Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

311 results about "Manufacturing operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing operations concern the operation of a facility, as opposed to maintenance, supply and distribution, health, and safety, emergency response, human resources, security, information technology and other infrastructural support organizations.

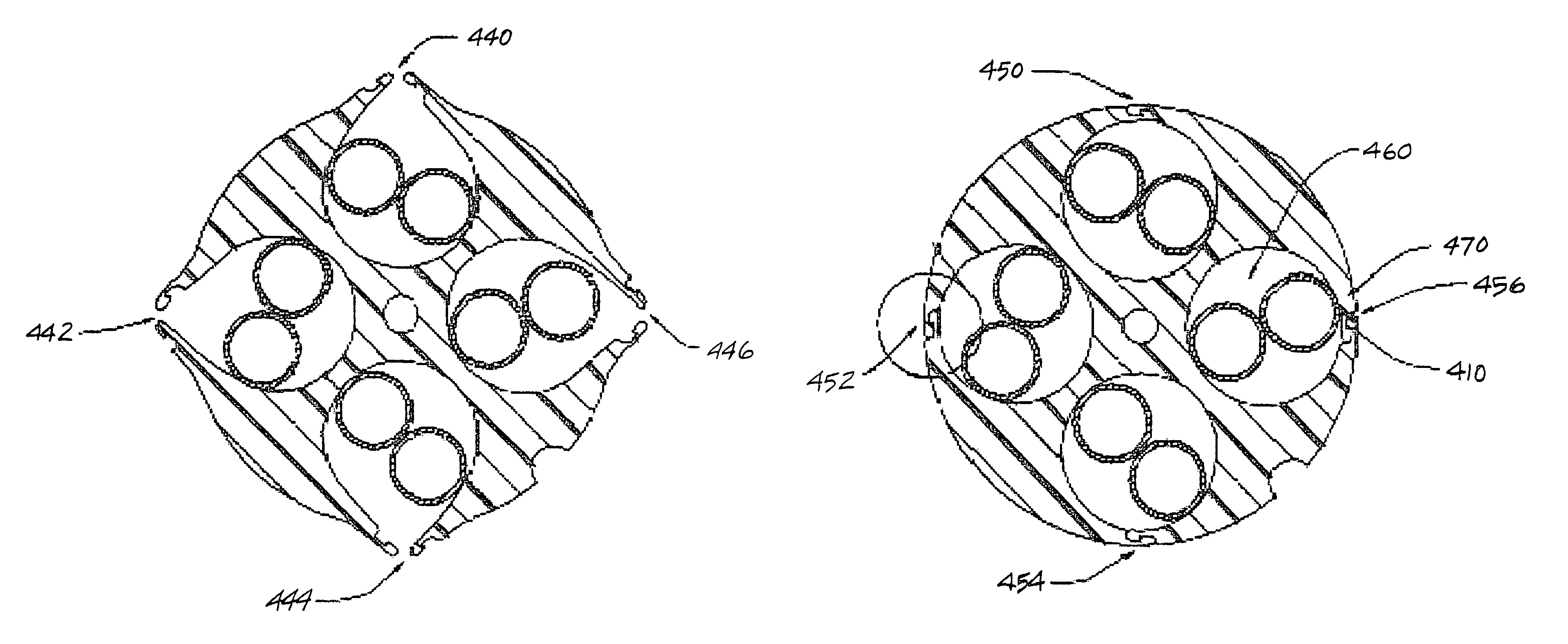

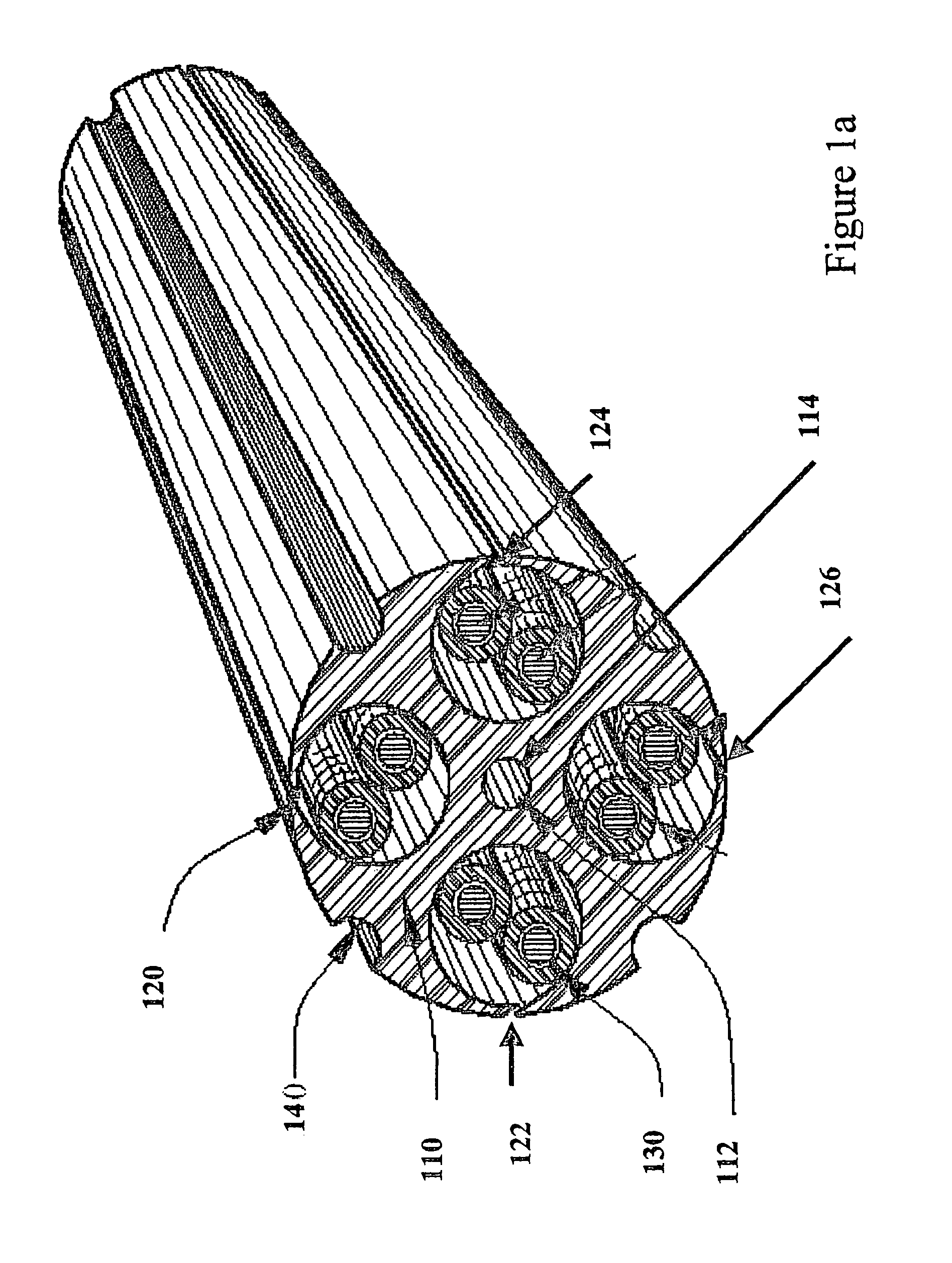

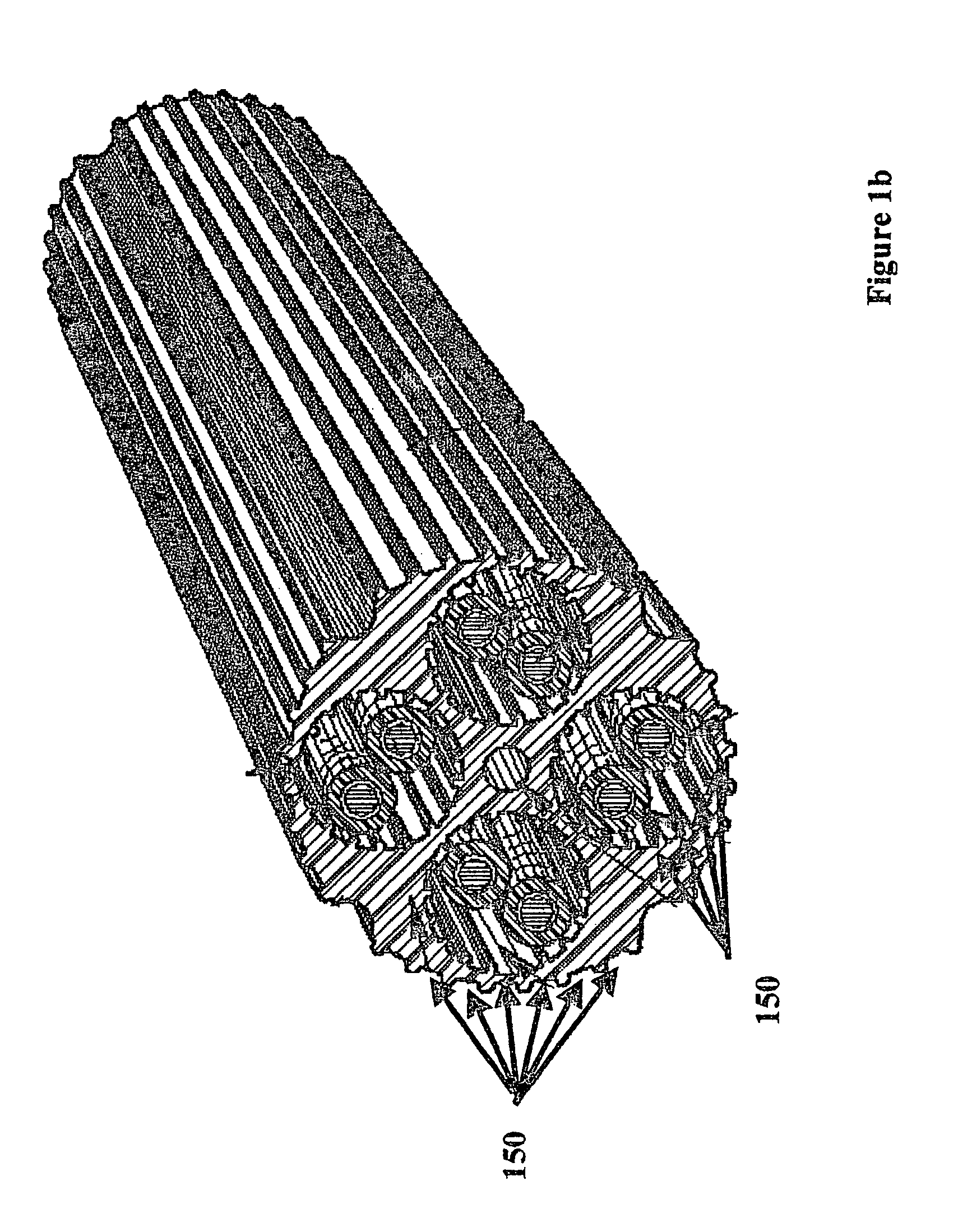

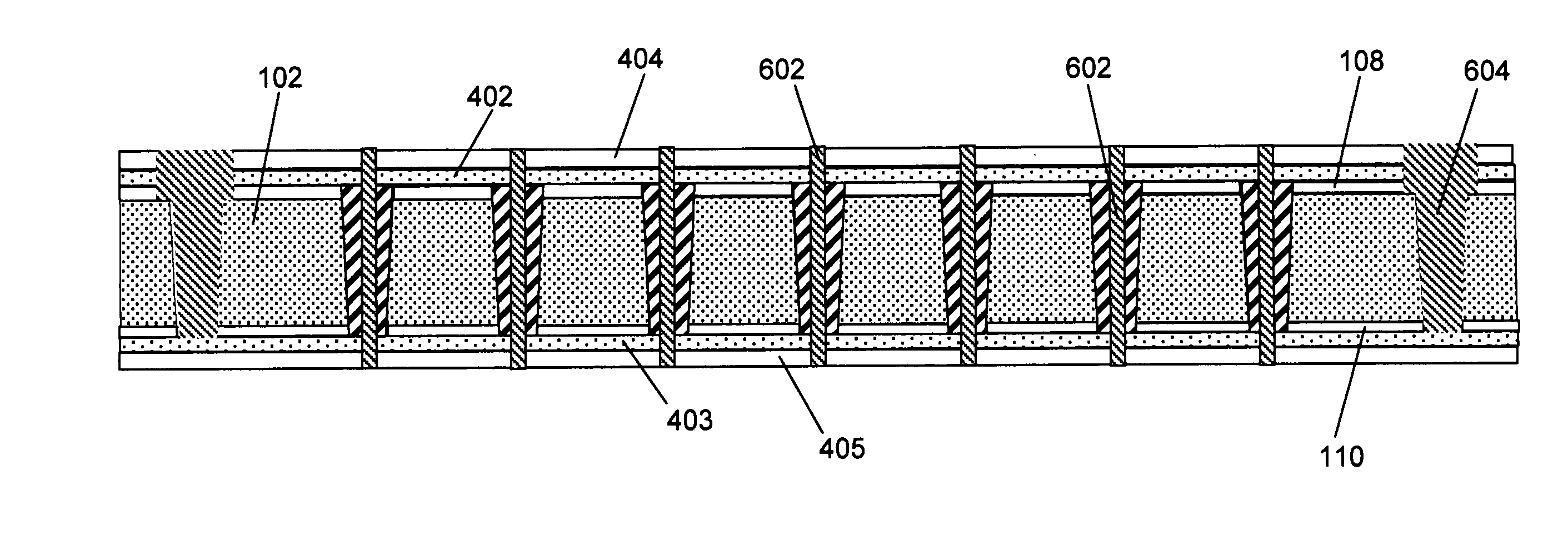

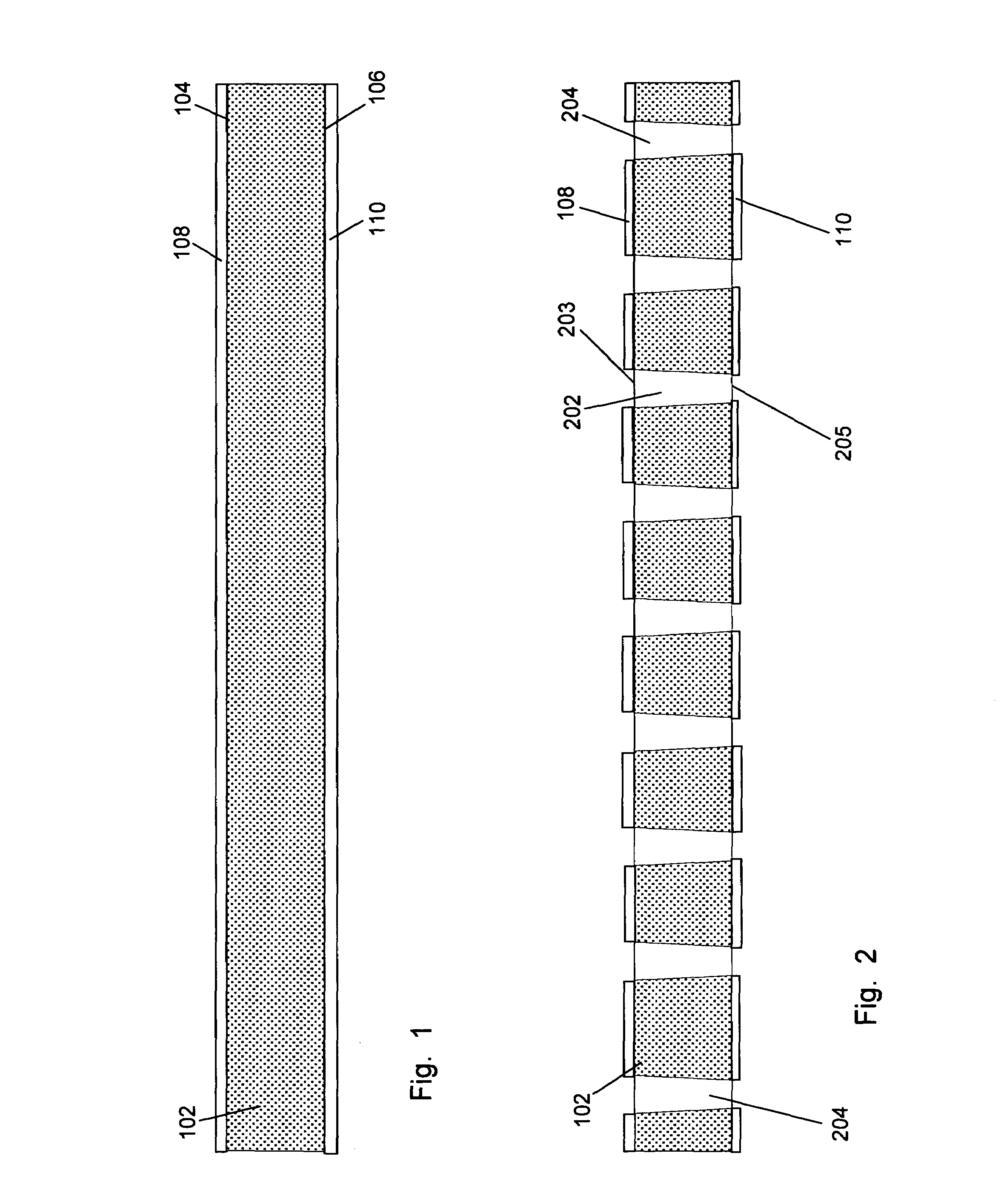

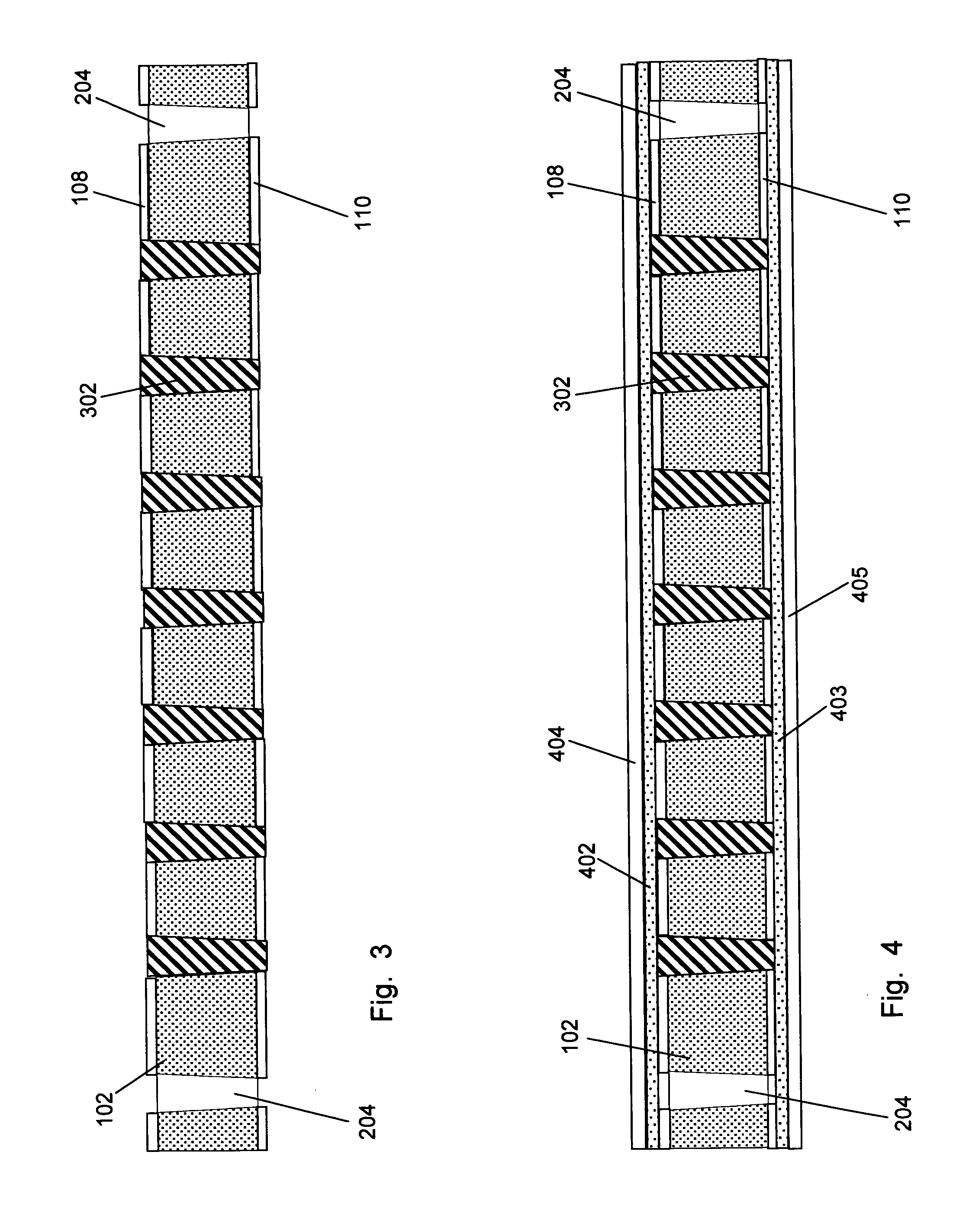

High performance support-separator for communications cables

InactiveUS7098405B2Improve NEXT controlReduce needInsulated cablesOptical light guidesElectrical conductorHigh performance communication

The present invention includes a high performance communications cable for transmission media that includes core support-separators which define clearance channels to maintain spacing between transmission media or transmission media pairs. The core support-separator can be either interior to a cable jacket or be employed singularly without the benefit of a jacket and extends along the longitudinal length of the communications cable. The core support-separator has a central region that may include flap-tops along the radial edge that are available for partial or complete sealing of the clearance channels during manufacturing operations. The central region may also include a hollow center portion and include various geometric shapes to provide proper spacing between conductors. Each of the defined clearance channels allow for disposal therein of metal conductors and / or optical fibers.

Owner:CABLE COMPONENTS GROUP

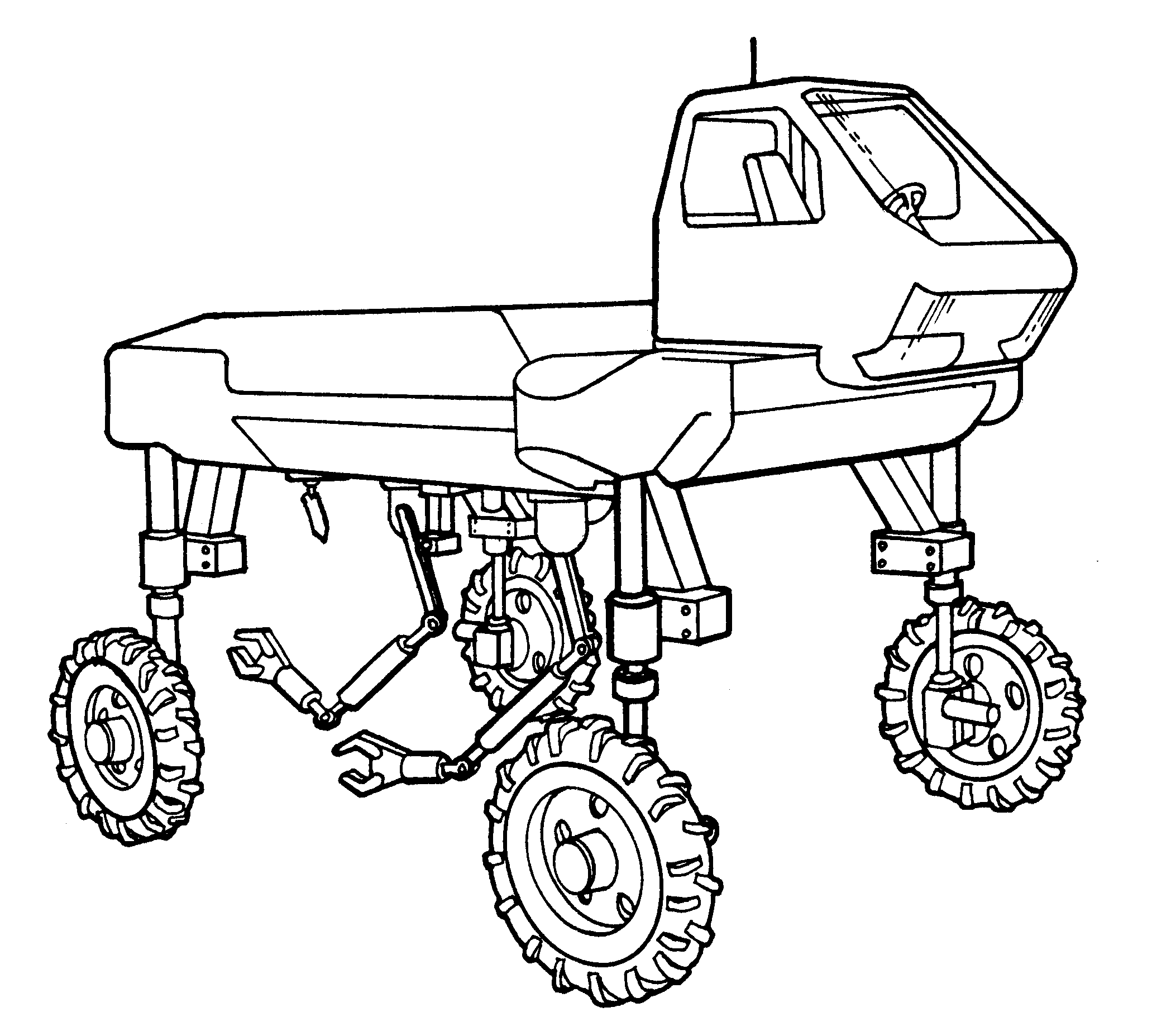

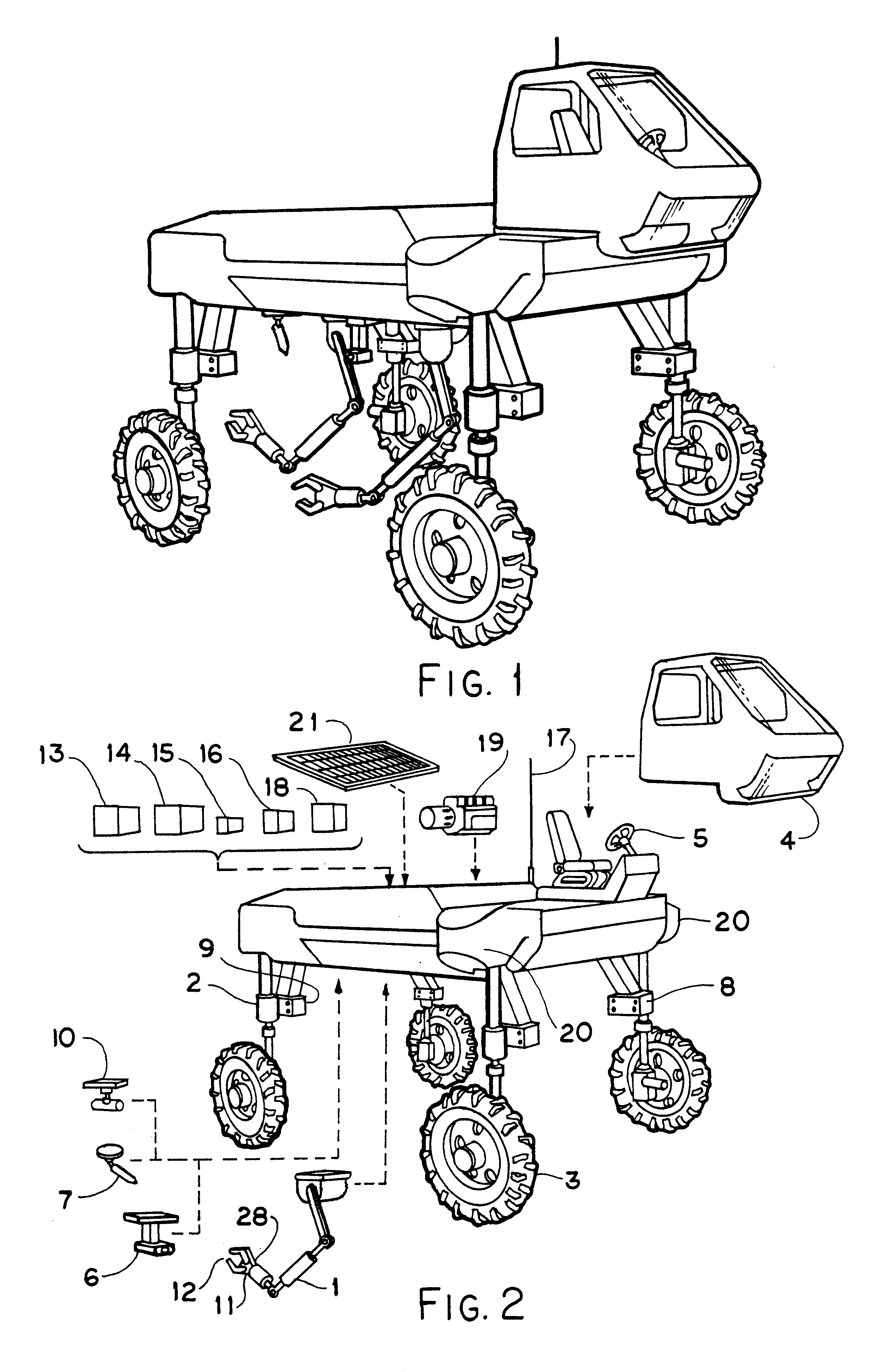

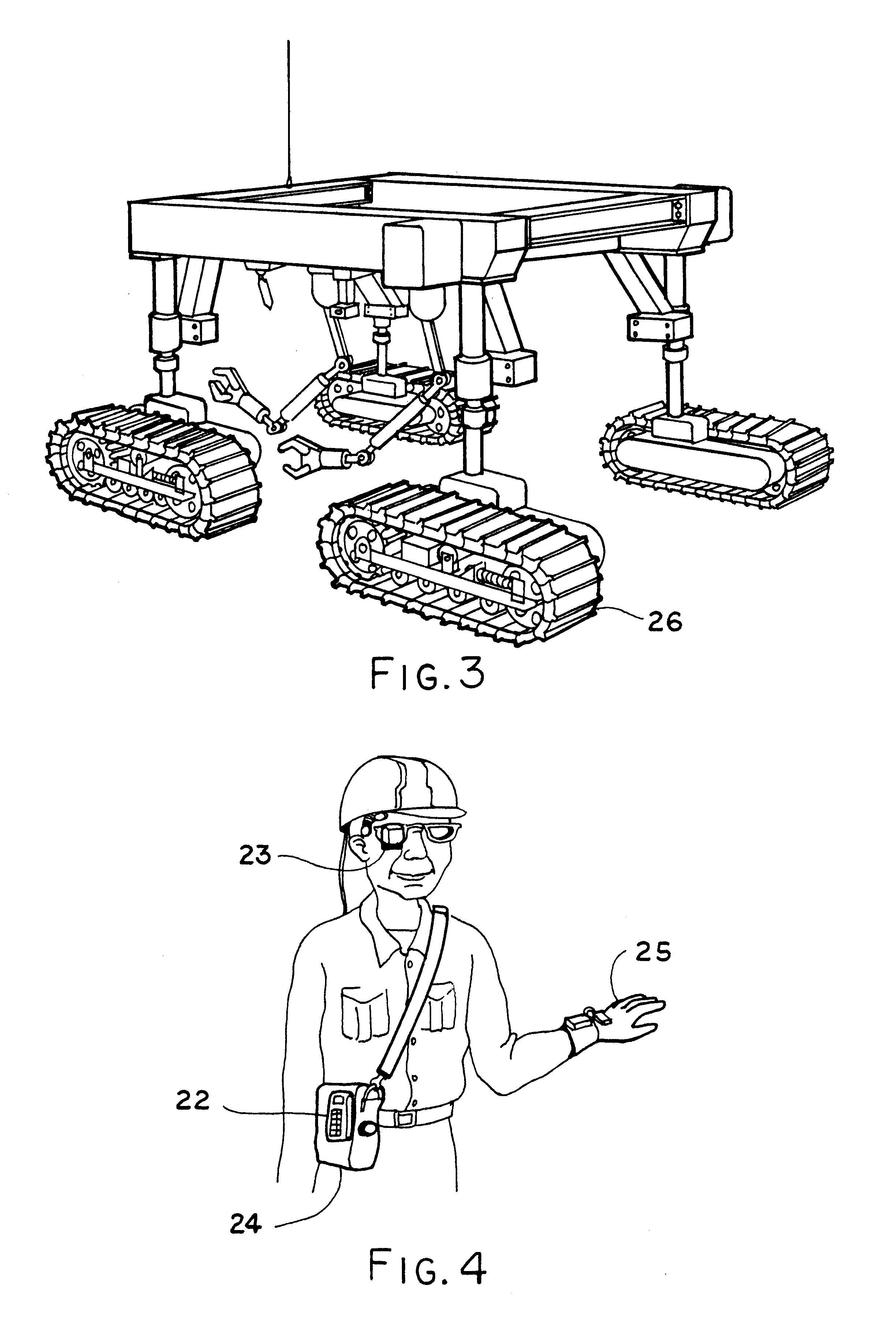

Flexible agricultural automation

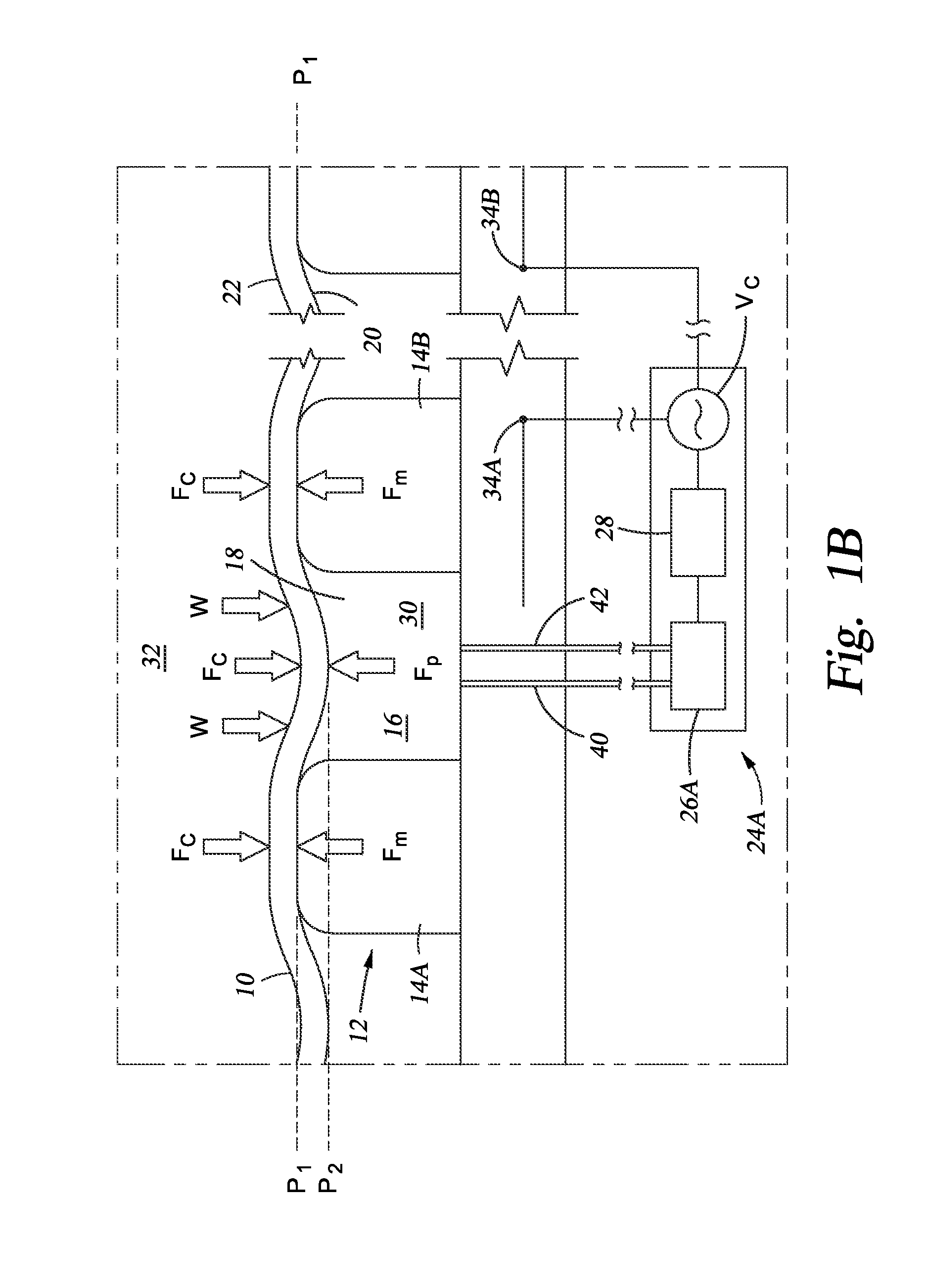

InactiveUS6671582B1High precisionQuality improvementOptical radiation measurementPosition fixationAgricultural engineeringAssembly line

Agricultural operations by applying flexible manufacturing software, robotics and sensing techniques to agriculture. In manufacturing operations utilizing flexible machining and flexible assembly robots, work pieces flow through a fixed set of workstations on an assembly line. At different stations are located machine vision systems, laser based raster devices, radar, touch, photocell, and other methods of sensing; flexible robot armatures and the like are used to operate on them. This flexible agricultural automation turns that concept inside out, moving software programmable workstations through farm fields on mobile robots that can sense their environment and respond to it flexibly. The agricultural automation will make it possible for large scale farming to take up labor intensive farming practices which are currently only practical for small scale farming, improving land utilization efficiency, while lowering manpower costs dramatically.

