Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1126 results about "Overwrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An overwrap or wrap is applied over an item or is applied over another form of packaging. It is often made of plastic film (sometimes called Polywrapping) or paper.

Smoking article

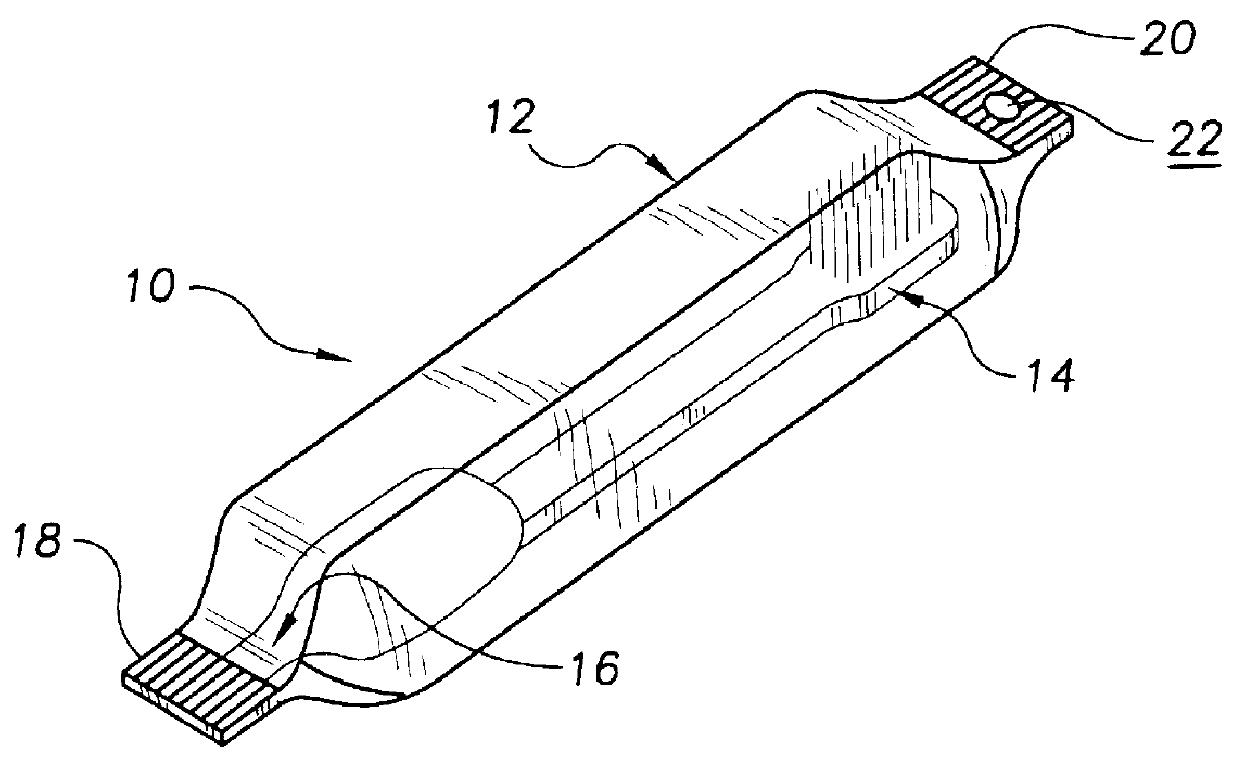

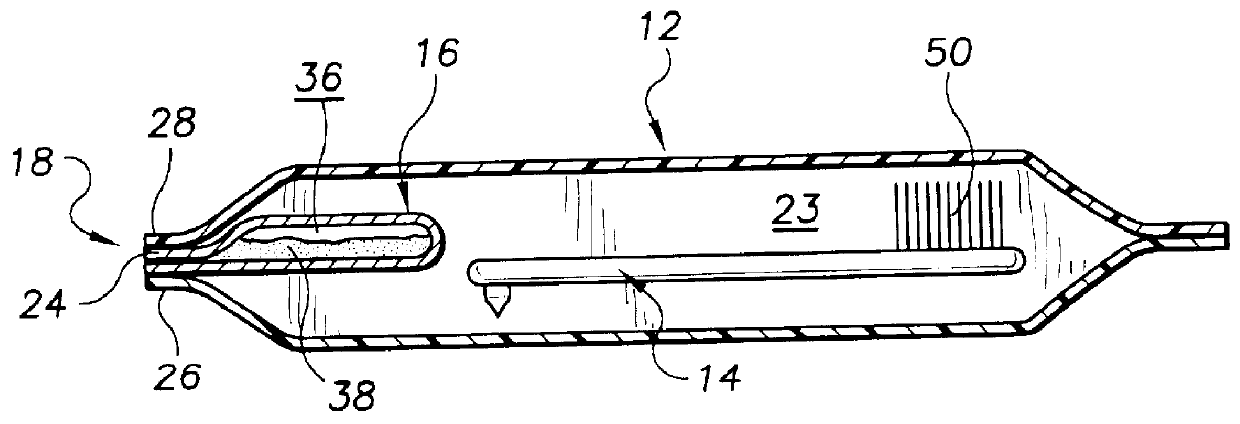

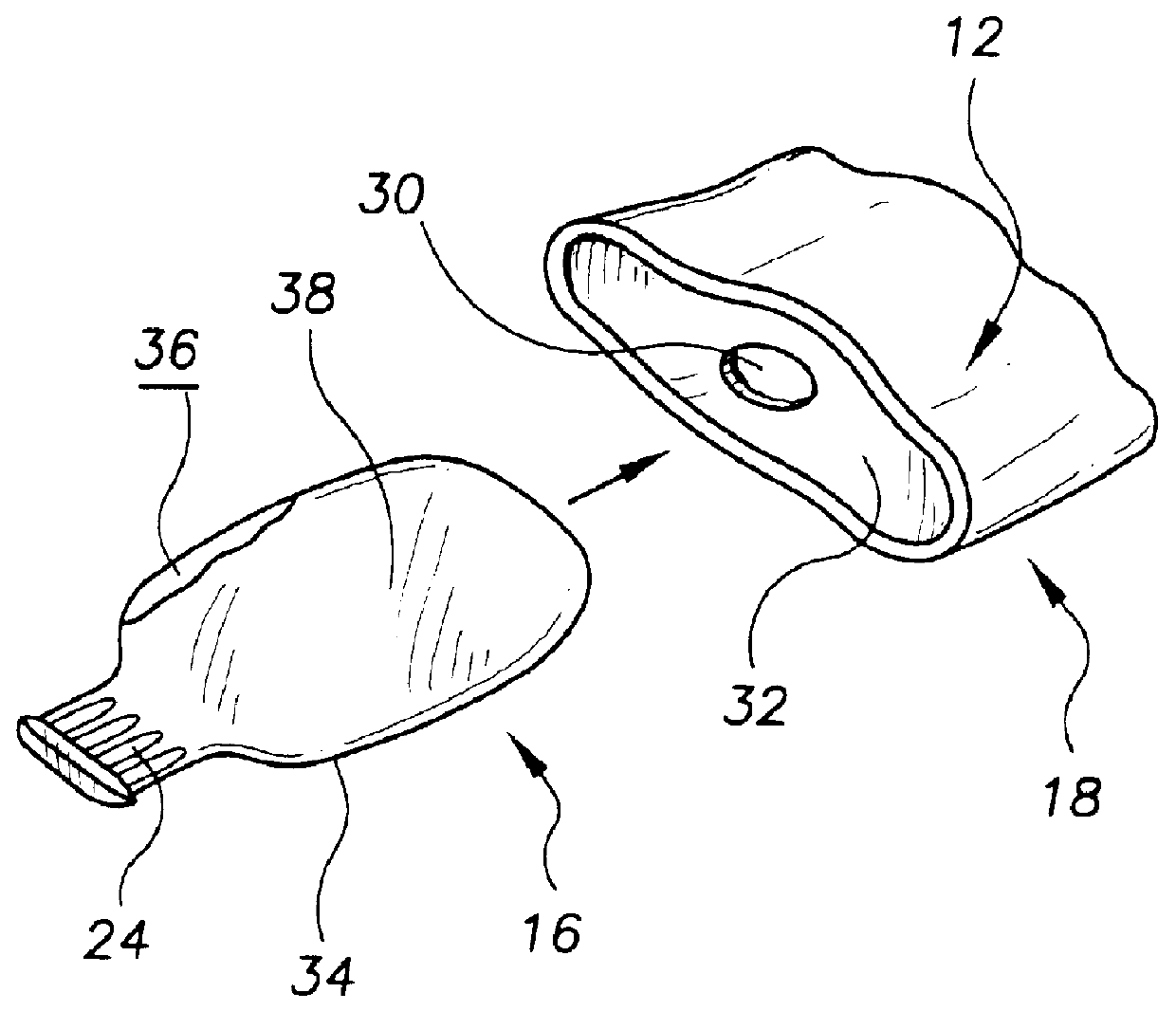

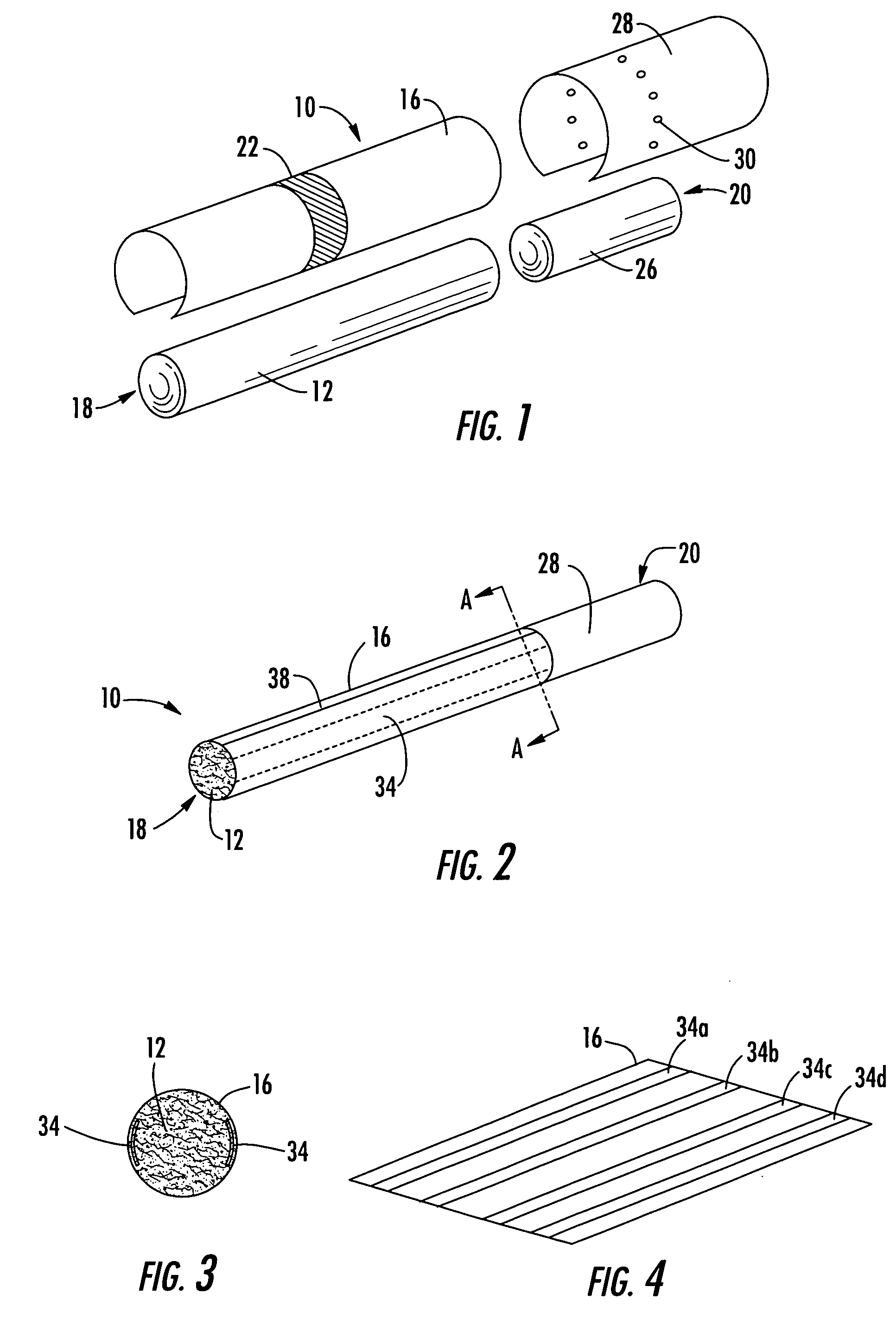

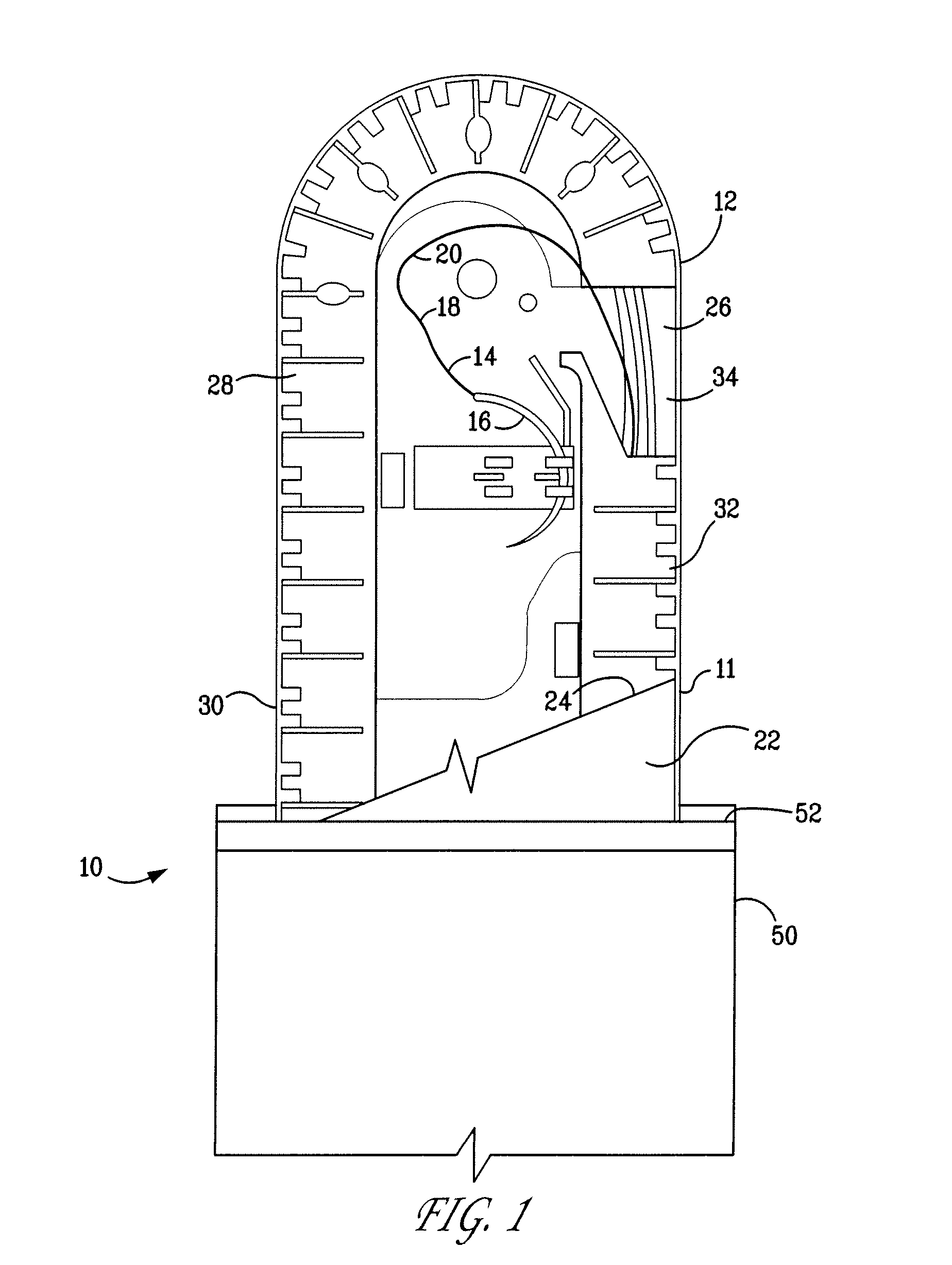

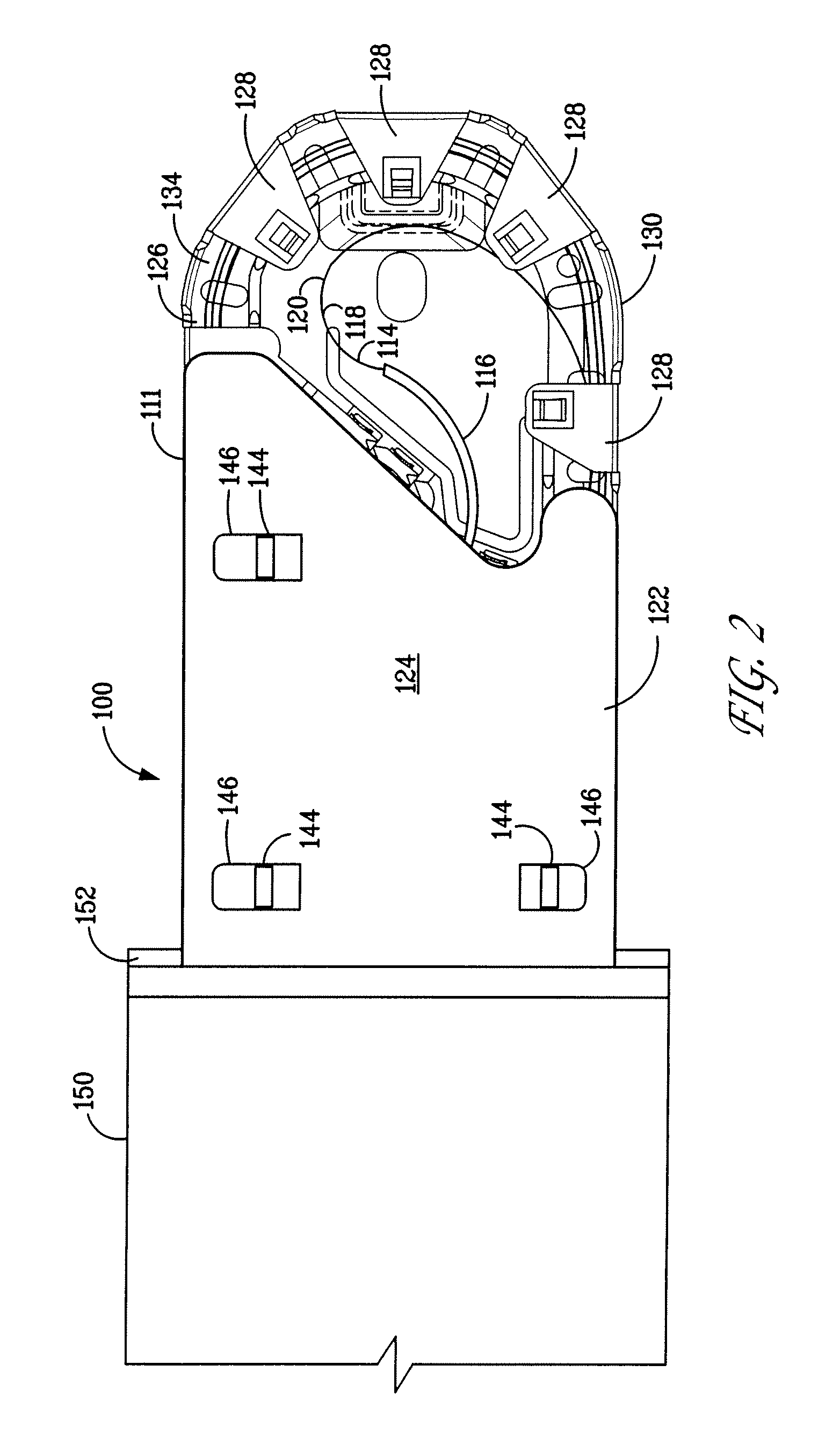

A smoking article, such as a cigarette, comprises a lighting end and a mouth end. The smoking article possesses an aerosol-generation system that includes (i) a heat generation segment, and (ii) an aerosol-generating region or segment. A mouth end piece segment can be located at the mouth end of the smoking article. A segment of tobacco cut filler, gathered tobacco paper, or other type of flavor source material, can be positioned between the mouth end piece segment and the aerosol-generation segment. Optionally, segment composed of tobacco cut filler can be positioned so as to provide a lighting end segment. The smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the mouth end piece segment, the aerosol generation segment, at least a portion of the length of the heat generation segment, any segment located between the mouth end piece and aerosol generation segments, and at least a portion of the length of the optional lighting end segment. Alternatively, the smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the aerosol-generating segment, at least a portion of the length of the heat generation segment, at least a portion of any segment located downstream from the aerosol-generating segment, and at least a portion of the length of the optional lighting end segment, thereby forming a cigarette rod; and the cigarette rod is connected or attached to a filter element using a tipping type of material and arrangement.

