Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57869 results about "Metallurgy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are called alloys. Metallurgy is used to separate metals from their ore. Metallurgy is also the technology of metals: the way in which science is applied to the production of metals, and the engineering of metal components for usage in products for consumers and manufacturers. The production of metals involves the processing of ores to extract the metal they contain, and the mixture of metals, sometimes with other elements, to produce alloys. Metallurgy is distinguished from the craft of metalworking, although metalworking relies on metallurgy, as medicine relies on medical science, for technical advancement. The science of metallurgy is subdivided into chemical metallurgy and physical metallurgy.

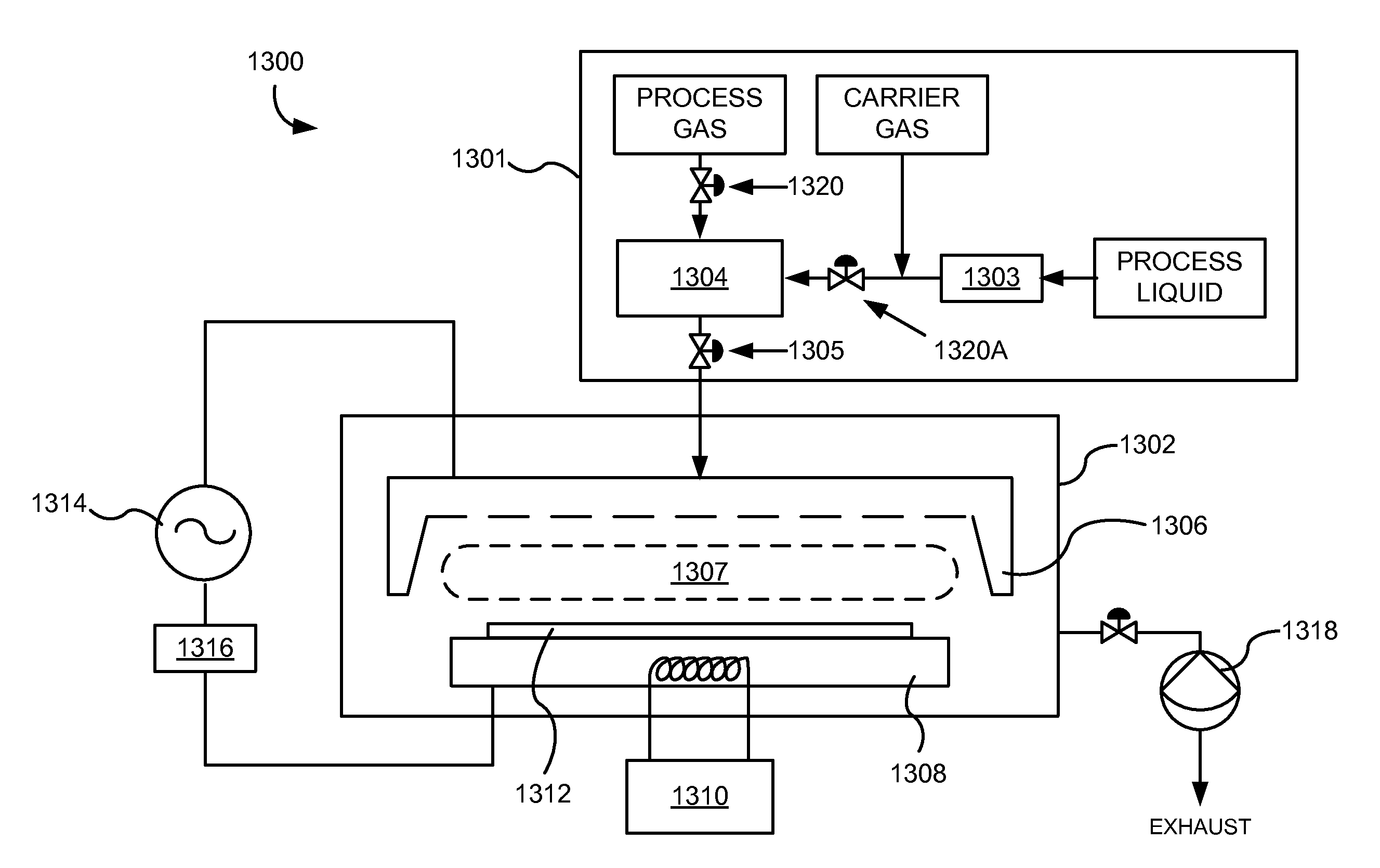

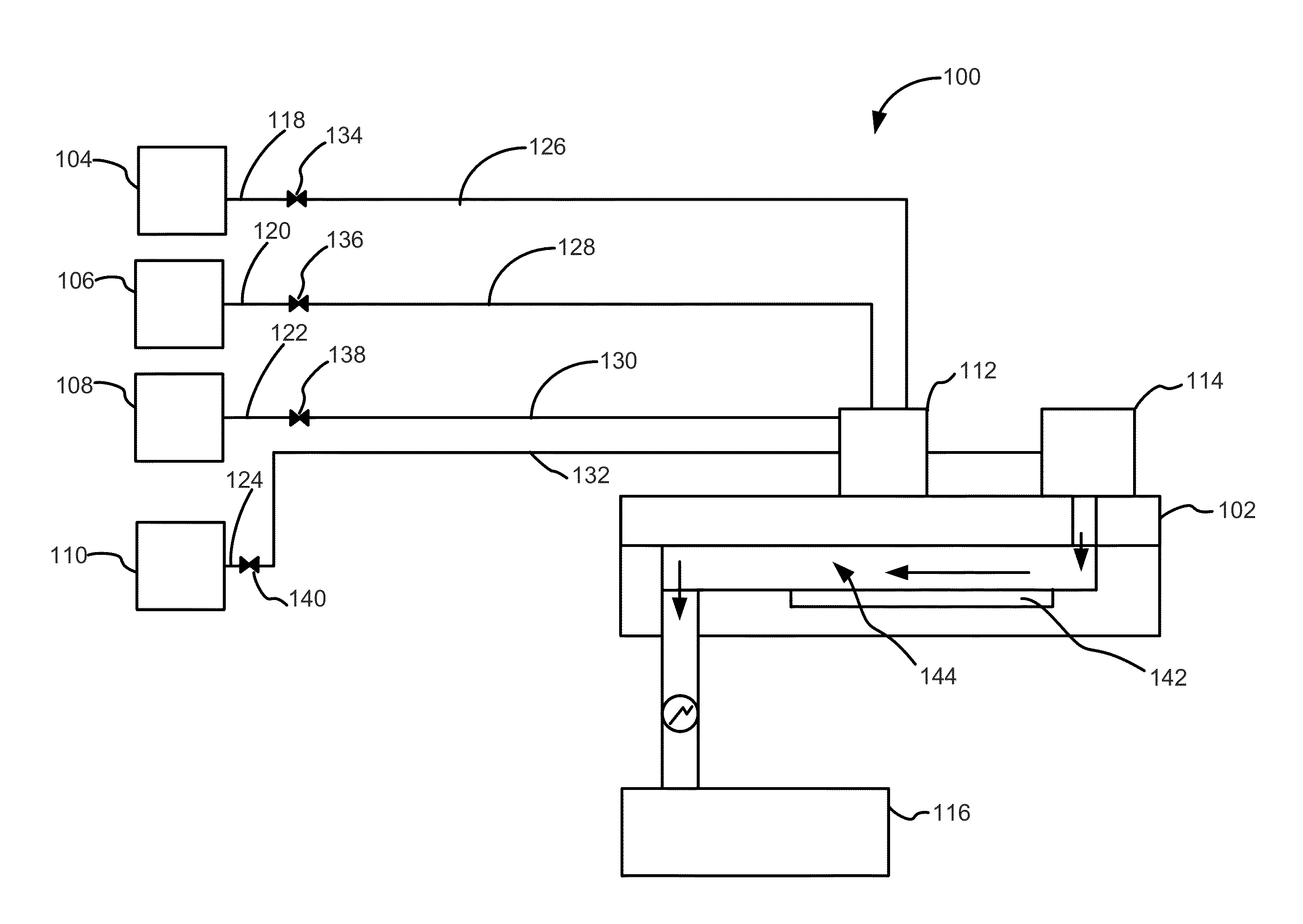

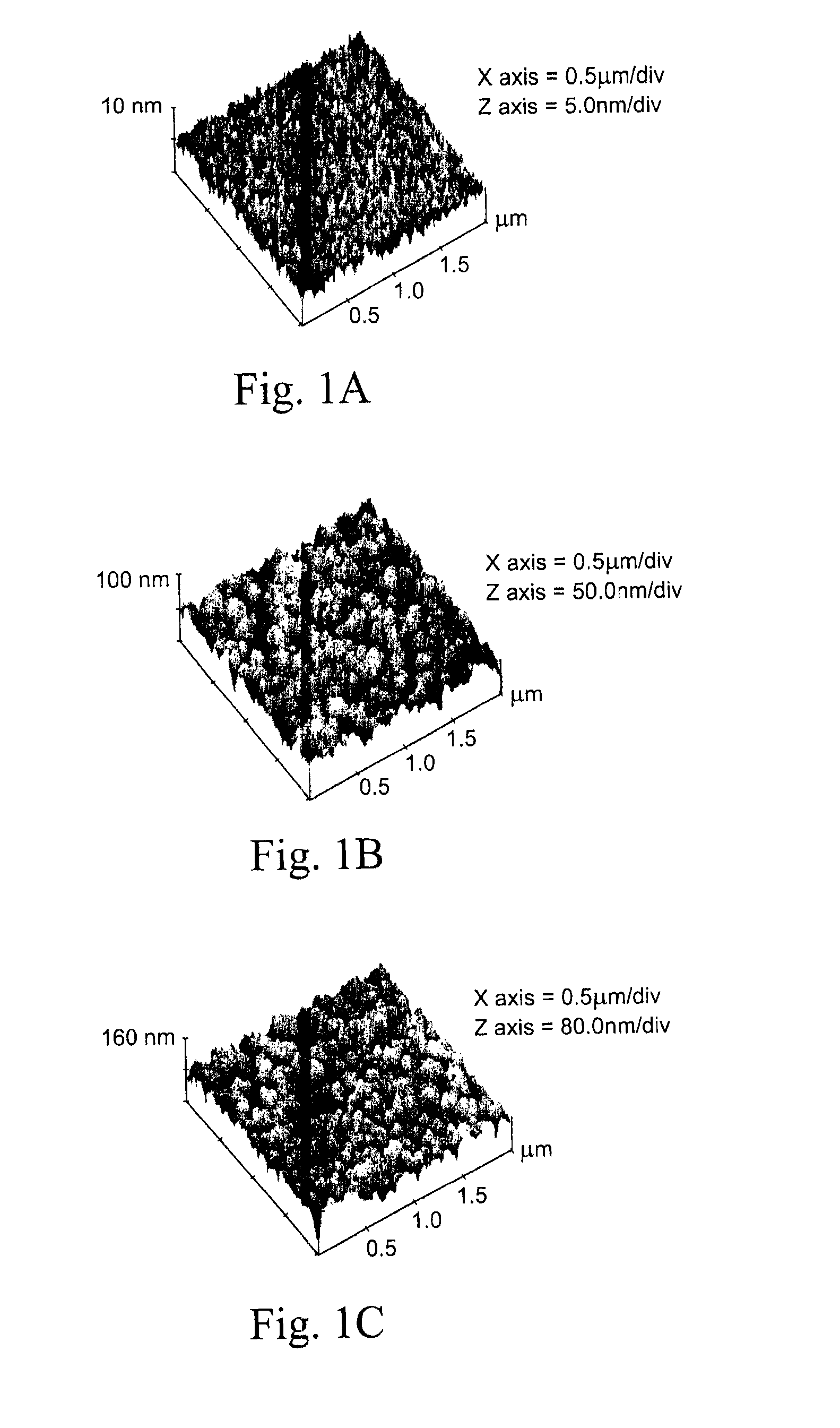

Liquid precursors for the CVD deposition of amorphous carbon films

ActiveUS20050287771A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDual frequencyHydrogen

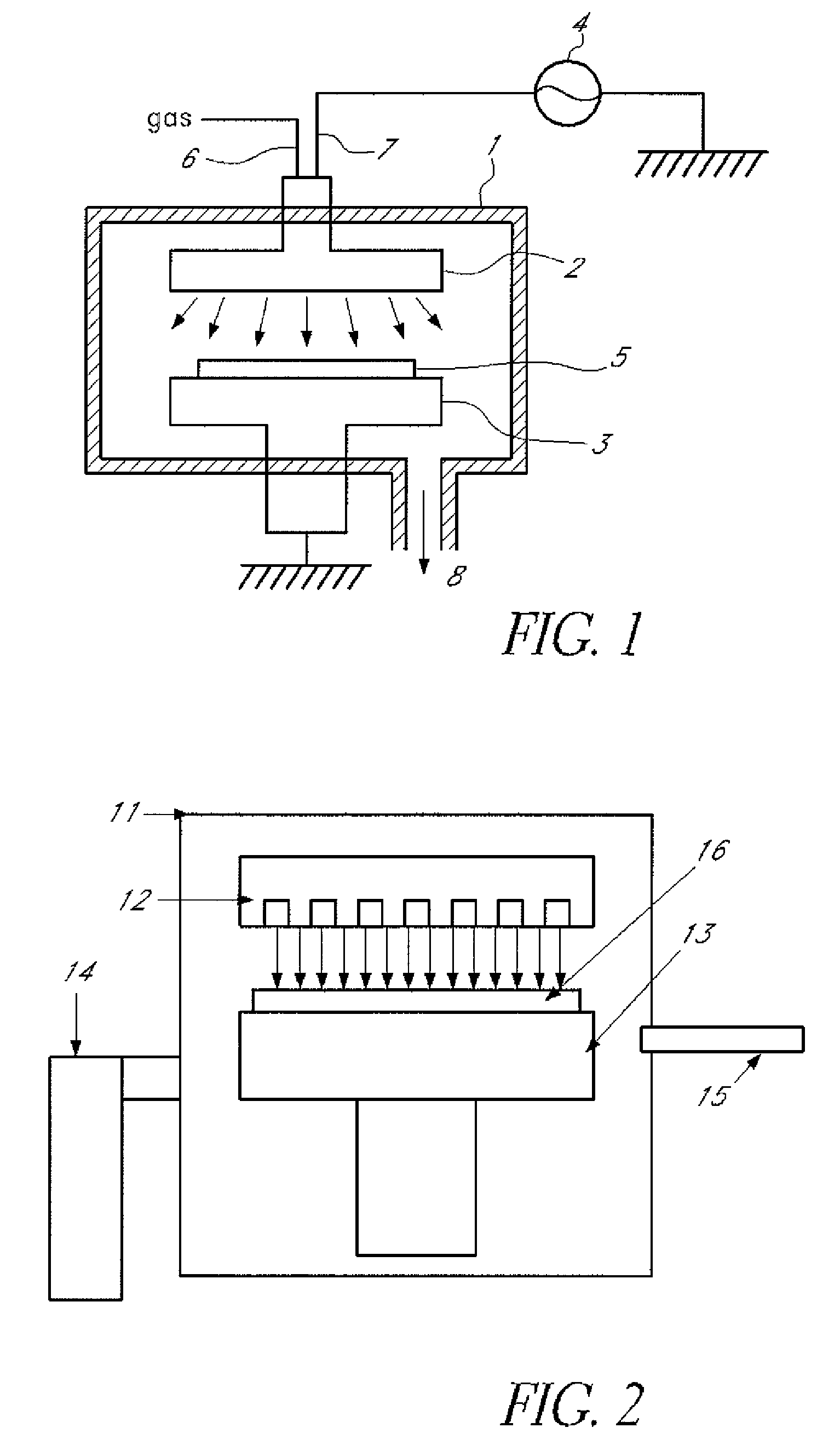

Methods are provided for depositing amorphous carbon materials. In one aspect, the invention provides a method for processing a substrate including positioning the substrate in a processing chamber, introducing a processing gas into the processing chamber, wherein the processing gas comprises a carrier gas, hydrogen, and one or more precursor compounds, generating a plasma of the processing gas by applying power from a dual-frequency RF source, and depositing an amorphous carbon layer on the substrate.

Owner:APPLIED MATERIALS INC

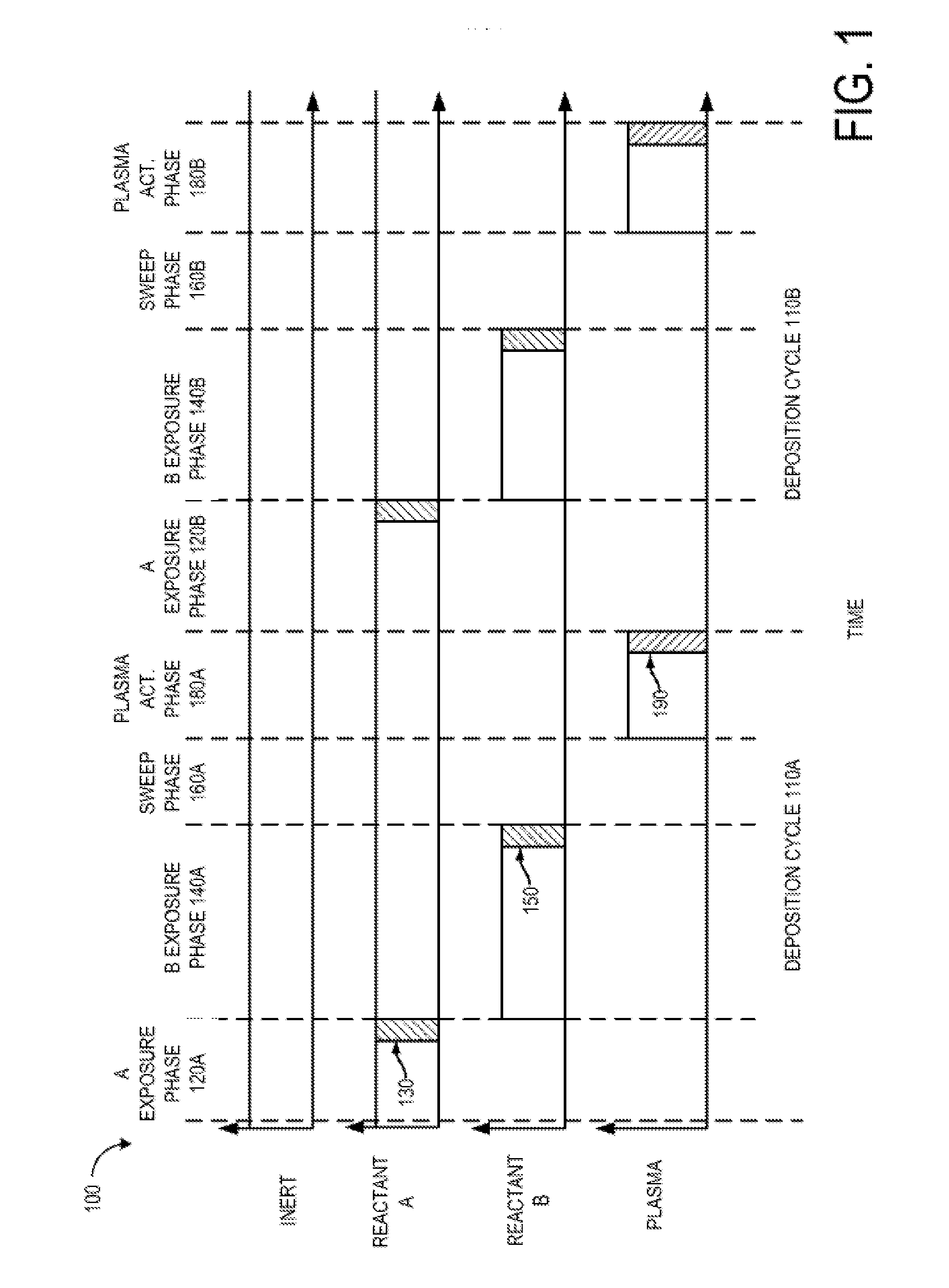

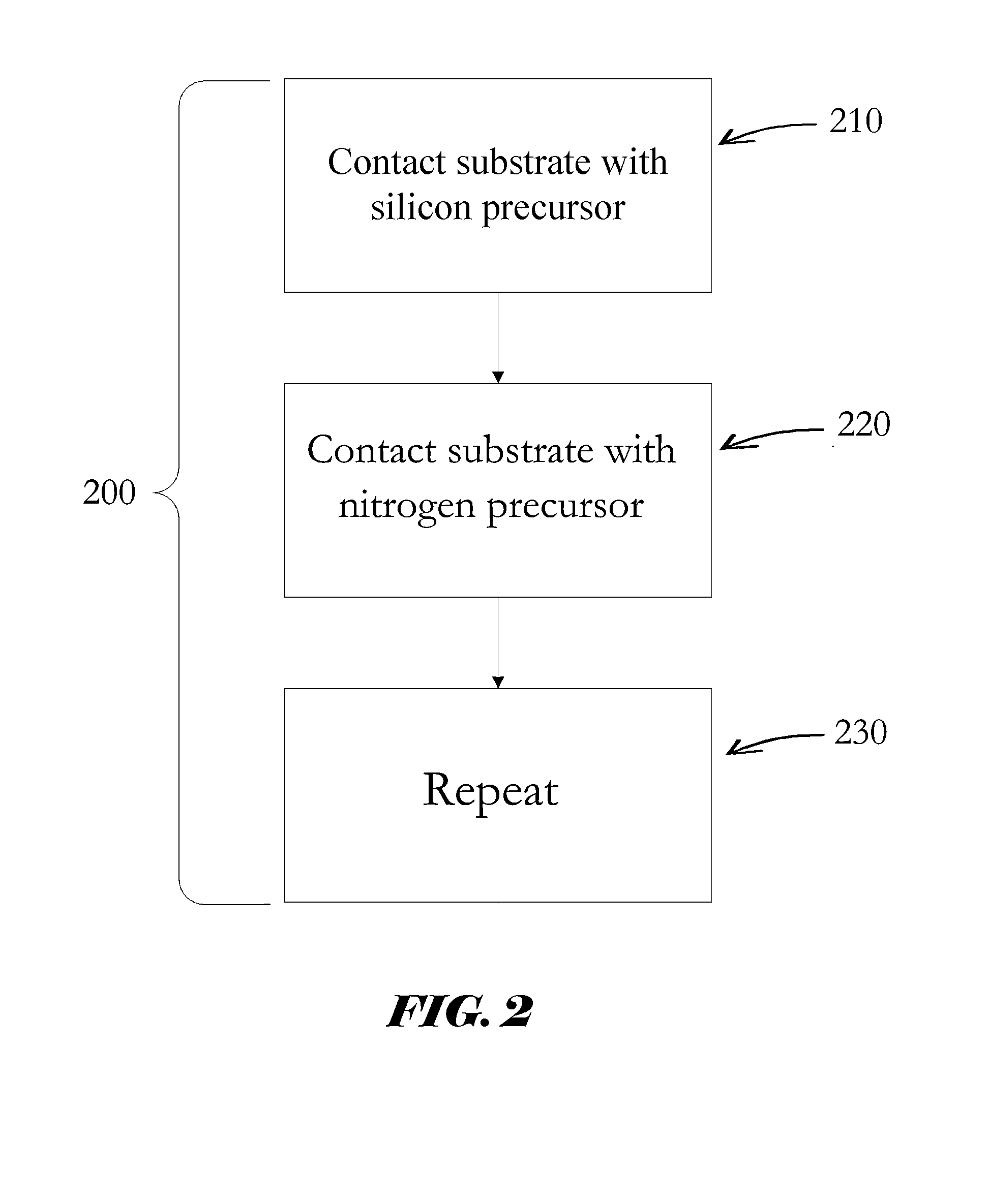

Silicon nitride films and methods

InactiveUS20110256734A1Reduce carbon contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsSemiconductor

Described are methods of making SiN materials on substrates, particularly SiN thin films on semiconductor substrates. Improved SiN films made by the methods are also included.