Owner:HANLEY BRIAN P

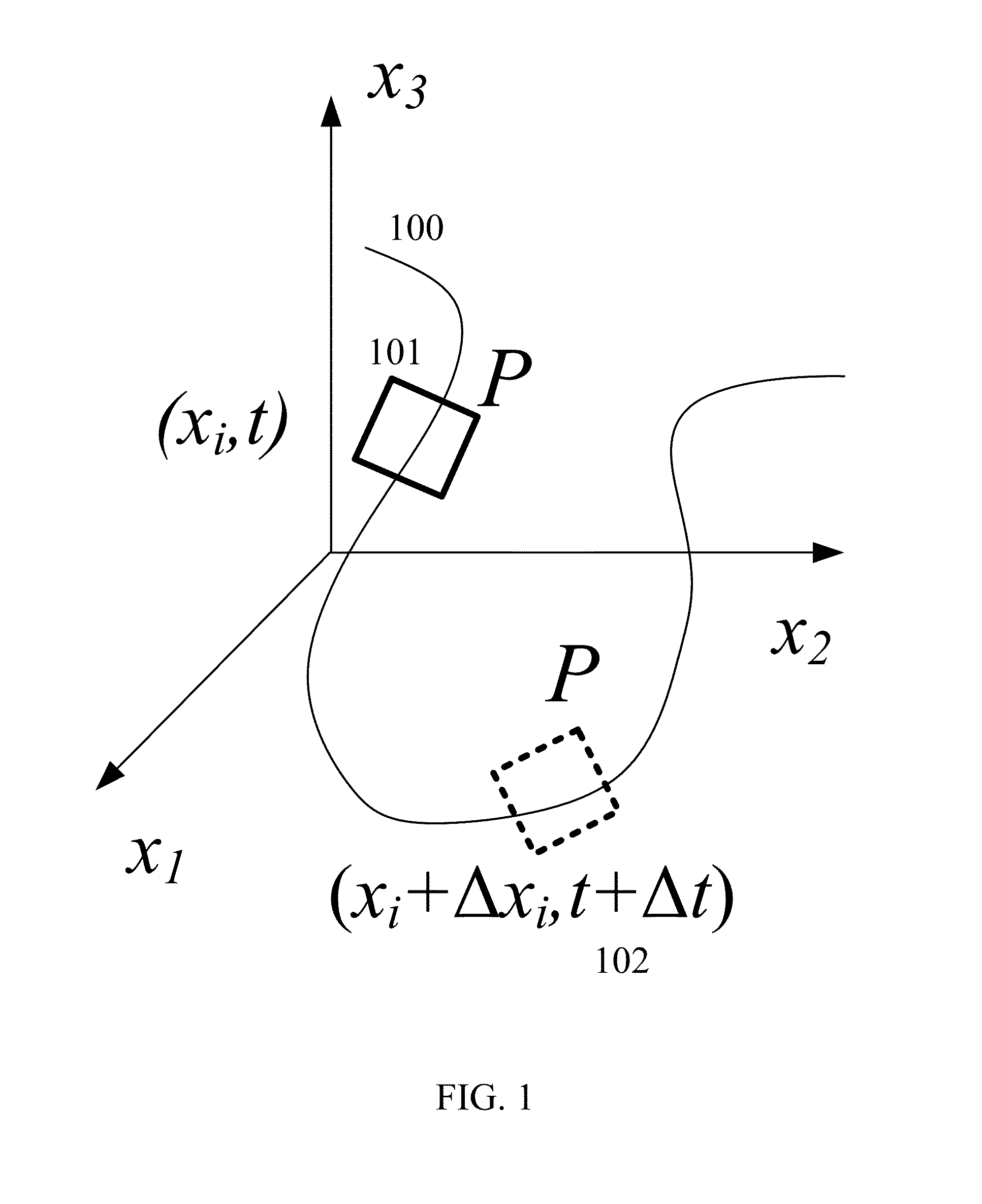

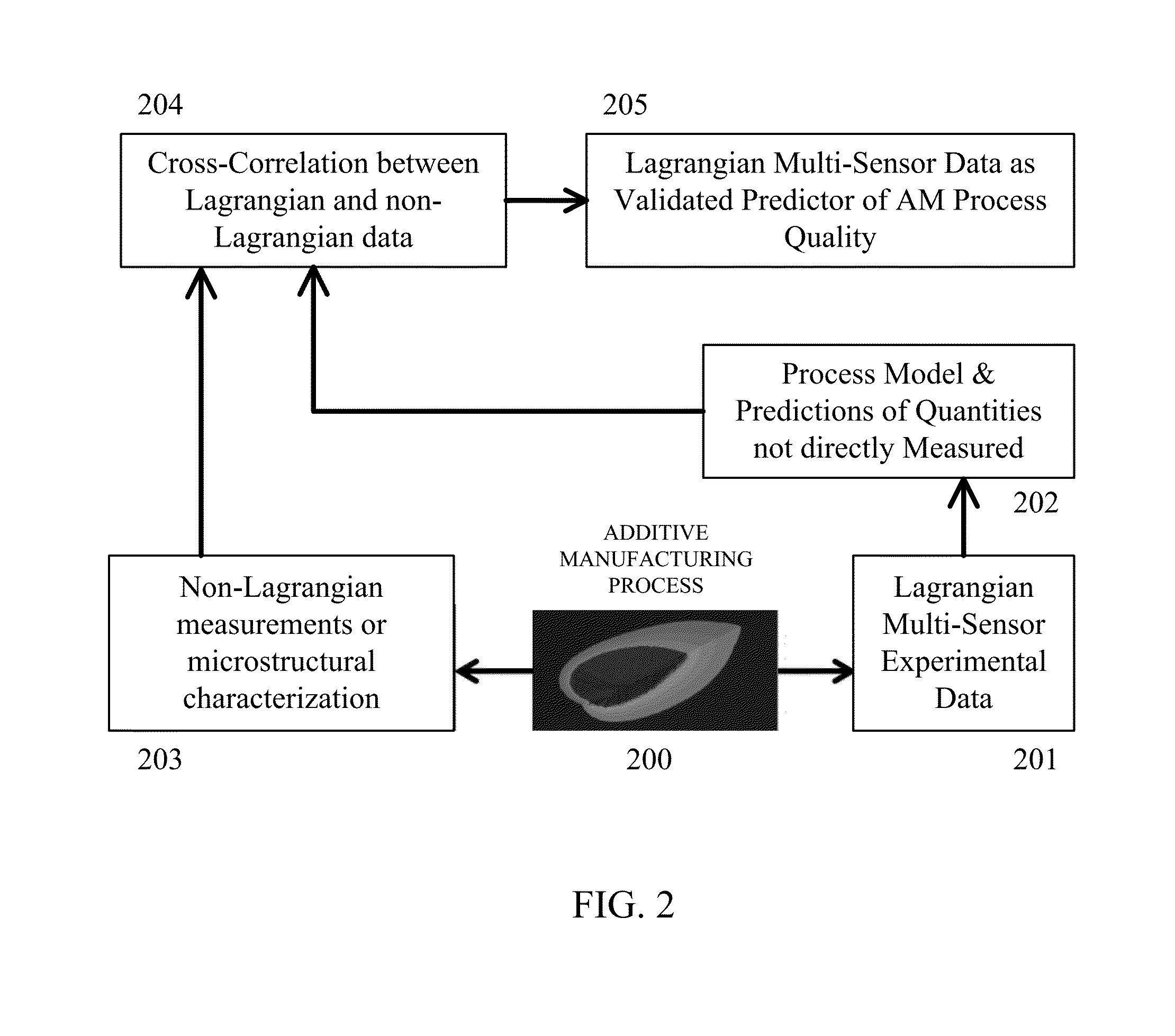

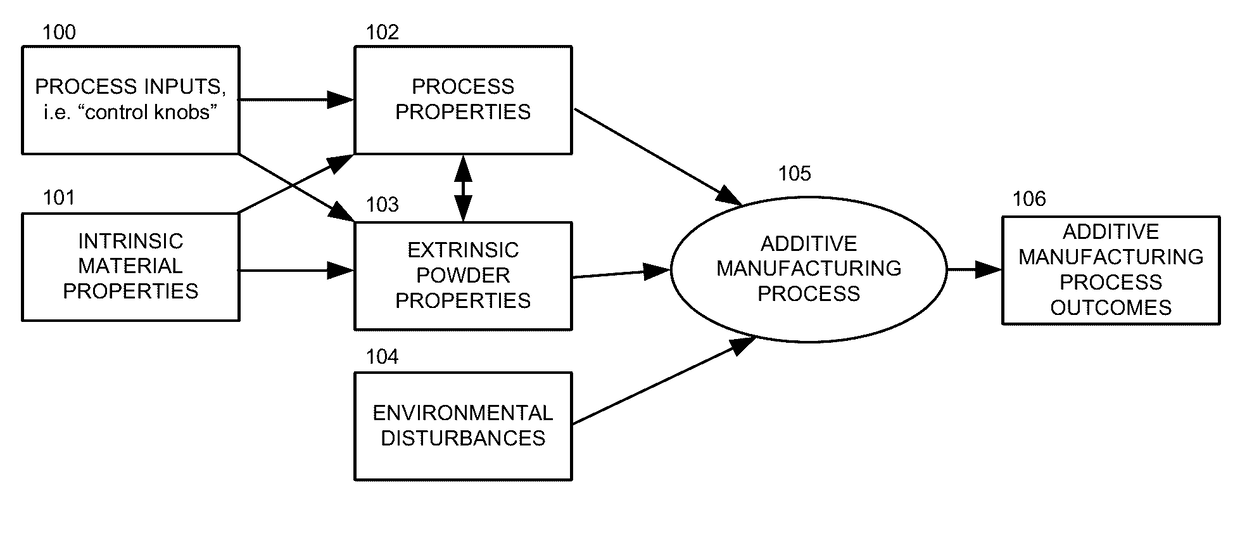

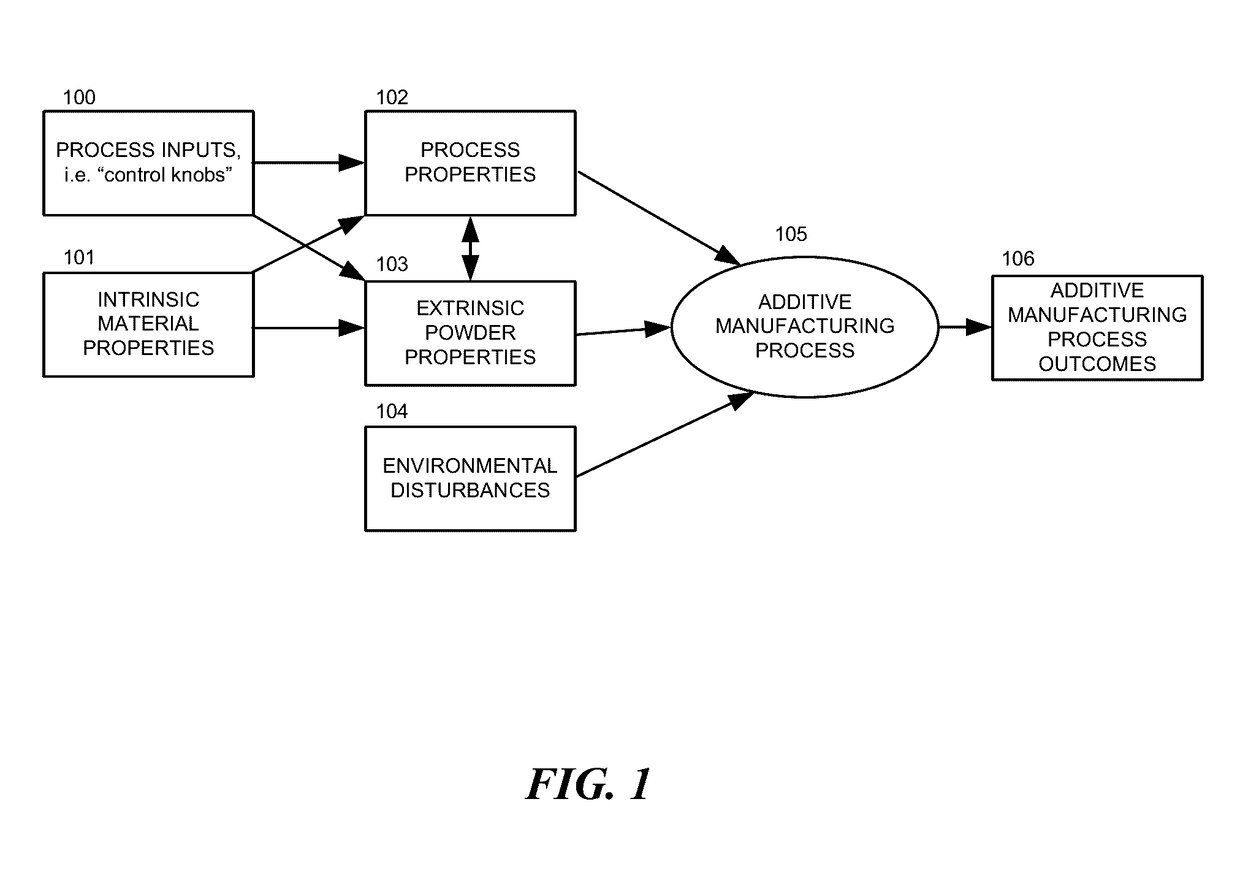

Multi-sensor quality inference and control for additive manufacturing processes

ActiveUS20160185048A1Increase chanceAdditive manufacturing apparatusIncreasing energy efficiencyInference systemManufacturing operations

This invention teaches a multi-sensor quality inference system for additive manufacturing. This invention still further teaches a quality system that is capable of discerning and addressing three quality issues: i) process anomalies, or extreme unpredictable events uncorrelated to process inputs; ii) process variations, or difference between desired process parameters and actual operating conditions; and iii) material structure and properties, or the quality of the resultant material created by the Additive Manufacturing process. This invention further teaches experimental observations of the Additive Manufacturing process made only in a Lagrangian frame of reference. This invention even further teaches the use of the gathered sensor data to evaluate and control additive manufacturing operations in real time.

Owner:SIGMA LAB OF ARIZONA

Systems and methods for additive manufacturing operations

ActiveUS20170090462A1Sufficient accuracySolve the lack of resolutionProgramme controlAdditive manufacturing apparatusManufacturing operationsAdditive layer manufacturing

This disclosure describes various system and methods for monitoring photons emitted by a heat source of an additive manufacturing device. Sensor data recorded while monitoring the photons can be used to predict metallurgical, mechanical and geometrical properties of a part produced during an additive manufacturing operation. In some embodiments, a test pattern can be used to calibrate an additive manufacturing device.

Owner:SIGMA LAB OF ARIZONA

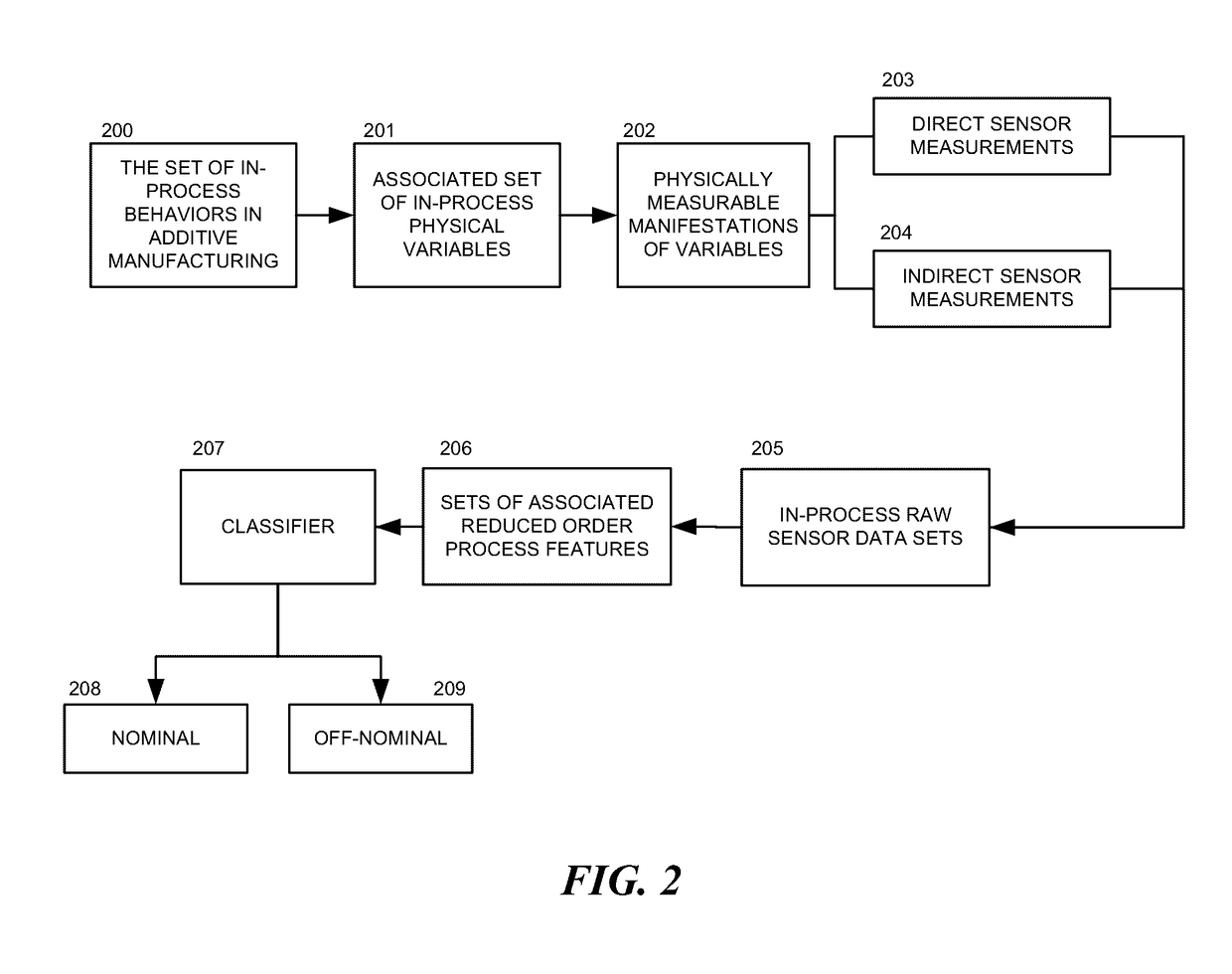

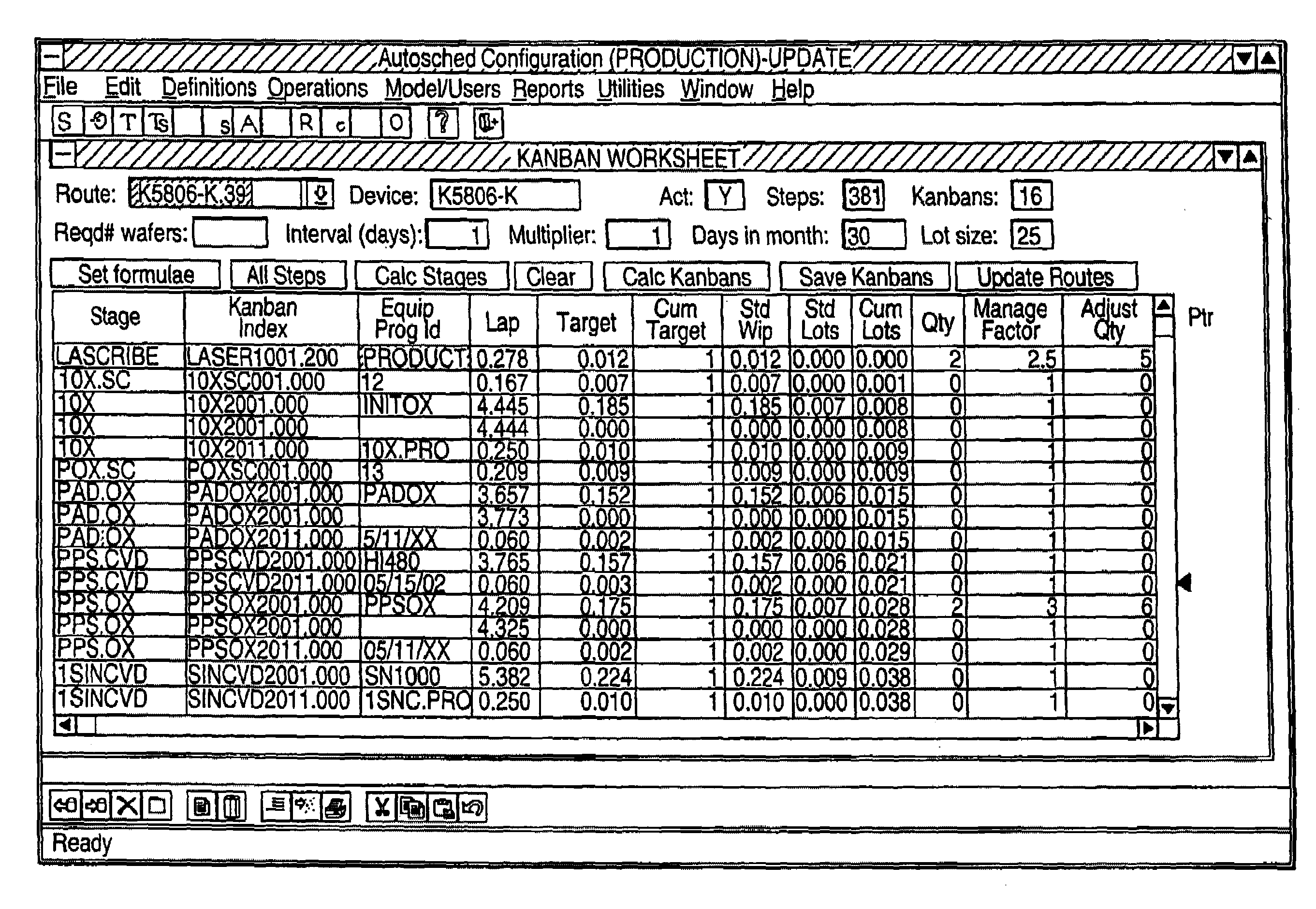

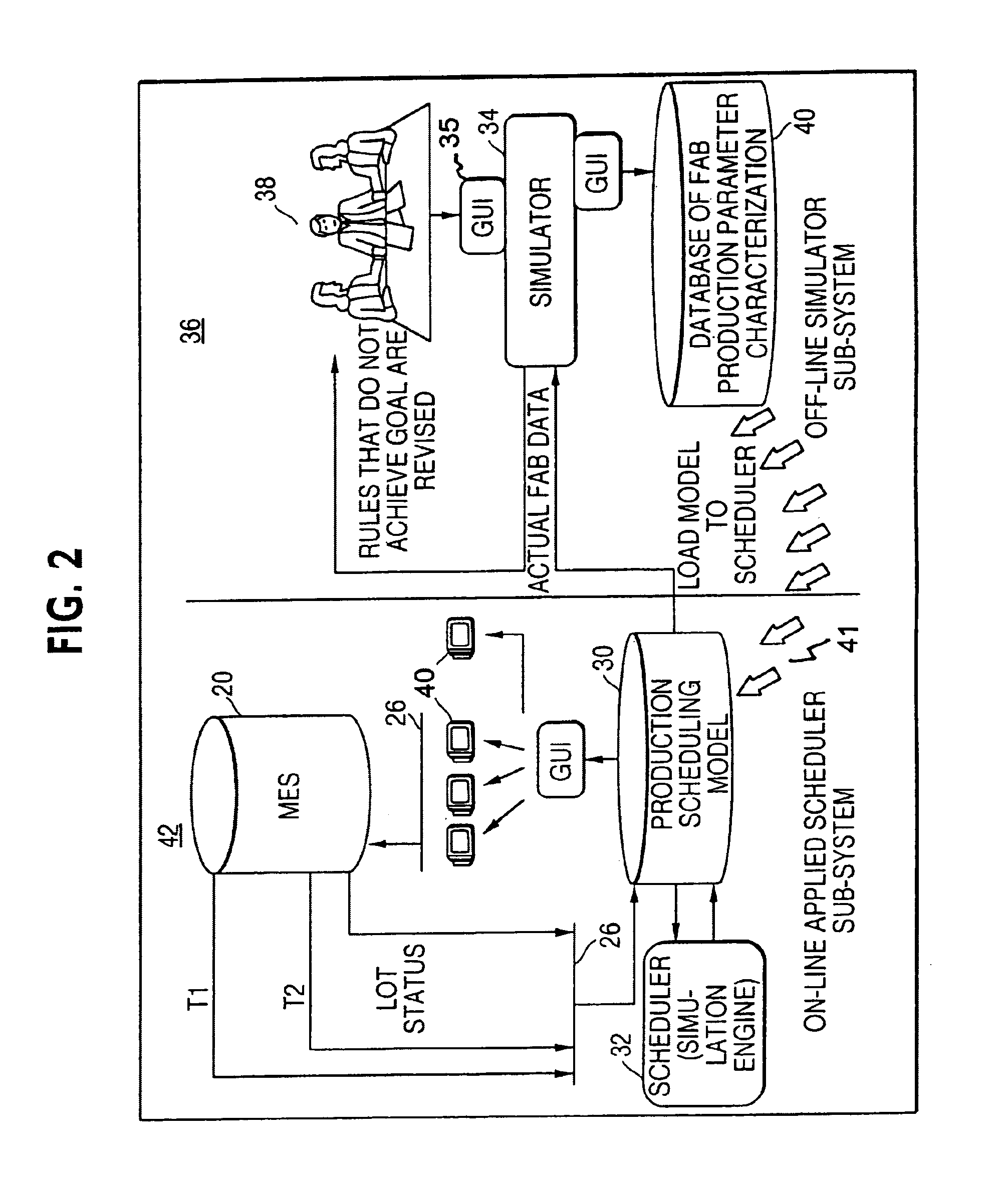

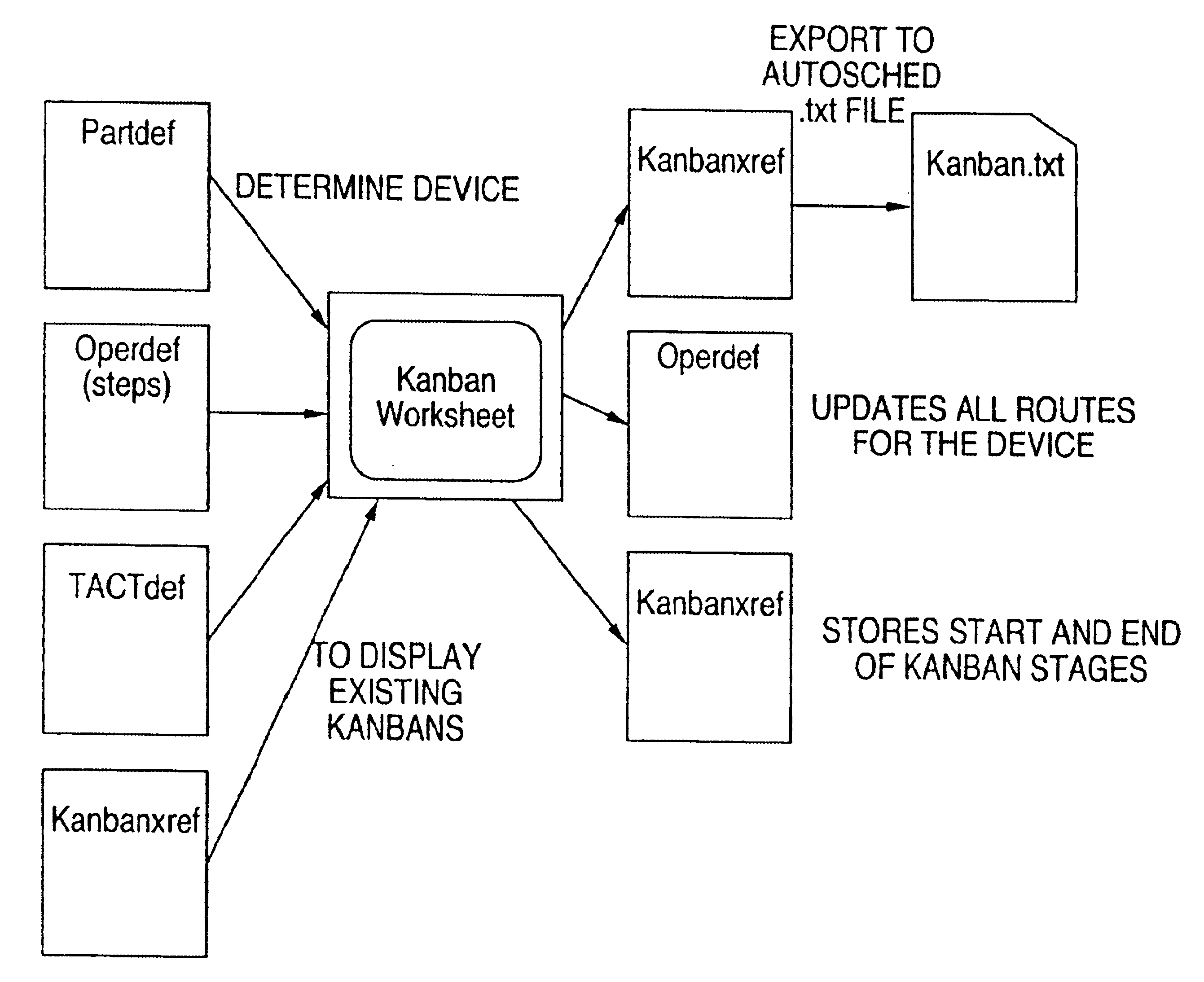

Electronic Kanban worksheet for the design and implementation of virtual or electronic Kanban systems

InactiveUS7020594B1ForecastingSpecial data processing applicationsManufacture execution systemSystems design

An integrated wafer fab production characterization and scheduling system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated characterization / scheduling system provides manufacturing with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on actual production system. Furthermore, simulation models are used to create short term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, a, and real time lot move updates.

