Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209 results about "Agricultural automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

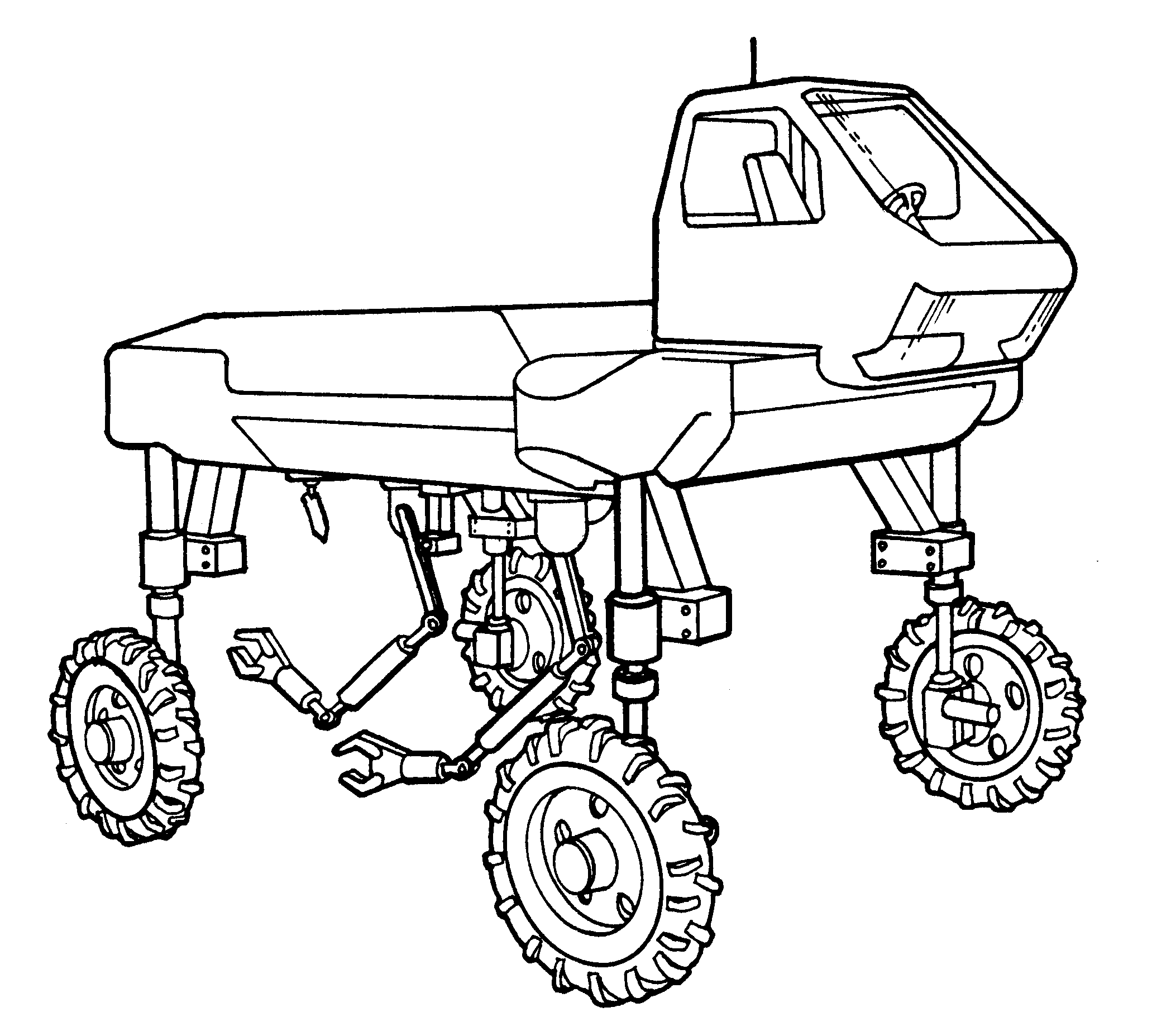

Flexible agricultural automation

InactiveUS6671582B1High precisionQuality improvementOptical radiation measurementPosition fixationAgricultural engineeringAssembly line

Agricultural operations by applying flexible manufacturing software, robotics and sensing techniques to agriculture. In manufacturing operations utilizing flexible machining and flexible assembly robots, work pieces flow through a fixed set of workstations on an assembly line. At different stations are located machine vision systems, laser based raster devices, radar, touch, photocell, and other methods of sensing; flexible robot armatures and the like are used to operate on them. This flexible agricultural automation turns that concept inside out, moving software programmable workstations through farm fields on mobile robots that can sense their environment and respond to it flexibly. The agricultural automation will make it possible for large scale farming to take up labor intensive farming practices which are currently only practical for small scale farming, improving land utilization efficiency, while lowering manpower costs dramatically.

