Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2280 results about "Gas release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tapered post, showerhead design to improve mixing on dual plenum showerheads

Owner:NOVELLUS SYSTEMS

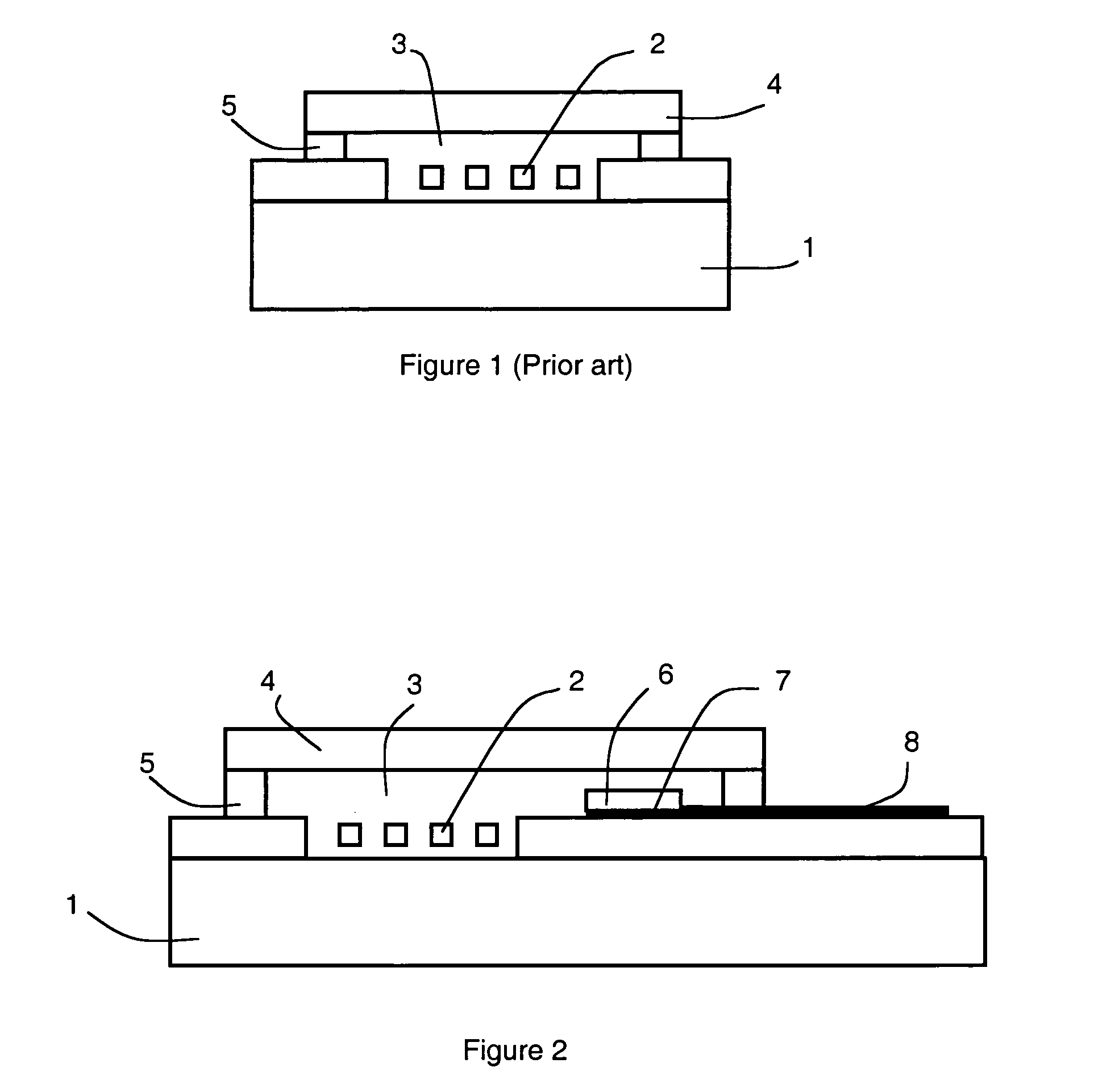

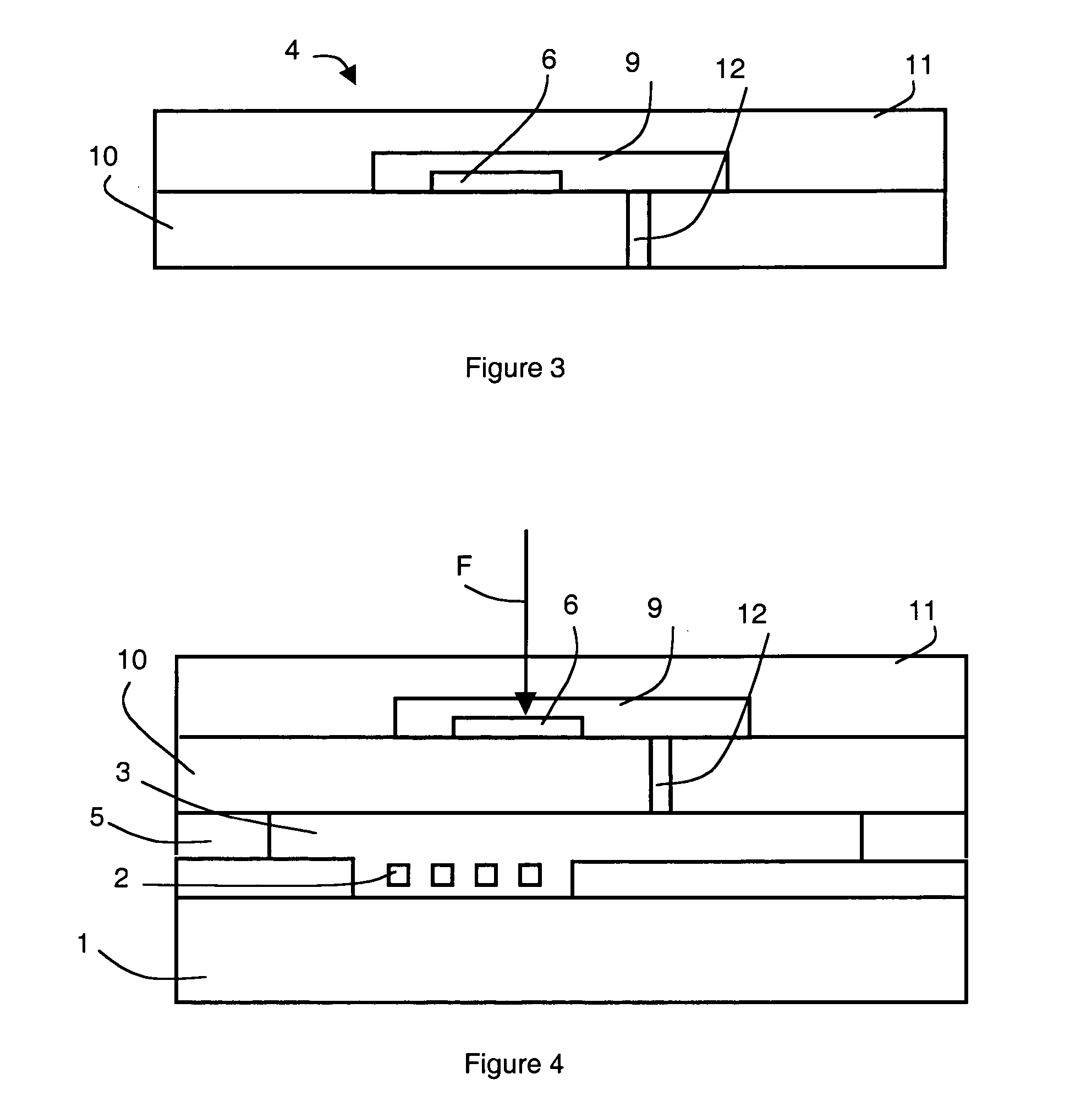

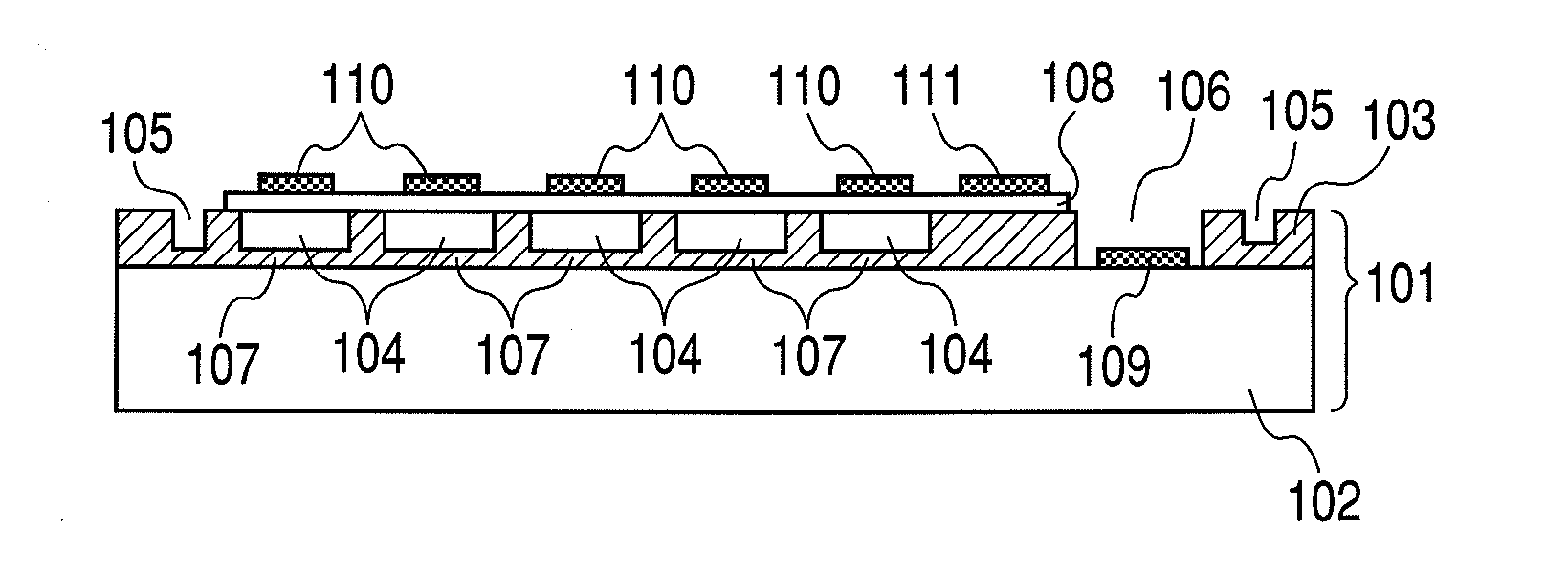

Integrated electromechanical microstructure comprising pressure adjusting means in a sealed cavity and pressure adjustment process

ActiveUS20040080035A1Simple processEasy to controlSemiconductor/solid-state device detailsSolid-state devicesCombustionEngineering

The integrated electromechanical microstructure comprises a base substrate and a cavity closed by a protective cover. Means for adjusting the pressure in the cavity after the protective cover has been sealed comprise at least one element made of pyrotechnic material combustion whereof releases gas into the cavity. The pressure in the cavity can thus be adjusted independently from the sealing process. Selective ignition of the elements made of pyrotechnic material can be achieved by heating electrical resistors or by laser beams coming from outside the microstructure and directed selectively towards the elements made of pyrotechnic material through a transparent zone of the protective cover.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

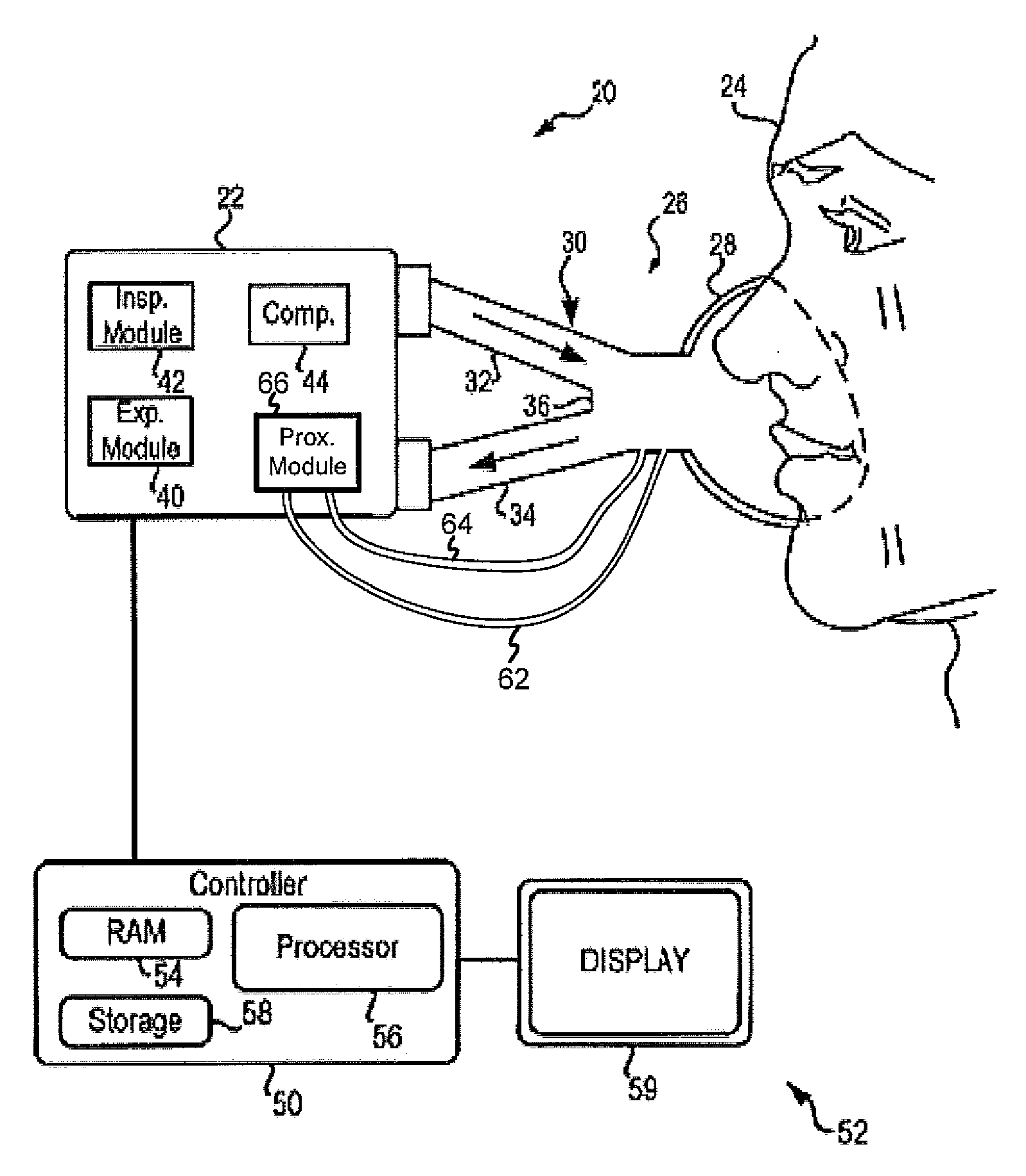

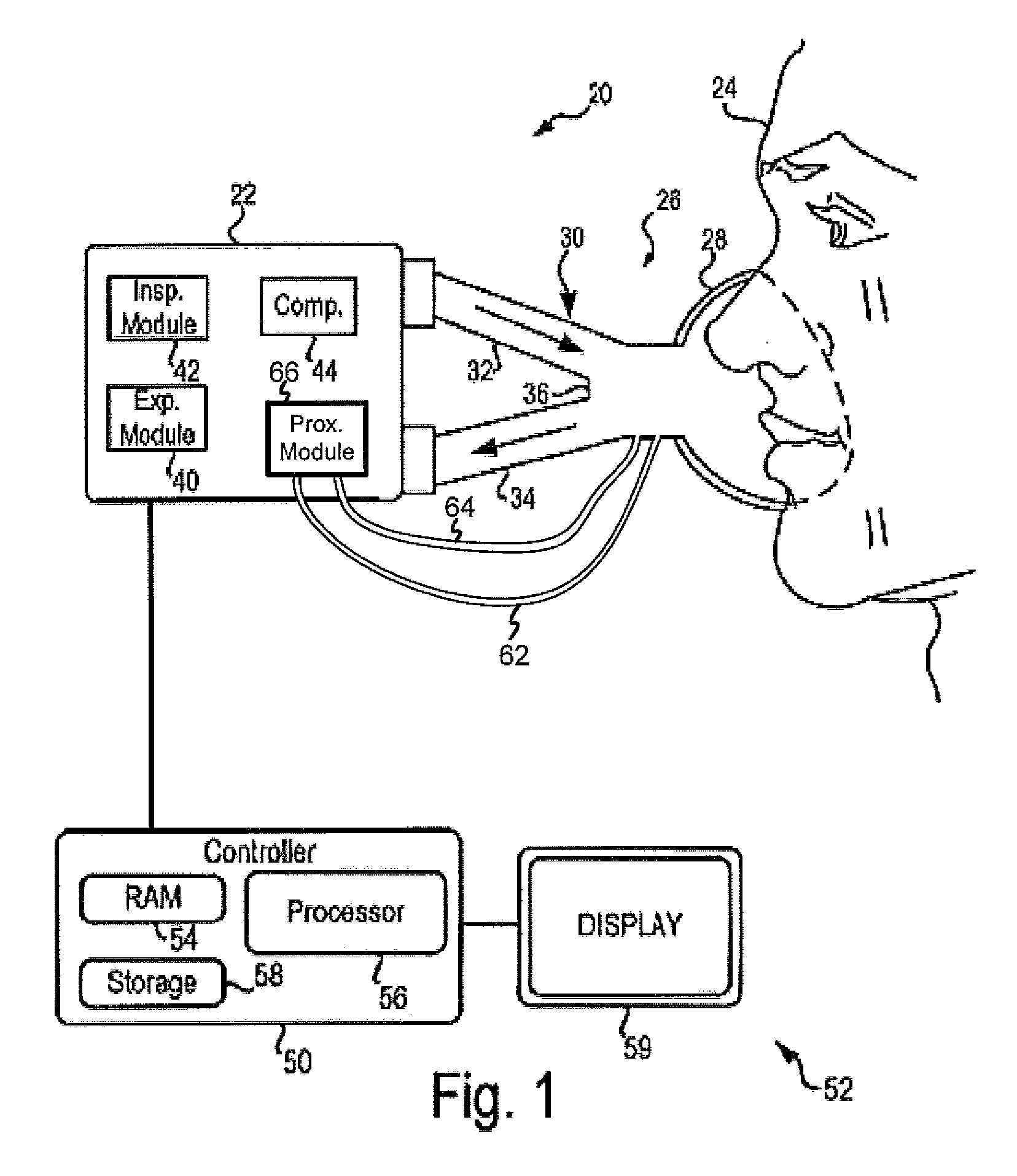

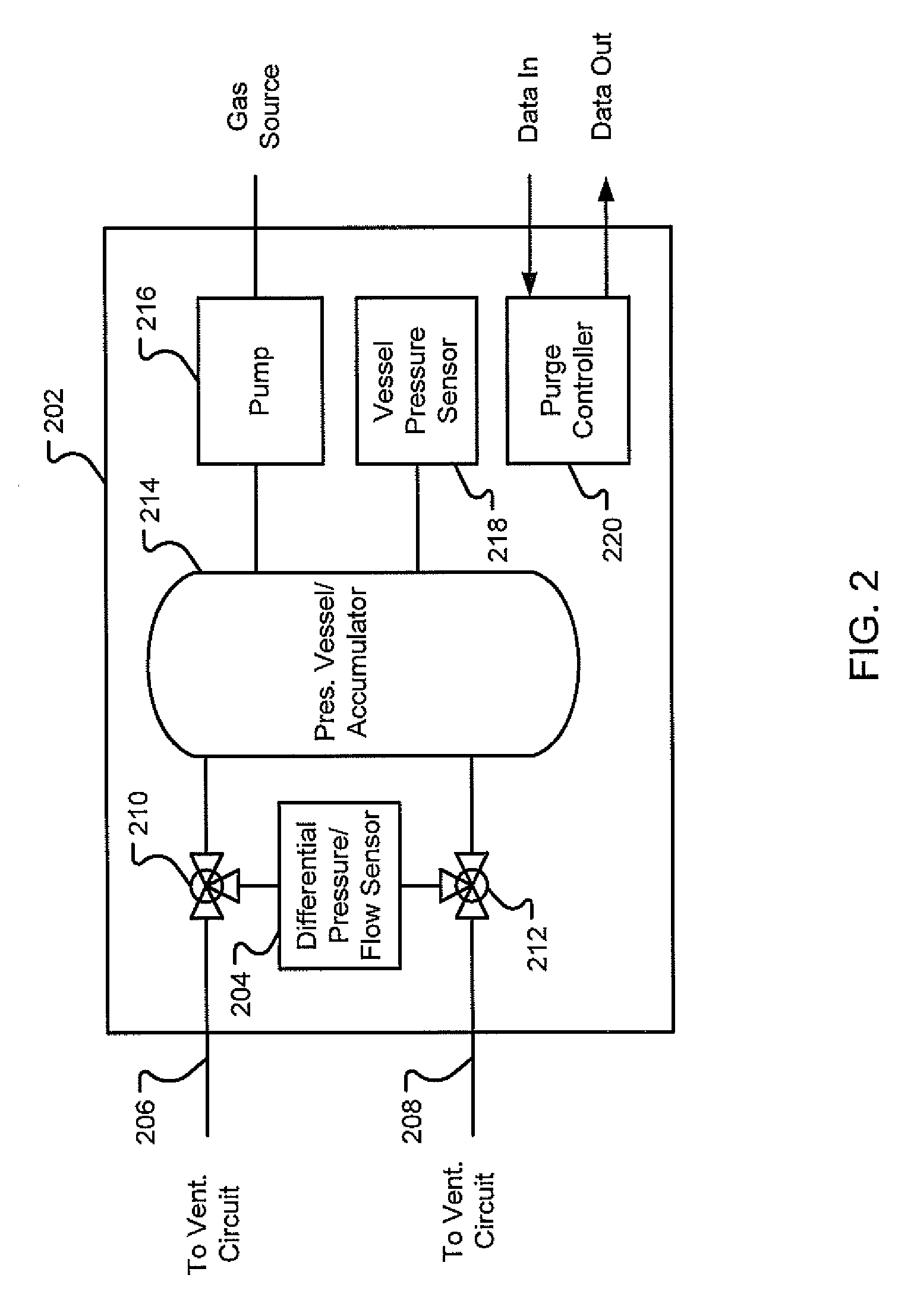

Inverse Sawtooth Pressure Wave Train Purging In Medical Ventilators

InactiveUS20100051029A1RespiratorsOperating means/releasing devices for valvesEngineeringGas release

This disclosure describes systems and methods for purging narrow diameter sensor tubing, occasionally referred to as “sensor lines”, in a ventilation system. The disclosure describes a novel approach in which a series of short, periodic releases of pressurized gas through the sensor tubes are used to clear any blockages due to condensation or patient secretions.

Owner:TYCO HEALTHCARE GRP LP

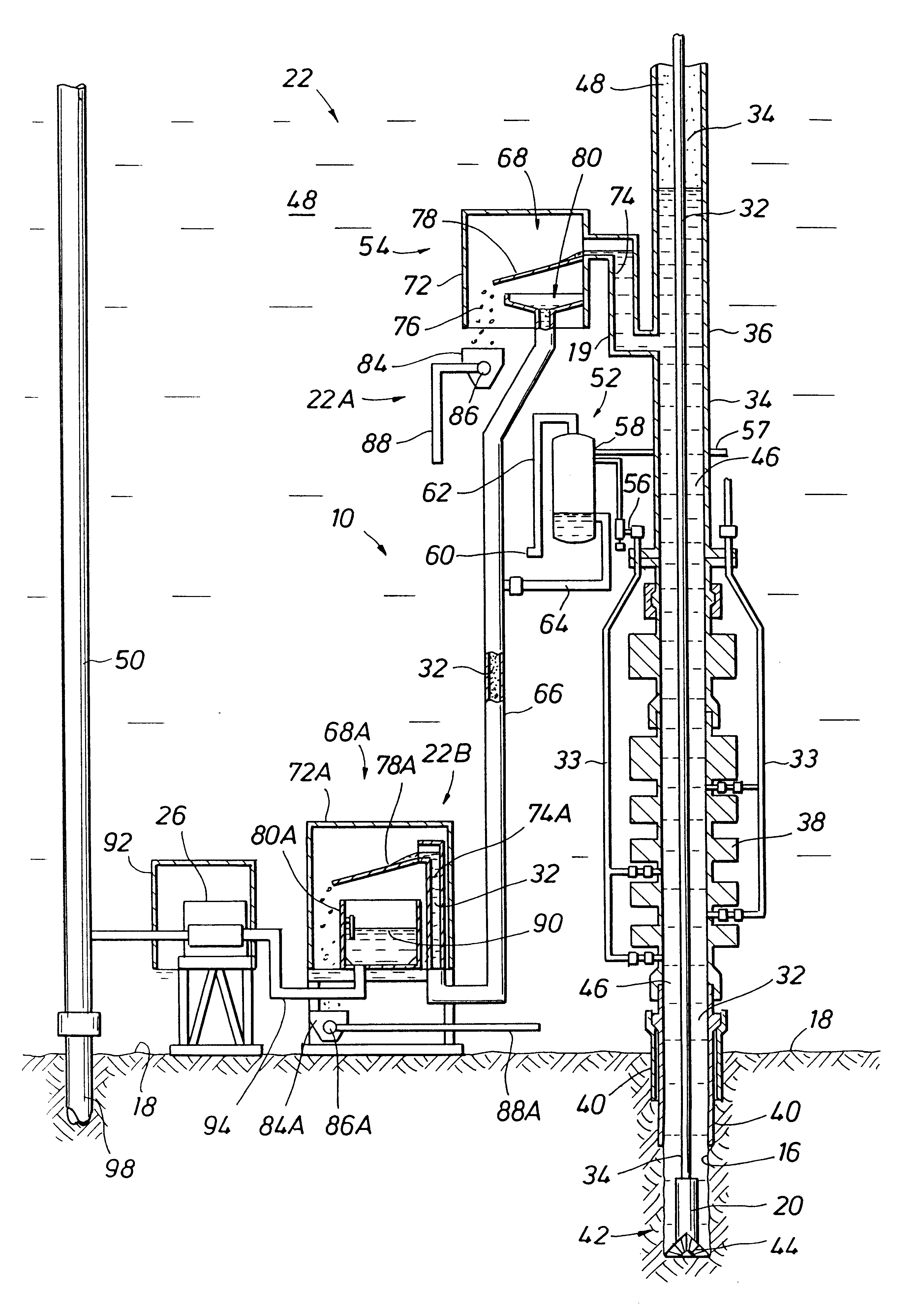

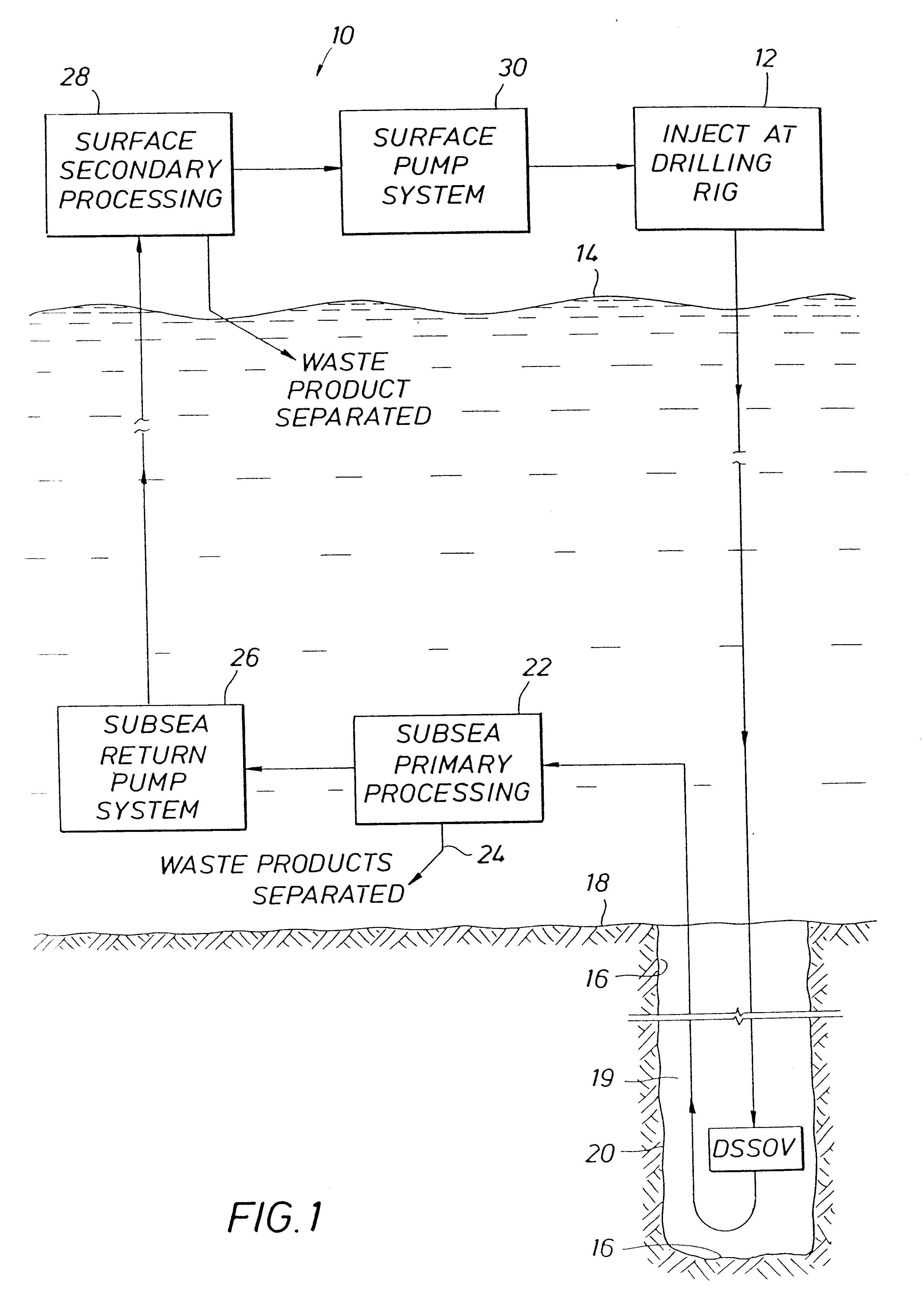

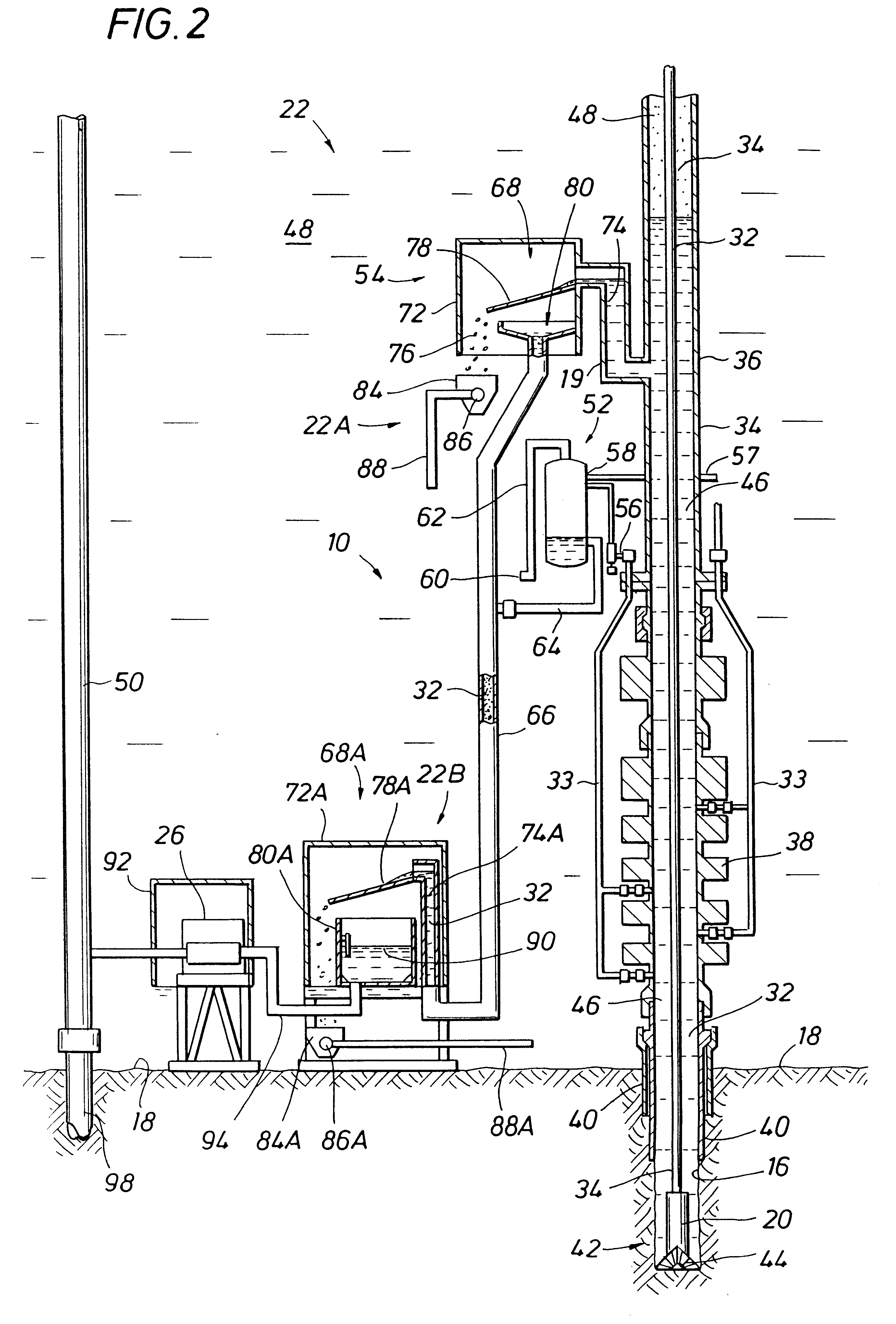

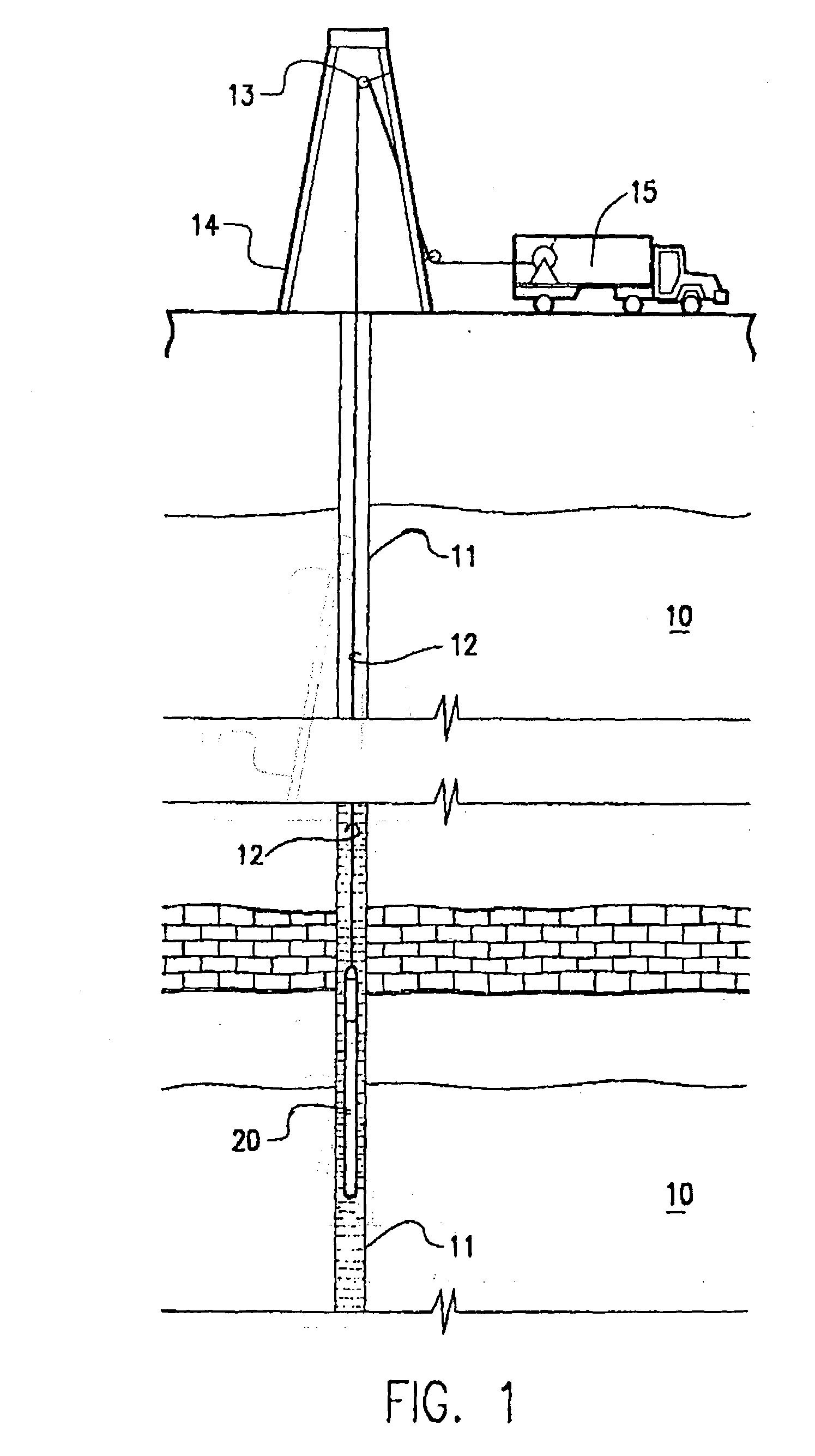

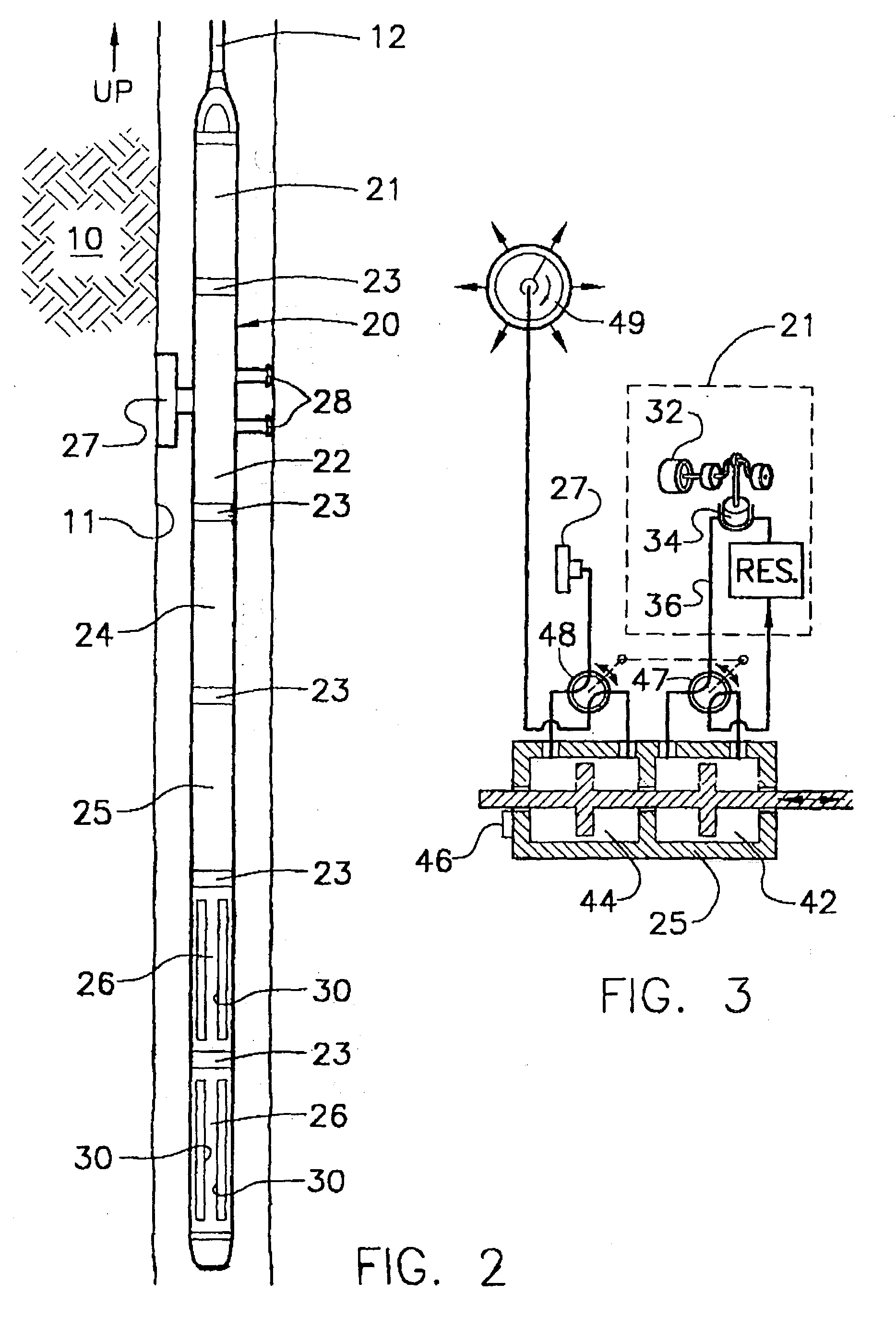

Subsea gas separation system and method for offshore drilling

A subsea gas separation system use in drilling an offshore well includes a subsea blowout preventor connected to the well and a gas separator connected to the blowout preventor near the seafloor. Gas released into the well bore during a well control event is removed at the separator and not returned with the drilling mud recirculated to the surface. A method offshore drilling includes a mud circulation circuit established leading down the drill string, through the drill bit, up the borehole, through a subsea pump, and to the surface through a return riser. The subsea pump is protected during critical well control events by removing gas released into the mud at a gas separator located upstream of the subsea pump and in communication with the blowout preventor.

