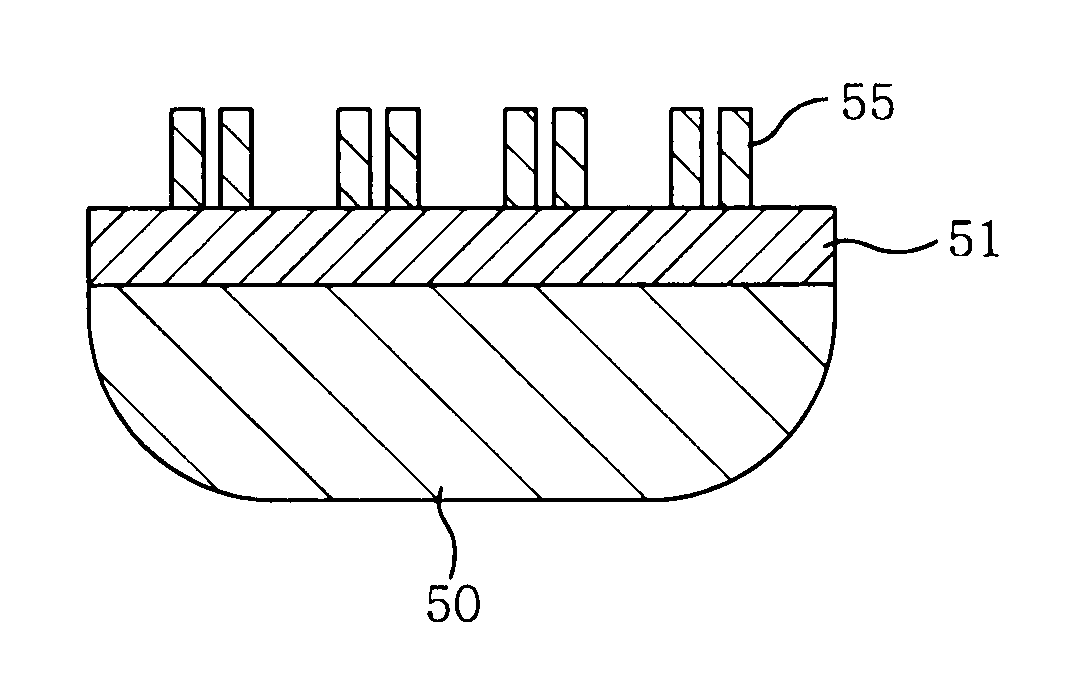

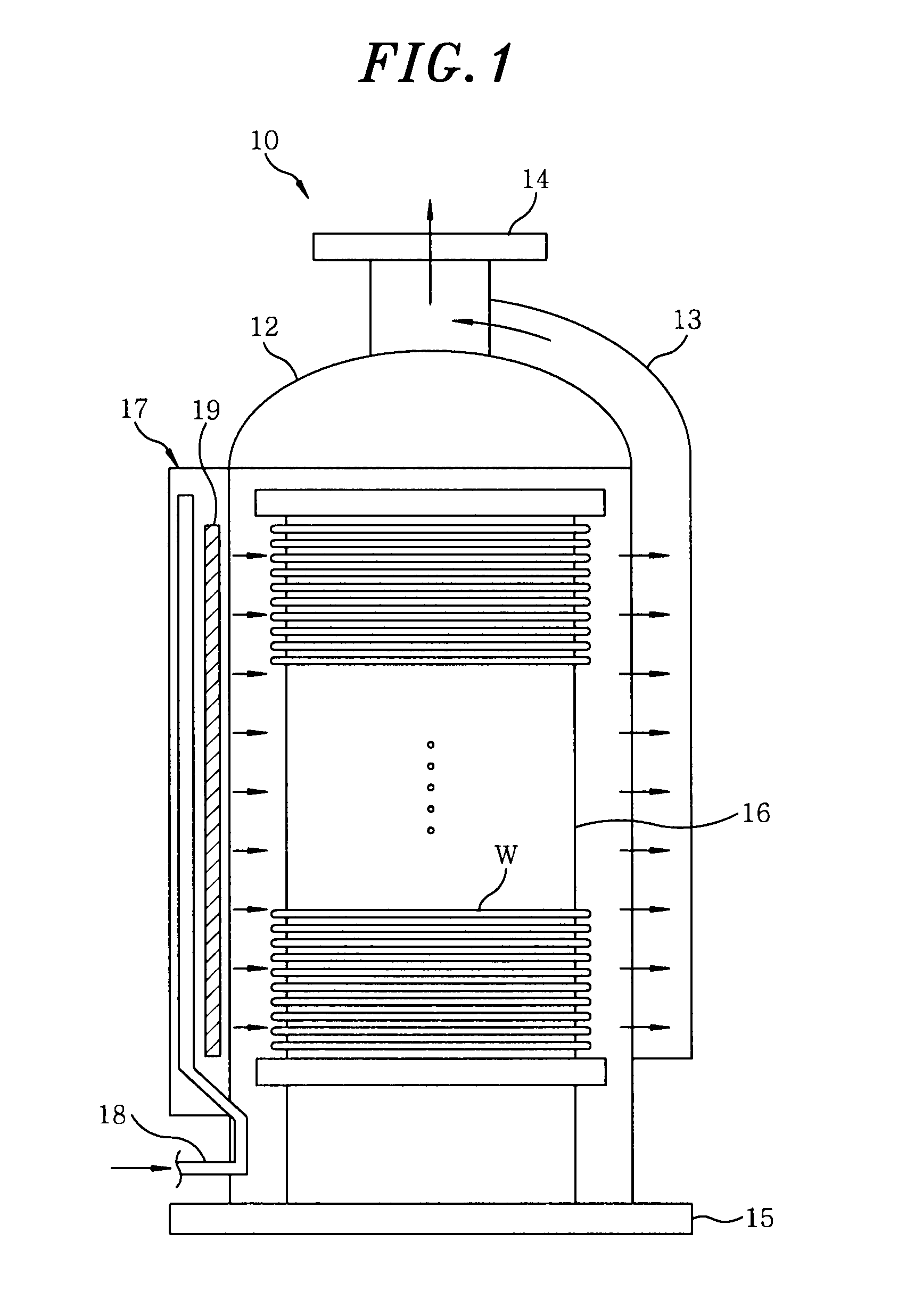

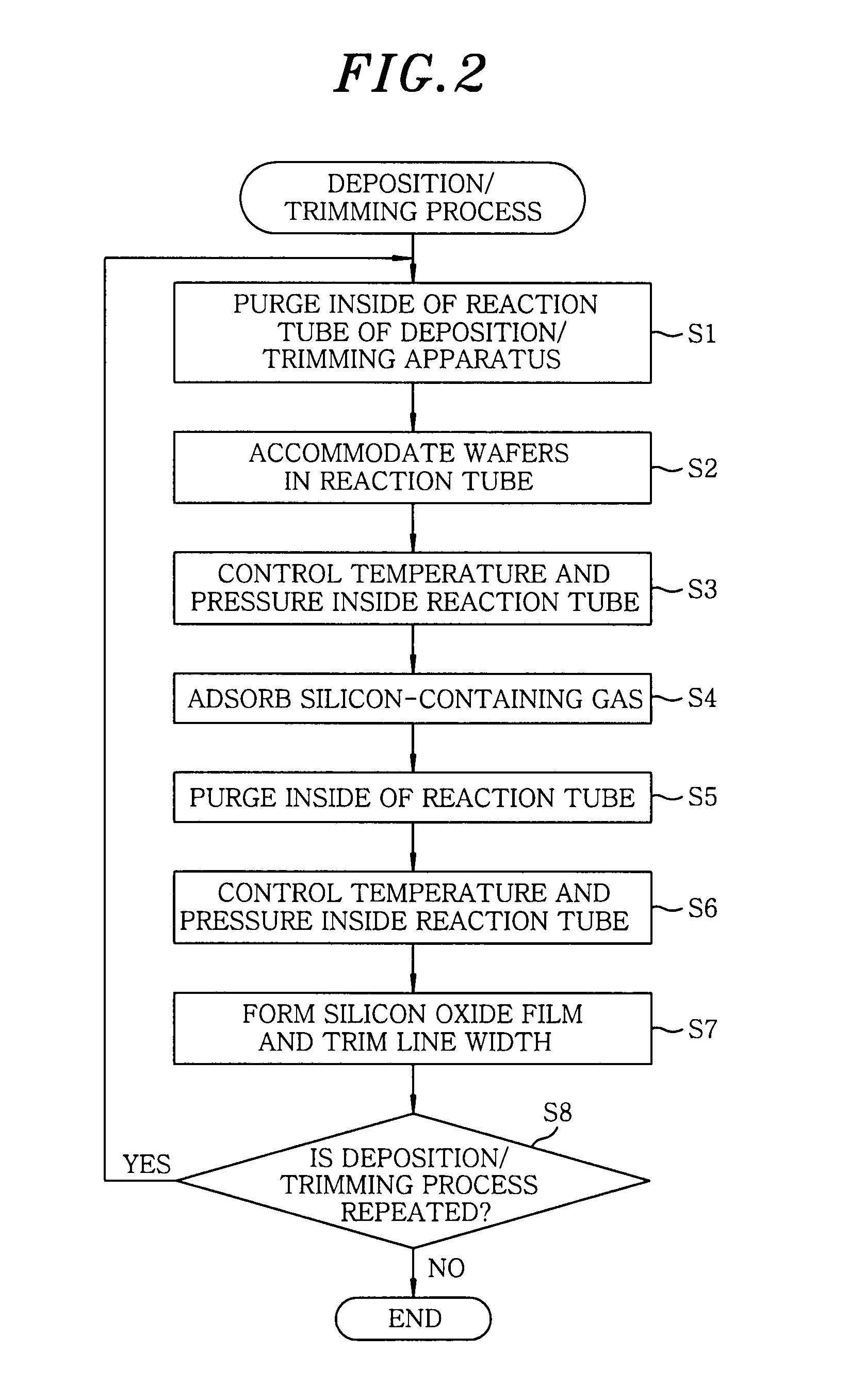

Substrate processing method

ActiveUS20100233885A1Electric discharge tubesSemiconductor/solid-state device manufacturingOrganic filmLine width

A method for processing a substrate including a processing target layer and an organic film, include: a deposition / trimming process of forming a reinforcement film on a surface of the organic film and, at the same time, trimming a line width of a line portion of the organic film constituting an opening pattern. The deposition / trimming process includes an adsorption process for allowing a silicon-containing gas to be adsorbed onto the surface of the organic film and an oxidation process in which the line width of the organic film is trimmed while the adsorbed silicon-containing gas is converted into a silicon oxide film. A monovalent aminosilane is employed as the silicon-containing gas.

