Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3126 results about "Ozone generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

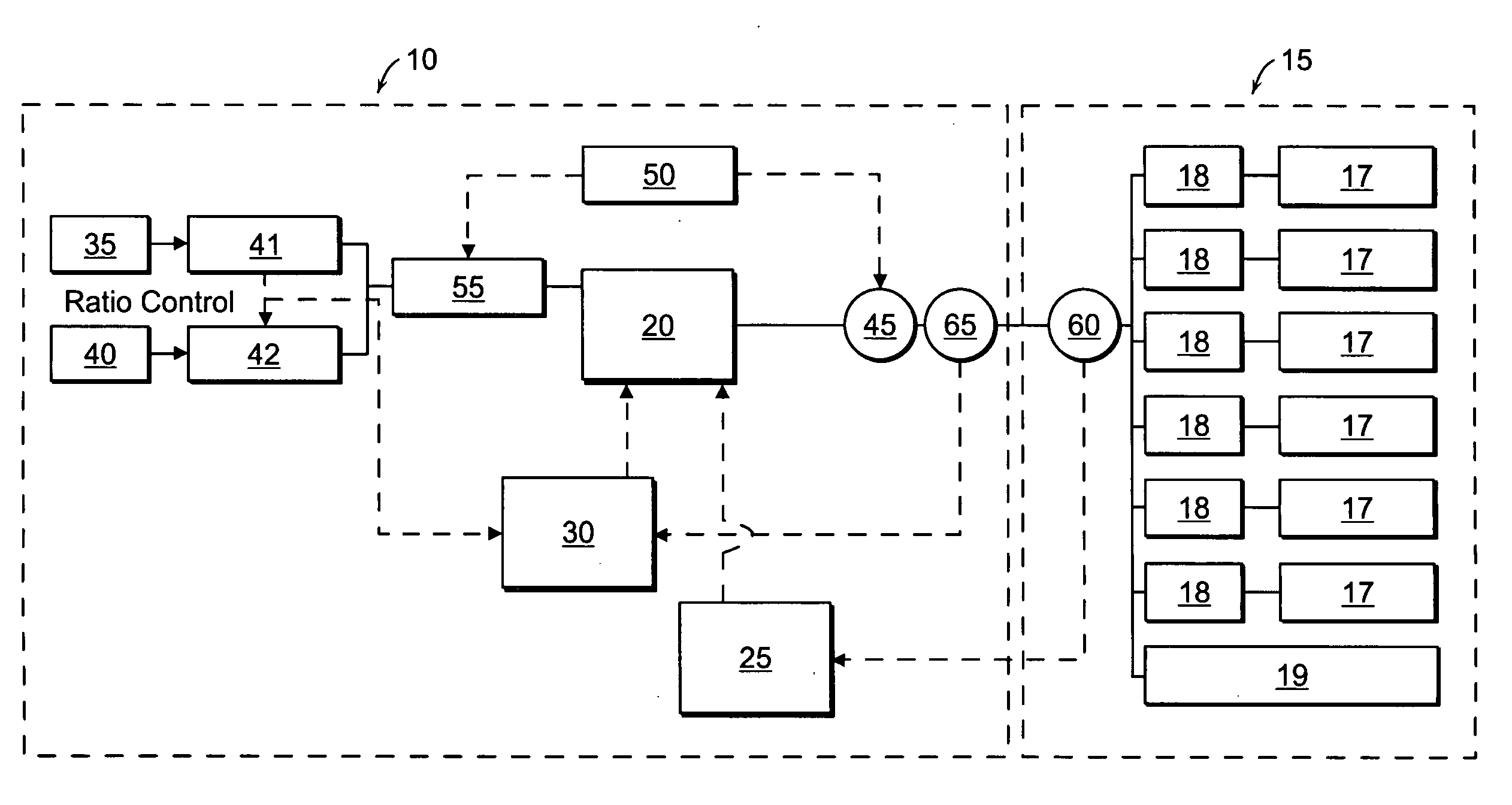

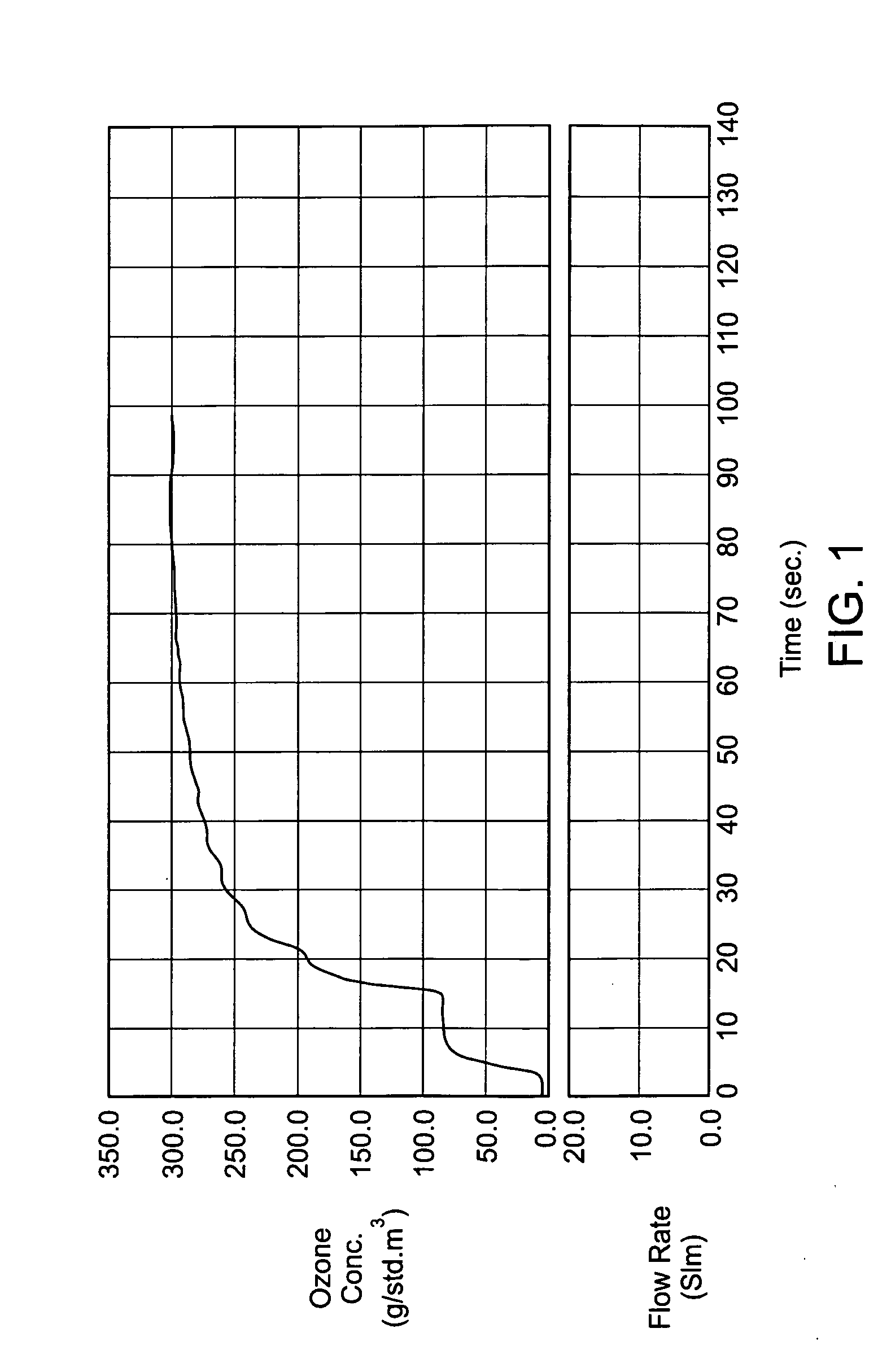

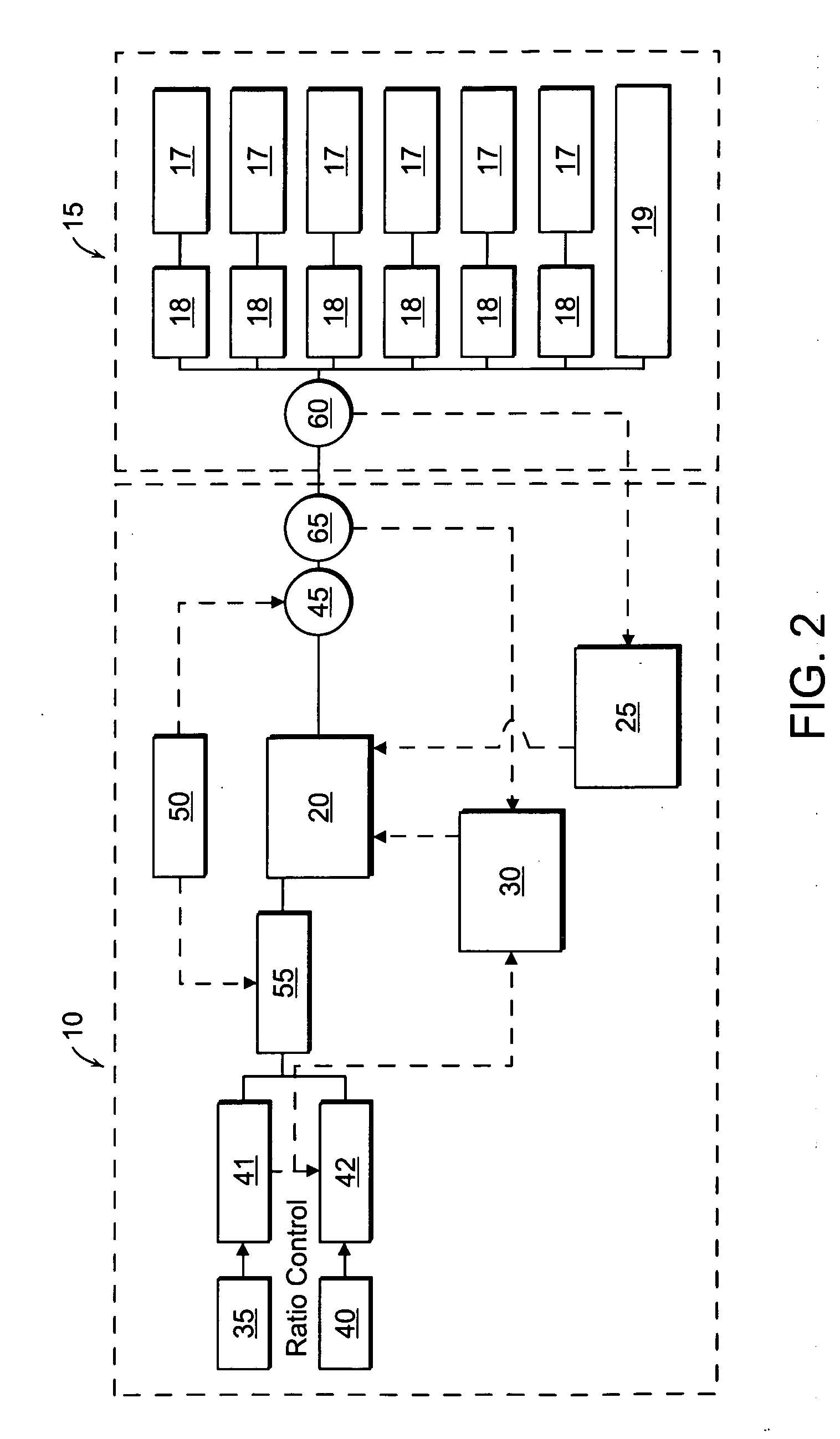

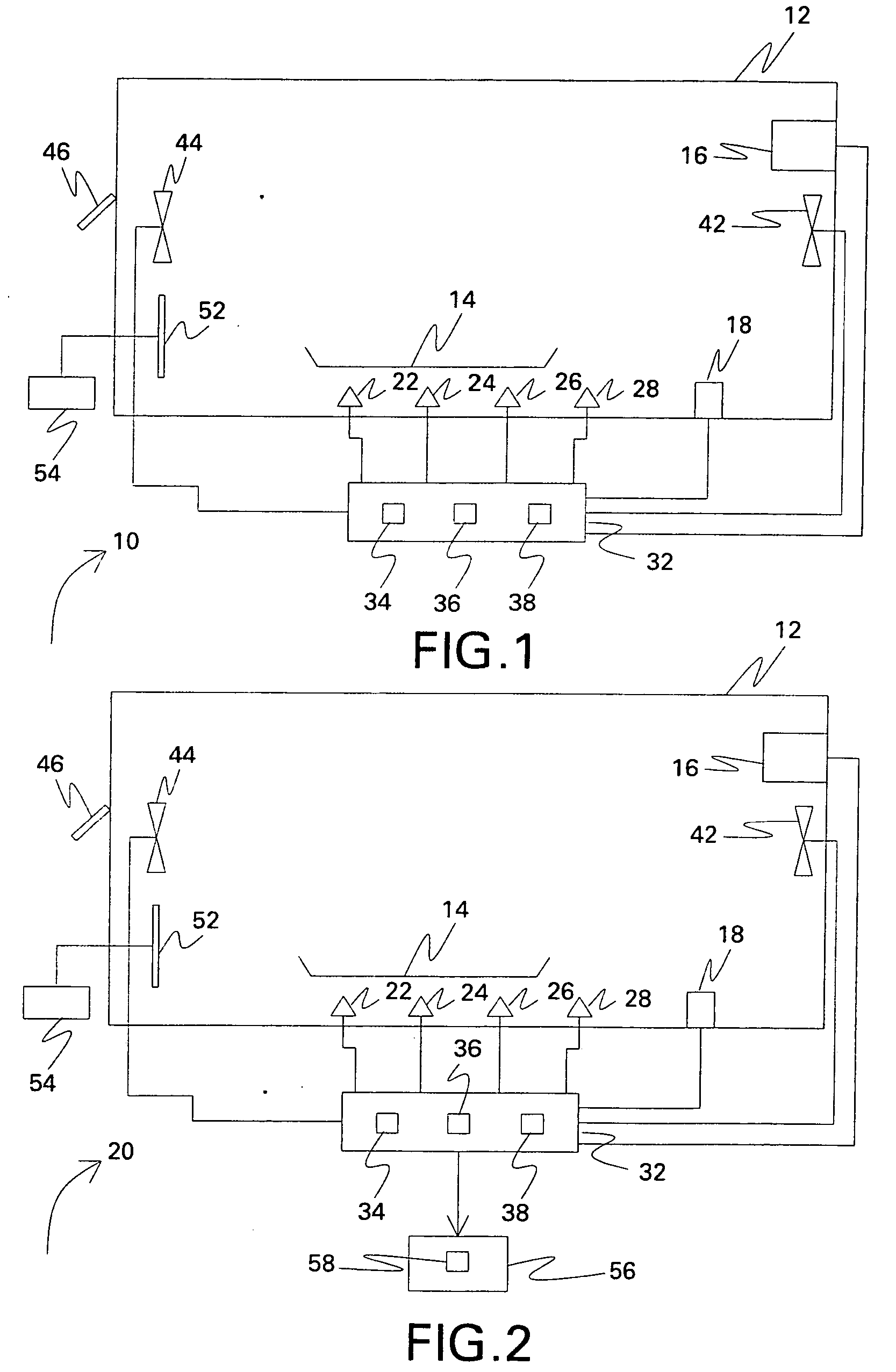

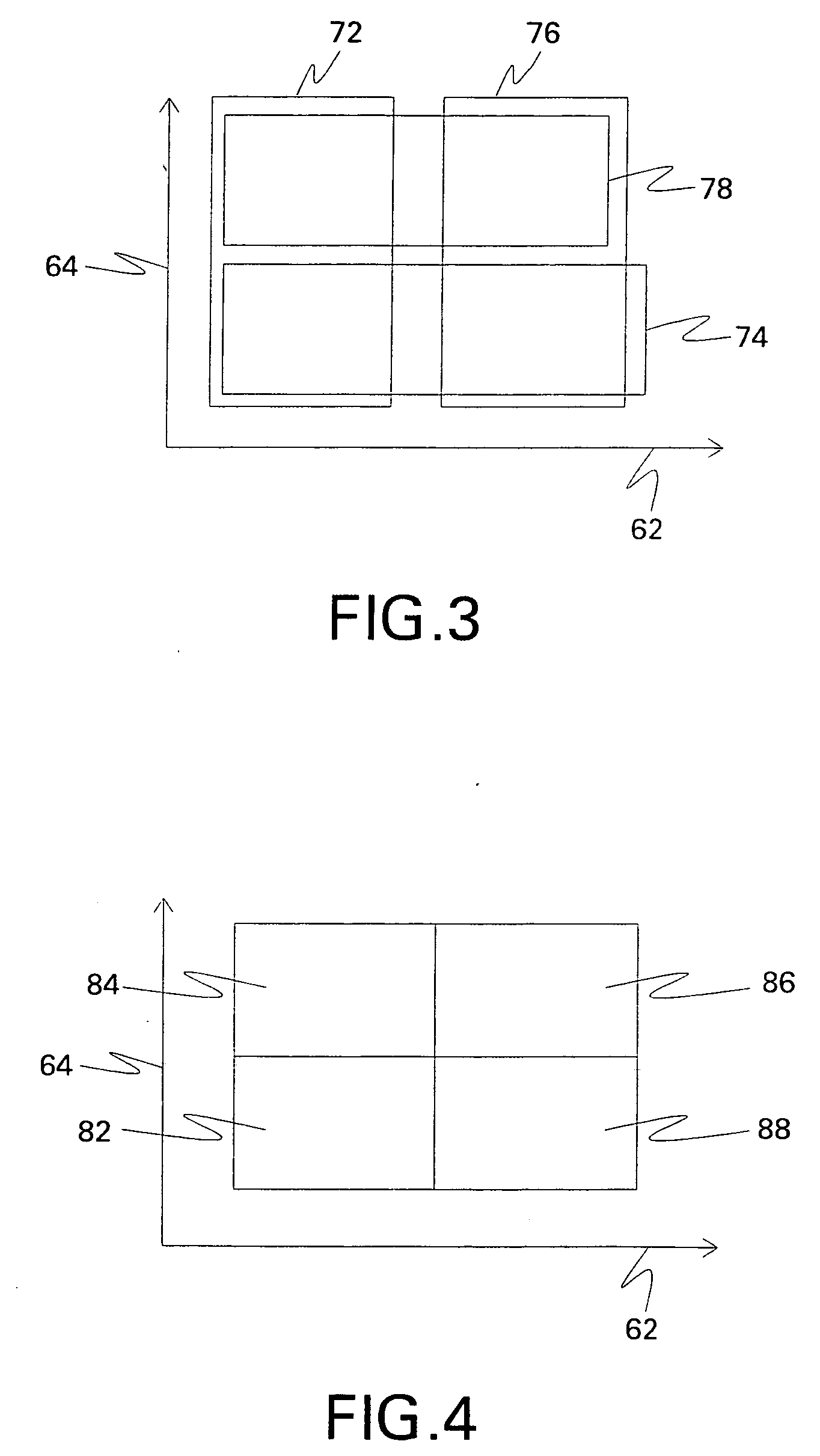

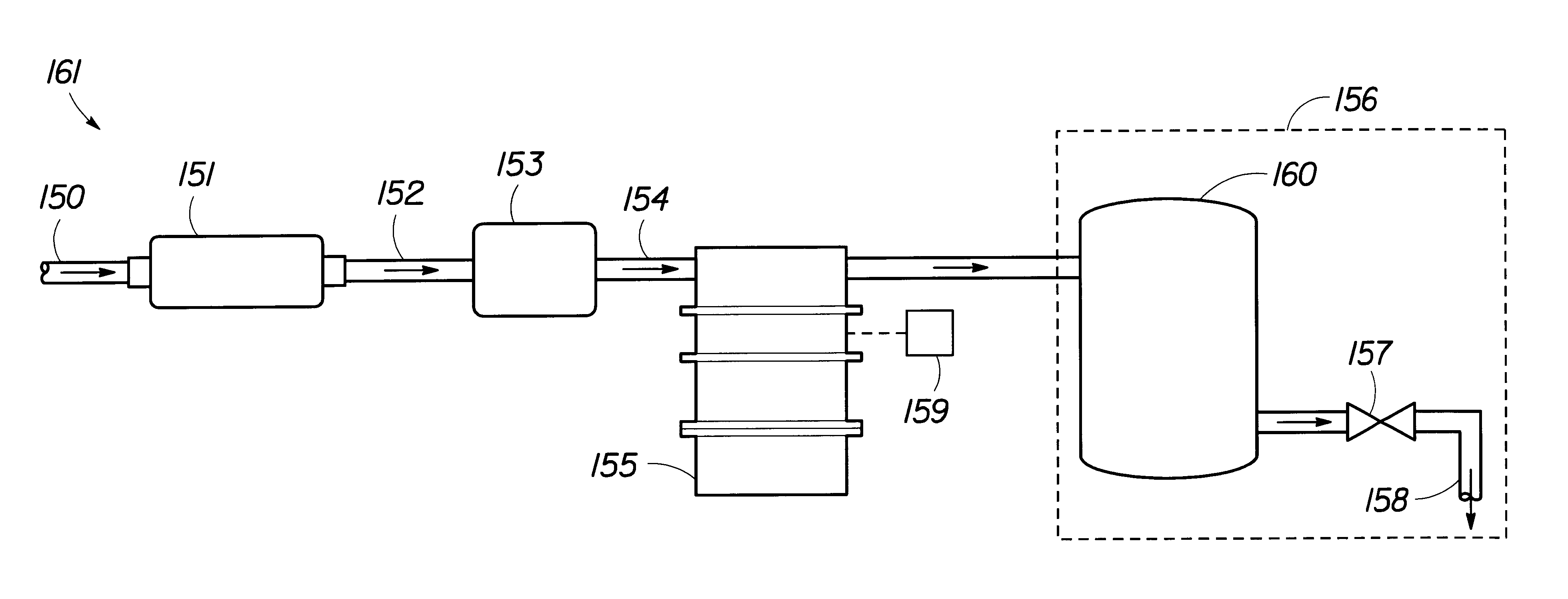

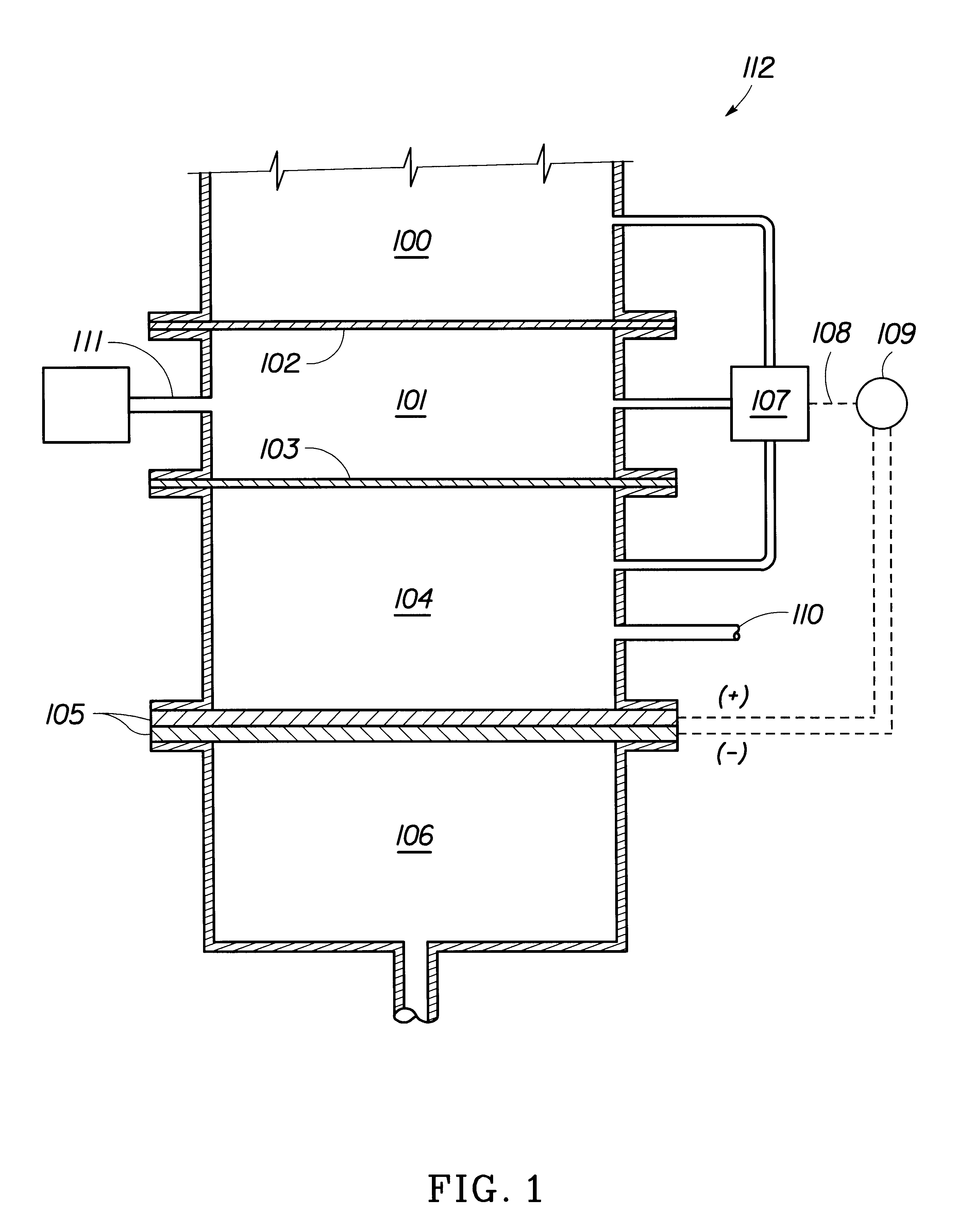

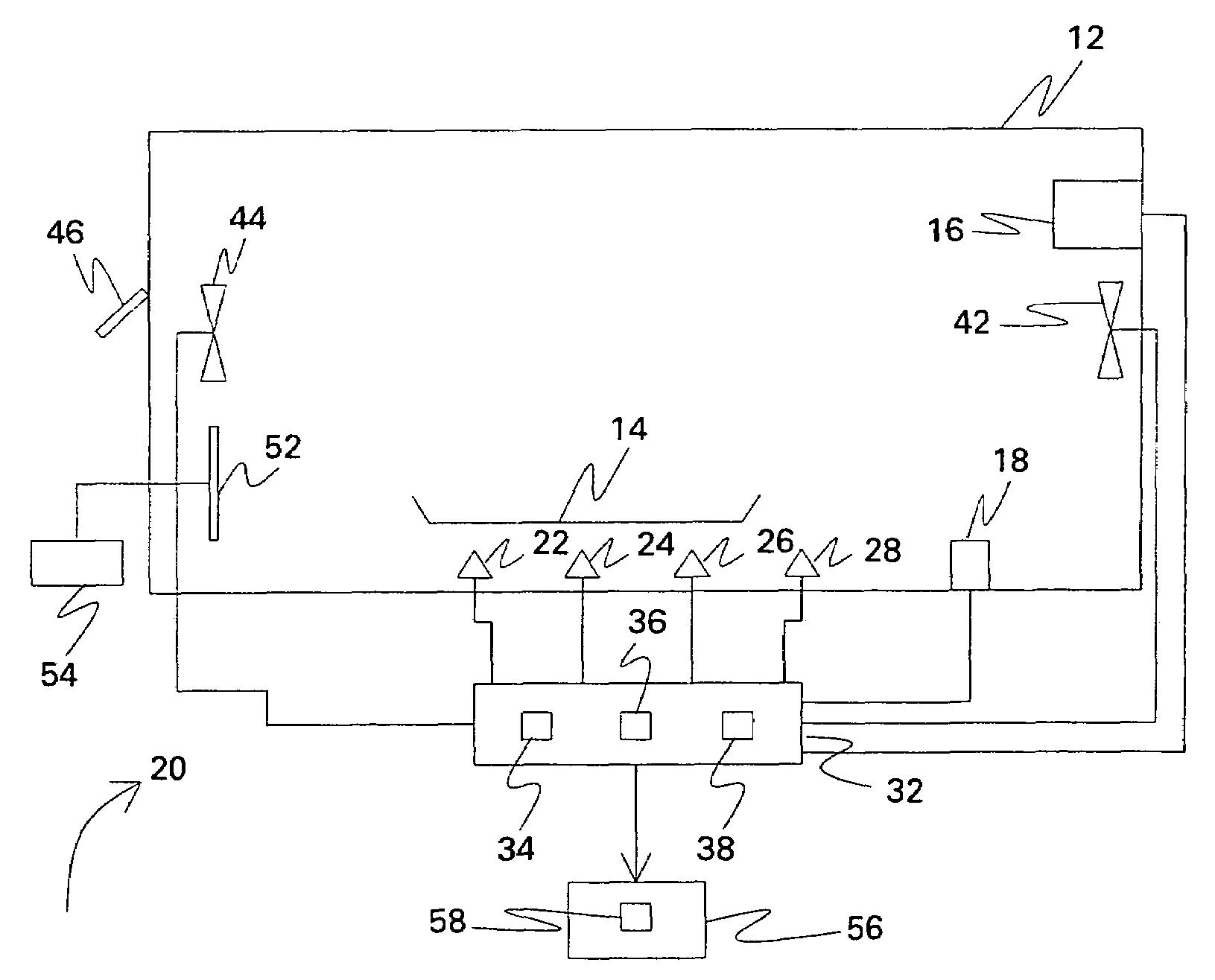

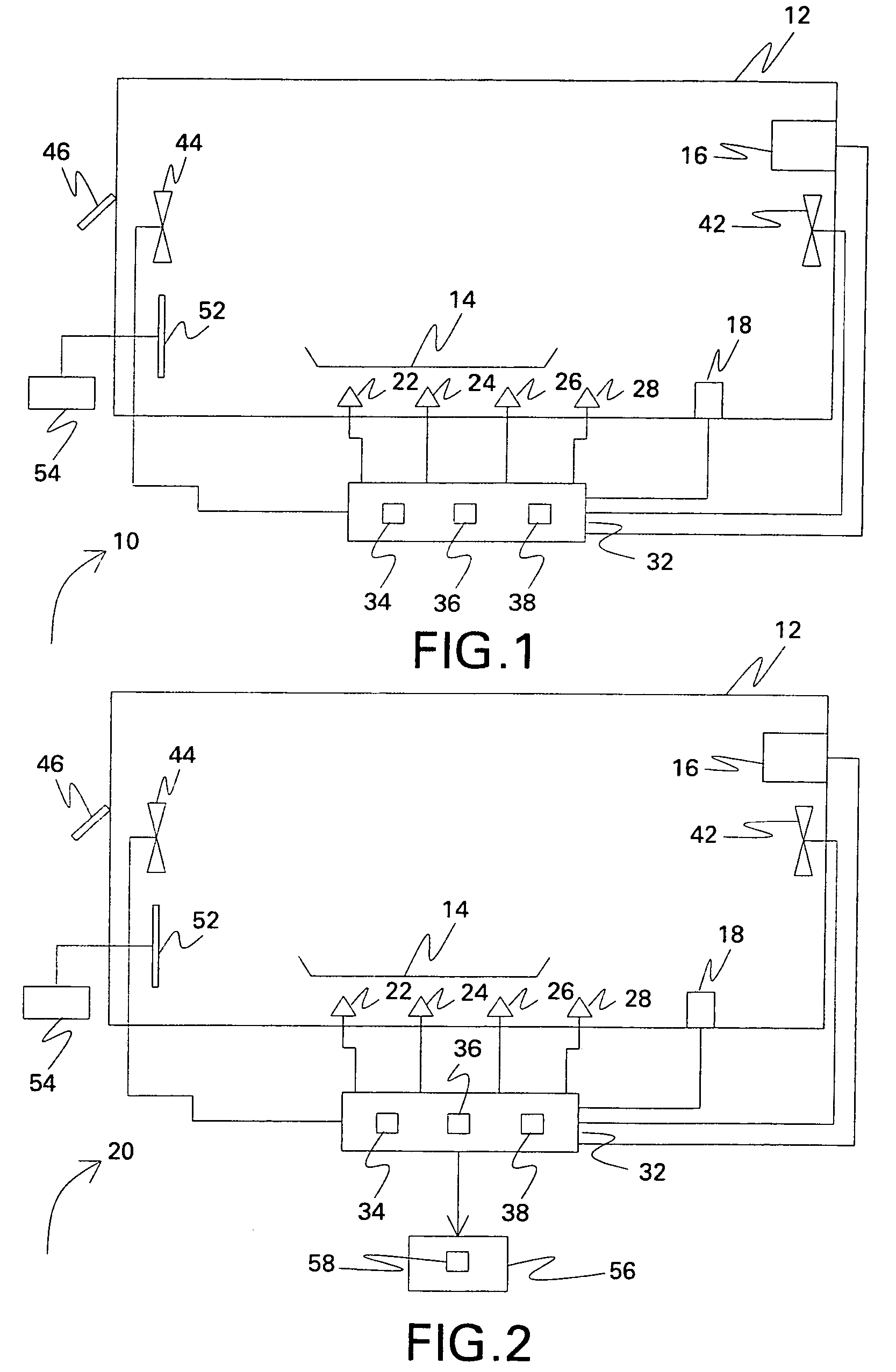

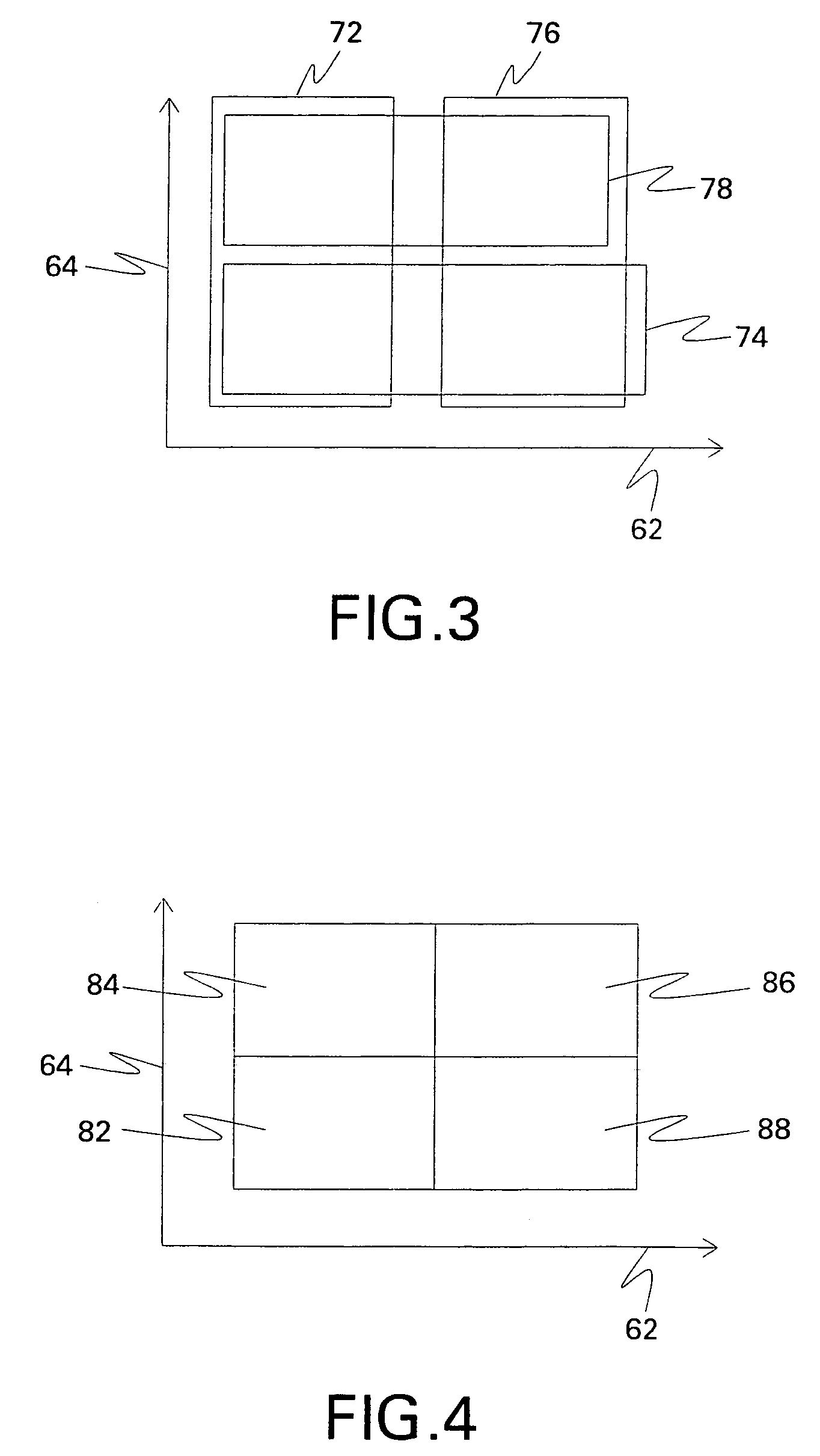

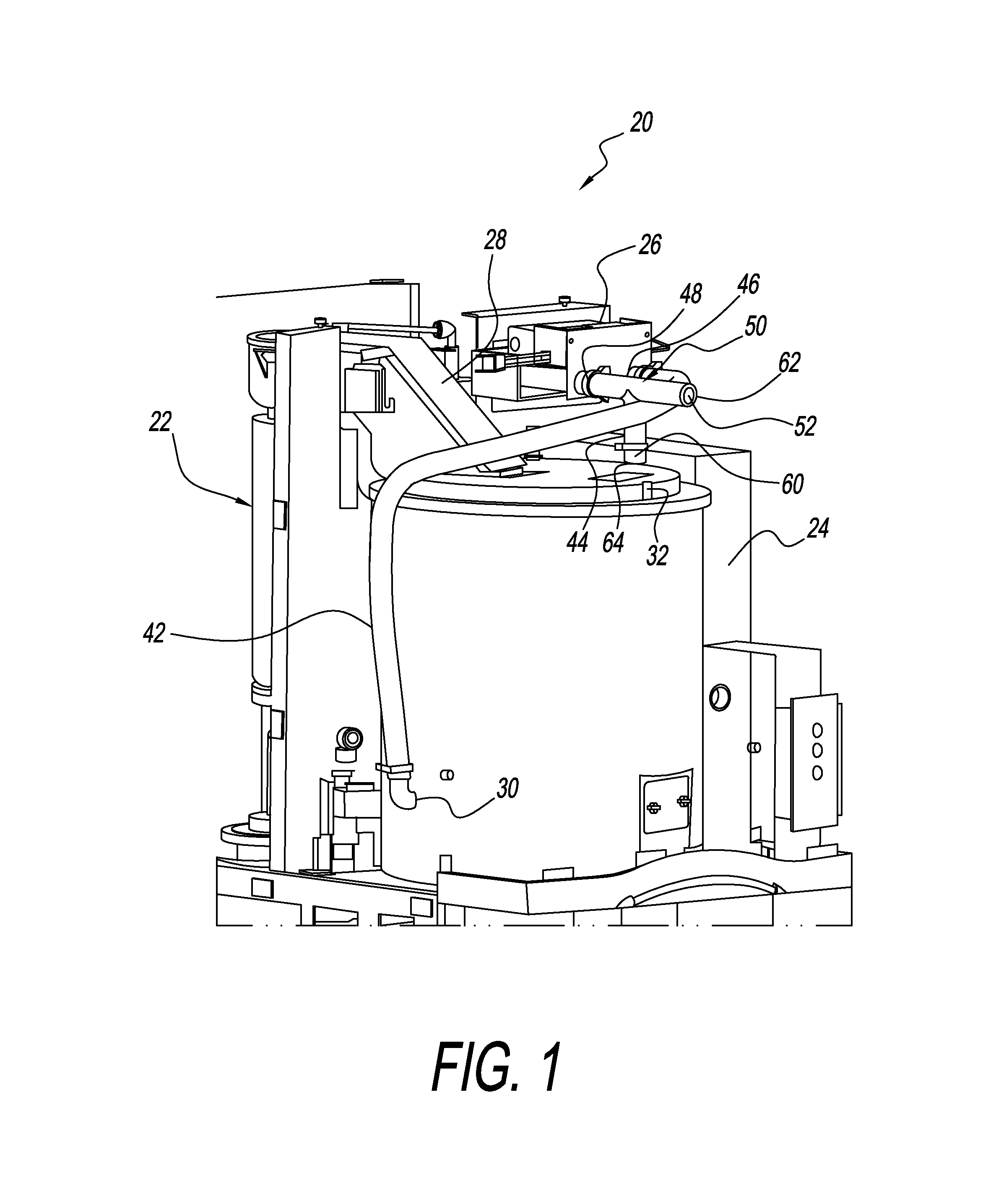

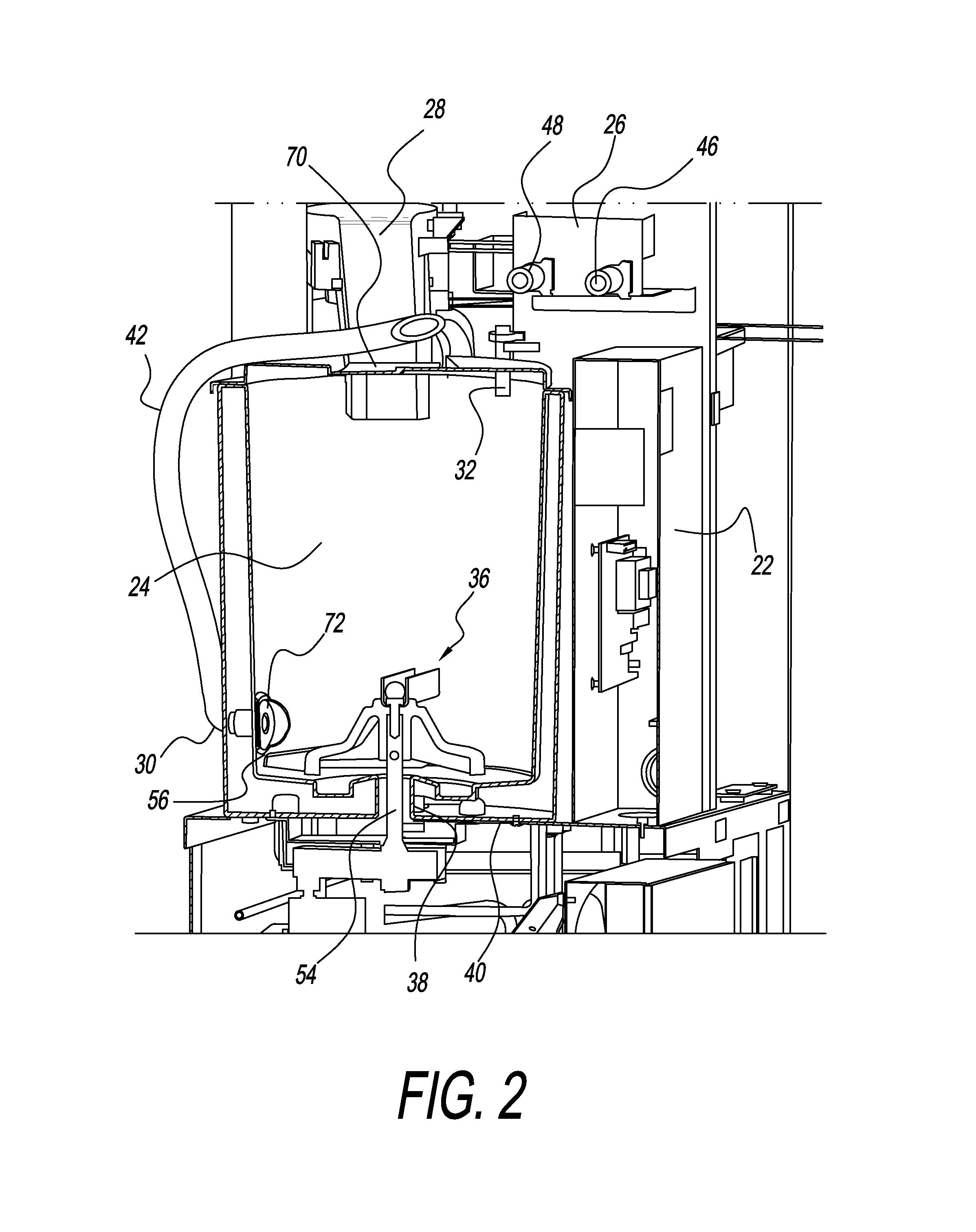

Ozone system for multi-chamber tools

ActiveUS20070020160A1Simplify System DesignReduce equipment costsSemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOzone generatorControl theory