Owner:SHELL OFFSHORE

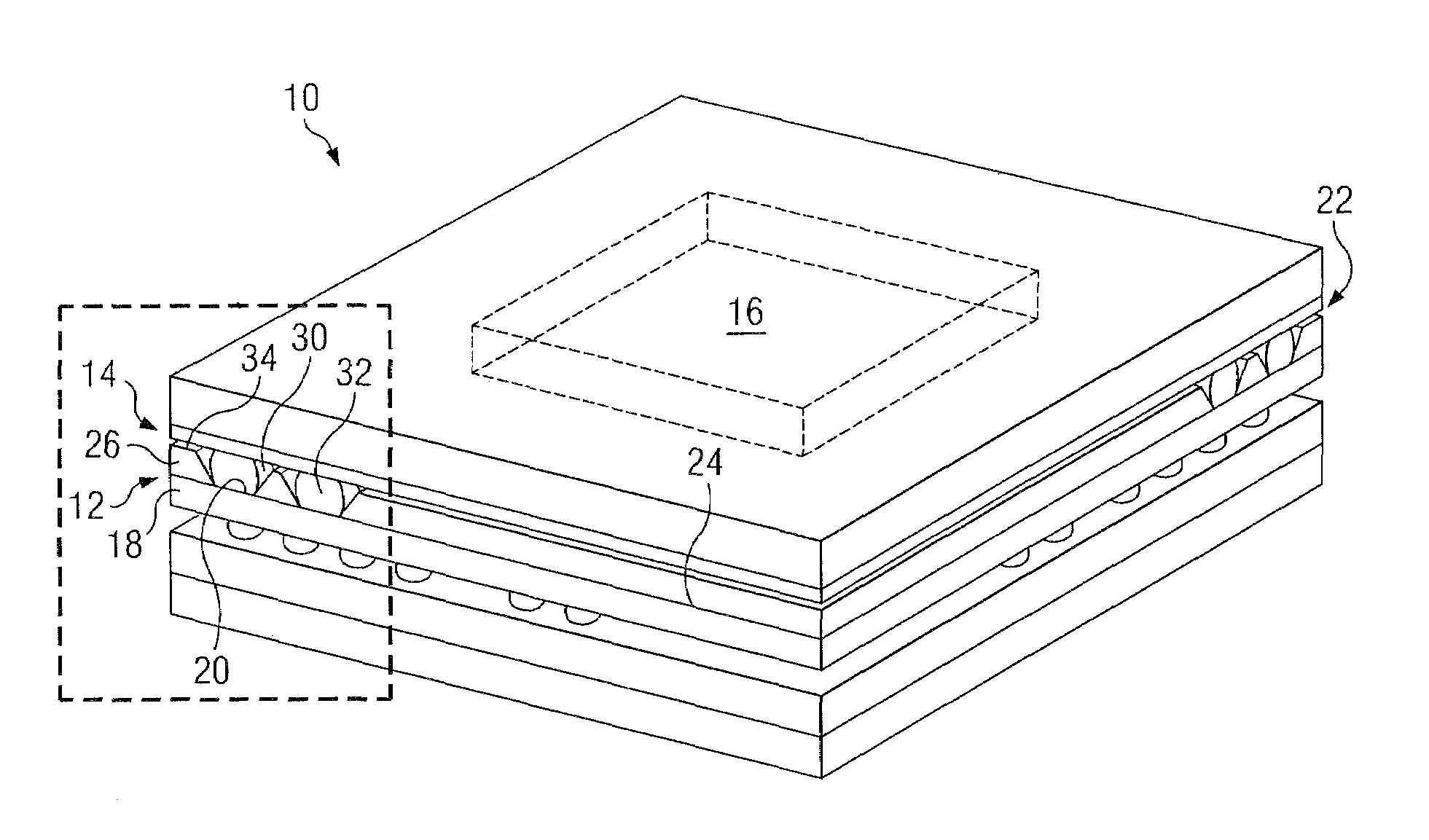

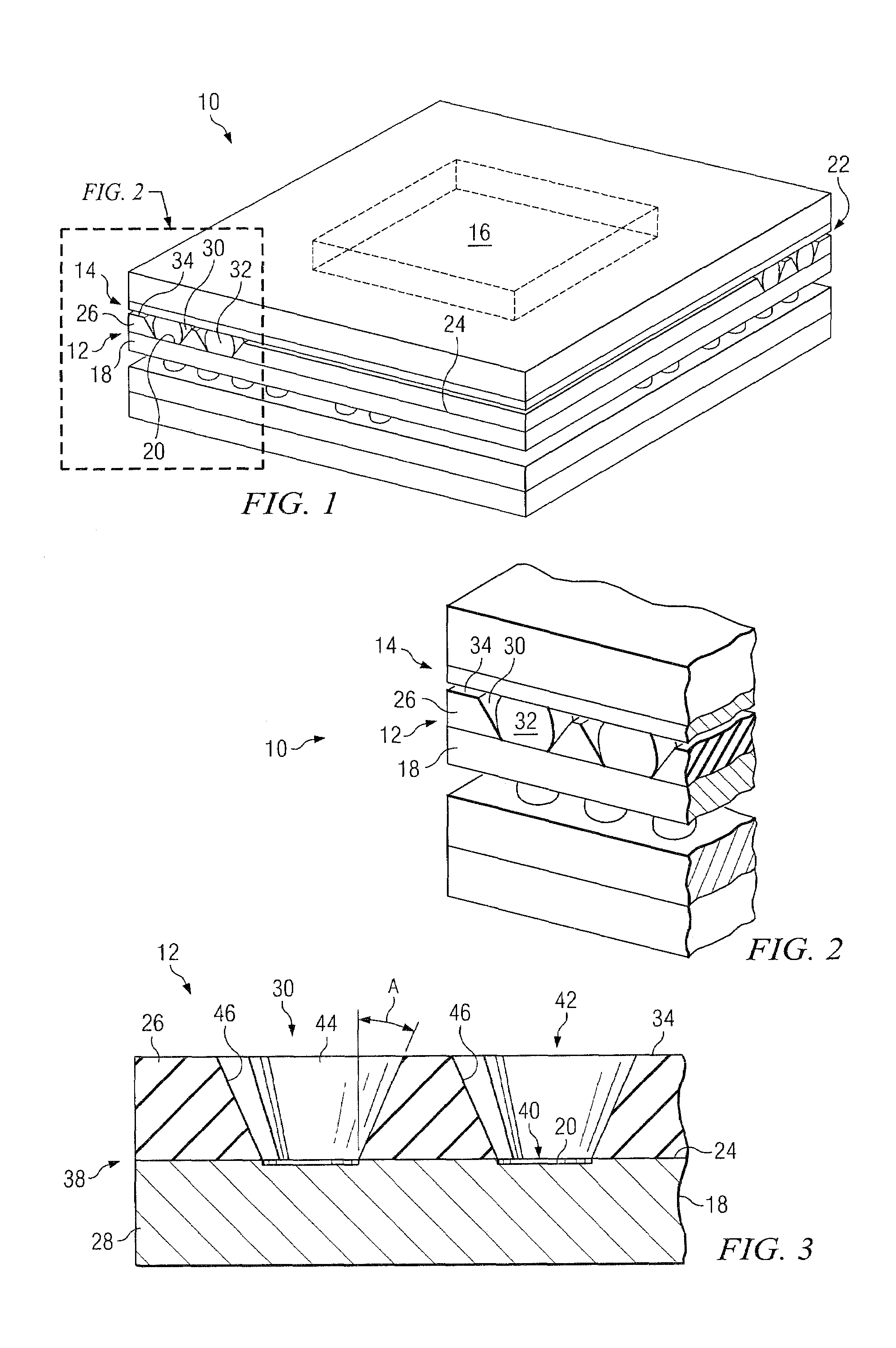

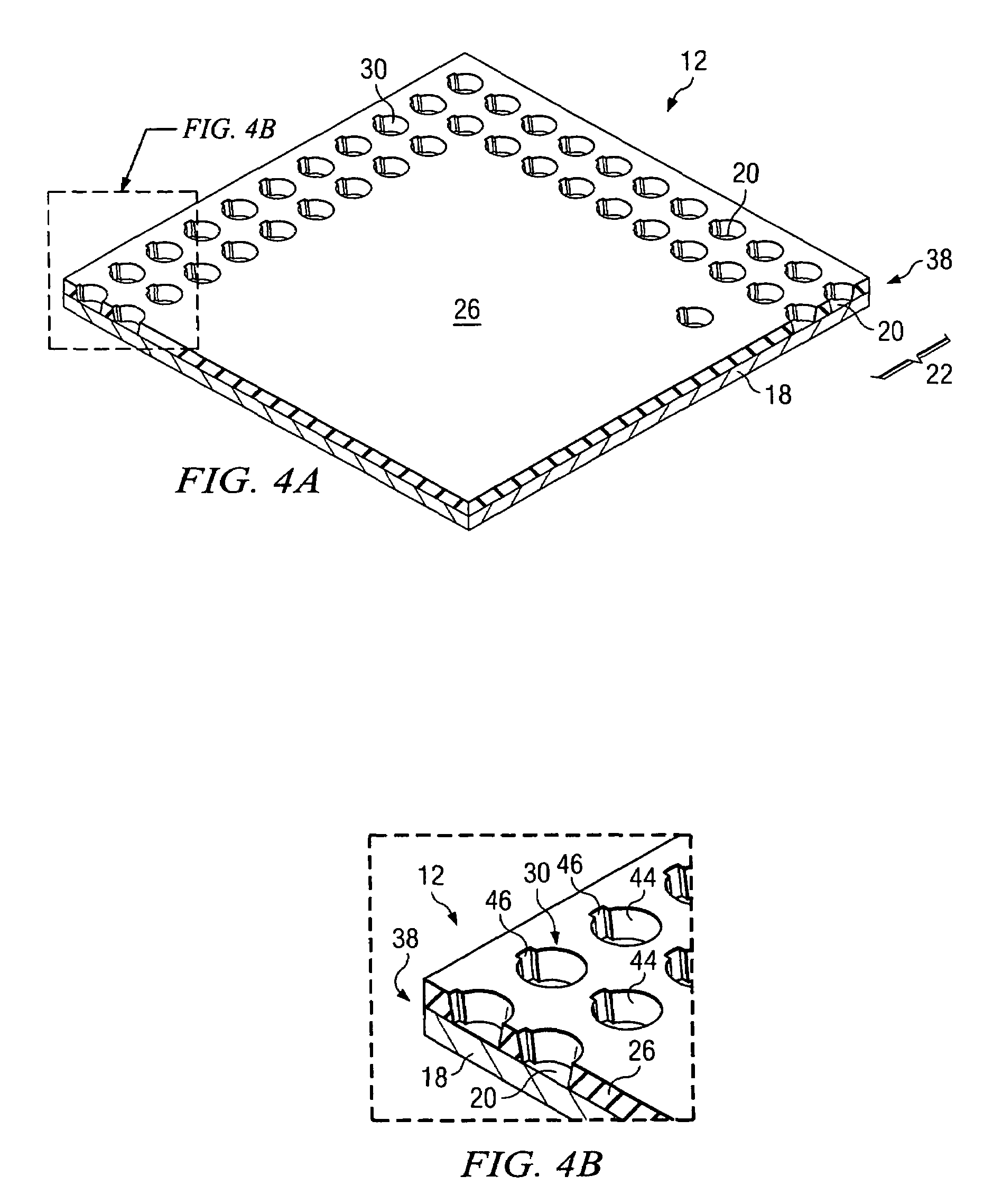

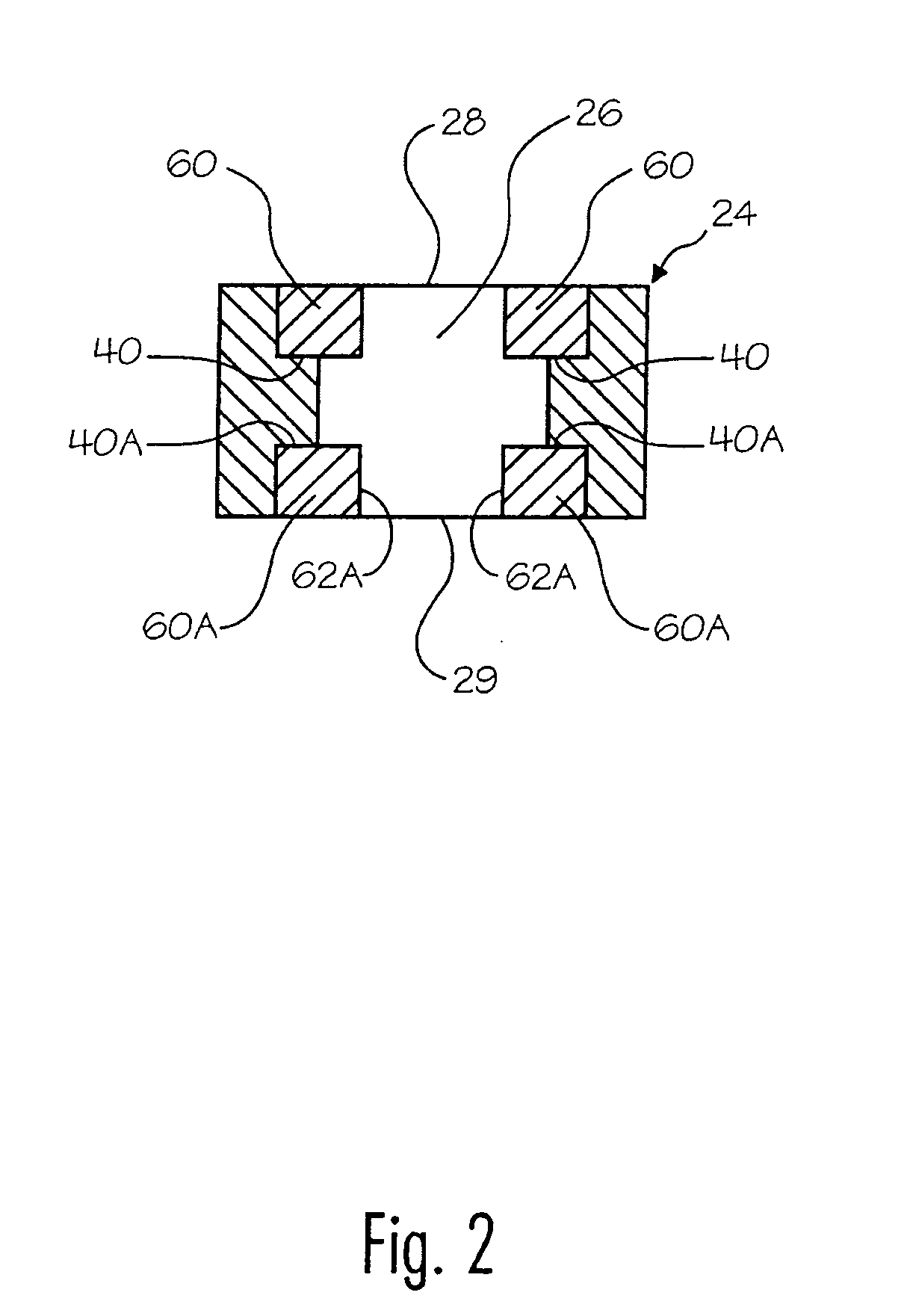

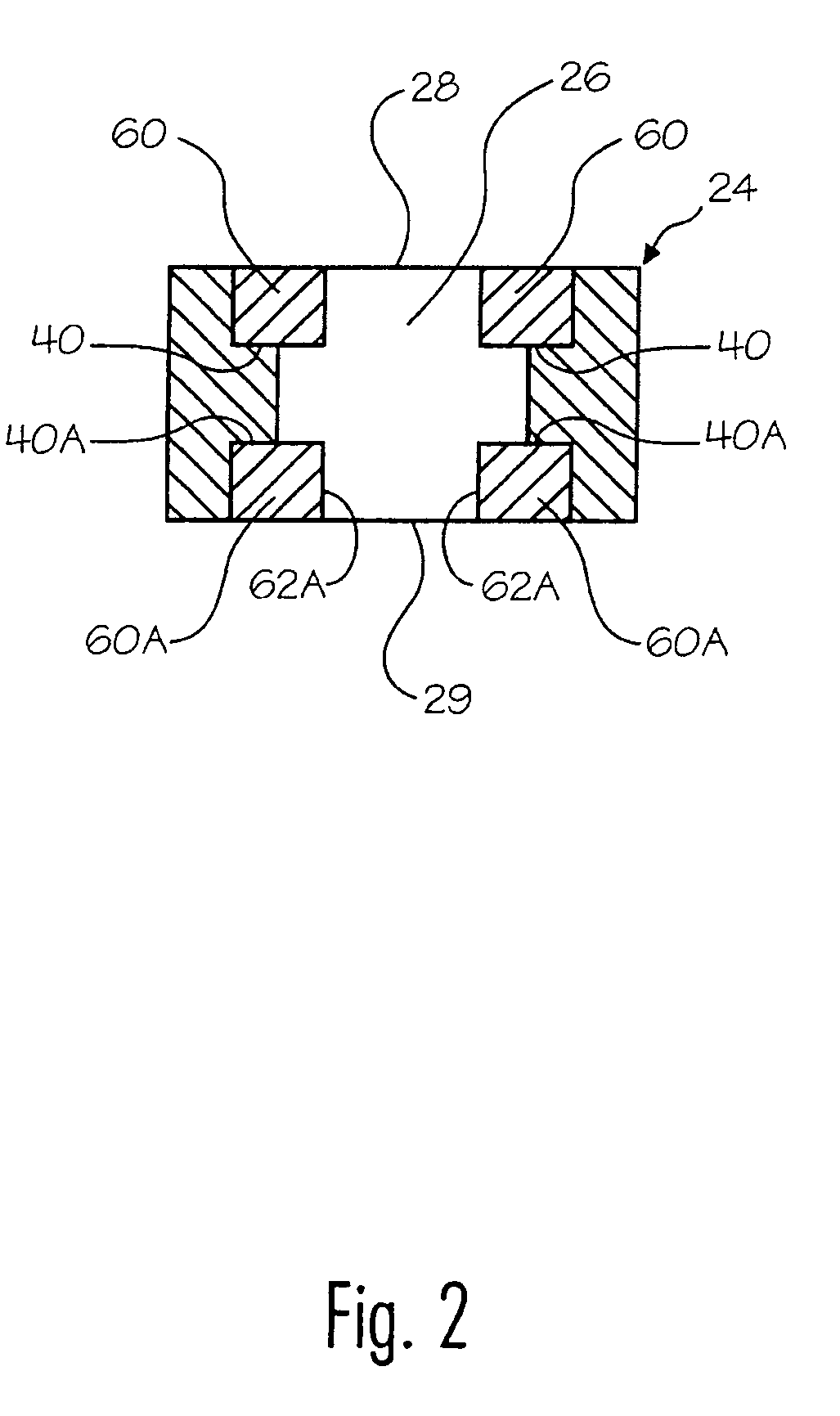

Package-on-package semiconductor assembly

ActiveUS7675152B2Improve robustnessReduce warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

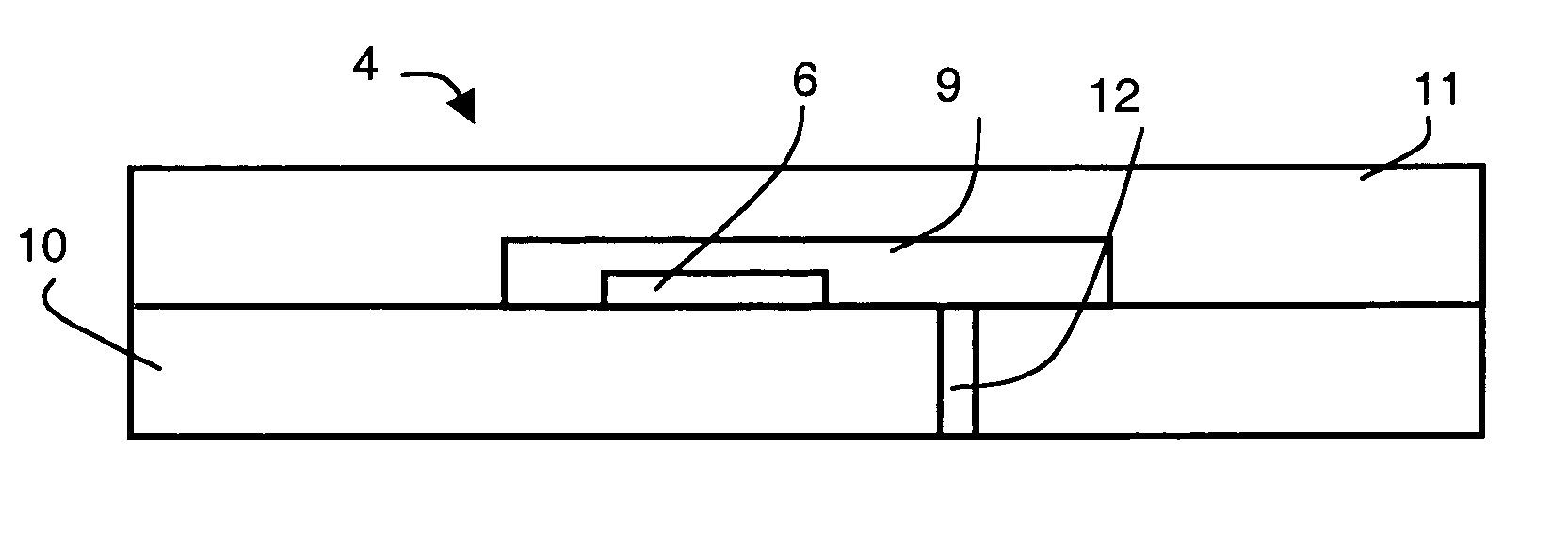

Disclosed are methods and devices for providing improved semiconductor packages and POP IC assemblies using the improved packages with reduced warping. According to disclosed embodiments of the inventions, a packaged semiconductor device for use in a POP assembly includes an encapsulated region generally defined by the substrate surface. The encapsulant is provided with contact apertures permitting external communication with contacts on the substrate and coupled to an encapsulated chip. Preferred embodiments of the invention are described in which the contact aperture sidewalls are angled within the range of approximately 10-30 degrees or more from vertical and in which the contact aperture is provided a gas release channel to permit gas to escape during reflow.

