Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1785results about "Drying using combination processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

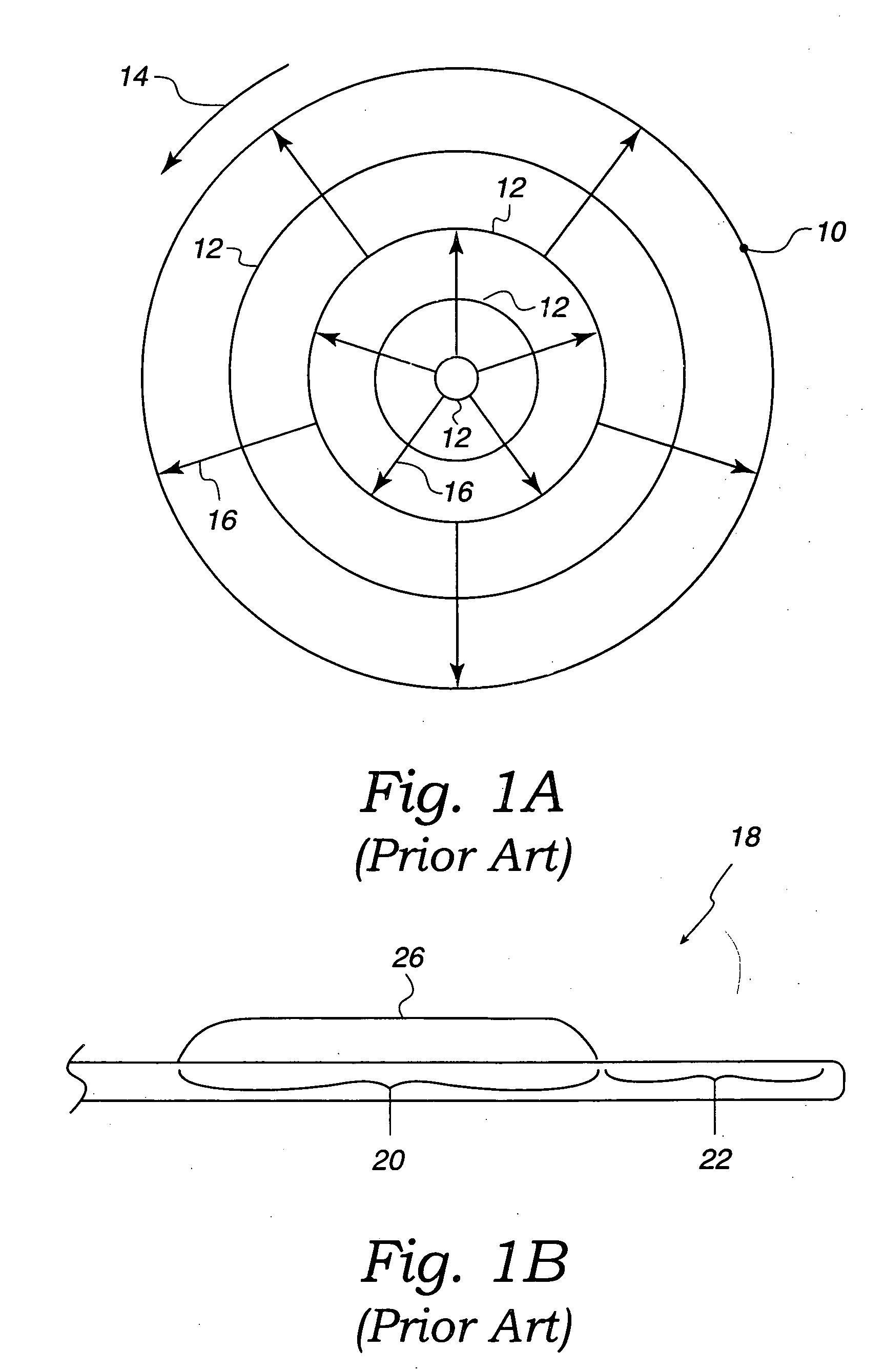

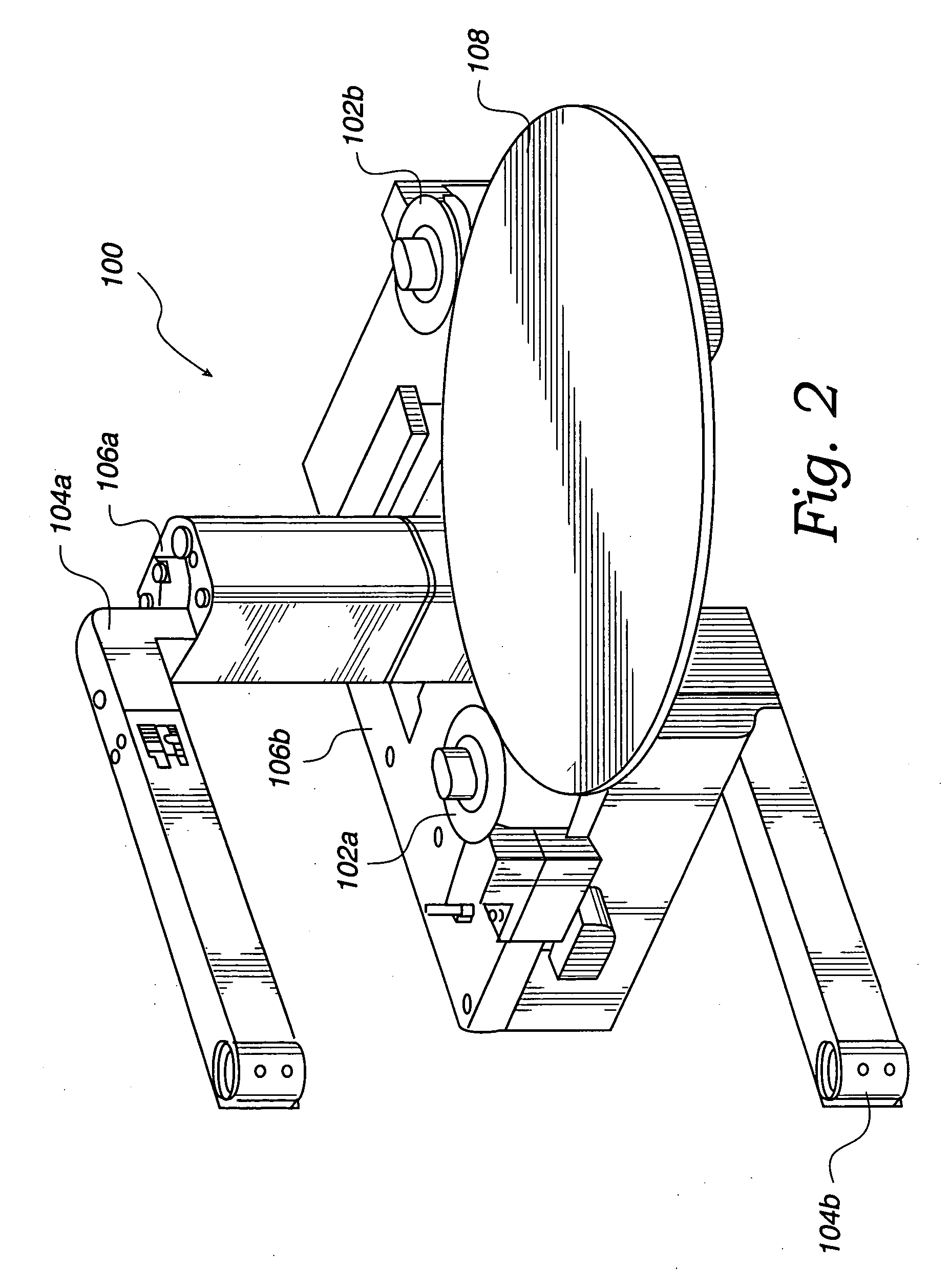

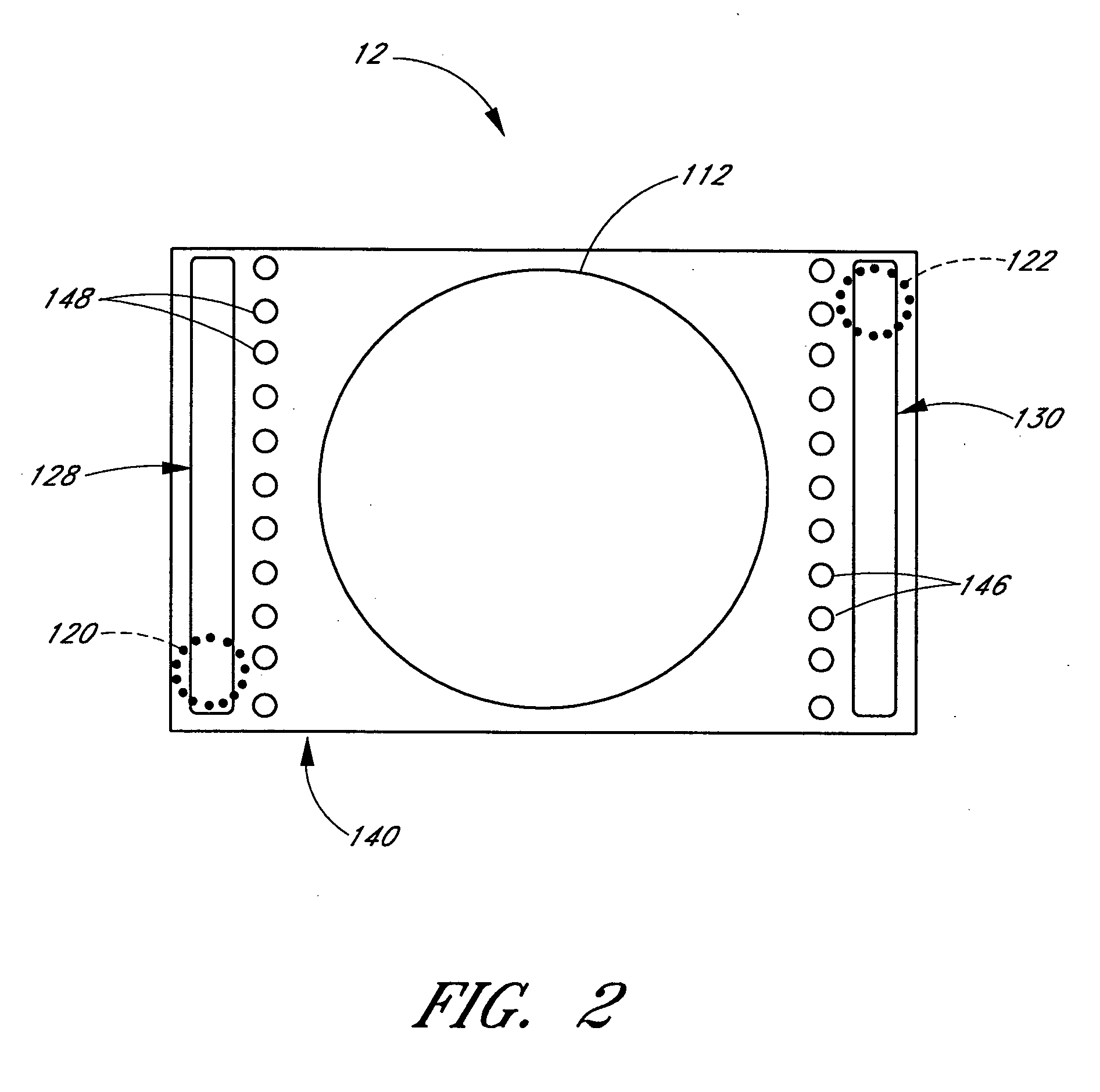

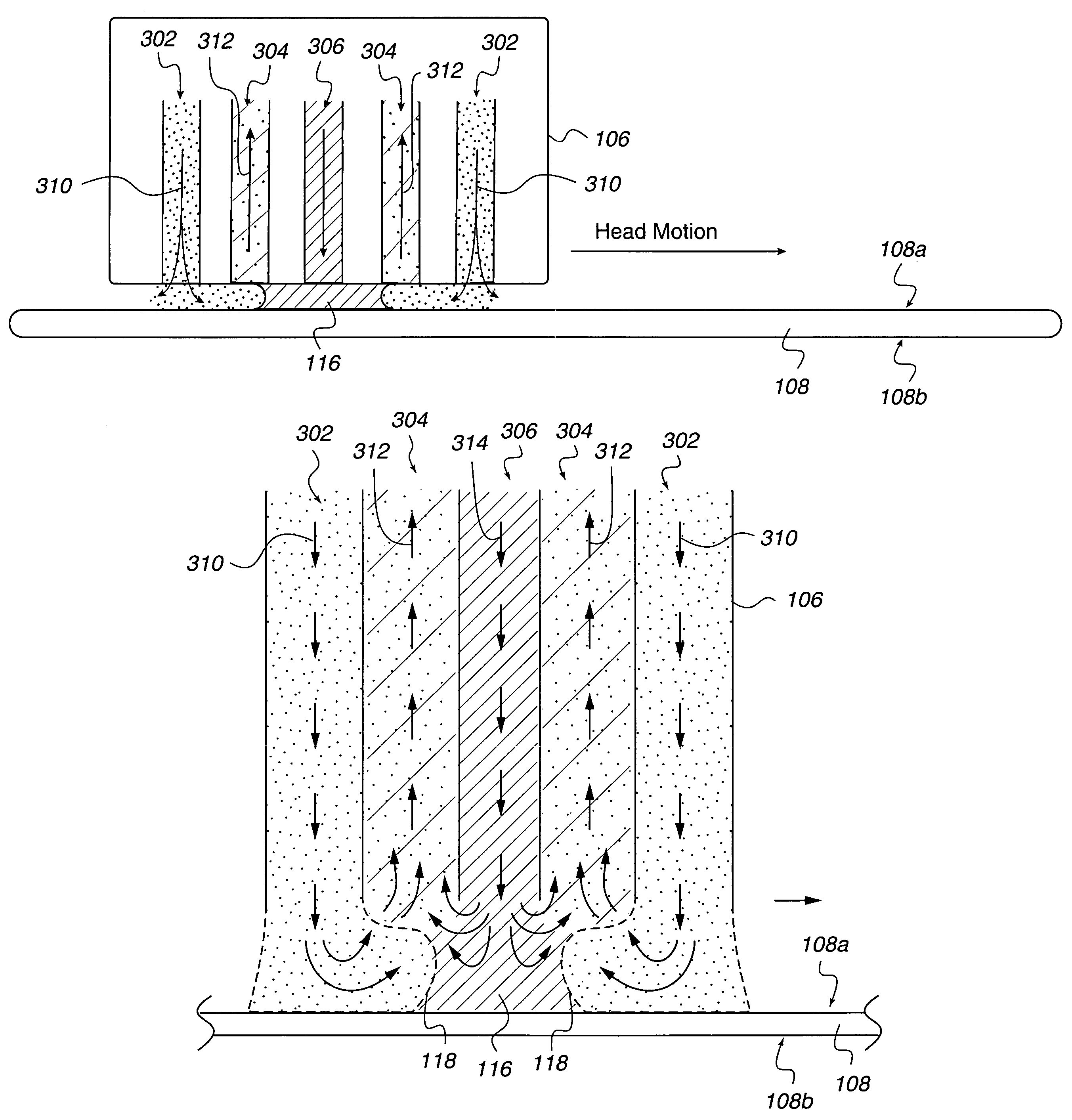

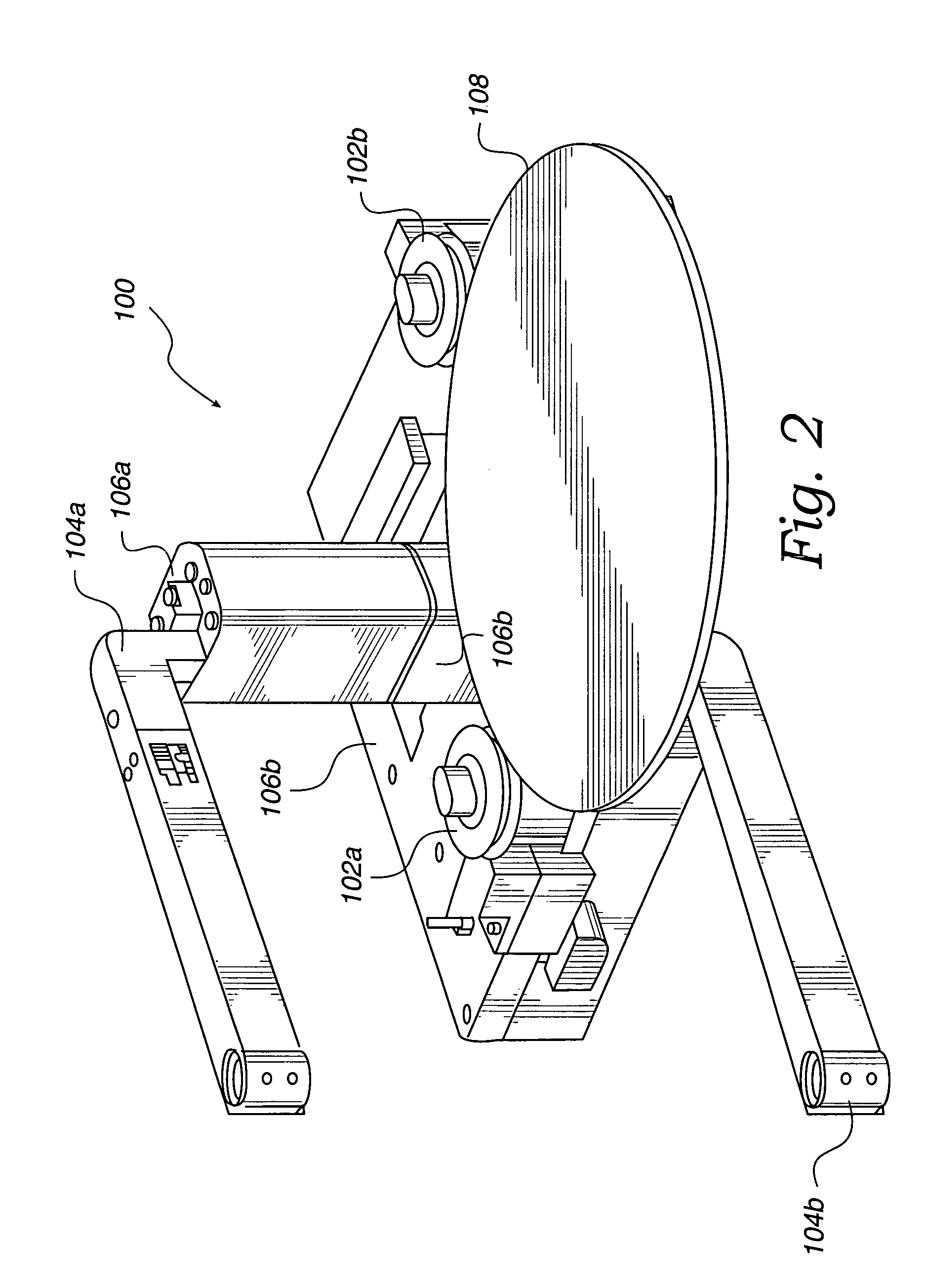

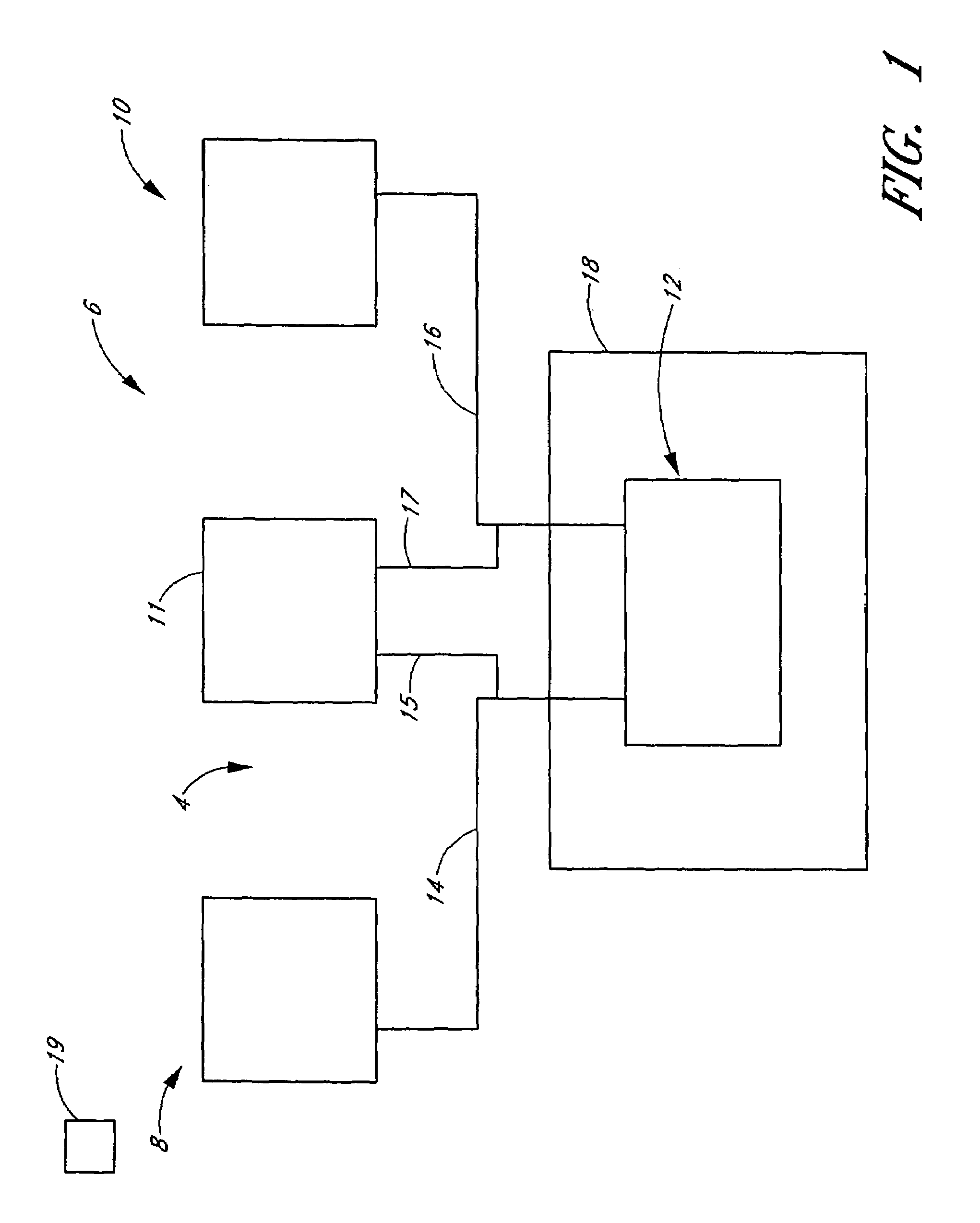

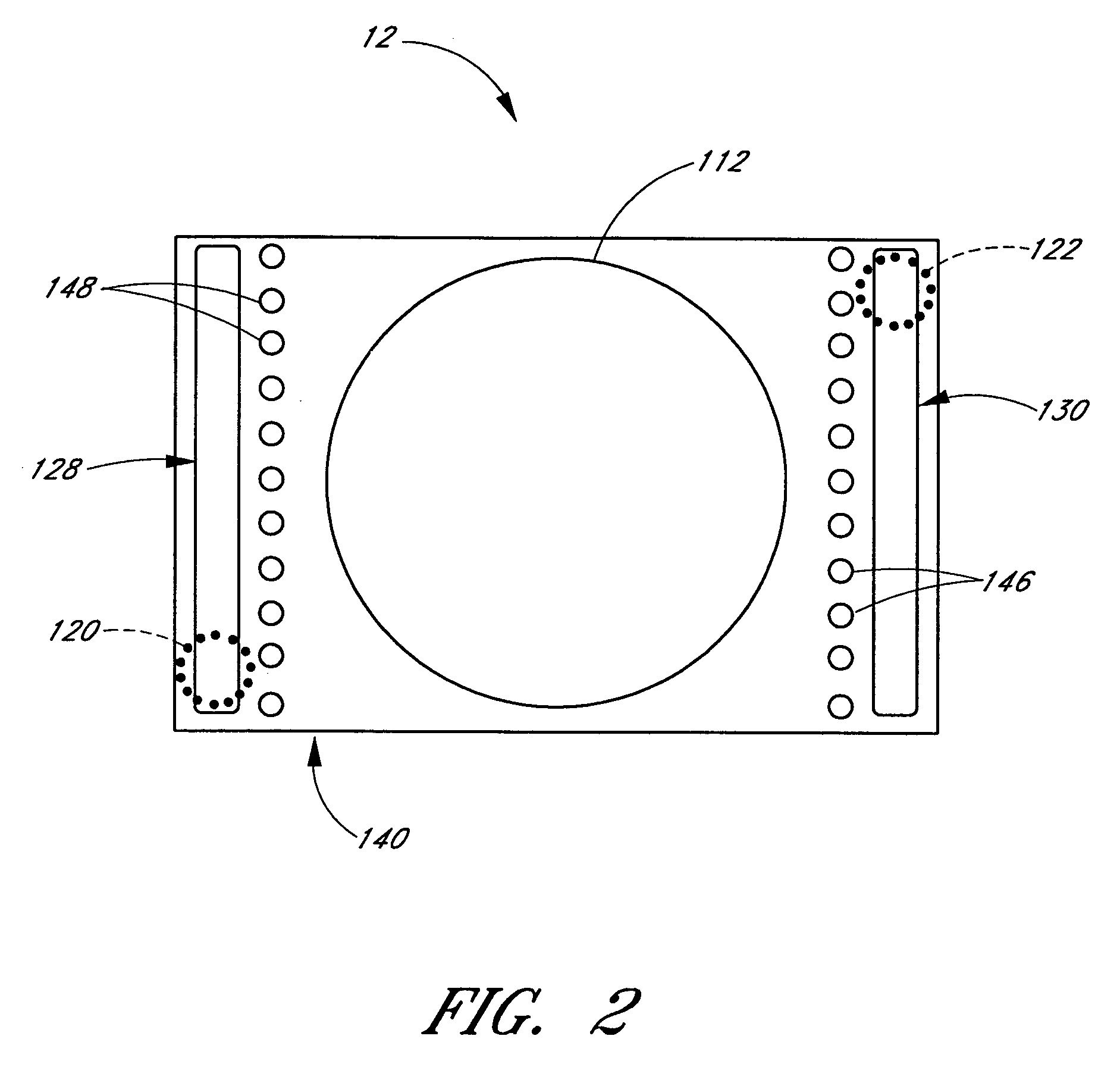

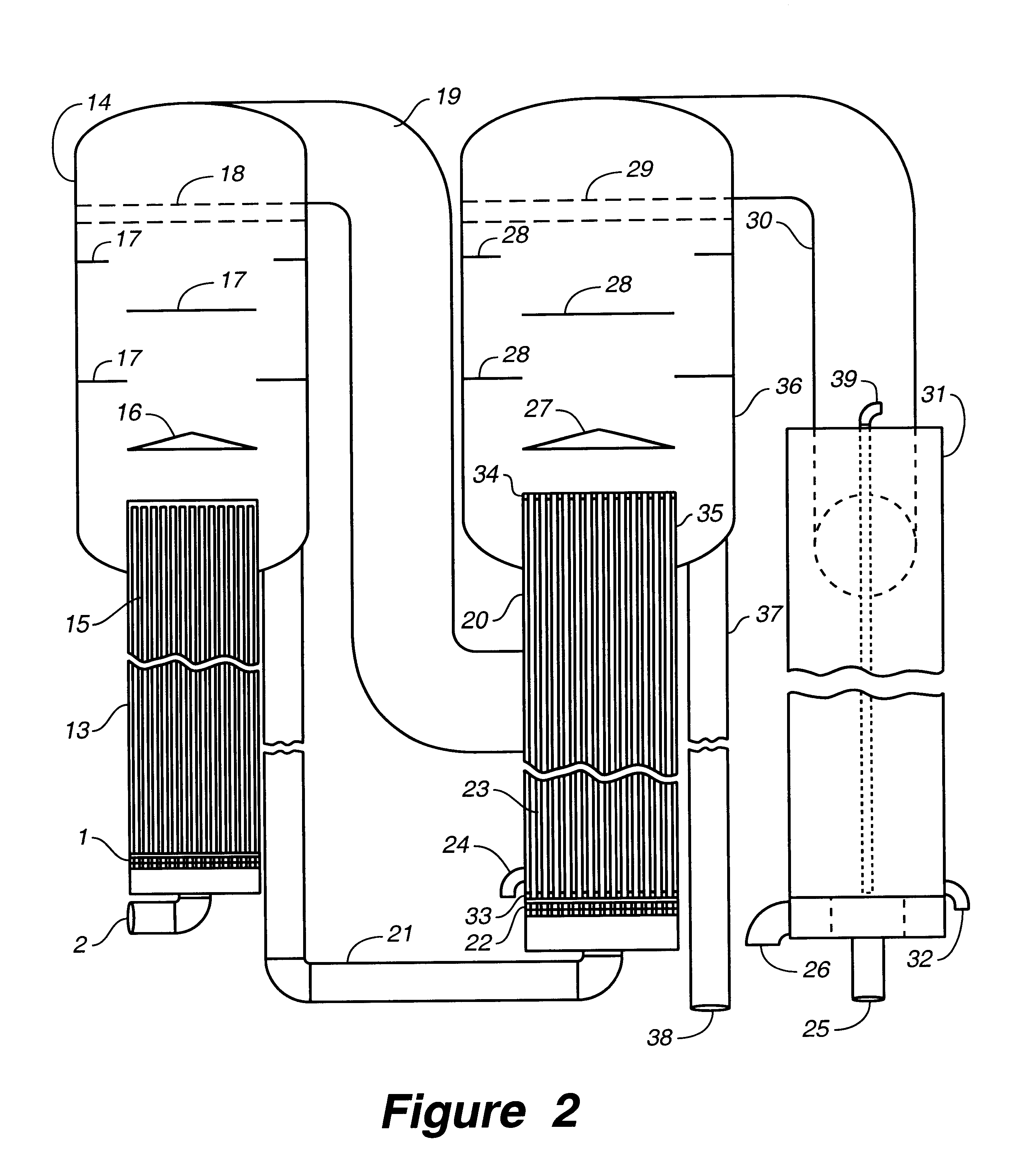

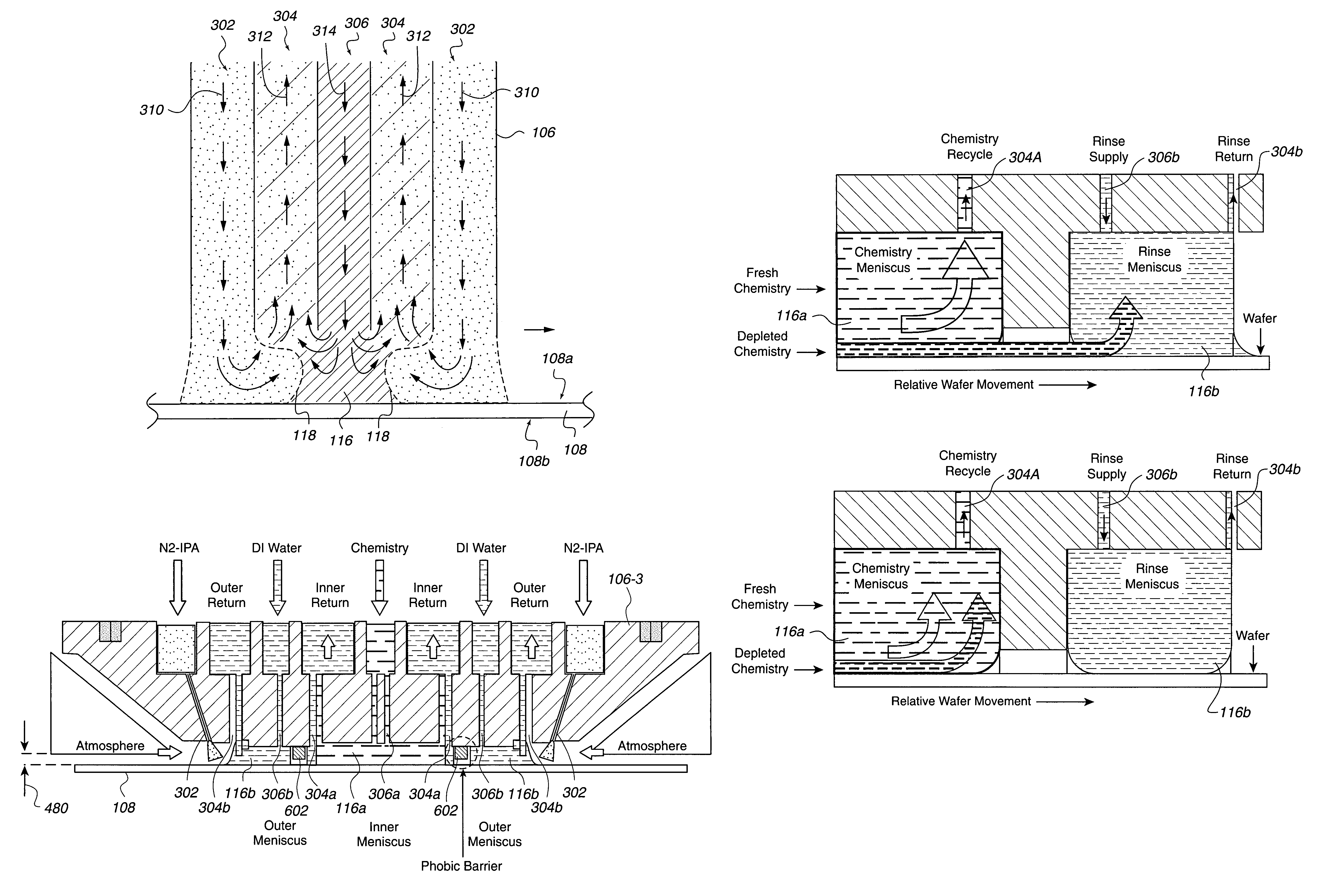

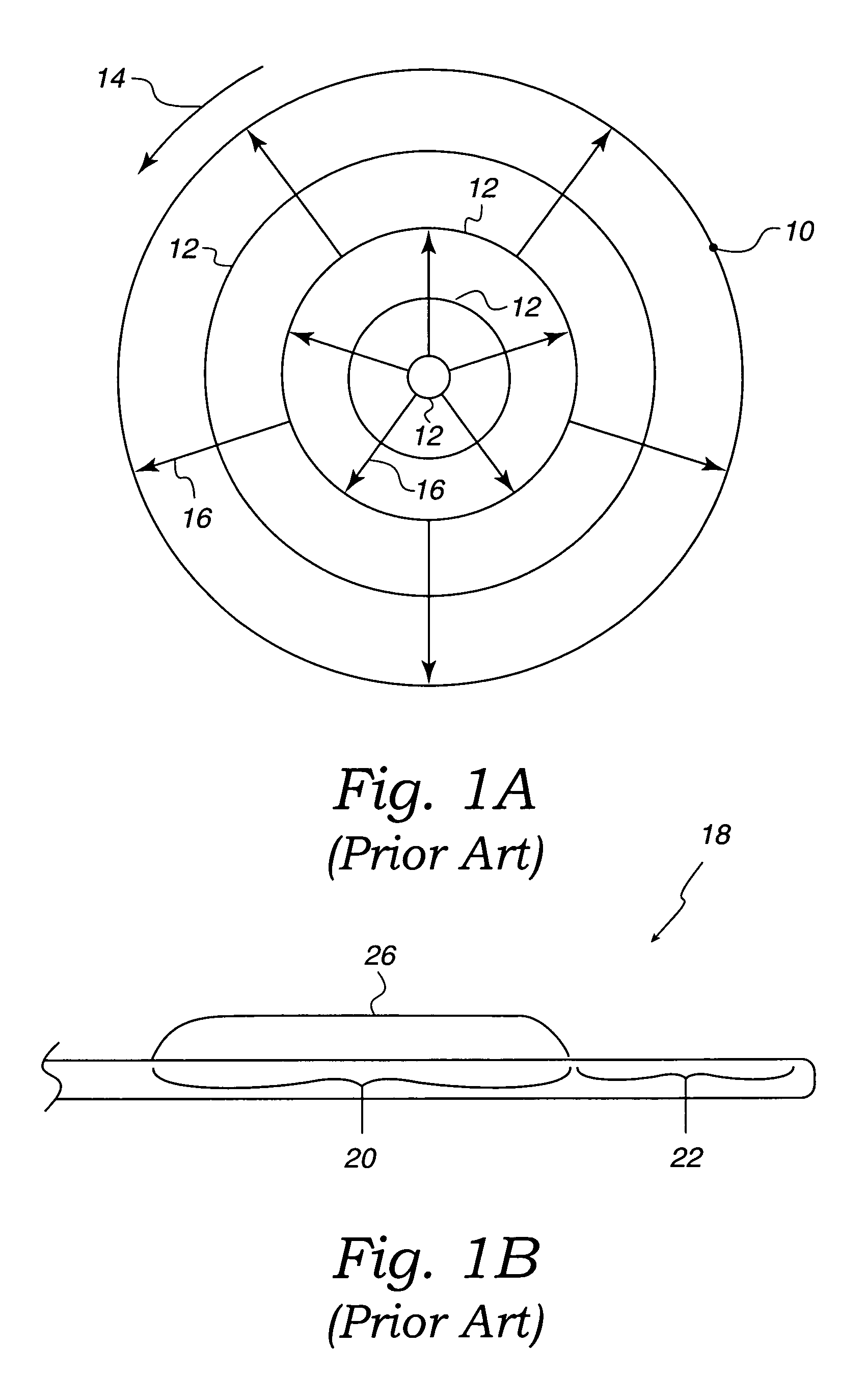

Concentric proximity processing head

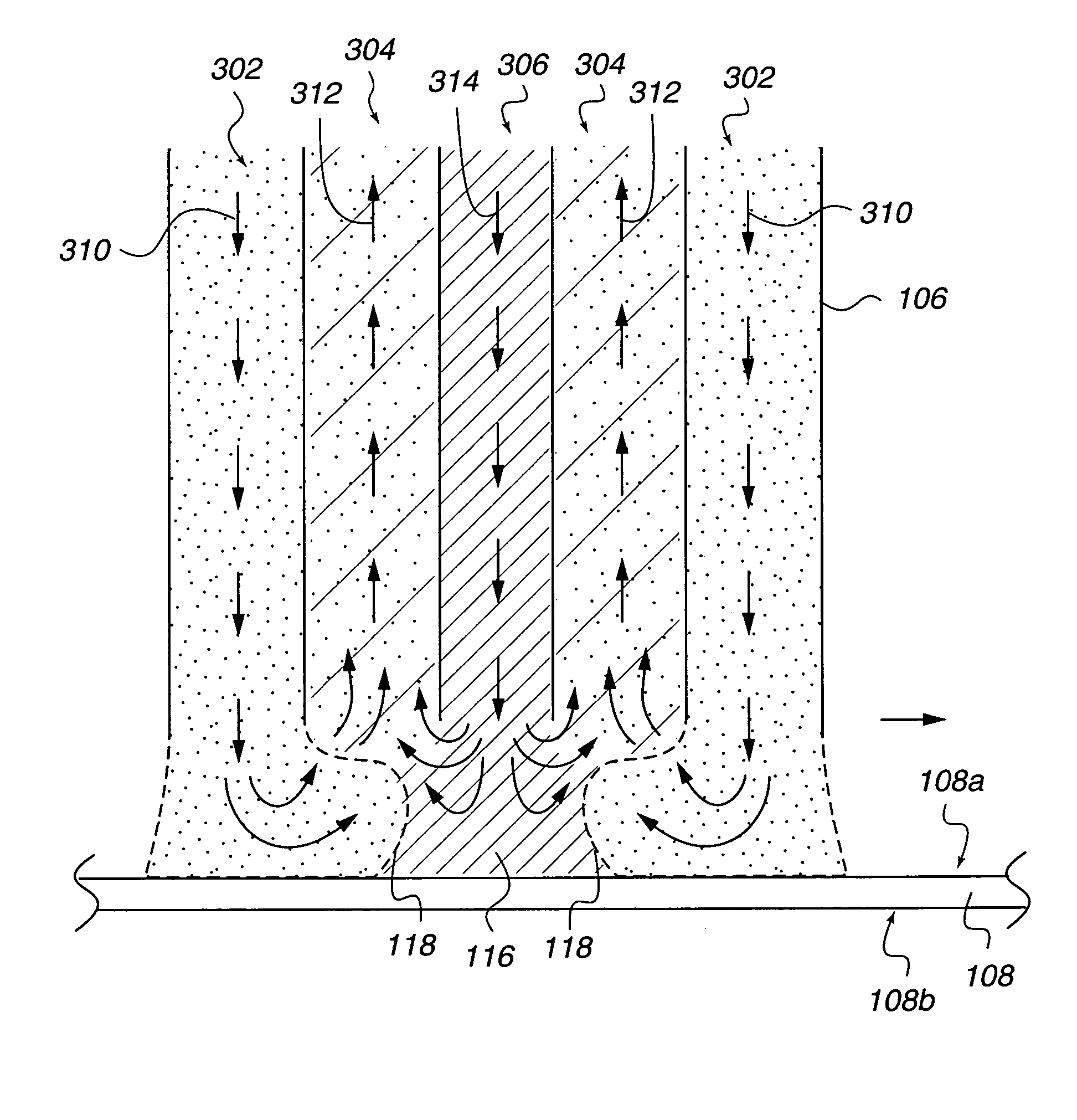

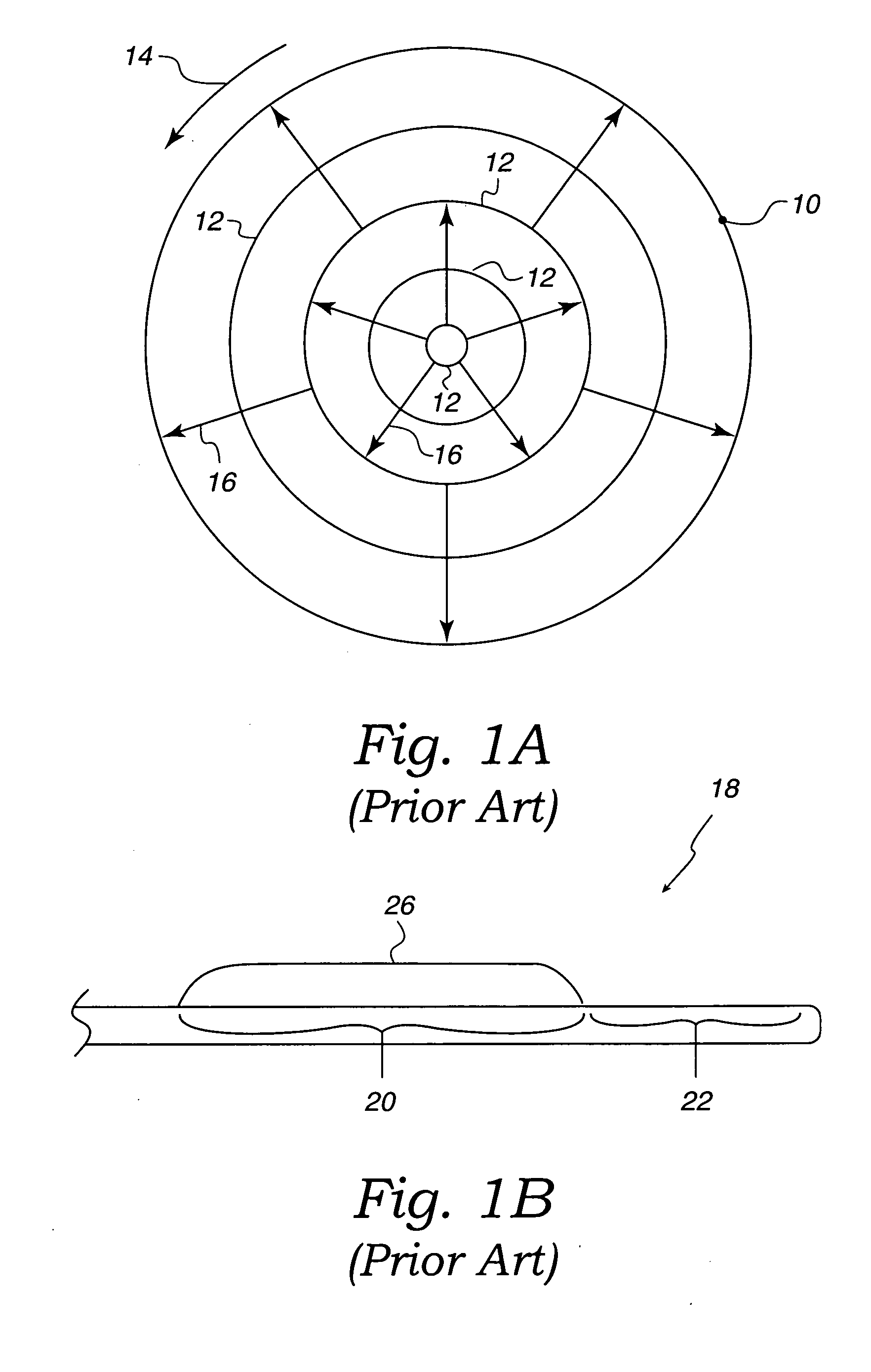

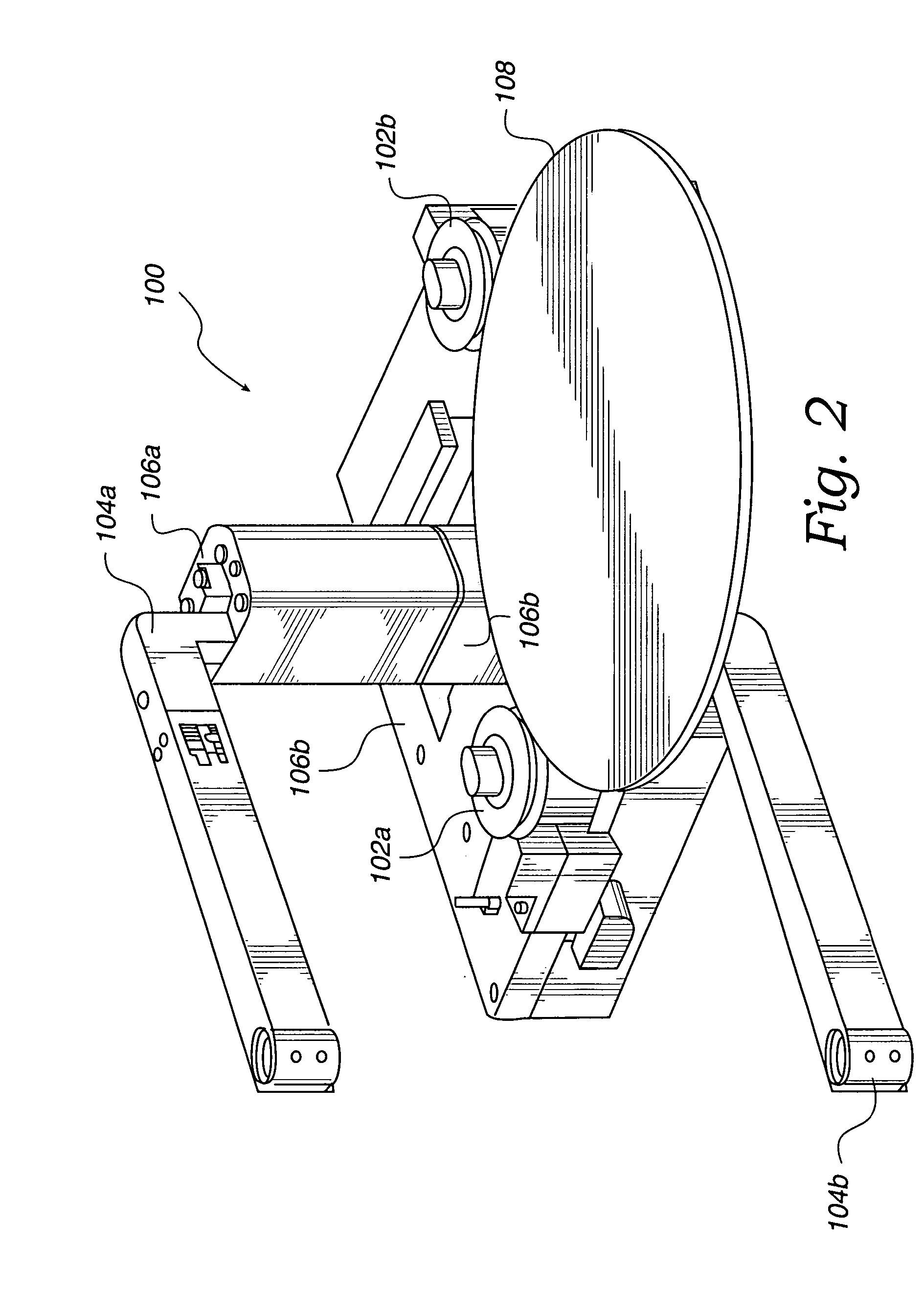

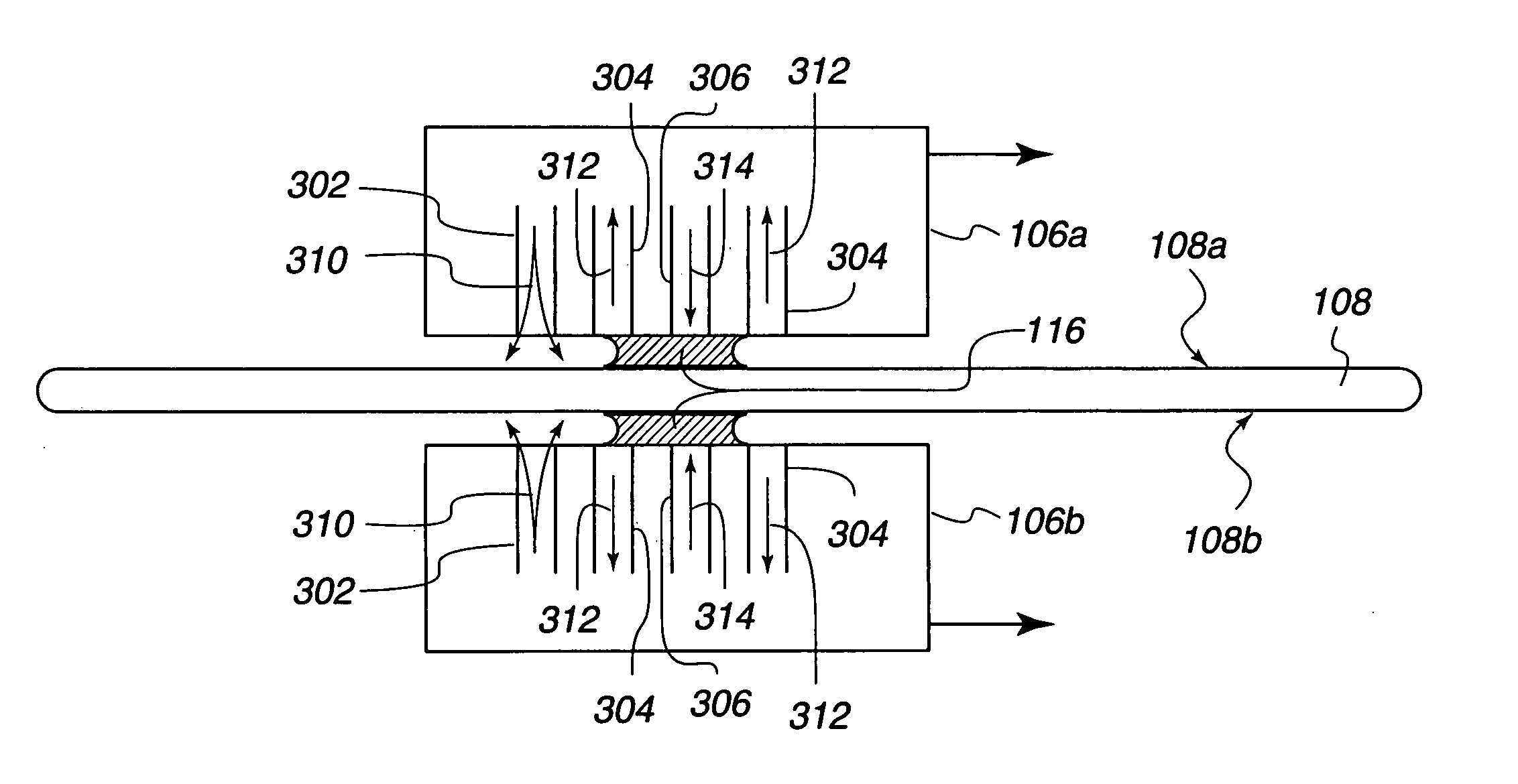

InactiveUS20050217137A1Efficient processingImprove Wafer YieldDrying using combination processesDrying solid materials without heatEngineeringMeniscus

In one of the many embodiments, a method for processing a substrate is disclosed which includes generating a first fluid meniscus and a second fluid meniscus at least partially surrounding the first fluid meniscus wherein the first fluid meniscus and the second fluid meniscus are generated on a surface of the substrate.

Owner:LAM RES CORP

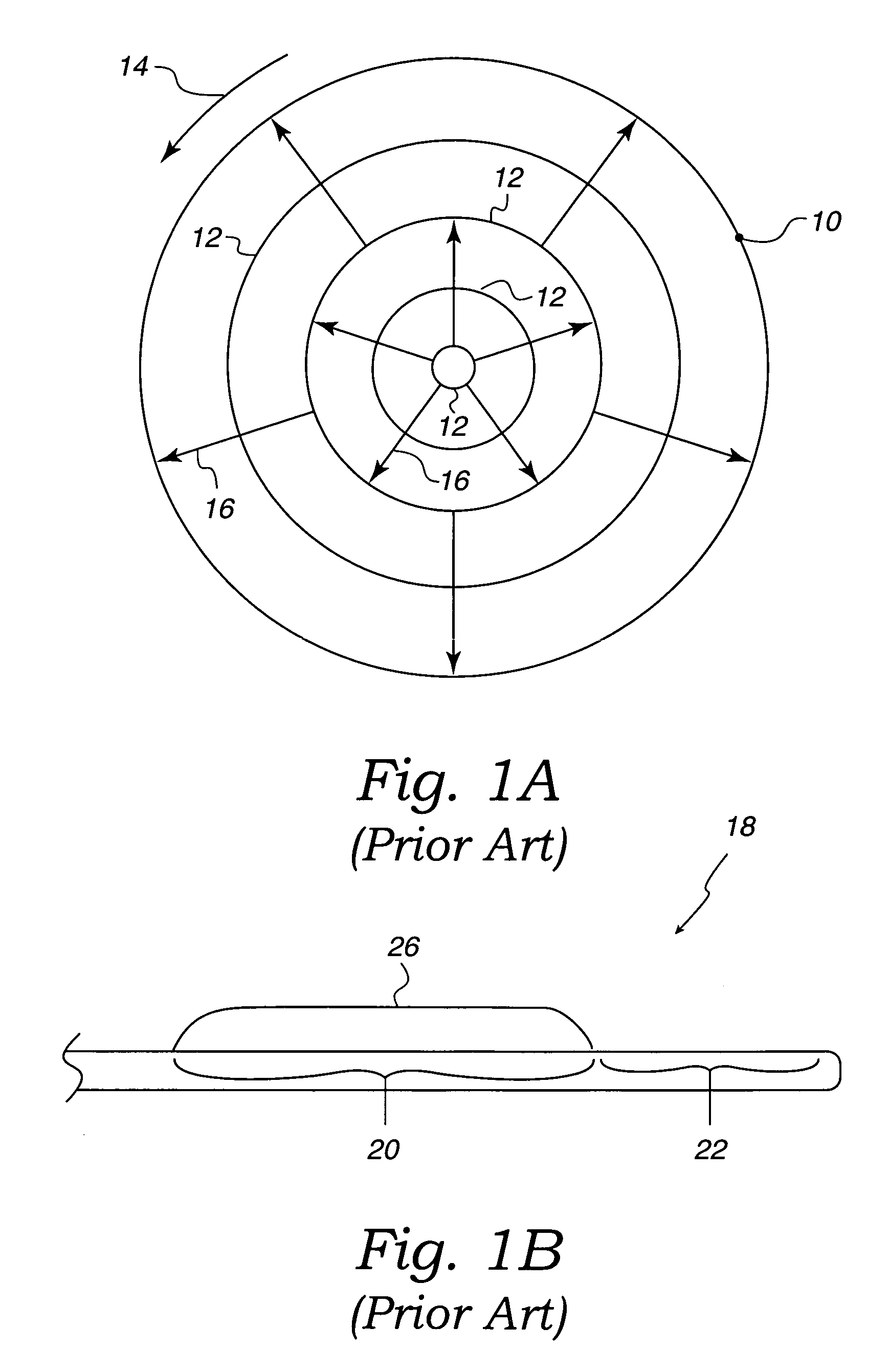

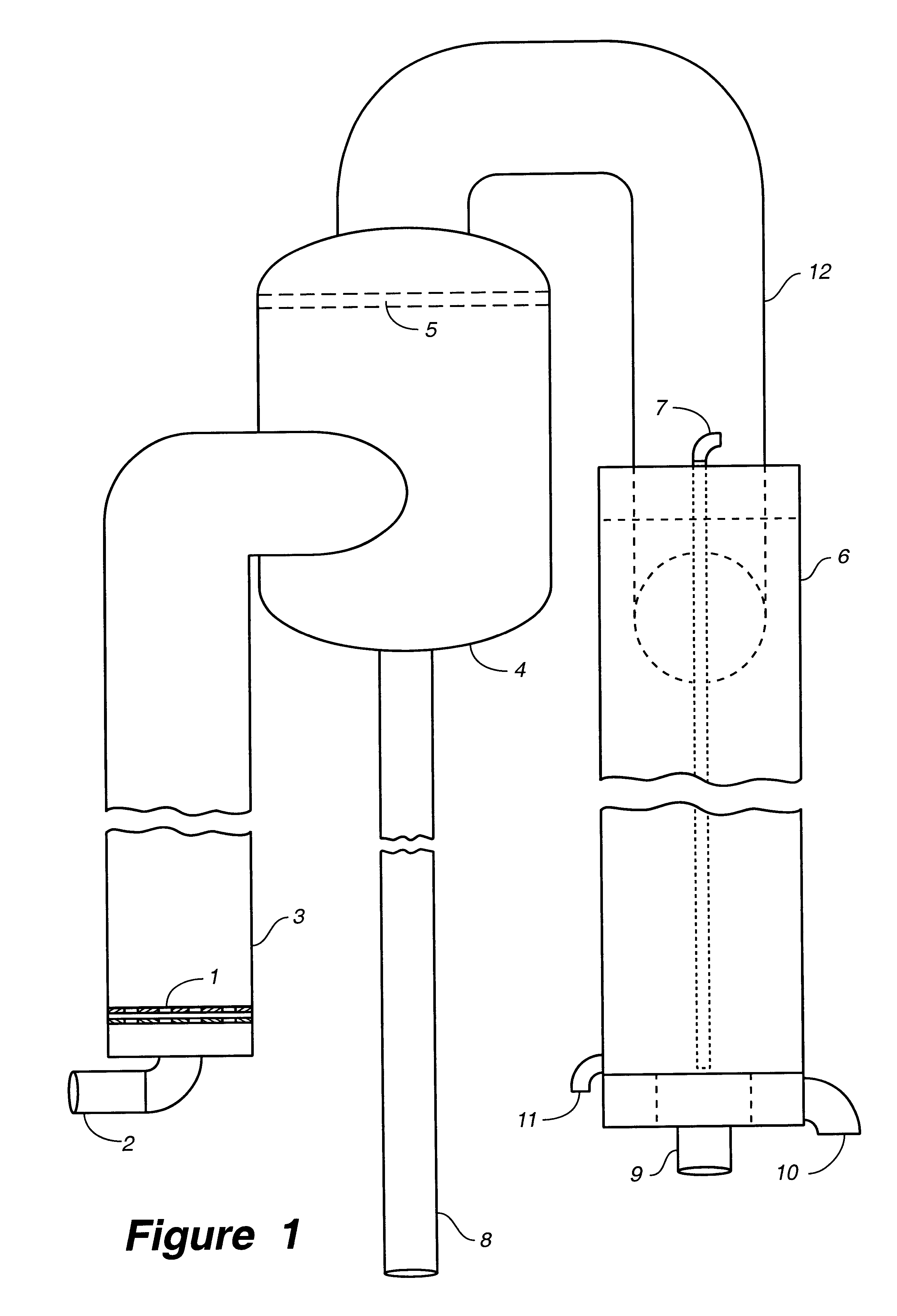

Phobic barrier meniscus separation and containment

