Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135382 results about "Chemical engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical engineering is a branch of engineering that uses principles of chemistry, physics, mathematics, biology, and economics to efficiently use, produce, design, transport and transform energy and materials. The work of chemical engineers can range from the utilisation of nano-technology and nano-materials in the laboratory to large-scale industrial processes that convert chemicals, raw materials, living cells, microorganisms, and energy into useful forms and products.

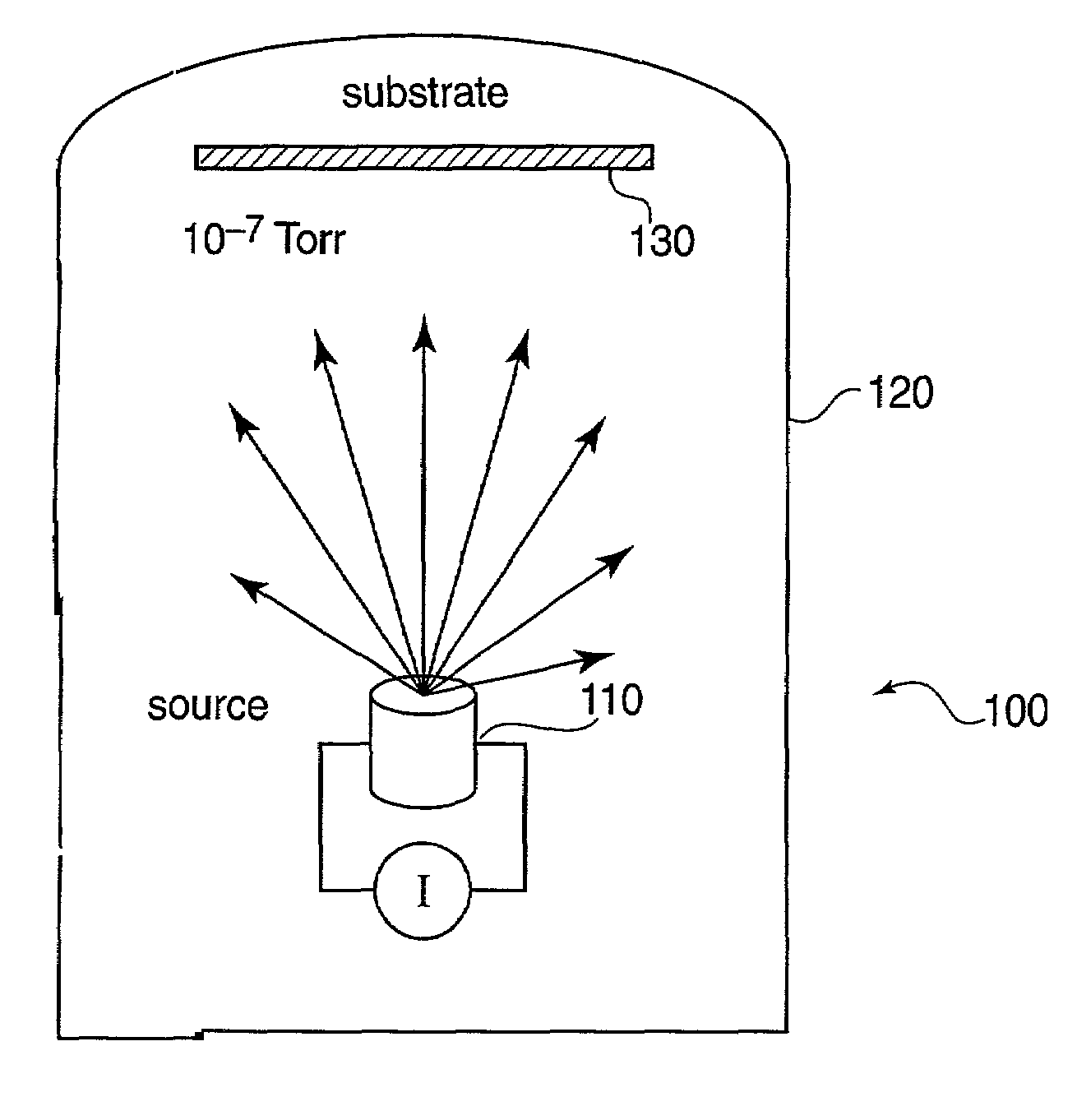

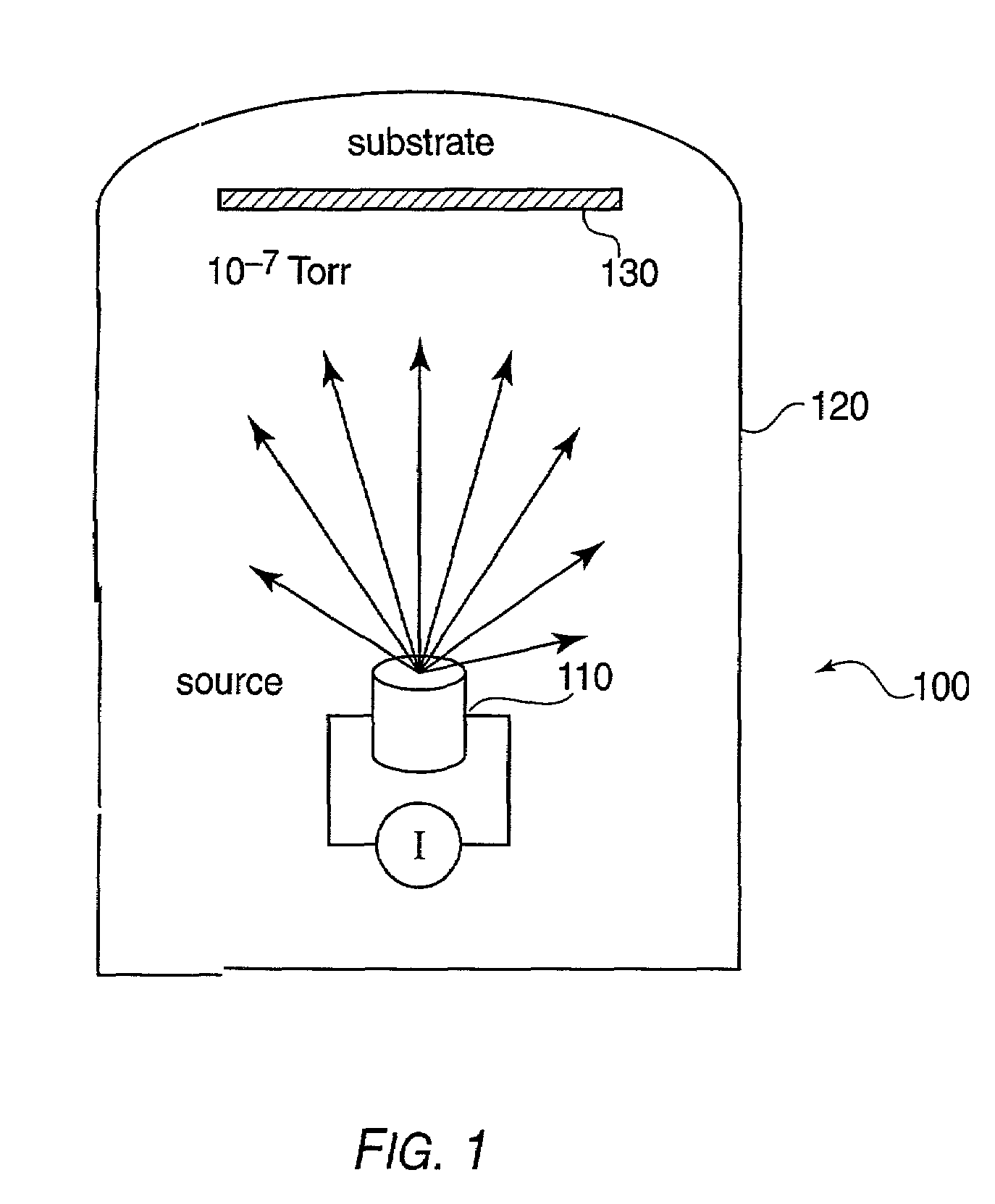

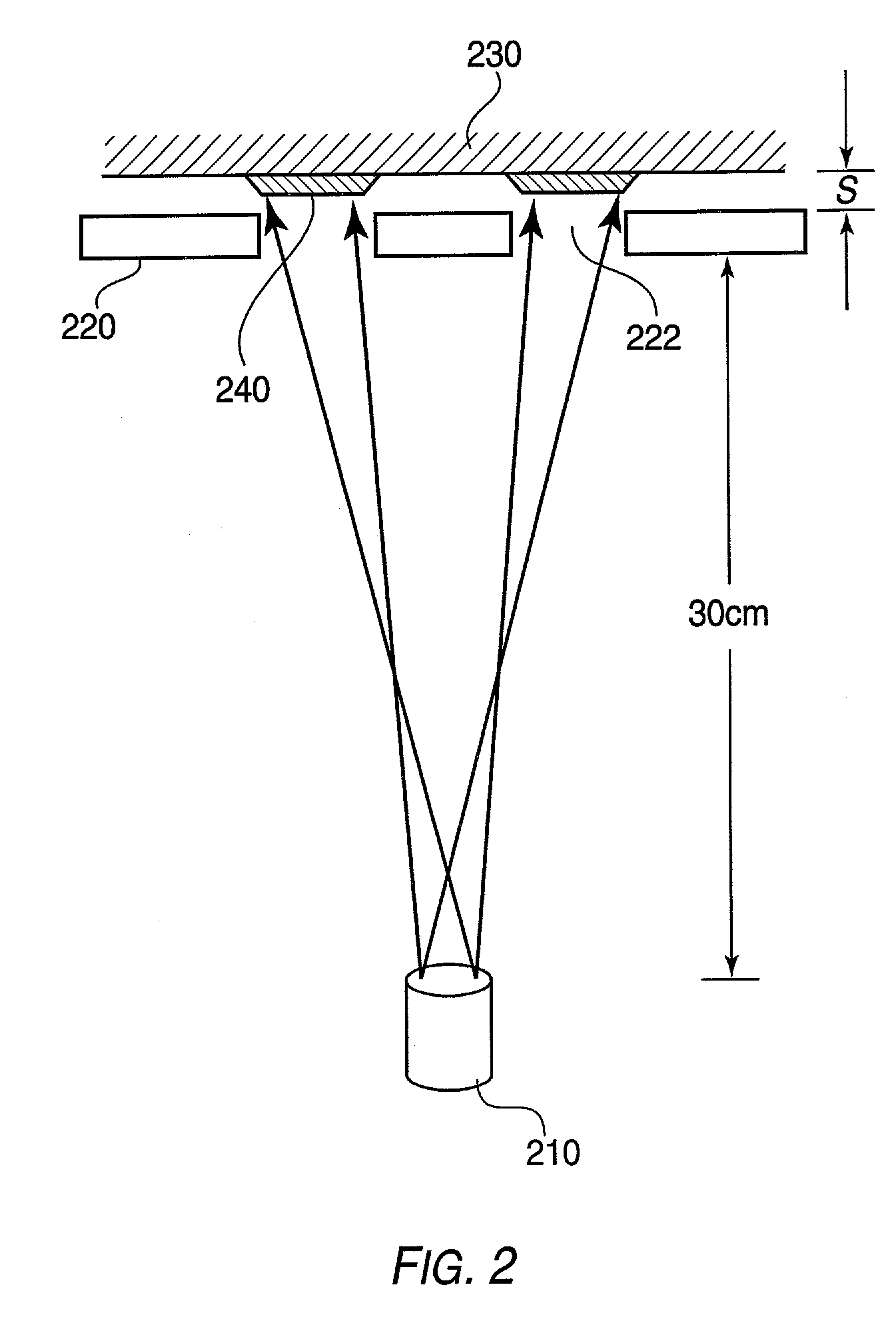

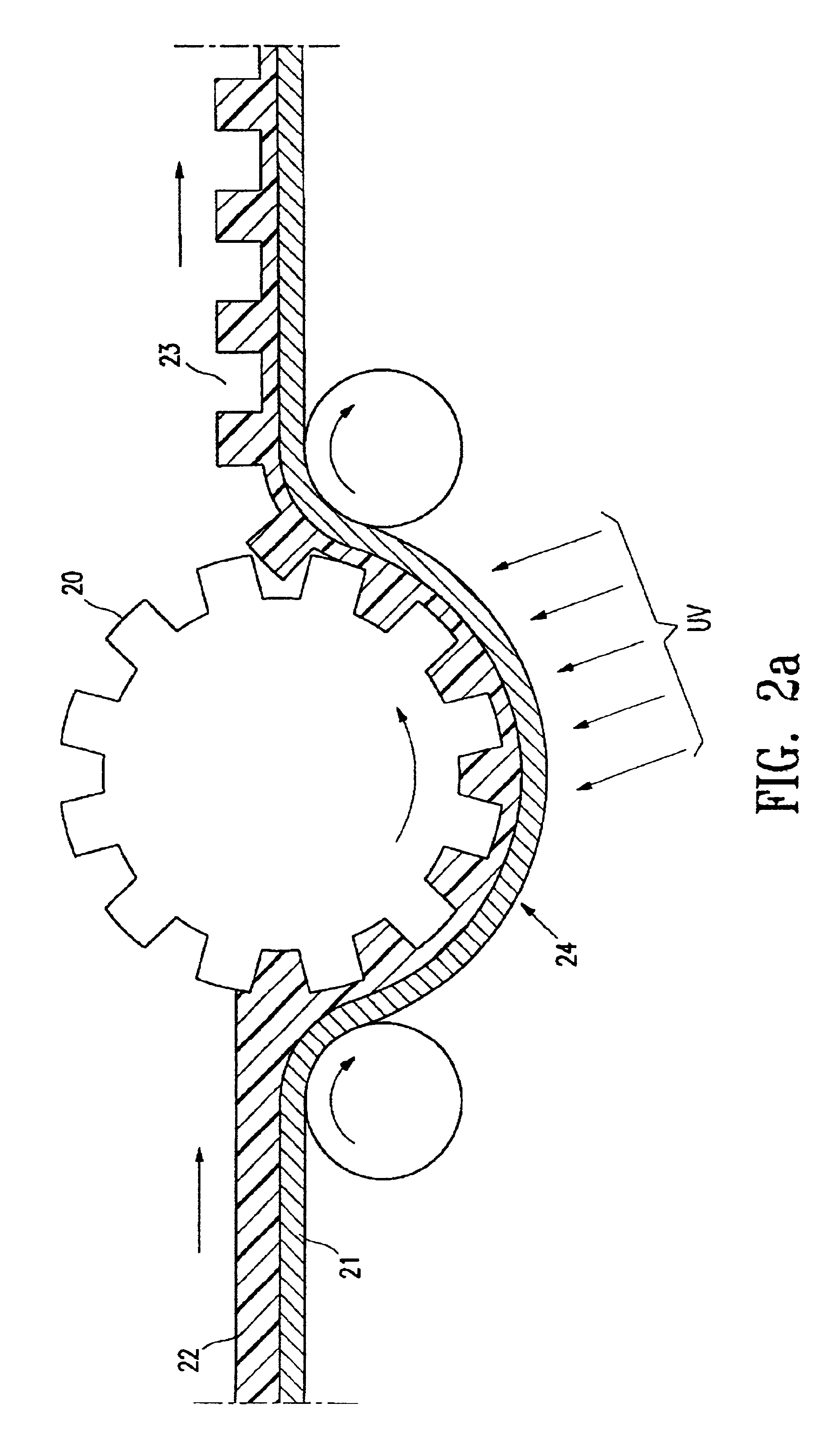

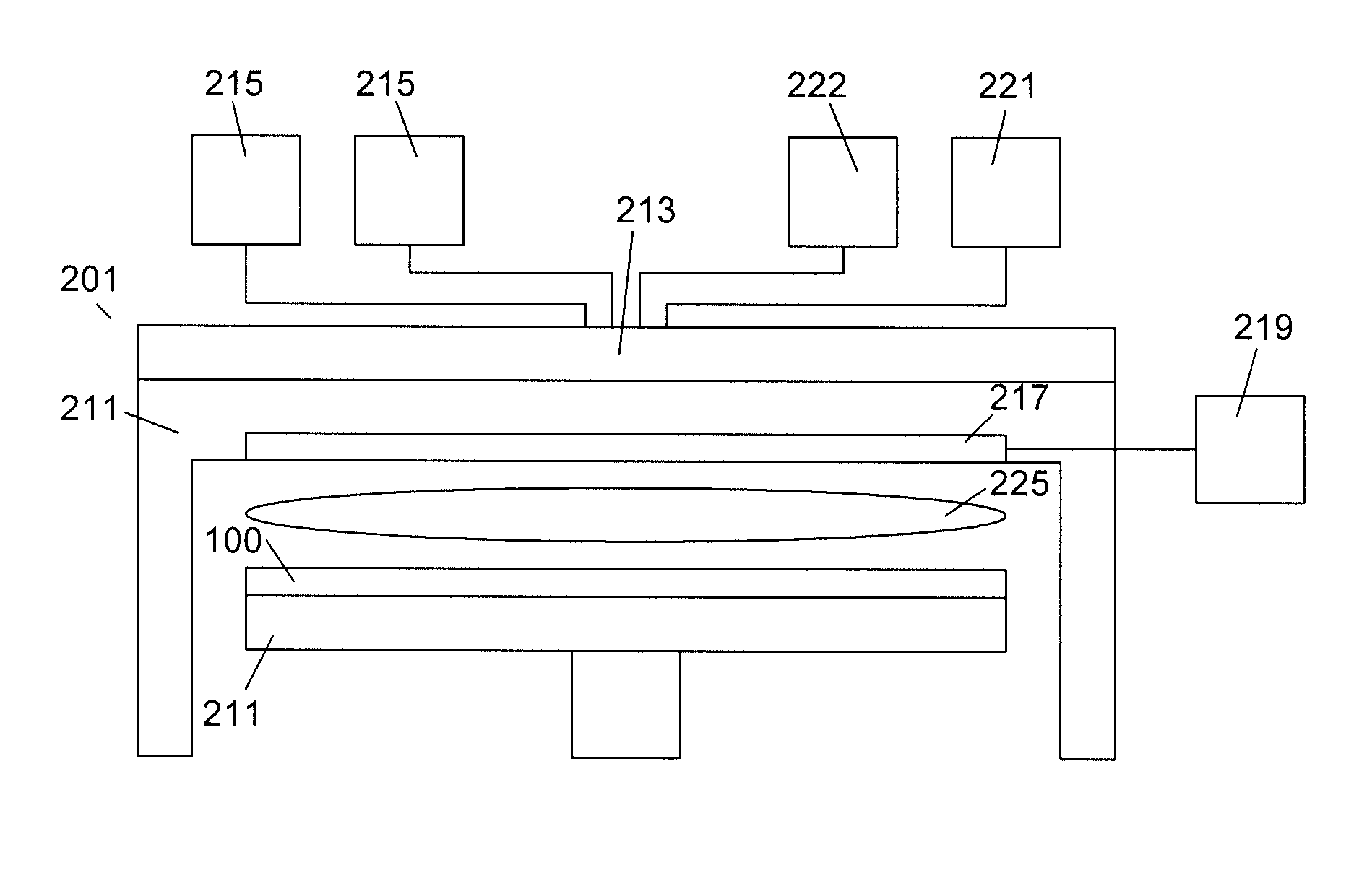

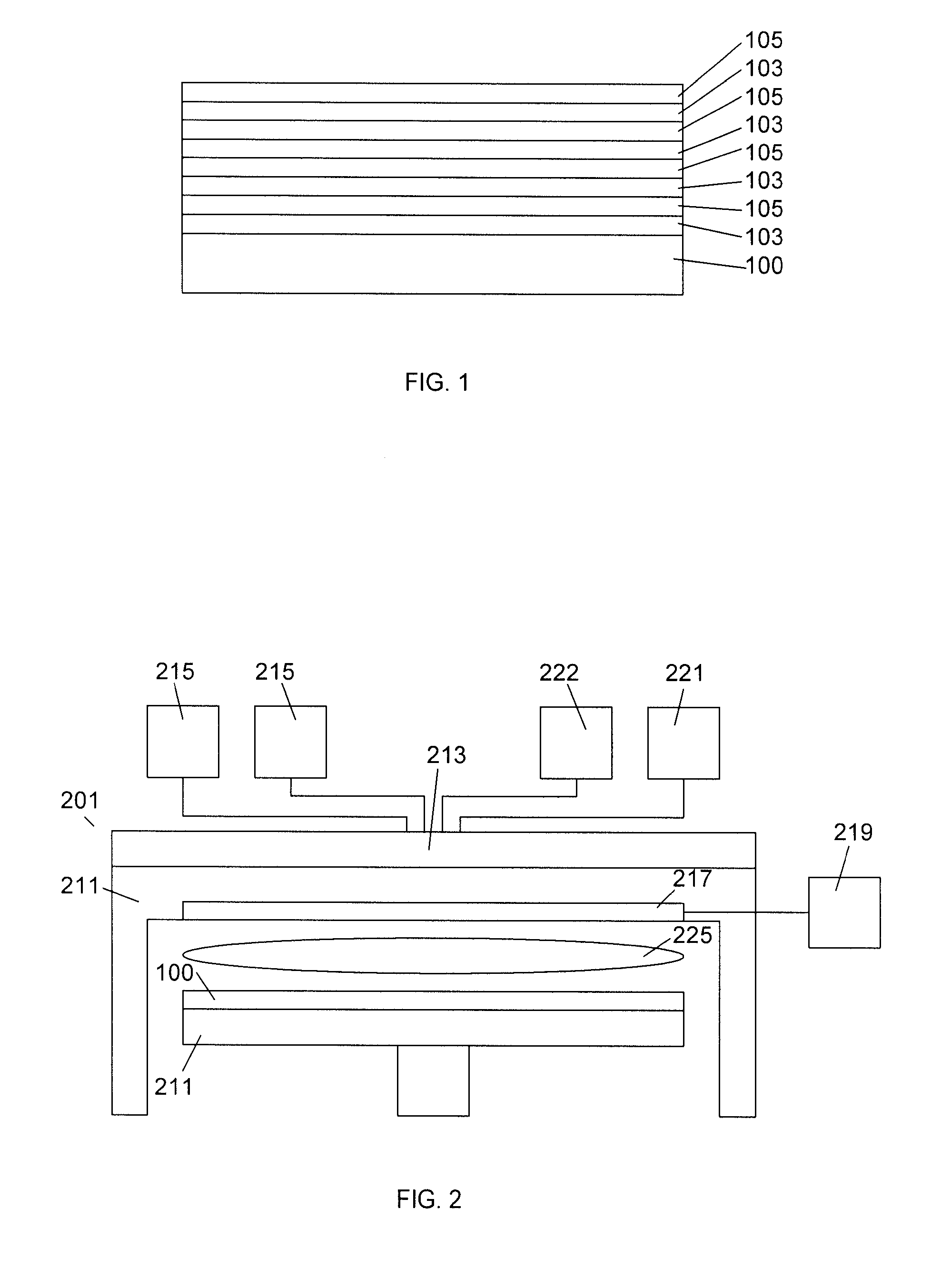

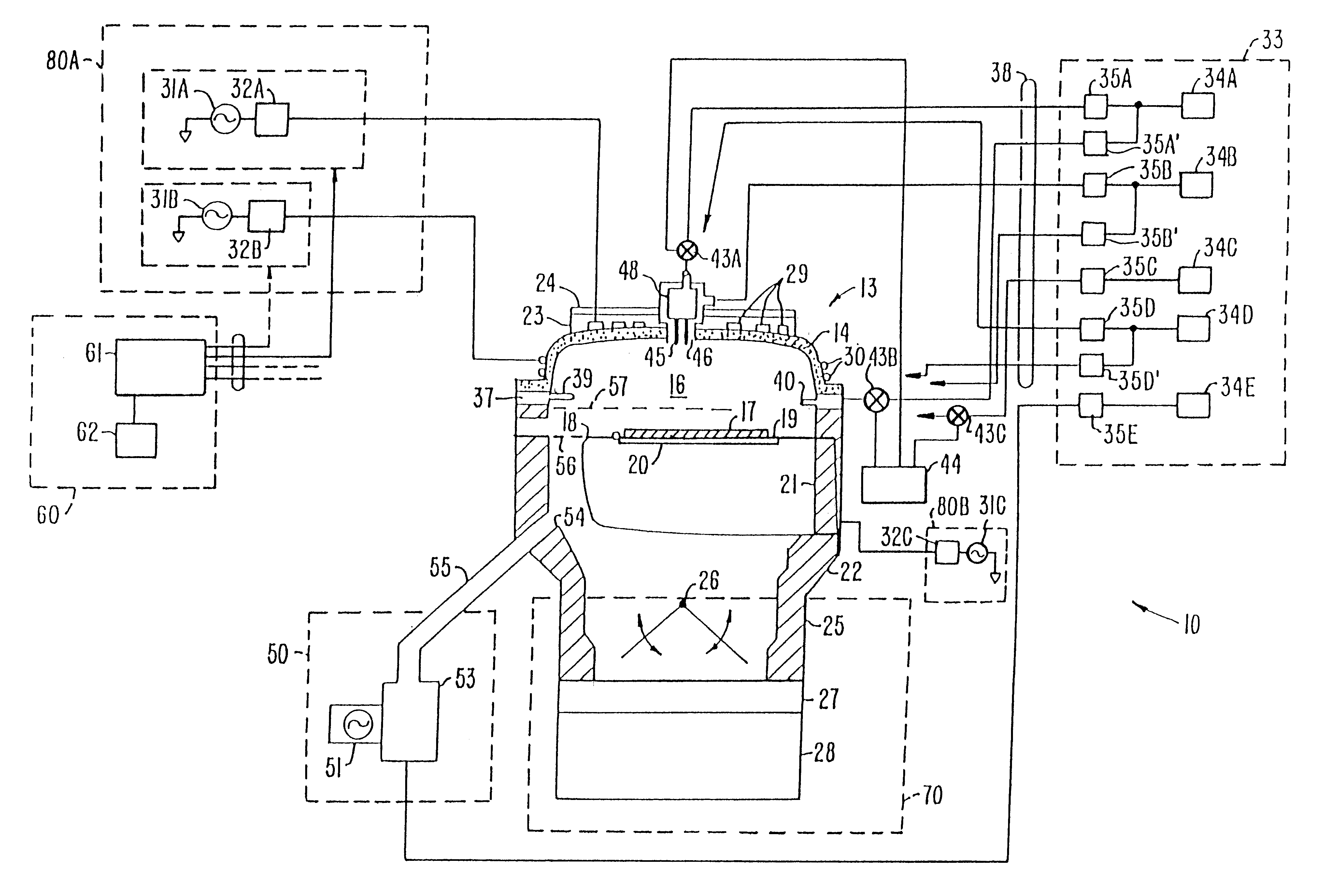

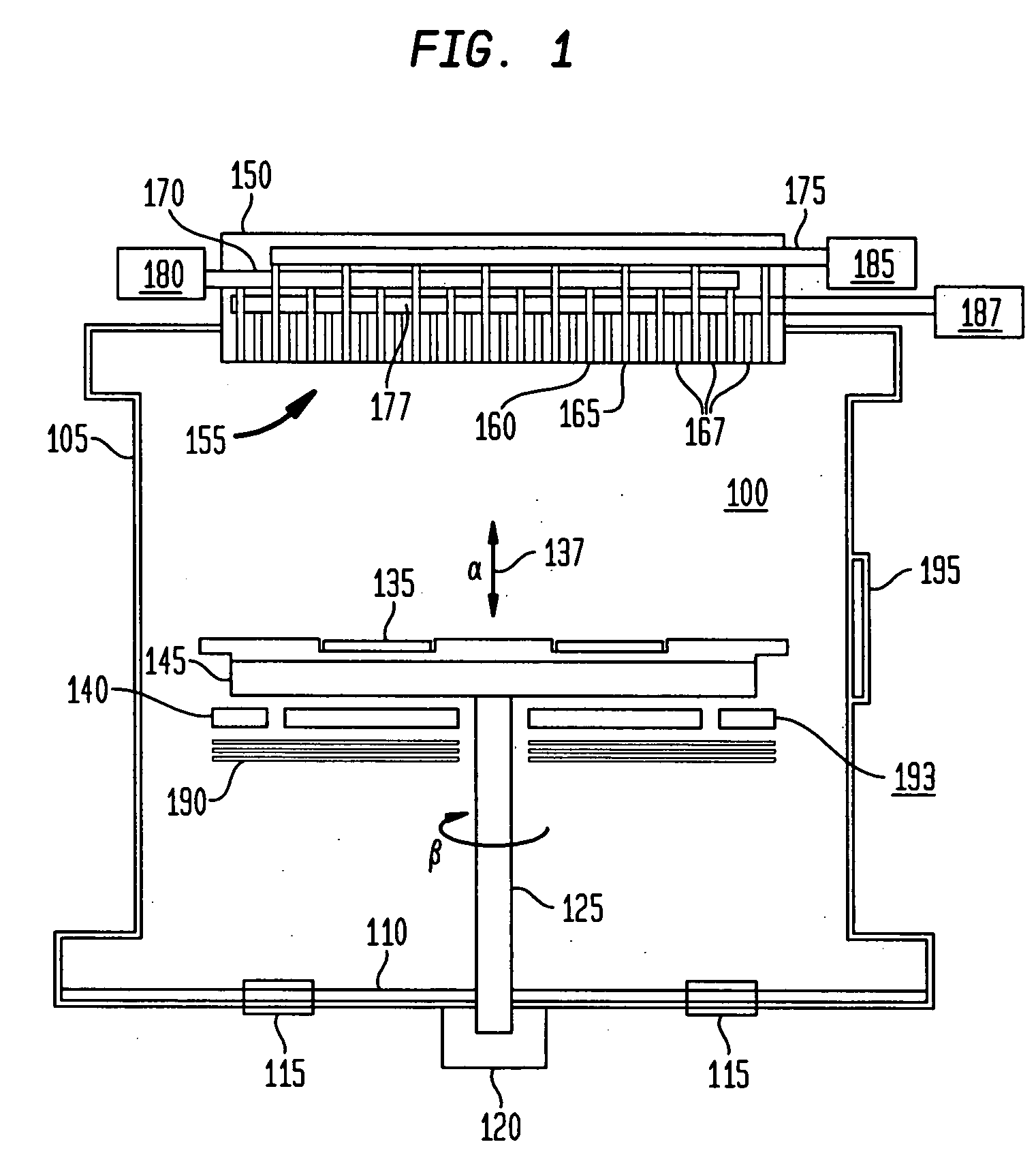

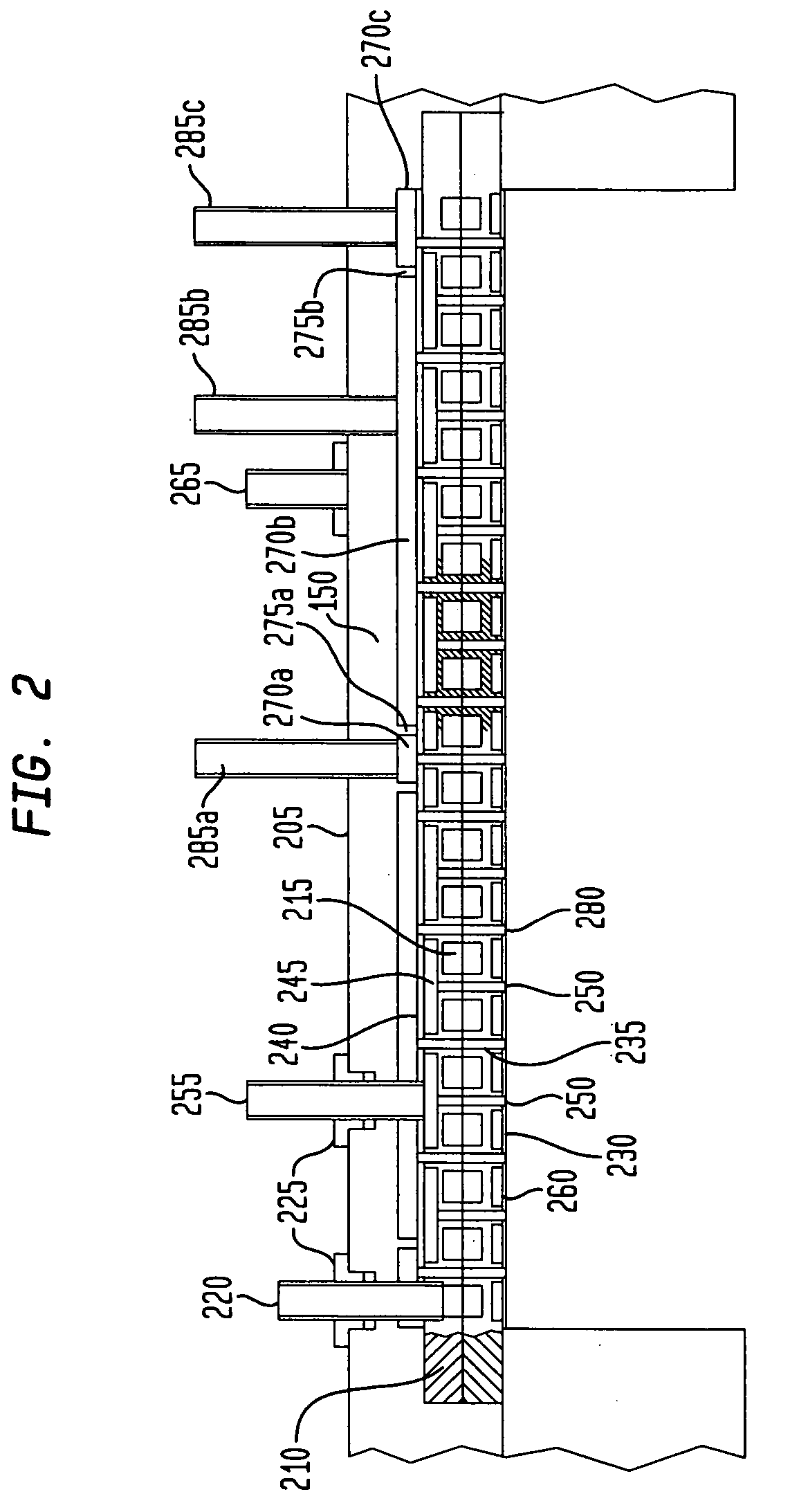

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

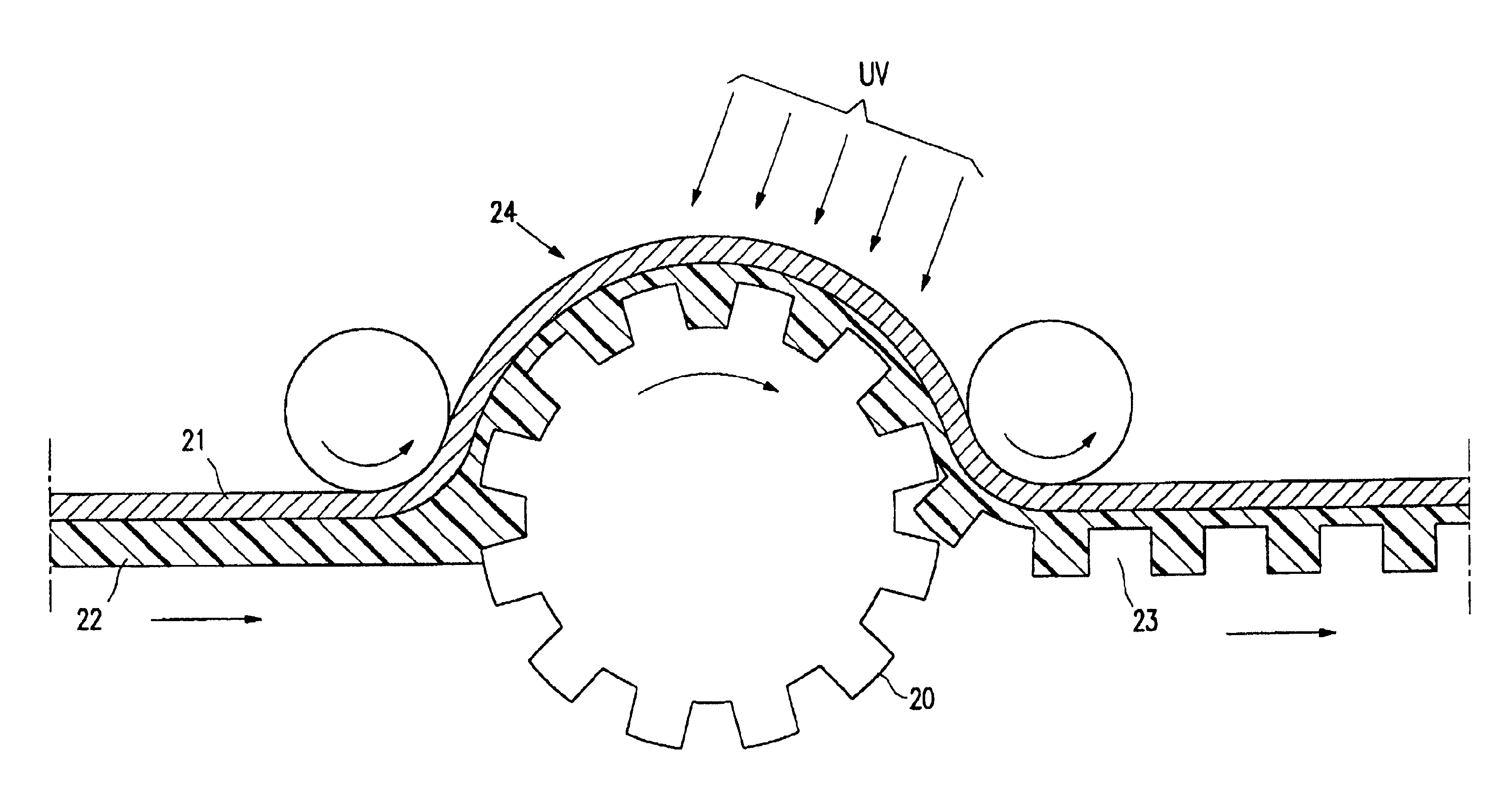

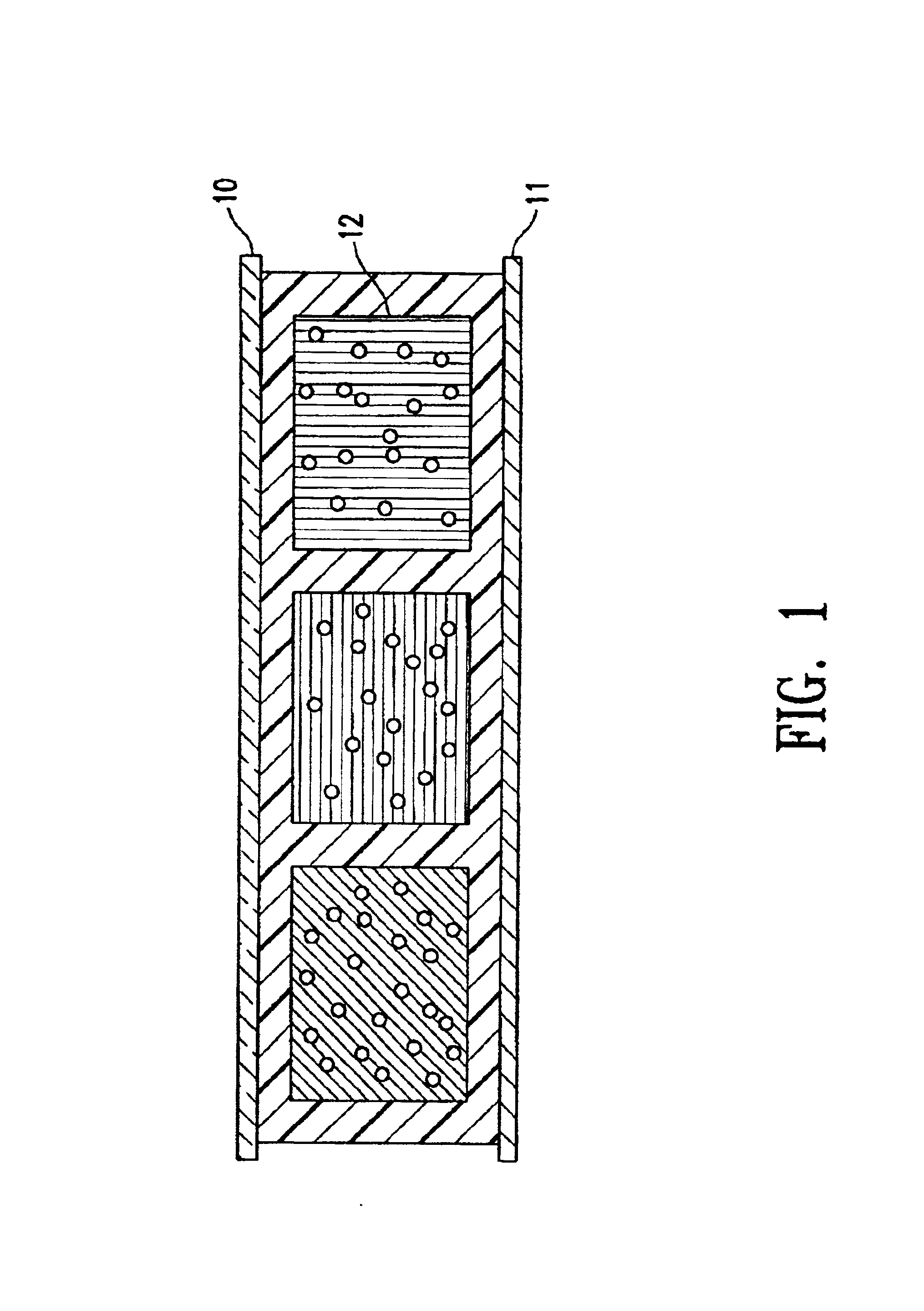

Electrophoretic display and novel process for its manufacture

InactiveUS6930818B1Excellent color addressabilityIncrease contrastStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresesDisplay device

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

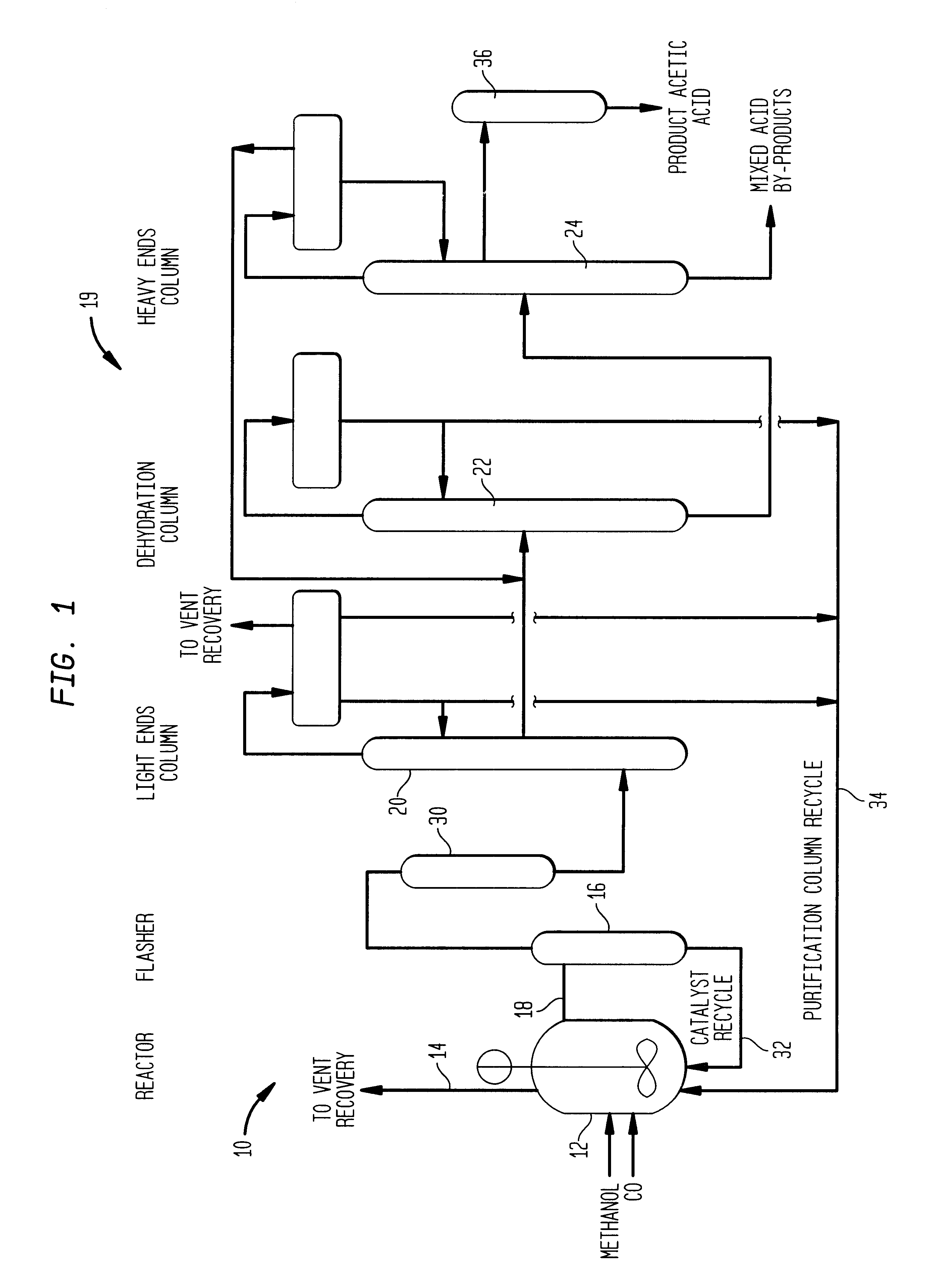

Method and apparatus for sequesting entrained and volatile catalyst species in a carbonylation process

