Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Efficiently circulated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

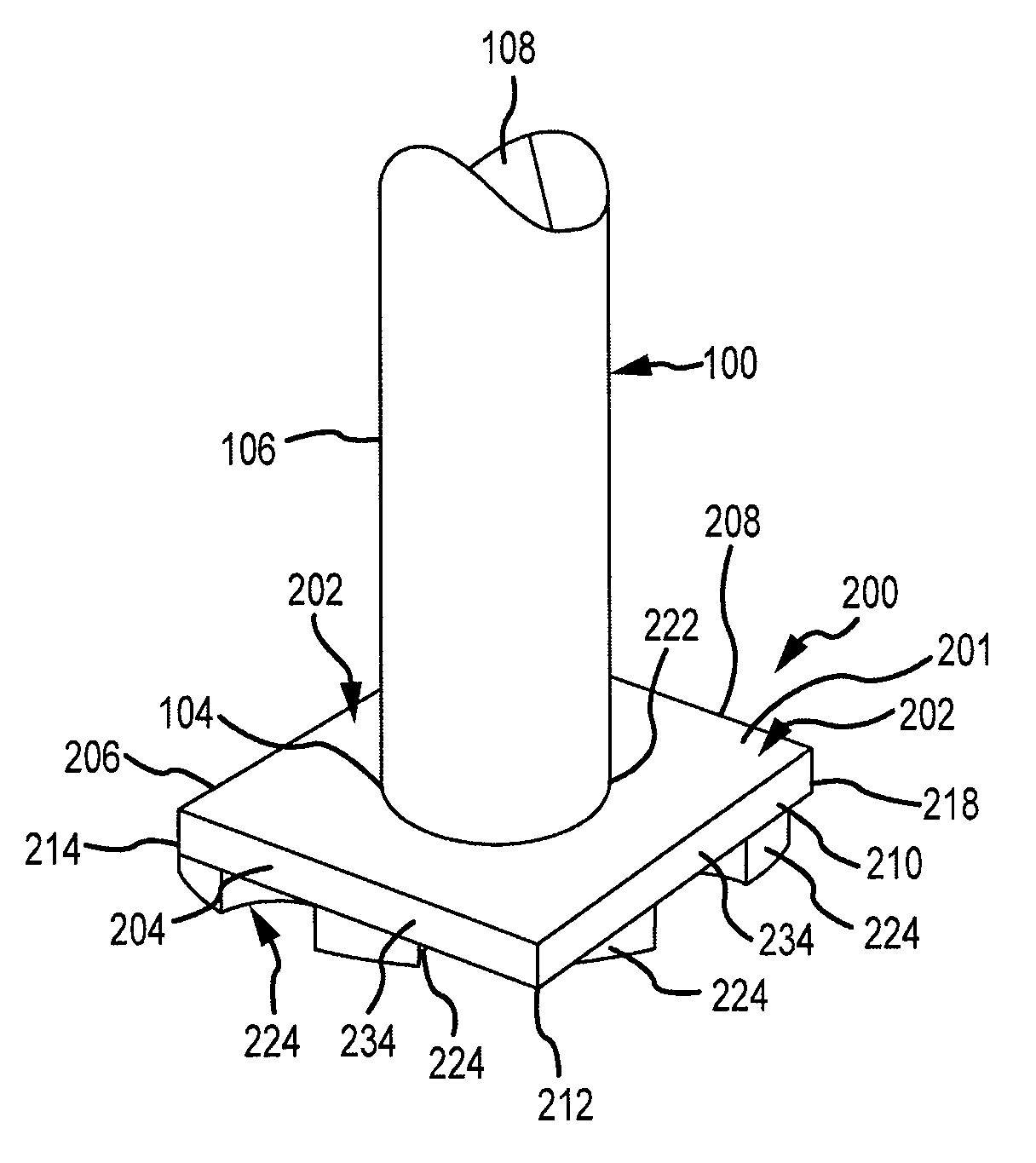

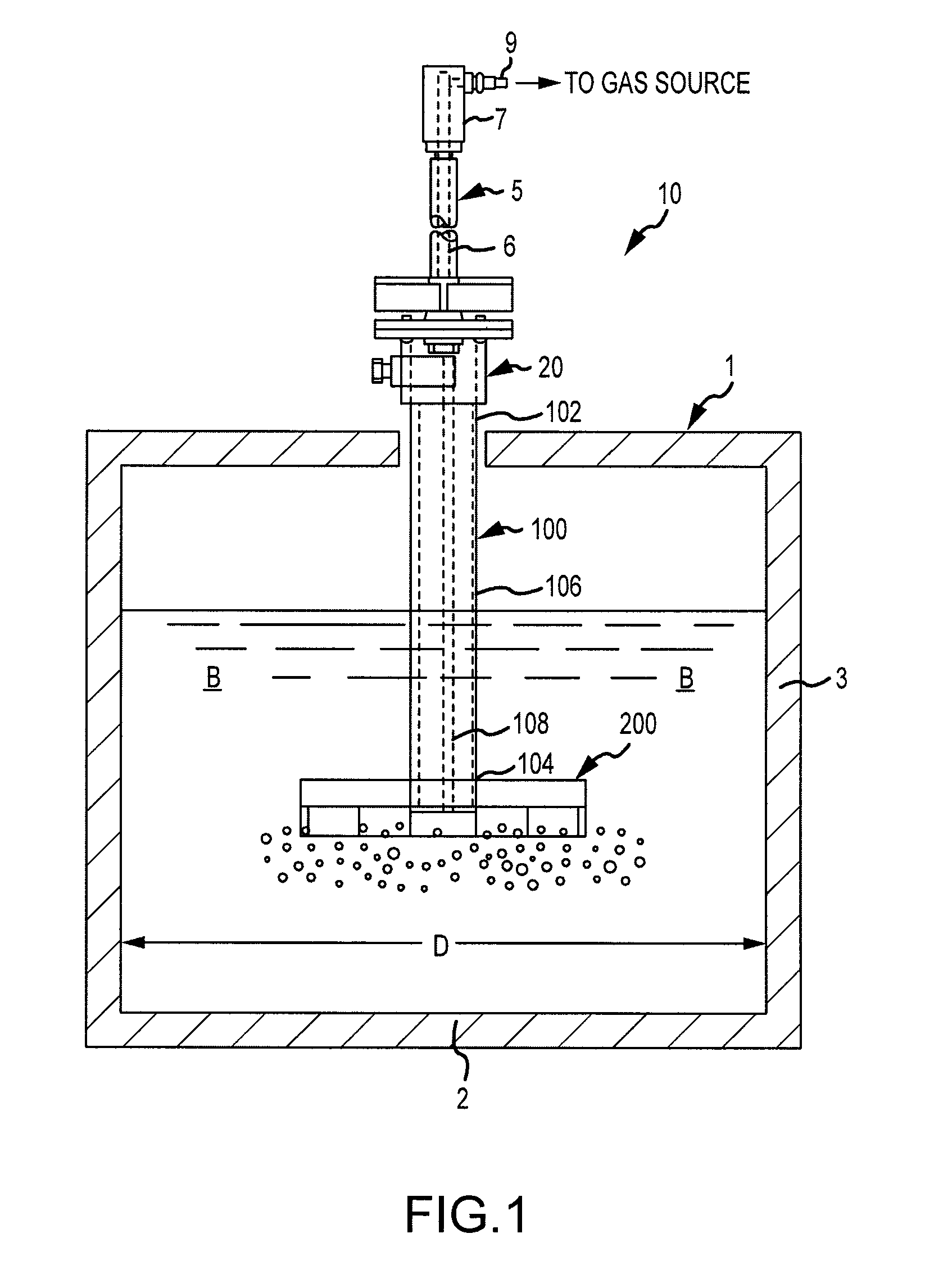

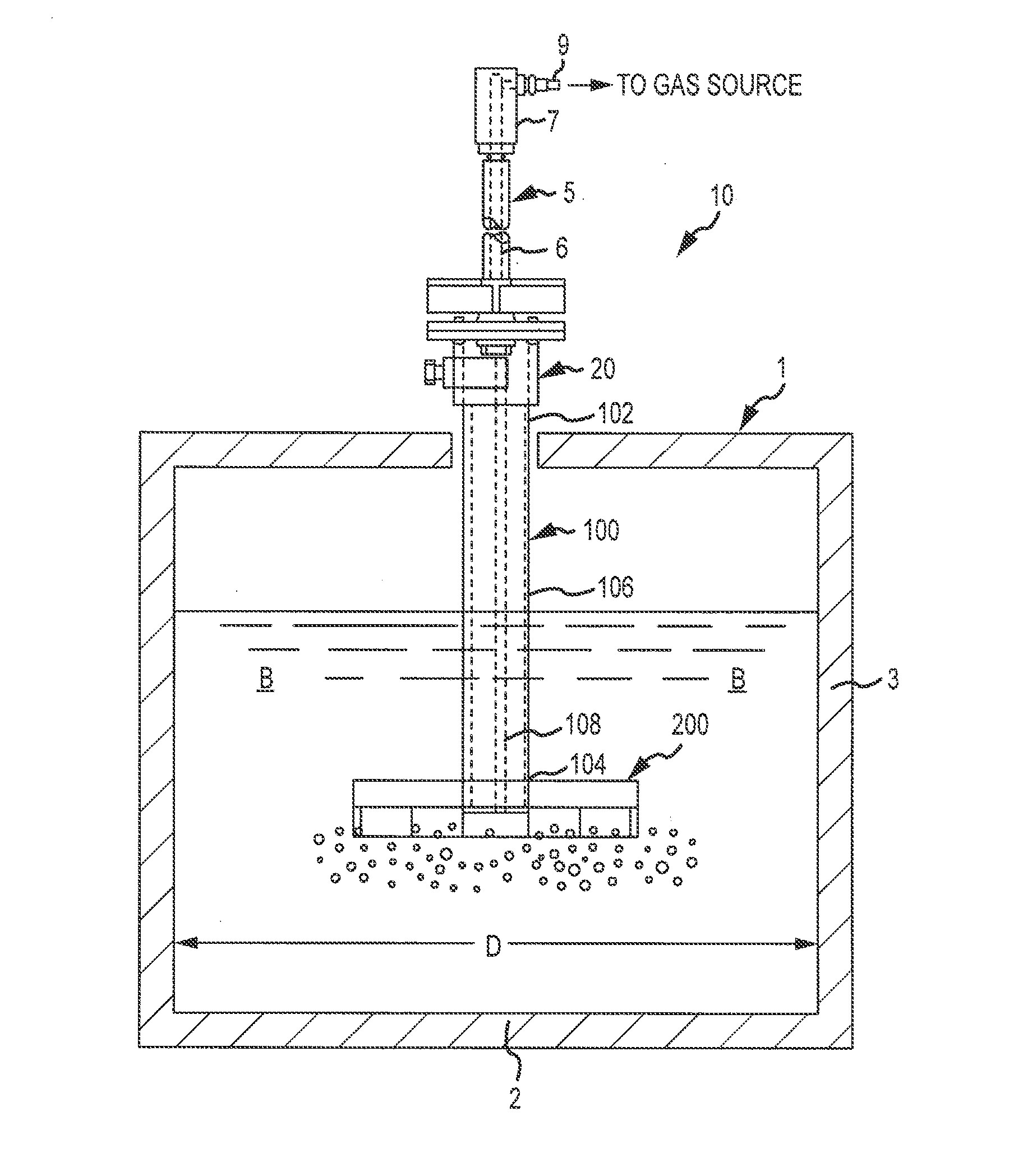

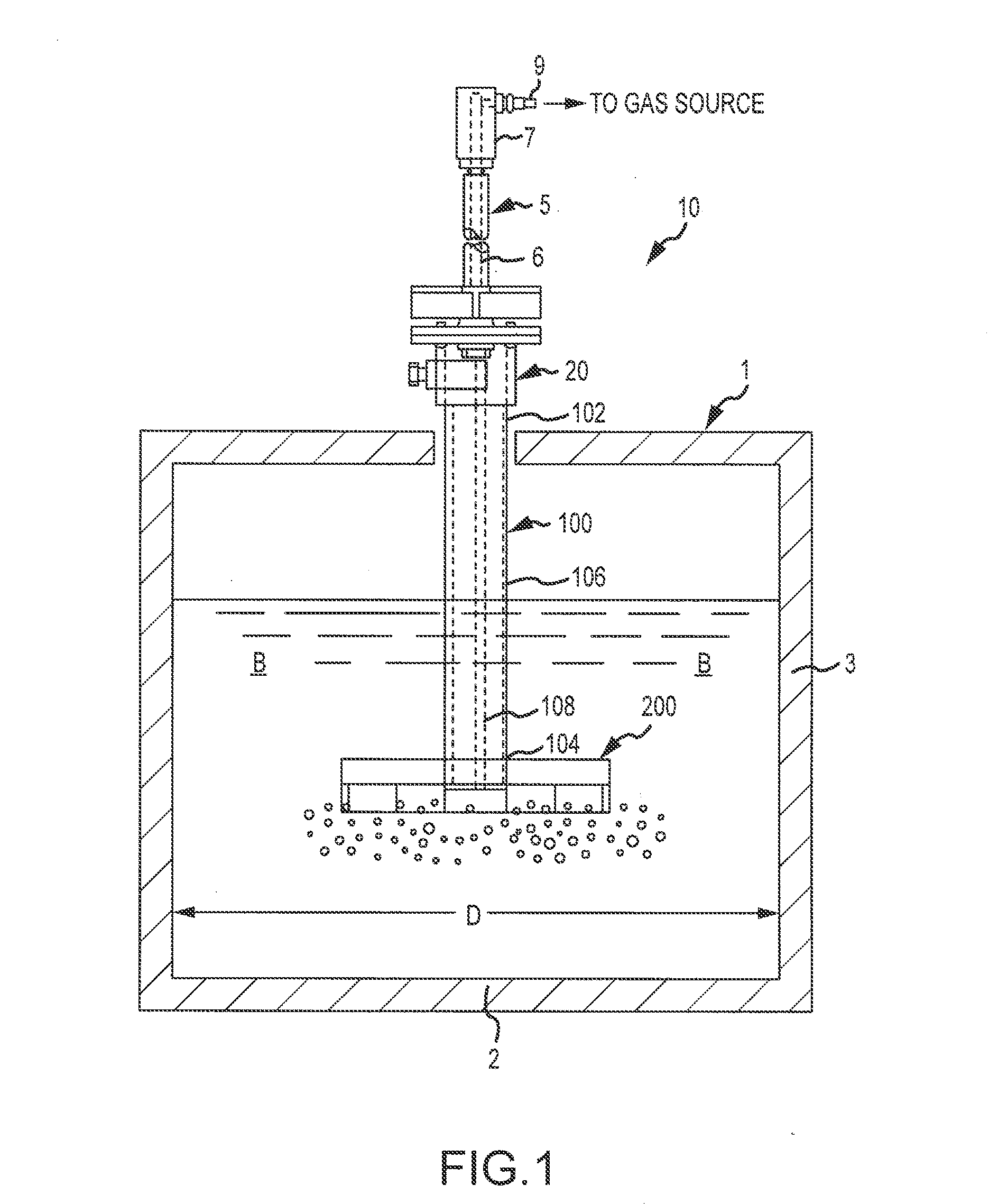

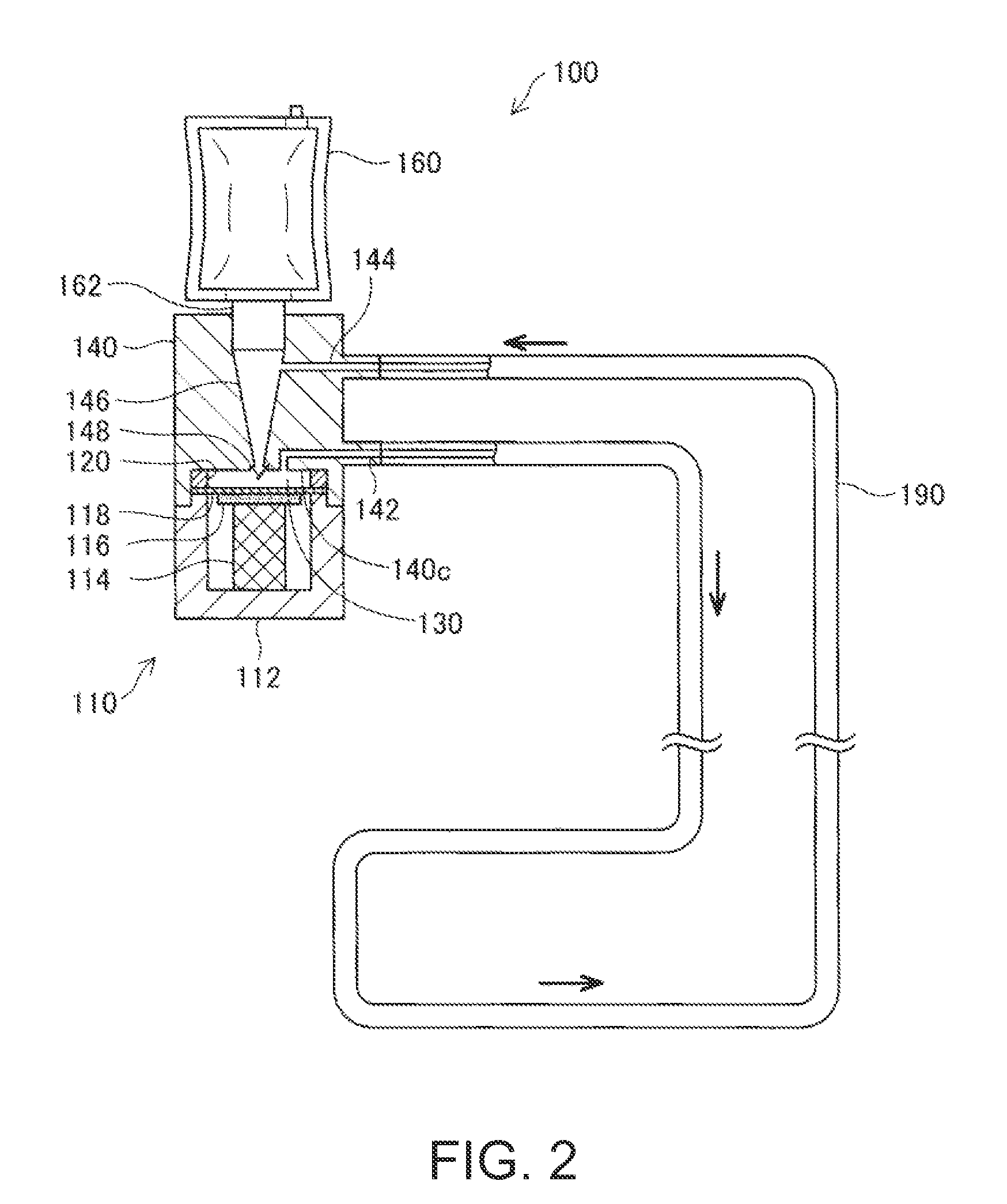

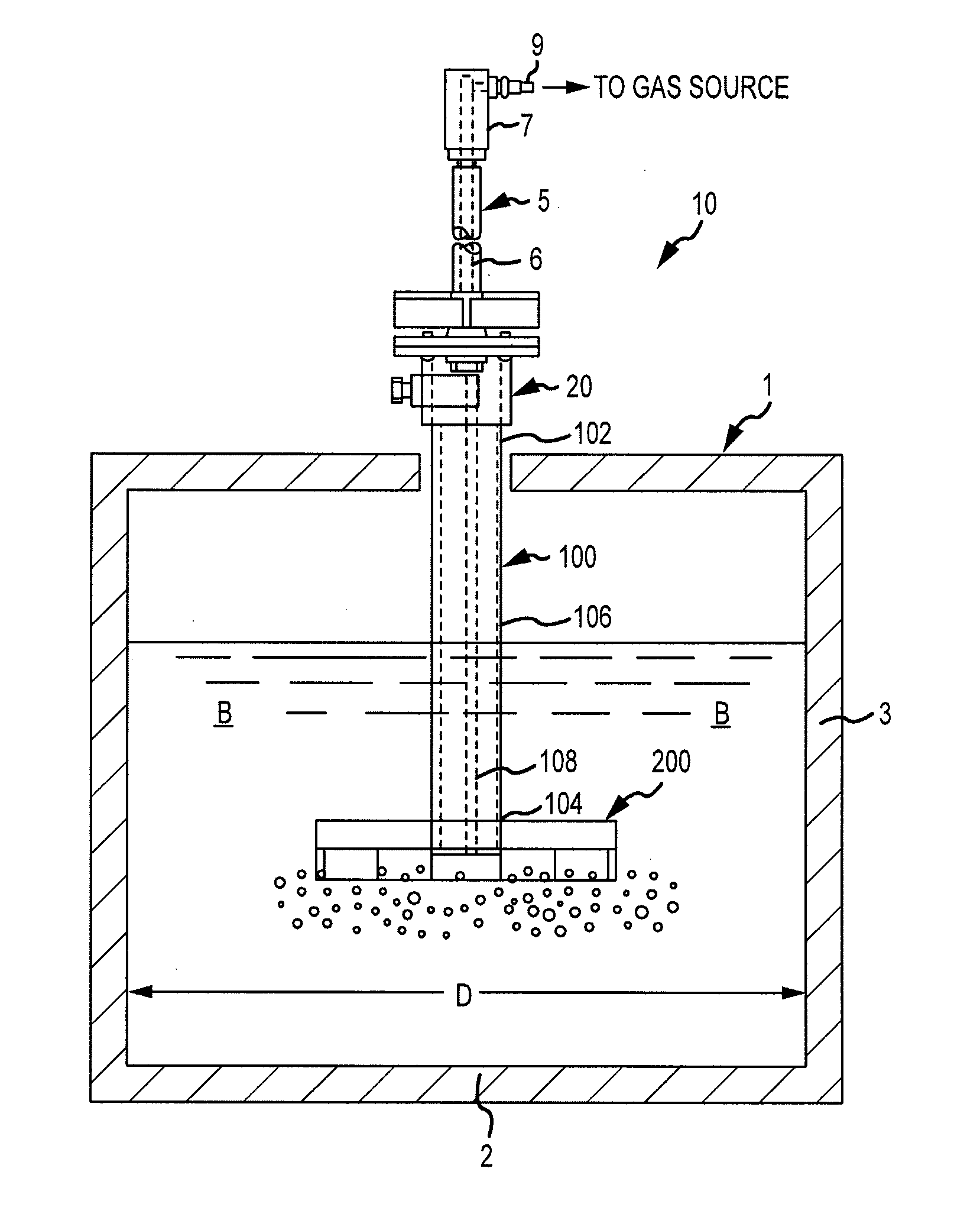

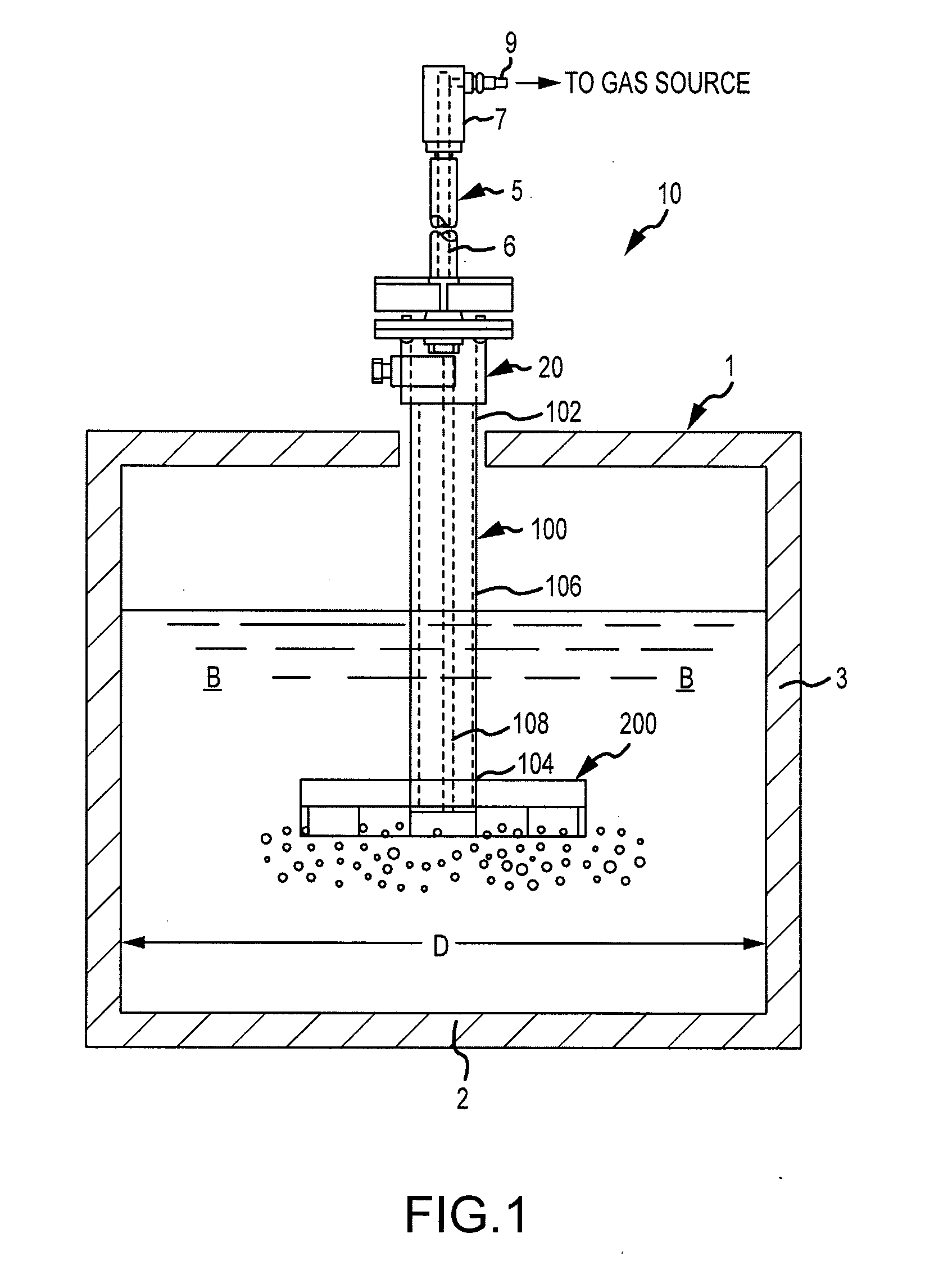

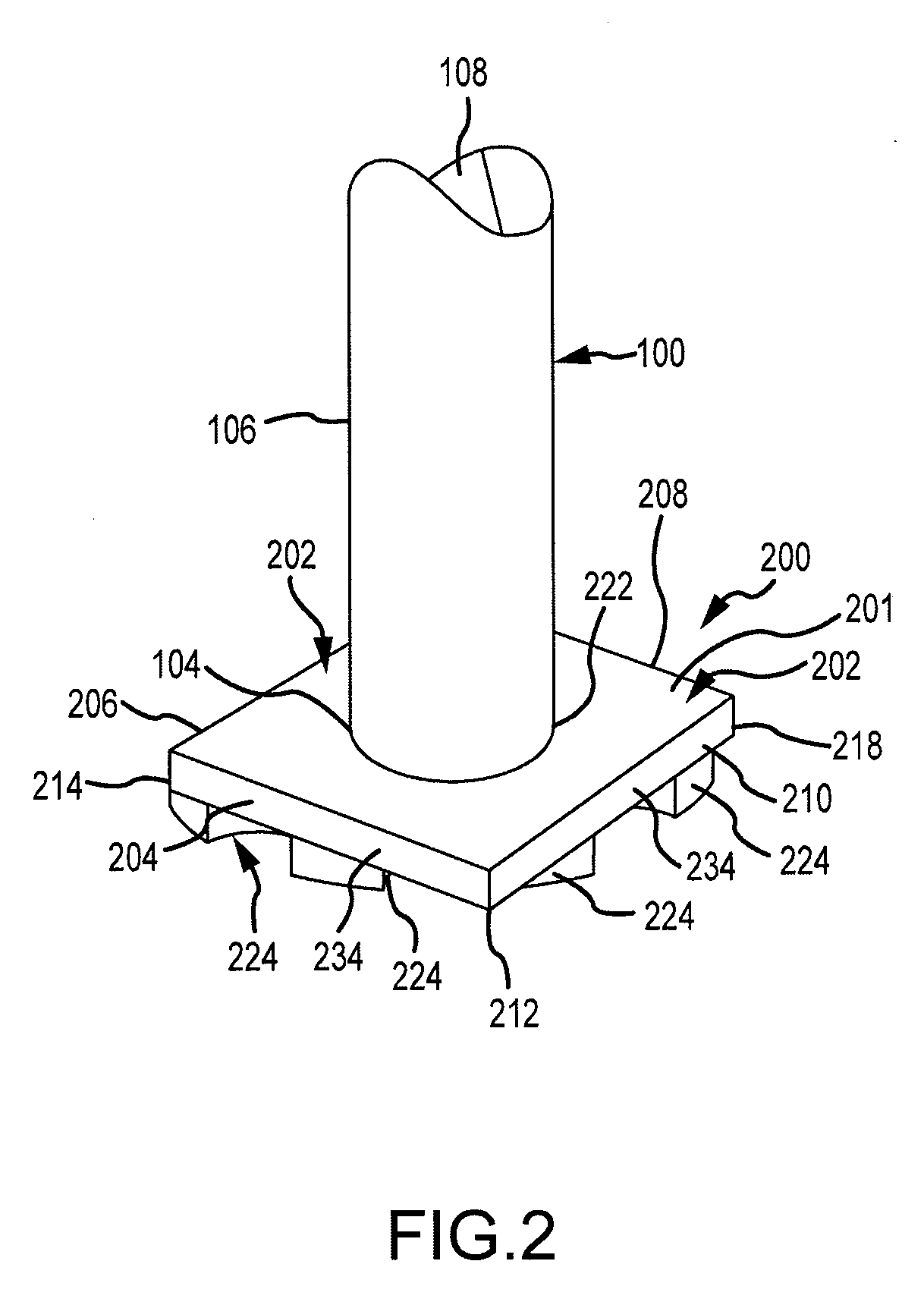

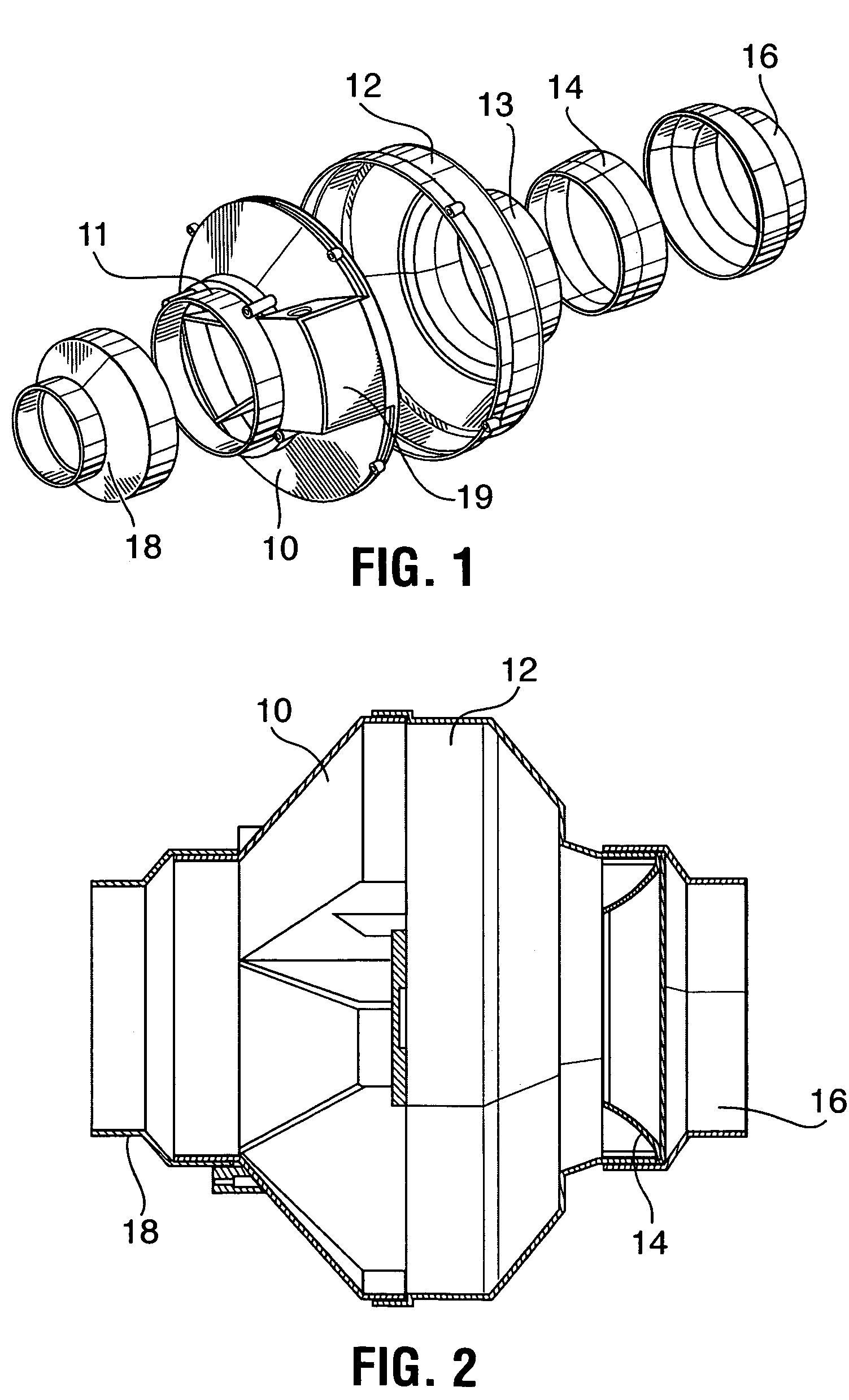

Rotary degasser and rotor therefor

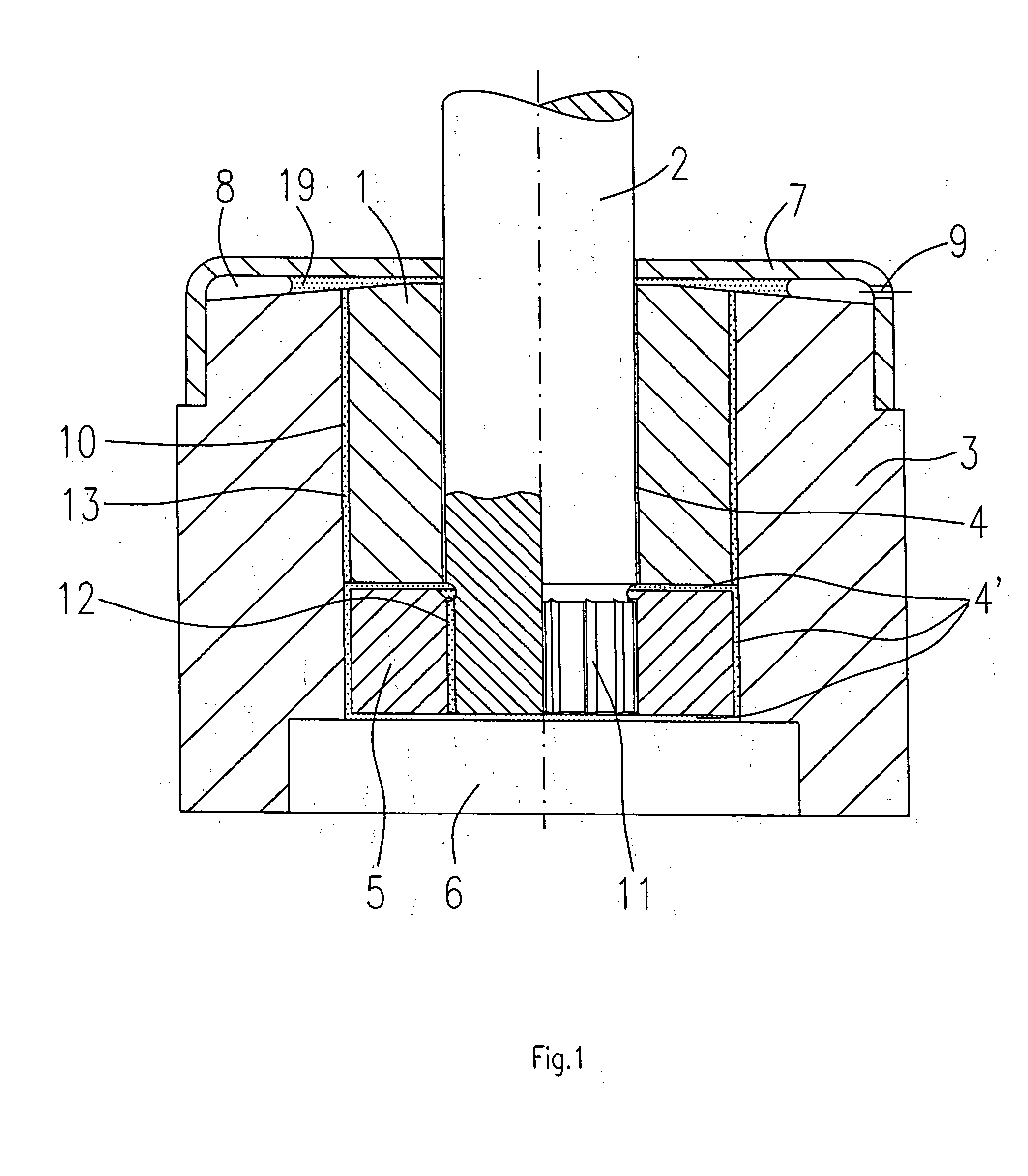

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

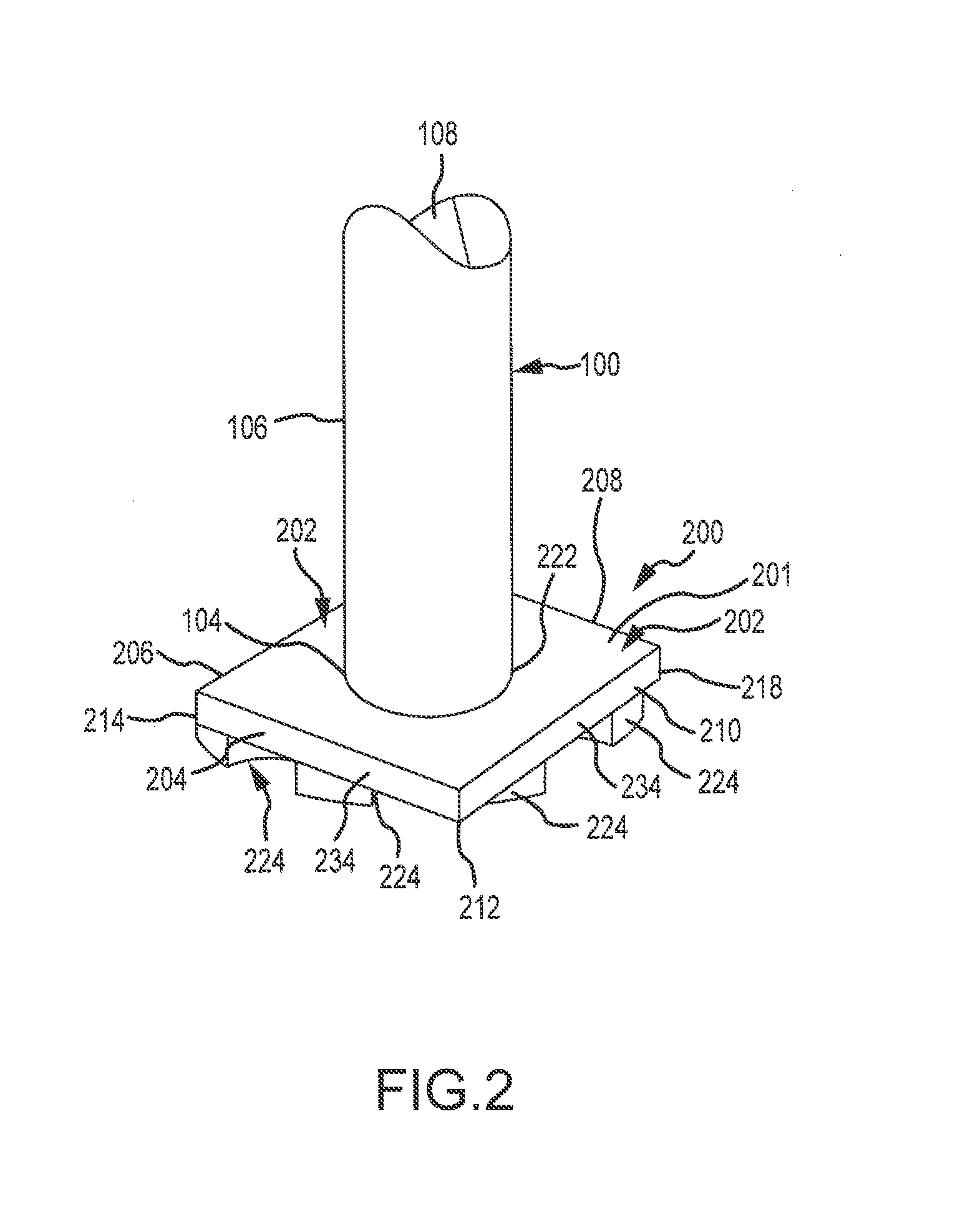

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Rotary degasser and rotor therefor

ActiveUS20140008849A1Efficiently circulatedWell mixedStirring devicesBlade accessoriesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Inline fan housing assemblies

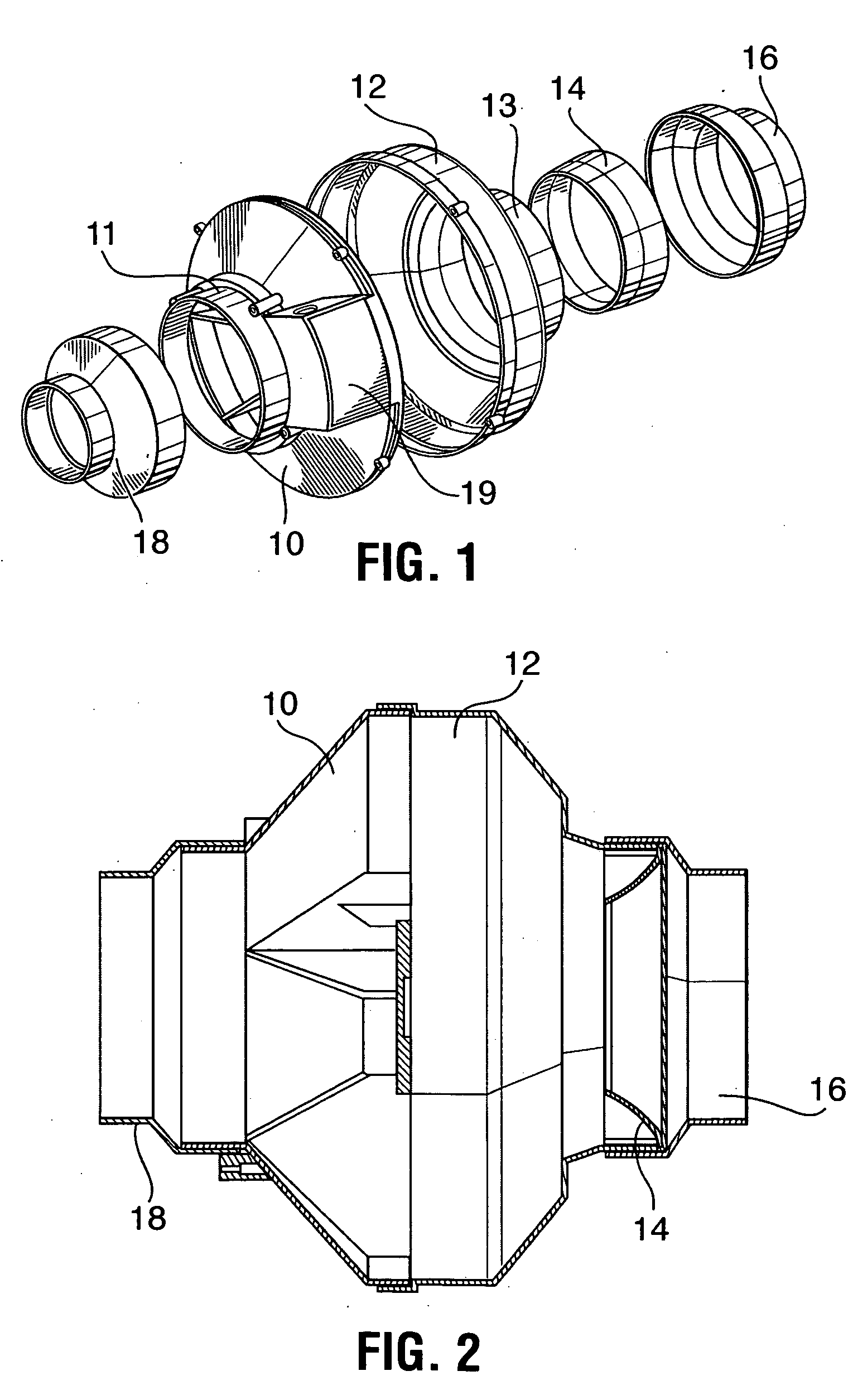

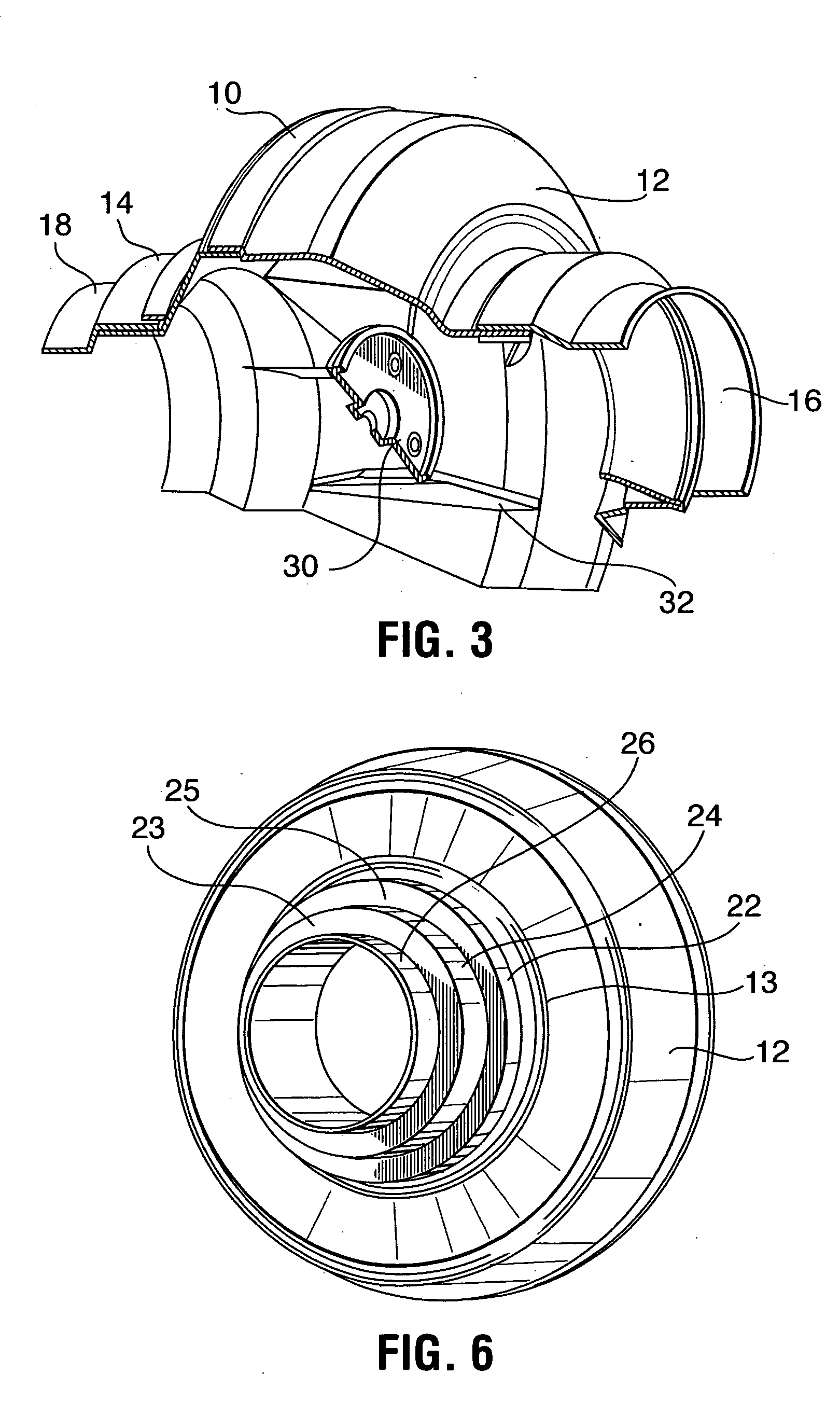

ActiveUS20050214145A1Guarantee effective circulationEfficiently circulatedPump componentsLighting and heating apparatusImpellerEngineering

The present invention relates to an inline fan housing assembly adaptable for connection with conduits of various diameters. The inline fan housing assembly comprises a connector collar for connection to the inlet or exhaust ports of the fan housings to adapt the fan housings for connection to a variety of conduits having diameters not designed to connect with the inlet or exhaust ports of the fan housing. The inline fan housing assembly also comprises an inner inlet ring for adapting the inlet port of the inline fan housing to direct air into motorized impellor of various sizes mounted within the inline fan housing. The connector collars of the present invention contain one or more steps, each step suitable for connection with a conduit of a different diameter. In one exemplary embodiment, the inner steps of the connection collar are removable thereby allow for increased air flow through the connection.

