Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3614 results about "Glass material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass is a hard material that can be made in many shapes. It is usually transparent, but it can also be made in colours. Glass is mainly made of silica; glass made of silica only is called silica glass.

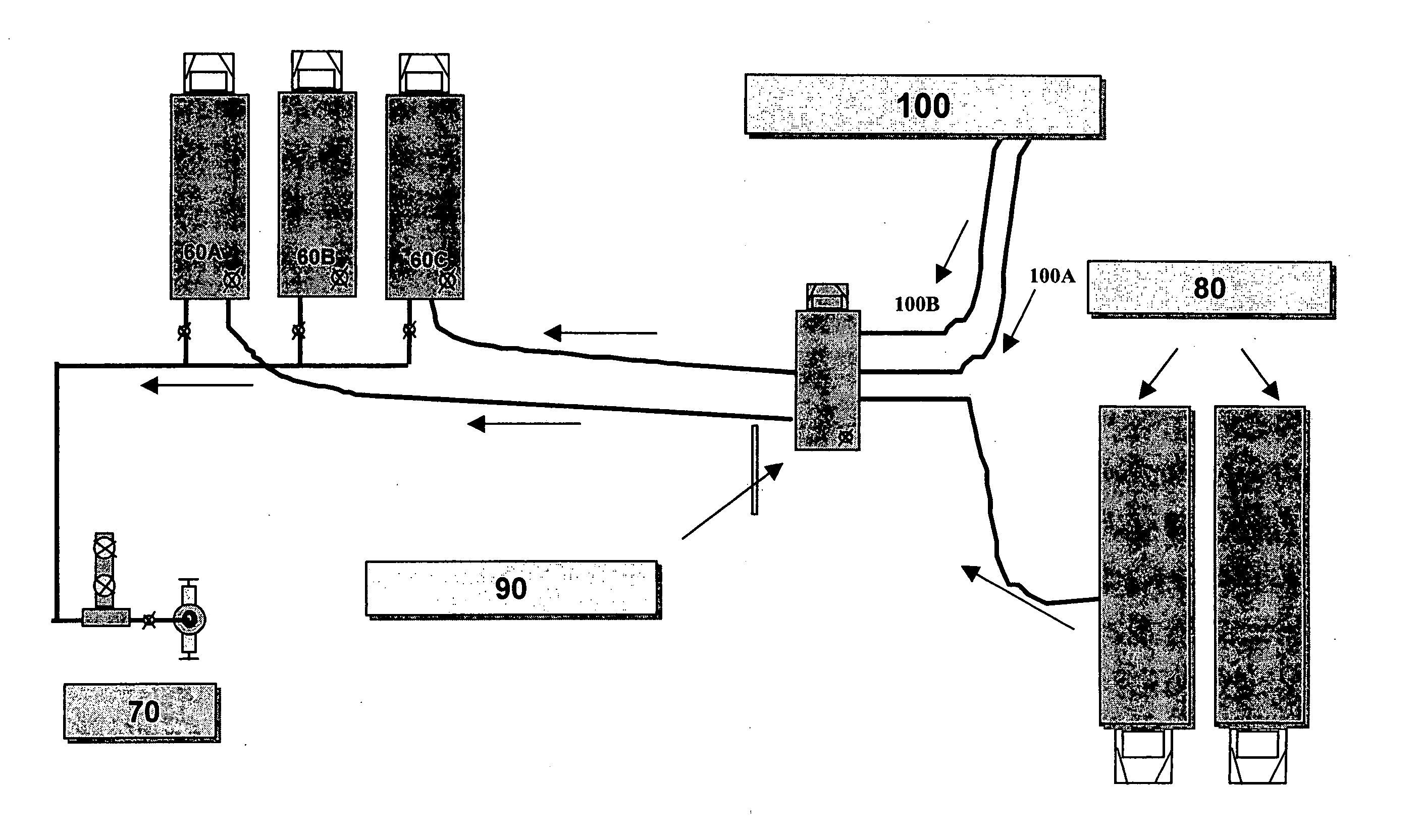

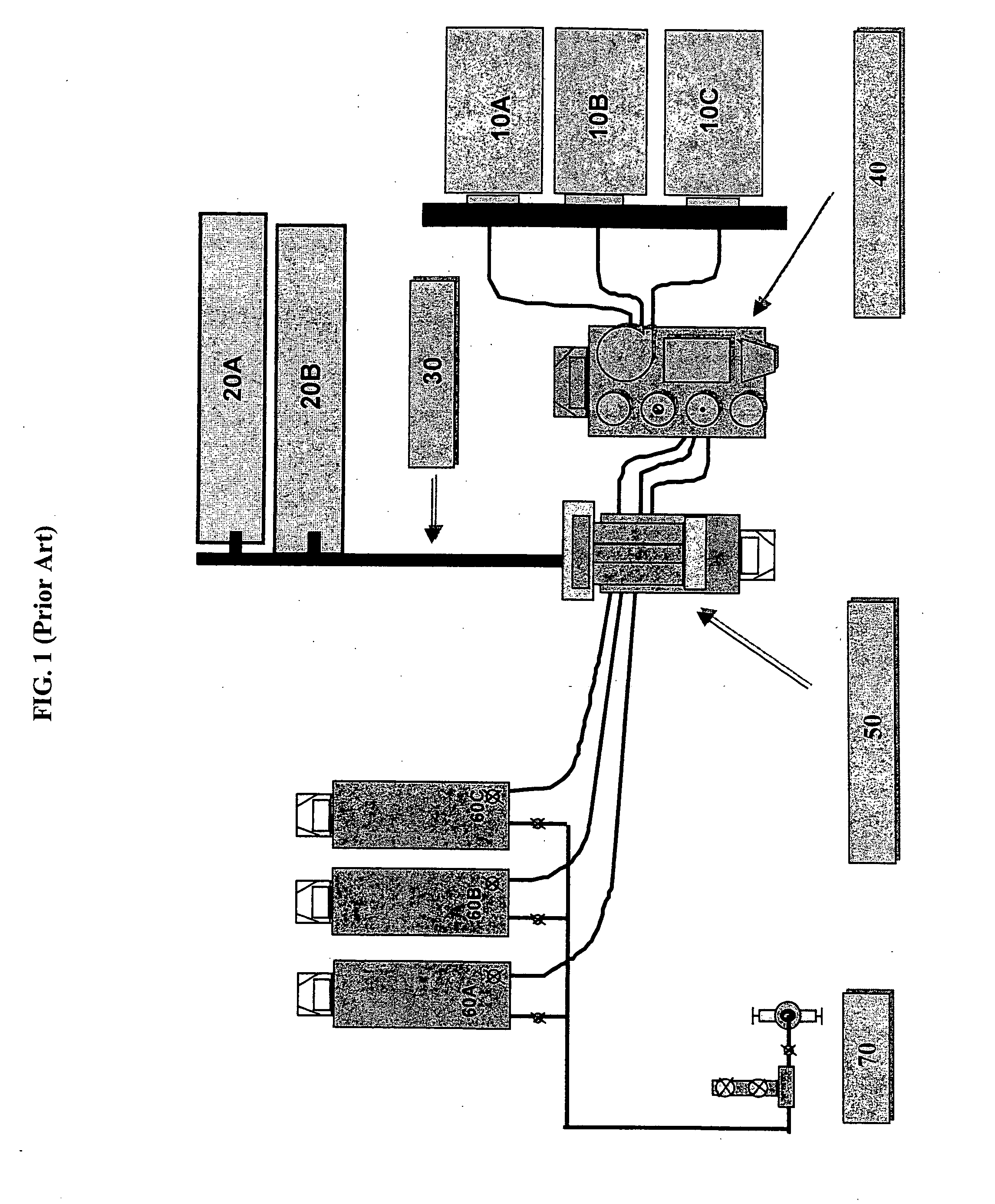

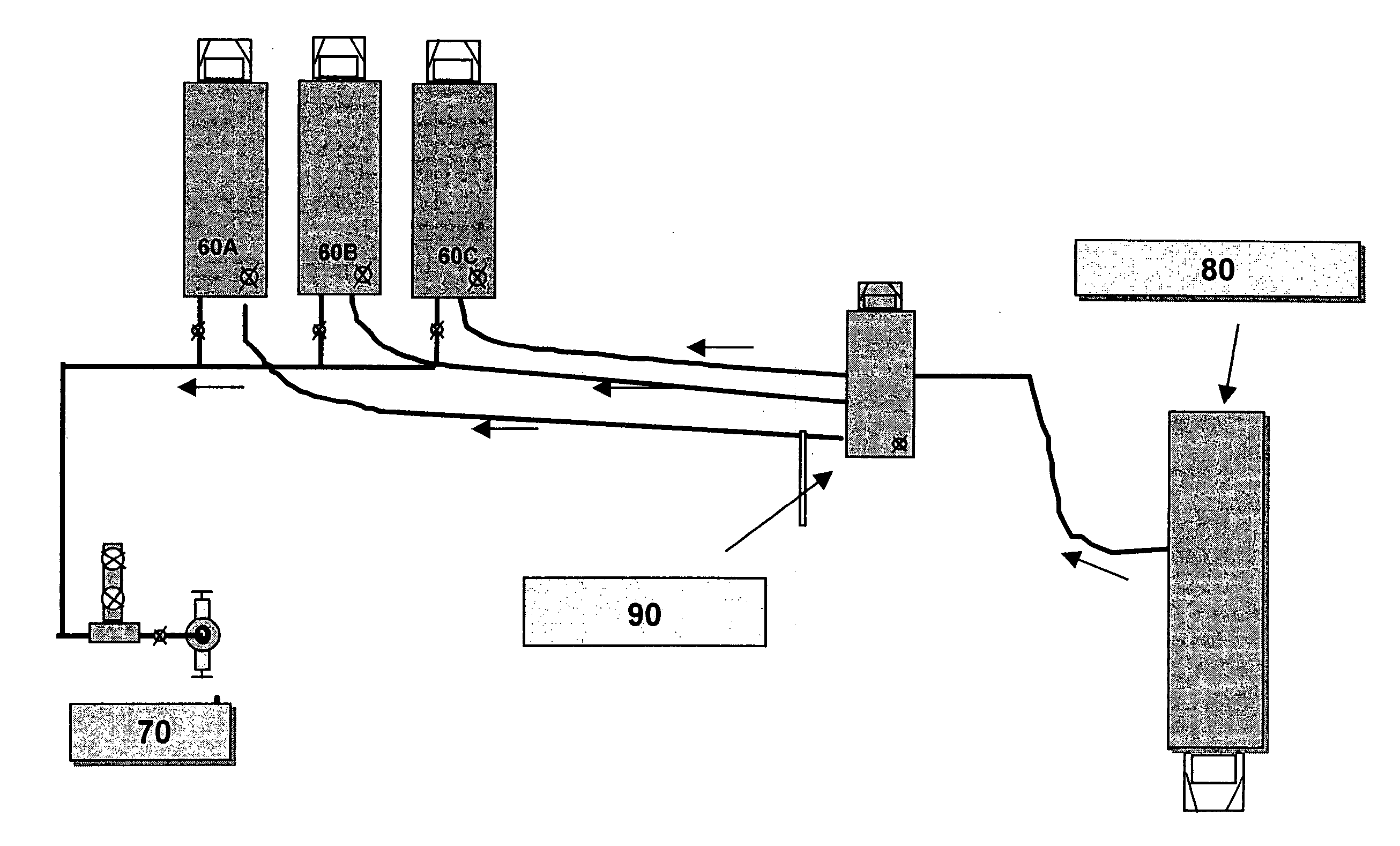

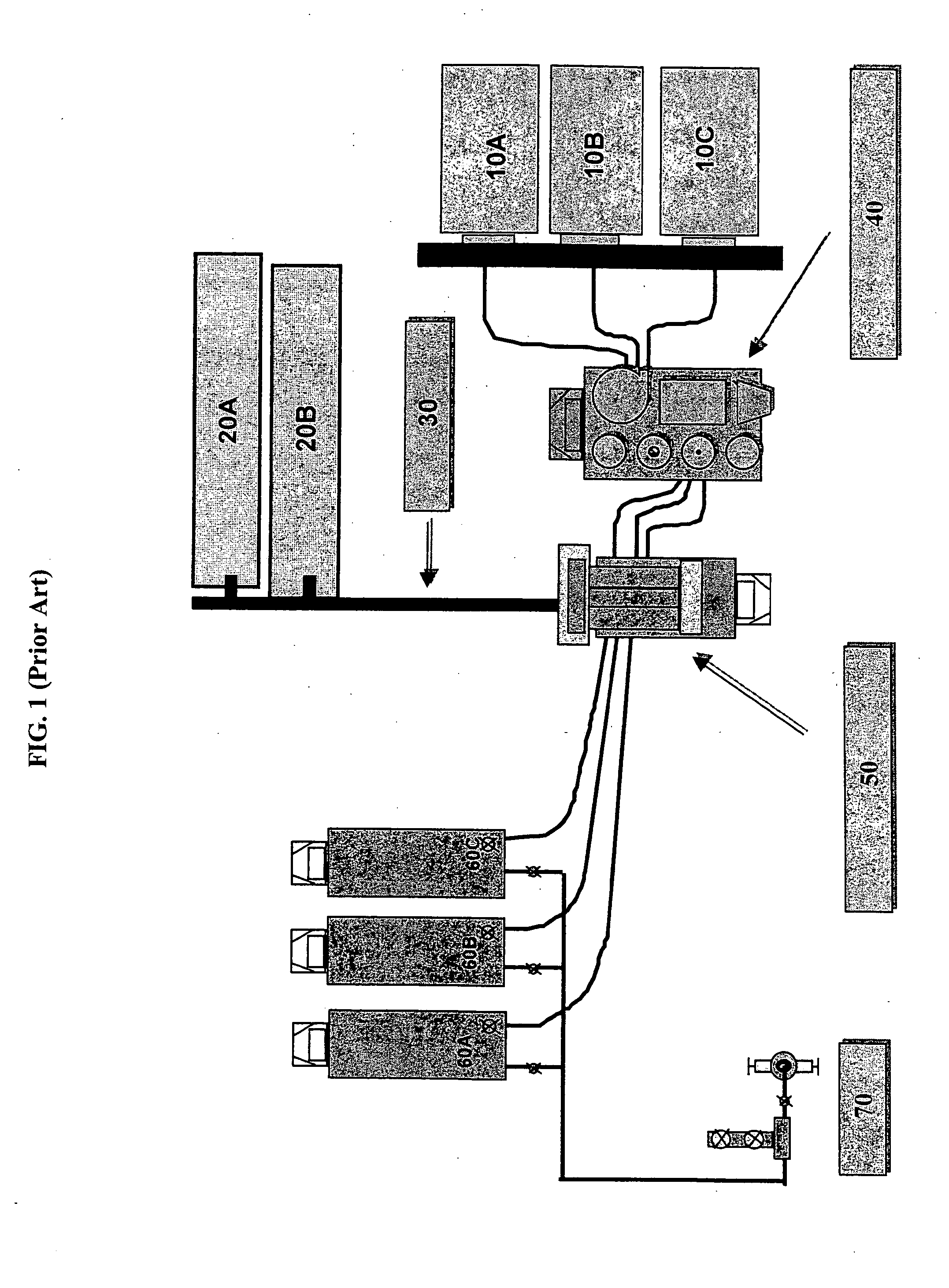

Methods and compositions of a storable relatively lightweight proppant slurry for hydraulic fracturing and gravel packing applications

InactiveUS20050028979A1Improve system performanceEliminate needFluid removalDrilling compositionParticulatesMetallurgy

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that utilize relatively lightweight and / or substantially neutrally buoyant particulates. Particles that may be employed include particulates of naturally occurring materials that may be optionally strengthened or hardened by exposure to a modifying agent; porous materials including selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials; and well treating aggregates composed of an organic lightweight material and a weight modifying agent. The relatively lightweight particulate may be suspended as a substantially neutral buoyant particulate and stored with a carrier fluid as a pumpable slurry.

Owner:BAKER HUGHES INC

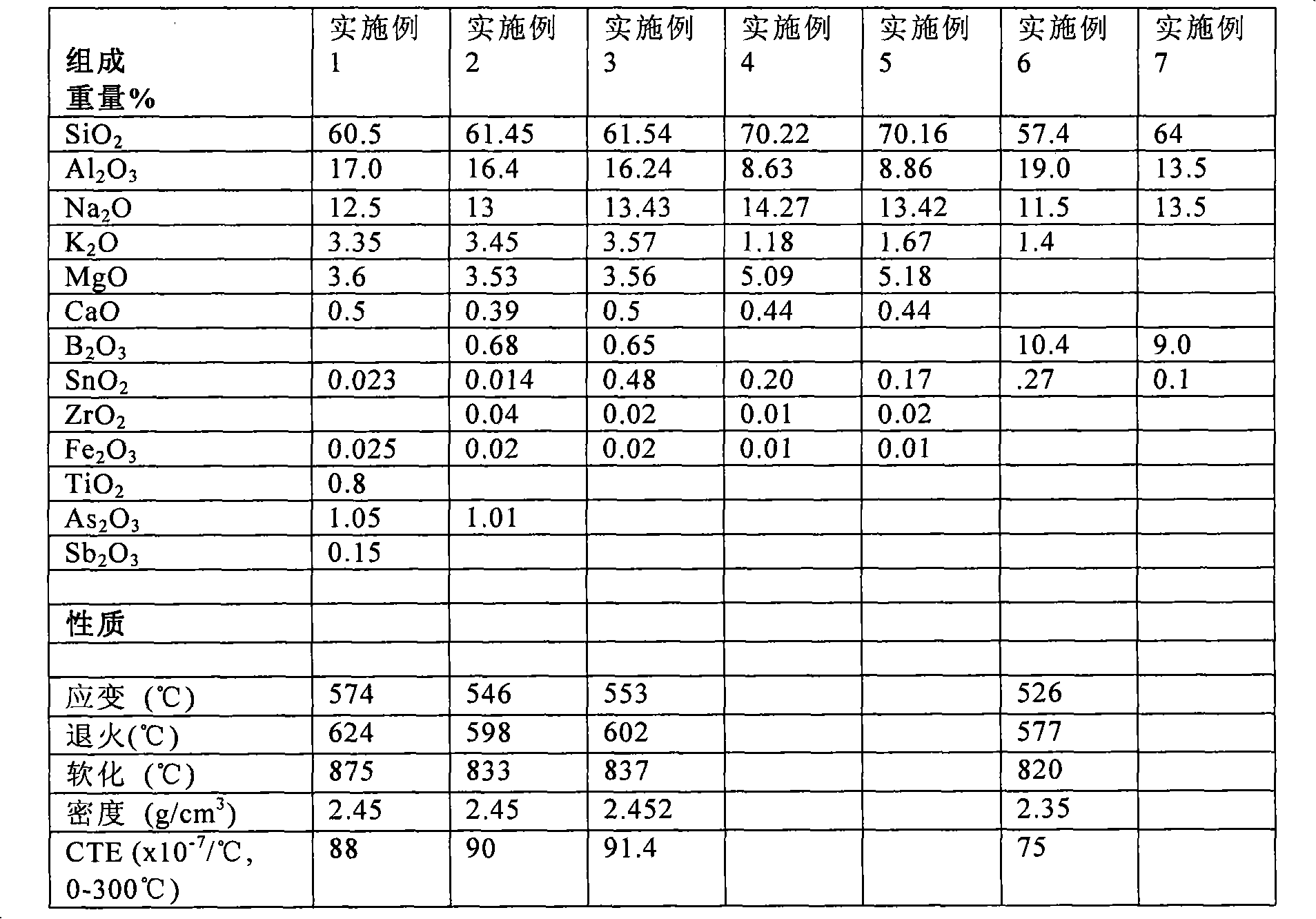

Strengthened glass substrate and process for producing the same

ActiveUS20100087307A1Excellent devitrification proofHigh mechanical strengthGlass/slag layered productsThin material handlingDevitrificationMetallurgy

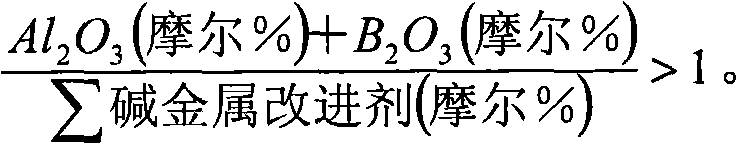

An object of the invention is to obtain a glass substrate having high mechanical strength by reconciling suitability for ion exchange and devitrification proof in a glass. The strengthened glass substrate of the invention is a strengthened glass substrate having a compression stress layer in the surface thereof, the glass substrate having a glass composition including, in terms of % by mass, 40-70% of SiO2, 12-25% of Al2O3, 0-10% of B2O3, 0-8% of Li2O, 6-15% of Na2O, 0-10% of K2O, 13-20% of Li2O+Na2O+K2O, 0-3.9% of MgO, 0-5% of CaO, 0-5% of ZnO, 0-6% of ZrO2, and 0-5% of SrO+BaO, the value of (MgO+ZrO2+ZnO) / (MgO+ZrO2+ZnO+Al2O3) in terms of mass proportion being from 0.25 to 0.45. The above-mentioned strengthened glass can be produced by melting raw glass materials mixed together so as to result in the given glass composition, forming the melt into a sheet by an overflow downdraw process, and then conducting an ion exchange treatment to form a compression stress layer in the glass sheet surface.

Owner:NIPPON ELECTRIC GLASS CO LTD

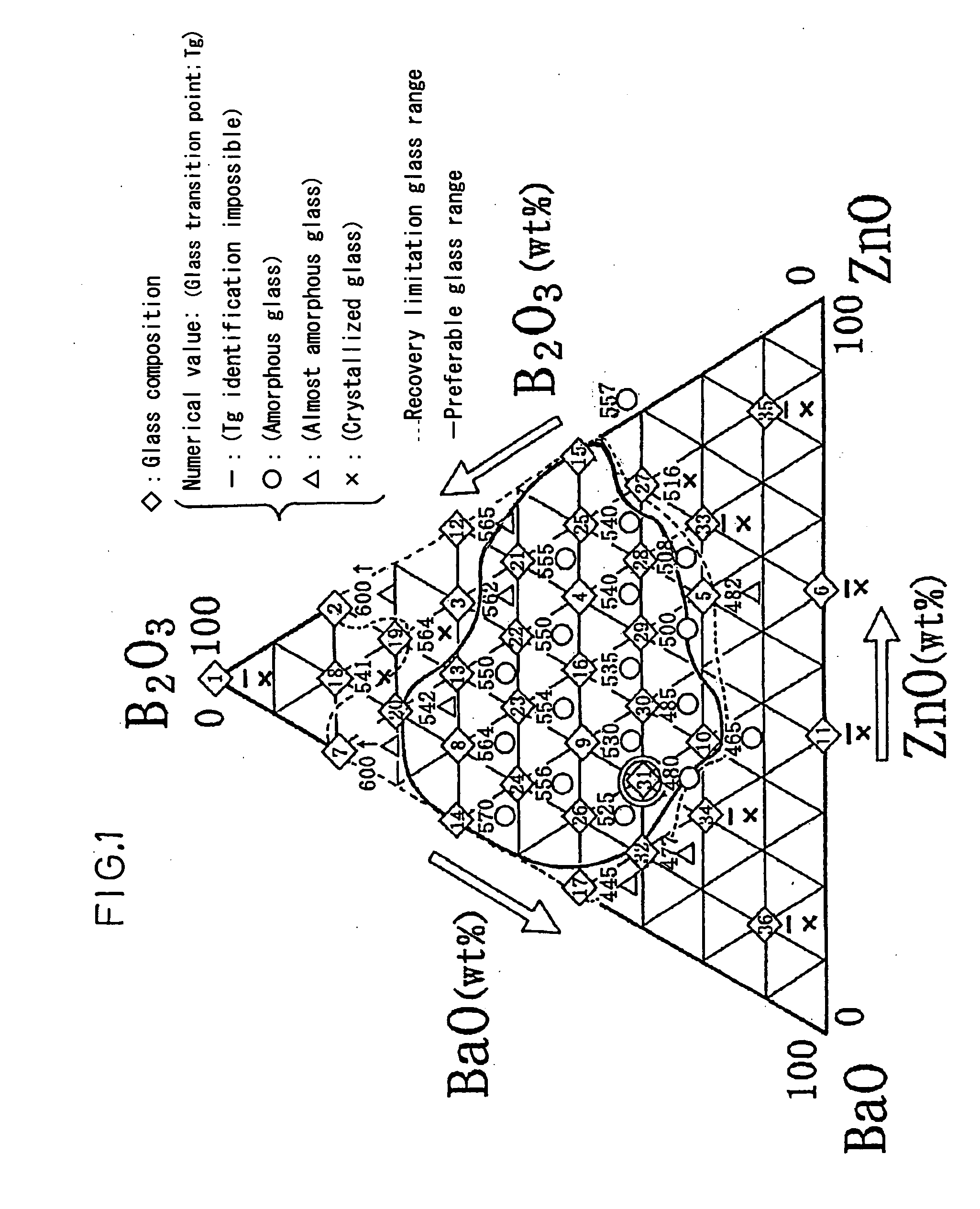

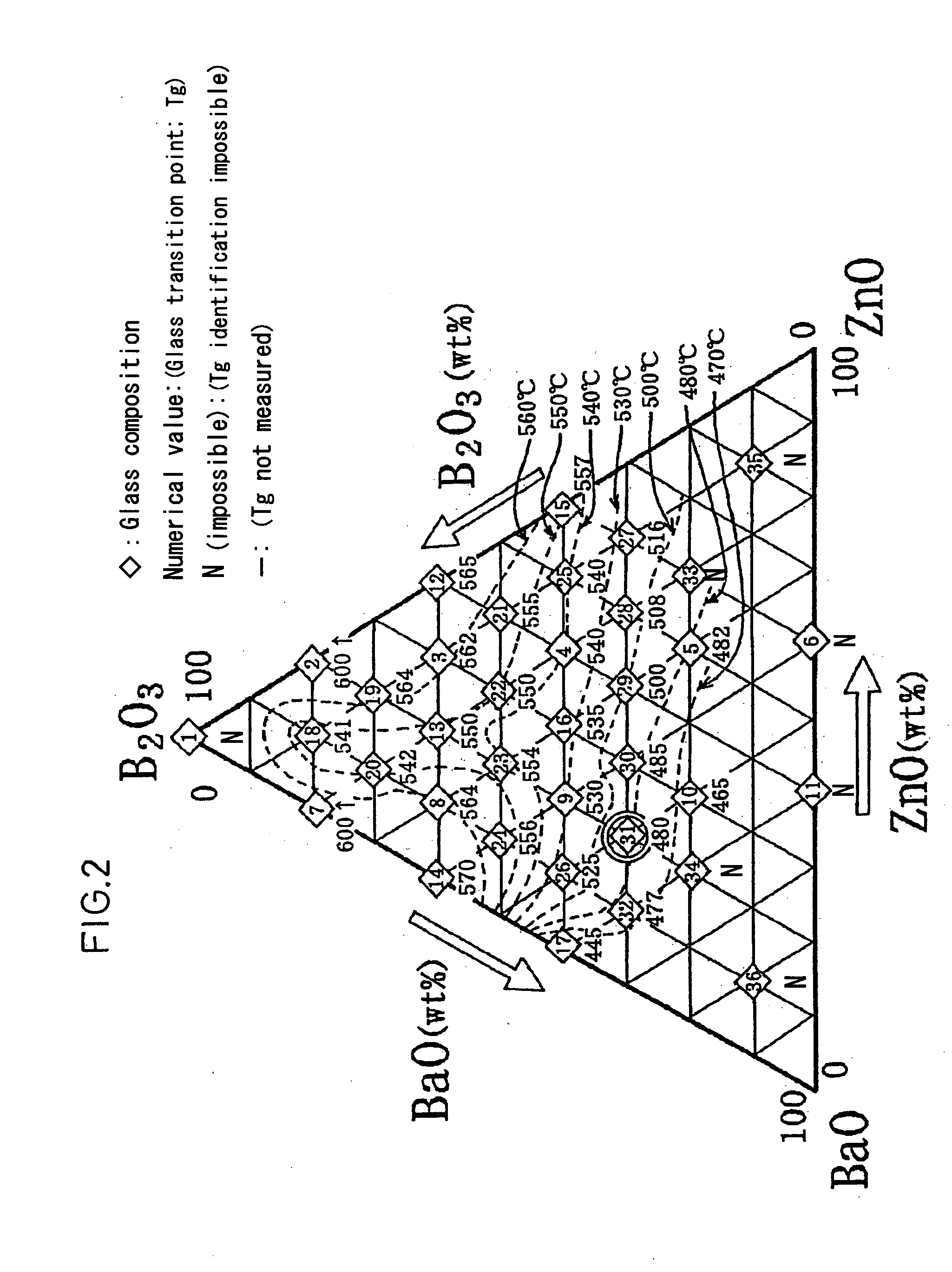

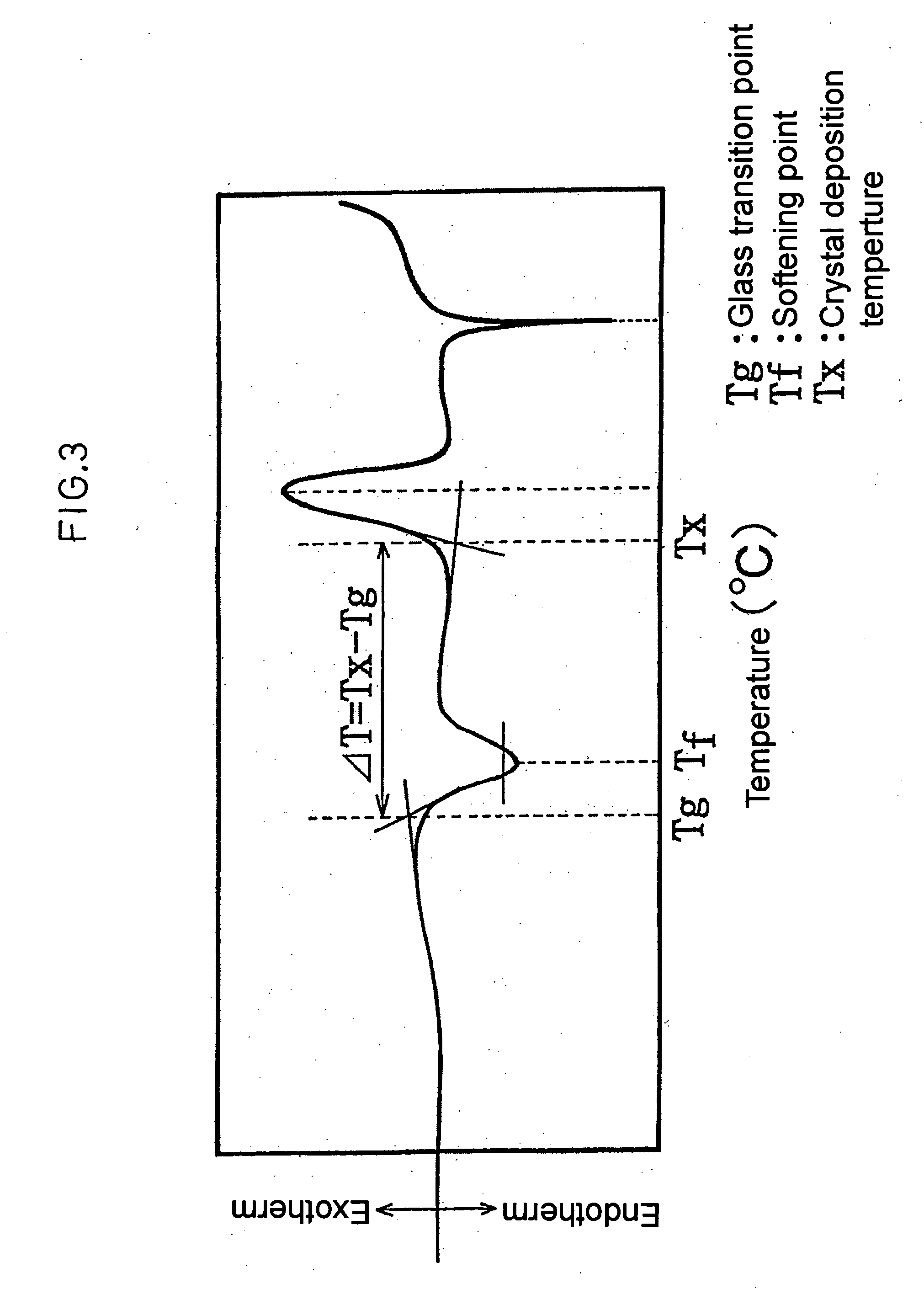

Lead-free glass material for use in sealing and, sealed article and method for sealing using the same

ActiveUS20050233885A1Solve the lack of practicalityPreferable sealing qualityAdditive ingredientThermal expansion

Provided with a glass composition including a network-former oxide composed of any one of or both of B2O3 and V2O5 of 20-80% by weight, ZnO of 0-60% by weight and BaO of 0-80% by weight, wherein at least one of ZnO and BaO is included as an essential ingredient. The present invention is a glass material for use in sealing, which is of lead-free series, can be used for sealing at a low processing temperature and within a wide temperature range, has a low thermal expansion coefficient, superior adhesion, superior sealing processability, superior adherence, superior chemical stability, superior strength and the like and comprises sufficient practical performance to substitute for lead glass.