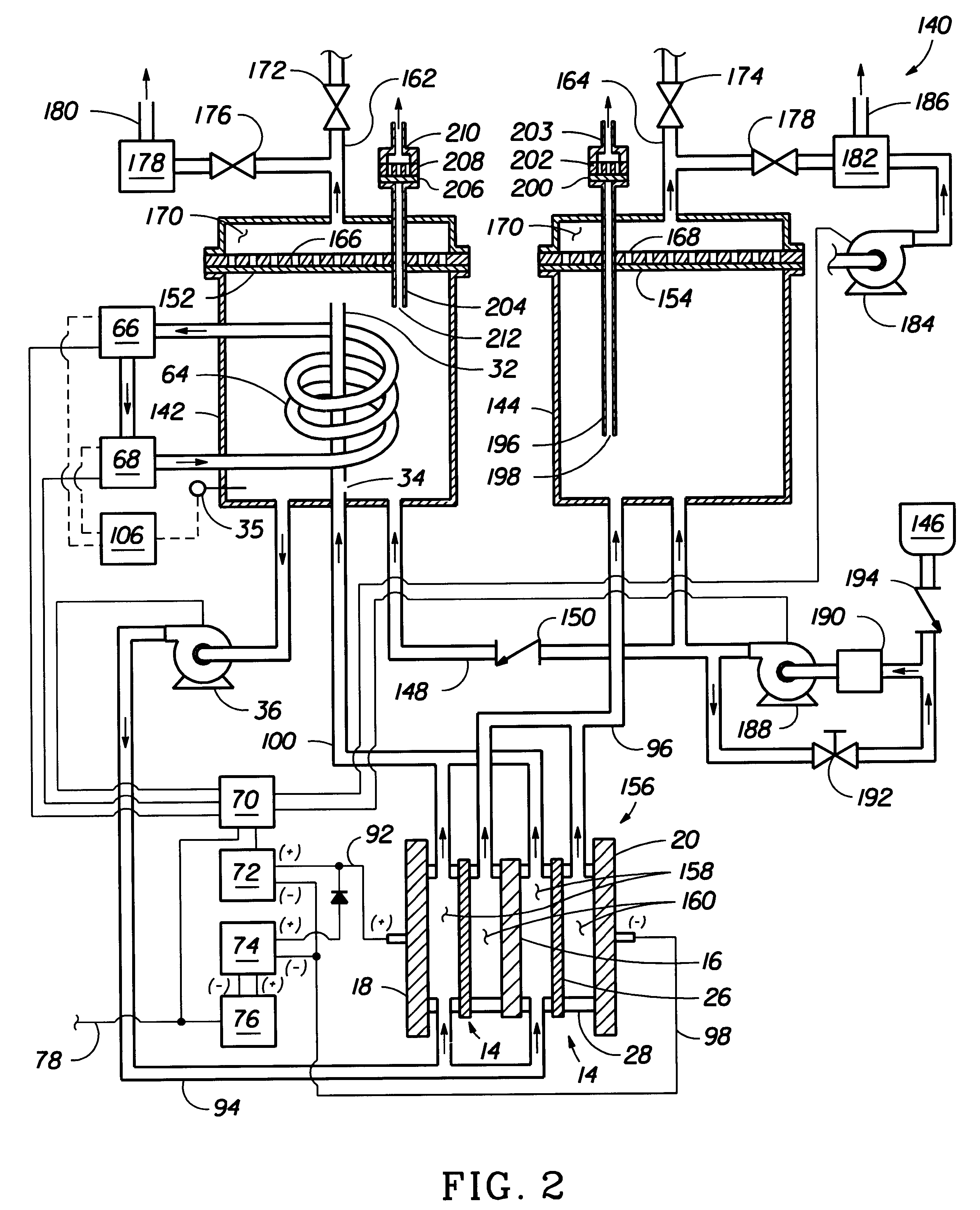

An improved system and method for controlling ozone concentration in connection with a multi-chamber tool. The system and method involve a first and a second concentration controller in combination with an ozone generator. The first concentration controller detects an EVENT (i.e., one of the chambers in the multi-chamber tool coming on-line or off-line) and in response provides a power instruction to the ozone generator in accordance with a predictive control algorithm. The first concentration controller has a fast (i.e, about 1 second) response time. The second concentration controller is masked from the ozone generator during the EVENT, but otherwise controls the generator after an interval of time has lapsed after the EVENT. The second concentration controller has a slower response time than the first concentration controller, however the second concentration controller provides the system with long-term stability and can be used to provide updated data to the predictive control algorithm.

Owner:MKS INSTR INC

System and method for preserving food

System and method for preserving food. Embodiments of the system include a food compartment to store food and a user interface configured to receive user input relating to the preservation of the food stored. The system also includes a humidity sensor configured to sense a humidity level, an ozone generator configured to generate ozone gas, an ozone sensor configured to sense an ozone level and a gas sensor configured to sense a level of residual gases inside the food compartment. The system further includes a controller, responsive to the user interface, the humidity sensor, the ozone sensor and the gas sensor. In one embodiment, the controller preserves the food stored in the food compartment as a function of the user input, the humidity level, the ozone level, the residual gas level and as a function of a type of the food stored in the food compartment.