Owner:SONY CORP +1

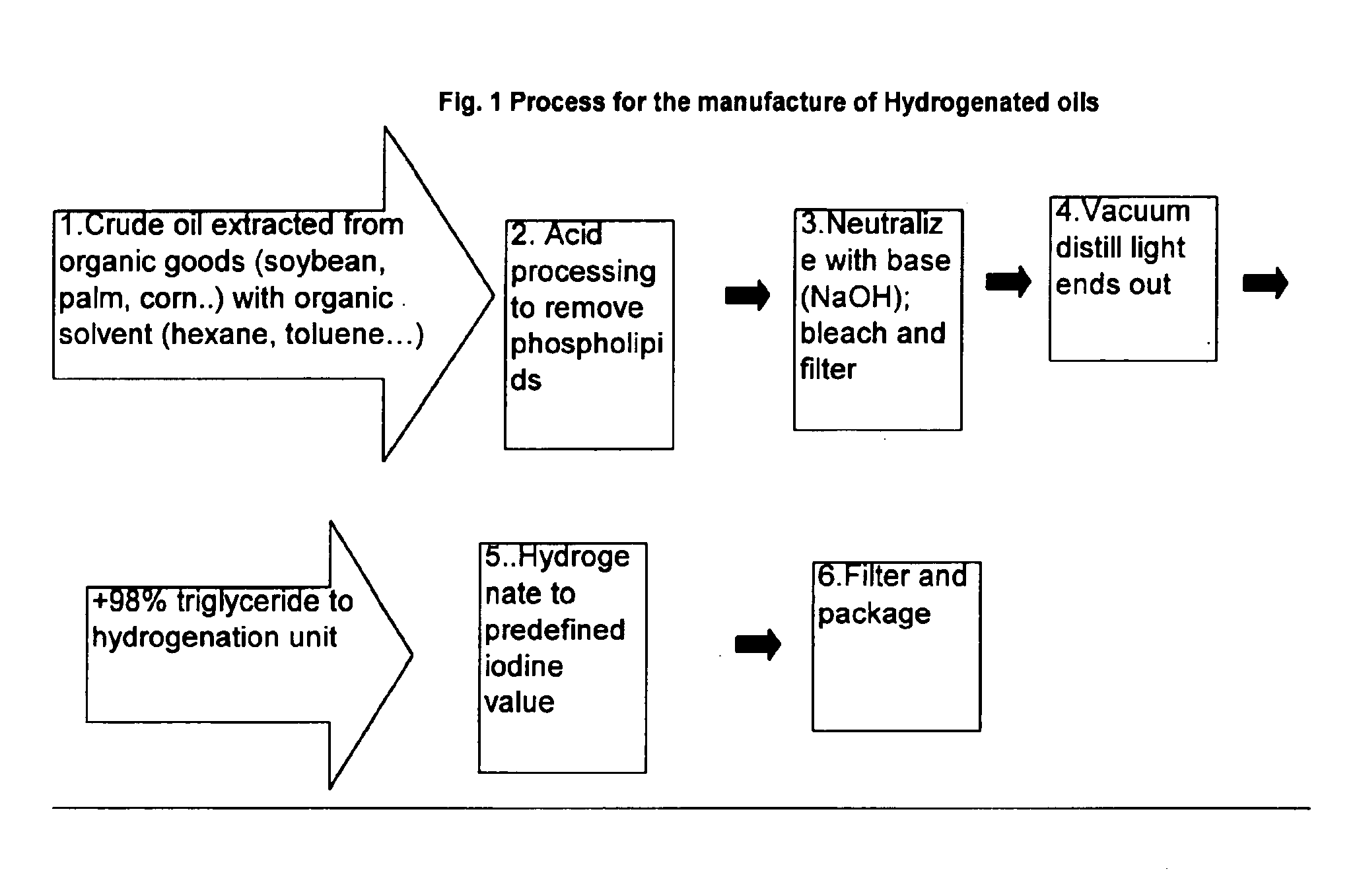

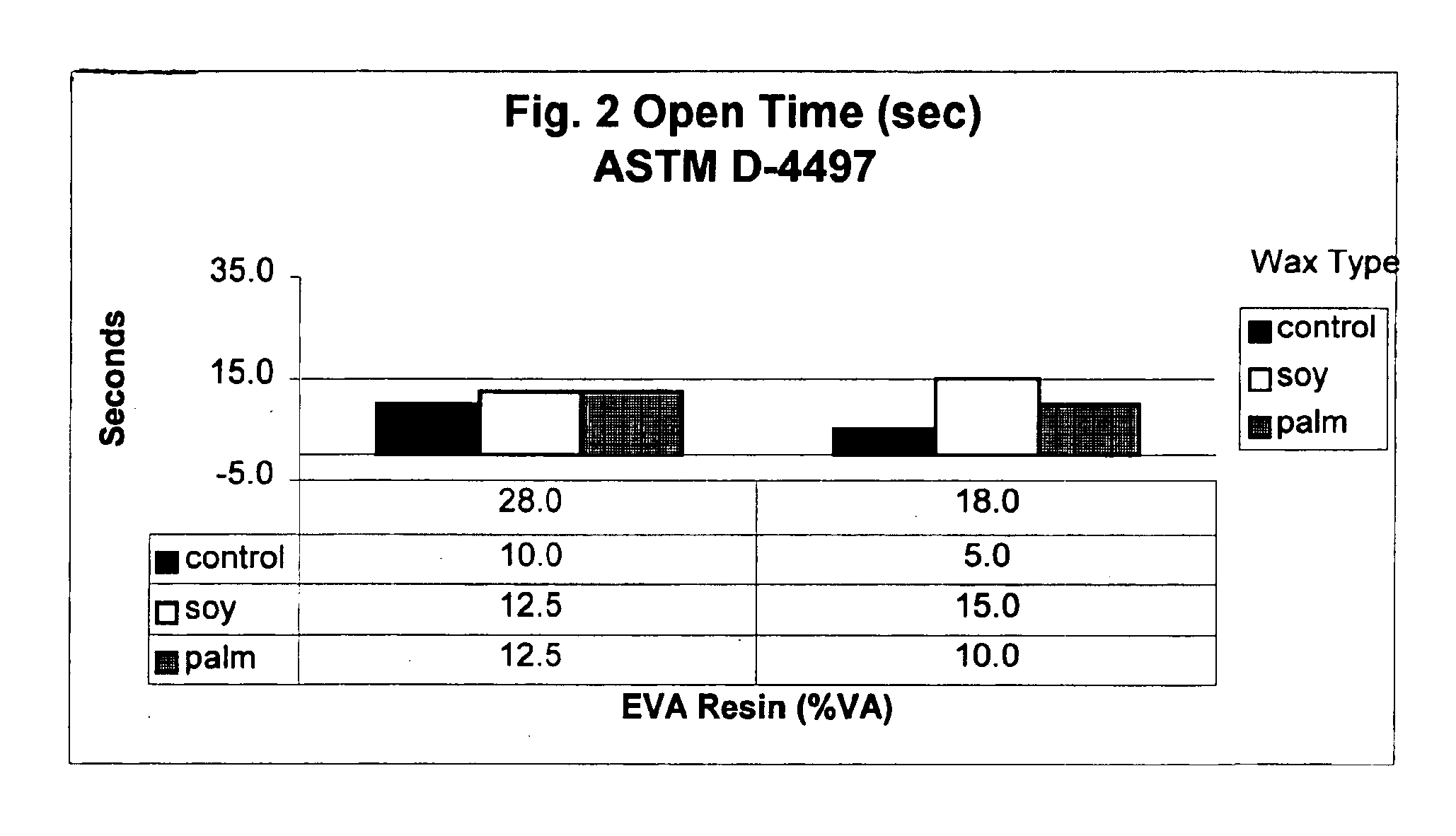

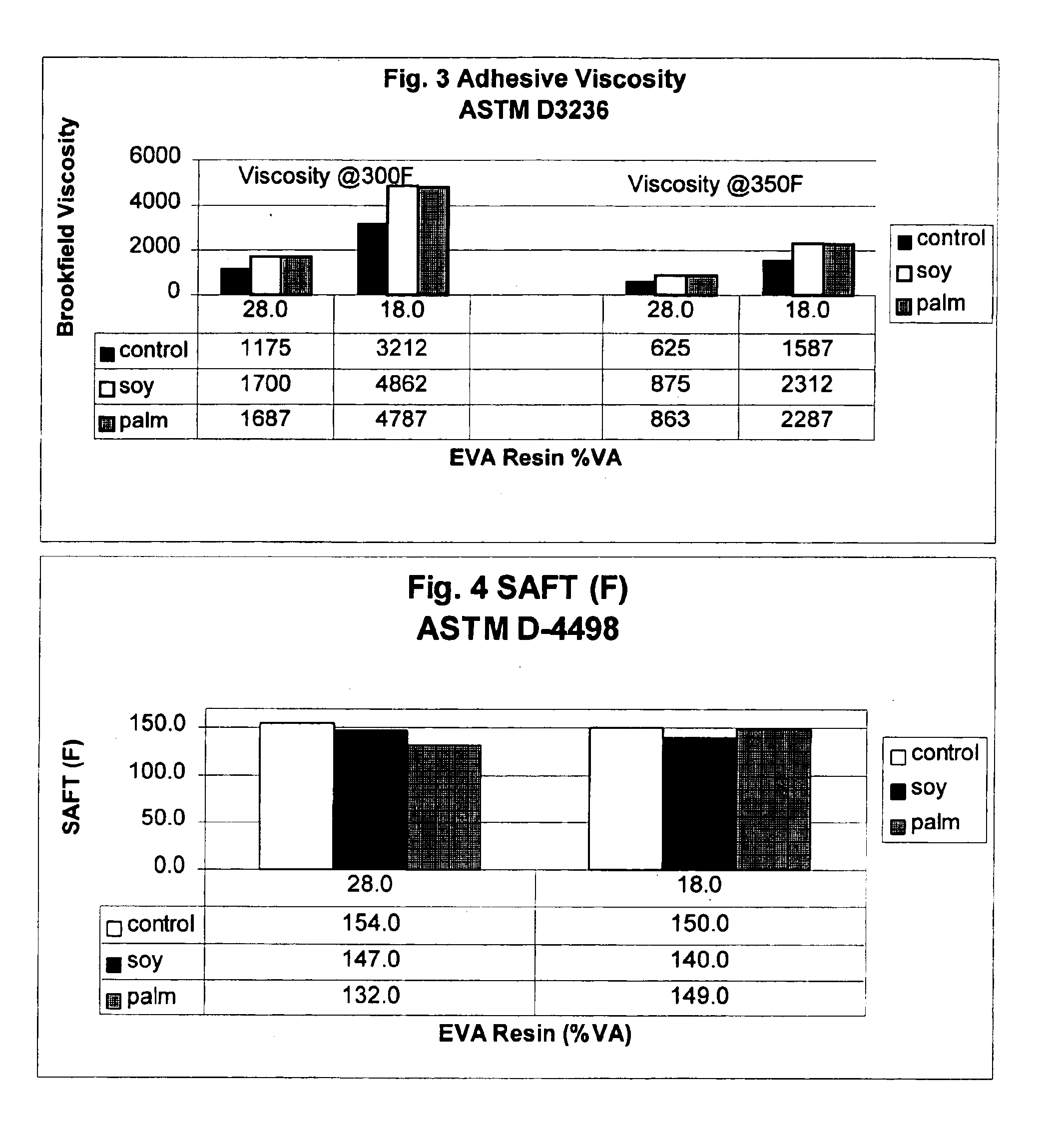

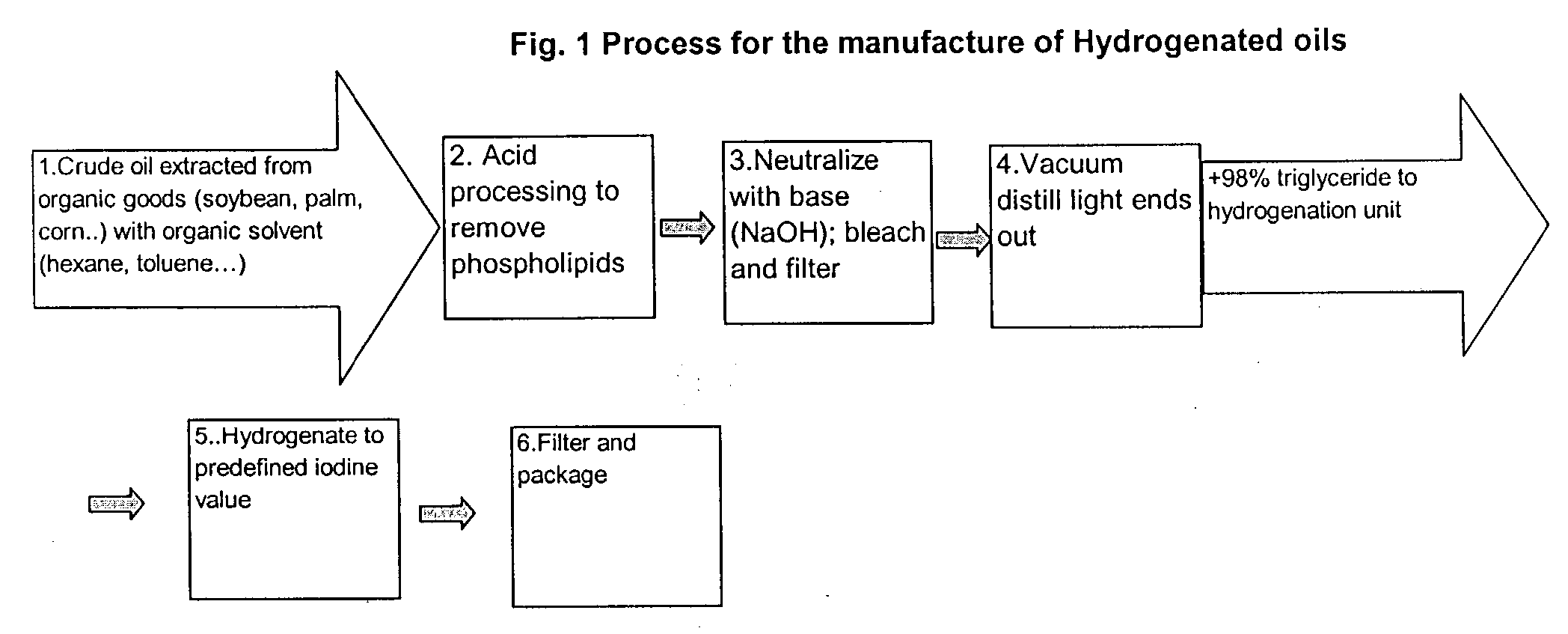

Wax for hot melt adhesive applications

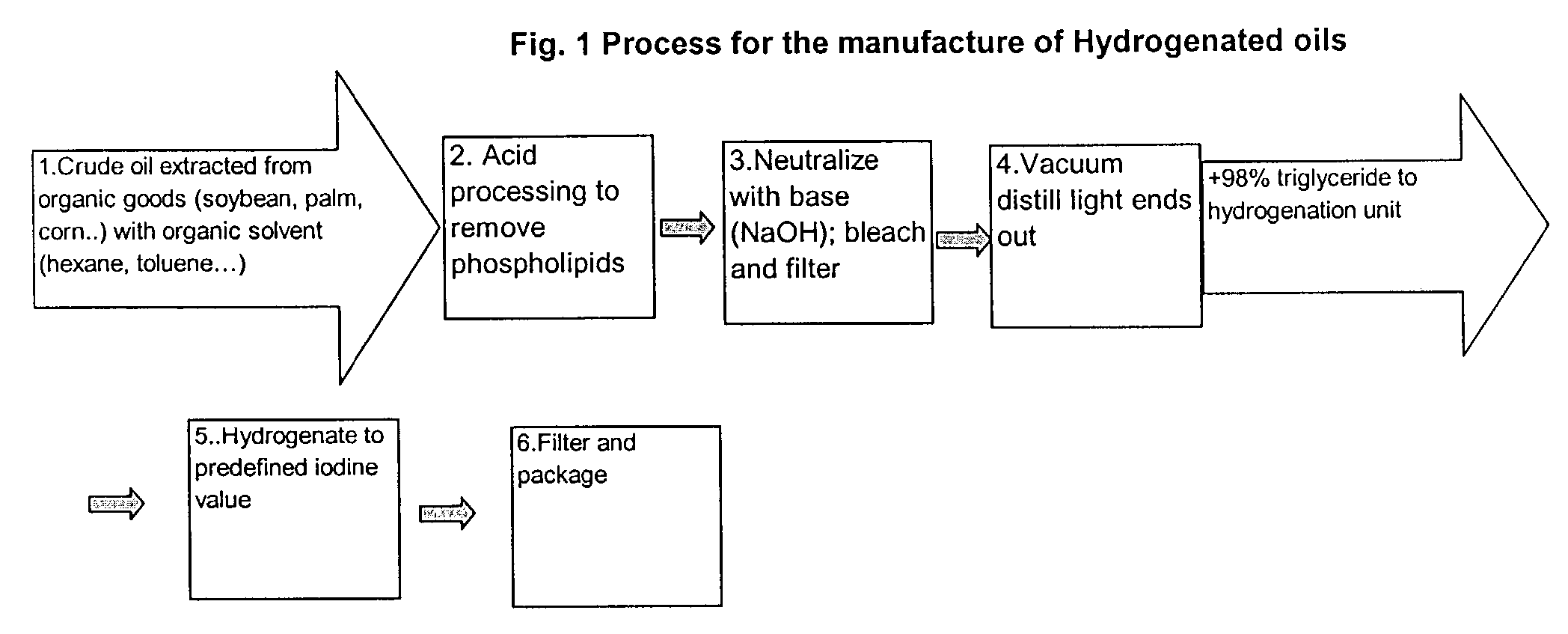

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

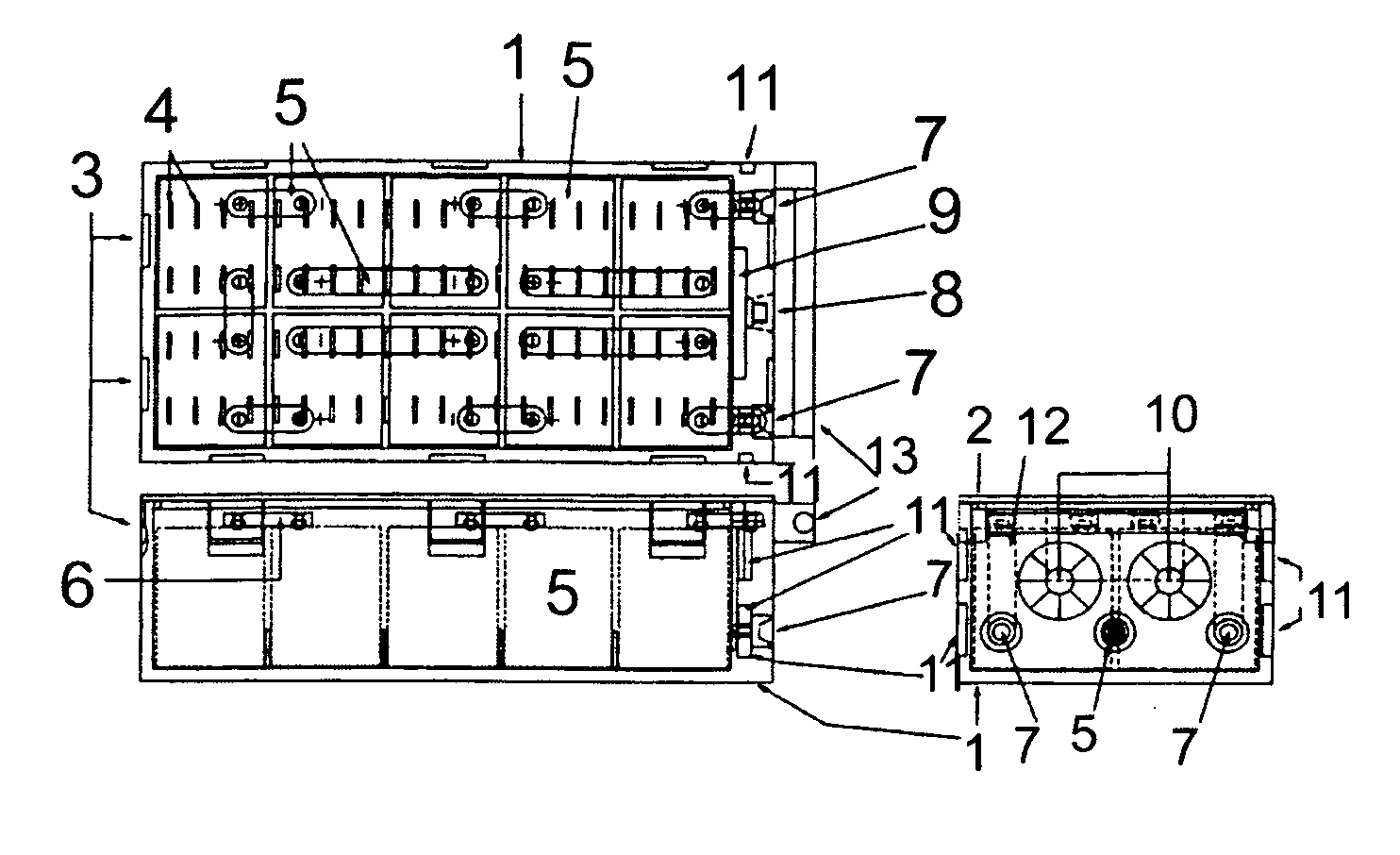

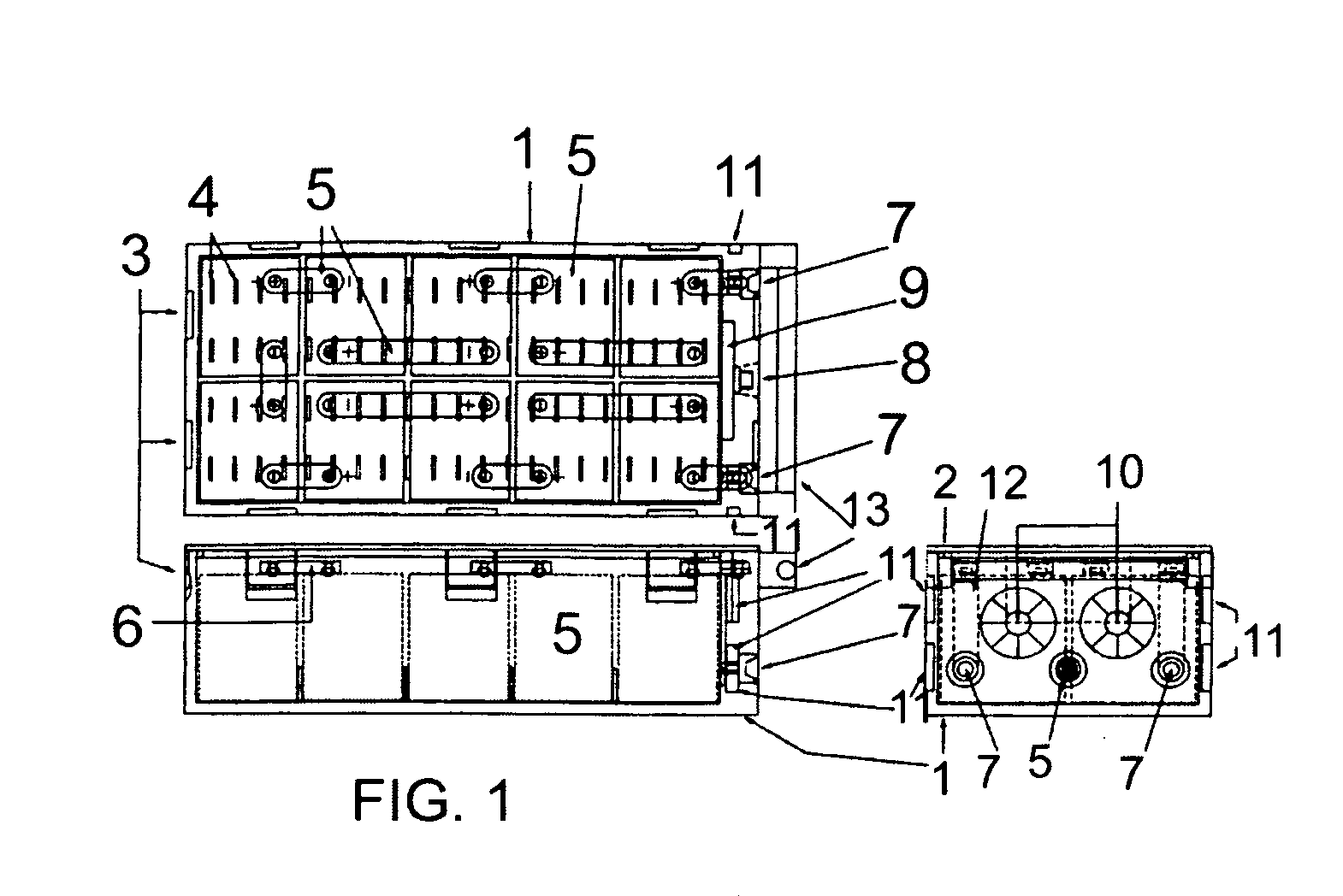

Comprehensive engineering / operation system for electric vehicle and smart networked and decentralized power storage

InactiveUS20100292877A1Easily inserted into and removedPrevent tamperingDigital data processing detailsRailway vehiclesSmart Battery SystemData logger

Comprehensive, Systematic and Practical Engineering / Manufacture / Operation / Management System for Electric Vehicle with dual usage for Decentralized Smart Power Storage that includes: Smart Battery Subsystem (SBS), which includes the Smart Battery Assembly (SBA) with embedded computer / data logger and the Battery Compartment (BC) on the EV and in the Swapping Recharge Stations (RS); the computers on the EV and RS; hardware and software for the SBA Exchange / Recharge / Maintenance / Management / Billing Subsystem; the Smart Decentralized Energy Storage Subsystem for on-line, off-line and / or emergency uses. The SBA can be swapped at RS or recharged at home or any recharge stations, or dismounted / mounted easily in garage or during roadside service. The SBA could include the built-in charge controller and inverter. All the subsystems are indispensable parts or options for this invented integrated system.

Owner:GABRIELLE W LEE +1

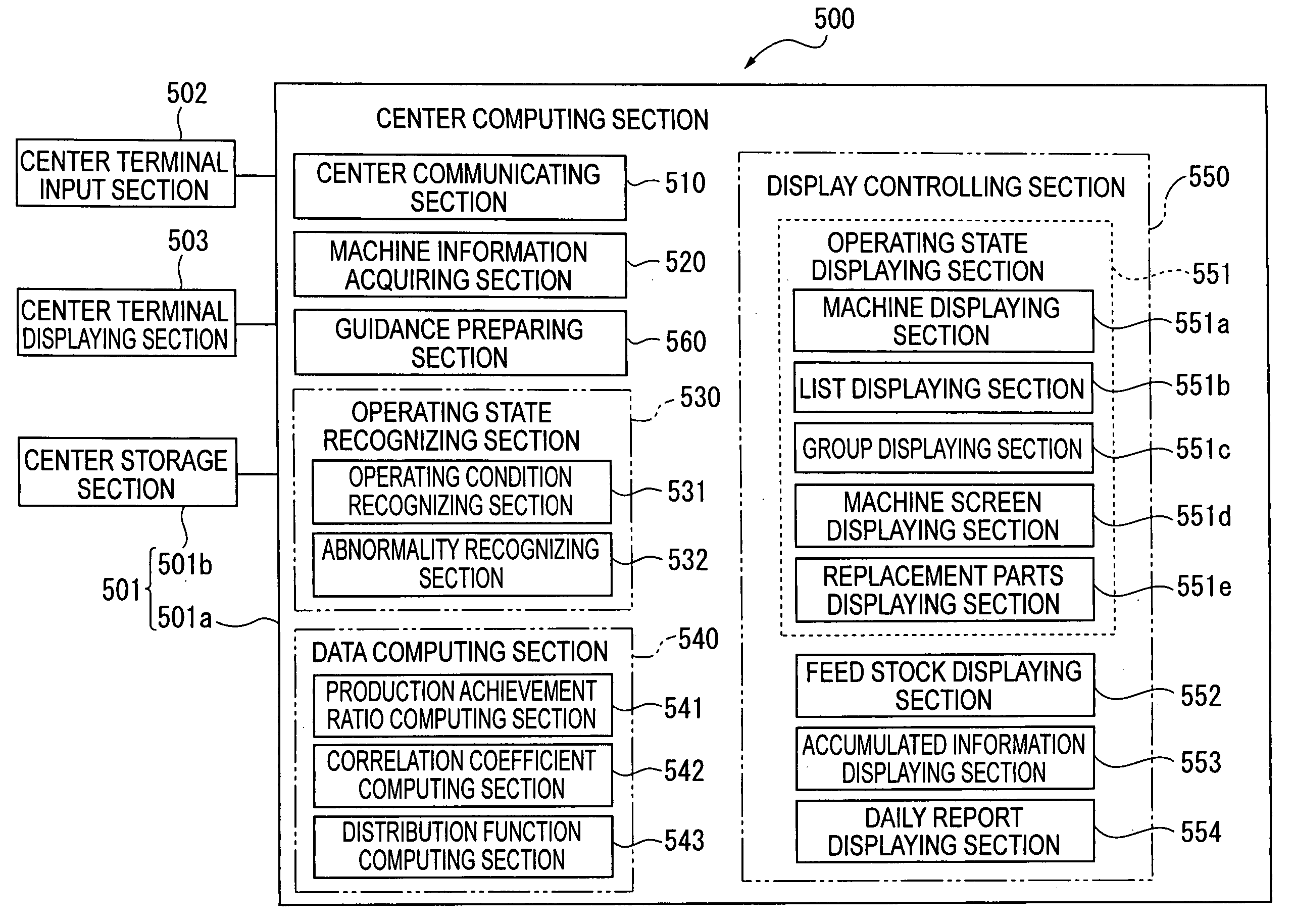

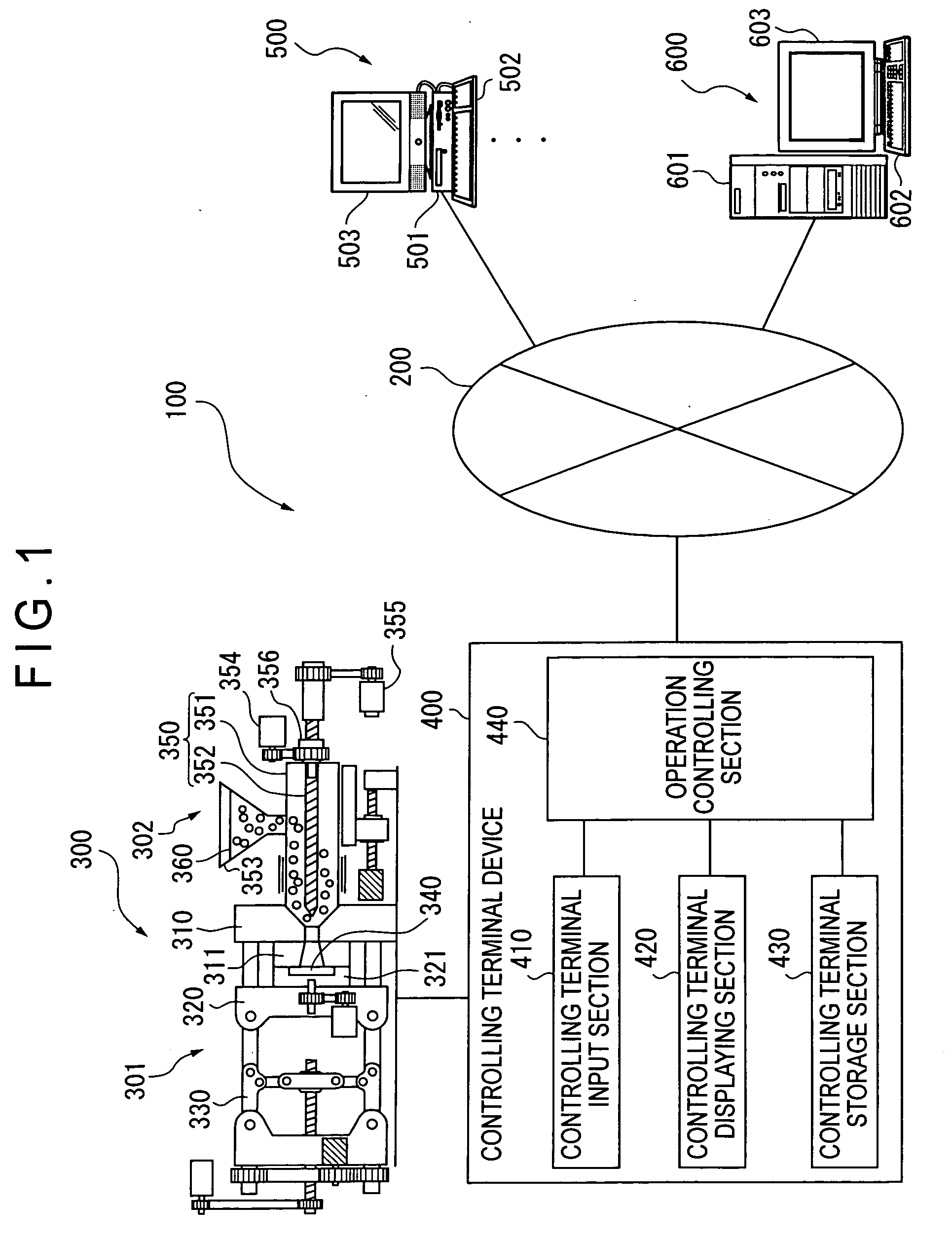

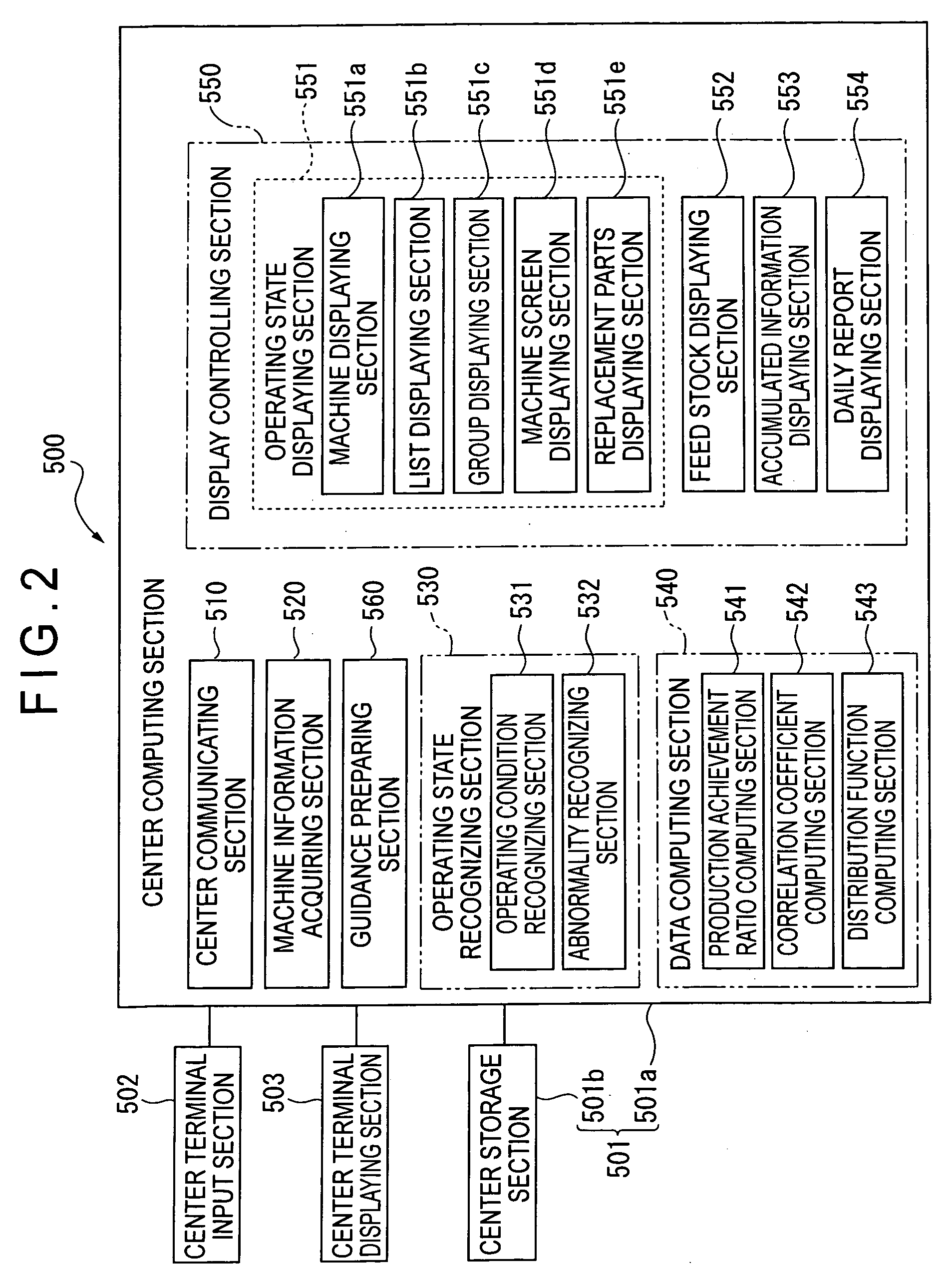

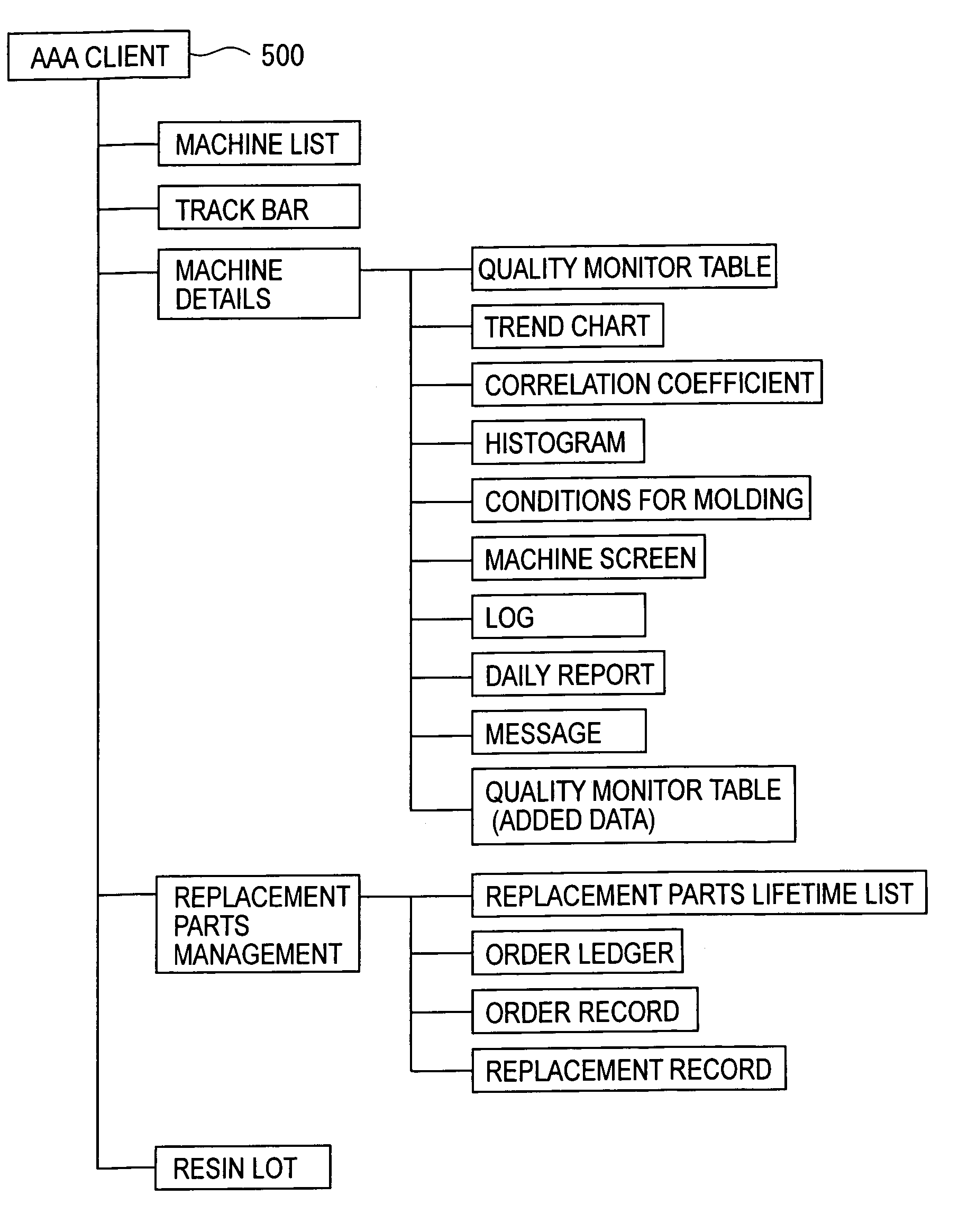

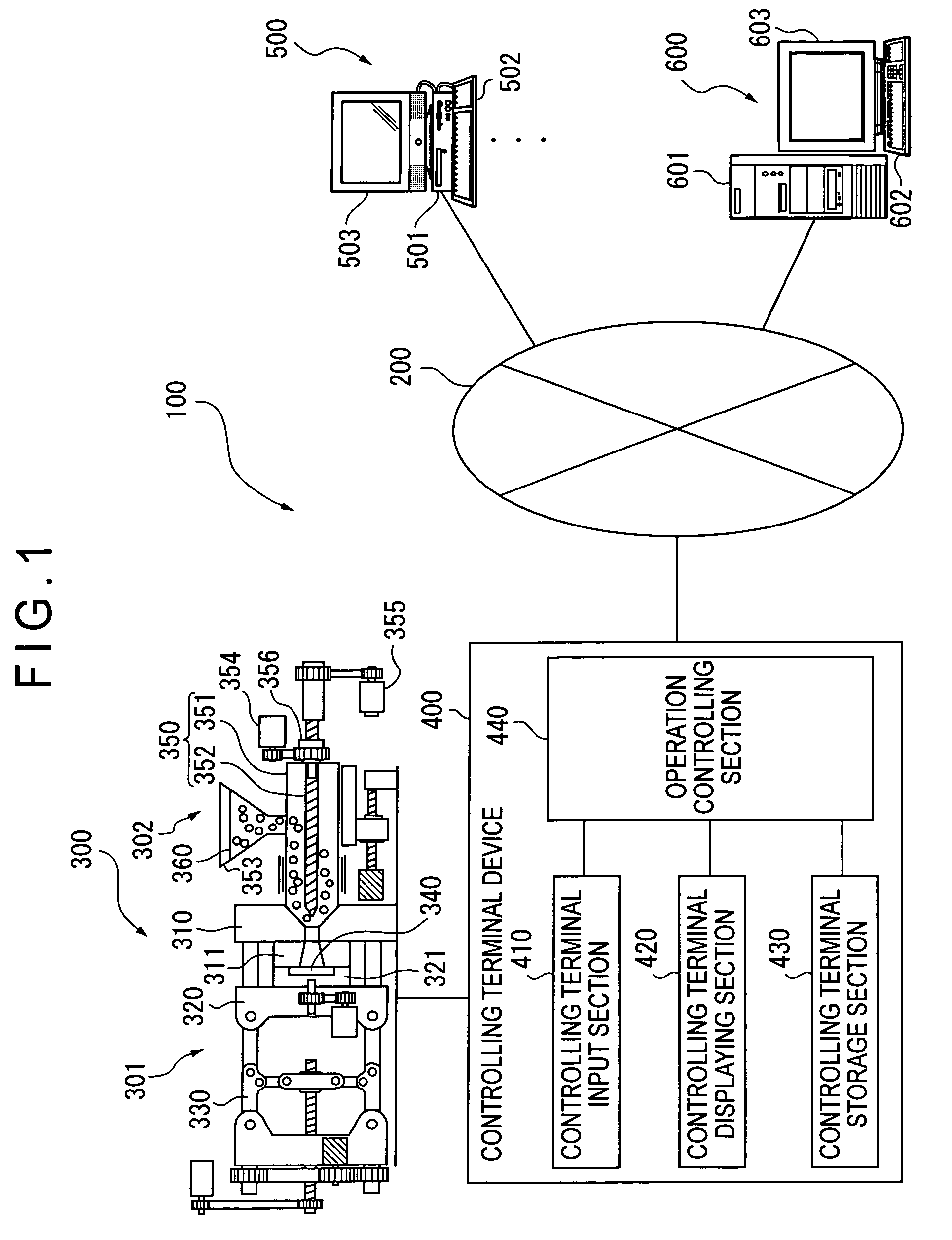

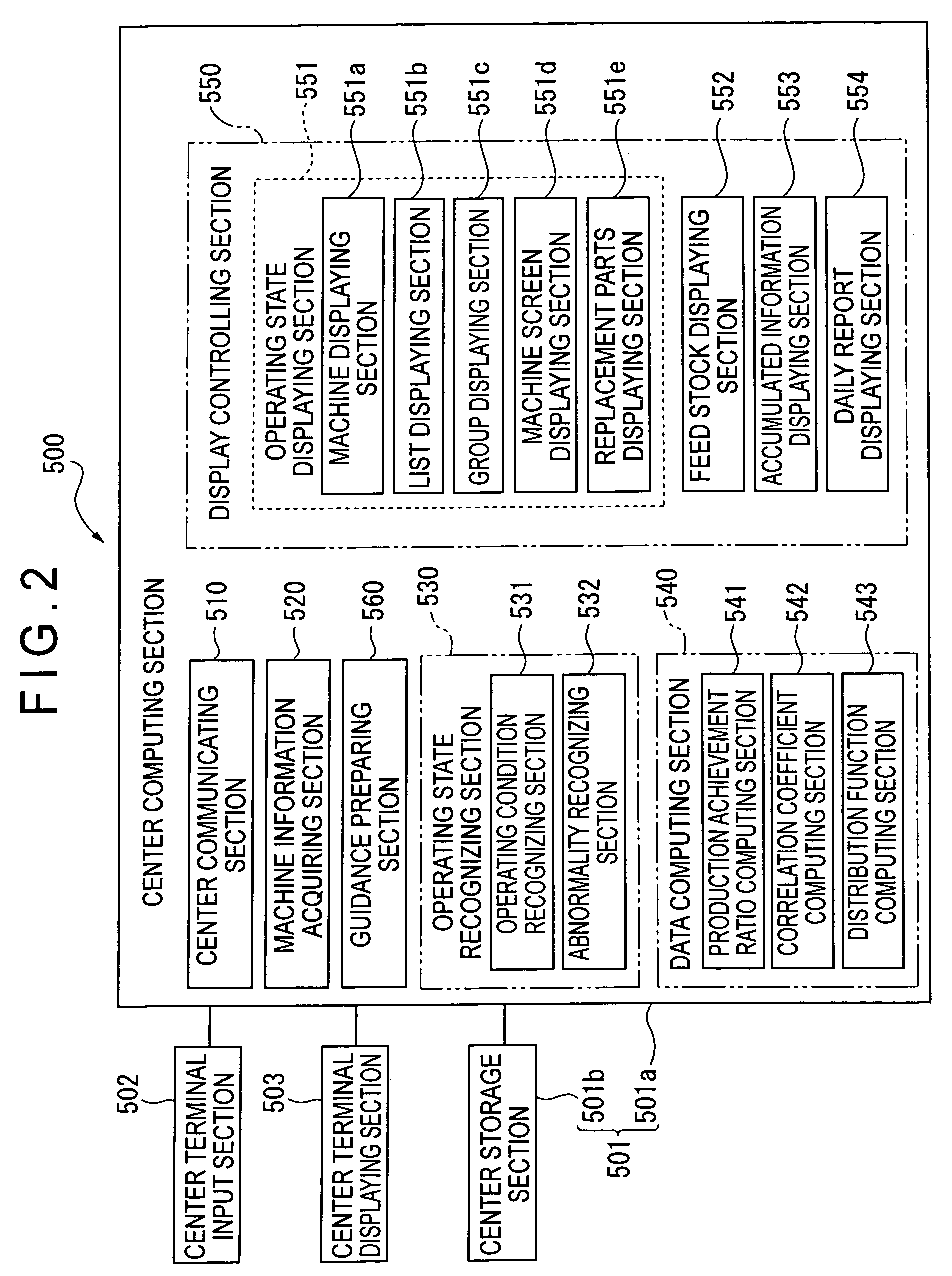

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS20040148136A1Efficient replacementEasy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