A method and apparatus for sequestering entrained or volatile catalyst species in a carbonylation process includes contacting the product stream with a vinyl pyridine or a vinyl pyrrolidone resin bed which is operative to sequester entrained or volatile catalytic species. The invention is particularly useful in connection with the iridium catalyzed carbonylation of methanol wherein the loss of entrained or volatile catalyst species depletes the catalytic content of the reactor. The resin may be digested in order to recover the catalytic metals.

Owner:CELANESE INT CORP

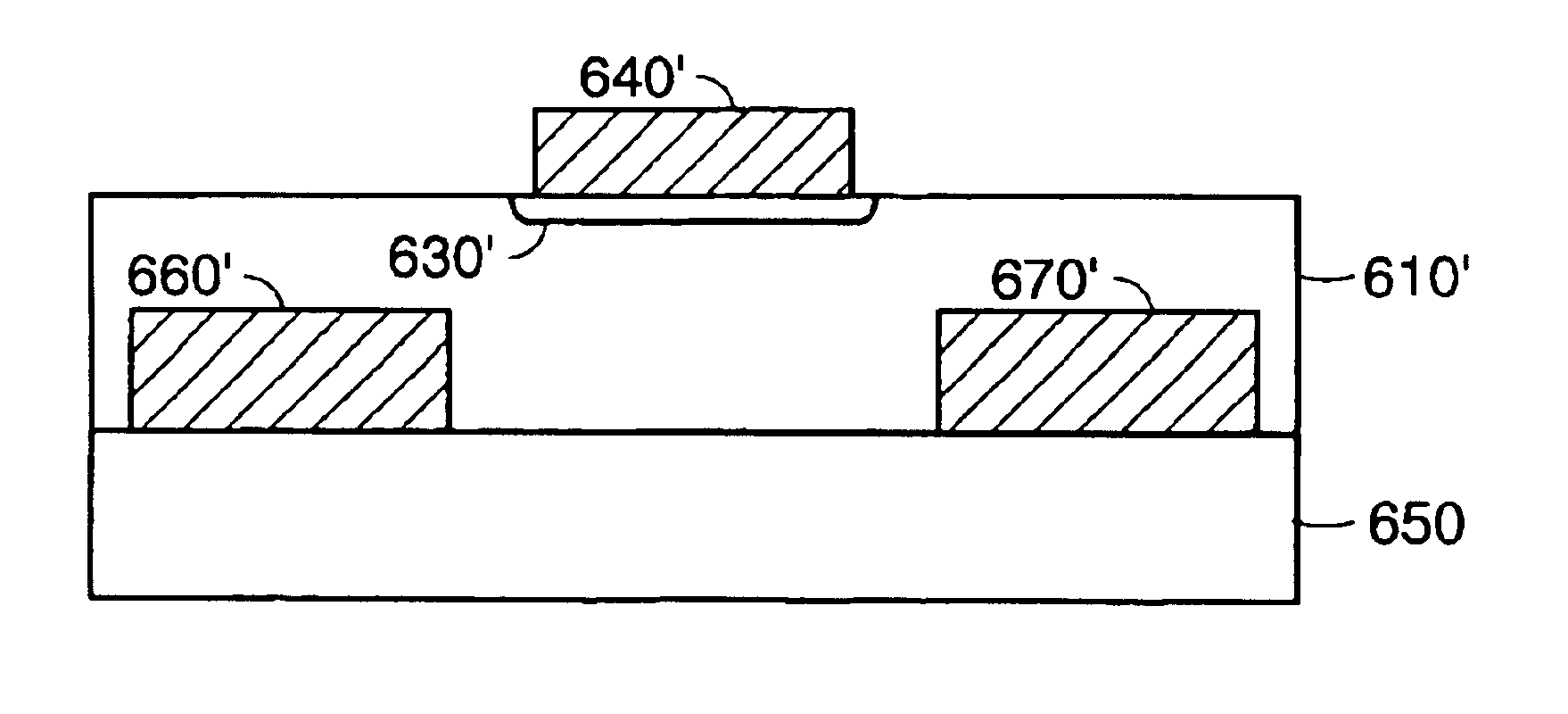

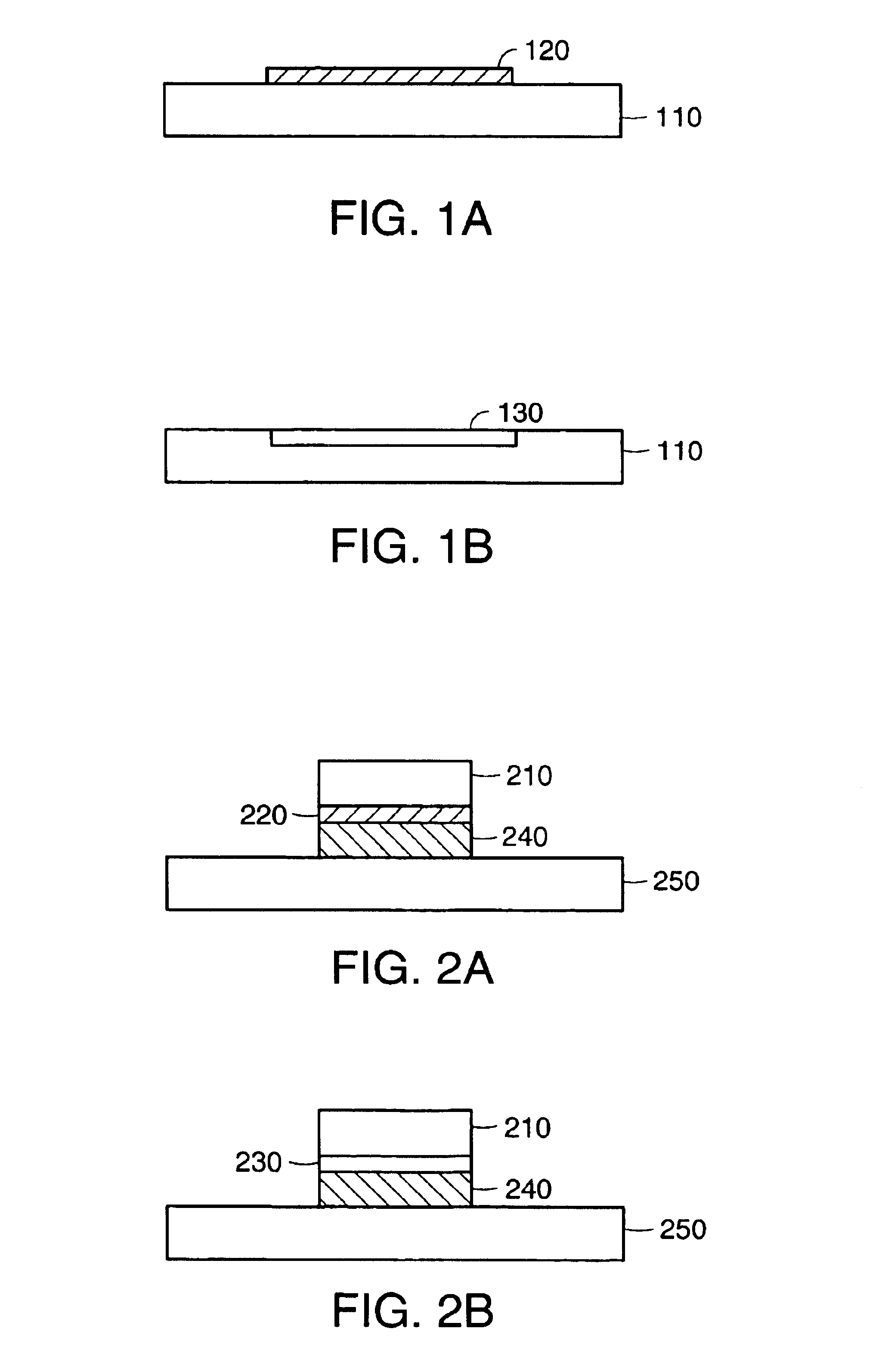

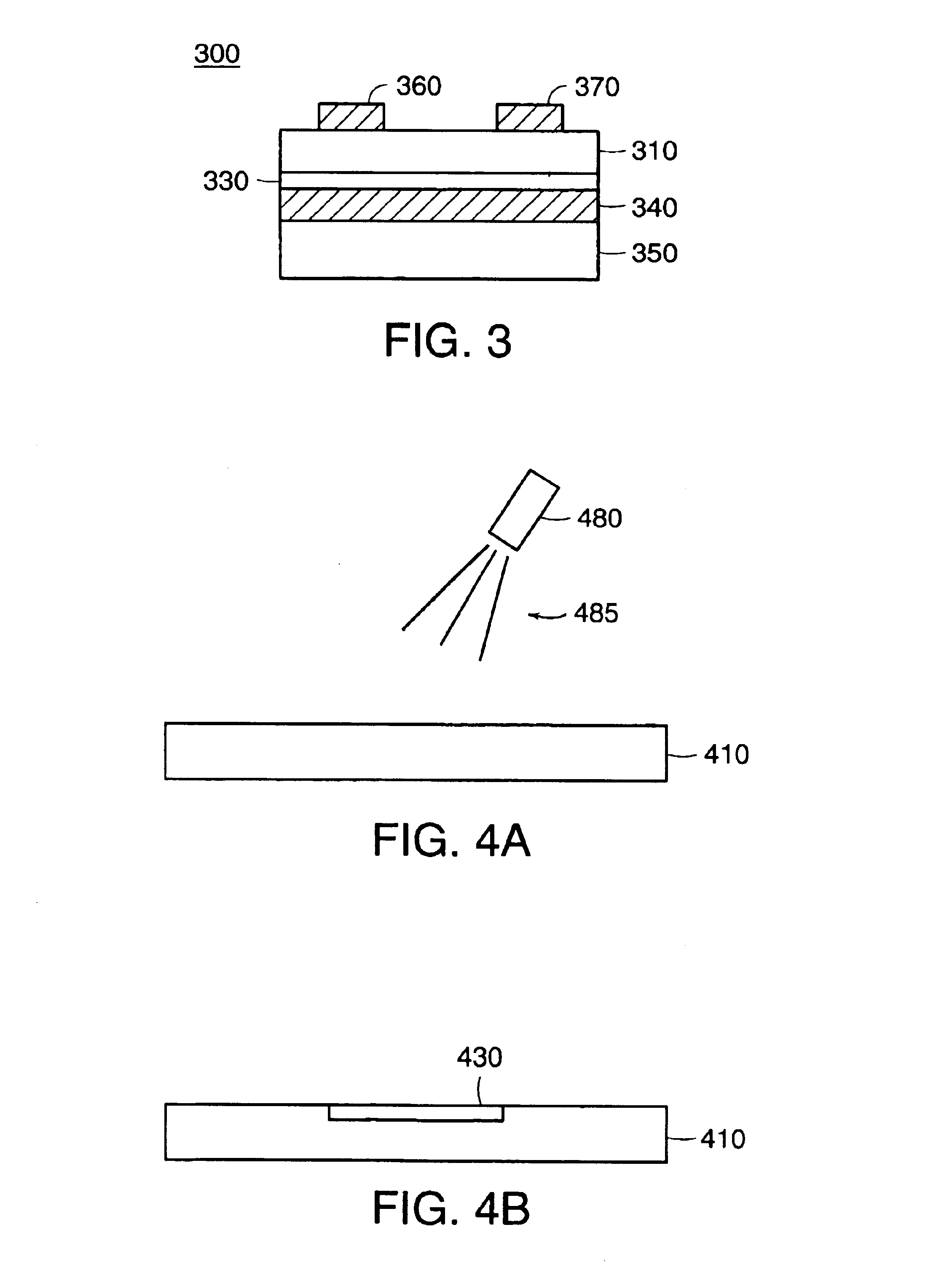

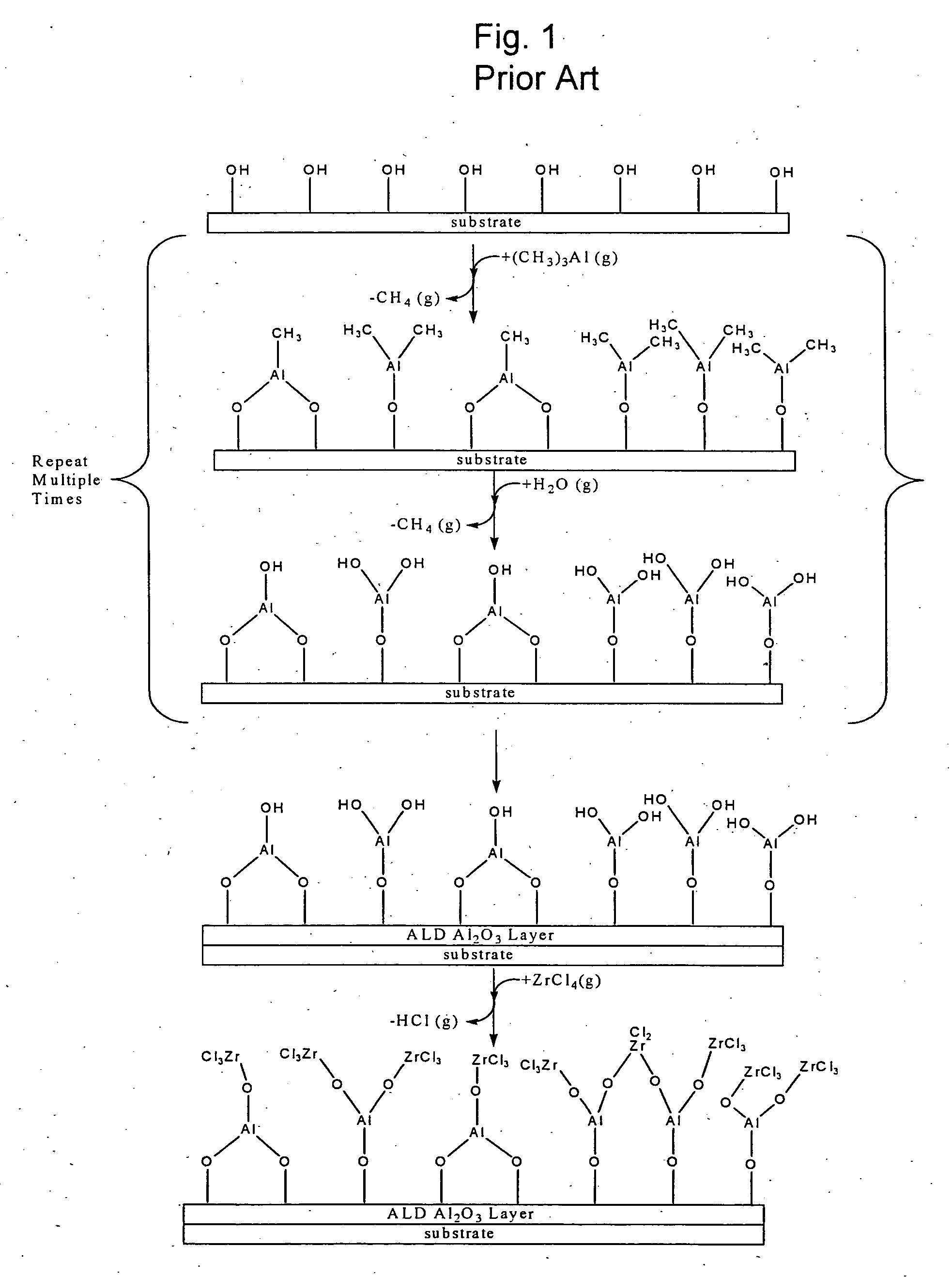

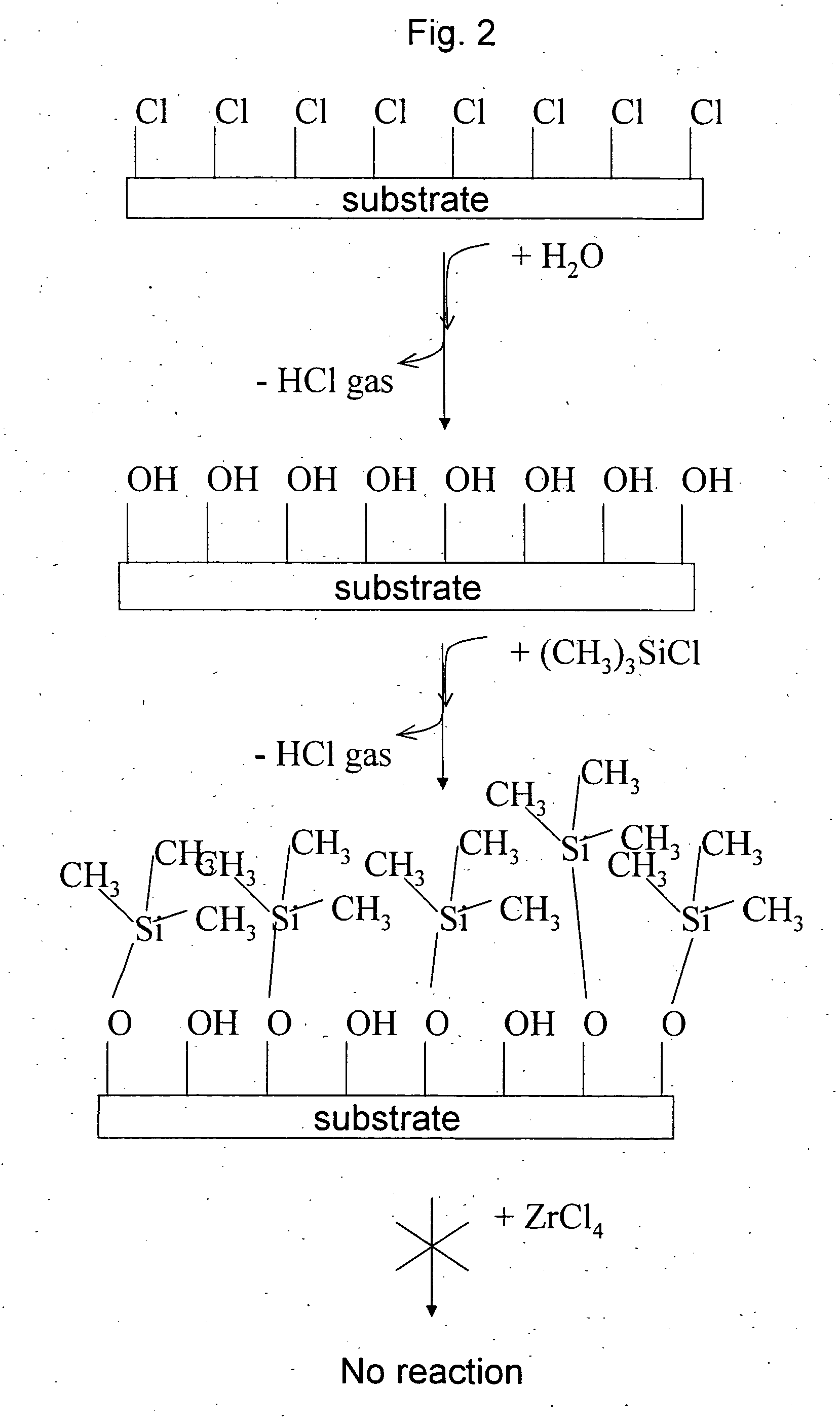

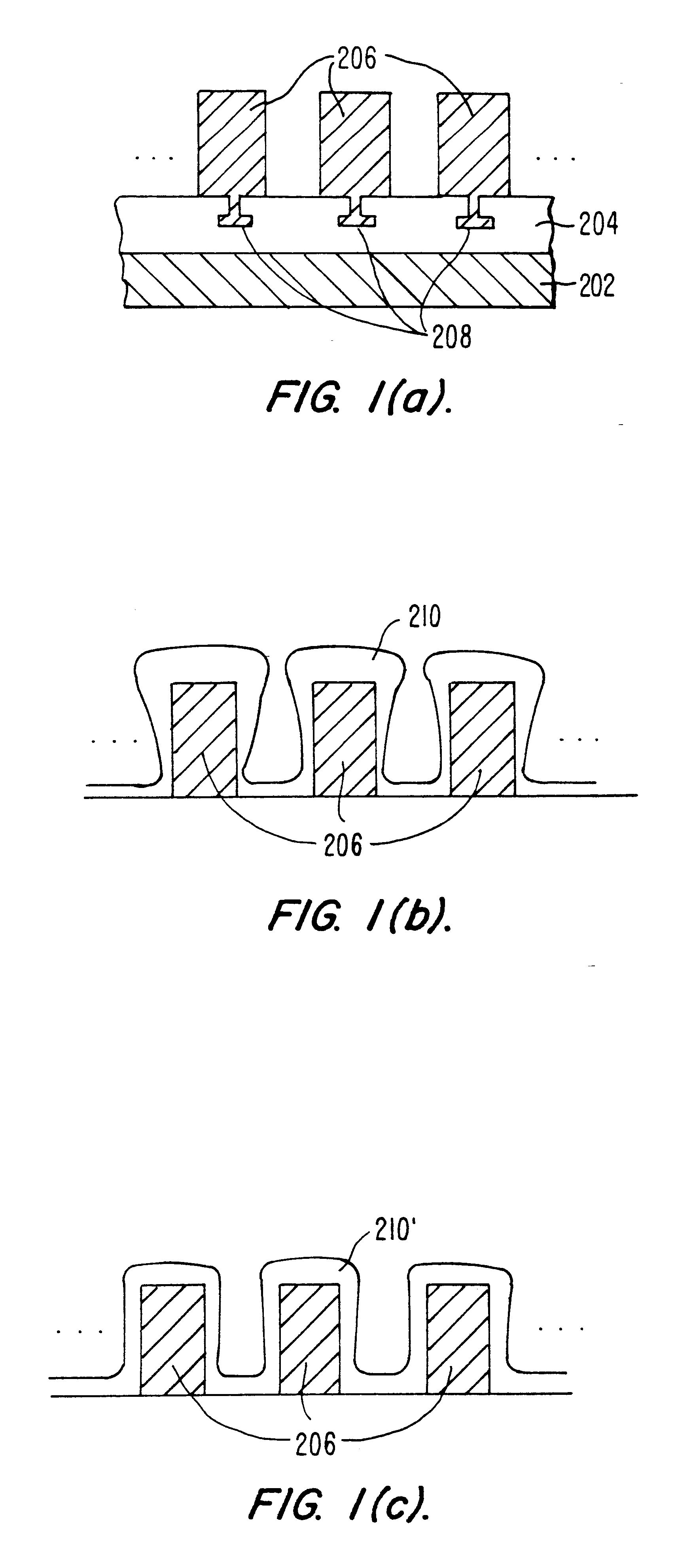

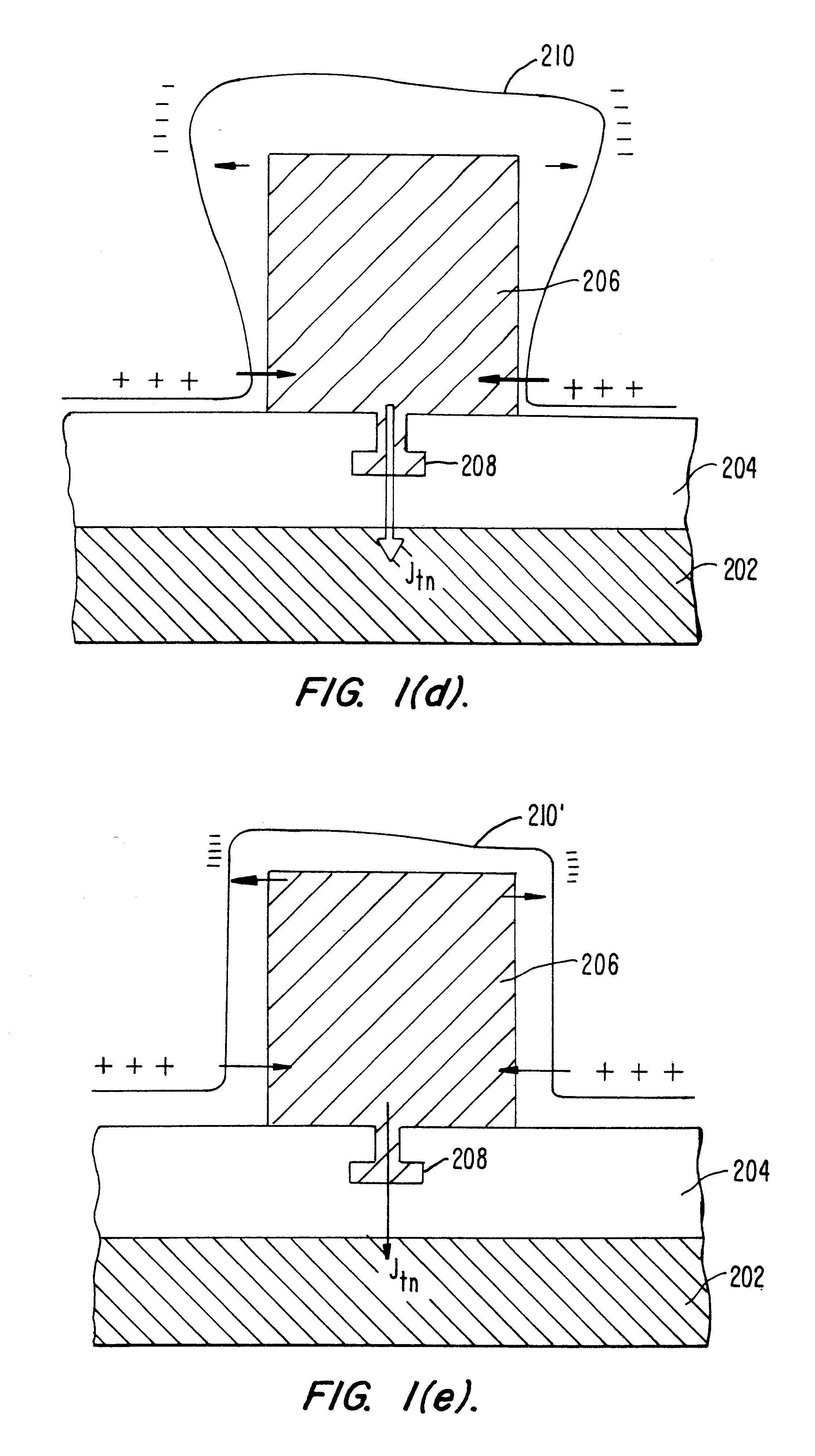

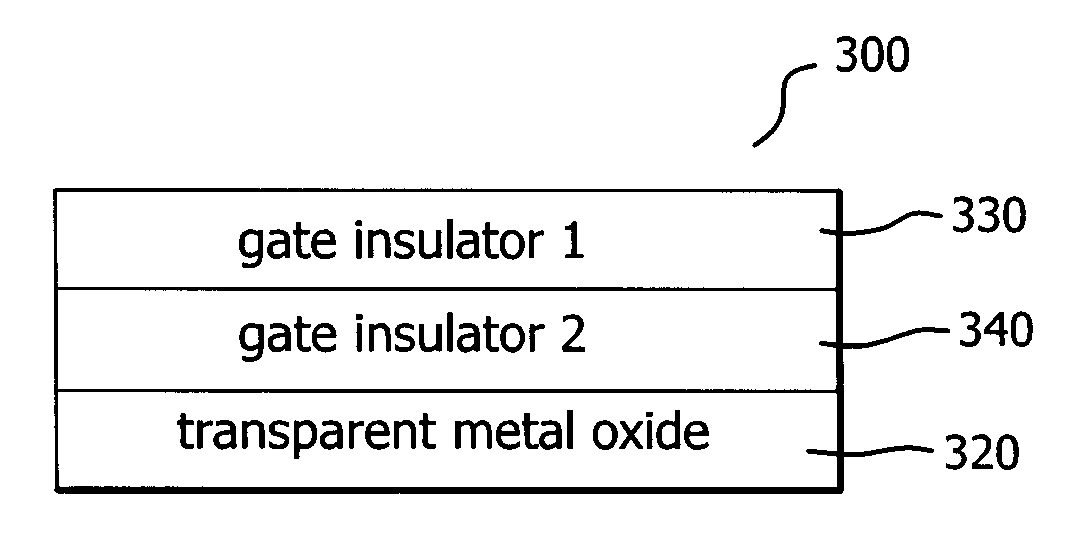

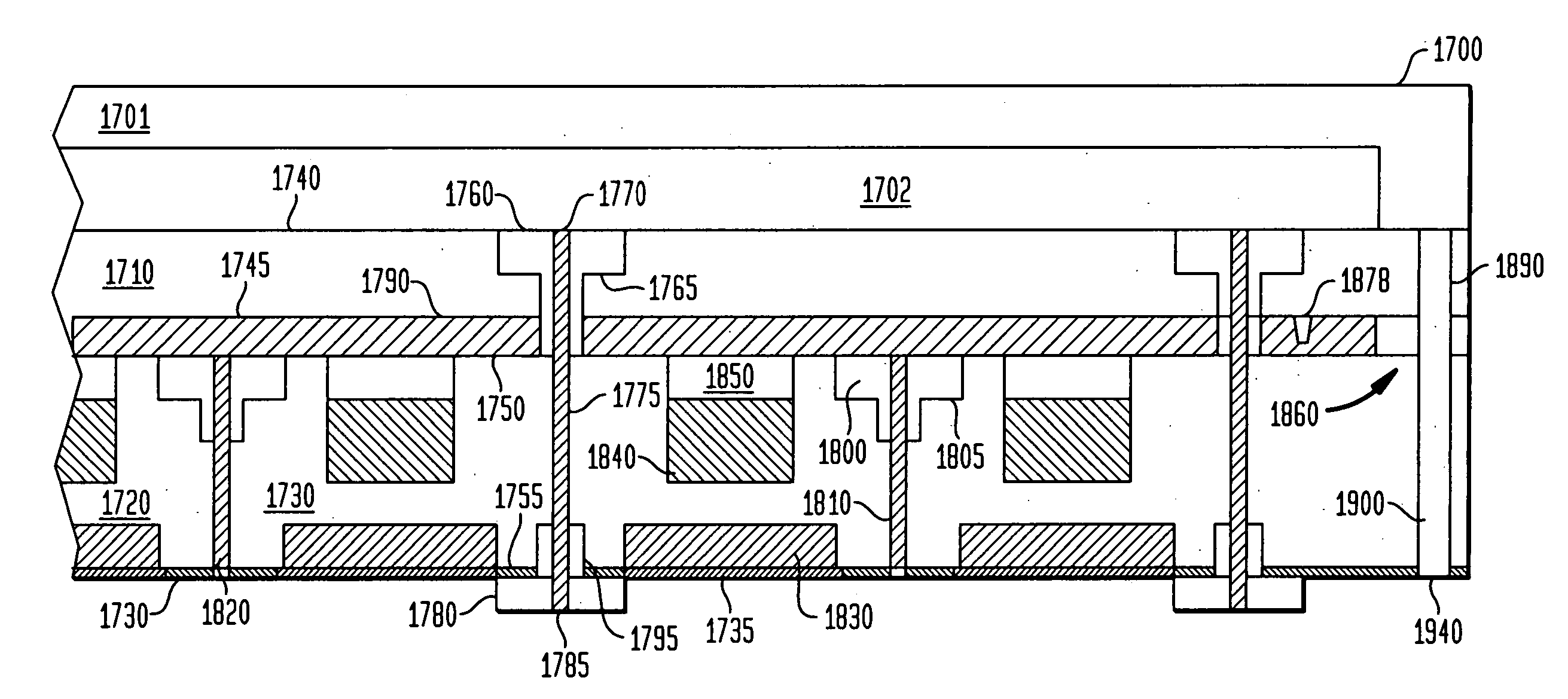

Reactive formation of dielectric layers and protection of organic layers in organic semiconductor device fabrication

InactiveUS6842657B1Use is harmfulDamage is causedSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerOrganic semiconductor

In one embodiment of the invention, a method of manufacturing a semiconductor device comprises the steps of: a) providing an organic semiconductor layer; b) depositing a reactive species on a portion of the organic semiconductor layer; and c) reacting the reactive species with the portion of the organic layer to form a dielectric layer.