Owner:NOVELLUS SYSTEMS

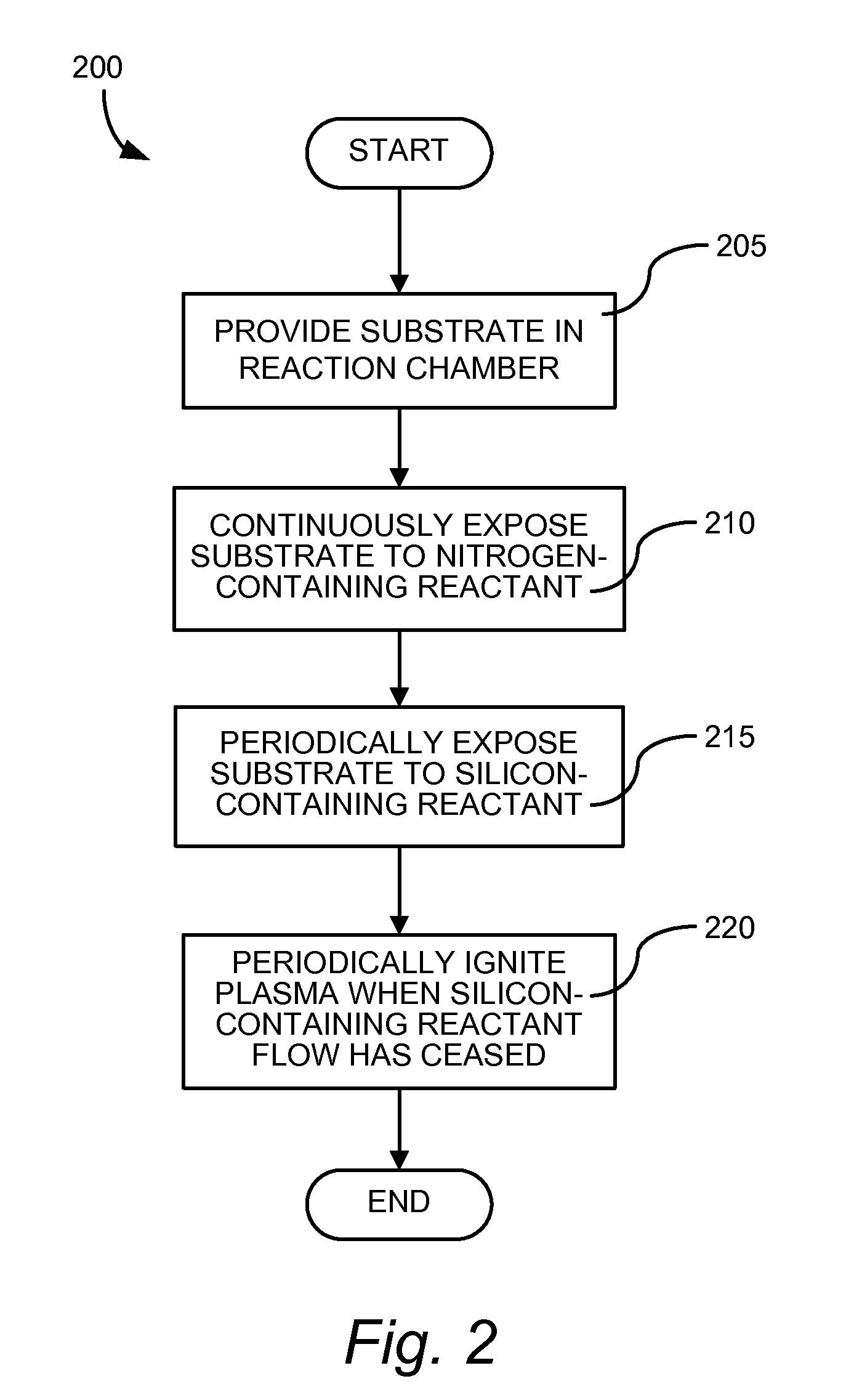

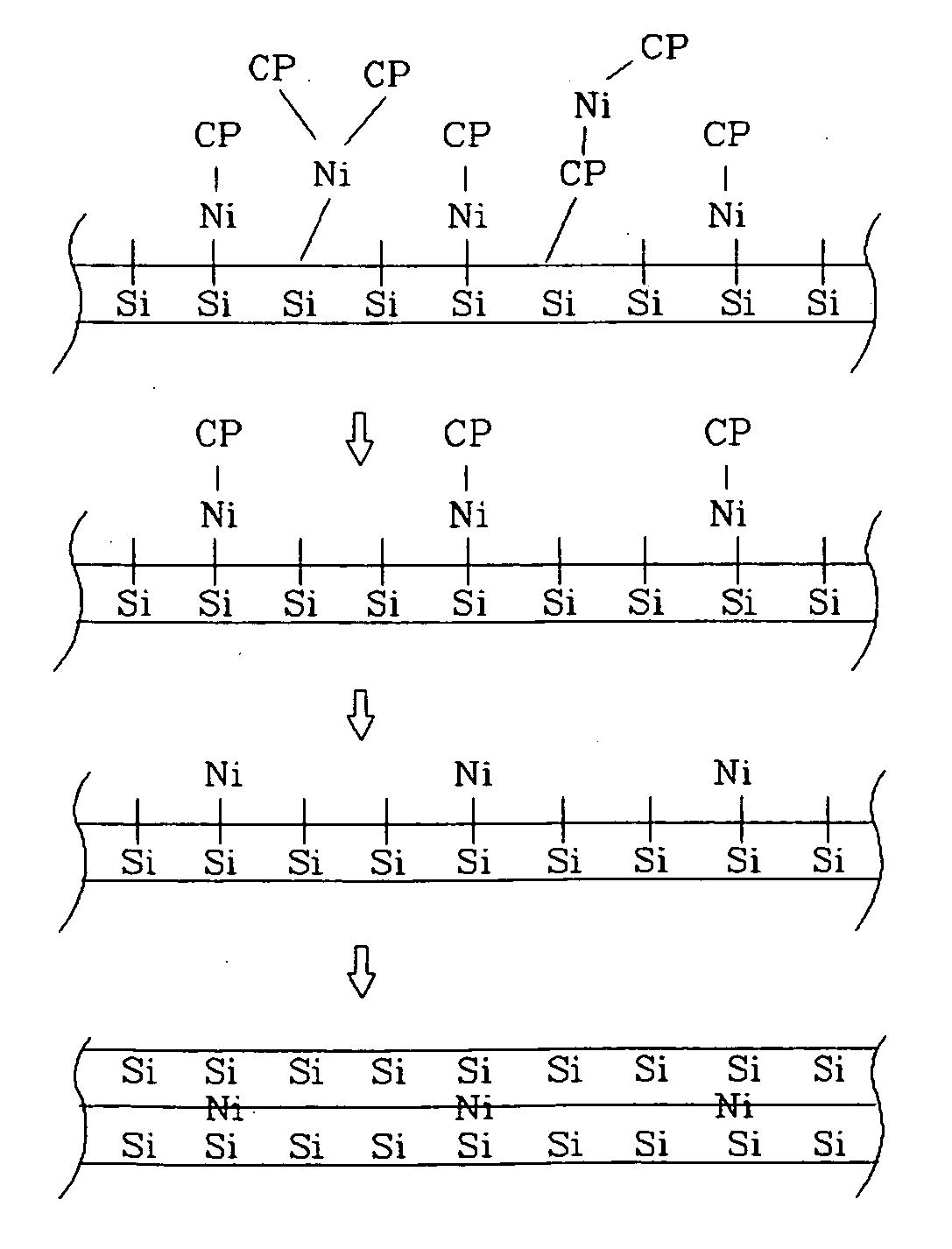

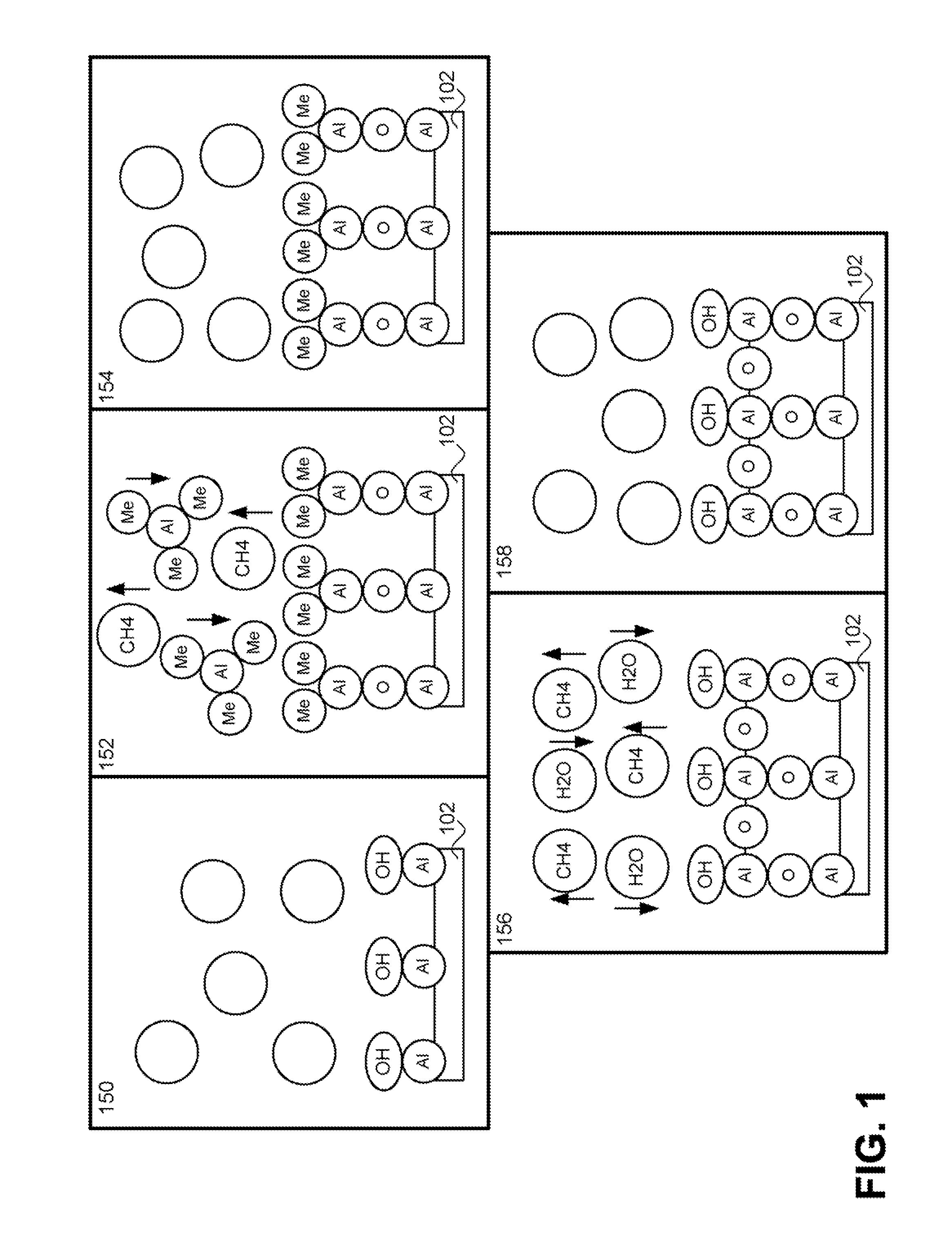

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

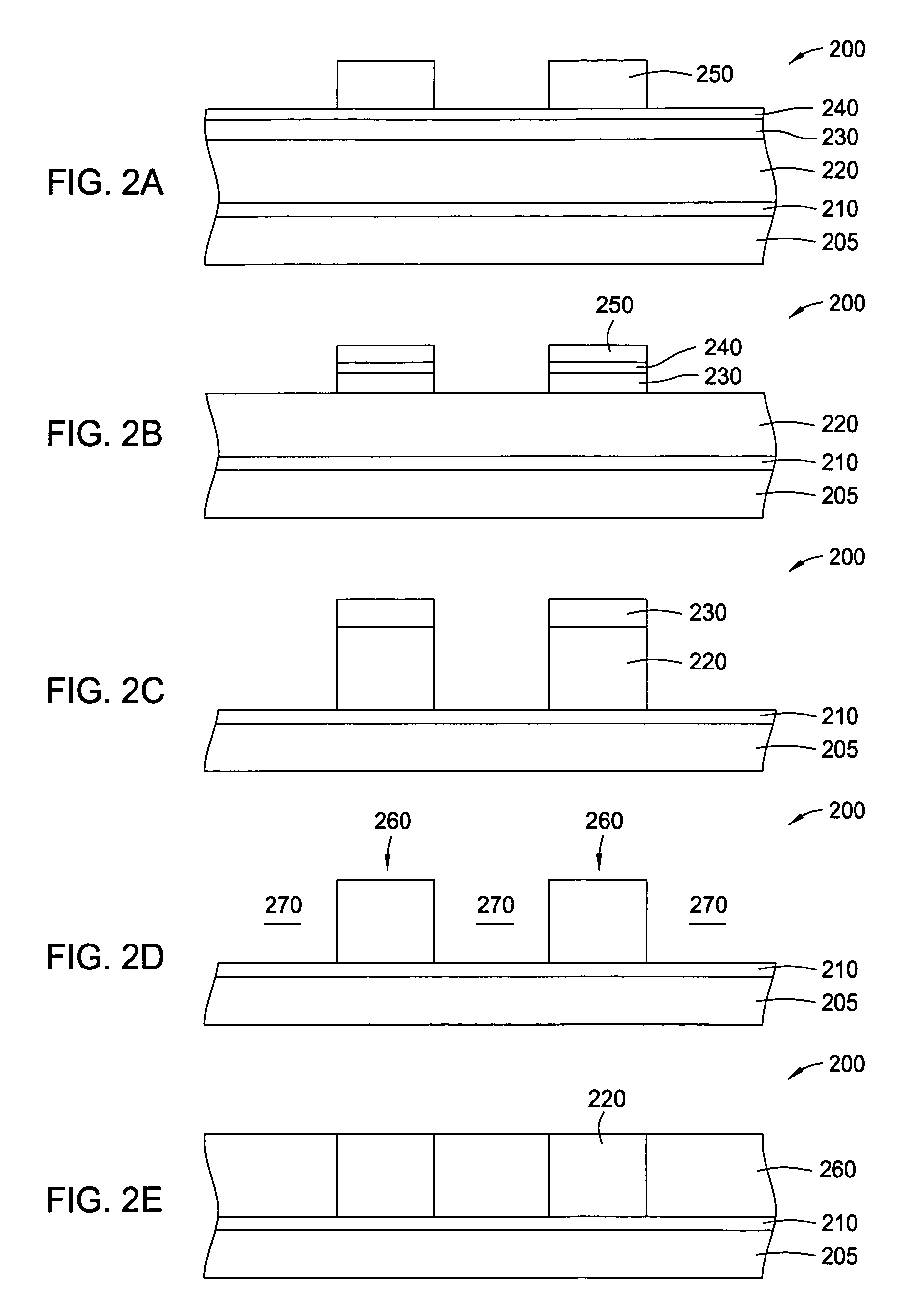

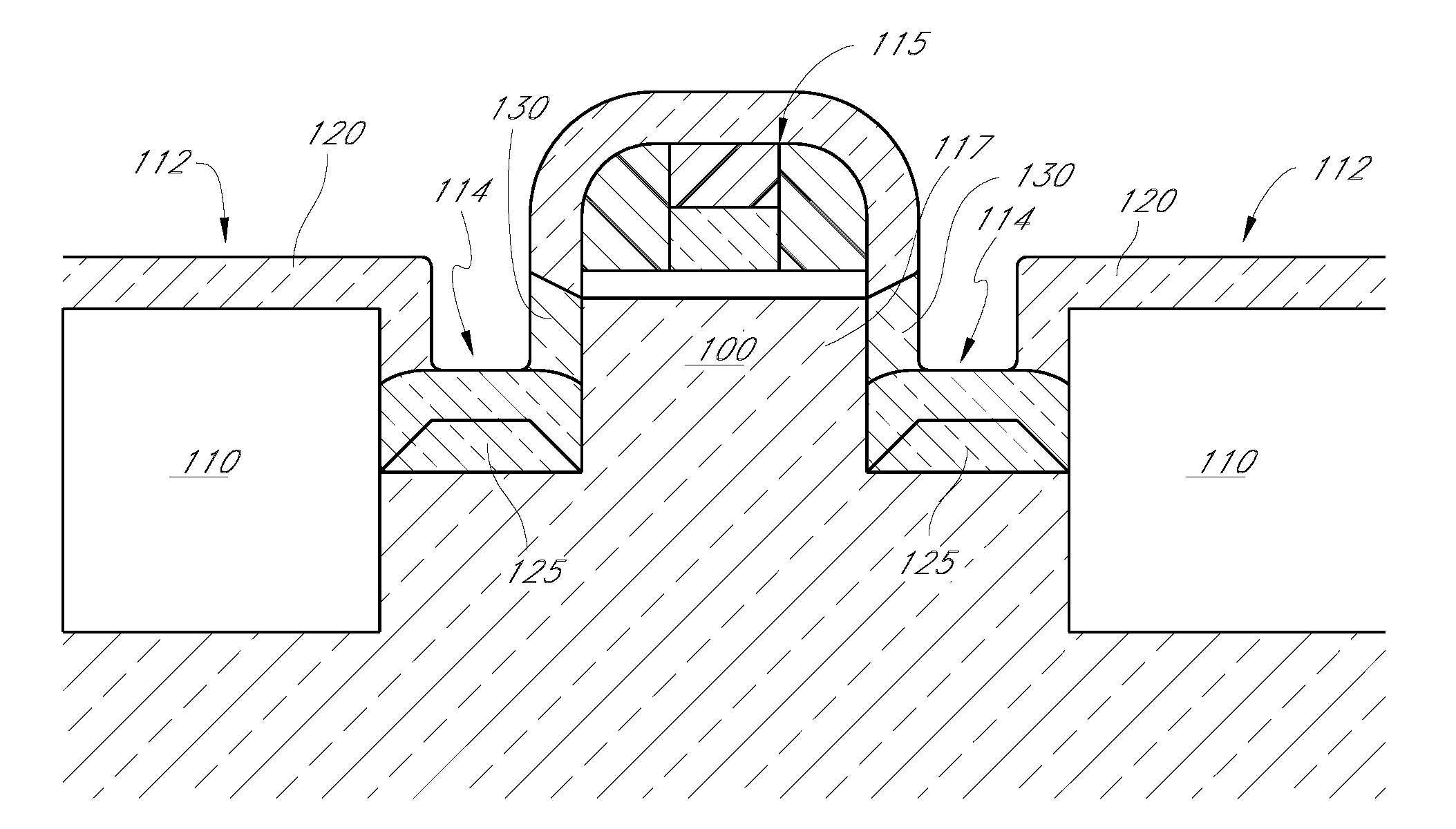

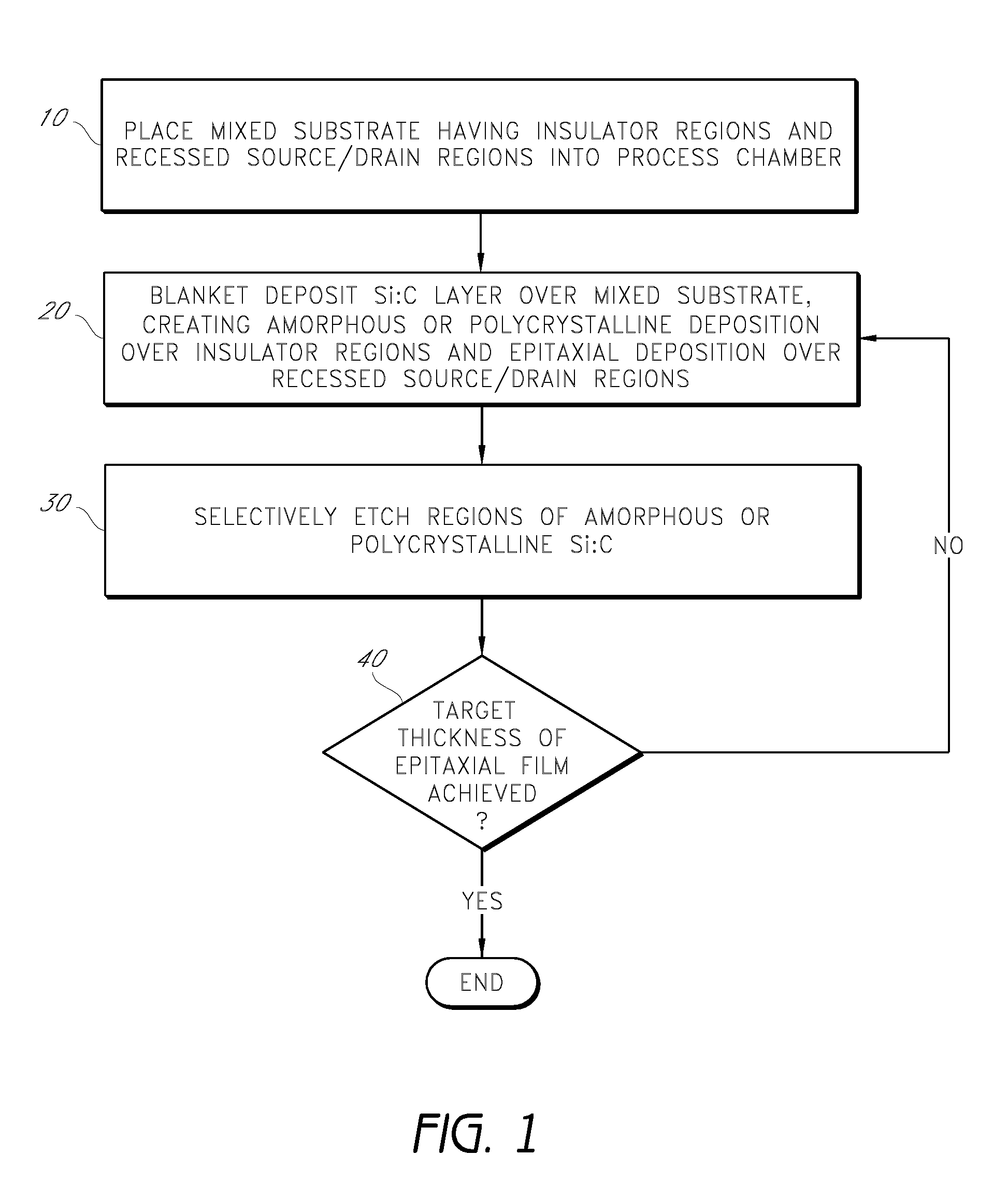

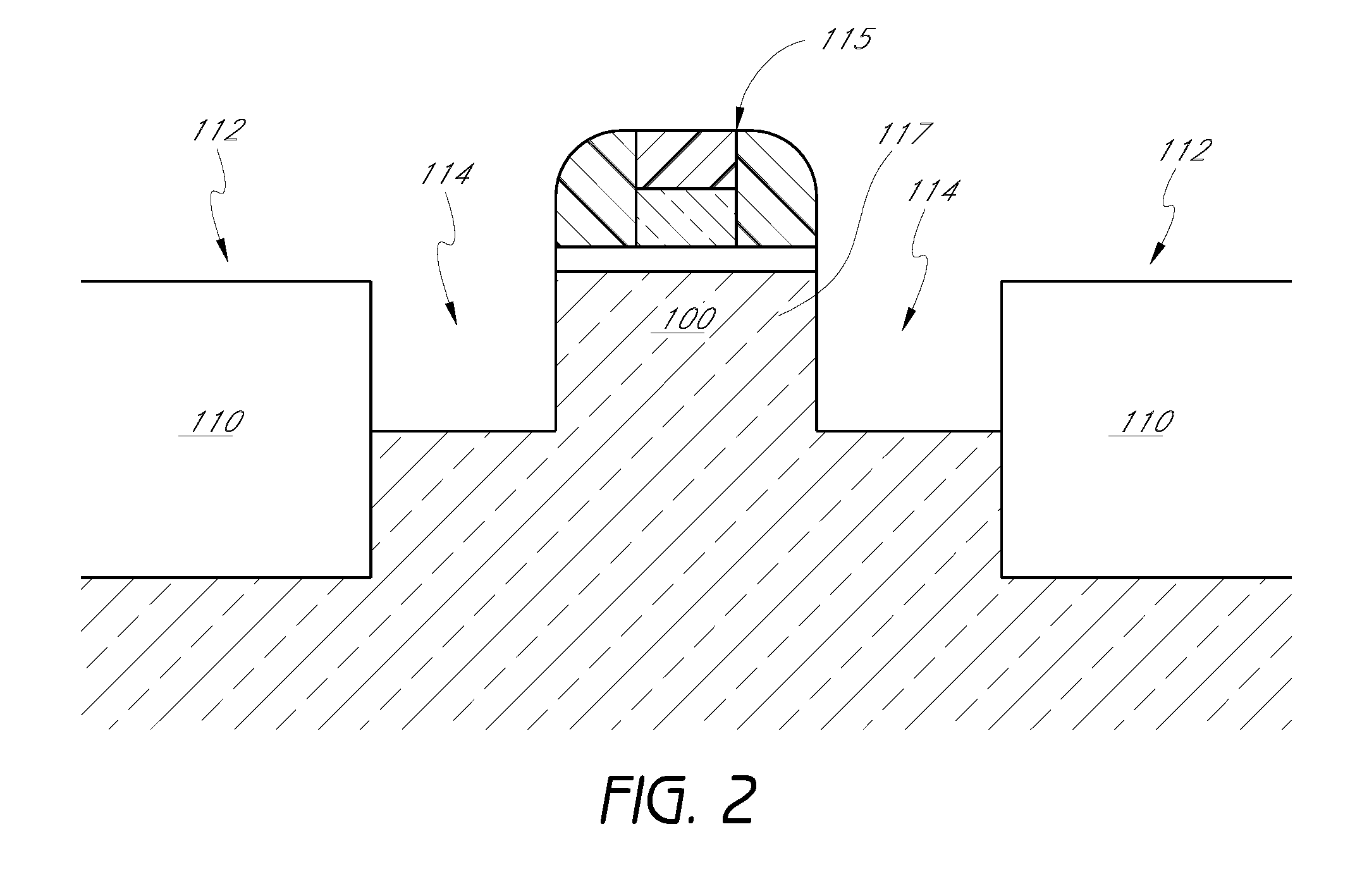

Selective epitaxial formation of semiconductor films

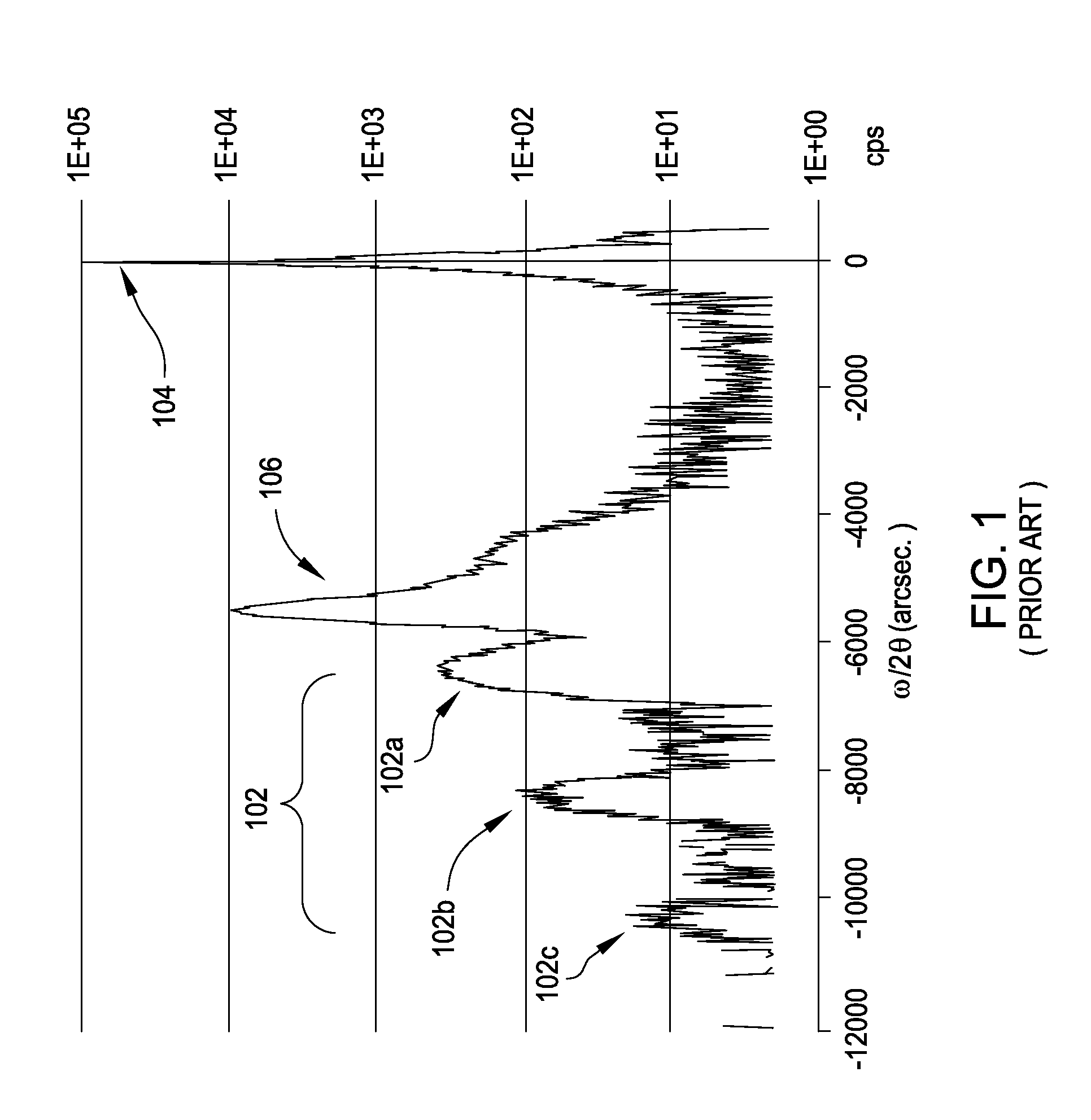

ActiveUS8278176B2Semiconductor/solid-state device manufacturingSemiconductor devicesCyclic processMetallurgy

Epitaxial layers are selectively formed in semiconductor windows by a cyclical process of repeated blanket deposition and selective etching. The blanket deposition phases leave non-epitaxial material over insulating regions, such as field oxide, and the selective etch phases preferentially remove non-epitaxial material while deposited epitaxial material builds up cycle-by-cycle. Quality of the epitaxial material improves relative to selective processes where no deposition occurs on insulators. Use of a germanium catalyst during the etch phases of the process aid etch rates and facilitate economical maintenance of isothermal and / or isobaric conditions throughout the cycles. Throughput and quality are improved by use of trisilane, formation of amorphous material over the insulating regions and minimizing the thickness ratio of amorphous:epitaxial material in each deposition phase.

