Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

998 results about "Automated guided vehicle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

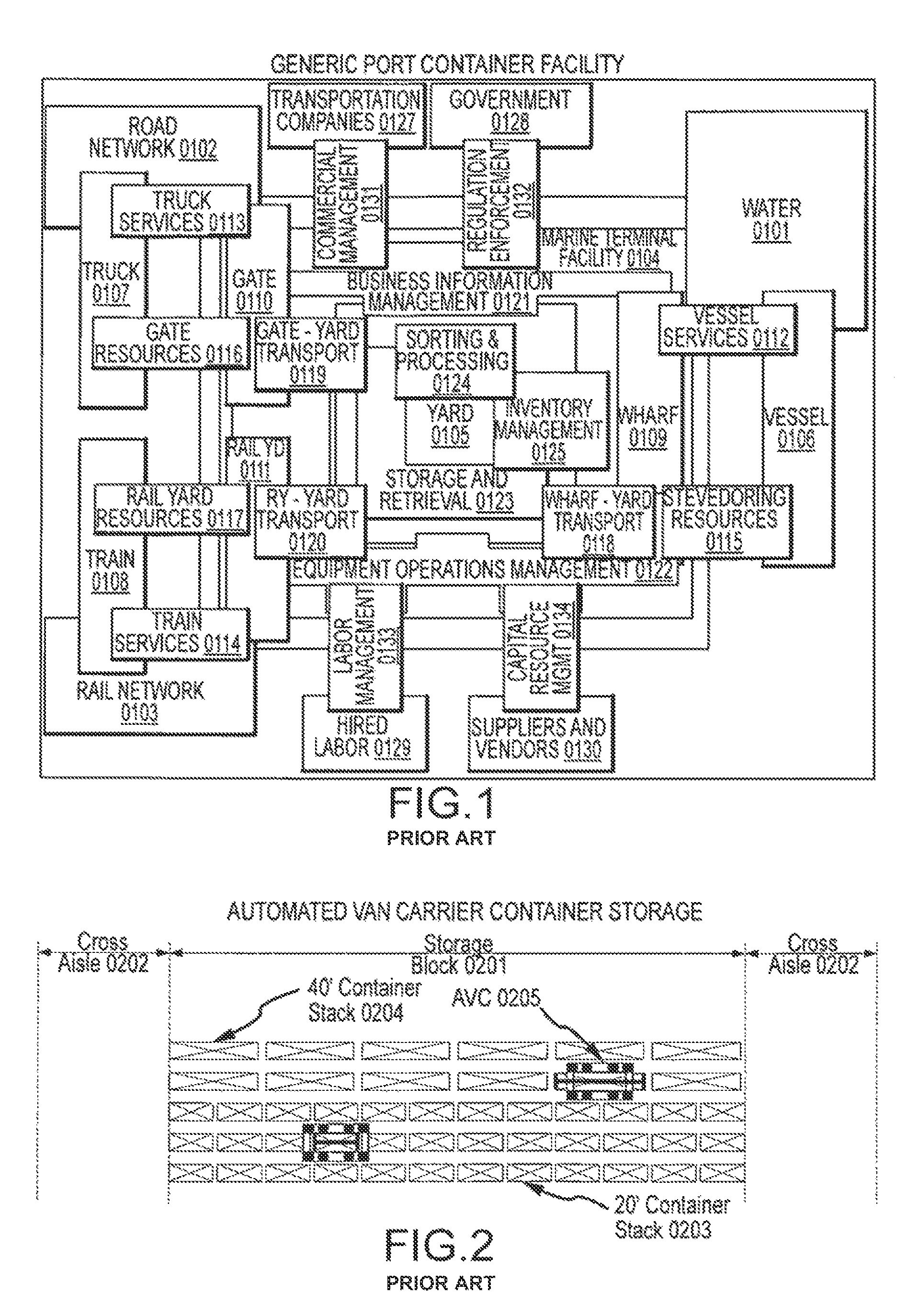

An automated guided vehicle or automatic guided vehicle (AGV) is a portable robot that follows along marked long lines or wires on the floor, or uses radio waves, vision cameras, magnets, or lasers for navigation. They are most often used in industrial applications to transport heavy materials around a large industrial building, such as a factory or warehouse. Application of the automatic guided vehicle broadened during the late 20th century.

Method and system for automated transport of items

ActiveUS20160176638A1Programme controlAutonomous decision making processAutomated guided vehicleIndustrial engineering

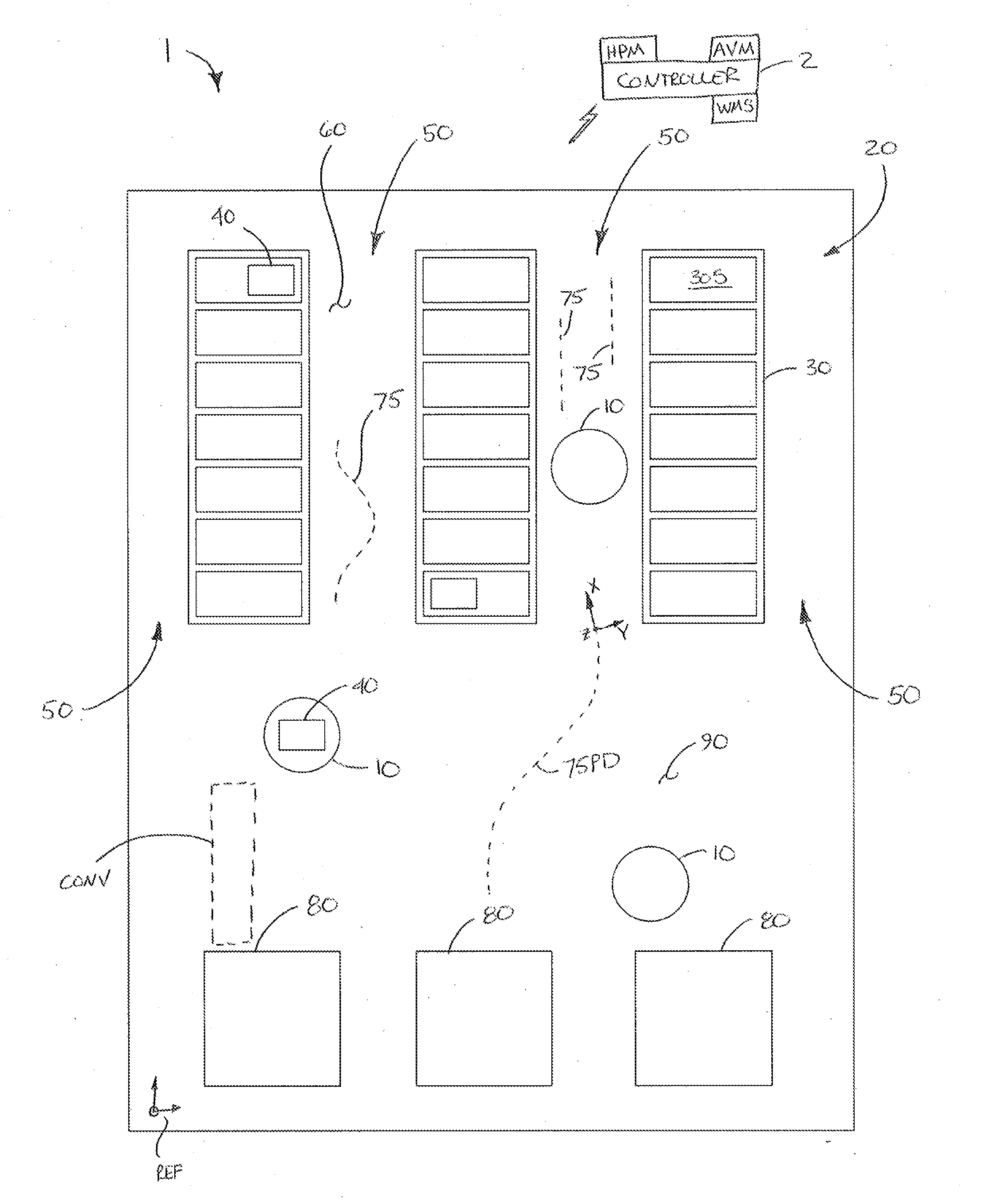

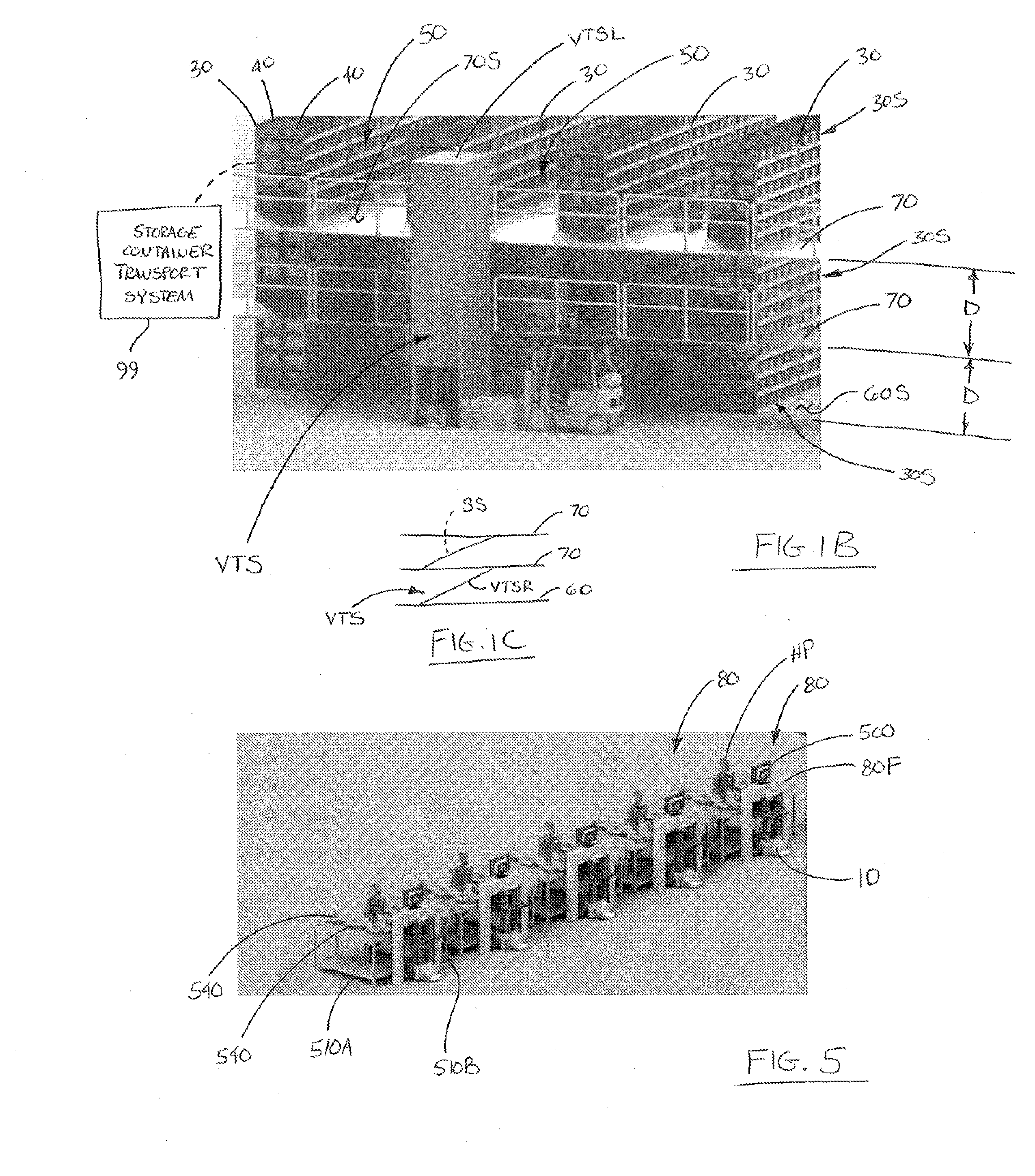

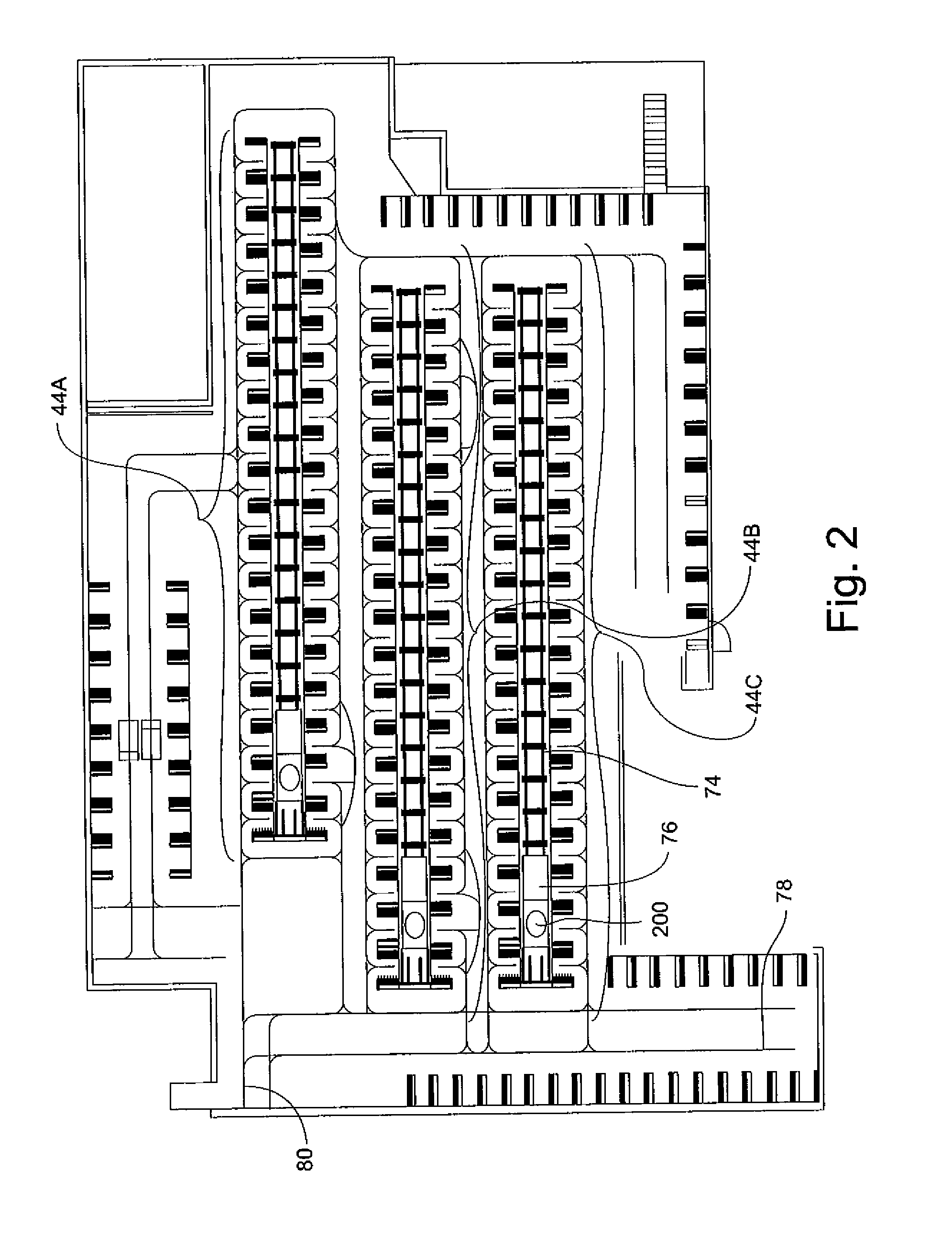

An automated distribution center includes an array with storage locations arranged along aisle(s) having a floor, and a mezzanine platform above the floor, the floor and mezzanine being configured for human picker access to the storage locations, an automated guided vehicle (AGV) configured for traverse of the floor and mezzanine to the storage locations, and for transporting a storage container to and from the storage locations, the floor and mezzanine each having an undeterministic traverse surface for the AGV, the AGV is configured so that the surface provides holonomic selectable paths for the AGV substantially everywhere on the surface, each path being selectable by the AGV, and an order filling station, where one or more goods are picked from container(s) to fill order(s), wherein the AGV is configured to pick the container from a storage location and transport the container on the surface between the storage array and the station.

Owner:NEXTSHIFT ROBOTICS INC

Palletizing systems and methods

InactiveUS20080131255A1Increase order filling efficiencyImprove filling efficiencyLoadersPackagingCustomer orderAutomatic guidance

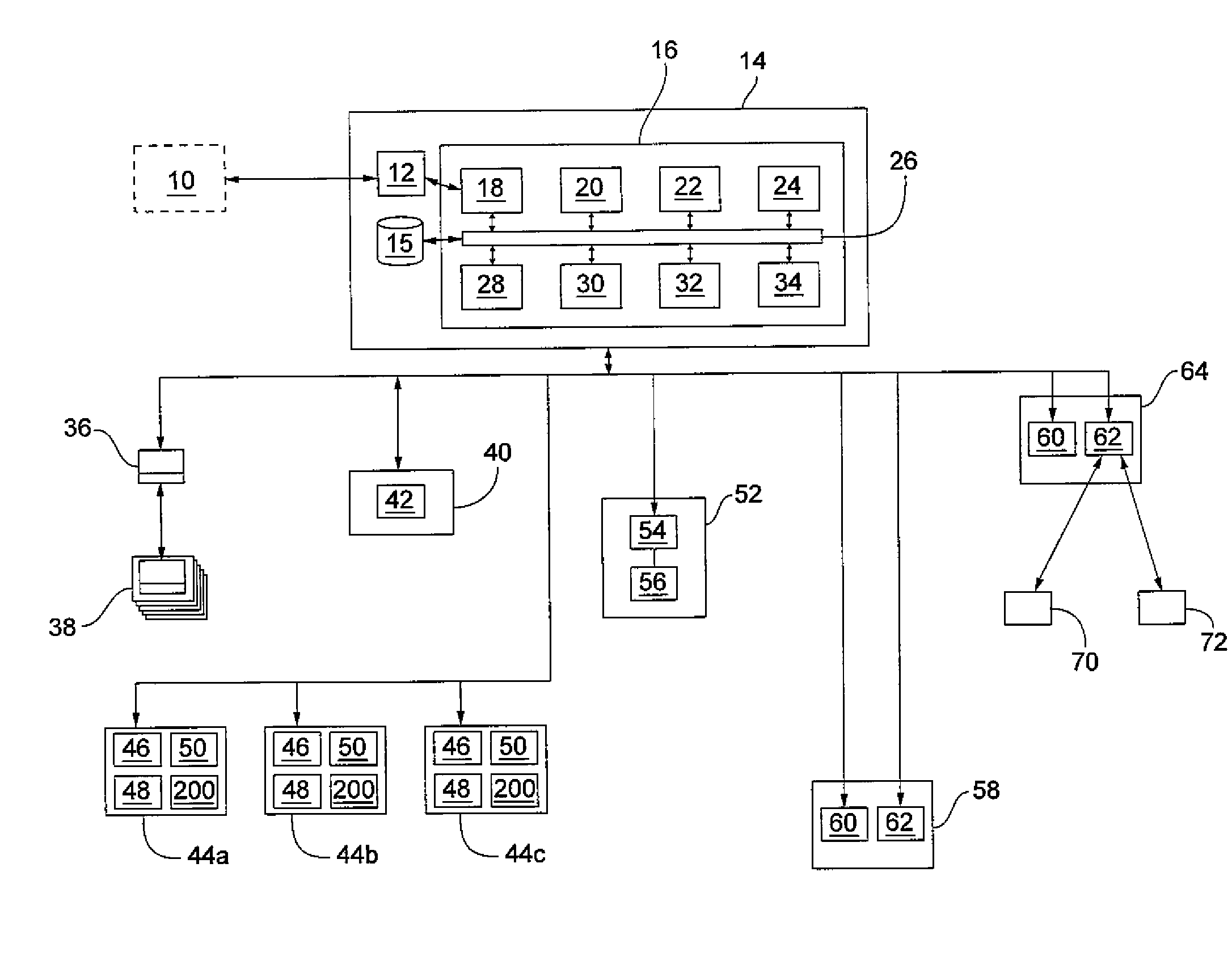

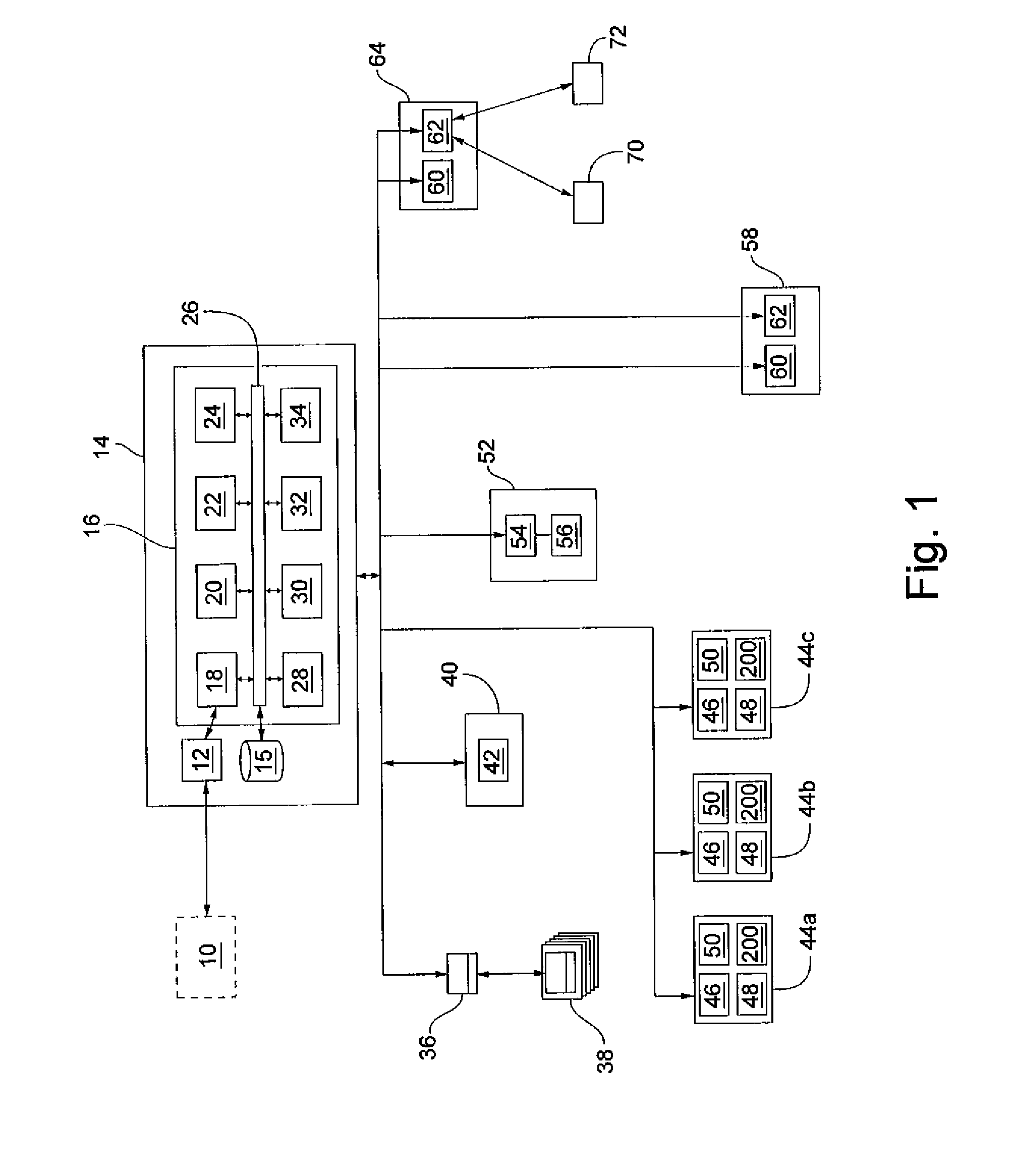

Palletizing systems and methods increasing the efficiency at which pallets of mixed products are built. The systems and methods include a pallet building module for receiving customer orders and generating pallet building instructions for arranging the products on the pallets, among other functions. The pallet building module is in communication with a number of robot cells that include source products and pallet building robots for building pallets based upon instructions generated by the pallet building module. The system includes other modules for system control including conveyor controllers, forklift controllers, and automatic guided vehicle controllers, among other controllers. Methods for building pallets of mixed product from source products within more than one robot cell.