Owner:R J REYNOLDS TOBACCO COMPANY

Heat-shrinkable anti-fomitic device

Owner:M TECH INC

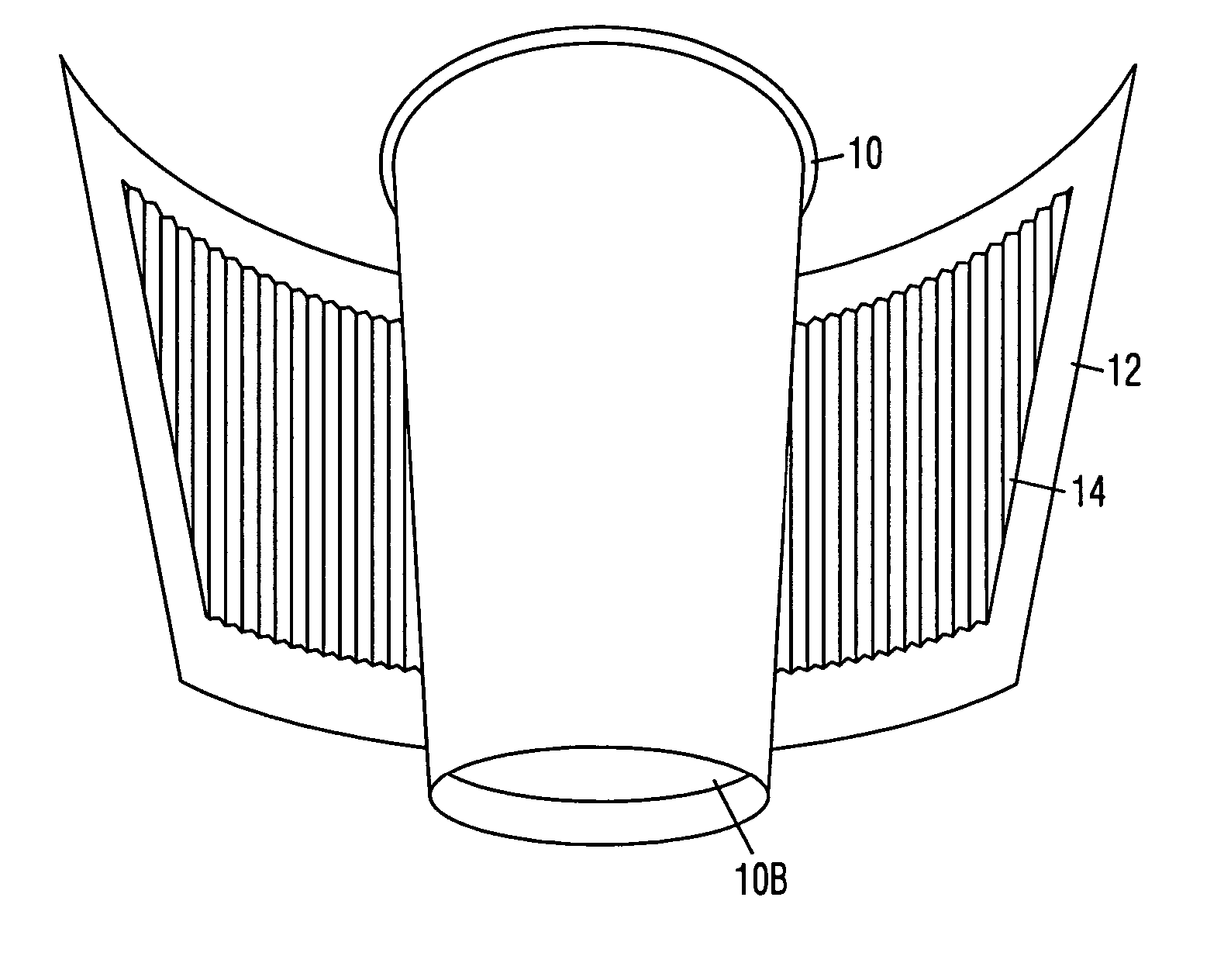

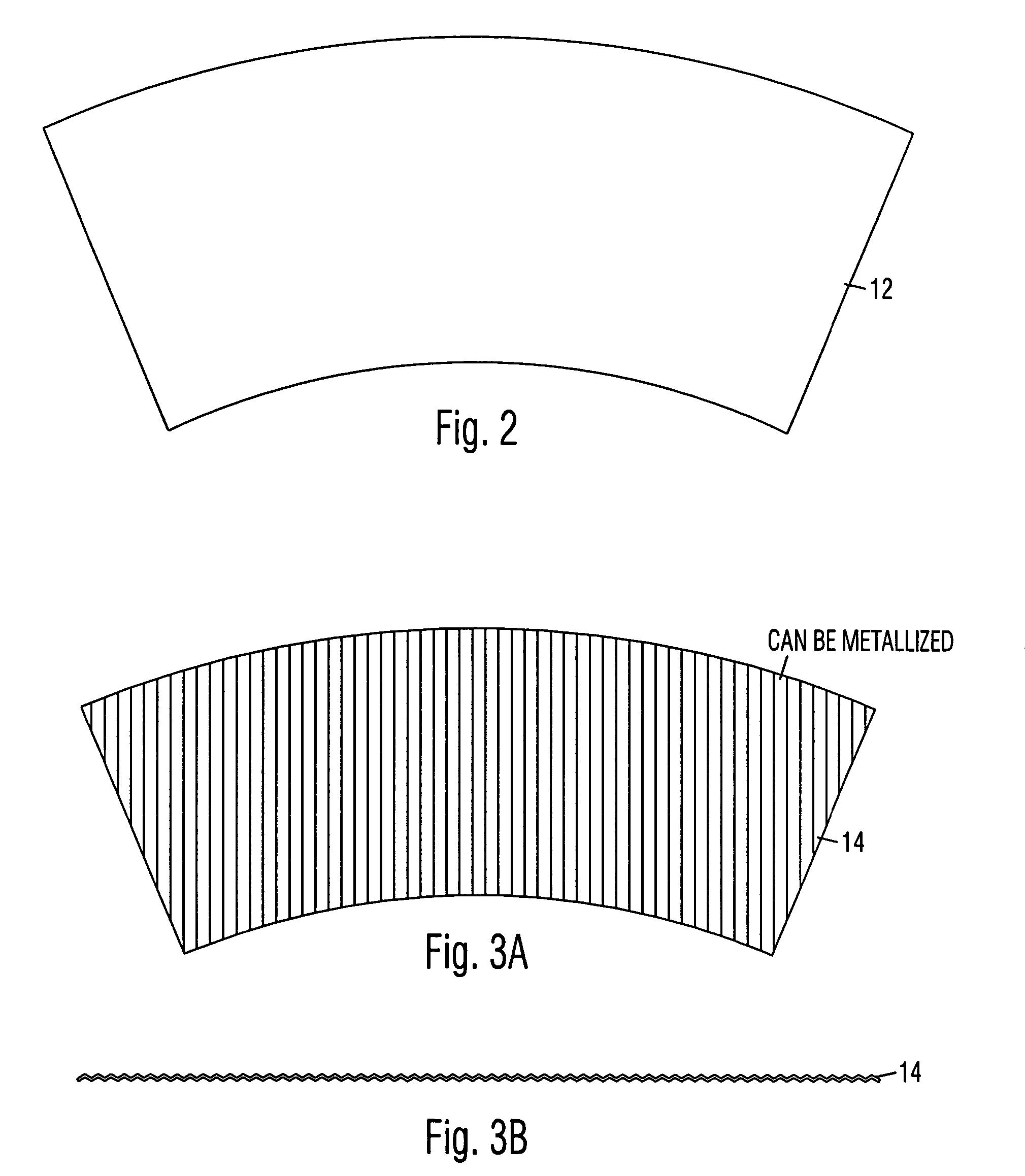

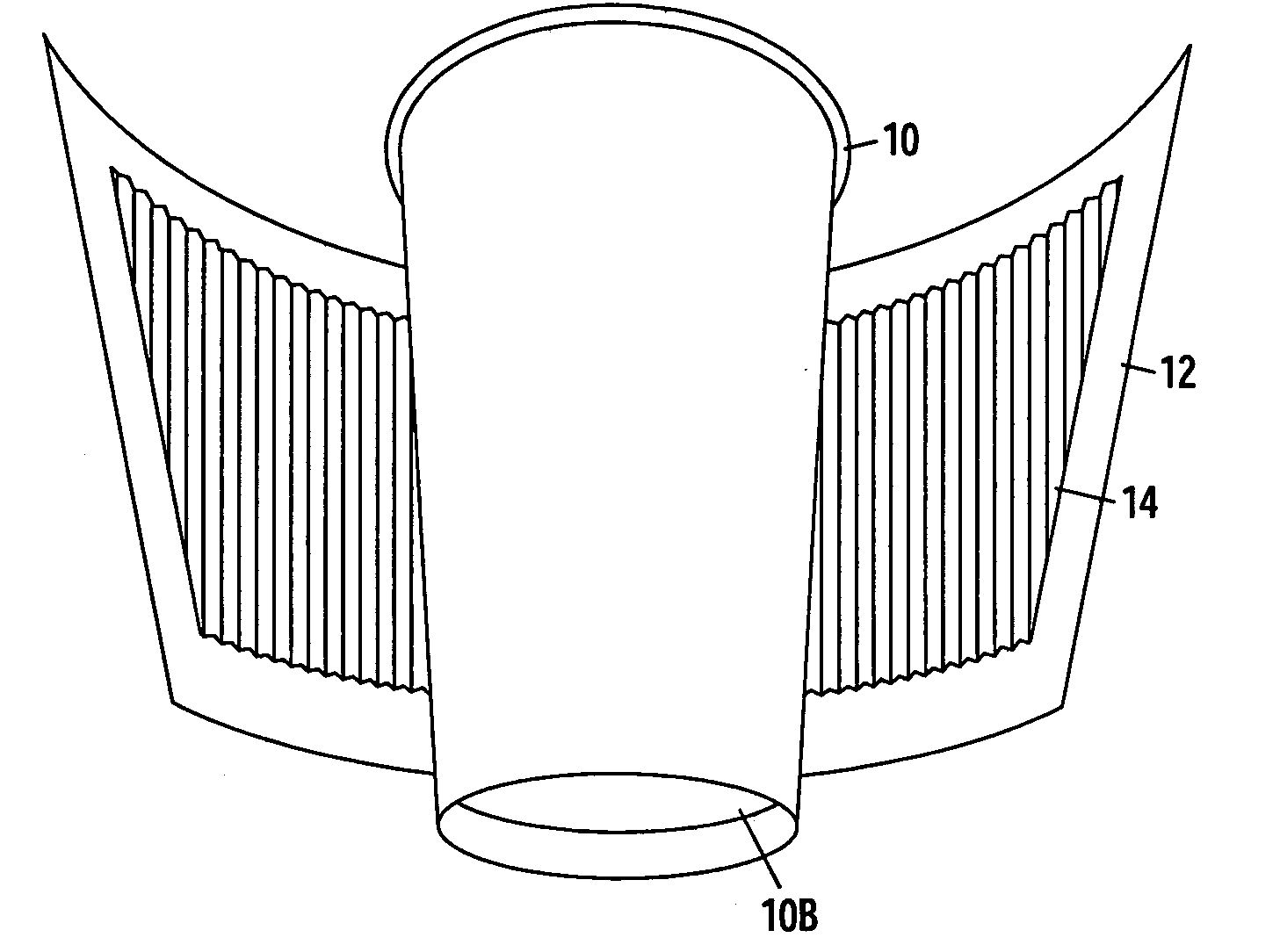

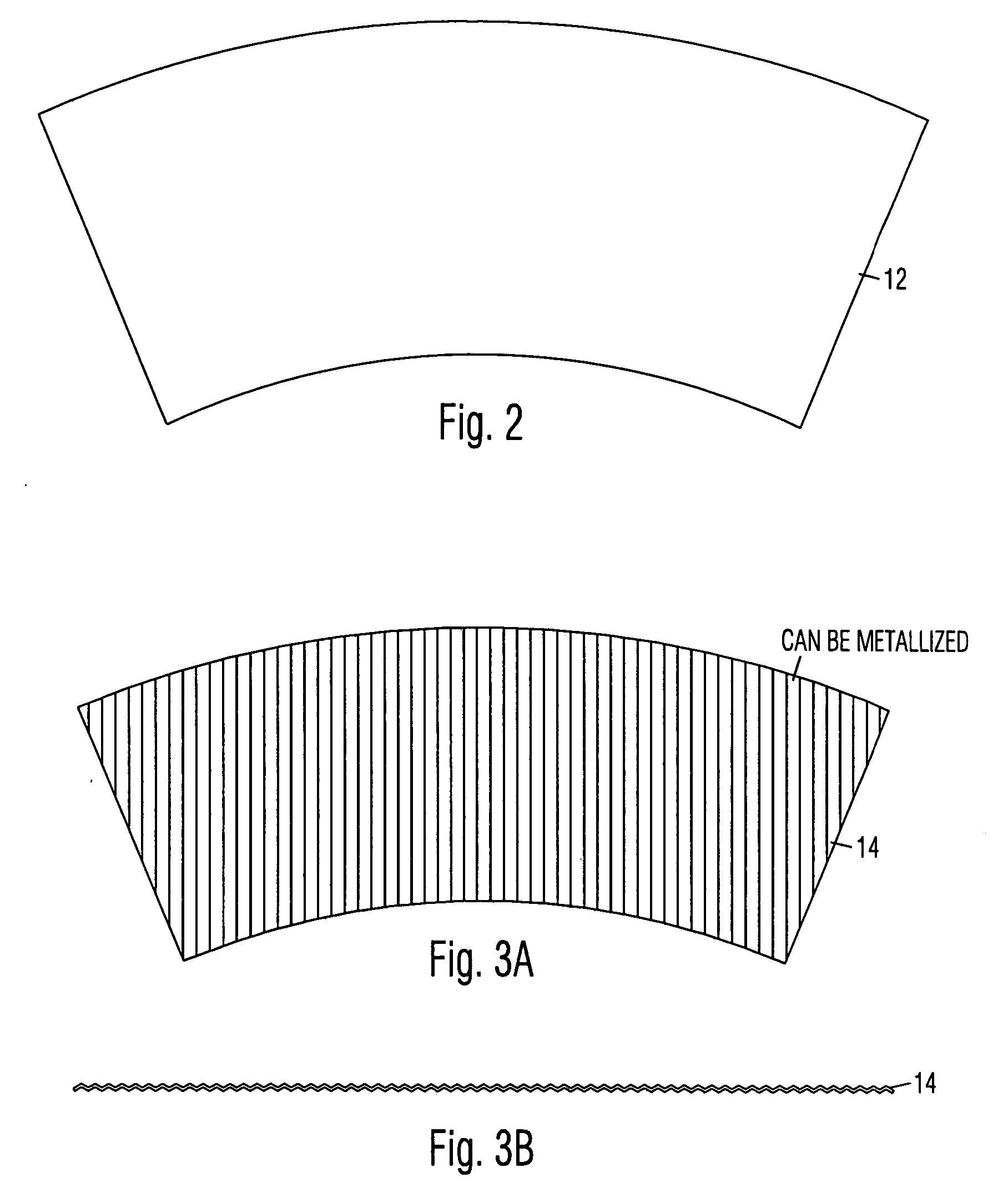

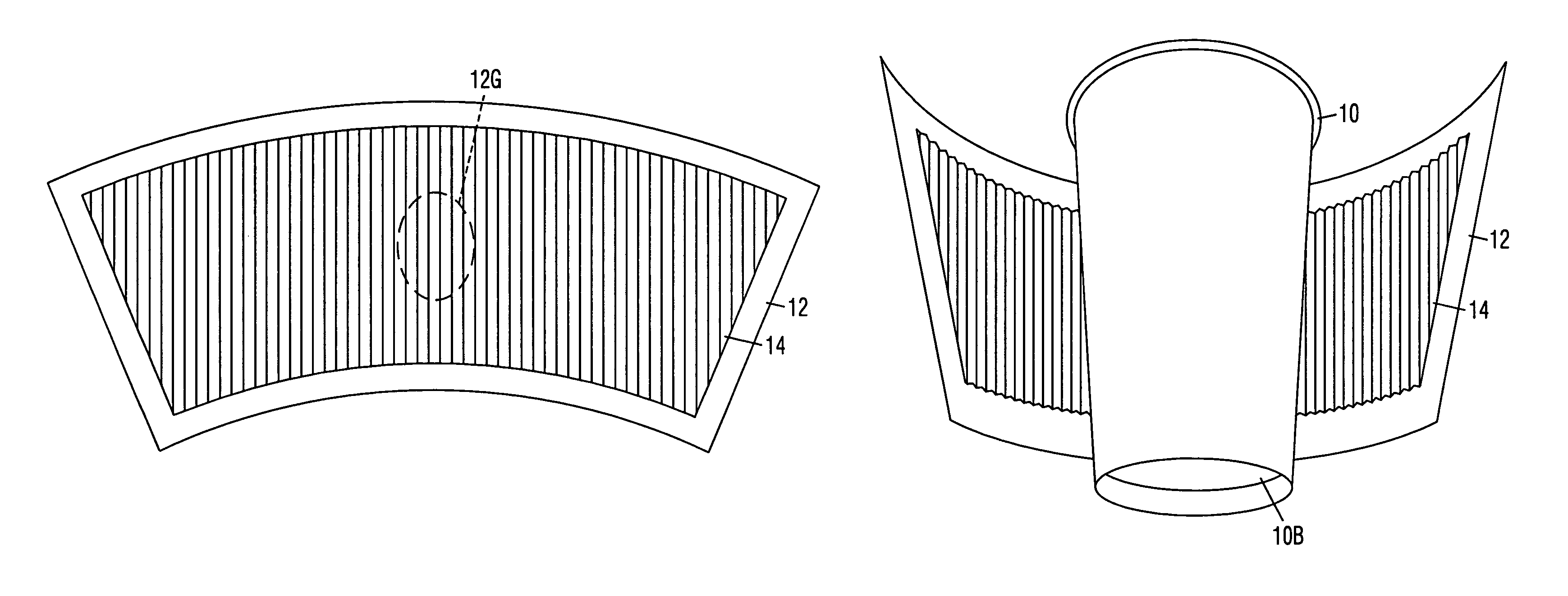

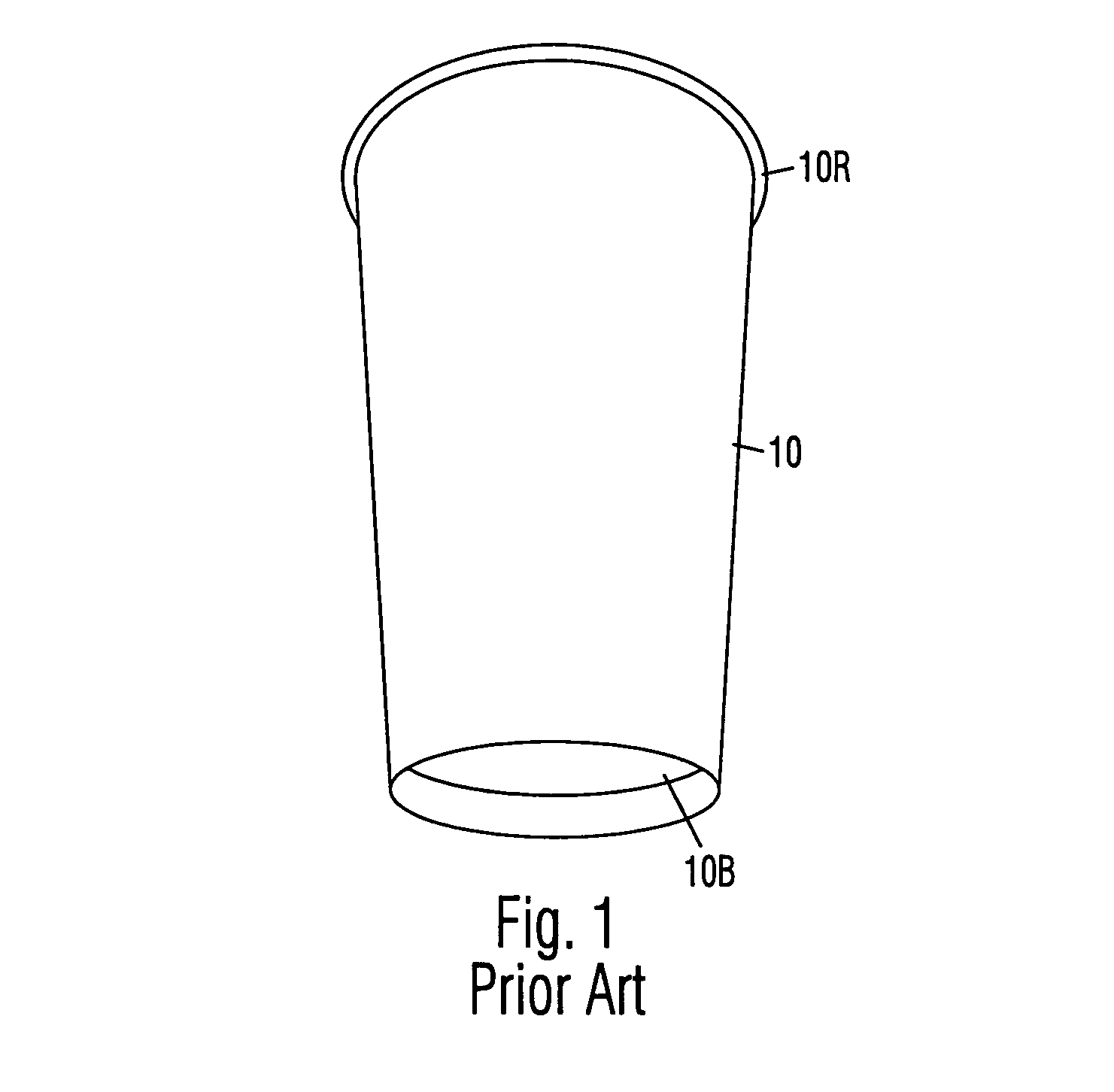

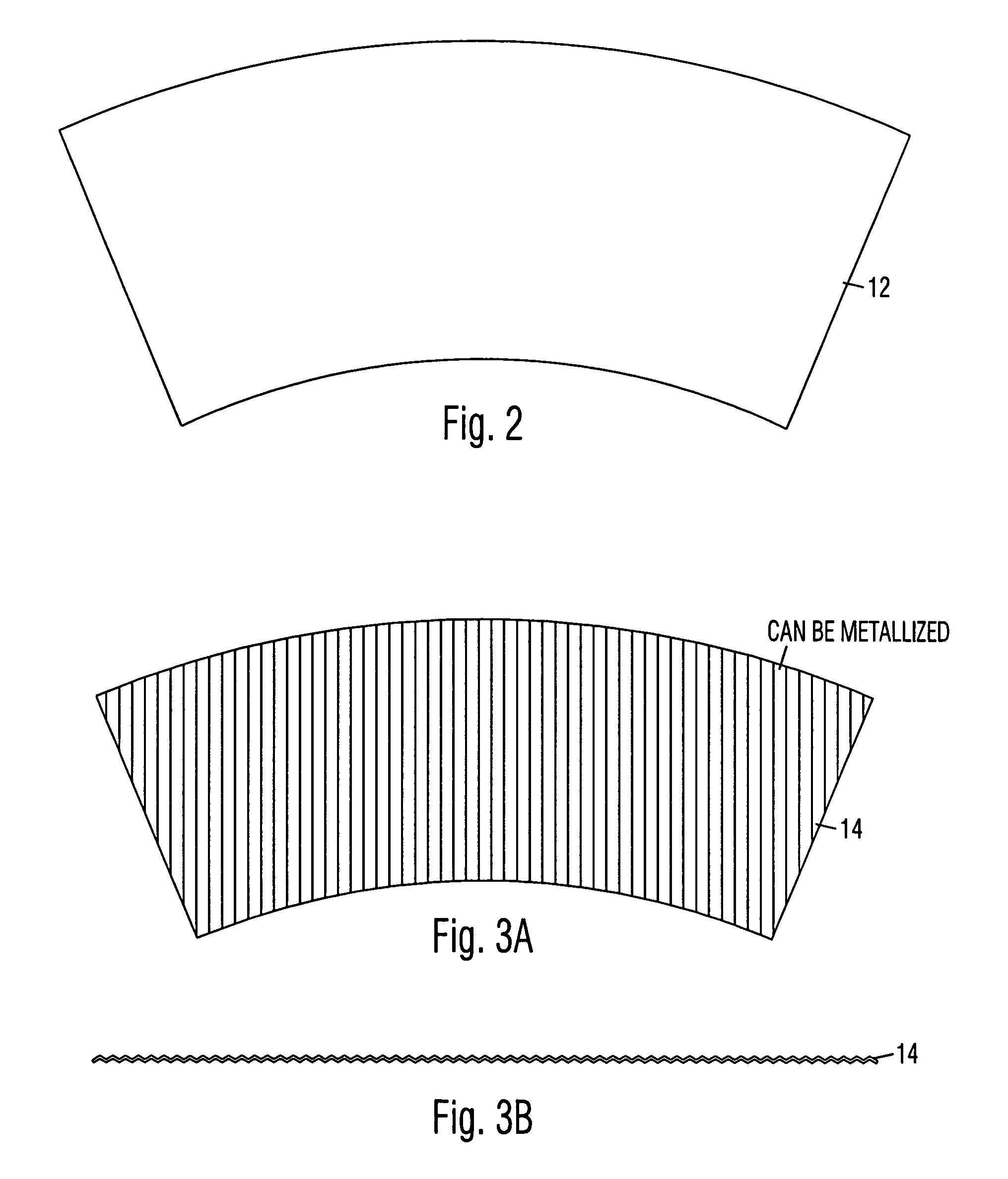

Insulating cup wrapper and insulated container formed with wrapper

A thermally insulated cup is formed from a single-walled paper or plastic inner cup and an insulating outer wrapper. The insulating outer wrapper comprises a paper base sheet or outer sidewall blank, optionally printed on one side, and a corrugated paper or foamed plastic insulating insert. The insulating insert is similar in shape to the outer sidewall blank but smaller in size. The insert is glued in a centered position to the non-printed side of the sidewall blank to form a two-layered insulating wrapper. Less than 20% of the area of the insert is glued to the base sheet. Specifically, no glue is applied to the area adjacent to the cut side edges of the insert, and as such these edges are not attached to the base sheet. The wrapper is then wrapped around the single walled inner cup. The side edges of the base sheet of the wrapper overlap and are sealed directly together to form a side seam. The side seam is itself adhesively secured to the side wall of the inner cup. The side edges of the insert do not come between the seal between the side seam of the base sheet and the inner cup. The wrapper can also be adhered to the inner cup by one or more beads of cold glue (paste adhesive) or a thin layer of polyethylene (or similar heat sealing material) can be pre-applied to the inside cut edges of the base sheet. This is then heat-activated immediately prior to wrapping the wrapper around the inner cup, and pressing the overlapping side seam to the sidewall of the inner cup to simultaneously glue the side seam together, and to glue the insulating wrapper to the side wall of the cup.

Owner:GPCP IP HLDG LLC

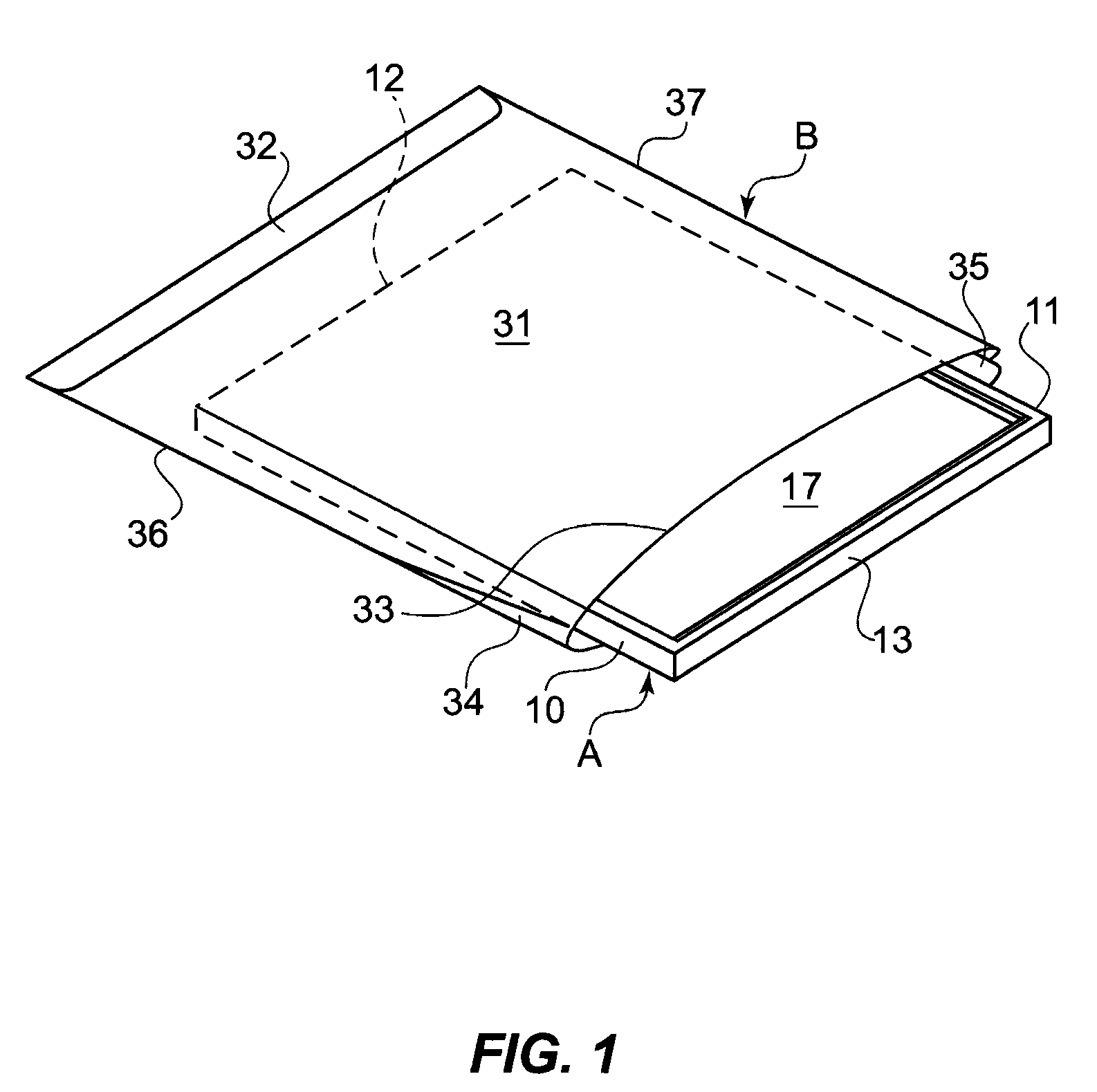

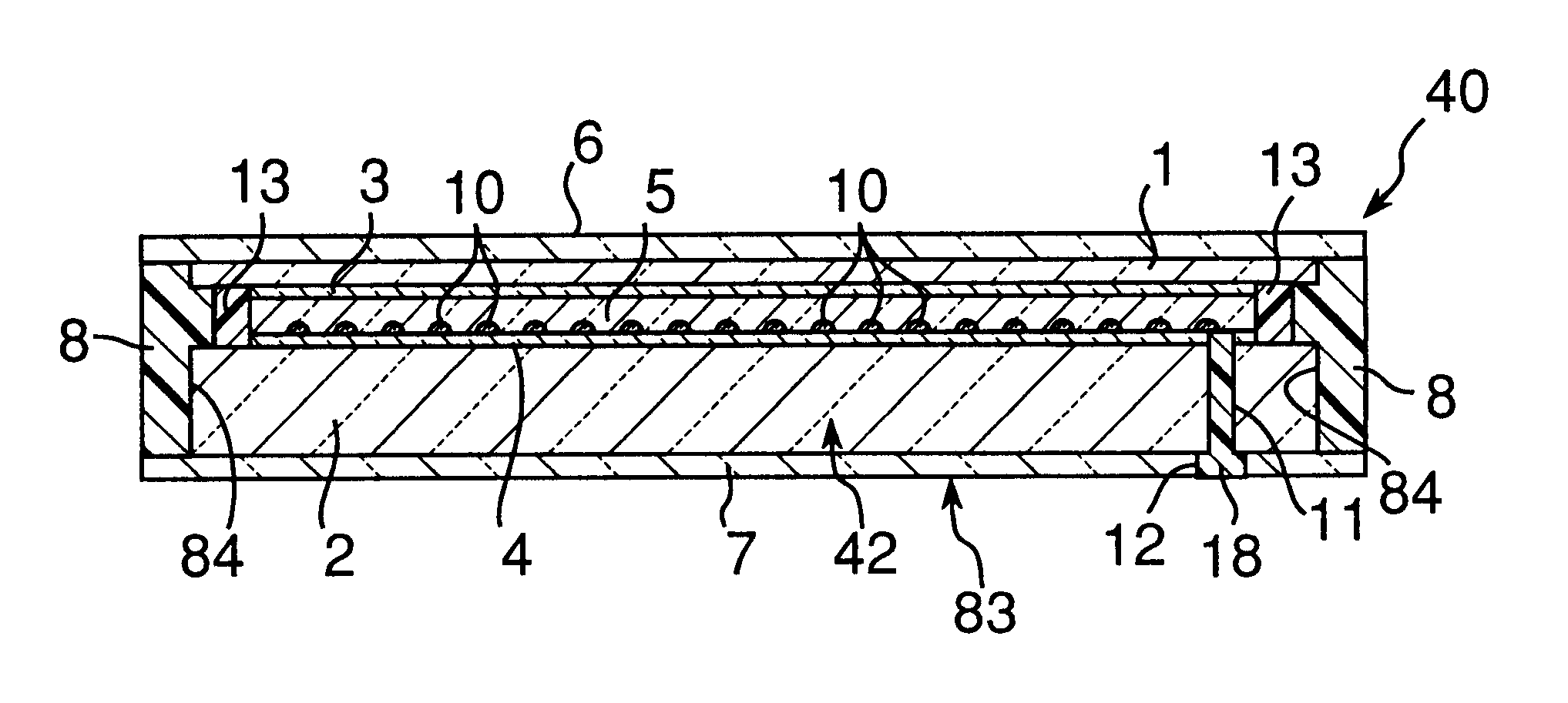

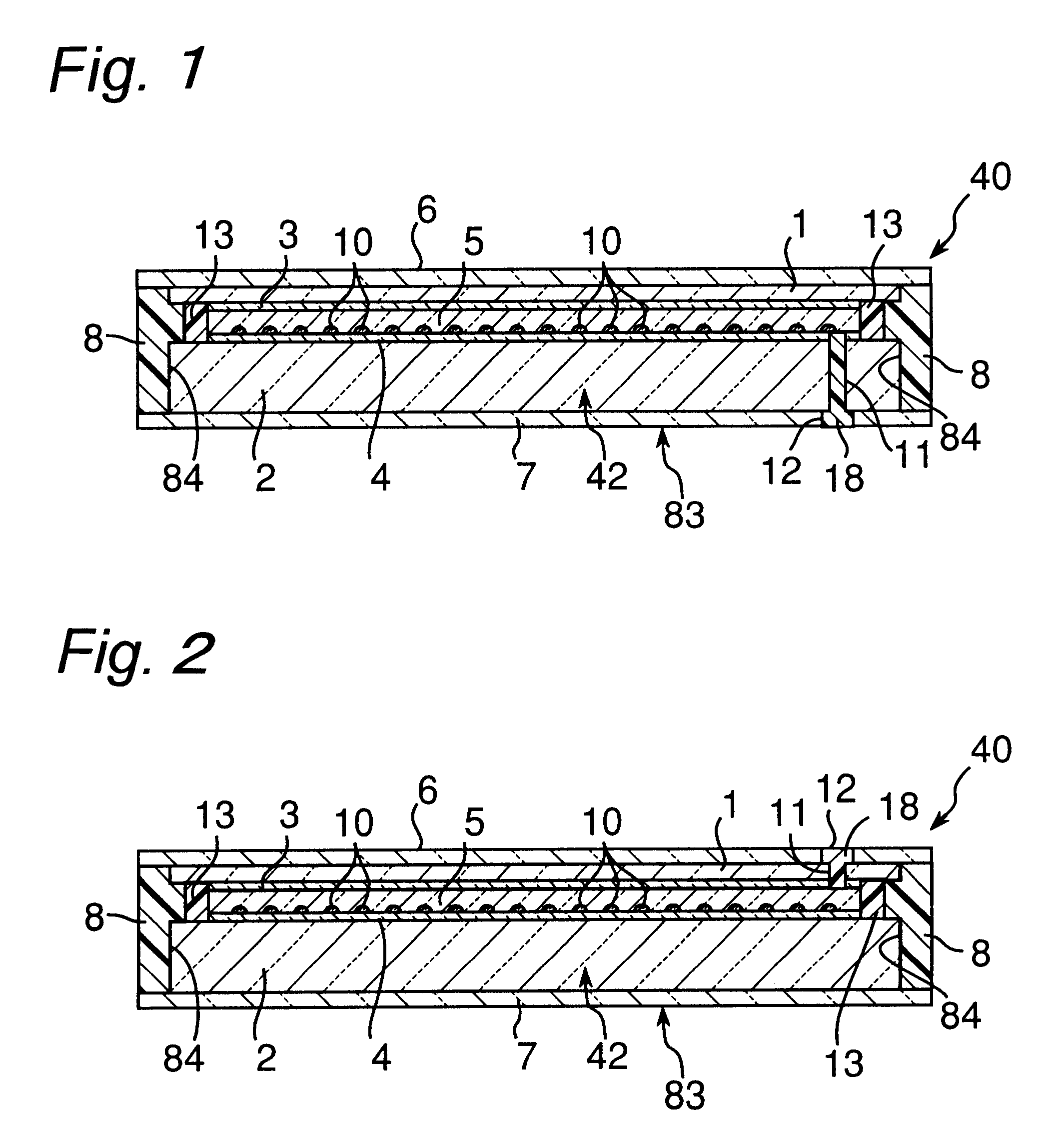

Touch panel device

InactiveUS6556189B1Prevent liquid leakageTransmission systemsCathode-ray tube indicatorsTouchpadEngineering

The sides of a touch panel are entirely covered with and sealed in an outer package. The touch panel includes a transparent insulating liquid that is sealed in a space formed by adhering an upper electrode film and a lower electrode body at edges thereof. The transparent insulating liquid transparently shows or exposes at least an operation area of the touch panel.

Owner:NISSHA PRINTING COMPANY

Insulating cup wrapper and insulated container formed with wrapper

InactiveUS20050236468A1Extended shelf lifeImprove propertiesDomestic cooling apparatusLighting and heating apparatusAdhesiveThin layer

A thermally insulated cup is formed from a single-walled paper or plastic inner cup and an insulating outer wrapper. The insulating outer wrapper comprises a paper base sheet or outer sidewall blank, optionally printed on one side, and a corrugated paper or foamed plastic insulating insert. The insulating insert is similar in shape to the outer sidewall blank but smaller in size. The insert is glued in a centered position to the non-printed side of the sidewall blank to form a two-layered insulating wrapper. Less than 20% of the area of the insert is glued to the base sheet. Specifically, no glue is applied to the area adjacent to the cut side edges of the insert, and as such these edges are not attached to the base sheet. The wrapper is then wrapped around the single walled inner cup. The side edges of the base sheet of the wrapper overlap and are sealed directly together to form a side seam. The side seam is itself adhesively secured to the side wall of the inner cup. The side edges of the insert do not come between the seal between the side seam of the base sheet and the inner cup. The wrapper can also be adhered to the inner cup by one or more beads of cold glue (paste adhesive) or a thin layer of polyethylene (or similar heat sealing material) can be pre-applied to the inside cut edges of the base sheet. This is then heat-activated immediately prior to wrapping the wrapper around the inner cup, and pressing the overlapping side seam to the sidewall of the inner cup to simultaneously glue the side seam together, and to glue the insulating wrapper to the side wall of the cup.

Owner:INSULAIR

Insulating cup wrapper and insulated container formed with wrapper

A thermally insulated cup is formed from a single-walled paper or plastic inner cup and an insulating outer wrapper. The insulating outer wrapper comprises a paper base sheet or outer sidewall blank, optionally printed on one side, and a corrugated paper or foamed plastic insulating insert. The insulating insert is similar in shape to the outer sidewall blank but smaller in size. The insert is glued in a centered position to the non-printed side of the sidewall blank to form a two-layered insulating wrapper. Less than 20% of the area of the insert is glued to the base sheet. Specifically, no glue is applied to the area adjacent to the cut side edges of the insert, and as such these edges are not attached to the base sheet. The wrapper is then wrapped around the single walled inner cup. The side edges of the base sheet of the wrapper overlap and are sealed directly together to form a side seam. The side seam is itself adhesively secured to the side wall of the inner cup. The side edges of the insert do not come between the seal between the side seam of the base sheet and the inner cup. The wrapper can also be adhered to the inner cup by one or more beads of cold glue (paste adhesive) or a thin layer of polyethylene (or similar heat sealing material) can be pre-applied to the inside cut edges of the base sheet. This is then heat-activated immediately prior to wrapping the wrapper around the inner cup, and pressing the overlapping side seam to the sidewall of the inner cup to simultaneously glue the side seam together, and to glue the insulating wrapper to the side wall of the cup.

Owner:GPCP IP HLDG LLC

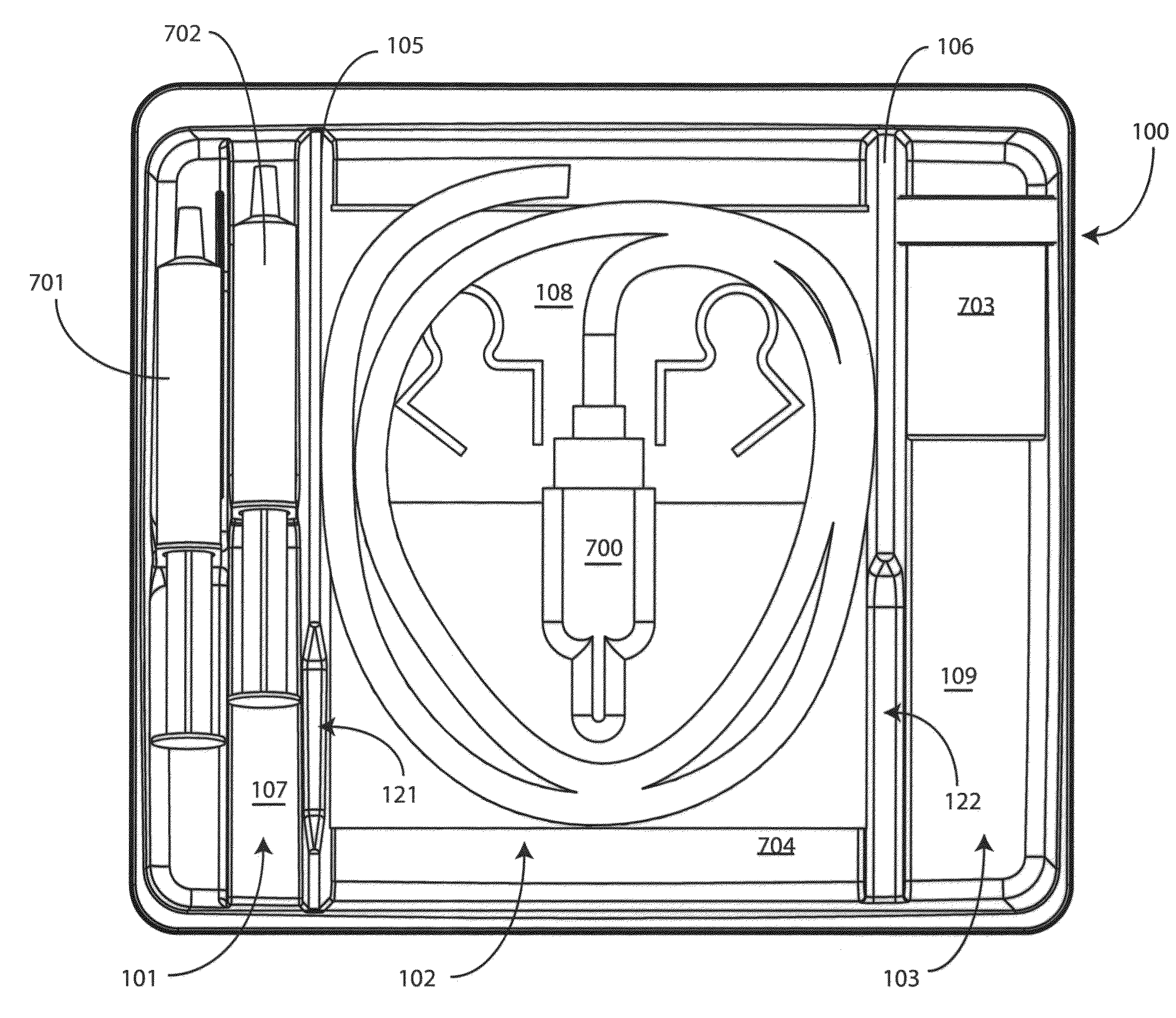

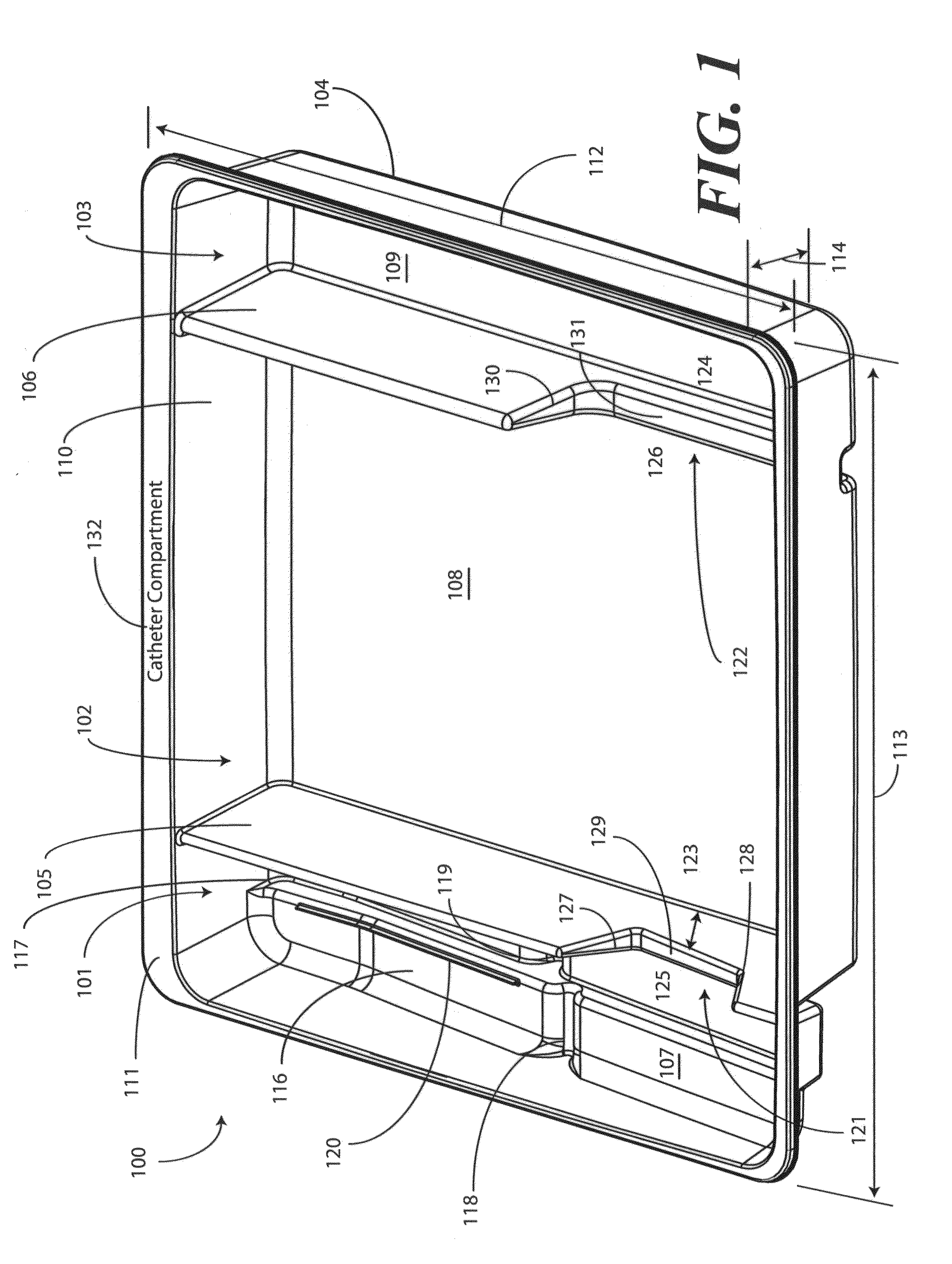

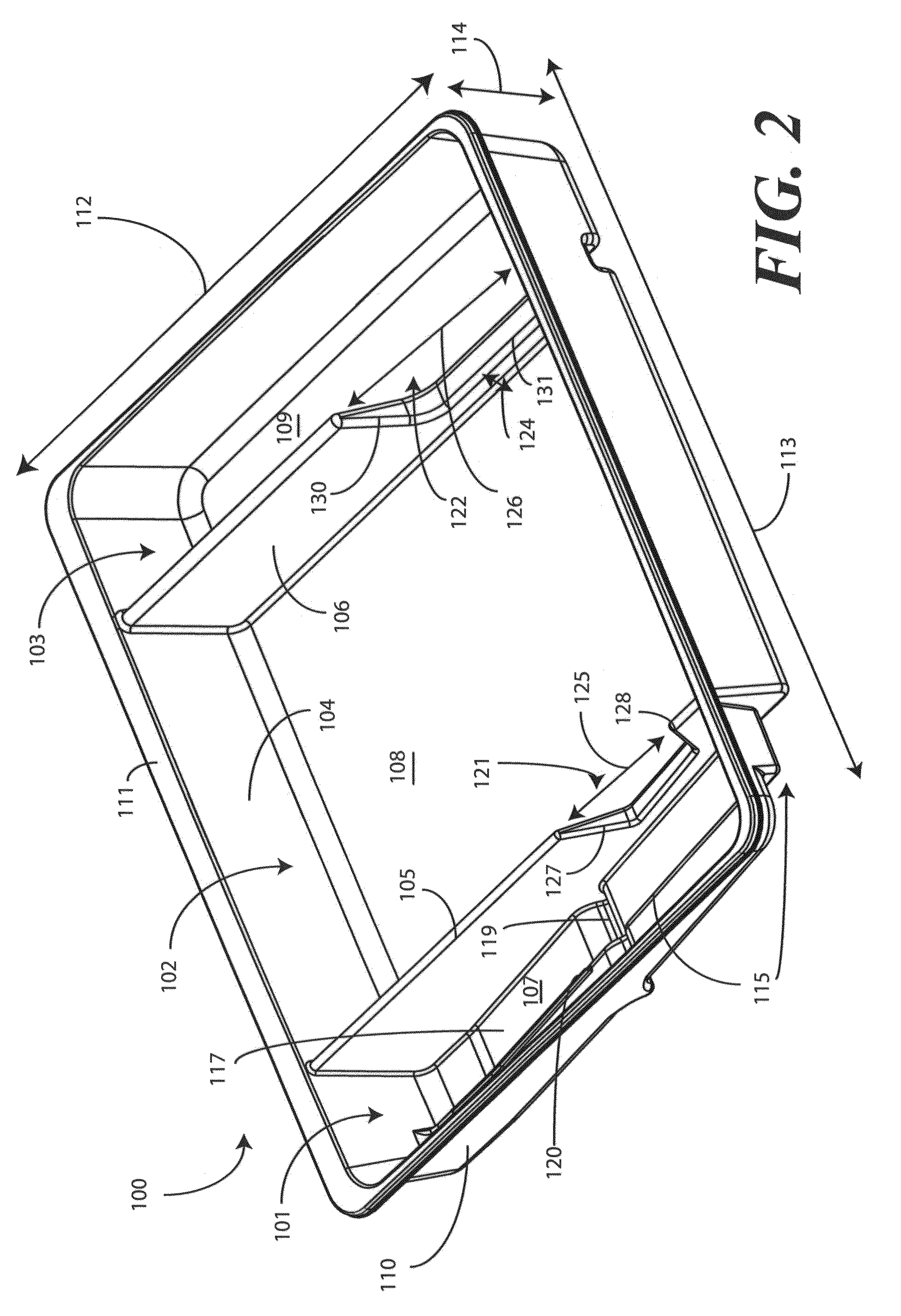

Catheter tray, packaging system, instruction insert, and associated methods

Printed instructions (4000) can be included with the tray (100) in a medical procedure kit. The printed instructions (4000) can include instructional material (4202), such as pictorial, step-by-step instructions for using the medical procedure kit. The printed instructions (4000) can be configured as a booklet. The printed instructions (4000) can be adhesively attached to outer packaging (4201), and can include a peelable label (4402) that is separable from the printed instructions (4000) and is configured for attachment to medical records. Colorization of the various components can assist in ensuring safe usage of the medical procedure kit.