InactiveUS20050217135A1Improve Wafer YieldIncrease productionDrying using combination processesDrying solid materials with heatBiomedical engineeringMeniscus

In one of the many embodiments, a method for processing a substrate is provided which includes generating a first fluid meniscus and a second fluid meniscus on a surface of the substrate where the first fluid meniscus being substantially adjacent to the second fluid meniscus. The meniscus also includes substantially separating the first fluid meniscus and the second fluid meniscus with a barrier.

Owner:LAM RES CORP

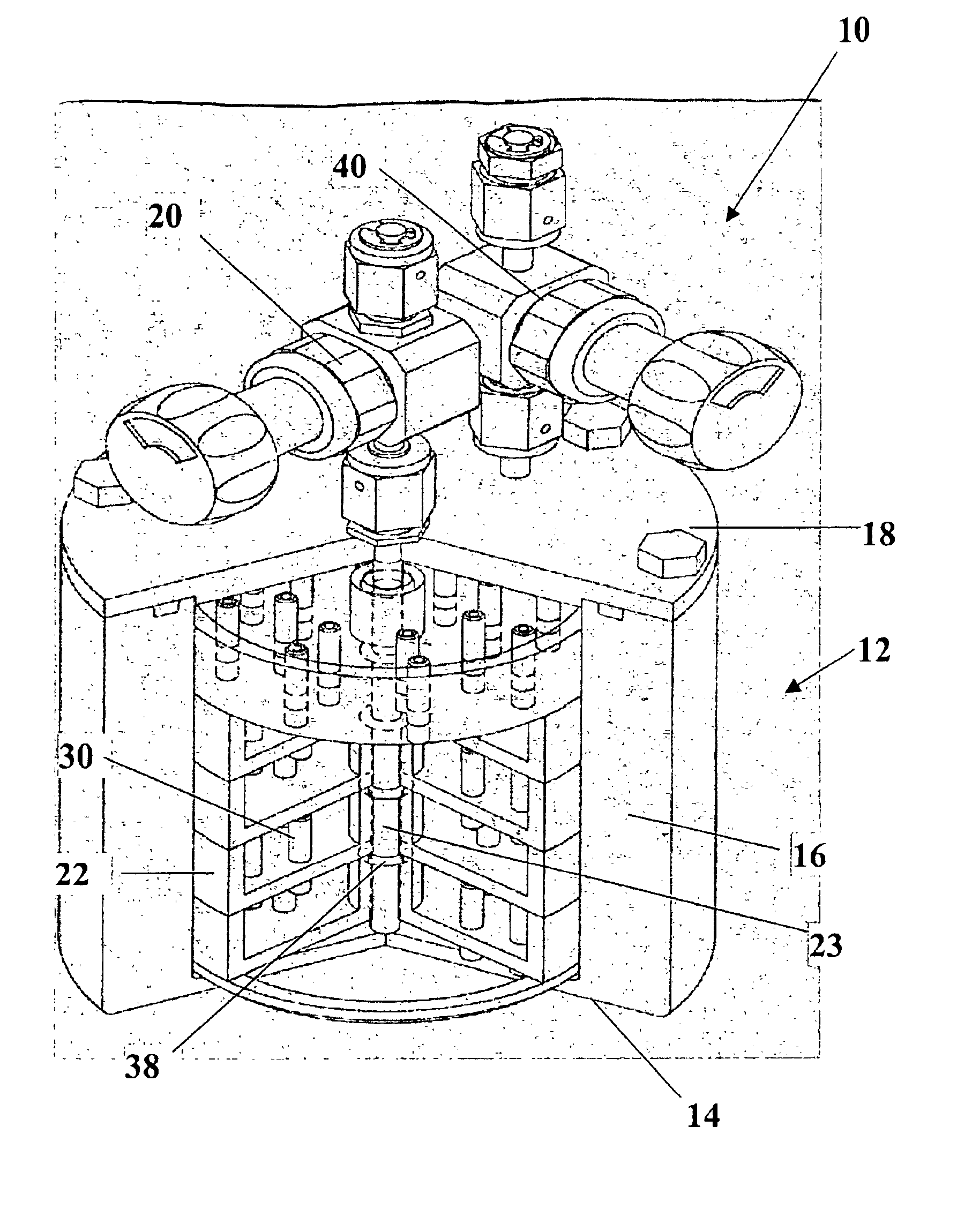

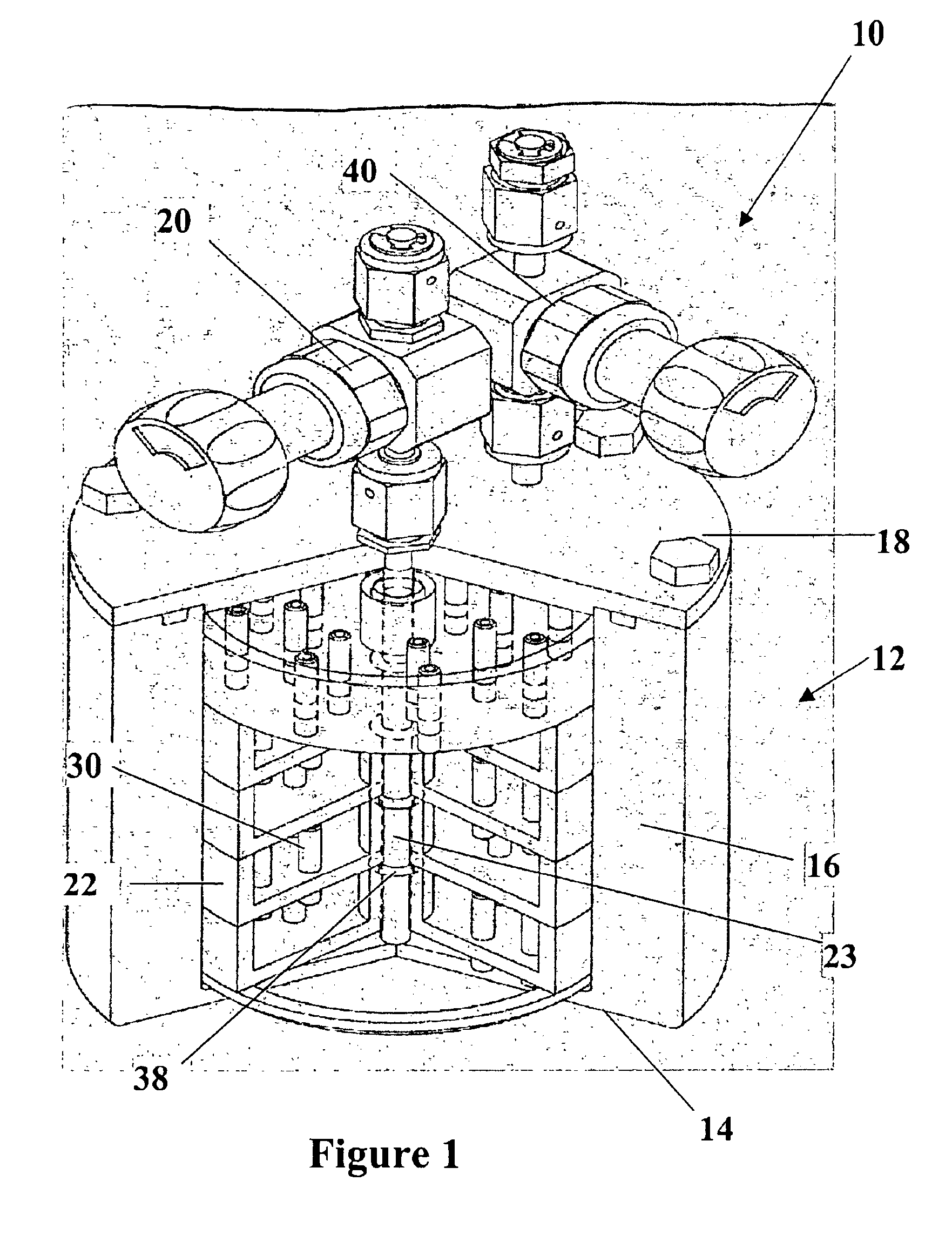

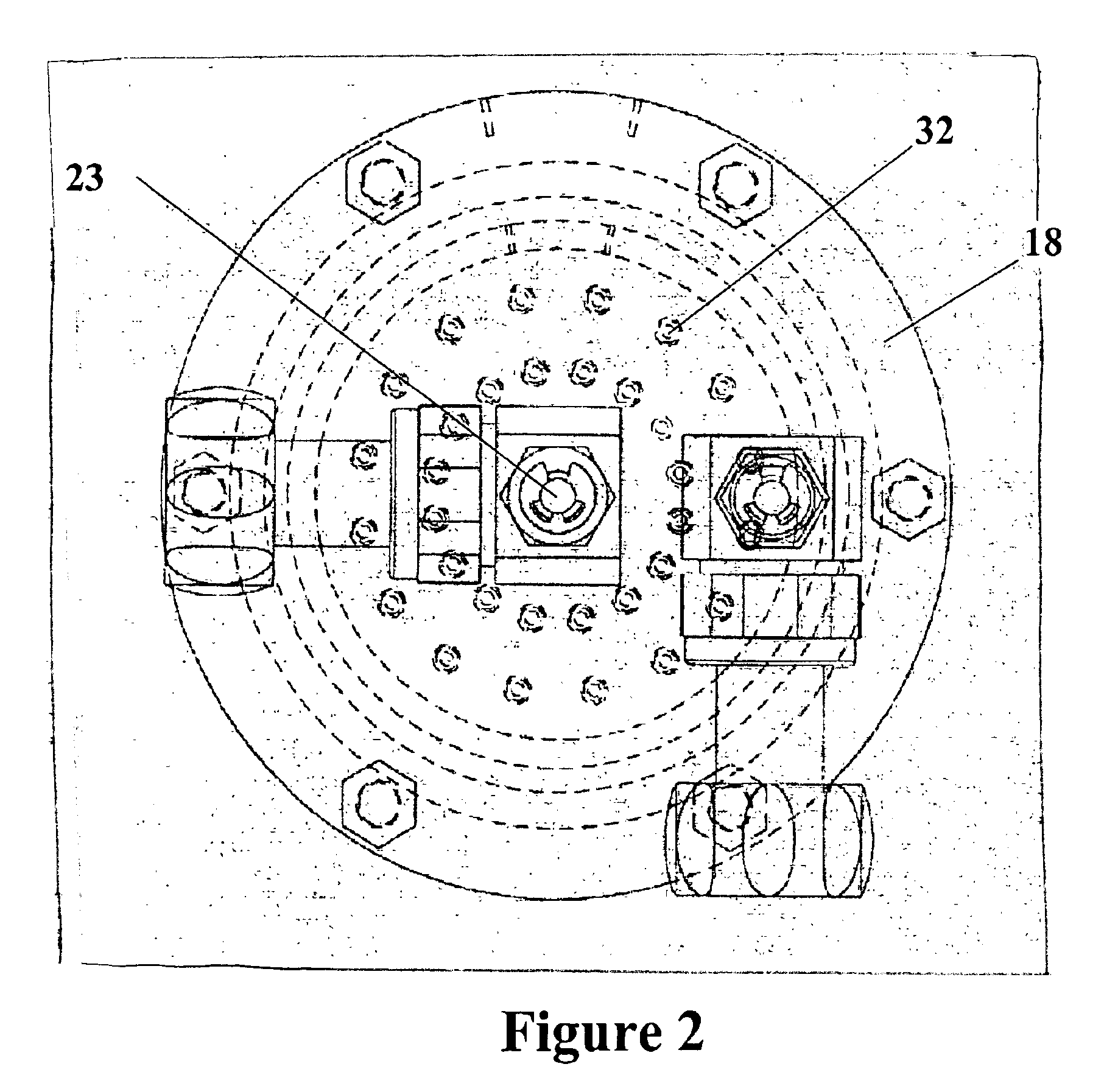

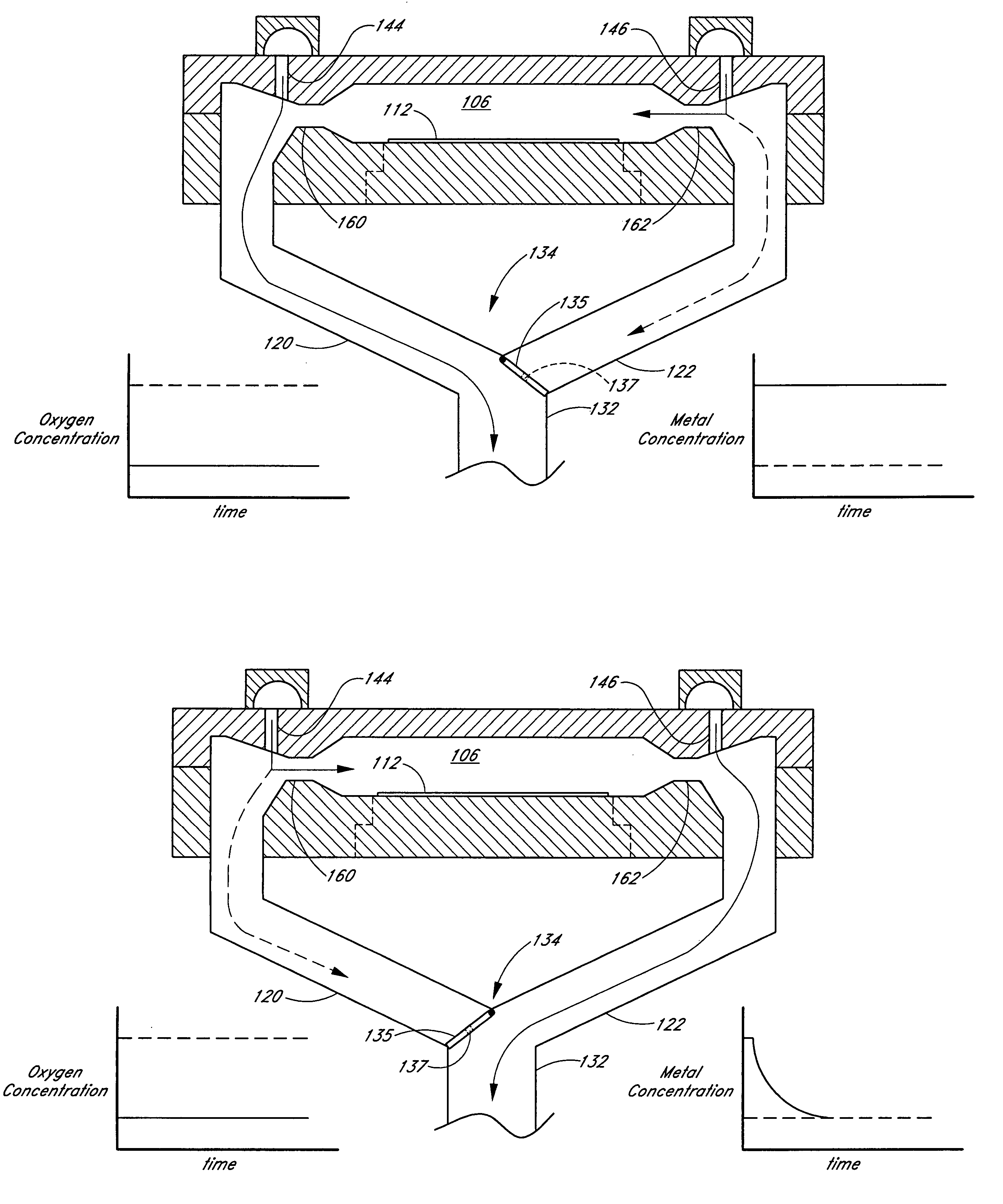

Reaction system for growing a thin film

ActiveUS20050241176A1Extension of timeLong stepDrying using combination processesDrying solid materials with heatControl systemDiffusion barrier

A reactor defines a reaction chamber for processing a substrate. The reactor comprises a first inlet for providing a first reactant and to the reaction chamber and a second inlet for a second reactant to the reaction chamber. A first exhaust outlet removes gases from the reaction chamber. A second exhaust outlet removes gases from the reaction chamber. A flow control system is configured to alternately constrict flow through the first and second exhaust outlets. The reactor chamber is configured to for a diffusion barrier within the reaction chamber.