Owner:HANLEY BRIAN P

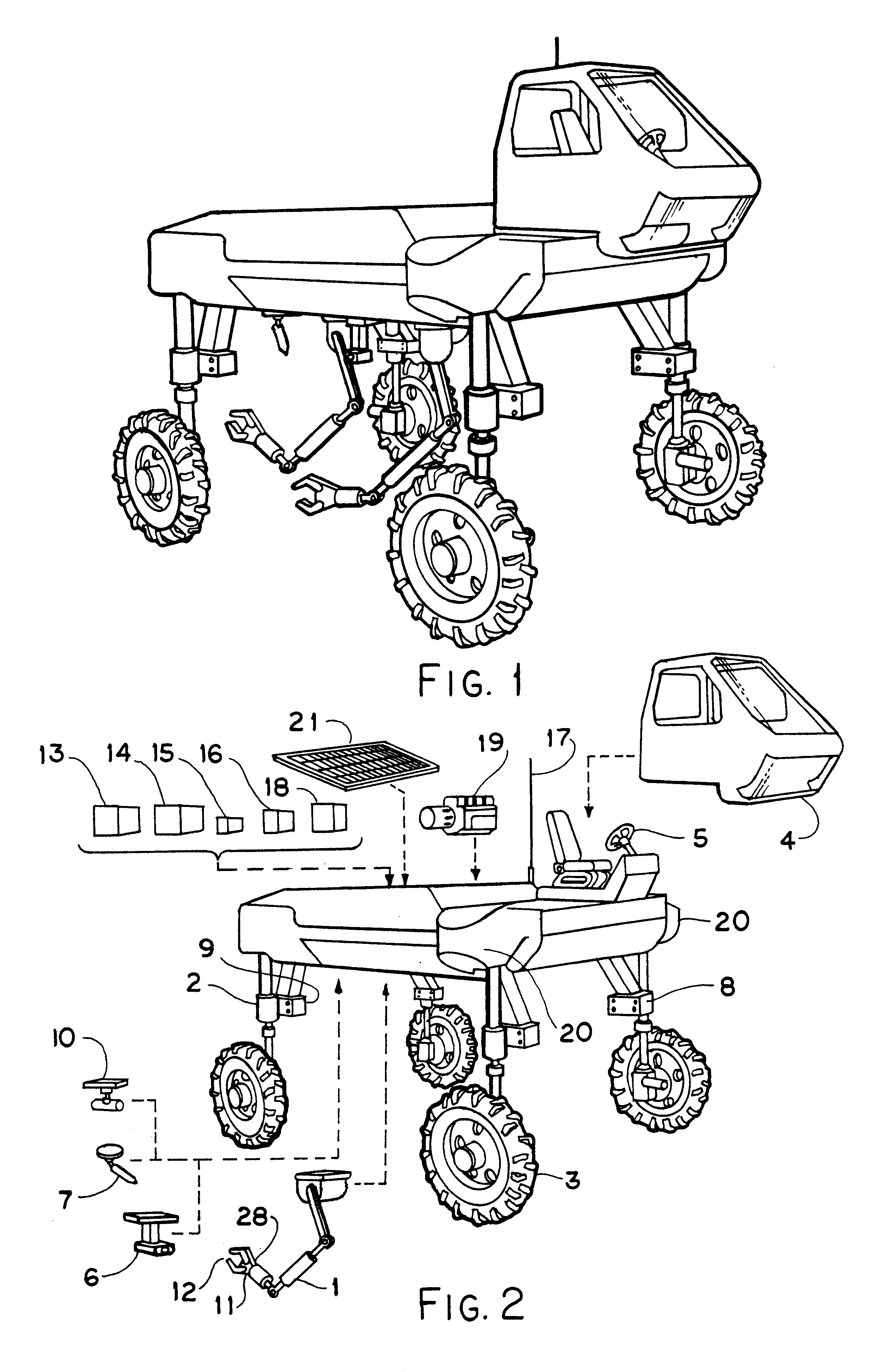

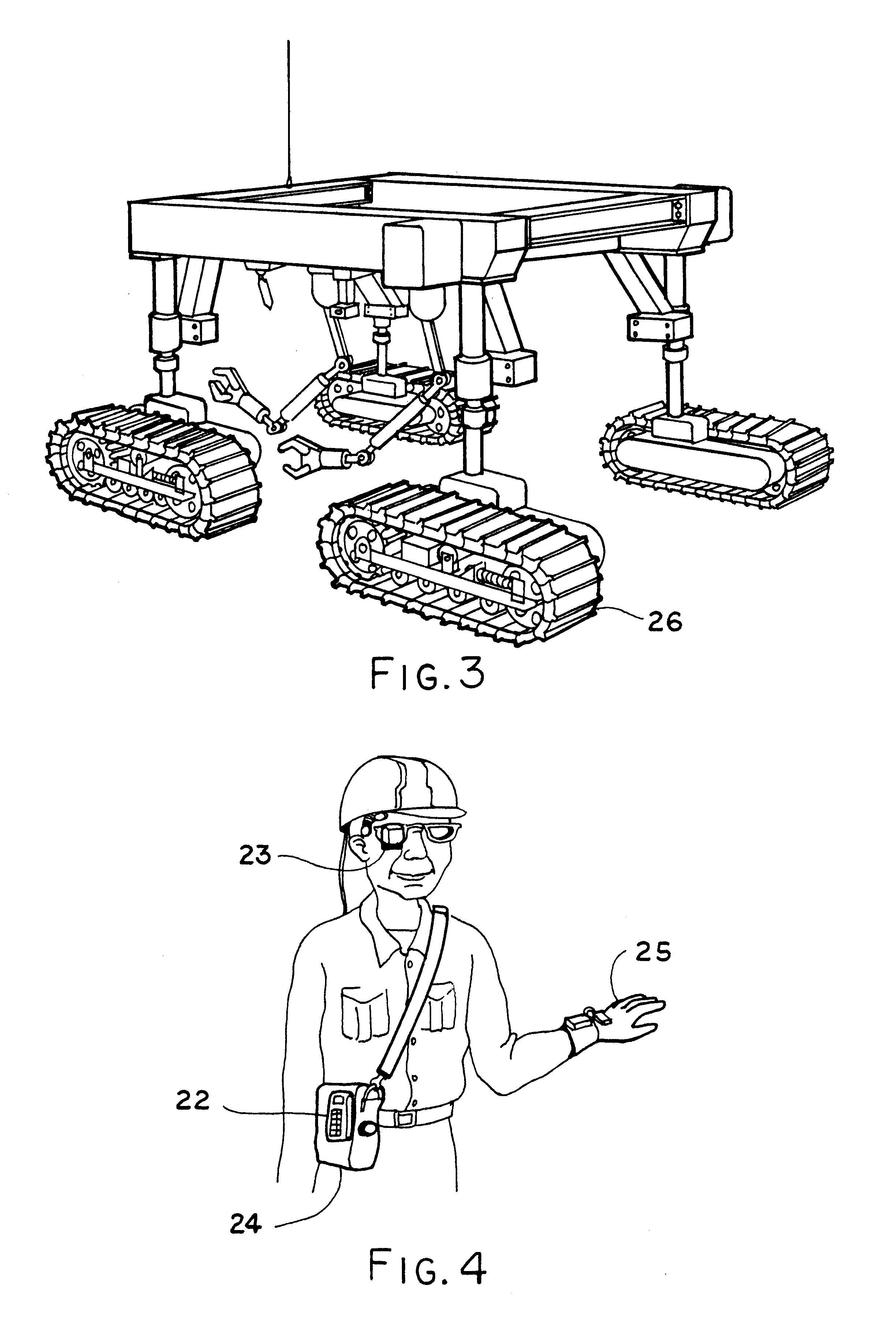

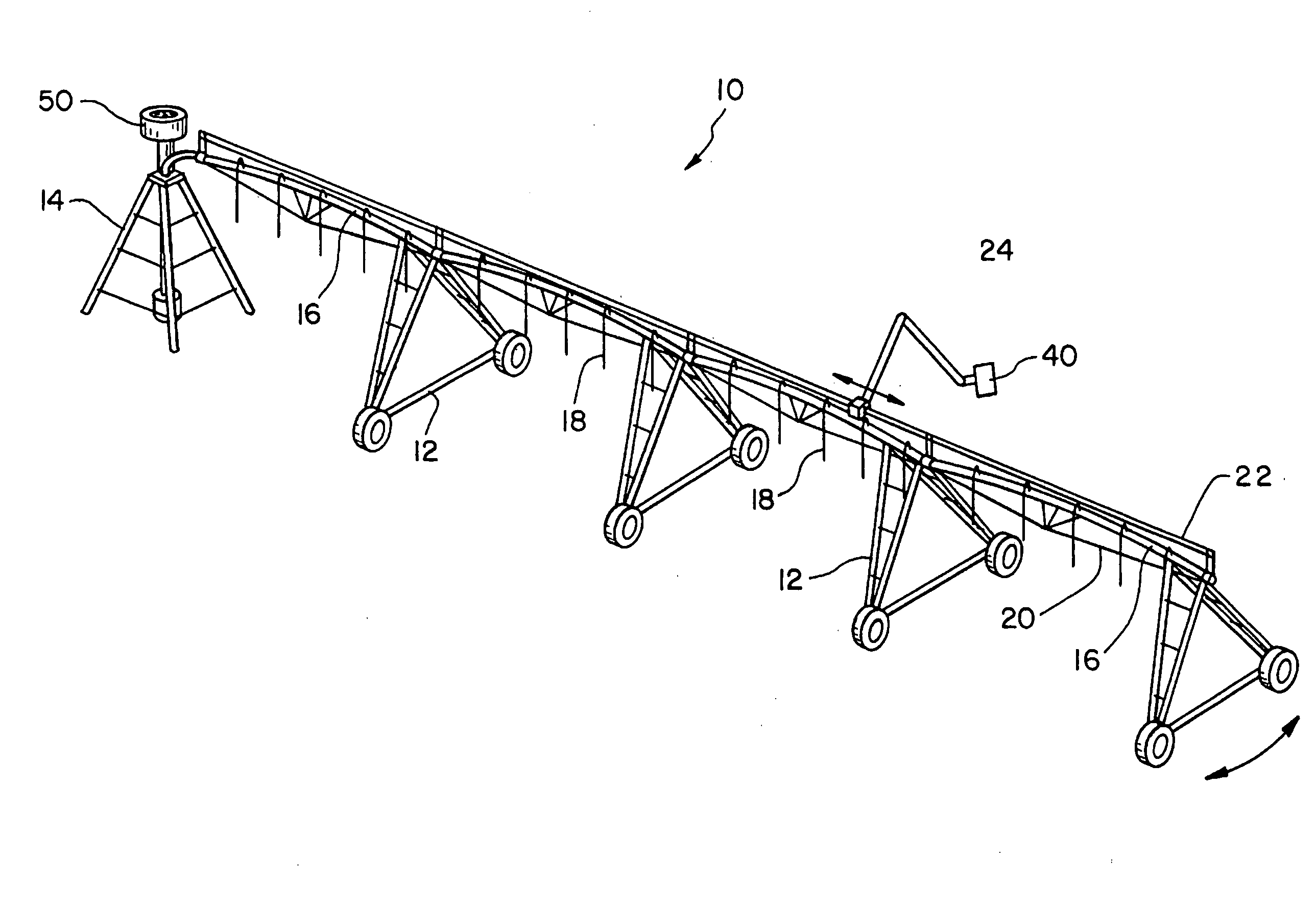

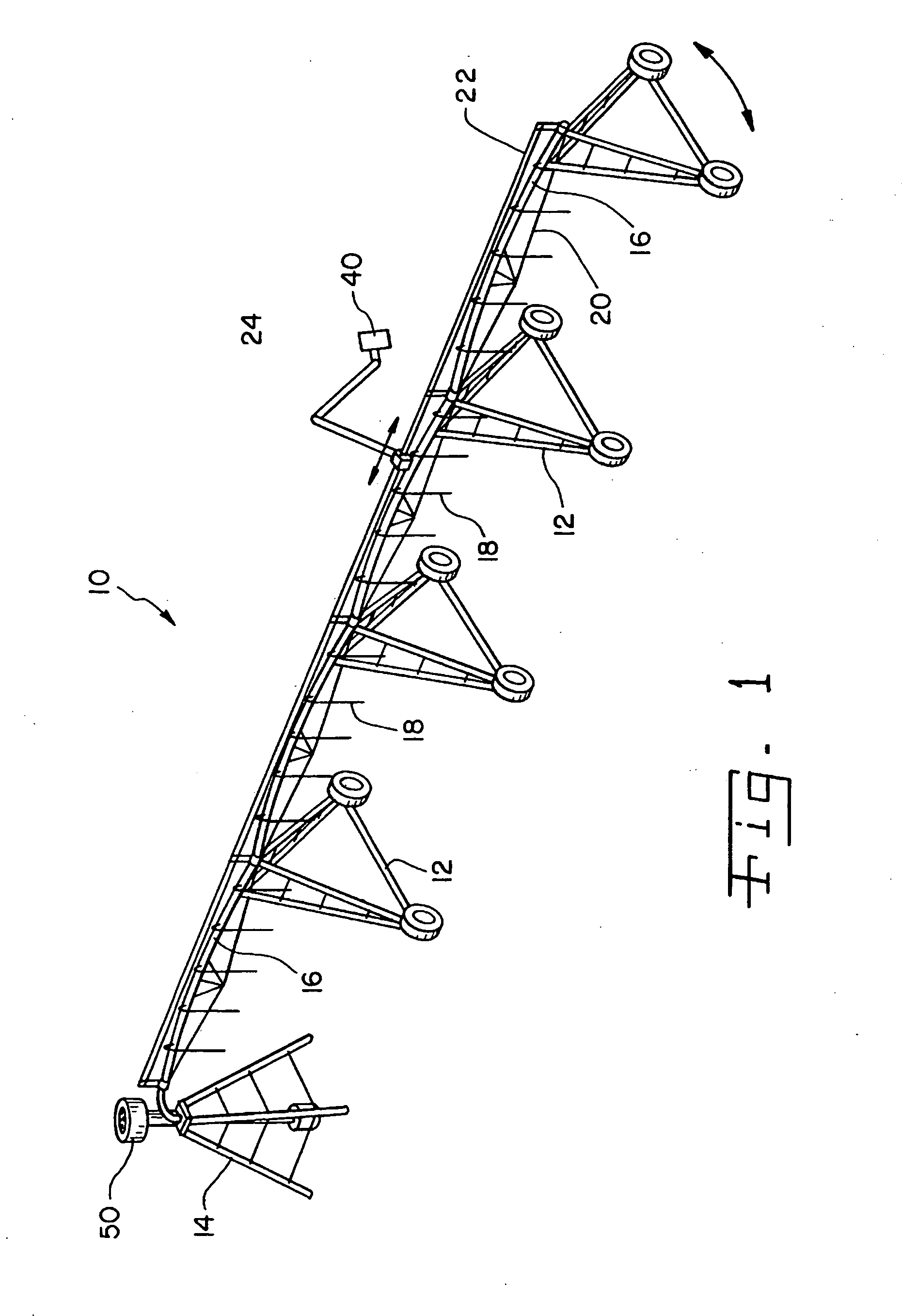

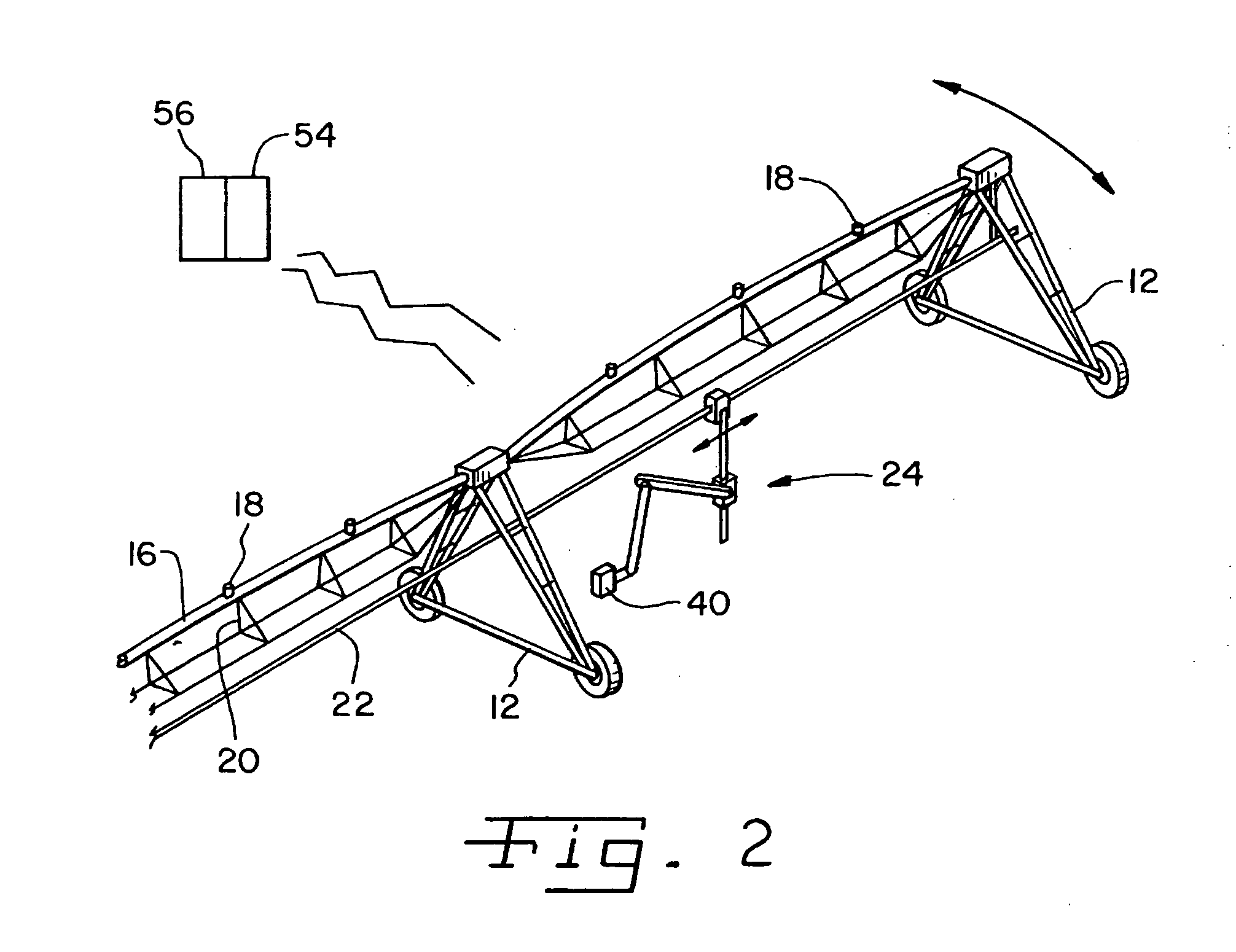

Agricultural automation system with field robot

InactiveUS20080046130A1Watering devicesMovable spraying apparatusAgricultural engineeringEngineering

An agricultural automation system for use in an agricultural area includes an implement caddy carrying a plurality of implements, an elongate transport structure, and a field robot movable along the elongate transport structure. The field robot includes an arm movable in at least one direction different from the movement along the elongate transport structure. The field robot interfaces with the implement caddy for coupling the arm with at least one selected implement, such as a tool or sensor.