Owner:MEDLINE IND LP

Child-resistant and senior-friendly blister card package

InactiveUS7063211B2Easy to useImprove the level ofSmall article dispensingOther accessoriesPackage designEngineering

The present invention is a novel child-resistant senior-friendly blister card packaging that is cheap and easy to manufacture. The packaging requires a push-peel-push method for opening, which is cognitively and physically challenging for children and mentally impaired adults. Yet, competent adults can easily open the package, especially after reading instructions. More specifically, opening the package requires the user to: 1) Push through an aperture to create a pull tab; 2) Pull on the pull tab to remove a panel; and 3) Push the blister to force the contents through the blister's seal. Furthermore, the packaging is designed to be tear resistant and to halt any propagation of a tear. Advantageously, the present invention is designed such that information such as instructions and product information can be easily printed directly on the packaging. Moreover, users may also record information directly on the packaging. Thus, the present invention not only provides child-resistant and senior-friendly features, but also provides convenience for viewing and recording information.

Owner:KEY PAK TECH

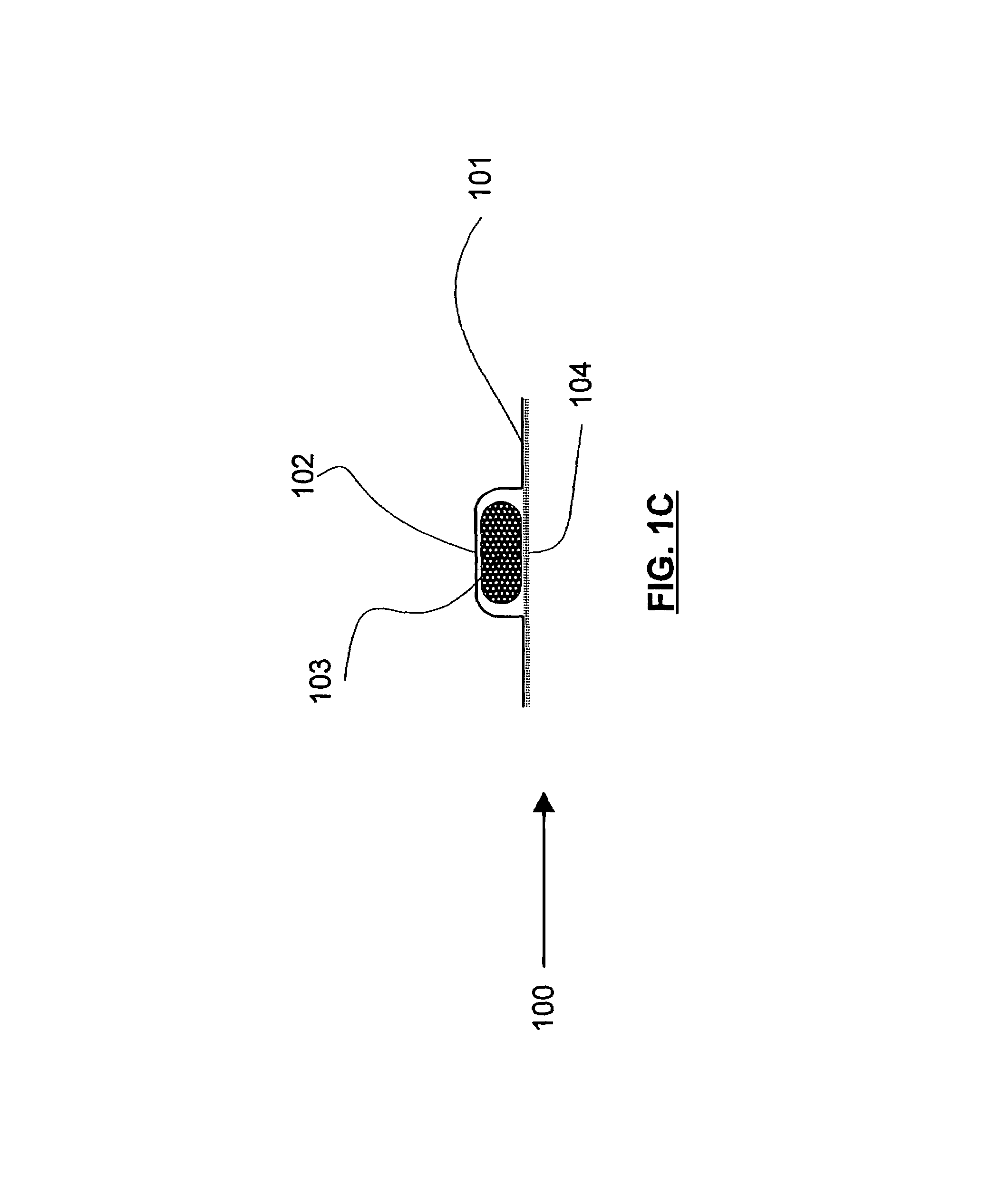

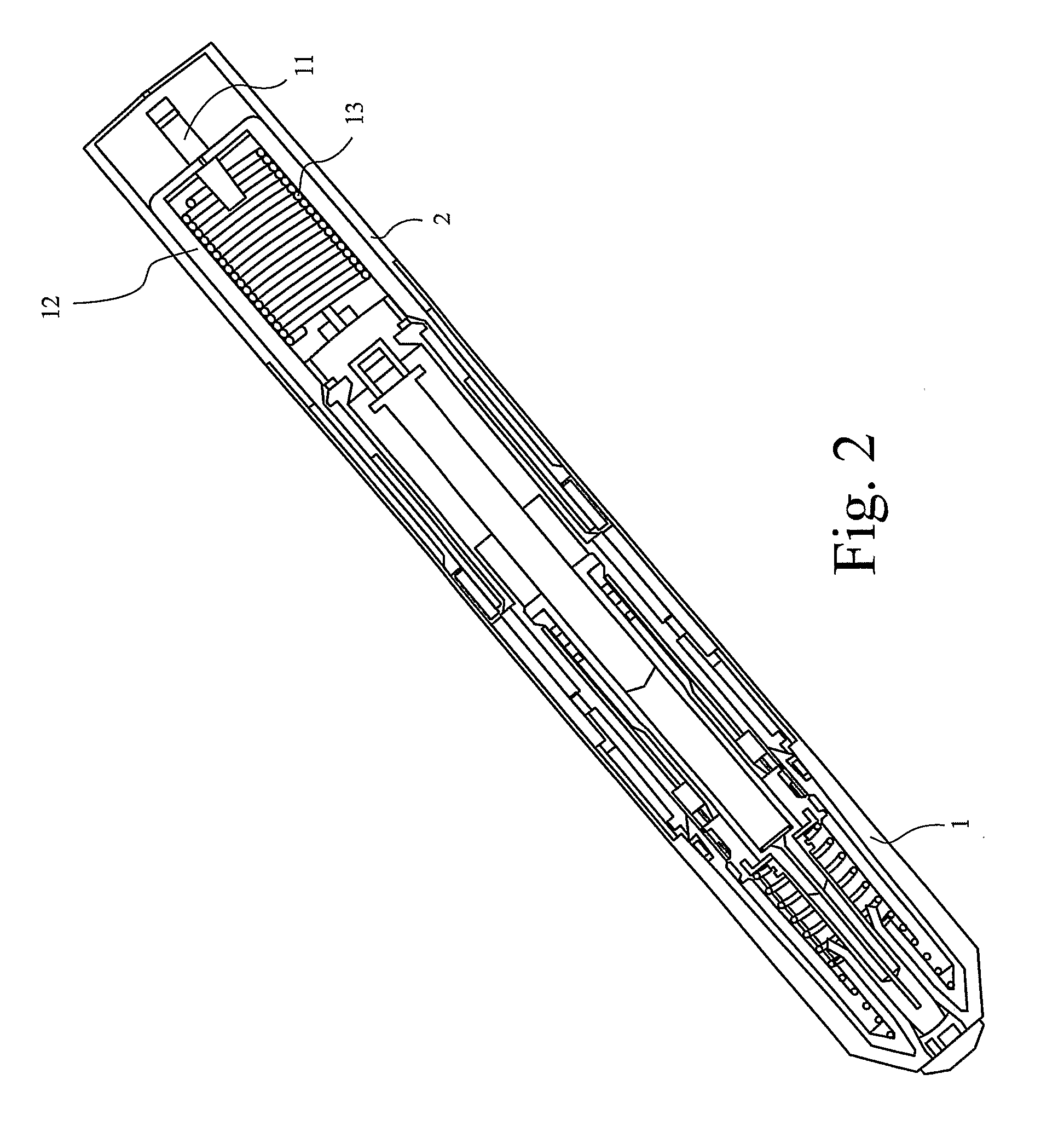

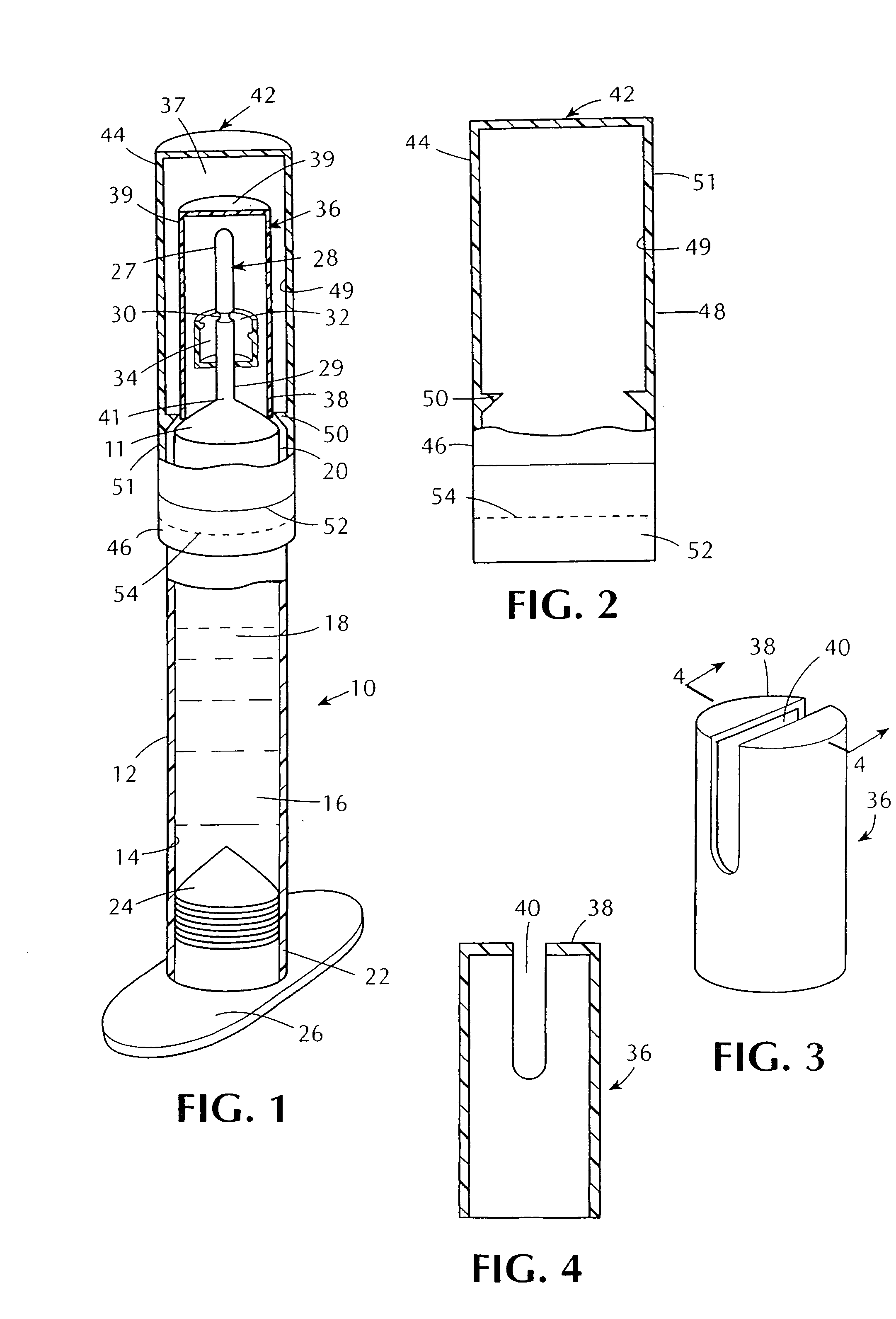

Autoinjector having an outer packaging and a needle sheath removing means

InactiveUS20120130342A1Reduce deliveryActuation can be preventedDispensing apparatusAutomatic syringesAutoinjectorSyringe needle

An autoinjector device for delivering a dose of medicament including a syringe including a needle wherein, prior to use of the device, the needle is substantially covered by a needle sheath (107). The autoinjector further includes a housing (112) in which said syringe is located, an outer packaging in which said housing is located, where the outer packaging comprising a front packaging (101) part and a rear packaging part. The autoinjector also includes needle sheath removing means (103) associated with said front packaging part (101), wherein, prior to use of the device, said front and rear packaging parts cooperate together to entirely enclose said housing, syringe and needle sheath, and wherein, upon axial separation of said front and rear packaging parts, said needle sheath removing means is capable of causing axial separation of said needle sheath from said needle so as to remove said needle sheath therefrom.