Owner:ASM IP HLDG BV

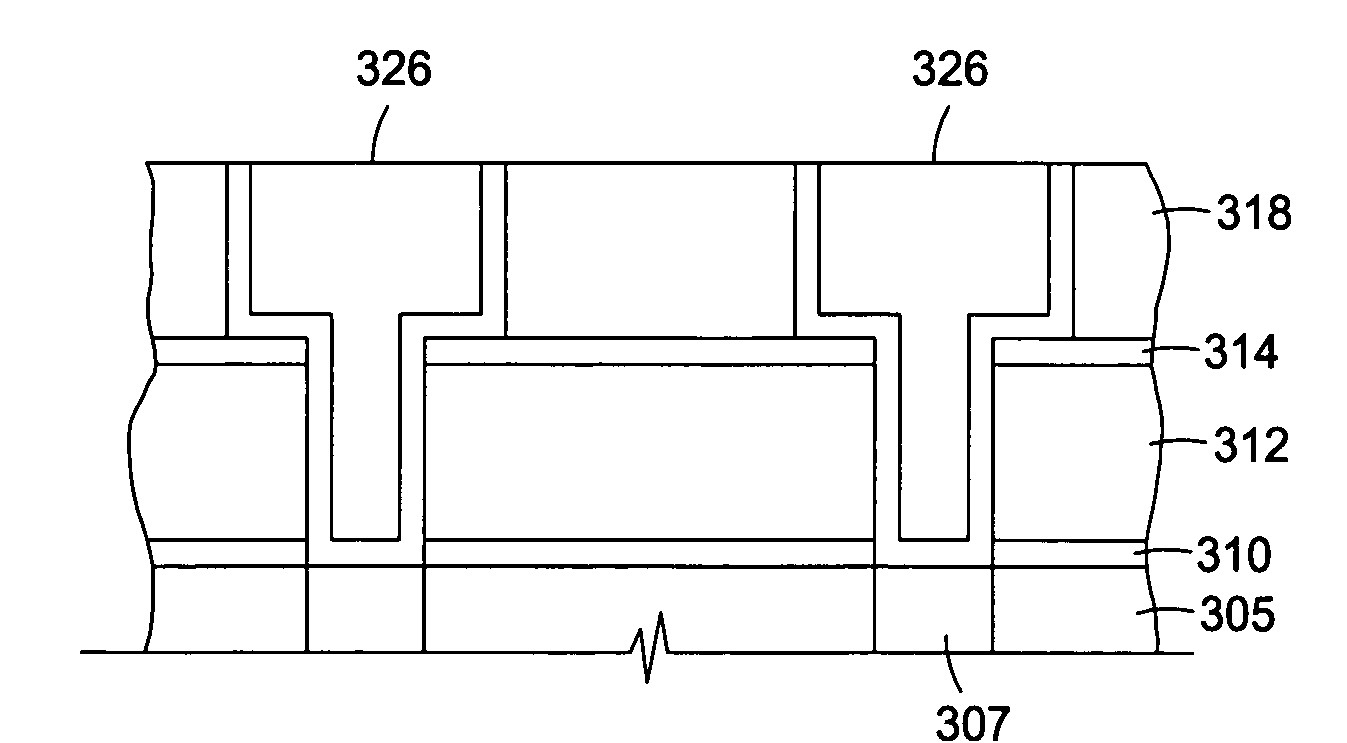

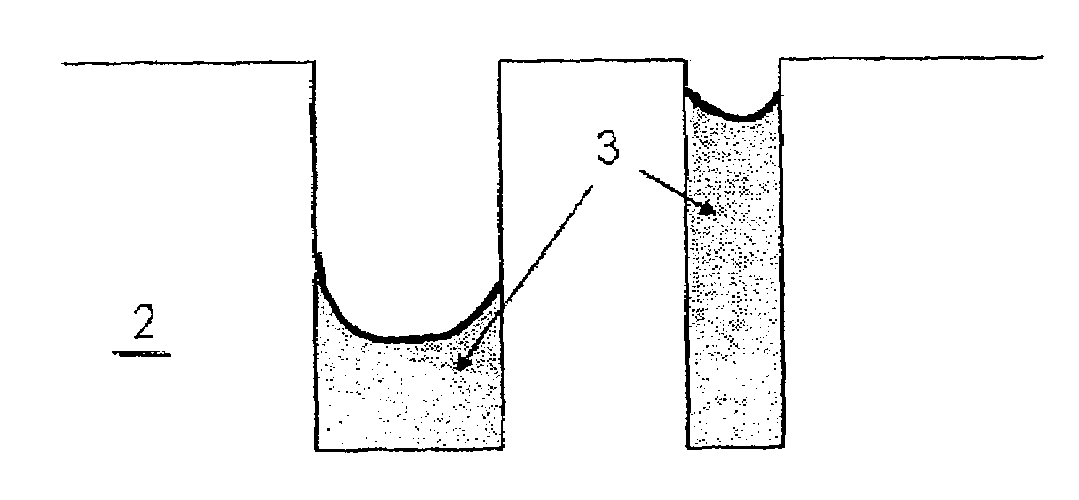

Device isolation technology on semiconductor substrate

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

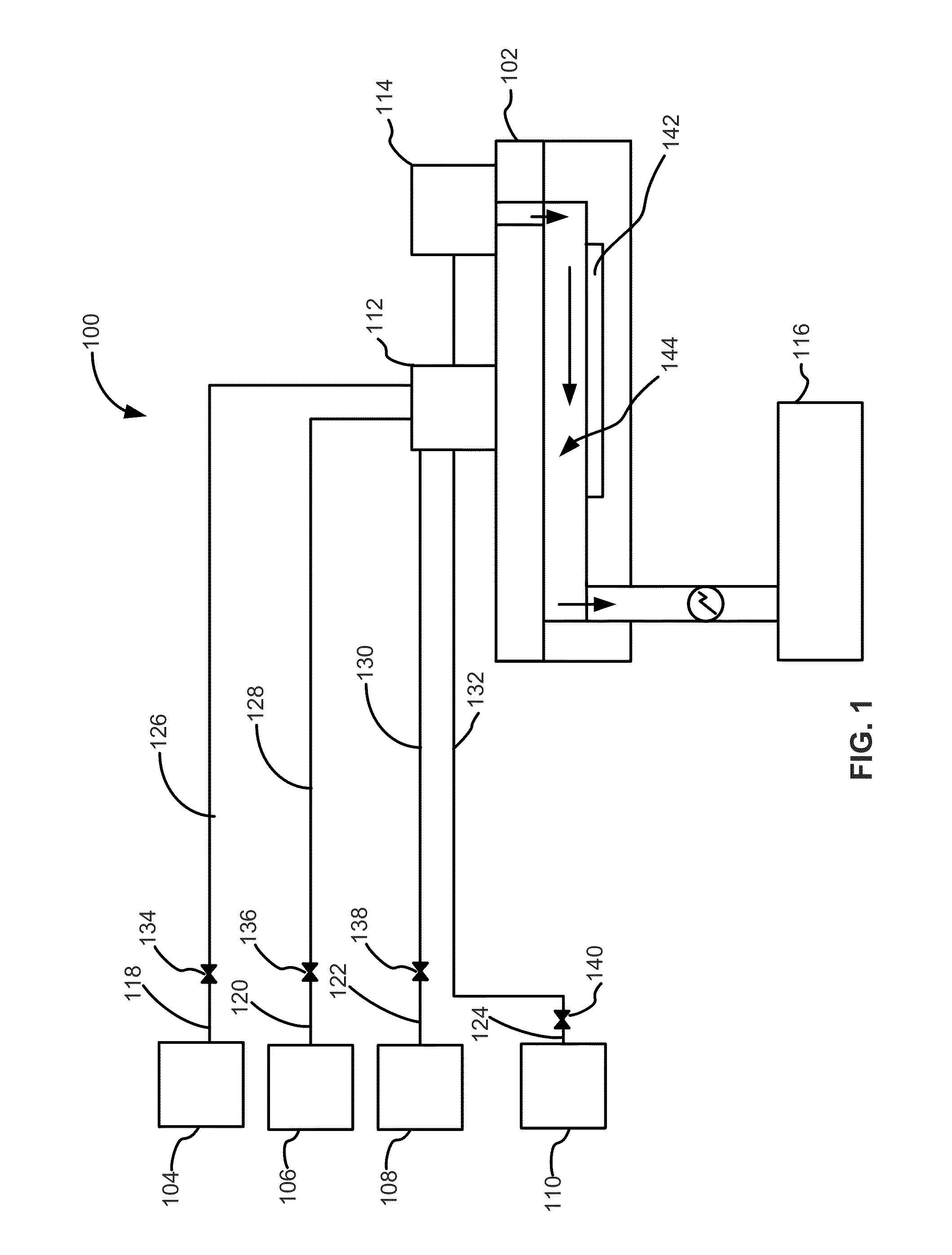

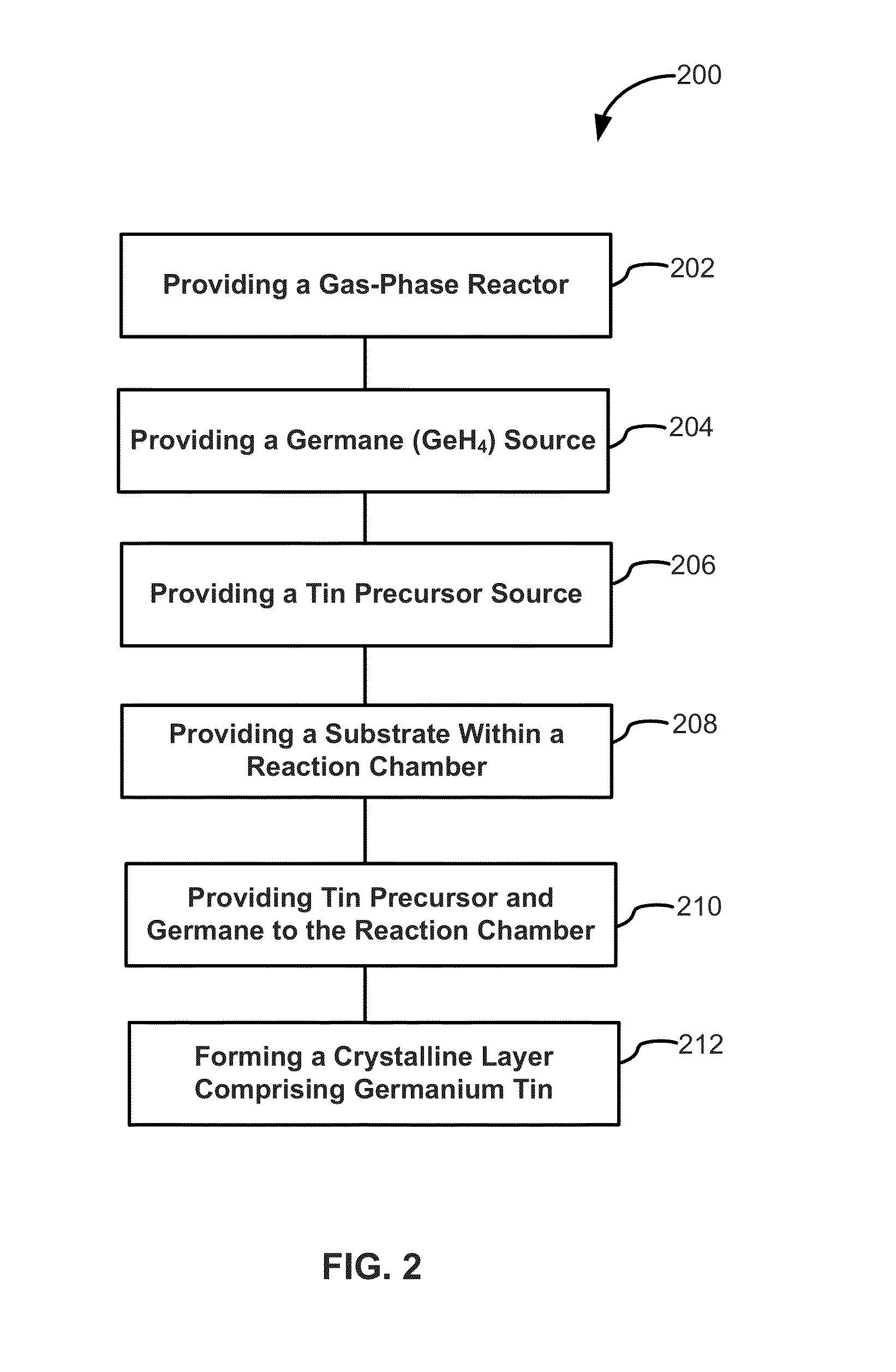

Methods of forming films including germanium tin and structures and devices including the films

ActiveUS20150048485A1Polycrystalline material growthSemiconductor/solid-state device manufacturingMaterials scienceChemical vapor deposition

Methods of forming germanium-tin films using germane as a precursor are disclosed. Exemplary methods include growing films including germanium and tin in an epitaxial chemical vapor deposition reactor, wherein a ratio of a tin precursor to germane is less than 0.1. Also disclosed are structures and devices including germanium-tin films formed using the methods described herein.

Owner:ASM IP HLDG BV

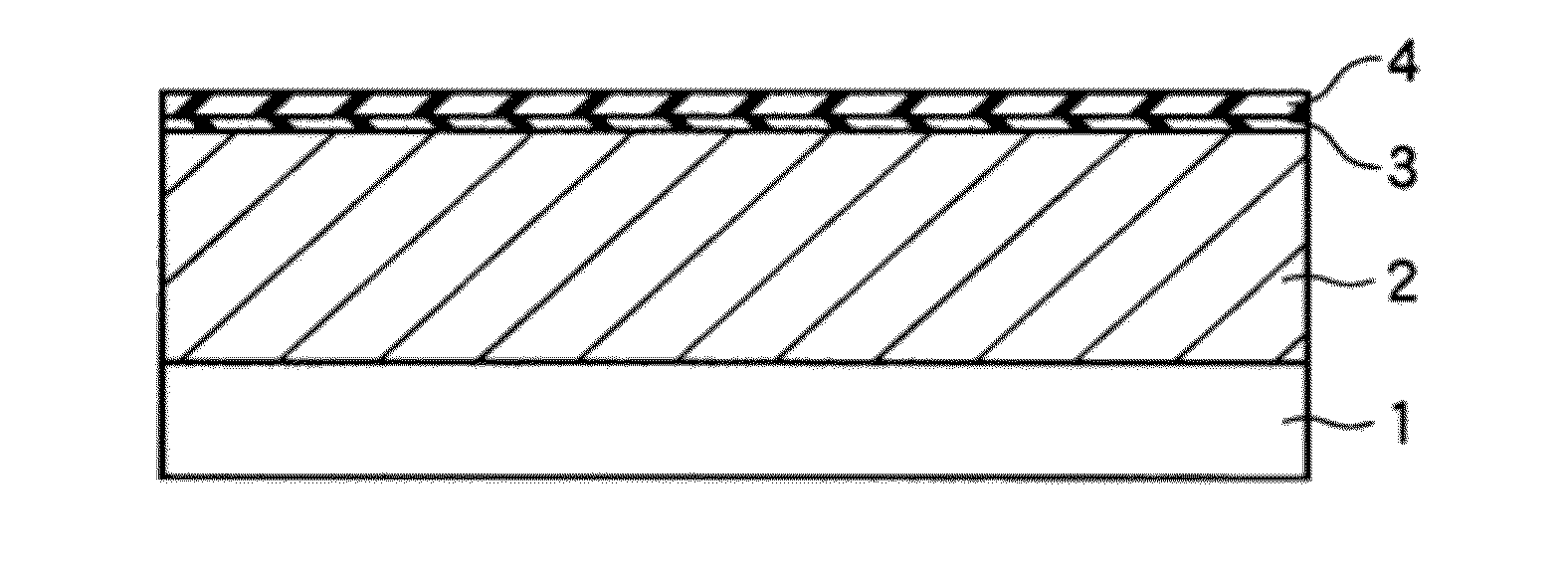

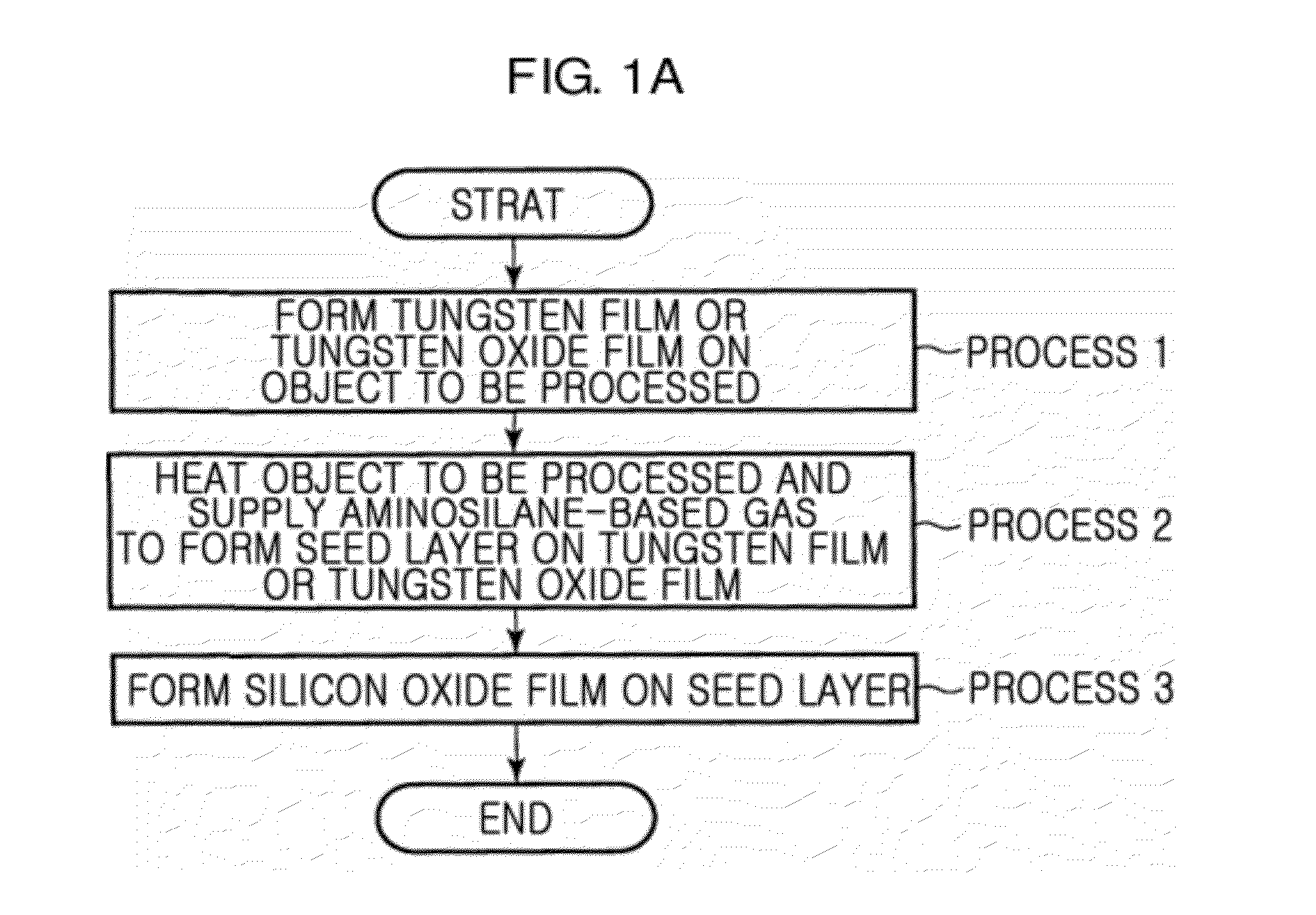

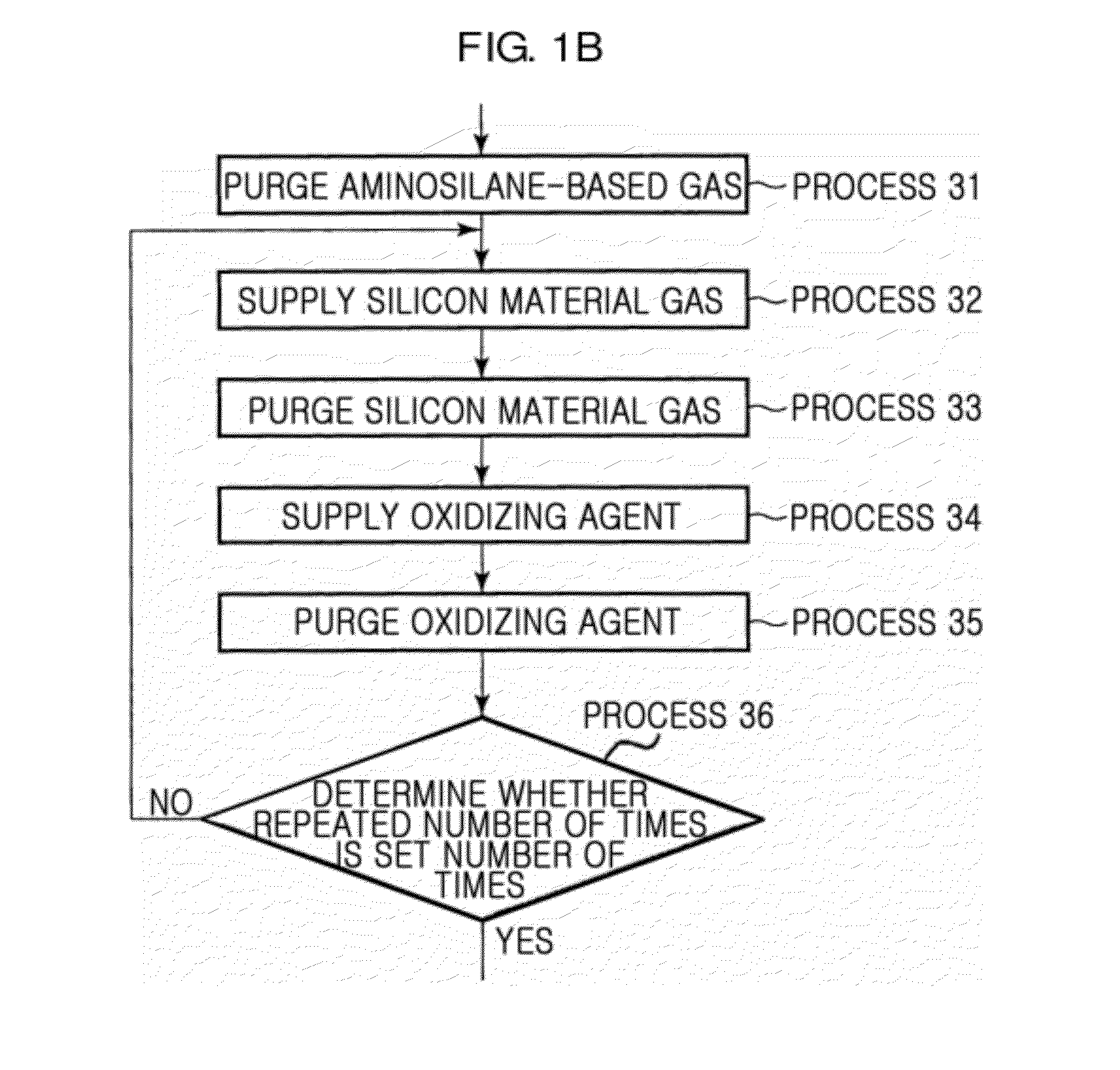

Film-forming method and film-forming apparatus for forming silicon oxide film on tungsten film or tungsten oxide film

InactiveUS20120164327A1Reduce incubation timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingTungsten filmSilicon oxide

A film-forming method includes forming a tungsten film or a tungsten oxide film on an object to be processed, forming a seed layer on the tungsten film or the tungsten oxide film, and forming a silicon oxide film on the seed layer, wherein the seed layer formed on the tungsten film or the tungsten oxide film is formed by heating the object to be processed and supplying an aminosilane-based gas to a surface of the tungsten film or the tungsten oxide film.

