Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9702results about "Tobacco preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

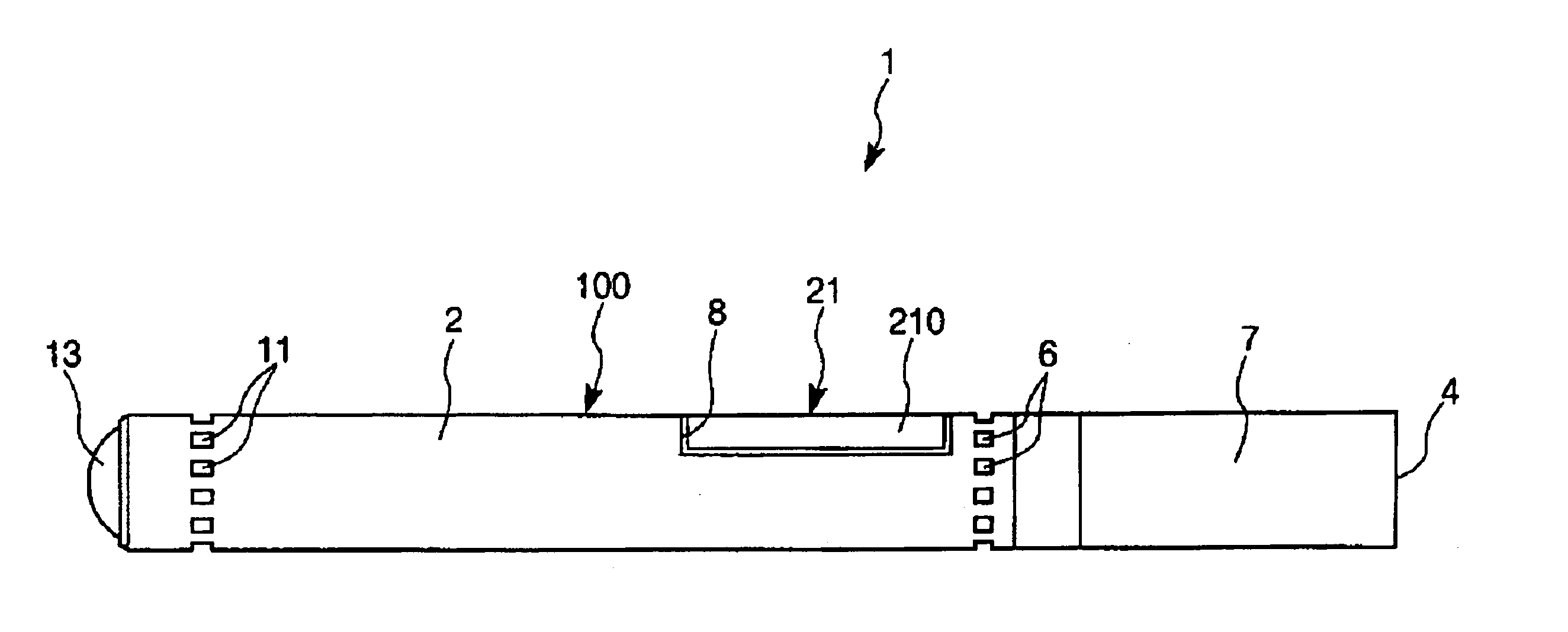

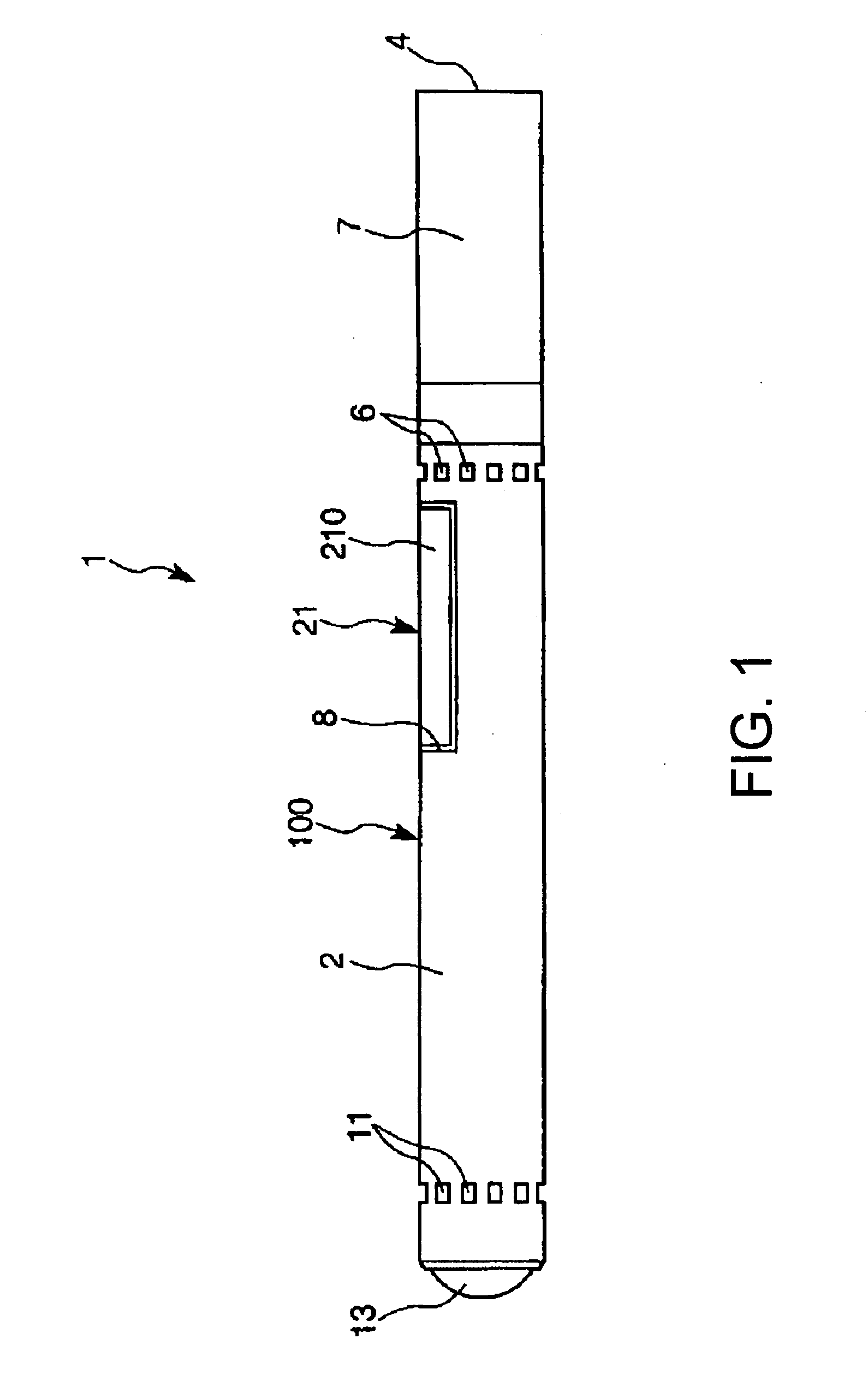

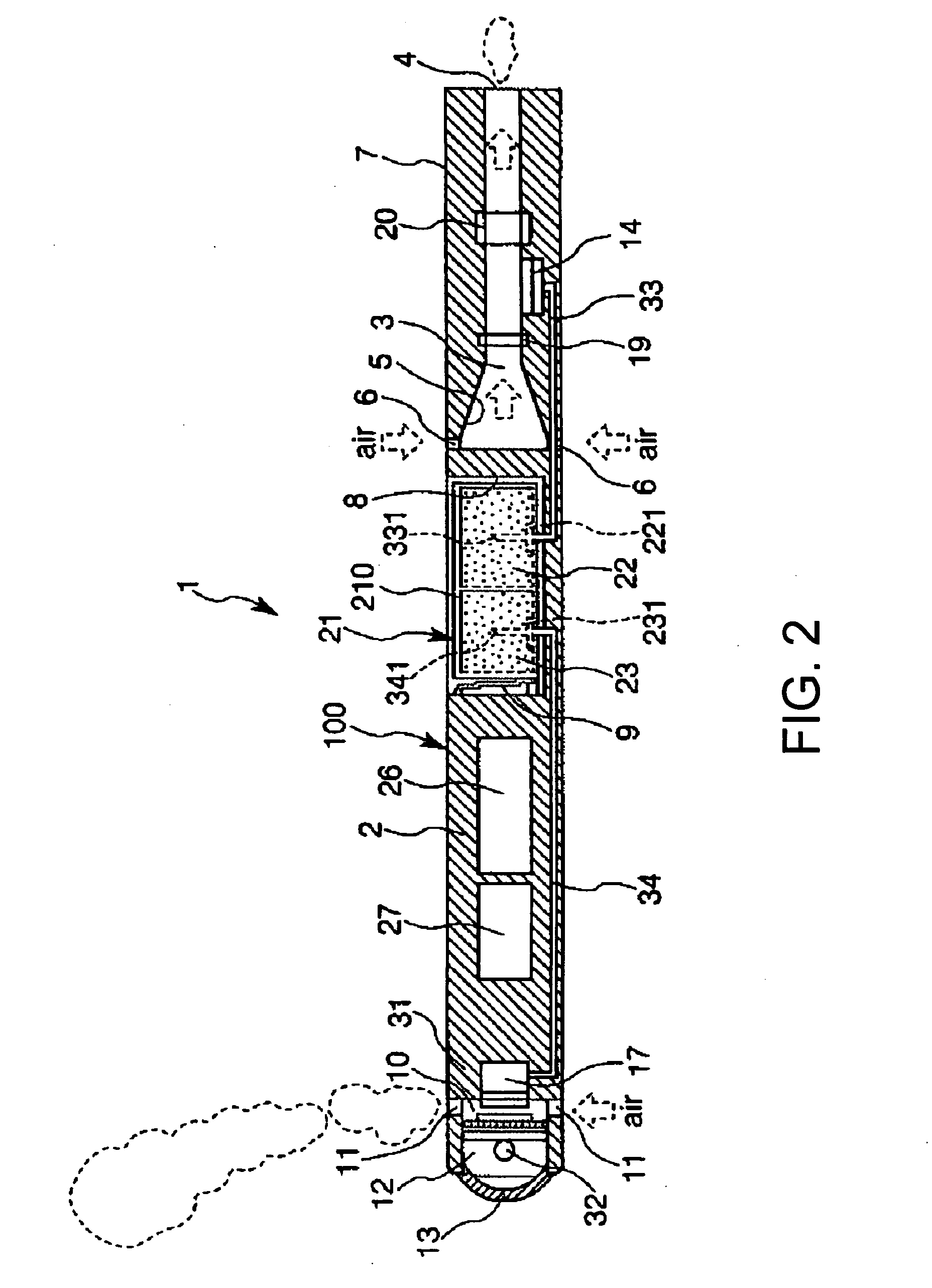

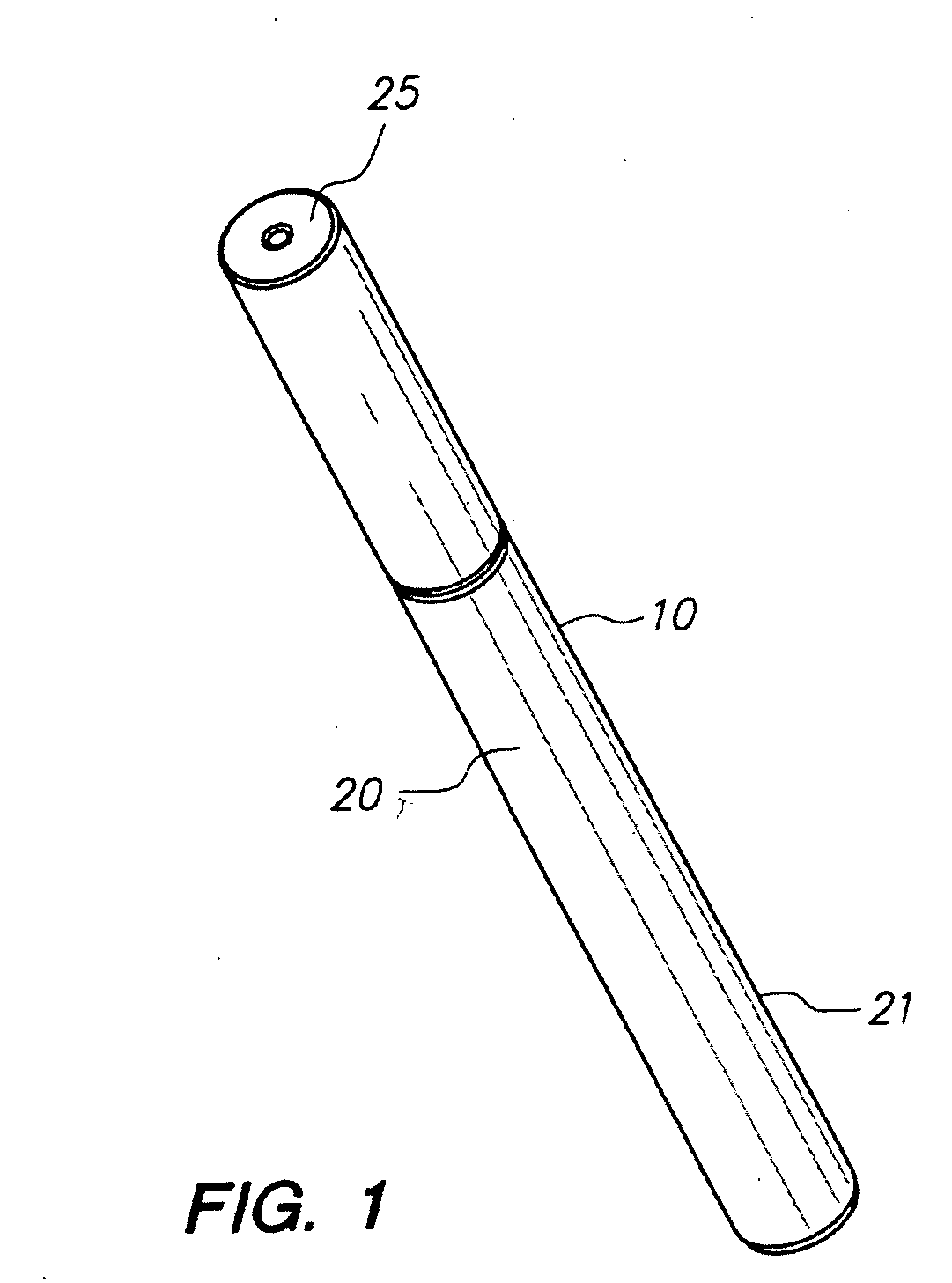

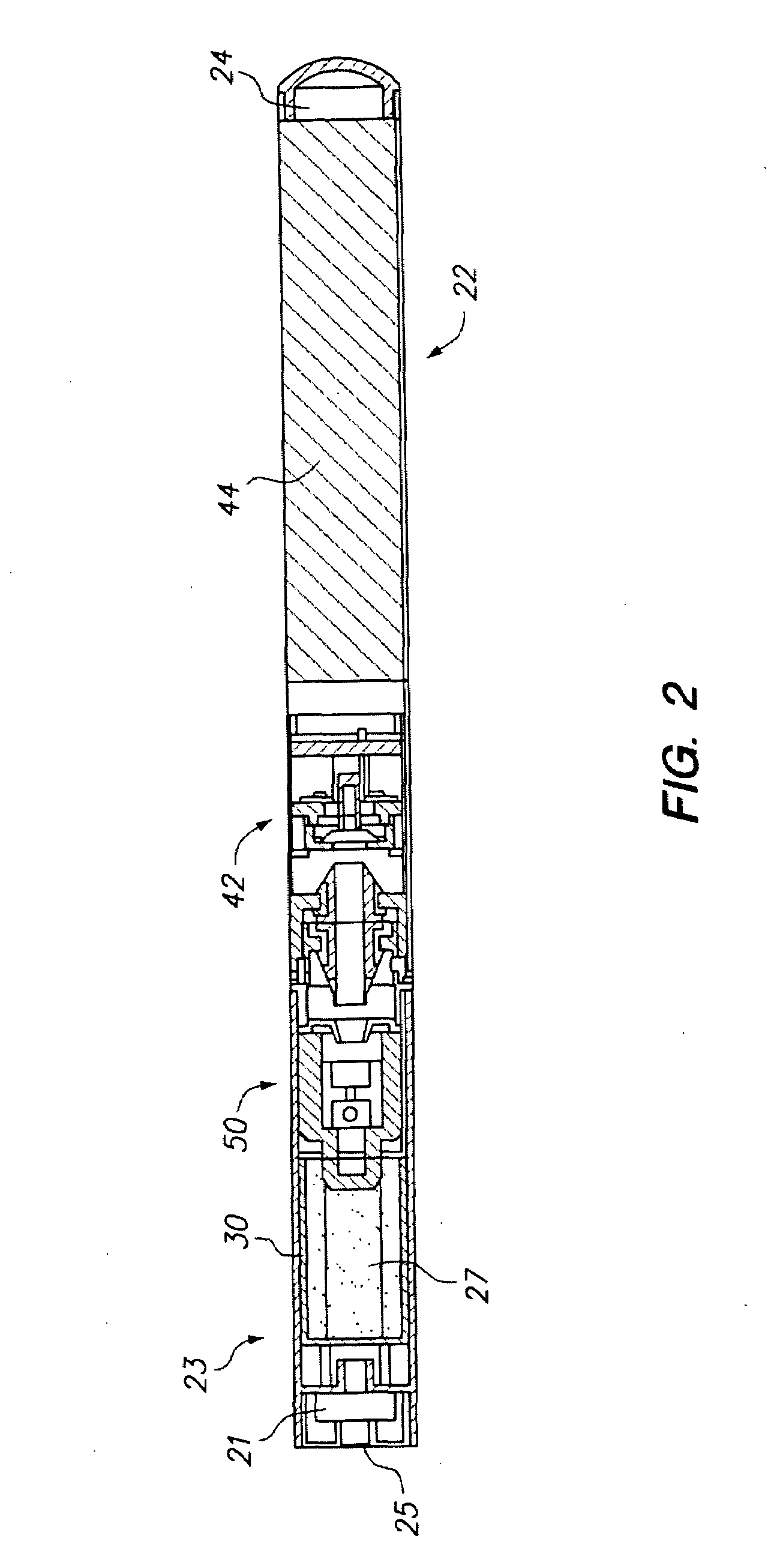

Tobacco-containing smoking article

ActiveUS7726320B2Tobacco preparationTobacco treatmentElectrical resistance and conductanceEngineering

