Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8836results about "Picking devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

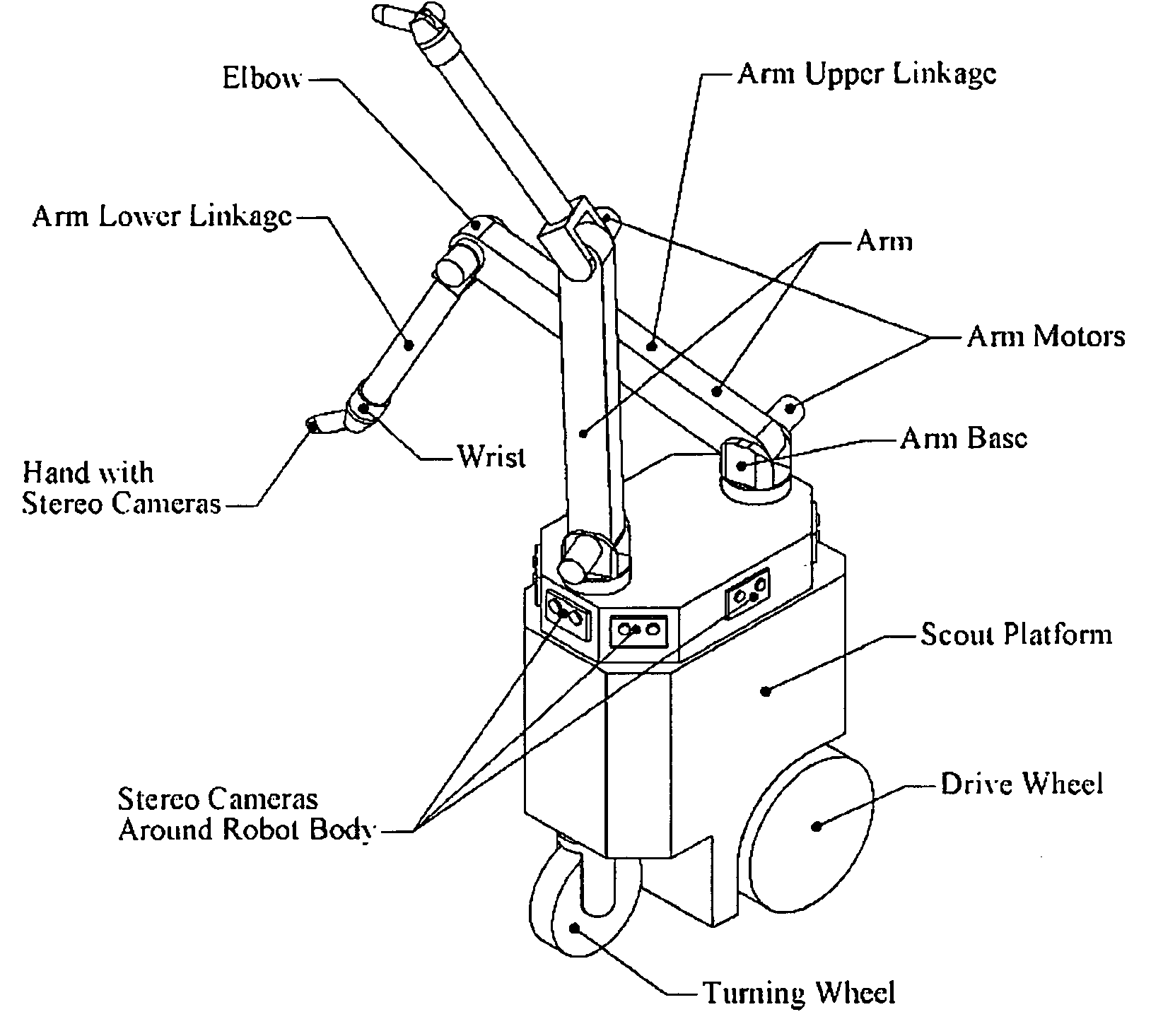

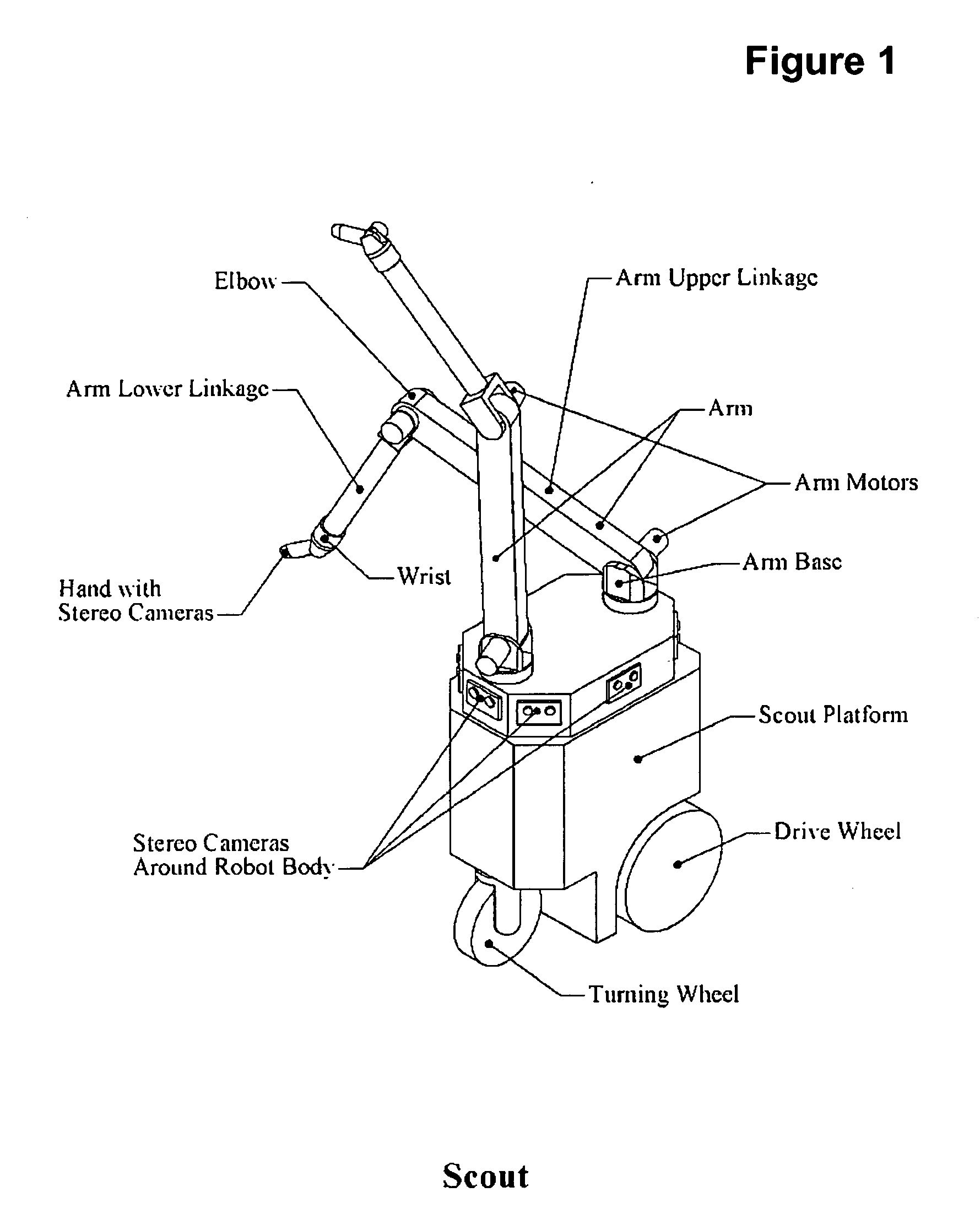

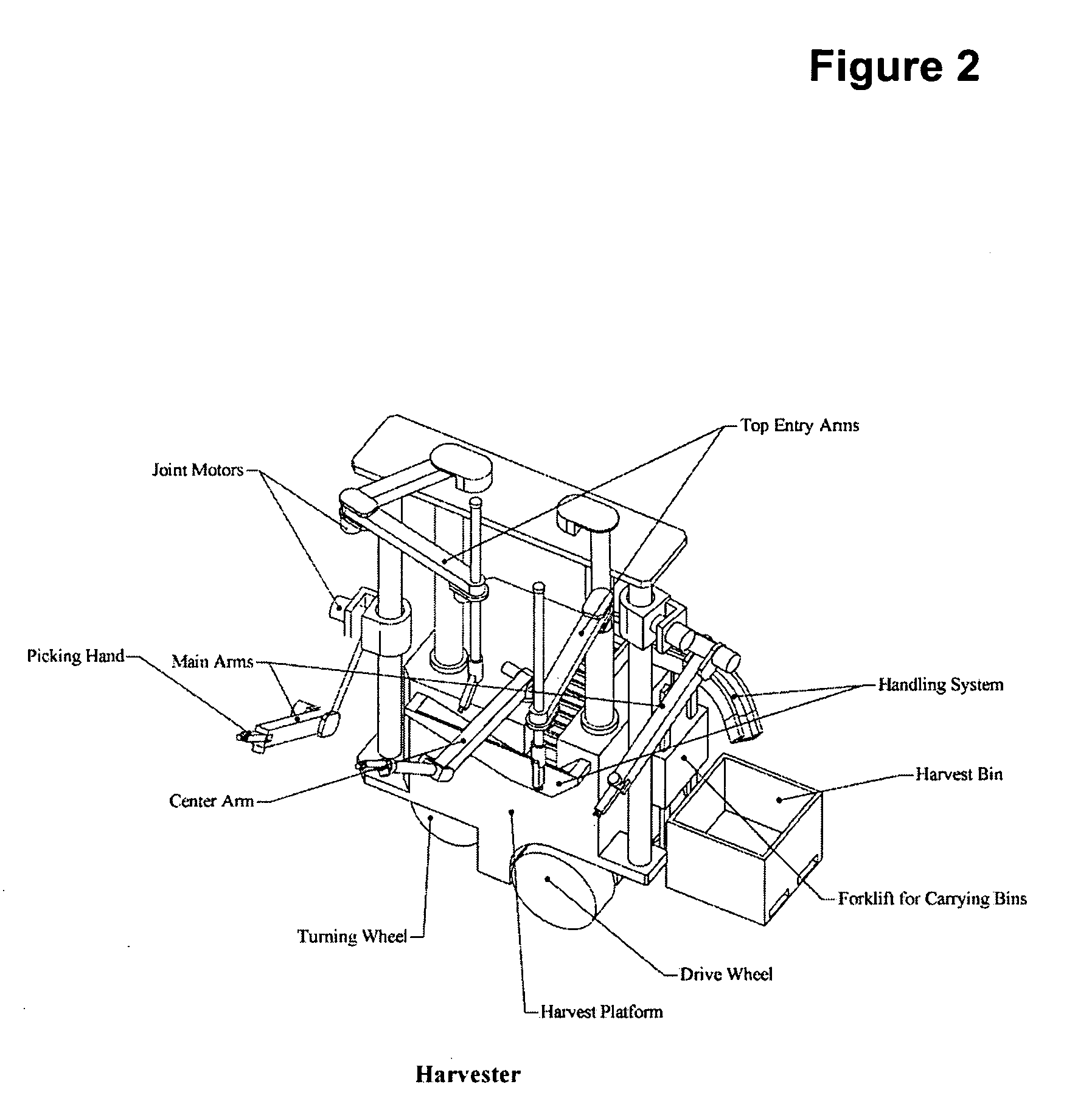

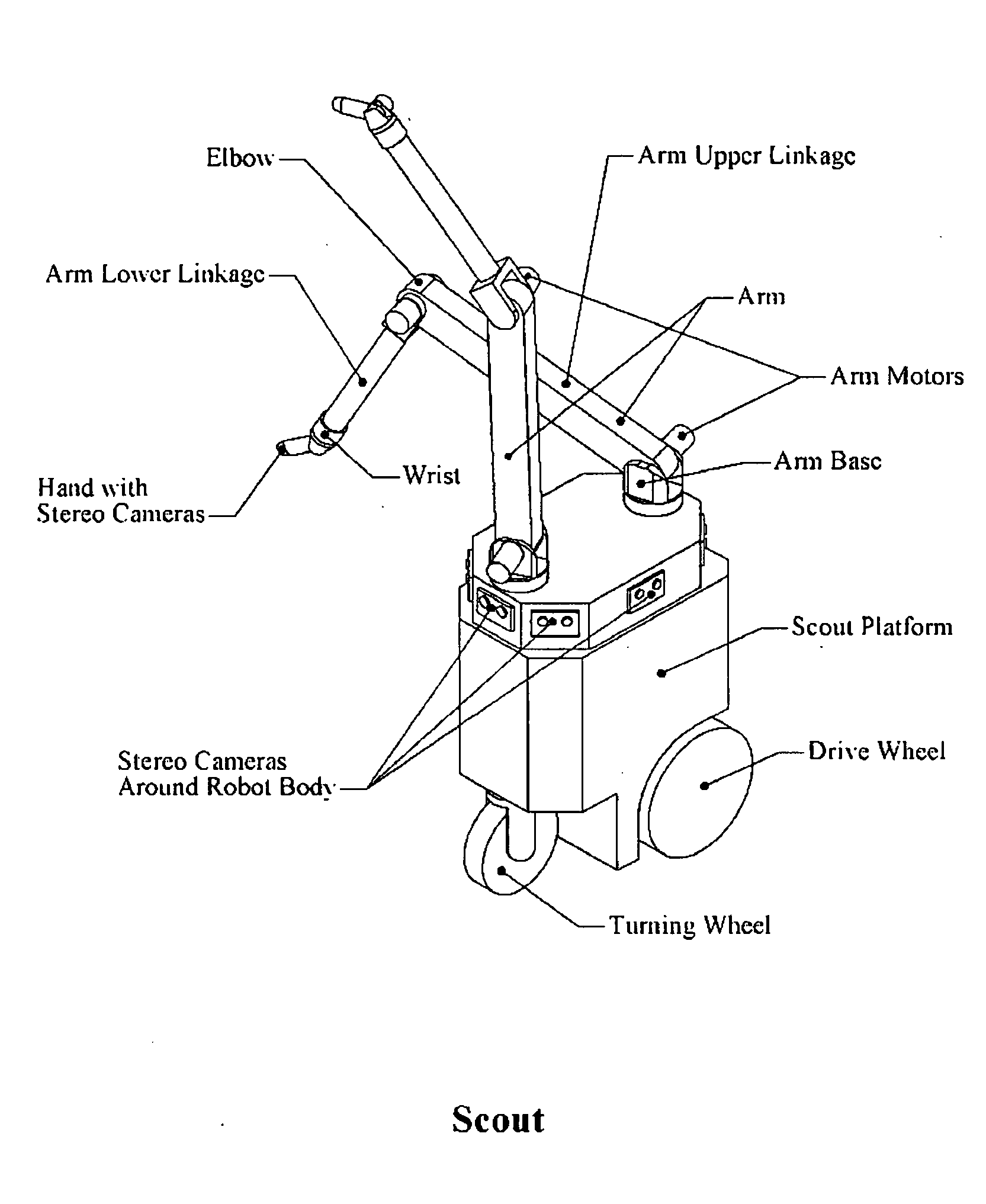

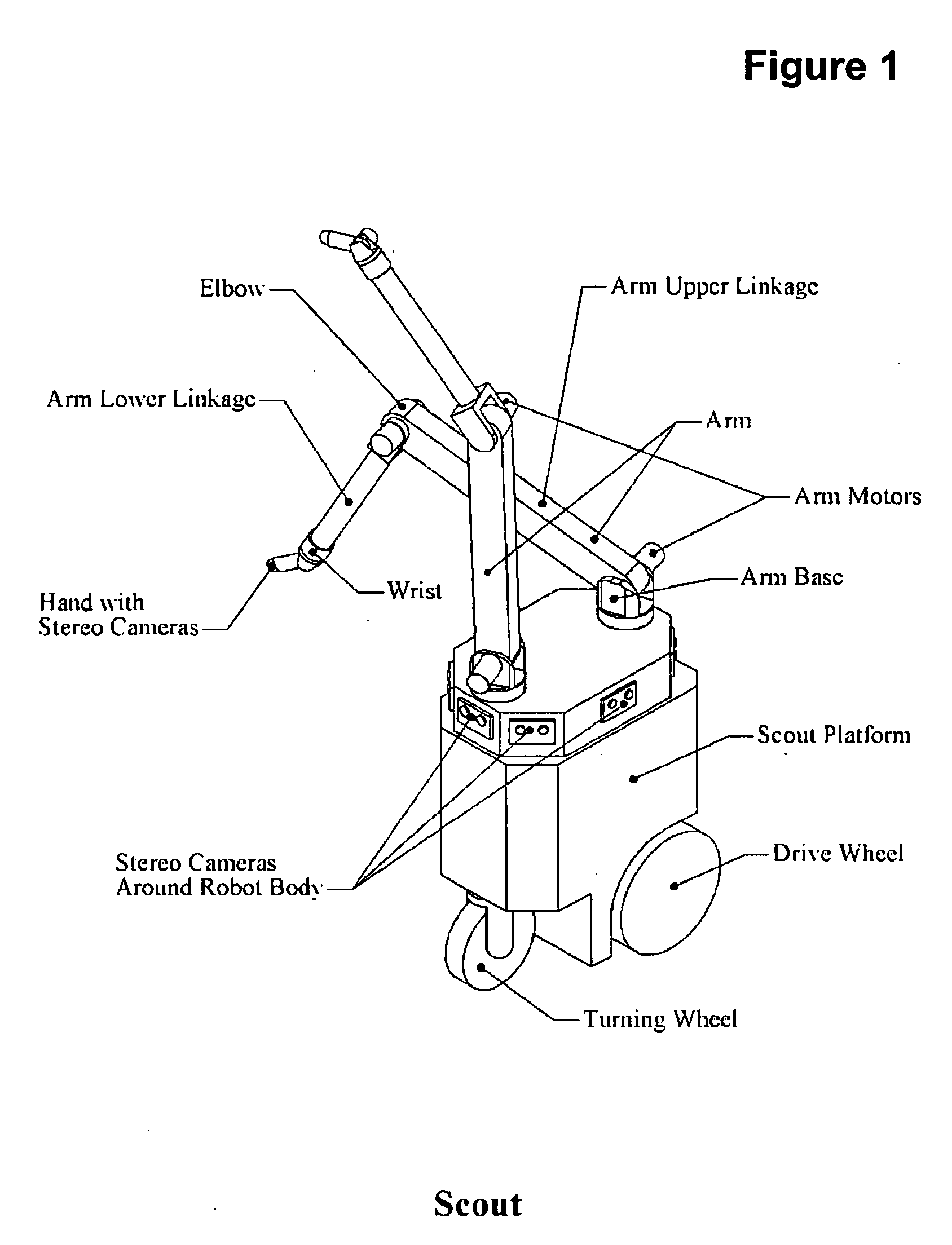

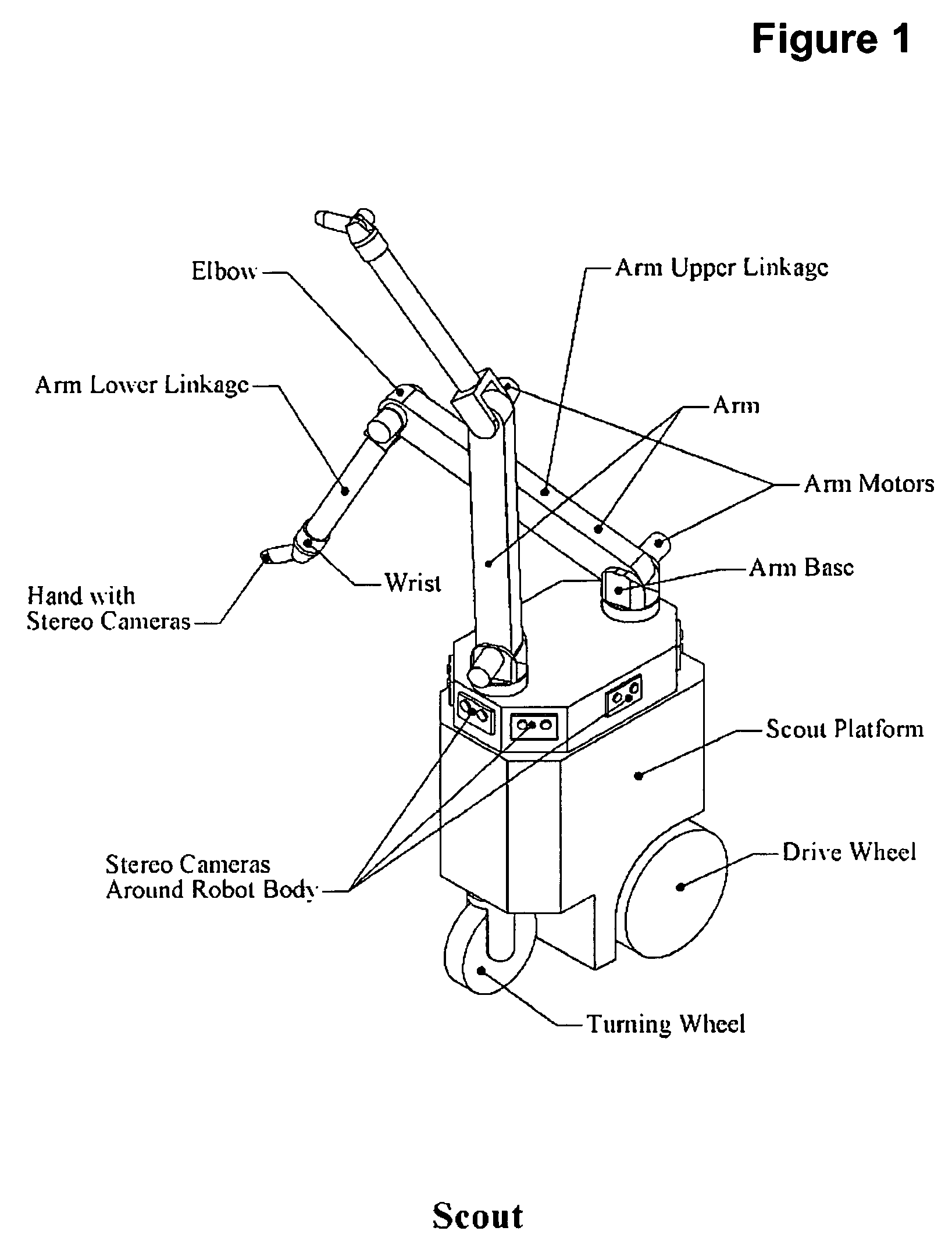

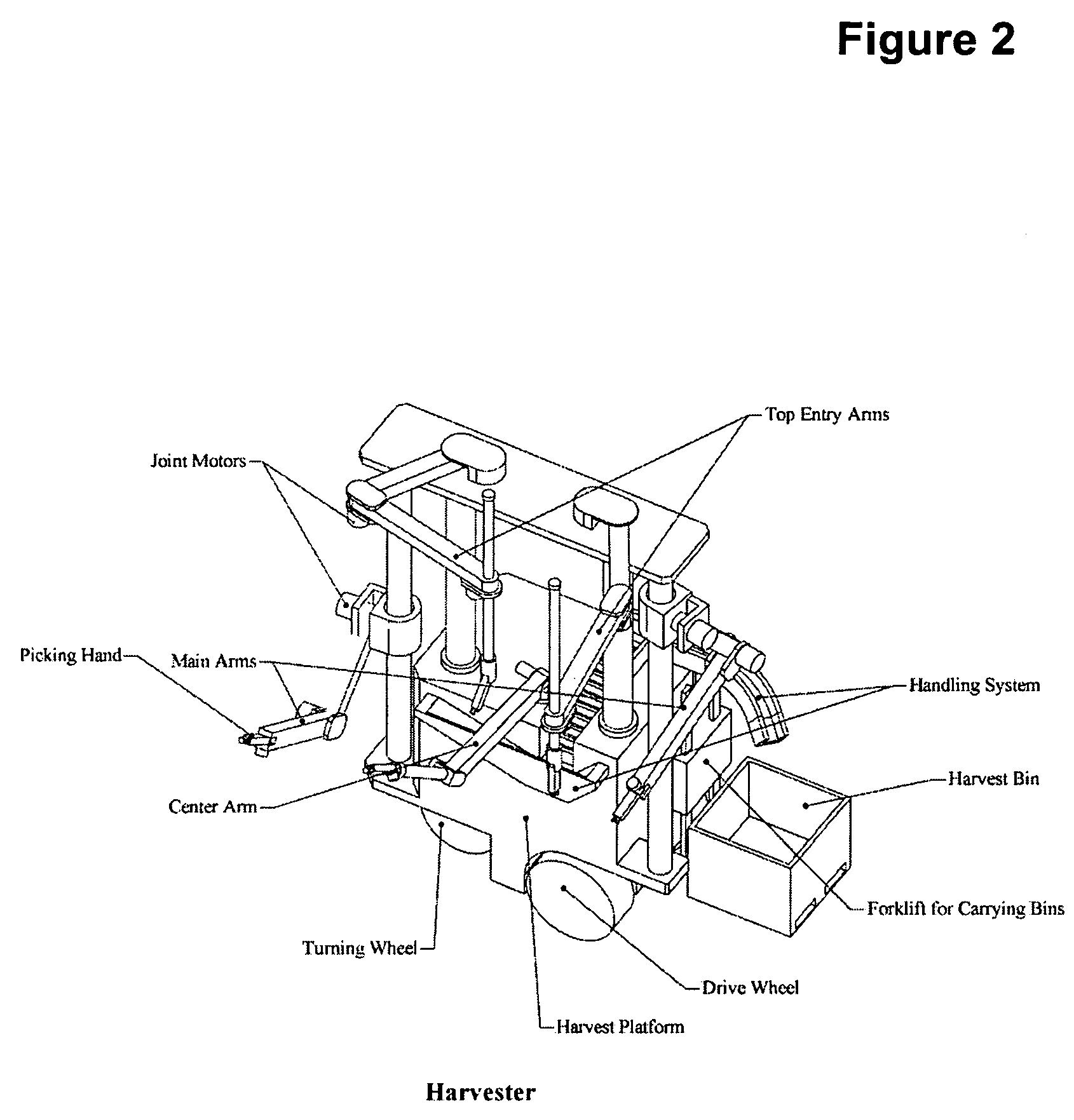

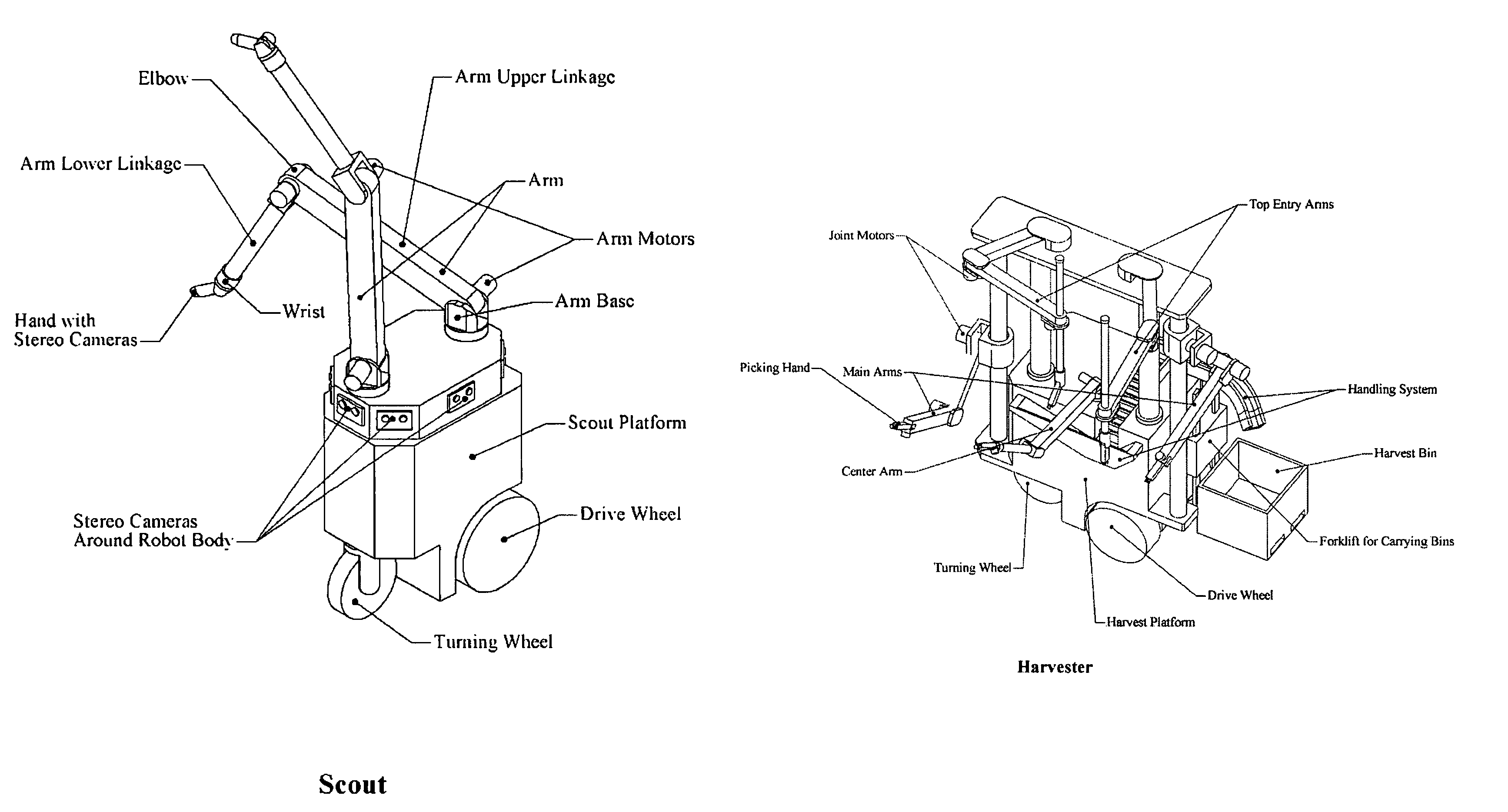

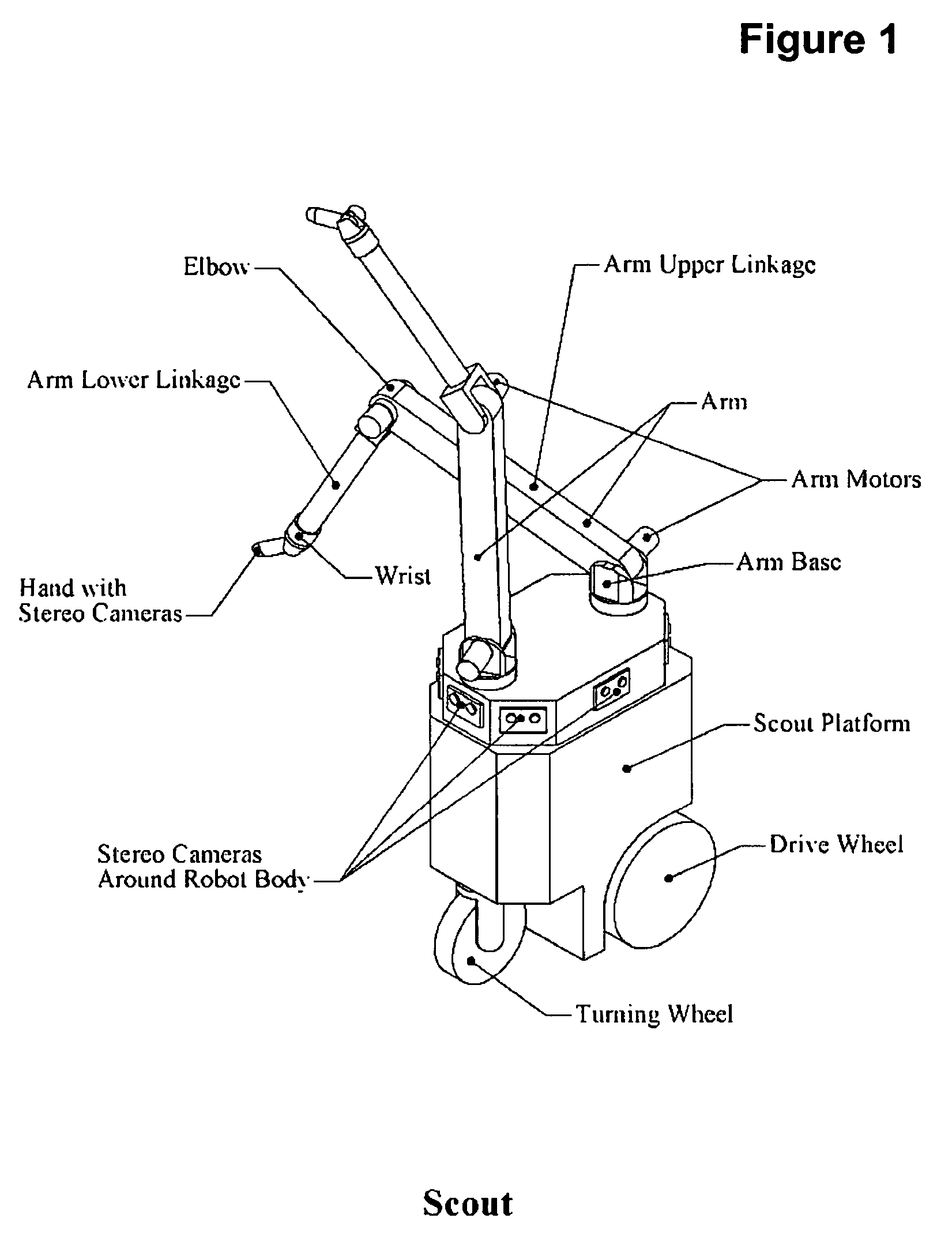

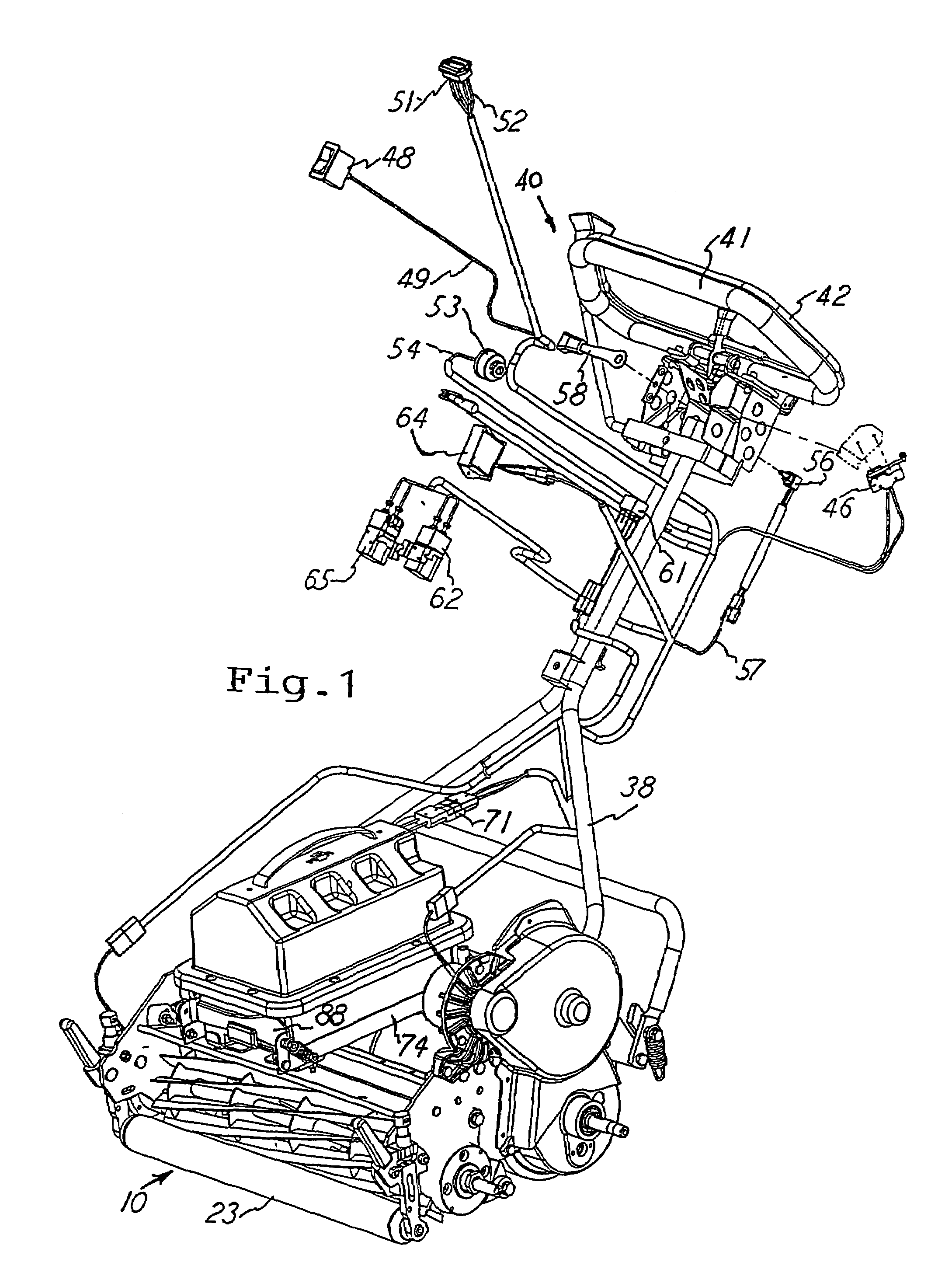

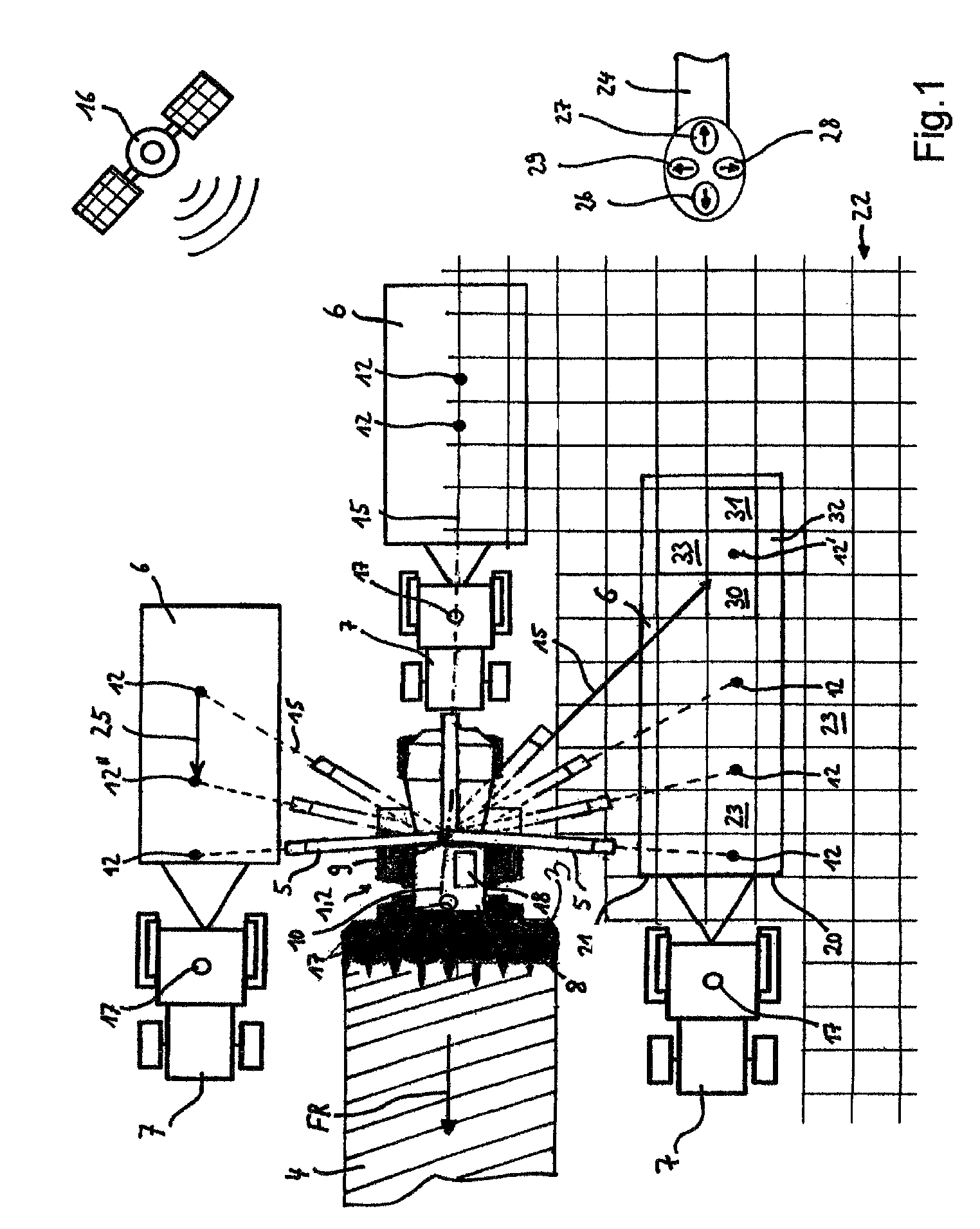

Agricultural robot system and method

InactiveUS20060213167A1Maximize efficiencyMaximizing cost-effectivenessAnalogue computers for trafficMowersMachine visionAction plan

An agricultural robot system and method of harvesting, pruning, culling, weeding, measuring and managing of agricultural crops. Uses autonomous and semi-autonomous robot(s) comprising machine-vision using cameras that identify and locate the fruit on each tree, points on a vine to prune, etc., or may be utilized in measuring agricultural parameters or aid in managing agricultural resources. The cameras may be coupled with an arm or other implement to allow views from inside the plant when performing the desired agricultural function. A robot moves through a field first to “map” the plant locations, number and size of fruit and approximate positions of fruit or map the cordons and canes of grape vines. Once the map is complete, a robot or server can create an action plan that a robot may implement. An action plan may comprise operations and data specifying the agricultural function to perform.

Owner:VISION ROBOTICS

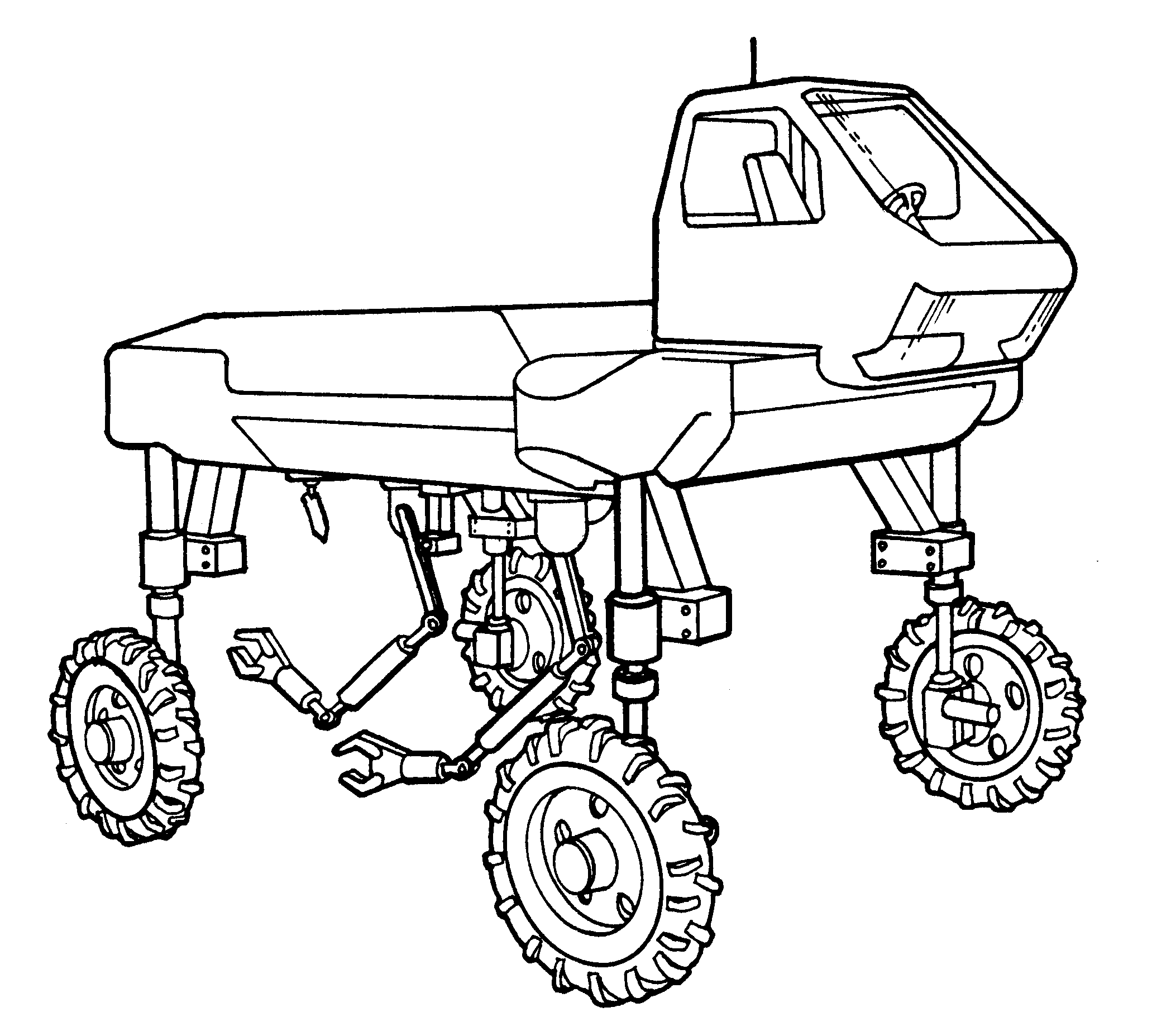

Flexible agricultural automation

InactiveUS6671582B1High precisionQuality improvementOptical radiation measurementPosition fixationAgricultural engineeringAssembly line