Owner:TOKYO ELECTRON LTD

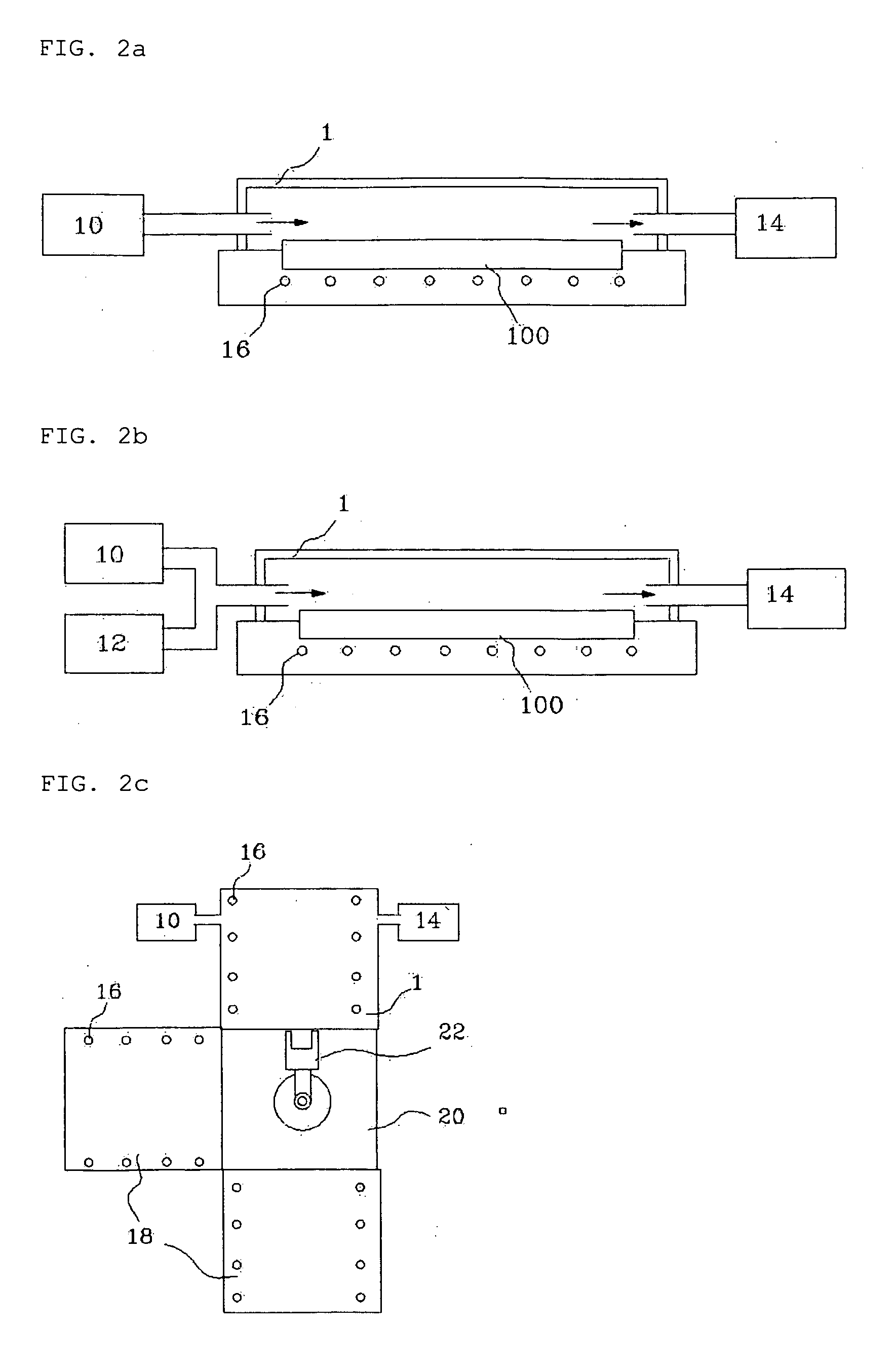

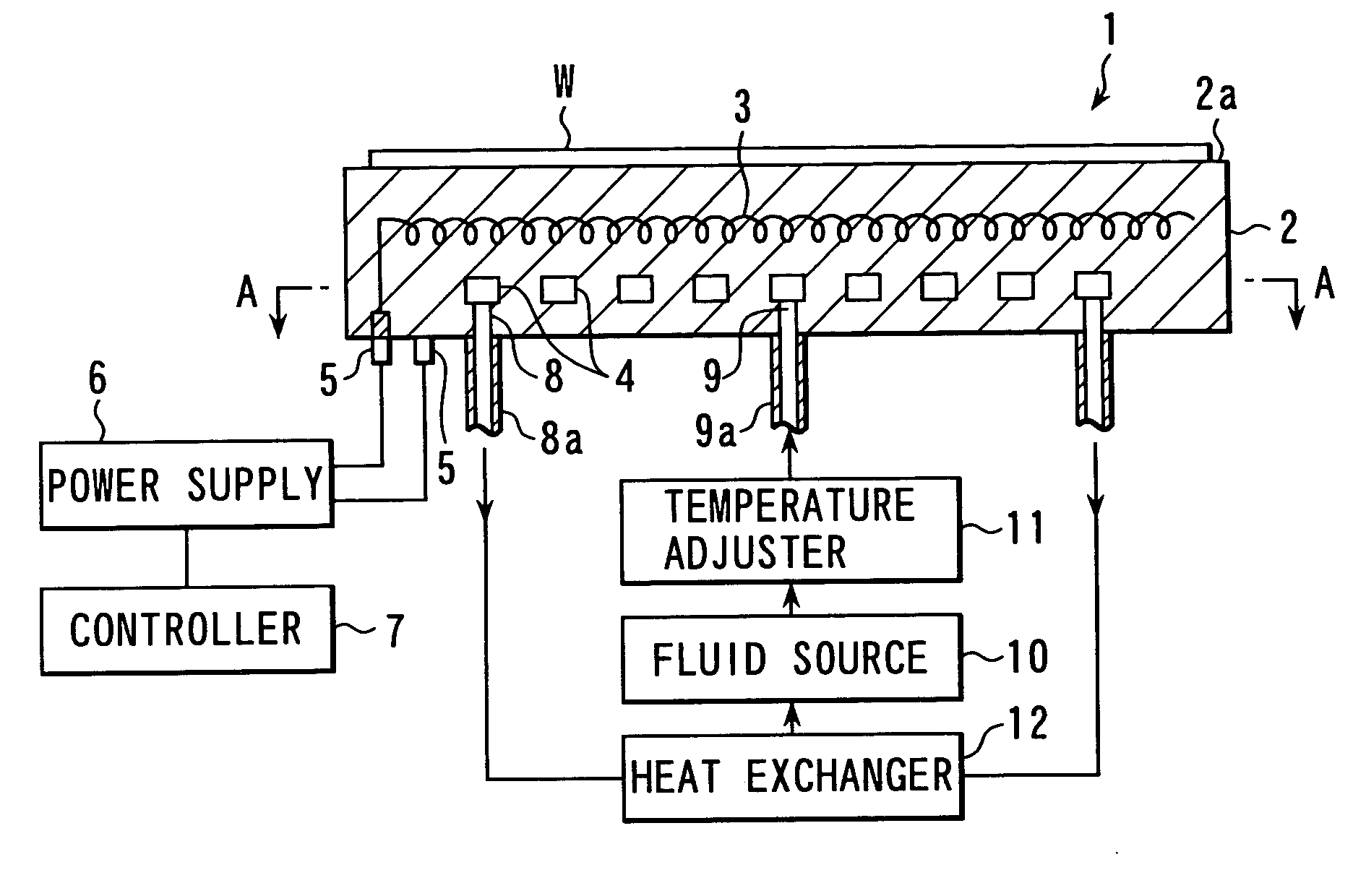

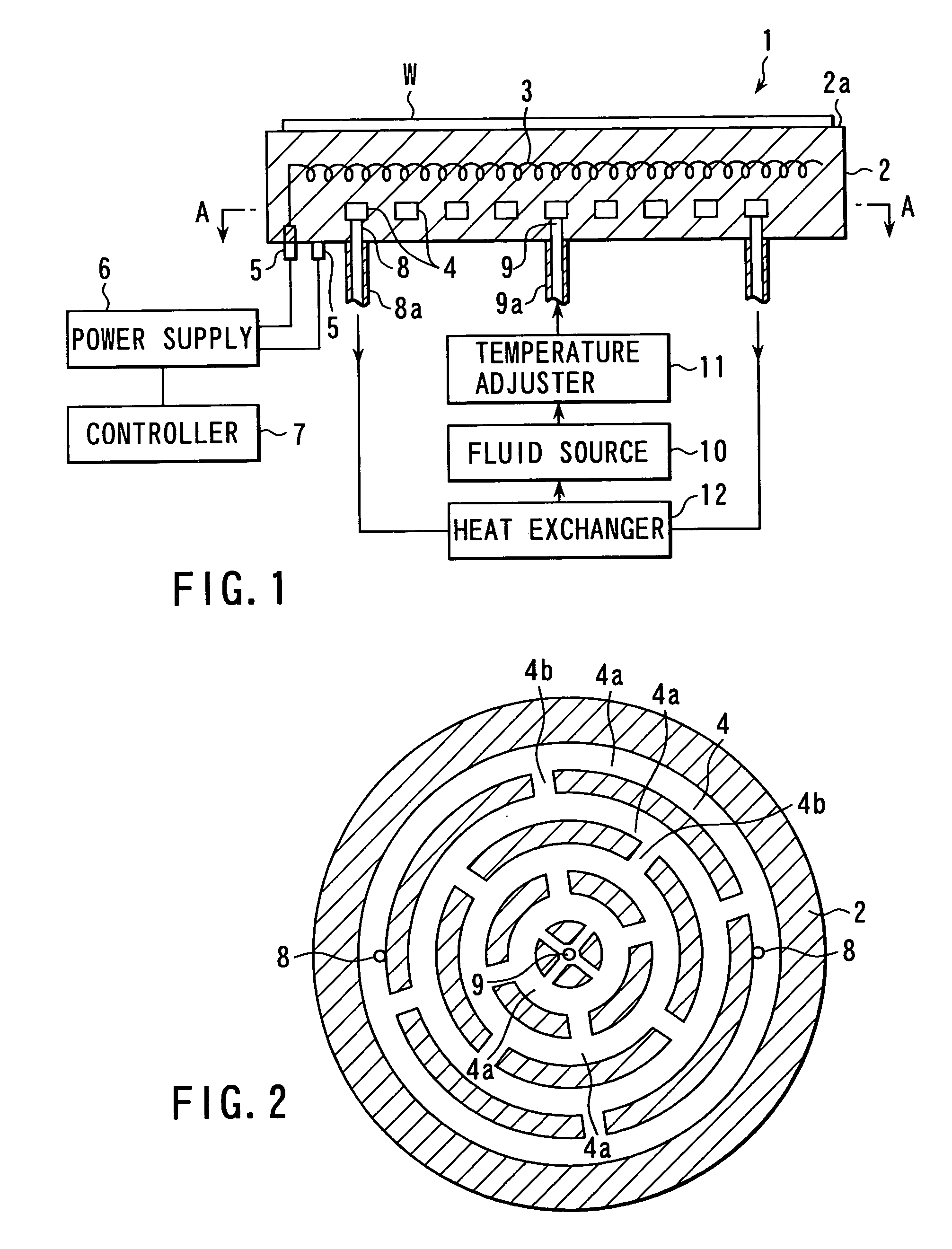

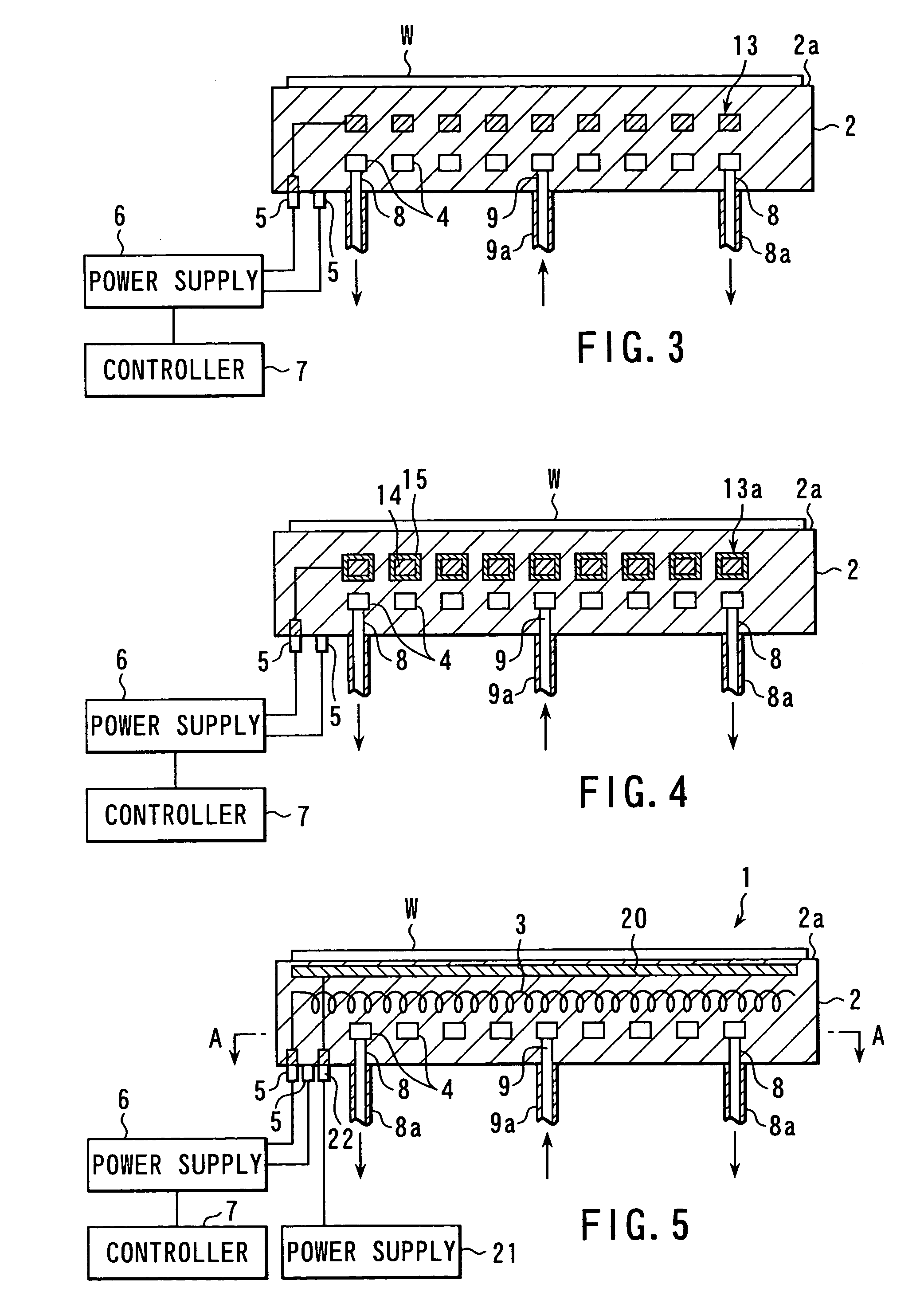

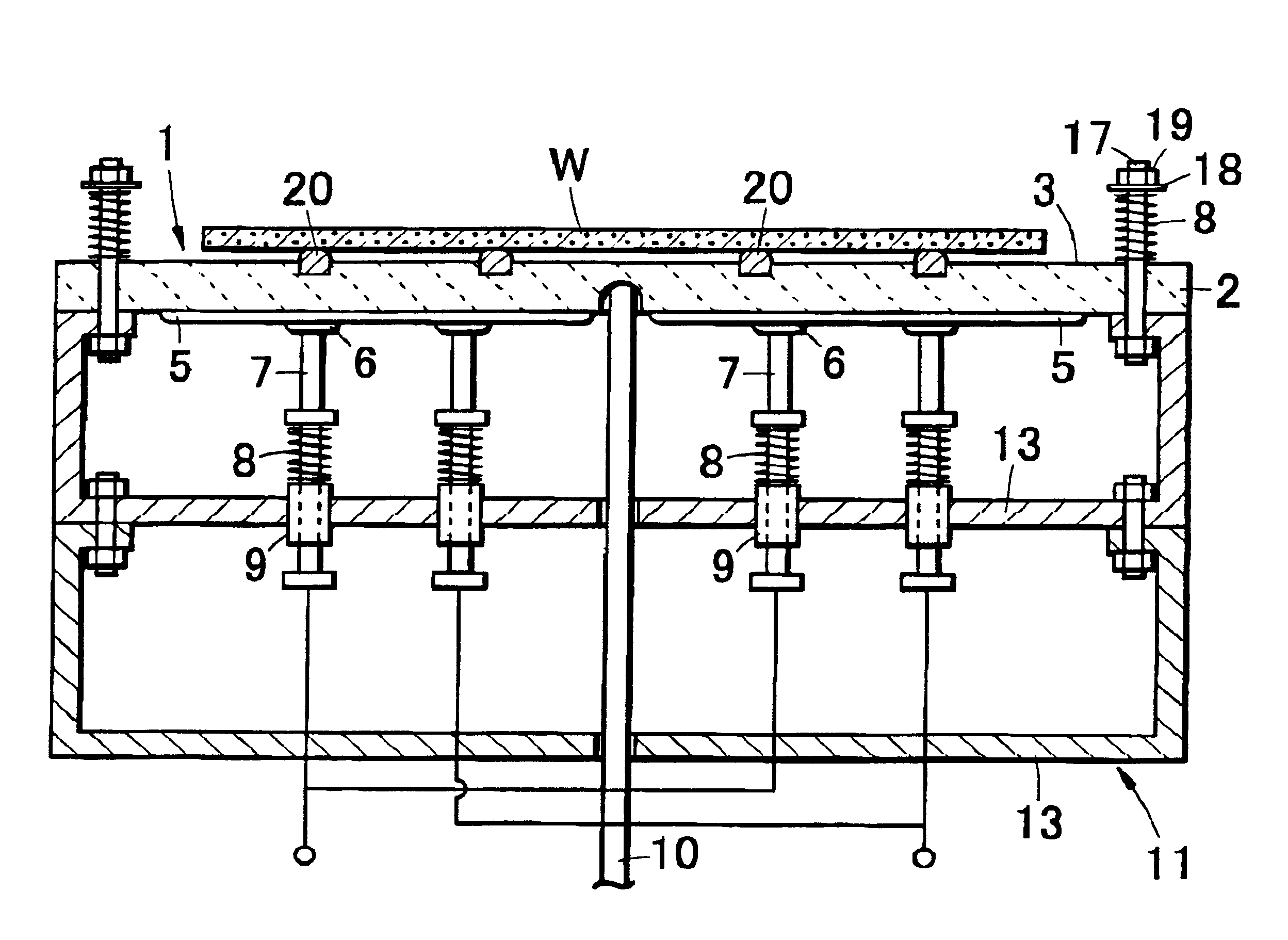

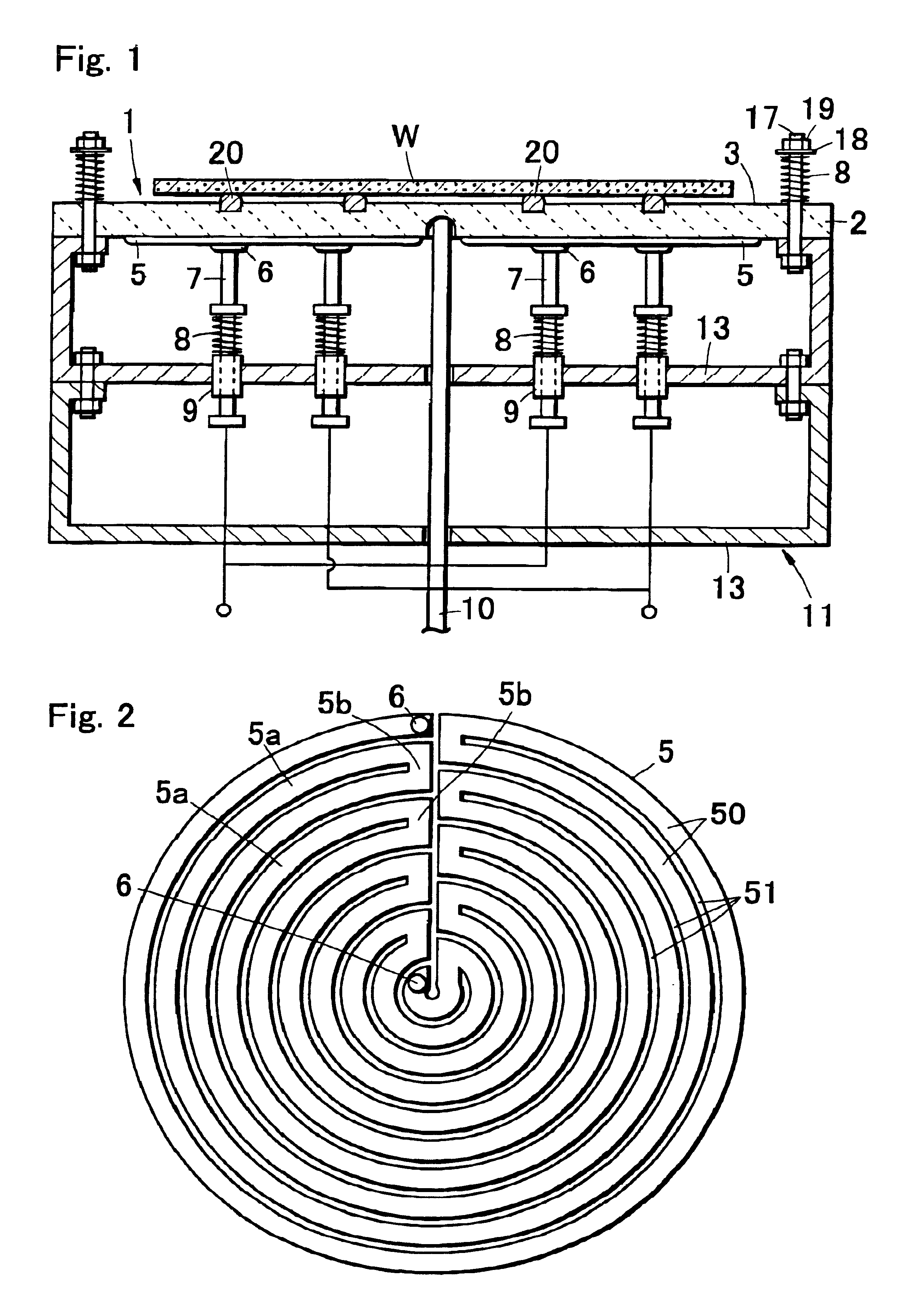

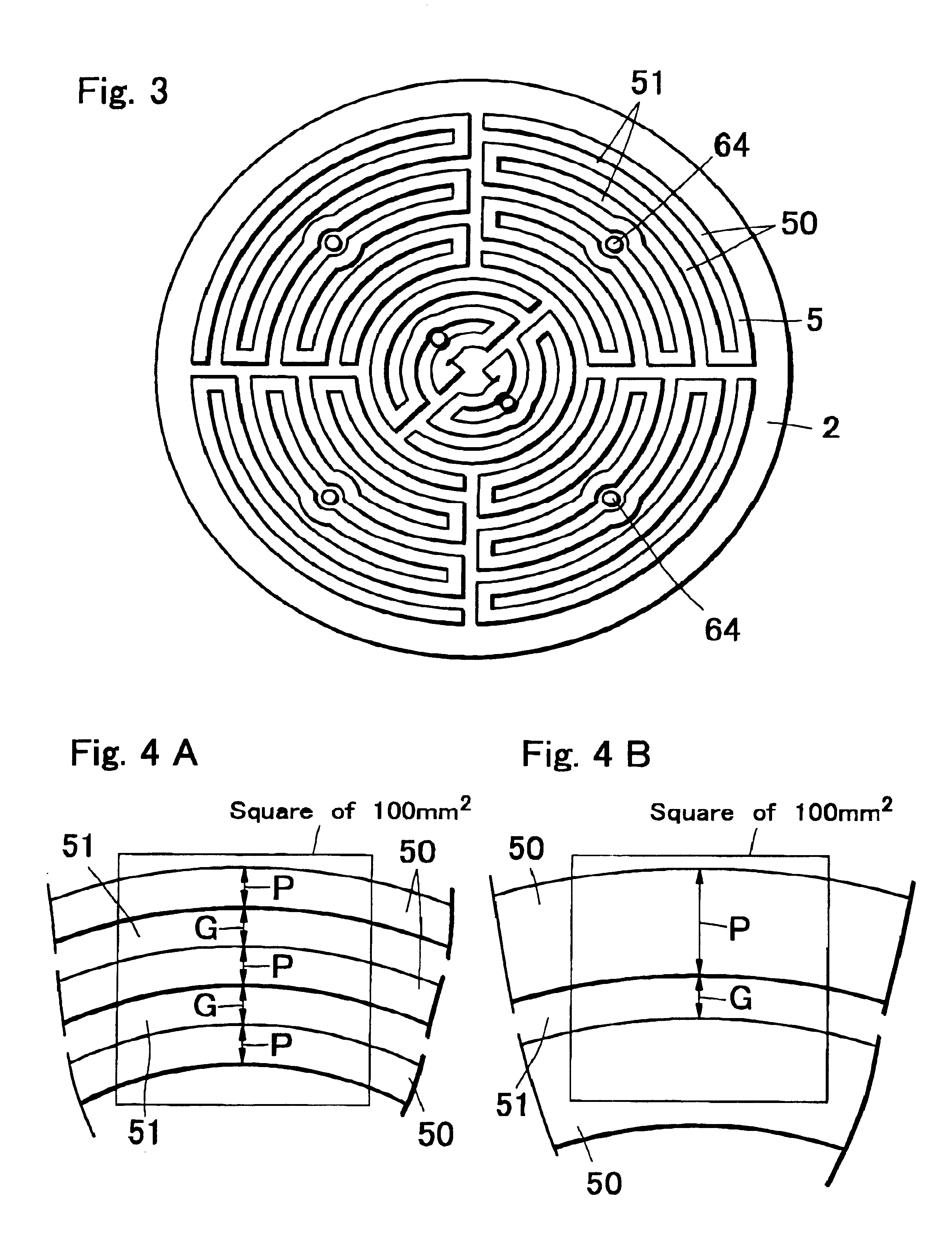

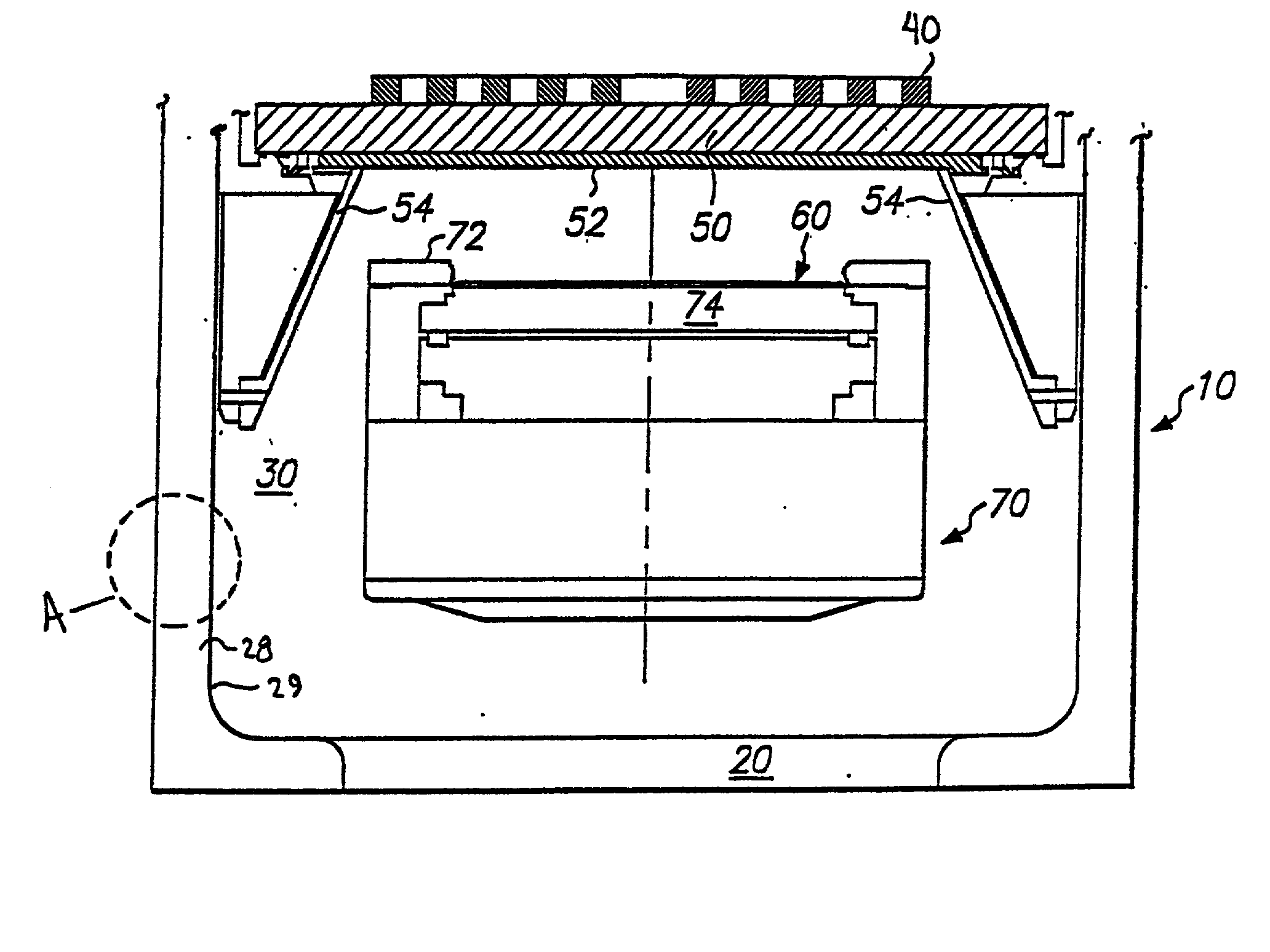

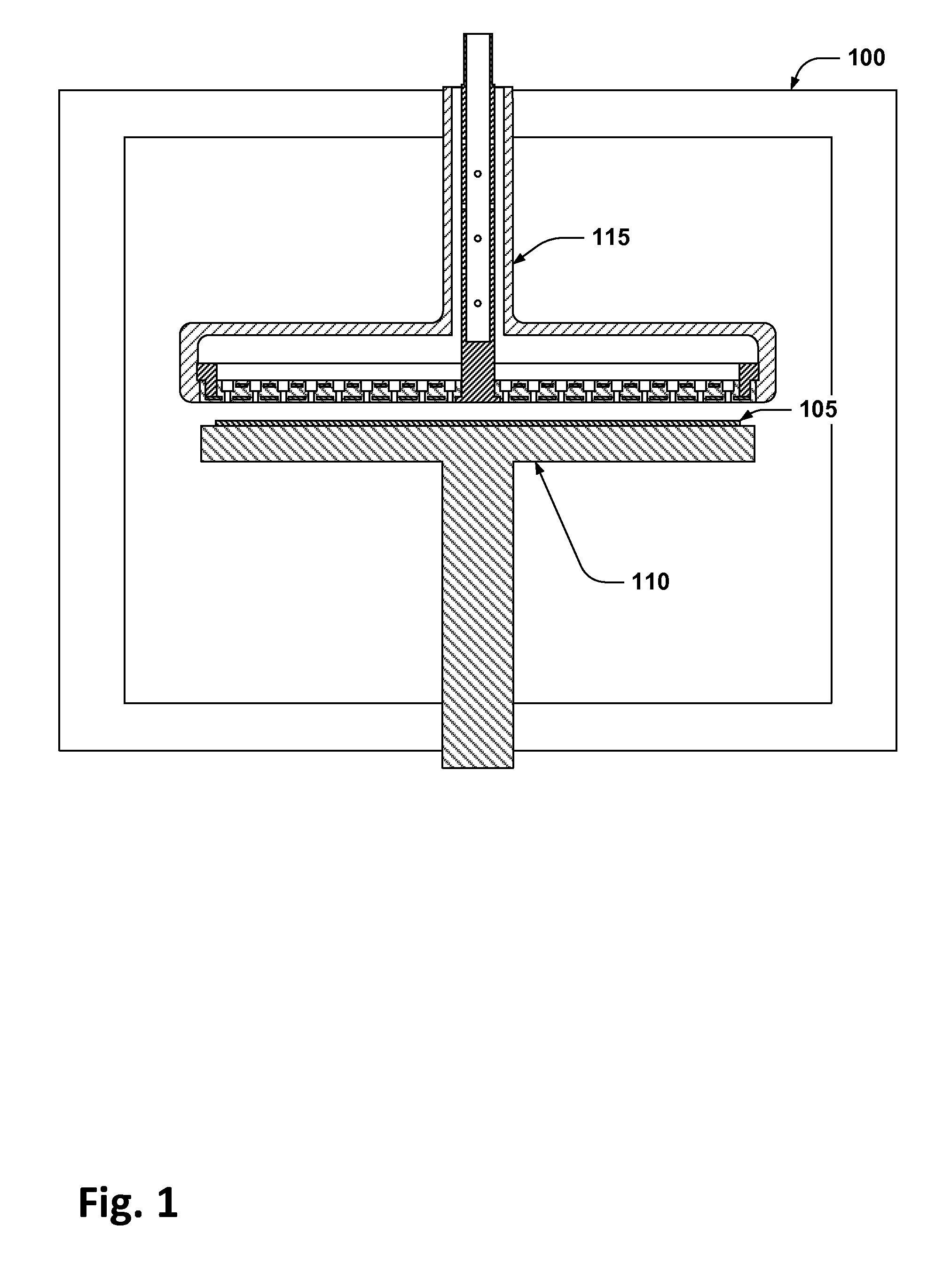

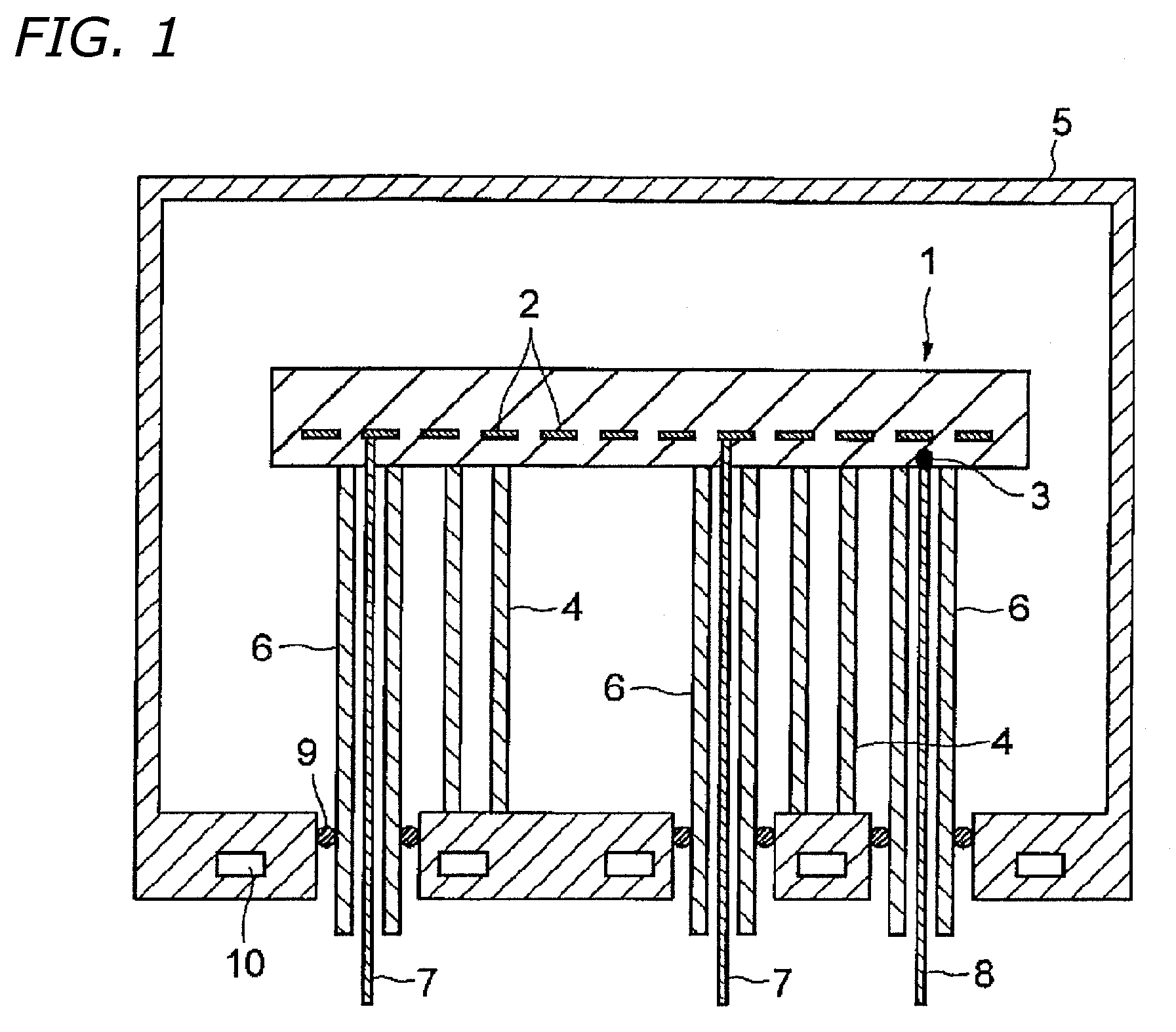

Ceramic heater system and substrate processing apparatus having the same installed therein

InactiveUS6951587B1Improve cooling efficiencyUniform heating effectSemiconductor/solid-state device manufacturingOhmic-resistance heatingMetallurgyGas supply

A ceramic heater system has a ceramic heater base having a substrate-mounting surface formed on the top surface thereof and a heater, buried in the heater base, for heating a substrate. A fluid passage is formed buried in the heater base below where the heater is buried. The heater base is cooled as a fluid whose temperature is lower than the temperature of the heater base is let flow in the fluid passage. A substrate processing apparatus has the ceramic heater system installed in a process chamber whose vacuum state can be maintained, a gas supply mechanism for feeding a gas into the process chamber, and a power supply. The substrate processing apparatus performs a heat treatment, etching and film deposition on a substrate placed in the process chamber.