Owner:HAIER US APPLIANCE SOLUTIONS INC

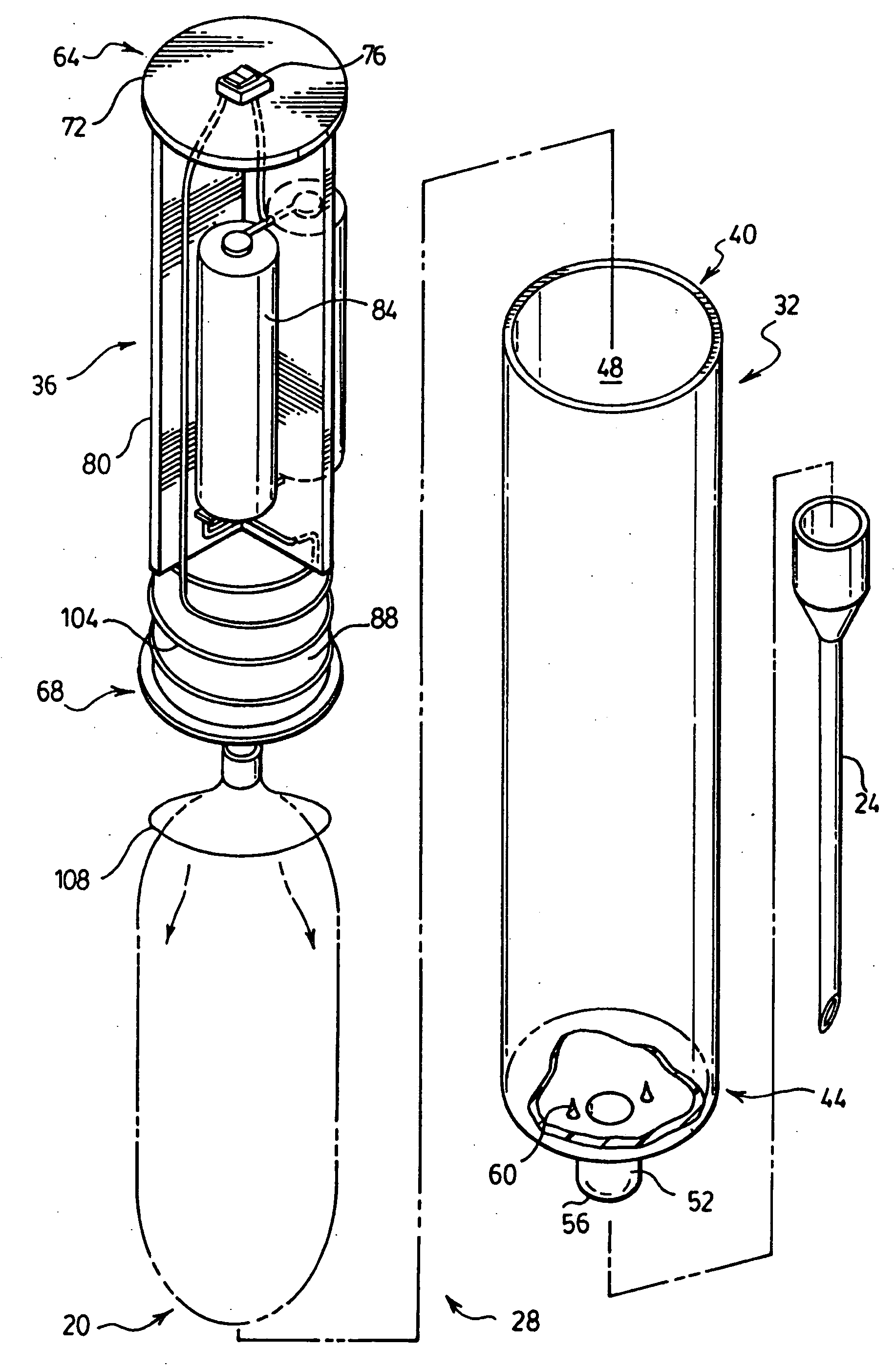

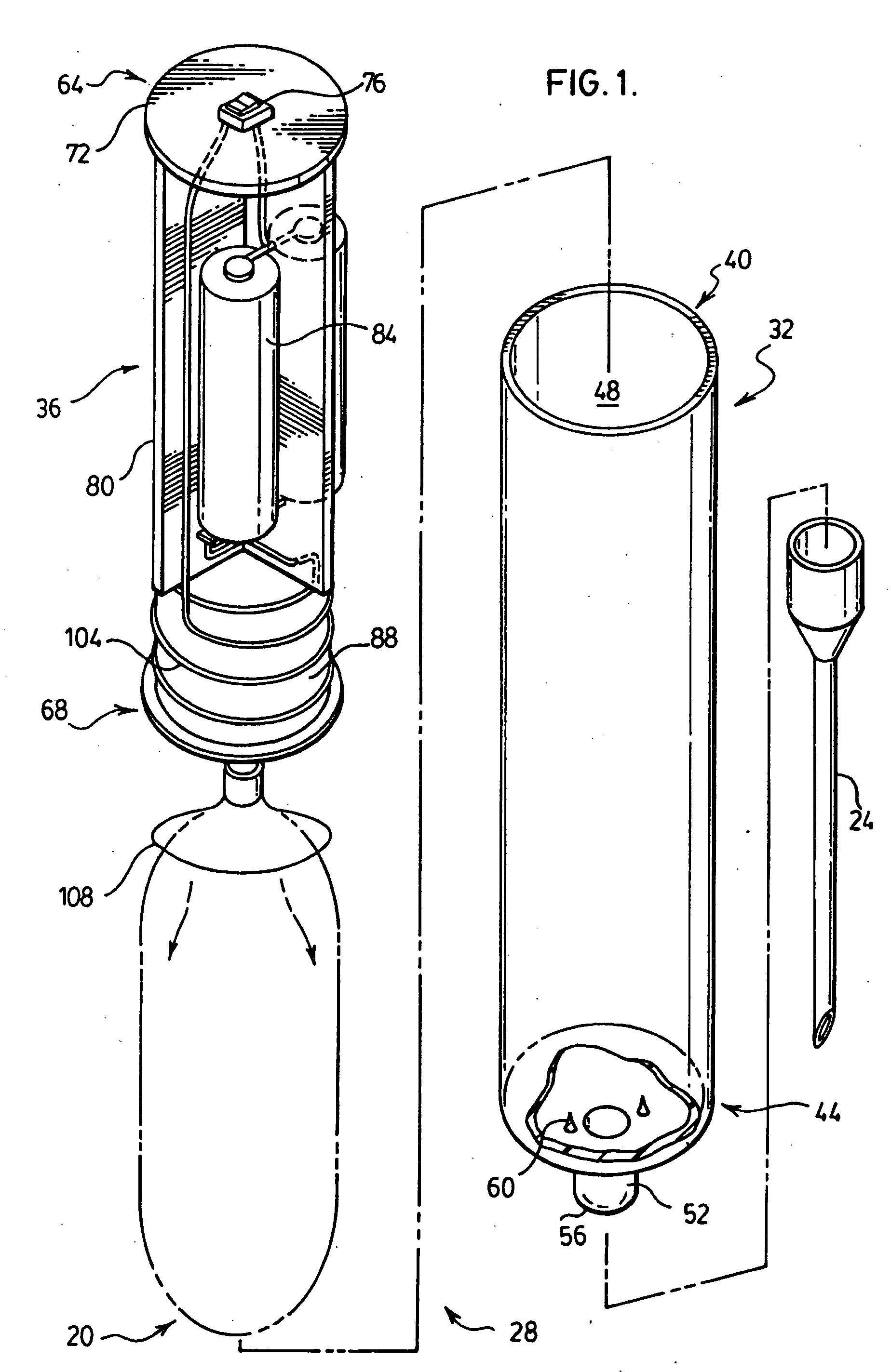

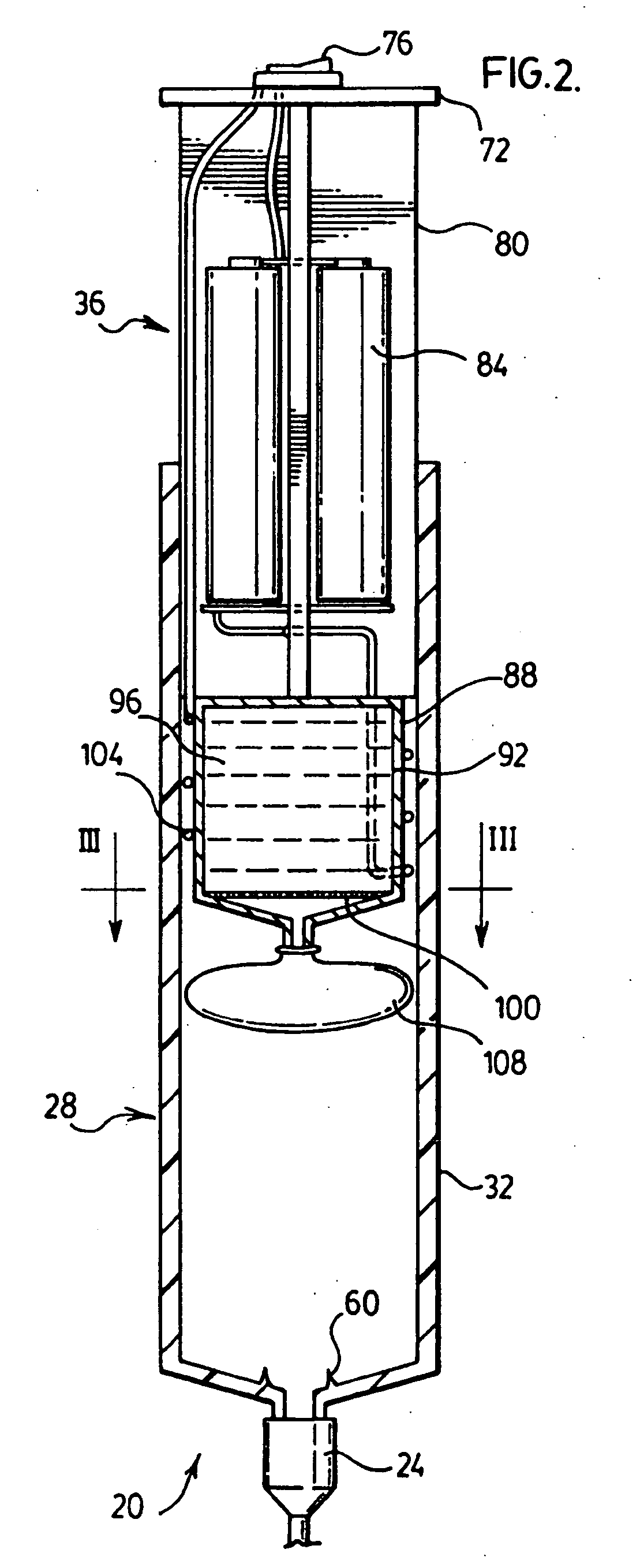

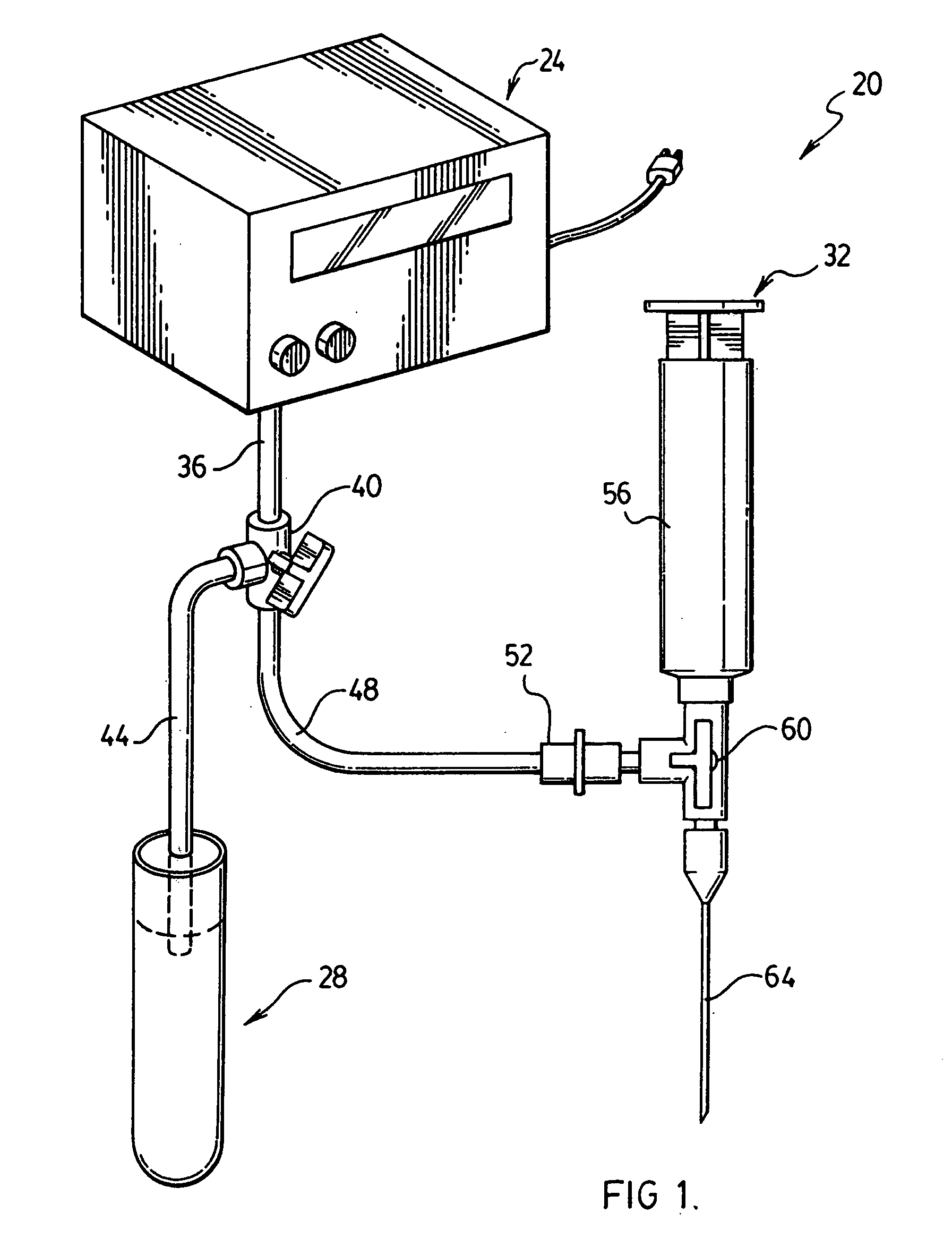

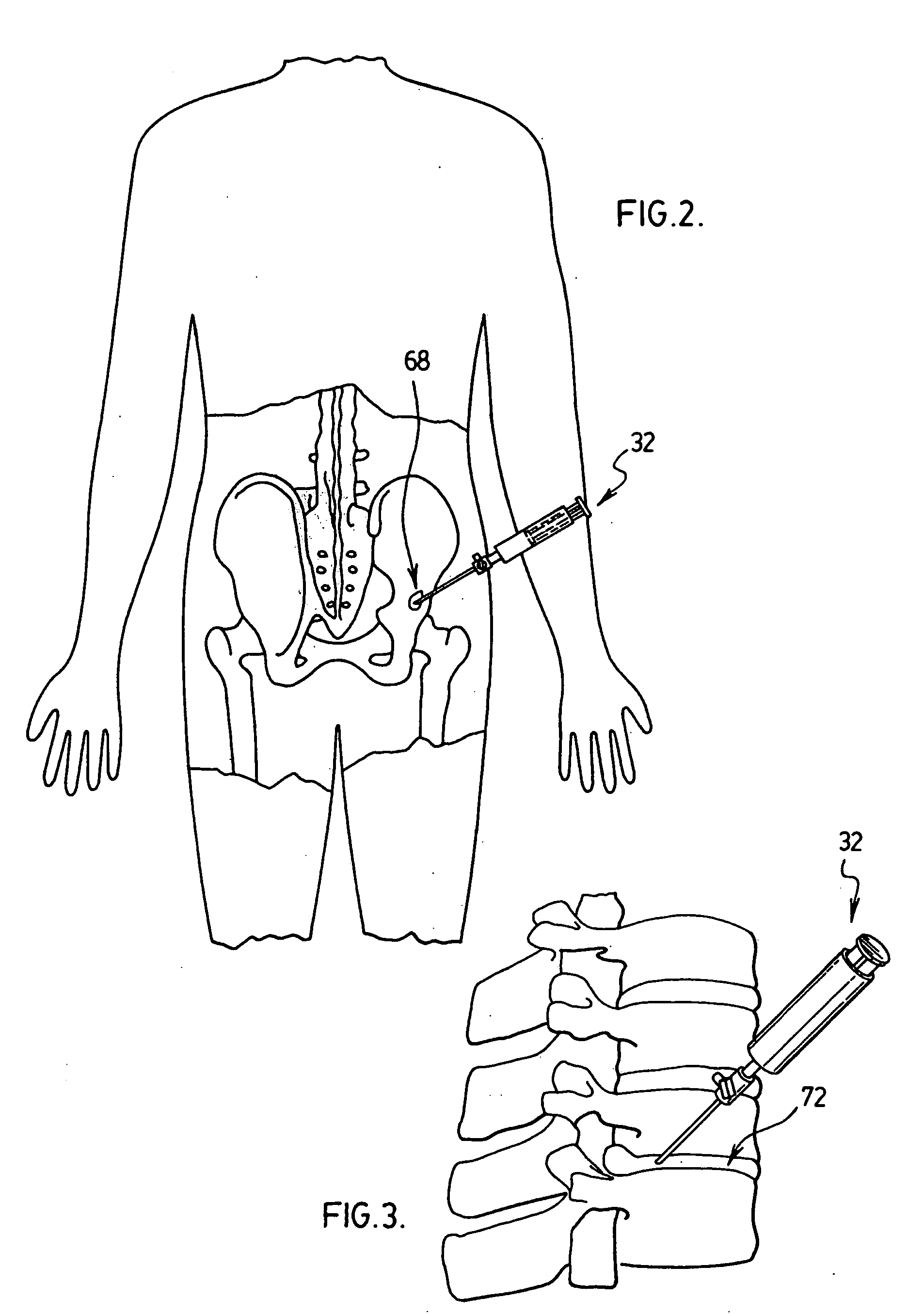

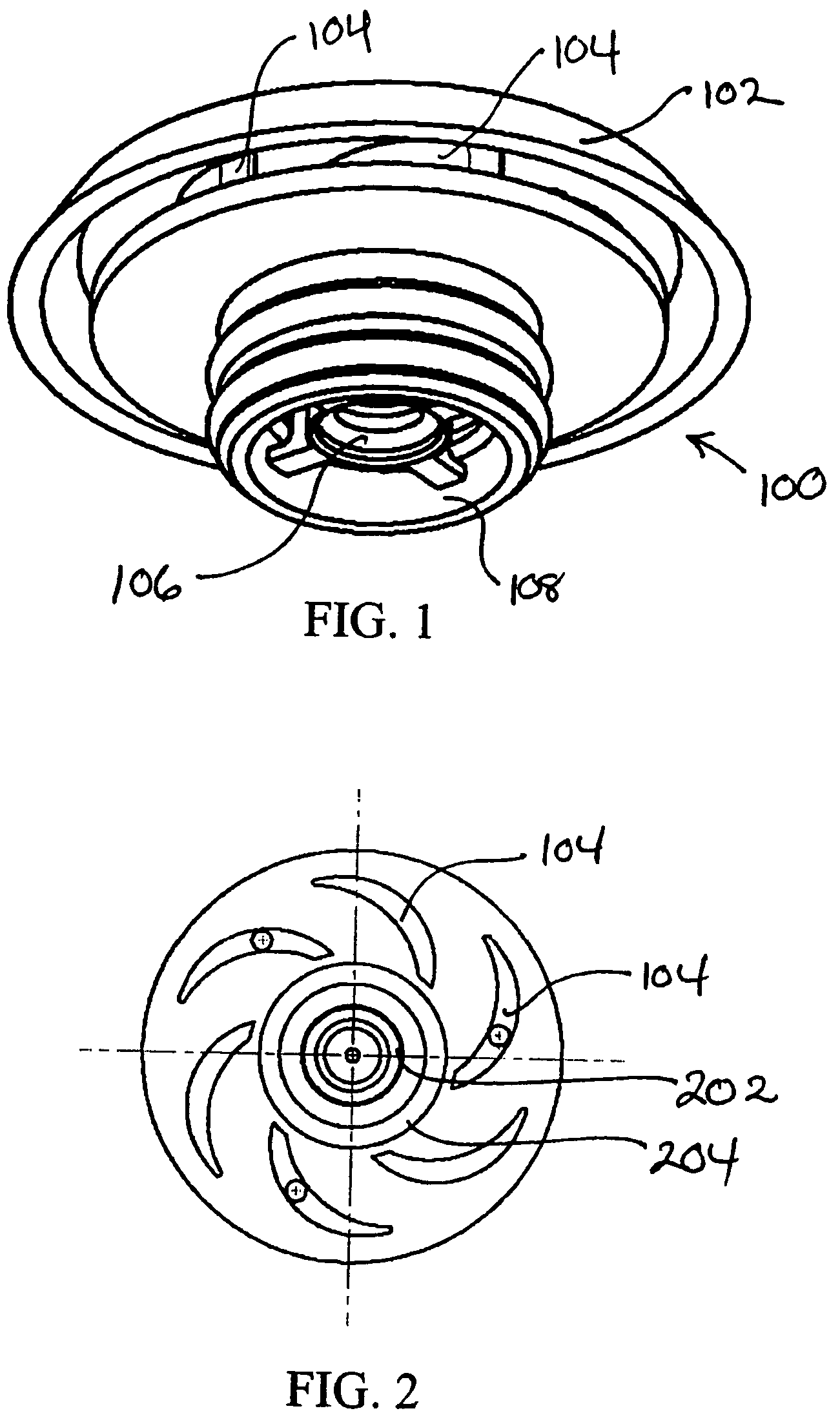

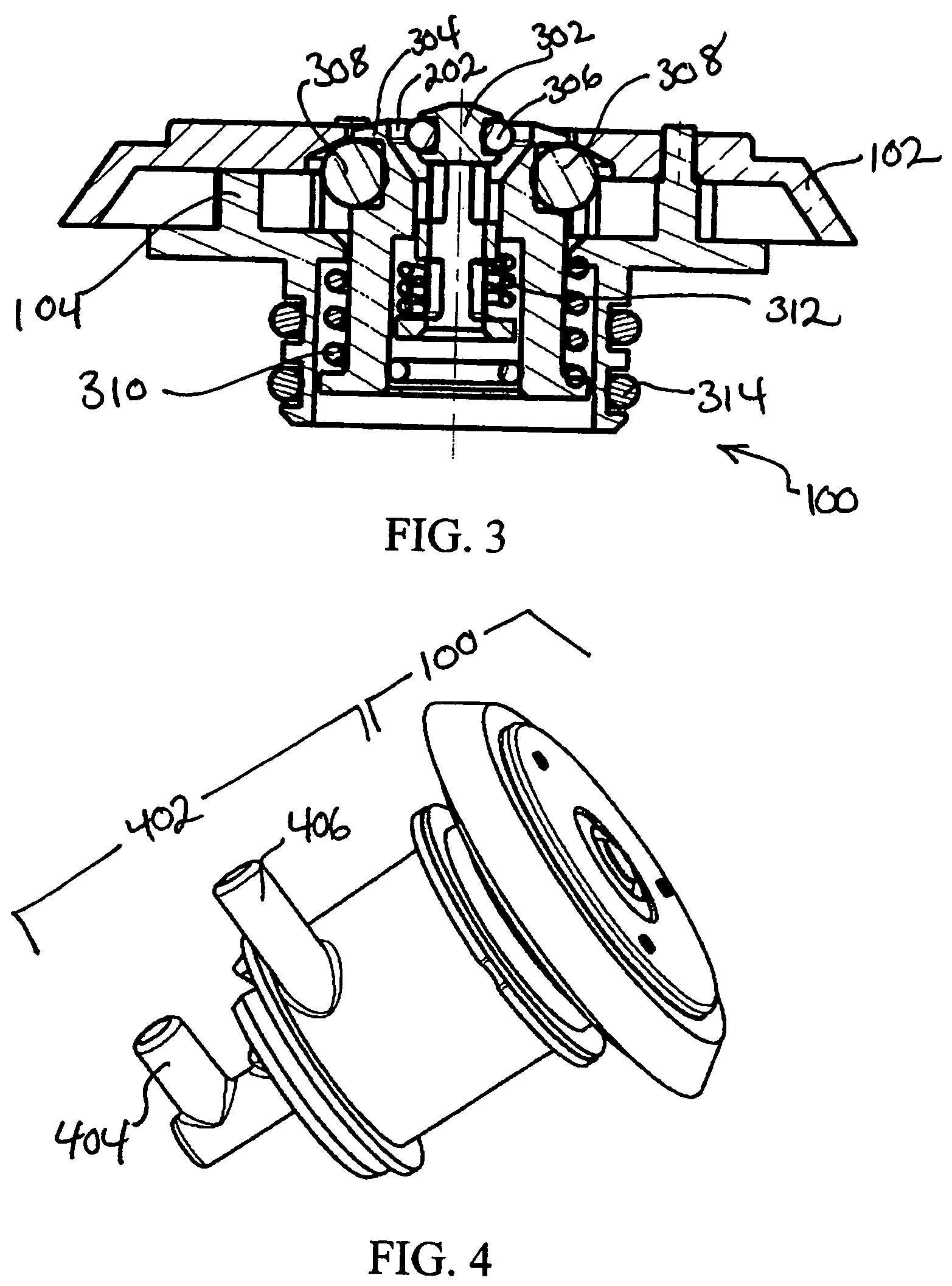

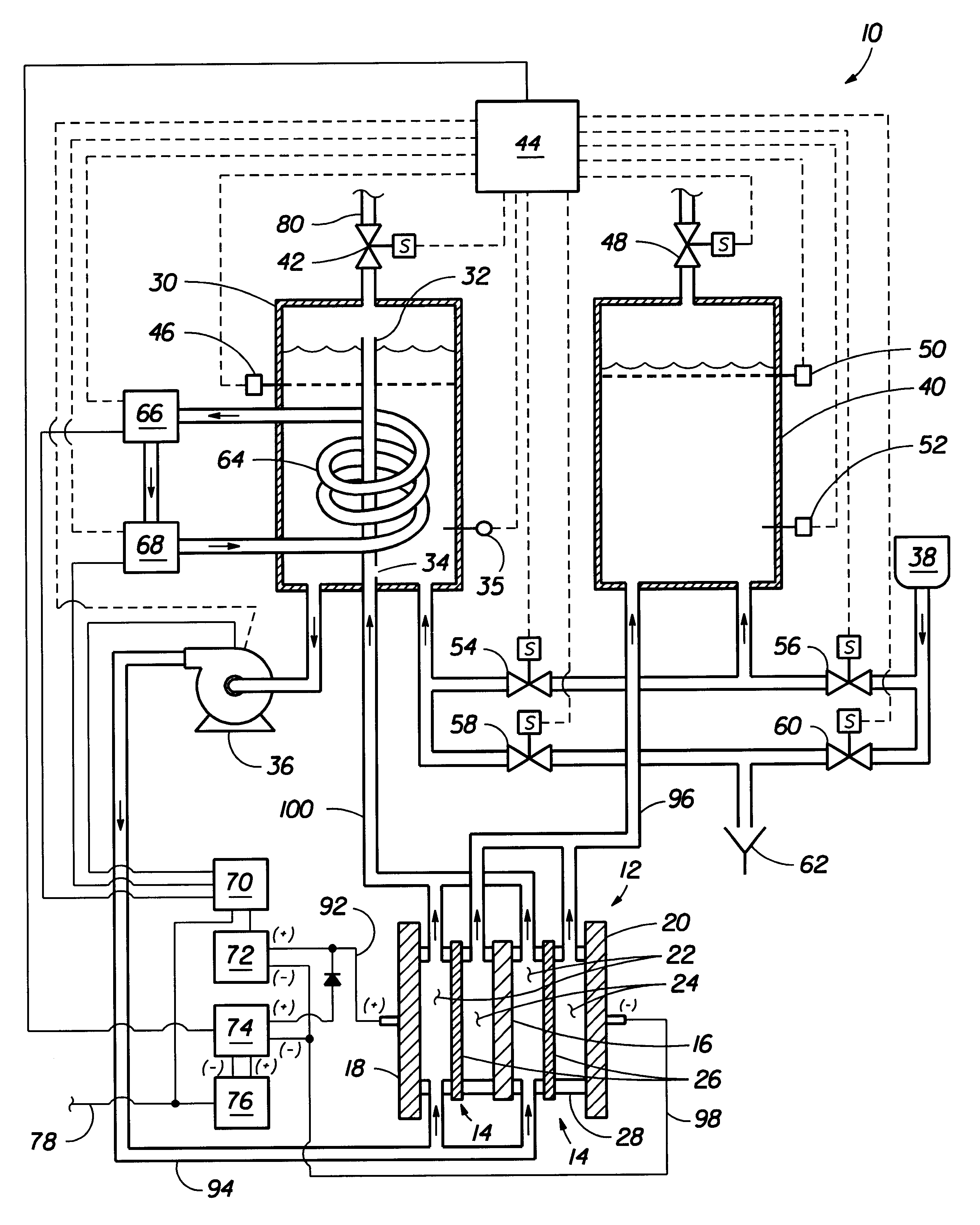

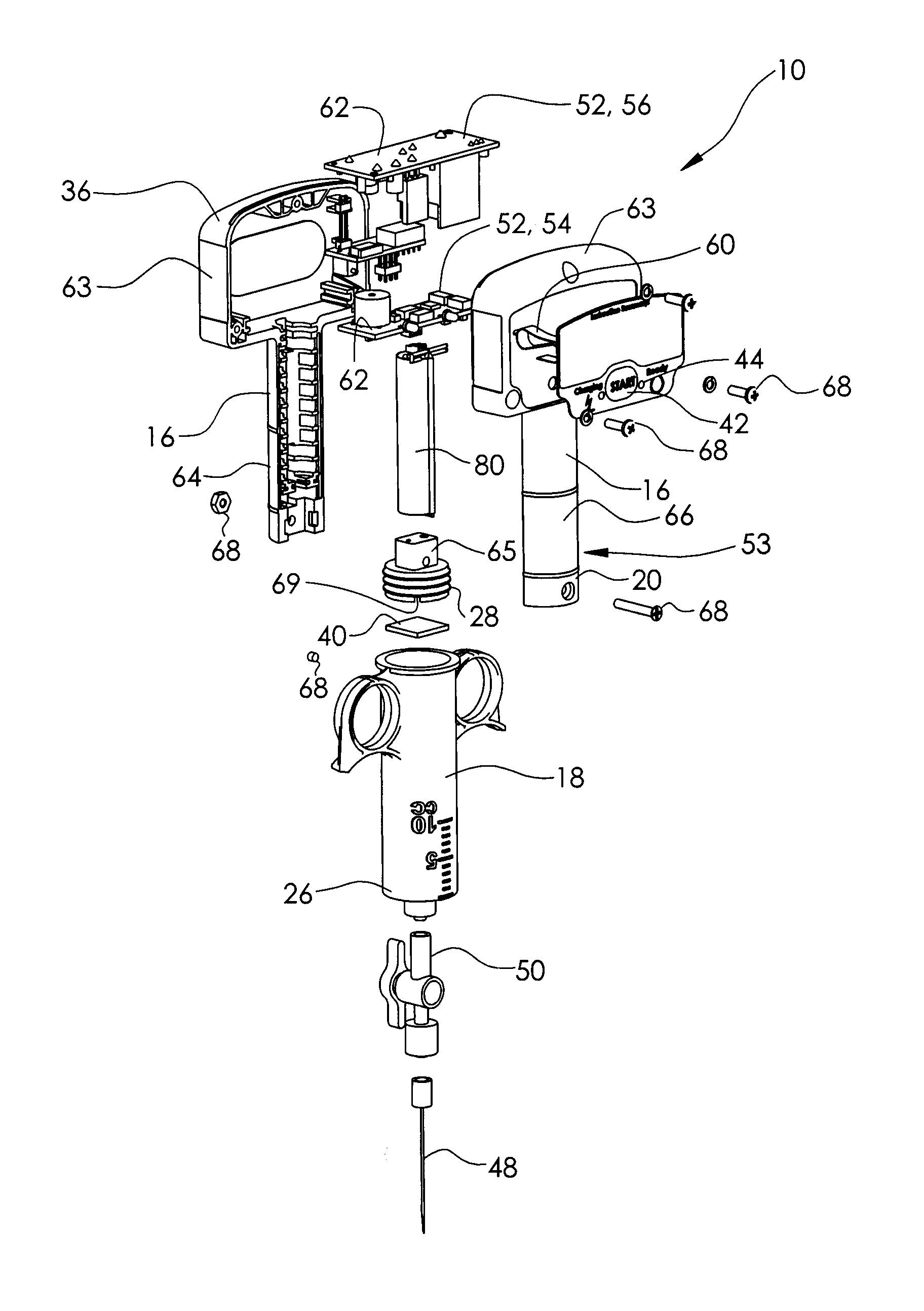

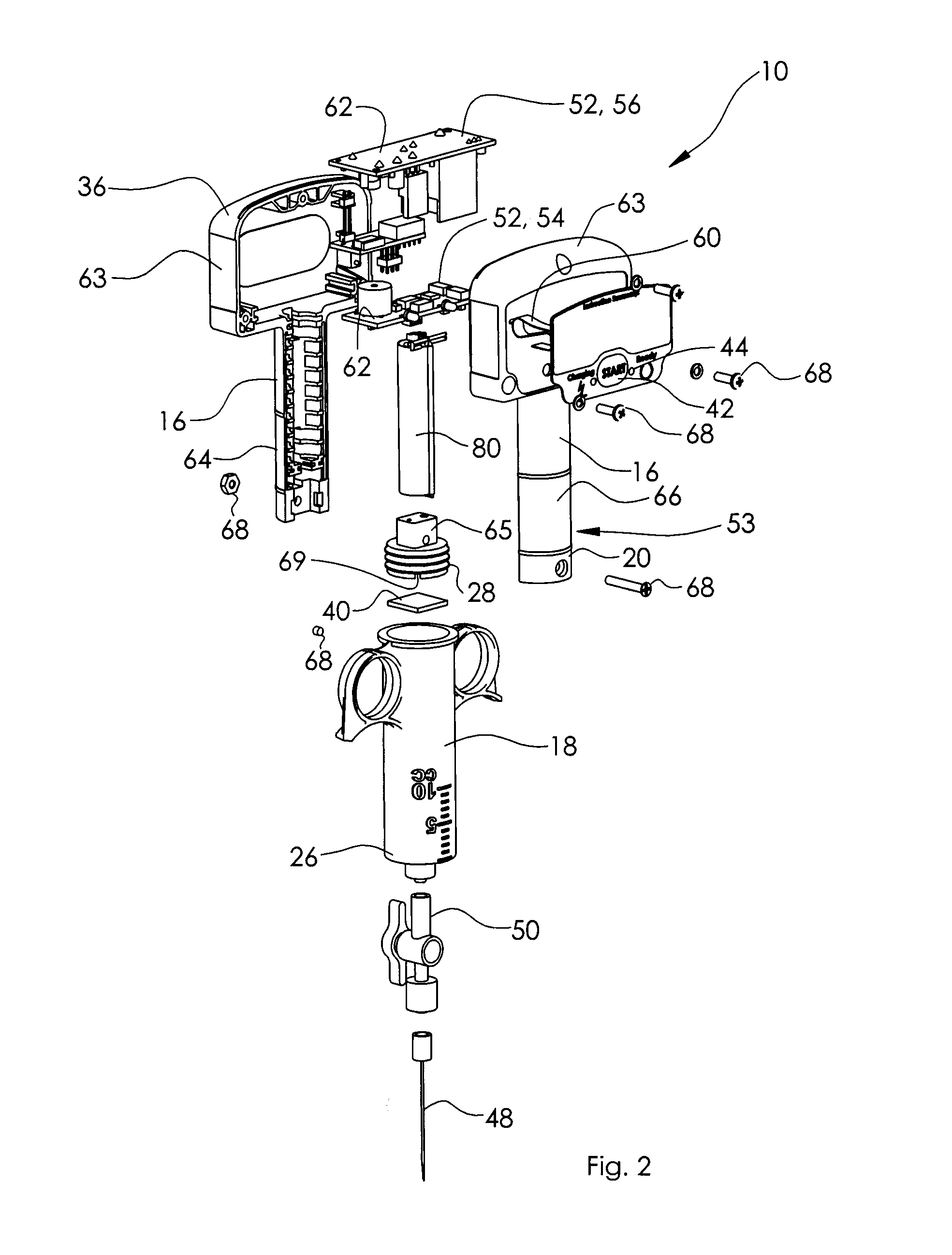

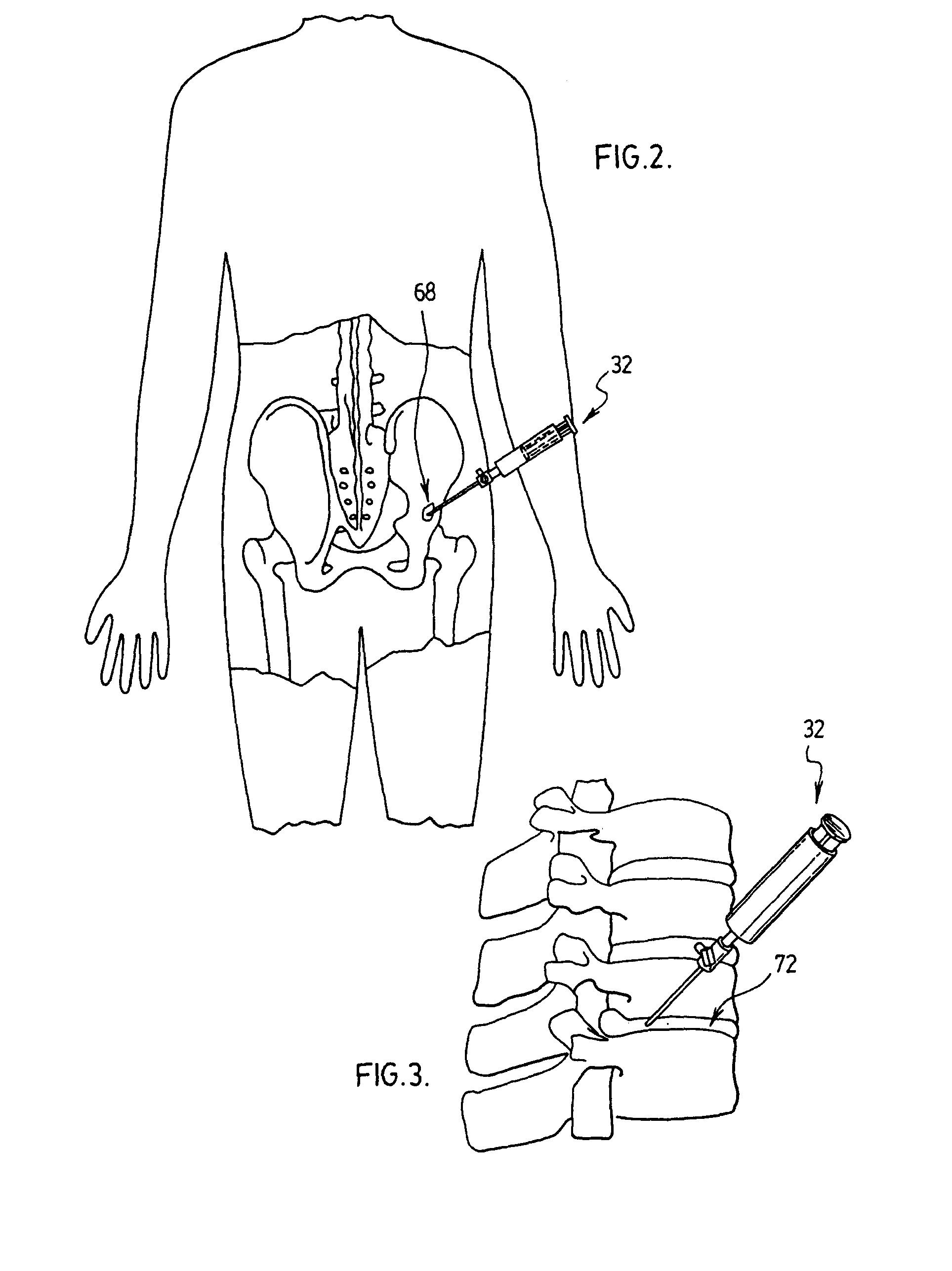

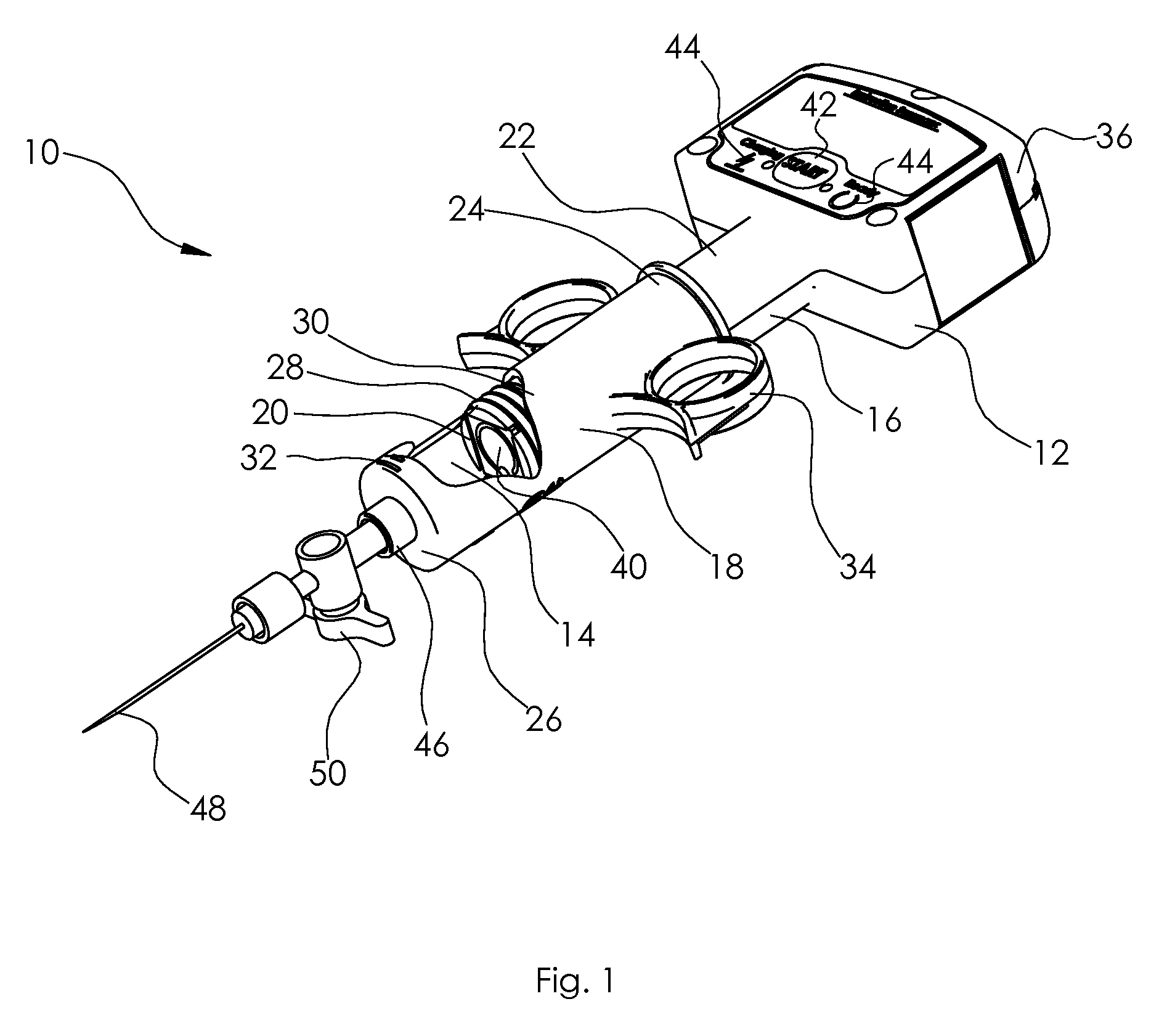

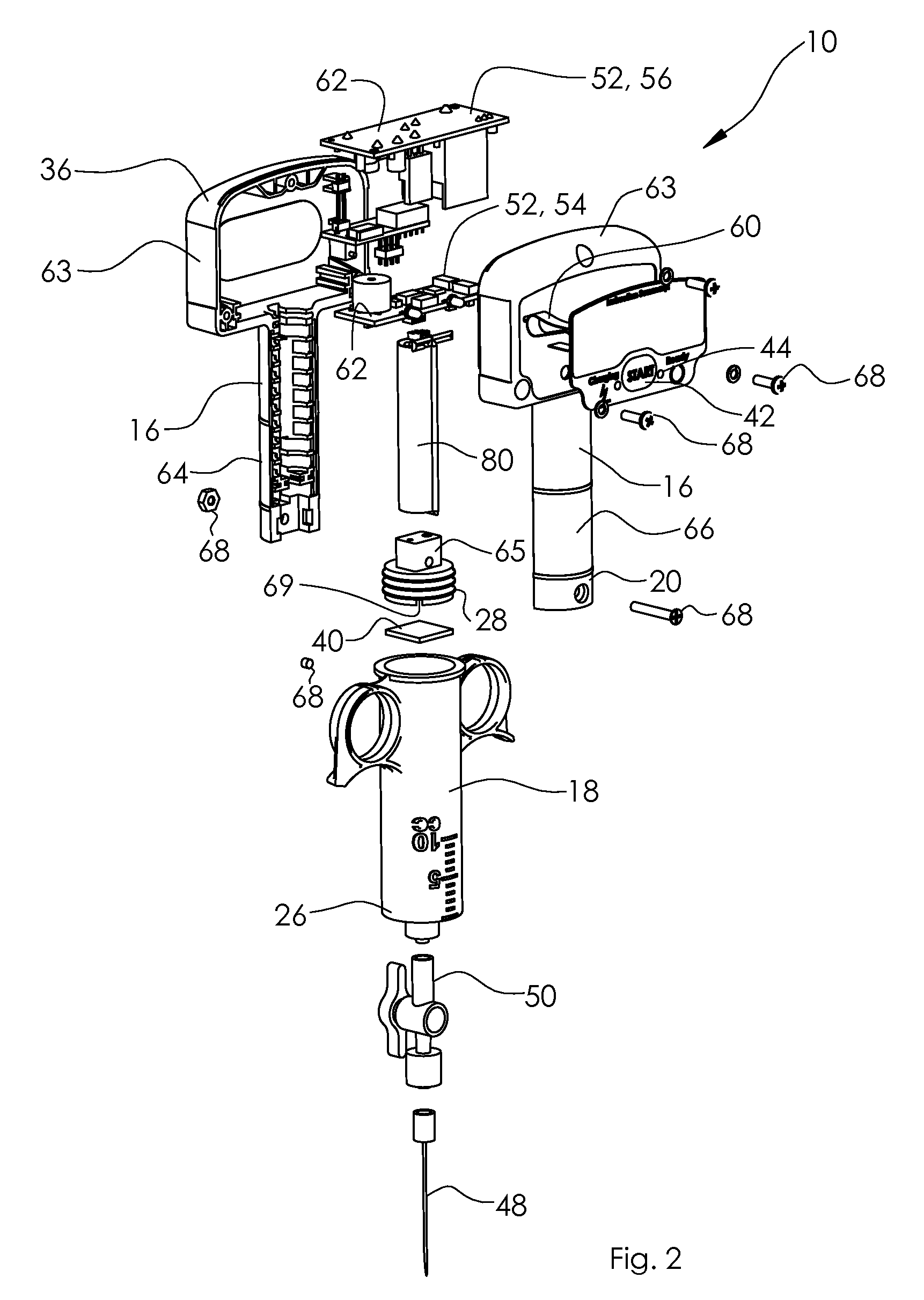

Apparatus and method for administering a therapeutic agent into tissue

An apparatus for administering a therapeutic is provided. In various embodiments, the apparatus includes a syringe having a barrel and a plunger and having an ozone generator associated therewith. The generator is initiated and a therapeutic gas is accumulated within the barrel, at which point it can be delivered from the barrel into a target site via a needle, thereby delivering therapeutic effects to that target site.

Owner:ACTIVEO

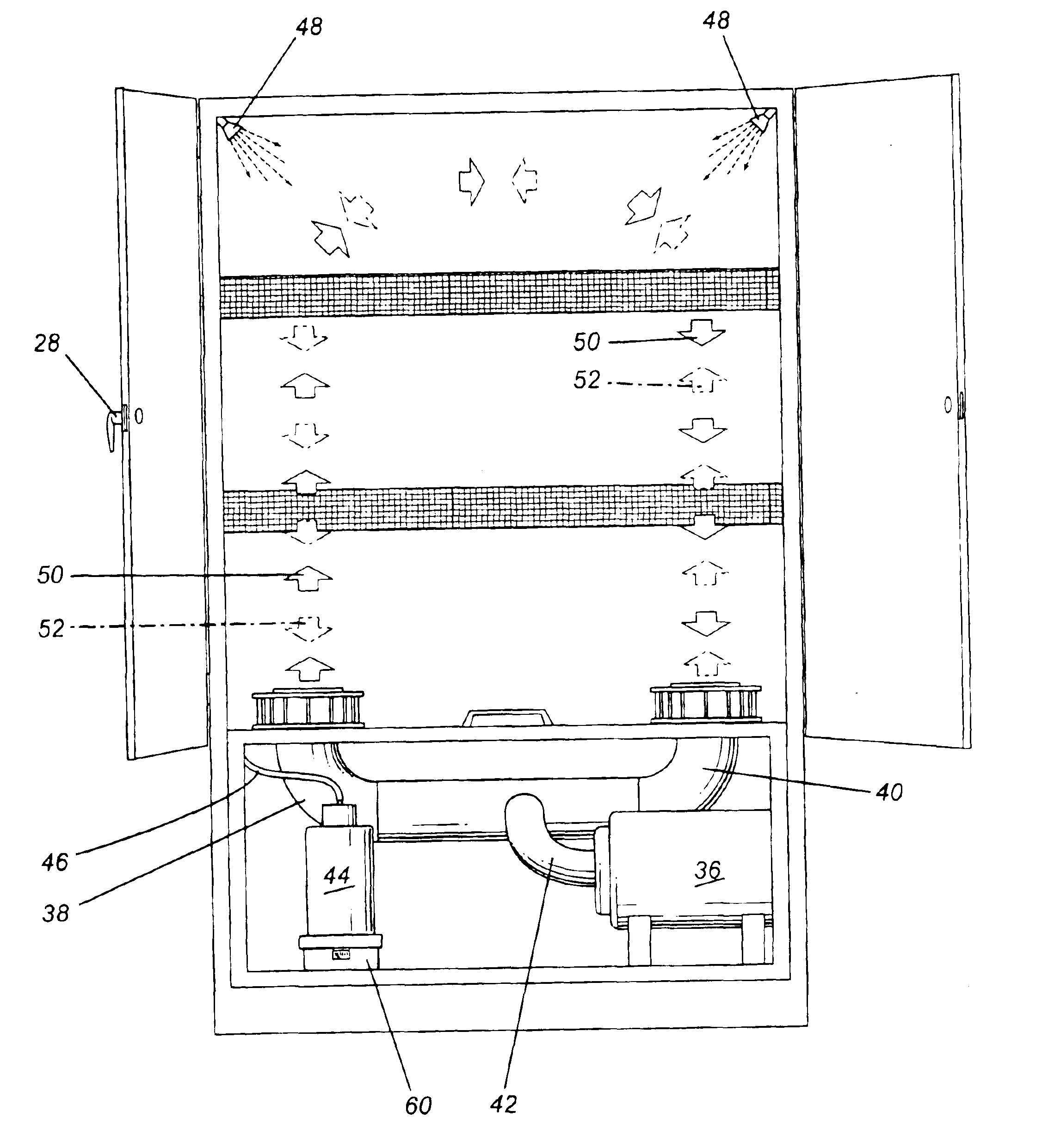

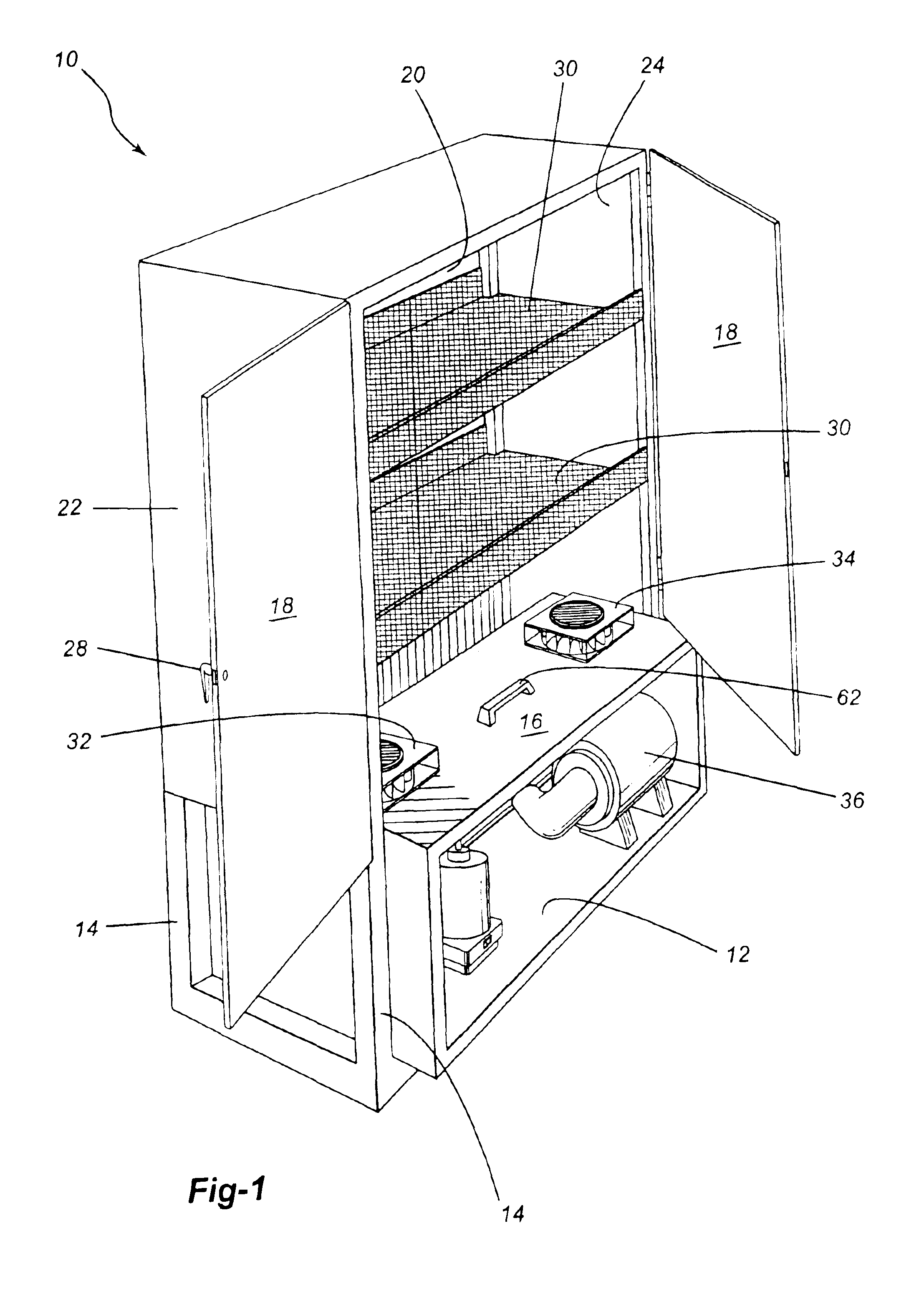

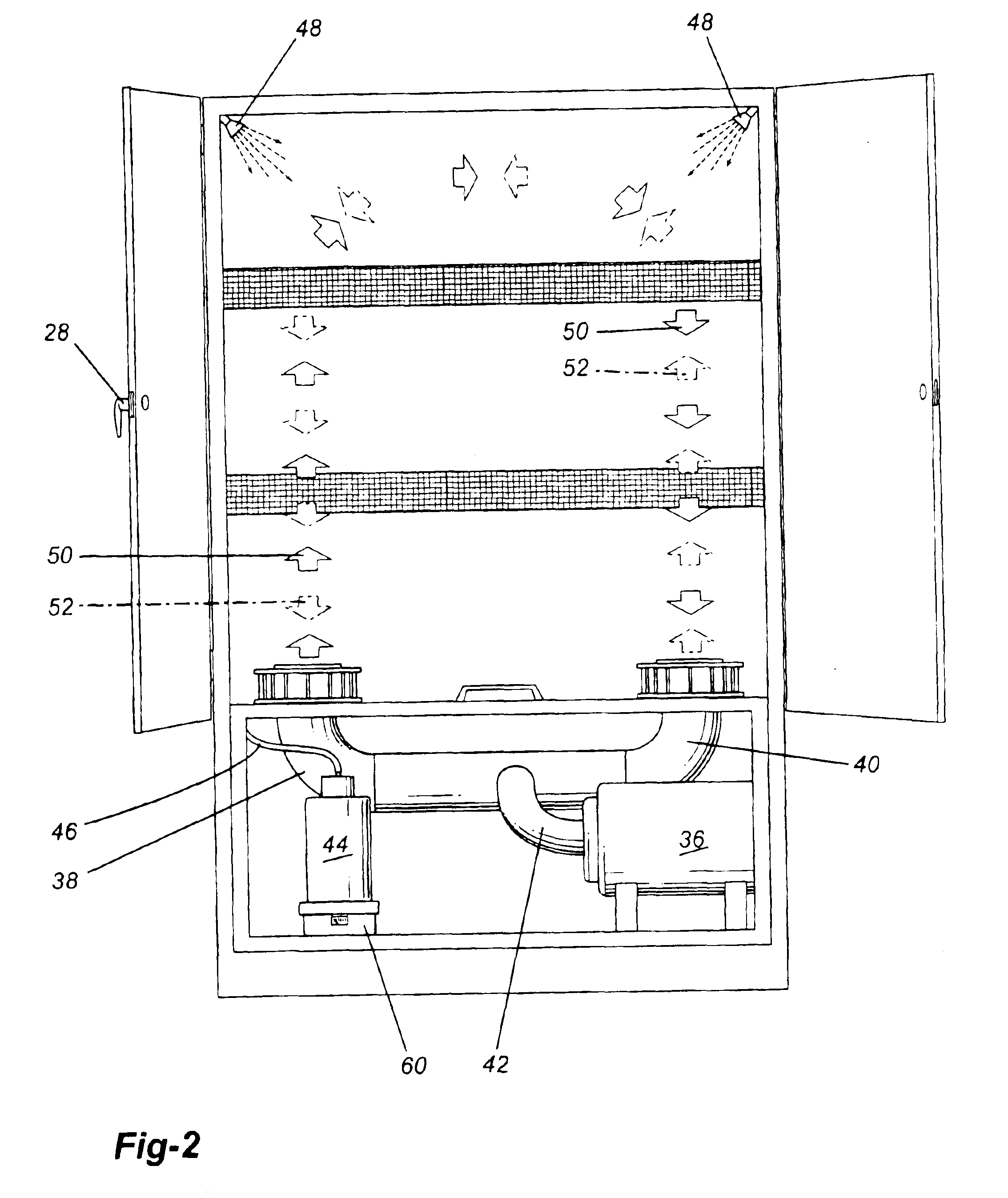

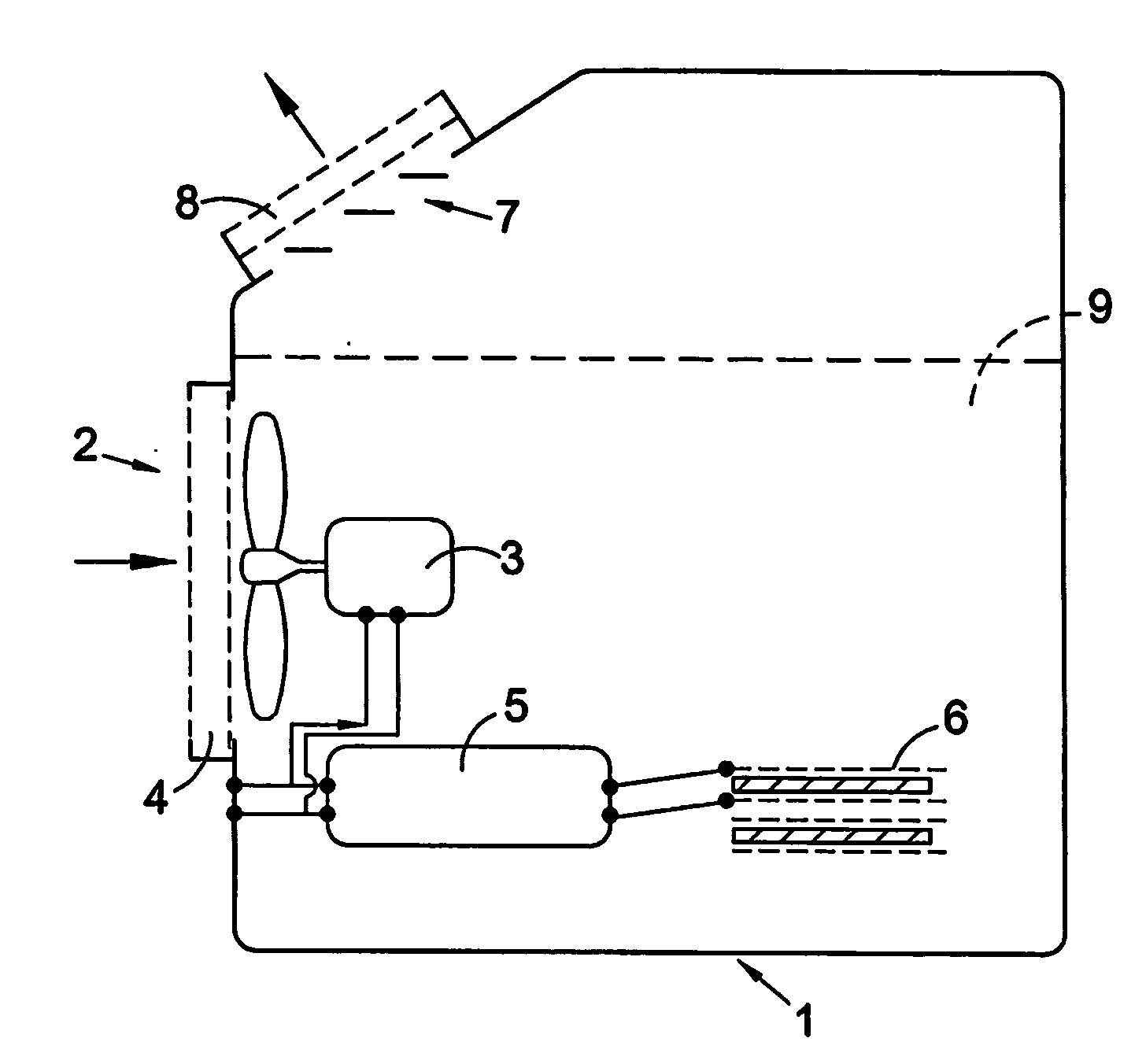

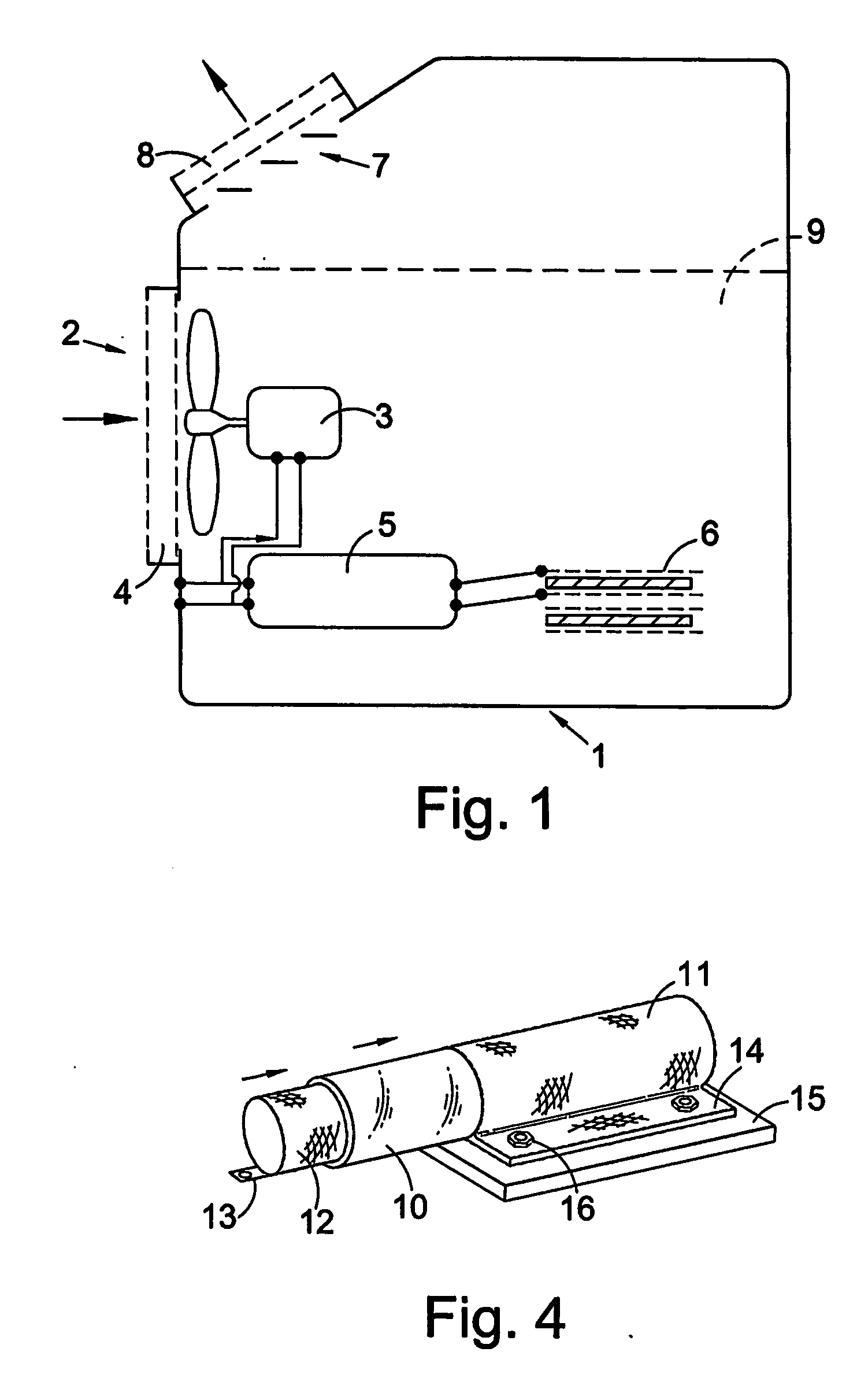

Sanitizing cabinet for sports equipment

InactiveUS6889449B2Suitable for useProcess environmental protectionDrying using combination processesDrying solid materials with heatOzone generatorSports equipment

There is provided a method and apparatus for sanitizing sports equipment which comprises a cabinet which can be sealed, first and second conduits in fluid communication with the cabinet, an ozone generator, and fans for circulating ozone containing gas through the conduits into the cabinet, the fans being operative to circulate the ozone containing gas in a first direction and subsequently in a reverse direction. There is also provided a fluid storage device, the fluid storage device being associated with a spray action to spray the fluid into the cabinet after the ozone has been circulated.