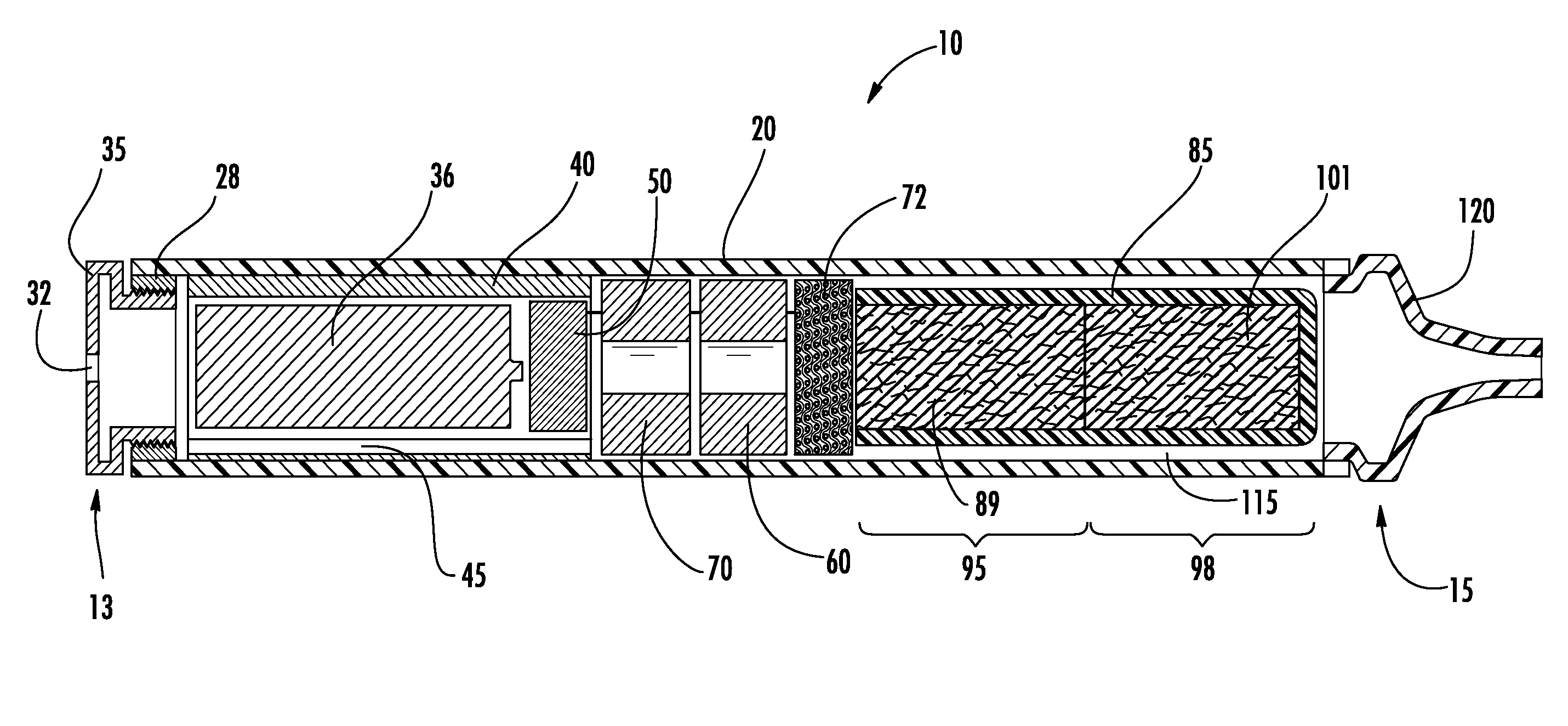

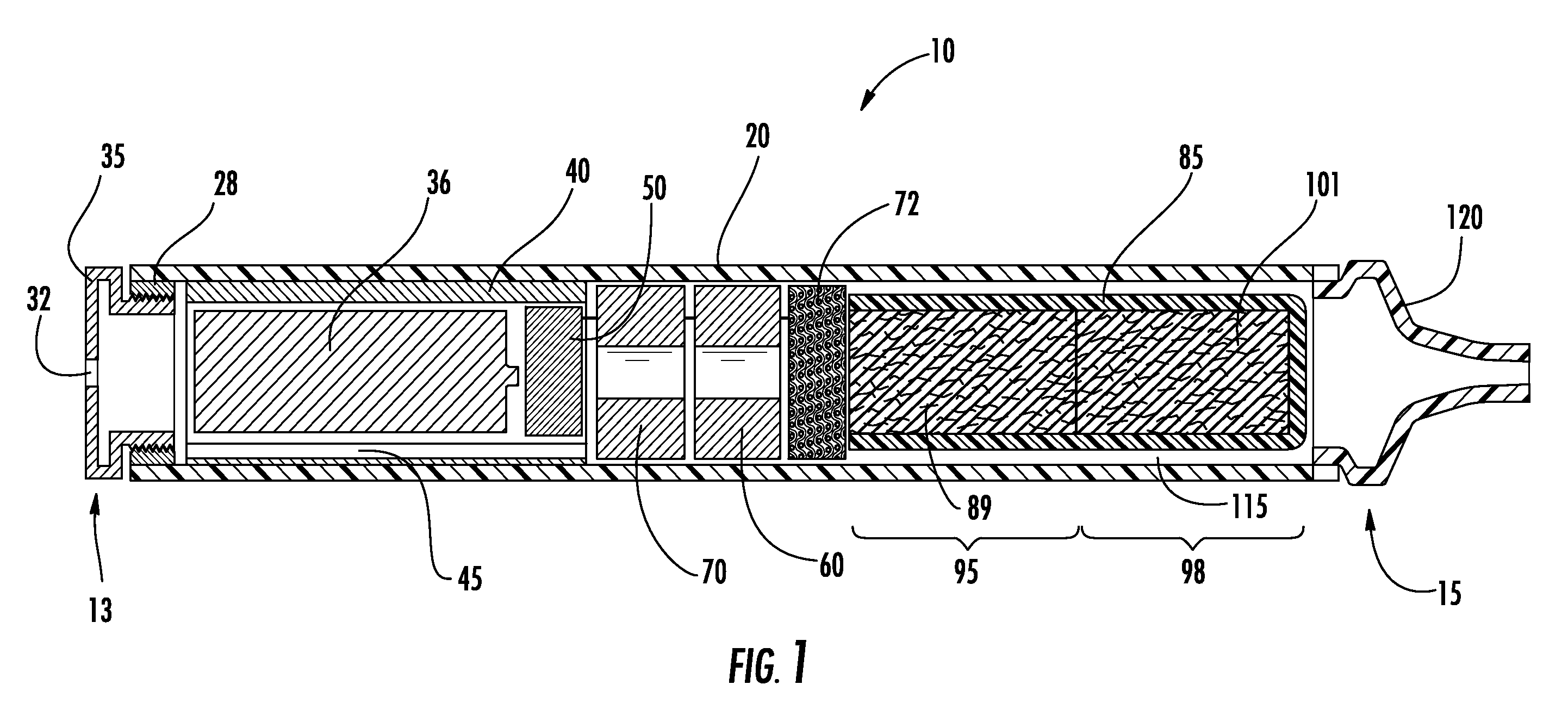

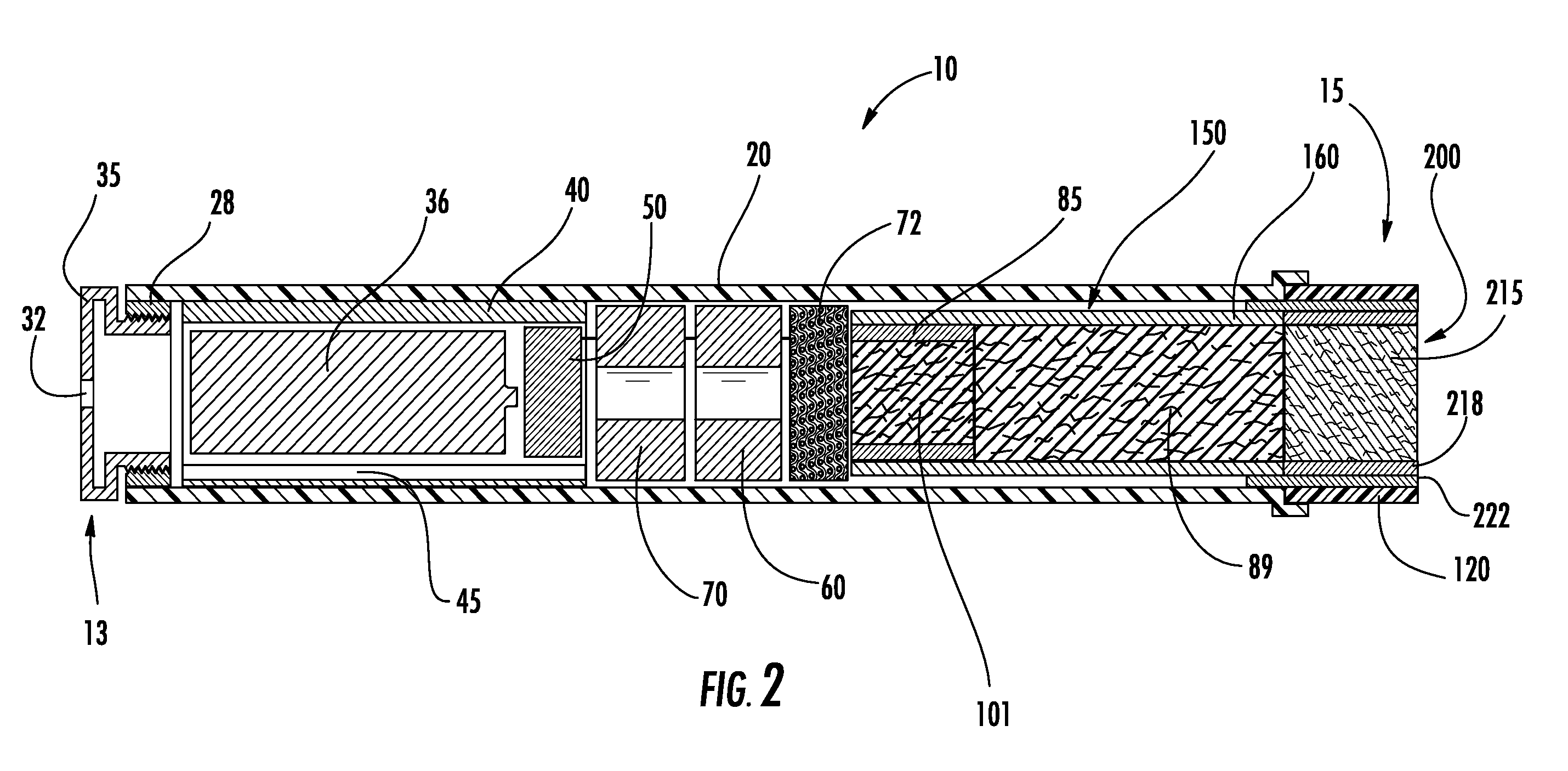

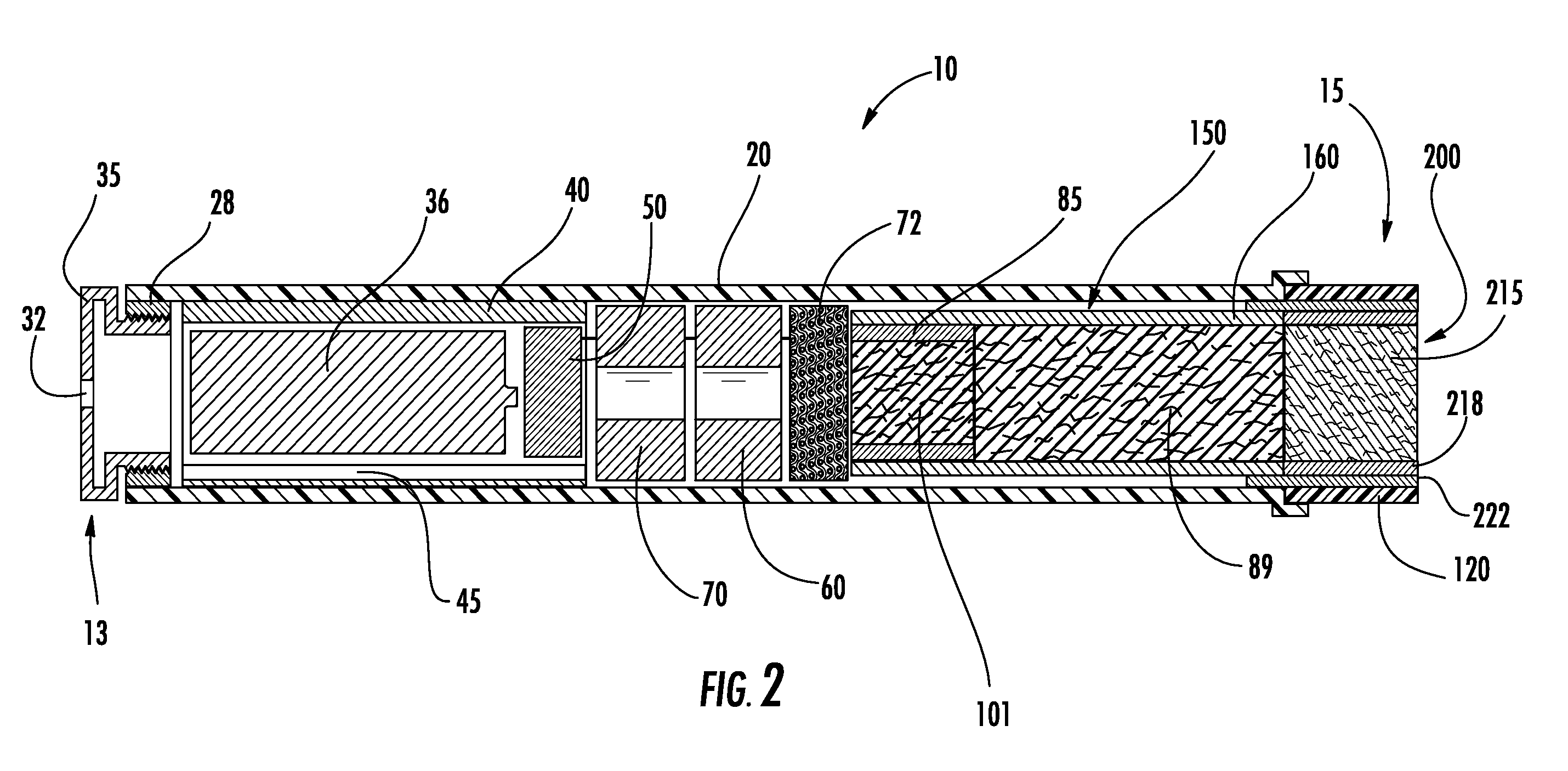

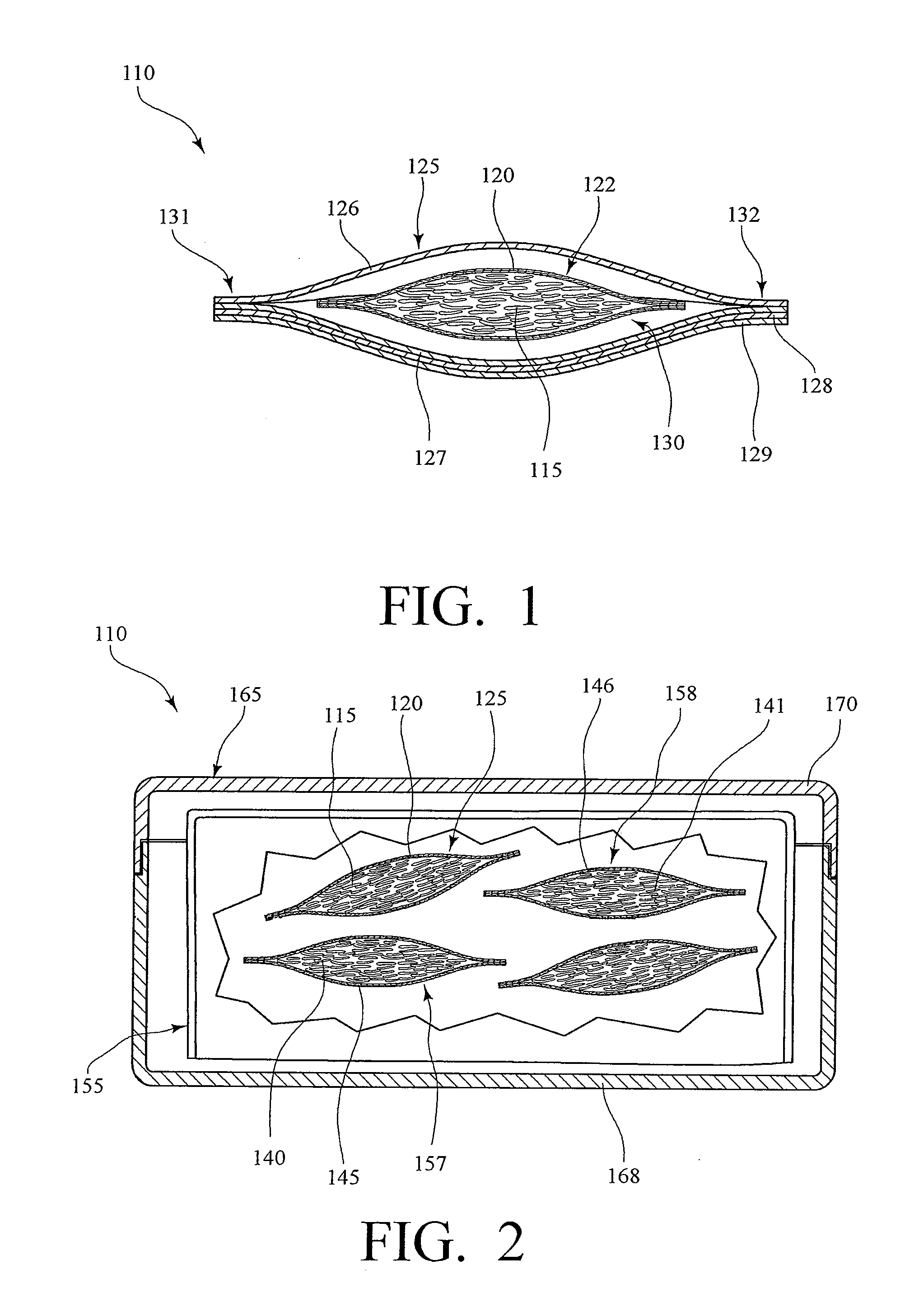

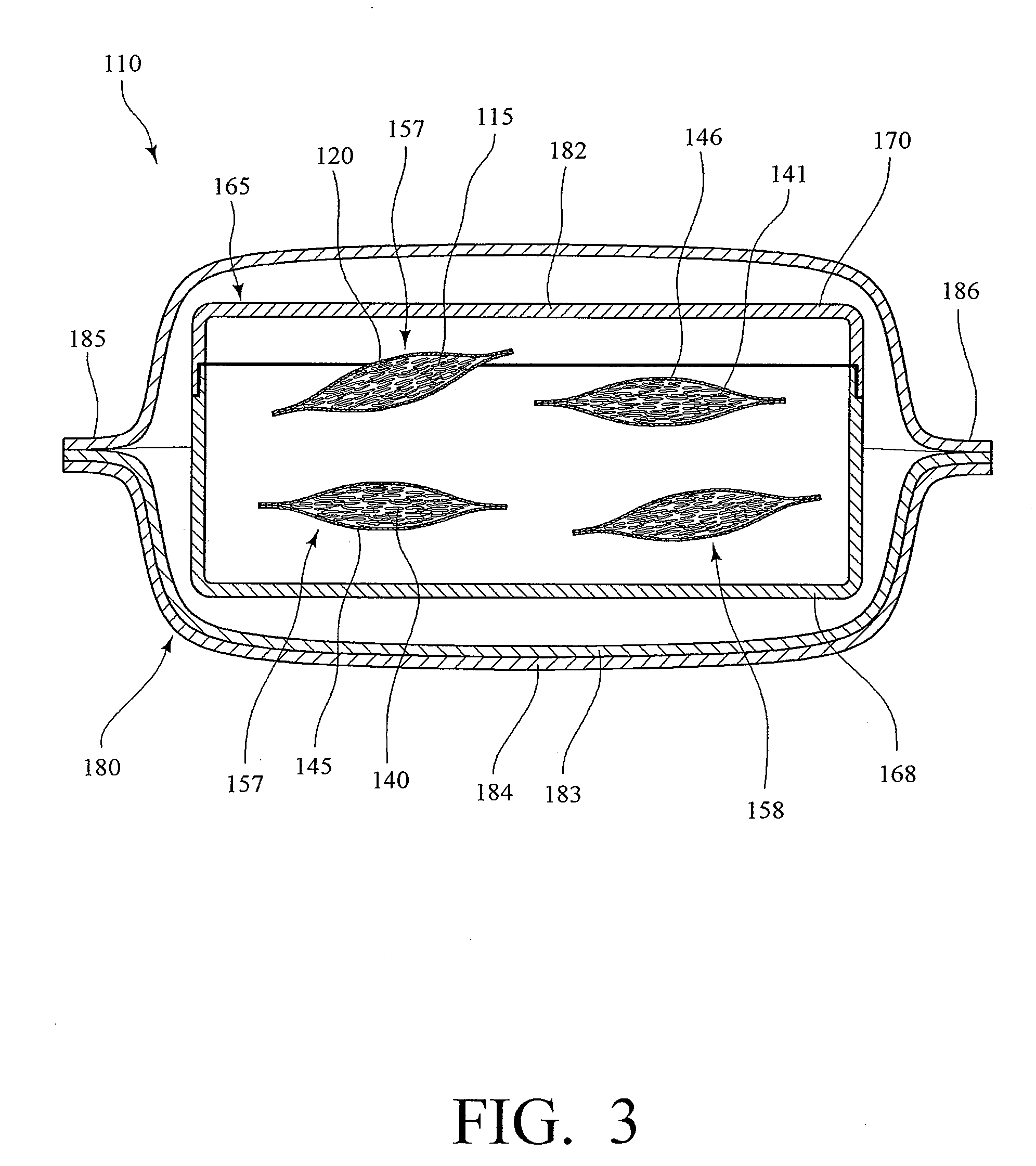

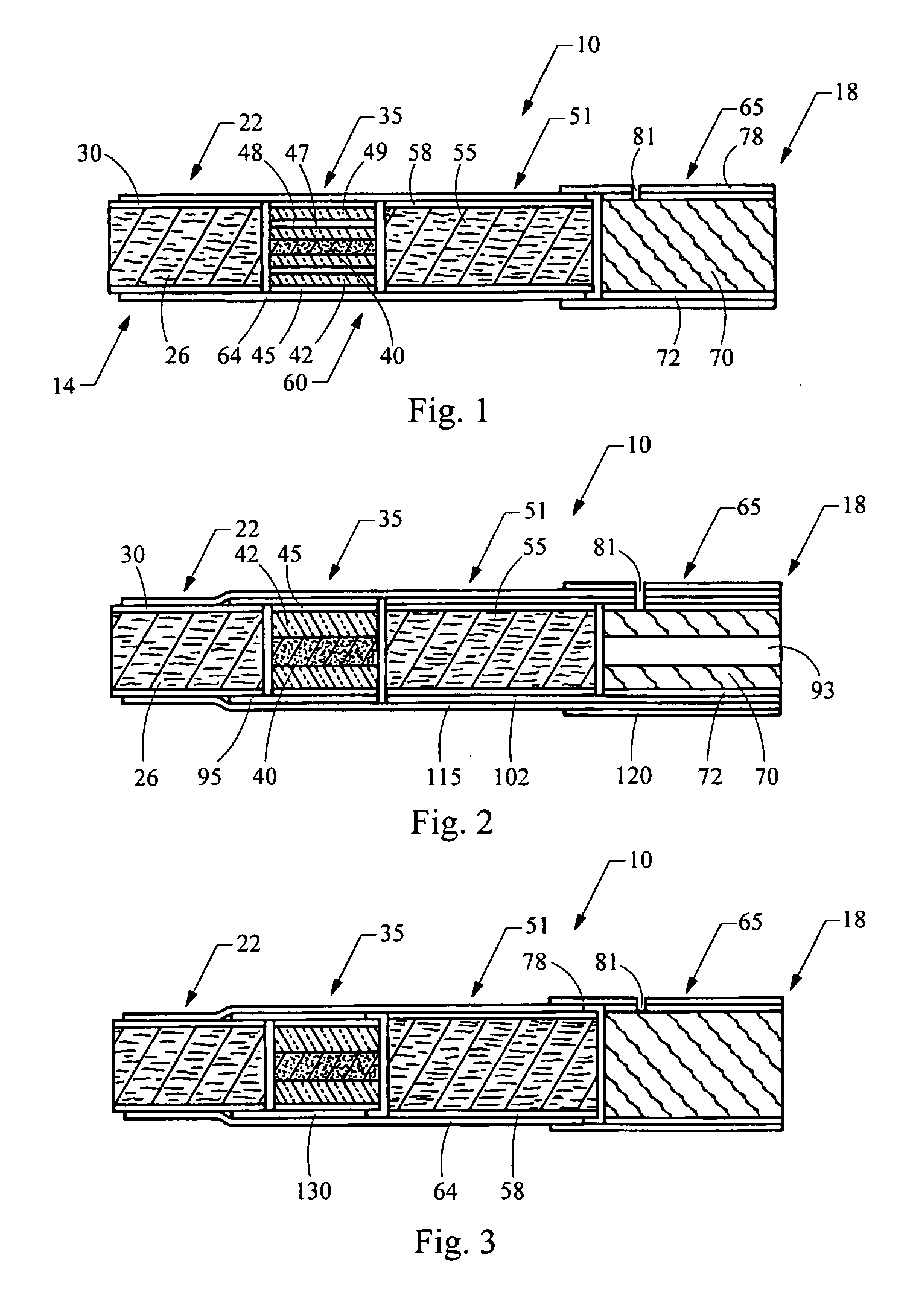

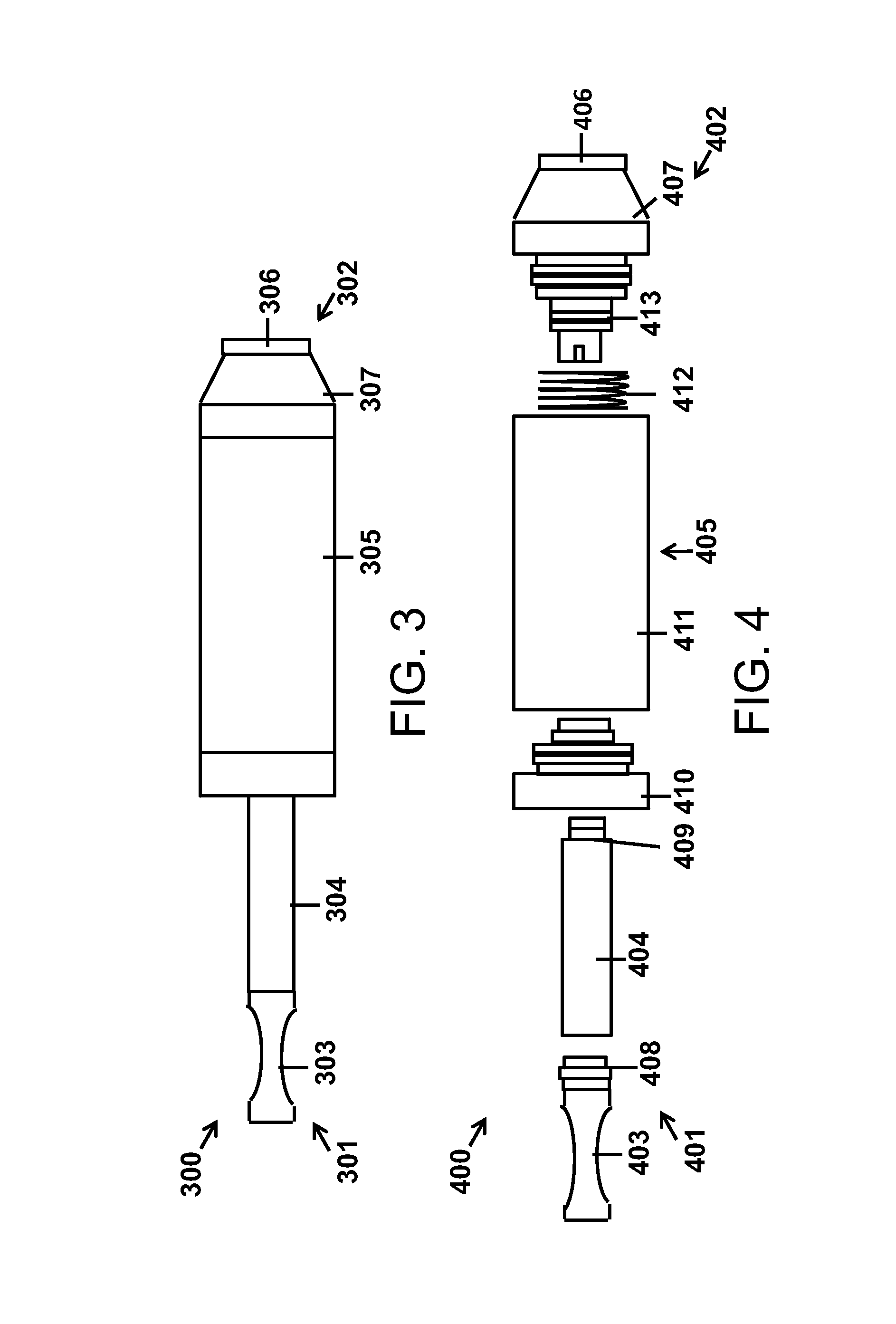

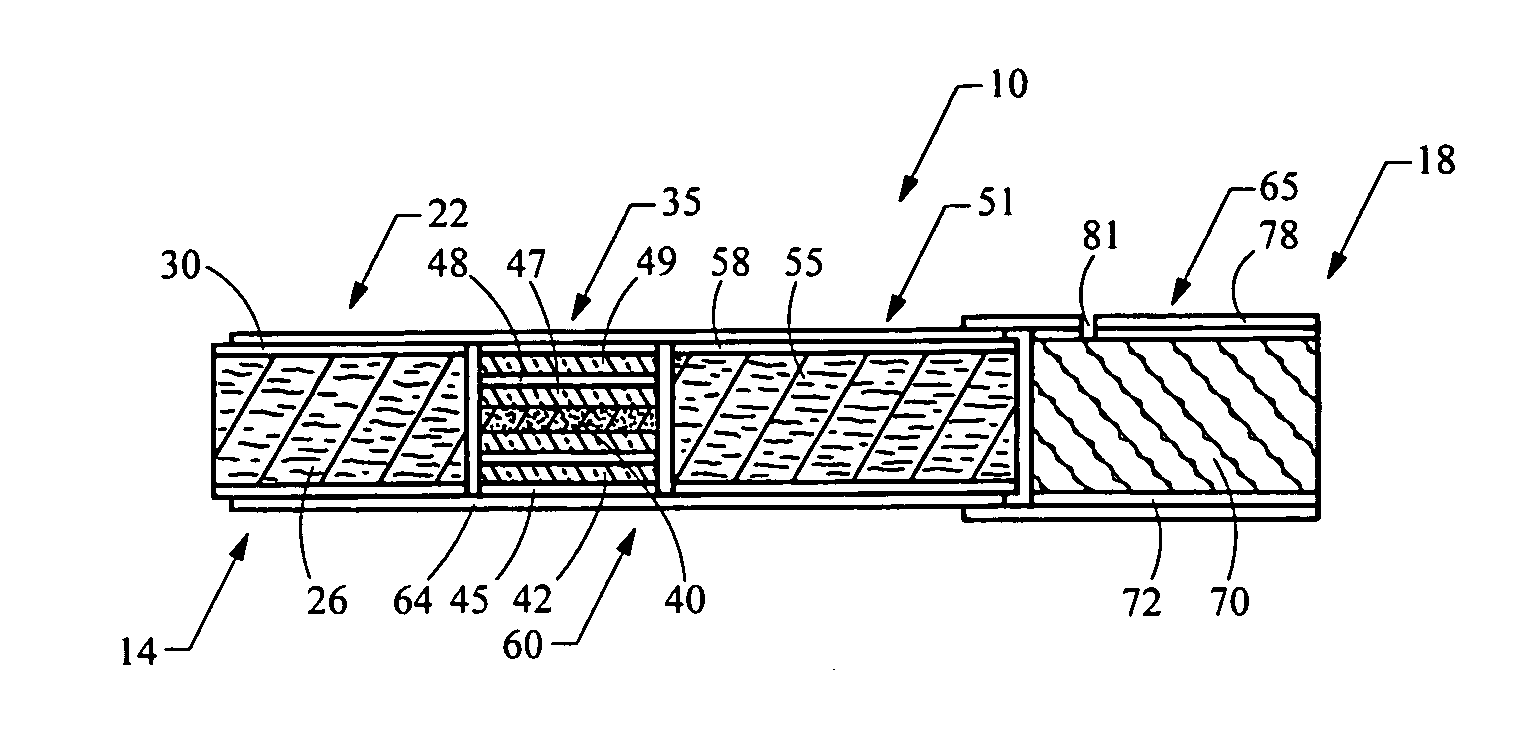

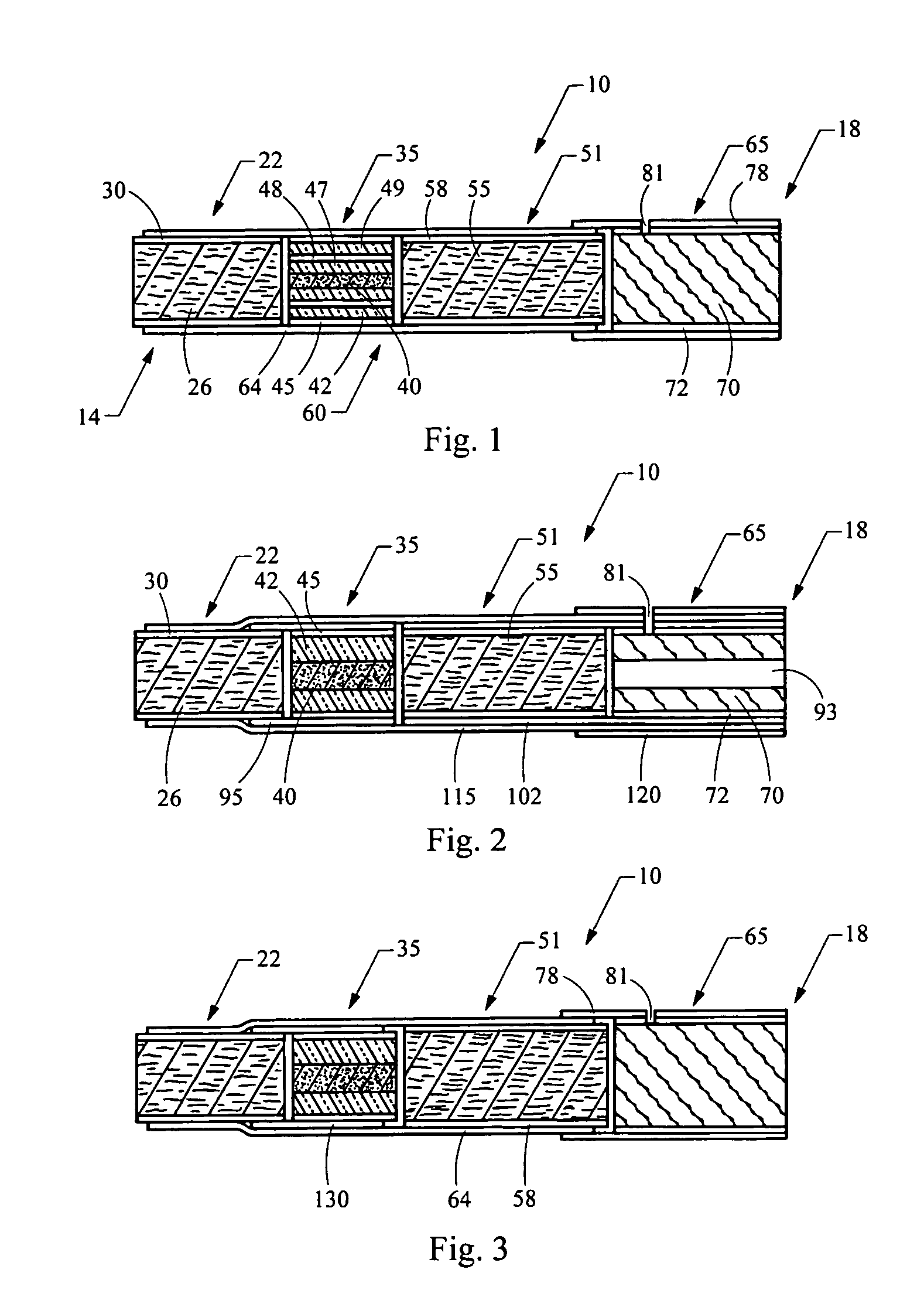

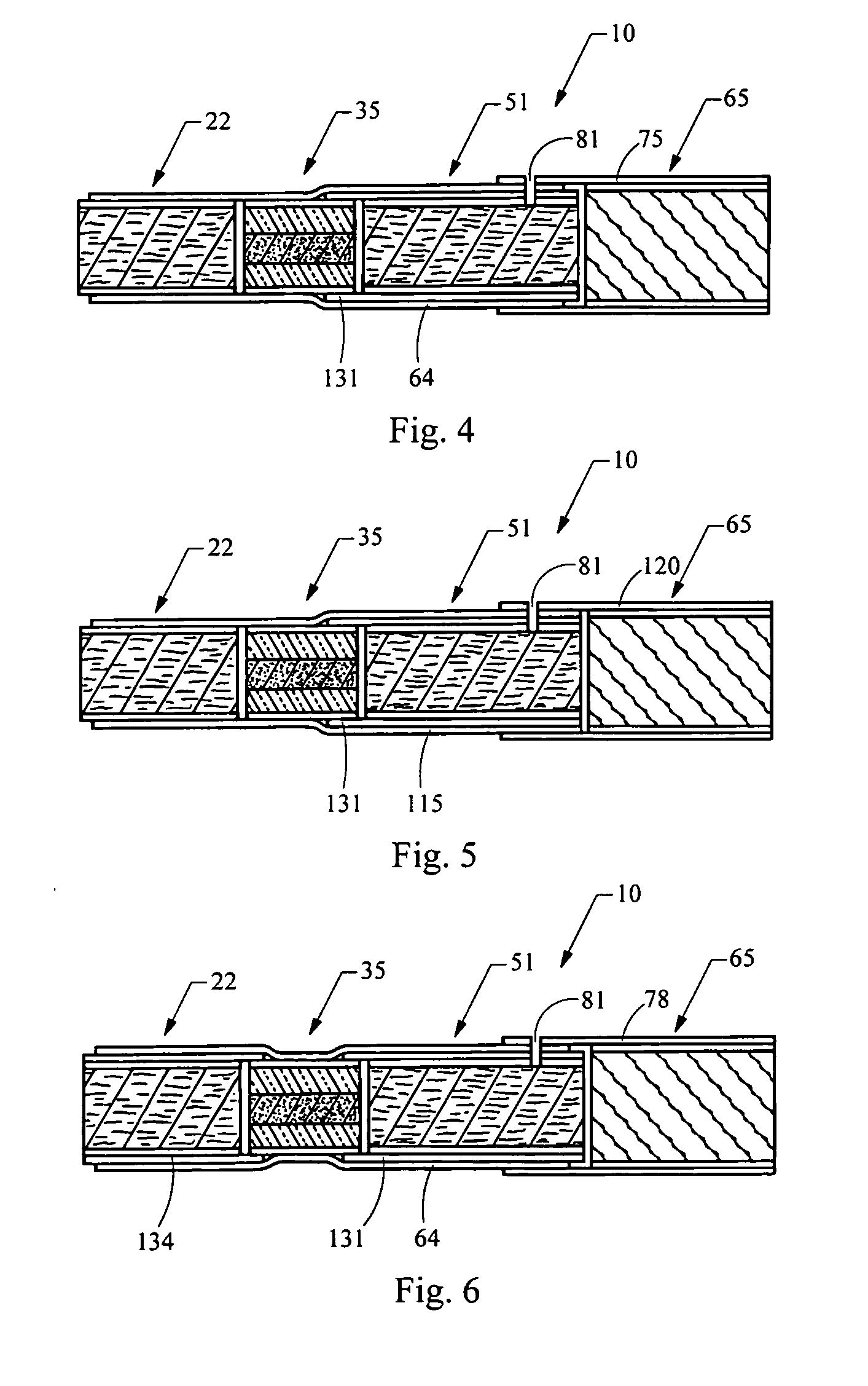

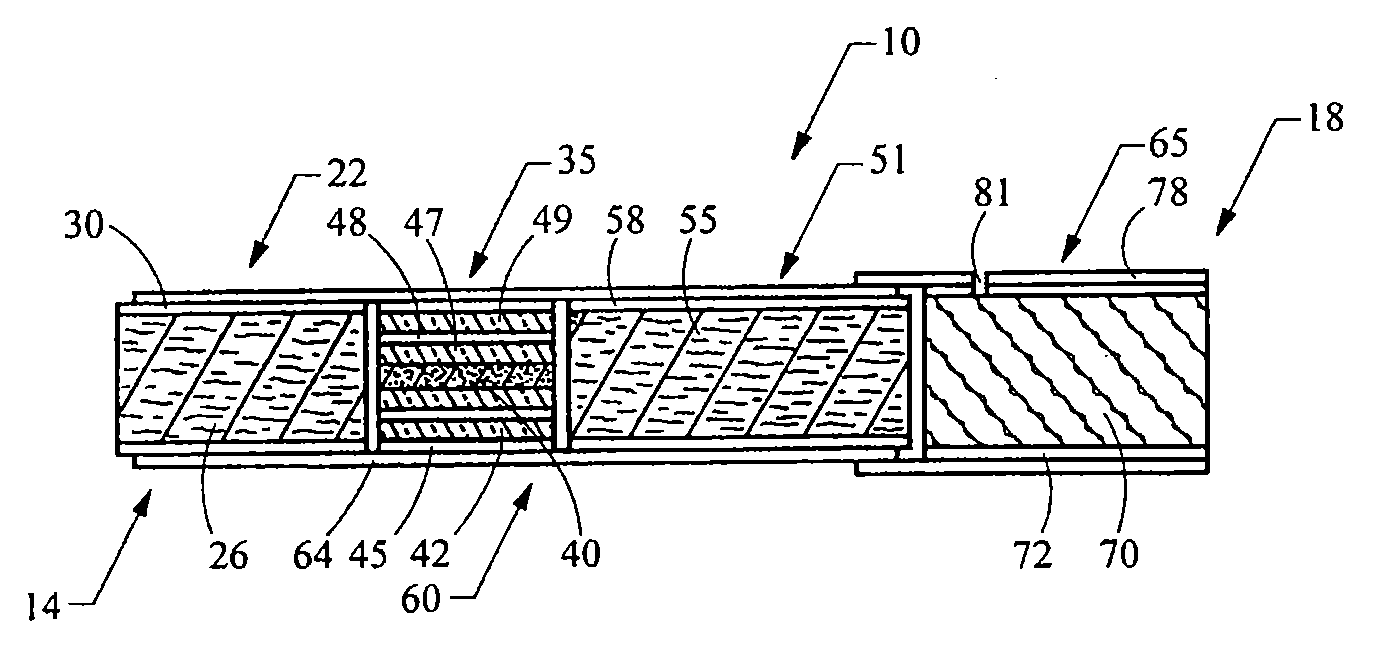

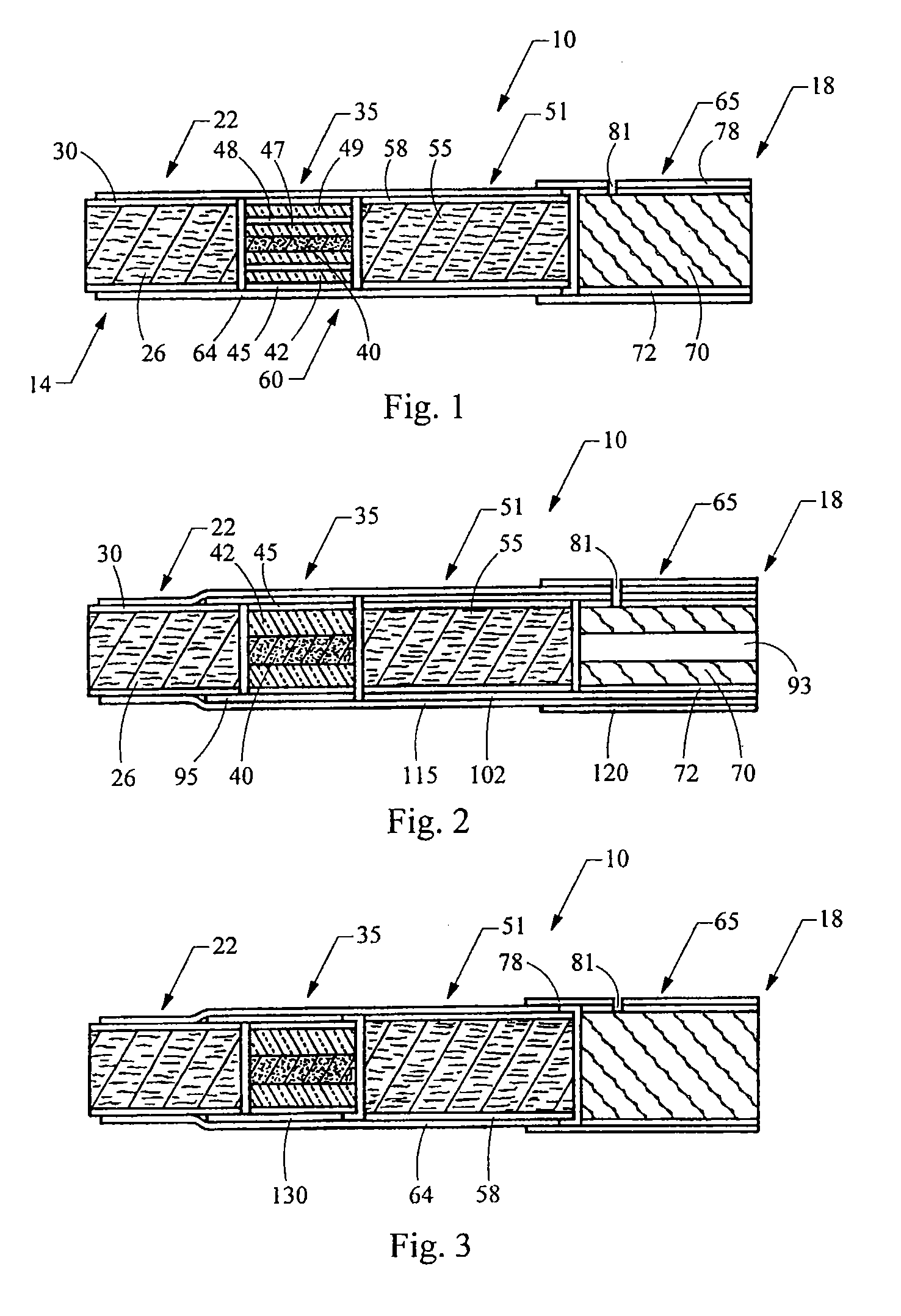

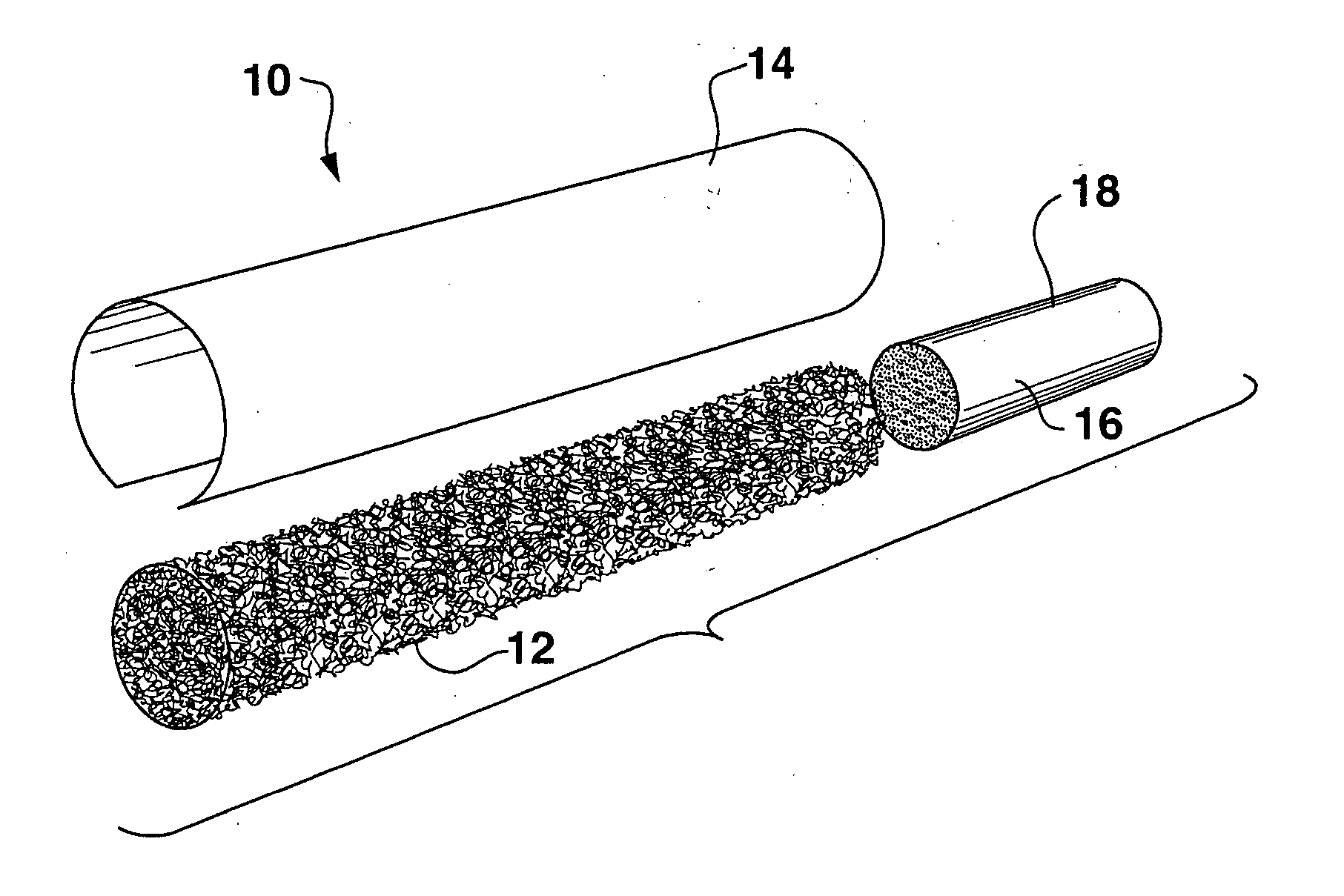

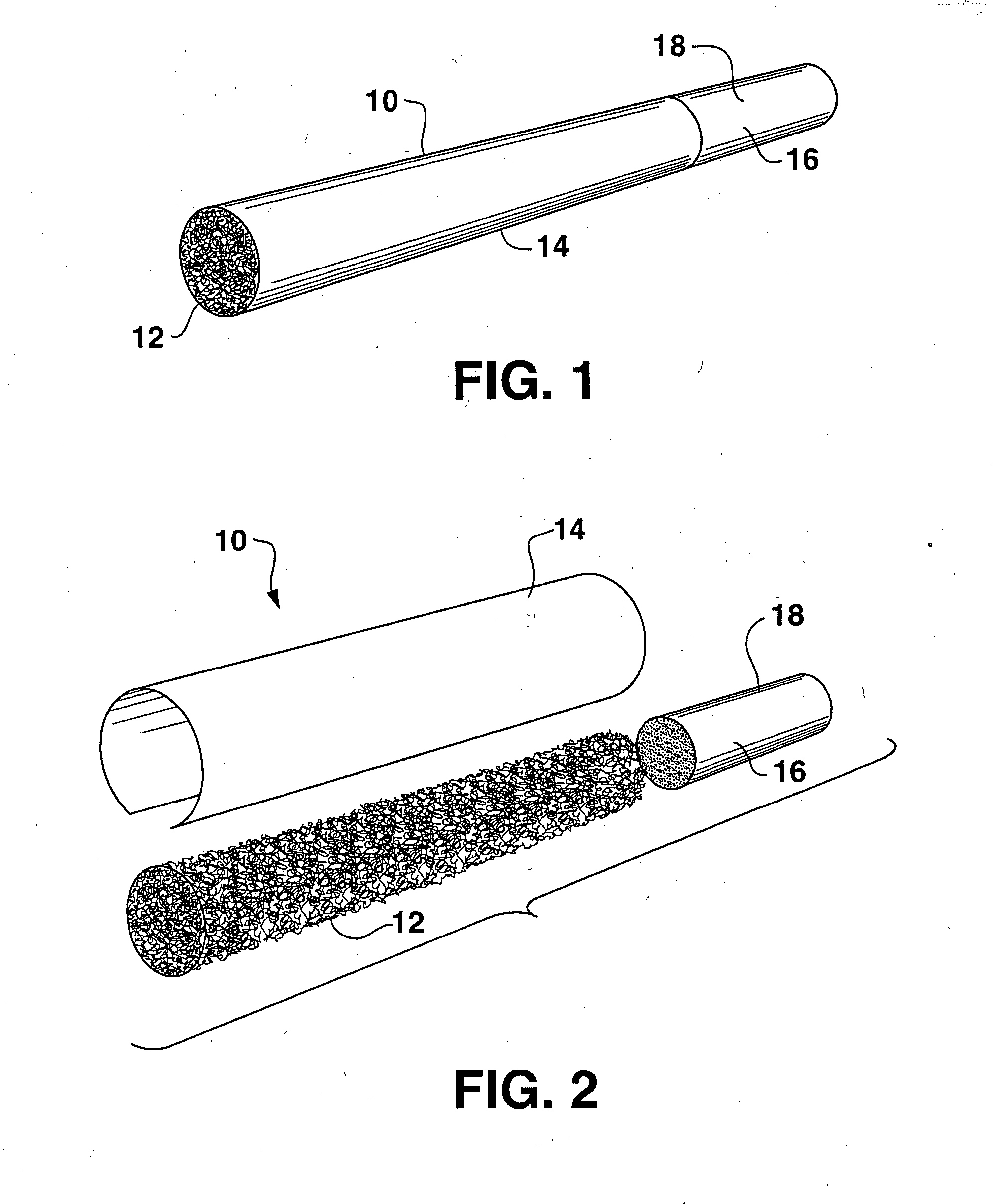

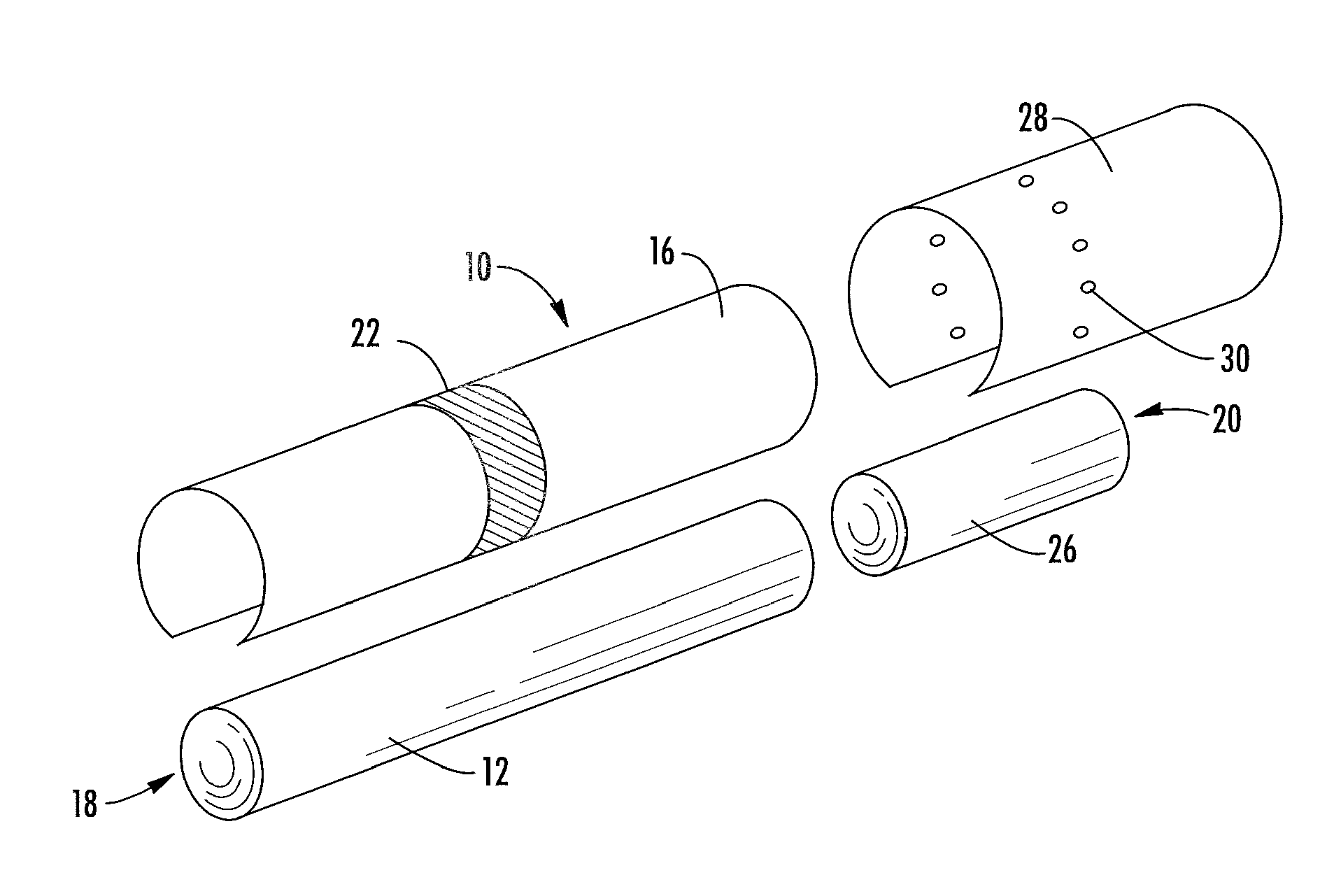

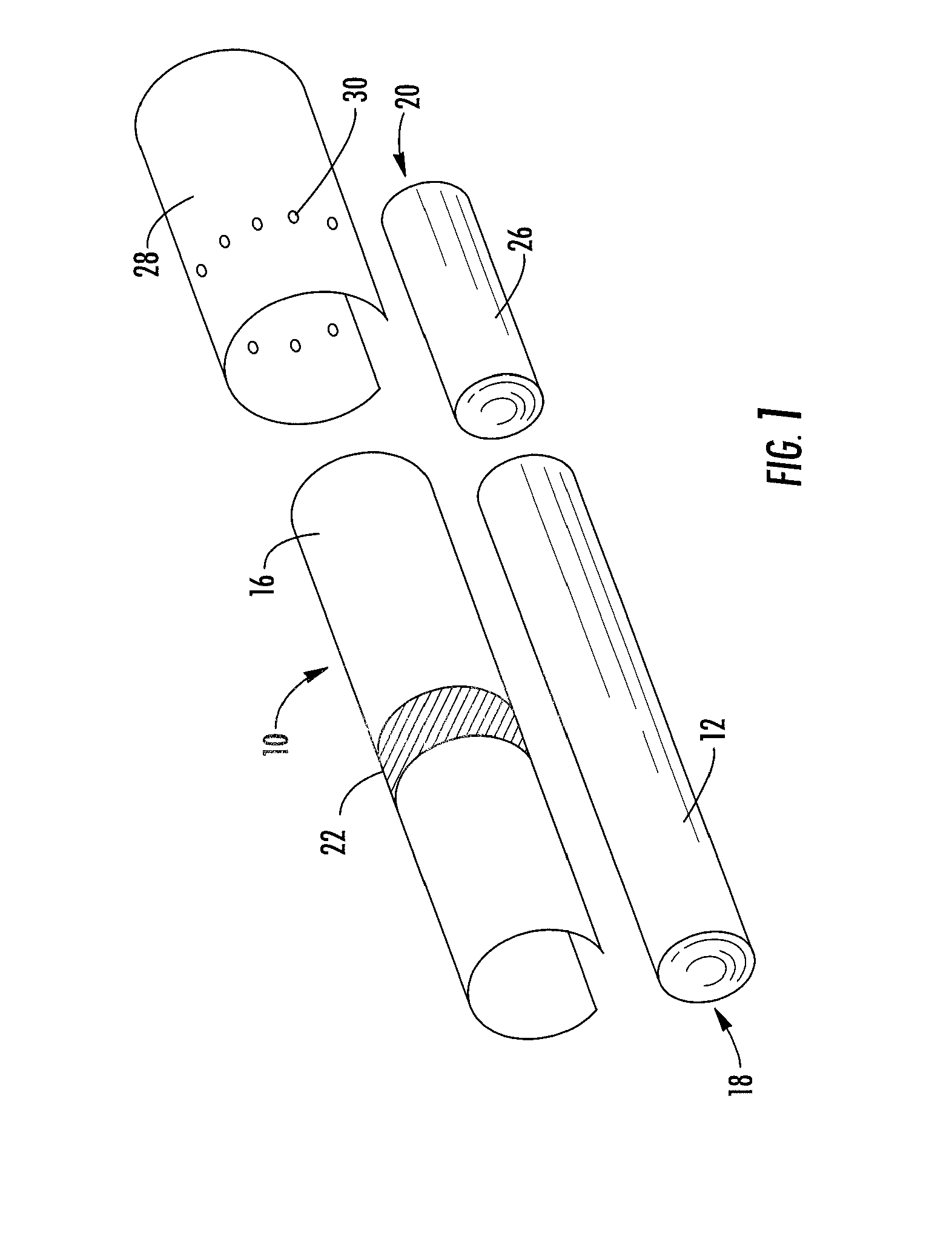

A smoking article may include a cigarette incorporated within an electrically powered aerosol generating device that acts as a holder for that cigarette. The smoking article possesses at least one form of tobacco. The smoking article also possesses a mouth-end piece that is used by the smoker to inhale components of tobacco that are generated by the action of heat upon components of the cigarette. A representative smoking article possesses an outer housing incorporating a source of electrical power (e.g., a battery), a sensing mechanism for powering the device at least during periods of draw, and a heating device (e.g., at least one electrical resistance heating element) for forming a thermally generated aerosol that incorporates components of tobacco. During use, the cigarette is positioned within the device, and after use, the used cigarette is removed from the device and replaced with another cigarette.