Owner:TOKYO ELECTRON LTD

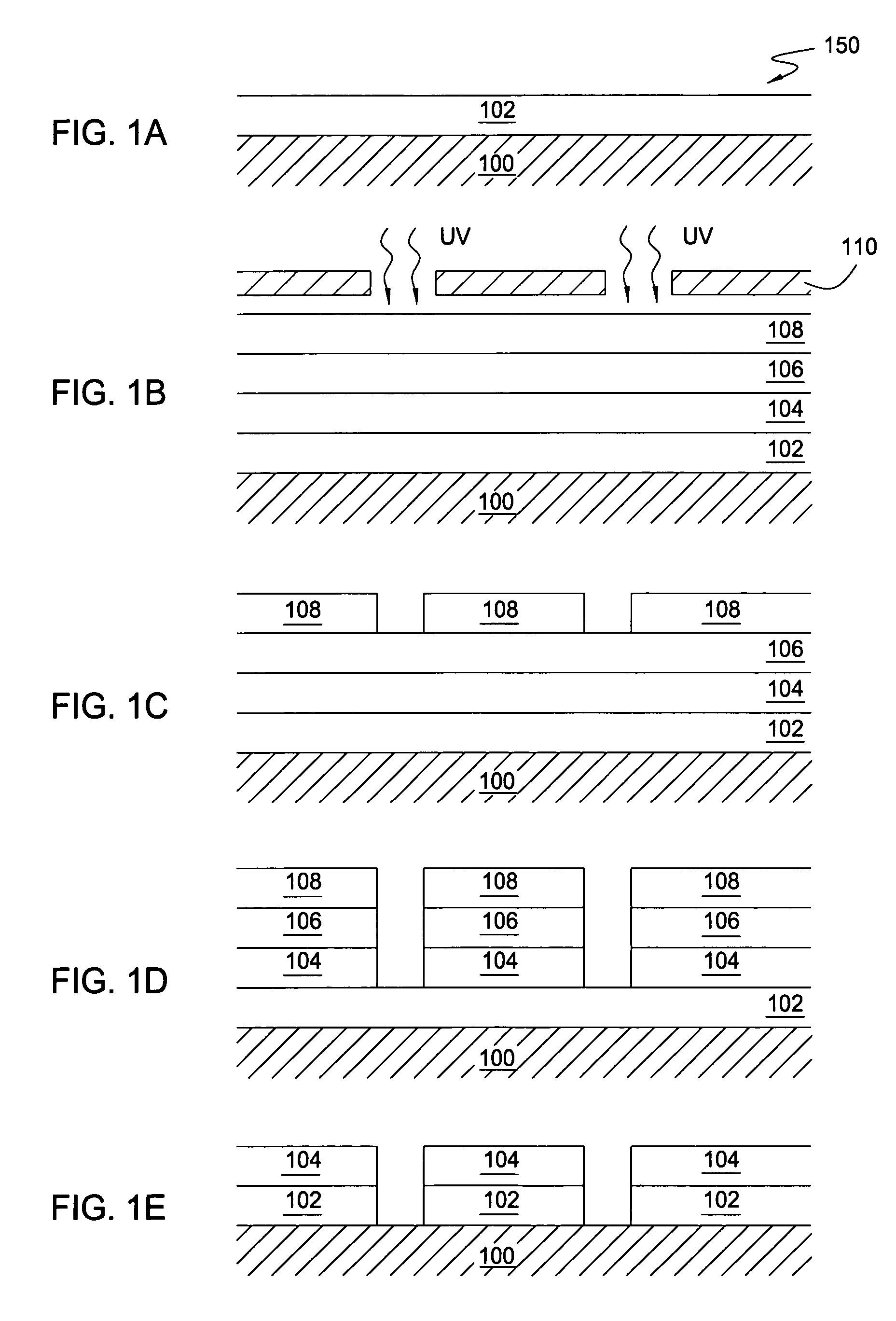

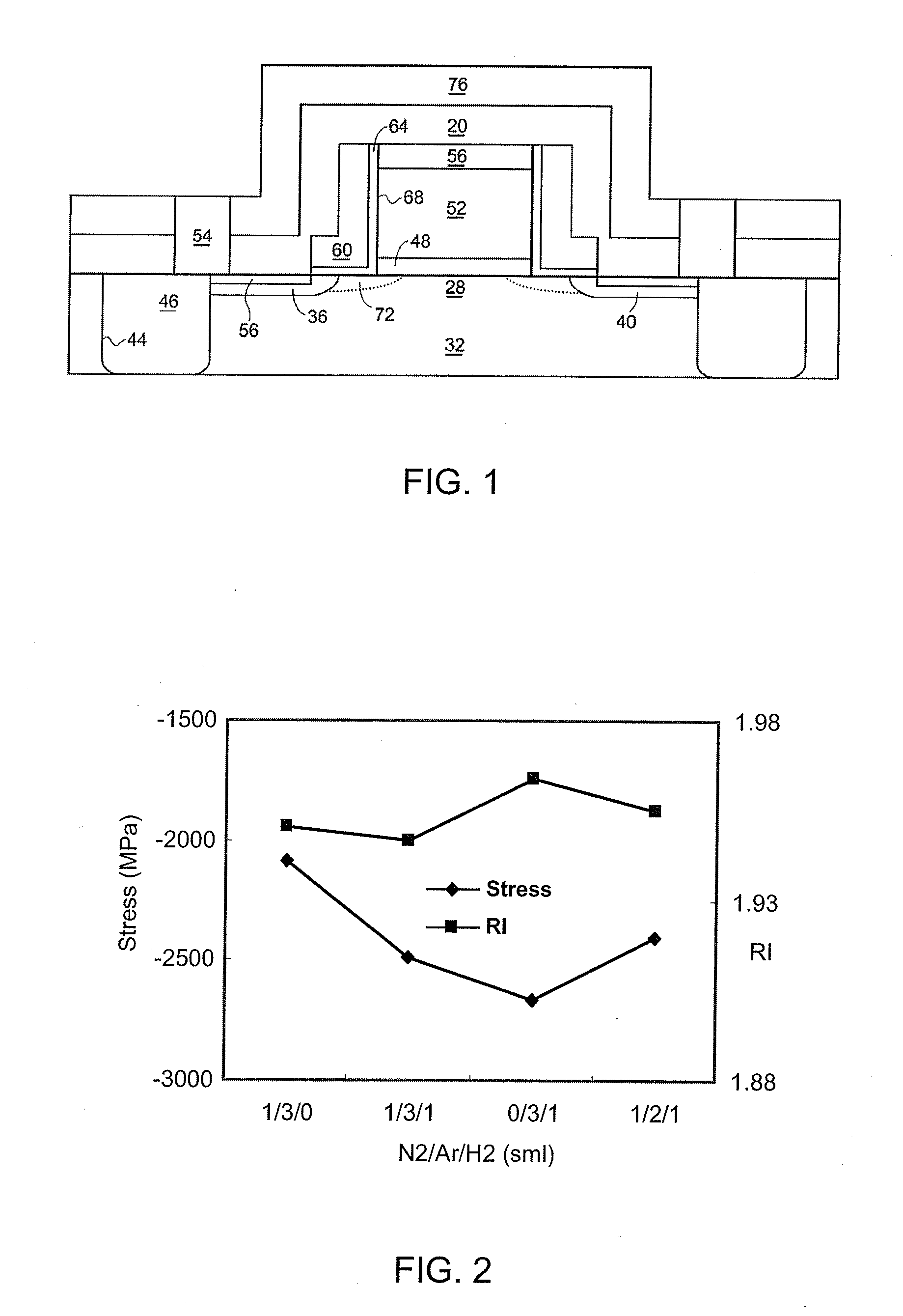

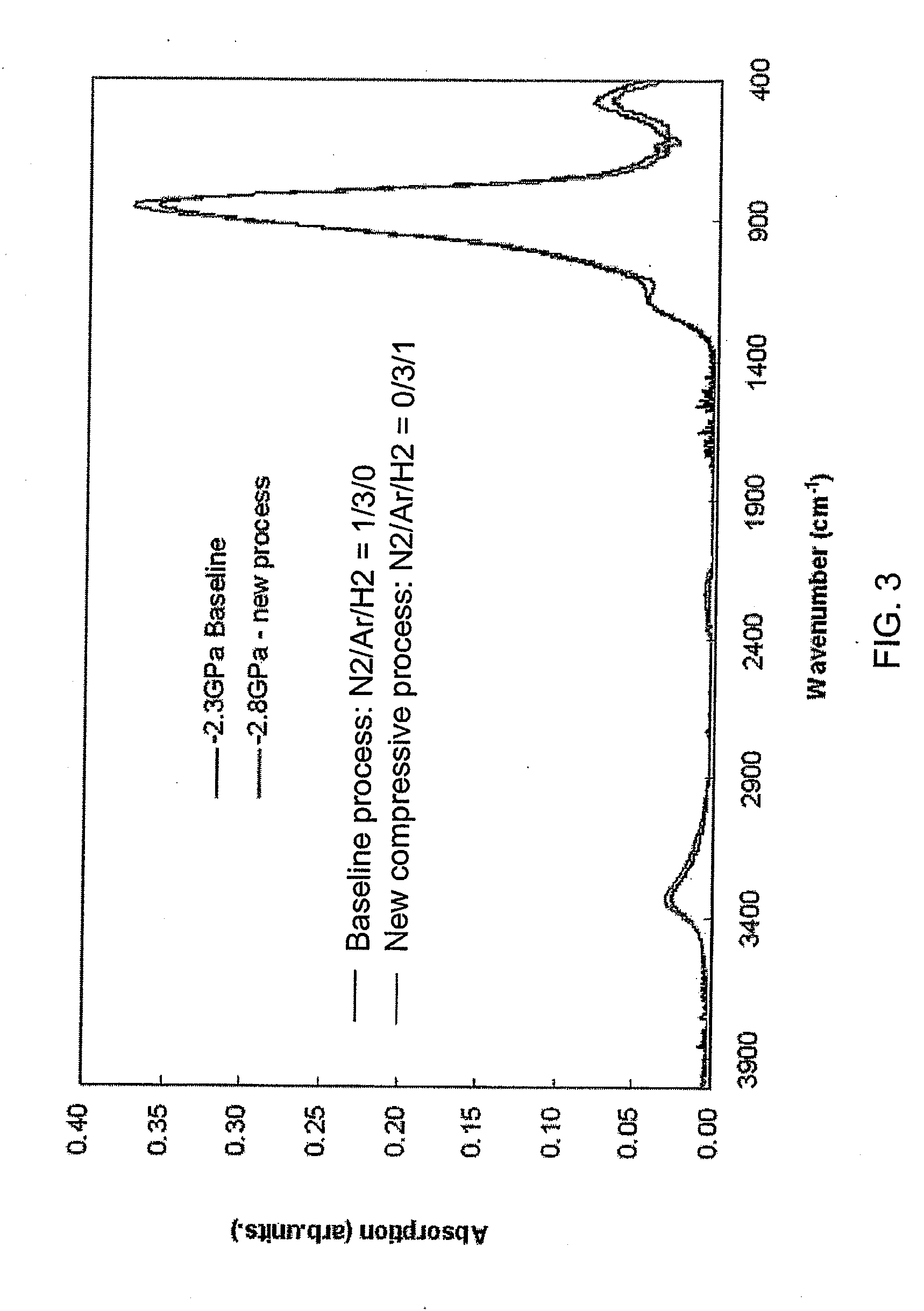

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

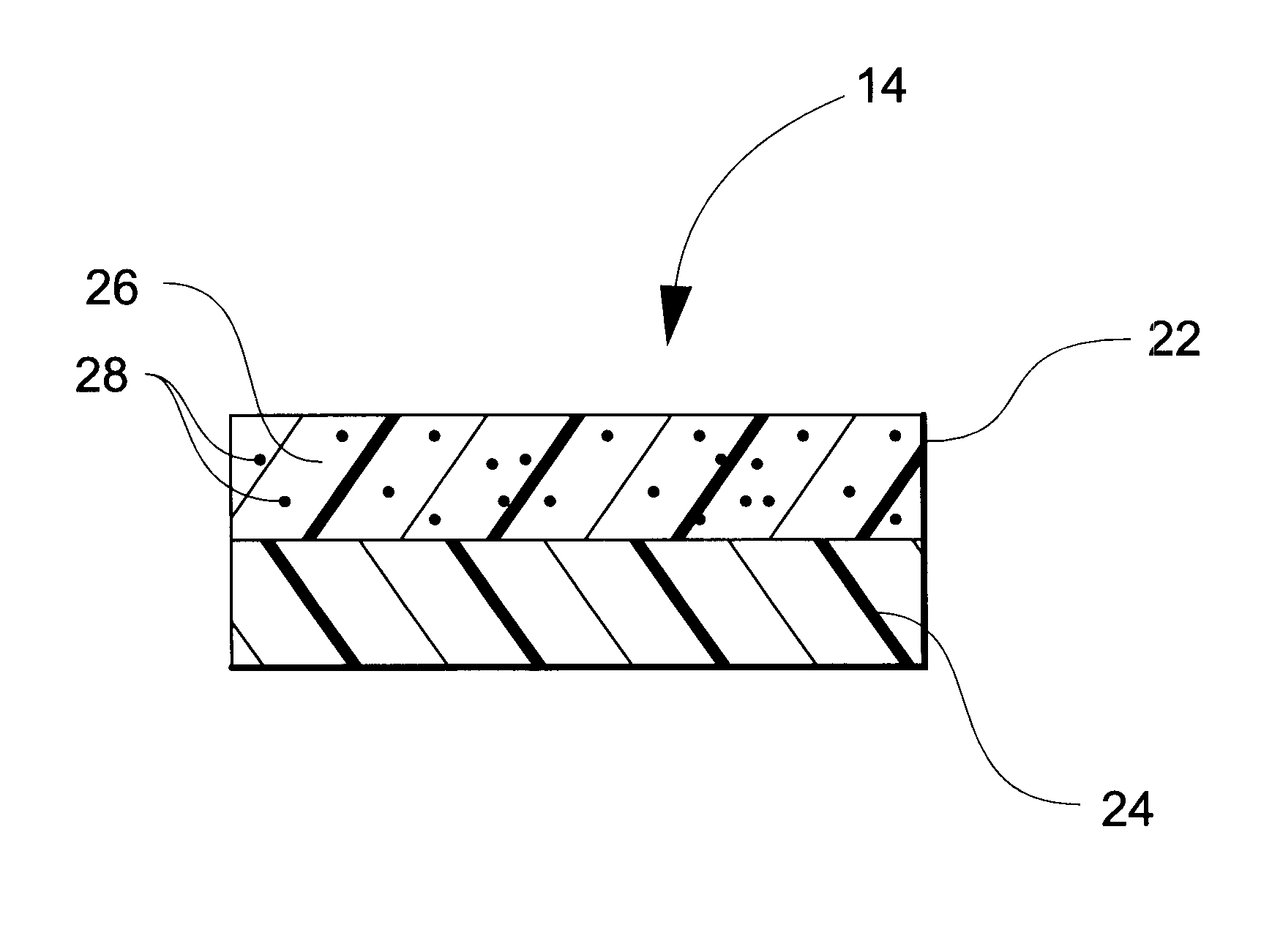

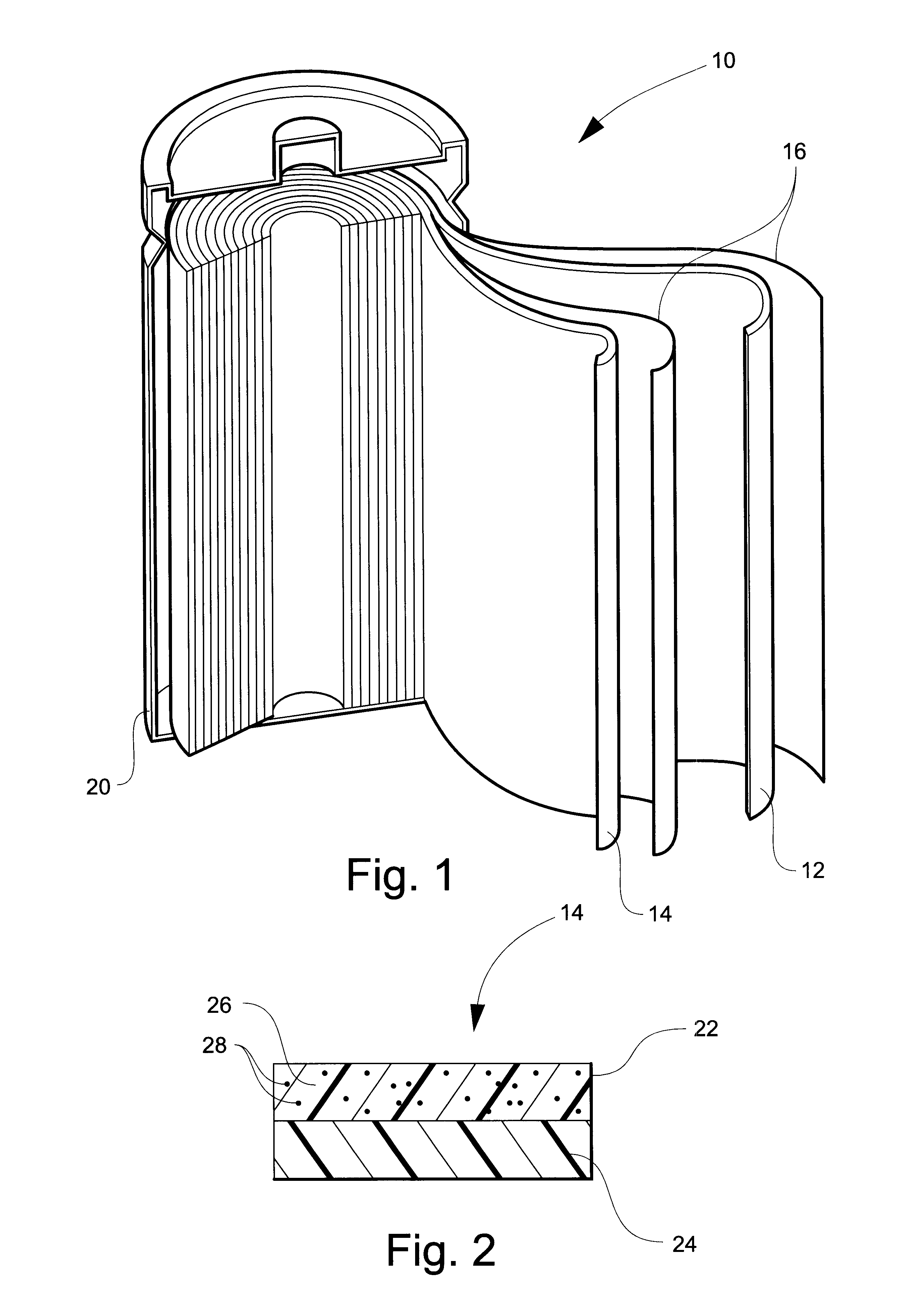

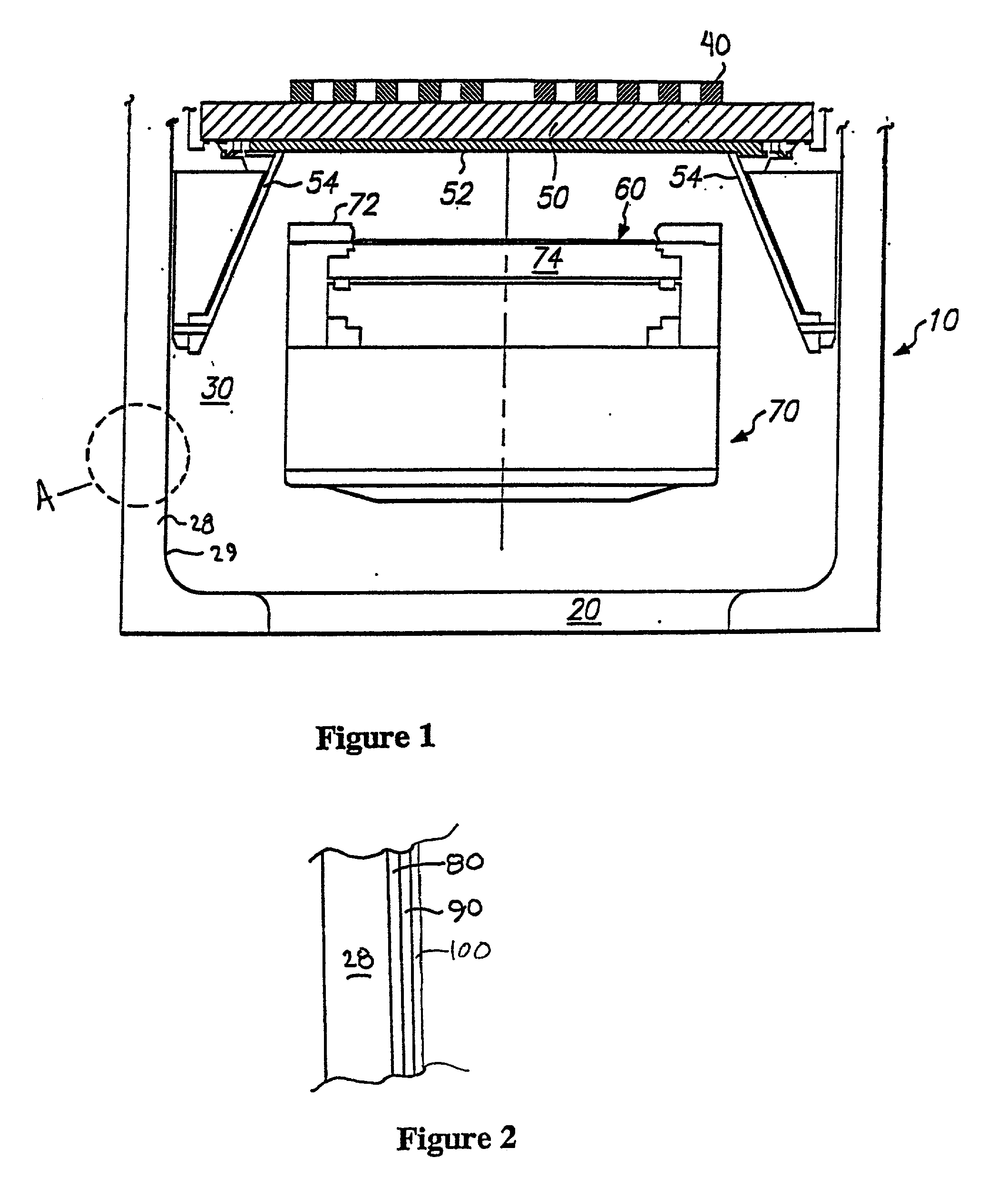

Separator for a high energy rechargeable lithium battery

InactiveUS6432586B1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesCeramic compositeMetallurgy

The instant invention is directed to a separator for a high energy rechargeable lithium battery and the corresponding battery. The separator includes a ceramic composite layer and a polymeric microporous layer. The ceramic layers includes a mixture of inorganic particles and a matrix material. The ceramic layer is adapted, at least, to block dendrite growth and to prevent electronic shorting. The polymeric layer is adapted, at least, to block ionic flow between the anode and the cathode in the event of thermal runaway.

Owner:CELGARD LLC

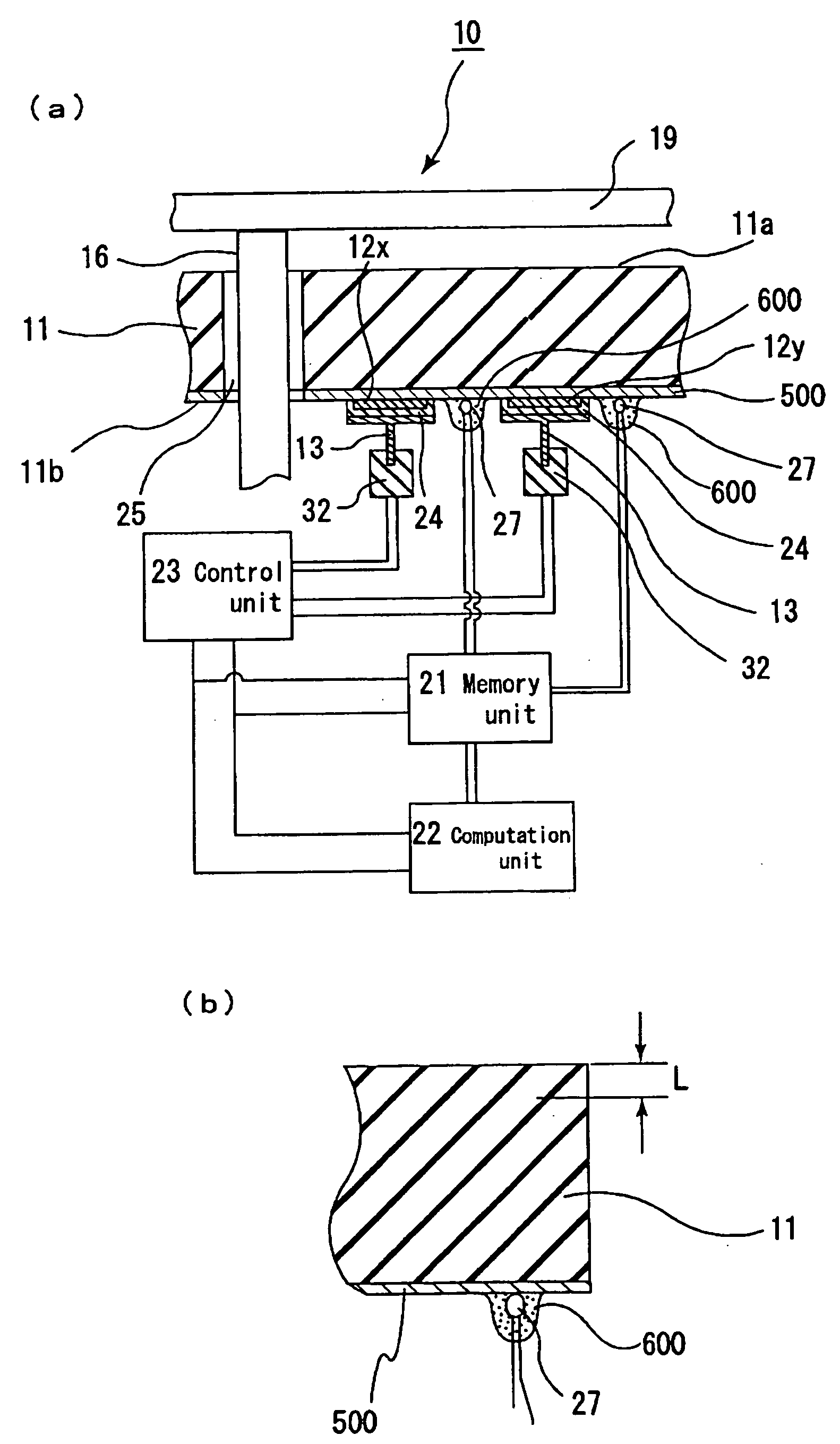

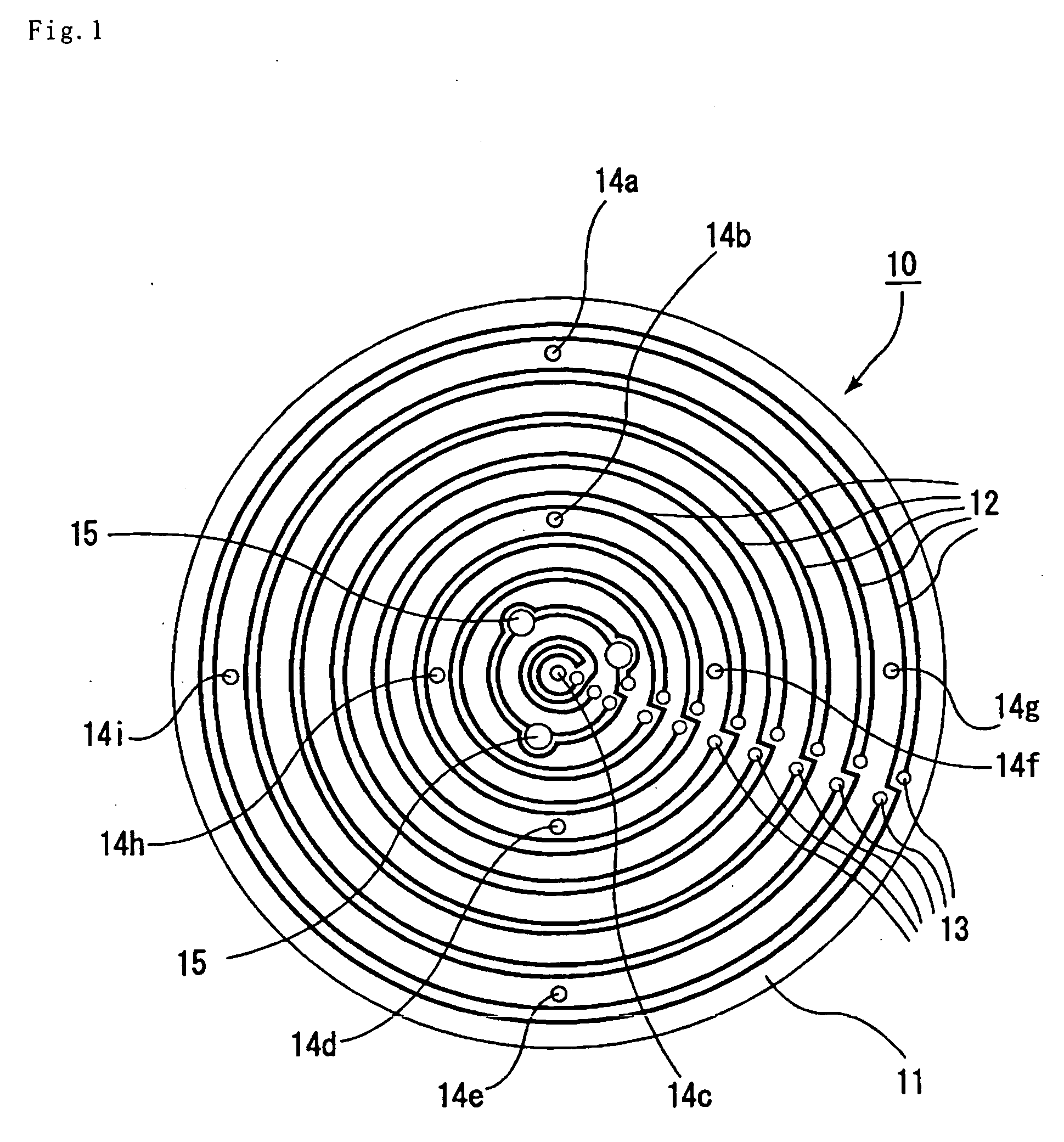

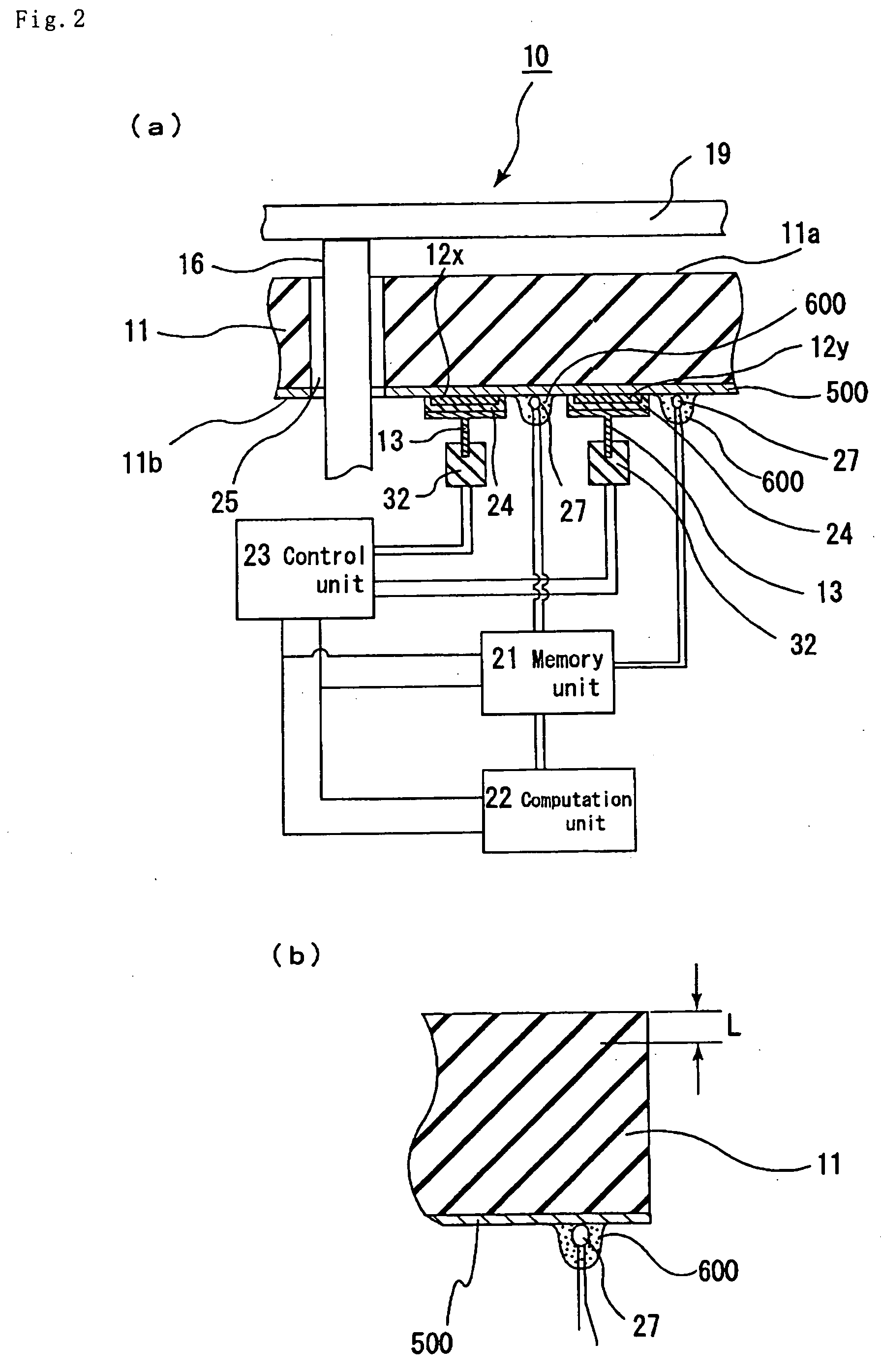

Wafer heating apparatus

InactiveUS6753507B2Semiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgyHeat generation