Owner:SILVER STEVE

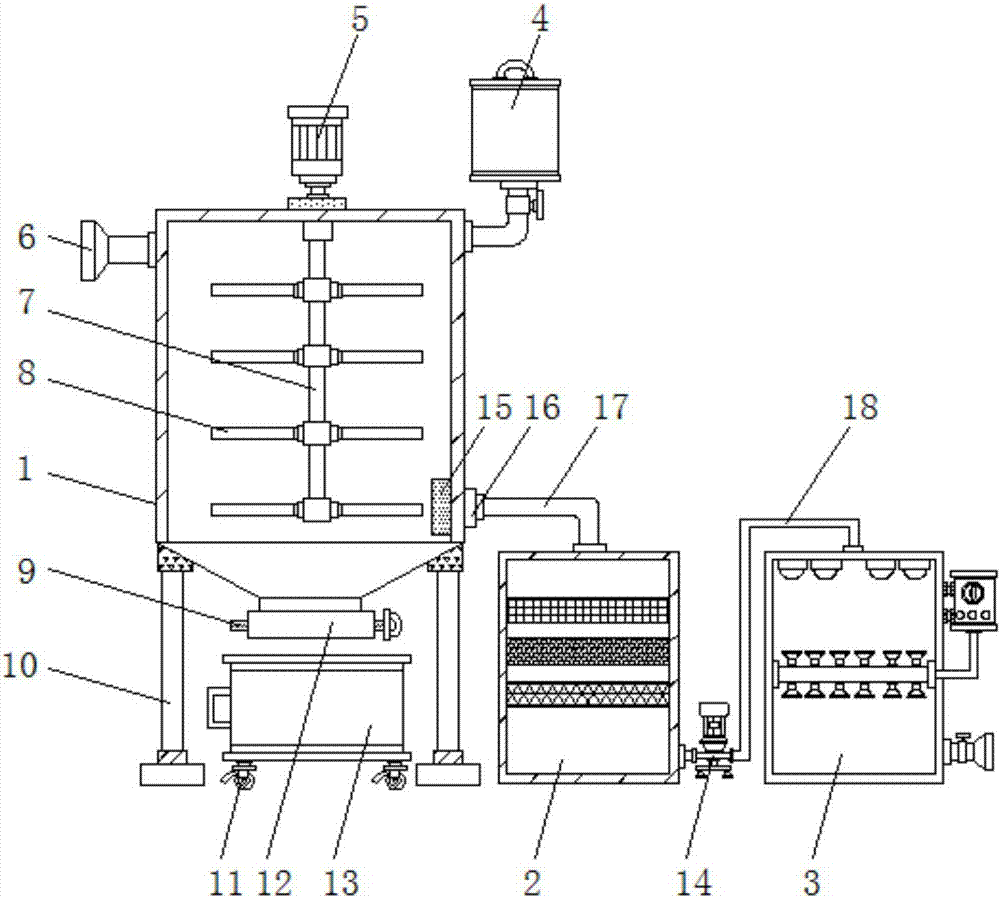

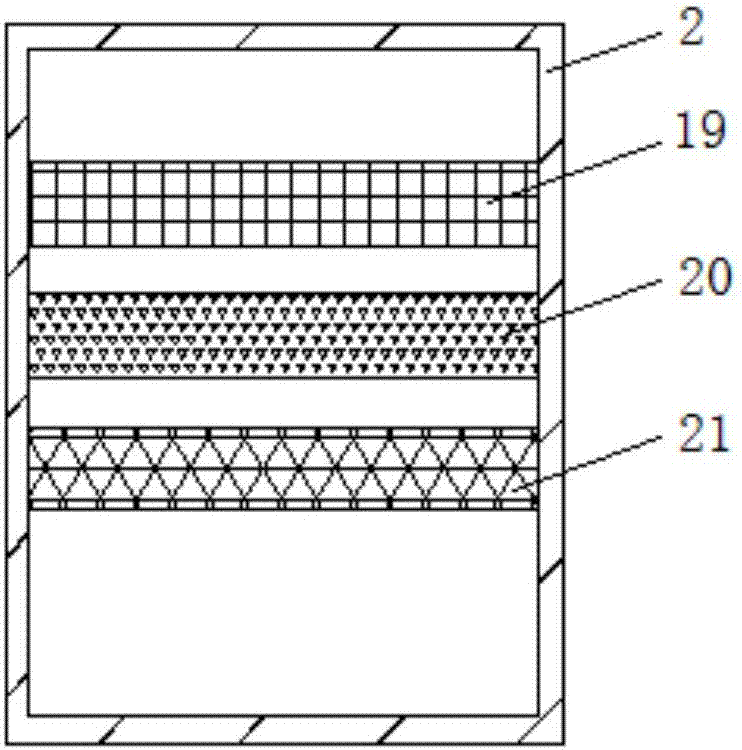

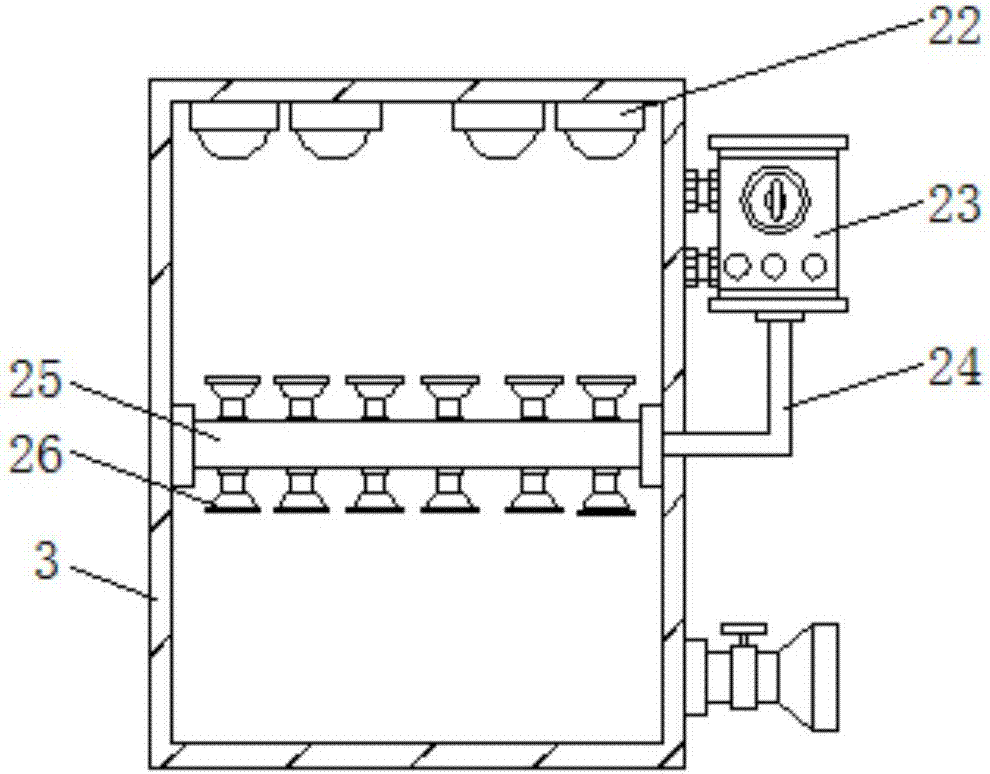

Sewage treatment unit with good practicality

InactiveCN107010792AEasy to handleRemove fullyWater/sewage treatment by irradiationSpecific water treatment objectivesSludgeActivated carbon filtration

The invention discloses a sewage treatment unit with good practicality. The sewage treatment unit comprises a settling box, a purifying box and a disinfection box, wherein the top end of one side of the settling box is provided with a chemical reagent tank; the top of the settling box is provided with a stirring motor; a sludge discharge outlet is formed in the bottom end of the settling box; the interior of the purifying box is provided with, from top to bottom, a magnet adsorption screen, a biomembrane filter screen and an active carbon filter screen; the sidewall of the disinfection box is provided with an ozone generator; and gas-distributing pipes are arranged in the disinfection box. The sewage treatment unit provided by the invention can effectively eliminate heavy metals, microbes, organic harmful substances, particulate matters and other impurities in water, is capable of removing pigments and peculiar smell in water, and has improved sewage treatment effect; and since the ozone generator is mounted on the sidewall of the disinfection box, ozone generated by the ozone generator can be used for sterilization and disinfection of purified clear water after purification of sewage, so sewage is allowed to reach discharge standard.

Owner:盐城百利豪环保机械制造有限公司

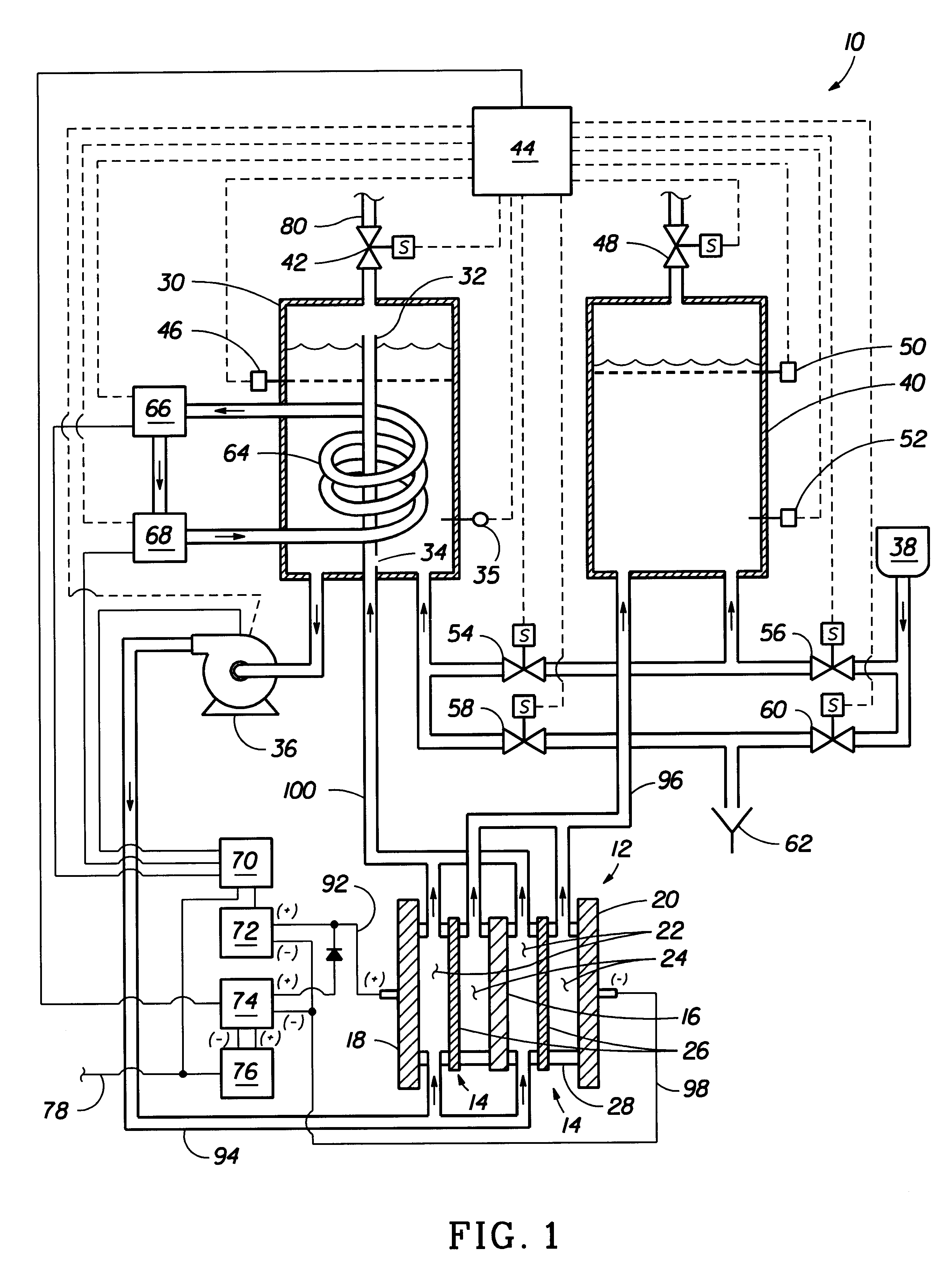

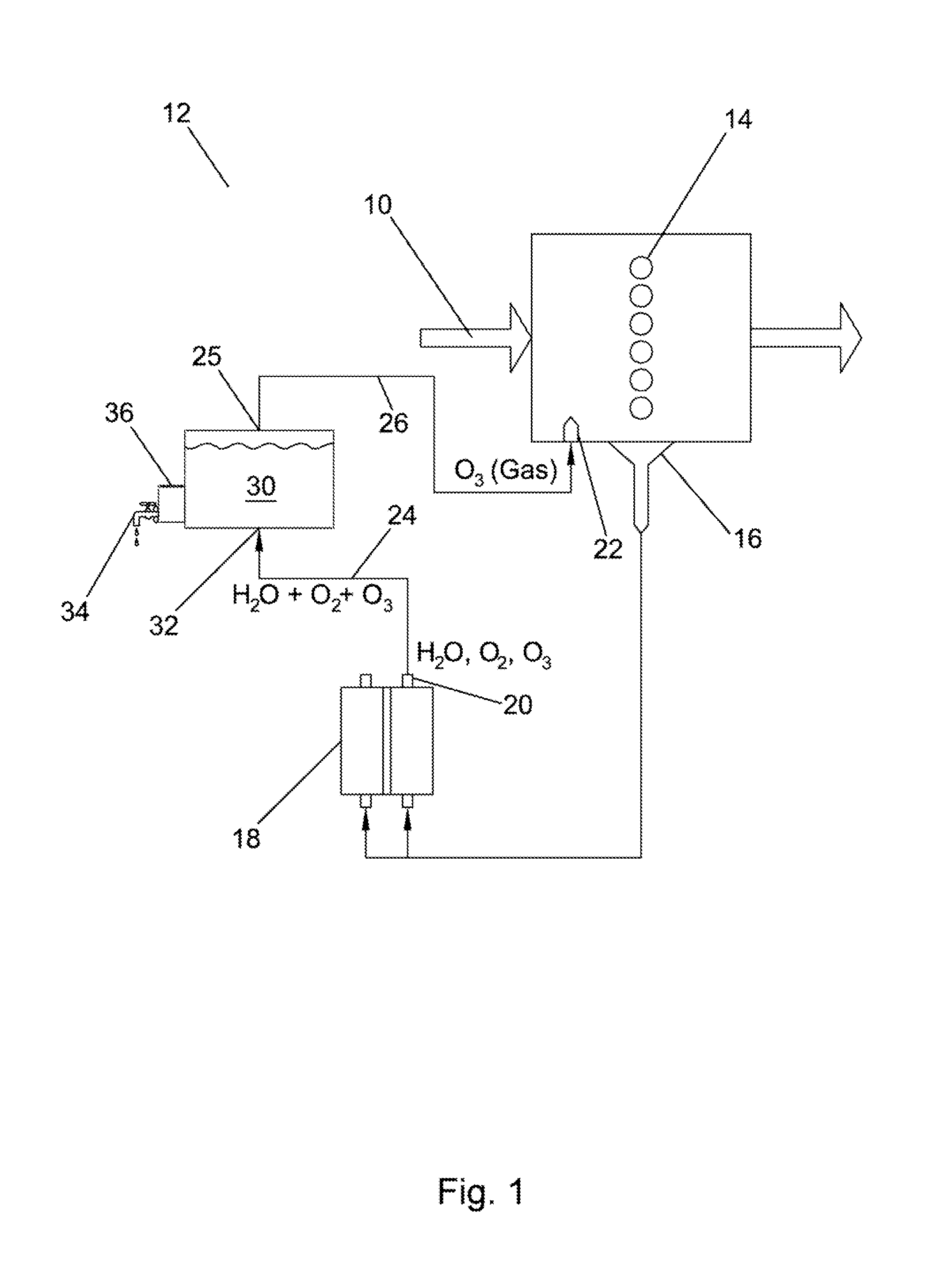

Microorganism control of point-of-use potable water sources

InactiveUS6458257B1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesOzone generatorMedical equipment

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

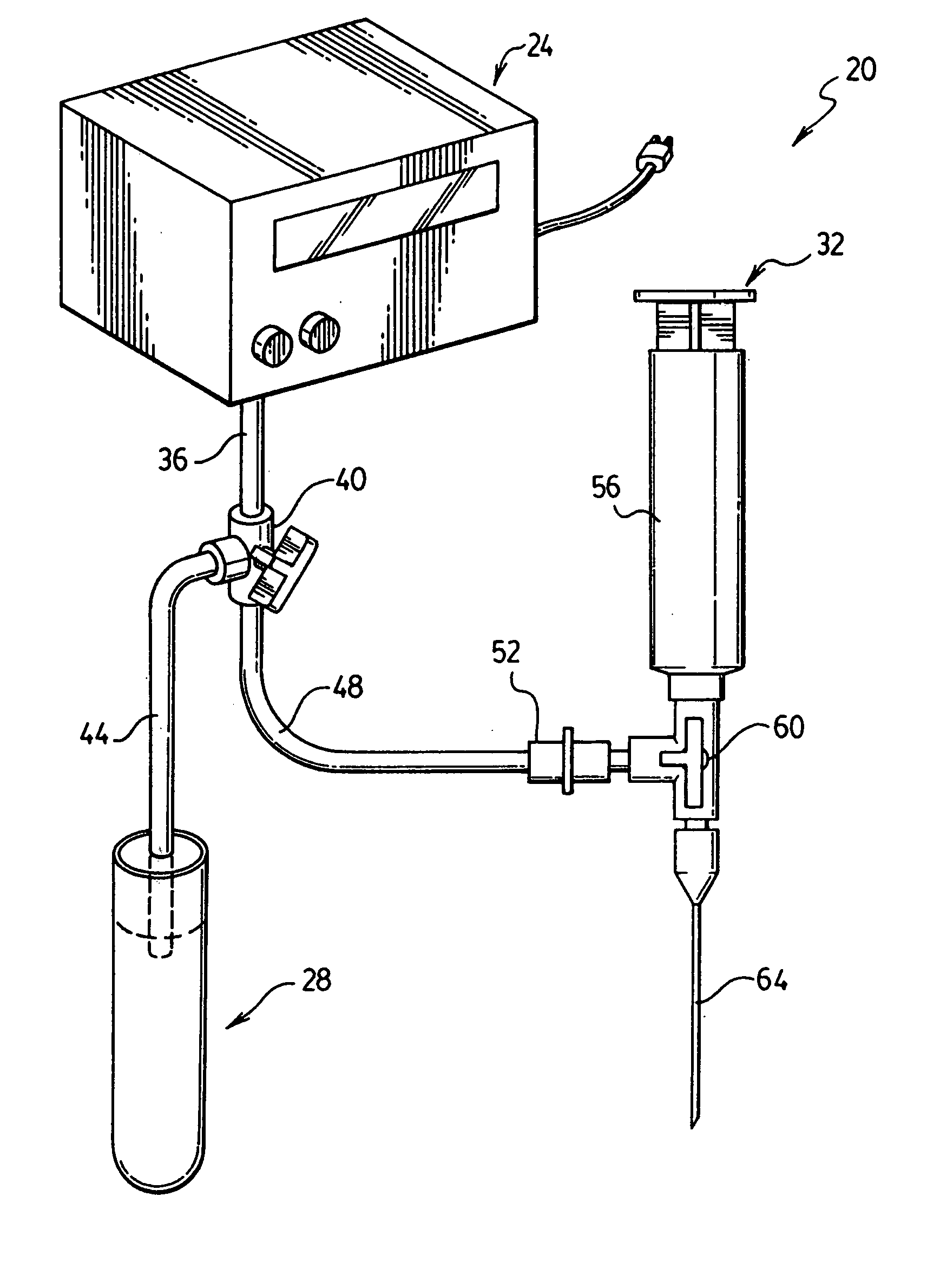

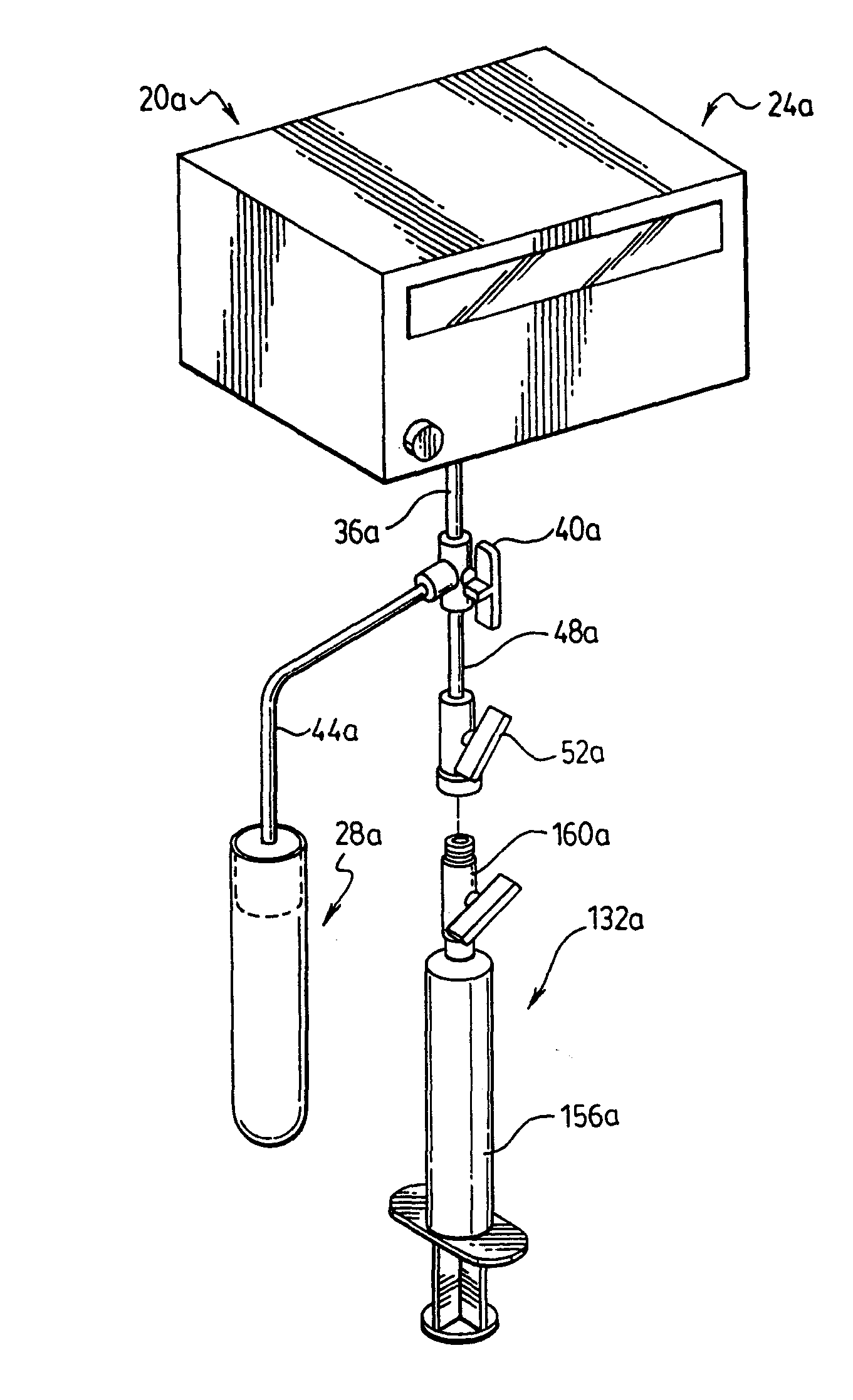

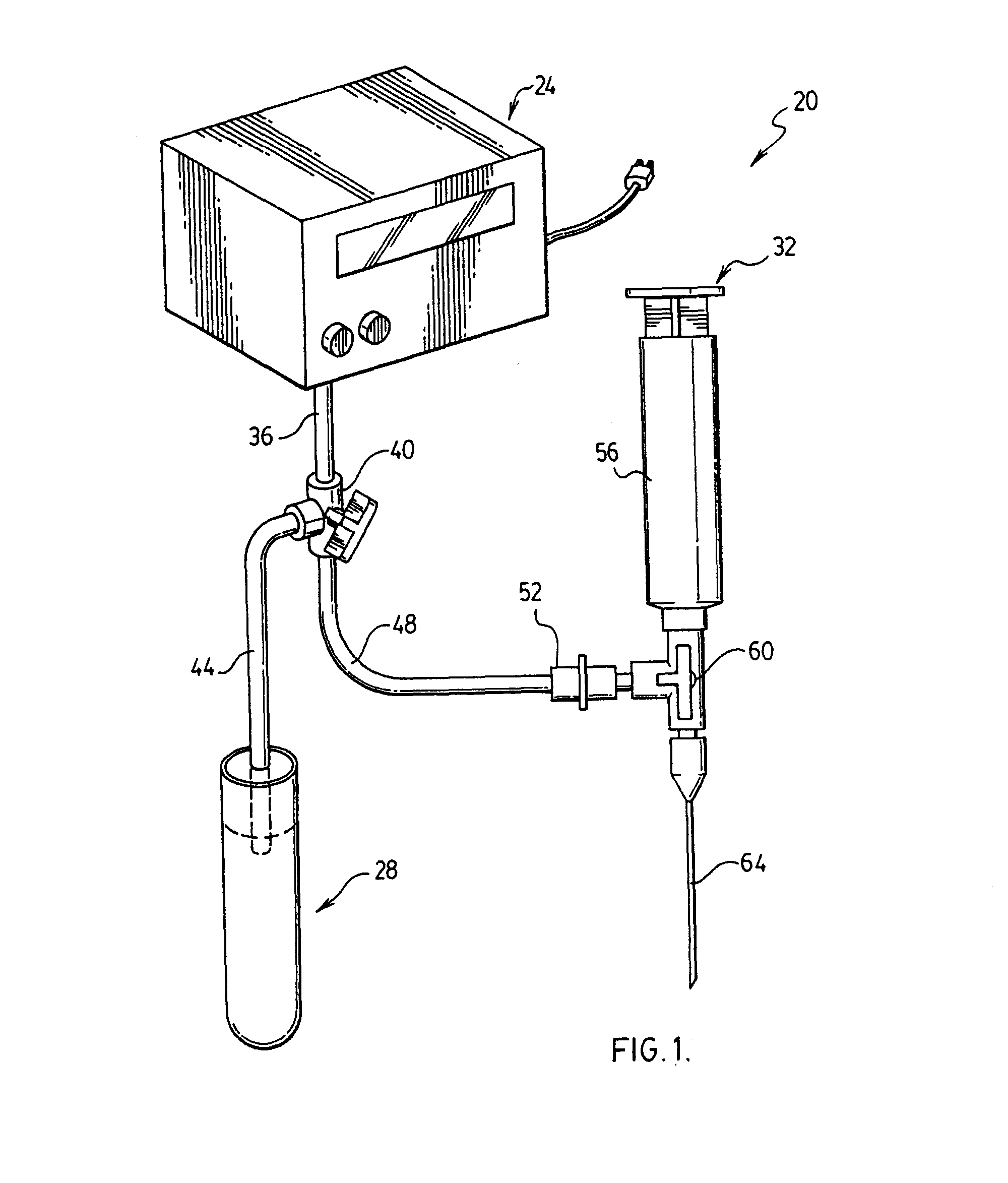

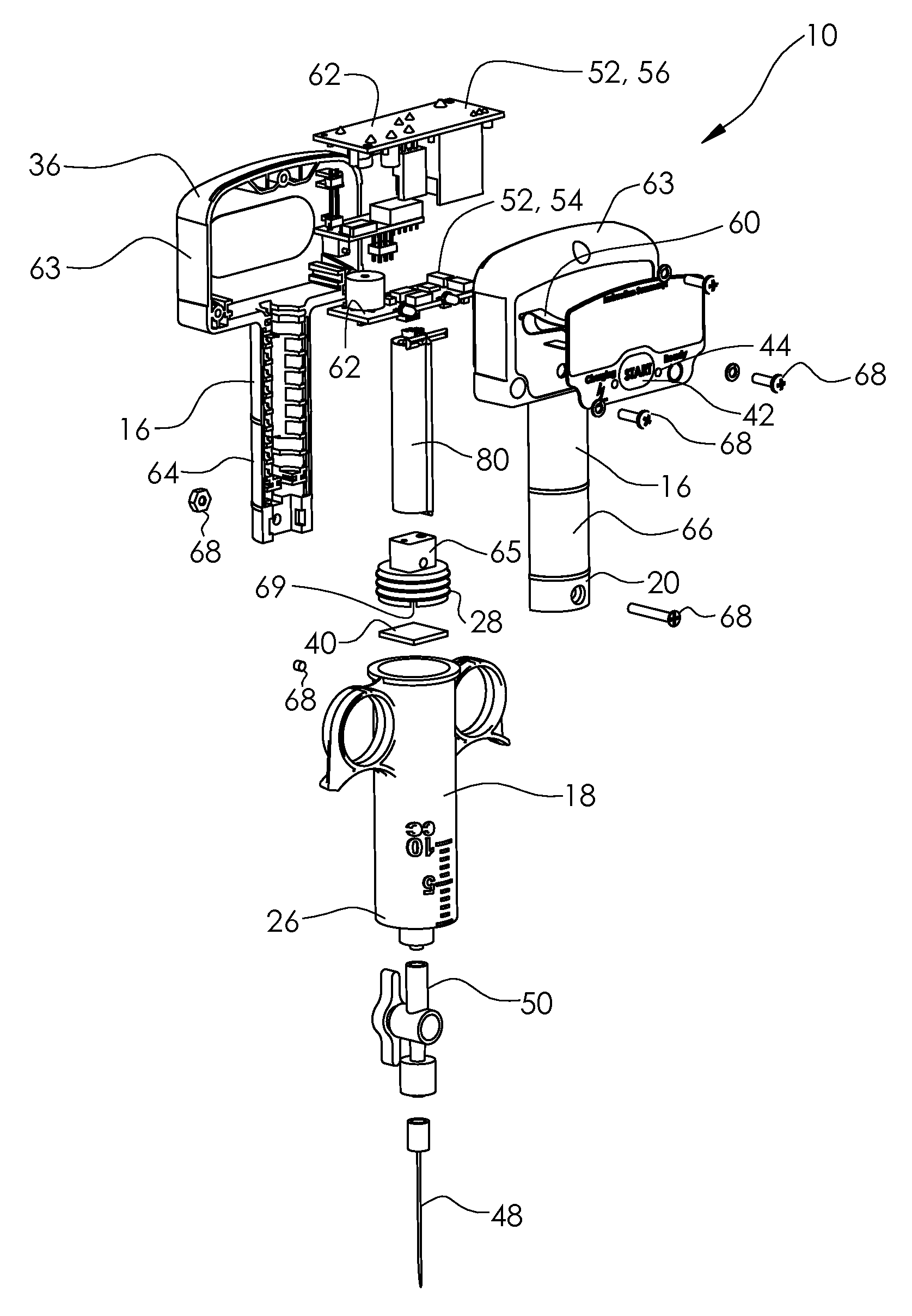

Apparatus and method for administering a therapeutic agent into tissue

An apparatus for administering a therapeutic agent is provided. The apparatus, in an embodiment, includes an ozone generator connected to a scavenger and an ozone administrator via network of tubing and valves. When activated and the valves placed in the proper position, the ozone generator will fill the ozone administrator with ozone. The ozone generator can then be turned off and the valves moved so that the administrator can be disconnected from the remainder of the apparatus. The administrator is typically in the form of a syringe and needle. Once the syringe and needle is filled with ozone, the needle can be inserted into a tissue and the ozone expressed therefrom into the tissue. Various other apparatuses and methods are also contemplated.