Owner:DEERE & CO

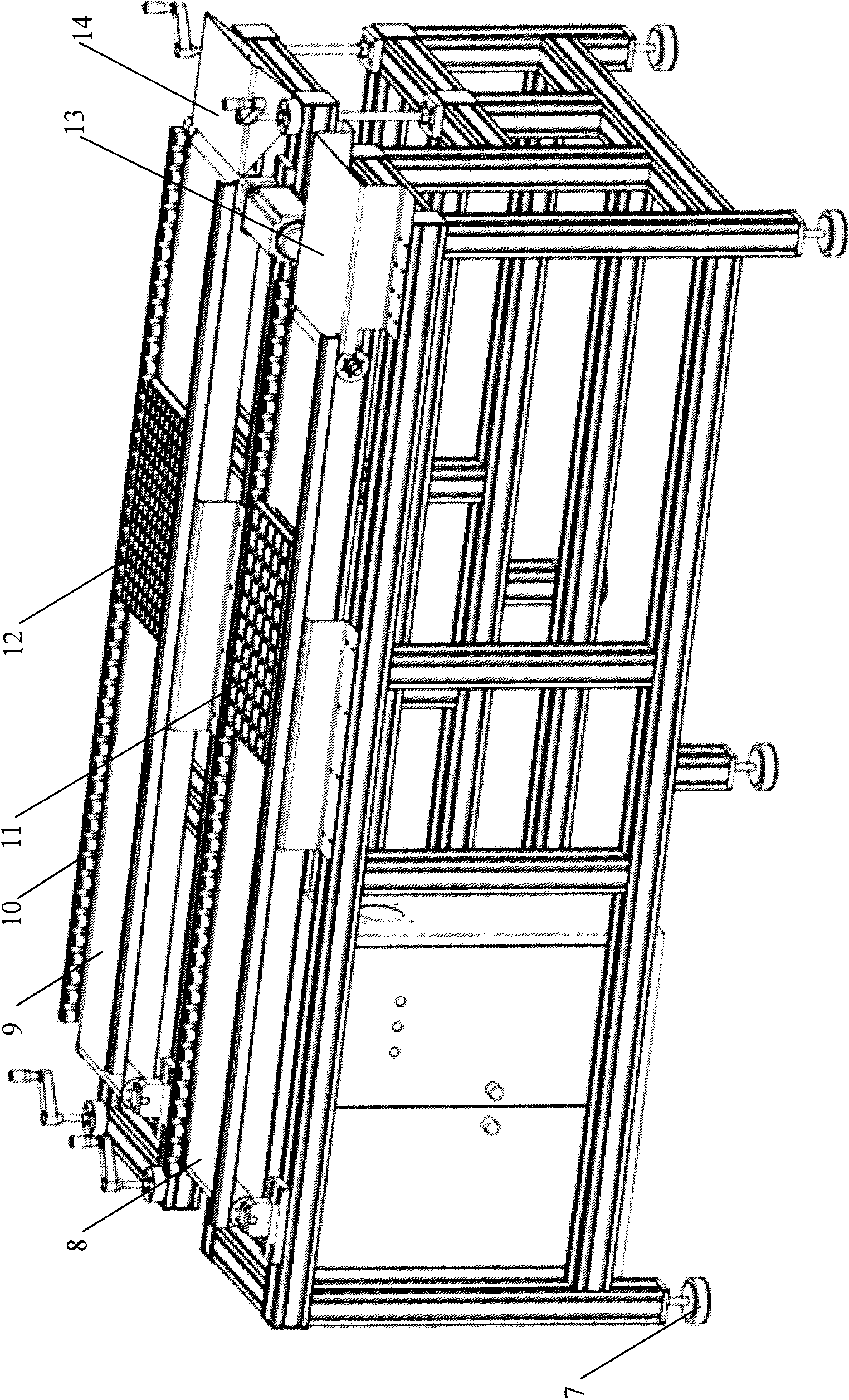

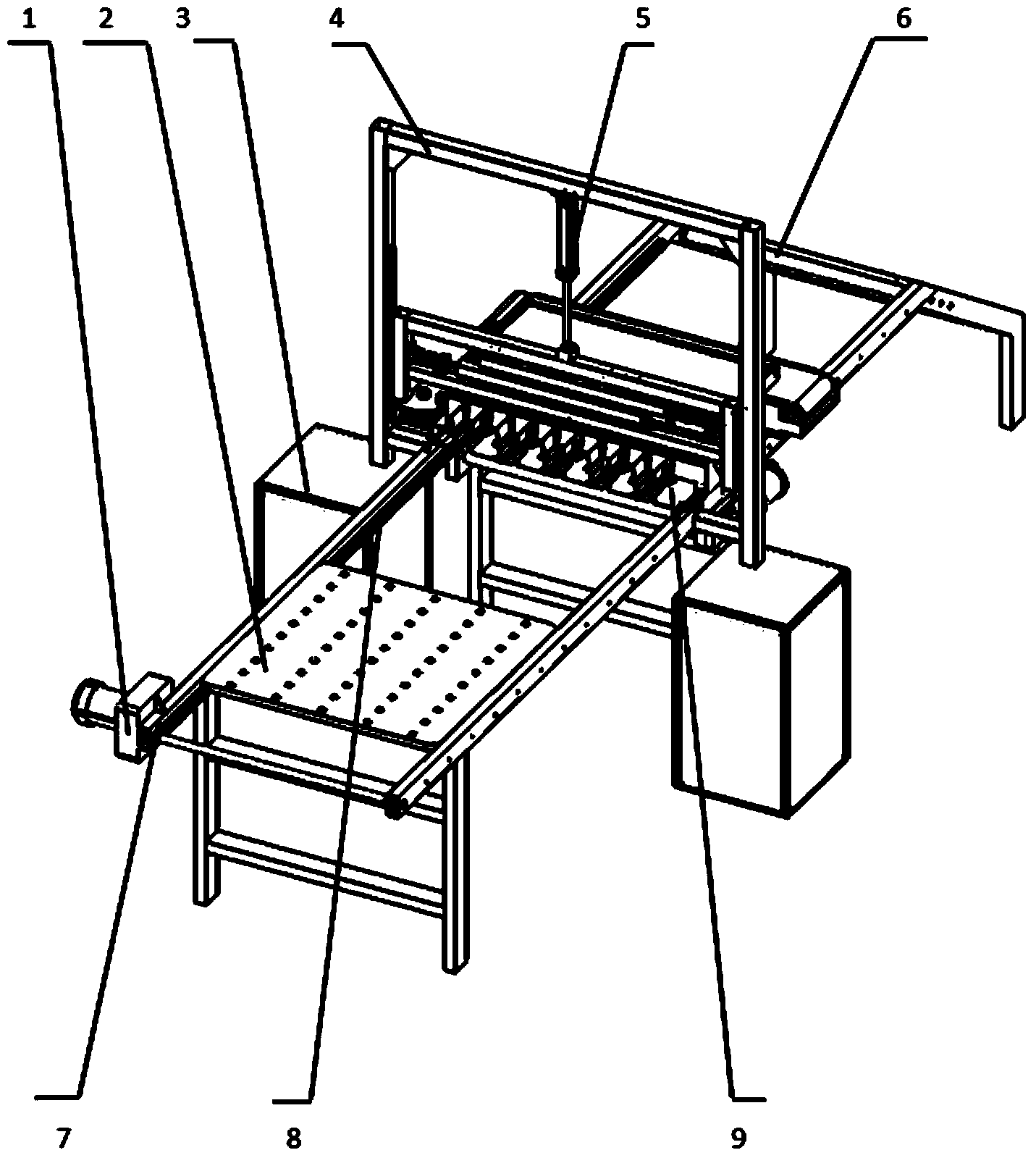

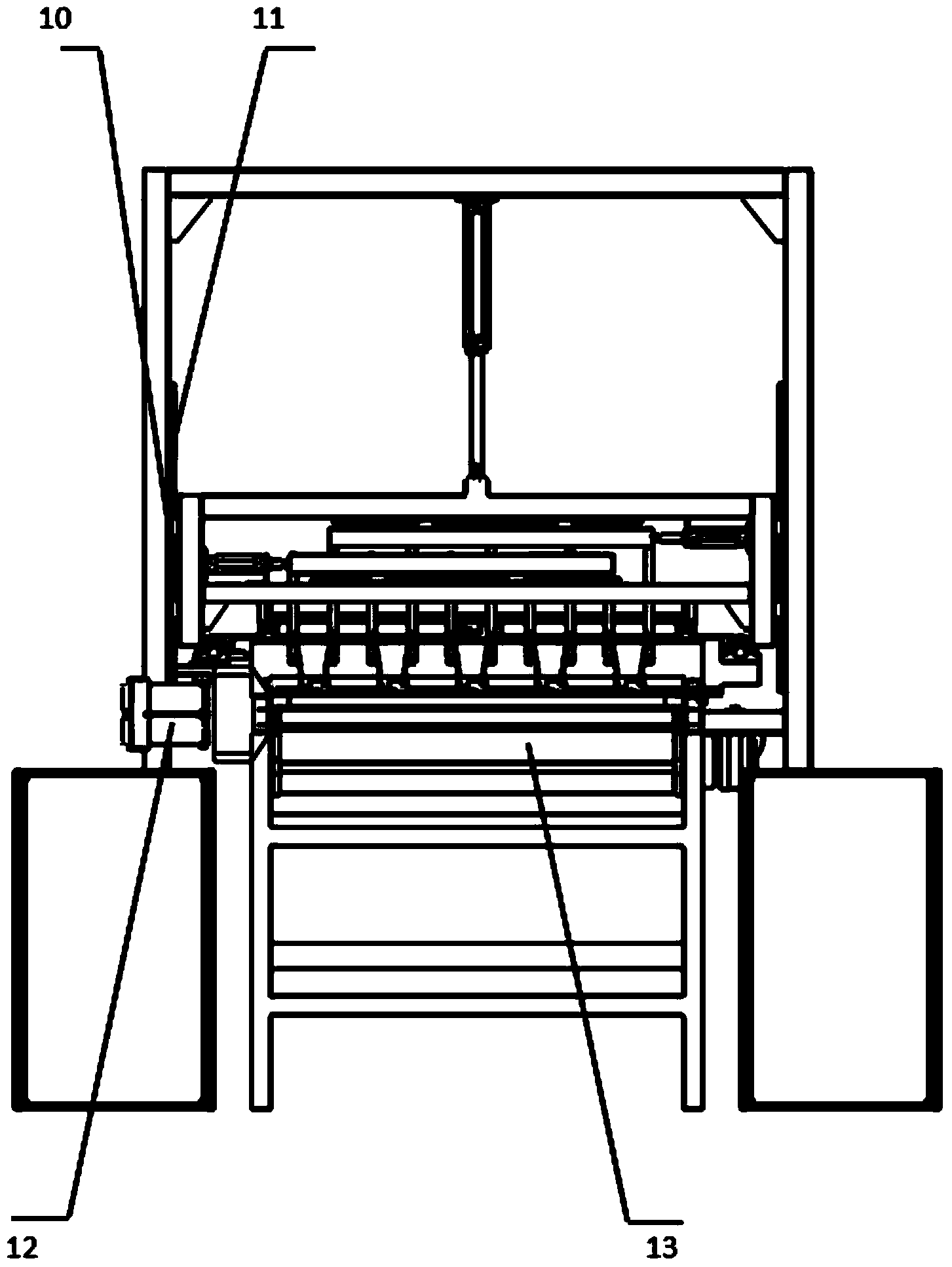

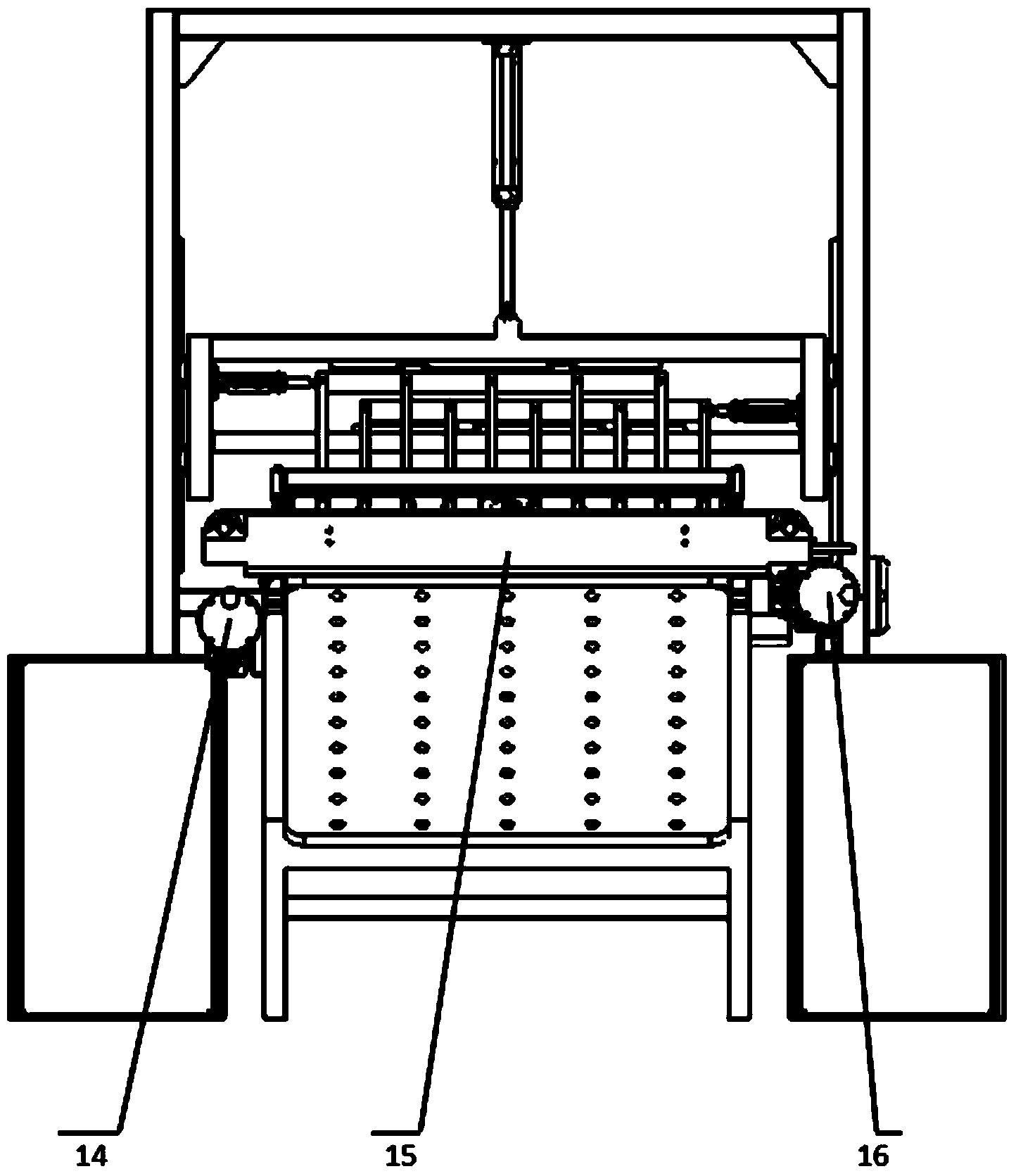

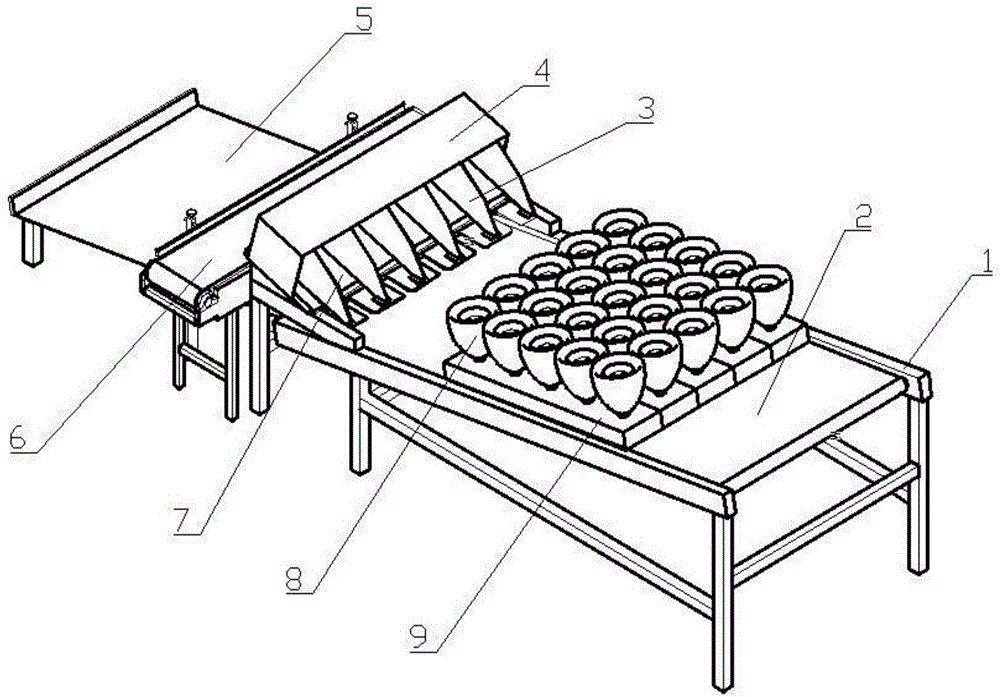

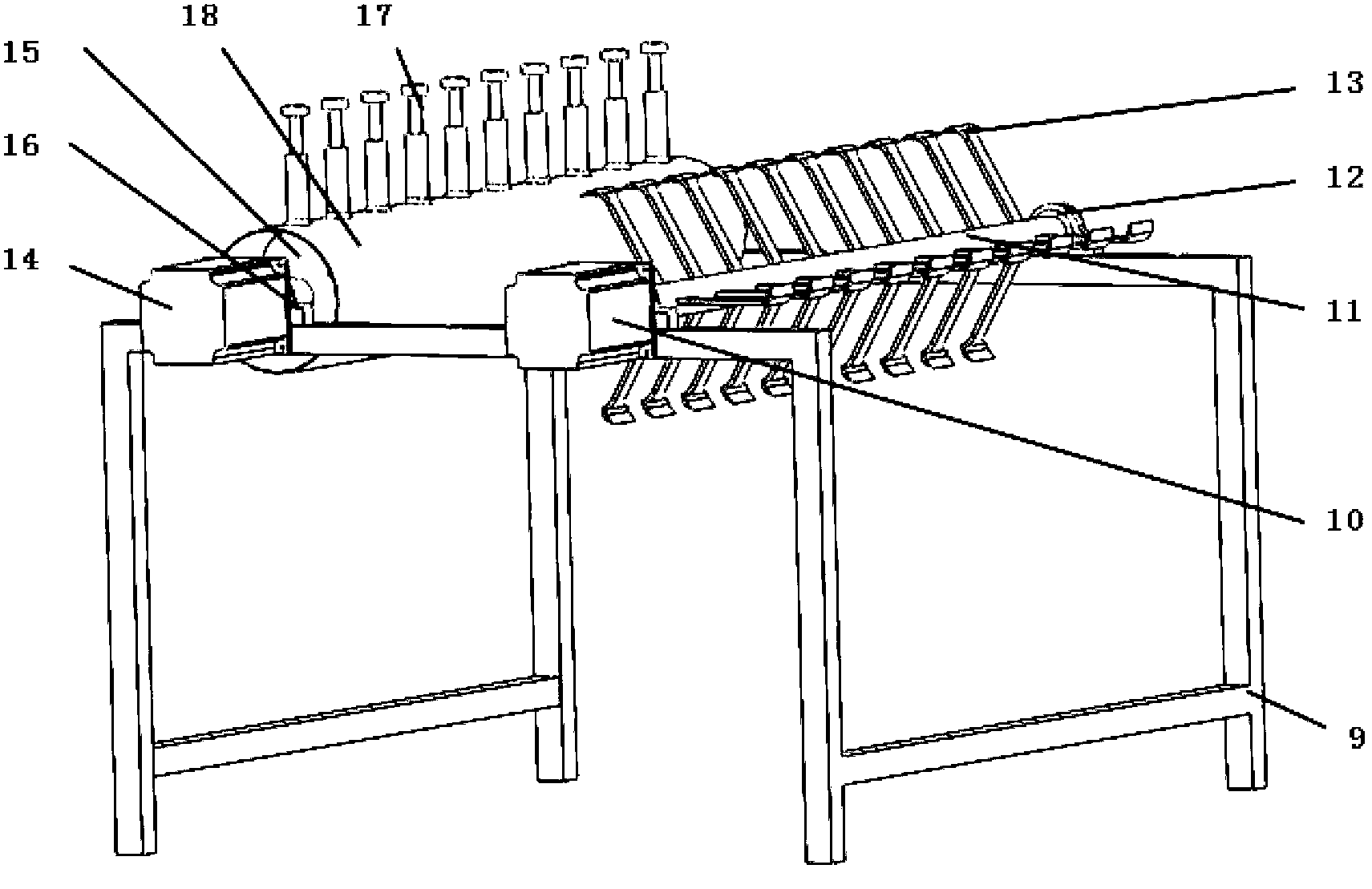

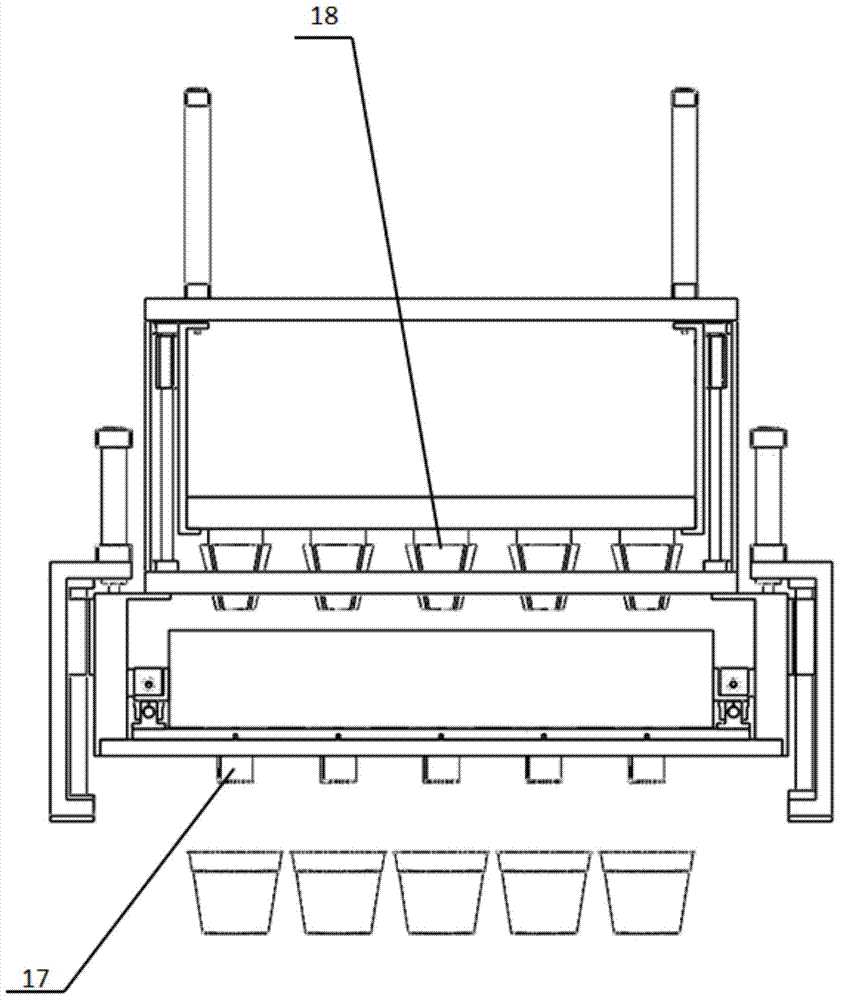

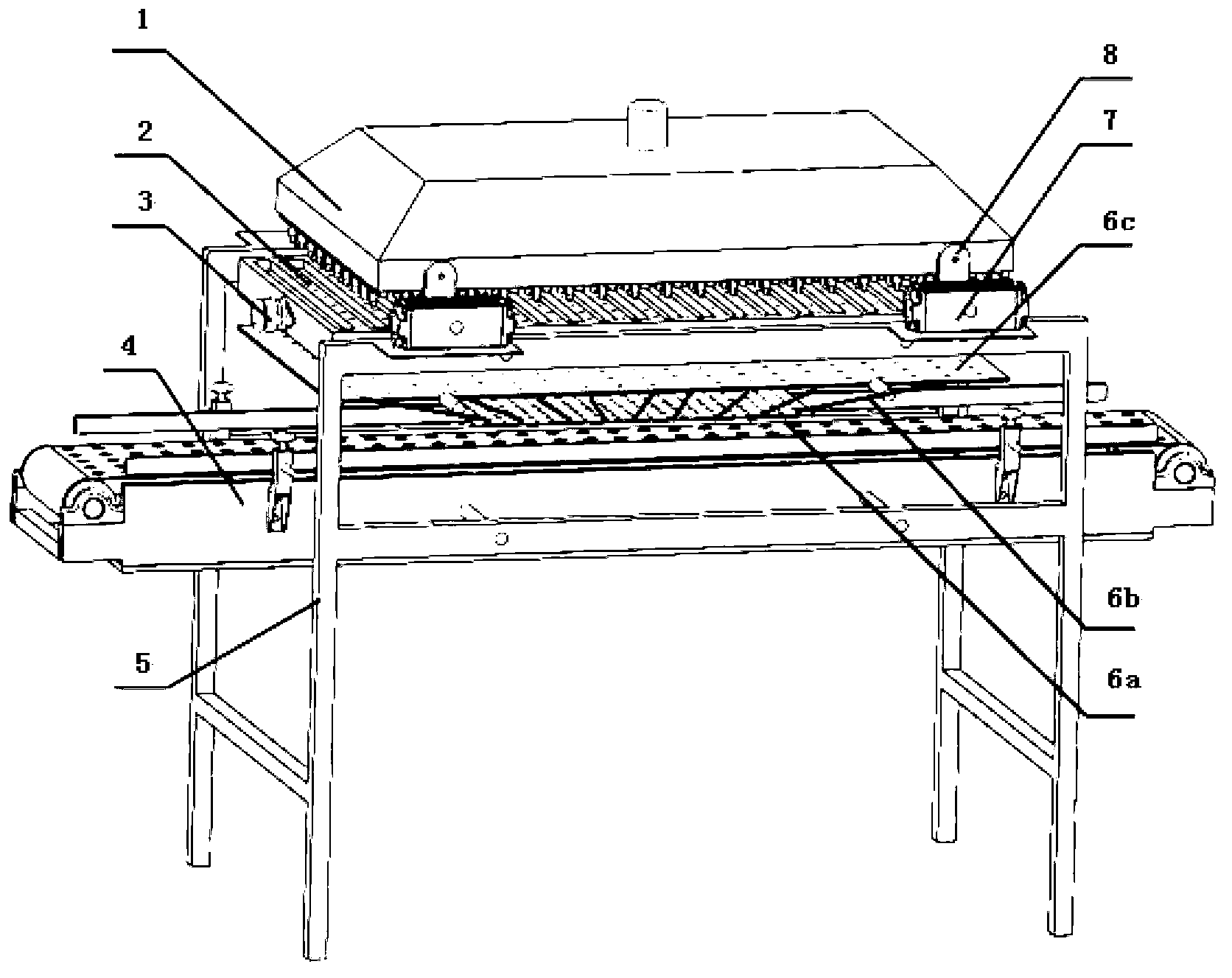

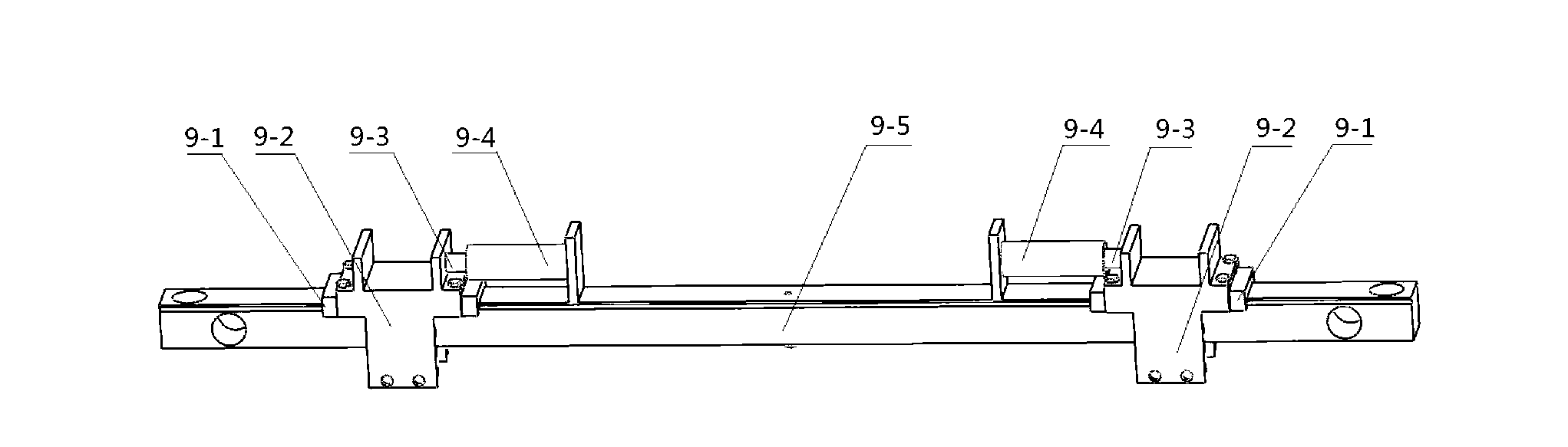

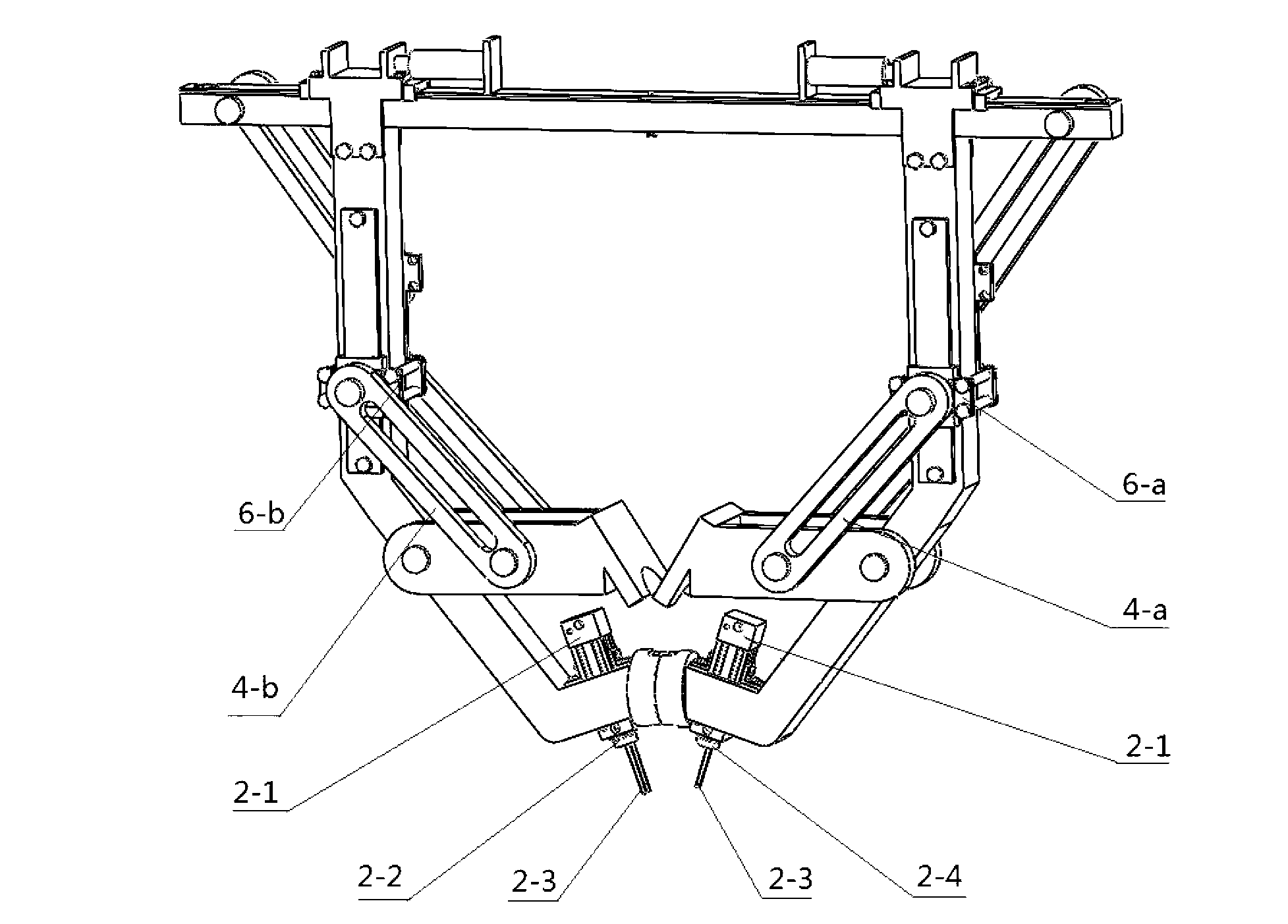

Automated potted-seedling transplanting machine for greenhouse

InactiveCN101843200AHigh degree of automationEasy to installConveyorsTransplantingGreenhouseEngineering

The invention relates to an automated potted-seedling transplanting machine for a greenhouse, belonging to the field of an automated seedling transplanting device in facility agriculture. The transplanting machine comprises a potted tray transport mechanism (2) and a potted seedling transplanting mechanism (6), wherein the potted tray transport mechanism (2) is installed on a machine frame and is used for transporting a potted tray to a specified transplanting work position; the potted seedling transplanting mechanism (6) is used for clipping a seedling out from the potted tray, transporting the seedling to a space above another empty potted tray and then implanting the seedling; and a control box (1) is arranged below the machine frame (4), an operating button for starting and stopping the complete machine is arranged in the control box (1), and the control box (1) can carry out integrating control on all the mechanisms. The transplanting machine can transplant the seedlings of multiple crops, the transplanting work can be completed by simply arranging a potted tray containing a seedling and an empty potted tray to be implanted on the potted tray transport mechanism and taking the potted tray the transplanting work of which is completed away from the potted tray transport mechanism by only one operating person, and other procedures of spraying, disinfecting and the like can be subsequently carried out after the transplanting work is completed. The transplanting machine has the advantages of high automation degree and simple and reliable operation.