Owner:E INK CORPORATION

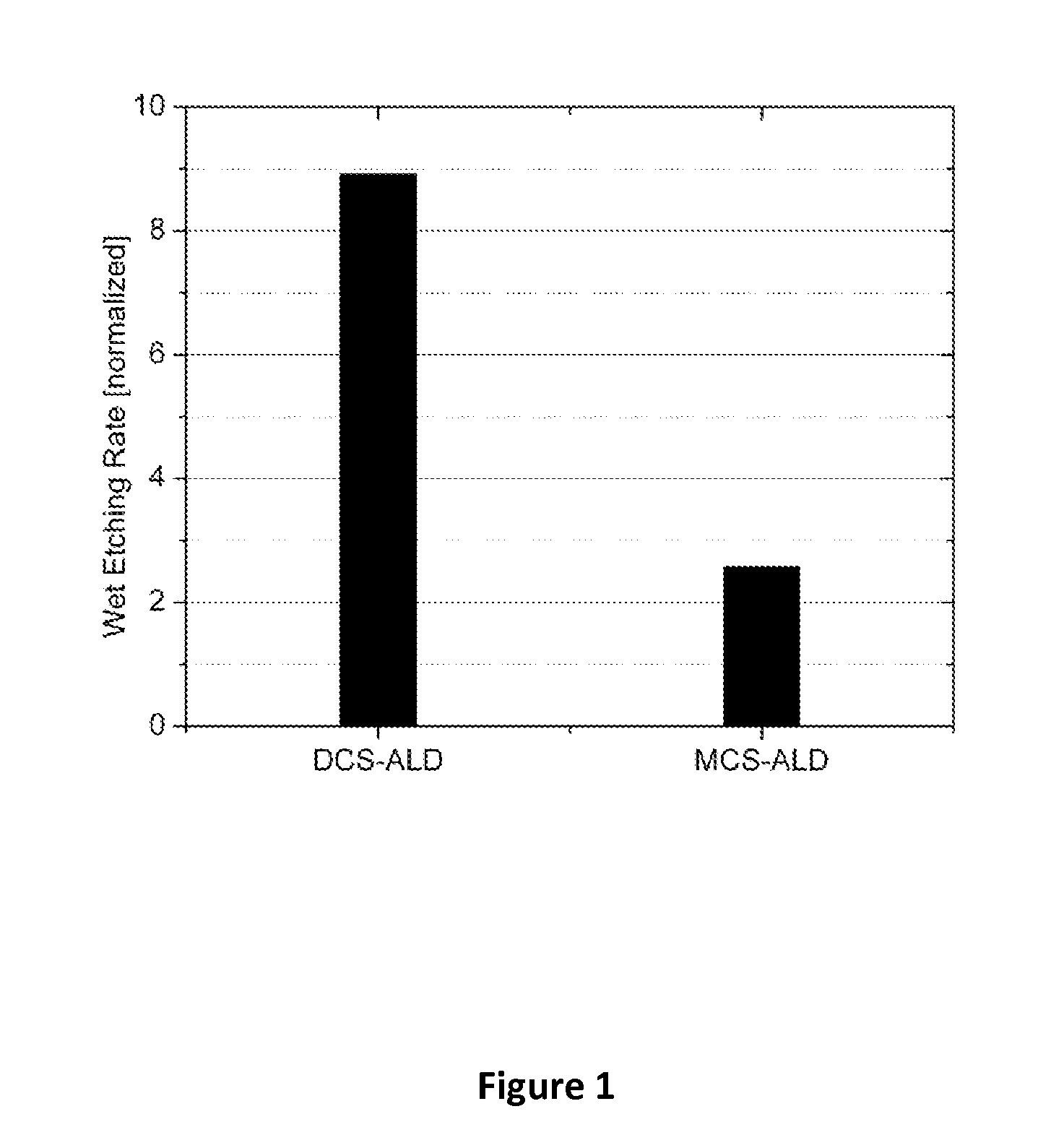

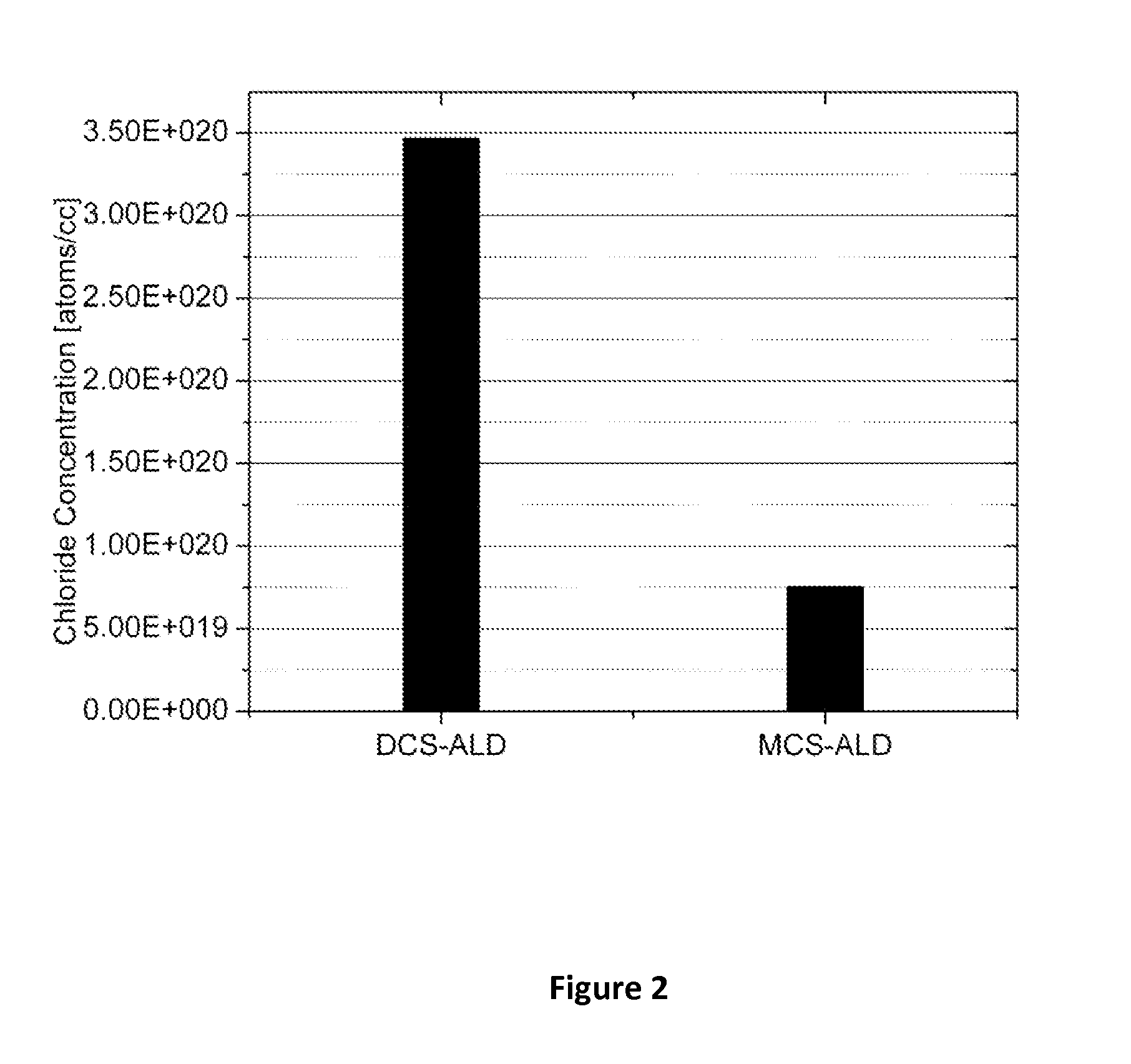

Low Temperature Deposition of Silicon-Containing Films

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

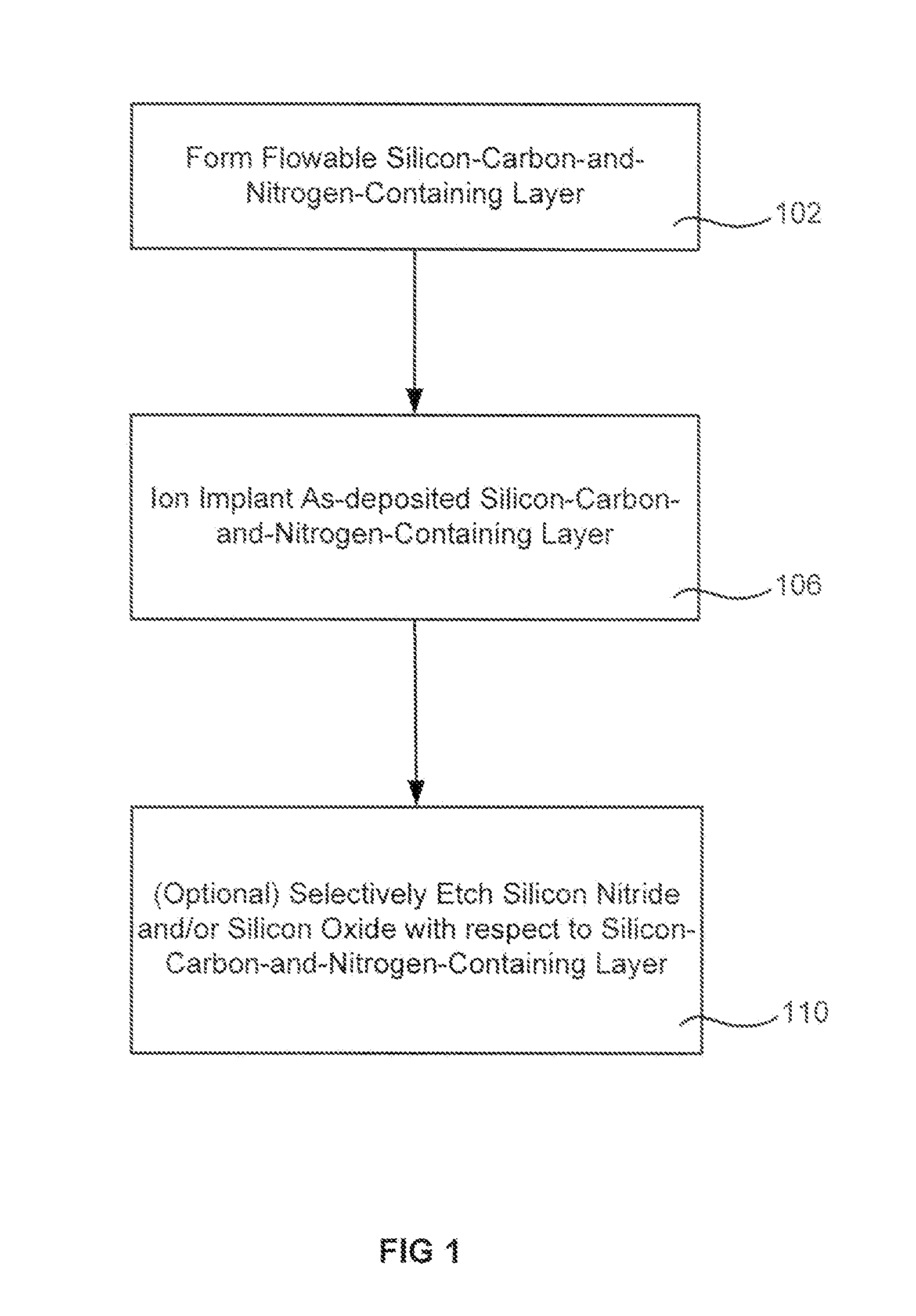

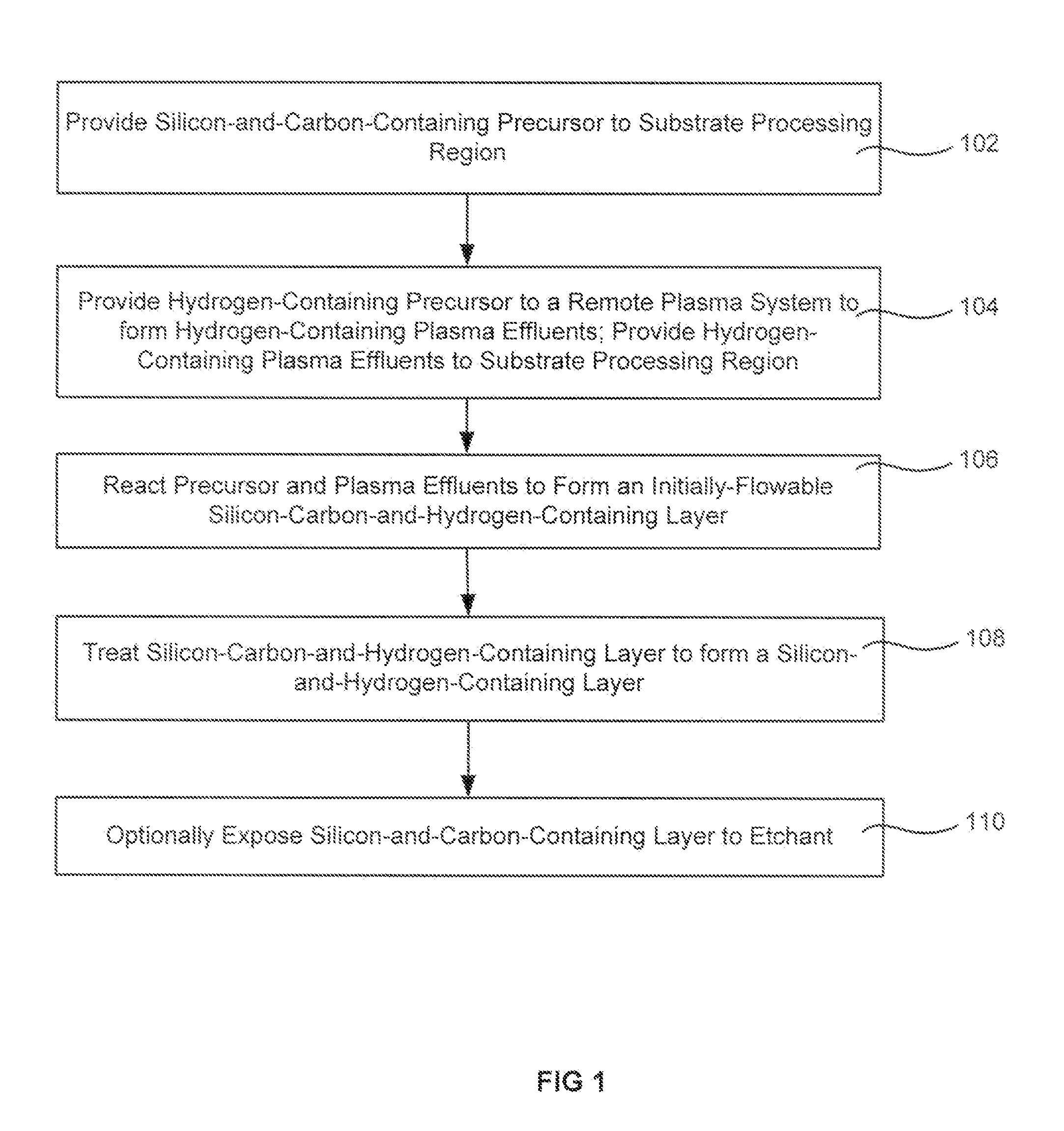

Doping of dielectric layers

InactiveUS20130217243A1Increase etch tolerancePrevent shrinkageSemiconductor/solid-state device manufacturingDeposition temperaturePhysical chemistry

Methods are described for forming and treating a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is ion implanted to increase etch tolerance, prevent shrinkage, adjust film tension and / or adjust electrical characteristics. Ion implantation may also remove components which enabled the flowability, but are no longer needed after deposition. Some treatments using ion implantation have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