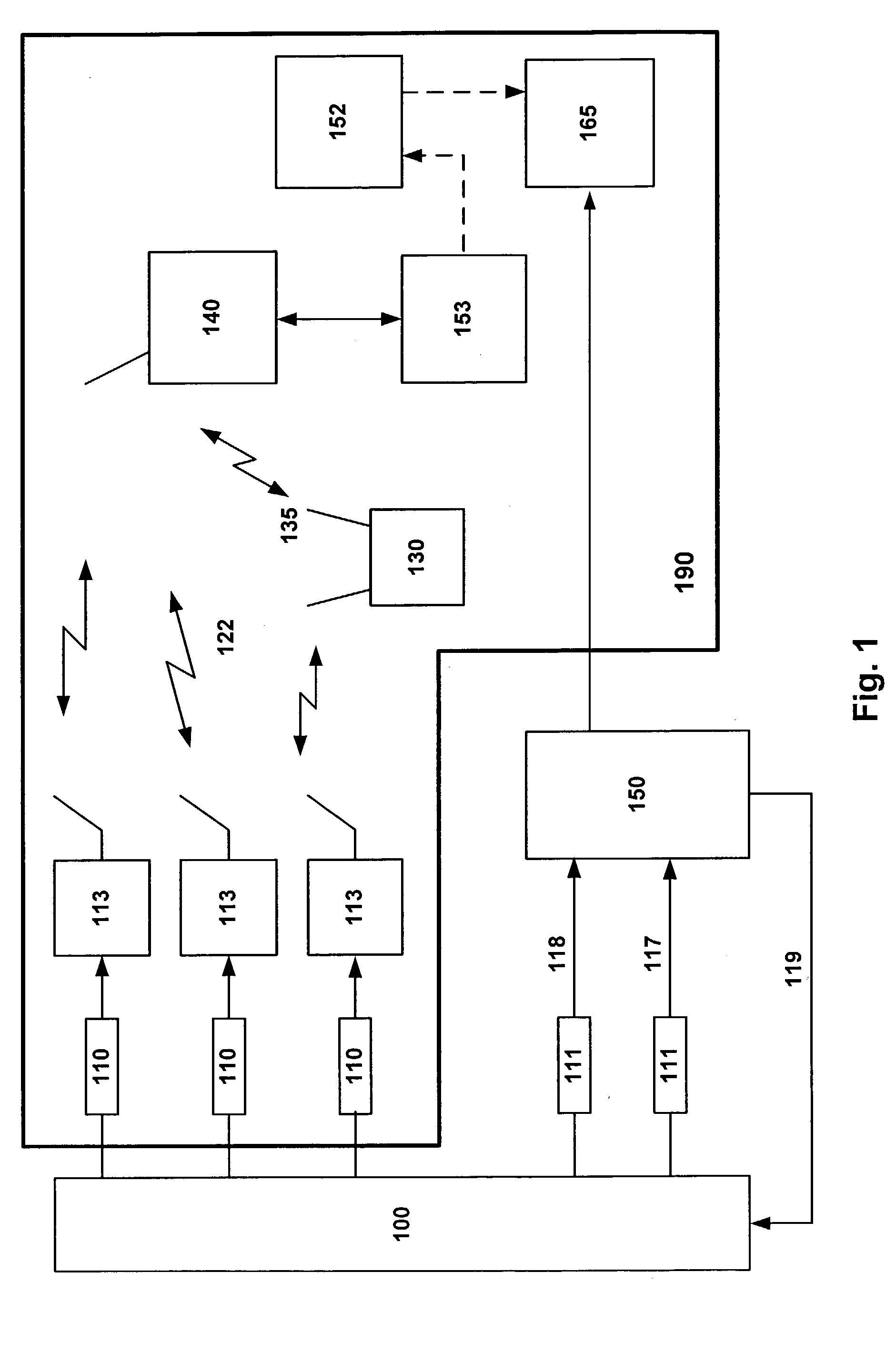

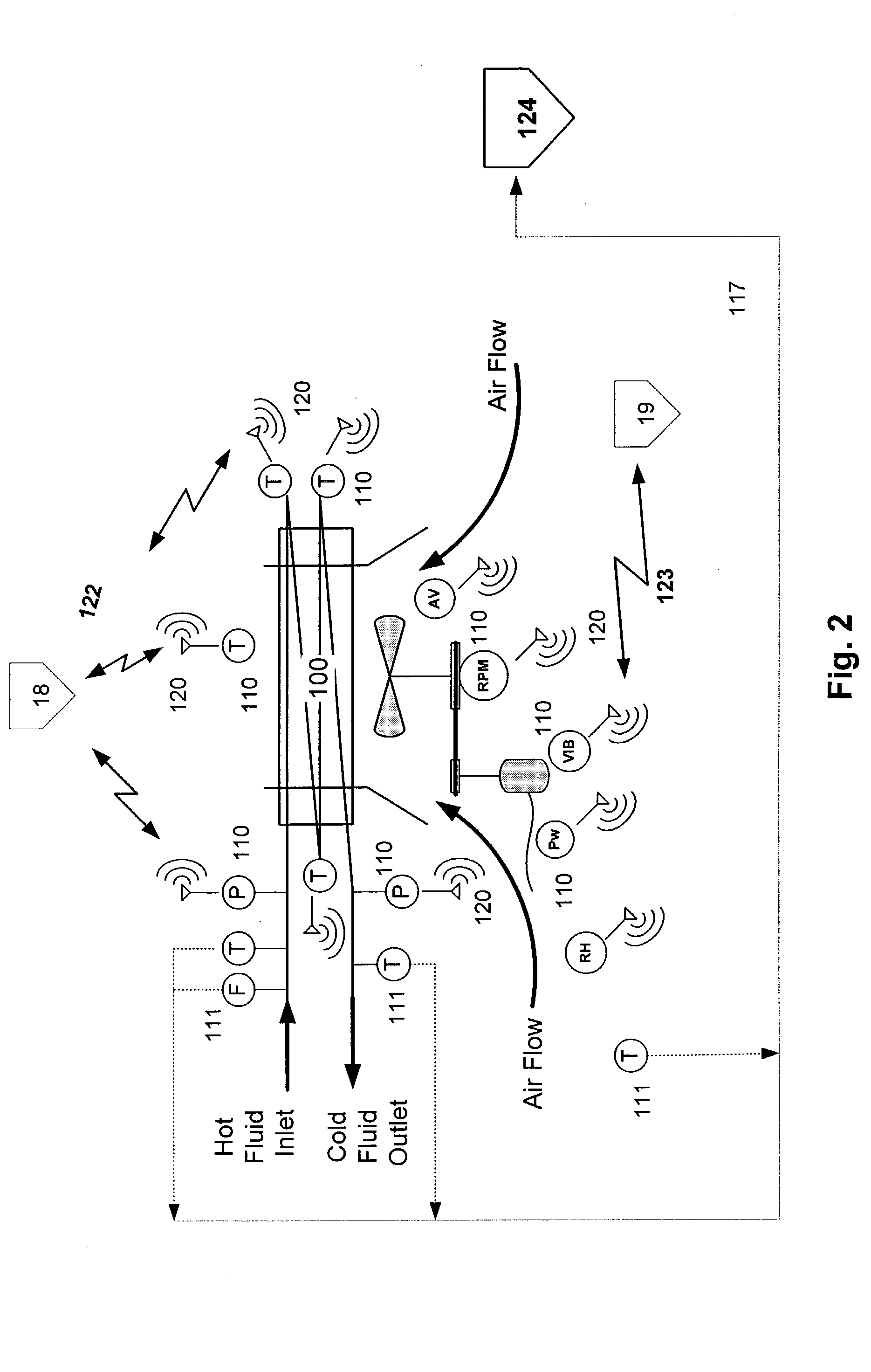

Temporary wireless sensor network system

InactiveUS20030204371A1Plant parameters regulationNuclear energy generationData streamNetworked system

The invention is an integrated temporary wireless network system for controlling, collecting, processing, and responding to data generated by a plurality of sensors configured for measuring data associated with operation of, and the environment related to, commercial, industrial and manufacturing operations, processes and equipment located within a fixed geographic area; a plurality of Wireless-Nodes, one coupled to each sensor, configured and adapted for wirelessly transmitting the data, via a Repeater if necessary, to a Base-Station, configured for receiving the data and connected to a primary computer; a CPU coupled with the primary computer and; a memory operatively connected to the CPU, the memory containing a program adapted to be executed by the CPU and the CPU and memory cooperatively adapted to perform data flow control from the plurality of Wireless-Nodes, data storage, and diagnostic analysis of the transmitted sensor data.

Owner:CHEVROU USA INC

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS7117050B2Easy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

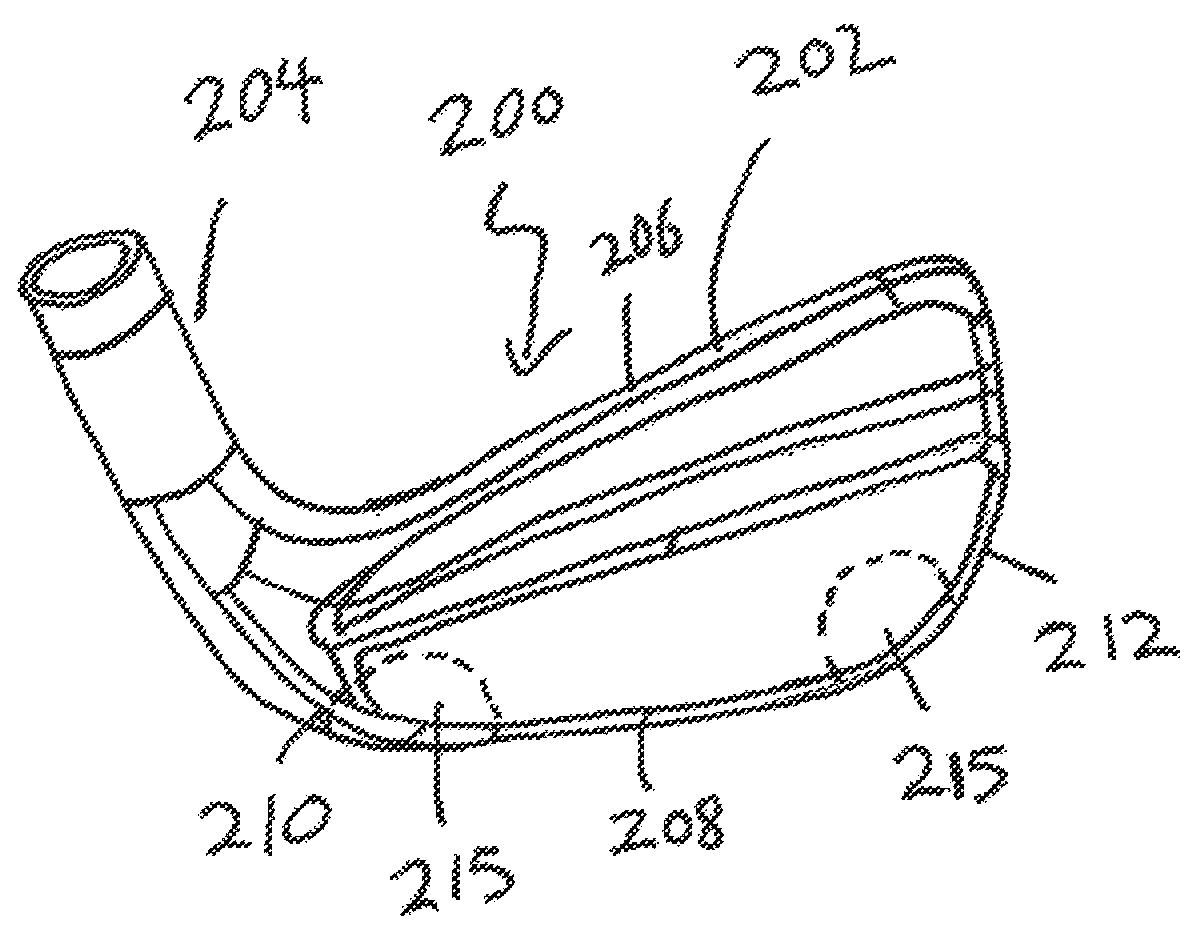

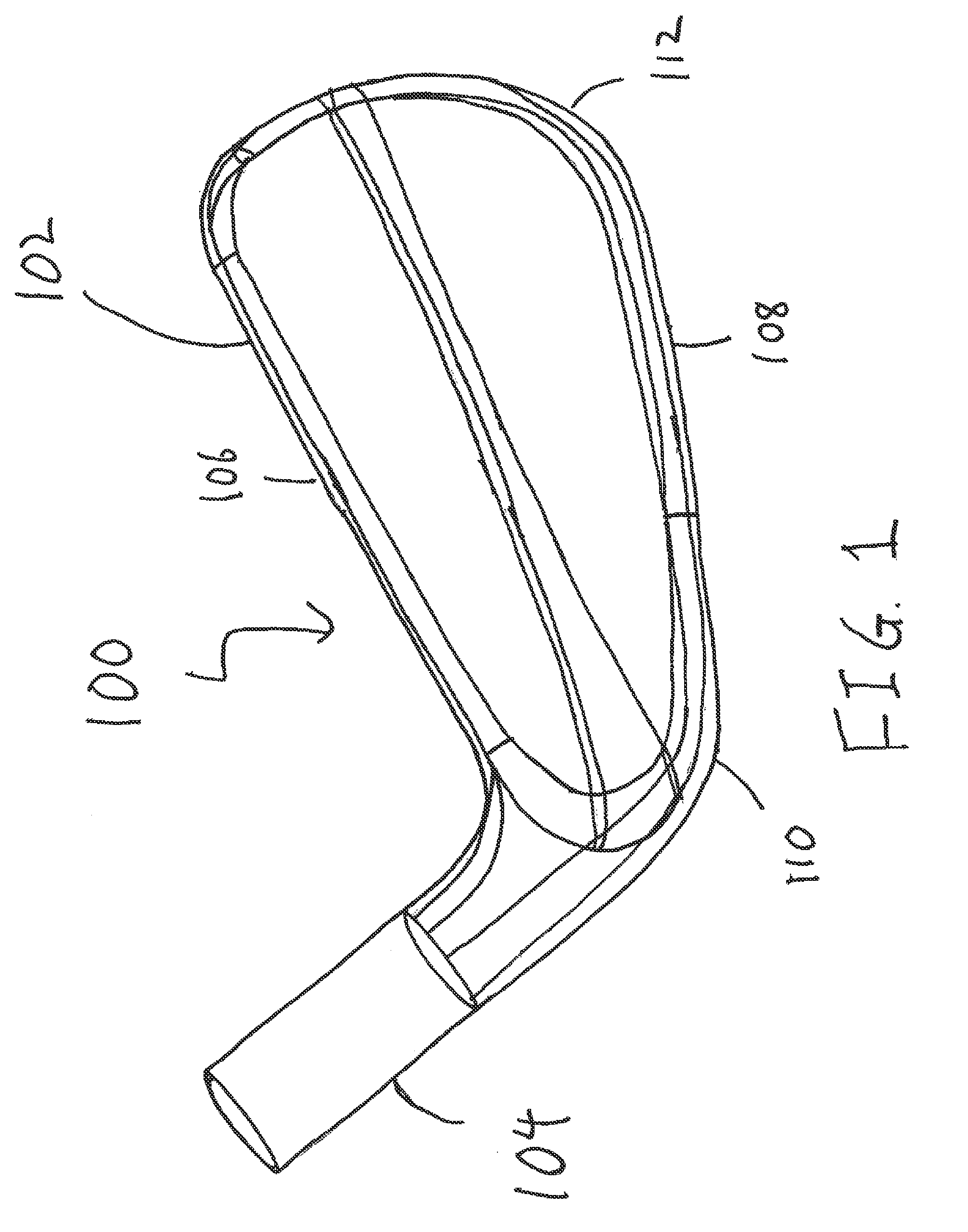

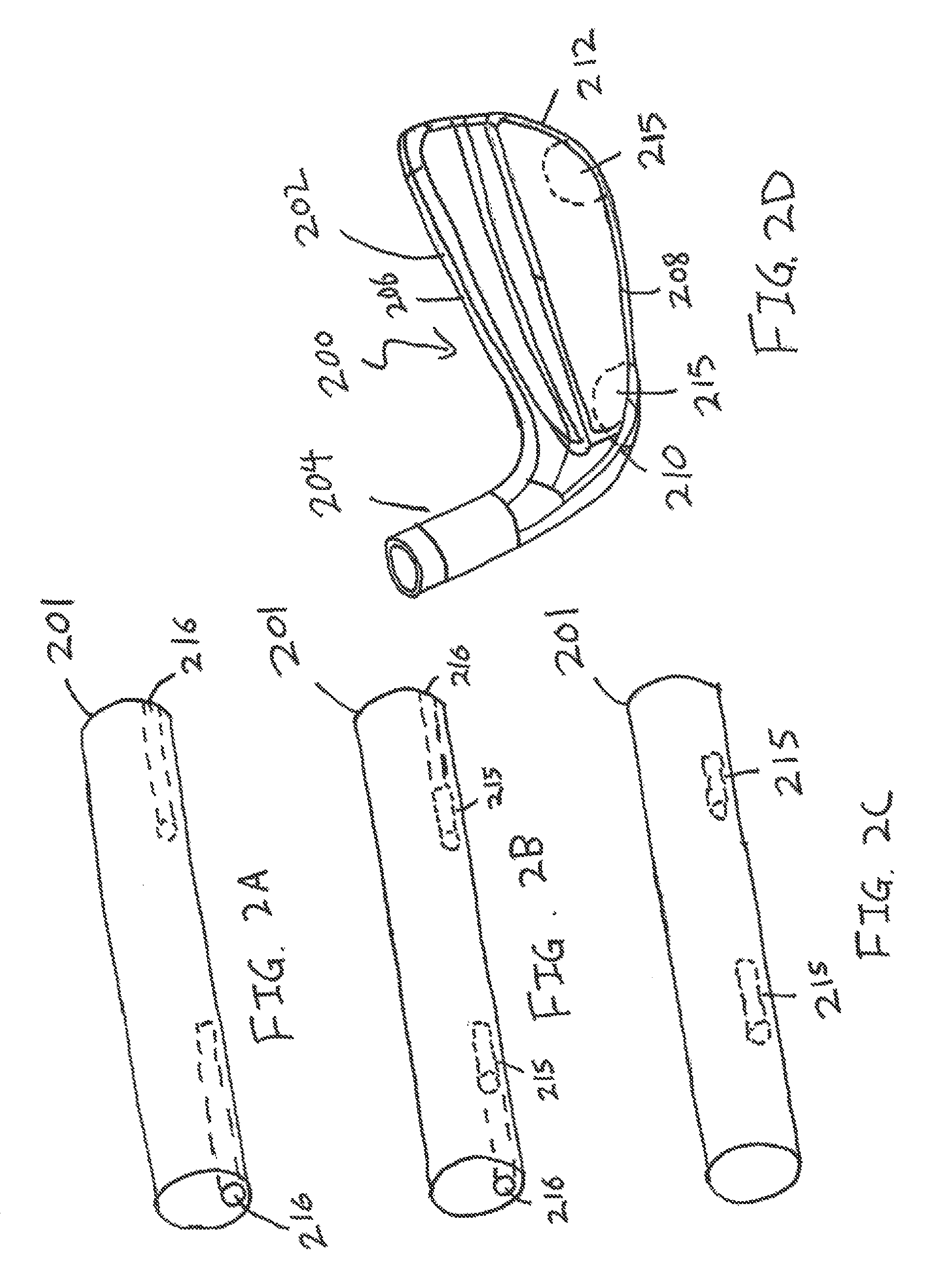

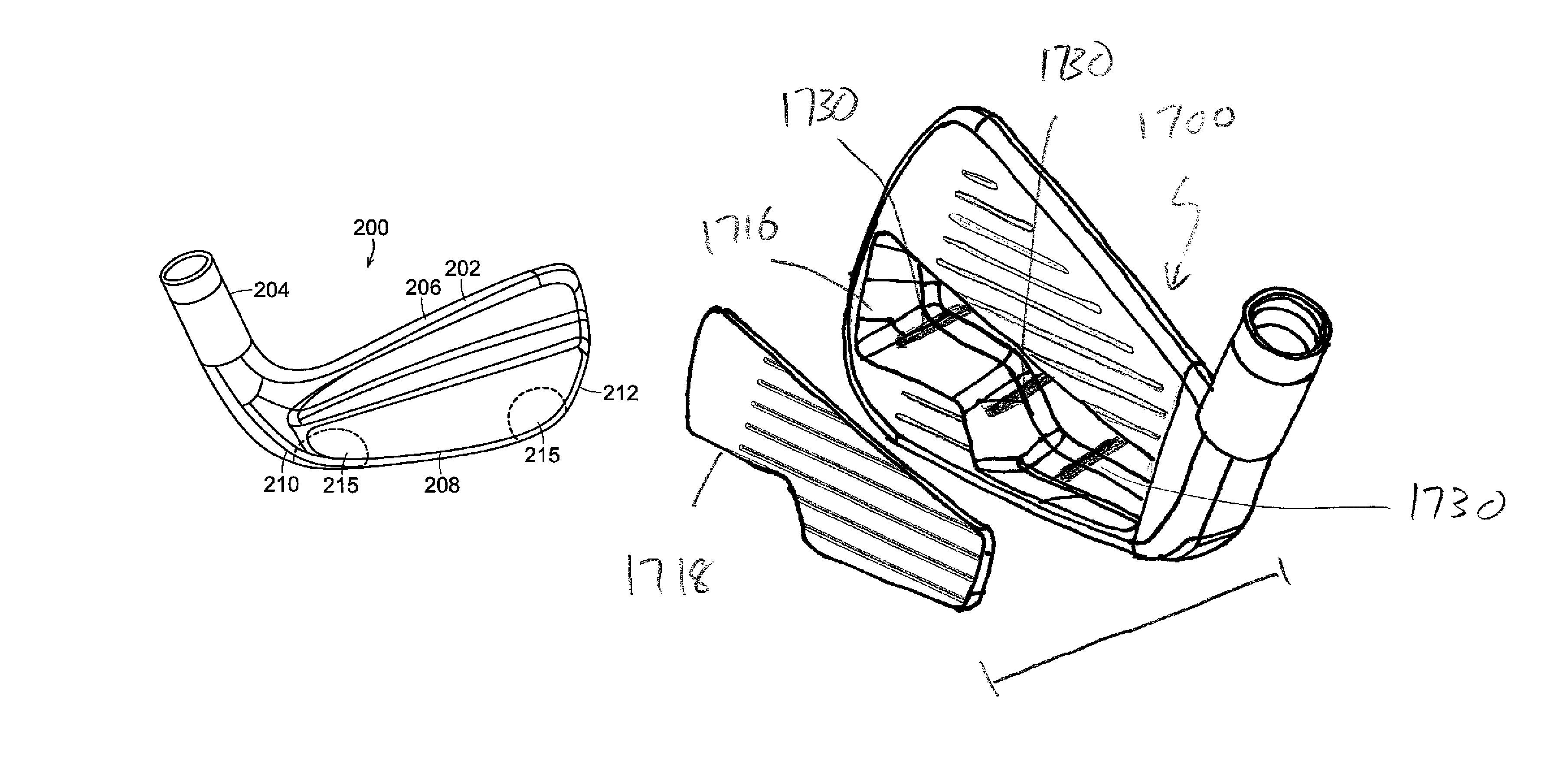

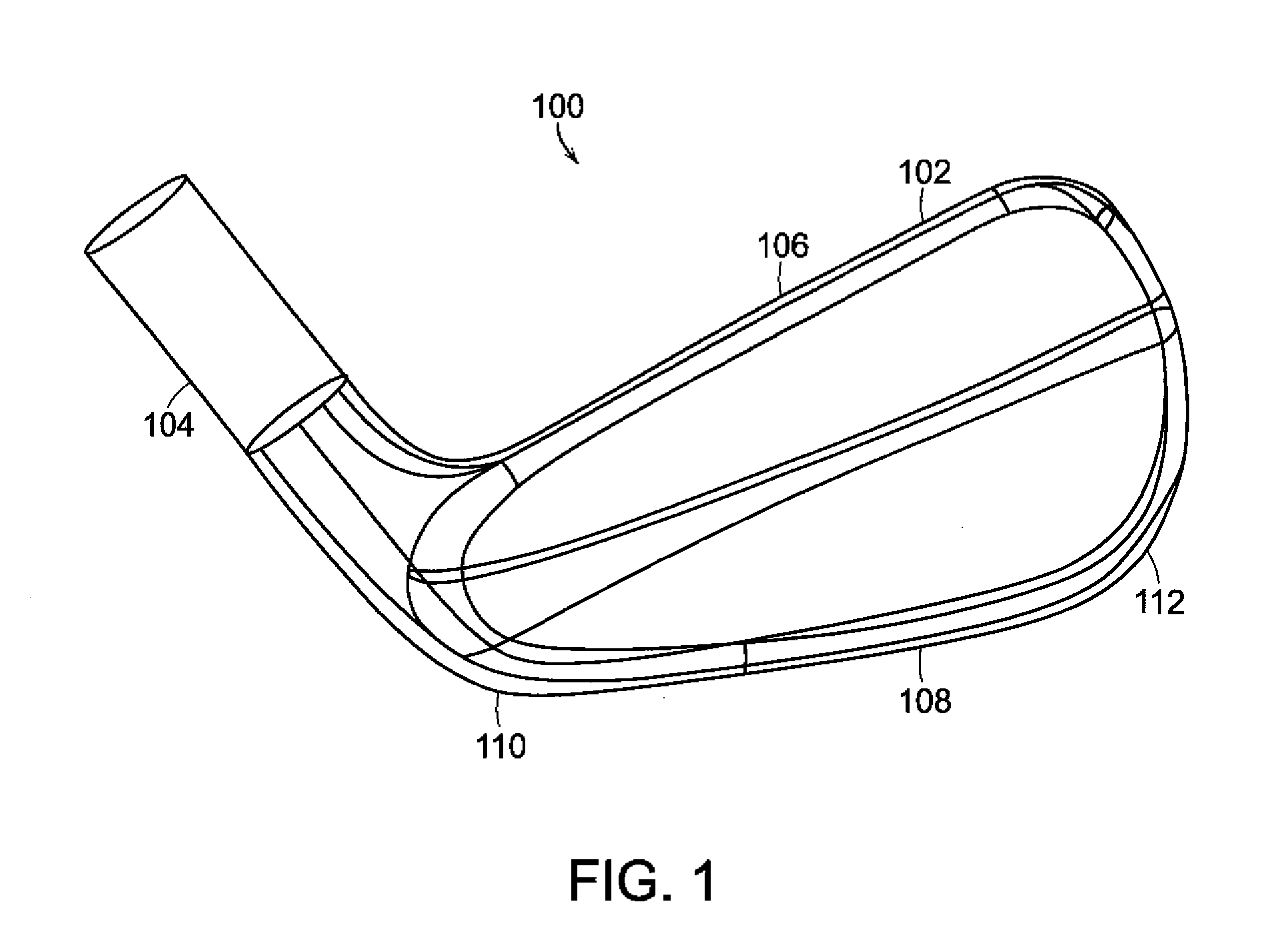

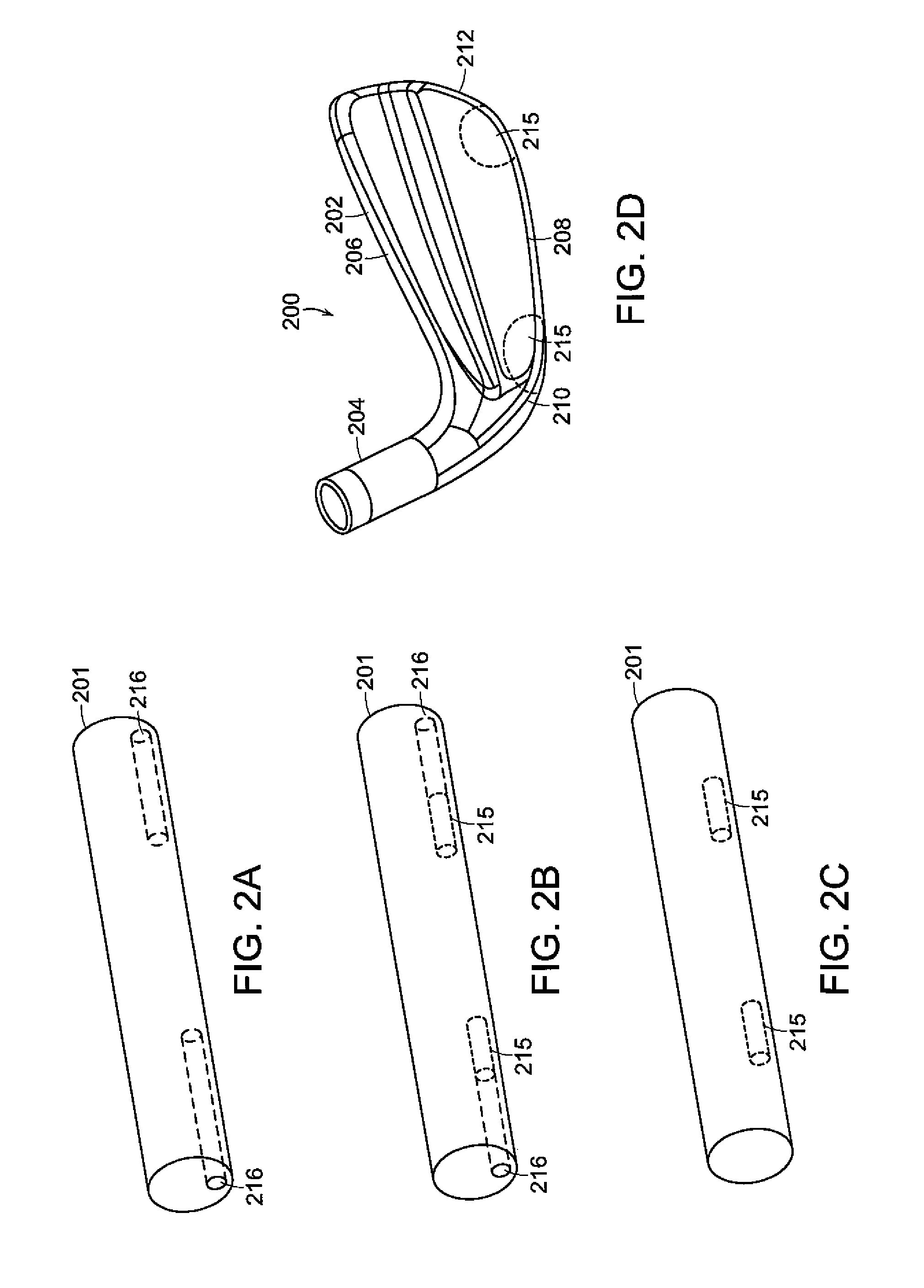

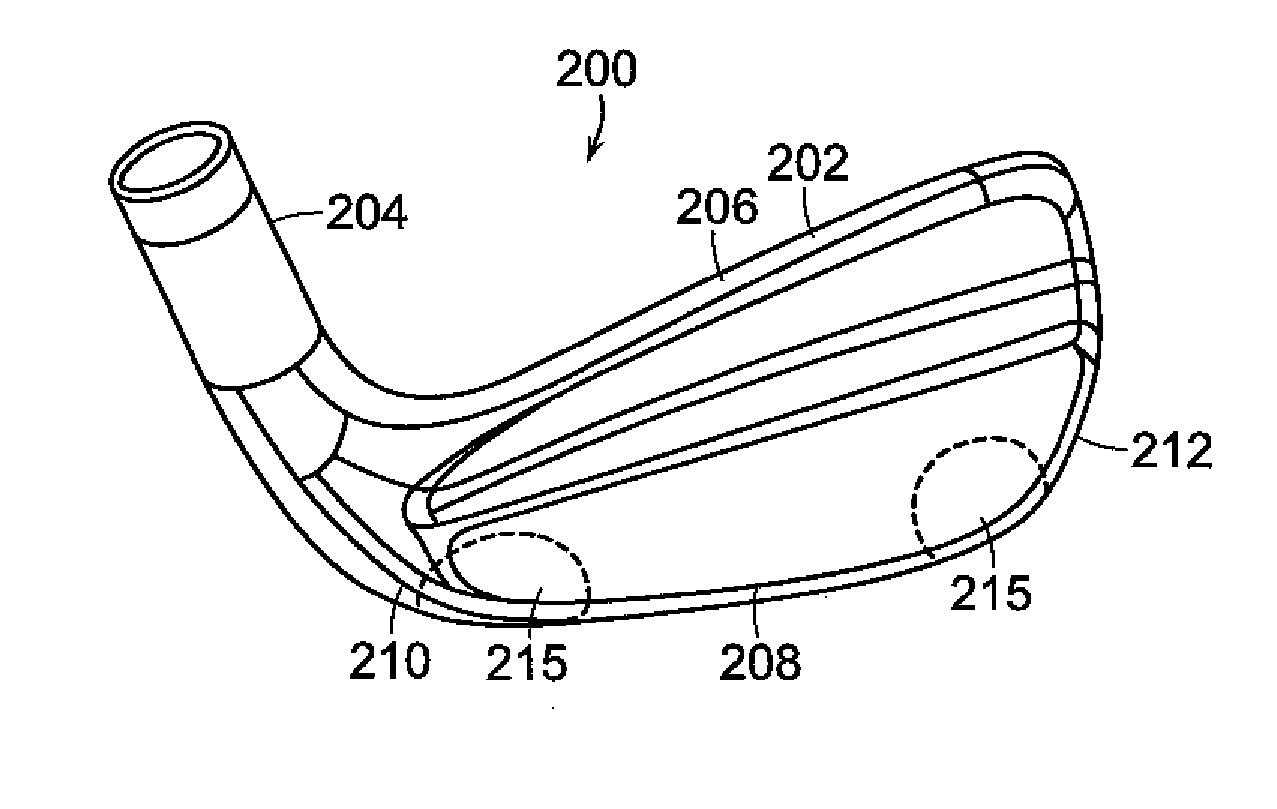

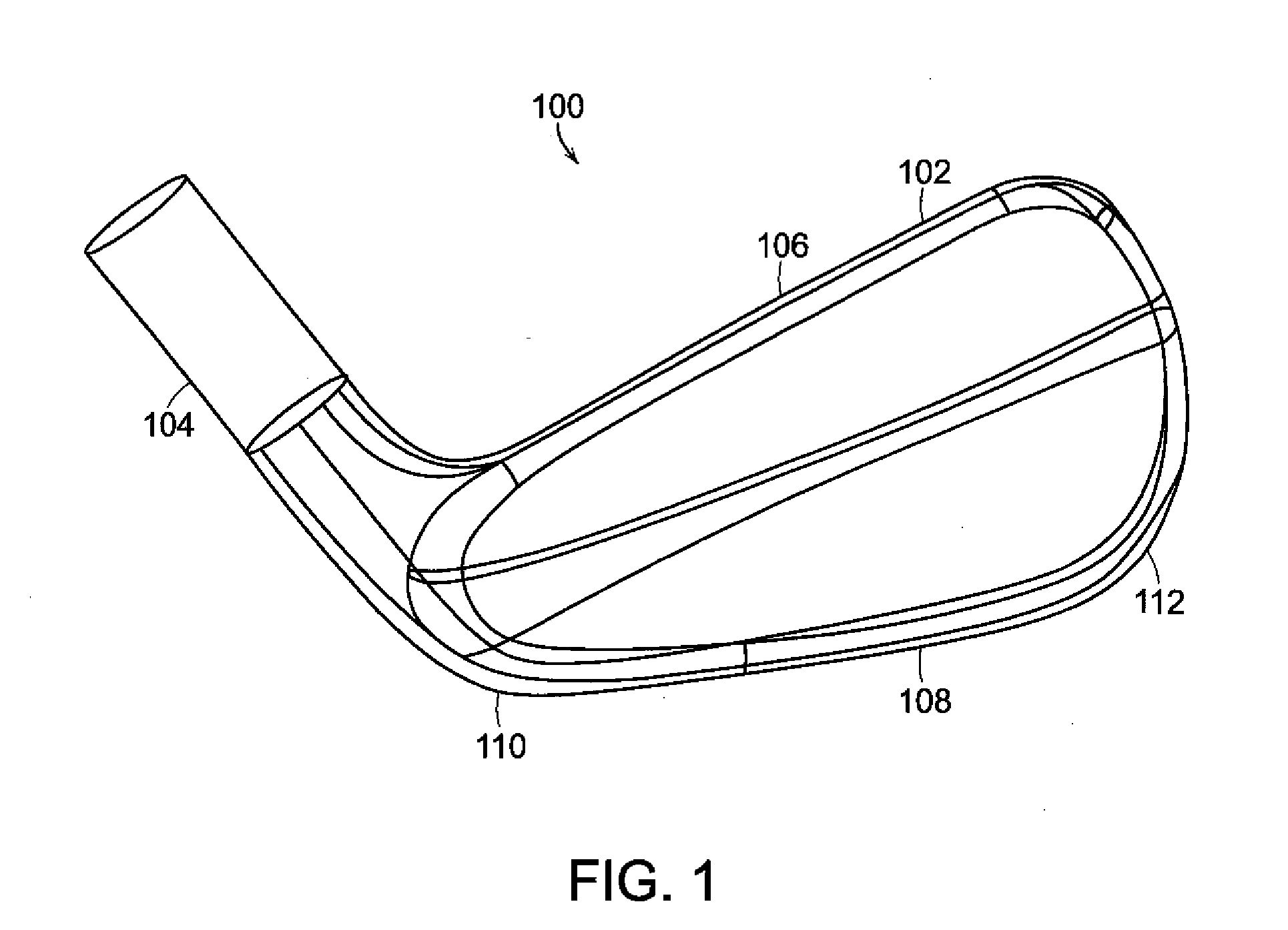

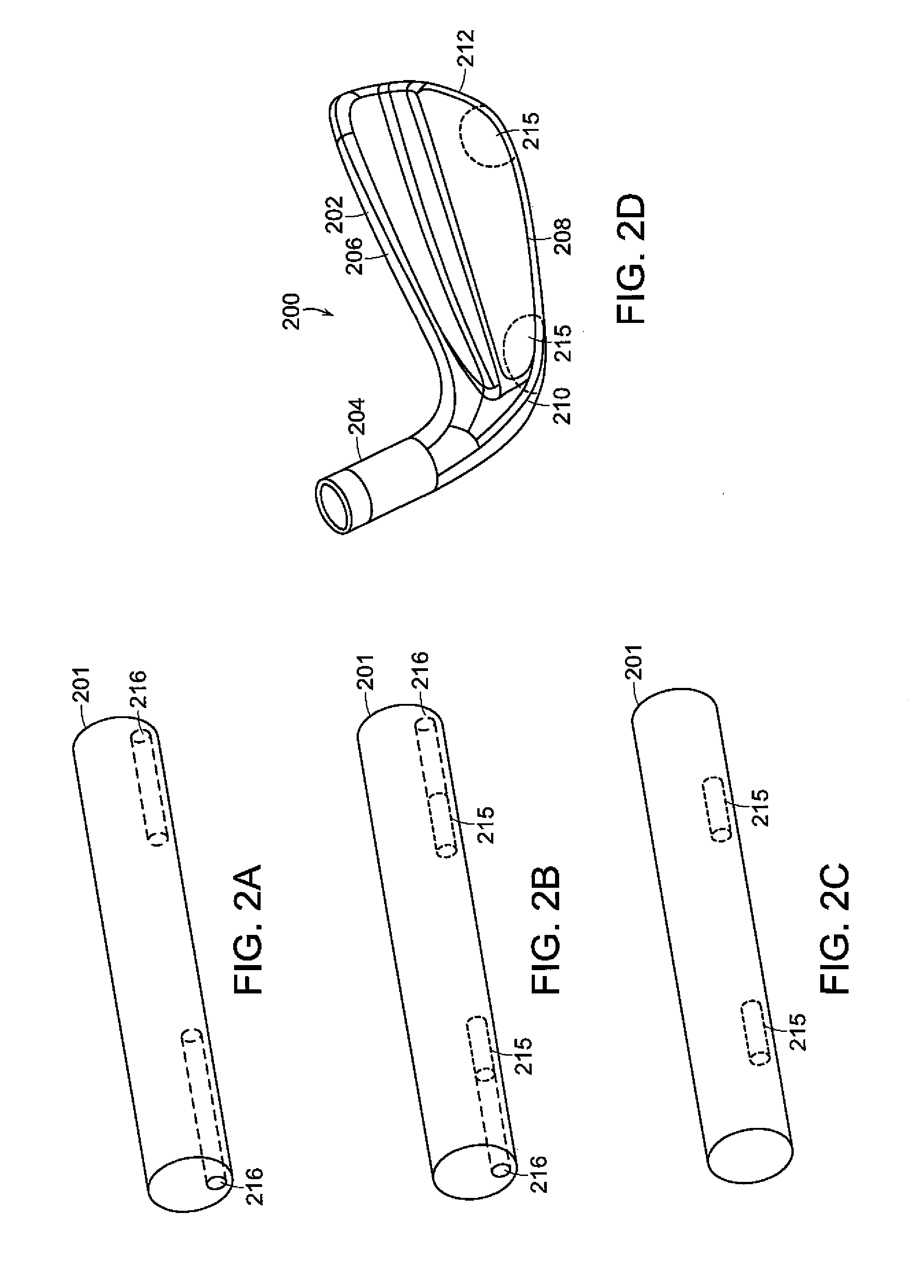

Co-forged golf club head and method of manufacture

A co-forged iron type golf club is disclosed. More specifically, the present invention discloses a co-forged iron type golf club with the body portion made out of a first material and at least one weight adjustment portion monolithically encased within the body portion of the co-forged iron type golf club head without the need for secondary attachment or machining operations. The present invention creates of an iron type golf club head from a pre-form billet that already contains two or more materials before the actual forging process resulting in a multi-material golf club head that doesn't require any post manufacturing operations such as machining, welding, swaging, gluing, and the like.