Owner:RAI STRATEGIC HLDG INC

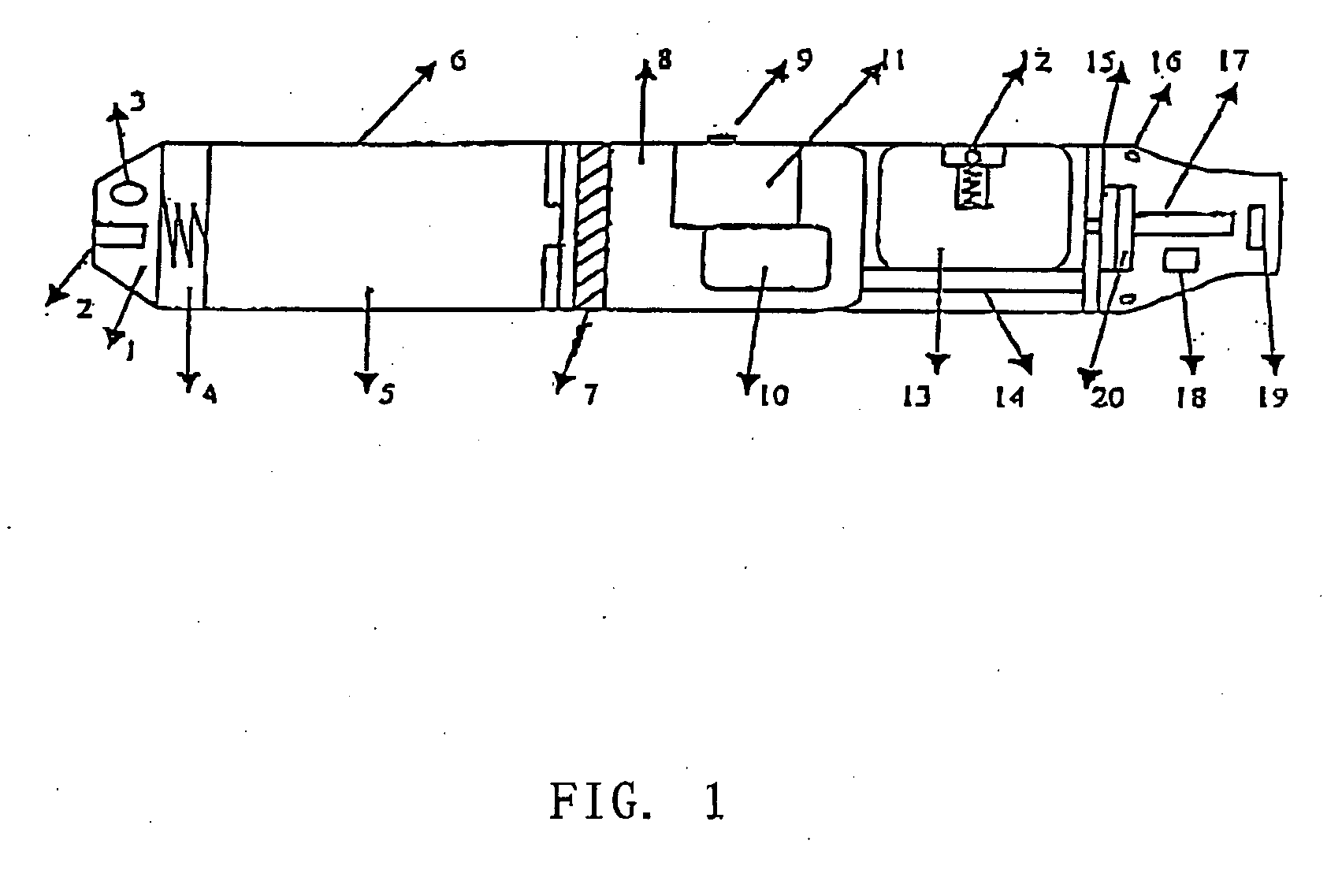

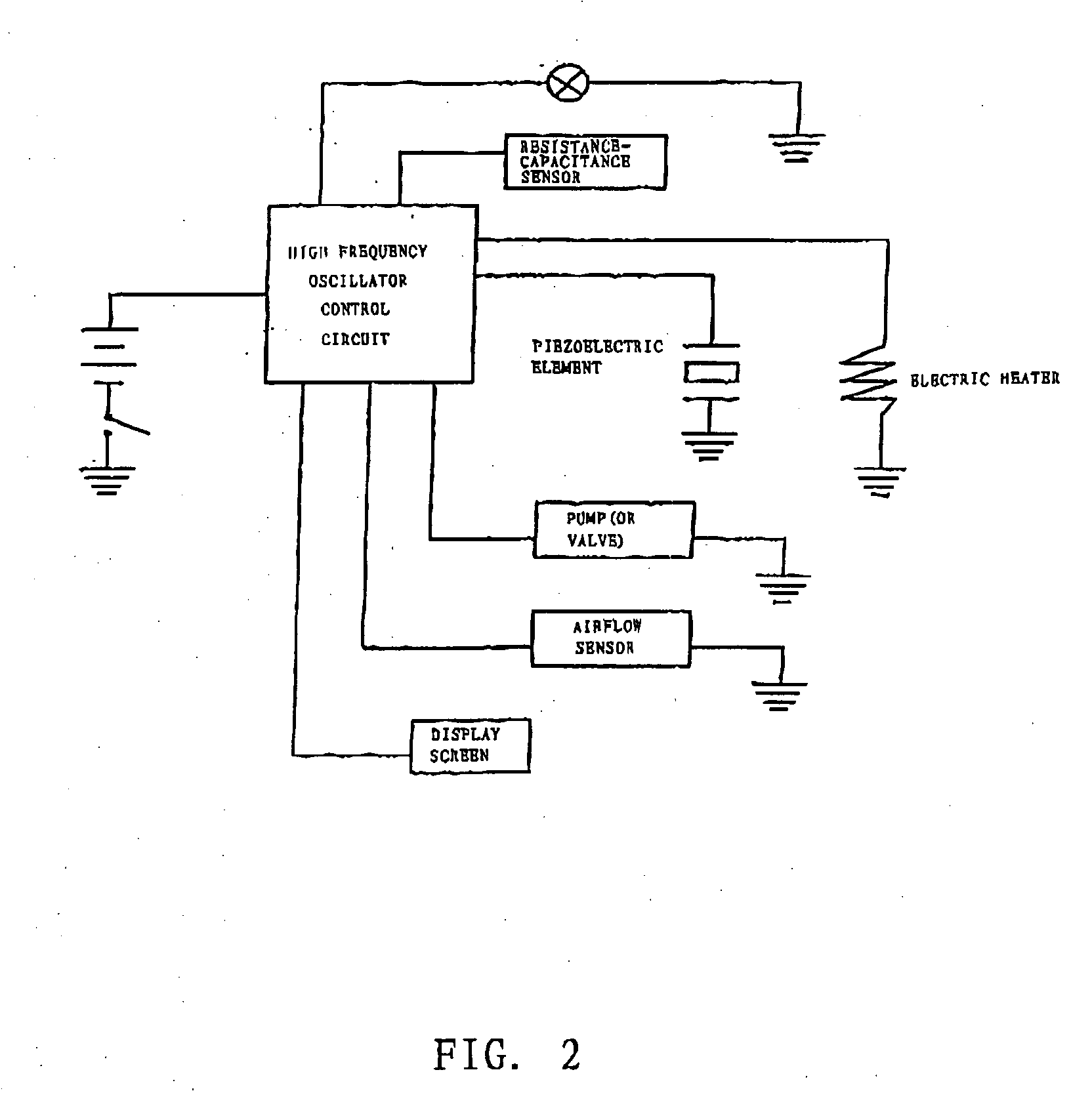

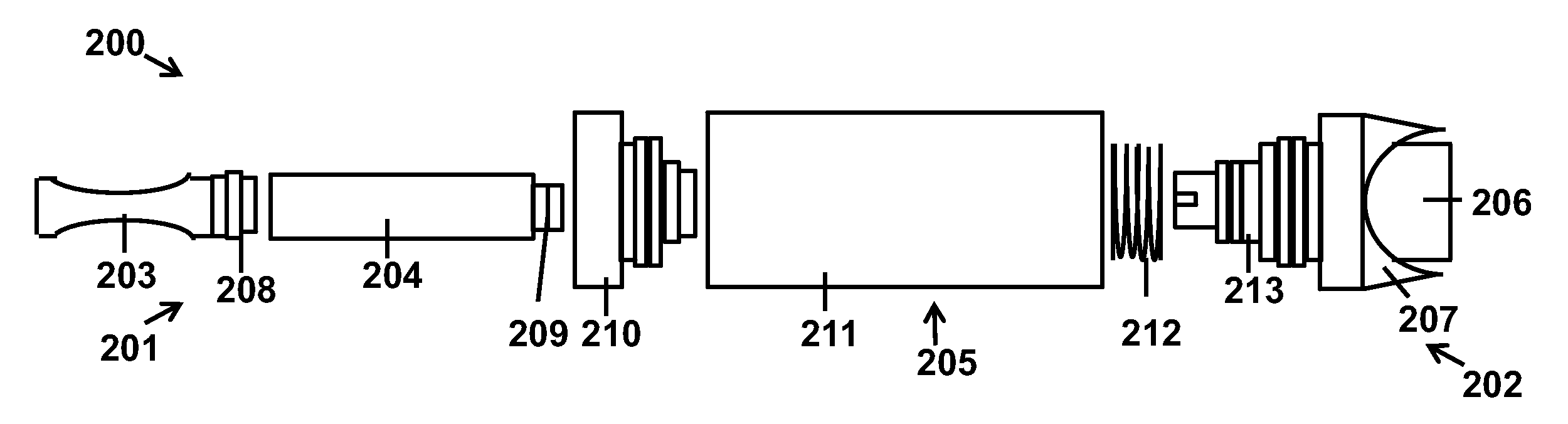

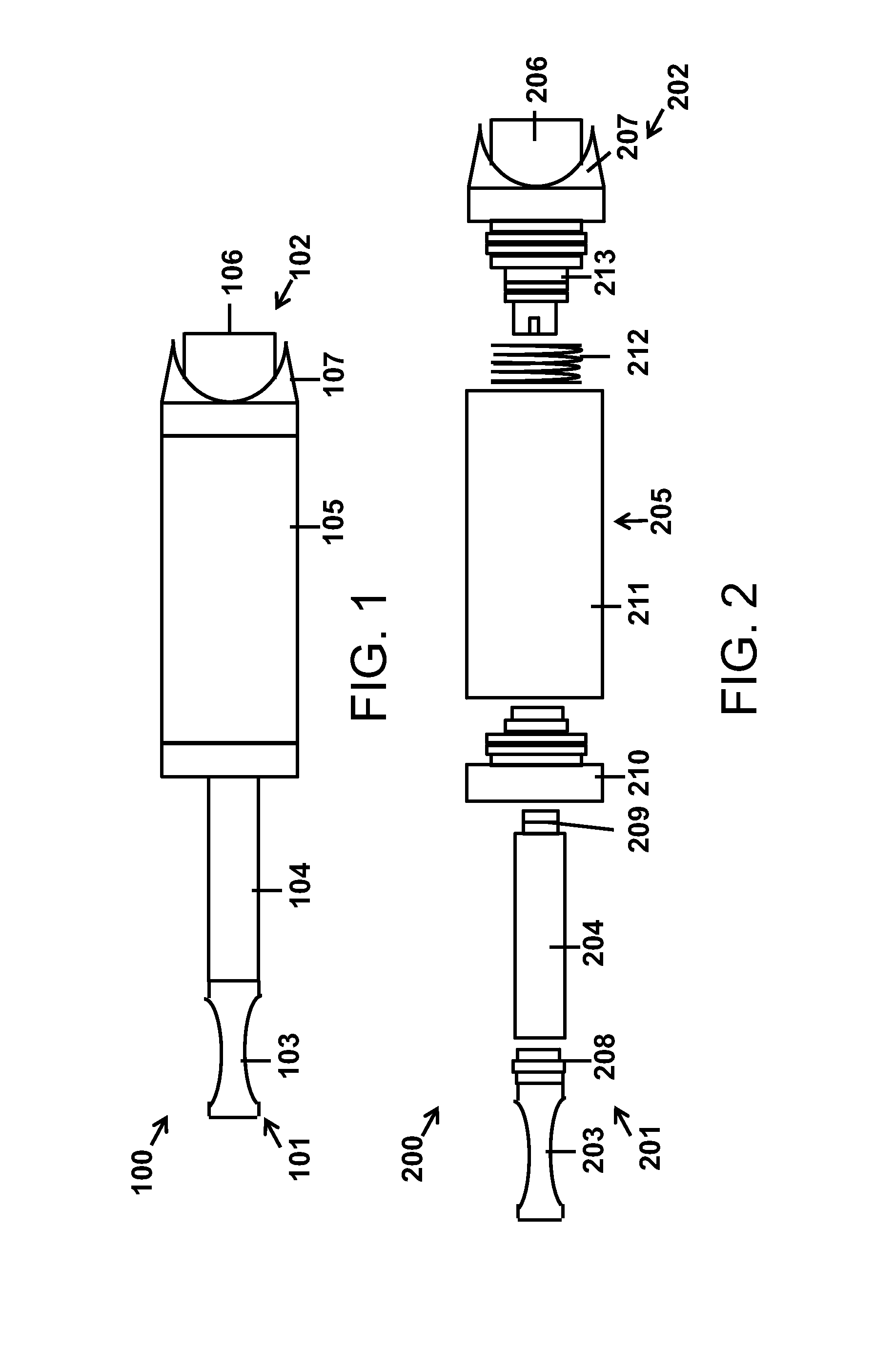

Flameless electronic atomizing cigarette

InactiveUS20060196518A1Reduce cancer riskTobacco preparationBatteries circuit arrangementsEngineeringElectric control

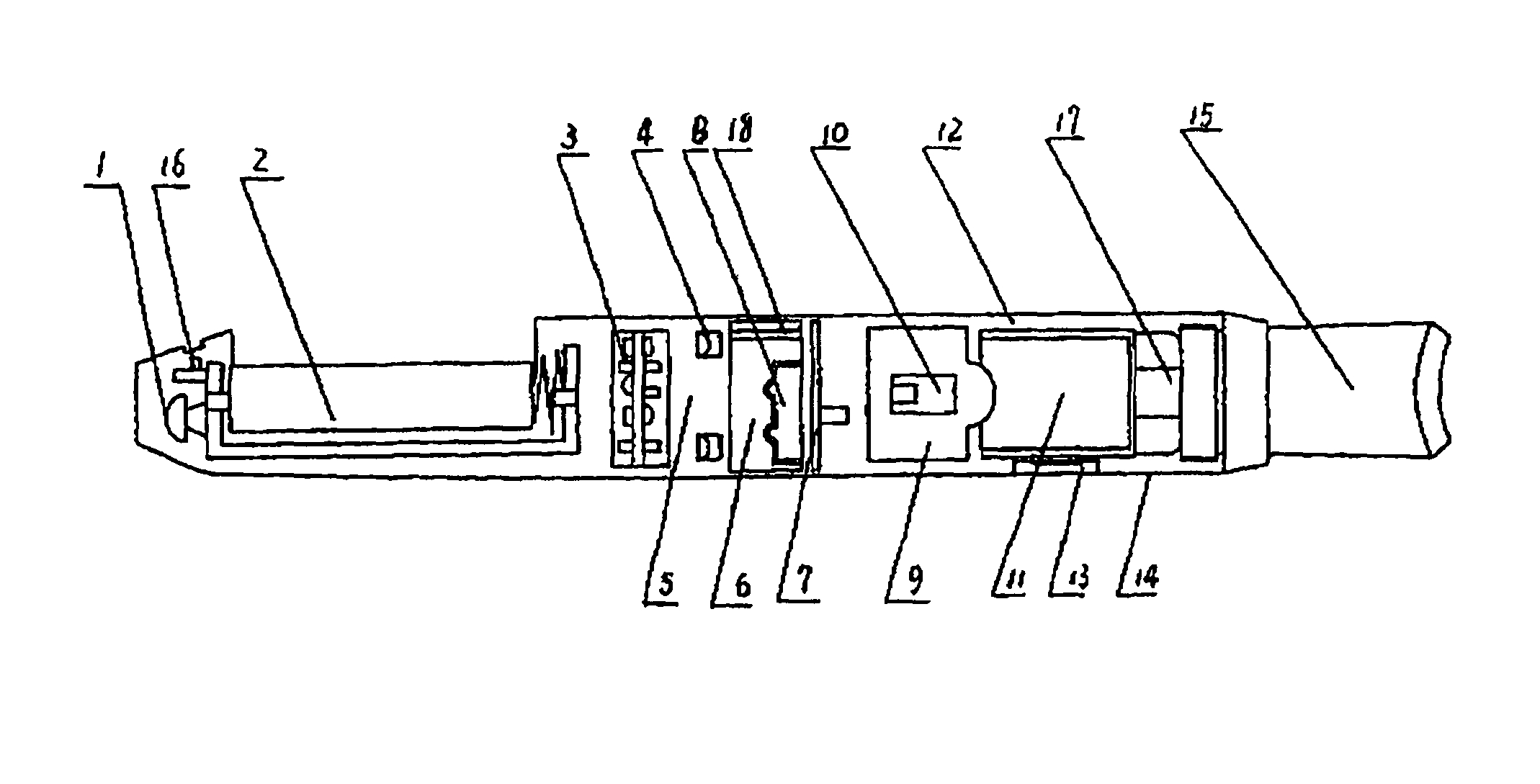

The invention relates to a non-smokable electronic spray cigarette which only comprises nicotine without harmful tar. The cigarette includes a smoke mouth integer comprised with a shell, a cell, a high frequency ionzer, nicotine solution storage and its container, control circuit, a display screen, a human contact sensor, a piezoelectric supersound atomizer, a high temperature vaporization nozzle and attachments, an electro-thermal vaporization nozzle installed in the air suction end of the shell goes through an electric control pump or a valve with a measuring chamber and a liquid storage container which contains nicotine solution and is connected to the electric control pump or a valve with a one-way flow valve, the control circuit plate has four export ends individually connected with the high frequency ionizer, electric heater, pump or valve and the display screen, a human resistence sensor and an air flow sensor are connected to the input end of the control circuit. The advantages of the present invention are smoking without tar, reducing the cancerogenic risk, the user still feel smoking and experiercing the excitement, the cigarette is no need to be lit and is no fire danger.

Owner:FONTEM HLDG 1

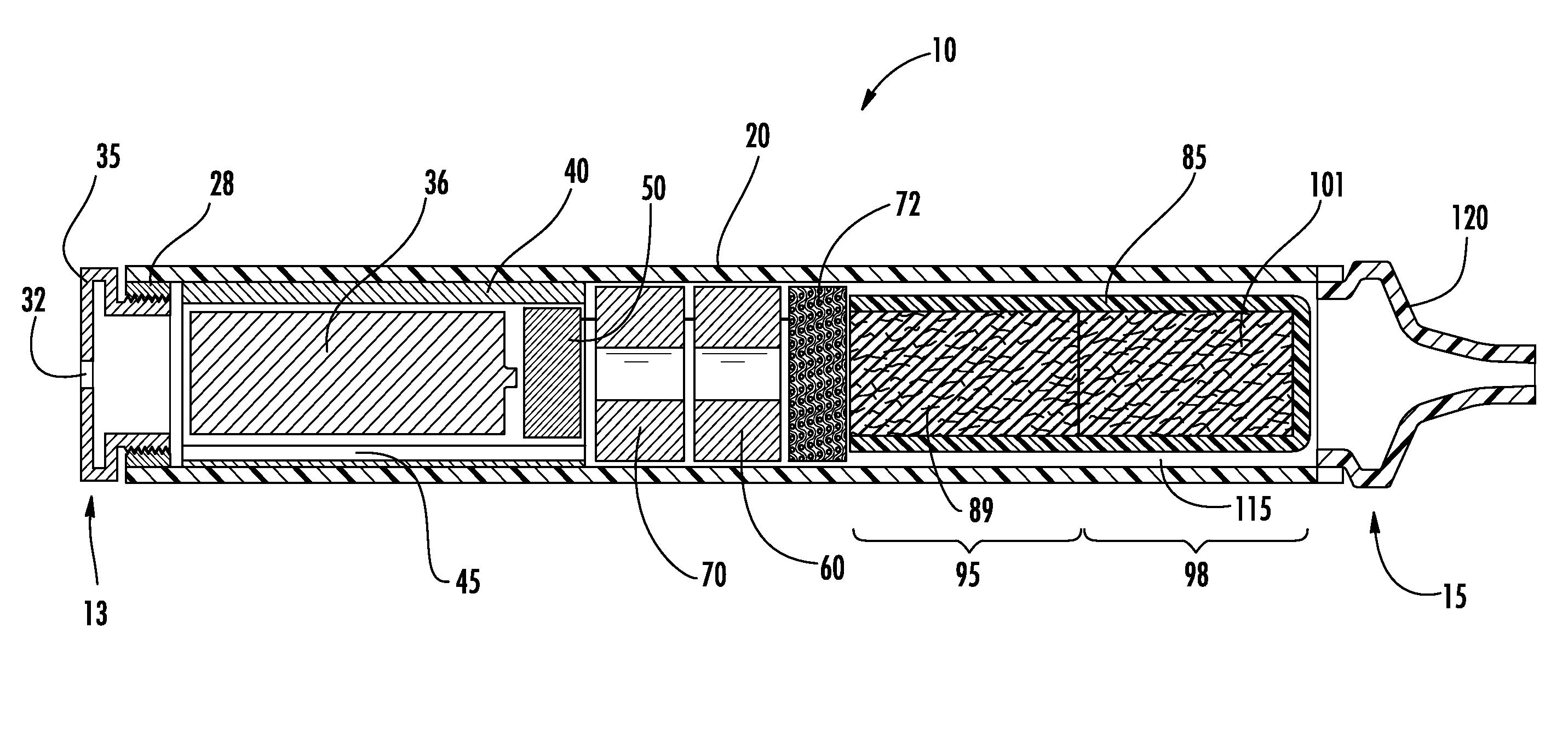

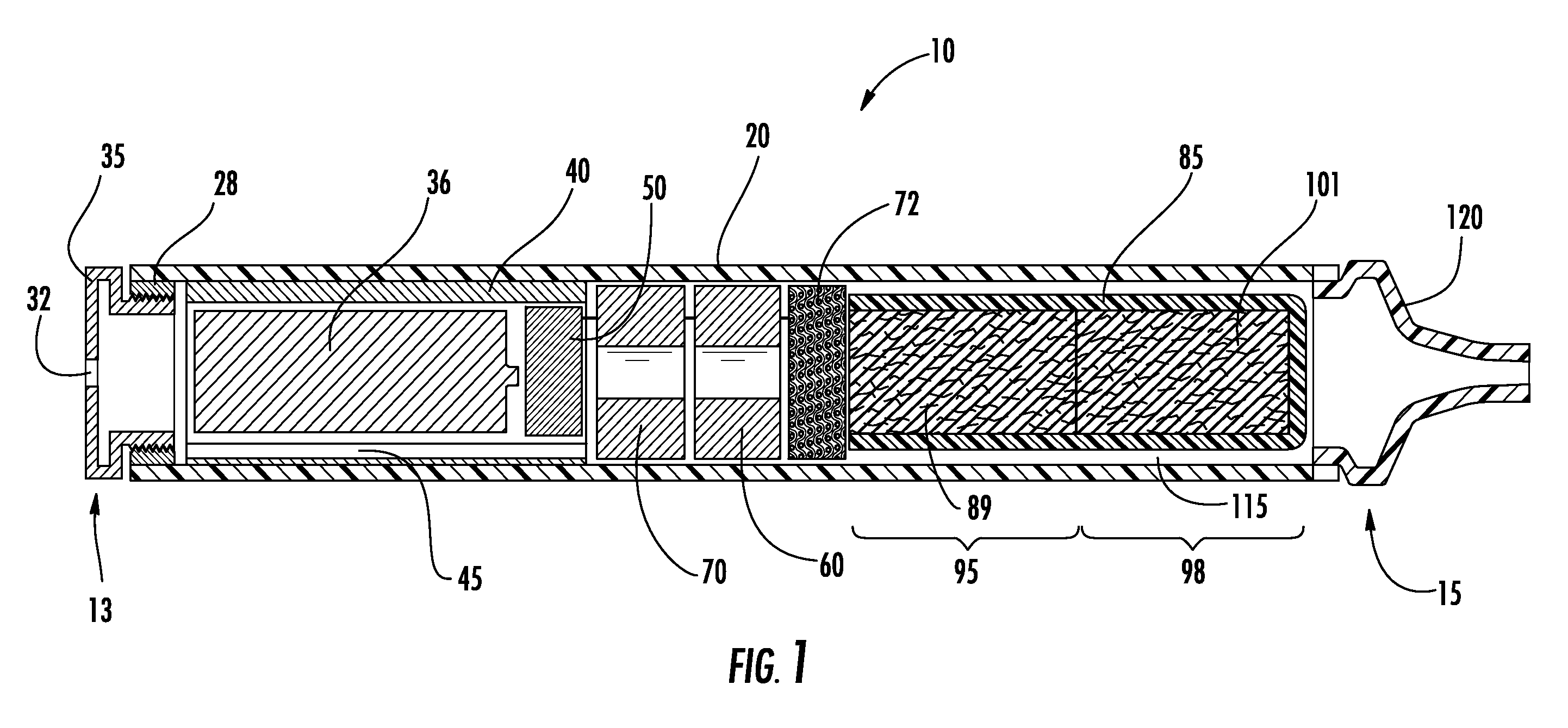

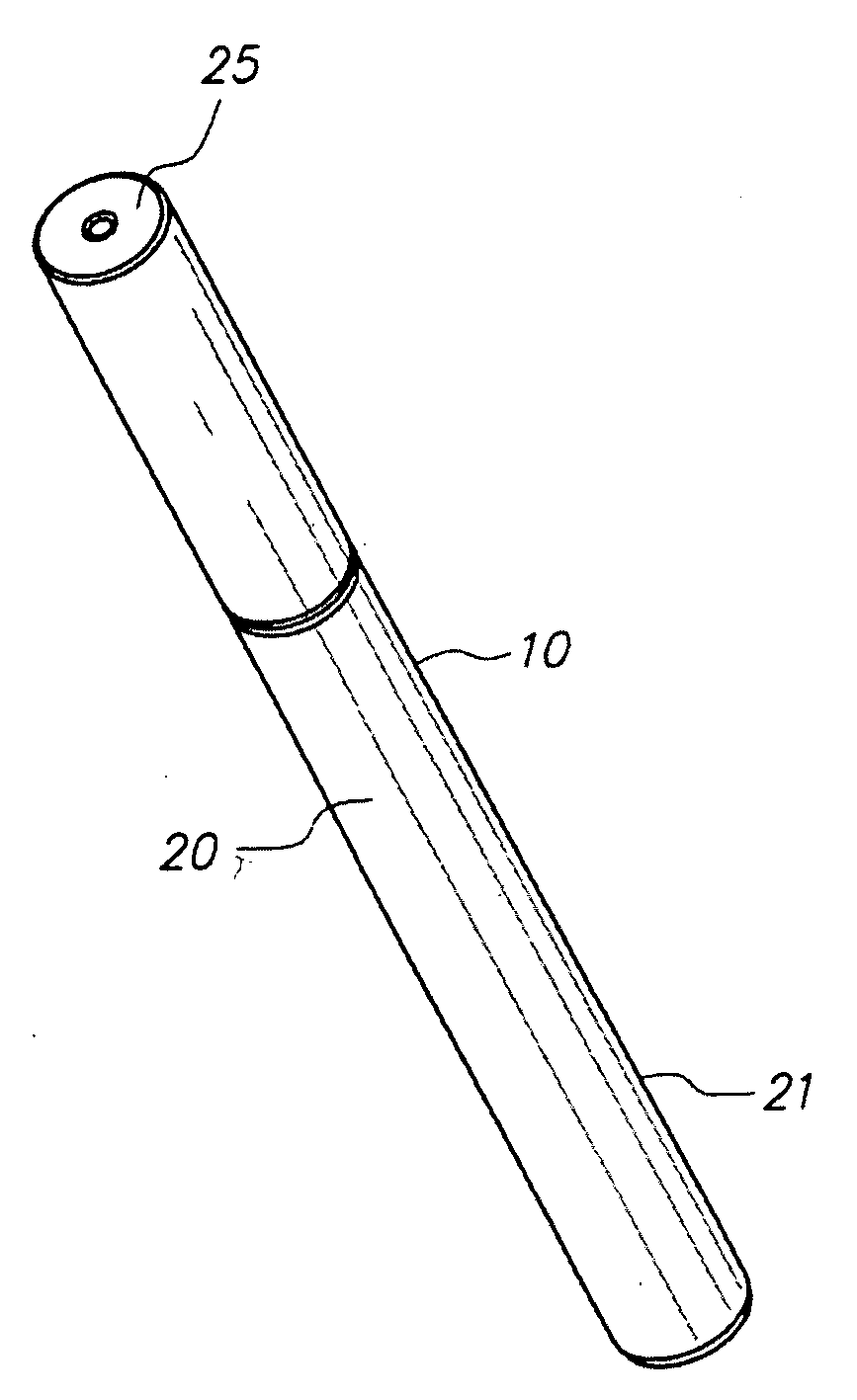

Tobacco-Containing Smoking Article

ActiveUS20080092912A1Tobacco preparationTobacco treatmentElectrical resistance and conductanceEngineering

A smoking article may include a cigarette incorporated within an electrically powered aerosol generating device that acts as a holder for that cigarette. The smoking article possesses at least one form of tobacco. The smoking article also possesses a mouth-end piece that is used by the smoker to inhale components of tobacco that are generated by the action of heat upon components of the cigarette. A representative smoking article possesses an outer housing incorporating a source of electrical power (e.g., a battery), a sensing mechanism for powering the device at least during periods of draw, and a heating device (e.g., at least one electrical resistance heating element) for forming a thermally generated aerosol that incorporates components of tobacco. During use, the cigarette is positioned within the device, and after use, the used cigarette is removed from the device and replaced with another cigarette.