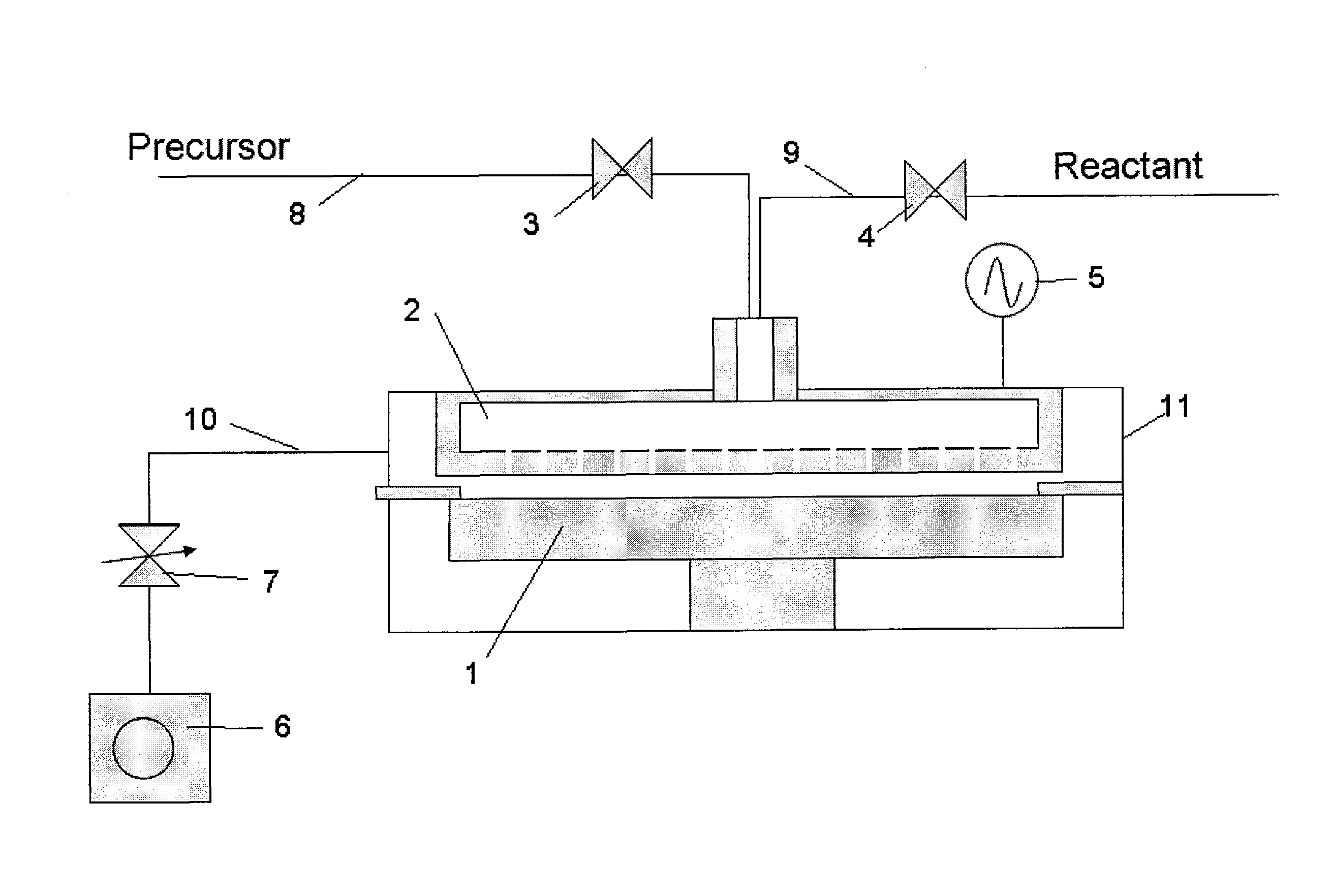

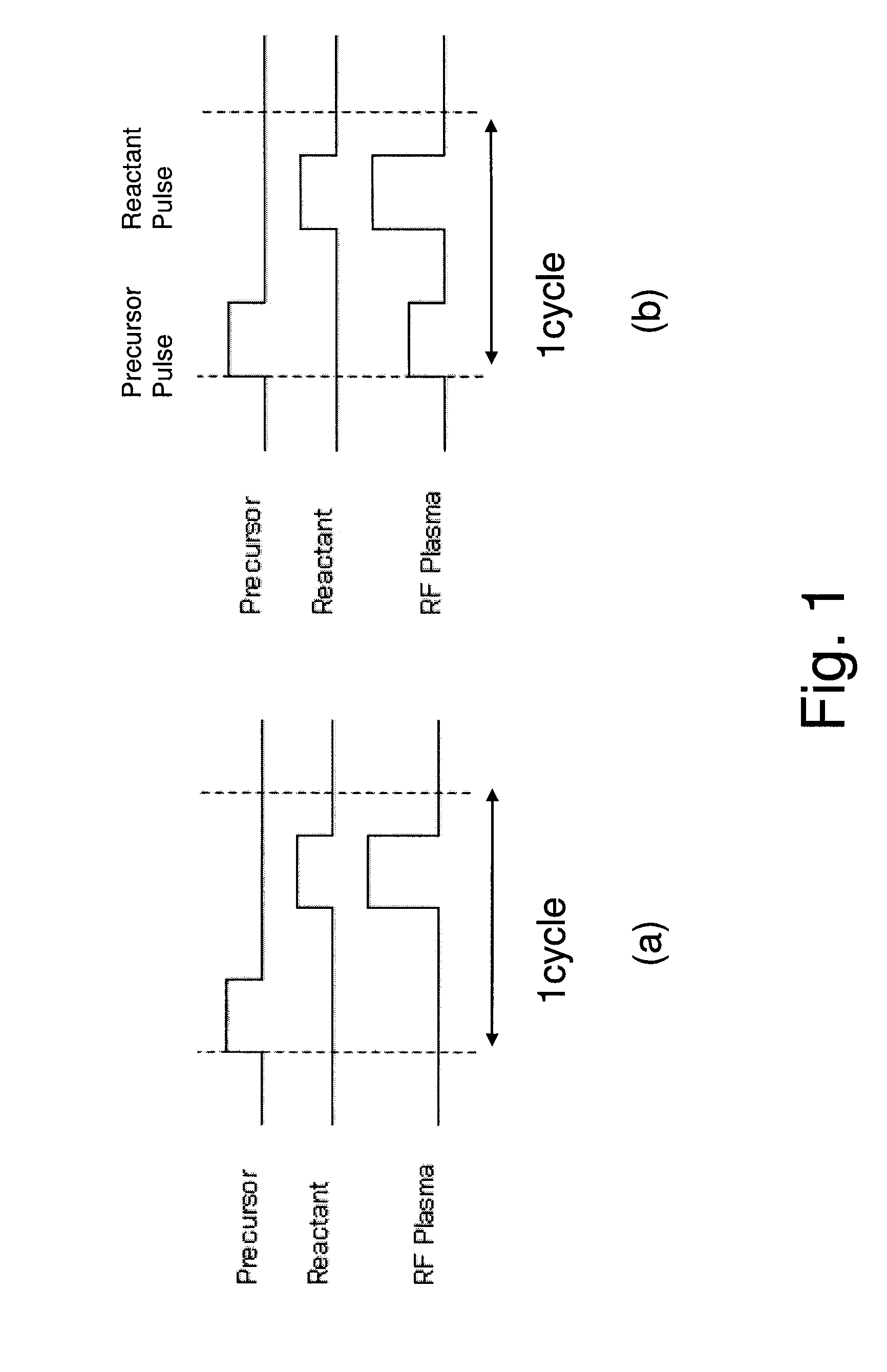

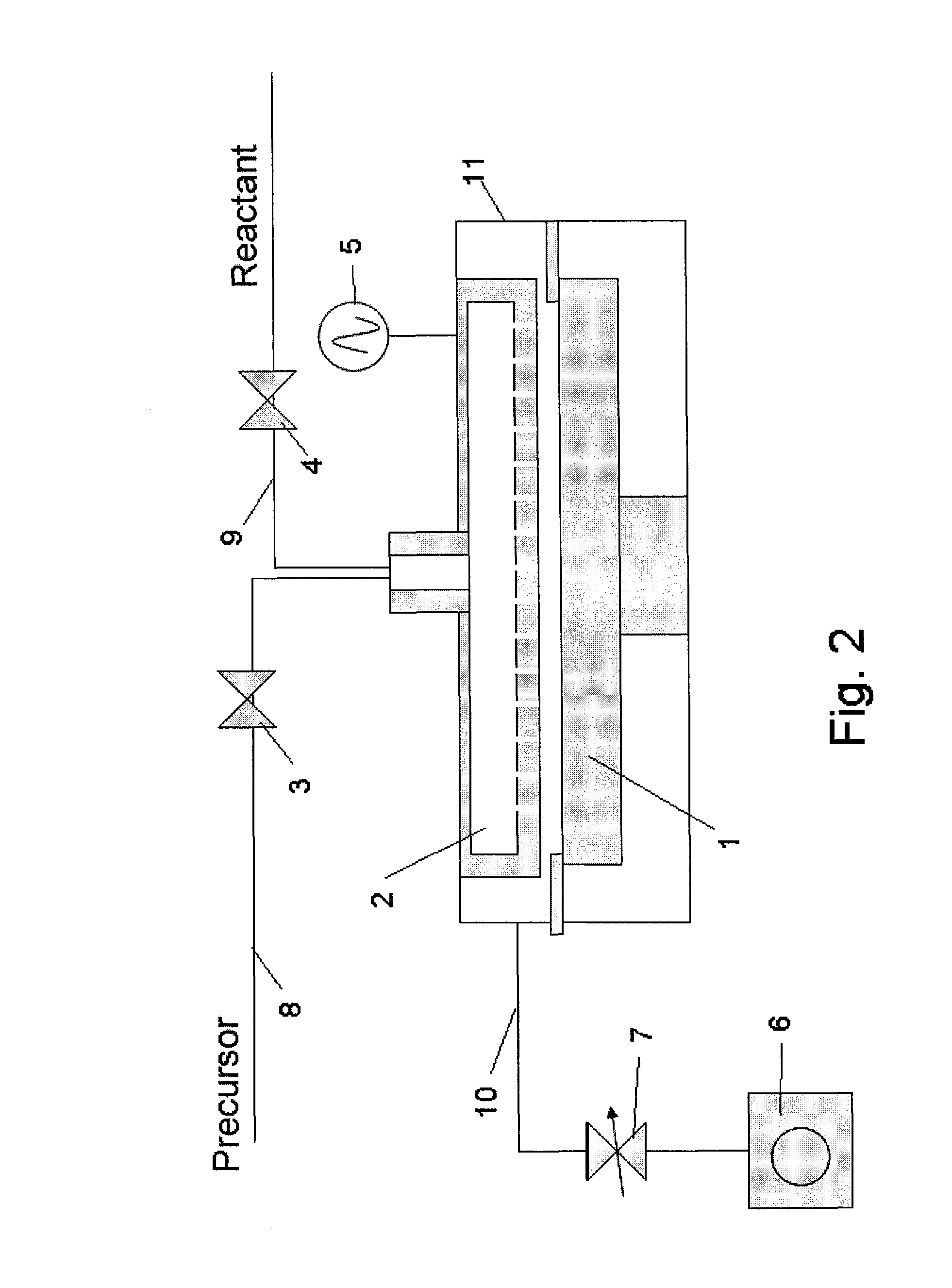

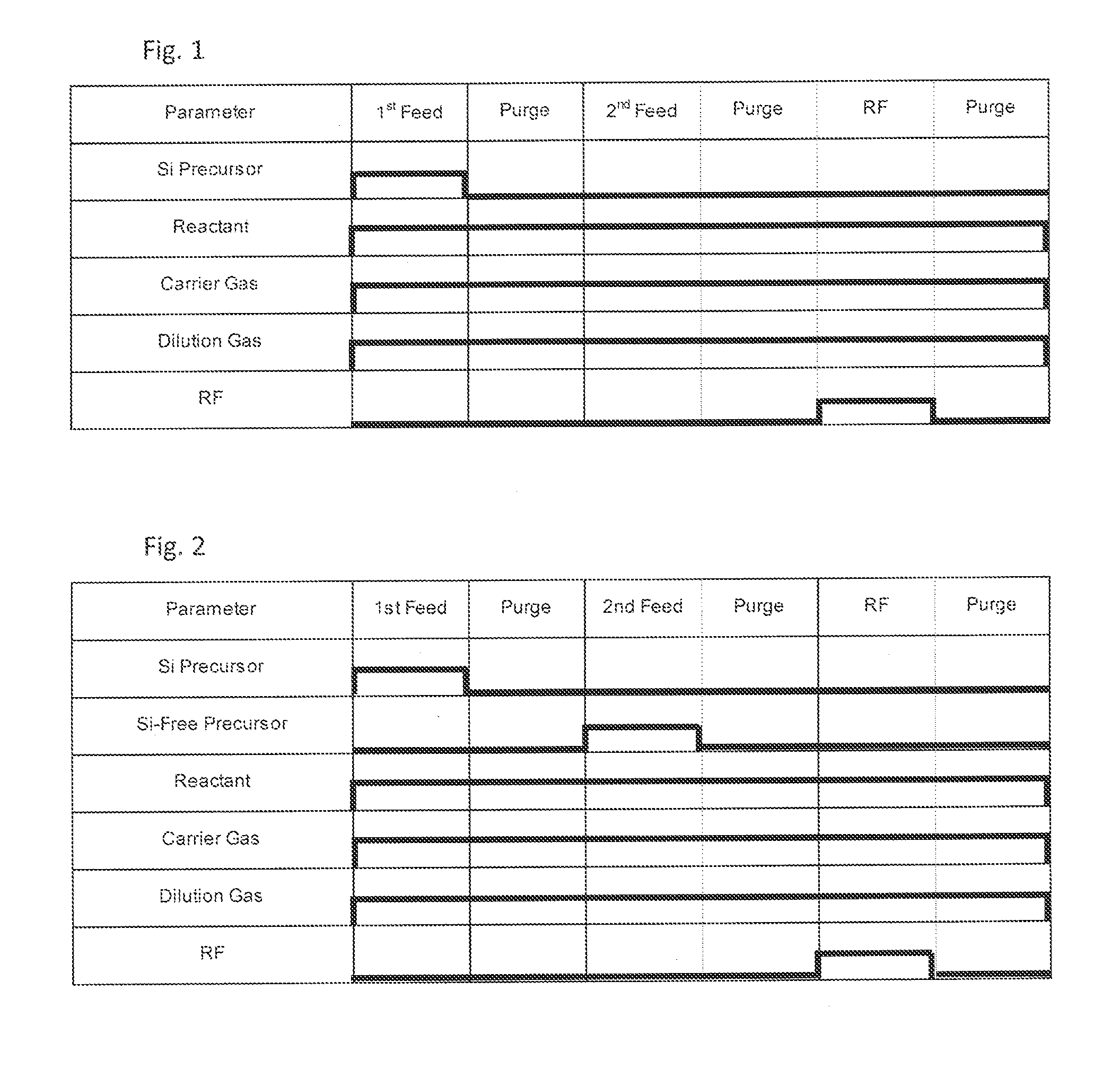

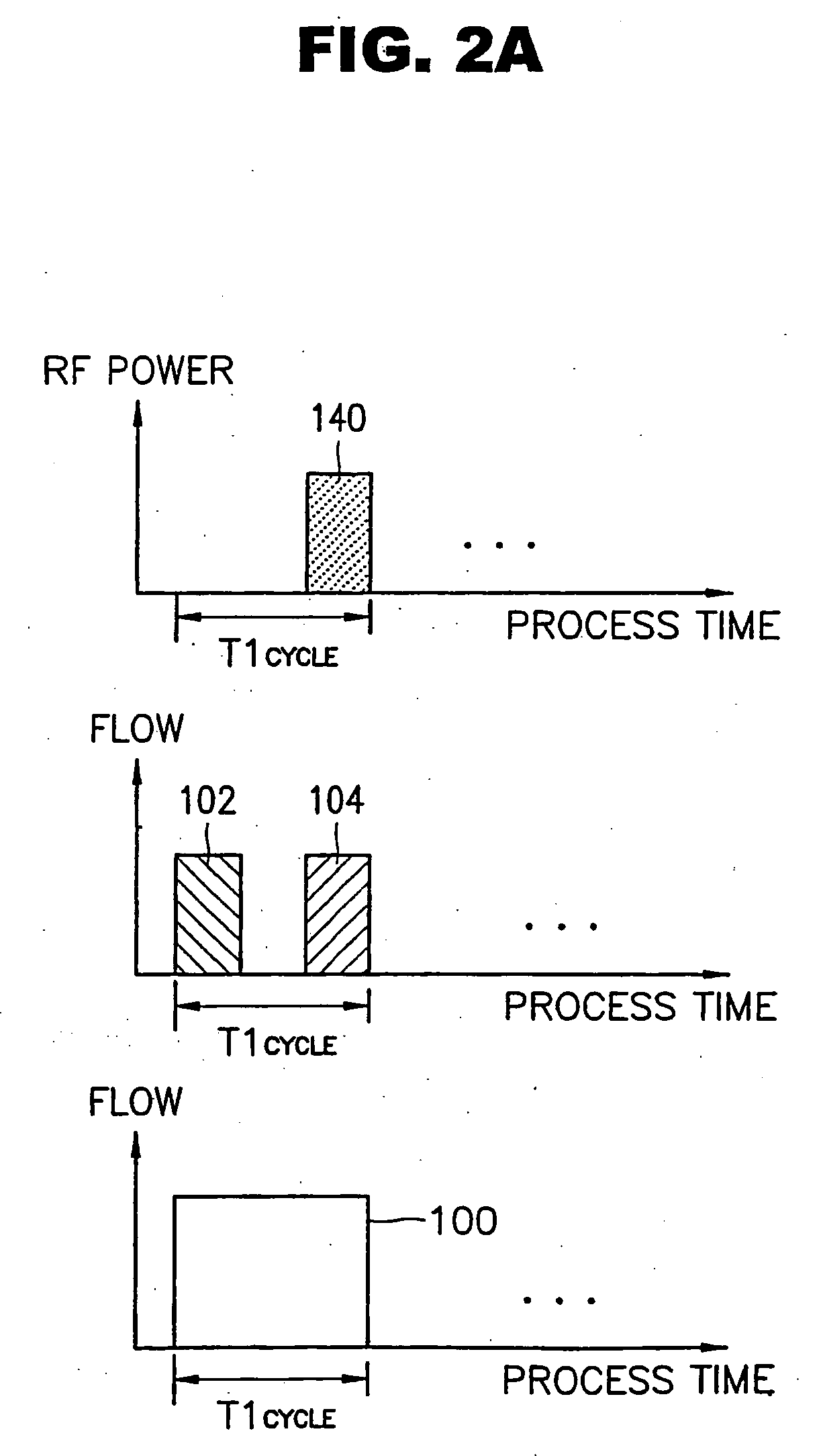

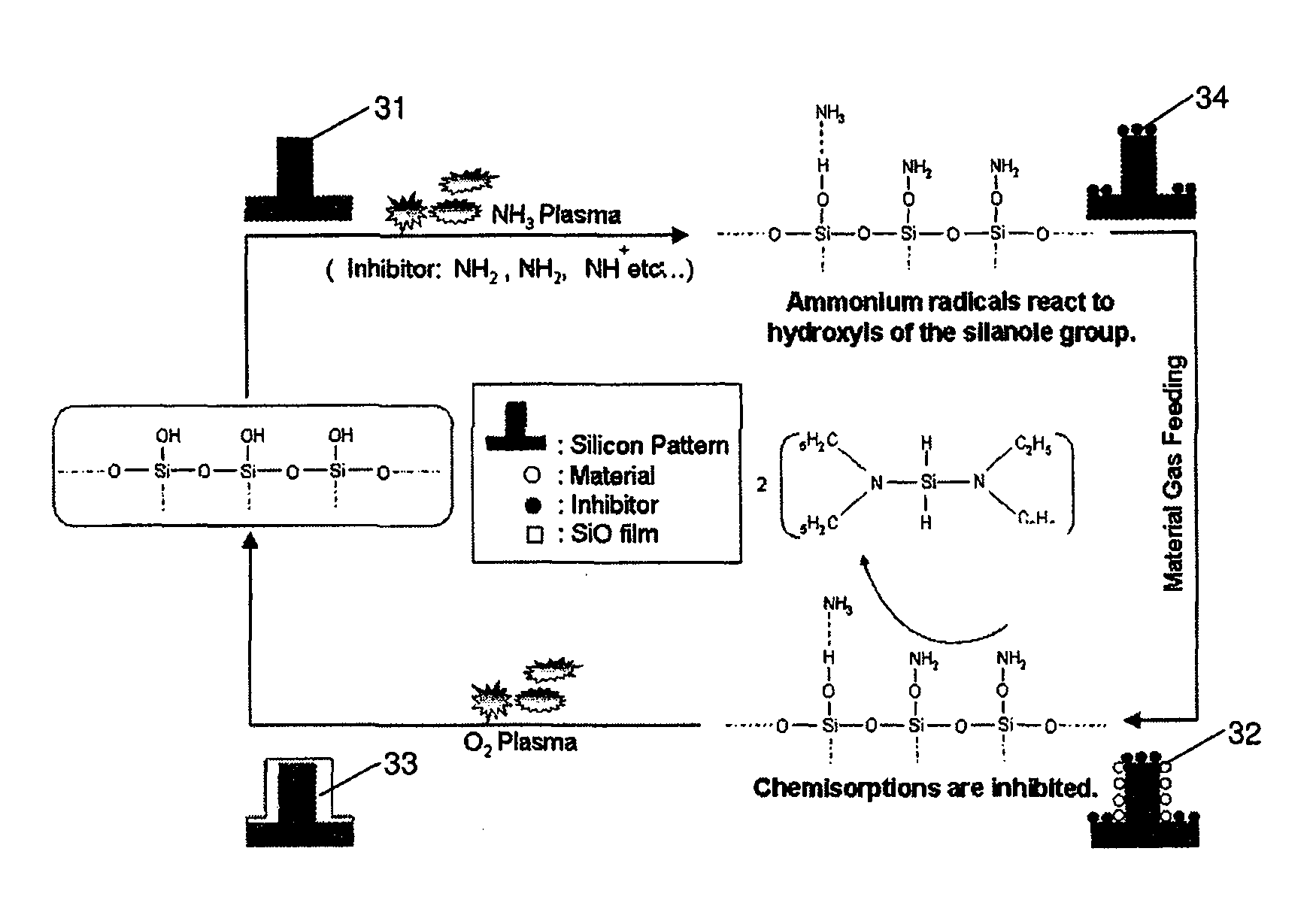

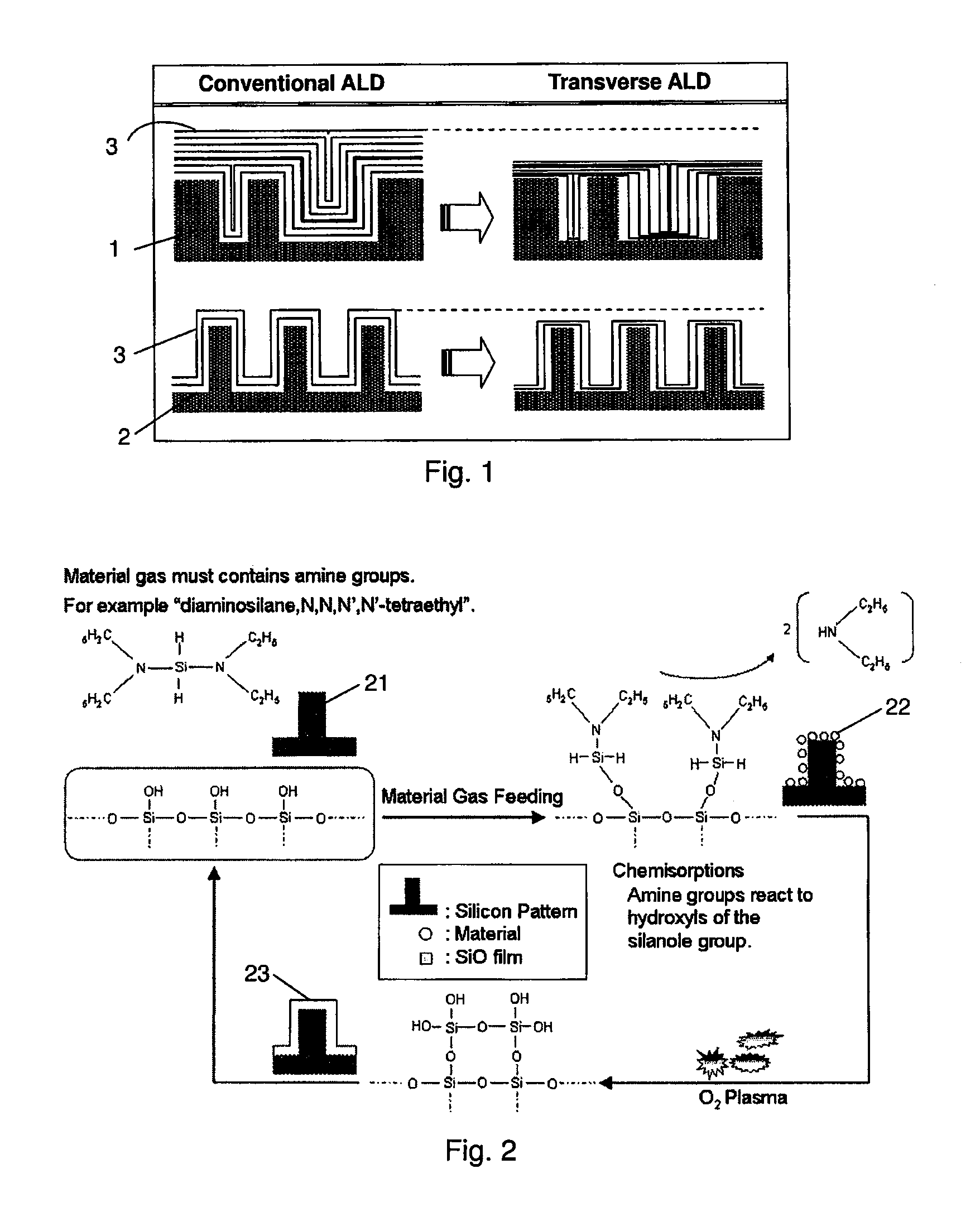

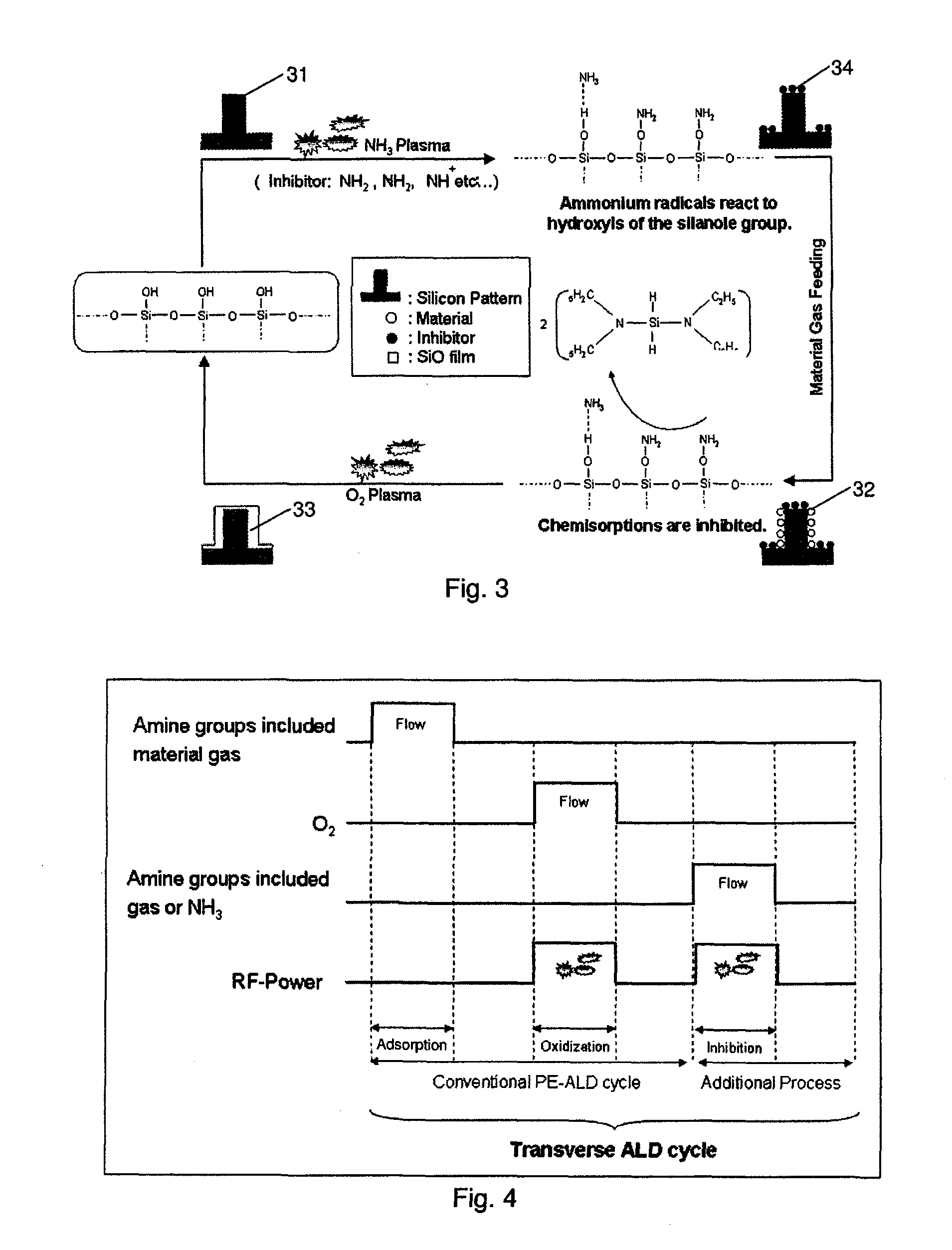

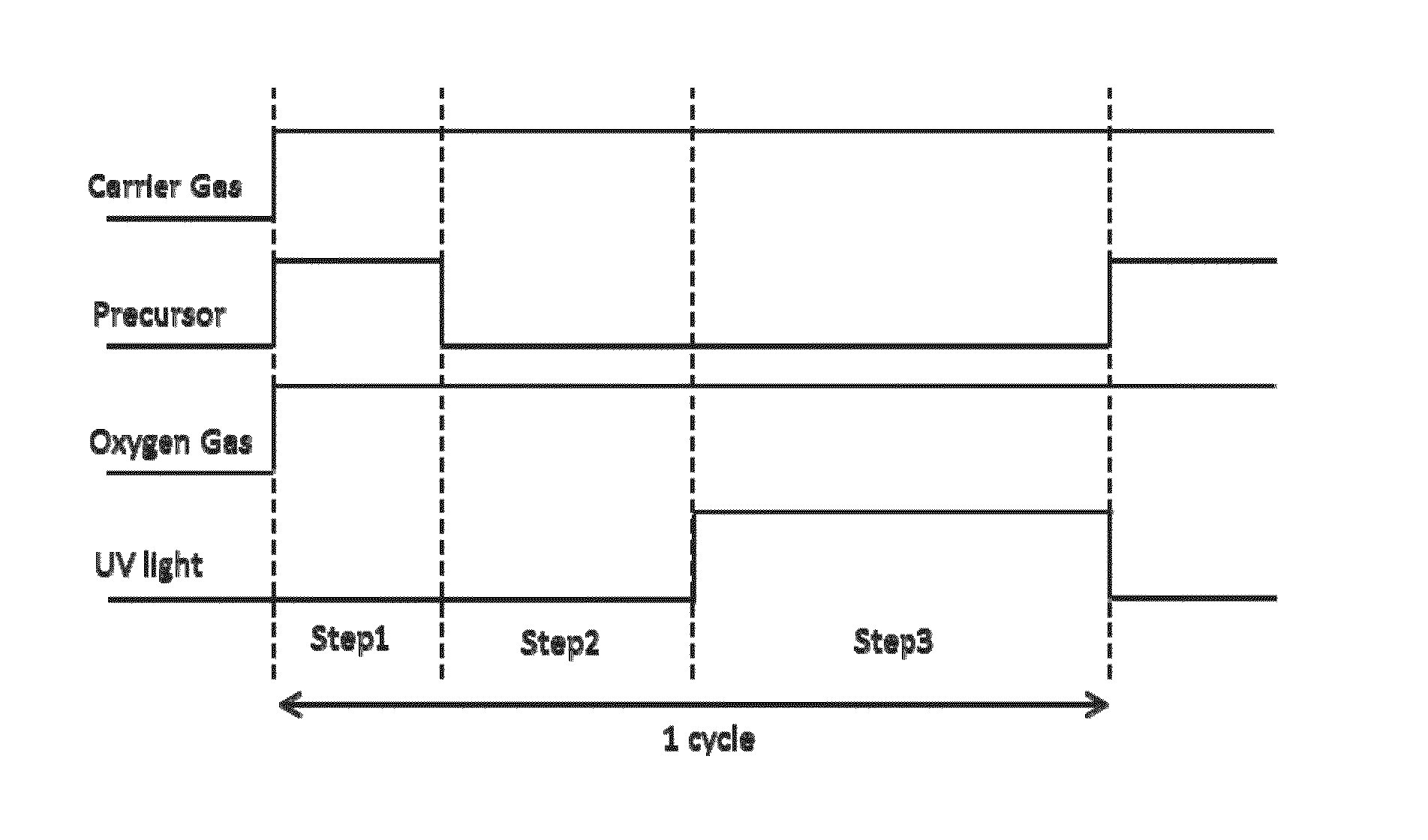

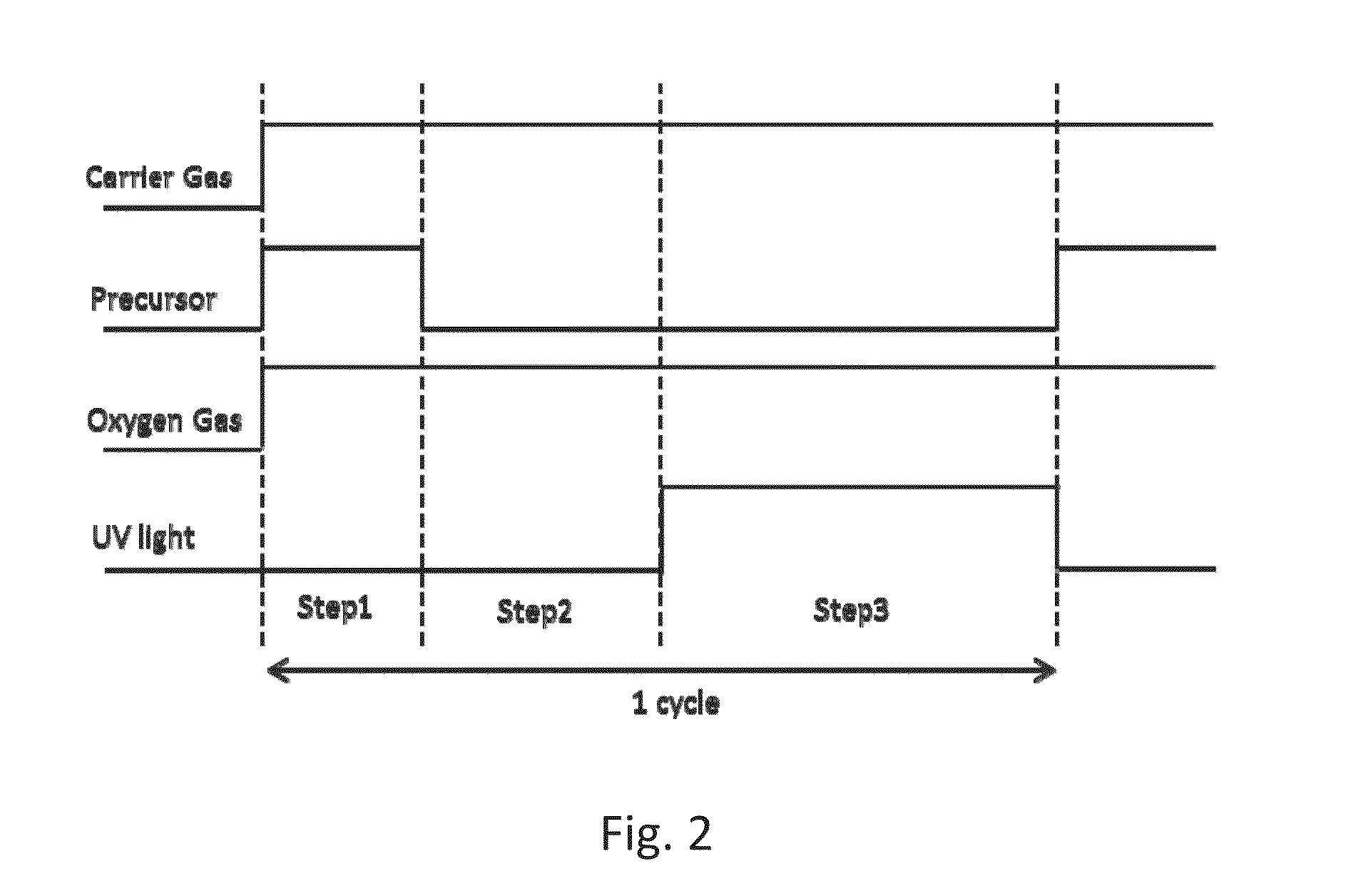

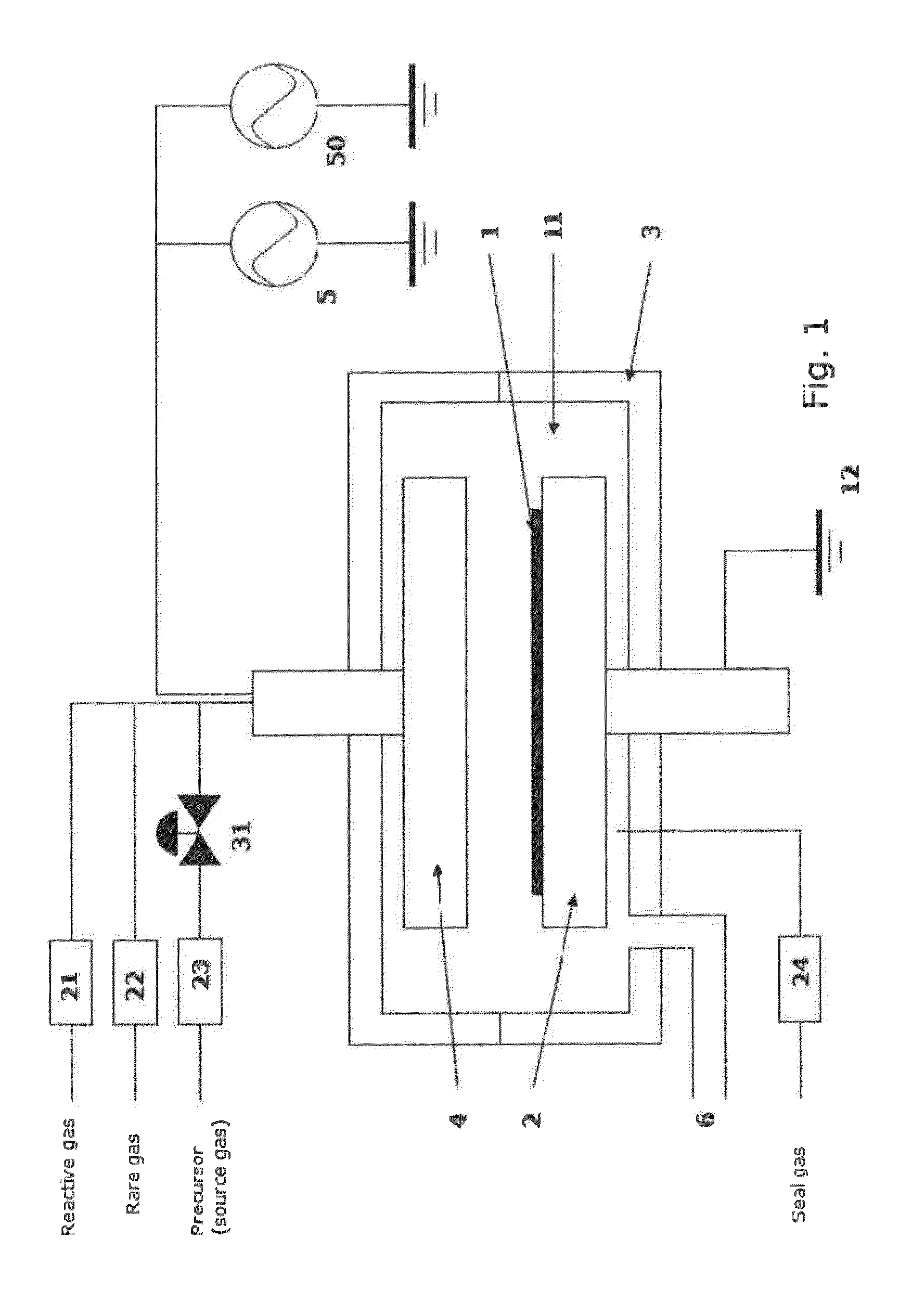

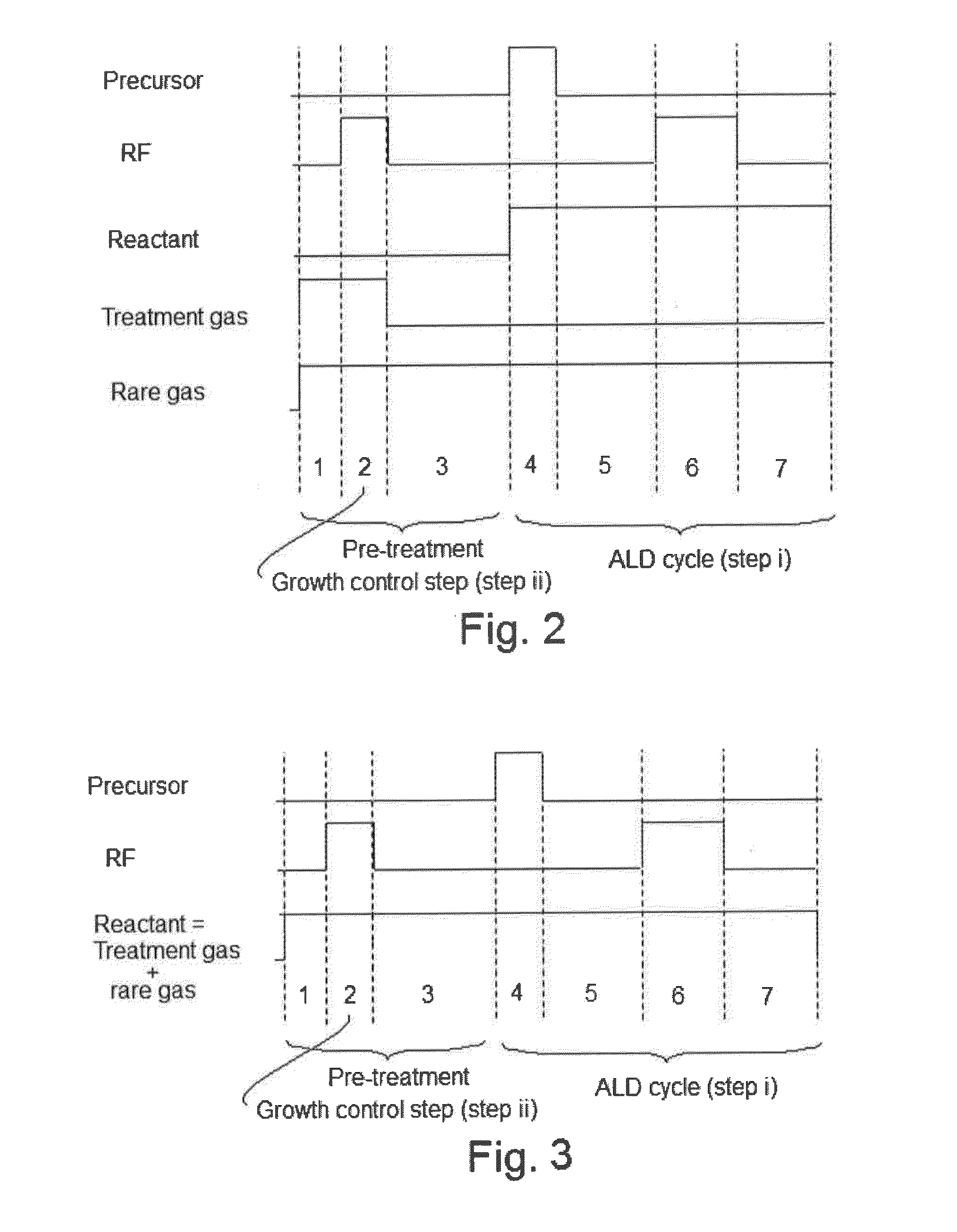

Method of Forming Insulation Film by Modified PEALD

ActiveUS20100124621A1Increase coverageImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringPhysical chemistry