Owner:ASM IP HLDG BV

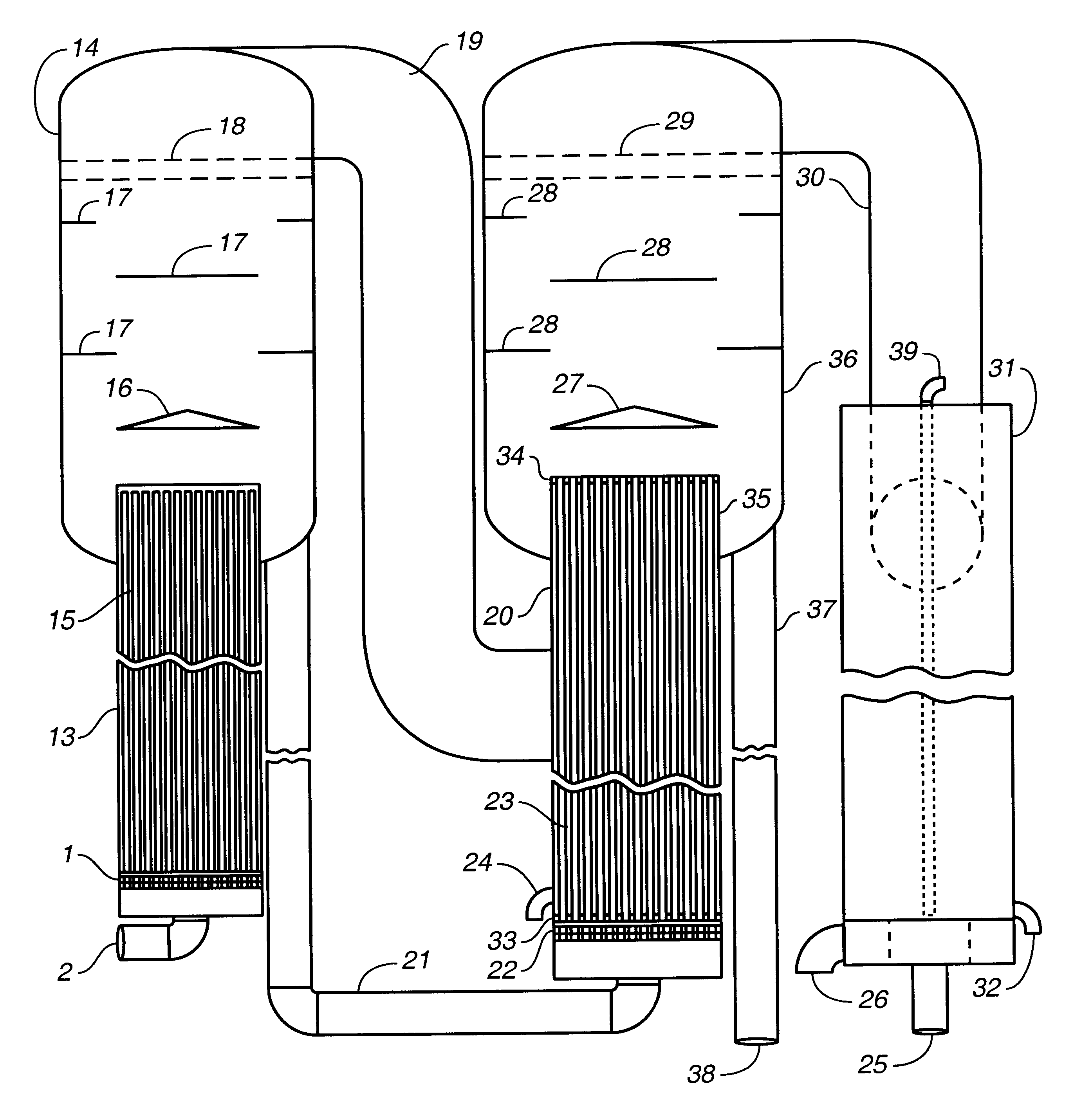

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

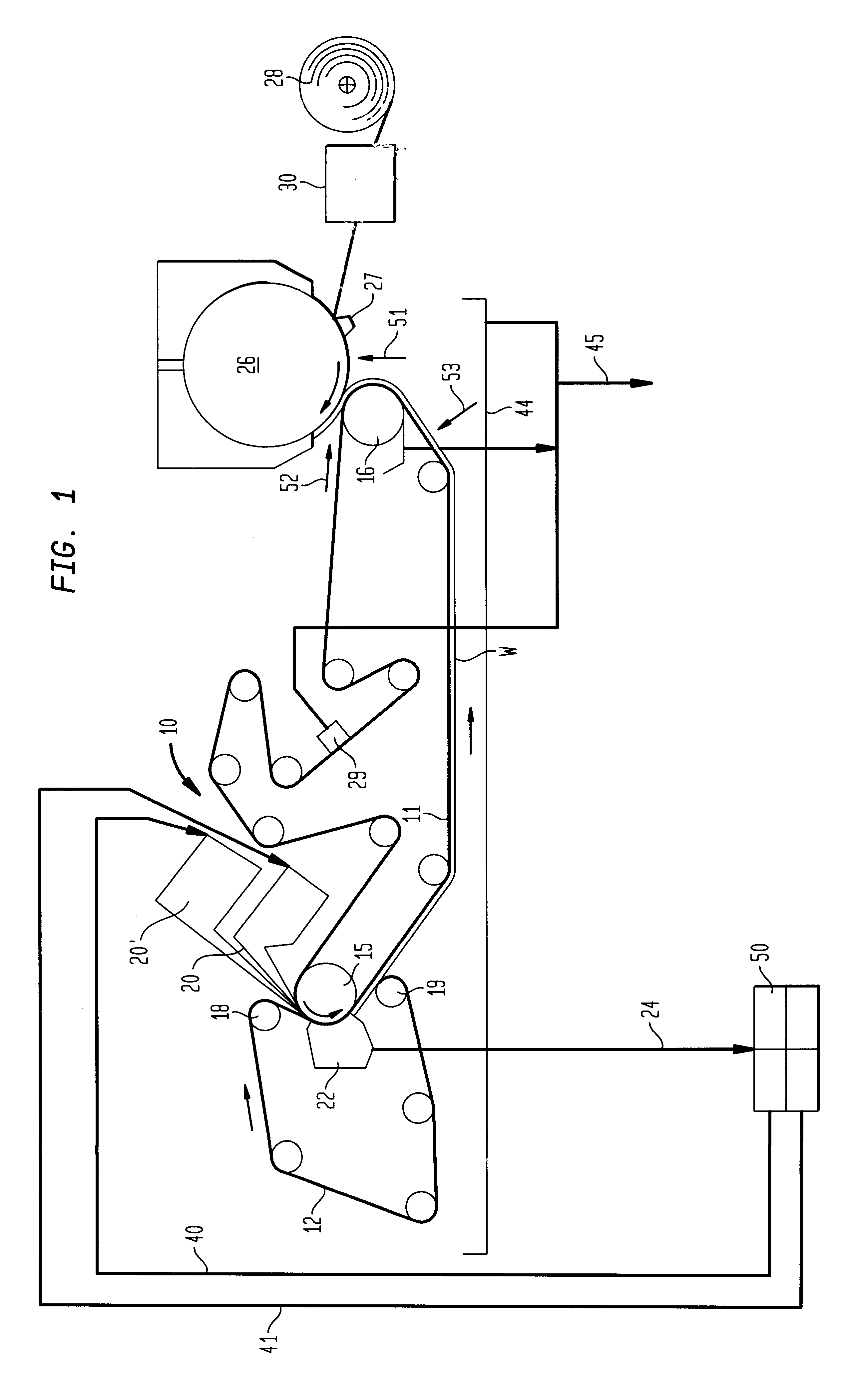

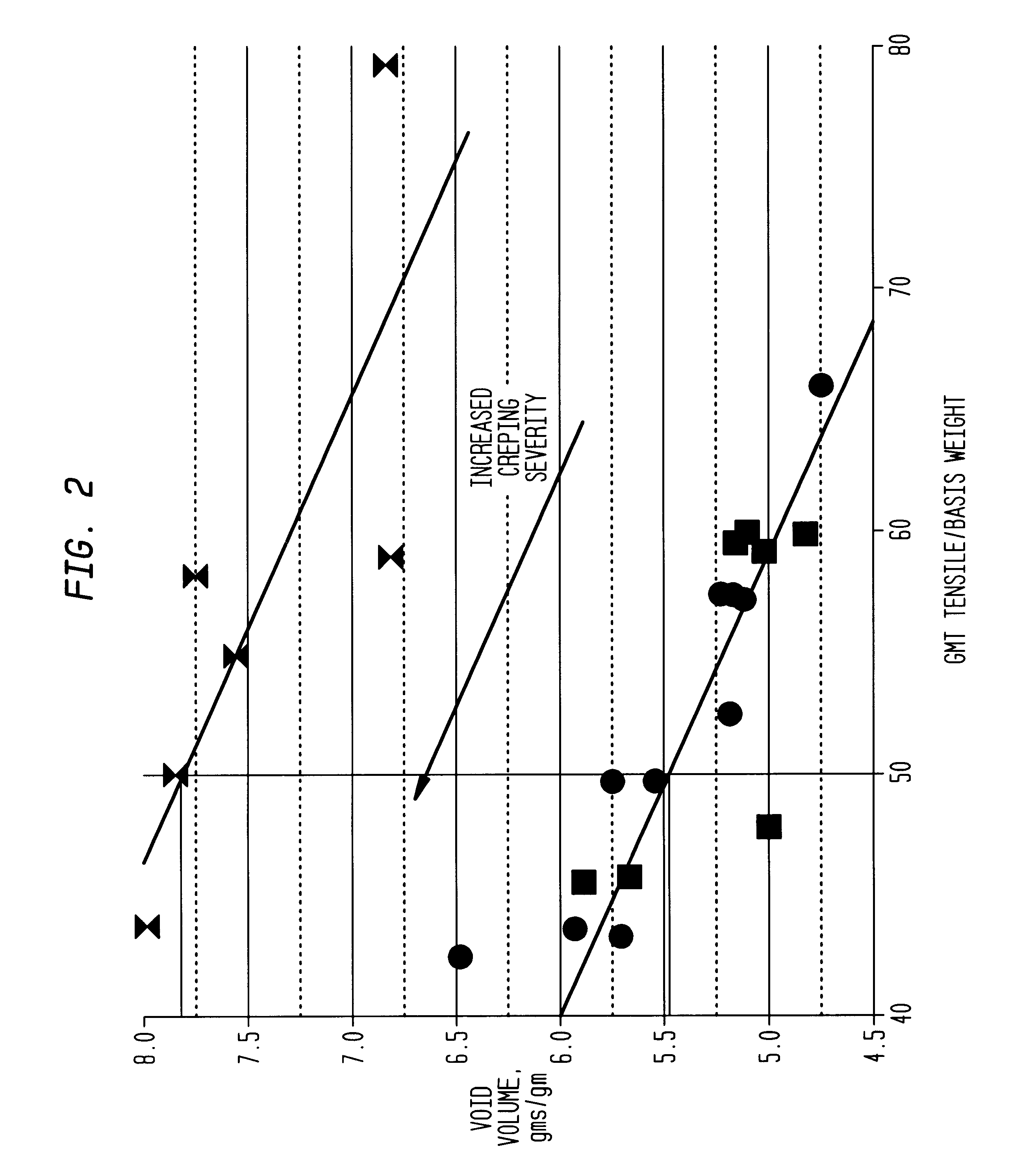

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

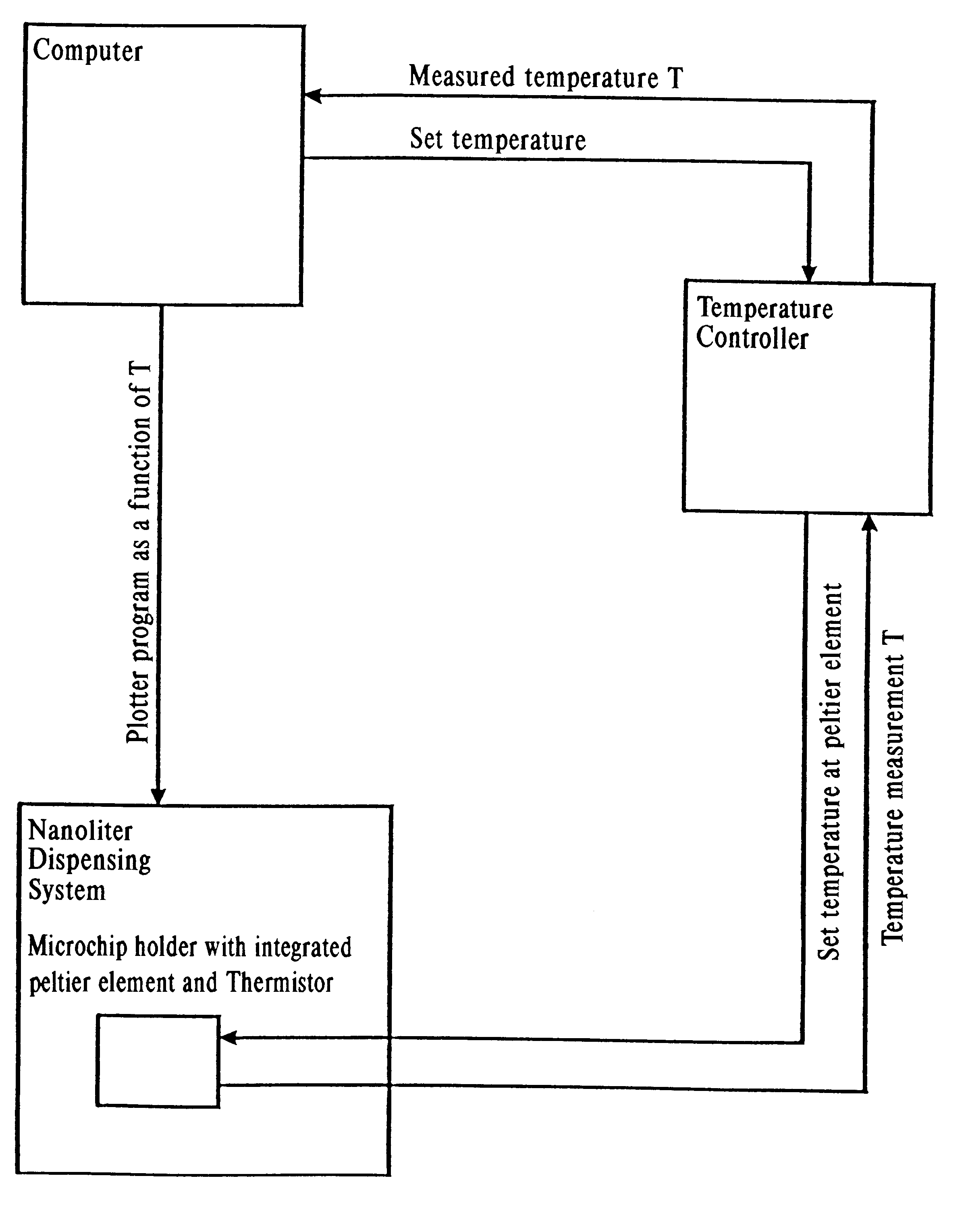

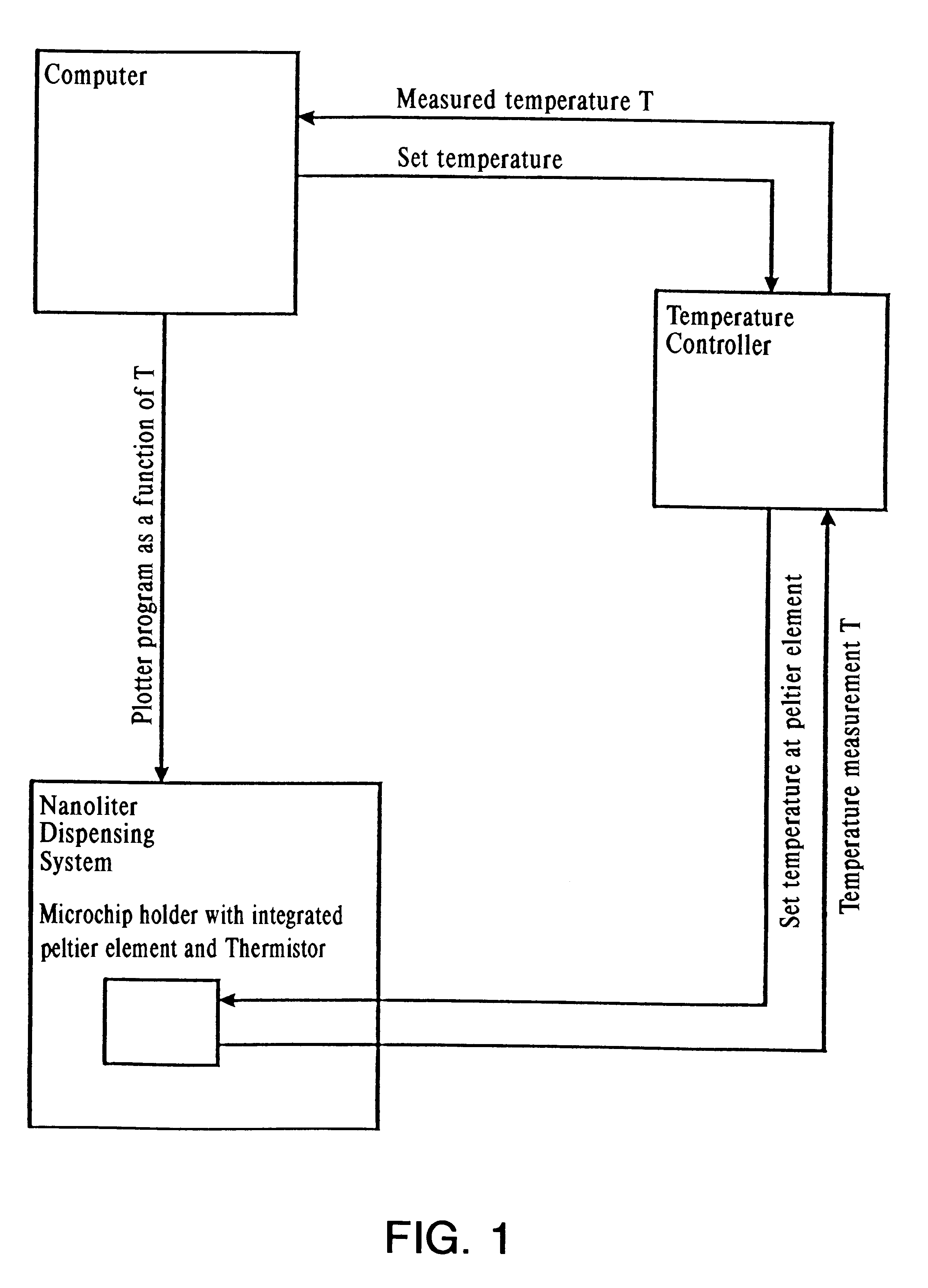

Systems and methods for performing reactions in an unsealed environment

InactiveUS6485913B1Drying using combination processesMicrobiological testing/measurementTemperature controlBiomedical engineering

Open systems for performing submicroliter reactions are provided. The systems can include a support for performing the reaction; a liquid dispensing system for dispensing a submicroliter amount of a liquid to a site on or in the support; a temperature controlling device for regulating the temperature of the support; and an interface for controlling the amount of liquid dispensed from the liquid dispensing system are provided. Methods using the systems are also provided.

Owner:AGENA BIOSCI

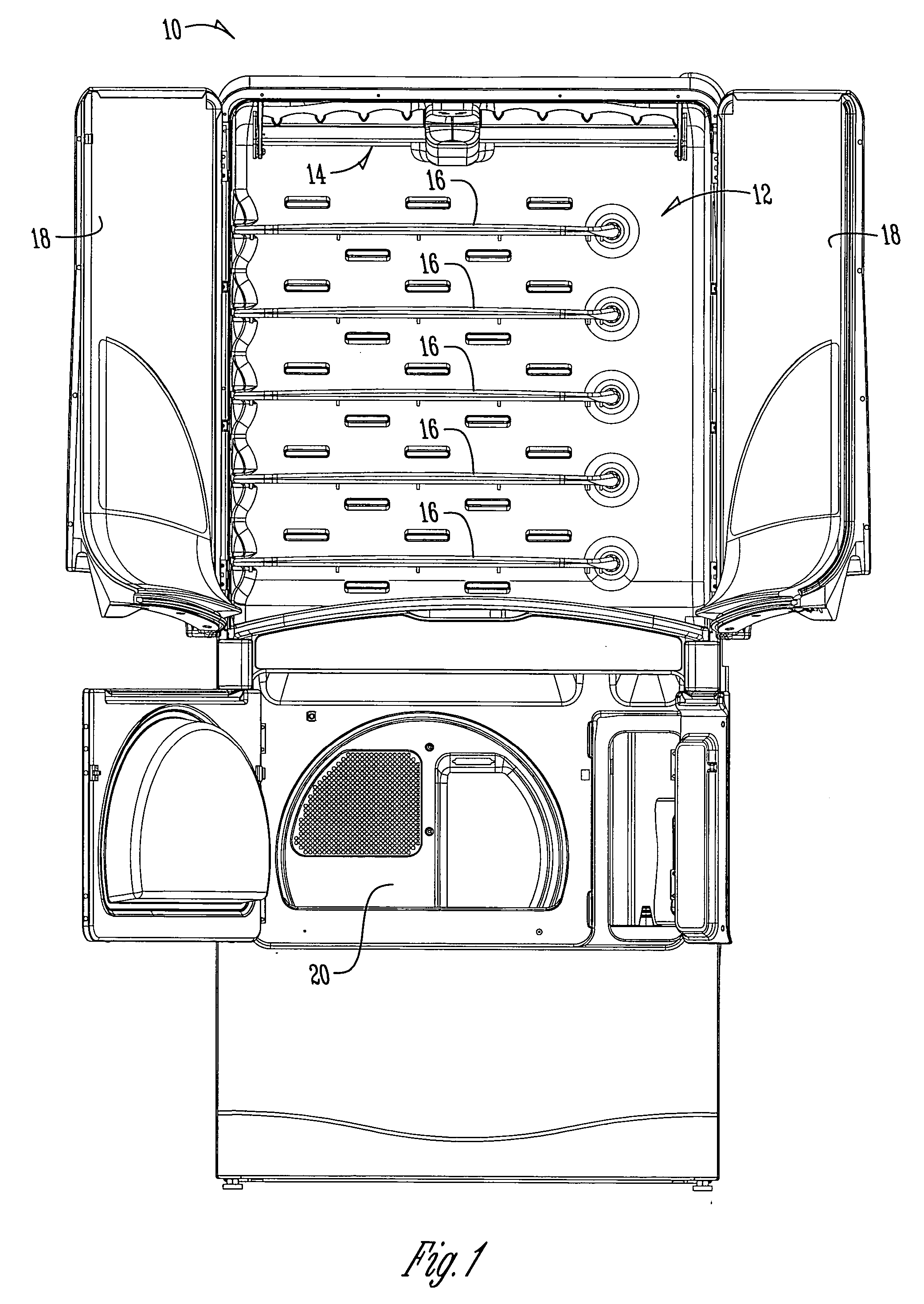

Clothes drying apparatus and method of drying clothes

InactiveUS6868621B1Not to damageEfficient systemDrying using combination processesDrying solid materials with heatEngineeringMechanical engineering

A clothes drying apparatus is provided. This clothes drying apparatus comprises a cabinet with an interior region to receive clothes. At least one door is operably connected to the cabinet to allow access to the interior region thereof. Attached to the cabinet is a first intake passage for accessing and receiving air from the exterior environment of a building. A vacuum unit is also attached to the cabinet. This vacuum unit draws air from the exterior of the building, through the passage, and into the interior region of the cabinet. A second passage linked to the interior environment and a switching mechanism may also be provided to permit selective operation of the clothes drying apparatus to draw air from outdoors or indoors based on environmental conditions. Also provided is a method of drying clothes with the clothes drying apparatus.

Owner:GRIMM BROS PLASTIC

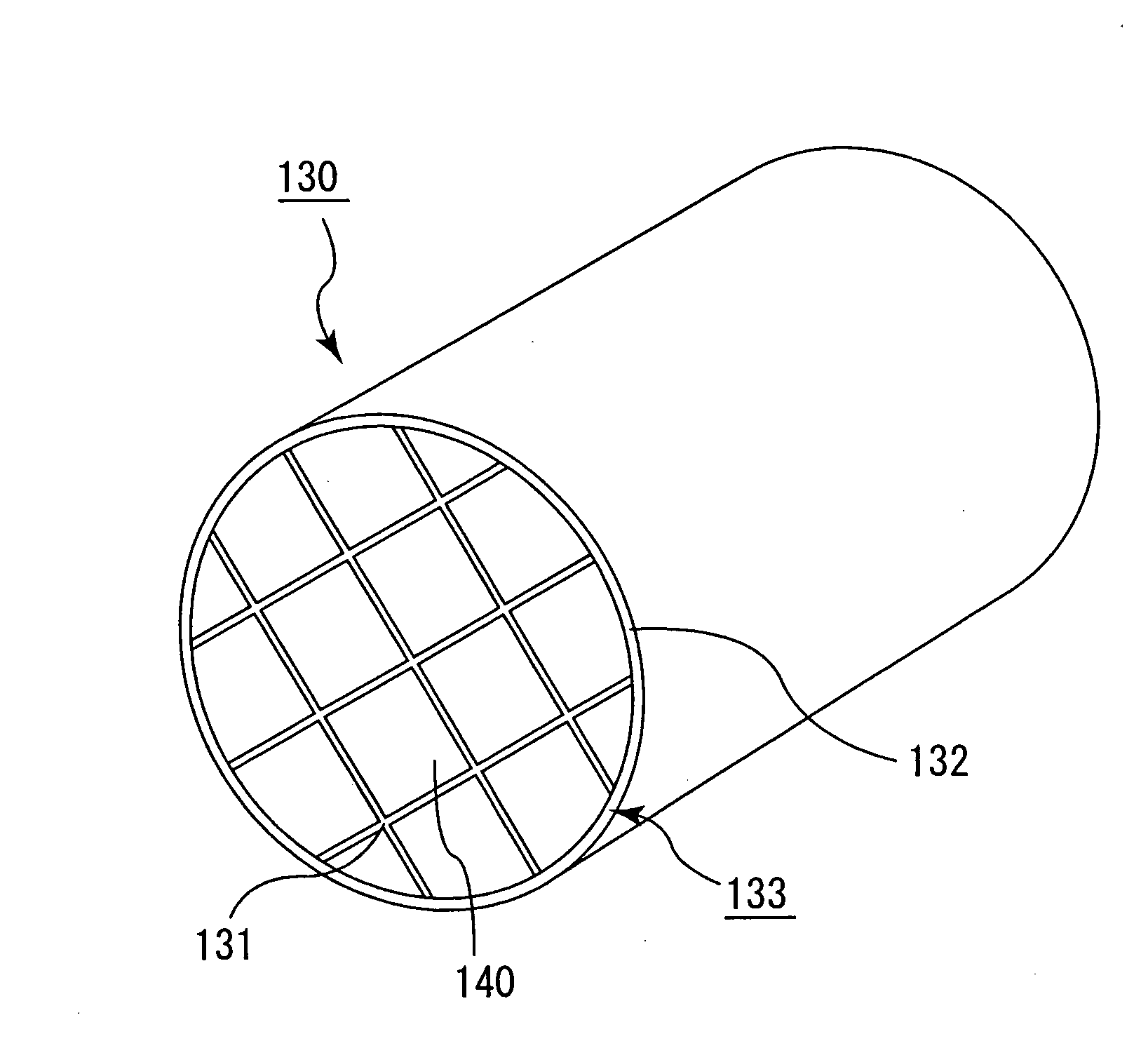

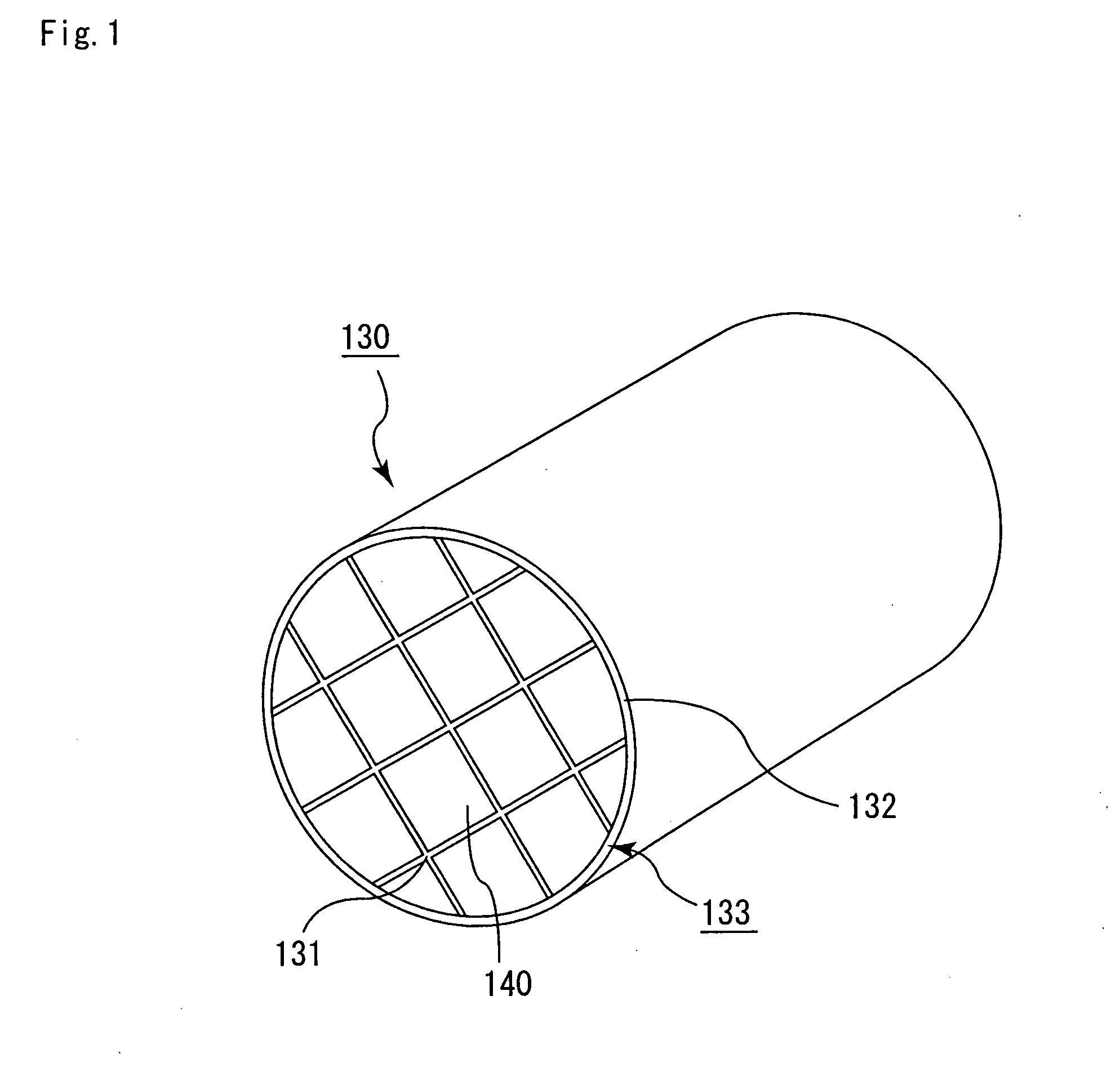

End-face heating apparatus, end-face drying method for honeycomb aggregated body, and method for manufacturing honeycomb structured body

InactiveUS20070199205A1Drying using combination processesDrying solid materials with heatHoneycomb structureMaterials science

An end-face heating apparatus of the present invention comprises: a heating tool that is placed almost in parallel with an end face of a honeycomb aggregated body in which a plurality of pillar-shaped honeycomb fired bodies are integrated with one another by interposing a sealing material paste layer formed on the side face of the honeycomb fired body; a heating tool translation device for translating said heating tool toward said honeycomb aggregated body; and a holding jig that holds said honeycomb aggregated body.