Owner:TOKYO ELECTRON LTD

Luminescence device and display apparatus

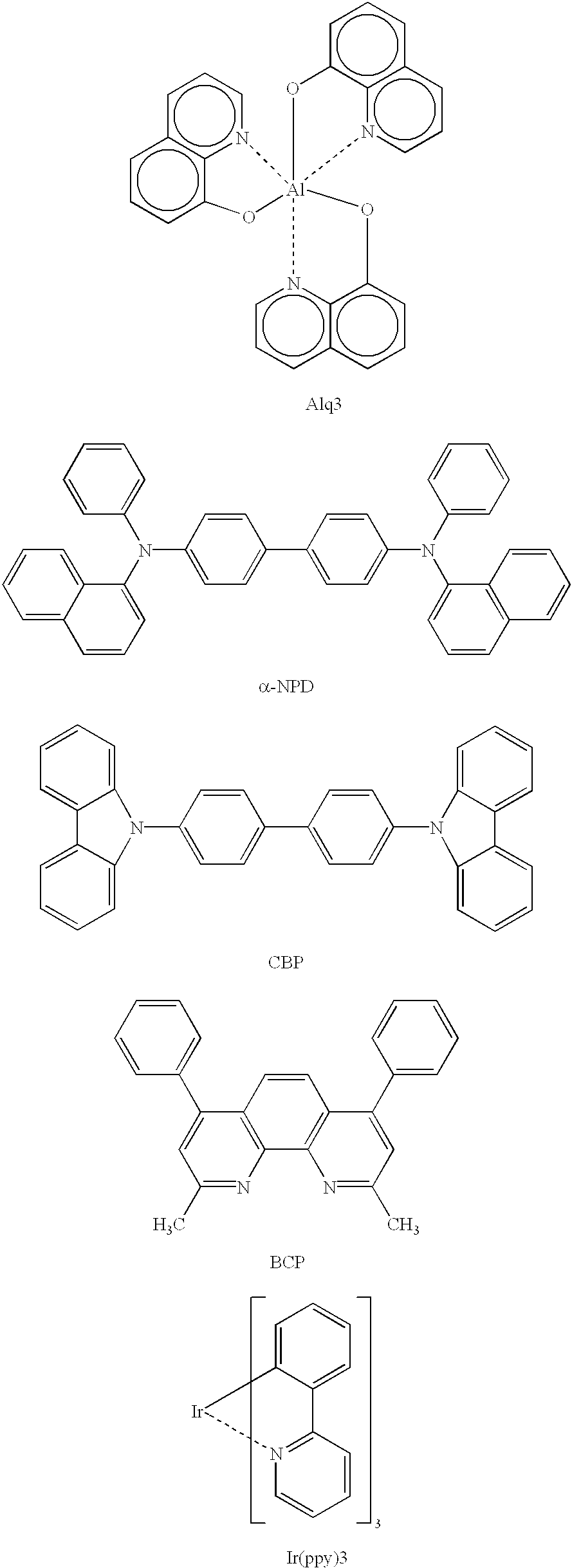

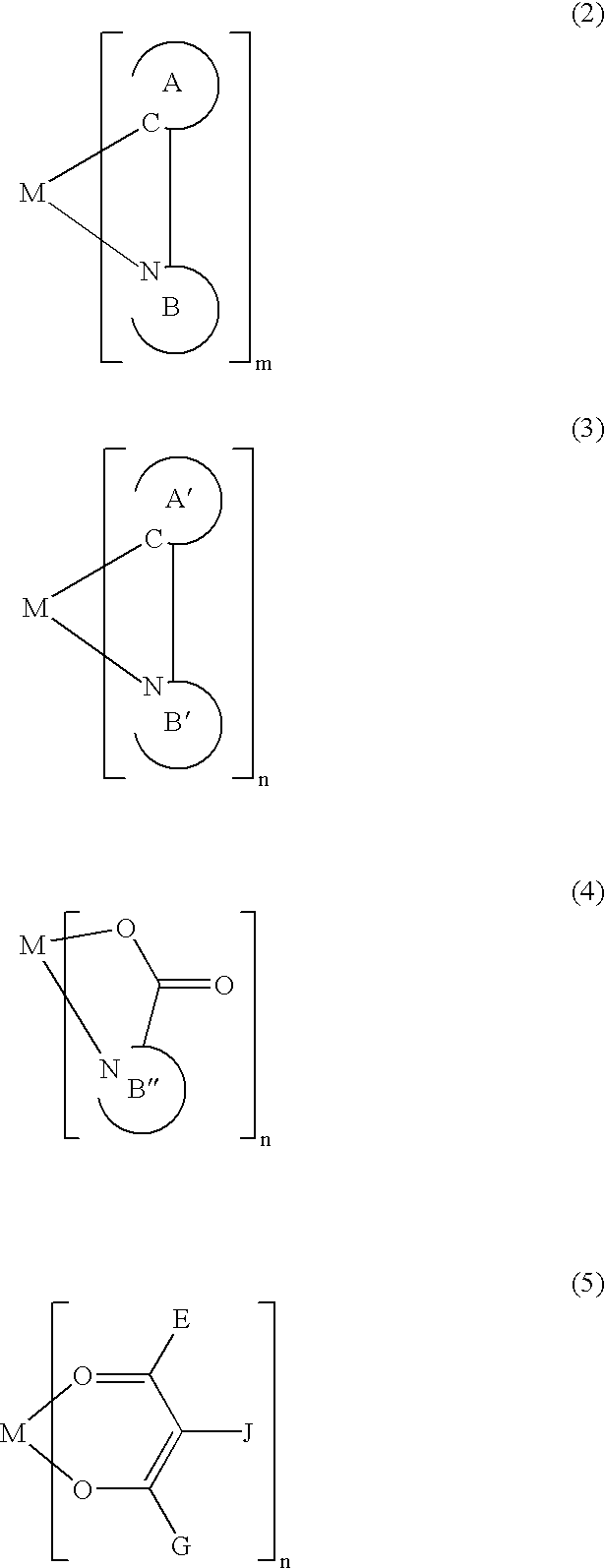

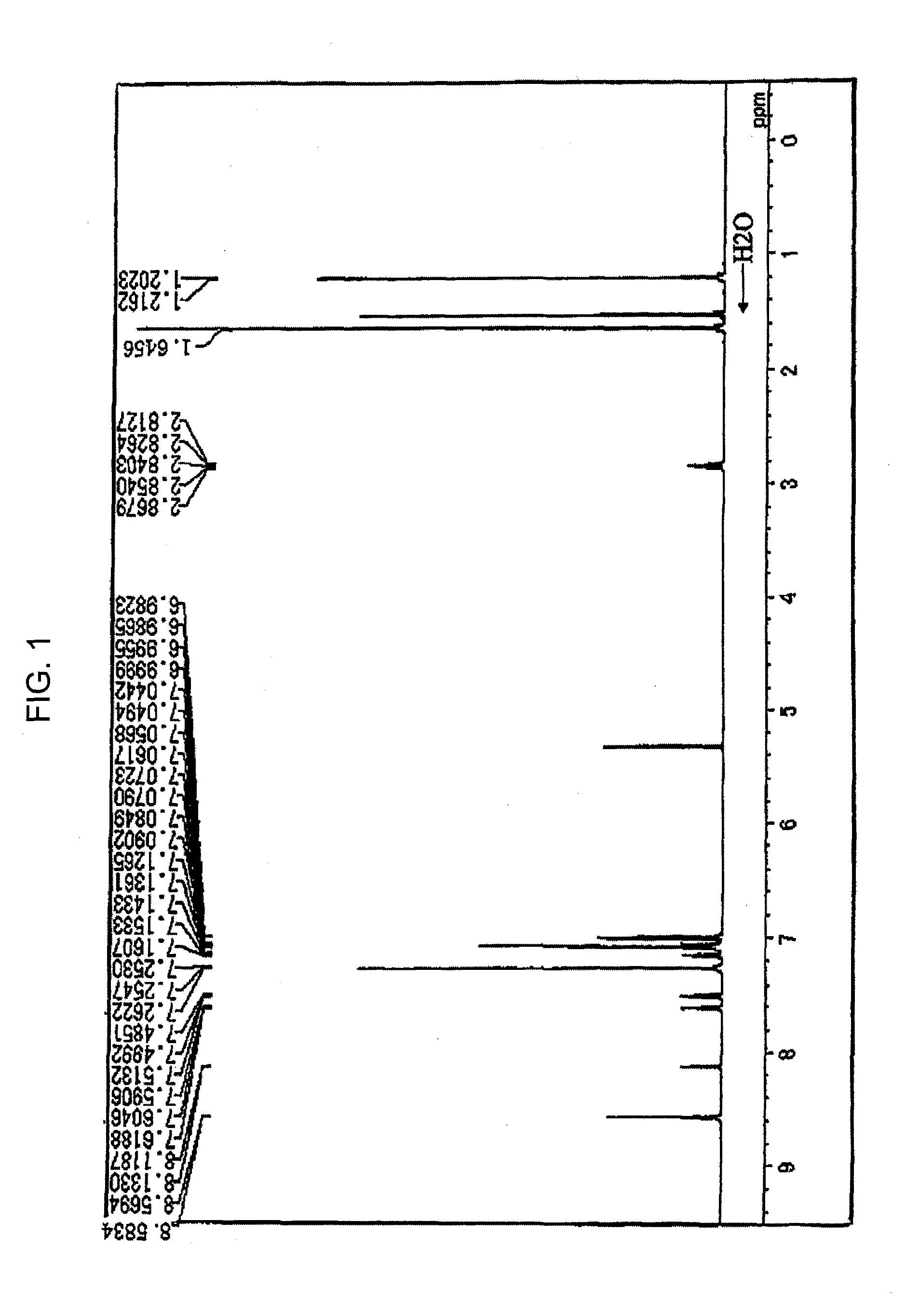

InactiveUS20030059646A1High luminous intensityIndium organic compoundsDischarge tube luminescnet screensOrganic filmHigh concentration

In a luminescence device formed of one or plural layers of organic film between a cathode and an anode, at least one layer is a luminescence layer, and a luminescence molecule of a metal coordination compound having a basic structure represented by formula (1) below and having a substituent on at least one of cyclic groups A and B is incorporated as a guest in a host material at a concentration of at least 8 wt. %, which is higher than a concentration at which a luminescence molecule of a similar structure but having no substituent exhibits a maximum luminescence efficiency to form the luminescence layer. As a result, a high-efficiency luminescence device is provided, which is less liable to cause concentration extinction even when a luminescence molecule is contained at a high concentration relative to the host material in the luminescence layer.

Owner:CANON KK

Material for organic electroluminescent element and organic electroluminescent element employing the same

InactiveUS20080102311A1Bright enoughImprove efficiencySilicon organic compoundsDischarge tube luminescnet screensOrganic electroluminescenceLight emission

A material for electroluminescence devices comprising an aromatic amine derivative having a specific structure having bulky substituents at end portions and an organic electroluminescence device comprising an organic thin film layer which comprises a single layer or a plurality of layers comprising at least a light emitting layer and is disposed between an anode and a cathode, wherein at least one layer in the organic thin film layer comprises the material for organic electroluminescence devices singly or as a component of a mixture. The electroluminescence device having a long life and exhibiting a great luminance of emitted light and a great efficiency of light emission can be obtained by using the material.

Owner:IDEMITSU KOSAN CO LTD

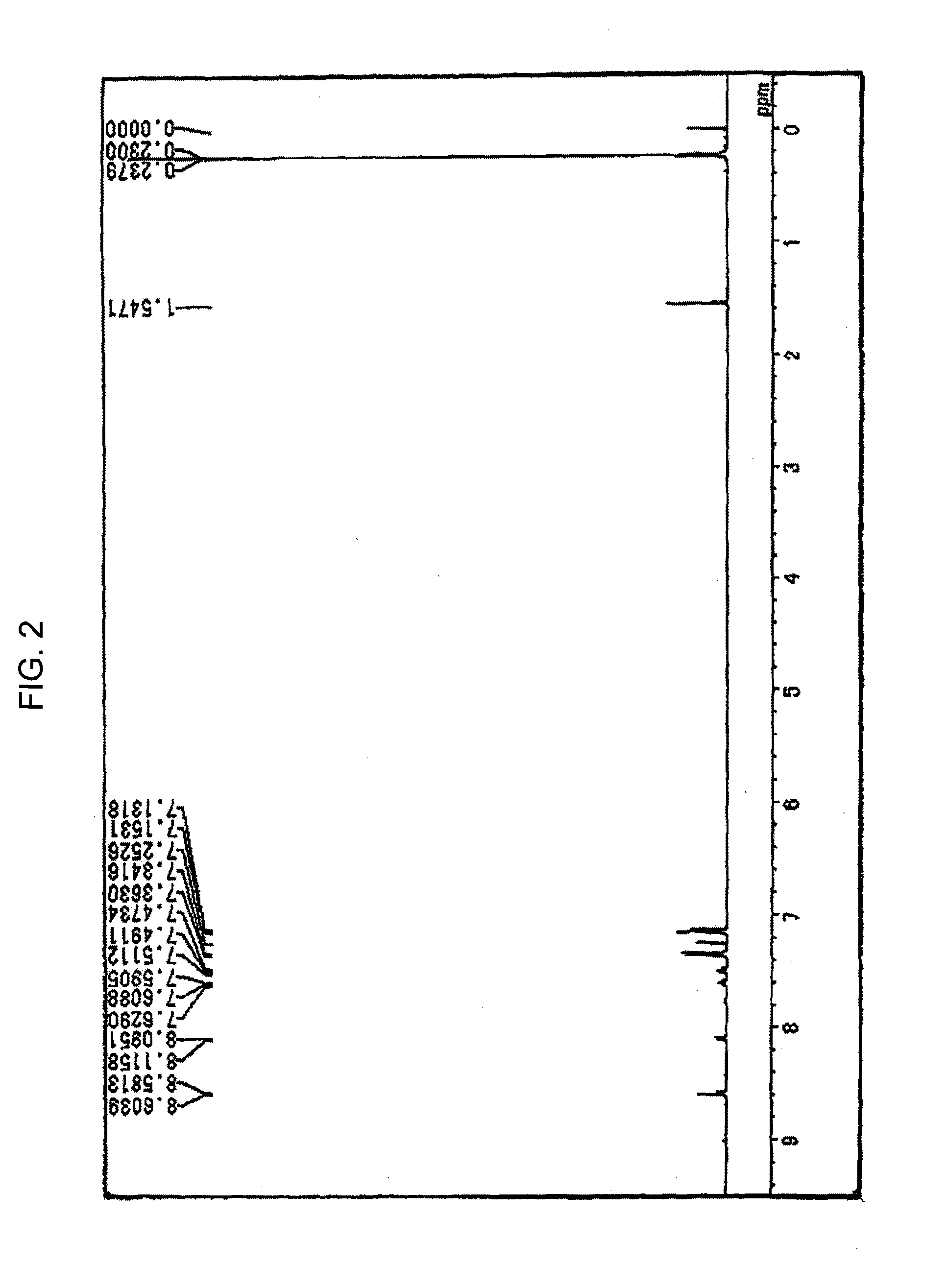

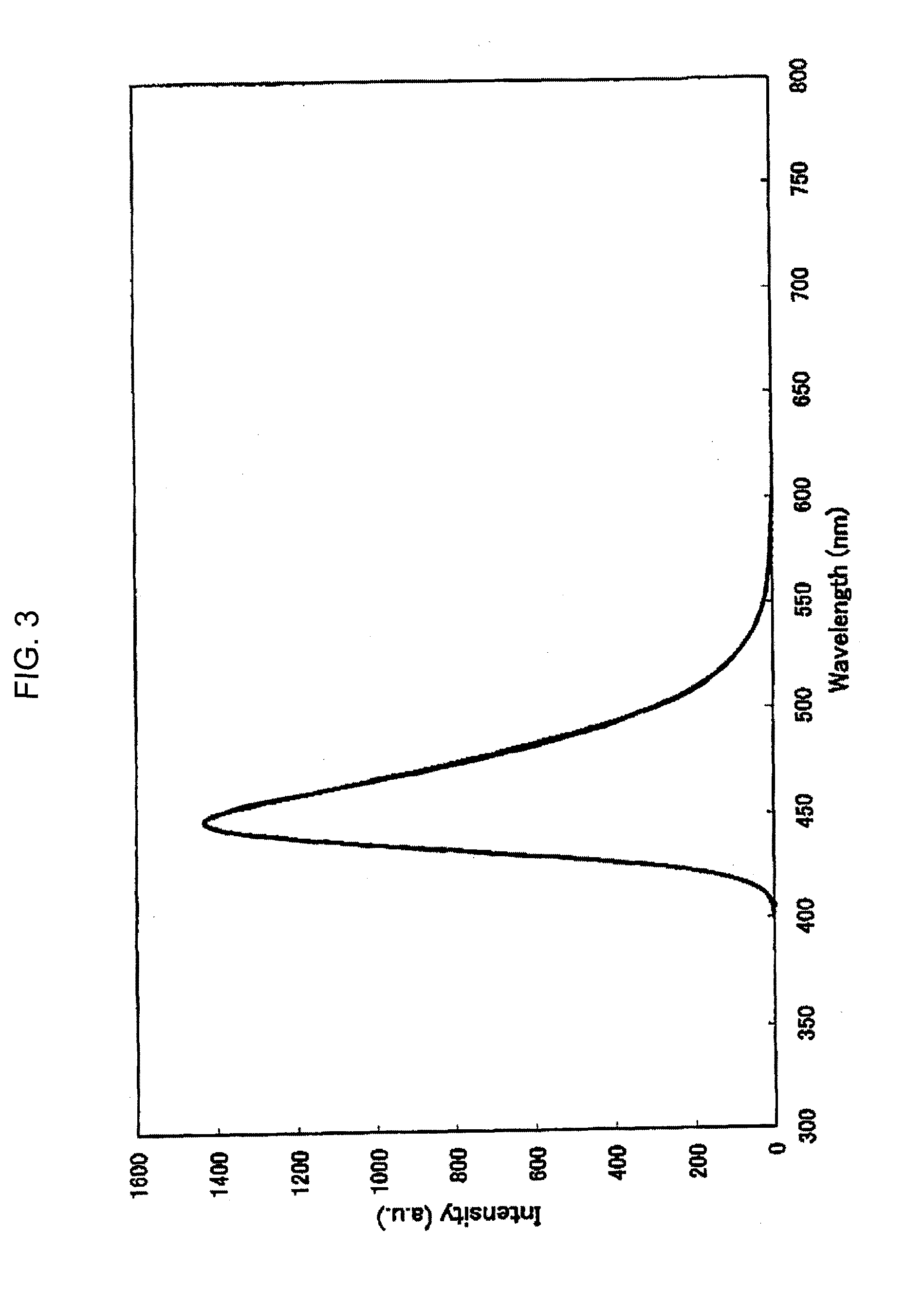

Benzanthracene derivative and electroluminescence device using the same

ActiveUS20070273272A1Improve efficiencyGood chromaSilicon organic compoundsDischarge tube luminescnet screensOrganic filmOrganic electroluminescence