Owner:TRANSBOTICS CORPORATION

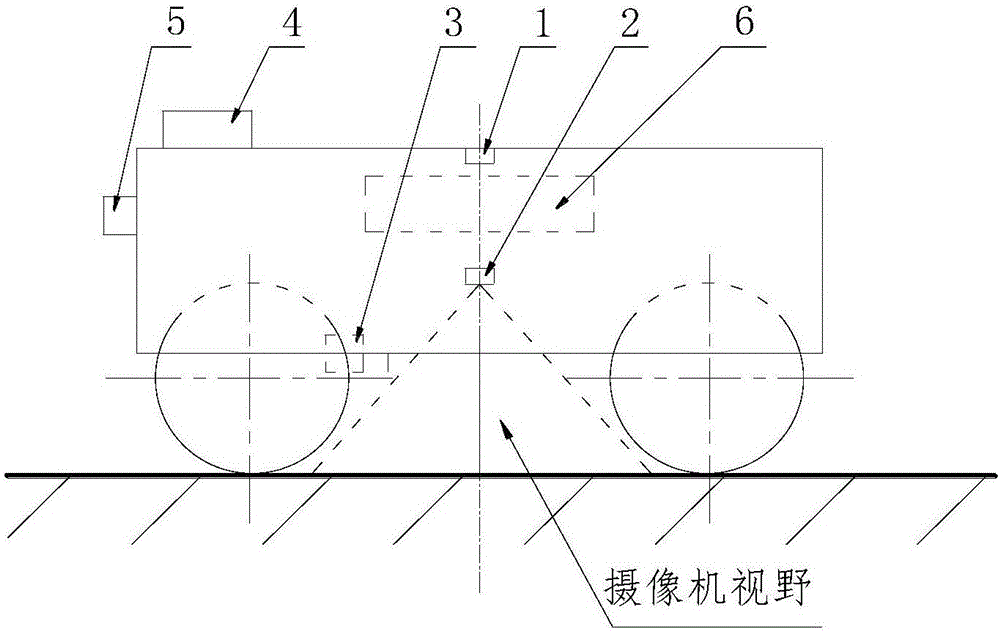

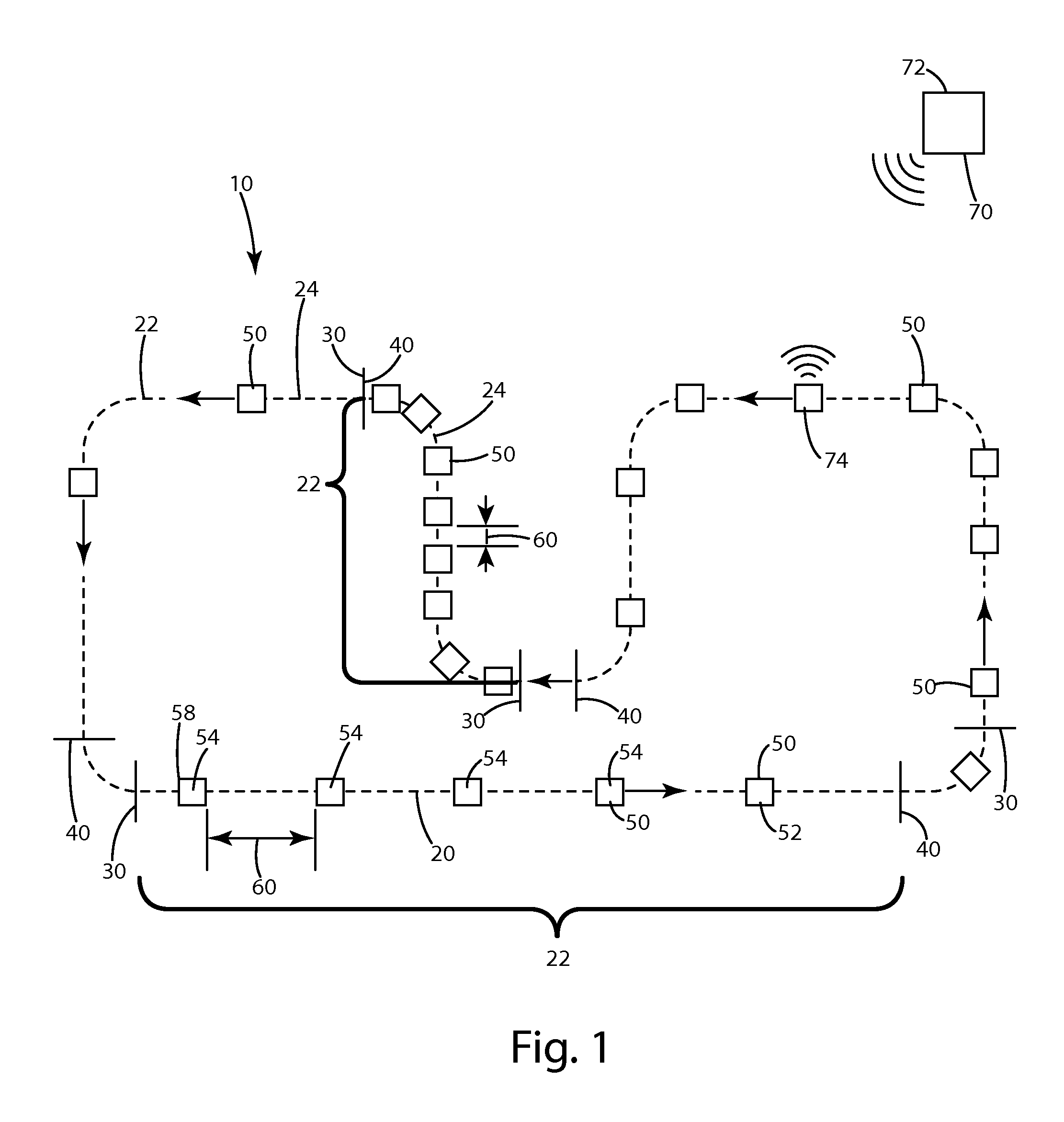

Reactive automated guided vehicle vision guidance system

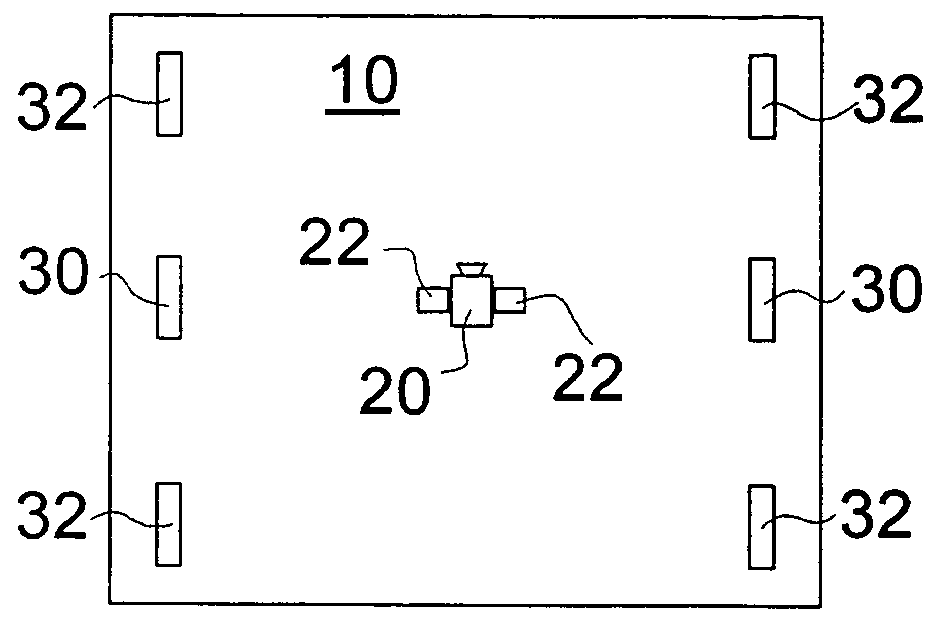

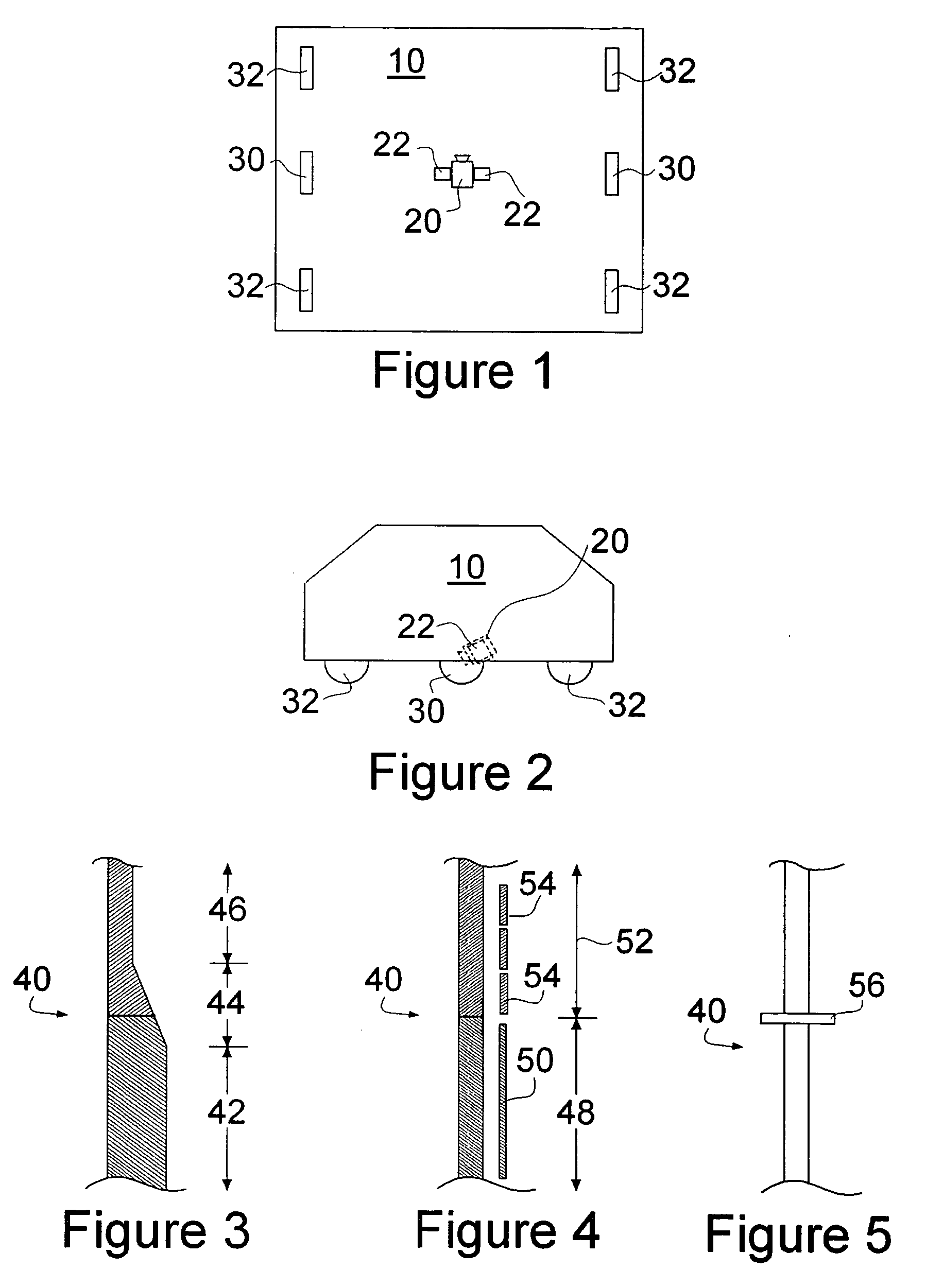

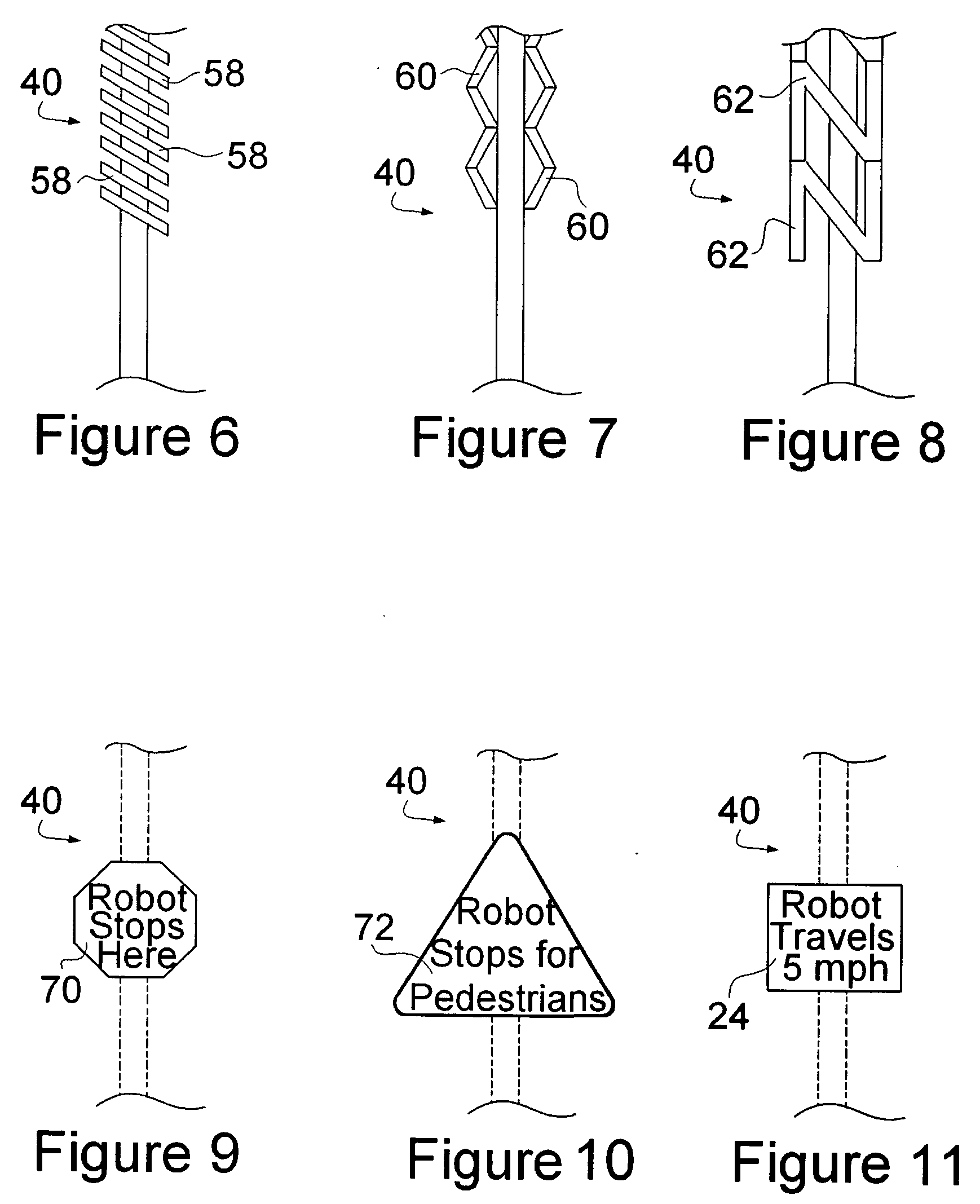

InactiveUS20060064212A1Enhance customer understandingIncrease usageAutomatic initiationsVehicle position/course/altitude controlGuidance systemDrive wheel

A reactive AGV system includes an AGV vision guidance system which places the camera system and controlled lighting sources between the drive wheels of the AGV to shield from ambient light and provide a constant lighting condition. The AGV guide path includes physical path properties for controlling AGV behavior. Visual Parameters of the guide path such as line thickness, line color, the presence and form of a secondary control line, or the presence of distinct a line elements may all be used as visual input control signals for the AGV. Additionally viewable icons are used for controlling AGV routing. These icons may, preferably, also be human readable to enhance the customer understanding and therefore usage of the system.

Owner:CYCLE TIME CORP

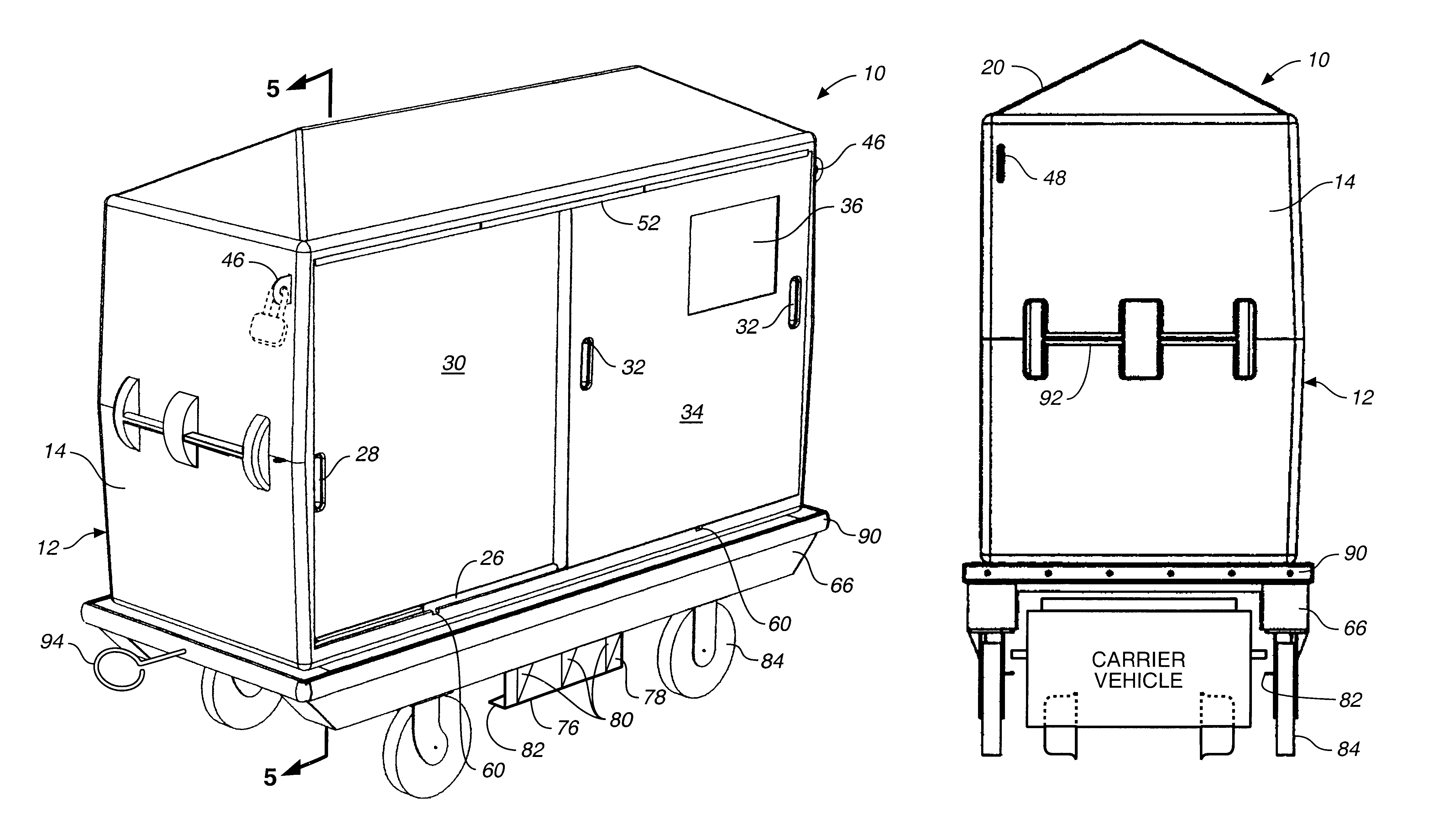

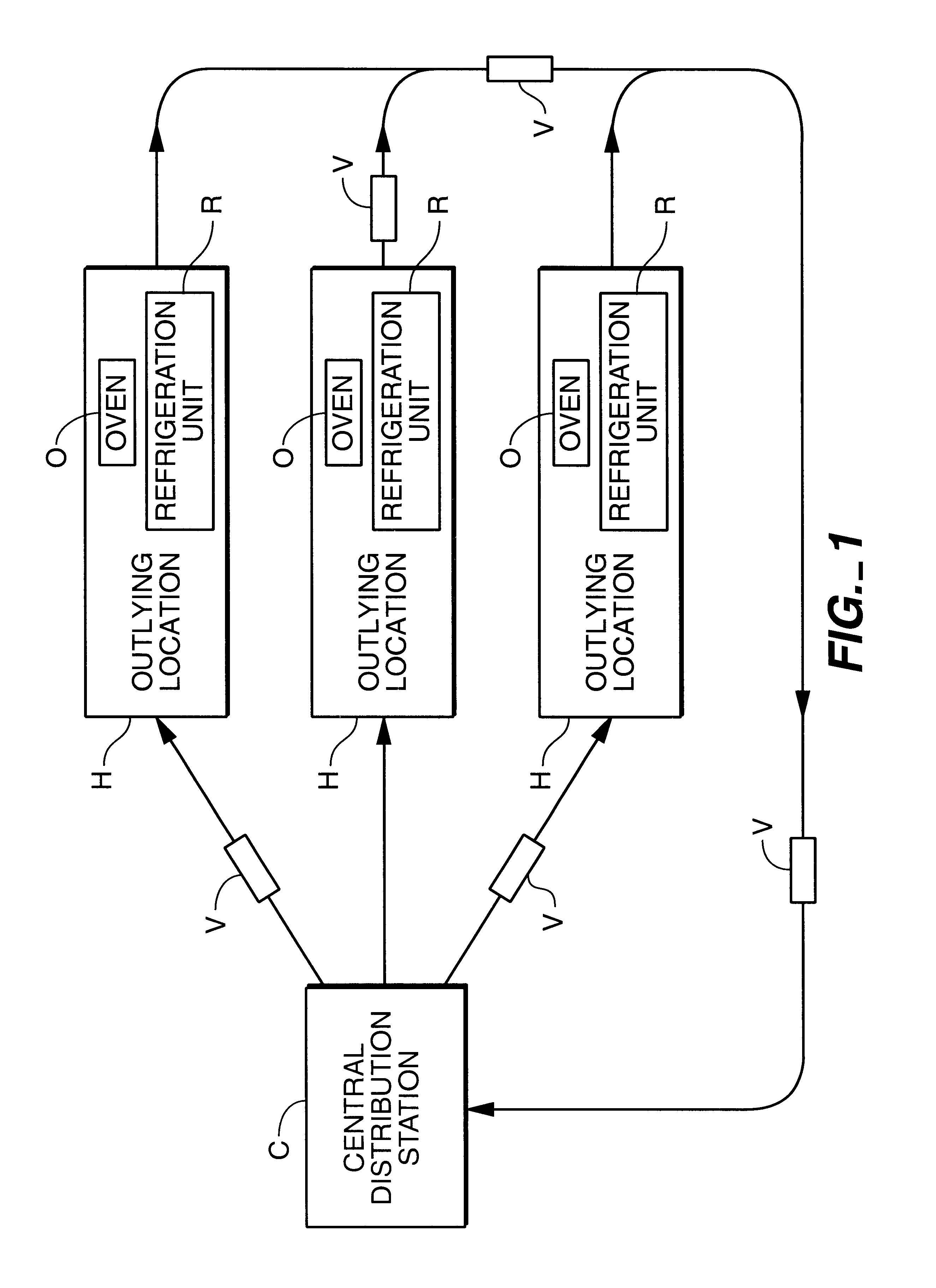

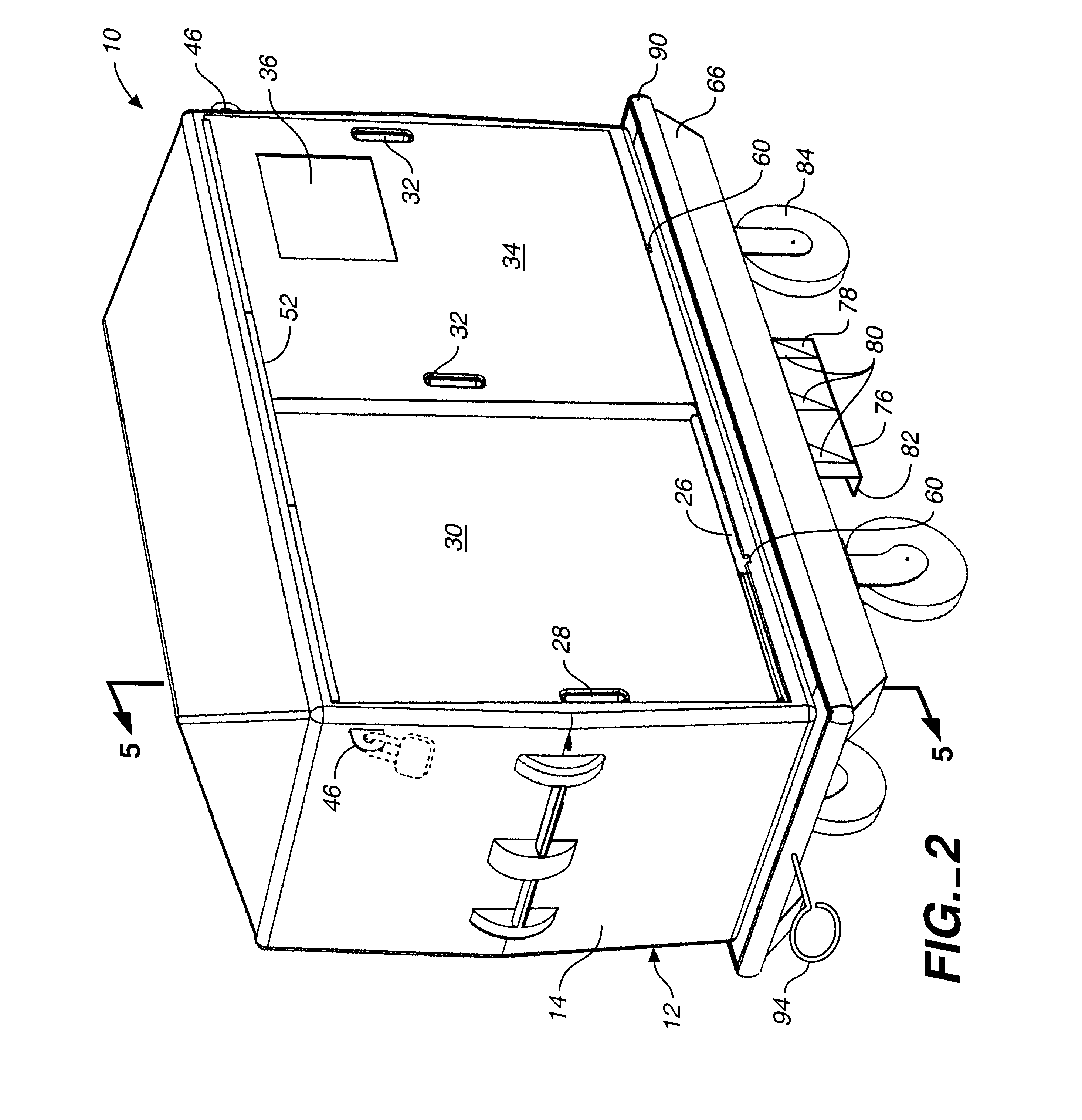

Meal delivery cart

InactiveUS6672601B1Durable and impervious to waterAvoid excessive absorptionVentilationService system furnitureDelivery vehicleAutomated guided vehicle

An improved meal delivery system and a method for delivery of pre-cooked, chilled meals from a central distribution station to a plurality of remote locations in cooperation with an Automatic Guided Vehicle system, and in particular a one-piece, molded, insulated meal-delivery cart for transportation of chilled meals.