Owner:IBIDEN CO LTD

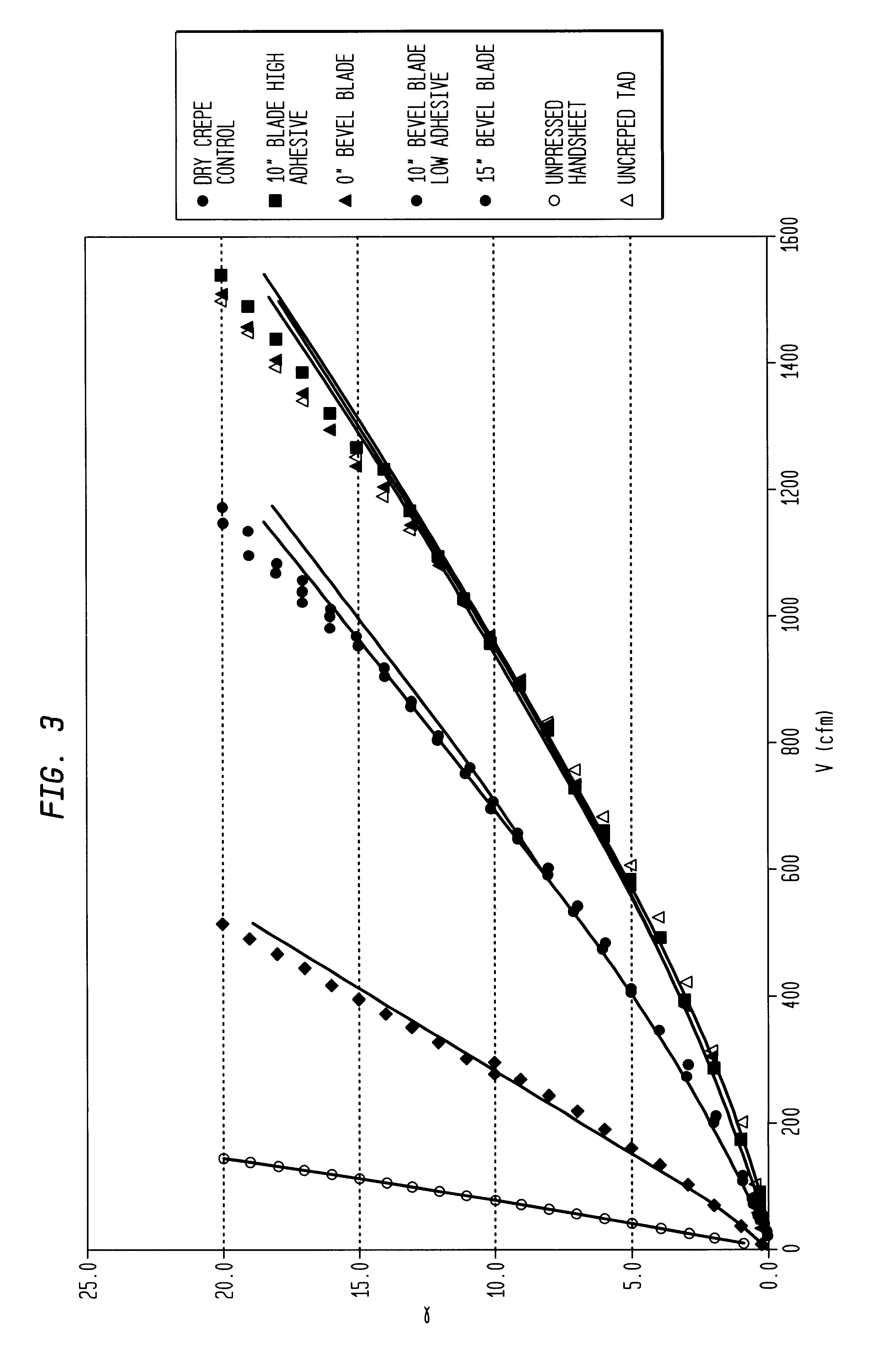

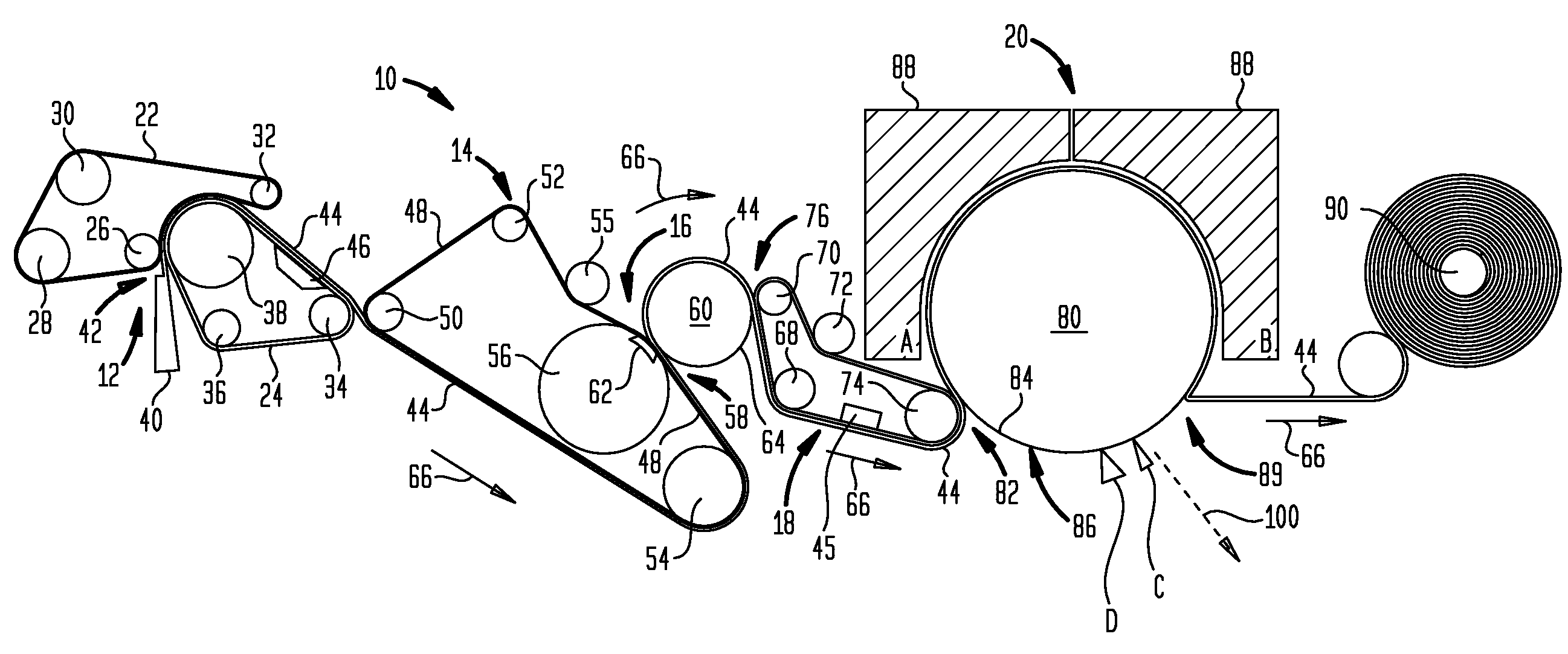

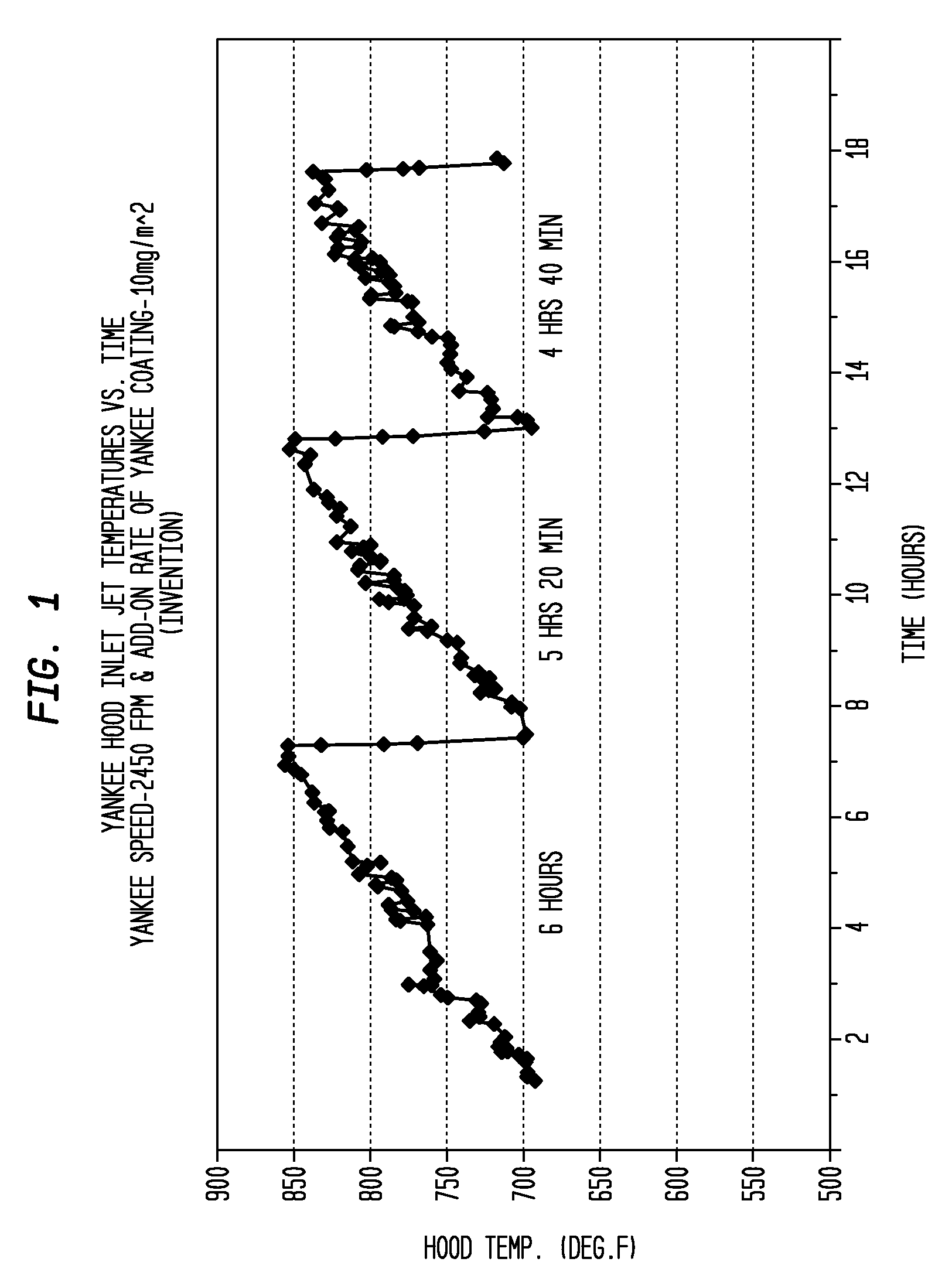

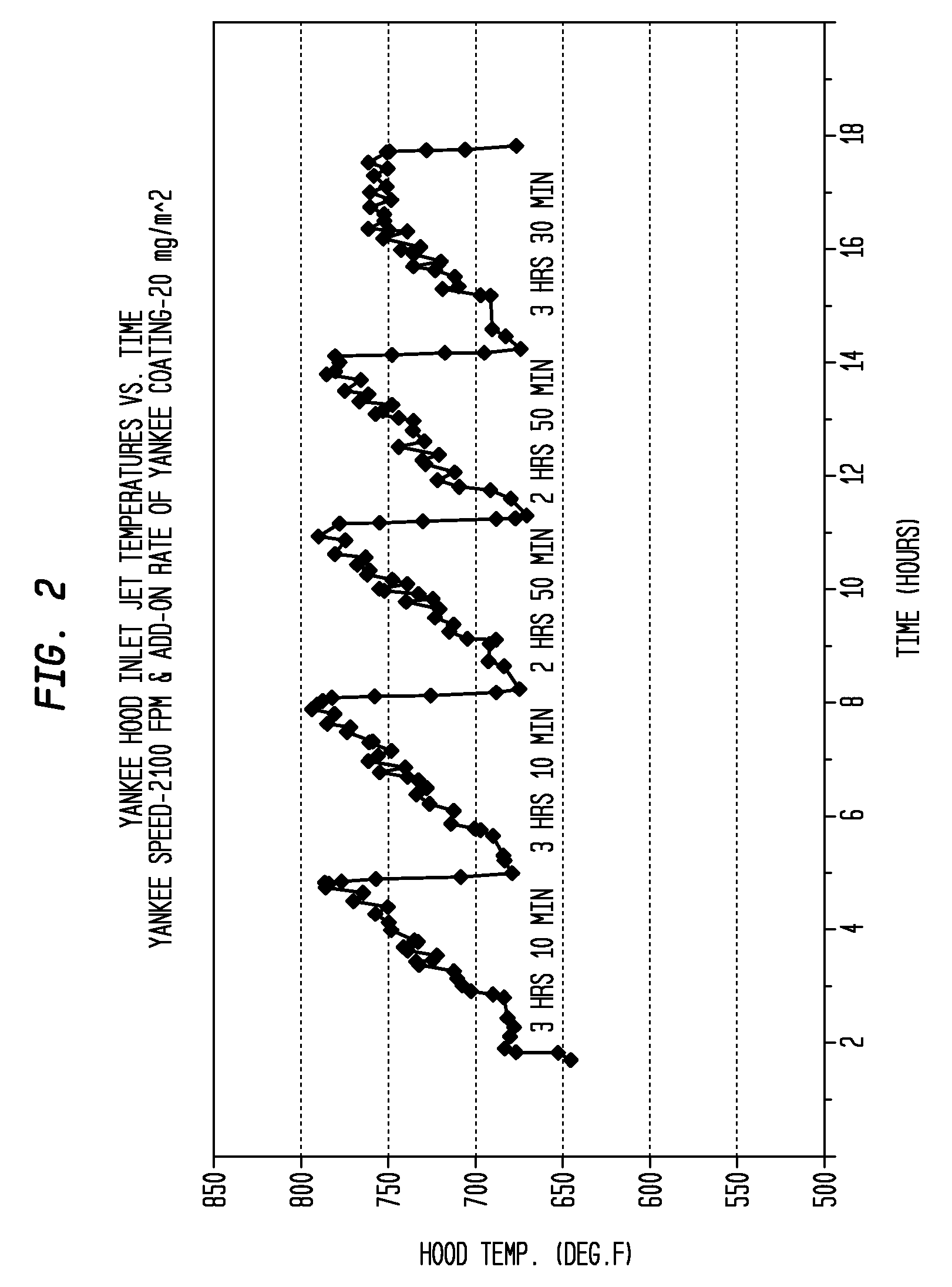

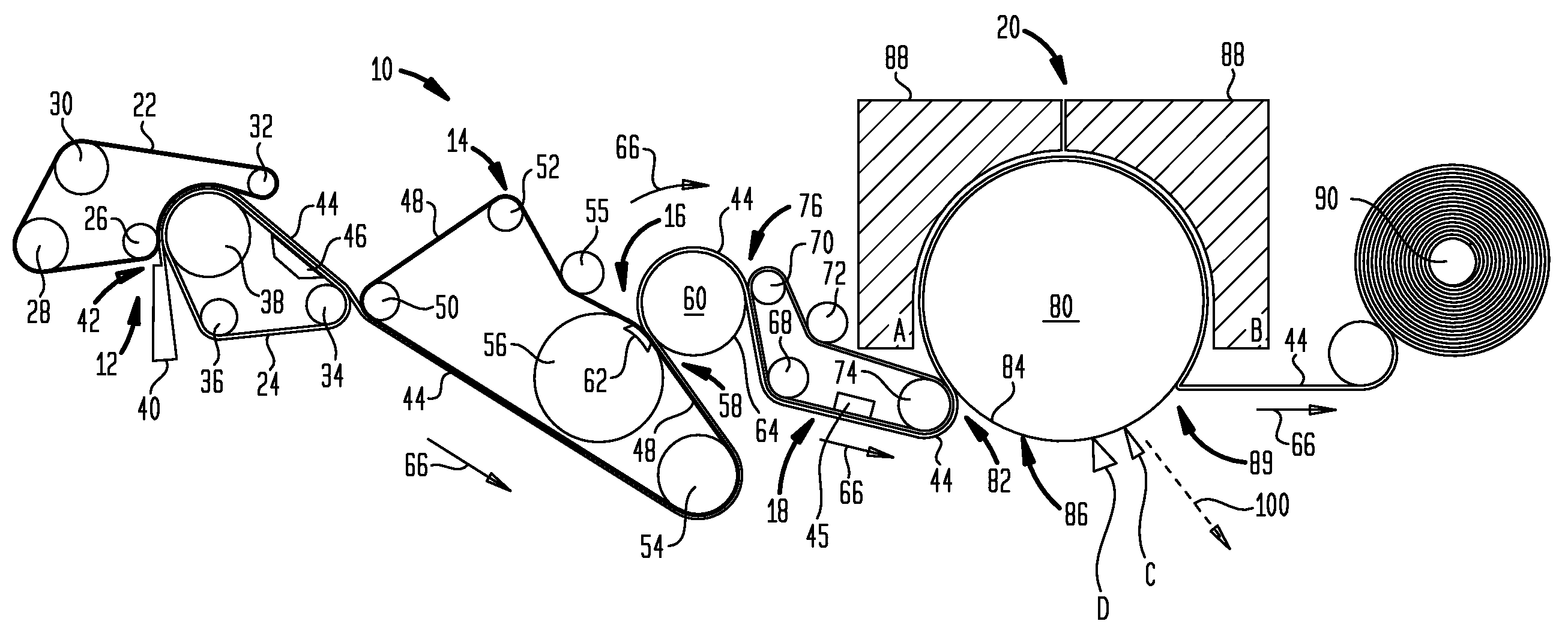

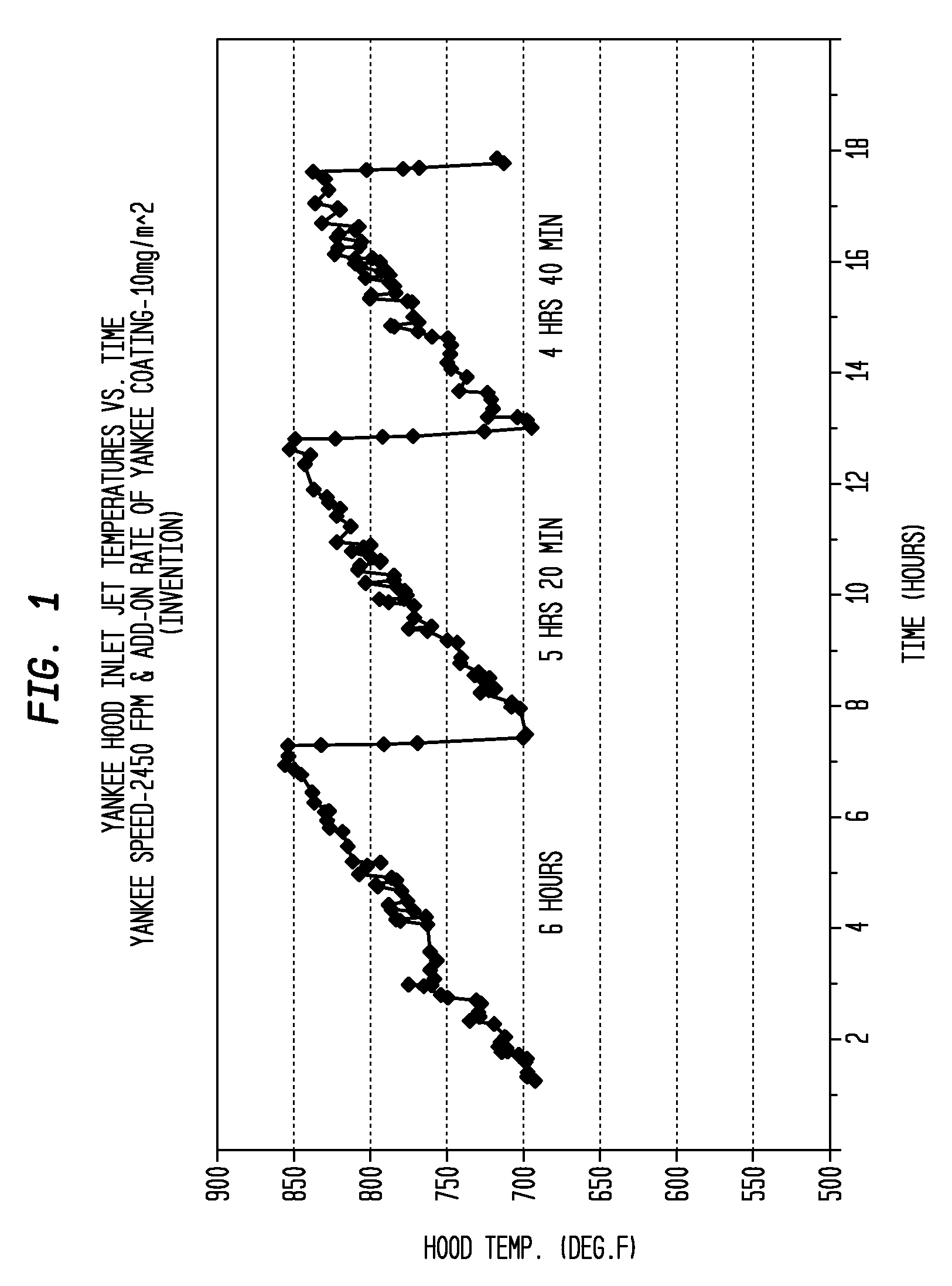

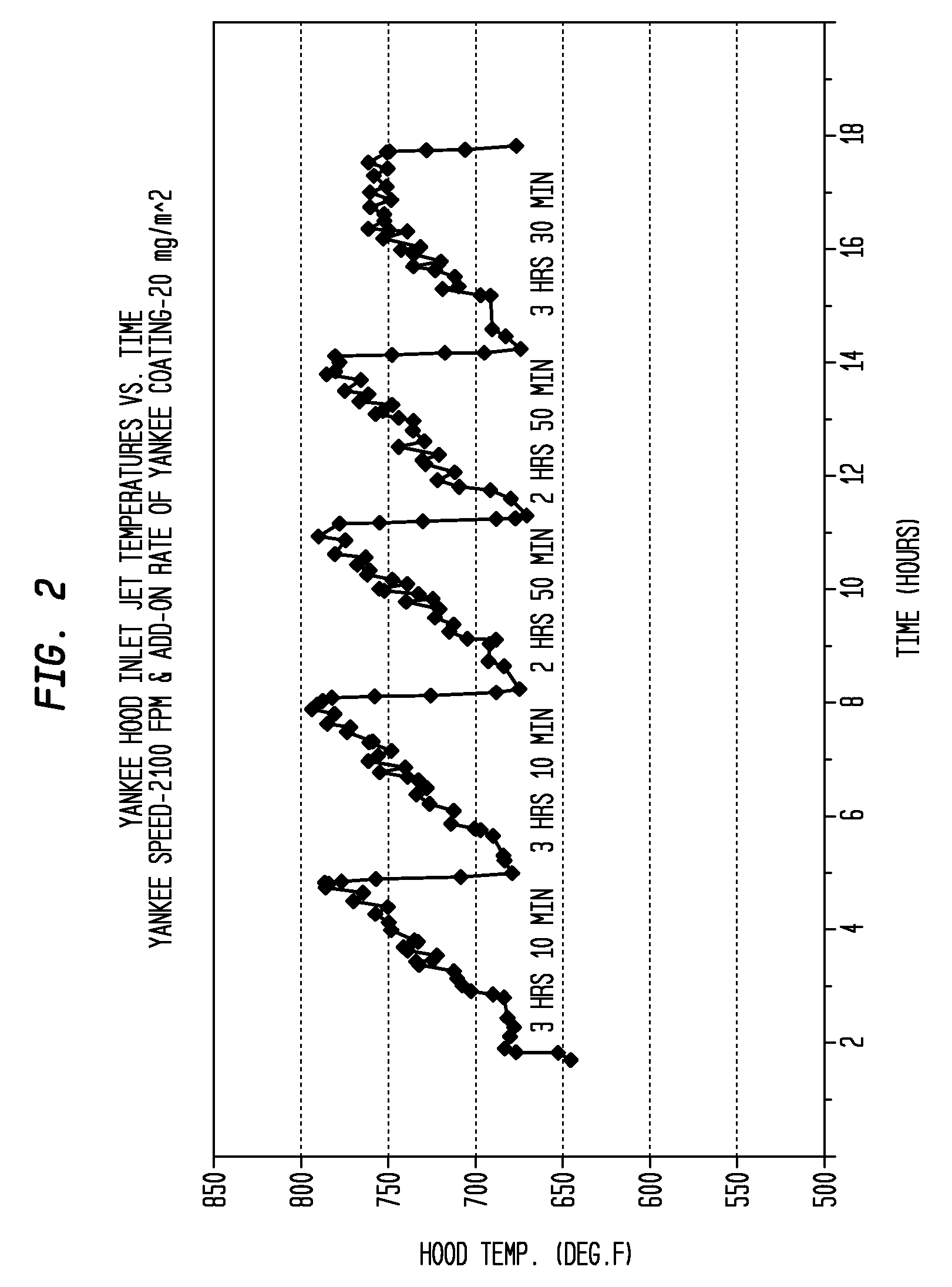

Fabric-crepe process with prolonged production cycle and improved drying

ActiveUS7608164B2Increases the amount of production available from a paper machineKeep dryNon-fibrous pulp additionDrying using combination processesAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

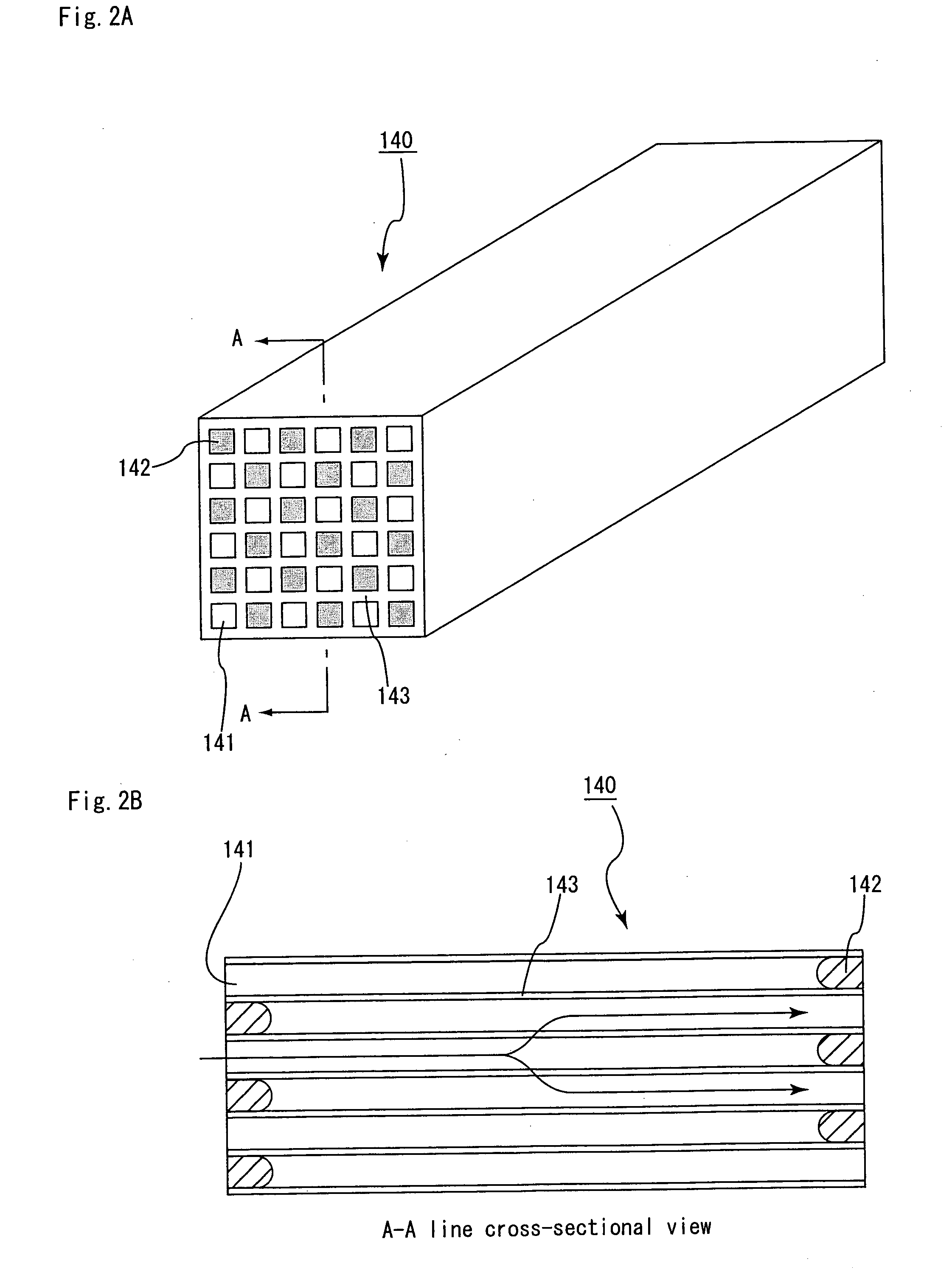

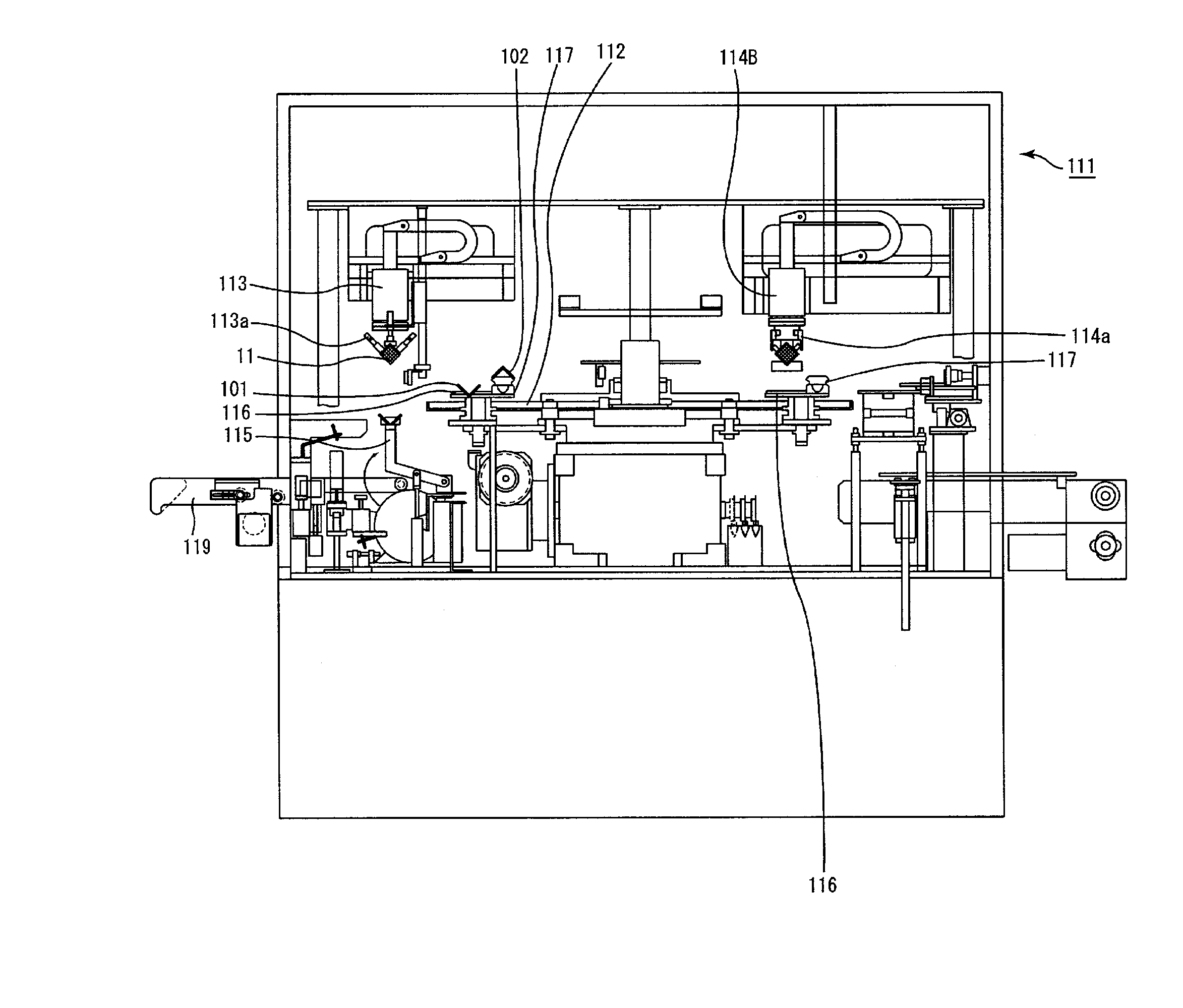

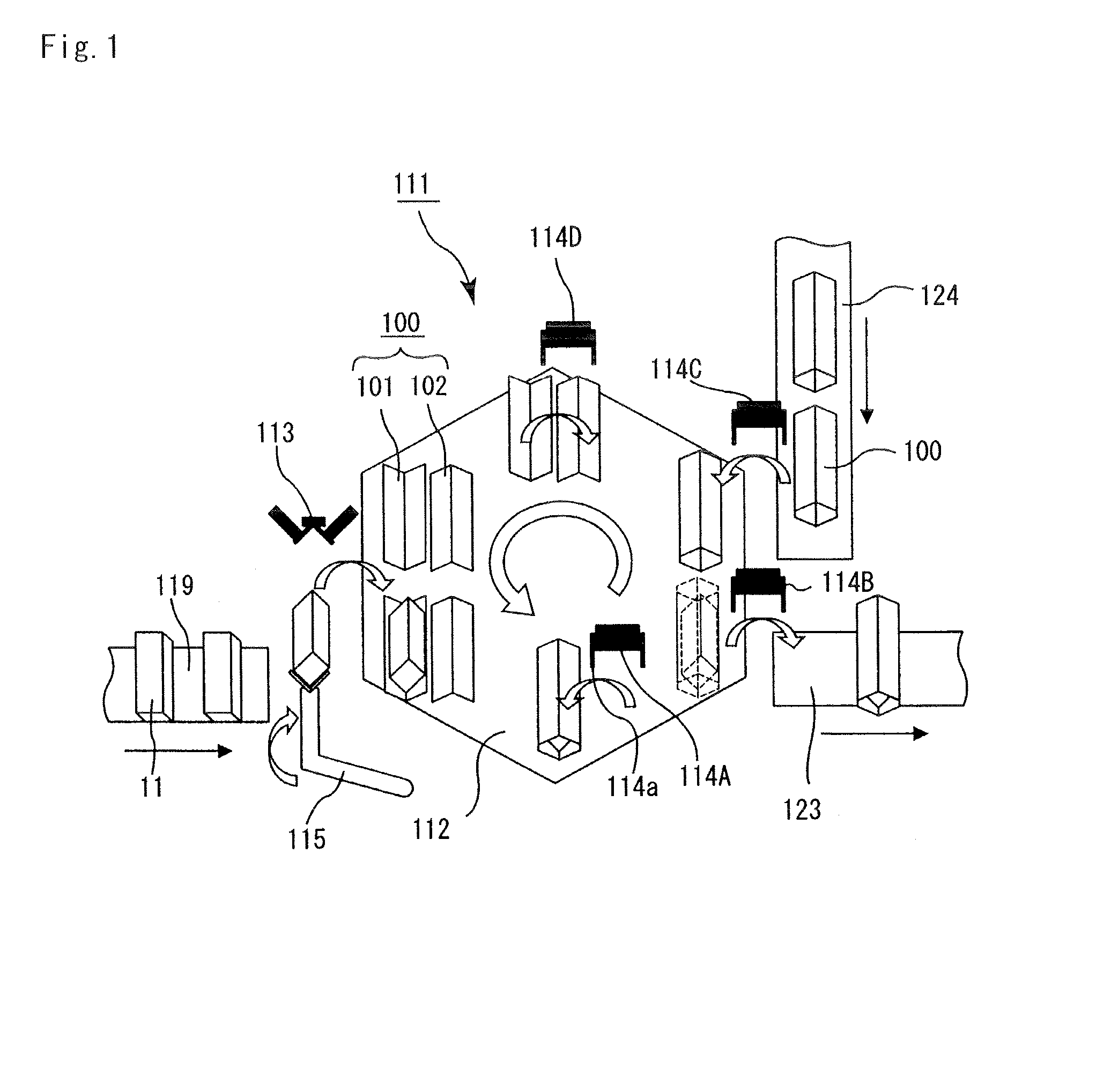

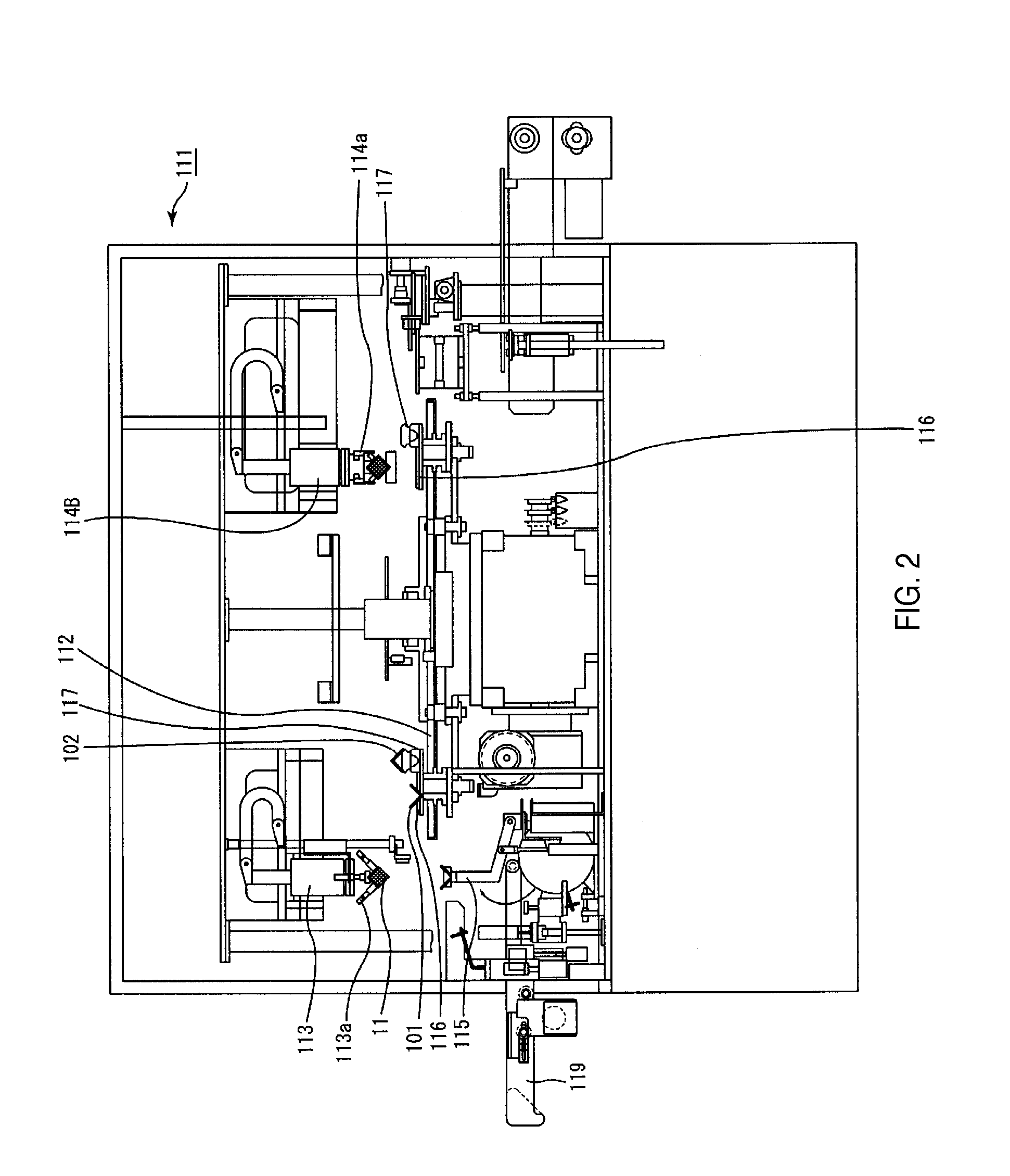

Drying jig assembling apparatus, drying jig disassembling apparatus, drying jig circulating apparatus, drying method of ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080106008A1Drying using combination processesAuxillary shaping apparatusHoneycomb structureClosed state

A drying jig circulating apparatus includes a drying jig assembling apparatus for assembling a drying jig on a movable table, a drying apparatus for drying a ceramic molded body held by the drying jig, and a drying jig disassembling apparatus for disassembling the drying jig on a movable table, and a drying jig circulating conveyor for transporting the drying jig from the disassembling apparatus to the assembling apparatus. The drying jig is configured by two or more separate jigs with a fixing member that integrates the separate jigs, or formed by one openable jig with a fixing member for maintaining a closed state. The drying jig assembling apparatus further includes a molded body mounting mechanism, a ceramic molded body holding mechanism, and a jig delivering mechanism. The drying jig disassembling apparatus further includes a jig receiving mechanism, a jig releasing mechanism, and a molded body taking-out mechanism.