Owner:BEIJING UNIV OF TECH

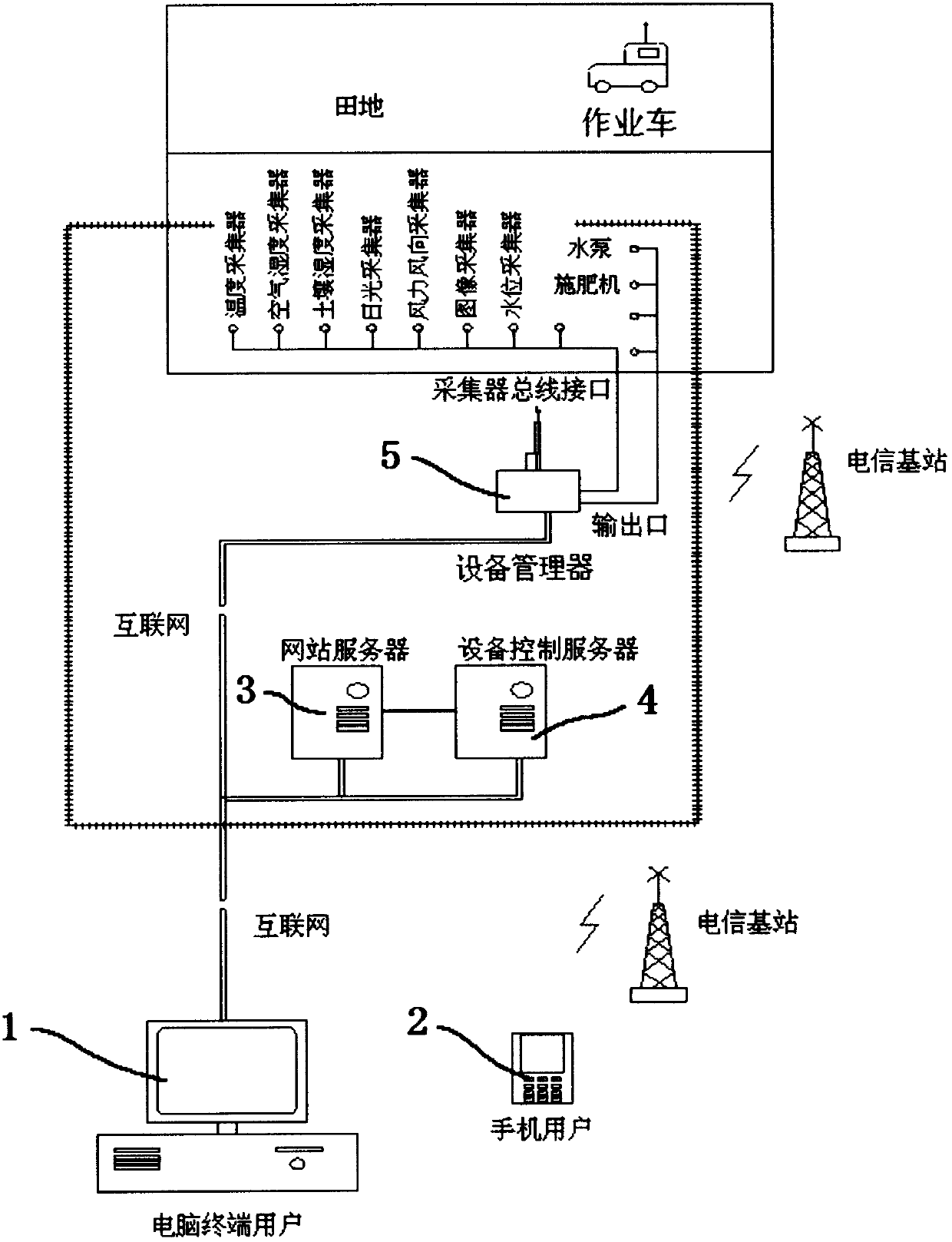

Cloud-based water-saving irrigation automatic control and information management system

ActiveCN105706860AReduce in quantitySave labor costsData processing applicationsWatering devicesAutomatic controlAgricultural irrigation

The invention discloses a cloud-based water-saving irrigation automatic control and information management system and relates to the field of agricultural irrigation, in particular to a cloud-based water-saving irrigation automatic control and information management system which can automatically diverting water for irrigation by monitoring water quantity, climates and soil conditions.The management system is characterized in that the irrigation system conducts data exchange and calculation through a remote database and a remote computer by monitoring the soil conditions in real time, and irrigation is conducted in time according to the growing demands of crops.The management system can be widely applied to waterline building projects, agricultural automation irrigation projects, and water conservancy automation monitoring and controlling projects in agricultural efficient water-saving irrigation.The system is high in automation and information management degree, compared with a traditional offline management mode, the system has the advantages that at least one half or above number of system operation managers (such as charging people, line patrol people and equipment maintenance people for later-period operation and maintenance) can be reduced, and the labor cost for later-period operation and maintenance can be greatly saved.

Owner:YUNNAN JUNLIAN TECH CO LTD

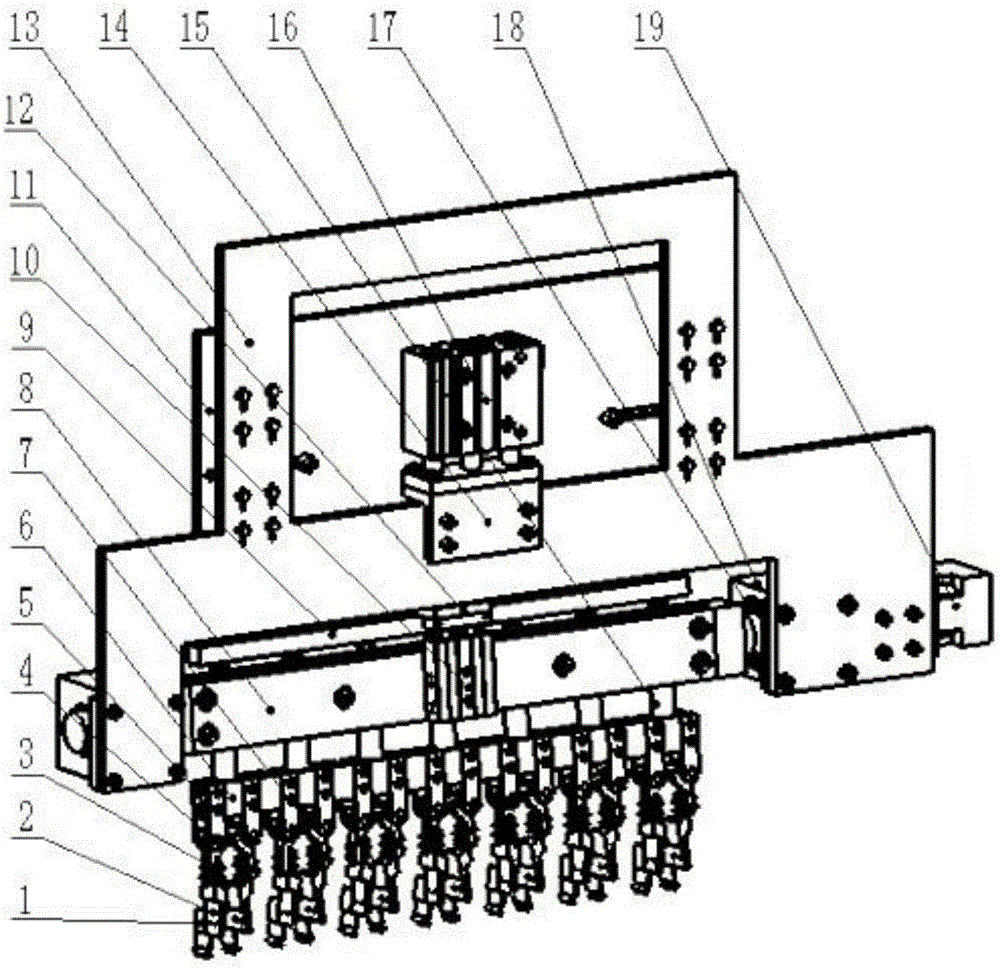

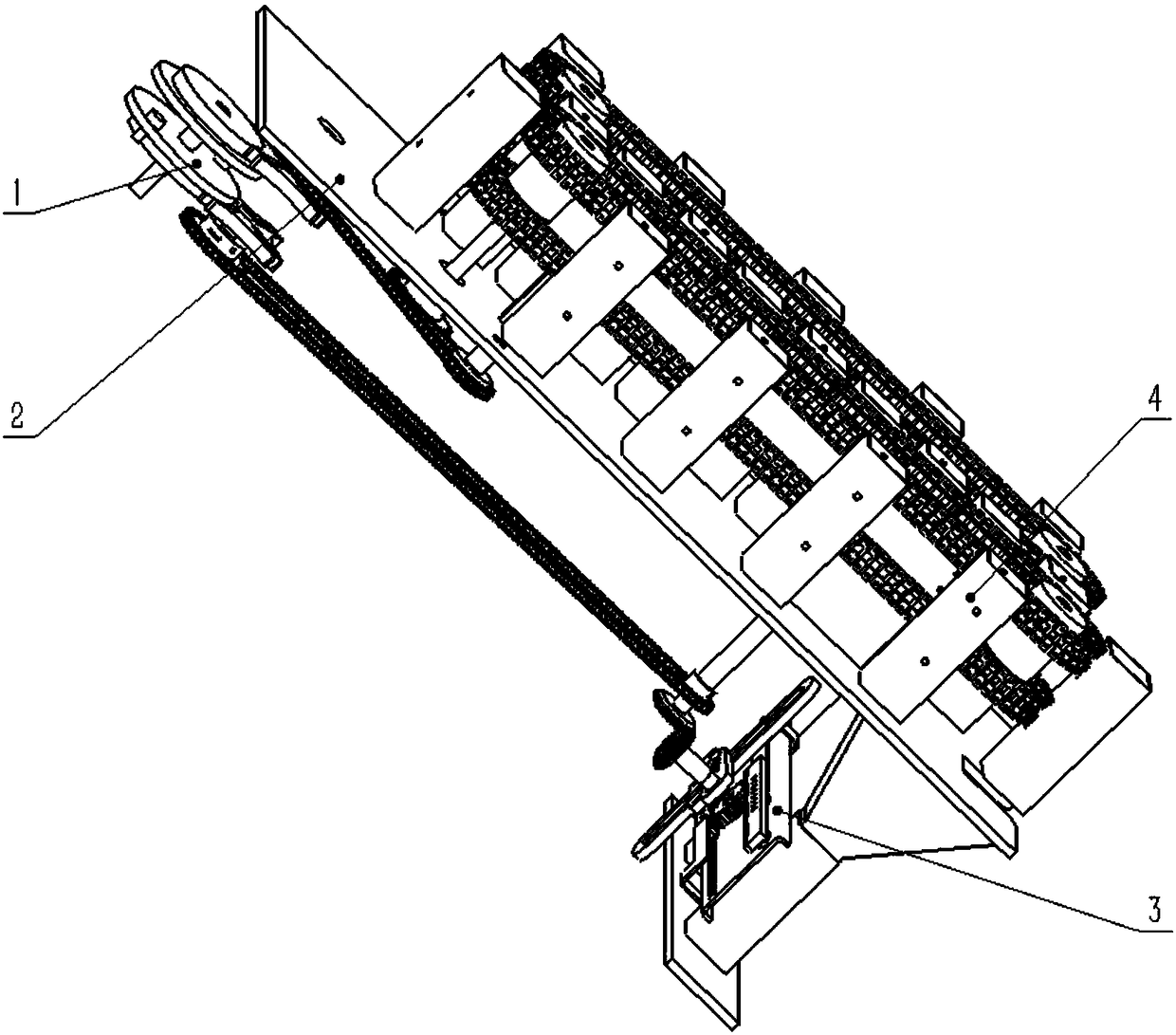

Greenhouse aeroponic culture vegetable harvesting machine

The invention provides a greenhouse aeroponic culture vegetable harvesting machine, and belongs to the field of facility agricultural automation. The greenhouse aeroponic culture vegetable harvesting machine comprises a field planting plate transport mechanism, a vegetable clamping mechanism, a root cutting mechanism and a vegetable transport mechanism. Vegetables are planted in field planting holes of field planting plates, after the vegetables are ripe, the field planting plates planted with the ripe vegetables are conveyed to working positions through the field planting plate transport mechanism, the vegetable clamping mechanism clasps the ripe vegetables, the root cutting mechanism cuts off root systems of the vegetables growing on the field planting plates, rolling rollers below the field planting plate transport mechanism coil the cut-off root systems of the vegetables away, the vegetable clamping mechanism lifts the vegetables and moves the vegetables to the vegetable transport mechanism for next operation, and the field planting plates from which the vegetables are harvested are fed to a recycling bin through the transport mechanism. The harvesting requirements of different foliage aeroponic culture vegetables are met, and after the vegetables are transported, the harvested vegetables can continue to be disinfected and packaged. The greenhouse aeroponic culture vegetable harvesting machine is high in automation degree, simple in operation, stable in working, and capable of reducing labor to a certain degree.

Owner:BEIJING UNIV OF TECH

Greenhouse potted flower transplanting machine

The invention relates to a greenhouse potted flower transplanting machine, and belongs to the field of agricultural automated device seedling transplanting equipment. The machine is mainly used for transplanting flowers from pots with smaller sizes to pots with larger sizes. The machine comprises a pot blanking device, a primary soil covering device, a secondary soil covering device, a transplanting device, a large pot linear conveying mechanism, a small pot conveyor belt, a pot poking mechanism, a large pot conveyor belt, and a rubbing mechanism. The small pot is manually placed on the conveyor belt. Through rubbing, the small pot is positioned into a place requiring transplanting. The large pots are initially empty pots. With the pot blanking device, the pots are neatly blanked on the large-pot conveyor mechanism. Through primary soil covering and secondary soil covering, a cavity with a shape similar to the small pot is formed in the large pot. The pot poking mechanism pushes the large pot onto the large pot conveyor belt, such that the large pot enters the transplanting place. The rubbing mechanism rubs the small pot, and the transplanting mechanism transplants the flower in the small pot into the large pot. With the device, transplanting of various sizes of pots can be satisfied, automation degree is high, and operation is simple and reliable.

Owner:BEIJING UNIV OF TECH

Automatic flower transplanting device

InactiveCN102715035AMeet transplantHigh degree of automationFlower-pot fillingAgricultural automationMechanical engineering

An automatic flower transplanting device belongs to the field of automatic seedling transplanting equipment in protected agriculture. A conveyor of original flowerpots and a conveyor of empty flowerpots respectively convey the original flowerpots and the empty flowerpots into a transplanted flower pot positioning device. An earthing device for empty flowerpots is used for earthing the empty flowerpots before the empty flowerpots are conveyed into the transplanted flower pot positioning device. A flowerpot rubbing device is disposed below a position, at which the transplanted flower pot positioning device positions the original flowerpots and is used for rubbing the original flowerpots being positioned. A flower transplanting gripper above the transplanted flower pot positioning device is used for transplanting flowers from the positioned and rubbed original flowerpots to the empty flowerpots. A flowerpot collecting device is adjacent to the back of the transplanted flower pot positioning device and is used for collecting the flowerpots containing the transplanted flowers and arranging and positioning the flowerpots. The automatic flower transplanting device is available for transplanting and the like of various flower plants, and is applicable to various specifications of flowerpots, high in automation level and simple and reliable to operate during transplanting.