Owner:ZEHNDER VERKAUFS UND VERW

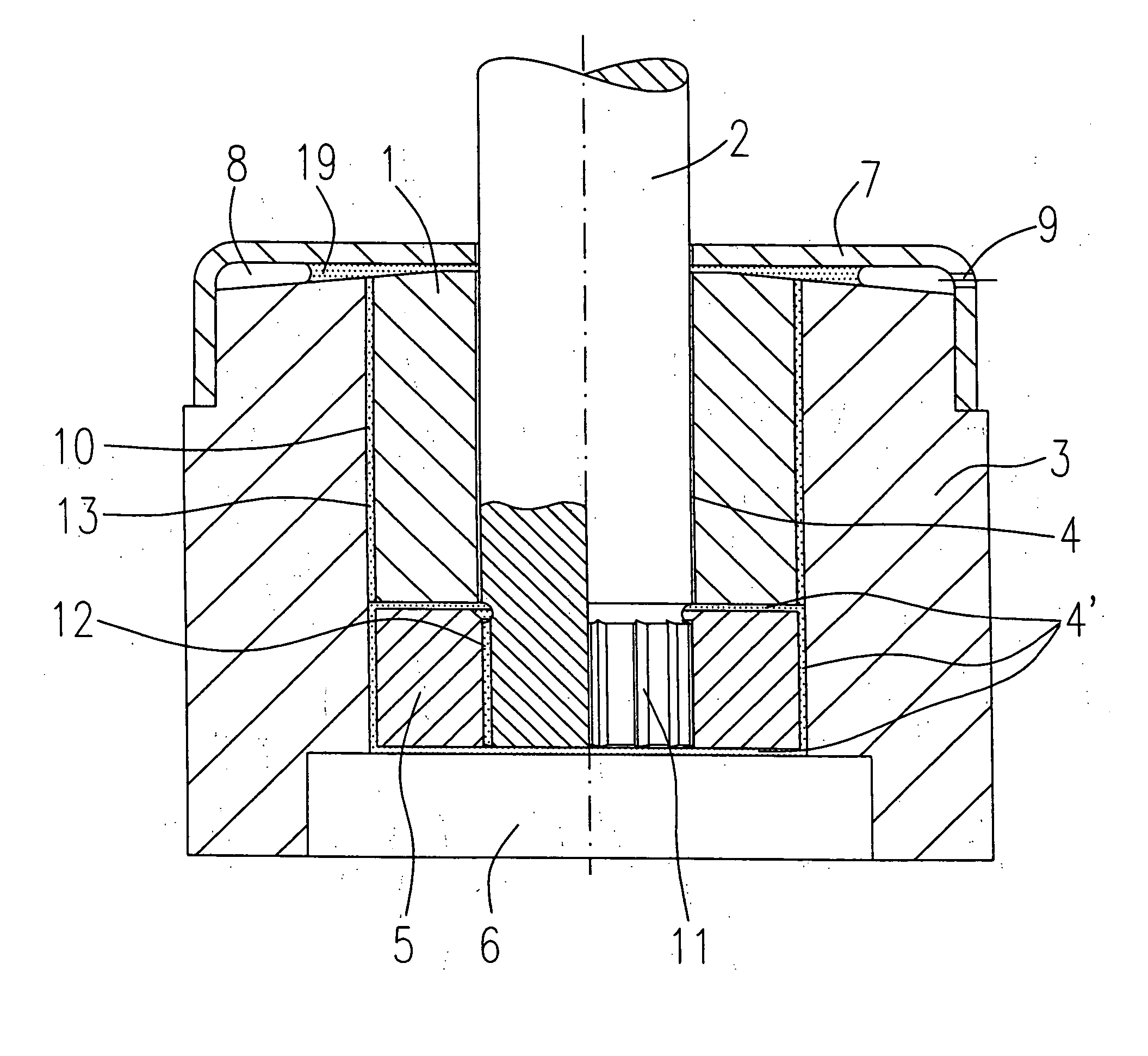

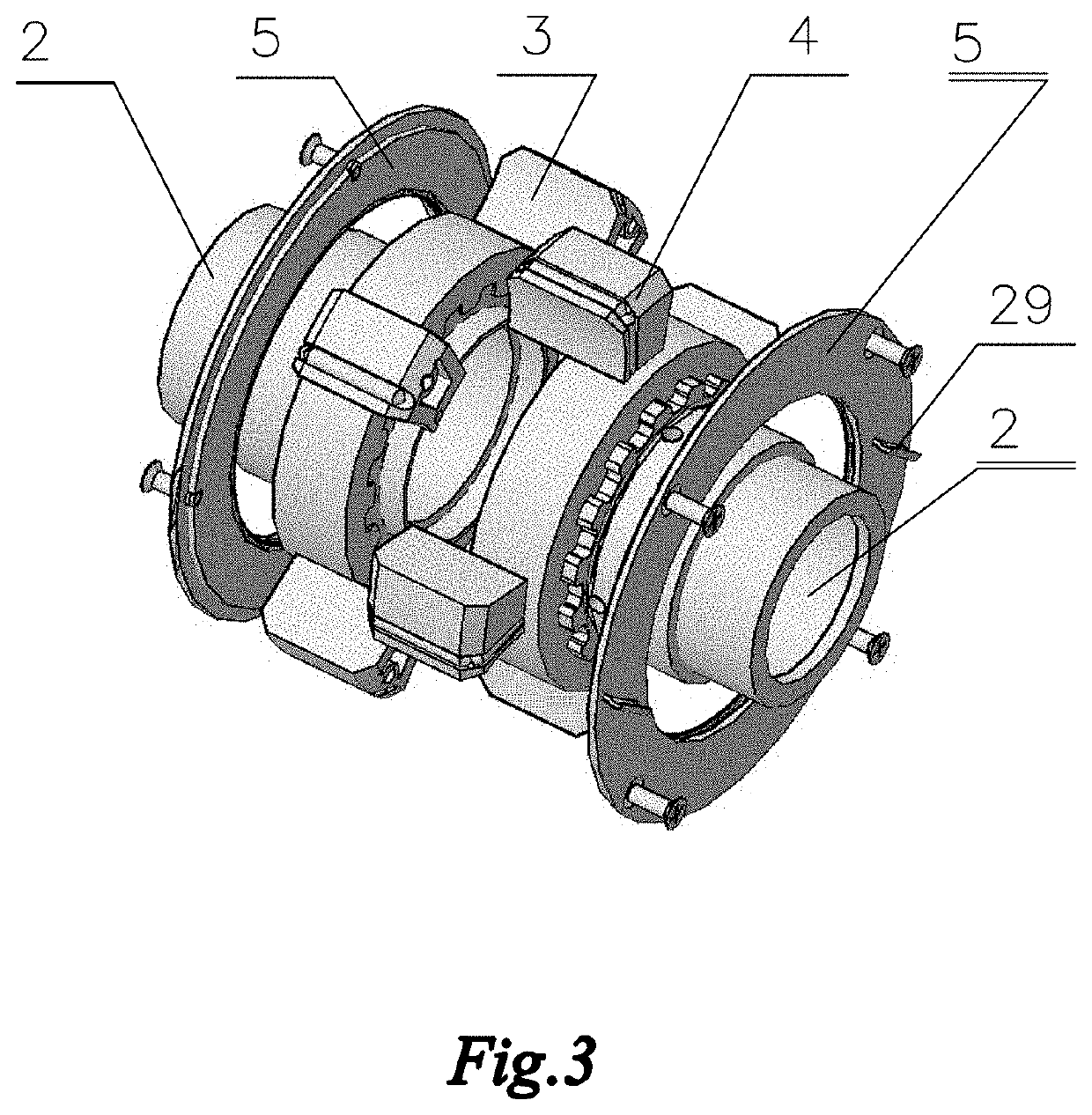

Hydrodynamic bearing system

InactiveUS20050084189A1Guarantee effective circulationAvoid problemsShaftsRecord information storageHard disc driveKnurling

The invention relates to a hydrodynamic bearing system particularly for use as a rotary bearing in a spindle motor for a hard disk drive, comprising a shaft, a thrust plate firmly connected to the shaft by means of a pressfit connection and a bearing sleeve closed at least at one end by a cover plate, the bearing sleeve enclosing the shaft and the thrust plate with a slight radial or axial spacing forming a concentric bearing gap filled with a lubricant. In the hydrodynamic bearing system according to the invention, it is provided that the outer circumference of the shaft, in the area of connection with the thrust plate, has a surface interrupted by regular depressions, preferably formed by knurling, in order to decrease the contact surface proportion of the fit surface. As an alternative, the inner circumference of the thrust plate can also be knurled in the area of connection with the shaft.

Owner:MINEBEA CO LTD

Transplant production system

InactiveUS7278237B2Efficient productionWeaken energyClimate change adaptationAgriculture gas emission reductionTemperature controlInterior space

Owner:MKV DREAM

Waste treatment method

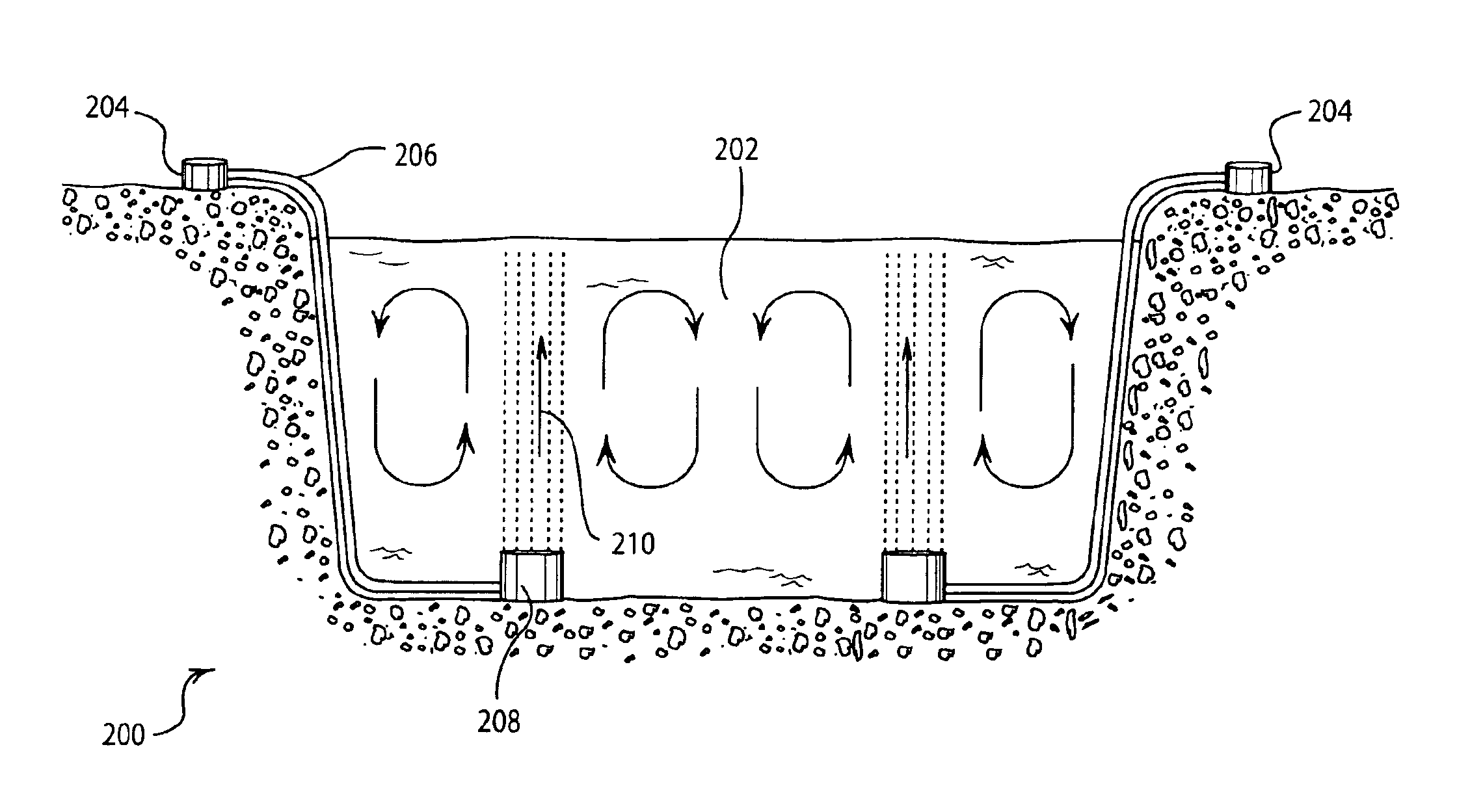

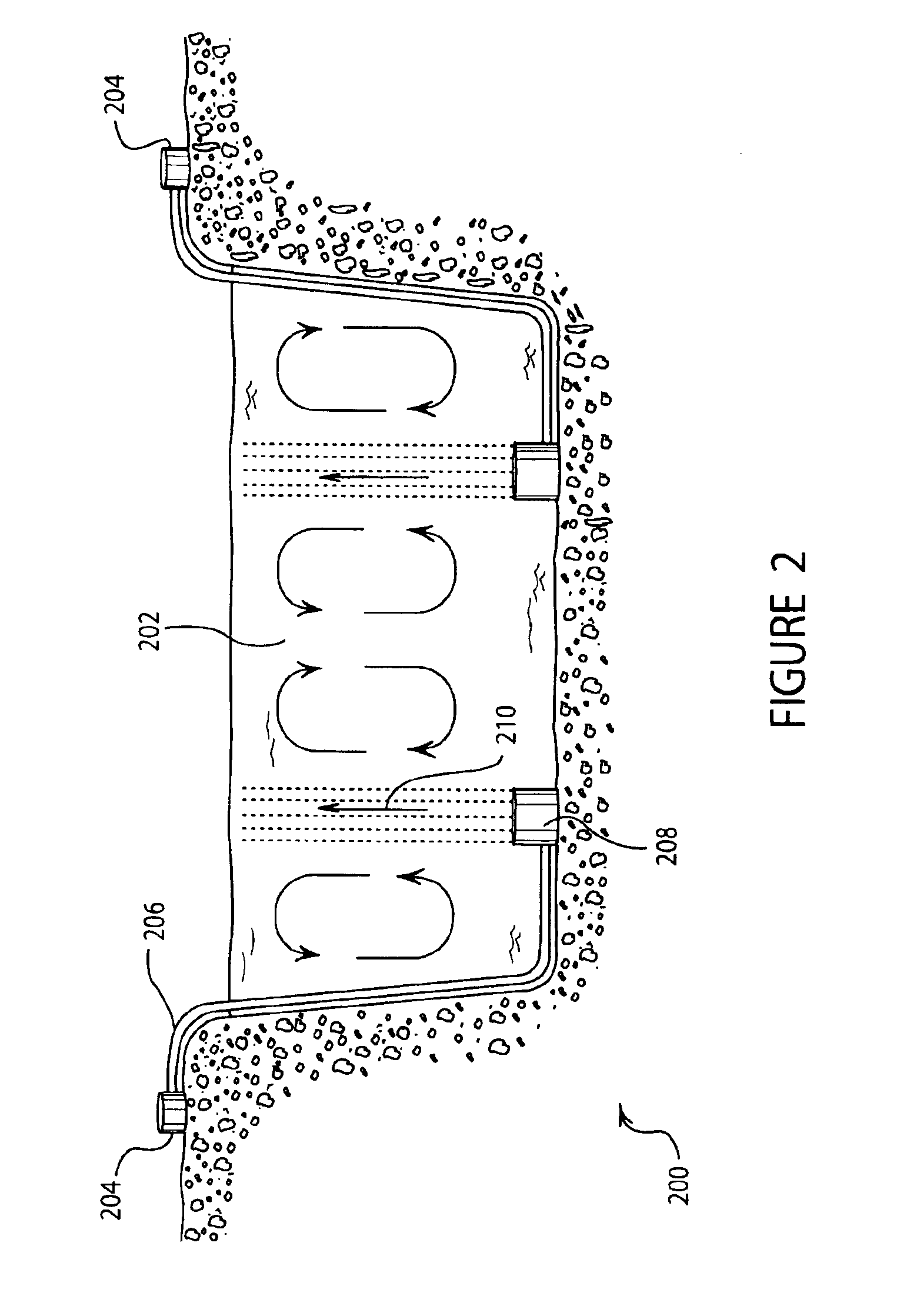

InactiveUS7279104B2Efficiently and effectively break down solid and liquid wasteEfficiently circulatedTreatment using aerobic processesEnergy based wastewater treatmentBiological wasteWaste treatment

Owner:WATERPURE TECH +1

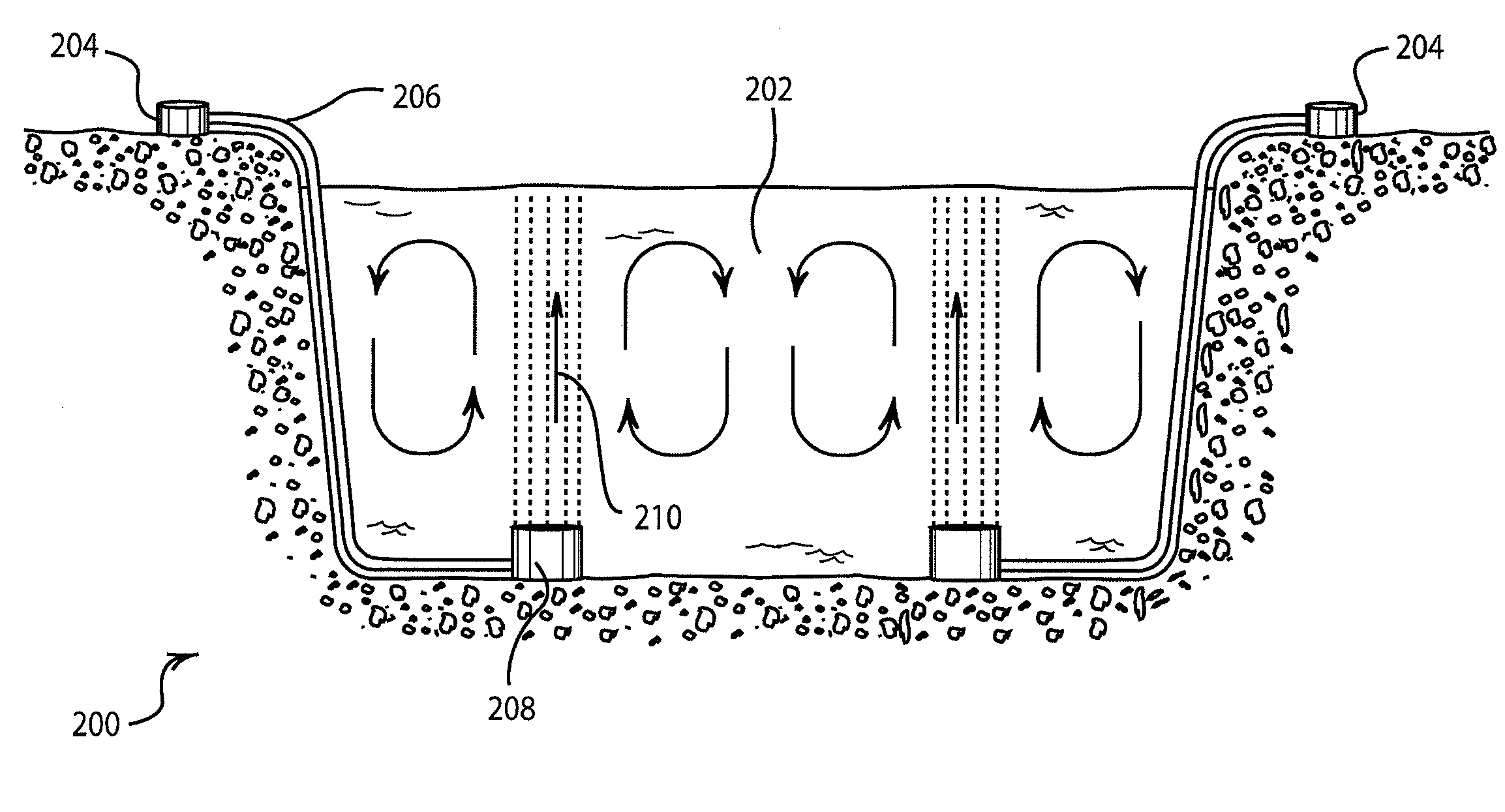

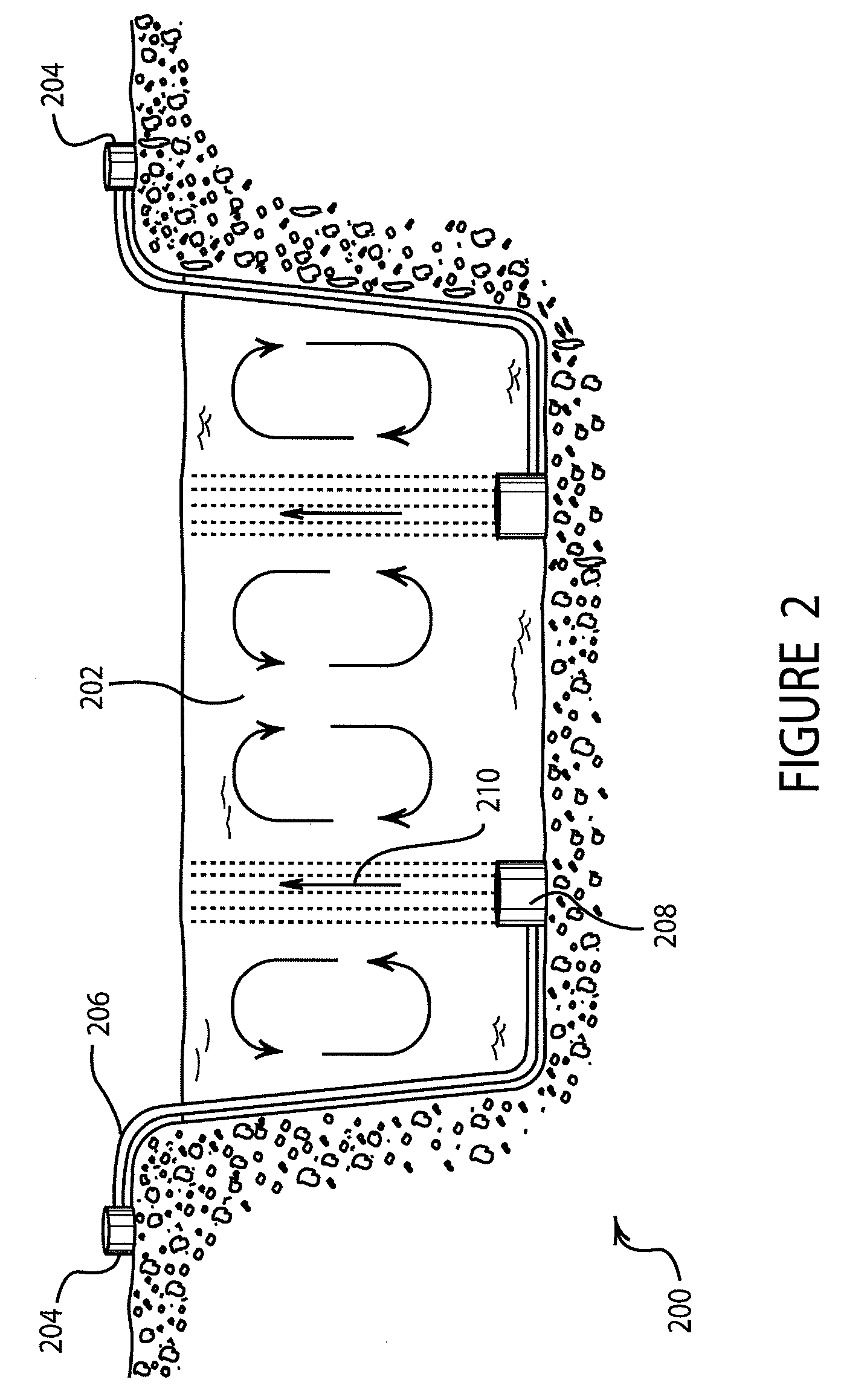

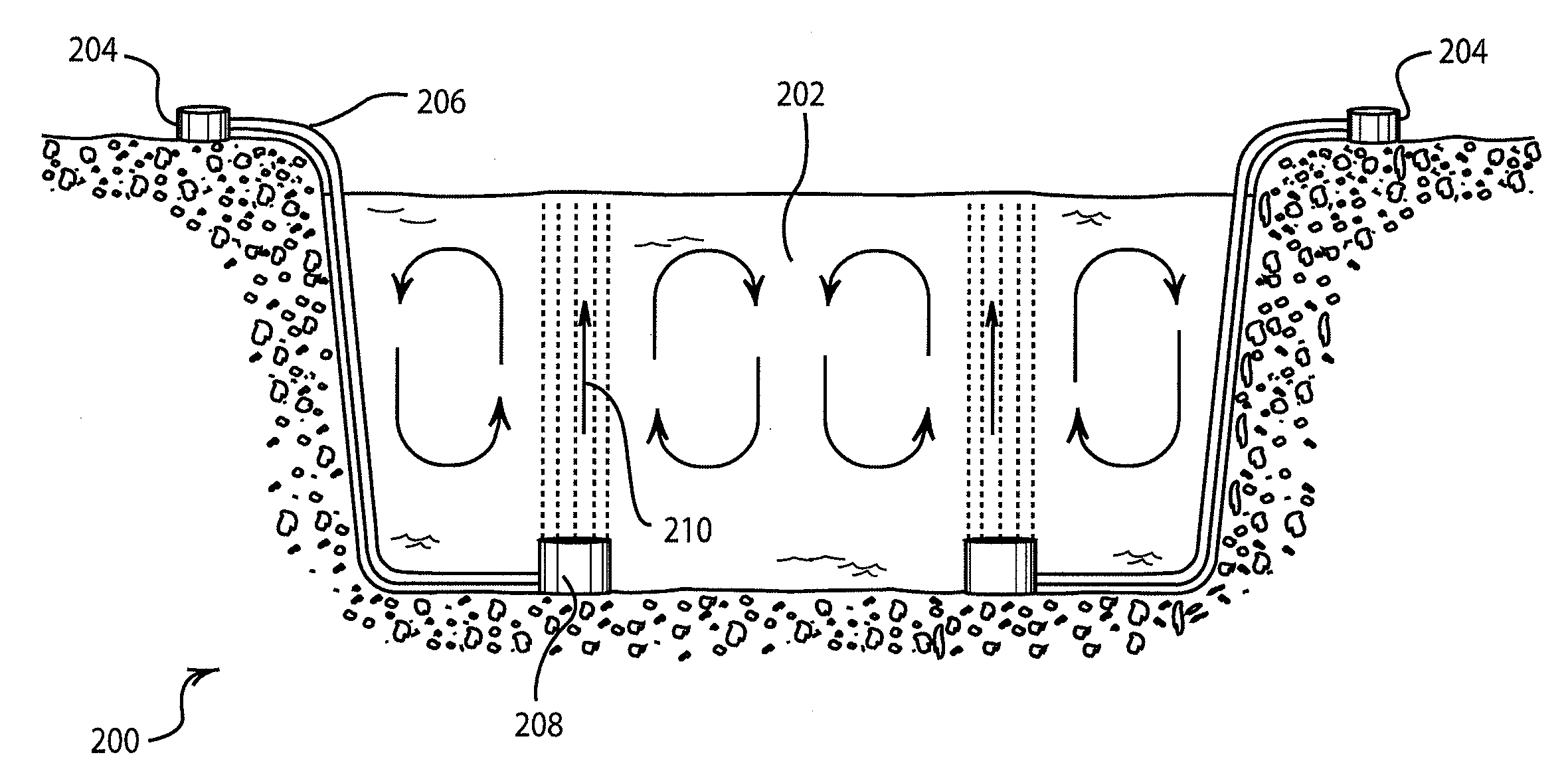

Waste treatment method

InactiveUS20060186042A1Small amount of energySignificant degreeTreatment using aerobic processesEnergy based wastewater treatmentEngineeringEnvironmental engineering

Disclosed is a system and method for treating domestic and industrial biological waste using diffusers to force circulation and aerate a treatment lagoon. Several lagoons may be used in series to treat raw waste and different variations may be employed to stepwise process the waste. A blend of aerobic and anaerobic microbes is chosen to remove undesired species initially present in the waste or later formed therein, as well as to process the waste itself, depending on the nature of the waste. Aeration with slightly ozonated or oxygenated air facilitates rapid and complete processing of large amounts of waste.