Owner:IBIDEN CO LTD

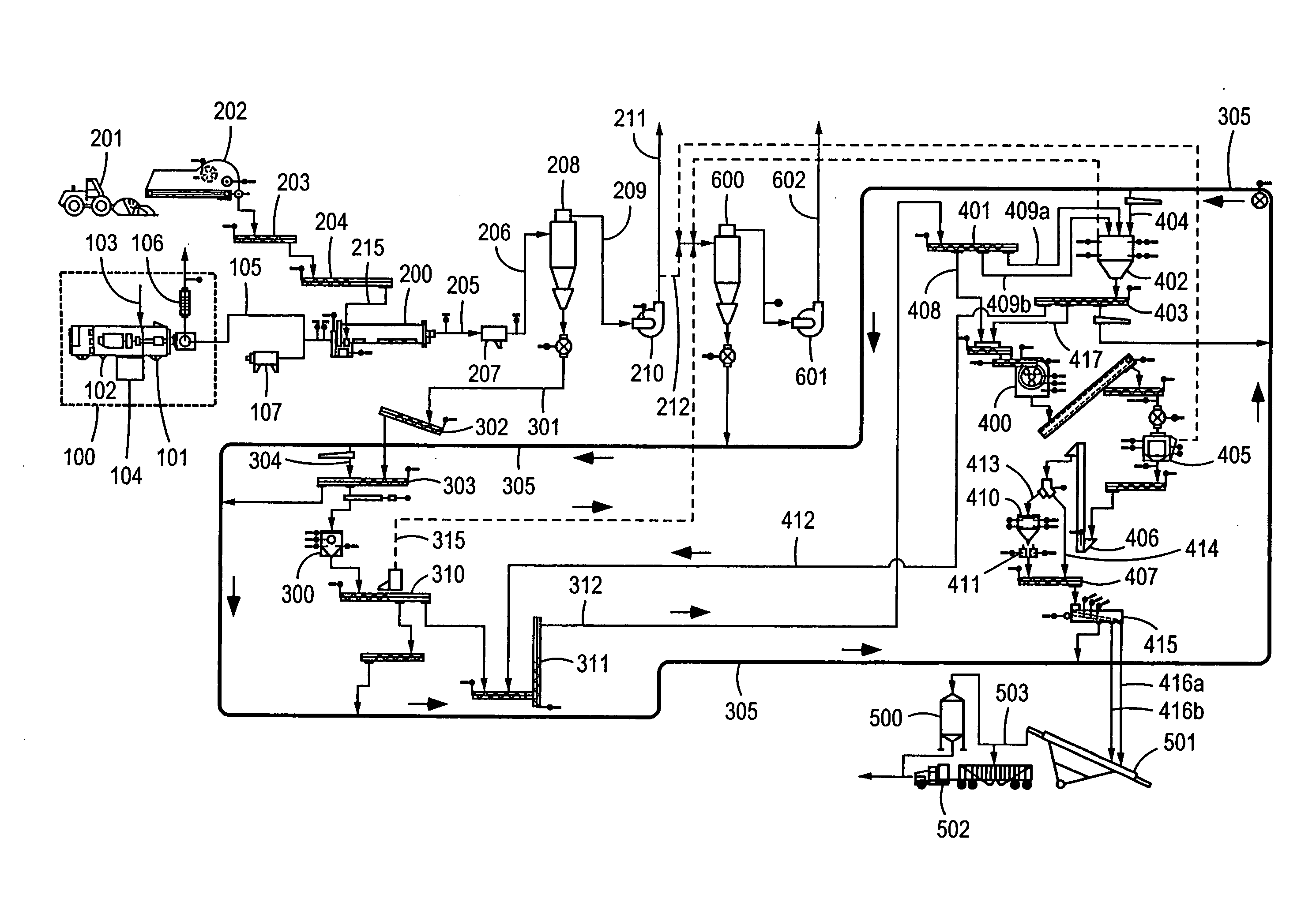

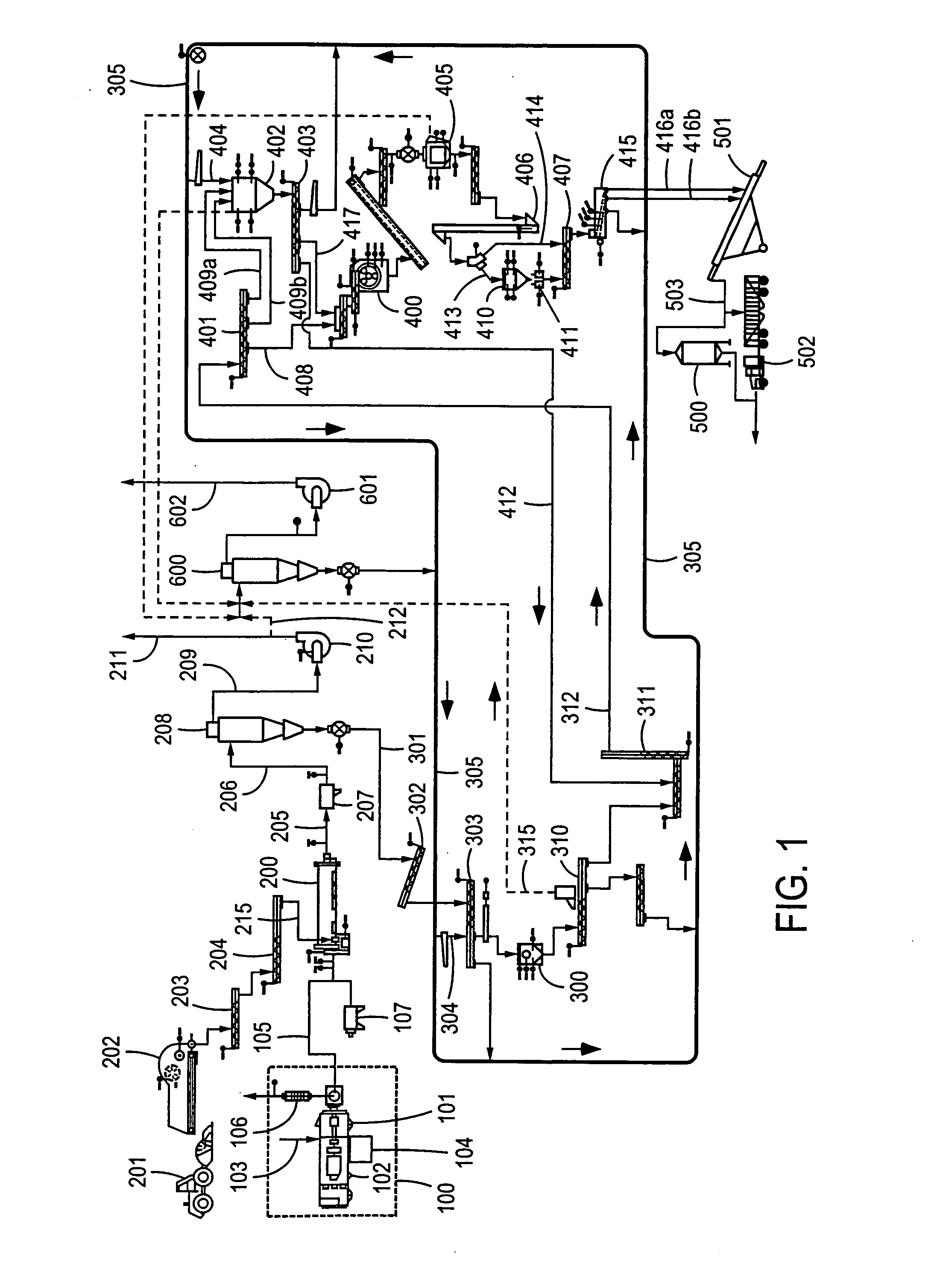

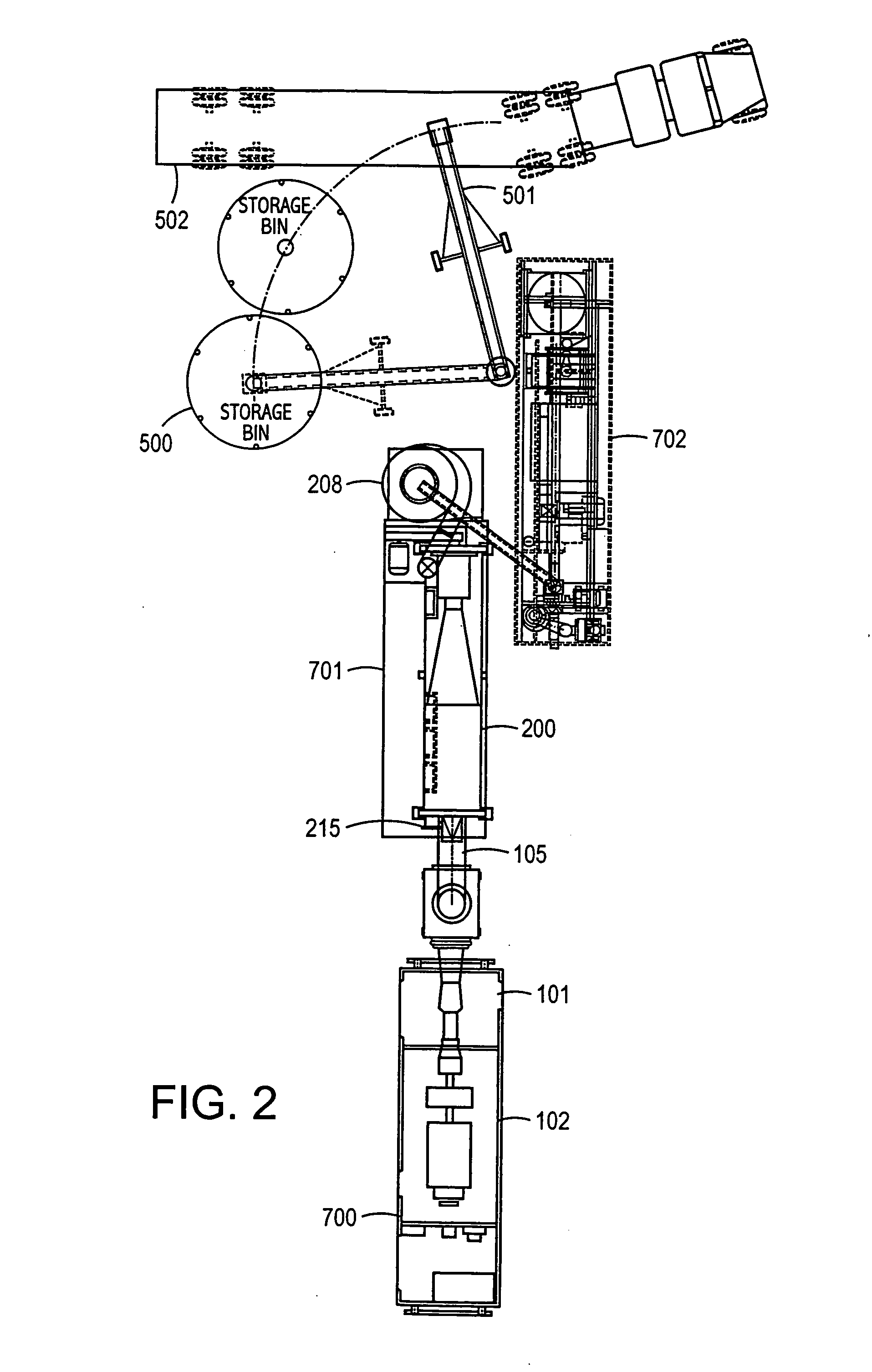

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

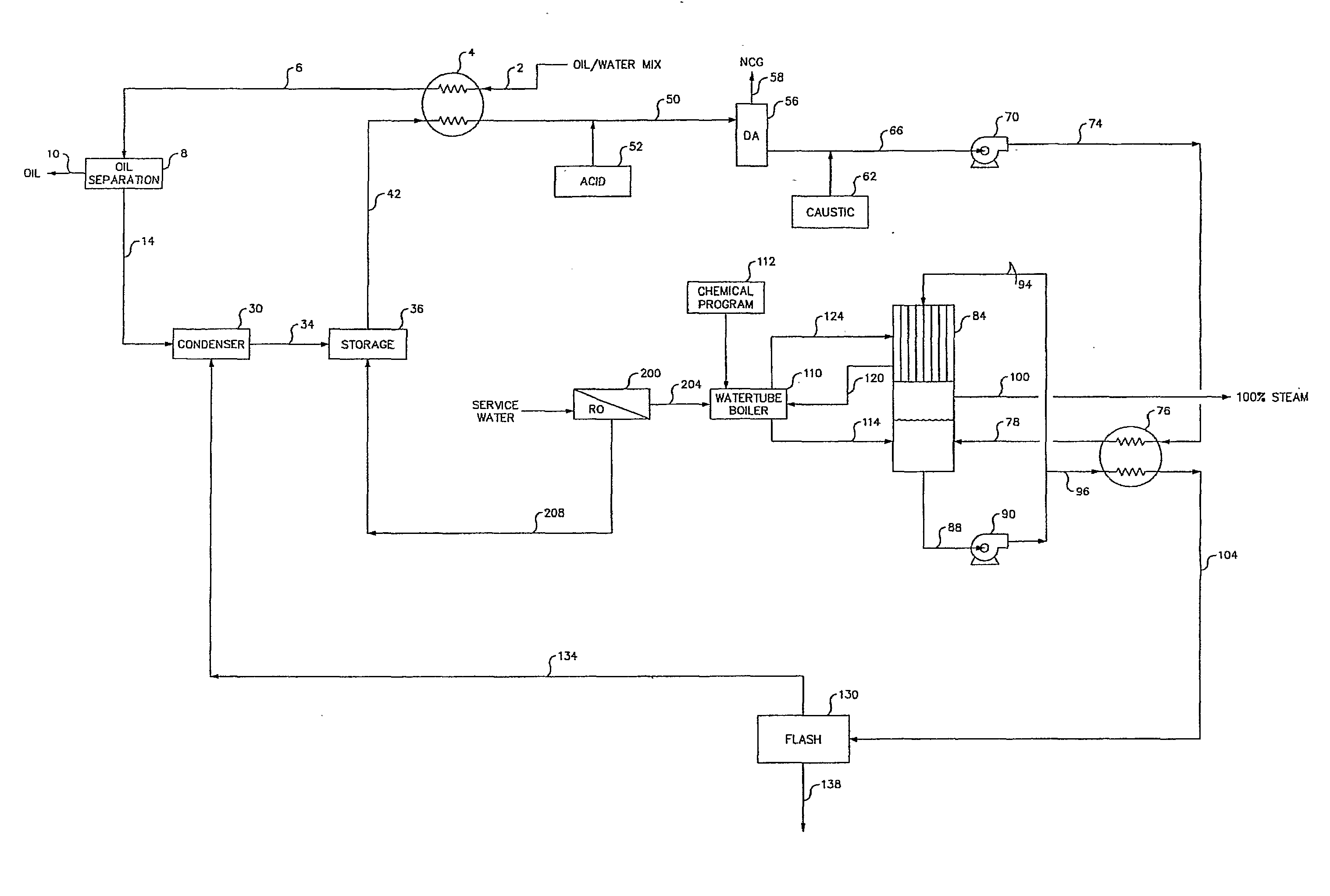

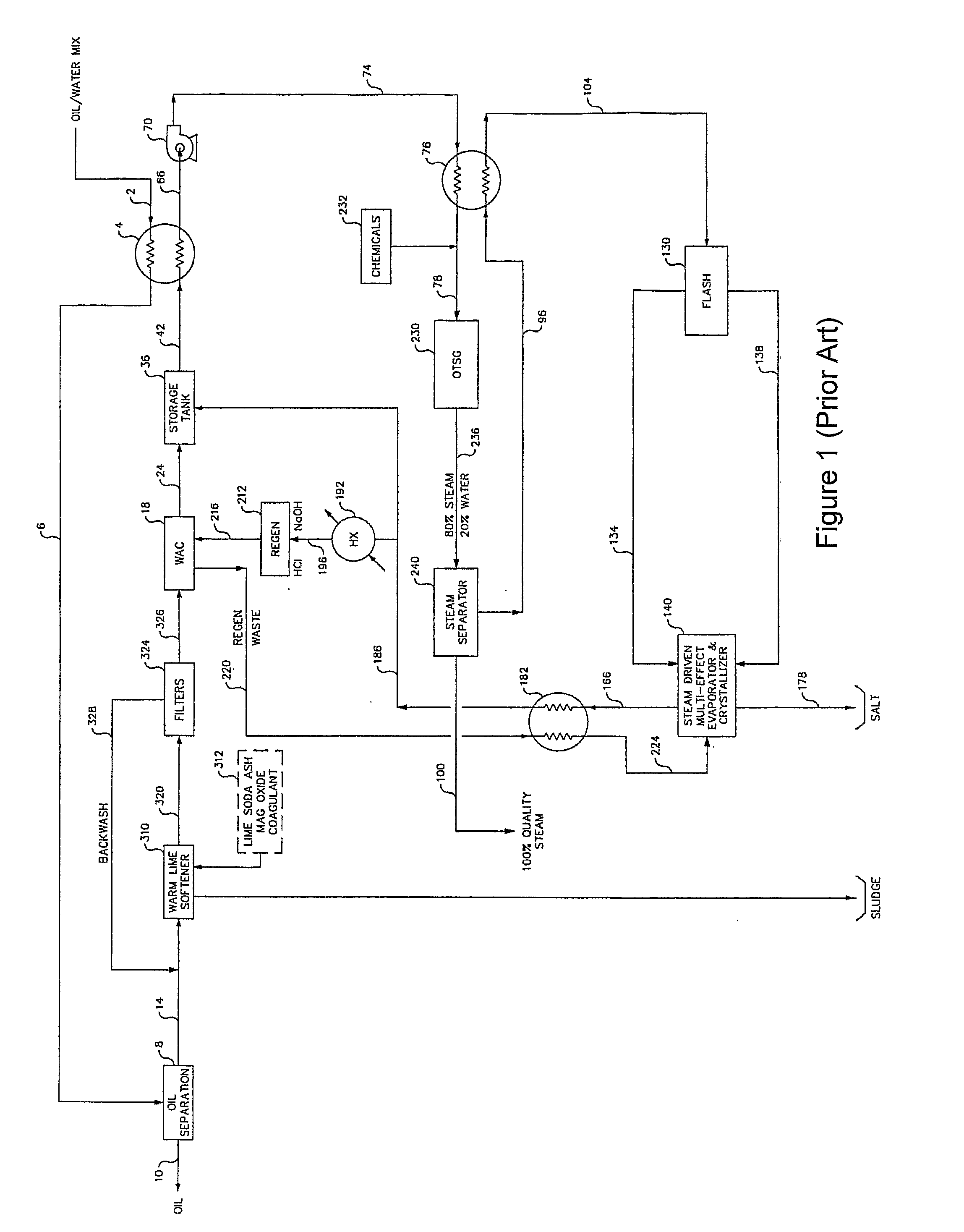

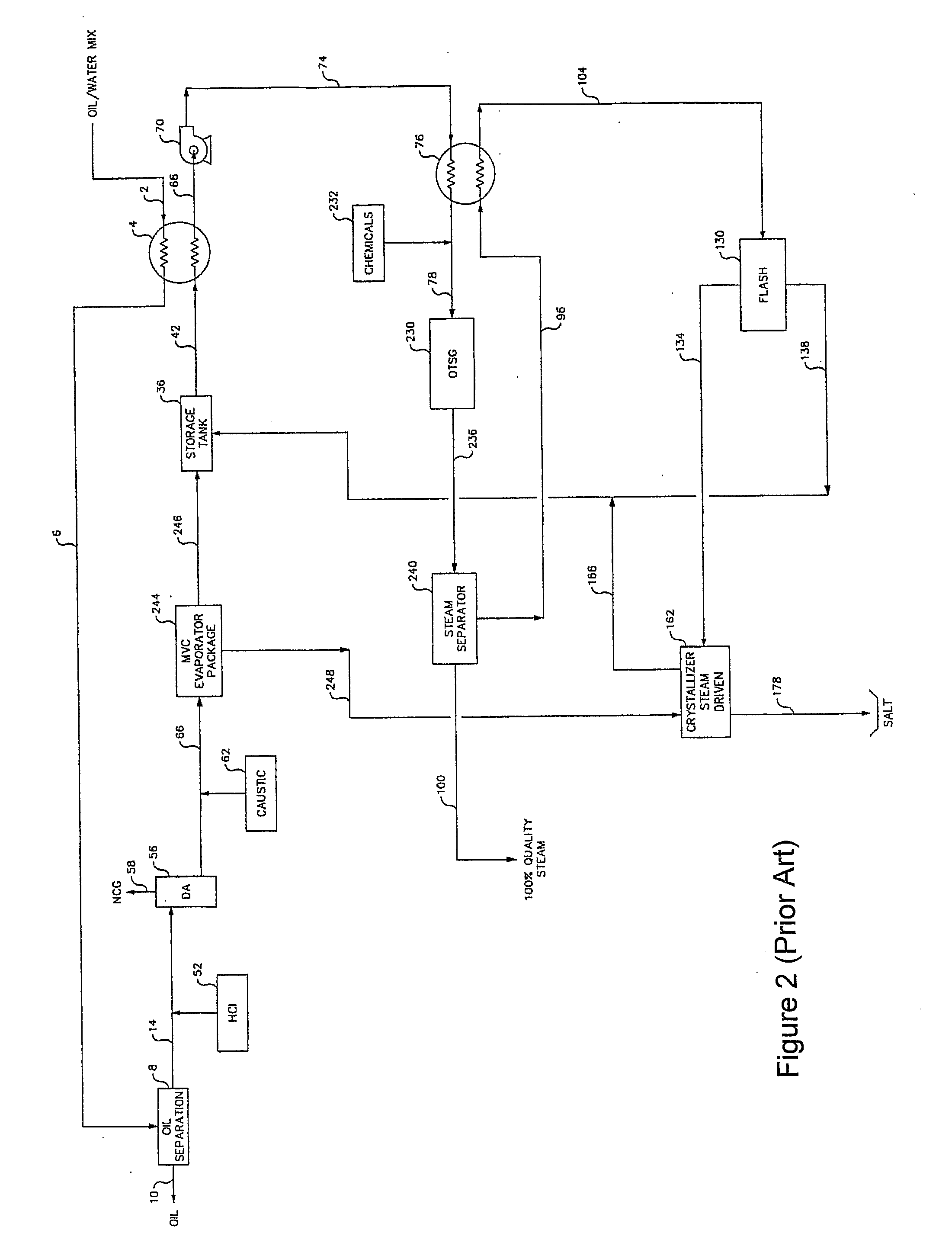

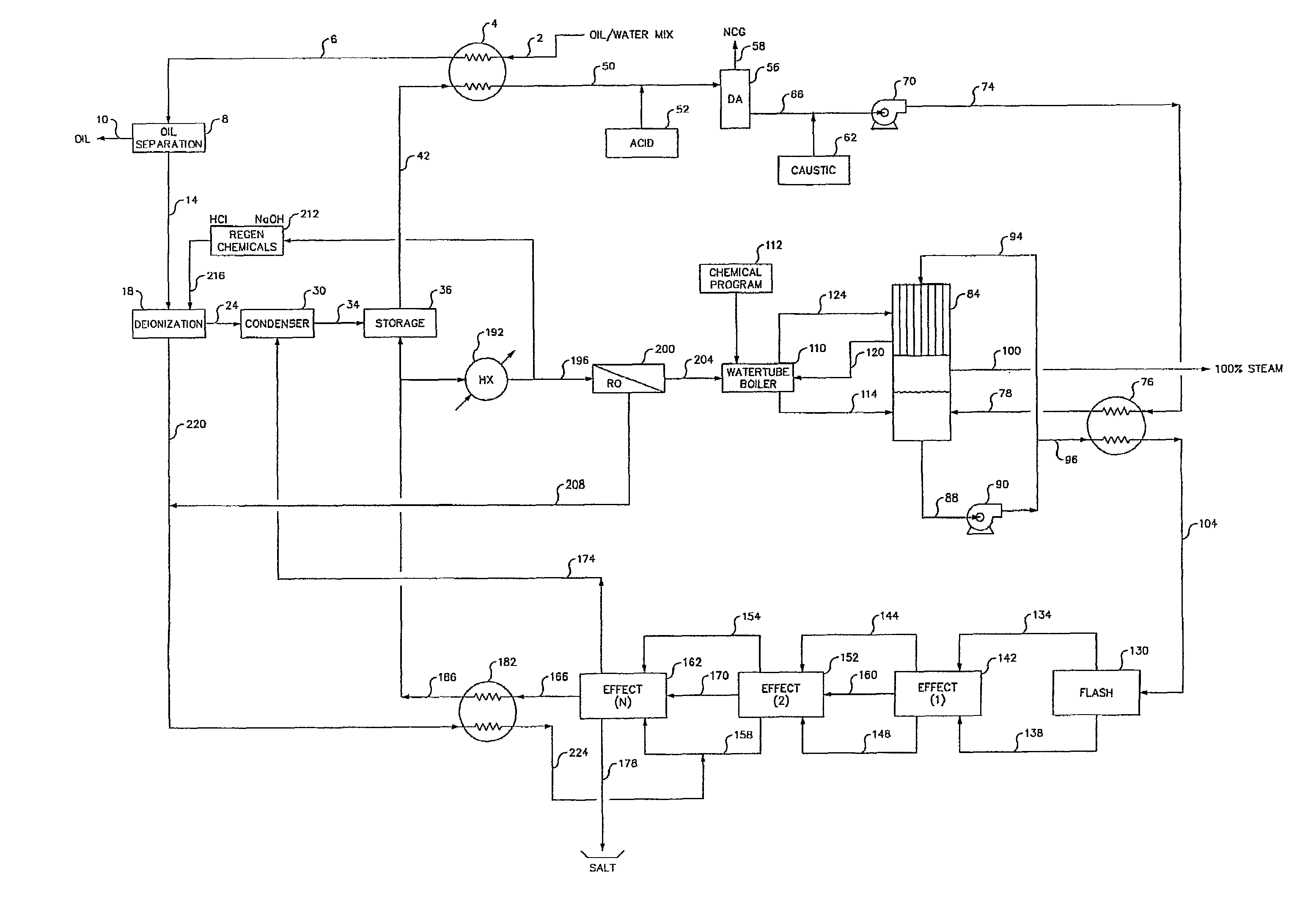

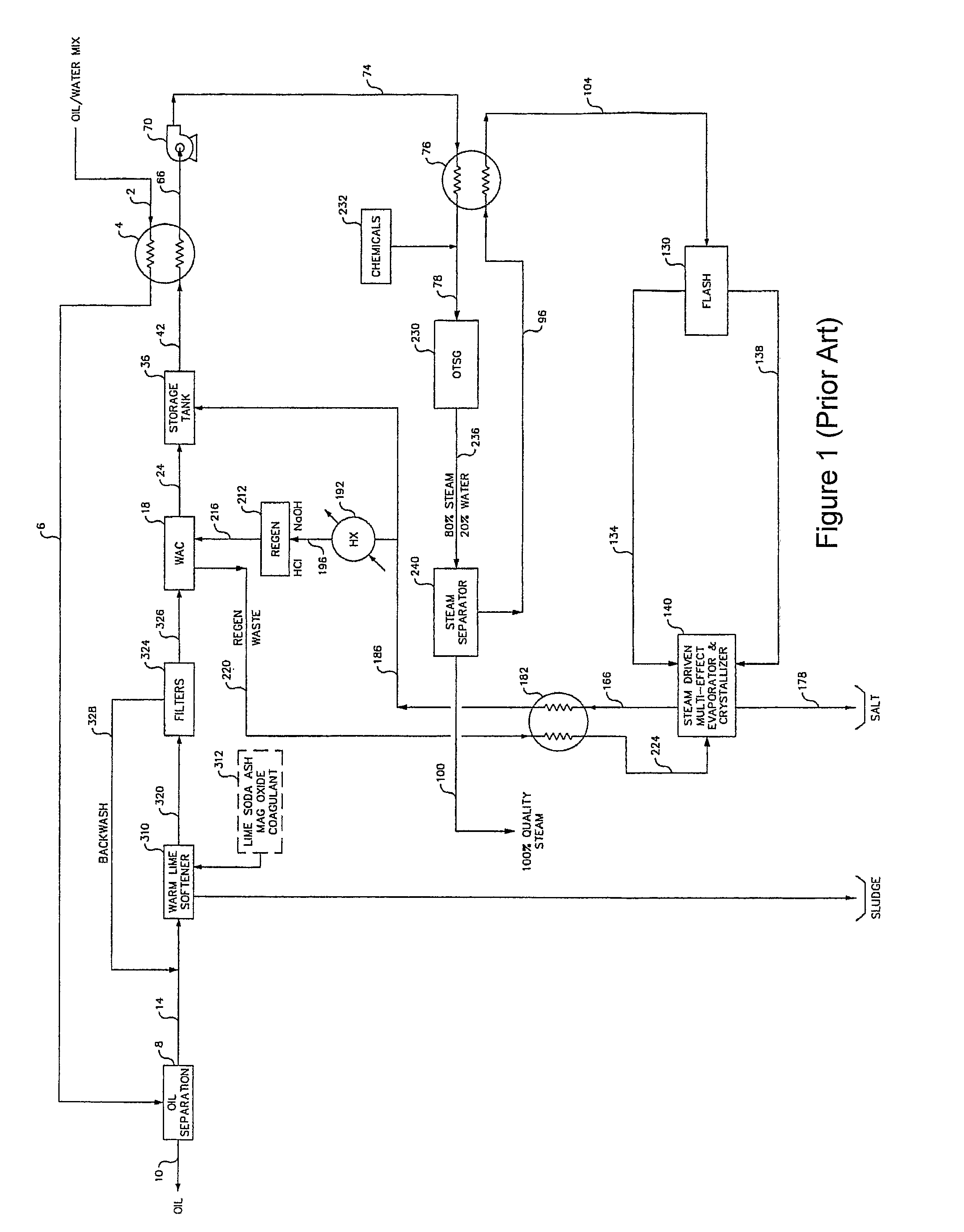

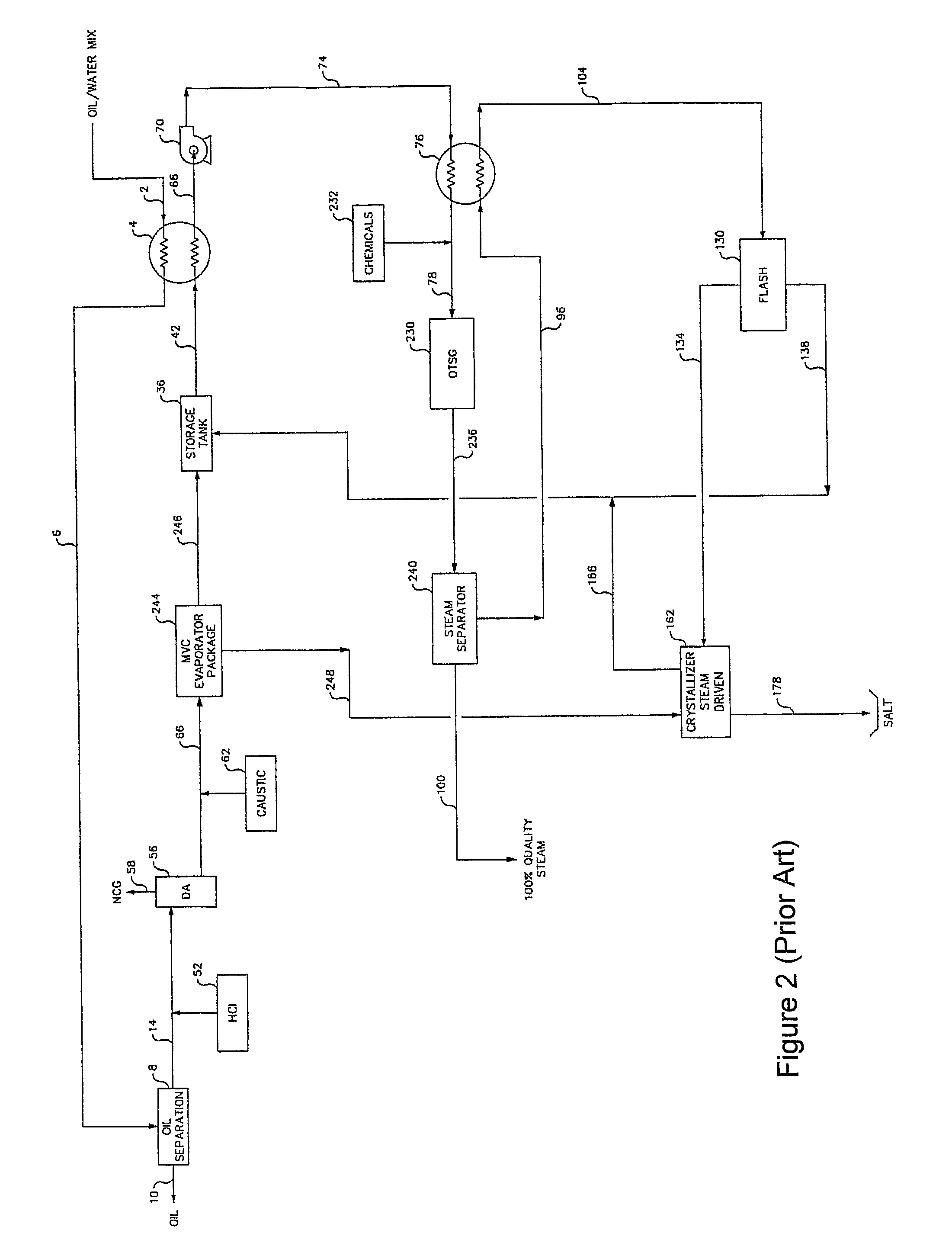

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

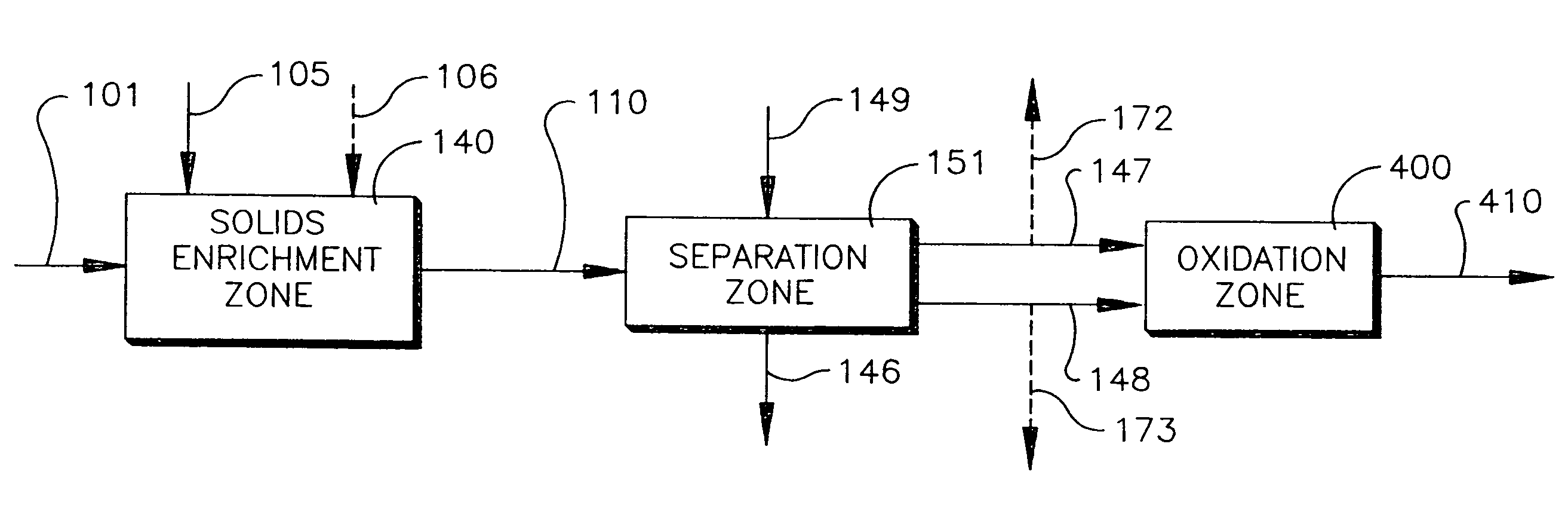

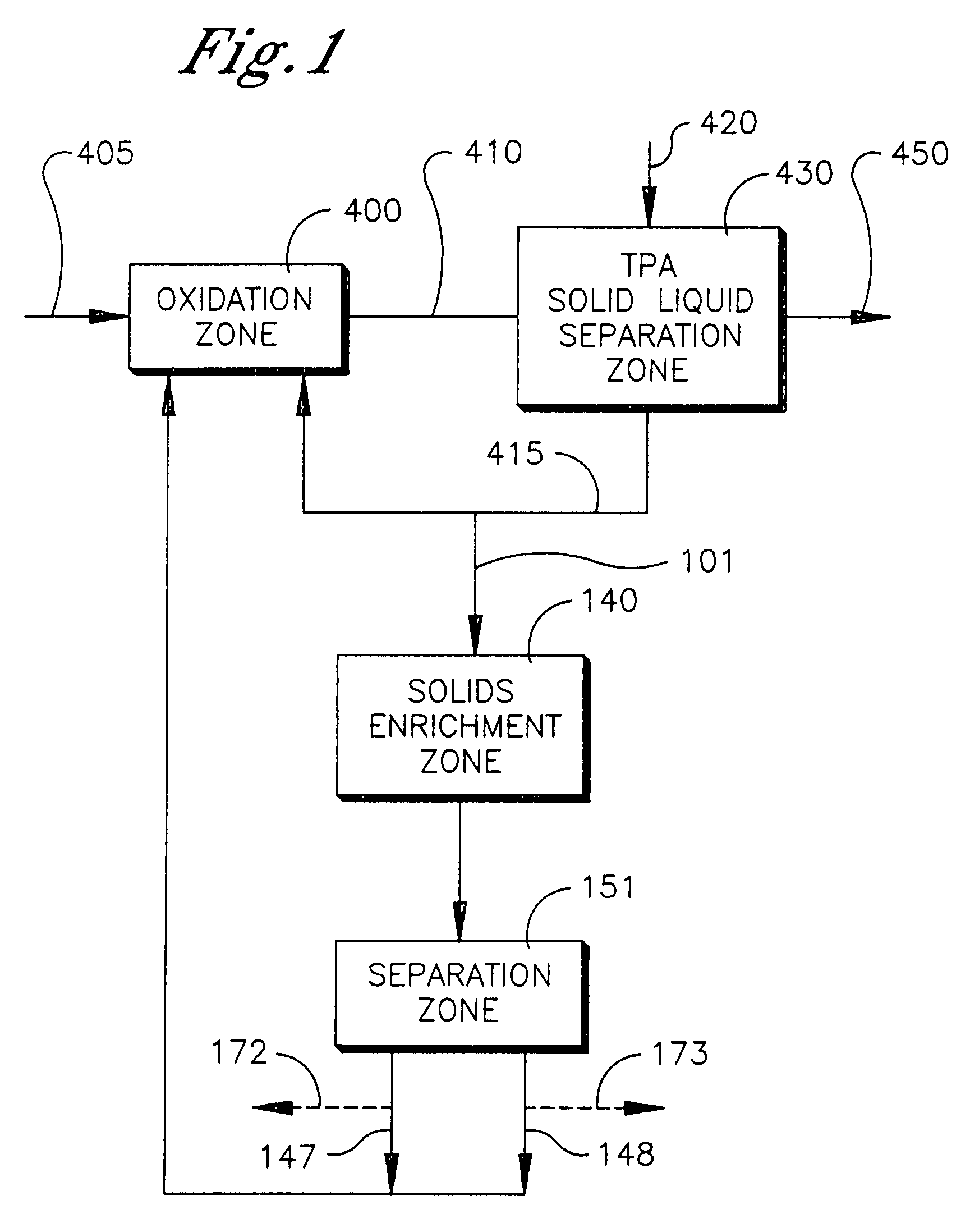

Process for removal of impurities from an oxidizer purge stream

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

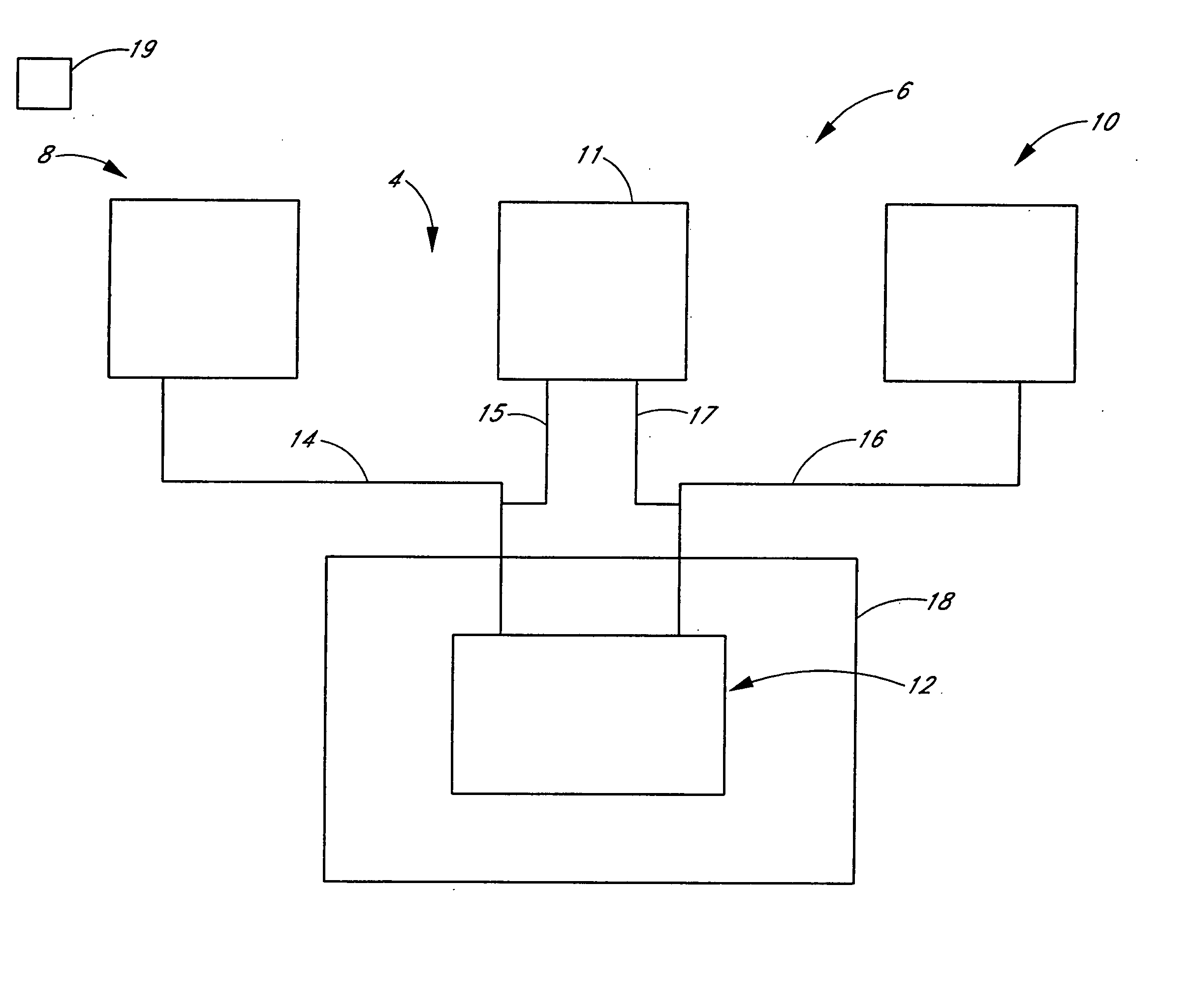

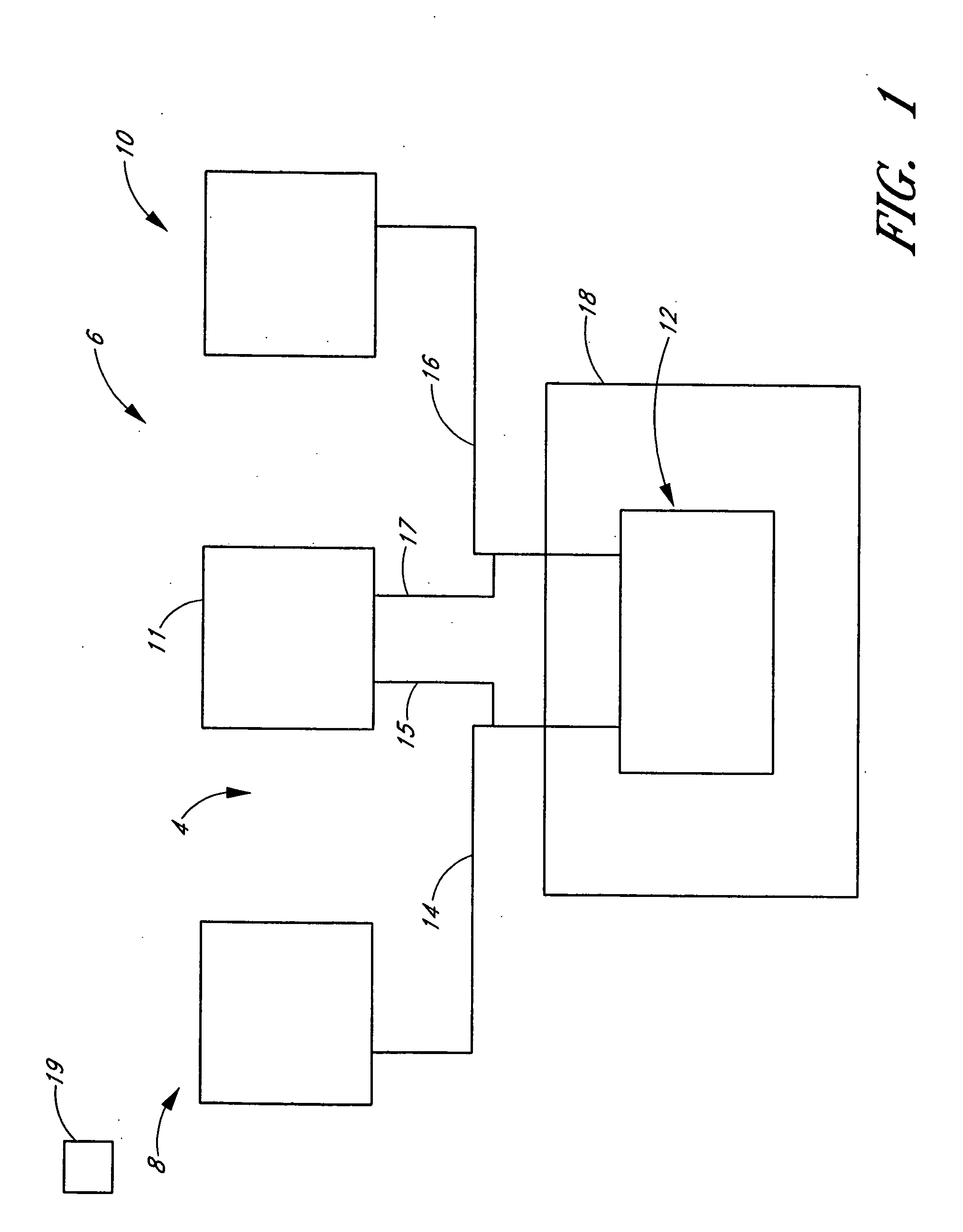