Owner:BEIJING UNIV OF TECH

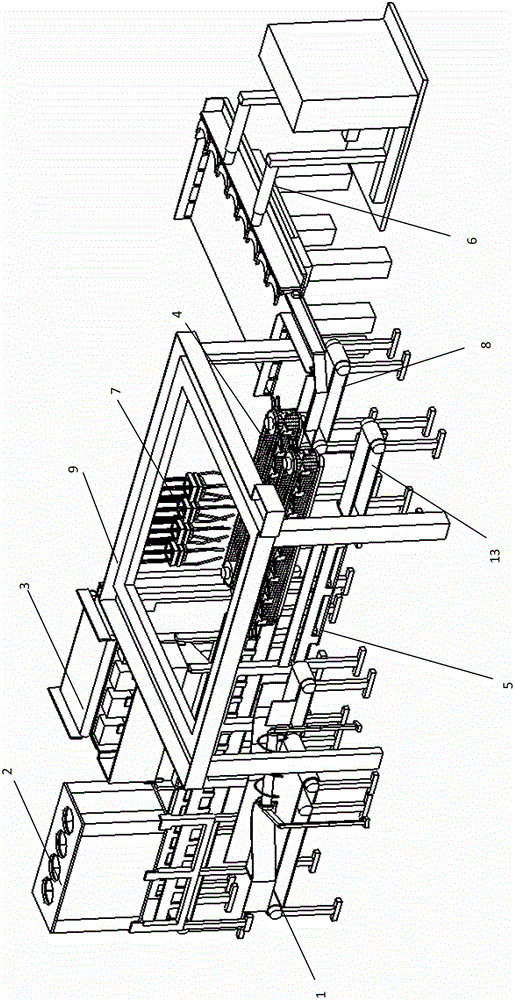

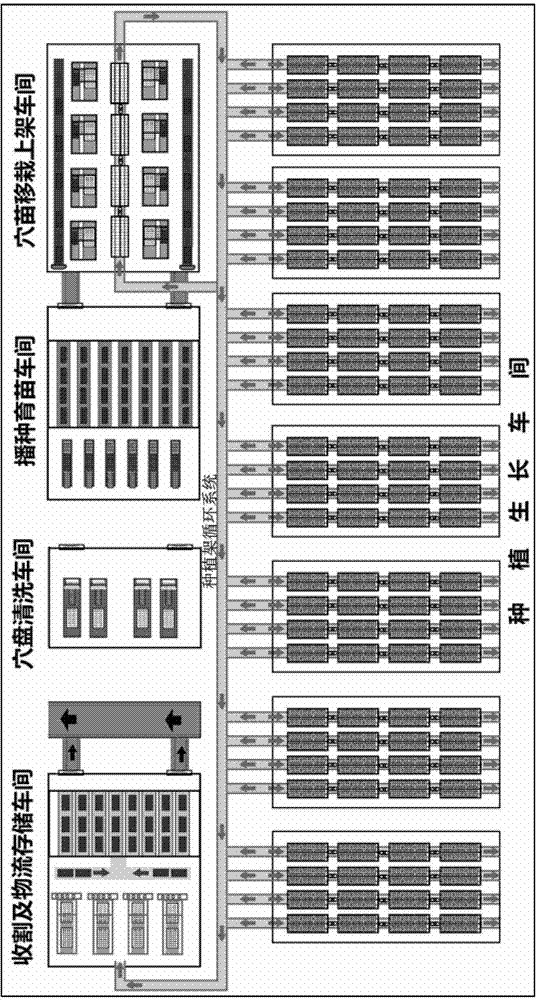

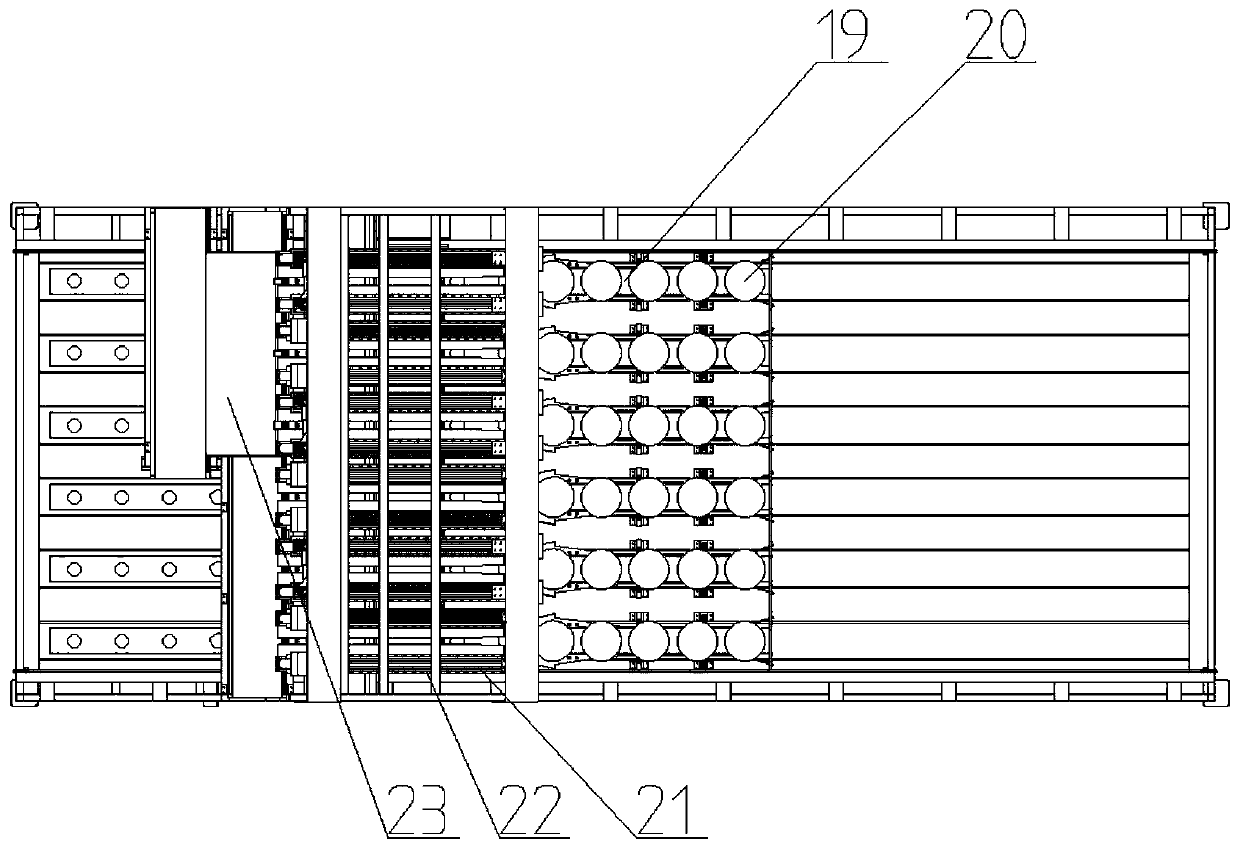

Automated vegetable planting and harvesting production line

InactiveCN102893799AQuality assuranceEasy maintenanceTransplantingCultivating equipmentsProduction lineAgricultural automation

An automated vegetable planting and harvesting production line belongs to the field of agricultural automation. In the invention, a planting shelf circulating system is used for the transportation among a hole-grown vegetable seedling transplanting and shelving workshop, a plantation and growth workshop and a reaping and logistic storage workshop and comprises the steps of: connecting an empty planting shelf conveying passage in the planting shelf circulating system to the hole-grown vegetable seedling transplanting and shelving workshop, wherein empty planting shelves are used for loading and transplanting seedbeds with seedlings in holes; in the hole-grown vegetable seedling transplanting and shelving workshop, conveying the shelved seedlings in the holes to the plantation and growth workshop through a planting shelf conveying passage of the planting shelf circulating system; conveying the planting shelves loaded with vegetables to the reaping and logistic storage workshop through the planting shelf circulating system via a harvesting and conveying passage of the planting shelf circulating system when the seedlings in the holes are ripe and grow into vegetables; and returning empty planting shelves off which the vegetables are taken to the workshop of transplanting and putting the vegetable seedlings in holes on the shelves through the empty planting shelf conveying passage of the planting shelf circulating system, so as to realize circulation of the planting shelves. The an automated vegetable planting and harvesting production line has the advantages of high degree of automation, simple and reliable operation, wide suitability and convenience for popularization and application.

Owner:BEIJING UNIV OF TECH

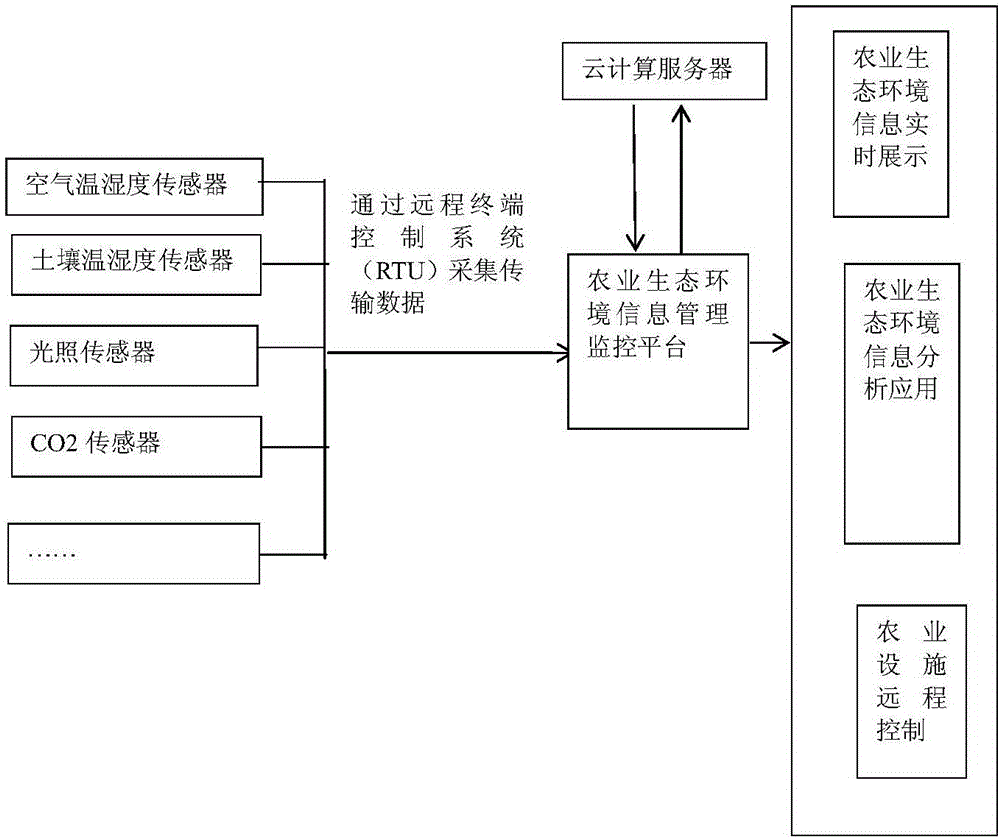

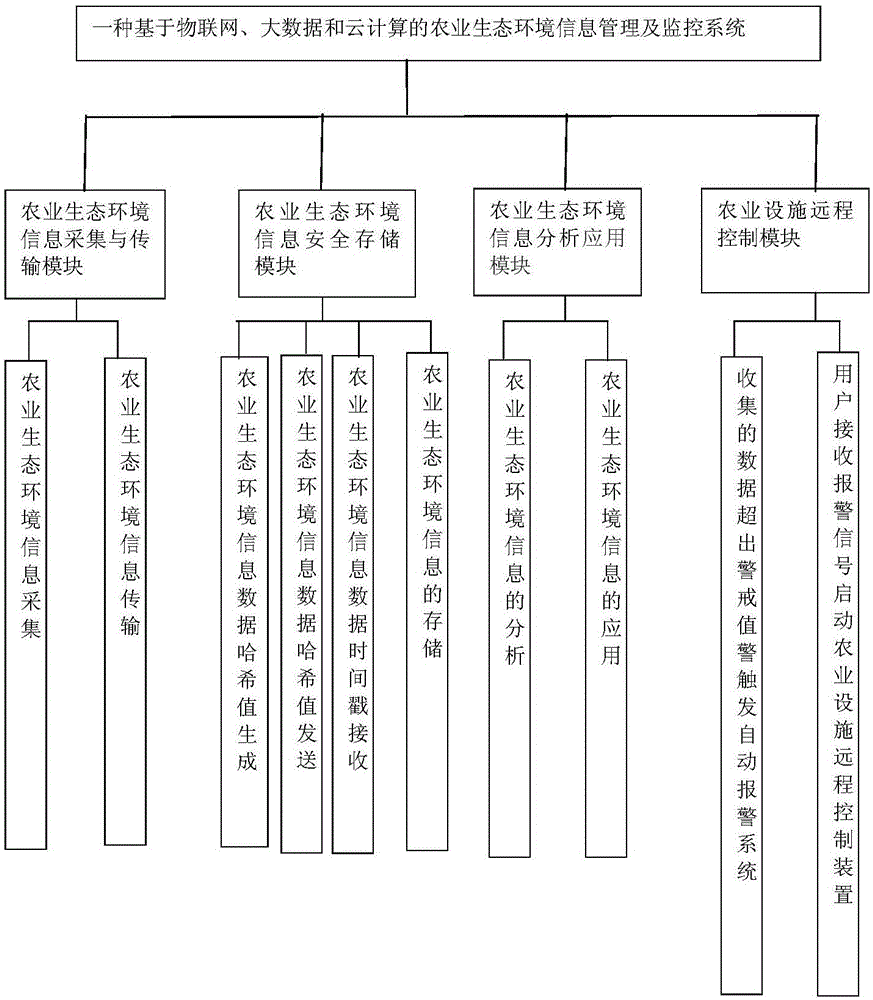

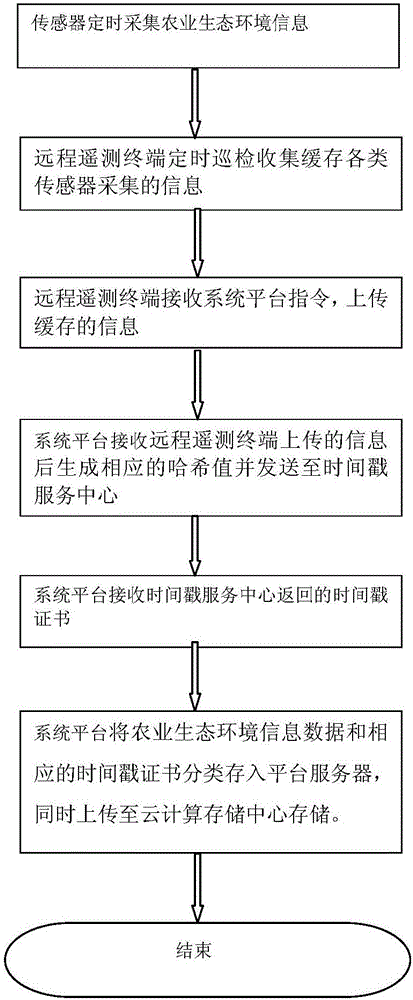

Agricultural ecological environment information management and monitoring method and system based on Internet of Things, big data and cloud computing

InactiveCN106254476AImprove modern technologyImprove management levelData processing applicationsMeasurement devicesInformation analysisEcological environment

The invention relates to an agricultural ecological environment information management and monitoring method and a system based on Internet of Things, big data and cloud computing, which belong to the technical field of computers and network. The method and the system comprehensively use the Internet of Things, the big data, the cloud computing and an electronic data preservation technology, the agricultural ecological environment information is managed and monitored, and through a sensor, a cloud computing platform and the like, the agricultural production process is monitored in real time, remote diagnosis and early warning are carried out, and an agricultural automatic device is remotely controlled to complete related work. The system comprises an agricultural ecological environment information acquisition and transmission module, an agricultural ecological environment information safety storage module, an agricultural ecological environment information analysis and application module and an agricultural facility remote control module. Through the system of the invention, high-efficiency factory farm can be realized, the modern technology and the management level of the agriculture can be improved, and as the electronic data preservation technology is used, the agricultural ecological environment information reliability can be ensured, and the agricultural ecological environment information effective use can be ensured.

Owner:沈阳君农哥科技股份有限公司

Automatic planting vegetable harvester

ActiveCN106664955AAchieving Root Cutting HarvestHigh degree of automationHarvestersAgricultural engineeringTransfer mechanism

The invention discloses an automatic planting vegetable harvester, and belongs to the field of facility agriculture automation. The automatic planting vegetable harvester comprises a conveying and recycling mechanism, a root-cutting harvesting mechanism and a vegetable transfer mechanism. Vegetables are planted in a preset planting board, the planting board is conveyed to a working position by the conveying and recycling mechanism after the vegetables are mature, afterwards, a separation plate and a lift-off plate of the root-cutting harvesting mechanism are used for separating and lifting off the mature vegetables for a distance respectively in the propelling process, a cutting-off mechanism drives a blade to separate the vegetables from roots, the cut vegetables are carried away by the vegetable transfer mechanism and subsequently operated, the planting board is continuously conveyed forwards to board recycling position by the conveying and recycling mechanism, so that the planting board is conveniently recycled. The automatic planting vegetable harvester meets harvesting of planting vegetables of different leaf types, and the harvested vegetables can be continuously cleaned, packaged and the like after being transported. The automatic planting vegetable harvester is high in automation degree and efficiency, simple to operate and stable in working, and labor can be reduced.

Owner:BEIJING UNIV OF TECH

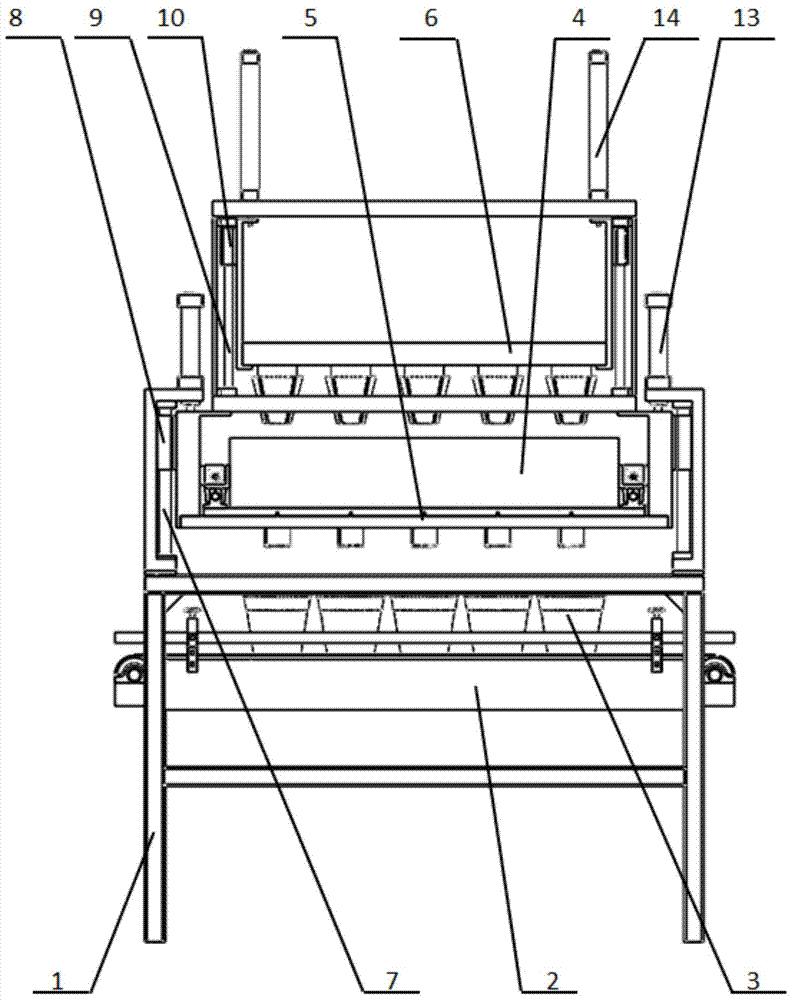

Flowerpot soil filling device

InactiveCN103858698AGuaranteed stabilityGuaranteed accuracyFlower-pot fillingEngineeringAgricultural automation

The invention provides a flowerpot soil filling device. A flowerpot is accurately positioned under a soil cabin fully filled with soil substrates through a flowerpot positioning device, then, the soil cabin releases the soil substrates for fully filling the flowerpot, the soil filling work is completed, and the flowerpot soil filling device belongs to the field of facility agriculture automation equipment and comprises a support frame, a flowerpot conveying device, a soil cabin, a rocker arm, an air cylinder, a soil scraping plate, a flowerpot and a flowerpot positioning device, wherein the flowerpot conveying device conveys the flowerpot to a position under the soil cabin, the flowerpot is accurately positioned through the flowerpot positioning device, and then, a rocker arm fixed shaft rotates through being driven by the air cylinder so that the soil cabin is opened, the soil substrates fall down from the soil cabin for fully filling the flowerpot, and the primary soil filling work in the flower transplanting process is completed. The soil filling device provided by the invention belongs to an important part in the automation flower transplanting production line, the mechanical structure is simple and reasonable, the automation degree is high, and the synchronous soil filling work of several flowerpots can be completed.