Owner:ACTIVEO

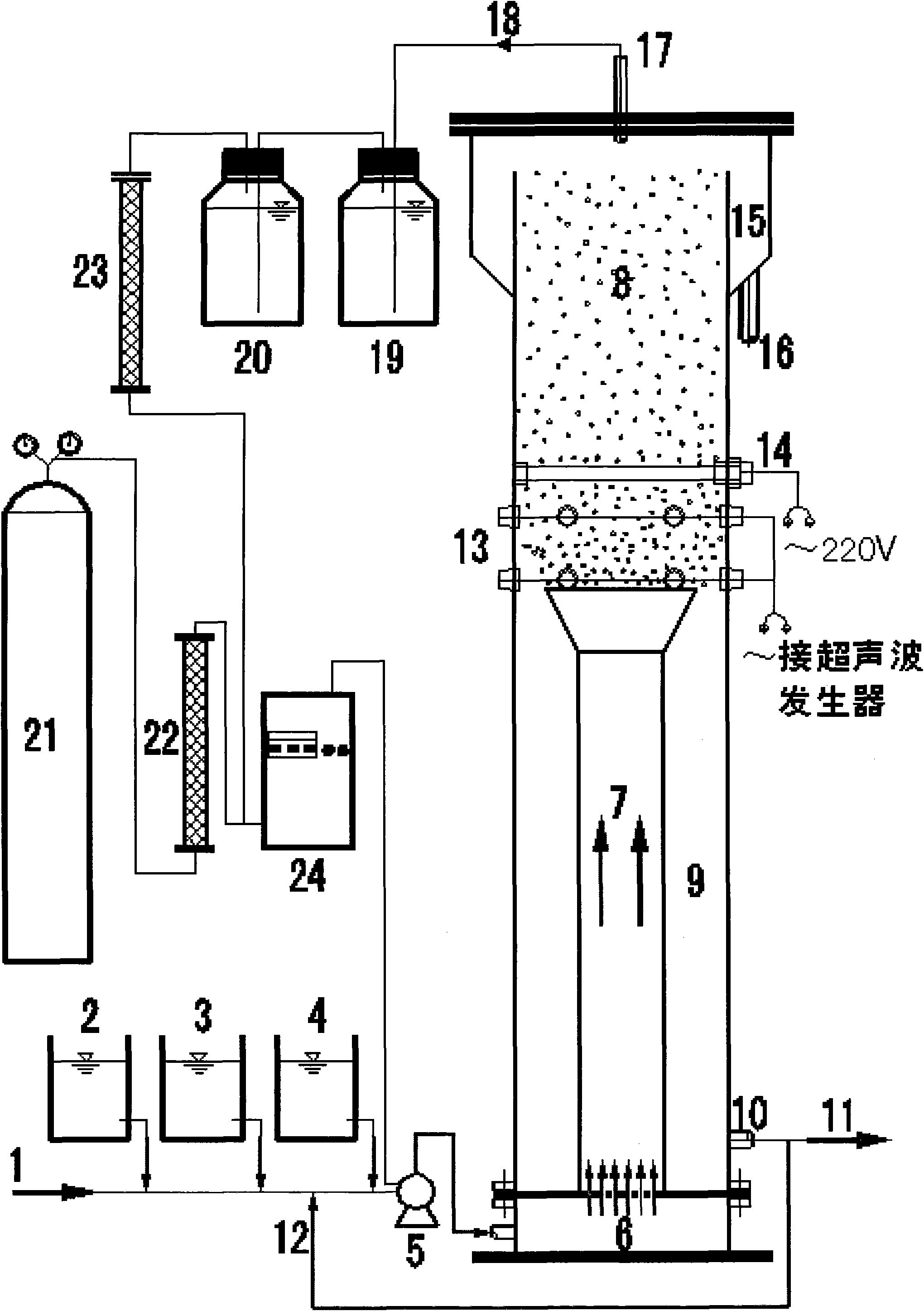

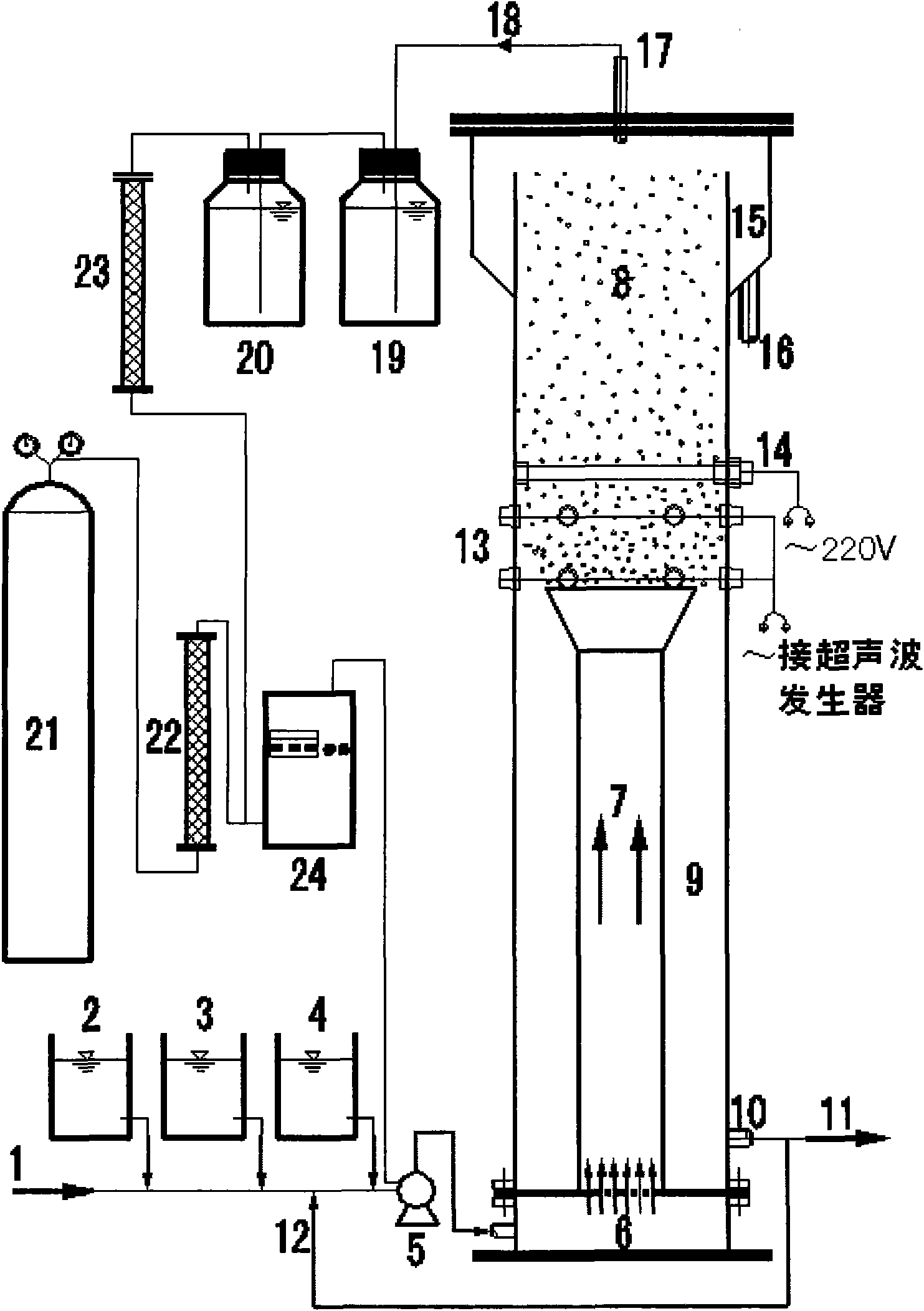

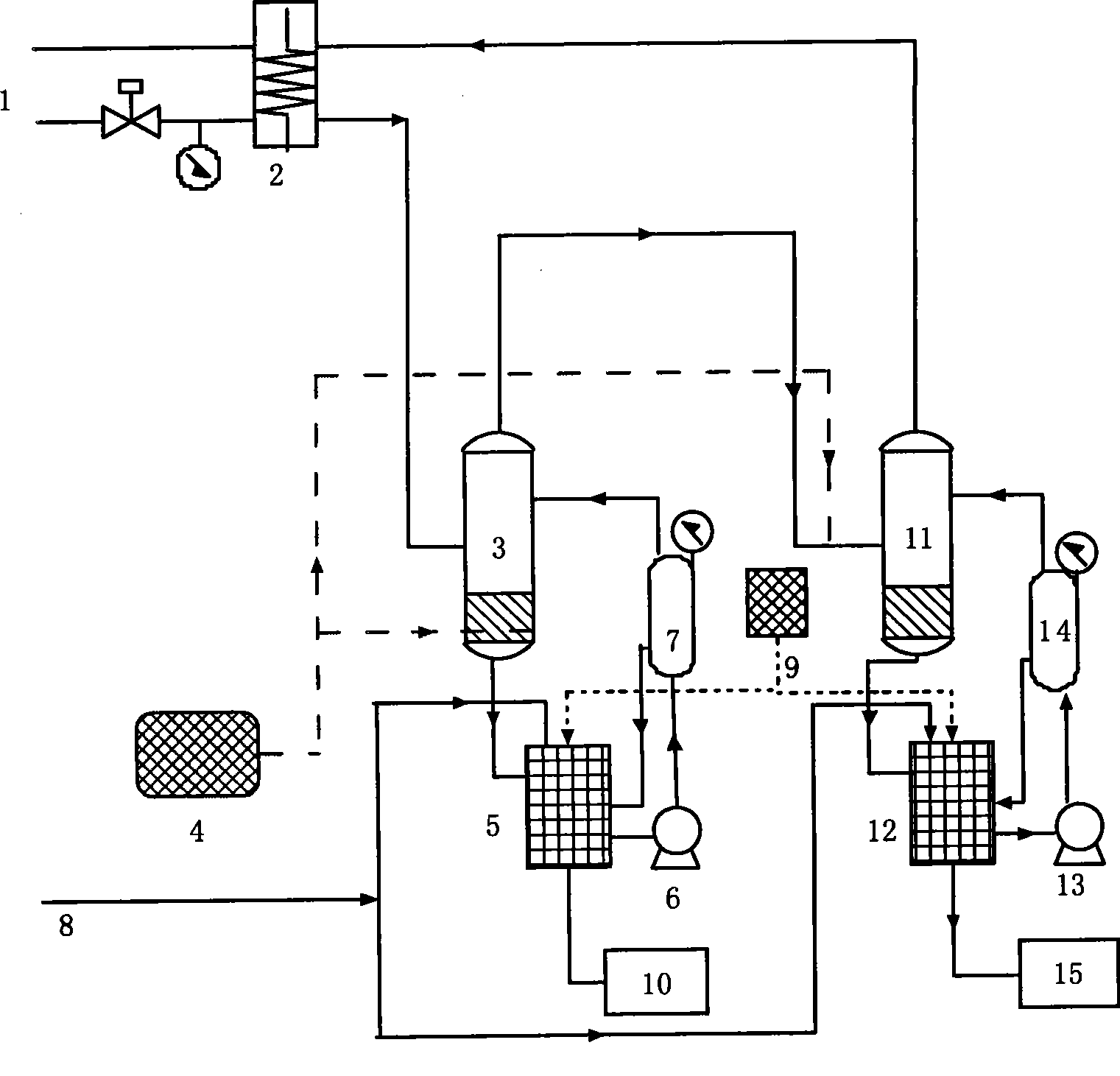

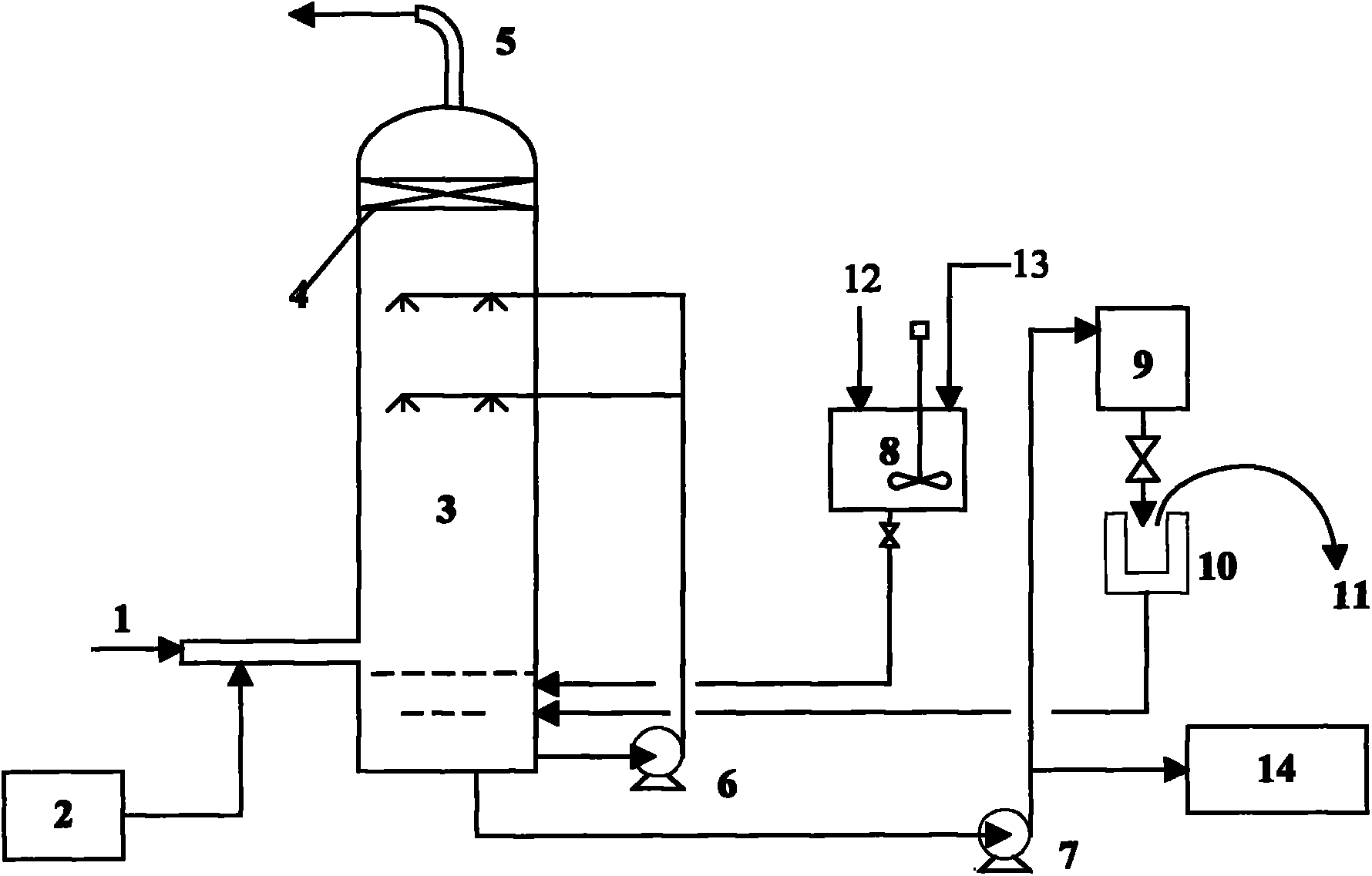

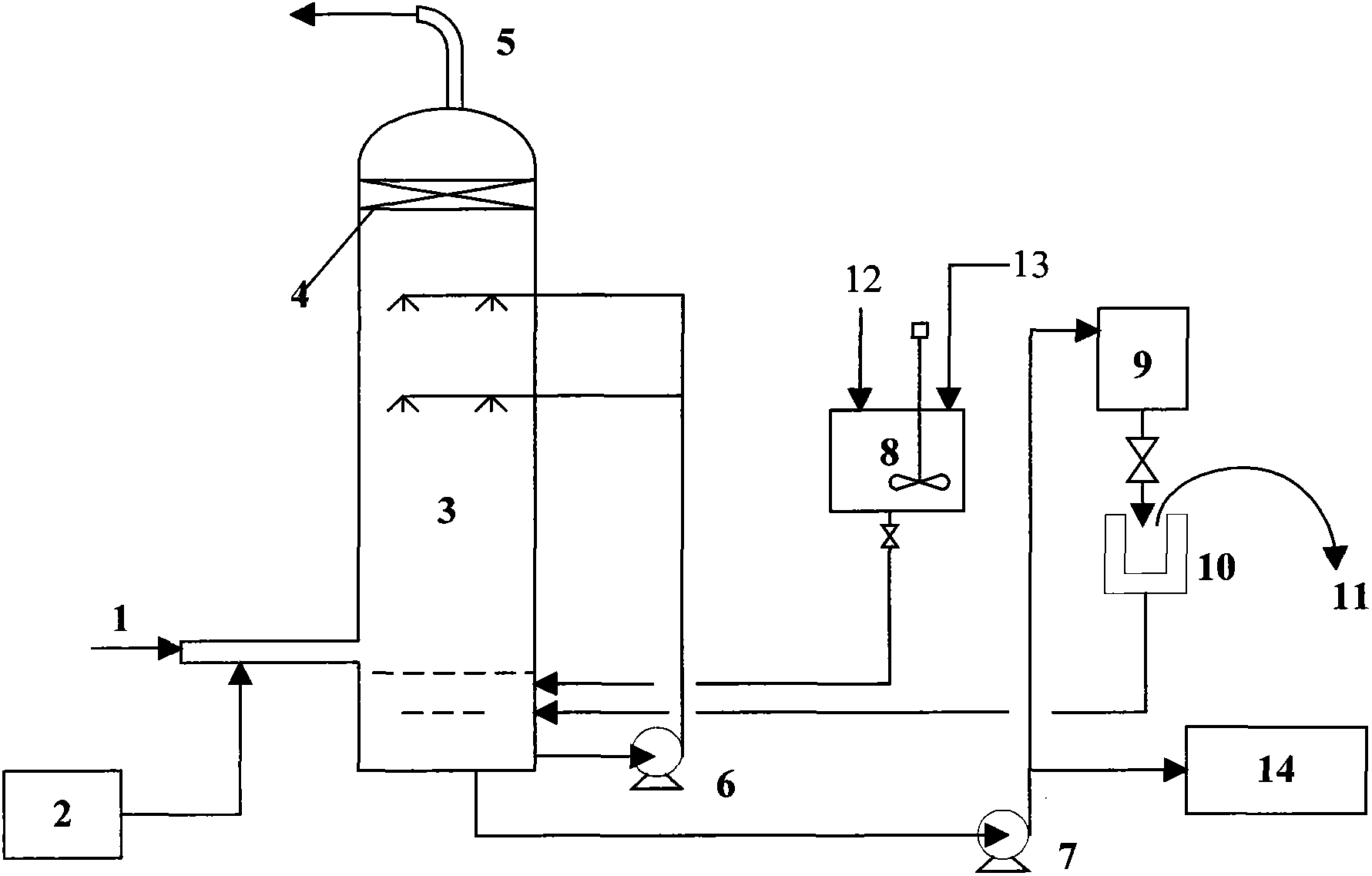

Novel multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower

ActiveCN102115253AReduce pollutionImprove efficiencyWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsOzone generatorActivated carbon

The invention belongs to a multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower mainly aiming at the treatment of refractory industrial wastewater. Influent (1) and O3 generated by an ozone generator (24) are injected into a water distribution cabin through a dissolved gas pump (5) and enter a micro-bubble release contact area (7) through a pore plate to release dissolved gas; Liquid which contains slag flows upwards and enters a floating slag separation area (8), liquid which contains no slag flows downwards and enters a gas-liquid separator (9), one part of effluent (10) is drained from a drain hole (11), and one part of the effluent (10) is refluxed to a dissolved gas pump intake pipe (12); an ultrasonic vibrator (13) and an ultraviolet light source (14) provide an ultrasonic and ultraviolet synergetic catalysis action; floating slag overflows to a collecting groove (15) and is drained through a drain hole (16); and a coagulant, powder activated carbon and hydrogen peroxide are added by adding systems (2, 3, 4) to provide a coagulation action and the synergetic catalysis action of PAC (powdered activated carbon) and H2O2. Tail gas is refluxed to the ozone generator through a drain hole (17), a one-way valve (18), gas suction tanks (19 and 20) and a dryer (23). The oxidation tower is compact in structure and has high treatment efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

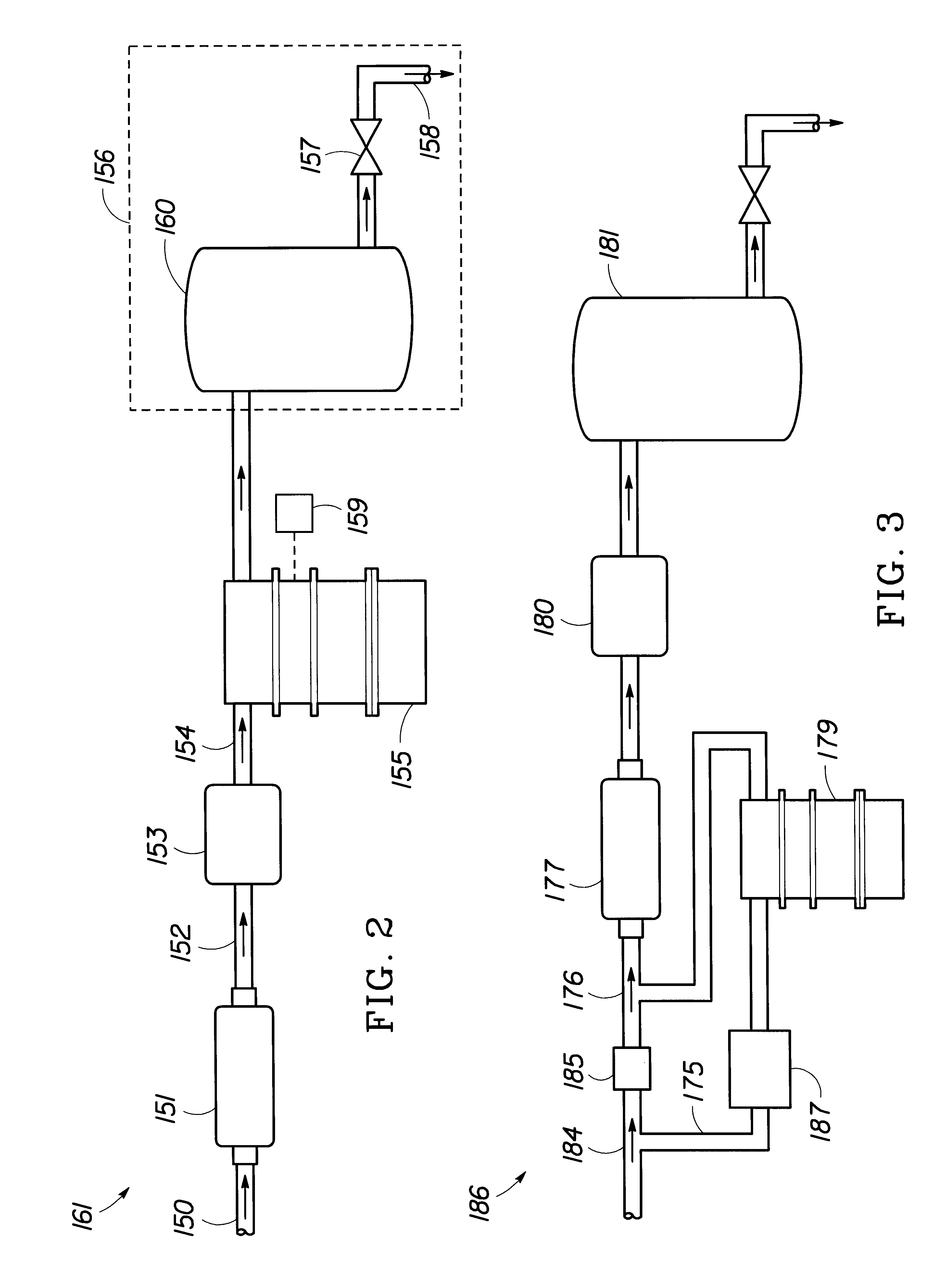

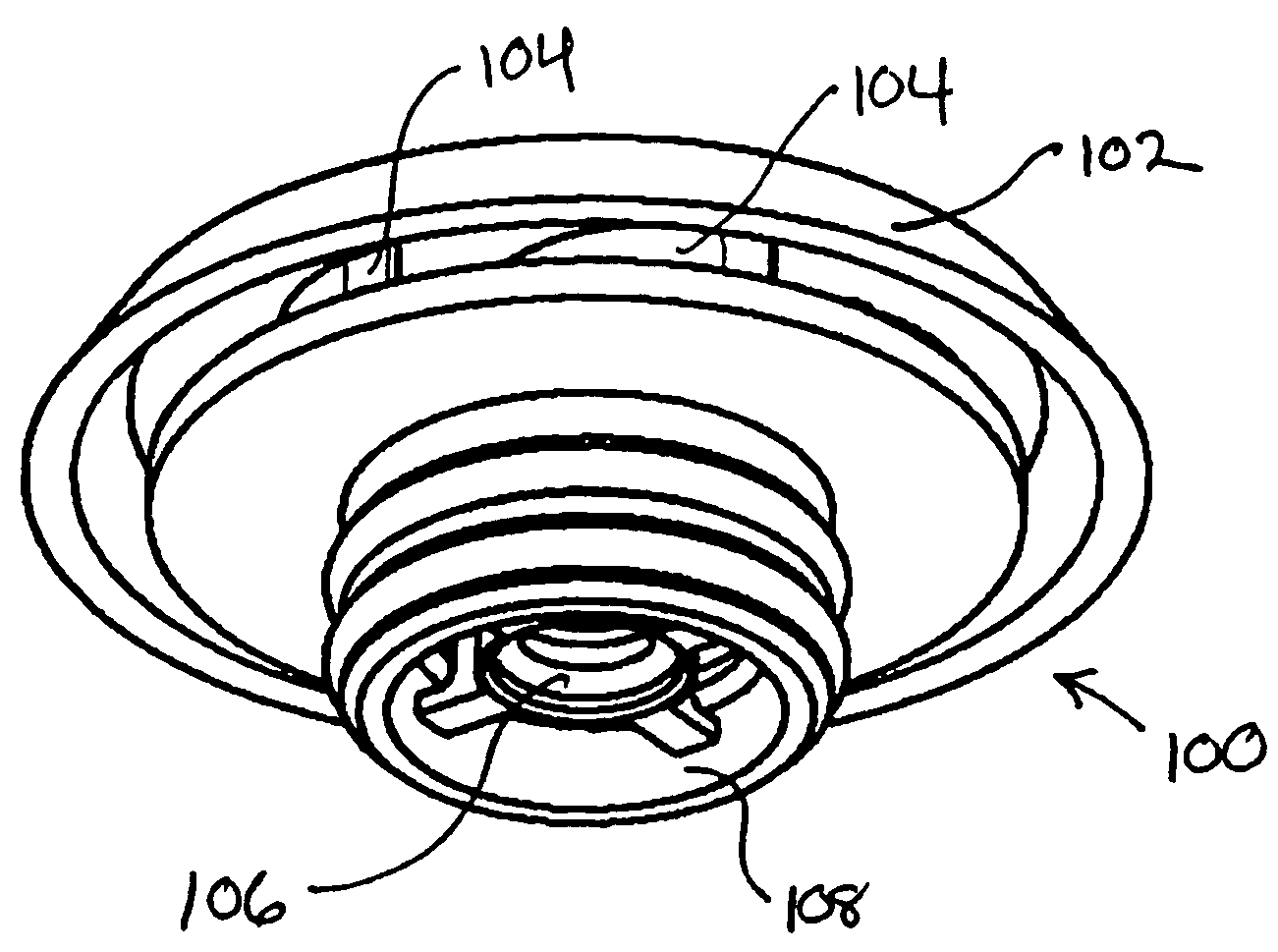

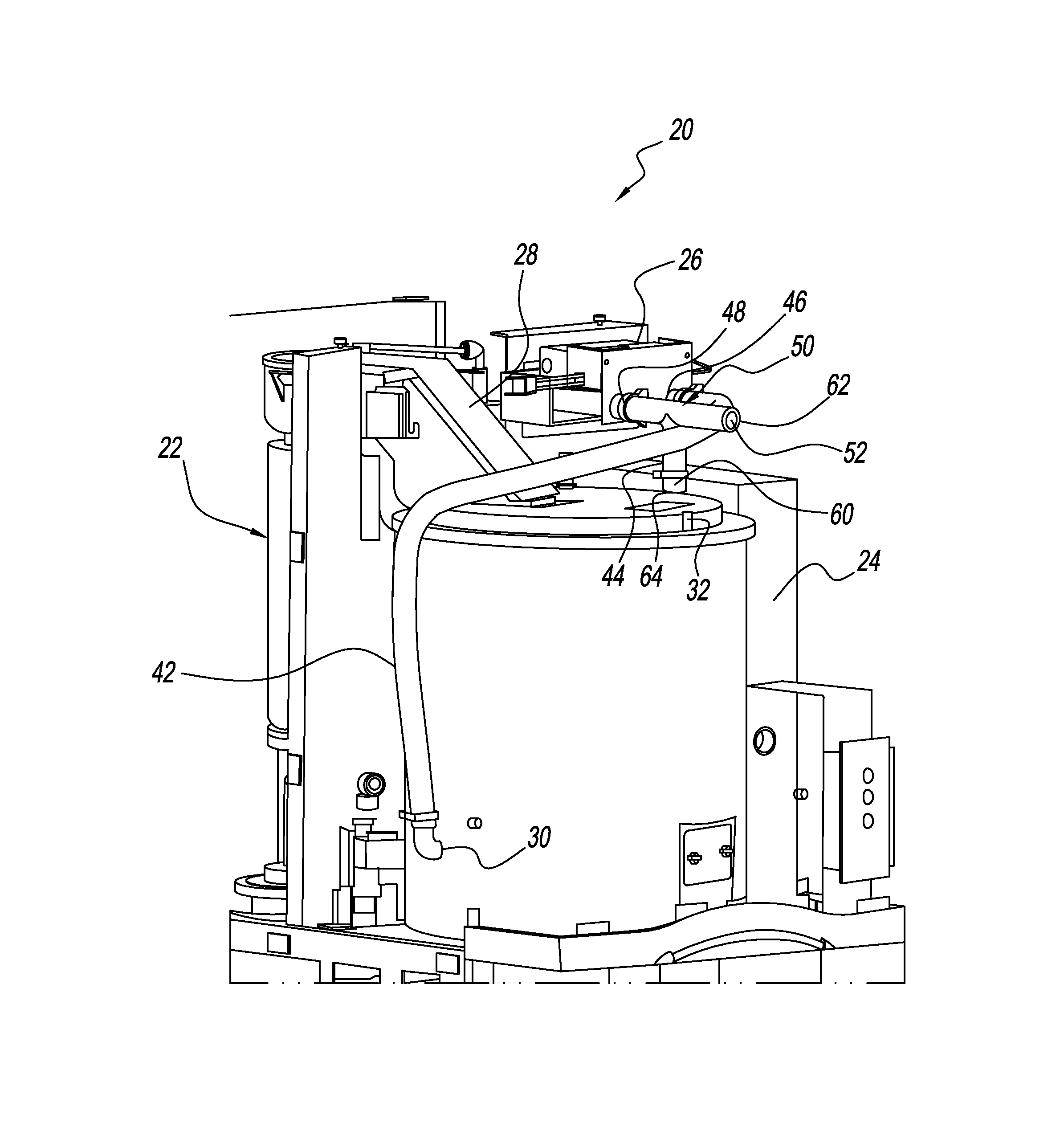

Sanitization system and system components

InactiveUS7767168B2Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

Electrolyzer

An ozone generator which operates at constant pressures to produce a continuous flow of ozone in an oxygen stream having from 10% to 18% by weight of ozone. The ozone generator includes one or more electrolytic cells comprising an anode / anode flowfield, a cathode / cathode flowfield, and a proton exchange medium for maintaining the separation of ozone and oxygen from hydrogen. The ozone generator also has an anode reservoir which vents oxygen and ozone and a cathode reservoir which vents hydrogen. The anode reservoir can be filled from the cathode reservoir while continuing to produce ozone. The ozone generator is readily configured for self-control using a system controller programmed to operate the anode reservoir at a constant pressure.

Owner:LYNNTECH

Methods and apparatus for disinfecting and/or deodorizing an article

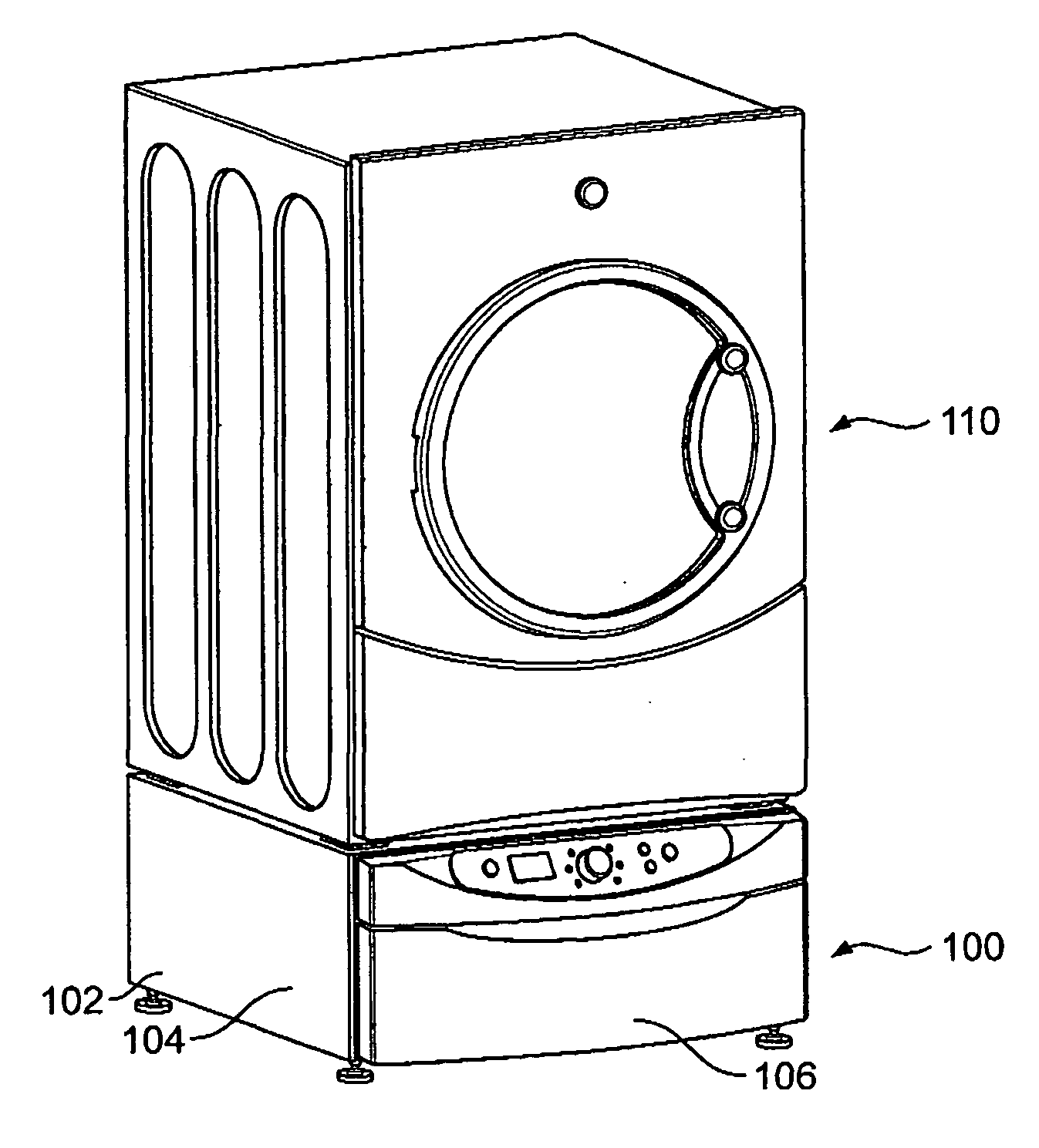

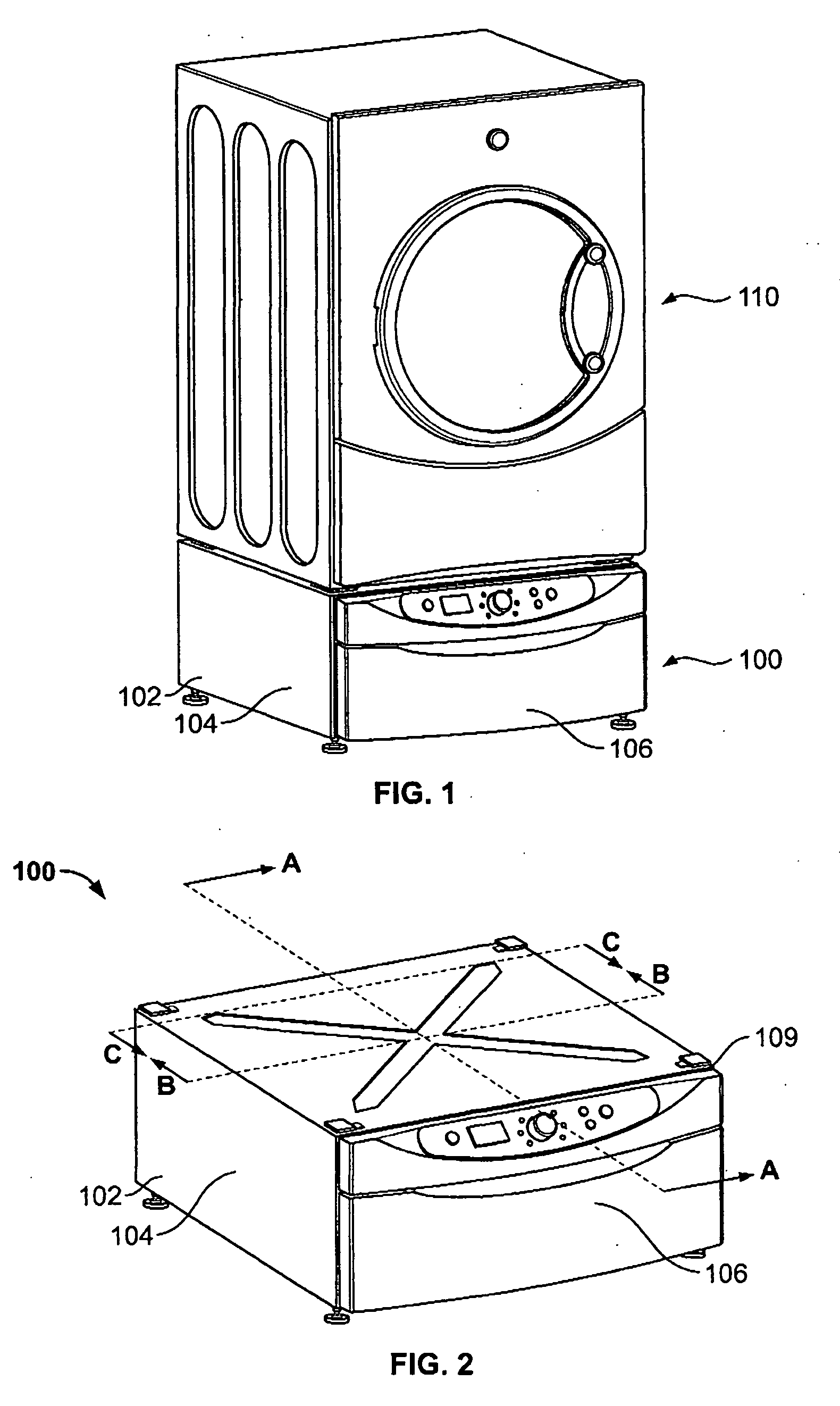

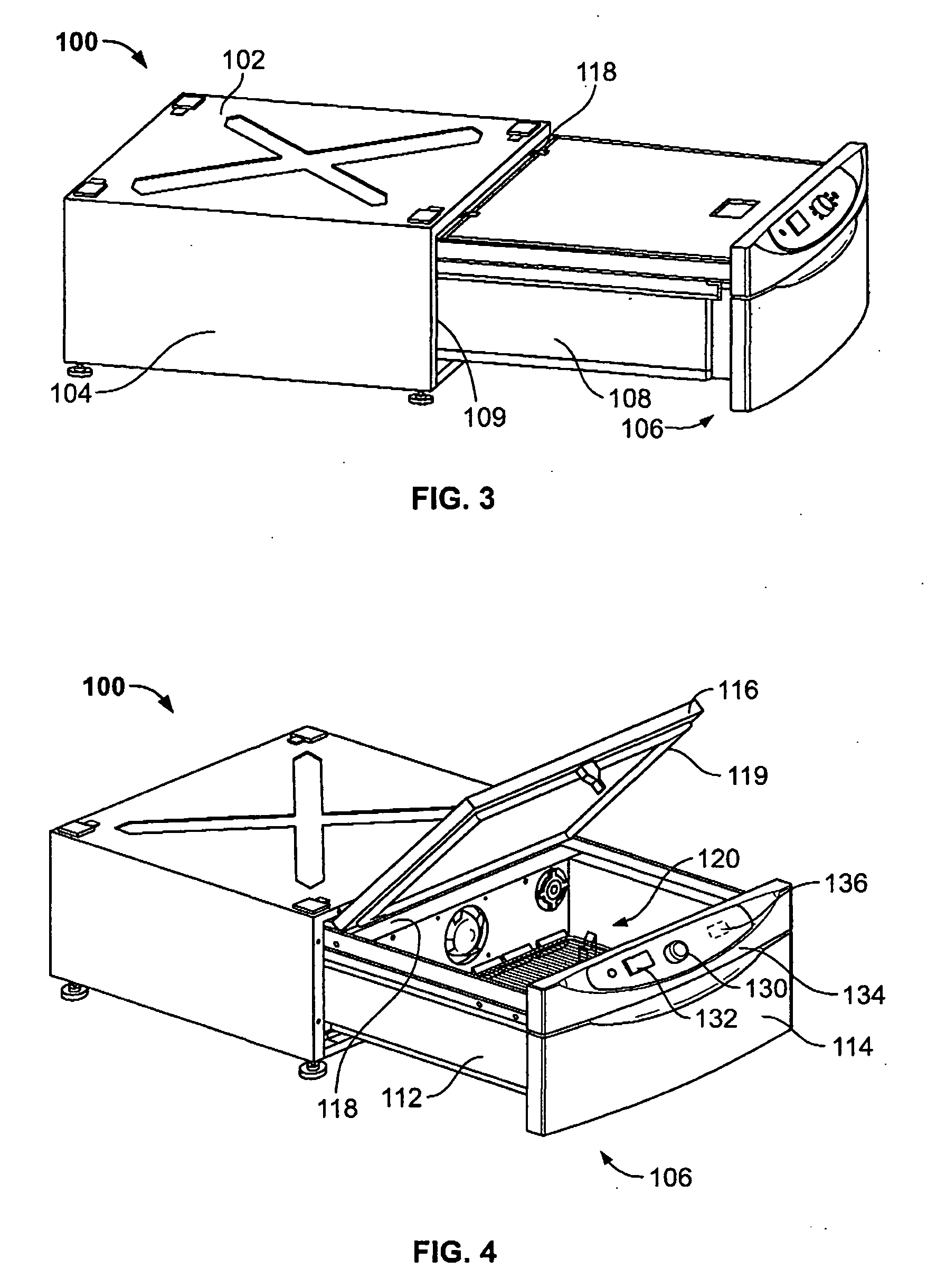

InactiveUS20080159907A1Other washing machinesLavatory sanitoryOzone generatorEnvironmental engineering

An apparatus includes a cabinet defining a chamber, a drawer slidably positioned within the chamber and movable between an open position and a closed position, the drawer defining a compartment configured to receive a load, in the closed position the drawer coupled to the cabinet and restricting air flow exiting the cabinet. The apparatus includes an ozone generator configured to selectively generate ozone into the compartment, an ozone conversion device configured to selectively convert ozone to oxygen, and a sensor configured to detect a level of ozone within the compartment and generate a signal representative of the level of ozone. A controller is operatively coupled to the ozone generator, the ozone conversion device and the sensor, and is configured to activate one of the ozone generator and the ozone conversion device in response to a signal received from the sensor.

Owner:GENERAL ELECTRIC CO

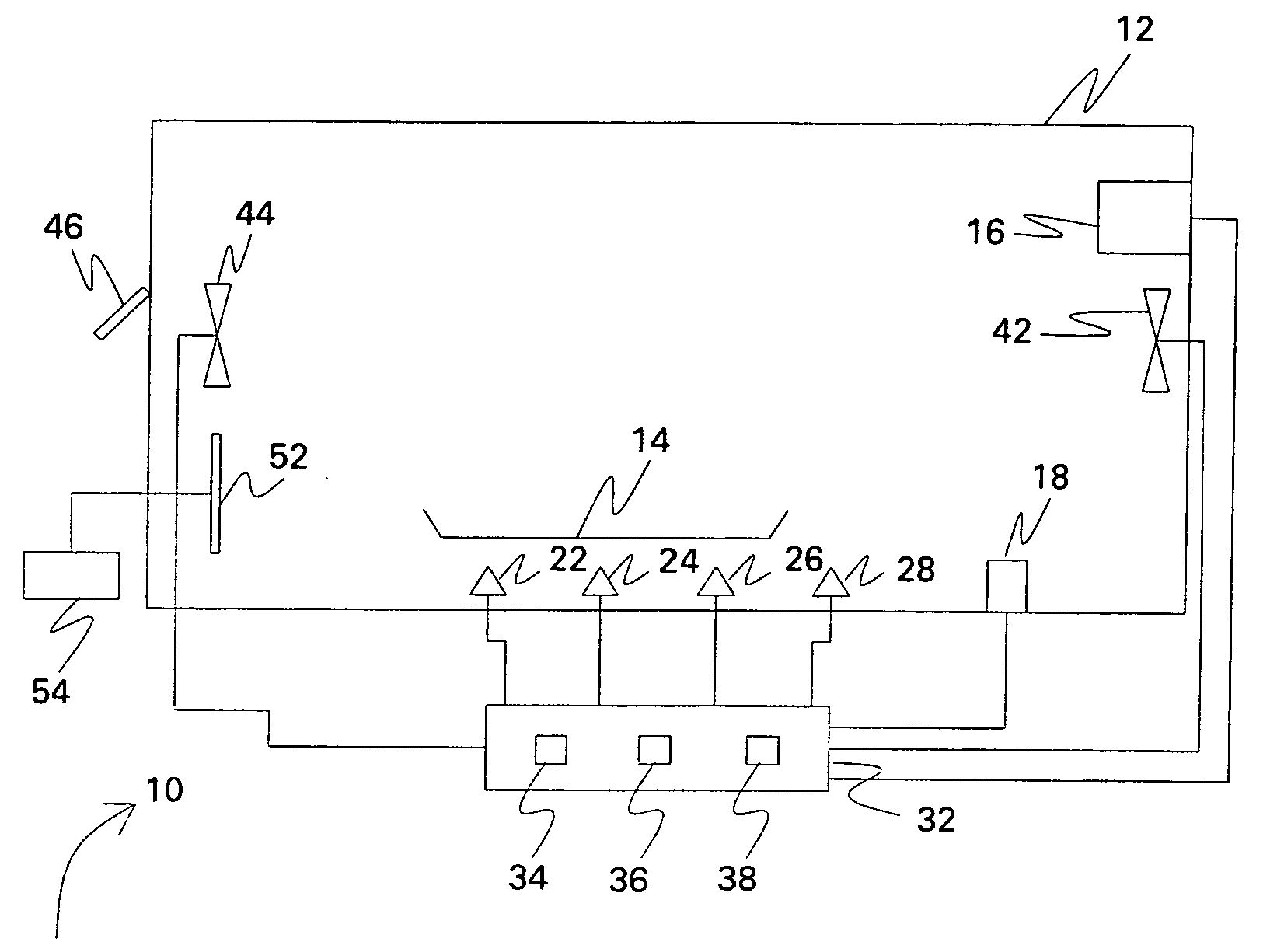

Process and apparatus for treating a workpiece such as a semiconductor wafer

InactiveUS6869487B1Reduce pollutionProcessing speedPrinted circuit assemblingLighting and heating apparatusOzone generatorCompound (substance)

A novel chemistry, system and application technique reduces contamination of semiconductor wafers and similar substrates and enhances and expedites processing. A stream of liquid chemical is applied to the workpiece surface. Ozone is delivered either into the liquid process stream or into the process environment. The ozone is preferably generated by a high capacity ozone generator. The chemical stream is provided in the form of a liquid or vapor. A boundary layer liquid or vapor forms on the workpiece surface. The thickness of the boundary layer is controlled. The chemical stream may include ammonium hydroxide for simultaneous particle and organic removal, another chemical to raise the pH of the solution, or other chemical additives designed to accomplish one or more specific cleaning steps.