Owner:RAI STRATEGIC HLDG INC

Electronic atomization cigarette

ActiveUS7832410B2Reduce cancer riskTobacco preparationNervous disorderVapor–liquid separatorEngineering

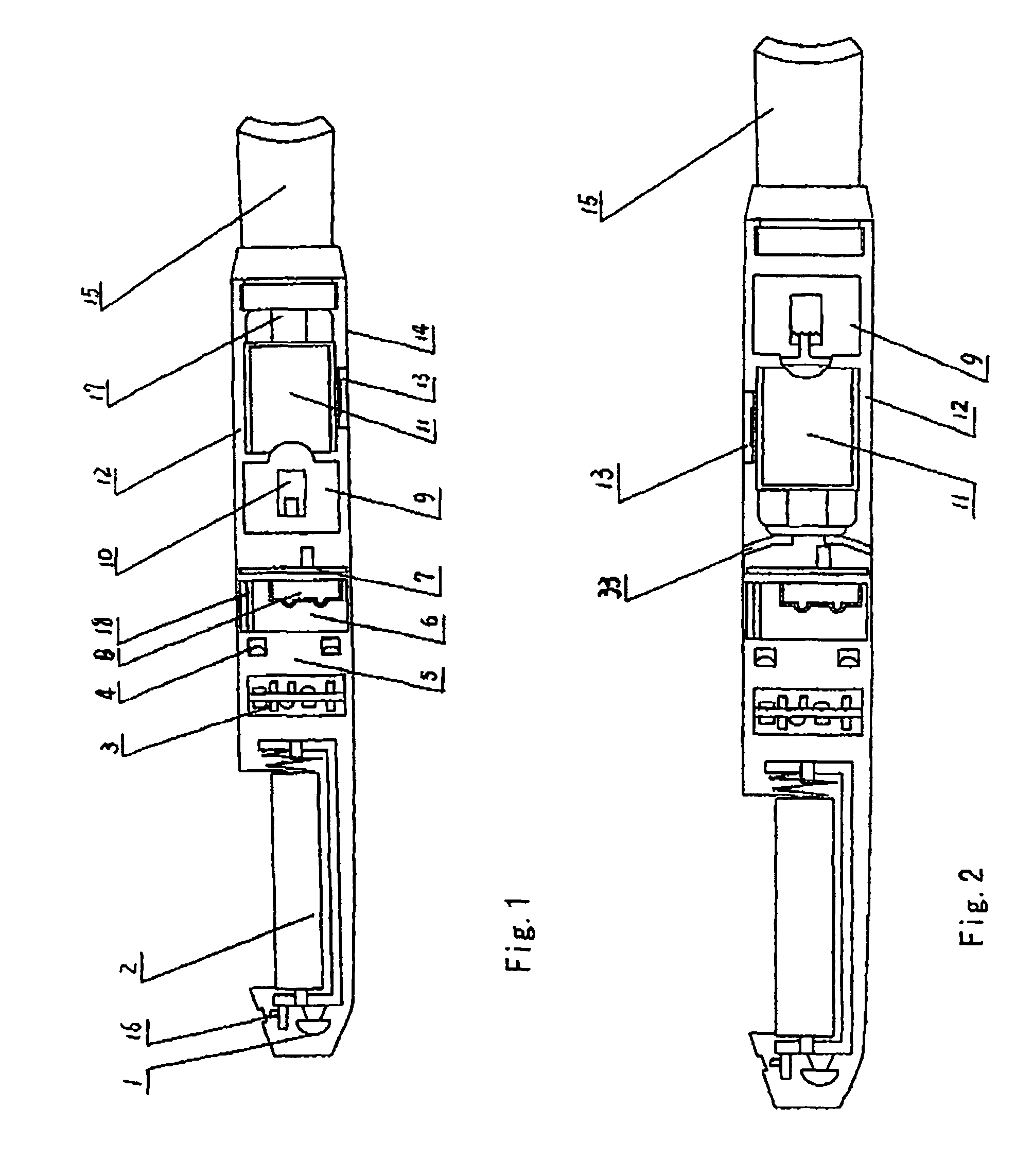

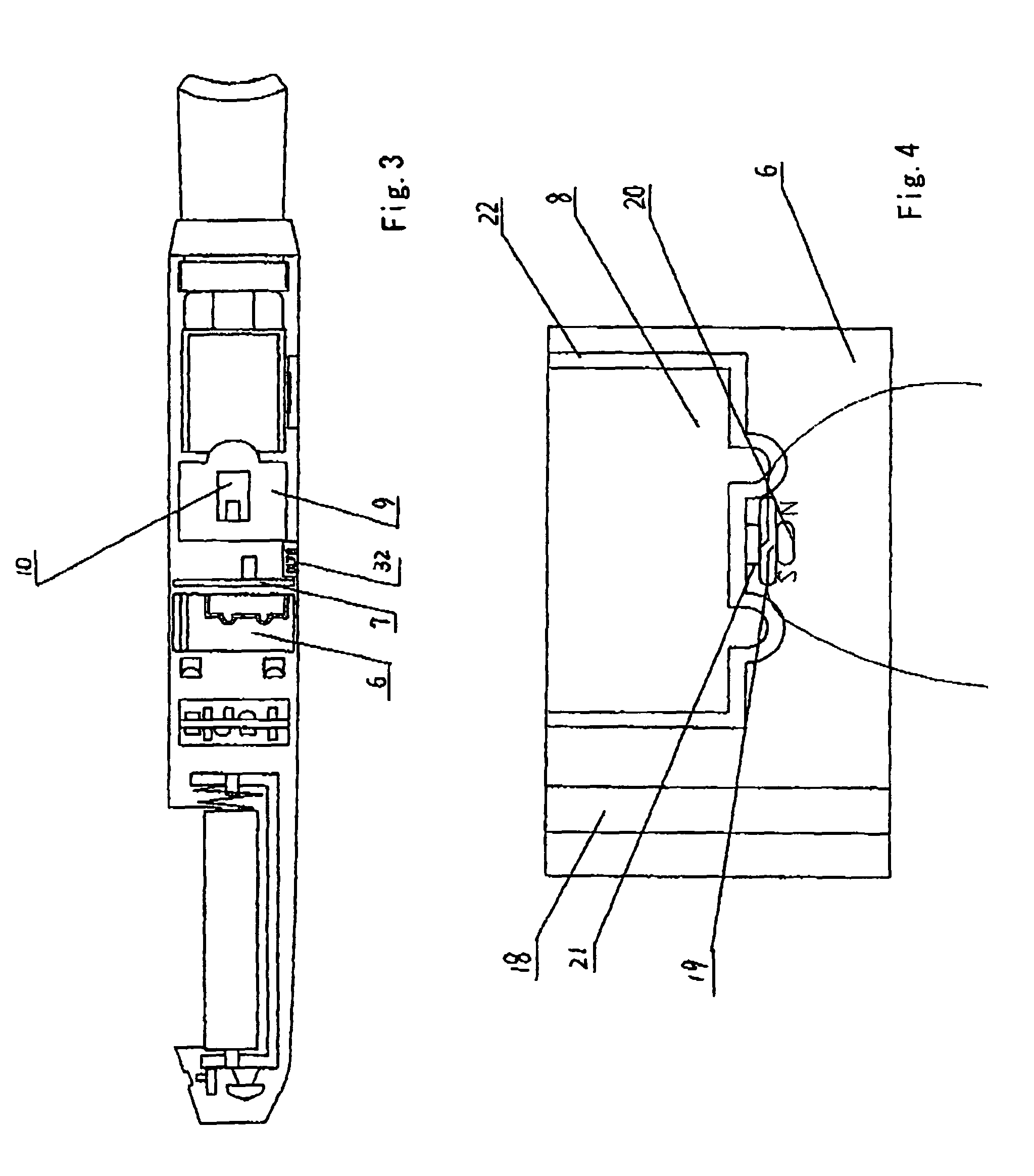

The invention relates to an electronic atomization cigarette which only contains nicotine without harmful tar. The electronic atomization cigarette includes a shell and a mouthpiece. The external wall of the shell has an air inlet. An electronic circuit board, a normal pressure cavity, a sensor, a vapor-liquid separator, an atomizer, a liquid-supplying bottle are sequentially provided within the shell, wherein the electronic circuit board comprises an electronic switching circuit and a high frequency generator. A stream passage of the sensor is provided on one side of the sensor, and a negative pressure cavity is provided in the sensor. The atomizer and the liquid-supplying bottle is in contact with each other. An atomization cavity is arranged in the atomizer. A retaining ring for locking the liquid-supplying bottle is provided between one side of the liquid-supplying bottle and the shell, and an aerosol passage is provided on the other side of the liquid-supplying bottle. The air inlet, normal pressure cavity, vapor-liquid separator, atomizer, aerosol passage, gas vent and mouthpiece are sequentially interconnected.

Owner:FONTEM VENTURES

Electronic cigarette

InactiveUS20050016550A1Efficient disseminationGood adhesionTobacco preparationCigar manufactureInhalationEngineering

An electronic cigarette is provided. The electronic cigarette includes a casing having an inhalation hole and a substantially cylindrical configuration, ejection means (first ejection means) provided in the casing and at least one ejection head. Pressure in a cavity filled with a liquid flavor generating medium is changed by driving an actuator to eject the flavor generating medium as droplets from a nozzle in communication with the cavity. Control means provided in the casing controls the driving of the ejection means.

Owner:SEIKO EPSON CORP

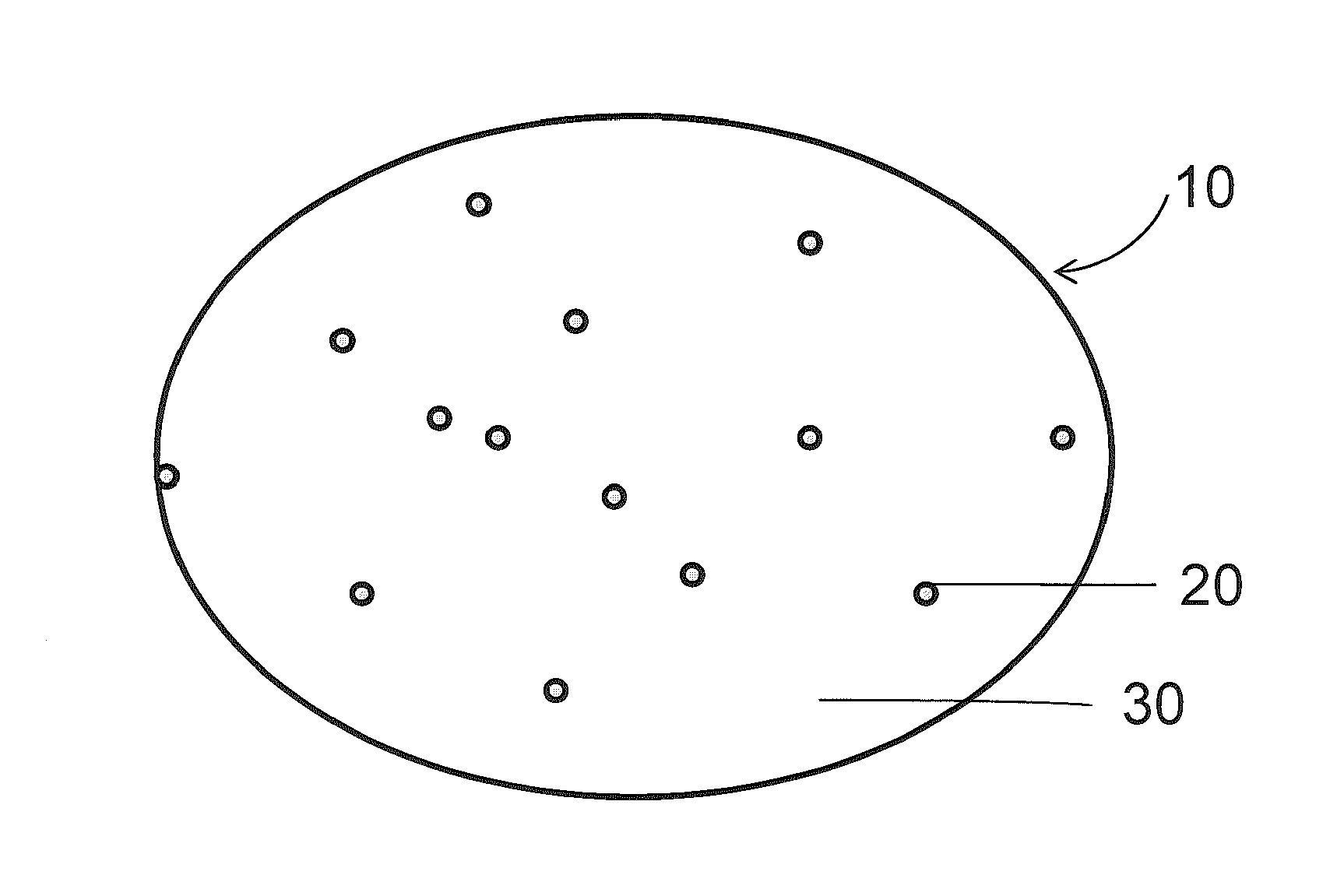

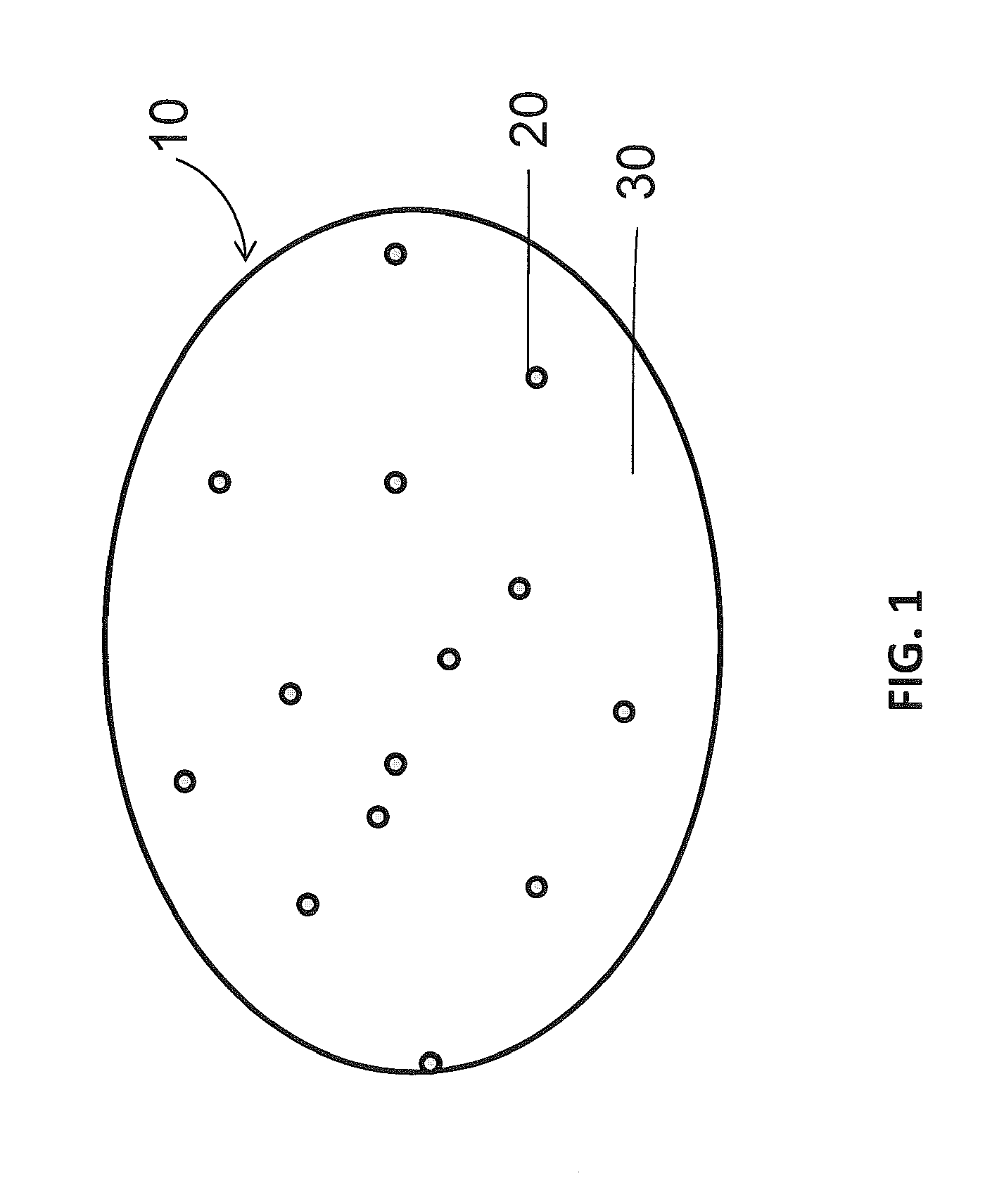

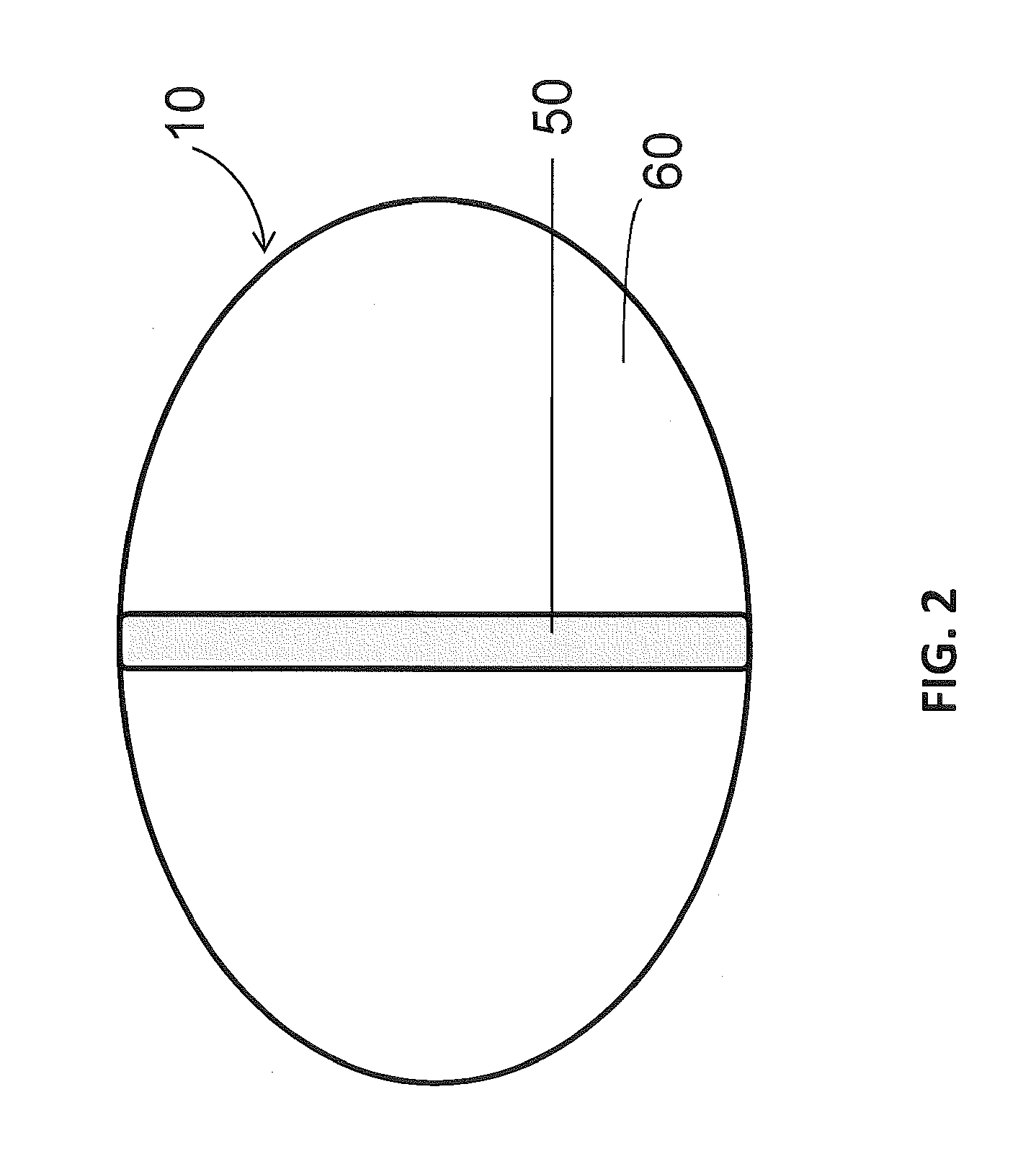

Smokeless tobacco

InactiveUS20080173317A1Improve barrier propertiesObstruct passageTobacco preparationTobacco treatmentSodium bicarbonateEngineering

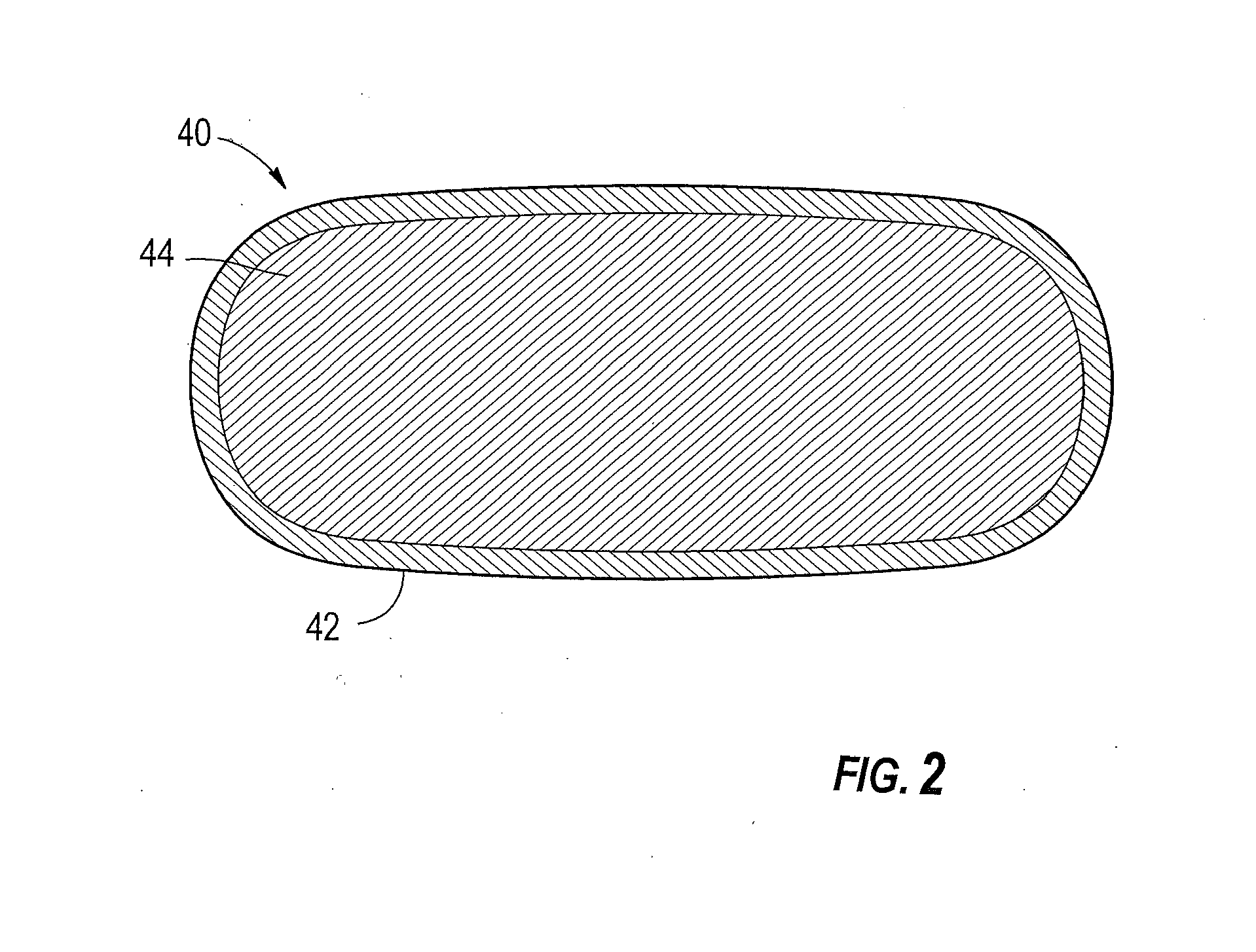

A smokeless tobacco product is provided. A water-permeable pouch containing a tobacco formulation and configured for insertion into the mouth of a user of that product is provided. The tobacco formulation includes granular tobacco and a buffer comprised of sodium carbonate and sodium bicarbonate. An outer packaging material enveloping the pouch is provided and is sealed so as to allow a controlled environment to be maintained within.

Owner:R J REYNOLDS TOBACCO COMPANY

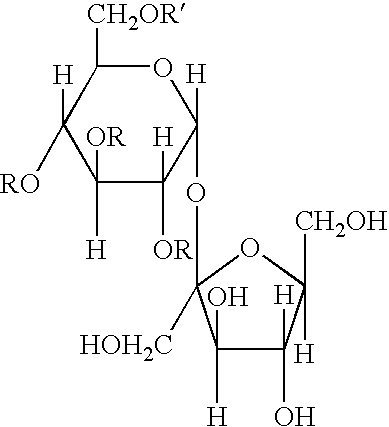

Method of reducing the sucrose ester concentration of a tobacco mixture

InactiveUS7025066B2Altering flavorAltering aroma characteristicTobacco preparationTobacco treatmentFlavor3-methylbutyric acid

The flavor and aroma characteristics of the smoke of a tobacco blend incorporating Oriental tobacco are improved by subjecting that blend to heat treatment. Oriental tobacco having a relatively high sucrose ester content is combined with a second dissimilar Oriental tobacco material and / or a non-Oriental tobacco material to form a tobacco mixture, and that mixture is heated for a time and under conditions sufficient to reduce the concentration of sucrose esters in the Oriental tobacco. Tobacco blends having reduced levels of sucrose esters yield smoke that does not possess undesirable off-notes provided by pyrolysis products of those sucrose esters; namely, 2-methylpropionic acid, 3-methylbutyric acid and 3-methylpentanoic acid.