Owner:WATERPURE TECH +1

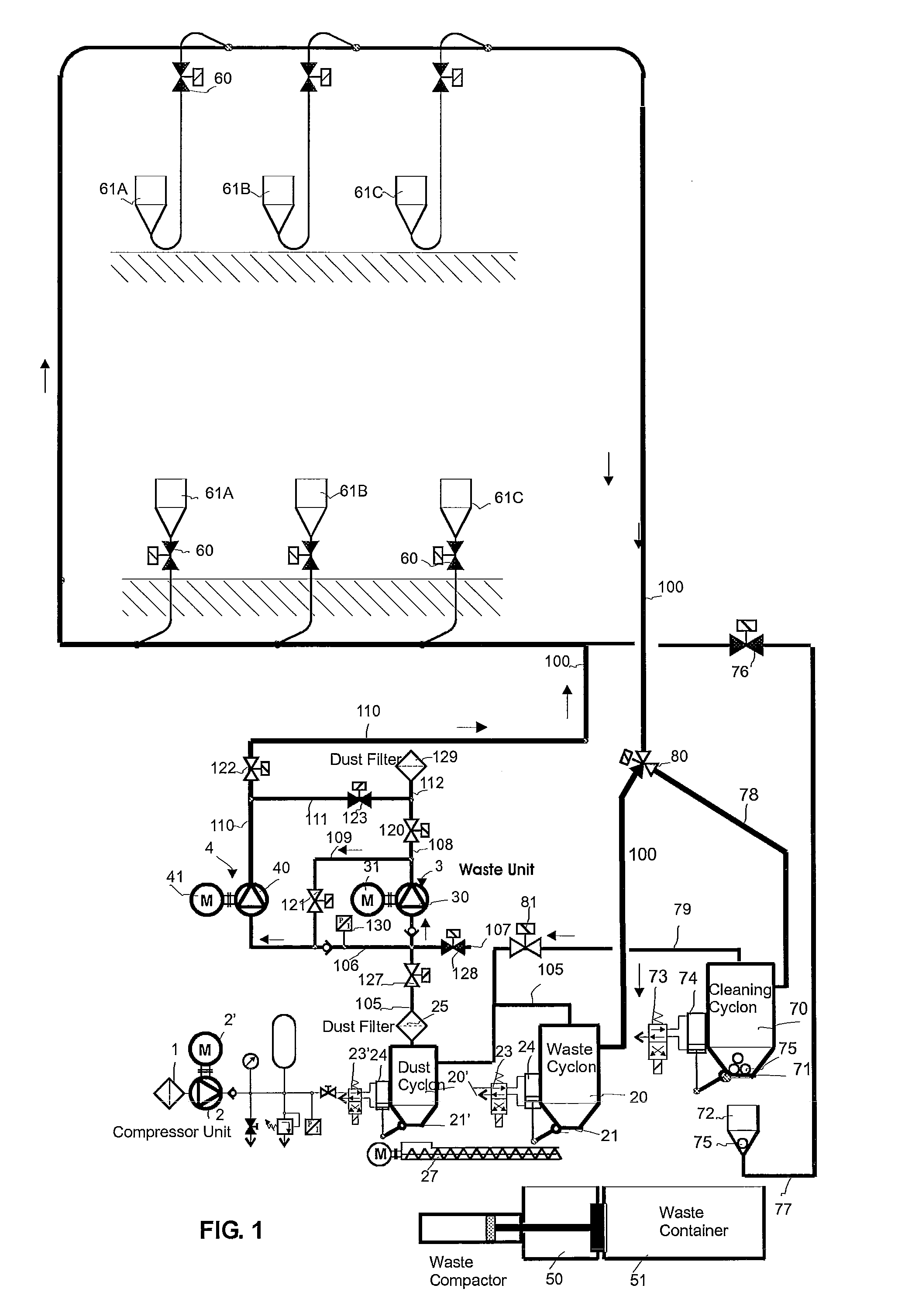

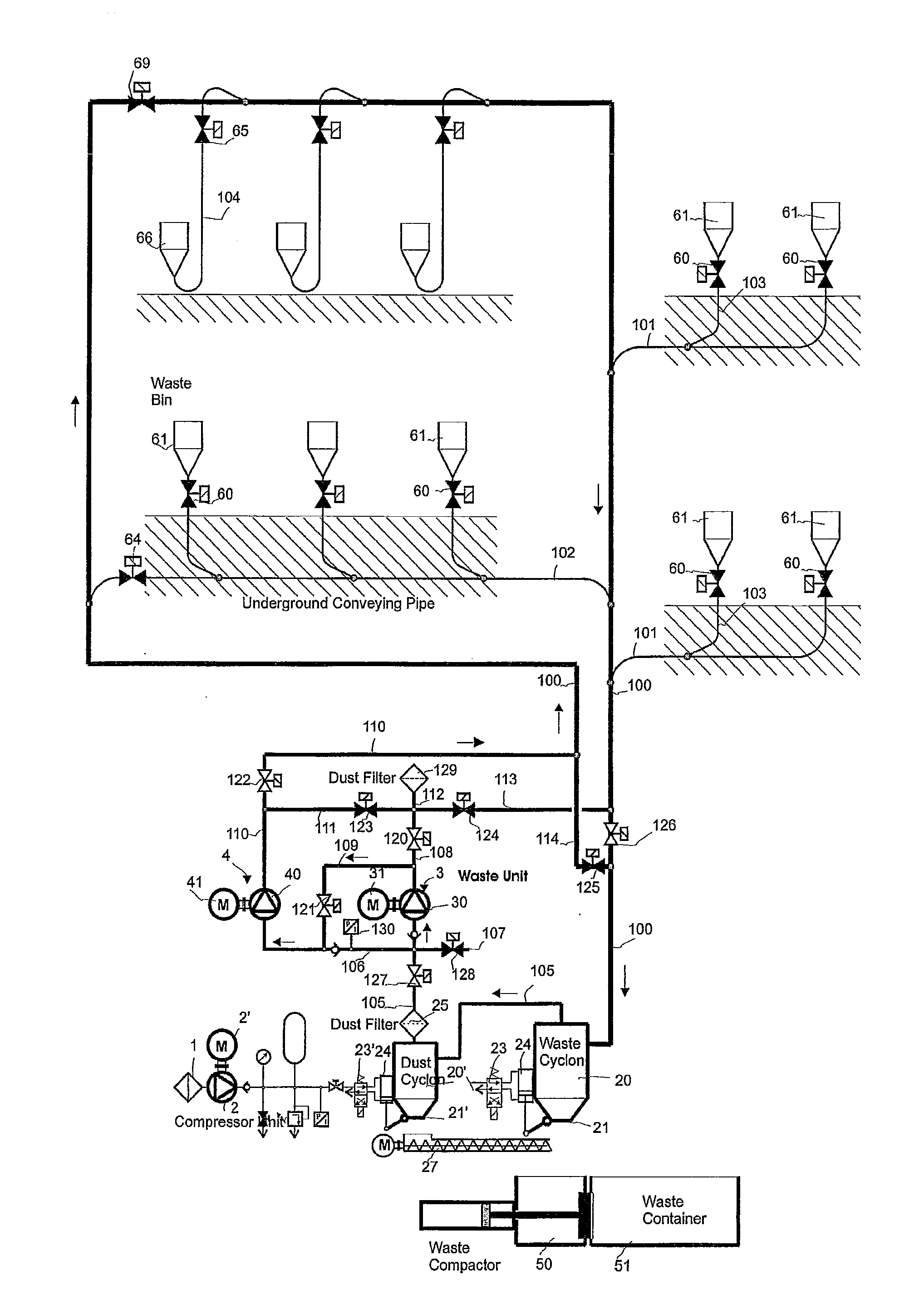

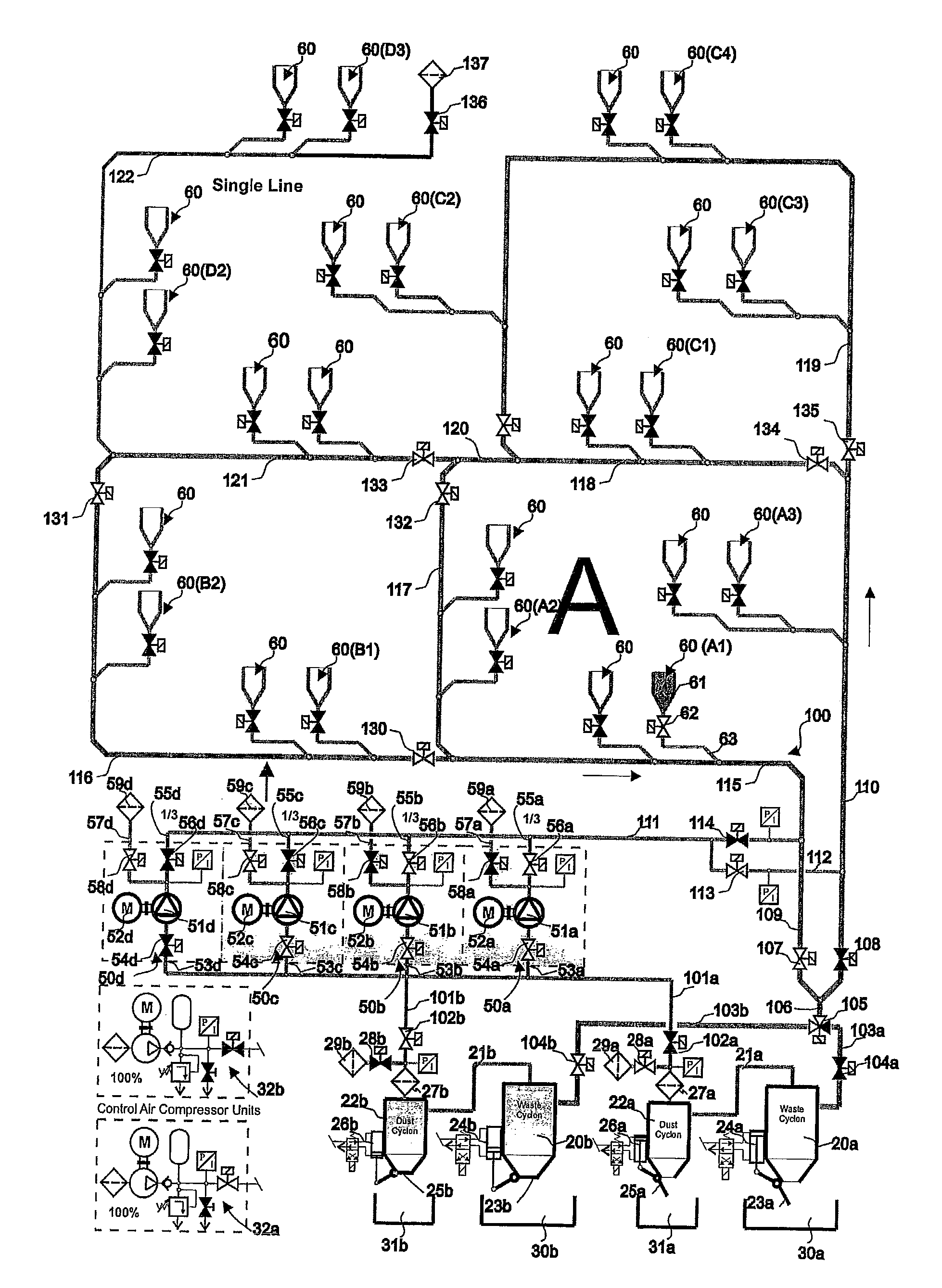

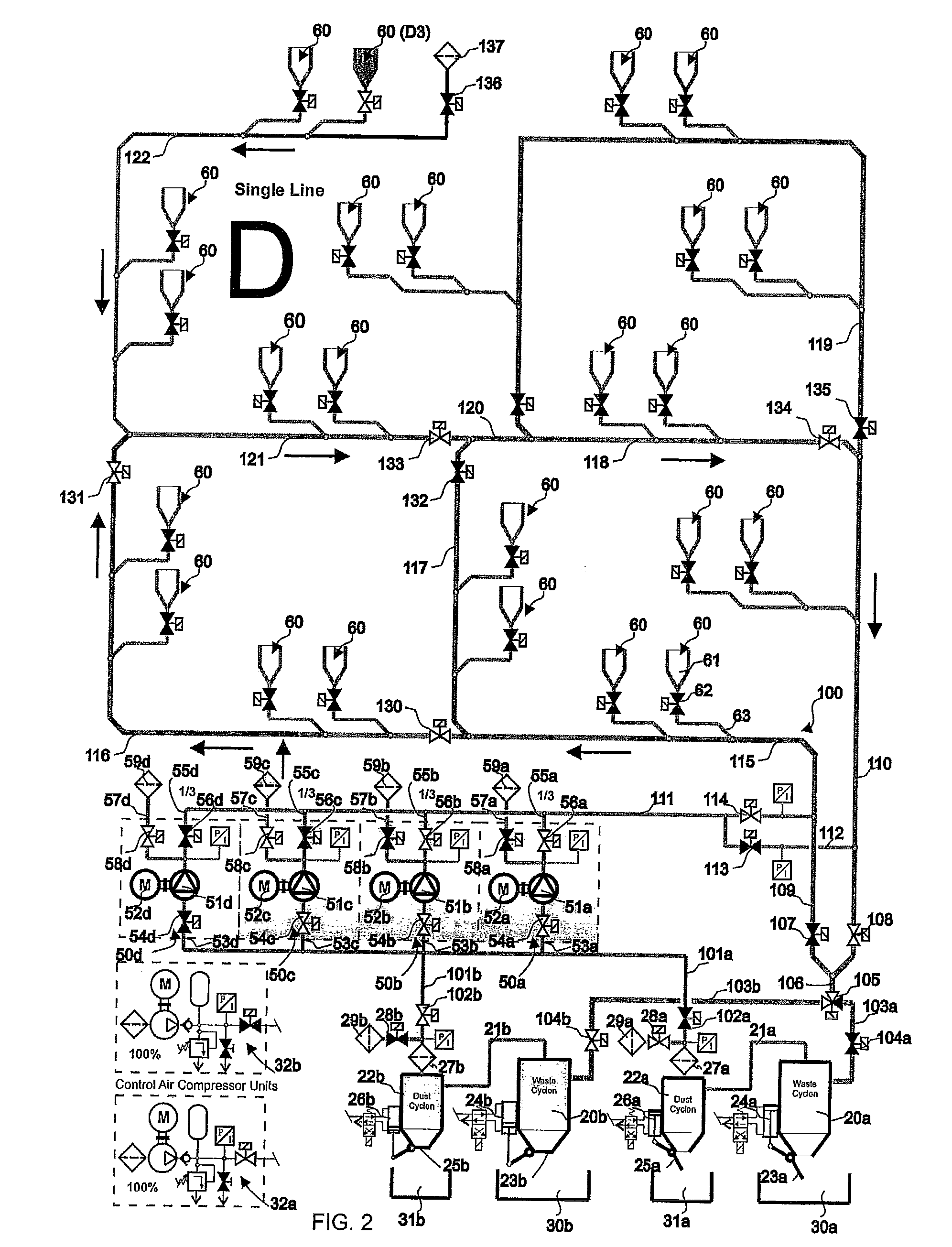

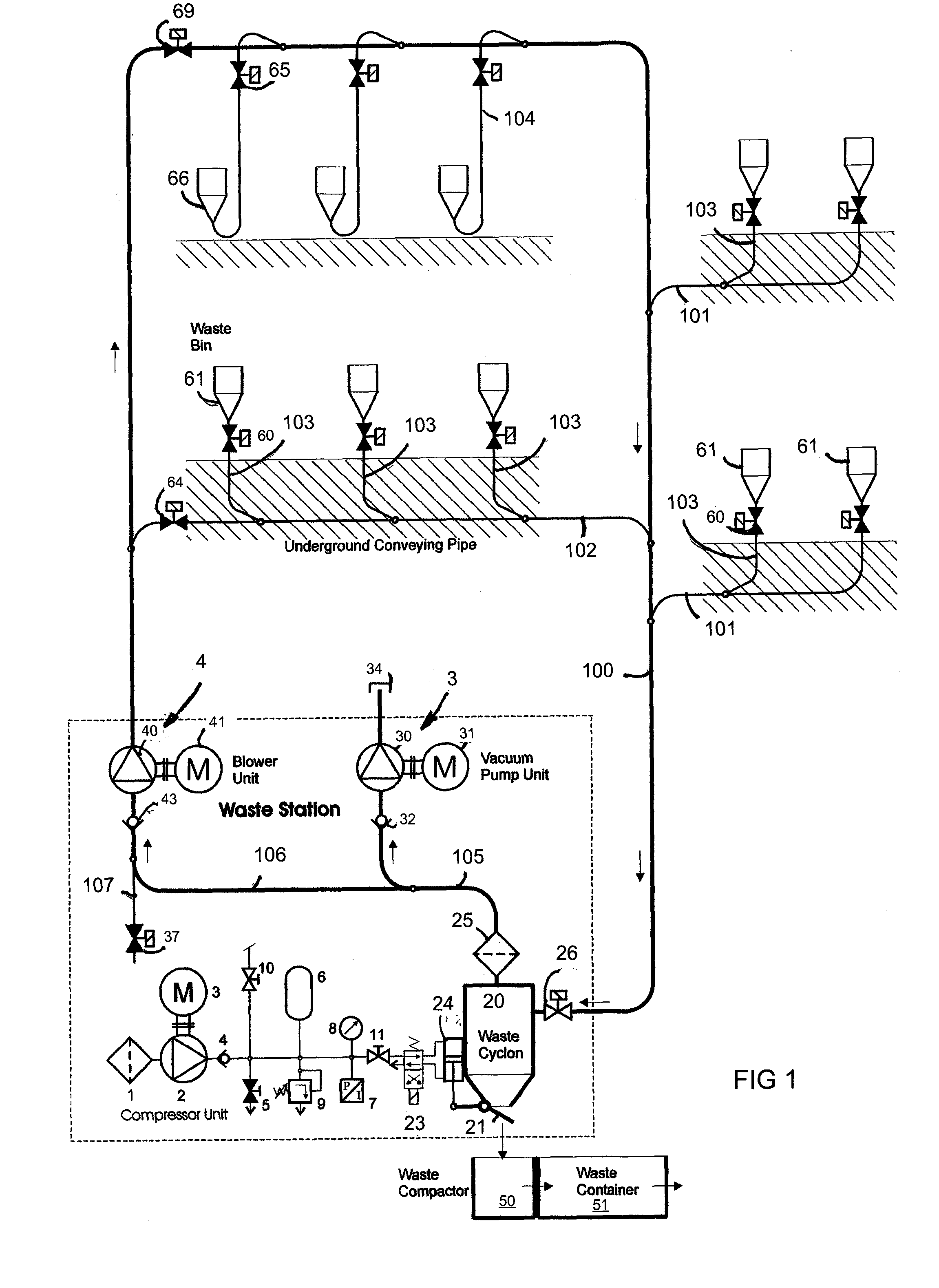

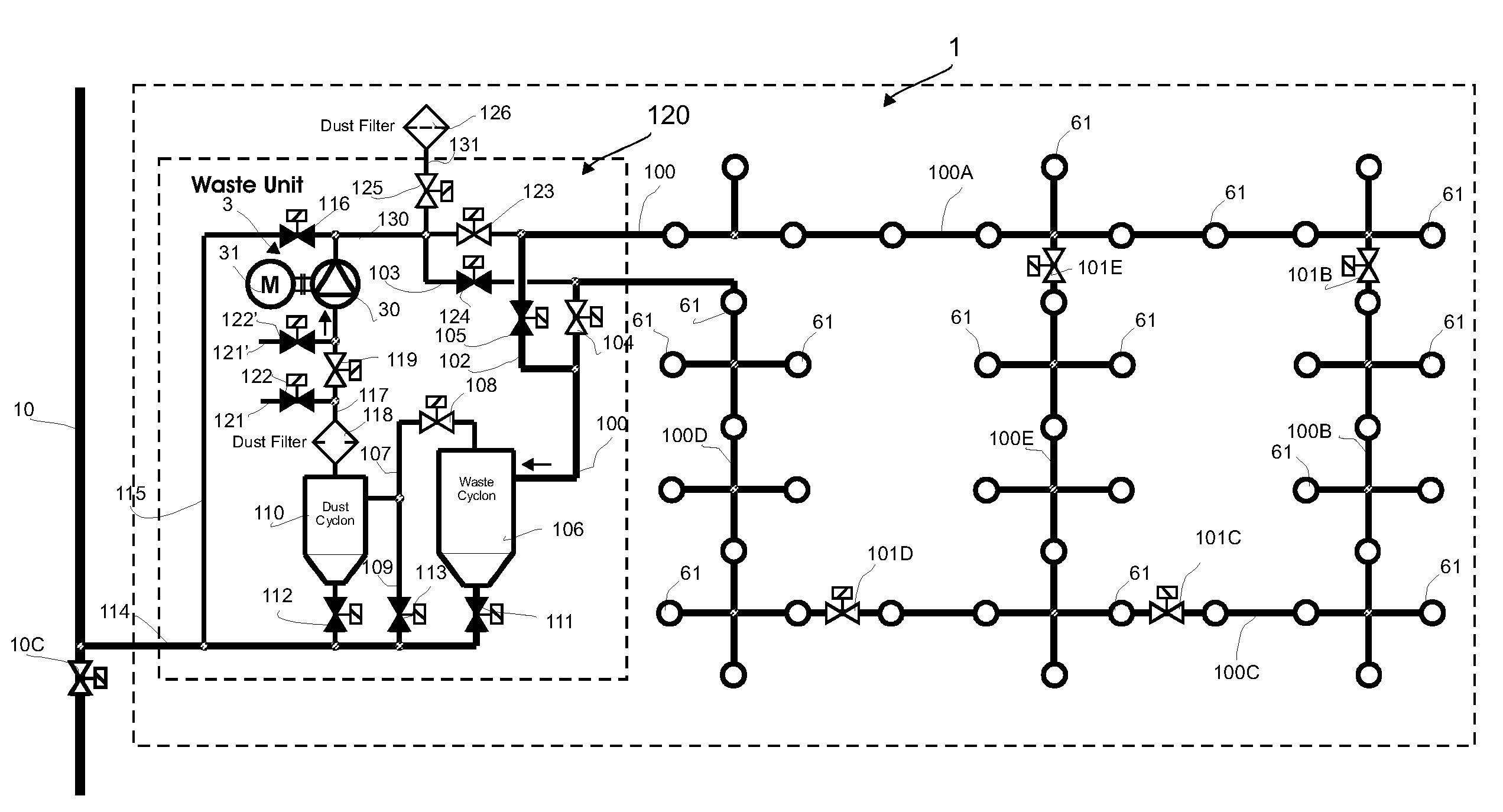

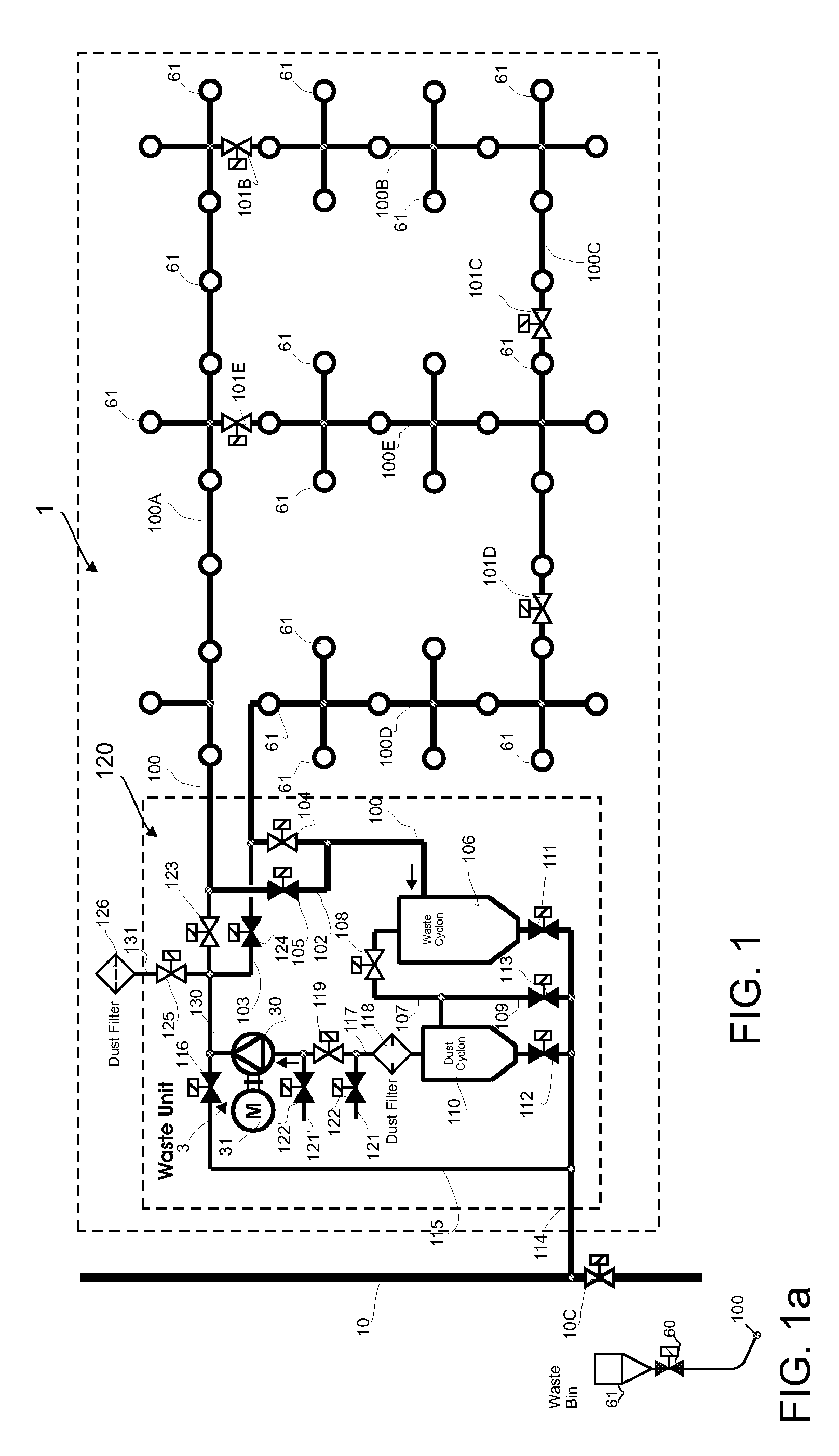

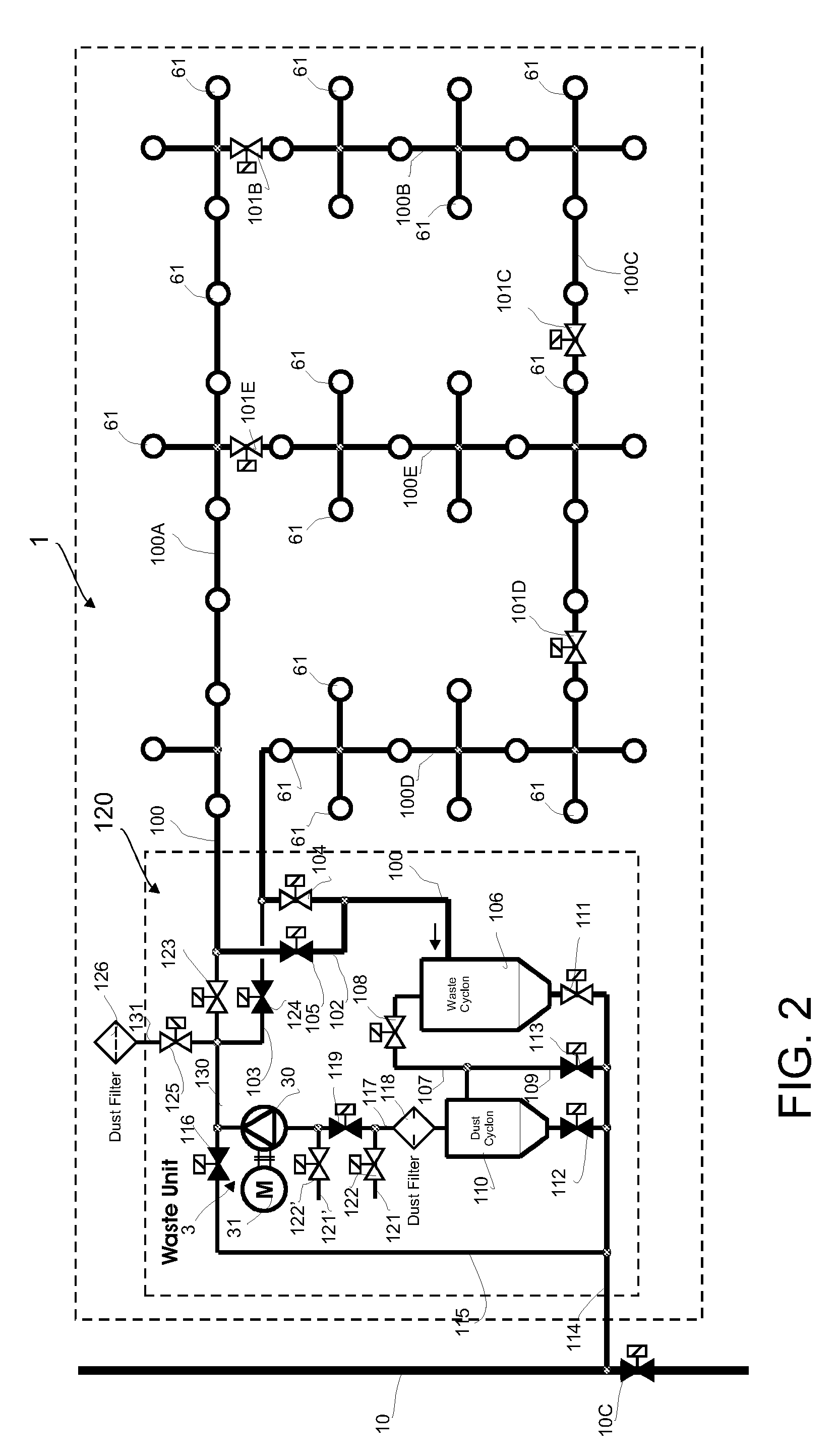

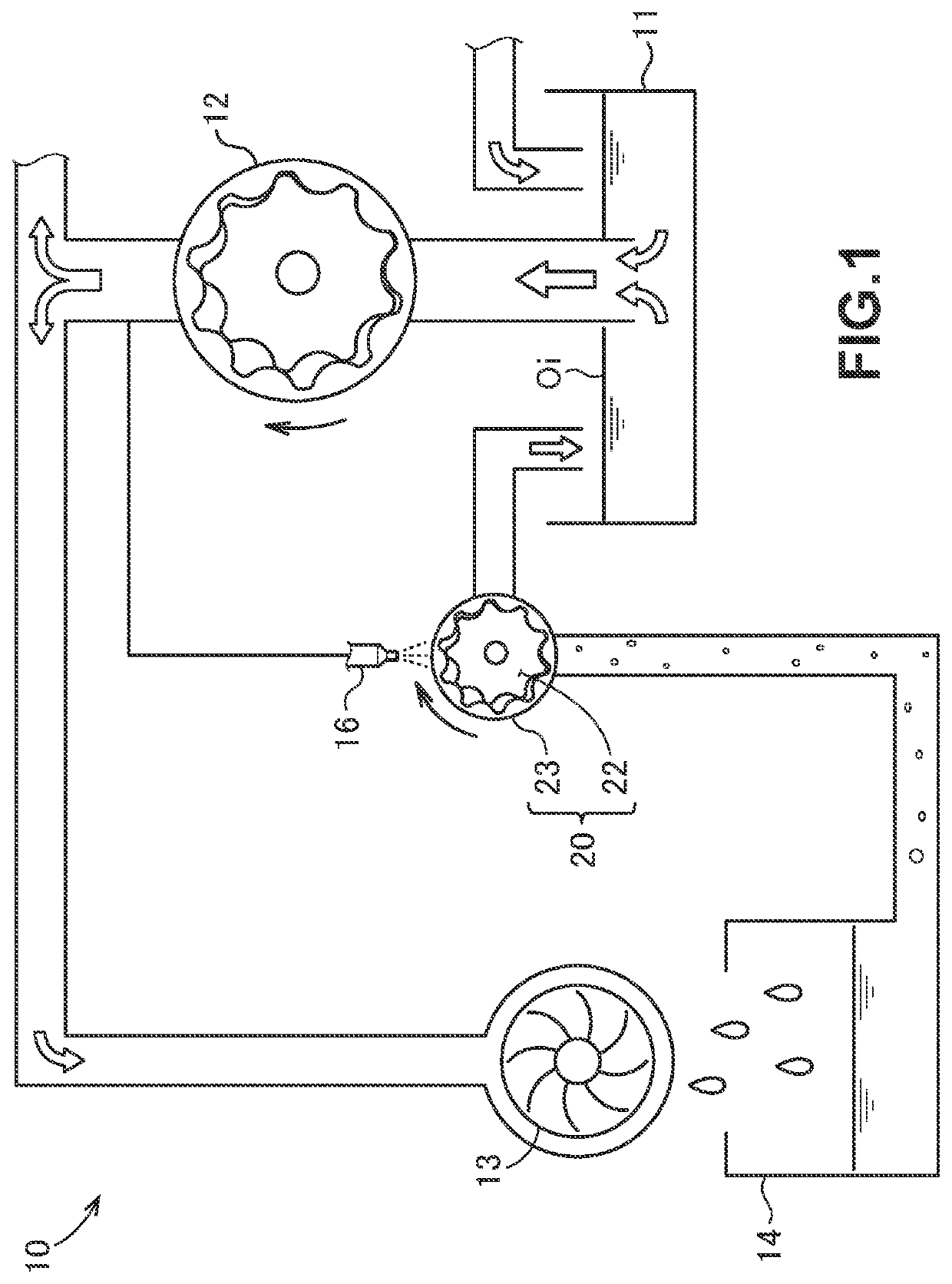

Pneumatic material conveying system

InactiveUS20100296880A1Guarantee effective circulationLower the volumeRefuse gatheringBulk conveyorsPressure differenceDelivery system

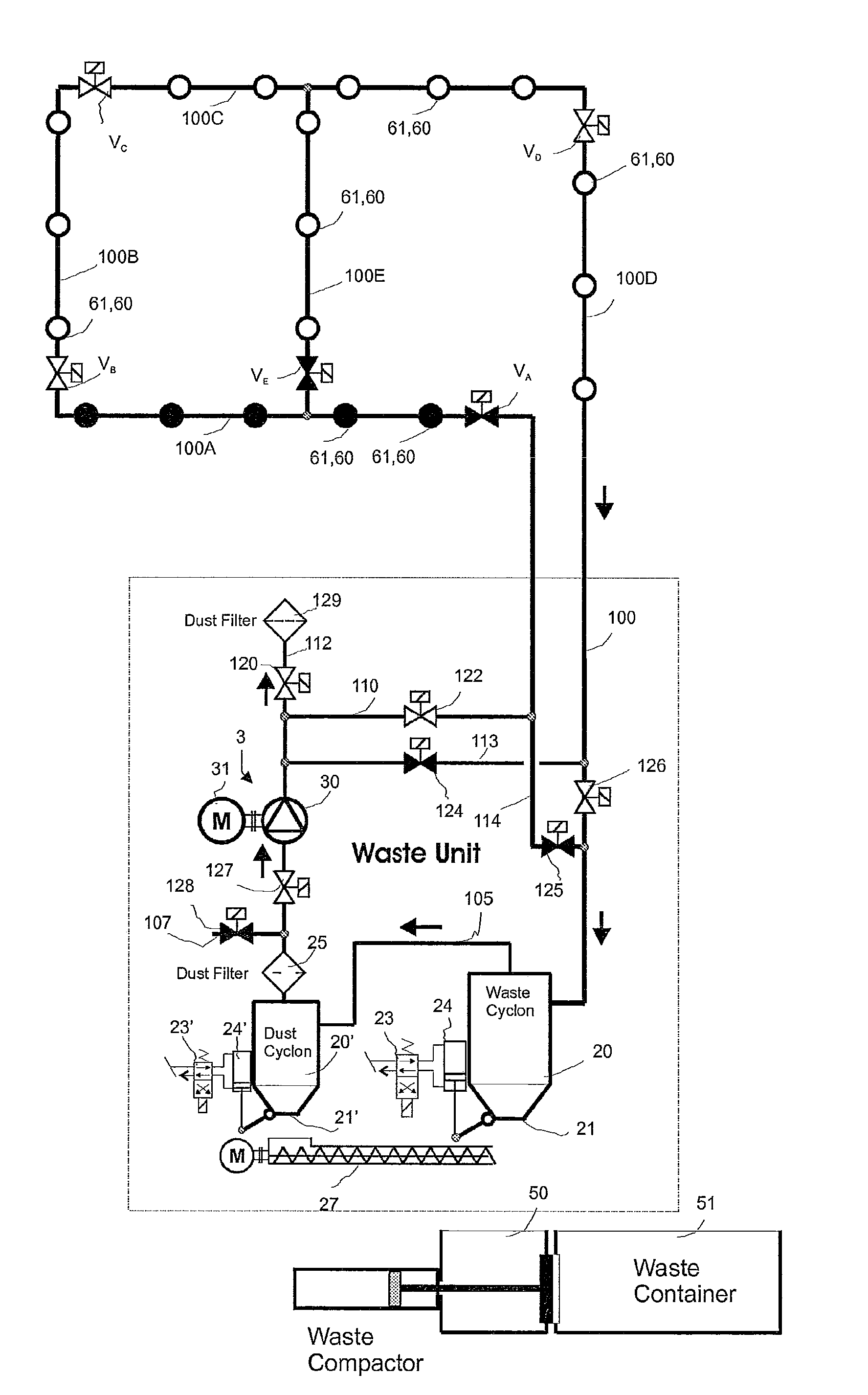

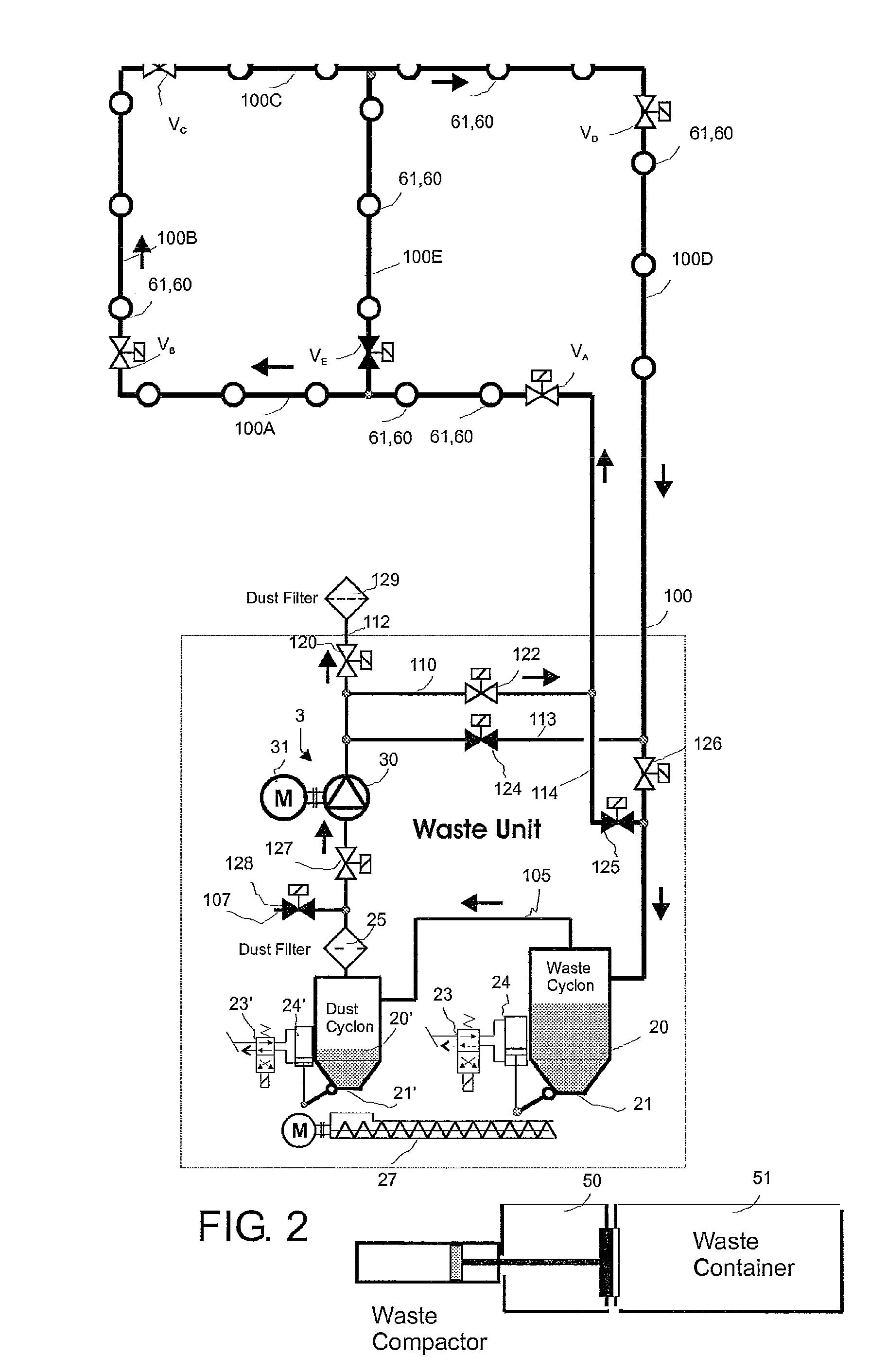

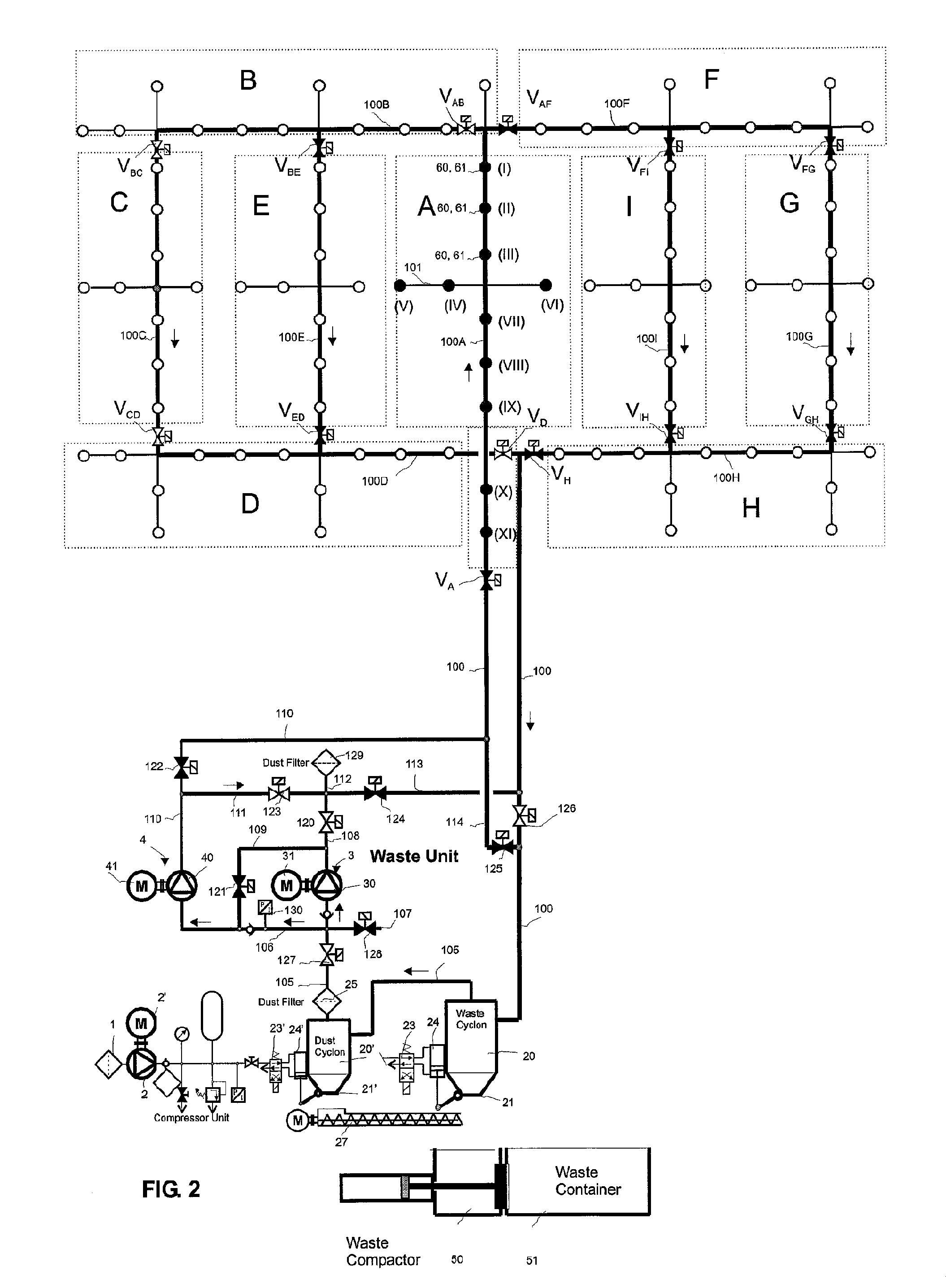

A pneumatic material conveying system, particularly a waste conveying system, which conveying system comprises at least one feed point (61, 66) of material, particularly of waste material, a material conveying pipe (100, 101, 102) which is connectable to the feed point (61, 66), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100, 101, 102) at least during the conveyance of the material. At least a part of the conveying pipe (100) and conveying air channels (105, 106) is formed as at least one circuit in which the suction side of at least one vacuum generator (3) is connected, and the system comprises at least one blower device (4) the suction side of which is connected to the air channel (105, 106) coming from the separator device (20) of the circuit and the blowing side to the conveying pipe (100) or a section of the circuit in connection with the conveying pipe so that it is possible to circulate air with the blower device (4) in said circuit.

Owner:MARICAP OY

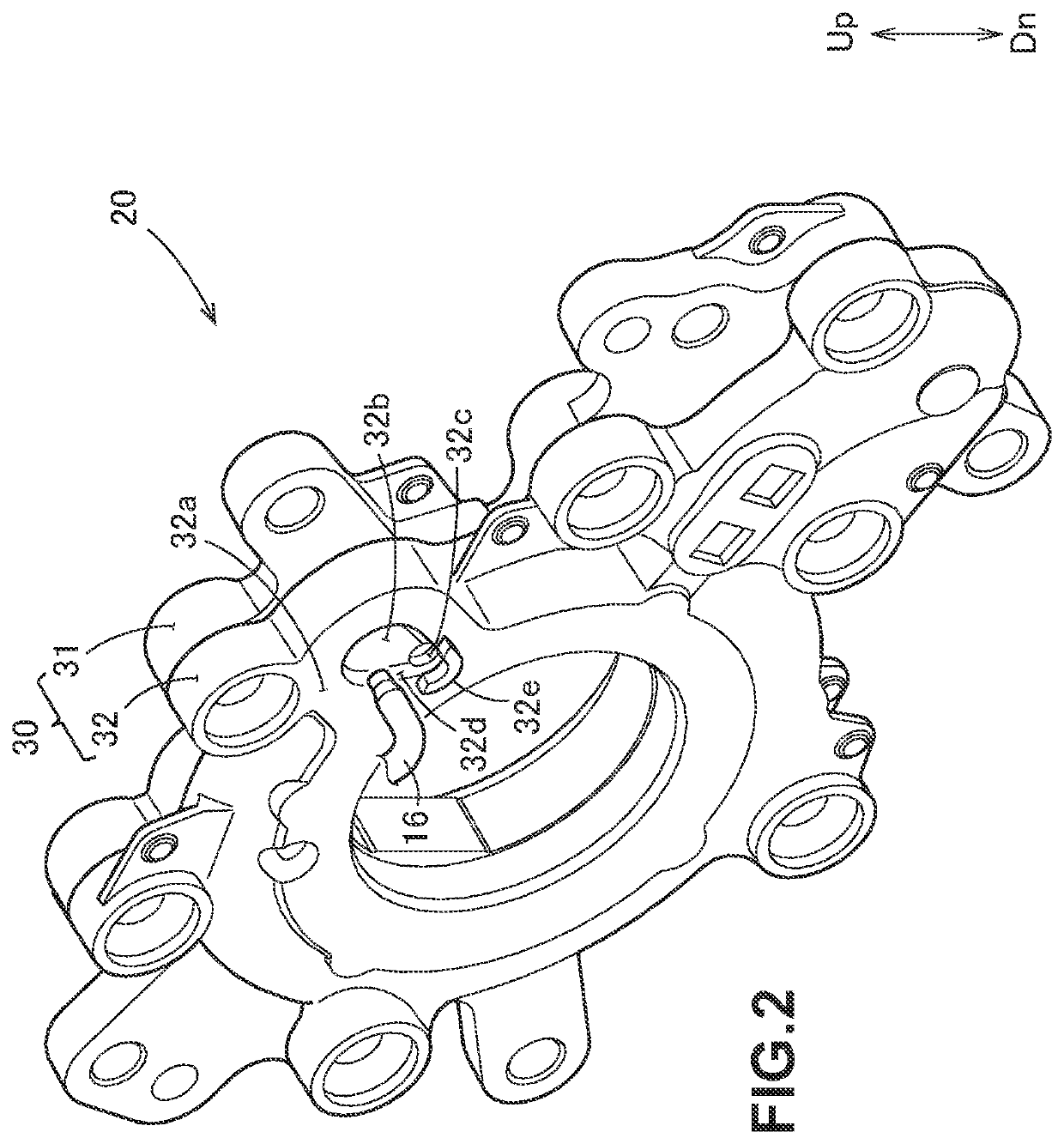

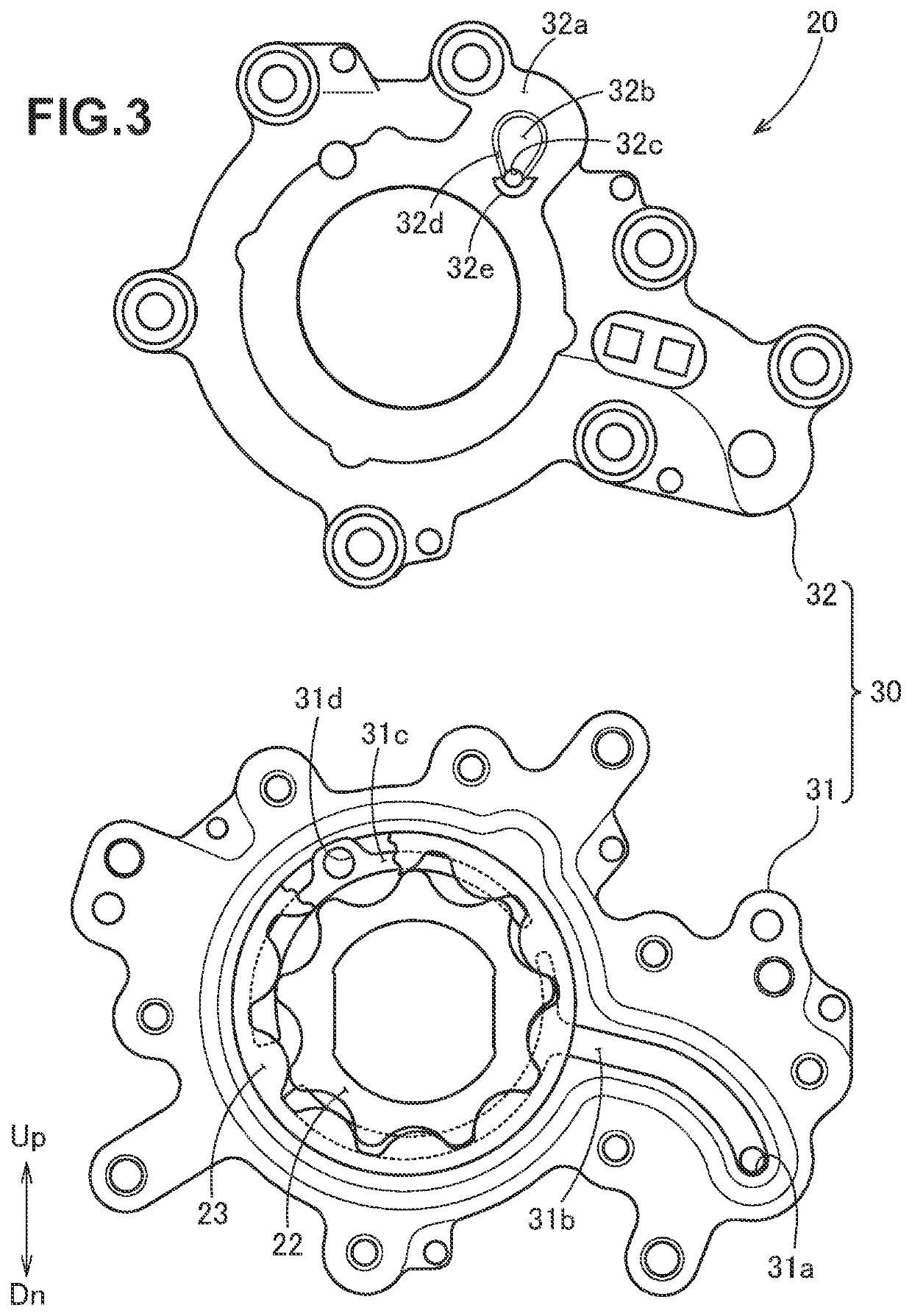

Accessory arrangement for a refrigerator door and can holder for a refrigerator

InactiveUS20060010829A1Useful widthEfficiently circulatedLighting and heating apparatusBuilding componentsEngineeringRefrigerated temperature