Owner:YAMATO ELECTRONICS

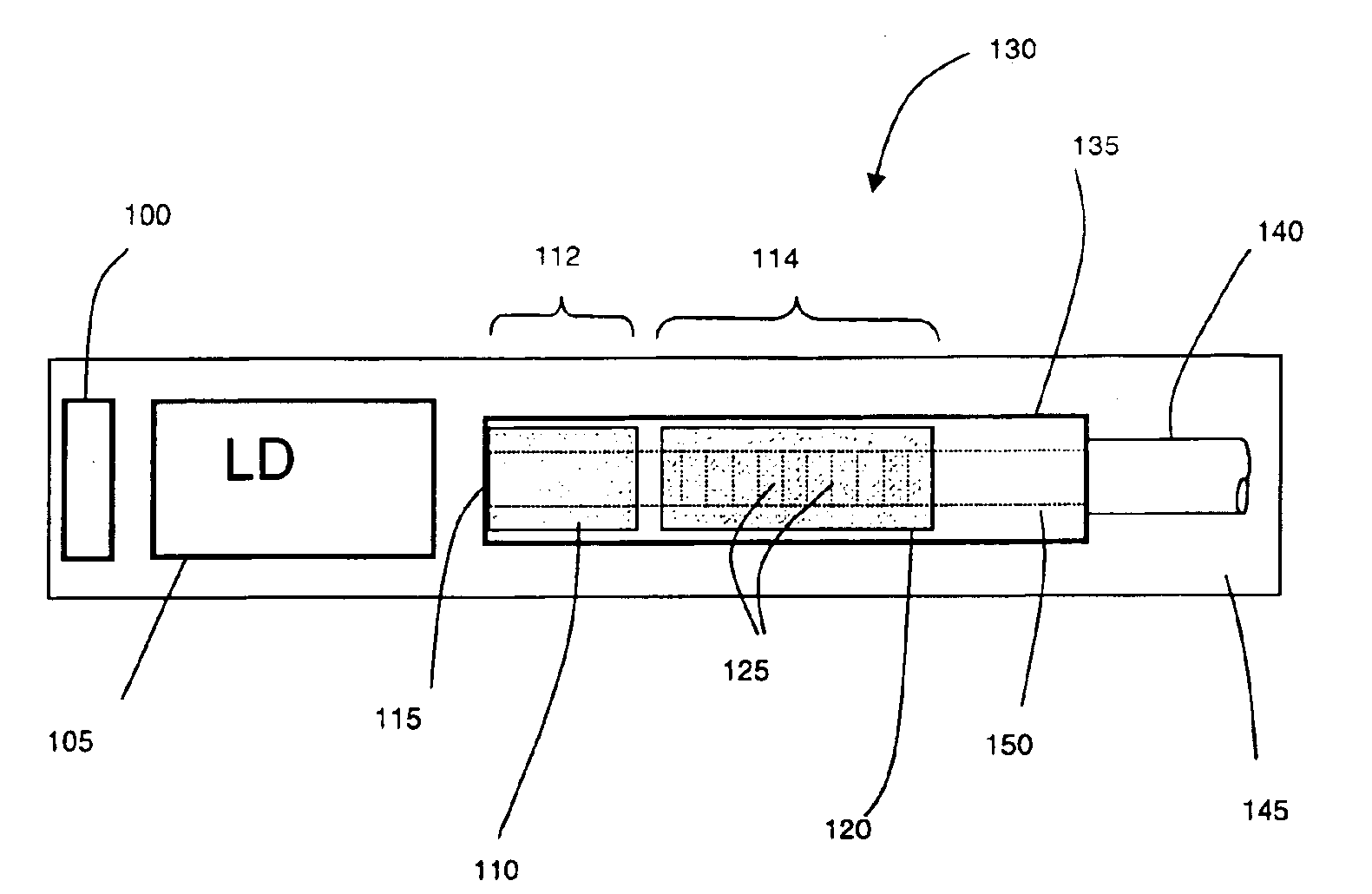

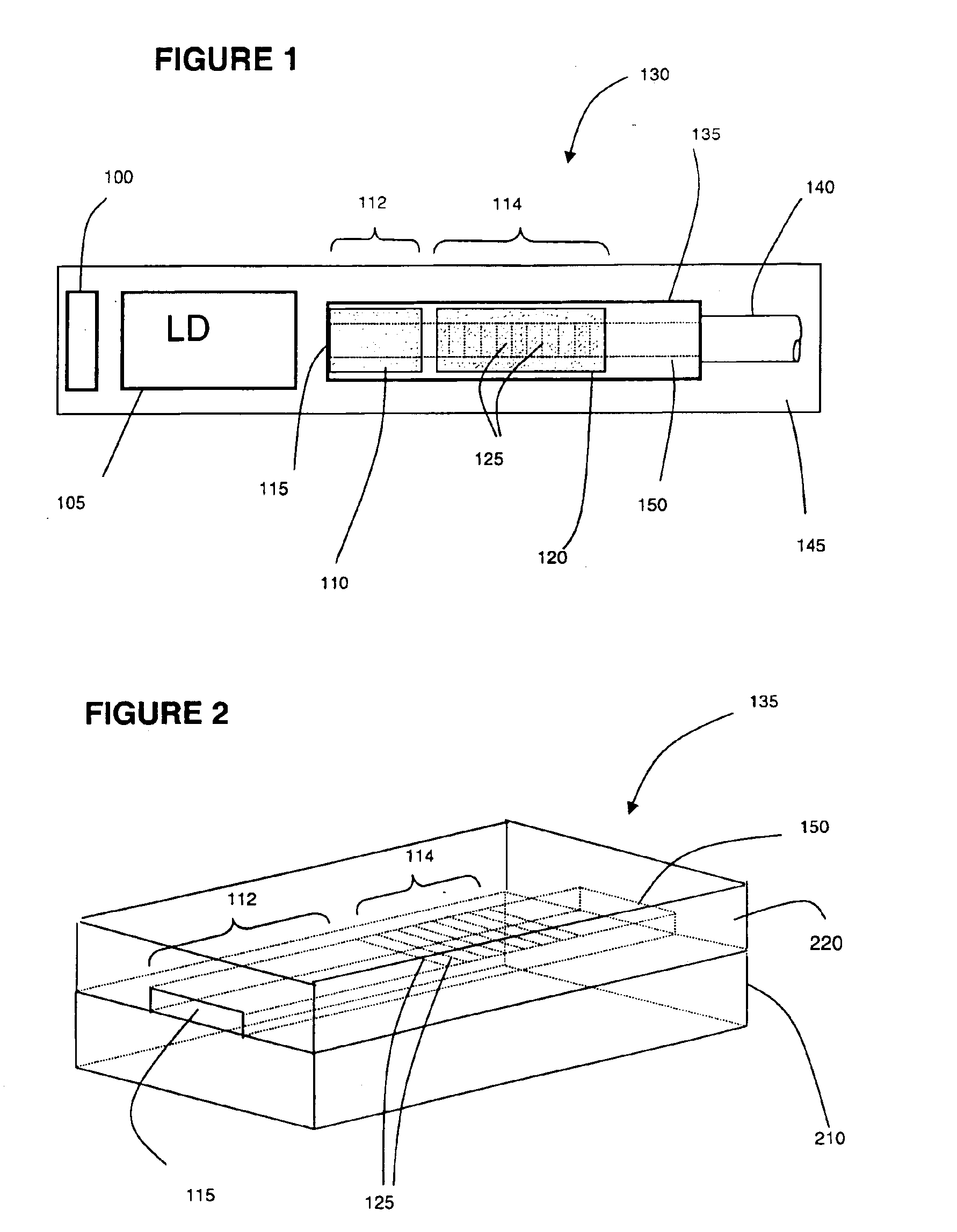

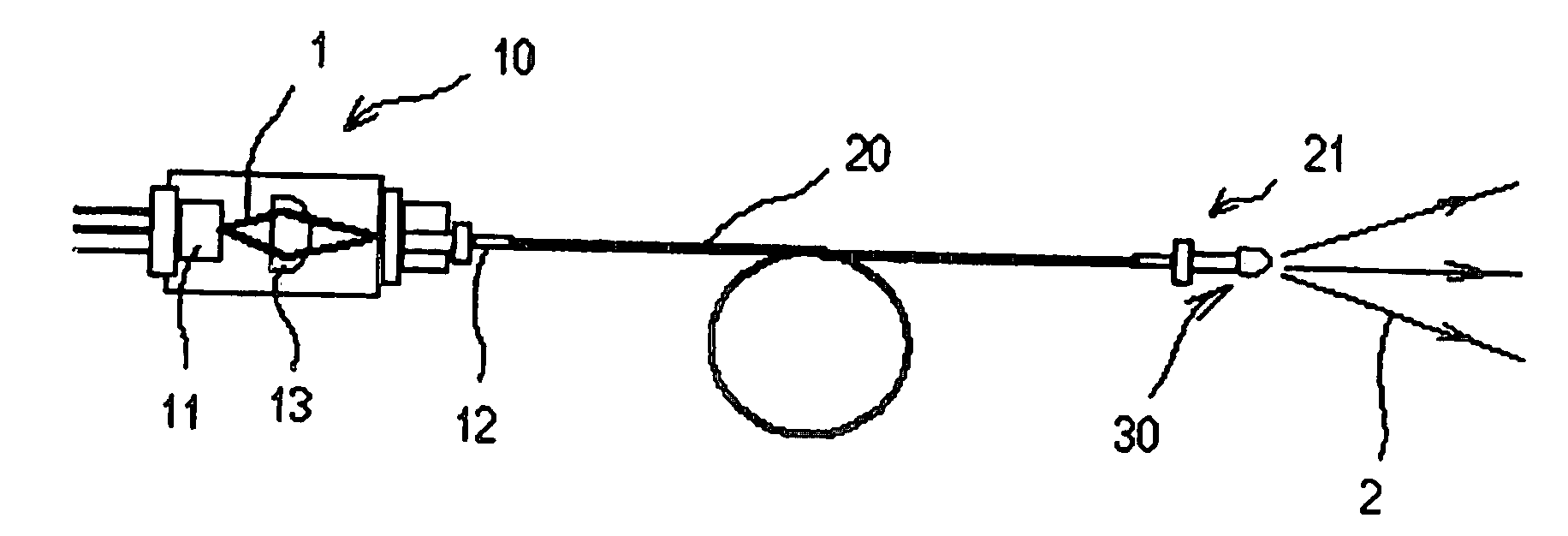

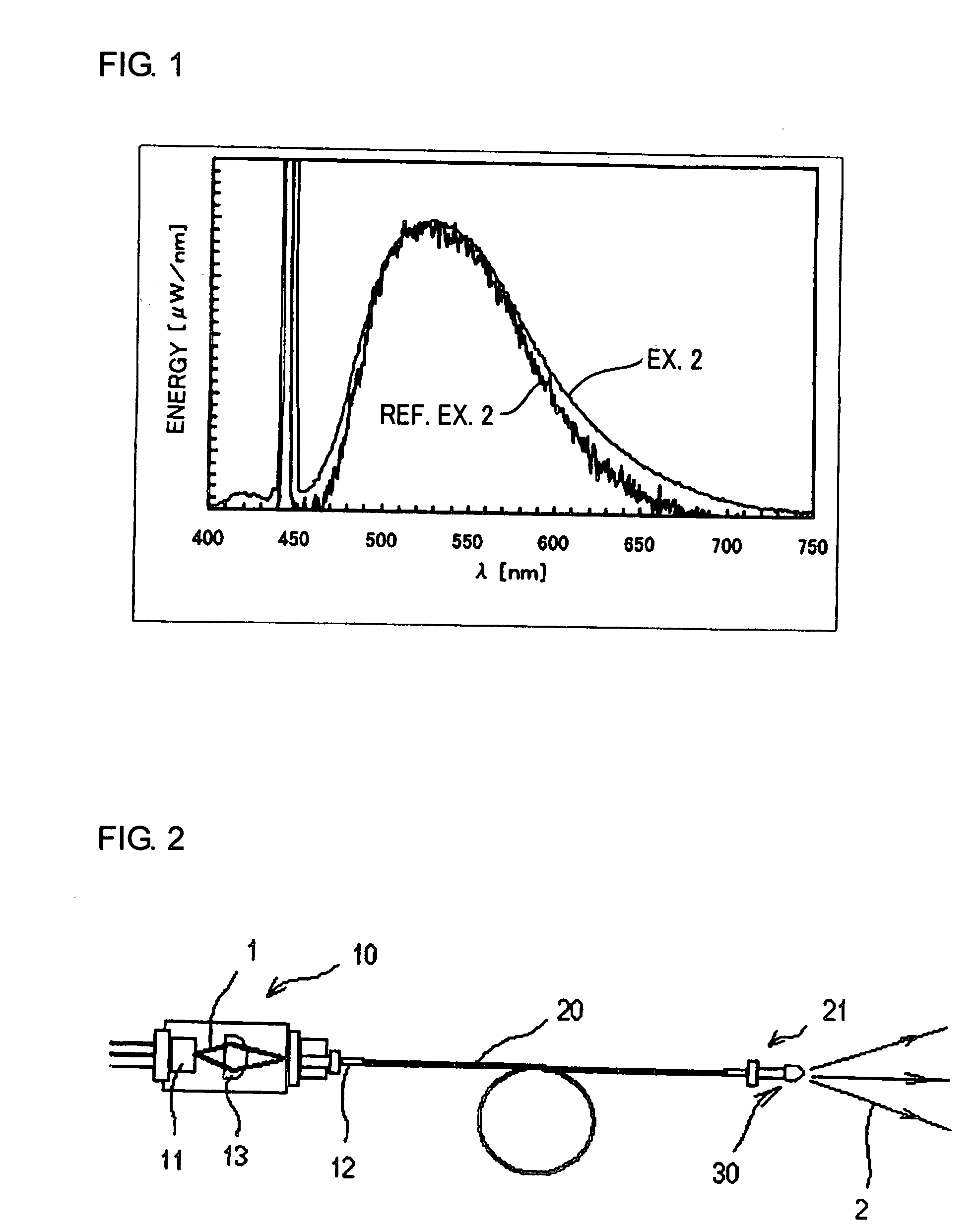

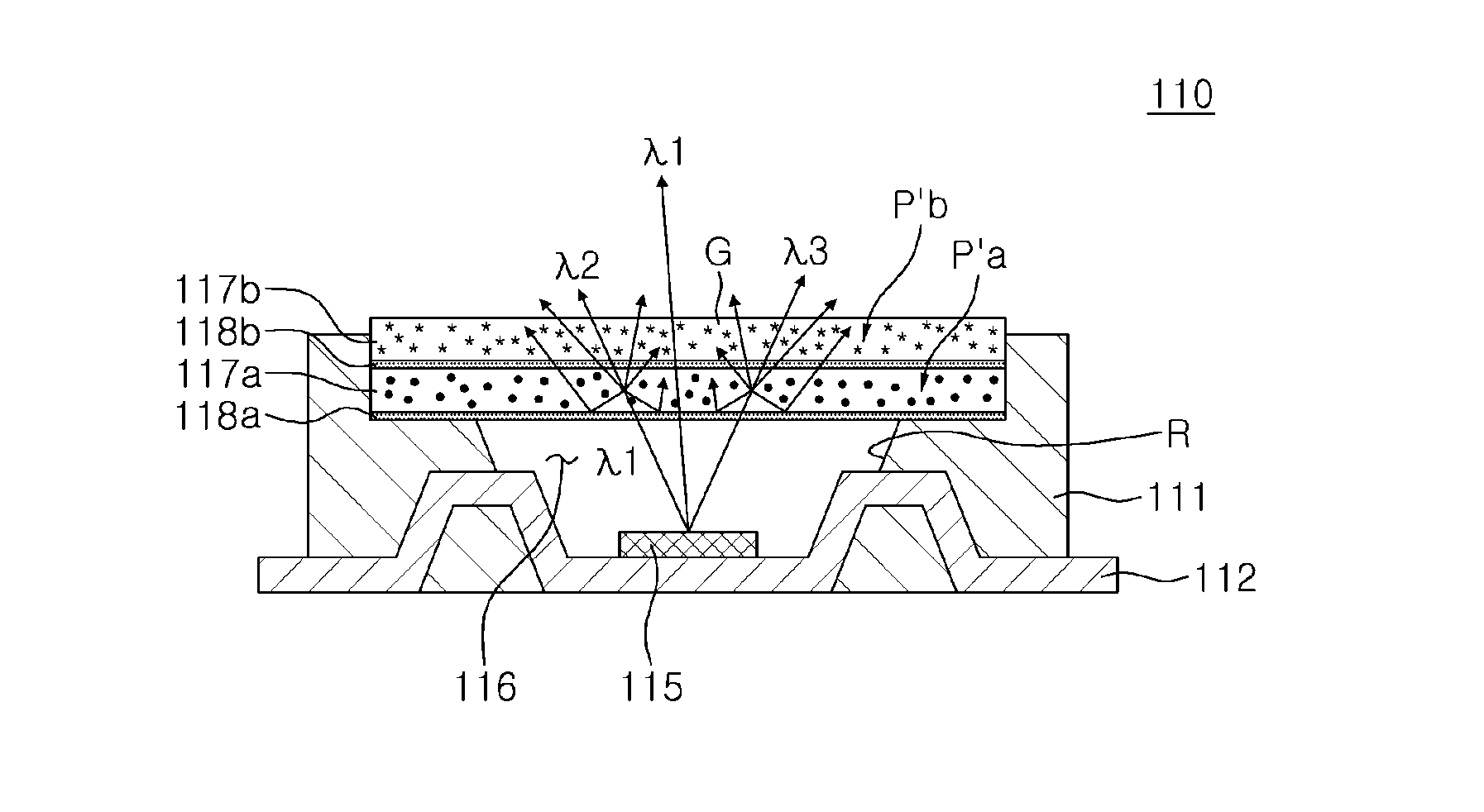

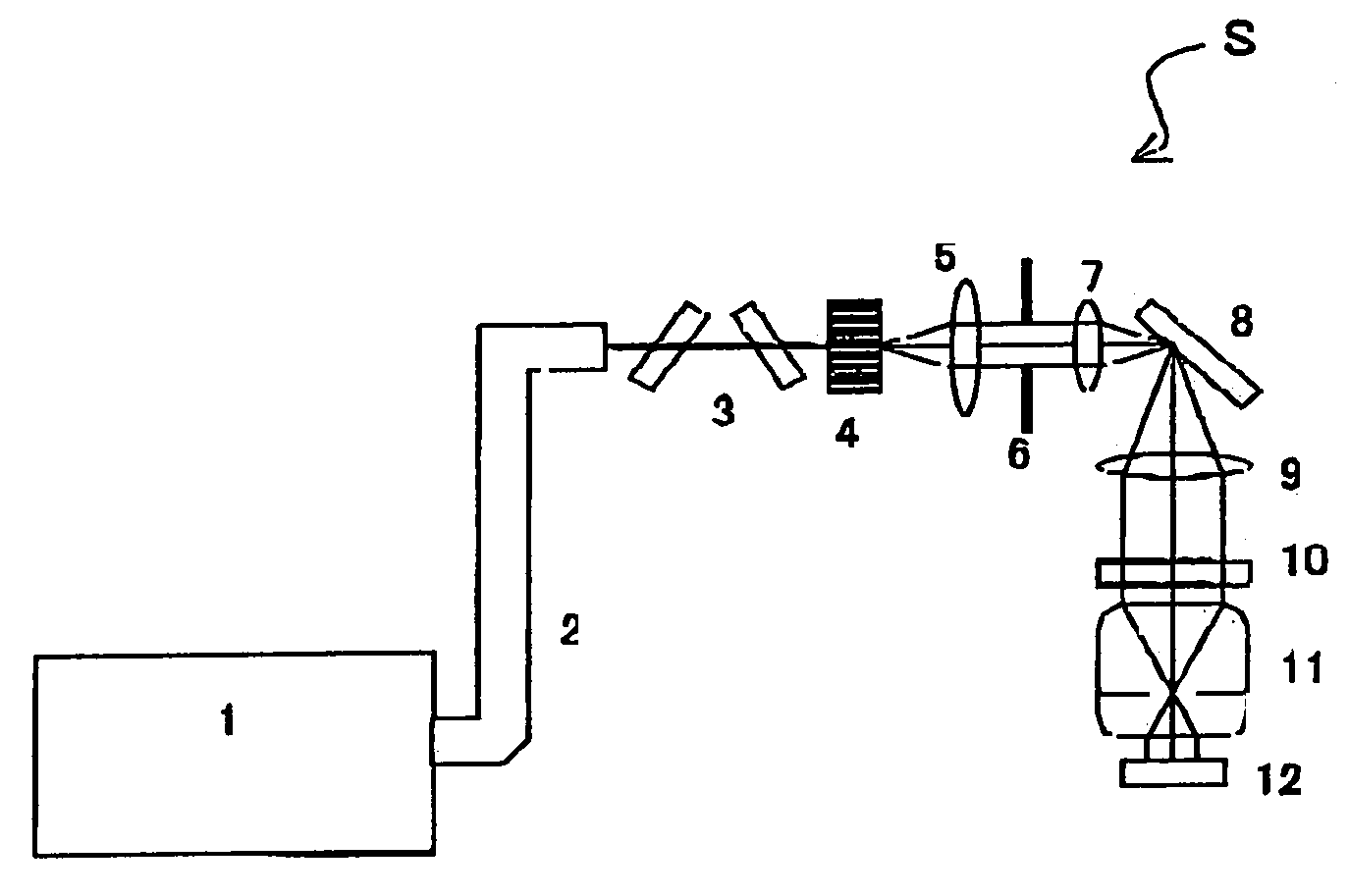

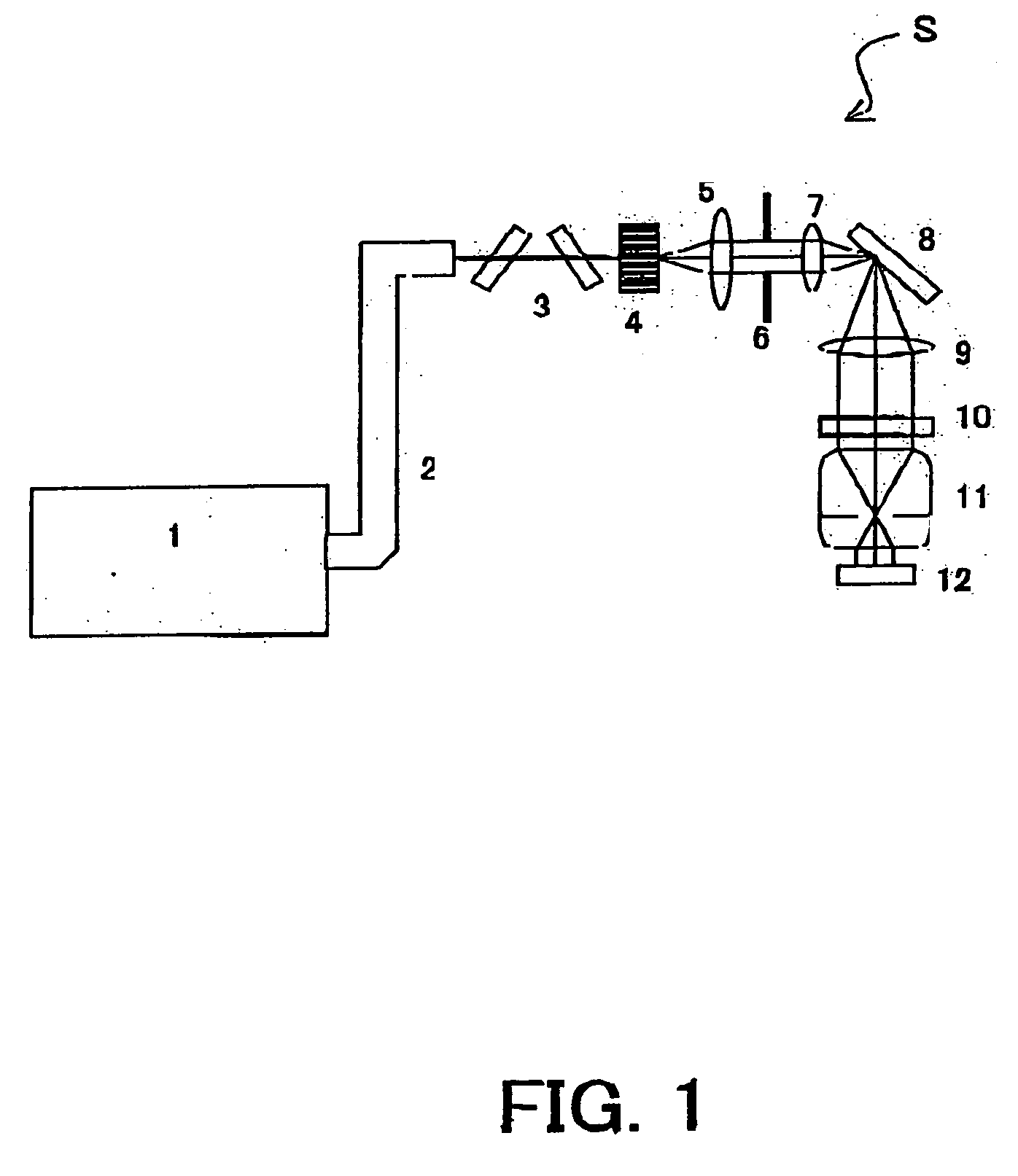

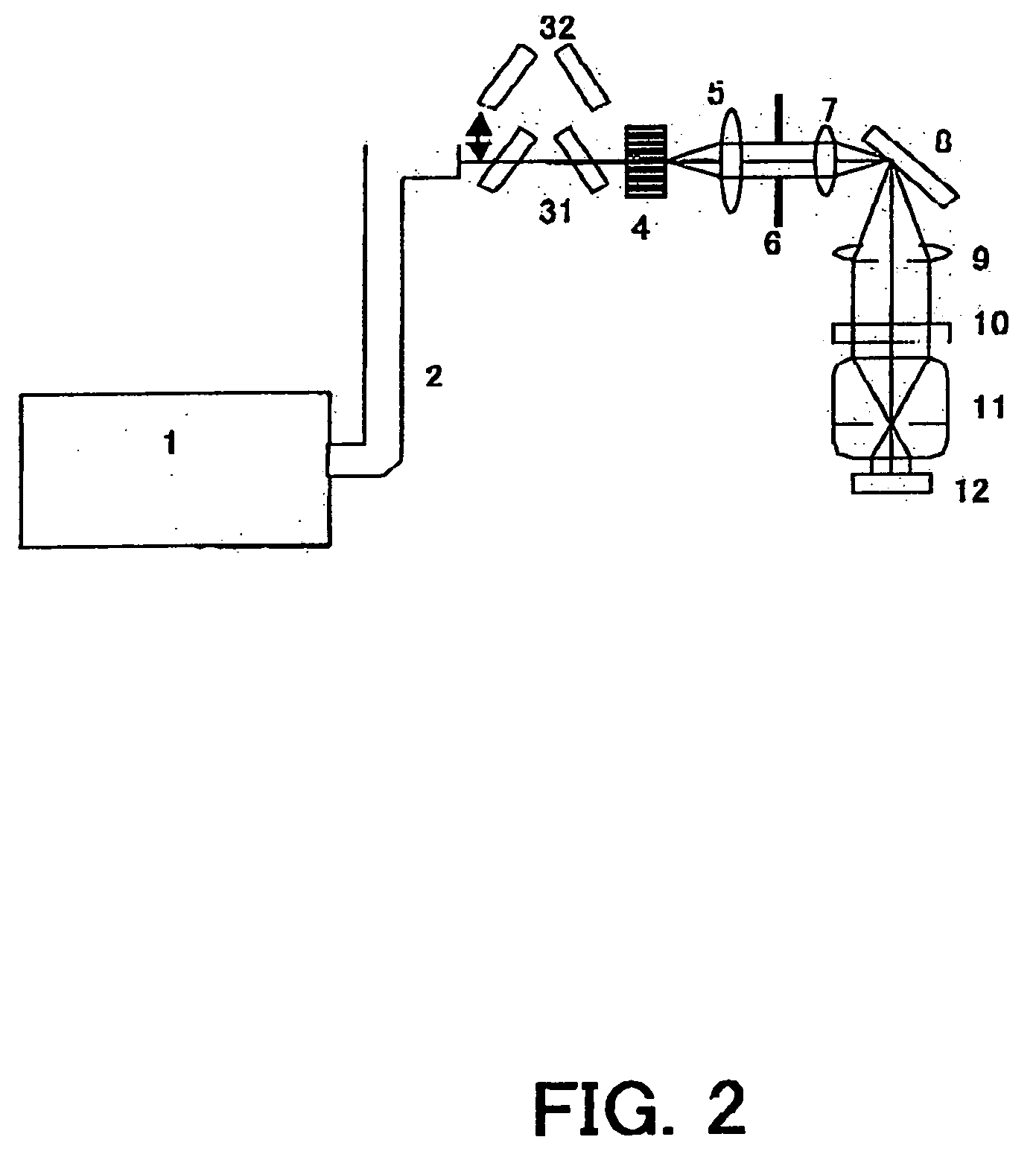

Tunable optical source

InactiveUS6920159B2Consider flexibilityControl of the refractive index of the glass materialSemiconductor laser structural detailsOptical resonator shape and constructionOptical radiationCoupling

A tunable optical source comprises a laser diode and an external optical feedback device. The feedback device has a waveguiding portion fabricated at least in part out of a glass material having both organic and inorganic components. A control device is provided for controlling the refractive index of the glass material so as to change the wavelength of feedback to the laser diode. The glass material may for example have thermo-optic properties and the control device might then be a heating device for heating the glass material. The feedback device can have more than one portion, a second portion for example having controllable coupling characteristics for coupling optical radiation into or out of the feedback device. It also preferably has a portion for controlling optical path length in the feedback device.

Owner:OPTITUNE

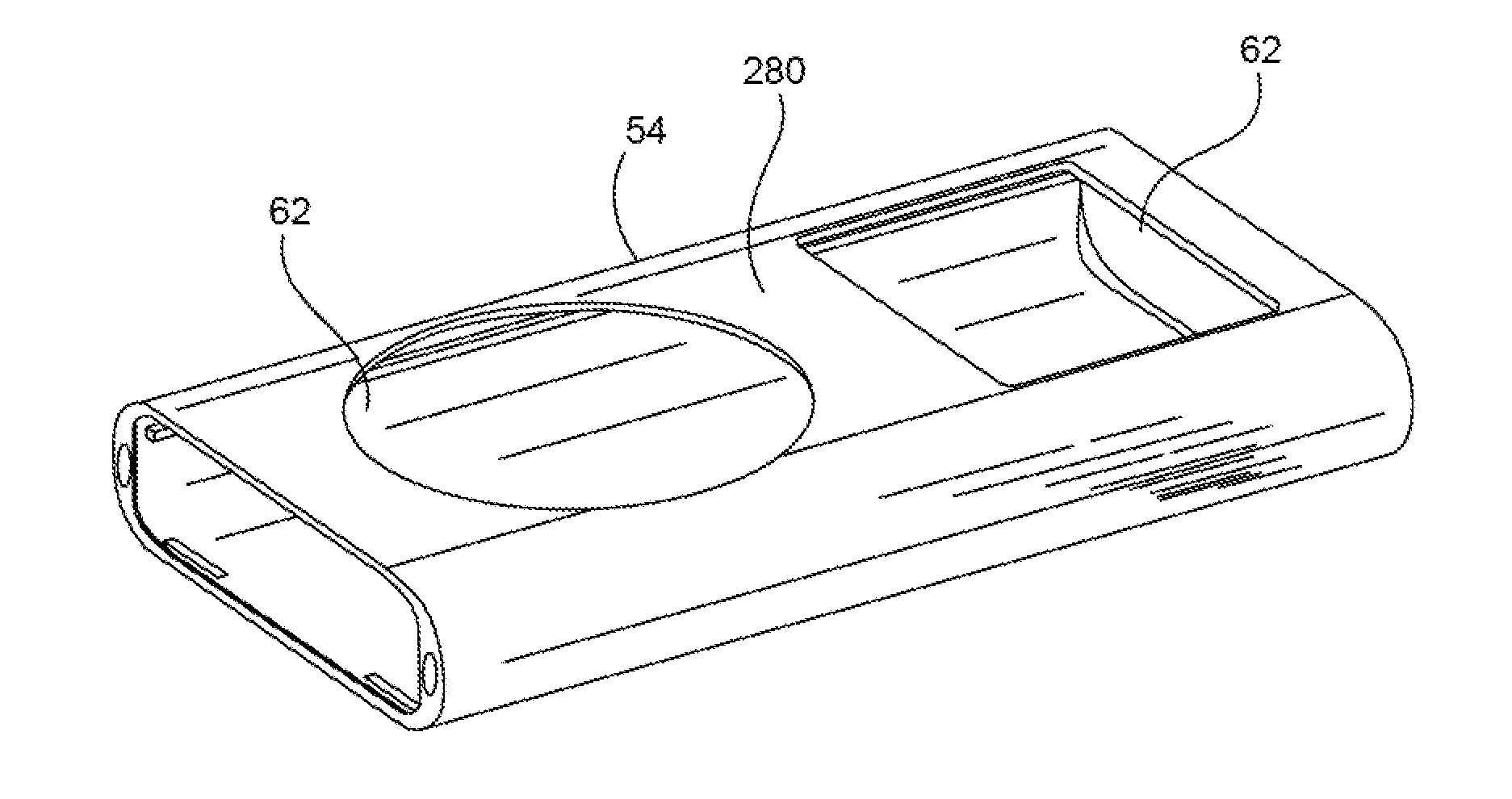

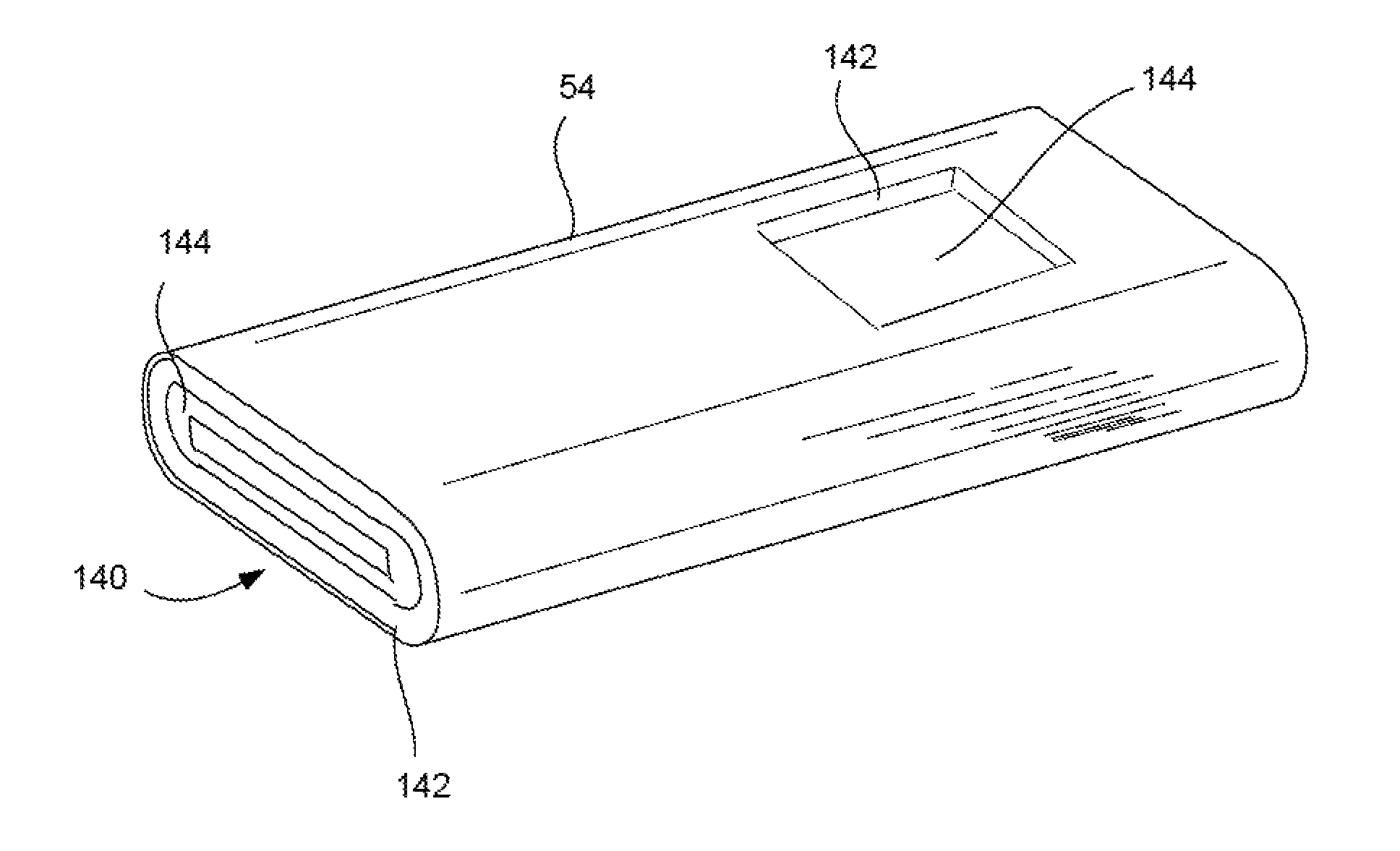

Glass enclosure

A handheld computing device that includes an enclosure having structural walls formed from a glass material that can be radio-transparent. The enclosure can be formed from a hollow glass tube or two glass members bonded together. A laser frit bonding process may be used to hermetically seal the two glass members together to create a water resistant electronic device.