Owner:COUNTY OF ALAMEDA THE A POLITICAL SUBDIV OF THE STATE OF CALIFORNIA

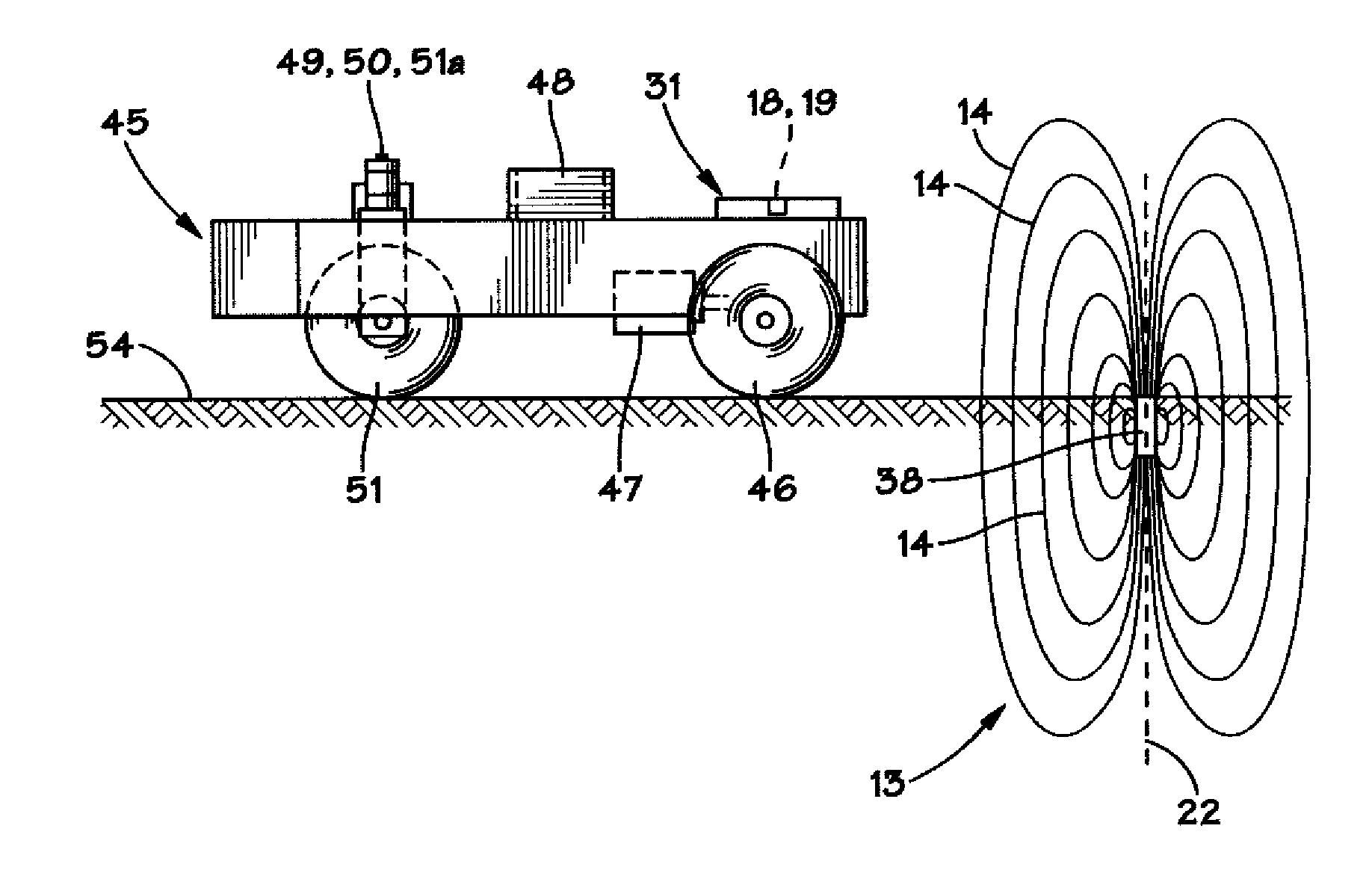

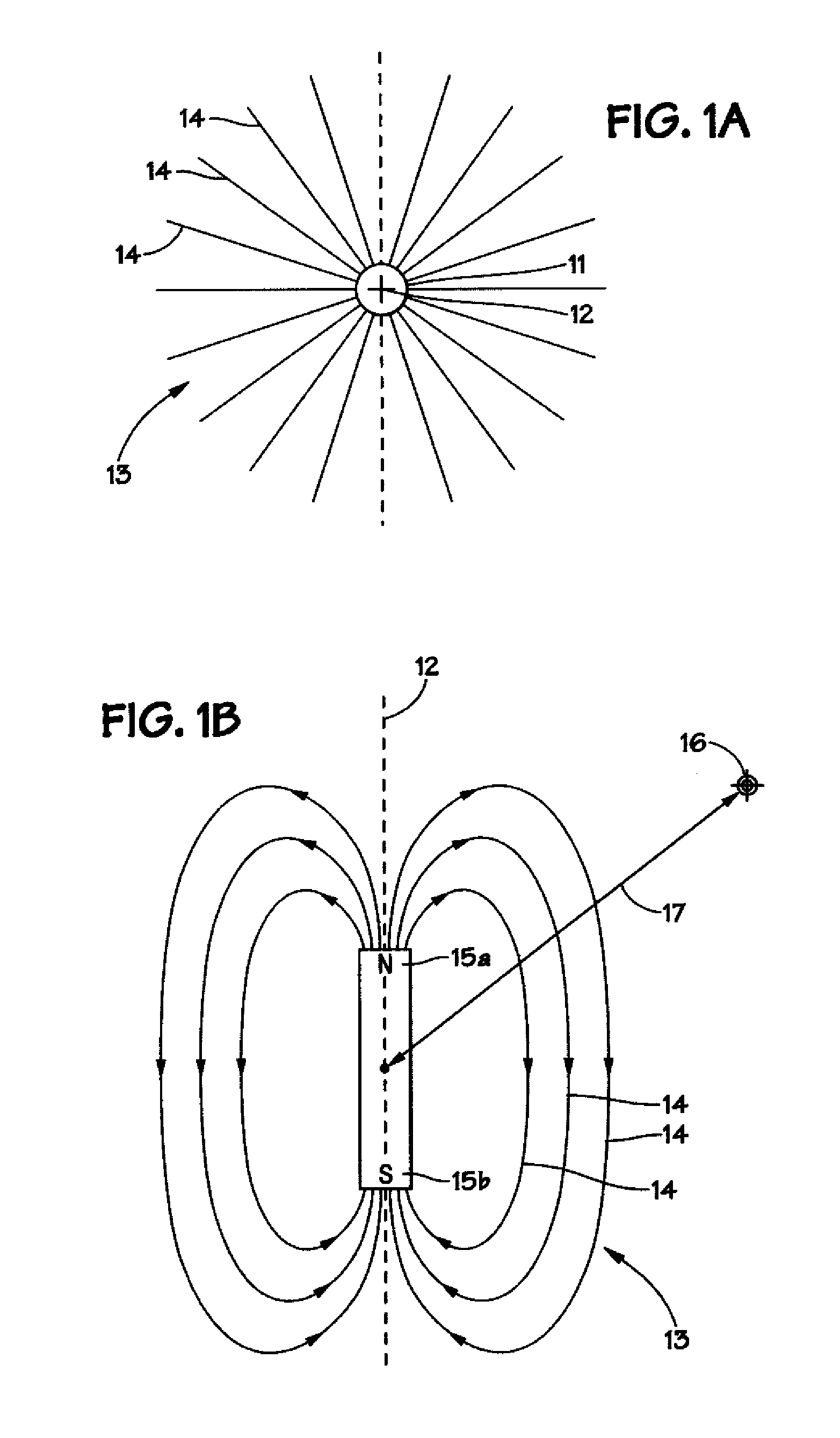

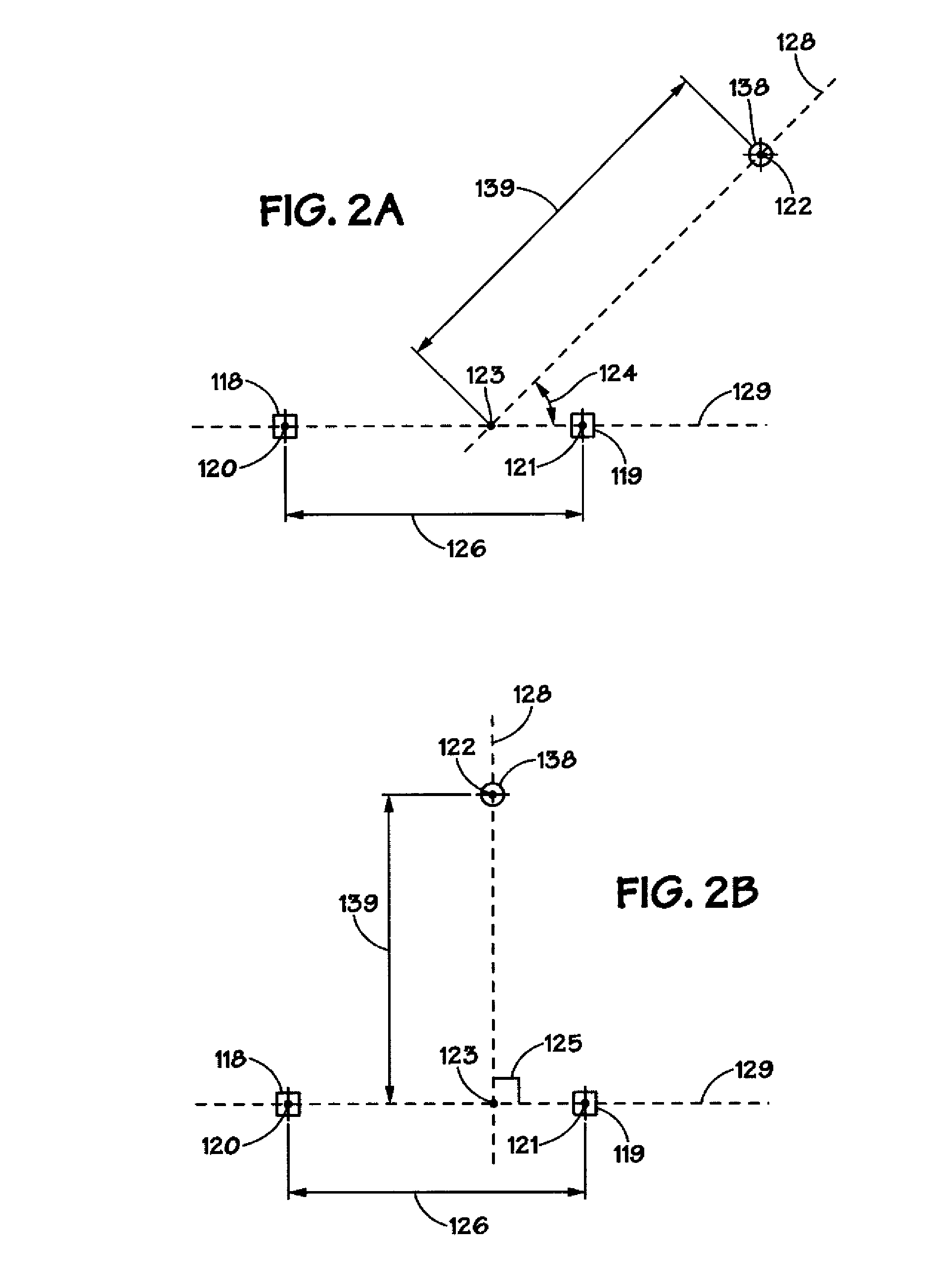

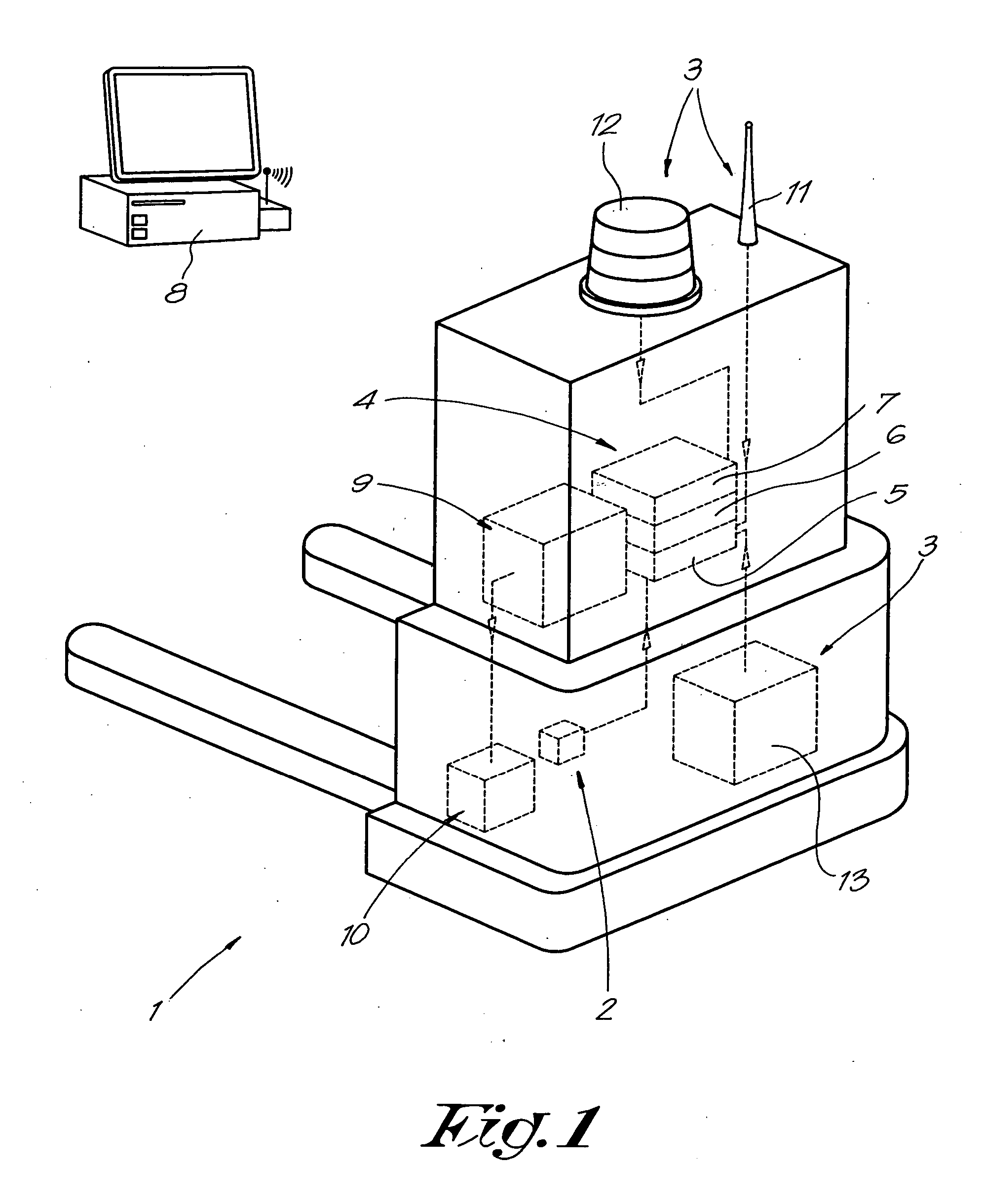

Magnet position locator

InactiveUS20090128139A1Well formedUsing electrical meansConverting sensor outputTriangulationSubject matter

In one illustrative embodiment, the present subject matter is directed to a device adapted to determine the position of a target magnet, wherein the device includes a pair of orthogonal magnetic field sensors laterally disposed along an axis that is substantially transverse to an axis defined by one that is nominally parallel to the direction of the target magnet. In another illustrative embodiment, the subject matter is adapted for use on an automated guided vehicle (AGV), whereby detection of the target magnet's location facilitates correction of the vehicle's heading and position while traversing an AGV system. The present subject matter is also directed to a method whereby the position of a target magnet may be determined by triangulation, utilizing trigonometric calculations based upon the strength and direction of the magnet field to determine the magnet's position relative to the magnetic field sensors.

Owner:JOHN BEAN TECH CORP

Automated guided vehicle navigation method based on two-dimension code positioning

ActiveCN104142683AEasy to deployReduce manufacturing costPosition/course control in two dimensionsVehiclesAutomated guided vehicleComputer science

The invention provides an automated guided vehicle navigation method based on two-dimension code positioning and relates to the technical field of navigation of automated vehicles. The automated guided vehicle navigation method based on two-dimension code positioning solves the technical problems that according to an existing method, deployment is not convenient, investment cost is high, and paths are not flexible. According to the automated guided vehicle navigation method based on two-dimension code positioning, a two-dimension code label array which is arranged in a mesh mode is attached to the ground of the site where an automated guided vehicle is applied, two-dimension code labels on the ground are obtained through a camera and are recognized when the automated guided vehicle advances, the automated guided vehicle is controlled to advance according to the position information contained in the two-dimension code labels, and thus navigation of the automated guided vehicle is achieved. The automated guided vehicle navigation method based on two-dimension code positioning has the advantages that deployment is convenient, investment cost is low, and the paths are flexible.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

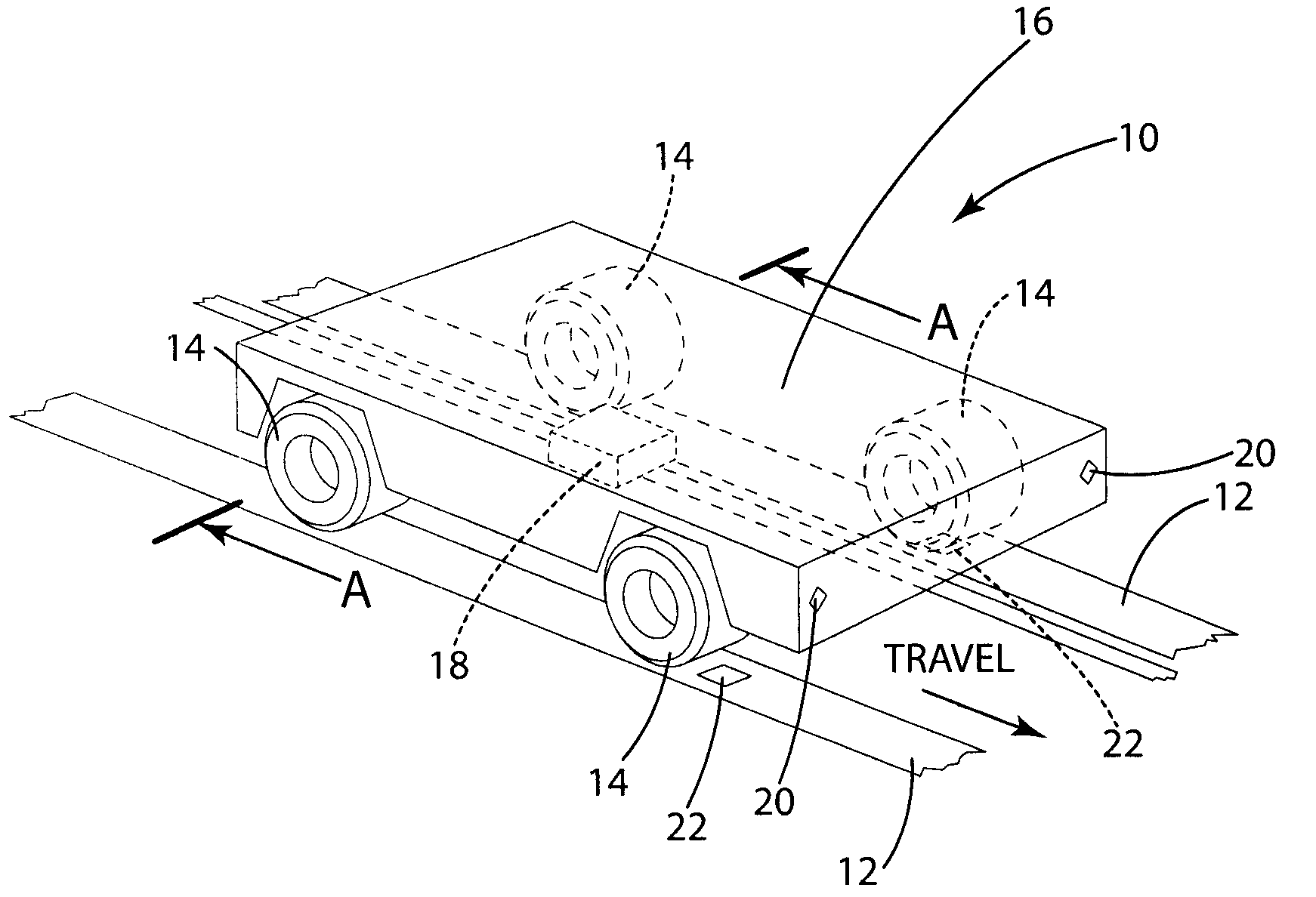

Variable path automated guided vehicle

InactiveUS20070179690A1Efficient transportWear minimizationNavigation instrumentsVehicle position/course/altitude controlWear patternAutomated guided vehicle

An automated guided vehicle and a method of controlling an automated guided vehicle which are capable of varying the travel path of the automatic guided vehicle in order to reduce wear patterns created in the floor of the material handling facility. The travel path of the AGV is varied by intentionally applying a deviation from a selected predetermined route along which the AGV is traveling.