Owner:ASM JAPAN

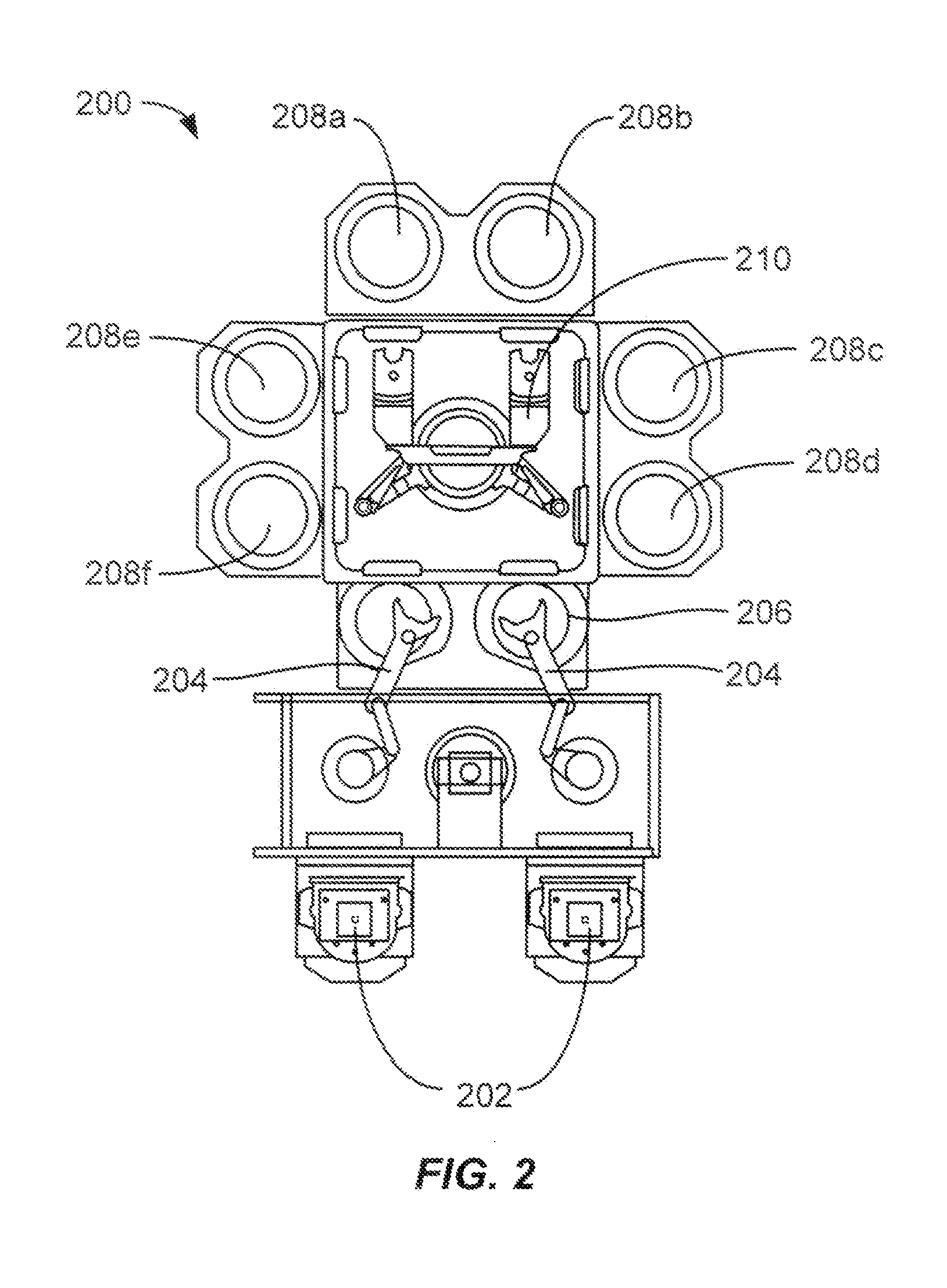

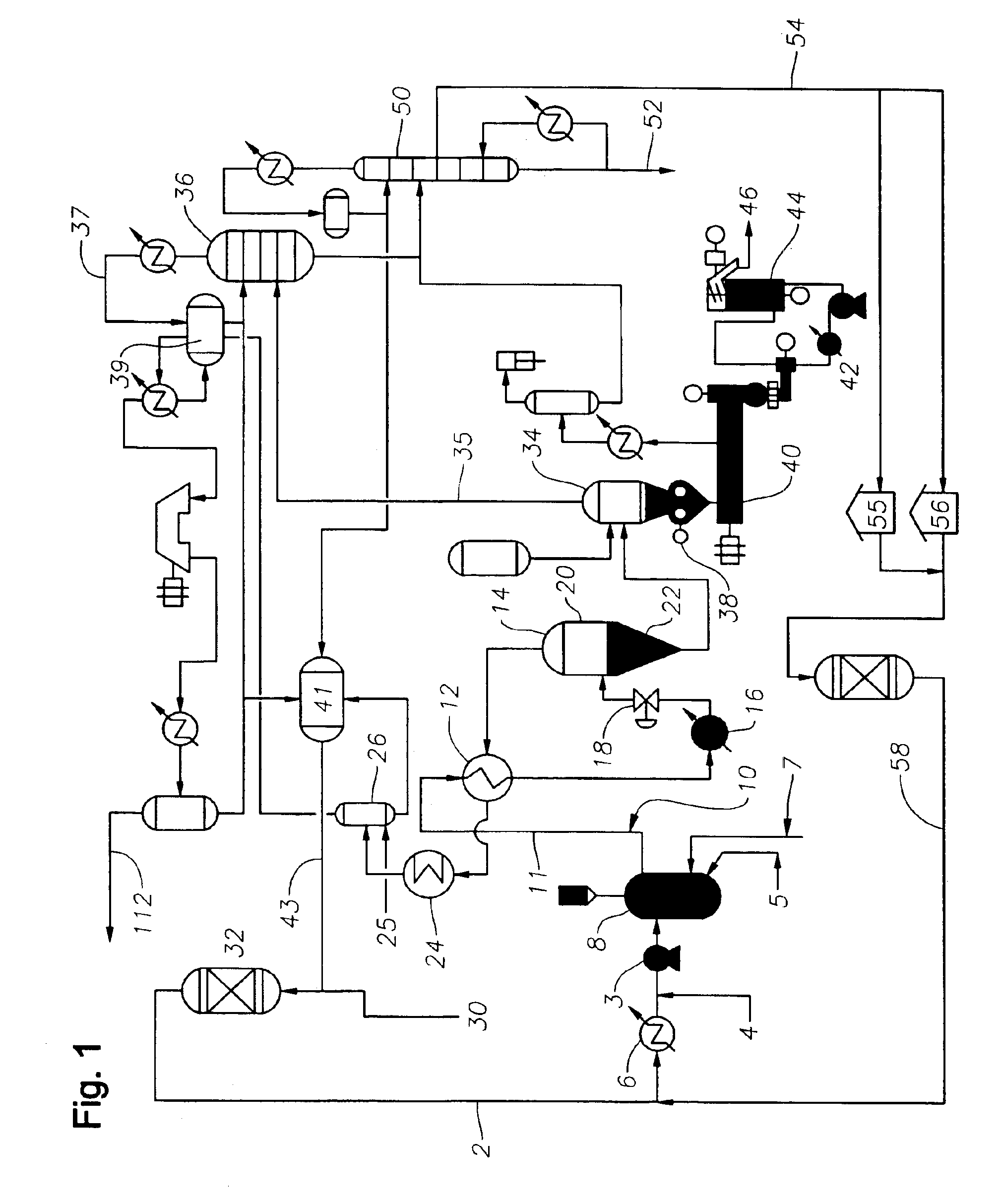

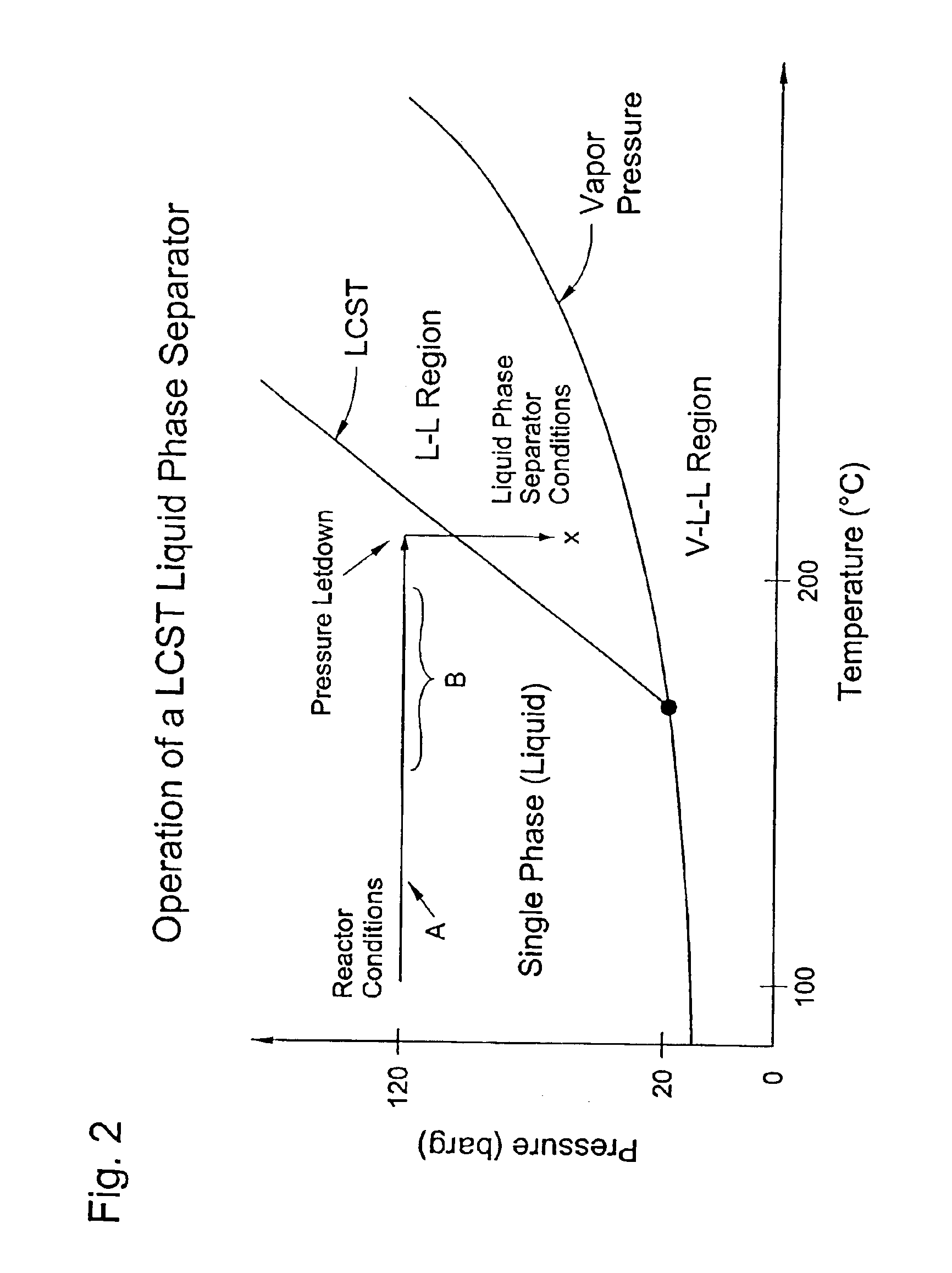

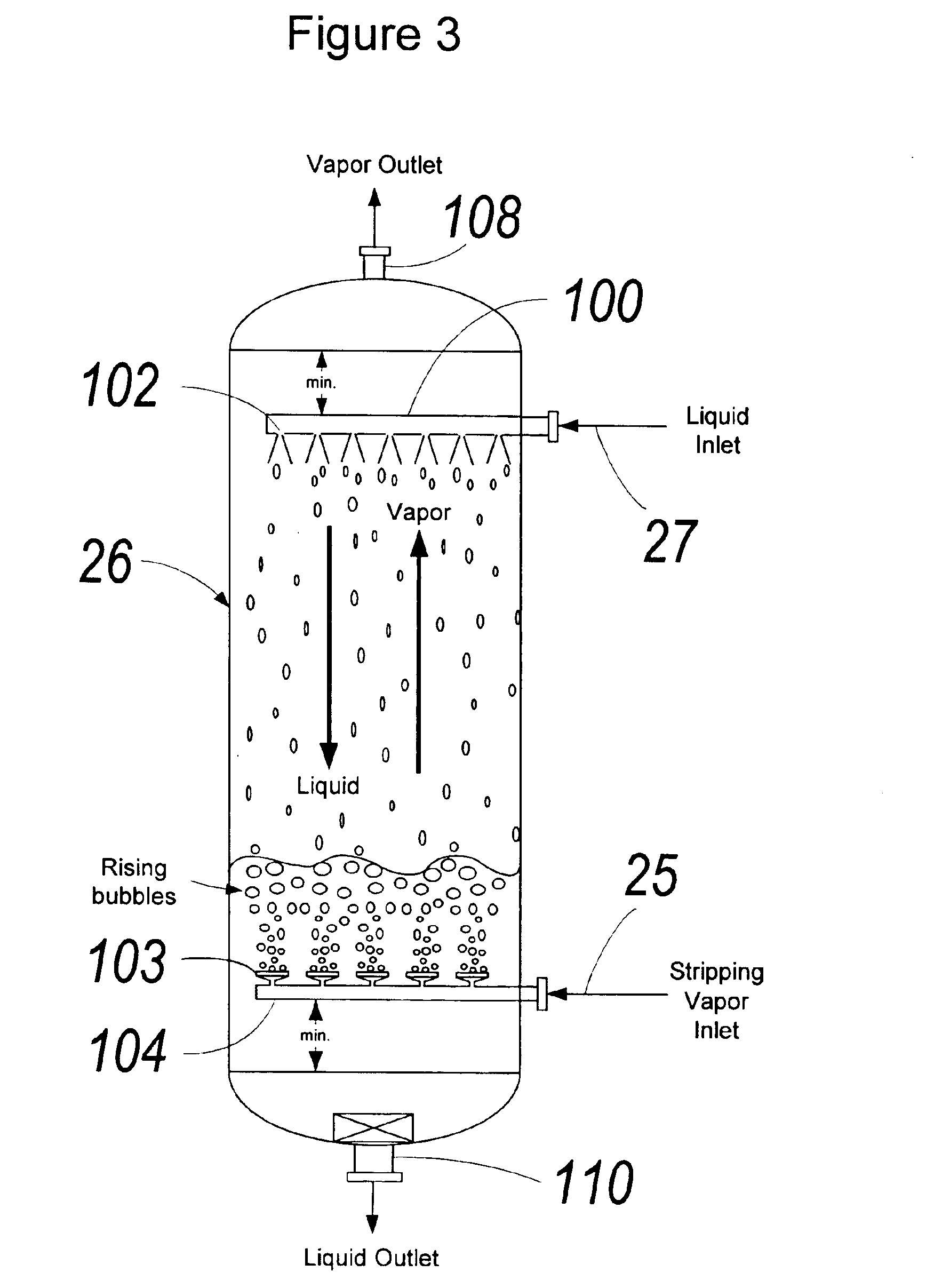

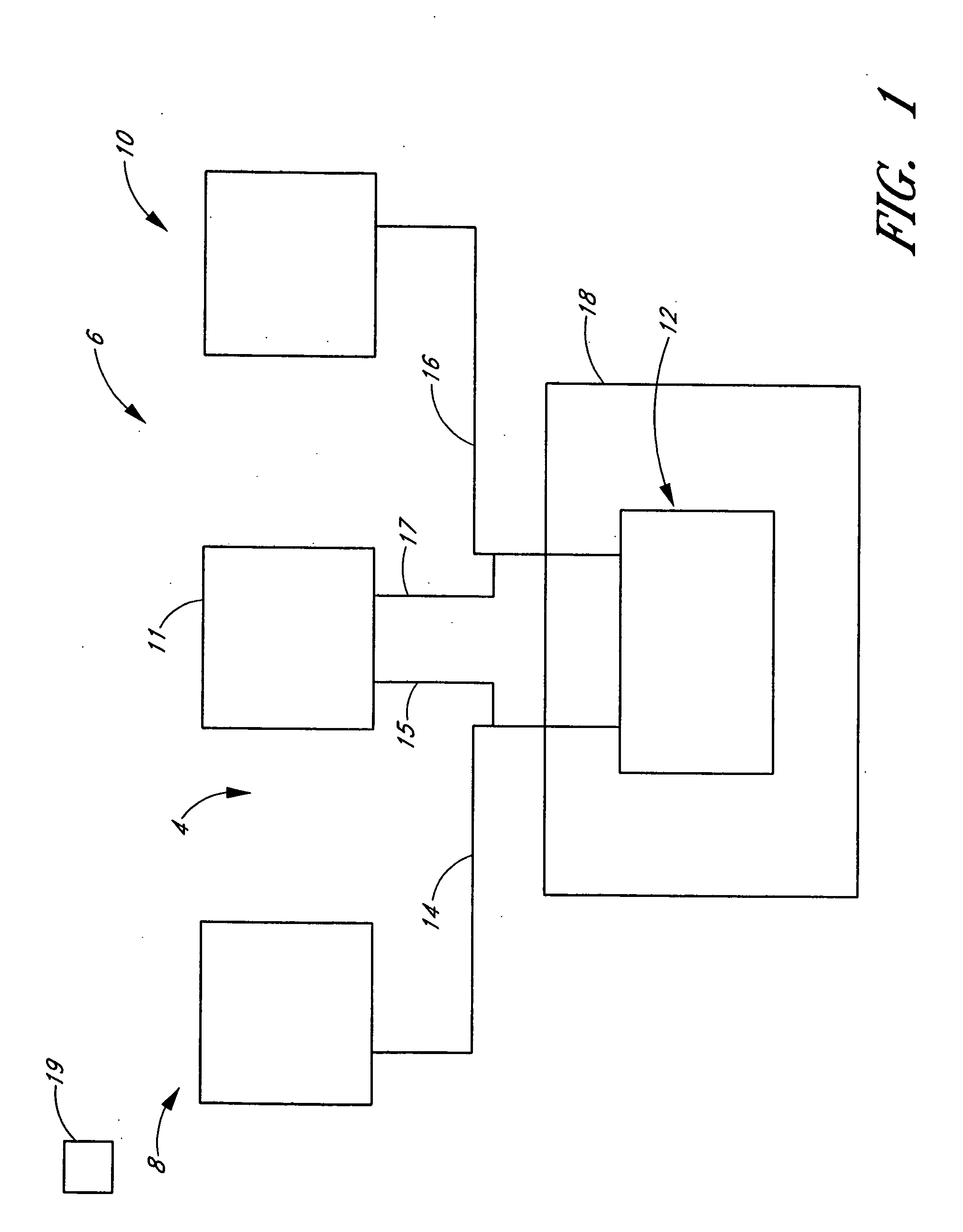

Processes and apparatus for continuous solution polymerization

InactiveUS6881800B2Process control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

InactiveUS20060040054A1Minimizing undesired chemisorptionReduce accumulationChemical vapor deposition coatingImproved methodDeposition process

This invention is directed to an improved method for preventing deposition residue buildup on the internal surfaces of an ALD reactor chamber. In an ALD deposition process, the surfaces of a substrate are treated with an initiating precursor generating a labile atom reactive with a deposition precursor. Excess initiating precursor is removed from the reactor and the substrate surface then is exposed to a deposition precursor reactive with the labile atom under conditions for generating a fugitive reaction product containing the labile atom and leaving a deposition product. The process is repeated generating alternate layers of initiation and deposition precursor reaction products. The improvement in the ALD process resides in passivating the internal surfaces of the reactor by removing labile atoms reactable with either the initiating or deposition precursors prior to effecting ALD deposition.

Owner:VERSUM MATERIALS US LLC

Modified oxygen reduced valve metal oxides

InactiveUS6639787B2Maintain good propertiesWear minimizationOxide/hydroxide preparationLiquid electrolytic capacitorsFluidized bedPhysical chemistry

Owner:GLOBAL ADVANCED METALS USA

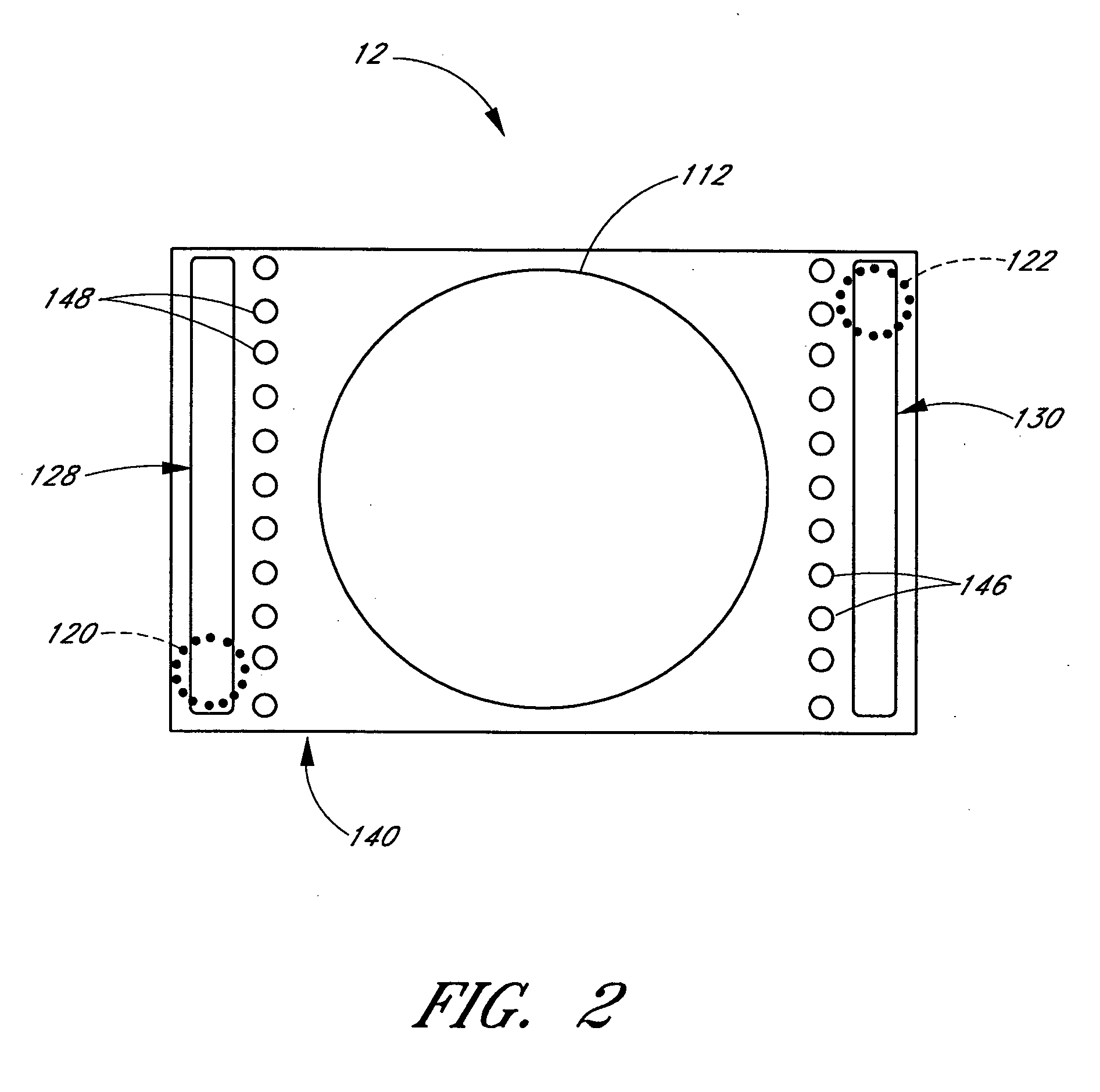

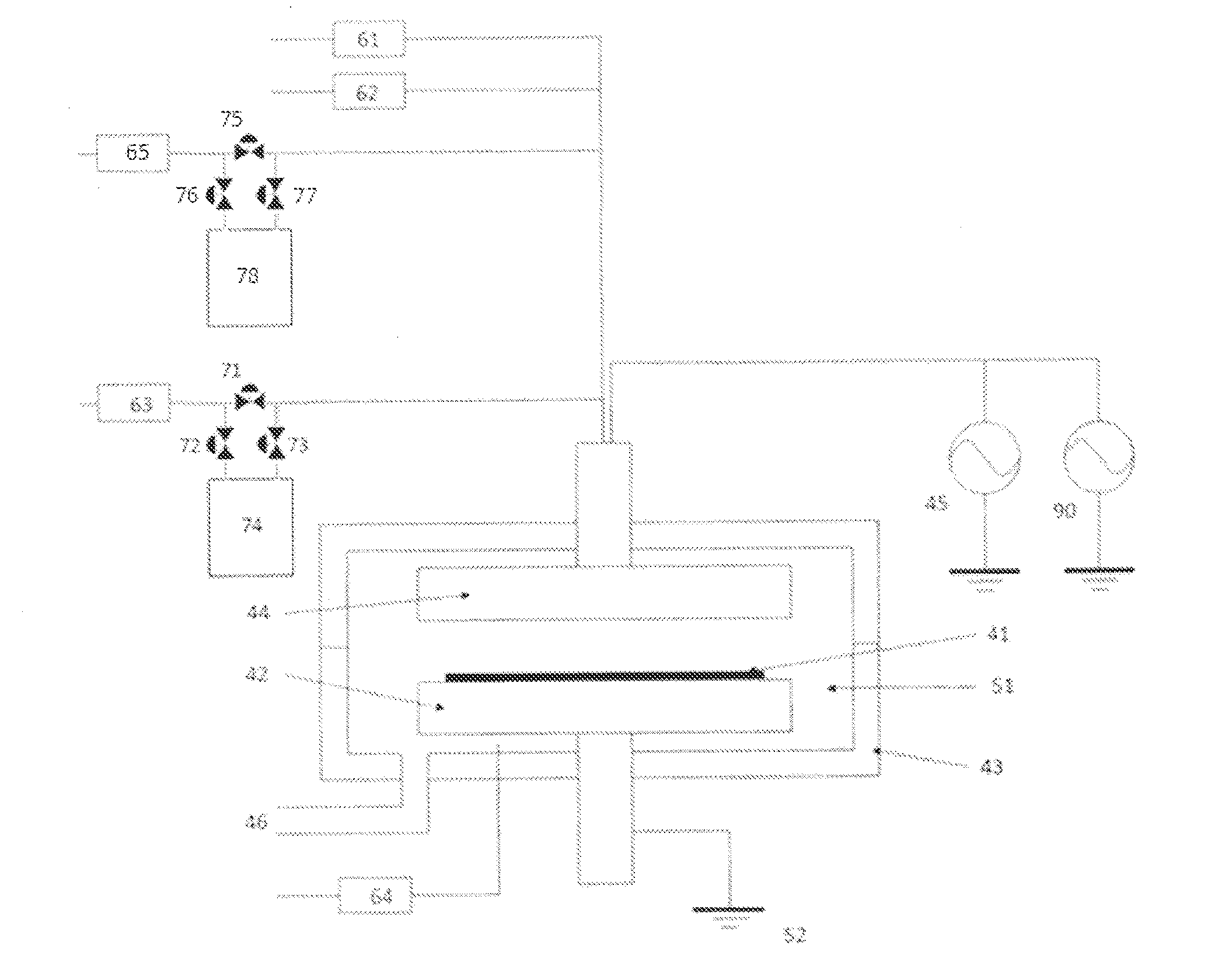

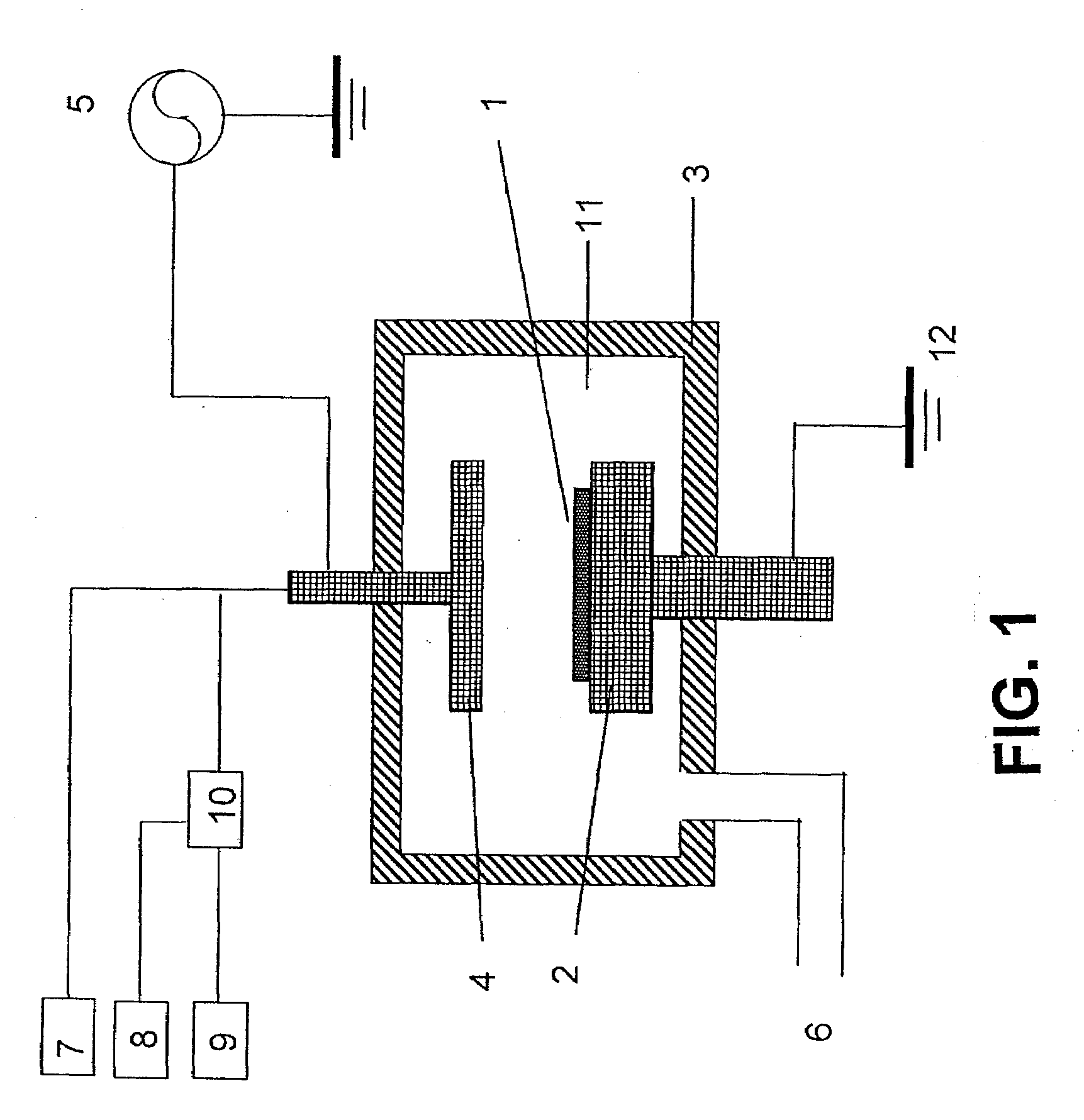

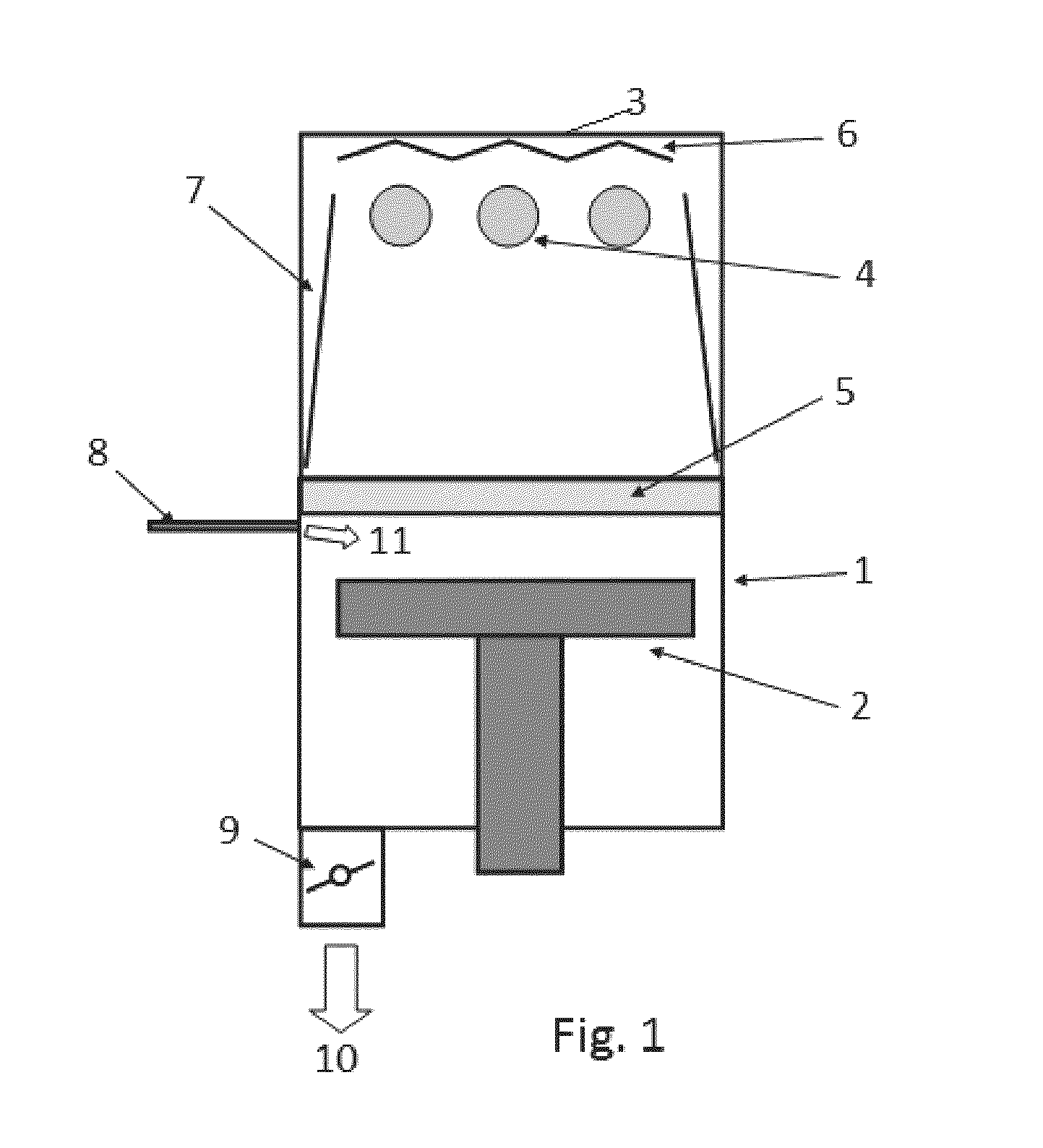

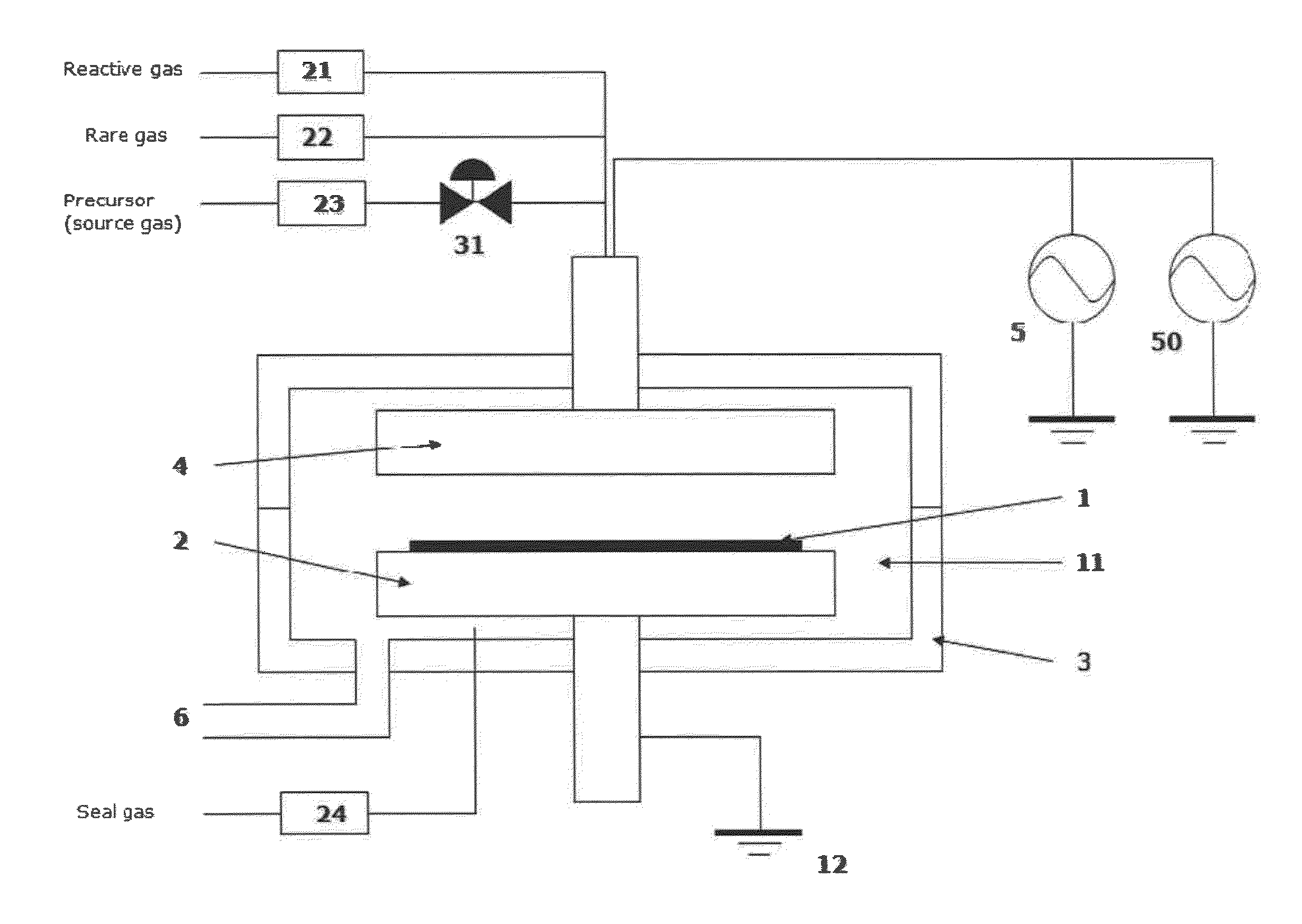

Reaction system for growing a thin film

ActiveUS20050241176A1Extension of timeLong stepDrying using combination processesDrying solid materials with heatControl systemDiffusion barrier

A reactor defines a reaction chamber for processing a substrate. The reactor comprises a first inlet for providing a first reactant and to the reaction chamber and a second inlet for a second reactant to the reaction chamber. A first exhaust outlet removes gases from the reaction chamber. A second exhaust outlet removes gases from the reaction chamber. A flow control system is configured to alternately constrict flow through the first and second exhaust outlets. The reactor chamber is configured to for a diffusion barrier within the reaction chamber.