A benzanthracene derivative having hydrogen atom at the 12-position, and an organic electroluminescence device having an organic thin film layer, which has one layer or a plurality of layers including at least a light emitting layer, is disposed between a cathode and an anode and contains the benzanthracene derivative in at least one layer in the organic thin film layer singly or as a component of a mixture. The electroluminescence device provides a great efficiency of light emission, has a long life and exhibits an excellent chromaticity.

Owner:IDEMITSU KOSAN CO LTD

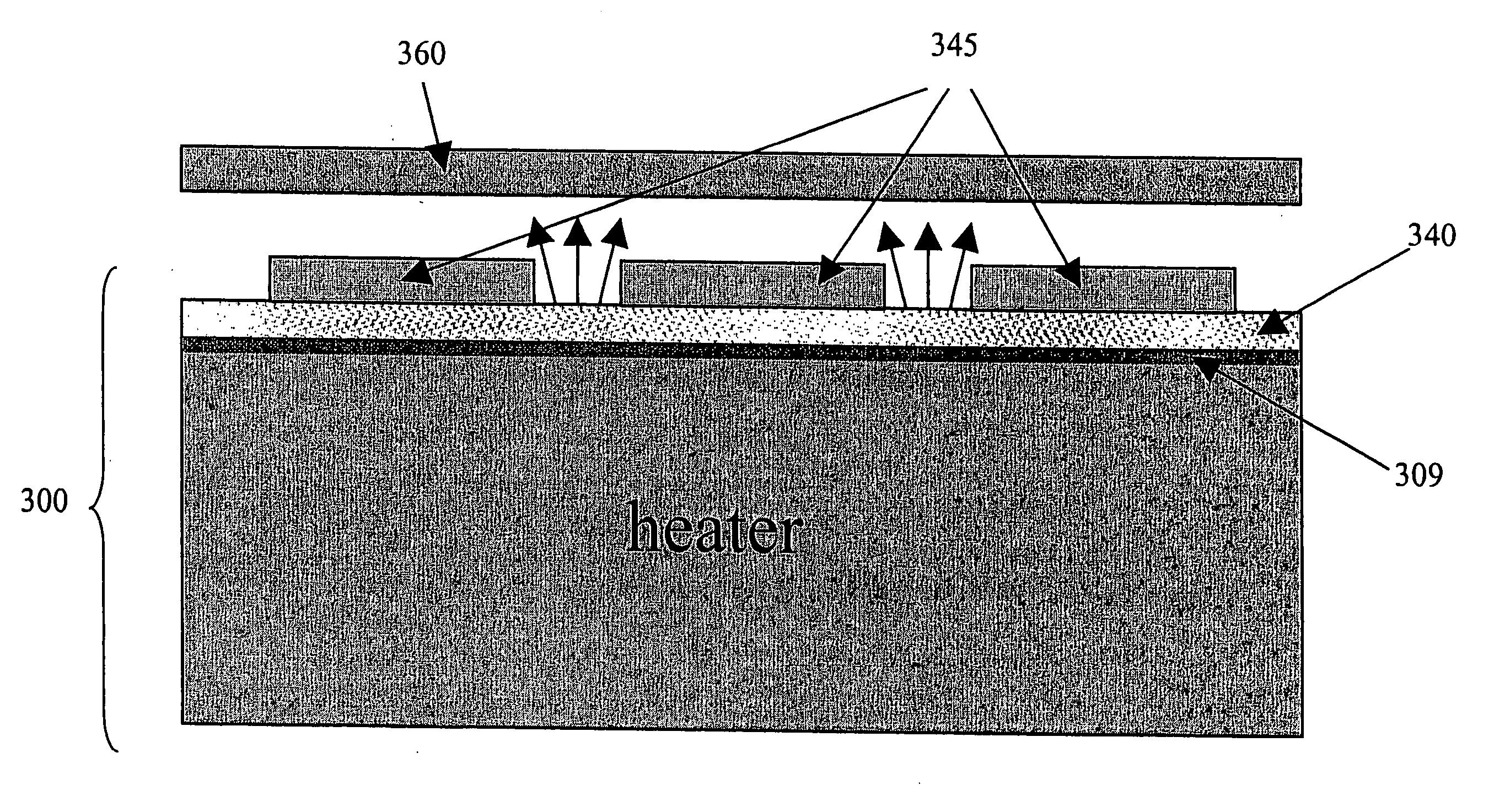

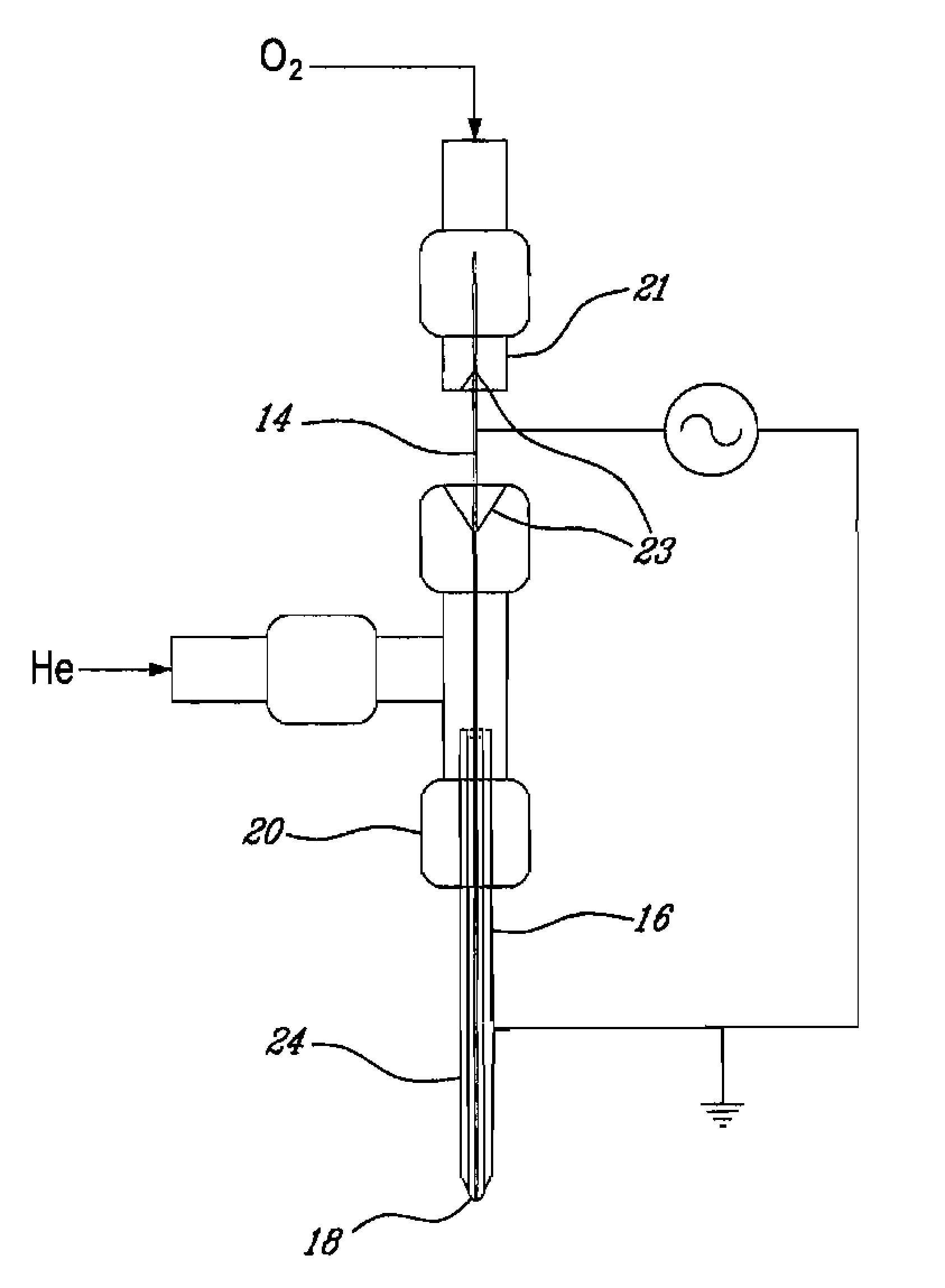

Method and apparatus for depositing LED organic film

In one embodiment the disclosure relates to an apparatus for depositing an organic material on a substrate, including a source heater for heating organic particles to form suspended organic particles; a transport stream for delivering the suspended organic particles to a discharge nozzle, the discharge nozzle having a plurality of micro-pores, the micro-pores providing a conduit for passage of the suspended organic particles; and a nozzle heater for pulsatingly heating the micro-pores nozzle to discharge the suspended organic particles from the discharge nozzle.

Owner:MASSACHUSETTS INST OF TECH

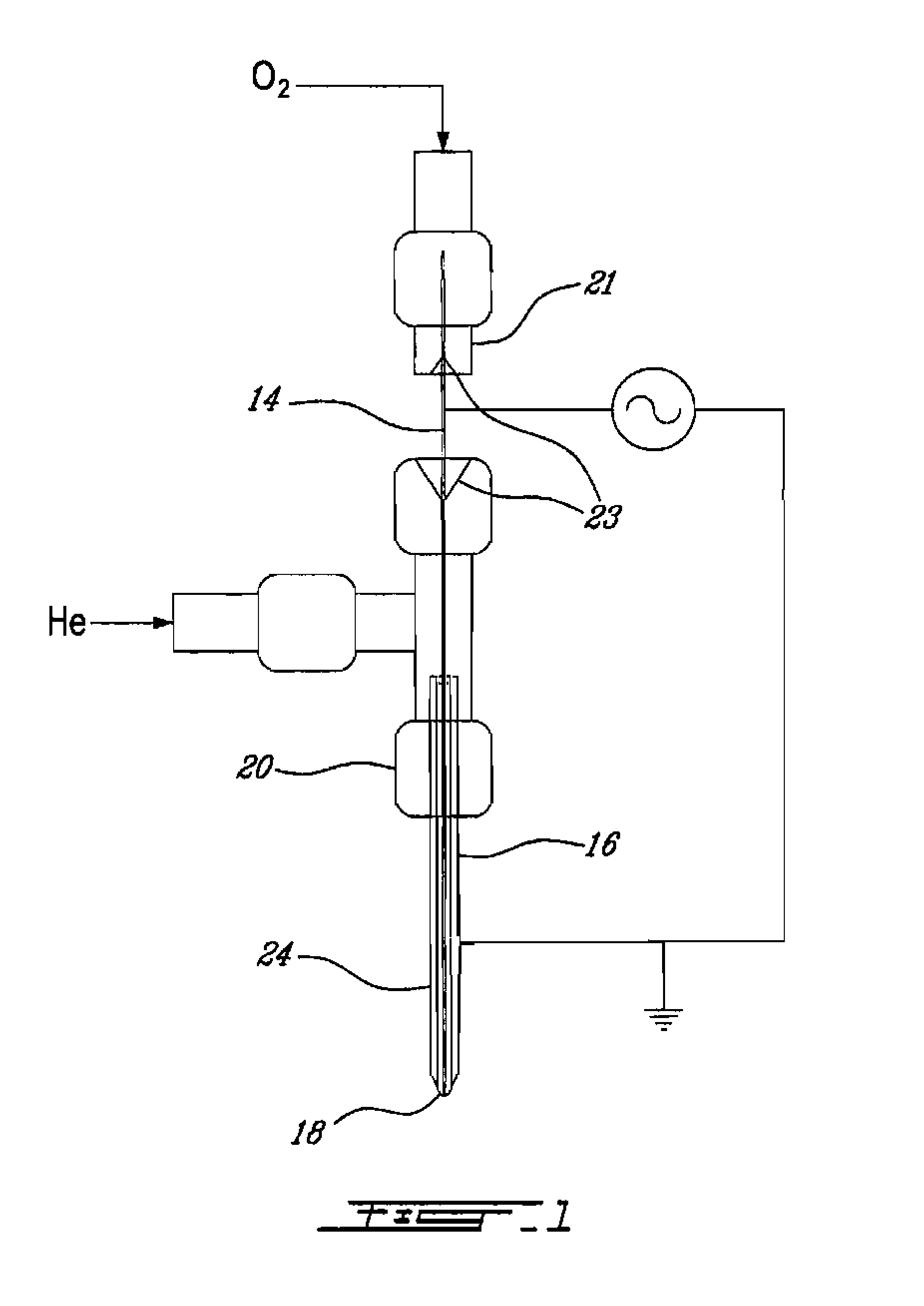

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may found applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