Owner:TEXAS INSTR INC

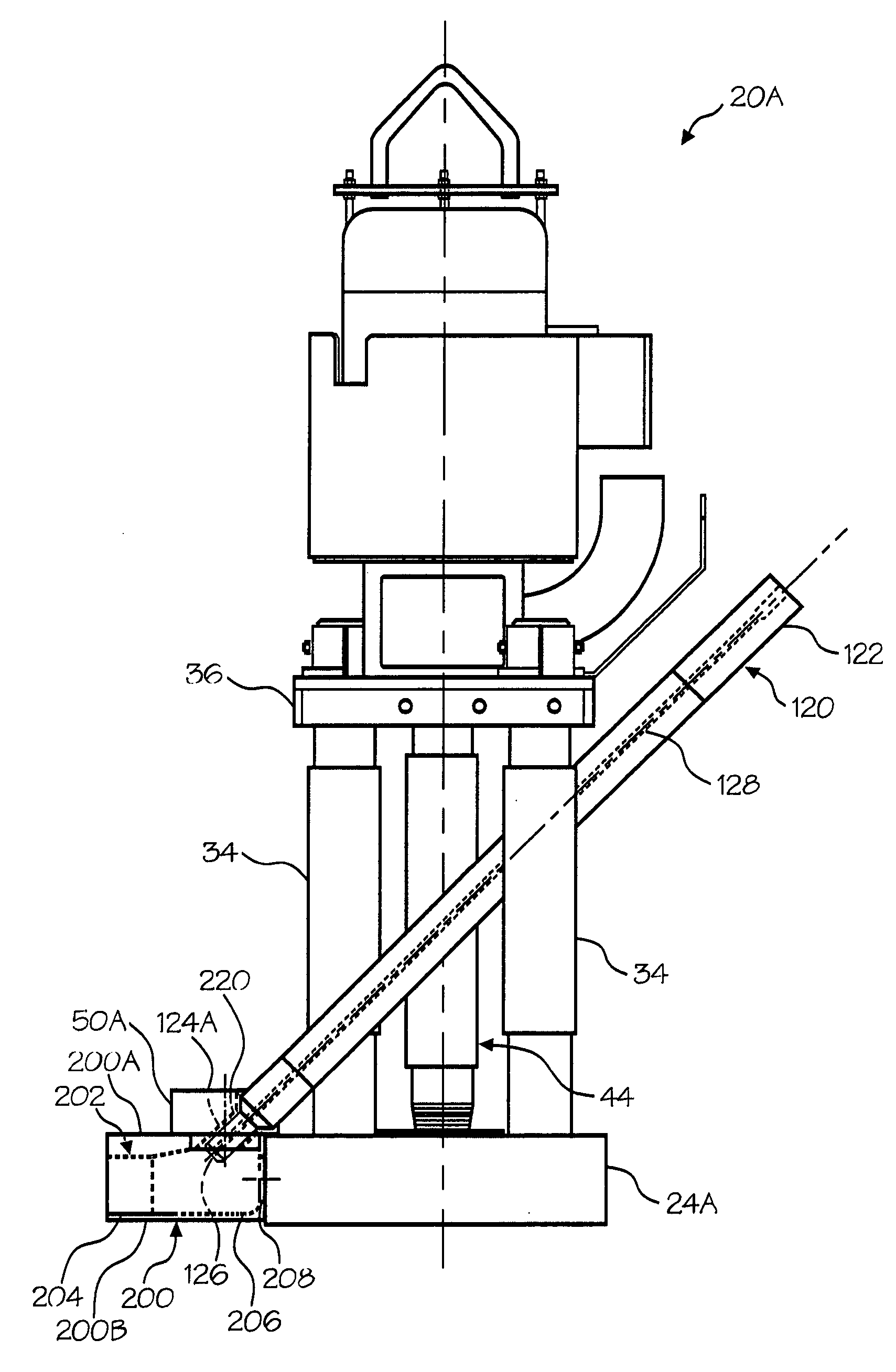

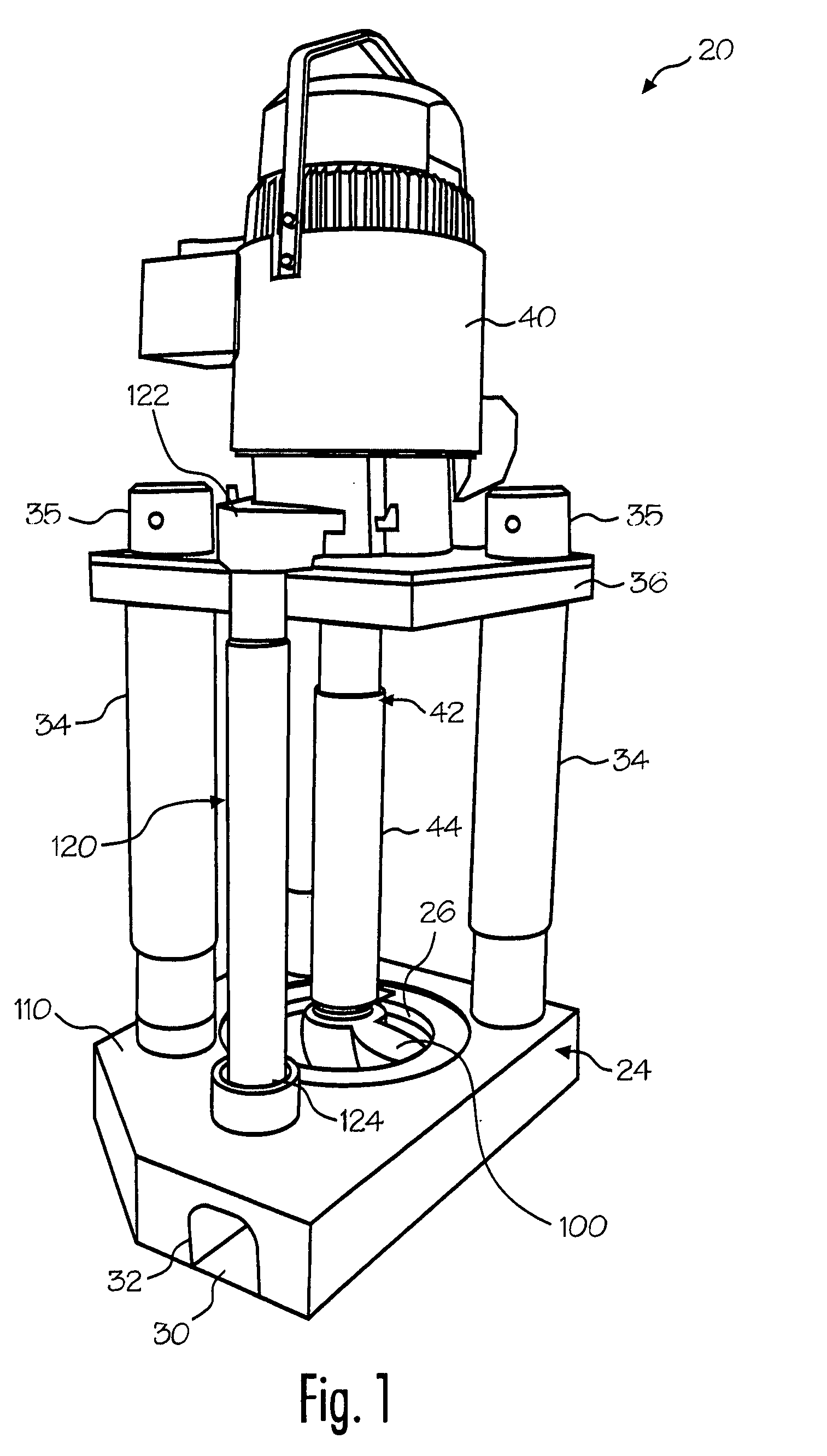

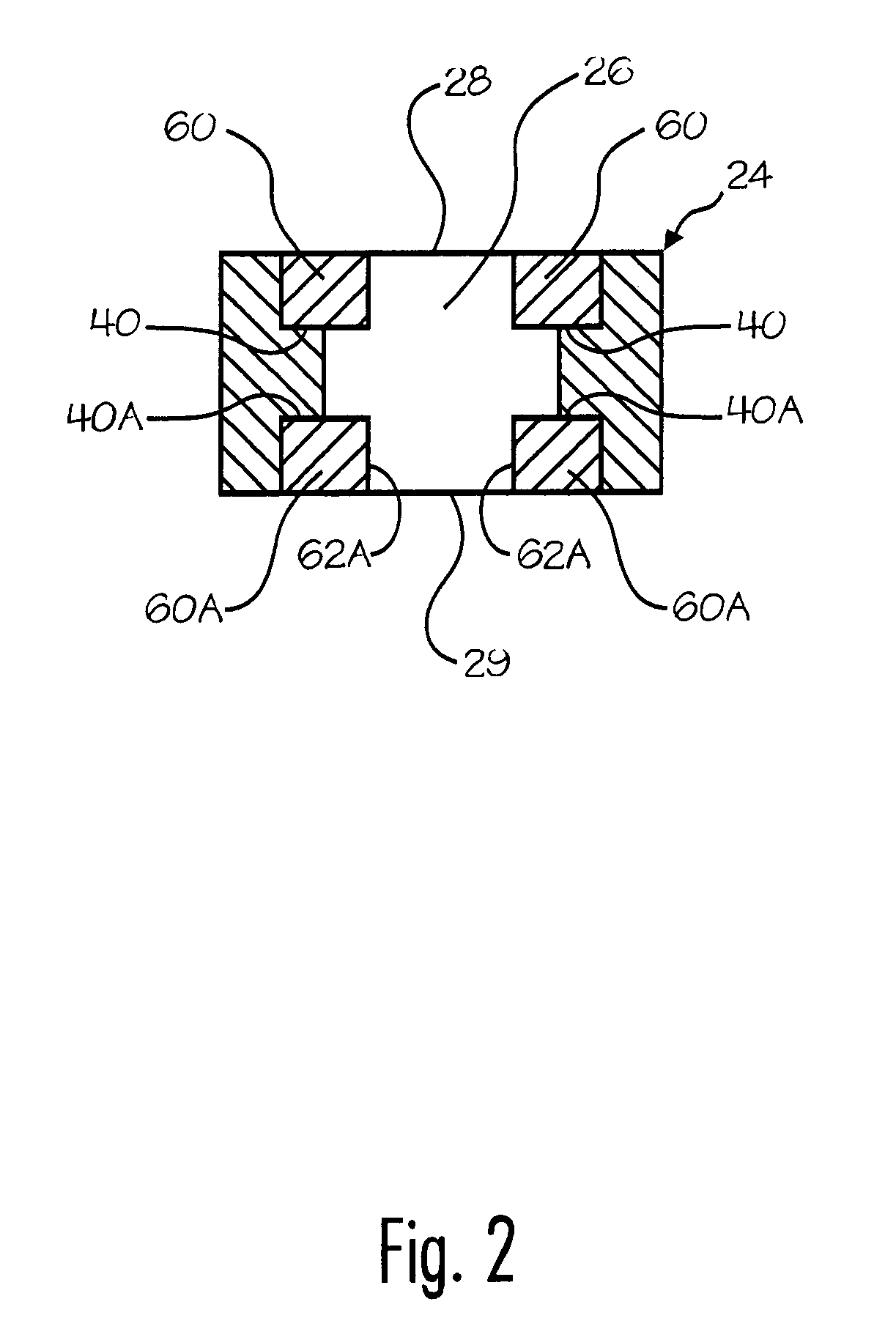

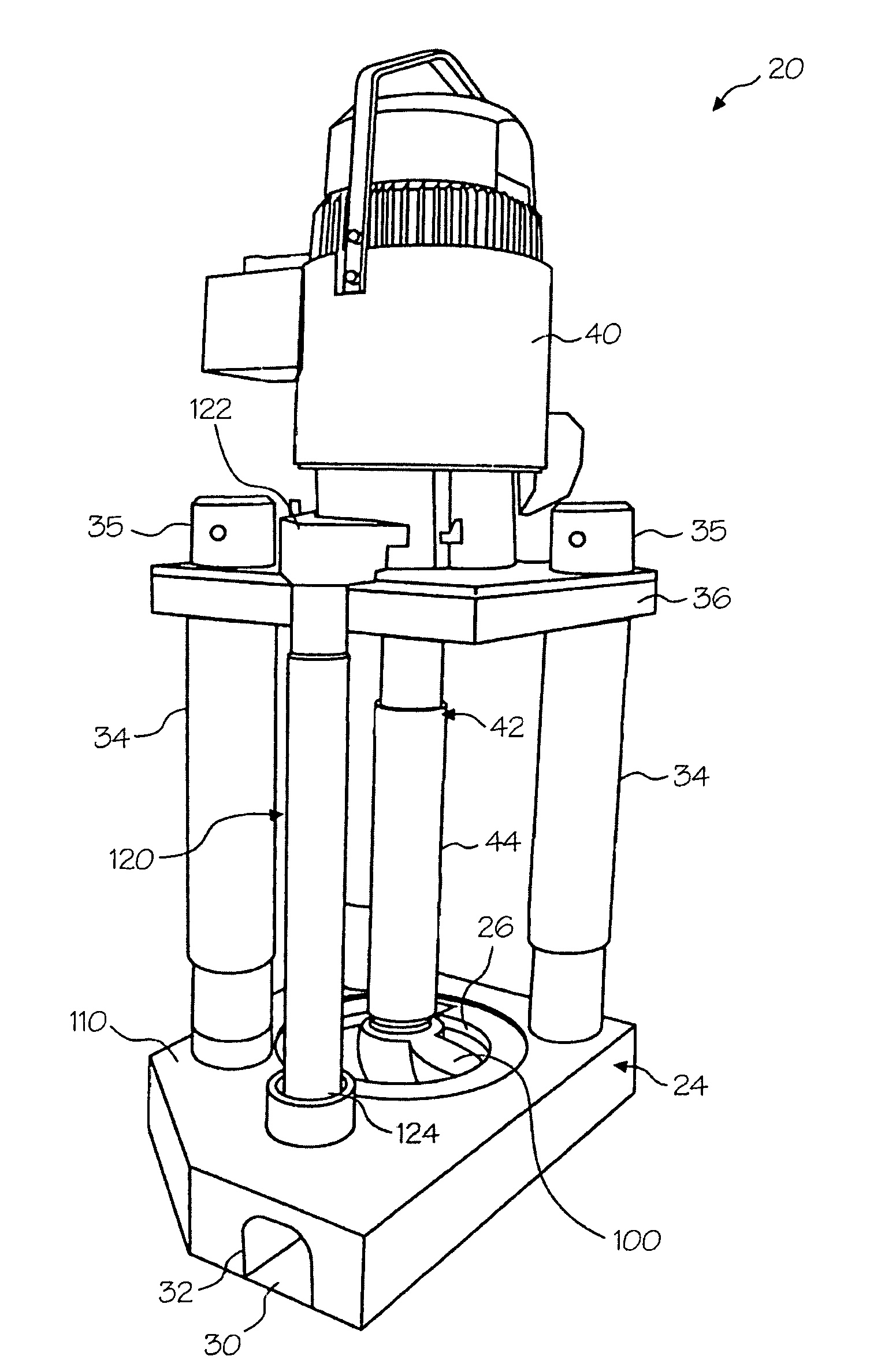

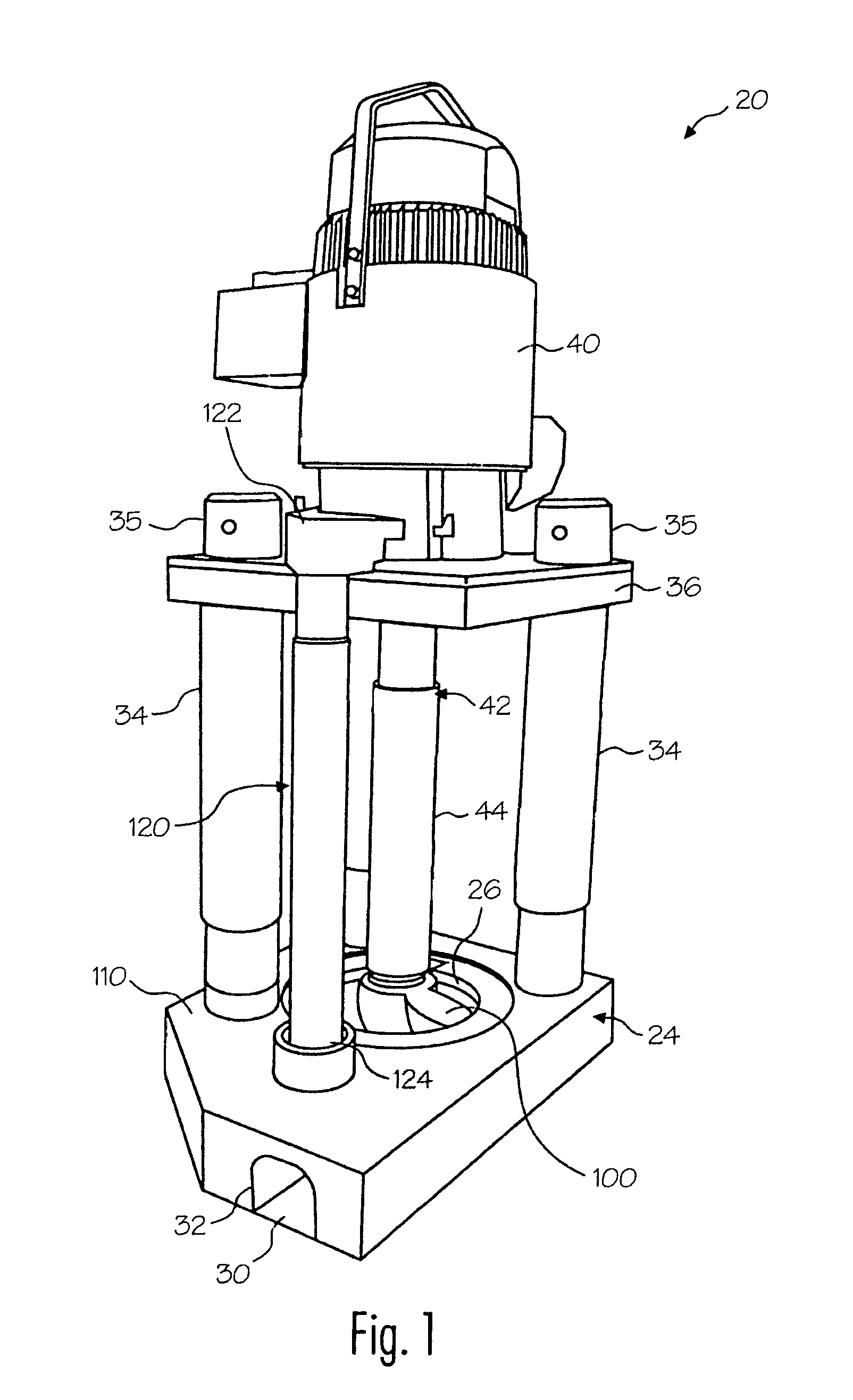

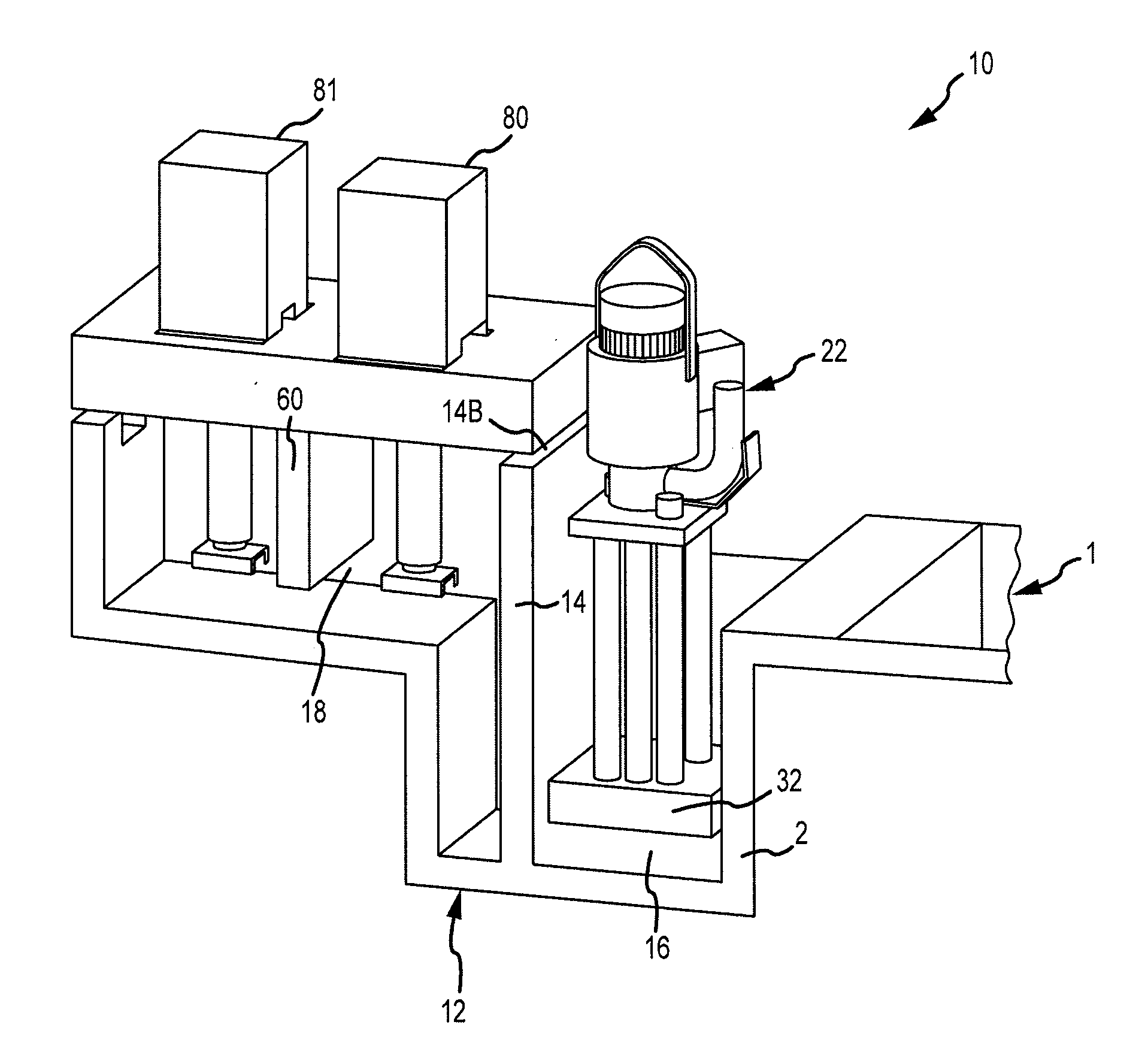

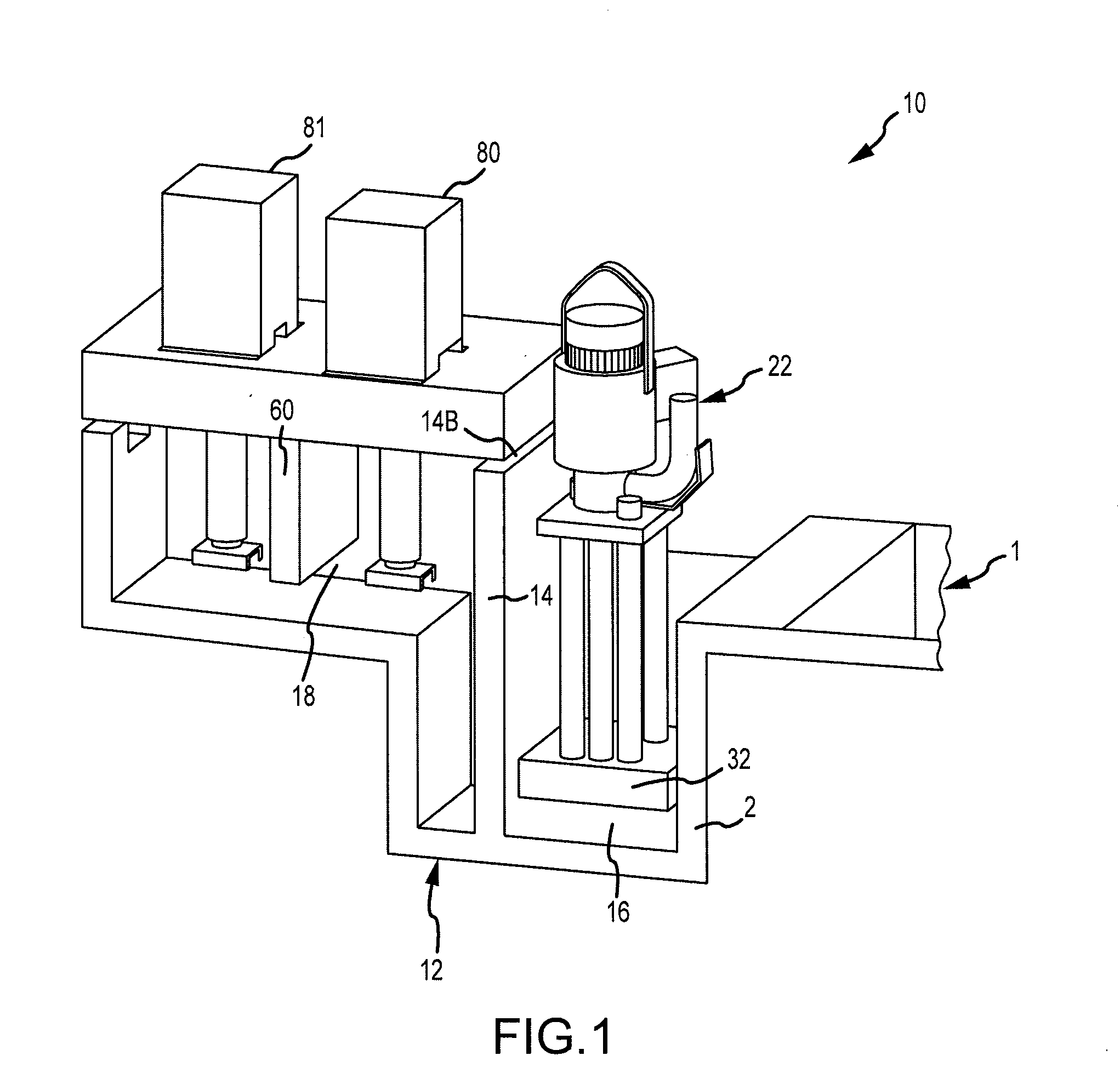

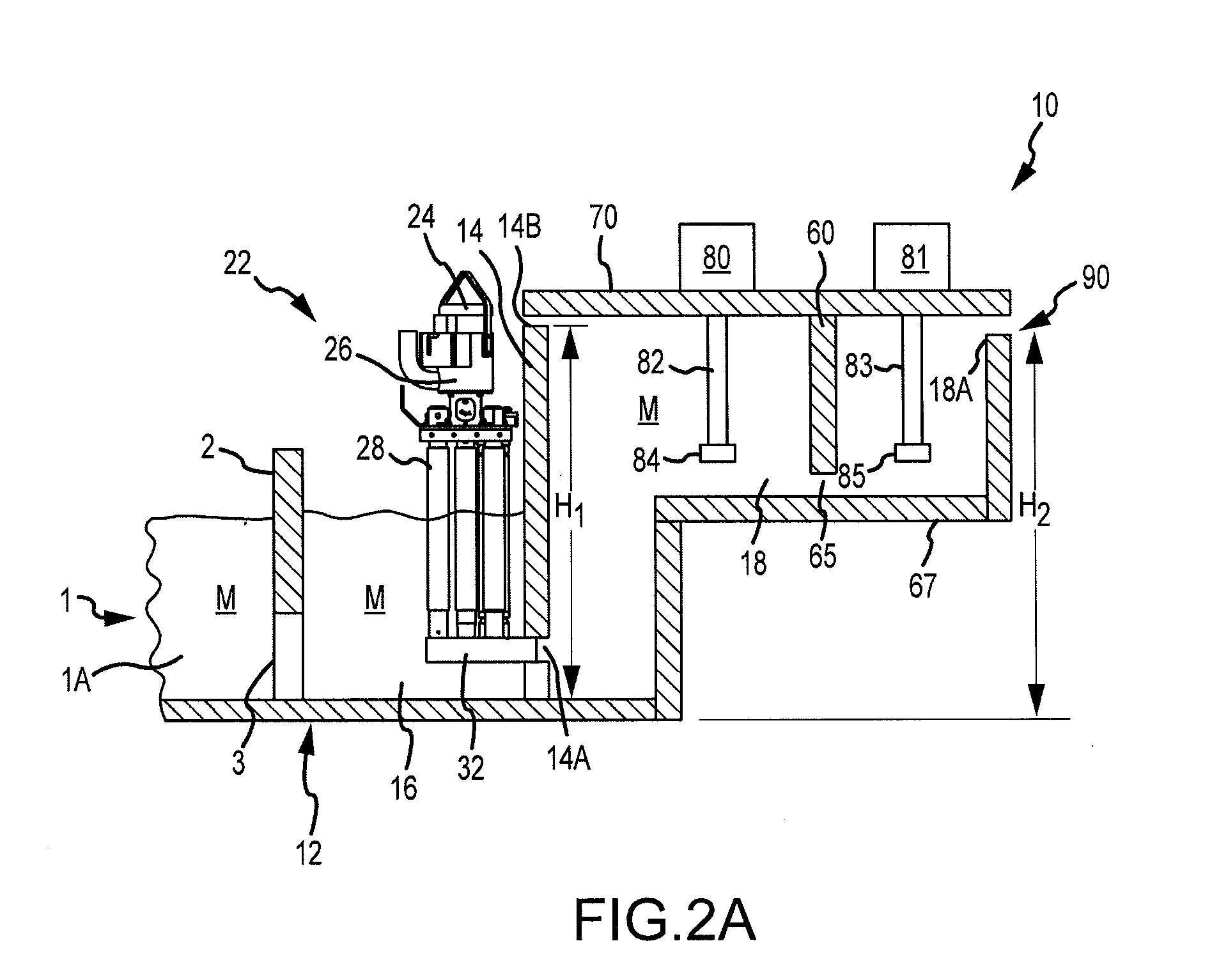

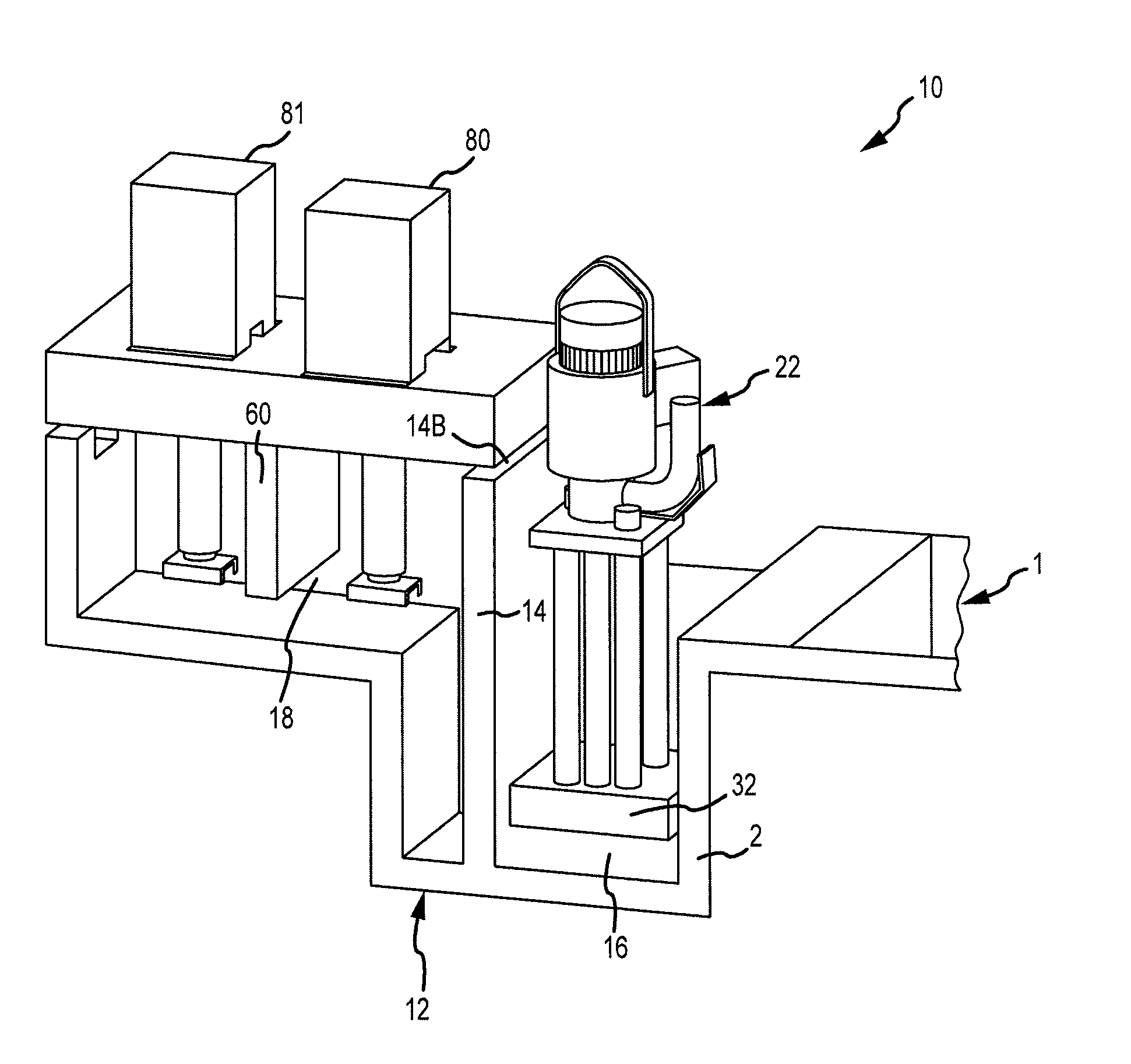

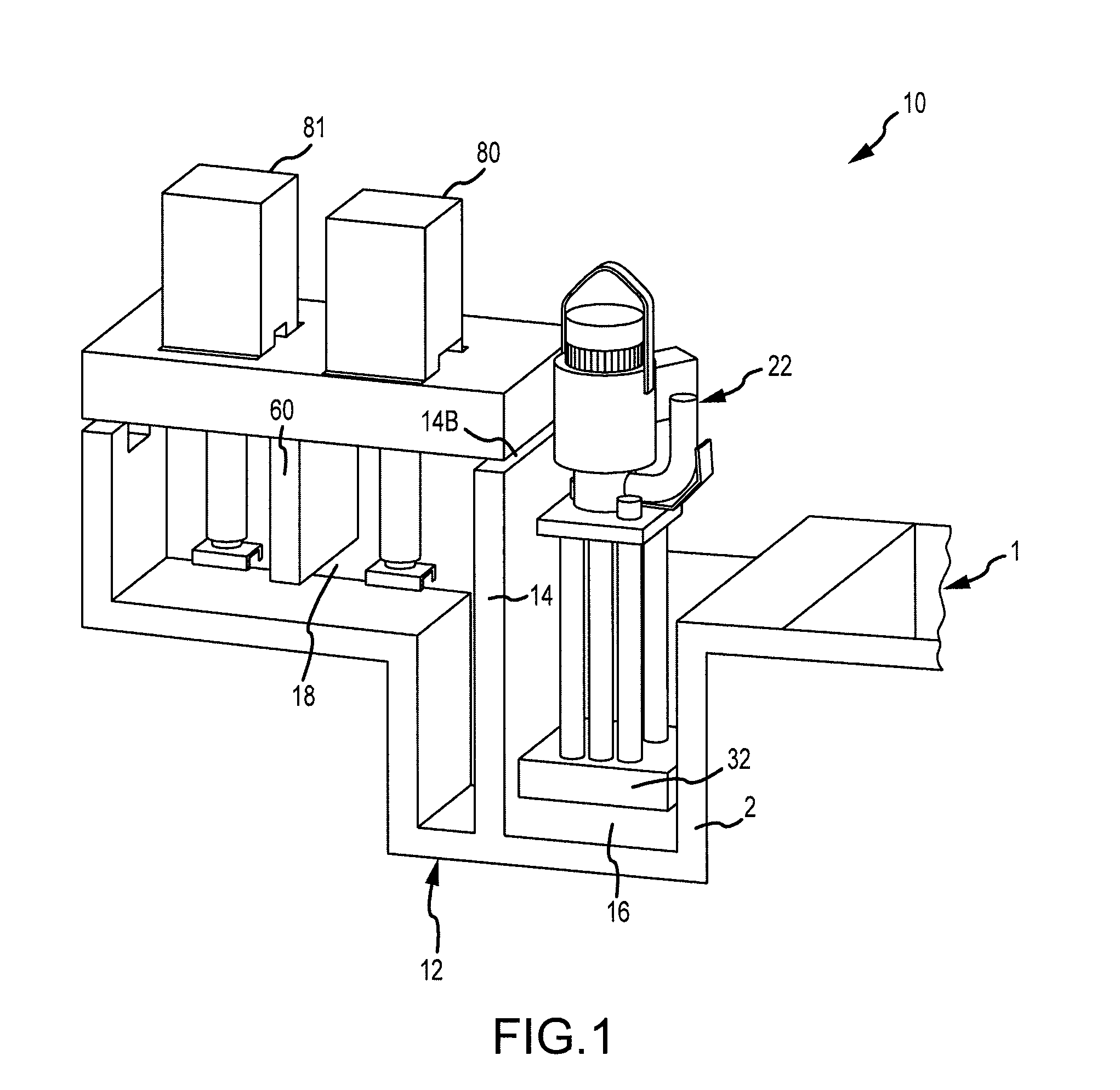

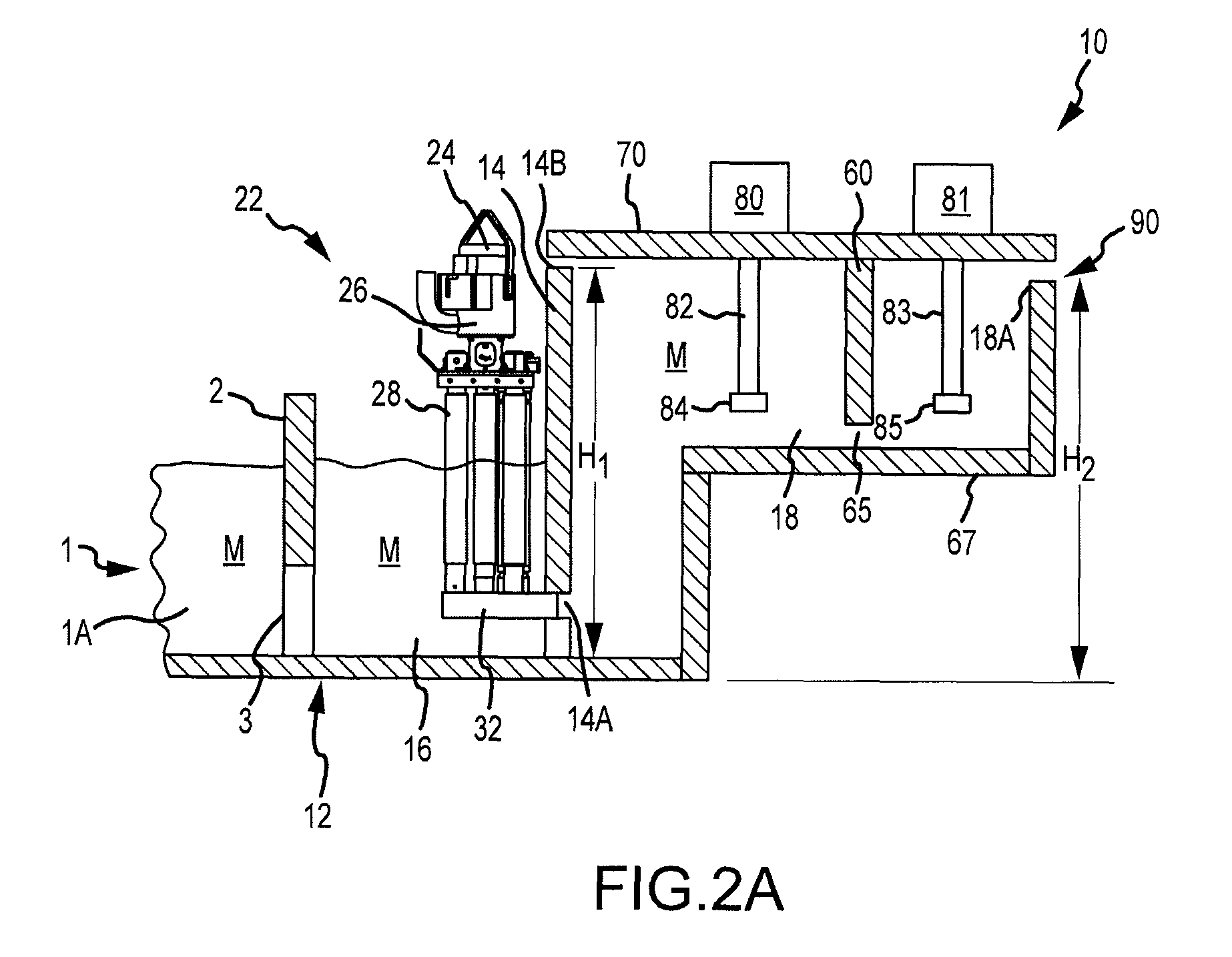

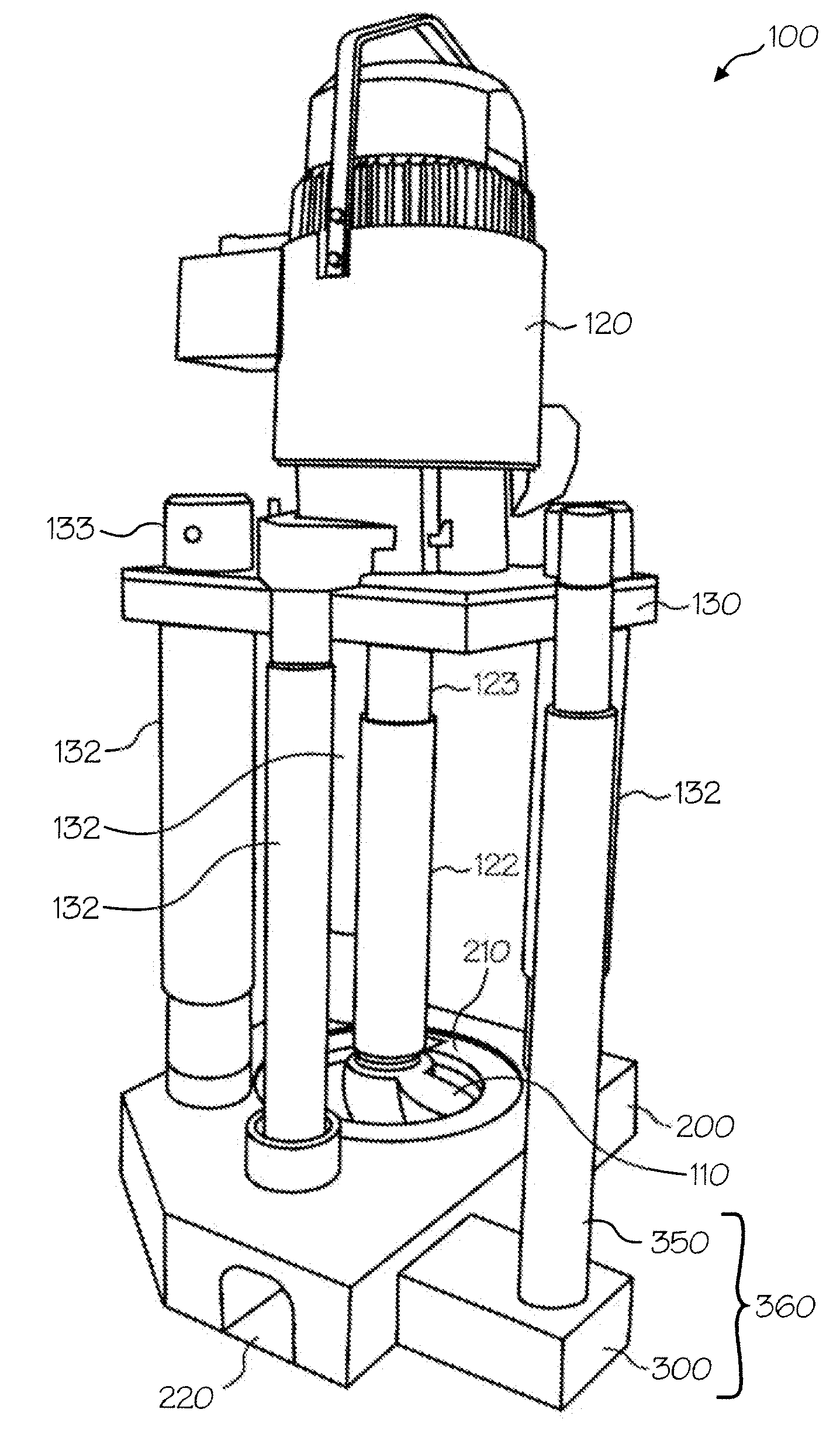

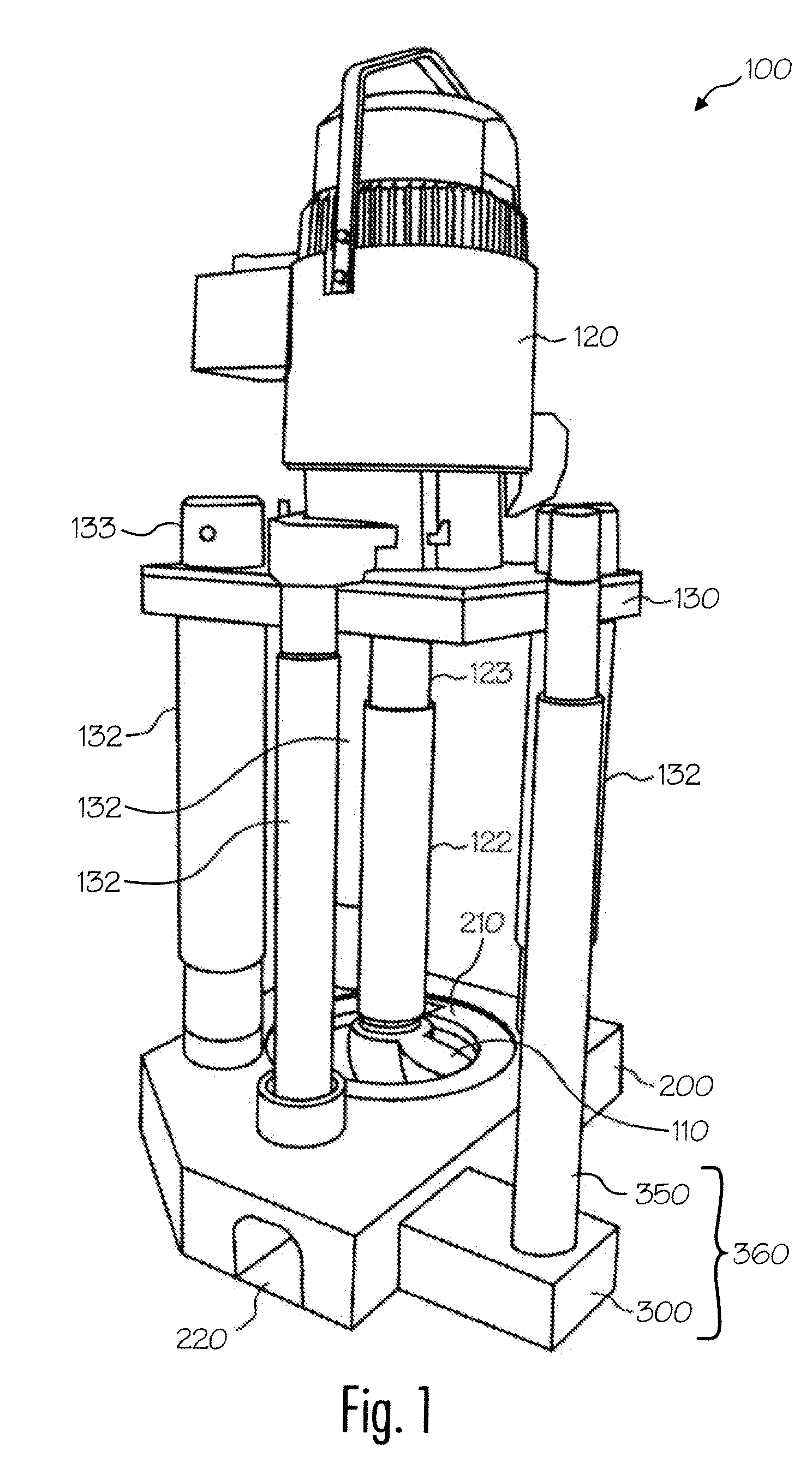

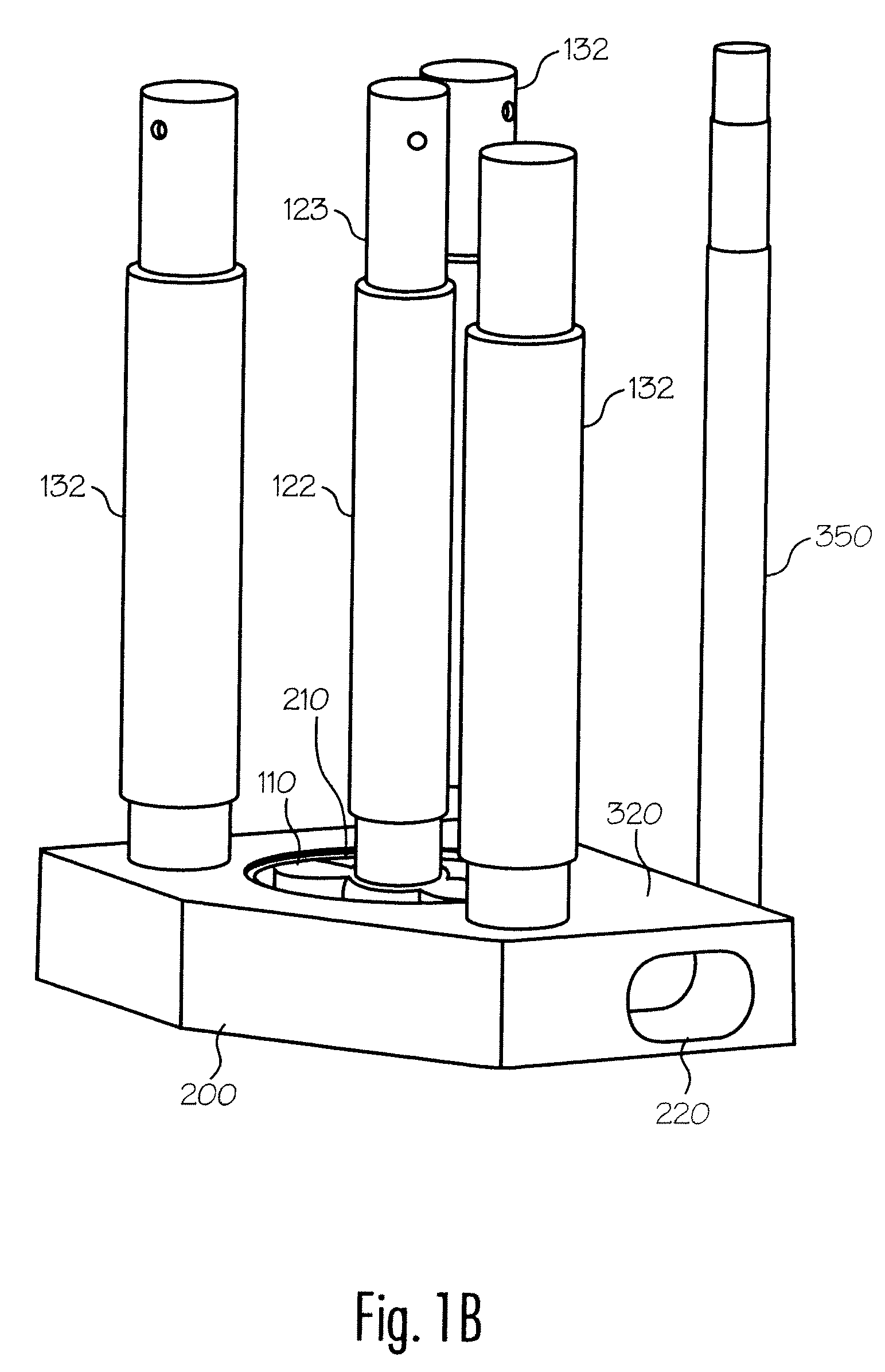

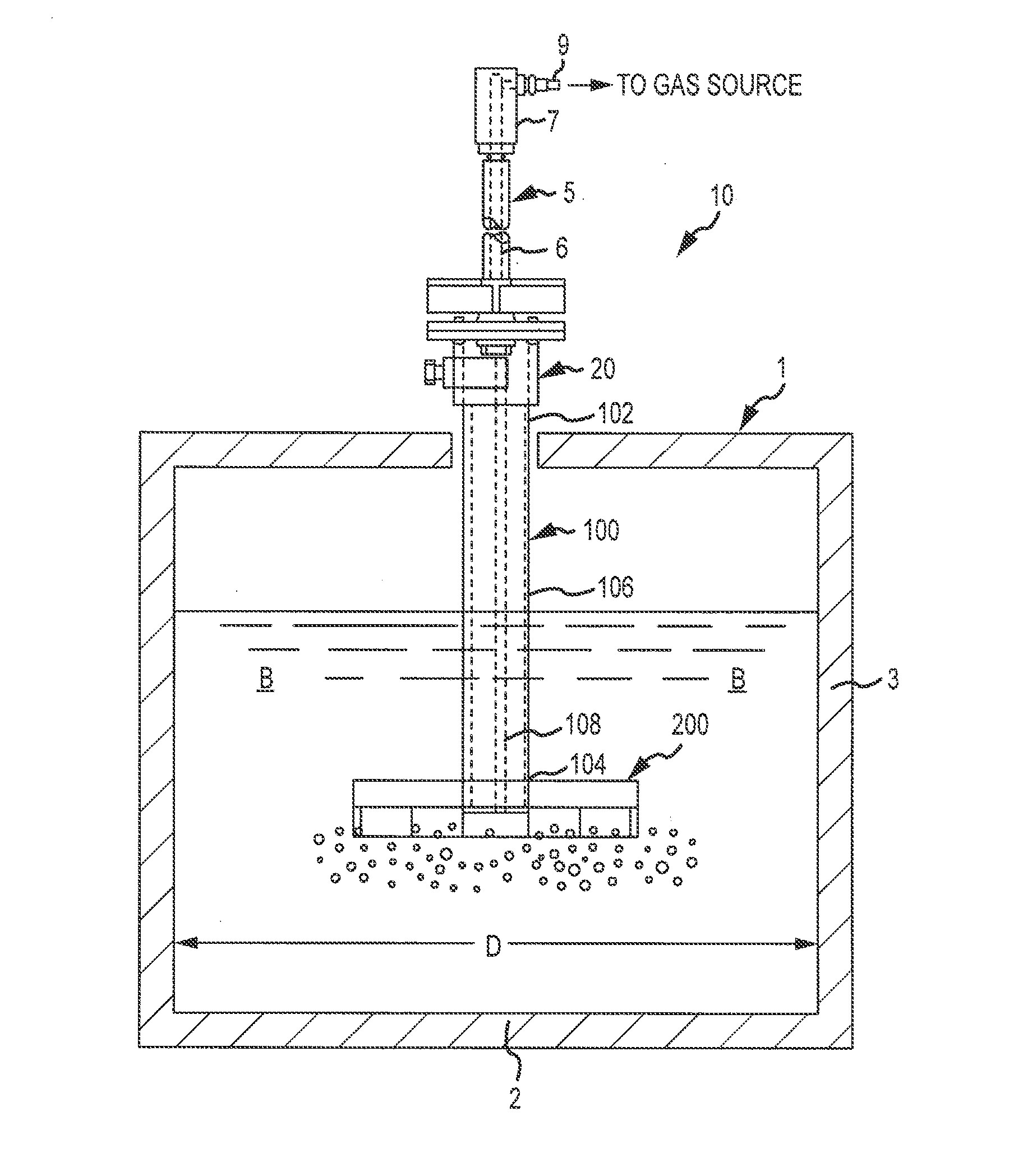

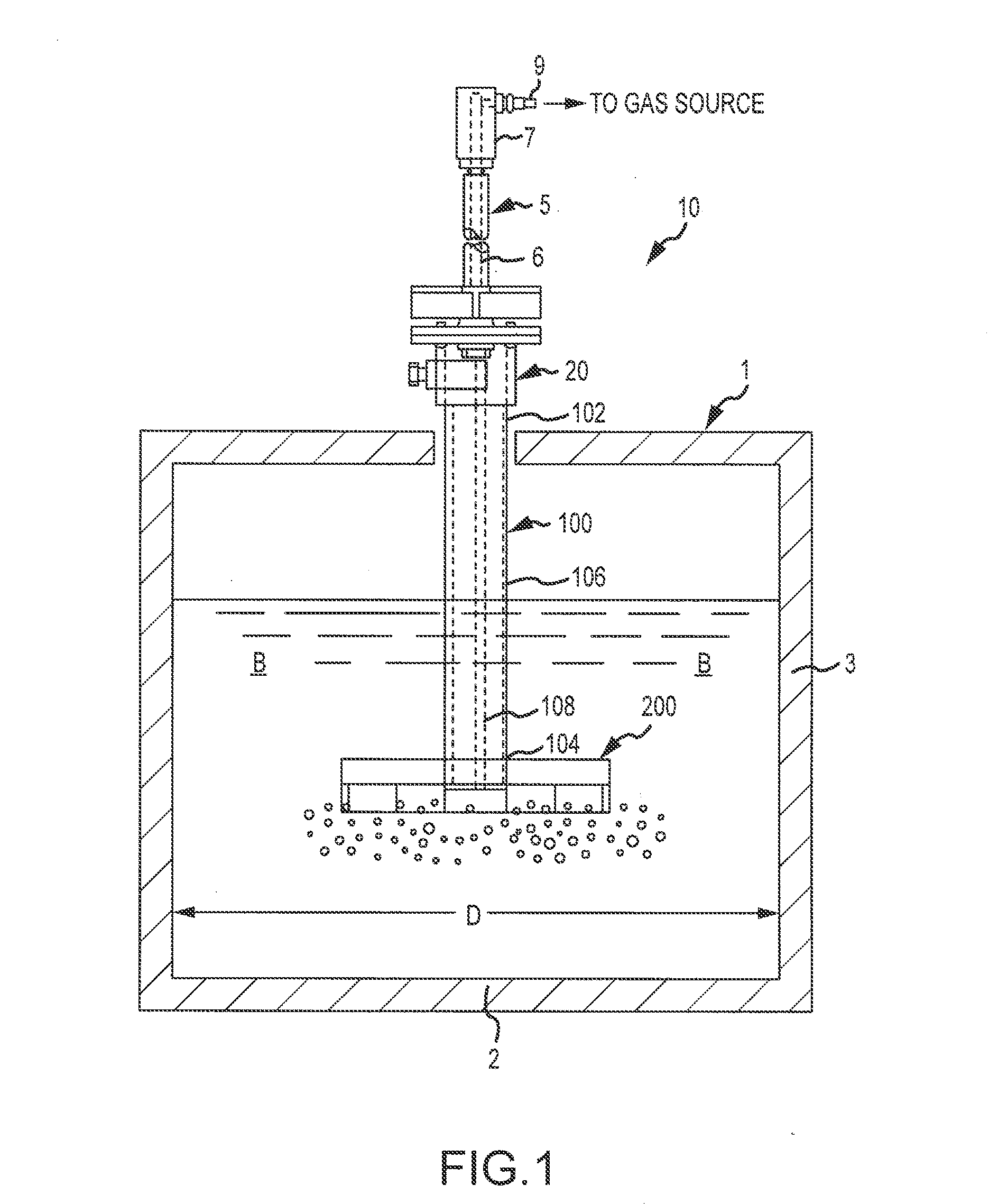

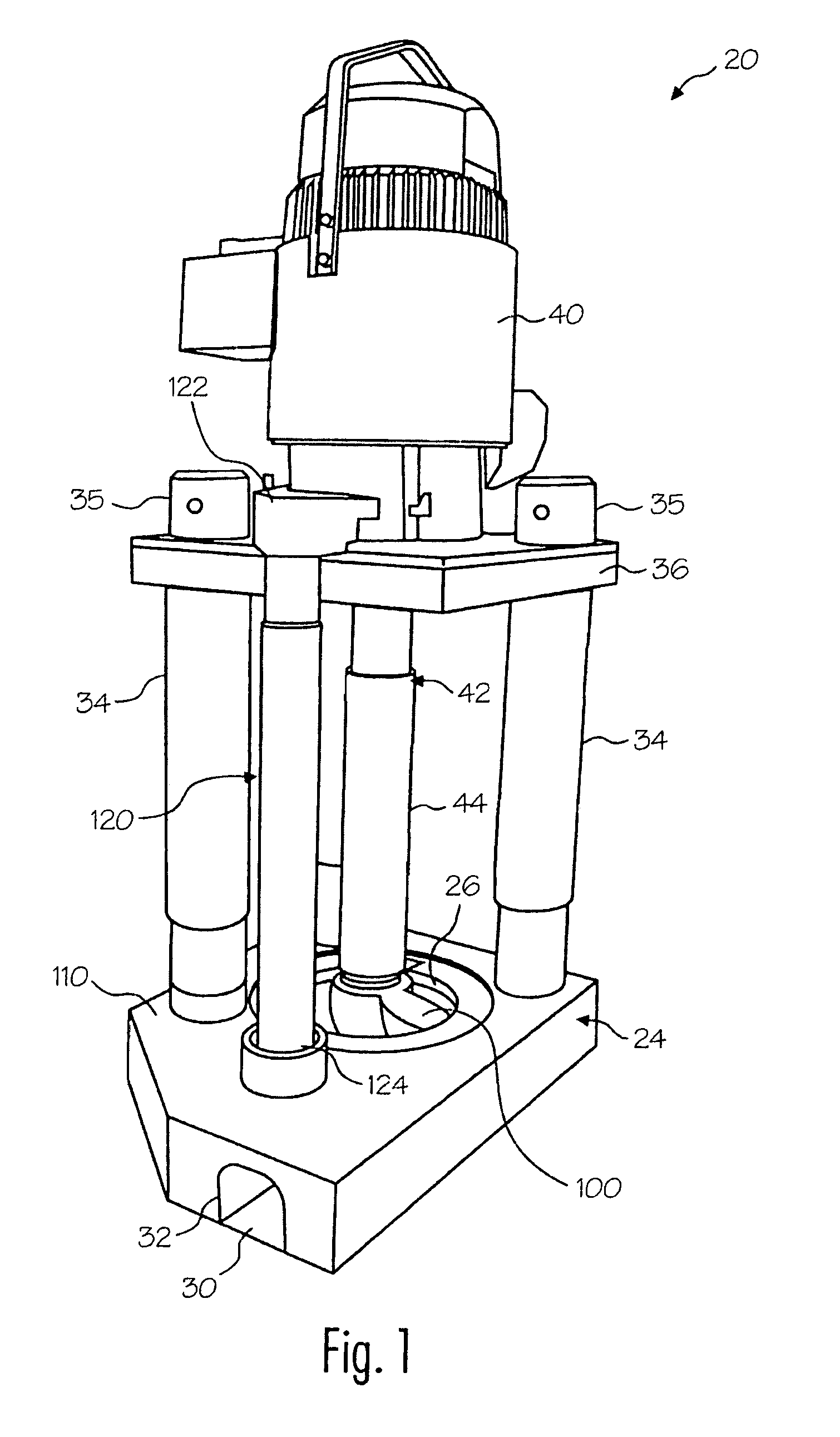

System for releasing gas into molten metal

InactiveUS20050013715A1Reduce amountReduce stressSpecific fluid pumpsEngine manufactureMetallurgyGas release