Owner:JERVIS B WEBB INT CO

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

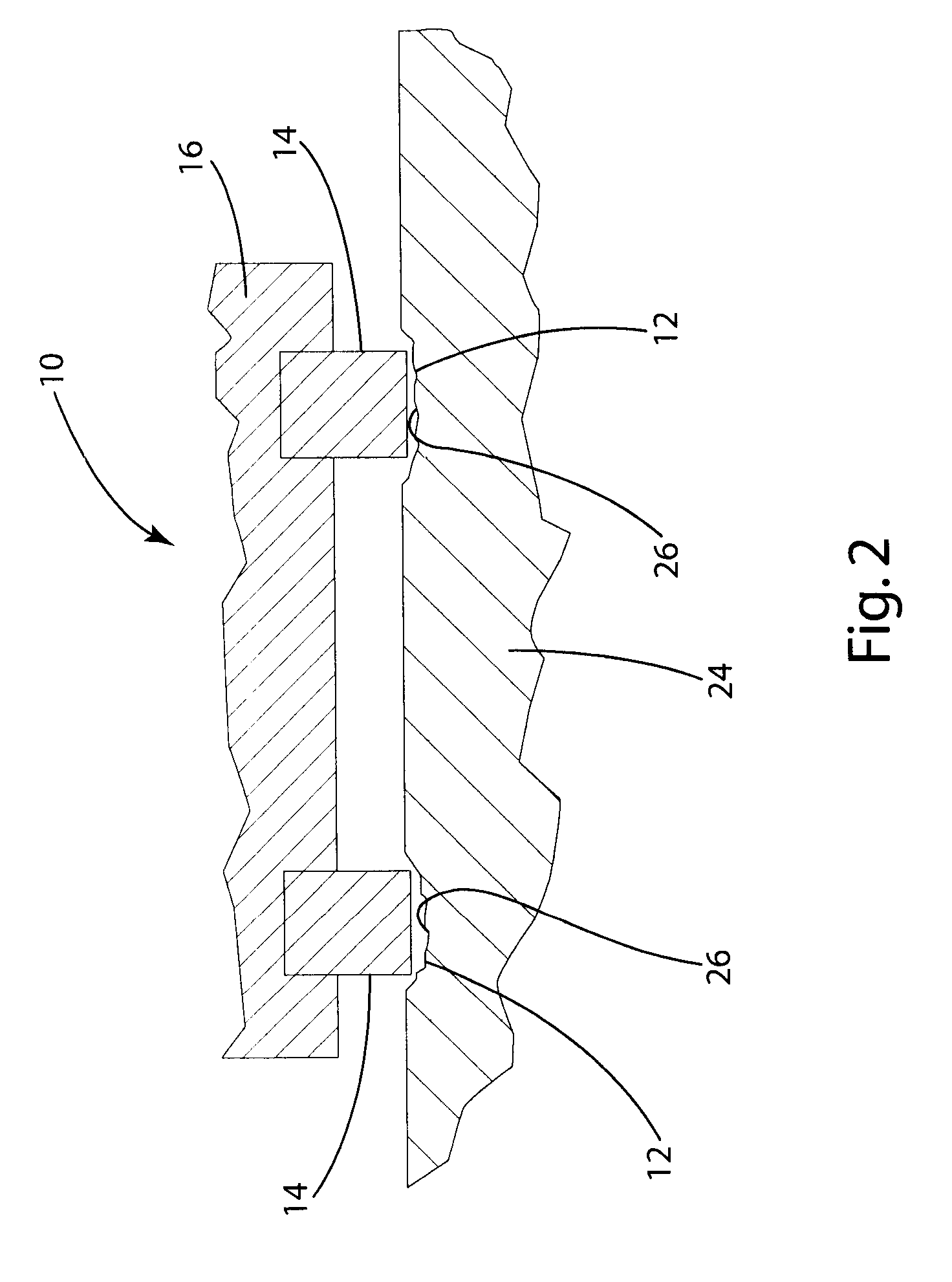

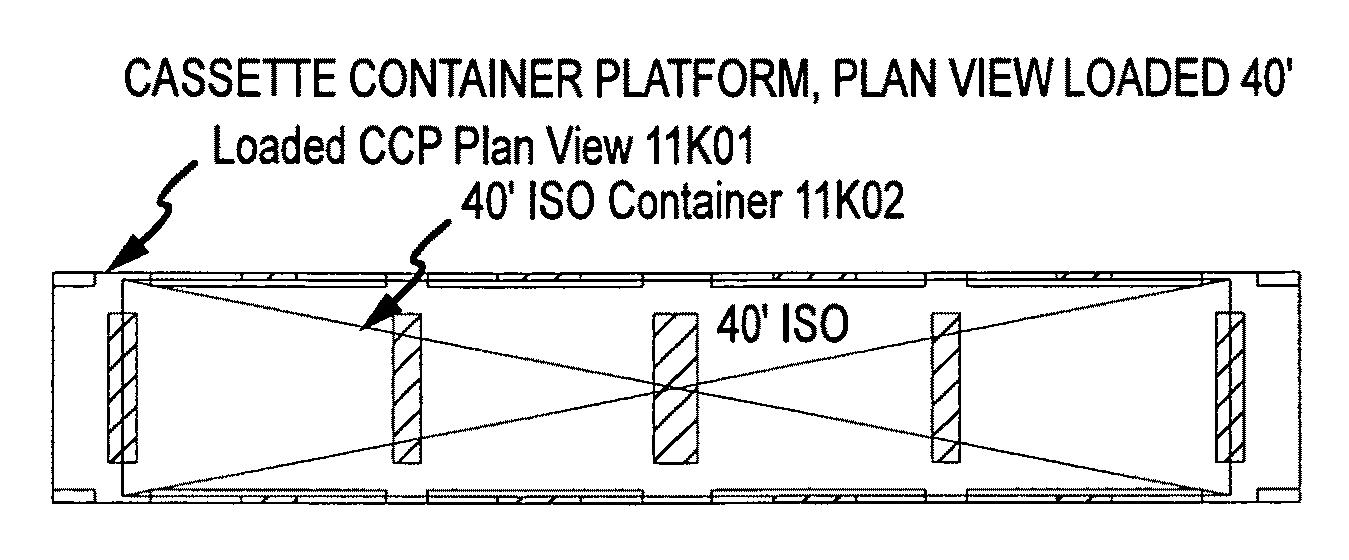

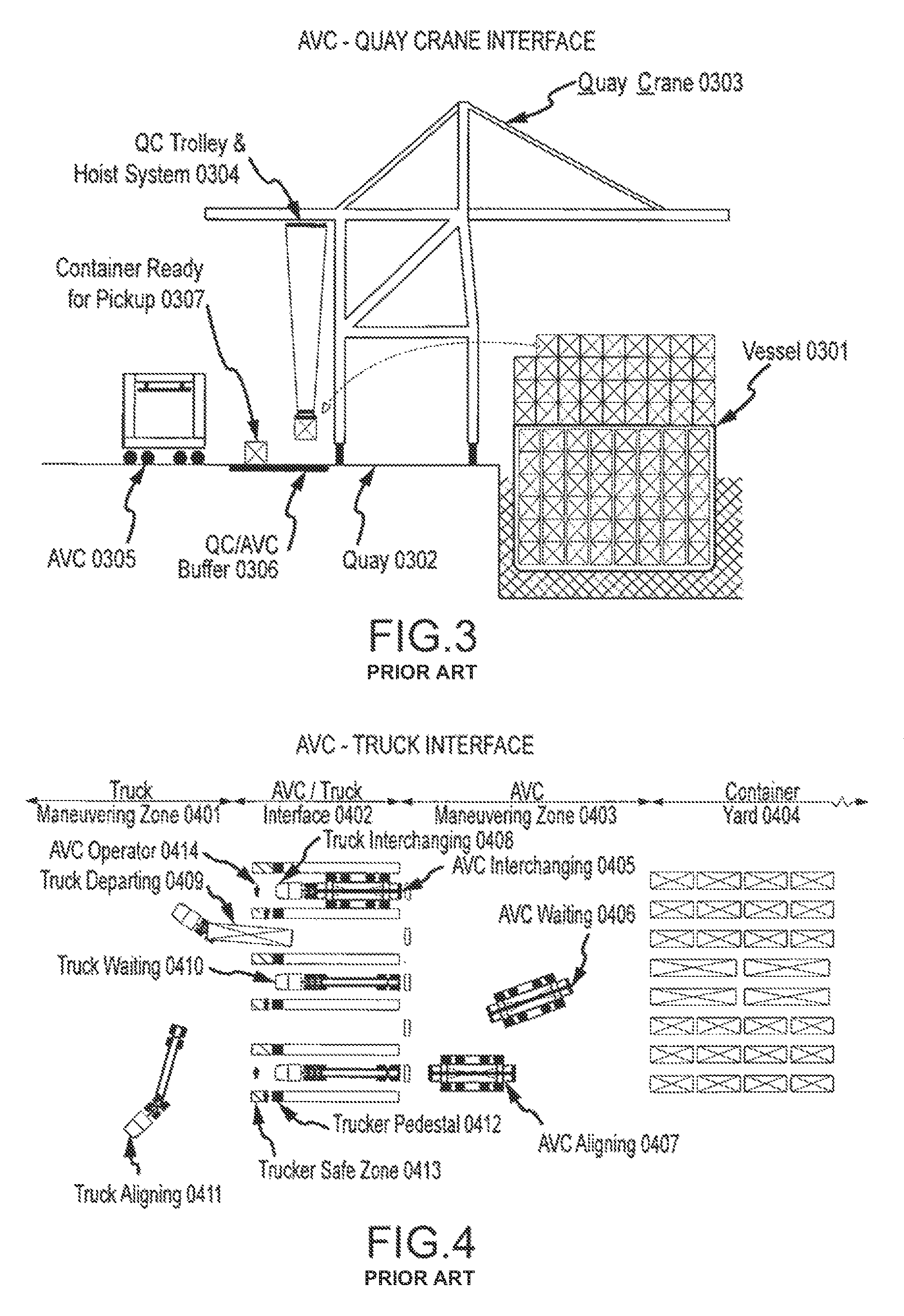

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

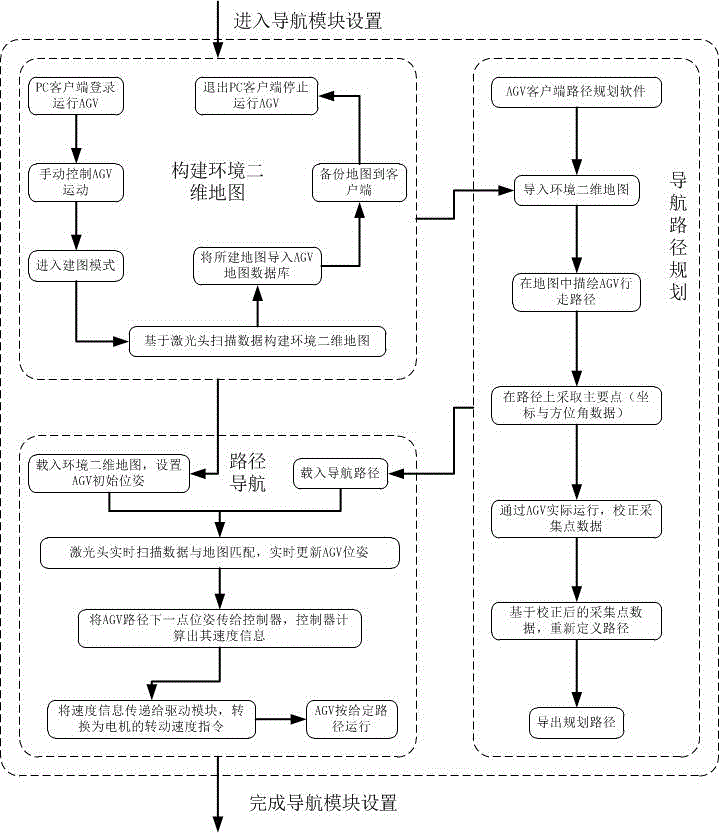

Automatic guided vehicle based on map matching and guide method of automatic guided vehicle

ActiveCN104596533AImprove environmental adaptabilityEasy to changeInstruments for road network navigationOptimum routeAutomated guided vehicle

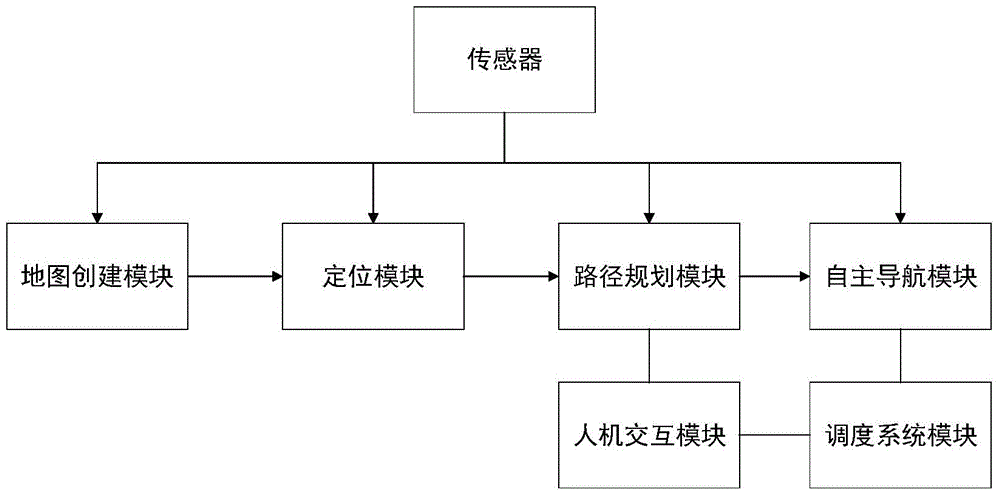

The invention provides an automatic guided vehicle based on map matching and a guide method of the automatic guided vehicle. The automatic guided vehicle comprises a map creation module, a location module, a human-machine interaction module, a route planning module, an autonomous navigation module and a dispatching system module, wherein the map creation module is used for creating an environmental map; the automatic guided vehicle utilizes the carried location module to match the observed local environmental information with a preliminarily created global map to obtain pose information under the global situation; the human-machine interaction module is used for displaying the information and working state of the automatic guided vehicle in the map in real time; the route planning module is used for planning a feasible optimum route in the global map; the automatic guided vehicle is autonomously navigated by virtue of the autonomous navigation module according to the planned route; the dispatching system module is used for dispatching the automatic guided vehicle closest to a calling site to go to work. By adopting the automatic guided vehicle, no other auxiliary location facility is needed, no alteration is made for the environment, the capability of the automatic guided vehicle is completely depended, the automatic guided vehicle is utterly ignorant to the environment, and no priori information is provided.

Owner:SHANGHAI JIAO TONG UNIV

Automatic guided vehicle, path planning method and device

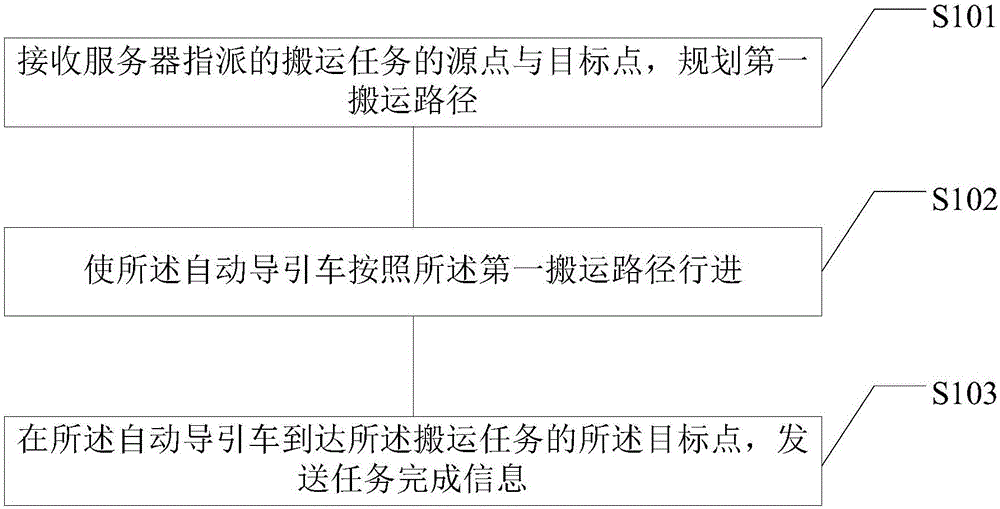

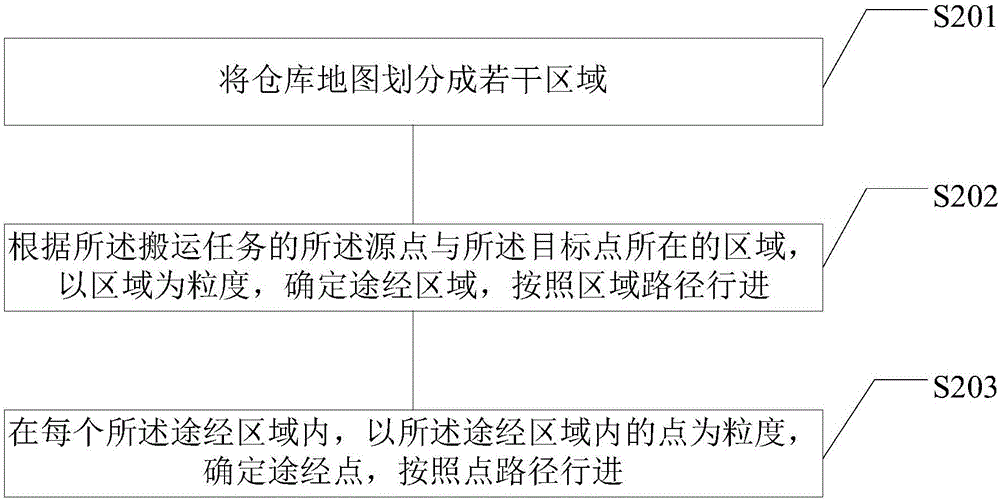

ActiveCN106647734ARelieve pressureScale upPosition/course control in two dimensionsVehiclesTask completionPlanning approach

The invention provides a path planning method and a device for an automatic guided vehicle, and relates to an automatic guided vehicle. The path planning method comprises the steps of receiving a source point and a target point of a conveyance task assigned by a server, planning a first conveyance path, driving the automatic guided vehicle to march forward according to the first conveyance path, and sending the task completion information when the automatic guided vehicle reaches the target point of the conveyance task. According to the technical scheme of the invention, the path planning method is applied to the automatic guided vehicle and a path planning task is assigned to the automatic guided vehicle to be executed. Therefore, the operation amount of the server is reduced and the cargo conveying efficiency is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

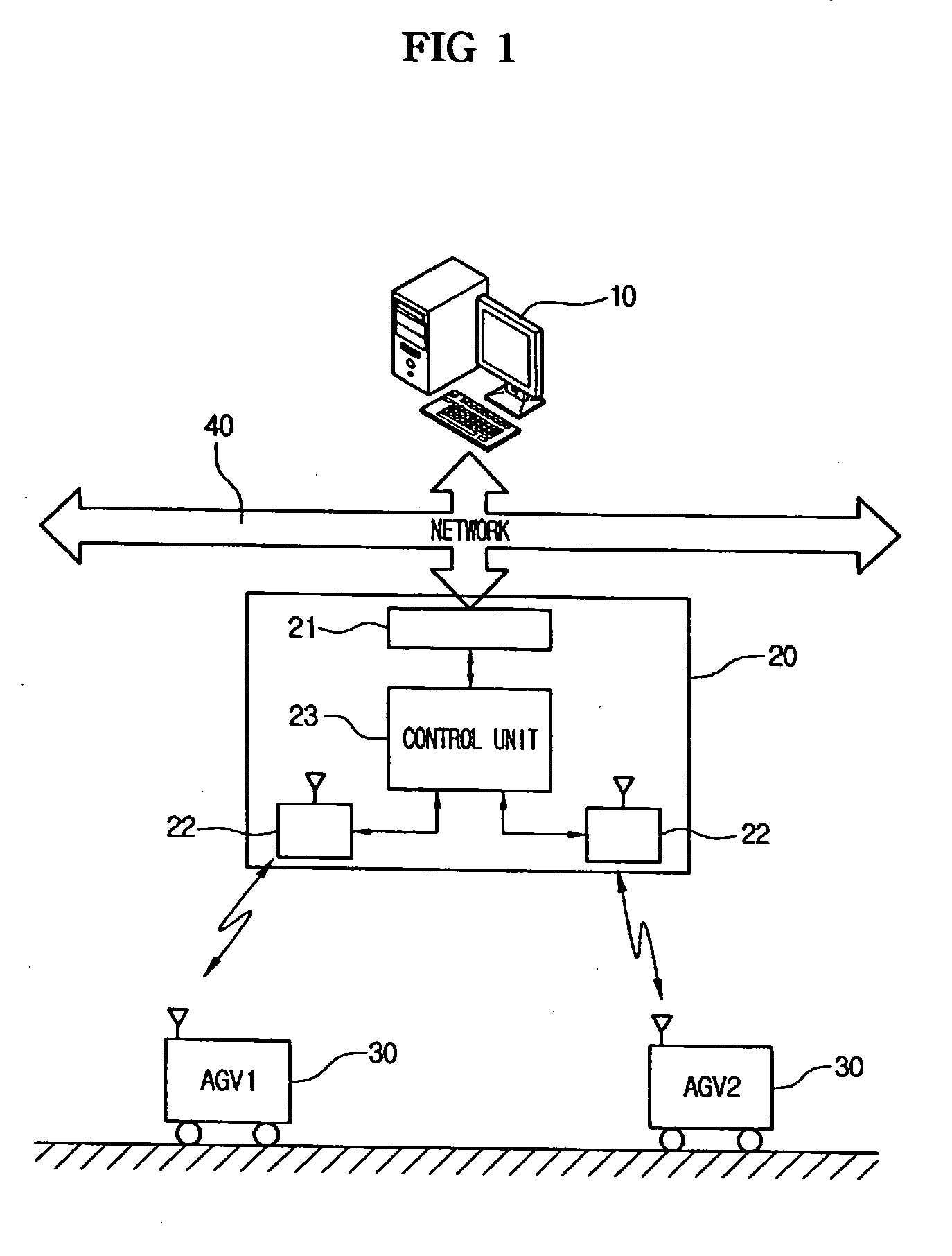

AGV control system and method

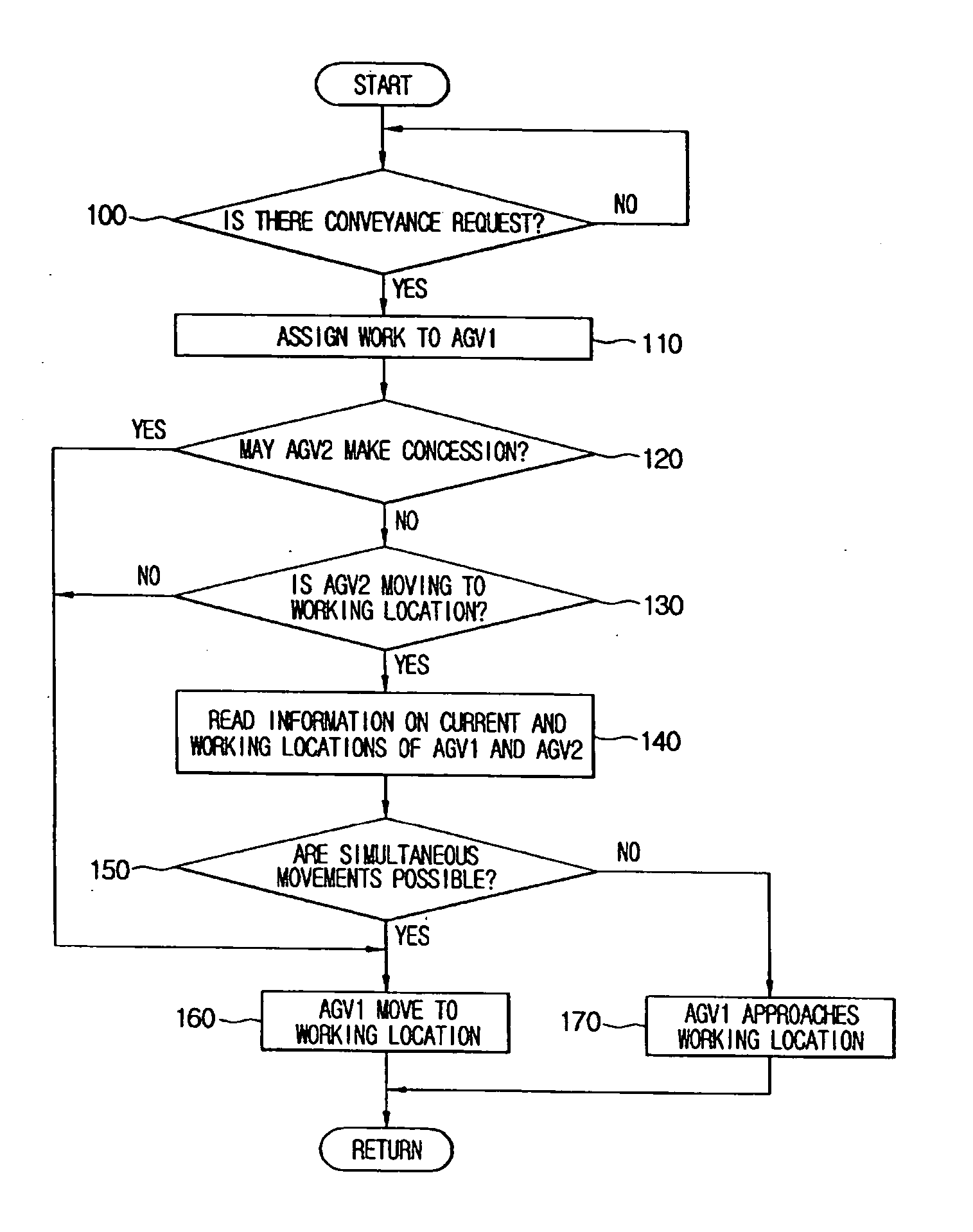

InactiveUS20050080524A1Conveying time can be reducedShorten the timeRailway componentsLogisticsControl systemAutomated guided vehicle

An automated guided vehicle control system and method which allows overall conveying time to be reduced by simultaneously moving a plurality of automated guided vehicles (AGVs) to working locations without interfering with each other. For this purpose, when there is a conveyance request, one of a plurality of the AGVs operated on a single guide path is assigned work. Further, it is determined whether another automated guided vehicle moving to a working location exists on the guide path. Also information on current and working locations of the automated guided vehicles is read if the automated guided vehicle moving to the working location exists on the guide path. Further, it is determined whether simultaneous movements are possible based on the read information. The automated guided vehicle waiting for work is moved if the simultaneous movements are possible. Accordingly, the overall convey time is reduced by simultaneously moving the AGVs to working locations or by previously moving the AGVs to optimal locations without interfering with each other, so that conveying efficiency of the AGVs is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

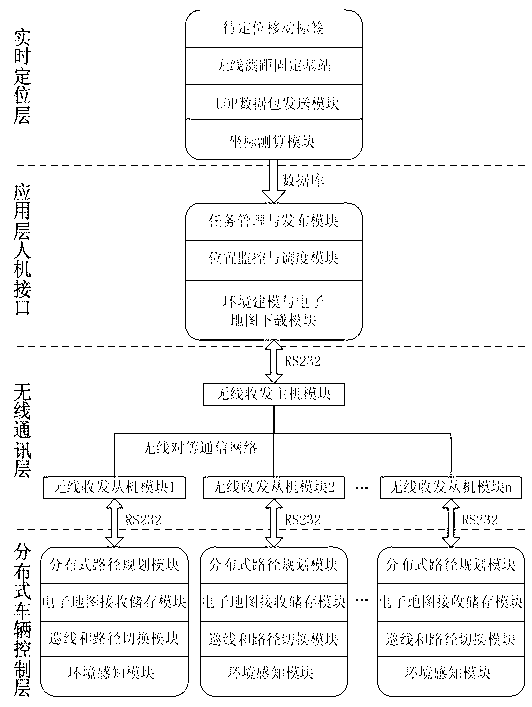

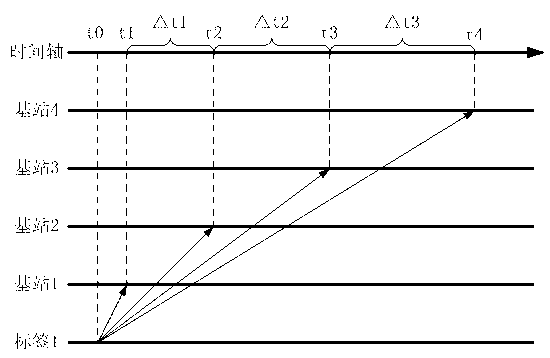

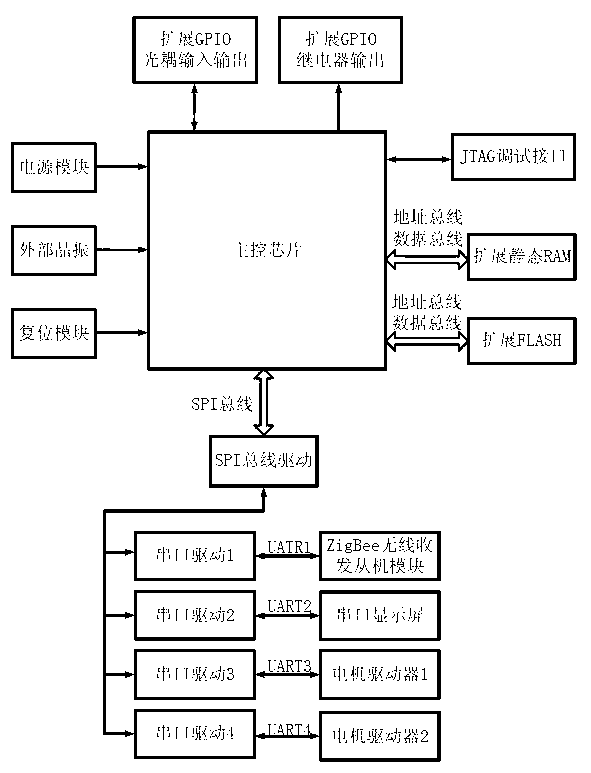

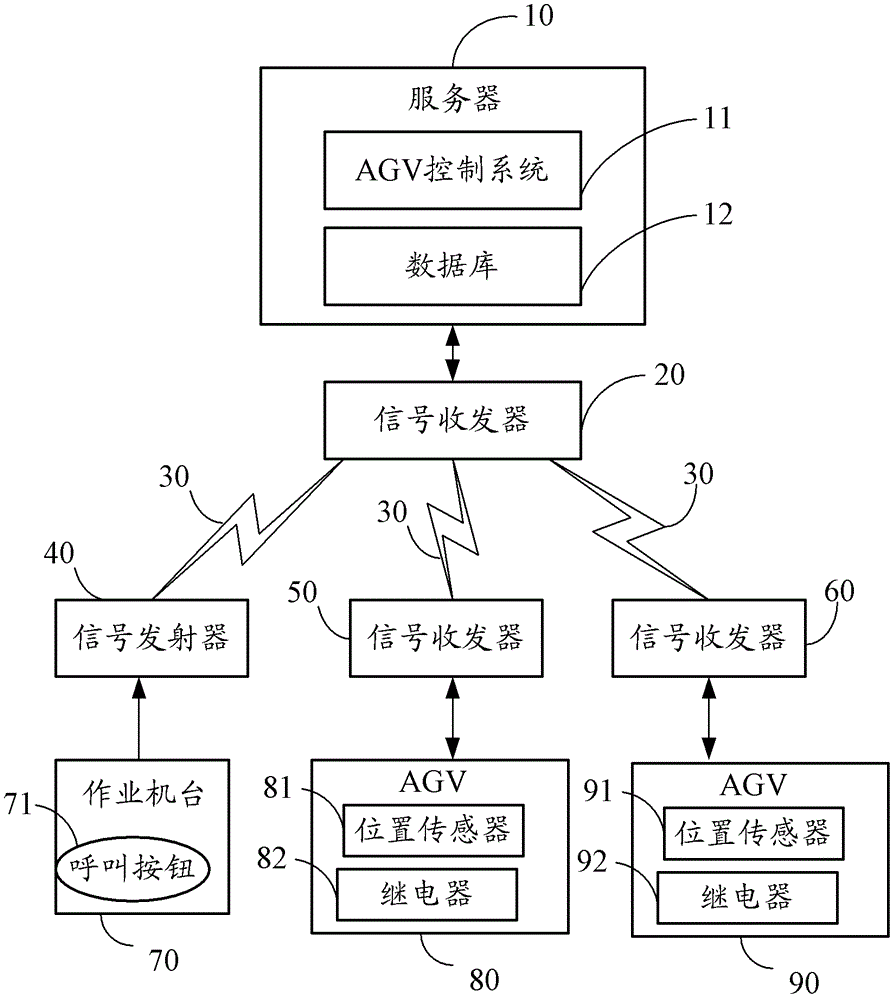

Automatic guided vehicle scheduling system and method based on global wireless precise positioning

InactiveCN103309350AEnsure safetyReduce communication burdenElectric/hybrid propulsionTotal factory controlWireless transceiverEnvironmental perception