Owner:BEIJING UNIV OF TECH

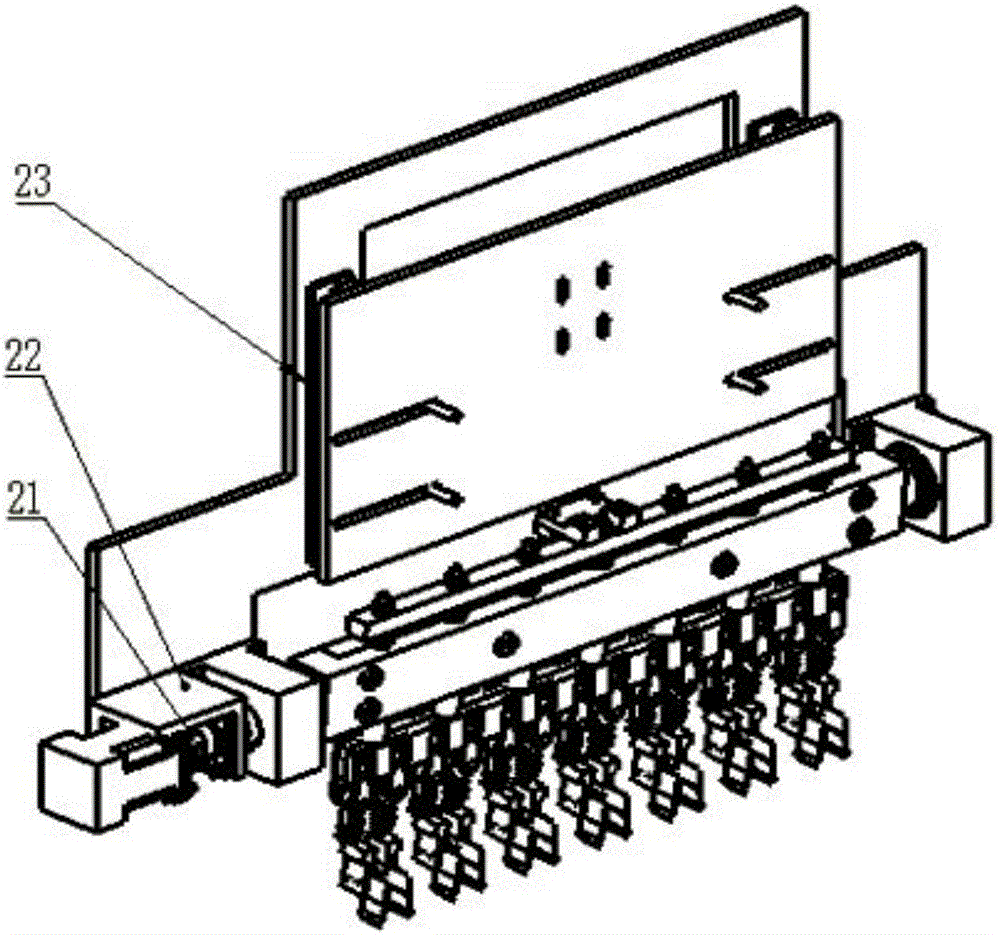

Root cutting harvest device for vegetables planted by modern greenhouse atomization

ActiveCN103262705AReasonable organizationEasy to install and maintainHarvestersGreenhouseEngineering

The invention discloses a root cutting harvest device for vegetable planted by modern greenhouse atomization, and belongs to the field of facility agriculture automation. The root cutting harvest device comprises a conveying mechanism, a root cutting mechanism, a transferring mechanism, a cup pressing mechanism and a cup ejecting mechanism. Vegetables are planted in a planting cup. A benzene plate is conveyed to a working position by the conveying mechanism. Vegetables growing on the benzene plate are subjected root cutting by the root cutting mechanism. Vegetables with roots cut are transferred by the transferring mechanism to a conveying belt to perform a next operation. The planting cup is still kept in a hole of the benzene plate by the cup pressing mechanism in a transferring process. The planting cup is ejected out of the hole of the benzene plate by the cup ejecting mechanism so as to drop into a planting cup recycling case. By the aid of the root cutting harvest device, root cutting harvest of different vegetables can be realized, processes such as spraying, disinfection and packaging can further be introduced after root cutting and clearing are finished. The root cutting harvest device is high in automatic degree, and easy and reliable to operate.

Owner:曹伟鹏 +1

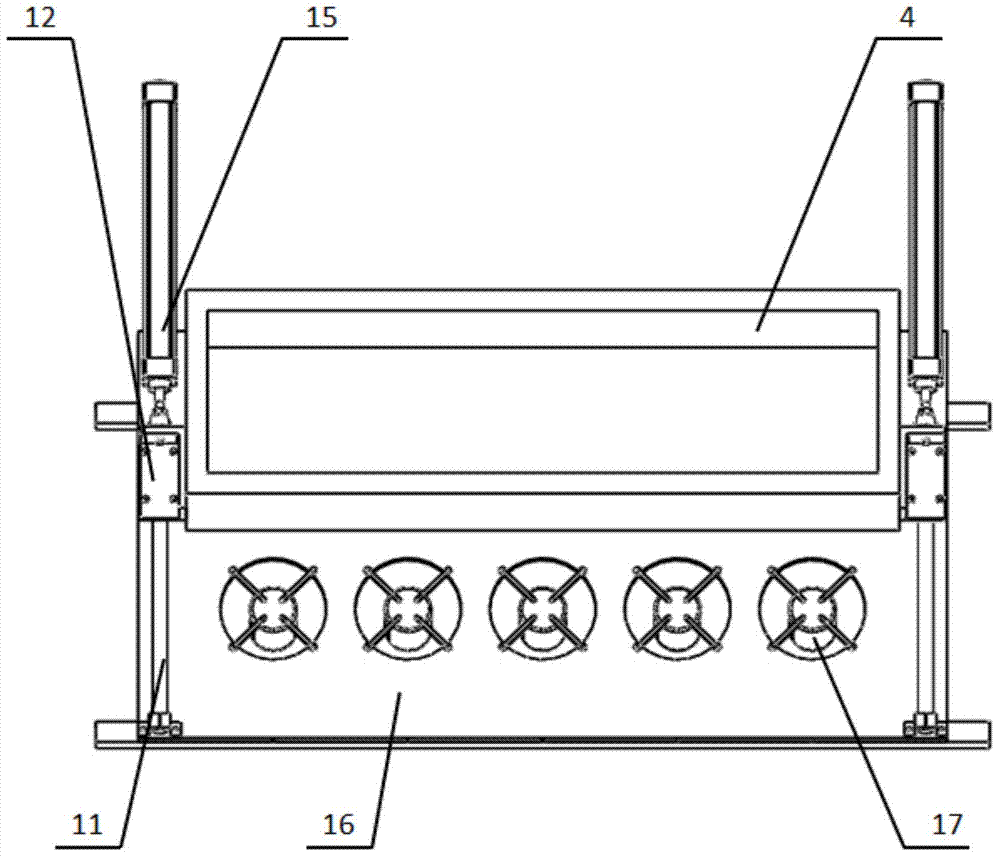

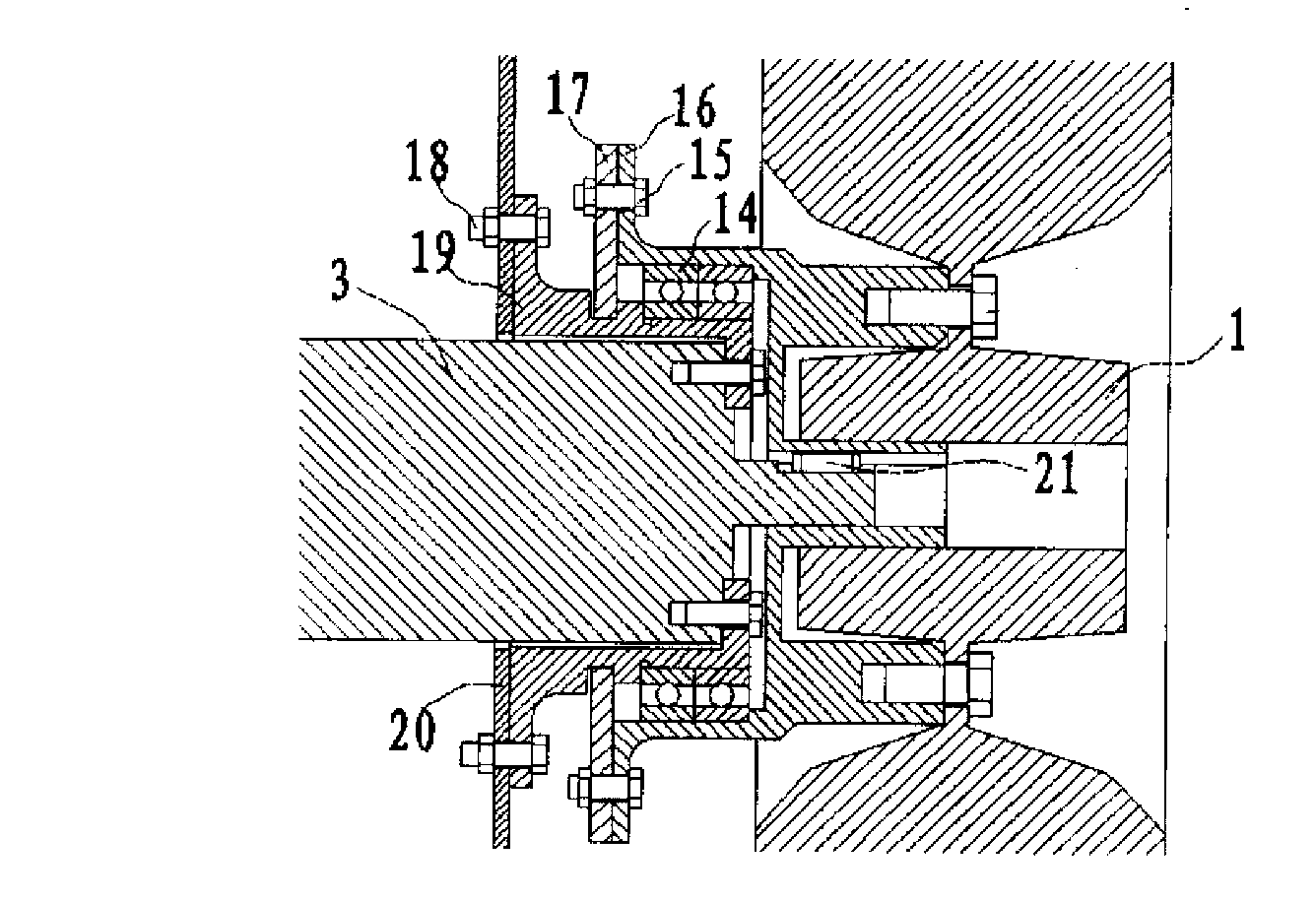

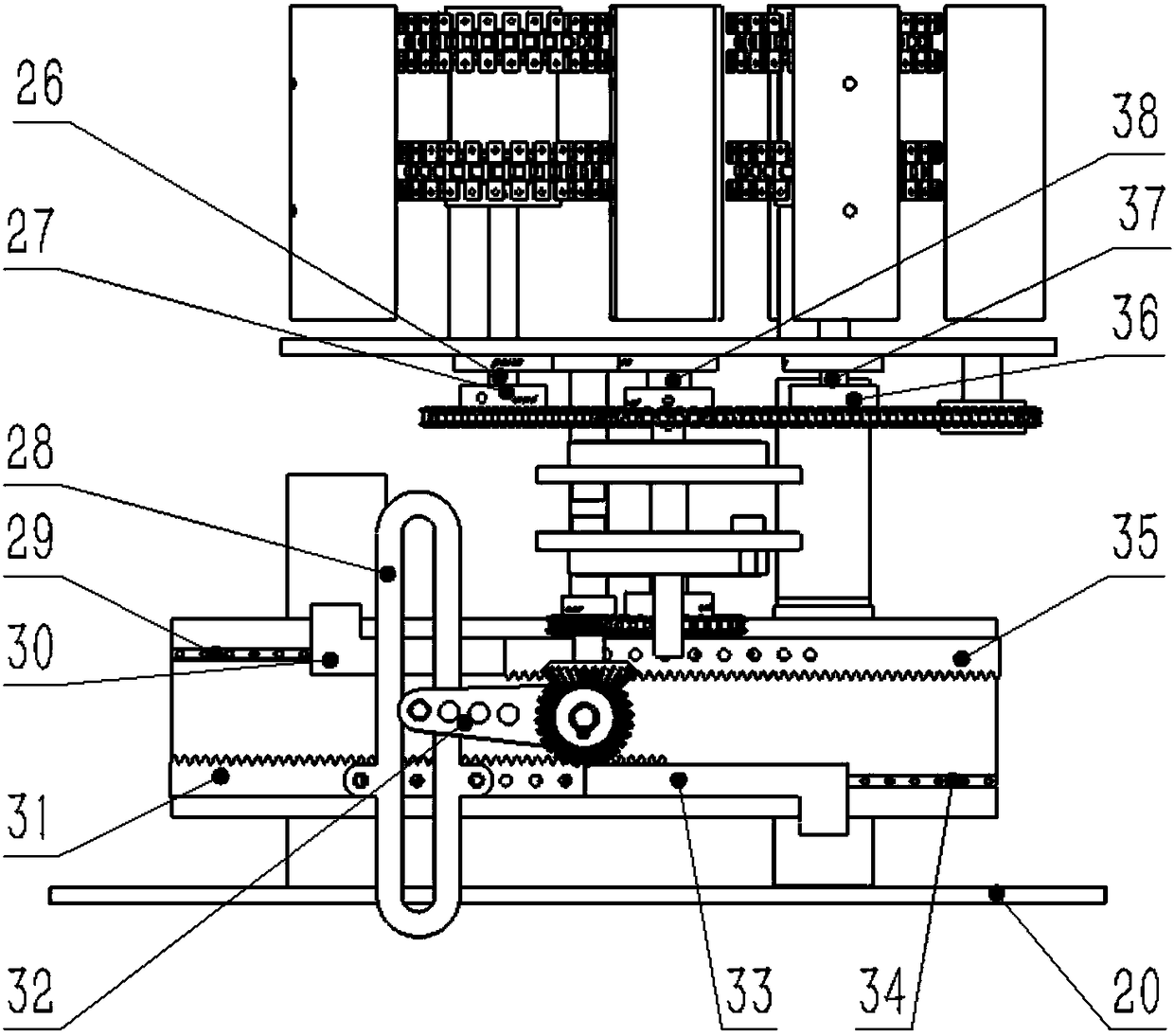

Die flowerpot earthing device

ActiveCN103477900AImprove work efficiencySimplify the transplanting processFlower-pot fillingDie castingEngineering

The invention belongs to the field of automation equipment of equipment agriculture and discloses a die flowerpot earthing device. On the basis of a die which is divided into two portions, a soil matrix is conveyed through a moving soil box, die casting and ramming are performed on the soil matrix in flowerpots, and an earthing step in the process when flower seedlings are transplanted from small flowerpots to big flowerpots is realized. The die flowerpot earthing device comprises a support, a flowerpot conveying device, the flowerpots, the horizontal moving soil box, a primary longitudinal moving die portion and a secondary longitudinal moving die portion. After the flowerpot conveying device conveys and positions the flowerpots below the longitudinal moving die portions, the primary longitudinal moving die portion descends, soil falling work is completed by the moving soil box, and finally the secondary longitudinal moving die portion descends to complete die casting and ramming work of the soil matrix. The die flowerpot earthing device is an important portion in an automatized transplanting production line; by a die casting mode, the flower seedlings carrying the soil matrix can be directly put into the big flowerpots after being taking out from the small flowerpots, and synchronous earthing work of multiple flowerpots can be realized.

Owner:BEIJING UNIV OF TECH

Four-wheel drive navigated spraying robot system

InactiveCN102696571AReduce labor intensityReduce usageInsect catchers and killersRobotic systemsControl signal

The invention discloses a four-wheel drive navigated spraying robot system which belongs to the technical field of agricultural automation. The system mainly comprises an electromagnetic sensor group, angle sensors, wheels, a bottom plate, a sprayer and a controller. The system adopts four direct-current motors to respectively drive the two front wheels and the two rear wheels. The spraying part adopts a spraying mode with spraying mechanisms on both sides, spray lances can be swung to adjust the distance between nozzles and crop, and the control of an electromagnetic spray control valve and a spray pump adopts a step-by-step control signal amplification mode to prevent the subsequent circuit from affecting the controller. The four-wheel drive navigated spraying robot system can automatically carry out spraying operation, decrease the labor intensity of manpower, protect the health of workers, reduce the dosage of pesticide, protect the environment and maintain the sustainable development of agricultural production.

Owner:CHINA AGRI UNIV

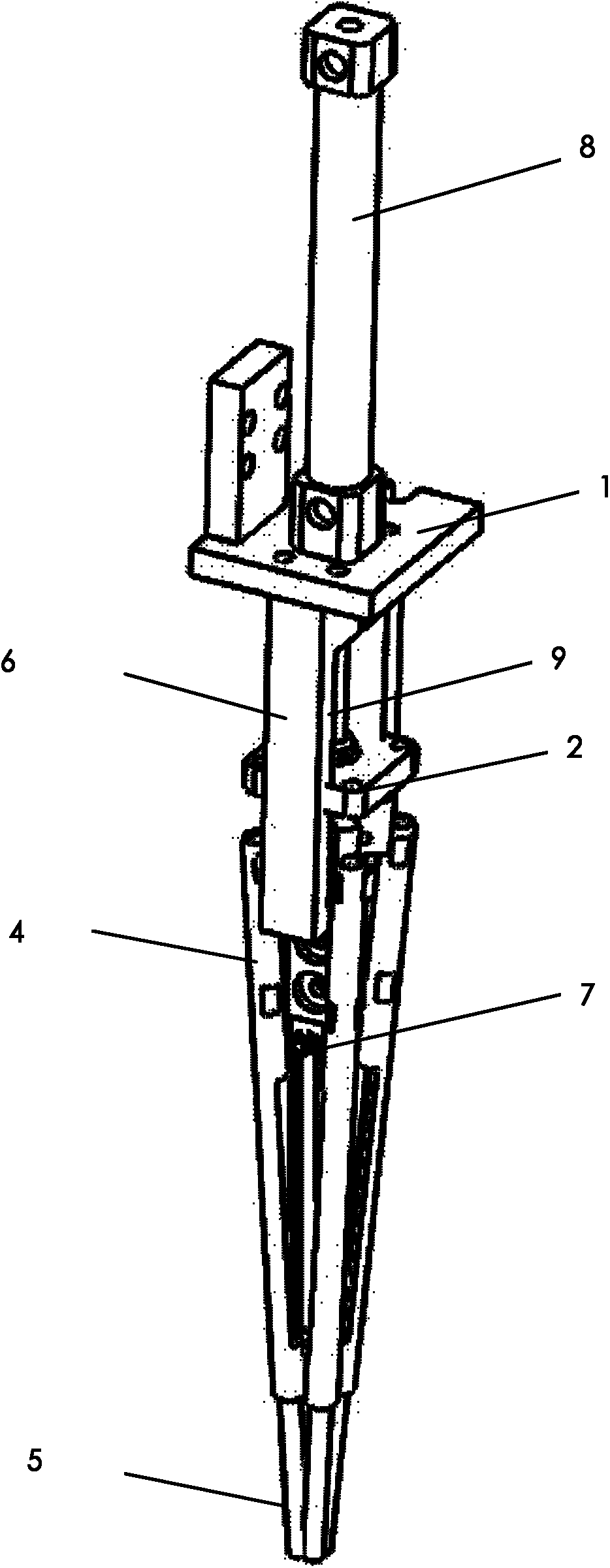

Tissue culture seedling transplanting gripper with scratching function

A tissue culture seedling transplanting gripper with a scratching function belongs to the field of facility agriculture automation seedling transplanting equipment, and comprises a cylinder connecting frame, a steel needle frame, a wedge bench, guide tubes, steel needles, a gripper seat, springs, a cylinder, a cylinder push rod, and movable shafts; the cylinder is mounted above the cylinder connecting frame; the gripper seat is mounted below the cylinder connecting frame; the steel needle frame and the wedge bench are fixed at the front end of the cylinder push rod; a projection is disposed at the inner side of the parallel guide tube, and the projection is provided with a hole; each of the four guide tubes is mounted on the gripper seat by the movable shaft which passes through the hole on the projection, and can rotate around the movable shaft; the four guide tubes are uniformly distributed at the periphery of the outside of the gripper seat, and are mounted parallel to the cylinderaxis. the spring is mounted at the lower part of a group of two guide tubes facing each other, and the two ends of the spring are respectively fixed on the two guide tubes; one end of one steel needle is fixed on the steel needle frame, and the other end is inserted into the guide tube. The invention is applicable to transplanting between different aperture disks, has a compact structure, and is convenient for installation and maintenance.