Owner:KYOCERA CORP

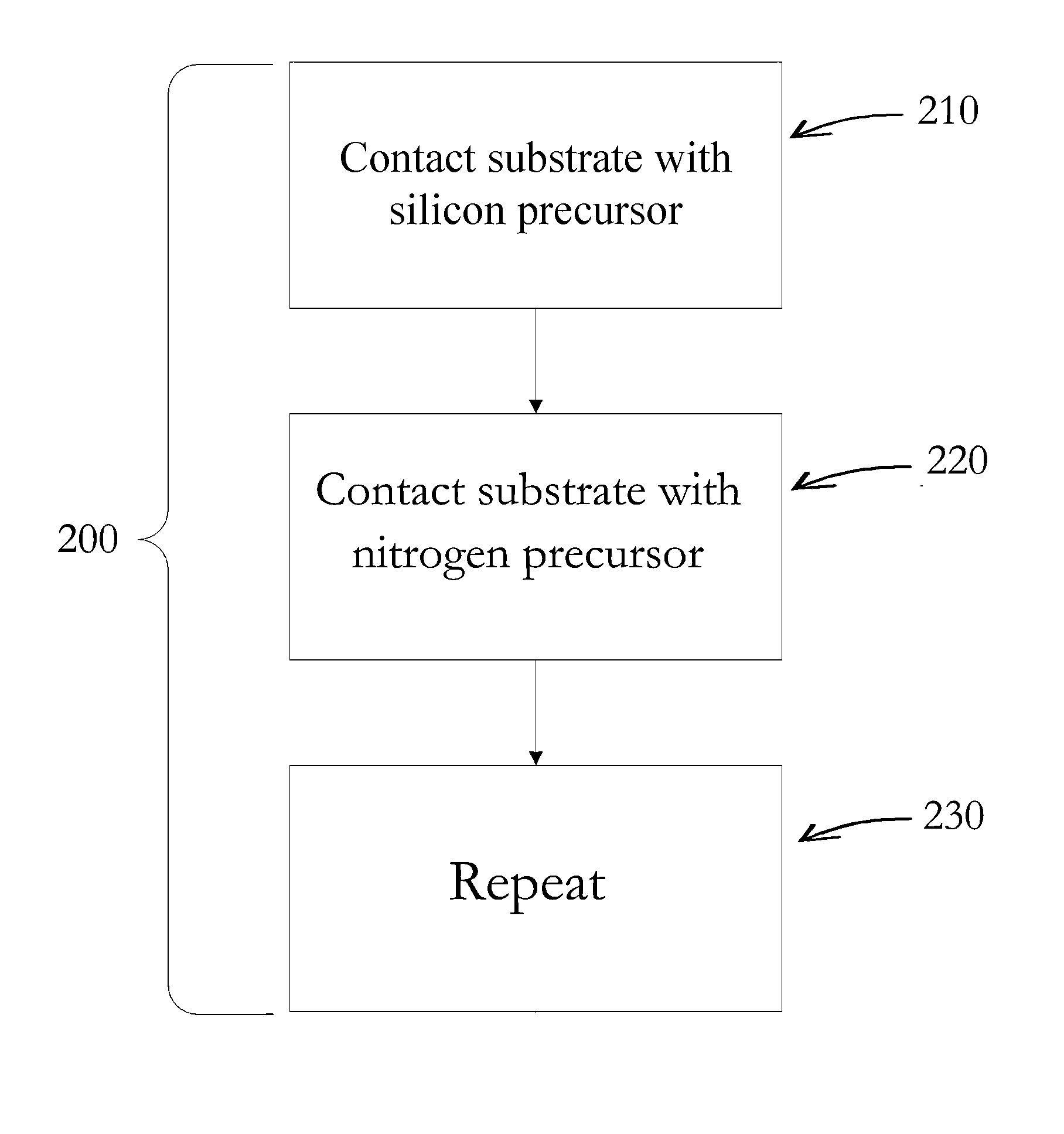

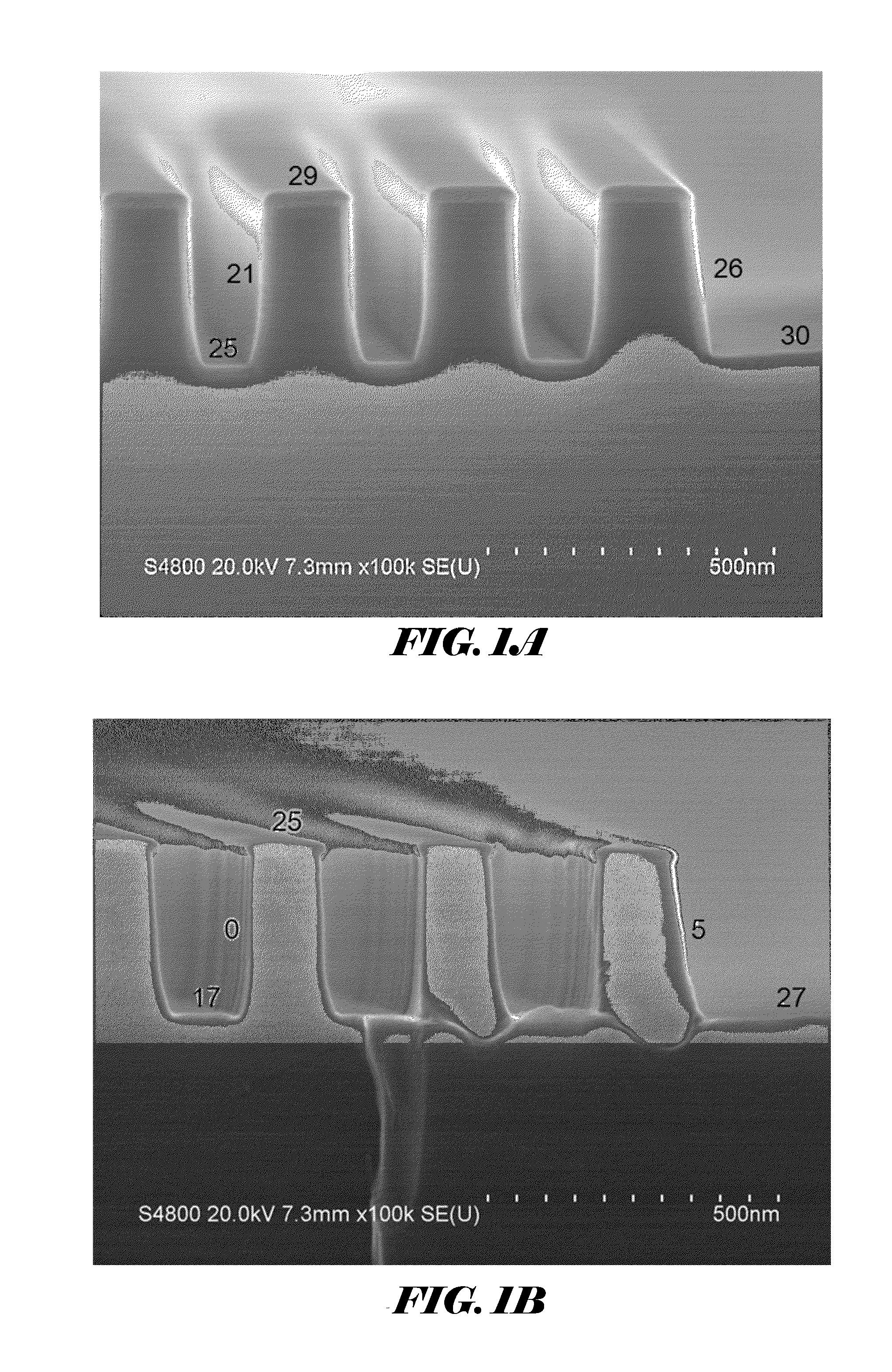

Si PRECURSORS FOR DEPOSITION OF SiN AT LOW TEMPERATURES

ActiveUS20140273528A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyAtomic layer deposition

Methods and precursors for depositing silicon nitride films by atomic layer deposition (ALD) are provided. In some embodiments the silicon precursors comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%).

Owner:ASM IP HLDG BV

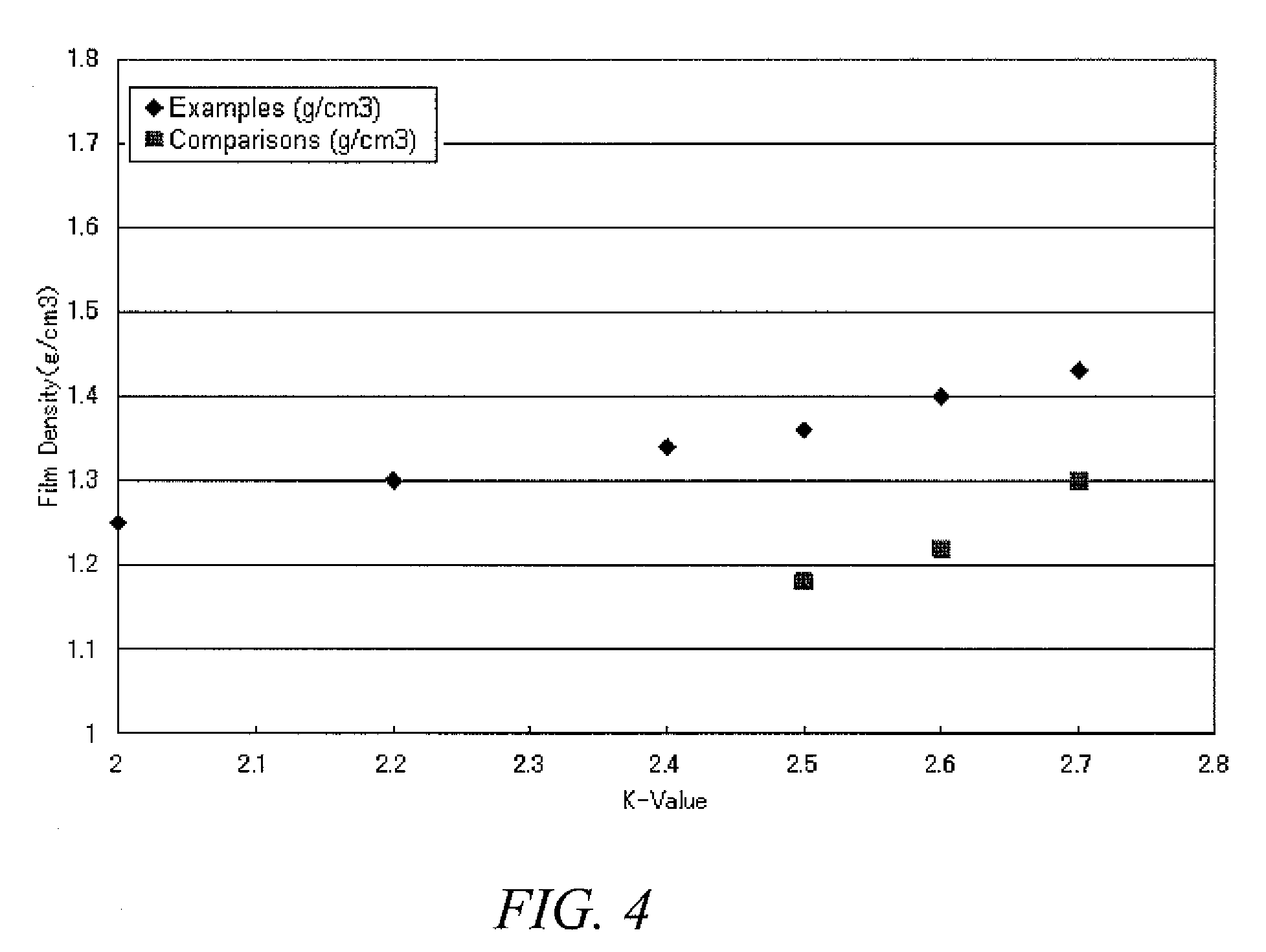

Sealing pores of low-k dielectrics using CxHy

A semiconductor method of manufacturing involving porous and / or carbon containing, low-k dielectrics is provided. The method includes forming a hydrocarbon of the general composition CxHy on the surface of the low-k dielectric. The hydrocarbon layer includes depositing a precursor material, preferably C2H4 or (CH3)2CHC6H6CH3. In accordance with embodiments of this invention, carbon diffuses into the low-k dielectric, thereby reducing carbon depletion damage caused by plasma processing or etching. Surface dielectric pores damaged by plasma processing are also repaired by sealing them with the CXHY layer. Embodiments include semiconductor devices, such as devices having damascene interconnect structures, manufacturing using methods provided.

Owner:TAIWAN SEMICON MFG CO LTD

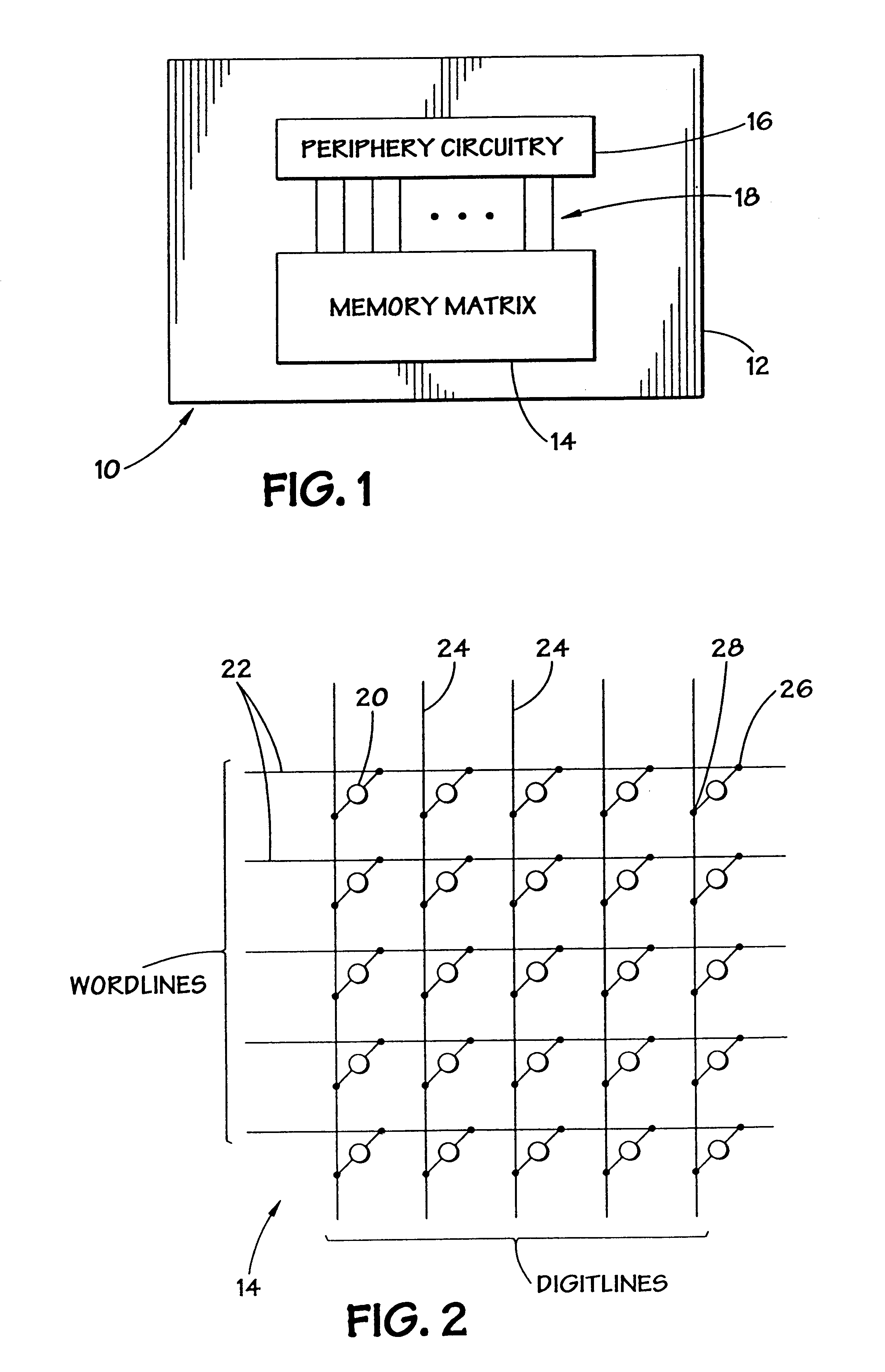

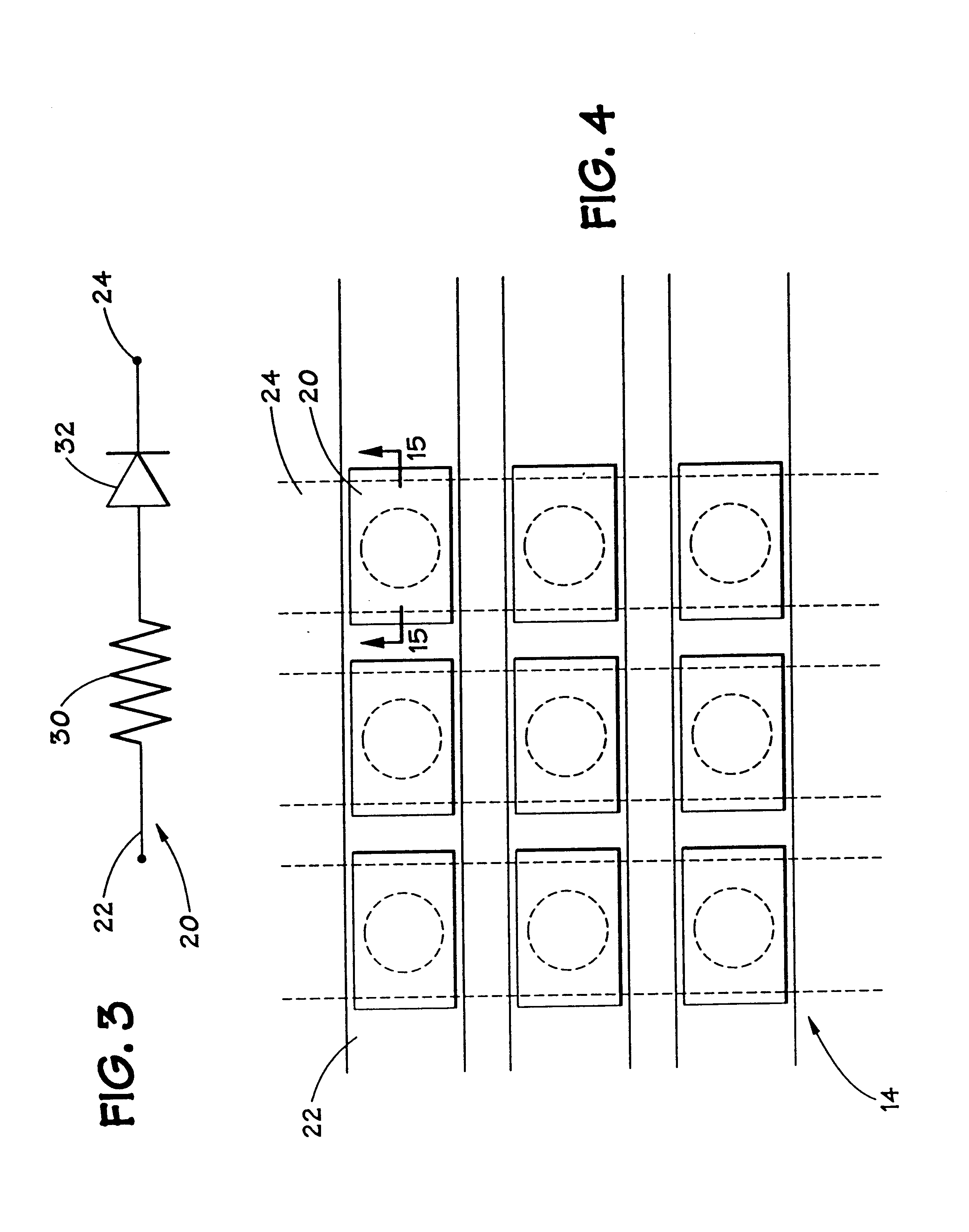

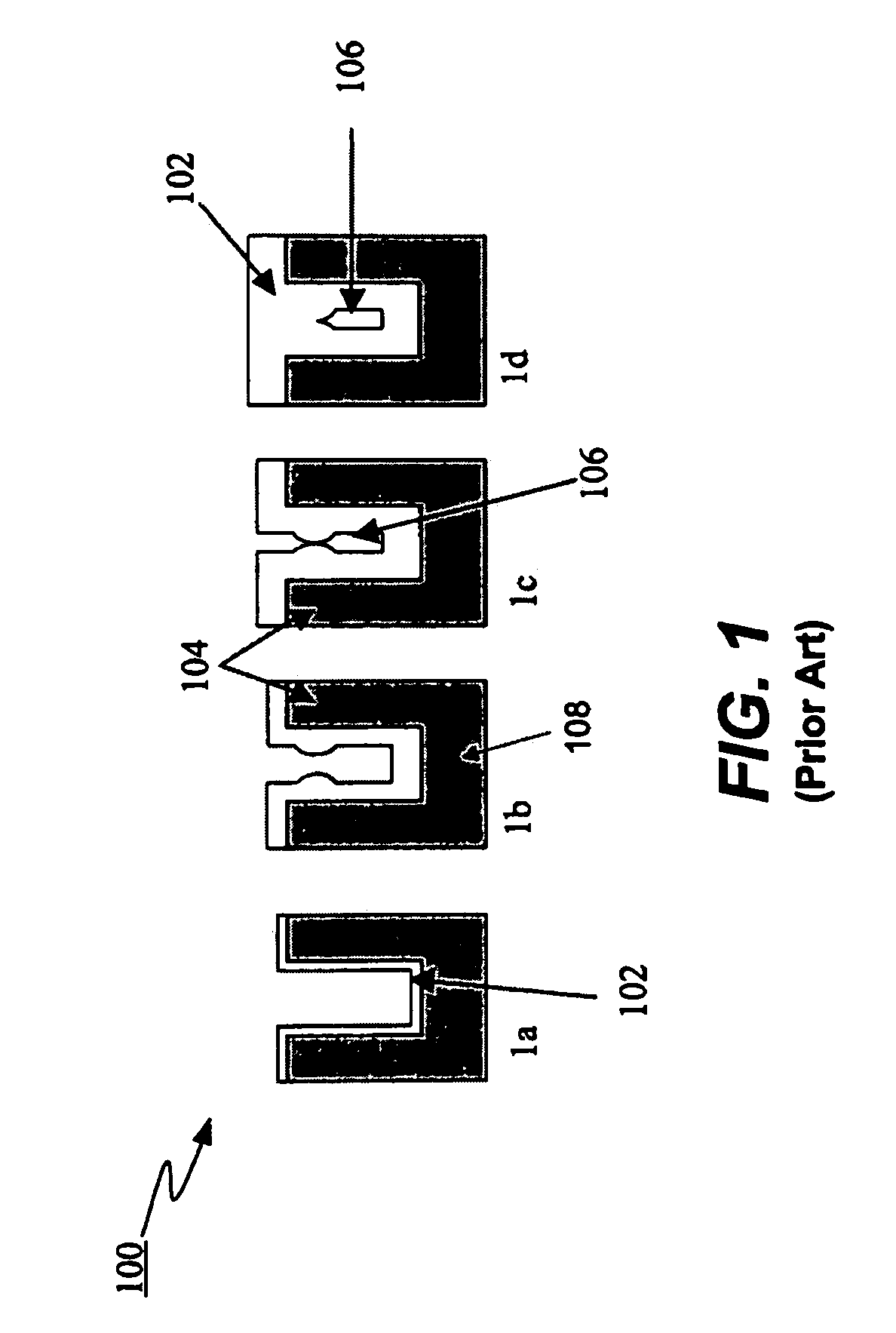

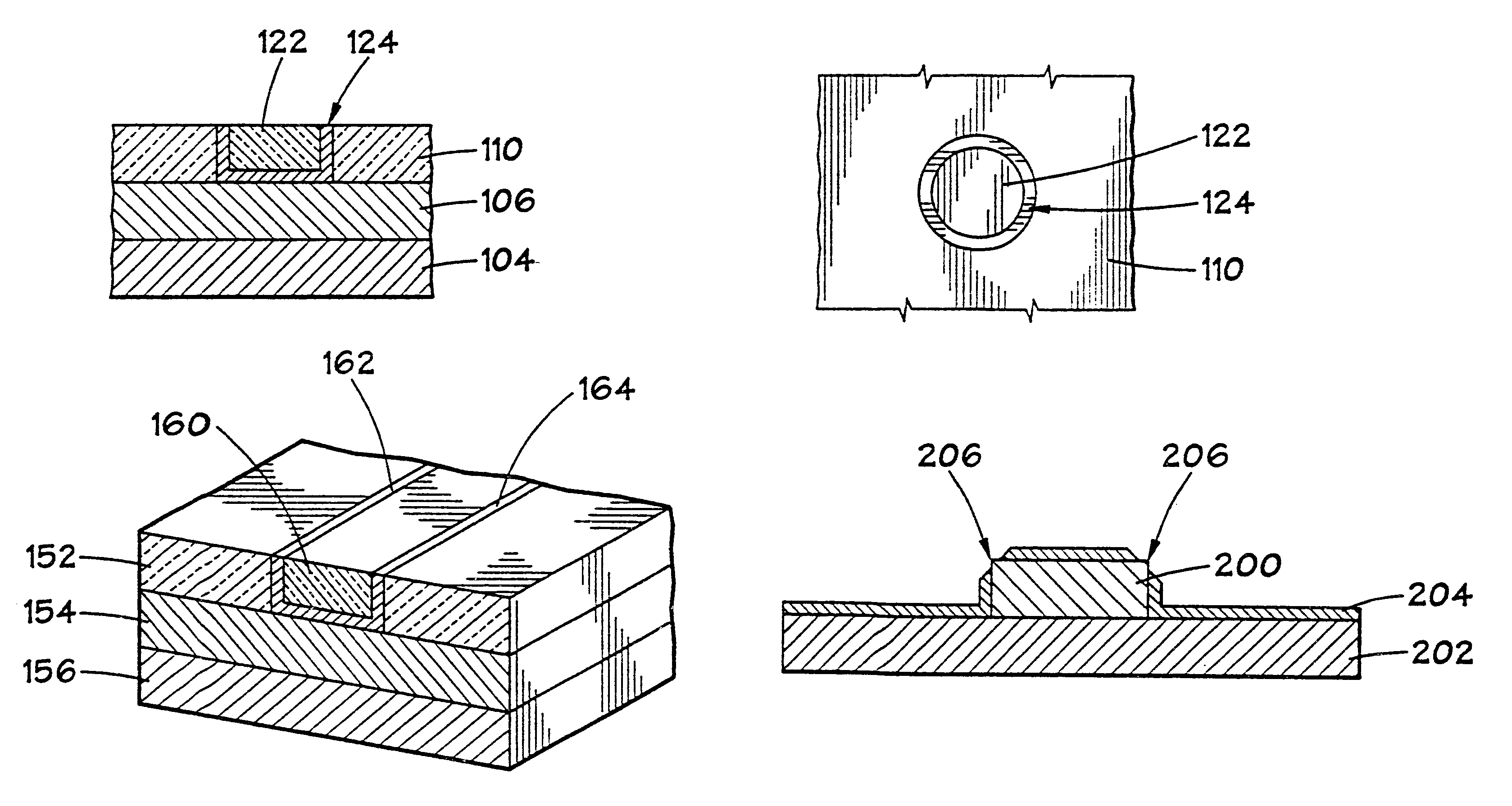

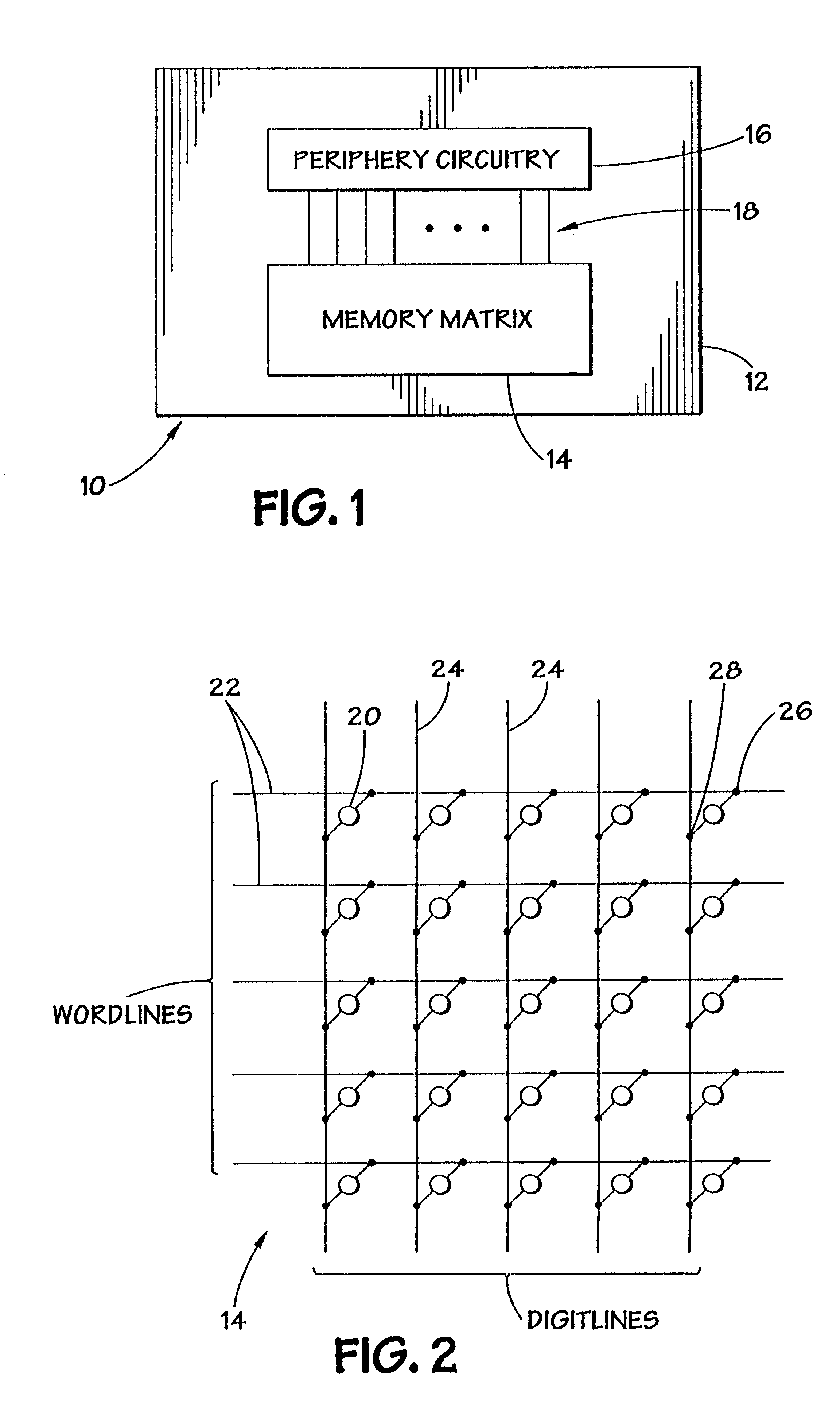

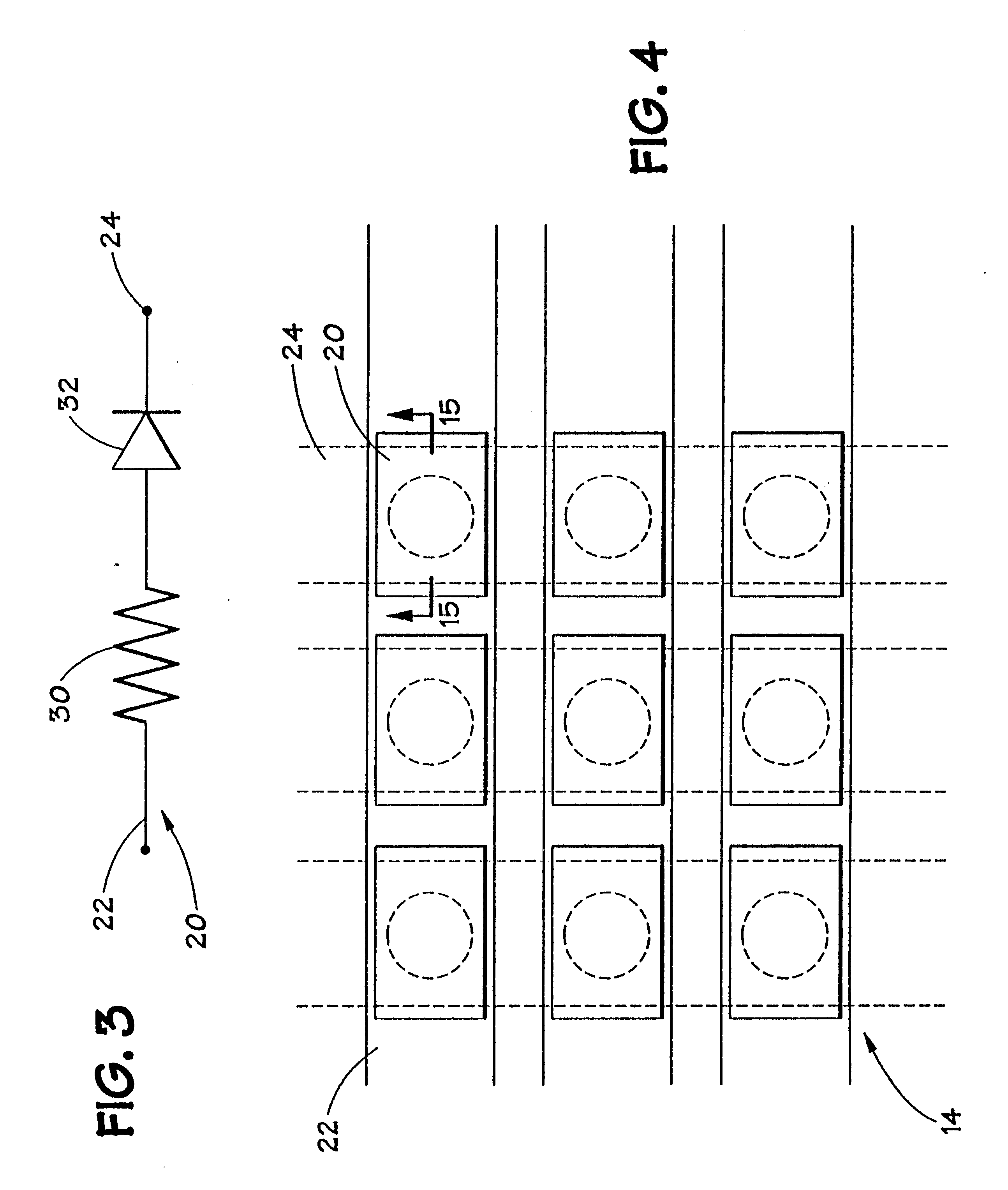

Memory elements and methods for making same

Annular, linear, and point contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