Owner:APPLE INC

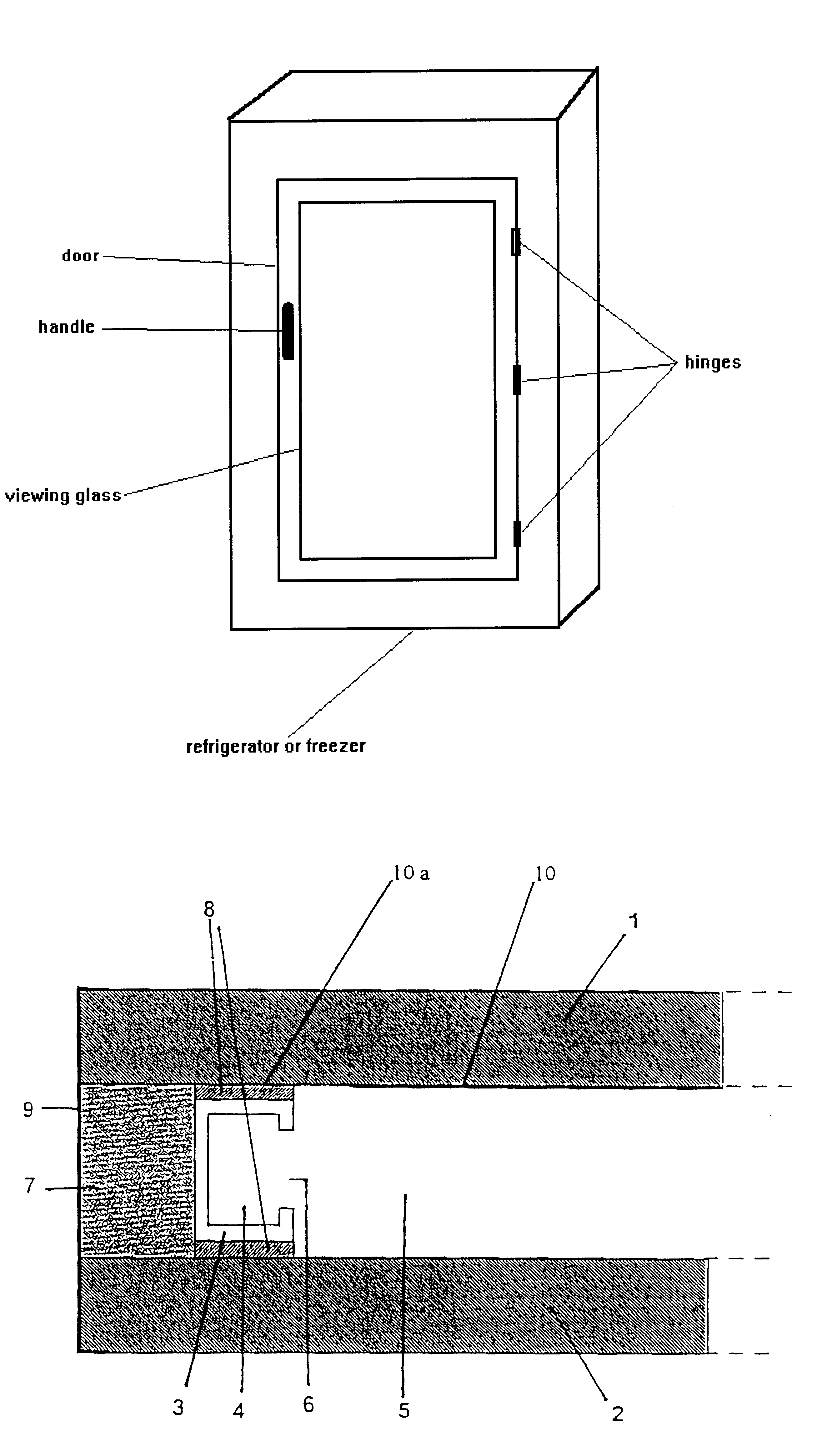

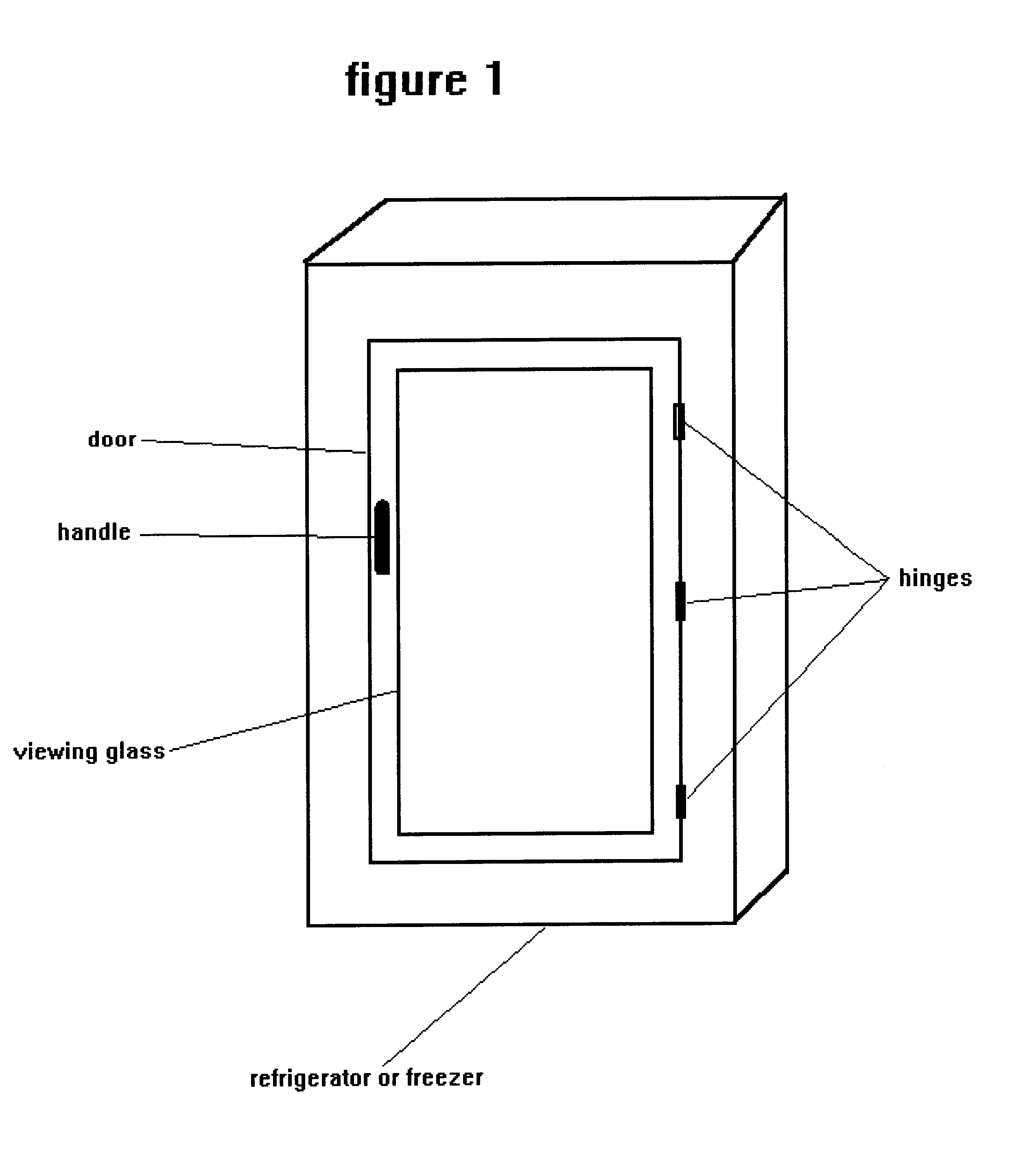

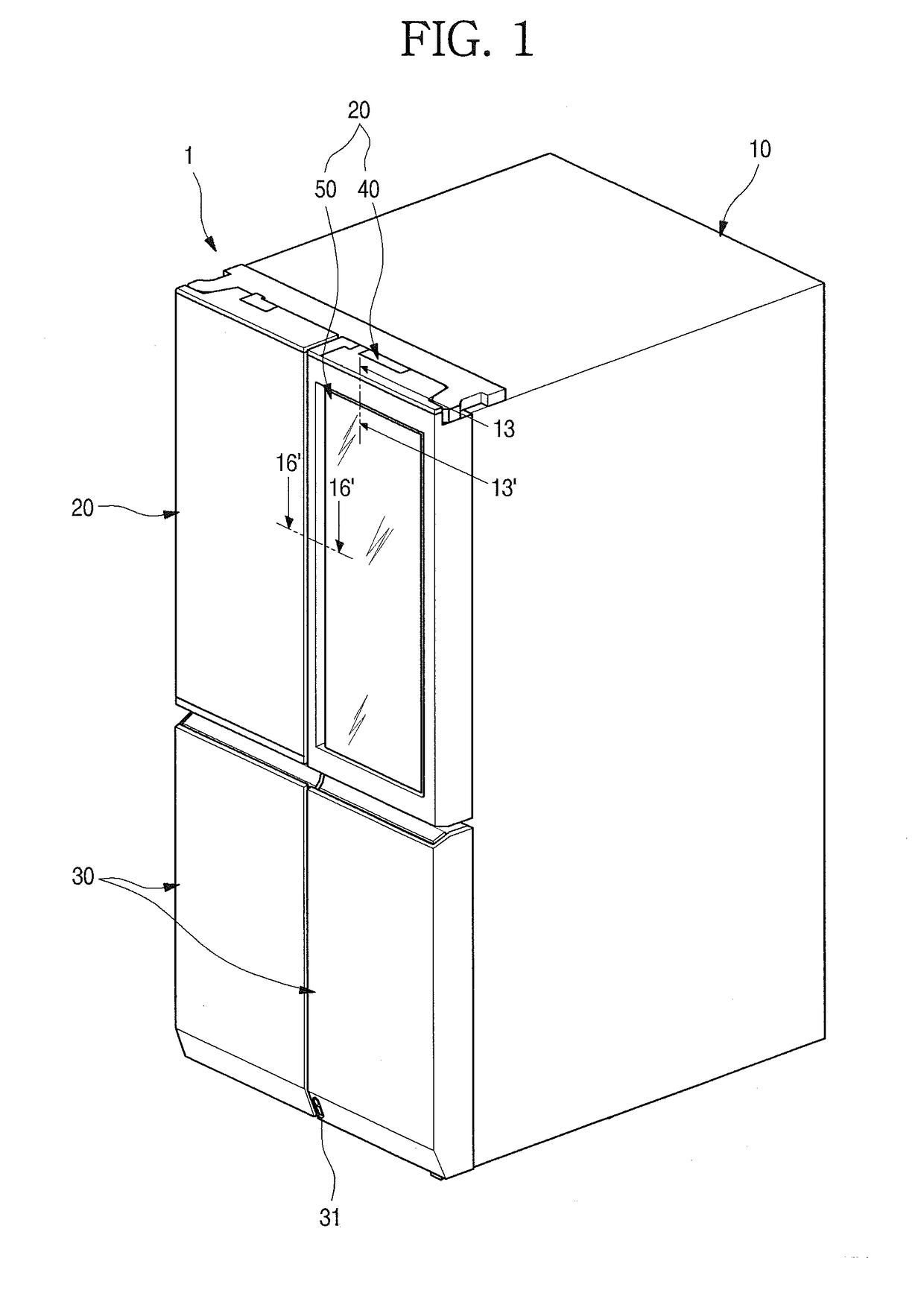

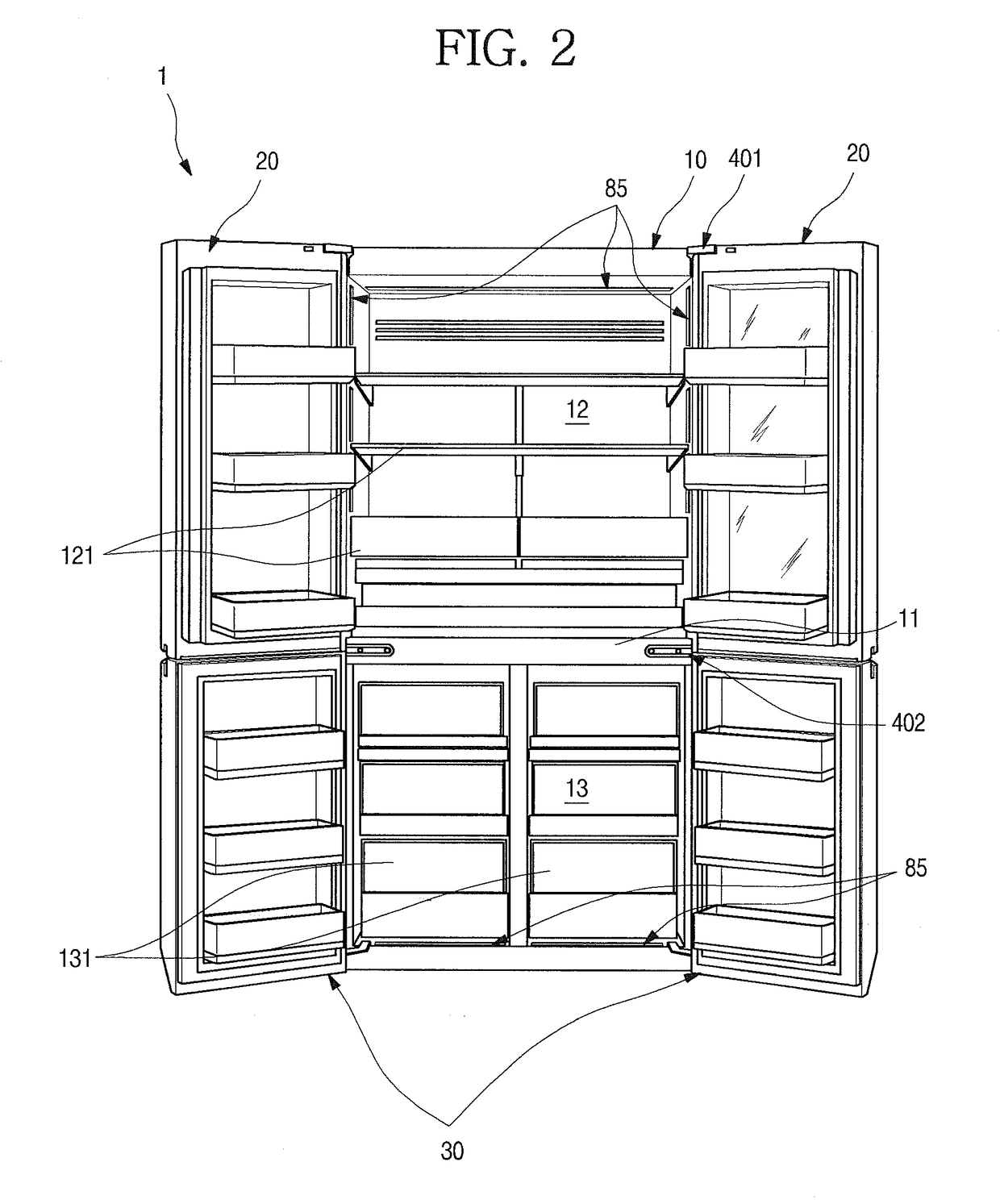

Appliance such as a refrigerator or freezer with a transparent viewing door and a method of manufacture of a refrigerator or freezer with a transparent viewing door

InactiveUS6268594B1Reduce formationLittle process outlayShow cabinetsConductive layers on insulating-supportsFlat glassInsulated glazing

A multipane insulating glass for appliances having an inner-chamber temperature which is lower than the ambient temperature, in particular for viewing doors of refrigerators and freezers comprises at least two panes which are of approximately equal size and are arranged at a distance from one another. The distance is maintained by a spacer which runs continuously around the vicinity of the edge. One of the two outer panes is provided with an electrically conductive, transparent coating on its side which faces towards the space between the panes. In this glass, the coating, which is applied to the entire surface, is deactivated in the peripheral area of the pane, containing the contact surface for the spacer. Also, a process for producing coated flat glass materials for such insulating glass materials, as described above.

Owner:GLAS SCHOTT +1

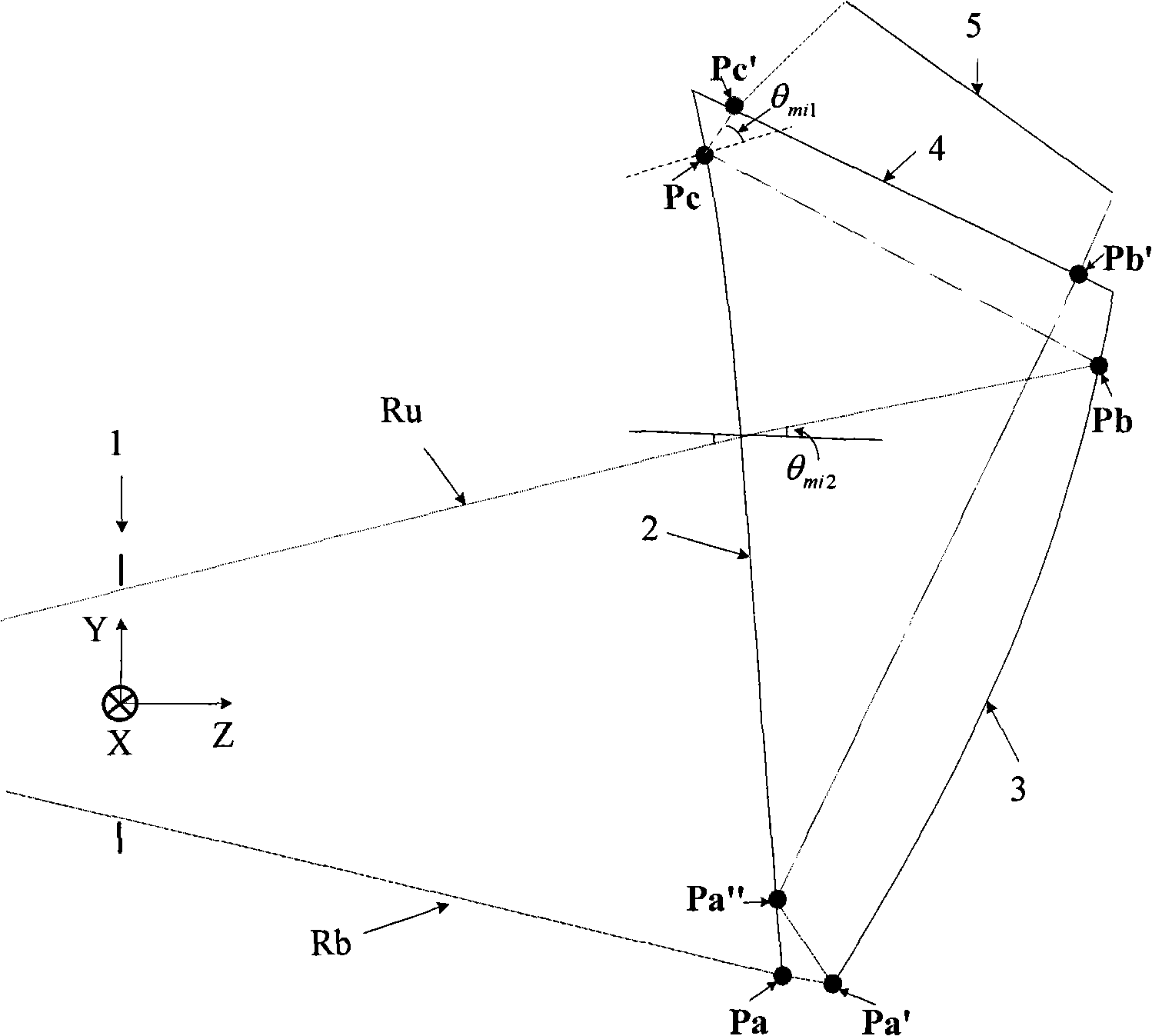

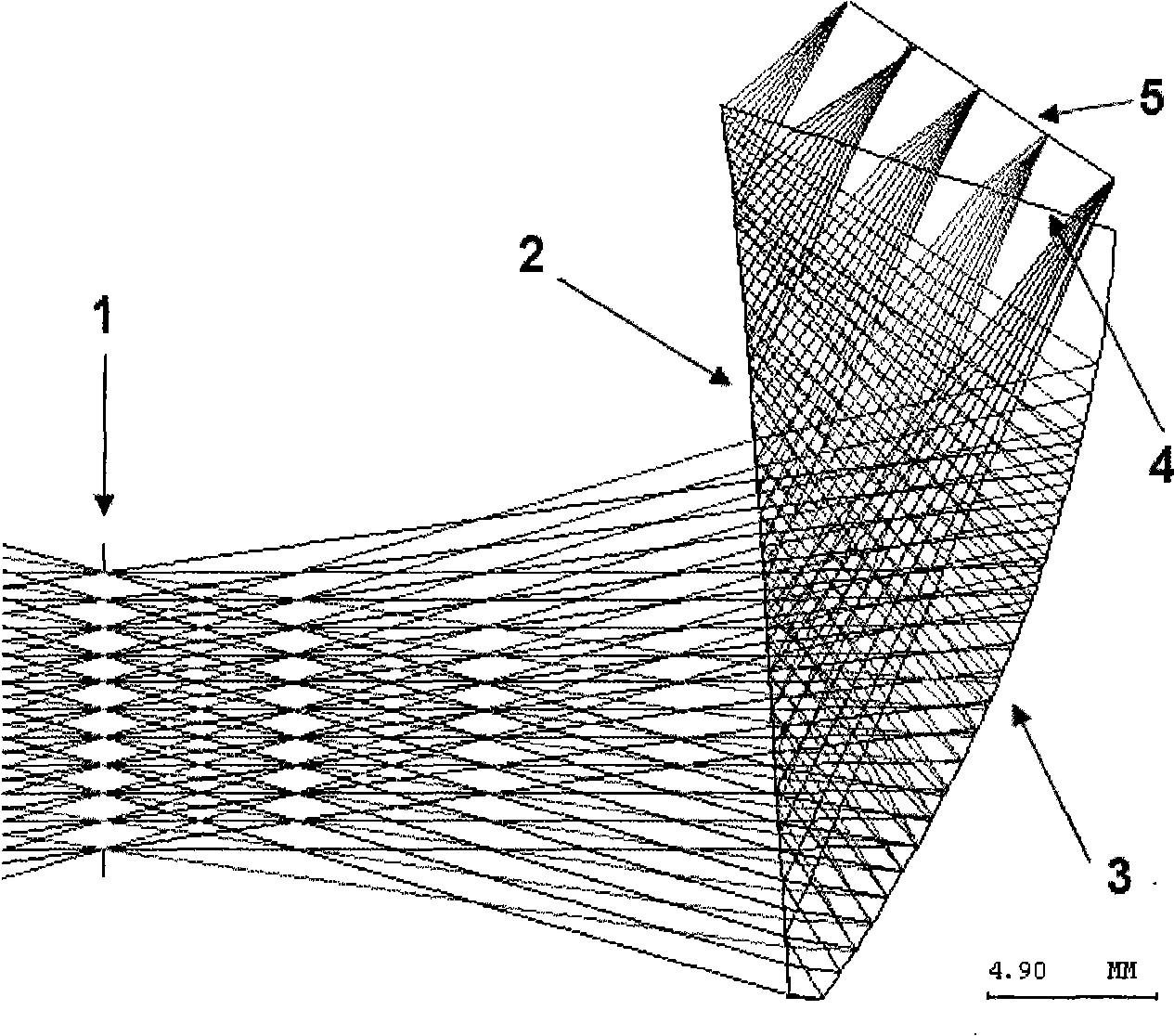

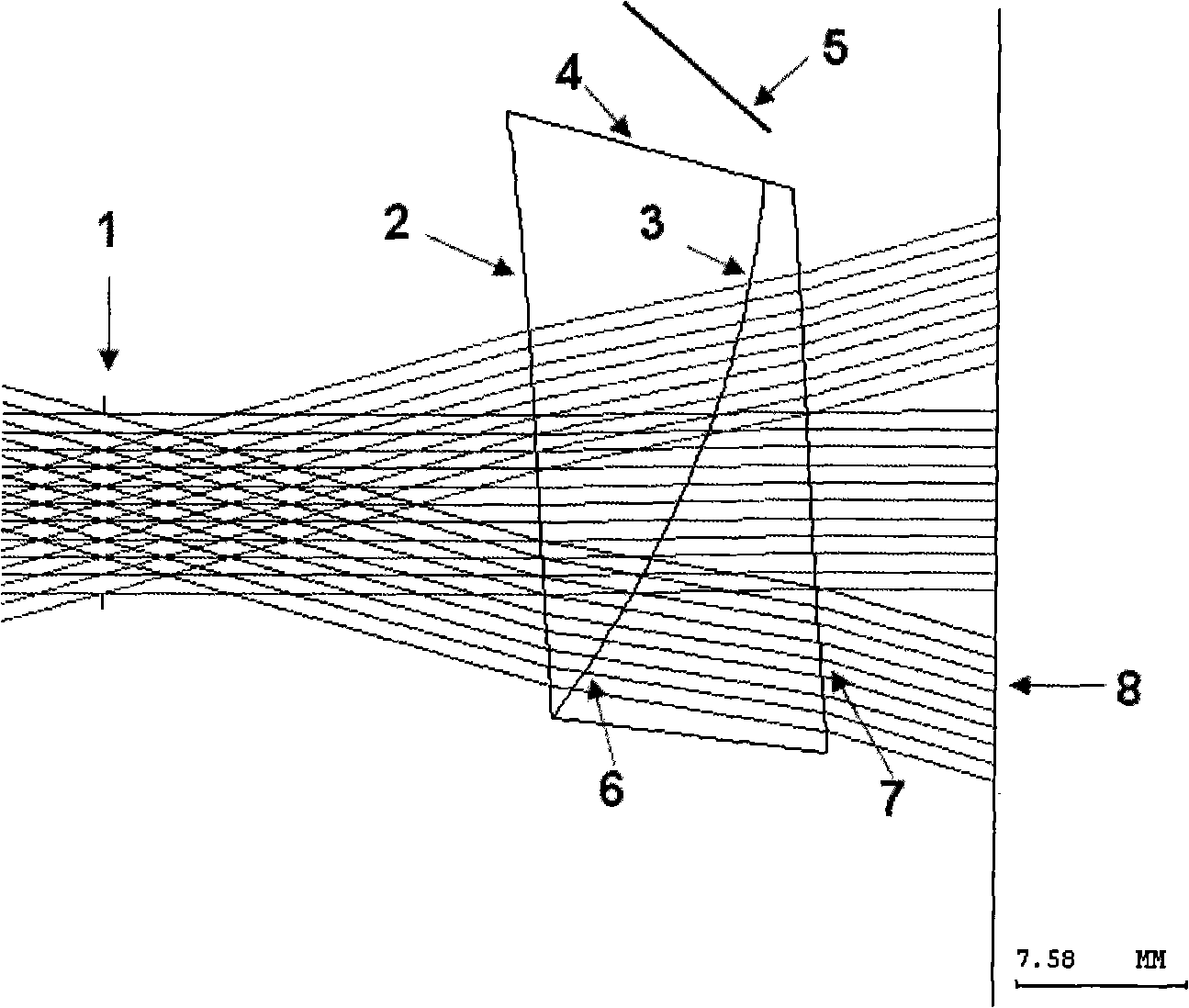

Optical system of light and small-sized big angular field free curved surface prism helmet display

The invention relates to a small and light wide-field free-form surface prism HMD optical system, which belongs to the field of optical system and device design and is applied to the virtual reality and augmented reality field. The invention comprises a free-form surface prism with three optical surfaces, and a micro-image display; the free-form surface prism is made of plastic glass materials with the refractive index greater than 1; the three free-form optical surfaces are concave surfaces, which meet one of the three surface-type equations, and the location relationship of each surface meets three condition equations; the incident angle formed between the widest-field upper edge rays emitted by an LCD and the second free-form surface meets the total reflection conditions; and an image source element is an LCD of 0.61 or 0.59 inches. The small and light wide-field free-form surface prism HMD optical system is light and compact and has the advantages of good aberration correction and high light energy utilization rate; the optical system enables the observer to see clear images in a wide field of view, and the displayed images do not have apparent brightness attenuation and can not easily cause visual fatigue to the observer.

Owner:BEIJING NEDPLUSAR DISPLAY TECH CO LTD

Glass enclosure

ActiveUS8824140B2Digital data processing detailsCasings with display/control unitsFritBonding process