Owner:BEIJING UNIV OF TECH

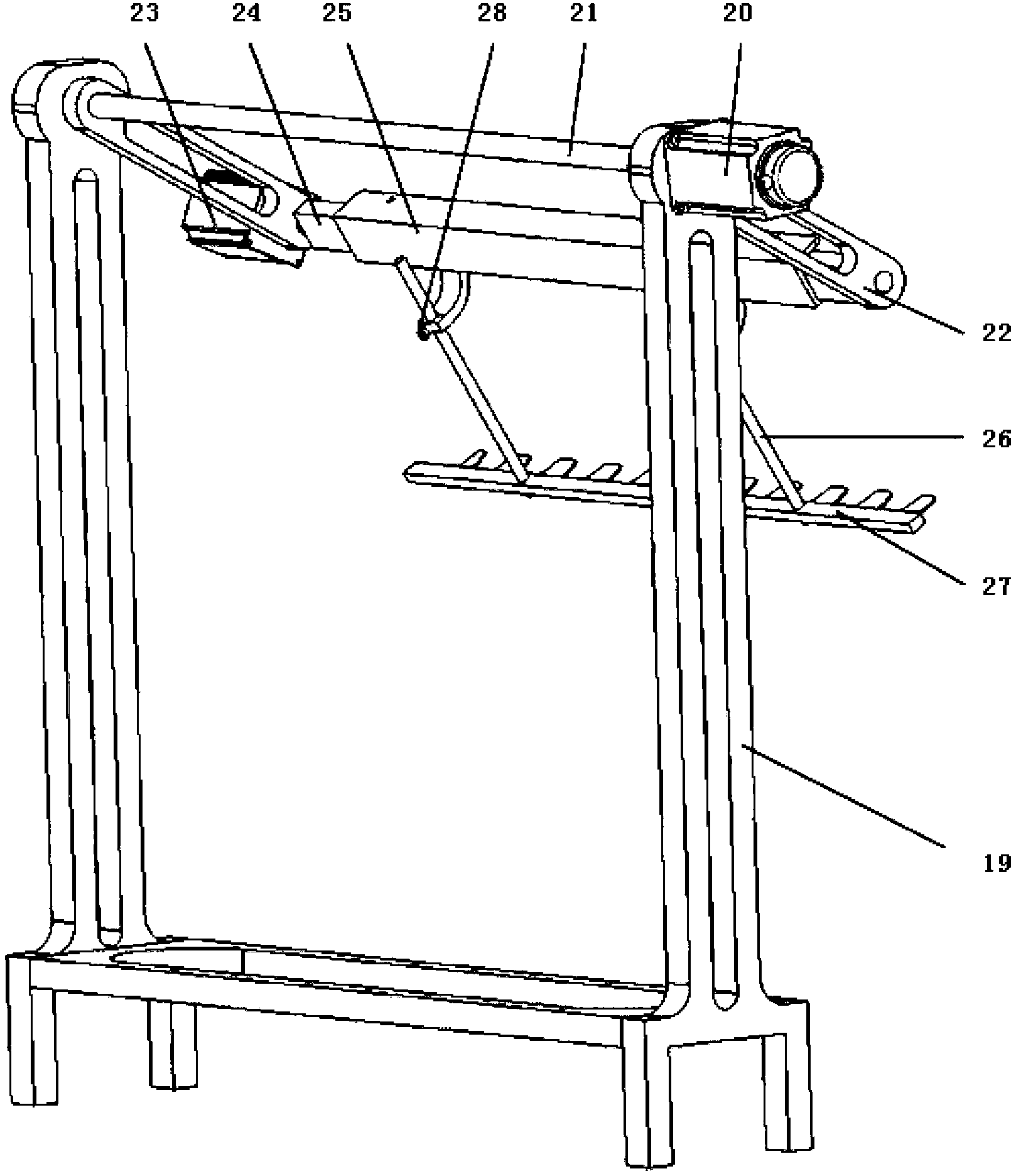

Field planting plate vegetable harvesting mechanism

The invention relates to a field planting plate vegetable harvesting mechanism, and belongs to the field of facility agriculture automation. The field planting plate vegetable harvesting mechanism comprises a portal frame, a vegetable clamping paw and a vegetable root cutting paw. A greenhouse aeroponic cultivation vegetable harvesting paw gathers and clamps vegetables planted into field planting holes in field planting plates through the vegetable clamping paw, root cutting processing is carried out on the clamped vegetables through the vegetable root cutting paw, the vegetables are clamped, and the auxiliary clamping effect on the vegetable clamping paw is achieved. The vegetable clamping paw used for clamping the mature vegetables and the vegetable root cutting paw vertically move on a portal frame table, and the vegetables are transported. The field planting vegetable harvesting mechanism is higher in automatic degree, easy to operate, stable in work and capable of reducing manpower to a certain degree.

Owner:BEIJING UNIV OF TECH

Internet-of-things-based crop growth management method and system

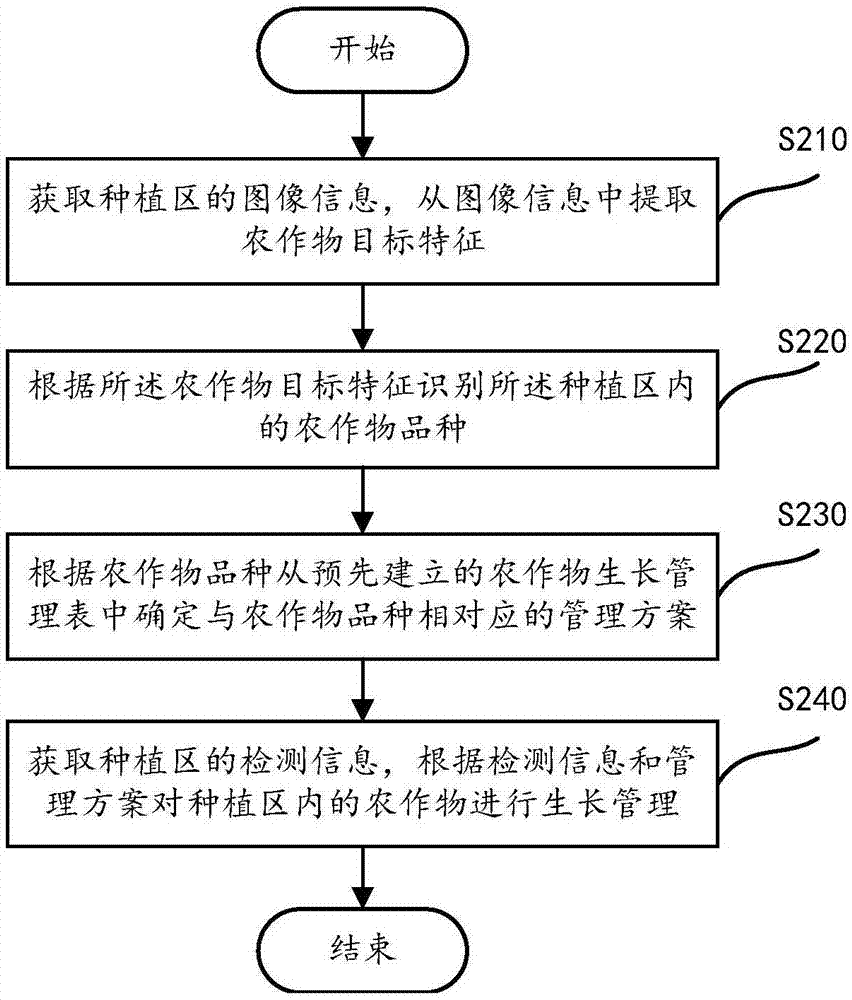

InactiveCN107392104ARealize unified managementReduce yield variabilityData processing applicationsClimate change adaptationGrowth managementAgricultural automation

The invention relates to an internet-of-things-based crop growth management method and system. The method comprises the steps of obtaining image information of a planting region and extracting crop target features from the image information; identifying a crop variety in the planting region according to the crop target features; determining a management scheme corresponding to the crop variety in a pre-established crop growth management table according to the crop variety; and obtaining detection information of the planting region, and performing growth management on crops in the planting region according to the detection information and the management scheme. Therefore, the yield difference of the crops planted by different planters is reduced; the land utilization rate and the economic incomes of the planters are increased; and the agricultural automation level is improved.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

Tray type fruit and vegetable preservative film packaging device

ActiveCN104003006AImprove packaging efficiencyImprove efficiencyWrapping material feeding apparatusWrappingEngineeringAgricultural automation

The invention relates to a tray type fruit and vegetable preservative film packaging device and belongs to the field of agricultural automation devices. The device comprises a tray pushing part, a film conveying part and a film covering and sealing part. The device is an automation device which conducts preservative film packaging on fruits and vegetables and the plastic tray so as to achieve packaging automatically and efficiently. According to the tray pushing part, the film conveying part and the film covering and sealing part, the packaging processes of film pressing, packaging and film cutting and sealing are achieved for the fruits and vegetable in the tray, packaging requirements can be effectively met, operation time can be shortened, and the preservative film packaging efficiency of the vegetables, the fruits and the like with the tray can be improved. A linear slide rail and a liner slide block are respectively of a symmetrical structure, so that all the parts of the packaging device run stably, and the stability of the whole system is ensured. The film covering and sealing part is of a linkage structure, so that drive is effectively simplified, the cost is reduced, and device coordination is improved.

Owner:BEIJING UNIV OF TECH

Direction-variable linkage type plug seedling cuttage gripper

ActiveCN106211886AImprove coordinationCompact structureTransplantingAgricultural engineeringAgricultural automation

The invention provides a drection-variable linkage type plug seedling cuttage gripper and belongs to the field of agricultural automation seedling transplanting equipment. The gripper comprises spring sheets, spring sheet mounting blocks, gripper clamping blocks, gripper supporting plates, top rods, gripper supporting plate mounting frames, rod claw mounting blocks, a rotating shaft, a top plate, a lower cylinder, a seedling carrying plate mounting block, a top rod mounting block, a seedling carrying plate, a cylinder-seedling conveying plate mounting block, a sleeve, an upper cylinder, a linear bearing, a bearing, a bearing mounting seat, a rotary motor, a coupler, a motor mounting seat and a linear guide rail. The spring sheets are cuttage seedling gripping parts of the gripper; each gripper comprises two spring sheets. The gripper is capable of directly carrying out cuttage of a row of flower seedlings at the same time; meanwhile, the cuttage conditions of the flower seedlings can be adjusted; the cuttage consistency is ensured while the damage to the flower seedlings can also be avoided; and meanwhile, the gripper is simple and stable in structure, high in automation degree, and has a relatively high application value.

Owner:BEIJING UNIV OF TECH

Automatic harvester for vegetables planted in planting troughs

InactiveCN110140513AImprove harvesting efficiencyVersatileHarvestersAgricultural engineeringAgricultural automation

The invention belongs to the field of automatic agricultural equipment and discloses an automatic harvester for vegetables planted in planting troughs. The automatic harvester comprises a planting trough conveying mechanism, a vegetable clamping conveying mechanism, a vegetable root cutting mechanism and a transfer conveying mechanism. The planting troughs with ripe vegetables are placed on a planting trough bearing platform and pushed by push rods to realize a conveying process of the planting troughs on the harvester. Along with forward movement of the planting troughs, vegetable leaves on two sides of the planting troughs are gathered together gradually, then vegetables are lift up and separated from the planting troughs after the planting troughs enter the vegetable clamping conveyingmechanism, root systems of the vegetables are cut in a clamping conveying process, the cut root systems are collected through a root system transfer conveying belt, and the vegetables are distributedand conveyed to a packaging workshop through vegetable transfer conveying belts. Complete harvesting of the vegetables planted in the planting troughs is realized. In addition, the automatic harvesteris high in automation degree, high in operation efficiency and reliable and stable in operation.

Owner:北京城农科工科技发展有限公司

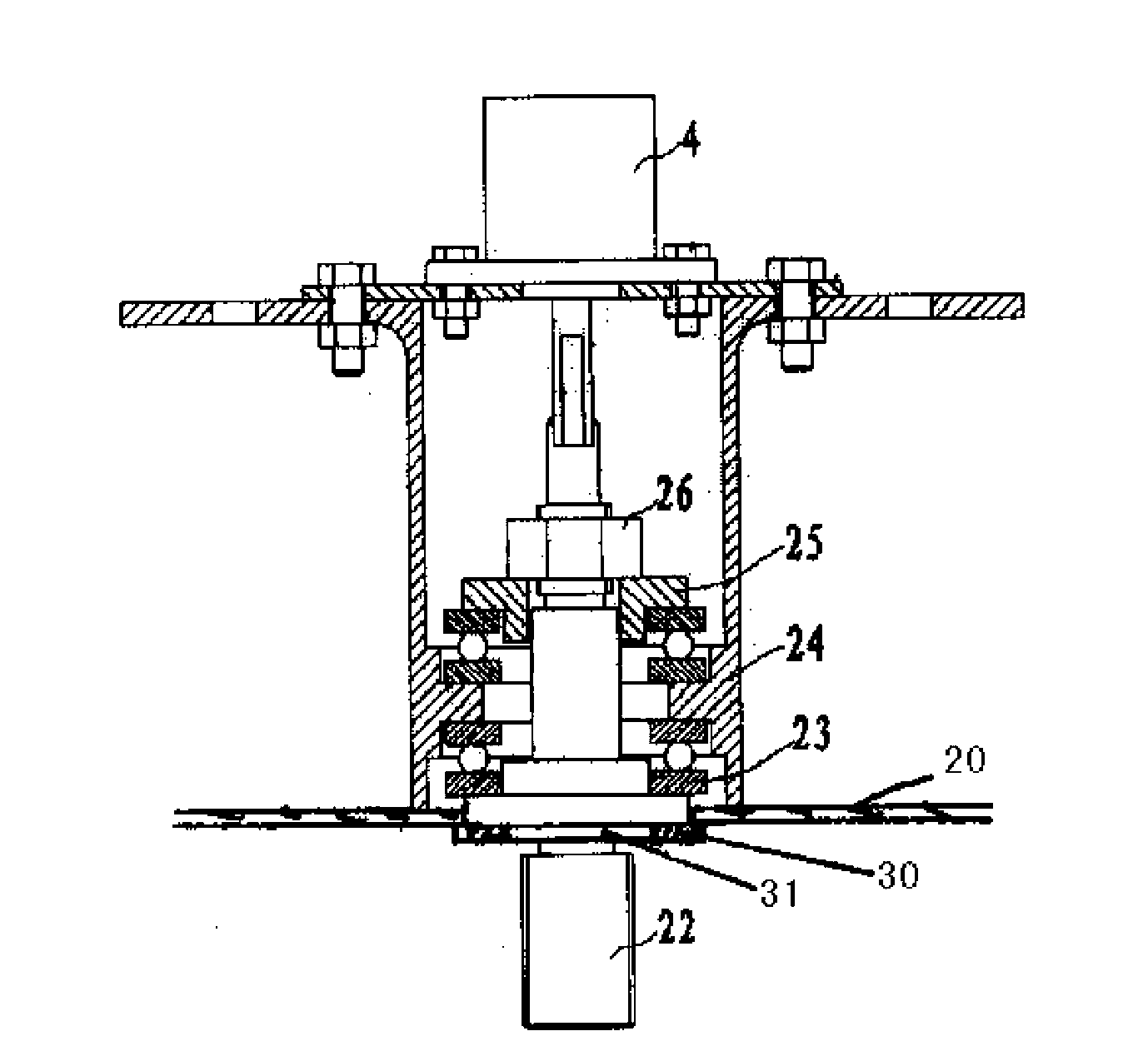

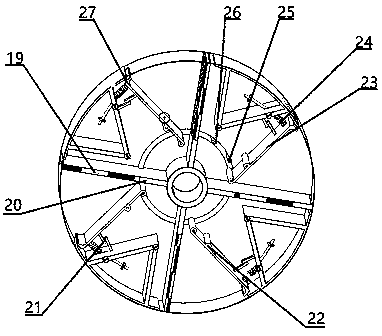

Tray whole-disc seeding device

InactiveCN103283353AImprove work efficiencyMake up for the disadvantage of low row-by-row seeding efficiencySingle grain seedersEngineeringExercise state

The invention provides a tray whole-disc seeding device which carries out whole-disc seed fetching and seeding by adopting mechanical vibration and vacuum adsorption manners, and belongs to the field of facility agriculture automation equipment. The tray whole-disc seeding device comprises a vibration seed storing groove, a pneumatic seed suction part, a seed guide part and transferring equipment. A vibrator mounted on the vertical wall of the seed storing groove serves as a vibration source to provide vibration so that seeds are at a boiling movement state and the pneumatic seed suction part can conveniently suck the seeds. The pneumatic seed suction part sucks out the seeds at the boiling movement state from the seed storing groove through a swinging mechanism driven by a swinging air cylinder; the seed storing groove stops vibration and the swinging air cylinder is swung to a seed storing hole position to release the seeds; the seeds are conveyed to a tray on the transferring equipment through the seed guide part until, so that a seeding process is finished. The tray whole-disc seeding device disclosed by the invention is reasonable in mechanical structure, low in cost, high in automation degree, stable and reliable in performance, and wide in applicable range.

Owner:BEIJING UNIV OF TECH

Transplanting machine seedling separating apparatus and operation method thereof

InactiveCN108174663ARealize continuous power inputReduce the probability of seedling deviationTransplantingIntermittent motionTransmitted power

The invention discloses a transplanting machine seedling separating apparatus and an operation method thereof, which belong to the field of transplanting machine seedling separating in agricultural automation facility. The transplanting machine seedling separating apparatus comprises a grooved pulley mechanism, a frame, a double-slider seedling separating mechanism, and an annular chain-type conveying apparatus; the annular chain-type conveying apparatus is arranged over the frame, the grooved pulley mechanism is arranged below the frame, the grooved pulley mechanism respectively transmits power to the double-slider seedling separating mechanism and the annular chain-type conveying apparatus respectively through chain transmission; the operation method can realize accurate seedling launching at an assigned position through mechanical linkage, realizes intermittent movement of an annular conveying chain, and the relatively stationary seedling launching operation can be reached.