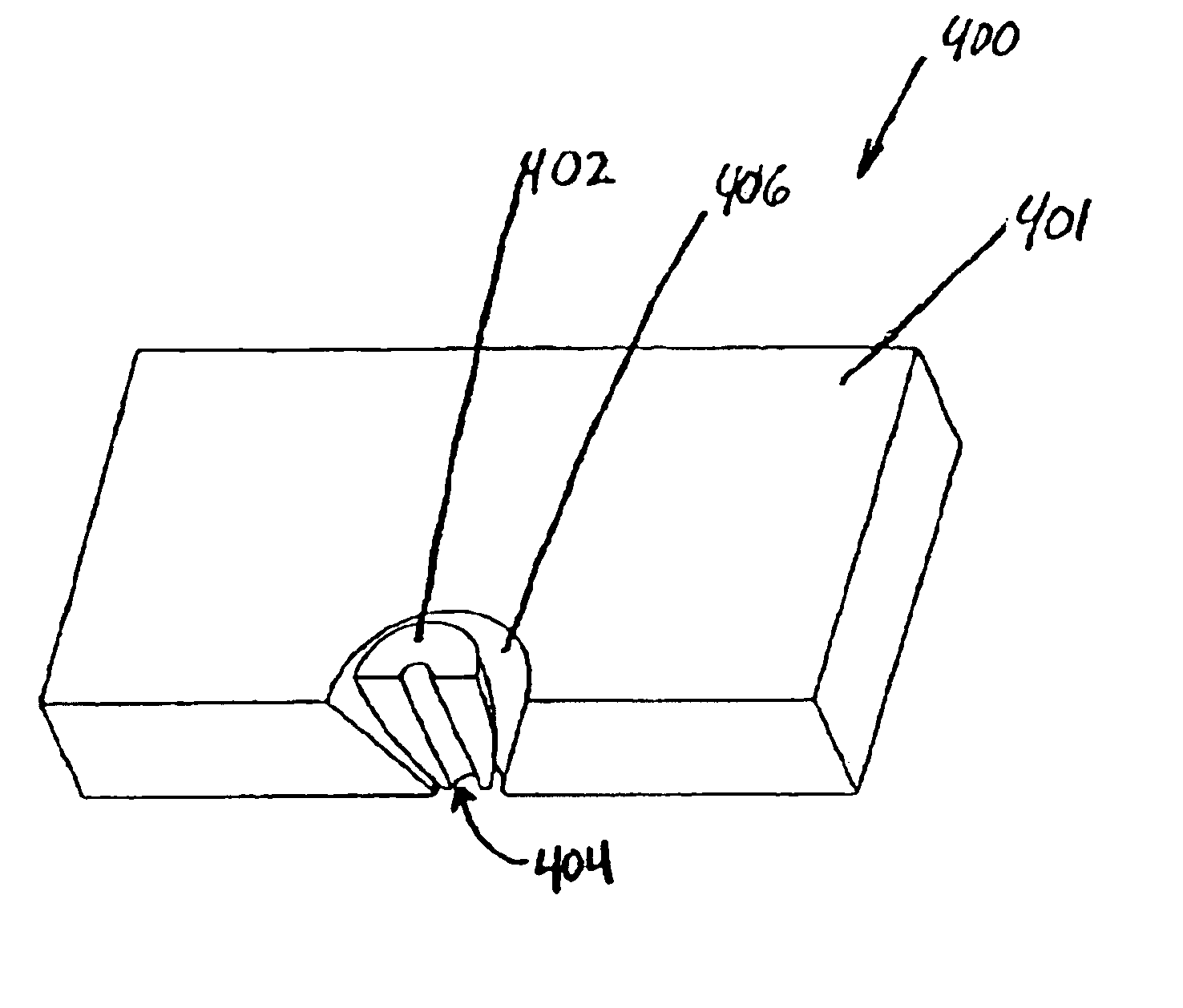

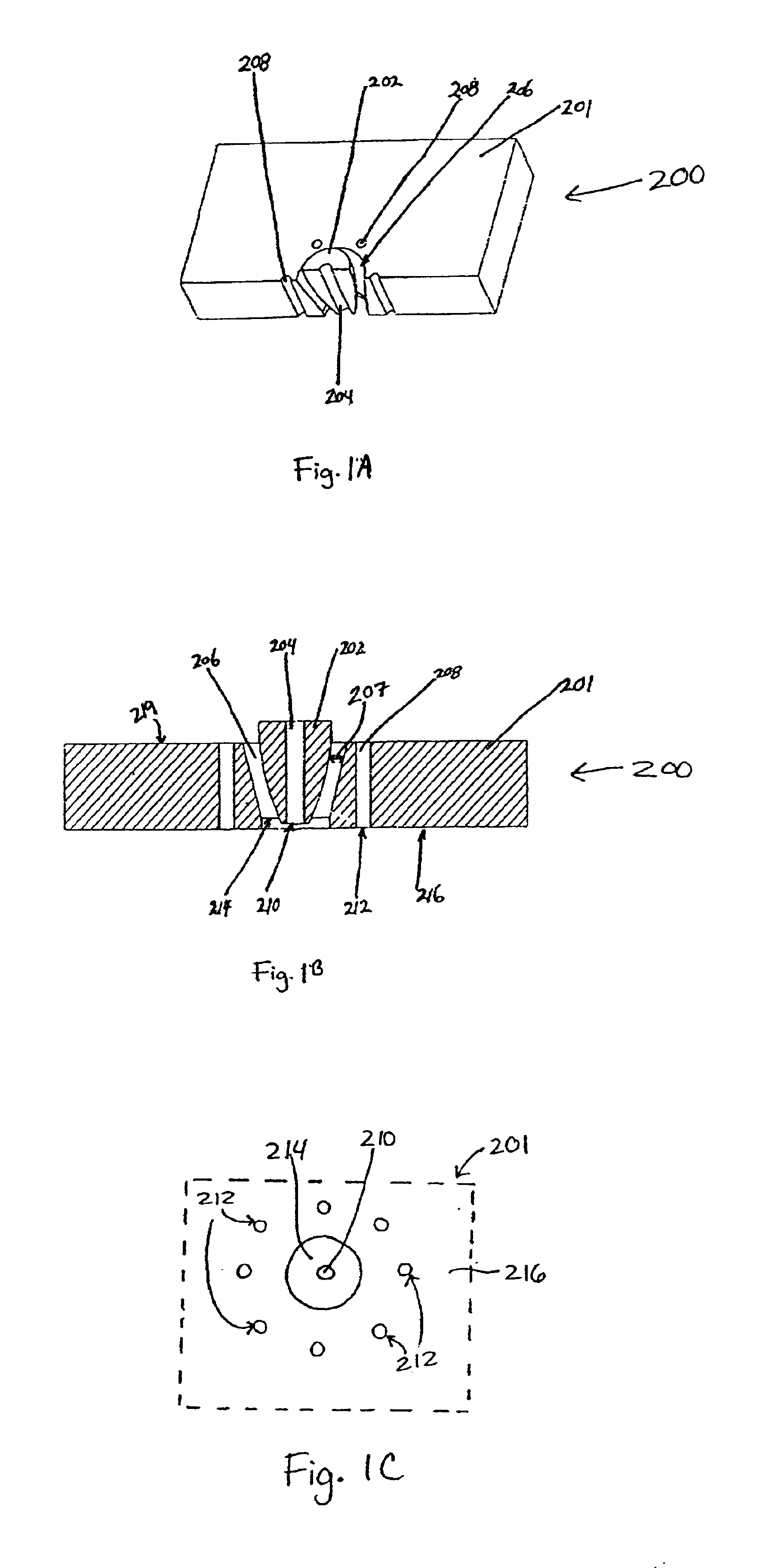

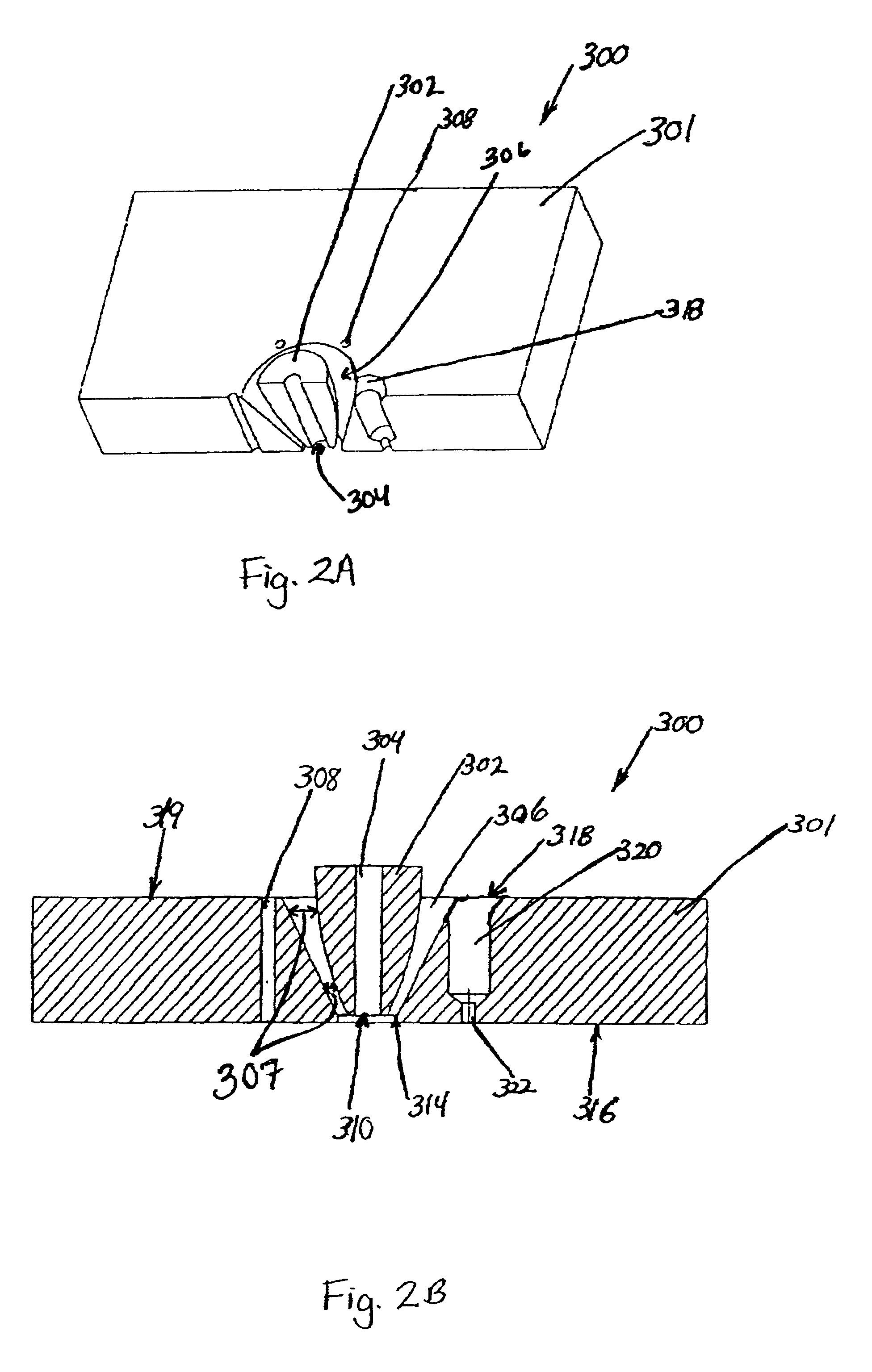

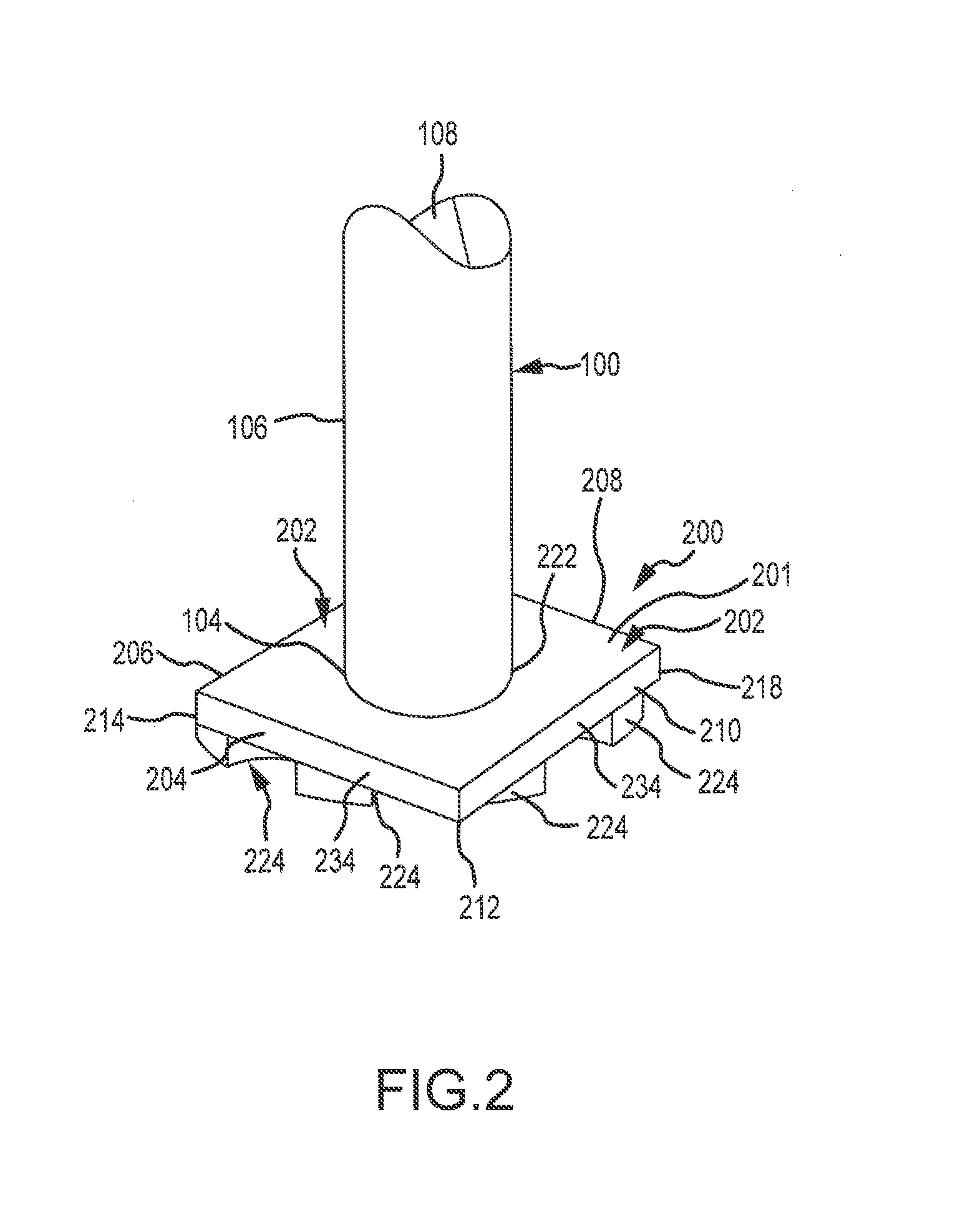

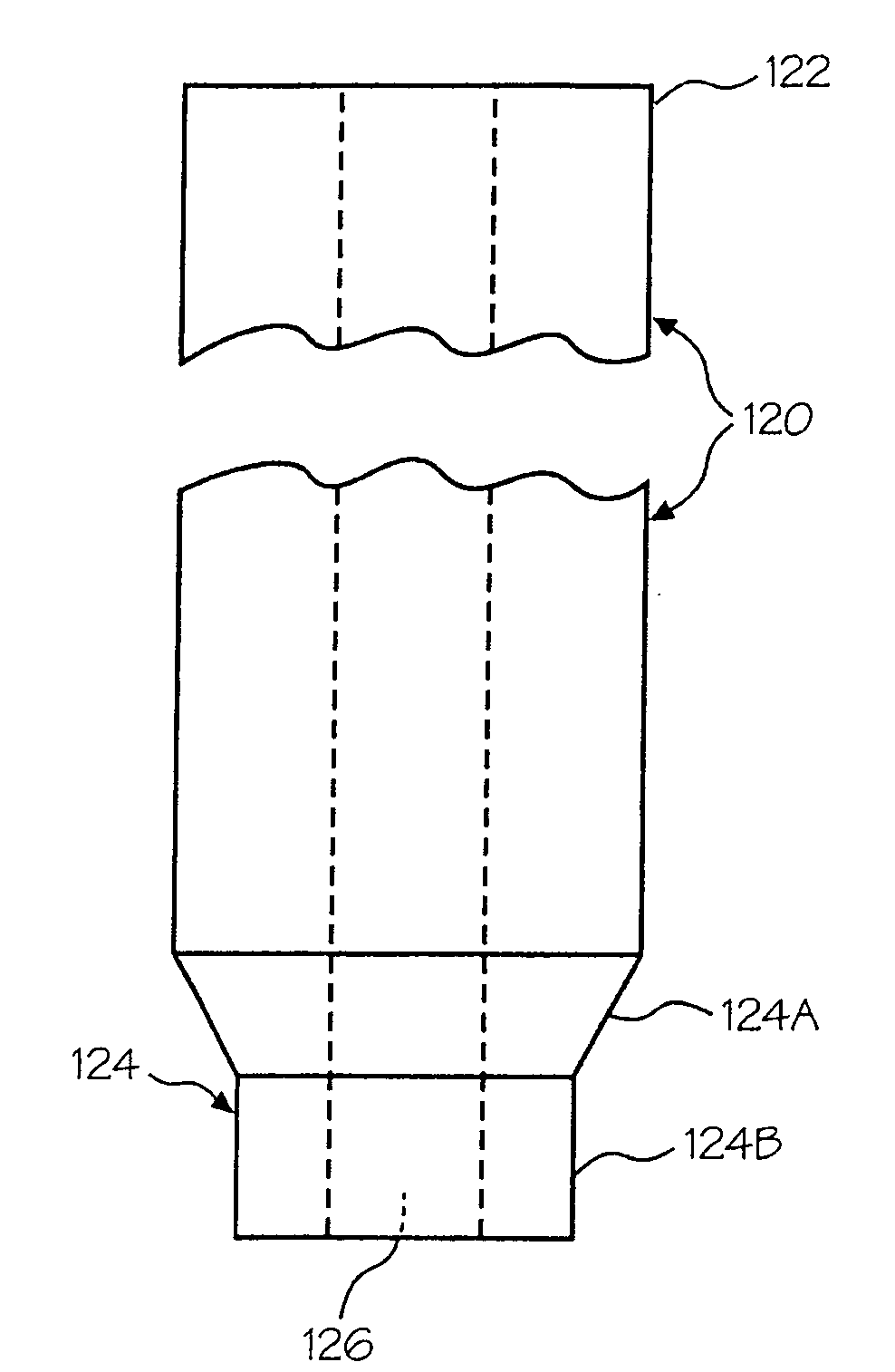

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:COOPER PAUL V

System for releasing gas into molten metal

InactiveUS20080213111A1Reduce amountIncrease the cross-sectional areaSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

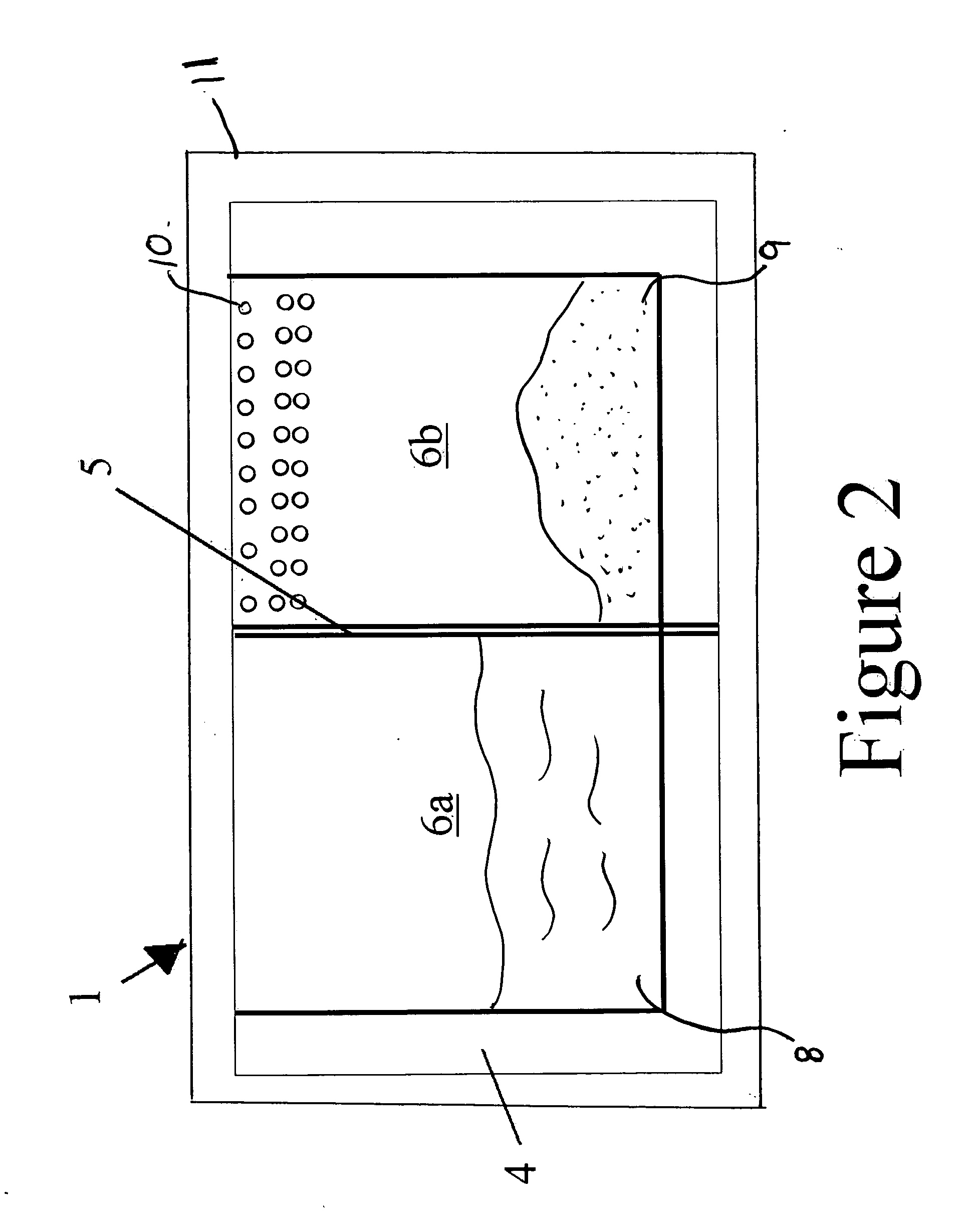

System and method for degassing molten metal

A system for adding gas to and transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, a device or structure, such as a molten metal pump, for generating a stream of molten metal, and one or more gas-release devices.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