An accessory arrangement for a refrigerator door, and accessories being in the form of can holders (20), median shelves (30), wire frame shelves (30a), and other means for supporting the products to be refrigerated, said door (10) of the refrigerator having an internal wall (11) carrying retaining means (12), which are identical to each other and disposed according to horizontal rows and vertical columns, each retaining means (12) being able to receive and retain, simply by fitting a respective engaging means (40) incorporated to one of said accessories to be removably affixed to the internal wall (11) of the door (10). The distances between the vertical columns of the retaining means (12) and the widths of the accessories are designed so that the useful width of said internal wall (11) is fully occupied with multiple accessories adjacently disposed side by side.

Owner:MULTIBRAS SA ELETRODOMESTICOS

Method and apparatus in pneumatic material conveying system

InactiveUS20100310327A1Efficiently circulatedLower the volumeBulk conveyorsRefuse gatheringPressure differenceDelivery system

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material with a pump device (3) the suction side of which is connected to at least one separator device (20) and further to the conveying pipe (100) on its return side so that at least part of conveying air on the pressure side of the pump is led in the circuit on the supply side of the conveying pipe (100).

Owner:MARICAP OY

Method and apparatus in pneumatic material conveying system

InactiveUS20100307537A1Improve automationEfficiently circulatedMechanical cleaningPressure cleaningEngineeringPressure difference

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material with at least one first pump device, such as a vacuum unit (3), and with at least one second pump device, such as a blower unit (4).