Owner:ACUSHNET CO

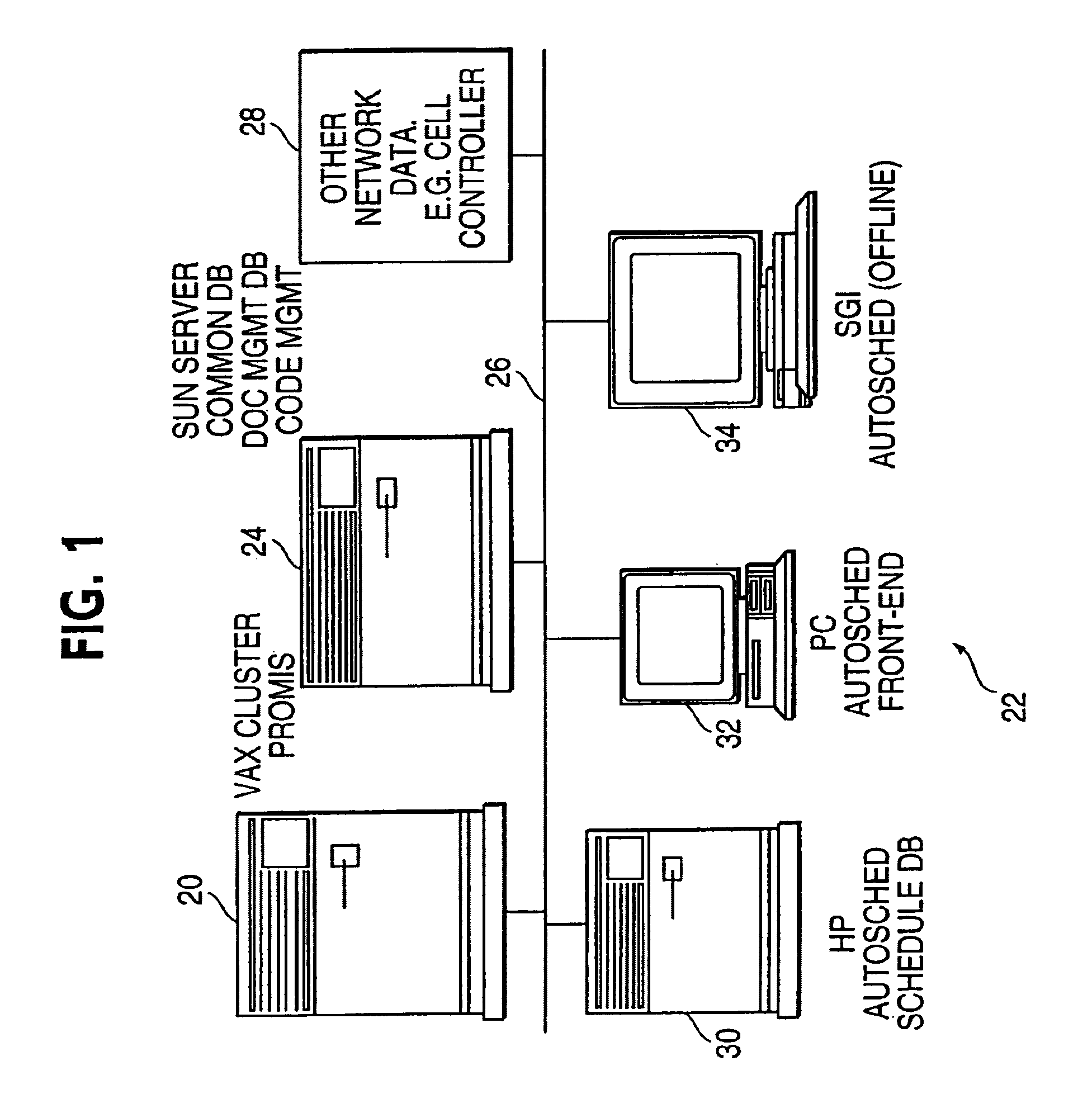

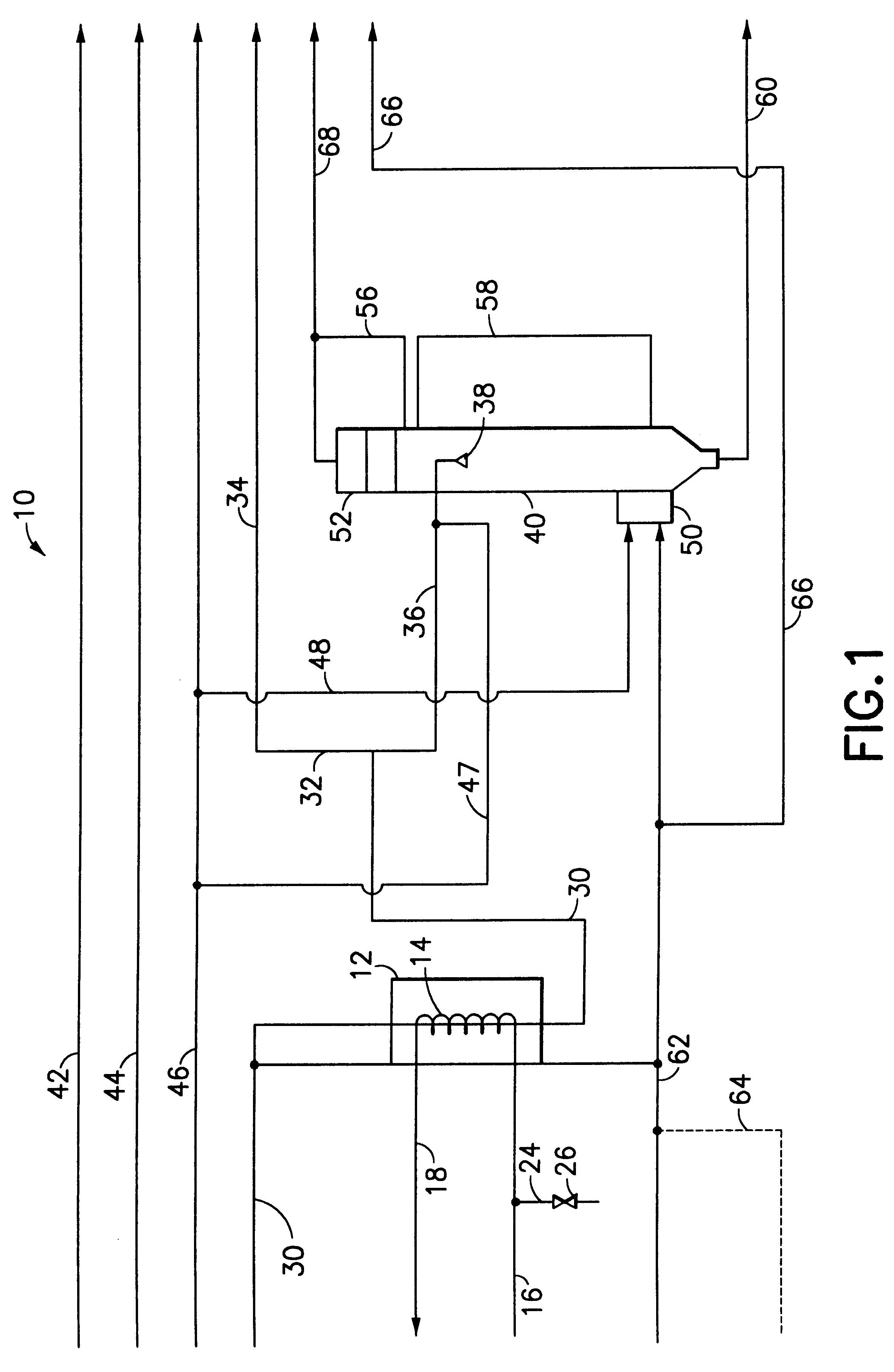

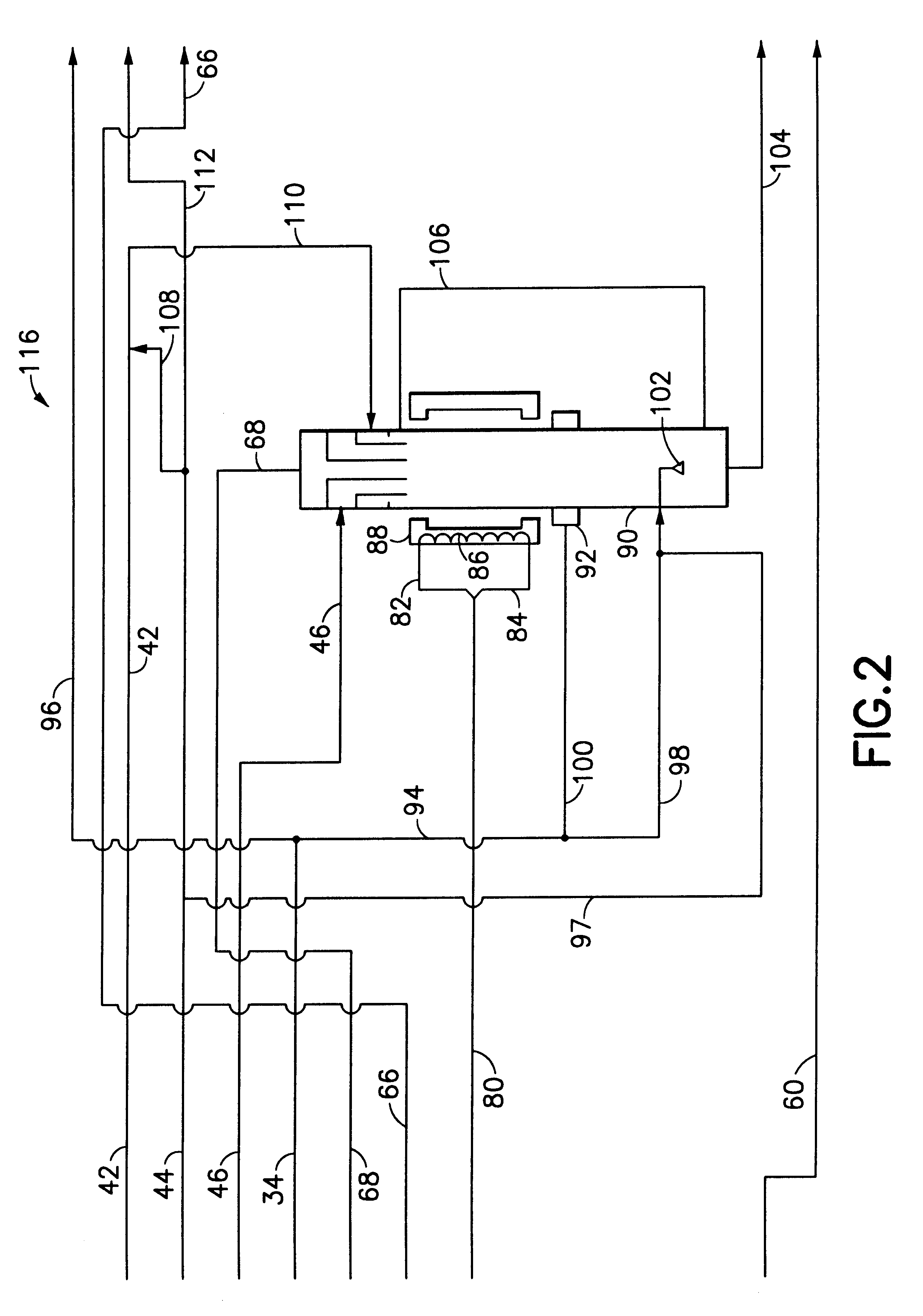

Integrated wafer fabrication production characterization and scheduling system

InactiveUS6889178B1Technology managementTotal factory controlManufacture execution systemWafer fabrication

An integrated wafer fab production scheduling and simulation system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated system provides manufacturers with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on an actual production system. Furthermore, simulation models are used to create short-term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, and real time lot move updates.

Owner:SONY CORP +1

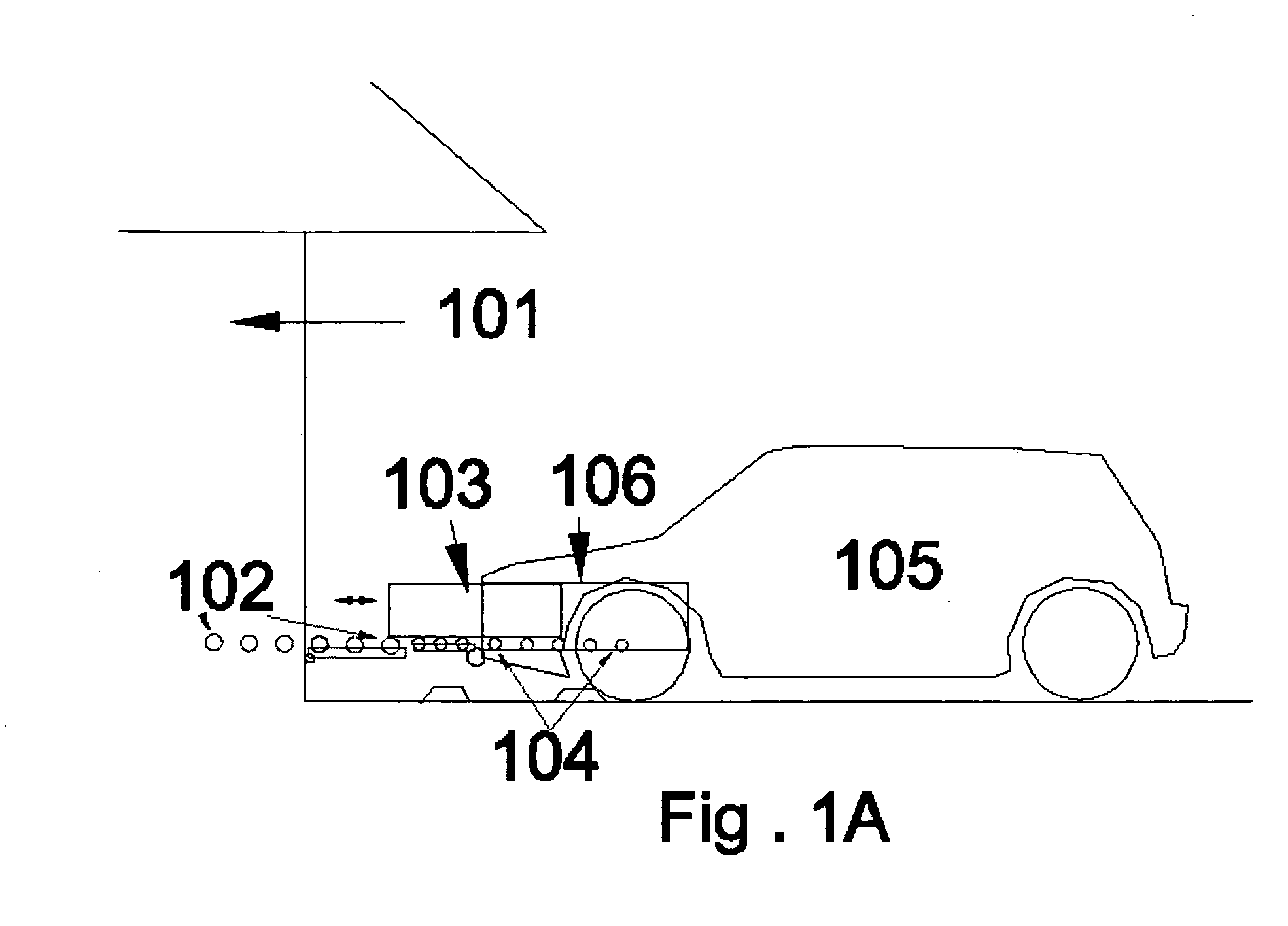

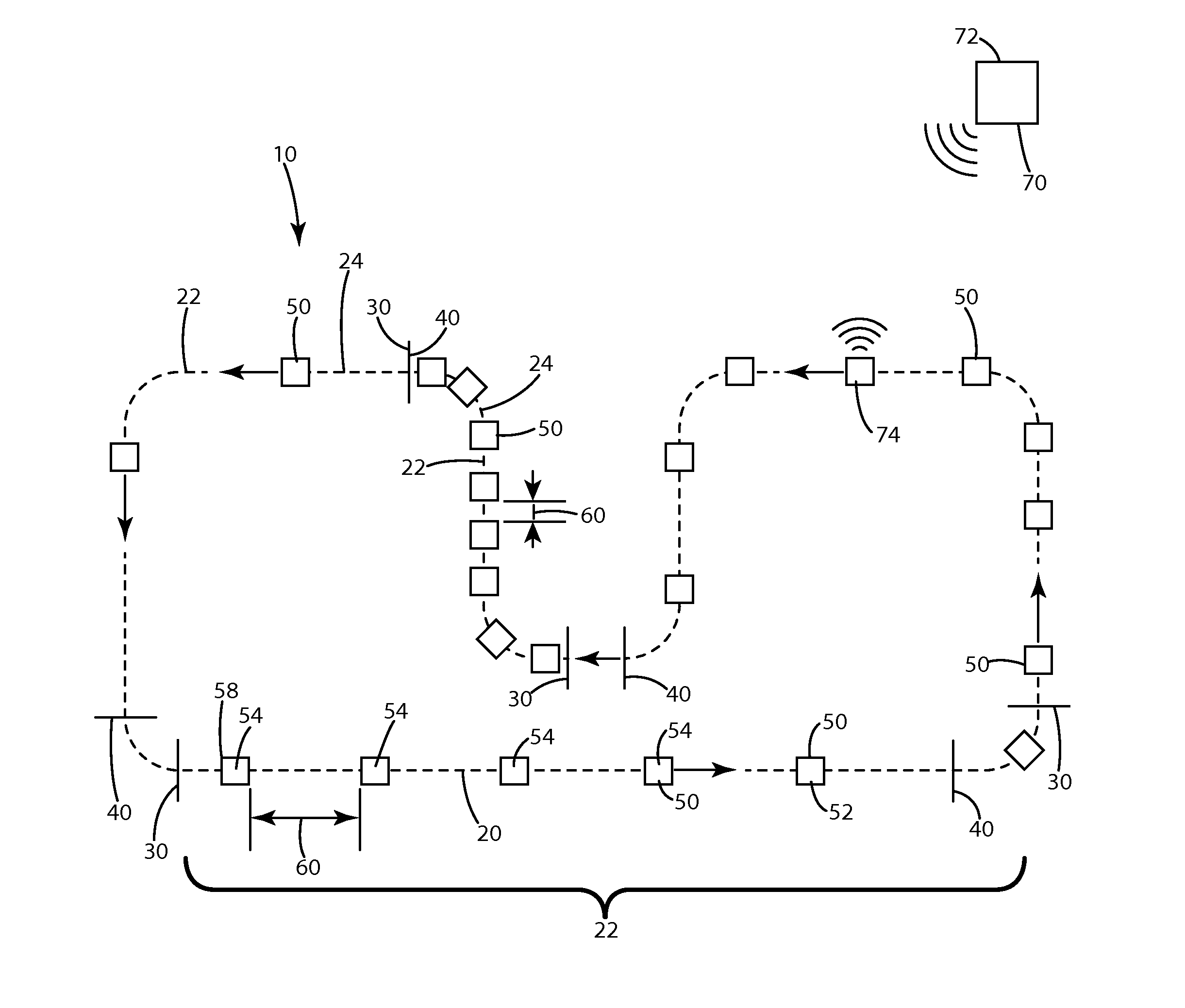

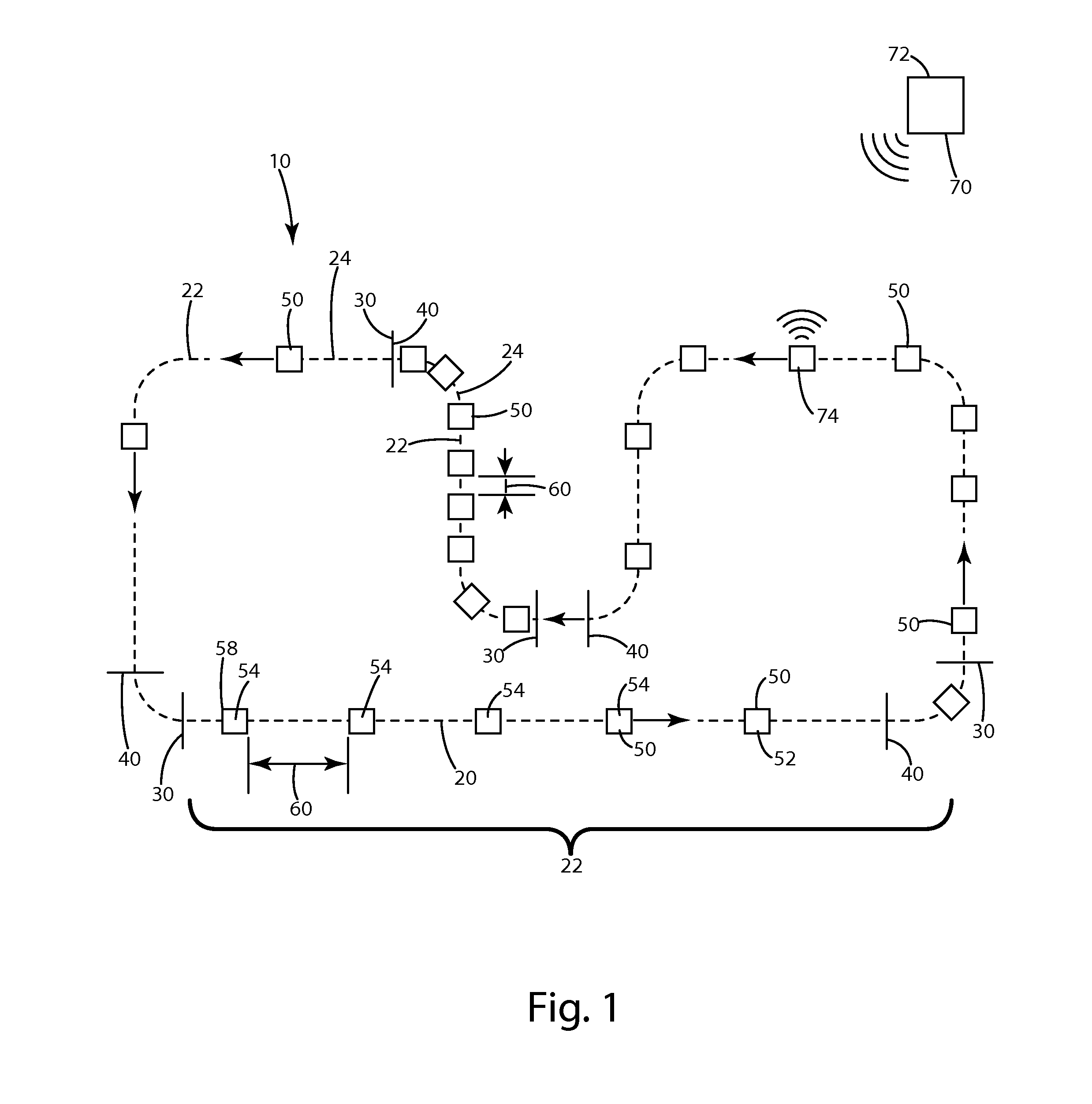

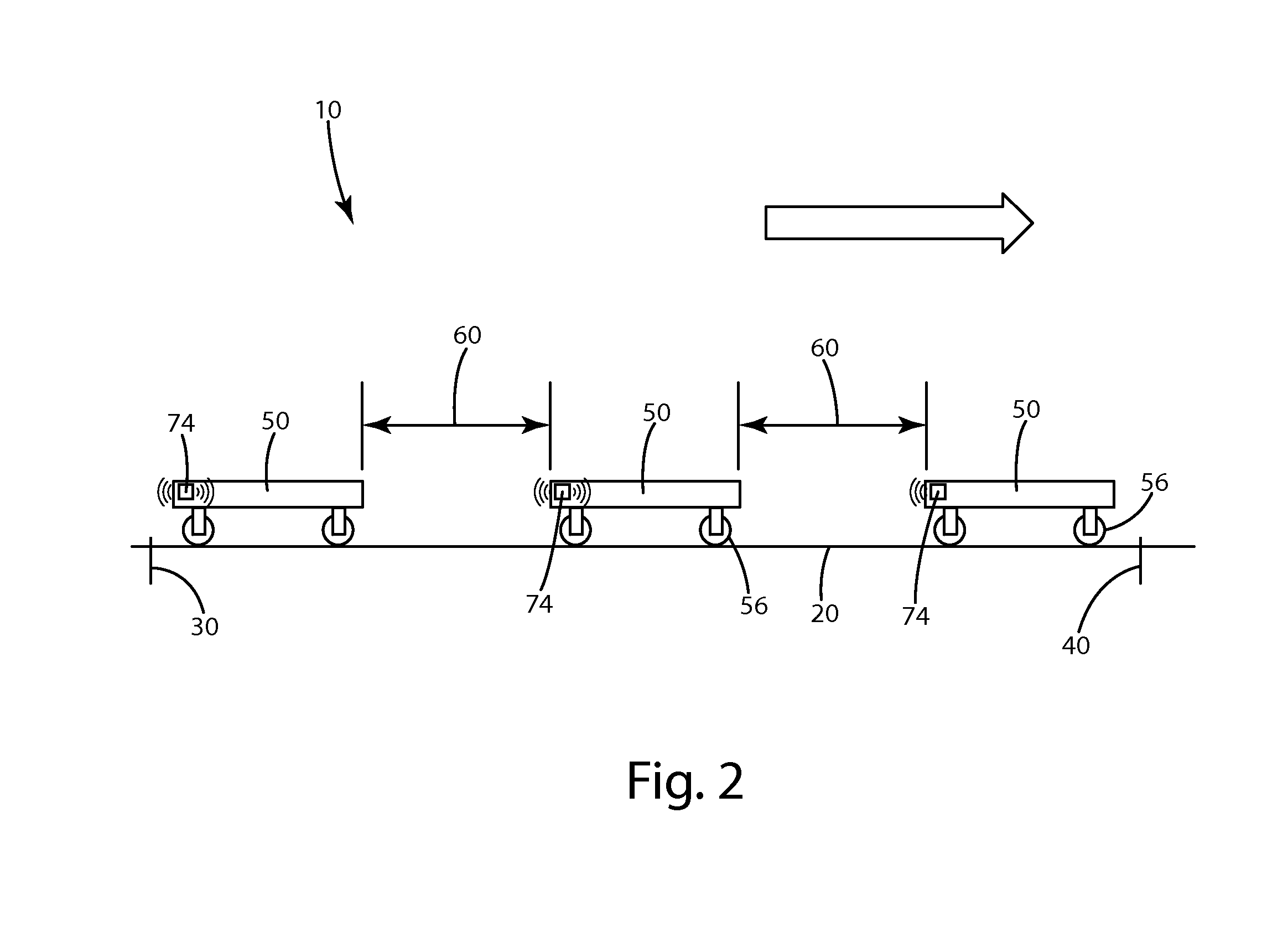

Method of material handling with automatic guided vehicles

A system and method of automatic guided vehicles (AGVs) that is capable of providing synchronized travel along a line or path while maintaining a desired takt time such that regular manufacturing operations may be performed to material or workpieces on the vehicle without the need for a traditional conveyor systems.

Owner:JERVIS B WEBB INT CO

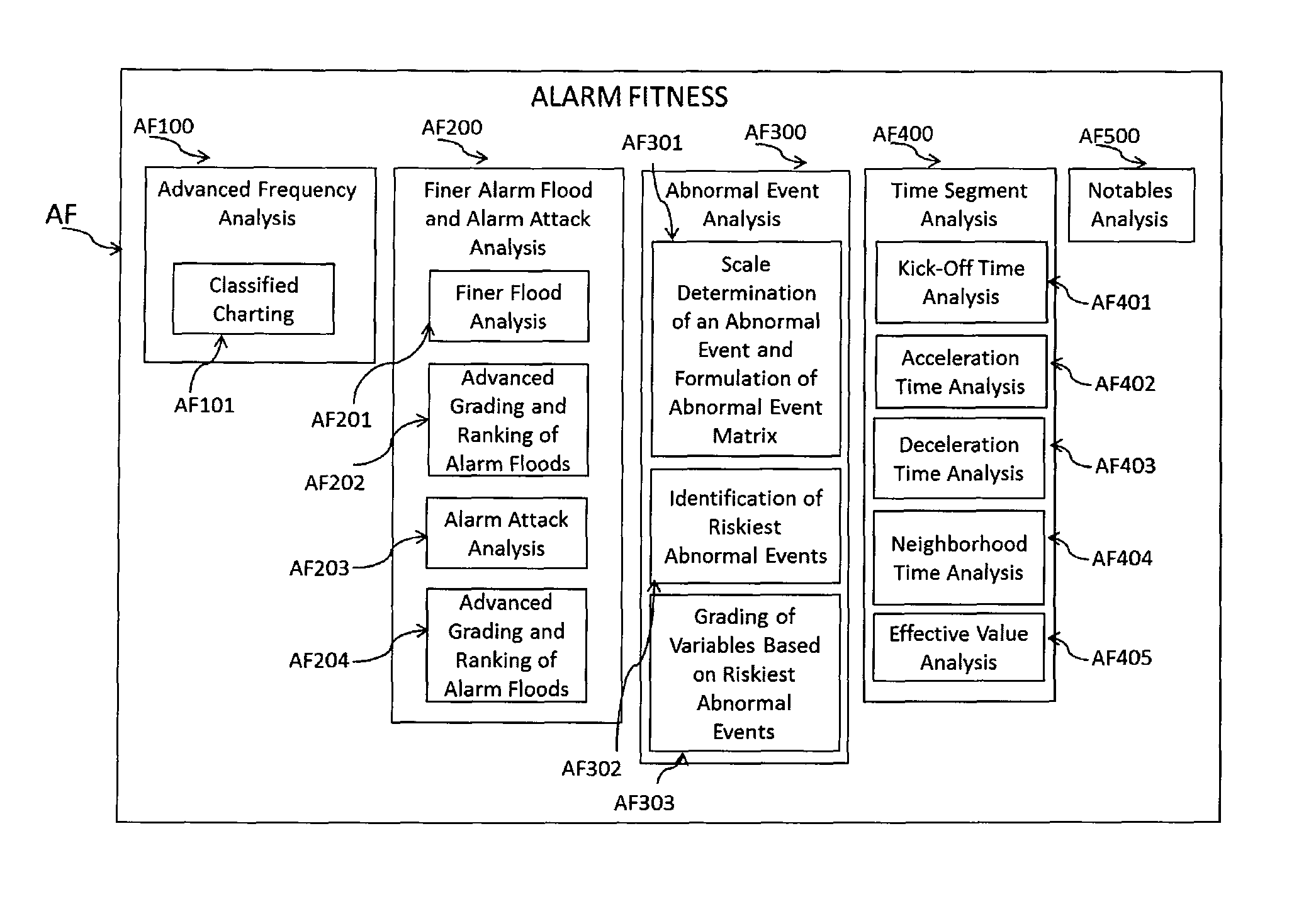

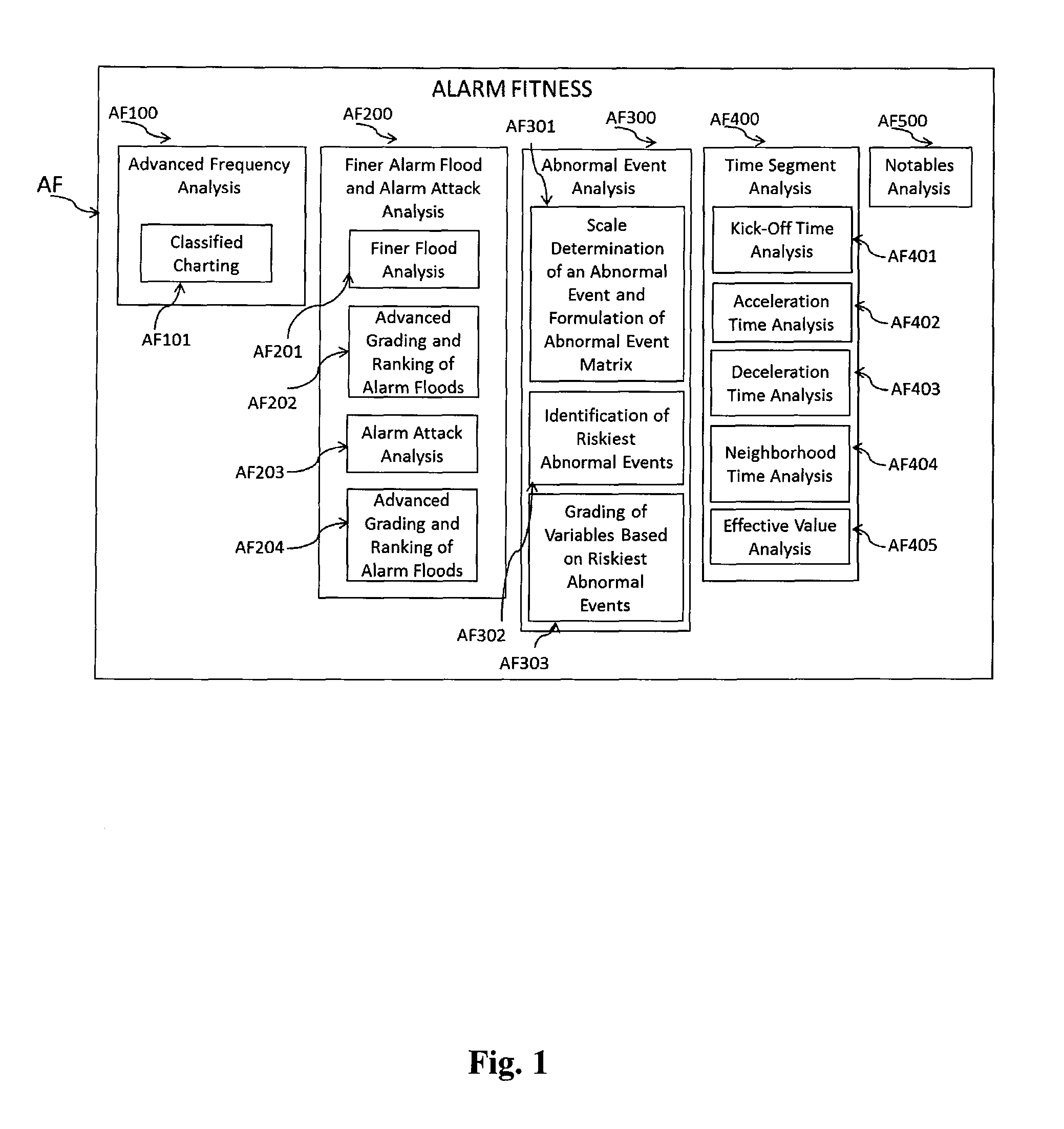

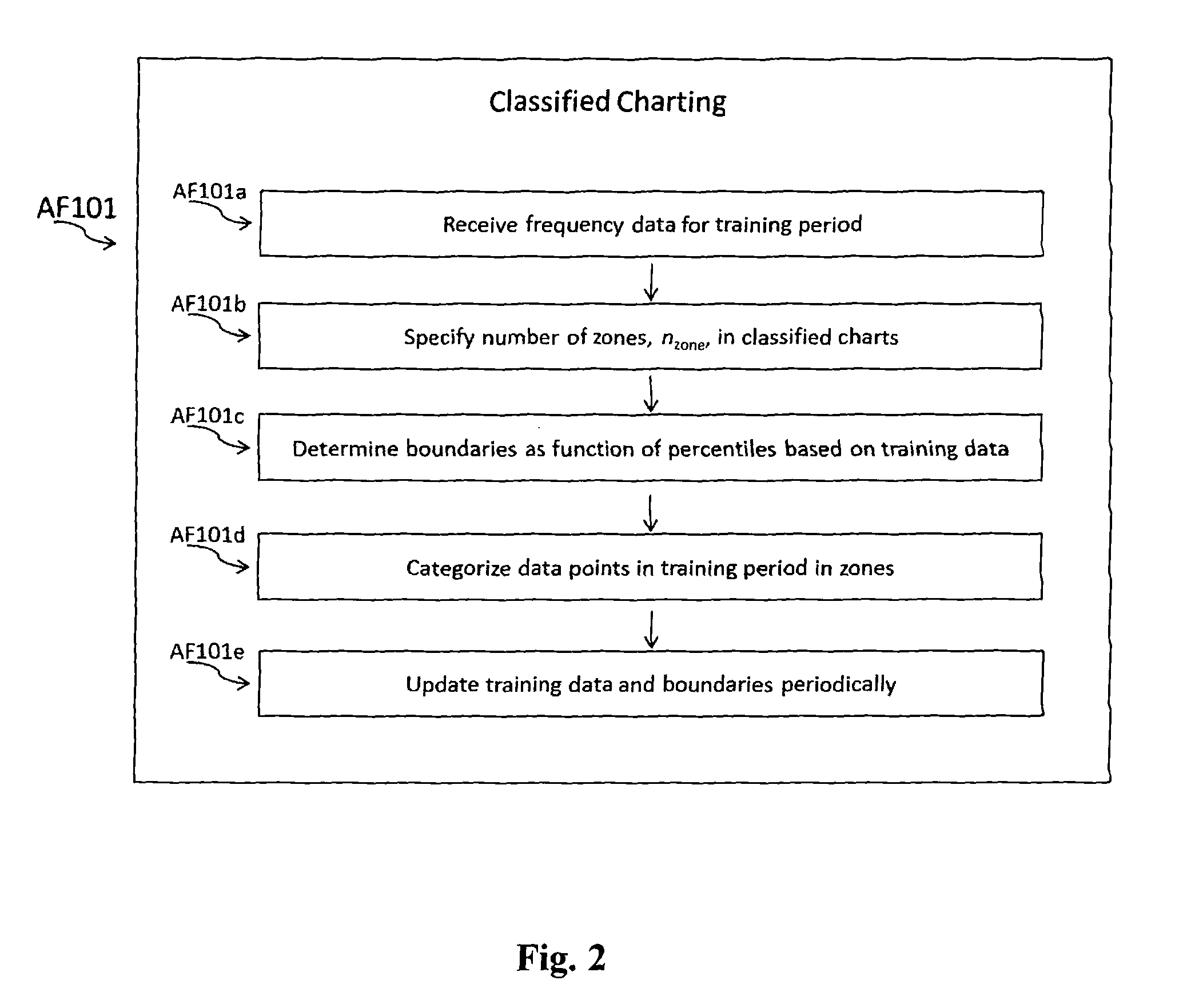

Dynamic prediction of risk levels for manufacturing operations through leading risk indicators