Agricultural operations by applying flexible manufacturing software, robotics and sensing techniques to agriculture. In manufacturing operations utilizing flexible machining and flexible assembly robots, work pieces flow through a fixed set of workstations on an assembly line. At different stations are located machine vision systems, laser based raster devices, radar, touch, photocell, and other methods of sensing; flexible robot armatures and the like are used to operate on them. This flexible agricultural automation turns that concept inside out, moving software programmable workstations through farm fields on mobile robots that can sense their environment and respond to it flexibly. The agricultural automation will make it possible for large scale farming to take up labor intensive farming practices which are currently only practical for small scale farming, improving land utilization efficiency, while lowering manpower costs dramatically.

Owner:HANLEY BRIAN P

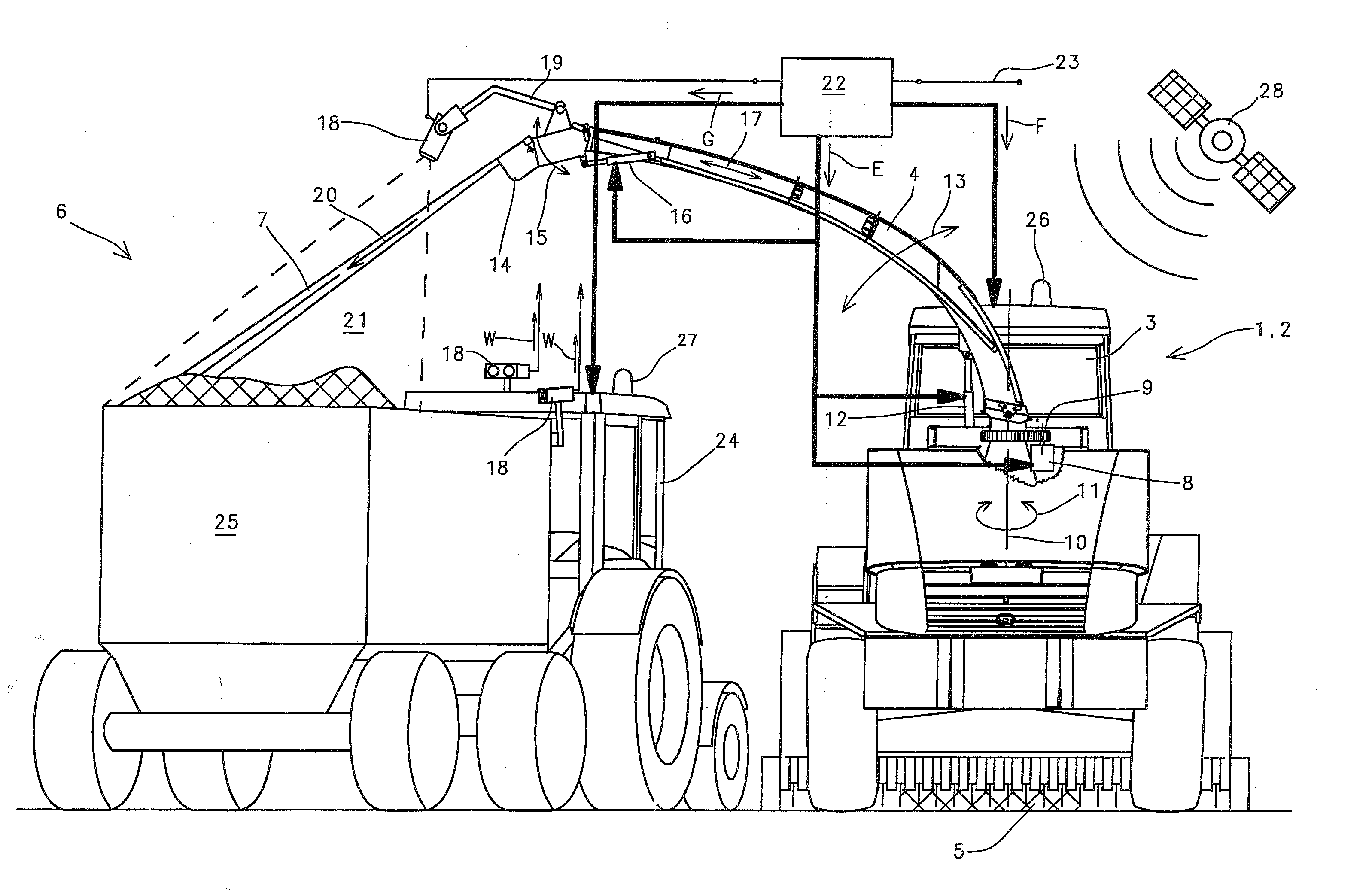

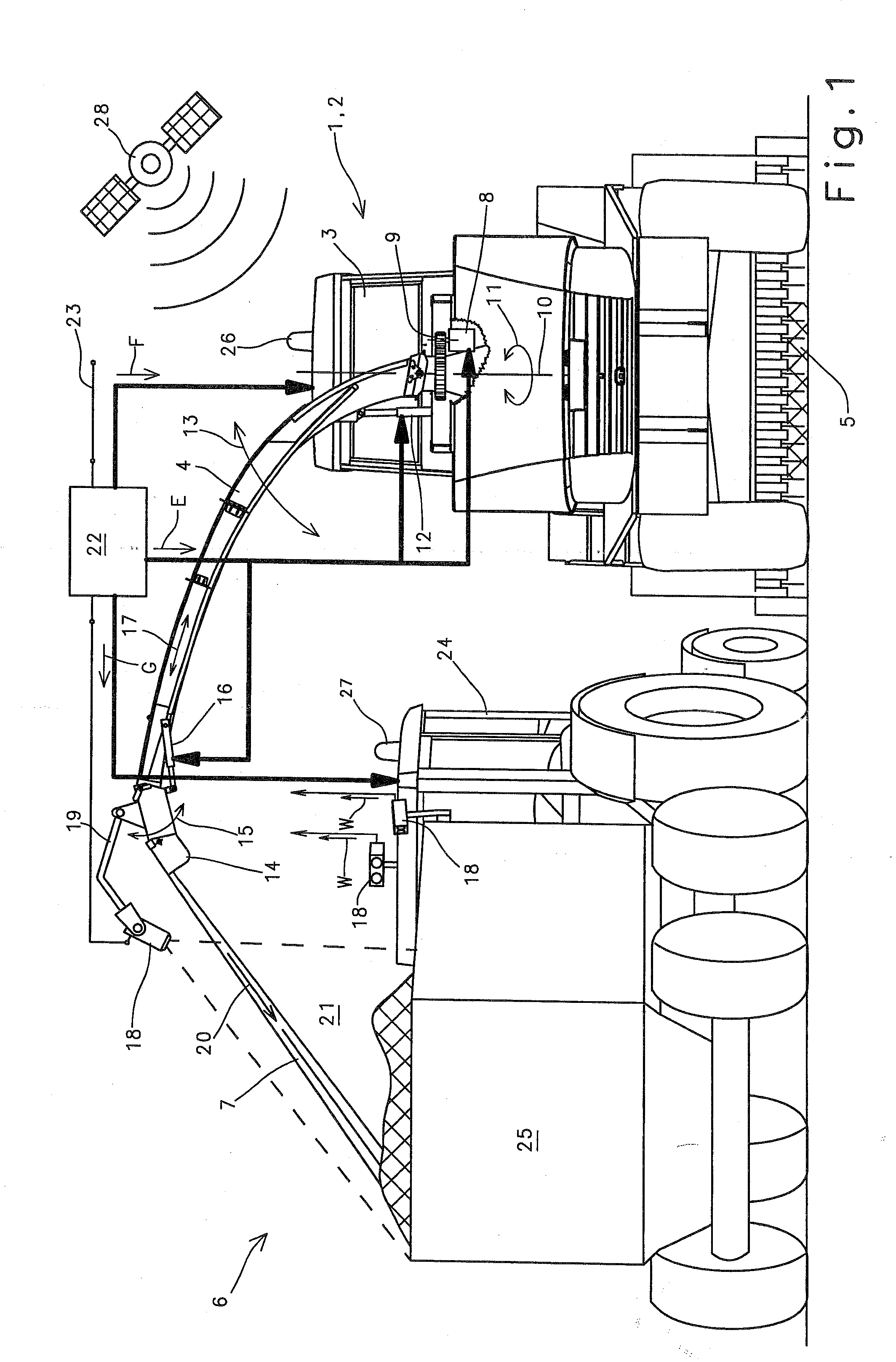

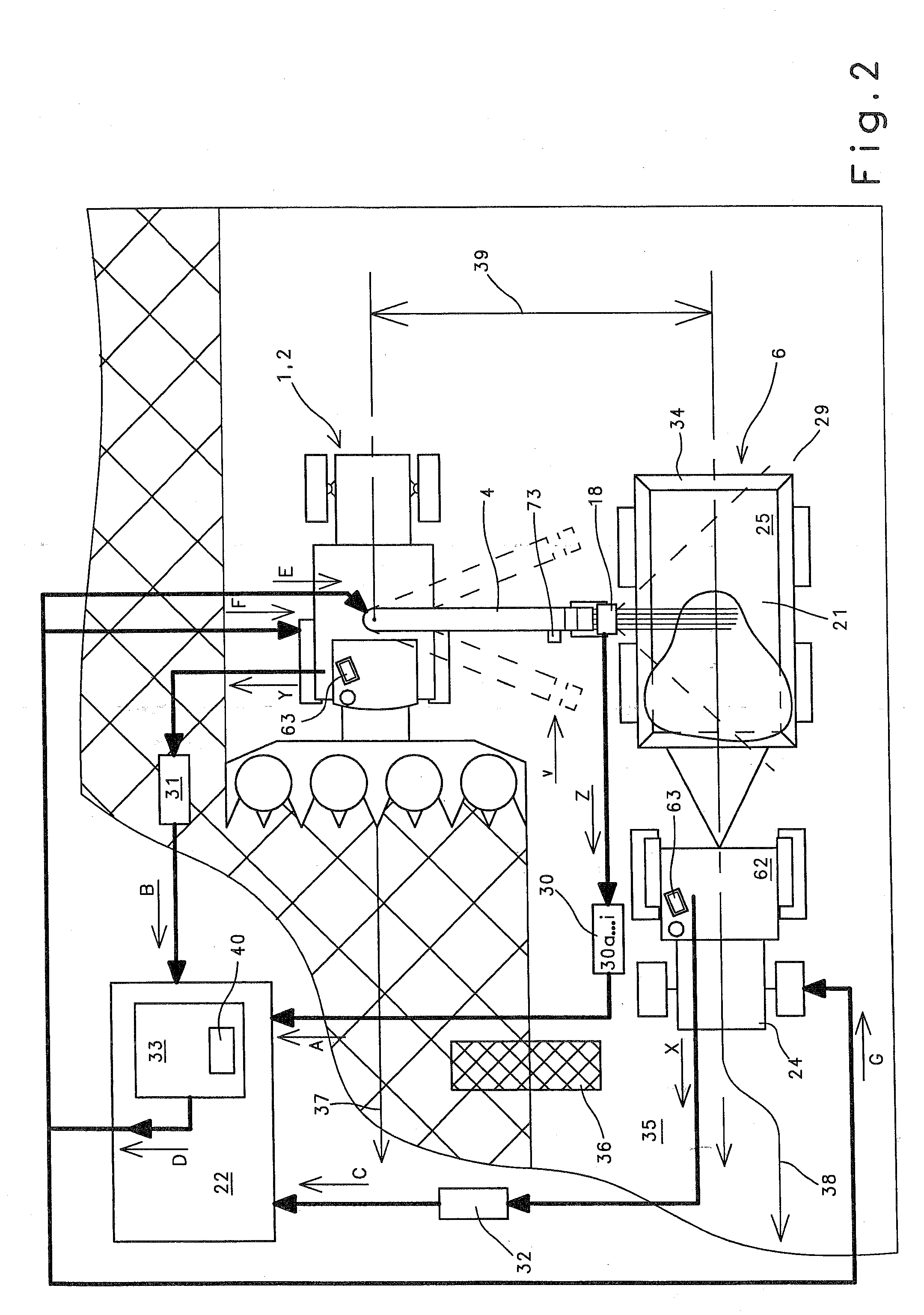

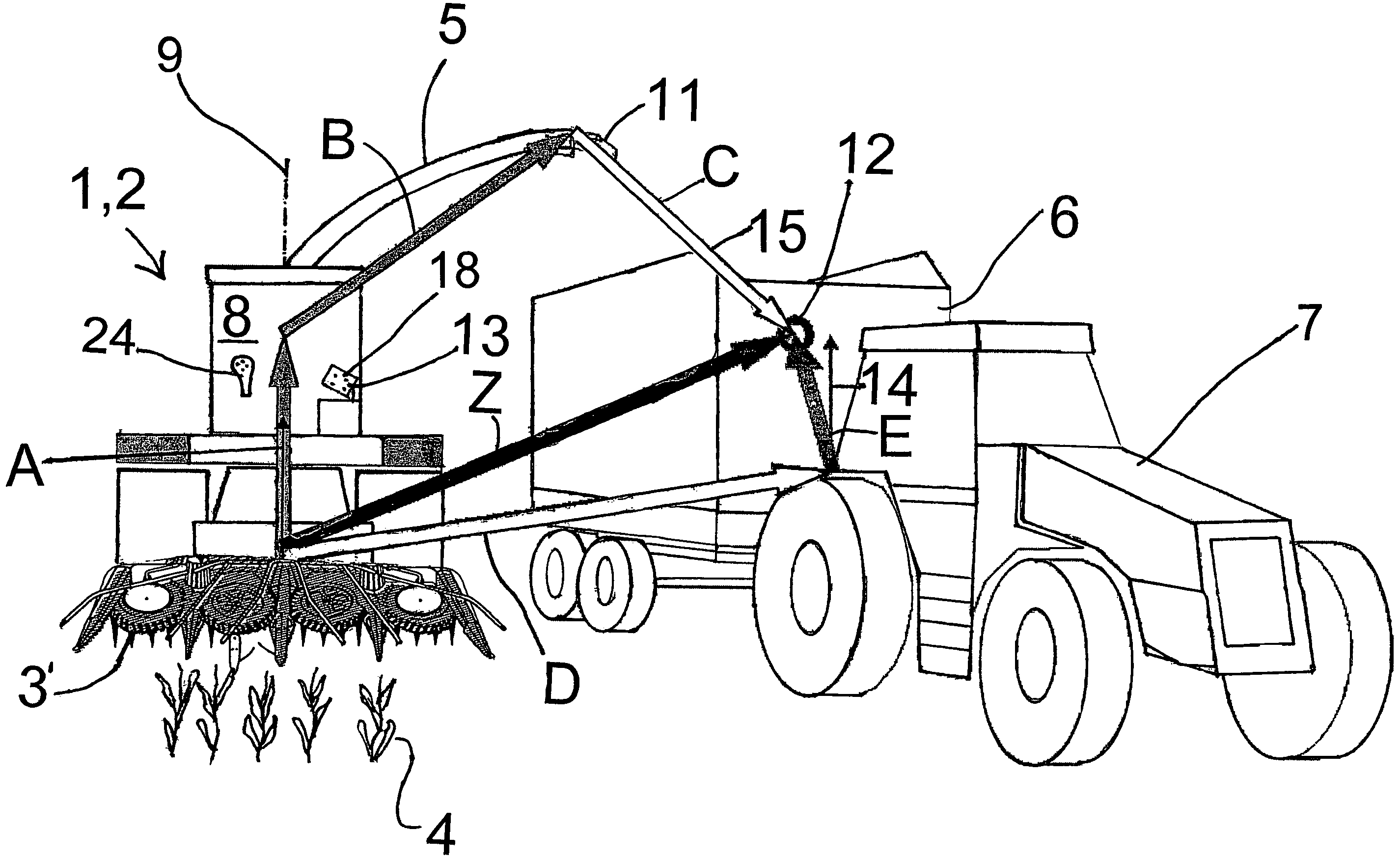

Agricultural working machine

InactiveUS20090044505A1Improving visibility conditionIncrease awarenessMowersPicking devicesAgricultural scienceForage harvester

The invention relates to an agricultural working machine (1), in particular a forage harvester (2), with at least one spout (4) for conveying received and processed crop (7) to a transport vehicle (6, 25), wherein an electro-optical device (18) is provided for the direction control of the spout (4) at least during the process of conveying to the transport vehicle (6, 25), and wherein the electro-optical device (18) detects characteristic parameters (30) of the spout (4) and characteristic parameters (30) of the transport vehicle (6) and / or the agricultural working machine (1). This ensures that a control of a spout (4) of agricultural working machines (1, 2) is provided which almost completely relieves the operator of the agricultural working machine (1, 2) of the task of monitoring the spout.