Material for organic electroluminescent device and organic electroluminescent device using same

ActiveUS20070128467A1Solve low luminous efficiencyImprove heat resistanceGroup 4/14 element organic compoundsDischarge tube luminescnet screensOrganic filmThin membrane

Provided is a material for an organic electroluminescence device, which is composed of a compound having a specific structure; and is capable of providing an organic electroluminescence device having a high luminous efficiency, excellent heat resistance, and a long lifetime while having no pixel defects, and an organic electroluminescence device using the same. The organic electroluminescence device comprises an organic thin film layer composed of one or more layers including at least a light-emitting layer and sandwiched between a cathode and an anode. In the organic electroluminescence device, at least one layer of the organic thin film layer comprises the material for an organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

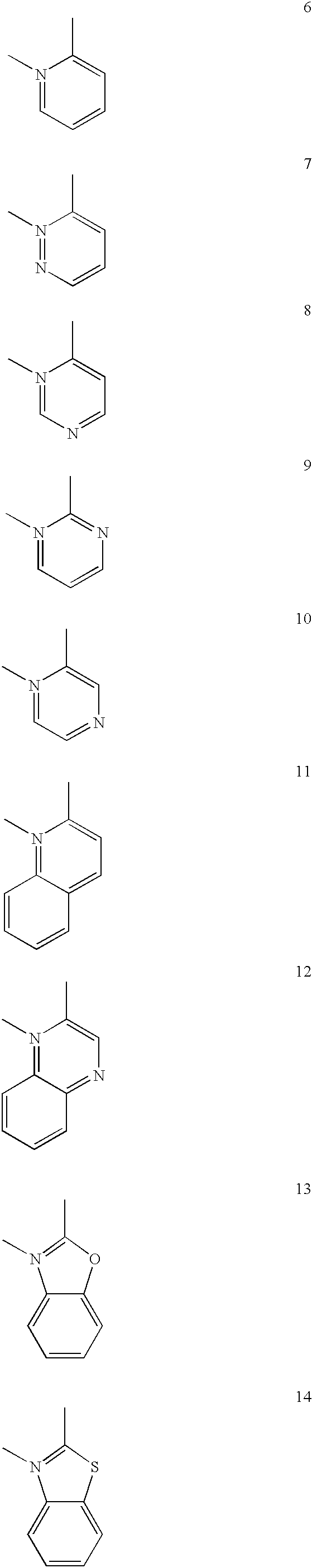

Material for organic electroluminescence device and organic electroluminescence device utilizing the same

InactiveUS20070190355A1Solve low luminous efficiencyLong life-timeOrganic chemistryDischarge tube luminescnet screensOptoelectronicsOrganic electroluminescence

Provided is a material for an organic electroluminescence (EL) device having high luminous efficiency, high thermostability, and a long lifetime, and an organic EL device utilizing the same. The material for an organic EL device is composed of a compound of a specified structure having a nitrogenous ring. The organic EL device has an organic thin film layer composed of one or more layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode. In the organic EL device, at least one layer of the organic thin film layer contains the material for an organic EL device.

Owner:IDEMITSU KOSAN CO LTD

Material for organic electroluminescence device and electroluminescence device employing the same

ActiveUS20070141387A1Improve efficiencyImprove heat resistanceSilicon organic compoundsDischarge tube luminescnet screensOrganic filmThin membrane

A material for organic electroluminescence devices comprising a compound having a specific structure and an organic electroluminescence device comprising an organic thin film layer which comprises one layer or a plurality of layers comprising at least a light emitting layer and disposed between a cathode and an anode, wherein at least one layer in the organic thin film layer comprises the material for organic electroluminescence devices, are provided. The material provides the organic electroluminescence device exhibiting a great efficiency of light emission, having no defect pixels, exhibiting excellent heat resistance and having a long life.