Owner:ASM IP HLDG BV

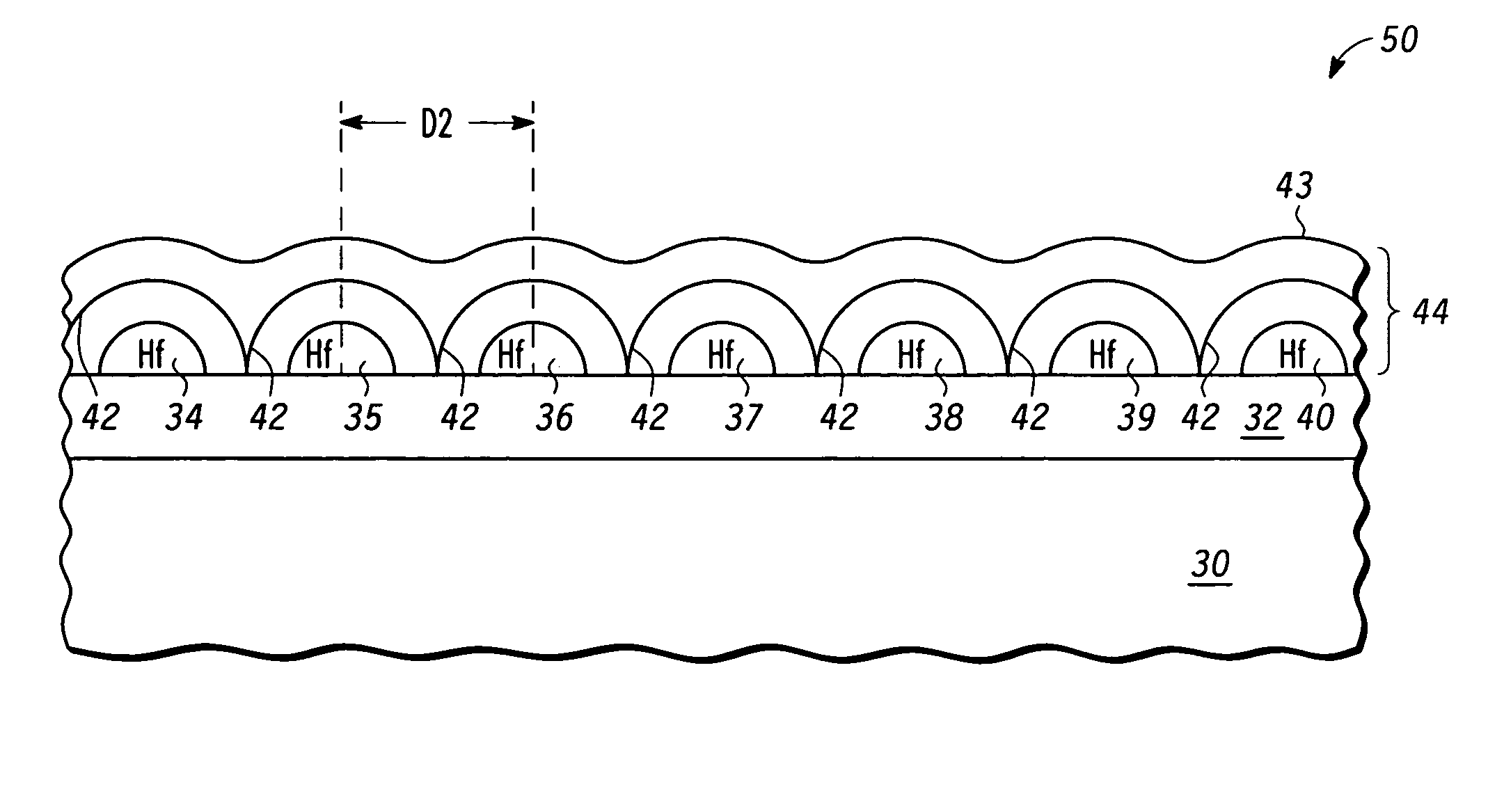

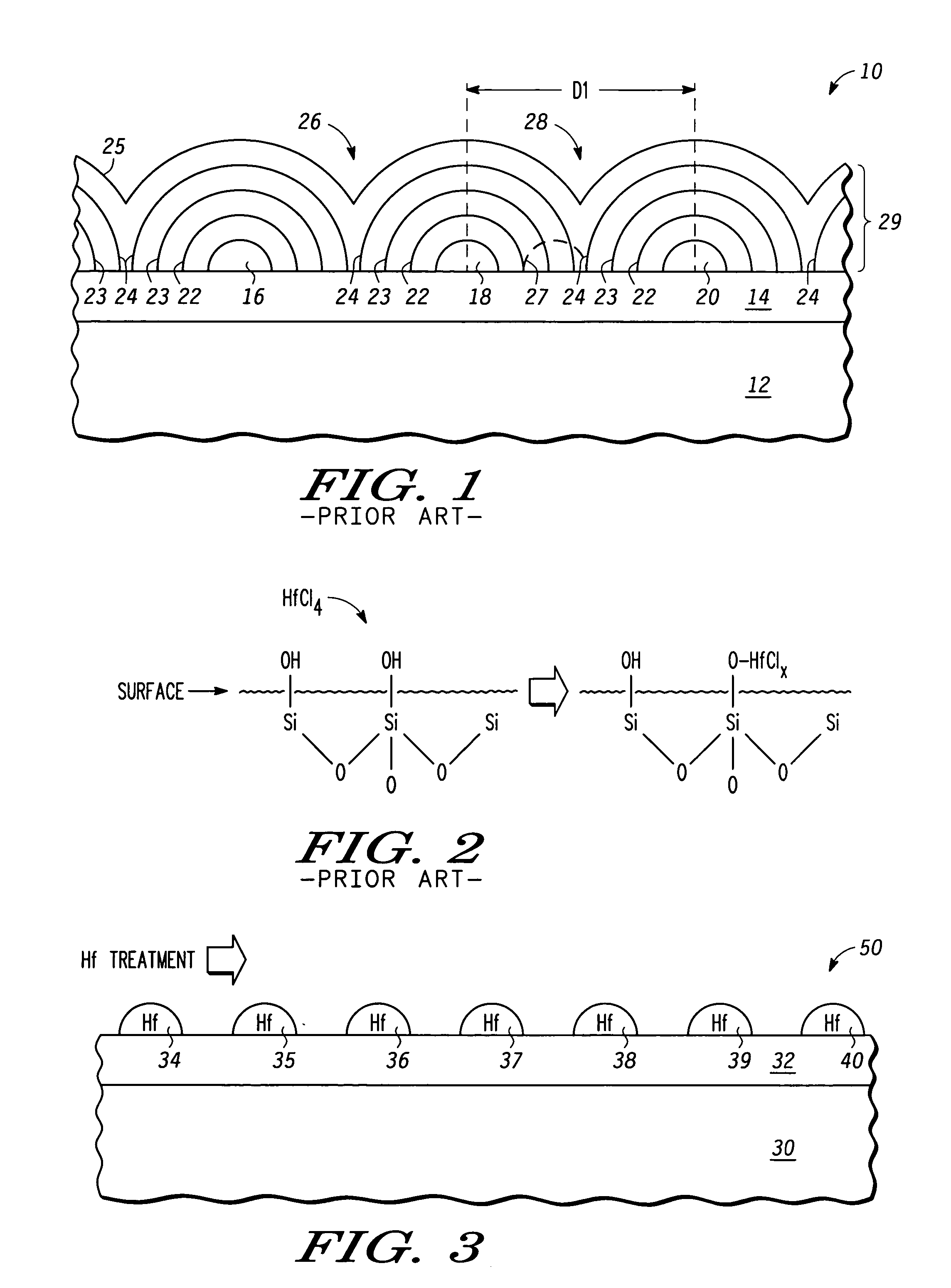

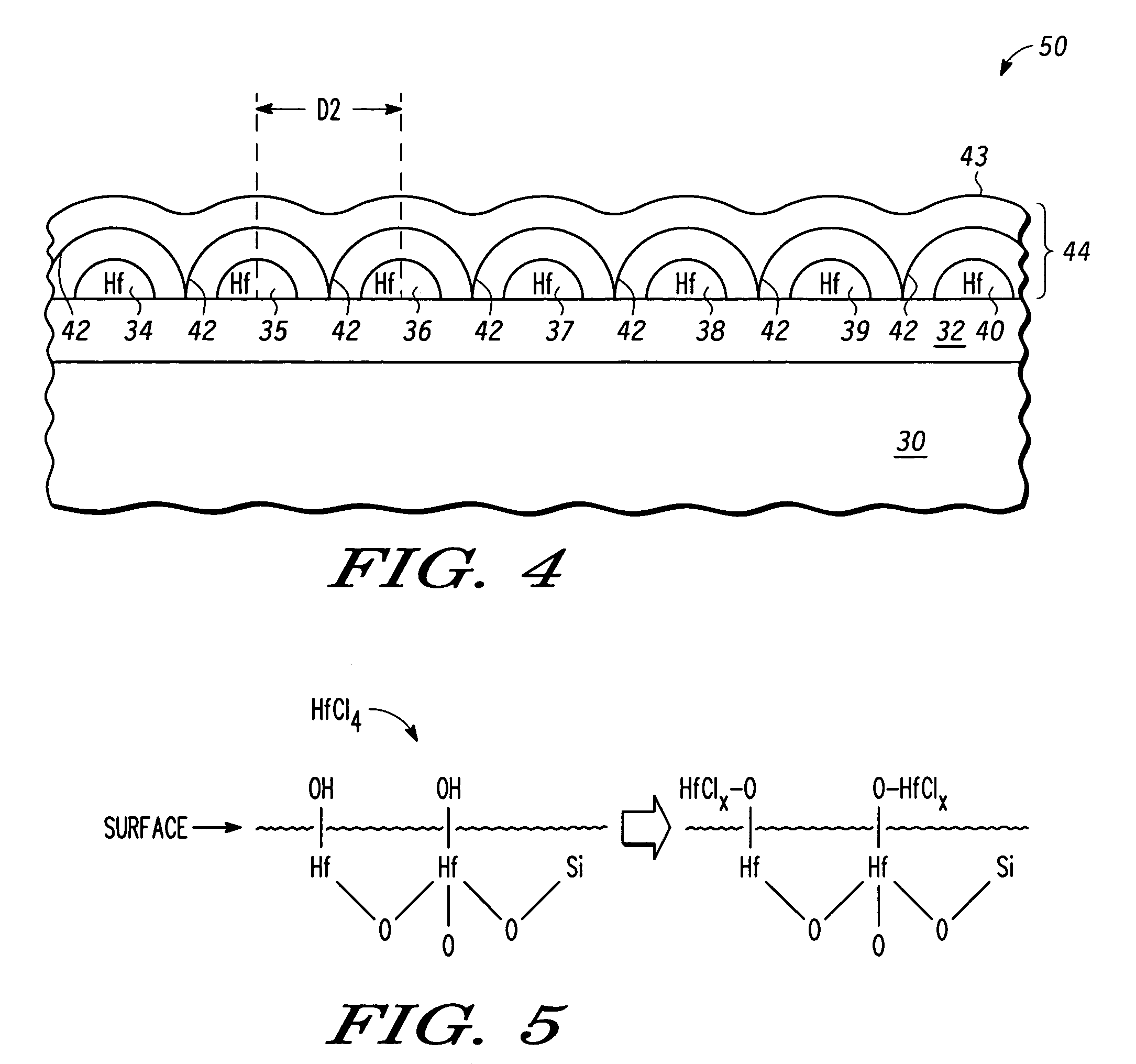

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS7132360B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMaterial growthPhysical chemistry

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

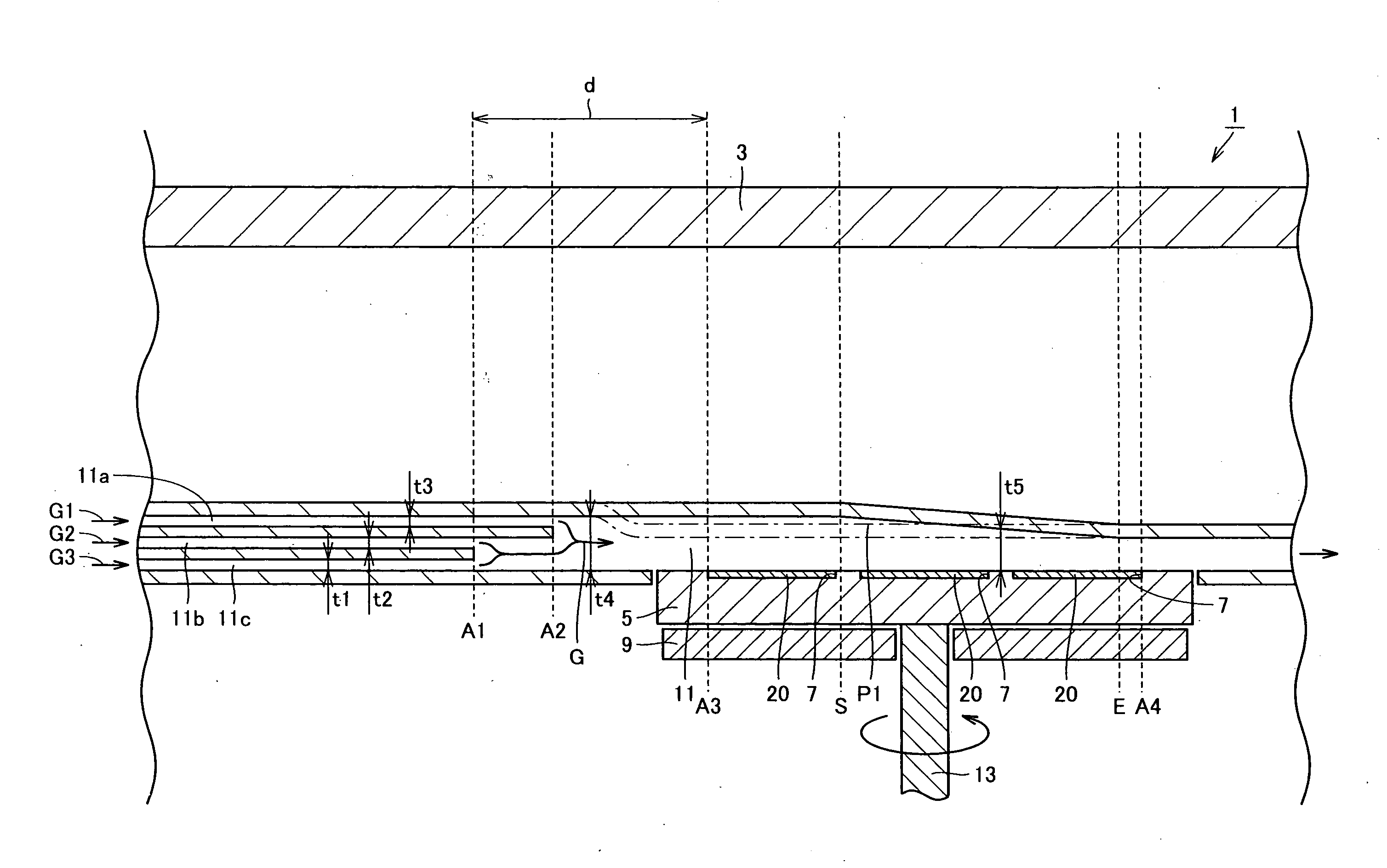

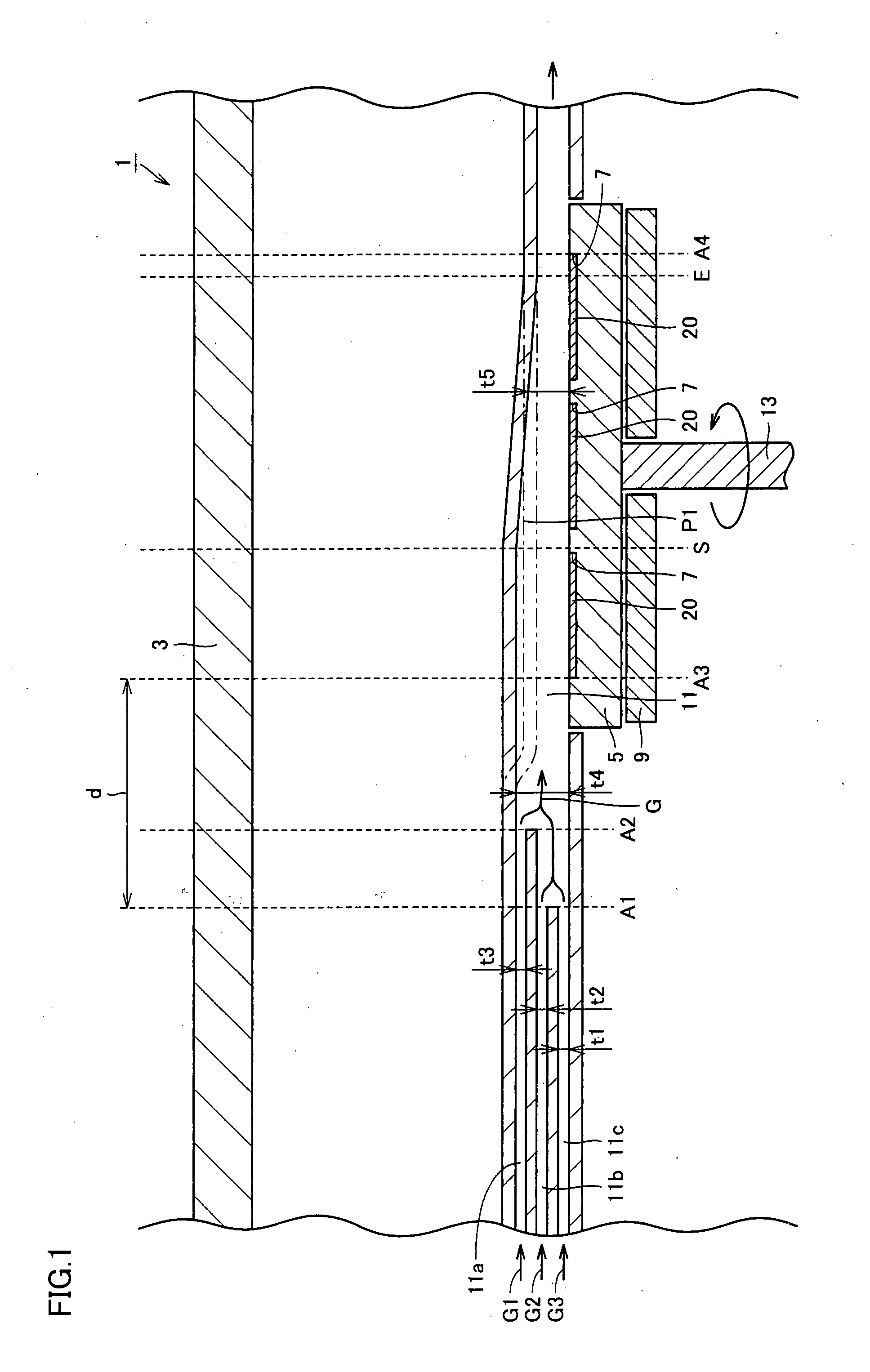

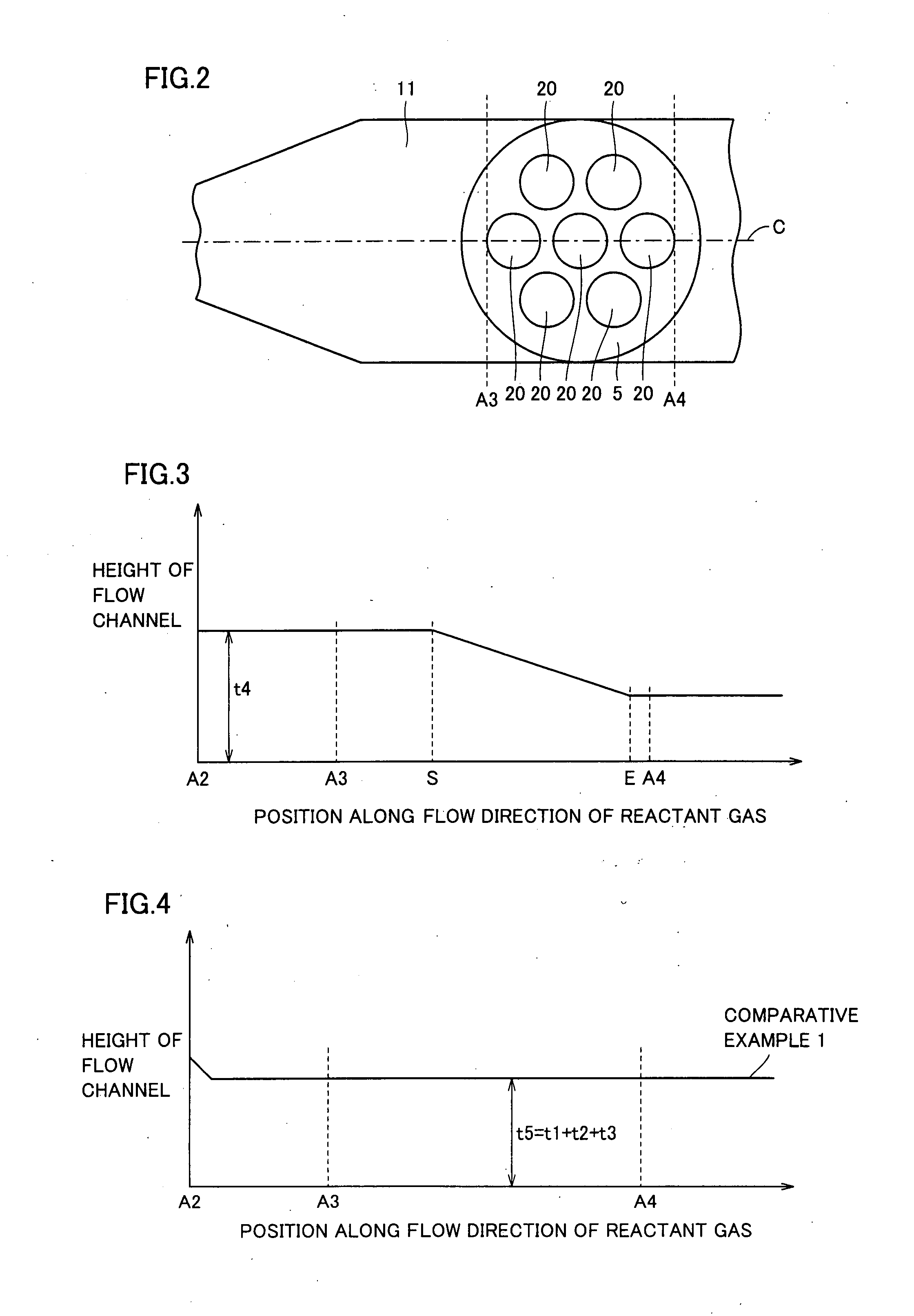

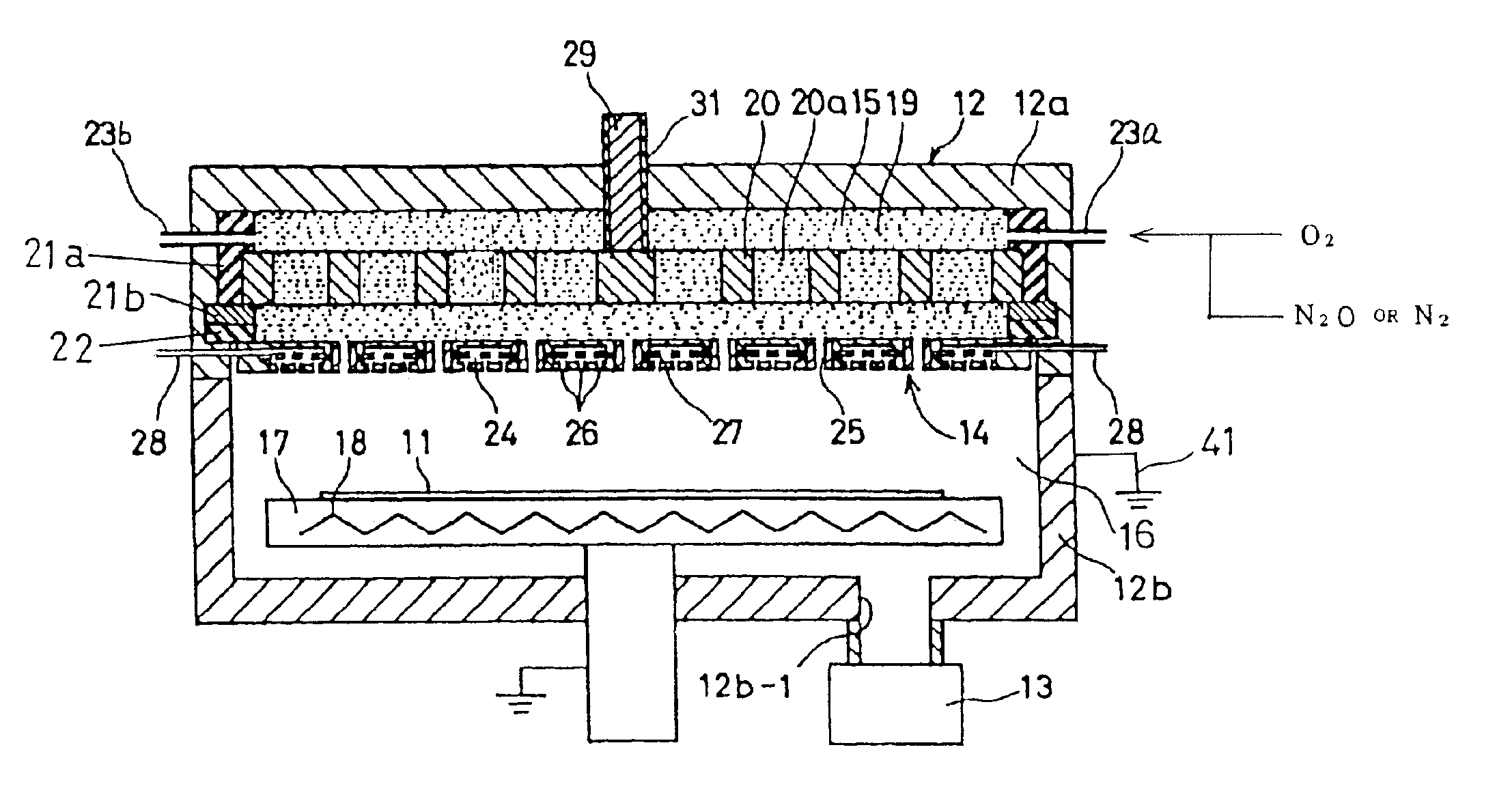

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

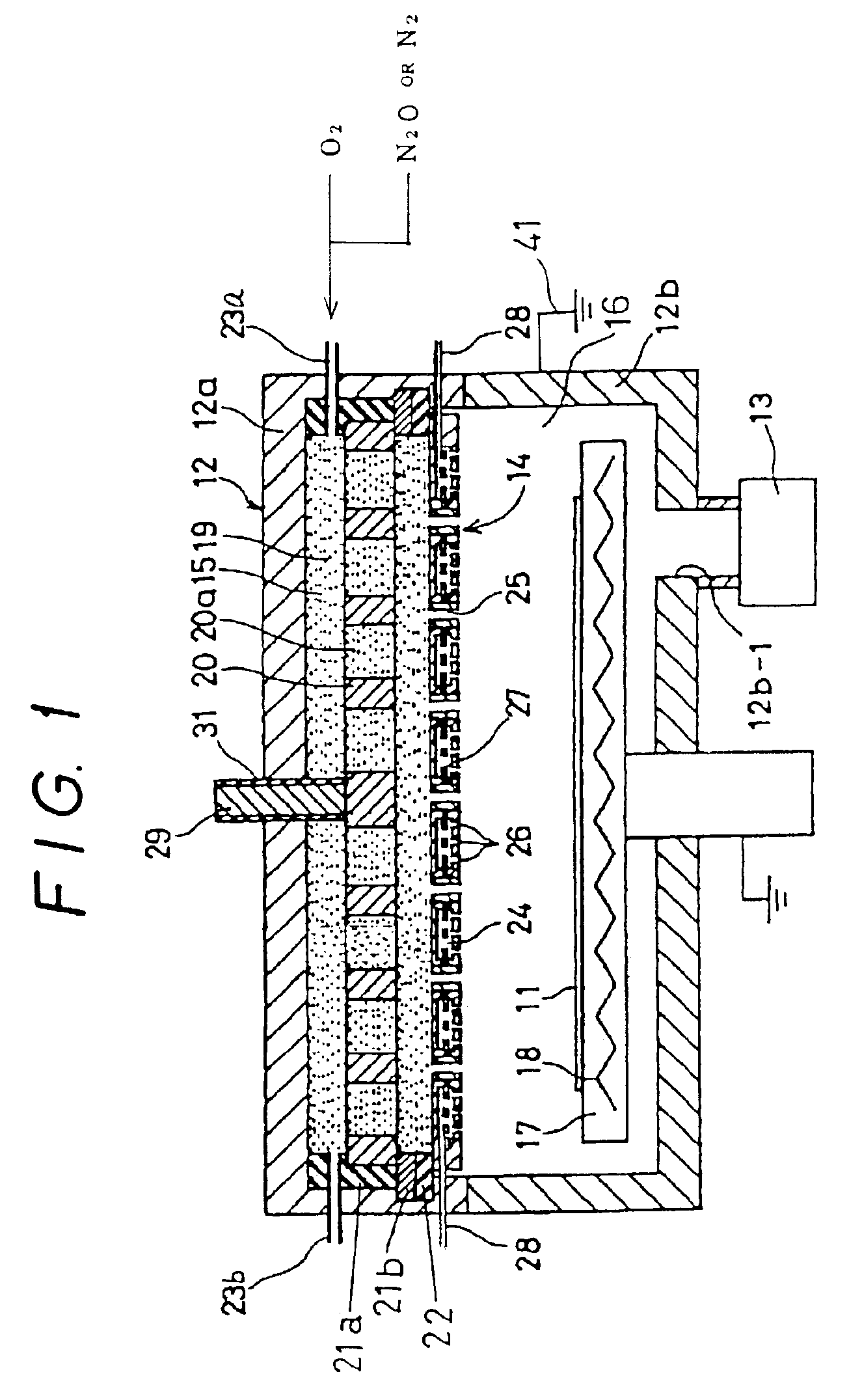

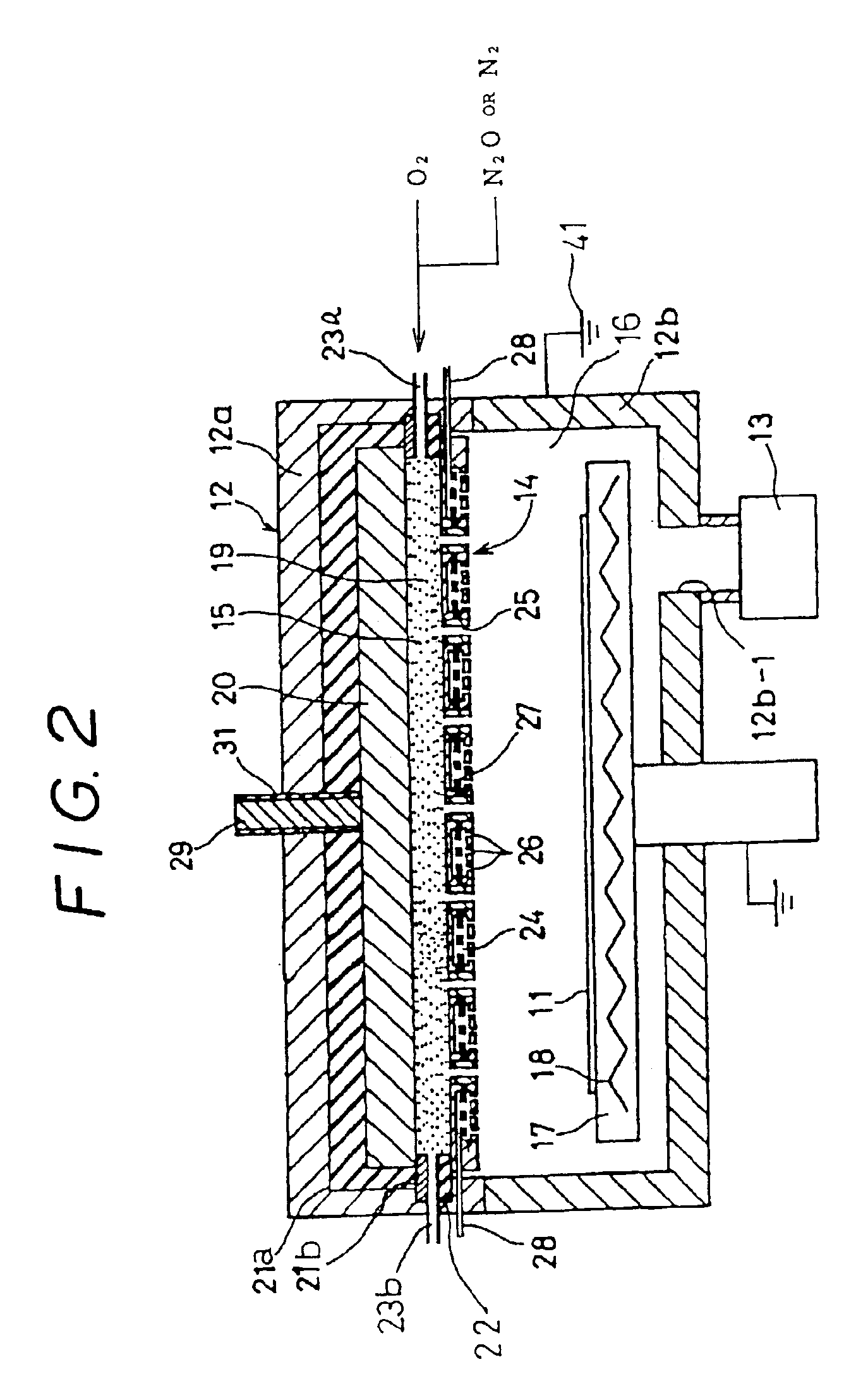

Silicon oxide film formation method

InactiveUS6955836B2Improve efficiencyQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysical chemistrySilicon oxide

A silicon oxide film formation method enhances the efficiency of generating atomic oxygen and improves film quality of a silicon film (SiO2 film) in forming the silicon oxide film using an RS-CVD system. Nitrogen atom containing gas (N2 gas, NO gas, N2O gas, NO2 gas or the like) is added to oxygen atom containing gas (O2 gas, O3 gas or the like) introduced into a plasma generating space in a vacuum container to produce plasmas with these gases and to thereby increase the quantity of atomic oxygen generated by the plasmas in the plasma generating space.

Owner:ANELVA CORP +1

Method for Forming Conformal Nitrided, Oxidized, or Carbonized Dielectric Film by Atomic Layer Deposition

ActiveUS20150147483A1Easy to oxidizeEasily and nitridedSpecial surfacesChemical vapor deposition coatingAtomic layer depositionSilicon

A method for forming a film on a patterned surface of a substrate by atomic layer deposition (ALD) processing includes: adsorbing onto a patterned surface a first precursor containing silicon or metal in its molecule; adsorbing onto the first-precursor-adsorbed surface a second precursor containing no silicon or metal in its molecule; exposing the second-precursor-adsorbed surface to an excited reactant to oxidize, nitride, or carbonize the precursors adsorbed on the surface of the substrate; and repeating the above cycle to form a film on the patterned surface of the substrate.