Owner:AGROCOM & AGRARSYST

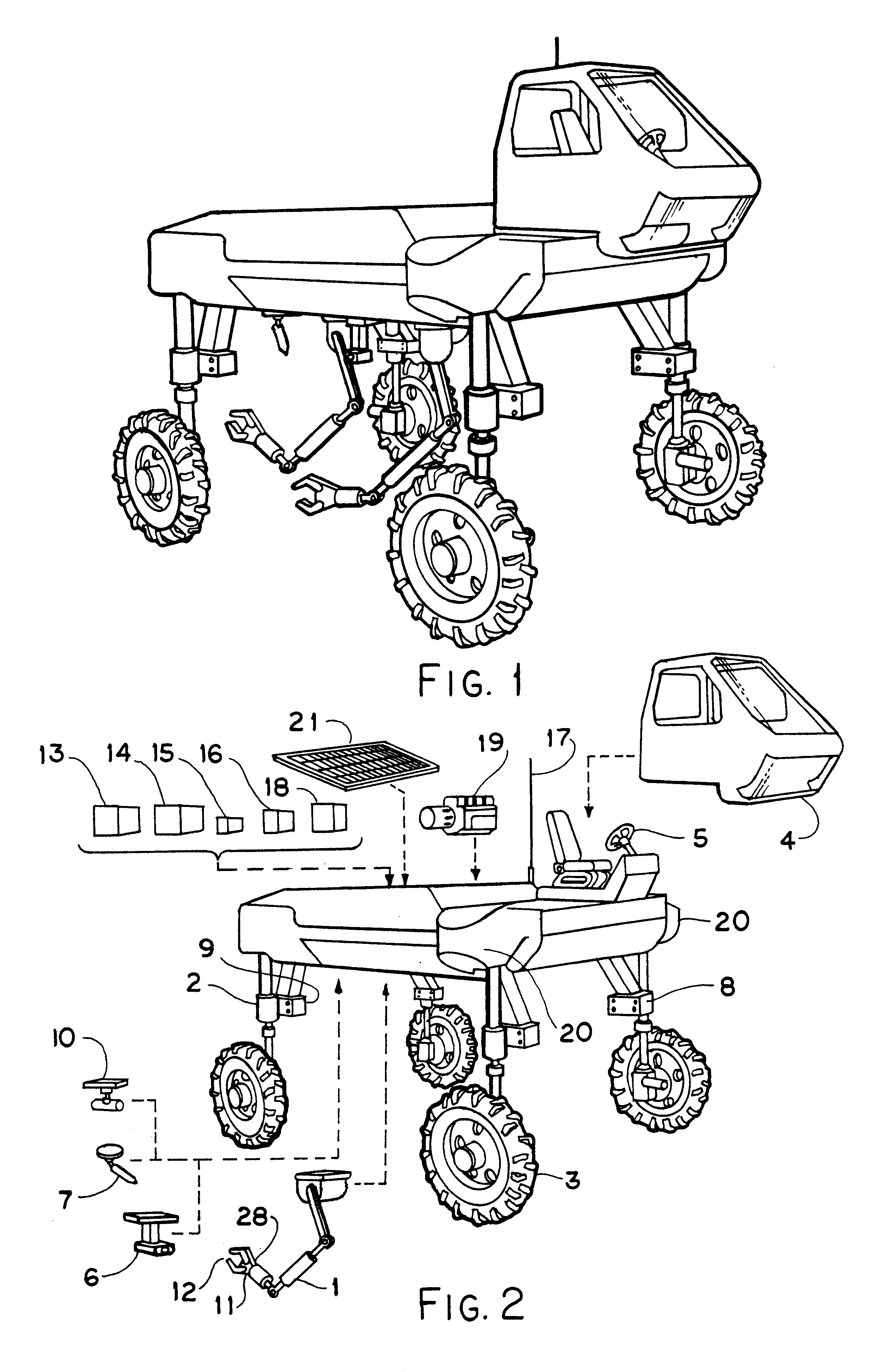

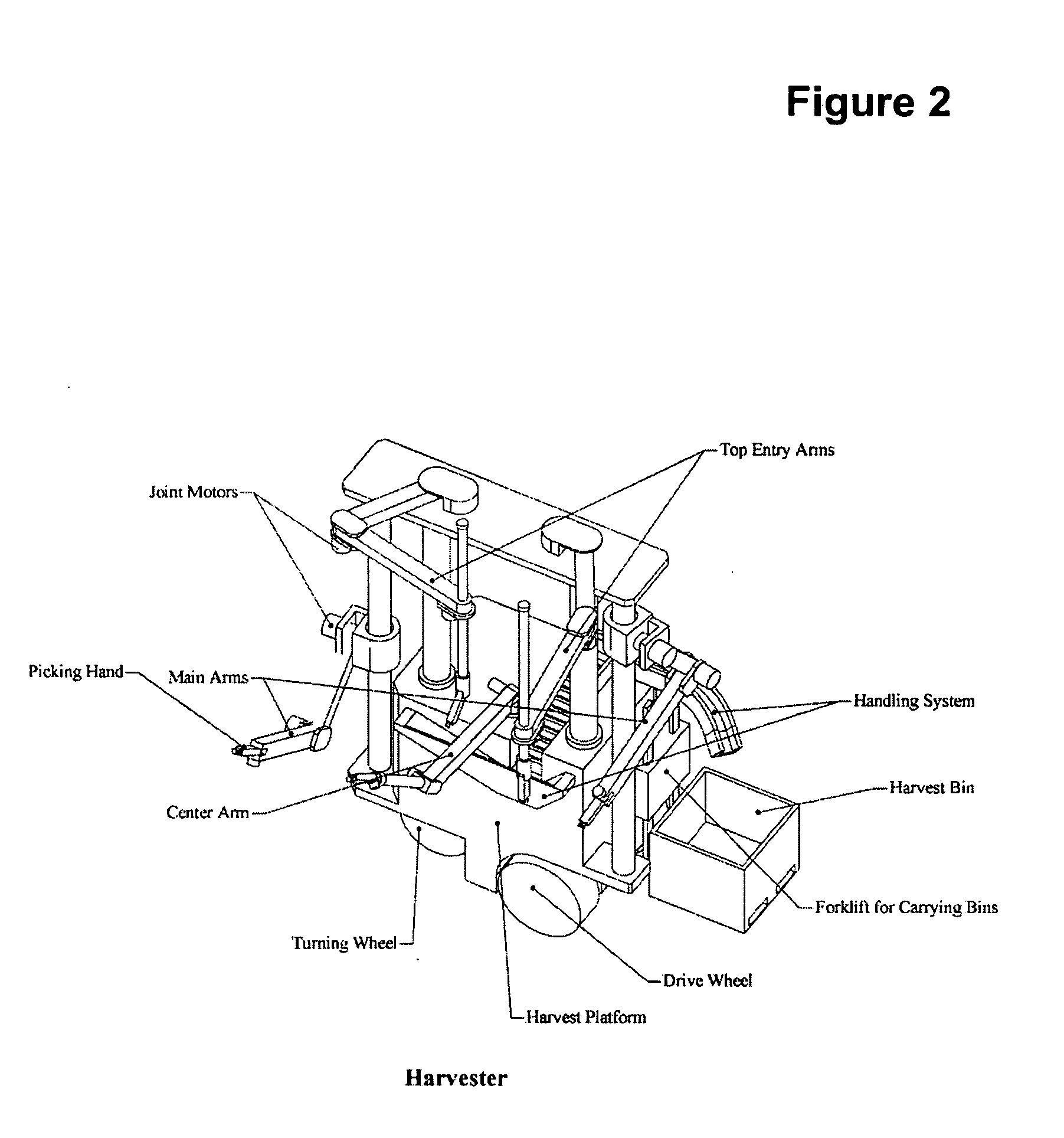

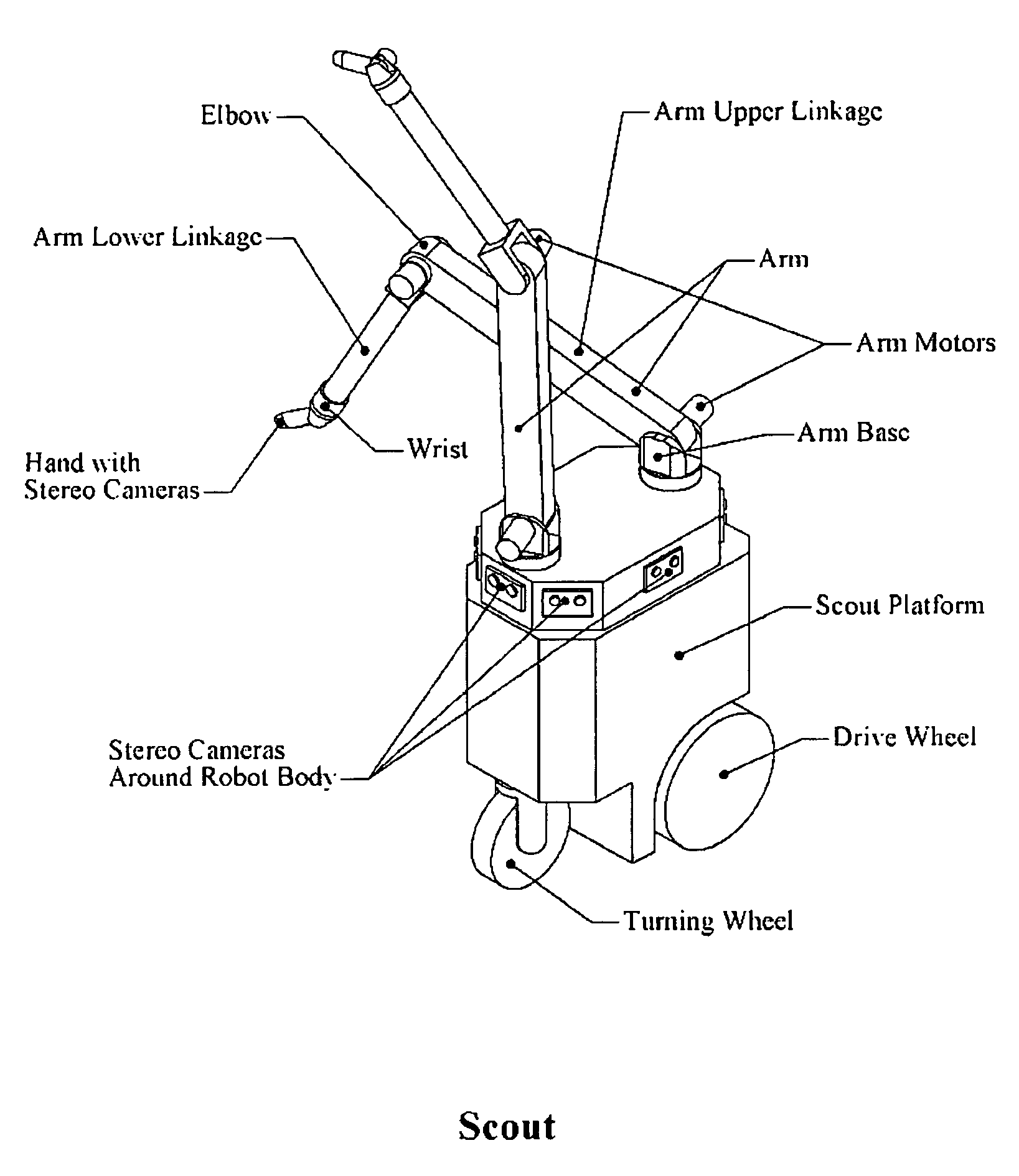

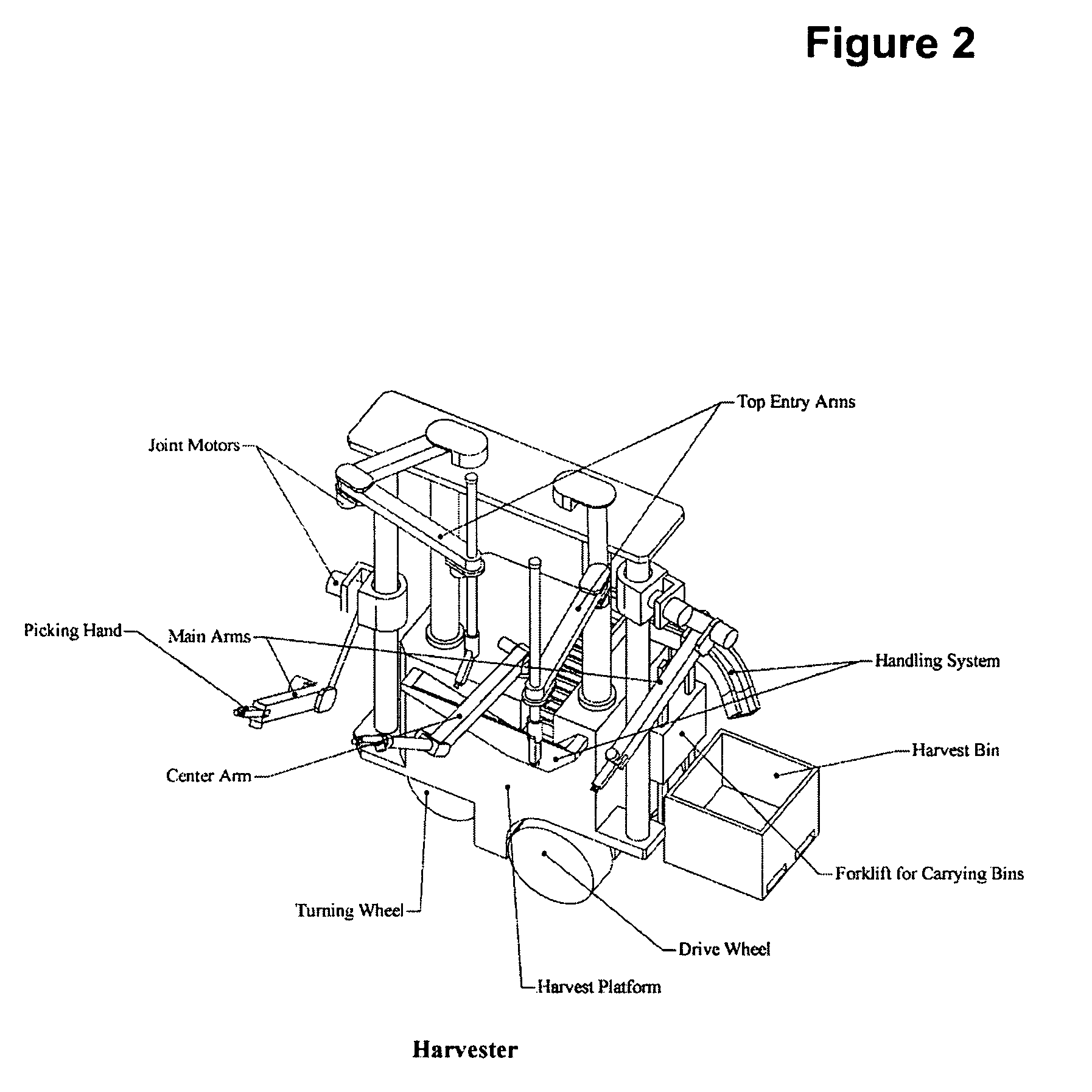

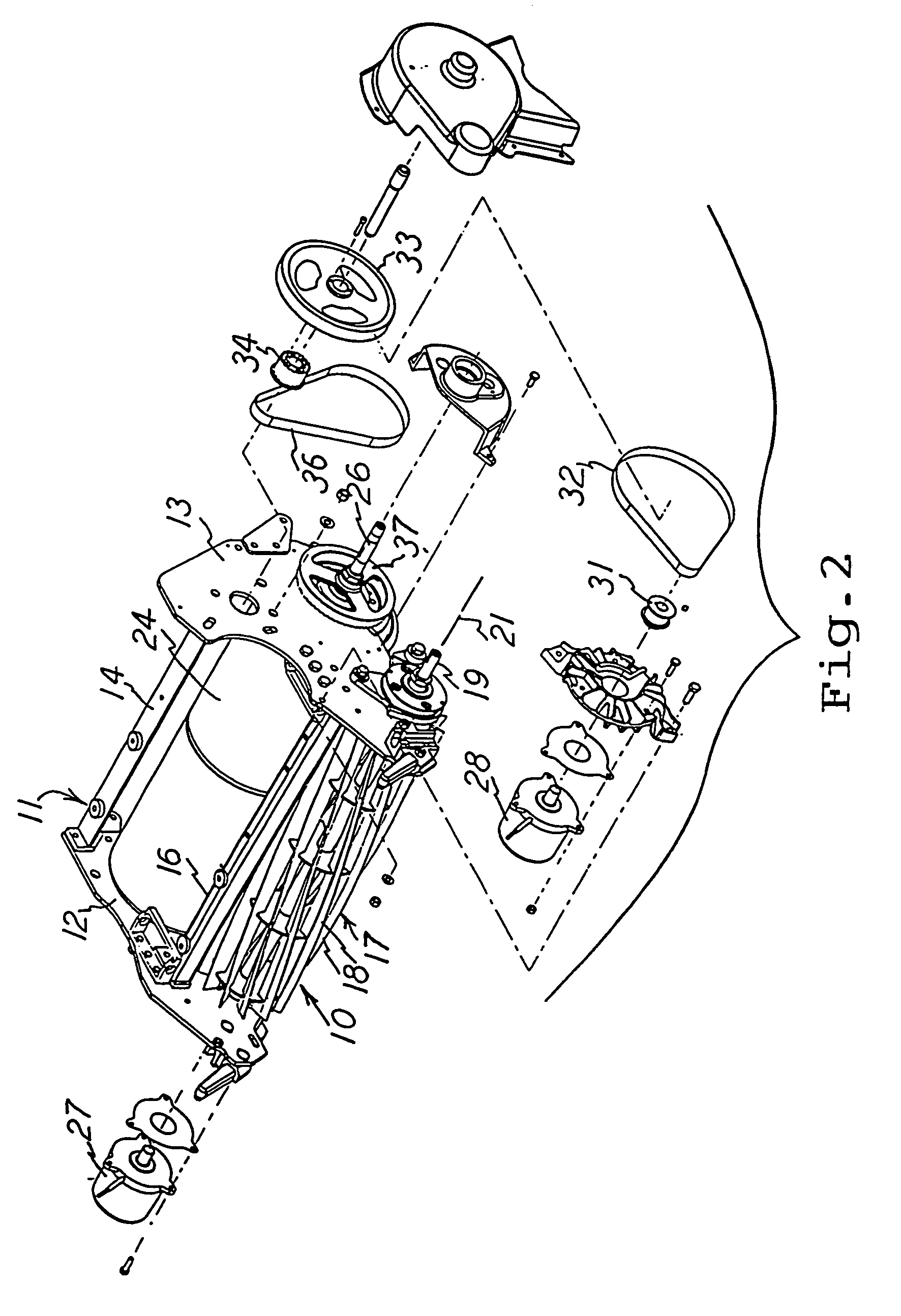

Robot mechanical picker system and method

InactiveUS20050126144A1Improve efficiencyLow costAnalogue computers for trafficMowersRobot planningSimulation

Embodiments of the invention comprise a system and method that enable robotic harvesting of agricultural crops. One approach for automating the harvesting of fresh fruits and vegetables is to use a robot comprising a machine-vision system containing rugged solid-state digital cameras to identify and locate the fruit on each tree, coupled with a picking system to perform the picking. In one embodiment of the invention a robot moves through a field first to “map” the field to determine plant locations, the number and size of fruit on the plants and the approximate positions of the fruit on each plant. A robot employed in this embodiment may comprise a GPS sensor to simplify the mapping process. At least one camera on at least one arm of a robot may be mounted in appropriately shaped protective enclosure so that a camera can be physically moved into the canopy of the plant if necessary to map fruit locations from inside the canopy. Once the map of the fruit is complete for a field, the robot can plan and implement an efficient picking plan for itself or another robot. In one embodiment of the invention, a scout robot or harvest robot determines a picking plan in advance of picking a tree. This may be done if the map is finished hours, days or weeks before a robot is scheduled to harvest, or if the picking plan algorithm selected requires significant computational time and cannot be implemented in “real time” by the harvesting robot as it is picking the field. If the picking algorithm selected is less computationally intense, the harvester may calculate the plan as it is harvesting. The system harvests according to the selected picking plan. The picking plan may be generated in the scout robot, harvest robot or on a server. Each of the elements in the system may be configured to communicate with each other using wireless communications technologies.

Owner:VISION ROBOTICS

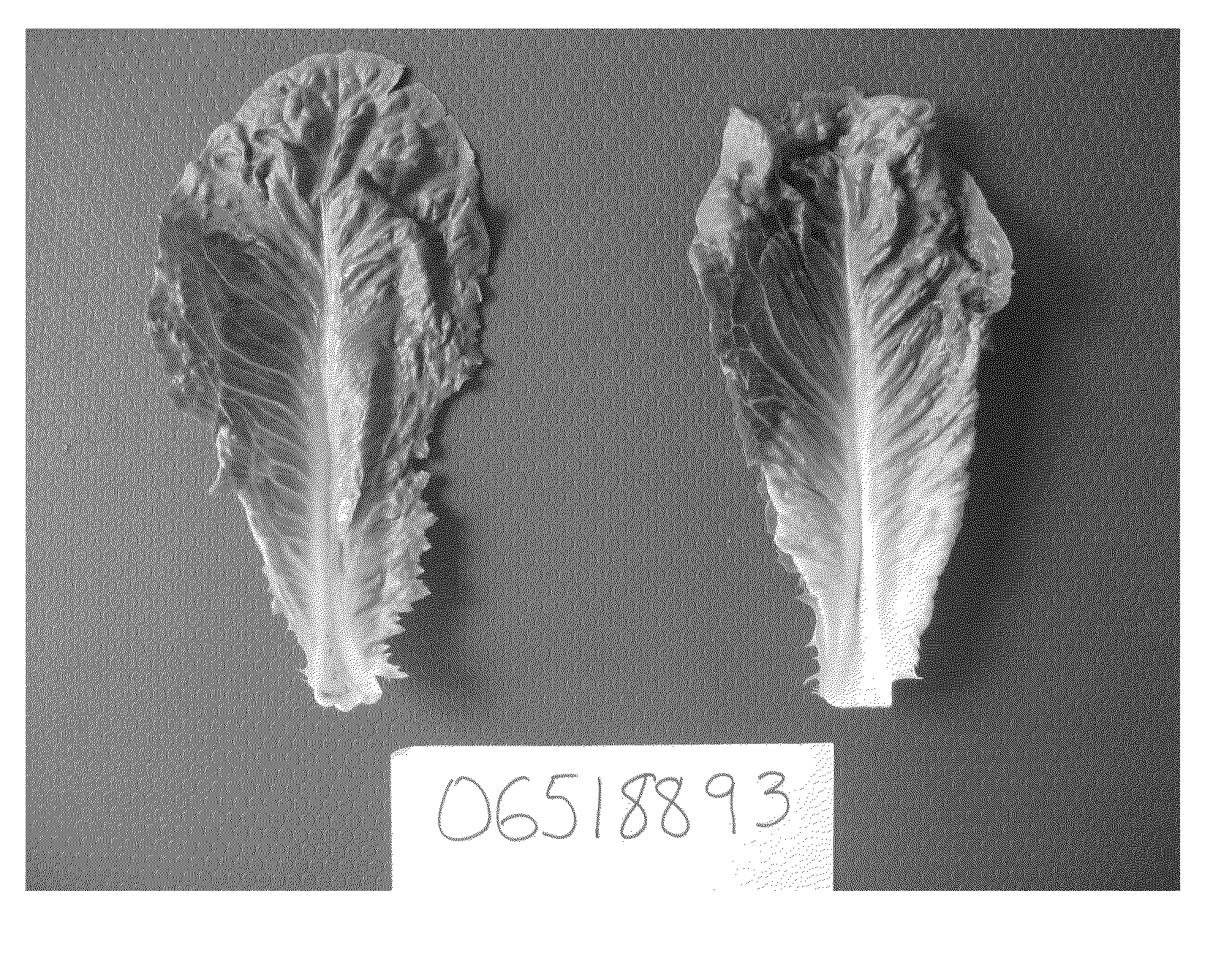

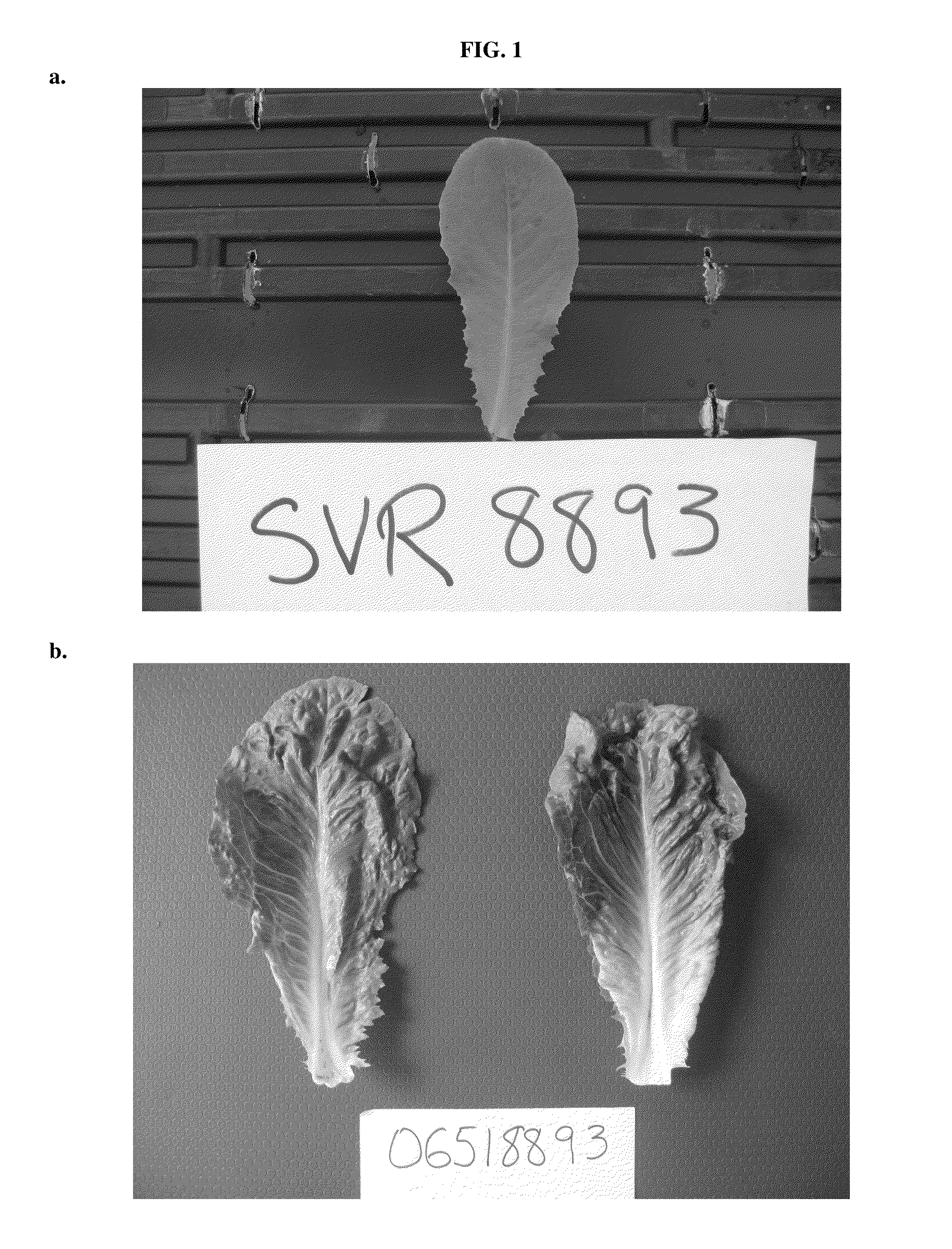

Lettuce line ps 06518893

ActiveUS20140072693A1Animal feeding stuffOther foreign material introduction processesBiologyTissue culture

The invention provides seed and plants of the lettuce line designated PS 06518893. The invention thus relates to the plants, seeds and tissue cultures of lettuce line PS 06518893, and to methods for producing a lettuce plant produced by crossing a plant of lettuce line PS 06518893 with itself or with another lettuce plant, such as a plant of another line. The invention further relates to seeds and plants produced by such crossing. The invention further relates to parts of a plant of lettuce line PS 06518893, including the gametes of such plants.

Owner:SEMINIS VEGETABLE SEEDS

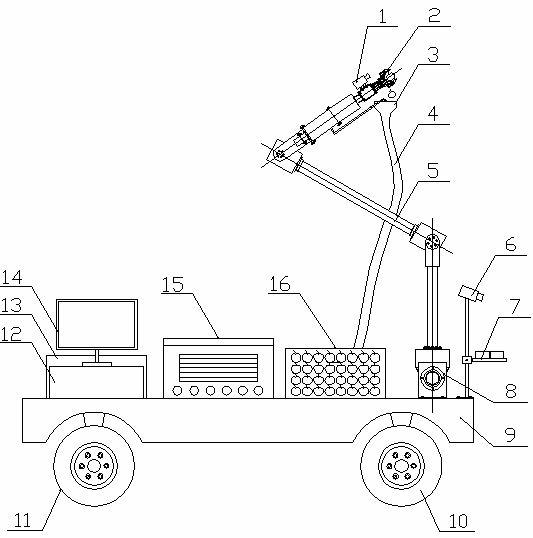

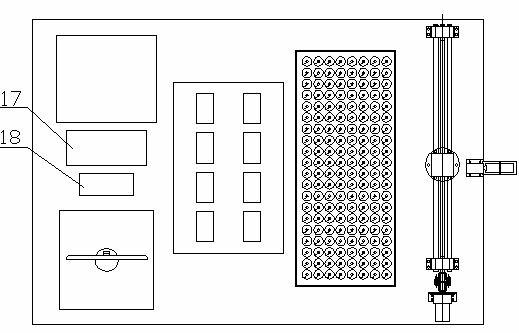

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

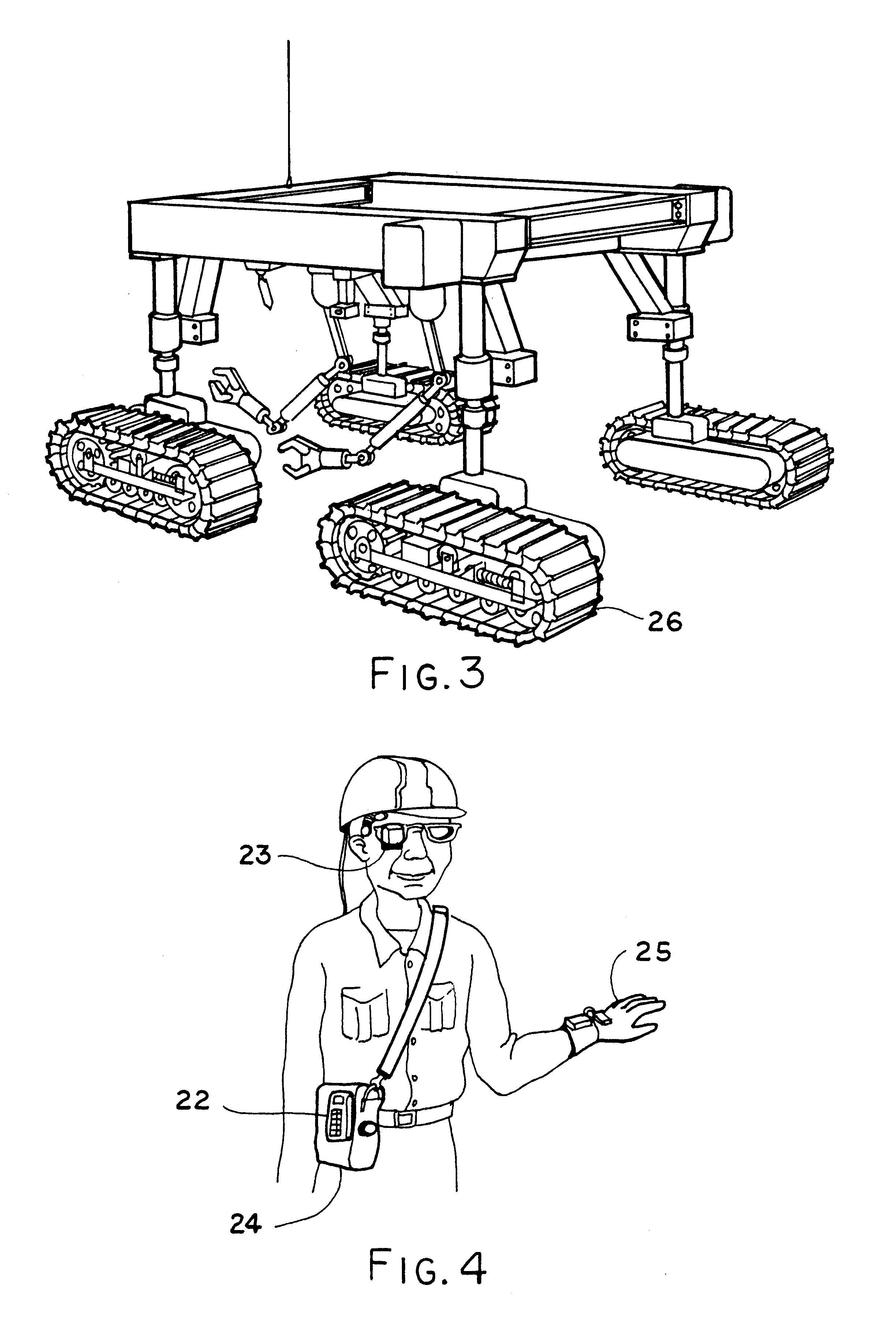

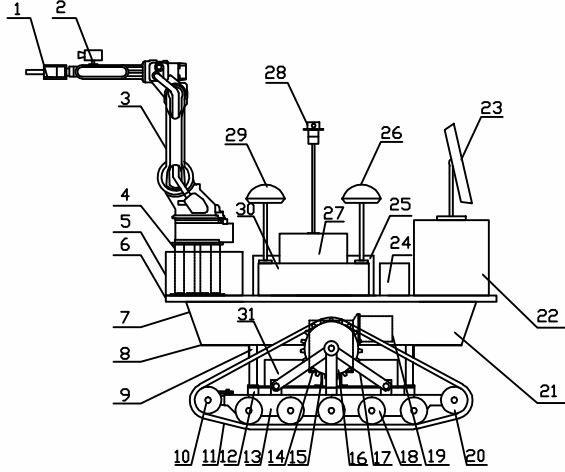

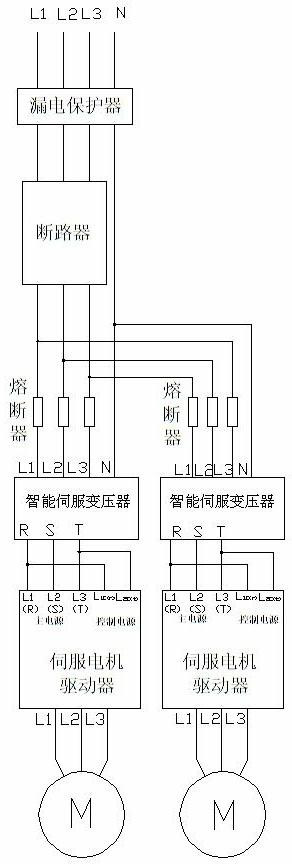

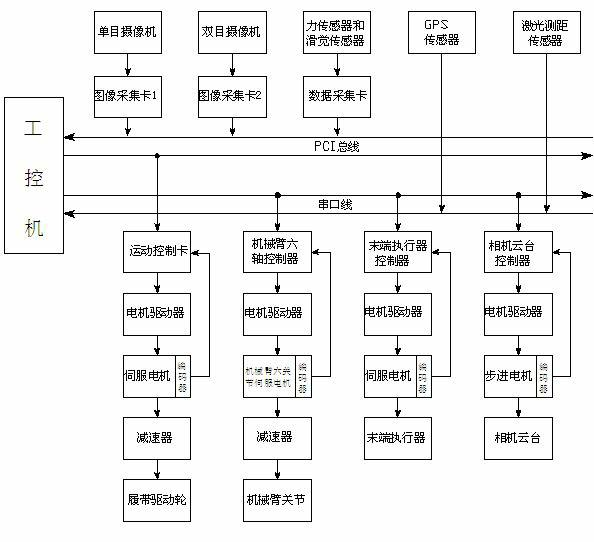

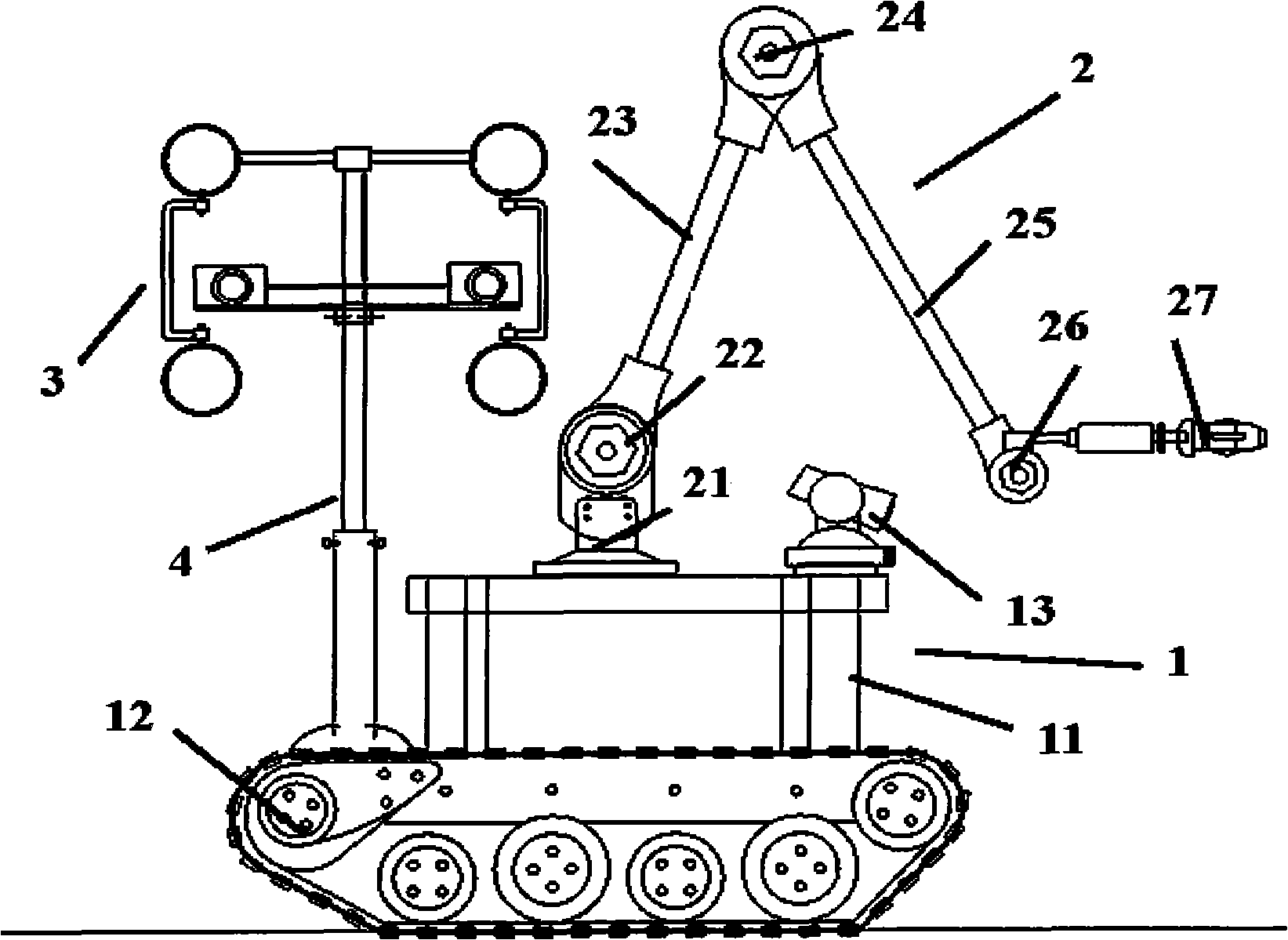

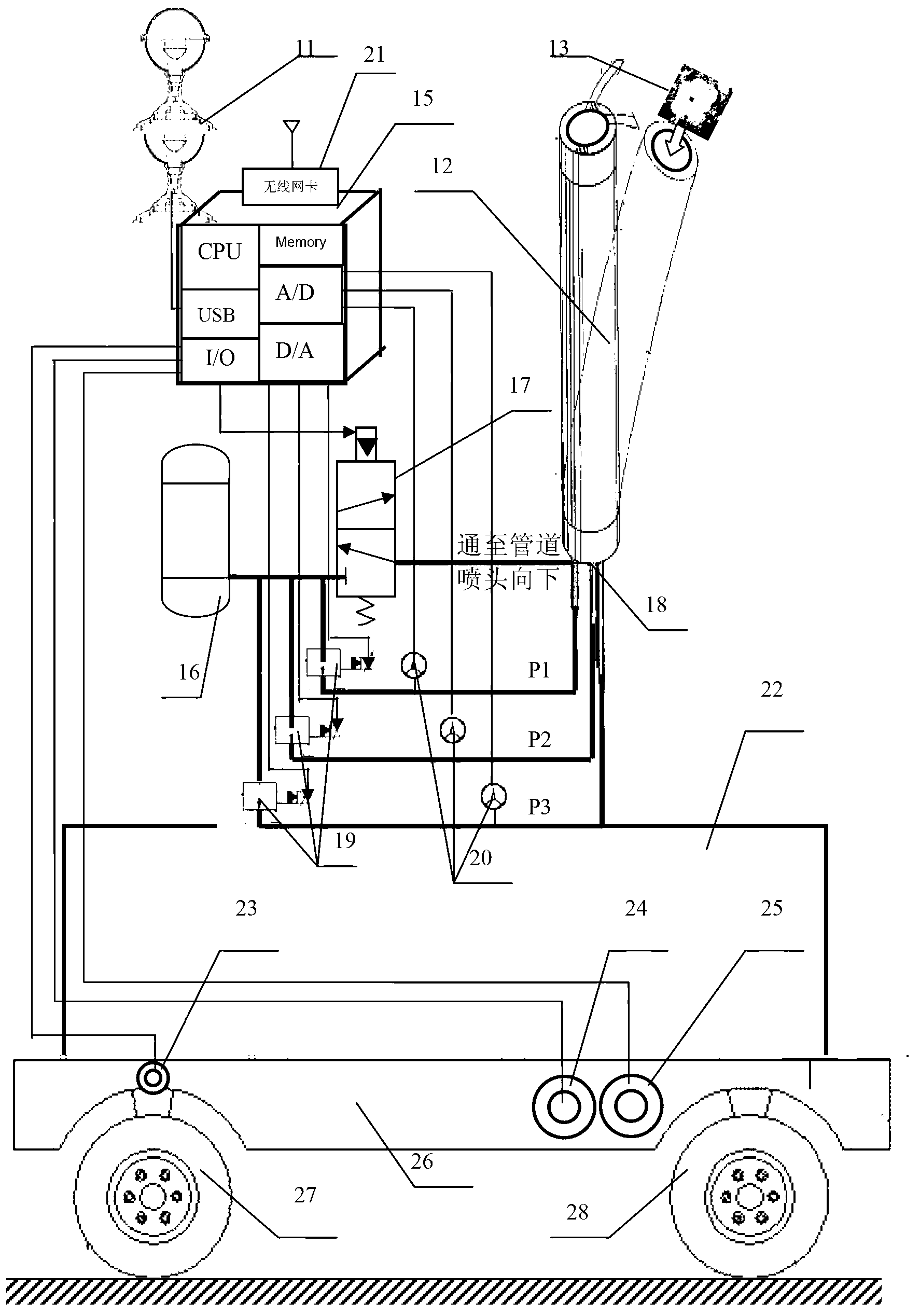

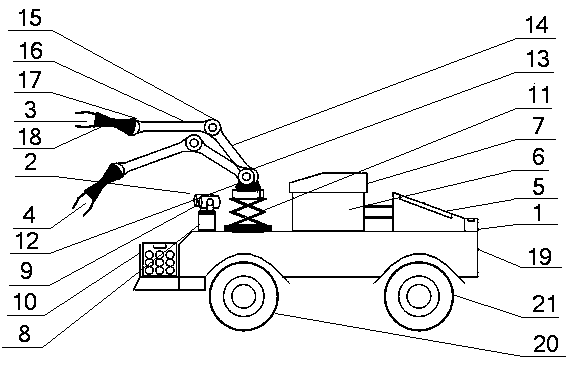

Automatic-navigation crawler-type mobile fruit picking robot and fruit picking method

InactiveCN102165880AFully automated pickingSimple structureProgramme-controlled manipulatorPicking devicesSimulationActuator

The invention discloses an automatic-navigation crawler-type mobile fruit picking robot which comprises a mechanical execution system and a control system and is characterized in that the mechanical execution system comprises an intelligent movable platform, a fruit picking mechanical arm and a two-finger type manipulator, wherein the intelligent movable platform comprises two crawler assemblies, an experimental facility fixing rack, a supporting stand column, a cross beam, a speed reducer and the like; and the control system comprises an industrial personal computer, a motion control card, a data collecting card, an image collecting card, an encoder, a GPS (global position system), a monocular zooming camera assembly, a binocular camera, a laser ranging sensor, a control circuit and the like. The automatic-navigation crawler-type mobile fruit picking robot integrates the fruit picking mechanical arm, the two-finger type manipulator, the intelligent movable platform and the sensor system, integrates multiple key technologies such as fruit identification, motion of the picking mechanical arm, grabbing of a tail-end executer, automatic navigation and obstacle avoidance of the movable platform, and the like, and really realizes automatic and humanized fruit picking.