Owner:IDEMITSU KOSAN CO LTD

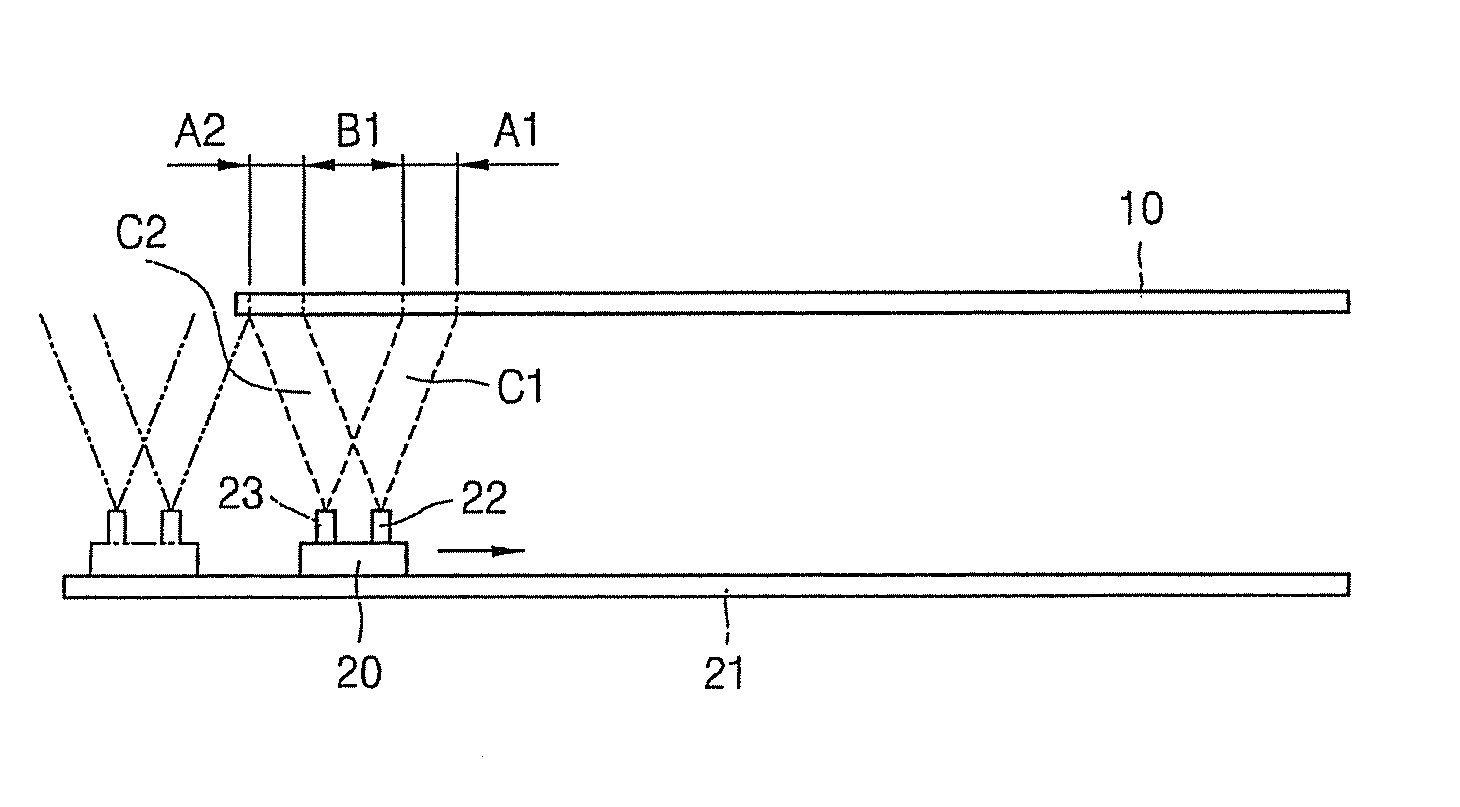

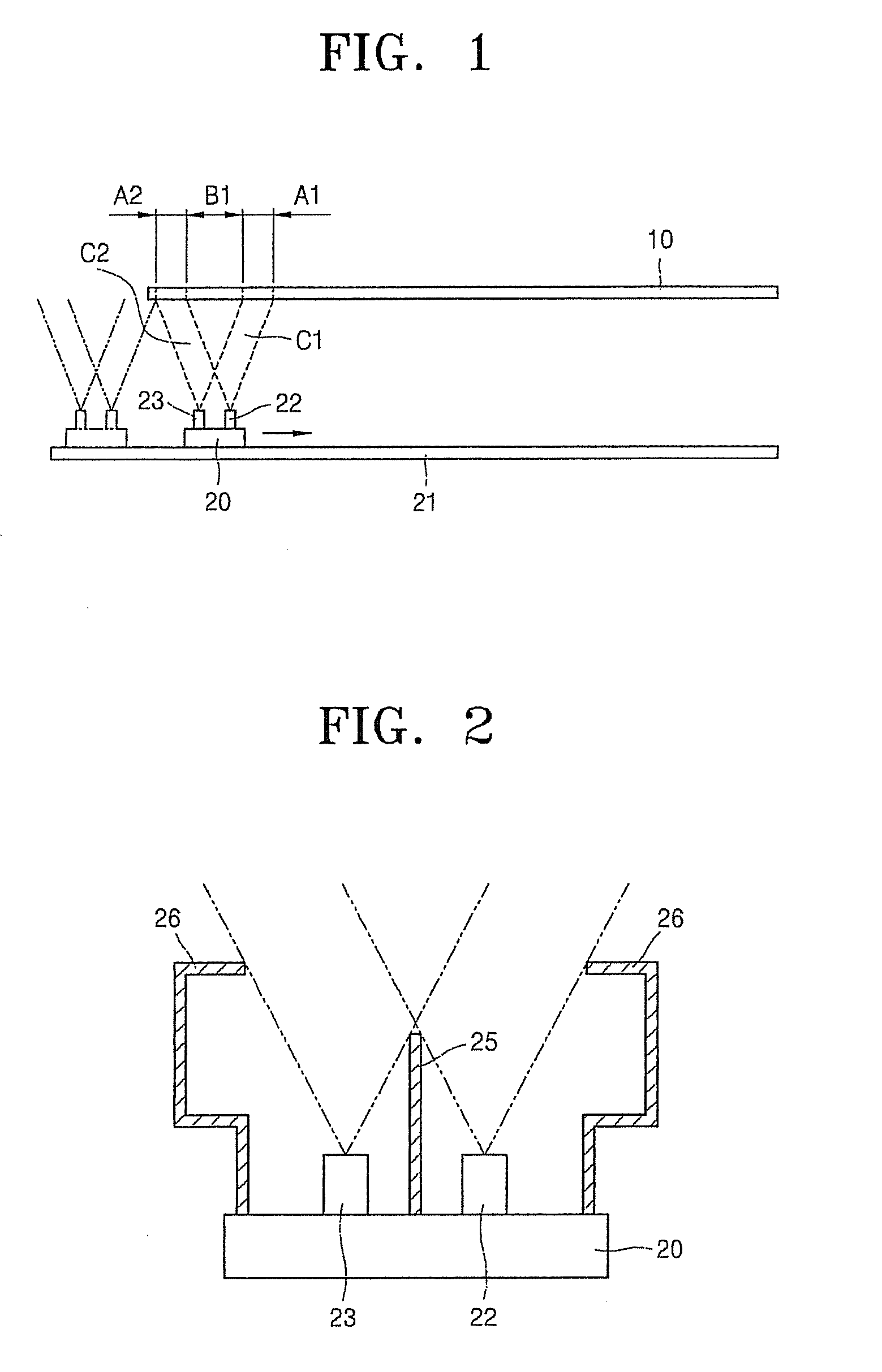

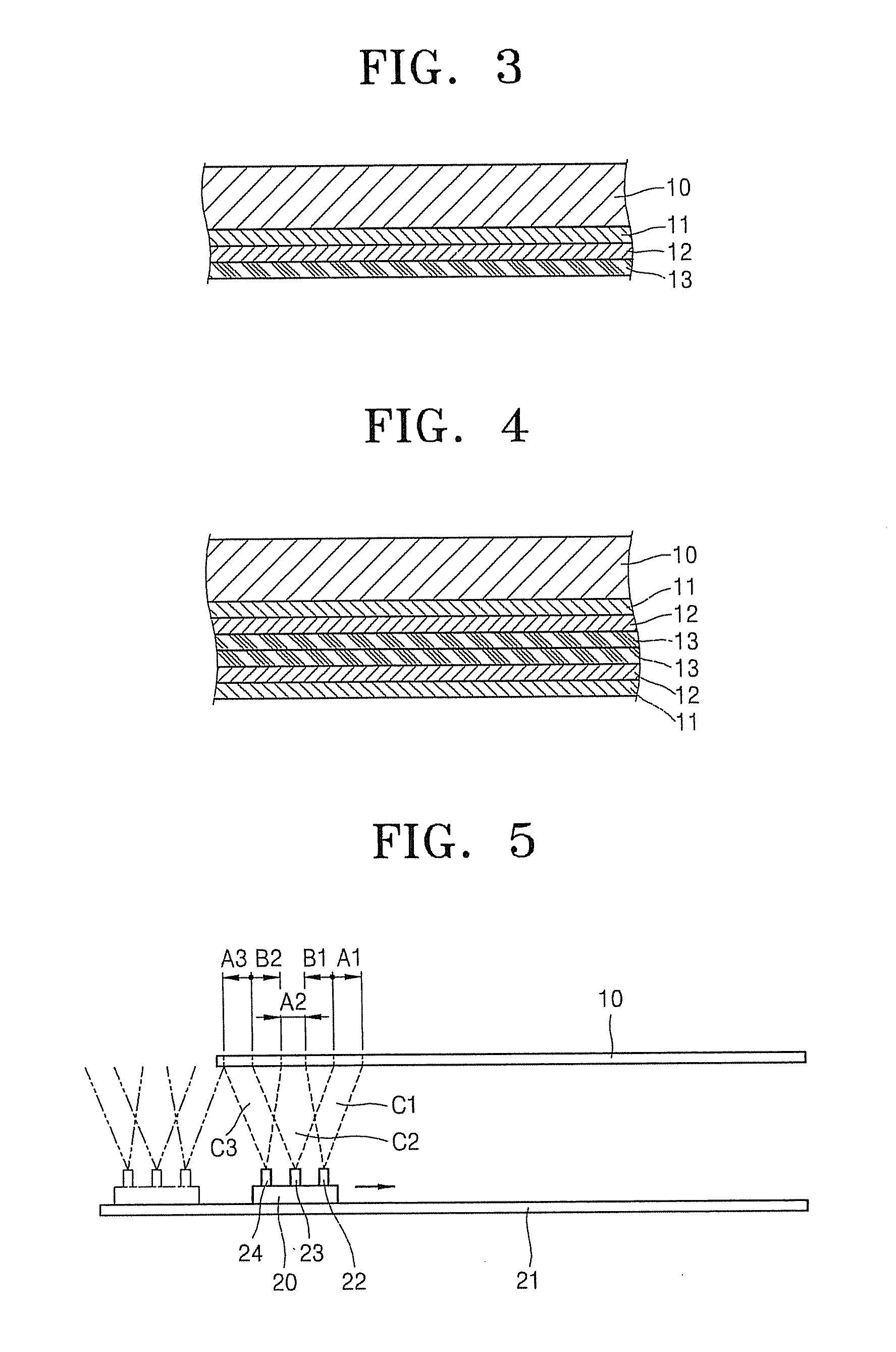

Evaporating method for forming thin film

ActiveUS20090232976A1Efficient stackingQuality improvementElectrical apparatusElectroluminescent light sourcesOrganic filmSingle process

A method of forming a plurality of multi-layer organic films in a single process includes preparing a first evaporating source that evaporates a first evaporating source material onto a first deposition region and a second evaporating source that evaporates a second evaporating source material onto a second deposition region, wherein the first evaporating source material and the second evaporating source material are different from each other, adjusting the first evaporating source and the second evaporating source in order to obtain a first overlapping region in which the first deposition region and the second deposition region overlap each other, driving the first evaporating source and the second evaporating source to deposit the first evaporating source material and the second evaporating source material onto a portion of an object to be processed, and moving the first evaporating source and the second evaporating source from a first end of the object to a second end of the object to form a multilayer film comprising a first layer that is a deposition of only the first evaporating source material, a second layer that is a deposition of a mixture of the first evaporating source material and the second evaporating source material and a third layer that is a deposition of only the second source material.