Owner:ASM IP HLDG BV

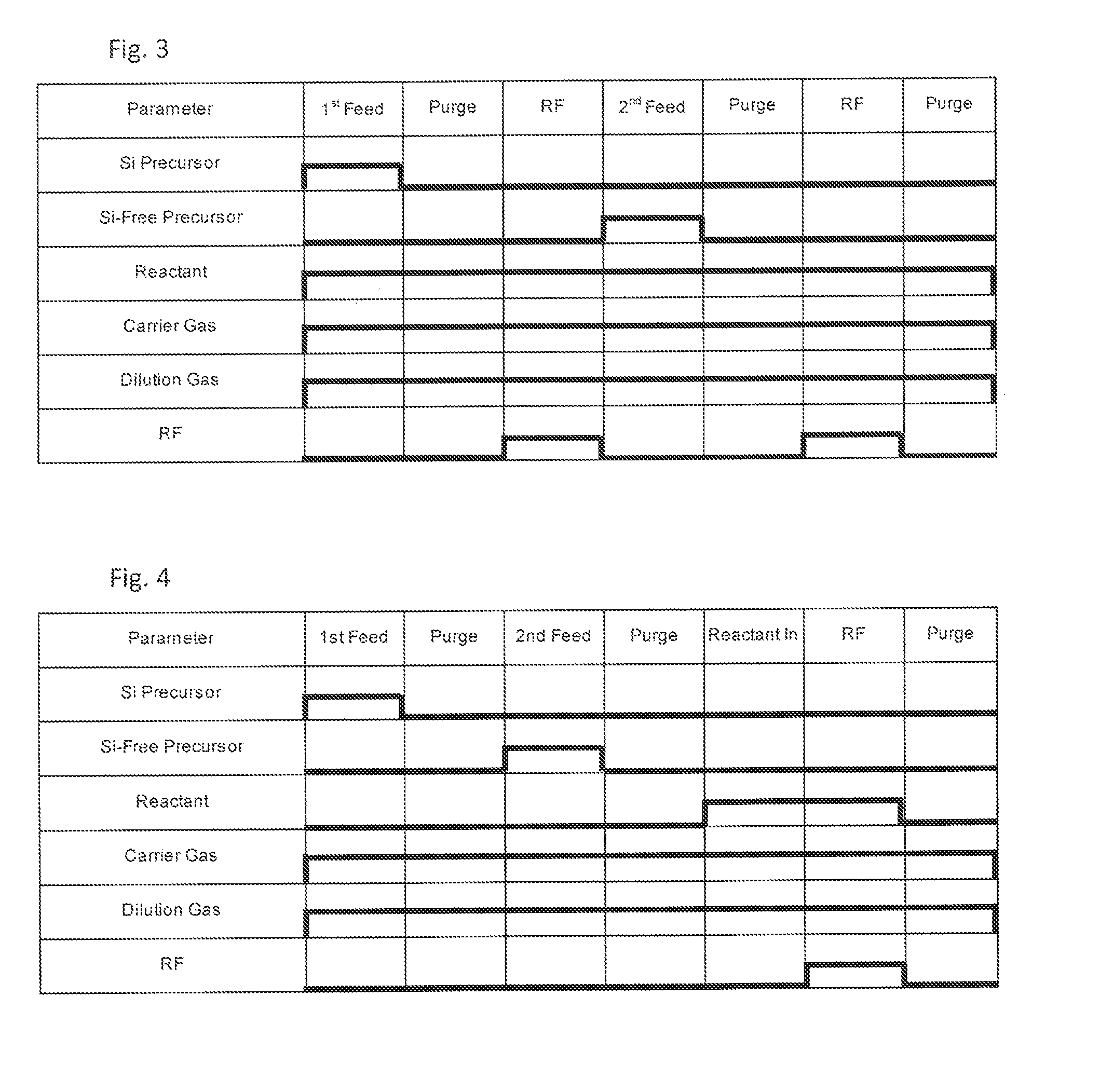

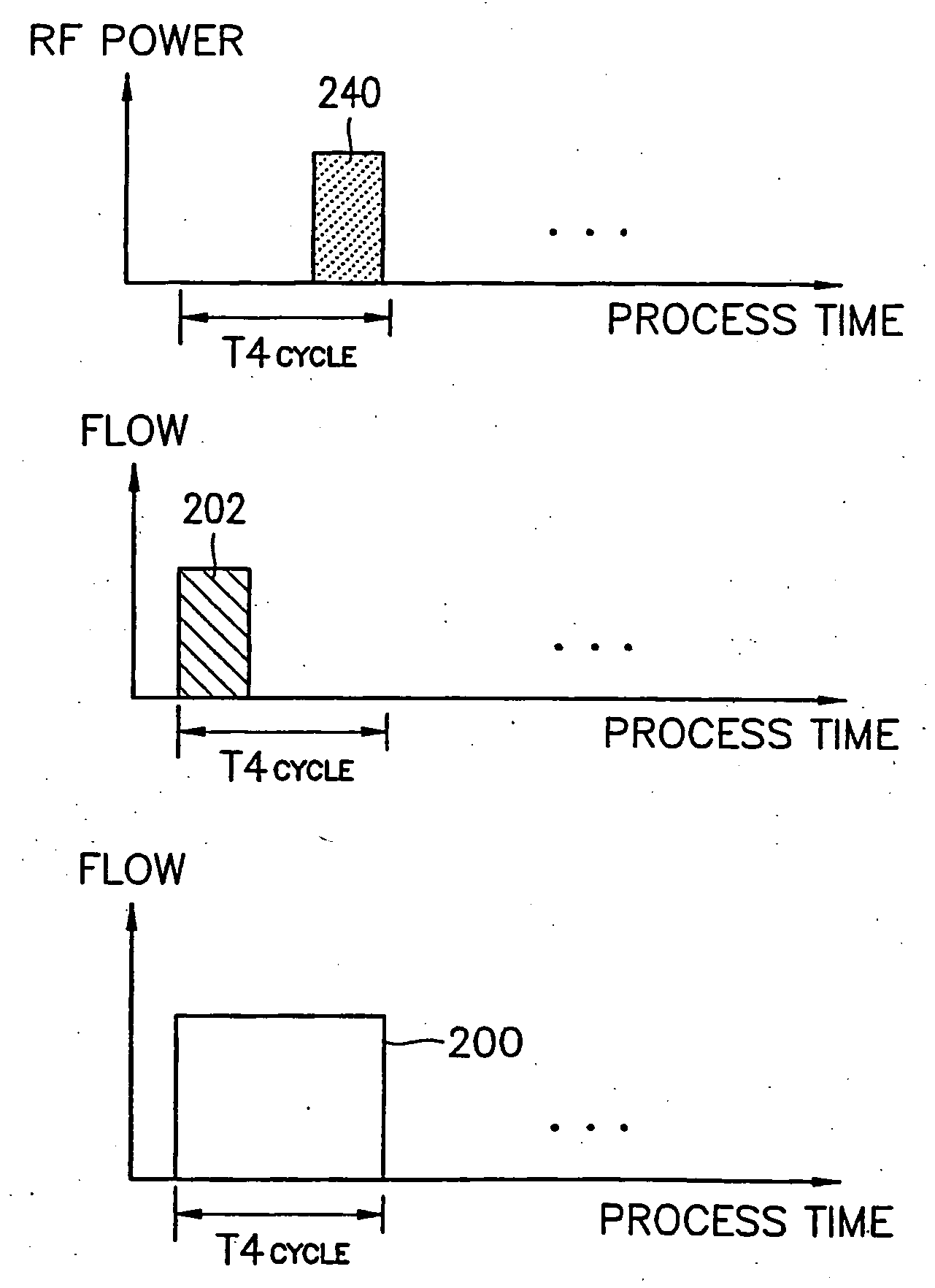

Method for forming thin film

InactiveUS20050037154A1Prolonged durationIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin layerProduct gas

Method for forming a thin film at low temperature by using plasma pulses is disclosed. While a purge gas or a reactant purge gas activated by plasma is continuously supplied into a reactor, a source gas is supplied intermittently into the reactor during which period plasma is generated in the reactor so that the source gas and the purge gas activated by plasma reacts, so that a thin film is formed according to the method. Also, a method for forming a thin layer of film containing a plural of metallic elements, a method for forming a thin metallic film containing varied contents by amount of the metallic elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , and a method for forming a thin film containing continuously varying compositions of the constituent elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , are disclosed. The methods for forming thin films disclosed here allows to shorten the purge cycle duration even if the reactivity between the source gases is high, to reduce the contaminants caused by the gas remaining in the reactor, to form a thin film at low temperature even if the reactivity between the source gases is low, and also to increase the rate of thin film formation.

Owner:ASM GENITECH KOREA

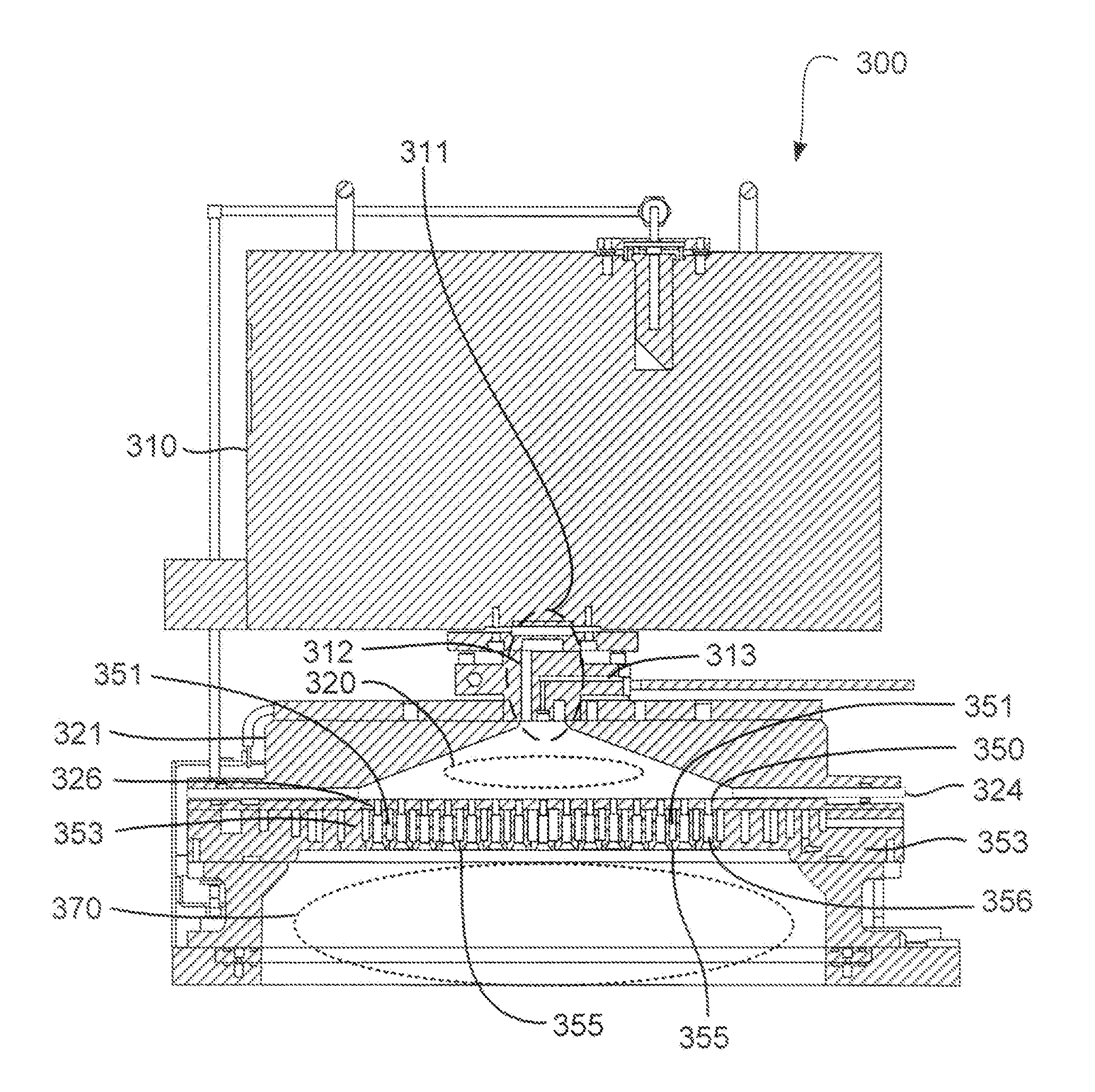

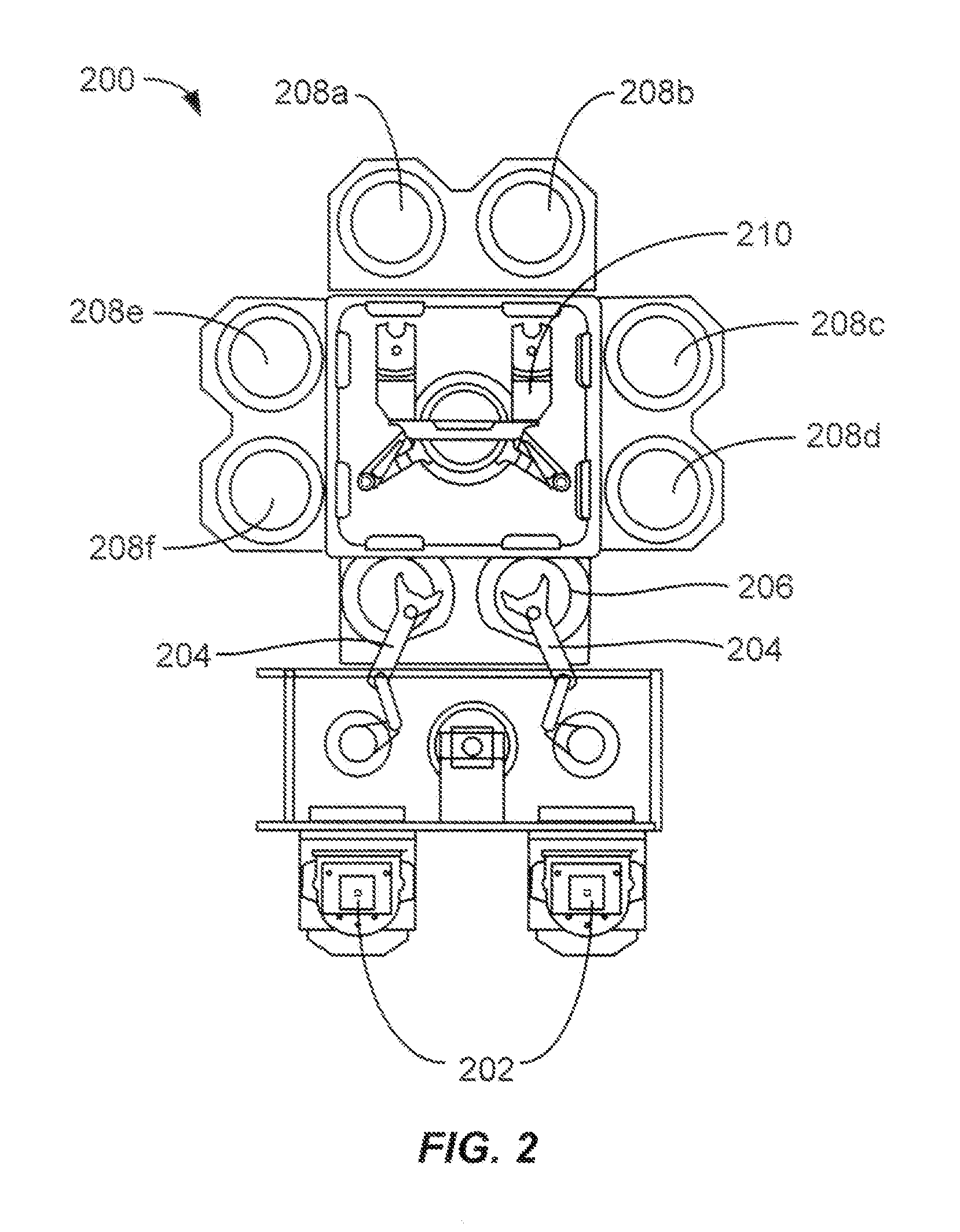

Flowable silicon-and-carbon-containing layers for semiconductor processing

InactiveUS20130217239A1Decreases beneficially low wet etch rateReduce hydrogen contentSemiconductor/solid-state device manufacturingCarbon layerHydrogen

Methods are described for forming and curing a gapfill silicon-and-carbon-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor excited by a radical hydrogen precursor that has been activated in a remote plasma region. Exemplary precursors include 1,3,5-trisilapentane (H3Si—CH2—SiH2—CH2—SiH3) as the silicon-and-carbon-containing precursor and hydrogen (H2) as the hydrogen-containing precursor. The hydrogen-containing precursor may also be a hydrocarbon, such as acetylene (C2H2) or ethylene (C2H4). The hydrogen-containing precursor is passed through a remote plasma region to form plasma effluents (the radical hydrogen precursor) which are flowed into the substrate processing region. When the silicon-and-carbon-containing precursor combines with the plasma effluents in the substrate processing region, they form a flowable silicon-carbon-and-hydrogen-containing layer on the semiconductor substrate.

Owner:APPLIED MATERIALS INC

PECVD oxide-nitride and oxide-silicon stacks for 3D memory application

ActiveUS8076250B1Improve bonding interfaceAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesMaterials science3d memory

A layer stack of different materials is deposited on a substrate in a single plasma enhanced chemical vapor deposition processing chamber while maintaining a vacuum. A substrate is placed in the processing chamber and a first processing gas is used to form a first layer of a first material on the substrate. A plasma purge and gas purge are performed before a second processing gas is used to form a second layer of a second material on the substrate. The plasma purge and gas purge are repeated and the additional layers of first and second materials are deposited on the layer stack.

Owner:APPLIED MATERIALS INC

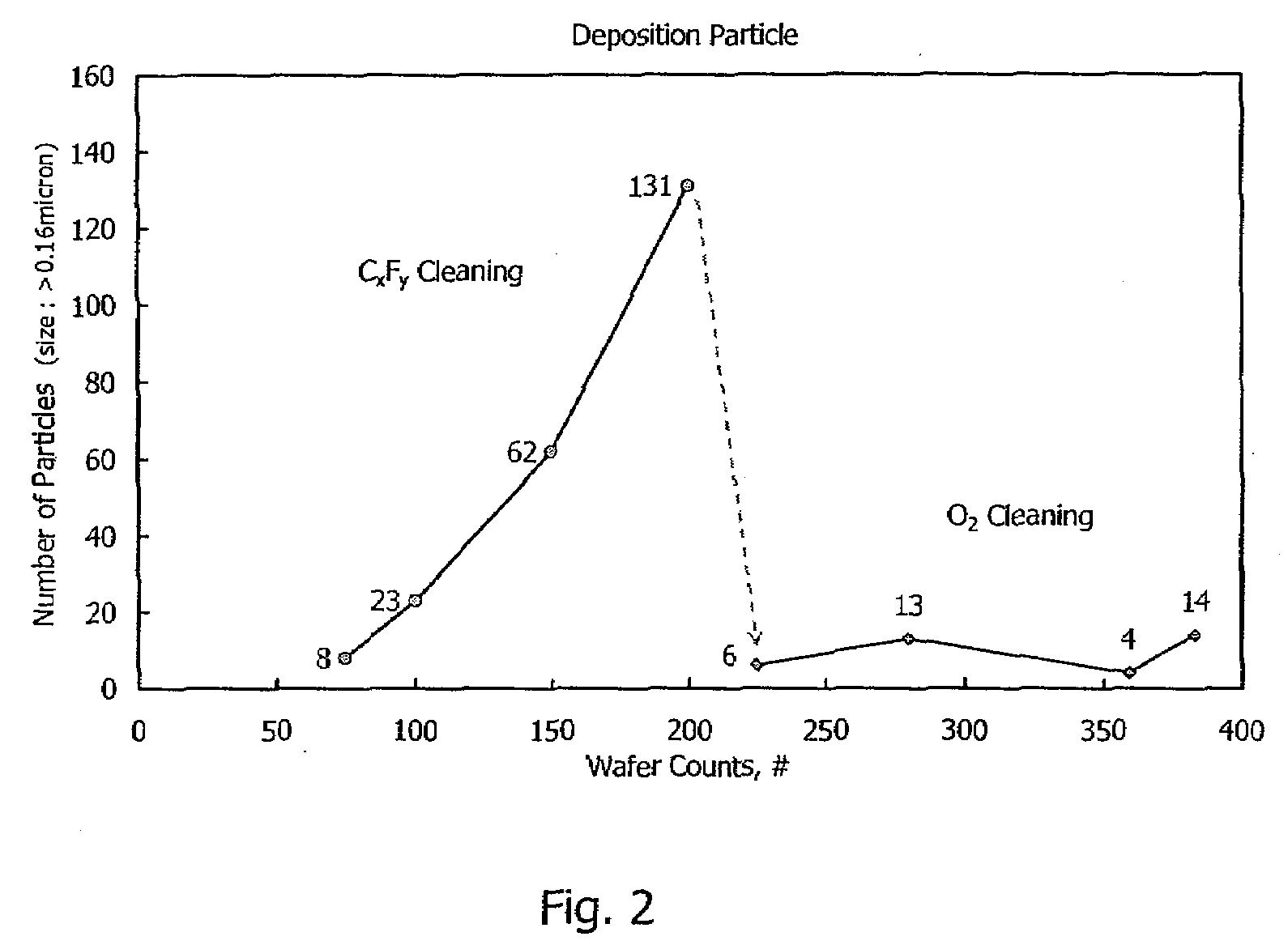

Method of self-cleaning of carbon-based film

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

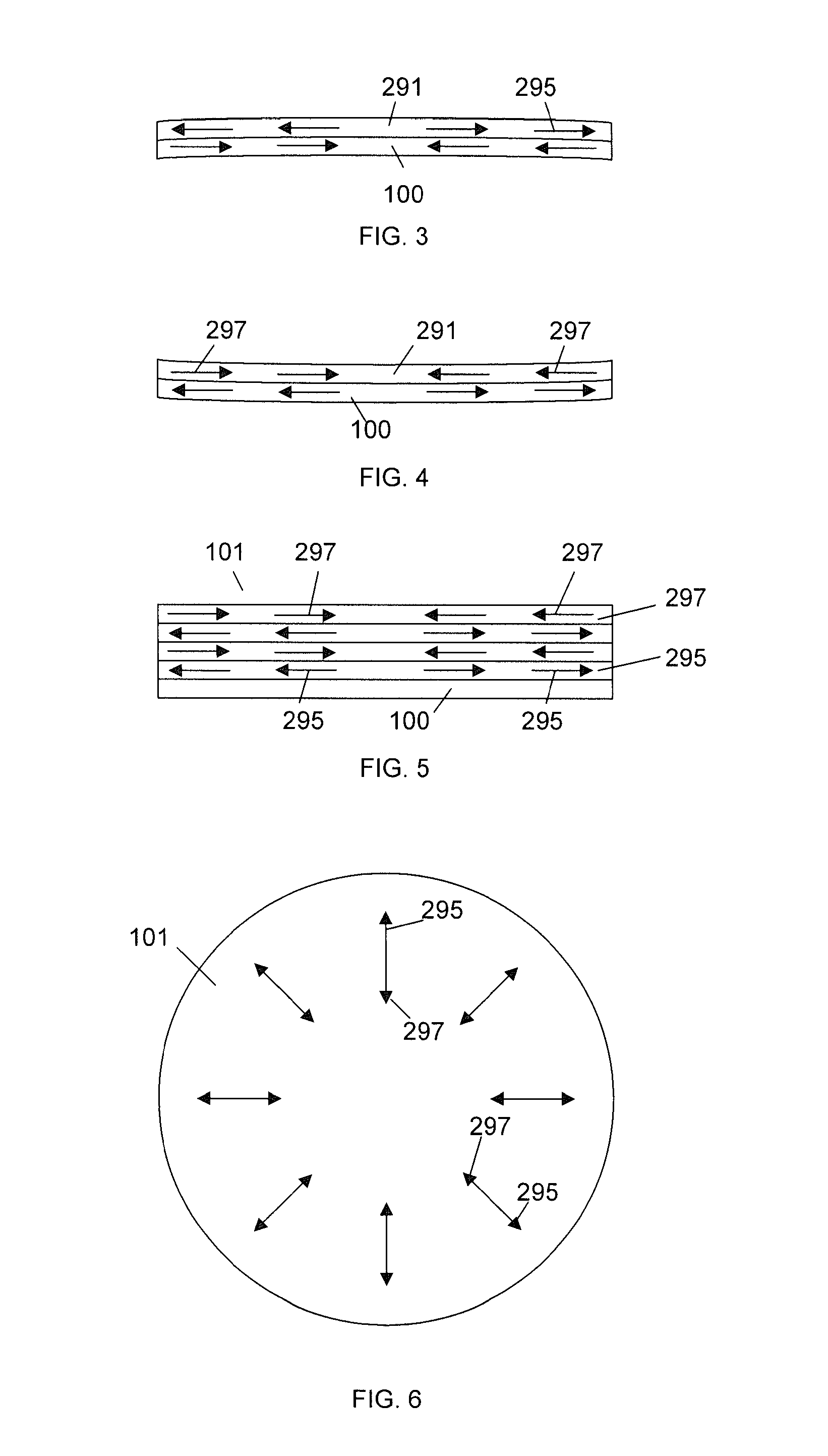

Atomic layer deposition for controlling vertical film growth

ActiveUS8592005B2Improve directionVacuum evaporation coatingSputtering coatingPhysical chemistryThin membrane

Owner:ASM JAPAN

Apparatus for reducing plasma charge damage for plasma processes

InactiveUS7036453B2Reducing plasma discharge damageReduce morbidityElectric discharge tubesSemiconductor/solid-state device manufacturingMaterials sciencePhysical chemistry

A method is provided for depositing a thin film on a substrate in a process chamber with reduced incidence of plasma charge damage. A process gas containing a precursor gases suitable for forming a plasma is flowed into a process chamber, and a plasma is generated from the process gas to deposit the thin film on the substrate. The precursor gases are flowed into the process chamber such that the thin film is deposited at the center of the substrate more rapidly than at an edge of the substrate.

Owner:APPLIED MATERIALS INC

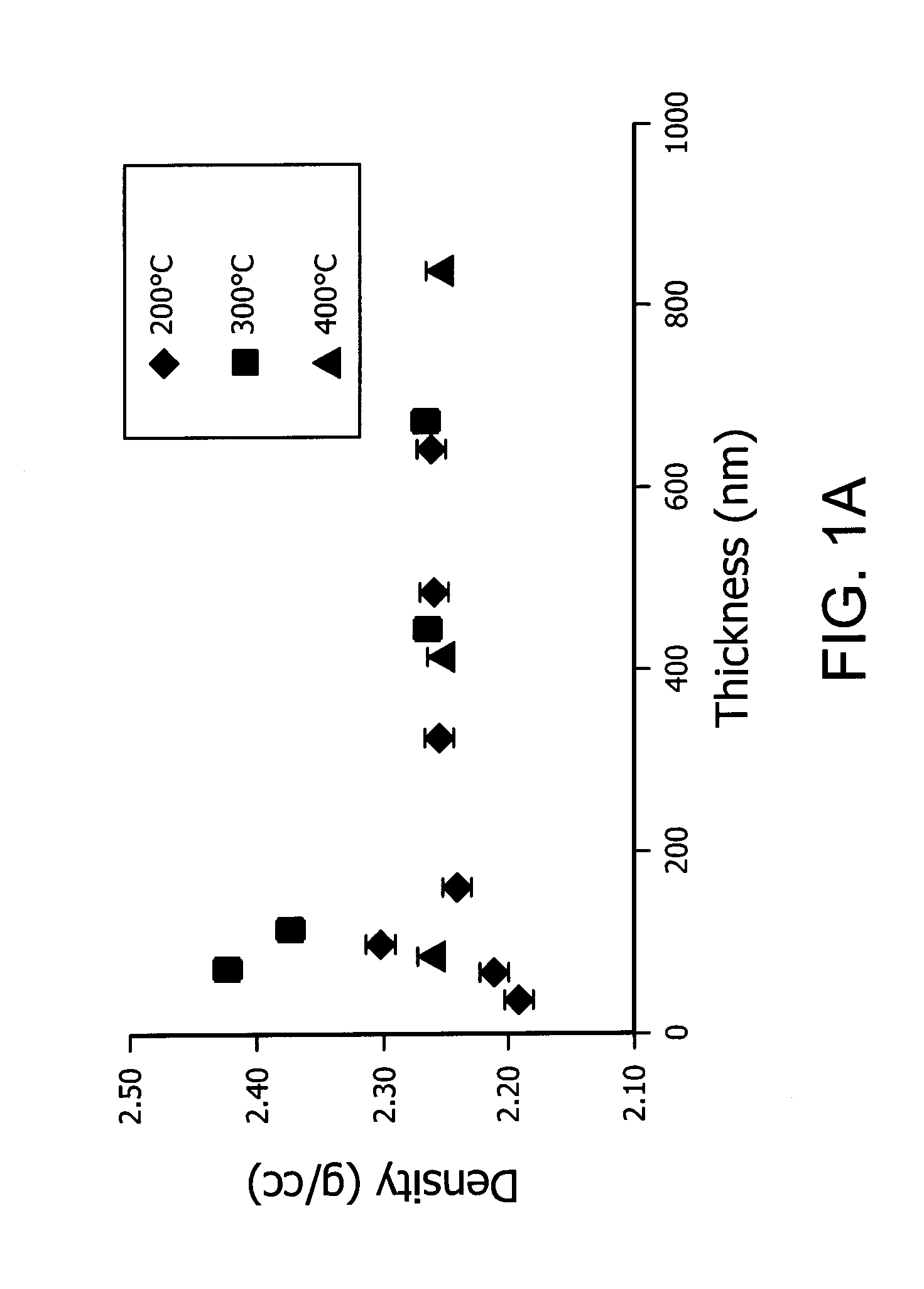

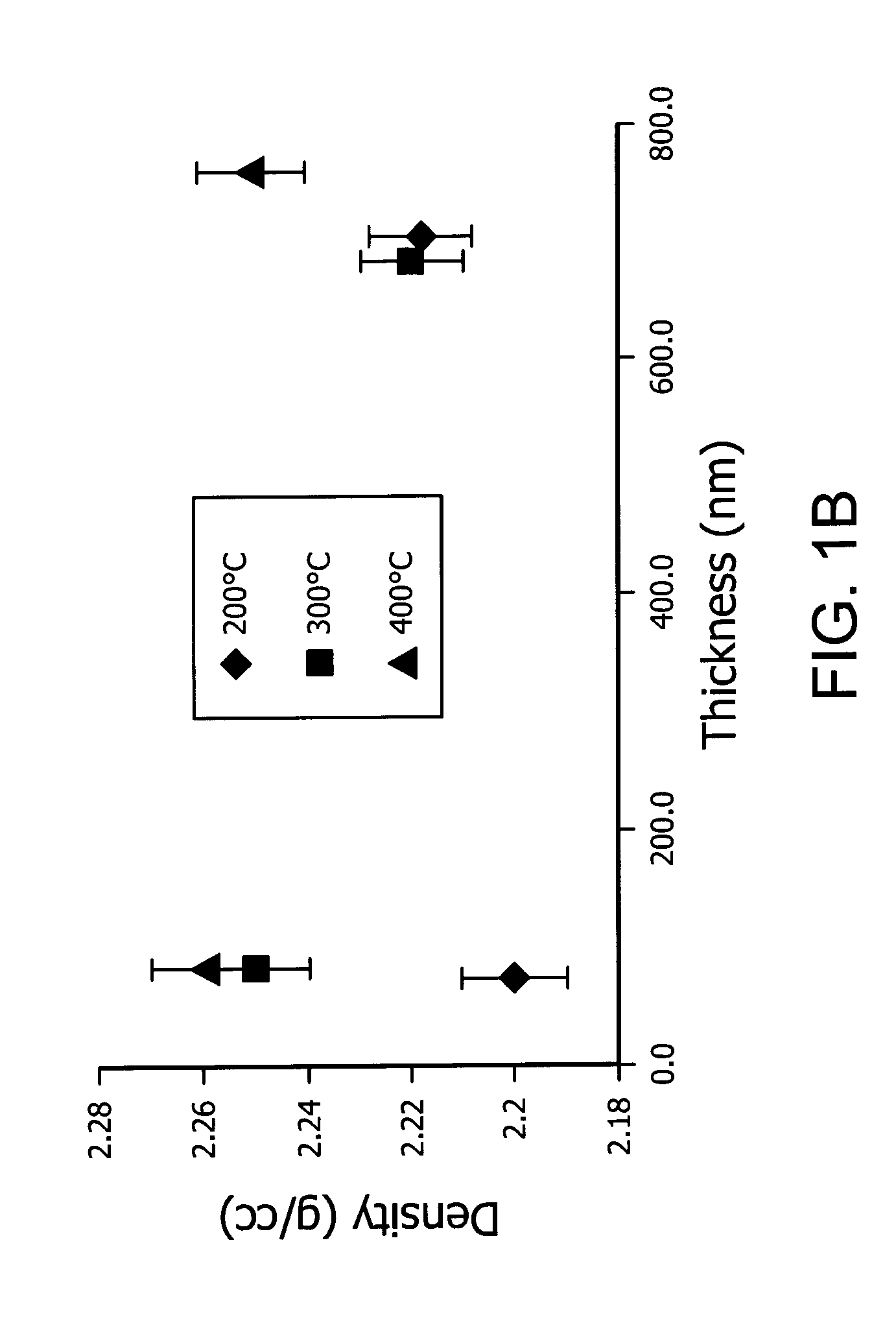

Compositions and methods for making silicon containing films

ActiveUS20150014823A1Semiconductor/solid-state device detailsSolid-state devicesTriethylsilaneDeposition process

Described herein are low temperature processed high quality silicon containing films. Also disclosed are methods of forming silicon containing films at low temperatures. In one aspect, there are provided silicon-containing film having a thickness of about 2 nm to about 200 nm and a density of about 2.2 g / cm3 or greater wherein the silicon-containing thin film is deposited by a deposition process selected from a group consisting of chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD), cyclic chemical vapor deposition (CCVD), plasma enhanced cyclic chemical vapor deposition (PECCVD, atomic layer deposition (ALD), and plasma enhanced atomic layer deposition (PEALD), and the vapor deposition is conducted at one or more temperatures ranging from about 25° C. to about 400° C. using an alkylsilane precursor selected from the group consisting of diethylsilane, triethylsilane, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