Owner:NANJING AGRICULTURAL UNIVERSITY

Tobacco having reduced nicotine and nitrosamines

InactiveUS20050072047A1Reduce the amount requiredImprove availabilityBiocideTobacco preparationNicotiana tabacumJasmonate

Aspects of the present invention concern tobacco having reduced nicotine and nitrosamines, which is used to manufacture consumer tobacco products, and methods to produce such tobacco. More specifically, embodiments include methods to reduce nicotine and nitrosamines in tobacco crops by applying auxin, auxin analogs, and jasmonate antagonists during the cultivation of such tobacco crops. Tobacco generated using said methods and consumer tobacco products obtained therefrom are also embodiments.

Owner:VECTOR TOBACCO LLC

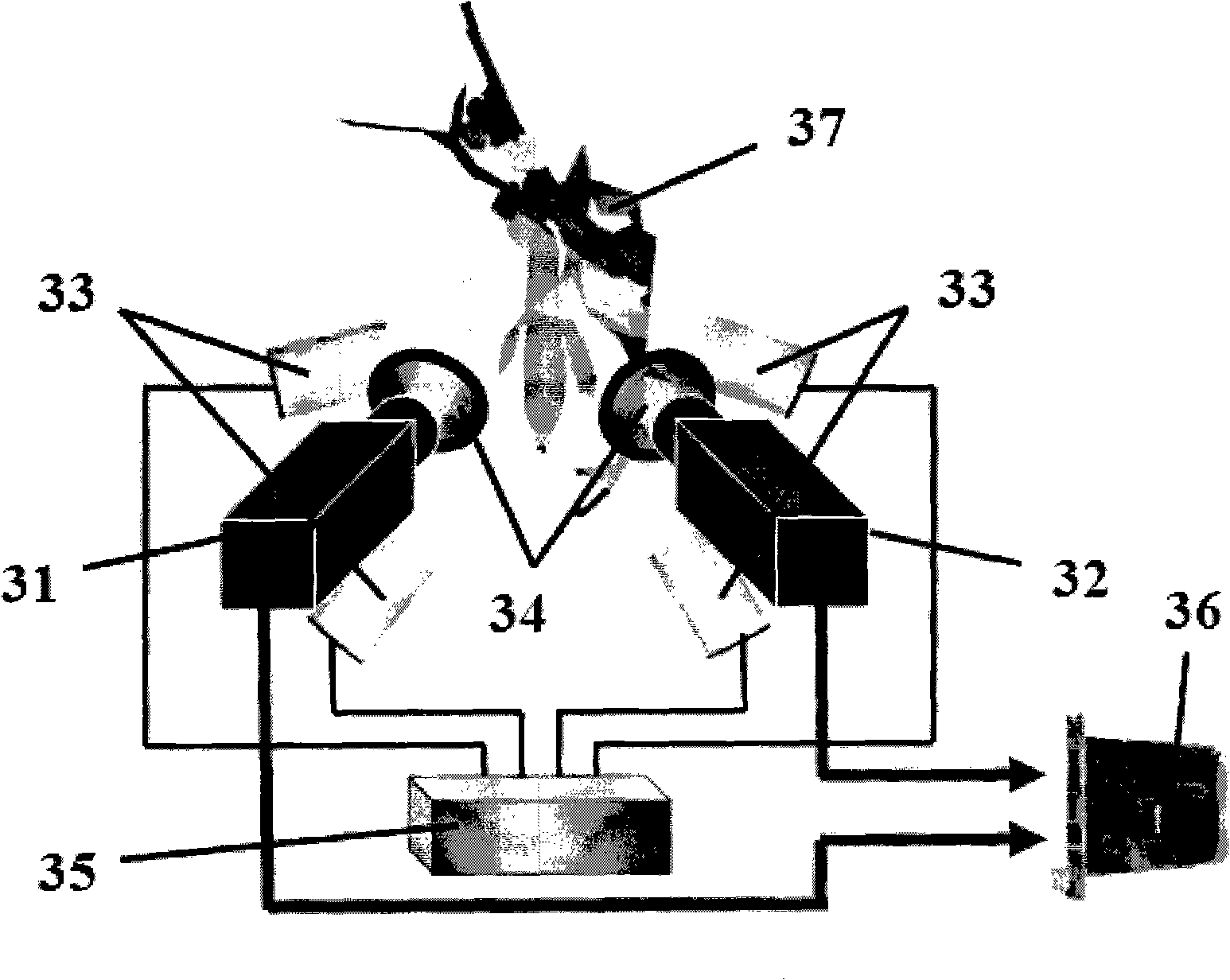

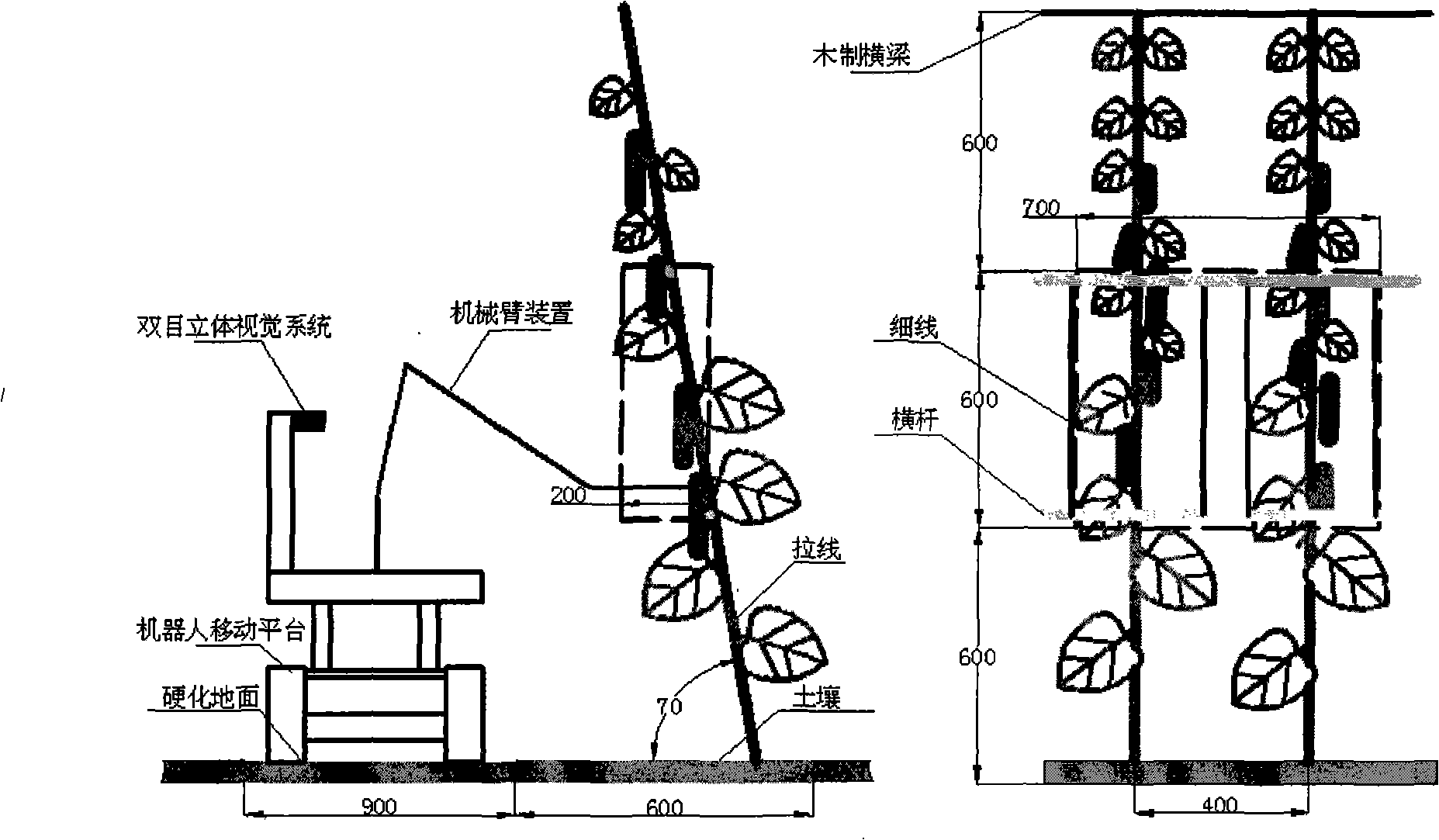

Cucumber picking robot system and picking method in greenhouse

The invention discloses a cucumber picking robot system in a greenhouse environment. The robot system comprises a binocular stereo vision system, a mechanical arm device and a robot mobile platform; the binocular stereo vision system is used for acquiring cucumber images, processing the images in real time and acquiring the position information of the acquired targets; the mechanical arm device is used for capturing and separating the acquired targets according to the position information of the acquired targets; and the robot mobile platform is used for independently moving in the greenhouse environment; wherein, the binocular stereo vision system comprises two black and white cameras, a dual-channel vision real-time processor, a lighting device and an optical filtering device; the mechanical arm device comprises an actuator, a motion control card and a joint actuator; and the robot mobile platform comprises a running mechanism, a motor actuator, a tripod head camera, a processor and a motion controller. The invention also discloses a cucumber picking method in the greenhouse environment. The method of combining machine vision and agricultural machinery is adopted to construct the cucumber picking robot system which is suitable for the greenhouse environment, thus realizing automatic robot navigation and automatic cucumber reaping, and reducing the human labor intensity.

Owner:SUZHOU AGRIBOT AUTOMATION TECH

Agricultural robot system and method

An agricultural robot system and method of harvesting, pruning, culling, weeding, measuring and managing of agricultural crops. Uses autonomous and semi-autonomous robot(s) comprising machine-vision using cameras that identify and locate the fruit on each tree, points on a vine to prune, etc., or may be utilized in measuring agricultural parameters or aid in managing agricultural resources. The cameras may be coupled with an arm or other implement to allow views from inside the plant when performing the desired agricultural function. A robot moves through a field first to “map” the plant locations, number and size of fruit and approximate positions of fruit or map the cordons and canes of grape vines. Once the map is complete, a robot or server can create an action plan that a robot may implement. An action plan may comprise operations and data specifying the agricultural function to perform.

Owner:VISION ROBOTICS

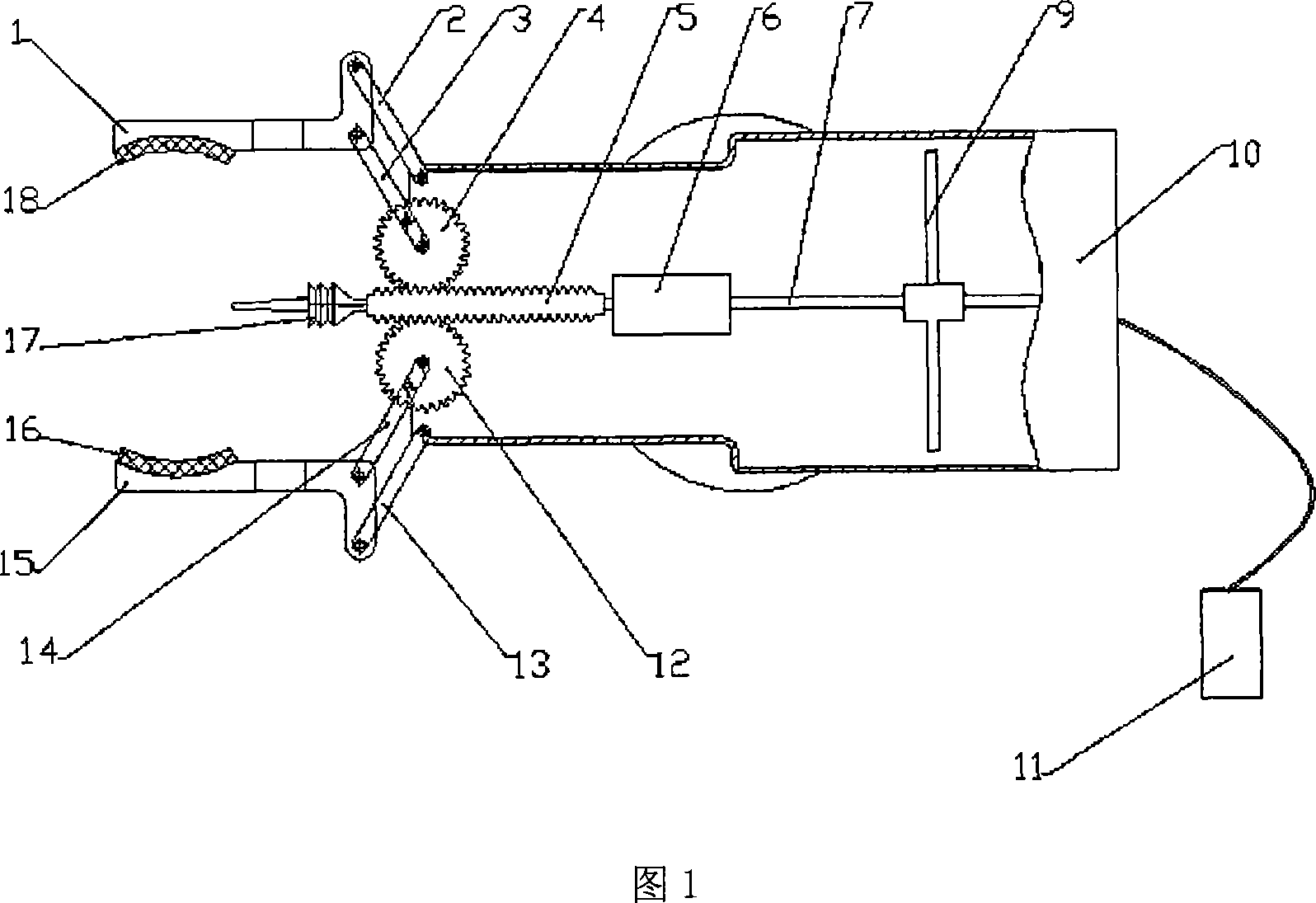

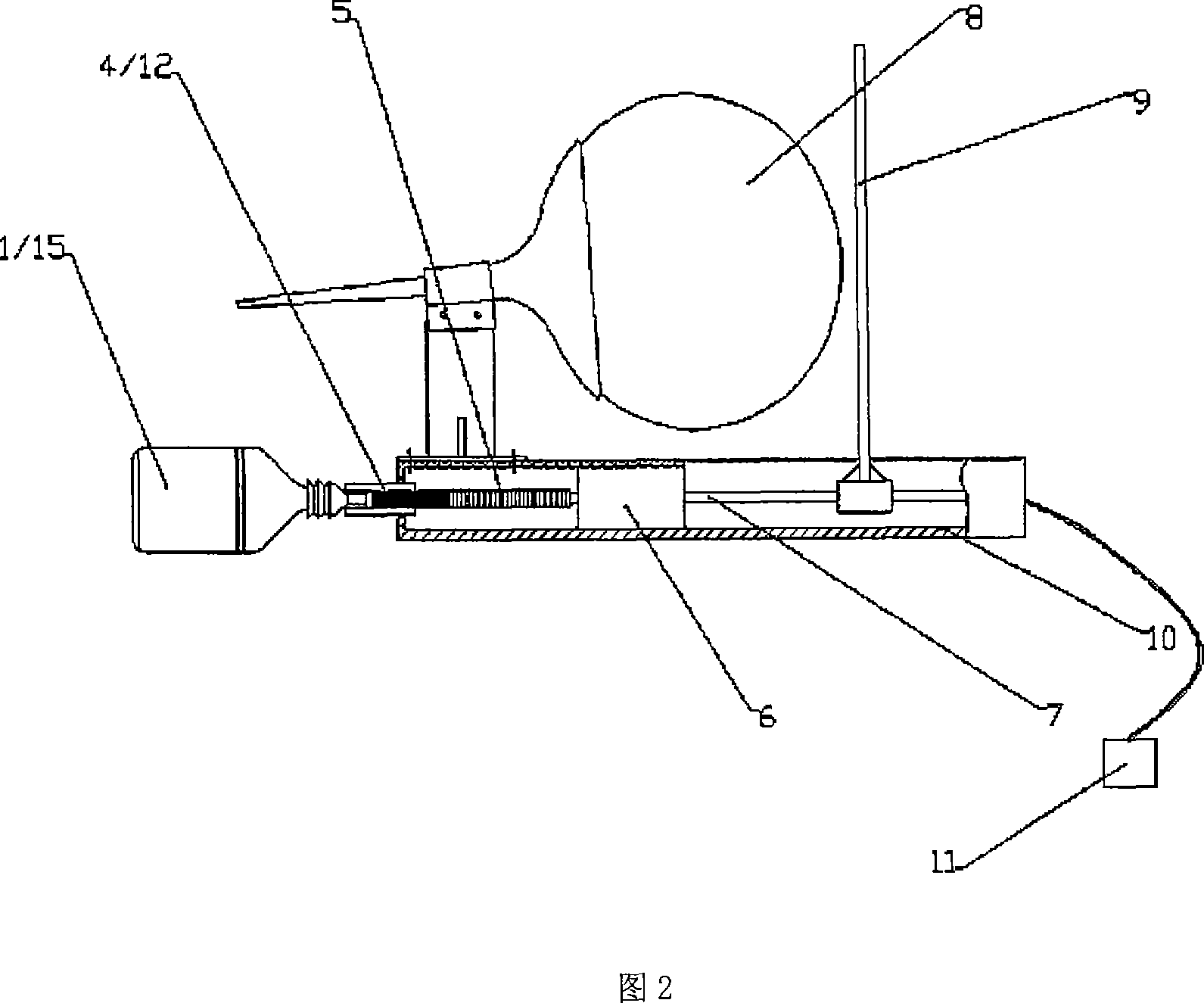

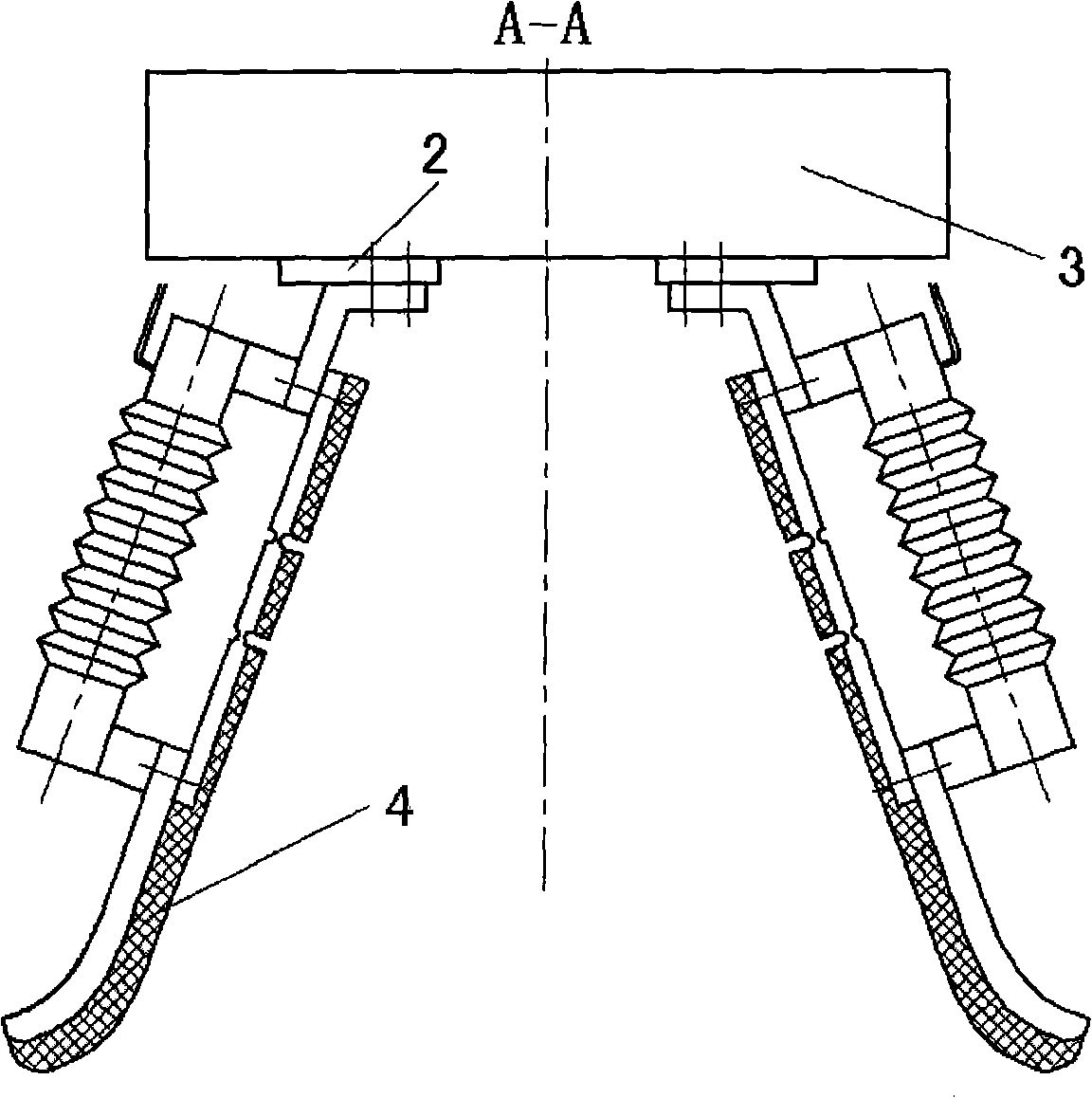

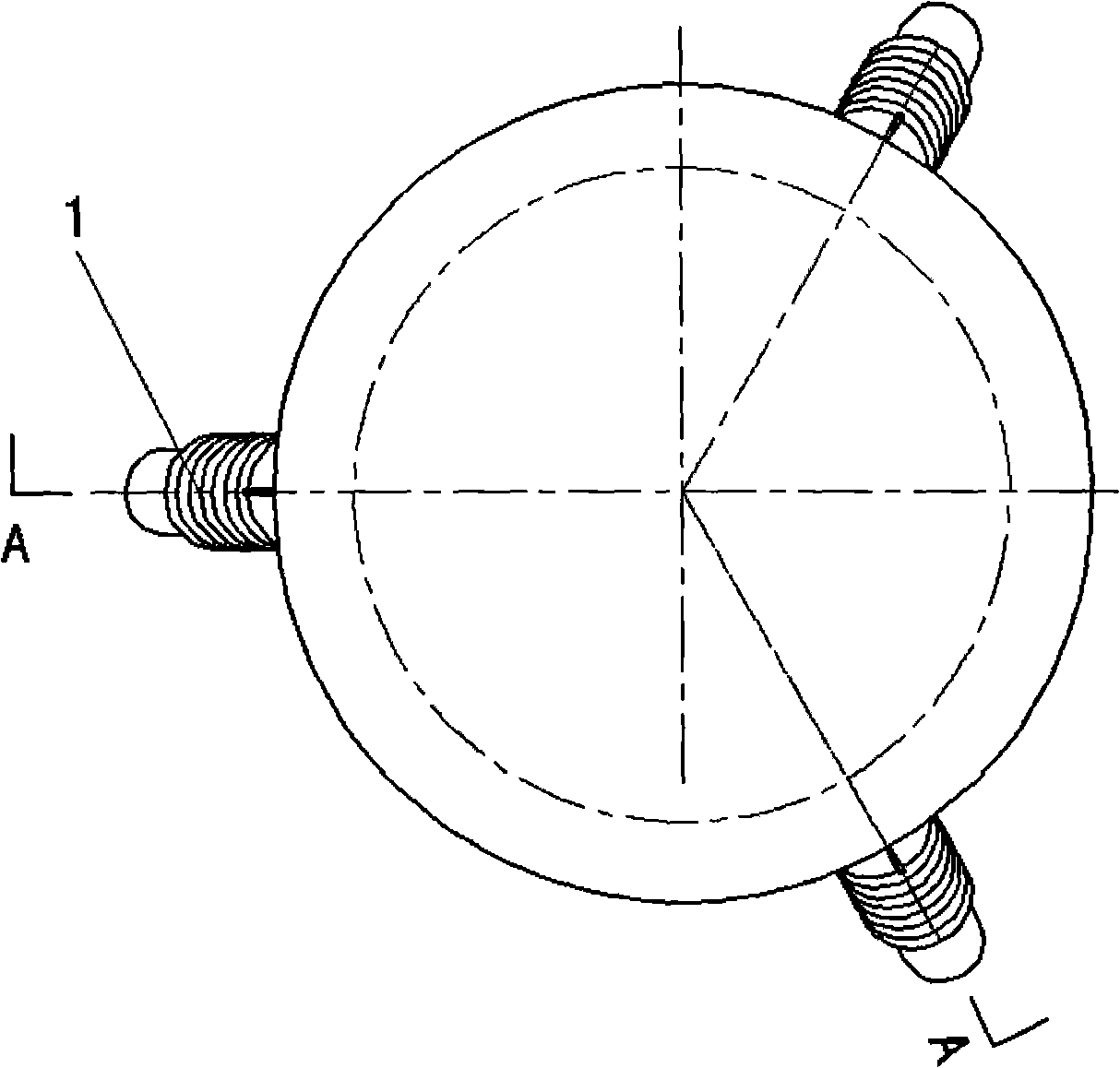

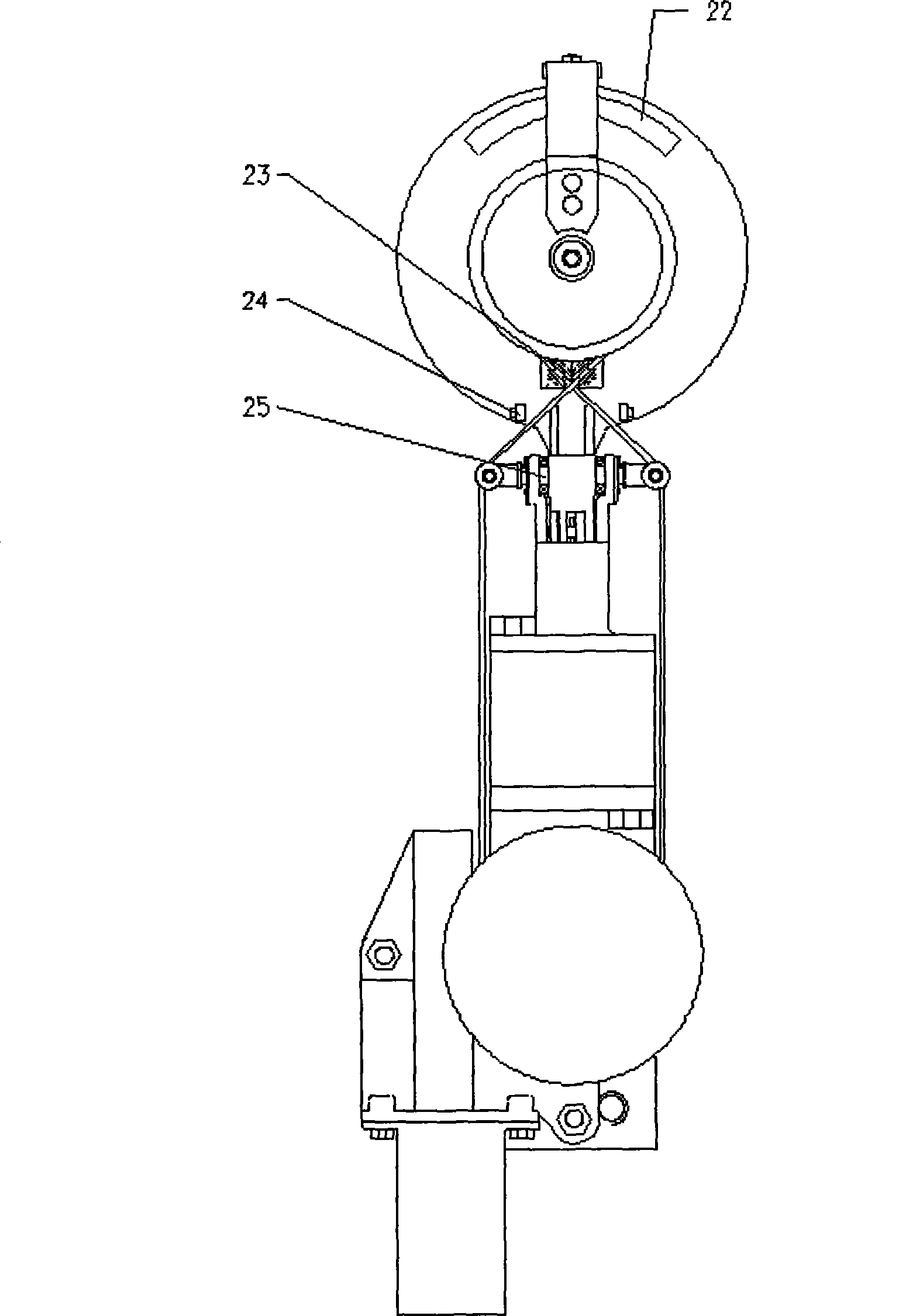

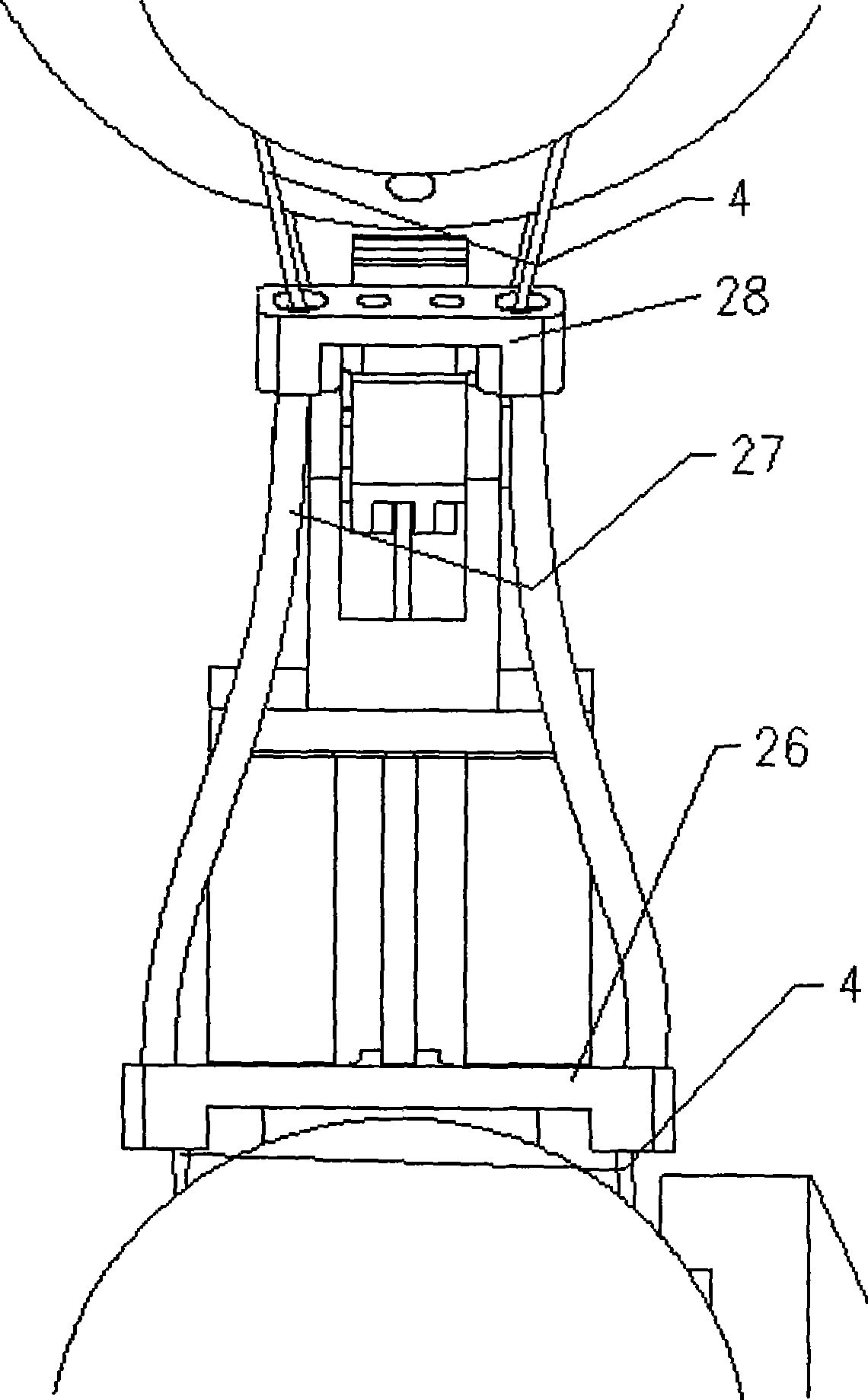

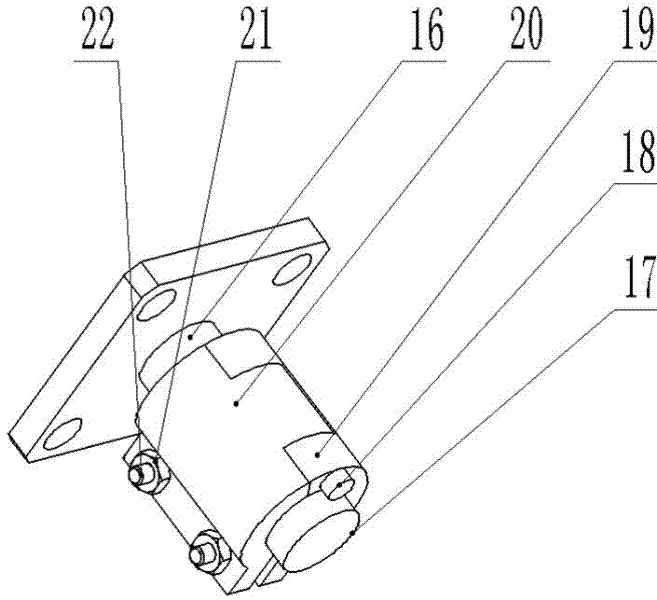

Linear motor driven terminal executor of picking robot

InactiveCN101066022ACompact structureHigh precisionGripping headsPicking devicesLinear motorActuator

The present invention relates to picking robot technology, and is especially one kind of linear motor driven terminal executor of picking robot. The linear motor driven terminal executor consists of fingers, link rod and crank, gears, linear motor, air bag, push plate, casing, vacuum generator, sucking disc, fixing clip and other parts. The mover of the linear motor moves linearly to drive the sucking disc back and forth for sucking the fruit, to make the fingers open or close to hold the fruit via the transmission of the gears, crack and the four-rod mechanism, and to drive the push plate forwards for compressing the air bag to blow out leaves and facilitating picking. The present invention needs only one motor, and has compact structure, high precision and smooth and reliable motion.