Owner:R J REYNOLDS TOBACCO COMPANY

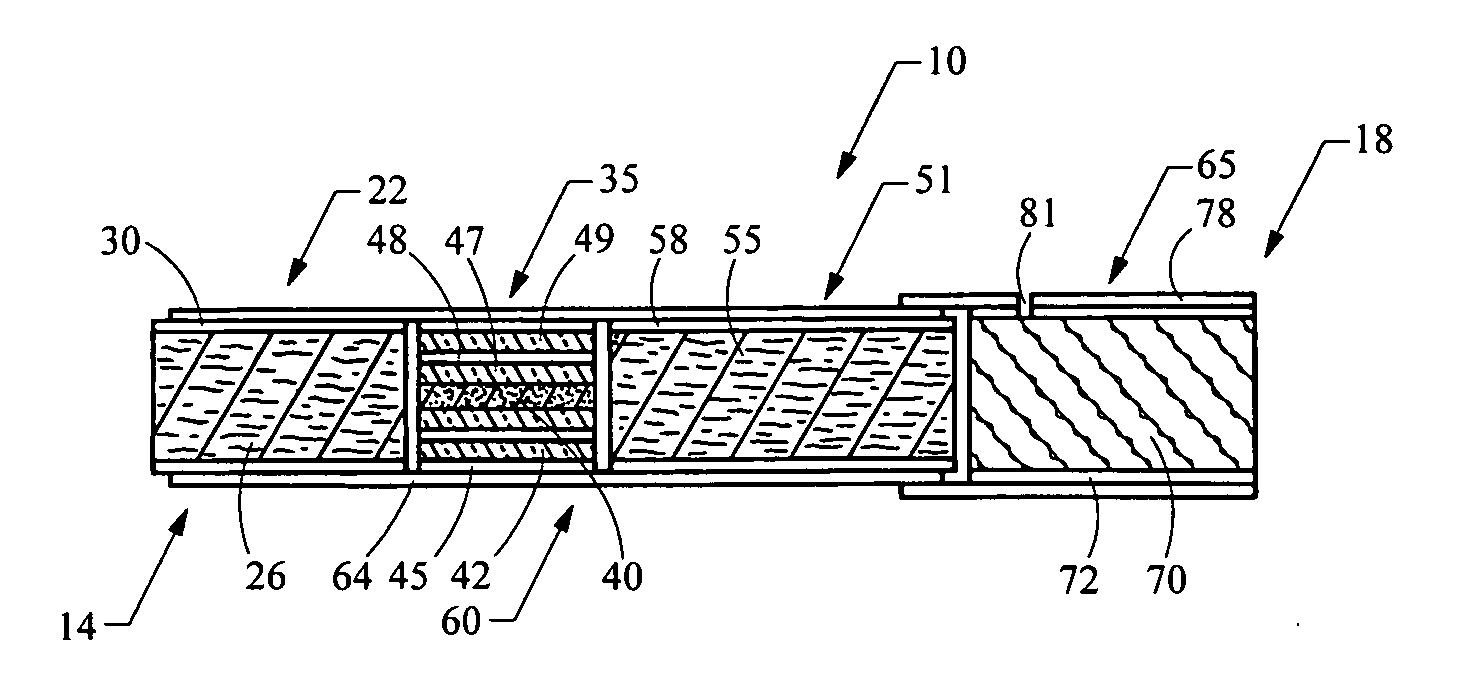

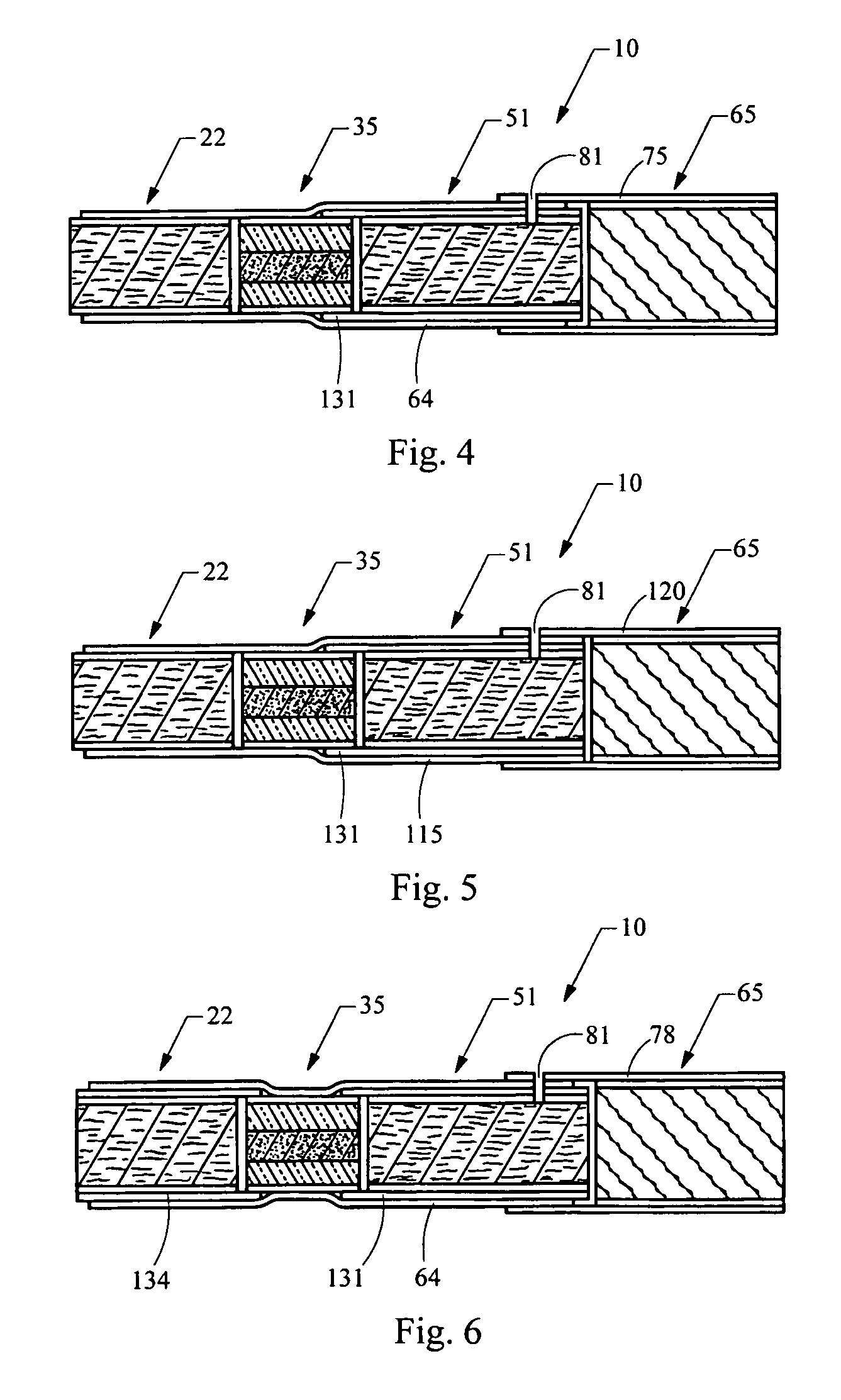

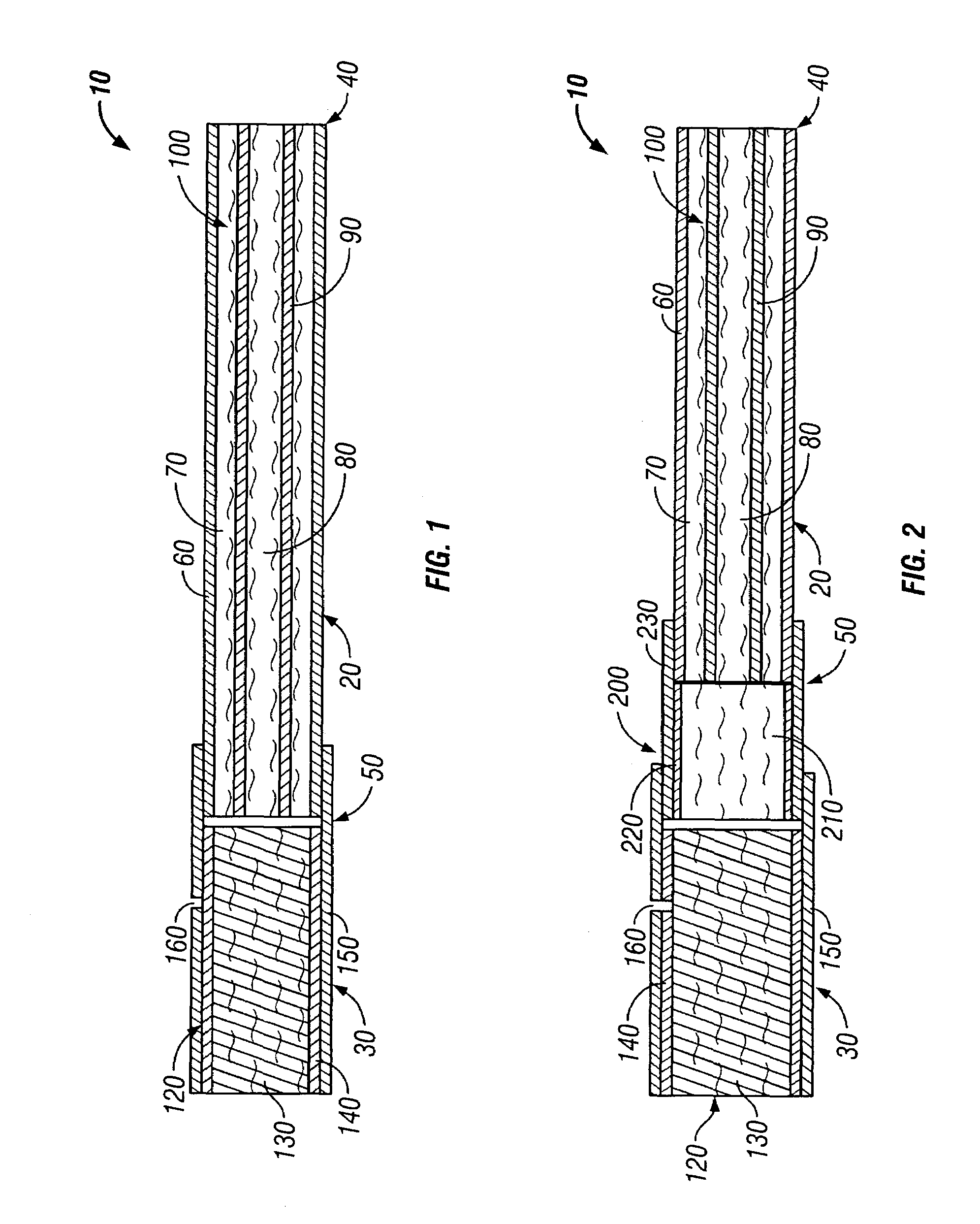

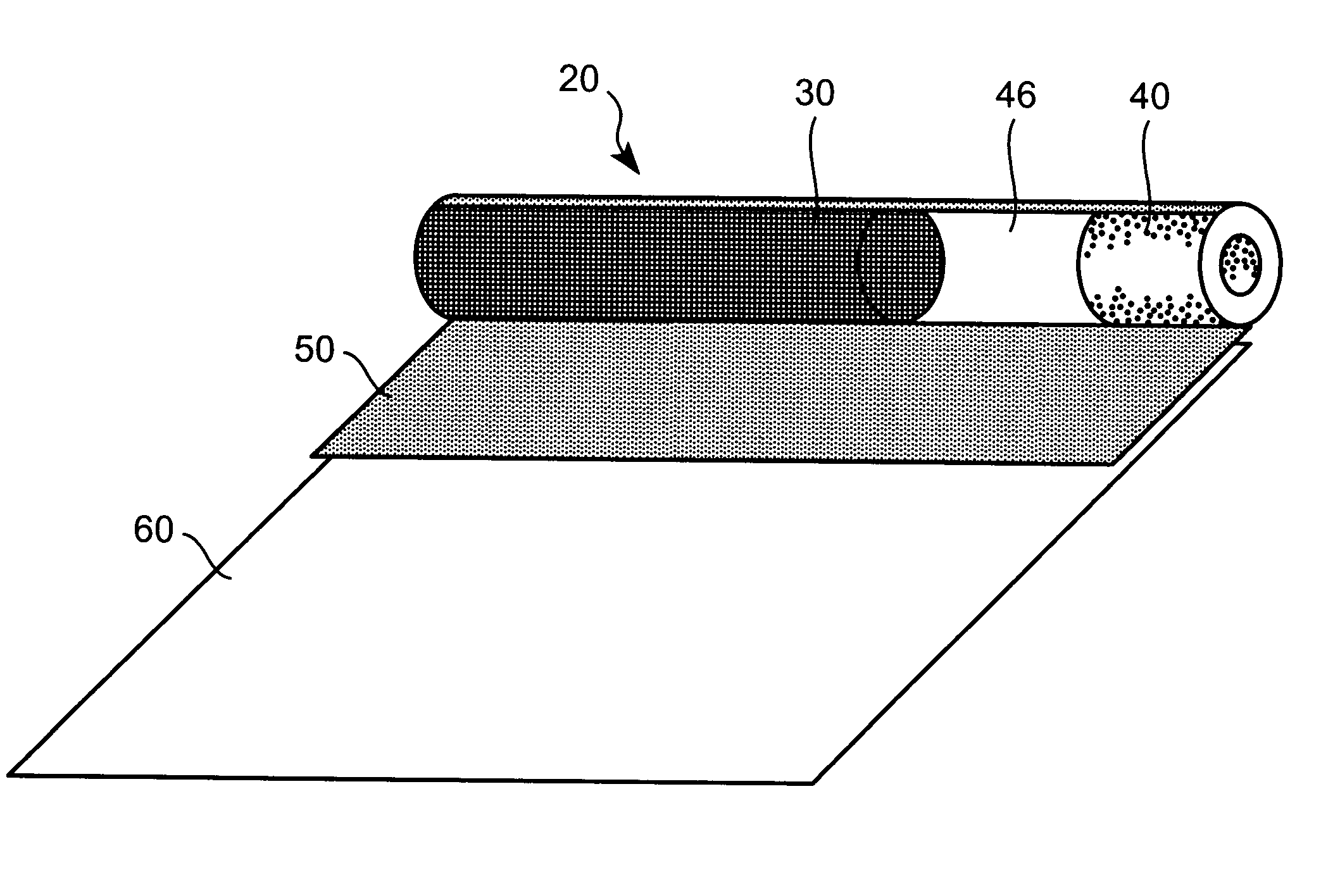

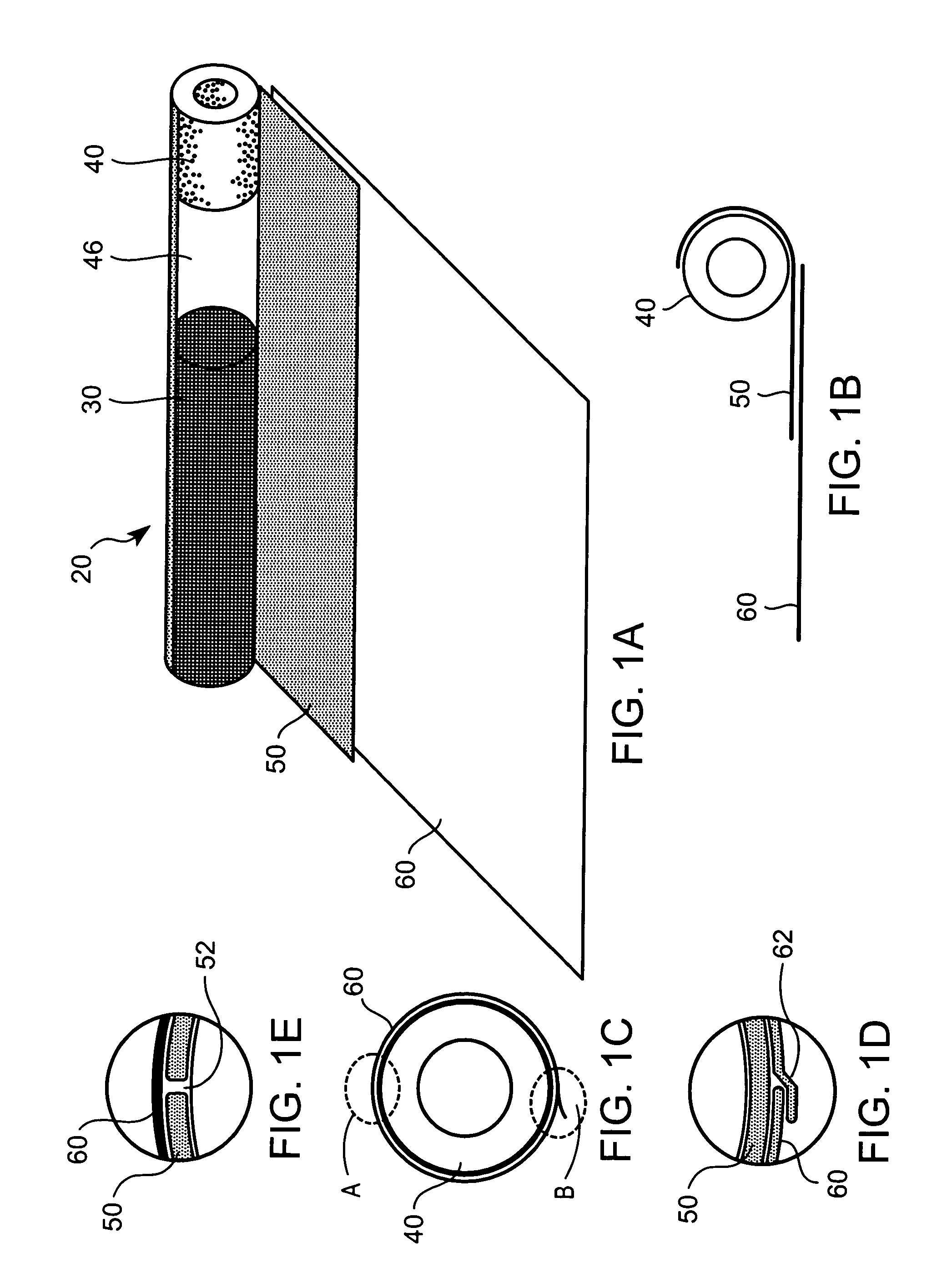

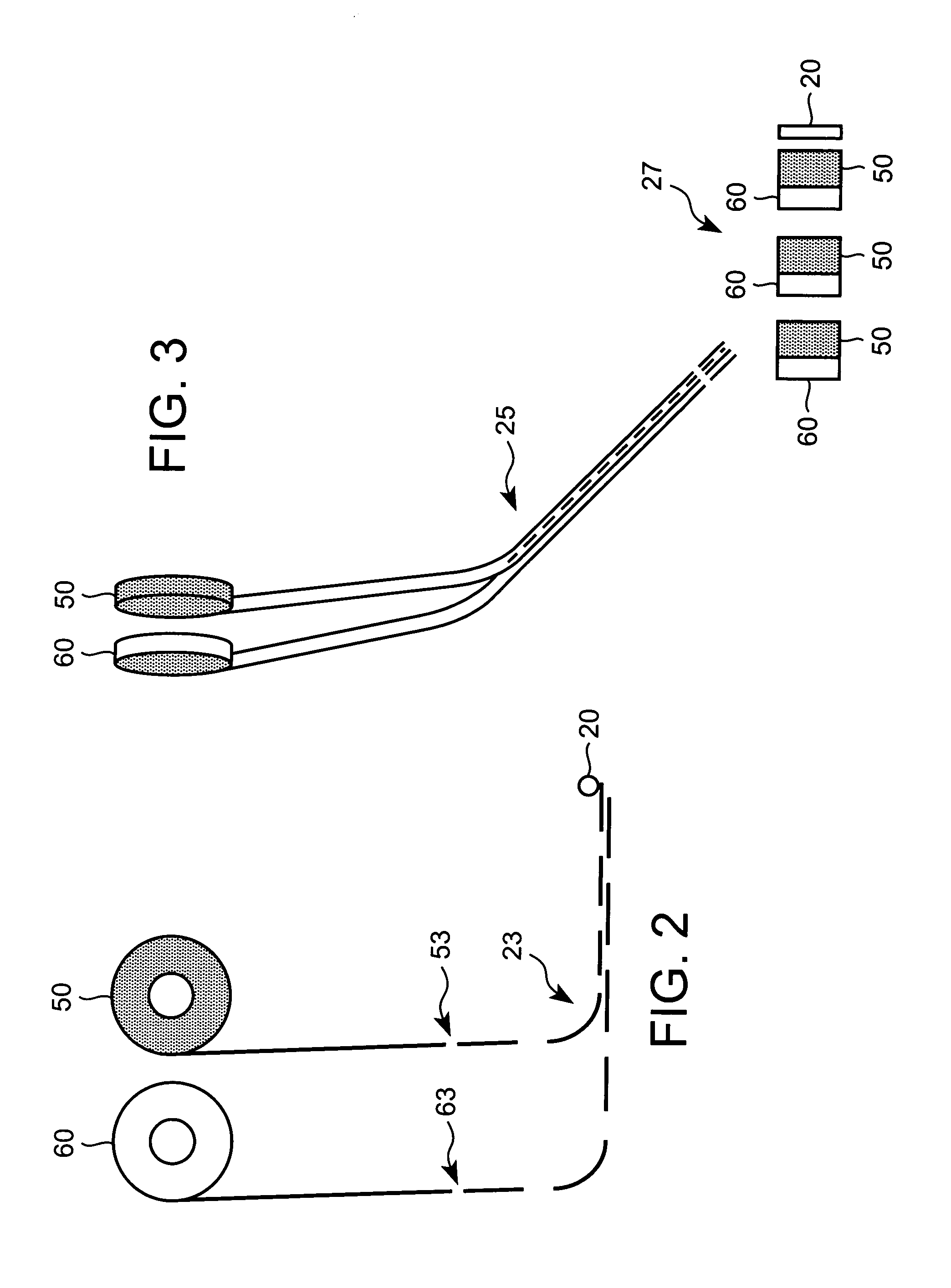

Smoking article

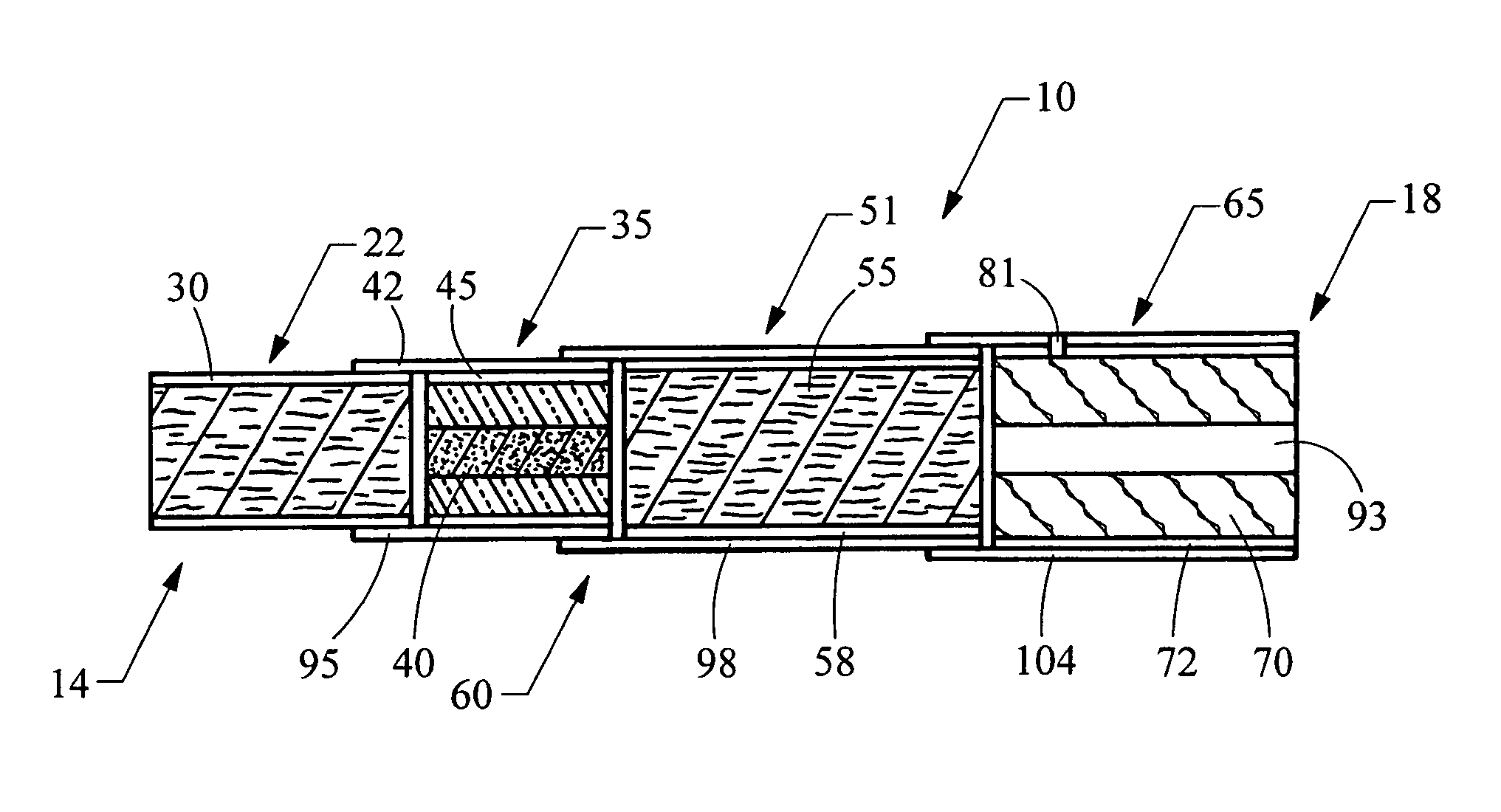

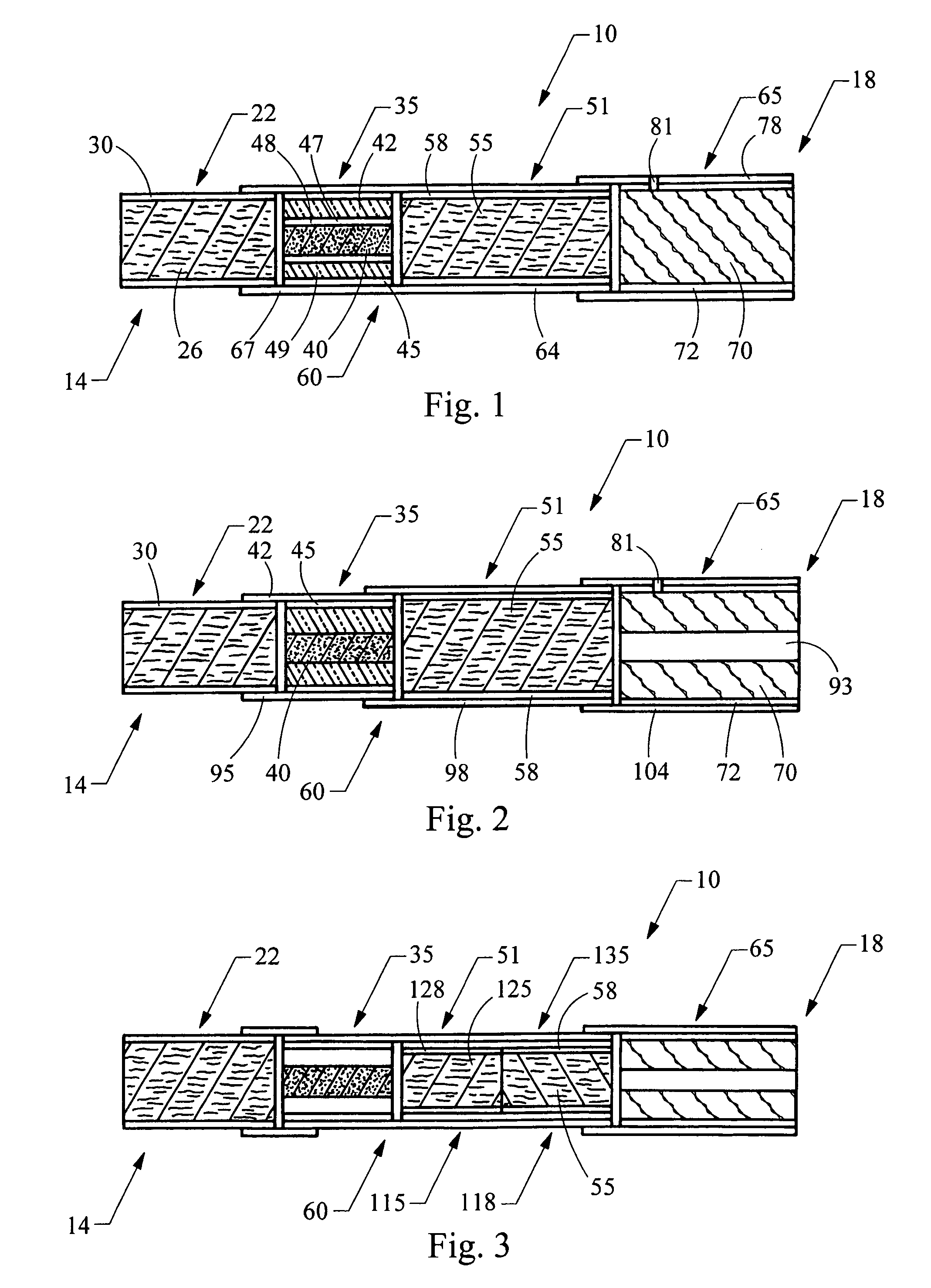

A smoking article, such as a cigarette, comprises a lighting end and a mouth end. The smoking article possesses an aerosol-generation system that includes (i) a heat generation segment, and (ii) an aerosol-generating region or segment. A mouth end piece segment can be located at the mouth end of the smoking article. A segment of tobacco cut filler, gathered tobacco paper, or other type of flavor source material, can be positioned between the mouth end piece segment and the aerosol-generation segment. Optionally, segment composed of tobacco cut filler can be positioned so as to provide a lighting end segment. The smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the mouth end piece segment, the aerosol generation segment, at least a portion of the length of the heat generation segment, any segment located between the mouth end piece and aerosol generation segments, and at least a portion of the length of the optional lighting end segment. Alternatively, the smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the aerosol-generating segment, at least a portion of the length of the heat generation segment, at least a portion of any segment located downstream from the aerosol-generating segment, and at least a portion of the length of the optional lighting end segment, thereby forming a cigarette rod; and the cigarette rod is connected or attached to a filter element using a tipping type of material and arrangement.