Owner:SAMSUNG DISPLAY CO LTD

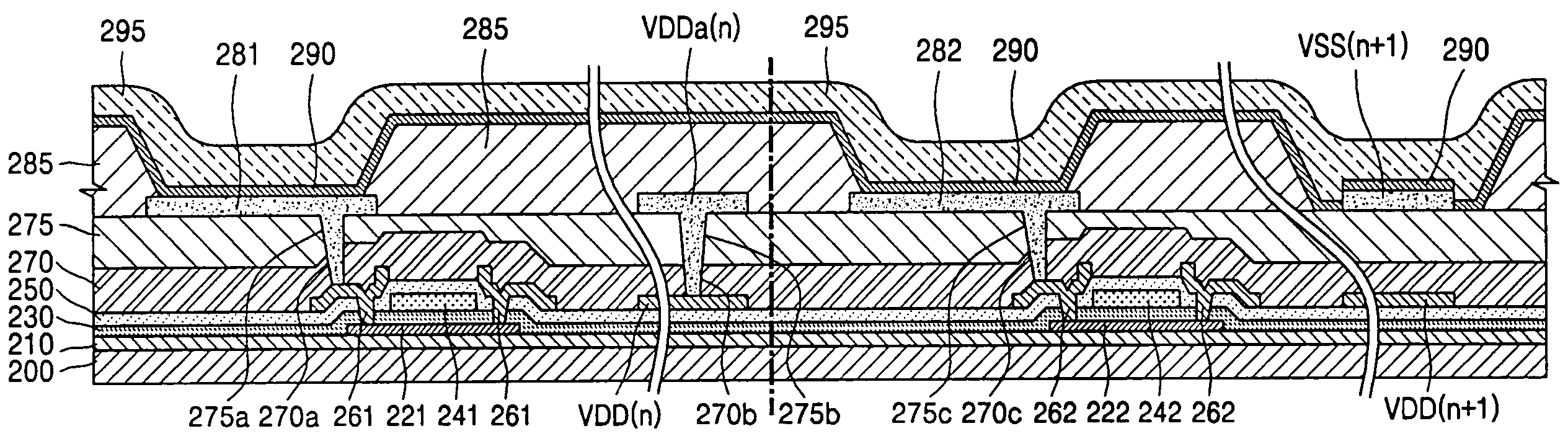

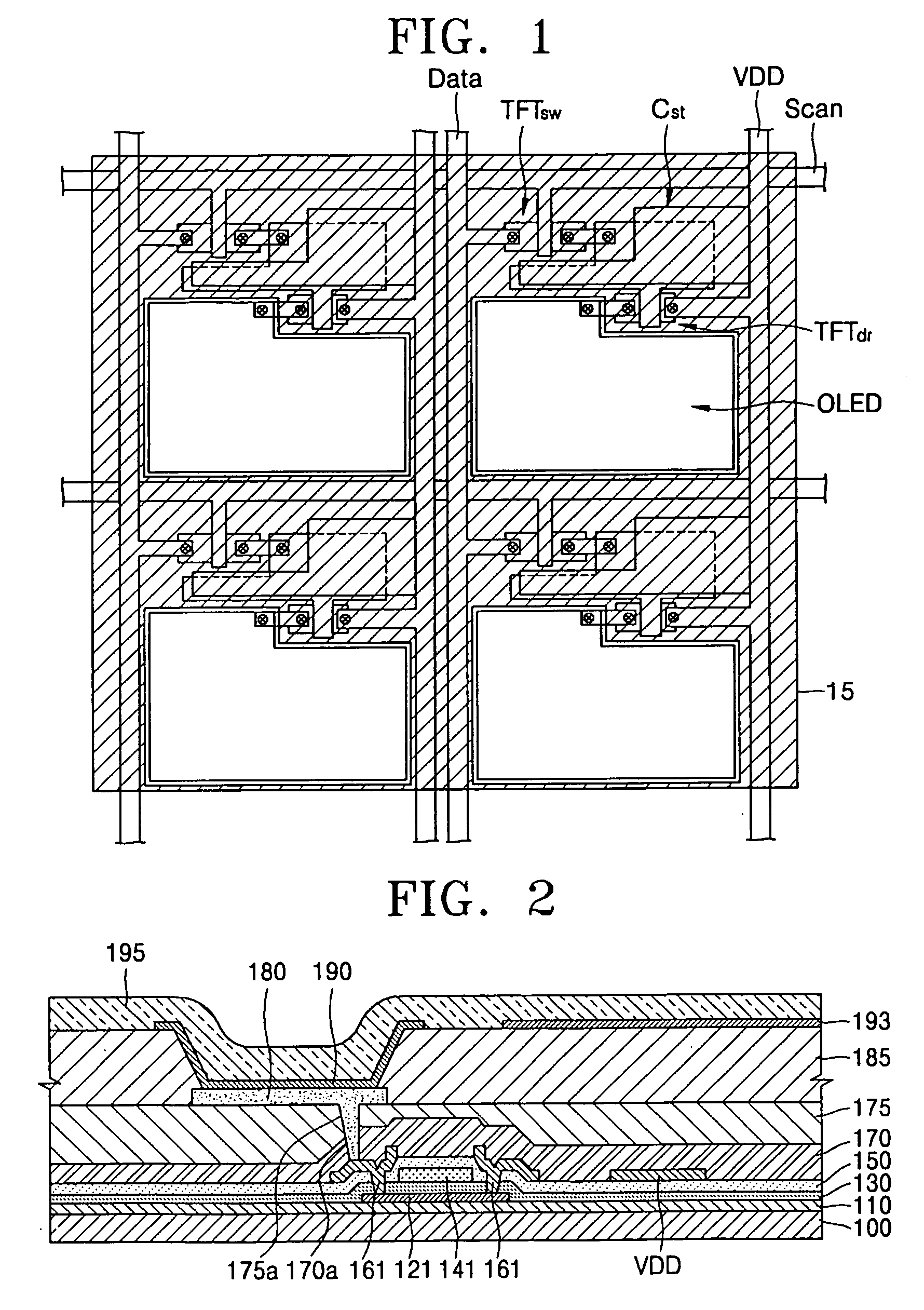

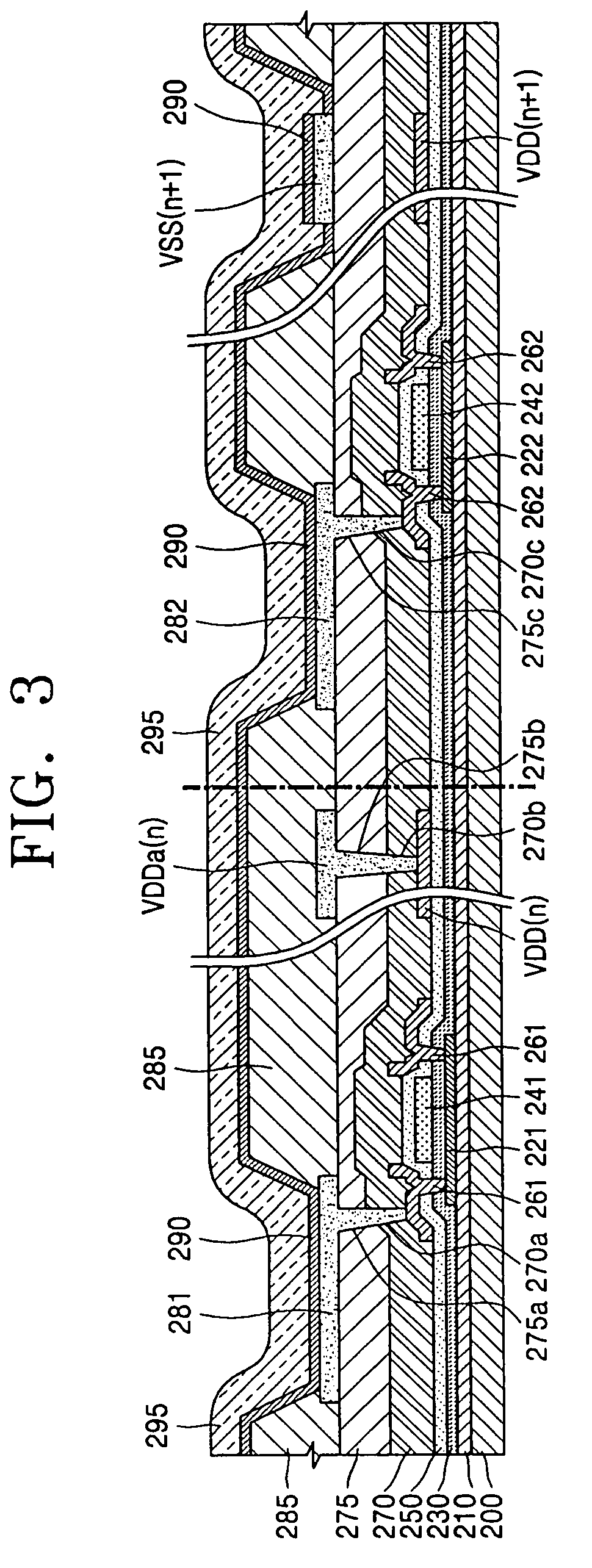

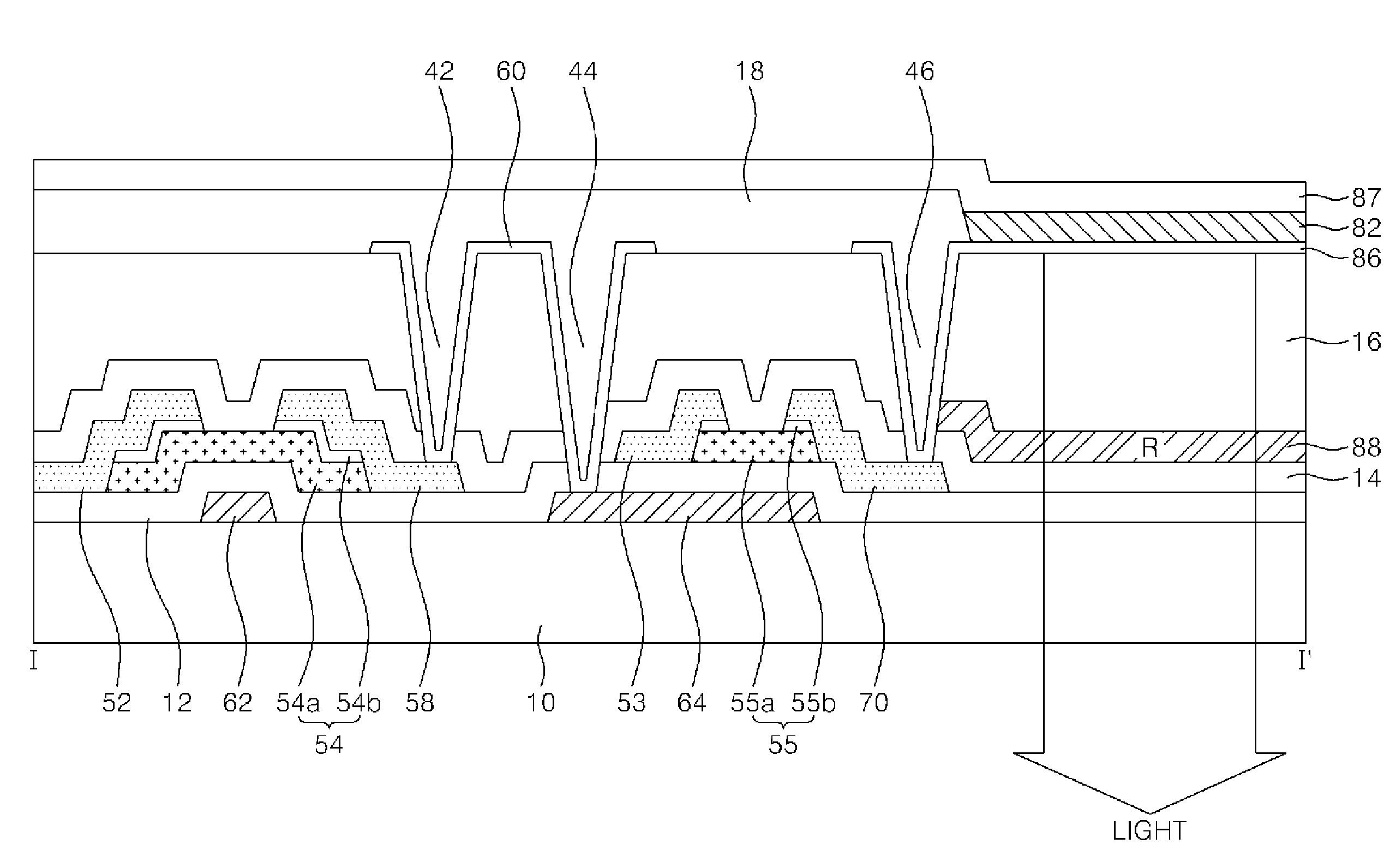

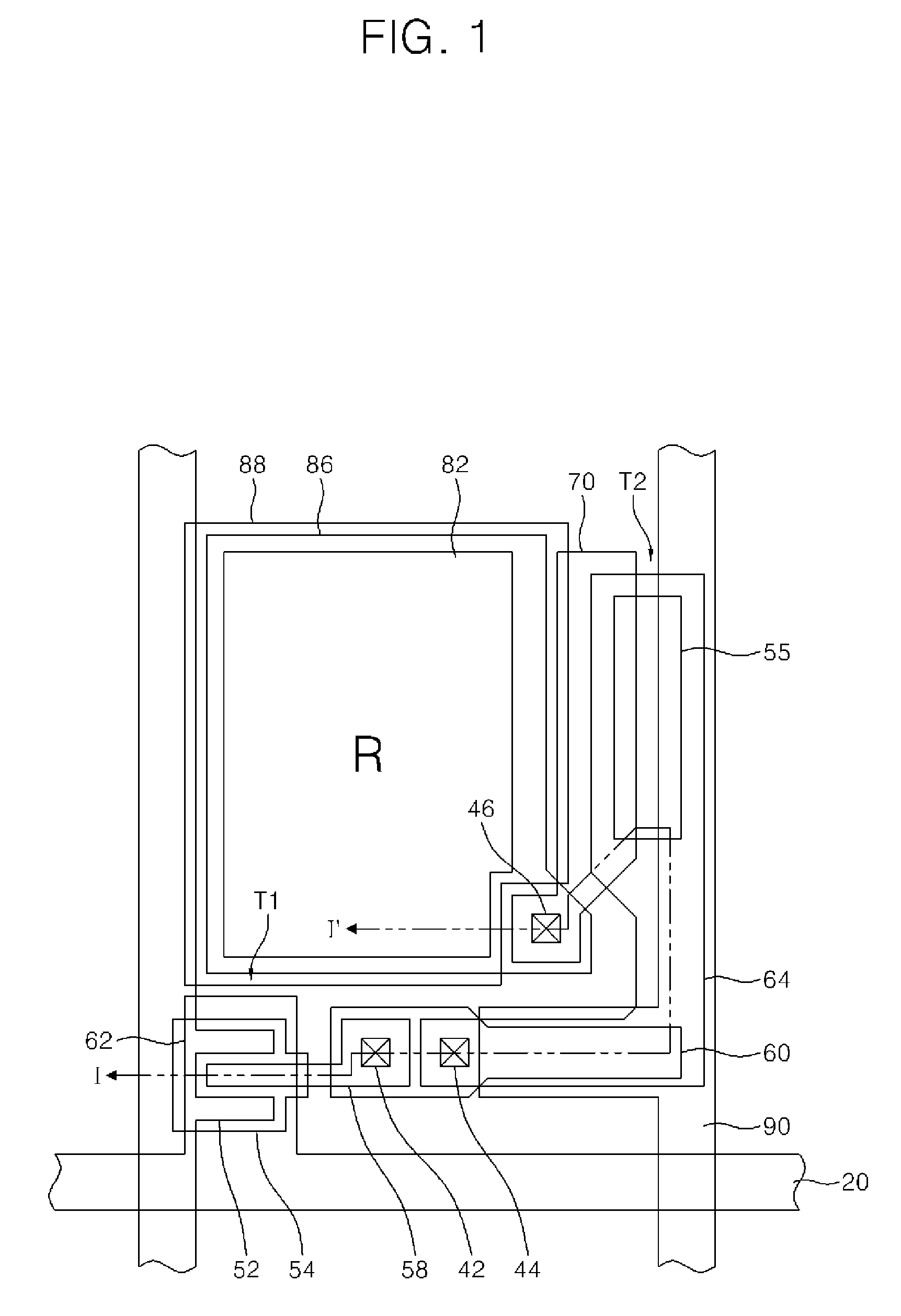

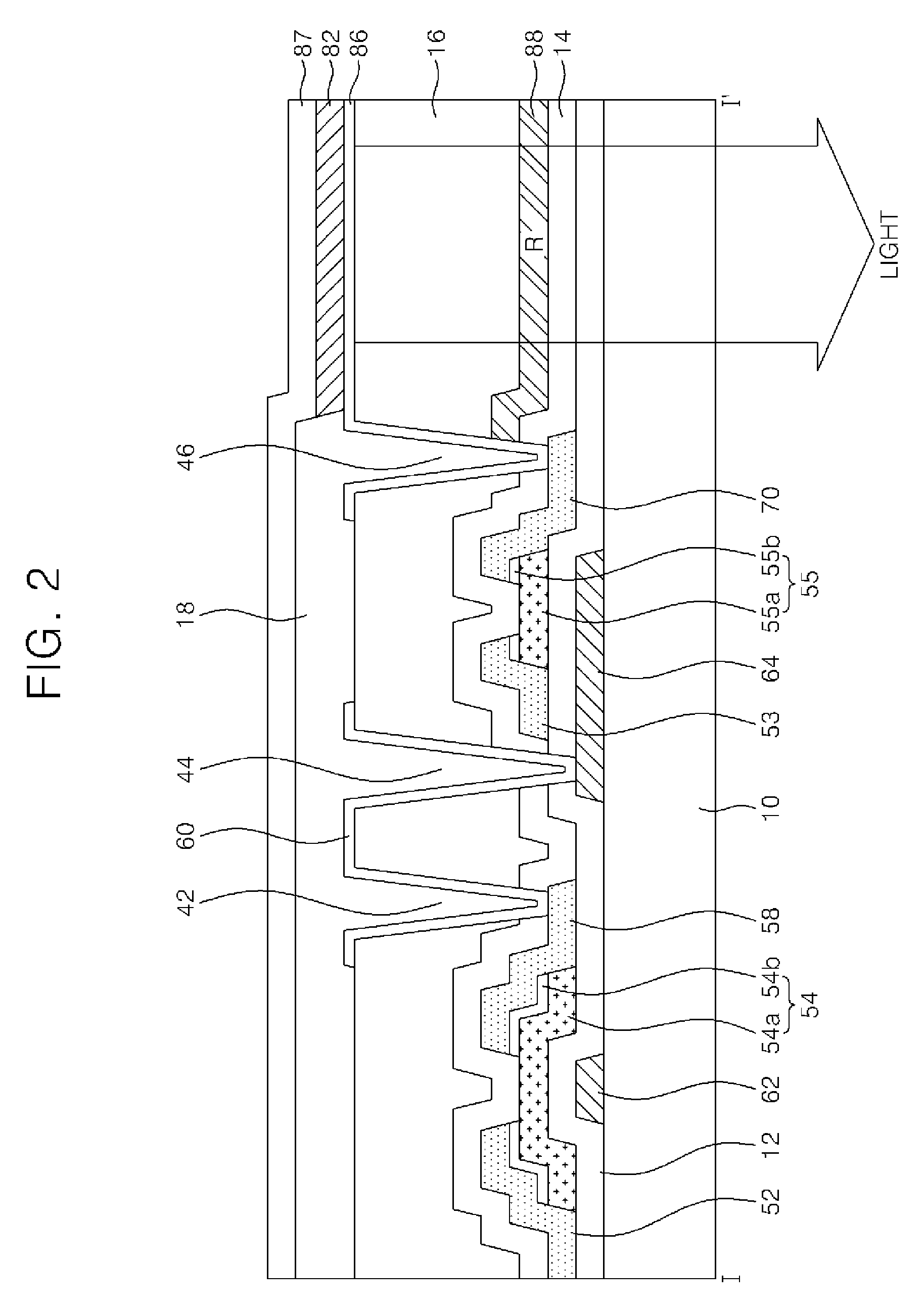

Organic electro-luminescent display device and method of manufacturing the same

ActiveUS20050179374A1Improving imaging characteristicsIncrease brightnessDischarge tube luminescnet screensNon-macromolecular adhesive additivesOrganic filmDisplay device

An organic electroluminescence device which includes a power line formed on the same layer as source and drain electrodes of a thin film transistor (TFT) and formed on a substrate on which the TFT is formed, a first insulating layer formed on the TFT, a lower electrode that electrically connected to one of the source and drain electrodes of the TFT and disposed on the first insulating layer, a first auxiliary power line and a second auxiliary power line formed on the same layer as the lower electrode in the second insulating layer, a second insulating layer formed on an edge portion of the lower electrode and not formed on the second auxiliary power line, wherein an opening that exposes a portion of the lower electrode is formed, an organic film formed on a substrate; and an upper electrode formed on the substrate.

Owner:SAMSUNG DISPLAY CO LTD

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source of reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may find applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

Biscarbazole derivatives and organic electroluminescence

ActiveUS20120223295A1Improve current efficiencyLong life-timeOrganic chemistryNanoinformaticsOrganic filmThin membrane

Provided are an organic electroluminescence device having high current efficiency and a long lifetime, and a biscarbazole derivative for realizing the device. The biscarbazole derivative has a specific substituent. The organic EL device has a plurality of organic thin-film layers including a light emitting layer between a cathode and an anode, and at least one layer of the organic thin-film layers contains the biscarbazole derivative.