Owner:MARICAP OY

Method and apparatus in pneumatic material conveying system

InactiveUS20100272520A1Easy to cleanEasy to performBulk conveyorsRefuse gatheringEngineeringPressure difference

A method for sortingly conveying materials in a pneumatic material conveying system, such as a waste conveying system, in which method, material being conveyed is fed from at least one feed point and conveyed in a conveying pipe (100) by means of a pressure difference to a reception point in which the material is separated from conveying air in a separator device (20). In the method, different material sorts are fed from one or more feed points (61A, 61B, 61C) at a time and conveyed to a reception site for at least a part of the conveying travel in the same conveying pipe and, in the method, at least a part of the conveying pipe (100) is cleaned between the conveying processes of different materials or at least when required.

Owner:MARICAP OY

Waste stream digestion method

InactiveUS6929746B2Less amountSignificant degreeBio-organic fraction processingTreatment using aerobic processesMicroorganismWaste stream

Disclosed is a system and method of digesting raw animal waste using diffusers to force circulation and aerate a digesting lagoon. Several lagoons may be used in series to treat raw waste and different variations may be employed to successively digest raw waste. Aeration with slightly ozonated air facilitates a blend of aerobic and anaerobic microbes to quickly and completely digest large amounts of raw animal waste.

Owner:KEETON JR JIMMIE A

Method in pneumatic material conveying system and a pneumatic material conveying system

InactiveUS20100303559A1Efficient arrangementLower the volumeBulk conveyorsRefuse gatheringEngineeringPressure difference

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material with at least one first pump device, such as a vacuum unit (3), and with at least one second pump device, such as a blower unit (4).

Owner:MARICAP OY

Method and apparatus in a pneumatic materials moving system

InactiveUS20120201614A1Good effectLower the volumeRefuse gatheringBulk conveyorsAir cyclePressure difference

Method in a pneumatic materials moving system, having at least one input point with a material transfer pipe connected to an input point. At least one separating device, in which the material to be conveyed is separated from the conveying air. A pressure difference and / or a conveying air current in the transfer pipe. At least during conveyance of the material with at least one pump unit at least one transfer pipe section in which conveying air is circulated and at least one transfer pipe section in which conveying air is not circulated. The conveying route of the material in the transfer piping is formed partly from the transfer pipe section in which conveying air is not circulated and partly from the transfer pipe section in which conveying air is circulated.

Owner:MARICAP OY

Liquid circulating device and medical apparatus

InactiveUS20130243616A1Guaranteed smooth progressEfficiently circulatedFlexible member pumpsFluid jet surgical cuttersElectrical resistance and conductanceInlet channel

A liquid circulating device includes a pump chamber whose volume is changed by a volume changing unit; an inlet channel that is an inflow passage of the liquid to the pump chamber; a liquid resistance element; an outlet channel; a circulation channel of a length L through which the liquid circulates from the outlet channel to the inlet channel; and a pressure regulating mechanism that contains the liquid of a volume Vb during the non-operation of the volume changing unit and supplies the contained liquid as part of the circulating liquid during the operation of the volume changing unit. When the compliance of the circulation channel is defined as Cs, and the pressure of the liquid in the circulation channel at the position of a length x from the outlet channel during the operation of the volume changing unit is defined as P(x), the volume Vb satisfies a predetermined relationship.

Owner:SEIKO EPSON CORP

Method in pneumatic material conveying system and a pneumatic material conveying system

InactiveUS20100278598A1Efficiently arrangedEfficiently circulatedRefuse gatheringBulk conveyorsEngineeringPressure difference

A method for feeding and conveying material in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. Underpressure is provided in the conveying pipe (100) at least at the point of the feed point (61) intended to be emptied, the feed points are emptied to the conveying pipe (100) using an emptying sequence in which first is emptied a feed point located closer to the separator device (20) in the material conveying direction and next a feed point (61) located substantially farther from the separator device (20) in the material conveying direction.

Owner:MARICAP OY

Method and apparatus in pneumatic material conveying system

InactiveUS20100278596A1Guarantee effective circulationLower the volumeRefuse gatheringBulk conveyorsAir cyclePressure difference

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material and, in the method, conveying air circulation is connected, at least momentarily, to a reverse direction in relation to the normal conveying direction, at least in a section of the circuit, which section of the circuit is formed by at least a part of the conveying pipe (100), advantageously for removing a possible blockage.

Owner:MARICAP OY

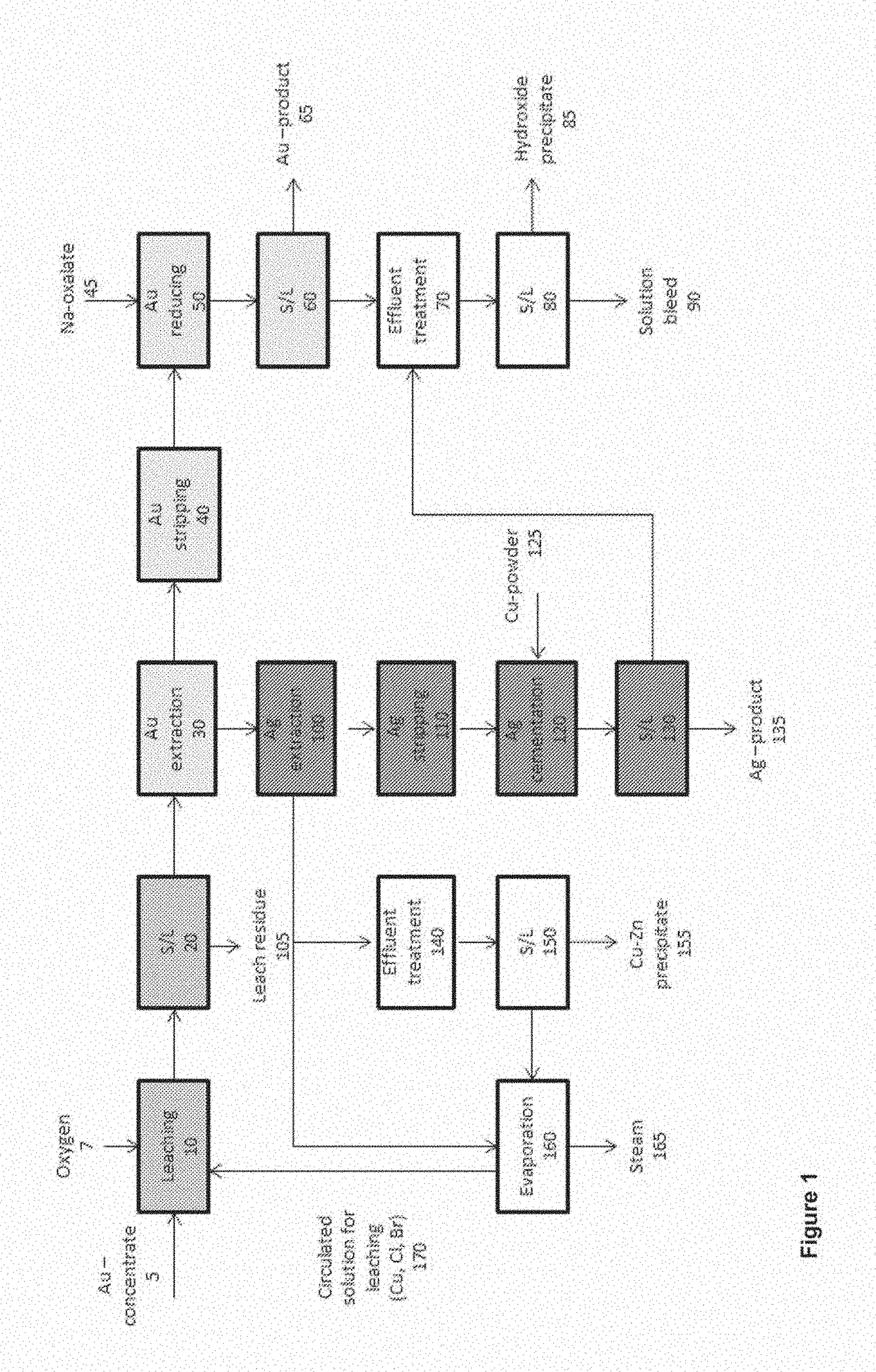

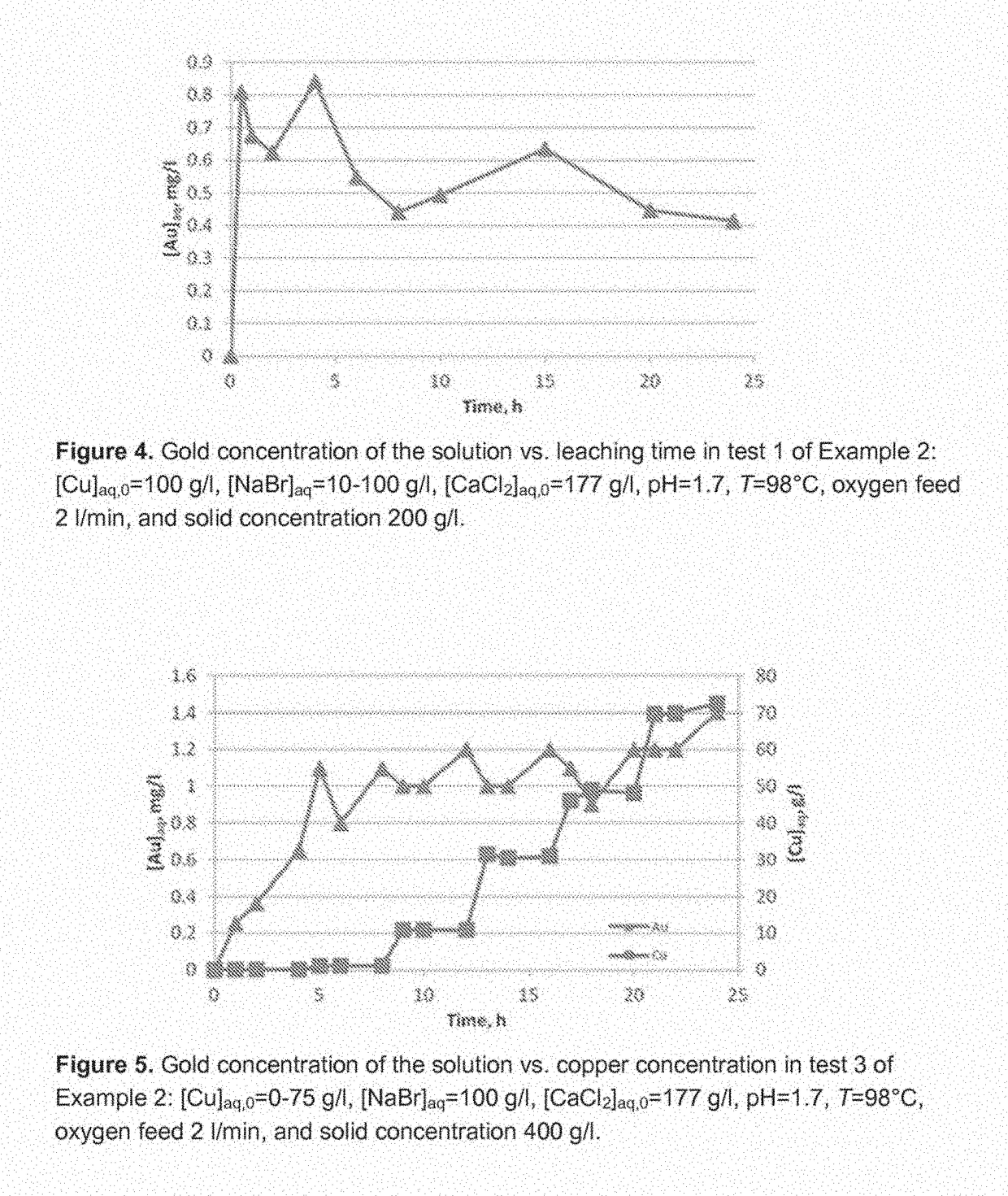

Method of preparing a gold-containing solution and process arrangement for recovering gold and silver

ActiveUS20160068927A1High yieldGuarantee effective circulationProcess efficiency improvementChlorideMaterials science

The invention relates to a method for preparing a gold-containing solution by chloride leaching from gold-bearing raw materials. A further object of the invention is to provide a method for recovering gold and optionally silver from the prepared gold-containing solution. The invention relates also to a process arrangement for recovering gold and optionally silver.

Owner:METSO OUTOTEC (FINLAND) OY

Rotary degasser and rotor therefor

ActiveUS20110140320A1Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Inline fan housing assemblies

ActiveUS7374399B2Efficiently circulatedPump componentsLighting and heating apparatusImpellerEngineering

The present invention relates to an inline fan housing assembly adaptable for connection with conduits of various diameters. The inline fan housing assembly comprises a connector collar for connection to the inlet or exhaust ports of the fan housings to adapt the fan housings for connection to a variety of conduits having diameters not designed to connect with the inlet or exhaust ports of the fan housing. The inline fan housing assembly also comprises an inner inlet ring for adapting the inlet port of the inline fan housing to direct air into motorized impellor of various sizes mounted within the inline fan housing. The connector collars of the present invention contain one or more steps, each step suitable for connection with a conduit of a different diameter. In one exemplary embodiment, the inner steps of the connection collar are removable thereby allow for increased air flow through the connection.

Owner:ZEHNDER VERKAUFS UND VERW

Blood circulation system

ActiveUS20170224901A1Stably transferring bloodGuarantee effective circulationOther blood circulation devicesControl devicesControl cellNormal control

An artificial heart and lung apparatus includes a roller pump; a blood removal line; a first blood transfer line; a blood removal rate sensor; a control unit that performs the linked control of the roller pump in correspondence with a blood removal rate; and a blood transfer rate adjustment unit that instructs the roller pump to transfer a blood transfer rate. The blood transfer rate adjustment unit includes an operation amount input unit to which an operation amount from an arbitrary circumferential position can be input, and which outputs a pulse signal according to the input operation amount. A counter adds and subtracts pulse signals output from the operation amount input unit, and outputs a resultant as blood transfer rate adjustment data. The counter performs a counting operation with respect to the circumferential position of the operation amount input unit when blood transfer control transitions to the normal control.

Owner:SENKO MED INSTR MFG CO LTD

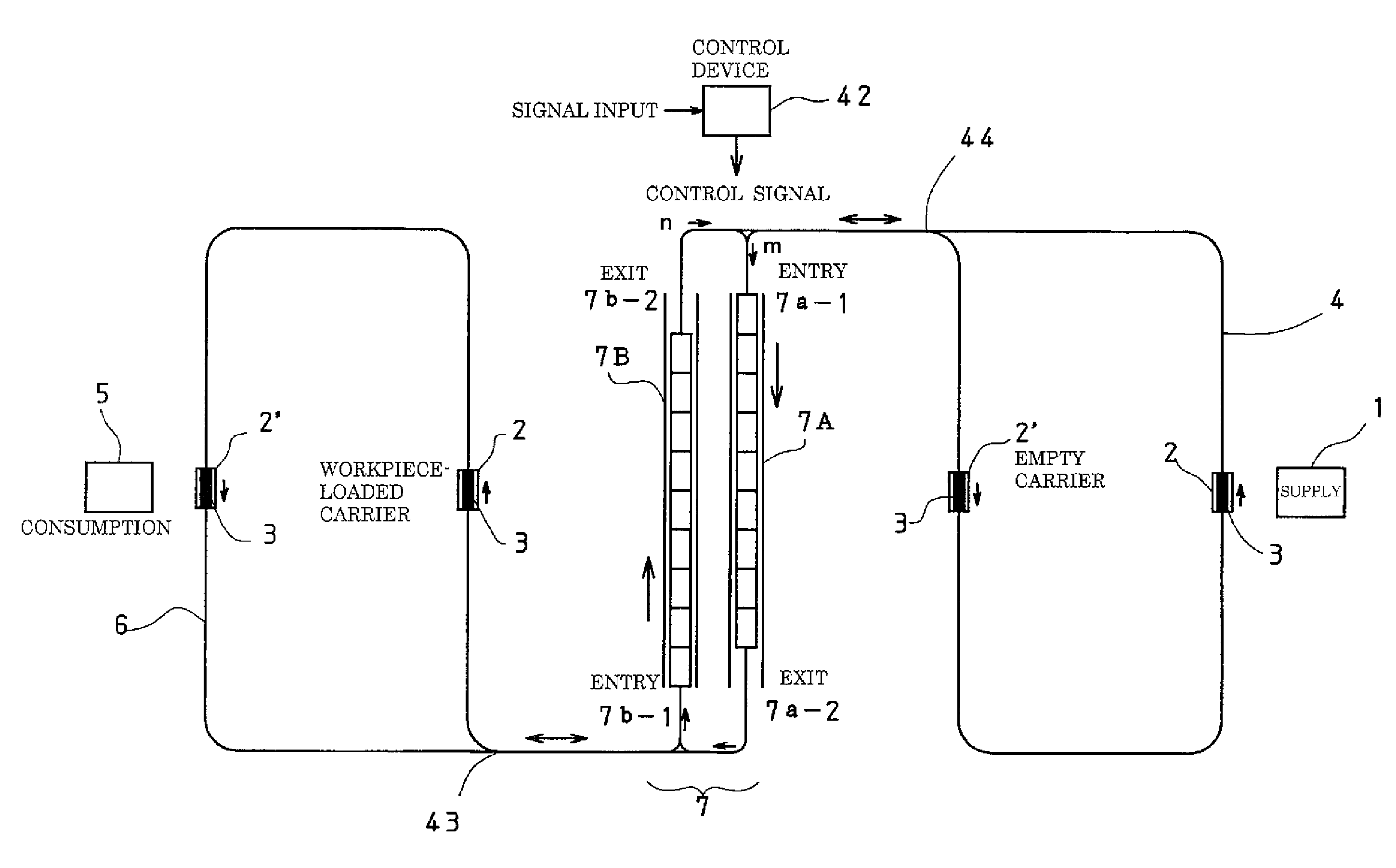

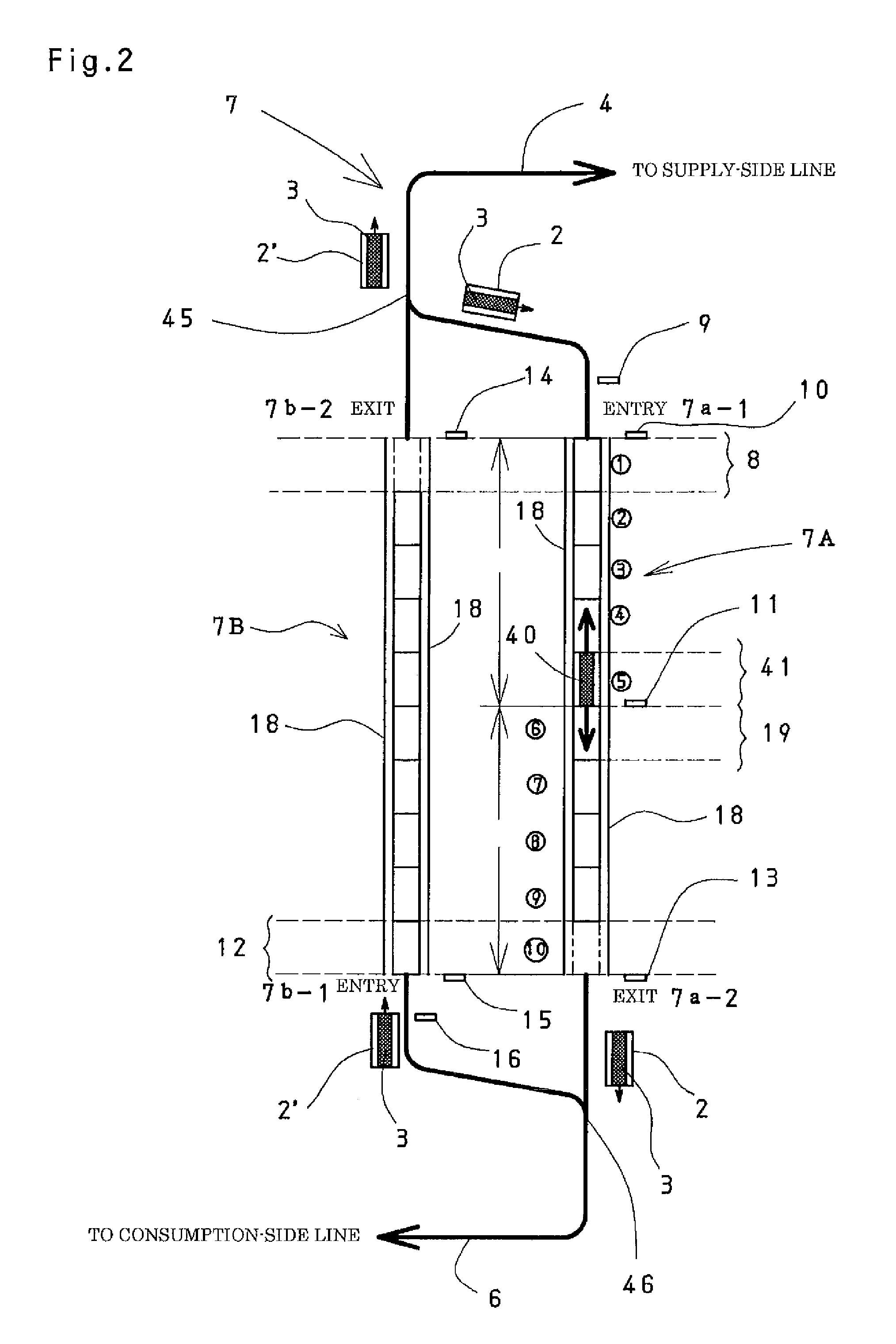

Workpiece transportation system comprising automated transport vehicles and workpiece carriers

InactiveUS20090317217A1Easy to createEasy to changeProgramme controlLifting devicesComputer control systemAutomated guided vehicle

A conveyance facility system for transporting an appropriate amount of work at a time at an appropriate time to the consumption side area by automatically controlling through a computer control system an automated guided vehicle for allowing a truck that has mounted the work in the supply side area to travel accompanying the vehicle from the supply side area to the consumption side area along the guidance course of the automated guided vehicle, and allowing the empty truck that has unloaded the work in the consumption side area to return to the supply side area. The work conveyance facility system comprises a plurality of work mounting trucks (2) for loading and conveying work, an automated guided vehicle (3) for allowing the work mounting truck (2) to travel accompanying the vehicle to a set position and releasing the truck thereat, and a guidance course of the automated guided vehicle (3). The guidance course is constituted of a supply side line (4) for loading the work onto the work mounting truck (2) in the supply area (1) and driving the truck, a consumption side line (6) for leading in the work mounting truck (2) and driving the empty work mounting truck (2′) that has unloaded the work in the consumption area (5), and a buffer line (7) for coupling the supply side line (4) with the consumption side line (6).

Owner:YAZAKI IND CHEM CO LTD

Method and apparatus in a pneumatic material conveying system, and a waste conveying system

InactiveUS20130004248A1Effective distributionGuaranteed uptimeBulk conveyorsRefuse gatheringThermodynamicsProcess engineering

Method in a pneumatic material conveying system, such as in a waste conveying system, which conveying system comprises at least one input point (61) of material, more particularly of waste material, a material conveying pipe (100), which can be connected to an input point (61), and a separating device, in which the material to be transferred is separated from the conveying air, and also means for achieving a pressure difference and / or a conveying air flow in the conveying pipe (100) at least during the transfer of material. In the method material is conveyed from an input point (61) to the separating means (106) or an accumulator tank of a subsystem (1), where the material is separated from the conveying air, and in a second phase the separating means (106) or the accumulator tank of the subsystem (1) is emptied.