Owner:JIANGSU UNIV

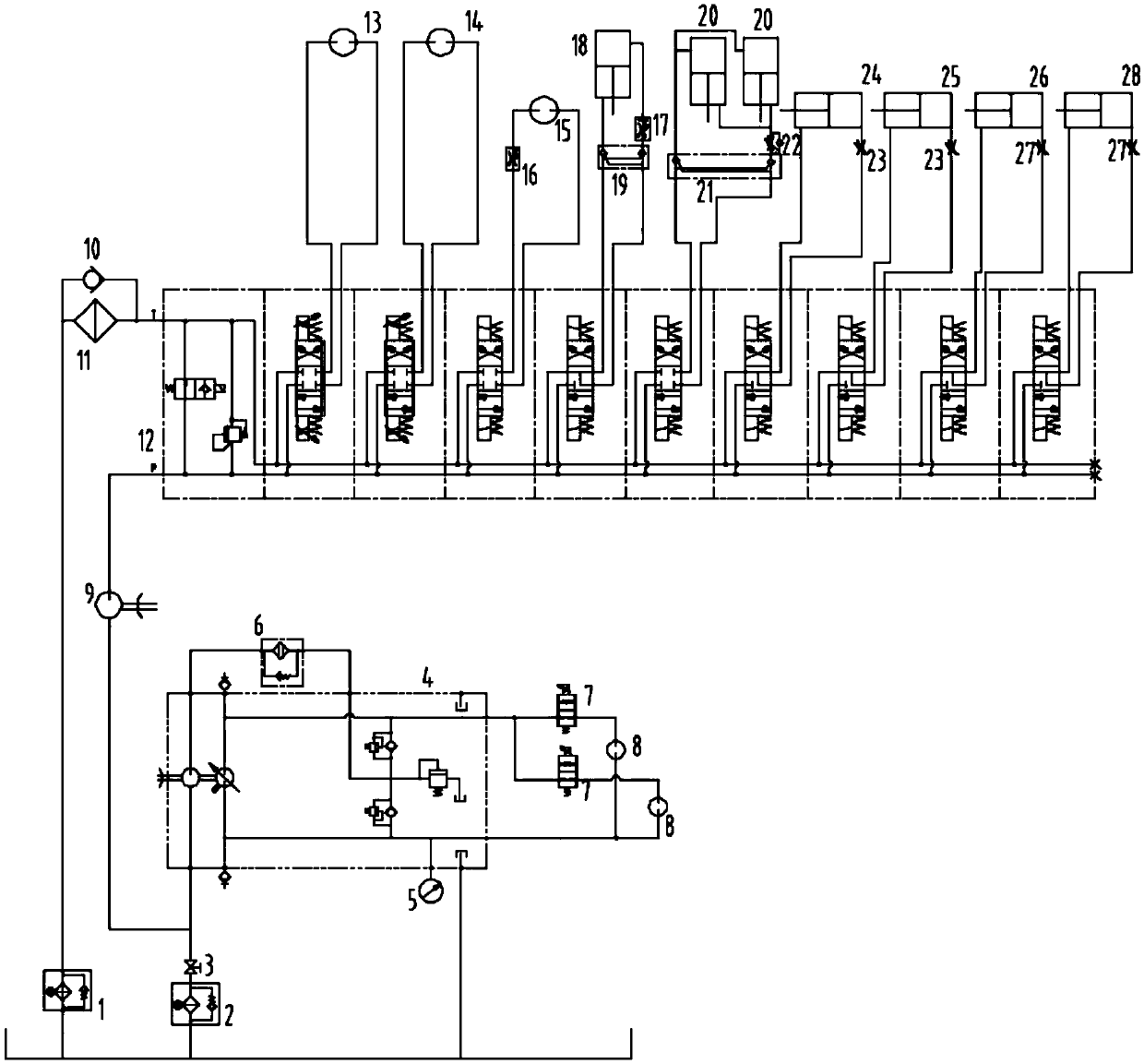

Hydraulic system of orchard picking equipment

PendingCN109515177AMeet actual job needsGuaranteed uptimeConveyorsPicking devicesHydraulic cylinderMechanical equipment

The invention belongs to the field of orchard mechanical equipment and particularly relates to a hydraulic system of orchard picking equipment. Power is provided for an up-installed conveying system and a chassis steering system simultaneously through a constant displacement pump. Flow input of a stacking conveying belt motor and a main conveying belt motor is controlled through a proportional multi-way valve. Control over the extending-and-contracting movement speed of a hydraulic cylinder is achieved through a speed regulation valve. Functions such as automatic conveying of fruit picking andautomatic cartoning of fruits are achieved. Problems that labor capacity of pure manual picking is large, picking efficiency is low and the picking cost is high are solved. The characteristics that fruit harvesting is strong in seasonality and short in harvesting time are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

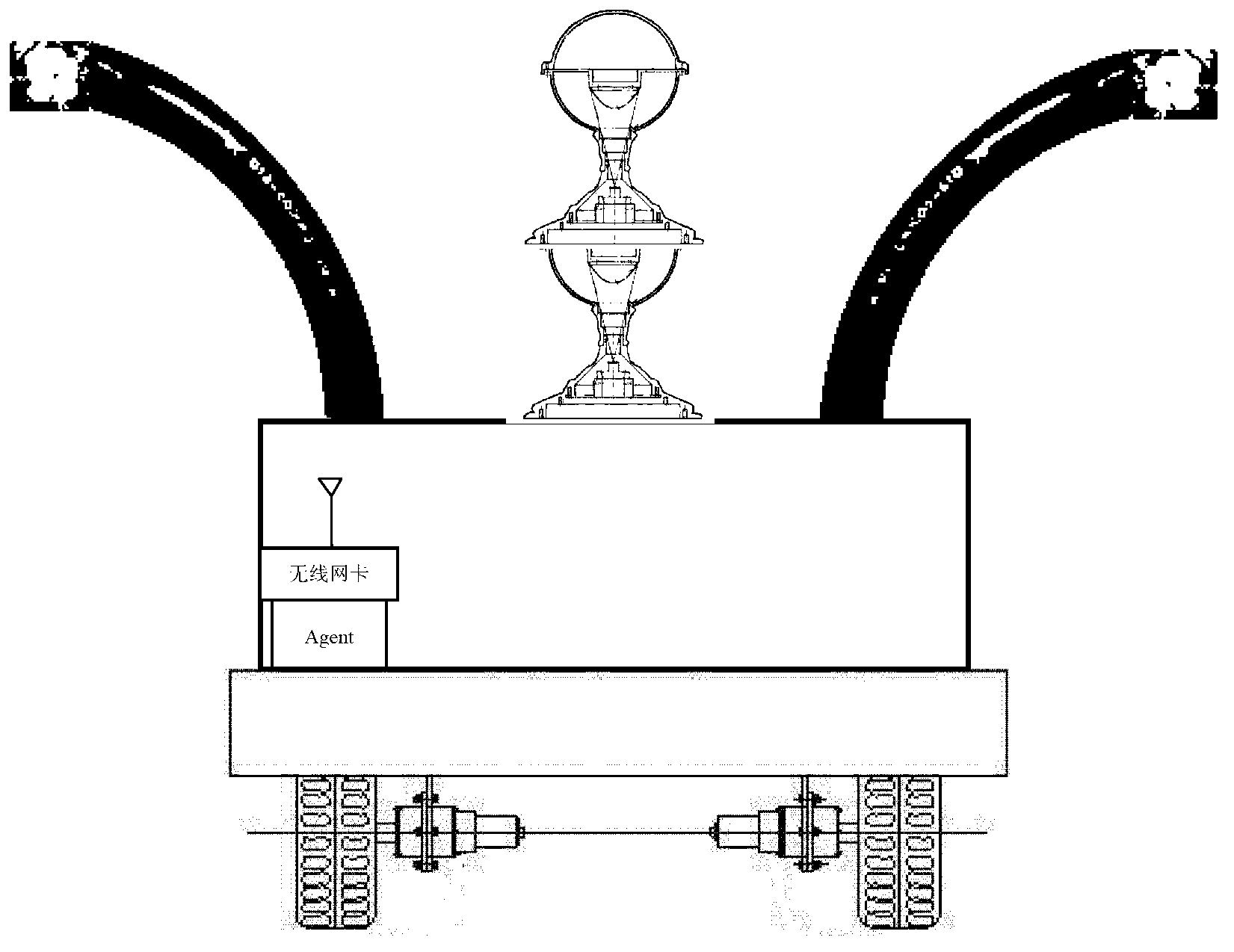

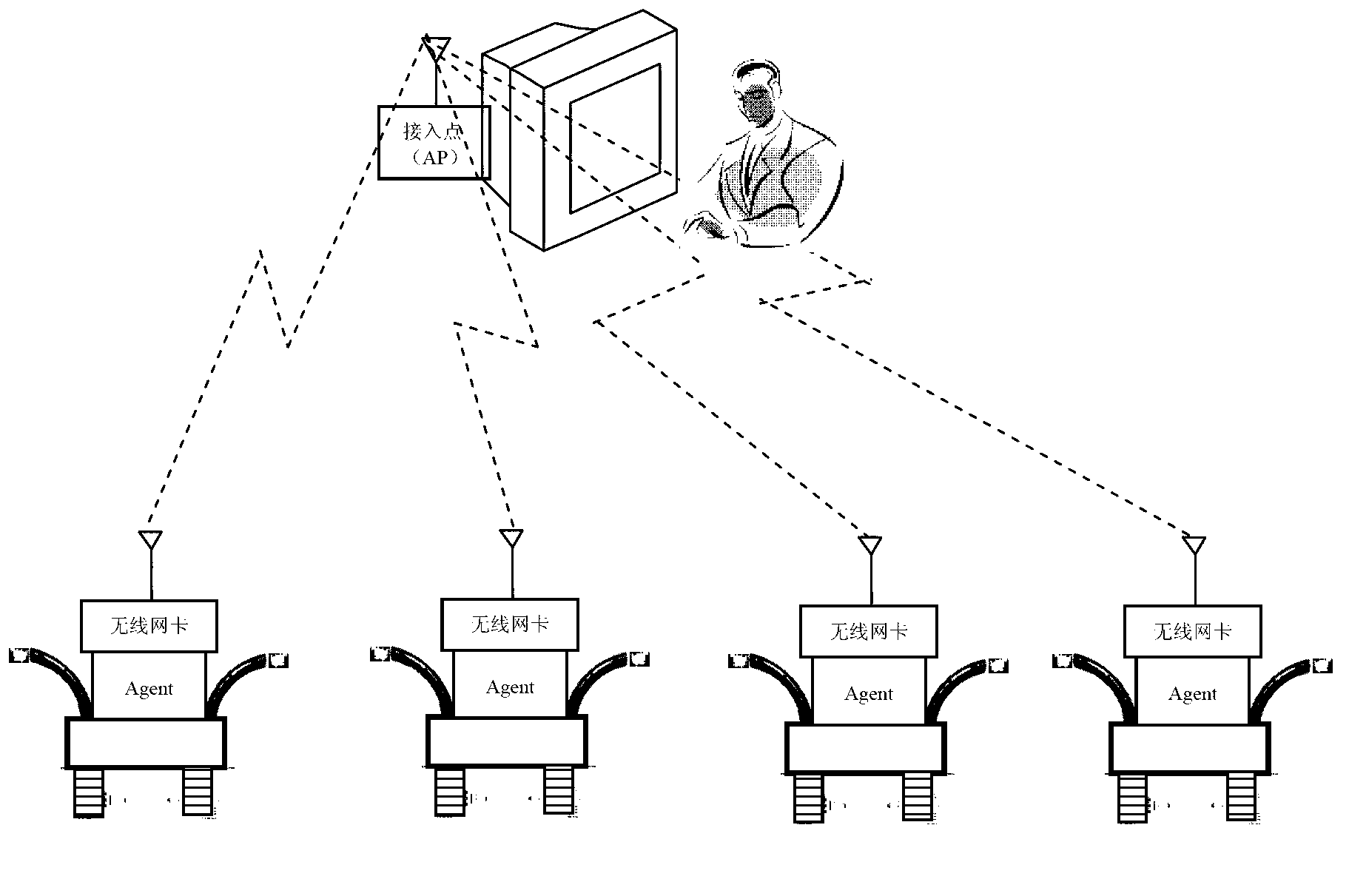

Autonomous navigation and man-machine coordination picking operating system of picking robot

ActiveCN102914967AImprove practicalityReduce the level of intelligent control requiredPicking devicesAdaptive controlStereoscopic videoMan machine

An autonomous navigation and man-machine coordination picking operating system of a picking robot comprises a travelling unit of the picking robot, a picking robot arm, an Agent, a wireless sensor network, a computer and a panoramic stereoscopic visual sensor. The Agent has functions of autonomous navigation, obstacle avoidance, positioning and path planning and the like, the wireless sensor network is used for completing man-machine coordination picking information interaction, the computer is used for providing long-distance intervention and management for picking administrators during man-machine coordination picking operation, and the panoramic stereoscopic visual sensor is used for acquiring panoramic stereoscopic video images in a picking area. The autonomous navigation and man-machine coordination picking operating system of the picking robot is fine in natural flexibility, simple in mechanism, low in control complexity, limited intelligent, high in picking efficiency, fine in environmental adaptation, and low in manufacturing and maintenance costs., Picking objects and crop are not damaged during picking.

Owner:ZHEJIANG UNIV OF TECH

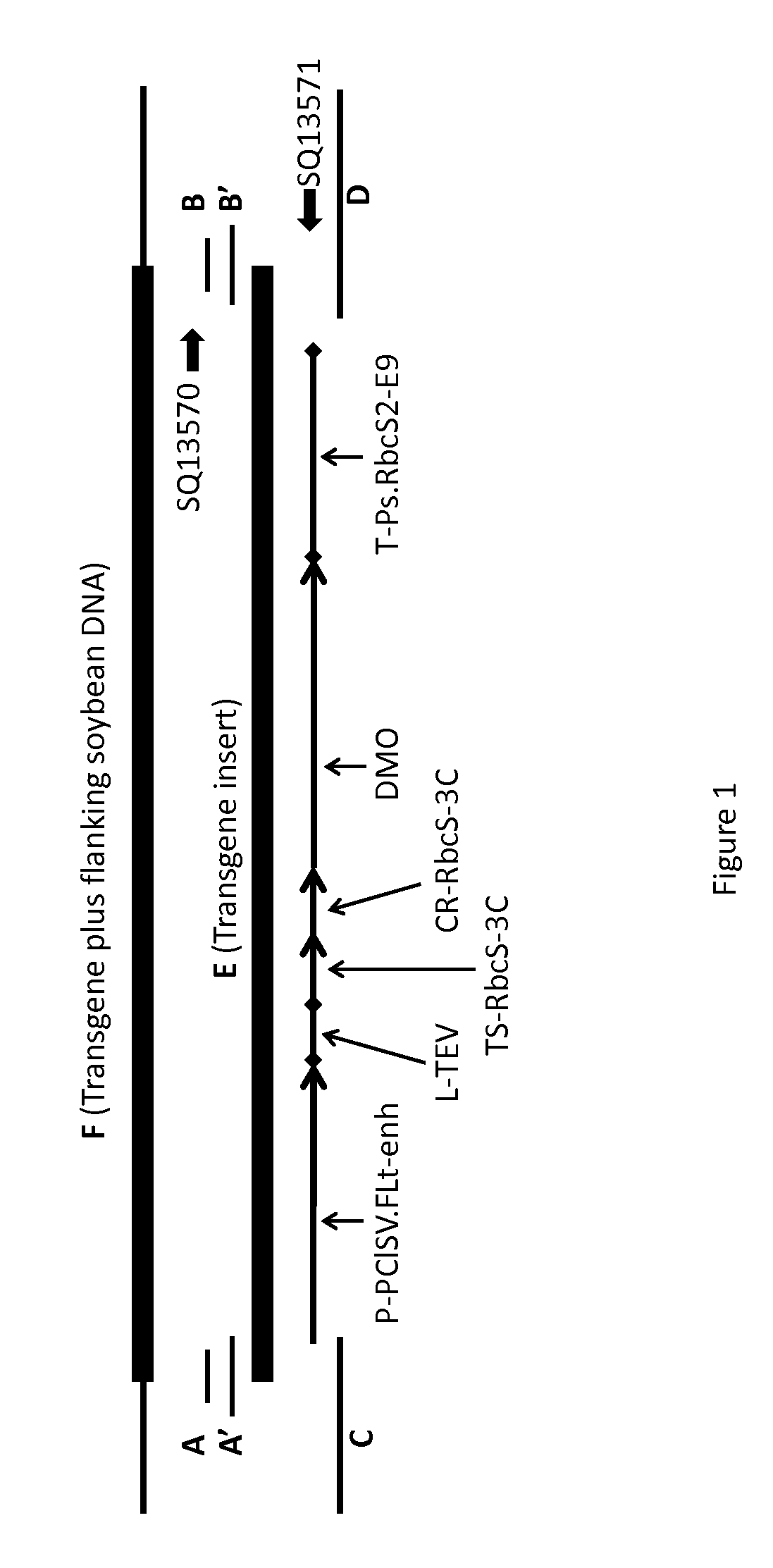

Soybean transgenic event mon 87708 and methods of use thereof

The invention provides a transgenic soybean event MON 87708 plant and plants, plant cells, seeds, plant parts, and commodity products derived from event MON 87708. The invention also provides polynucleotides specific for event MON 87708 and plants, plant cells, seeds, plant parts, and commodity products comprising polynucleotides specific for event MON 87708. The invention also provides methods related to event MON 87708.

Owner:MONSANTO TECH LLC

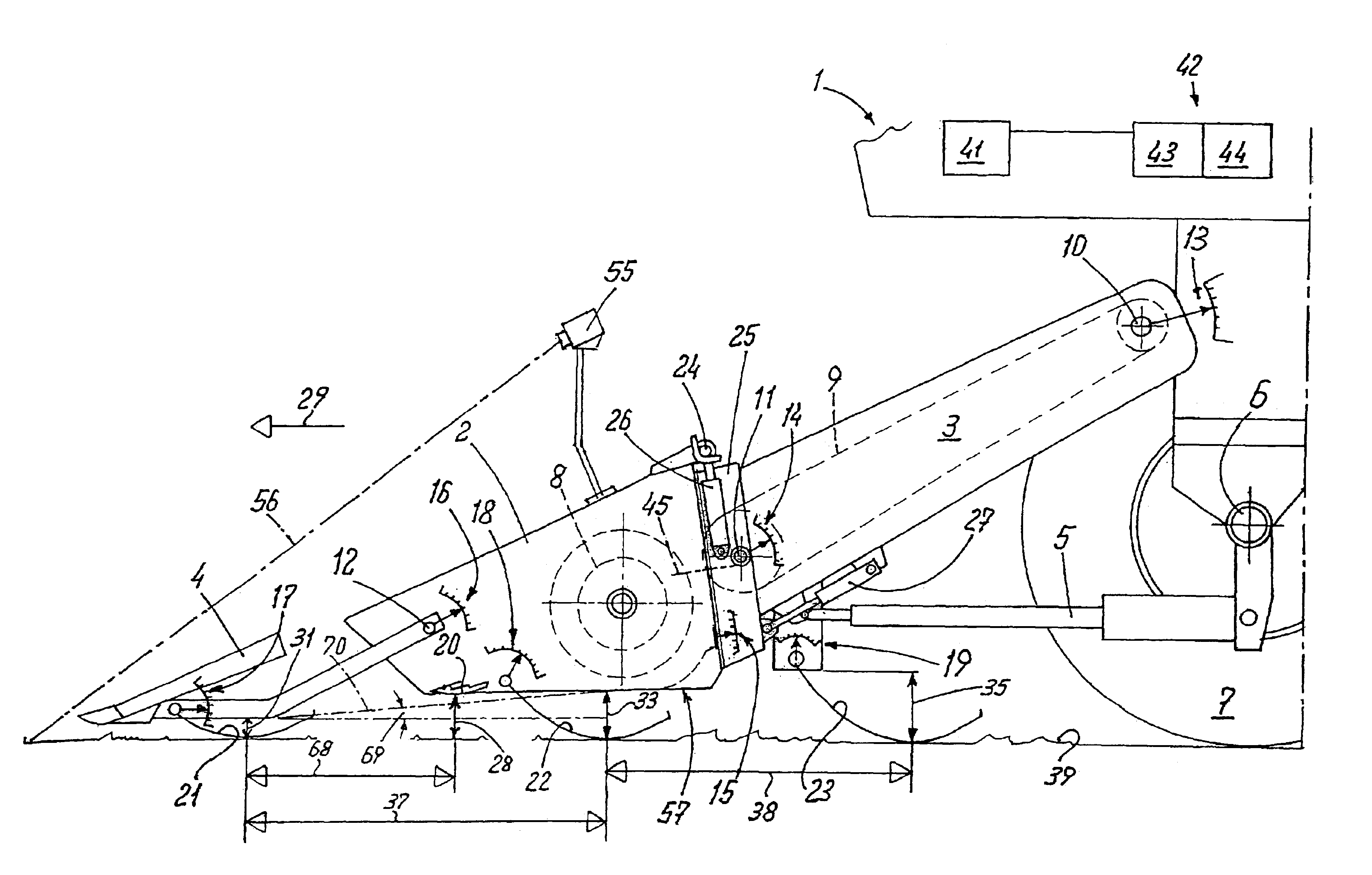

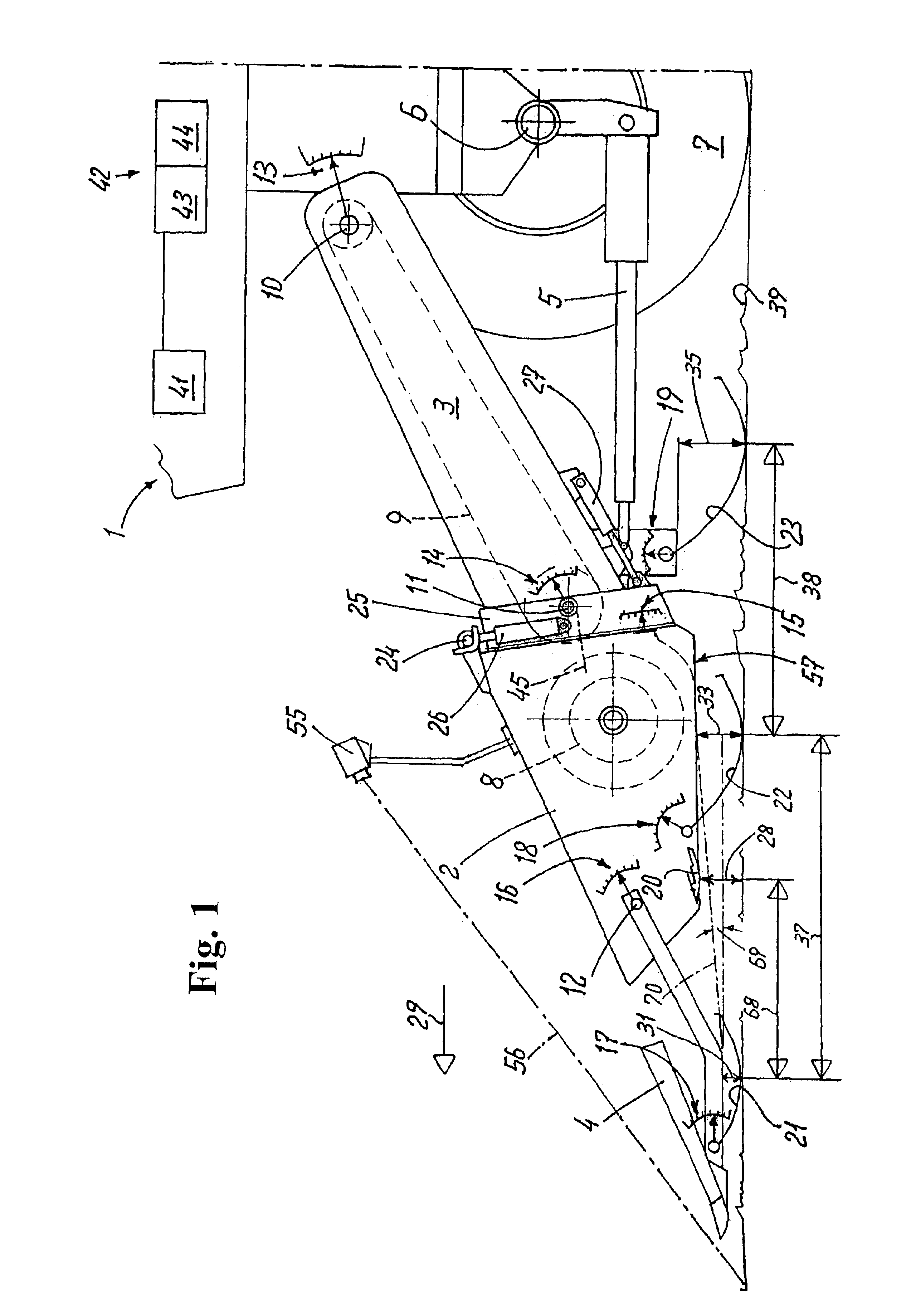

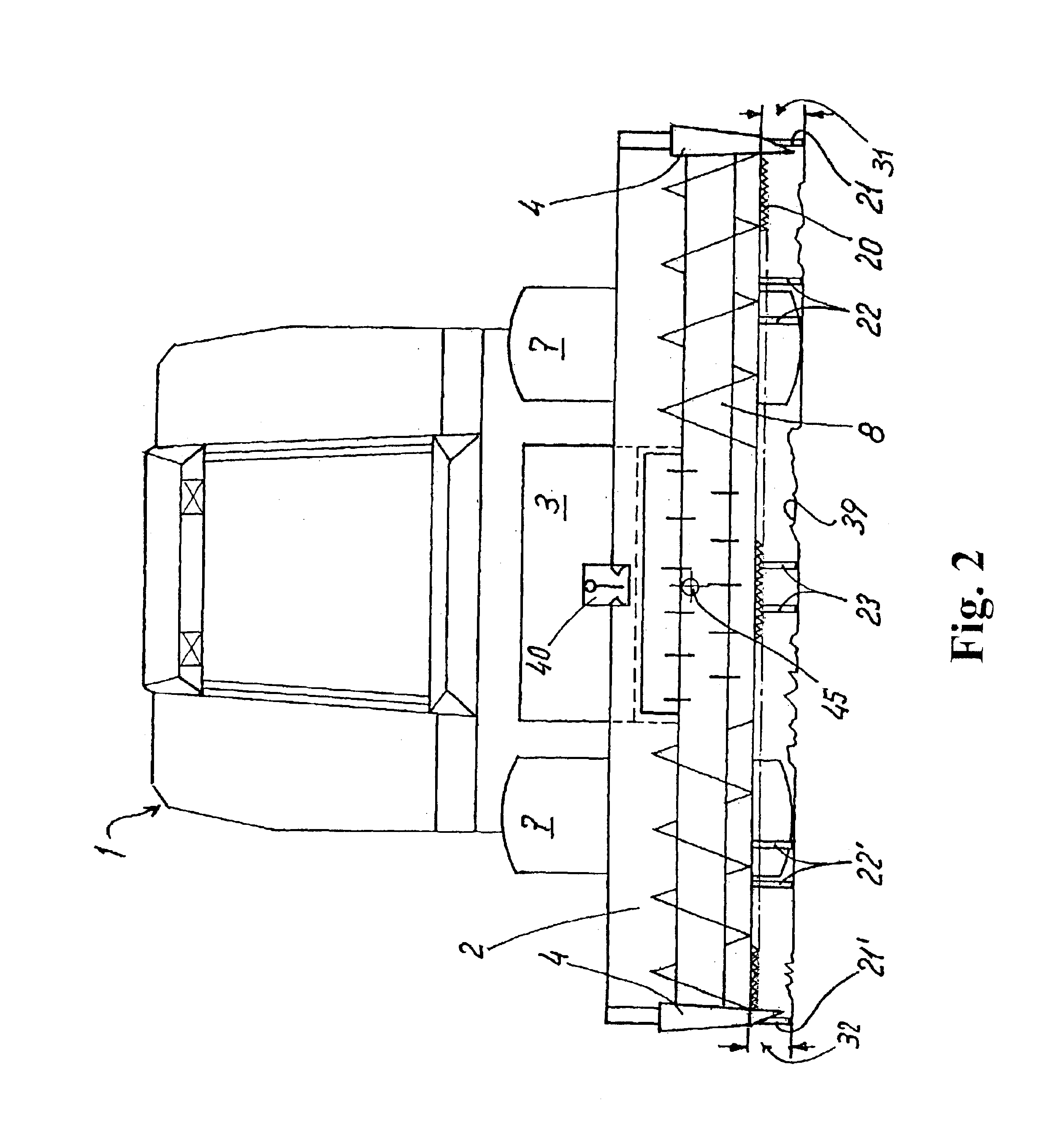

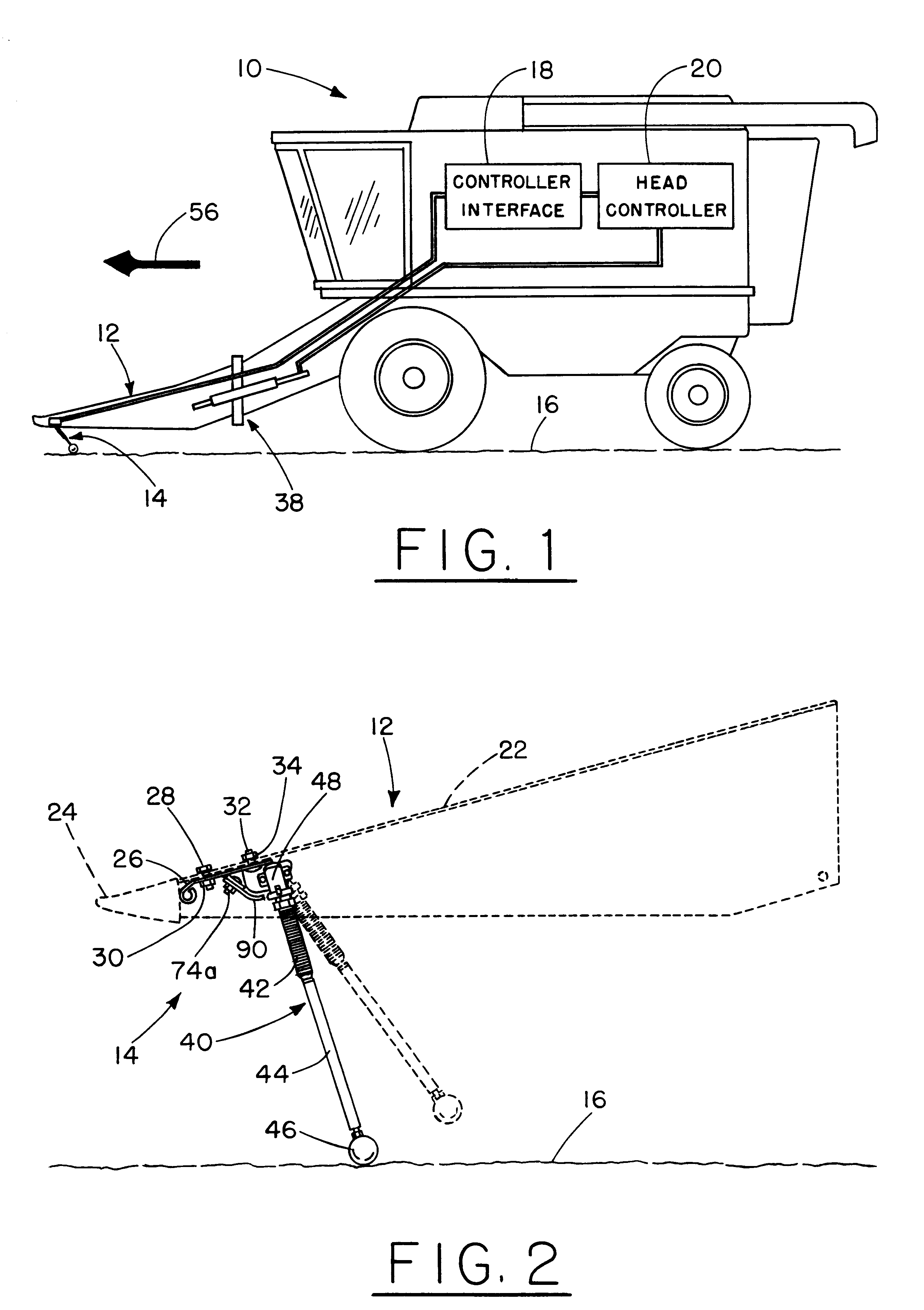

Position control for a crop pickup device

A position control for a crop pickup device which is mounted for vertical movement relative to an agricultural harvester. A measuring device is provided for determining the distance from the crop pickup device to the ground, wherein the position of the crop pickup device relative to the ground is adjustable by one control device as a function of the measured ground distance. The distance to the ground is determined by the measuring device at two points spaced from each other in the direction of travel. As a result, advantageously the inclination of the ground can be determined and used for optimized control of ground simulation of the crop pickup device. Additionally, the cutting angle can be adapted automatically to the slope of the ground, to avoid crop losses and impede damage to the grain header.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

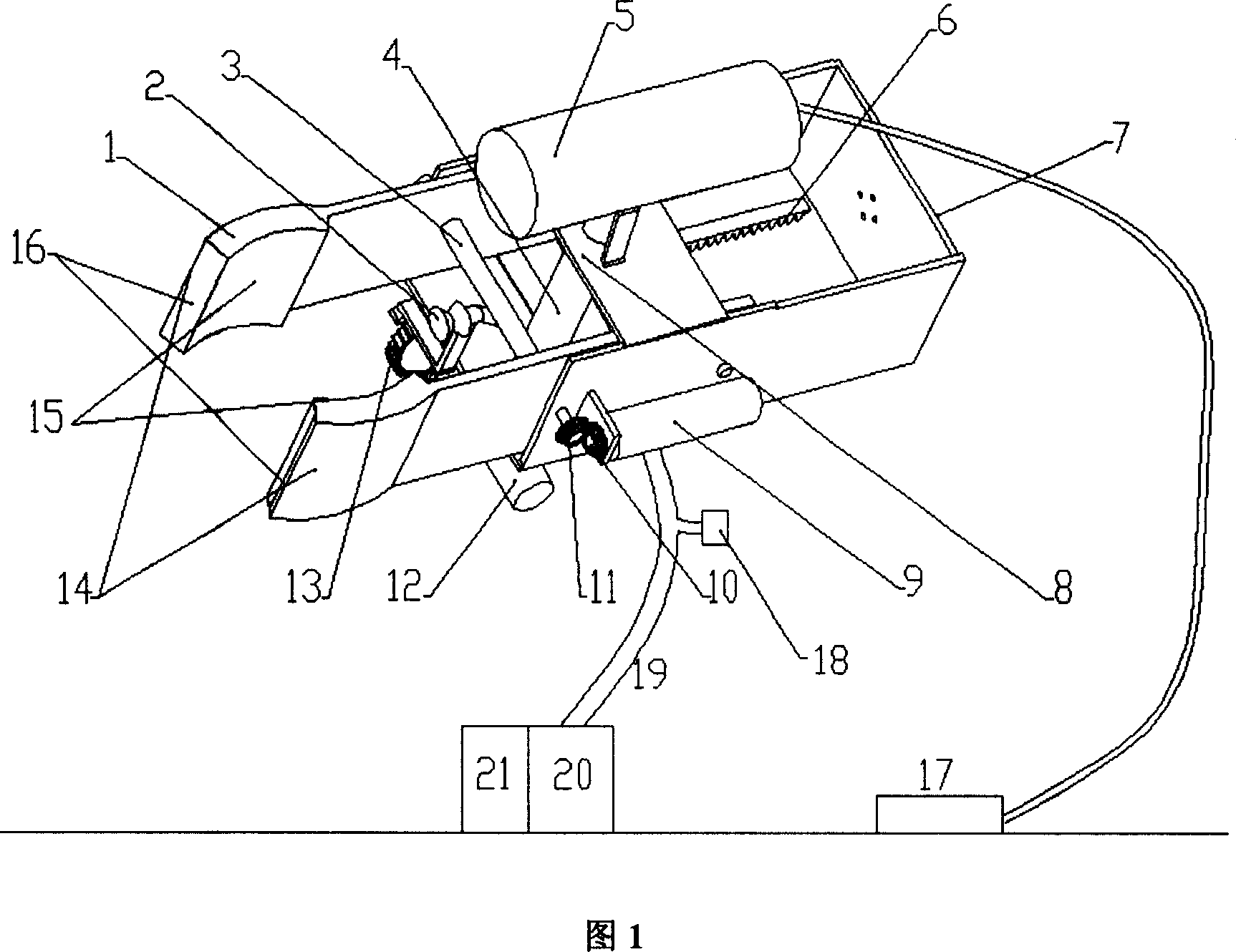

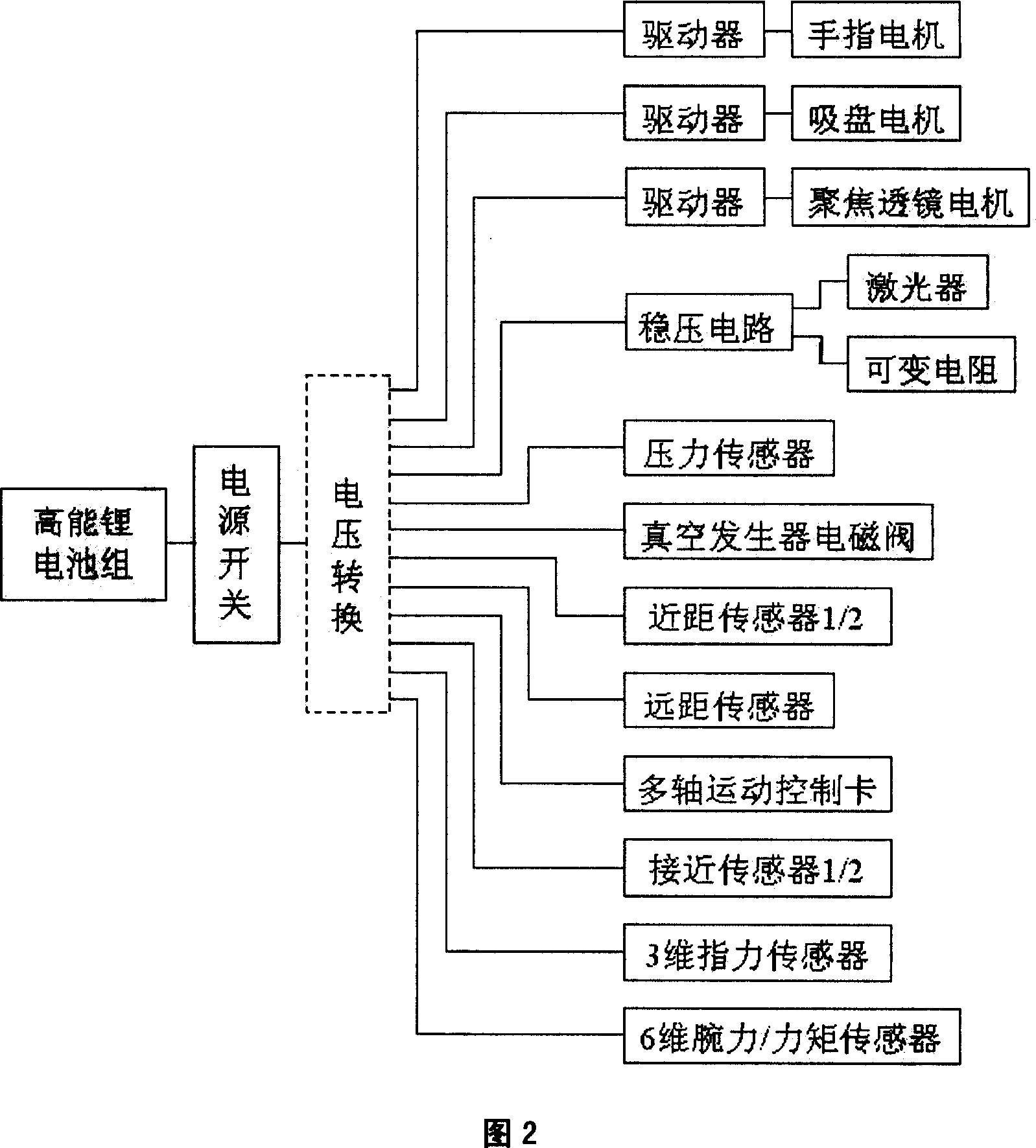

Terminal executor of fruit and vegetable picking robot

InactiveCN101019484ARealize intelligent pickingGuaranteed qualityProgramme-controlled manipulatorGripping headsProximity sensorHigh energy

The terminal executor of fruit and vegetable picking robot consists of an executing device, a sensing system and a power system. The executing device consists of a vacuum chuck mechanism, a holding finger mechanism and a cutting laser mechanism; the sensing system consists of a servo motor coder, a near distance sensor, a long distance approach sensor, a finger force sensor, a wrist force sensor and a pressure sensor installed in different parts of the executing device; and the power system powers the devices and elements in the terminal executor with high energy lithium battery and through voltage conversion. By means of the information sensing of the sensors, the present invention can adsorb, grab and separate to realize the intelligent picking of fruits in high quality.