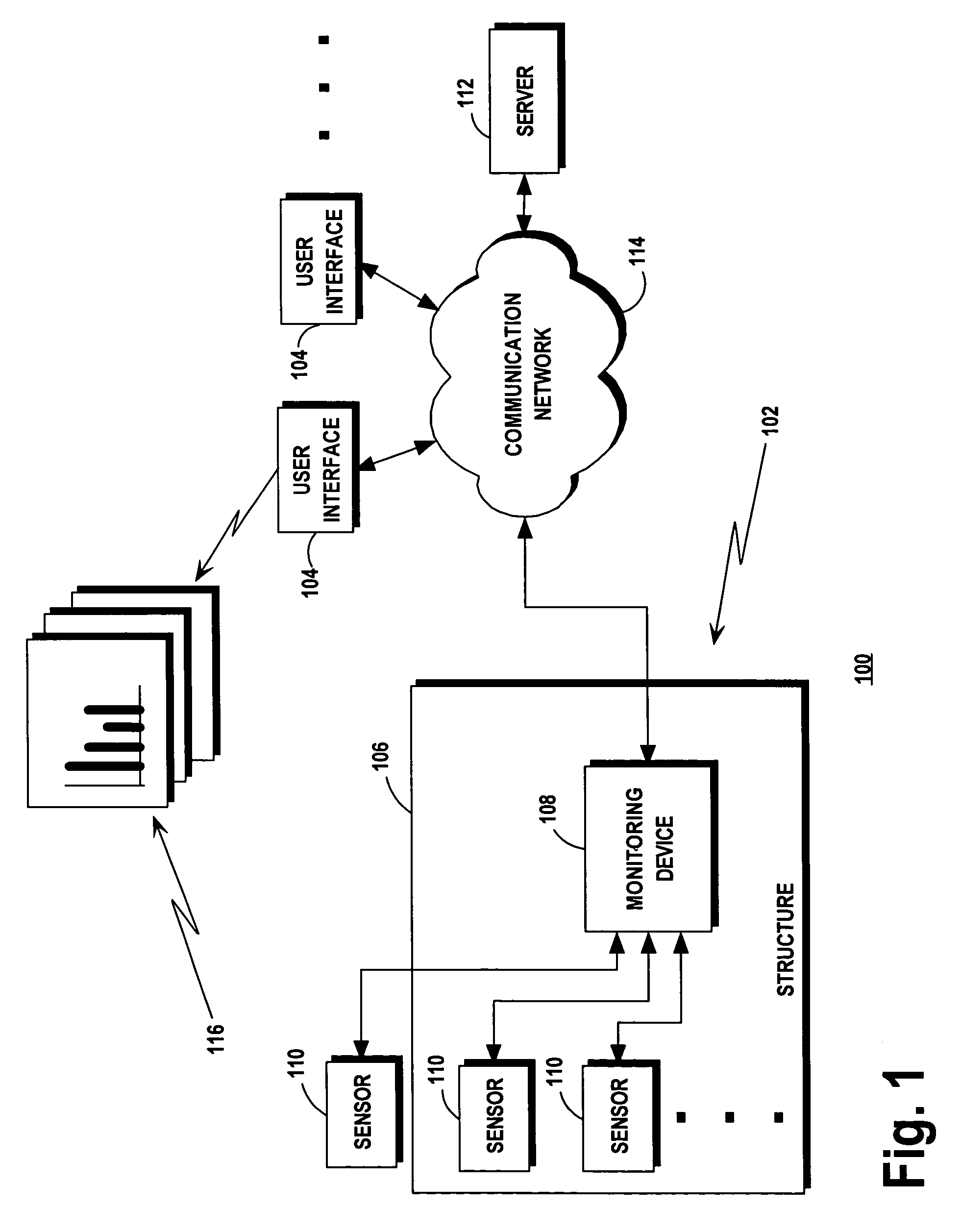

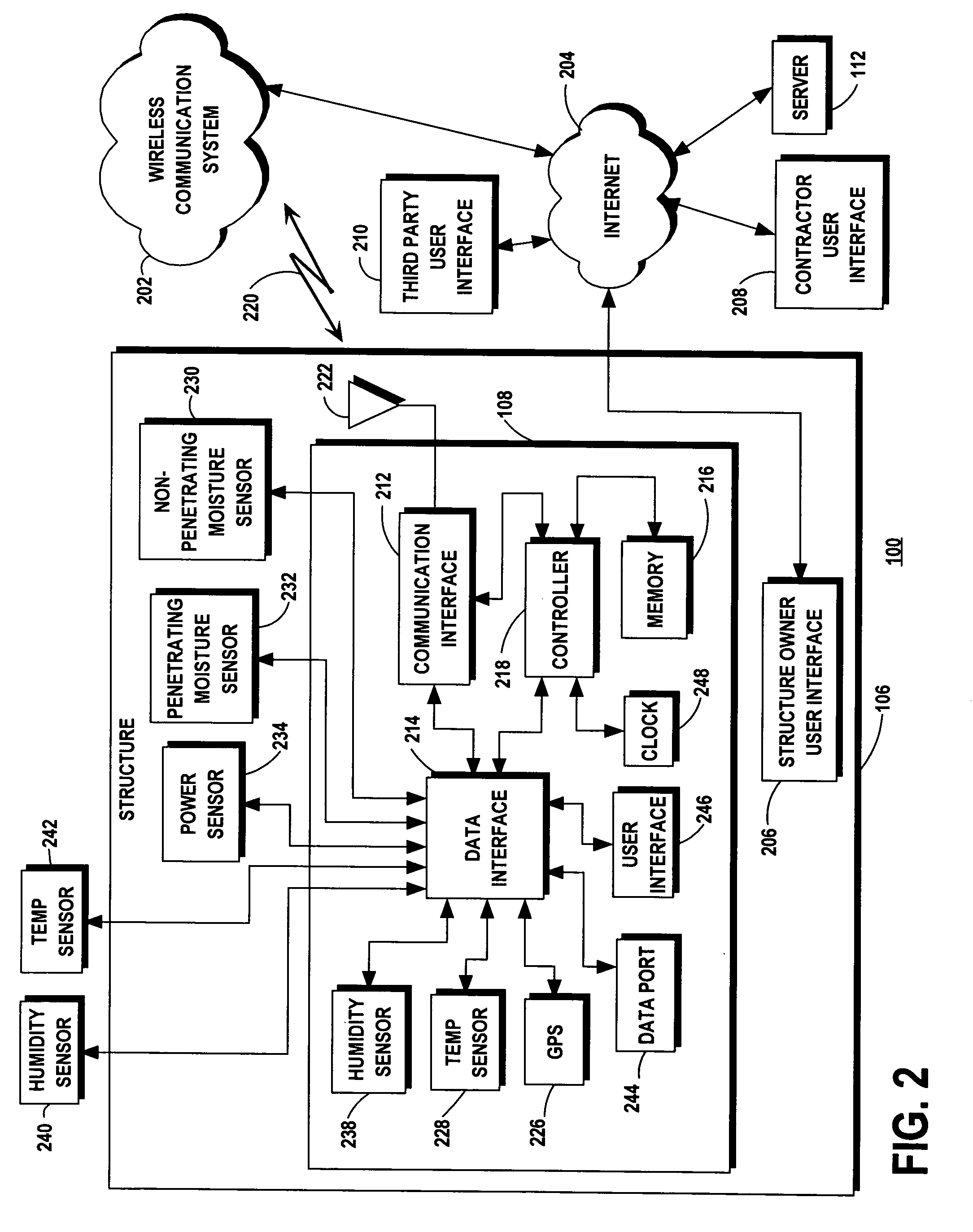

Apparatus, system and method for monitoring a drying procedure

ActiveUS20050285748A1Drying using combination processesMechanical apparatusStructure of Management InformationComputer science

An apparatus, system, and method provide drying procedure information through a user interface. A monitoring device transmits drying procedure data measured by sensors within a structure undergoing the drying procedure to a server. In response to requests received through a communication network from a user interface, the server transmits the drying procedure information that is presented through the user interface. A variety of information and services related to the drying procedure may be provided through the user interface.