Owner:R J REYNOLDS TOBACCO COMPANY

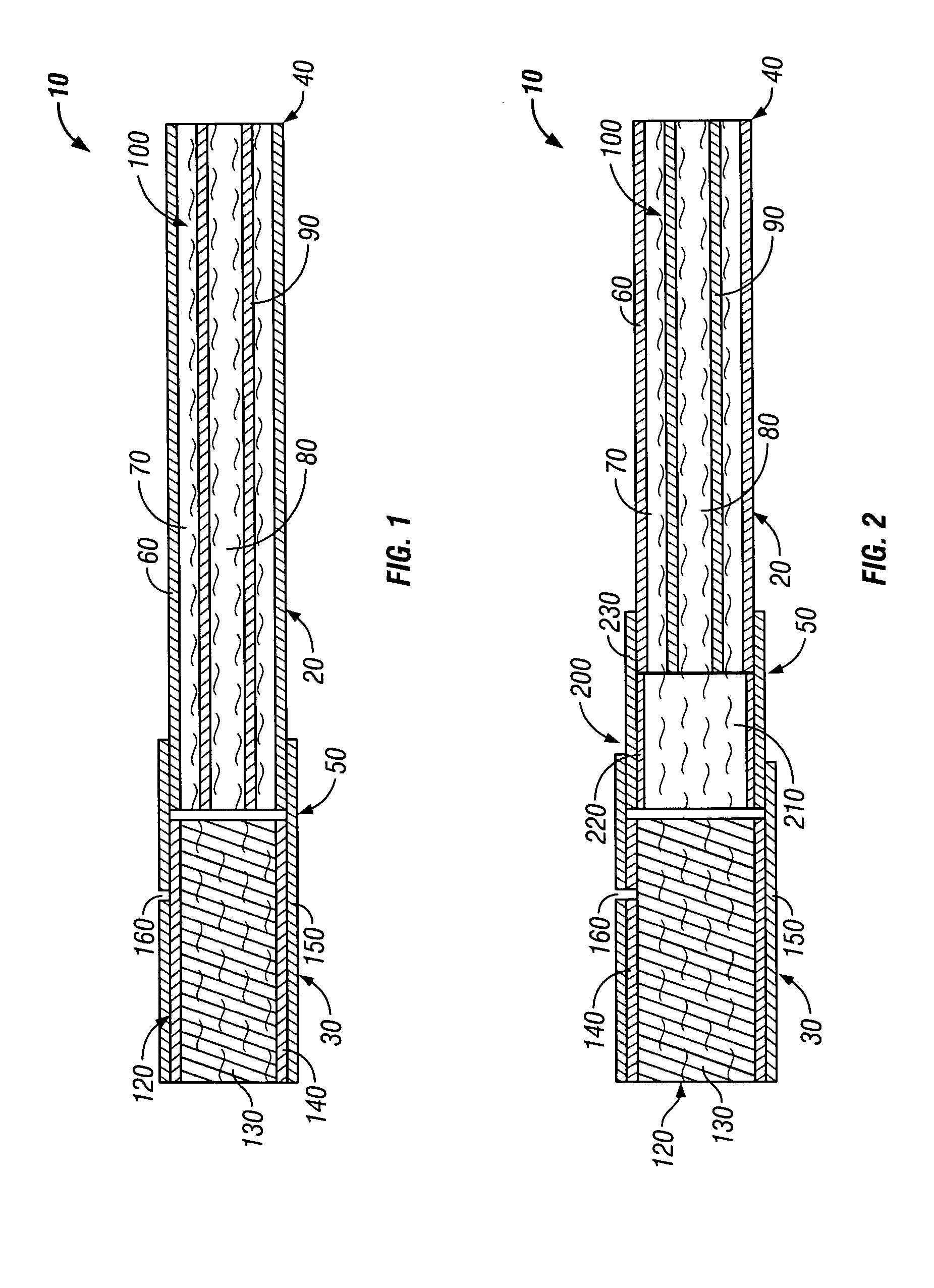

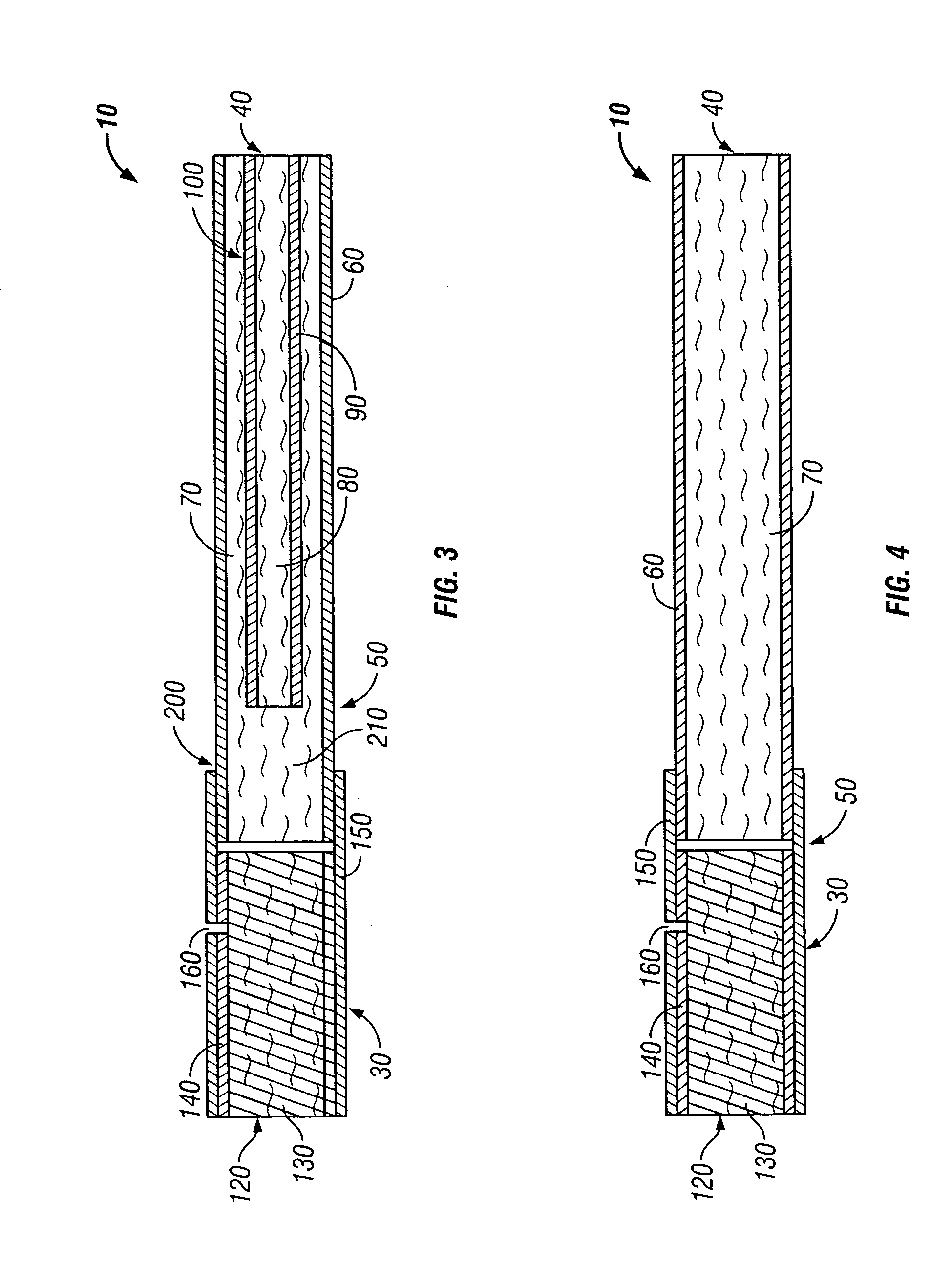

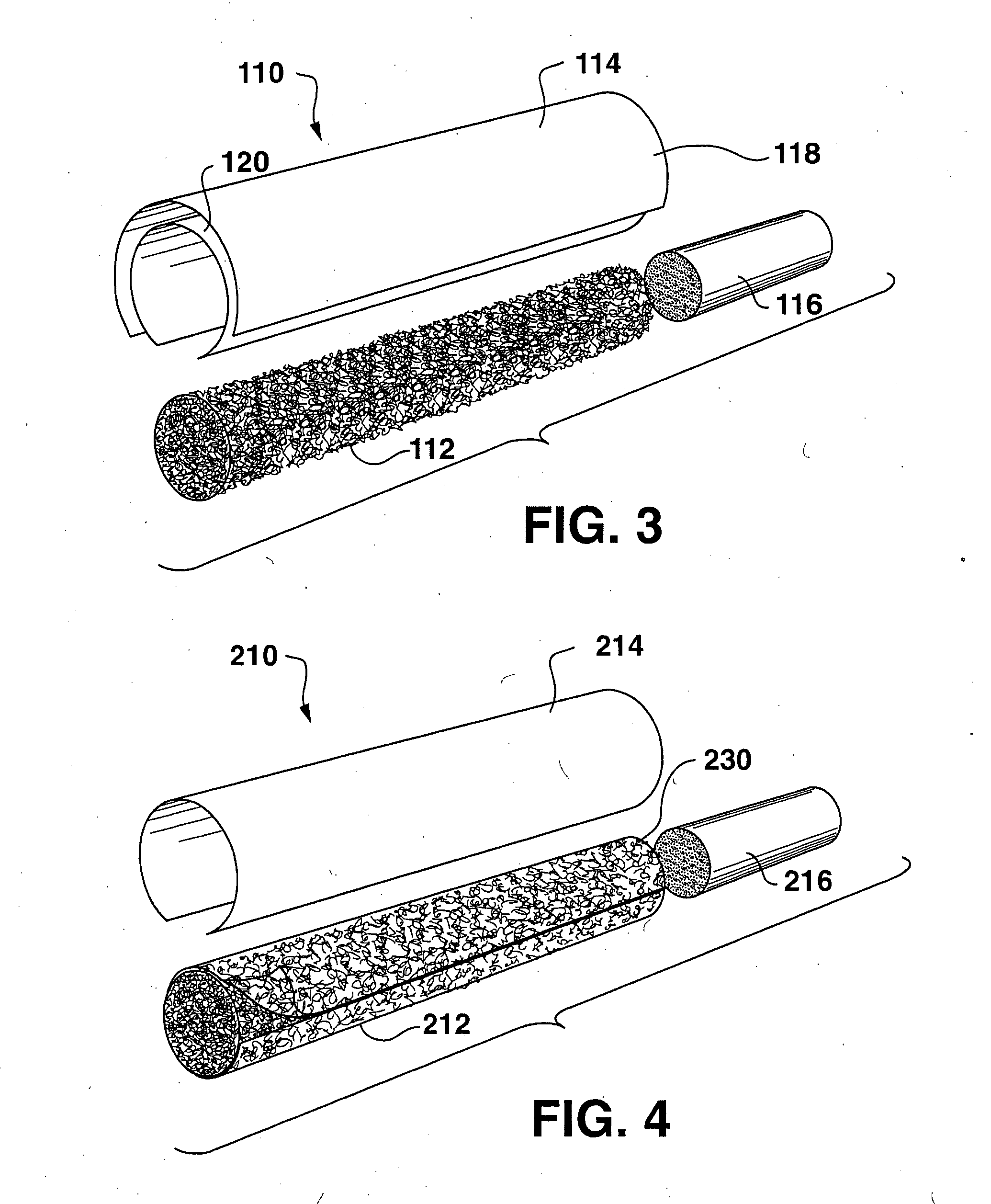

Smokable rod for a cigarette

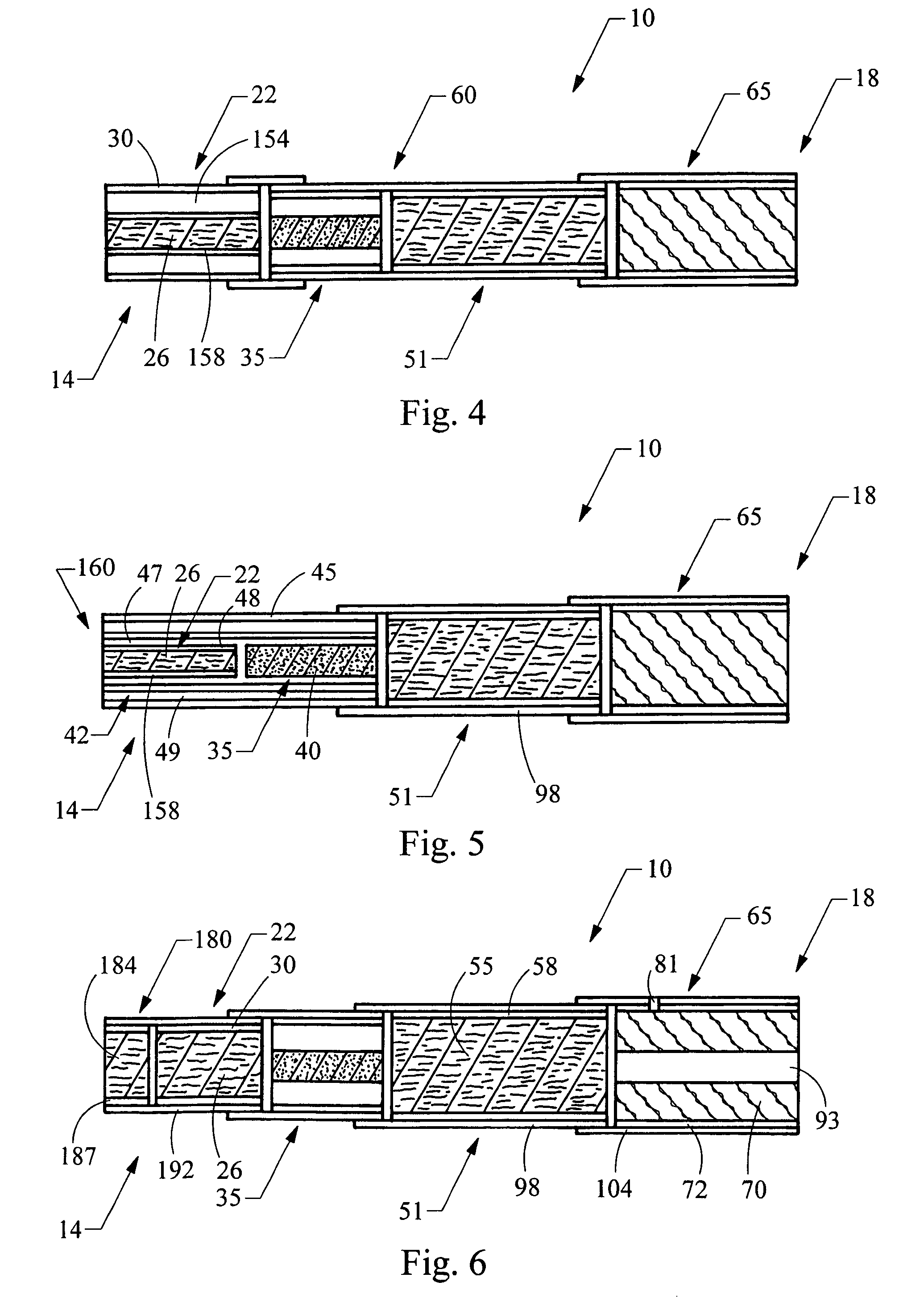

InactiveUS20050066986A1Not easily dislodgedNot overly flakeyTobacco preparationCigar manufactureEngineeringTobacco smoke

A smokable rod for a smoking article, such as a cigarette, possesses a co-axial or concentric construction. A longitudinally extending inner core of tobacco cut filler is positioned within a smokable rod. The outer material that circumscribes the inner core in an annular fashion is composed of a tobacco material treated with an optional burn suppressing agent, and the outer material acts as a substrate for an aerosol forming material. A preferred aerosol forming material is glycerin. An outer paper wrapper circumscribes the length of the smokable rod, and another paper wrapping material also can circumscribe the inner core material. In use, one end of the smokable rod is lit. When the opposite end of the smokable rod is drawn upon, an aerosol composed of tobacco smoke, thermal decomposition products of tobacco, and volatilized aerosol forming material, is provided. Alternatively, a smokable rod can be provided by positioning the tobacco cut filler in the outer annular region, and by constructing the inner core portion using the tobacco material treated with aerosol forming material and an optional burn suppressing agent. Alternatively, a smokable rod possesses a single blend of smokable materials; at least a portion the smokable material being a tobacco material carrying a relatively high amount of aerosol forming material; and optionally at least a portion of the smokable material being in intimate contact with a burn suppressing agent. A filtered cigarette can be produced by attaching a filter element to one end of any of those smokable rods.

Owner:R J REYNOLDS TOBACCO COMPANY

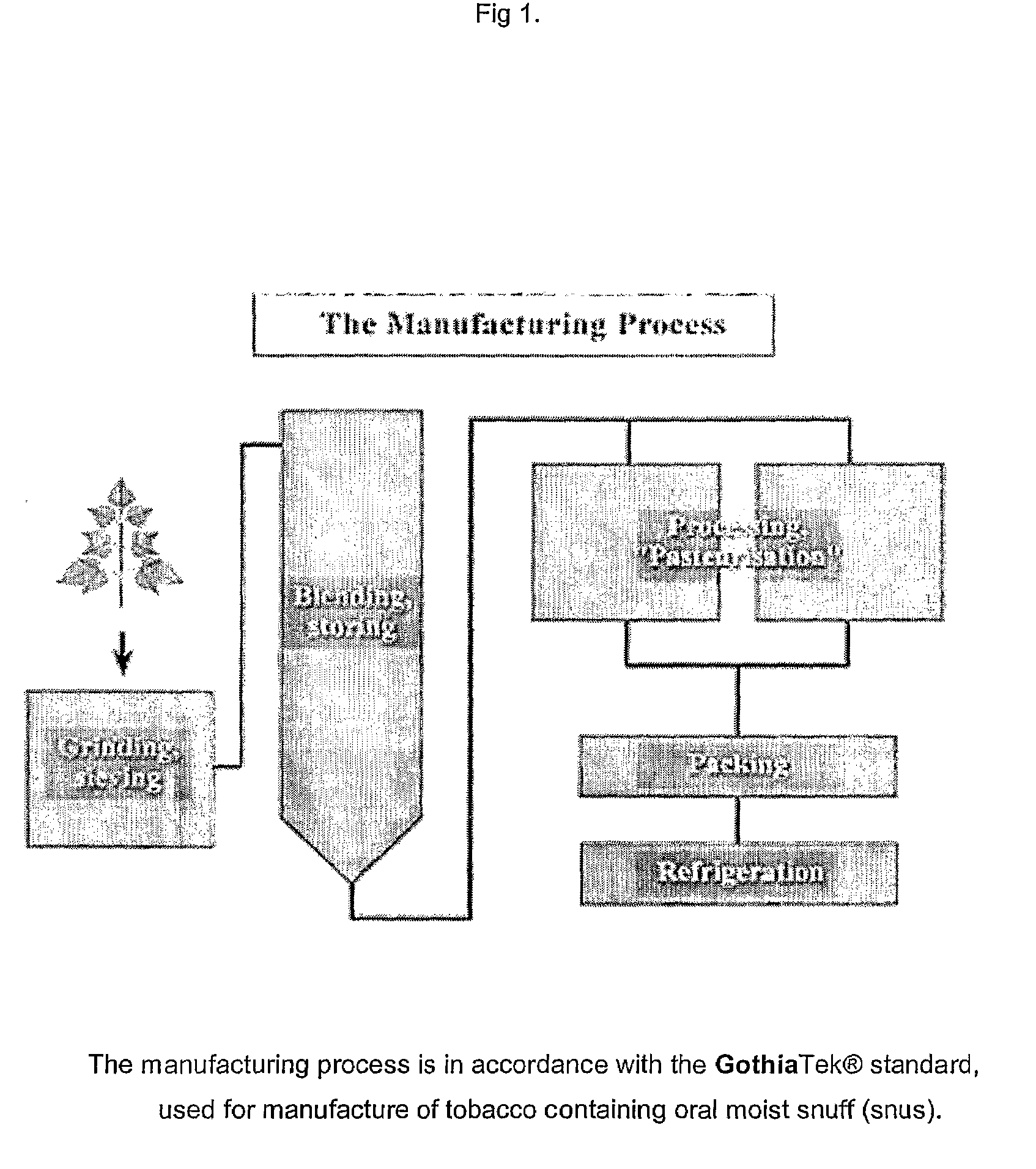

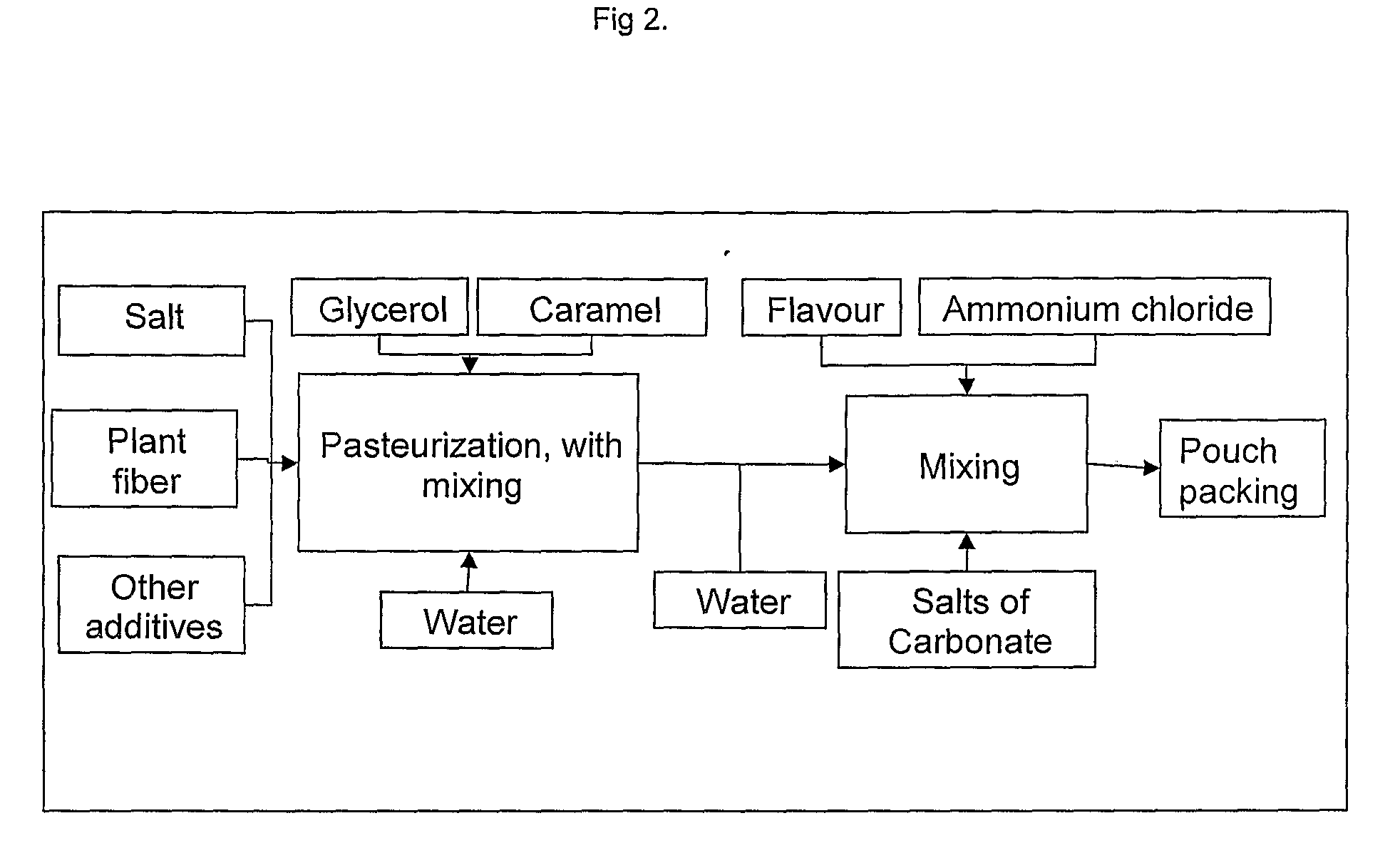

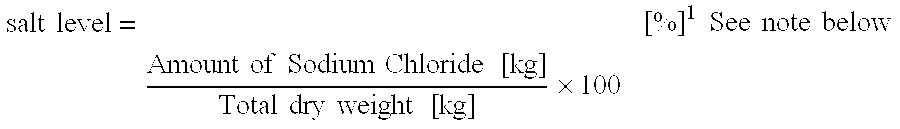

Moist snuff non-tobacco composition and a method for producing thereof

InactiveUS20090065013A1Extended shelf lifeReduced activityTobacco preparationTobacco treatmentMoist snuffFood science

Owner:SWEDISH MATCH NORTH EURO

Tobacco processing

InactiveUS6895974B2Lower Level RequirementsInhibition formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:R J REYNOLDS TOBACCO COMPANY

E-Cigarette With Vitamin Infusion

InactiveUS20100200008A1Prevent negative consequenceImprove health benefitsTobacco preparationTobacco devicesInhalationEnvironmental health

Owner:TAIEB ELI

Electronic Cigarette Refilling Apparatus

InactiveUS20120167906A1Reduced adverse health consequenceEasily and quickly refilledTobacco preparationTobacco pipesEngineeringElectronic cigarette

An electronic cigarette including an atomizer, a cartridge, a mouthpiece, a power switch, and an electronic cigarette refilling apparatus for use therein is disclosed. A method of dispensing a liquid into an electronic cigarette and a method of inhaling a vapor from an electronic cigarette are also disclosed.

Owner:GYSLAND DAVID

Smoking article

Owner:R J REYNOLDS TOBACCO COMPANY

Smoking article

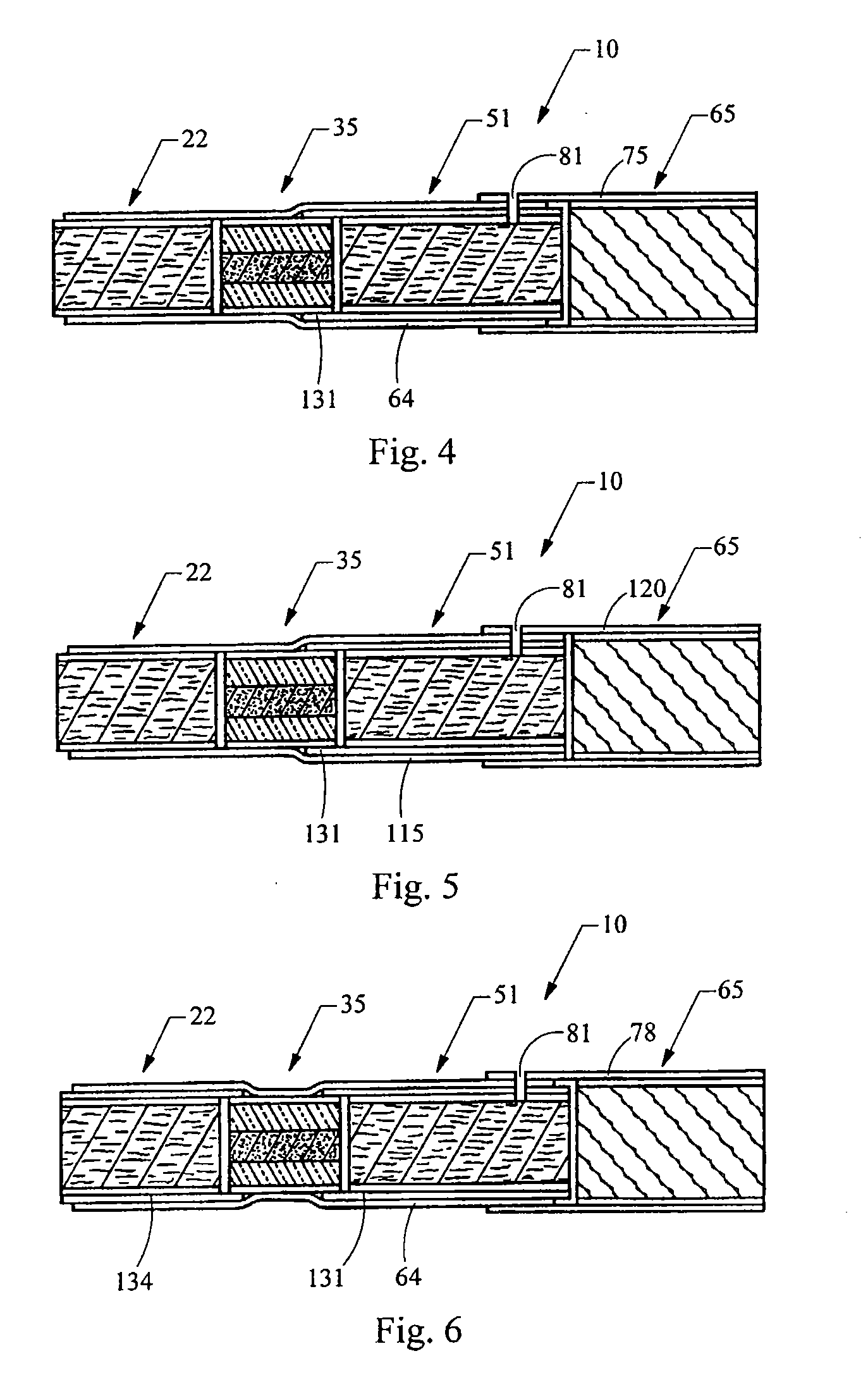

ActiveUS20070215168A1Reduce amountCarbon reductionTobacco preparationTobacco treatmentEngineeringFood flavor

A smoking article, such as a cigarette, includes a carbonaceous heat source. A mouth end piece segment is located at the mouth end of the smoking article, and the mouth end piece segment allows the smoking article to be placed in the mouth of the smoker to be drawn upon. The smoking article further incorporates an aerosol-generating segment located between the heat generation segment and the mouth end piece segment. The aerosol-generating segment incorporates an aerosol-forming material (e.g., glycerin and flavors). The heat generation segment is in a heat exchange relationship with the aerosol-generating region such that heat generated by the burning fuel element acts to volatilize aerosol-forming material for aerosol formation. The carbonaceous heat source is in intimate contact with coarse, fine or ultrafine particles of materials such as cerium oxide, or mixtures of cerium oxide and palladium chloride.

Owner:R J REYNOLDS TOBACCO COMPANY

Smoking Article

A smoking article, such as a cigarette, comprises a lighting end and a mouth end. The smoking article possesses an aerosol-generation system that includes (i) a heat generation segment, and (ii) an aerosol-generating region or segment. A mouth end piece segment can be located at the mouth end of the smoking article. A segment of tobacco cut filler, gathered tobacco paper, or other type of flavor source material, can be positioned between the mouth end piece segment and the aerosol-generation segment. Optionally, segment composed of tobacco cut filler can be positioned so as to provide a lighting end segment. The smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the mouth end piece segment, the aerosol generation segment, at least a portion of the length of the heat generation segment, any segment located between the mouth end piece and aerosol generation segments, and at least a portion of the length of the optional lighting end segment. Alternatively, the smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the aerosol-generating segment, at least a portion of the length of the heat generation segment, at least a portion of any segment located downstream from the aerosol-generating segment, and at least a portion of the length of the optional lighting end segment, thereby forming a cigarette rod; and the cigarette rod is connected or attached to a filter element using a tipping type of material and arrangement.