Owner:THE MEDICAL HOUSE

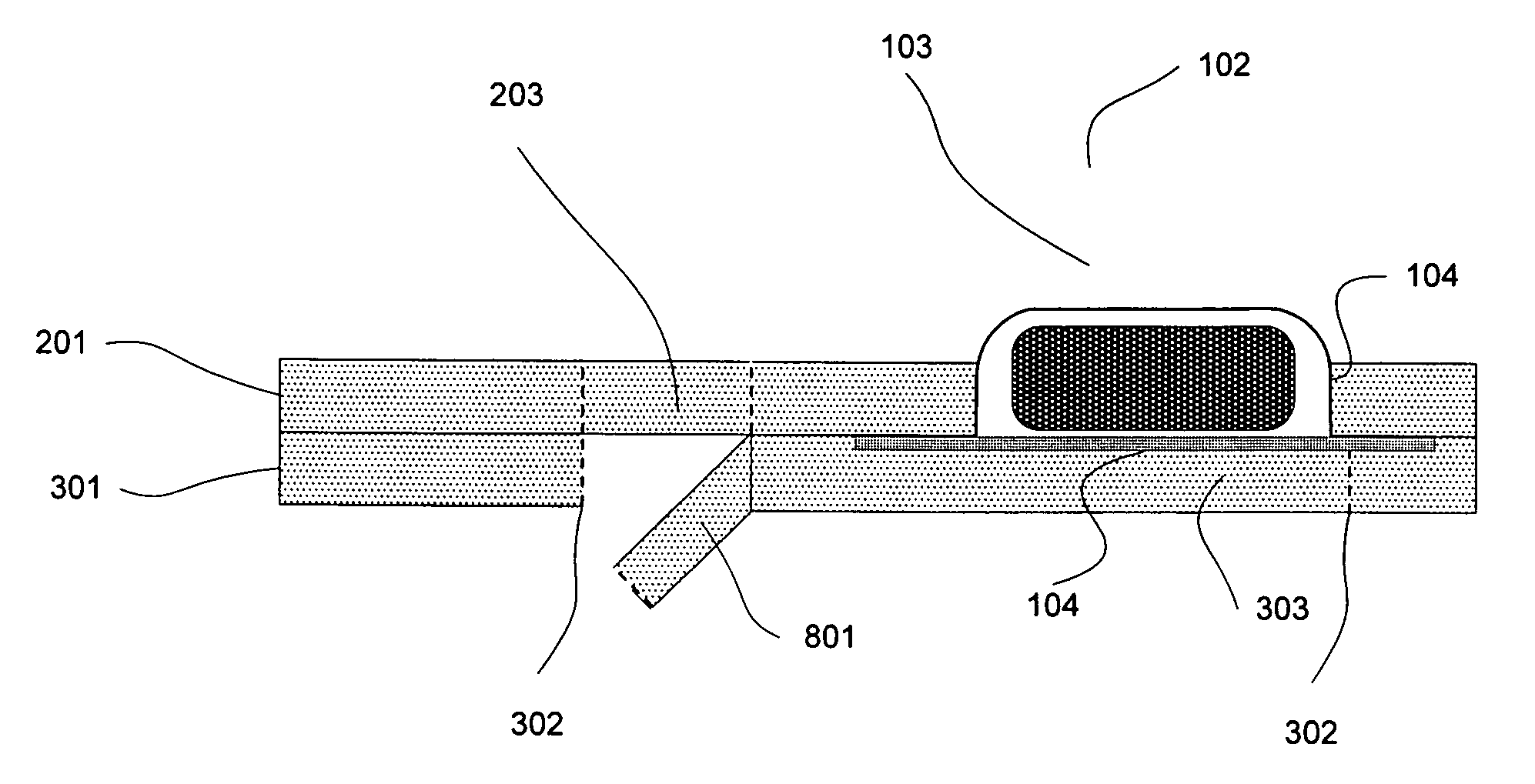

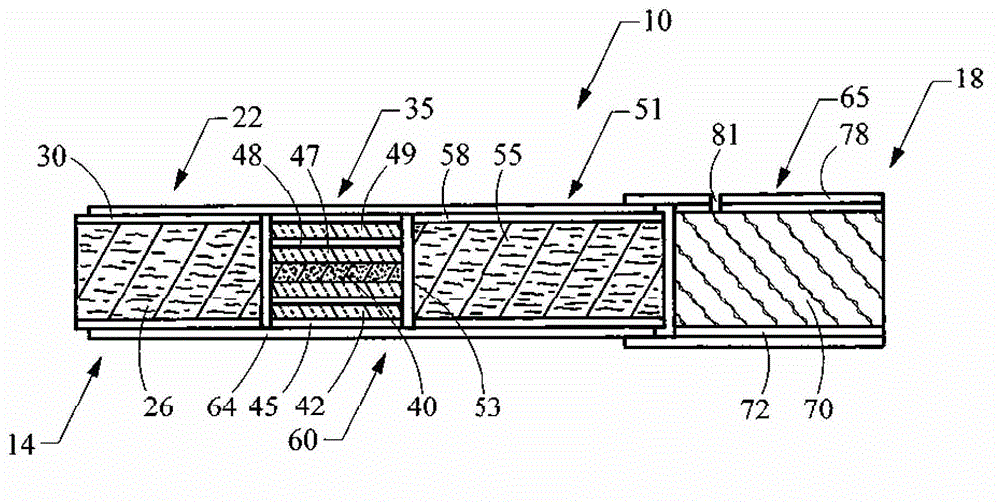

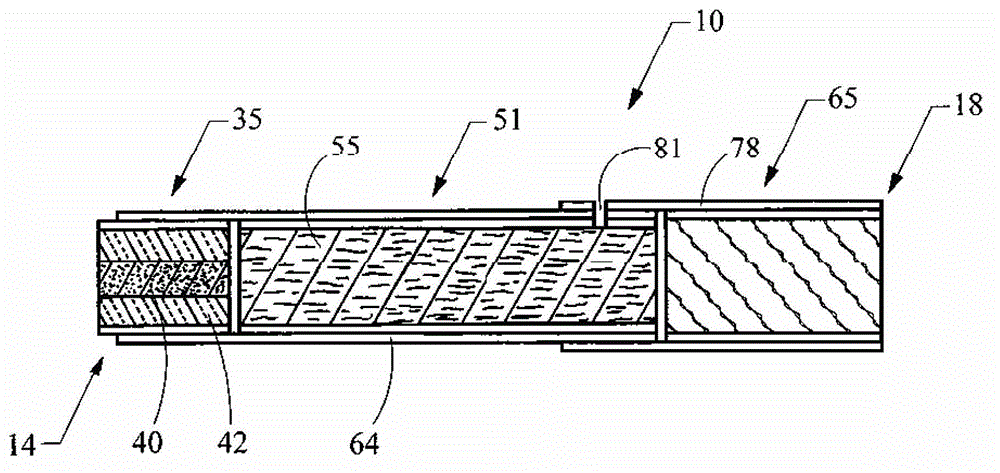

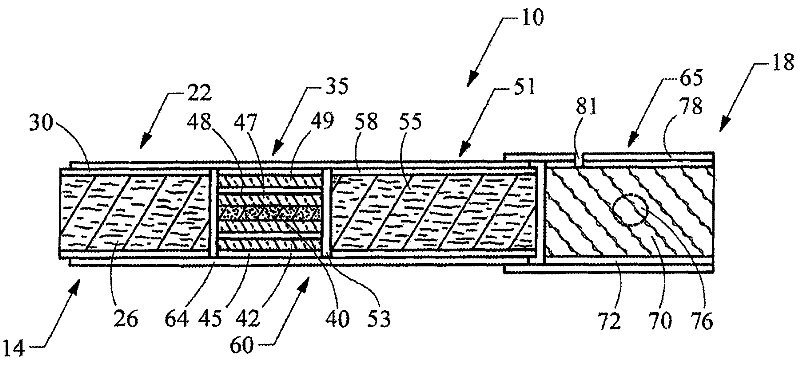

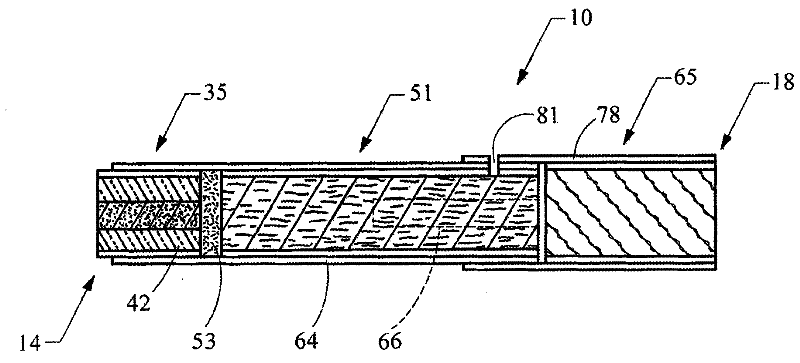

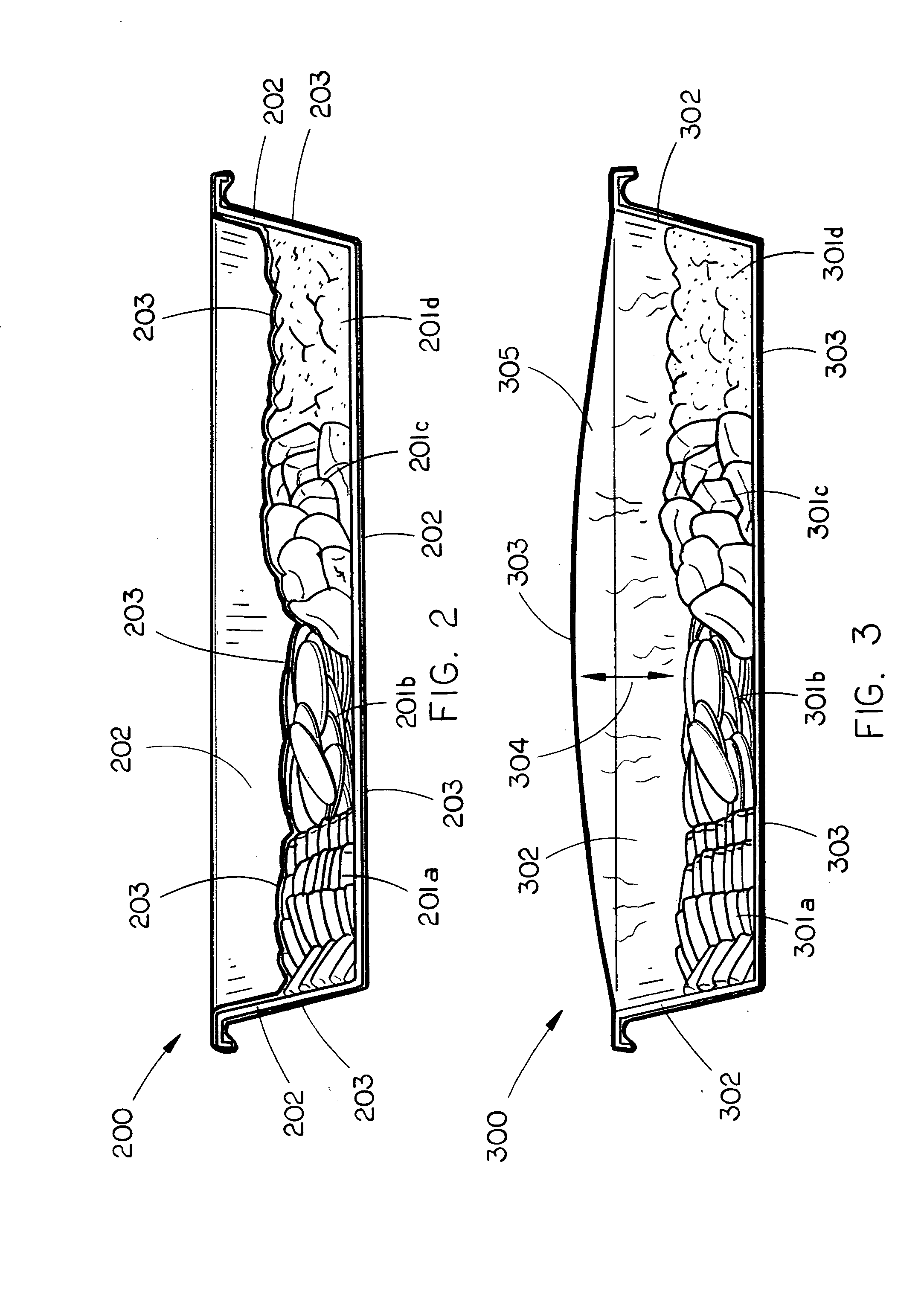

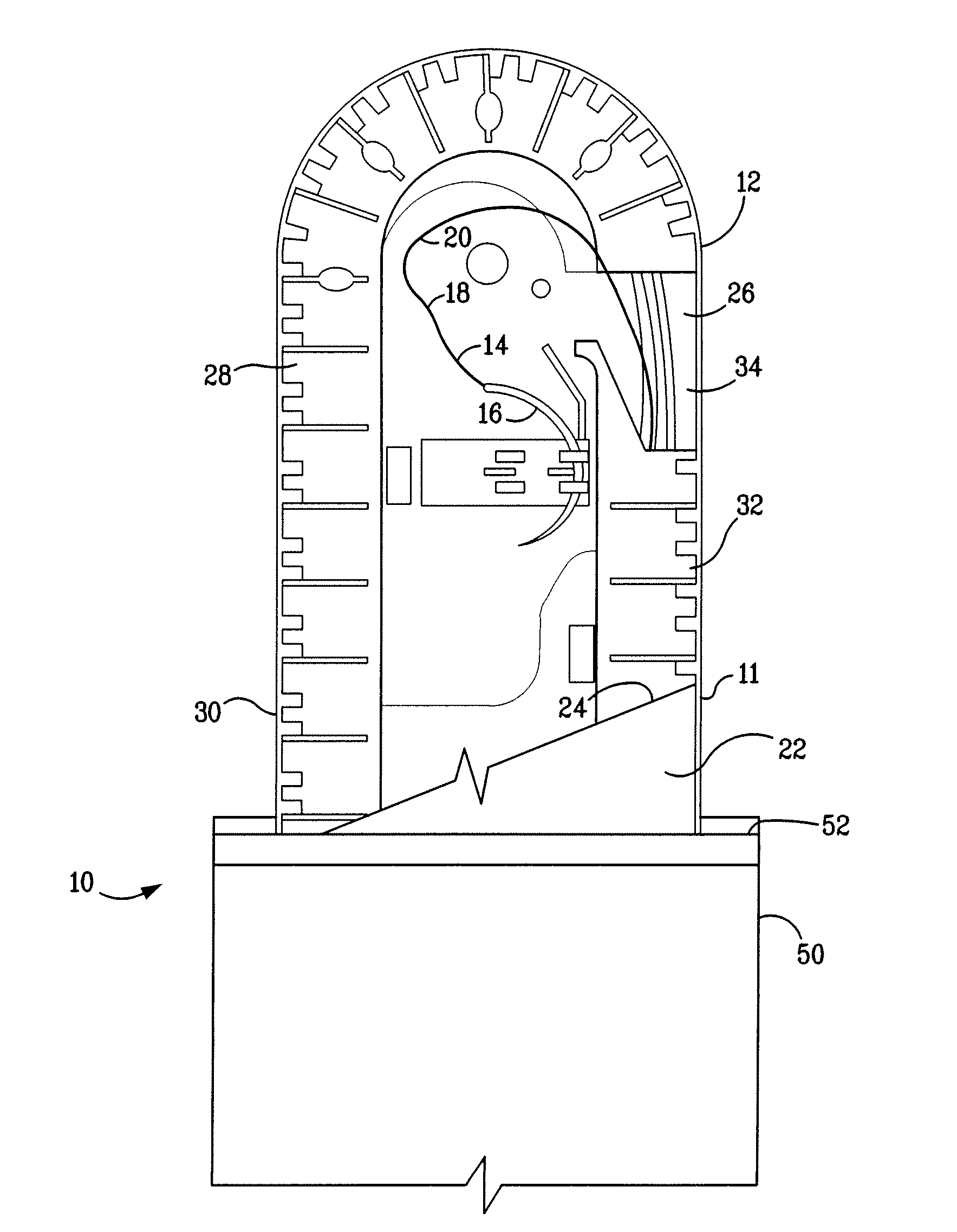

Segmented smoking article

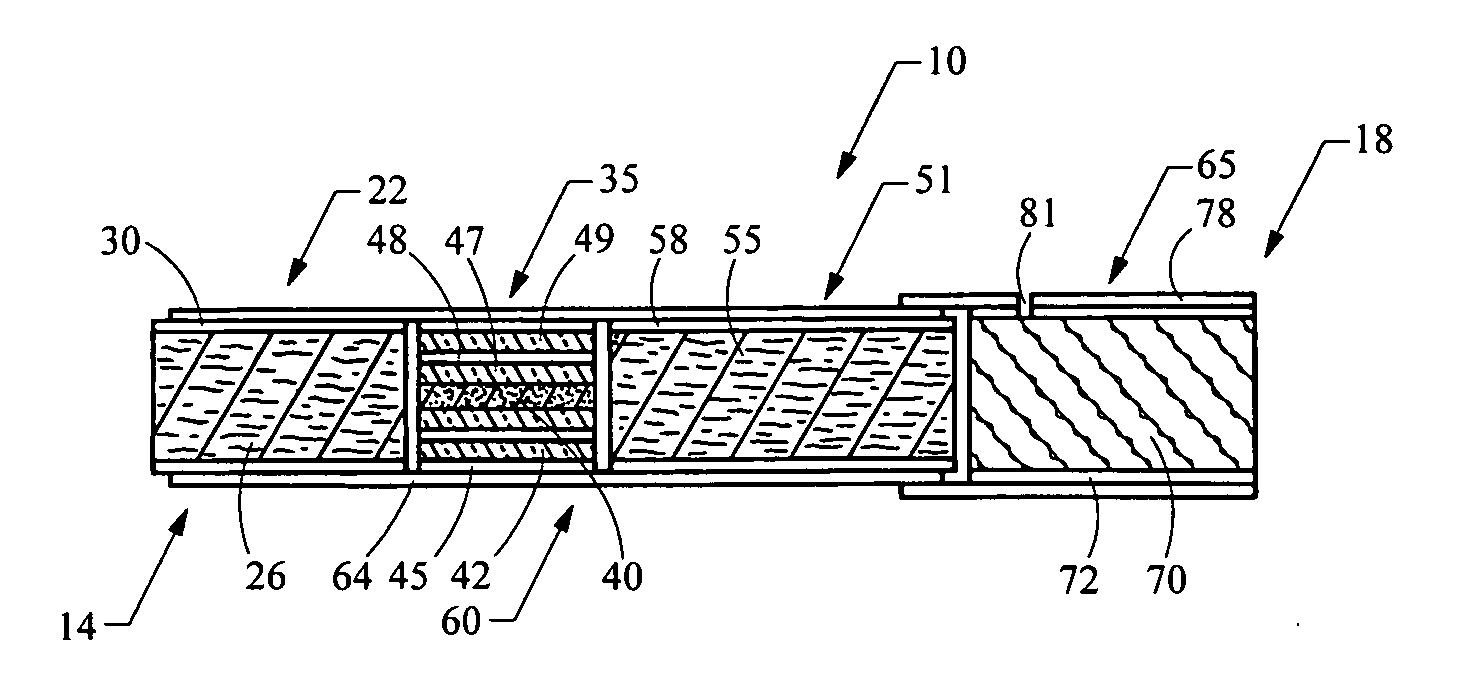

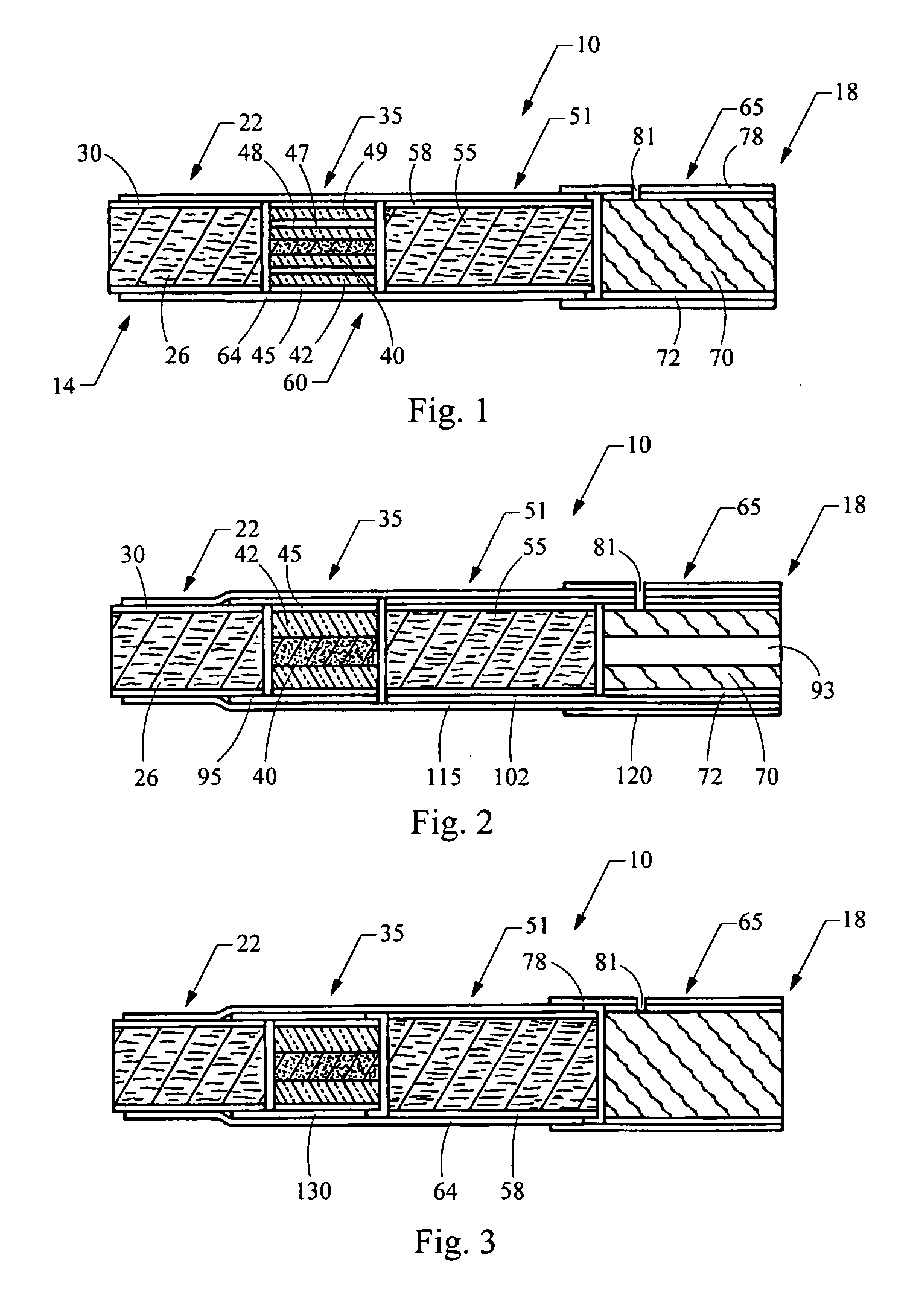

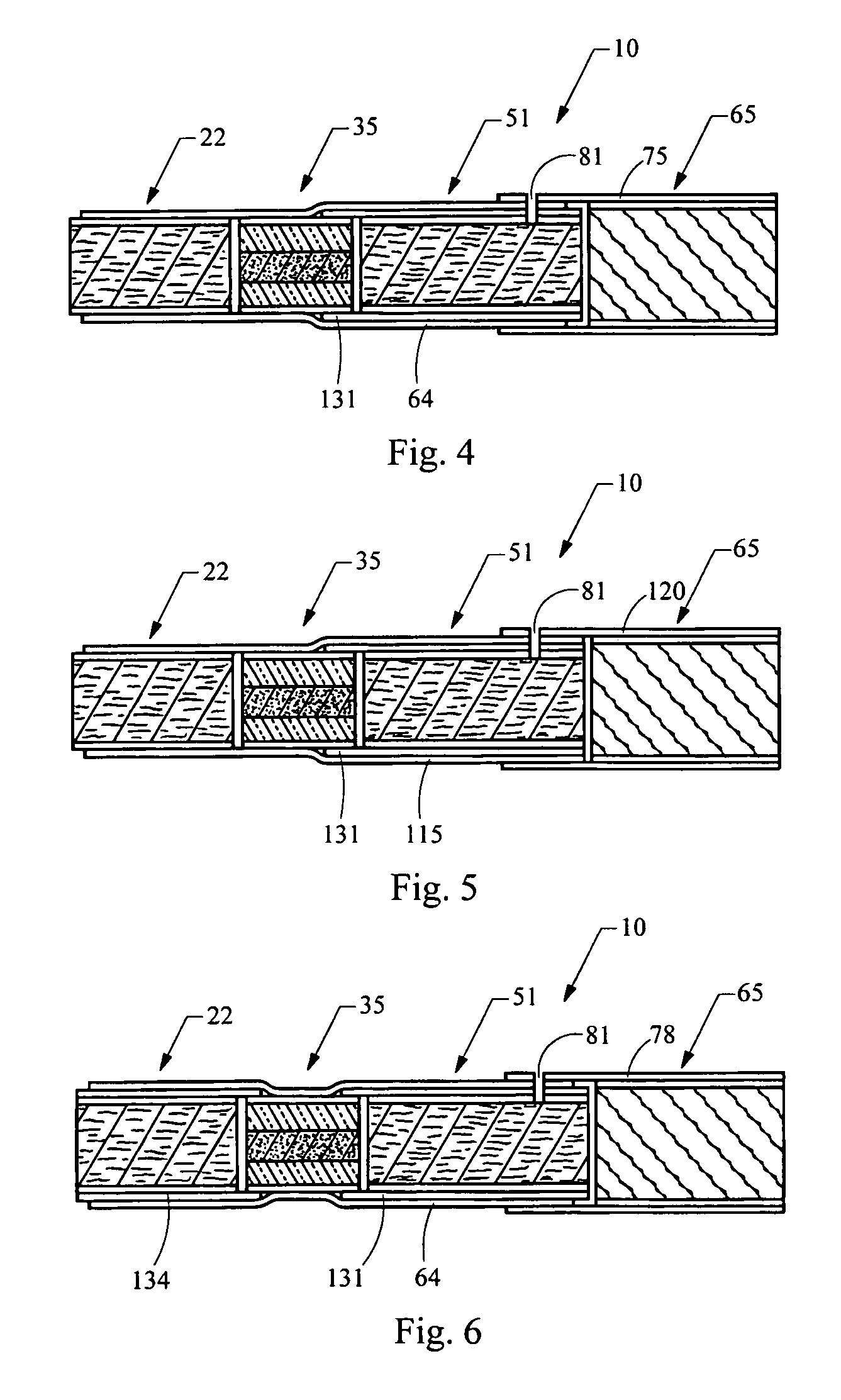

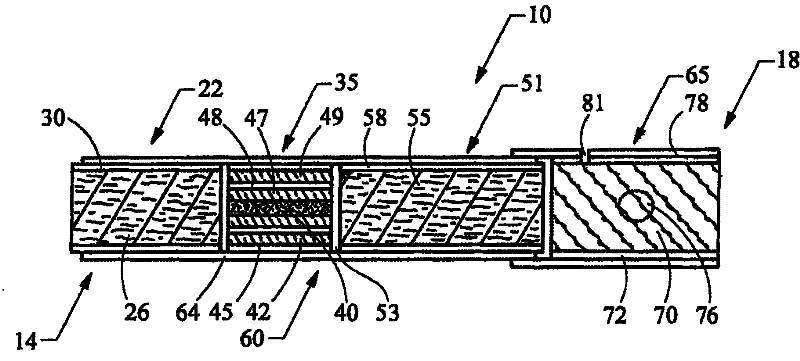

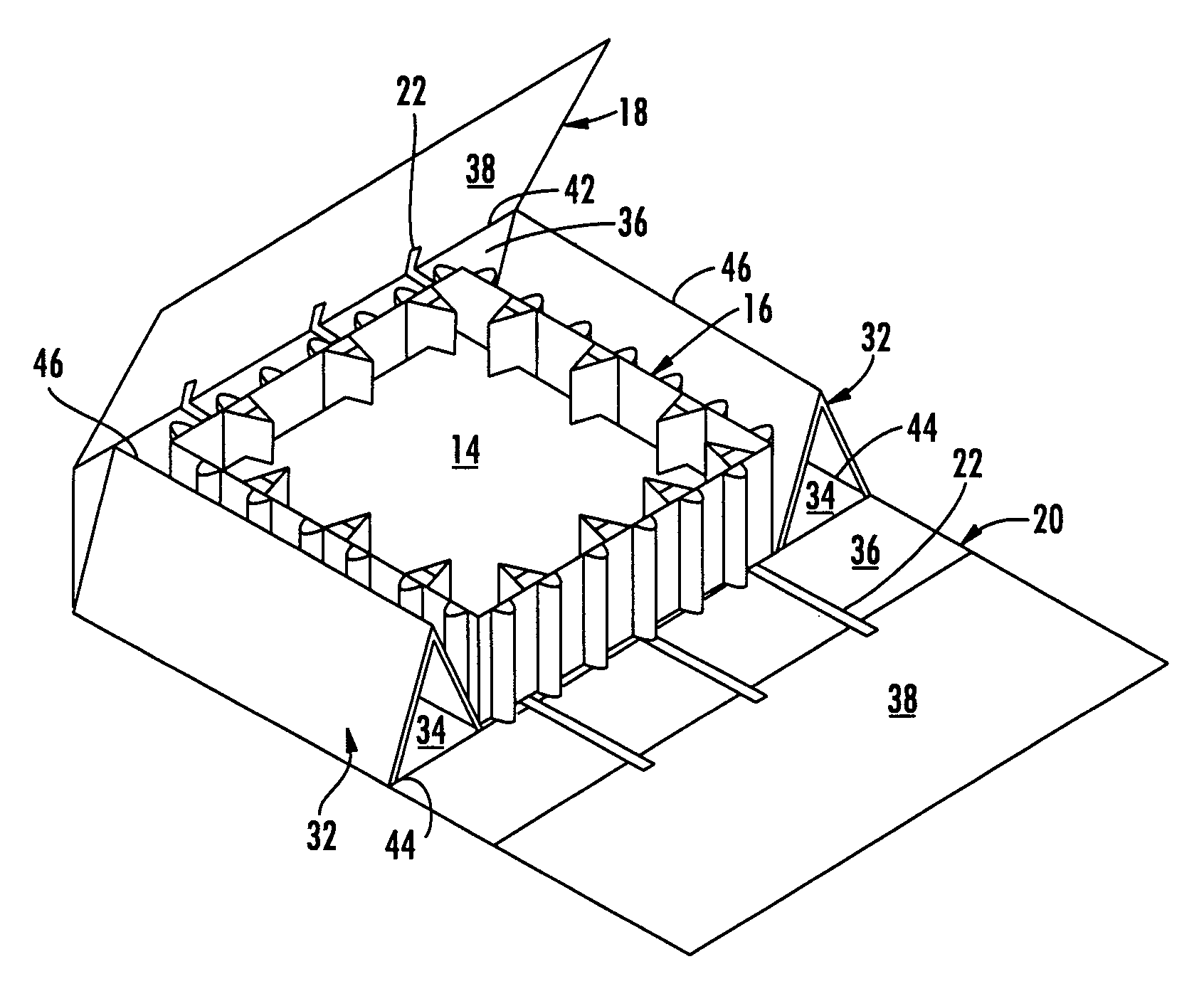

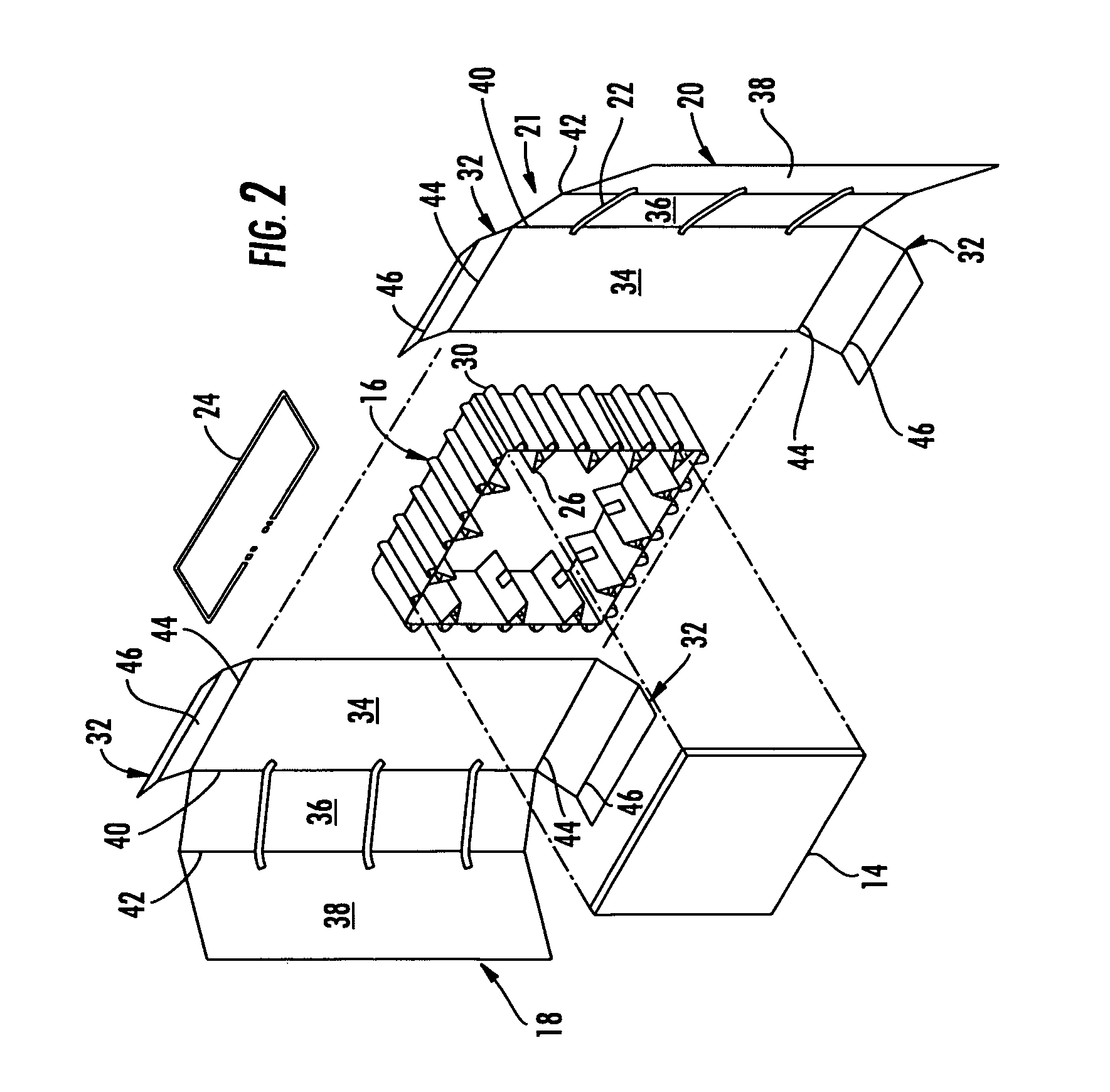

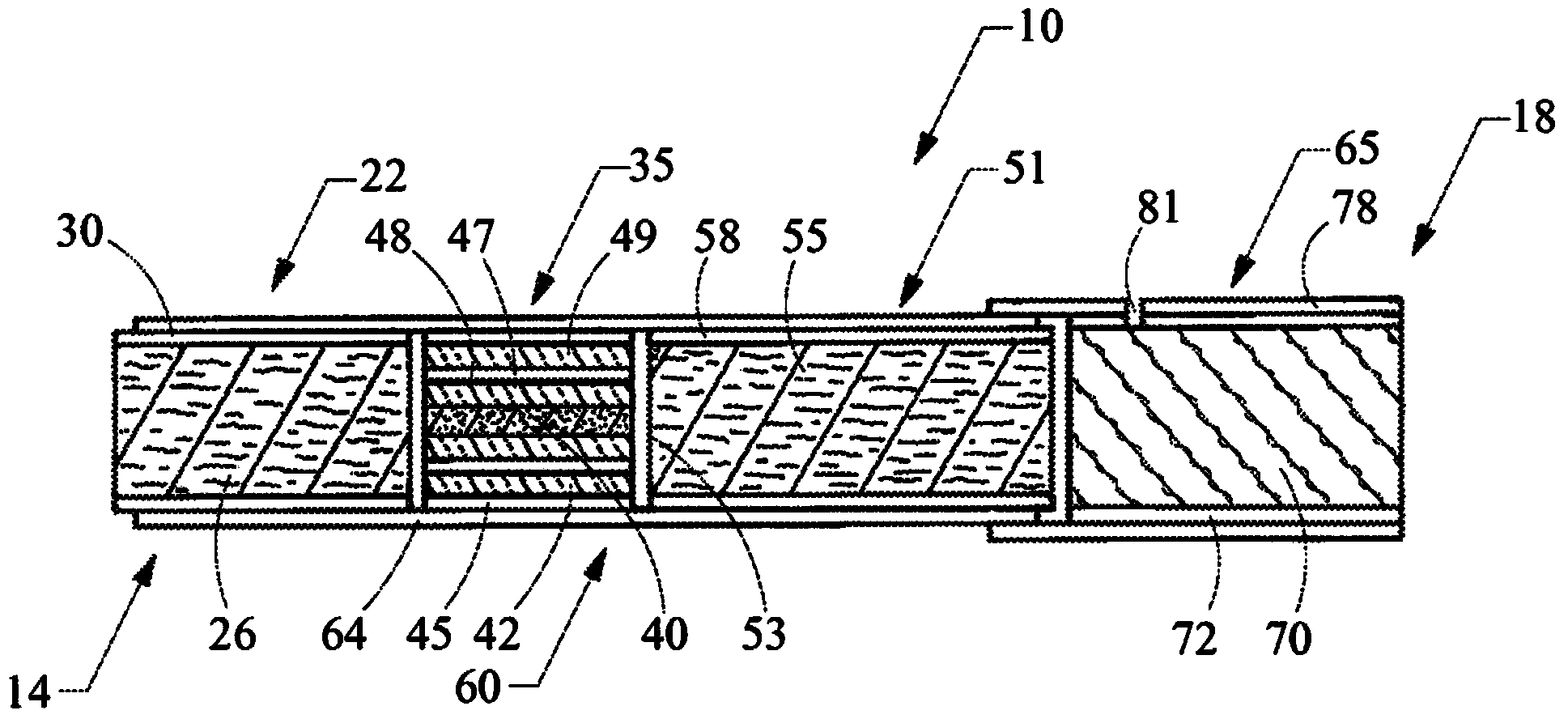

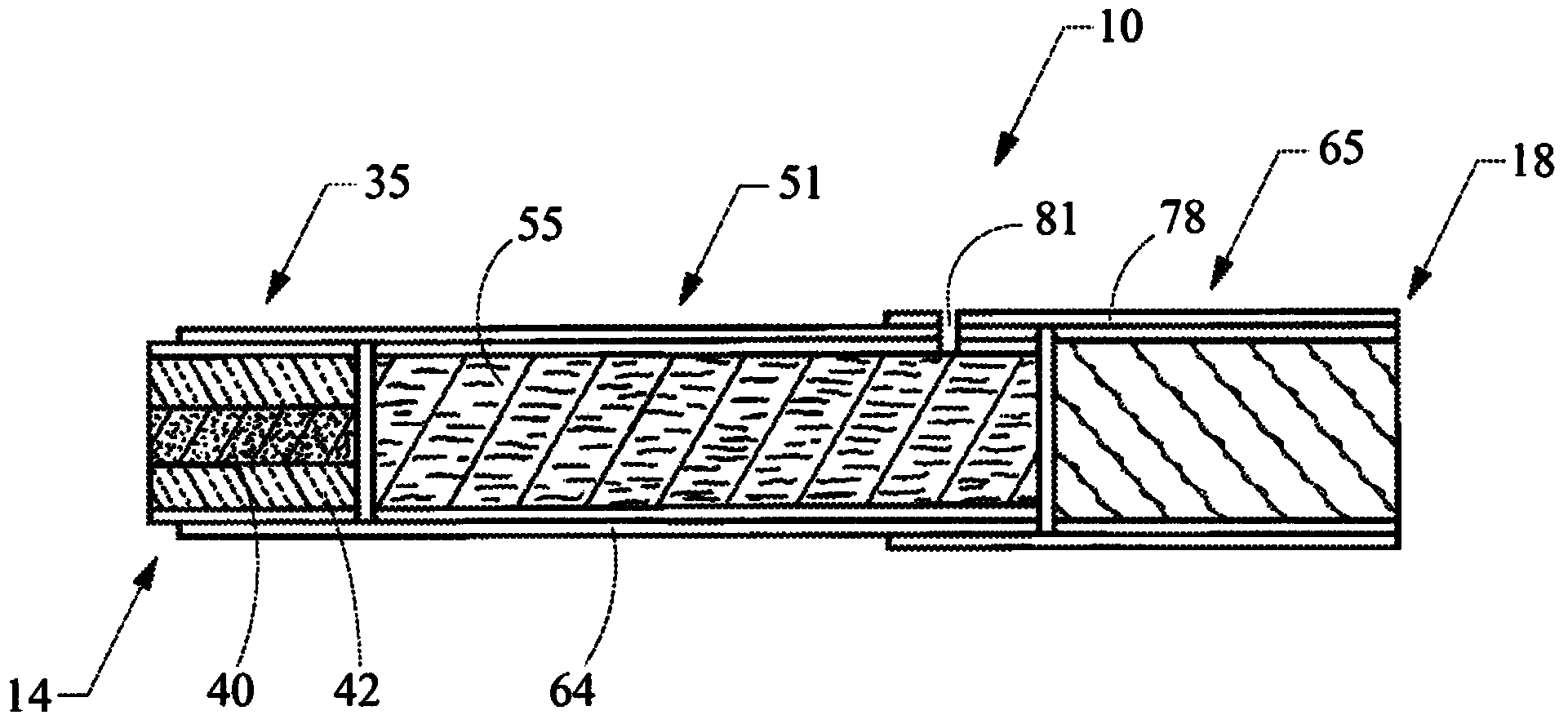

A cigarette includes lighting (14) and mouth ends (18). It may include a smokable segment (22) disposed at the lighting end. It also includes a mouth-end segment(65); an aerosol-generation system disposed between the lighting and mouth ends, which includes (i) a heat-generation segment (35) adjacent the smokable segment, including a heat source (40) configured to be activated by combustion of a smokable material and an insulation layer (42), which may be formed of a non-glass material that is woven, knit, or both and (ii) an aerosol-generating segment(51) including a substrate (55), which may be monolithic and / or which may include a stitch -bonded portion, with aerosol-forming material disposed between, but physically separate from, each of the heat generation segment and the mouth end; a piece of outer wrapping material (58) that provides an overwrap around at least a portion of the aerosol-generating segment, the heat-generation segment, and at least a portion of the smokable segment; those segments being connected together by the overwrap (64) to provide a cigarette rod; that is connected to the cigarette rod using tipping material (78).