Owner:RM2

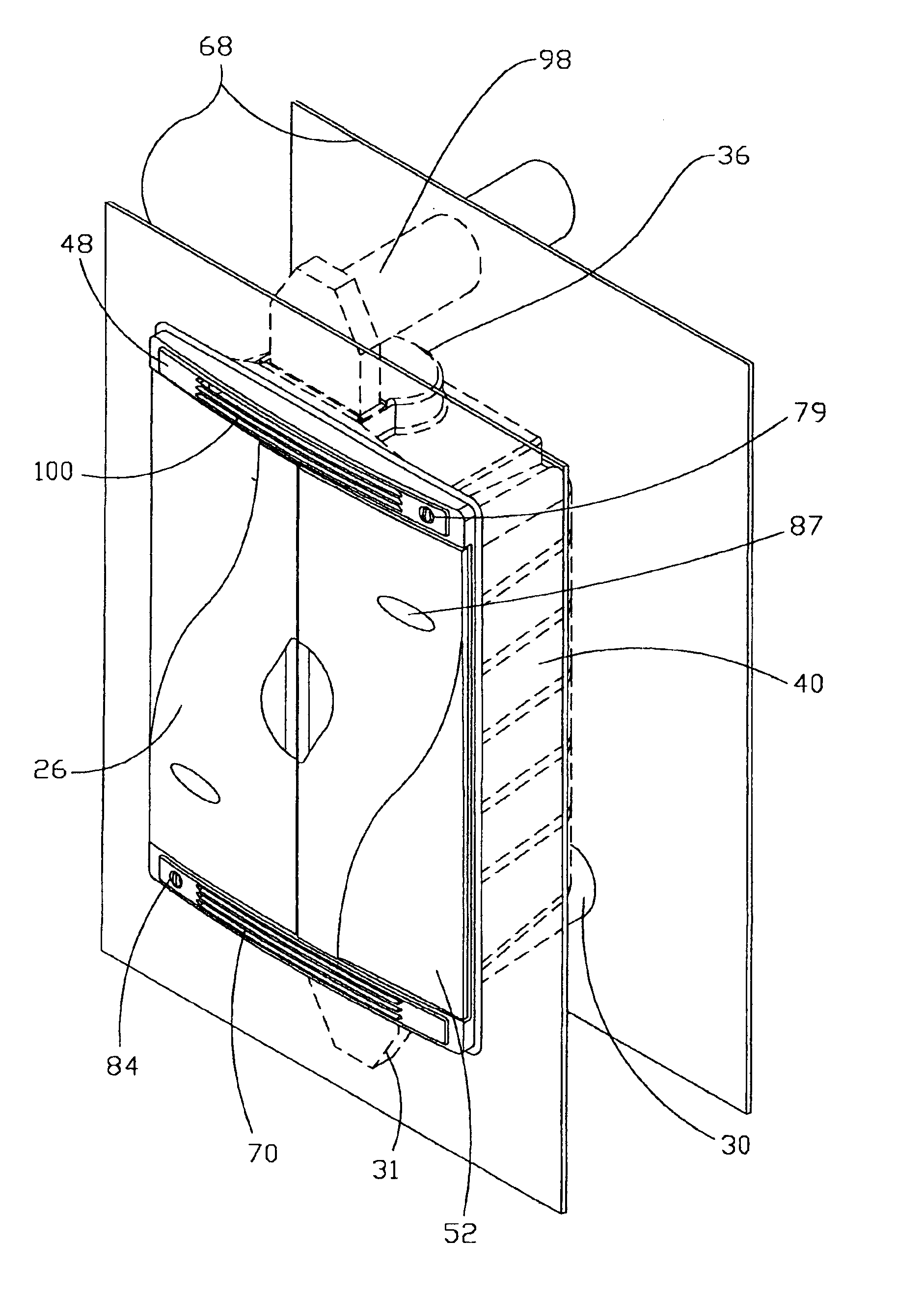

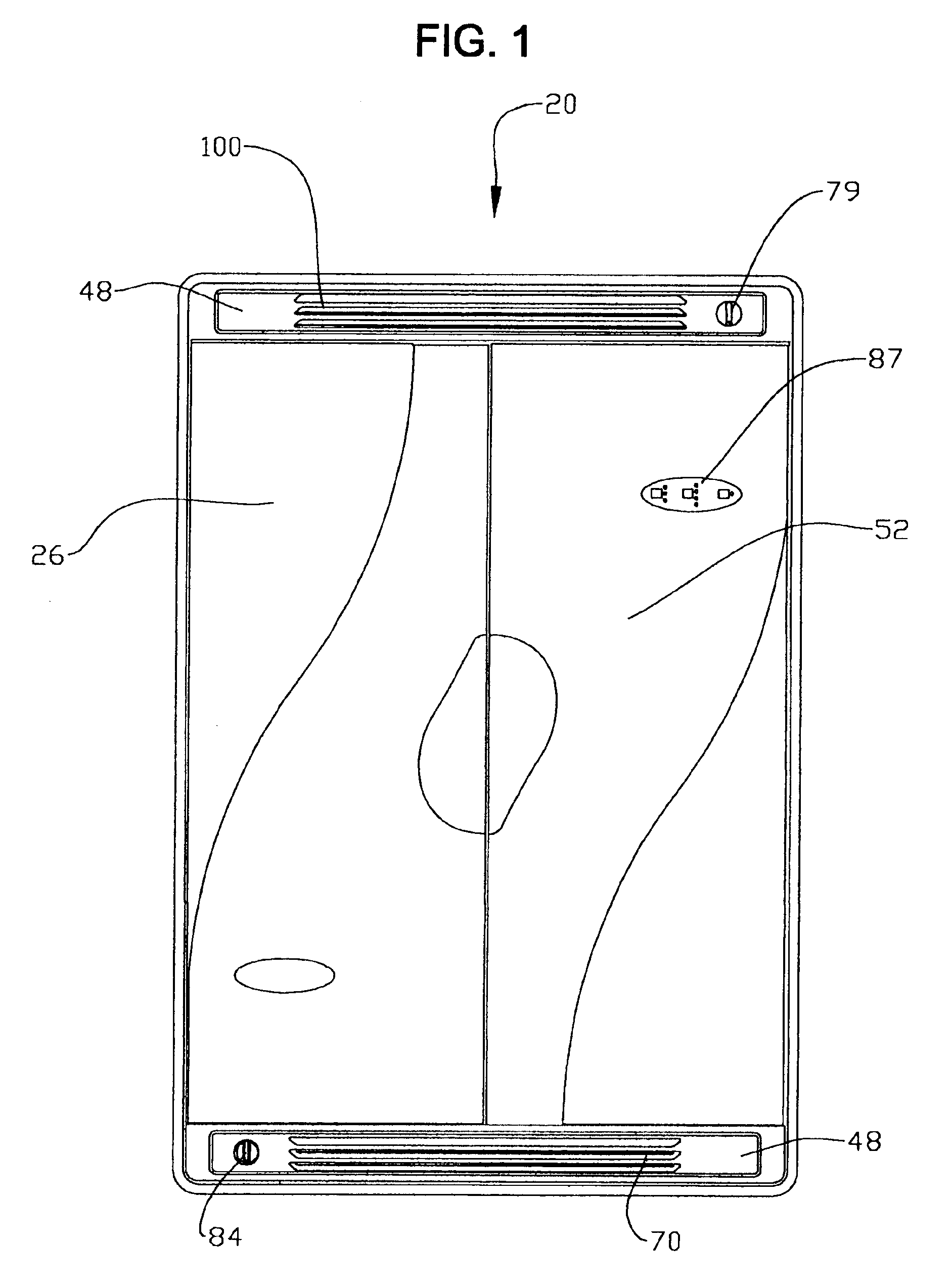

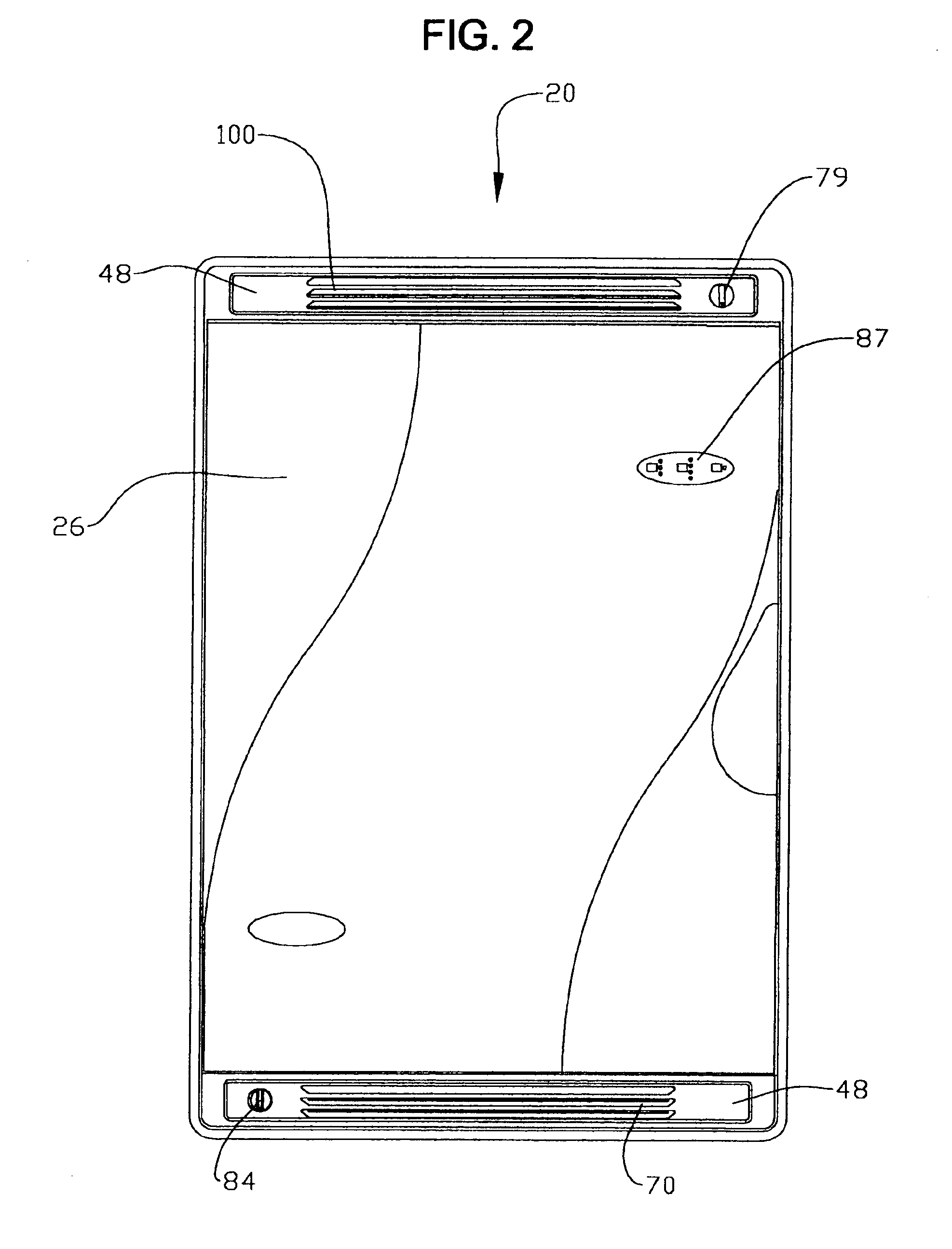

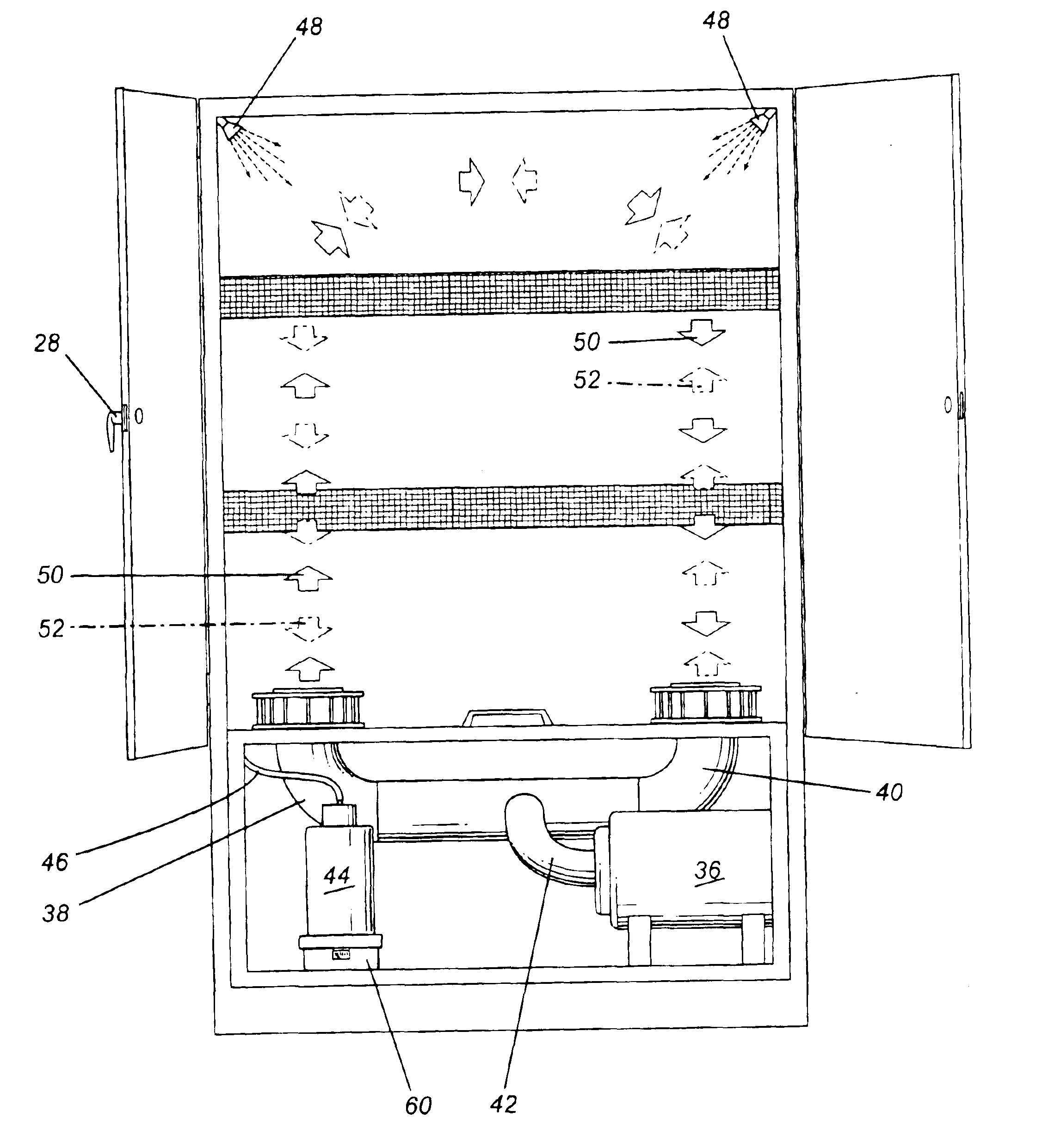

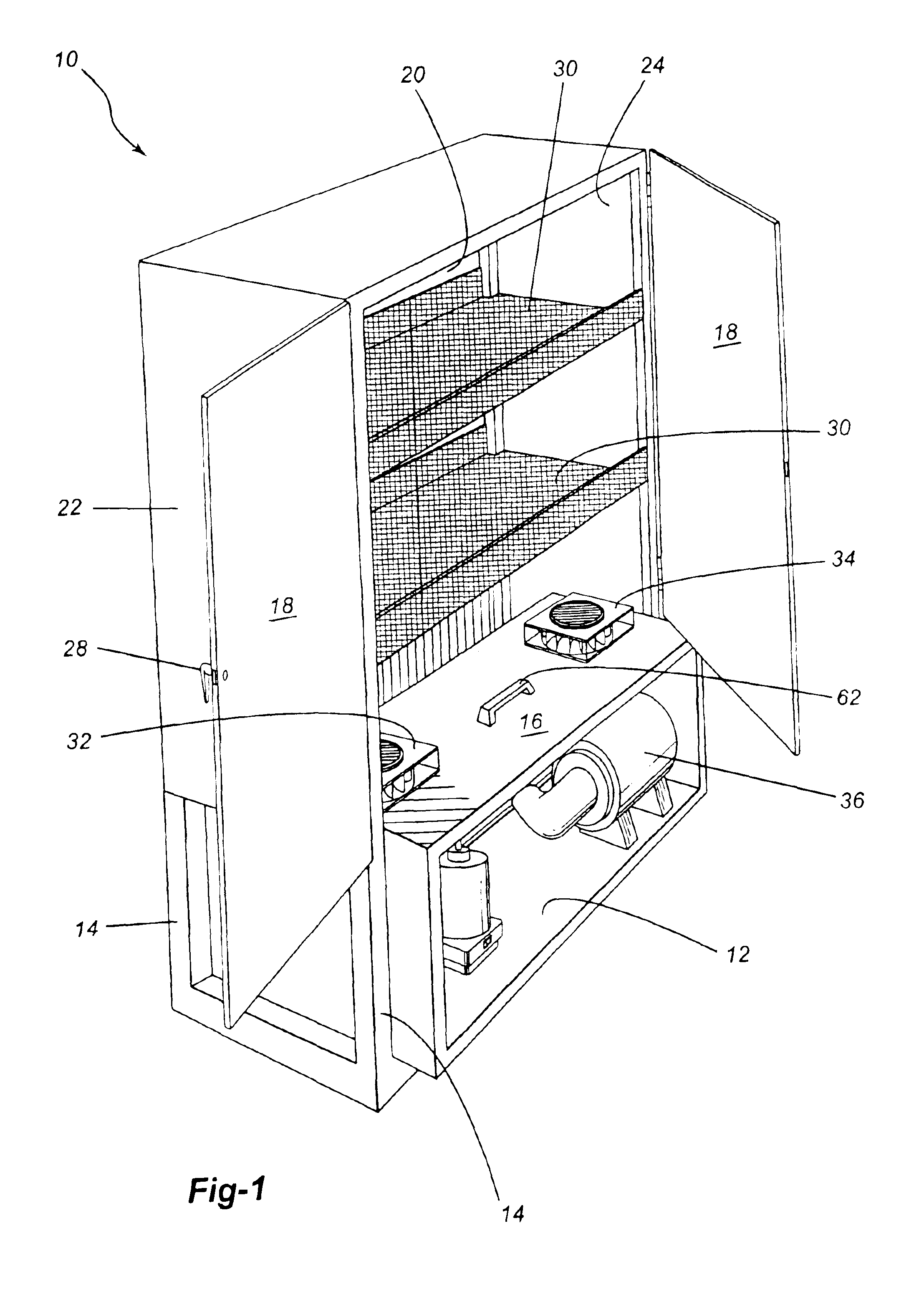

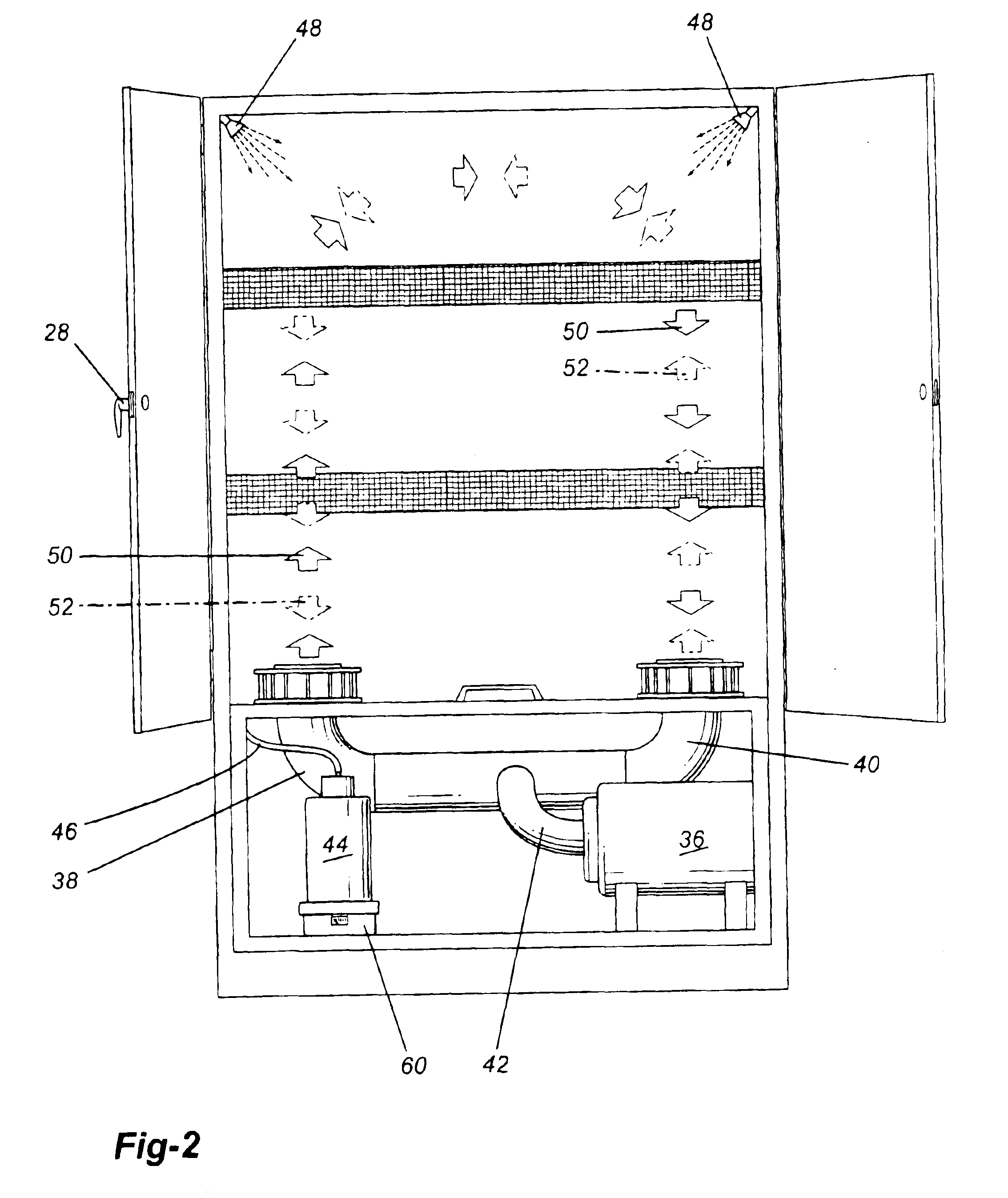

Sanitizing cabinet for sports equipment

InactiveUS6889449B2Suitable for useProcess environmental protectionDrying using combination processesDrying solid materials with heatOzone generatorSports equipment

There is provided a method and apparatus for sanitizing sports equipment which comprises a cabinet which can be sealed, first and second conduits in fluid communication with the cabinet, an ozone generator, and fans for circulating ozone containing gas through the conduits into the cabinet, the fans being operative to circulate the ozone containing gas in a first direction and subsequently in a reverse direction. There is also provided a fluid storage device, the fluid storage device being associated with a spray action to spray the fluid into the cabinet after the ozone has been circulated.

Owner:SILVER STEVE

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

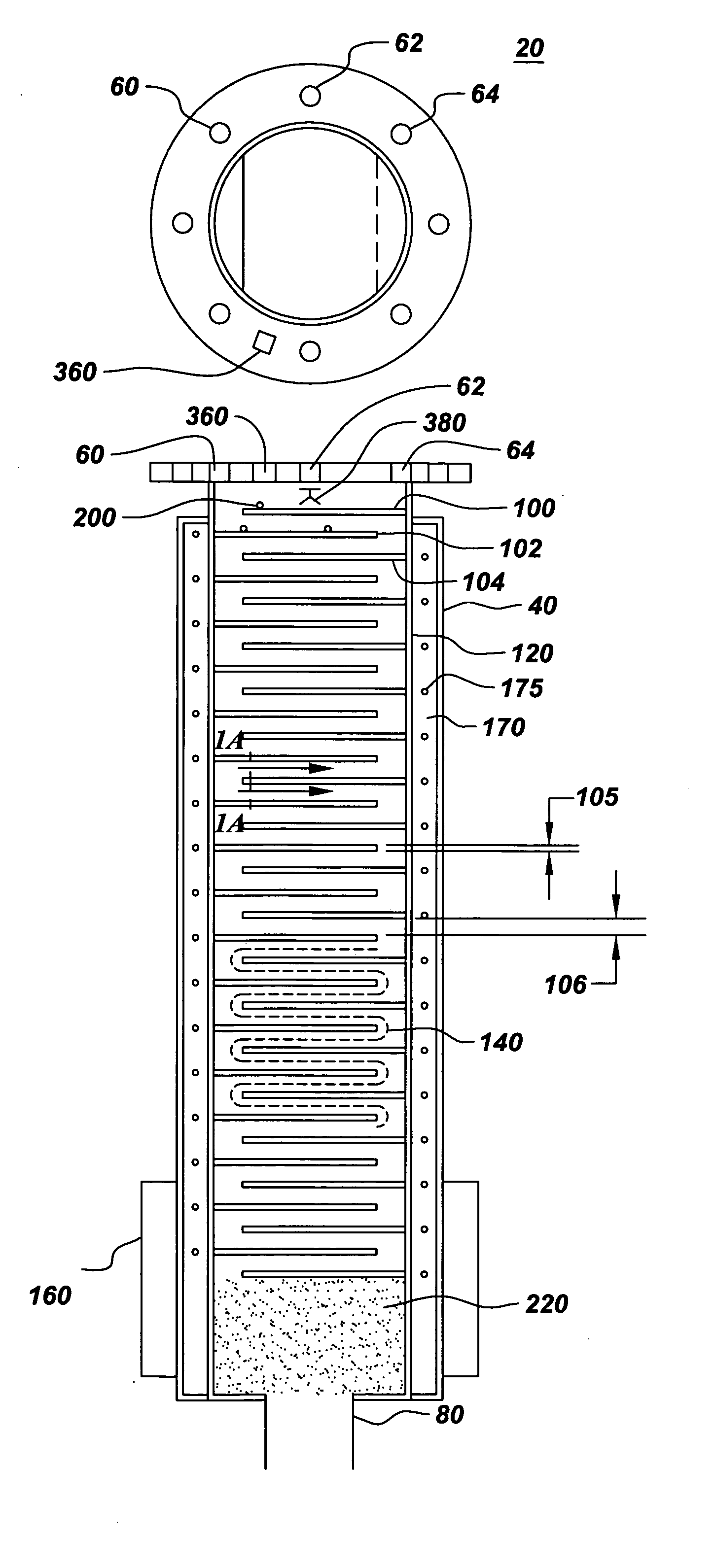

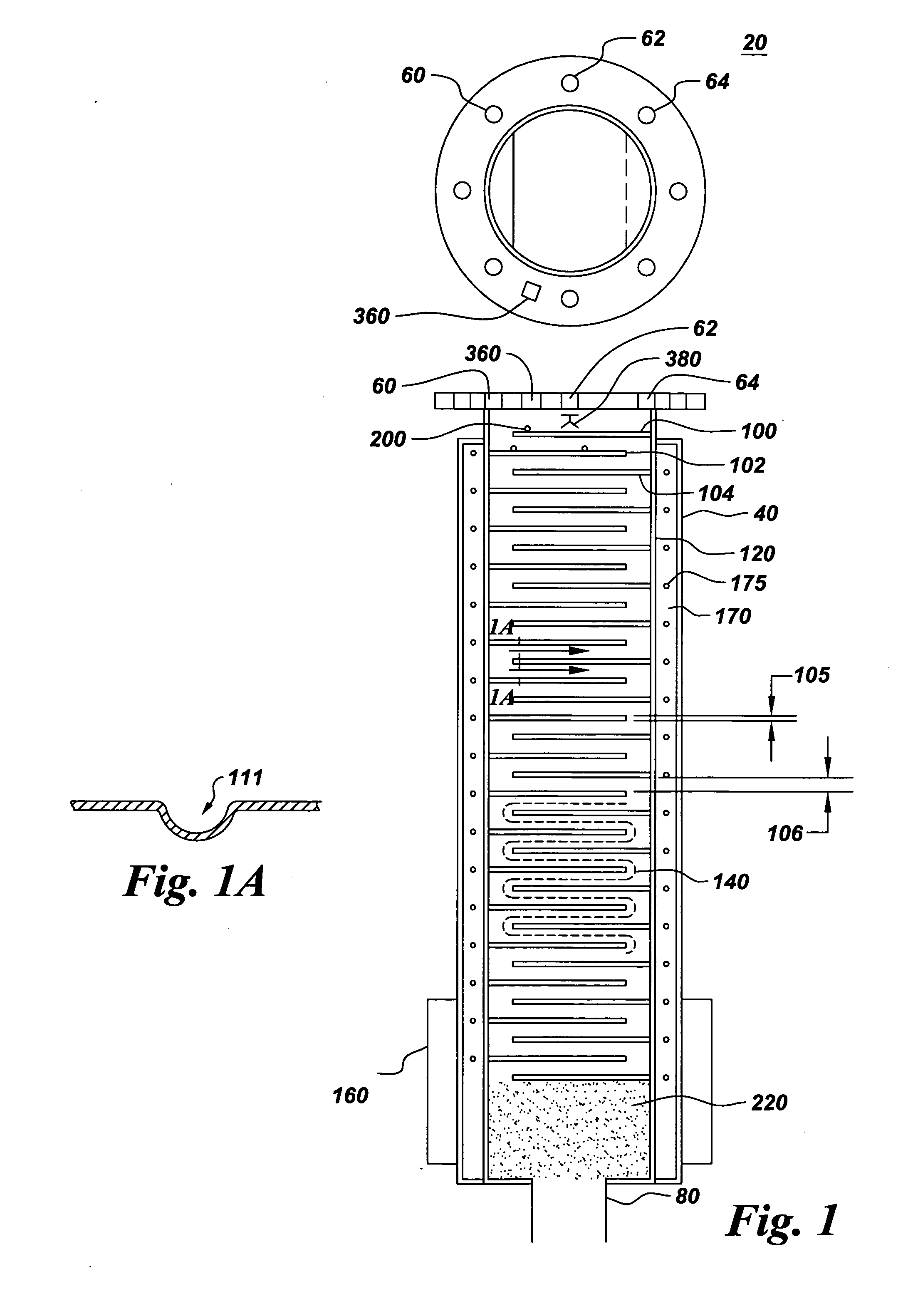

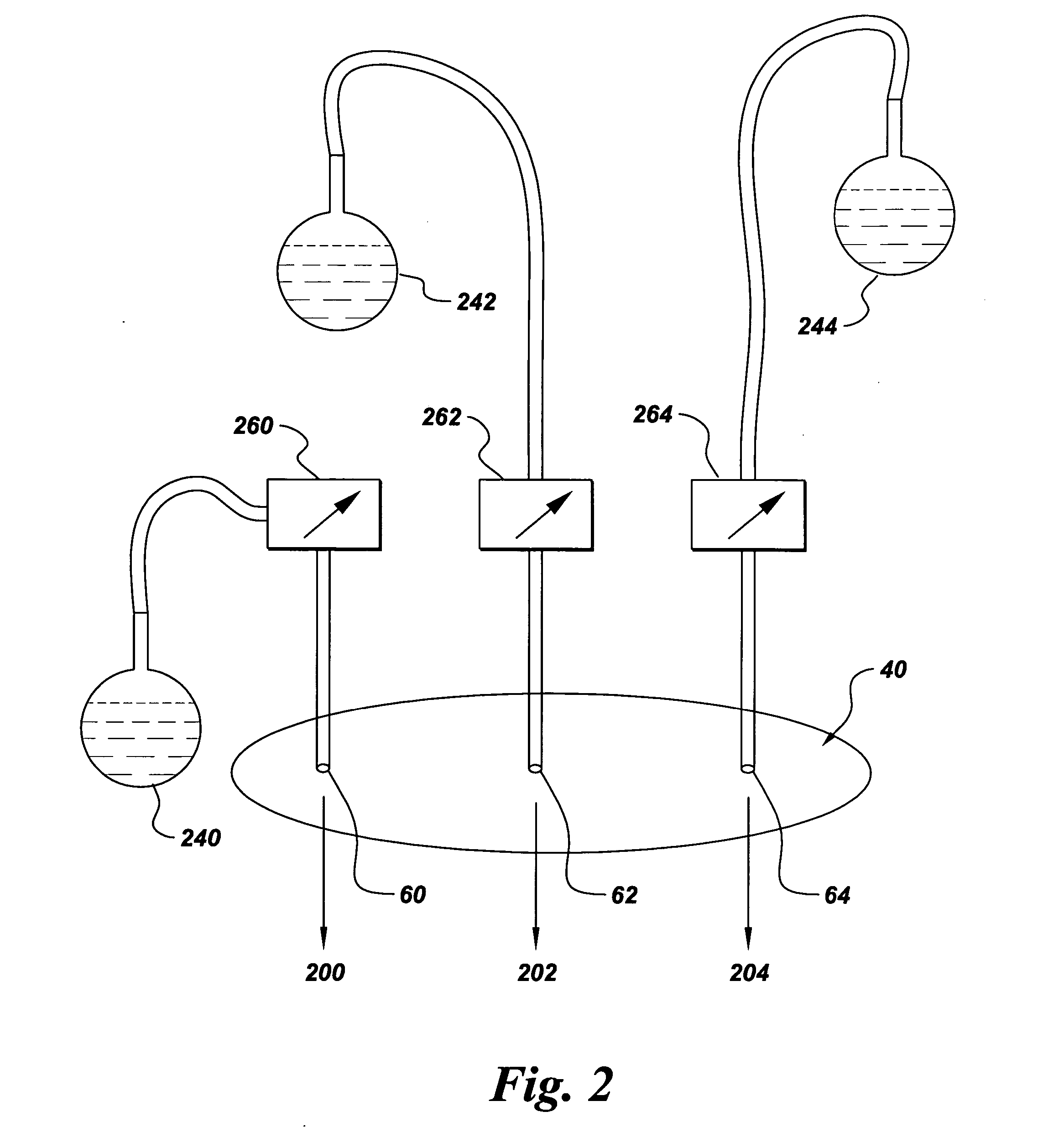

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

Phobic barrier meniscus separation and containment

InactiveUS6988326B2Increase productionHigh yieldDrying using combination processesDrying solid materials with heatBiomedical engineeringMeniscus

Owner:LAM RES CORP

Reaction system for growing a thin film

ActiveUS7020981B2Extension of timeLong stepDrying using combination processesDrying solid materials with heatControl systemPhysical chemistry

A reactor defines a reaction chamber for processing a substrate. The reactor comprises a first inlet for providing a first reactant and to the reaction chamber and a second inlet for a second reactant to the reaction chamber. A first exhaust outlet removes gases from the reaction chamber. A second exhaust outlet removes gases from the reaction chamber. A flow control system is configured to alternately constrict flow through the first and second exhaust outlets. The reactor chamber is configured to for a diffusion barrier within the reaction chamber.

Owner:ASM IP HLDG BV

Pressurized vapor cycle liquid distillation

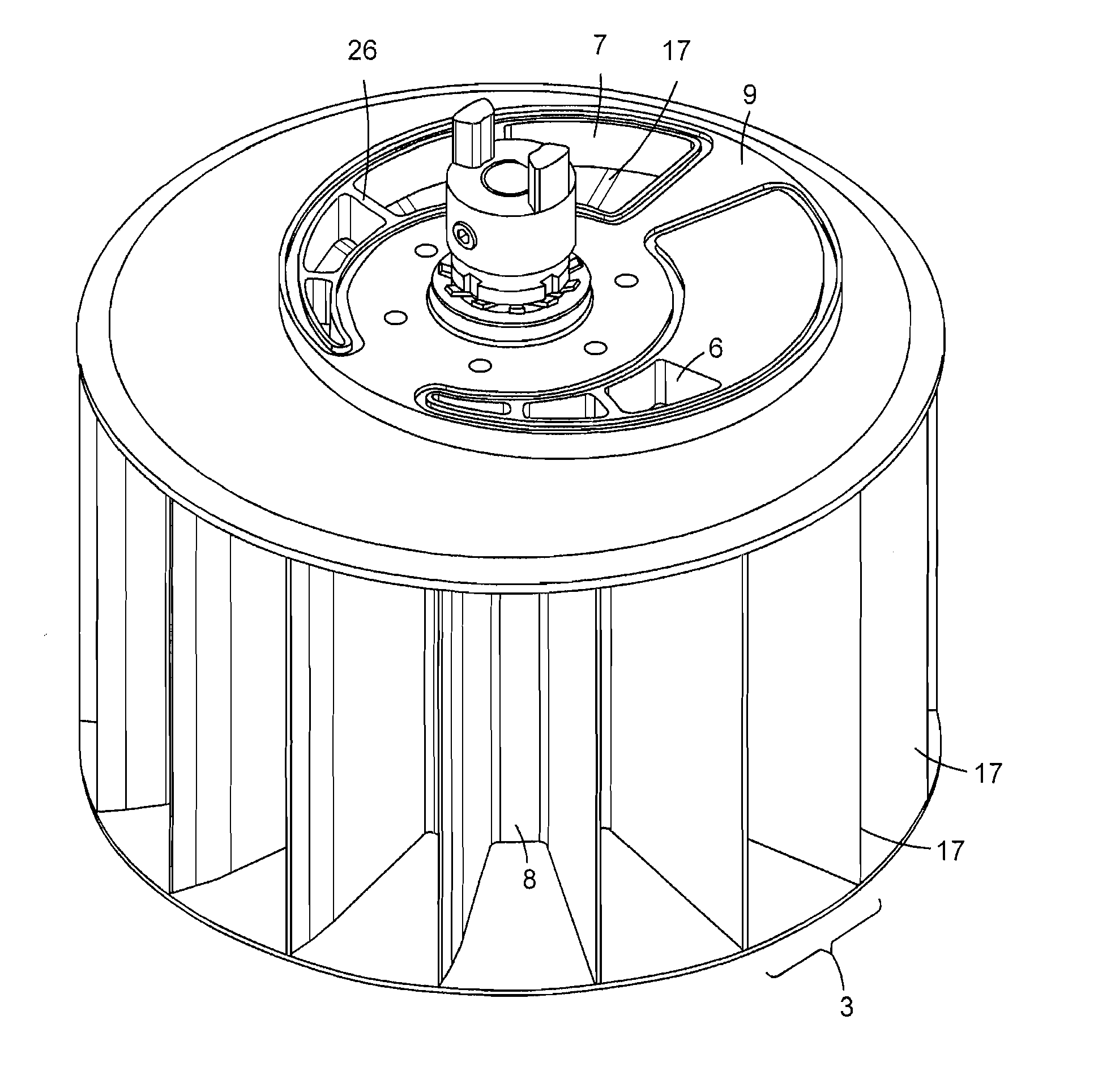

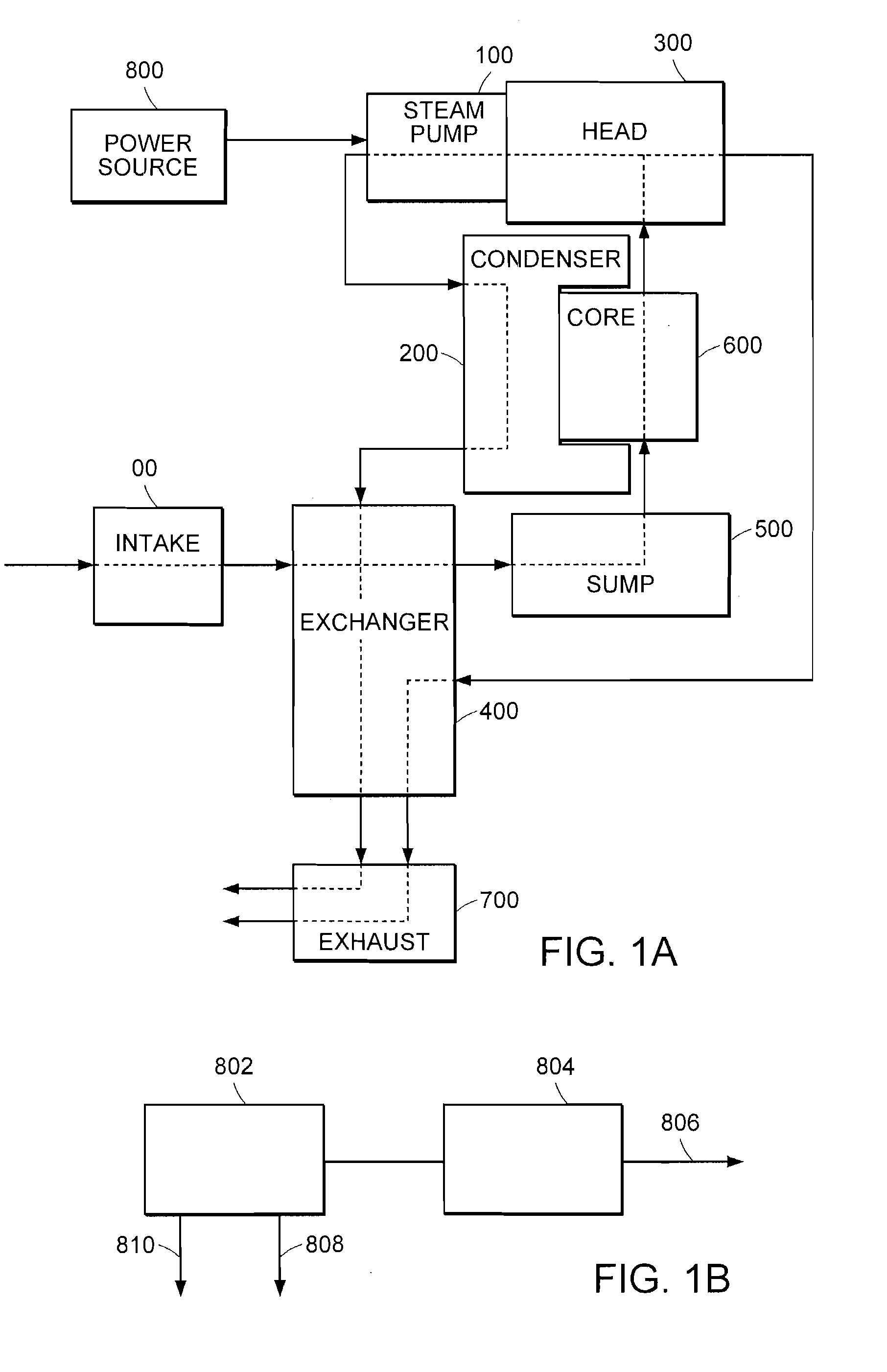

ActiveUS20070017192A1Easy maintenanceImprove efficiencyCombination devicesDrying using combination processesHeat managementDistillation

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

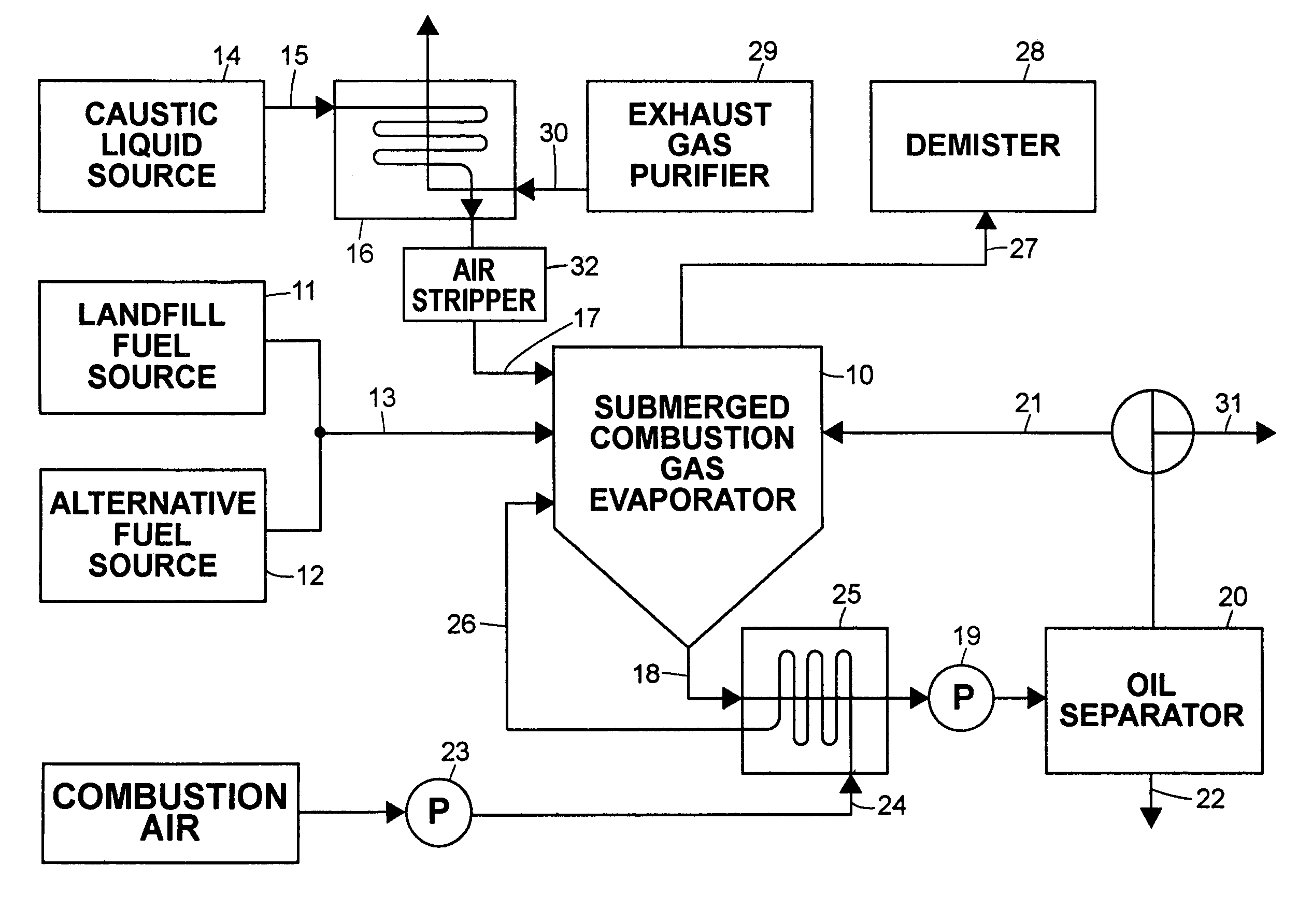

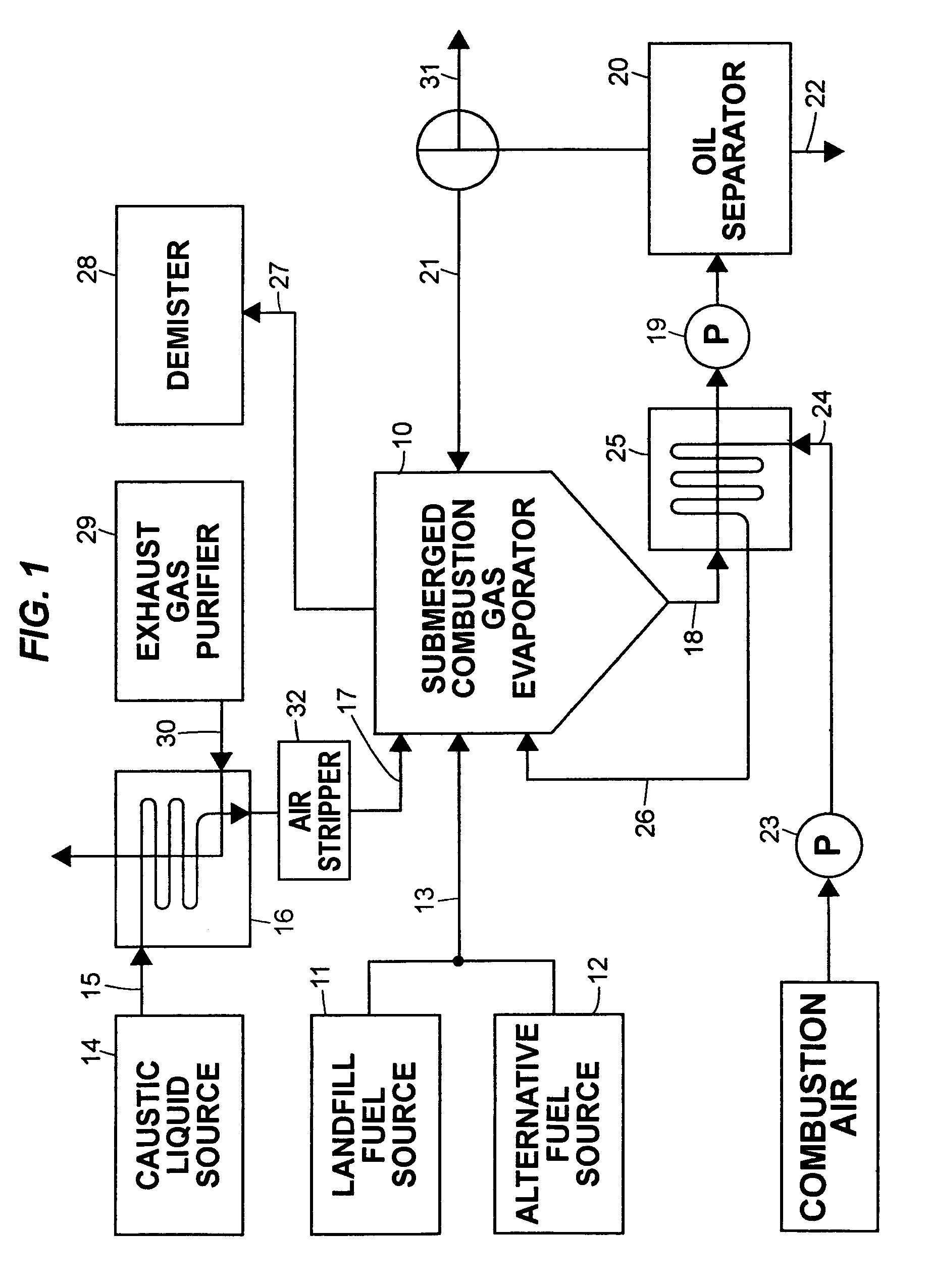

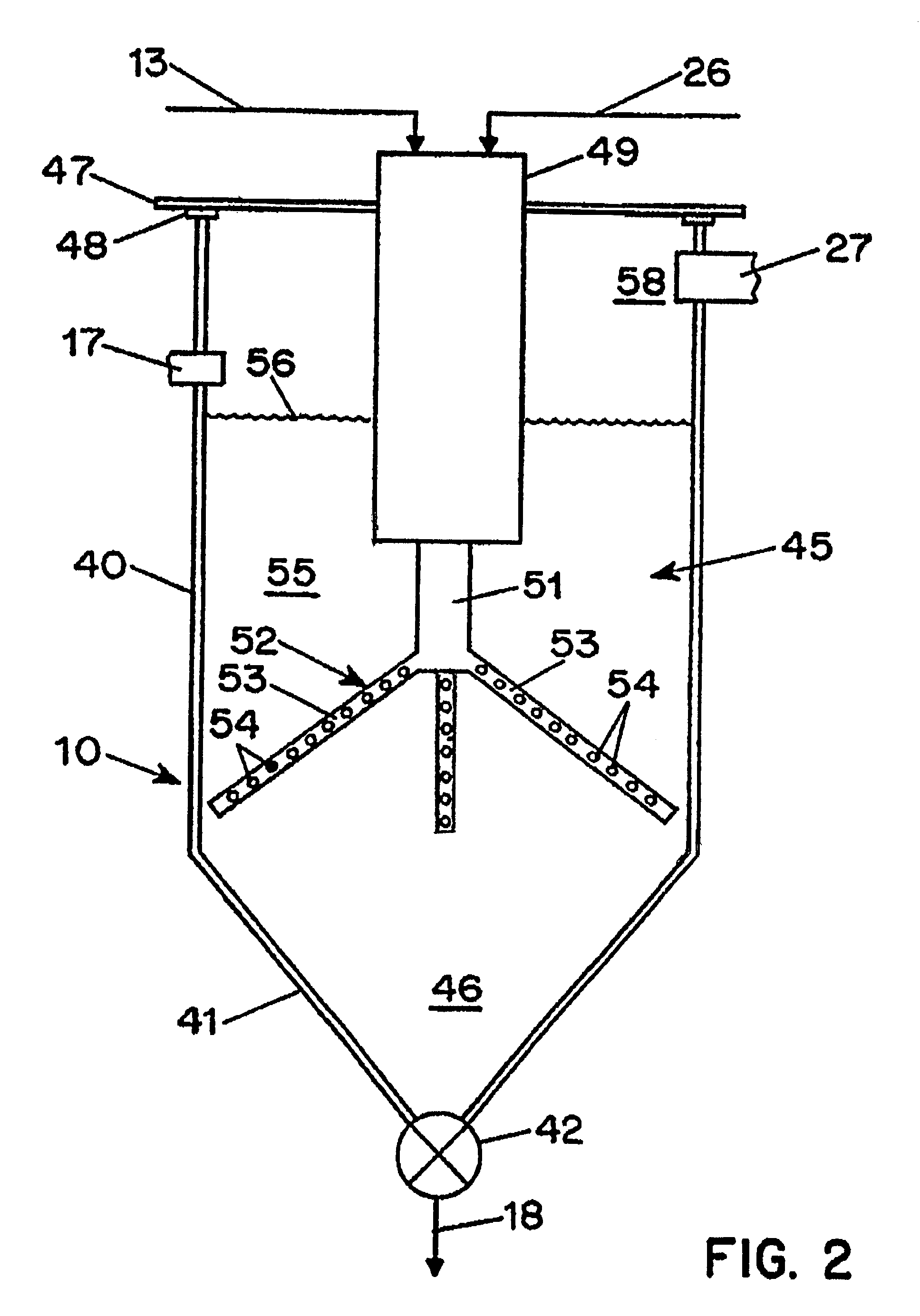

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

Barometric evaporation process and evaporator

InactiveUS6254734B1Reduce and minimize amountIncrease supplyDrying using combination processesDistillation regulation/controlChemistryVapor phase

A process for the evaporation of an available warm or hot liquid under a vacuum by applying a pressure drop thereon initiating flash-down evaporation, and followed by further flash-down evaporation under an applied pressure gradient whereby the residual liquid is raised by the vapor produced to an elevation sufficient for subsequently discharging the residual liquid from vacuum without a pump; and by separating the vapor phase from the residual liquid phase before condensing the vapor produced into distilled liquid.