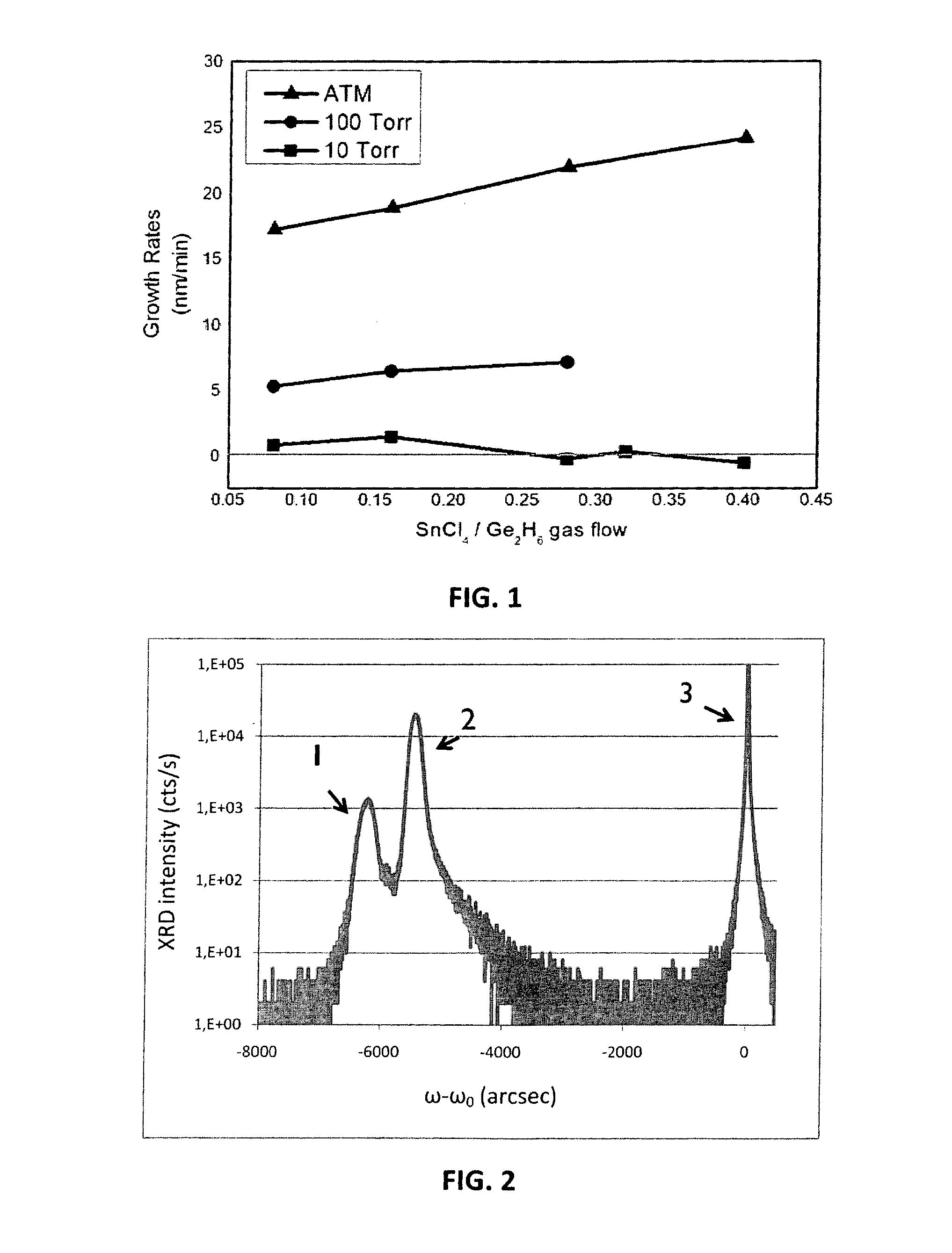

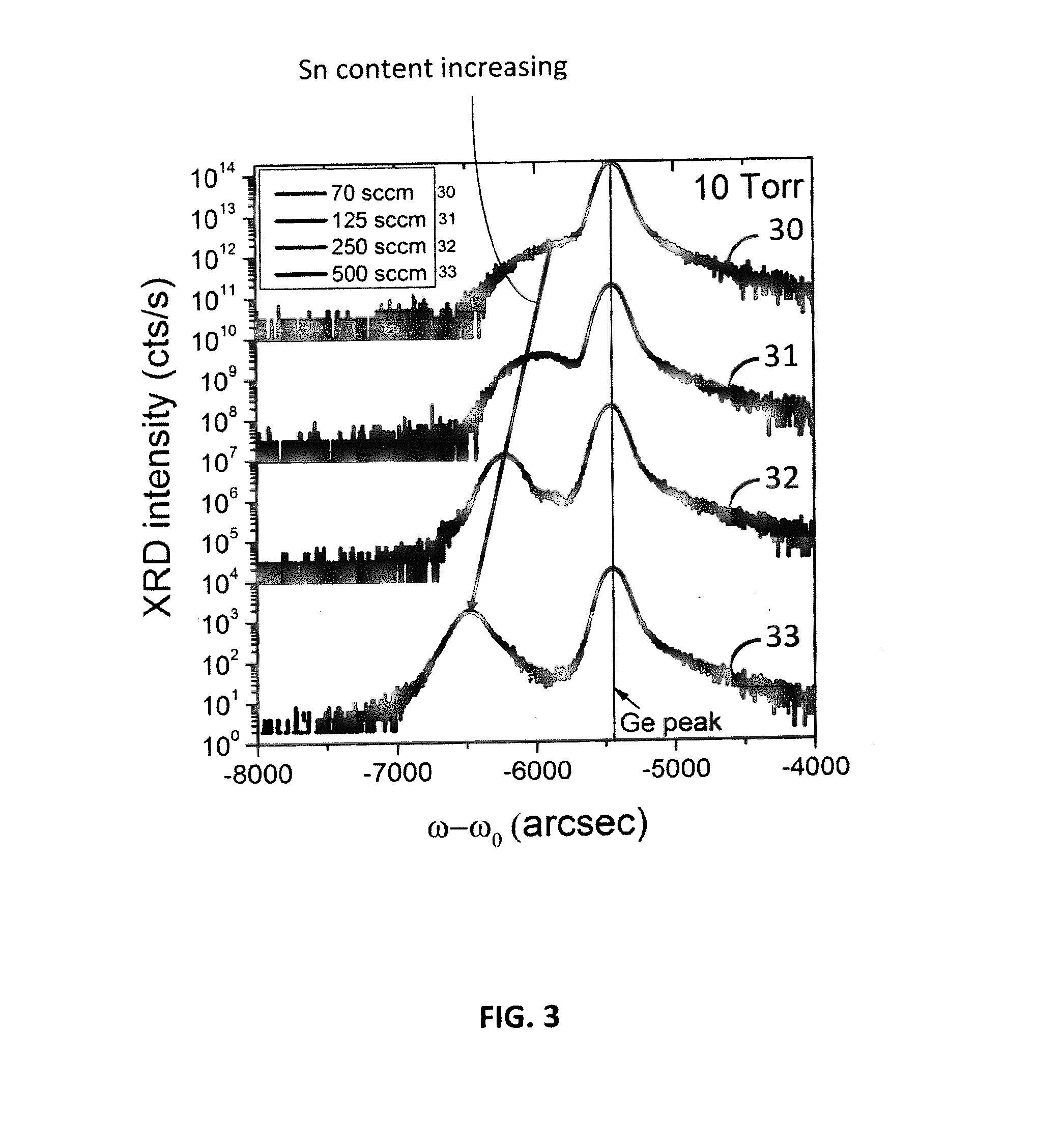

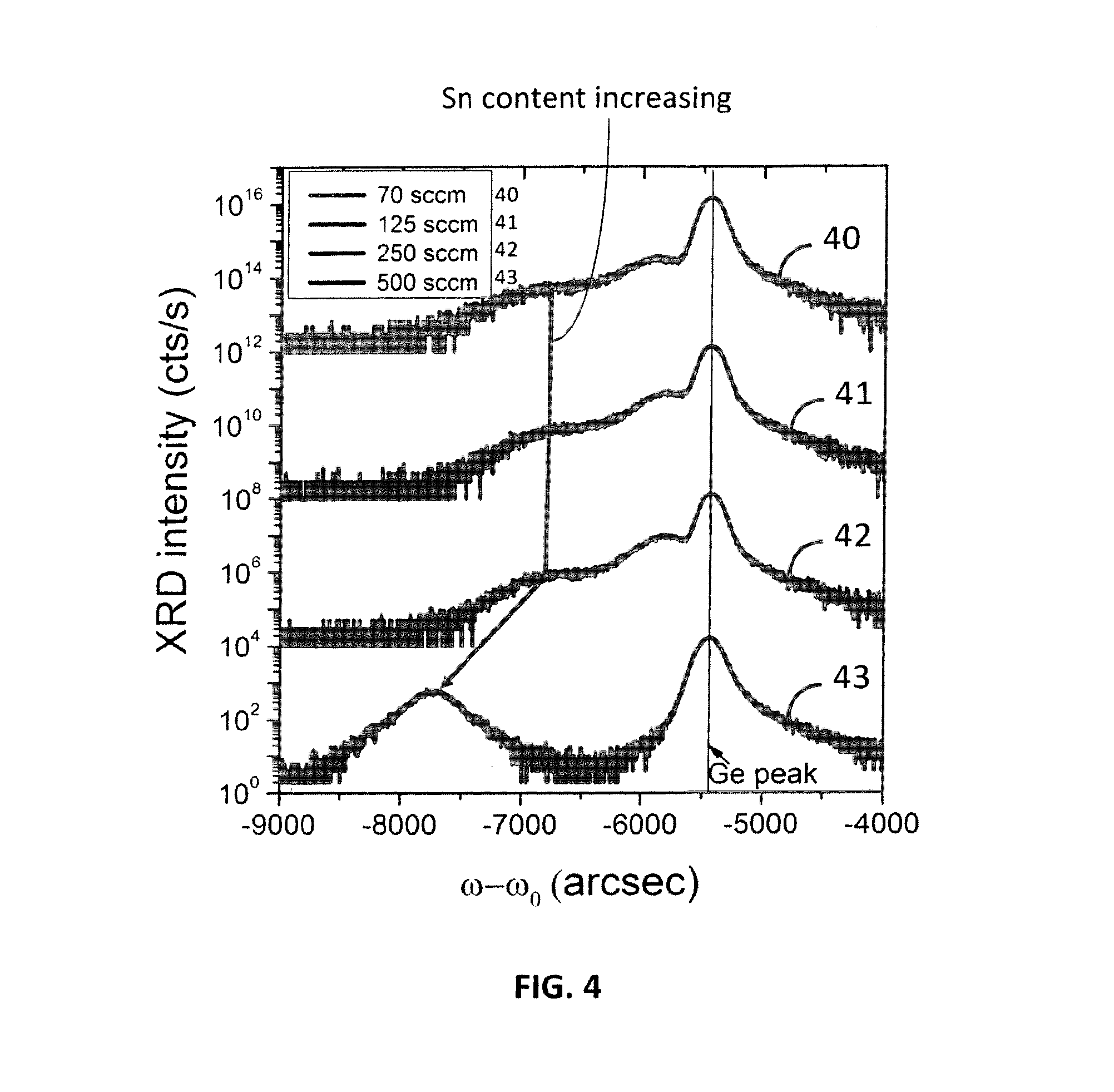

Method for Growing a Monocrystalline Tin-Containing Semiconductor Material

InactiveUS20140020619A1Efficiently provideEfficient methodPolycrystalline material growthAdditive manufacturing apparatusSemiconductor materialsPhysical chemistry

Disclosed are methods for growing Sn-containing semiconductor materials. In some embodiments, an example method includes providing a substrate in a chemical vapor deposition (CVD) reactor, and providing a semiconductor material precursor, a Sn precursor, and a carrier gas in the CVD reactor. The method further includes epitaxially growing a Sn-containing semiconductor material on the substrate, where the Sn precursor comprises tin tetrachloride (SnCl4). The semiconductor material precursor may be, for example, digermane, trigermane, higher-order germanium precursors, or a combination thereof. Alternatively, the semiconductor material precursor may be a silicon precursor.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

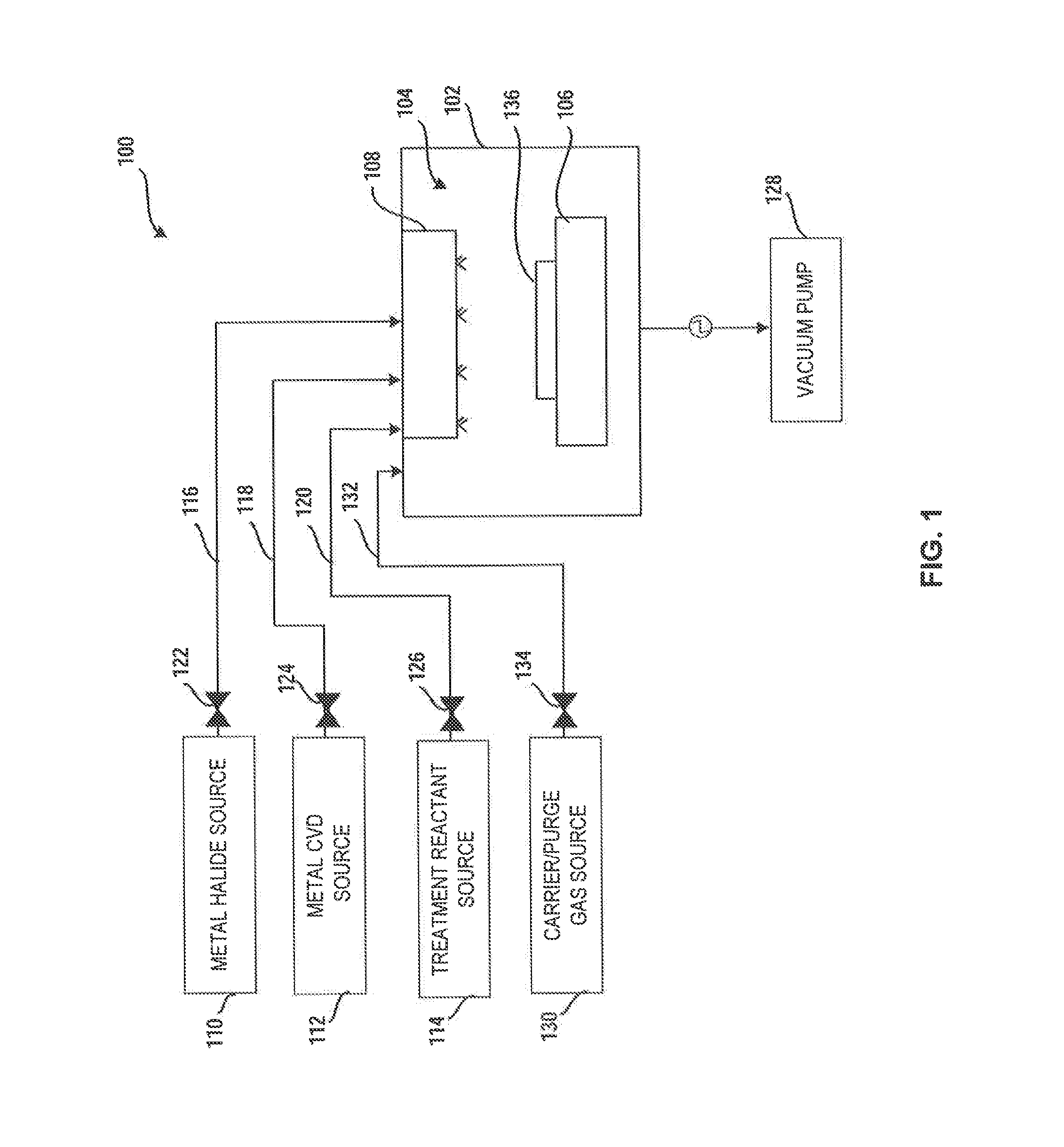

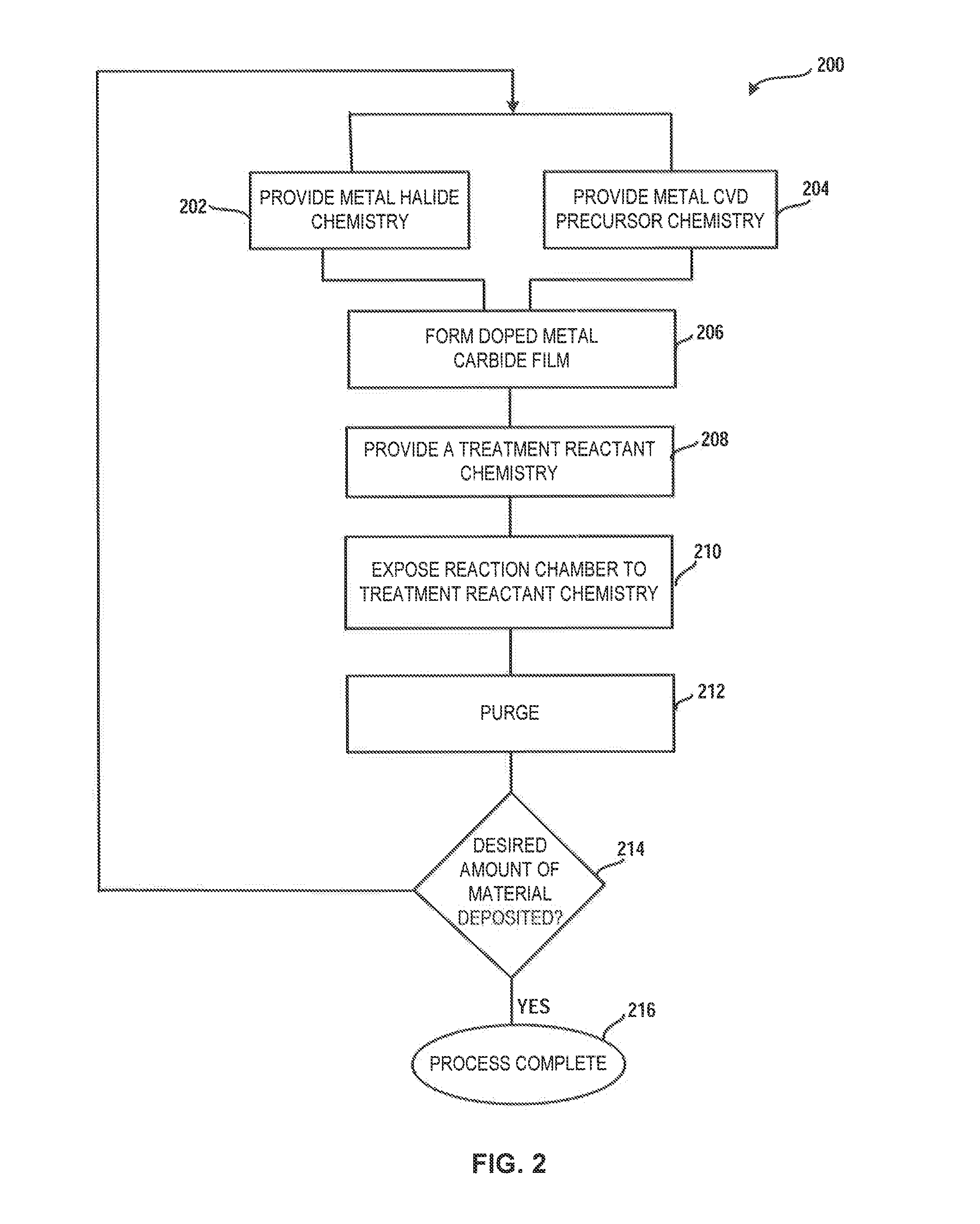

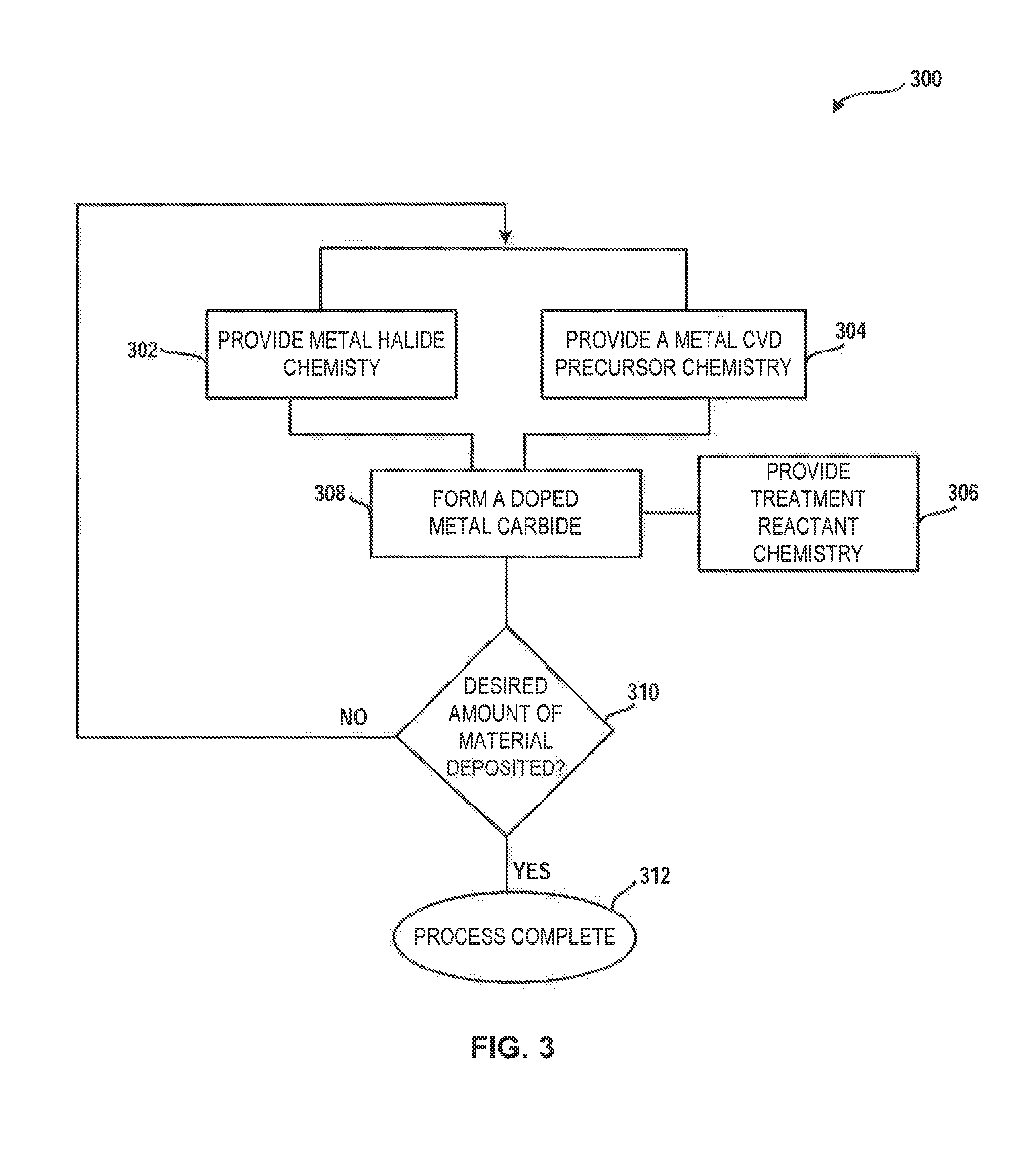

Method and system for treatment of deposition reactor

ActiveUS20140220247A1Substrate throughput can be increasedReduce operating costsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTitanium carbideMetal membrane

A system and method for treating a deposition reactor are disclosed. The system and method remove or mitigate formation of residue in a gas-phase reactor used to deposit doped metal films, such as aluminum-doped titanium carbide films or aluminum-doped tantalum carbide films. The method includes a step of exposing a reaction chamber to a treatment reactant that mitigates formation of species that lead to residue formation.

Owner:ASM IP HLDG BV

Method for restoring porous surface of dielectric layer by UV light-assisted ALD

ActiveUS9136108B2Good step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemisorptionOrganic chemistry

A method for restoring a porous surface of a dielectric layer formed on a substrate, includes: (i) providing in a reaction space a substrate on which a dielectric layer having a porous surface with terminal hydroxyl groups is formed as an outer layer; (ii) supplying gas of a Si—N compound containing a Si—N bond to the reaction space to chemisorb the Si—N compound onto the surface with the terminal hydroxyl groups; (iii) irradiating the Si—N compound-chemisorbed surface with a pulse of UV light in an oxidizing atmosphere to oxidize the surface and provide terminal hydroxyl groups to the surface; and (iv) repeating steps (ii) through (iii) to form a film on the porous surface of the dielectric layer for restoration.

Owner:ASM IP HLDG BV

Method for Forming Silicon-Containing Dielectric Film by Cyclic Deposition with Side Wall Coverage Control

ActiveUS20130330933A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric membranePhysical chemistry

A method of forming a dielectric film having Si—C bonds and / or Si—N bonds on a semiconductor substrate by cyclic deposition, includes: (i) conducting one or more cycles of cyclic deposition in a reaction space wherein a semiconductor substrate is placed, using a Si-containing precursor and a reactant gas; and (ii) before or after step (i), applying a pulse of RF power to the reaction space while supplying a rare gas and a treatment gas without supplying a Si-containing precursor, whereby a dielectric film having Si—C bonds and / or Si—N bonds is formed on the semiconductor substrate.

Owner:ASM IP HLDG BV

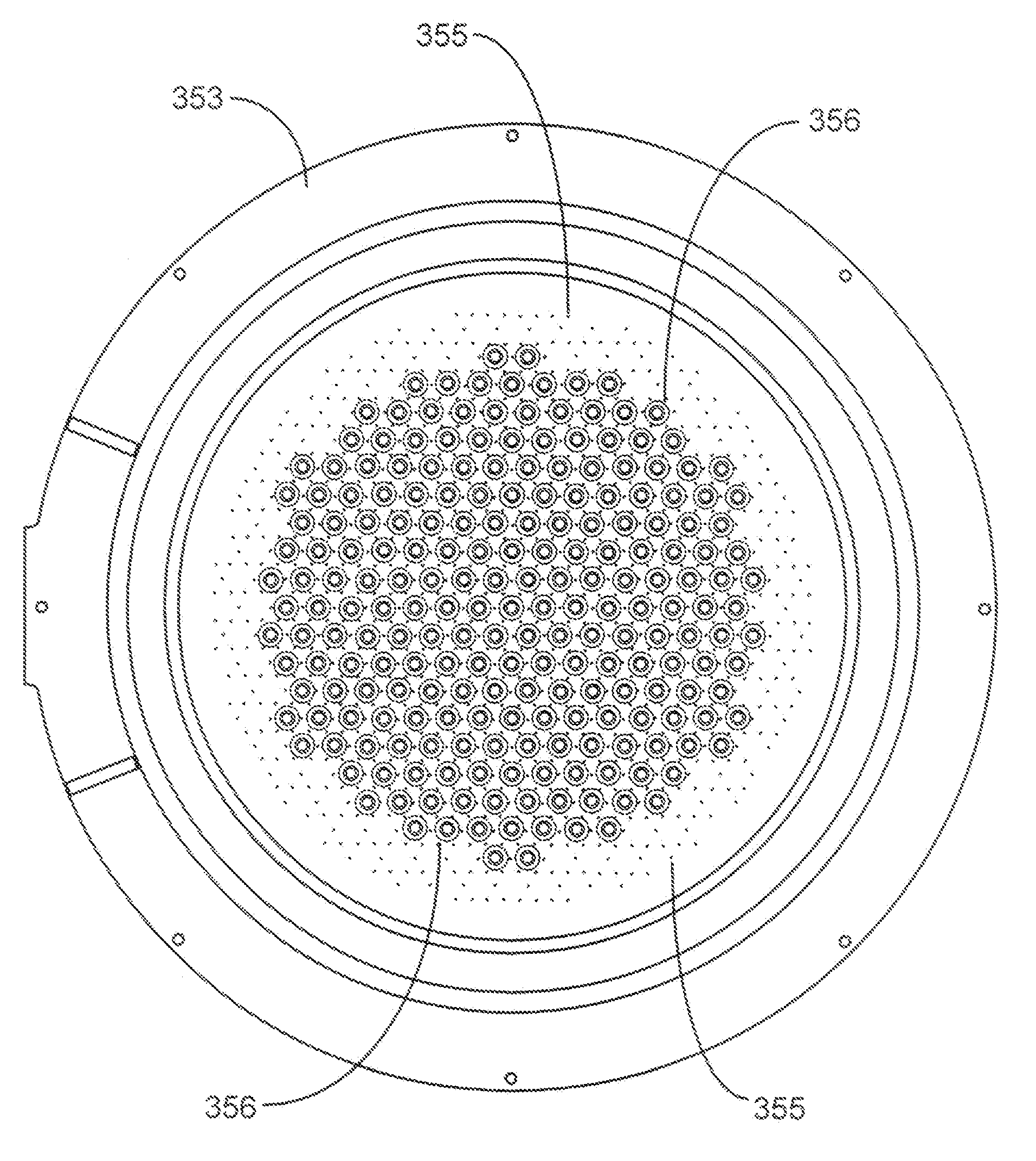

Multi-gas distribution injector for chemical vapor deposition reactors

A gas distribution injector for chemical vapor deposition reactors has precursor gas inlets disposed at spaced-apart locations on an inner surface facing downstream toward a substrate carrier, and has carrier openings disposed between the precursor gas inlets. One or more precursor gases are introduced through the precursor gas inlets, and a carrier gas substantially nonreactive with the precursor gases is introduced through the carrier gas openings. The carrier gas minimizes deposit formation on the injector. The carrier gas openings may be provided by a porous plate defining the surface or via carrier inlets interspersed between precursor inlets. The gas inlets may removable or coaxial.

Owner:VEECO INSTR

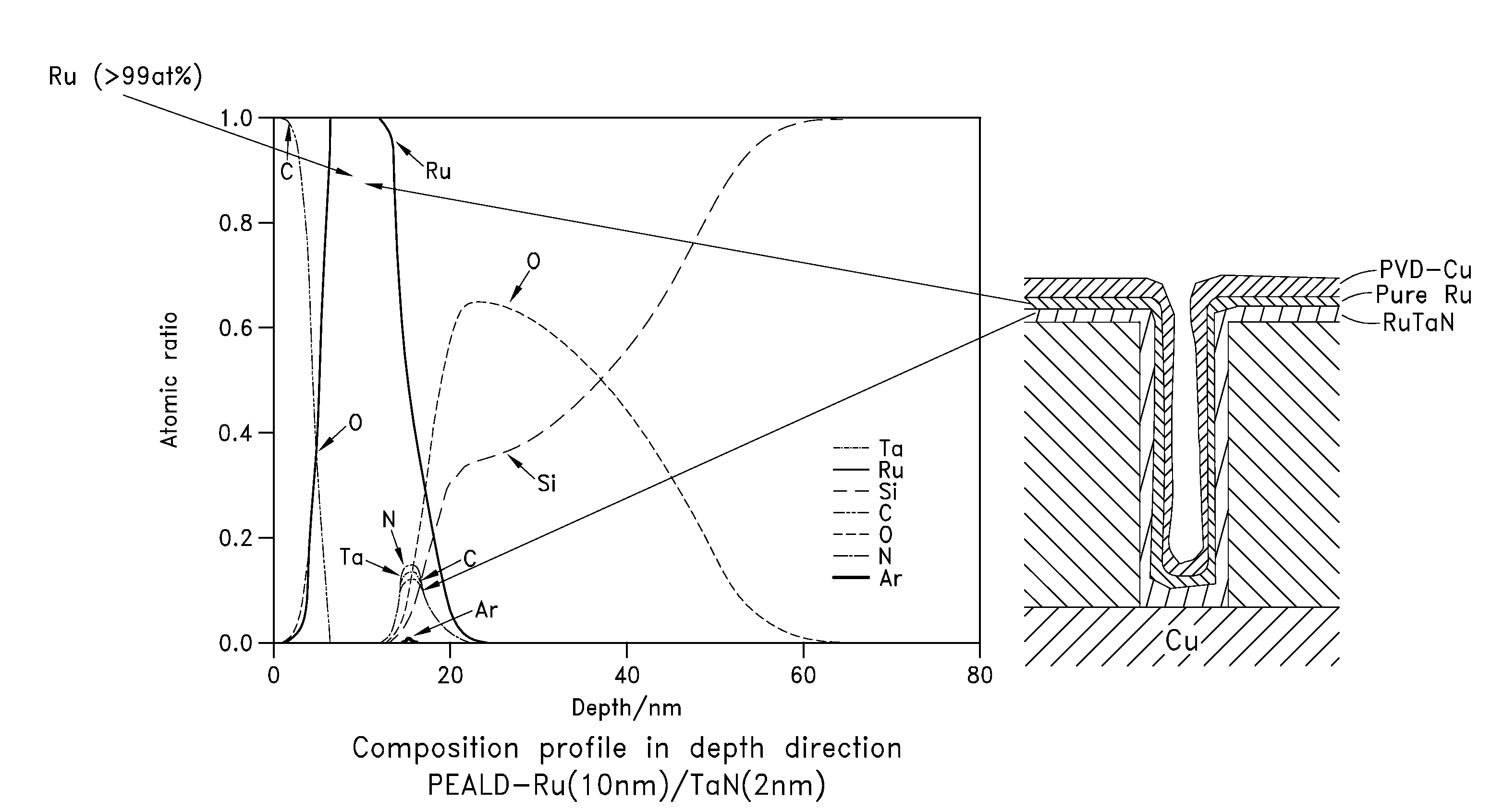

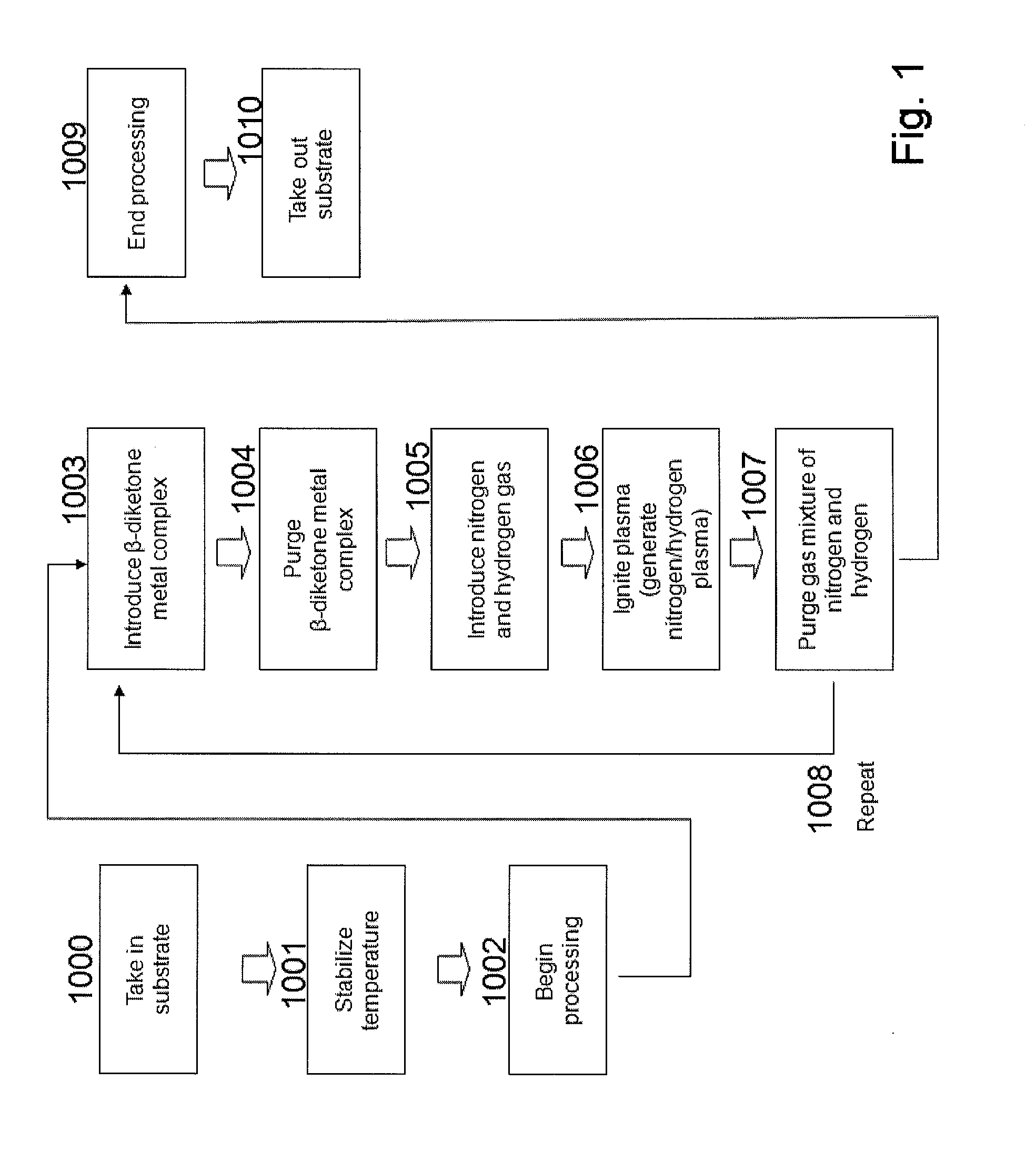

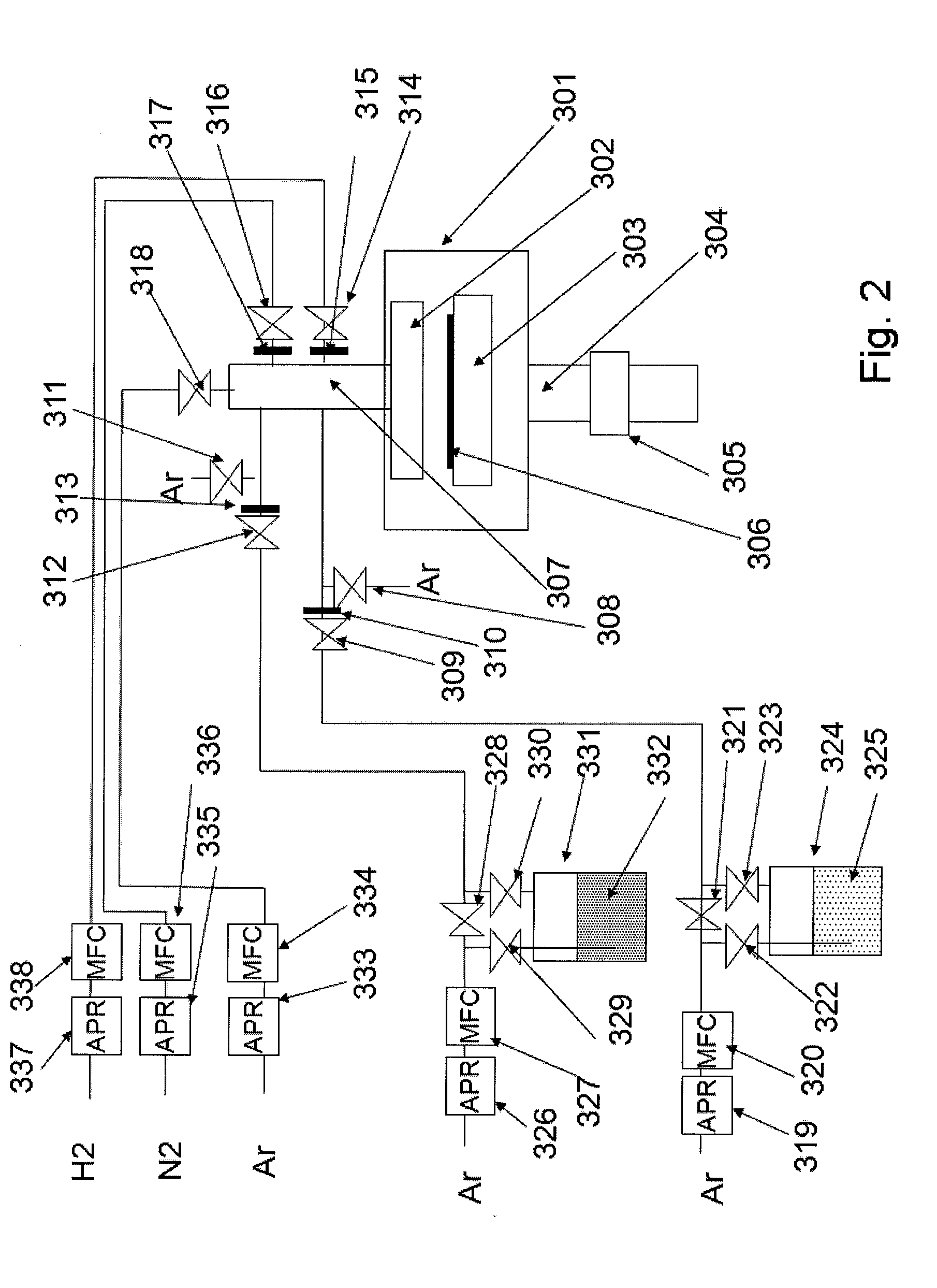

Method for forming metal film by ald using beta-diketone metal complex

ActiveUS20100092696A1Improve shielding effectRapid and reliable mannerVacuum evaporation coatingPretreated surfacesDiketoneHydrogen

A method of forming a single-metal film on a substrate by plasma ALD includes: contacting a surface of a substrate with a β-diketone metal complex in a gas phase; exposing molecule-attached surface to a nitrogen-hydrogen mixed plasma; and repeating the above steps, thereby accumulating atomic layers to form a single-metal film on the substrate.

Owner:ASM JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com