Owner:R J REYNOLDS TOBACCO COMPANY

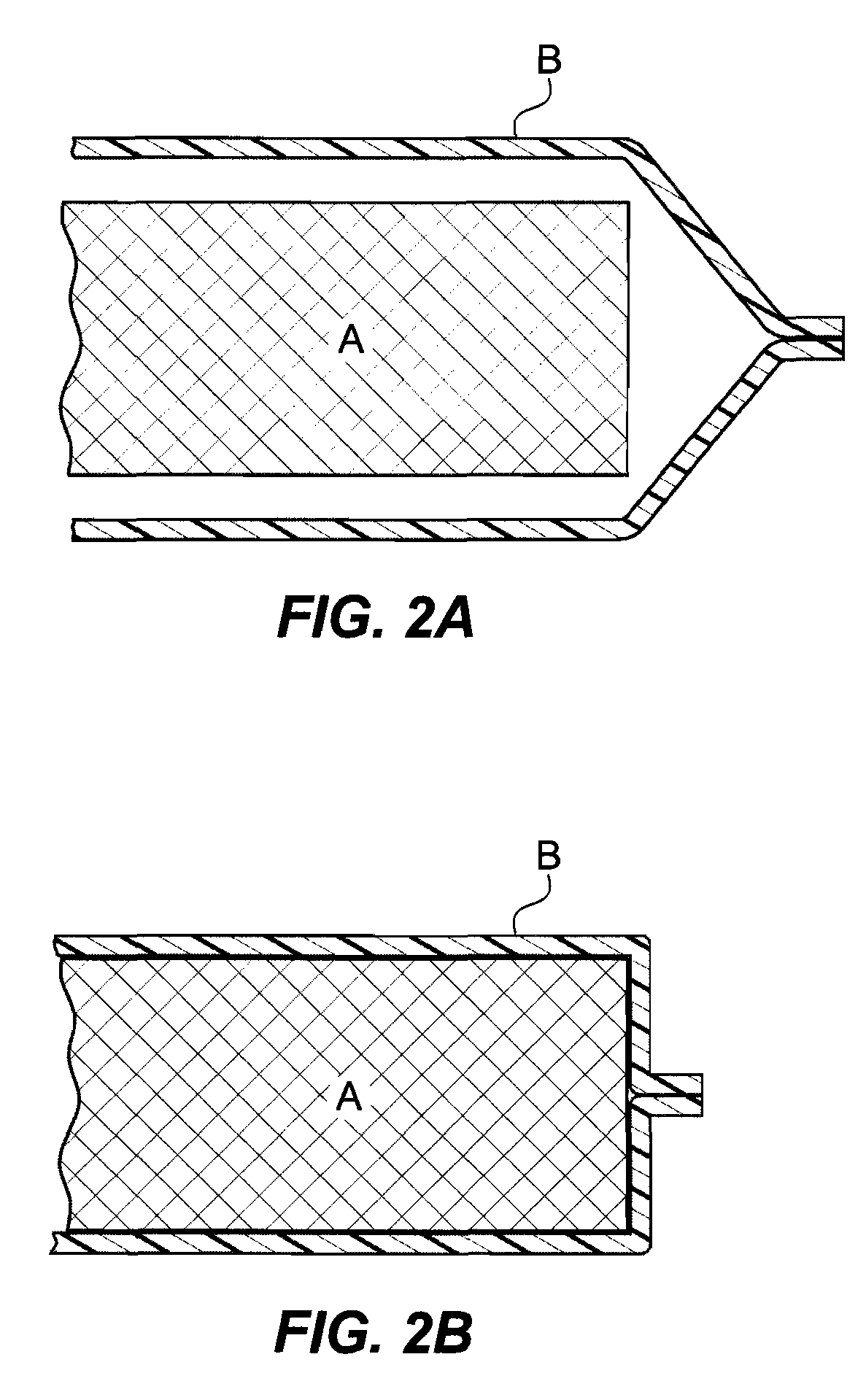

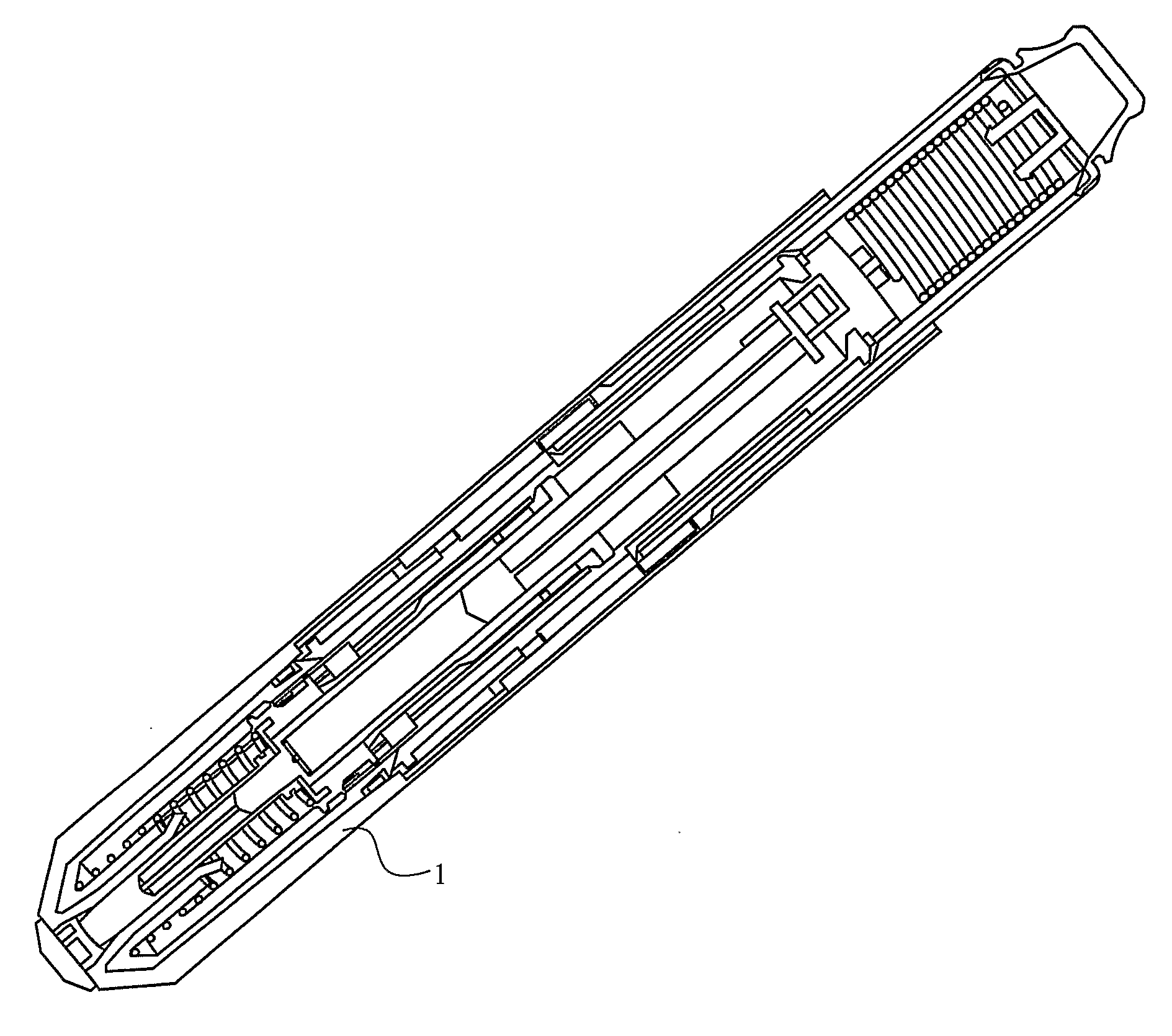

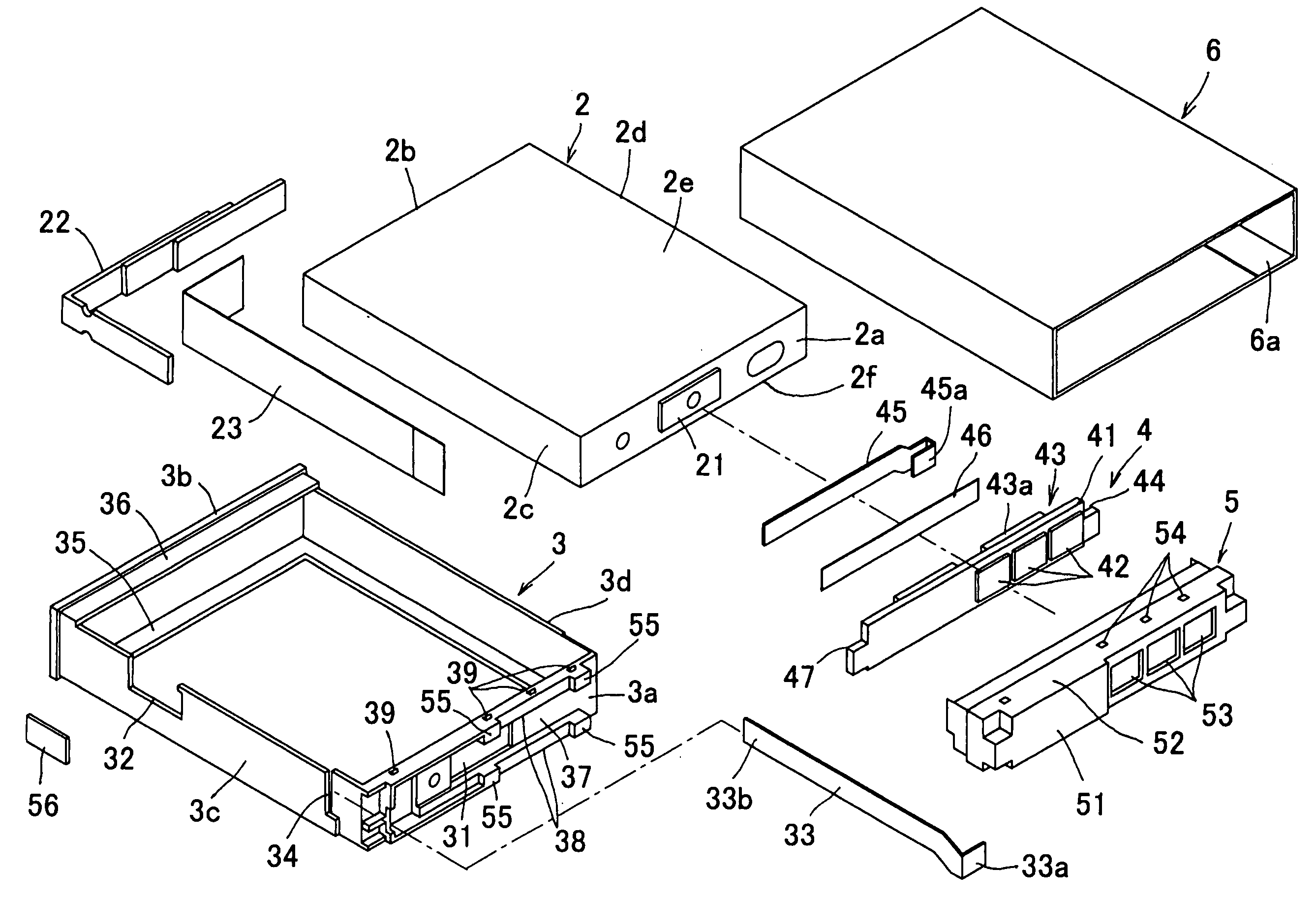

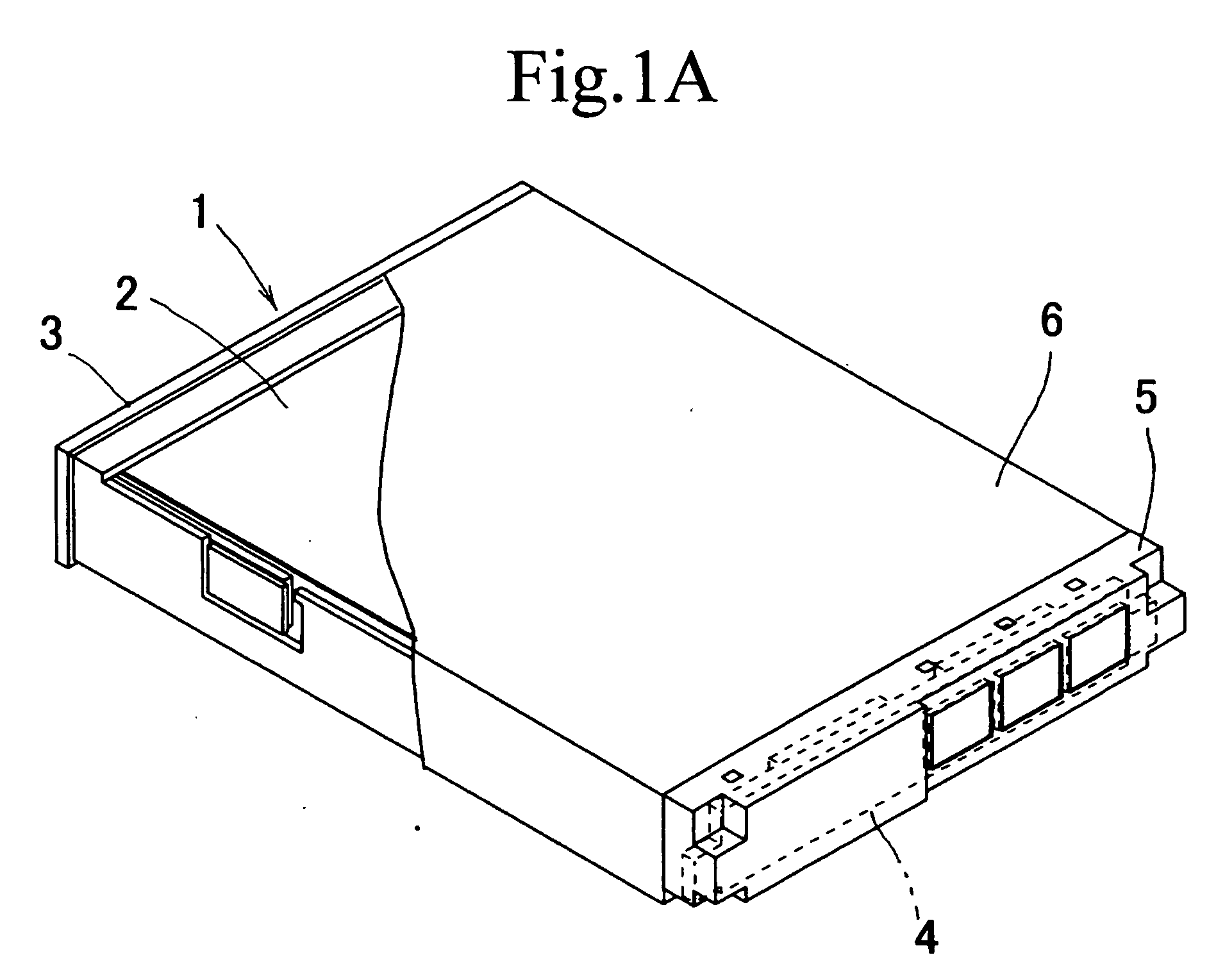

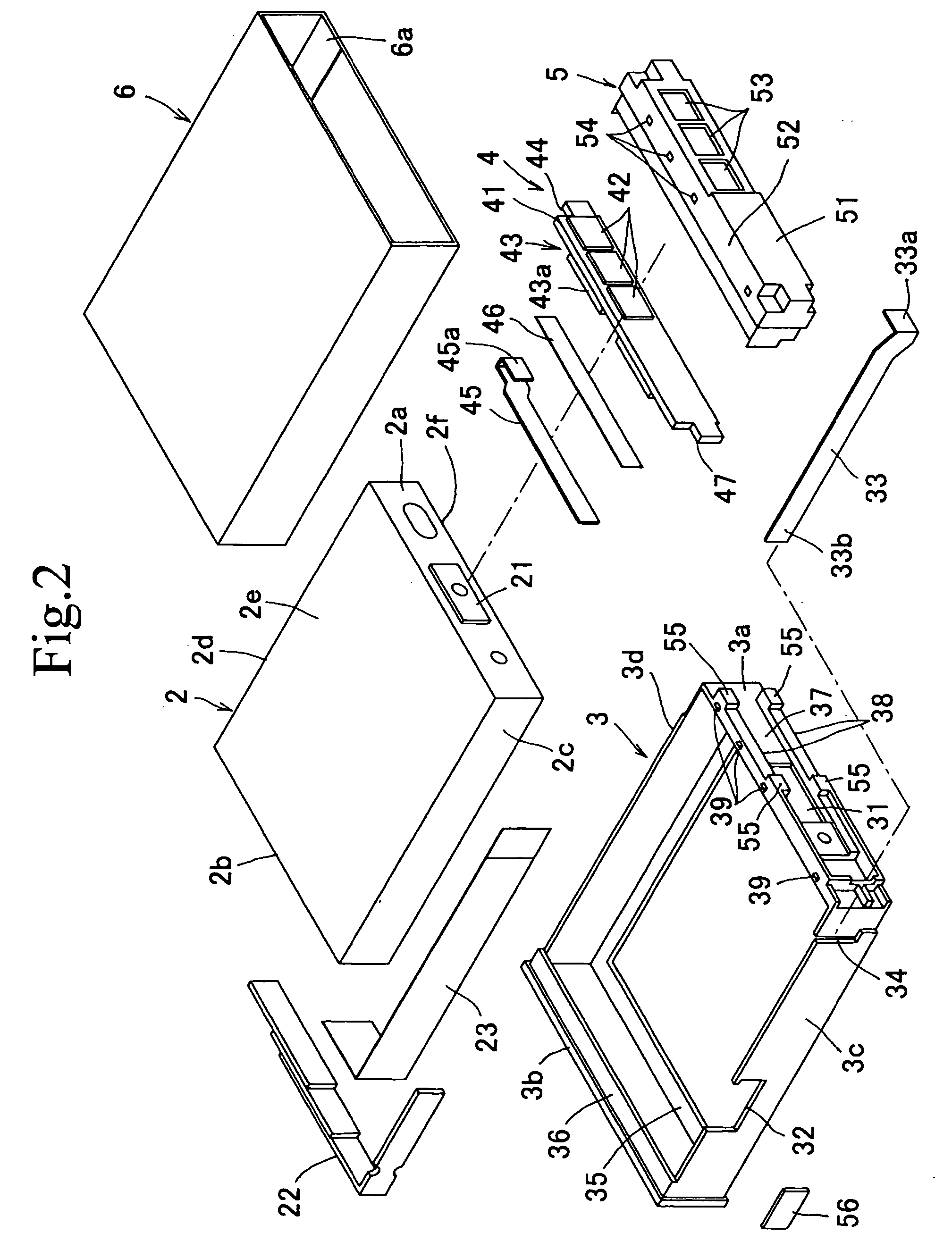

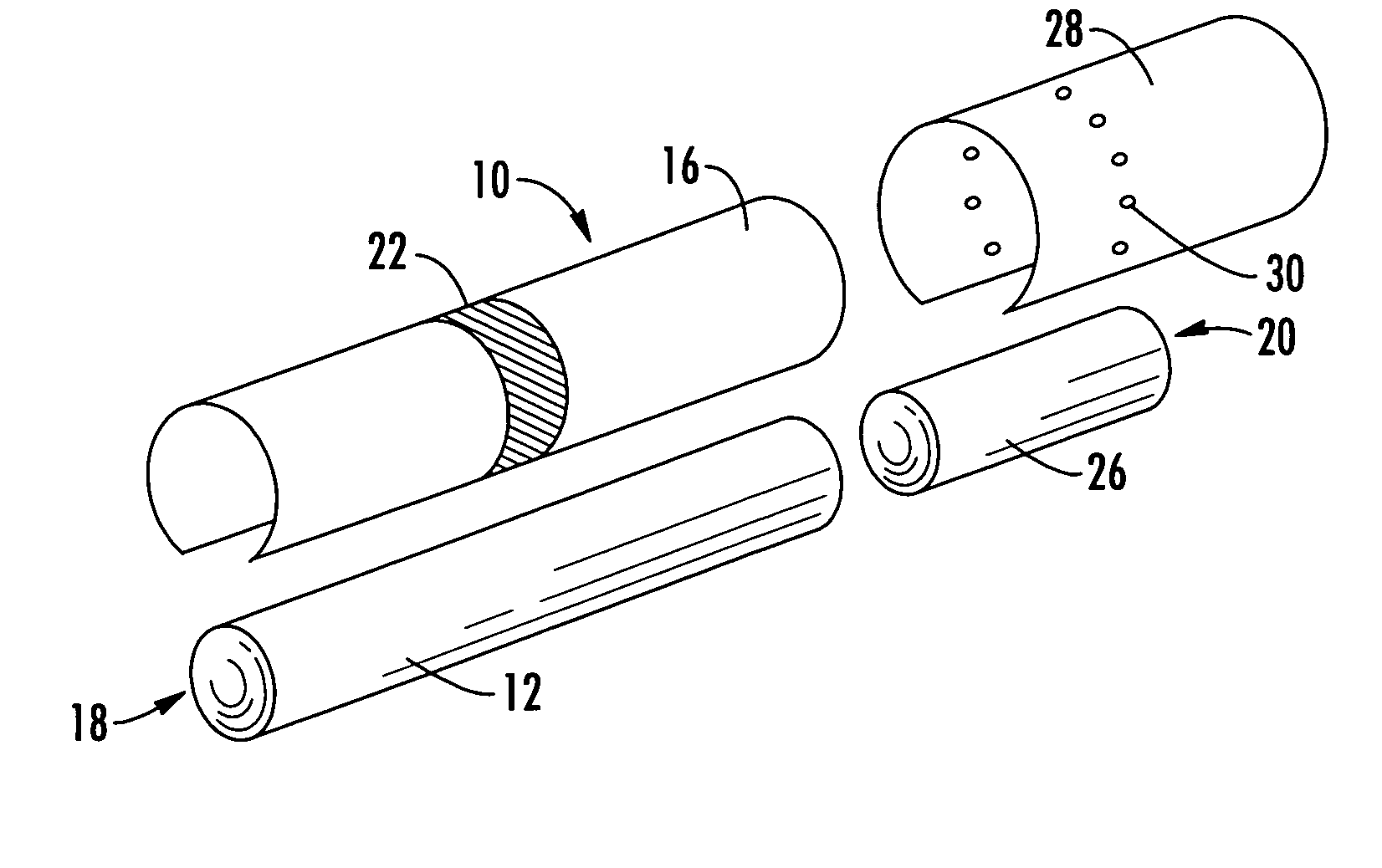

Structure of thin battery covered by outer packaging film, battery pack, and method for manufacturing battery pack

InactiveUS20050112415A1Easy to implementLow costPrimary cell maintainance/servicingFinal product manufactureBattery cellBattery pack

To provide a thinner, lighter battery pack and to reduce the cost by eliminating the need for a battery case. A thin battery pack structure using an outer packaging film (battery pack) is constructed by a flat and rectangular shaped battery cell, a flat and rectangular shaped frame portion accommodating the battery cell, a circuit board unit disposed on the outer side surface of the frame portion, a cap portion mounted on one ends of the frame portion and the battery cell so as to sandwich the circuit board unit with the outer side surface of the frame portion, and an outer packaging film for integrally covering the rectangular battery cell and the frame portion.

Owner:SONY CORP

Barrier fluoropolymer film-based liners and packaging comprising same

A container liner comprises at least one sheet bounded along portions thereof to form at least one peripheral seam, with the at least one sheet including a first fluoropolymer layer, a barrier film layer, and a third layer bonded along at least peripheral portions thereof. Any of such layers may be peripherally bonded to form a gap or pocket therebetween, or bonded along substantially entire major surfaces thereof. Surface modification may be employed to facilitate bonding of materials having otherwise dissimilar surface energies. The resulting liner is adapted for storing and dispensing high purity chemical reagents, e.g., by placing the liner in an overpack, and applying pressurizing gas to a space between the liner and the overpack for progressive compaction of the liner to dispense its contents.

Owner:ADVANCED TECH MATERIALS INC

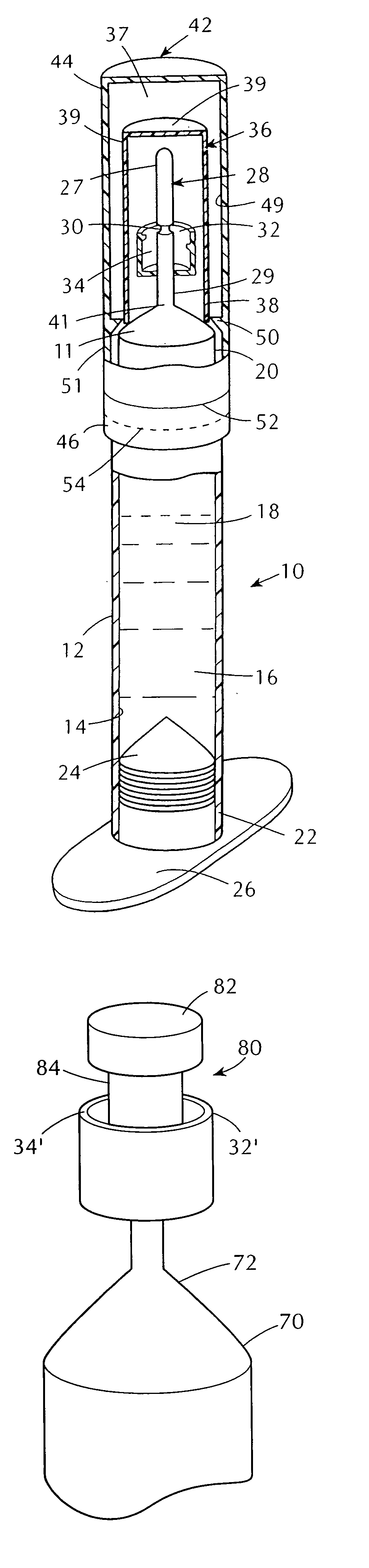

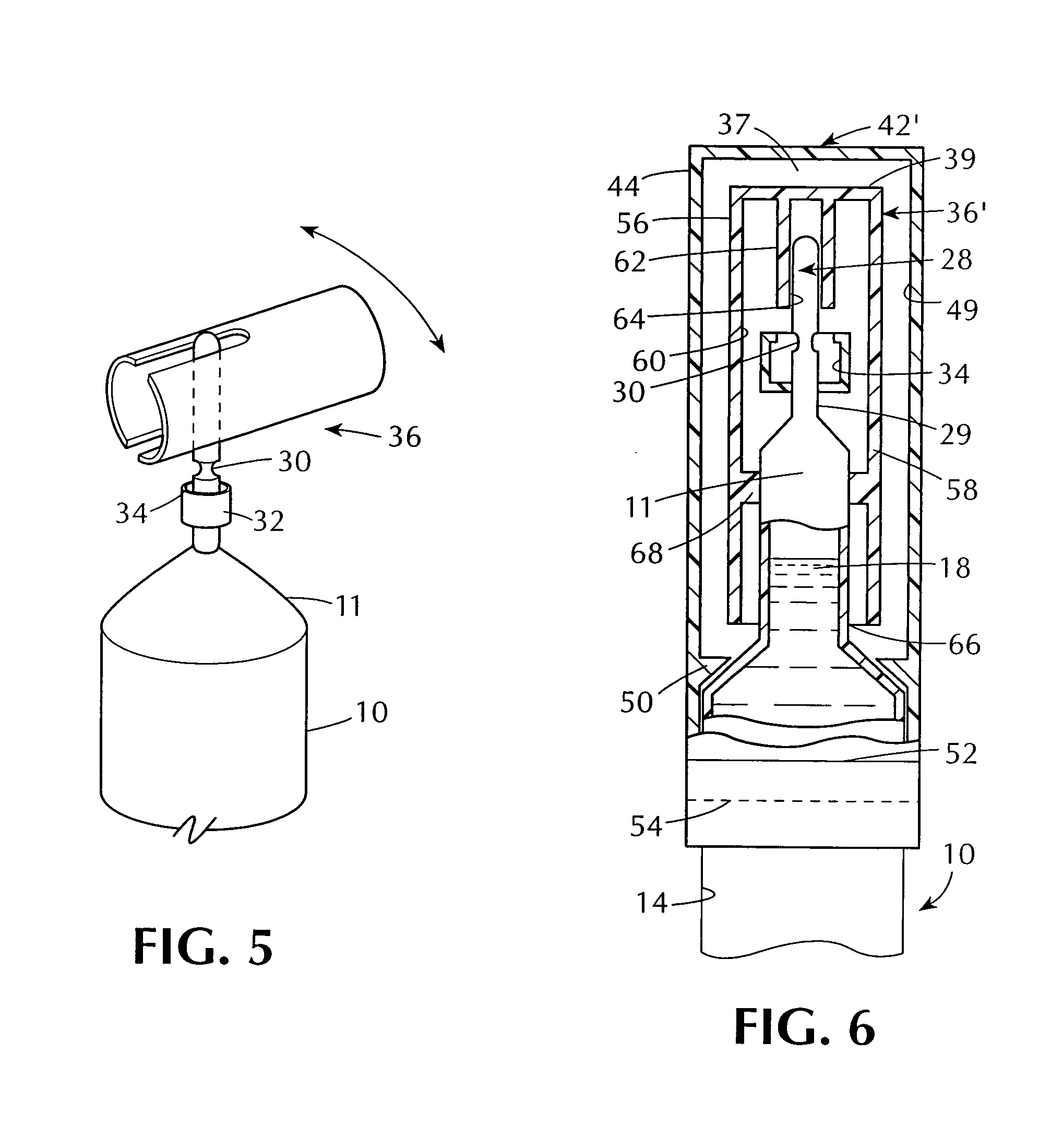

Tamper evident syringe barrel

A prefilled syringe of cartridge barrel having a tamper evident closure. Tamper evidence is provided by: a frangible tip seal which is integral with the tapered tip of the barrel; a frangible tip cap covering the tip, the tip seal and a portion of the distal end of the barrel; and an overwrap covering the frangible tip cap and the distal end of the barrel sealed to the distal end of the barrel by a tamper evident seal. The tapered tip is optionally equipped with a luer collar to receive an external luer connector. Alternatively, the tapered tip can be provided with a bore therethrough which can be closed with an elastomeric plug and the external connector can be a tubing conduit.

Owner:BRACCO DIAGNOSTICS

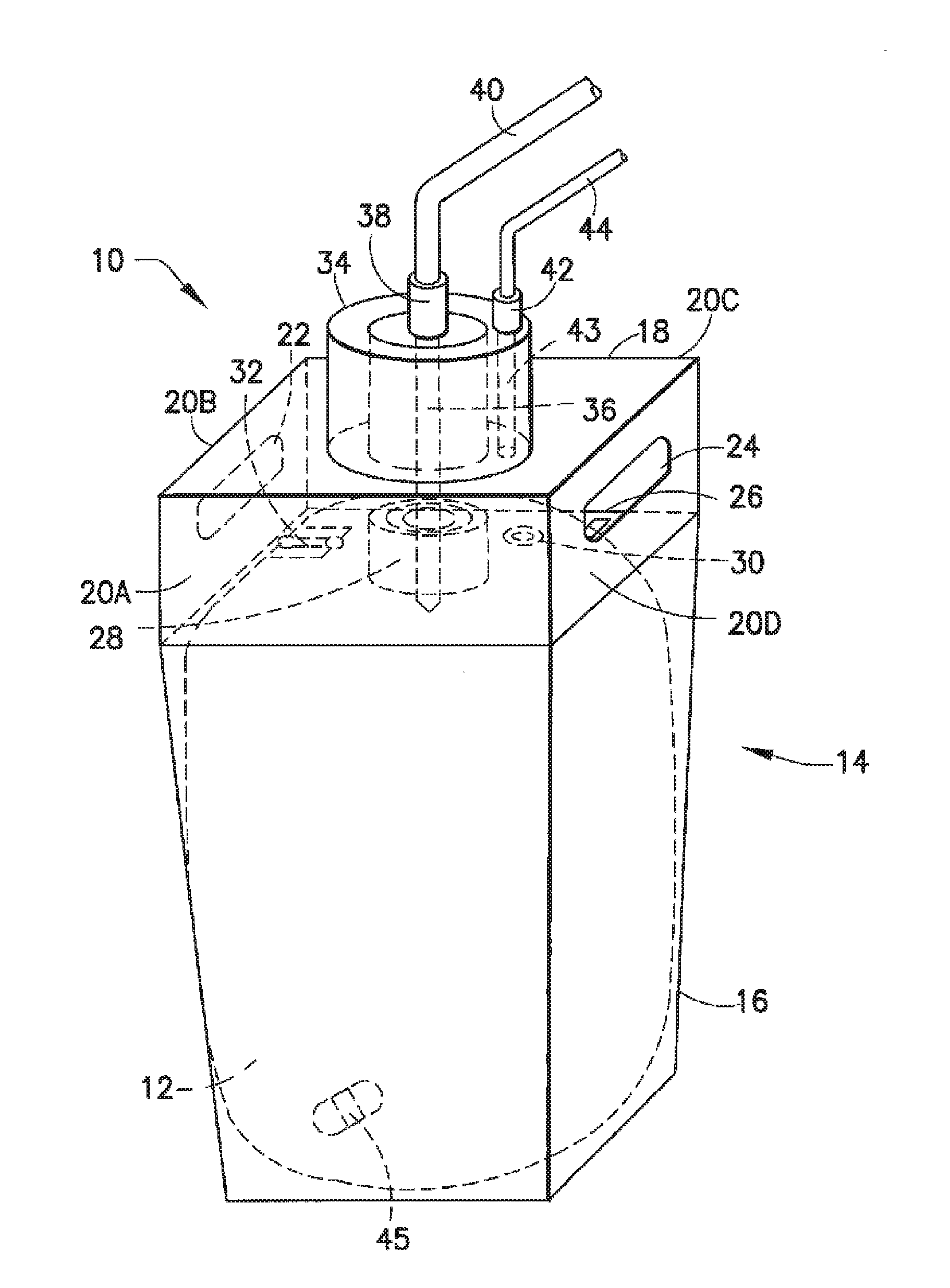

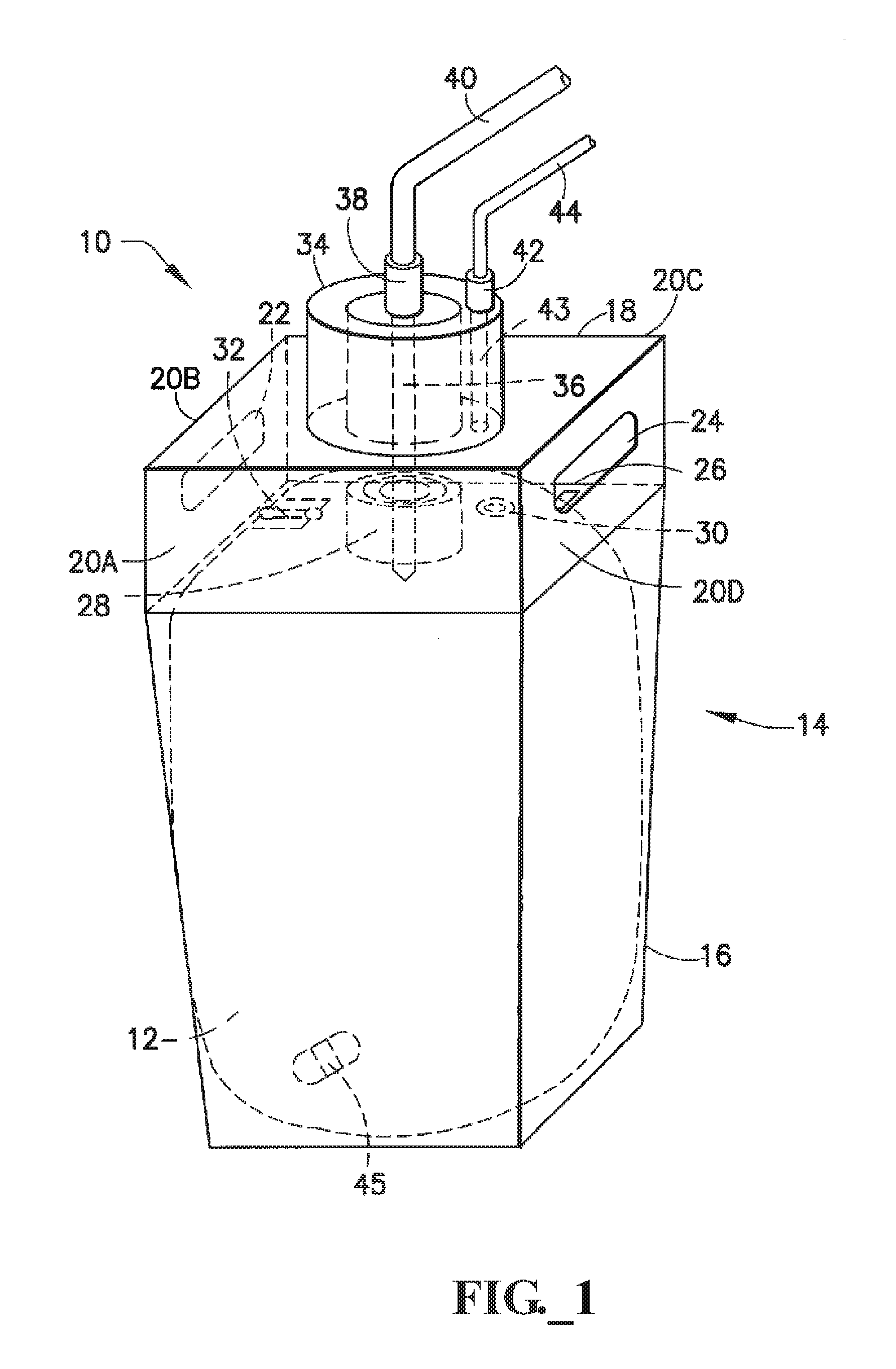

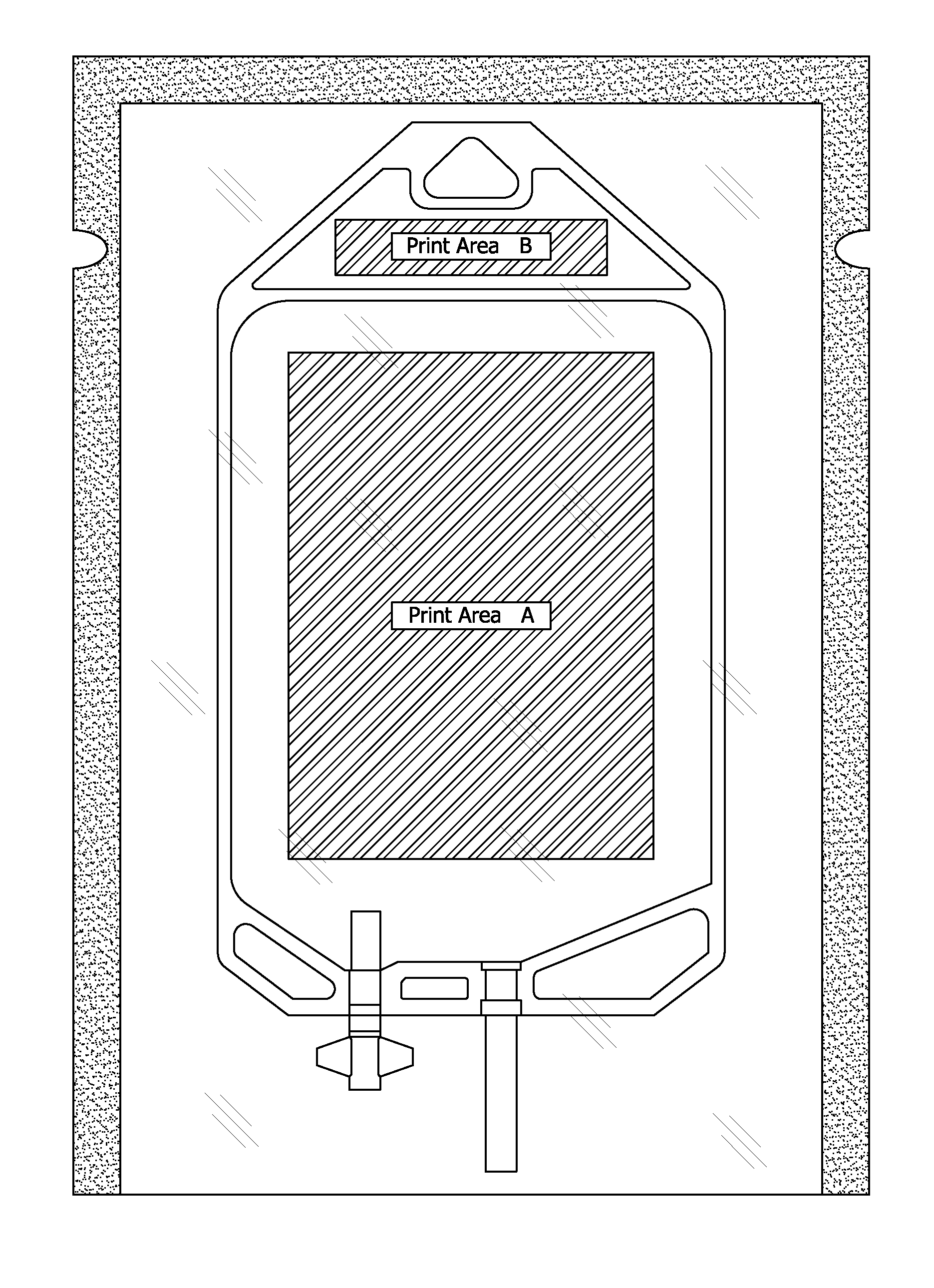

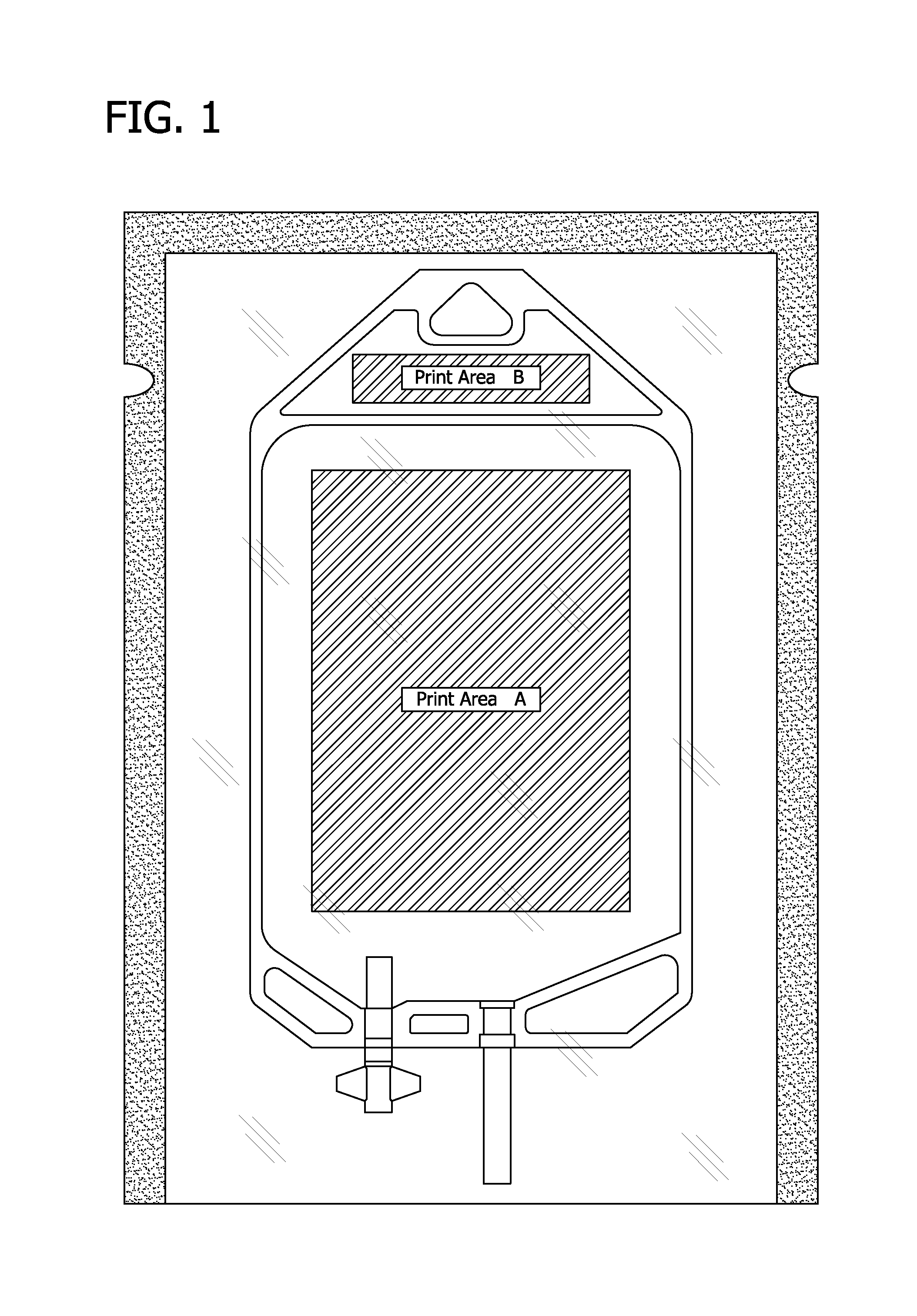

Packaging system for preserving a nonoxygenated hemoglobin based oxygen therapeutic product

The present invention relates generally to a packaging system for preserving a nonoxygenated hemoglobin based oxygen therapeutic agent. More specifically, the present invention relates to a transparent overwrap packaging system comprising a primary product contacting package, a secondary package comprising a multilayer high barrier oxygen overwrap.