ActiveUS20130063264A1Raise the possibilityImprove securityTesting/monitoring control systemsAlarmsRisk levelDisposal waste

Provided are methodologies to properly assess and manage operational risks at operations sites, e.g., a manufacturing, production or processing facility, such as a refinery, chemical plant, fluid-catalytic-cracking units, or nuclear energy plant, or a biological or waste management facility, airport or even financial institutions, or at any facility in which operations are often accompanied by risk associated with many high-probability, low-consequence events, often resulting in near-misses. In some operations, processes are monitored by alarms, but the invention operates on either process data or alarm data. The methods are based upon measurement of one or more variables, and / or utilization and management of the concept of “hidden process near-miss(es)” to identify a change or escalation, if any, in probability of occurrence of an adverse incident. The methodologies combine a plurality of subsets (also useful independently) of dynamically calculated leading risk indicators for dynamic risk management.

Owner:NEAR MISS MANAGEMENT

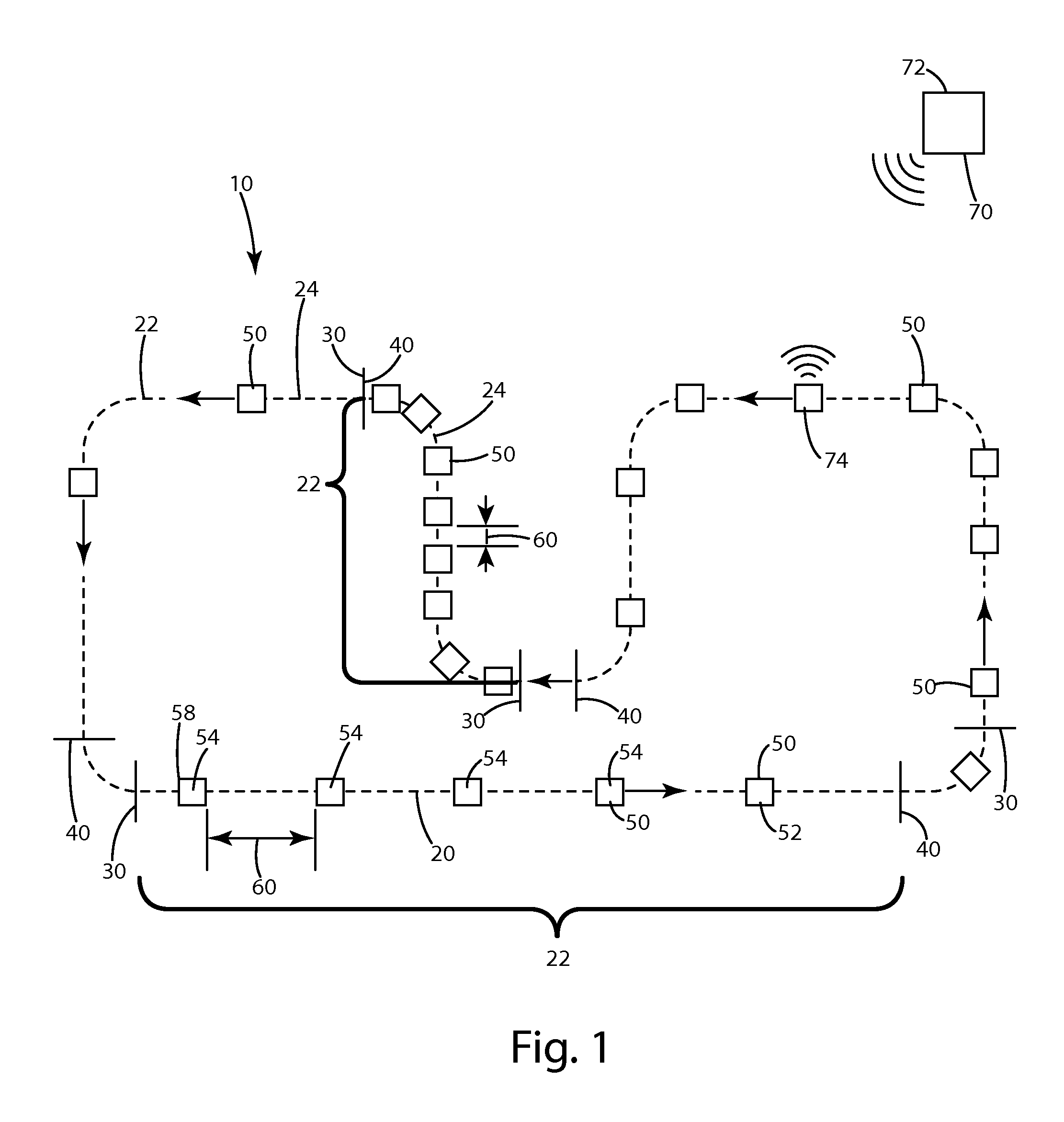

Method of material handling with automatic guided vehicles

ActiveUS20140172223A1Clear distance traveledDecrease in paceVehicle position/course/altitude controlDistance measurementAutomated guided vehicleManufacturing operations

A system and method of automatic guided vehicles that are capable of providing synchronized travel along a line or path such that regular manufacturing operations may be performed to material or workpieces on the vehicle without the need for a traditional conveyor systems.

Owner:JERVIS B WEBB INT CO

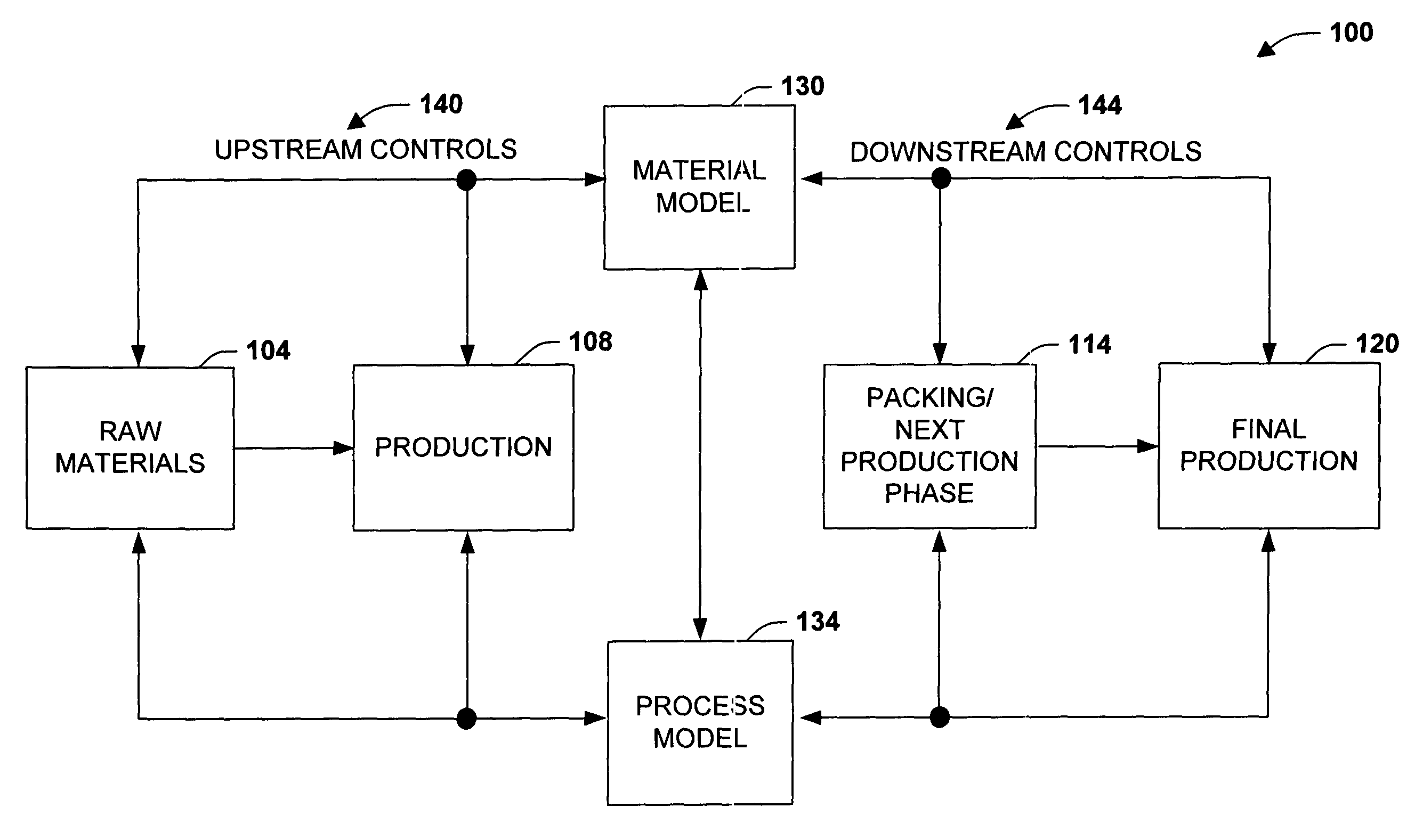

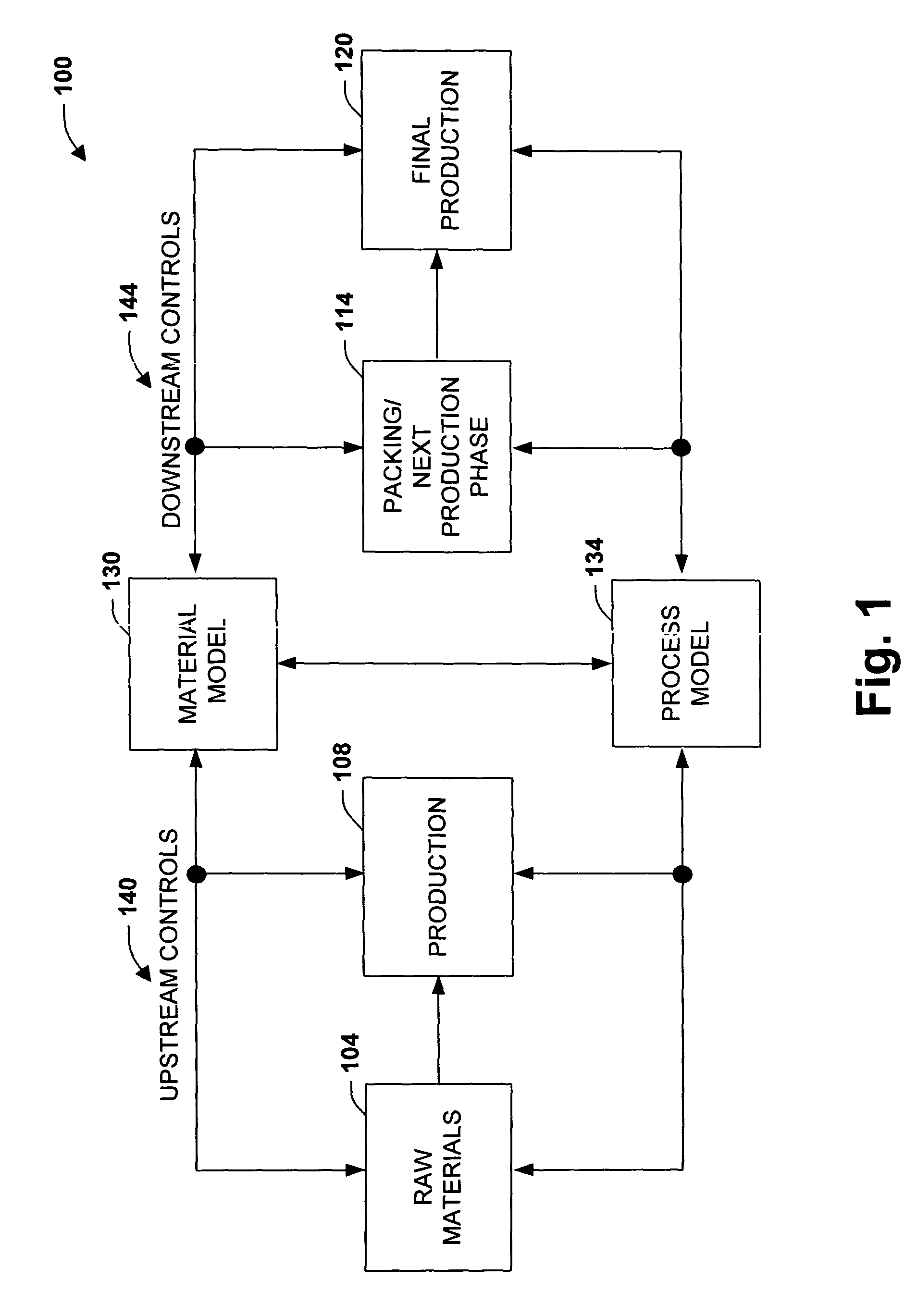

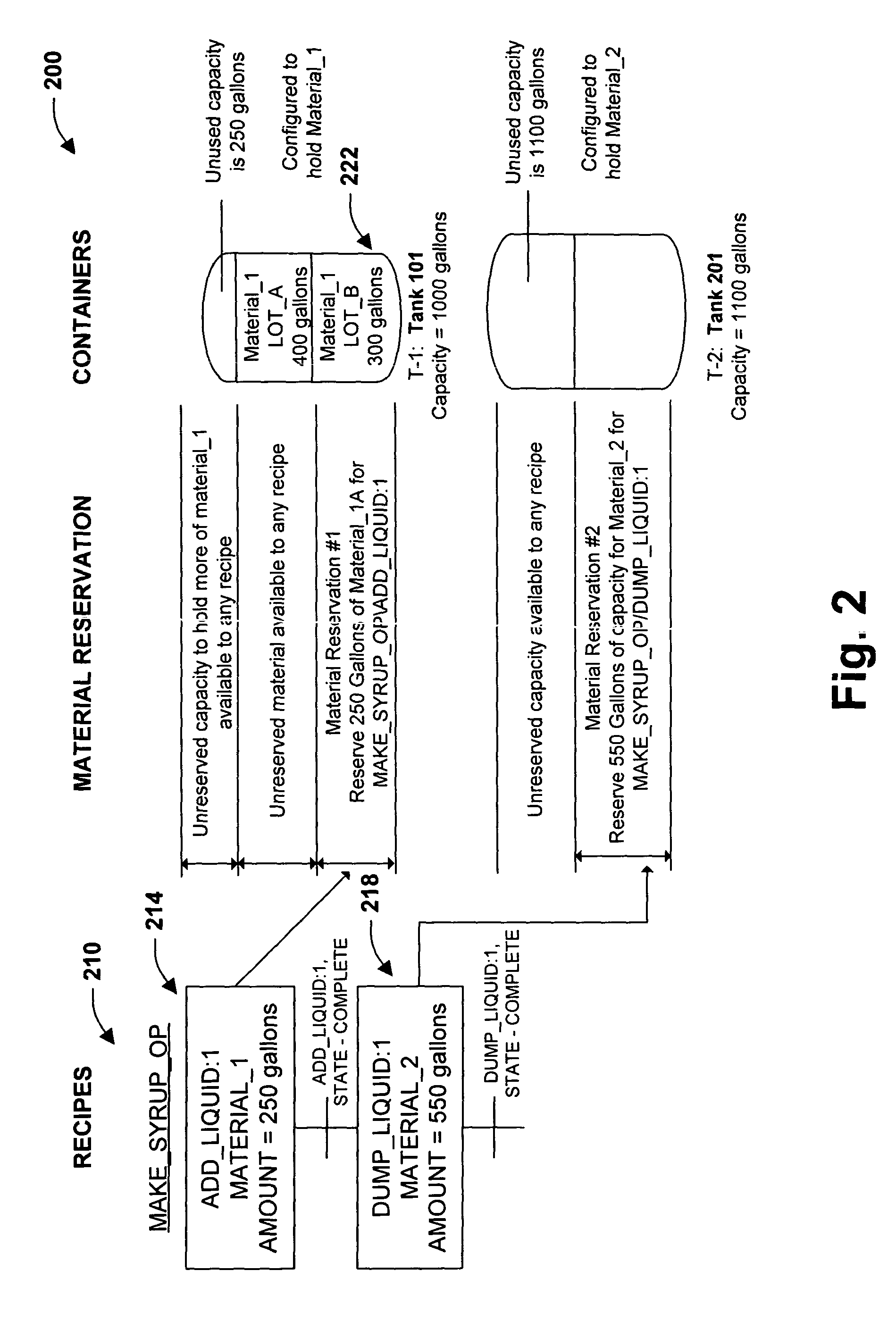

Material reservation distribution system and method

InactiveUS20050065626A1Easy to optimizeEfficient managementProgramme controlHand manipulated computer devicesBatch processingManufacturing operations

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

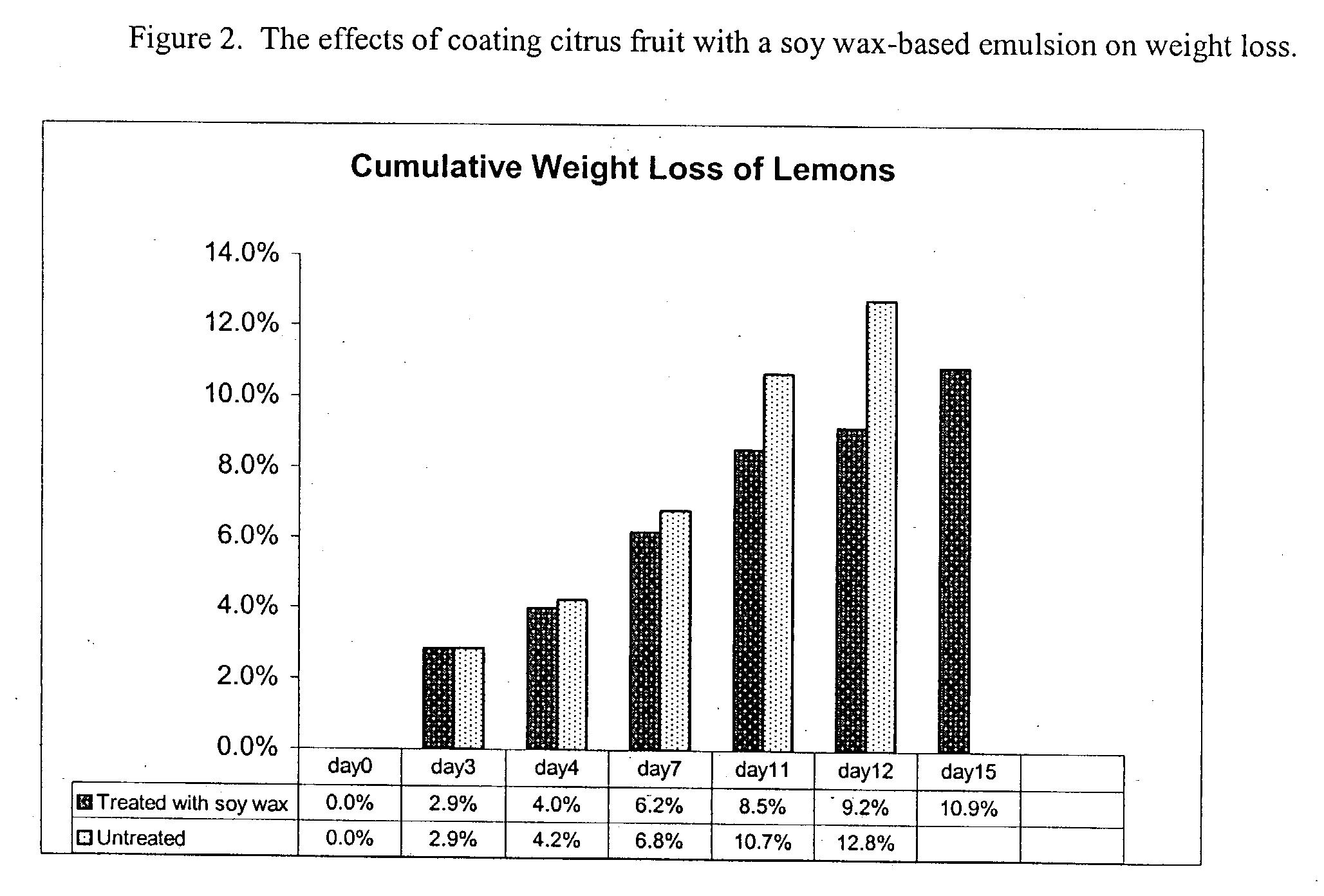

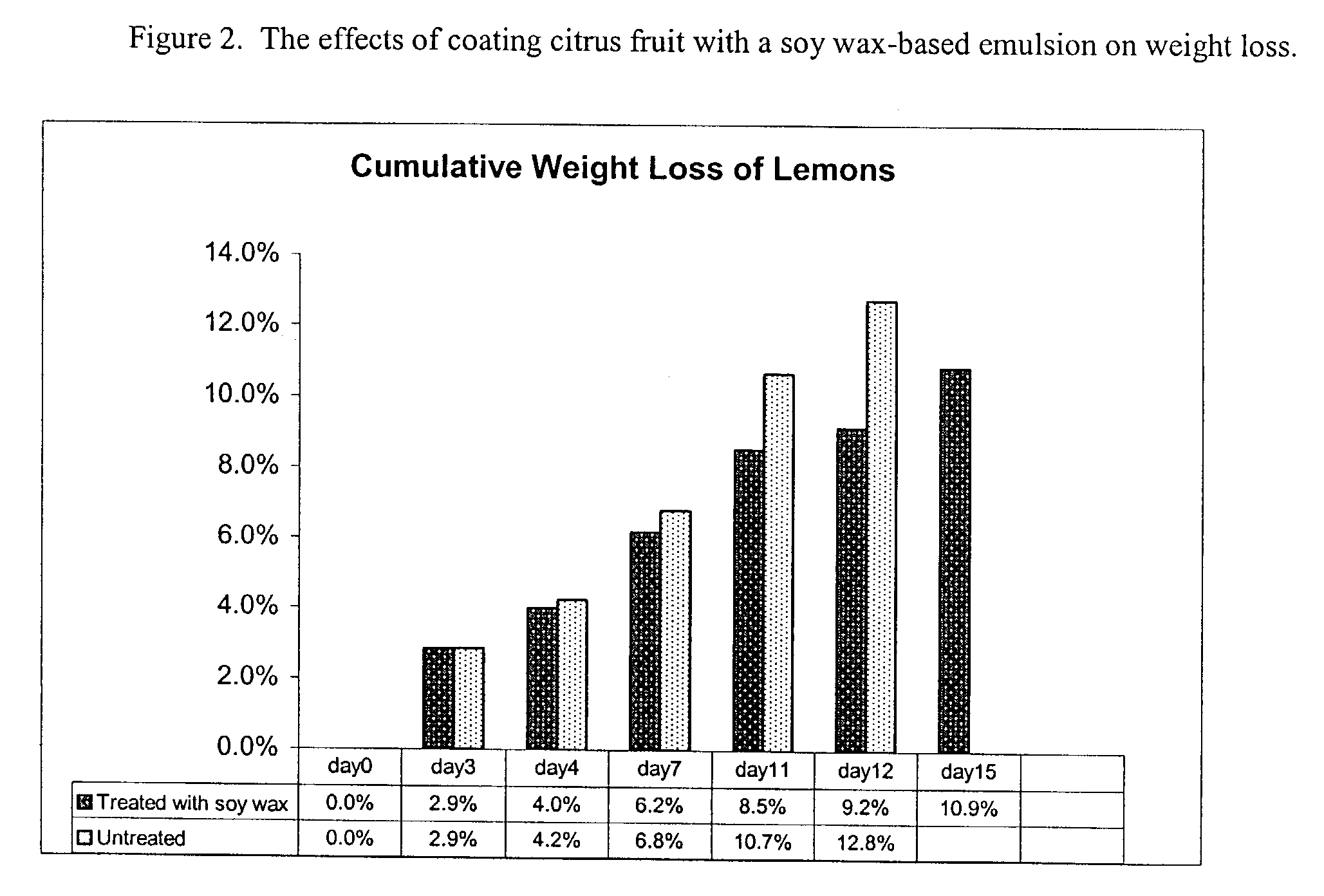

Novel wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid or ricinoleic acid. The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:MARCUS OIL & CHEM

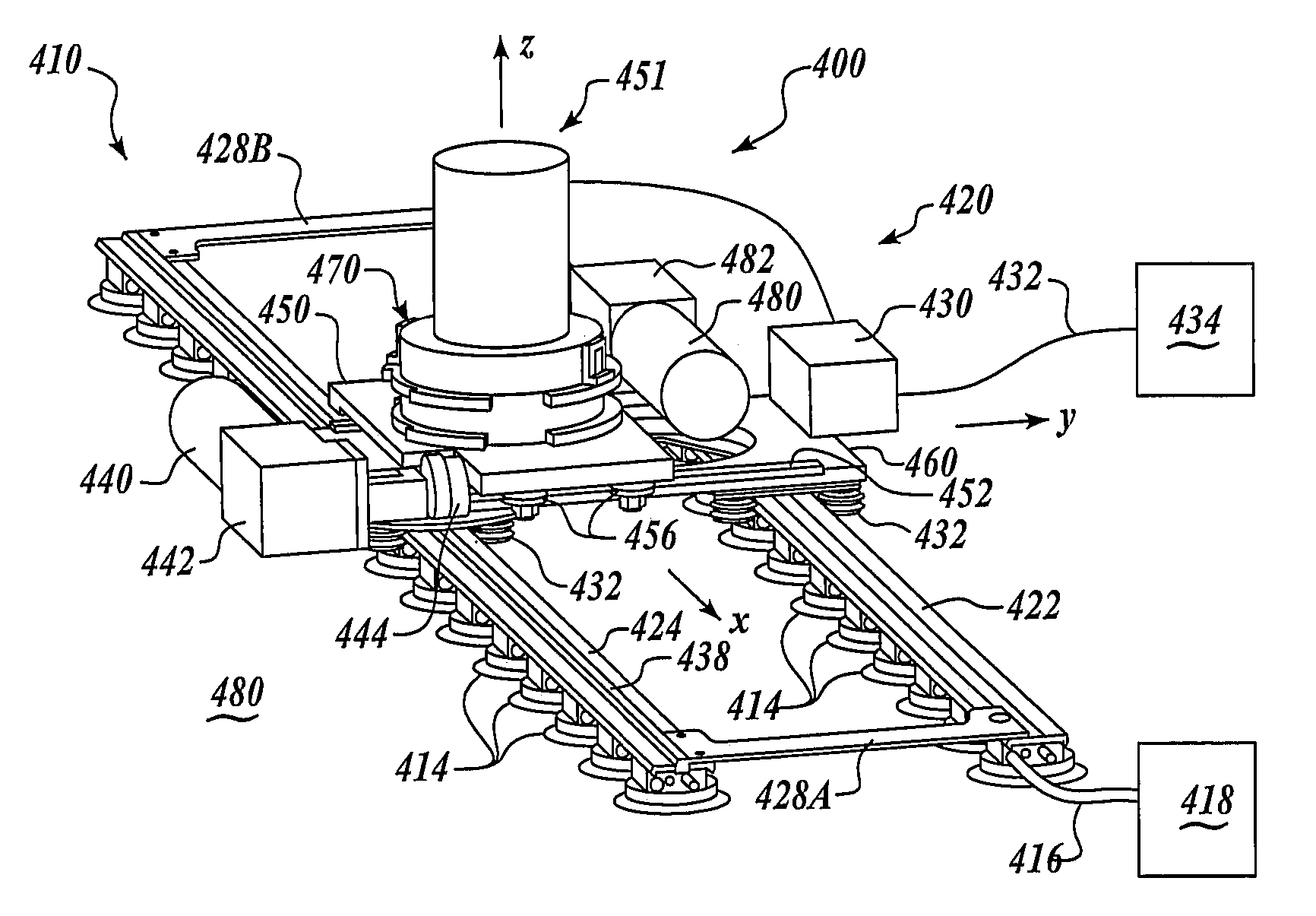

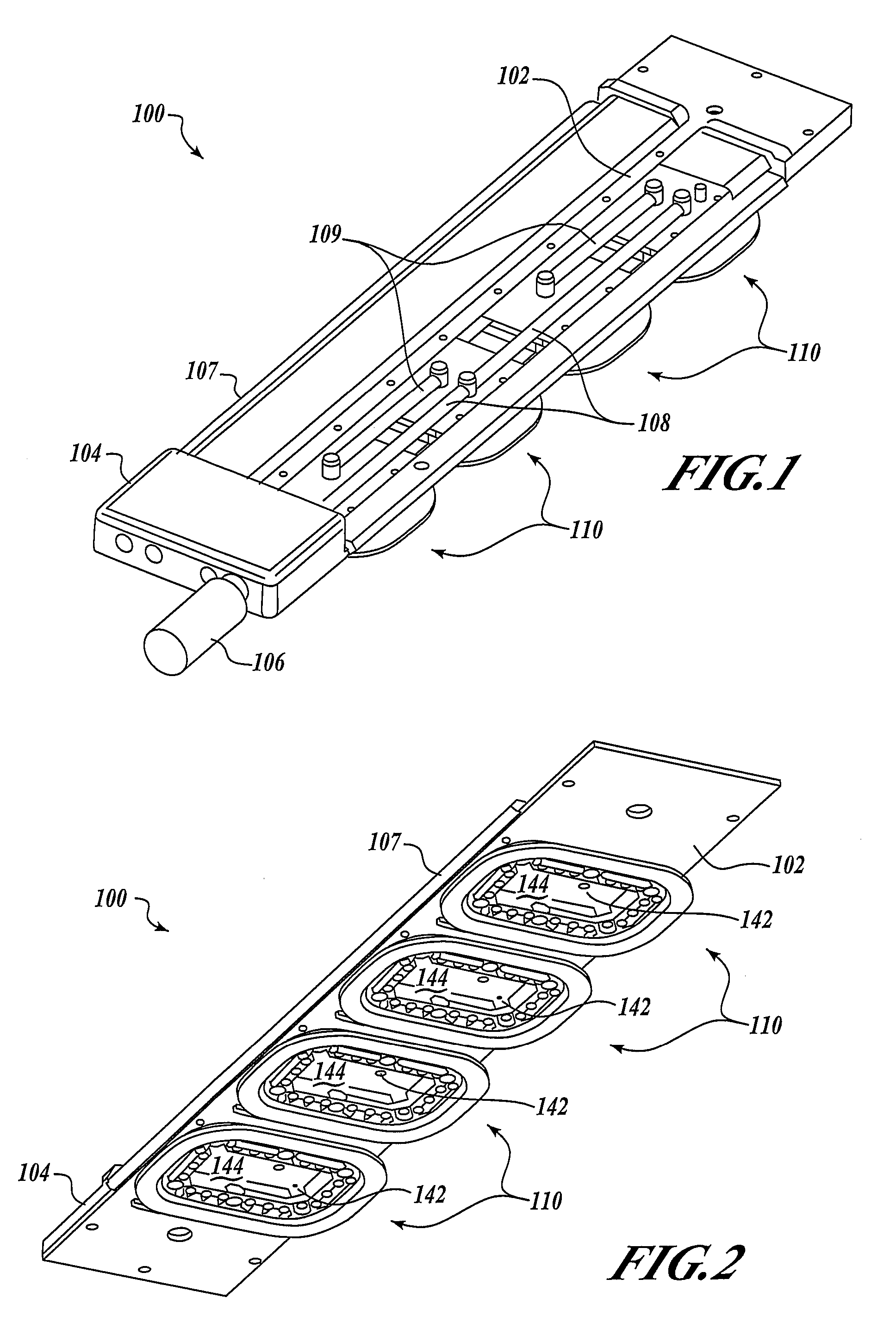

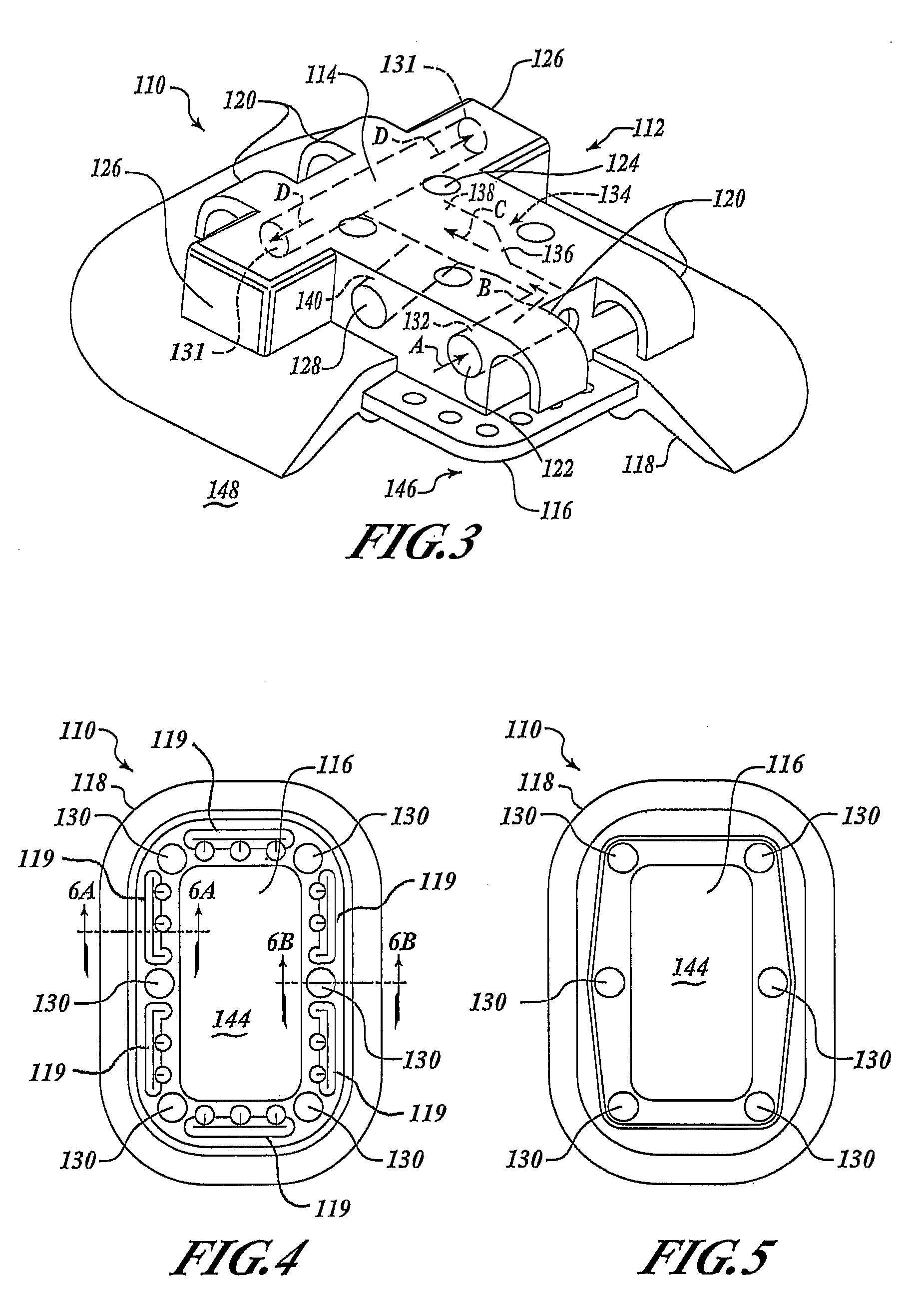

Apparatus and methods for manufacturing operations

ActiveUS7406758B2Improve efficiencyImprove throughputDrilling/boring measurement devicesThread cutting machinesEngineeringManufacturing operations

Apparatus and methods for manufacturing operations are disclosed. In one embodiment, a vacuum cup assembly includes a housing having a vacuum generator formed therein, and a compliant sealing member coupled to the housing. The vacuum generator is coupleable to a source of pressurized fluid and is adapted to generate a reduced pressure region. The sealing member forms an enclosable region in fluid communication with the reduced pressure region. In another embodiment, a method of performing a manufacturing operation includes installing a coordinating pin into an indexing hole, the coordinating pin including a quantum of indexing information. The quantum of indexing information is sensed, and a manufacturing operation is performed based at least partially on the quantum of indexing information.