Owner:APPLE INC

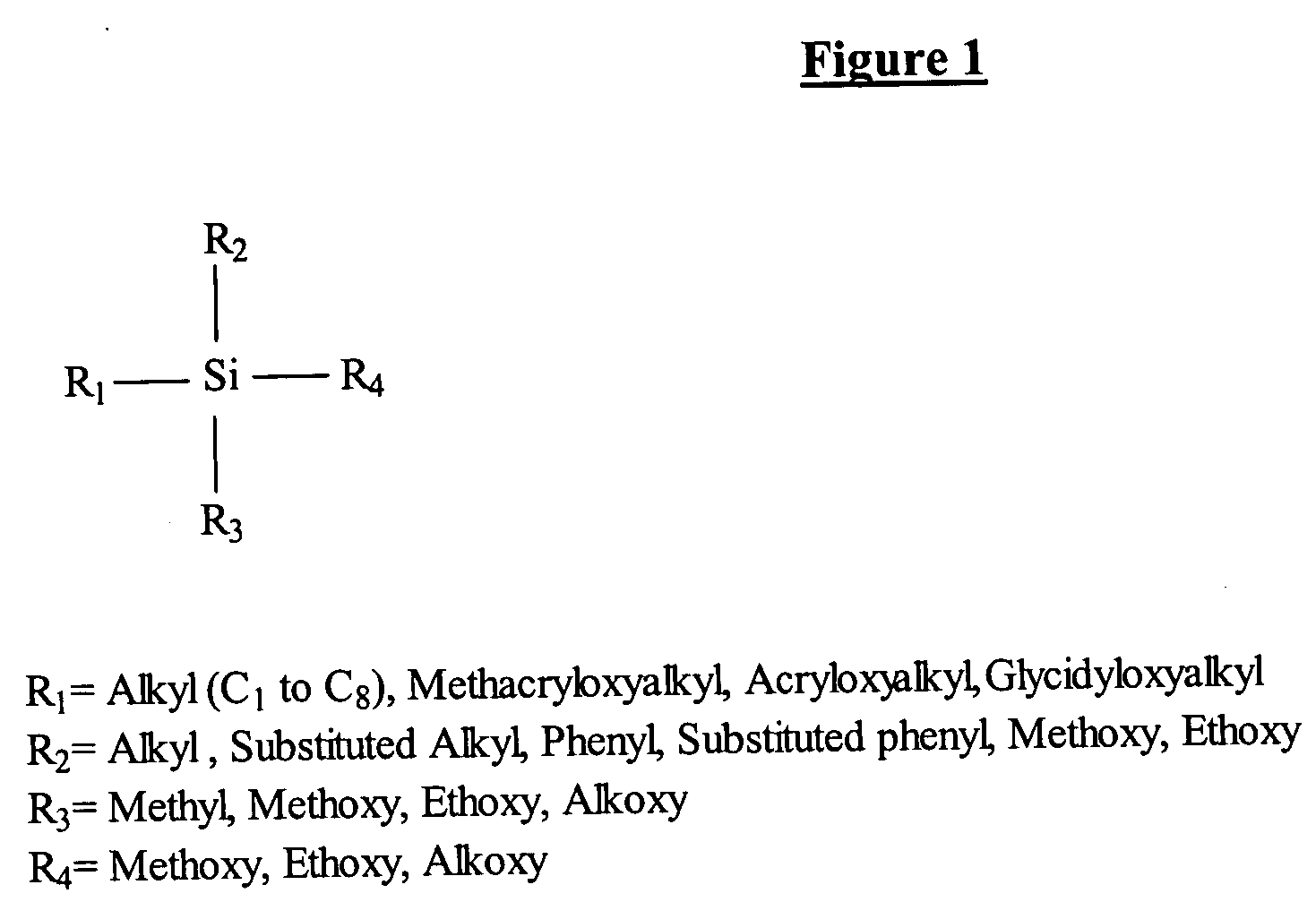

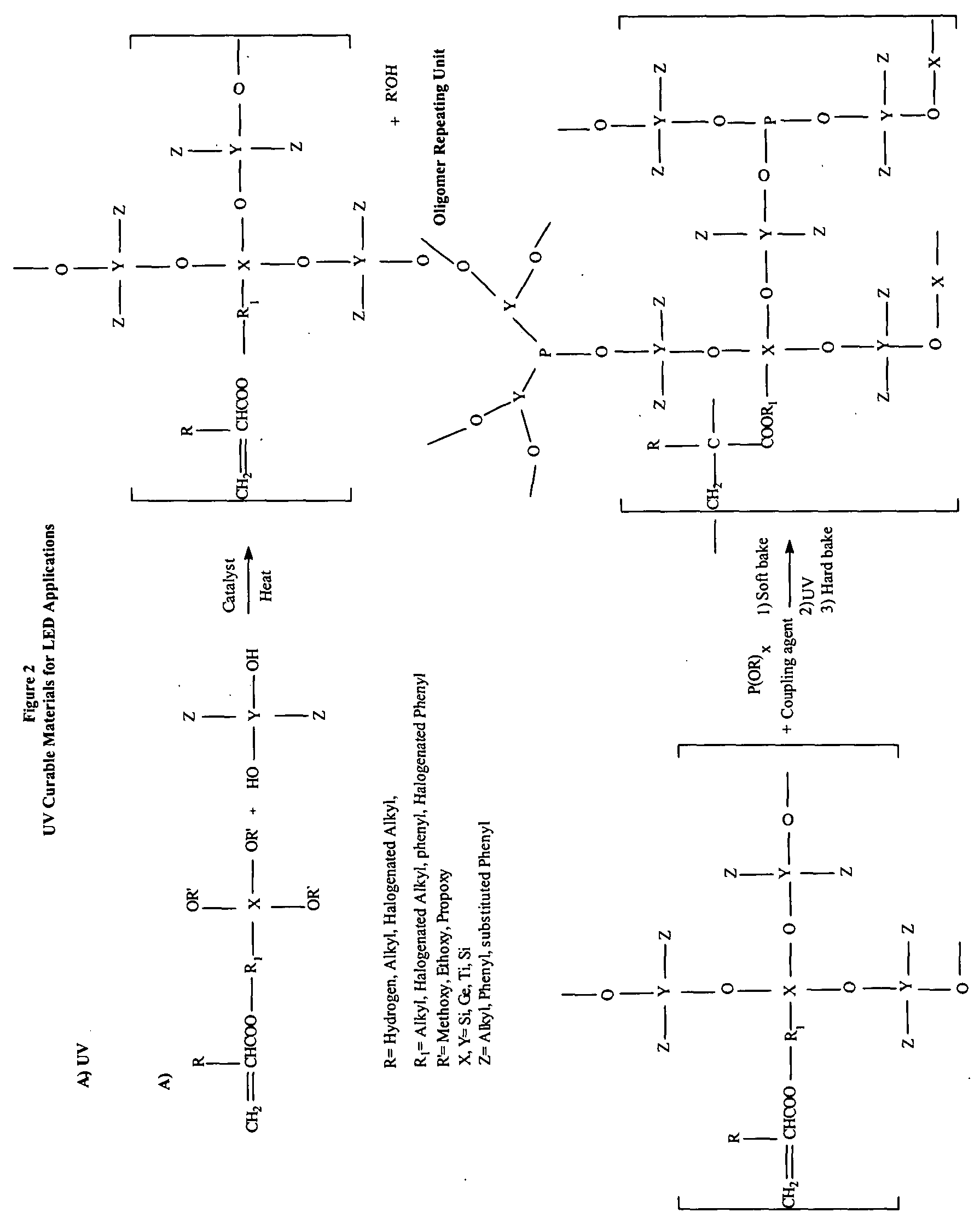

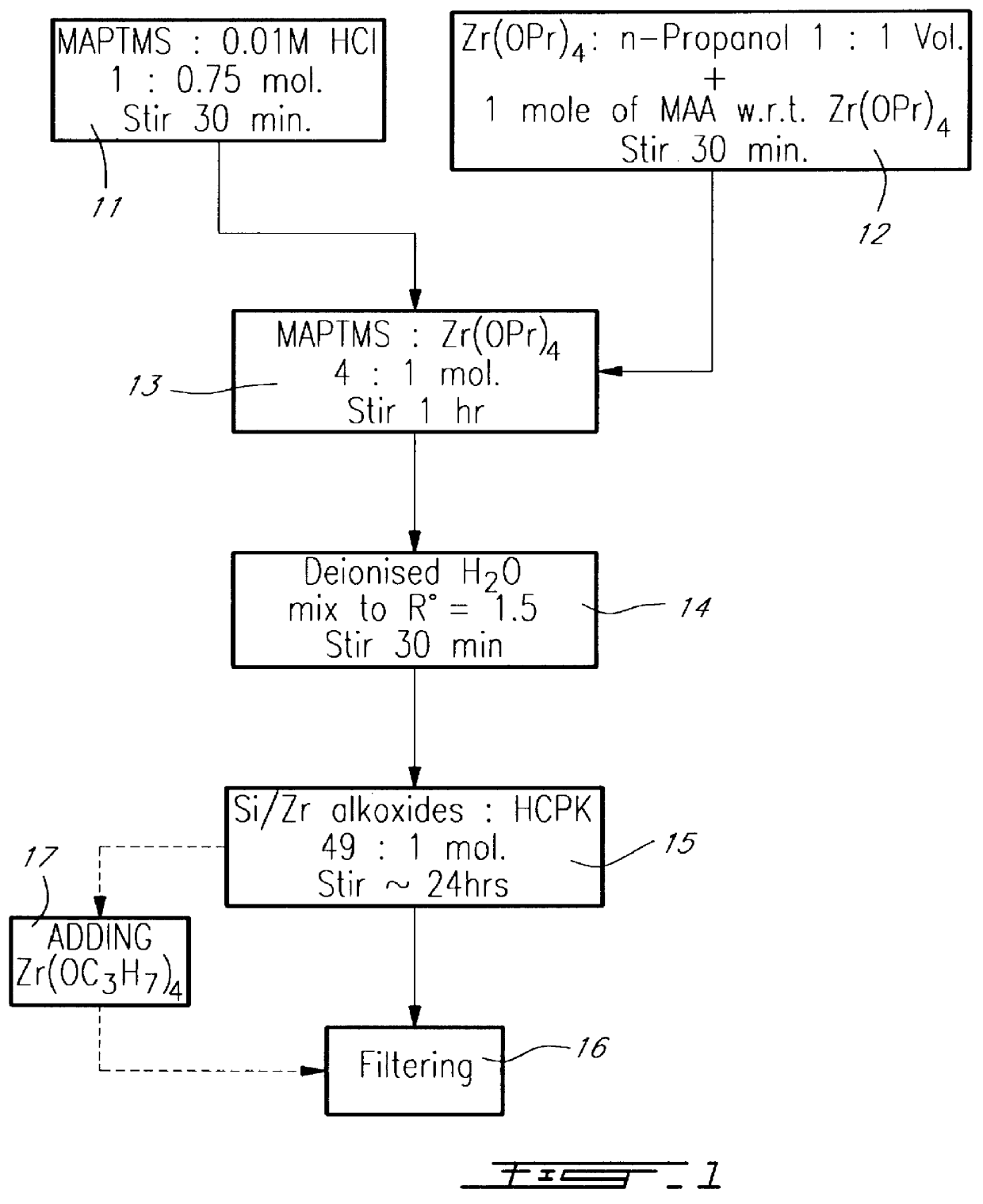

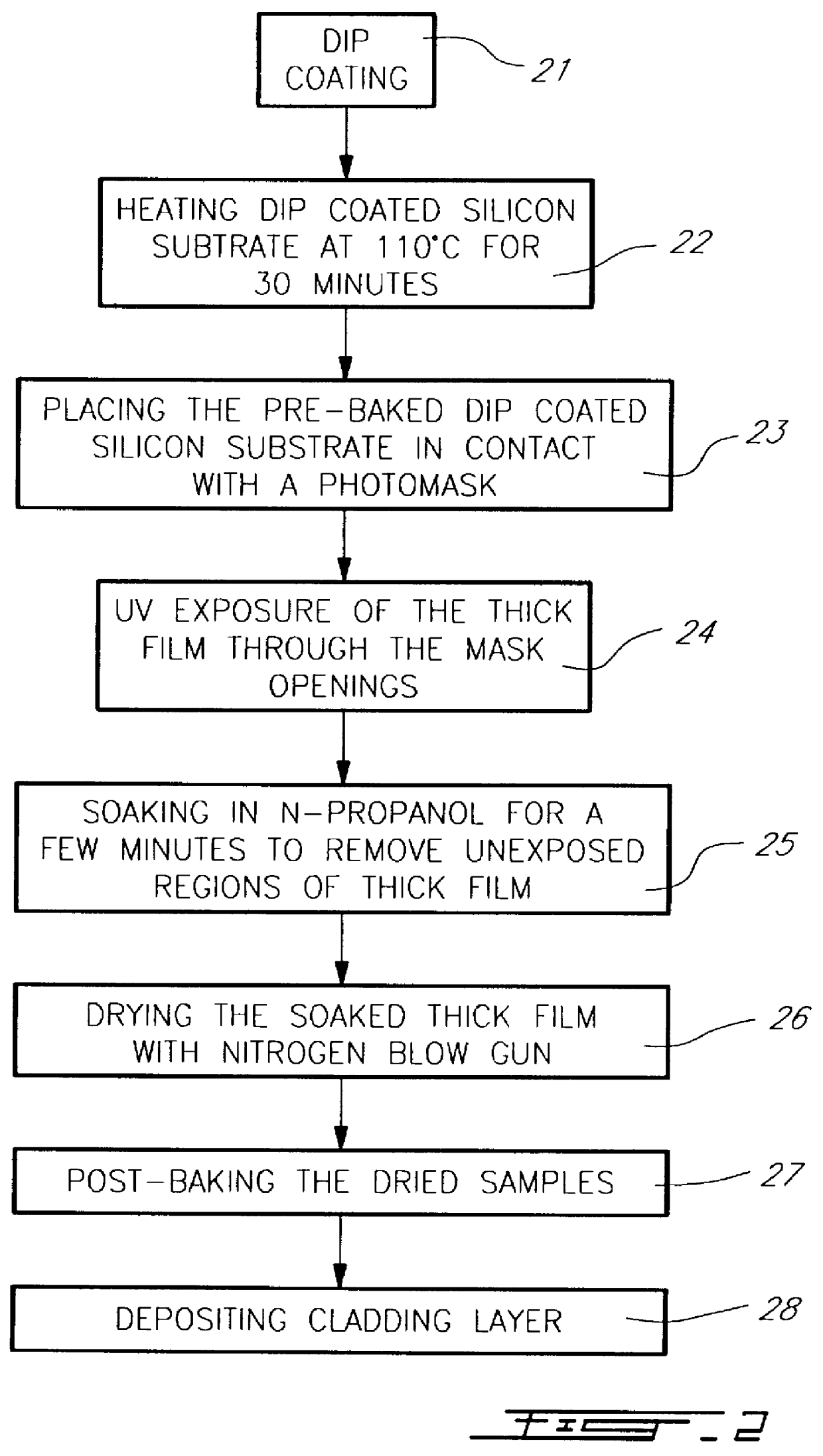

High performance sol-gel spin-on glass materials

InactiveUS20050022697A1Improve adaptabilityIncrease flexibilityGroup 4/14 element organic compoundsPhotomechanical apparatusSilanesRoom temperature

Hybrid sol-gel materials are provided, which may be produced by the reaction of an alkyl or dialkyl substituted trialkoxysilane or dialkoxysilane reacting with a silane diol, wherein said alkyl group has from 1 to 8 carbon atoms. A process is also provided for patterning the sol-gel spin-on glass material by: a) coating a substrate with the spin-on glass material; b) exposing the coated substrate of step a) to UV illumination in a desired pattern; c) post-exposure baking the coated substrate of step b) at a temperature from 100° C. to 120° C. for 30 to 60 minutes; d) cooling the coated substrate of step c) to room temperature; e) removing the non-exposed areas of the coating on the coated substrate of step d); f) drying the coated substrate of step e); g) hard baking the coated substrate of step f) at a temperature from 120° C. and 150° C. for 1 to 3 hours.

Owner:GULA CONSULTING LLC

Methods and compositions of a storable relatively lightweight proppant slurry for hydraulic fracturing and gravel packing applications

InactiveUS20080087429A1Improve system performanceHigh elastic modulusFluid removalDrilling compositionParticulatesMetallurgy

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that utilize relatively lightweight and / or substantially neutrally buoyant particulates. Particles that may be employed include particulates of naturally occurring materials that may be optionally strengthened or hardened by exposure to a modifying agent; porous materials including selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials; and well treating aggregates composed of an organic lightweight material and a weight modifying agent. The relatively lightweight particulate may be suspended as a substantially neutral buoyant particulate and stored with a carrier fluid as a pumpable slurry.

Owner:BAKER HUGHES HLDG LLC

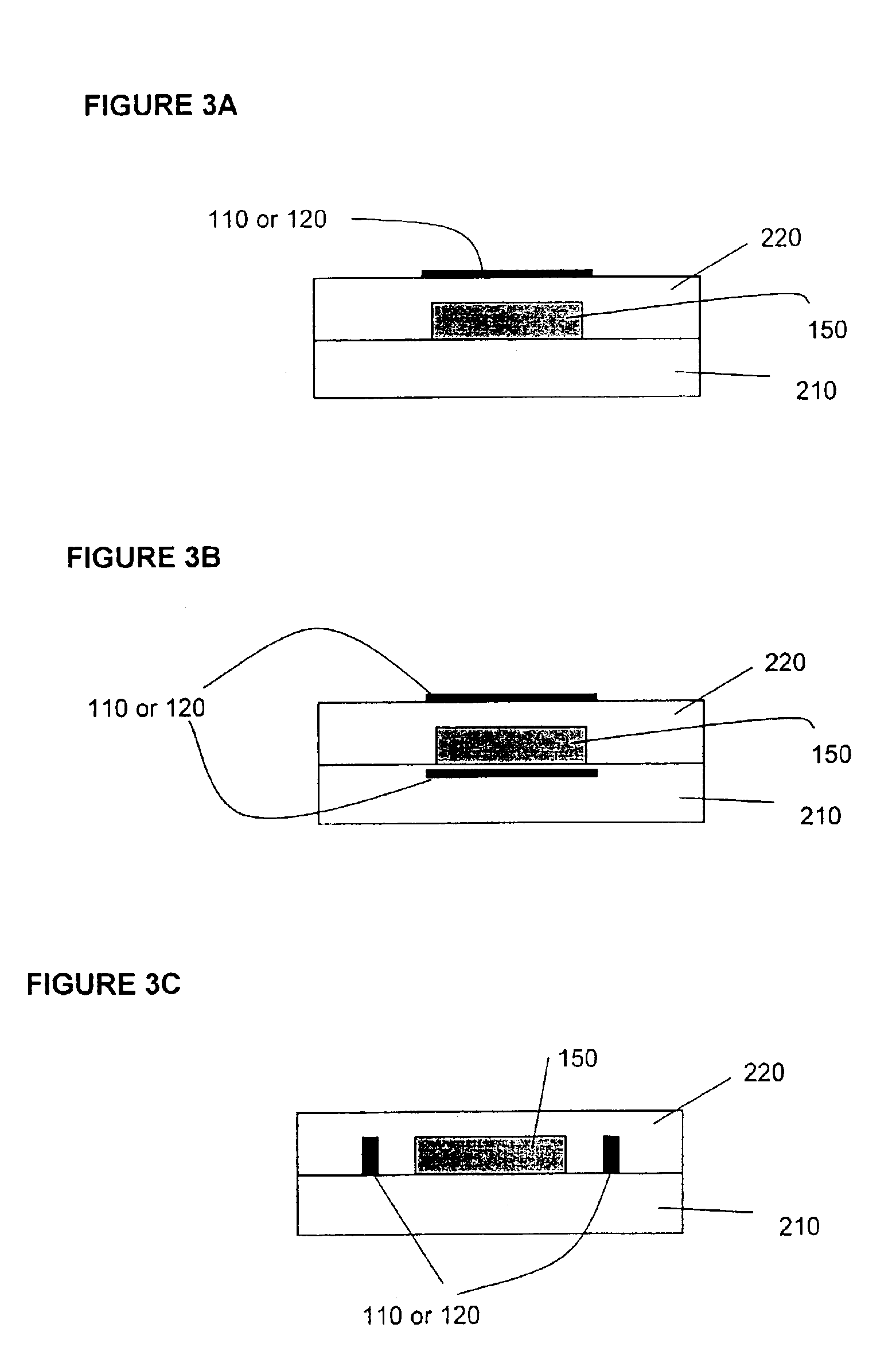

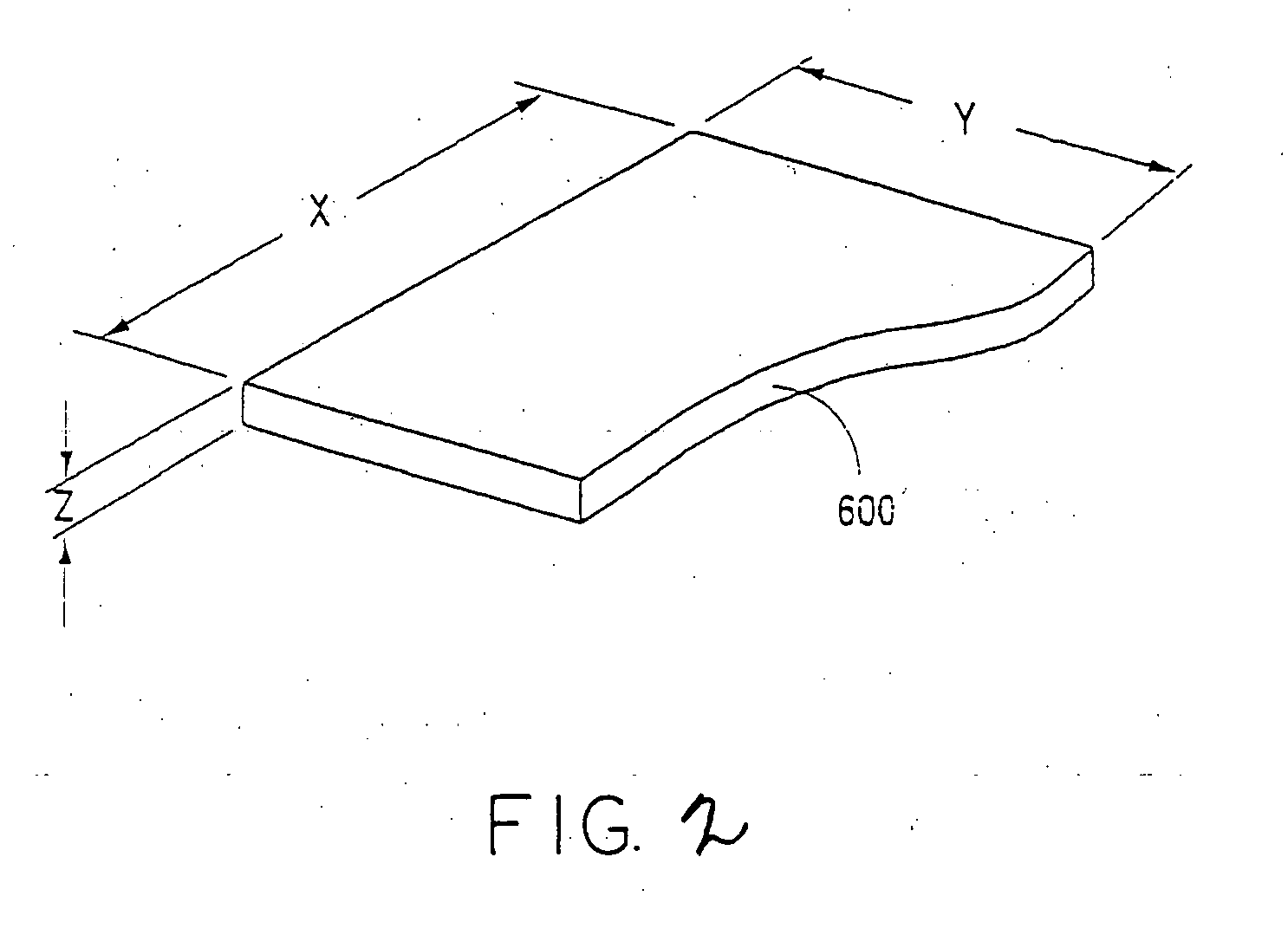

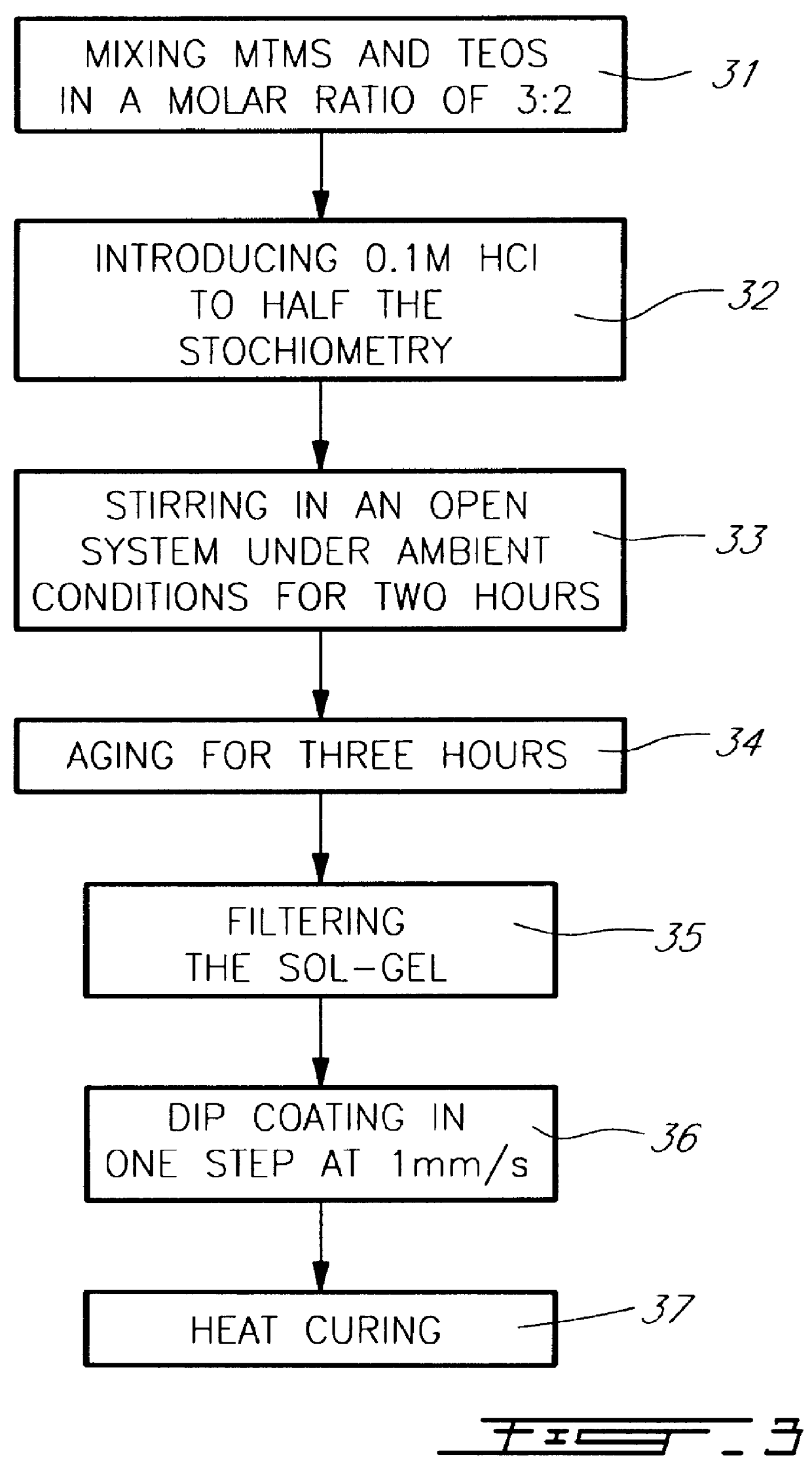

Solvent-assisted lithographic process using photosensitive sol-gel derived glass for depositing ridge waveguides on silicon

InactiveUS6054253ARapid thermal annealingSimple wayPhotomechanical apparatusOriginals for photomechanical treatmentRidge waveguidesSolvent

The process for fabricating a ridge waveguide on a substrate uses a photosensitive sol-gel glass material prepared, according to a first embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) and methacrylic acid (H2C=C(CH3)COOH) or, according to a second embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) with bis(s-butoxy)aluminoxytriethoxysilane. A thick film of photosensitive sol-gel glass material is first dip coated on at least a portion of the substrate. A photomask is applied to the film of photosensitive sol-gel glass material, and this sol-gel material is exposed to ultraviolet radiation through the opening(s) of the photomask to render a portion of the film insoluble to a given solvent and thereby imprint the ridge waveguide in that film. The thick film is then soaked in this solvent, for example n-propanol to dissolve the unexposed portion of the sol-gel film and leave on the substrate the exposed film portion and therefore the ridge waveguide. The ridge waveguide is heat cured and the heat cured ridge waveguide is covered with a cladding layer.

Owner:MCGILL UNIV - THE ROYAL INSTION FOR THE ADVANCEMENT OF LEARNING

Method of manufacturing glass melt and method of manufacturing molded glass material

A method of manufacturing glass melt and a method of manufacturing molded glass material by forming glass melt. In the method of manufacturing glass melt, the glass melt containing fluorine is prepared by melting glass raw materials and refining the resulting glass melt. The refining is conducted in a refining vat equipped with a flow inlet through which flows glass melt obtained by heating and melting the glass raw materials, and a flow outlet through which flows glass melt that has been refined, with the level of the glass melt being maintained in such a manner that the flow inlet and flow outlet remain beneath the surface of the glass melt and the glass melt does not contact external air. The method of manufacturing a molded glass material comprises the step of molding the glass melt produced by the above method.

Owner:HOYA CORP

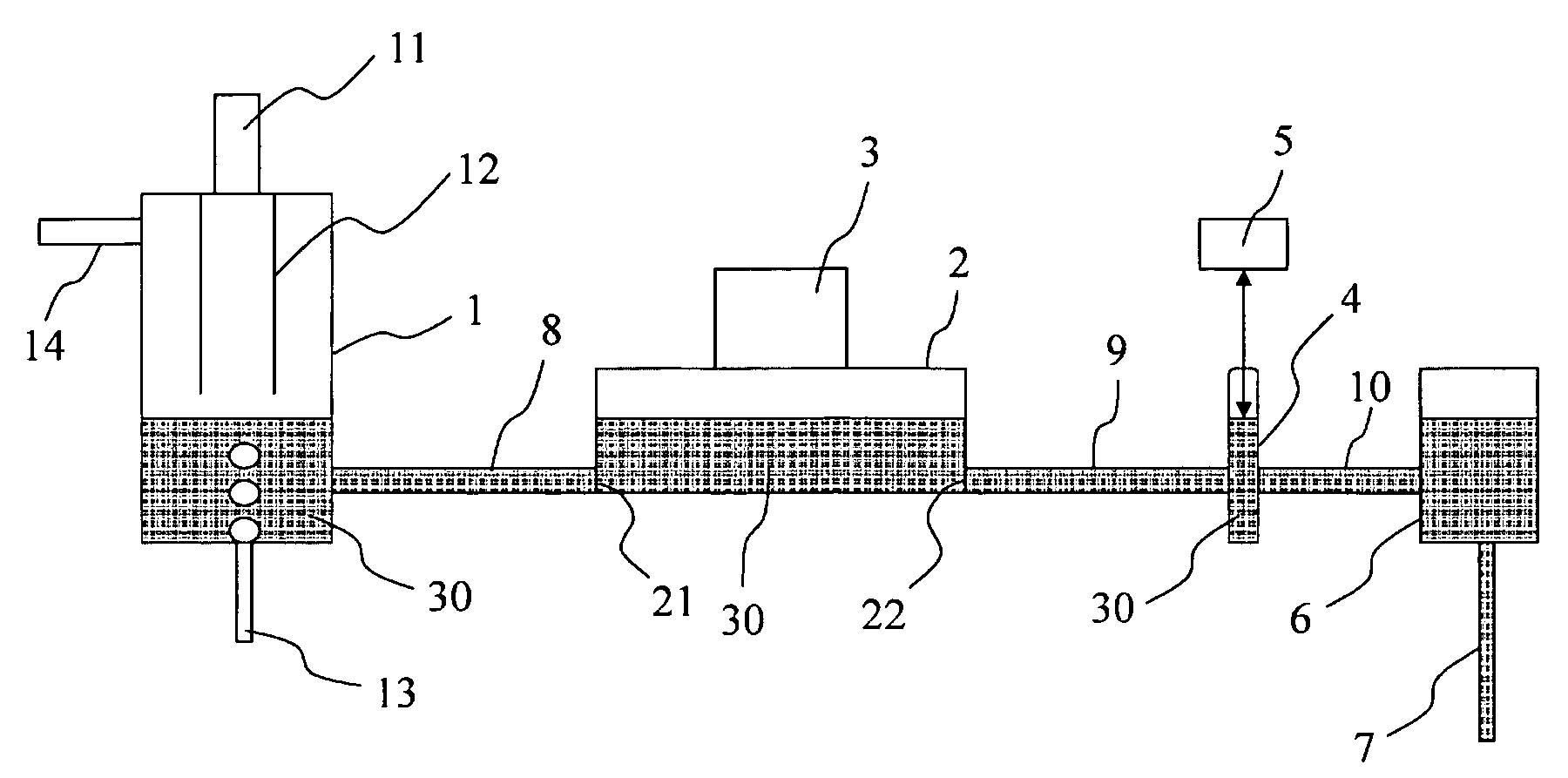

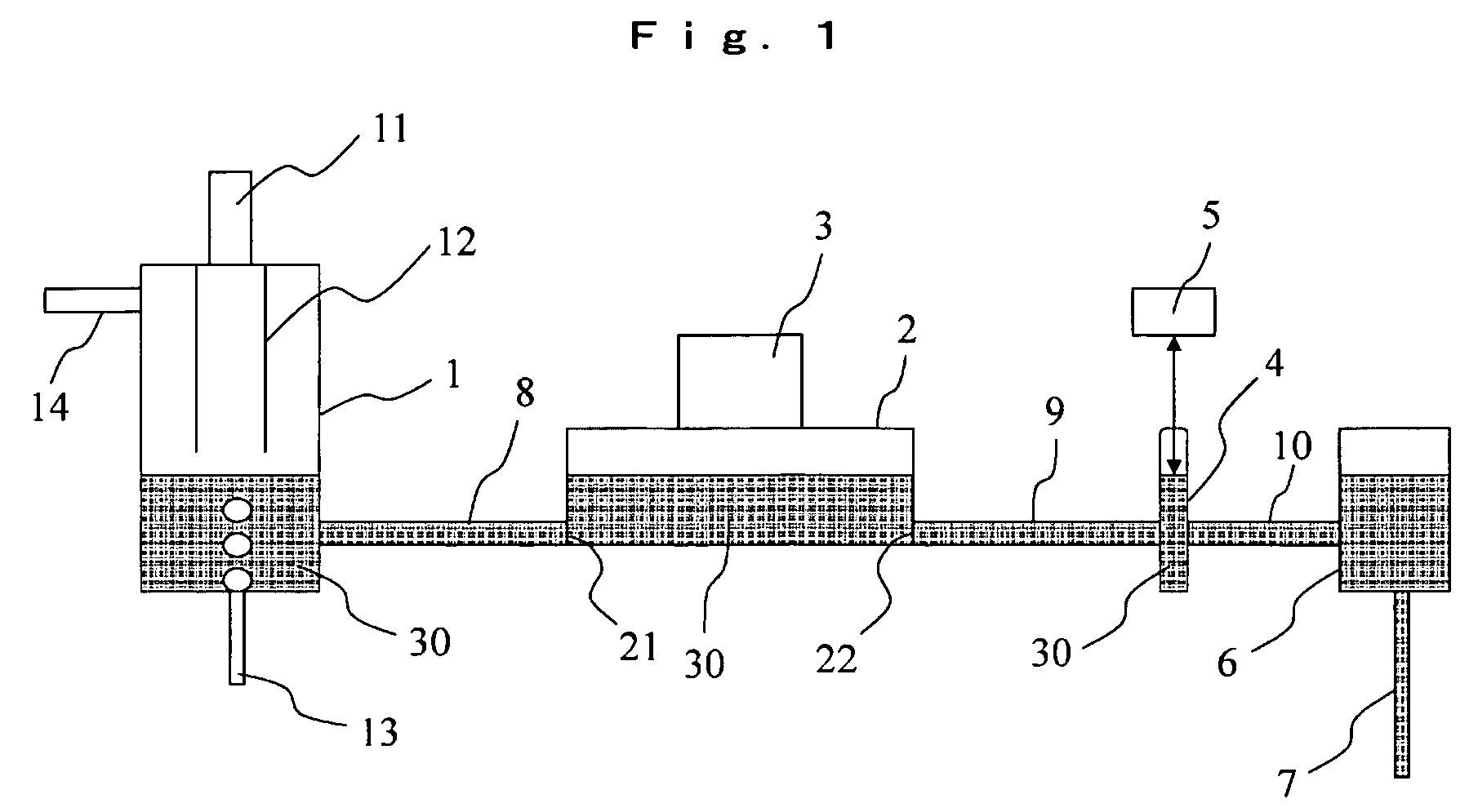

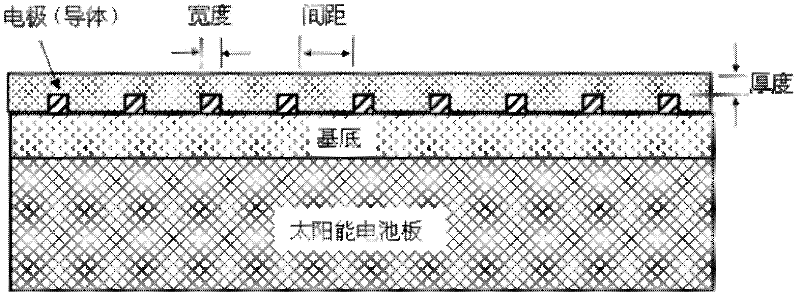

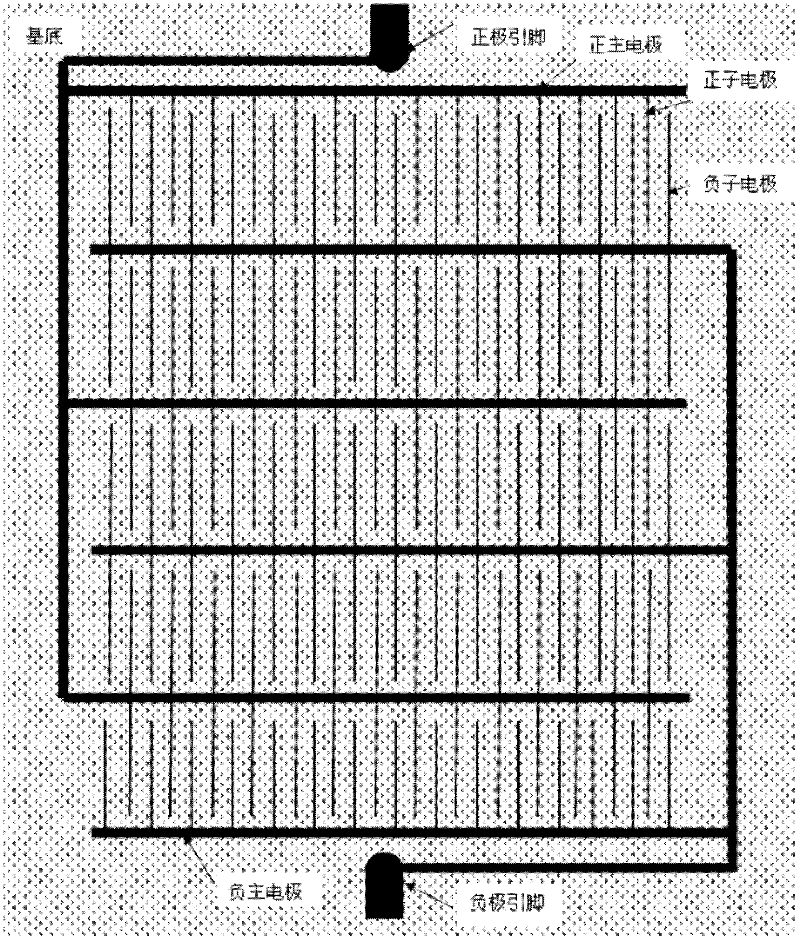

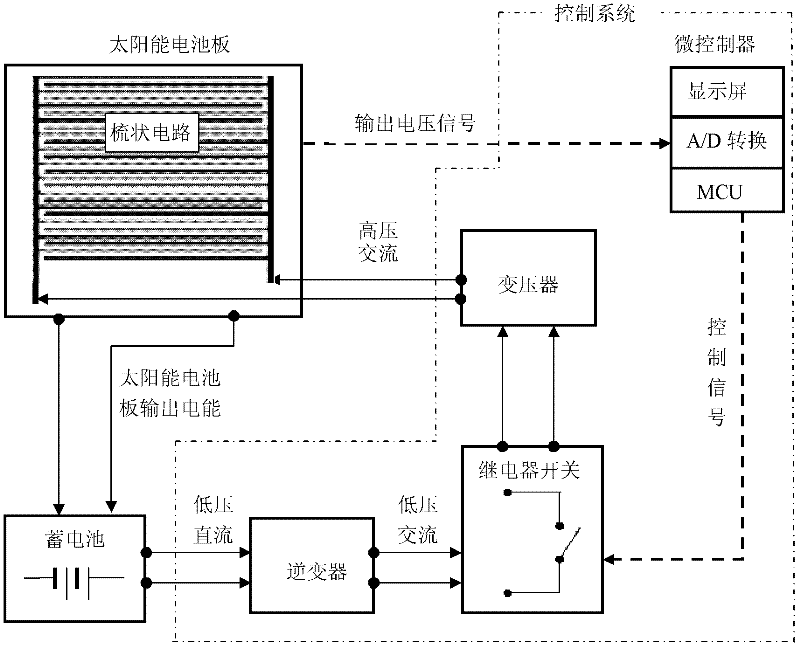

Solar cell panel dedusting comb-shaped circuit and working system thereof

InactiveCN102231394AReduce consumptionImprove power generation efficiencyElectrostatic cleaningPhotovoltaic energy generationMicrocontrollerArray data structure

Provided is a solar cell panel dedusting system which is composed of a solar cell panel dedusting comb-shaped circuit, a solar energy storage battery and a control system. The comb-shaped circuit is composed of a substrate, a circuit layer and a superficial layer. The substrate is formed by a glass material. The interface layer is composed of pins of positive and negative electrodes, an array parallel main electrode and parallel period alternatively distributed comb-shaped sub-electrodes. The surface of the circuit layer is covered with a transparent insulating protection film. The control system comprises an inverter, a relay, a transformer and a microcontroller. The microcontroller monitors the solar cell panel output voltage signal in real time. When the surface of the solar cell panelis covered with dust and the light transmittance is reduced, leading to the output voltage is lower than a preset critical value, a one-chip microcomputer emits an instruction to close the relay. Then the solar cell panel dedusting comb-shaped circuit is conducted. The charge particles jump up and fly to the edge under the effect of a traveling wave electric field force and the effect of dedusting is achieved. When the output voltage signal is higher than the preset critical value, the one-chip microcomputer emits an instruction to open the relay so that the dedusting loop is cut off.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