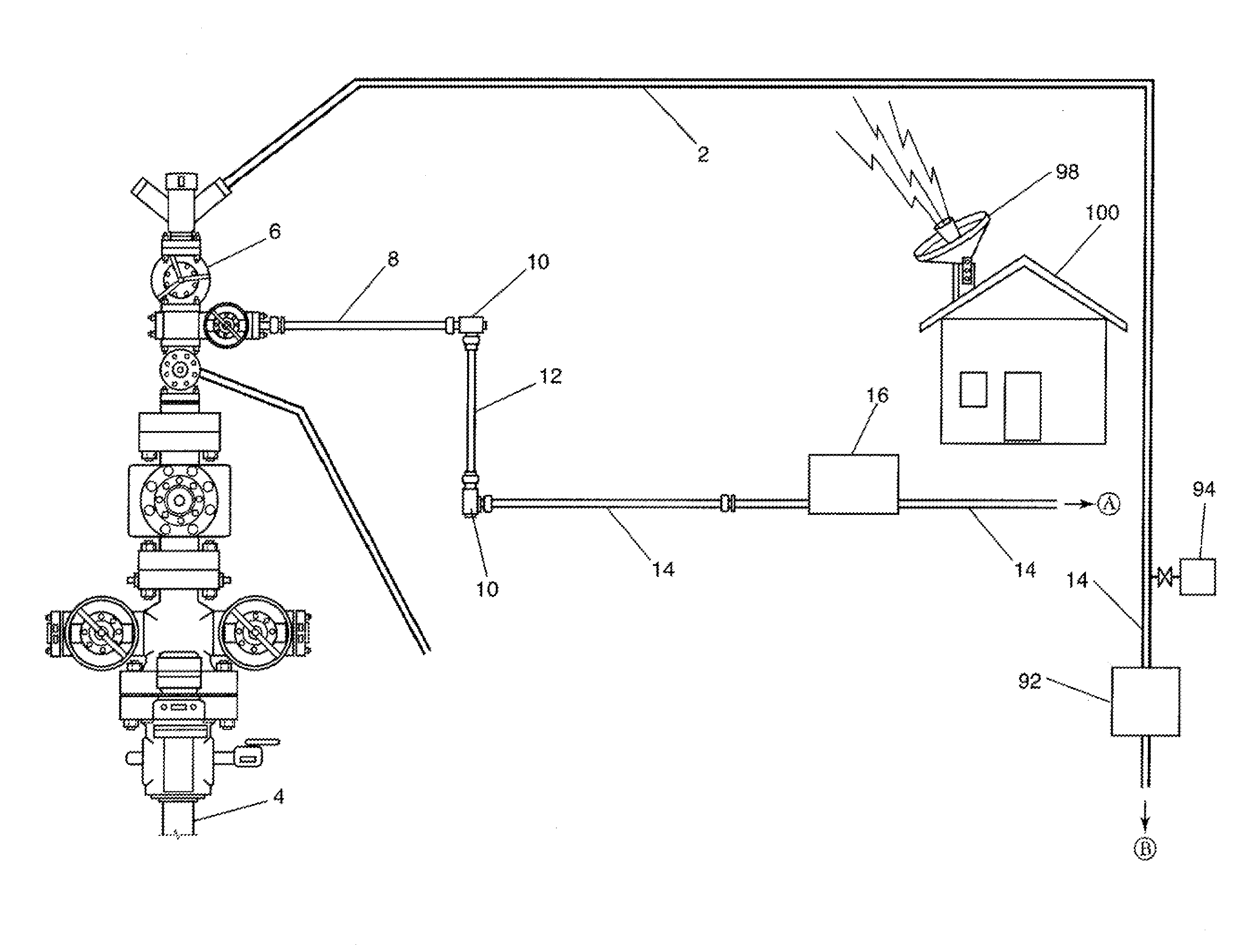

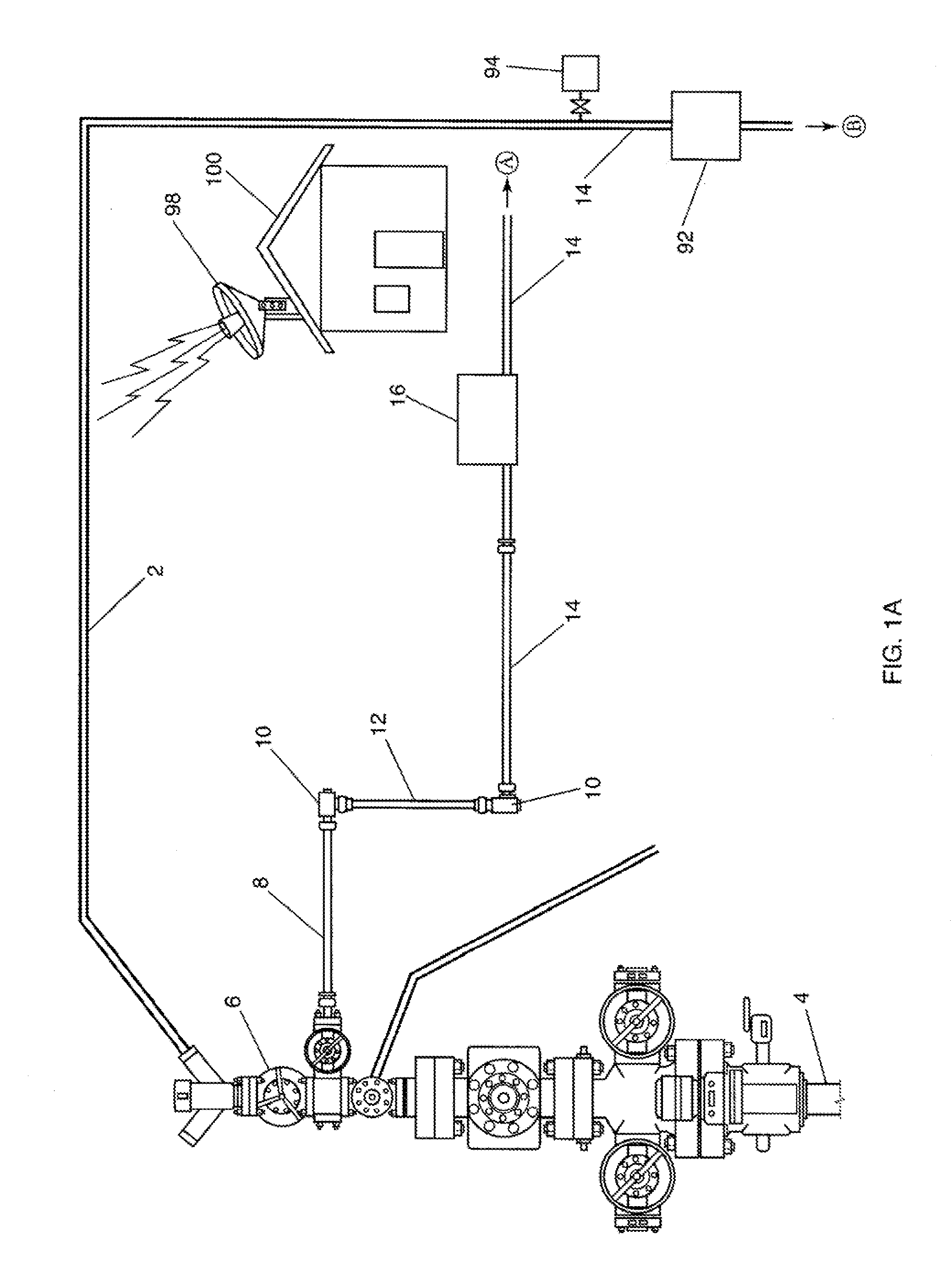

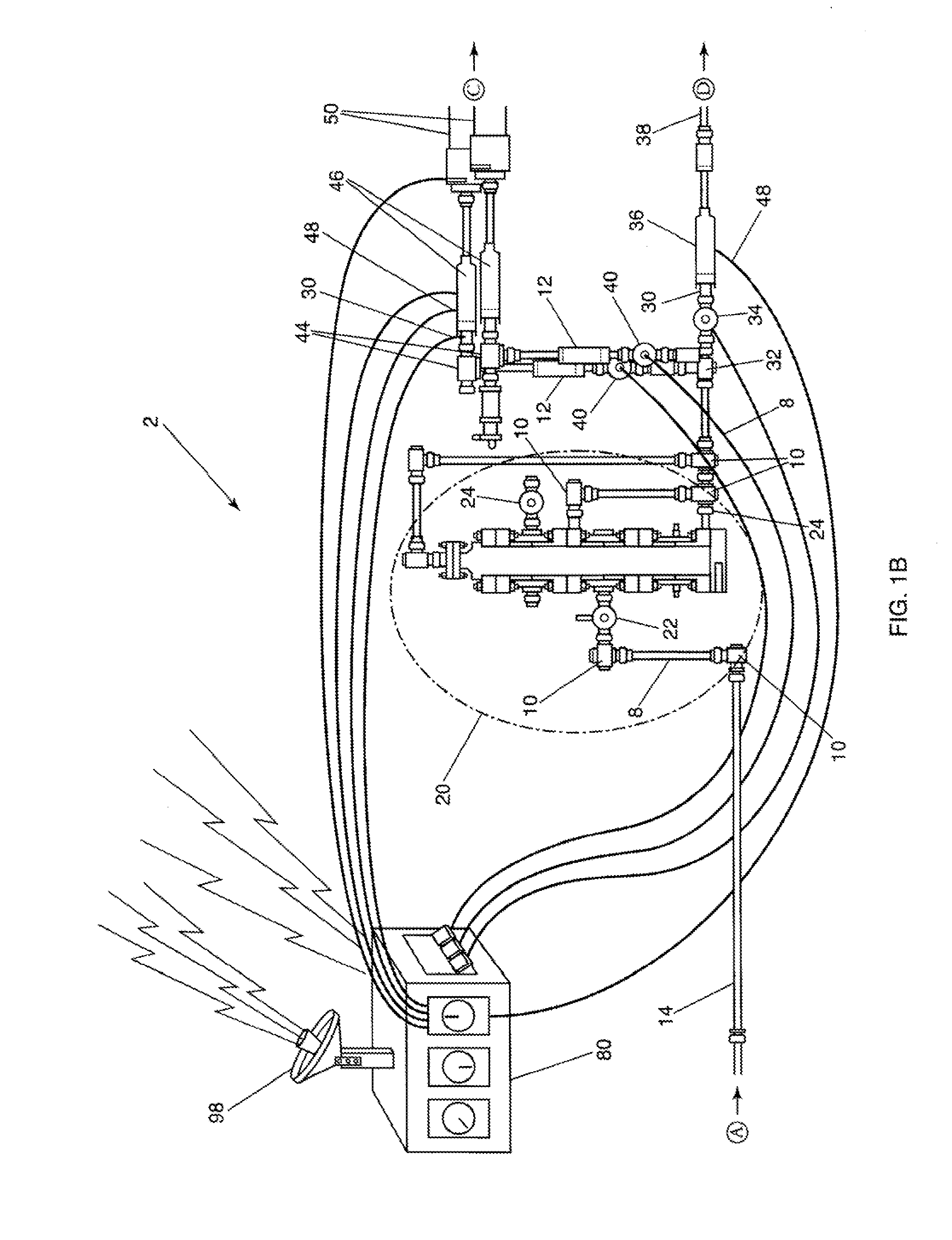

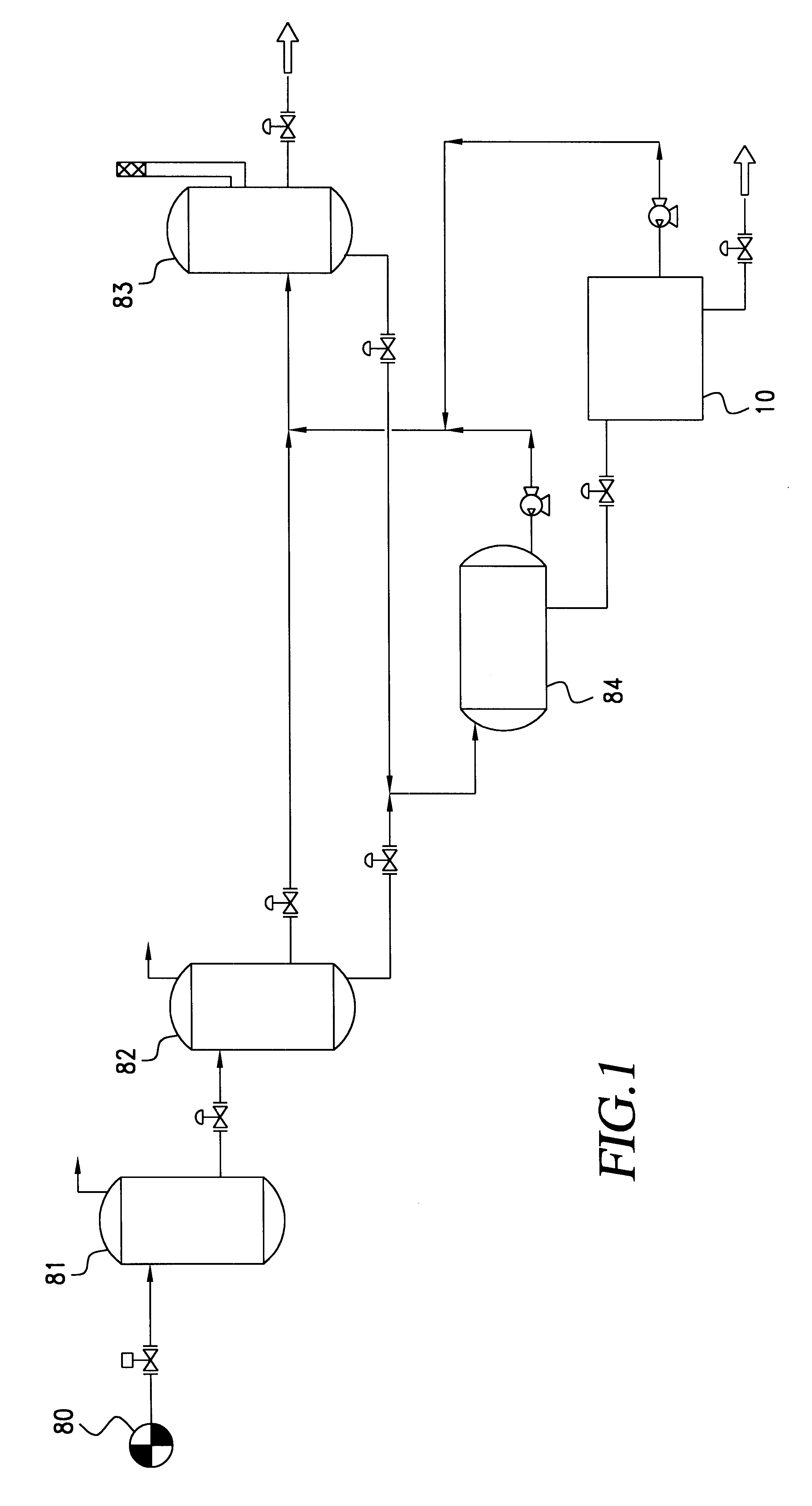

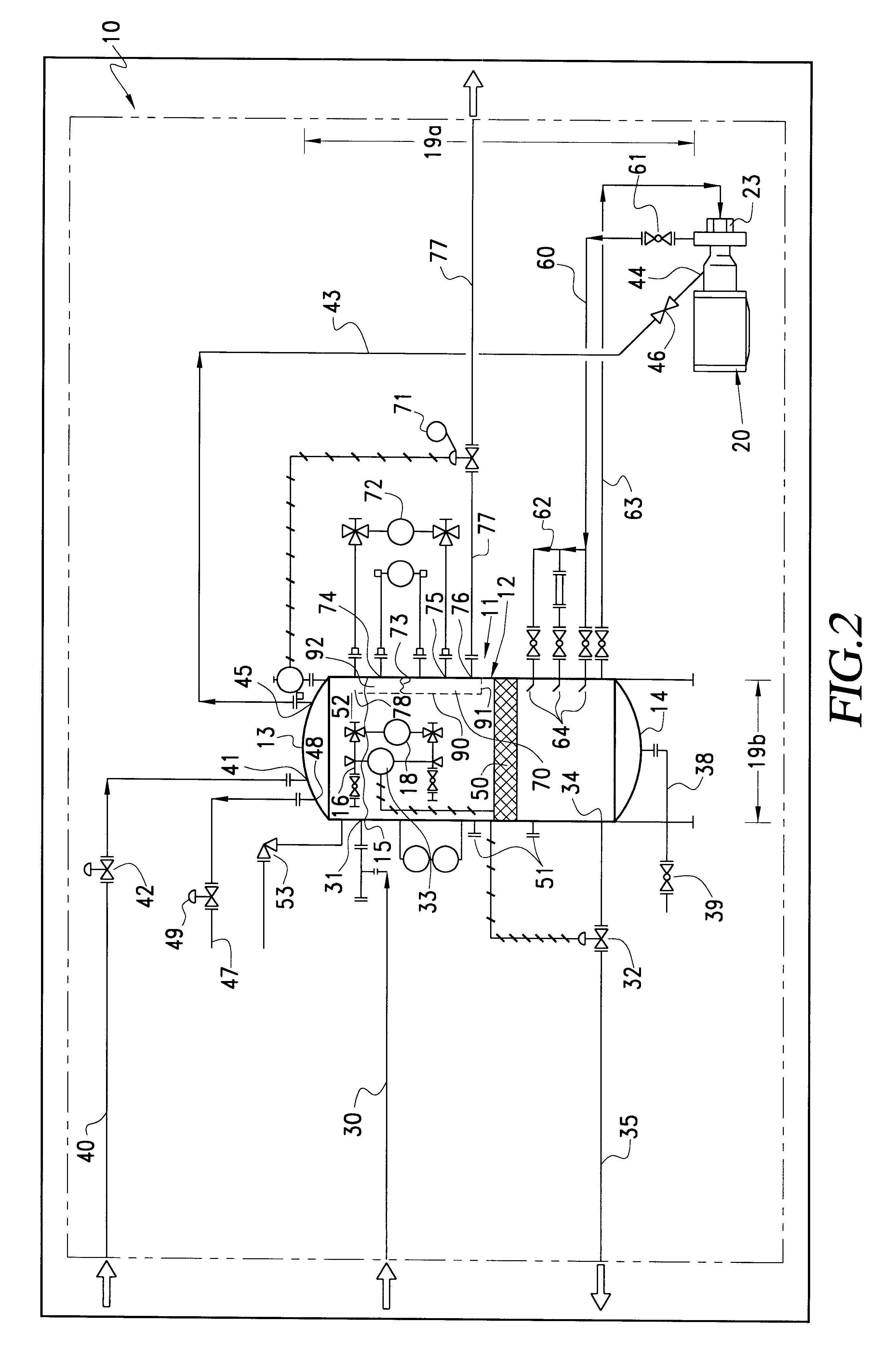

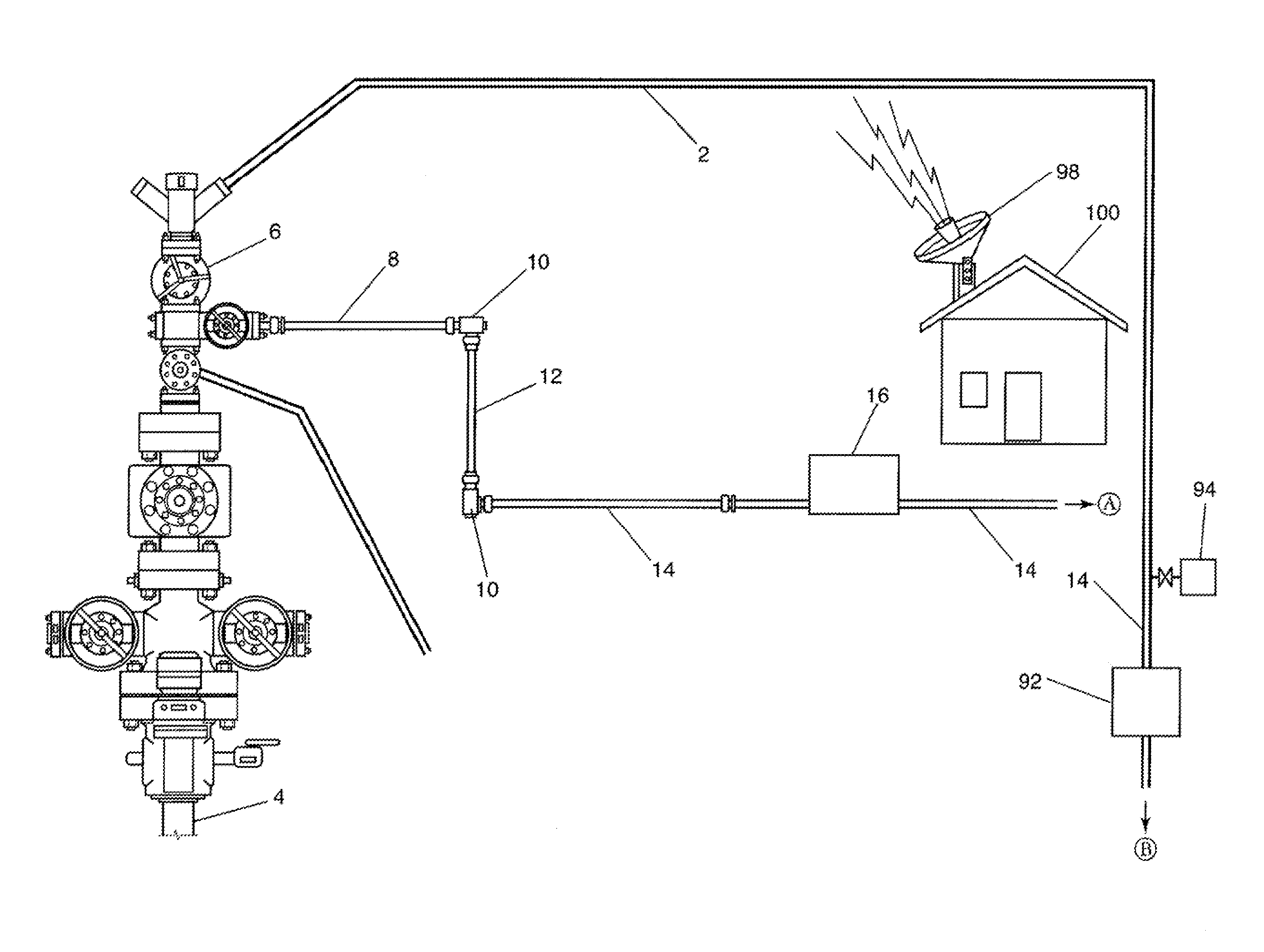

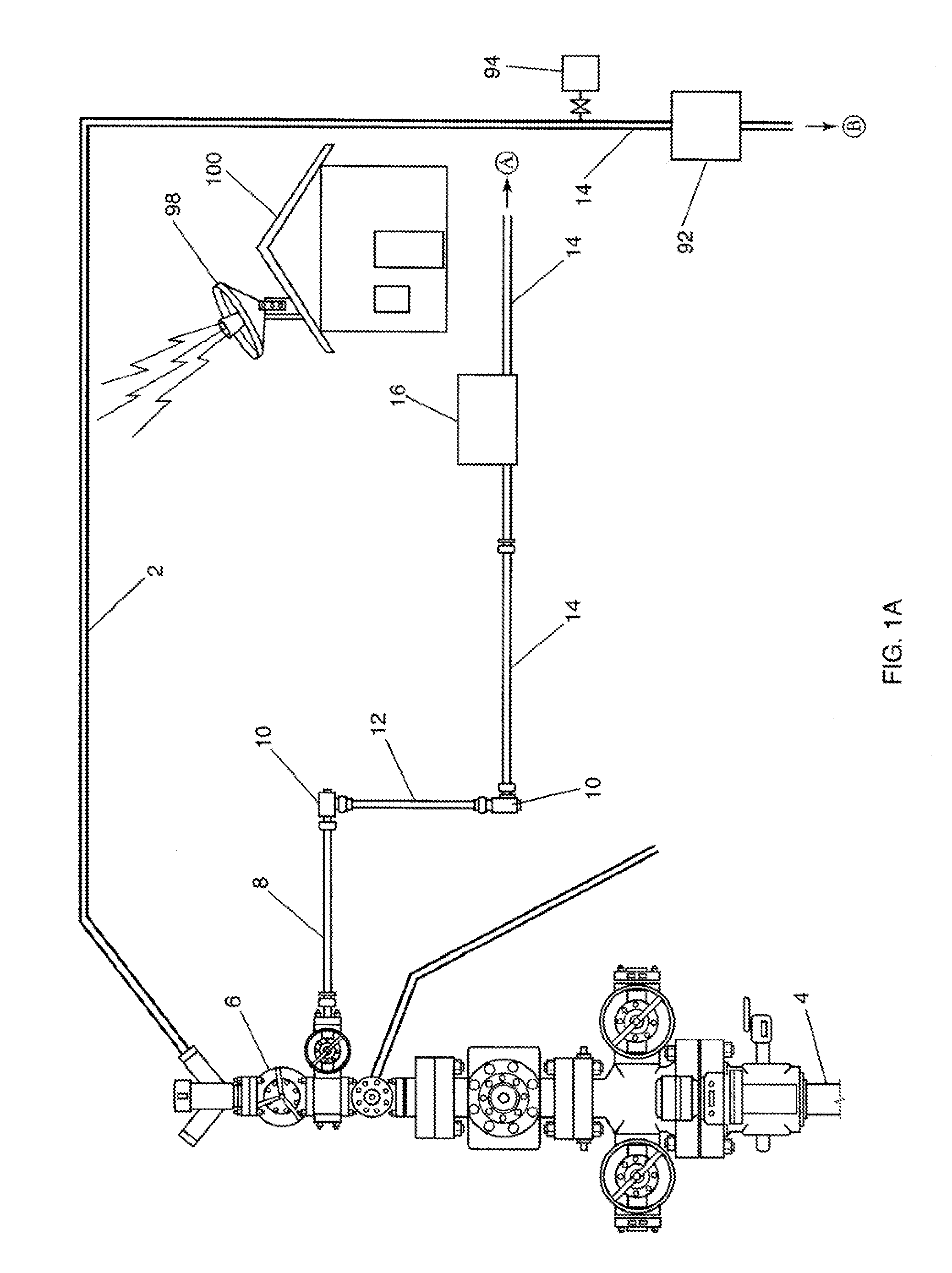

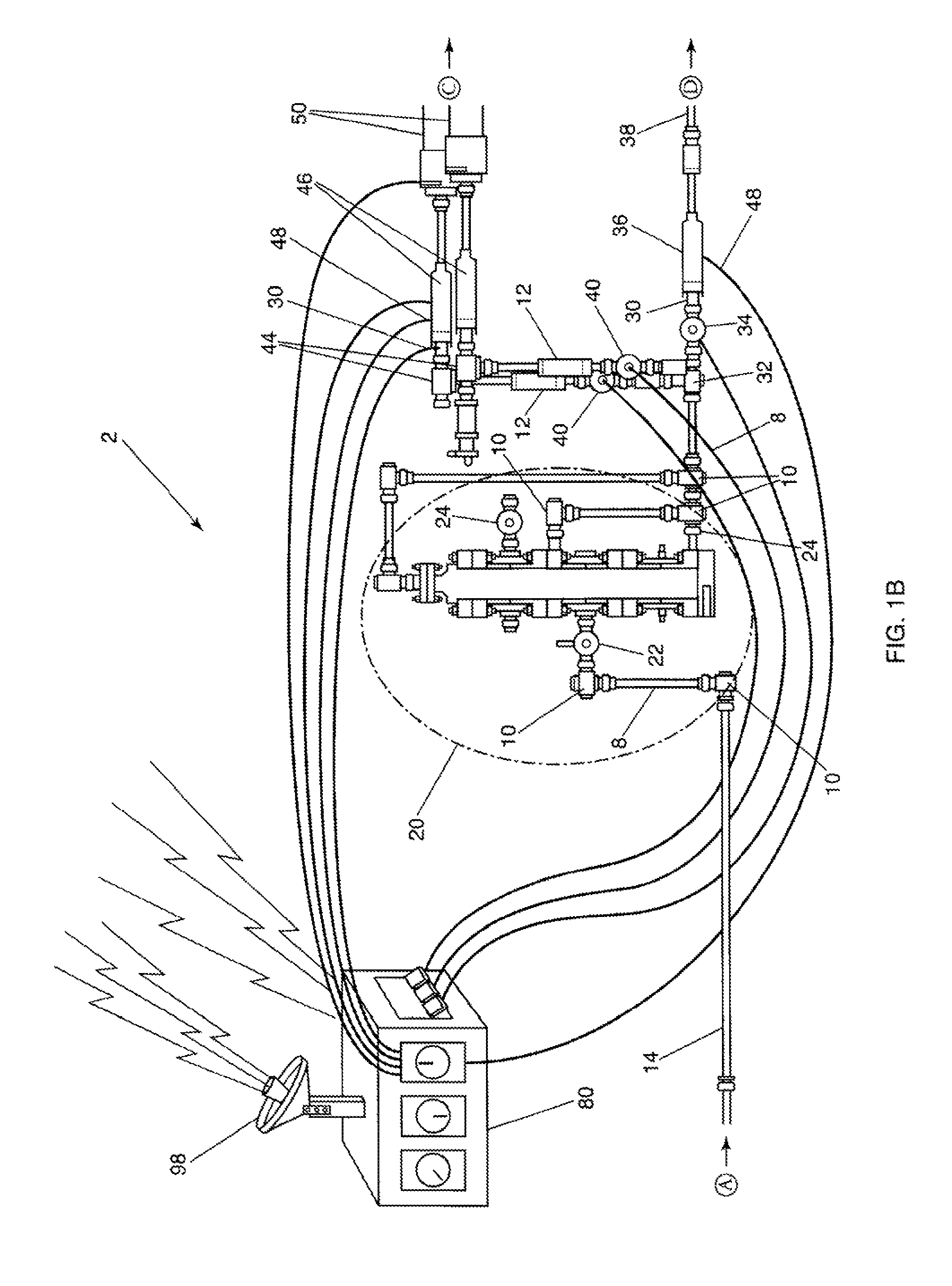

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

System and method for degassing molten metal

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

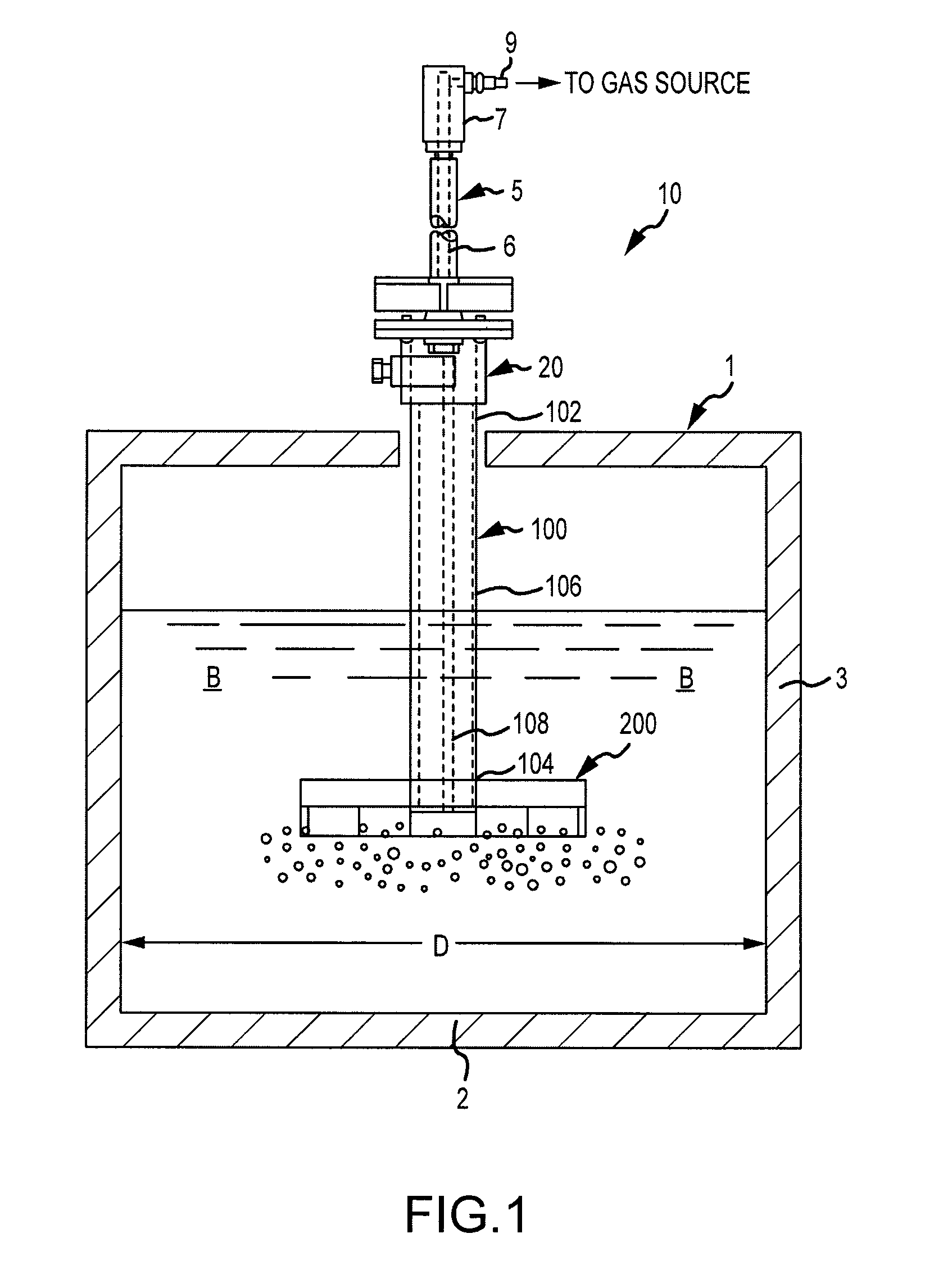

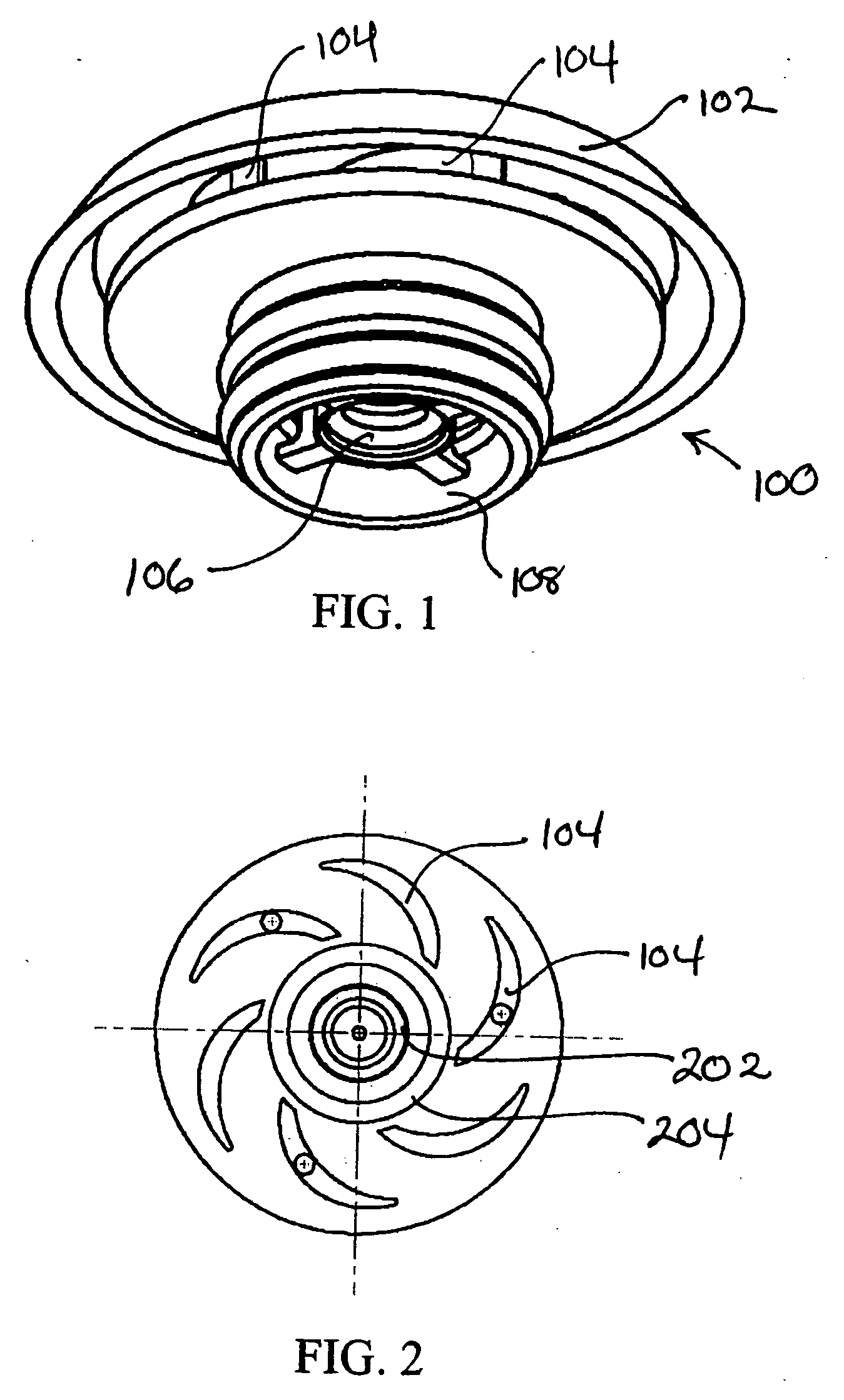

Rotary degasser and rotor therefor

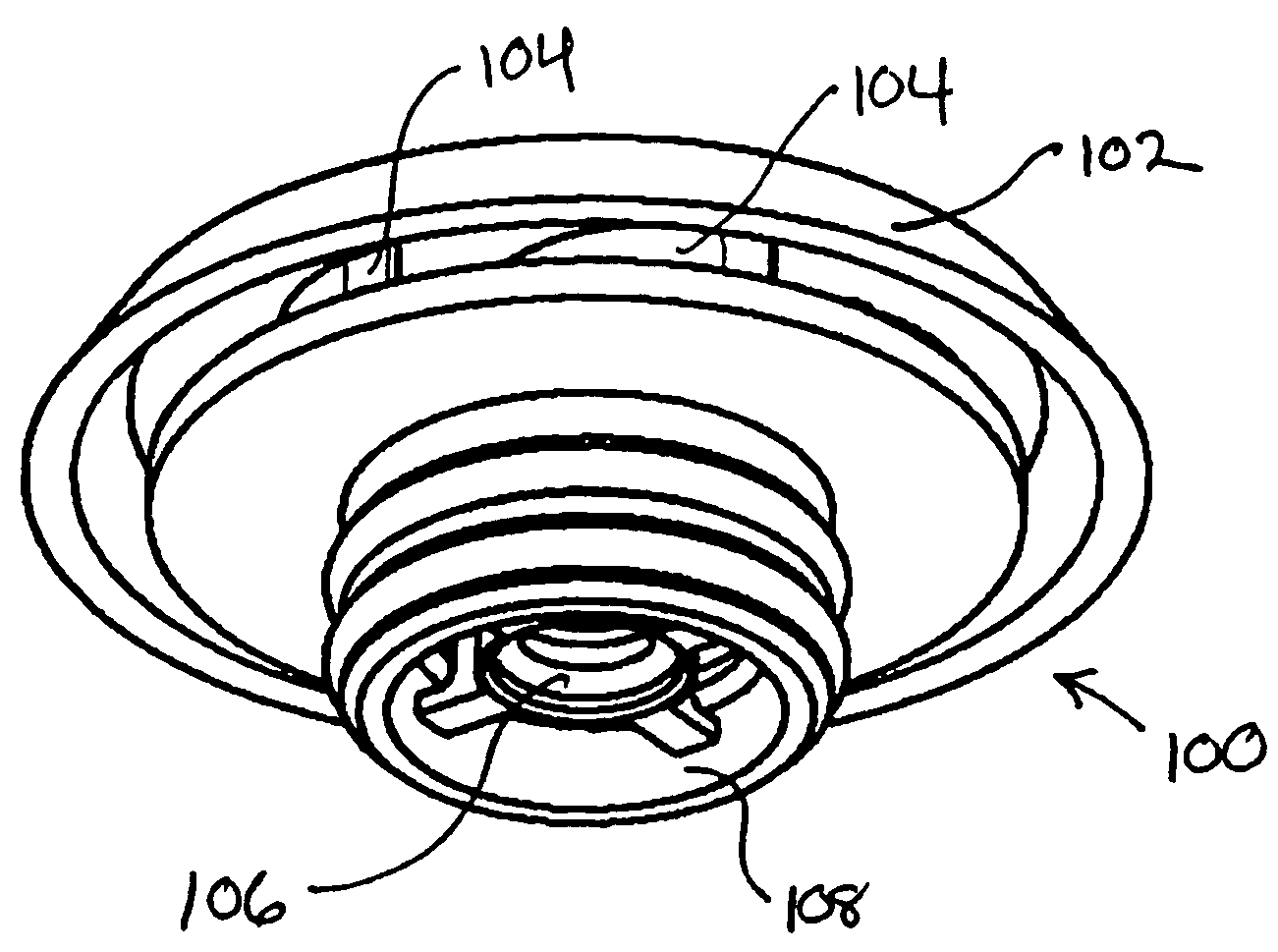

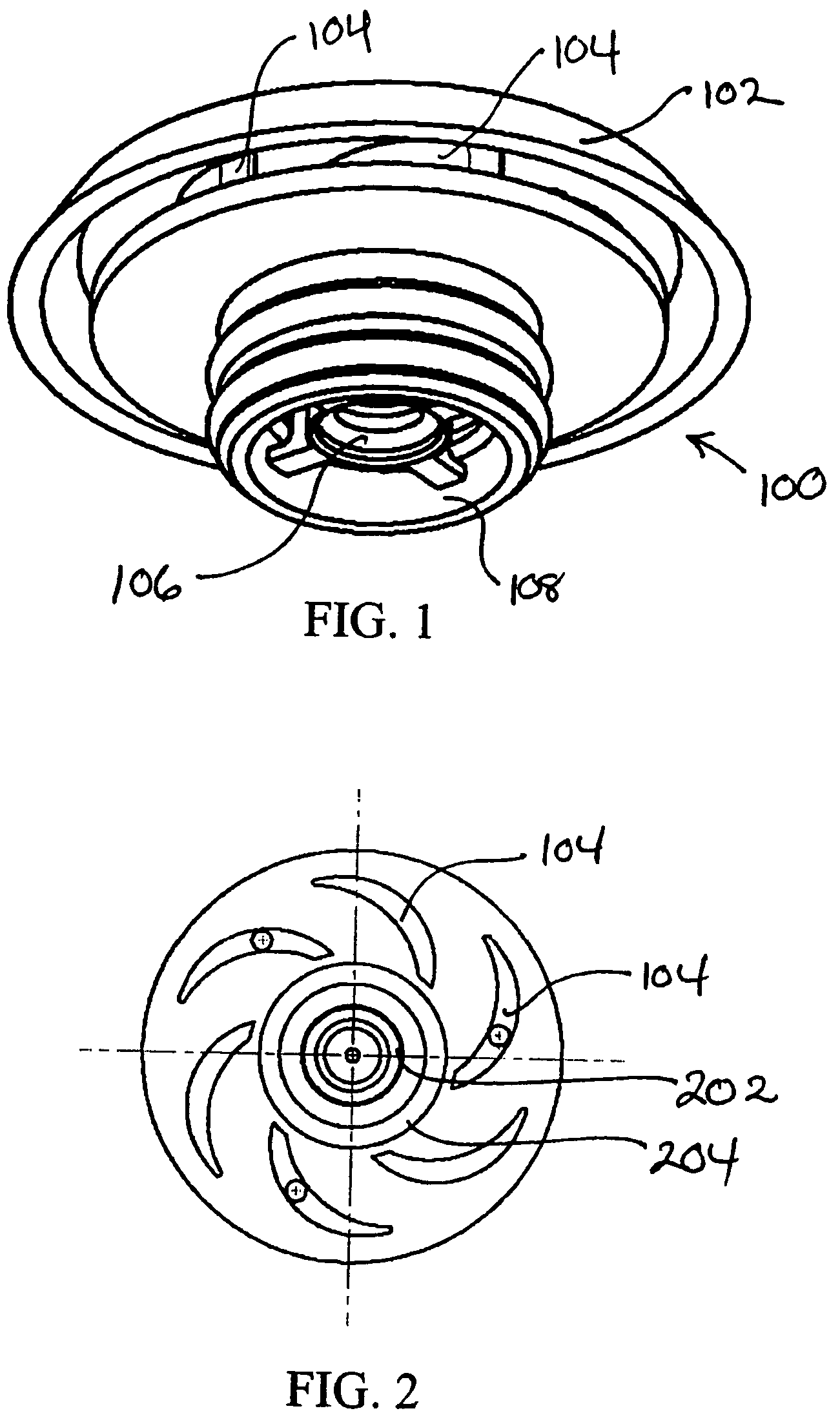

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Process for producing capacitive electromechanical conversion device, and capacitive electromechanical conversion device

InactiveUS20110084570A1Poor bondingBeacon systems using ultrasonic/sonic/infrasonic wavesWave amplification devicesBond interfaceEngineering

A process for producing a capacitive electromechanical conversion device by bonding together a substrate and a membrane member to form a cavity sealed between the substrate and the membrane member, the process for producing a capacitive electromechanical conversion device comprises the steps of: providing a gas release path penetrating from a bonded interface between the substrate and the membrane member to the outside, and forming the cavity by bonding the membrane member with the substrate with the gas release path provided; the gas release path being provided at a location where the path does not communicate with the cavity.