Owner:R J REYNOLDS TOBACCO COMPANY

Low-density tobacco filler and a method of making low-density tobacco filler and smoking articles therefrom

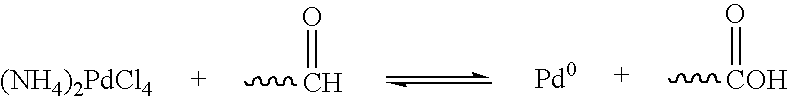

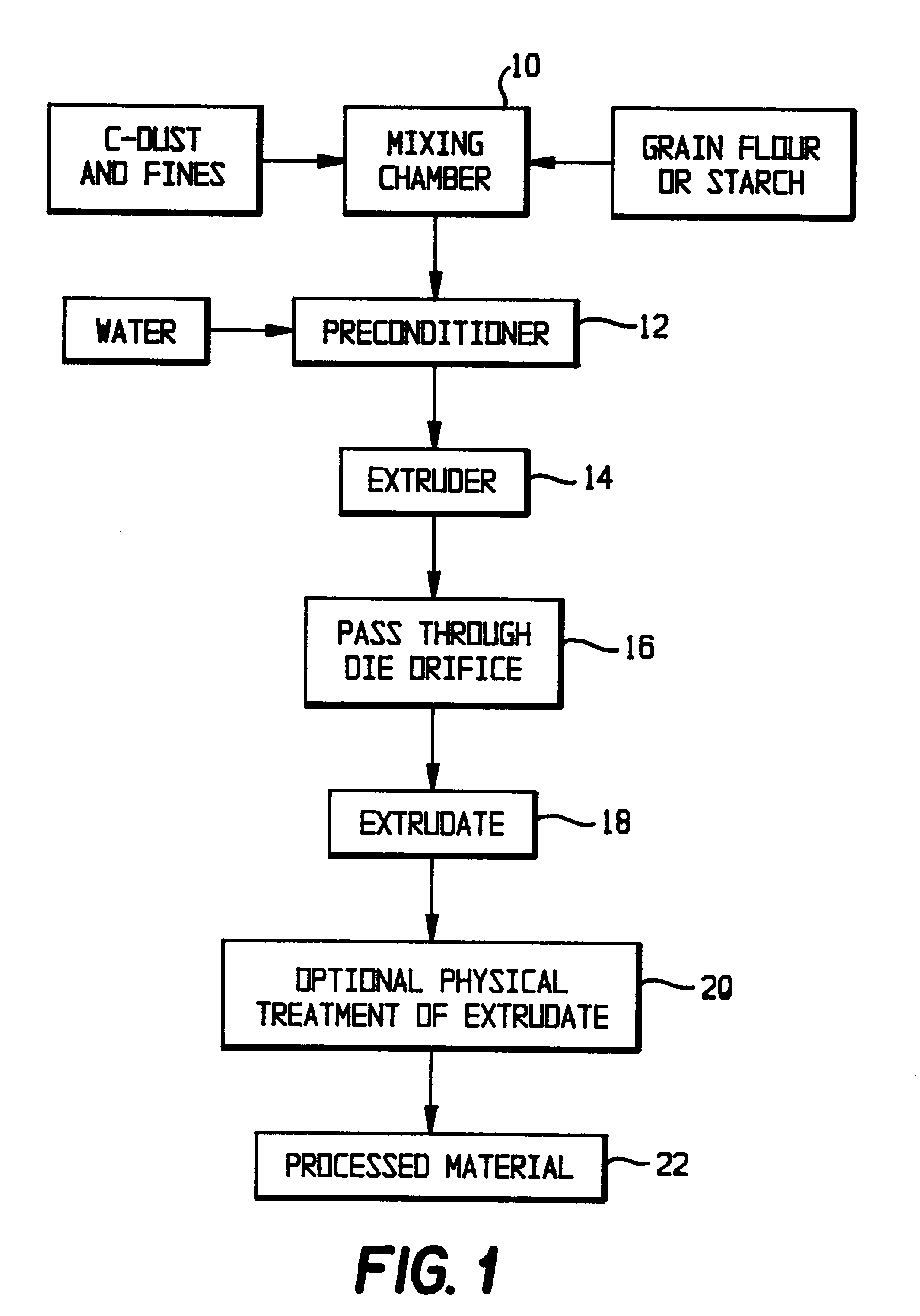

InactiveUS6182670B1Pleasing tobacco odorImprove the smoke effectTobacco preparationDough treatmentSolventLow density

A low-density filler material for cigarettes from either a low-density tobacco composition or an extruded grain or starch composition. The low-density tobacco composition and a method of making the low-density tobacco composition by extruding a mixture of tobacco and flour or tobacco and starch under conditions whereby the solvent in the extruded mixture flashes into vapor upon release from the extrusion head. The low-density tobacco composition is formed without the aid of an added binder. The low-density flour or starch material and a method of making it by extruding flour or starch with a filler material such as calcium carbonate under conditions whereby the solvent in the extruded mixture flashes into vapor upon extrusion through the orifice die. The extruded composition can then be cut and used in place of cut tobacco filler.

Owner:R J REYNOLDS TOBACCO COMPANY

Methods for hindering formation of tobacco-specific nitrosamines

ActiveUS7650892B1Inhibition formationHindering TSNA formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:AMERICAN SNUFF CO LLC

Thermal treatment process for tobacco materials

ActiveUS20100300463A1Alter natureAlter characterTobacco preparationTobacco treatmentArgininePhenylalanine

A method of thermally processing a tobacco material is provided, the method including the steps of (i) mixing a tobacco material, water, and an additive selected from the group consisting of lysine, glycine, histidine, alanine, methionine, glutamic acid, aspartic acid, proline, phenylalanine, valine, arginine, di- and trivalent cations, asparaginase, saccharides, phenolic compounds, reducing agents, compounds having a free thiol group, oxidizing agents, oxidation catalysts, plant extracts, and combinations thereof, to form a moist tobacco mixture; (ii) heating the moist tobacco mixture at a temperature of at least about 60° C. to form a heat-treated tobacco mixture; and (iii) incorporating the heat-treated tobacco mixture into a tobacco product. Heat-treated tobacco composition prepared according to the method are also provided, such as heat-treated smokeless tobacco composition comprising a tobacco material, water, flavorant, binder, and filler, the heat-treated smokeless tobacco composition having an acrylamide content of less than about 2000 ppb.

Owner:R J REYNOLDS TOBACCO COMPANY

Remelted ingestible products

ActiveUS20130274296A1Reduce exposureHigh heating temperatureBiocideTobacco preparationSemi solidTemperature sensitive

A method of preparing an orally ingestible hard boiled product, comprising: i) heating a sugar material to a first temperature sufficient to liquefy the sugar material; ii) cooling the liquefied sugar material to provide a cooled sugar material having a solid or semi-solid form; iii) heating the cooled sugar material to a second temperature, which is lower than the first temperature; iv) combining the sugar material with one or more temperature sensitive ingredients before, during, or after said heating step iii), but after said cooling step ii), such that an intimate mixture of the second liquefied sugar material and the one or more temperature sensitive ingredients is provided; and v) cooling the intimate mixture to form an orally ingestible product. Orally ingestible hard boiled products prepared according to this method are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Tobacco having reduced nicotine and nitrosamines

InactiveUS20050072047A1Reduce the amount requiredImprove availabilityBiocideTobacco preparationNicotiana tabacumJasmonate

Aspects of the present invention concern tobacco having reduced nicotine and nitrosamines, which is used to manufacture consumer tobacco products, and methods to produce such tobacco. More specifically, embodiments include methods to reduce nicotine and nitrosamines in tobacco crops by applying auxin, auxin analogs, and jasmonate antagonists during the cultivation of such tobacco crops. Tobacco generated using said methods and consumer tobacco products obtained therefrom are also embodiments.

Owner:VECTOR TOBACCO LLC

Smokable rod for a cigarette

ActiveUS7503330B2Not easily dislodgedNot overly flakeyTobacco preparationNon-fibrous pulp additionEngineeringTobacco smoke

A smokable rod for a smoking article, such as a cigarette, possesses a co-axial or concentric construction. A longitudinally extending inner core of tobacco cut filler is positioned within a smokable rod. The outer material that circumscribes the inner core in an annular fashion is composed of a tobacco material treated with a burn suppressing agent, and the outer material acts as a substrate for an aerosol forming material. In use, one end of the smokable rod is lit, and the tobacco cut filler of the inner core burns to yield tobacco smoke. The outer material smolders, and hence thermal decomposition products of the outer tobacco material and volatilized aerosol forming material are produced. When the opposite end of the smokable rod is drawn upon, an aerosol composed of tobacco smoke, thermal decomposition products of tobacco, and volatilized aerosol forming material, is provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Smoking articles having reduced carbon monoxide delivery

InactiveUS20050005947A1Reduce penetrationReduce ignition proclivityTobacco preparationNon-fibrous pulp additionCarbonateReducing agent

The present invention is directed to smoking articles having reduced carbon monoxide delivery are described. A carbon monoxide reducing agent is incorporated into the smoking article in order to reduce carbon monoxide levels in mainstream smoke. The carbon monoxide reducing agent may be, for instance, in metal oxide or in metal carbonate. The carbon monoxide reducing agent may be incorporated into a wrapper and / or into a column of smokable filler that are used to construct the smoking article.

Owner:SCHWEITZER MAUDUIT INT INC

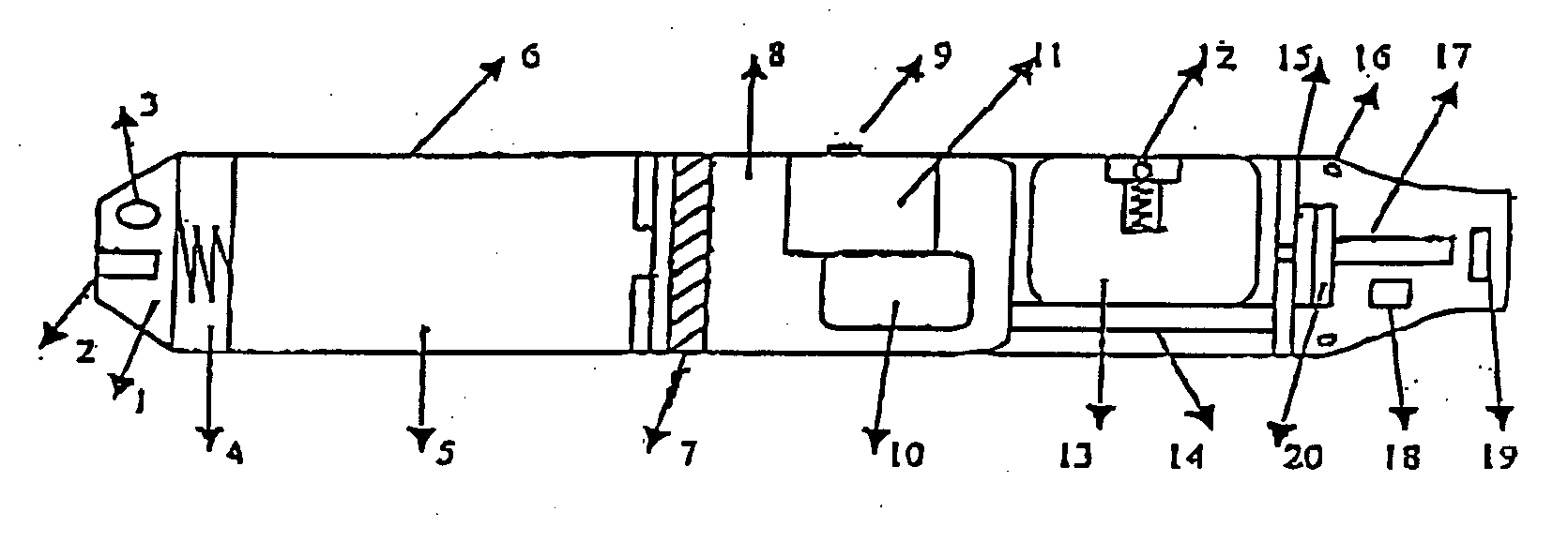

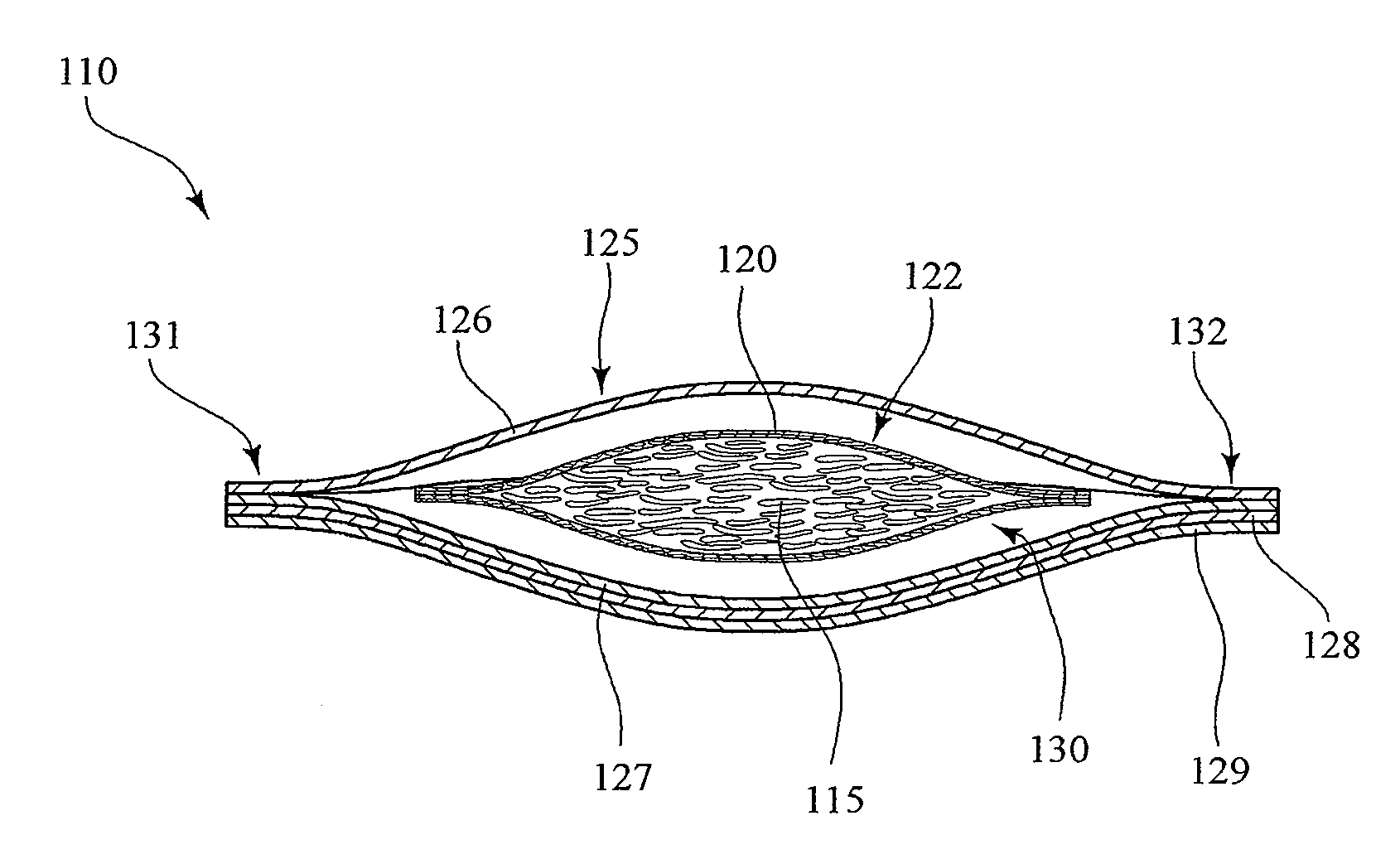

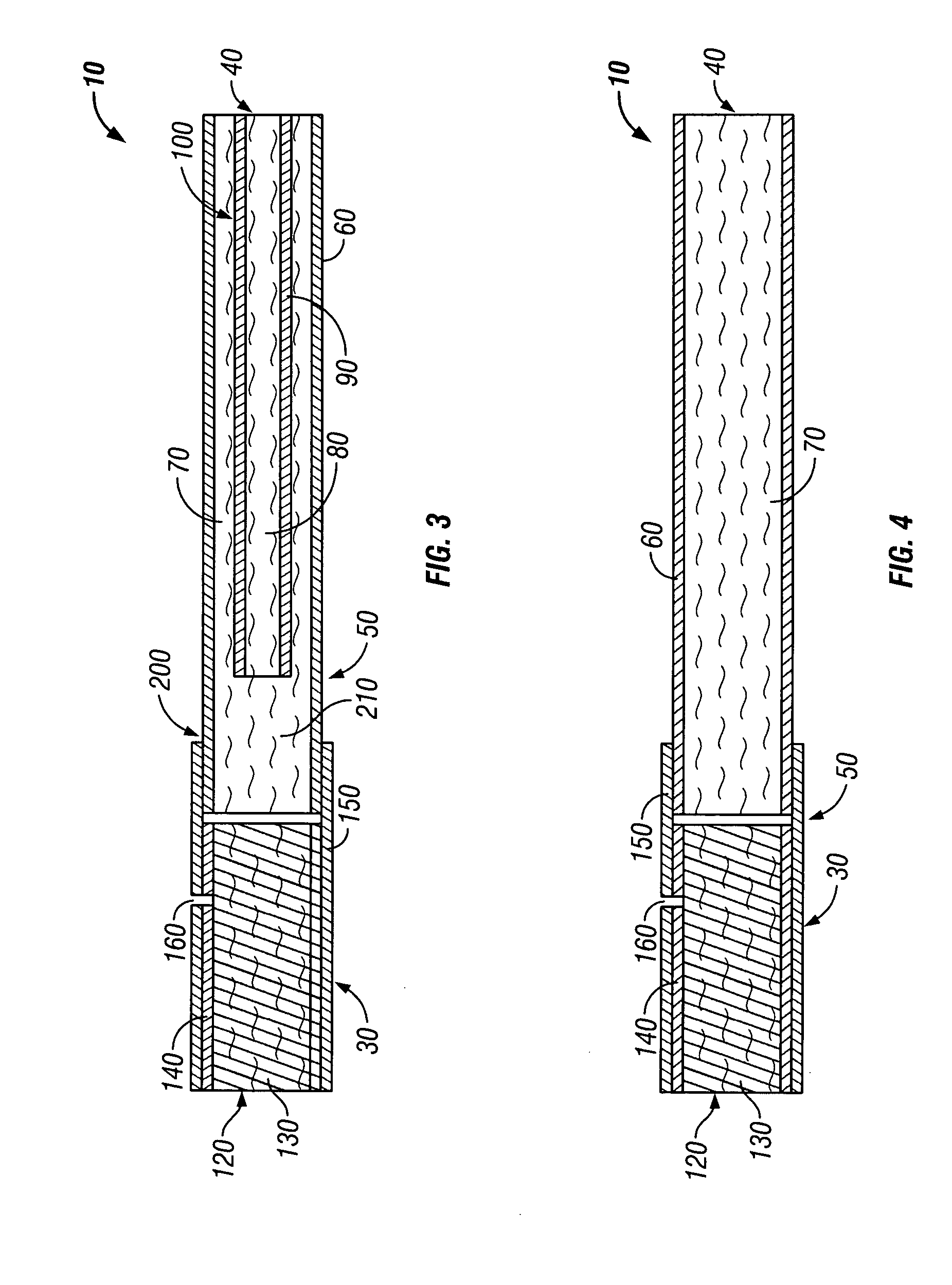

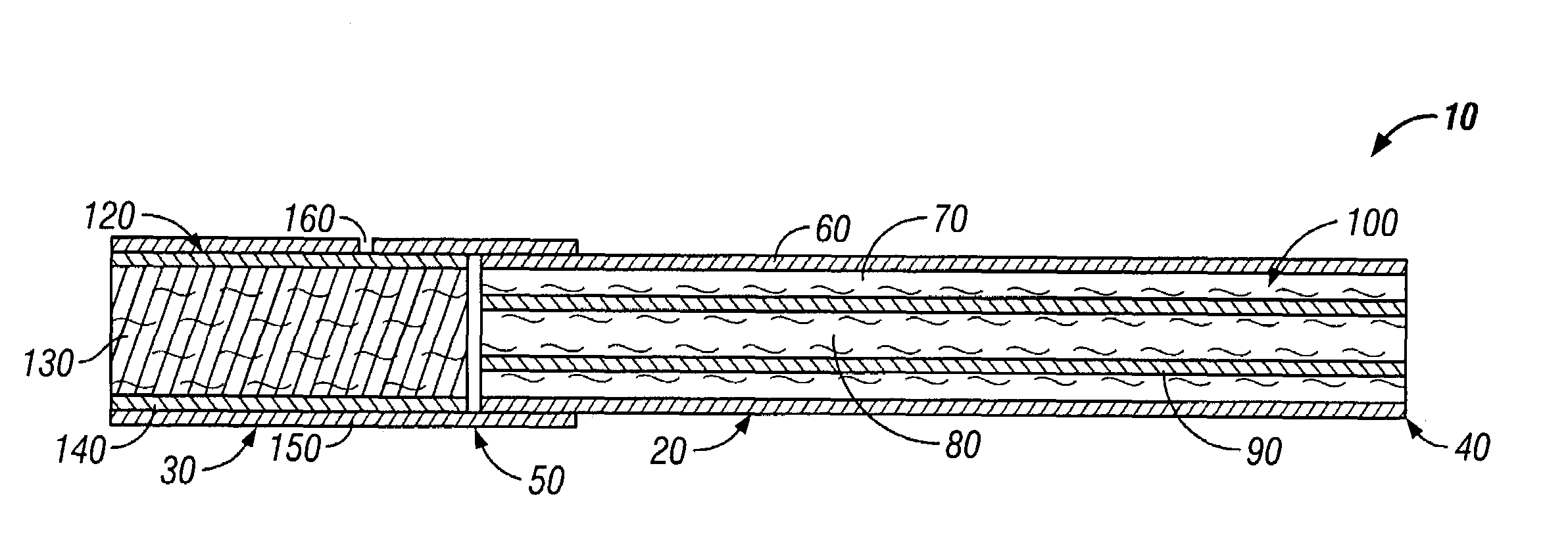

Opposed seam electrically heated cigarette smoking system

An electrically heated cigarette smoking system includes a cigarette that is formed with a tobacco rod portion, a filter tube portion, a tobacco mat layer wrapped around the tobacco rod portion and the filter tube portion with opposite ends of the tobacco mat layer abutting along a seam parallel to the central axis of the cigarette and cigarette paper wrapped around the tobacco mat layer and bonded to itself along an overlapped seam that is offset from the seam of the tobacco mat layer. The method of manufacturing the cigarette includes wrapping the tobacco mat layer and the cigarette paper around the tobacco rod portion and the filter tube portion on a single, high-speed machine.

Owner:PHILIP MORRIS USA INC

Cannabidiol liquid composition for smoking

InactiveUS20150181924A1Tobacco preparationTobacco treatmentElectronic cigaretteIntensive care medicine

This application discloses a cannabidiol liquid composition for use in an electronic cigarette smoking device. The cannabidiol liquid composition may be used for pulmonary administration of cannabidiol for more effective absorption. A method of use for the cannabidiol liquid composition is also disclosed.

Owner:HDDC HLDG

Method for treating plants with probiotics

InactiveUS20130269719A1Reduction in asparagine contentReduce acrylamide contentTobacco preparationTobacco treatmentNicotiana tabacumTobacco product

Owner:R J REYNOLDS TOBACCO COMPANY

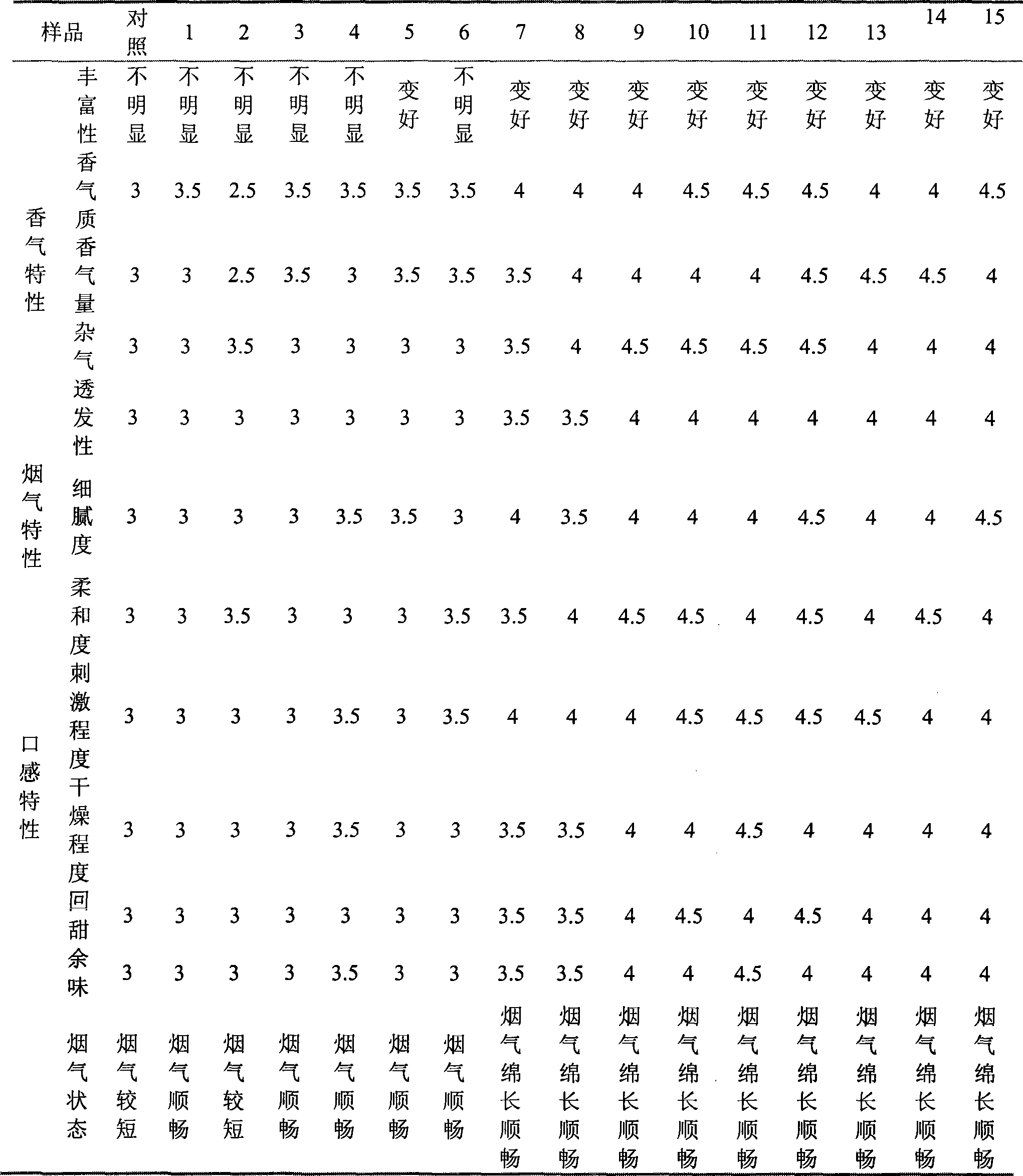

Ferment for tobacco fermentation and use thereof

ActiveCN101416778AIncrease aromaReduce mistTobacco preparationFungiNicotiana tabacumBacillus aryabhattai

The invention discloses a hametz used for fermenting tobacco and applications thereof. The hametz is characterized by comprising three strains of Bacillus subtilis, lactobacillus and microzyme, the viable count ratio of which is 10 to 50: 2 to 30: 2 to 30. The hametz can ferment waste material of the tobacco or the flavor used for producing natural cigarettes by using the tobacco and can be used for tobacco fermentation. The flavor used for the natural cigarettes prepared by the hametz has a velvet fragrance and can remarkably increase the fragrance, reduce the unpurified gas and reduce the thrill as well when the flavor is used in the cigarettes, thus leading the smoke gas to be lingering and smooth. The hametz used for fermenting tobacco leaves can remarkably shorten the alcoholizing time and improve the quality of the tobacco leaves.

Owner:SOUTH CHINA UNIV OF TECH

Smoking paper for smoking article

InactiveUS6138684AReduce decreaseExcellent in optical characteristicTobacco preparationNon-fibrous pulp additionPulp and paper industrySmoke paper

PCT No. PCT / JP96 / 01630 Sec. 371 Date May 7, 1997 Sec. 102(e) Date May 7, 1997 PCT Filed Jun. 14, 1996 PCT Pub. No. WO97 / 09483 PCT Pub. Date Mar. 13, 1997The paper for rolling a smoking article of the present invention contains particle-form calcium carbonate (30 to 60 wt %), calcined clay (5 to 30 wt %) and pulp. Furthermore, an alkaline metal salt is contained as a chemical additive. In addition, kaolin is contained in the paper. The basis weight of the paper falls within the range of 20 to 70 g / m2. Optical characteristics of the paper and the burning characteristics and ash characteristics of a cigarette are improved and the side stream smoke is reduced.

Thermal treatment process for tobacco materials

ActiveUS8434496B2Alter natureAlter characterTobacco preparationTobacco treatmentArgininePhenylalanine

A method of thermally processing a tobacco material is provided, the method including the steps of (i) mixing a tobacco material, water, and an additive selected from the group consisting of lysine, glycine, histidine, alanine, methionine, glutamic acid, aspartic acid, proline, phenylalanine, valine, arginine, di- and trivalent cations, asparaginase, saccharides, phenolic compounds, reducing agents, compounds having a free thiol group, oxidizing agents, oxidation catalysts, plant extracts, and combinations thereof, to form a moist tobacco mixture; (ii) heating the moist tobacco mixture at a temperature of at least about 60° C. to form a heat-treated tobacco mixture; and (iii) incorporating the heat-treated tobacco mixture into a tobacco product. Heat-treated tobacco composition prepared according to the method are also provided, such as heat-treated smokeless tobacco composition comprising a tobacco material, water, flavorant, binder, and filler, the heat-treated smokeless tobacco composition having an acrylamide content of less than about 2000 ppb.

Owner:R J REYNOLDS TOBACCO COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com