Owner:SEPHTON HUGO H

Concentric proximity processing head

InactiveUS6954993B1Maintain integrityEfficient processingDrying using combination processesDrying solid materials without heatEngineeringMeniscus

In one of the many embodiments, a method for processing a substrate is disclosed which includes generating a first fluid meniscus and a second fluid meniscus at least partially surrounding the first fluid meniscus wherein the first fluid meniscus and the second fluid meniscus are generated on a surface of the substrate.

Owner:LAM RES CORP

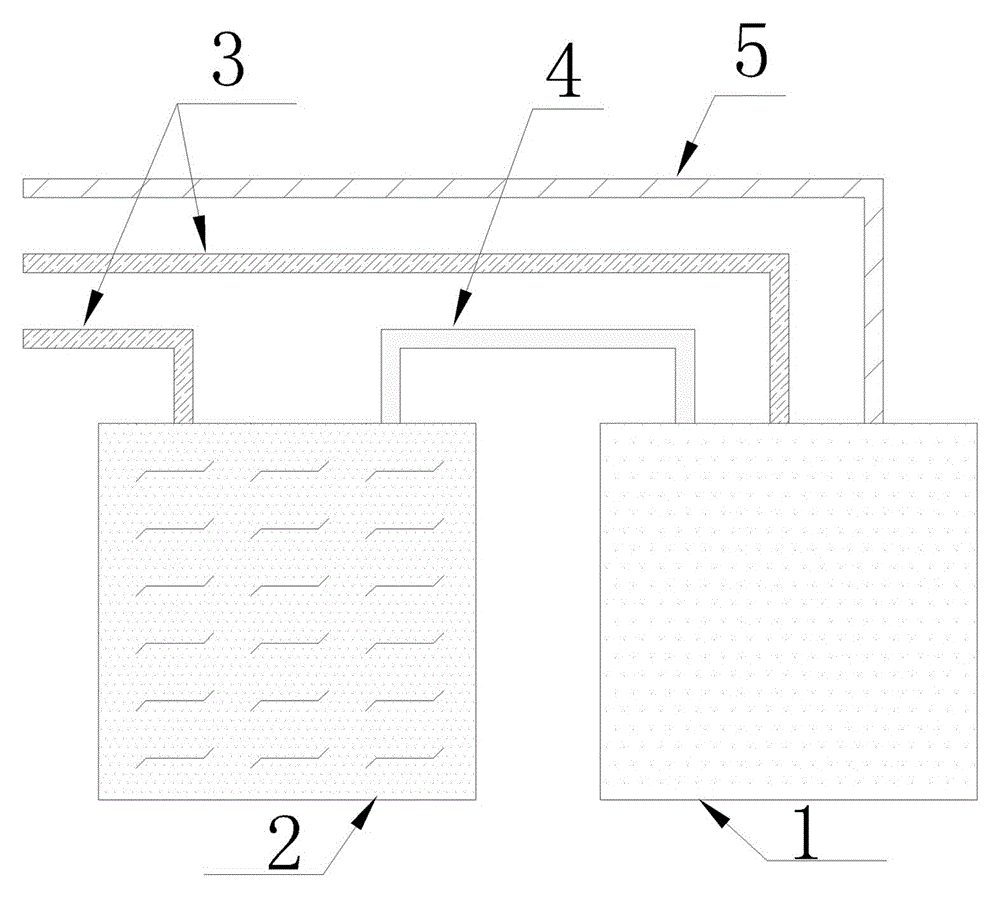

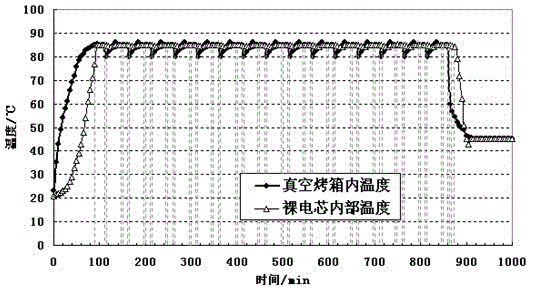

Rapid drying method for lithium ion battery cell

ActiveCN105115250ALow boiling pointImprove water removal effectDrying using combination processesBoiling pointNitrogen gas

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

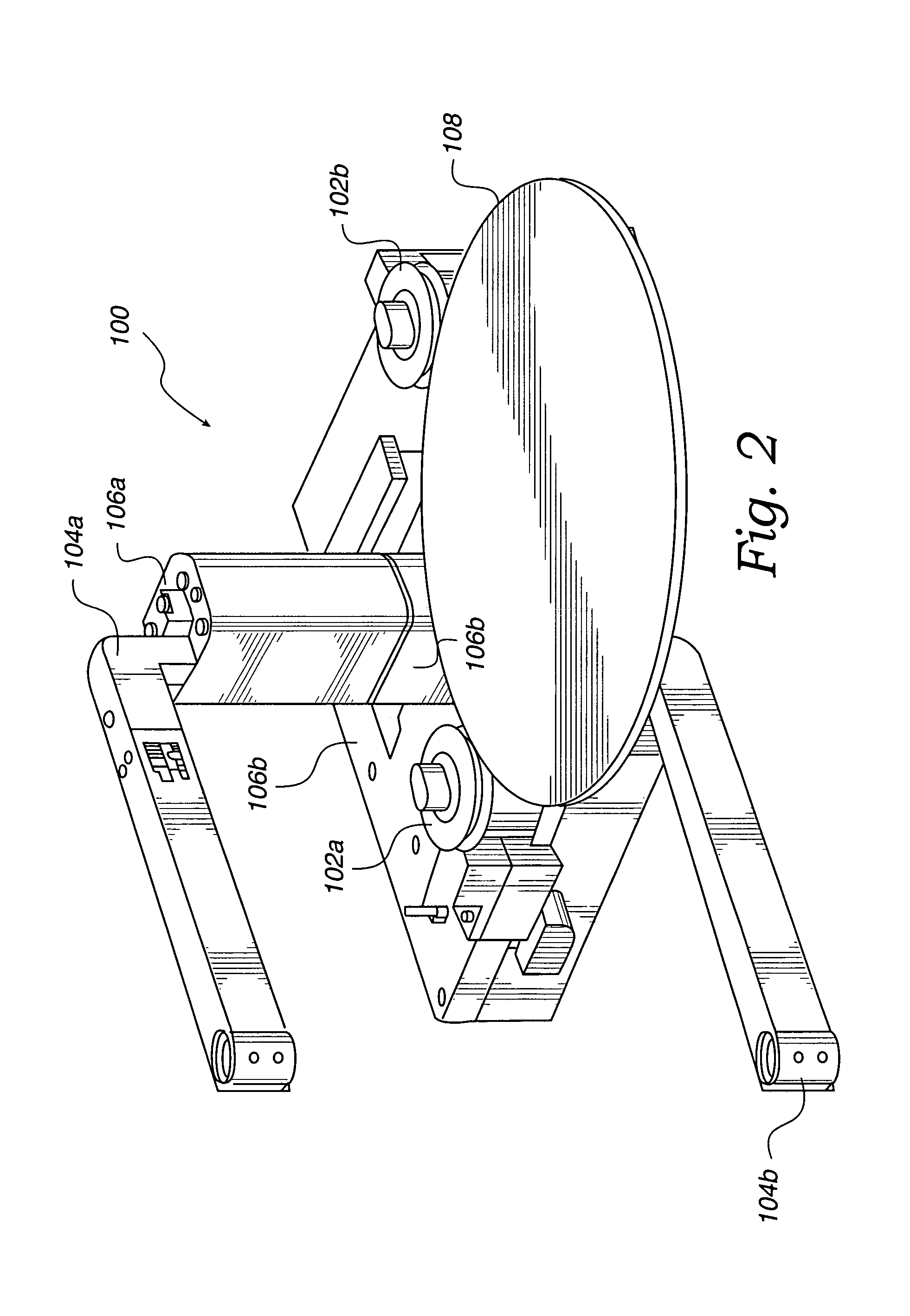

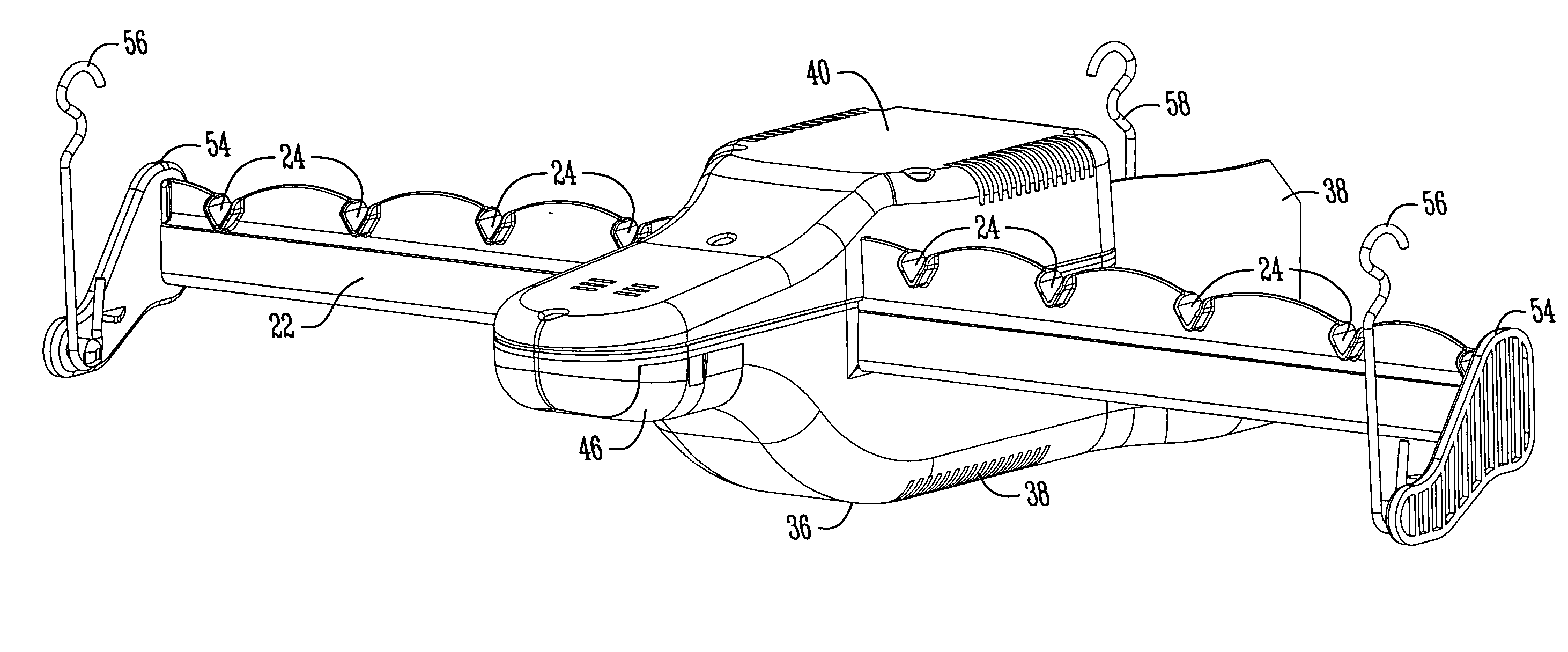

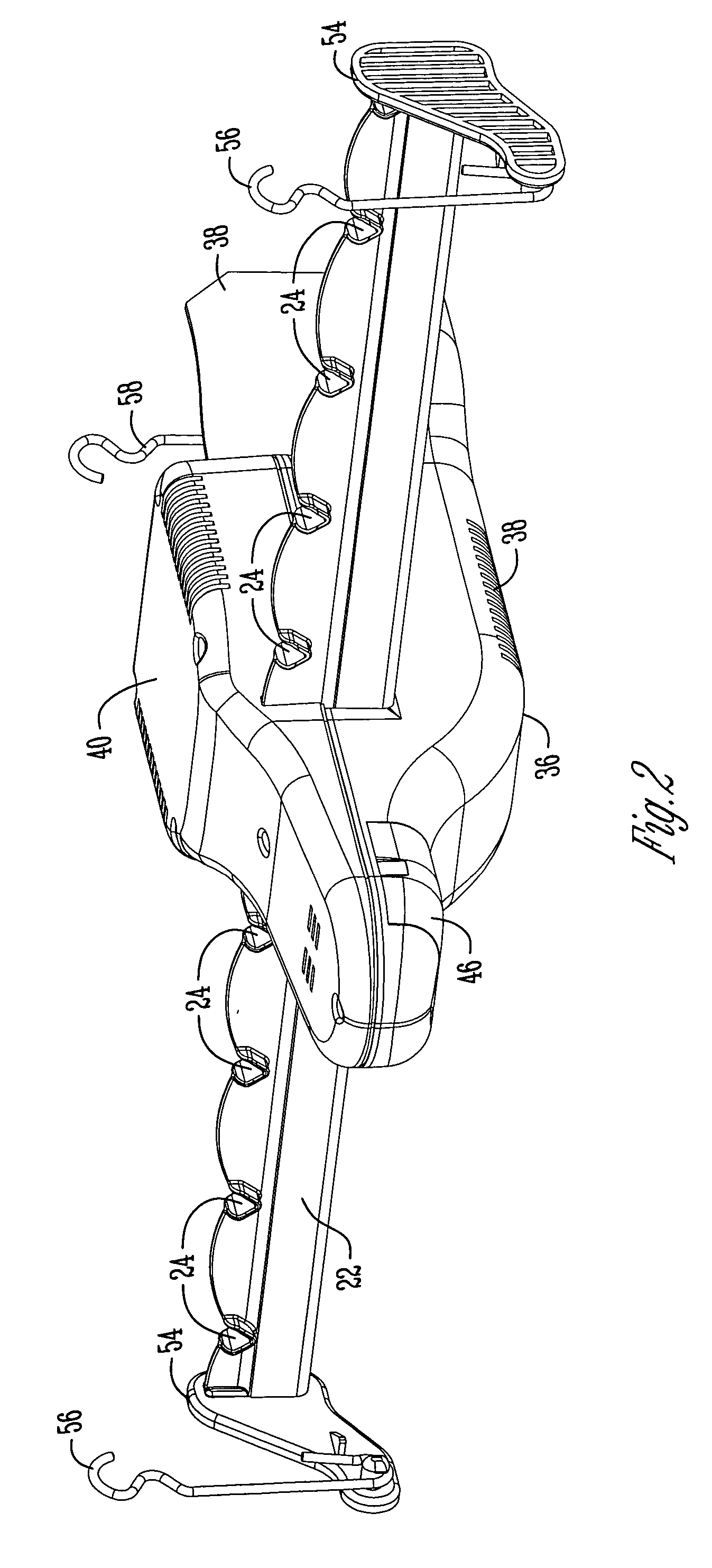

Drying cabinet shaker mechanism

InactiveUS20060037209A1Easy to disassembleDrying using combination processesDrying solid materials without heatDrive shaftClothes hanger

A clothes drying cabinet is provided with a shaker assembly including a bar suspended in the cabinet for supporting clothes hangers. A motor is mounted adjacent the bar and has a drive shaft. A drive weight is eccentrically mounted to the drive shaft of the motor so that upon actuation of the motor, the drive weight imparts a shaking motion to the bar so as to facilitate removal of wrinkles from the clothing on the hangers. A ballast weight may also be provided in the shaker assembly so as to evenly distribute the energy from the eccentric weight regardless of the weight of the clothes hanging on the bar.

Owner:MAYTAG

Fabric-Crepe Process With Prolonged Production Cycle and Improved Drying

ActiveUS20080264589A1Improve productivityLower levelDrying using combination processesNon-fibrous pulp additionAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

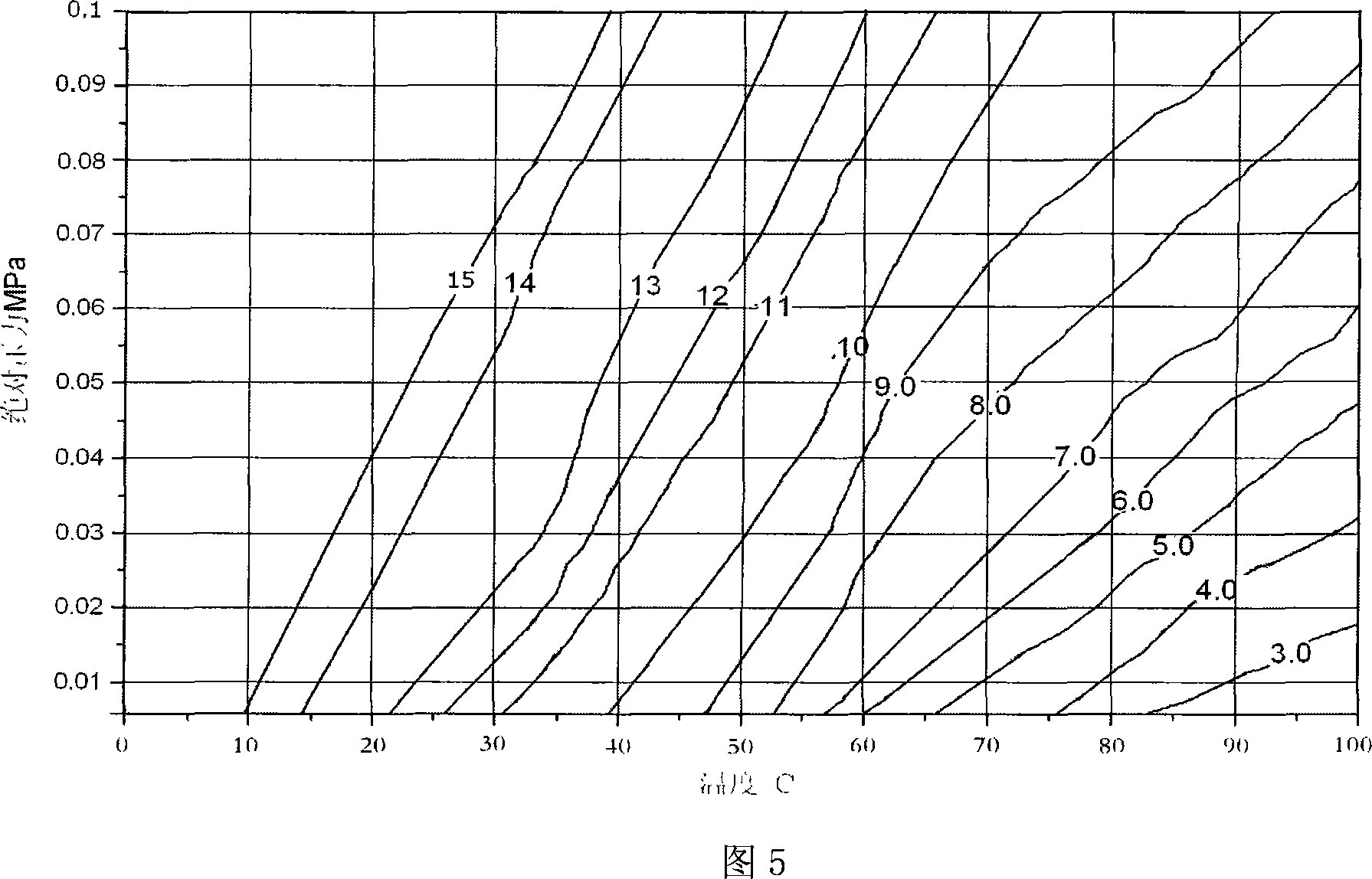

Wood drying method

InactiveCN101236048ADrying using combination processesDrying solid materials without heatPulp and paper industryEquilibrium moisture content

The invention discloses a method of log vacuum drying, which is adaptable to drying process of logs with minor diameter. The method comprises carrying out reheating to-be-dried wood, then keeping the reheating to-be-dried wood under vacuum circumstance, enabling drying media to flow along the longitudinal direction of the to-be-heated wood, controlling the temperature and value of absolute pressure according to corresponding graphs of previously determined medium temperature, the absolute pressure and equilibrium moisture content, charging cooling water in a heat exchange system when the final moisture content of the wood meeting the qualification and thereby realizing rapidly cooling and discharging, wherein the to-be-dried wood is log with minor diameter or plates and the ratio of the length of the to-be-dried wood and the average diameter or thickness is 5-15. The method of the invention enables the wood to be uniformly heated, and obviously shortens the time for the procedures of preheating the wood and drying, thereby largely increasing the production efficiency of drying the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY +1

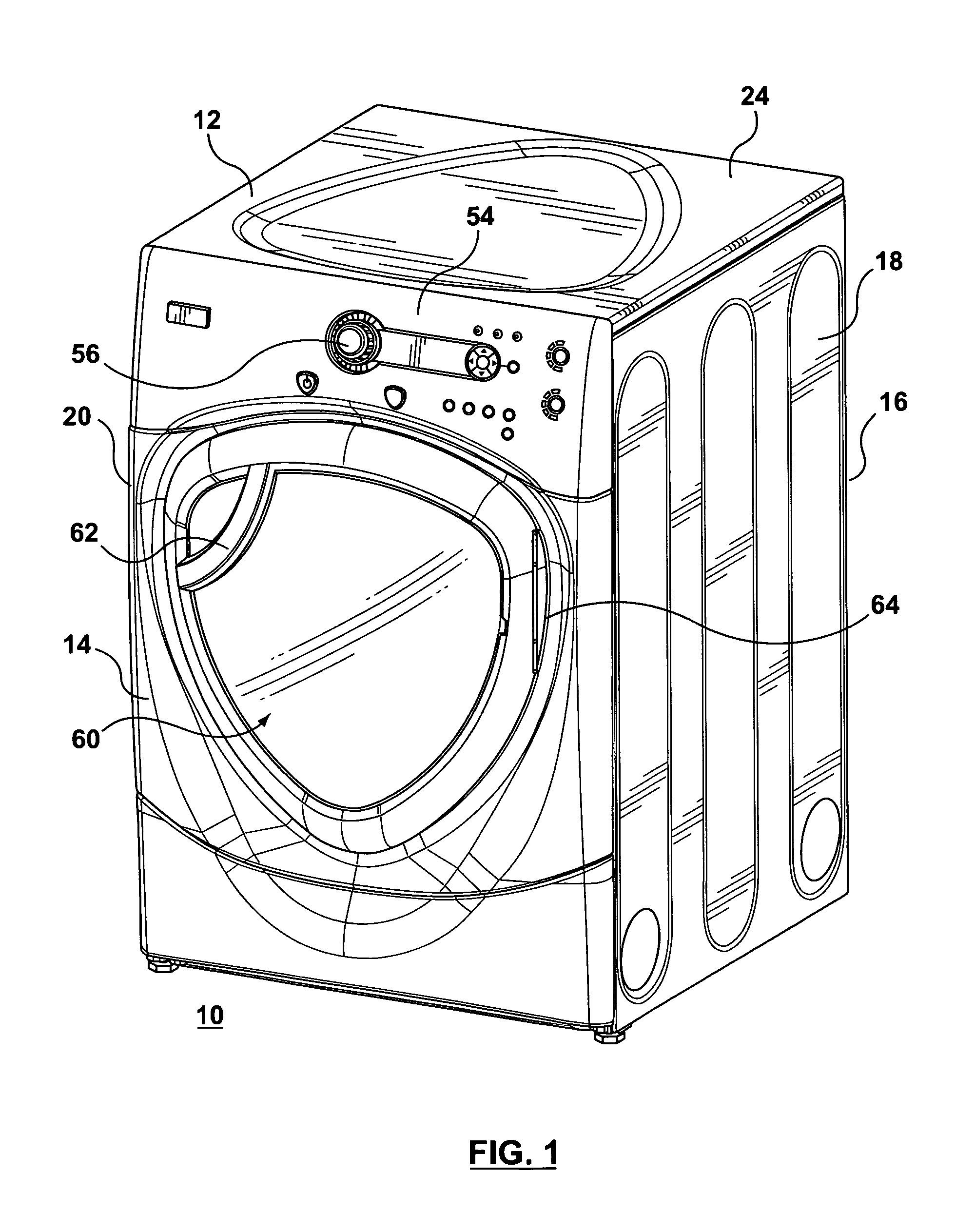

Clothes dryer apparatus and method for de-wrinkling clothes with reduced condensation

InactiveUS20100050464A1Reduce condensationReducing and eliminating wrinkleDrying using combination processesDrying gas arrangementsWrinkle skinProcess engineering

A clothes dryer has a drying drum with an airflow inlet and a motor for rotating the drum. A blower rotated by a fan motor flows air into, through, and out the drum. A refresh or touch-up de-wrinkle course is selected via a signal input on a control panel. Steam is supplied to the drum by a steam generating device, and heated air from a heater is supplied via the inlet. A controller operates the steam device and heater, in response to the course being selected, to supply to the drum a plurality of steam pulses of at least one first predetermined time and a heated air pulse after each steam pulse. Heated air pulses between steam pulses are intermediate pulses of at least one second predetermined time to reduce condensation in the dryer and the final pulse of heated air is of a duration to dry articles.

Owner:MABE CANADA

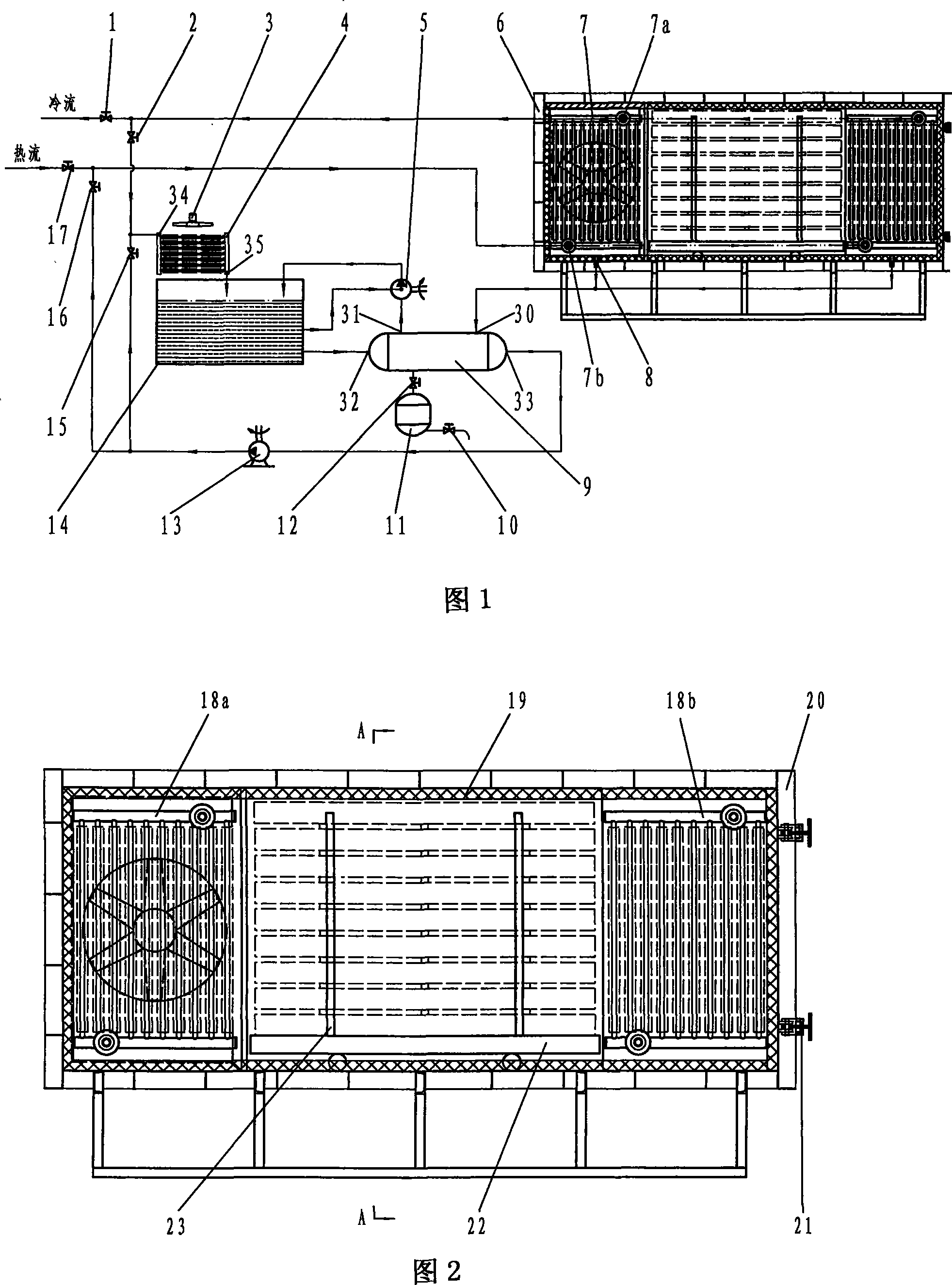

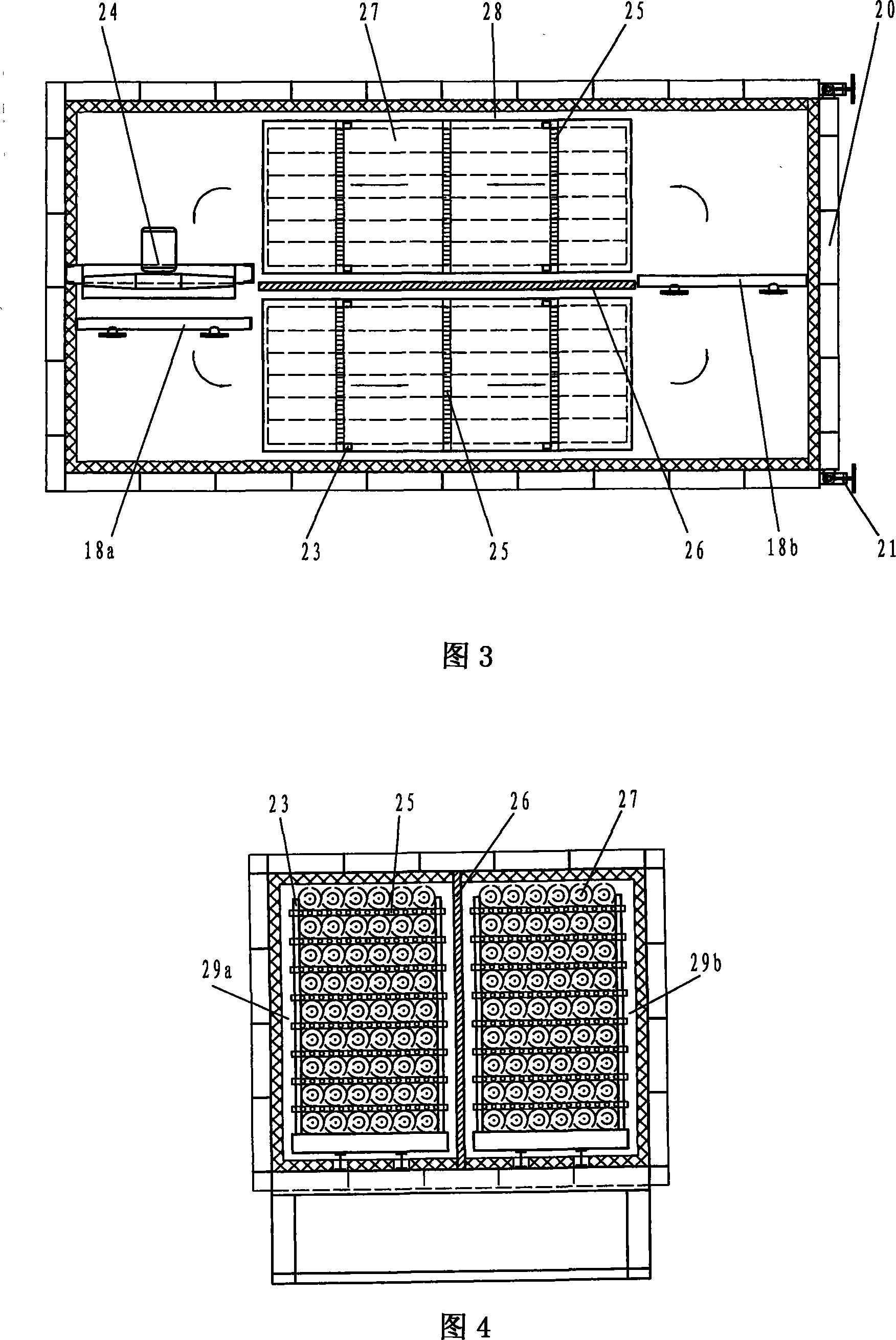

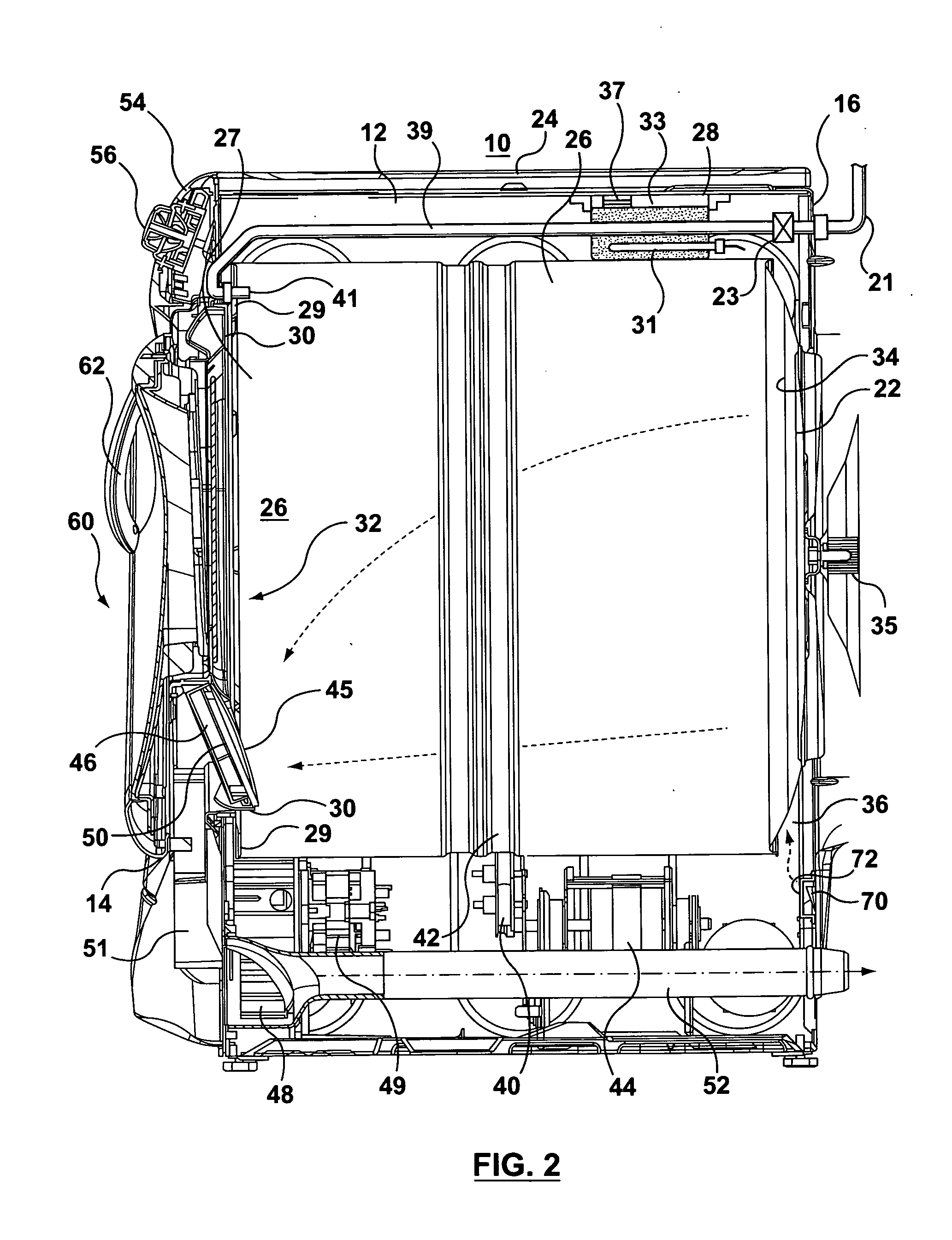

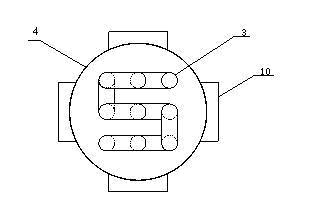

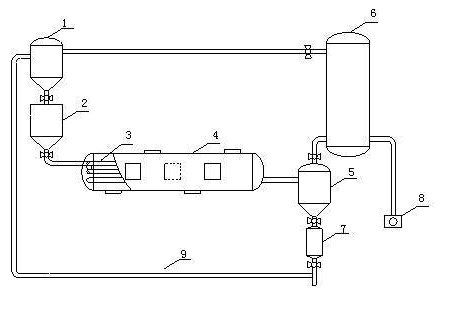

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com