Owner:IDEMITSU KOSAN CO LTD

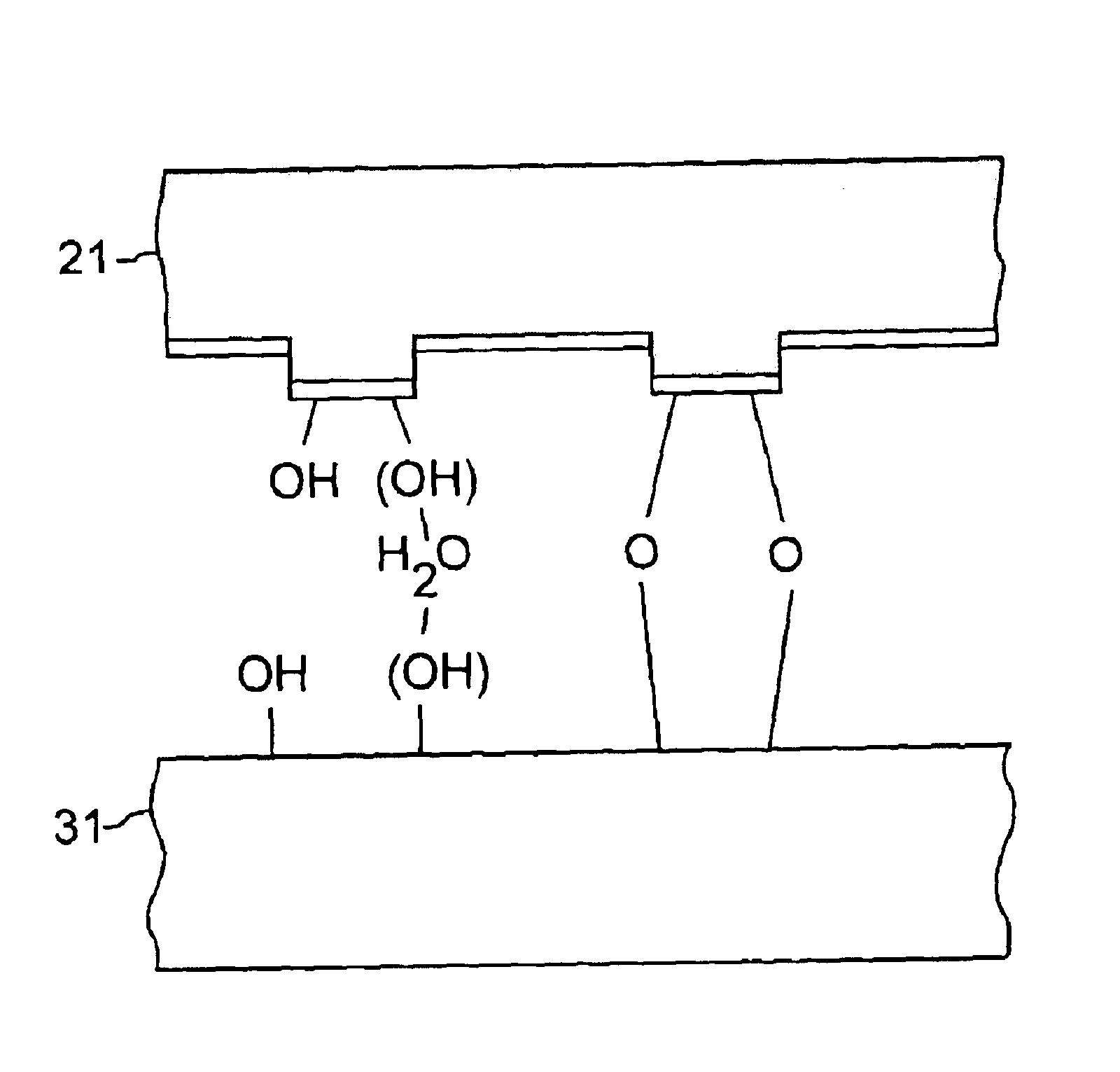

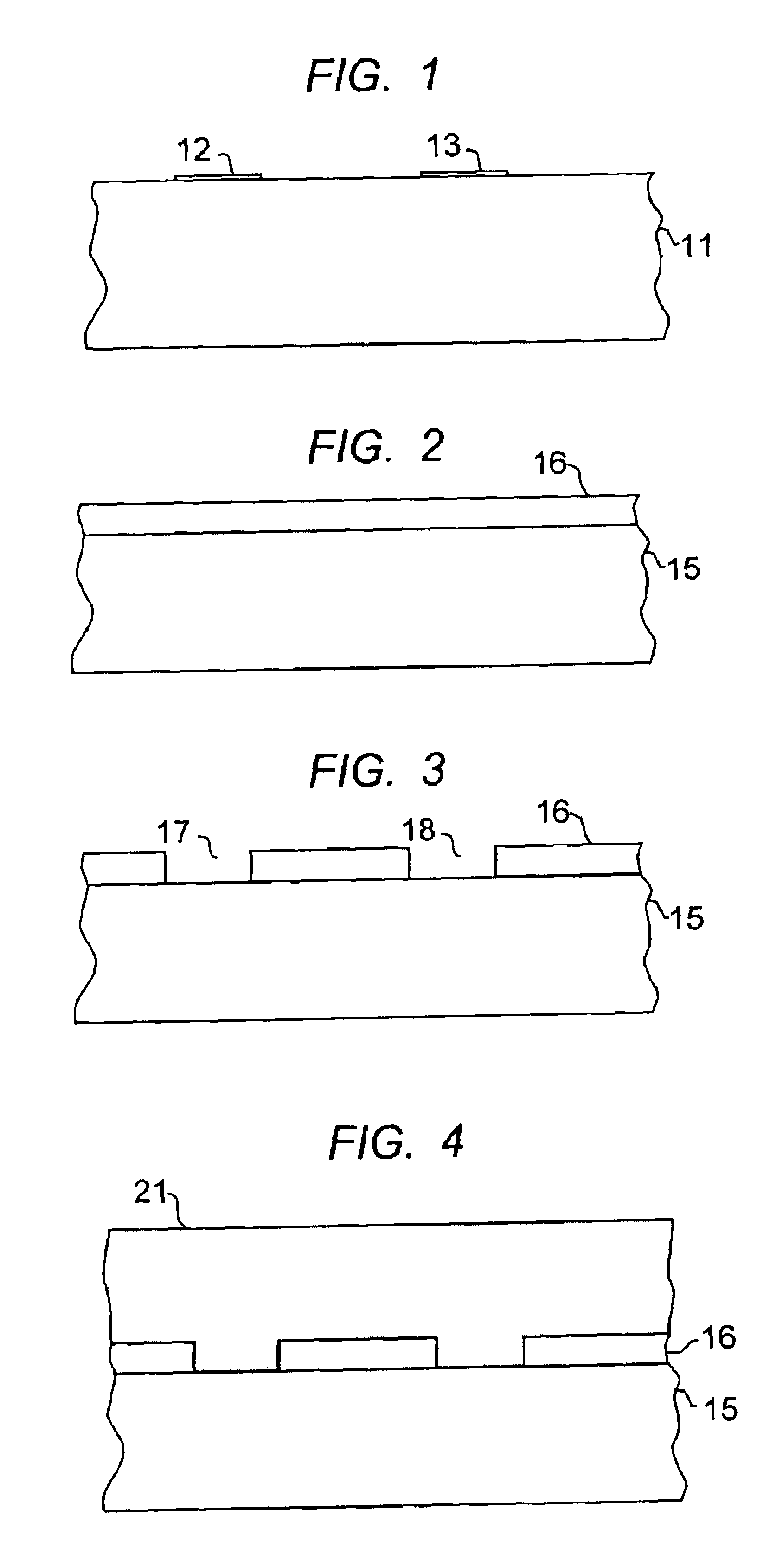

Forming nanoscale patterned thin film metal layers

The specification describes a contact printing technique for forming patterns of thin films with nanometer resolution over large areas. The procedure, termed here “nanotransfer printing (nTP)”, relies on tailored surface chemistries for transferring thin films, typically metal films, from the raised regions of a stamp to a substrate when these two elements are brought into intimate physical contact. This technique is purely additive, it is fast (<15 s contact times), and the printing occurs in a single processing step at room temperature in open air. nTP is capable of producing patterns with a wide range of features with sizes down to ˜100 nm, and edge resolution better than 25 nm. Electrical contacts and interconnects have been fabricated for high performance organic thin film transistors (TFTs) and complementary inverter circuits, to demonstrate one of the many potential applications for nTP.

Owner:ALCATEL-LUCENT USA INC +1

Deposition mask, method of manufacturing the same, and method of manufacturing electroluminescent display device having the same

InactiveUS20080118743A1Preventing a mask sheet from bendingElectroluminescent light sourcesVacuum evaporation coatingOrganic filmEngineering

A mask for depositing an organic film includes a mask sheet having at least two openings with different sizes and a blocking part formed in a region where the at least two openings are not formed. A supporting frame is formed on a back side of the mask sheet to support the mask sheet, and a mask frame receives a peripheral region of the supporting frame and supports a vertical pressure applied to the supporting frame and the mask sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

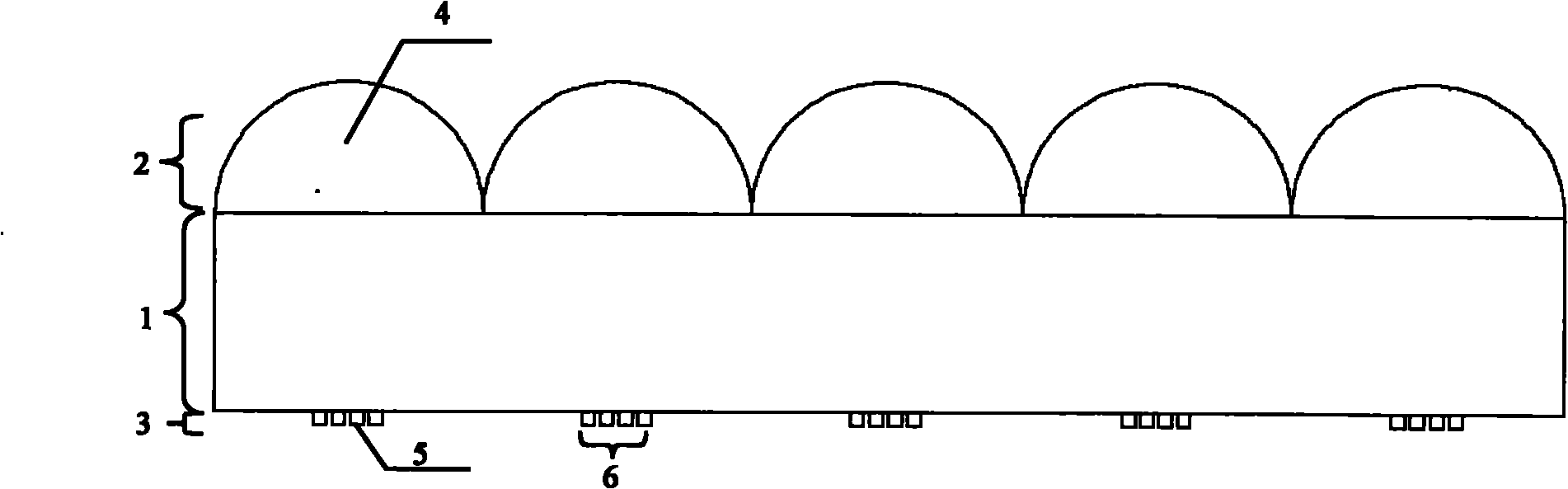

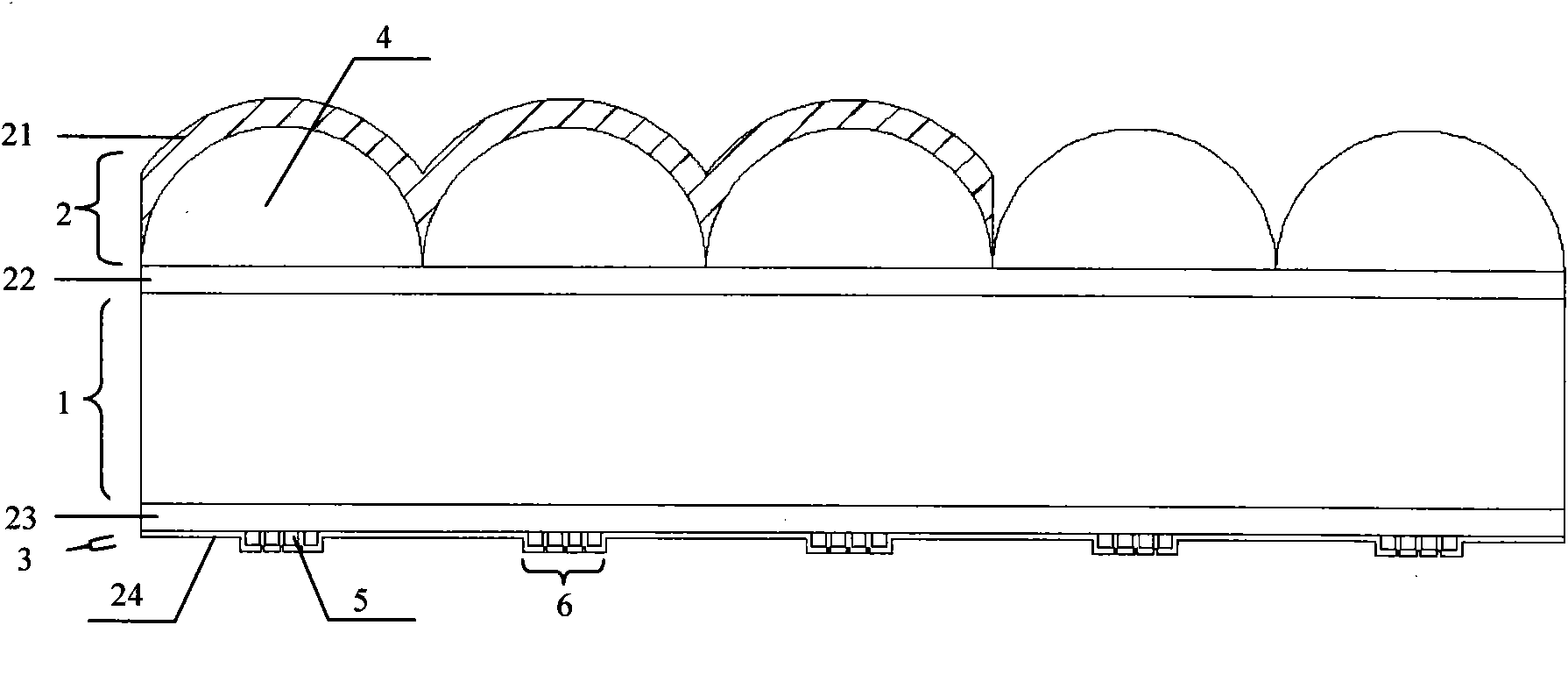

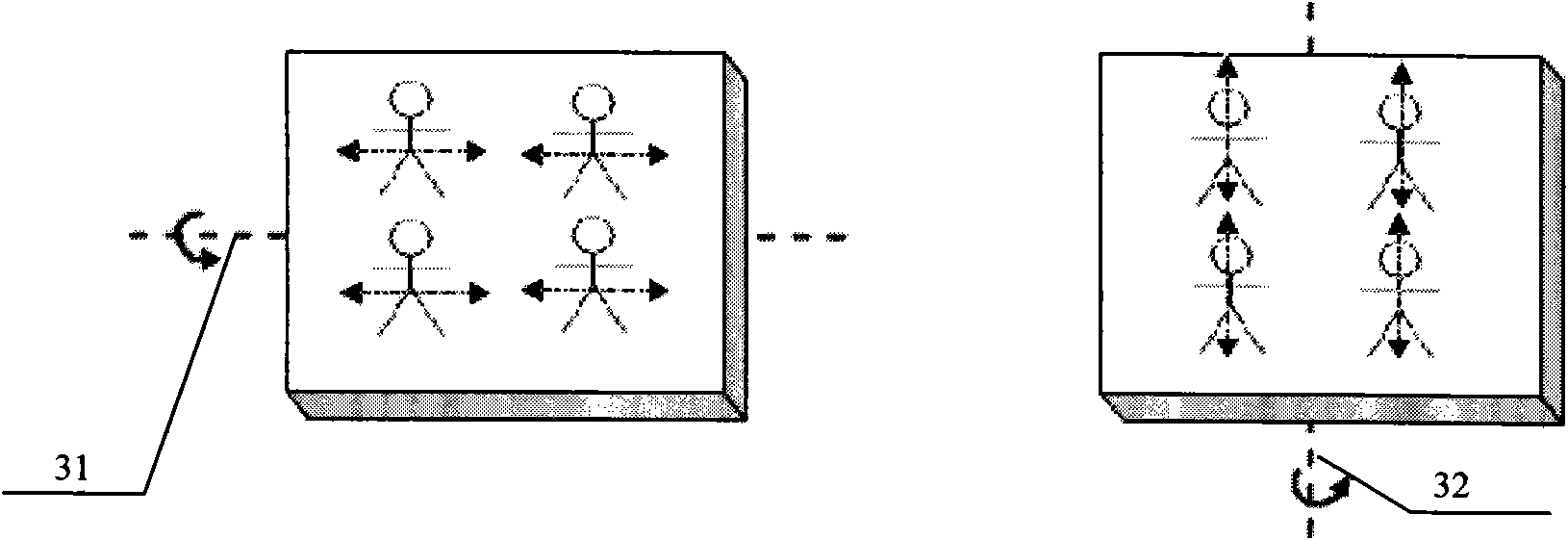

Safety film with dynamic three-dimensional effect

ActiveCN101850680AWith dynamic three-dimensional effectReduce thicknessOther printing matterLayered productsOrganic filmGraphics

The invention discloses a safety film with a dynamic three-dimensional effect, which comprises a microlens array layer, a substrate layer and a micro graphic layer. The micro graphic layer comprises at least six micro-graphics; and when the safety film is used, the micro graphic layer is arranged near the focal plane of the microlens array layer. The safety film is characterized in that the central coordinates of each microlens in the microlens array layer are distributed at random in the microlens array layer, and the microlenses in the microlens array layer correspond to the micro-graphics in the micro graphic layer. Due the use of the Moore amplification technology and the microlenses, the invention realizes multiple unique visual effects, reduces the process flow, and can be directly manufactured on the PET, PMMA, PC and other organic film materials in addition to ultraviolet imprinting. Moreover, the safety film has high performance.