Owner:JIANGSU UNIV

Agricultural robot system and method

InactiveUS7765780B2Improve efficiencyLow costAnalogue computers for trafficMowersEngineeringAgricultural crops

Robotic harvesting of agricultural crops. Robot moves through a field first to “map” the field to determine plant locations, number and size of fruit on plants and approximate positions of fruit on each plant. Once the map of the fruit is complete, the robot can plan and implement an efficient picking plan for itself or another robot. A scout robot or harvest robot determines a picking plan in advance of picking a tree. This may be done if the map is finished hours, days or weeks before a robot is scheduled to harvest, or if the picking plan algorithm selected requires significant computational time and cannot be implemented in “real time” by the harvesting robot as it is picking the field. The system harvests according to the selected picking plan. The picking plan may be generated in the scout robot, harvest robot or on a server.

Owner:VISION ROBOTICS

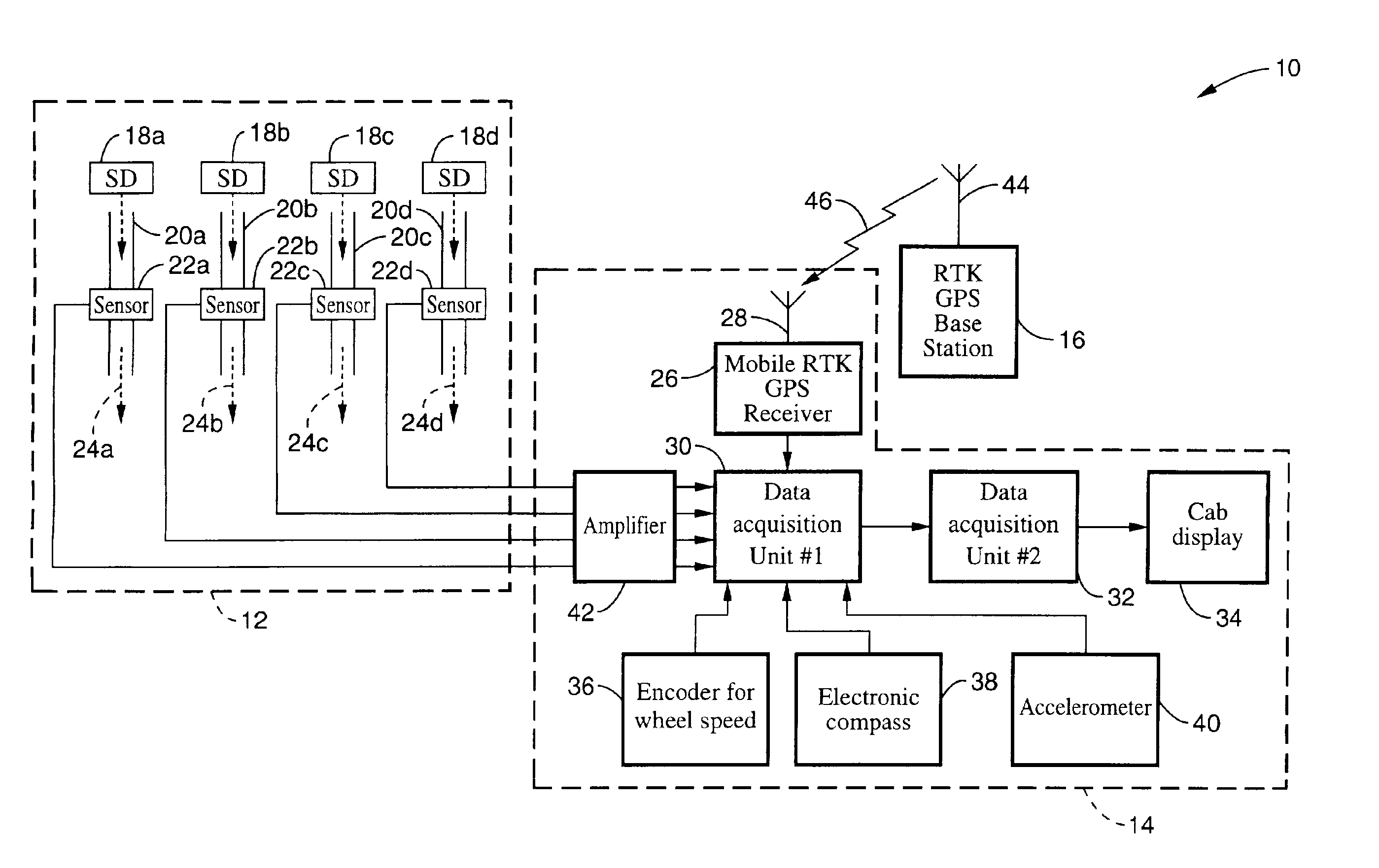

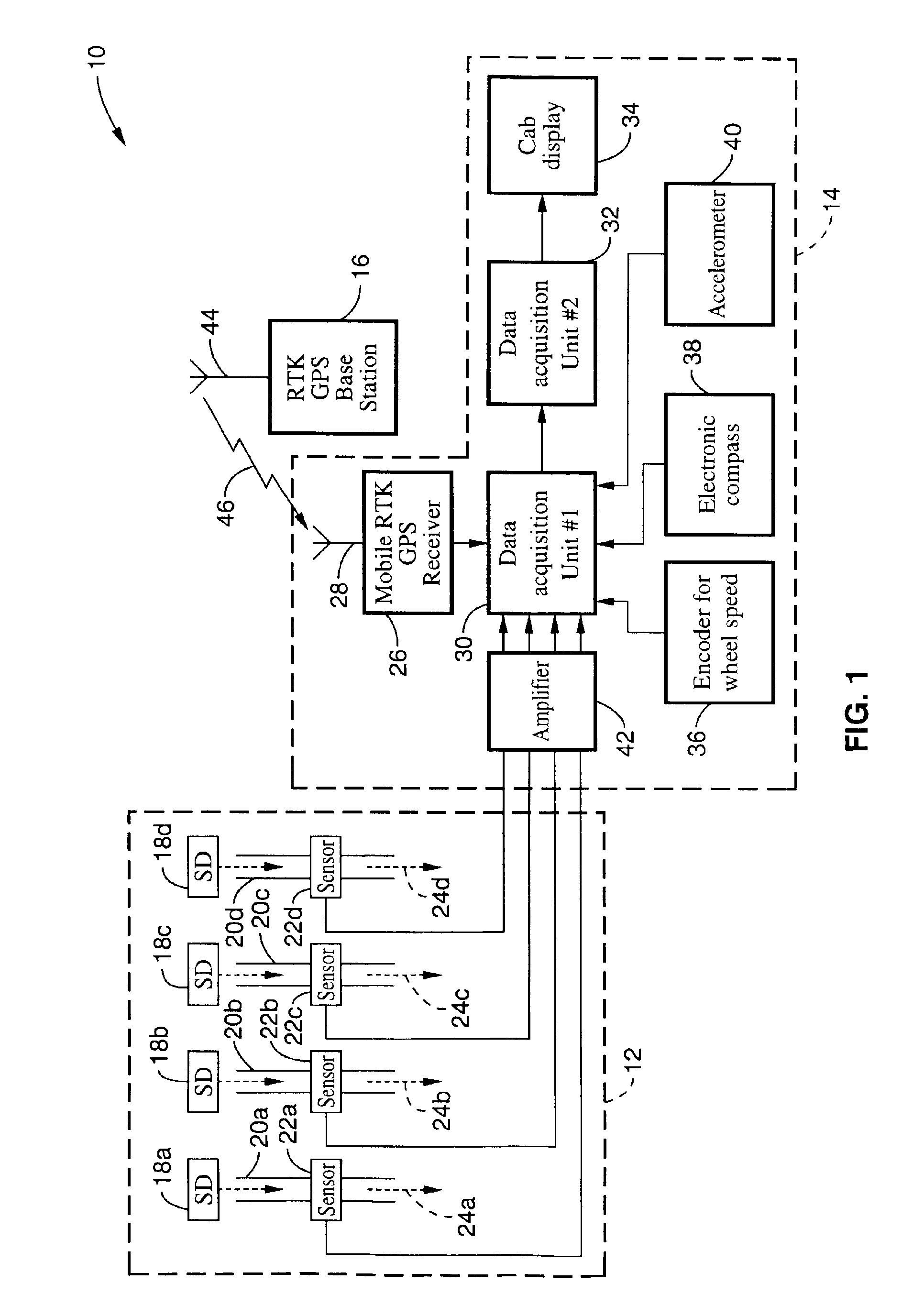

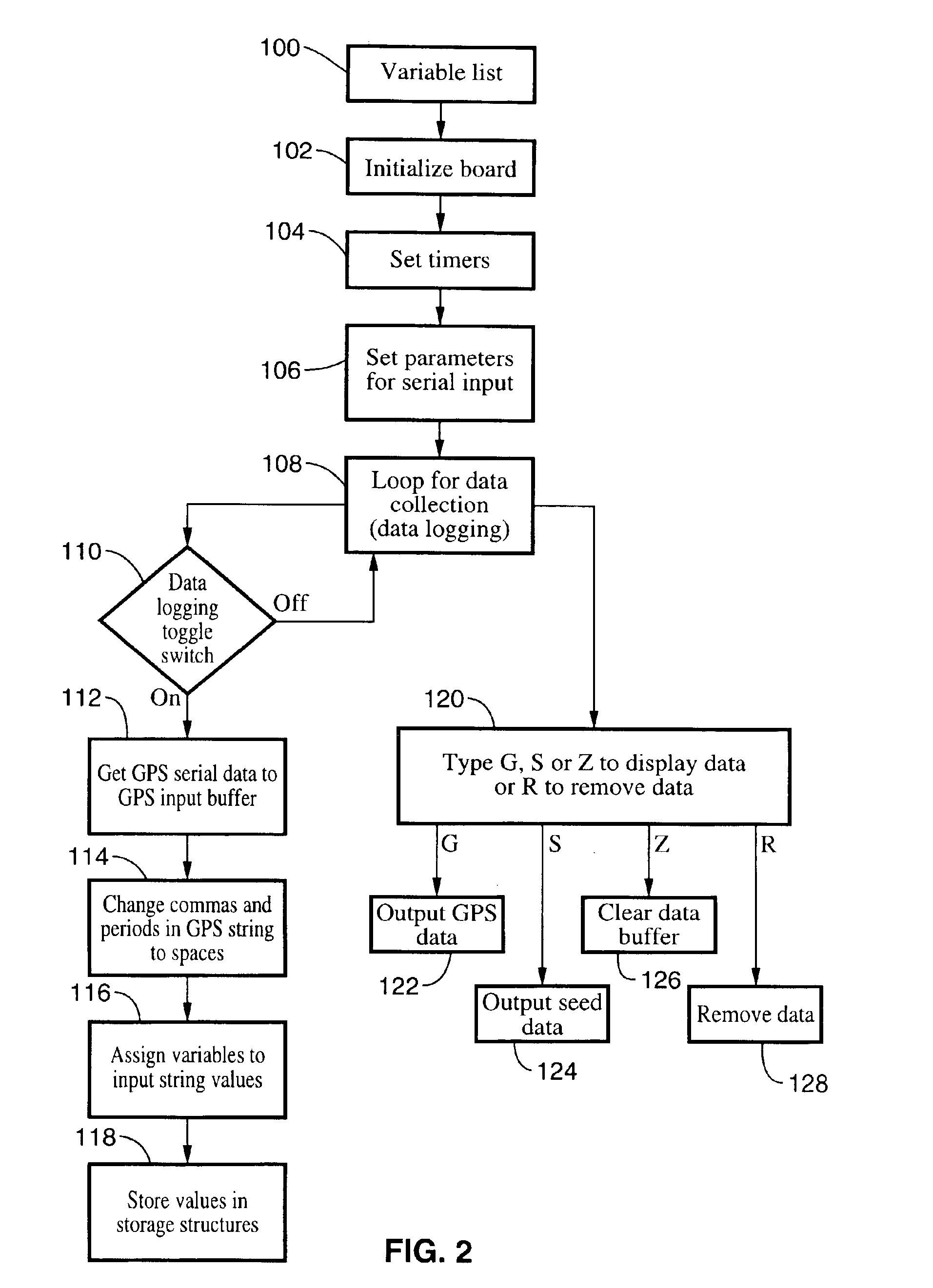

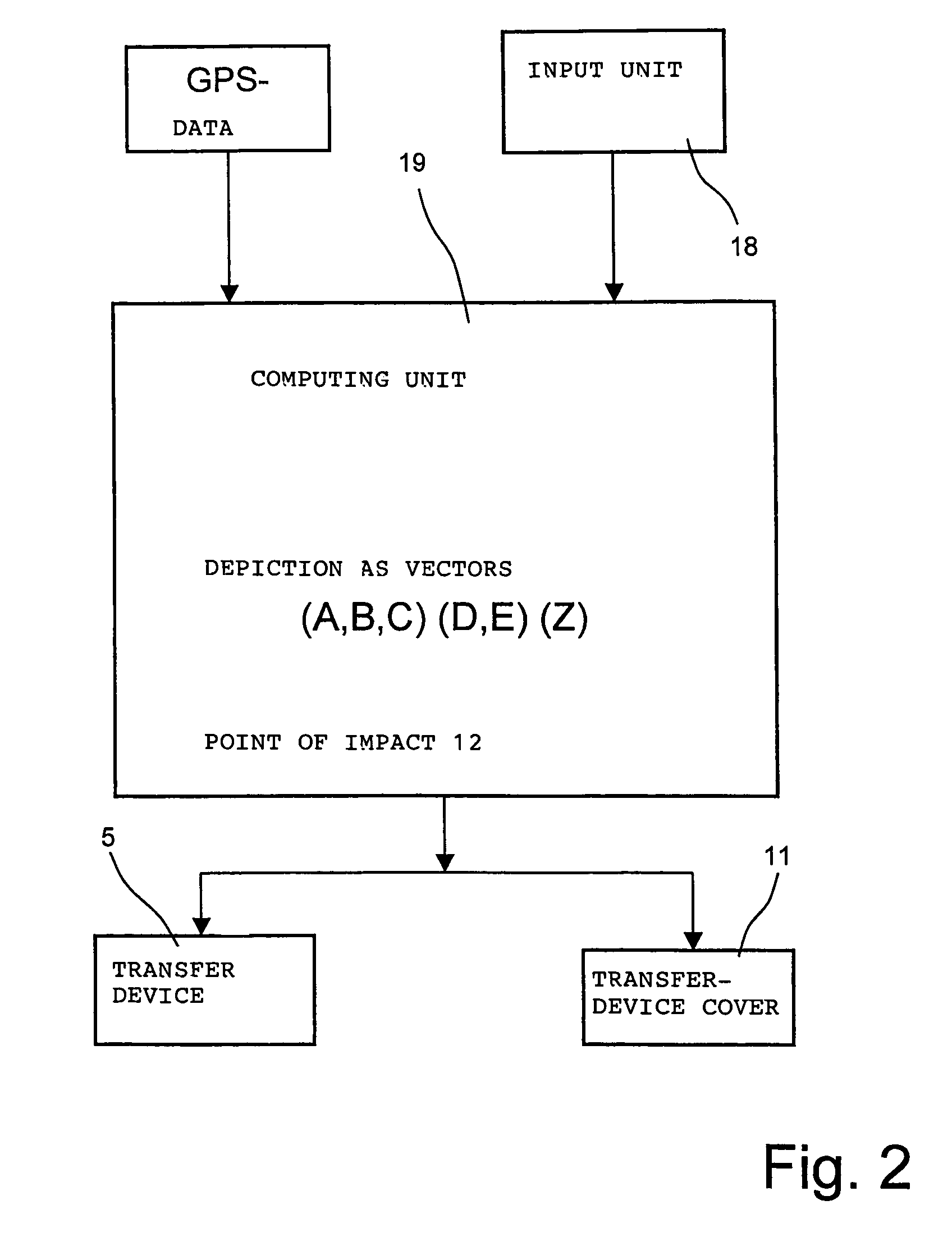

Method and apparatus for ultra precise GPS-based mapping of seeds or vegetation during planting

InactiveUS6941225B2Application can be controlledLow costMowersFertiliser distributersVegetationGps receiver

An ultra precise seed planter apparatus and method for generating a centimeter accuracy map of the location of seeds or vegetation as they are planted from an agricultural planting machine. The apparatus is fitted with a GPS receiver feeding a data logger, and optical sensors that are placed adjacent seed or vegetation dispenser. The data logger monitors GPS time and UTM coordinates, as well as the optical sensors. Ground speed and azimuth are also monitored. The seeds or vegetation are time-tagged as they are dispensed, and software is used to process the dispensing time and GPS location data and estimate the exact coordinates of each seed or plant and its distance from adjacent seeds or plants. As a result, a precise planting map is generated. The invention may also be used to determine the location to dispense seeds or vegetation, and activating the dispenser when that location is reached.

Owner:RGT UNIV OF CALIFORNIA

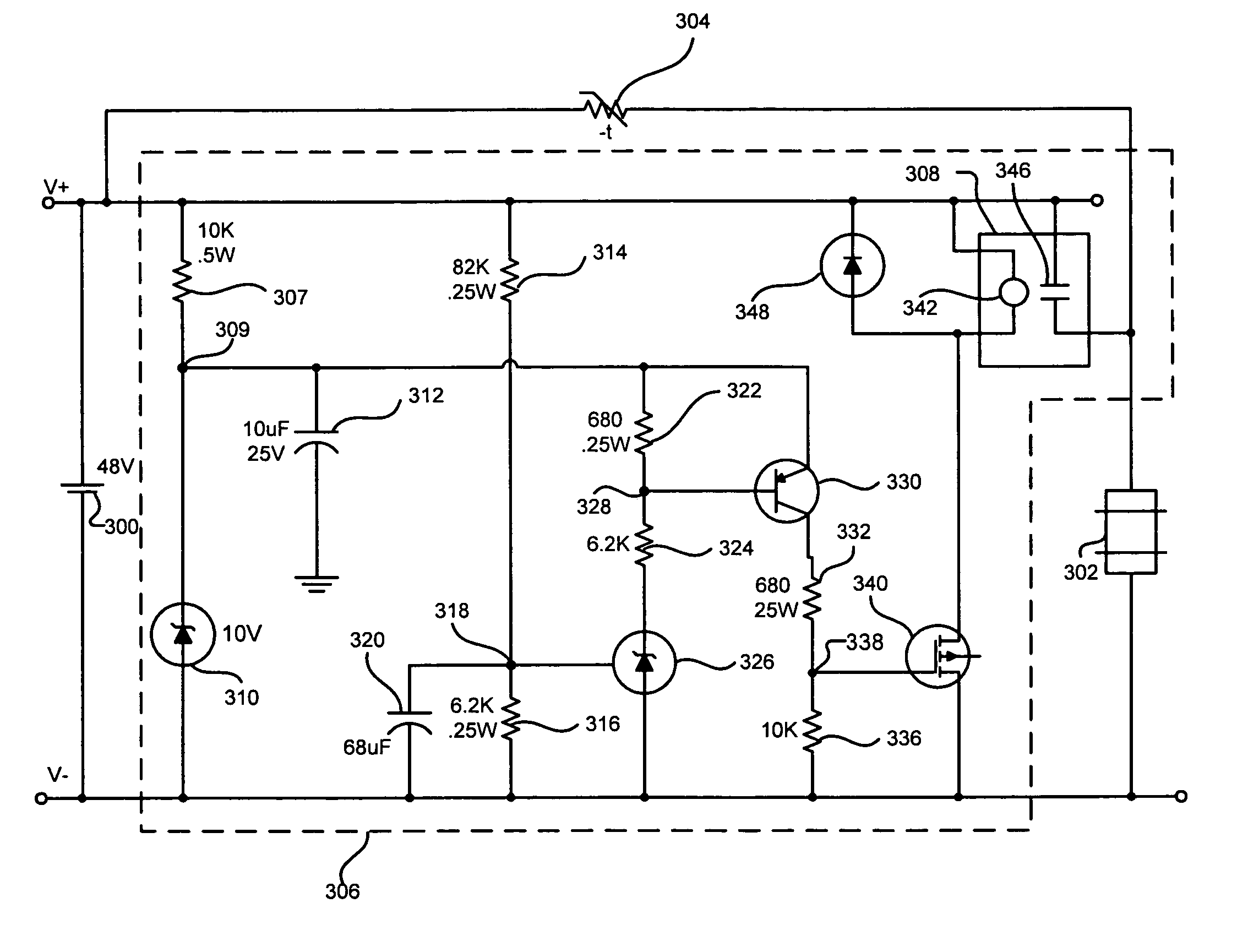

Battery-powered walk-behind greensmower

A greensmower having a cutting reel and a traction member and an independent electric circuit and motor for driving each. A handle is attached to the reel for mower guidance by an operator in a walk-behind position. Separate electric controls are connected to each motor for separate speeds for each motor and thereby control the clip rate of the mowing. There are low battery power read-outs and automatic shutoffs. Provision is made for traction powering of the mower even when the reel motor is not operating because of low battery power. A lift-out battery pack is shiftably mounted on the mower for producing the desired force of the mower on the ground.

Owner:TEXTRON INNOVATIONS

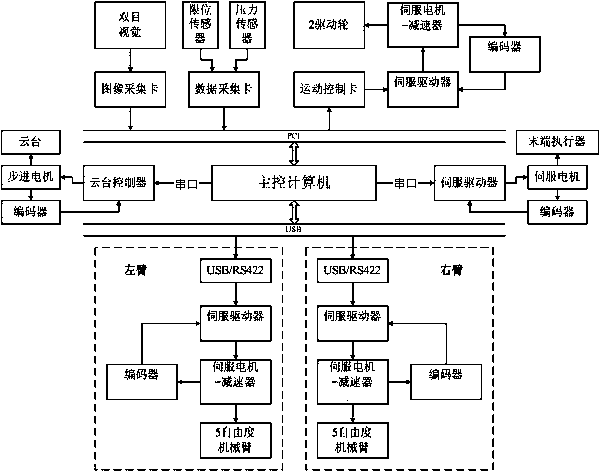

Double-manipulator fruit and vegetable harvesting robot system and fruit and vegetable harvesting method thereof

ActiveCN103503639ARealize automatic harvestingImprove work efficiencyProgramme-controlled manipulatorPicking devicesSimulationActuator

The invention discloses a double-manipulator fruit and vegetable harvesting robot system and a fruit and vegetable harvesting robot method of the double-manipulator fruit and vegetable harvesting robot system. According to the system, a binocular stereoscopic vision system is used for visual navigation of walking motion of a robot and obtaining of position information of harvested targets and barriers; a manipulator device is used for grasping and separating according to the positions of the harvested targets and the barriers; a robot movement platform is used for autonomous moving under the operation environment; a main control computer is a control center, integrates a control interface and all software modules, and controls the whole system. The binocular stereoscopic vision system comprises two color vidicons, an image collection card and an intelligent control cloud deck; the manipulator device comprises two five degree-of-freedom manipulator bodies, a joint servo driver, an actuator motor and the like; the robot movement platform comprises a wheel-type body, a power source and power control device and a fruit and vegetable harvesting device. Binocular vision and the double-manipulator bionic personification are used for building the fruit and vegetable harvesting robot, and autonomous navigation walking and automatic harvesting of the fruit and vegetable targets are achieved.

Owner:溧阳常大技术转移中心有限公司

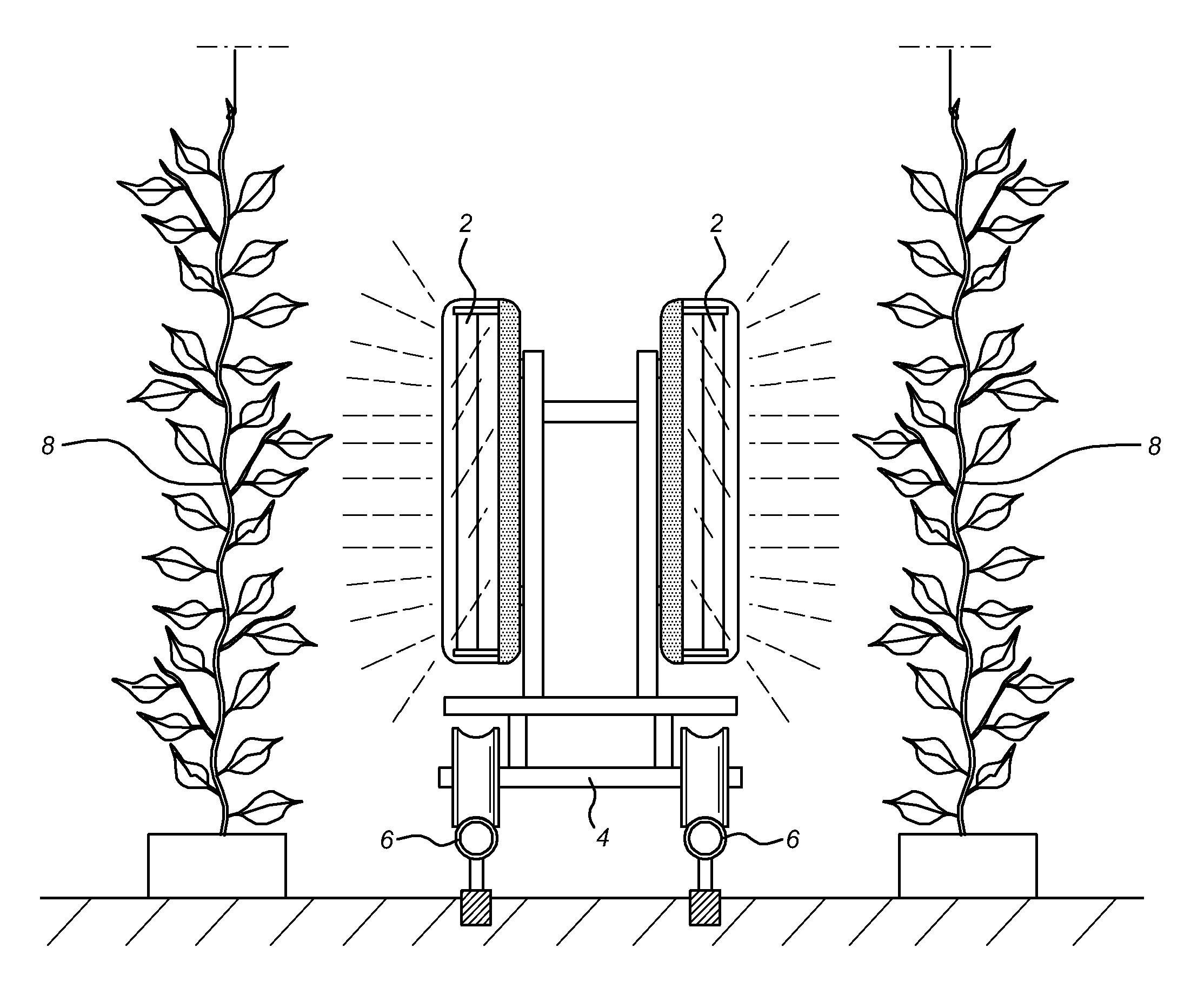

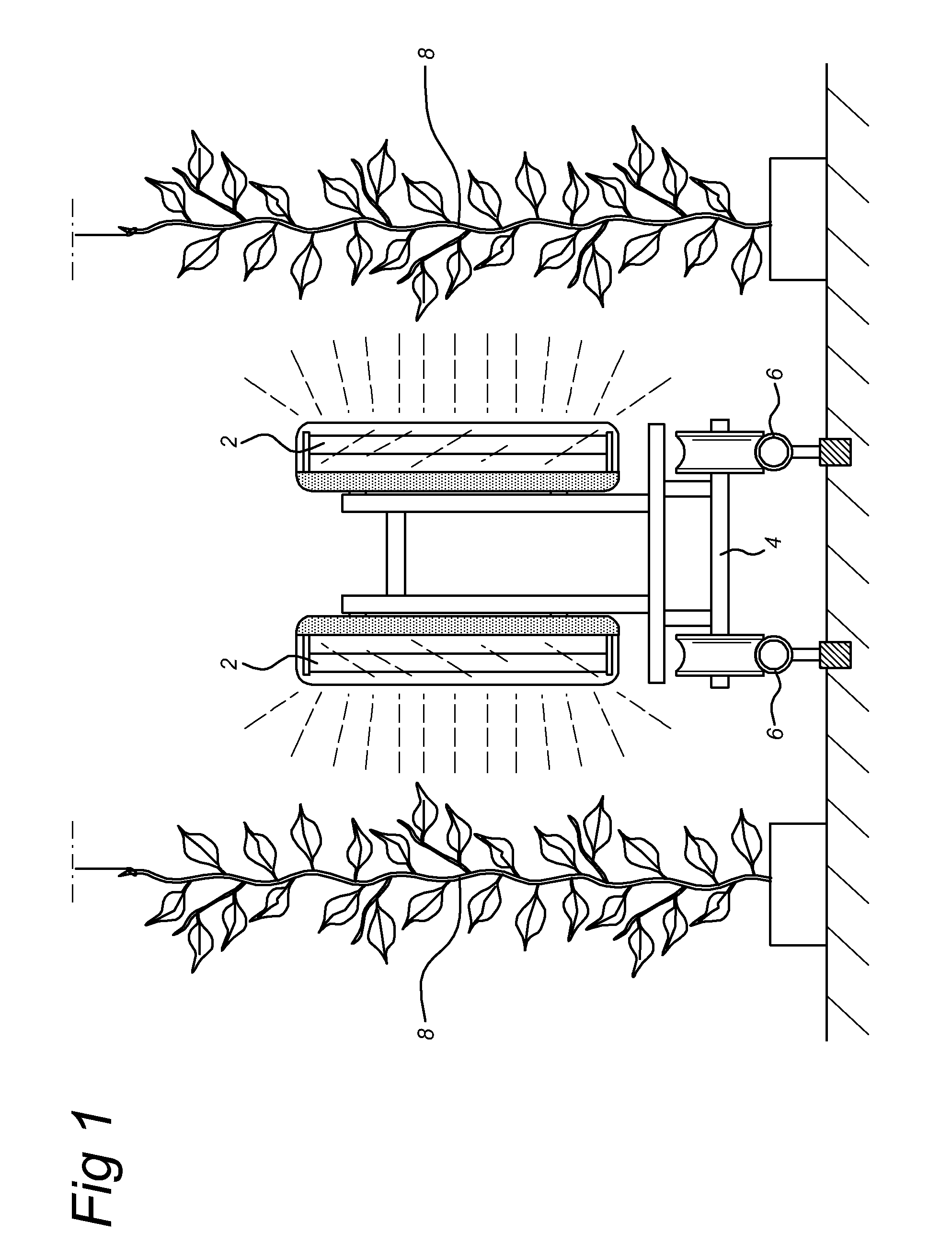

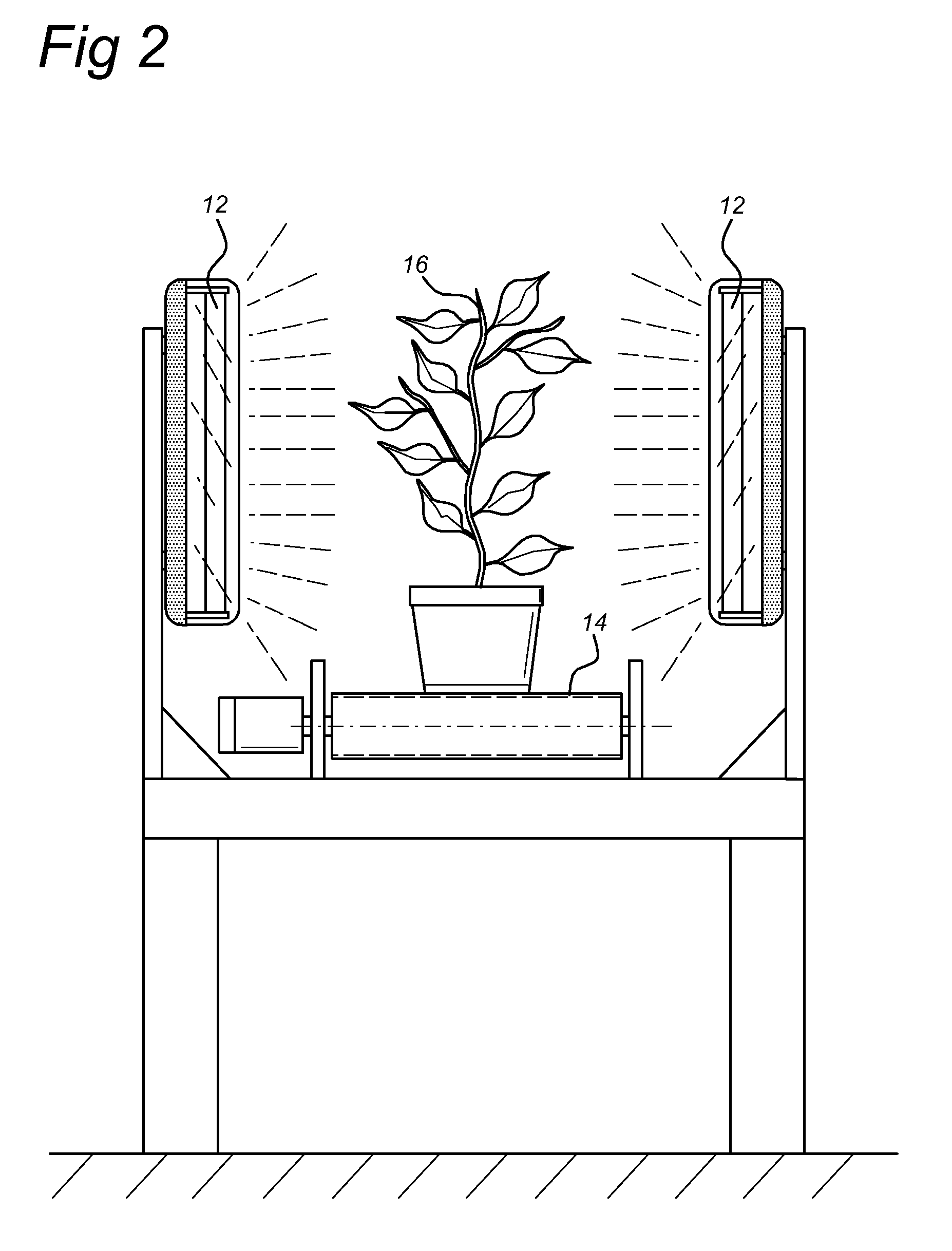

Methods for Treating Live Plants or Live Plant Parts or Mushrooms with UV-C Light

InactiveUS20090272029A1Increase humidityIncrease crop yieldDead plant preservationAgricultural machinesPlant TubersMushroom

The present invention relates to a method for controlling pathogen growth on live plants and mushrooms using UV-C light and an apparatus for use in the method. Also provided are methods for removing surplus leaves and methods for destroying aerial plant parts prior to harvest of underground roots, tubers or bulbs.