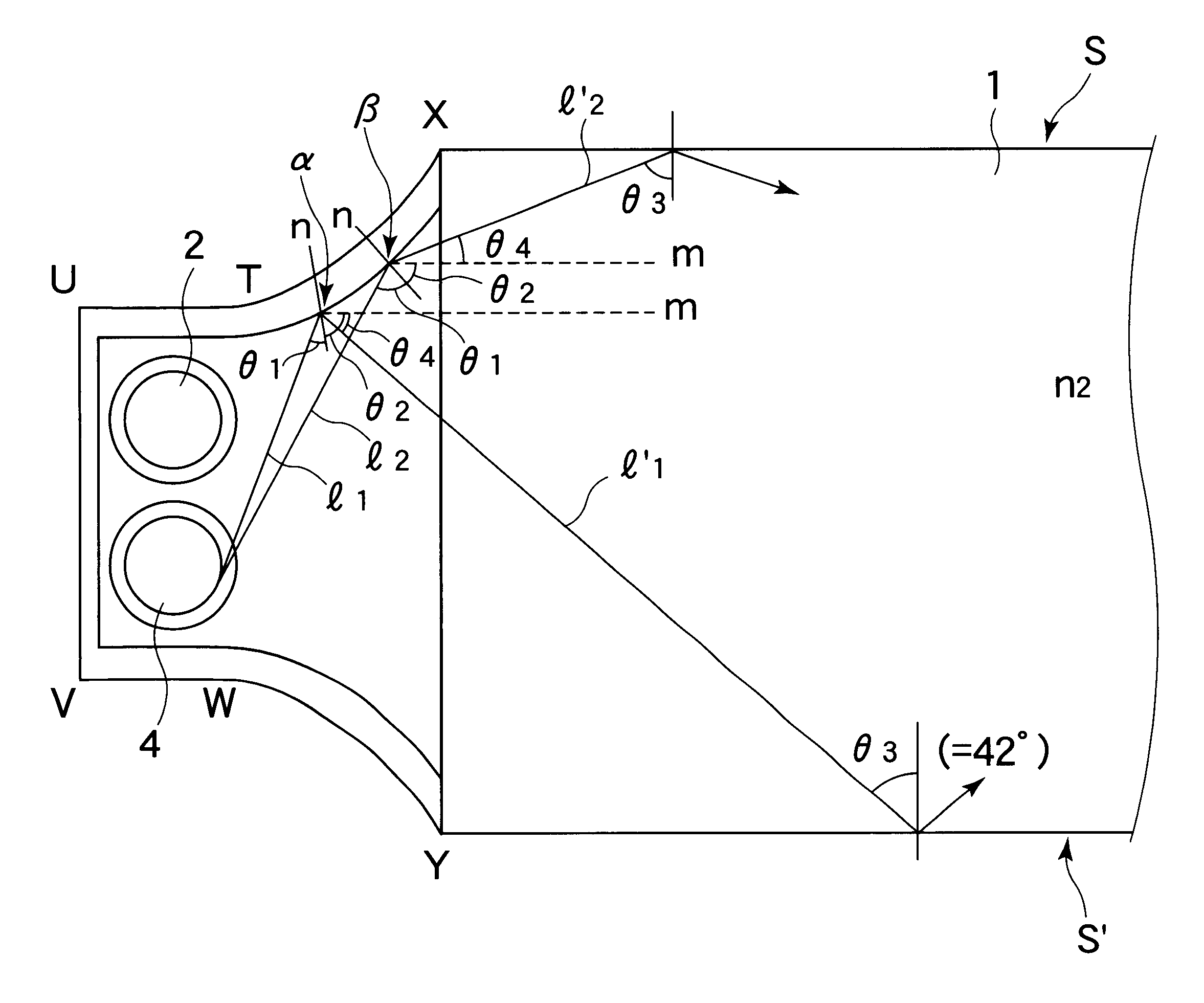

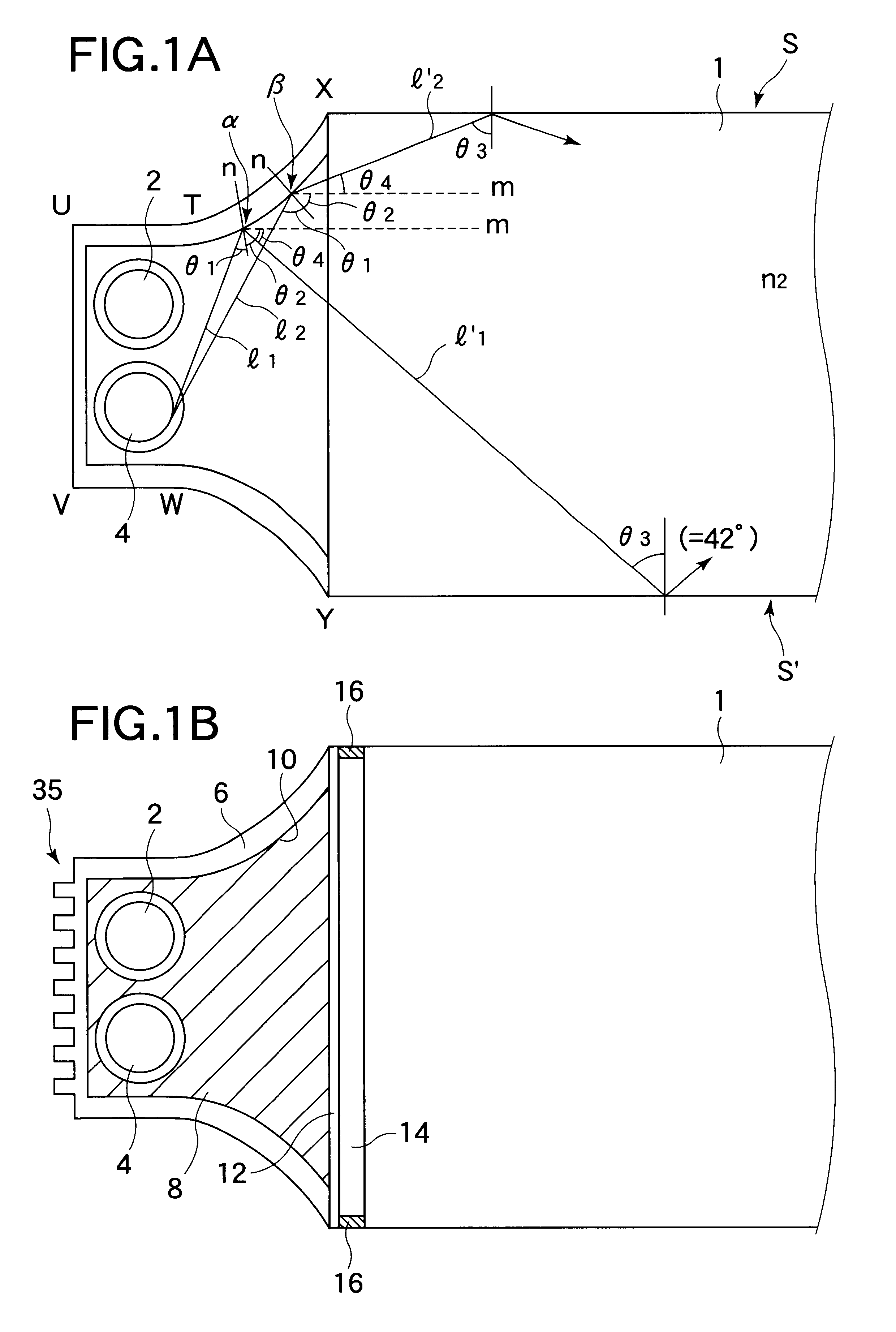

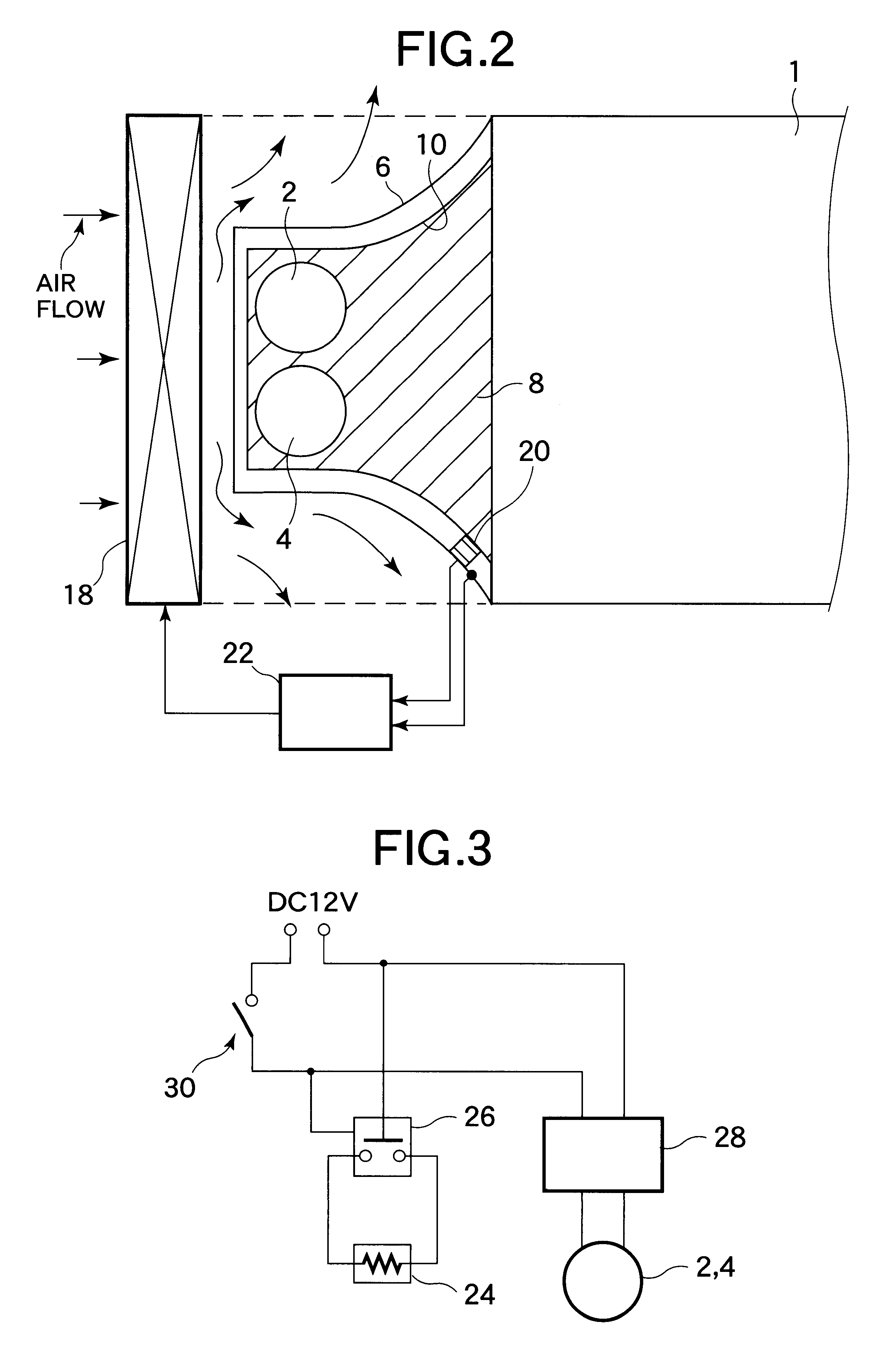

Lighting unit

InactiveUS6655810B2Effective reflectionIncrease brightnessMeasurement apparatus componentsLighting elementsLiquid-crystal displayRefractive index

The invention relates to a backlight unit for liquid crystal displays, etc.; and its object is to provide a backlight unit not involving the problem that the emitted light leaks out of the optical waveguide, even when the space around the cold-cathode tubes in the light source unit for it is filled with a liquid of which the refractive index is nearly the same as that of the glass material that forms the outer wall of the cold-cathode tubes. The backlight unit comprises a housing 6 which houses cold-cathode tubes 2, 4 therein and of which the inner surface is coated with a light reflector 10; a transparent liquid filled in the housing 6; and an optical waveguide 1 made of a transparent substance and having a light-emitting surface S. The reflective surface of the light reflector 10 has a cross-section profile of X-T-U-V-W-Y, on which the light emitted by the cold-cathode tubes 2, 4 is reflected, and the thus-reflected light is led to the light-emitting surface S of the optical waveguide 1 at an incident angle not smaller than the critical angle to the surface S.

Owner:SHARP KK

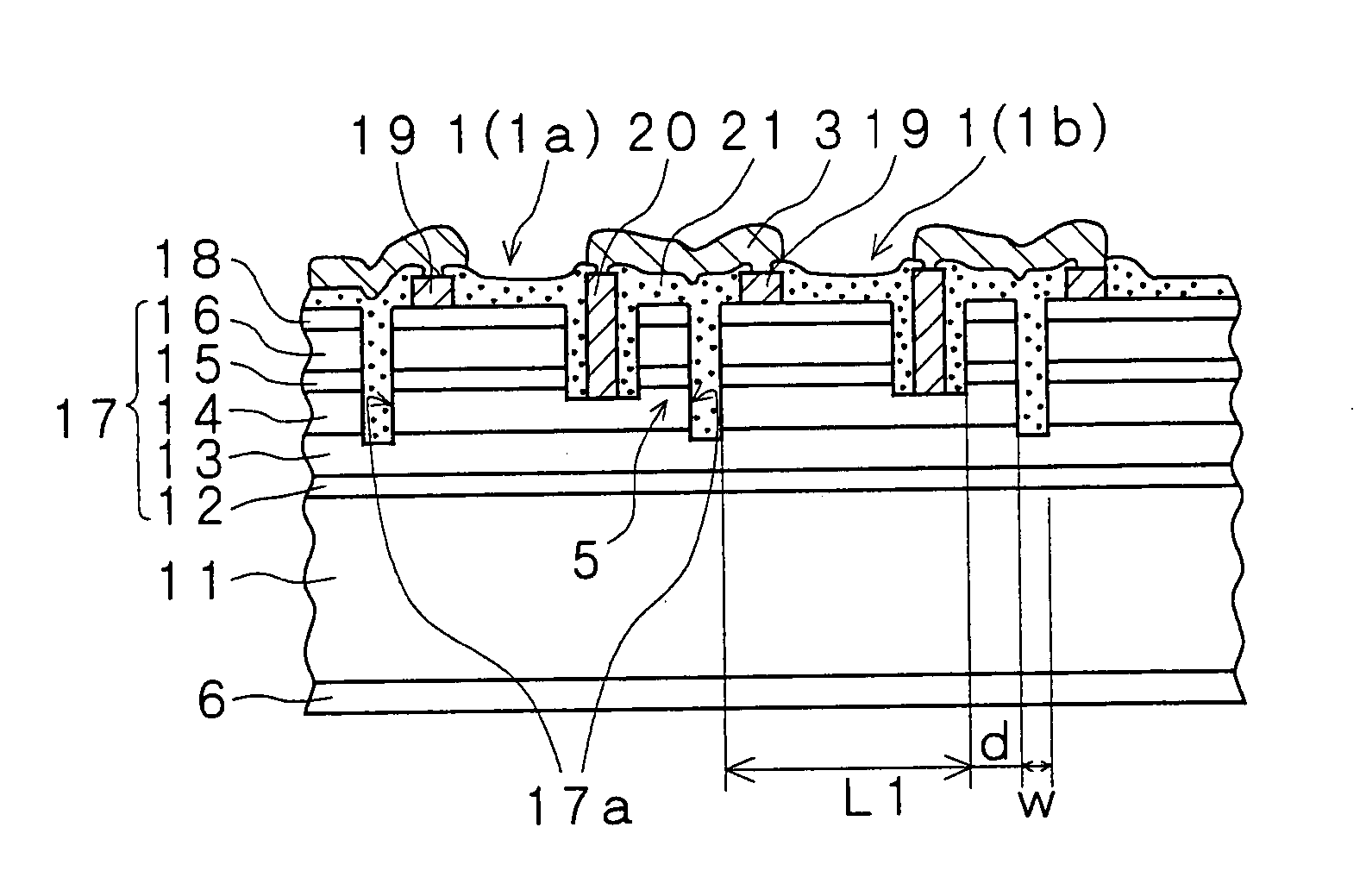

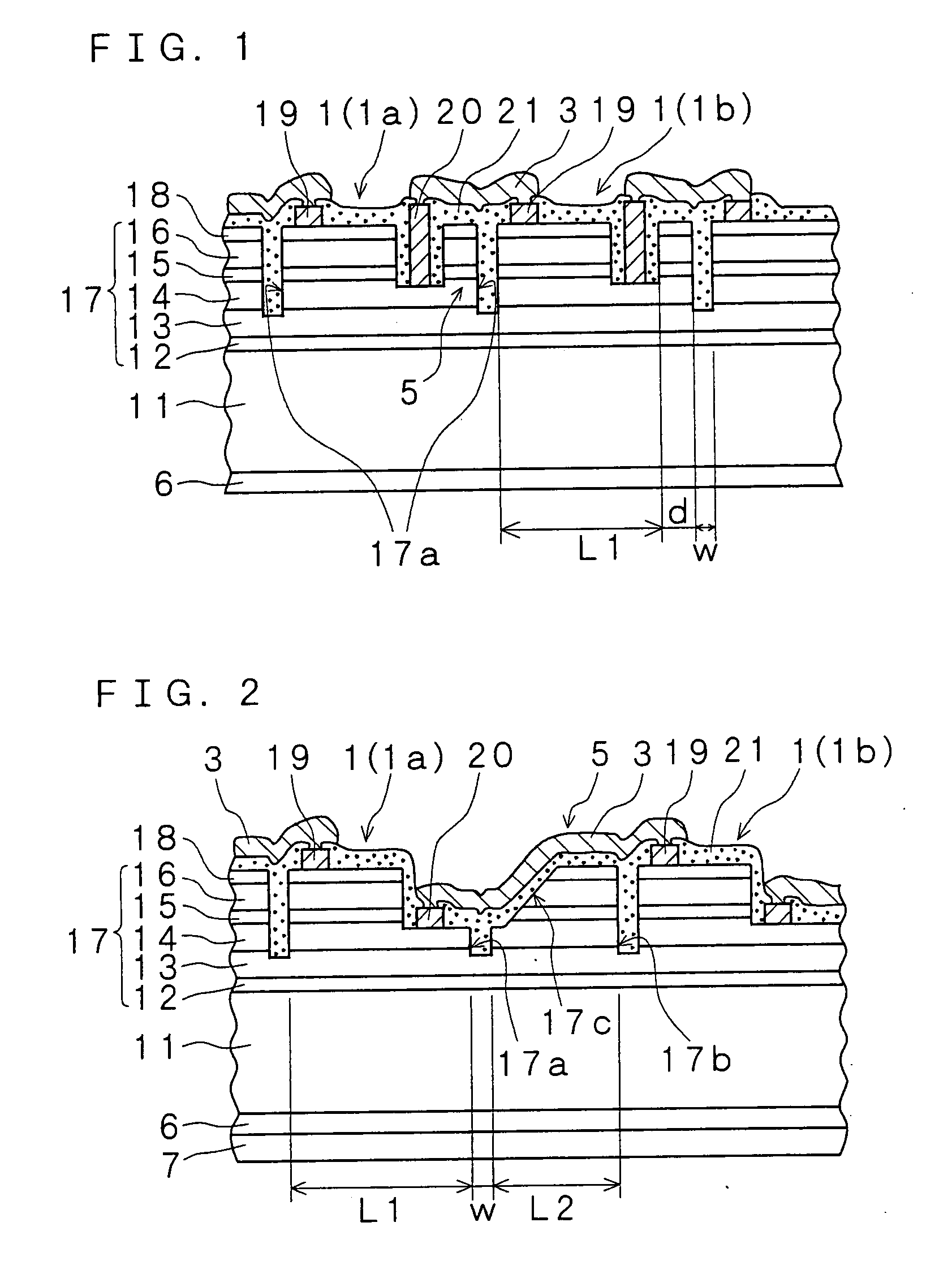

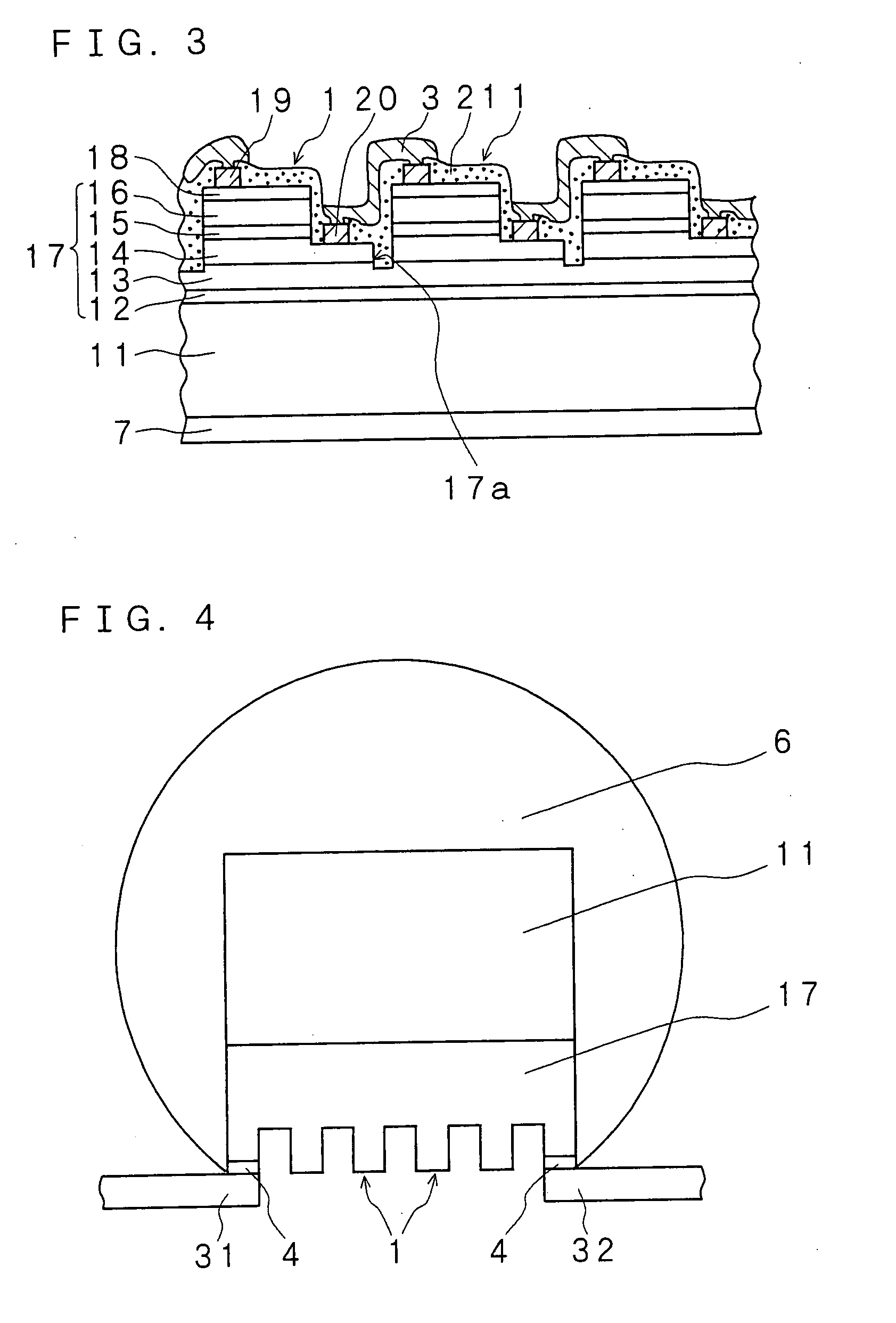

Semiconductor Light Emitting Device

InactiveUS20070278502A1Solid-state devicesLuminescent compositionsAlternating currentLight emitting device

There is provided a semiconductor light emitting device which can prevent flickering in illumination due to an alternative current drive, and sensing incongruity at a time of turning off a switch, by providing anti-flickering means in itself, when it is assembled in an illumination device without any extra parts therein. A plurality of light emitting units (1) are formed, by forming a semiconductor lamination portion (17) by laminating semiconductor layers on a substrate (11) so as to form a light emitting layer, by electrically separating the semiconductor lamination portion (17) into a plurality of units, and by providing a pair of electrodes (19) and (20). The light emitting units (1) are respectively connected in series and / or parallel with a wiring film (3). A fluorescent layer (6) containing a fluorescent material having an afterglow time of 10 msec or more and 1 sec or less and / or a layer containing a phosphorescent glass material are formed at a light emitting surface side of the plurality of light emitting units (1).

Owner:ROHM CO LTD

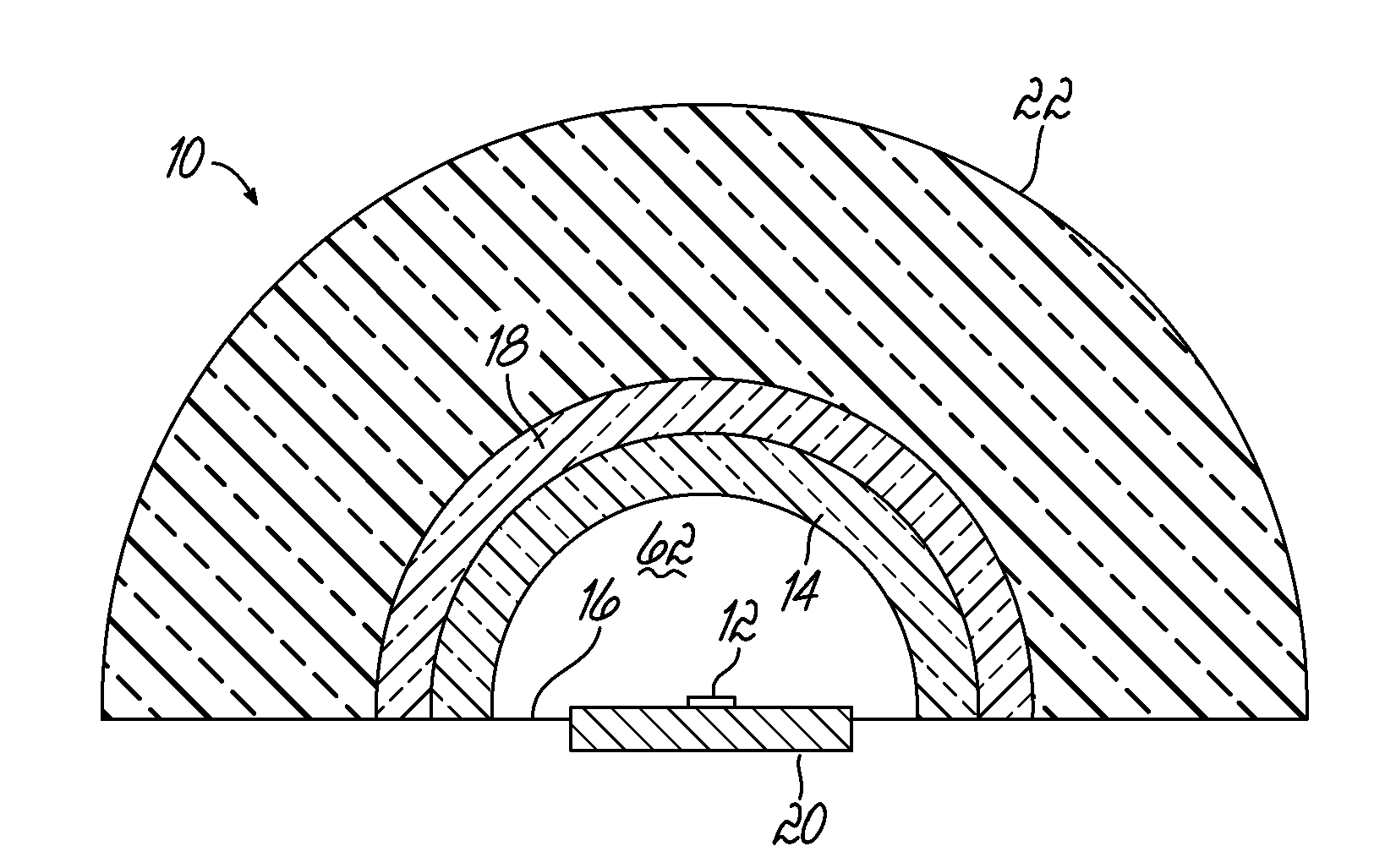

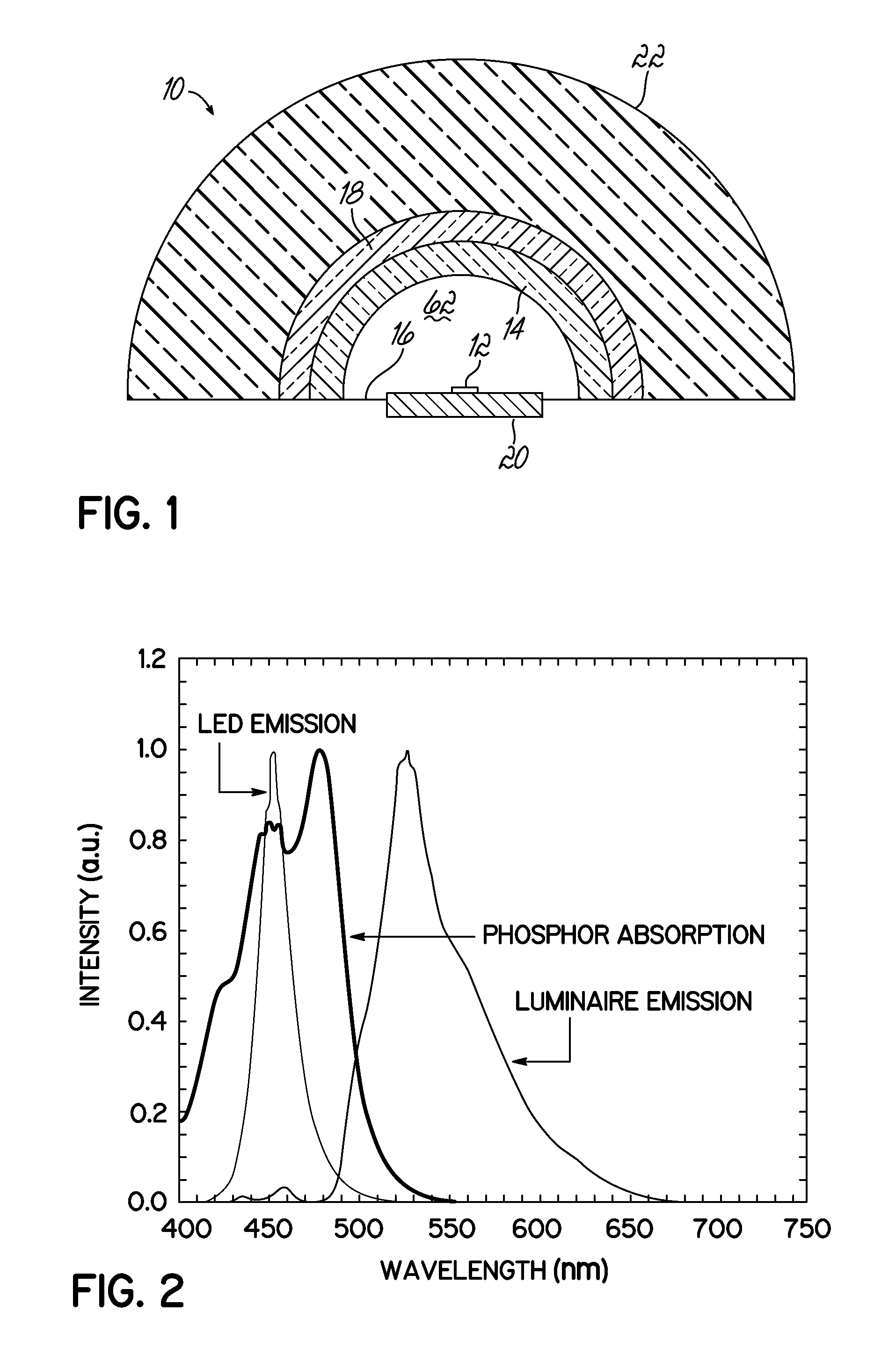

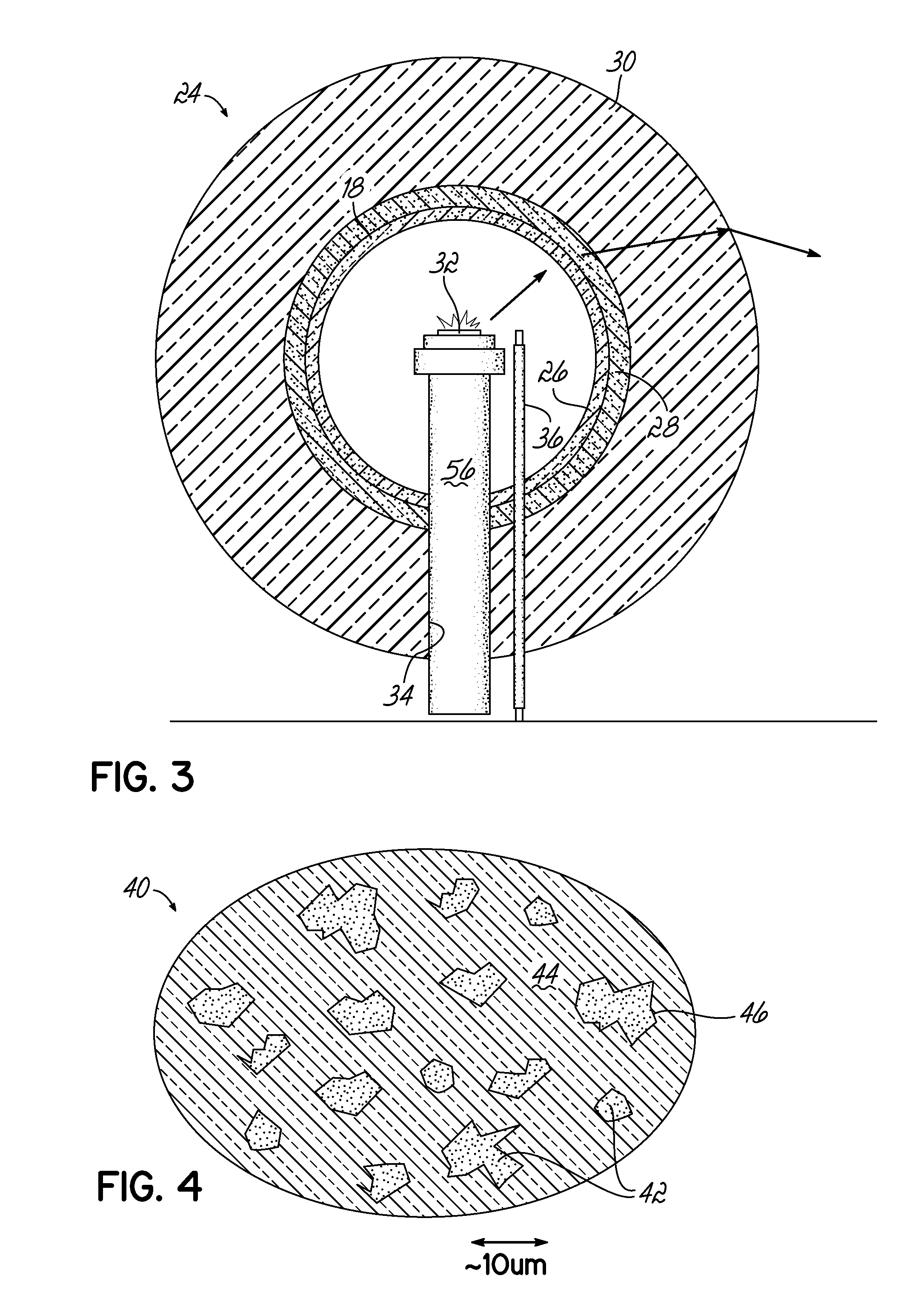

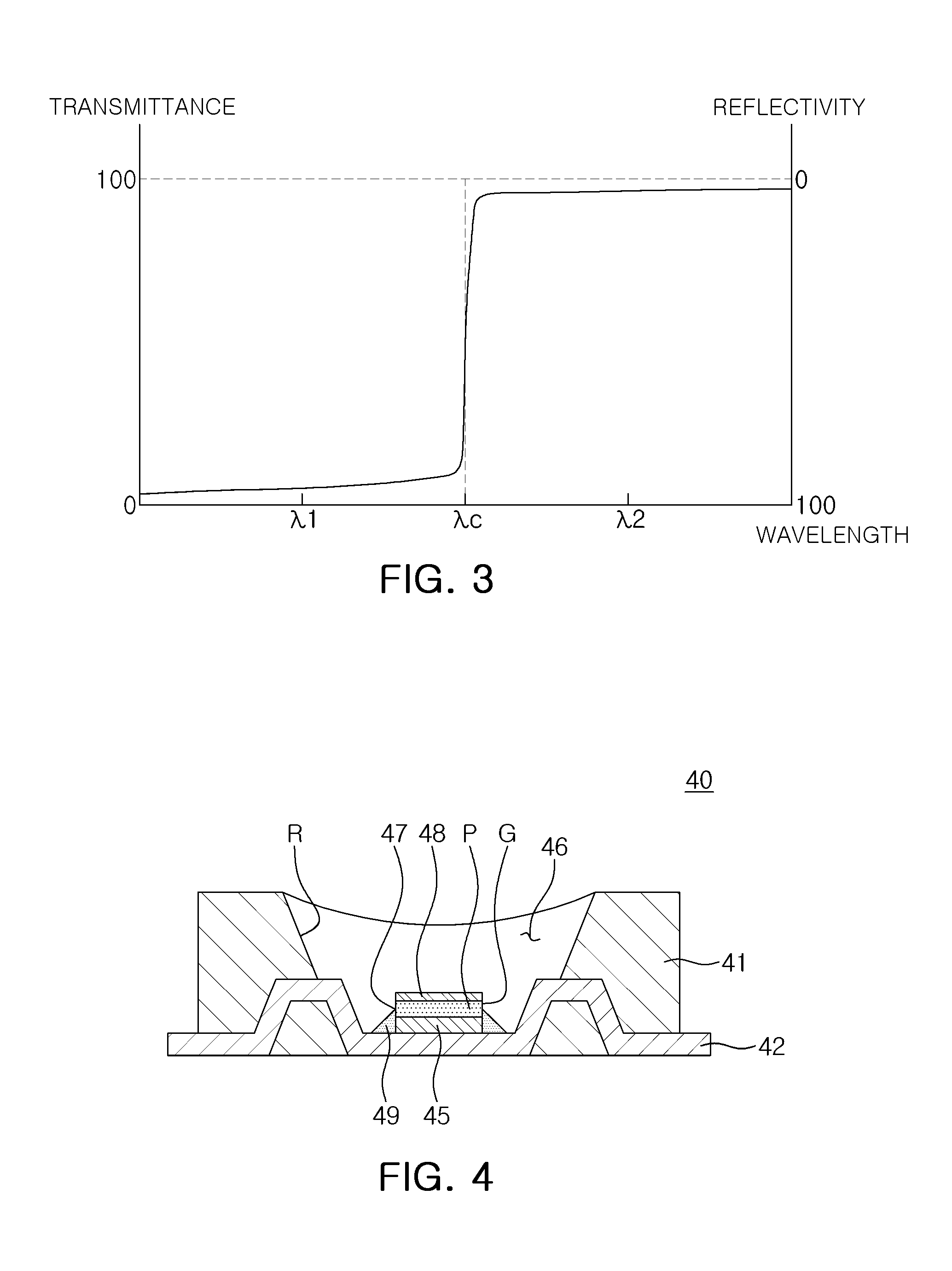

Nearly Index-Matched Luminescent Glass-Phosphor Composites For Photonic Applications

A light emitting composite material (40) comprising a glassy material (44) and a phosphor (14) suspended in the glassy material (44), wherein the refractive index of the phosphor (14) is approximately equal to the refractive index of the glass material. The light emitting composite material (40) can be used in phosphor-containing light emitting devices, solid-state laser (64) diodes, and as a luminescence collector (90).