Method for forming dielectric film using siloxane-silazane mixture

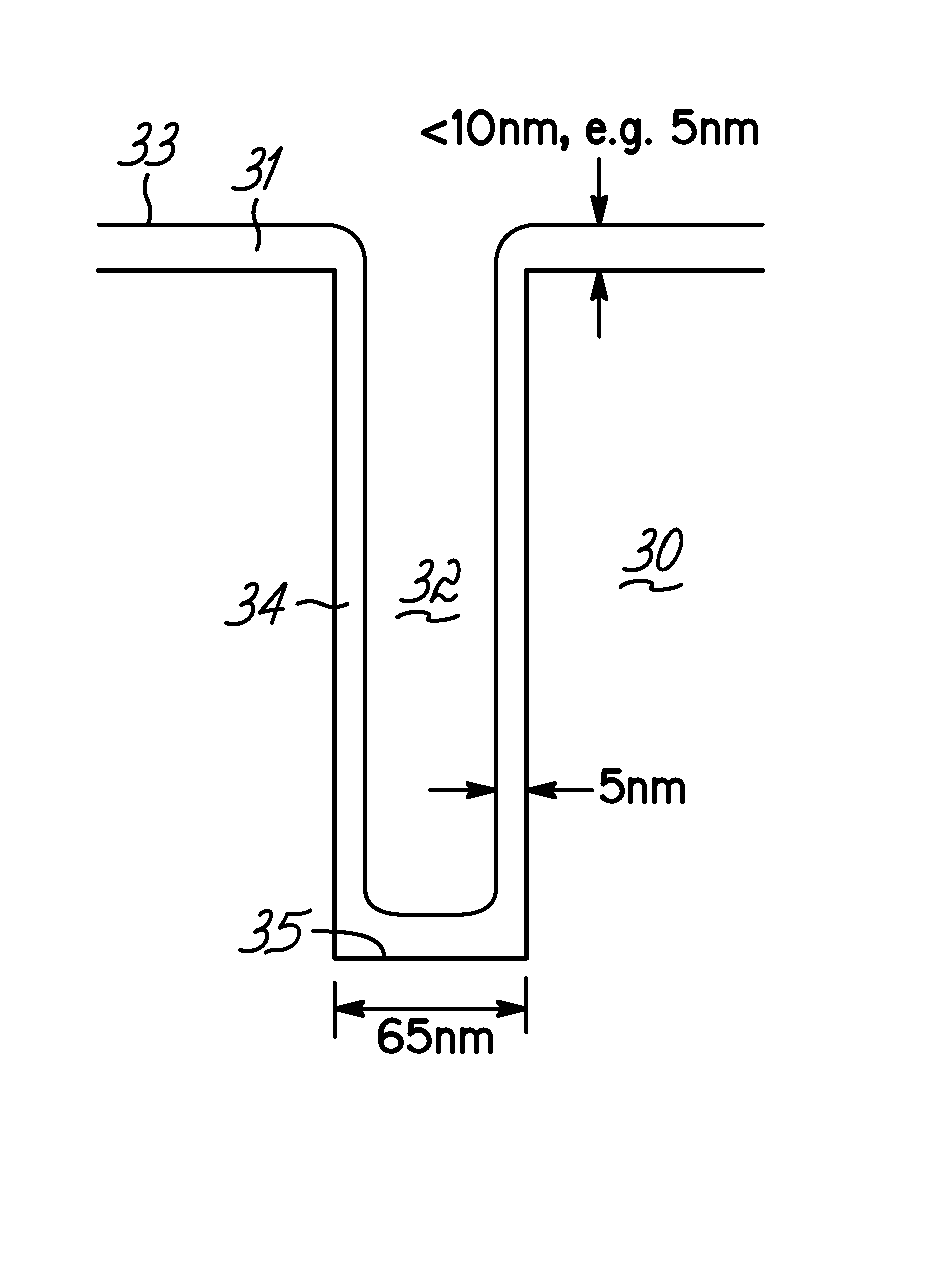

ActiveUS8003174B2High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

Owner:ASM JAPAN

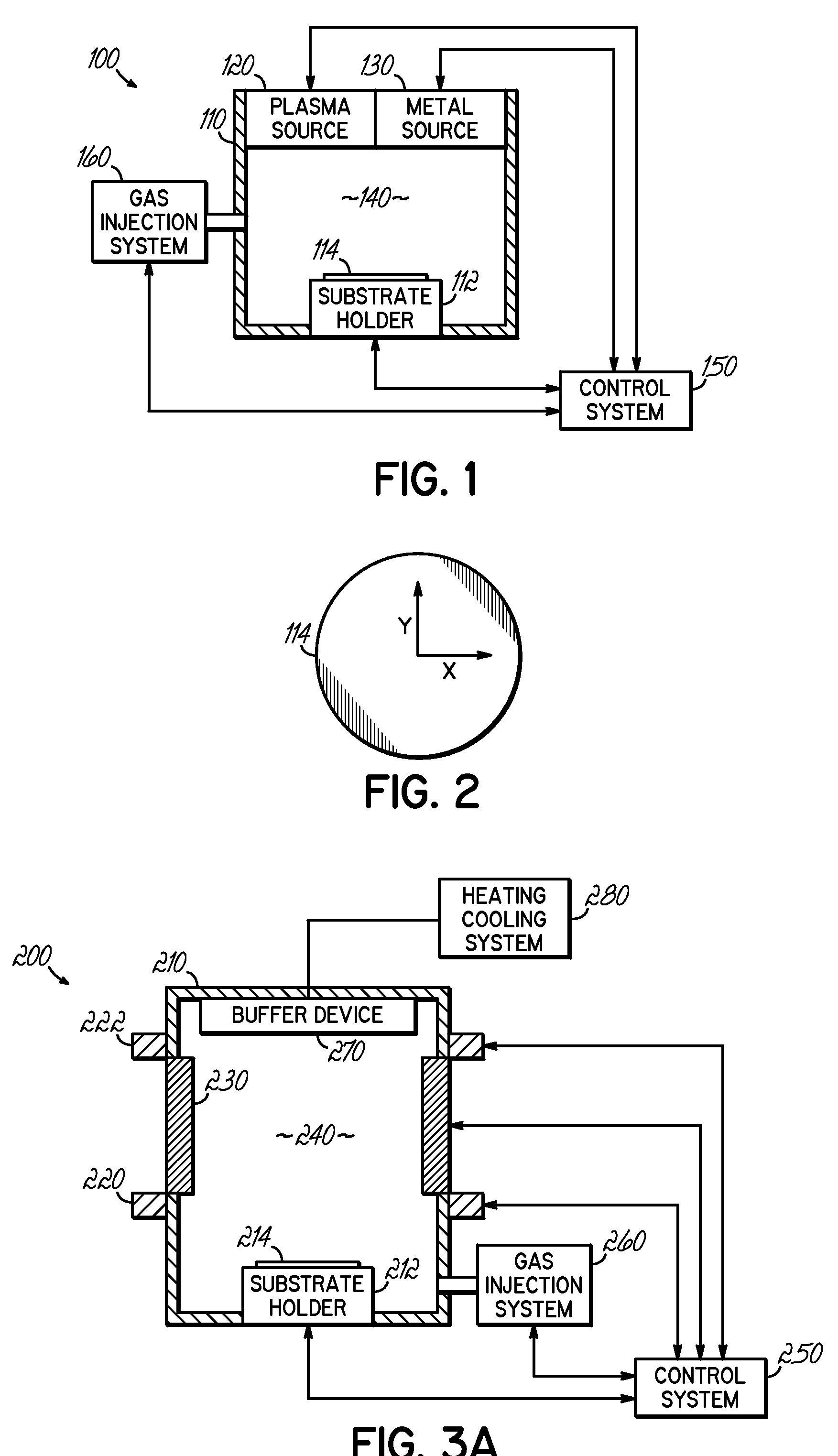

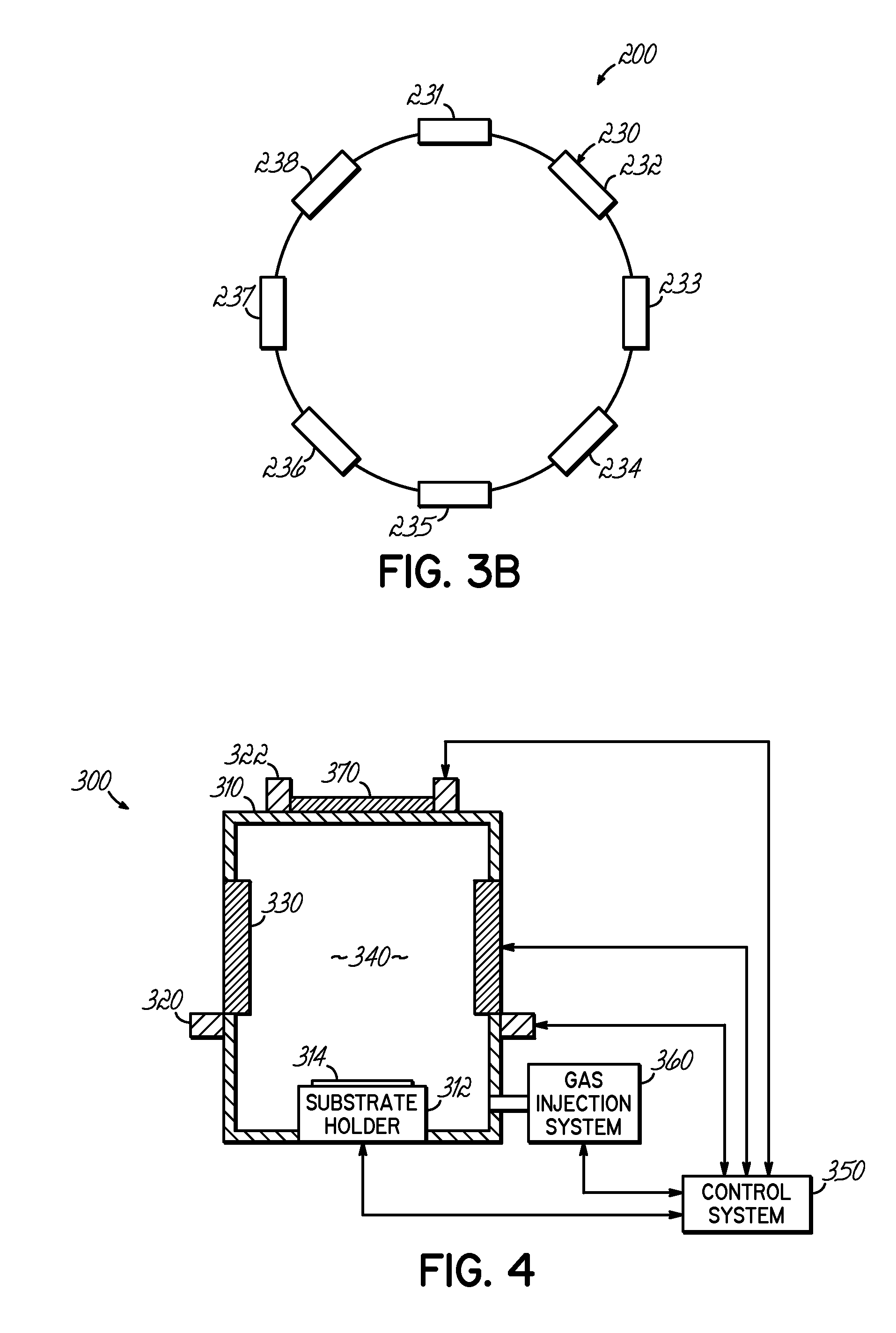

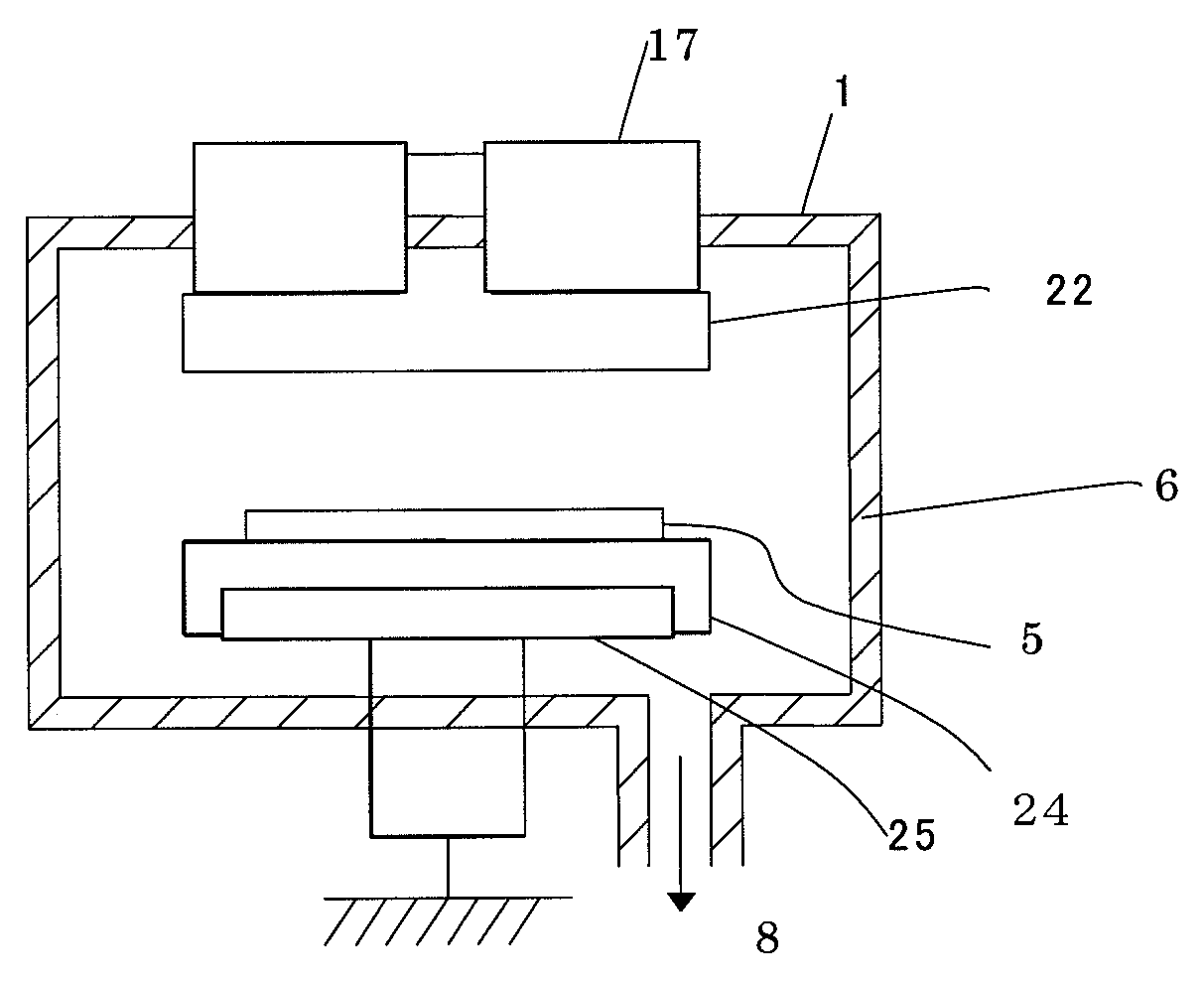

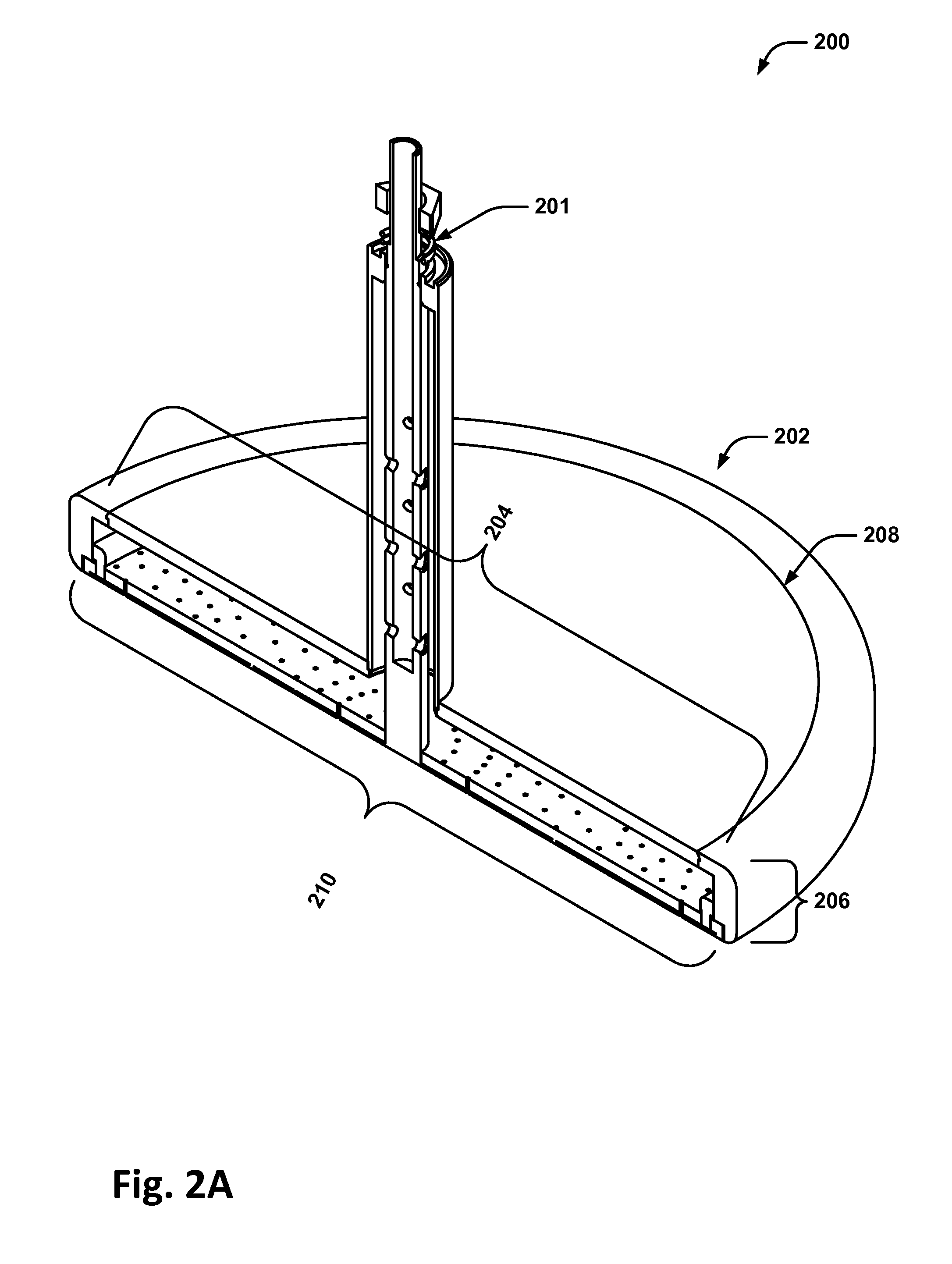

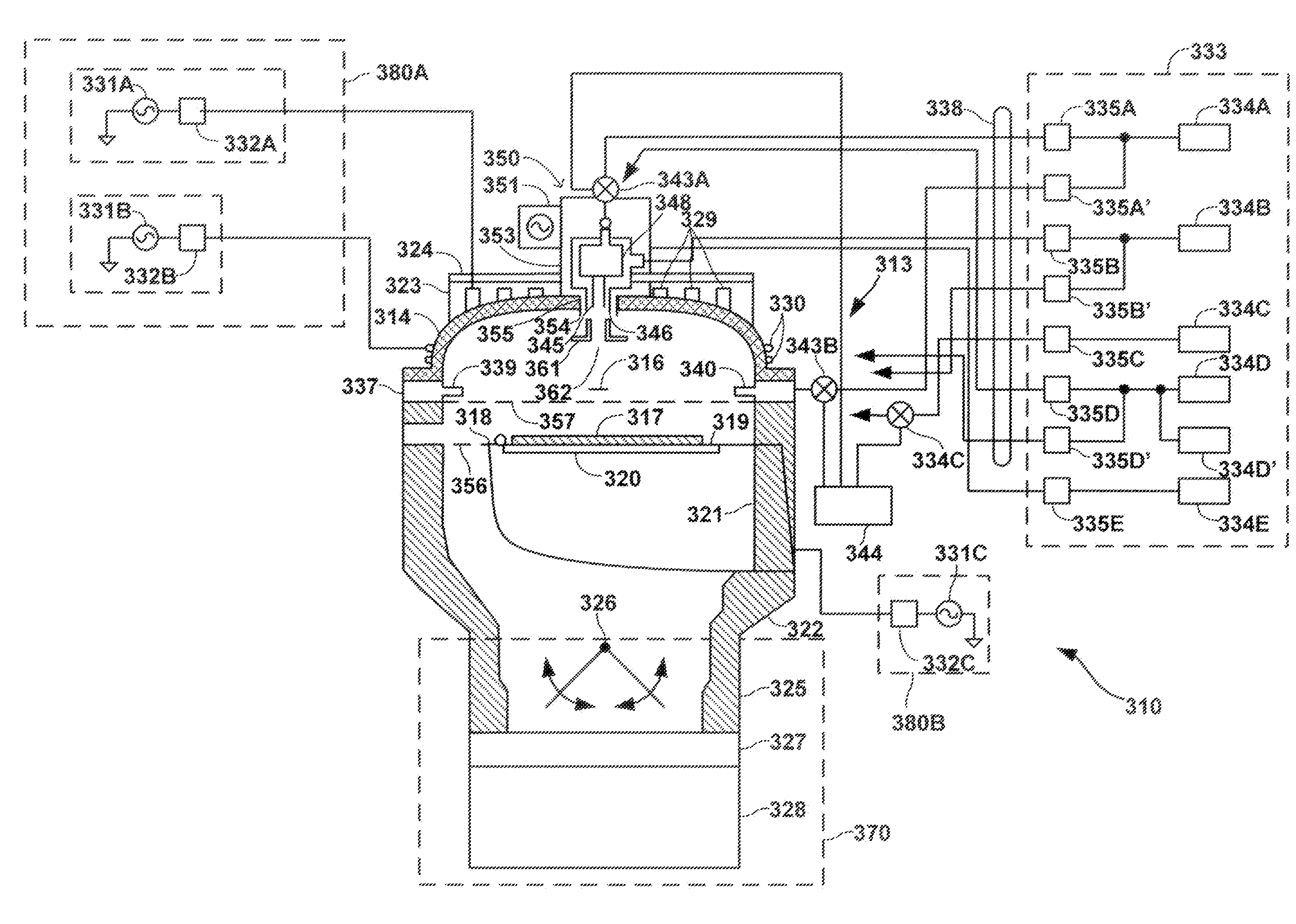

Method and apparatus of distributed plasma processing system for conformal ion stimulated nanoscale deposition process

InactiveUS20080026574A1Good coverageHigh aspect ratio (HAR) featuresVacuum evaporation coatingSputtering coatingPlasma densityHigh density

A deposition system and method of operating thereof is described for depositing a conformal metal or other similarly responsive coating material film in a high aspect ratio feature using a high density plasma is described. The deposition system includes a plasma source, and a distributed metal source for forming plasma and introducing metal vapor to the deposition system, respectively. The deposition system is configured to form a plasma having a plasma density and generate metal vapor having a metal density, wherein the ratio of the metal density to the plasma density proximate the substrate is less than or equal to unity. This ratio should exist at least within a distance from the surface of the substrate that is about twenty percent of the diameter of the substrate. A ratio that is uniform within plus or minus twenty-five percent substantially across the surface of said substrate is desirable. The ratio is particularly effective for plasma density exceeding 1012 cm−3, and for depositing film on substrates having nanoscale features with maximum film thickness less than half of the feature width, for example, at ten percent of the feature width.