Owner:THE BOEING CO

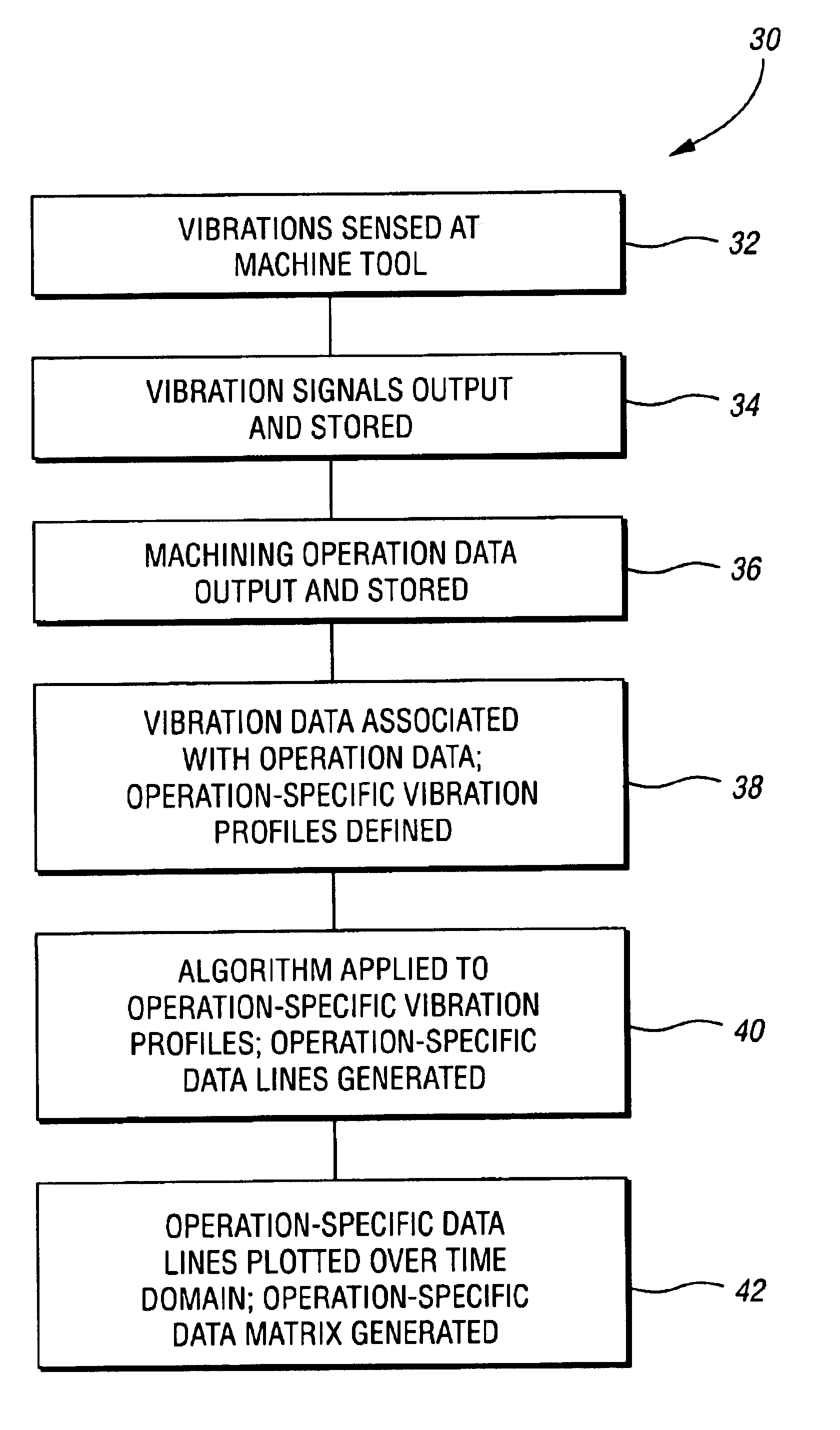

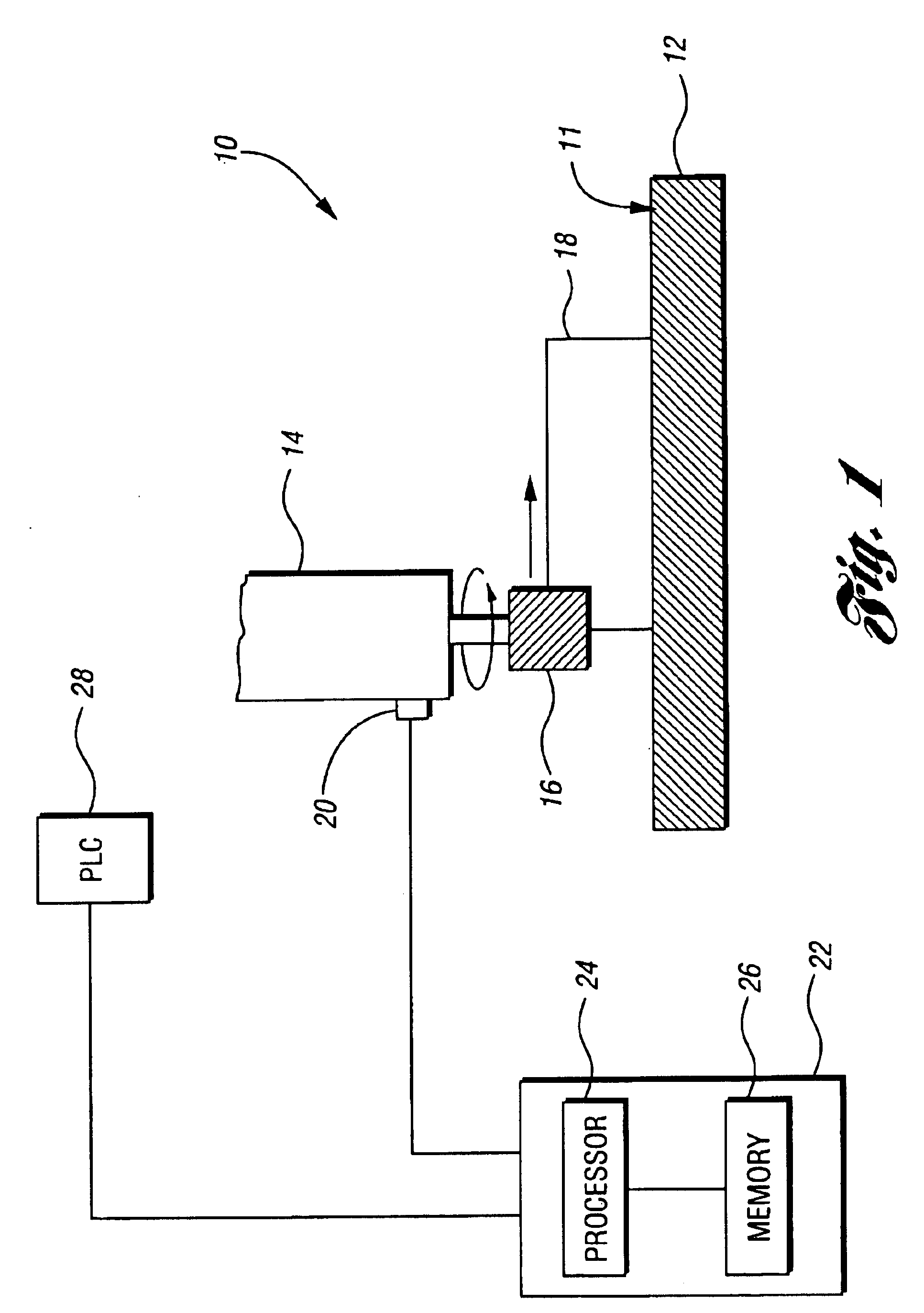

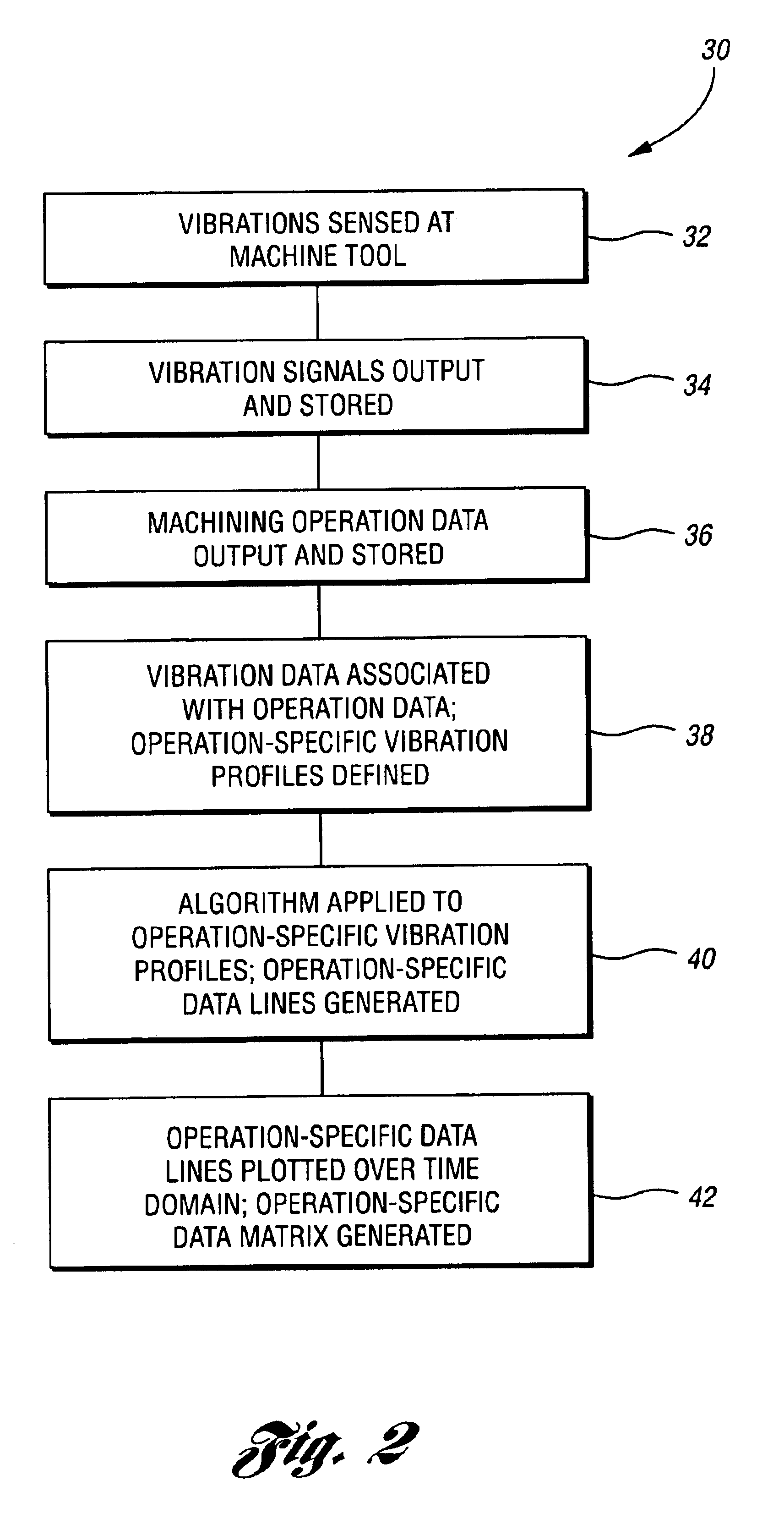

System and method for machining data management

InactiveUS6845340B2Facilitates generation of an operation-specific data matrixEasy retrievalProgramme controlDigital computer detailsTime domainData management

A system and method for machining data management is provided. Vibration and operation data are gathered from a machine tool and sent to a processing unit. The processing unit defines operation-specific vibration profiles, and generates an operation-specific data line for each profile. The data lines are stored in a memory for later retrieval. An output device is used to retrieve the data lines and plot them over a time domain to create an operation-specific data matrix useful in manufacturing operations analysis.

Owner:FORD MOTOR CO

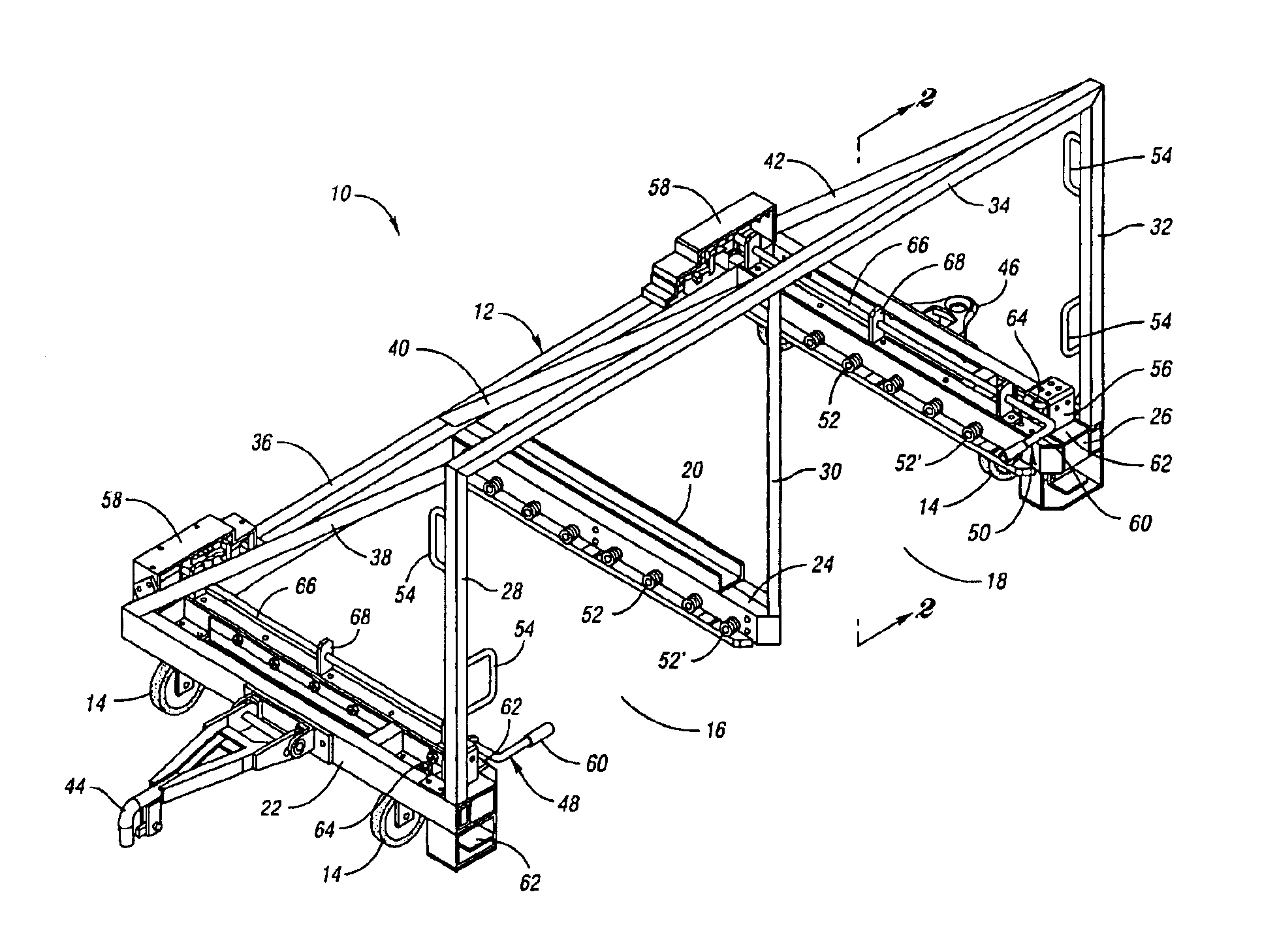

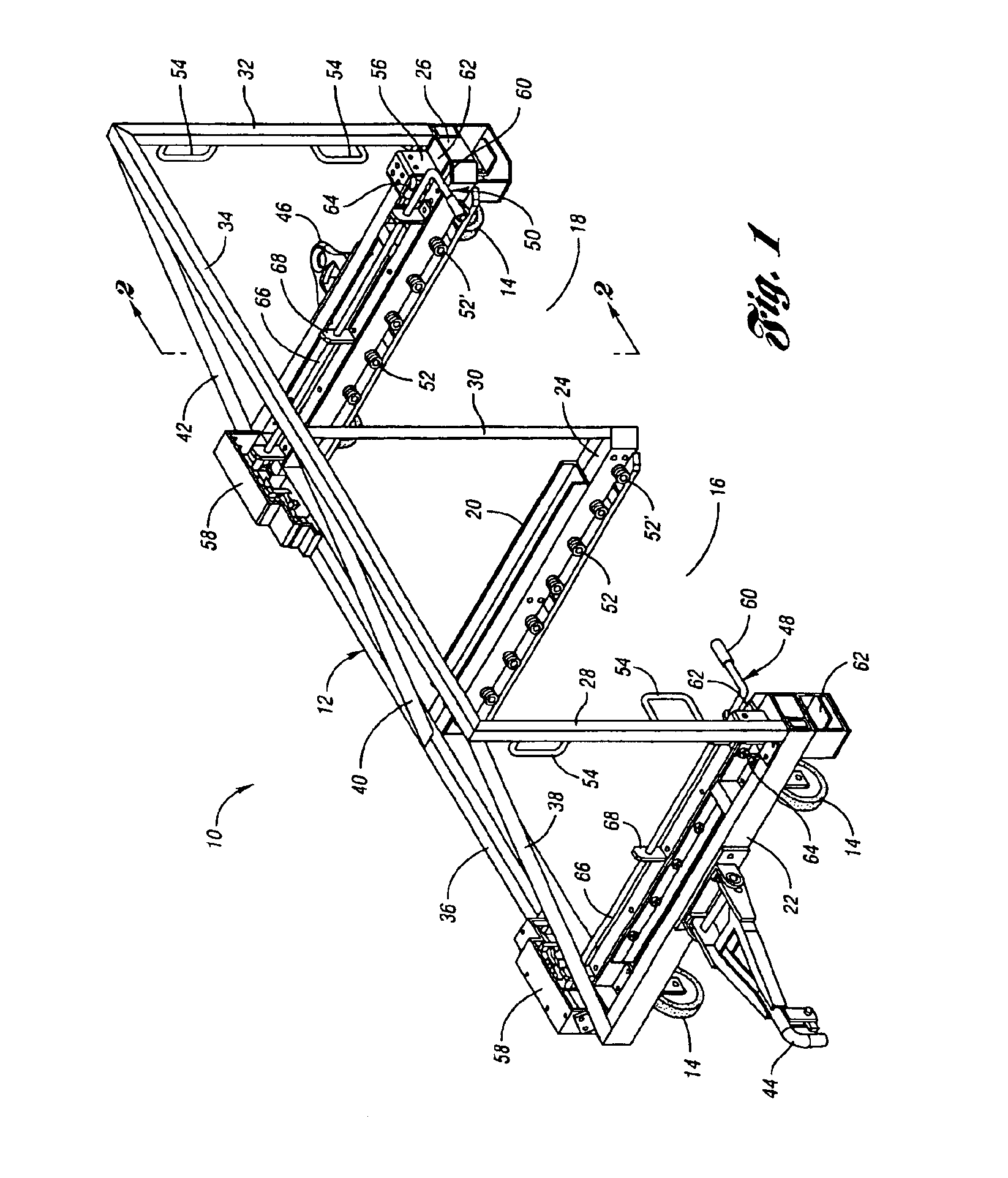

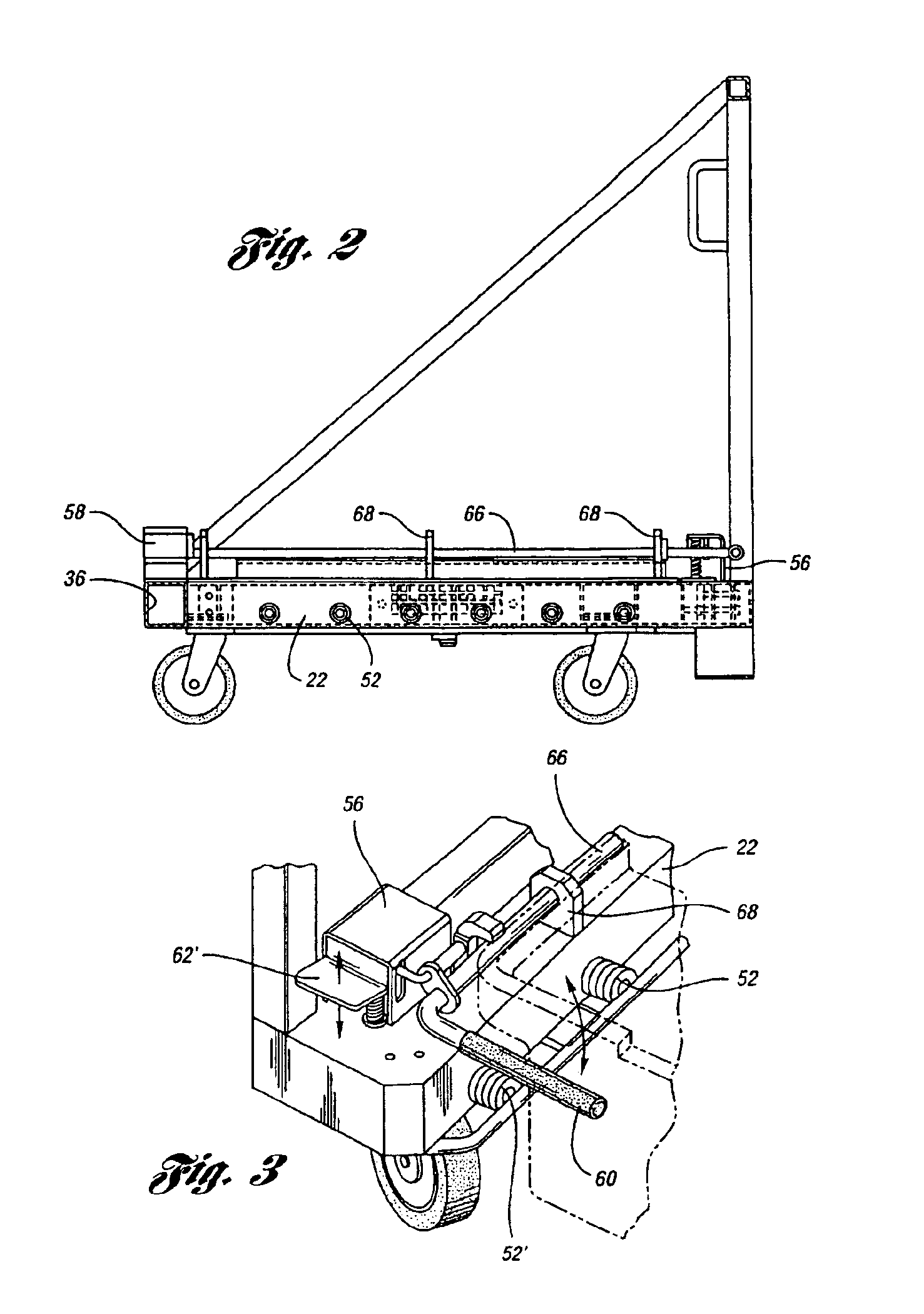

E-frame and dolly system for stocking production lines

InactiveUS6866463B2Semiconductor/solid-state device manufacturingVehicle with removable loadingProduction lineEngineering

A component part container delivery rack used in manufacturing operations. An E-frame defining at least two compartments that are open on at least one side that extends between the front and back ends of the rack. The frame is supported on a plurality of wheels and is adapted to receive a dolly in the compartment. Each dolly is removably received in one of the compartments and locked in place when placed in the delivery rack. The locking element includes a pivoting lever that is rotated to lock and unlock the dolly within the compartment. The dolly is supported on roller guide elements that guide the dollies as they are moved into and out of the compartment. The dollies are raised above the floor so that the wheels of the dollies do not contact the floor as it is transported by the rack.

Owner:FORD MOTOR CO

Wafer translator having a silicon core isolated from signal paths by a ground plane

ActiveUS20090224372A1Printed circuit assemblingElectrical measurement instrument detailsCopper platingCopper foil

Apparatus and methods are provided for wafer translators having a silicon core, an isolating conductive ground plane, and copper and subjacent resin layers disposed on the ground plane. A silicon substrate having at least one major surface coated with an electrically conductive layer is subjected to a number of printed circuit board manufacturing operations including, but not limited to, application of resin-coated copper foils; mechanical grinding of copper layers; mechanical drilling of via openings in a dielectric material; plating of copper, nickel, and gold layers; laser removal of metal; and chemical removal of metal; in order to produce a wafer translator having a silicon core. In further aspects of the present invention, alignment marks are formed and contact structures, such as stud bumps, are placed relative to a local set of alignment marks.

Owner:TRANSLARITY INC

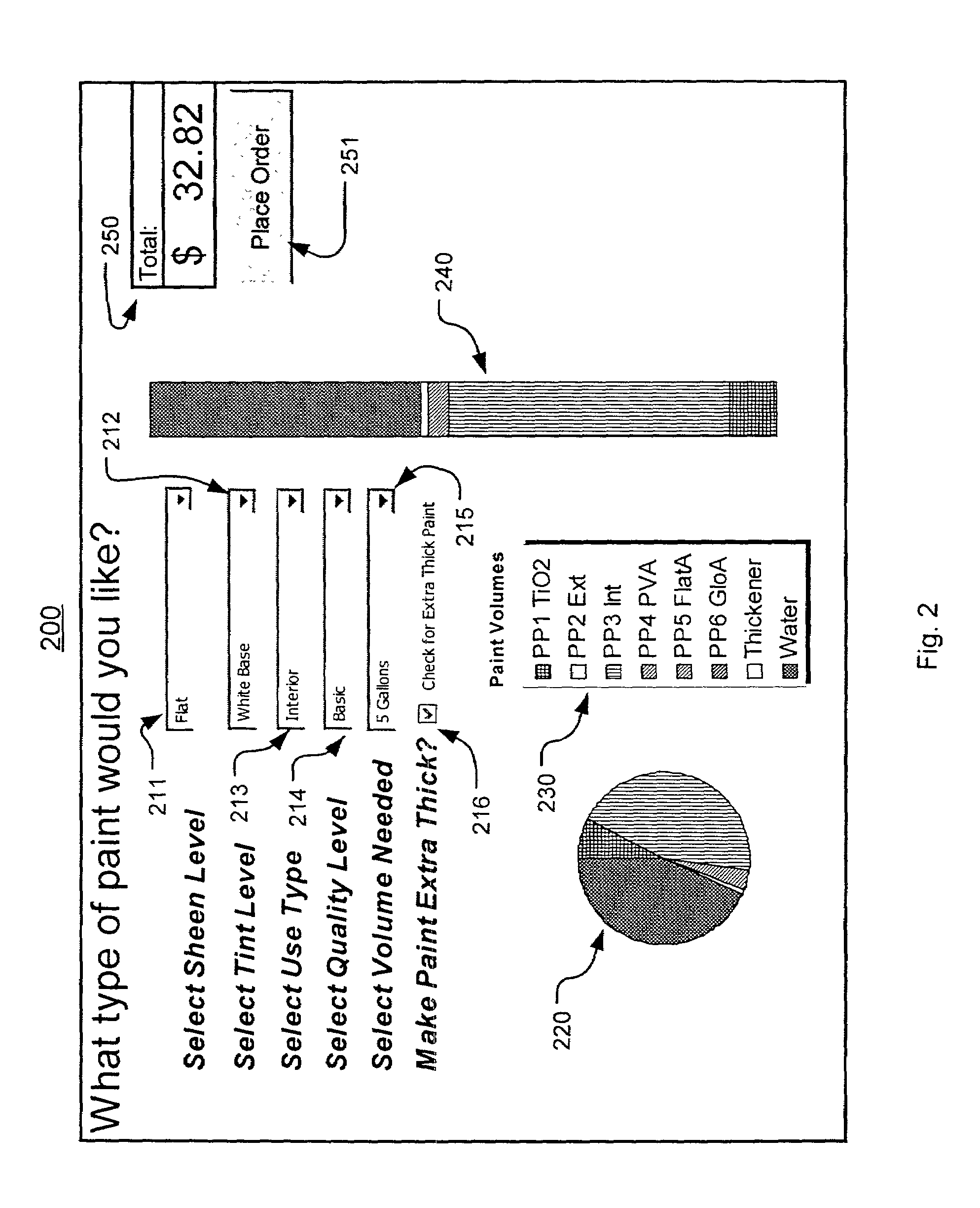

Distributed paint manufacturing system

InactiveUS7250464B2Less amountViscosity fluctuations are smallTransportation and packagingMixer accessoriesHybrid systemUser input

Owner:ROHM & HAAS CO

Co-forged golf club head and method of manufacture

A co-forged iron type golf club is disclosed. More specifically, the present invention discloses a co-forged iron type golf club with the body portion made out of a first material and at least one weight adjustment portion monolithically encased within the body portion of the co-forged iron type golf club head without the need for secondary attachment or machining operations. The present invention creates of an iron type golf club head from a pre-form billet that already contains two or more materials before the actual forging process resulting in a multi-material golf club head that doesn't require any post manufacturing operations such as machining, welding, swaging, gluing, and the like.

Owner:ACUSHNET CO

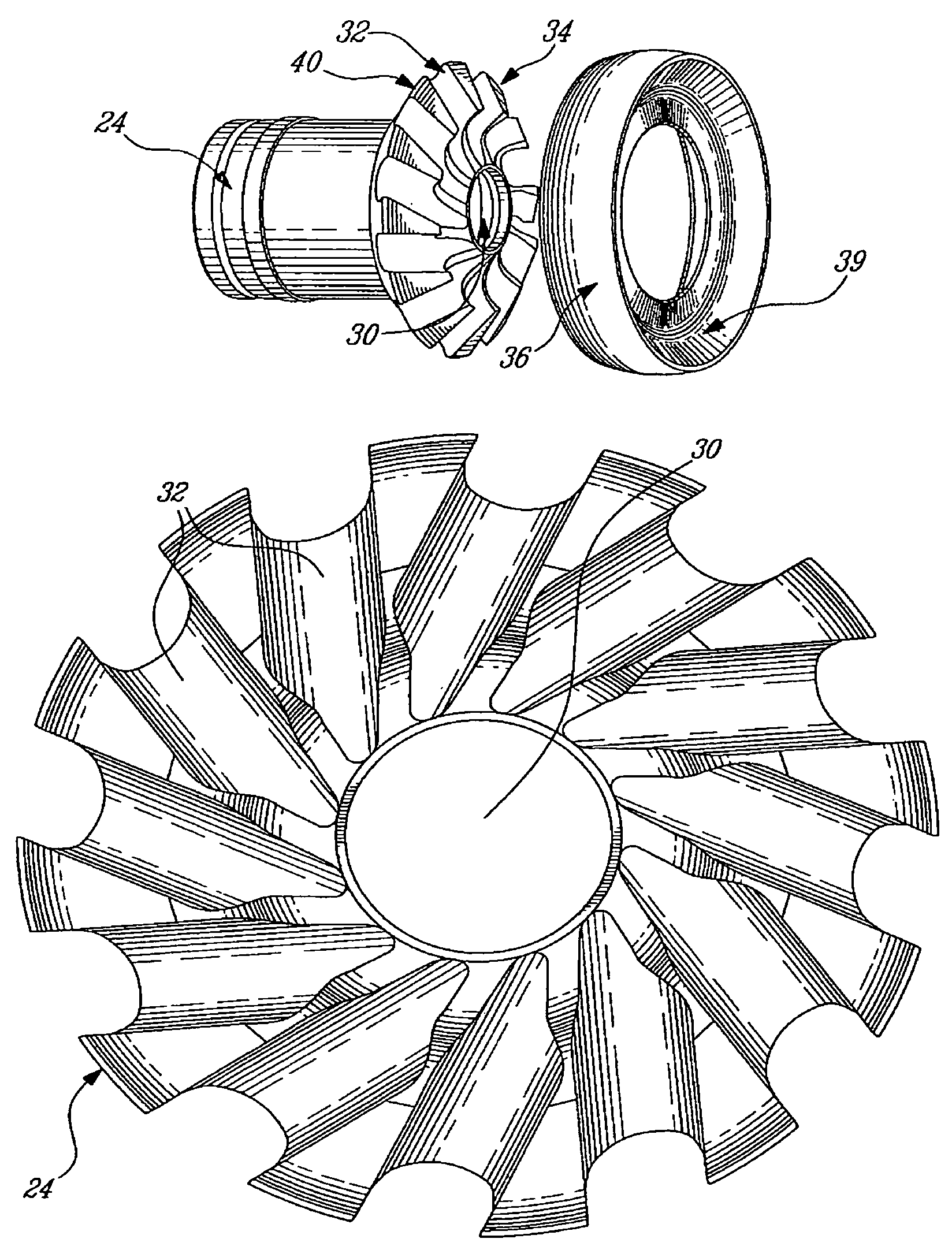

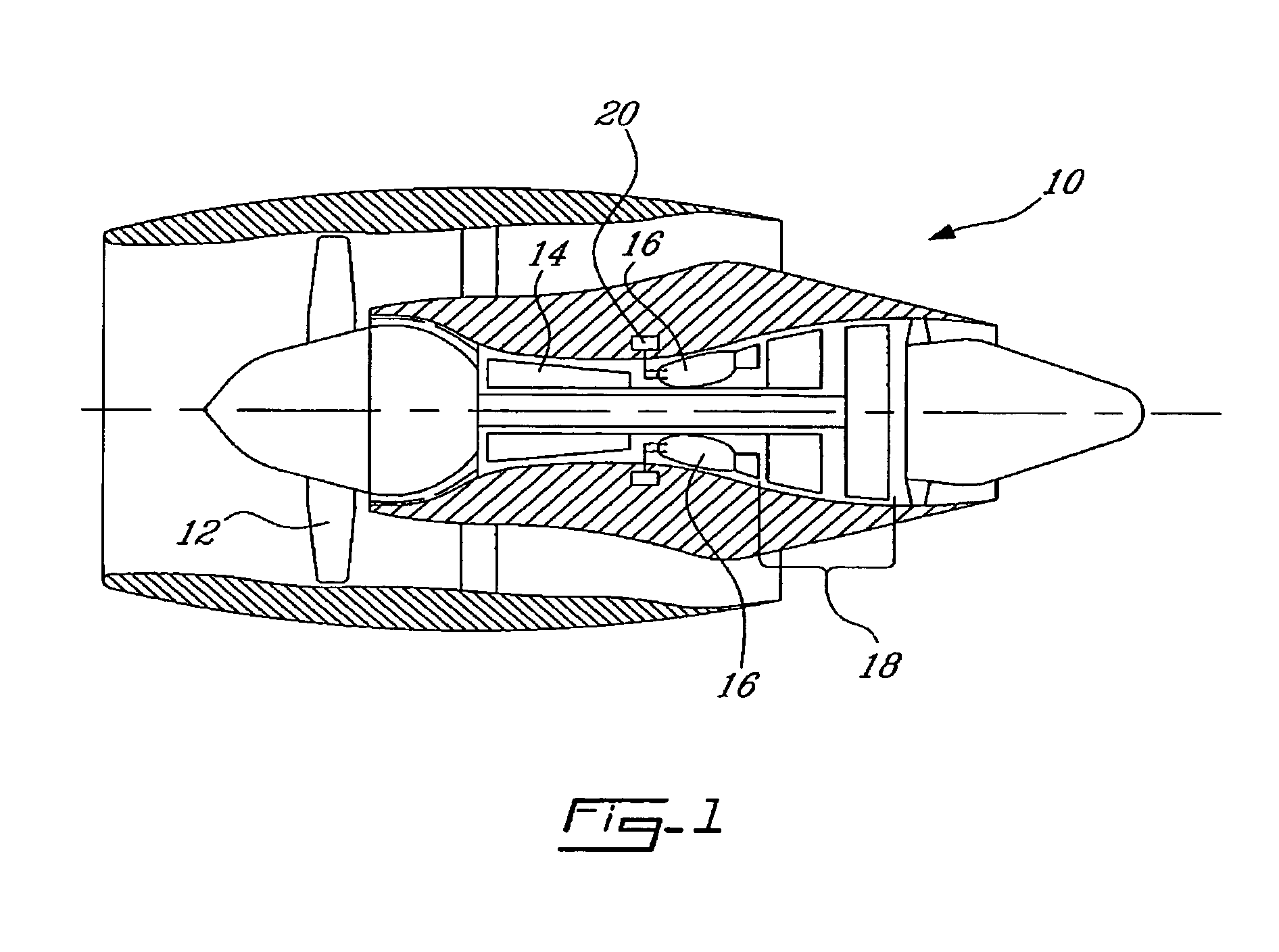

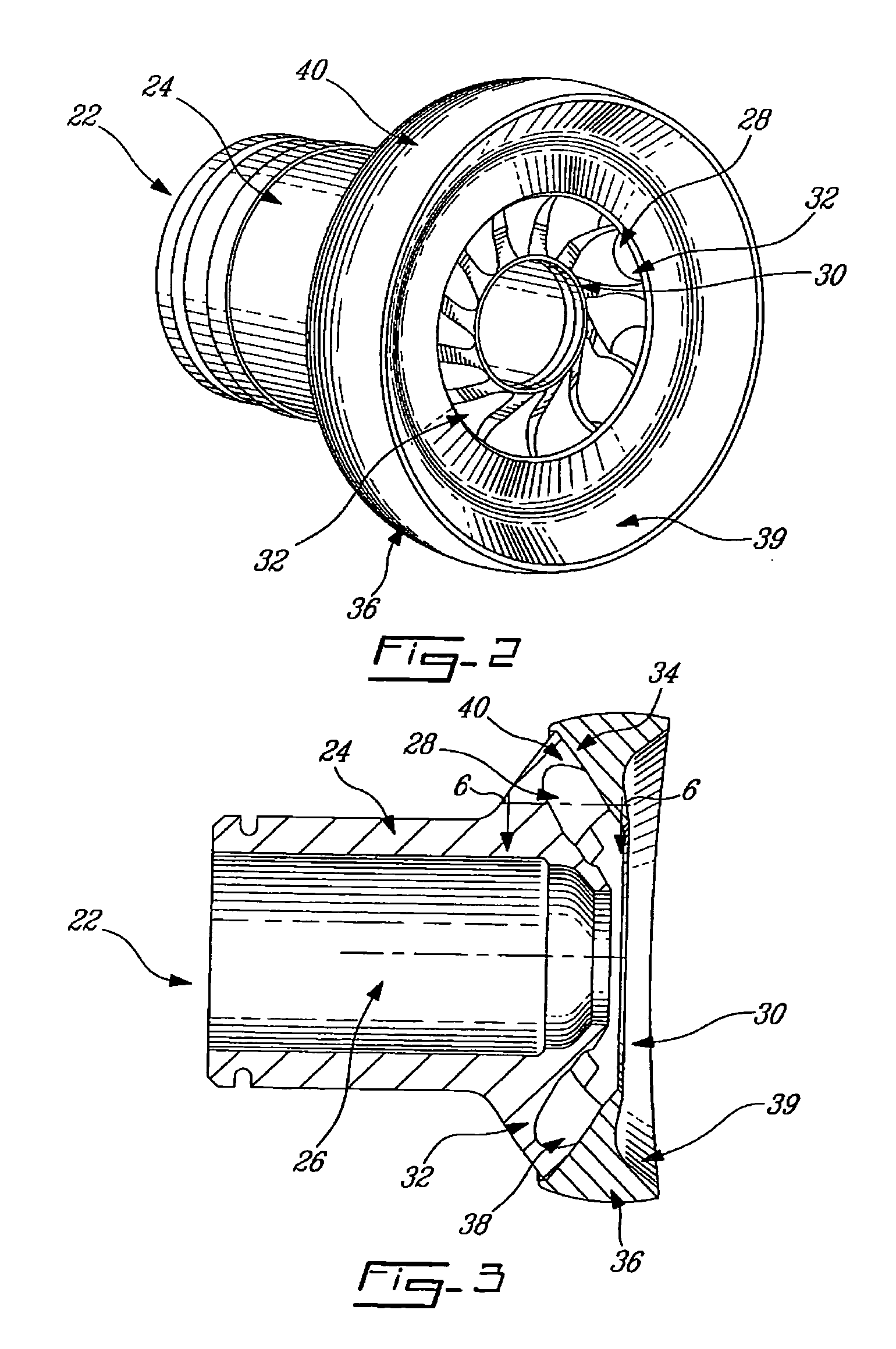

Modular fuel nozzle and method of making

A modular fuel nozzle configuration is defined which permits lower-cost manufacturing operations such as injection moulding to be employed. Also described is a method of making such a component.