The invention provides an automatic guided vehicle scheduling system based on global wireless precise positioning. The system comprises a real-time positioning layer, an application layer man-machine interface, a distributive vehicle control layer and a wireless communication layer; the real-time positioning layer comprises a to-be-positioning mobile tag, a wireless ranging fixed base station, a UDP (user datagram protocol) datagram transmission module and a coordinate calculation module; the application layer man-machine interface comprises a task management and publishing module, a position monitoring and scheduling module and an environmental modeling and electronic map downloading module; the distributive vehicle control layer comprises a distributive route planning module, an electronic map receiving and storing module, a line patrol and route switching module and an environmental perception module; and the wireless communication layer comprises a wireless transceiver host module, a wireless transceiver slave module and a wireless peer-to-peer communication network. According to the system and the method provided by the invention, as the global real-time wireless accurate timing technology is introduced, the positions of all AGVs (automated guided vehicles) in the system are monitored in real time, and are fed back to a centralized main control computer, so that the computer can perform uniform scheduling on all equipment in the system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

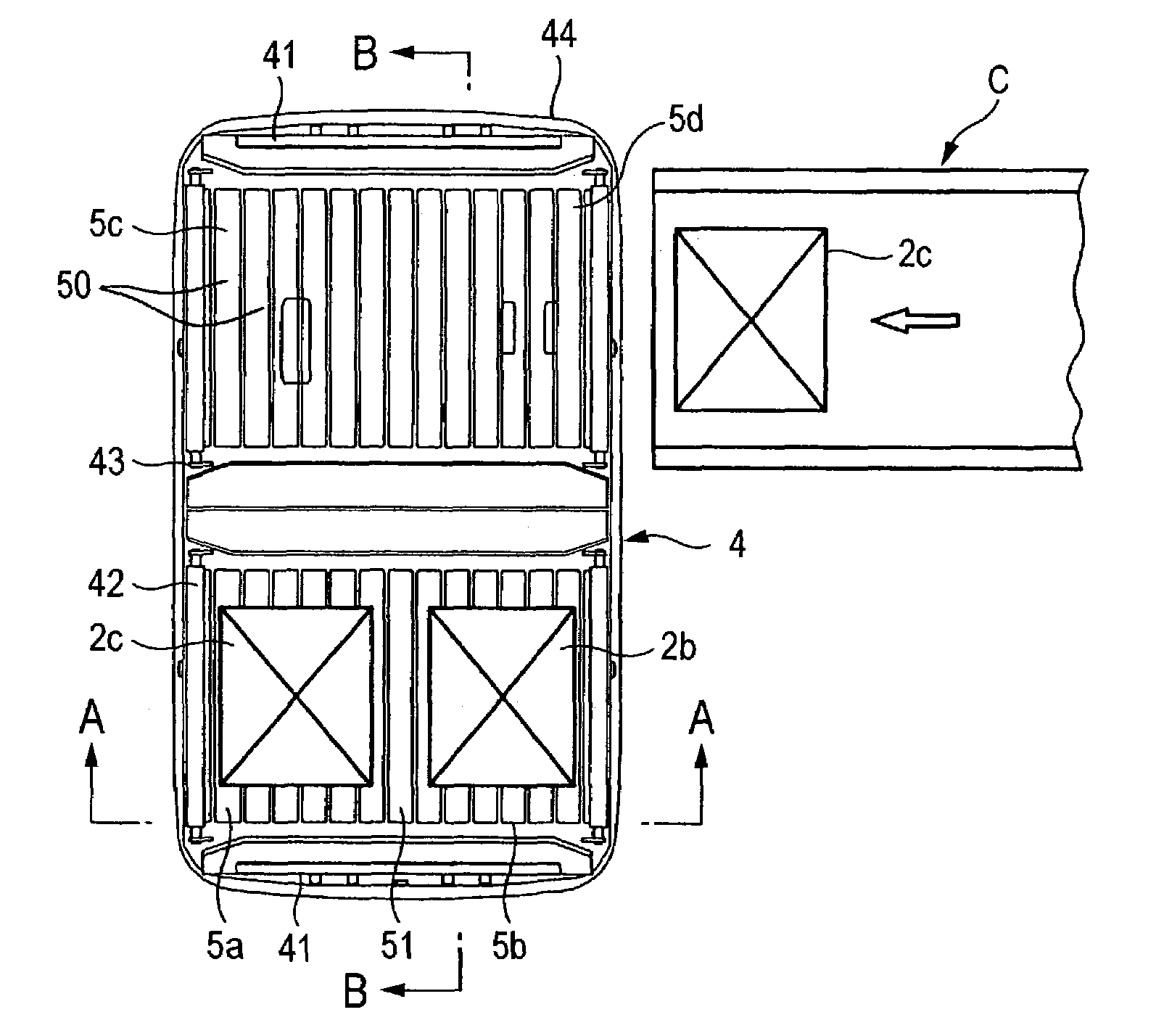

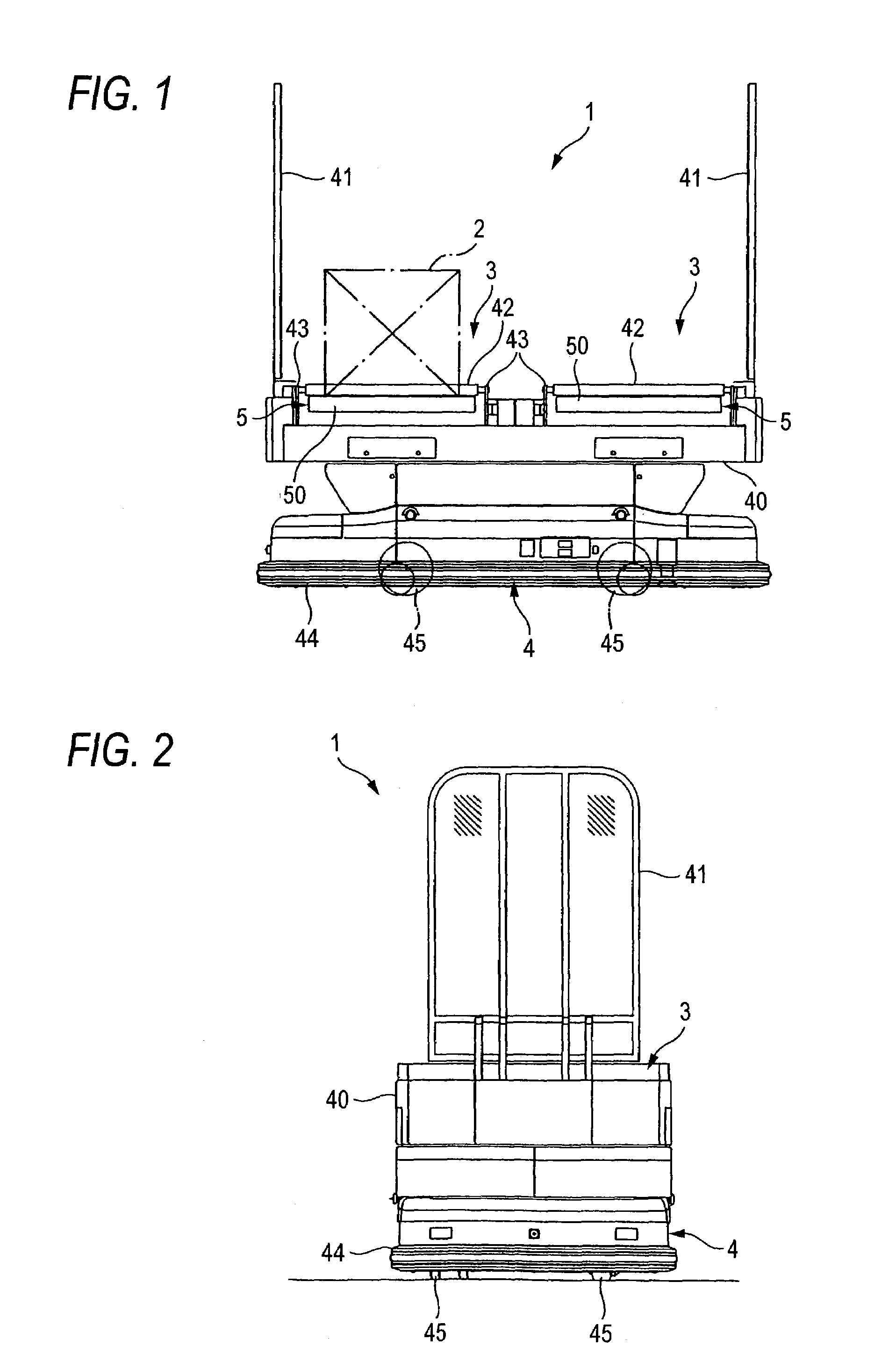

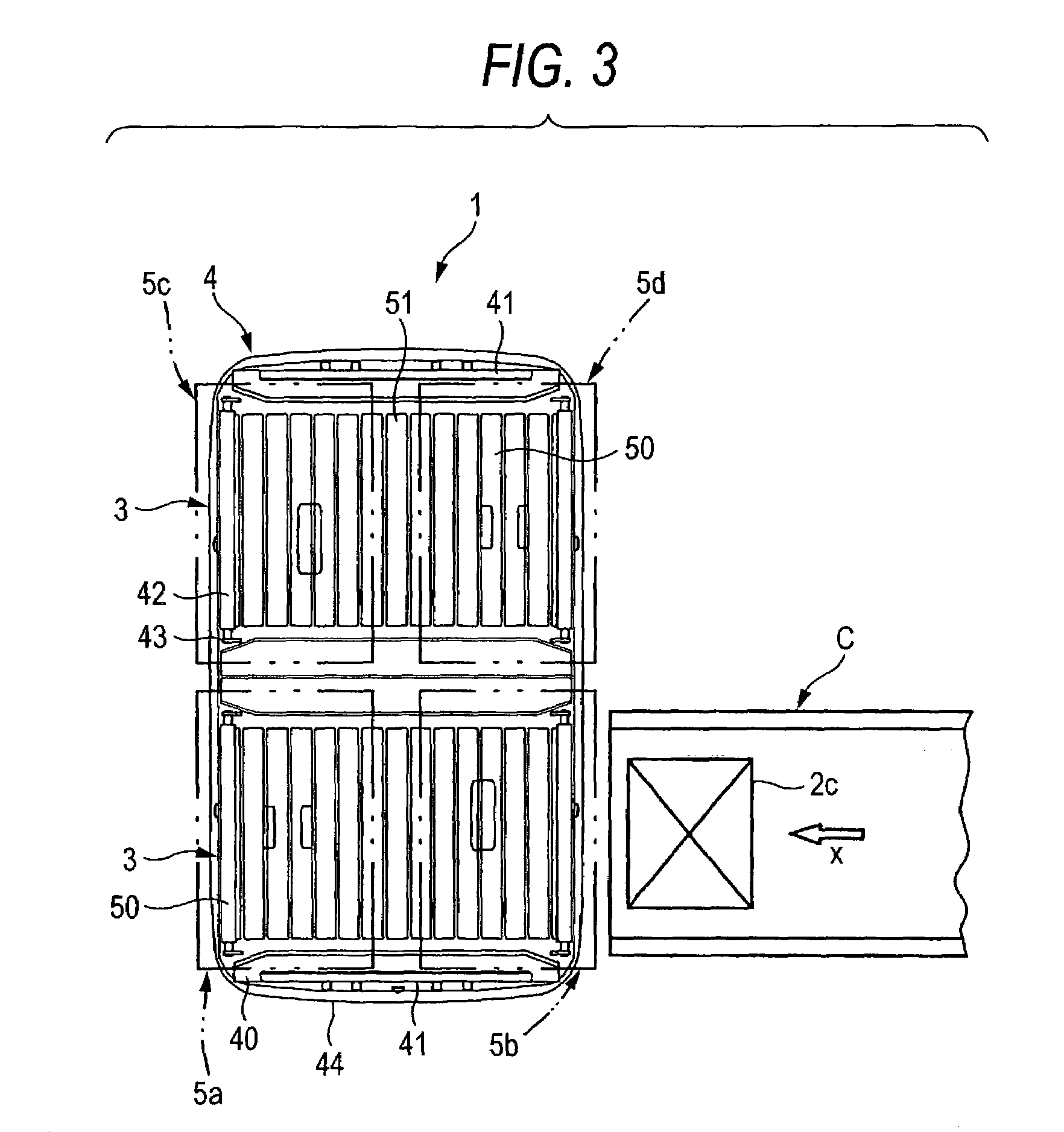

Automated guided vehicle

InactiveUS7008164B2Efficient transferRefuse receptaclesPropulsion by batteries/cellsAutomated guided vehicleEngineering

An automated guided vehicle has plural conveyors for transferring materials to be transferred mounted on a self-propelling dolly and juxtaposed in a transverse direction. Each of the conveyors includes plural part conveyors whose operation can be controlled individually and arranged in tandem in a transferred direction. One or three or more part conveyors may be disposed or arranged in tandem in the direction of the vehicular width. One or three or more part conveyors may be disposed or juxtaposed in the transverse direction.

Owner:NIPPON YUSOKI

Indoor AGV (Automated Guided Vehicles) path planning method based on improved A* algorithm

ActiveCN107990903AOptimizing Estimated Cost ValueHigh path safety factorInstruments for road network navigationNavigational calculation instrumentsPlanning approachAutomated guided vehicle

The invention discloses an indoor AGV (Automated Guided Vehicles) path planning method based on an improved A* algorithm. The method comprises the following steps: firstly, constructing an environmental map by adopting a grid method, and expanding the grid map according to the size of an AGV; then, optimizing a search strategy of a traditional A* algorithm, introducing a multi-value map model, cost function evaluation and path inflexion smoothing, and adding safety factors as path evaluation indexes; and finally, adding a starting point and a target point of the AGV to the grid map, adopting an improved distance evaluation function, taking the node with the smallest cost function as a node of the next step, gradually planning a running route of the AGV, and finally displaying the running route in an electronic map. Simulated analysis verifies that the AGV path planning based on the improved A* algorithm is higher in search route safety factor, smoother in path and higher in search speed.

Owner:SOUTHEAST UNIV

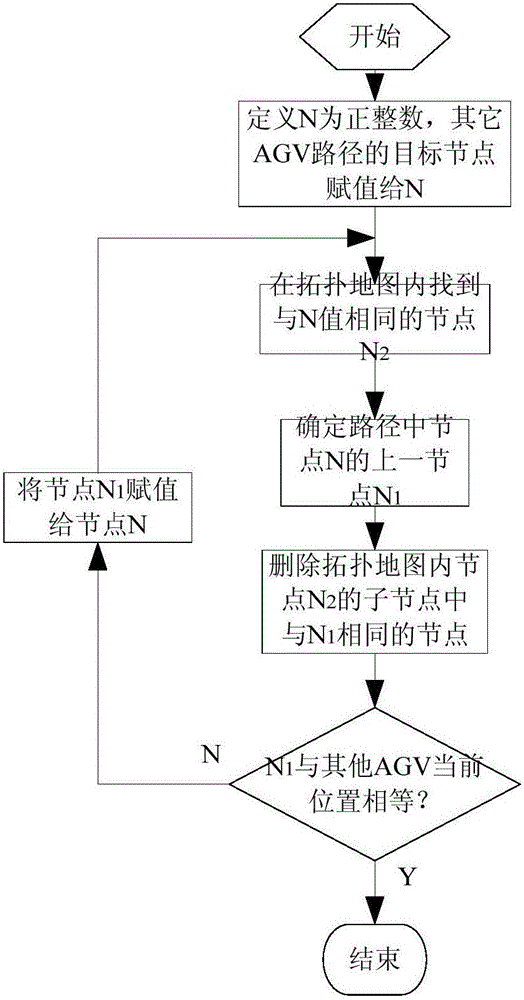

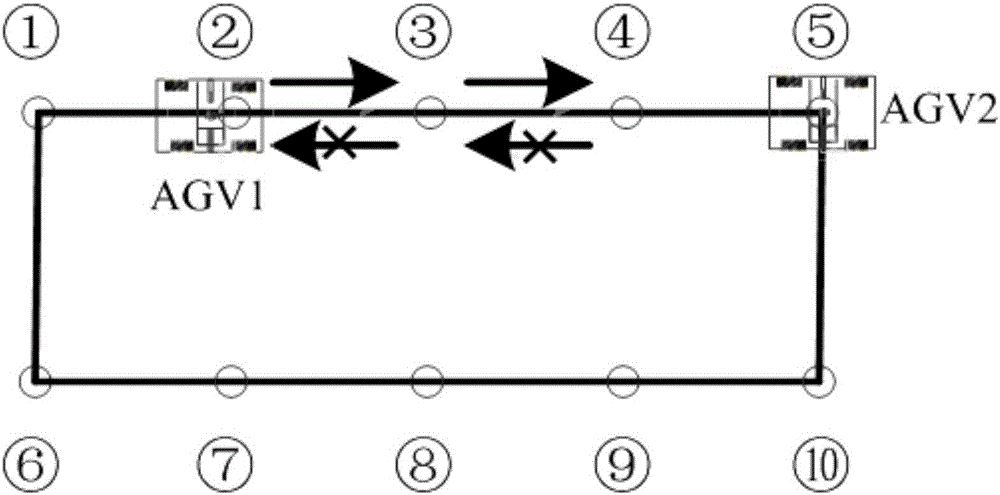

Multi-AGV scheduling method

ActiveCN106556406AEliminate conflictImprove operational efficiencyInstruments for road network navigationElectric/hybrid propulsionAutomated guided vehicleTime windows

The invention relates to a multi-AGV (automated guided vehicle) scheduling method, and belongs to the technical field of navigation and control. A scheduling system provided by the invention schedules a plurality of AGVs to automatically eliminate conflicts in a navigation process in order to complete task. The scheduling system reads established bidirectional path files, establishes and searches a topology map of AGV walking paths, selects an AGV to complete the task after receiving task information, and eliminates opposite conflicts among the AGVs when searching the paths for the AGVs; and time windows are added to the path nodes of all the AGVs in the walking process of the AGVs, and node conflicts and pursuit conflicts are eliminated depended on the time interval, so the running efficiency of the AGVs is improved.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

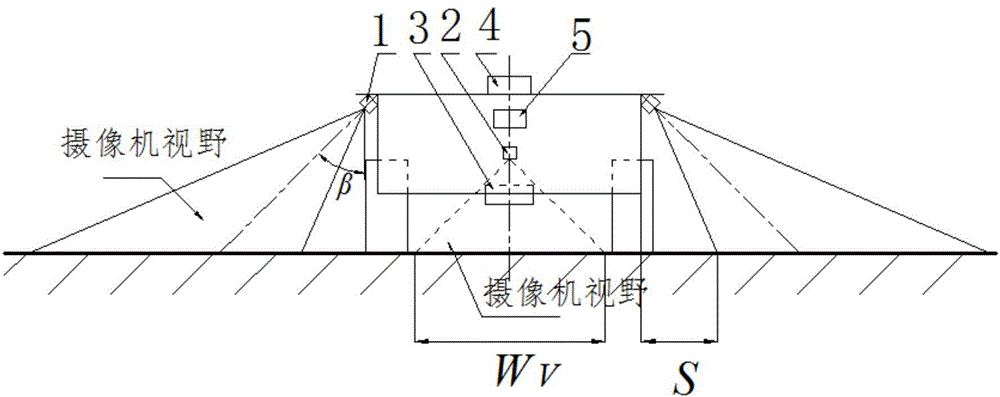

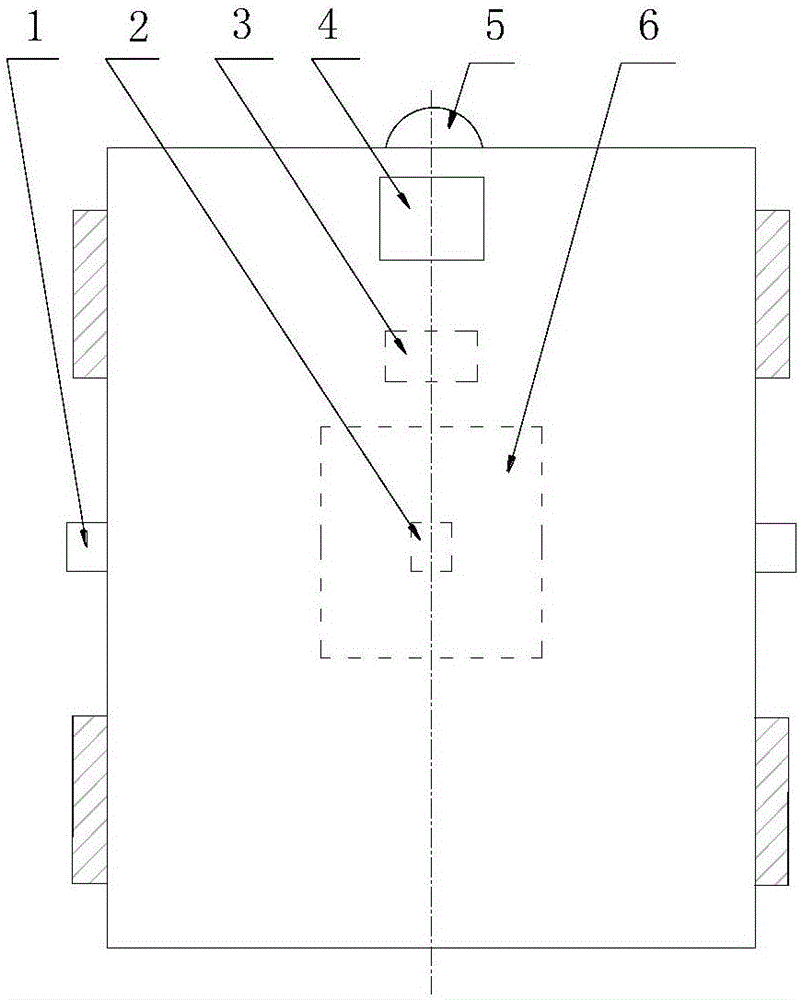

Guide device, landmark layout method and guide method based on multi-view vision and inertial navigation

ActiveCN106774335AGuaranteed flexibilityPrecise positioningPosition/course control in two dimensionsVehiclesAutomatic controlAutomated guided vehicle

The invention discloses a guide device, a landmark layout method and a guide method based on multi-view vision and inertial navigation, belonging to the automatic control field. The guide device comprises oblique-downward cameras, a vertical-downward camera, an inertial measurement unit, a barrier sensor, a radio frequency card reader and a guide controller, wherein the oblique-downward cameras are arranged on two sides of a vehicle body, the vertical-downward camera is arranged at the center of the vehicle body, the inertial measurement unit is arranged on the top of the vehicle body, the barrier sensor is arranged on the front side of the vehicle body, the radio frequency card reader is arranged at the bottom of the vehicle body, and the guide controller is electrically connected with the cameras, the inertial measurement unit, the barrier sensor and the radio frequency card reader. Color guiding marked lines are distributed on two sides of an operation path of an automatic guide vehicle (AGV), and radio frequency tags and colored positioning marks which are in positional coincident with each other are distributed on the guiding marked lines. A guide method of the AGV comprises the steps of carrying out region traffic navigation in a middle region between the guiding marked lines on two sides, and carrying out path tracking guide along with the guiding marked lines on one side. The guide method has cross-regional remote motion flexibility and intra-regional target positioning accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