Owner:OEM GRP LLC

Apparatus and method for treating and dispensing a material into tissue

An apparatus for administering a therapeutic is provided. In various embodiments, the apparatus includes a syringe having a barrel and a plunger and having a material treatment module associated therewith. The material treatment module may be an ozone generator that is initiated such that material containing ozone accumulates within the barrel. The material can then be delivered from the barrel into a target site via a needle, thereby delivering therapeutic effects to that target site.

Owner:ACTIVEO

Method for administering a therapeutic agent into tissue

An apparatus for administering a therapeutic agent is provided. The apparatus, in an embodiment, includes an ozone generator connected to a scavenger and an ozone administrator via network of tubing and valves. When activated and the valves placed in the proper position, the ozone generator will fill the ozone administrator with ozone. The ozone generator can then be turned off and the valves moved so that the administrator can be disconnected from the remainder of the apparatus. The administrator is typically in the form of a syringe and needle. Once the syringe and needle is filled with ozone, the needle can be inserted into a tissue and the ozone expressed therefrom into the tissue. Various other apparatuses and methods are also contemplated.

Owner:CERAMTEC

Ozone generator system and ozone generating method

ActiveUS20060049738A1Improve power generation efficiencyIncrease light intensityPhysical/chemical process catalystsElectrical discharge ozone preparationDielectricHigh concentration

An ozone generating system and an ozone generating method producing ozone at a high concentration and operating at high efficiency, in which a raw material gas with no nitrogen added and mainly containing oxygen is used. The amount of generation of NOX by-product is null. A raw material gas not containing nitrogen and mainly containing oxygen is supplied to an ozone generator, an AC voltage is applied to produce discharge light having wavelength of 428 nm to 620 nm, a catalytic material containing a photocatalytic material with a band gap energy of 2.0 eV to 2.9 eV is provided on an electrode or a dielectric in a discharge region, gas pressure is kept at 0.1 MPa to 0.4 MPa, and ozone is generated.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

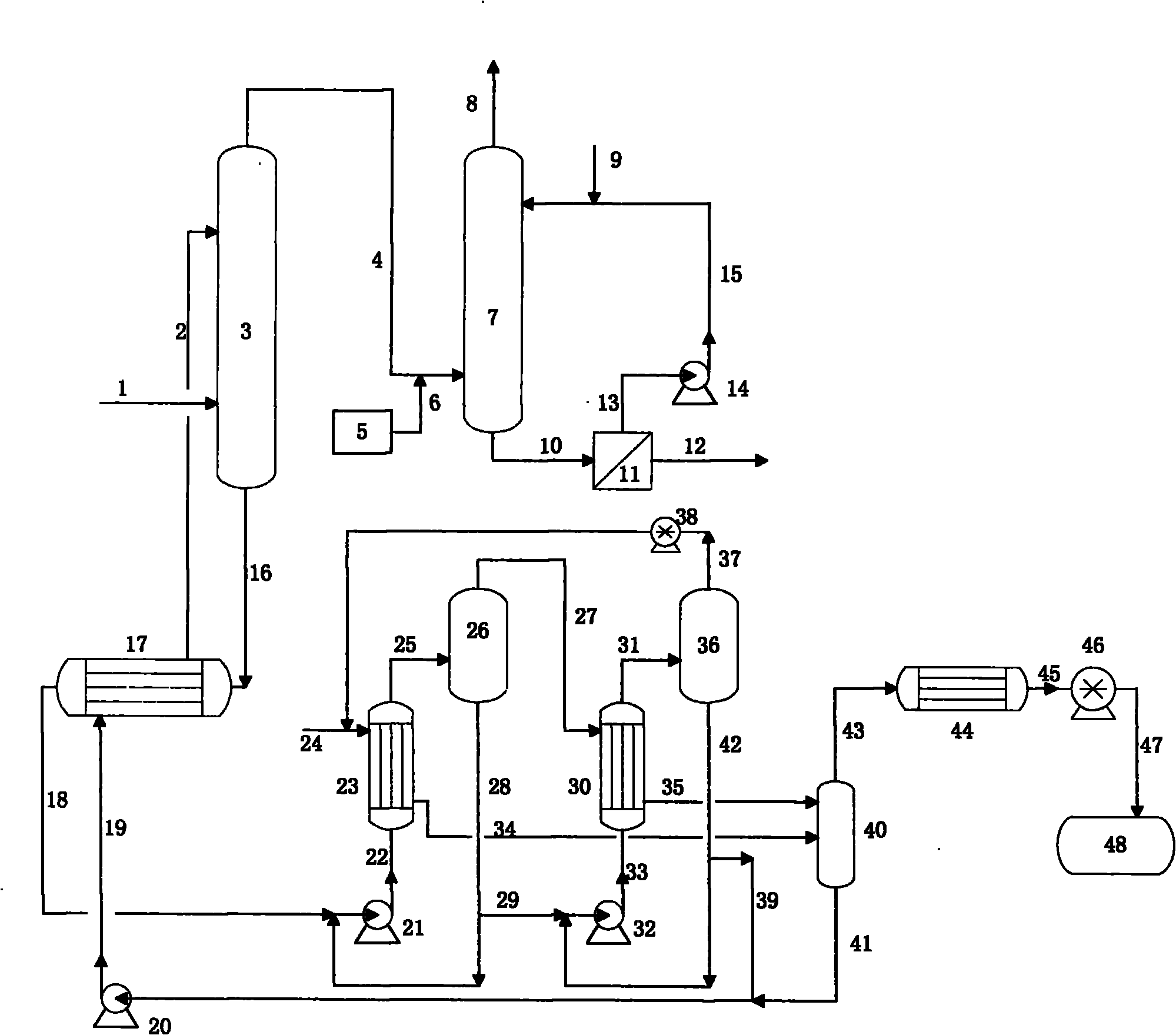

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

ActiveCN101485957ARealize separate recyclingAchieve denitrification efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a technique for processing flue gas of a coal burning boiler, and aims to provide a device and a method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing. The device comprises a flue which is connected with a heat exchanger, an alkali liquor washing tower A, and an alkali liquor washing tower B in sequence, wherein the insides of the alkali liquor washing tower A and the alkali liquor washing tower B are provided with a circular spraying device A and a circular spraying device B respectively; and an ozone generator is connected with a lower liquid phase area of the alkali liquor washing tower A and a pipeline in front of the circular spraying device B respectively. The novel method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing can achieve the denitration efficiency of more than 80 percent and desulfurization efficiency of more than 95 percent, and realize the reclaiming and reusing denitrated and desulfurized products in different devices respectively.

Owner:ZHEJIANG UNIV +1

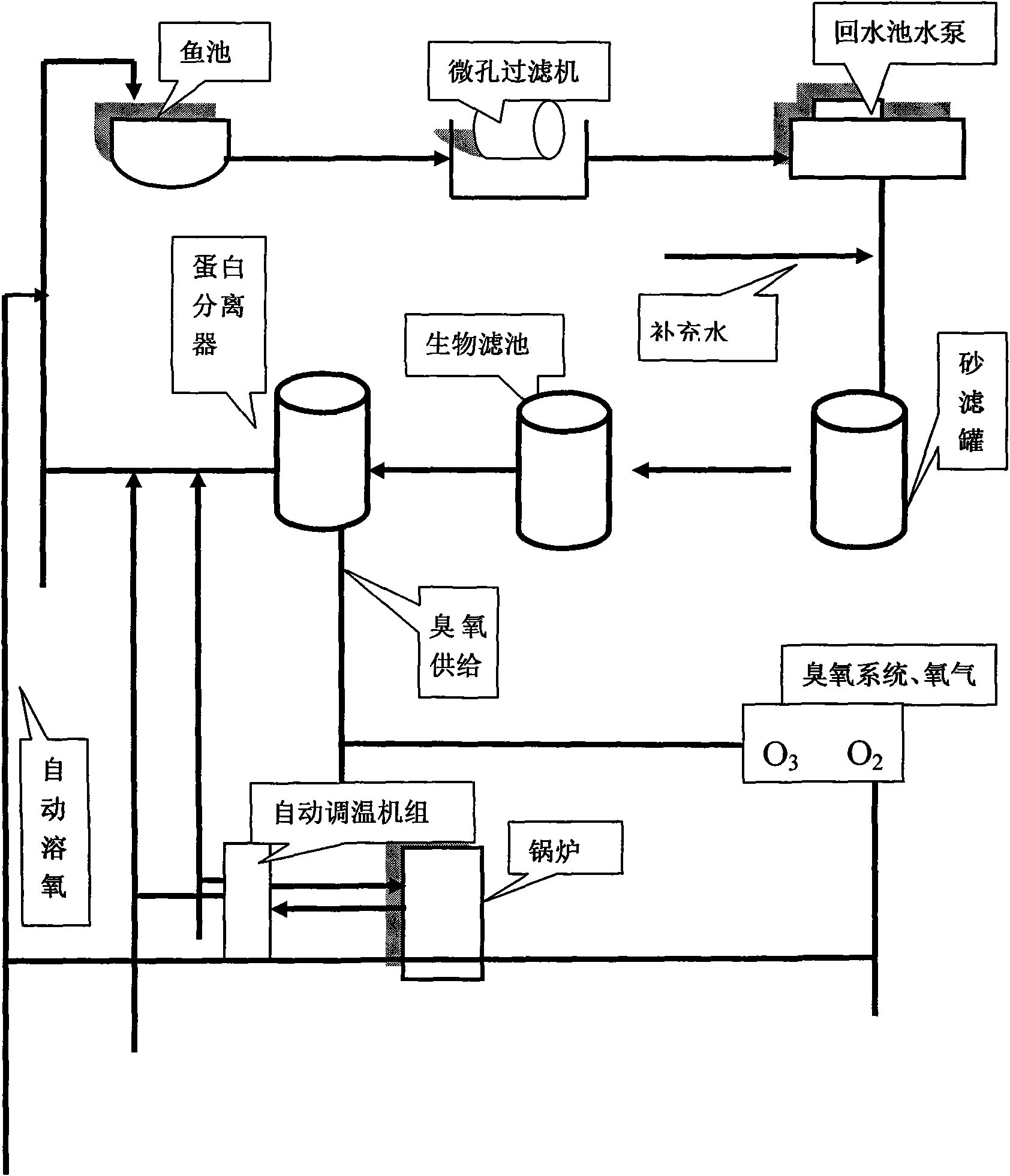

Intensive circulating water culture system

InactiveCN101606506AHigh densityImprove qualityPisciculture and aquariaMultistage water/sewage treatmentOzone generatorAquatic product

An intensive circulating water culture system comprises at least one water purification system which is configured in an aquaculture pond and mainly composed of a water pump, a filter and a sterilizing device. The water pump is at least arranged between a return water regulating pond and a sand filter tank, and the sand filter tank is then sequentially connected with a biofilter and a protein skimmer to form the filter; the water purification system is configured with a dissolved oxygen release device, and the device oxygenates the water purification system by connecting with the protein skimmer; and the water purification system is configured with an ozone generator and an automatic temperature regulating unit which are connected with the water purification system respectively by pipelines. The intensive circulating water culture system is characterized by simple structure, small occupied space, low cost, good circulating water treatment effect, meeting requirements for intensive aquaculture and the like.

Owner:陈能娟

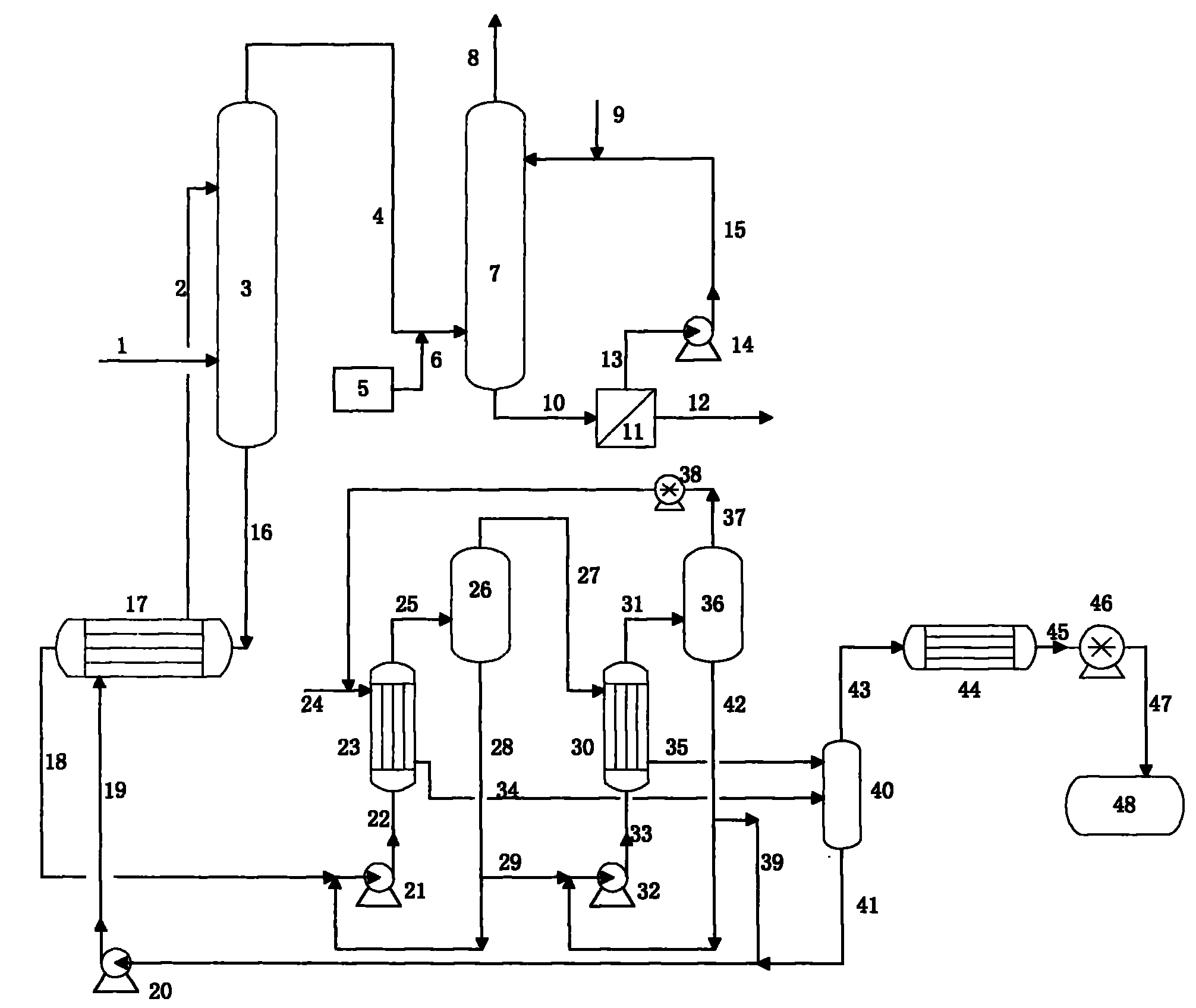

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

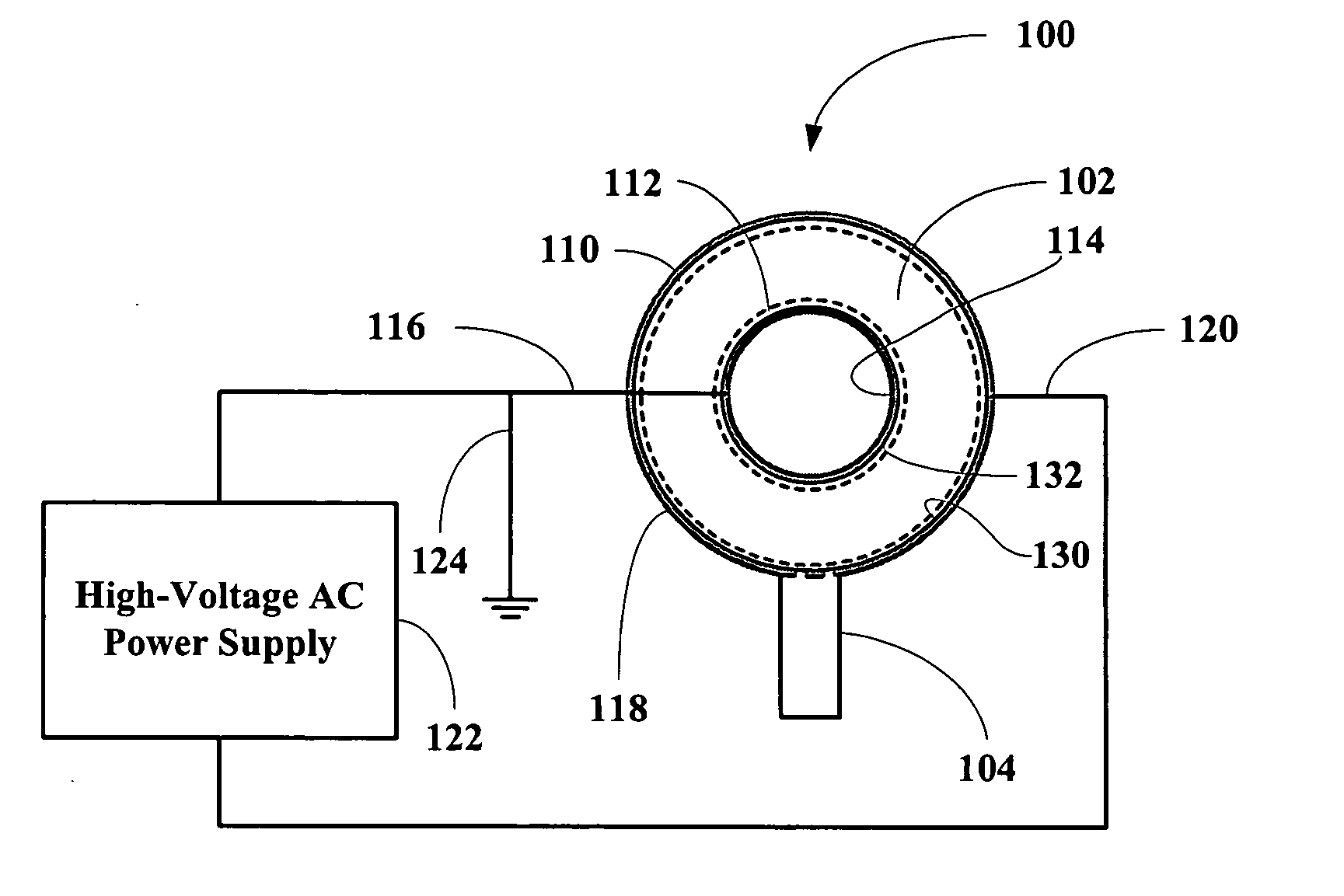

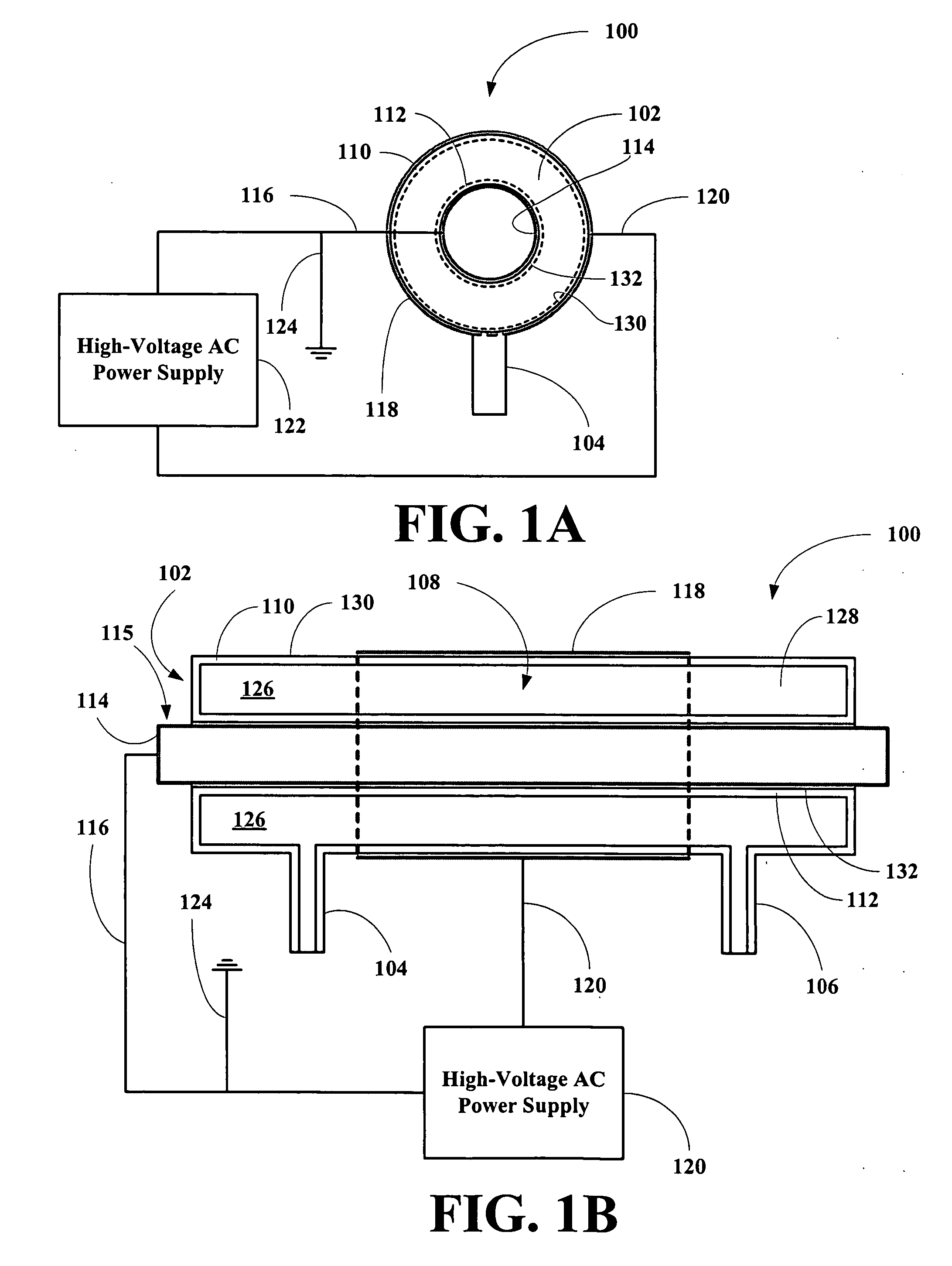

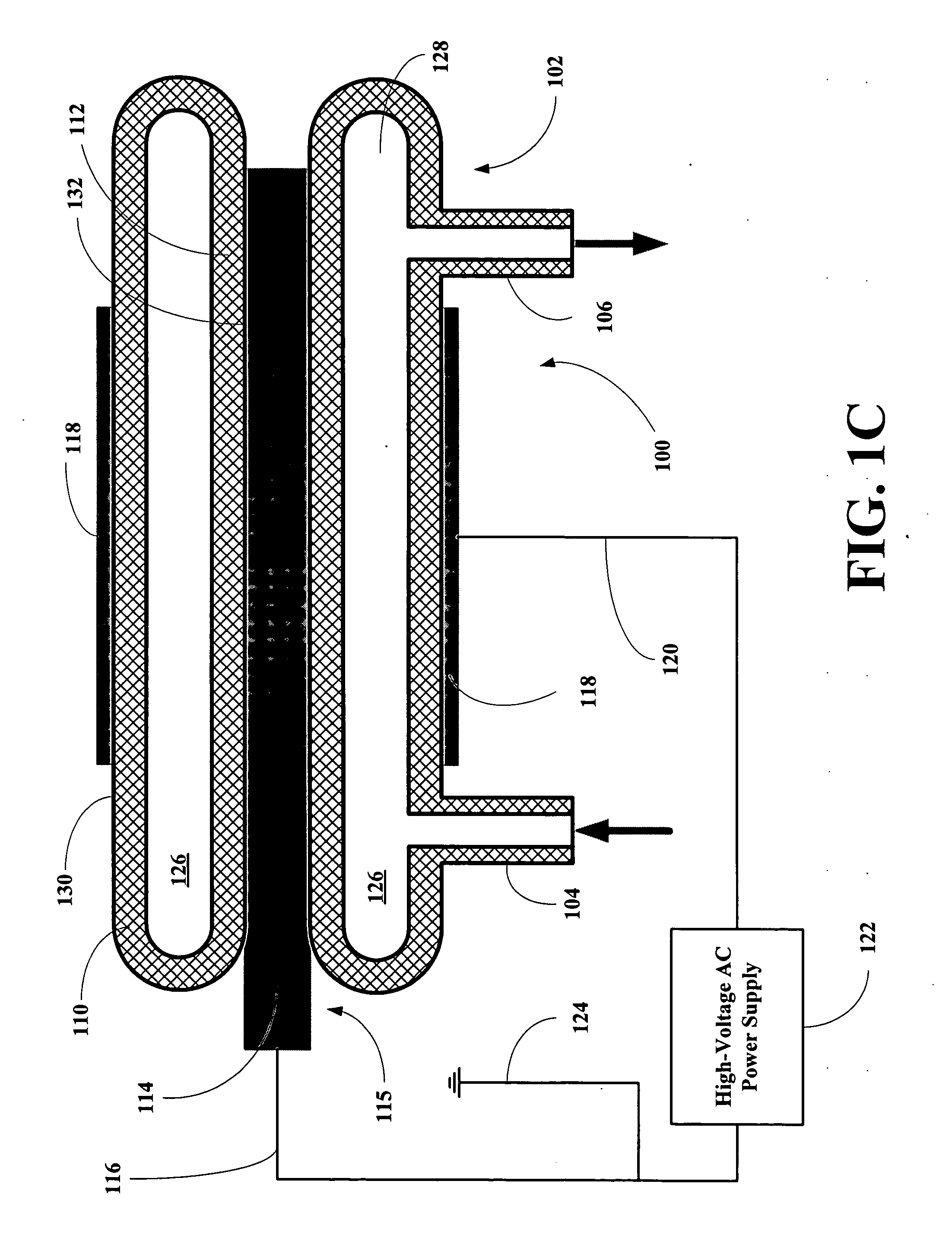

Ozone generator with dual dielectric barrier discharge and methods for using same

InactiveUS20050199484A1Electrical discharge ozone preparationEnergy based chemical/physical/physico-chemical processesPush pullEngineering

A new and novel ozone generator with a dual dielectric barrier discharge design is disclosed where high-purity ozone is generated and whose concentration can be varied over a wide range. The simplified design of the ozone generator cell possesses a gas inlet and outlet connected to an annular, sealed dielectric gas envelope that supports both inner and outer electrodes that do not come into contact with the gas. The design eliminates the need for gaskets, o-rings or other methods applied to seal the ozone cell and reduces problems associated with potential interaction resulting from material compatability issues. The applied high voltage is provided by a simple self-resonating, push-pull oscillating circuit whose efficiency is optimized through application of an appropriate impedance matching device. The ozone is concentration is adjusted by varying the pulse width duty cycle of the applied voltage and gas flow rate. The design configuration of the ozone generating cell also eliminates the need for forced air or liquid cooling by natural convective air currents and conductive means.

Owner:OLSTOWSKI FRANEK

Apparatus and Method For Treating and Dispensing a Material Into Tissue

An apparatus for administering a therapeutic is provided. In various embodiments, the apparatus includes a syringe having a barrel and a plunger and having a material treatment module associated therewith. The material treatment module may be an ozone generator that is initiated such that material containing ozone accumulates within the barrel. The material can then be delivered from the barrel into a target site via a needle, thereby delivering therapeutic effects to that target site.

Owner:ACTIVEO

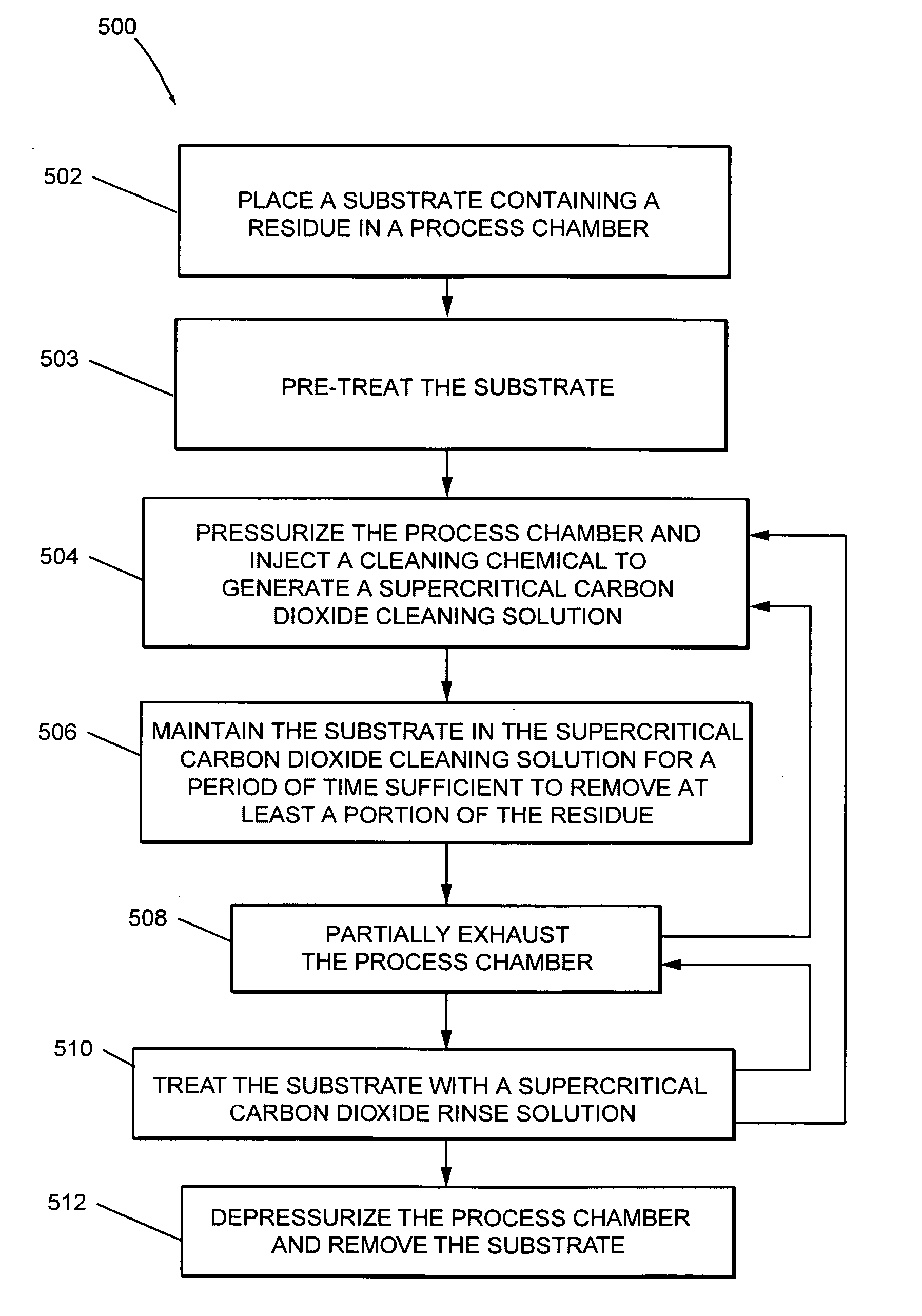

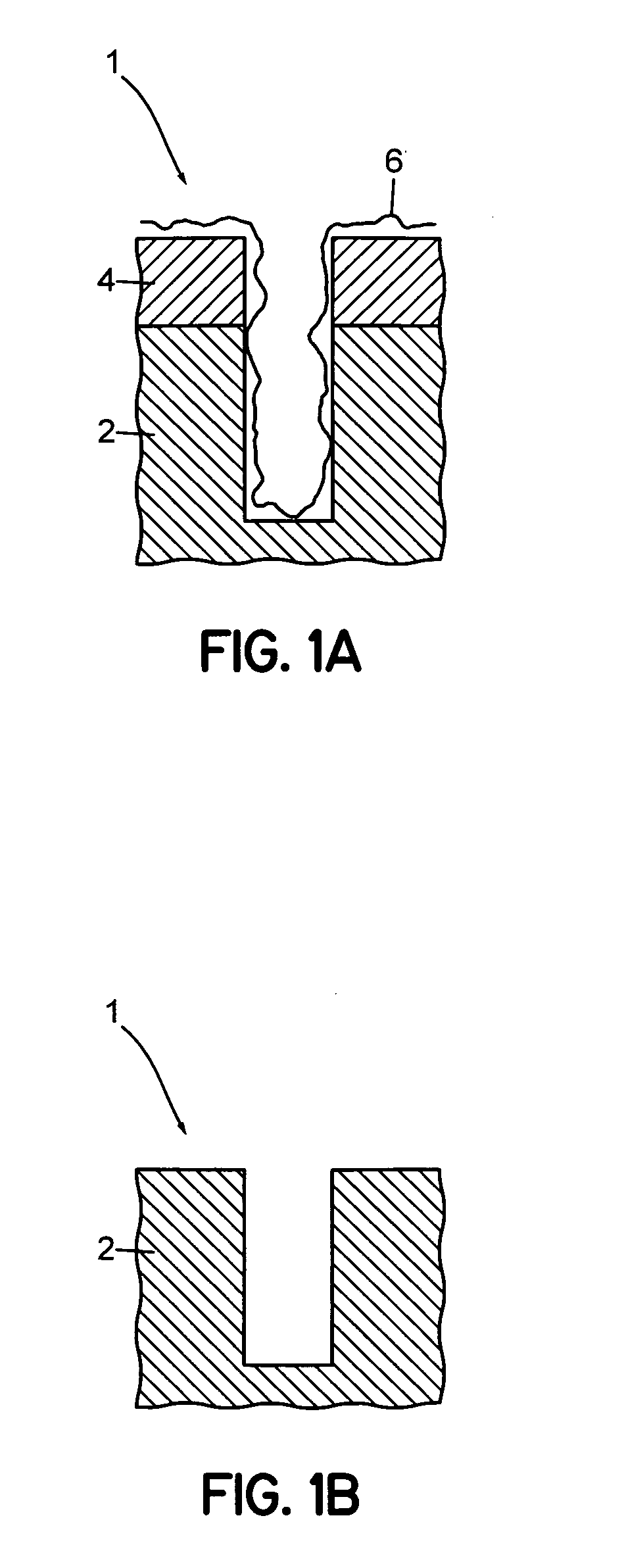

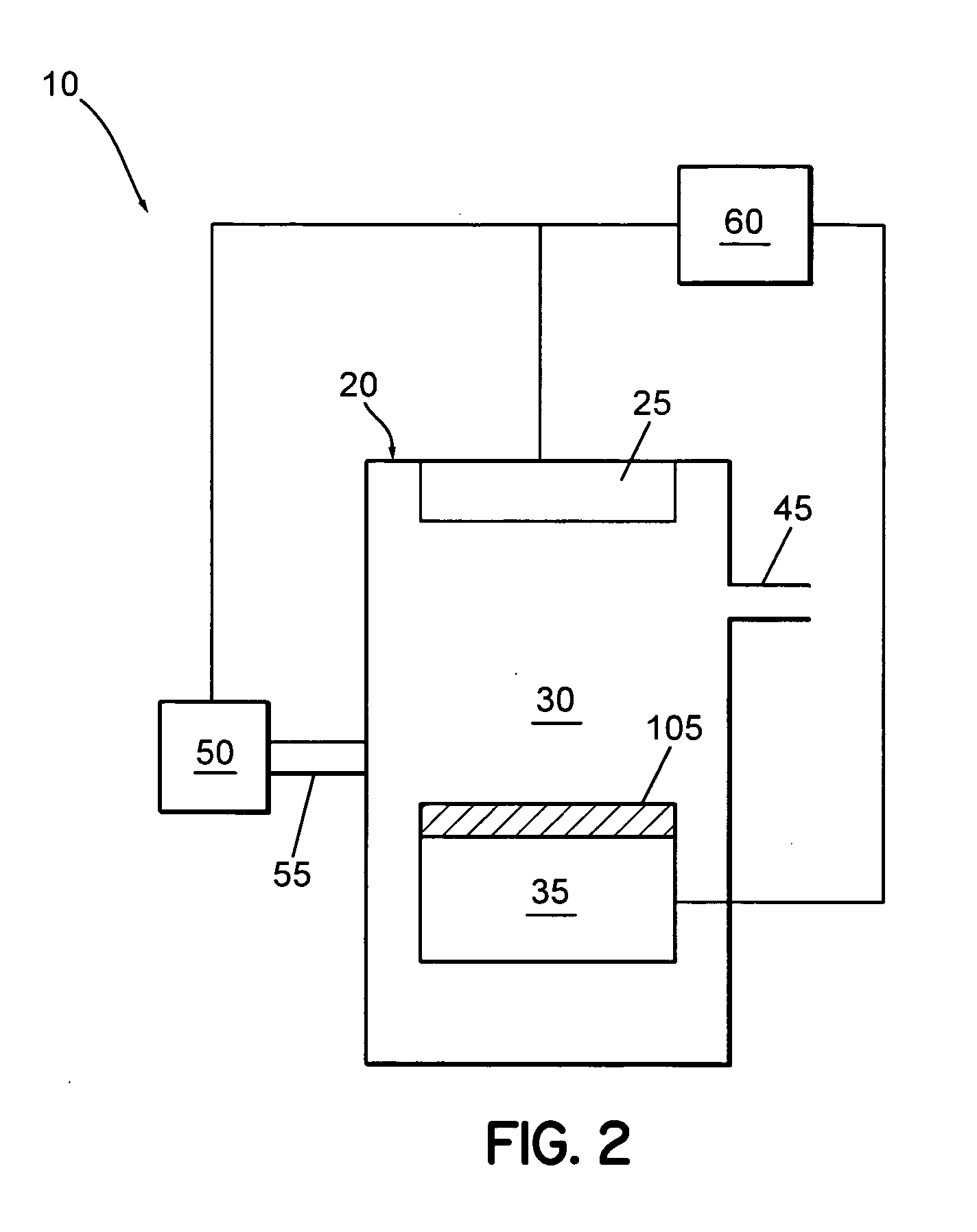

System for removing a residue from a substrate using supercritical carbon dioxide processing

InactiveUS20060102208A1Photomechanical apparatusSemiconductor/solid-state device manufacturingOzone generatorSolution processed

A film removal system for cleaning a substrate containing a micro-feature having a residue thereon. The film removal system includes a supercritical fluid processing system configured for treating the substrate witha supercritical carbon dioxide cleaning solution to remove the residue from the micro-feature, and for maintaining the supercritical carbon dioxide solution at a temperature between about 35° C. and about 80° C. during the treating. The film removal system further includes an ozone generator configured for providing an ozone processing environment for treating the substrate either prior to treating with the supercritical cleaning solution or concurrently therewith, and a controller configured for controlling the ozone generator and the supercritical fluid processing system.