Owner:CLEAN LIGHT

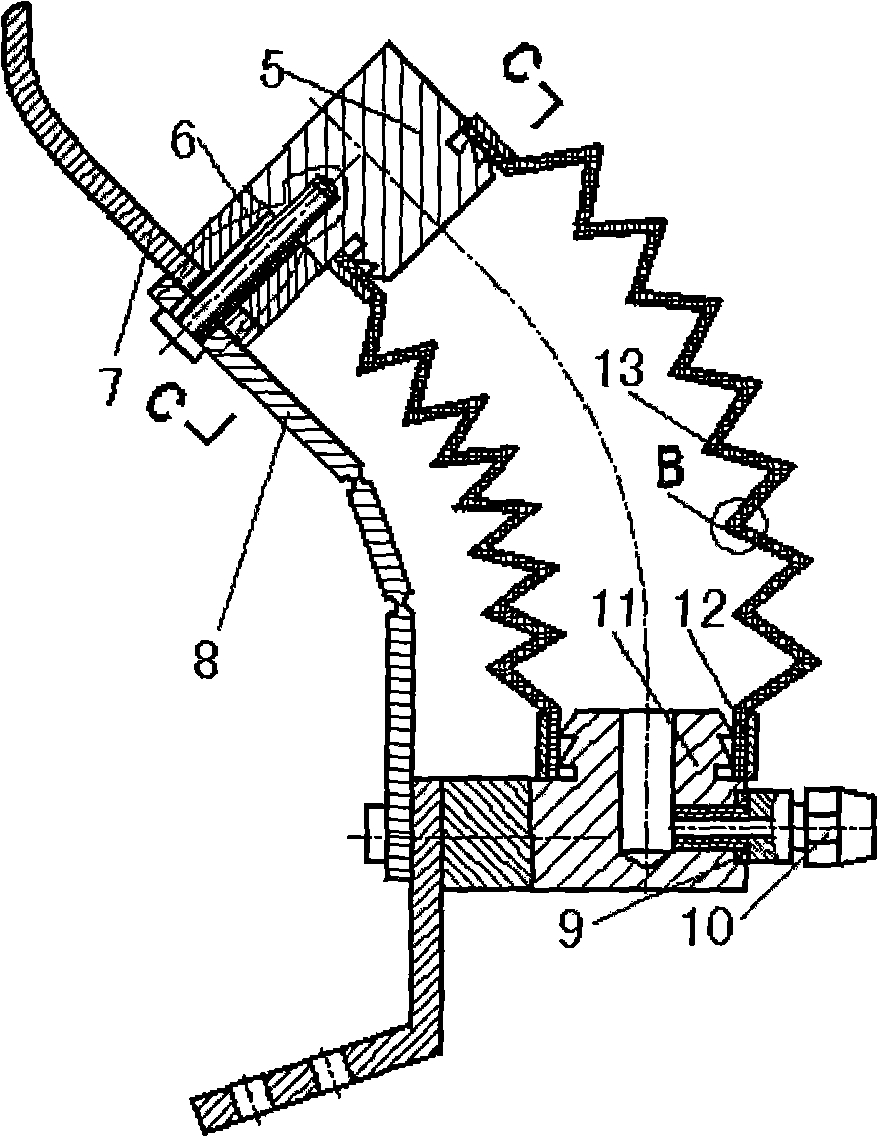

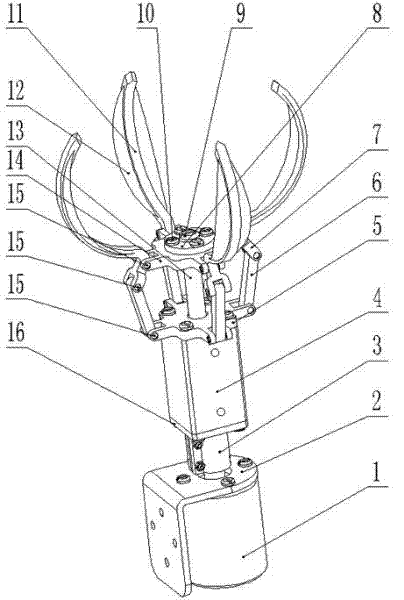

Articulated flexible manipulator

InactiveCN101554730AWith degrees of freedom and flexibilityBufferGripping headsPicking devicesSingle degree of freedomSize change

The invention relates to an articulated flexible manipulator which belongs to the technical field of the robots and the electromechanical integration. The manipulator is provided with three skillful fingers which are respectively arranged on three jaws of a three-jaw chuck, and the three skillful fingers produce chucking force by the function of fluid driving expansion muscle; each skillful fingeris provided with single artificial expansion muscle and a plurality of articulations with single degree of freedom, the artificial expansion muscle is flexible, axially-expandable, each smart fingeris assembled with a hinge framework or flexible hinge framework through the expansion muscle, the smart finger comprising a plurality of articulations with single degree of freedom is designed; the flexibility of the single expansion muscle and the structure of the articulations can realize the flexibility of the degree of freedom and the buffer of the chucking force, the skillful fingers have thecharacteristics of degree flexibility of freedom and chucking force buffer; and the manipulator is applied to chuck breakable brittle bodies and special bodies with shape and size change.

Owner:无锡锦臻自动化技术有限公司

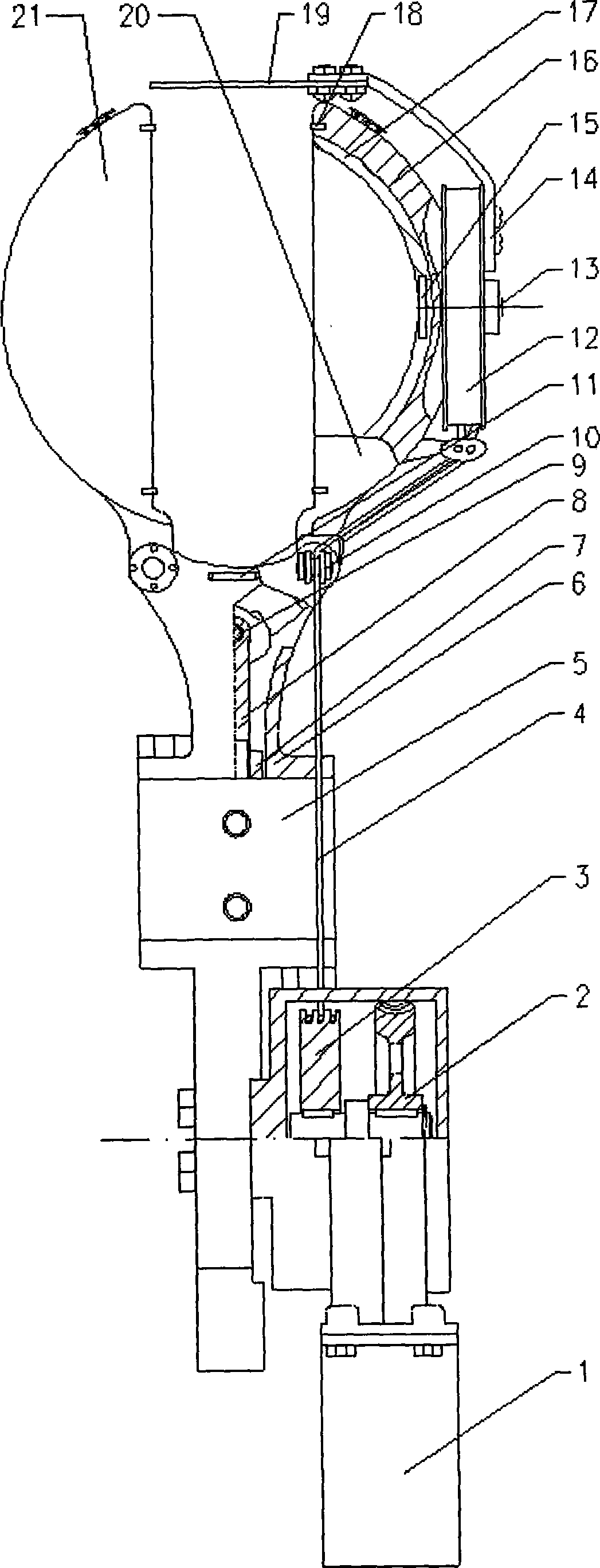

End effector of apple picking robot

InactiveCN101395989ASave the complicated processImprove versatilityProgramme-controlled manipulatorPicking devicesRobot end effectorActuator

The invention relates to an end effector of a fruit and vegetable picking robot. The end effector mainly consists of a clamping system, a cutting system and a sensor system. The clamping system mainly adopts a mechanism formed by cylinder sliding chutes to drive two fingers to open and close, thus realizing the action of grasping apples; the cutting system adopts a DC motor with 12V as the power source to drive blades to rotate nearly a circle around the fingers by the transmission of steel wires or the transmission of steel wire trolley wheels, thus cutting apple stems at any position along the circumferential direction of the fingers; the sensor system consists of an opto-electrical position switch, a pressure sensor, a micro-vision sensor, a touch sensor and a limit switch and plays a role of connecting motions and controlling the process during the process of clamping and cutting the apple stems. The end effector has a simple and reliable picking way, good commonality, low control difficulty, low cost, which ensures an intelligentized picking, thus meeting the demands of a football-like fruit picking robot and being conducive to realizing the practical utilization and commercialization of fruit picking robots.

Owner:JIANGSU UNIV

Transfer-assistance system

InactiveUS7537519B2Simple procedureReliable transmissionDigital data processing detailsMowersGuidance systemEngineering

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

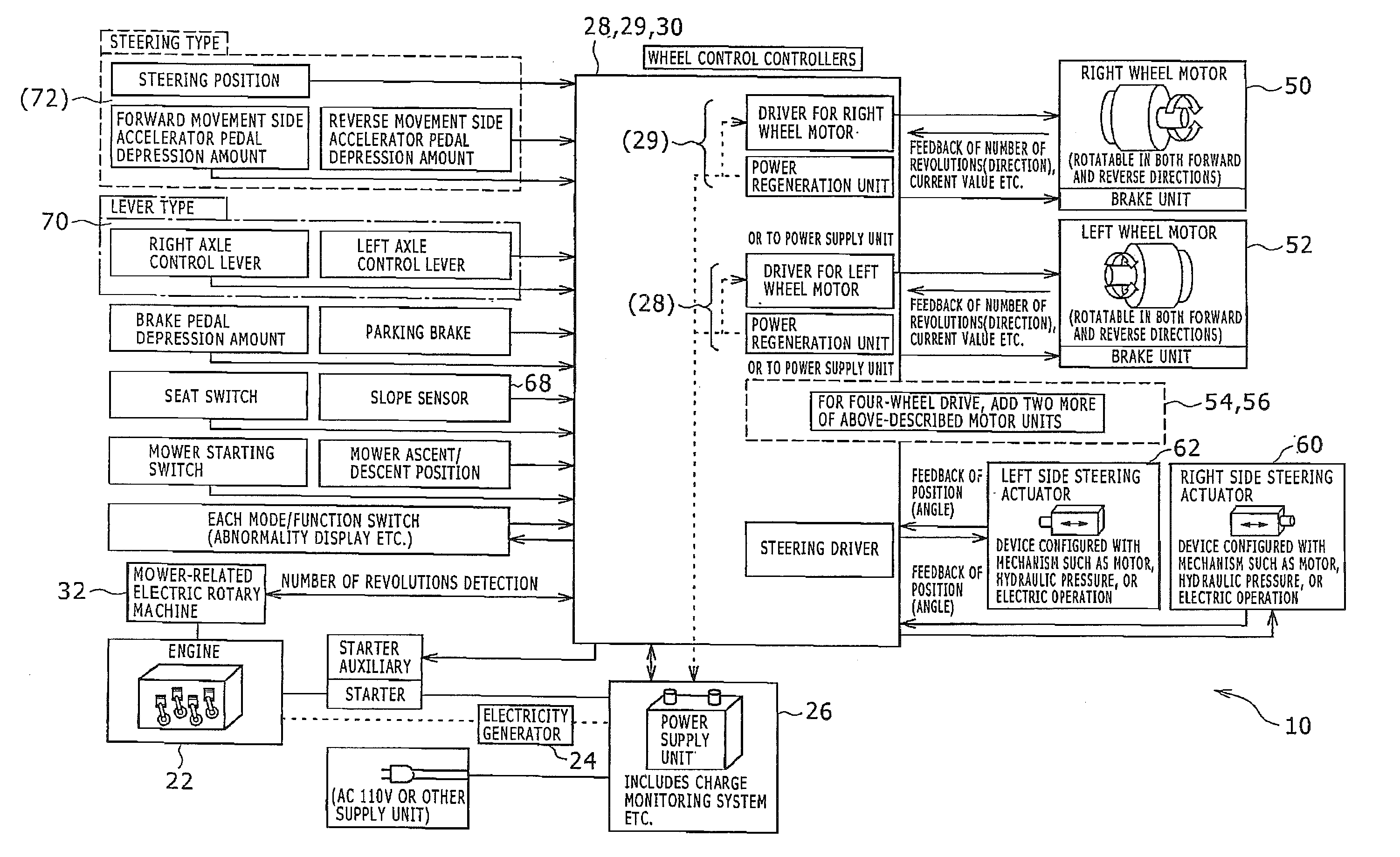

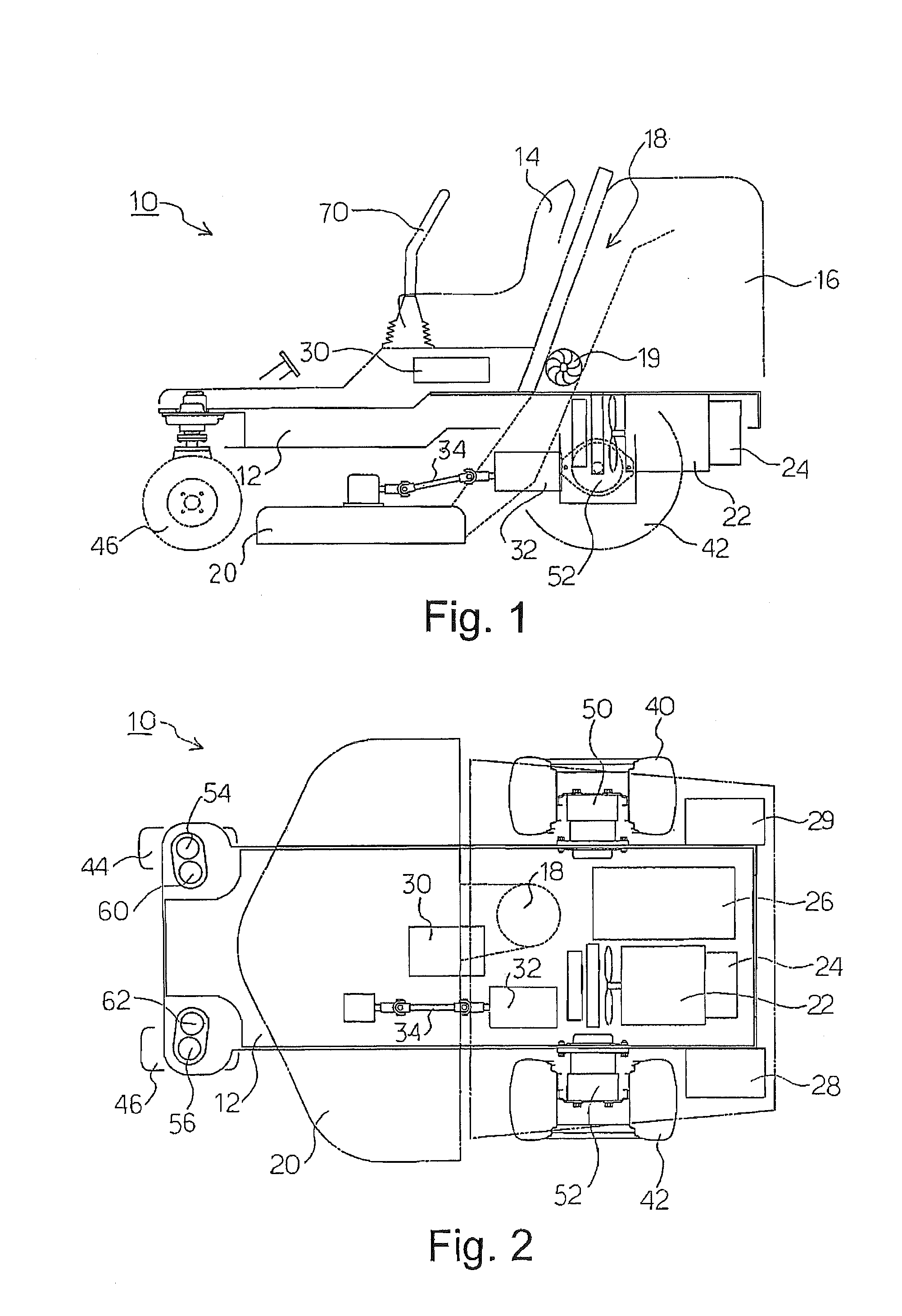

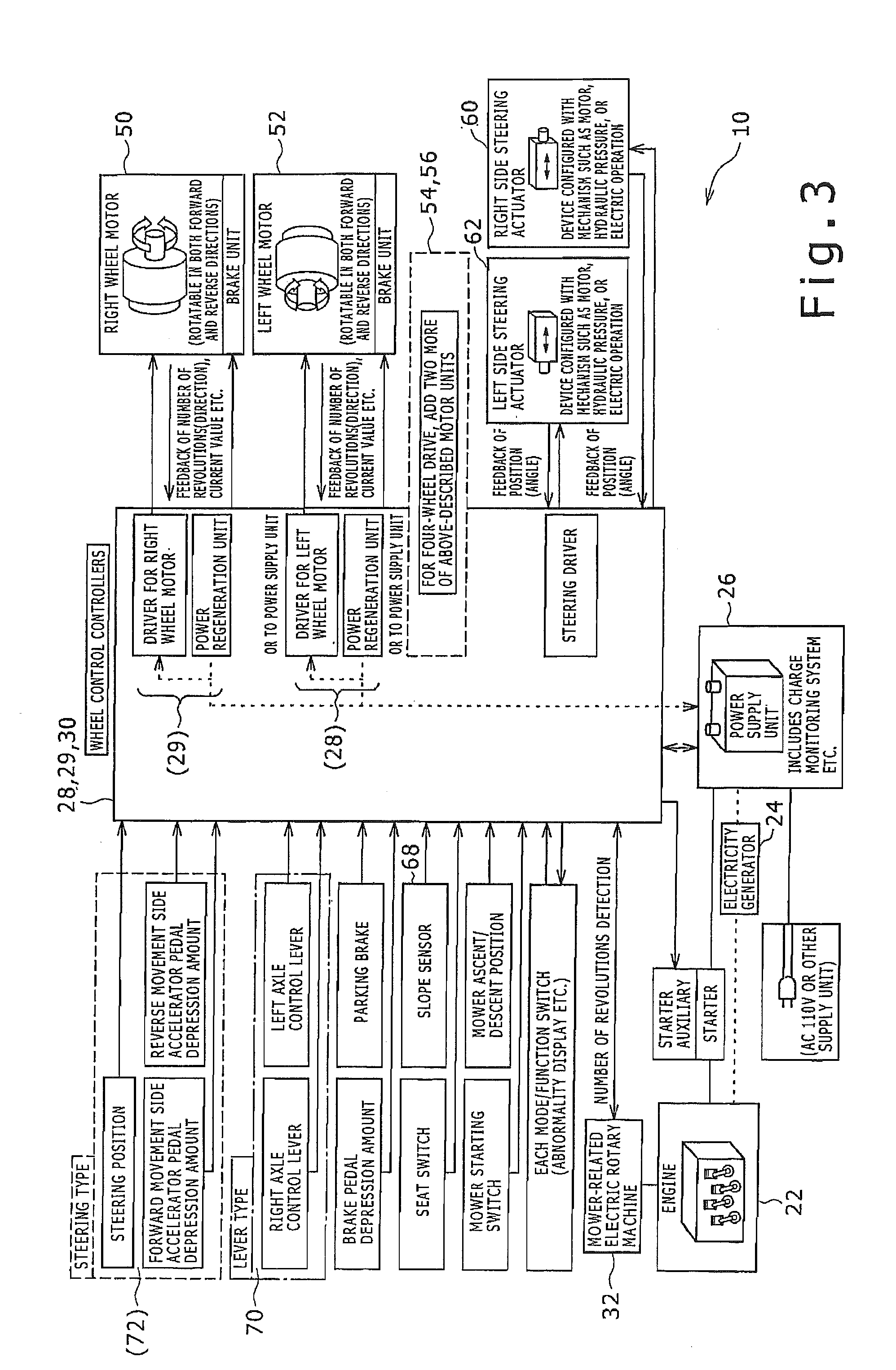

Control sysytem for motor-driven lawnmower vehicle

A control system for an engineless, motor-driven lawnmower vehicle includes electric motors and controllers. At least one of the electric motors is an electric drive motor connected to a drive wheel of the lawnmower vehicle to enable transmission of motive power. At least one other electric motor is a mower-related electric motor connected to a lawnmower rotary tool to enable transmission of motive power. At least one of the controllers is a drive wheel controller which includes a drive wheel driver and which controls operation of the electric drive motor in response to a signal from at least one operator sensor for detecting an operation amount of at least one operator. At least one controller controls to activate or stop the mower-related electric motor. At least one controller is connected to the drive wheel controller and transmits a control signal thereto in response to a signal from the operator sensor.

Owner:KANZAKI KOKYUKOKI MFG

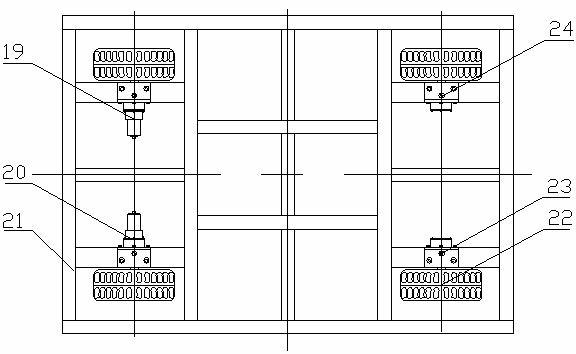

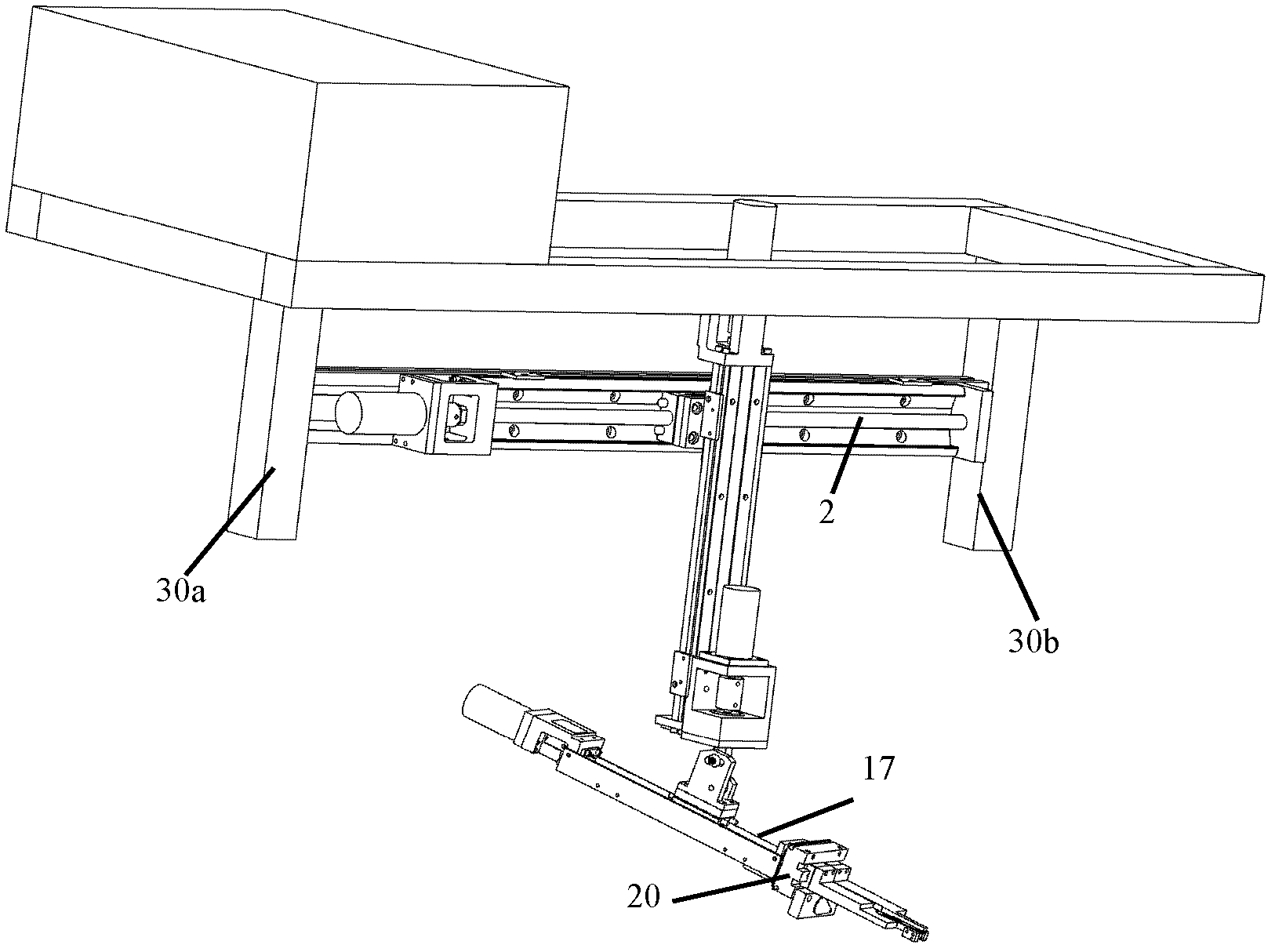

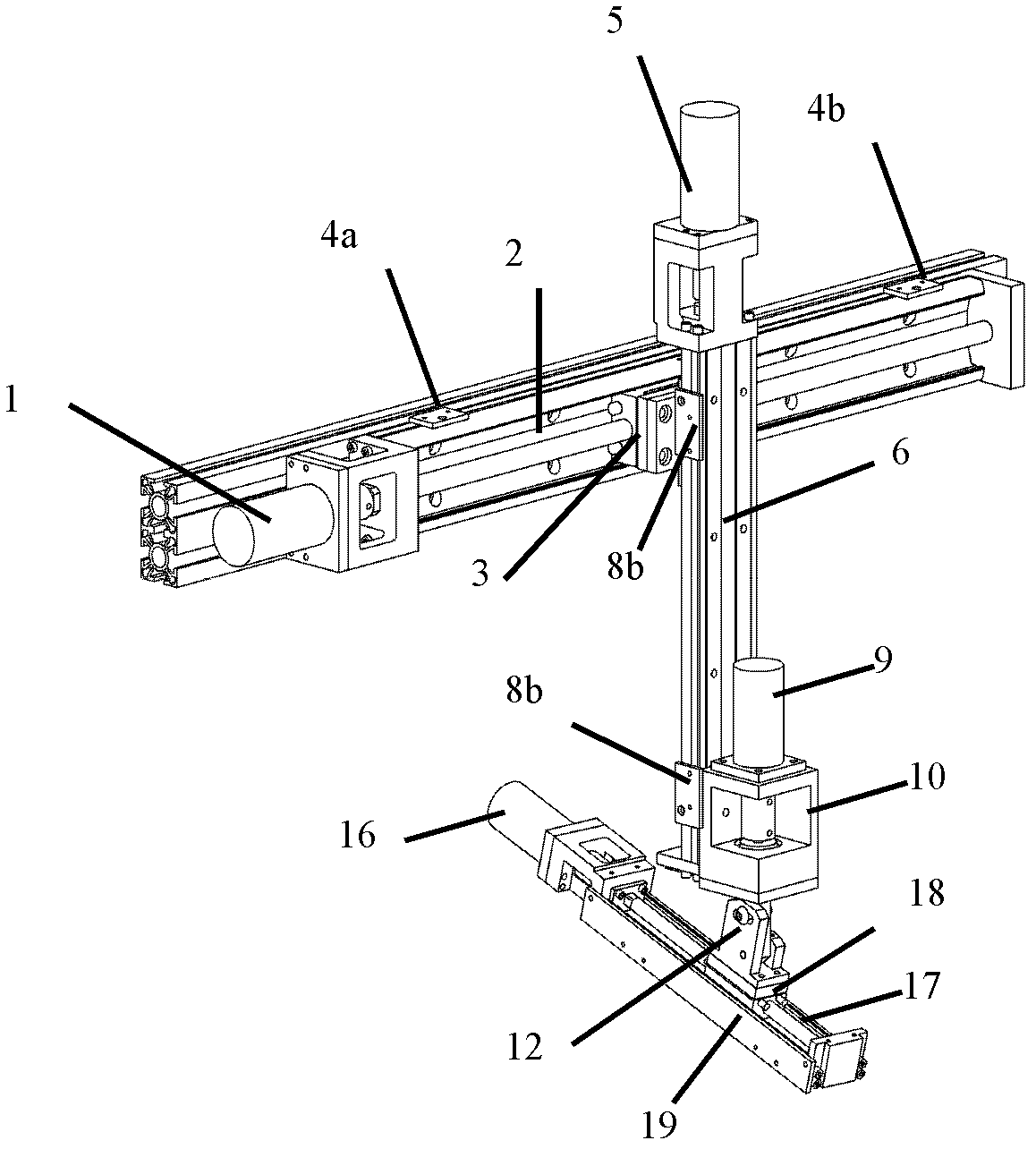

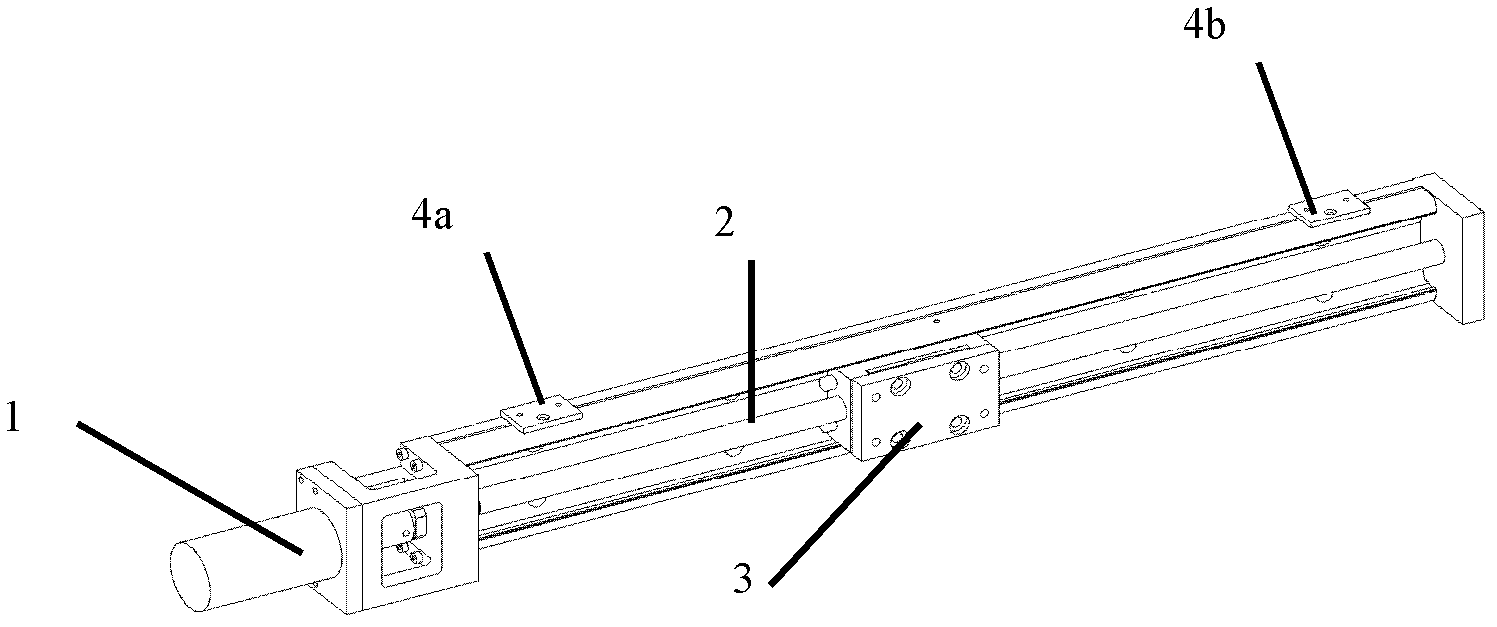

Accurate picking actuating mechanism of strawberry picking robot and ridge-culture strawberry picking robot

ActiveCN102577755APrecision pickingRealize continuous pickingPicking devicesAgricultural engineeringAgricultural machinery

The invention belongs to the field of agricultural machinery and relates to an accurate picking actuating mechanism of a strawberry picking robot and a ridge-culture strawberry picking robot. The accurate picking actuating mechanism of the strawberry picking robot comprises a mixed coordinate type motion device, a mechanical claw device connected with the mixed coordinate type motion device, and a supporting and connecting device used for fixing the mixed coordinate type motion device. The picking actuating mechanism is simple in structure, compact in volume and flexible in operation; moreover, the picking actuating mechanism is low in cost, thereby not only adapting to ridge-culture strawberry picking in different cultivation patterns, but also realizing multidirectional picking for strawberries positioned at different directions and at different positions. The ridge-culture strawberry picking robot comprises an accurate picking and gathering device and a wide-range movement supporting device of the accurate picking actuating mechanism of the strawberry picking robot and can realize continuous picking for ridge-culture strawberries.