Owner:CANON KK

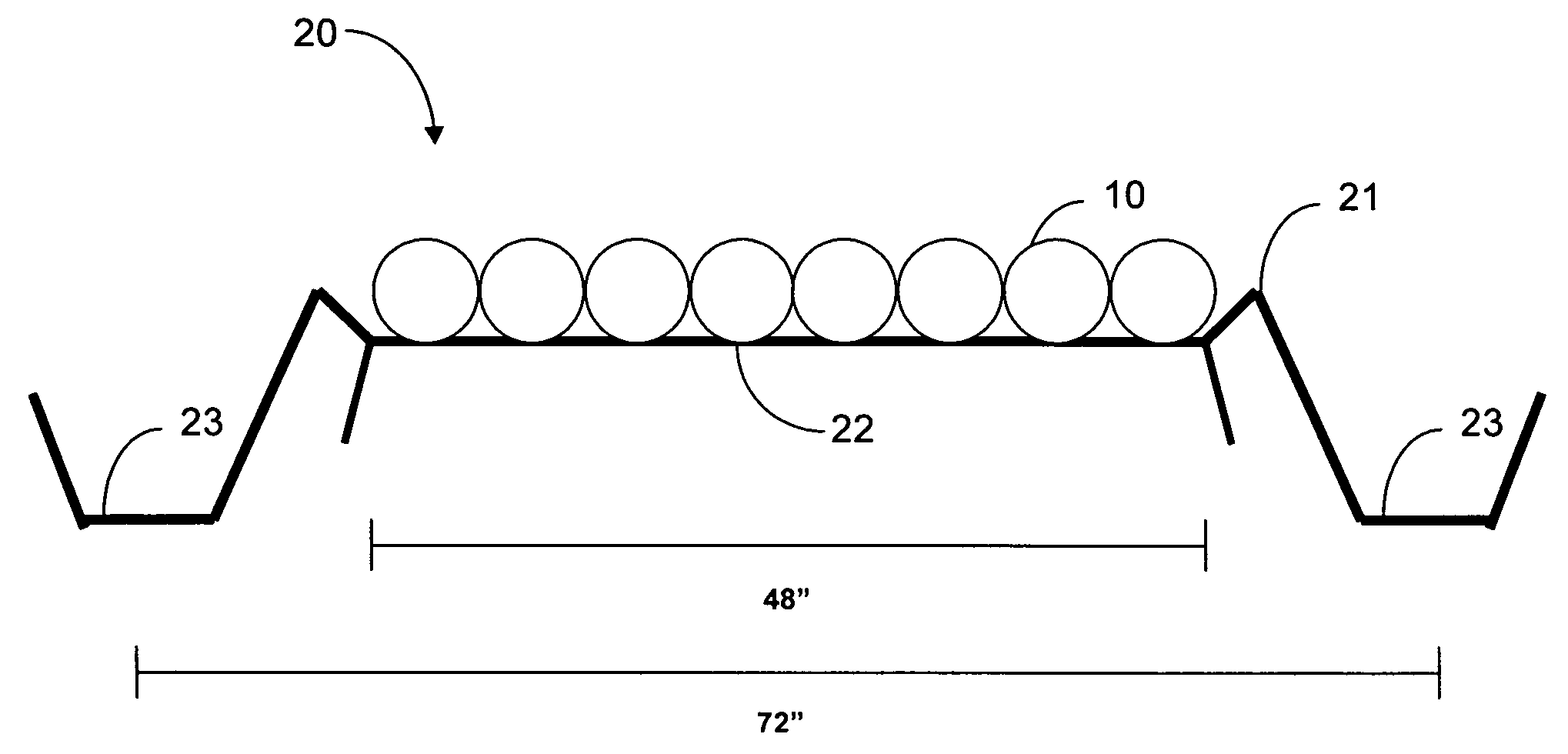

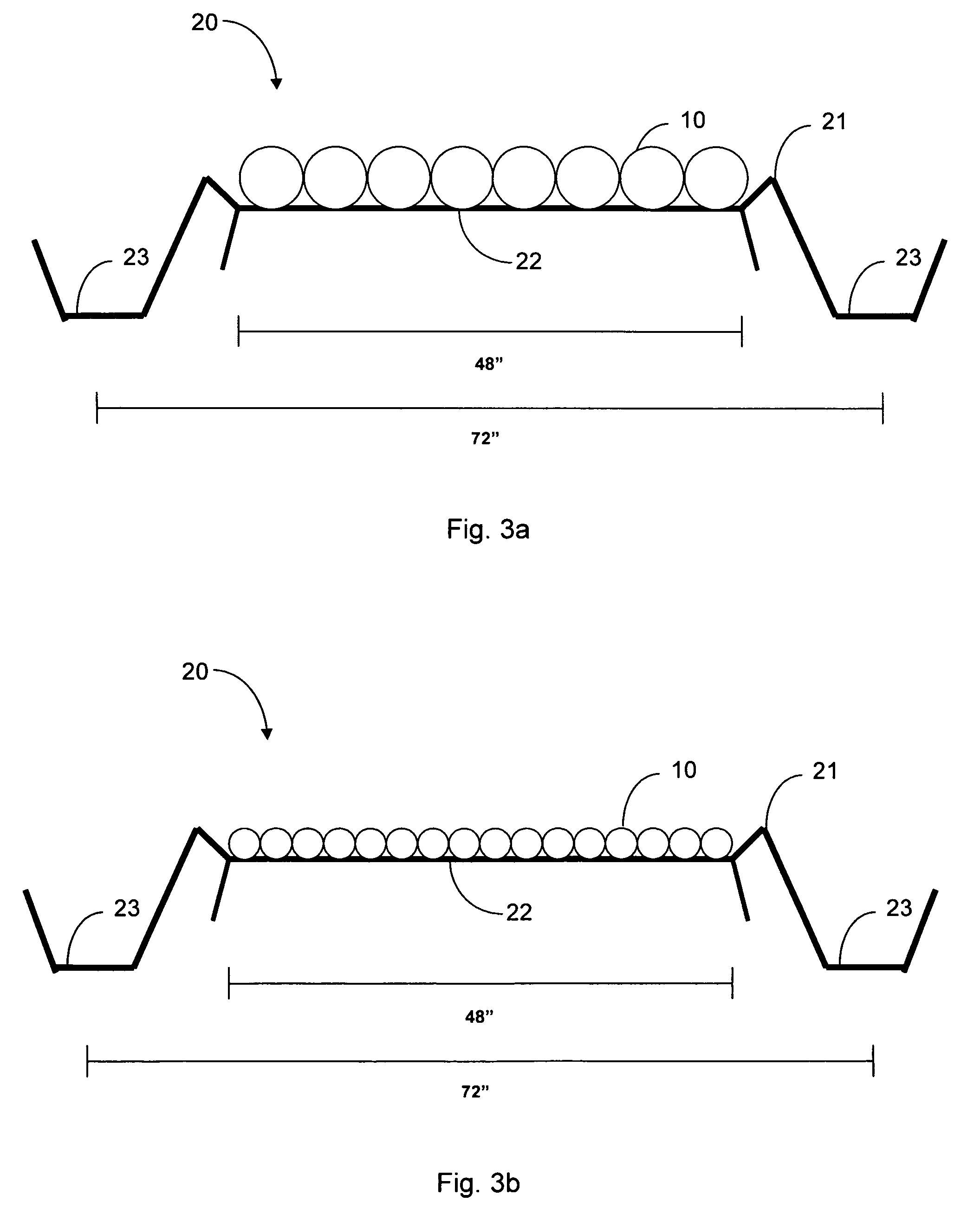

Pressurized flexible tubing system for producing Algae

InactiveUS20080311649A1Bioreactor/fermenter combinationsBiological substance pretreatmentsNuclear engineeringPlastic mulch

An apparatus for producing algae circulates algae fluid through flexible reactor tubing that is at least partially translucent to sunlight. The reactor tubing lies flat when not pressurized. Preferably, the reactor tubing is made of clear polyethylene with UV inhibitors, the polyethylene being between 6 and 15 mil thick. The reactor tubing preferably has a substantially circular cross-section with a 6 inch diameter and is preferably 1250 feet long. Gas relief valves allow gases generated during algae production to escape from the reactor tubing. CO2 may be injected into the algae fluid to stimulate photosynthesis. A circulation pump propels the algae fluid through the reactor tubing, keeping the reactor tubing pressurized and stationary without touching the reactor tubing, so that a rigid support structure is not needed. One or more layers of plastic mulch may be disposed above or below the reactor tubing to control temperature and sunlight exposure.

Owner:XL RENEWABLES

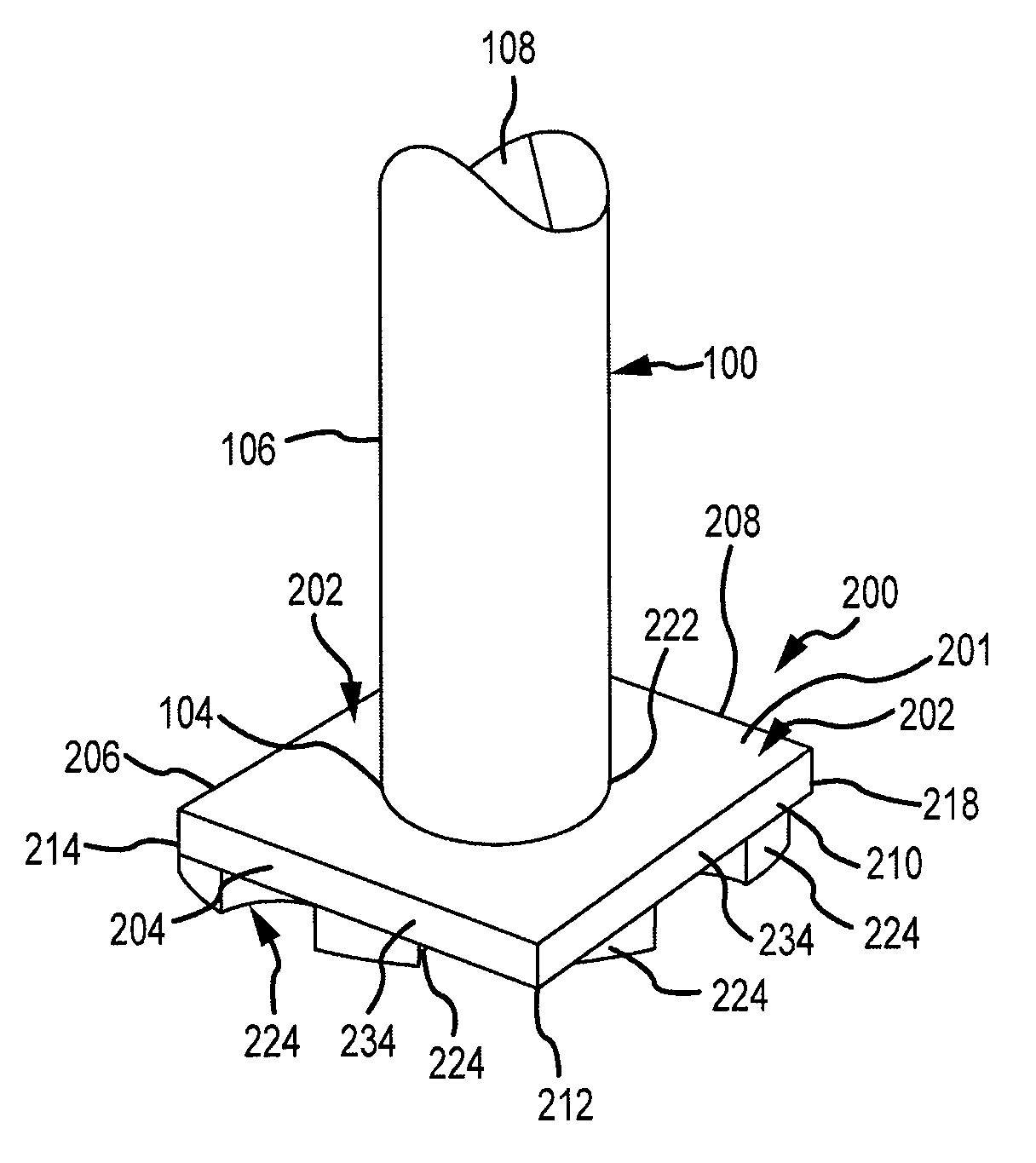

Gas transfer foot

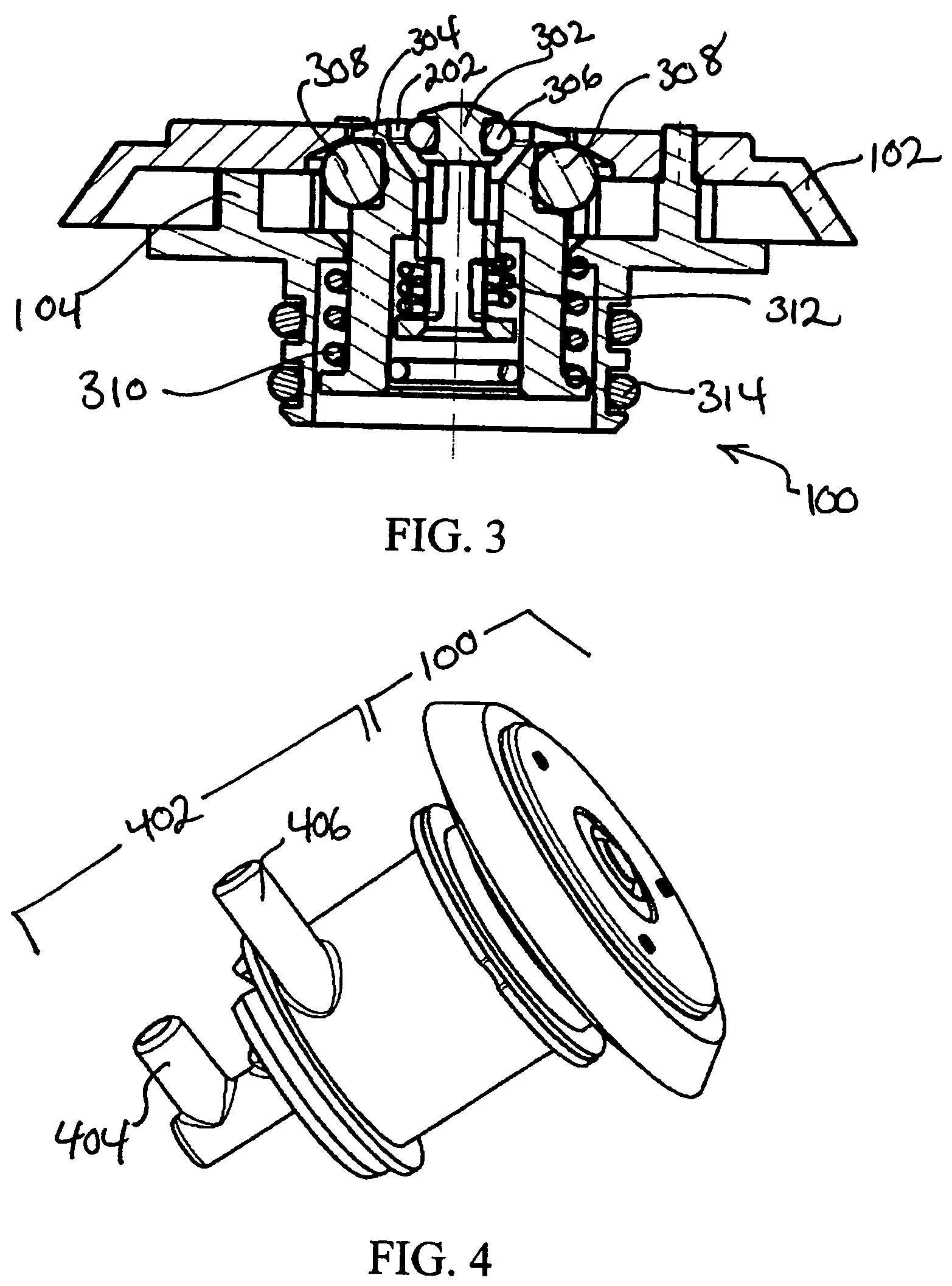

InactiveUS20090269191A1Specific fluid pumpsRotary non-positive displacement pumpsProduct gasEngineering

The present invention includes a molten metal pump and associated components that enable gas to be released into a stream of molten metal. The gas may be released into the molten metal stream (preferably into the bottom of the stream) flowing through a passage. Such a stream may be within the pump discharge and / or within a metal-transfer conduit extending from the pump discharge. The gas is released by using a gas-transfer foot that is positioned next to and is preferably attachable to the pump base or to the metal-transfer conduit. Preferably, the conduit (and / or discharge) in which the gas is released comprises two sections: a first section having a first cross-sectional area and a second section downstream of the first section and having a second cross-sectional area, wherein the second cross sectional area is larger than the first cross-sectional area. Preferably, the gas is released into or near the second section so that the gas is released into an area of relatively lower pressure.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

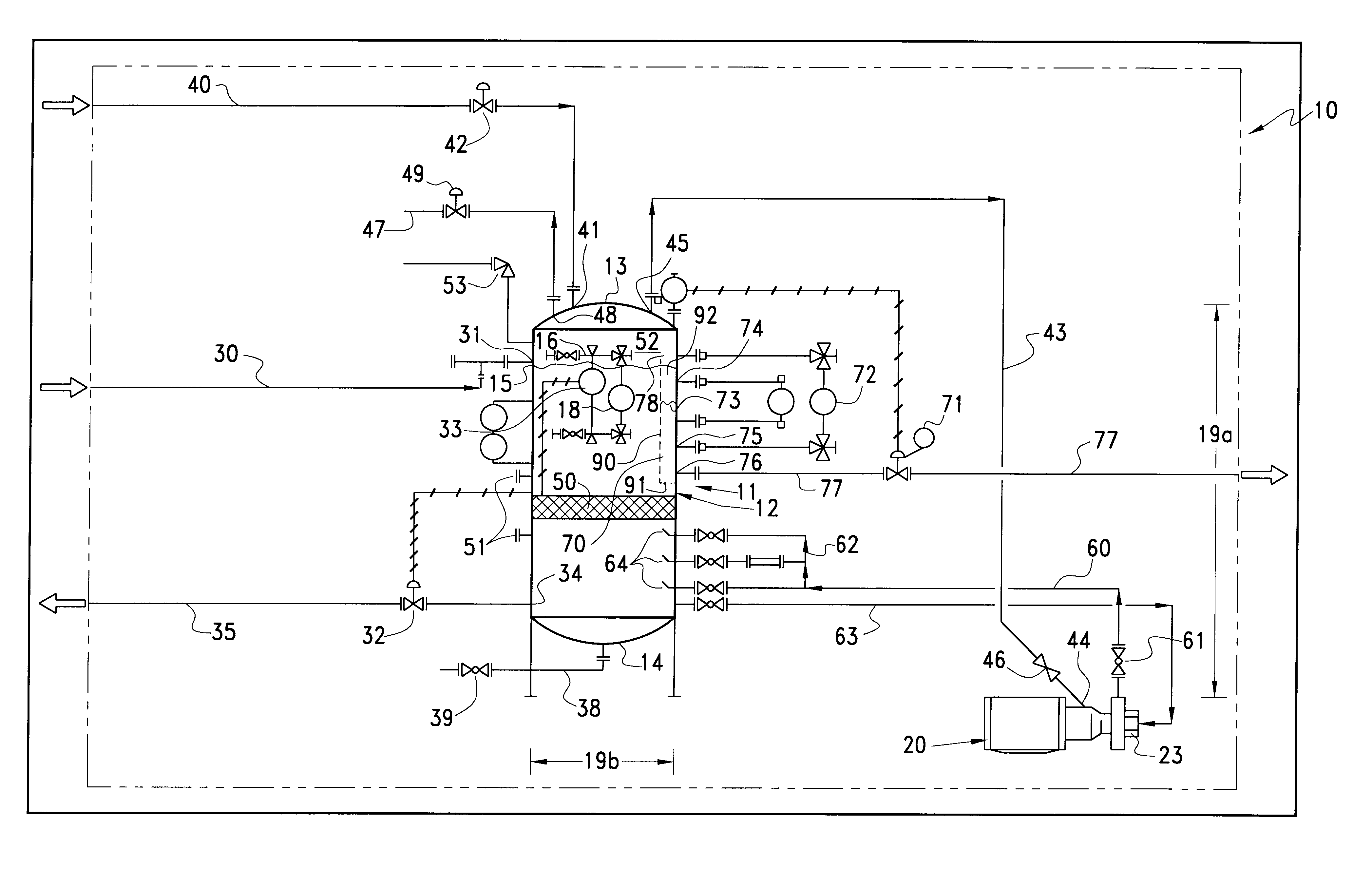

Flotation apparatus for clarifying produced water

InactiveUS6337023B1Fast oil separationWiden meansLiquid separation auxillary apparatusSettling tanks feed/dischargeDissolved gas flotationEngineering

A dissolved gas flotation apparatus and process for removing oils and other contaminants from produced water generated in the production of crude petroleum and natural gas. The invention is particularly designed for offshore applications, where space is limited and natural gas is readily available. The invention includes a vessel for receiving and maintaining a liquid level therein and a circulating pump for introducing tiny flotation gas bubbles into the vessel. Natural gas is used as a blanket gas for the vessel and as a source of gas fed into the pump, wherein the gas is mixed with the pumped liquid. The liquid / gas mixture is transferred into the vessel, wherein the gas releases from the liquid, thereby forming tiny, finely dispersed gas bubbles. The tiny gas bubbles rise vertically through the vessel and attach themselves to the oil and other contaminants suspended in the liquid and buoyantly transport the oil and other contaminants to the top of the vessel, where the gas is released and either recycled back to the recirculating pump or transferred out of the vessel for further processing, and the oil and other contaminants are collected in a reservoir for recovery. The clarified water is removed from the vessel through a liquid outlet line located near the bottom of the vessel.

Owner:SIEMENS ENERGY INC

Rotary degasser and rotor therefor

ActiveUS20140008849A1Efficiently circulatedWell mixedStirring devicesBlade accessoriesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Sanitization system and system components

InactiveUS7767168B2Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

Automated closed loop flowback and separation system

InactiveUS8424599B2Realize automatic adjustmentSurveyDrilling rodsHuman–machine interfaceAutomatic control

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

Method and apparatus for supercharging downhole sample tanks

A tank contains both Zeolite and a hydrate in a gas chamber formed beneath a piston in the sample tank. Out of safety considerations, we avoid using source cylinders of nitrogen whose pressures exceed 4000 psi. Thus, the gas chamber of the sample tank is initially pressurized by the source cylinder to no more than 4000 psi of nitrogen at room temperature at the surface. Nitrogen gas is sorbed onto the zeolite at room temperature. As the tank is heated by being lowered downhole, nitrogen desorbs from the zeolite and the gas pressure increases. However, once this tank reaches a temperature high enough to release the hydrate's water of hydration, the released water is preferentially sorbed by zeolite, displacing sorbed nitrogen, and causing the pressure in the gas volume to increase even further. Because well temperatures are not high enough to desorb water from zeolite, any water sorbed onto a Zeolite sorption site will permanently block released nitrogen from resorbing at that site. The process of lowering the tank downhole provides the necessary heating to make the entire process occur. Thus, if returned to the surface at room temperature with the original gas-chamber volume, the tank's pressure would not fall back to the original pressure (e.g., 4000 psi) but would be at a substantially higher pressure (e.g., 6000 psi or more depending on the amount of Zeolite used and gaseous nitrogen gas released).

Owner:BAKER HUGHES INC

System for releasing gas into molten metal

InactiveUS20080211147A1Reduce amountIncrease the cross-sectional areaMelt-holding vesselsSpecific fluid pumpsMetallurgyProduct gas

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

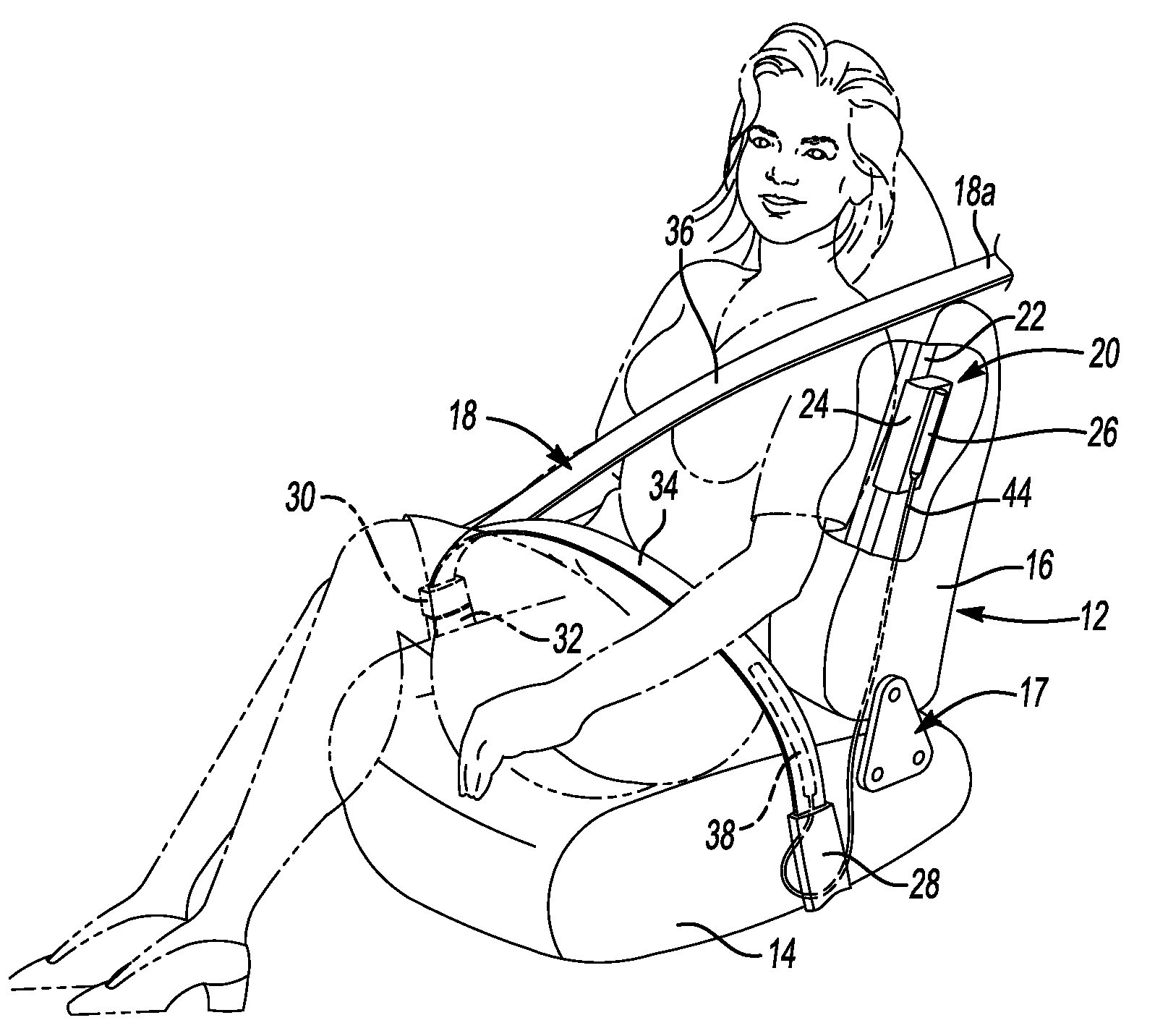

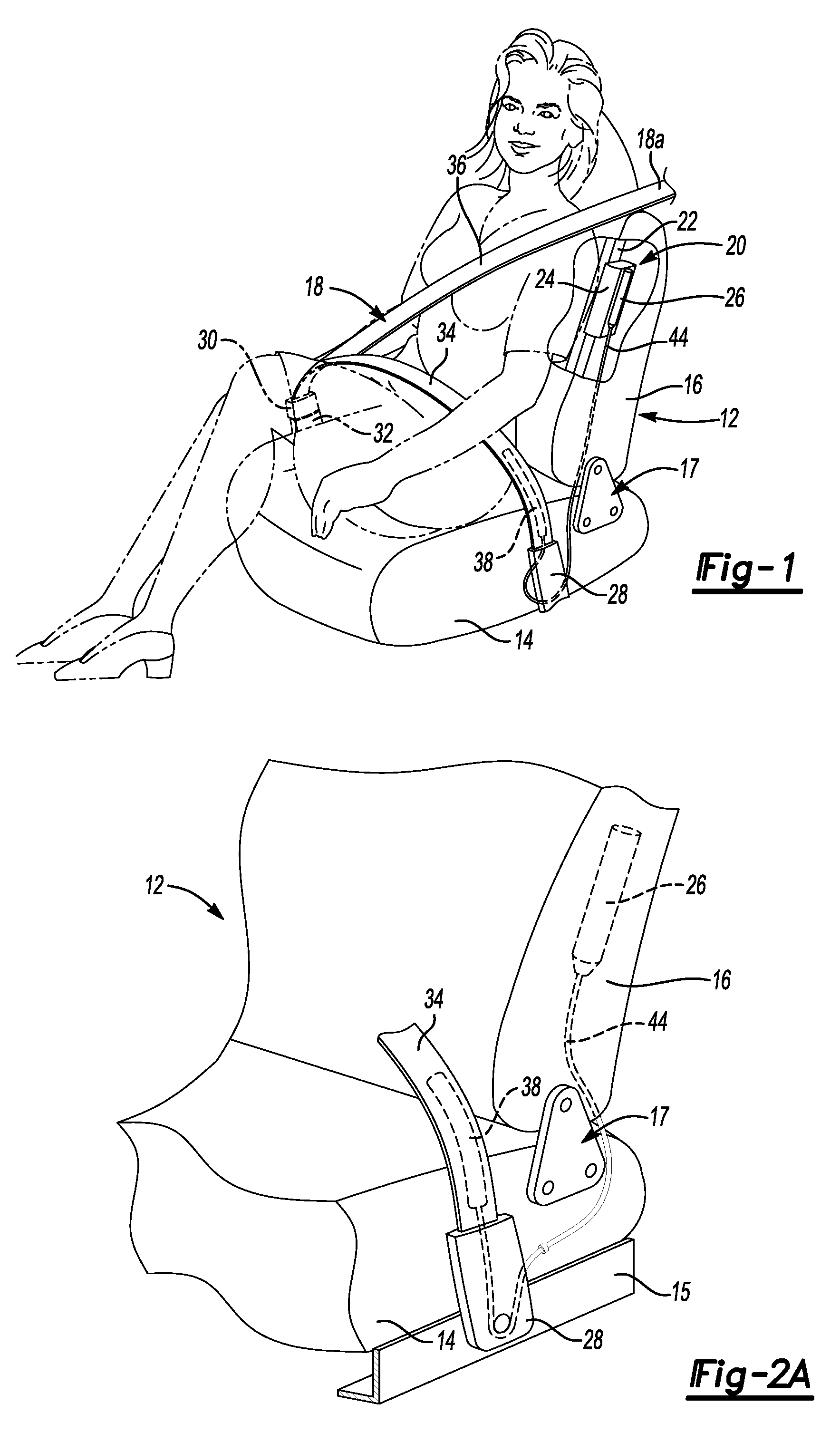

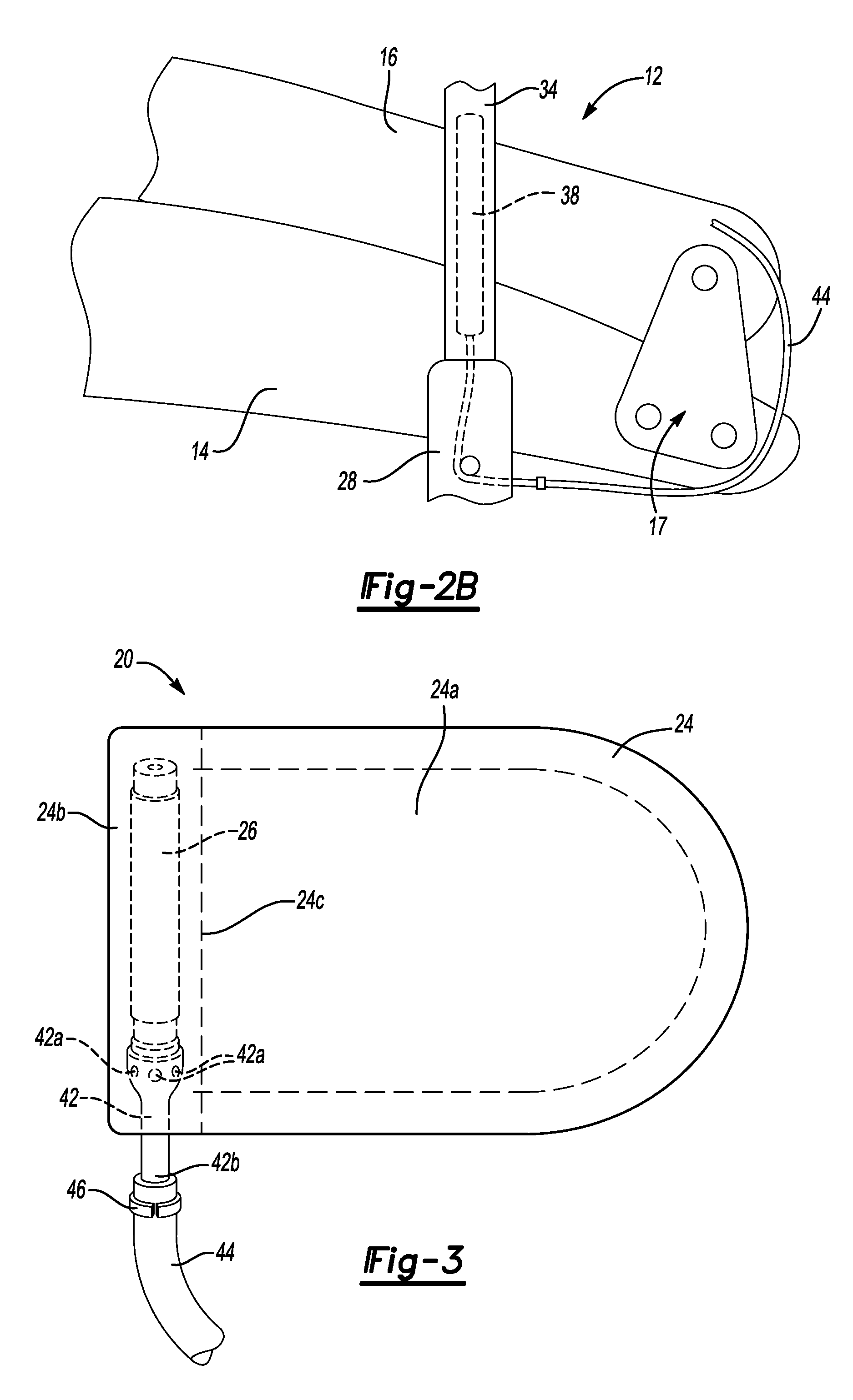

Integrated side airbag and inflatable belt

ActiveUS7677598B1Easy to assembleSimplifies design and constructionPedestrian/occupant safety arrangementLateral airbagBack rests

A vehicle seat and integrated side impact protection system includes a seat bottom, a seat back movably attached to the seat bottom, and a fold-flat mechanism within a lower portion of the seat back for permitting movement of the seat back between a seating configuration and a fold-flat configuration. An airbag module is located within an upper portion of the seat back adjacent the outboard side thereof and includes a side airbag and an inflator supplying inflation gasses. A lap belt extends between inboard and outboard sides of the seat and has an inflatable portion adjacent the outboard side of the seat. A gas conduit extends between the airbag module and the lap belt for conducting gasses released by the inflator to the inflatable portion of the lap belt. The gas conduit has a flexible portion permitting folding movement of the seat back.