Owner:SANGART INC

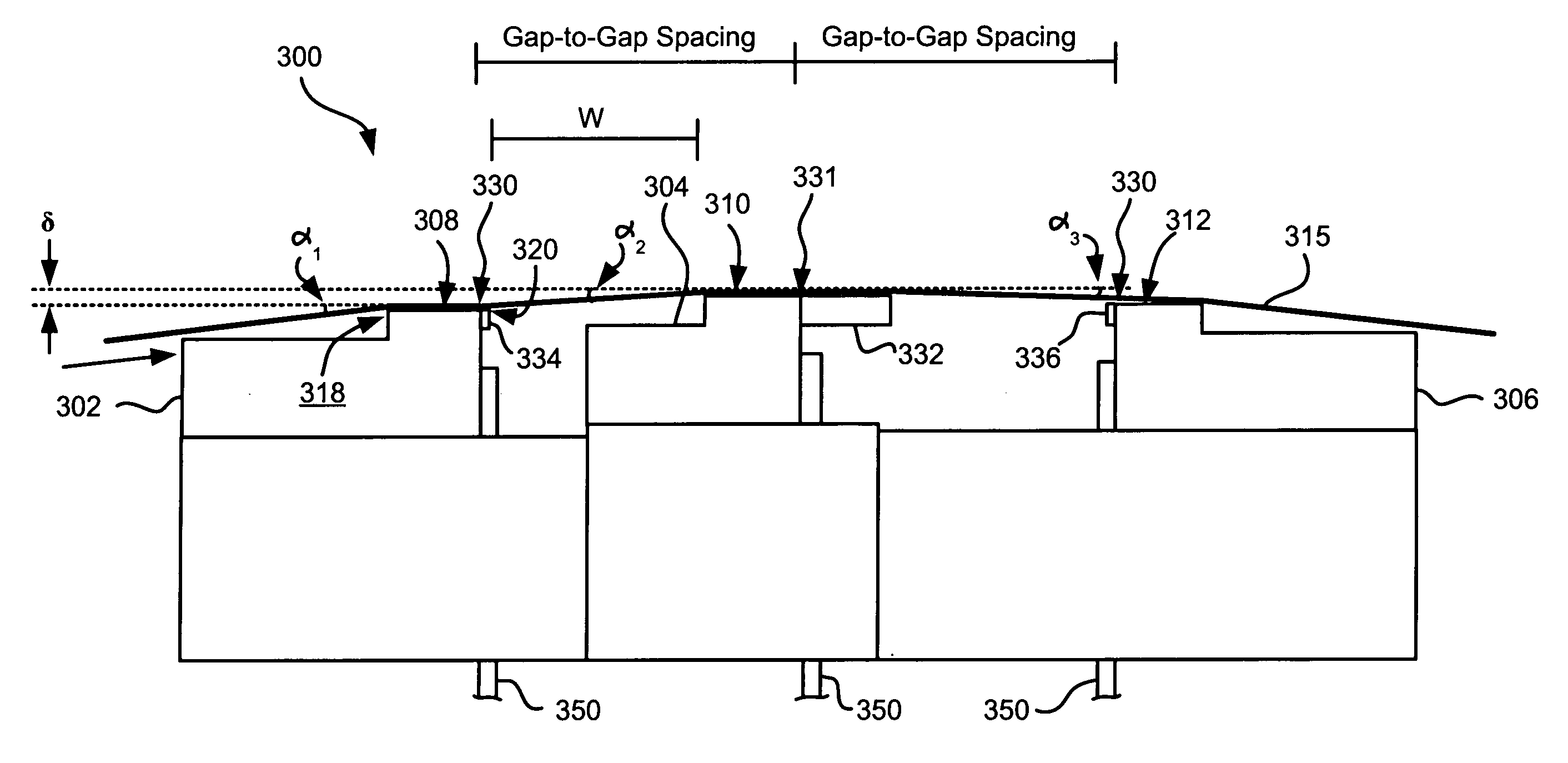

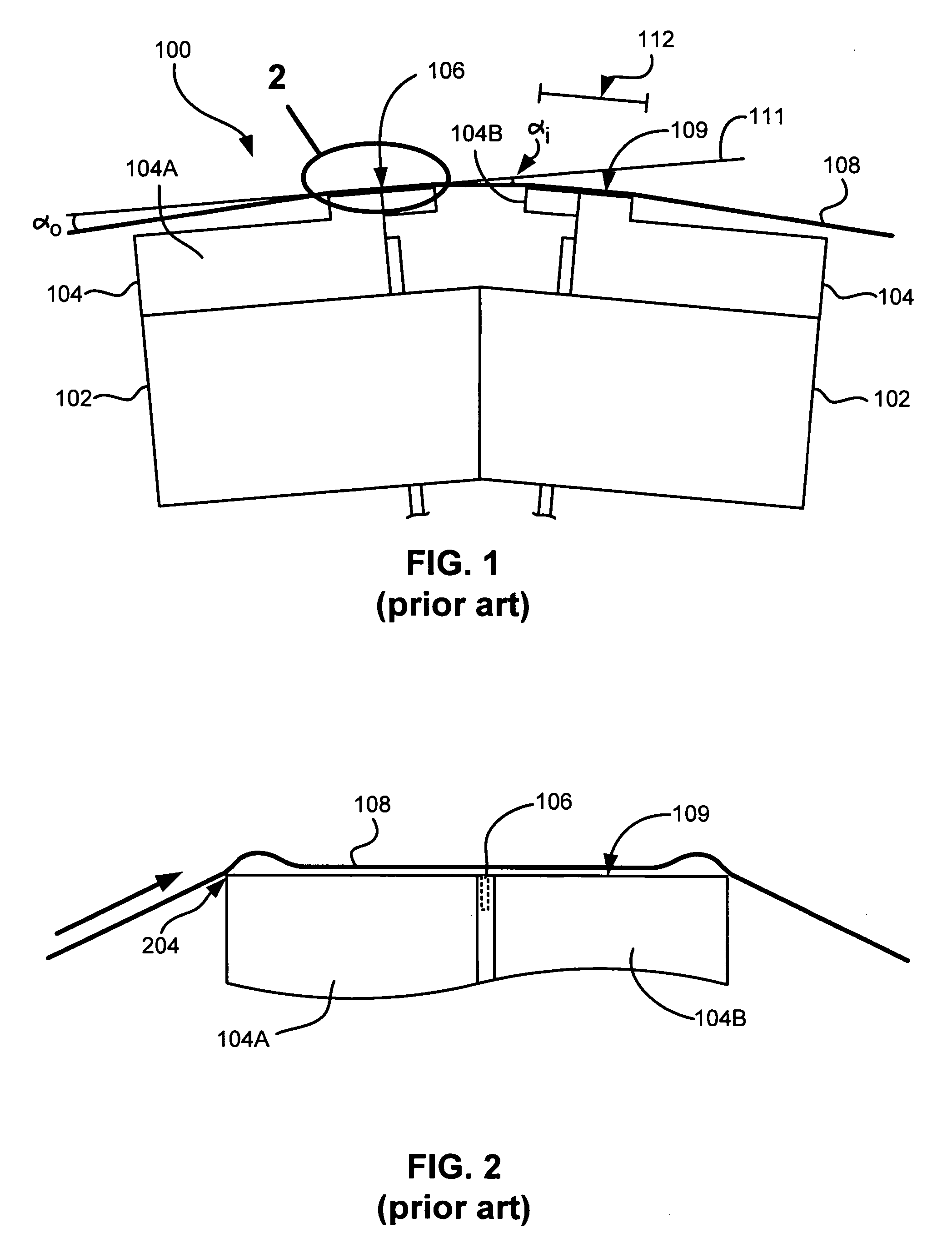

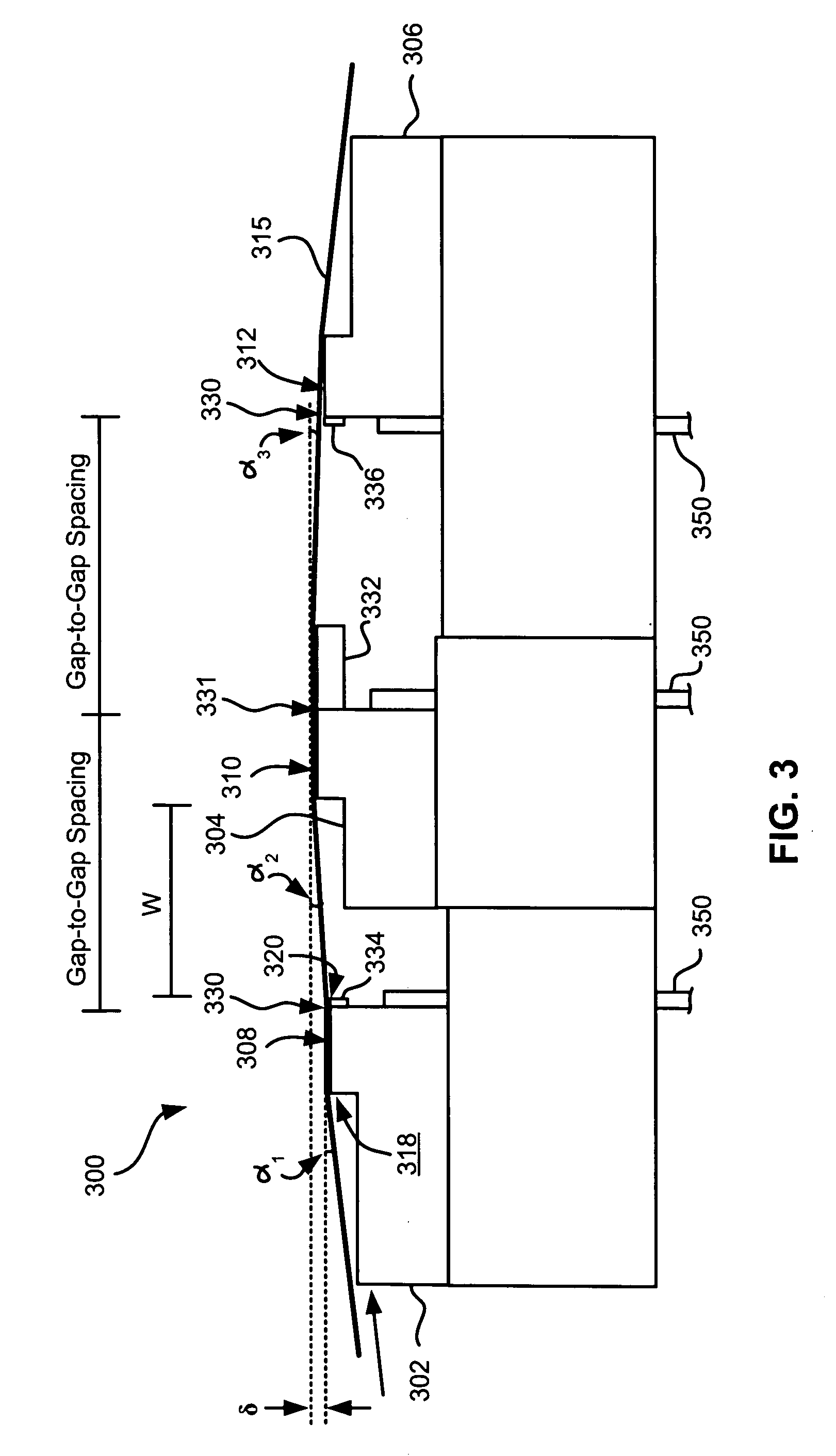

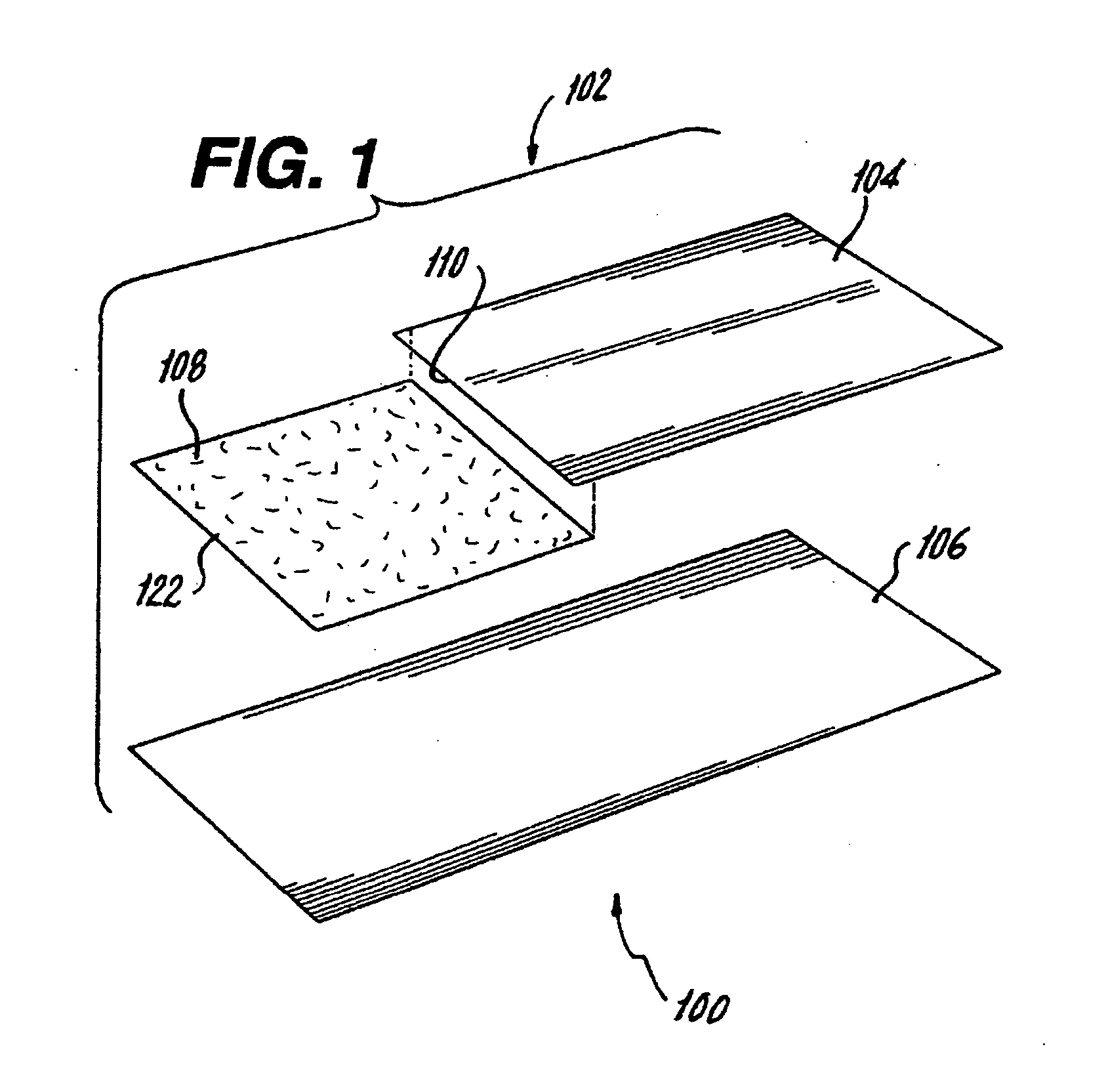

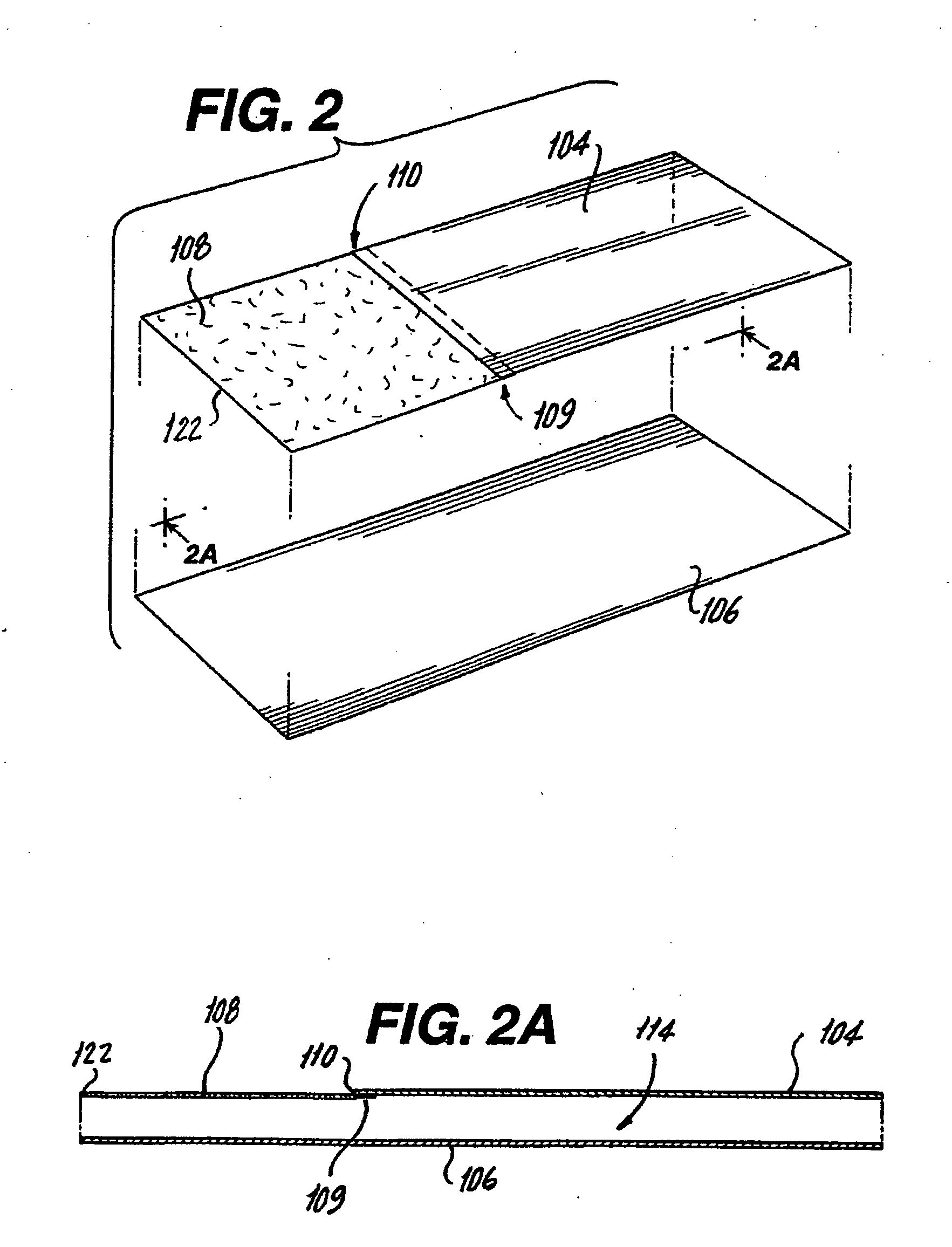

Flat profile tape head

InactiveUS20070047142A1Reduce wearAvoid excessive wearManufacture head surfaceRecord information storageEngineeringBearing surface

A magnetic head according to one embodiment includes a first module having a flat profile tape bearing surface, a second module having a flat profile tape bearing surface, and a third module having a flat profile tape bearing surface. The third module is positioned on an opposite side of the second module than the first module. The tape bearing surfaces of the first, second and third modules may lie along substantially parallel planes, may be configured in a tangent (angled) configuration, or may be configured in an overwrap configuration. Data writing and reading functions are usually performed by different modules at a given time.

Owner:IBM CORP

Segmented smoking article with insulation mat

A cigarette includes lighting and mouth ends. It may include a smokable segment disposed at the lighting end. It also includes a mouth-end segment; an aerosol-generation system disposed between the lighting and mouth ends, which includes (i) a heat-generation segment adjacent the smokable segment, including a heat source configured to be activated by combustion of a smokable material and an insulation layer of a non-glass material that is woven, knit, or both, and (ii) an aerosol-generating segment with aerosol-forming material disposed between, but physically separate from, each of the heat generation segment and the mouth end; a piece of outer wrapping material that provides an overwrap around at least a portion of the aerosol-generating segment, the heat-generation segment, and at least a portion of the smokable segment; those segments being connected together by the overwrap to provide a cigarette rod; that is connected to the cigarette rod using tipping material.

Owner:R J REYNOLDS TOBACCO COMPANY

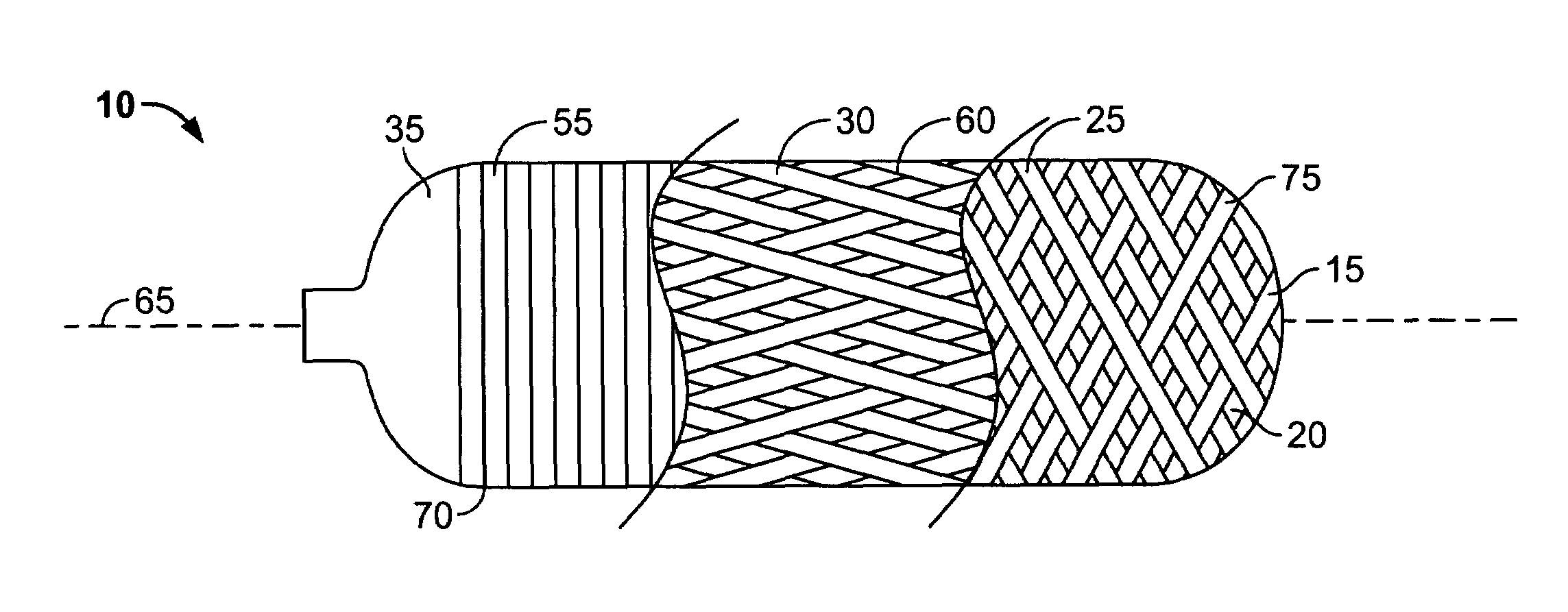

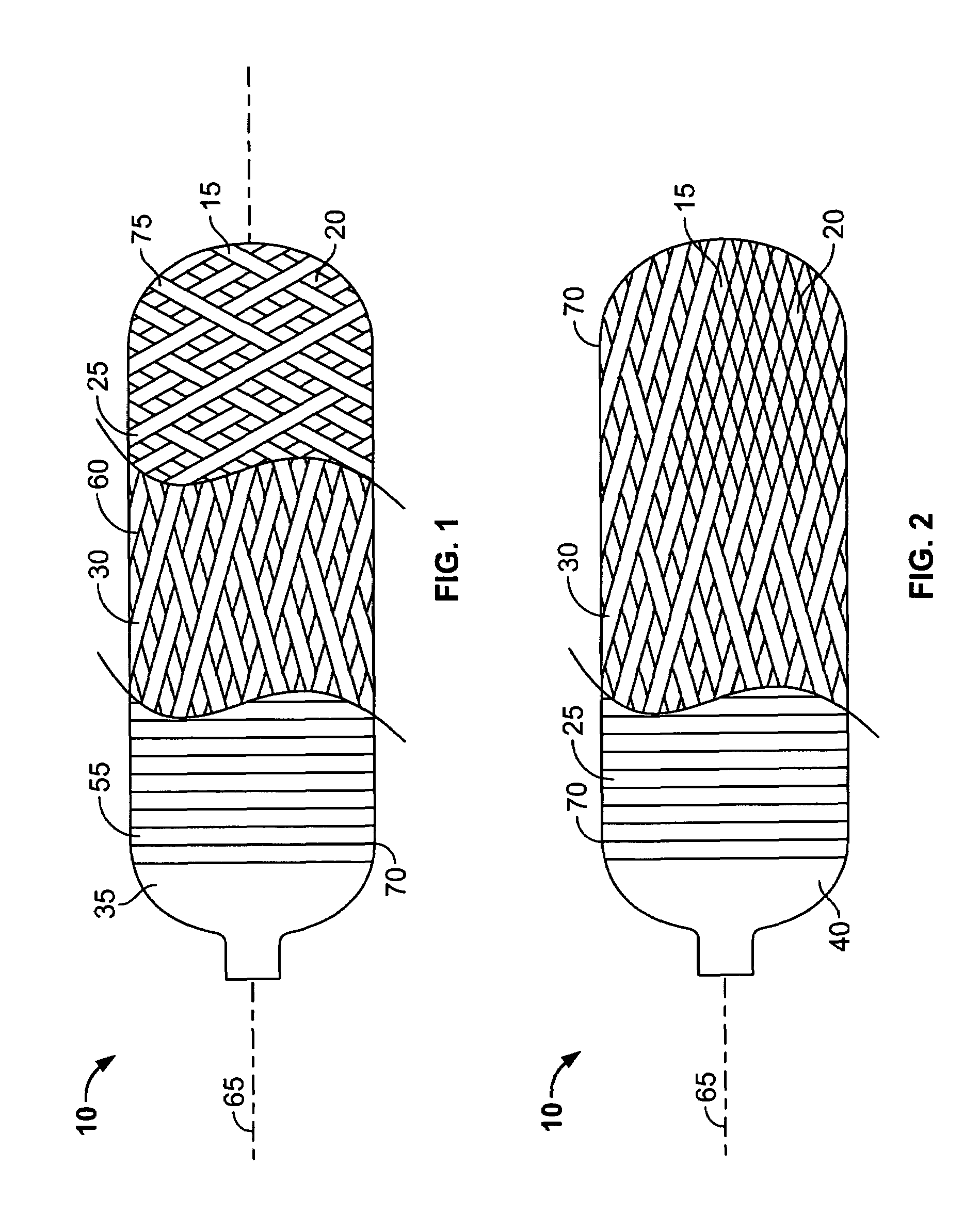

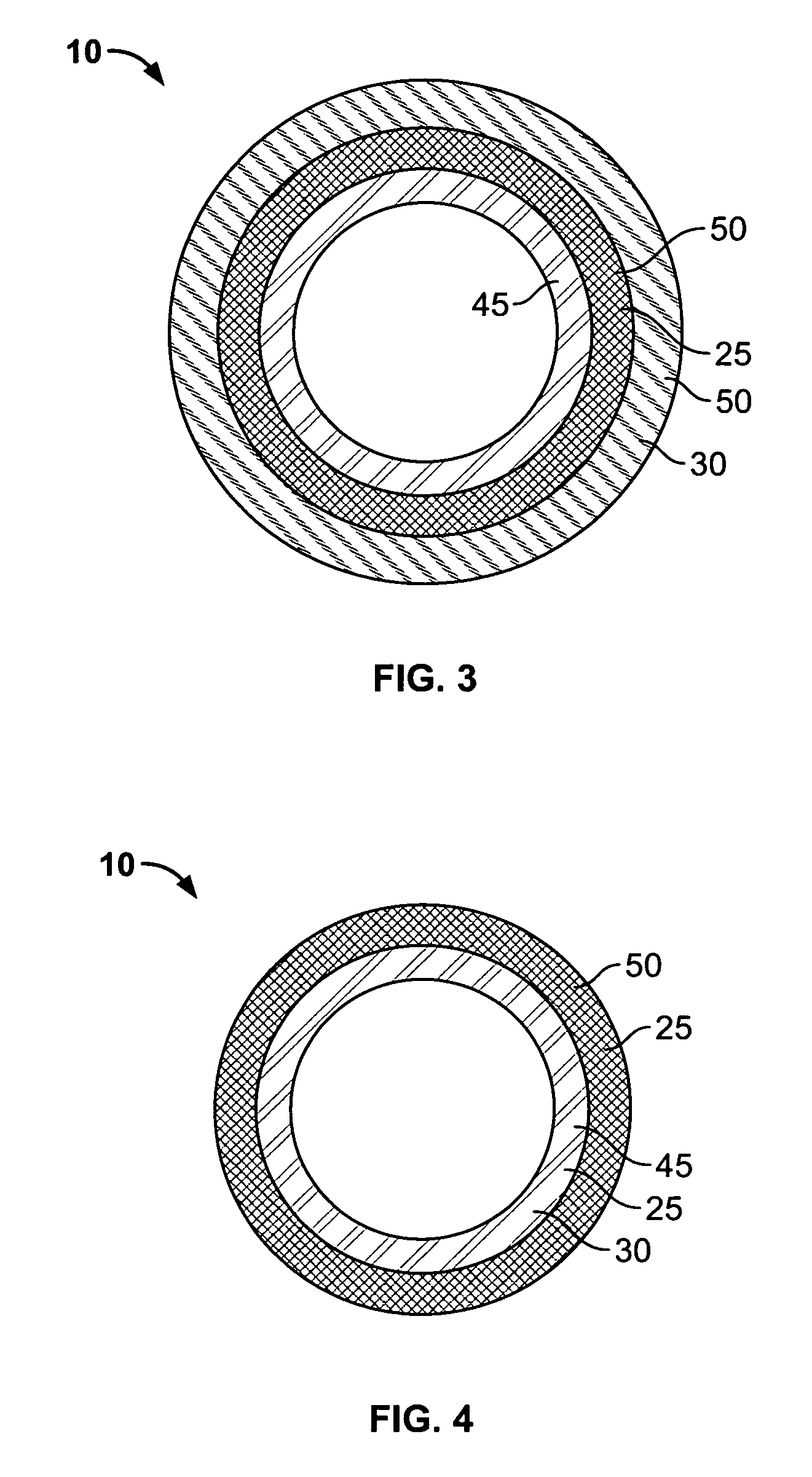

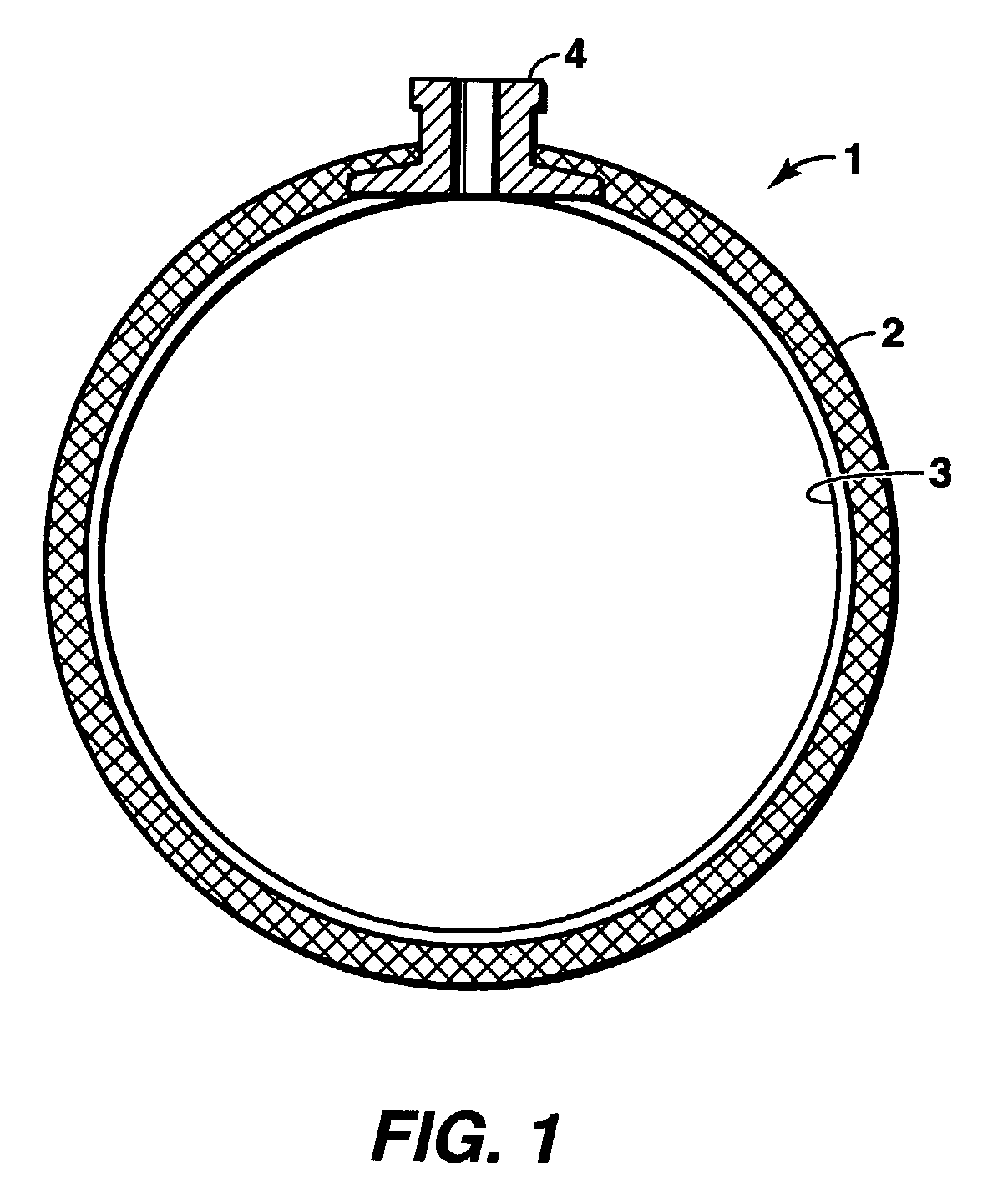

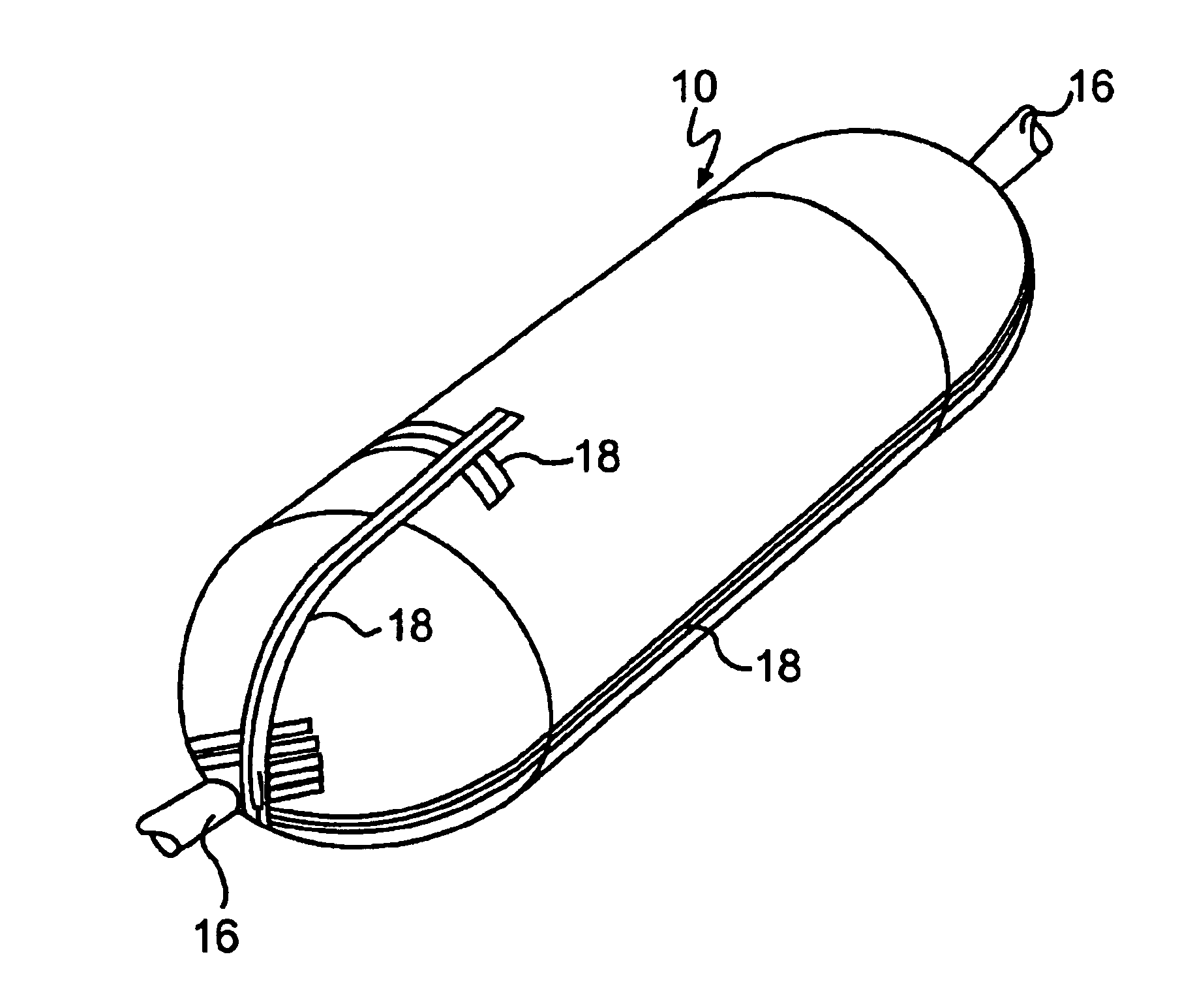

Pressure vessel with improved impact resistance and method of making the same

A composite overwrapped pressure vessel is provided which includes a composite overwrapping material including fibers disposed in a resin matrix. At least first and second kinds of fibers are used. These fibers typically have characteristics of high strength and high toughness to provide impact resistance with increased pressure handling capability and low weight. The fibers are applied to form a pressure vessel using wrapping or winding techniques with winding angles varied for specific performance characteristics. The fibers of different kinds are dispersed in a single layer of winding or wound in distinct separate layers. Layers of fabric comprised of such fibers are interspersed between windings for added strength or impact resistance. The weight percentages of the high toughness and high strength materials are varied to provide specified impact resistance characteristics. The resin matrix is formed with prepregnated fibers or through wet winding. The vessels are formed with or without liners.