Owner:QUARKSTAR

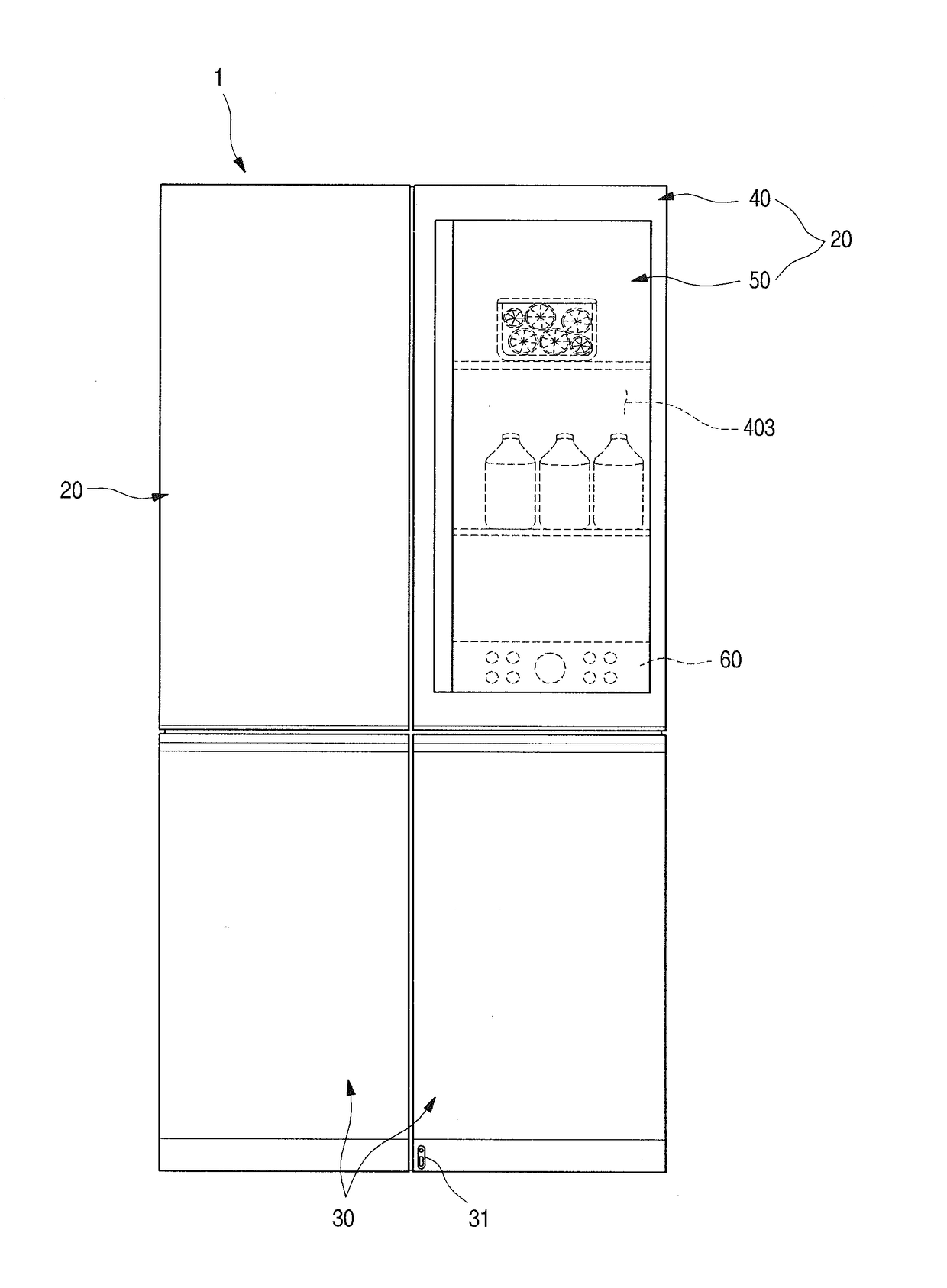

Refrigerator and control method thereof

ActiveUS20170191746A1Mechanical apparatusElectric circuit arrangementsEngineeringRefrigerated temperature

A refrigerator includes a cabinet defining a storage space, a main door for opening and closing the cabinet, the main door defining an opening part that is in communication with the storage space, a sub-door rotatably mounted on the main door and configured to open and close the opening part, a panel assembly forming a front surface of the sub-door and made of a half glass material, a detection device provided to the sub-door and configured to detect a user's operation, and a door lighting unit provided to the main door and configured to, based on the sub-door being closed, turn on and off according to a signal from the detection device to allow selective viewing of an inside of the opening part through the panel assembly.

Owner:LG ELECTRONICS INC

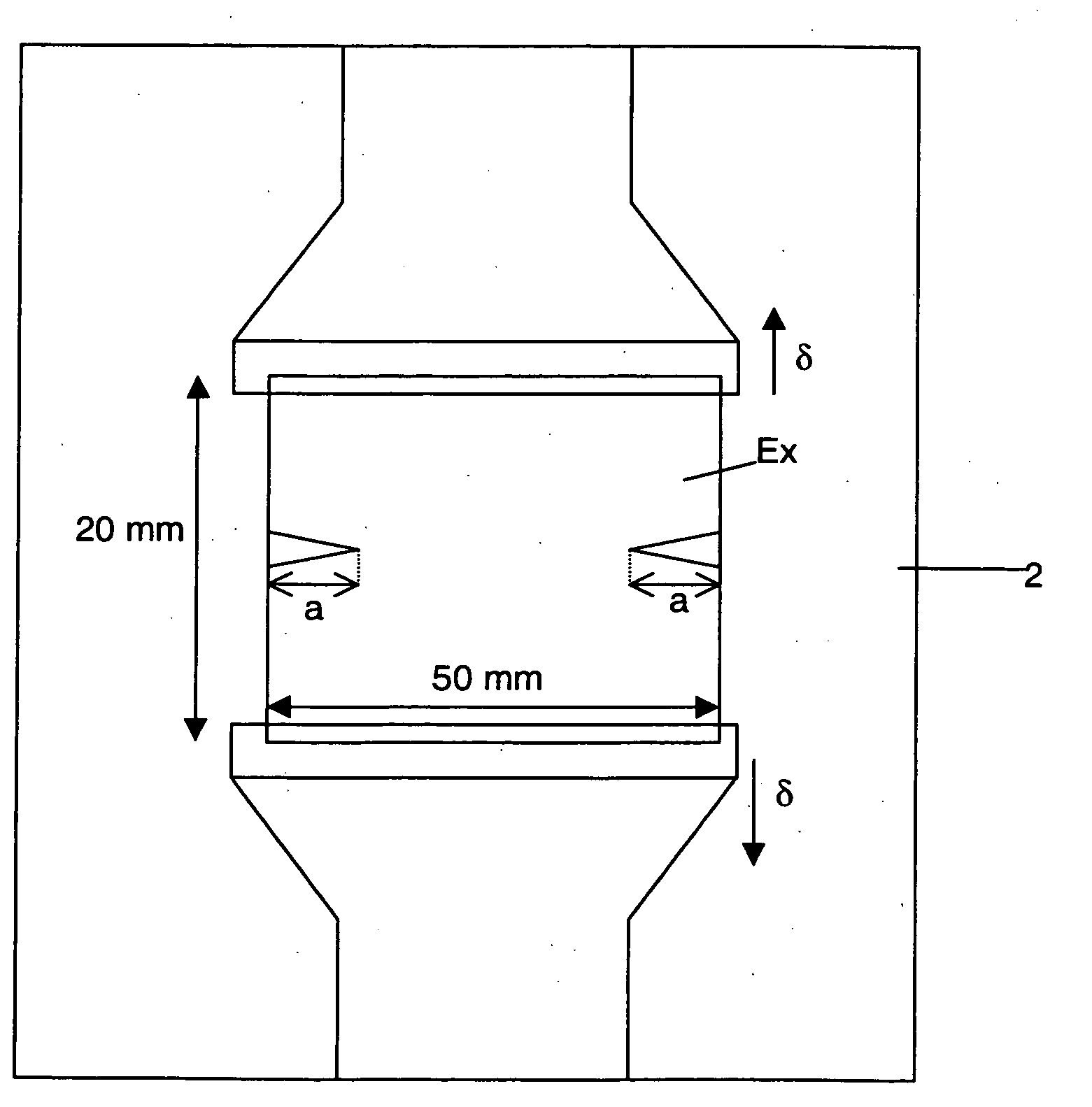

Durable glass housings/enclosures for electronic devices

The invention relates to glass articles suitable for use as electronic device housing / enclosure or protective cover which comprise a glass material. Particularly, a housing / enclosure / cover comprising an ion-exchanged glass exhibits the following attributes: (1) radio, and microwave frequency transparency, as defined by a loss tangent of less than 0.03 and at a frequency range of between 15 MHz to 3.0 GHz; (2) infrared transparency; (3) a fracture toughness of greater than 0.6 MPa*m<1 / 2>; (4) a 4-point bend strength of greater than 350 MPa; (5) a Vickers hardness of at least 450 kgf / mm<2> and a Vickers median / radial crack initiation threshold of at least 5 kgf; (6) a Young's Modulus ranging between about 50 to 100 GPa; (7) a thermal conductivity of less than 2.0 W / m DEG C; and (9) at least one of the following attributes: (i) a compressive surface layer having a depth of layer (DOL) greater and a compressive stress greater than 400 MPa, or, (ii) a central tension of more than 20 MPa.

Owner:CORNING INC

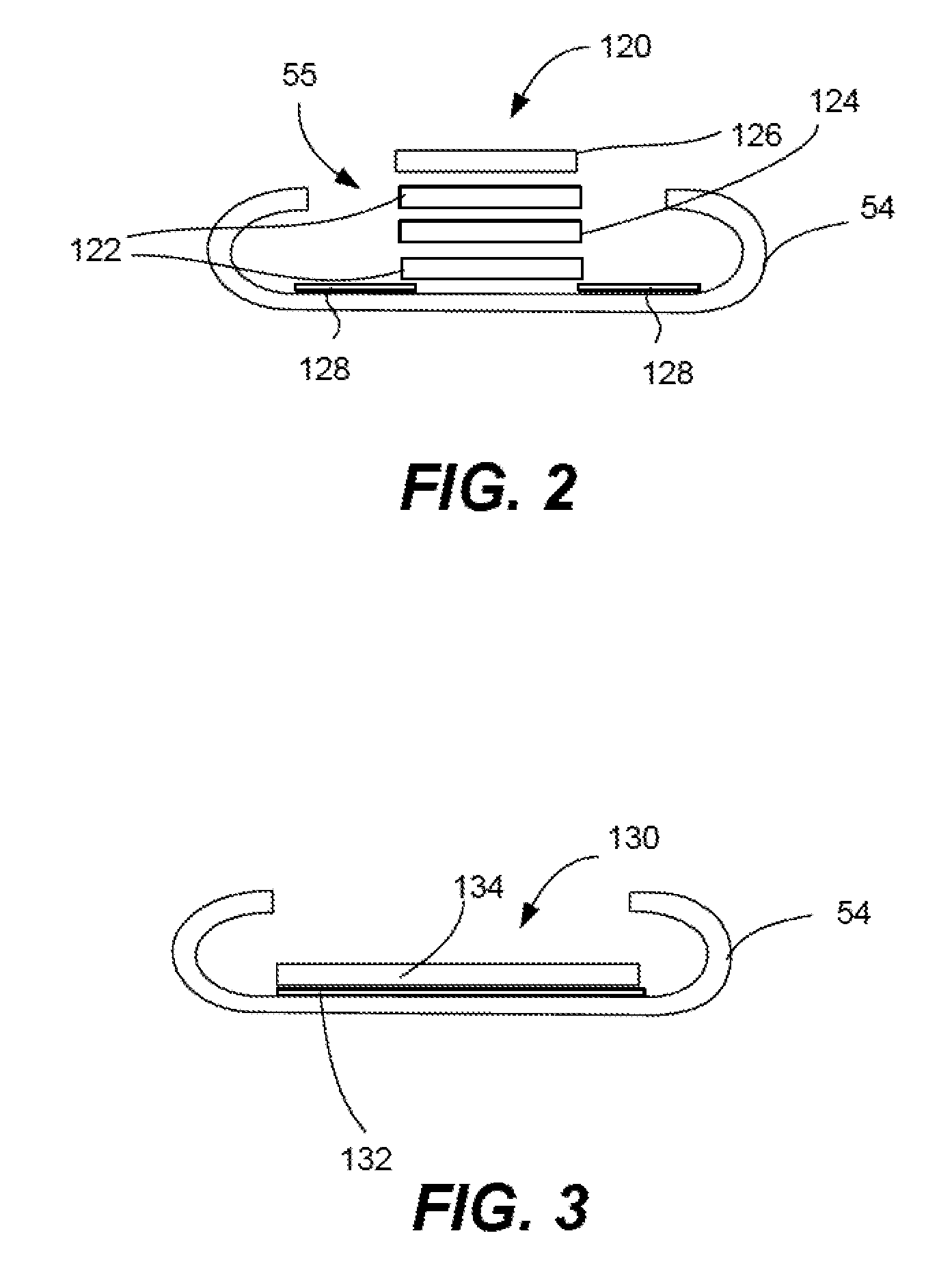

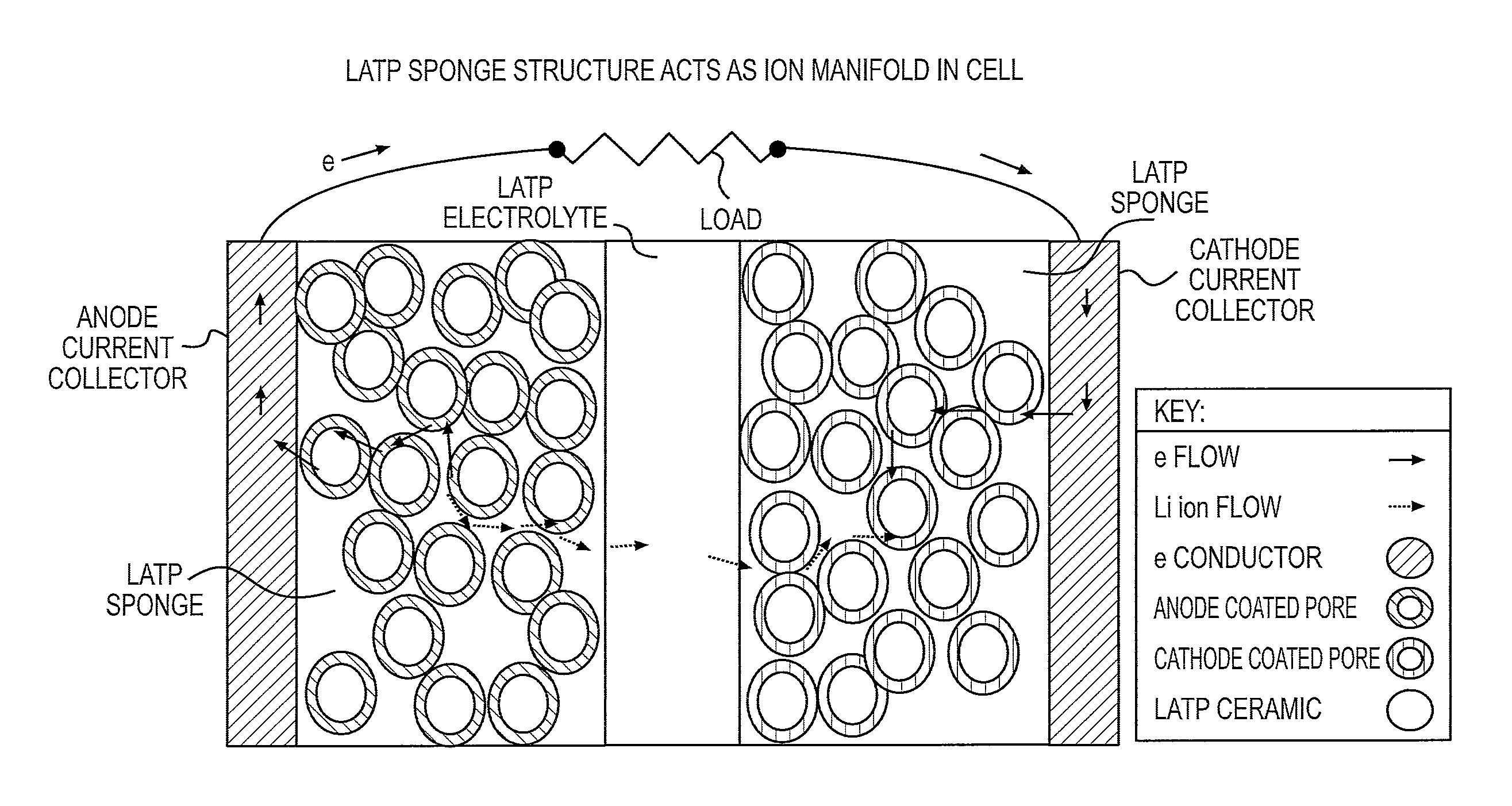

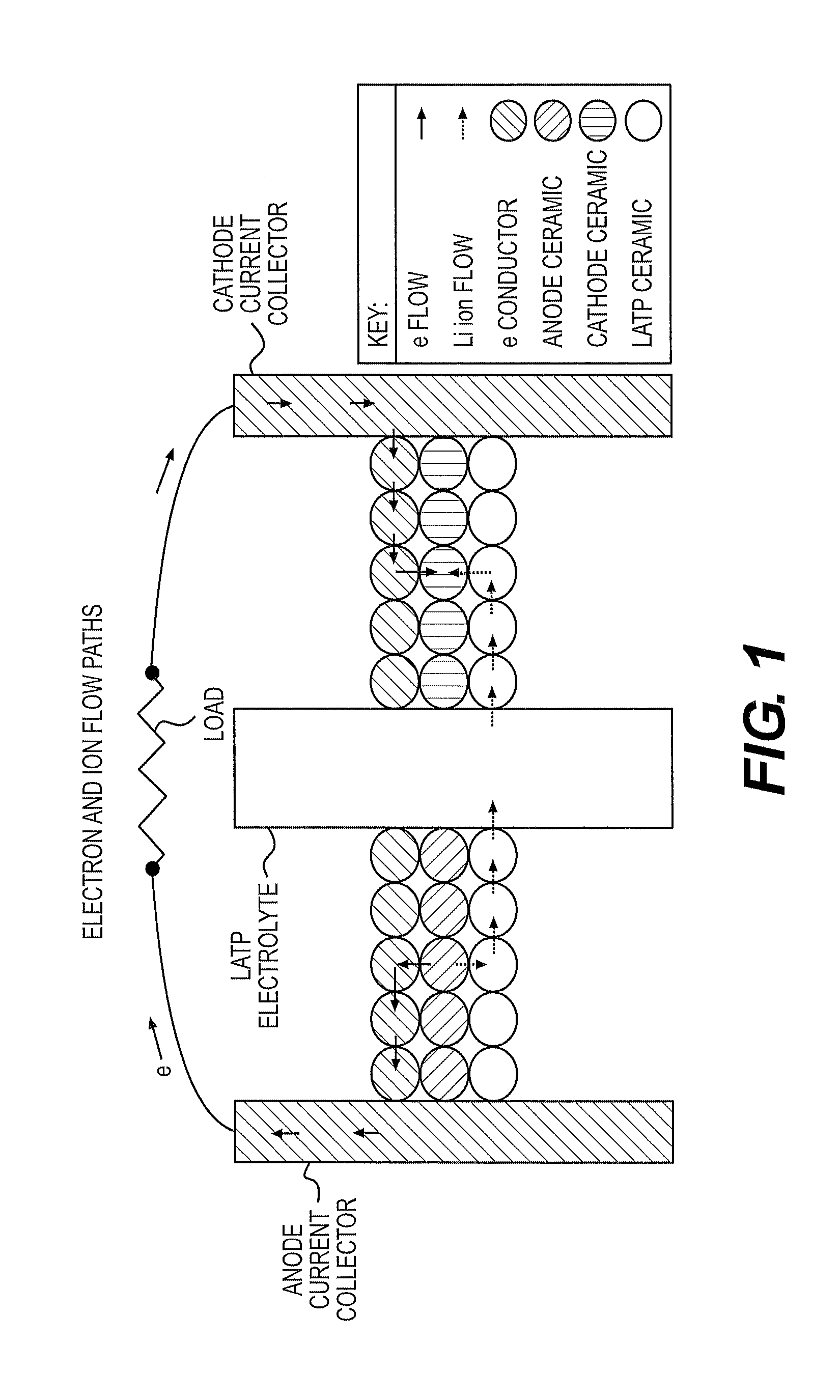

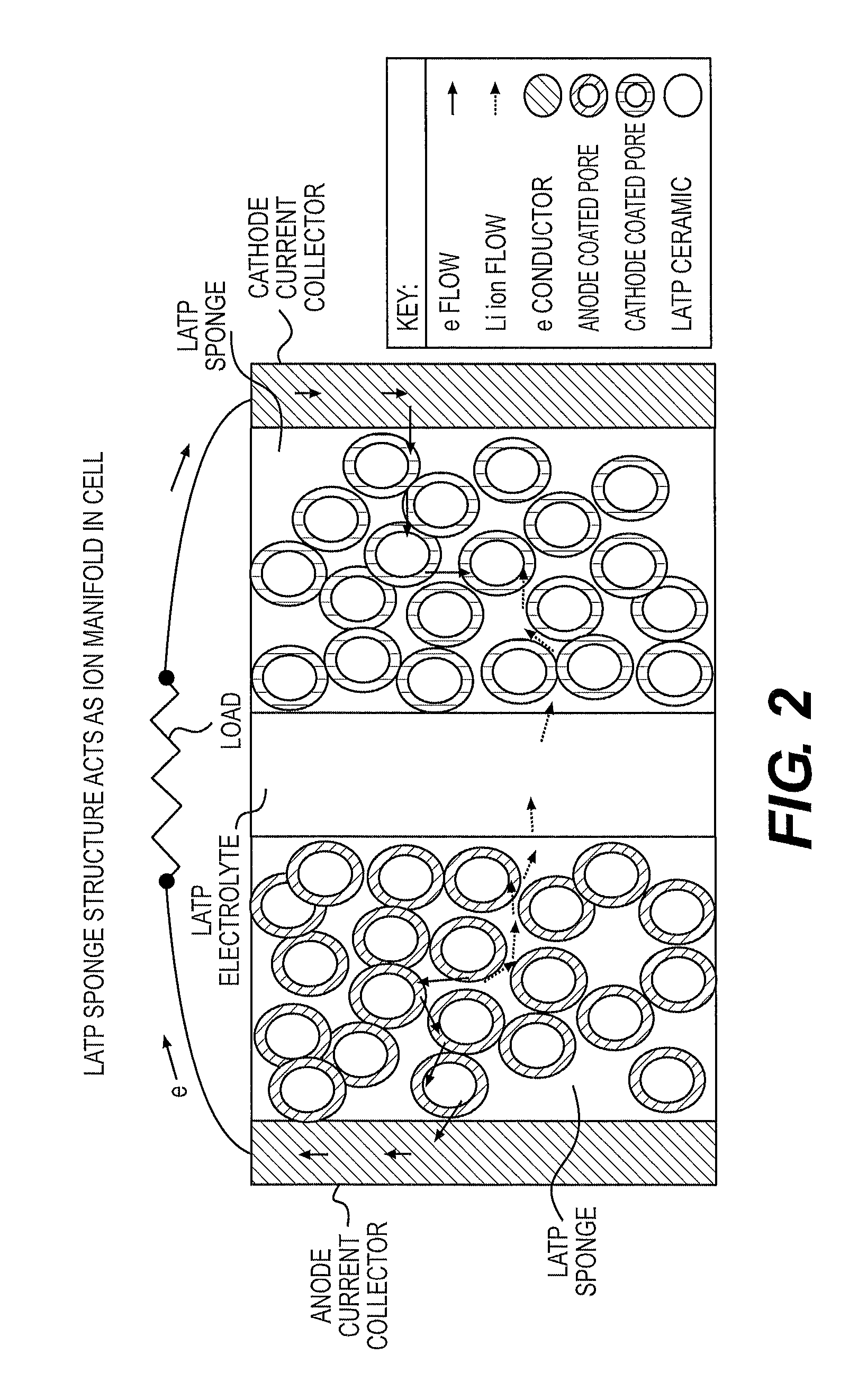

Multi layer ceramic battery

ActiveUS8304115B1High energyIncrease powerNon-aqueous electrolyte accumulatorsCell electrodesSolid state electrolyteMetallurgy

A practical solid-state battery composed primarily of ceramic or glass materials and containing no liquid, gel or polymeric electrolytes. The invention utilizes solid-state electrolyte materials with solid-state anode and cathode materials along with construction concepts utilized in the multi layered ceramic capacitor (MLCC) industry to result in a compact primary or secondary battery.

Owner:POLYMER INNOVATIONS

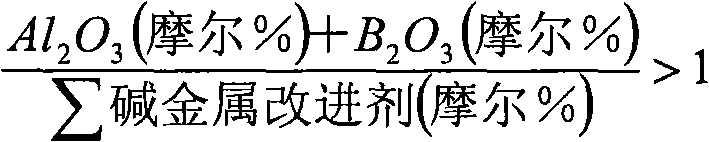

Transparent, colorless low-titania beta-quartz glass-ceramic material

Owner:EUROKERA SOC & NOM COLLECTIF

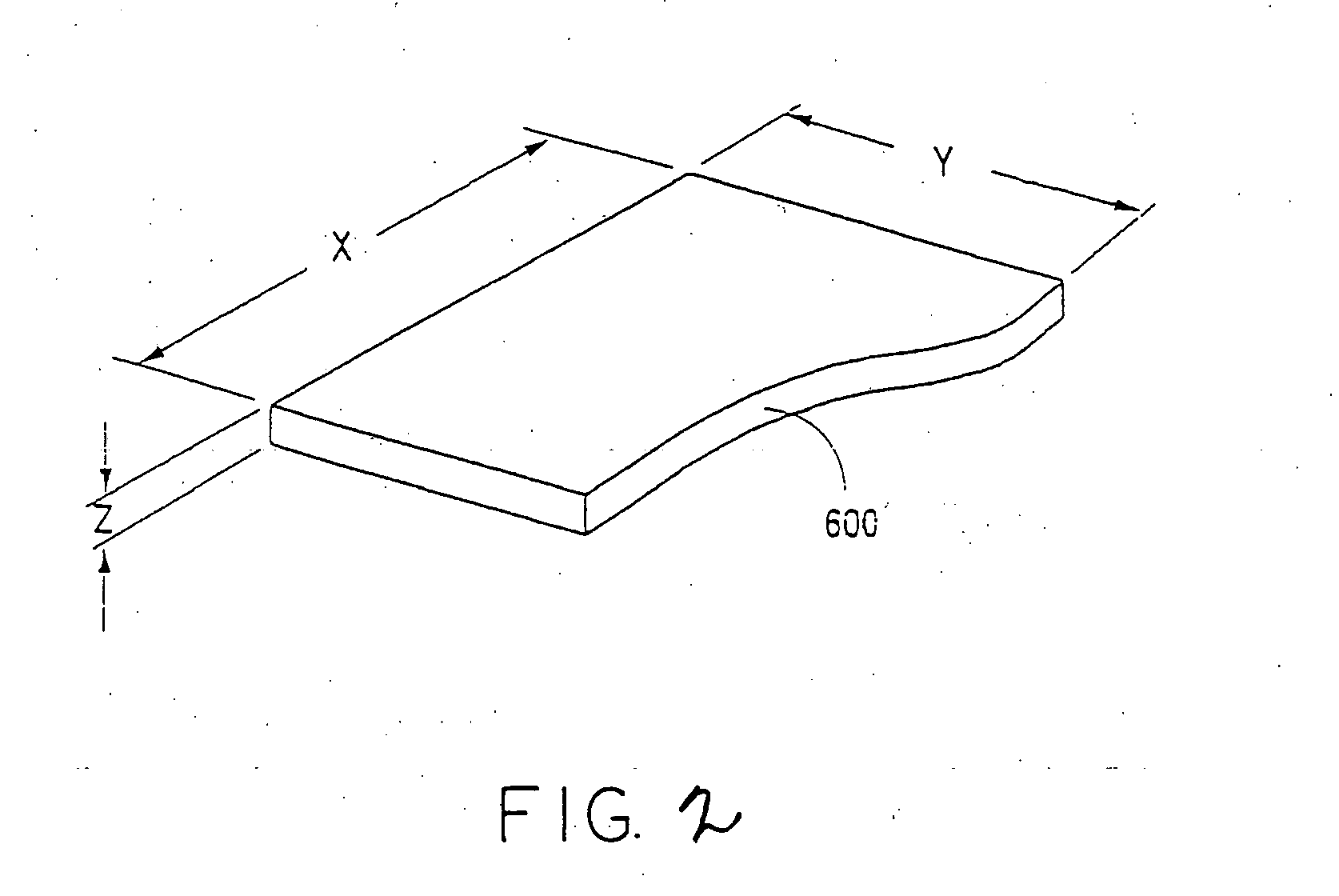

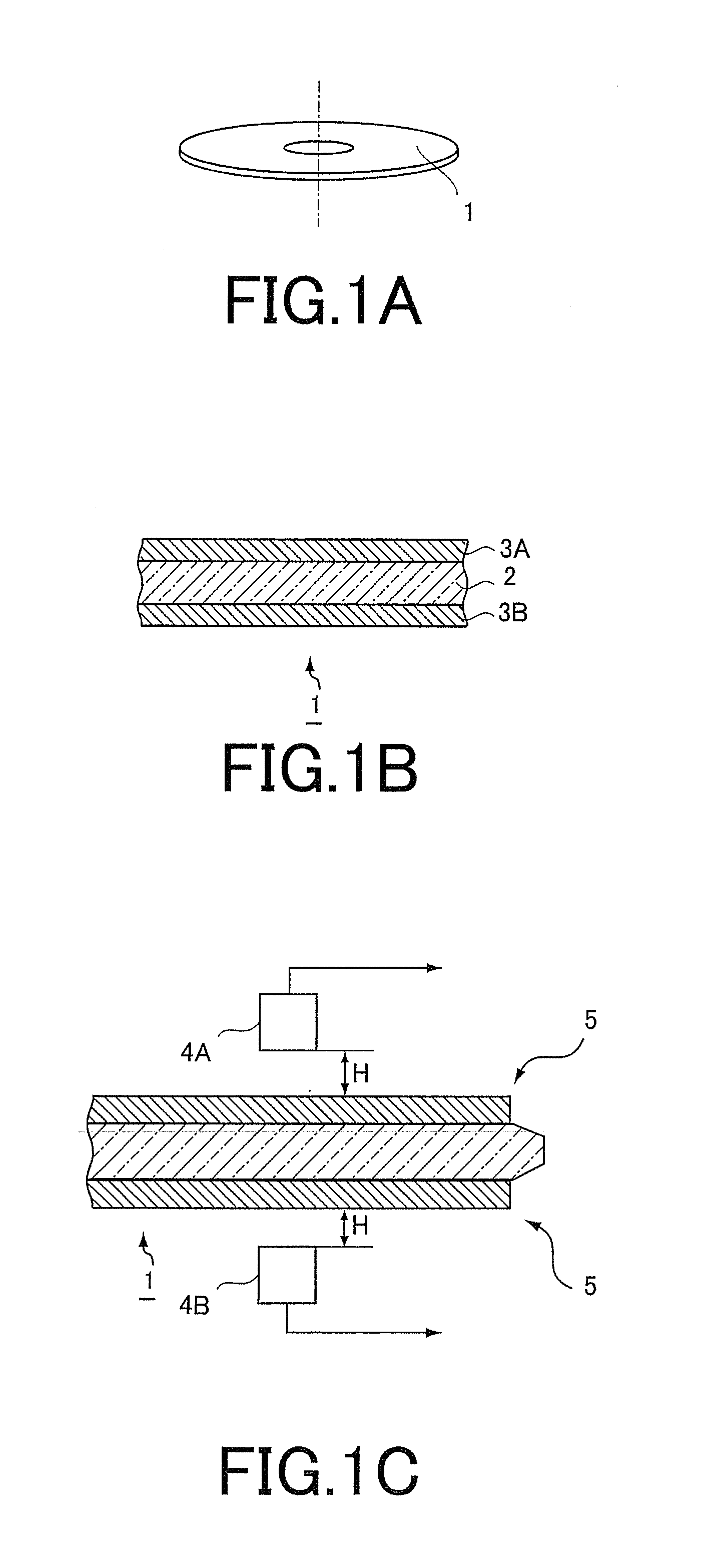

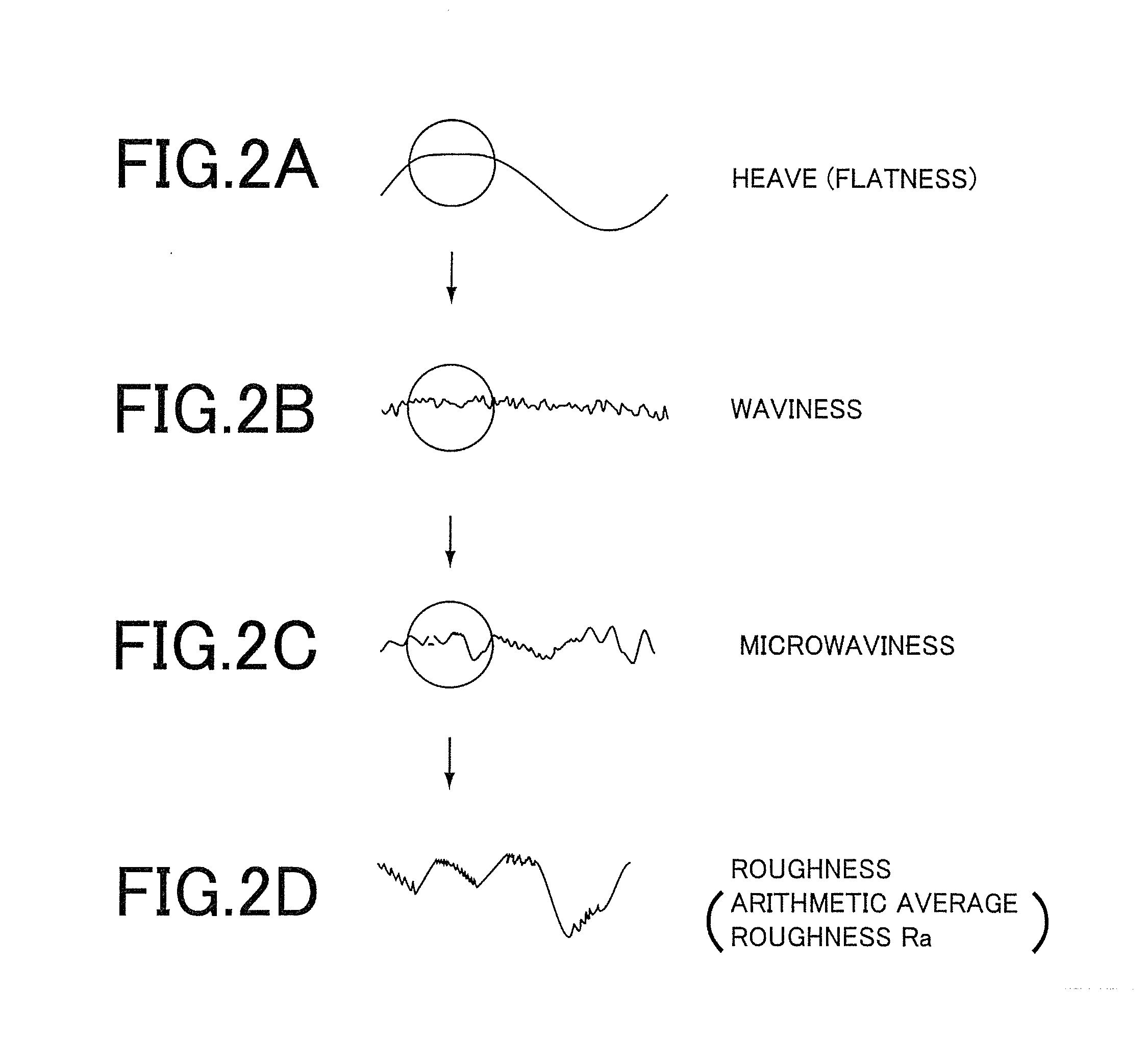

Glass substrate for magnetic disk and manufacturing method thereof

InactiveUS20110159321A1Good surface irregularity accuracyImprove impact resistanceMagnetic materials for record carriersRecord information storageFlat glassSurface roughness