Owner:MARICAP OY

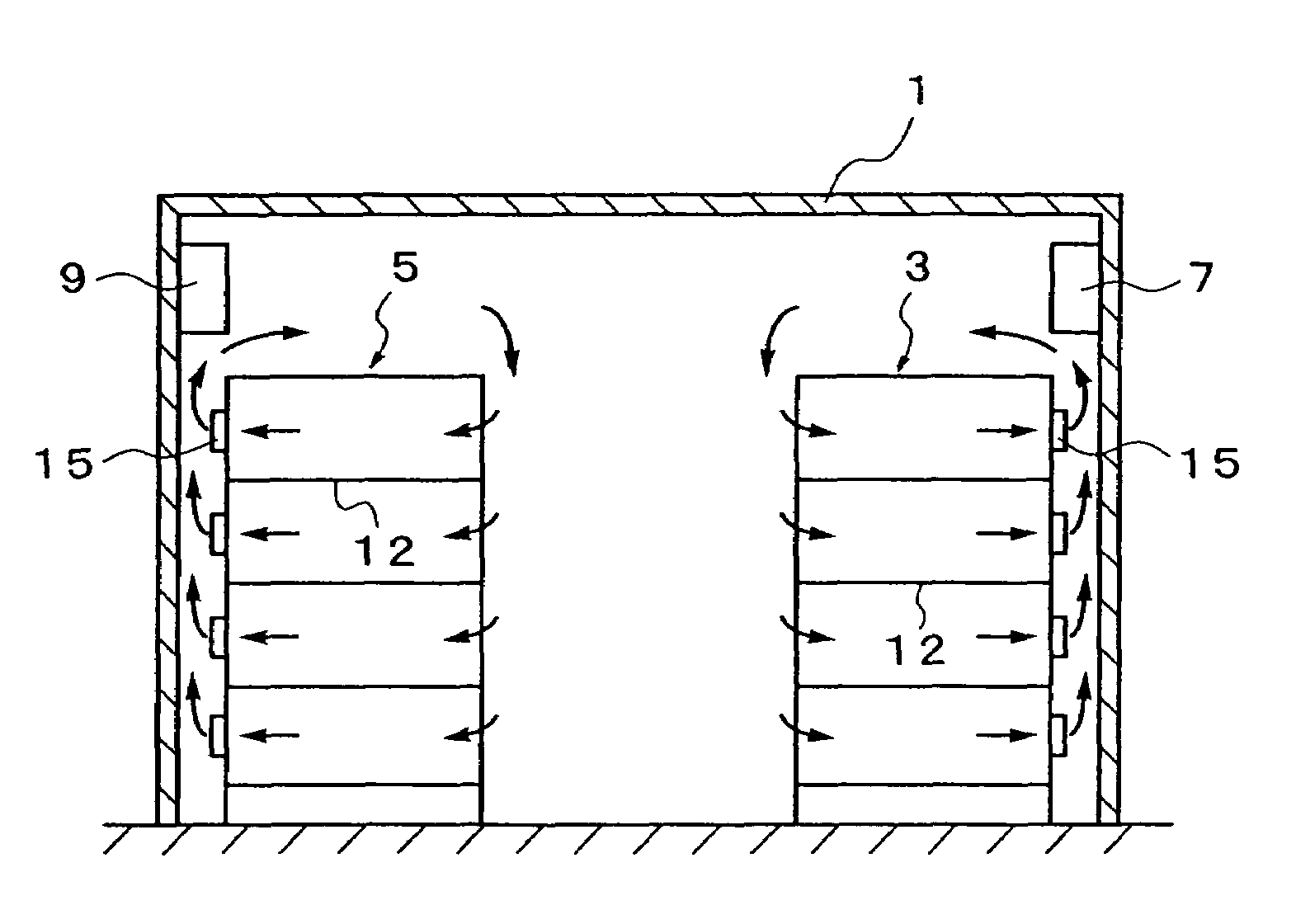

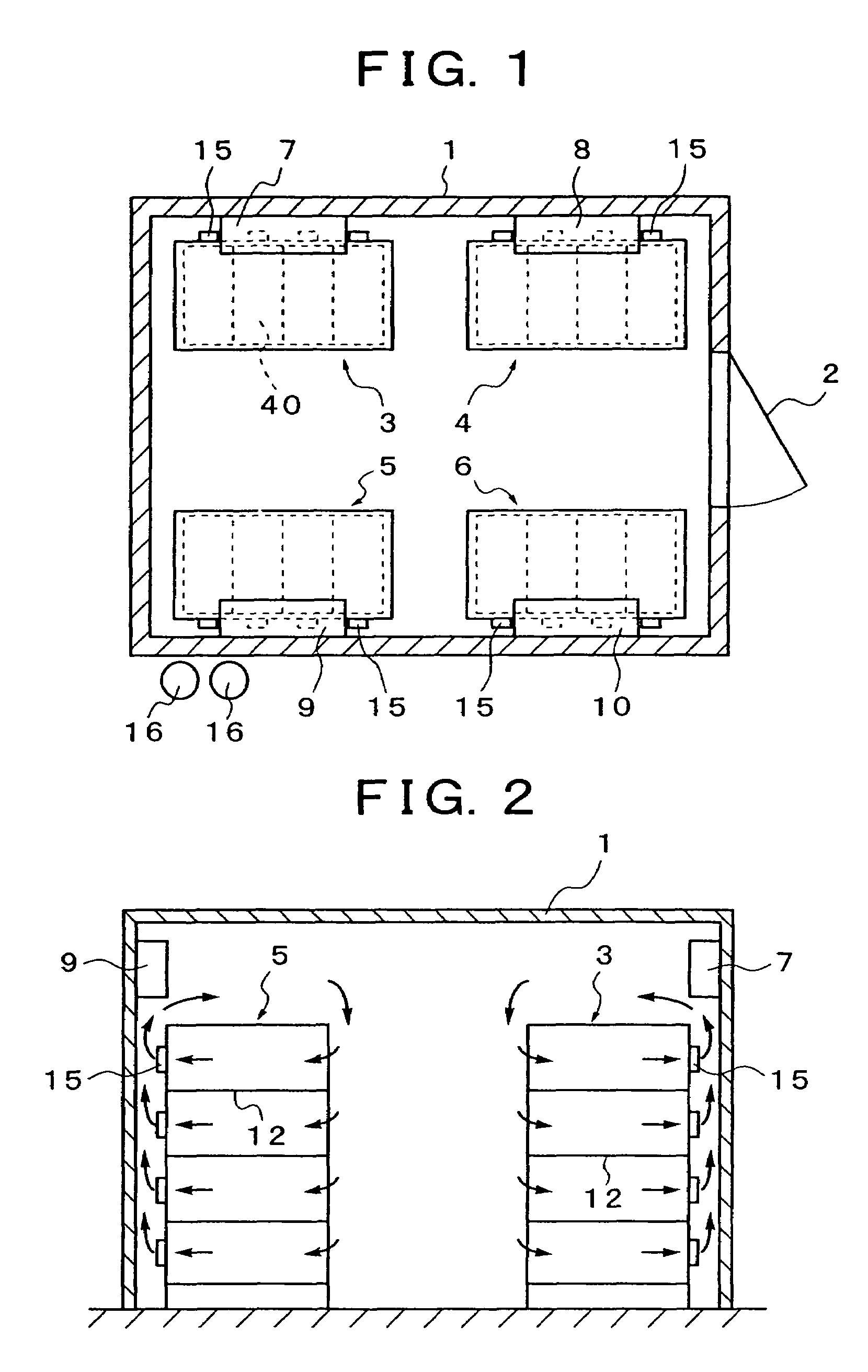

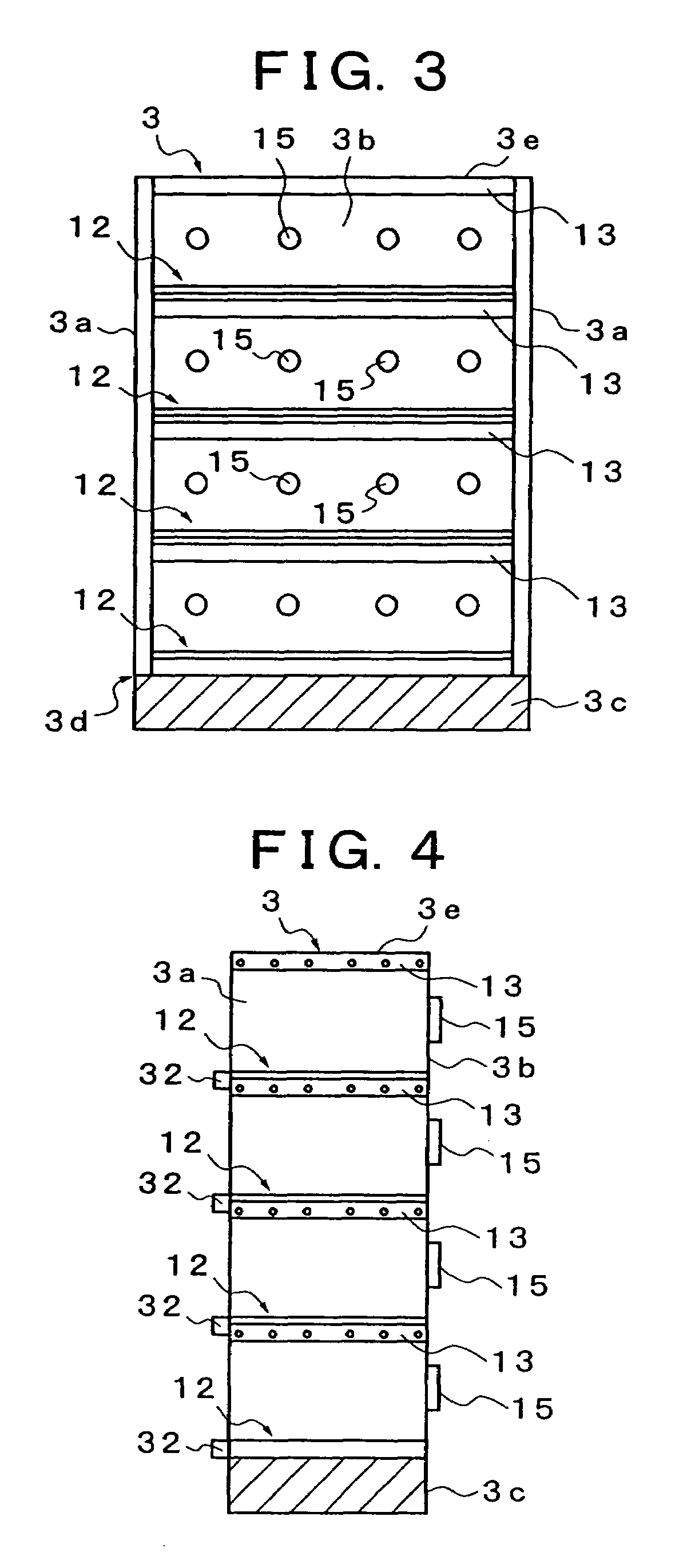

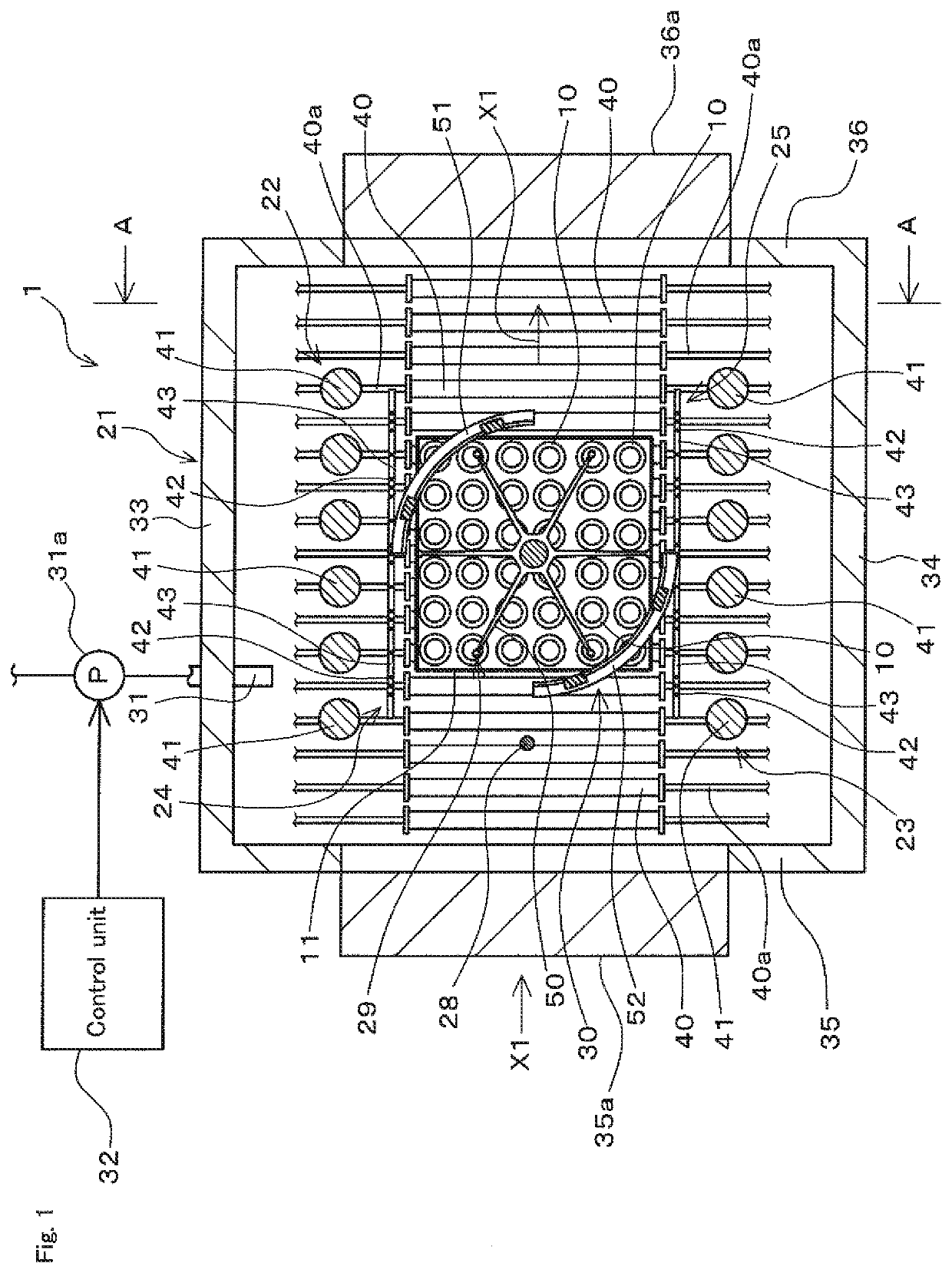

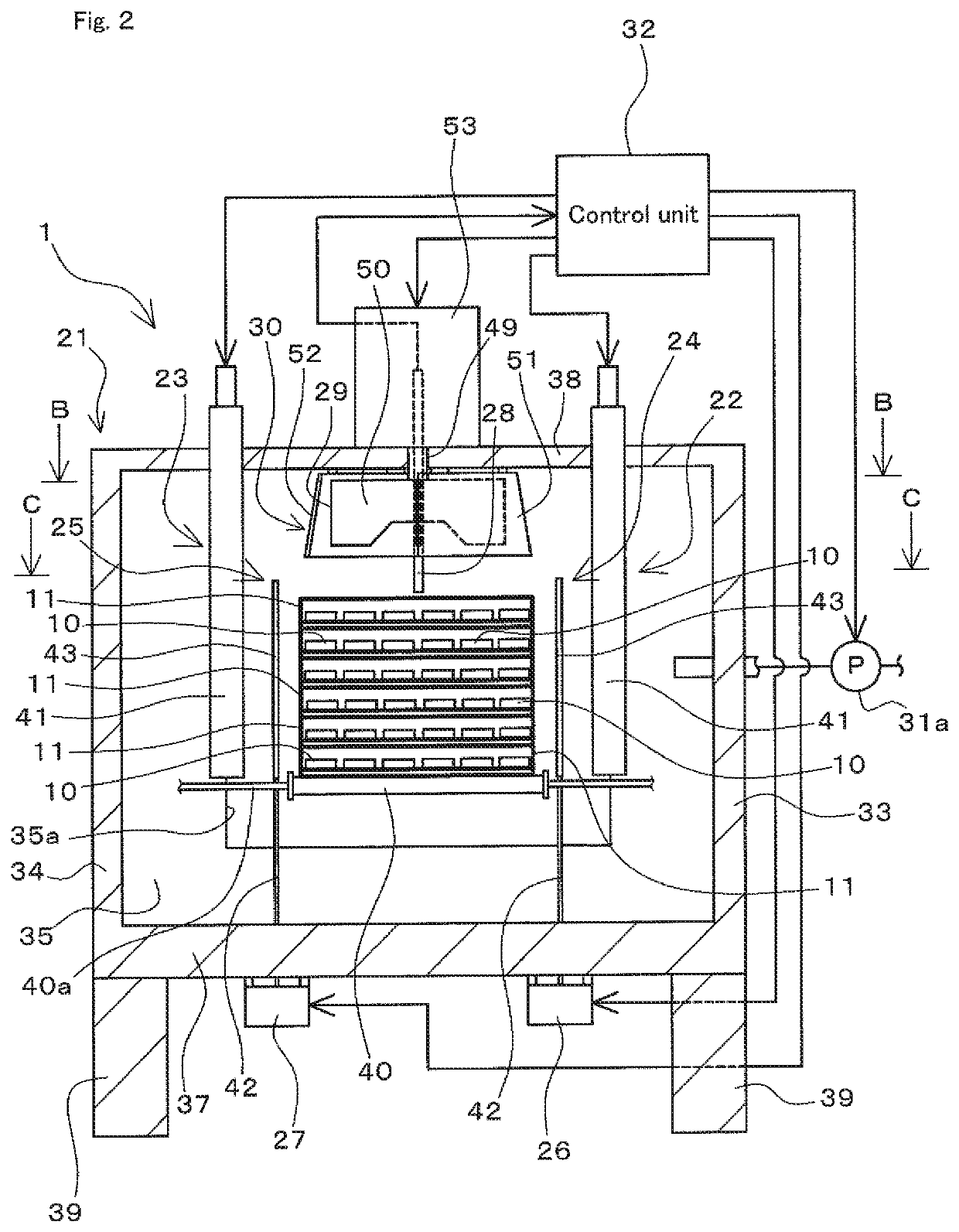

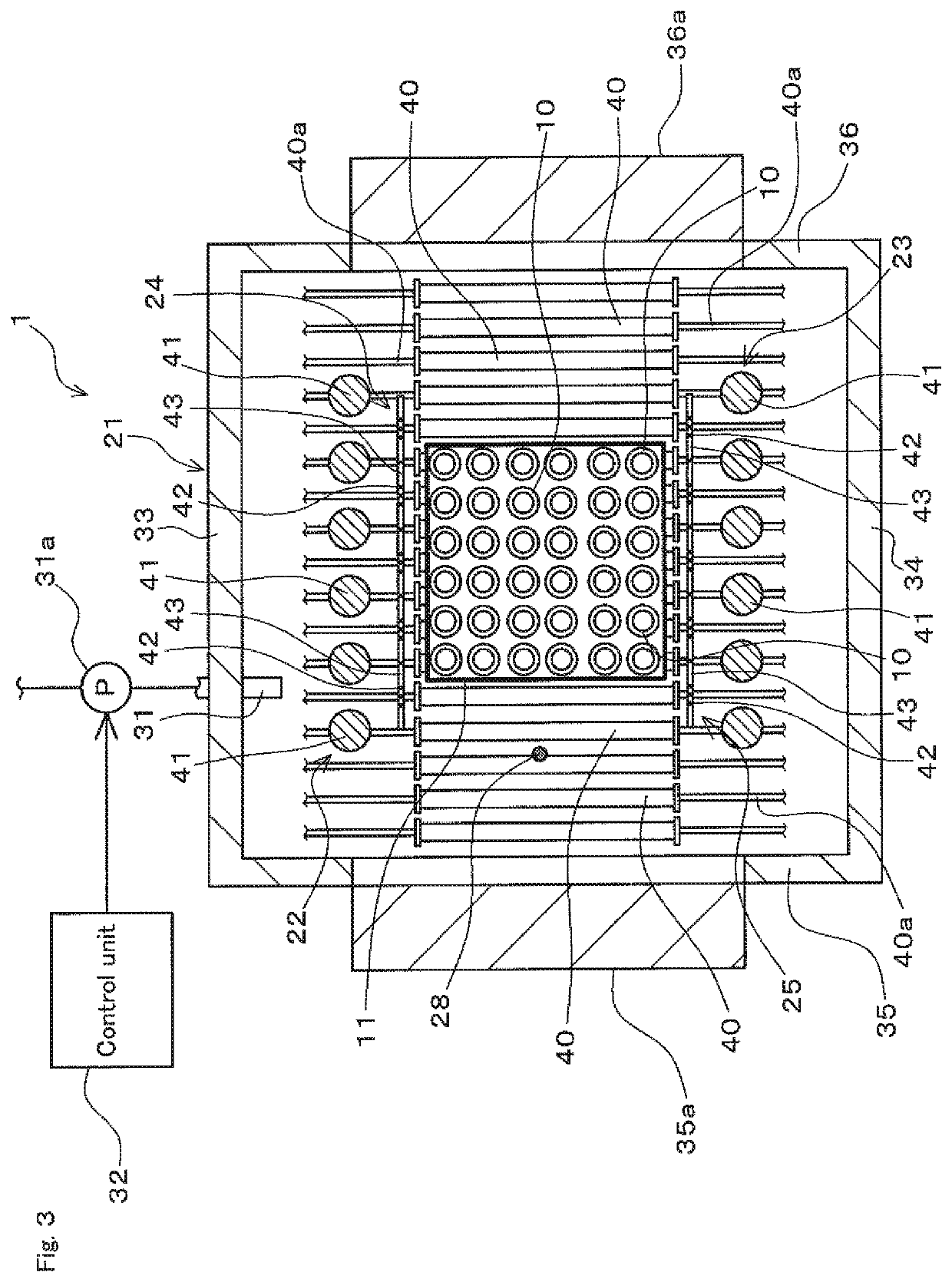

Heat treatment apparatus

ActiveUS20200080165A1Guarantee effective circulationEnsure efficient flowSolid state diffusion coatingFurnace typesEngineeringMechanical engineering

Workpieces are disposed between a pair of side walls in a heat treatment chamber. A centrifugal fan is disposed to face the workpieces inside the heat treatment chamber, and sucks gas from the workpiece side and generates air current. In regions at the respective side wall sides relative to an intermediate position between the pair of side walls, an air current regulation unit regulates the air current so as to restrict flows of the air current from the centrifugal fan to the respective side wall sides when a rotary blade of the centrifugal fan rotates in regions in which outer circumferential edge portions of the rotating rotary blade separate from the respective side walls, and allows the flows in regions in which the outer circumferential edge portions of the rotating rotary blade approach the respective side walls.

Owner:KOYO THERMO SYST CO LTD

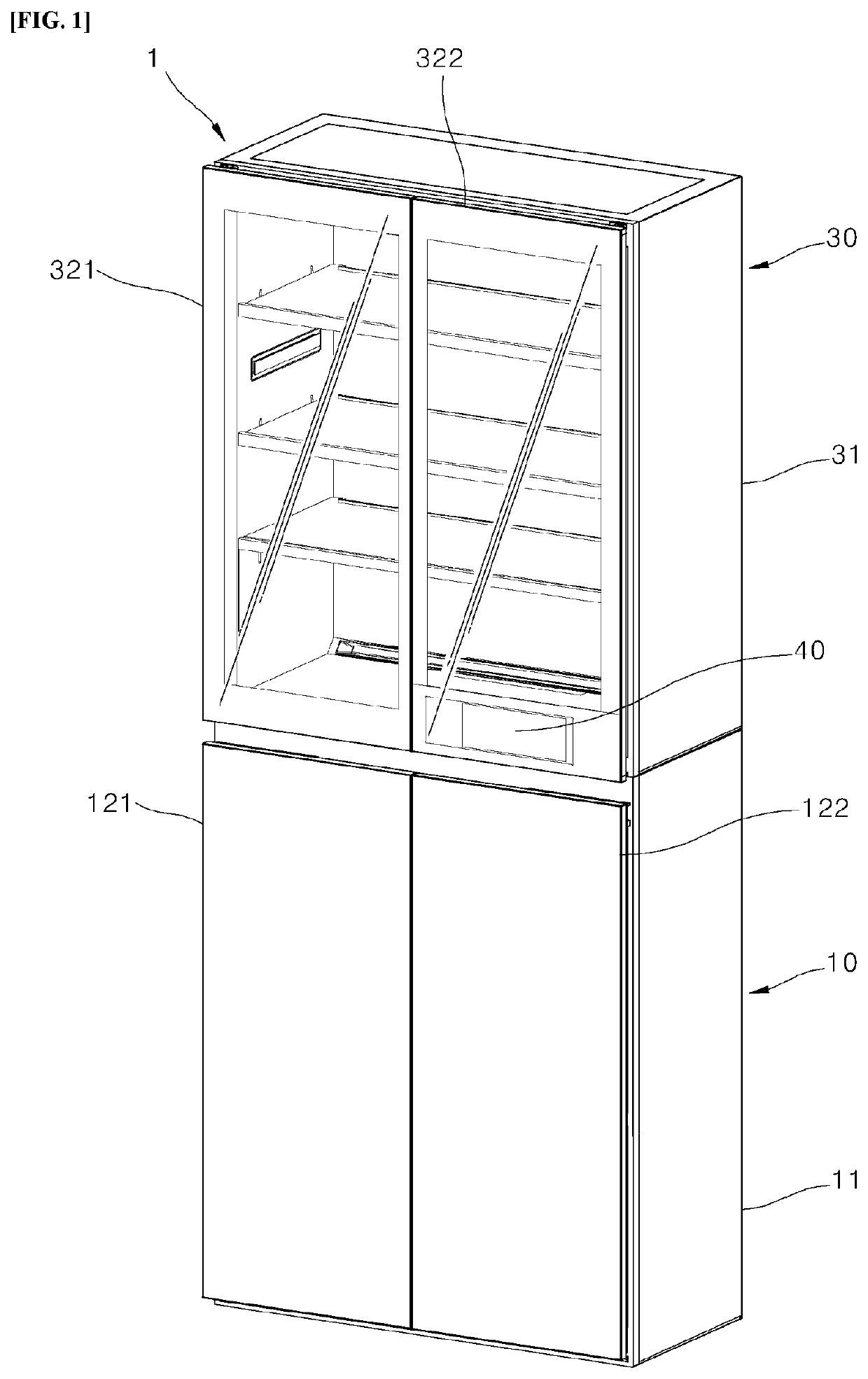

Shoe management apparatus

PendingUS20210401169A1Efficiently circulatedAvoid pollutionWardrobesMechanical apparatusInterior spaceEngineering

A shoe management apparatus including a cabinet including an inner space for storing shoes, an exhaust port disposed at a rear surface of the inner space and discharging air into the inner space, and a front discharge port disposed at an upper surface of the cabinet and discharging air from the inner space to outside of the shoe management apparatus.

Owner:LG ELECTRONICS INC

Method of preparing a gold-containing solution and process arrangement for recovering gold and silver

The invention relates to a method for preparing a gold-containing solution by chloride leaching from gold-bearing raw materials. A further object of the invention is to provide a method for recovering gold and optionally silver from the prepared gold-containing solution. The invention relates also to a process arrangement for recovering gold and optionally silver.