Owner:TOKYO ELECTRON LTD

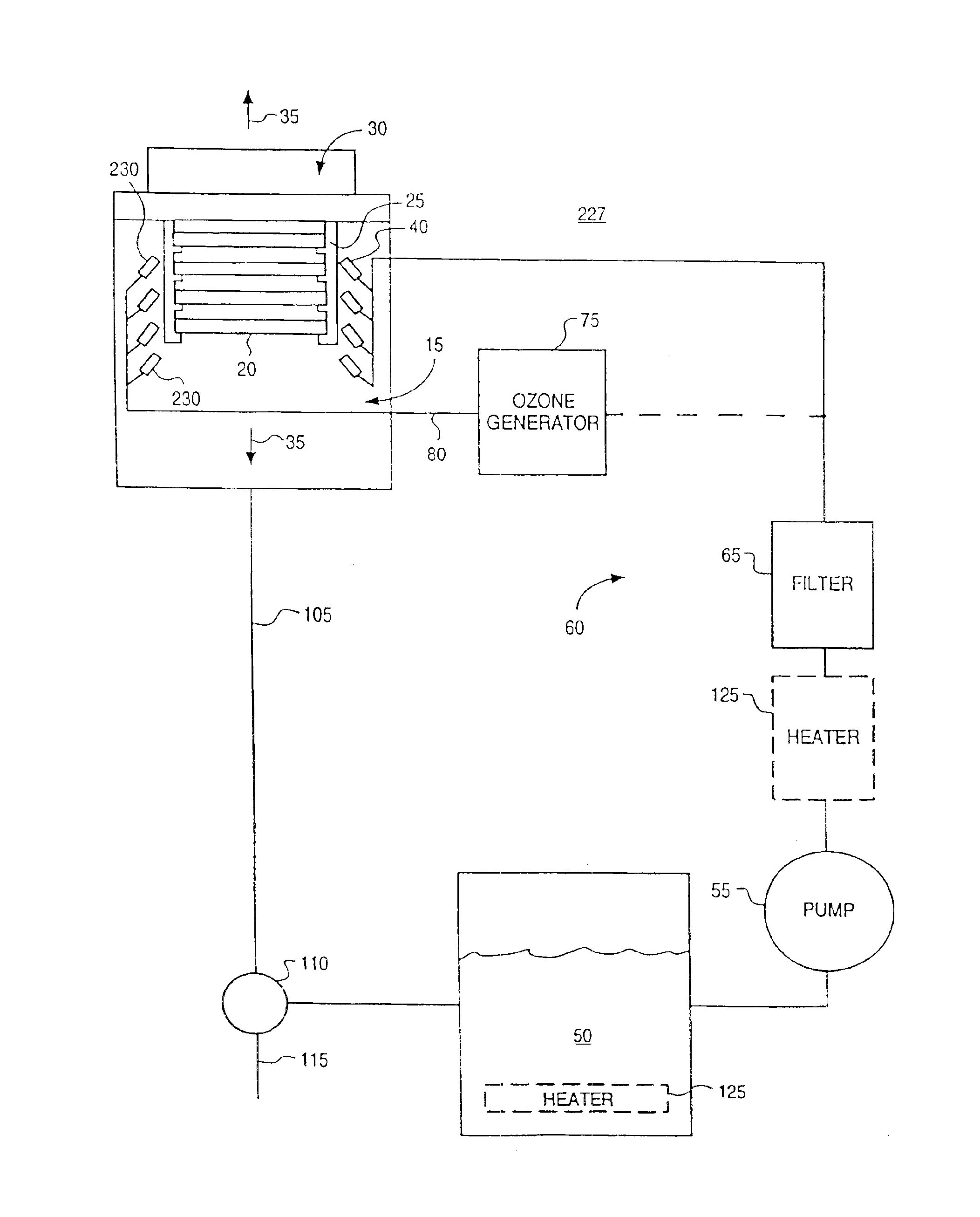

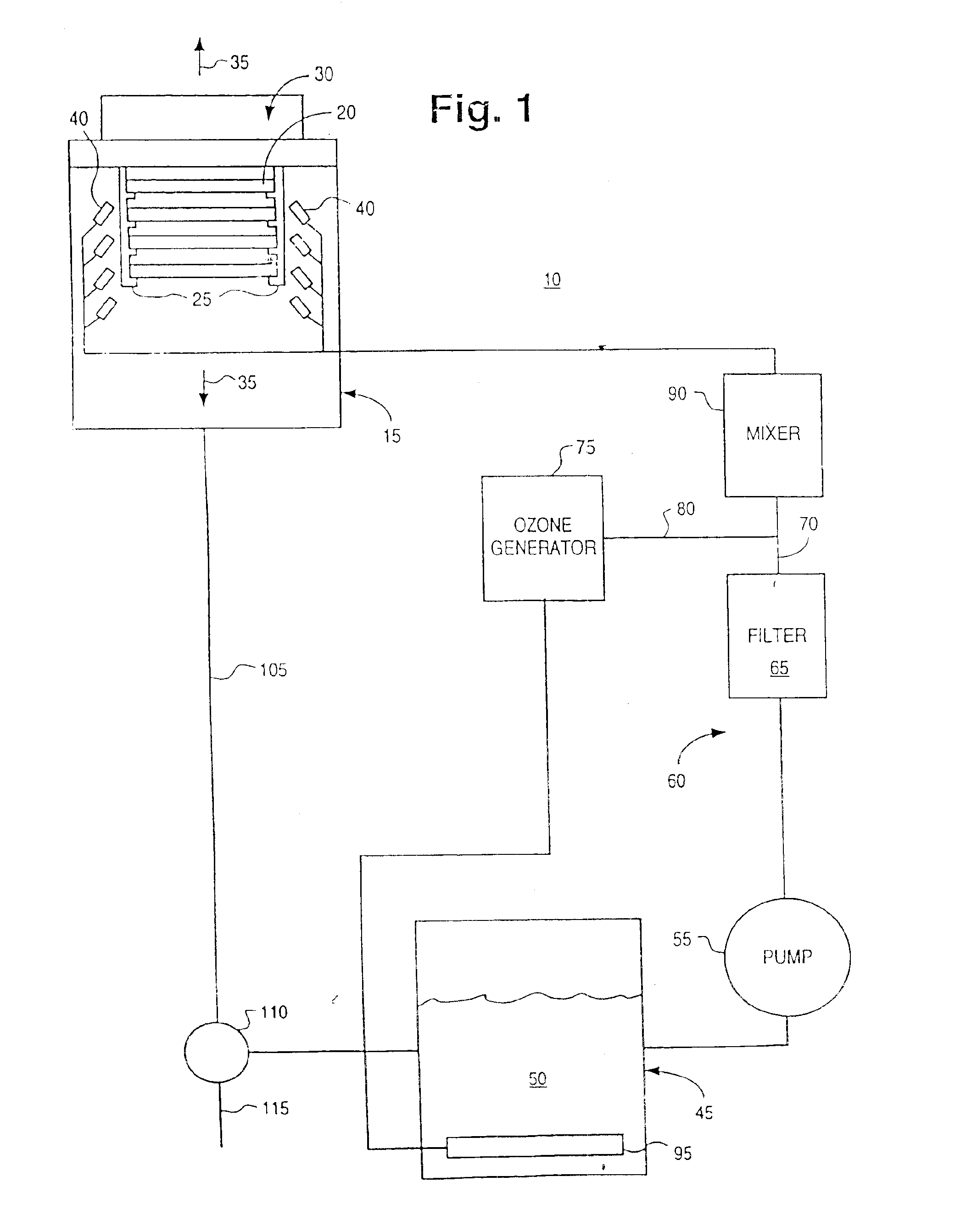

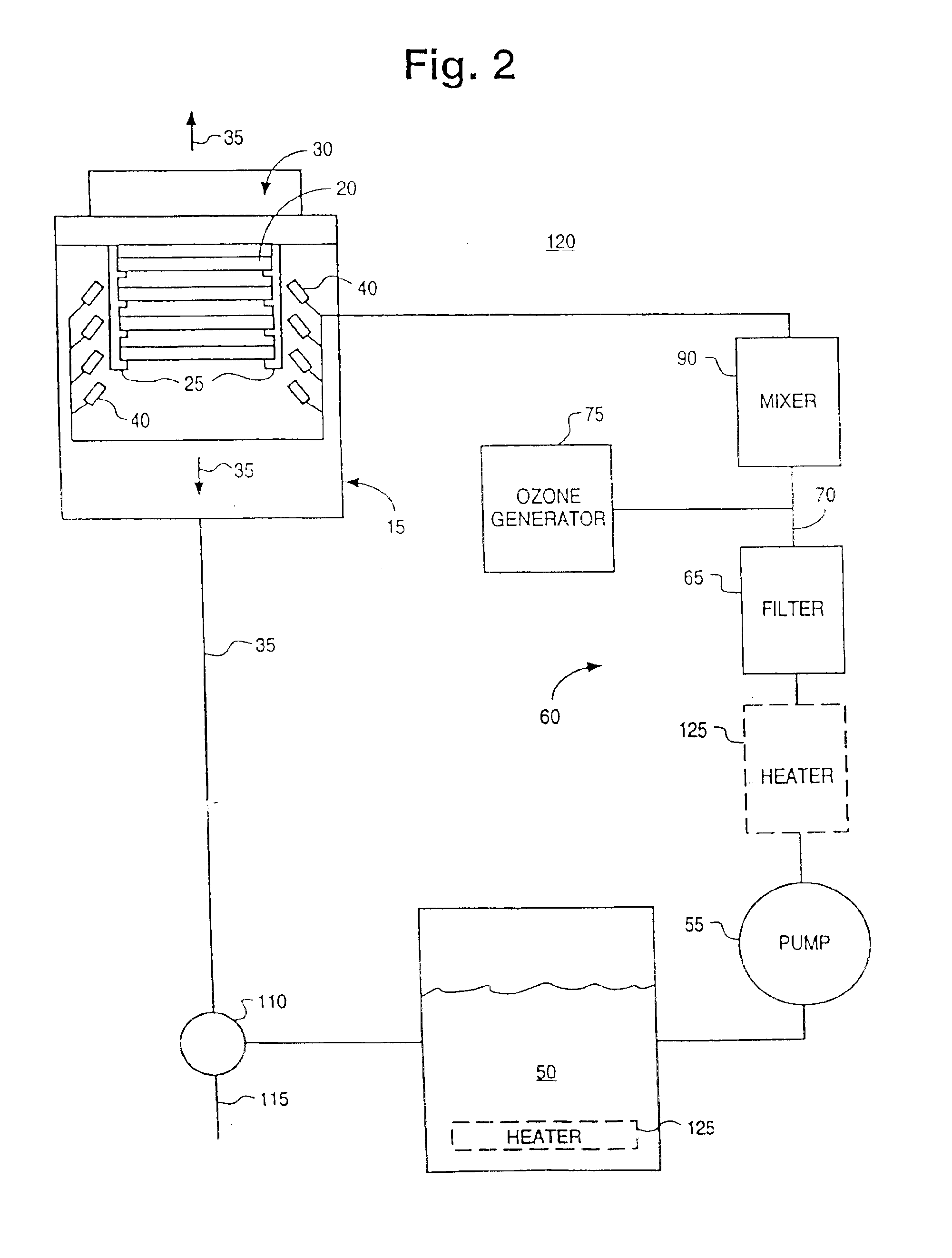

Sanitization system and system components

InactiveUS20050017380A1Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

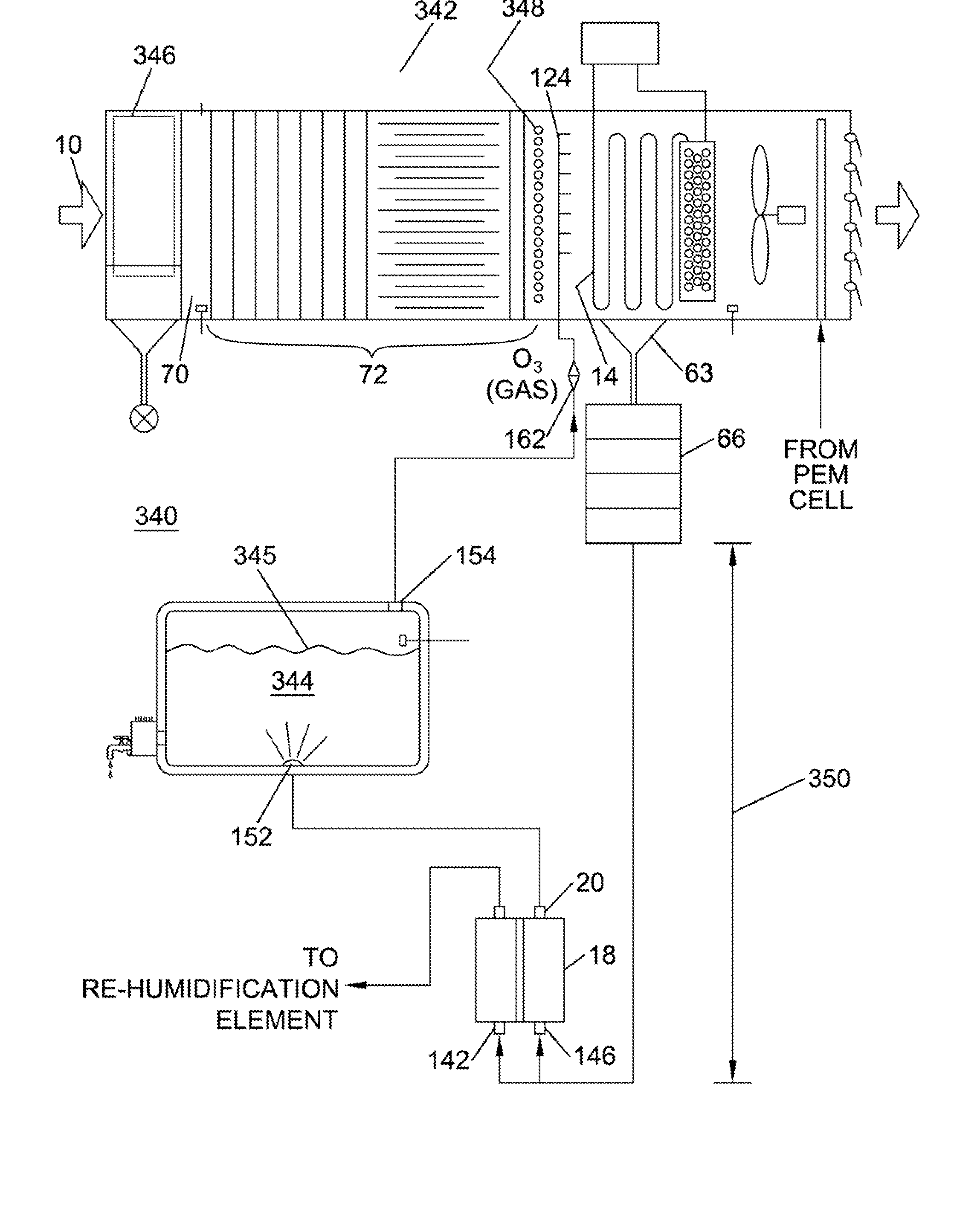

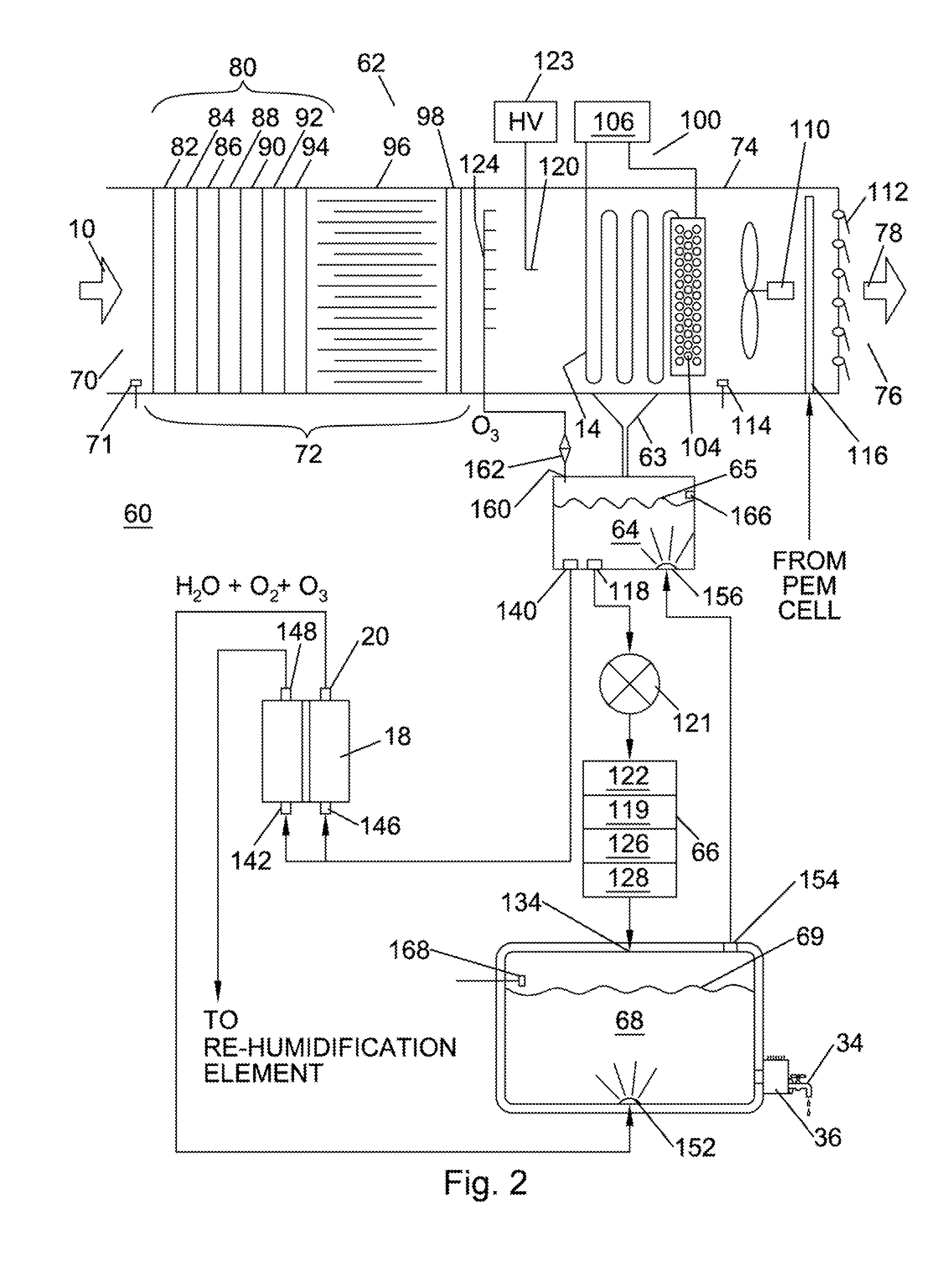

Apparatus and Method For Generating Water From an Air Stream

InactiveUS20070295021A1Fuel cell combinationsLighting and heating apparatusOzone generatorEnvironmental engineering

An apparatus and method for generating water from an air stream is disclosed. The apparatus has an inlet for receiving an air stream, a condensing element located in the air stream, a collector for gathering water vapor condensate that is formed on the condensing element when the condensing element temperature drops below the dew point temperature of the ambient air stream, and an ozone generator that precisely generates ozone required to disinfect the water vapor condensate. In some embodiments of the invention, the ozone is also added to the air stream for disinfecting the air stream and associated elements of the apparatus.

Owner:CONVERGITECH

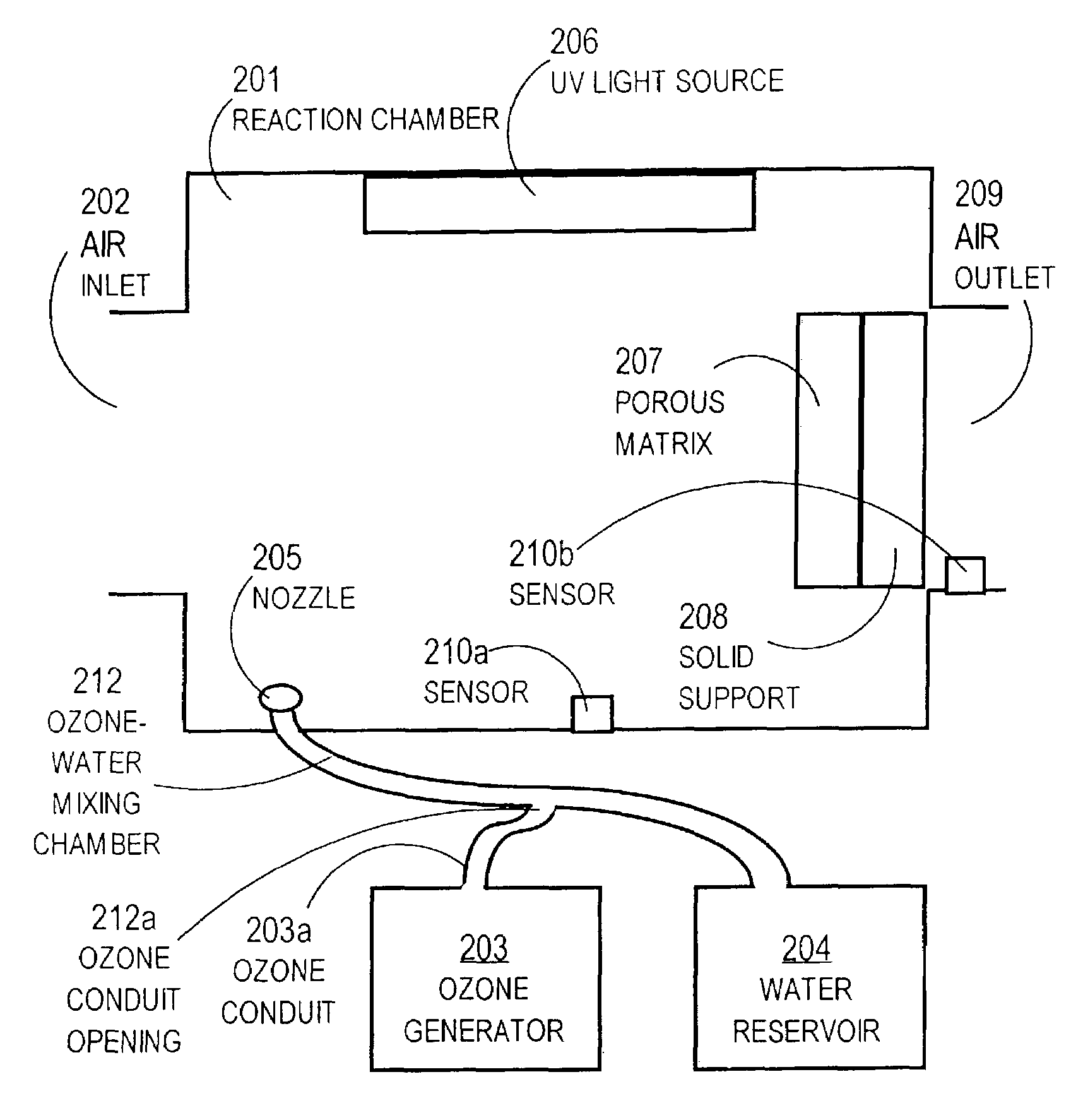

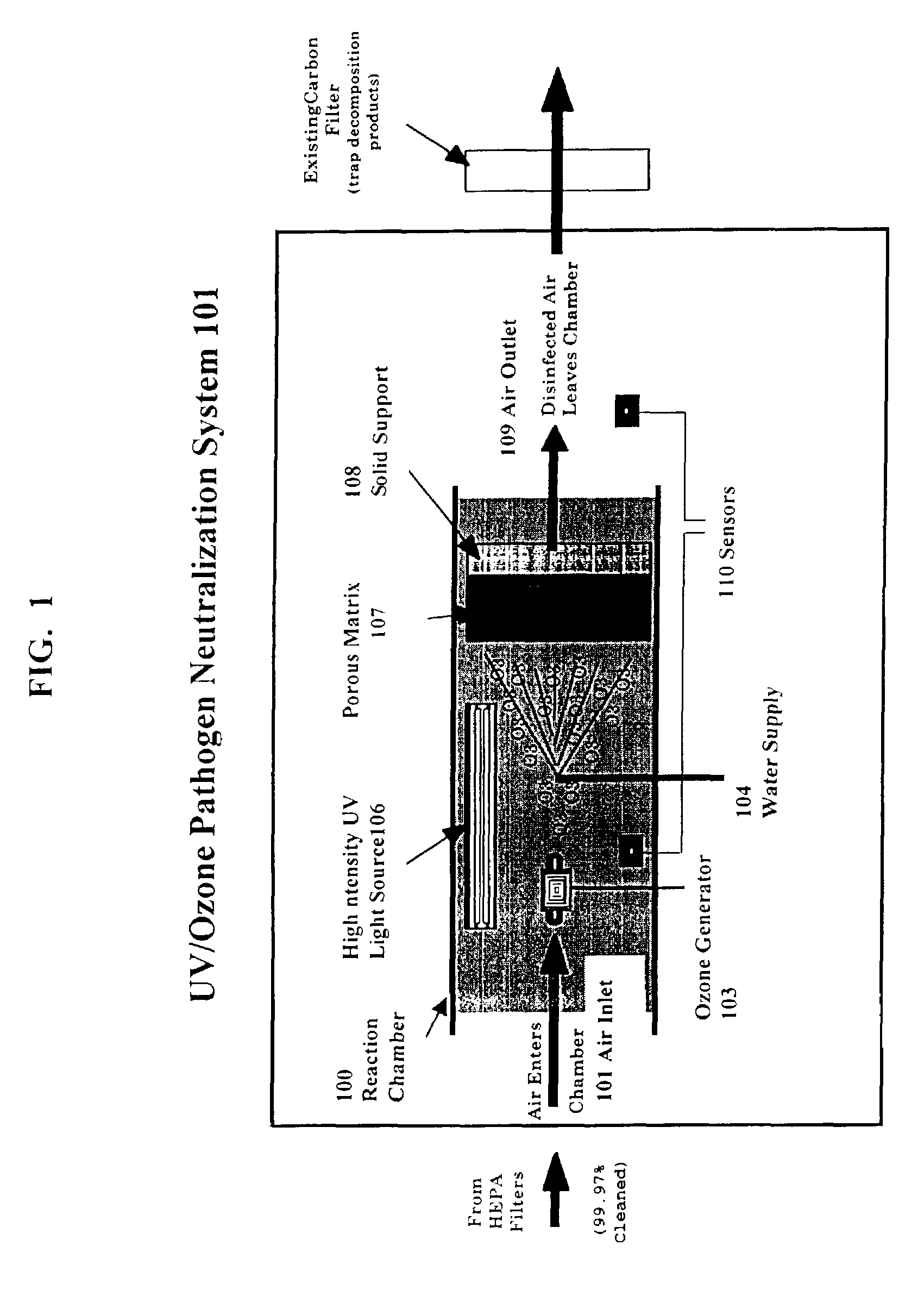

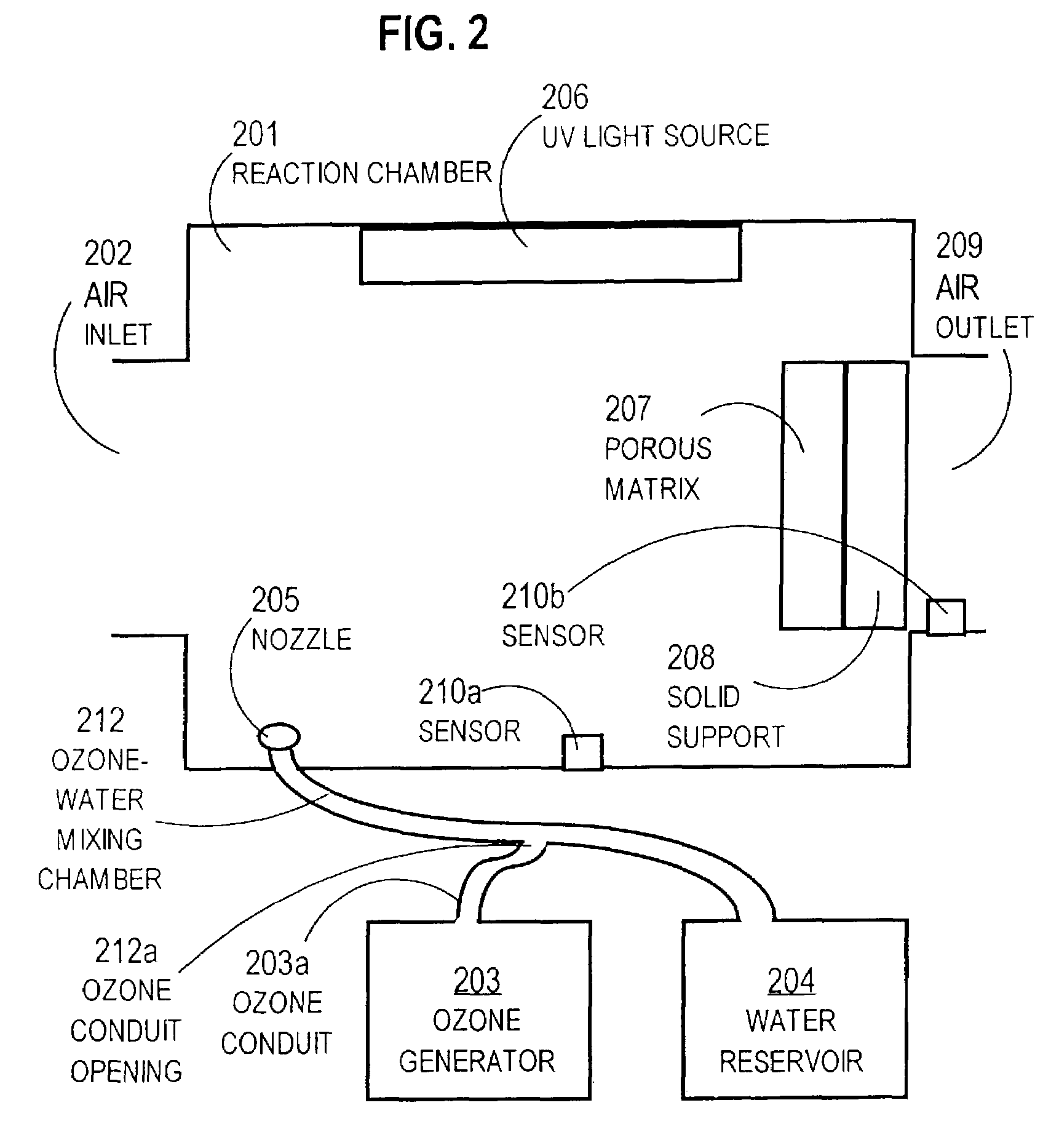

Method and apparatus for air treatment

InactiveUS7407633B2Easy to installDisinfecting airMechanical apparatusLighting and heating apparatusOzone generatorSpore

A method and apparatus is described for neutralizing airborne pathogens in ventilated air, and in heating or air conditioning systems. The pathogen neutralization system is effective against a wide spectrum of pathogens, it incorporates commercially available components, and it can be readily integrated into commercial HVAC systems where it neutralizes airborne pathogens in large volumes of ventilated air in real time without any chemical reagents. Typically, the system has a flow-through reaction chamber that contains a UV light source that emits short intense flashes of broad-spectrum UV light, a source of water vapor or spray, and an ozone generator. The system generates highly reactive ozone intermediates by irradiating ozone gas with UV light in the presence of water droplets or water vapor. The pathogens that can be neutralized by this system include bacteria, viruses, spores, fungi and parasites.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