Owner:SVG TECH GRP CO LTD

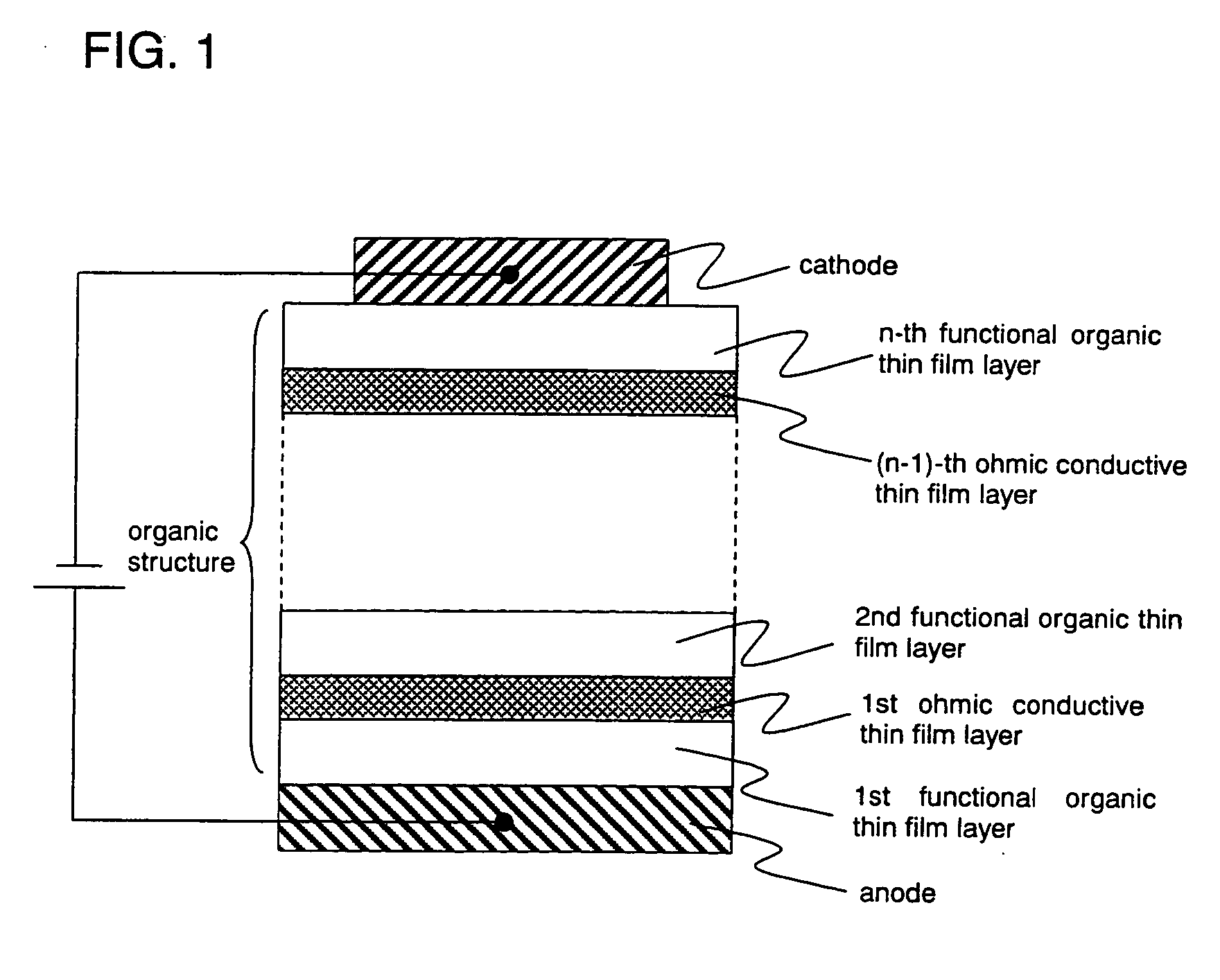

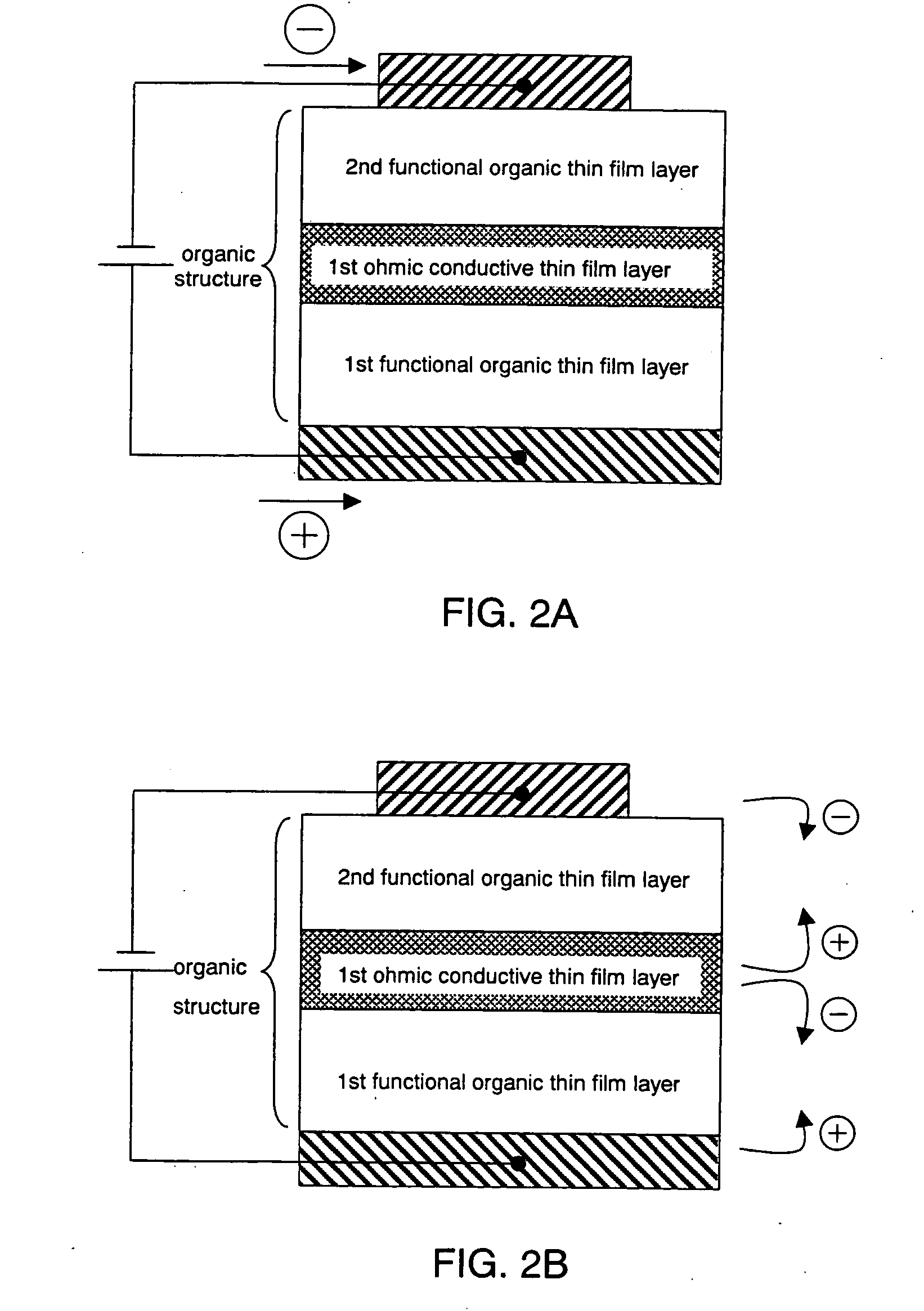

Organic semiconductor element

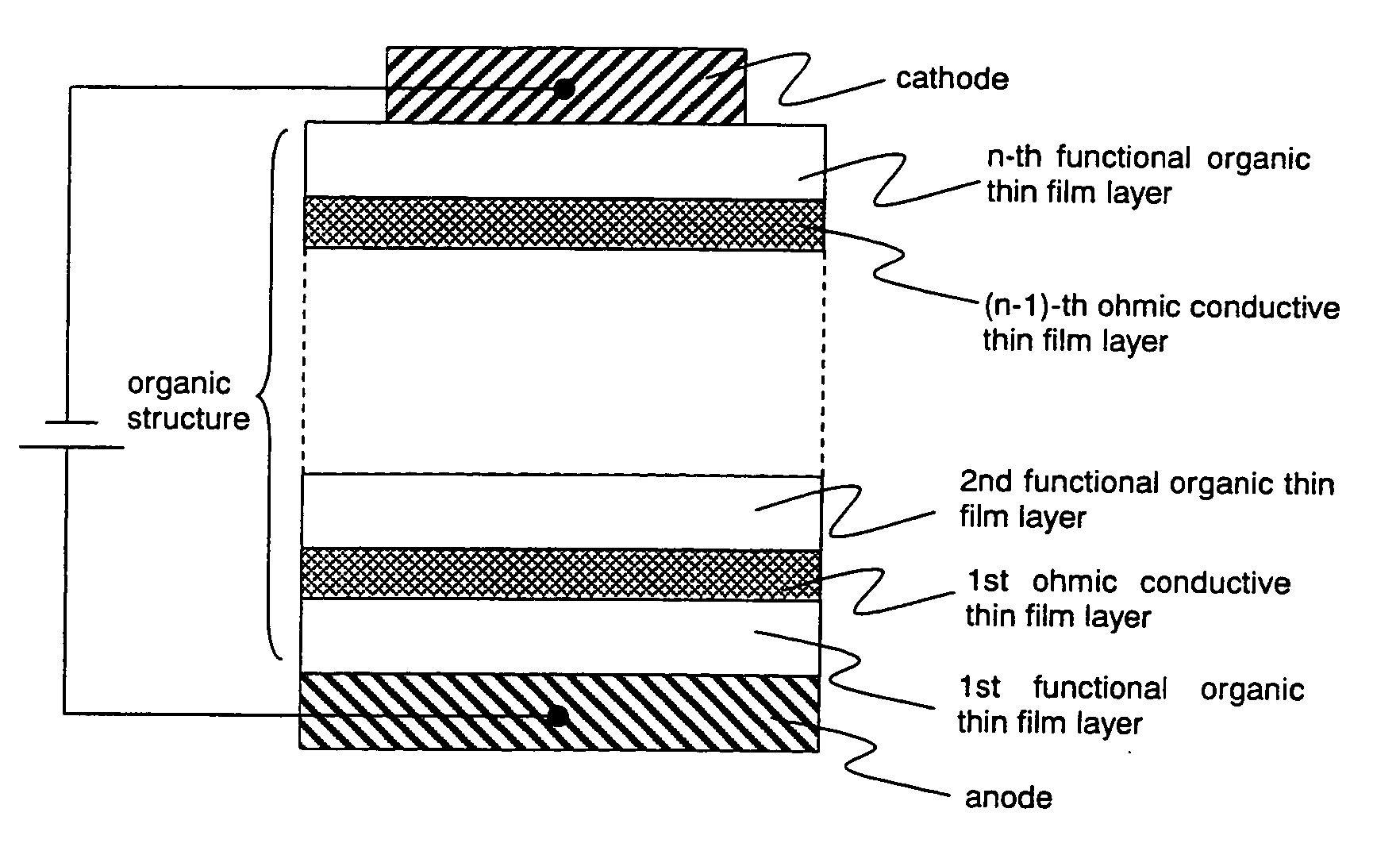

InactiveUS20060091797A1Improve reliabilityHigh yieldDischarge tube luminescnet screensFinal product manufactureOrganic structureOrganic semiconductor

By introducing new concepts into a structure of a conventional organic semiconductor element and without using a conventional ultra thin film, an organic semiconductor element is provided which is more reliable and has higher yield. Further, efficiency is improved particularly in a photoelectronic device using an organic semiconductor. Between an anode and a cathode, there is provided an organic structure including alternately laminated organic thin film layer (functional organic thin film layer) realizing various functions by making an SCLC flow, and a conductive thin film layer (ohmic conductive thin film layer) imbued with a dark conductivity by doping it with an acceptor and a donor, or by the like method.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com