Owner:FORD GLOBAL TECH LLC

Low-resistance and high-strength ion exchange membrane for chlor-alkali industry and preparation method of low-resistance and high-strength ion exchange membrane

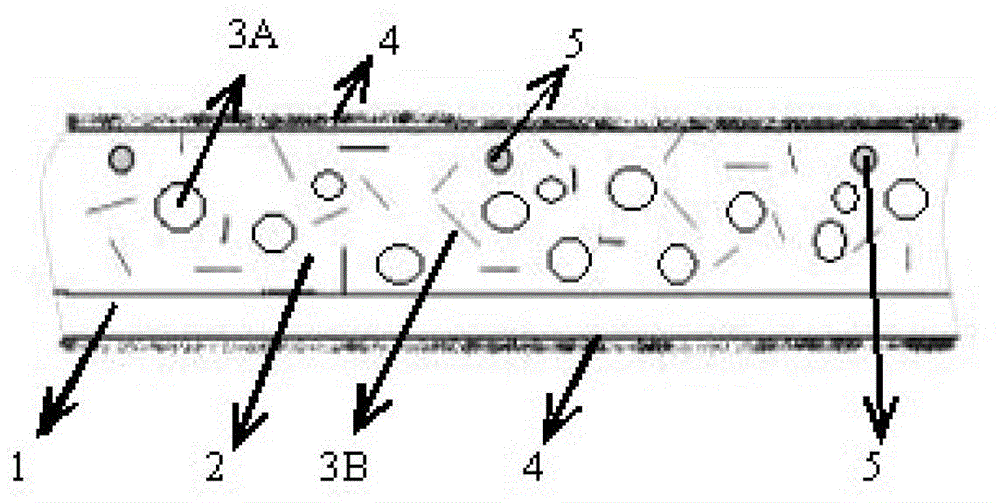

ActiveCN102978654AHigh mechanical strengthAvoid formingOrganic diaphragmsPhysical chemistryIon-exchange membranes

The invention relates to a low-resistance and high-strength ion exchange membrane for the chlor-alkali industry and a preparation method of the low-resistance and high-strength ion exchange membrane. The low-resistance and high-strength ion exchange membrane is a multi-layer composite membrane comprising a perfluorosulfonic ion exchange resin layer, a perfluoropropionate ion exchange resin layer, reinforced screen cloth and gas release coatings, wherein the perfluorosulfonic ion exchange resin layer with the thickness of 80-150 micrometers and the perfluoropropionate ion exchange resin layer with the thickness of 8-12 micrometers form a perfluorosulfonic ion exchange resin base membrane, the gas release coatings with 3-12 micrometers are arranged on two outer side surfaces of the base membrane, the reinforced screen cloth is arranged in the perfluorosulfonic ion exchange resin layer, and the perfluorosulfonic ion exchange resin layer is also internally provided with a nano pore and a nano cavity. The low-resistance and high-strength ion exchange membrane can be prepared through a melt co-extruding or multi-layer hot-pressing compounding process, can be used in an ion exchange membrane in the chlor-alkali industry, and has good mechanical property and electrochemical performance.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

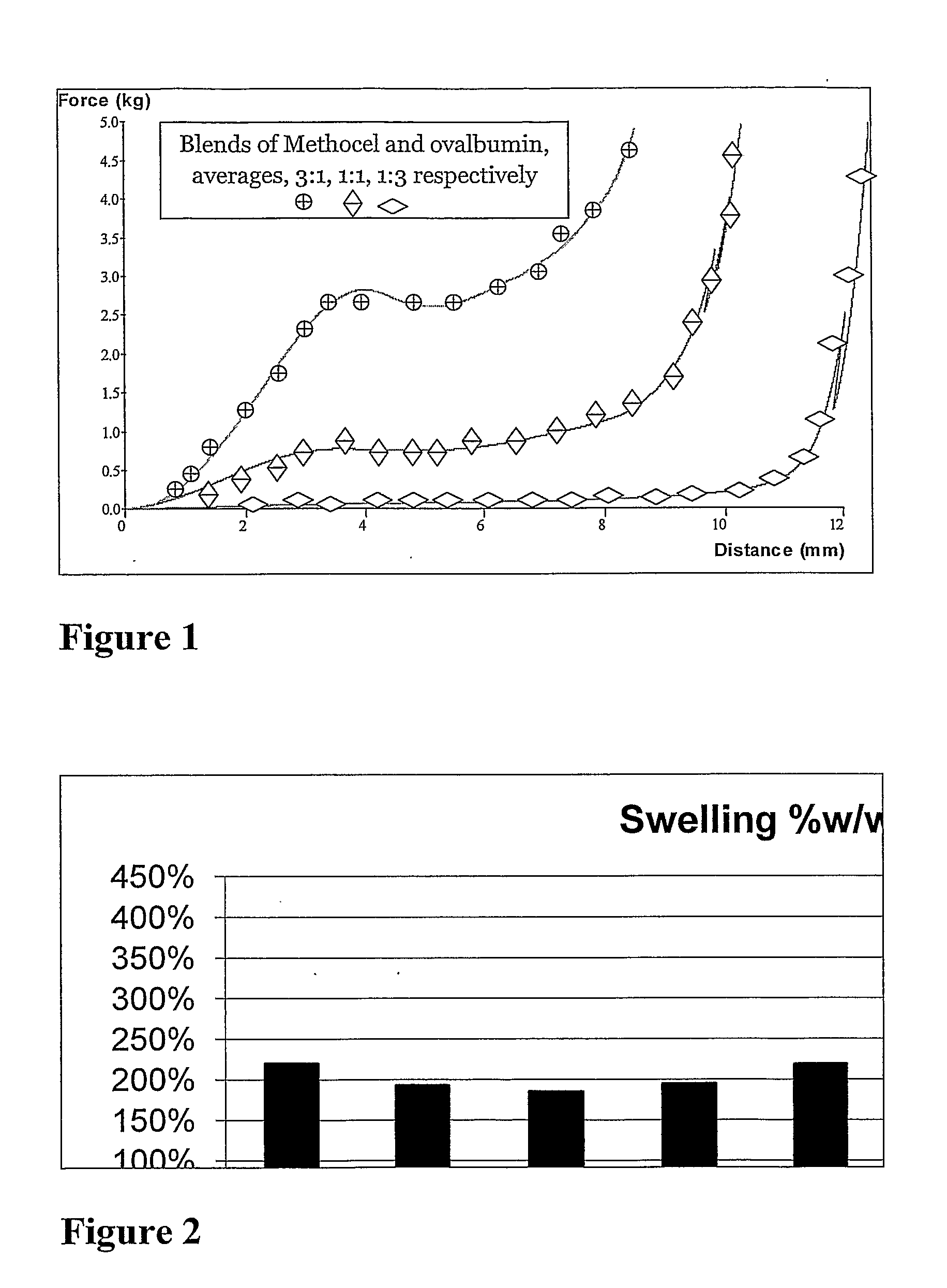

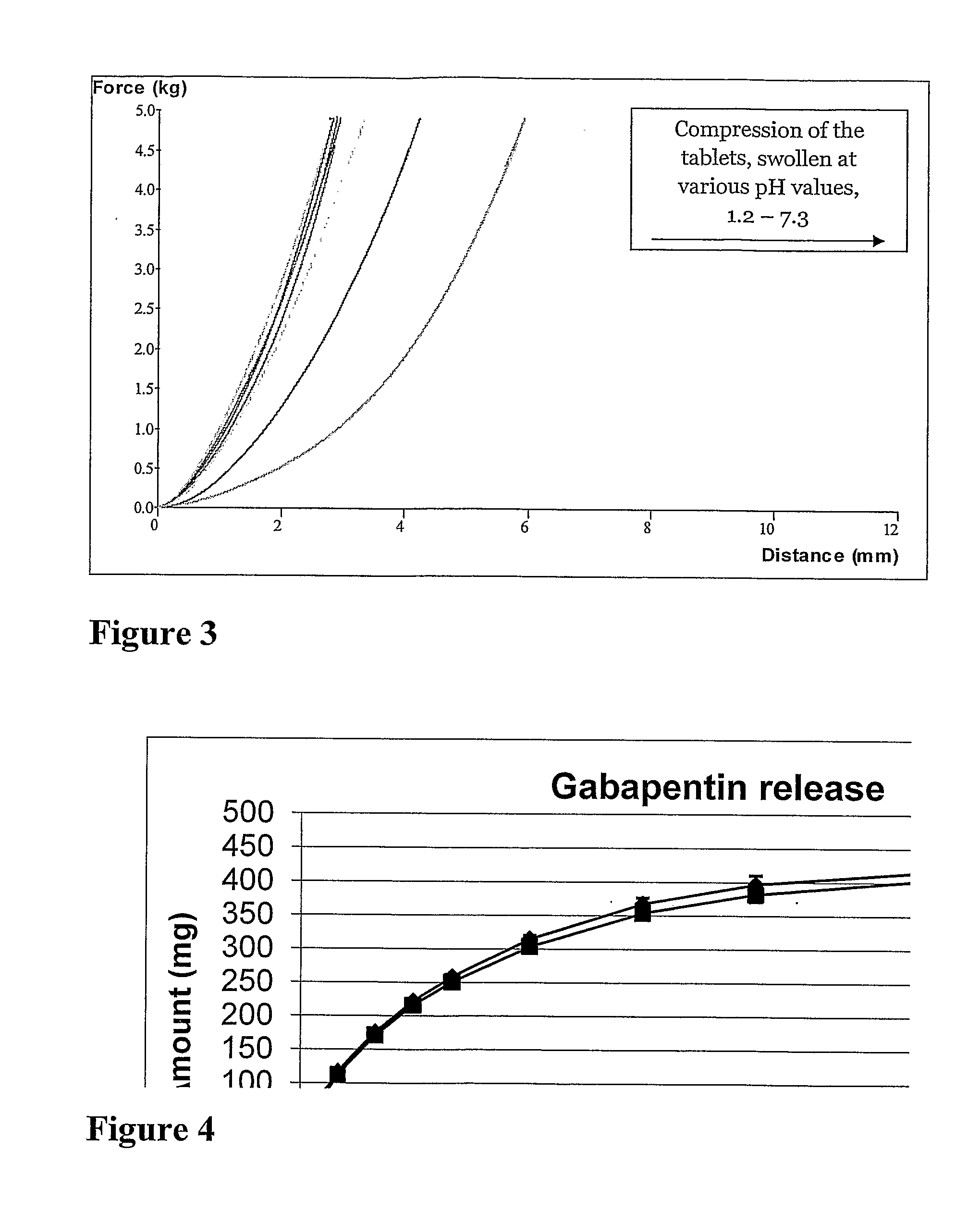

Novel gastroretentive delivery system

InactiveUS20110268666A1High mechanical strengthIncrease valueAntibacterial agentsBiocideAdditive ingredientGastric fluid

A novel gastroretentive delivery system comprising a tablet comprising a pharmaceutical ingredient or diagnostic, which tablet comprises a gas releasing ingredient or a tandem of two gas releasing ingredients, an ingredient capable of unrestricted swelling in gastric fluid, an ingredient capable of limiting the unrestricted swelling and a hardening ingredient. The said system is based on the use of three different gastroretentive mechanisms: flotation, swelling and mechanical strength, the three mechanisms acting in a complimentary way. Processes for manufacturing same and methods of treatment are also disclosed.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

Sanitization system and system components

InactiveUS20050017380A1Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

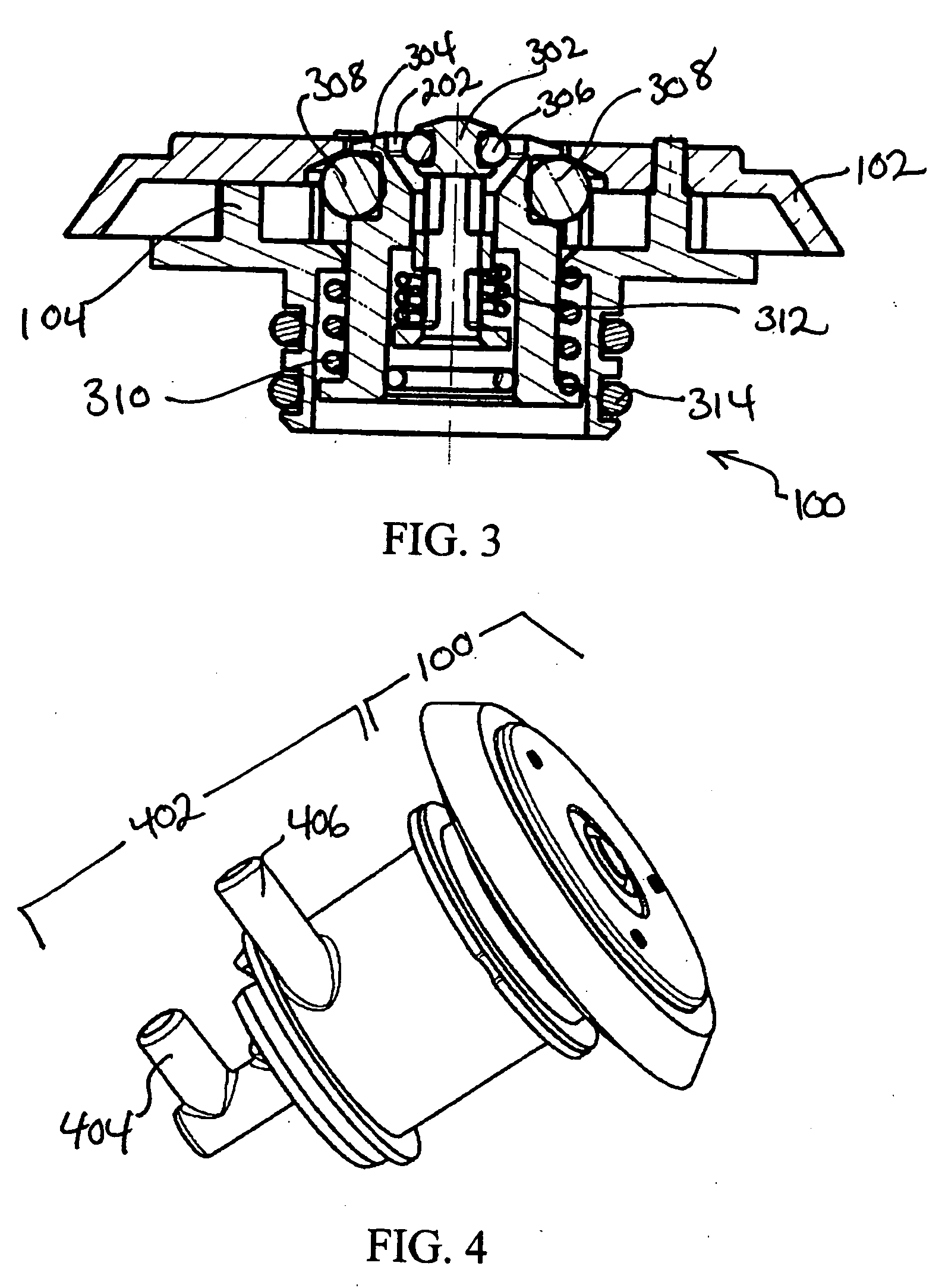

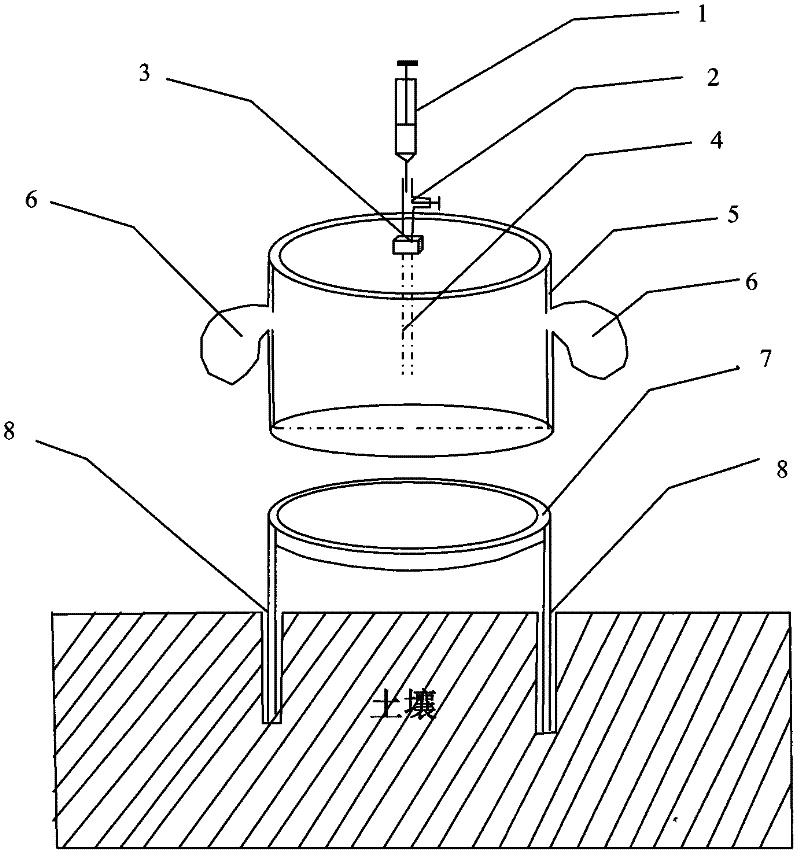

Buffer type soil gas sampling device

InactiveCN102252876APrevent air leakageGuaranteed reliabilityWithdrawing sample devicesGrasslandEngineering

The invention discloses a buffer type soil gas sampling device, belonging to the technical field of soil experimental facilities. The device consists of an injector, a valve, a gas-exhausting hole, a gas-exhausting conduit, a box body, gasbags, a water seal tank and a base. As the gasbags are additionally arranged on the box body, gas pressure inside / outside the box body during a whole storing and sampling process is always maintained in a balance state after the buffer adjustment of the gasbags, the box body is prevented from outward or inward gas leakage, and the quality of gas stored in the box body is maintained; meanwhile, the difficulty that natural release of soil gas is subjected to inhibition is also overcome, the reliability of measured data for gas released by soil is enhanced.The device has the advantages of reasonable design, simplicity for operating and low cost, and can be widely applied to gathering work for greenhouse gas emission in farmland, nudation, grassland andthe like.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

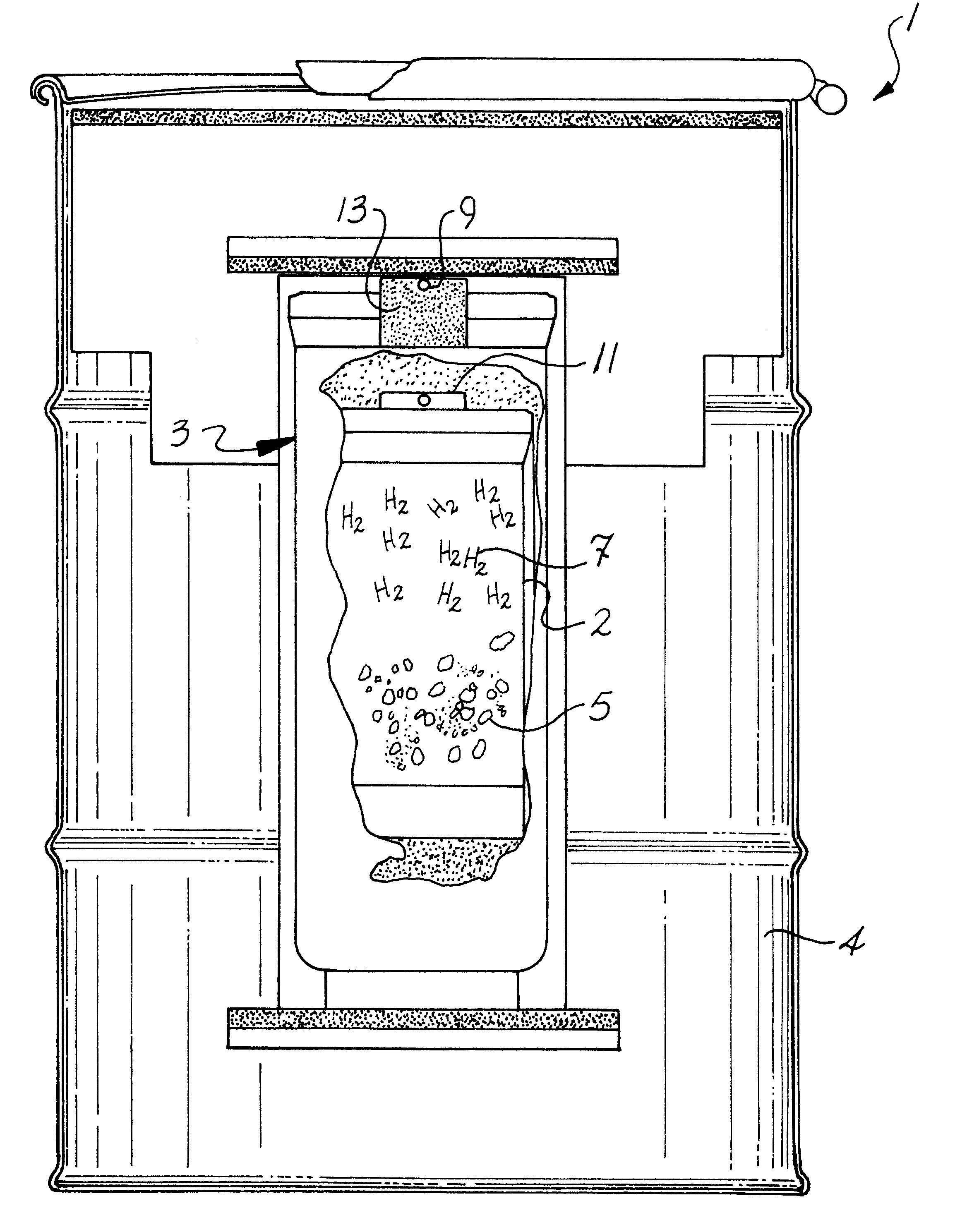

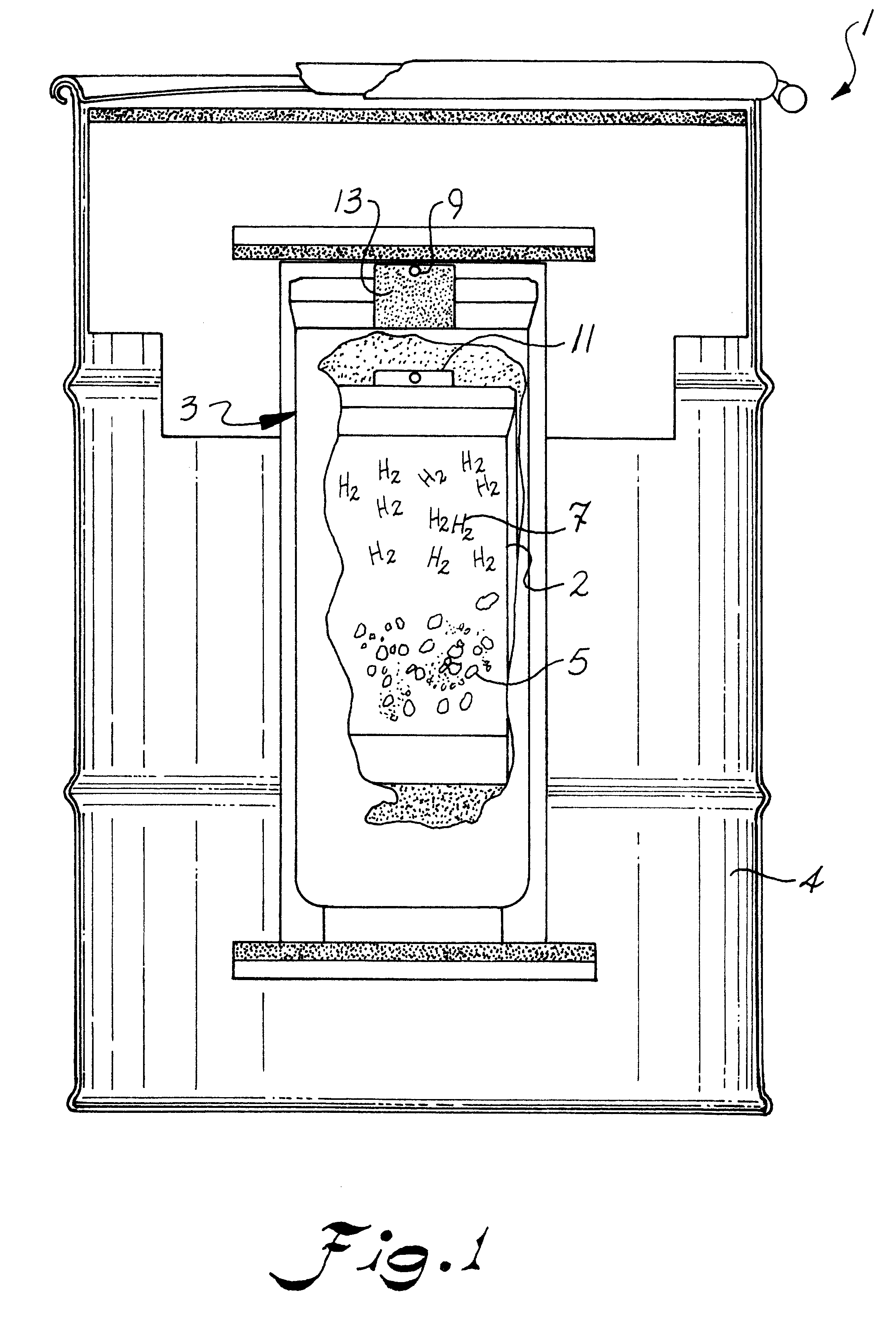

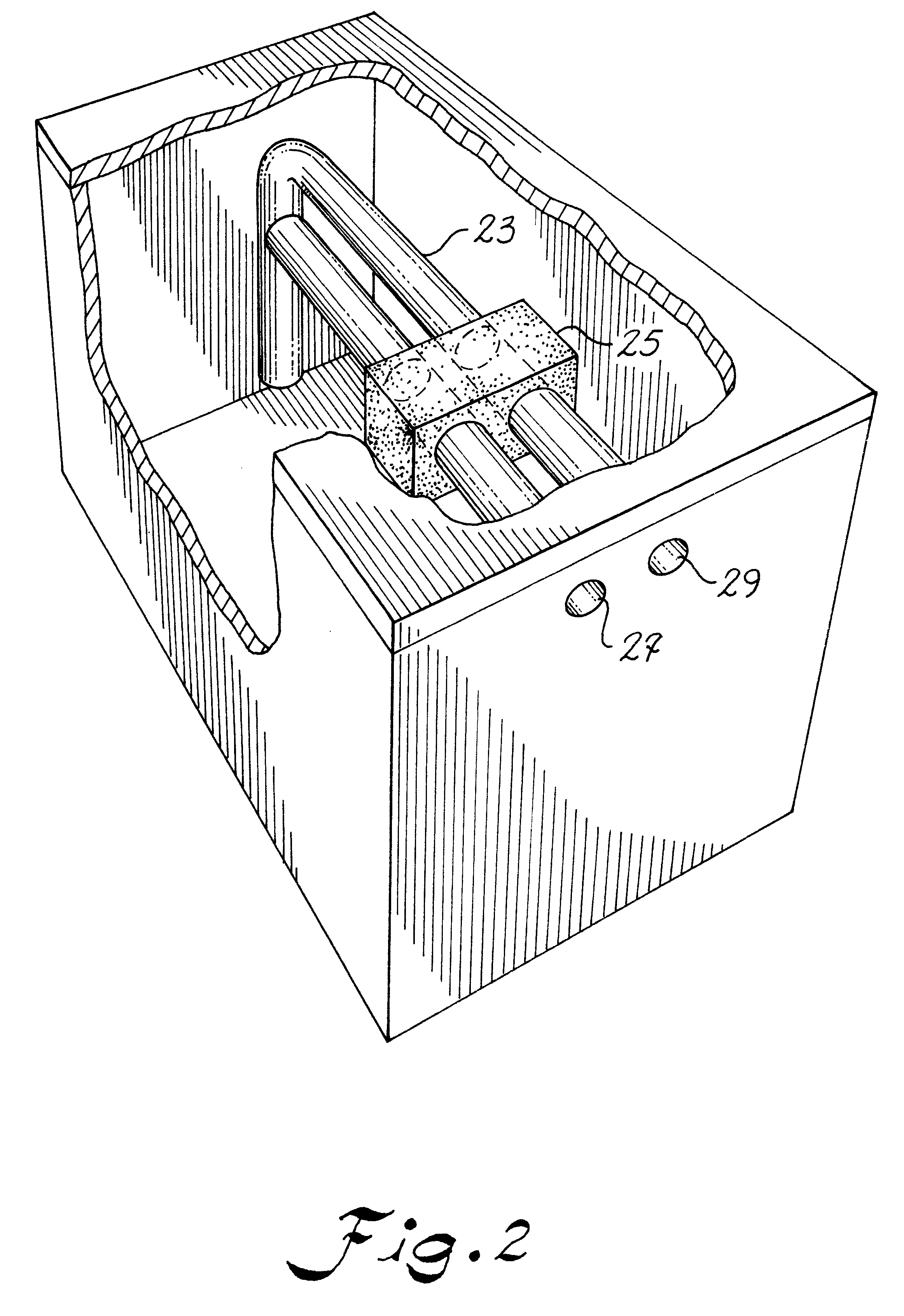

Container and method for absorbing and reducing hydrogen concentration

A method for absorbing hydrogen from an enclosed environment comprising providing a vessel; providing a hydrogen storage composition in communication with a vessel, the hydrogen storage composition further comprising a matrix defining a pore size which permits the passage of hydrogen gas while blocking the passage of gaseous poisons; placing a material within the vessel, the material evolving hydrogen gas; sealing the vessel; and absorbing the hydrogen gas released into the vessel by the hydrogen storage composition. A container for absorbing evolved hydrogen gas comprising: a vessel having an interior and adapted for receiving materials which release hydrogen gas; a hydrogen absorbing composition in communication with the interior, the composition defining a matrix surrounding a hydrogen absorber, the matrix permitting the passage of hydrogen gas while excluding gaseous poisons; wherein, when the vessel is sealed, hydrogen gas, which is released into the vessel interior, is absorbed by the hydrogen absorbing composition.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

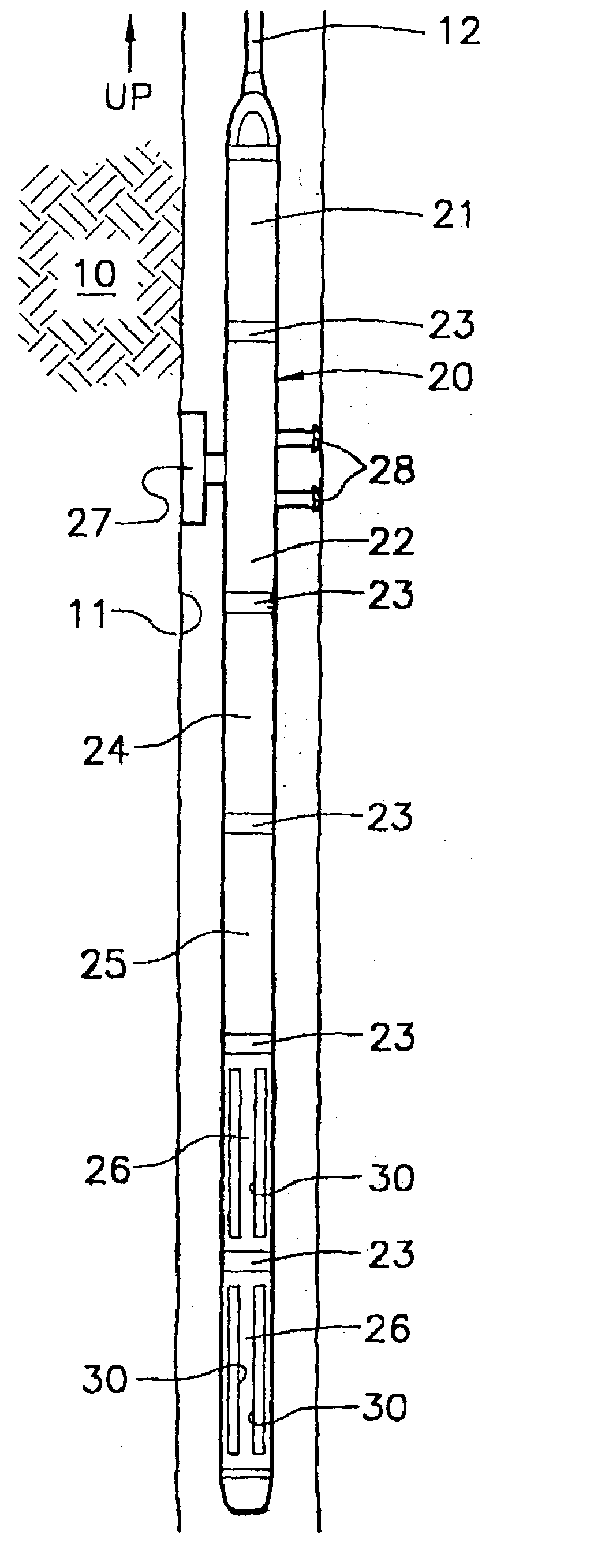

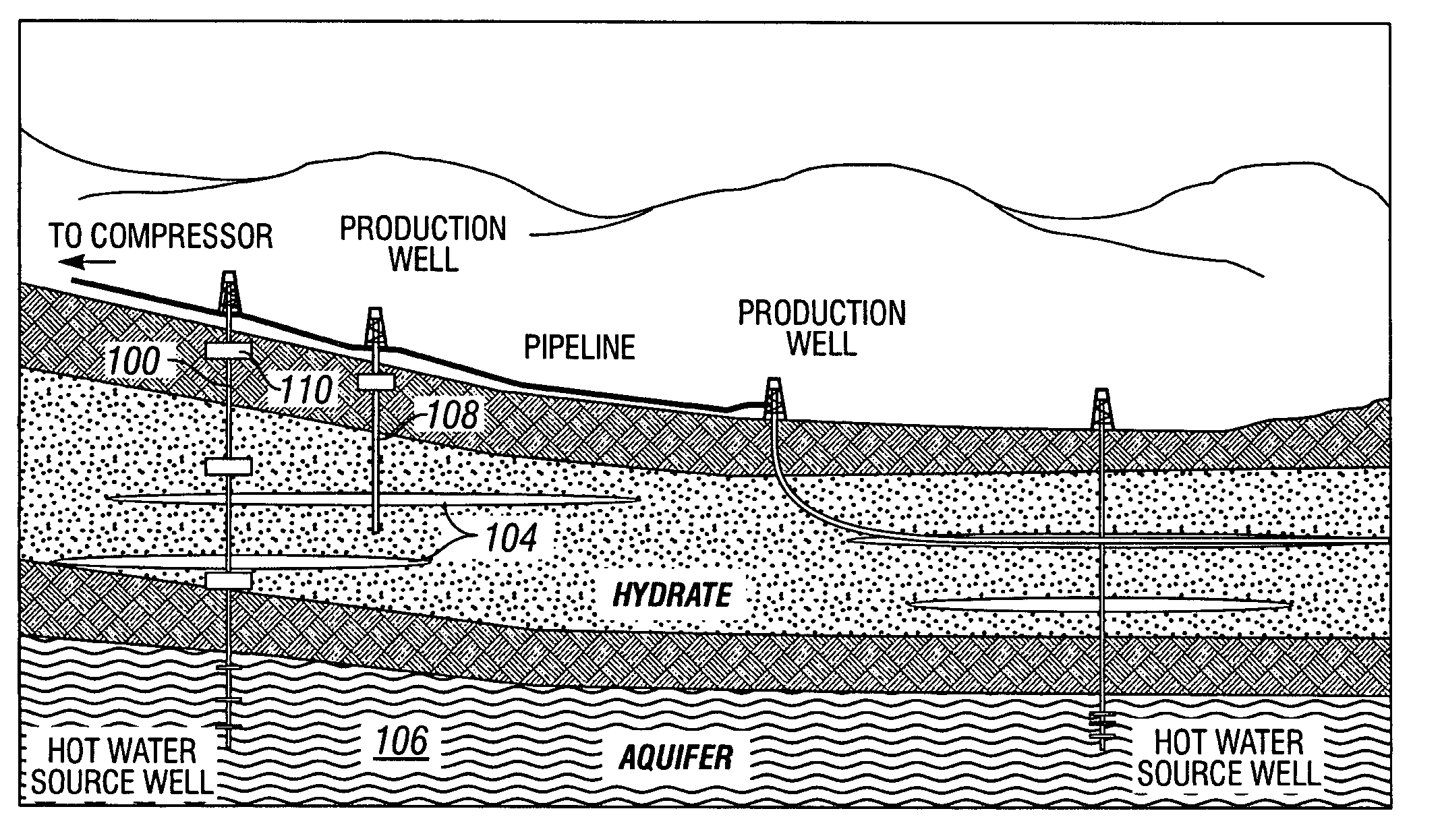

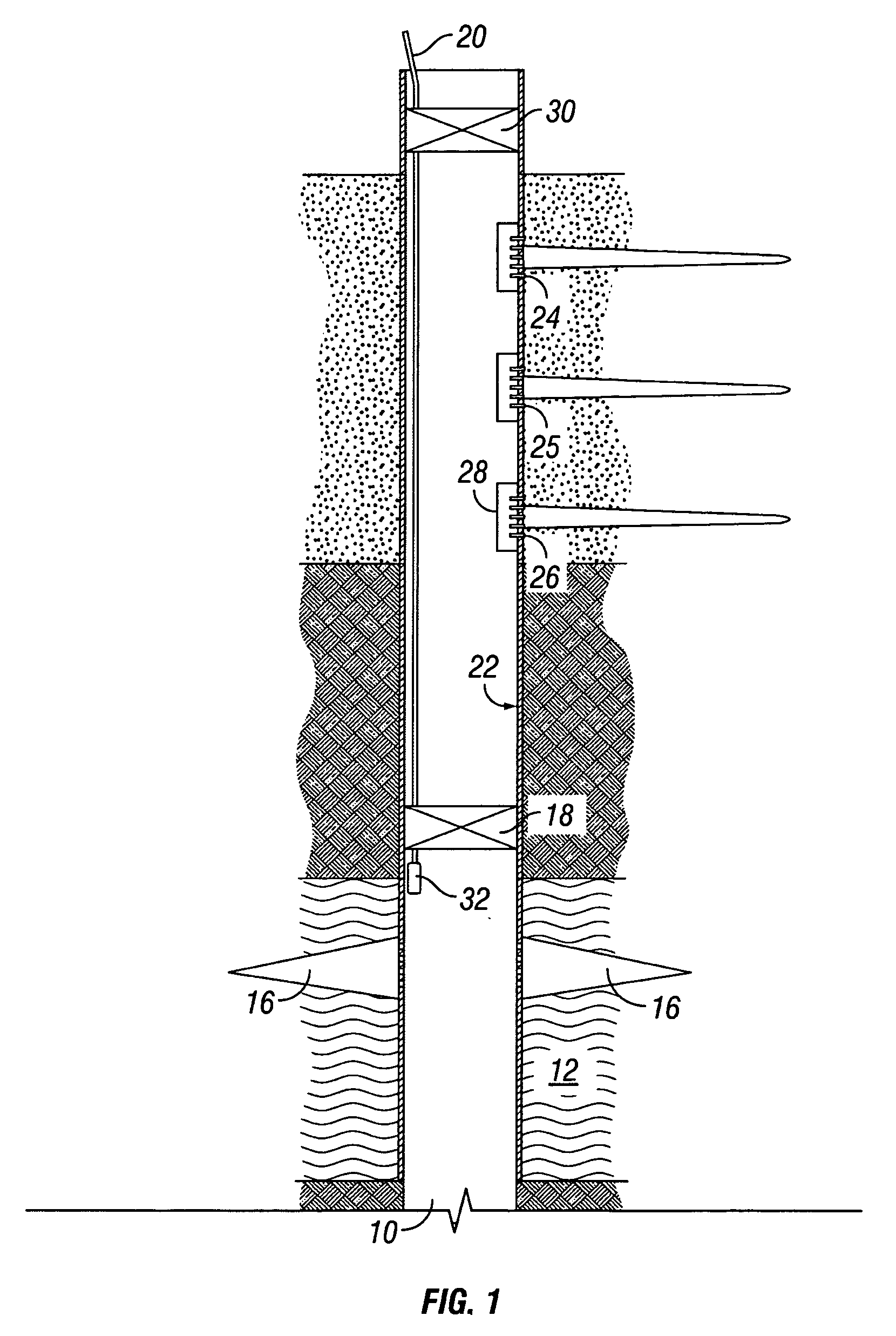

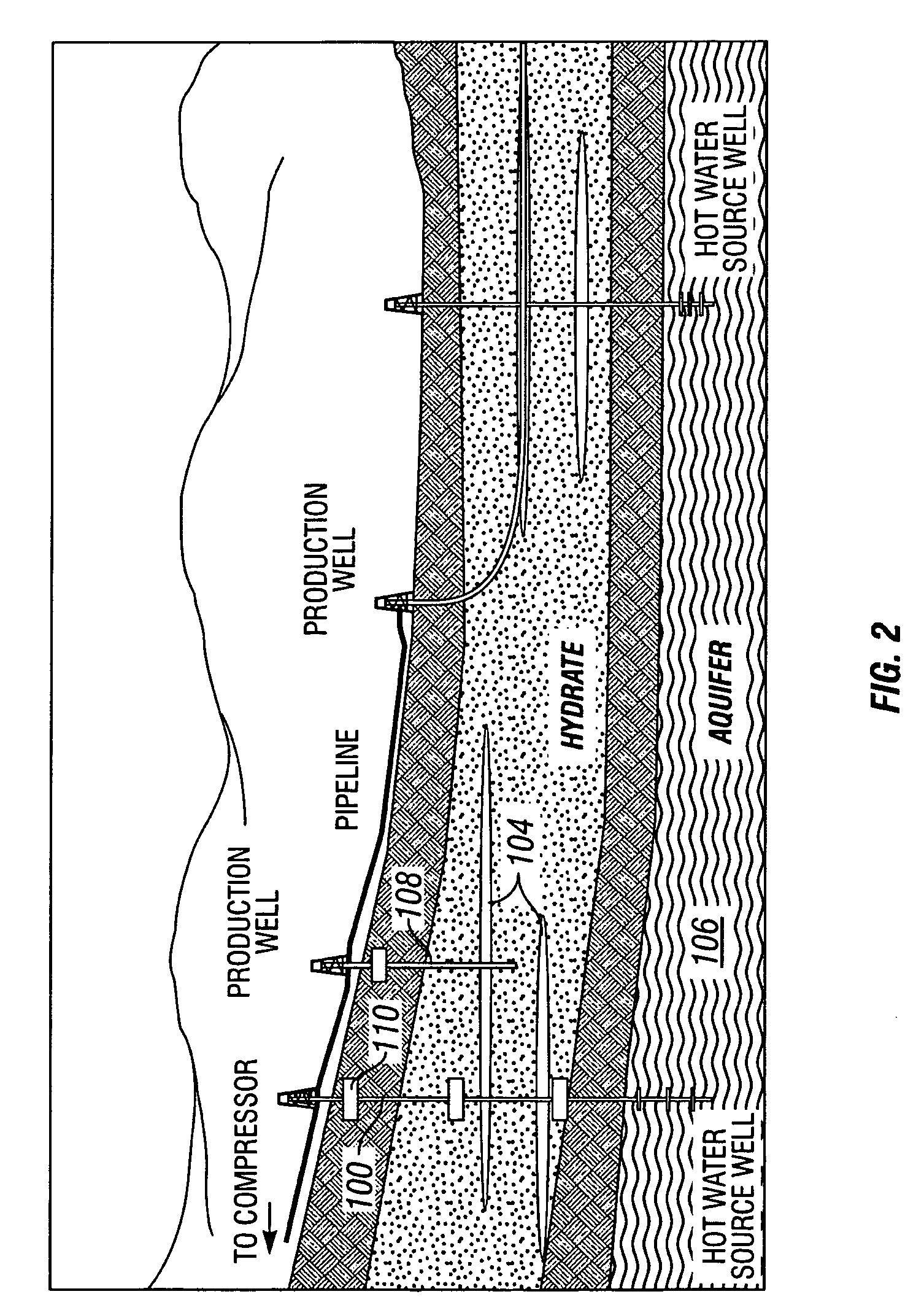

Method for exploitation of gas hydrates

InactiveUS7165621B2Prevent methane leakageSpeed up the processSurveyConstructionsWarm waterWater flow

A method and apparatus for producing gas from a hydrate formation includes the use of at least one wellbore which penetrates the hydrate formation and further extends into an aquifer below the hydrate formation. The aquifer provides relatively warm water which may be produced up and into the hydrate formation thereby causing the release of gas from the hydrate. Suitable flow control and monitoring equipment may be included to control the flow of water produced from the aquifer and gas produced from the hydrate formation.