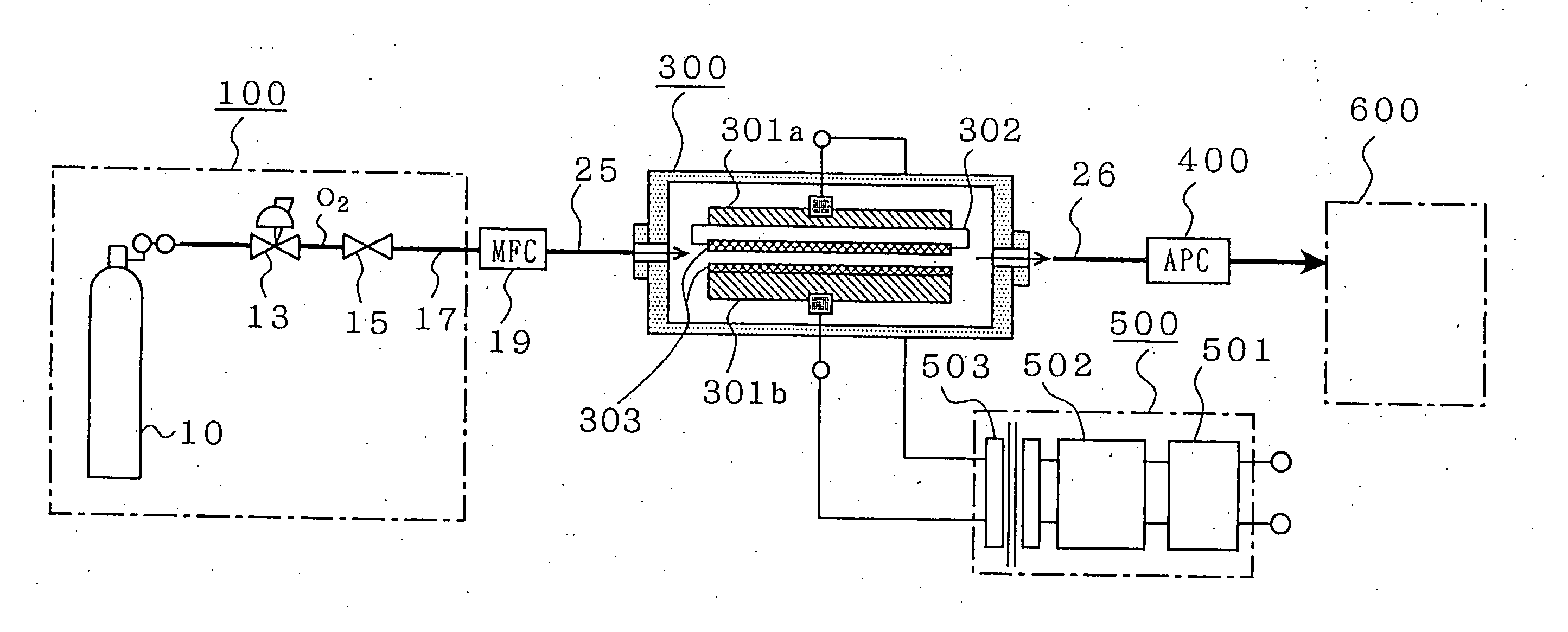

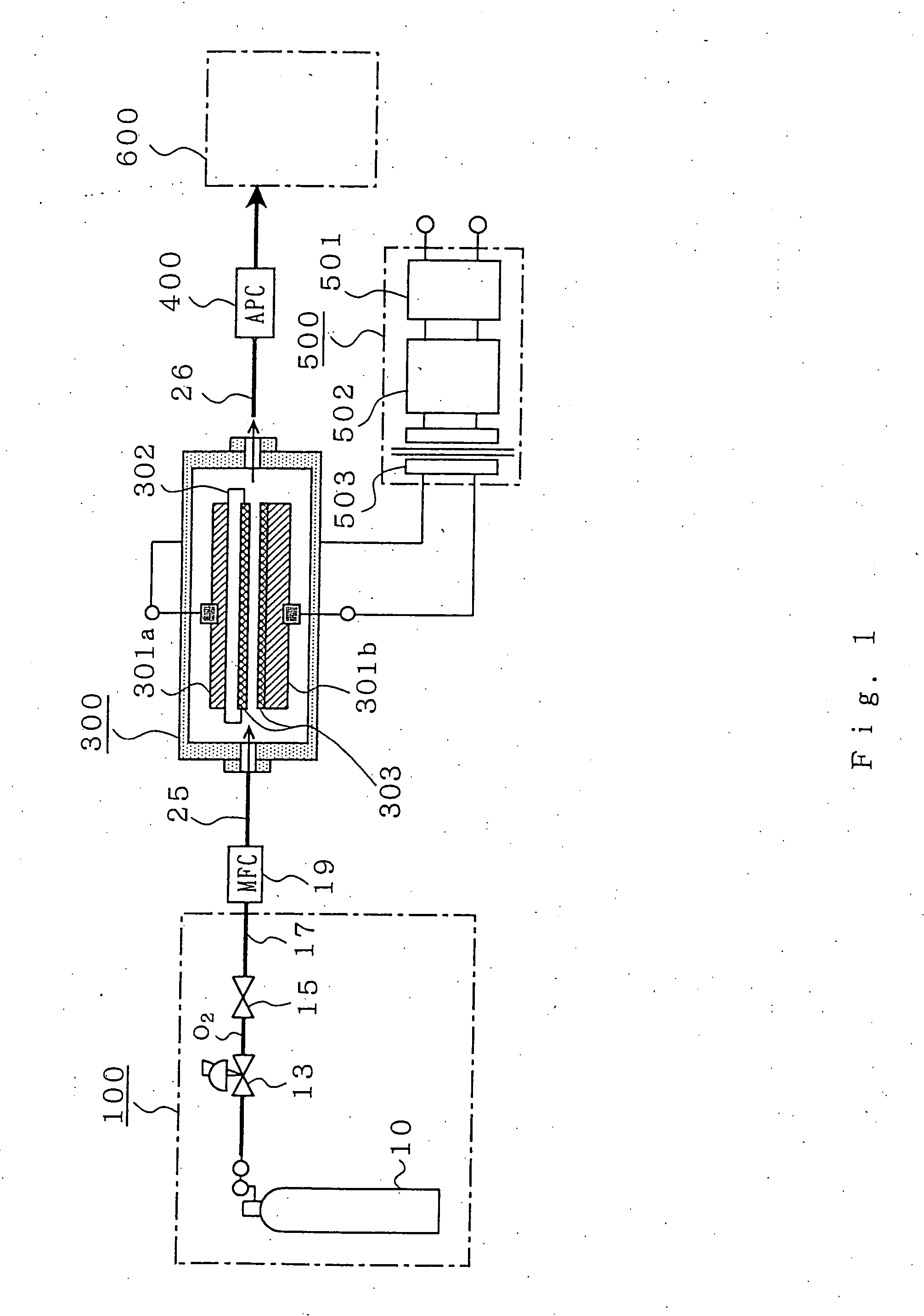

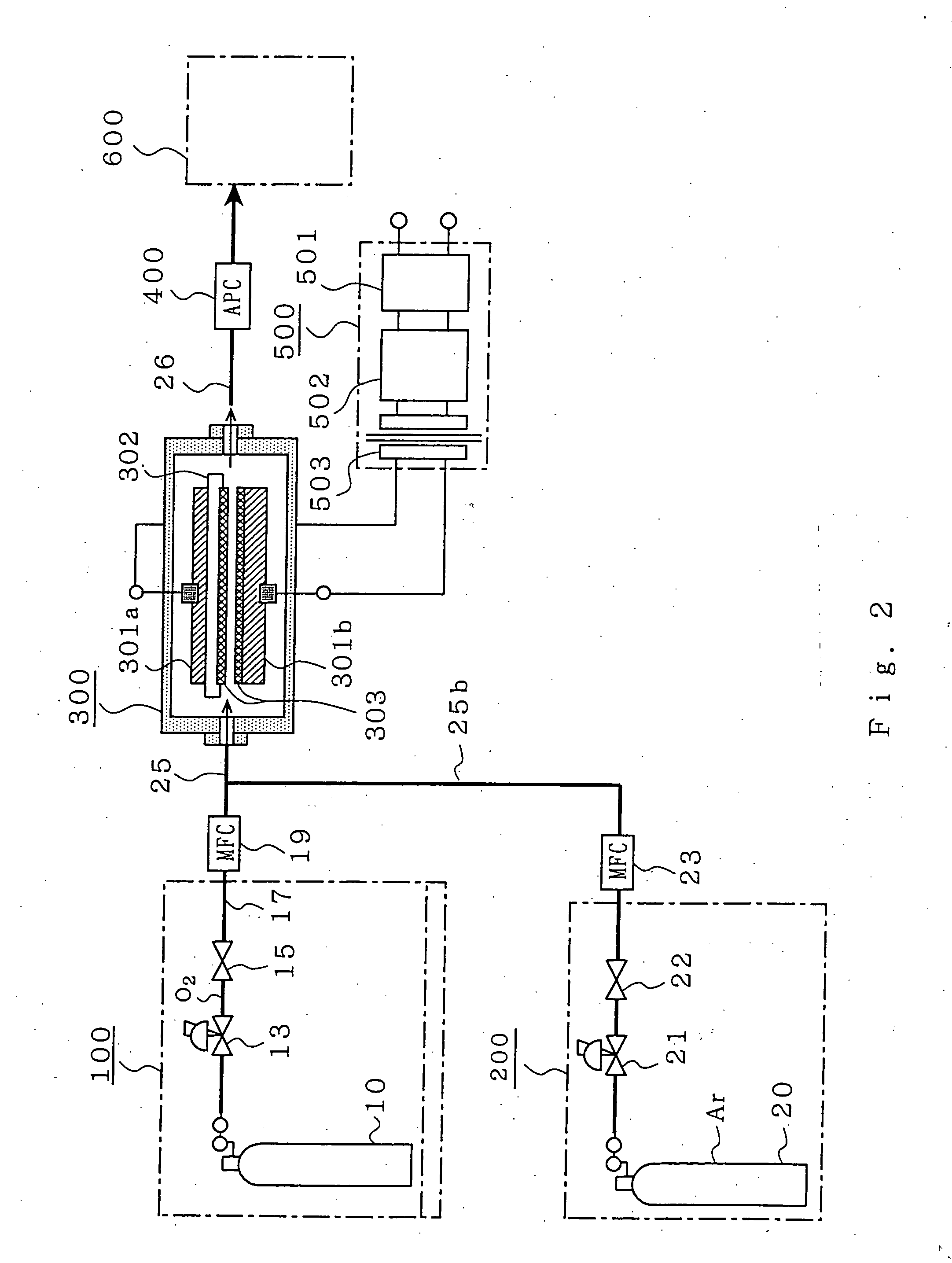

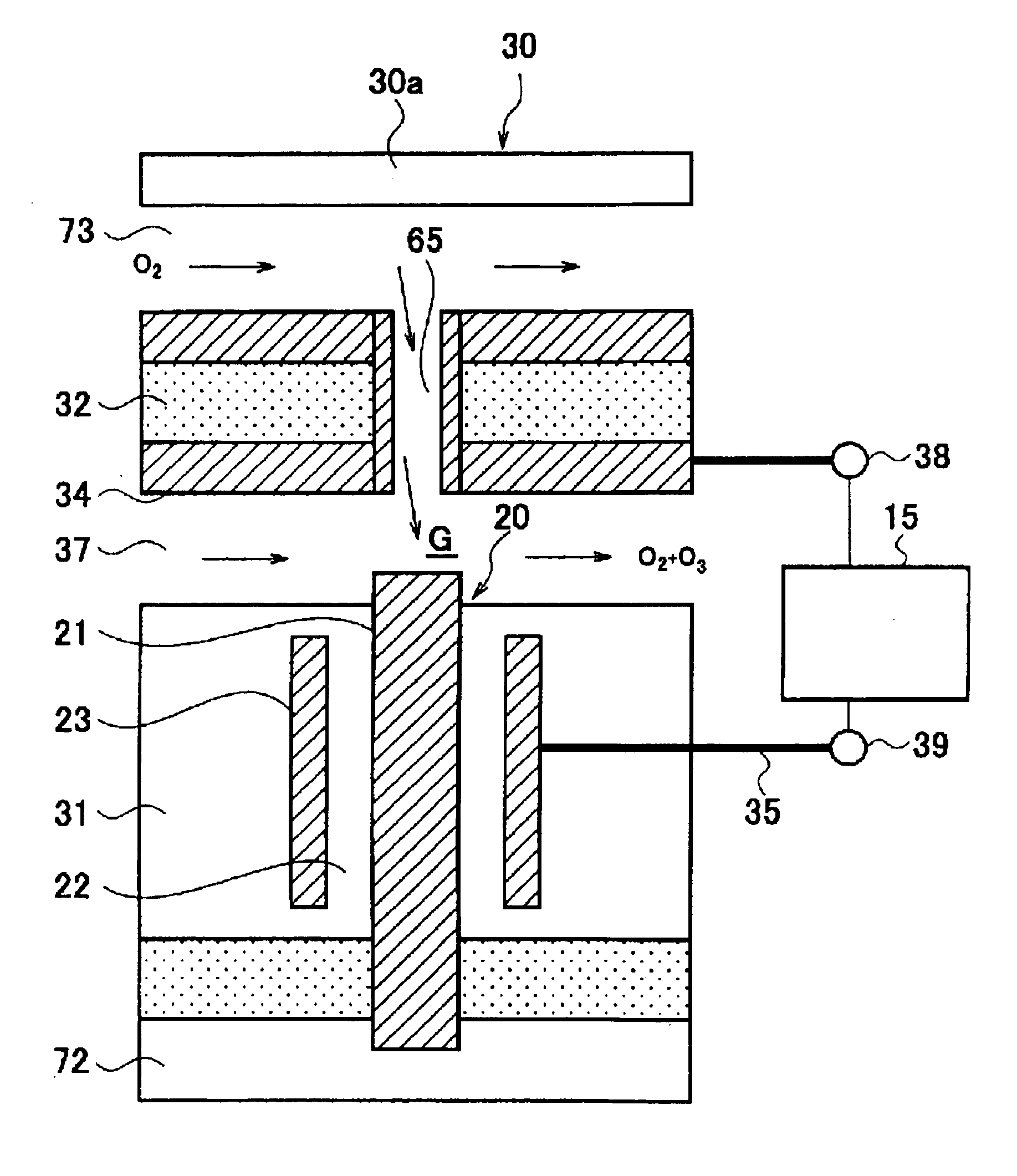

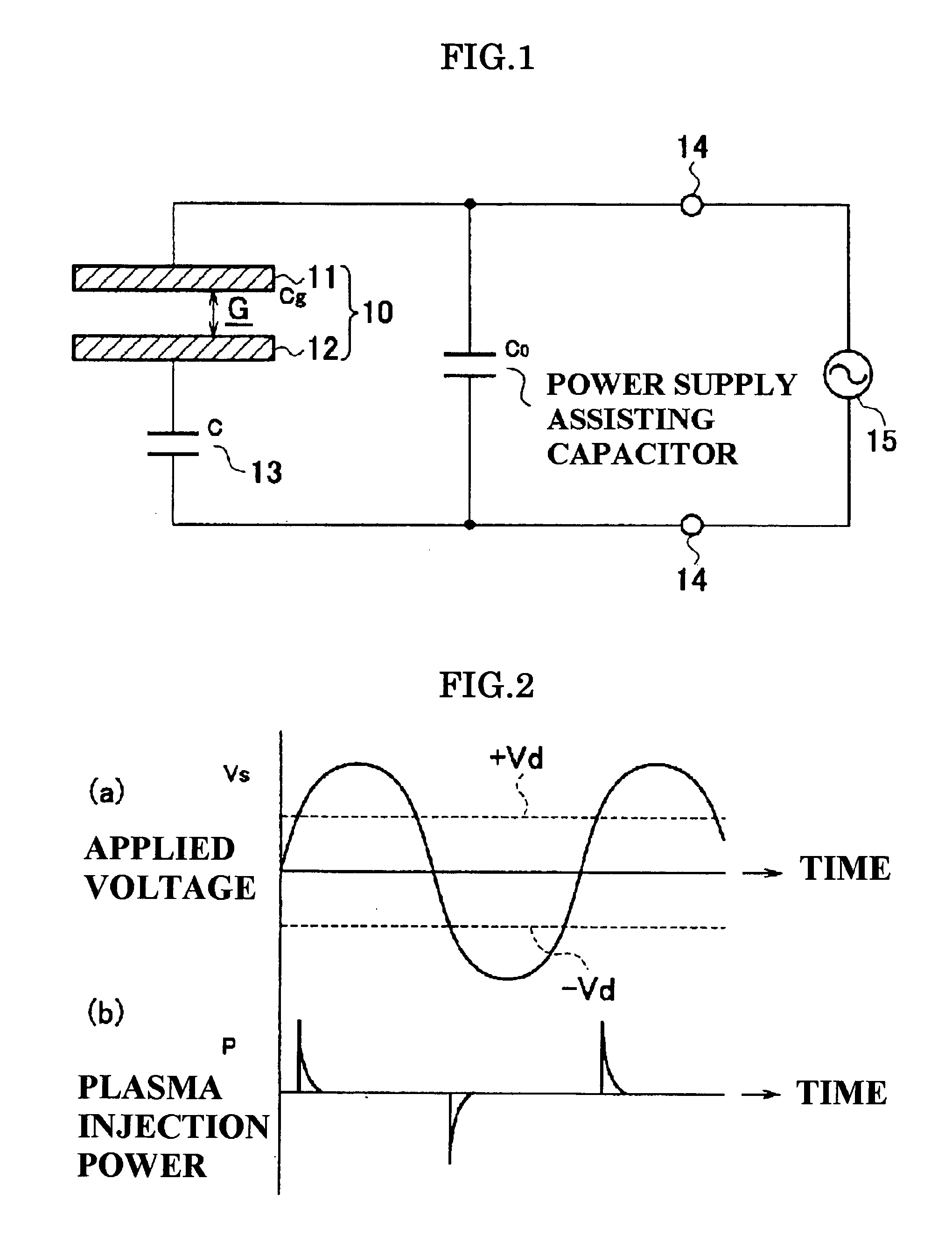

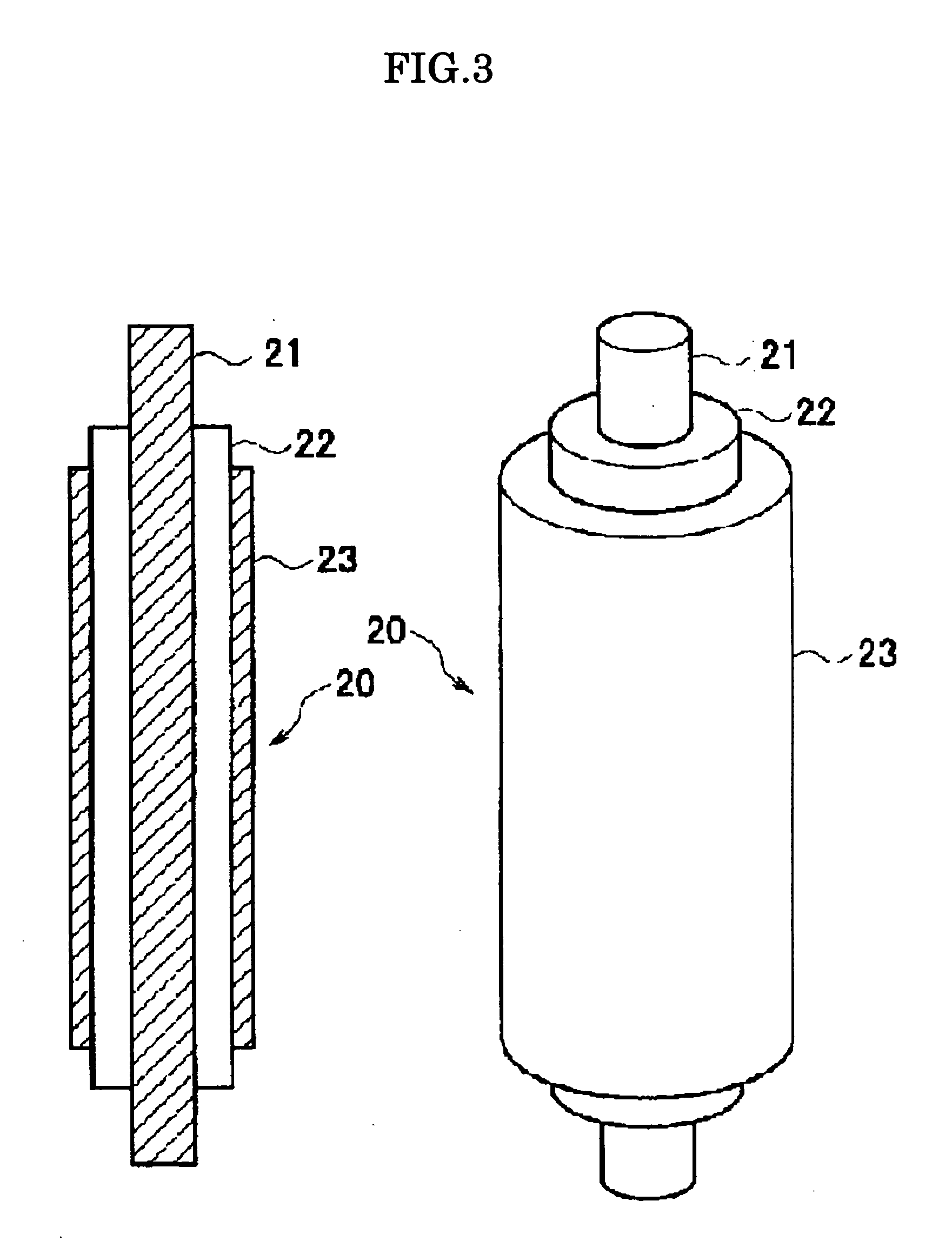

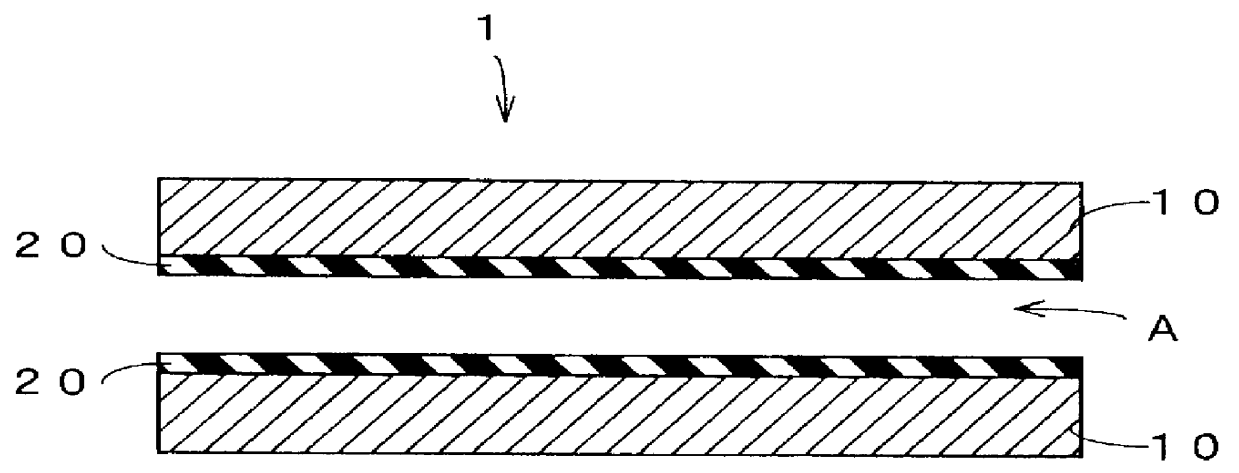

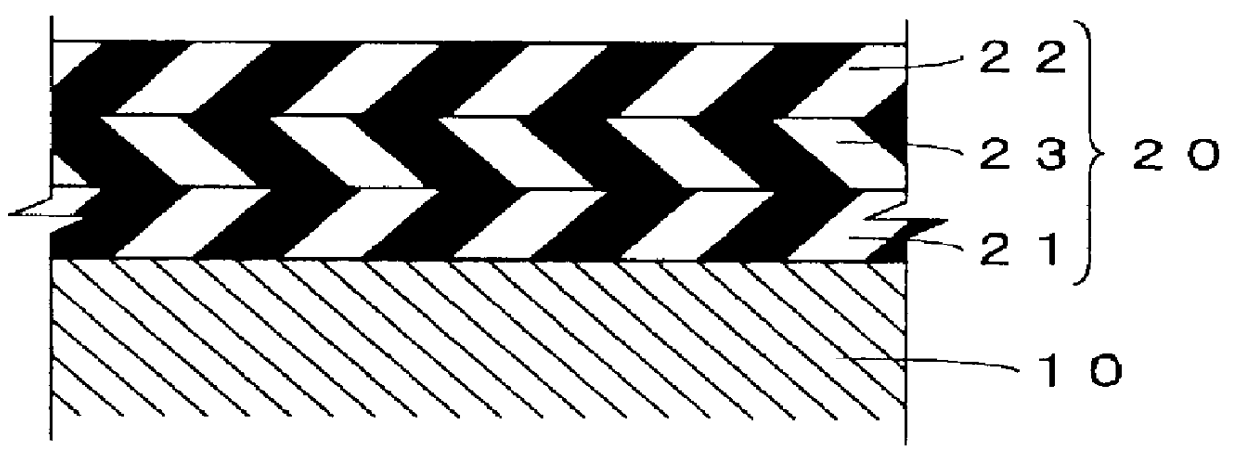

Plasma generator, ozone generator, substrate processing apparatus and manufacturing method of semiconductor device

ActiveUS20060189168A1Improve efficiencyHigh currentSemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOzone generatorElectricity

To provide a generator capable of generating plasma and ozone with high efficiency and easy to handle, with a simple structure. An electrode part 10 is formed of electrodes 11 and 12 without dielectric material interposed therebetween. An arc-extinguishing capacitor 13 as a charge storage part for storing charge is connected in series to the electrode part 10. An AC power source 15 generating plasma by causing self-arc-extinguishing discharge between the electrodes 11 and 12 by applying AC voltage to charge and discharge the arc-extinguishing capacitor 13, is connected to both ends of a circuit in which the electrode part 10 and the arc-extinguishing capacitor 13 are connected in series. The arc-extinguishing capacitor 13 and one electrode 12 of the electrode part 10 connected thereto are unitized, for making the electrode part multi-polarized. A unit is constituted of a floating electrode serving as both of the one electrode 12 of the electrode part 10 and one electrode of the arc-extinguishing capacitor 13, an insulating material provided around the floating electrode and a grounding electrode provided around the insulating material.

Owner:THREE TEC CO LTD +3

System and method for preserving food

Owner:HAIER US APPLIANCE SOLUTIONS INC

Sanitation system and method for ice storage and dispensing equipment

A system and methods for sanitation of ice storage equipment. An ozone generator provides a sanitizing agent comprised of a mixture of ambient air and ozone. The sanitizing agent is circulated through an ice storage bin. The sanitizing agent cleanses interior surfaces of the ice storage bin and also cleanses surfaces of an ice dispenser that dispenses ice from the ice storage bin.

Owner:MANITOWOC FOODSERVICE CO LLC

Recycled flue gas desulfurization and denitration method

The invention relates to a recycled flue gas desulfurization and denitration method, which sequentially comprises the following steps of: introducing flue gas of SO2 and NOx into a desulfurizing tower, and absorbing the SO2 with a desulfurizing agent (barren liquor) in the desulfurizing tower; desorbing the desulfurizing agent (rich liquor) which absorbs the SO2 through a multi-effect evaporator,releasing the SO2 gas, and concentrating the SO2 gas into liquid SO2 through condensation drying; making the desulfurized flue gas enter a denitration tower, injecting gaseous ozone from an ozone generator, oxidizing the NO in the flue gas, absorbing the oxidized NO by using a denitrifier to form nitrate; crystallizing and separating out the nitrate in the solution after the nitrate reaches certain concentration, and filtering and drying to obtain the nitrate product. The method turns the wastes into wealth, and the SO2 and NOx in the flue gas are recycled by higher-additional value liquid SO2 and nitrate products, so that the recycling and value maximization in the desulfurization and denitration process is realized. Due to the adoption of the technical scheme, the high desulfurization and denitration rate can be achieved, the desulfurization rate is over 96 percent, the denitration rate is more than 90 percent, and the purity of the nitrate product is over 96 percent. The method hasthe advantages of simple desulfurization and denitration process, low investment, and low operation cost for desulfurization and denitration, and solves the problems that the conventional desulfurization and denitration process has high cost, generates a side product of a mixture of sulfuric acid (sulfate) and nitric acid (nitrate), and has low additional value.

Owner:EAST CHINA UNIV OF SCI & TECH

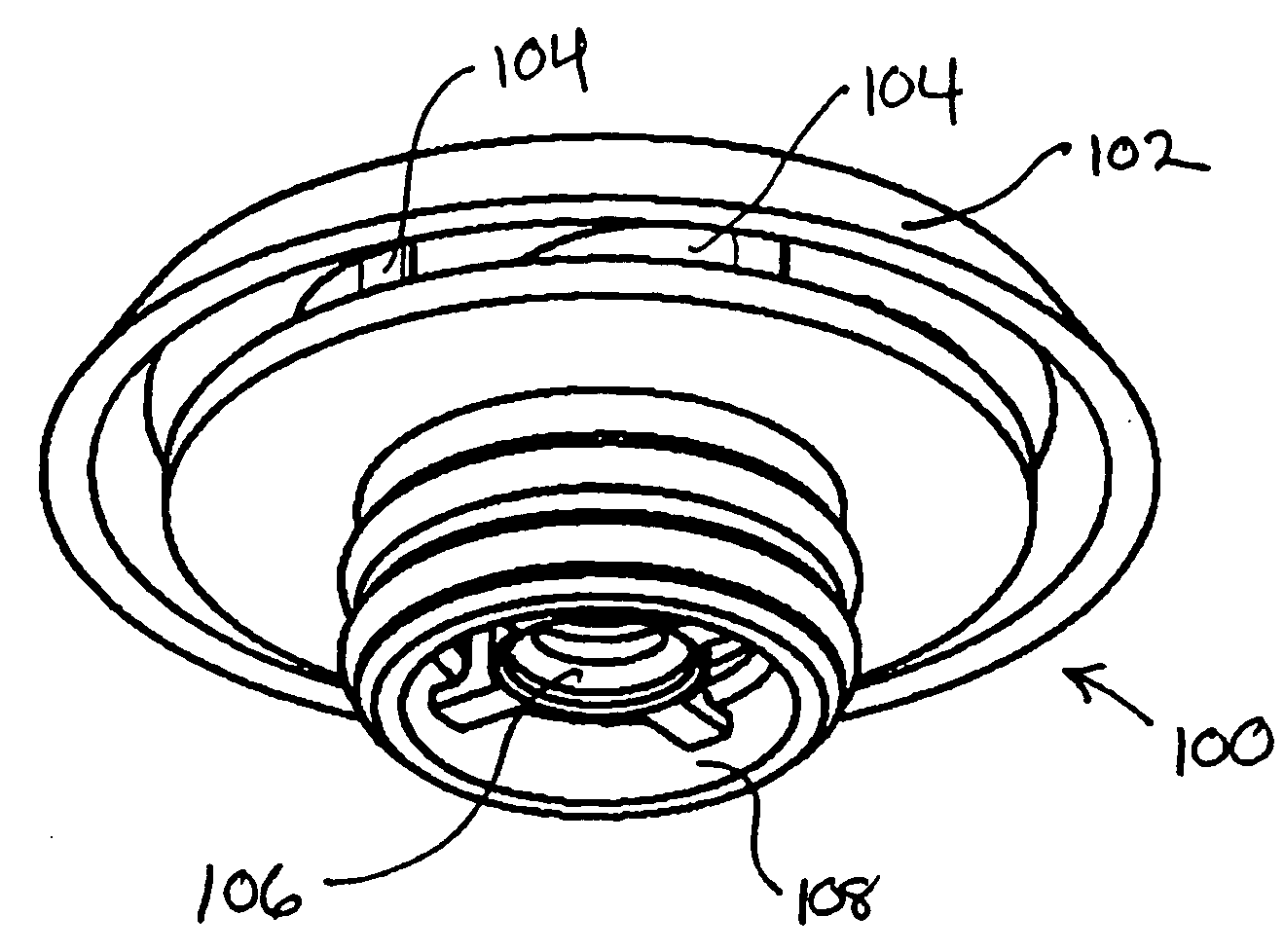

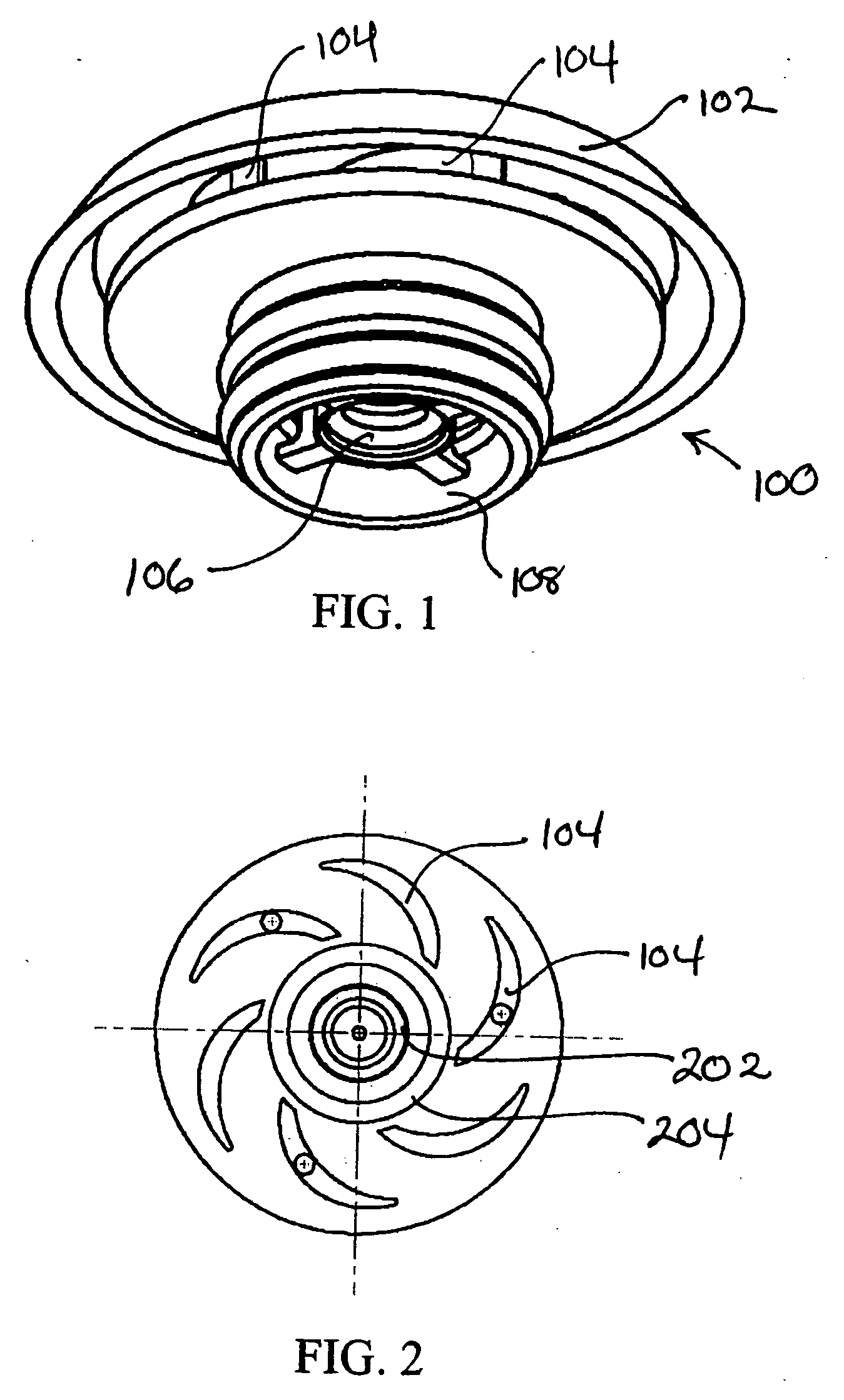

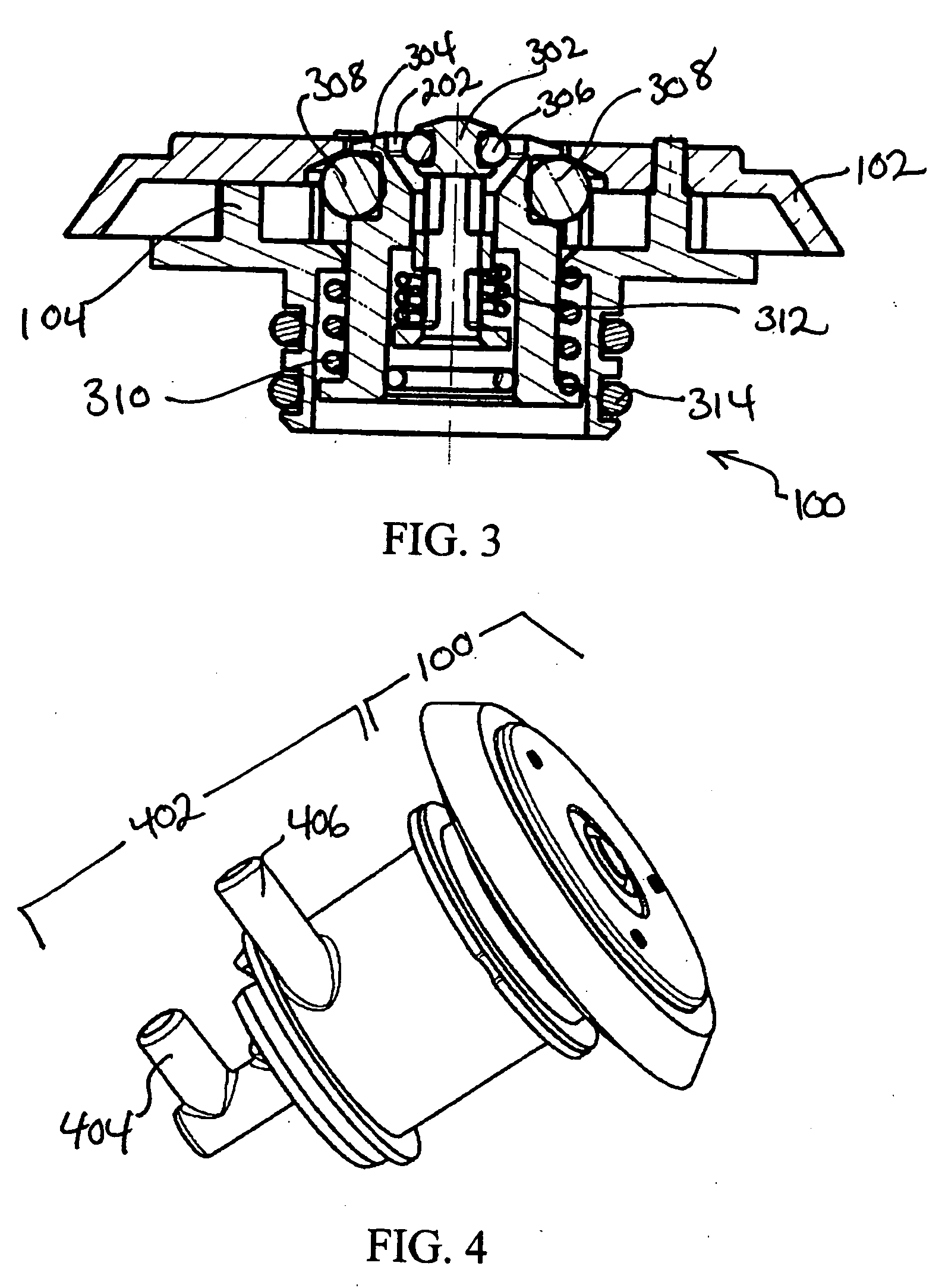

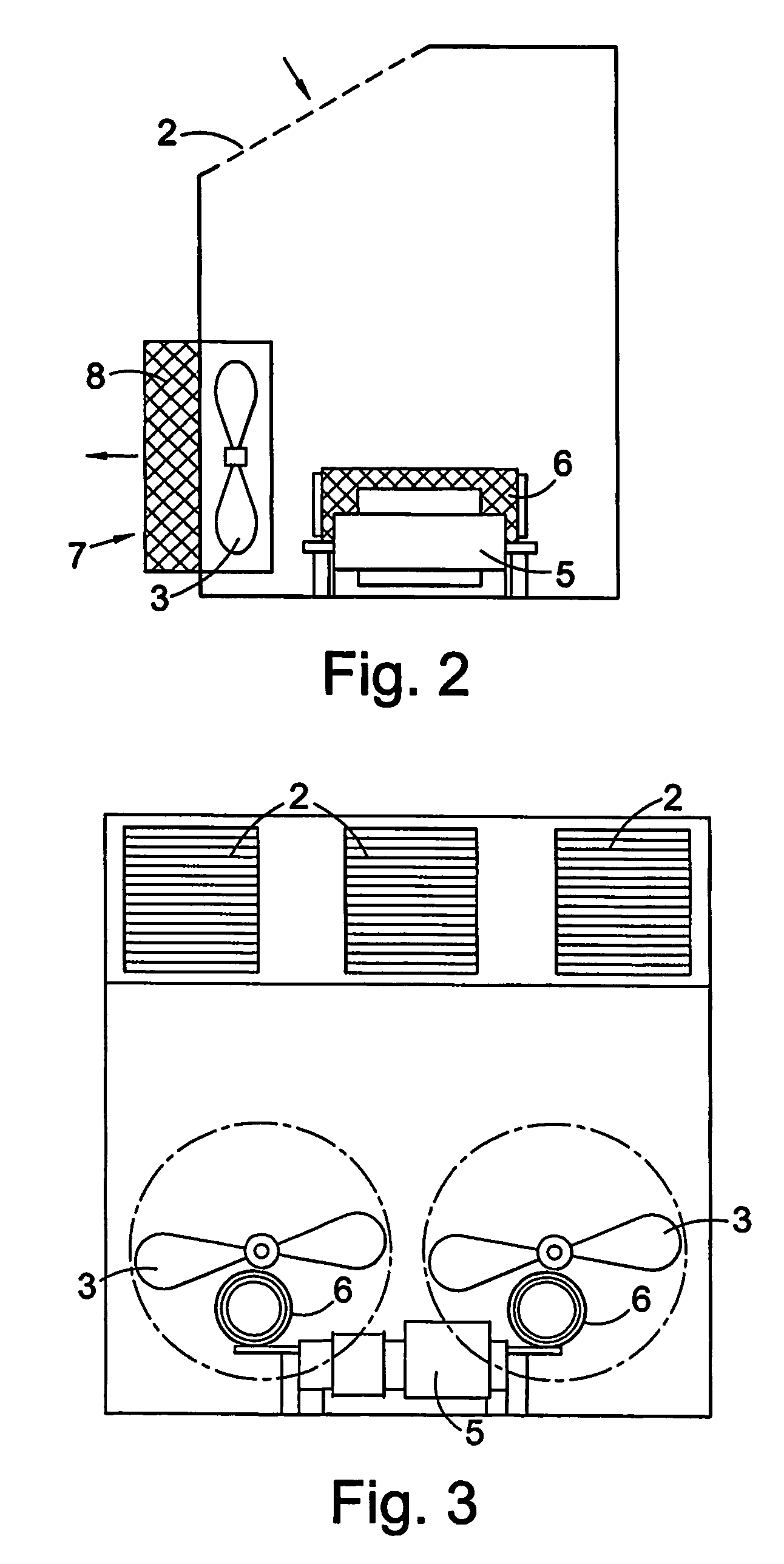

Air cleaning device

ActiveUS20060182672A1Minimize the numberReduce loadGas treatmentMechanical apparatusOzone generatorImpeller

The present invention provides an apparatus 1 for the treatment of air comprising a low power corona discharge ozone generator 5,6 inside a chamber 9 having an inlet 2 and an outlet 7, and at least one air flow impeller 3 for inducing a flow of air through the chamber 9. The ozone generator 5,6 is formed and arranged for generating a restricted concentration of ozone, within an inactivating zone 10 contained within the chamber 9, through which the air flow is passed. The restricted concentration is sufficient to inactivate airborne pollutant material entrained in the air flow, yet decays sufficiently outside the inactivating zone so that the concentration of ozone in the cleaned air expelled from the apparatus 1 is at a physiologically acceptable level without the use of an ozone decomposition catalyzer.

Owner:NOVAERUS UK LTD

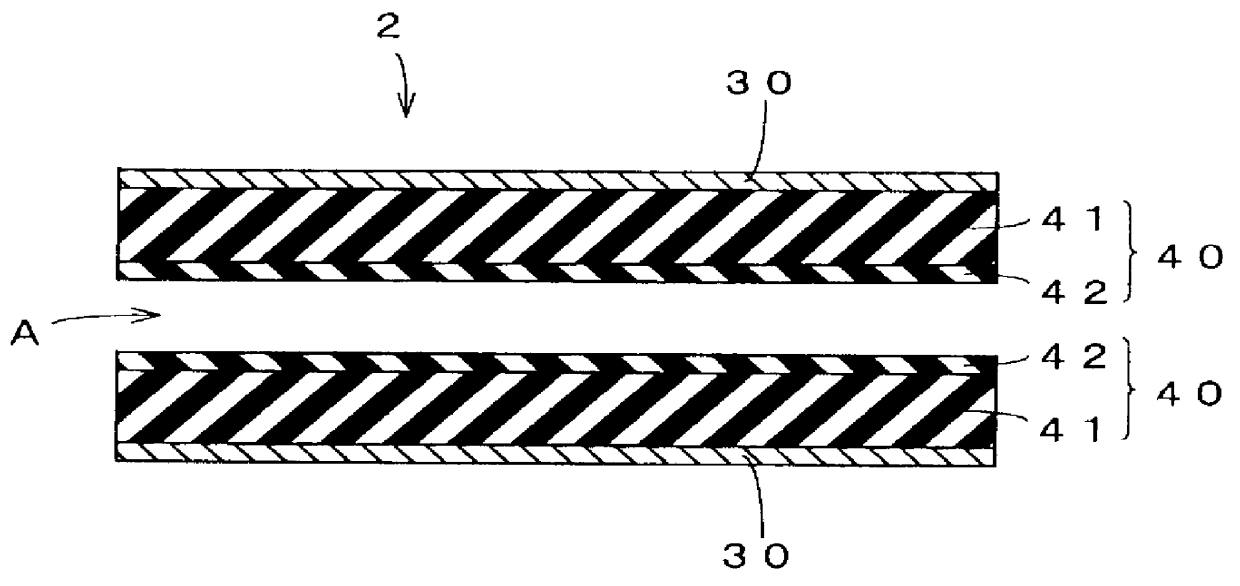

Discharge cell for ozone generator

InactiveUS6046533AEffectively suppress the time-related reduction in the ozone concentrationAvoid impuritiesLamp incadescent bodiesThermionic cathodesOzone generatorElectricity

A discharge cell for use in an ozone generator is provided which can suppress a time-related reduction in ozone concentration without adding a catalytic gas such as nitrogen gas to oxygen gas as a raw material gas. The discharge cell includes a pair of electrodes disposed in an opposed spaced relation with a discharge space therebetween, and a dielectric layer of a three-layer structure consisting of three ceramic dielectric layers successively stacked on at least one of the electrodes, wherein a first dielectric layer of the dielectric layer contacting the one electrode contains no titanium dioxide, wherein a second dielectric layer of the dielectric layer exposed to the discharge space contains titanium dioxide in a metal element ratio of not lower than 10 wt %.

Owner:SUMITOMO PRECISION PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com