Owner:JIANGSU UNIV

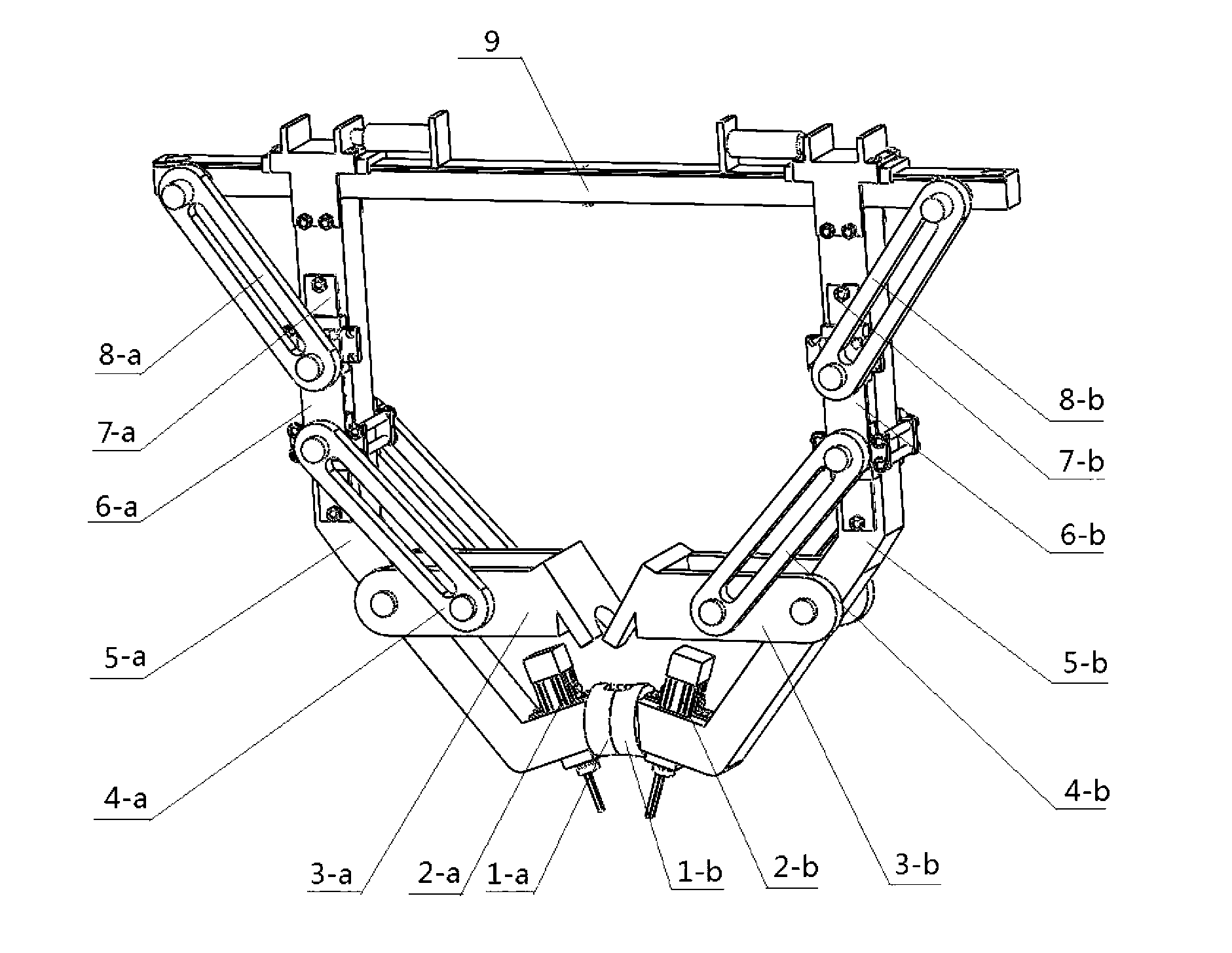

Flower transplanting paw with function of gathering leaves

ActiveCN103004342AAvoid the phenomenon of scratching seedlingsIncrease in sizeGripping headsTransplantingSymmetric designFixed frame

The invention relates to a flower transplanting paw with a function of gathering leaves, and belongs to the field of agricultural automatic offspring seed transplanting equipment. The structure has a symmetric design and is eudipleurally arranged on two sides of a transverse sliding device; an arm, a longitudinal sliding rail group, a longitudinal sliding block group, a sliding block linkage rod, a gathering plate, a synchronous gathering plate linkage rod, a catch fixing device and a paw are arranged on each side; the paw is fixedly connected with the tail end of the arm; the catch fixing device is fixedly connected with the lower part of the arm; the gathering plate is hinged with the middle of the arm; the longitudinal sliding rail group is fixedly connected with the upper part of the arm; the longitudinal sliding block group is arranged on the longitudinal sliding rail group; the arm is fixedly connected with the lower part of a paw fixing frame on one side of the transverse sliding device; the sliding block linkage rod is connected between a transverse moving device and the longitudinal sliding block group; and the synchronous gathering plate linkage rod is connected between the gathering plate and the longitudinal sliding block group. The flower transplanting paw can automatically gather the leaves during catching, so that the phenomenon of damage to seedlings is avoided; the automation degree is high; and the practicability and the applicability are high.

Owner:BEIJING UNIV OF TECH

Carding type branched fruit picking robot

The invention relates to a carding type branched fruit picking robot which is used for efficiently picking fruits such as wolfberries, glossy privet fruits and the like which are produced on low-level branches and distributed in a strip shape and belongs to the technical field of agricultural automation and robots. The robot comprises a mobile picking platform, a control cabinet, a machine vision system, a mechanical picking arm, a fruit collecting box and a carding type picking disk, wherein the mechanical picking arm, the control cabinet, the fruit collecting box and the machine vision system are mounted on the mobile picking platform, and the carding type picking disk is mounted on the mechanical picking arm. Existing general mechanical picking arms are abandoned, the self-developed carding type picking disk for branched fruit picking is used for picking the fruits, the robot is simple, reliable and efficient, and the picking efficiency can be greatly improved. The robot greatly promotes rural economic development and has inestimable significance in improving modernization and intelligentialization of Chinese agriculture and accelerating scientific progress of agriculture.

Owner:SHANDONG GUOXING SMARTECH CO LTD

Internet integrated operating system

InactiveCN102854851AEntertainingInterestingTransmissionProgramme total factory controlRoom temperatureThe Internet

The invention discloses an internet integrated operating system for agricultural automatic production management. According to the internet integrated operating system, automatic cultivation and harvest of agricultural mechanical equipment are remotely controlled in real time, multiple farms are subjected to feed addition, room temperature regulation and watering in real time, the appliance switches in the home are remotely controlled in real time, the family information is monitored, and automatic operation and monitoring are remotely controlled in remote mountains, rivers, seas and other super remote distance. According to the system, a farmer is not required to work in a field and can finish the agricultural work, so that the agriculture enters an automatic historic stage from a mechanical mode, heavy agricultural work is changed into work with entertainment and interestingness, the working efficiency is improved from the original several mu per person to several thousand mu even more per person, the farmer is only required to click the mouse at home, and several thousand mu of fields can be cultivated. After the system is popularized, 95 percent of farmers are liberated from farmlands according to prediction, and the system makes an immeasurable contribution to the social development.

Owner:深圳市深芯半导体有限公司

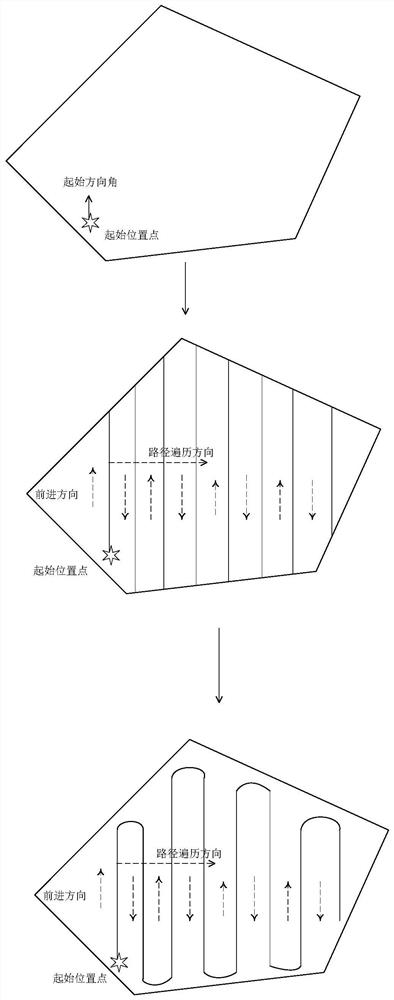

Reciprocating path planning method and device and electronic equipment

ActiveCN111750860AEnsure safetyImprove securityNavigational calculation instrumentsPathPingControl engineering

The embodiment of the invention provides a reciprocating path planning method and device and electronic equipment, and relates to the technical field of path planning. The method can be applied to polygonal operation land parcels. Specifically, the reciprocating path planning method comprises the step of confirming a first inspection edge and a second inspection edge in the advancing direction ofa current straight line segment; and determining a straight line terminal point of the current straight line segment based on the turning radius of operation equipment and a preset distance, so that aturning track taking the straight line terminal point as a starting point does not exceed the first inspection edge and the second inspection edge. Therefore, high-safety path planning can be realized in a full-automatic manner even in the case of land parcels with irregular shapes, and the development of agricultural automation is promoted.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

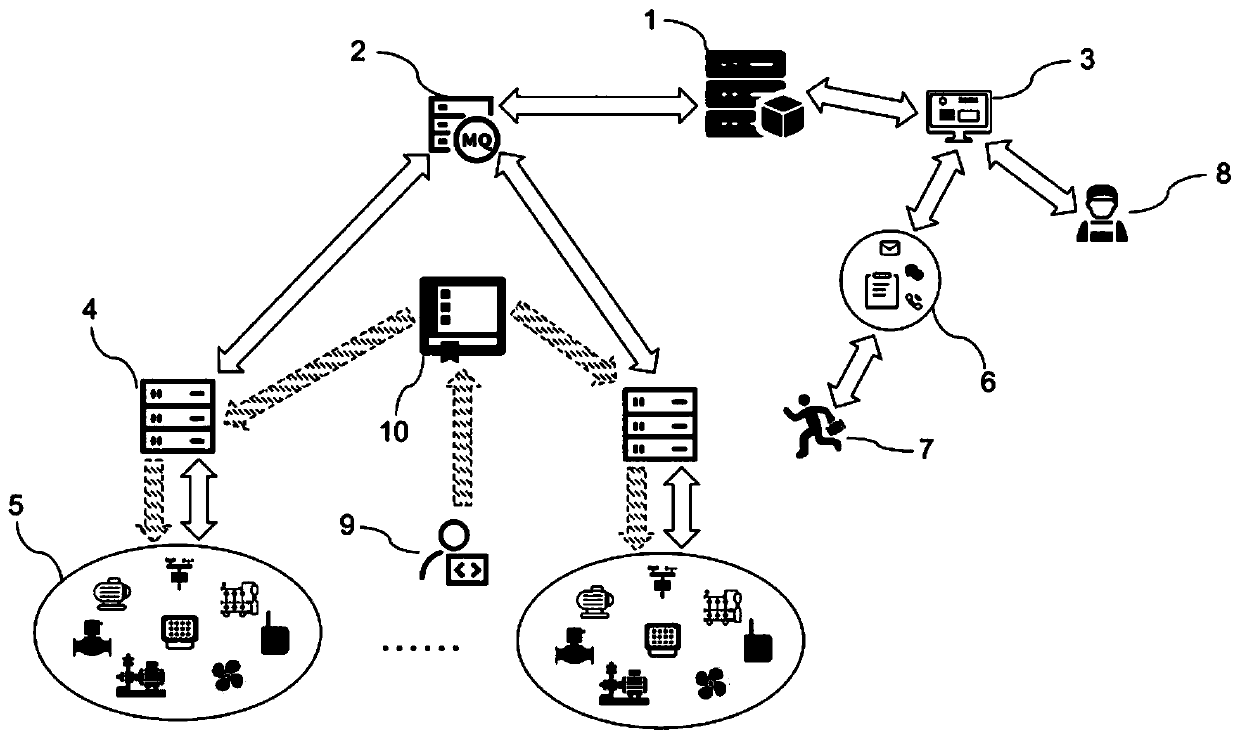

Agricultural automation equipment monitoring, operation and maintenance system

PendingCN111240925AGuaranteed uptimeReduce or avoid adverse effects of production managementVersion controlHardware monitoringApplication serverEdge server

The invention discloses an agricultural automation equipment monitoring, operation and maintenance system, which comprises an application server and a message proxy server, wherein the application server is used for running monitoring, operation and maintenance software / services, backing up and storing monitoring and operation historical data of each agricultural automation edge server, and is connected with a message proxy server; and the message proxy server is used for performing message proxy among the agricultural automation edge servers, the application server and the monitoring, operation and maintenance software. According to the agricultural automation equipment monitoring, operation and maintenance system, centralized operation, maintenance, monitoring and management can be carried out on agricultural automation equipment distributed at different geographic positions, the operation and maintenance efficiency is improved, adverse effects of abnormal conditions of the system onuser production management are reduced or avoided, and finally the operation effect of the agricultural automation equipment is improved.

Owner:昆明尚禾农业科技有限公司

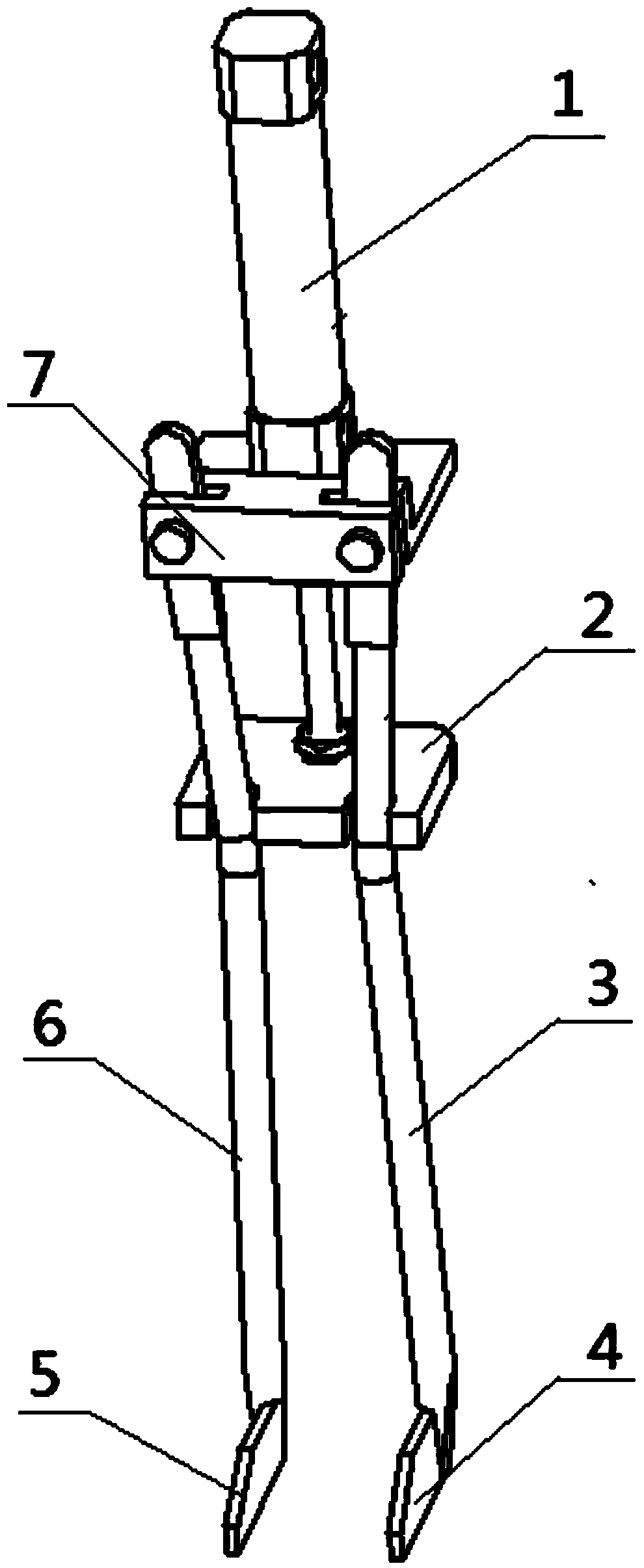

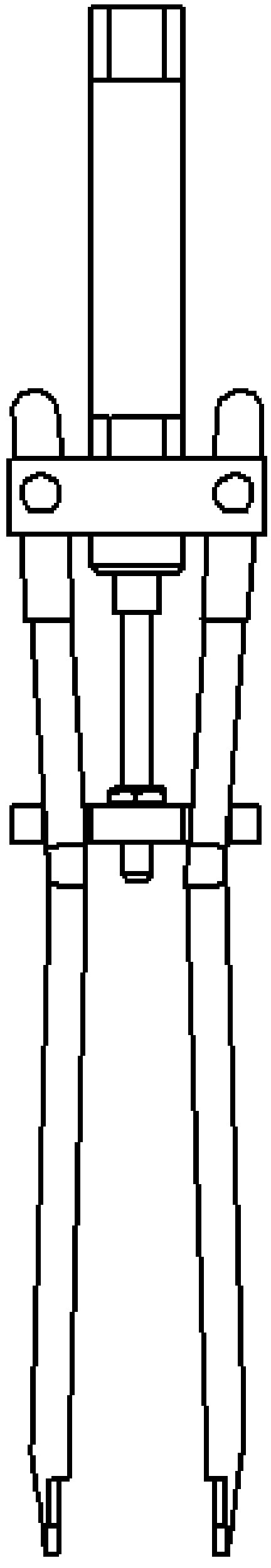

Stem-gripping type potted seedling transplanting claw

The invention relates to a stem-gripping type potted seedling transplanting claw, belonging to the field of agricultural automatic seedling transplanting equipment. The stem-gripping type potted seedling transplanting claw disclosed by the invention is composed of a driving cylinder, a push frame, a left arm, a left claw, a right claw, a right arm and a fixed frame; the fixed frame is in an L-shaped structure; the driving cylinder is installed on the fixed frame; the push frame is installed at the tail end of a push rod of the driving cylinder; two long holes are formed in the push frame; both the upper and lower sections of the left arm and the right arm are provided with a folded corner respectively; the upper ends of the left arm and the right arm are symmetrically hinged onto the fixed frame through a pin shaft respectively; the upper parts of the folded corners of the left arm and the right arm respectively penetrate through the two long holes in the push frame; the left claw and the right claw are fixedly connected with the tail ends of the left arm and the right arm respectively. The seedling injury rate is reduced while the stronger gripping capability is ensured in a manner of griping stems; the whole structure is only singly driven; the stem-gripping type potted seedling transplanting claw disclosed by the invention is simple in structure, high in automation degree and strong in practicability and reliability.

Owner:BEIJING UNIV OF TECH

Agricultural automation pineapple picking machine

The invention discloses an agricultural automation pineapple picking machine. The agricultural automation pineapple picking machine comprises a driving device, a picking device and a delivering counting device; the driving device is a power part of the machine; a double-shaft motor drives a driving wheel to rotate; a cutter disc in the centre of a frame is a main picking device; adjusting mechanisms are arranged on the two sides of a cutter disc frame; the delivering counting device is arranged below a fruit outlet position of the cutter disc; out-flow fruit enters a fruit storage box througha conveyor belt; a shearing device is arranged right below the cutter disc for shearing pineapple rods at the same height; a baffle plate is arranged between the cutter disc and the shearing device, so that a blocking phenomenon when the shearing pineapple rods enter equipment is avoided. An operating table is arranged at the top of the frame; an electric box is arranged on one side, close to an operator, of the frame. According to the equipment, the labour intensity can be lightened; the picking quality and the production efficiency are improved; the research and development of the equipmenthas very important significance in the field of pineapple picking.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Agricultural automatic irrigation detection control system and method

InactiveCN107896950APromote growthWon't wasteClimate change adaptationWatering devicesWireless controlSolenoid valve

The invention discloses an agricultural automatic irrigation detection control system and method. The control system comprises a soil temperature and humidity sensor, a water flow sensor, a sensor signal collector, a solenoid valve, a relay, a water pump, a monitoring center, a wireless control terminal and a power distribution system; the sensor signal collector is connected with a soil temperature and humidity sensor, the water flow sensor and the wireless control terminal separately, and the wireless control terminal is connected with the power distribution system, the relay and the monitoring center separately. Accordingly, the irrigation volume needed by crops can be intelligently and precisely judged, automatic irrigation is achieved, crop growth is facilitated, and the water resource cannot be wasted. Meanwhile, water needed by irrigation can be guaranteed, when a water delivery pipe leaks, an alerting signal is transmitted to a Web terminal automatically, related personnel arereminded to process the water delivery pipe in time, the irrigation efficiency is improved, and meanwhile waste of the water resource is avoided.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com