Owner:CHINA AGRI UNIV

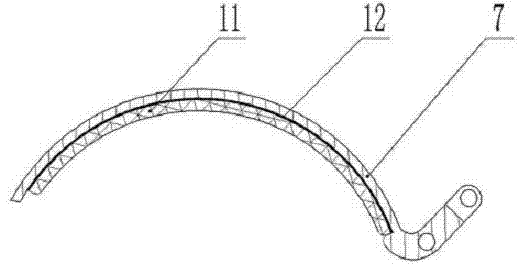

End effector of ball-like fruit picking robot

InactiveCN102227973AThere is no damage to the fruitCompact structureGripping headsPicking devicesThree-dimensional spaceEngineering

The invention discloses an end effector of a ball-like fruit picking robot. The end effector comprises a rotating machine assembly, a telescopic cylinder assembly and an arc-shaped finger cutting assembly. The end effector has the following advantages: a rotating machine is utilized to drive four arc-shaped blades to cut the fruit stem in any position between the four arc-shaped blades in a rotating manner via a coupling shaft assembly, thus omitting detection of the position of the fruit stem; a single-rod double-action cylinder drives four arc-shaped fingers to unfold and fold by way of extension and retraction of a piston rod; the space formed when the four arc-shaped fingers are folded is larger than the three-dimensional space of the fruits; the fingers are not contacted with the fruits during picking, thus ensuring that the fingers can rotate relative to the fruits, providing conditions for the arc-shaped blades to cut the fruit stems in a rotating manner and dispensing with complex pressure control for clamping the fruits; and the end effector has a reliable picking mode, low action control difficulty, low cost and strong universality.

Owner:NANJING INST OF TECH

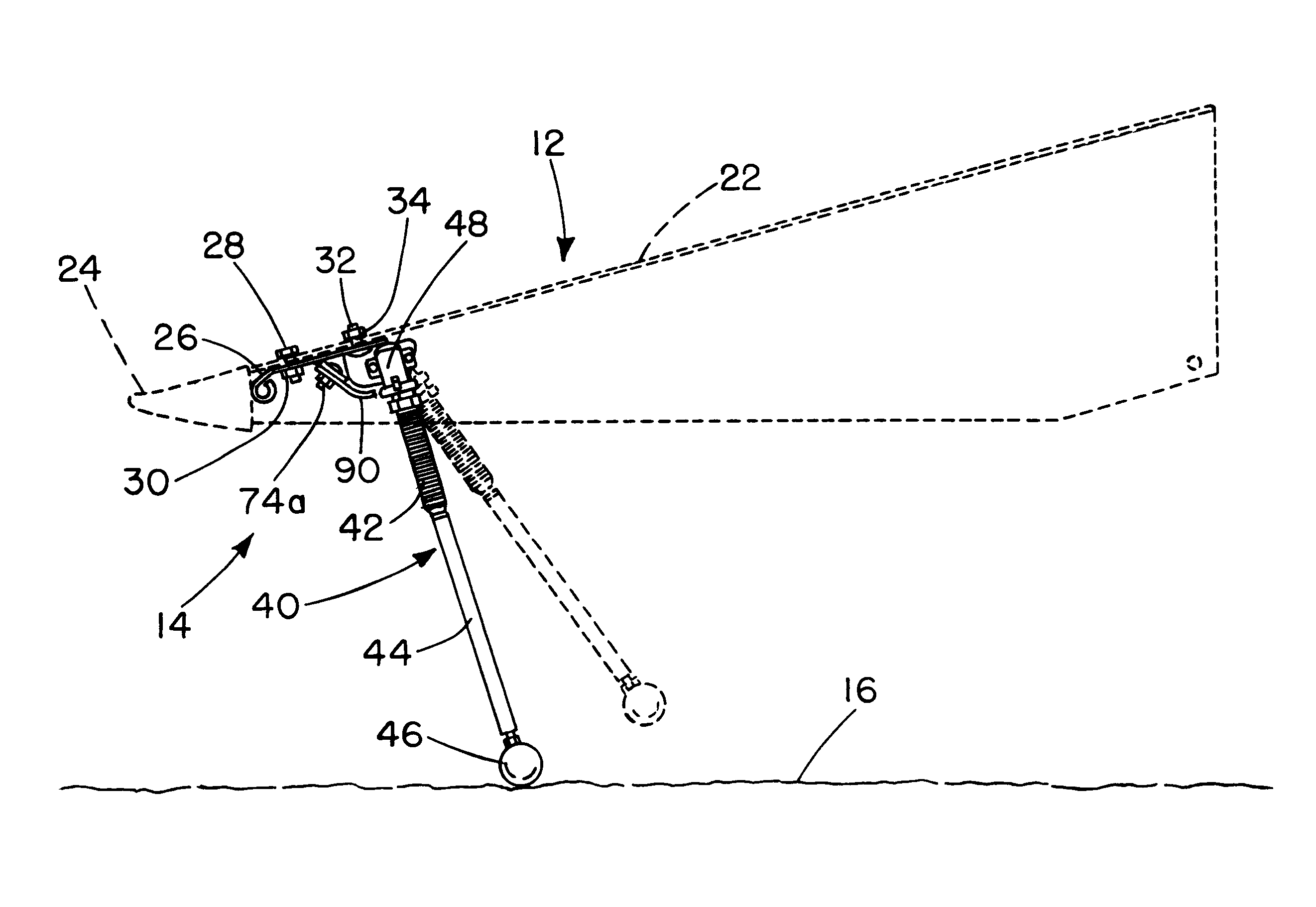

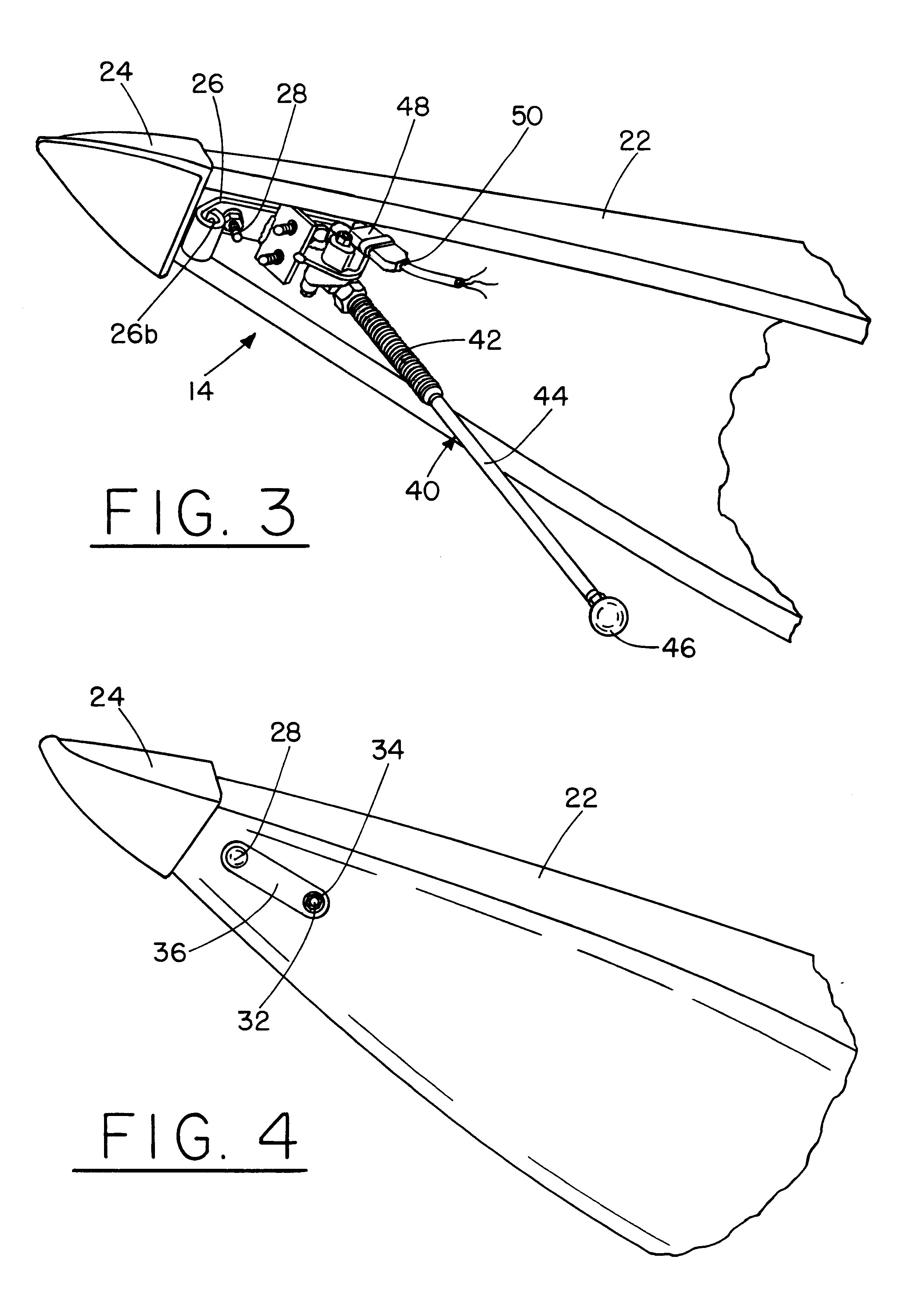

Combine header height control

InactiveUS6202395B1Accurate height positioningReduce combine ingestionAgricultural machinesMowersCoil springEngineering

An arrangement for controlling the height above or depth below an irregular surface of a body moving over or below the surface includes a rotation sensor coupled to a controller responsive to an angular deflection signal output by the rotation sensor. The rotation sensor and controller are mounted to a vehicle moving over the surface such as an agricultural vehicle traversing a field. A semi-rigid, flexible arm has a first end coupled to the rotation sensor with a ground engaging member attached to a second opposed end of the arm. In one embodiment, the flexible arm includes an elongated coil spring attached to a rigid shaft and the ground engaging member is a spherical ball attached to the shaft's distal end. The coil spring is pre-loaded to a selected bending or flexure force and permits the ground engaging member to impact obstructions in the field without damage to the rotation sensor. The coil spring also prevents damage to the rotation sensor when the vehicle is reversed in direction. The flexible arm may be urged downwardly to ensure that the ground engaging member contacts the soil and upward and downward rotation stops may be provided to limit rotation of the rotation sensor and flexible arm combination. When a plurality of rotation sensors and flexible arms are employed such as along the length of a combine header, each rotation sensor may be individually calibrated by rotating the sensor relative to the head unit to which it is mounted to permit all sensors to uniformly measure the height above or depth below the soil surface.

Owner:GRAMM RICHARD

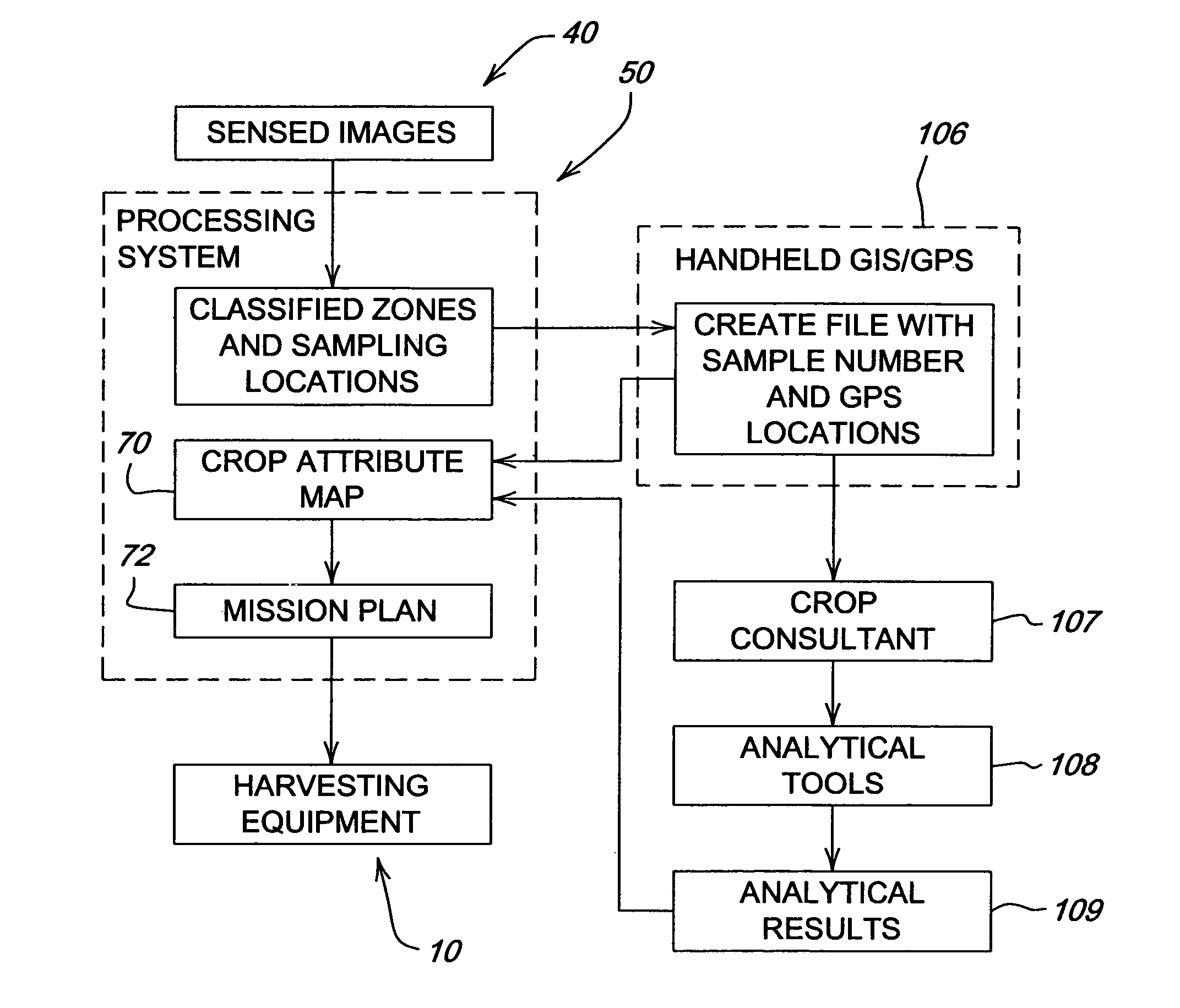

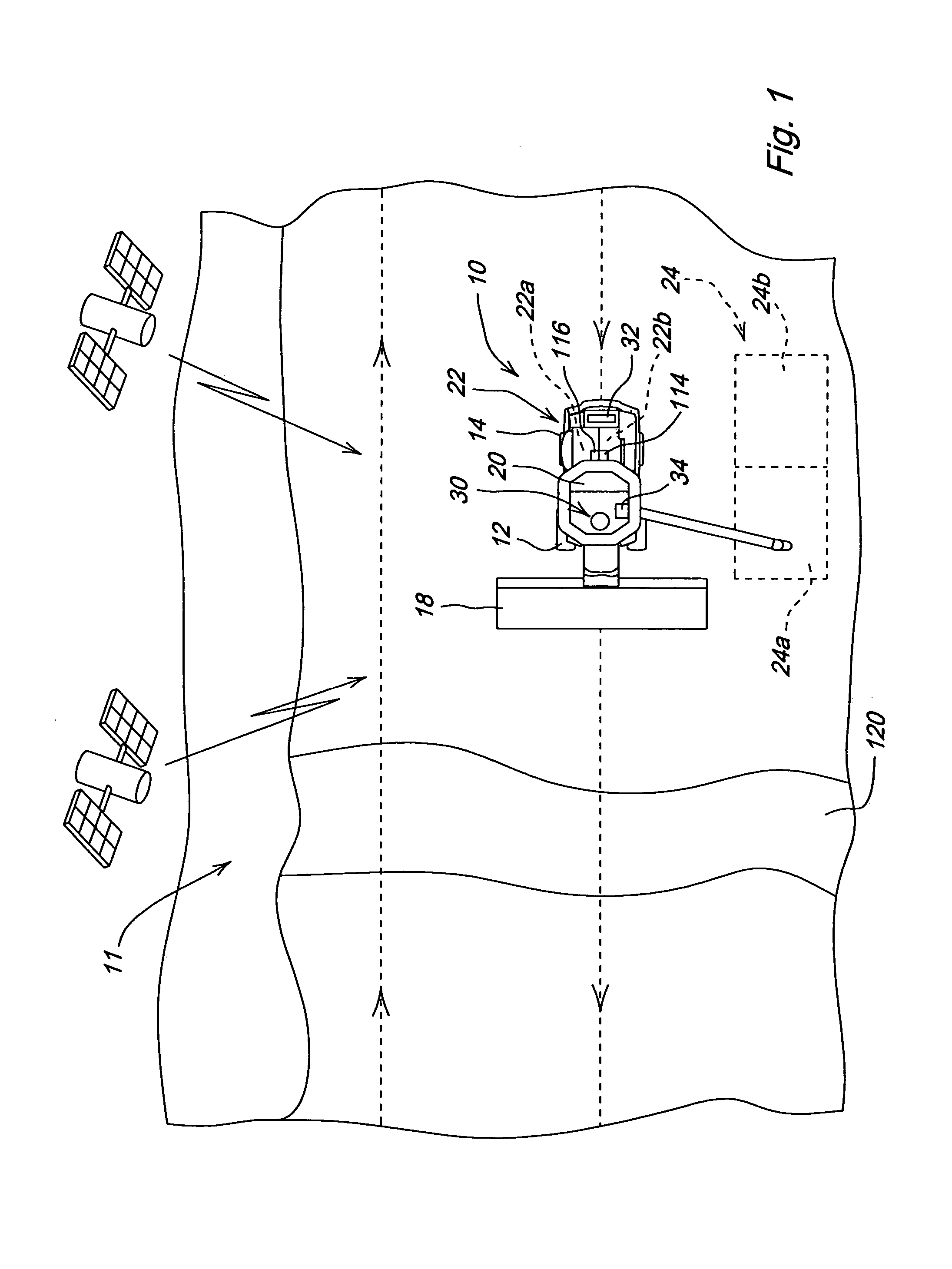

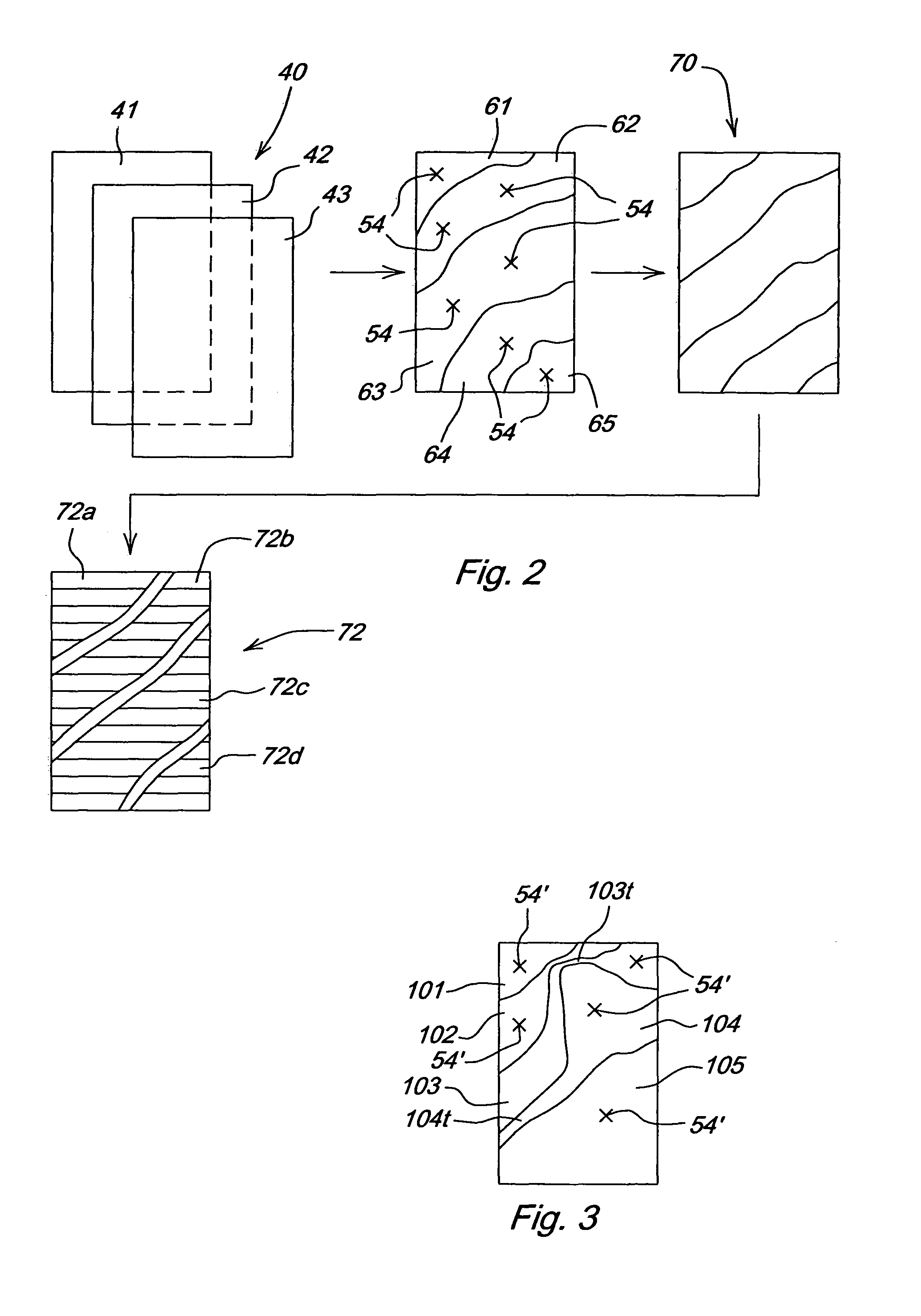

Crop attribute map input for vehicle guidance

ActiveUS7725233B2Accurate valueSegregation can be facilitatedAnalogue computers for trafficRoad vehicles traffic controlAnimal ForagingMission plan

A method for dividing a field into zones with similar crop attributes and developing a mission plan for steering the harvester to selectively harvest crops based on one or more of the attributes. The attributes include protein level, starch level, oil level, sugar content, moisture level, digestible nutrient level, or any other crop characteristic of interest. The method can be applied to selectively harvest and / or segregate according to attribute any crop, including grains such as wheat, corn, or beans, fruits such as grapes, and forage crops. Directed crop sampling provides absolute value and variance information for segregated batches of harvested crop.

Owner:DEERE & CO

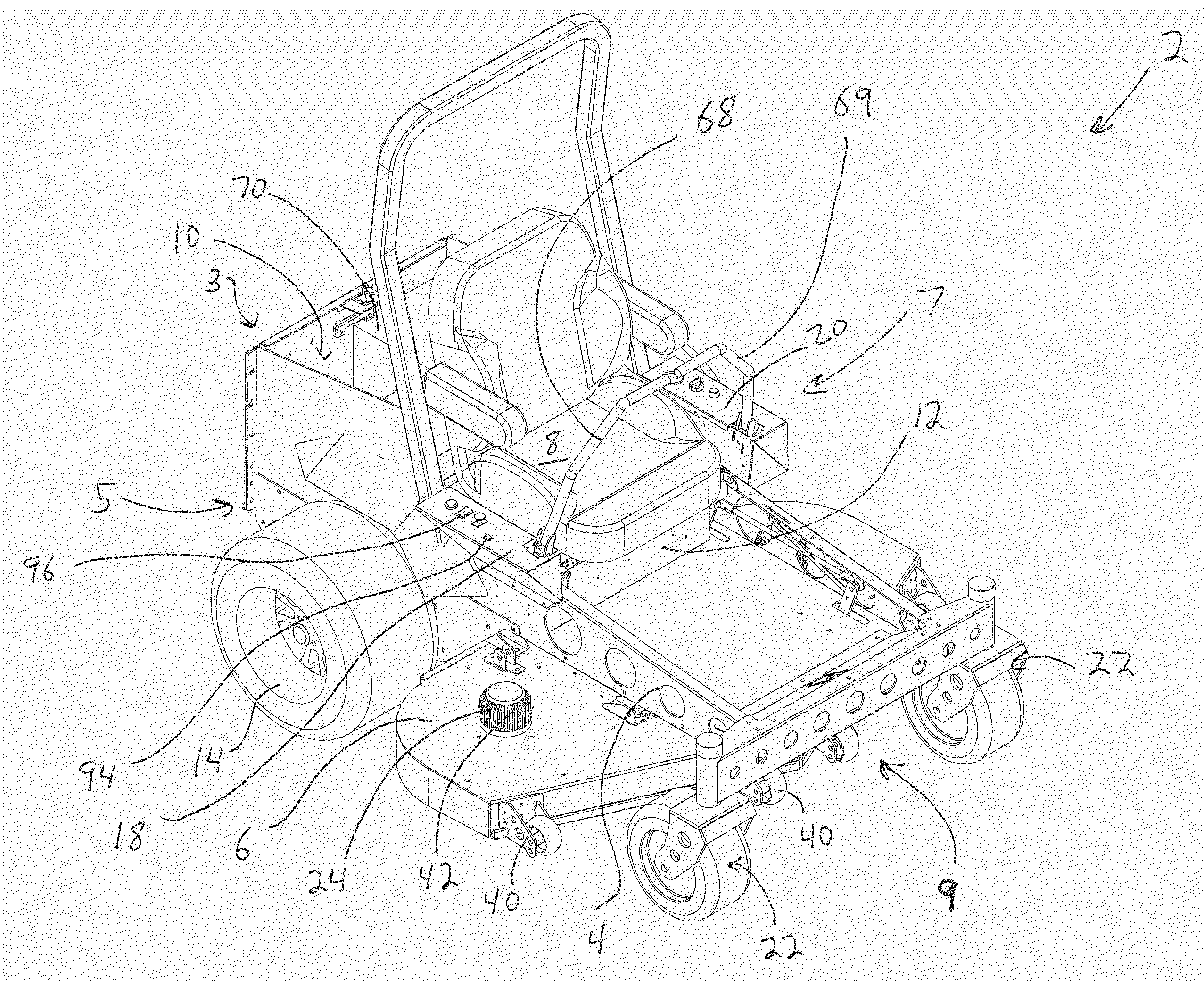

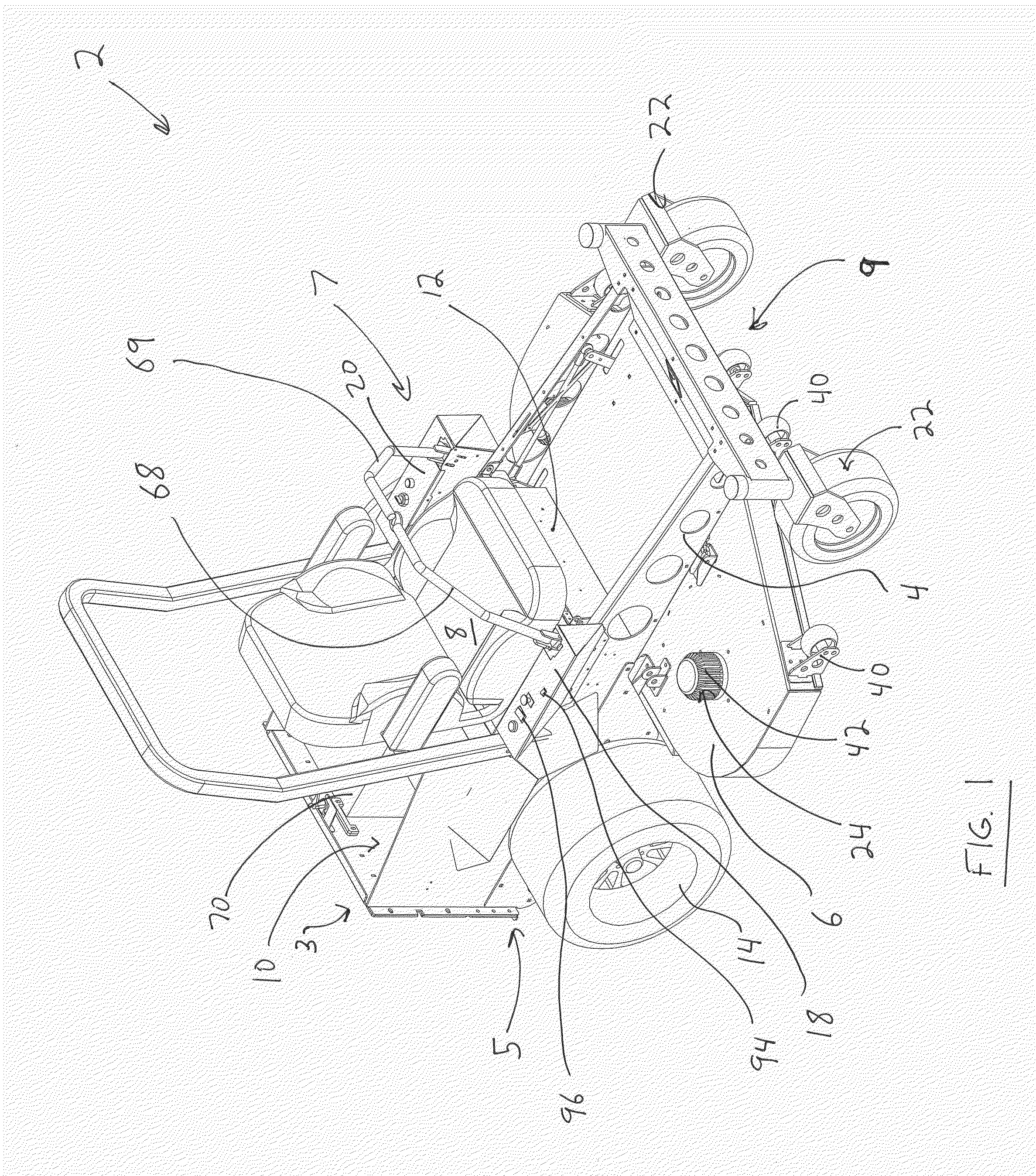

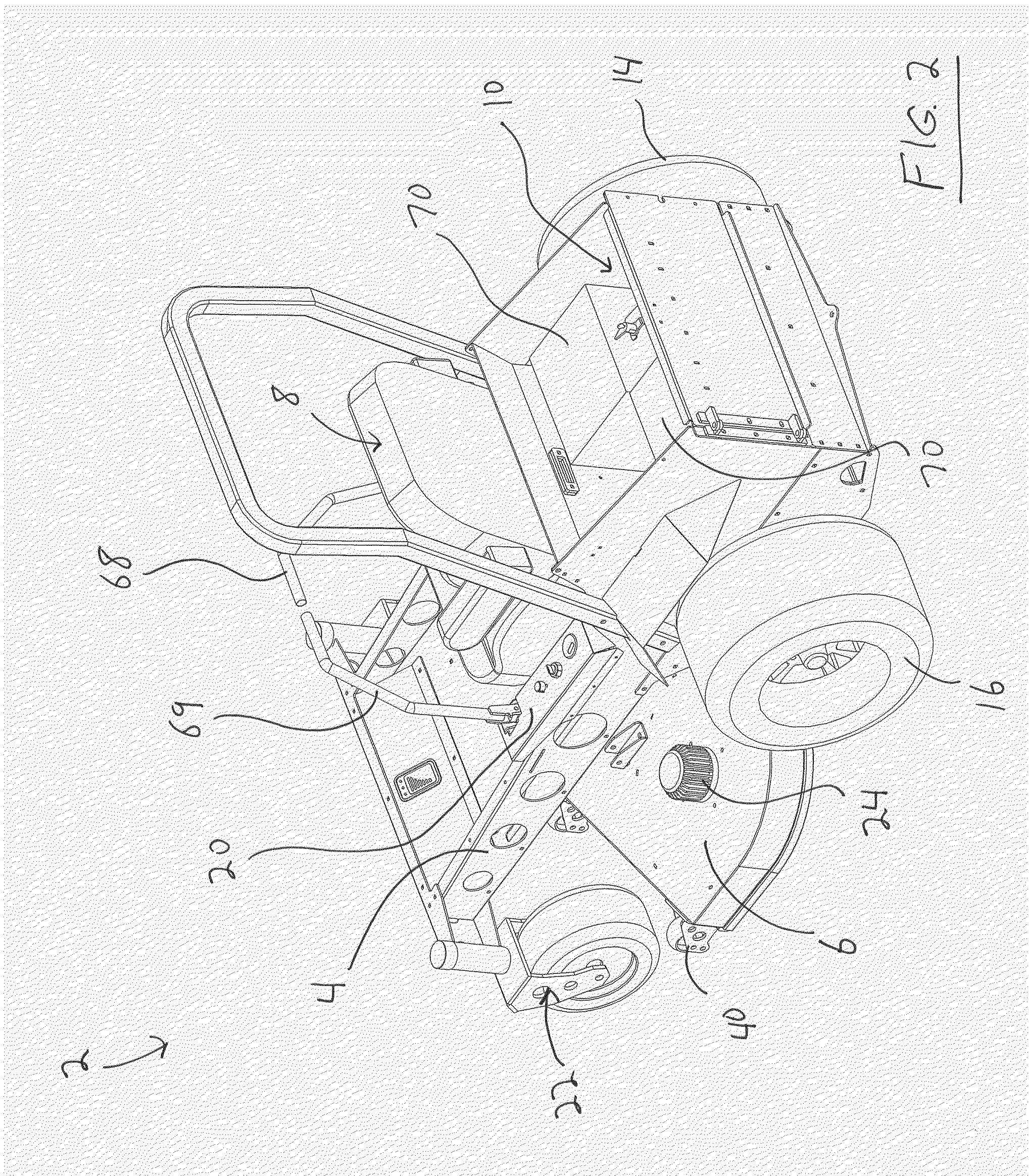

Electric mower apparatus and method of use

ActiveUS20160183451A1Decreasing maximum travel speedLawn-mowersPicking devicesElectricityDrive wheel

A battery-operated mower is described that includes a chassis supporting a first drive wheel and a second drive wheel, a battery pack, a first electric drive wheel motor interconnected to the first drive wheel and second electric drive wheel motor interconnected to the second drive wheel; one or more electric blade motors; an electric cooling fan in fluid communication with at least one of the first electric drive wheel motor and second electric drive wheel motor; one or more controllers for controlling the rotational speed of the first electric drive wheel motor, the second electric drive wheel motor, and the blade motors; and a left control actuator in communication with a first throttle sensor and a right control actuator in communication with a second throttle sensor, wherein the first throttle sensor and second throttle sensor are in communication with the one or more controllers.

Owner:GENERAC POWER SYSTEMS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com