Owner:SCHLUMBERGER TECH CORP

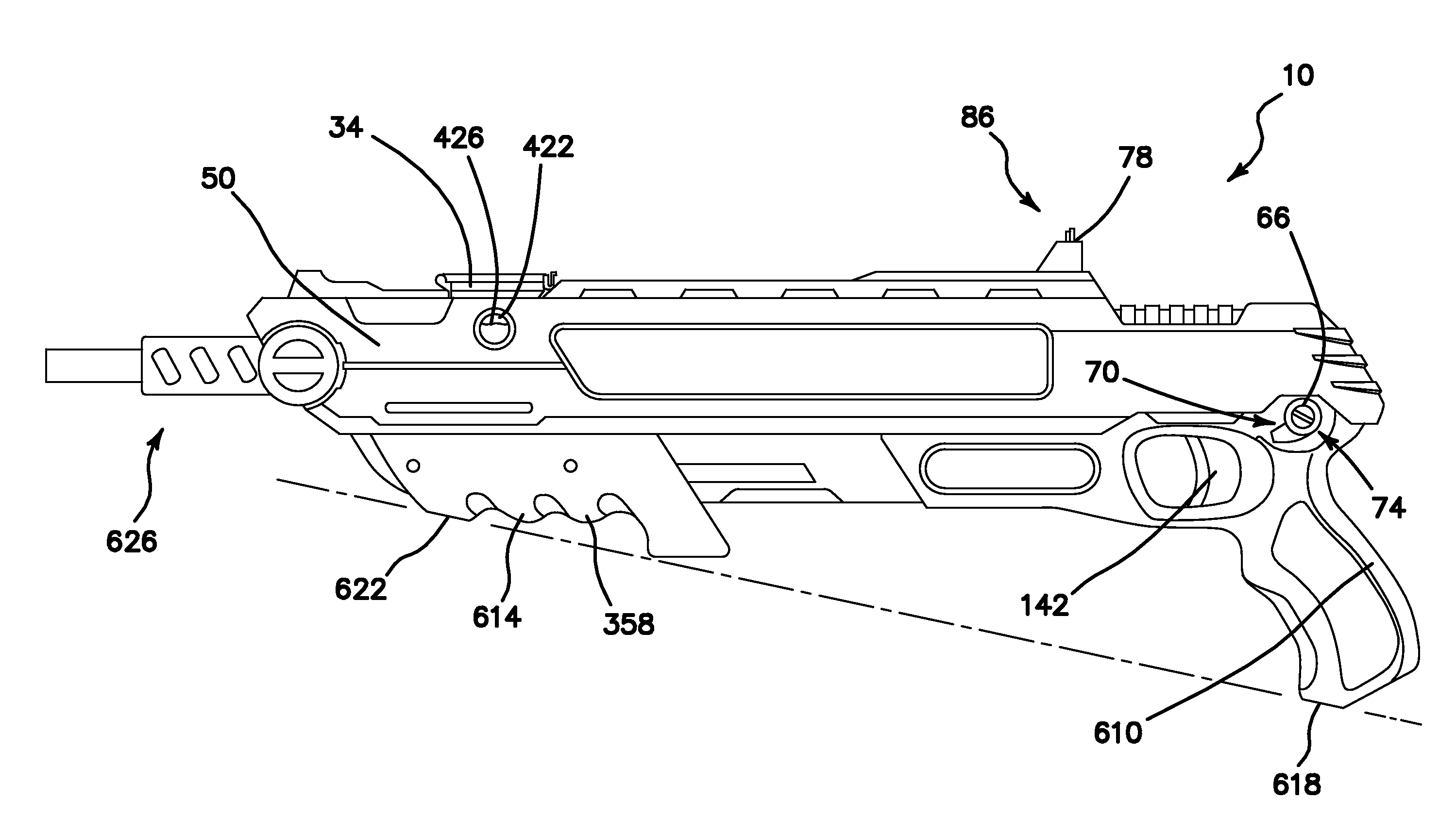

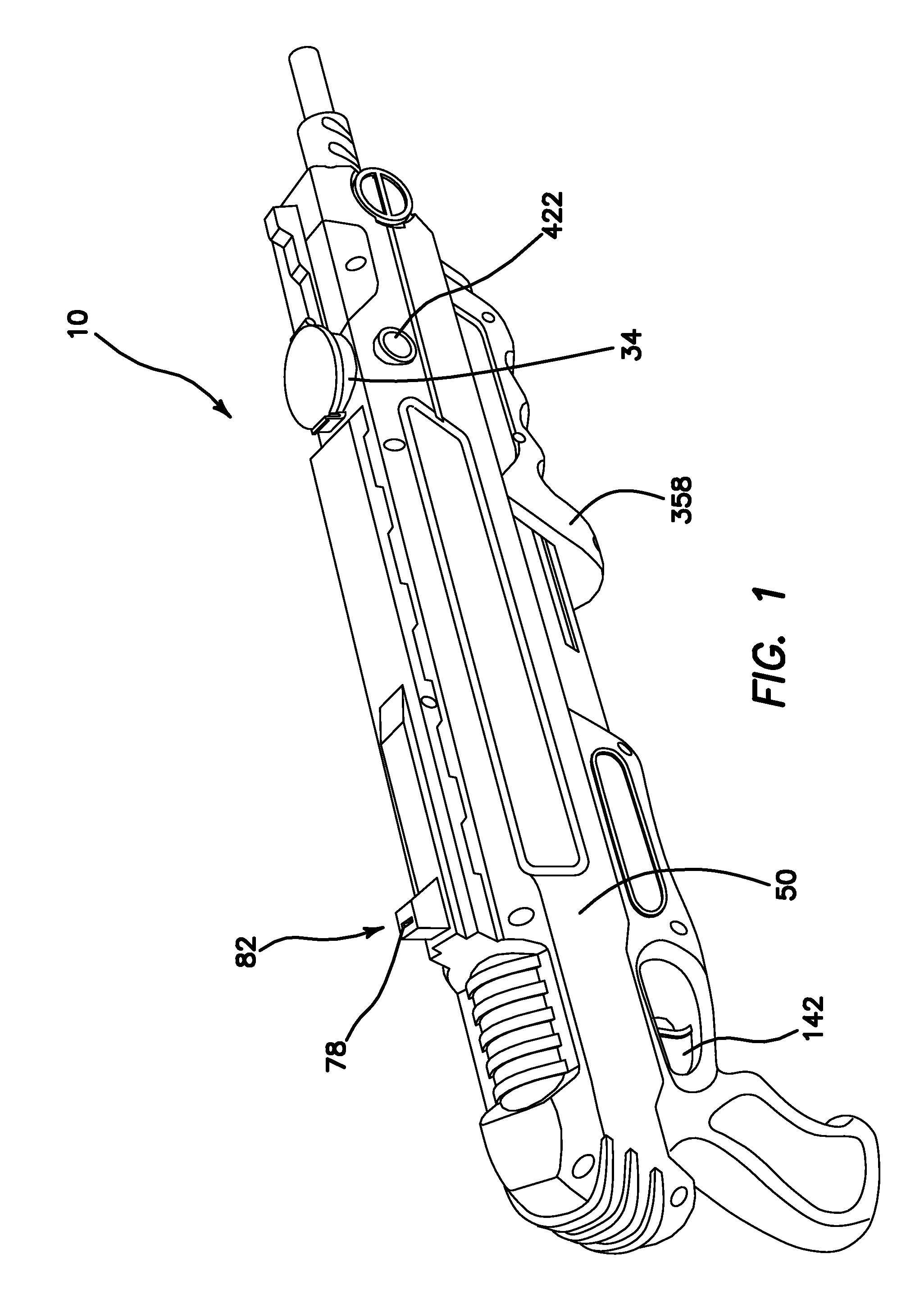

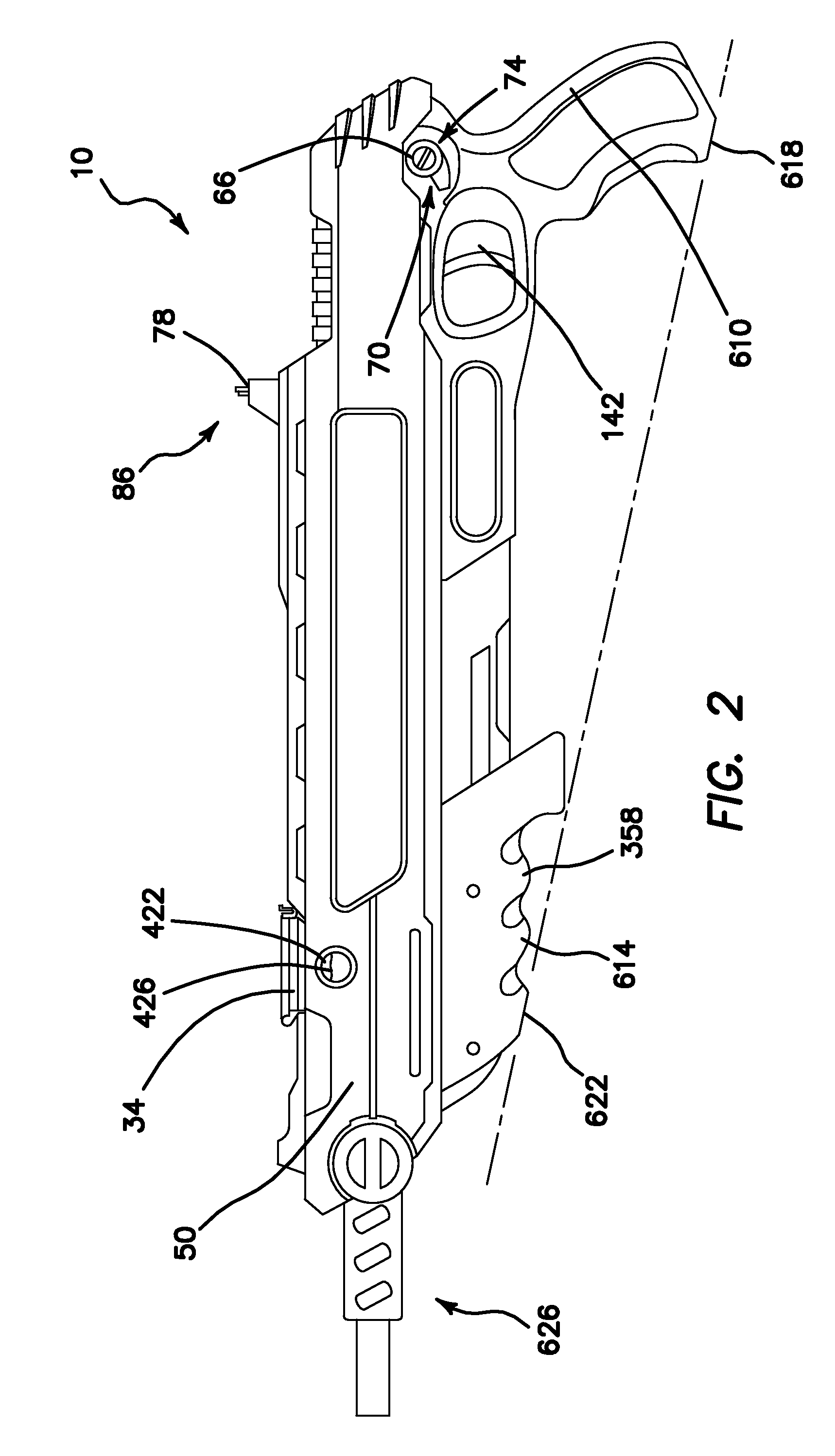

Bug killing gun

ActiveUS8251051B2Inhibition of activationLower surfaceProjectileSafety arrangementEngineeringGas release

A bug killing gun includes a compressed gas source fluidly connected to a chamber connected to a barrel. A compressed gas release mechanism is connected to the compressed gas source. A projectile storage magazine stores particulate projectiles and is located adjacent the chamber. A projectile loading mechanism moves the projectiles into the chamber from the magazine. A cocking mechanism is mechanically connected to the compressed gas source, the compressed gas release mechanism, and the projectile loading mechanism. A stock houses and supports the compressed gas source, the compressed gas release mechanism, the barrel, the chamber, the projectile storage magazine, the cocking mechanism and the projectile loading mechanism. When the gun is cocked, the projectile loading mechanism loads a predetermined quantity of the particulate projectiles into the chamber. When the compressed gas release mechanism is activated the projectiles are ejected from the chamber into the barrel and expelled from the gun.

Owner:MAGGIORE LOREN

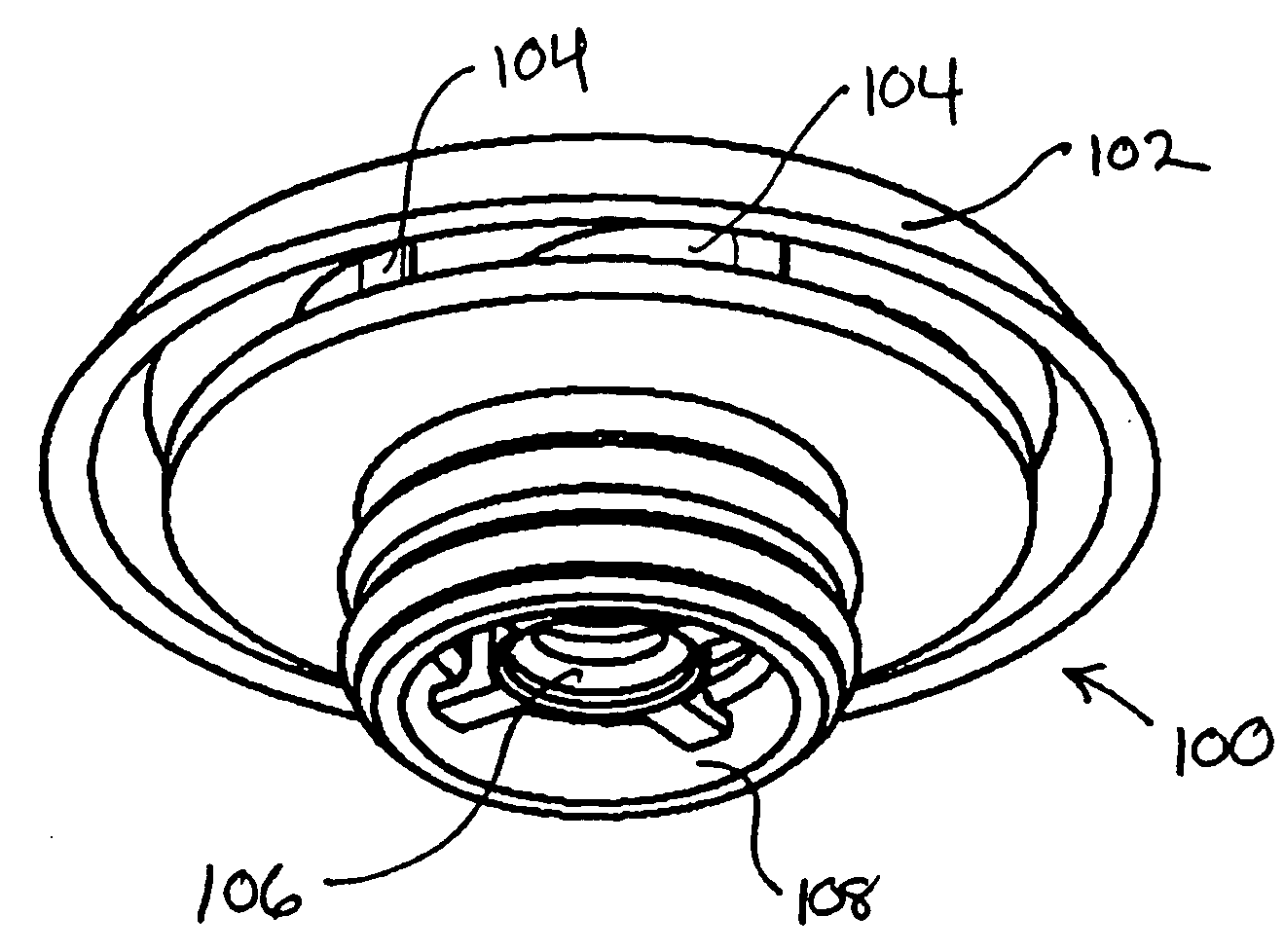

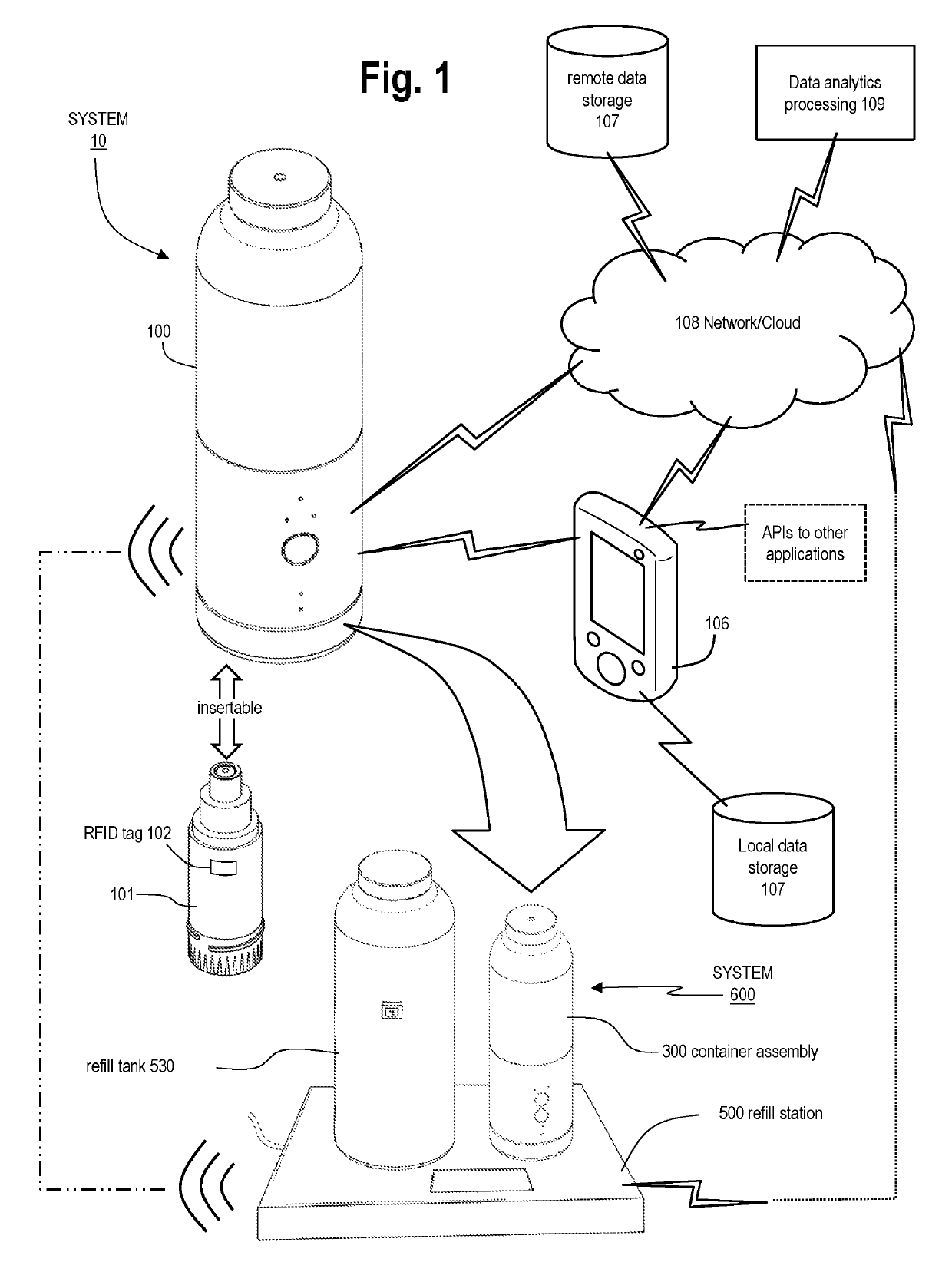

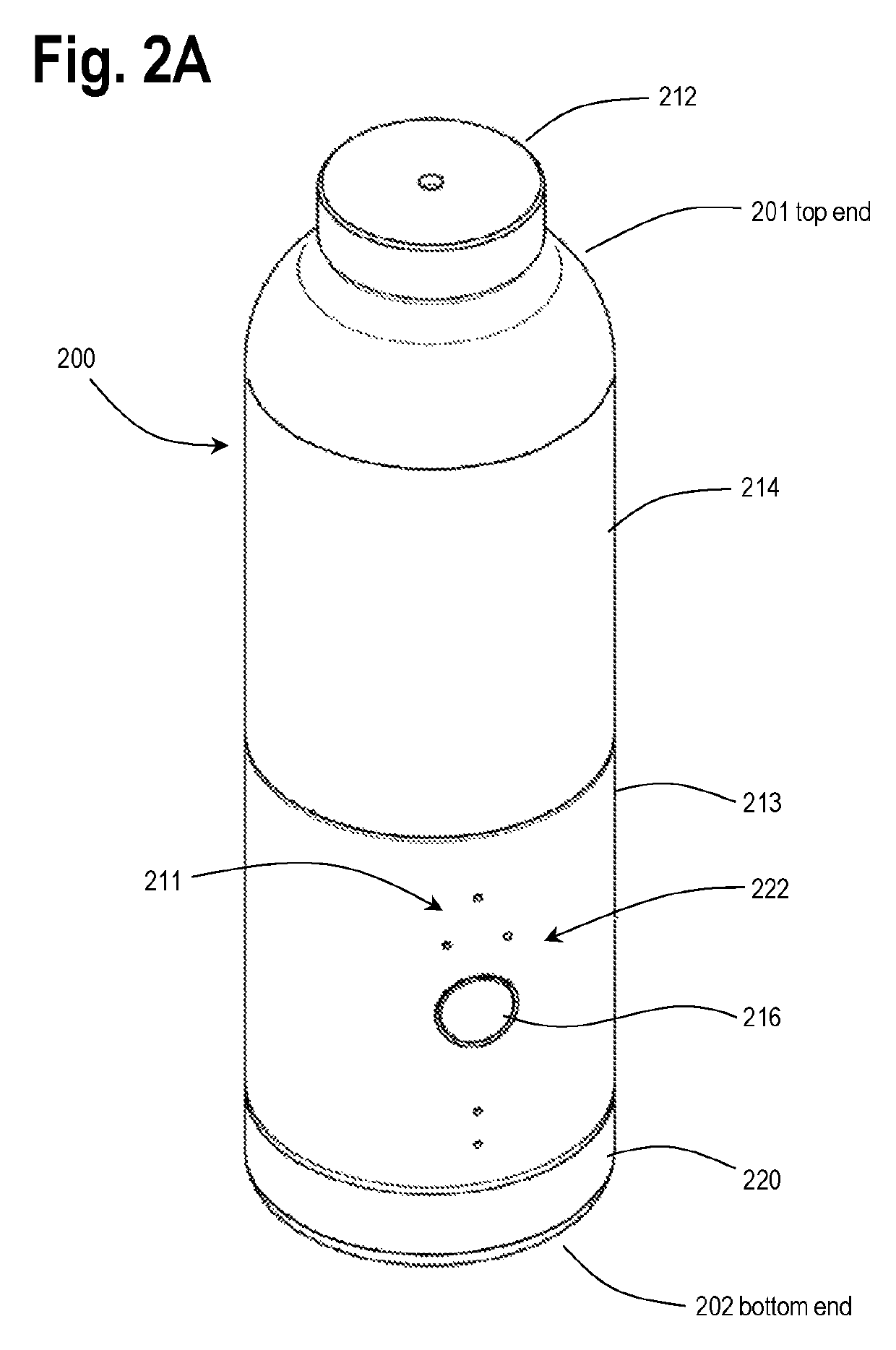

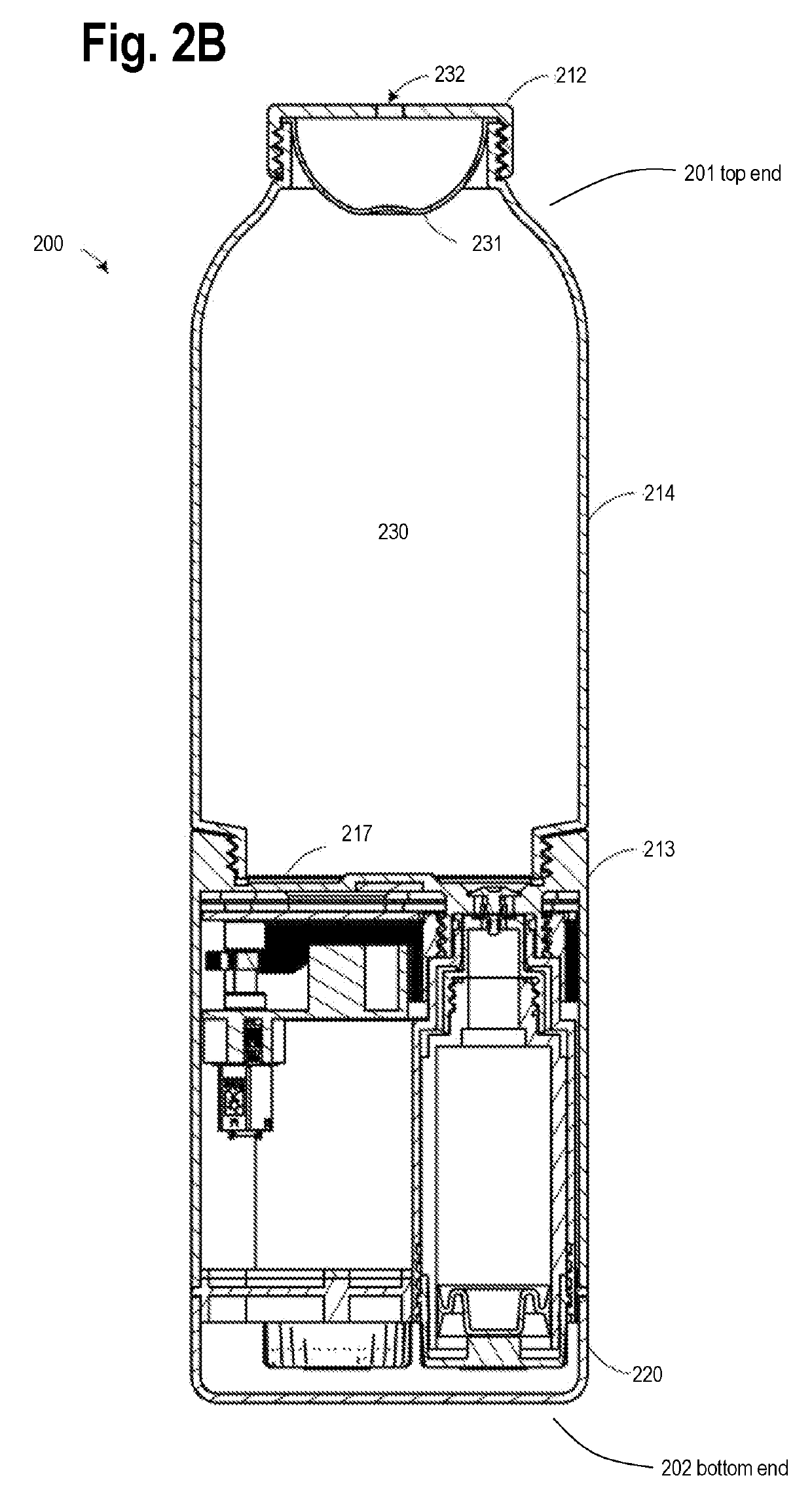

Portable systems and methods for adjusting the composition of a beverage

The systems and methods provide a container assembly comprising: a container having a known storage capacity for storing a liquid; an additive dispensing assembly, the additive dispensing assembly dispensing variable, non-zero quantities of one or more additives into the liquid stored in the container; one or more vessels that each contain one of the additives, of the one or more additives, to be dispensed into the liquid; and a gas dispensing assembly, the gas dispensing assembly releasing a gas into the liquid stored in the container, and the gas dispensing assembly including: an onboard gas tank; a valve assembly; and a gas outlet, and the valve assembly controlling flow of gas from the onboard gas tank, through the valve assembly, and to the gas outlet so as to output the gas into the liquid; and wherein the valve assembly, to perform the controlling the flow of gas, is movable between: an open position, in which flow of gas is allowed to flow from the onboard gas tank to the gas outlet; and a closed position in which the flow of gas is prevented to flow from the onboard gas tank to the gas outlet.

Owner:INFUZE L L C

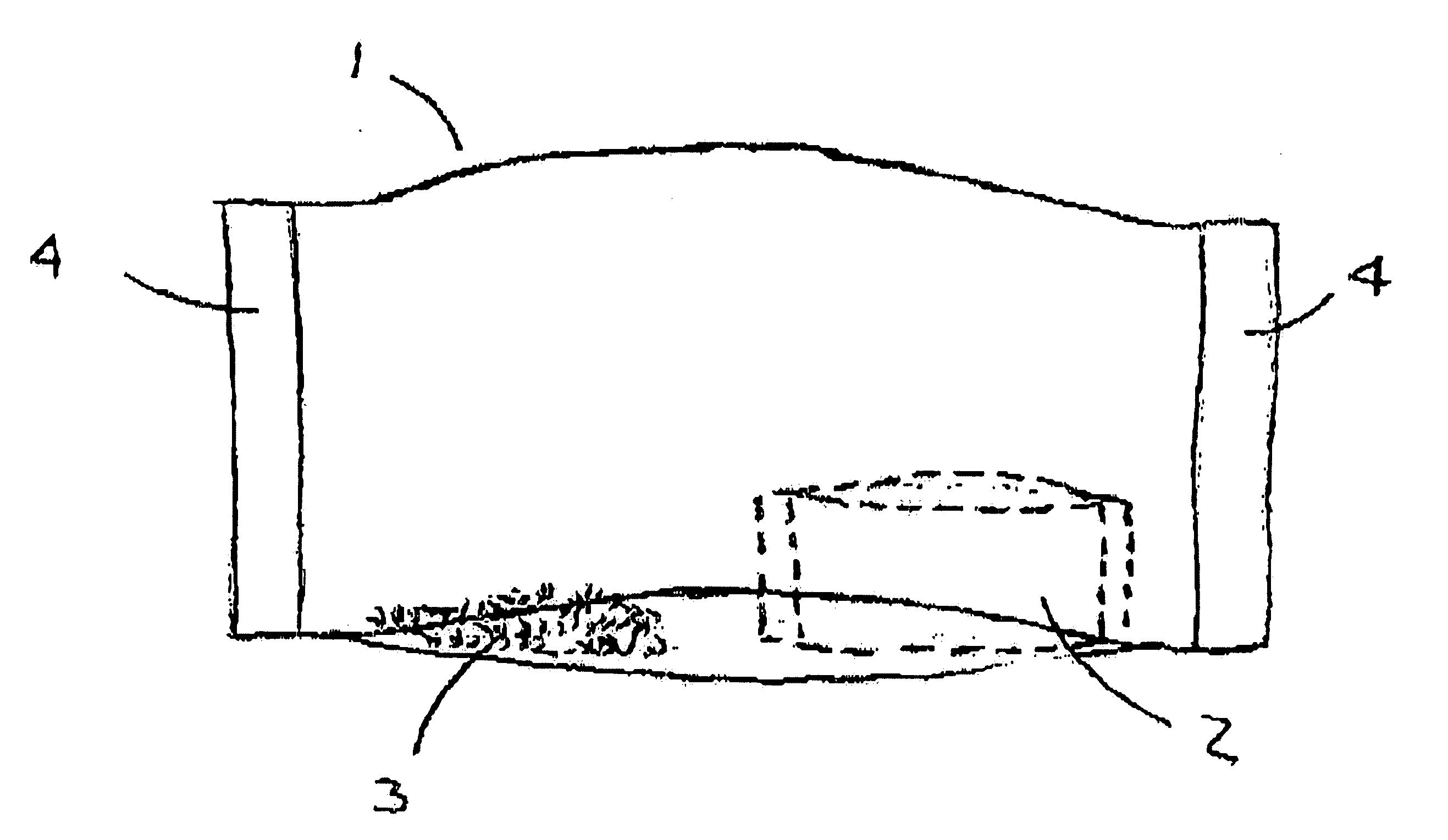

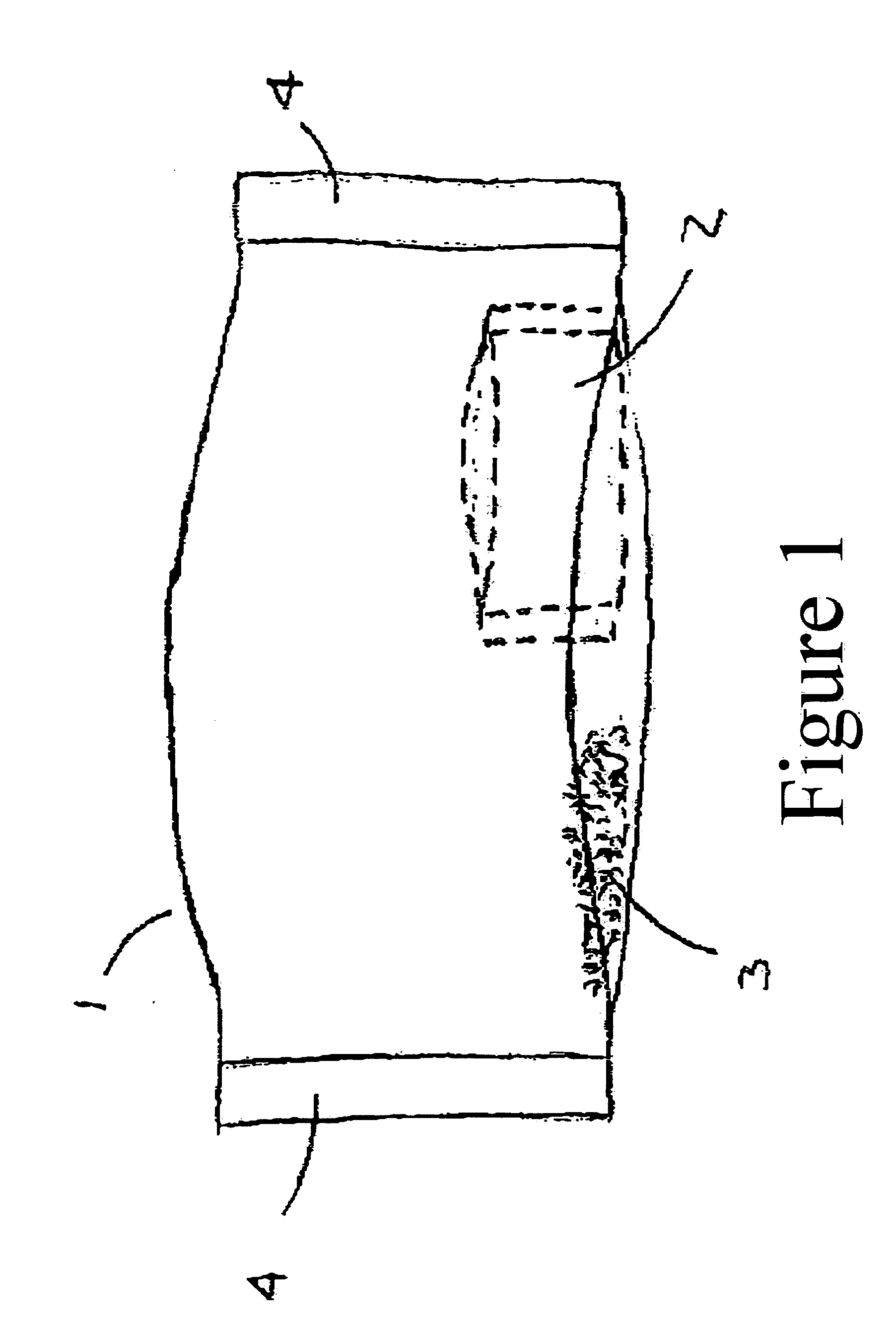

Gas-release packet with frangible sub-packet

Disclosed is a gas-release packet, comprising a flexible gas-permeable material enclosing or comprising one or more liquid-filled frangible sub-packets and a gas-producing chemical composition that is activated when in contact with said liquid.

Owner:KELLY ROBERT CHARLES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com