Owner:NASA

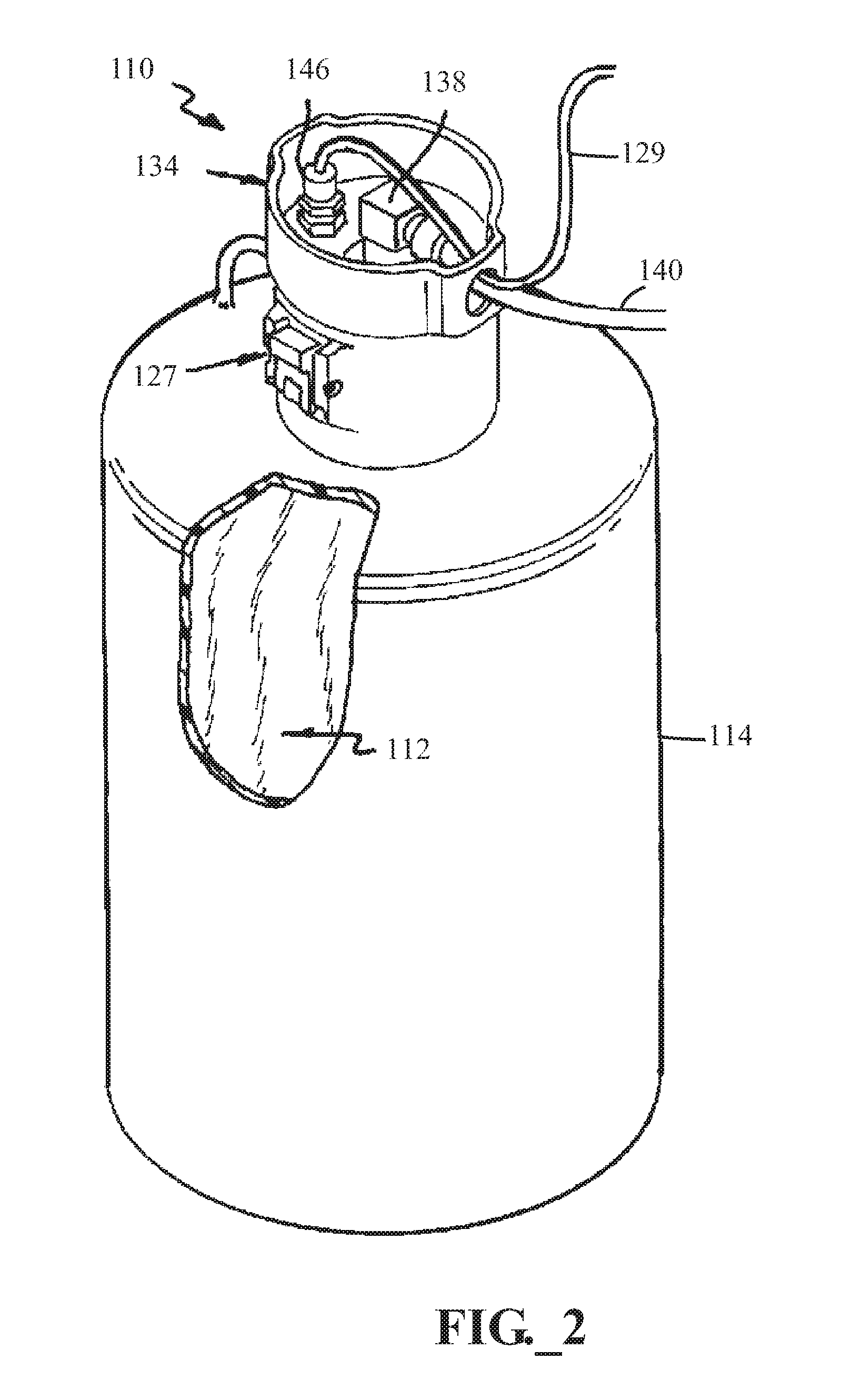

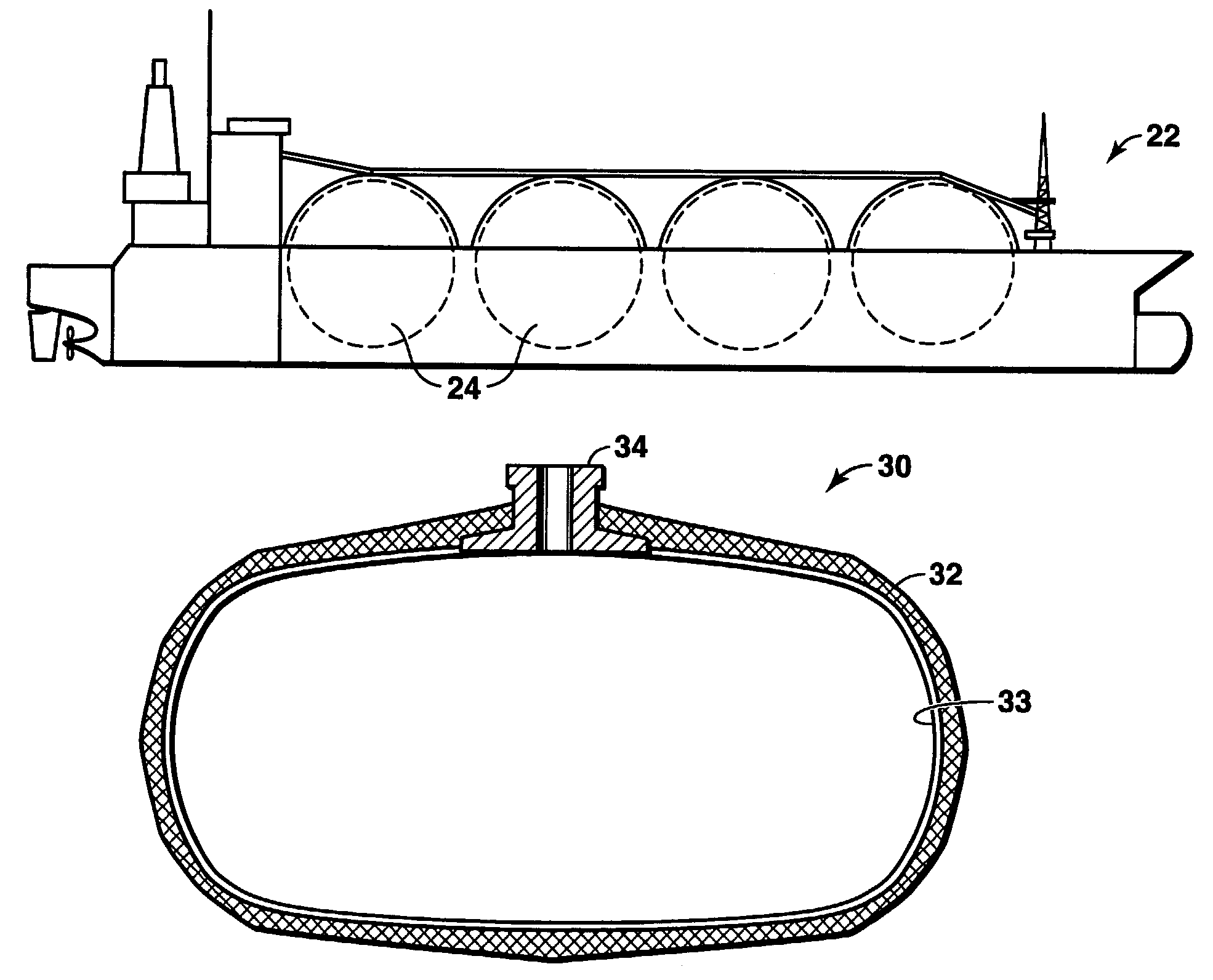

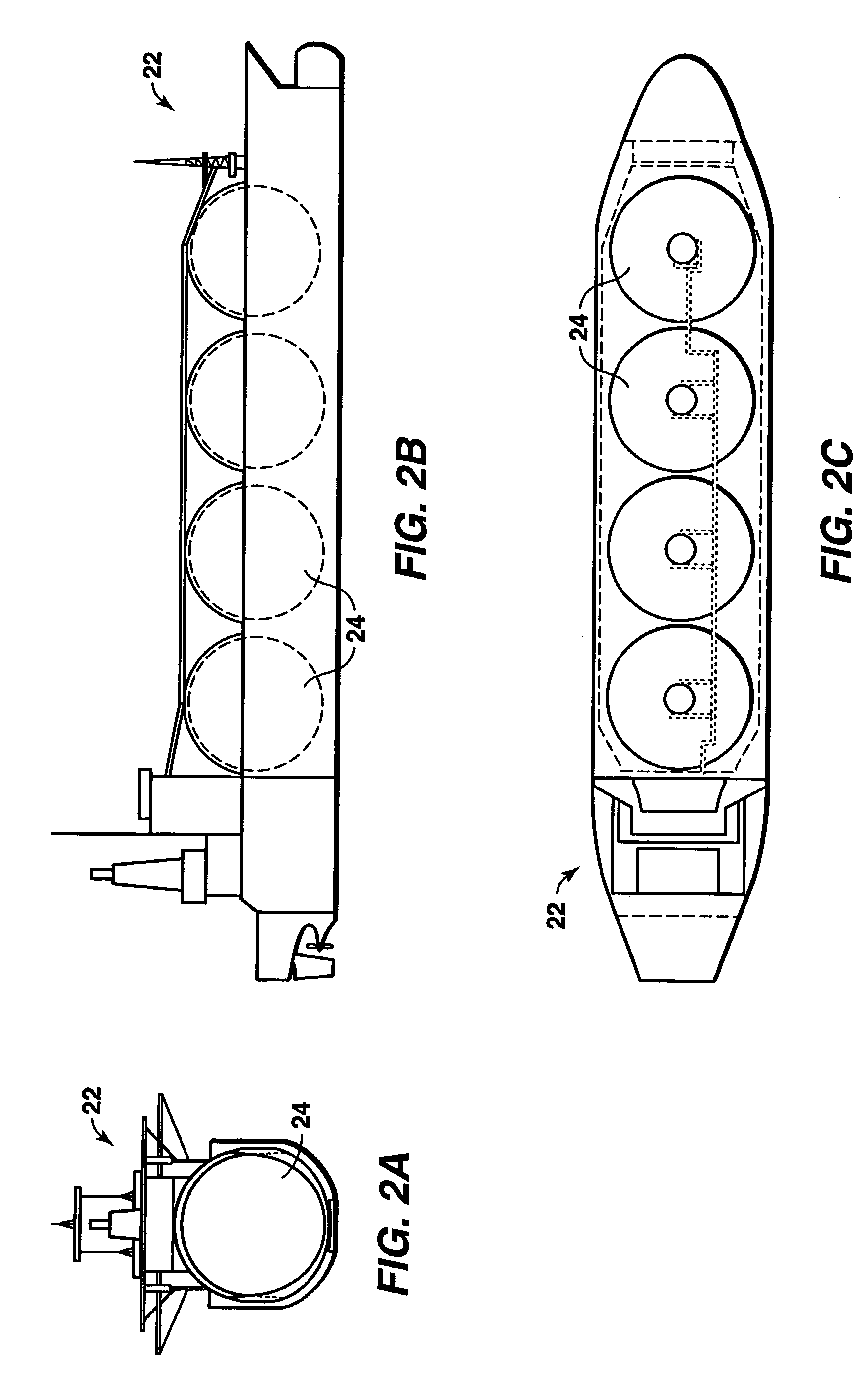

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

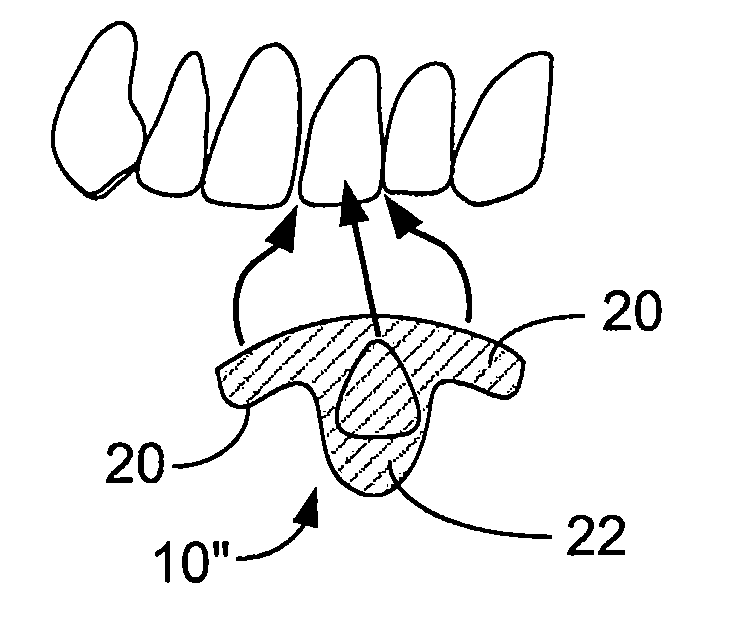

Dental composite delivery system

InactiveUS8197252B1Easy to pasteAvoid excessive accumulationDam holdersTooth clampsDental compositePolymer thin films

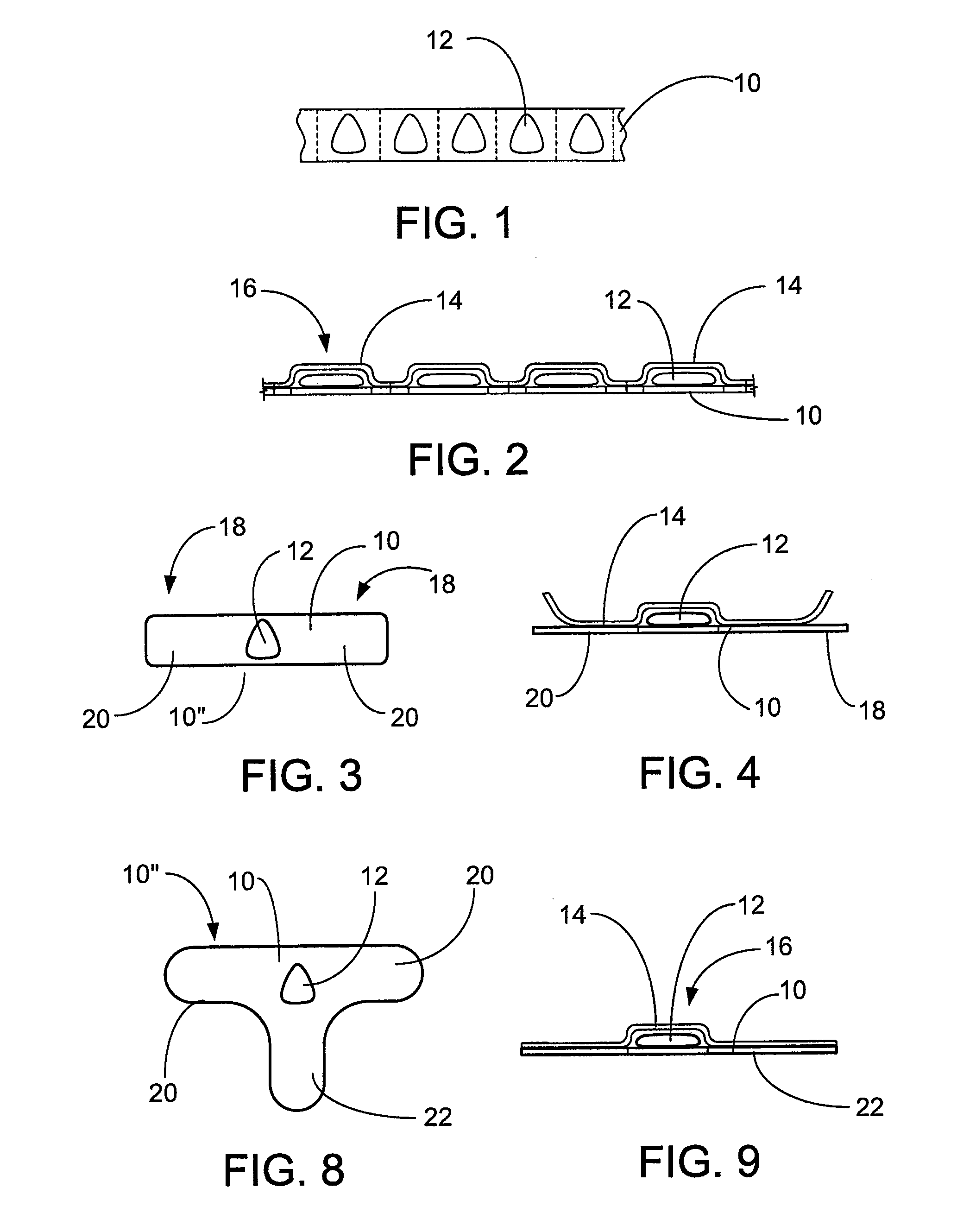

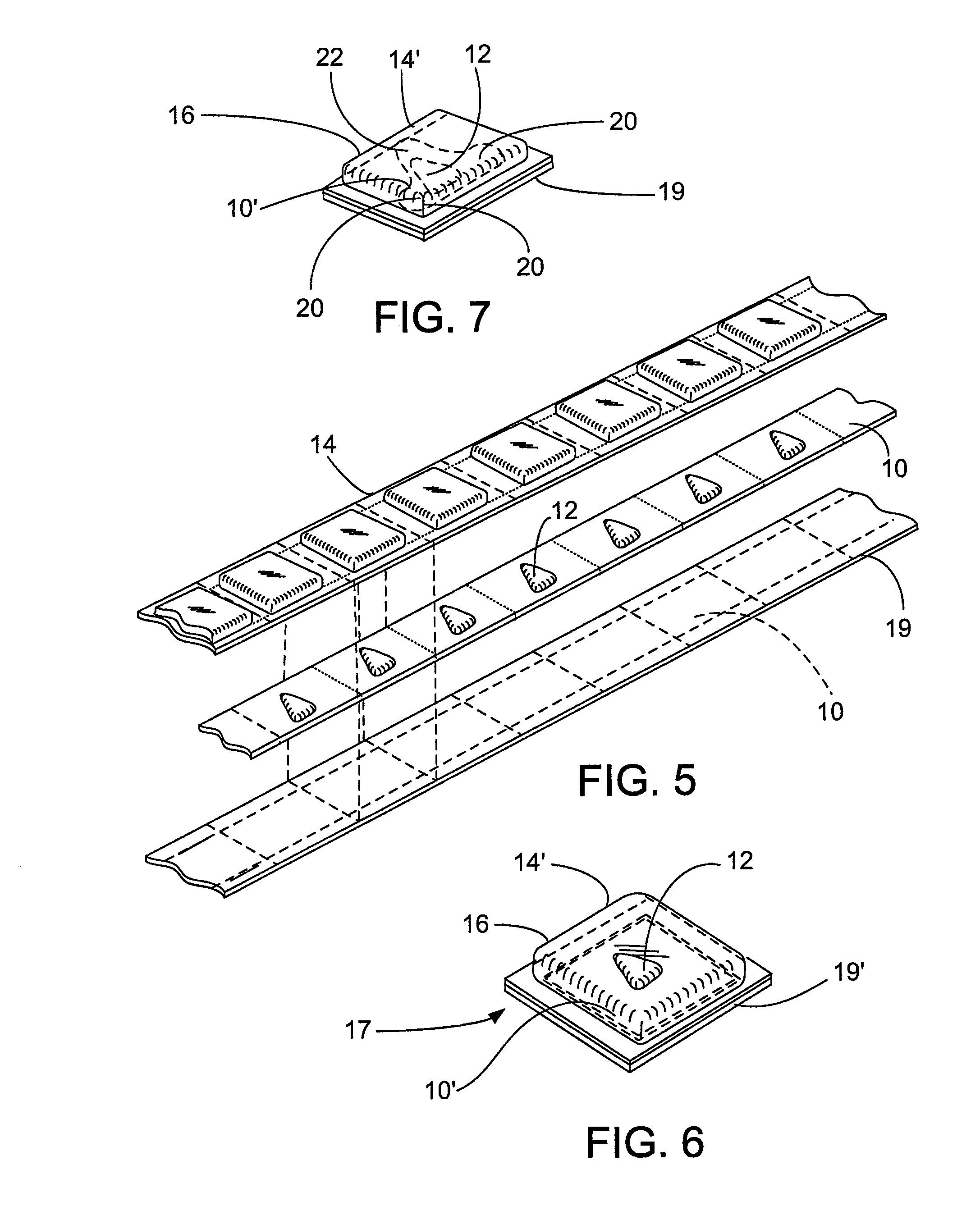

A packaged unit of composite for performing an aesthetic restoration. The unit is mounted on a polymeric film carrier material and is covered and sealed with the same or otherwise suitable covering film. The carrier film may be an elongated strip containing serially placed units of composite, each readily separable from the strip for individual usage. This packaging is in light restrictive outer packaging since the preferred unit of composite is of a light-cured material such as bis-GMA. In preferred packaging, the unit dose is singular and applicable to the tooth surface with the film carrier which is adapted with tabs to facilitate handling and the draping or damming of the subject tooth from adjacent teeth to facilitate application of the composite. The composite is then worked, i.e., formed on the tooth with the film intermediate the composite and the customary forming tools. In preferred embodiments, the single unit packaging of composite is mounted on a clear carrier film which includes embrasure tabs for selective insertion in the embrasure between the teeth, and in a further preferred embodiment, the carrier film includes an incisal tab to cover the incisal edge of the tooth. The clear carrier is contained in further outer packaging which limits actinic radiation from reaching the composite.

Owner:HARRISON III LOUIE V

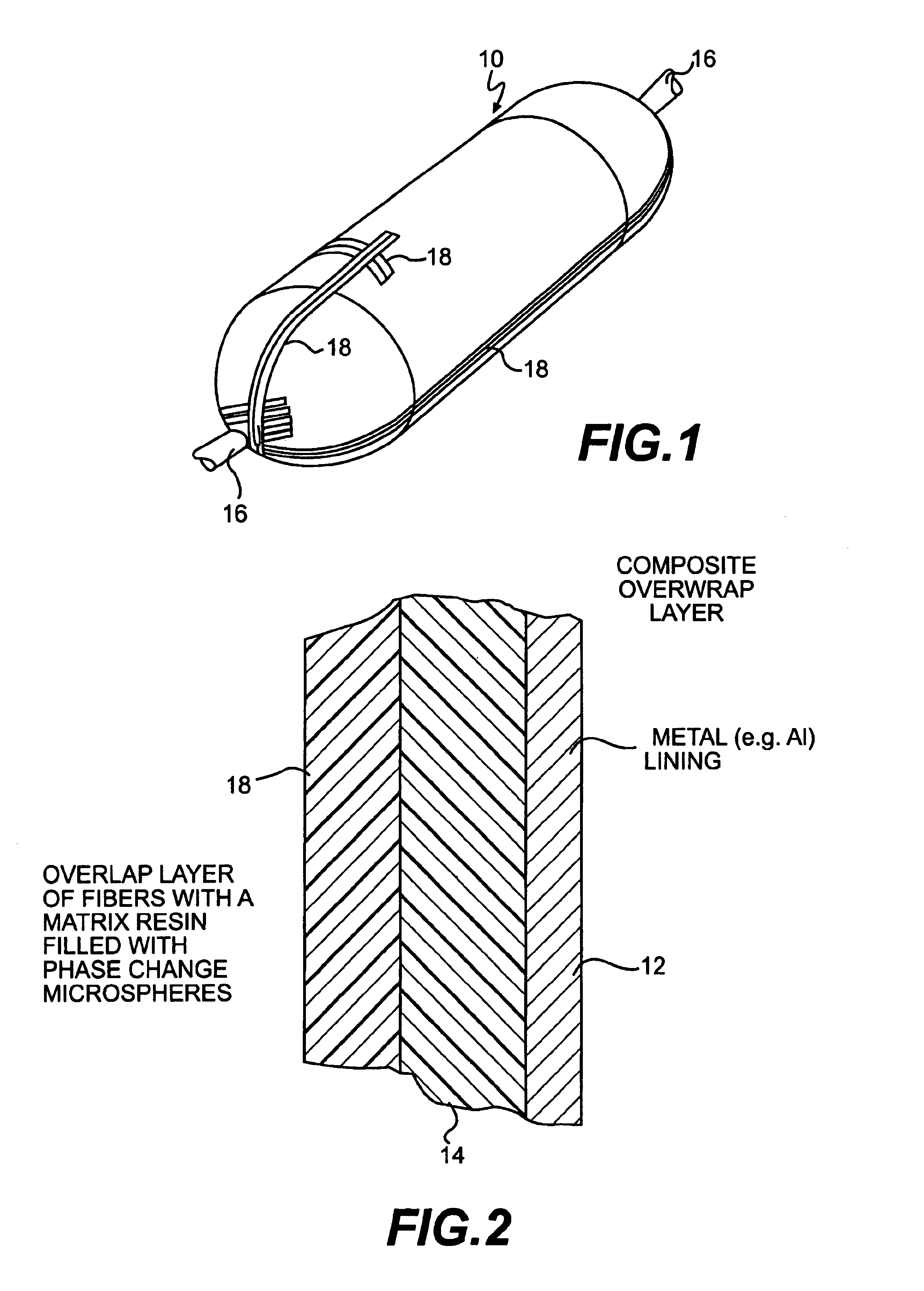

Pressure vessel with impact and fire resistant coating and method of making same

InactiveUS6953129B2Light weightIncrease heatGas handling applicationsLarge containersMicrosphereShock resistance

An impact and fire resistant coating laminate is provided which serves as an outer protective coating for a pressure vessel such as a composite overwrapped vessel with a metal lining. The laminate comprises a plurality of fibers (e.g., jute twine or other, stronger fibers) which are wound around the pressure vessel and an epoxy matrix resin for the fibers. The epoxy matrix resin including a plurality of microspheres containing a temperature responsive phase change material which changes phase in response to exposure thereof to a predetermined temperature increase so as to afford increased insulation and heat absorption.

Owner:NASA

Disposable toothbrush system

A disposable toothbrush system that includes a toothbrush and a one use supply of toothpaste that is easily carried in a pocket or the like and discarded after use. The disposable toothbrush system is packaged suitable for sale through vending machines and that includes a tubular, plastic film, outer package, a disposable toothbrush, and a toothpaste dispensing bladder assembly. The toothpaste dispensing bladder assembly includes a seamless, non-elastic, plastic film bladder member filled with toothpaste and has a dispensing end thereof adhesively attached to an interior surface of the tubular film outer package and heat sealed and crimped between two edge sections of the first end of the tubular, plastic film, outer package.

Owner:WILLIAMS MICHAEL D

Smoking articles comprising inner wrapping strips

InactiveUS20070157940A1Easy to controlIncrease chanceTobacco preparationNon-fibrous pulp additionFilling materialsEngineering

The present invention is directed to a cigarette comprising a tobacco rod having a smokable filler material contained within a circumscribing outer wrapping material, and one or more inner wrapping strips positioned between the tobacco rod and the outer wrapping material and extending longitudinally along the tobacco rod. The inner wrapping strips comprise a binder in the form of an alkali metal salt and comprise a total alkali metal content of at least about 30,000 μg based on the total weight of the inner wrapping strips. The total alkali metal content can be derived from the alkali metal salt binder alone or a combination of the alkali metal salt binder and a second alkali metal additive. The inner wrapping strips can exhibit an ignition temperature of at least about 625° C. and may comprise 1 to about 8 strips, each strip having a width of about 2 to about 10 mm.

Owner:R J REYNOLDS TOBACCO COMPANY

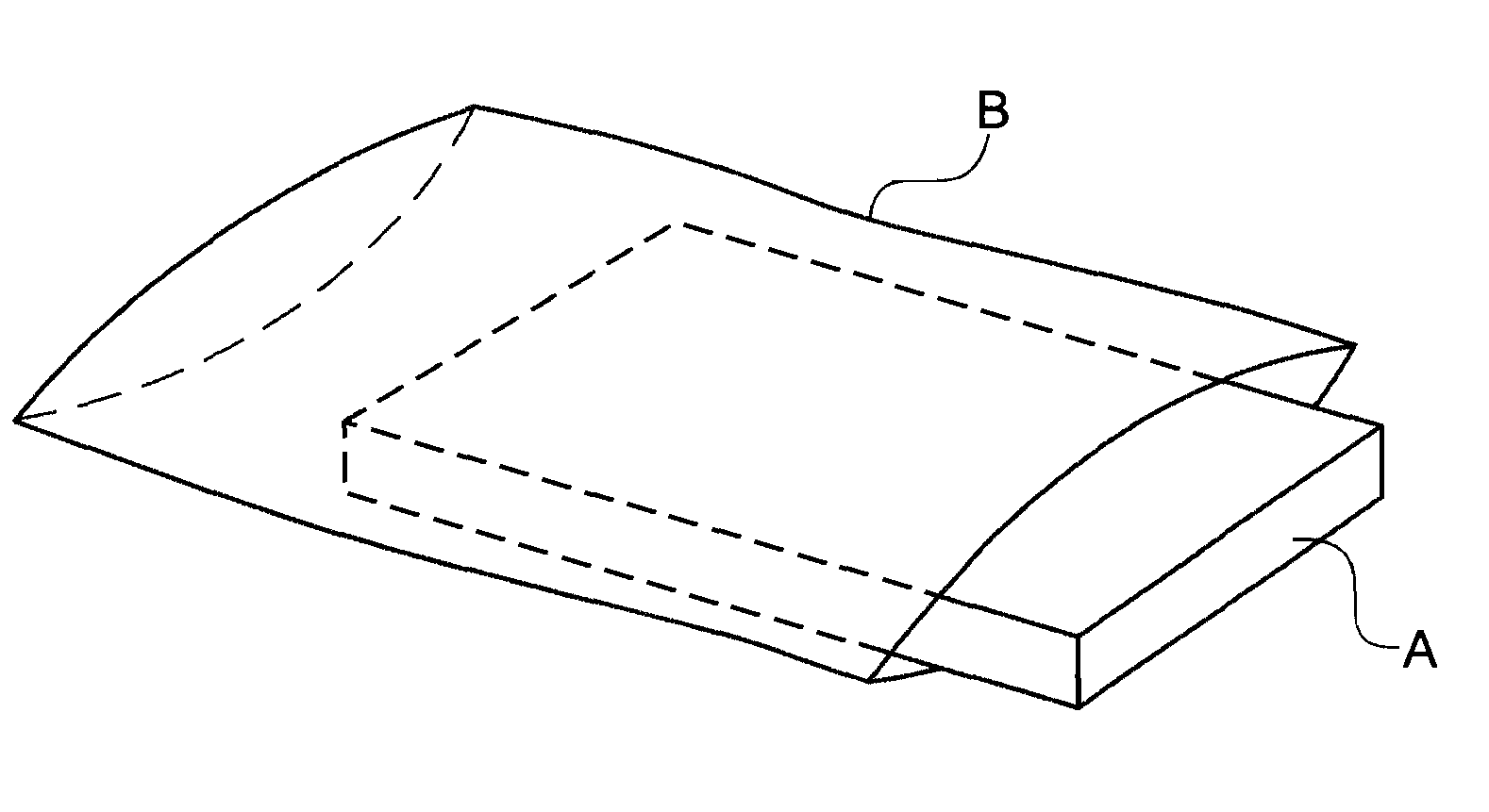

Package for shipping and storage of panel products

InactiveUS20050115860A1Containers to prevent mechanical damagePaper/cardboard containersEngineeringOverwrap

A package for storing and shipping flat panel products includes a shock- absorbing inner protective material, a telescoping outer packaging material, adjustable to the size of the product being shipped, and an outer binder, such as a plastic banding material. The inner wrapping material is provided around a circumferential edge of the product and is secured in place. The outer protective packaging material is provided around the wrapped product, adjusted to the appropriate size, and is bound in place with a plastic banding material which is wrapped longitudinally and secures the lateral and longitudinal position of the product within the package. The telescoping package includes slots for receiving and retaining the plastic banding material in position.

Owner:MERTZ WILLIAM JAMES II +6

Preserving a hemoglobin blood substitute with a transparent overwrap

InactiveUS7041800B1High purityExtended shelf lifePeptide/protein ingredientsMetal layered productsPolyolefinMedicine

Owner:OPK BIOTECH

Method and apparatus for packaging a drug-device combination product

InactiveUS20050241981A1Minimizing introductionPrevent oxidationSmall article dispensingAmpoulesDrug-device combination productHermetic seal

A package for a drug-device combination product includes an outer package including a first gas impermeable sheet and a second gas impermeable sheet hermetically sealed there to on three sides. A gas permeable header is attached to an unsealed side of the first sheet and sealed to the second sheet on two sides. The first and second gas impermeable sheets and the header form an interior and an opening communicating with the interior. A gas permeable inner package is disposed within the outer package. A product is sealed within the inner package. The inner package is placed within the outer package and a top end of the header is sealed to the second sheet. The outer package is then sealed by sealing the first gas impermeable sheet to the second gas impermeable sheet at a seal point below the point where the header attaches to the first sheet.