Owner:PRATT & WHITNEY CANADA CORP

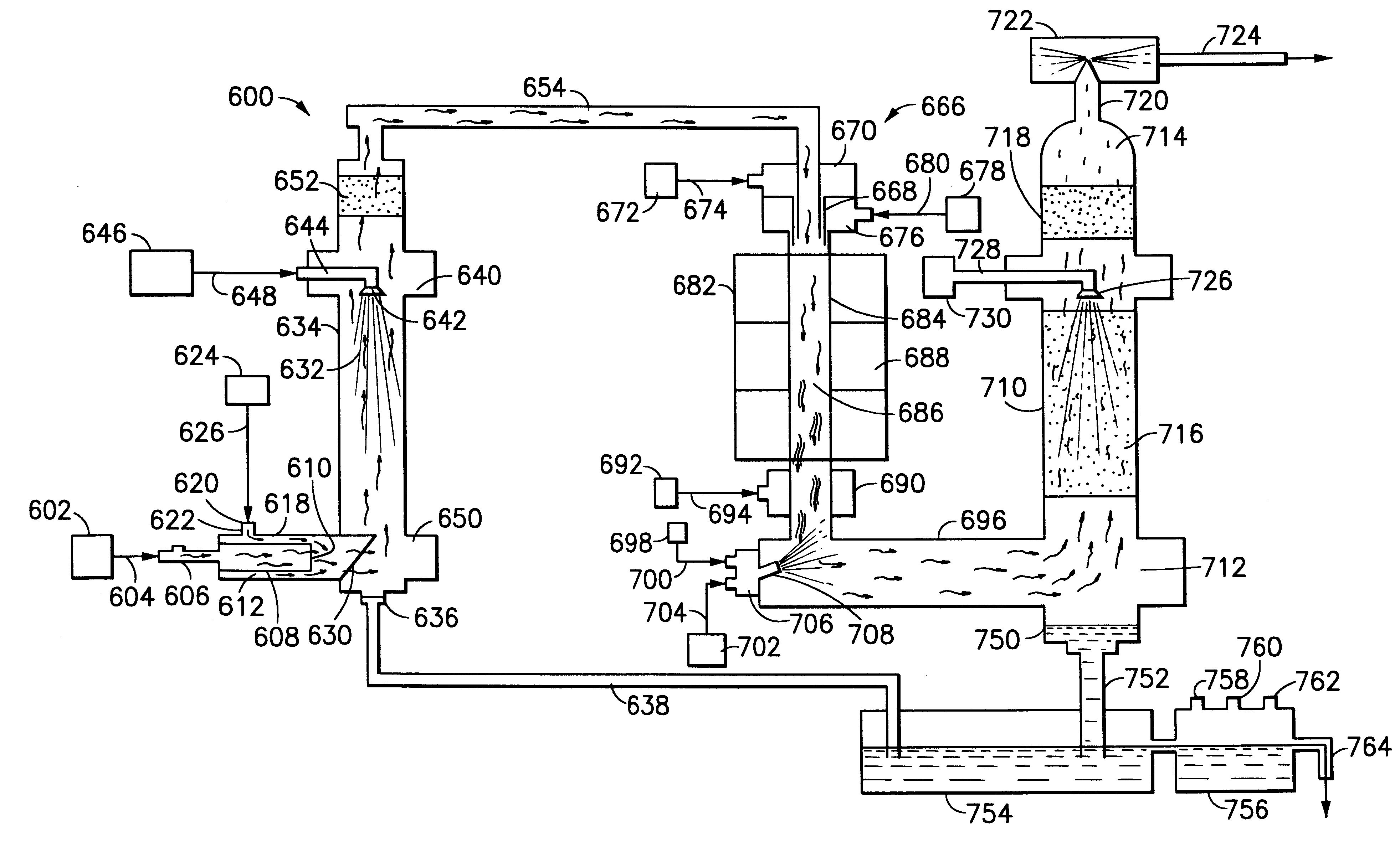

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6333010B1Reduce sensitivityReduced water requirementsCombination devicesGas treatmentEnvironmental engineeringProduct gas

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:BHT SERVICES PTE LTD

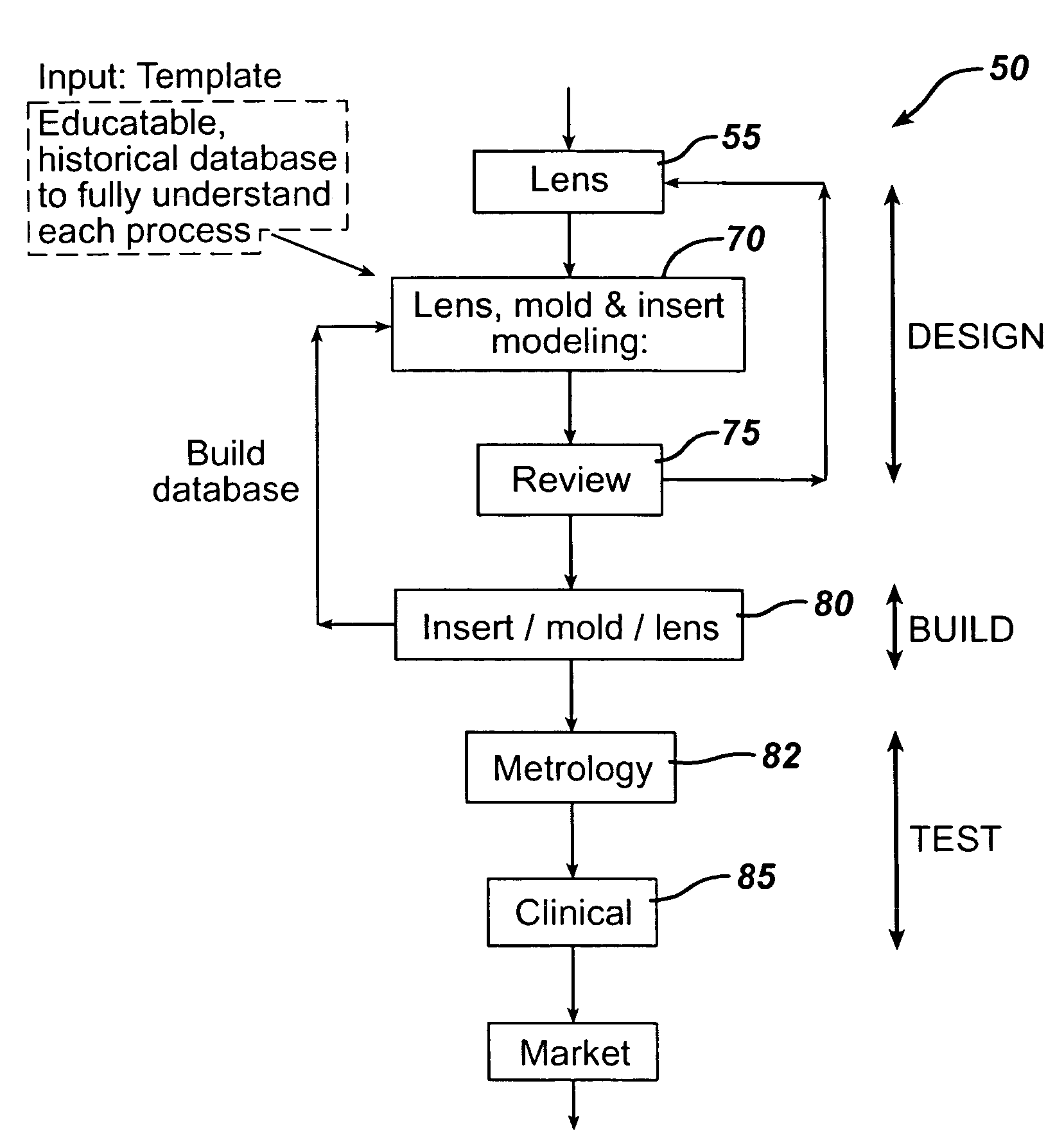

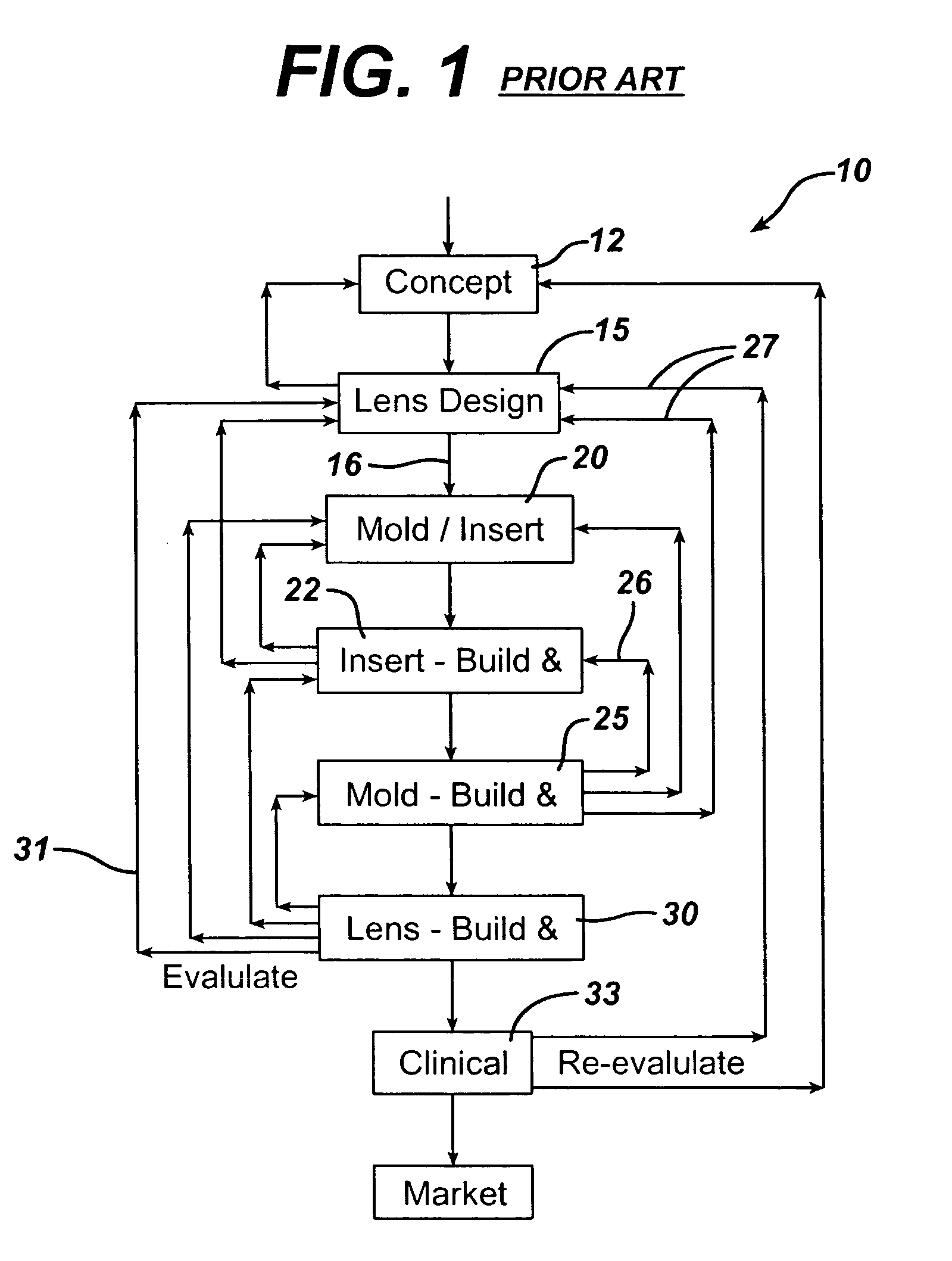

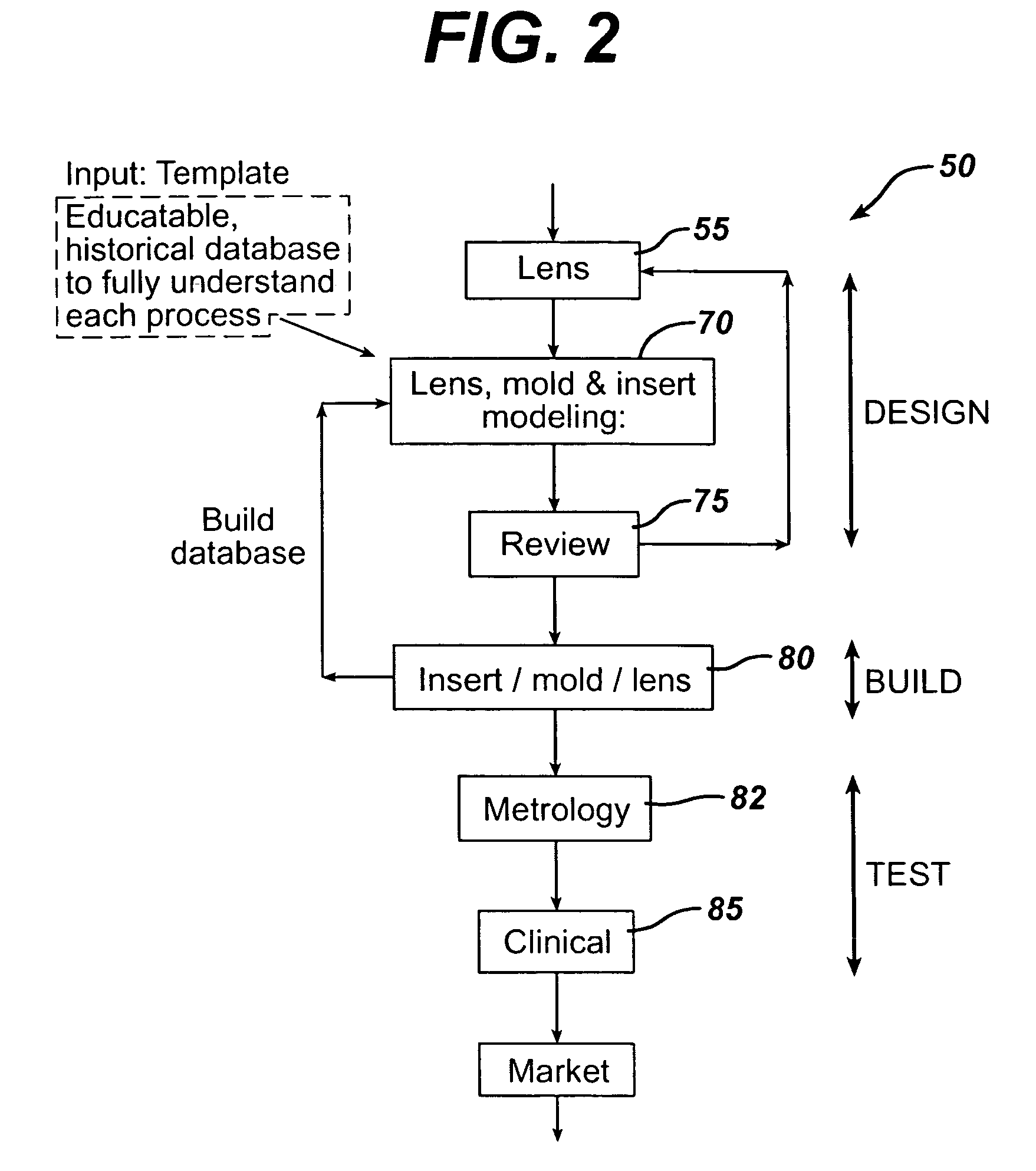

Design build test cycle reduction

InactiveUS7123985B2Error minimization% accurateTherapiesOptical articlesCamera lensDesign information

An ophthalmic lens design and modeling system comprises a user interface providing functionality for generating a template associated with a desired lens design to be manufactured, the template comprising design information sufficient for generating three-dimensional (3D) models of lens, and 3D models of associated components required for lens manufacture in an ophthalmic lens manufacturing system. The system further includes functionality for generating and / or specifying linking information, via the user interface, that governs the physical behavior of lens design features included in said template in accordance with one or more process parameters affecting lens manufacture and manufacture of associated components in an ophthalmic lens manufacturing system. The use of the template and design and linking information therein thus facilitates rapid lens modeling and lens manufacturing operations with greater accuracy, thereby reducing lens design build and test (DBT) cycle time.

Owner:JOHNSON & JOHNSON VISION CARE INC

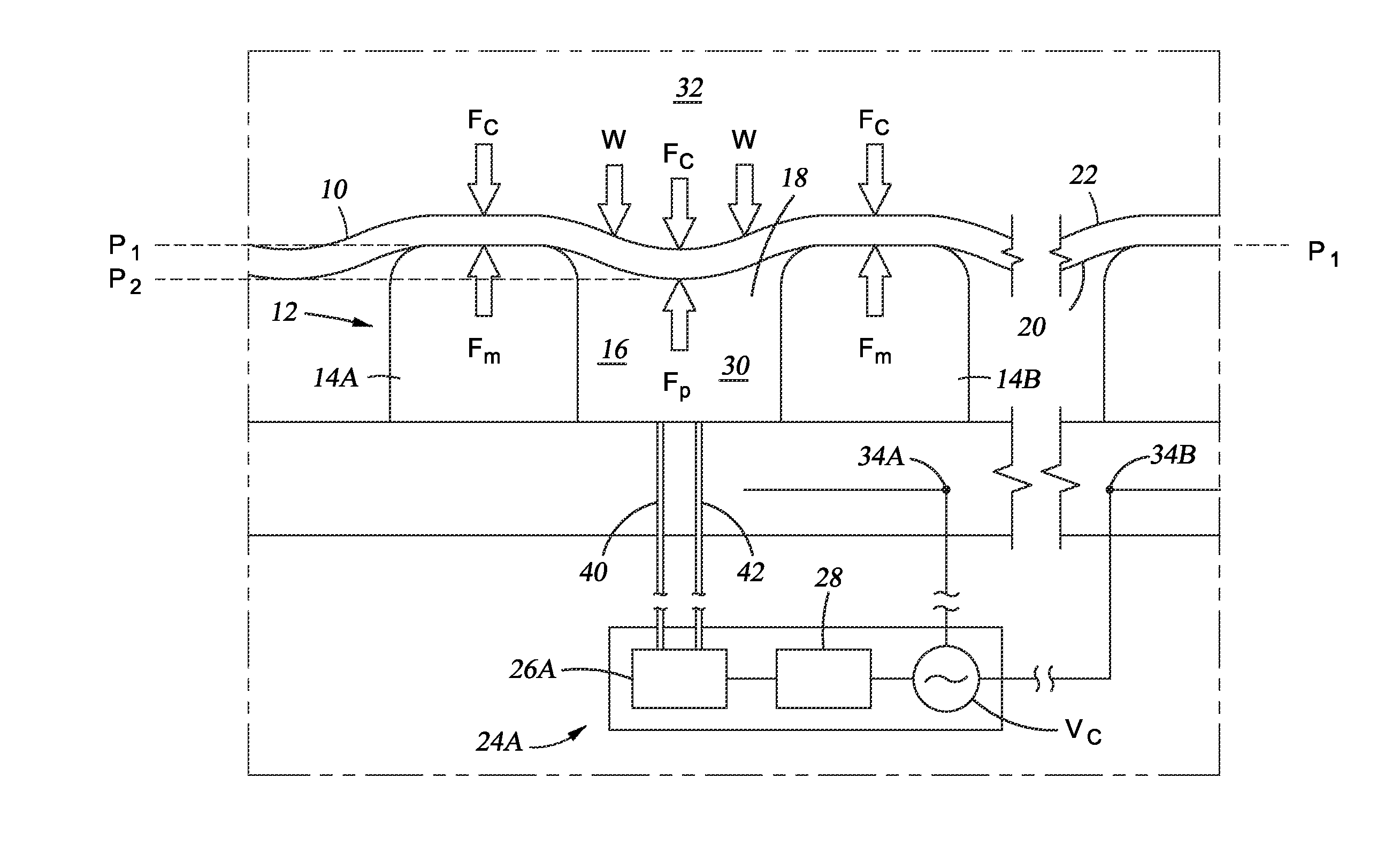

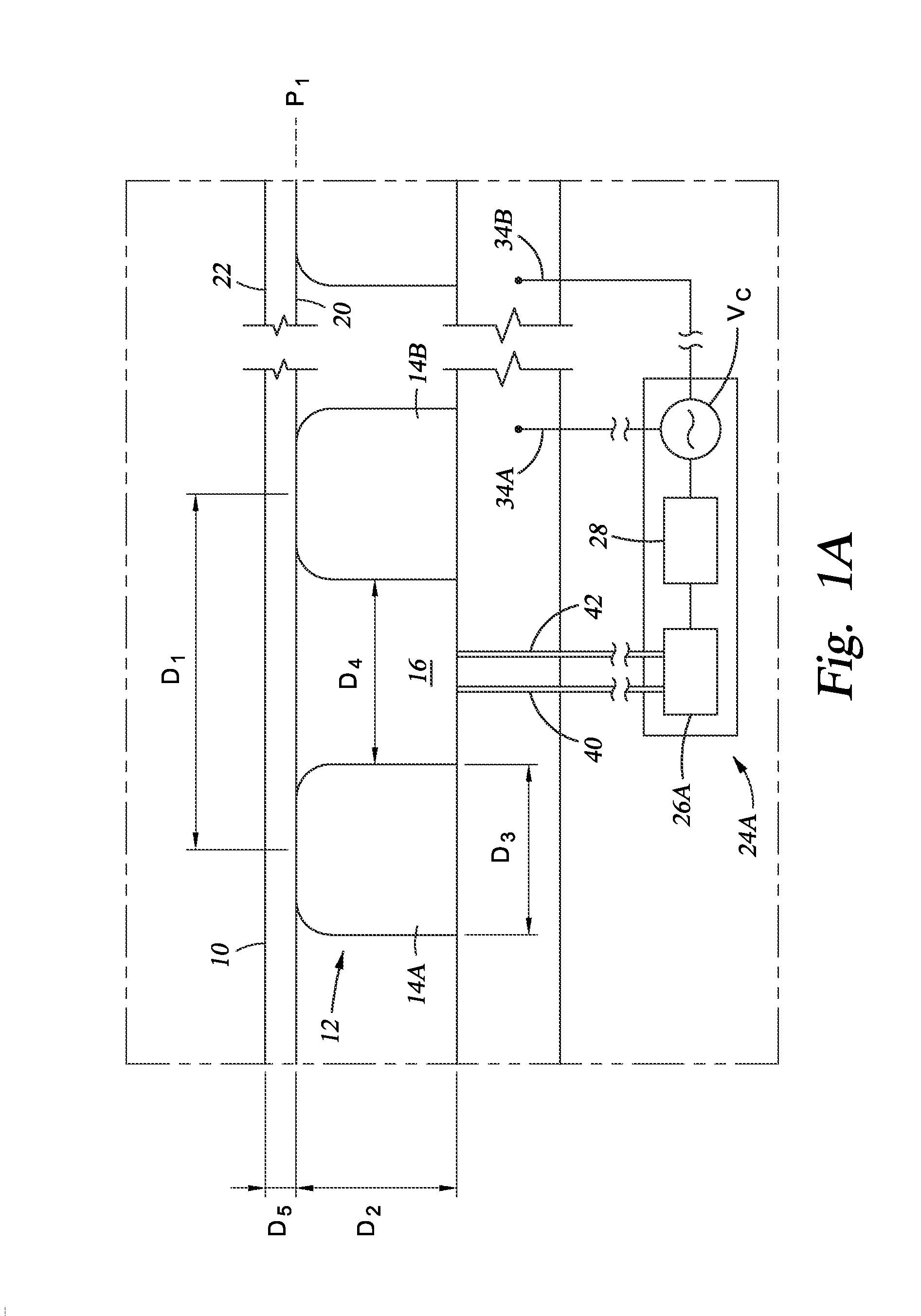

Control systems employing deflection sensors to control clamping forces applied by electrostatic chucks, and related methods

ActiveUS20150138687A1Avoid workpiece damageAvoid damageSemiconductor/solid-state device manufacturingControl systemManufacturing operations

A control system that includes deflection sensors which can control clamping forces applied by electrostatic chucks, and related methods are disclosed. By using a sensor to determine a deflection of a workpiece supported by an electrostatic chuck, a control system may use the deflection measured to control a clamping force applied to the workpiece by the electrostatic chuck. The control system applies a clamping voltage to the electrostatic chuck so that the clamping force reaches and maintains a target clamping force. In this manner, the clamping force may secure the workpiece to the electrostatic chuck to enable manufacturing operations to be performed while preventing workpiece damage resulting from unnecessary higher values of the clamping force.

Owner:APPLIED MATERIALS INC

Wax emulsion coating applications

Owner:MARCUS OIL & CHEM

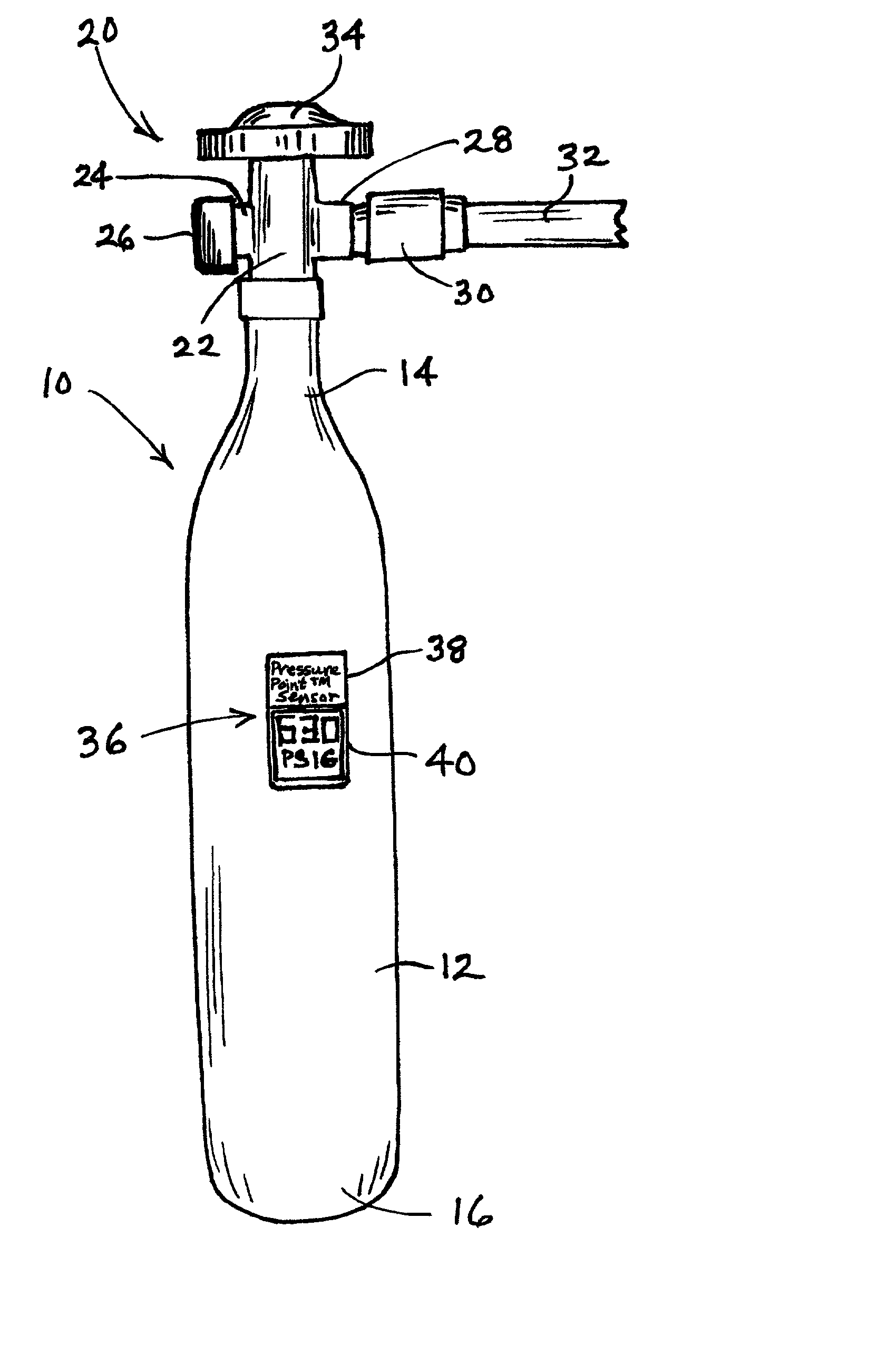

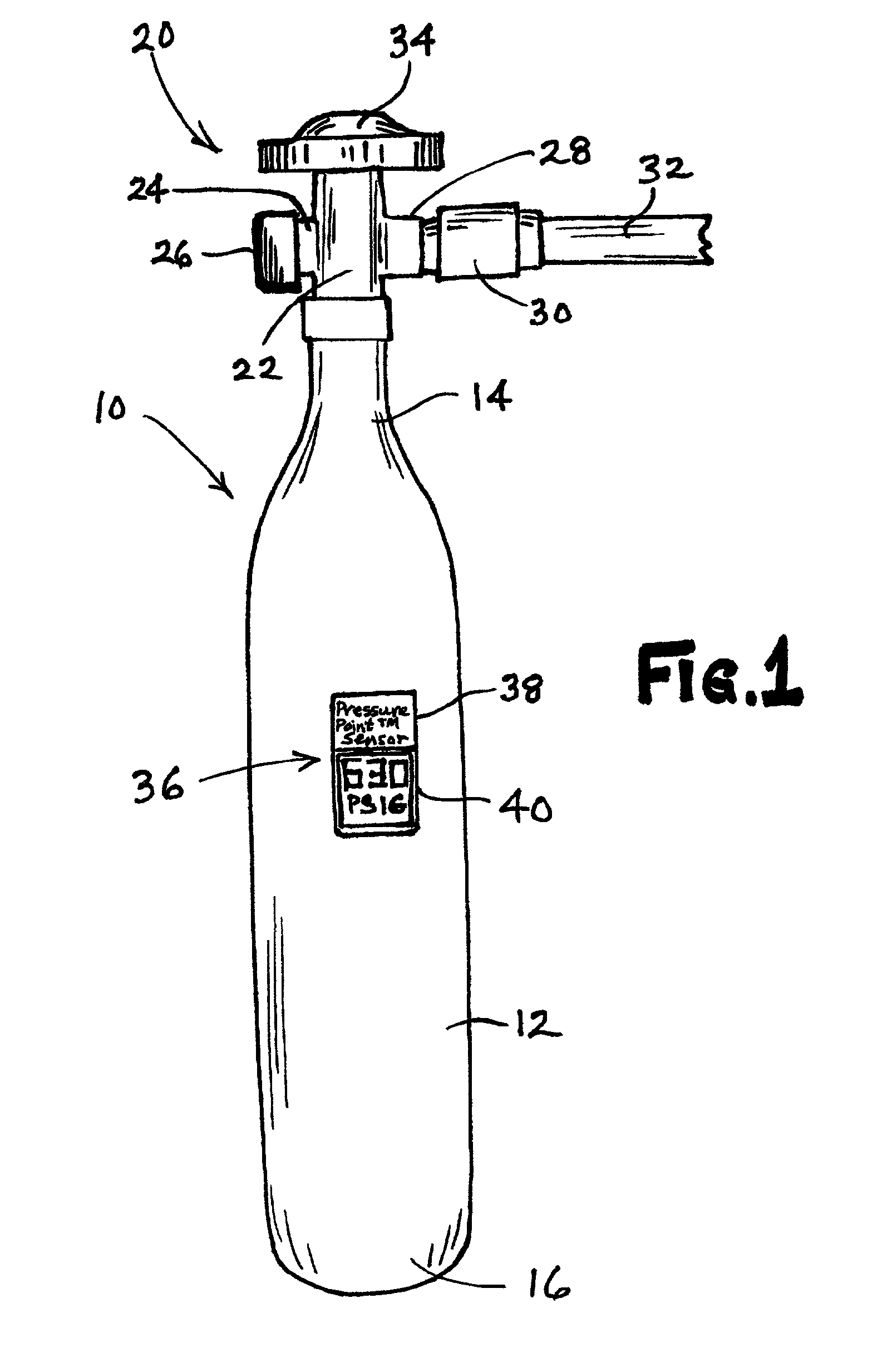

Fluid storage and dispensing system featuring ex situ strain gauge pressure monitoring assembly

InactiveUS20020134794A1Accurate detection and measurementAchieving voltage balanceVessel mounting detailsLiquid fillingEngineeringTire-pressure monitoring system

A fluid containment system including a vessel for containing a fluid that is discharged from the vessel in use or operation of the system. A pressure monitoring assembly including a strain-responsive sensor is disposed on an exterior wall surface of the vessel, to sense dynamic strain on the wall surface of such vessel that is incident to discharge of fluid from the vessel, and to responsively output a pressure-indicative response. Such arrangement is particularly useful in application to fluid storage and dispensing vessels containing interiorly disposed pressure regulator assemblies and holding liquefied gases or compressed gases, e.g., for use in semiconductor manufacturing operations.

Owner:ENTEGRIS INC

Co-forged golf club head and method of manufacture

A co-forged iron type golf club is disclosed. More specifically, the present invention discloses a co-forged iron type golf club with the body portion made out of a first material and at least one weight adjustment portion monolithically encased within the body portion of the co-forged iron type golf club head without the need for secondary attachment or machining operations. The present invention creates of an iron type golf club head from a pre-form billet that already contains two or more materials before the actual forging process resulting in a multi-material golf club head that doesn't require any post manufacturing operations such as machining, welding, swaging, gluing, and the like.

Owner:ACUSHNET CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com