The present invention provides a method for efficiently manufacturing a glass substrate for magnetic disk having good accuracy of a surface irregularity and an impact resistance. The method includes the steps of: performing press forming to molten glass to prepare a sheet glass material, the sheet glass material having a roughness of the principal surface of 0.01 μm or less and target flatness of a glass substrate for magnetic disk; chemically strengthening the sheet glass material by dipping the sheet glass material in a chemically strengthening salt, thereby preparing a disk substrate; polishing the principal surfaces of the disk substrate. A thickness of the sheet glass material prepared in the press forming step is larger than a target thickness of the glass substrate for magnetic disk by a polishing quantity of the principal surface polishing step.

Owner:HOYA CORP

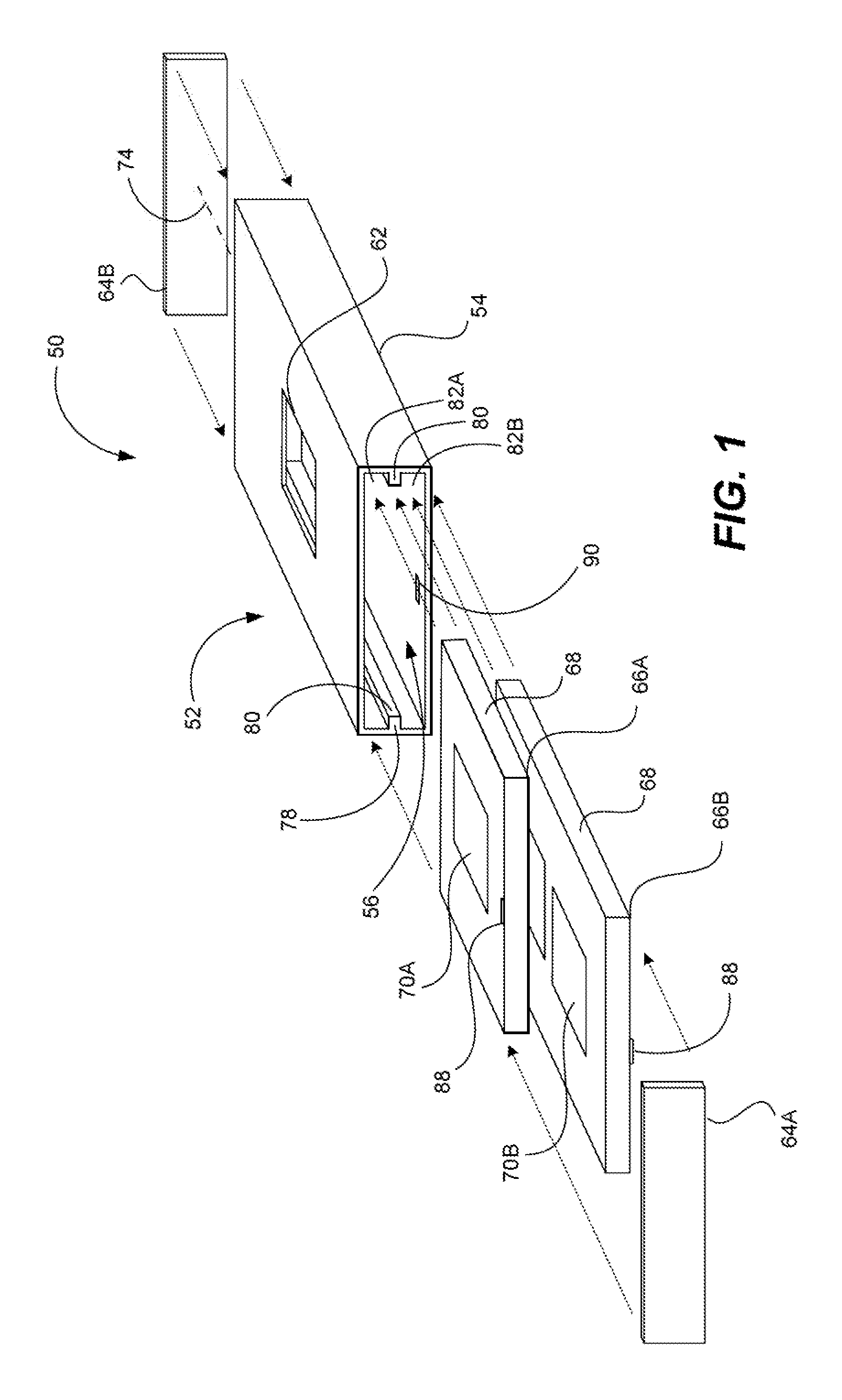

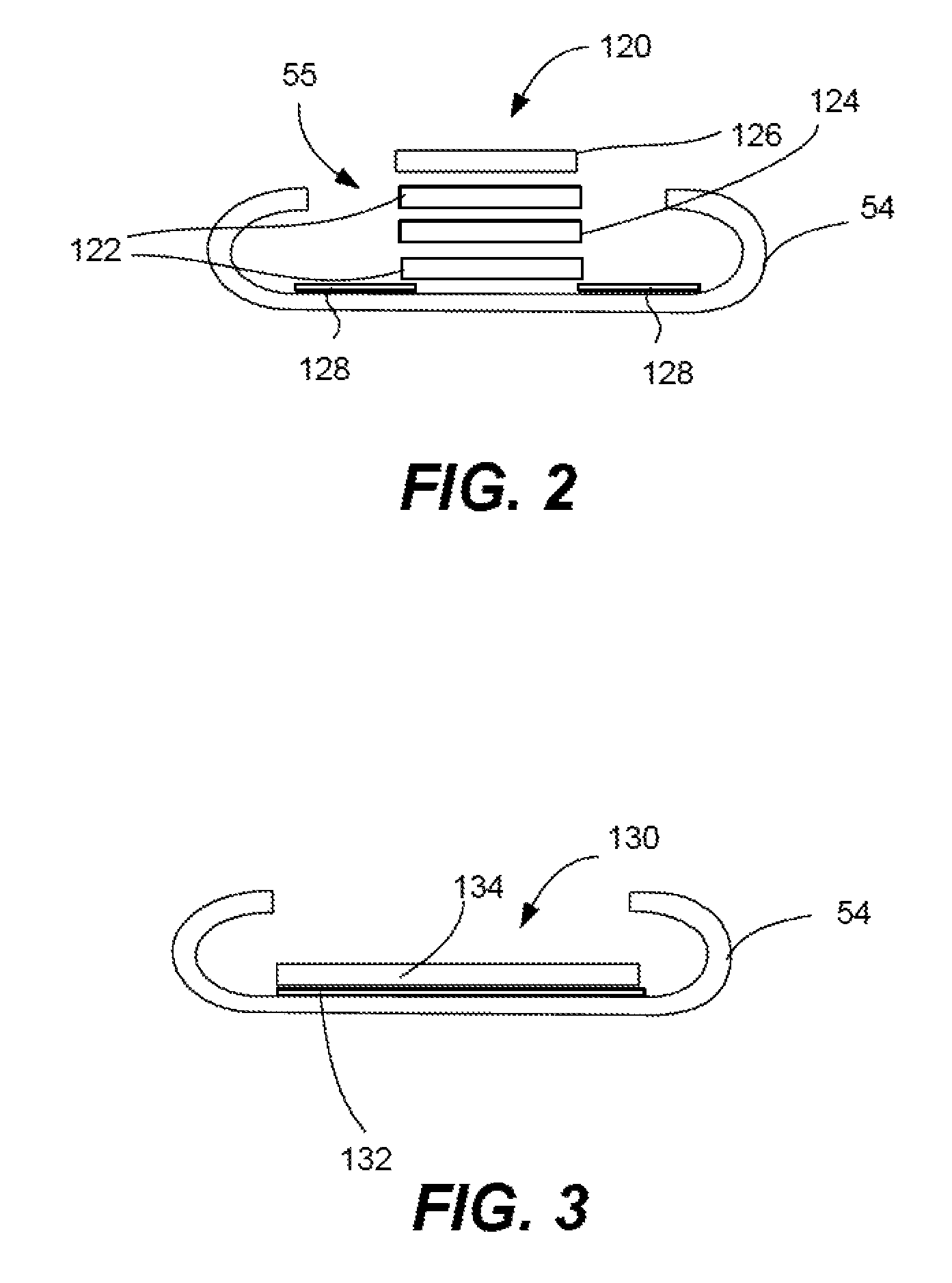

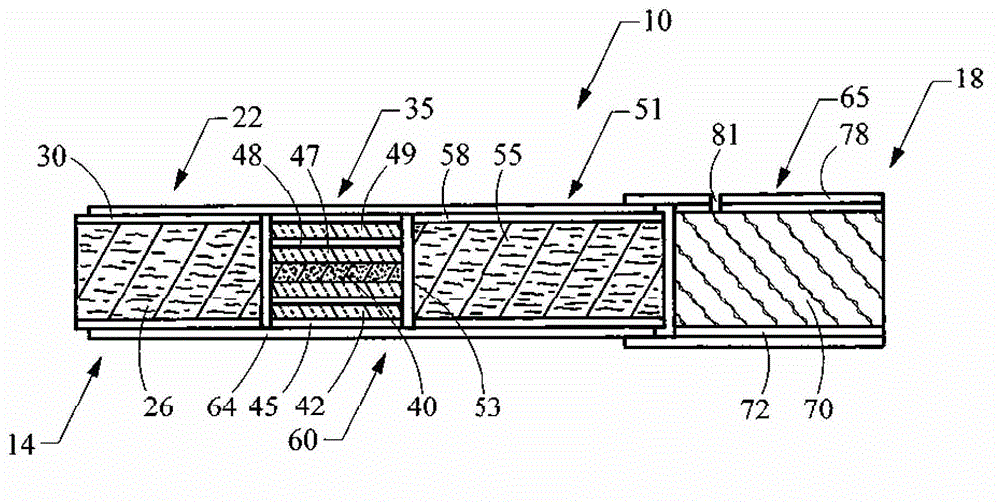

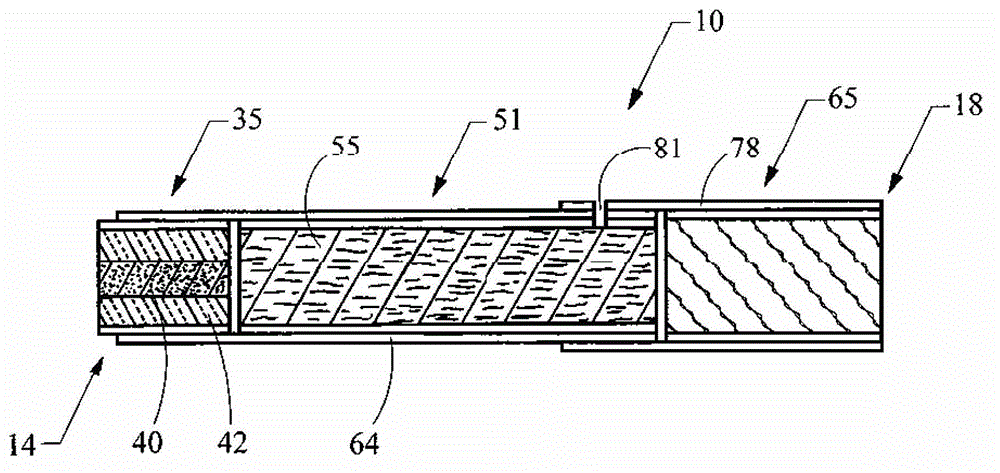

Segmented smoking article

A cigarette includes lighting (14) and mouth ends (18). It may include a smokable segment (22) disposed at the lighting end. It also includes a mouth-end segment(65); an aerosol-generation system disposed between the lighting and mouth ends, which includes (i) a heat-generation segment (35) adjacent the smokable segment, including a heat source (40) configured to be activated by combustion of a smokable material and an insulation layer (42), which may be formed of a non-glass material that is woven, knit, or both and (ii) an aerosol-generating segment(51) including a substrate (55), which may be monolithic and / or which may include a stitch -bonded portion, with aerosol-forming material disposed between, but physically separate from, each of the heat generation segment and the mouth end; a piece of outer wrapping material (58) that provides an overwrap around at least a portion of the aerosol-generating segment, the heat-generation segment, and at least a portion of the smokable segment; those segments being connected together by the overwrap (64) to provide a cigarette rod; that is connected to the cigarette rod using tipping material (78).

Owner:R J REYNOLDS TOBACCO COMPANY

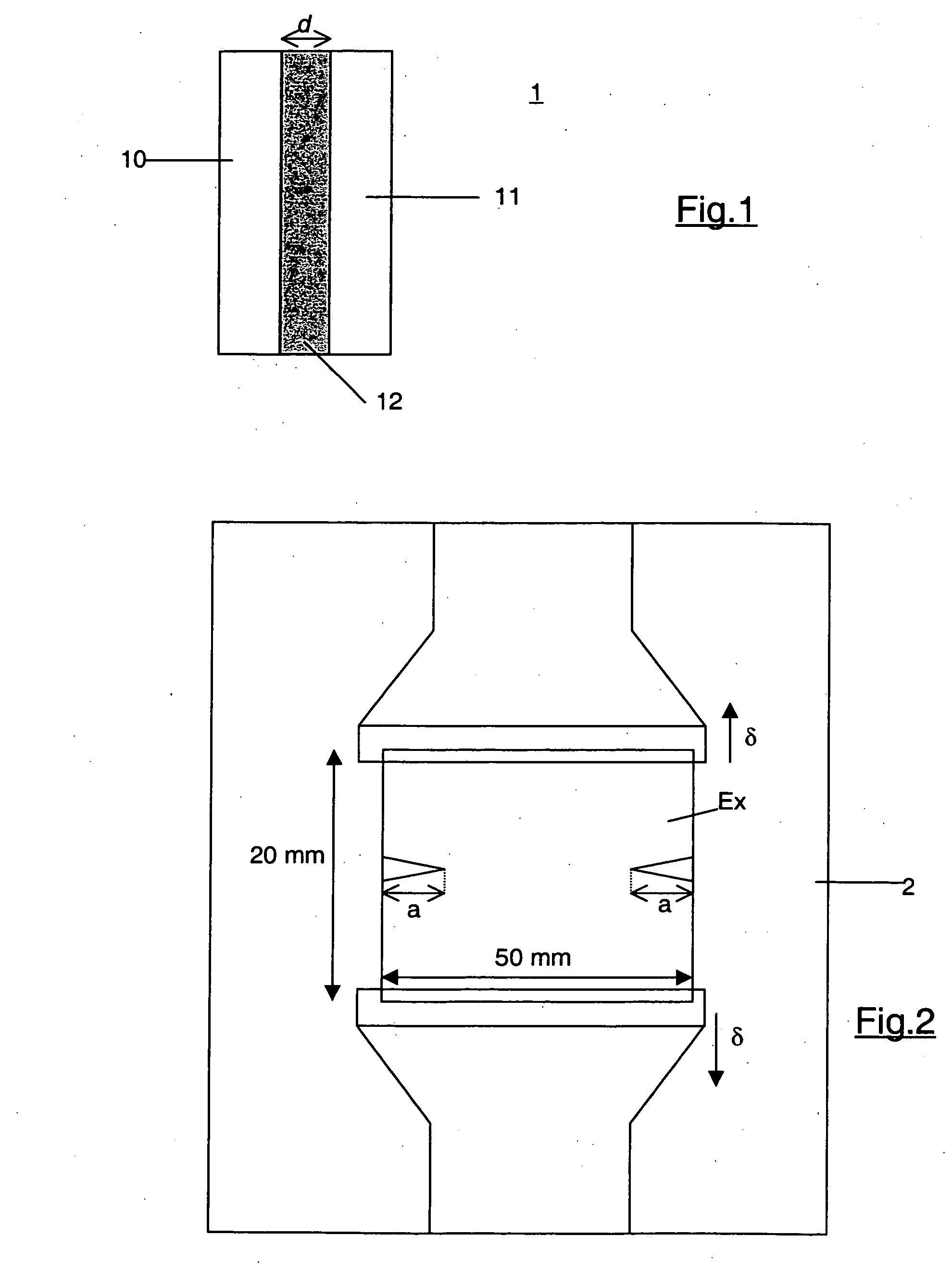

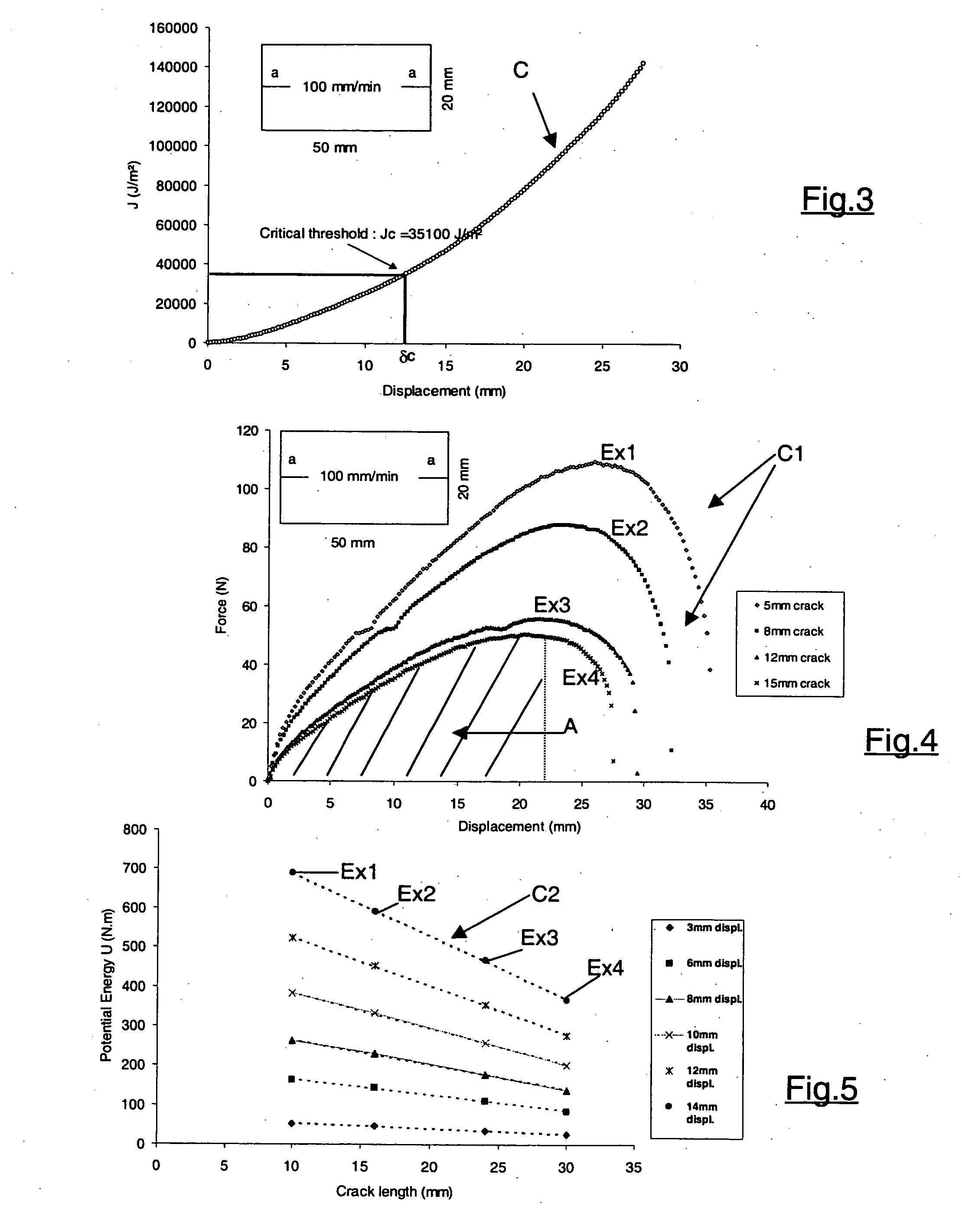

Laminated glazing material

ActiveUS20060070694A1Lamination ancillary operationsSynthetic resin layered productsCritical energyGlass sheet

A laminated glazing material with properties of acoustic insulation and mechanical strength. The laminated glazing material including two glass sheets and a single-ply intermediate layer of a thickness having the form of a polymer film. The thickness of the intermediate layer being defined as a function of a variable which is specific to the material, and which defines the critical energy value of the intermediate layer and is representative of the energy necessary for propagation of a crack initiated in the intermediate layer.

Owner:SAINT-GOBAIN GLASS FRANCE

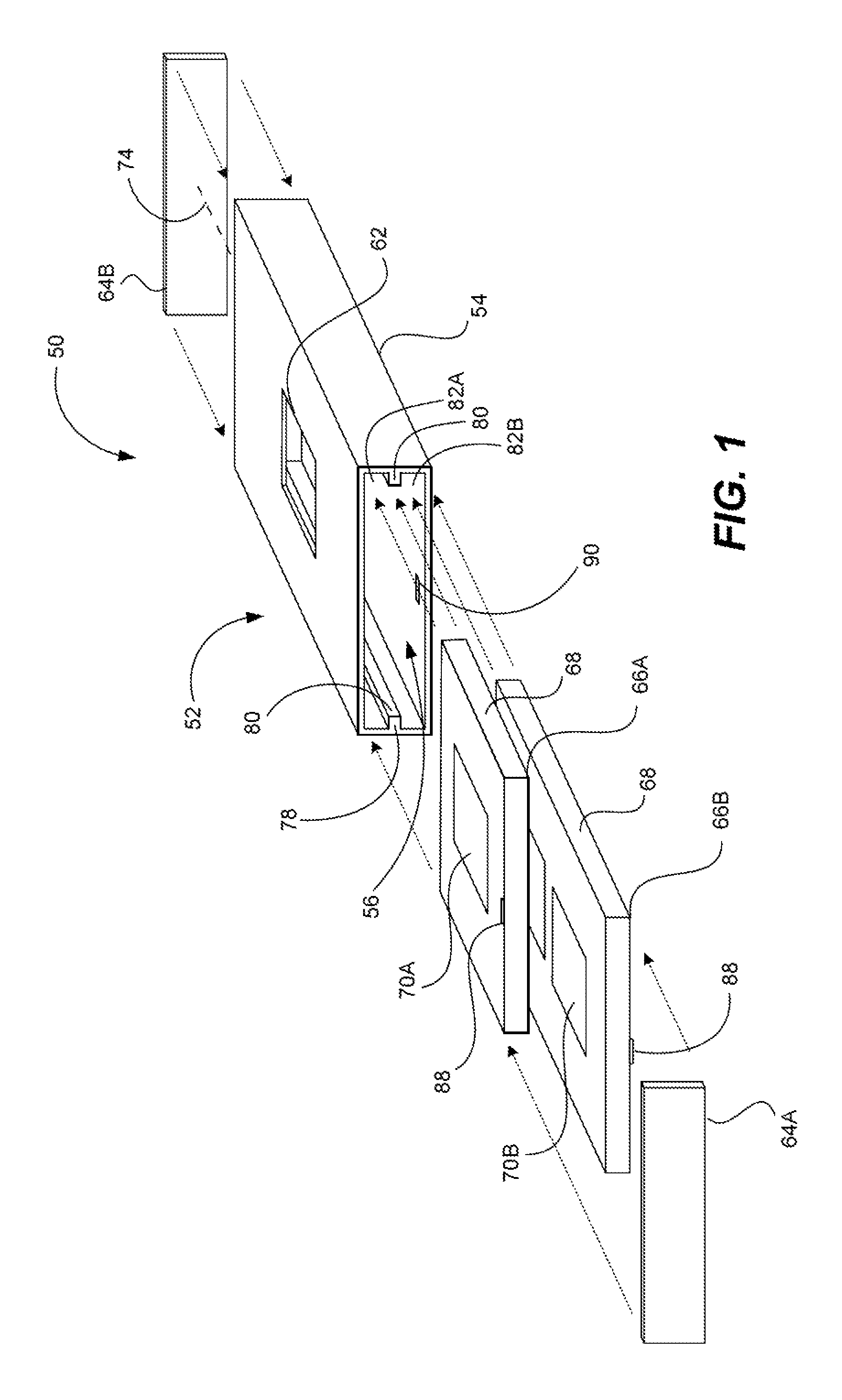

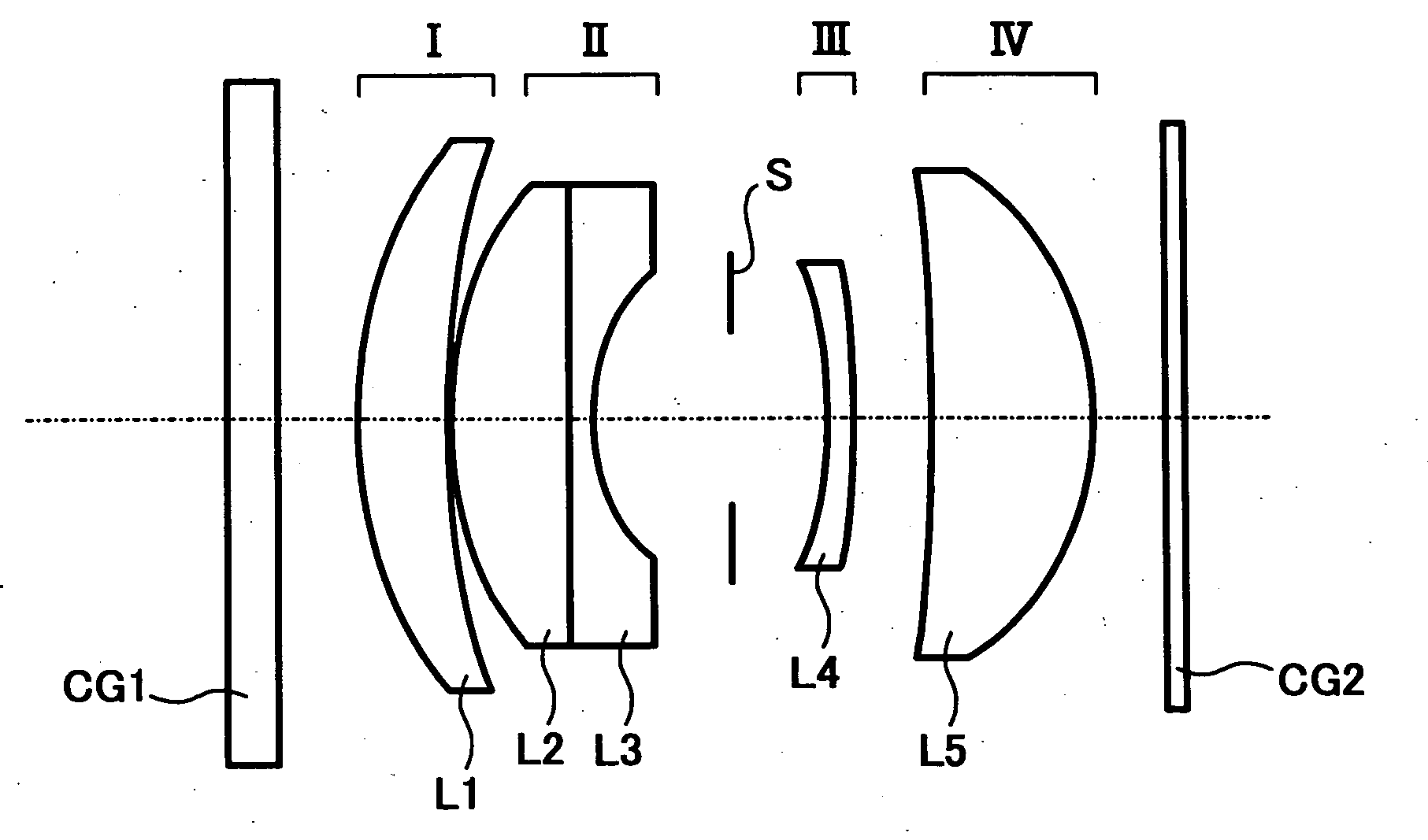

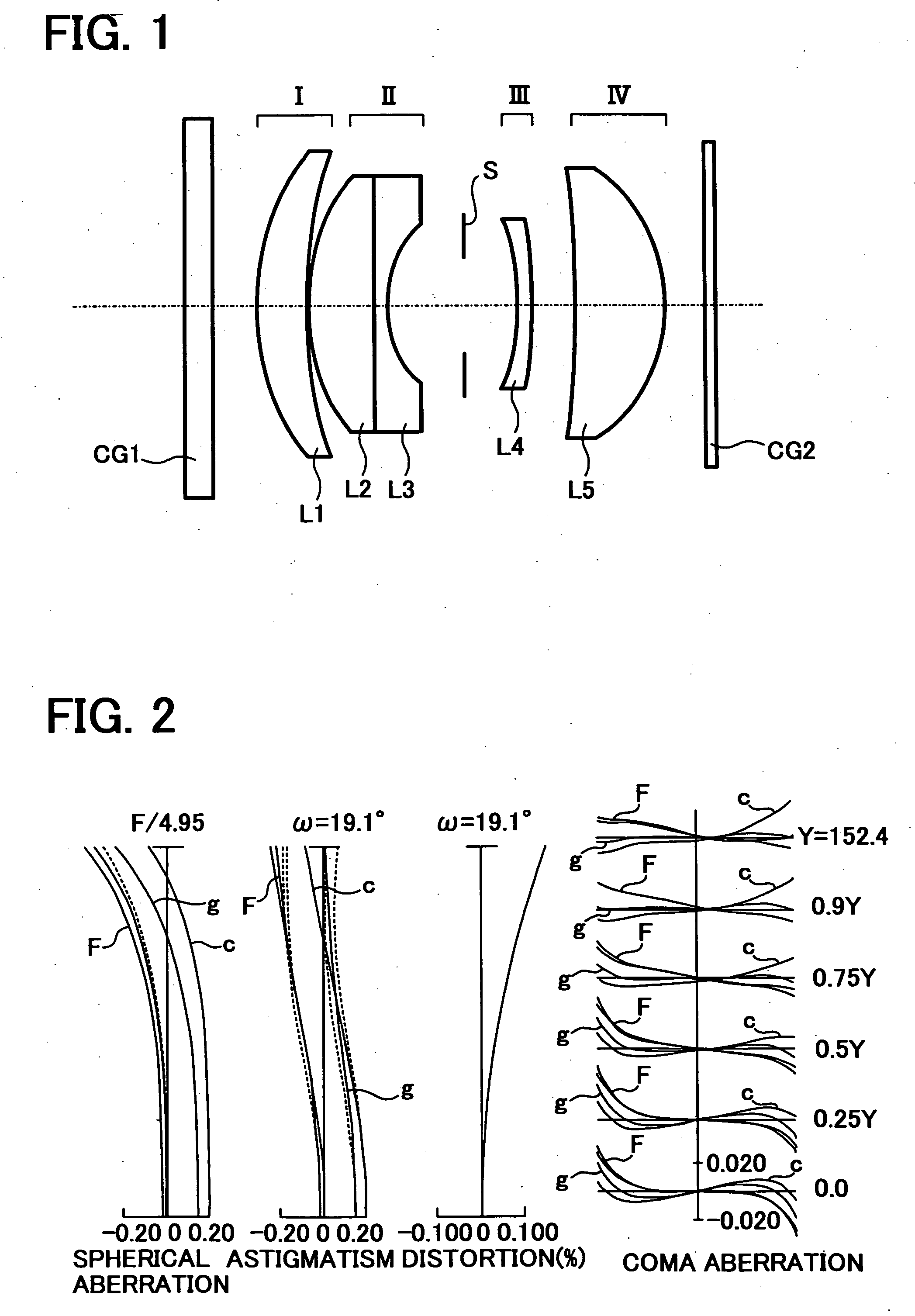

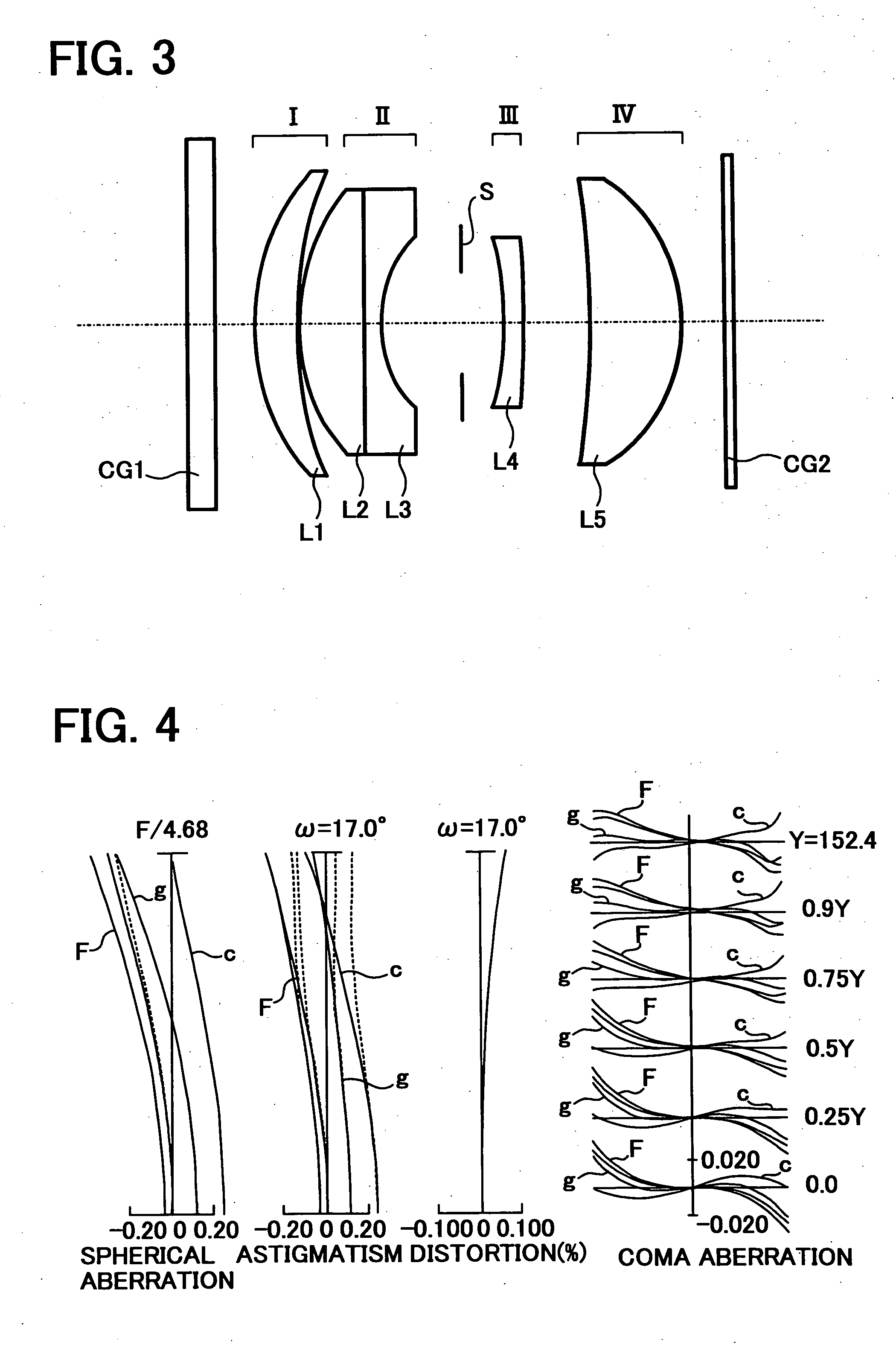

Original reading lens, original reading lens unit, original reading device, and image forming device