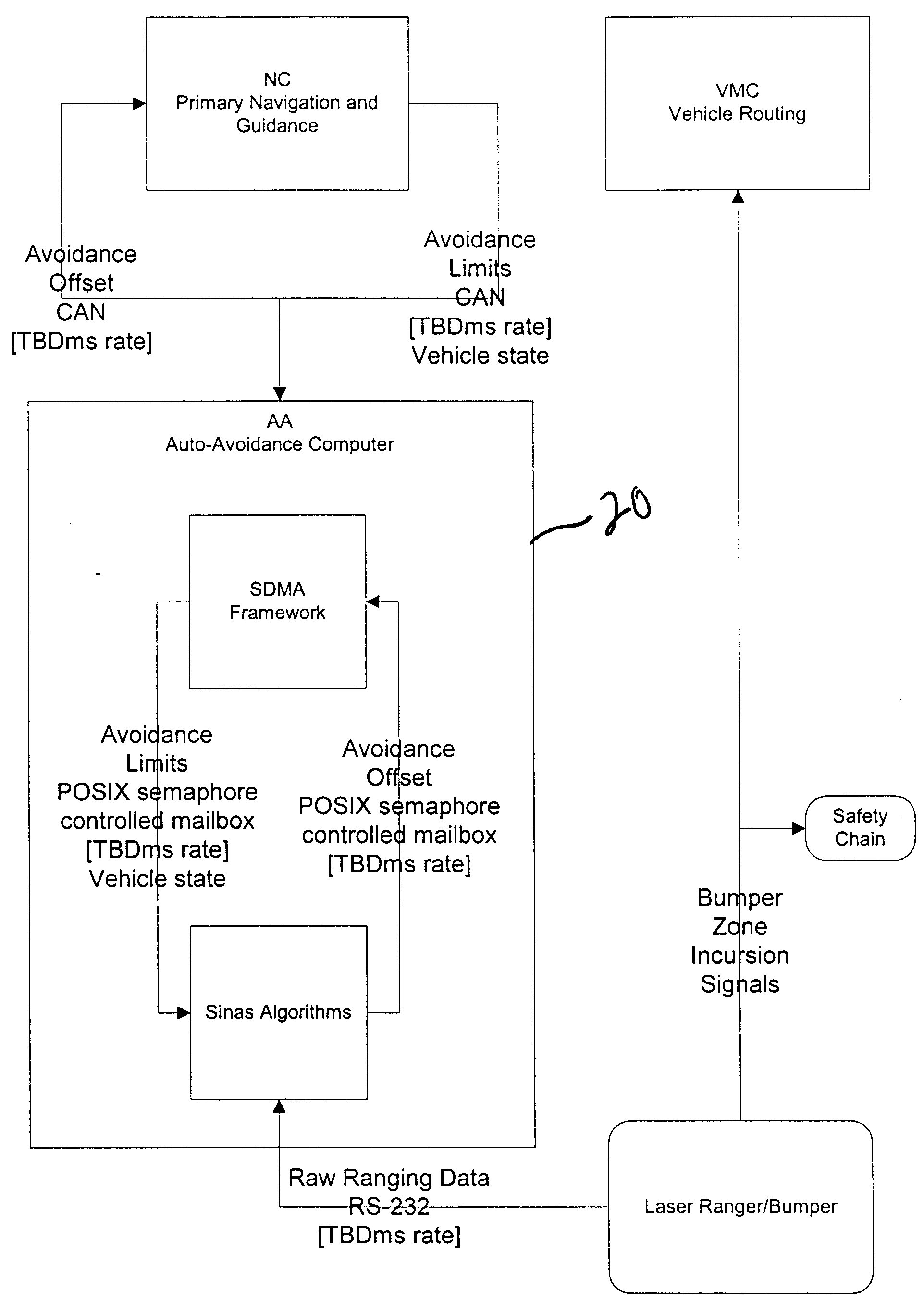

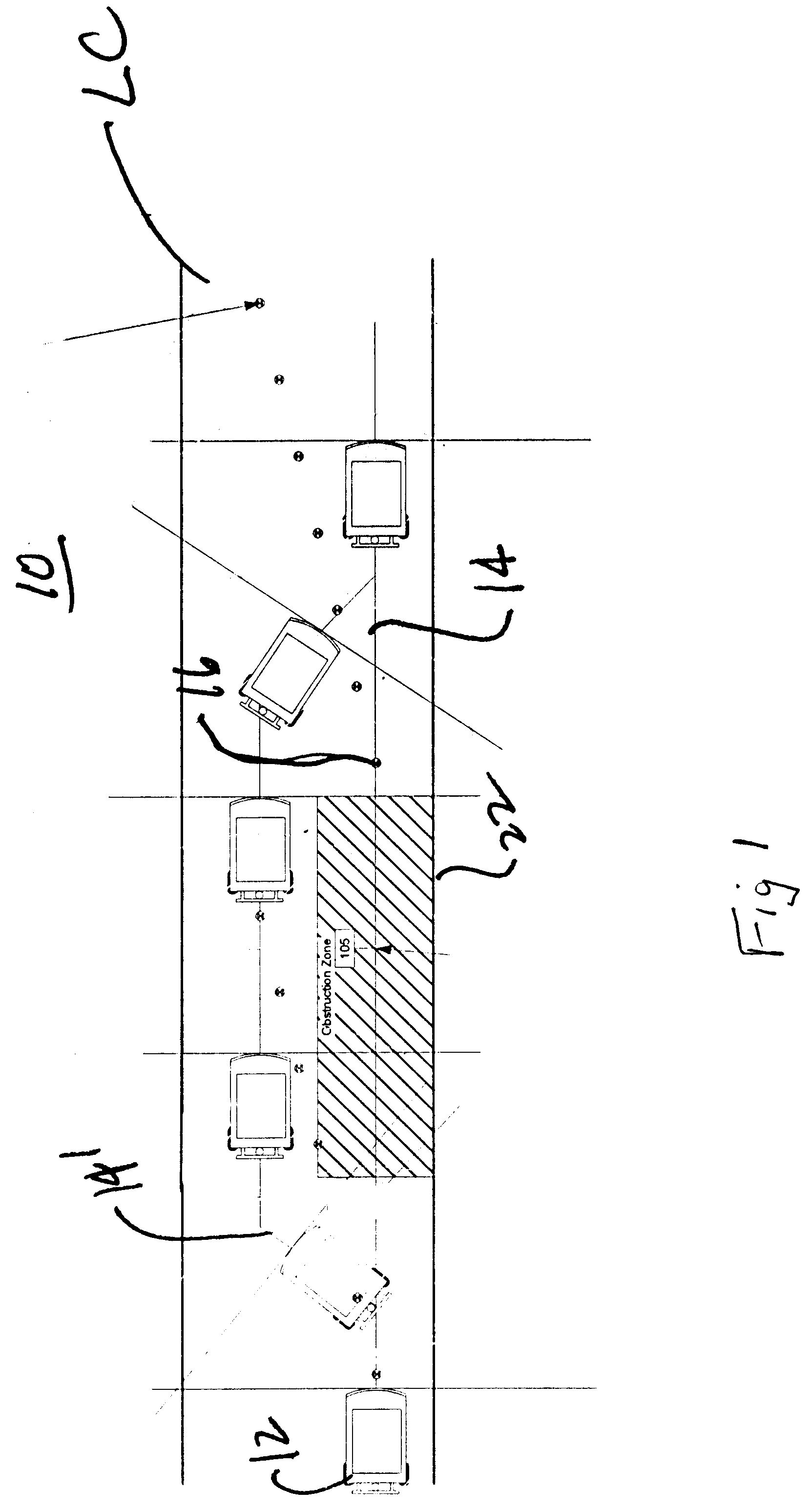

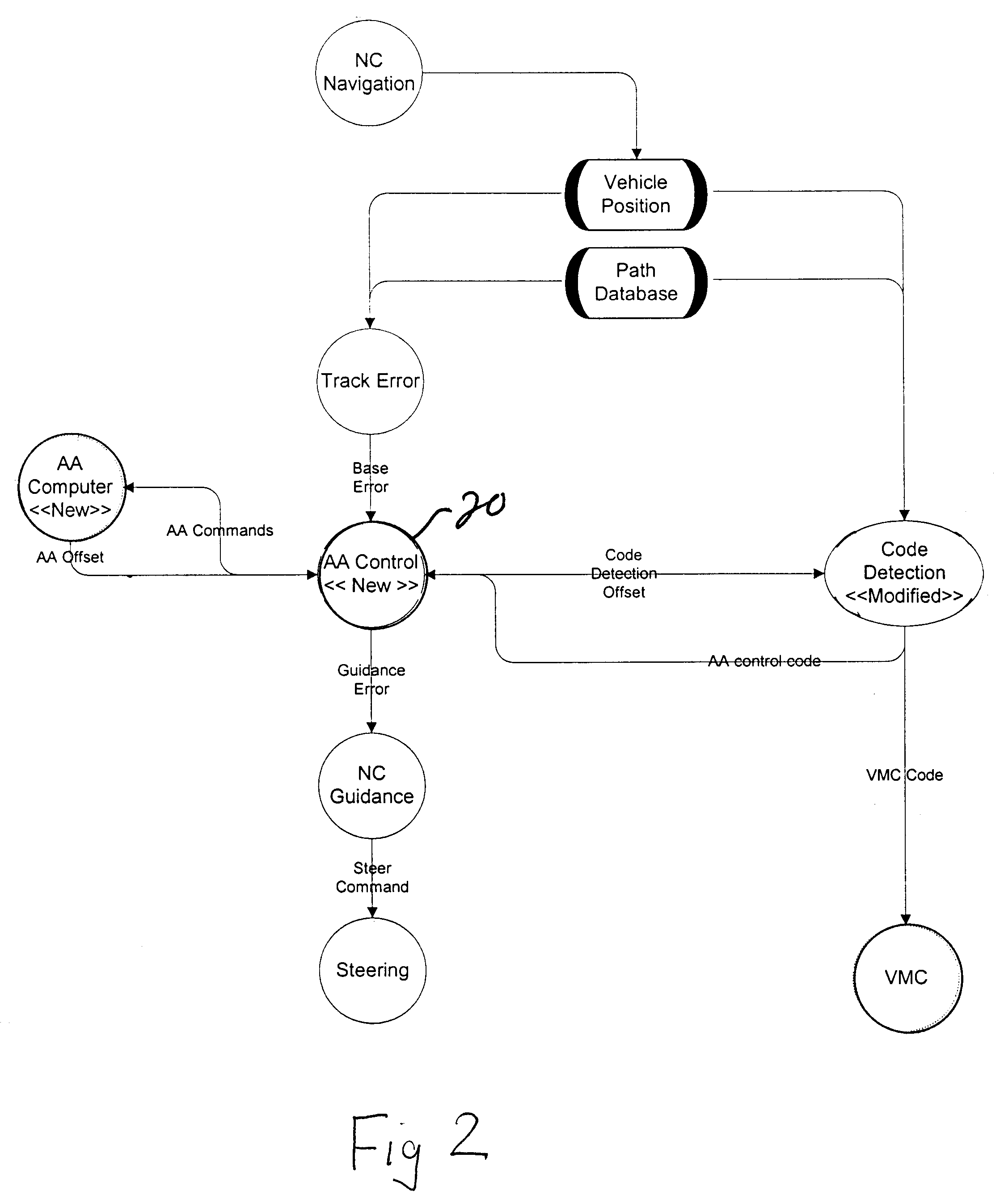

Dynamic object avoidance with automated guided vehicle

A method and apparatus for guiding an automated-guided vehicle includes providing a guide path defined with respect to a physical path and controlling a vehicle to generally follow the guide path. The presence of an obstacle at the guide path is detected, such as with a laser scanner, radar detector, or the like. The vehicle is controlled around the obstacle and back to the guide path. This may be accomplished by generating an offset to the guide path at the detected obstacle.

Owner:DEMATIC

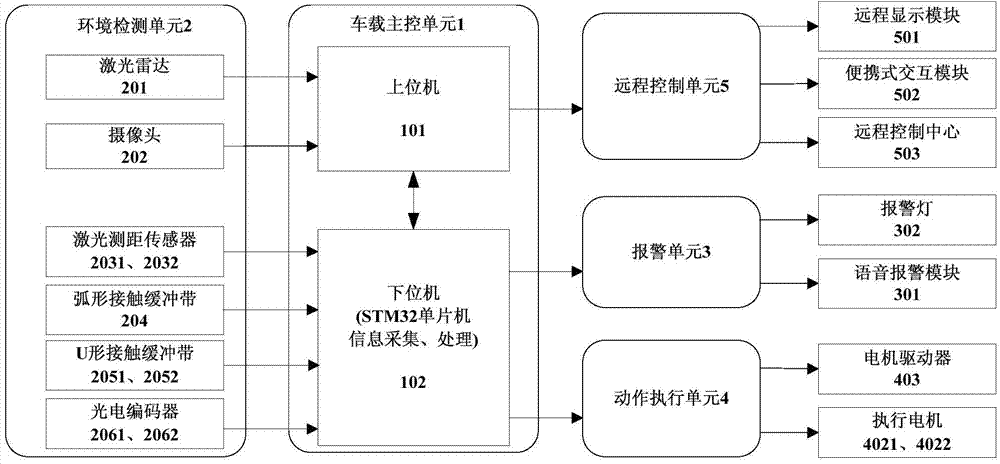

Intelligent anti-collision system of novel automated guided vehicle for material handling

ActiveCN103935365ARealize remote controlQuick managementAnti-collision systemsExternal condition input parametersLaser rangingRadar

The invention relates to an intelligent anti-collision system of a novel AGV for material handling. The system comprises a vehicle-mounted master control unit, an environment detecting unit, an action executing unit, an alarming unit and a remote control unit. The anti-collision system can achieve bidirectional multilayer protection on an AGV body. Forward protection of the AGV is achieved through a laser radar, an arc-shaped anti-collision buffer belt and a camera. Backward protection of the AGV is achieved through a laser distance measuring sensor and a U-shaped anti-collision buffer belt. A protection area of the anti-collision system is divided into a monitoring layer, a speed reduction layer and a parking layer from far to near. The detection data of the environment detecting unit are processed by the master control unit, and the AGV is controlled to execute corresponding actions, namely, normal running or speed reducing posture adjustment or parking. When a parking event occurs, the alarming unit gives an alarm, and the remote control unit is informed to carry out remote processing. The intelligent anti-collision system can effectively reduce the collision probability of the AGV, and the vehicle body is protected.

Owner:BEIJING SENSING TECH CO LTD

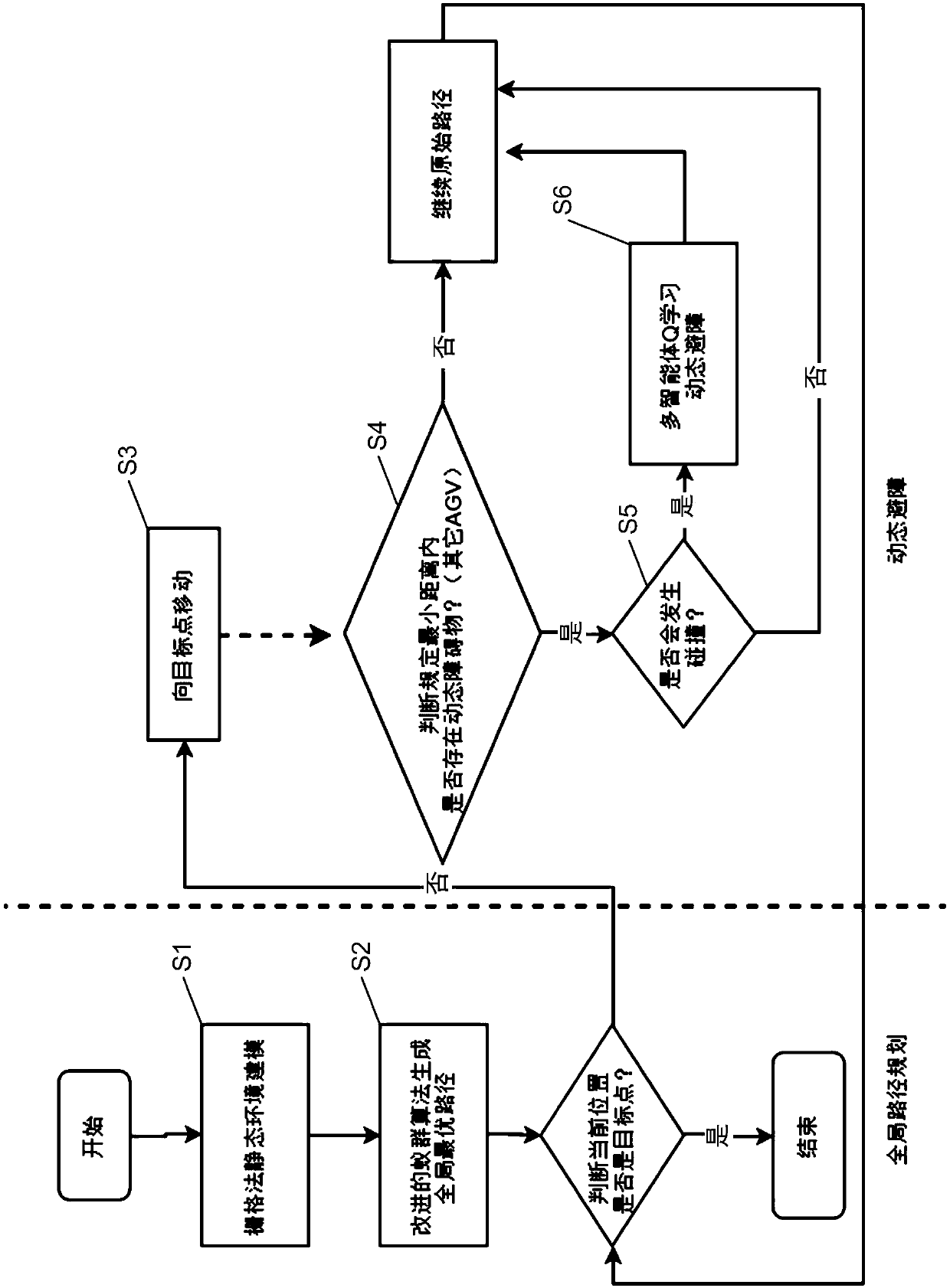

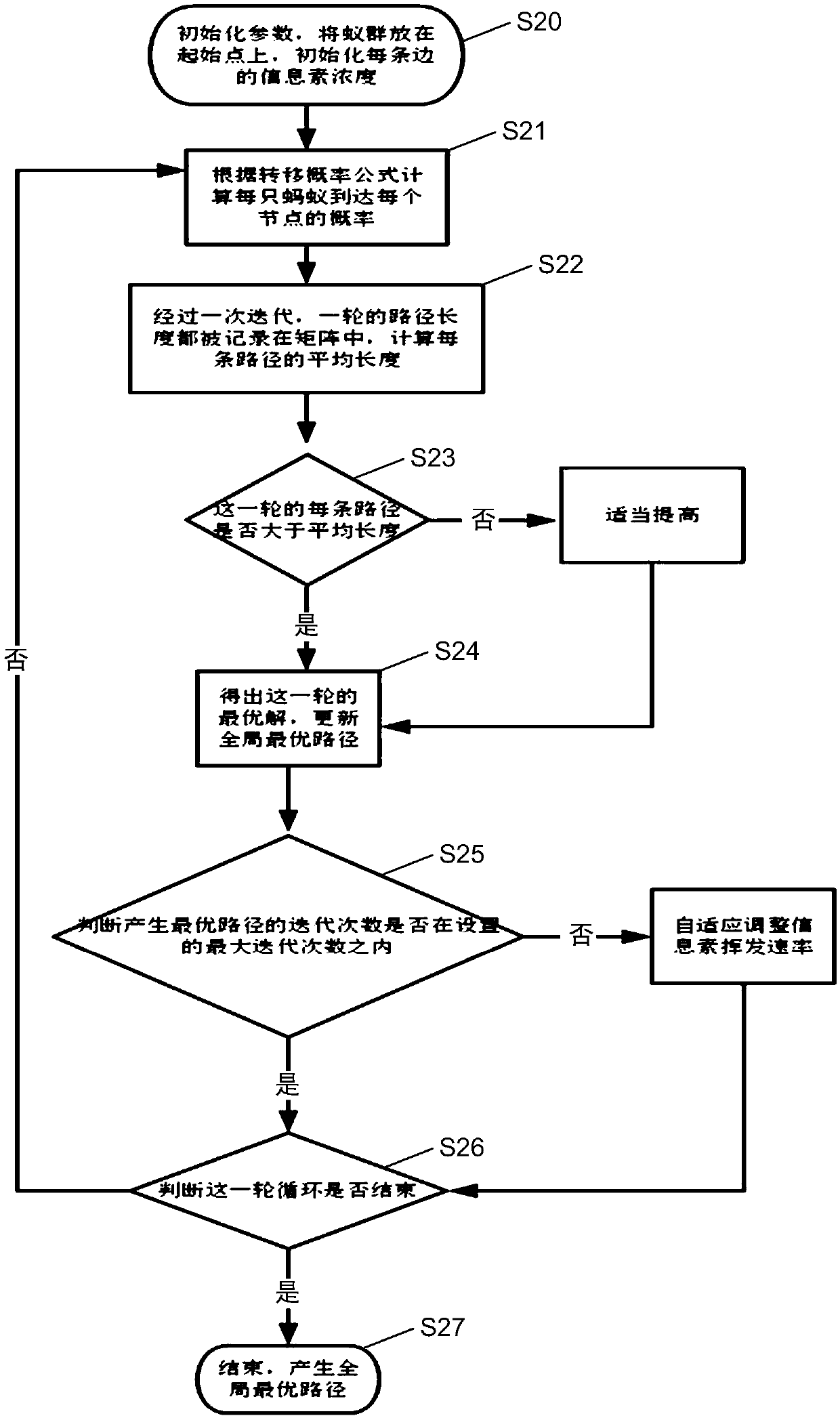

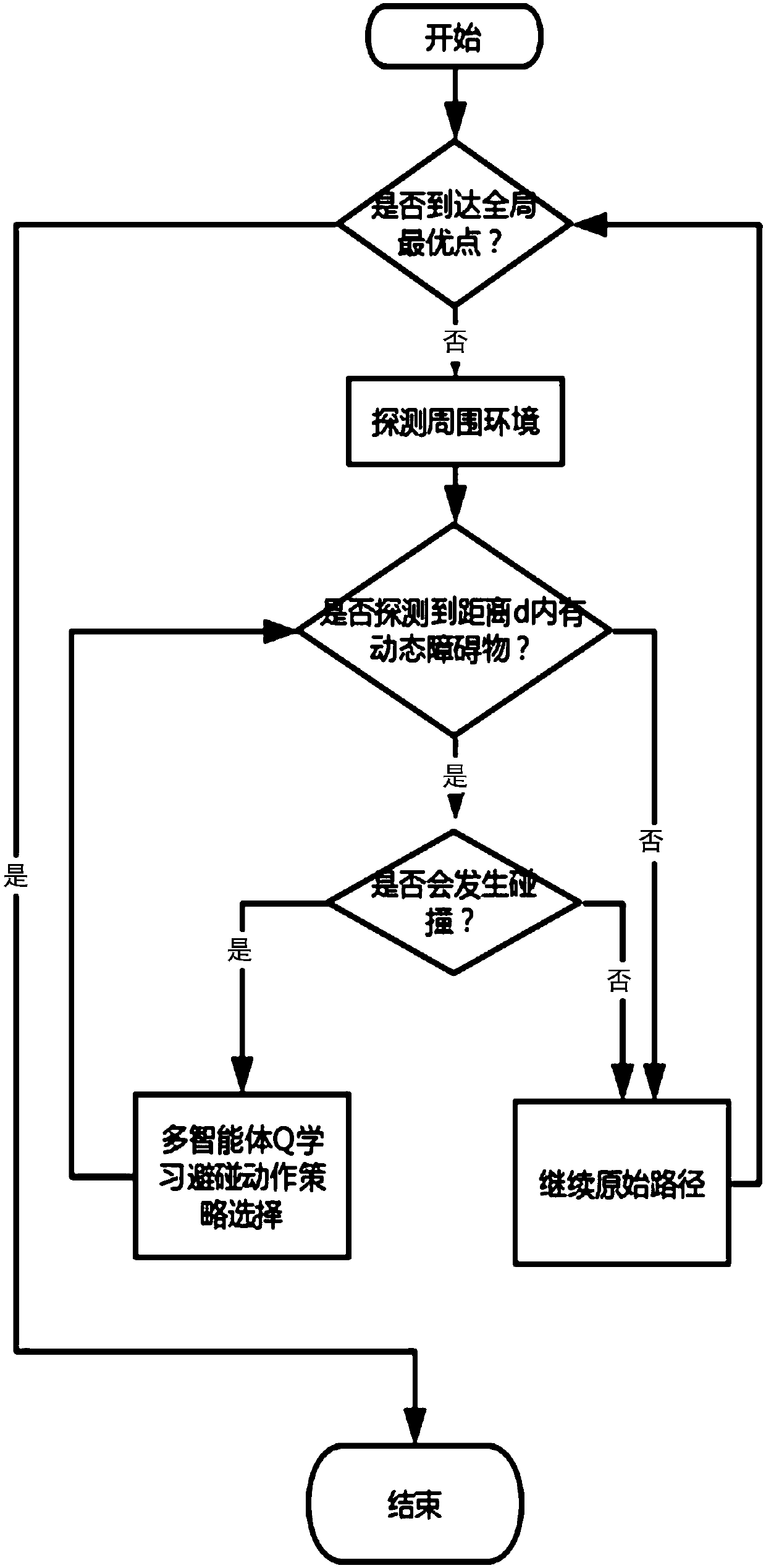

AGV (Automated Guided Vehicle) route planning method and system based on ant colony algorithm and multi-intelligent agent Q learning

ActiveCN108776483AOptimize global search capabilitiesFast convergencePosition/course control in two dimensionsAutomated guided vehicleEngineering

The invention discloses an AGV (Automated Guided Vehicle) route planning method and system based on an ant colony algorithm and multi-intelligent agent Q learning, improving the global optimization ability, realizing a case that an AGV learns how to avoid an obstacle in the interaction process by introducing the multi-intelligent agent Q learning into a route planning research of the AGV, and canplay independence and learning capacity of the AGV better. The AGV route planning method and system is characterized in that according to a static environment, carrying out modeling on an AGV operation environment by utilizing a grid method, and setting an initial point and a target point; according to coordinates of the initial point and the target point of the AGV, generating a global optimal route by the ant colony algorithm; enabling the AGV to move towards the target point according to the global optimal route, and when detecting that a dynamic obstacle exists in a minimum distance, carrying out selection of an obstacle avoidance strategy by an environment state corresponding to the multi-intelligent agent Q learning so as to take a corresponding obstacle avoidance action, and after ending obstacle avoidance, returning to an original route to continuously move.

Owner:YTO EXPRESS CO LTD

Method of material handling with automatic guided vehicles

ActiveUS20140172223A1Clear distance traveledDecrease in paceVehicle position/course/altitude controlDistance measurementAutomated guided vehicleManufacturing operations

A system and method of automatic guided vehicles that are capable of providing synchronized travel along a line or path such that regular manufacturing operations may be performed to material or workpieces on the vehicle without the need for a traditional conveyor systems.