Owner:METSO OUTOTEC (FINLAND) OY

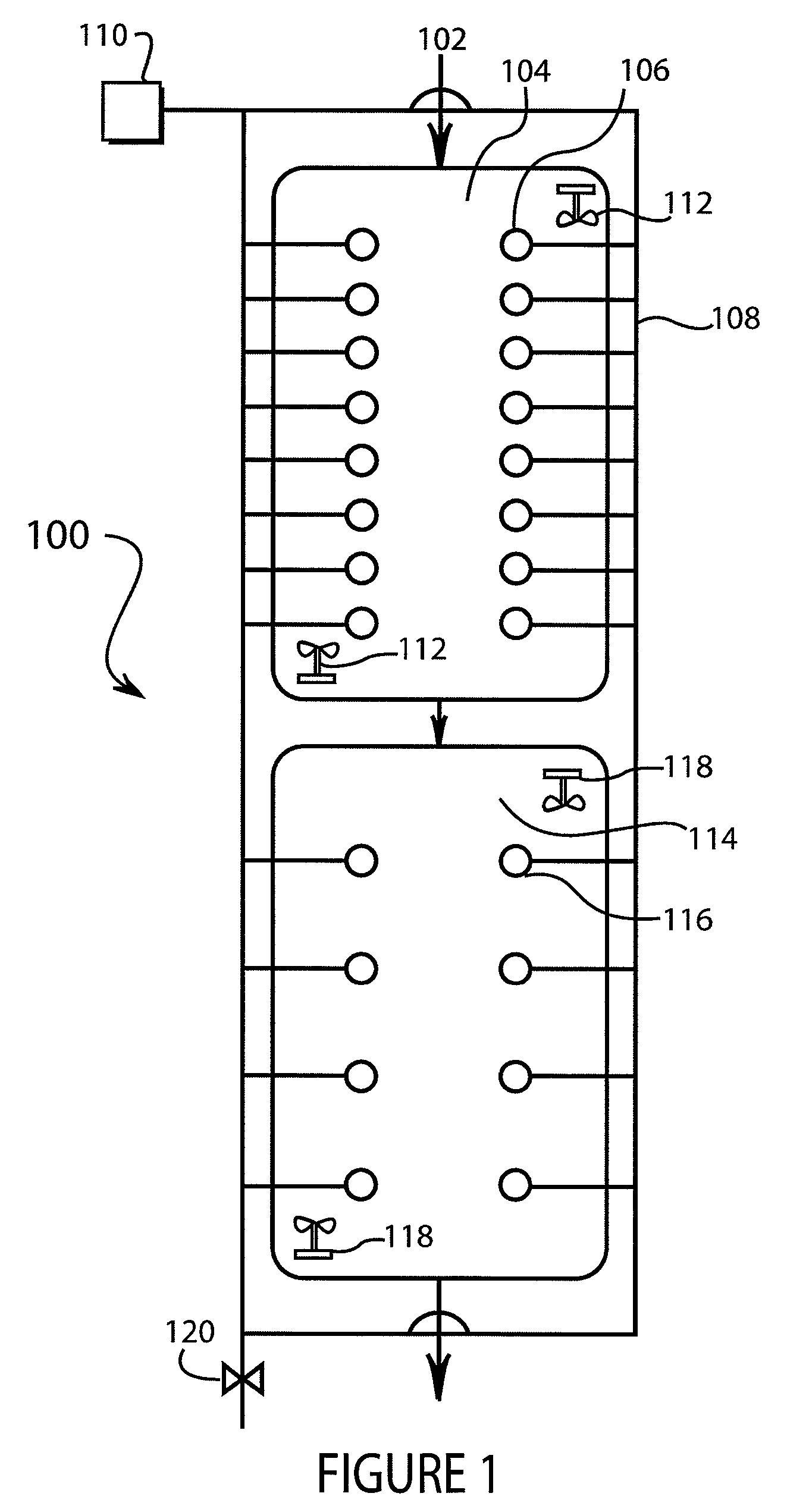

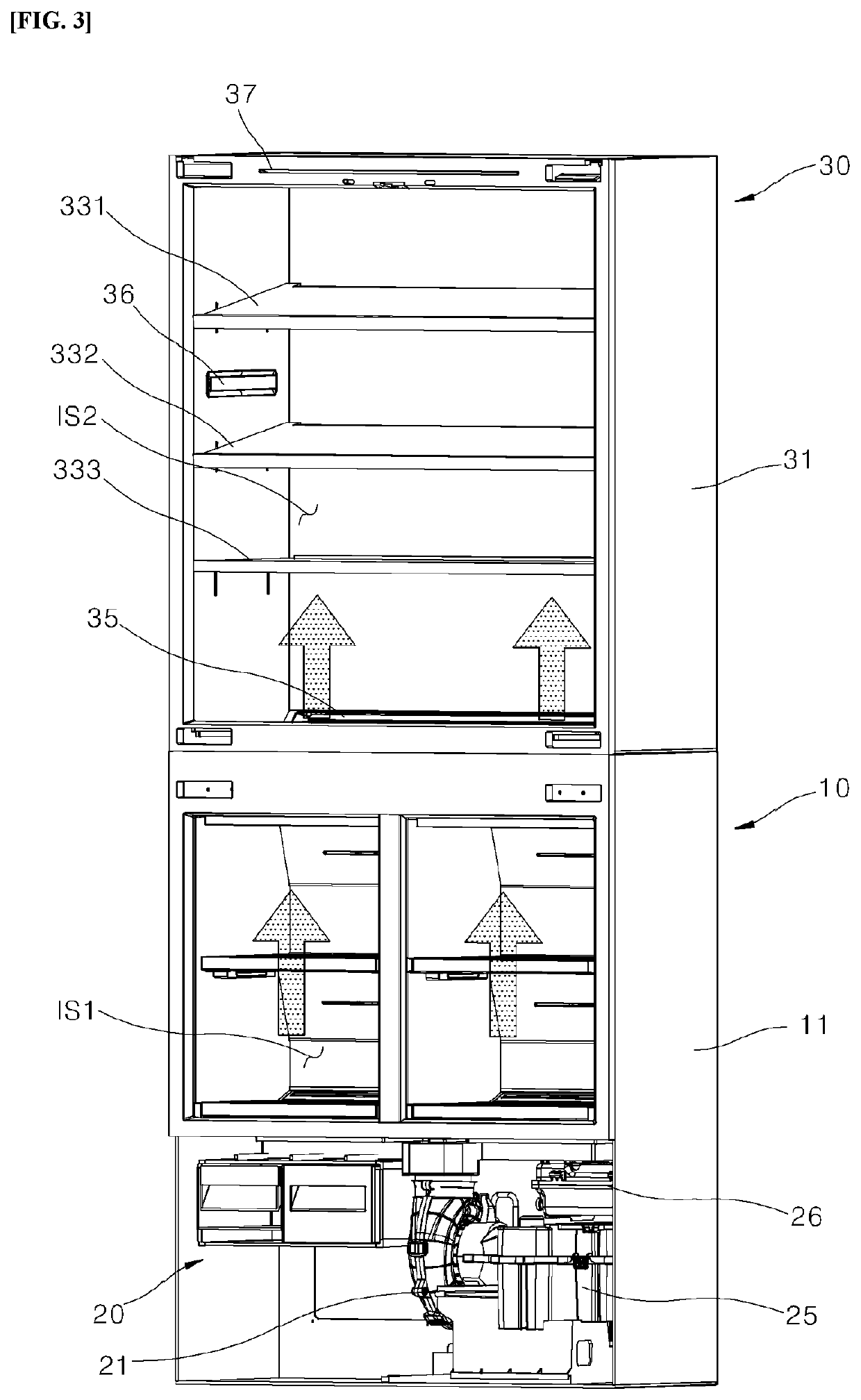

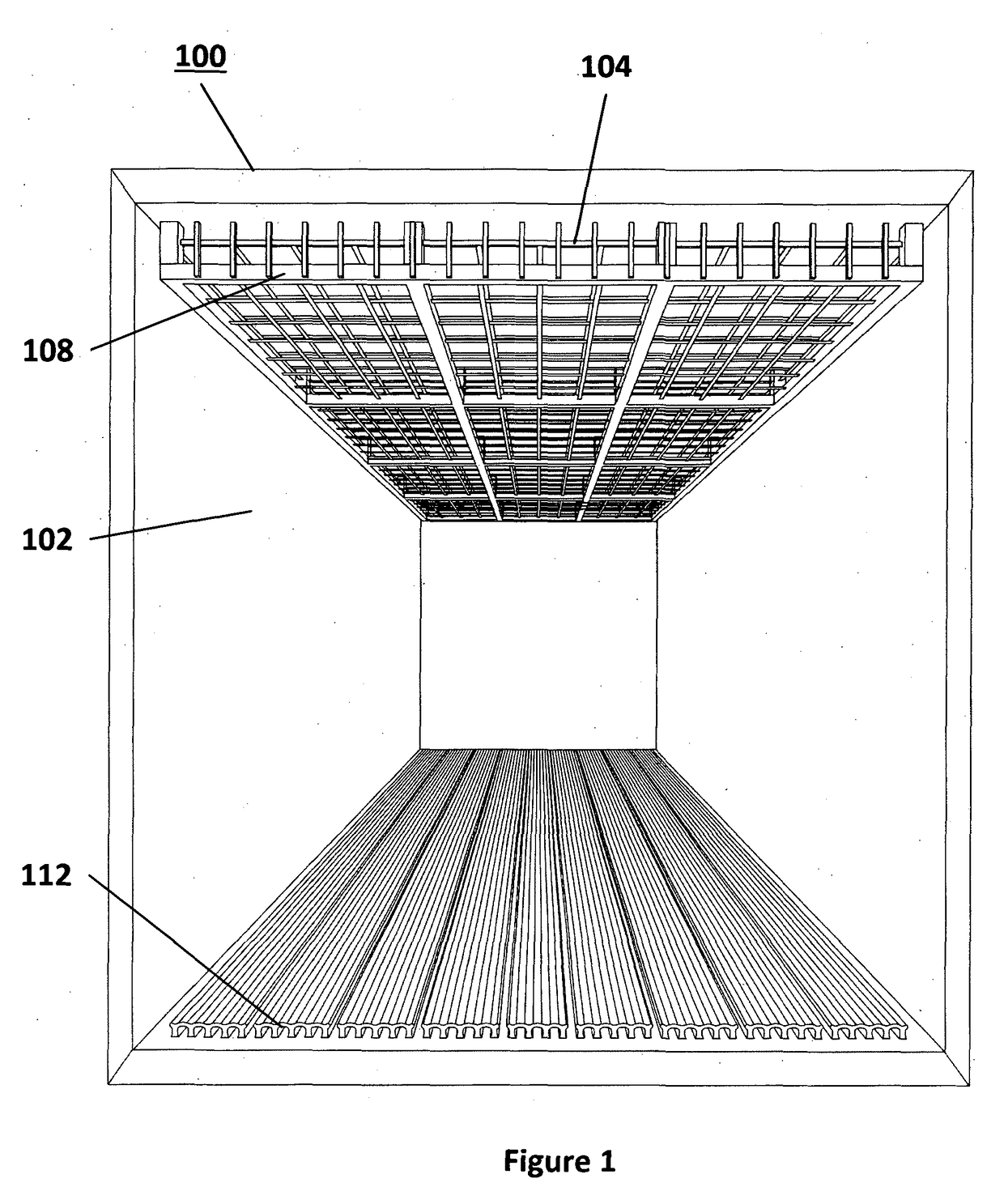

Cold storage system for transport

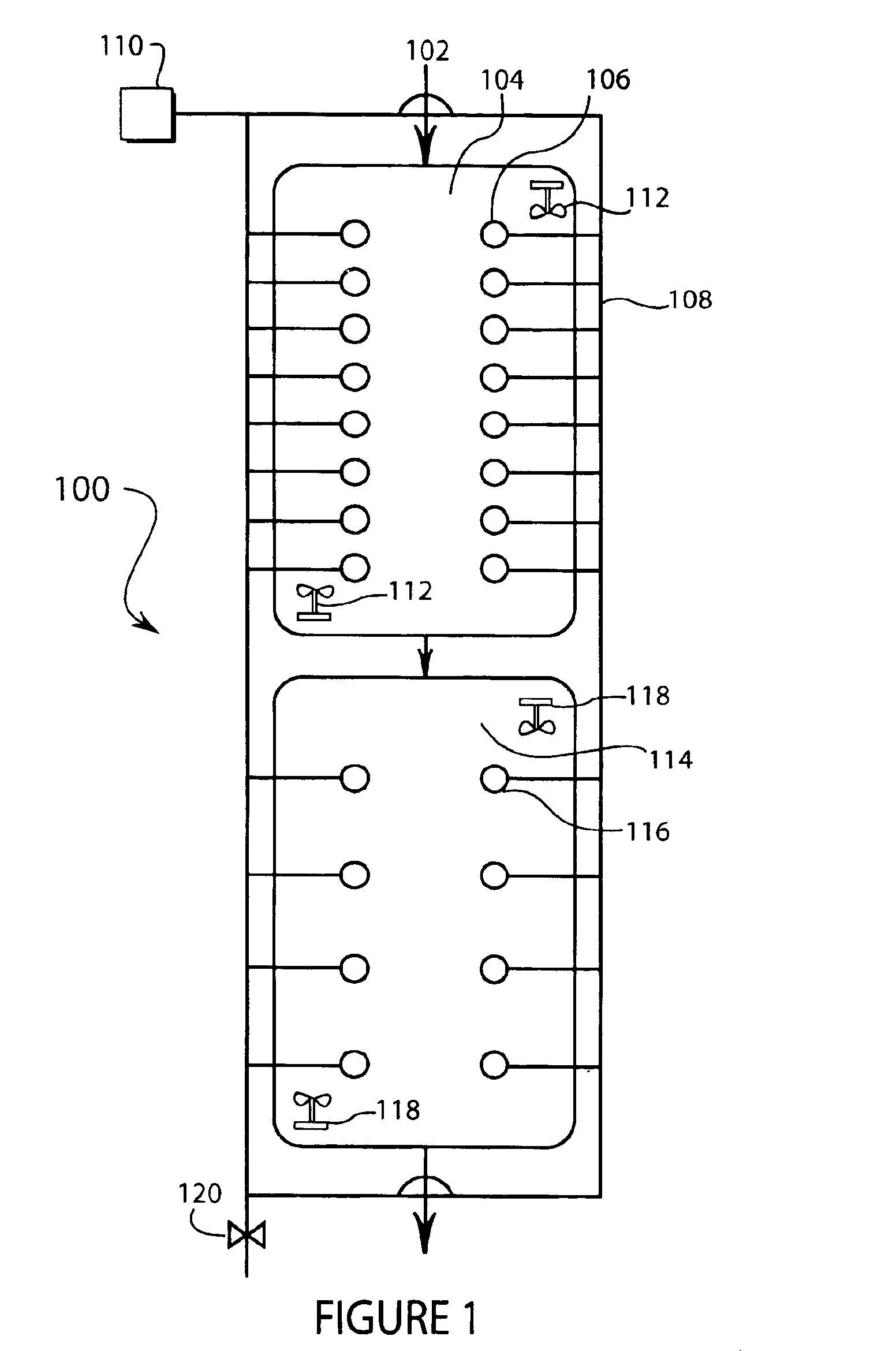

ActiveUS20180283763A1Maintain temperatureEffectively circulating airflowLighting and heating apparatusDomestic refrigeratorsThermal insulationEngineering

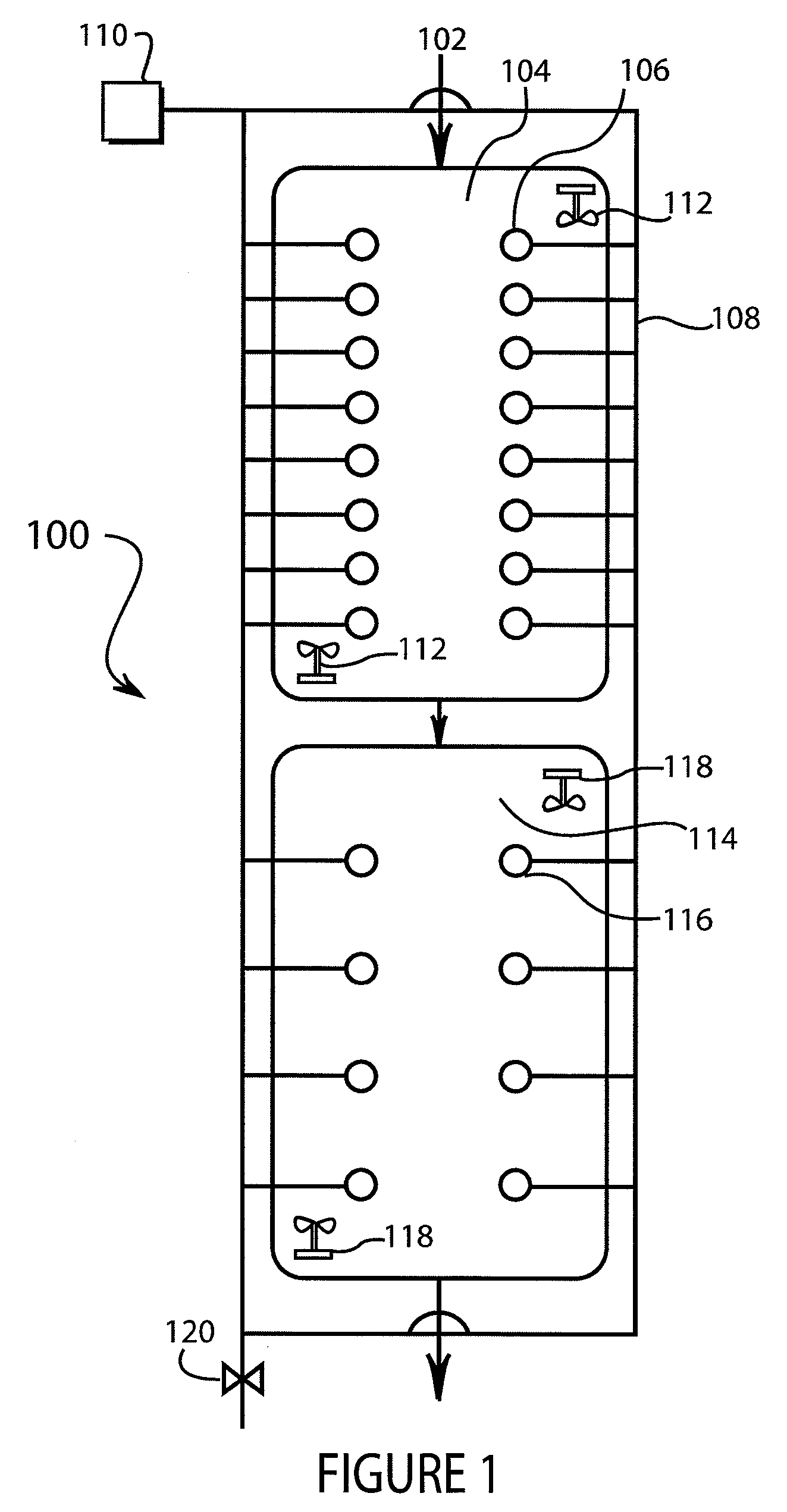

The present invention is directed to a system (100) maintaining chilled temperature in a cold storage (102) comprising: a plurality of coolant layers 104 uniformly placed on the roof of said storage (102); each coolant layer comprising multiple coolant plates (106) stacked in rows and columns; a compressor (110) generating airflow and circulating airflow in a circular pattern from top to bottom in said (storage 102); thereby maintaining temperatures in the range −25° C. to +25° C. in said storage; said plurality of coolant layers (104) being placed in close proximity to said compressor (110) for effectively circulating airflow; a coolant holder frame (108) for uniformly adjusting said multiple coolant plates (106) in said plurality of coolant layers (104), and allowing efficient airflow from top to bottom in said storage (102); base of said storage being provided with, holes (112), throughout for sucking the air circulated by said compressor (110) to improve the circulation of airflow in said storage (102); and said storage (102) being insulated to increase the thermal insulation coefficient to maintain the desired temperature in said storage, thereby freezing said coolant layers.

Owner:INNOVATION THRU ENERGY

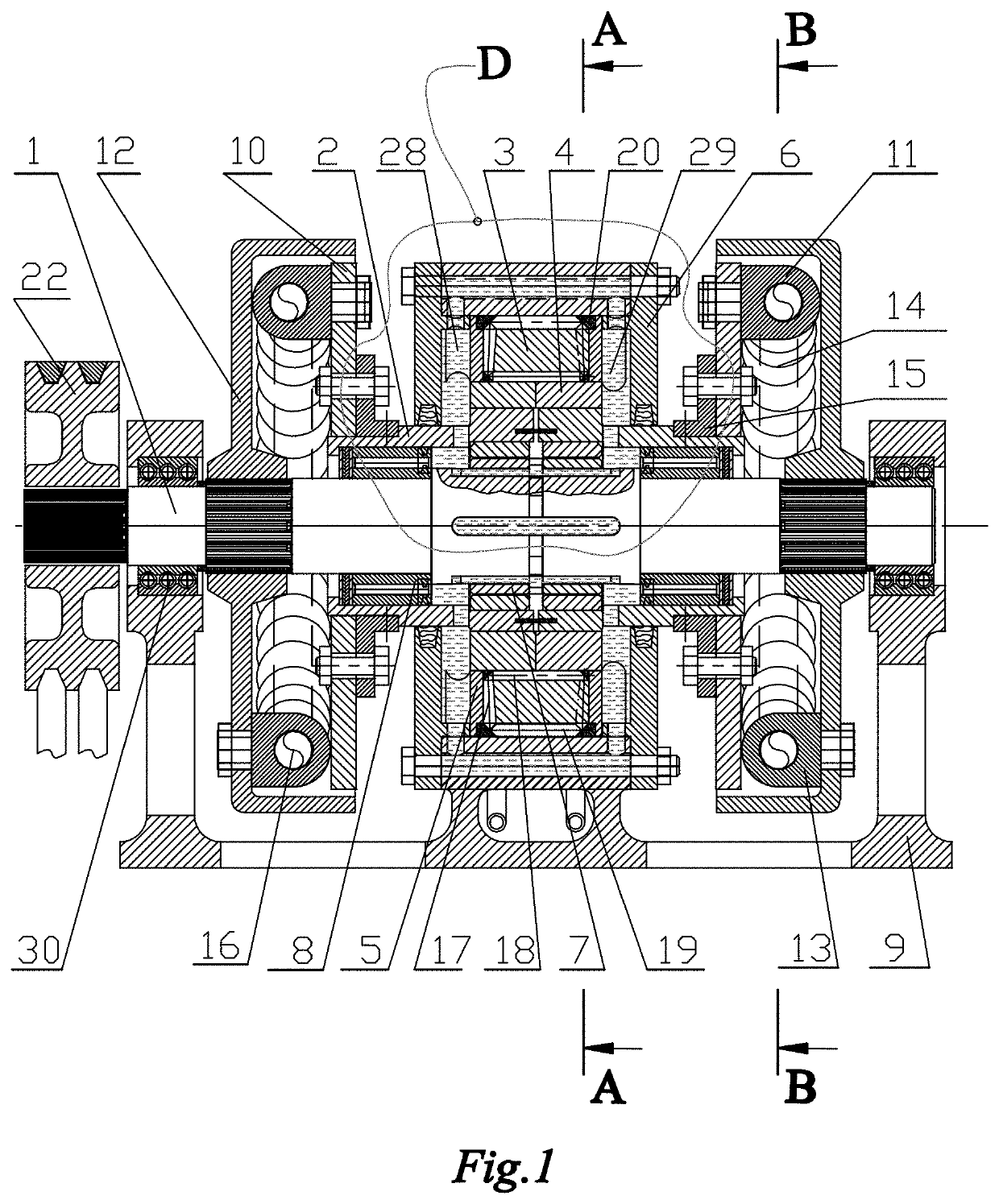

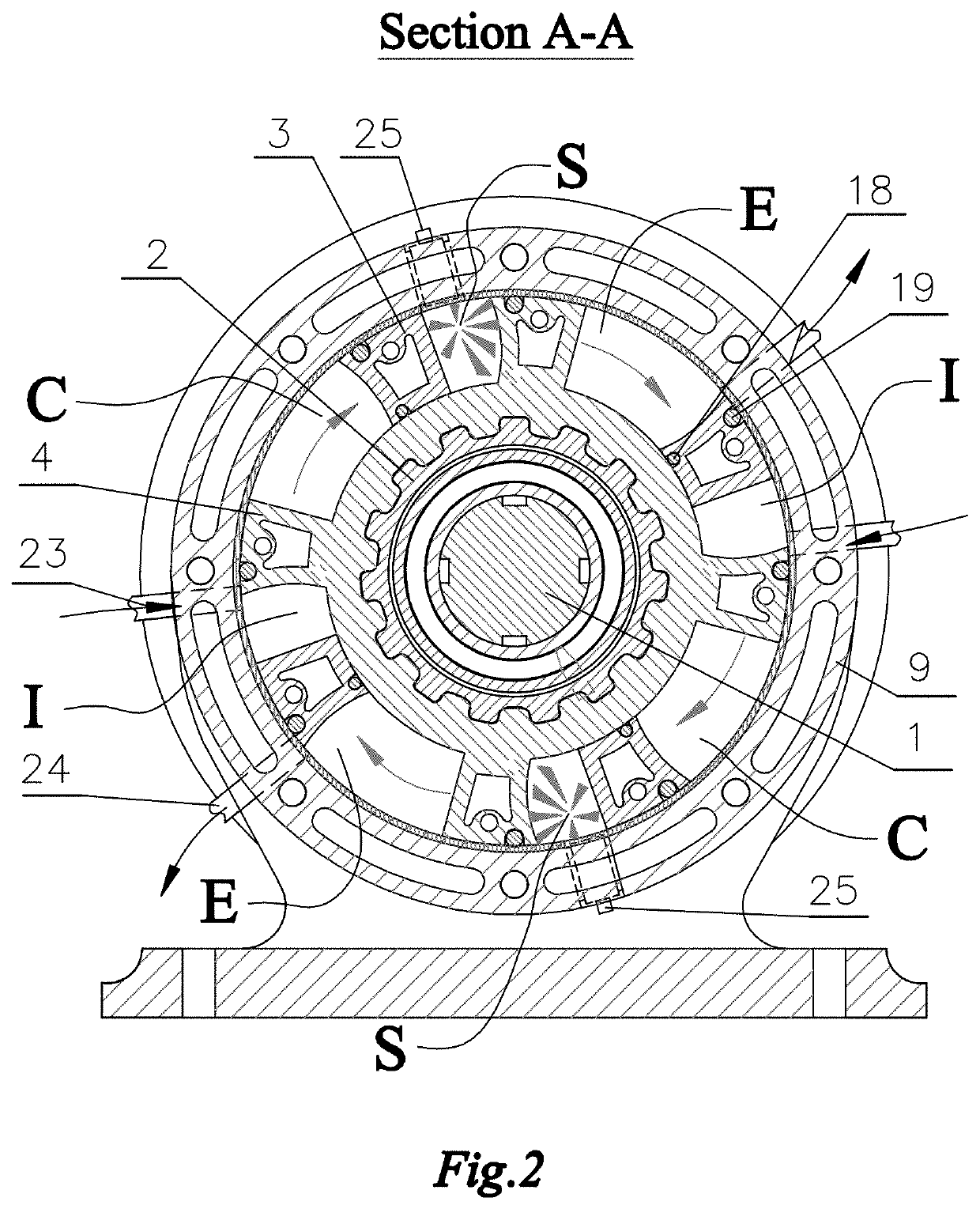

Rotary vane internal combustion engine

InactiveUS20210381425A1Easy accessGuarantee effective circulationInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberCooling chamber

Rotary vane internal combustion engine comprises of two rotors, nested in each other, placed in a cylindrical housing, wherein each rotor has at least two radial vanes rigidly attached to the rotor that form chambers for intake, compression, combustion, and exhaust. Each rotor, alternately engages with a shaft by overrunning one-way clutches and held from turning back, through the cushioning mechanisms, mounted on flywheels, which are rigidly attached on the shaft, wherein the assembled rotors from the outside are rigidly closed by flanges on each of which is mounted at least one blade, which are placed into formed cavity between rotors and caps of the housing thereby forming two cooling chambers through which coolant circulates around rotors through openings in the housing and through longitudinal grooves in the shaft. On the vanes mounted cylindrical and conical seals that exclude the need for lubrication.

Owner:STANETSKY ANATOLI

Scavenging pump

InactiveUS20220307393A1Guarantee effective circulationEfficiently circulatedMachines/enginesPressure lubrication with lubrication pumpGear wheelAir pump

A scavenging pump is utilized to draw oils from a catch tank that collects the oils supplied to components to an oil pan that reserves therein the oils. The scavenging pump includes gears to draw the oils, and a housing that stores therein the gears. An oil receiving portion capable of receiving the oils injected from the exterior is formed in an outer circumferential surface of the housing, and an oil introducing hole that introduces the oils injected to the oil receiving portion into the interior is opened at a position continuous from a lower part of the oil receiving portion and facing the gears.

Owner:YAMADA SEISAKUSHO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com