Owner:CODMAN & SHURTLEFF INC

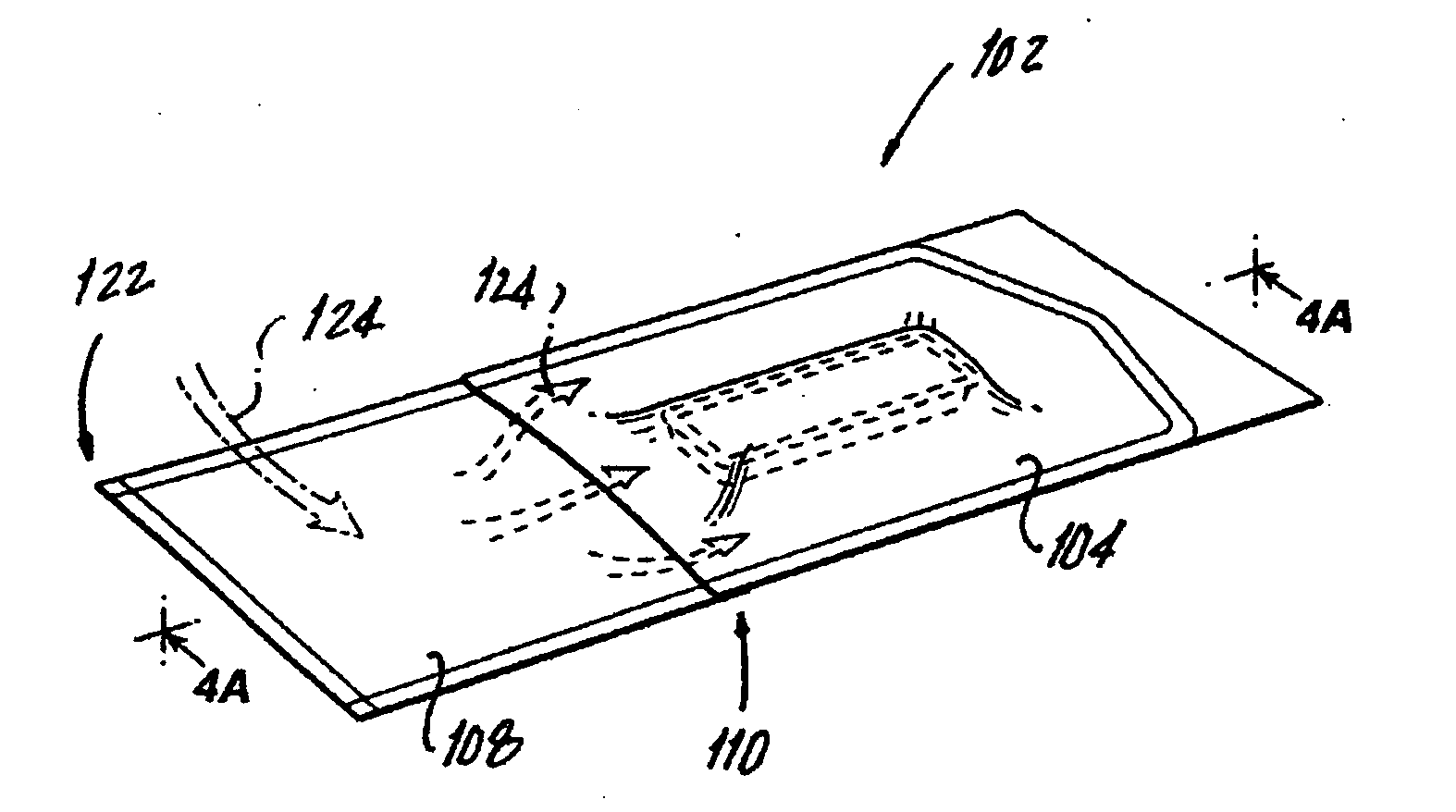

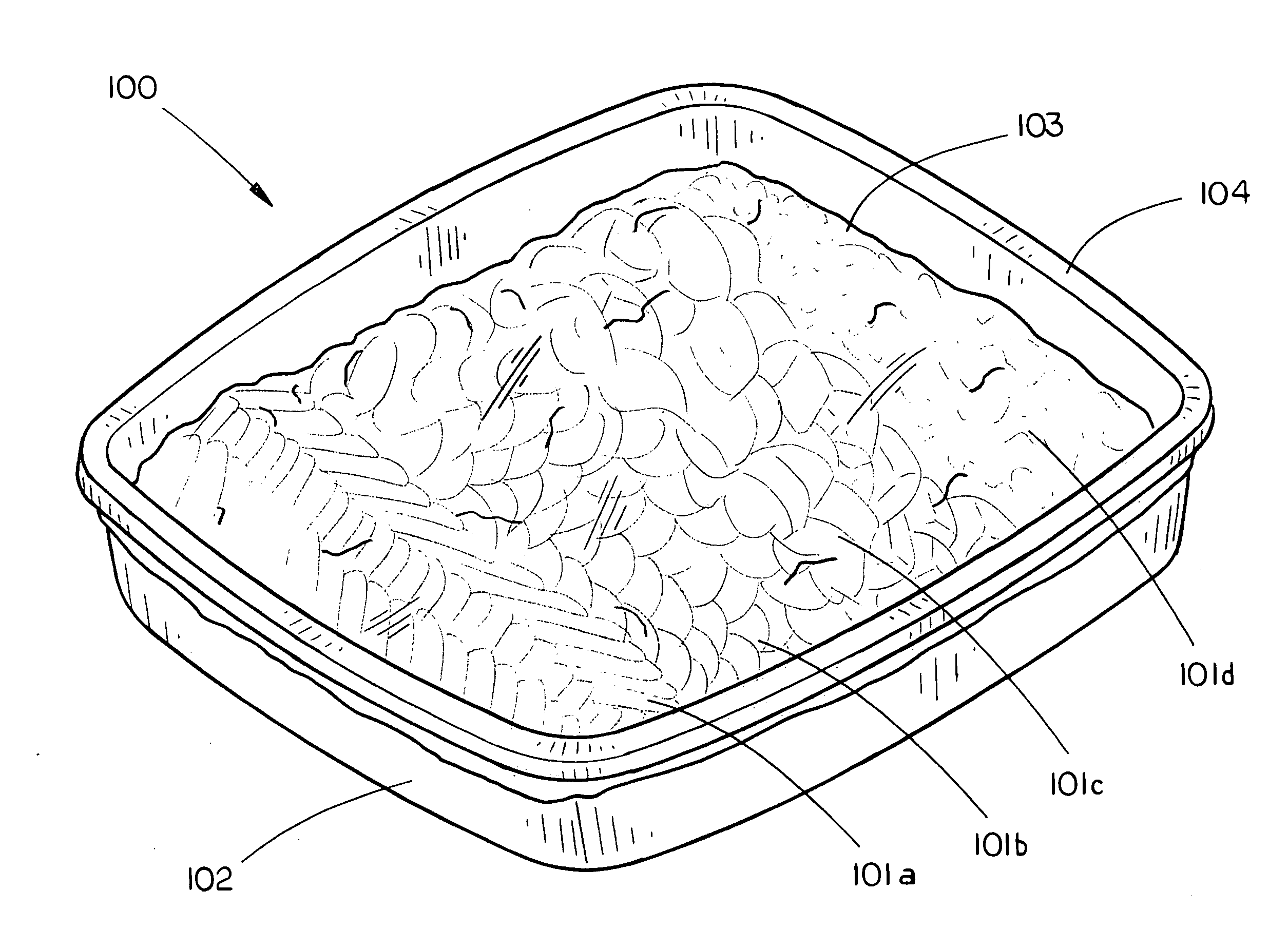

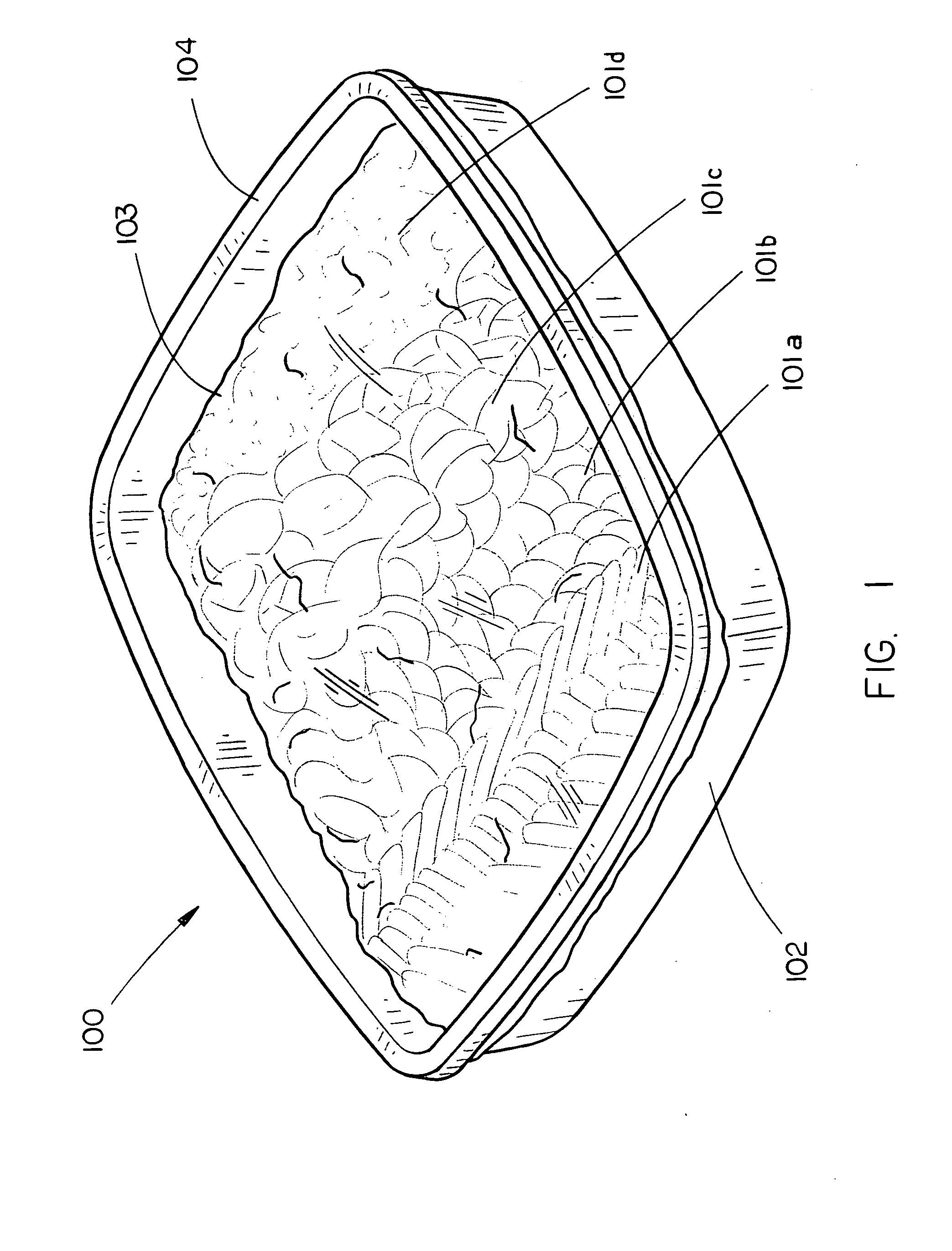

Dual-ovenable food packaging

The present invention is directed to a dual-ovenable food packaging, a method for packaging food and a method for cooking food.A dual-ovenable food packaging in accordance with the present invention may comprise: (a) a heat-resistant tray; (b) a non-venting plastic film overwrap, and (c) a food items.A method for packaging food may comprise the steps: (a) disposing a food item in a heat-resistant tray; (b) overwrapping the tray and food item with a non-venting plastic film overwrap; and (c) vacuum sealing the non-venting plastic film overwrap around the heat-resistant tray and food item.A method for cooking a food item may comprise the steps: (a) disposing a food item in a heat-resistant tray; (b) overwrapping the tray and food item with a plastic film; (c) vacuum sealing the plastic film around the heat-resistant tray and food item to create a sealed packaging; and (d) heating the sealed packaging with a heating device.

Owner:CONAGRA FOODS

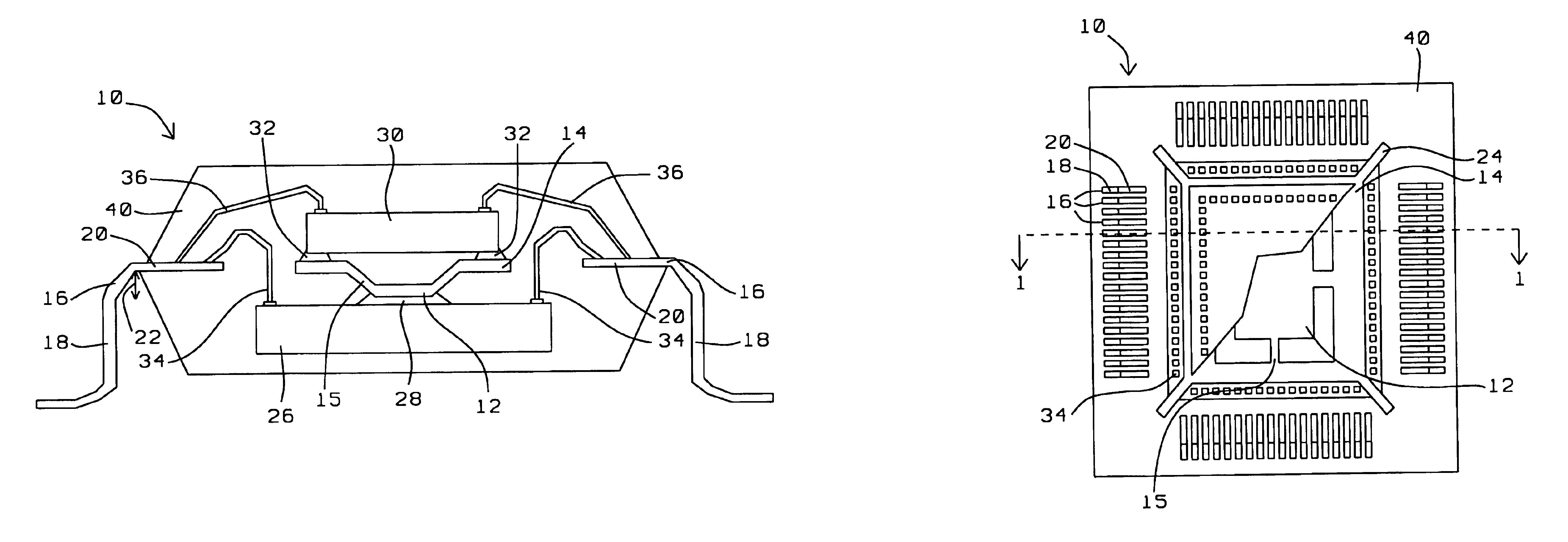

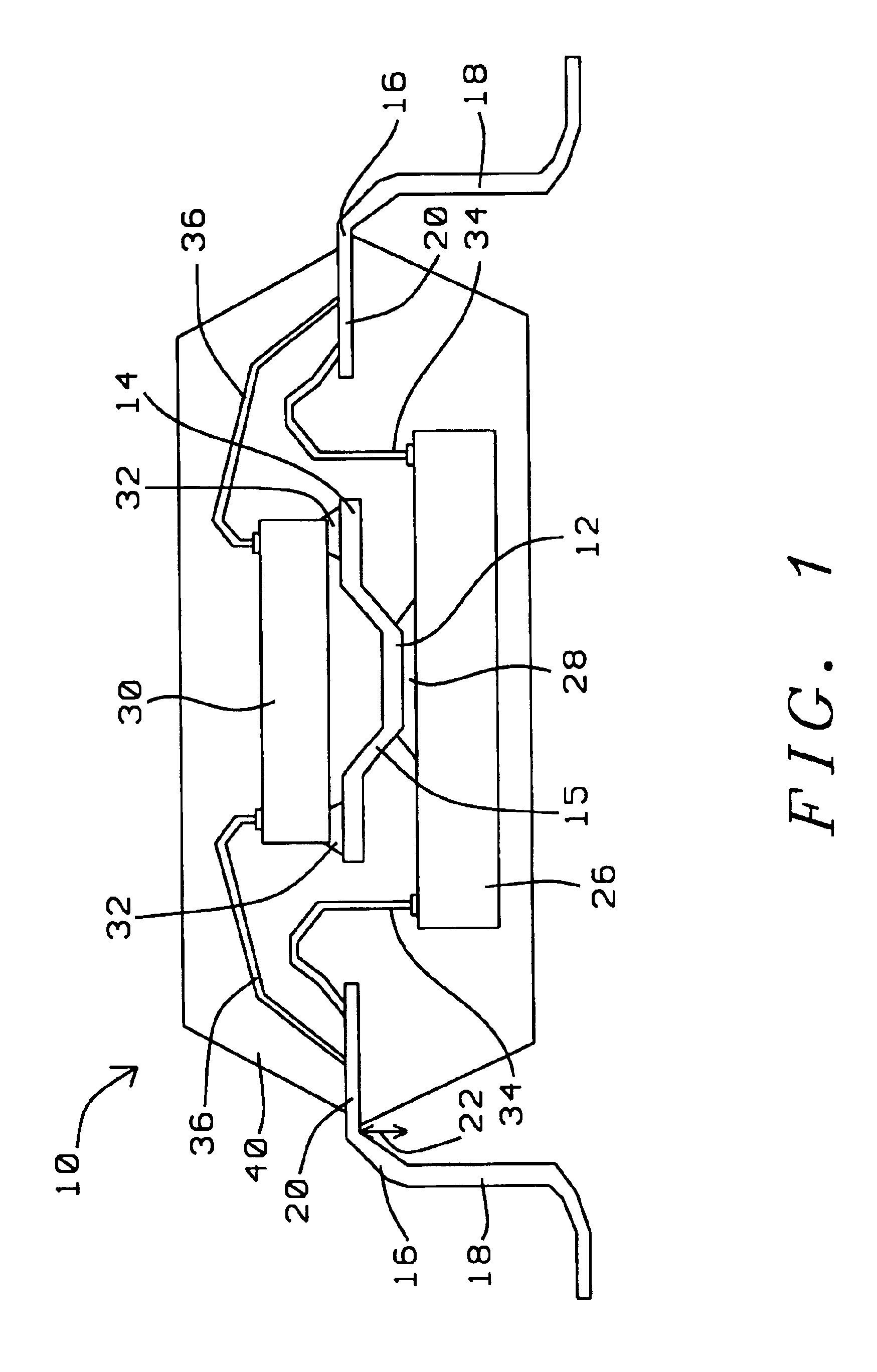

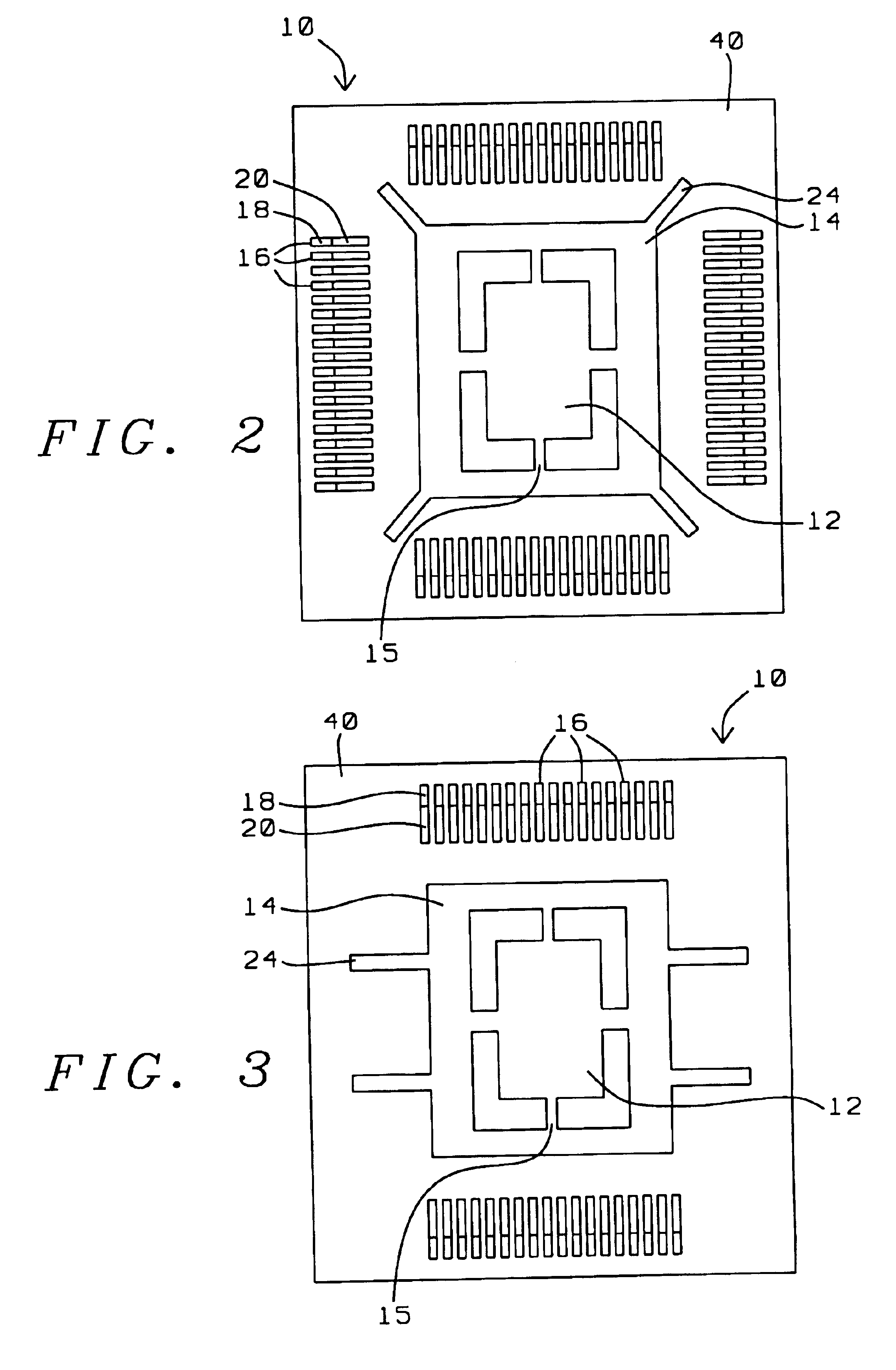

Leadframe for die stacking applications and related die stacking concepts

InactiveUS6841858B2Improve reliabilityIncrease volumeSemiconductor/solid-state device detailsSolid-state devicesLead frameOverwrap

A leadframe design (and method of forming the leadframe design), comprising: an inner die pad structure lying in a first plane; and an outer die pad structure supported by outer tie bars and connected to the inner die pad by inner tie bars. The outer die pad structure lying in a second plane spaced apart from the inner die pad structure first plane. An outer package surrounds at least the inner die pad structure and the inner tie bars. The outer die pad structure being supported by the outer tie bars. The outer package having outer walls. Lead fingers extend through the outer package outer walls and include respective inner portions extending into the outer package proximate the inner and outer die pad structures. The inner portions of the lead fingers lie in a third plane, wherein at least one of the inner die pad structure first plane and the outer die pad structure second plane lie outside of the lead finger inner portions third plane and wherein a first chip is affixed to the inner die pad structure and a second chip is affixed to the outer die pad structure.

Owner:STATS CHIPPAC LTD

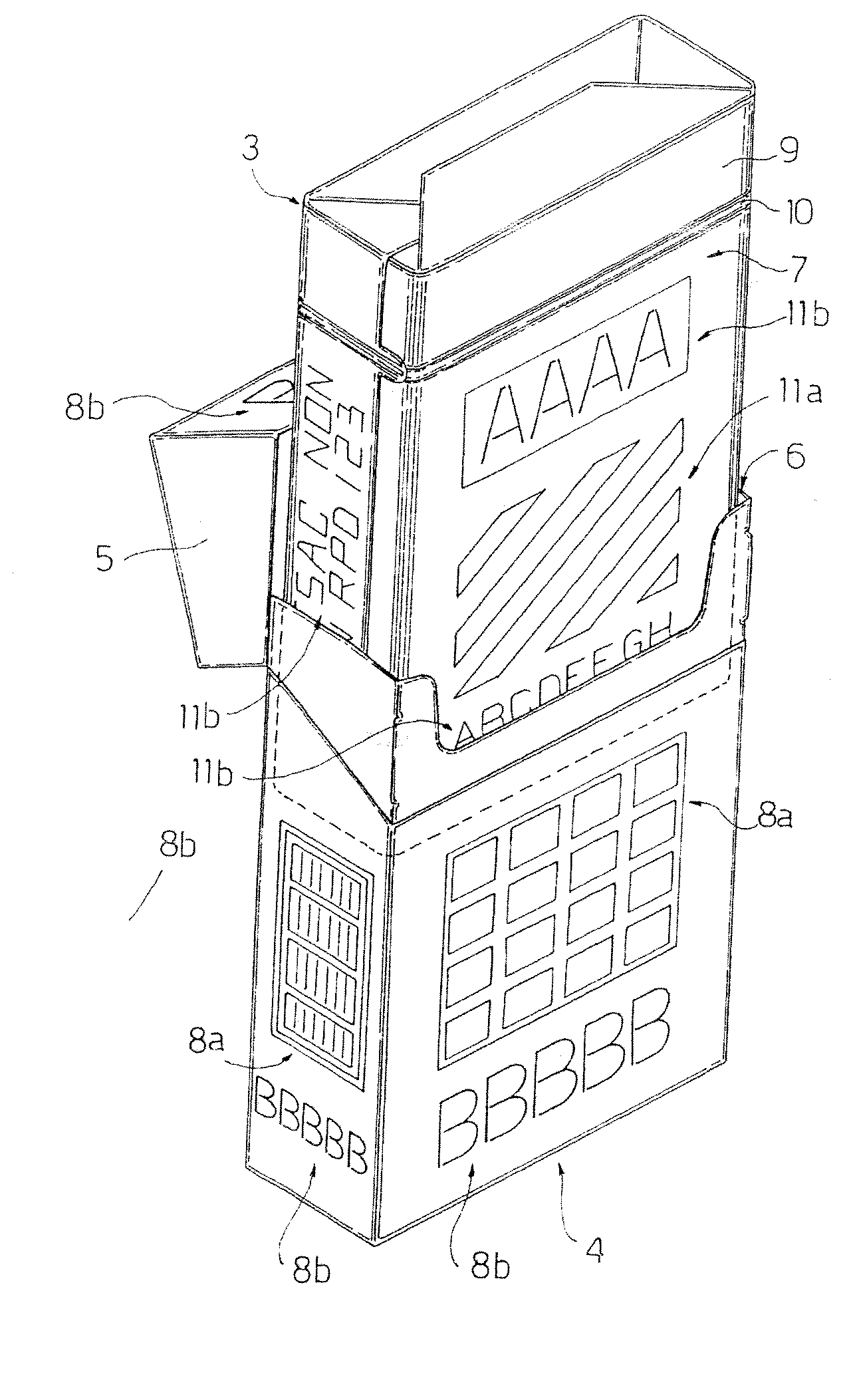

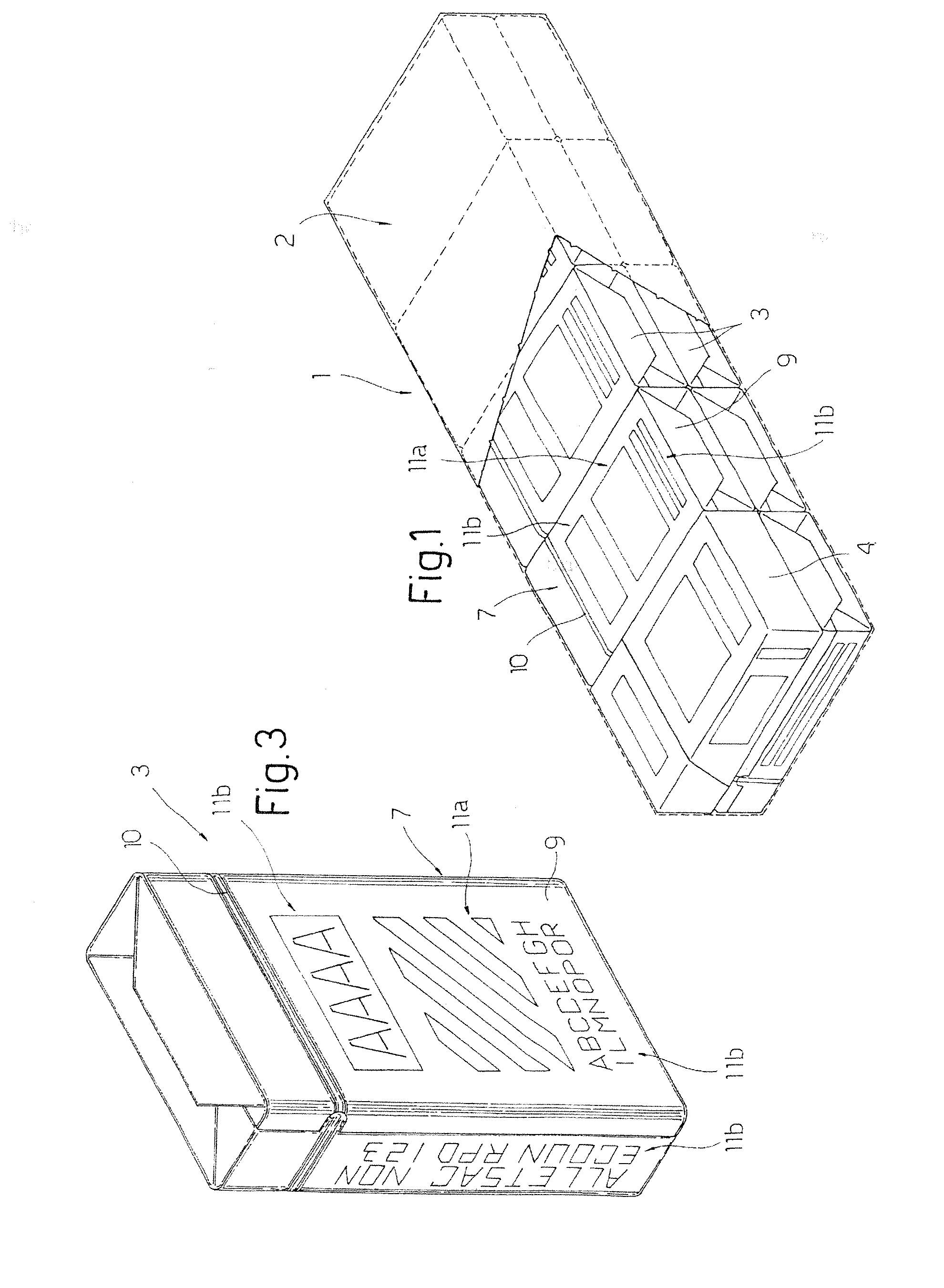

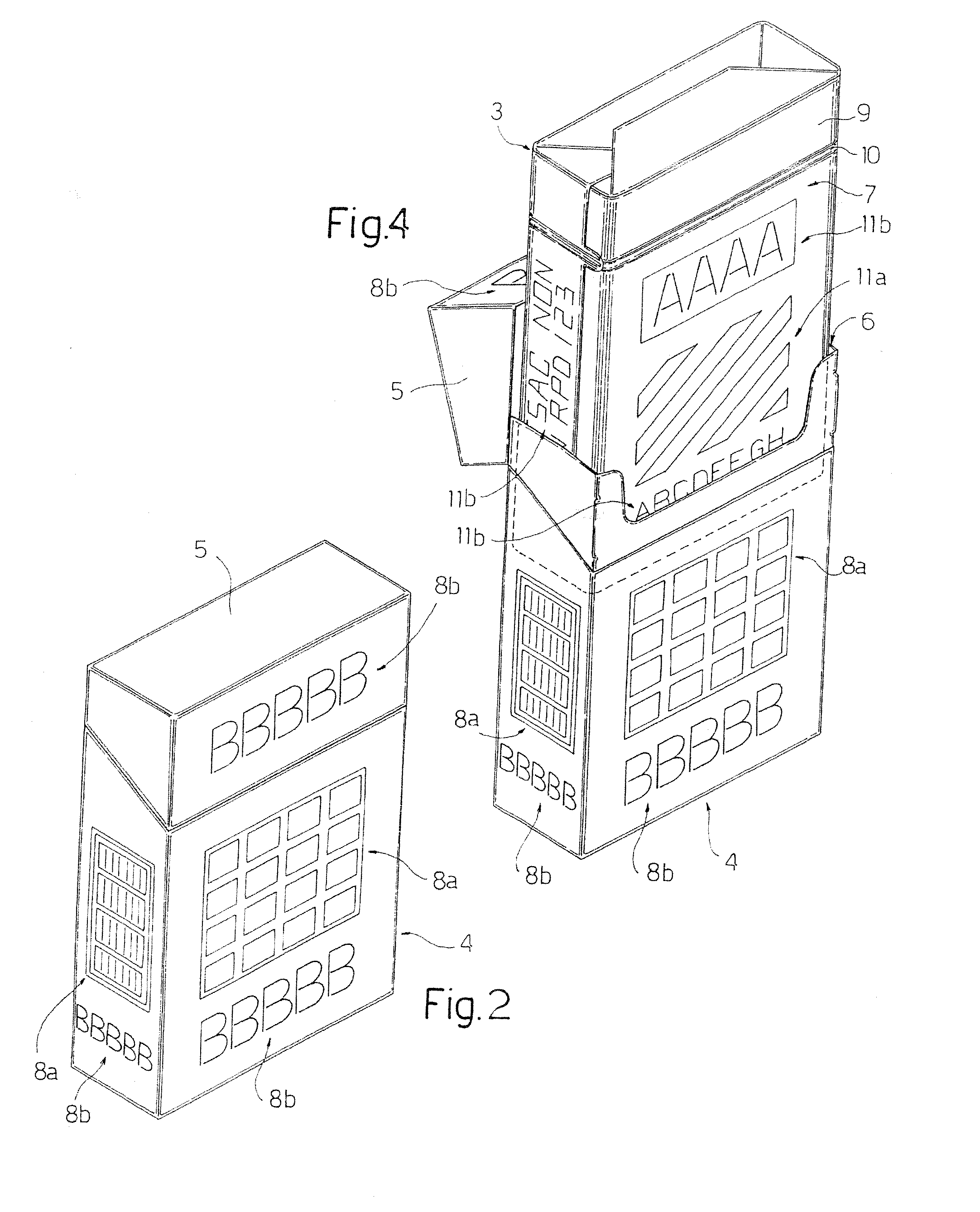

Carton of Soft Packets of Cigarettes, Containing a Reusable Rigid Box

InactiveUS20090071852A1Easy to produceDrawback can be obviatedContainers for flexible articlesPackage recyclingCartonEngineering

A carton of soft packets of cigarettes, having: an outer package; a group of soft packets of cigarettes housed inside the outer package, and each having an inner package having a first sheet of flexible packing material folded about a respective group of cigarettes; and at least one reusable rigid box housed inside the outer package and containing a soft packet of cigarettes, while the other soft packets of cigarettes serve as refills for the reusable rigid box; the inner package of each soft packet of cigarettes having a tear-off top portion separated from the rest of the inner package by a tear line.

Owner:GD SPA

Packaged antimicrobial medical device having improved shelf life and method of preparing same

ActiveUS20100163435A1Extended shelf lifeInhibition of colonizationSuture equipmentsSurgical furnitureMedicineBacterial colonization

A method of making a packaged antimicrobial suture having improved shelf life. The method comprising the steps of providing an inner package having a source of antimicrobial agent, providing an adsorbent material effective to adsorb a portion of the antimicrobial agent over time, positioning a suture within the inner package, the suture comprising one or more surfaces, covering the inner package with an outer package having an inner surface and subjecting the suture, the inner package and the inner surface of the outer package to time, temperature and pressure conditions sufficient to vapor transfer an effective amount of the antimicrobial agent from the antimicrobial agent source to the suture and the inner package, thereby substantially inhibiting bacterial colonization on the suture and the inner package, wherein the packaged antimicrobial suture exhibits improved shelf life. A packaged antimicrobial suture and a method of increasing the shelf life of a packaged antimicrobial medical device are also provided.

Owner:ETHICON INC

Segmented smoking article with substrate cavity

A cigarette includes lighting and mouth ends. It may include a smokable segment disposed at the lighting end. It also includes a mouth-end segment; an aerosol-generation system disposed between the lighting and mouth ends, which includes (i) a heat-generation segment adjacent the smokable segment, including a heat source and an insulation layer and (ii) an aerosol-generating segment including a substrate, which may include tobacco pellets and aerosol-forming material disposed in a substrate cavity between the heat generation segment and the mouth end; a piece of outer wrapping material that provides an overwrap around at least a portion of the aerosol-generating segment, the heat-generation segment, and at least a portion of the smokable segment and includes a foil strip laminated thereon; those segments being connected together by the overwrap to provide a cigarette rod; ; that is connected to the mouth-end segment using tipping material.

Owner:R J REYNOLDS TOBACCO COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com