Owner:JERVIS B WEBB INT CO

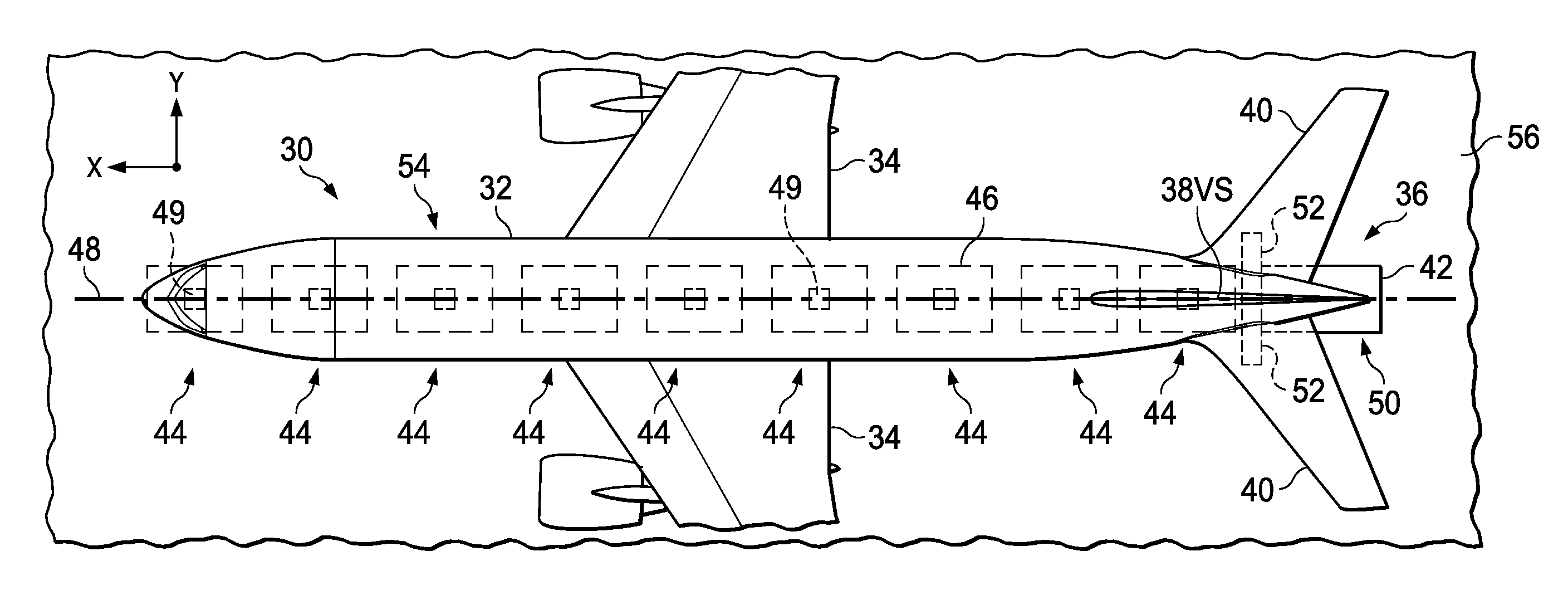

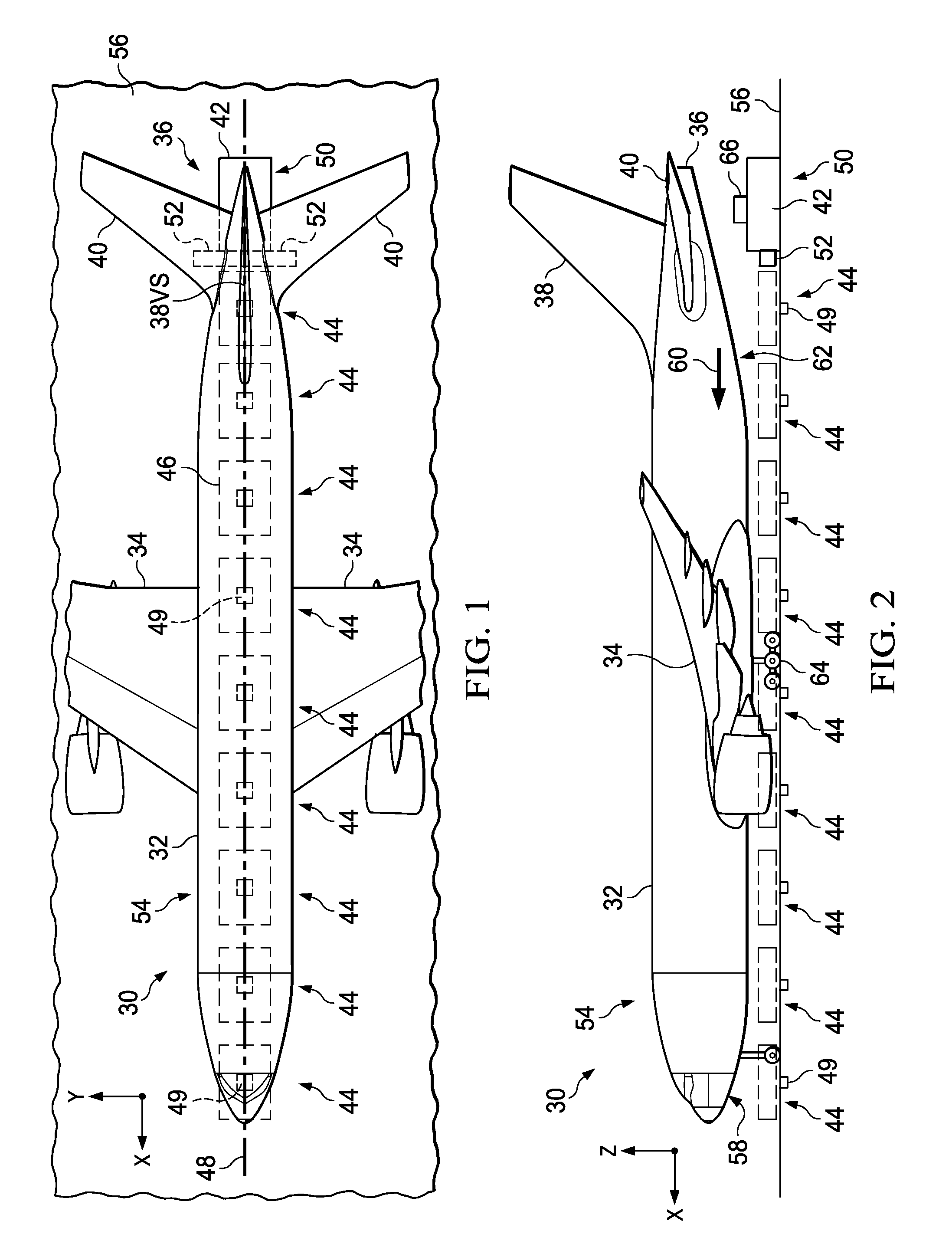

Performing Surface Treatments Using an Automated Guided Vehicle

ActiveUS20160130017A1Easy to reconfigureEliminate needProgramme-controlled manipulatorSpraying apparatusGuidance systemLimited access

A low-profile, automated guided vehicle (AGV) performs surface treatments over large areas of a structure having limited access, such as an aircraft underbelly. The AGV includes a movable gantry provided with automated robot. The robot has interchangeable end effectors for carrying out the surface treatments. Travel of the AGV relative to structure is controlled by a ground guidance system.

Owner:THE BOEING CO

AGV control system and method

InactiveUS7305287B2Shorten the timeRoad vehicles traffic controlActuated automaticallyControl systemAutomated guided vehicle

An automated guided vehicle control system and method which allows overall conveying time to be reduced by simultaneously moving a plurality of automated guided vehicles (AGVs) to working locations without interfering with each other. For this purpose, when there is a conveyance request, one of a plurality of the AGVs operated on a single guide path is assigned work. Further, it is determined whether another automated guided vehicle moving to a working location exists on the guide path. Also information on current and working locations of the automated guided vehicles is read if the automated guided vehicle moving to the working location exists on the guide path. Further, it is determined whether simultaneous movements are possible based on the read information. The automated guided vehicle waiting for work is moved if the simultaneous movements are possible. Accordingly, the overall convey time is reduced by simultaneously moving the AGVs to working locations or by previously moving the AGVs to optimal locations without interfering with each other, so that conveying efficiency of the AGVs is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

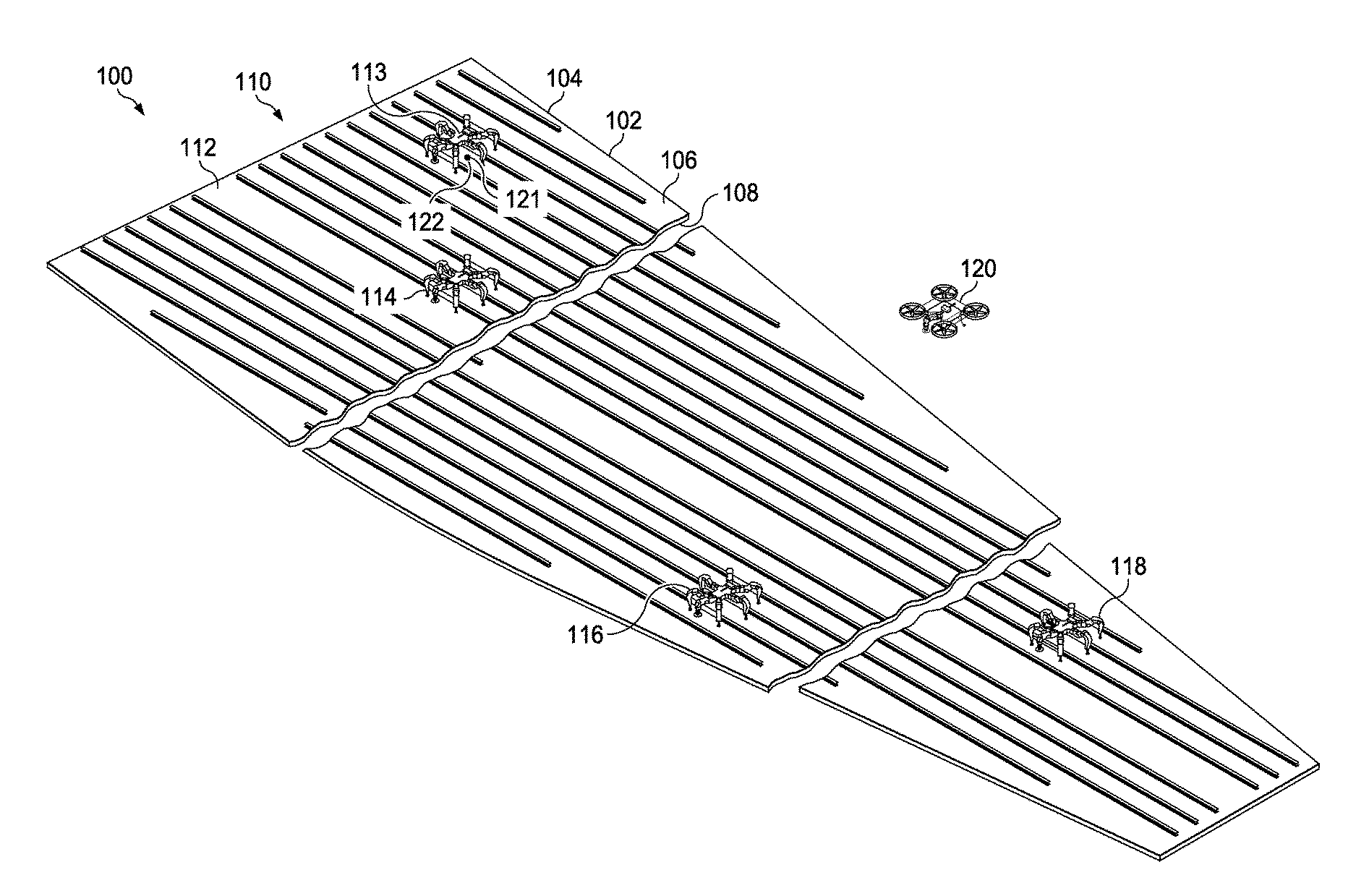

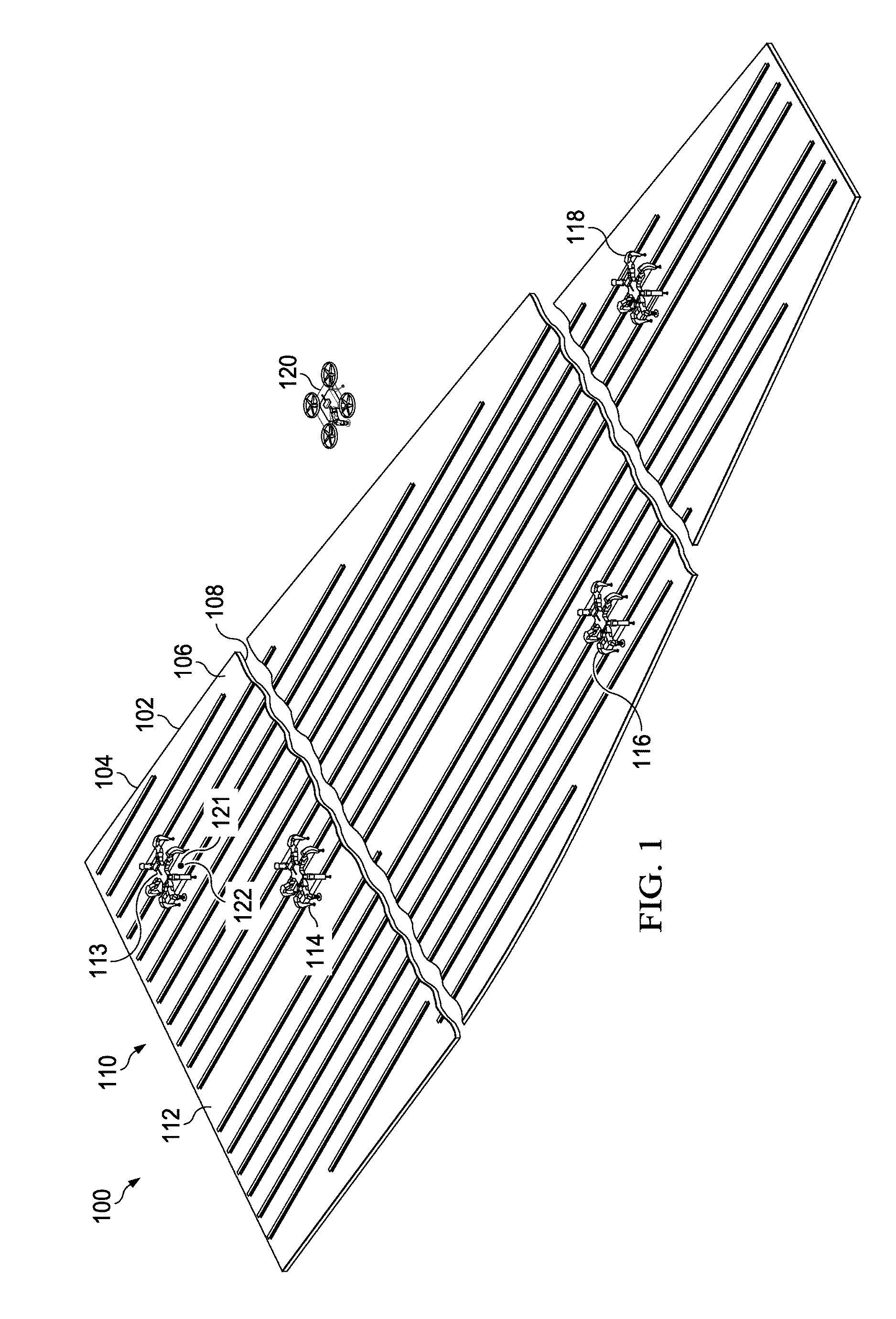

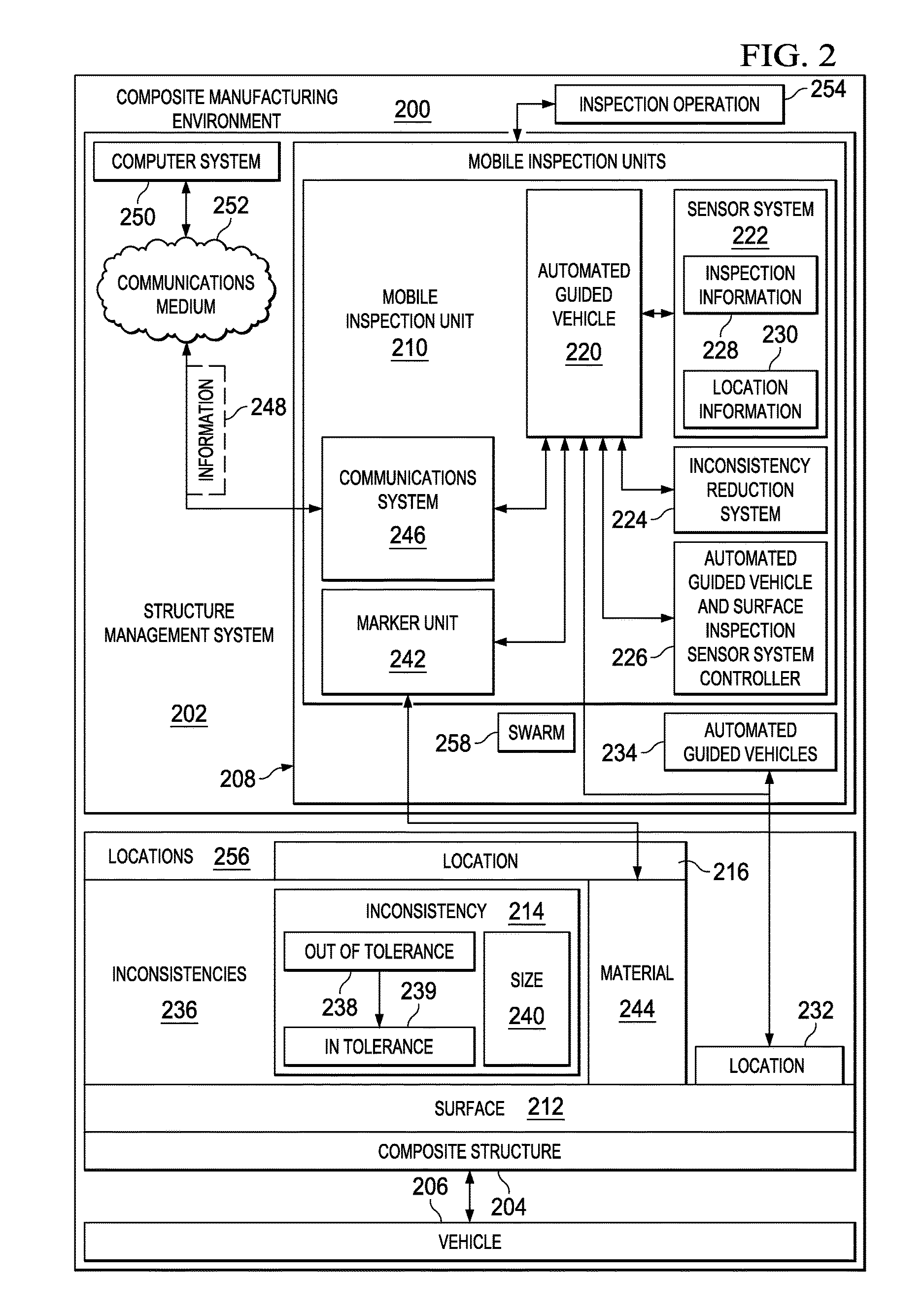

Automated Resin Ridge Reduction System

ActiveUS20160377424A1Reduce inconsistencyEfficient reduction of the inconsistencyVehicle testingAutonomous decision making processAutomated guided vehicleSensor system

An apparatus comprises an automated guided vehicle that moves on a surface of a composite structure during operation of the apparatus to inspect the composite structure, a surface inspection sensor system associated with the automated guided vehicle, and an automated guided vehicle and surface inspection sensor system controller in communication with the automated guided vehicle and the surface inspection sensor system.

Owner:THE BOEING CO

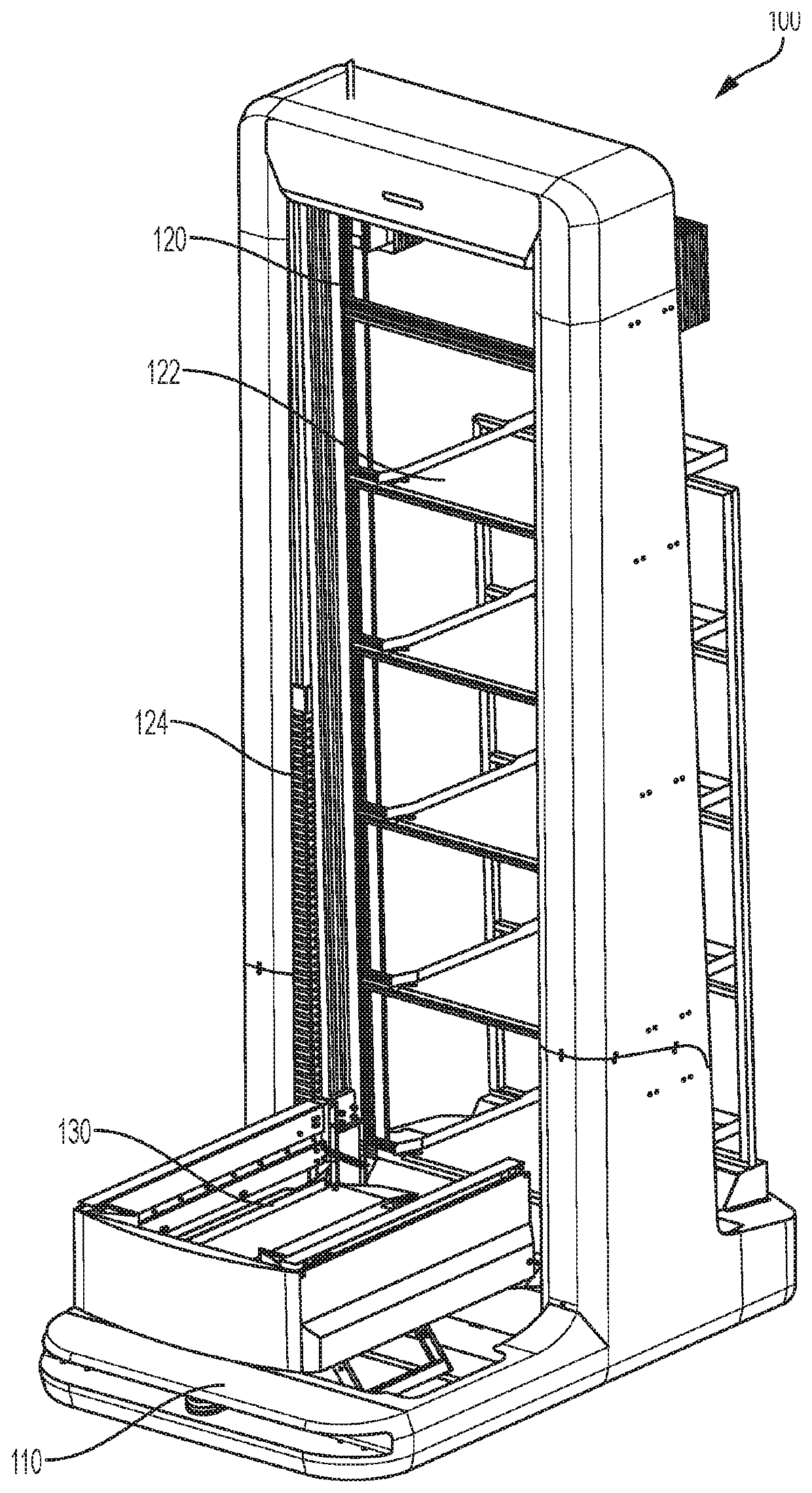

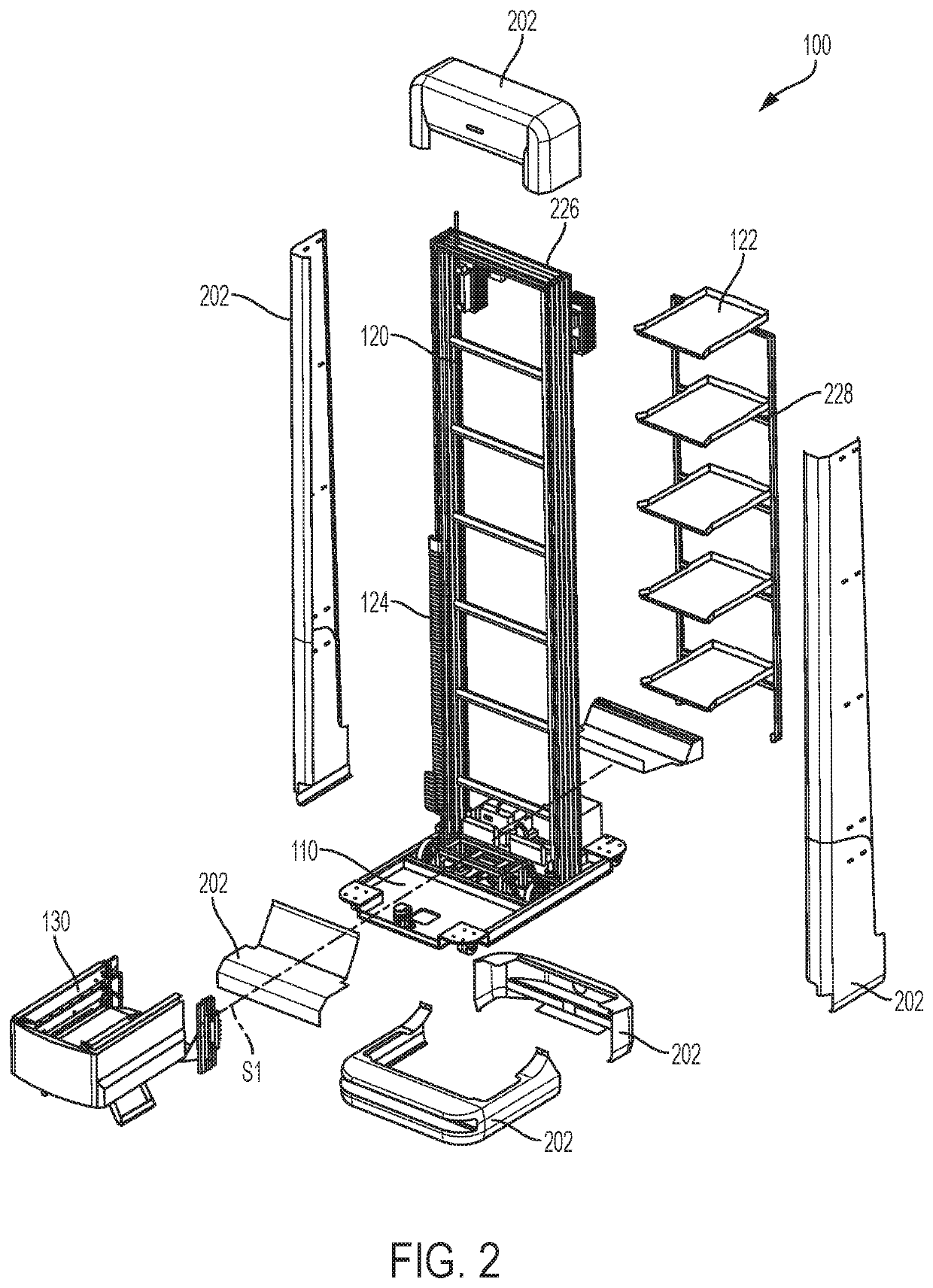

Automated guided vehicle designed for warehouse

PendingUS20190352092A1Agile, efficient and error-tolerantProgramme-controlled manipulatorImage analysisSystems designAutomated guided vehicle

An Automated Guided Robot (AGV) system designed for carrying, storing and retrieving inventory items to and from storage shelves. The AGV (100) can move between warehouse shelves and reach to the inside of a shelf without turning. The AGV (100) is equipped with a material handling device (130). The material handling device (130) comprises a lateral device that is configured to move in a lateral direction either to the right side or to the left side. The movement of the lateral device can be either rotational or translational. The material handling device (130) further comprises a retractable device that retracts or extends in a direction perpendicular to the lateral direction. The retractable device allows the material handling device (130) to extend into the storage shelf to fetch or place an inventory item.

Owner:HAI ROBOTICS CO LTD

Monocular vision AGV accurate positioning method and system based on multi-window real-time range finding

ActiveCN105955259ARealize the real-time ranging functionRealize reasonable obstacle avoidancePosition/course control in two dimensionsTime rangeAutomated guided vehicle

The invention discloses a monocular vision AGV (Automated Guided Vehicle) accurate positioning method and system based on multi-window real-time range finding. The method comprises according to a camera slanting installation mode, calibrating and measuring camera parameters and establishing a visual system real-time measuring model; setting a circular color lump on the ground to be used as the reference substance for parking positioning, identifying the circular color lump through the efficient algorithm of the visual system, and accurately extracting central position information; and in a view filed, setting a plurality of windows to process images a far-end window is used for an AGV to predetermine ground information so as to gradually decelerate; an intermediate window is used as a coarse positioning window, and used for adjusting poses; and a near-end window is used for accurate range finding and parking. The method allows an AGV to sense depth information, and has the advantages of high characteristic recognition rate, excellent arithmetic instantaneity, low cost and great extendibility. The horizontal distance deviation of AGV parking is stabilized at +-1 mm, the angle deviation is stabilized at +-1 DEG, and the parking error is stabilized at +- 2mm.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automatically guided vehicle with improved navigation

InactiveUS20050246078A1More precisionIncrease the speed of positioningActuated automaticallyAutomatic initiationsEngineeringAutomated guided vehicle

Automatically guided vehicle (AGV) with improved navigation which is provided with at least one measuring system for a relative position finding, characterized in that it is also provided with two or more measuring systems to determine the absolute position of the vehicle (1).