InactiveUS20050141103A1Small and readingSmall differencePictoral communicationLensRefractive indexImage formation

An original reading lens includes a four-group, five-element lens configuration including three positive lenses and two negative lenses, wherein the positive lens is constructed by a glass material of low dispersion, and the negative lens is constructed by a glass material of high dispersion, a partial dispersion θ gd is defined by θ gd=(ng−nd) / (nF−nc) by a refractive index nd of d line (587.56 nm), a refractive index nc of c line (656.27 nm), a refractive index nF of F line (486.13 nm), and a refractive index ng of g line (435.83 nm), a straight line connecting a coordinate point of a reference glass material K7, K7 (θ gd, ν d) and a coordinate point of a reference glass material F2, F2 (θ gd, ν d) on a plane with a coordinate system including the partial dispersion θ gd and an Abbe number ν d as orthogonal two axes is adopted as a reference line, and a partial dispersion deviation δθ gd which is the deviation from the reference line of the partial dispersion θ gd of the material is positive in one or more positive lens.

Owner:RICOH KK

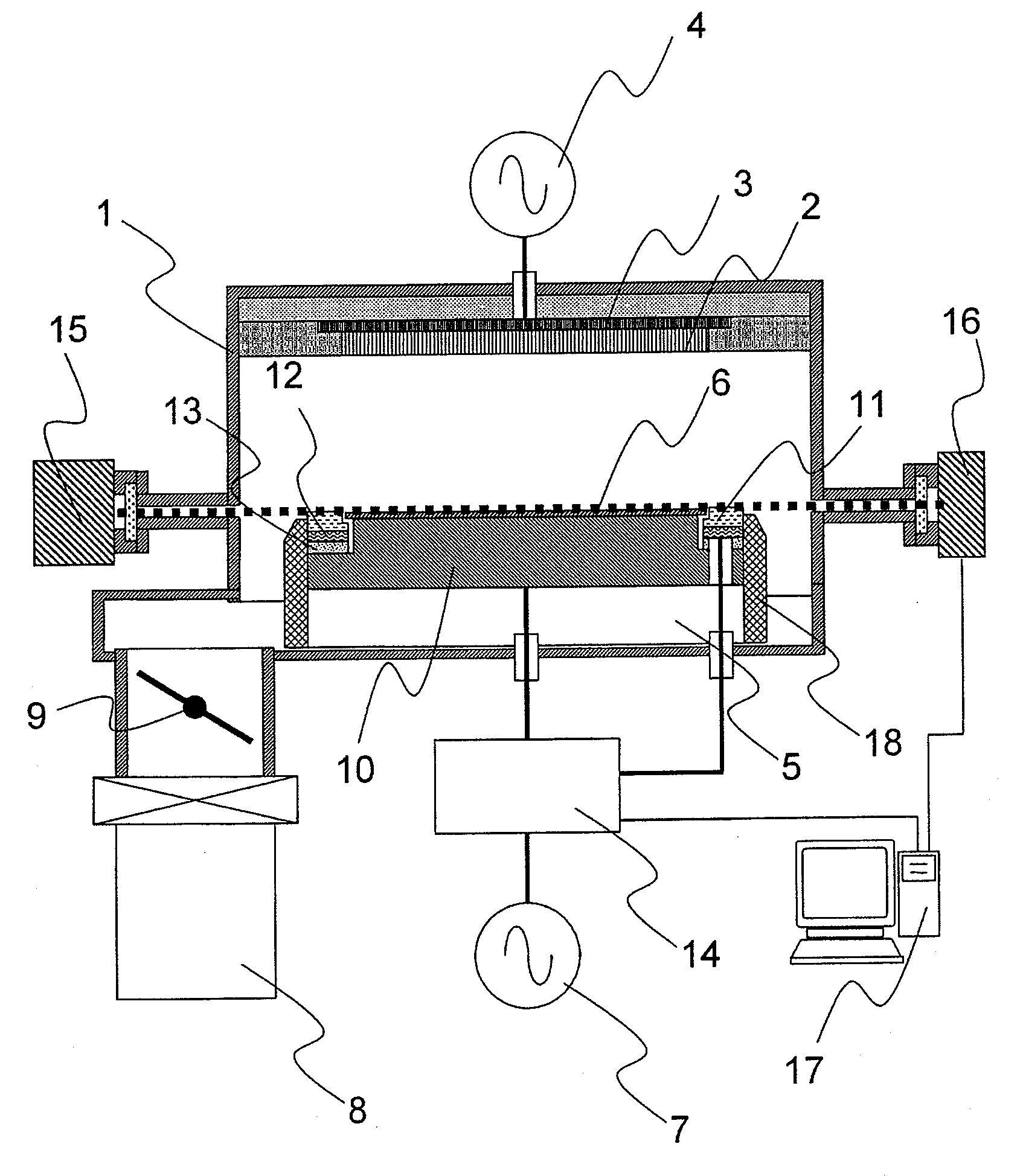

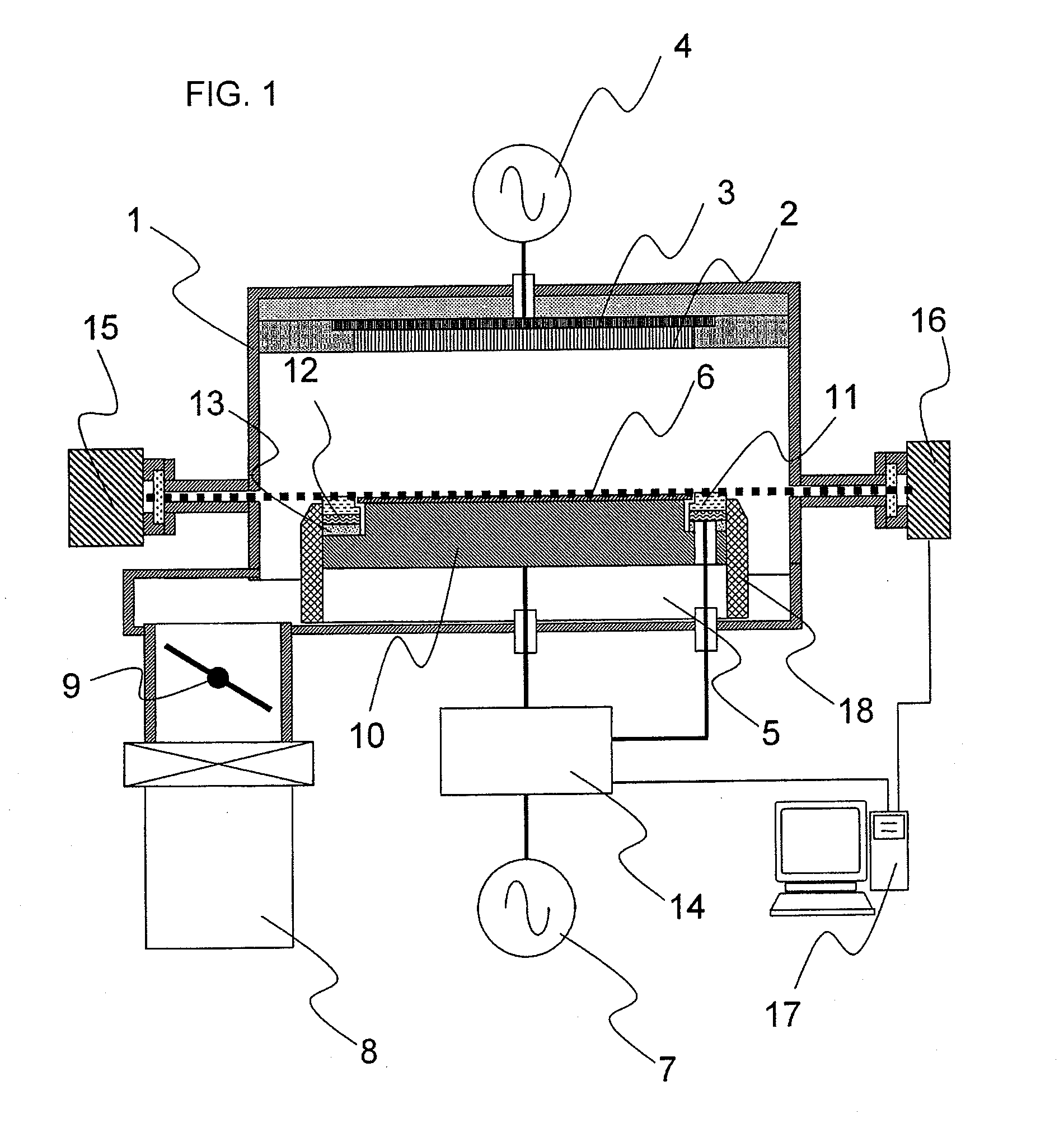

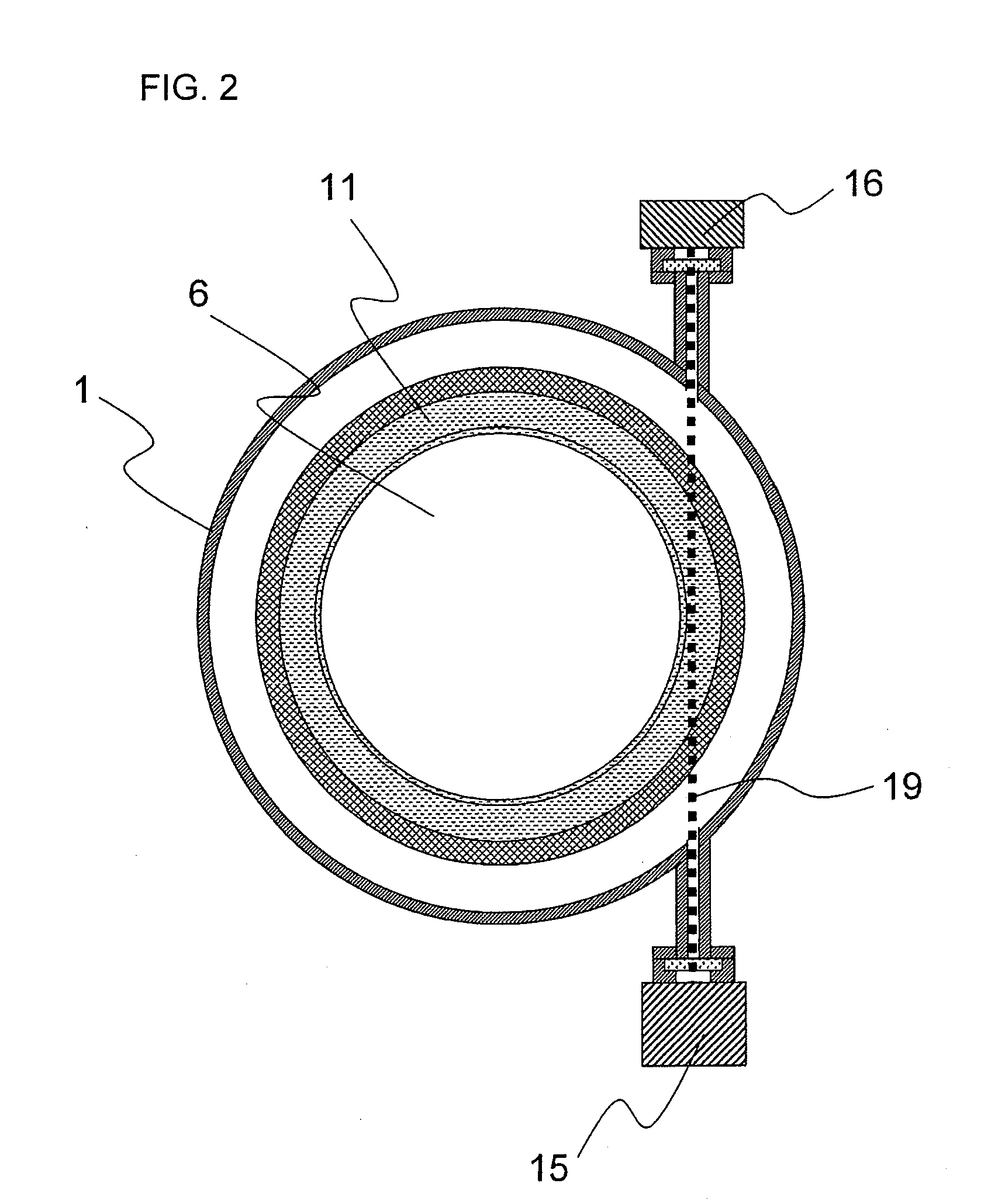

Plasma processing apparatus and plasma processing method

InactiveUS20100025369A1Curb tiltReduce in quantityElectric discharge tubesVacuum gauge using ionisation effectsEngineeringRadio frequency

To monitor the thickness of a focus ring consumed during wafer processing. A plasma processing apparatus includes a vacuum chamber 1, workpiece mounting means 5, high frequency electric power introducing means 4 and radio-frequency bias electric power introducing means 7 and processes a surface of a workpiece 6 using a plasma that is converted from a gas introduced into the vacuum chamber 1 by the action of a high frequency electric power introduced by the high frequency electric power introducing means 4. The plasma processing apparatus further includes an annular member 11 surrounding the workpiece 6 mounted on the workpiece mounting means 5, and a pair of tubes having an aspect ratio of 3 or higher and disposed on a side wall of the vacuum chamber 1 to face each other. Each tube is vacuum-sealed at a tip end thereof with a glass material. One of the tubes has a light source 15 disposed facing to the interior of the vacuum chamber on the atmosphere side of the glass material, and the other tube has light receiving means 16 disposed facing to the interior of the vacuum chamber on the atmosphere side of the glass material. The light receiving means 16 receives light passing across the surface of the annular member 11.

Owner:HITACHI HIGH-TECH CORP

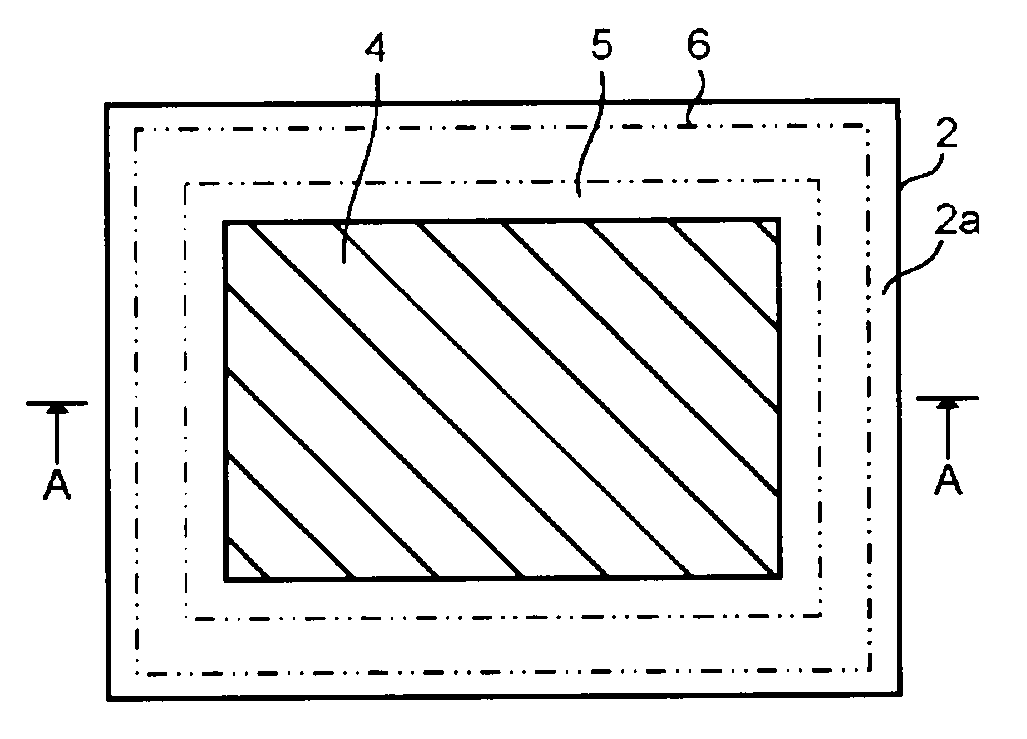

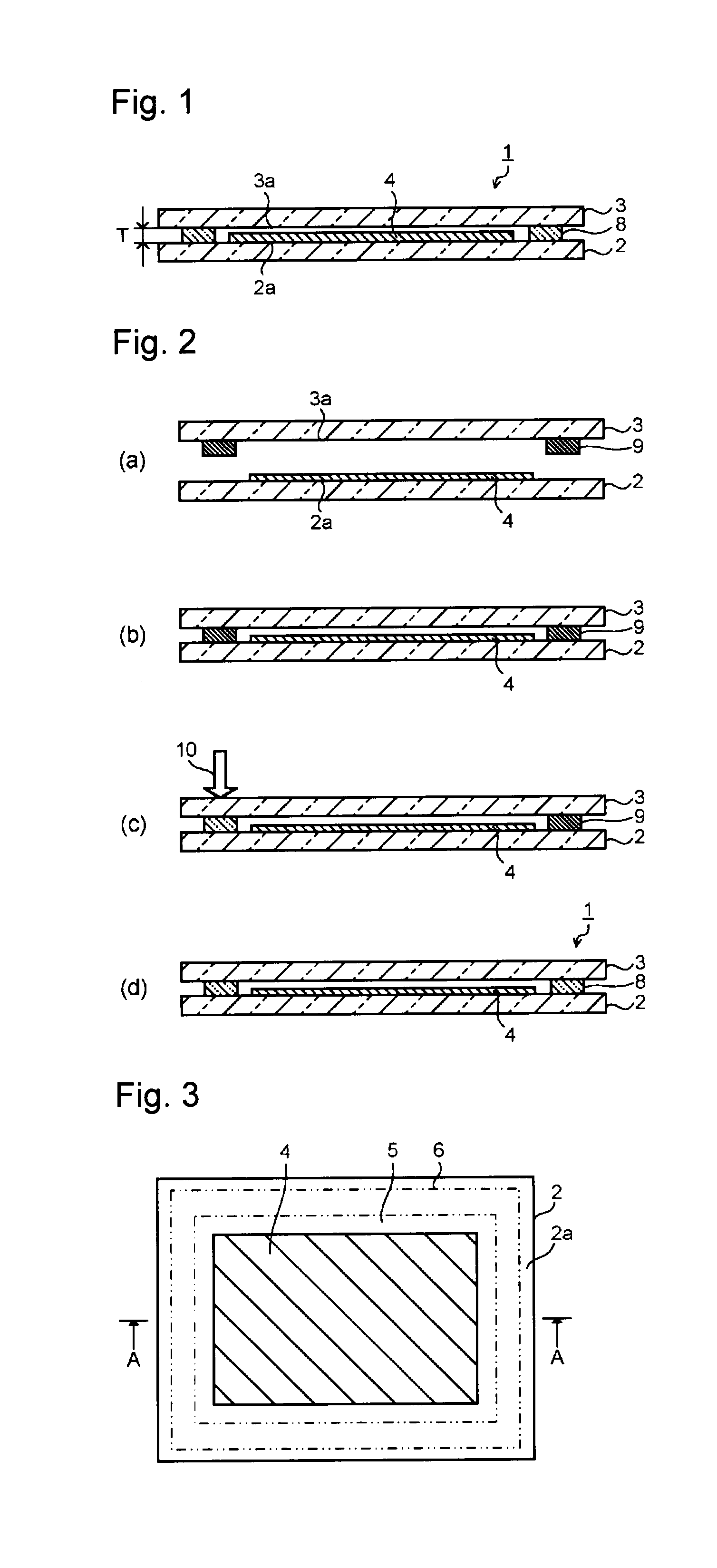

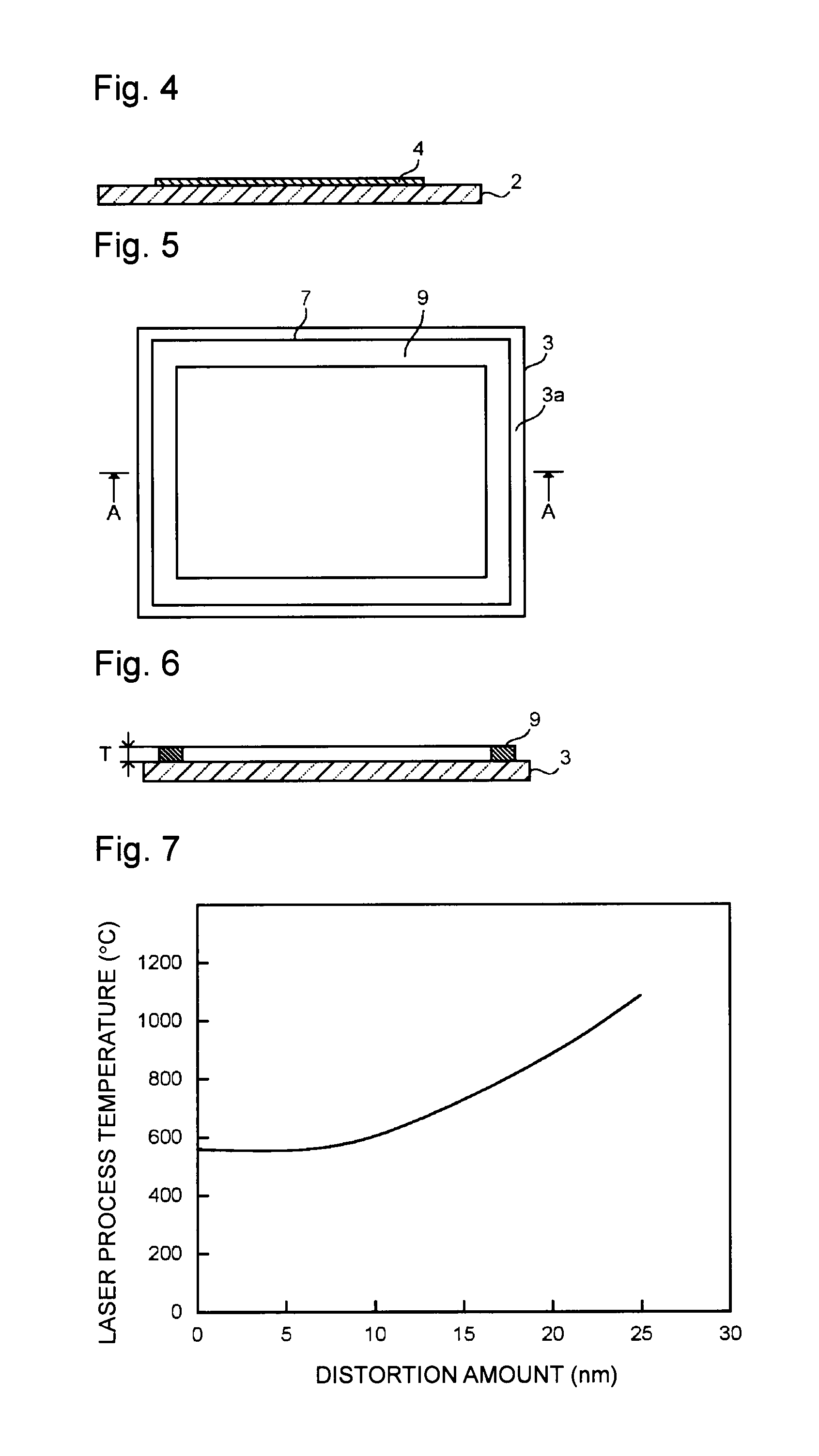

Glass member provided with sealing material layer, electronic device using it and process for producing the electronic device

ActiveUS20120147538A1Suppress generationImprove sealingElectric discharge tubesElectroluminescent light sourcesElectronLaser

The invention provides a glass member provided with a sealing material layer, which suppresses generation of failures such as cracks or breakage of glass substrates or a sealing layer even when the distance between two glass substrates is narrowed, and thereby makes it possible to improve the sealing property between the glass substrates and its reliability. A glass substrate has a surface provided with a sealing region, on which a sealing material layer having a thickness of at most 15 μm is formed. The sealing material layer includes a fired material of a glass material for sealing containing a sealing glass, a laser absorbent and optionally a low-expansion filler, wherein the total content of the laser absorbent and the low-expansion filler being the optional component in the glass material for sealing is within the range of from 2 to 44 vol %.

Owner:ASAHI GLASS CO LTD

Light emitting apparatus

ActiveUS20080030976A1High emission intensityImprove reliabilityDischarge tube luminescnet screensLamp detailsWeather resistancePhosphor

A light emitting apparatus with high emission intensity and that is superior in weather resistance and reliability is obtained. The light emitting apparatus includes a light source and a wavelength-converting member for converting the wavelength of light emitted from the light source, wherein the wavelength-converting member contains a phosphor subjected to a cleaning treatment and / or a coating treatment, in a glass material having a composition of SiO2: 30 to 50%, Li2O: 0 to 15%, Na2O: 0 to 10%, K2O: 0 to 10%, Li2O+Na2O+K2O: 20 to 30%, B2O3: 5 to 15%, MgO: 0 to 10%, BaO: 0 to 10%, CaO: 0 to 10%, SrO: 0 to 10%, Al2O3: 0 to 10%, ZnO: 0 to 15%, TiO2: 10 to 20%, Nb2O5: 1 to 5%, La2O3: 0 to 5%, and TiO2+Nb2O5+La2O3: 11 to 20% by mole percentage.

Owner:NICHIA CORP

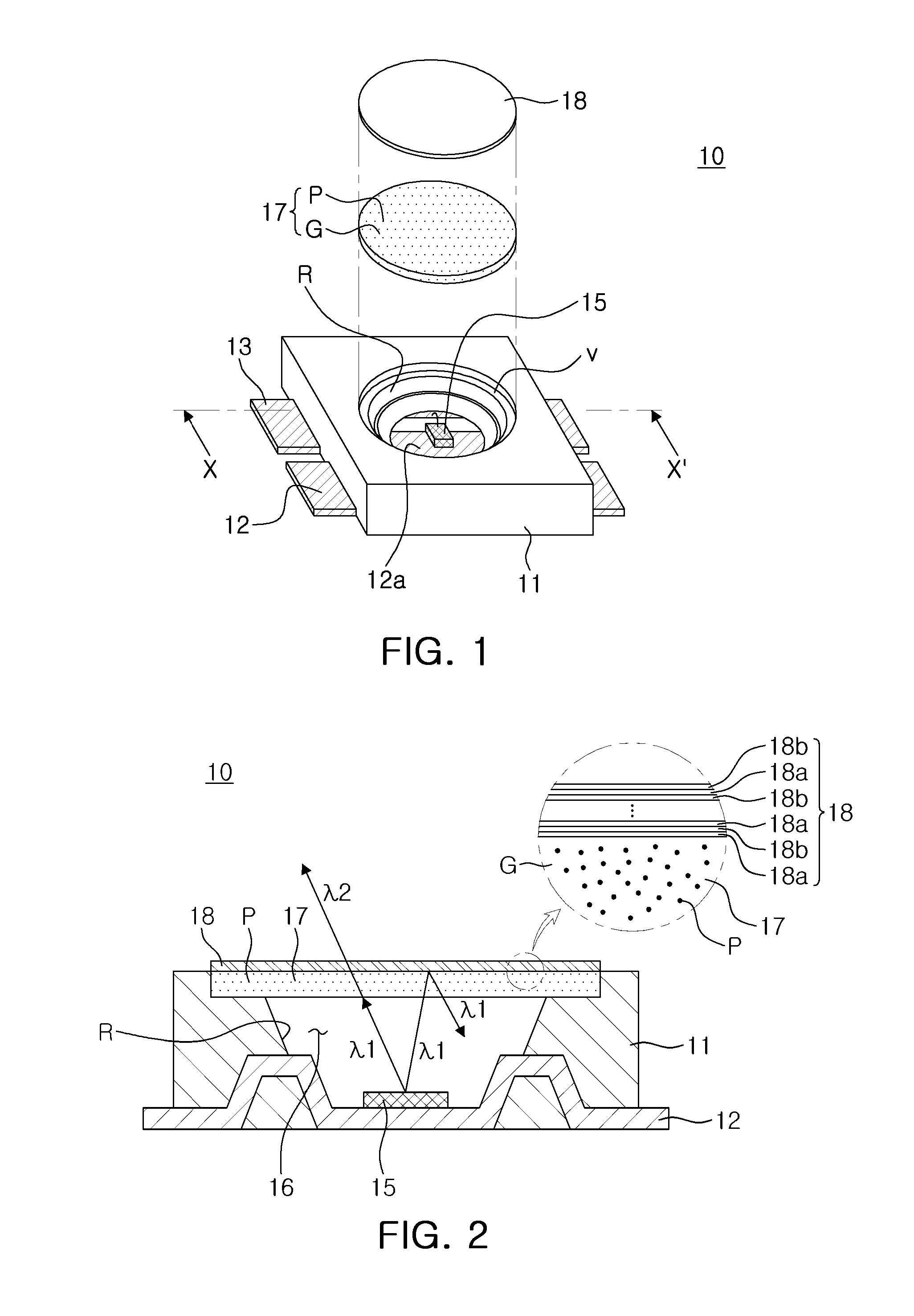

Semiconductor light emitting device package

ActiveUS20140264412A1High color purityExcellent luminanceSolid-state devicesSemiconductor devicesWavelength conversionLight emitting device

A semiconductor light emitting device package includes: a light emitting device; a wavelength conversion unit formed in a path of light emitted from the light emitting device and including a mixture of a wavelength conversion material and a glass material; and a reflective film disposed on an upper surface of the wavelength conversion unit and reflecting a partial amount of light emitted from the light emitting device and allowing a partial amount of light emitted from the light emitting device to be transmitted therethrough.

Owner:SAMSUNG ELECTRONICS CO LTD

Illumination optical system, exposure apparatus and device fabrication method

InactiveUS20050237527A1Coin countersSemiconductor/solid-state device manufacturingTarget surfaceOptical polarization

An illumination optical system for illuminating a target surface using light from a light source, said illumination optical system includes a polarizing element that is arranged in an optical path from the light source to the target surface, and adjusts a polarization ratio of the light, and an optical element that is arranged in an optical path from the polarizing element to the target surface, wherein the total birefringence of the optical element is m+2σ<1.0 nm / cm, where an average of birefringence amount of a glass material of the optical element is m, and standard variation birefringence amount of a glass material of the optical element is σ.

Owner:CANON KK

Low-density glass for flat panel display substrates

Disclosed is a glass material essentially free of BaO and alkali oxide particularly suitable for the glass substrate of LCDs. The glass material consists essentially, expressed in mole percent on an oxide basis, of 70–80%, preferably 72–77% of SiO2, 3–9%, preferably 4–7% of Al2O3, 8–18%, preferably 10–16% B2O3, 3–10%, preferably 3–8% of CaO, 0–4%, preferably 0–3% RO, 0–0.2%, preferably 0–0.1% SnO, 0–1%, preferably 0 to 0.5% of XO, where RO represents, collectively, MgO, SrO and ZnO, XO represents, collectively, TiO2, ZrO2, Y2O3 and La2O3. The glass has a strain point in the range of over about 600° C., a coefficient of thermal expansion (CTE) in the range of about 23–35×10−7 / ° C., a density lower than about 2.35 g / cm3, a liquidus temperature lower than or equal to about 1200° C. and a durability in BHF less than or equal to 0.5 mg / cm2 weight loss.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com