Owner:EGEMIN

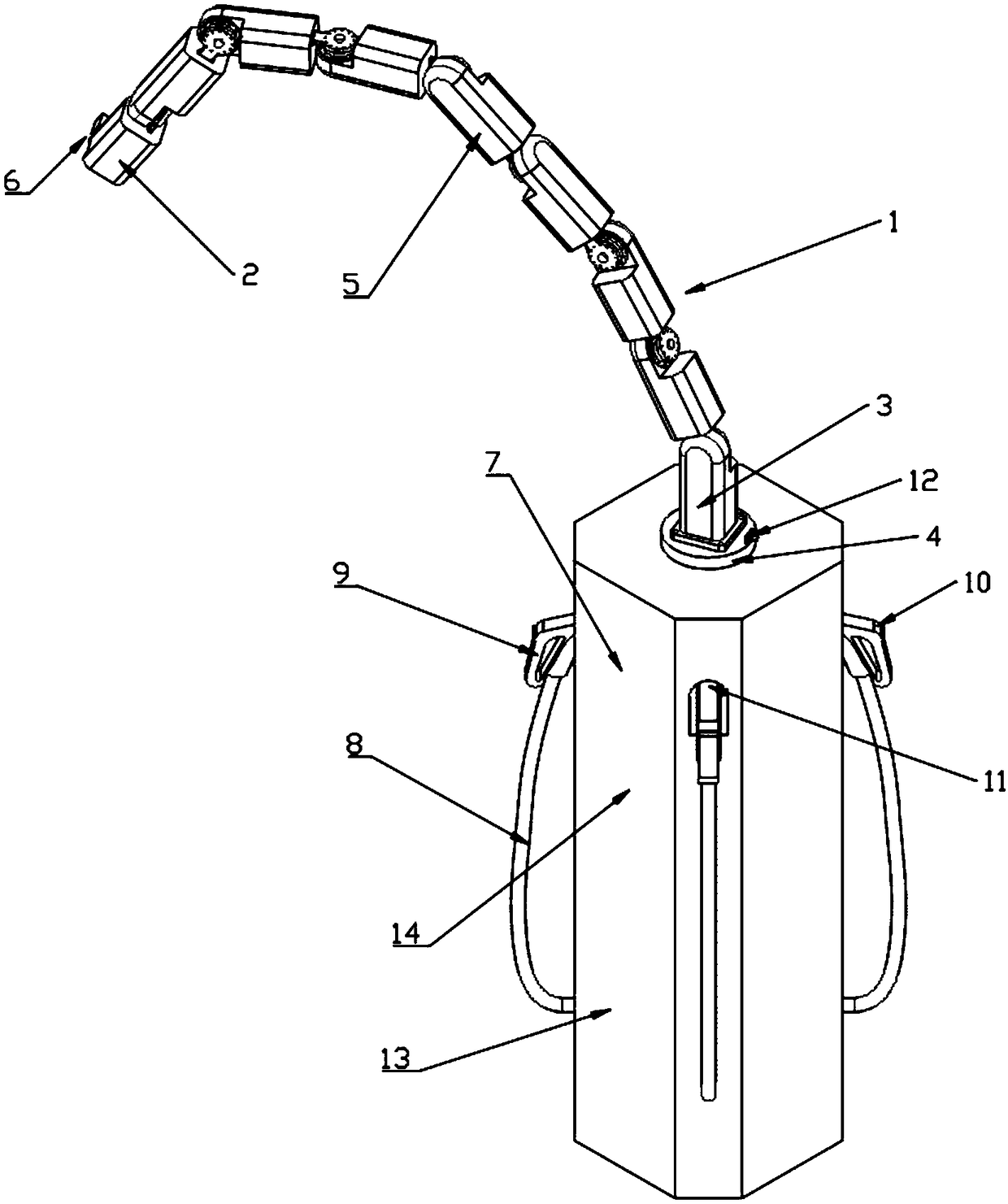

Automatic charging system based on snakelike-simulated mechanical arm and method

InactiveCN109435730AImprove gripCooperate accuratelyCharging stationsElectric vehicle charging technologyMicrocomputerControl system

The invention discloses an automatic charging system based on a snakelike-simulated mechanical arm. The automatic charging system comprises the snakelike-simulated mechanical arm, a charging device and a control system, and further comprises all control and execution modules, the control and execution modules are mutually matched, and whether to-be-charged vehicles exist or not can be automatically induced through a vehicle induction module; a charging-port pre-alignment module identifies charging ports through installed sensors, and general orientations of the charging ports are preliminarilycalculated; a main control module of a microcomputer is prepared, and is installed in a charging pile base, and the main control module controls the mechanical arm to clamp charging guns to move in the pre-alignment direction; an accurate alignment module of a snakehead-simulated joint accurately determines positions of the charging ports through the corresponding sensors and charges the to-be-charged vehicles. According to the automatic charging system based on the snakelike-simulated mechanical arm, vehicle using experiences of new-energy vehicles and automatic guide vehicles are greatly improved, the automatic charging requirements of automatic sites such as automatic-parking-place vehicles are met, a complete automatic parking and automatic inter-vehicle service system is formed, thelabor cost is greatly reduced, and the running efficiency is improved.

Owner:TONGJI UNIV

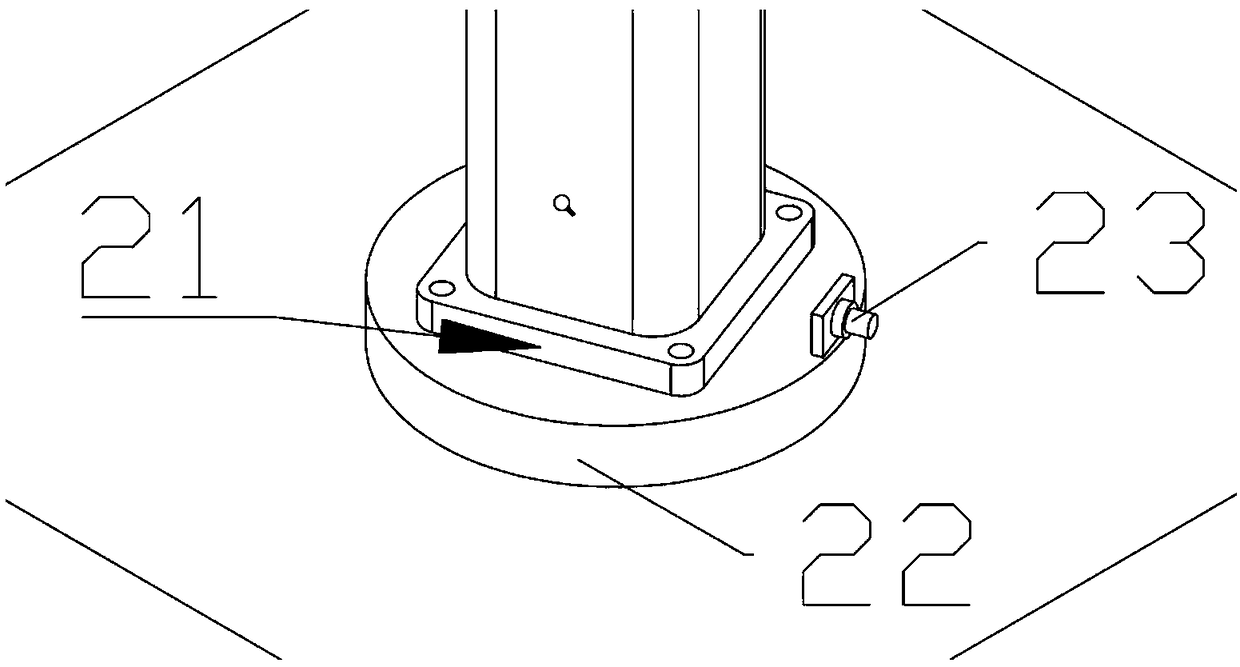

Automated guided vehicle (AGV) control system and method

InactiveCN102799177AFlexible controlPosition/course control in two dimensionsVehiclesSystems analysisControl signal

The invention discloses an automated guided vehicle (AGV) control system which is applicable to a server. The server communicates with an operation table and an AGV through a wireless network. The operation table sends a calling signal for material taking to the server, and the system analyzes the calling signal, determines a calling point position and searches the AGV according to the calling point position, wherein the AGV and a calling point are in the same area, and the AGV is idle and loaded with a raw material. Then, the system sets a first target position of the found AGV as the calling point position, determines a first movement route of the AGV according to initial and target positions of the AGV, and generates a first control signal according to the initial position, the first target position and the first movement route of the found AGV, so the AGV is controlled to move from the initial position to the first target position along the first movement route. The invention also provides an AGV control method.

Owner:GDS SOFTWARE SHENZHEN +1

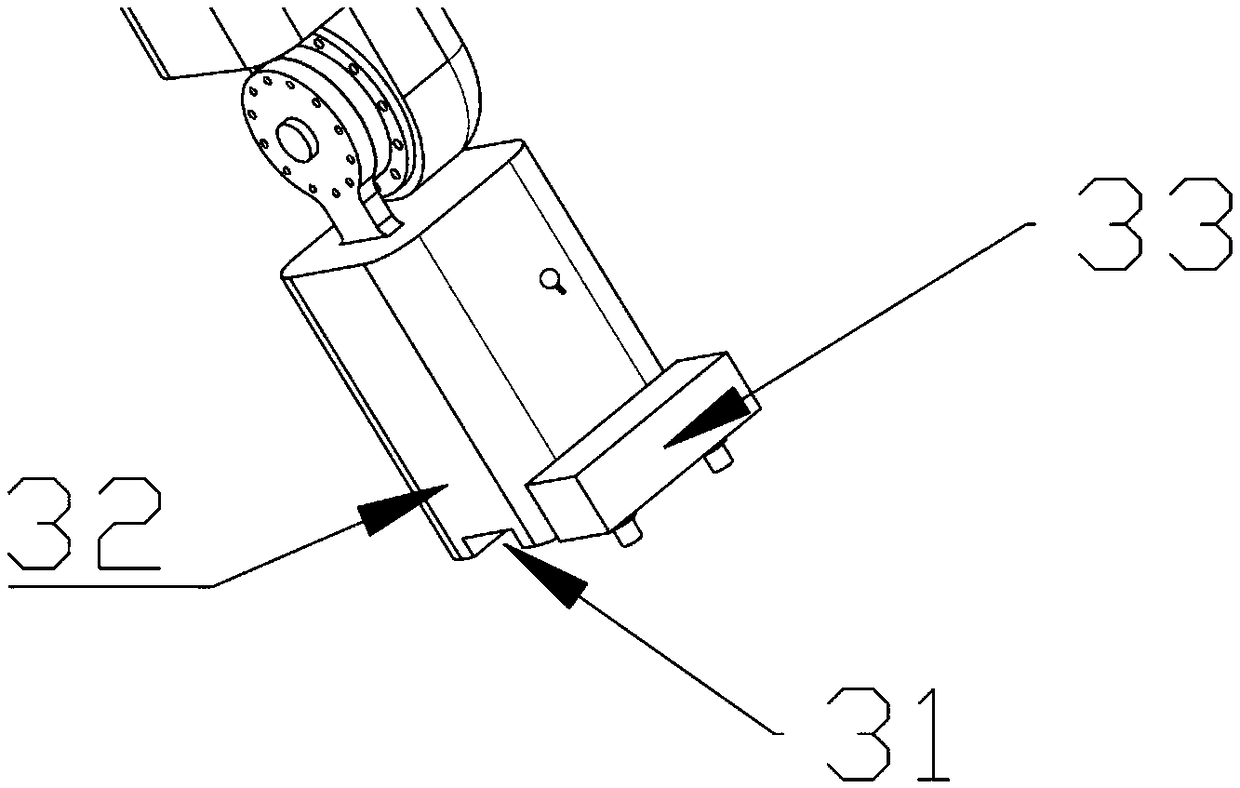

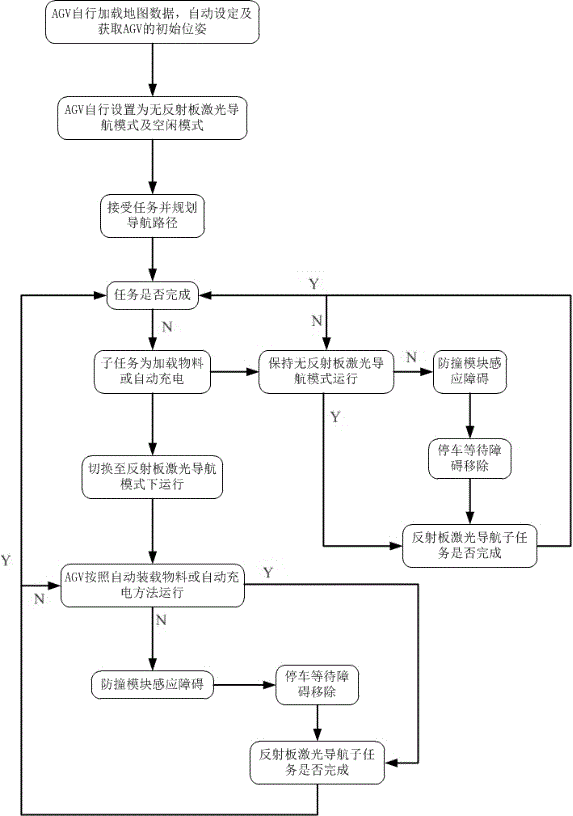

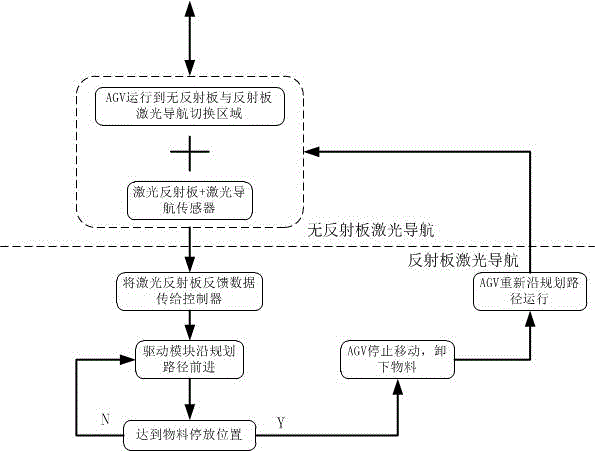

Blended laser navigation method of AGV (Automated Guided Vehicle)

InactiveCN105867389AConvenient automatic chargingA wide range of environmentsPosition/course control in two dimensionsVehiclesWorking environmentAutomated guided vehicle

The invention belongs to the technical field of navigation of AGVs (Automated Guided Vehicles), and aims to provide a blended laser navigation method of an AGV, which is applicable to a working environment having a high requirement on terminal locating accuracy and having no fixed running path. The blended laser navigation method comprises the following steps of step one, constructing a two-dimensional map of an environment; step two, planning a navigation path; step three, carrying out AGV path navigation by utilizing a reflector-free laser navigation mode, and enabling the AGV to walk according to the navigation path; step four, entering a reflector laser accurate locating mode when a laser reflector is detected by the AGV, carrying out accurate navigation of the AGV, and completing reserved work of the AGV. According to the blended laser navigation method of the AGV, provided by the invention, AGV material transporting can be reliably, stably, conveniently and flexibly realized in a mode that the accuracy degree meets the requirement, the requirement on the environment of an application place is low, and the applicability is wide. The blended laser navigation method not only can be applied to the field of industrial AGV application, but also can be applied to other application occasions, such as navigation of a service robot.

Owner:SHENZHEN LIZI ROBOT CO LTD

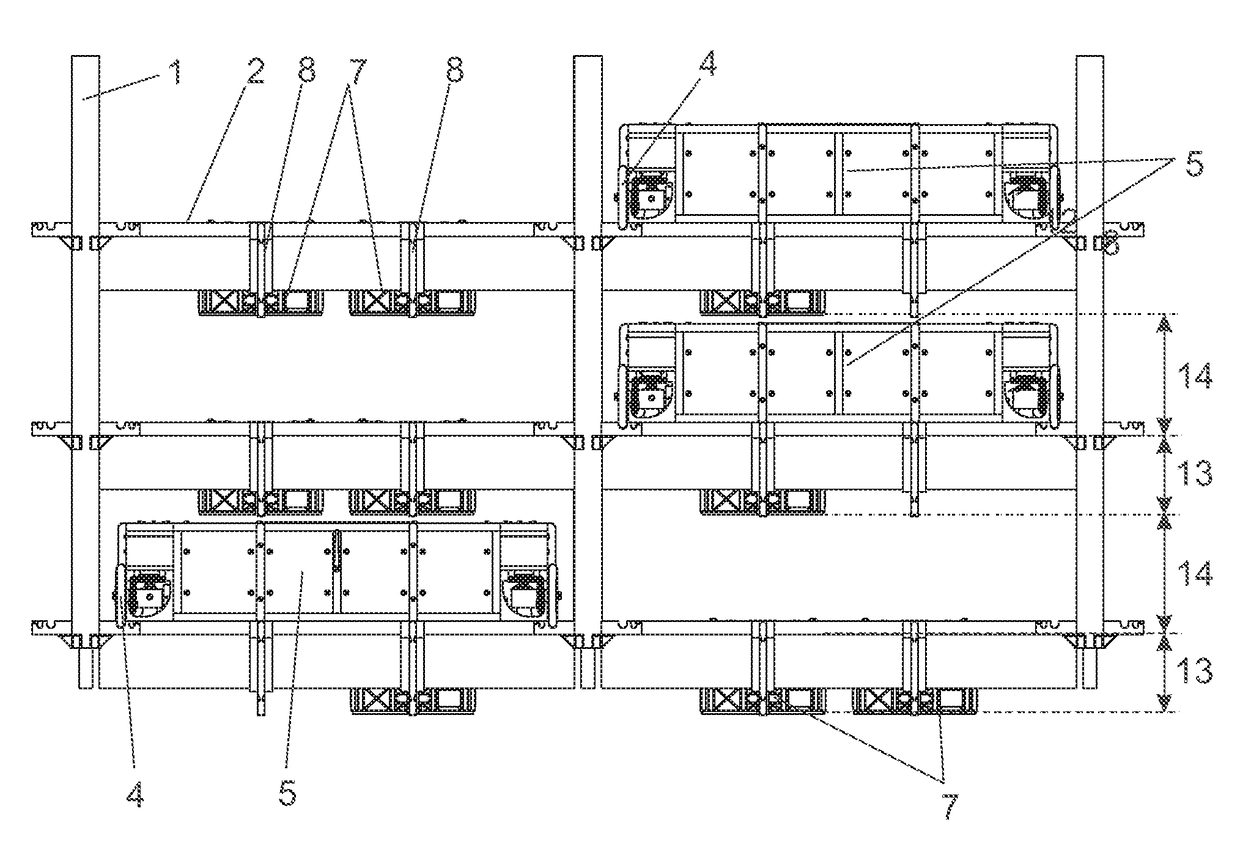

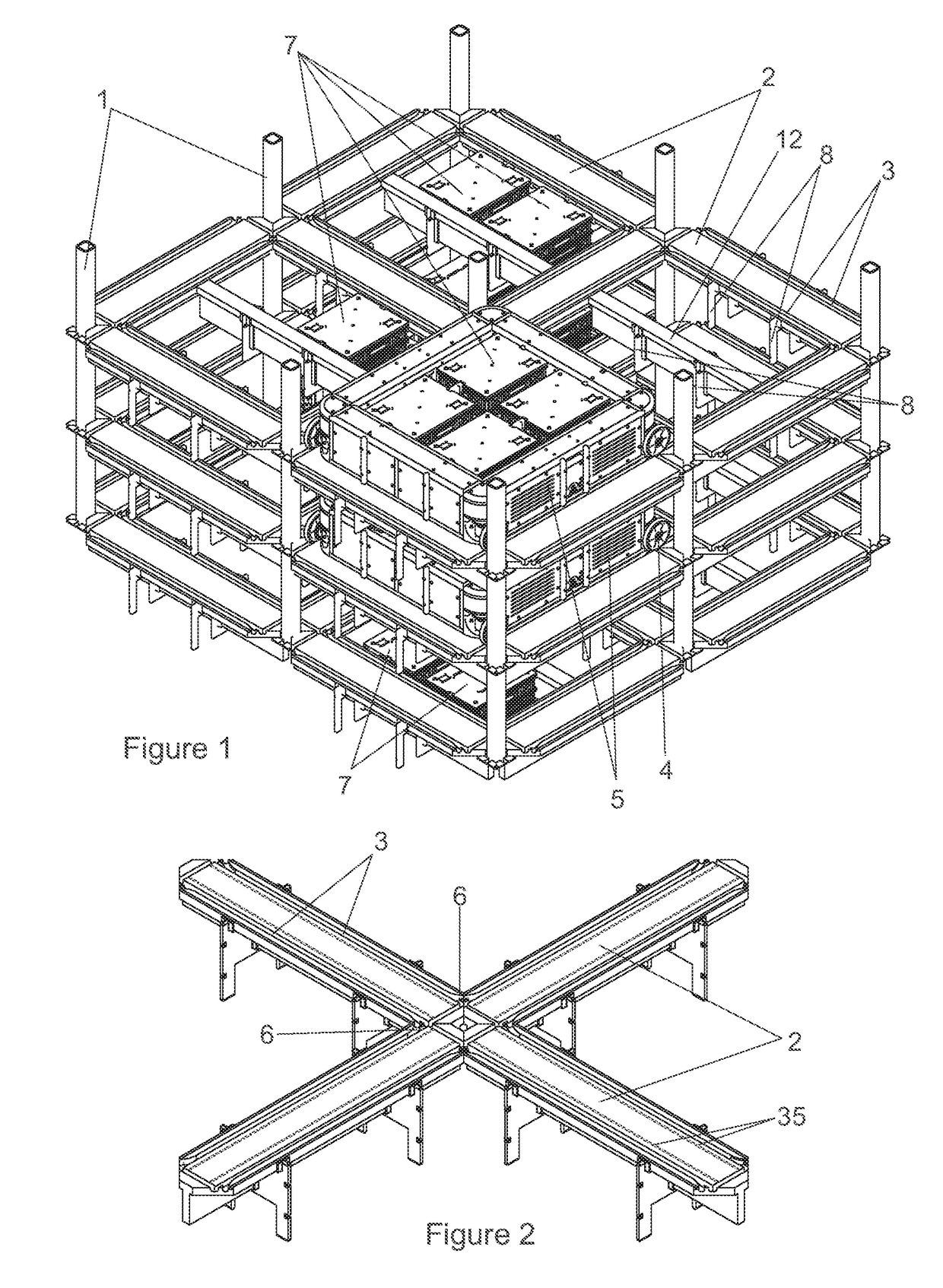

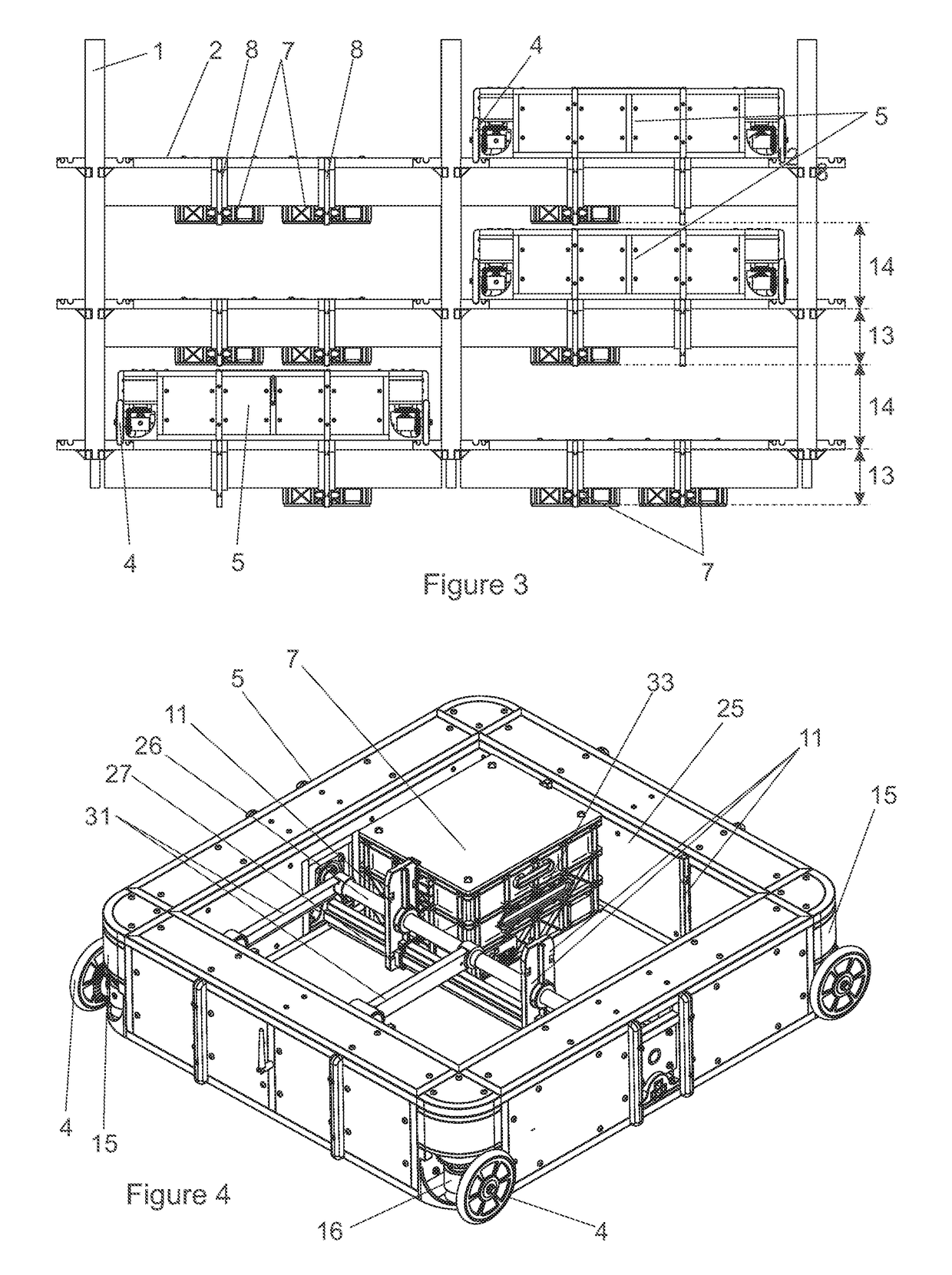

Warehouse system and transfer vehicle

ActiveUS20170305668A1Avoids and decreases bottleneckAvoids and decreases and constraintClosuresPackaging under vacuum/special atmosphereAutomated guided vehicleEngineering

A racking system and components are provided in which multiple storage positions are provided for individual storage boxes and automated guided vehicles are present to carry out automated placement, relocation and retrieval of boxes from storage positions in which they are located. The racking system has horizontally extending storage layers in each of which multiple storage positions are located and alternating vertically juxtaposed transfer layers in which automated guided vehicles are movable in at least two directions that are at right angles to each other to place, relocate and retrieve boxes to and from storage positions by vertical movement of the boxes into and out of storage positions in storage layers located above or below a transfer layer. The storage positions have associated with them storage guides for guiding boxes into and out of the storage positions and support arrangements for supporting the boxes in their storage positions.

Owner:NELSON MANDELA METROPOLITAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com