Owner:TOKYO ELECTRON LTD

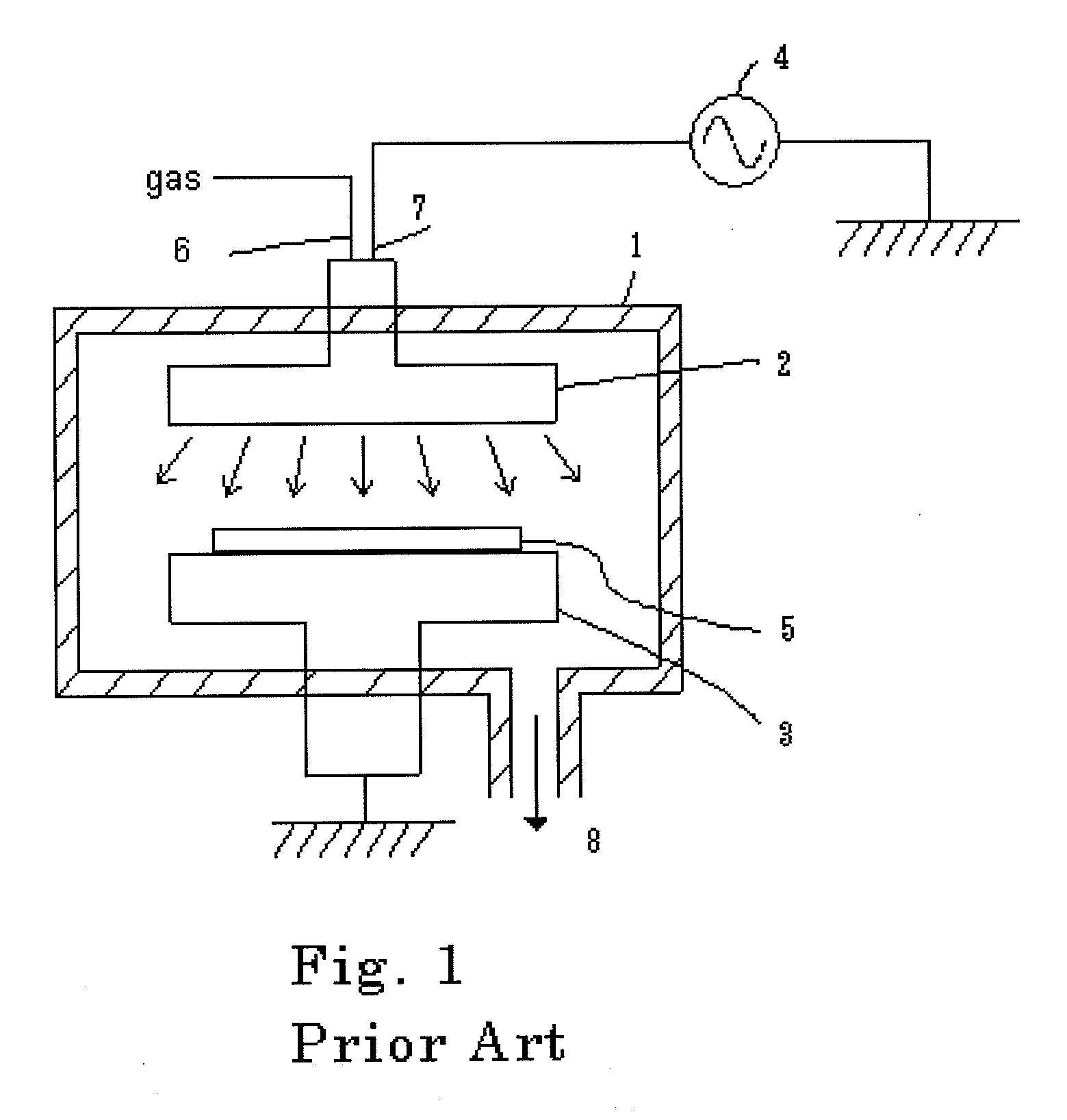

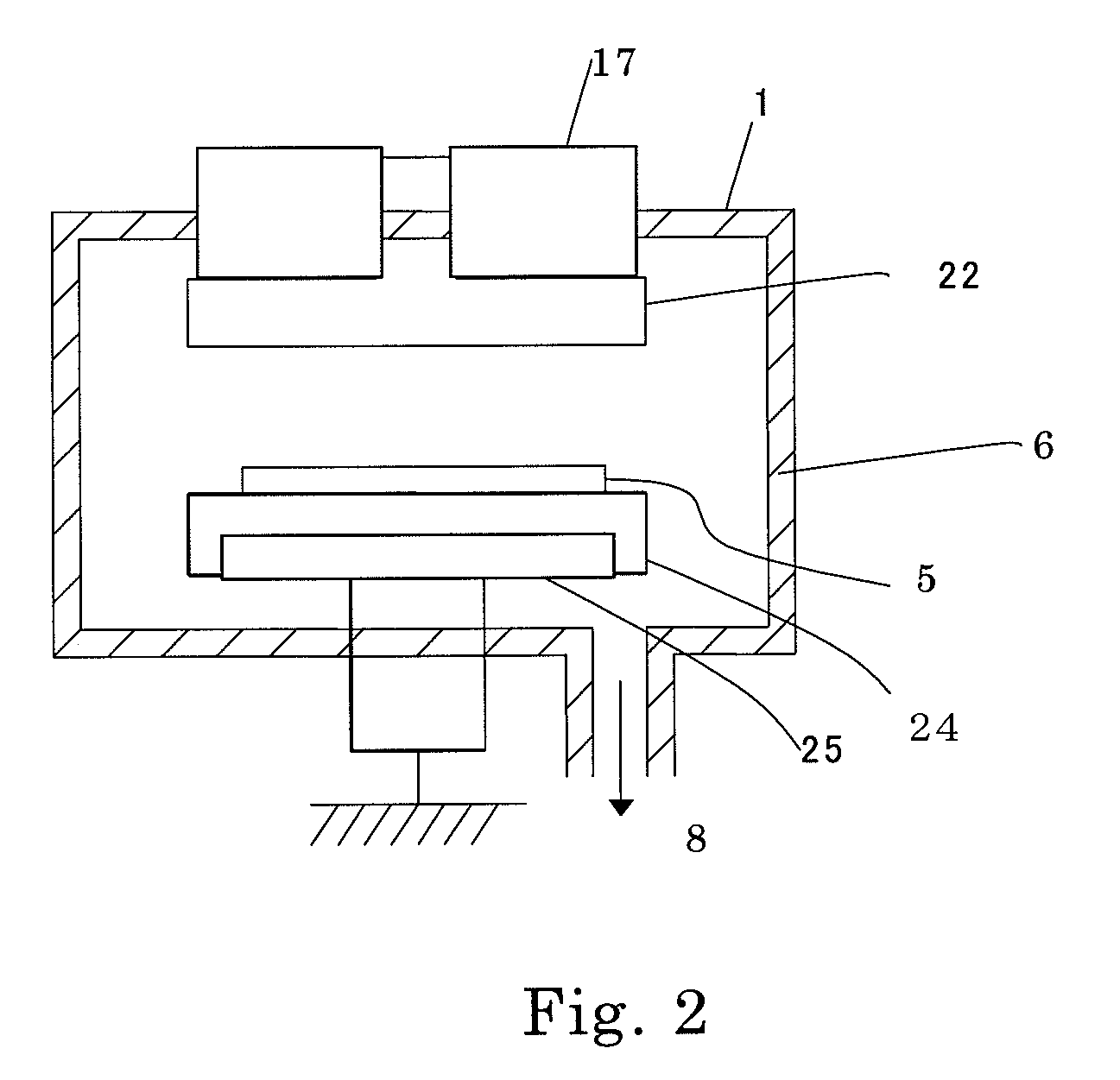

Plasma CVD apparatus having non-metal susceptor

InactiveUS20080299326A1Avoid Metal ContaminationConcerning long-term stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetallurgy

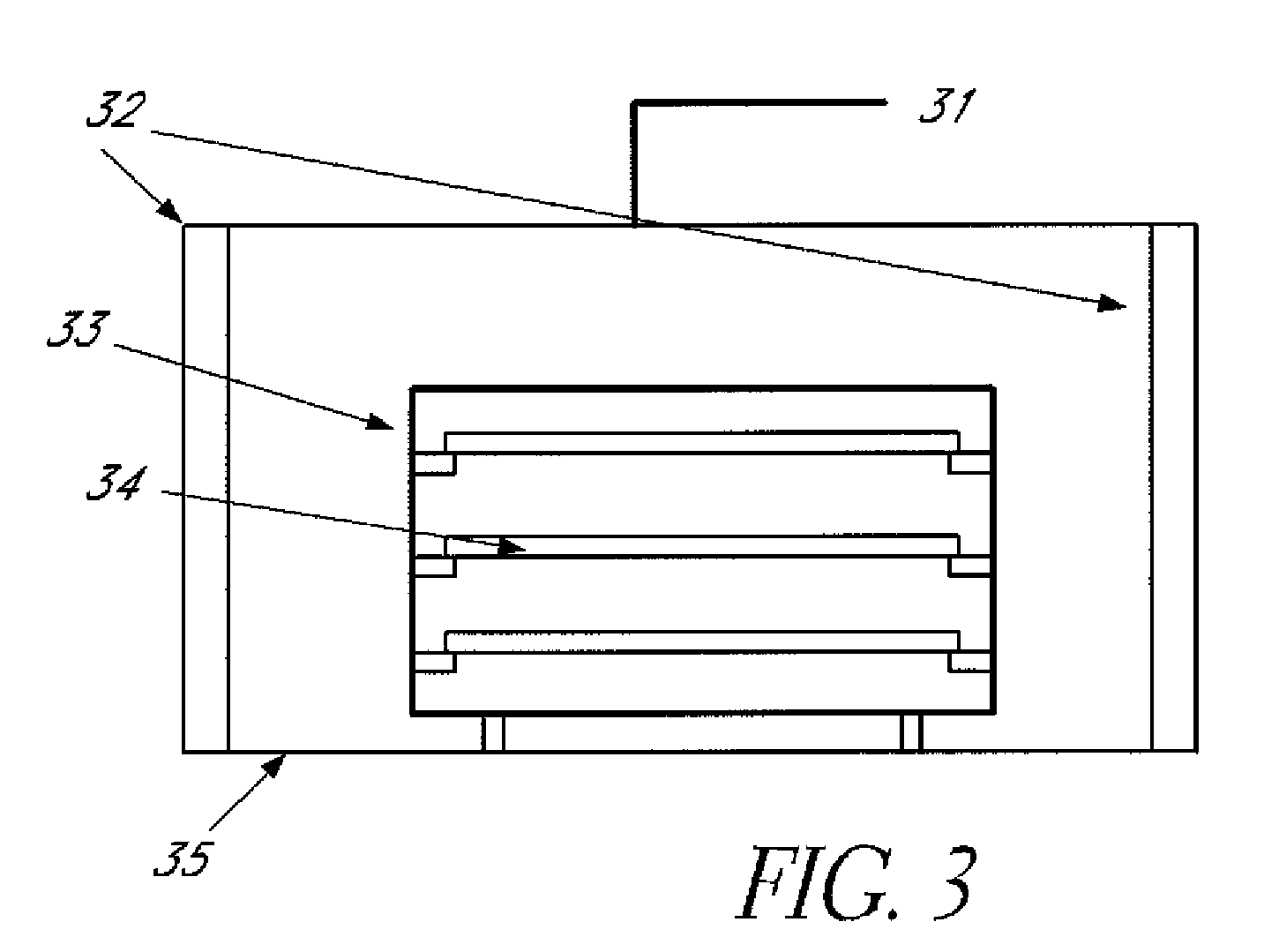

A plasma CVD apparatus includes: a cooling susceptor for placing a substrate thereon and serving as an electrode; and a shower plate for introducing gas toward the susceptor via multiple throughholes formed therein. The shower plate serves as an electrode and is disposed in parallel to the susceptor. The cooling susceptor is made of a ceramic material provided with a cooling fluid flow path for passing a cooling fluid therethrough.

Owner:ASM JAPAN

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

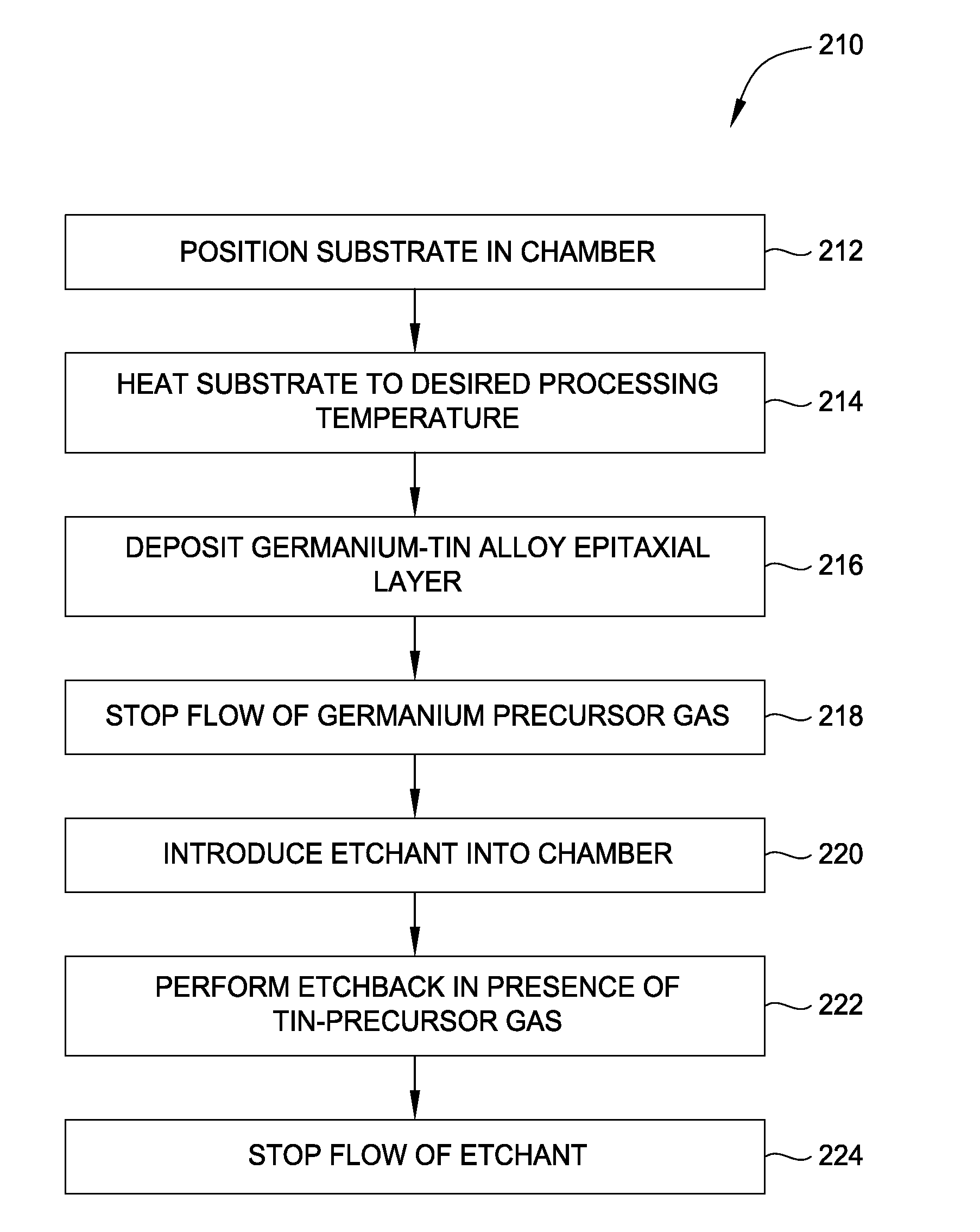

Method of semiconductor film stabilization

InactiveUS20130330911A1Polycrystalline material growthAfter-treatment detailsMetallurgySemiconductor

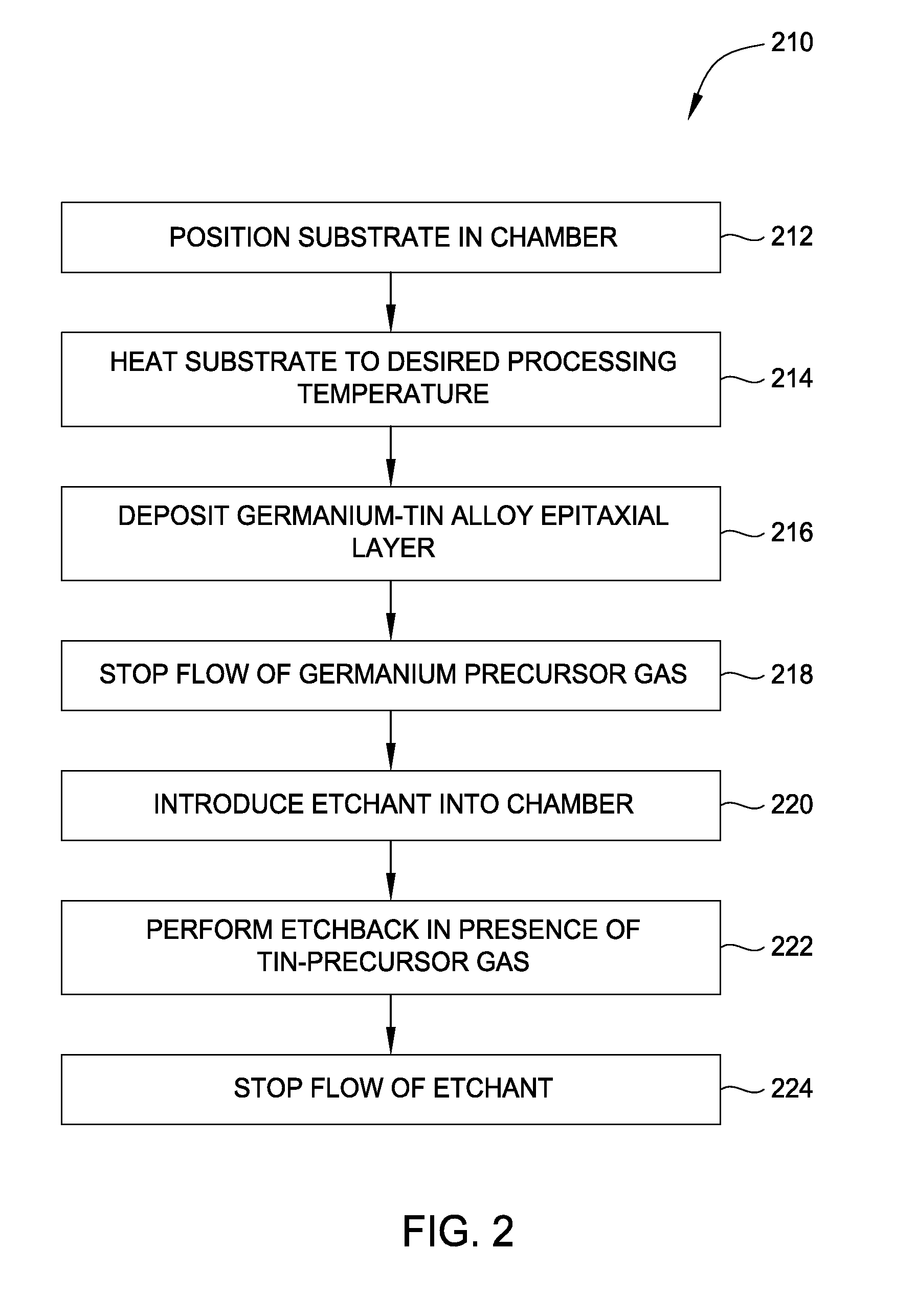

Embodiments of the invention generally relate to methods for forming silicon-germanium-tin alloy epitaxial layers, germanium-tin alloy epitaxial layers, and germanium epitaxial layers that may be doped with boron, phosphorus, arsenic, or other n-type or p-type dopants. The methods generally include positioning a substrate in a processing chamber. A germanium precursor gas is then introduced into the chamber concurrently with a stressor precursor gas, such as a tin precursor gas, to form an epitaxial layer. The flow of the germanium gas is then halted, and an etchant gas is introduced into the chamber. An etch back is then performed while in the presence of the stressor precursor gas used in the formation of the epitaxial film. The flow of the etchant gas is then stopped, and the cycle may then be repeated. In addition to or as an alternative to the etch back process, an annealing processing may be performed.

Owner:APPLIED MATERIALS INC

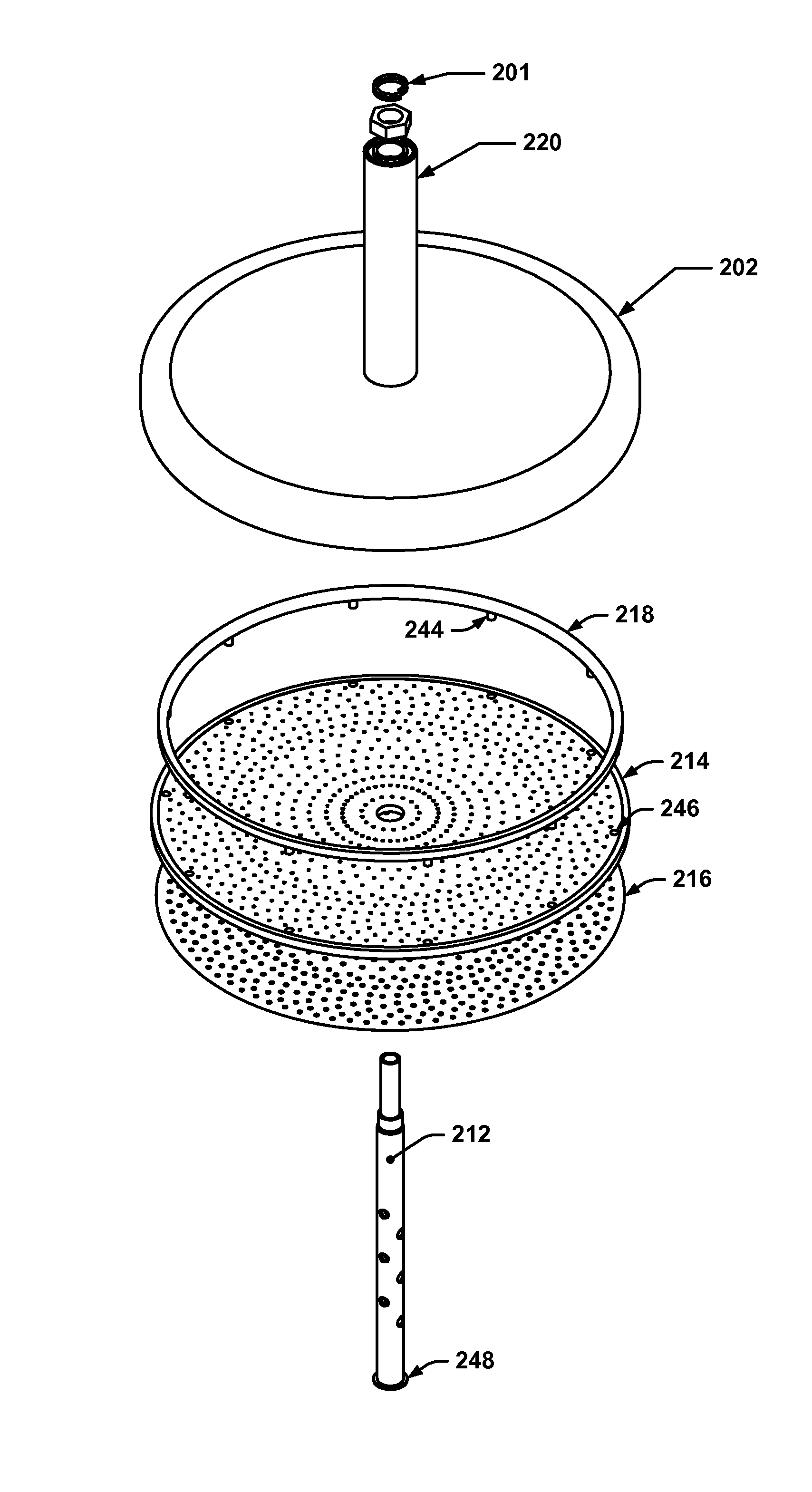

Hybrid ceramic showerhead

ActiveUS20120222815A1Large caliberSmall diameterSpraying apparatusSemiconductor/solid-state device manufacturingMetallurgyDc voltage

Various implementations of hybrid ceramic faceplates for substrate processing showerheads are provided. The hybrid ceramic showerhead faceplates may include an electrode embedded within the ceramic material of the faceplate, as well as a pattern of through-holes. The electrode may be fully encapsulated within the ceramic material with respect to the through-holes. In some implementations, a heater element may also be embedded within the hybrid ceramic showerhead faceplate. A DC voltage source may be electrically connected with the hybrid ceramic showerhead faceplate during use. The hybrid ceramic faceplates may be easily removable from the substrate processing showerheads for easy cleaning and faceplate replacement.

Owner:NOVELLUS SYSTEMS

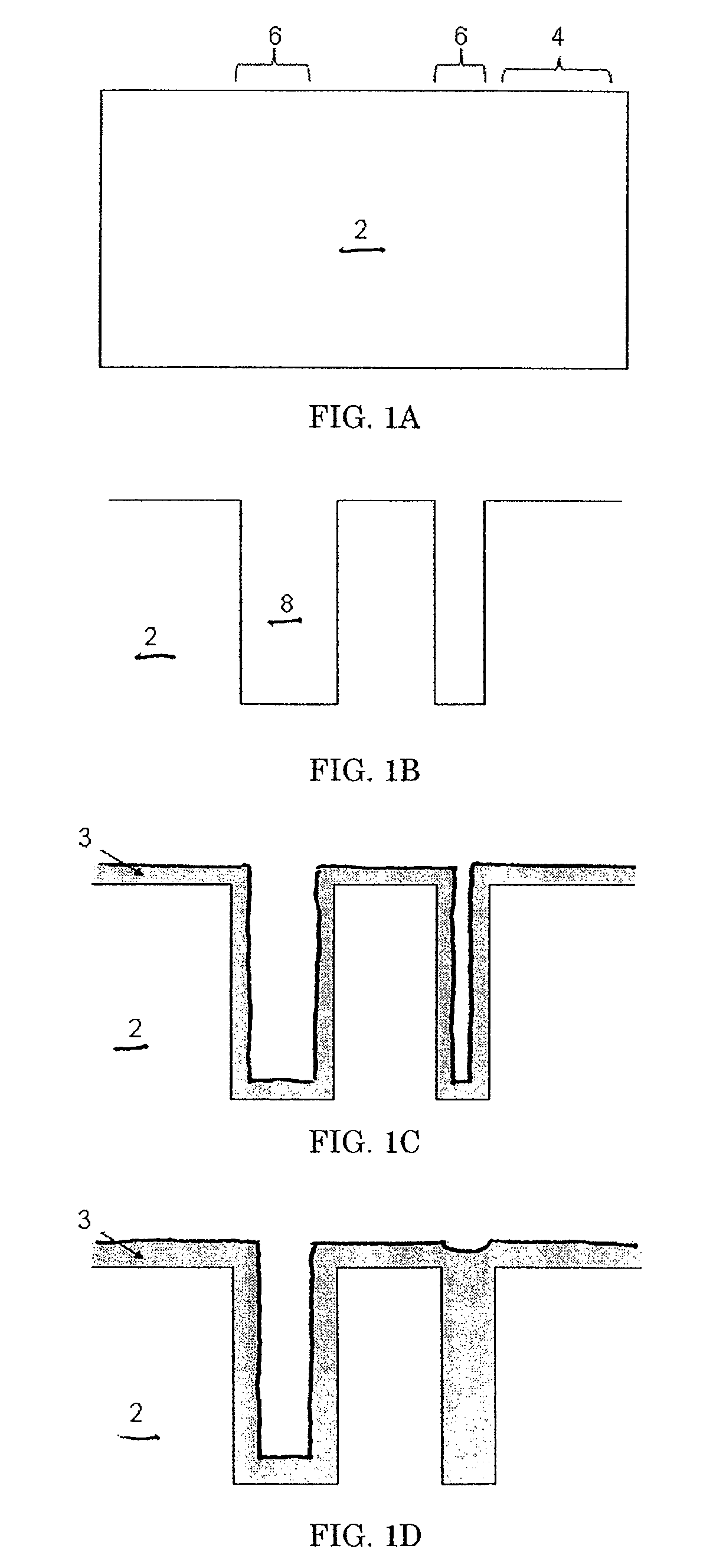

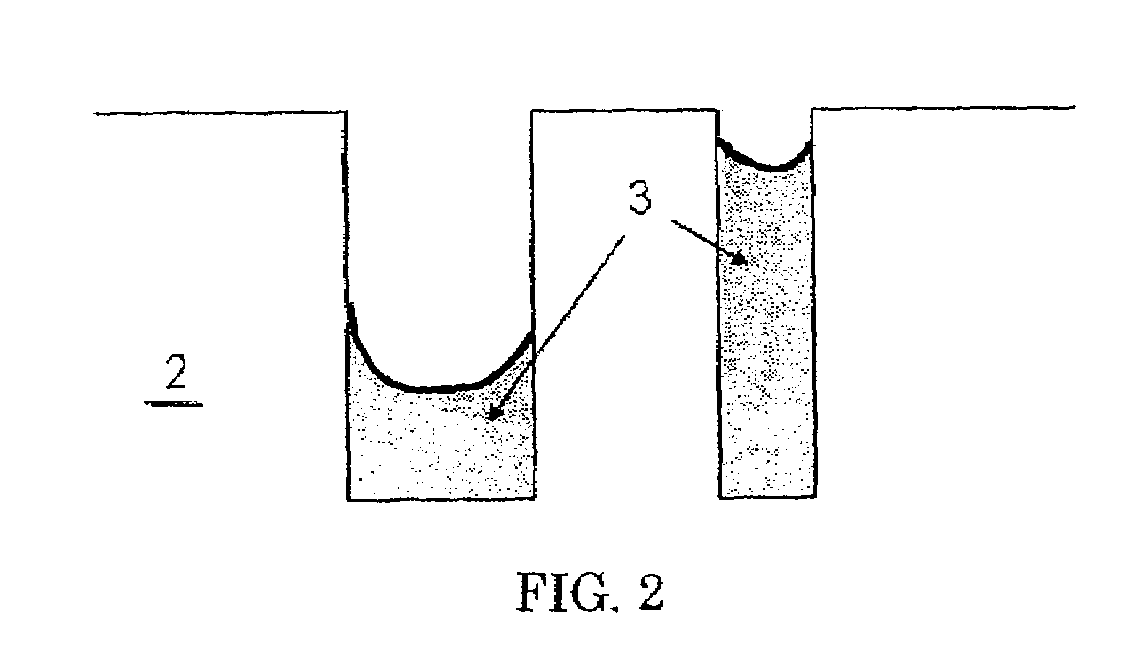

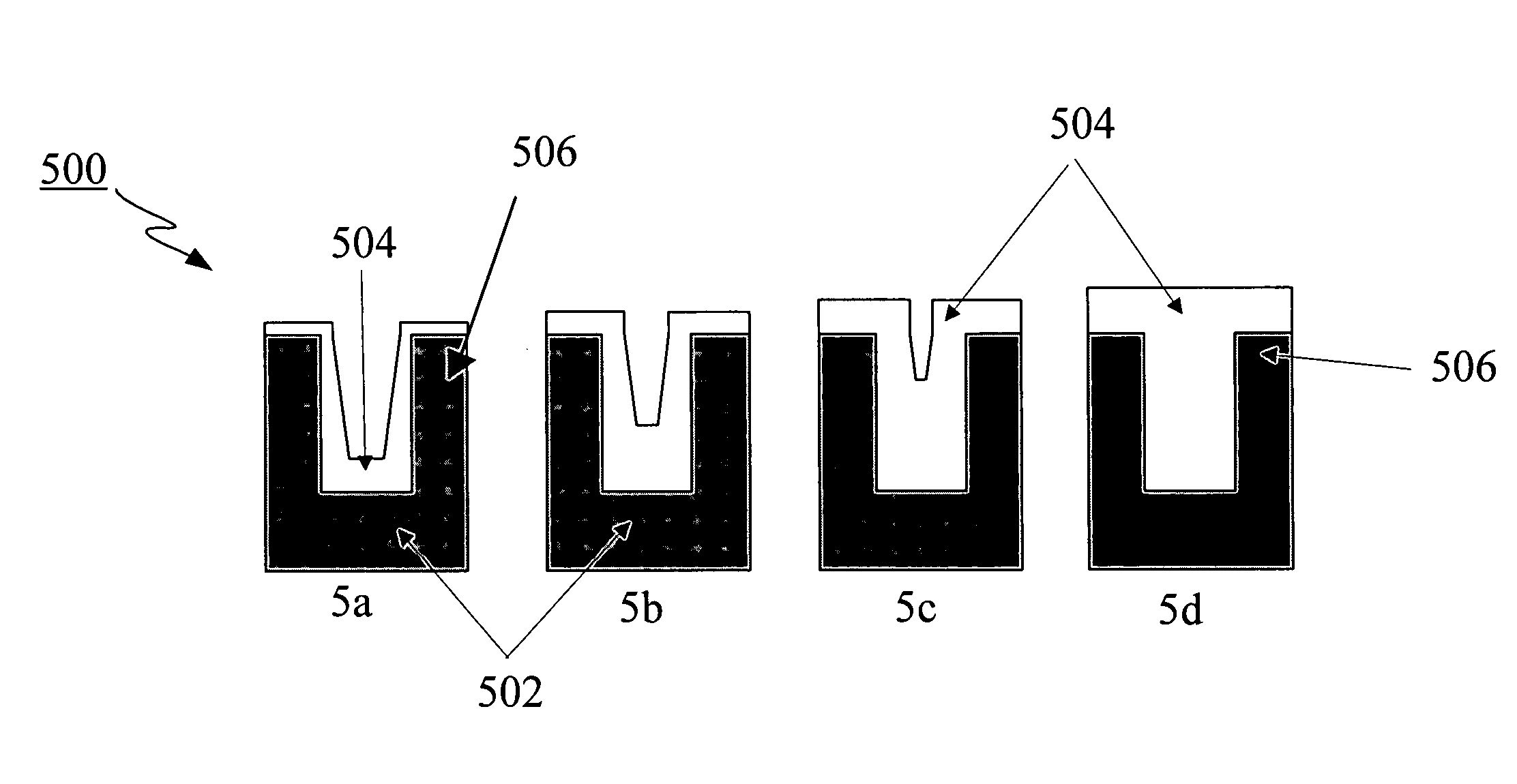

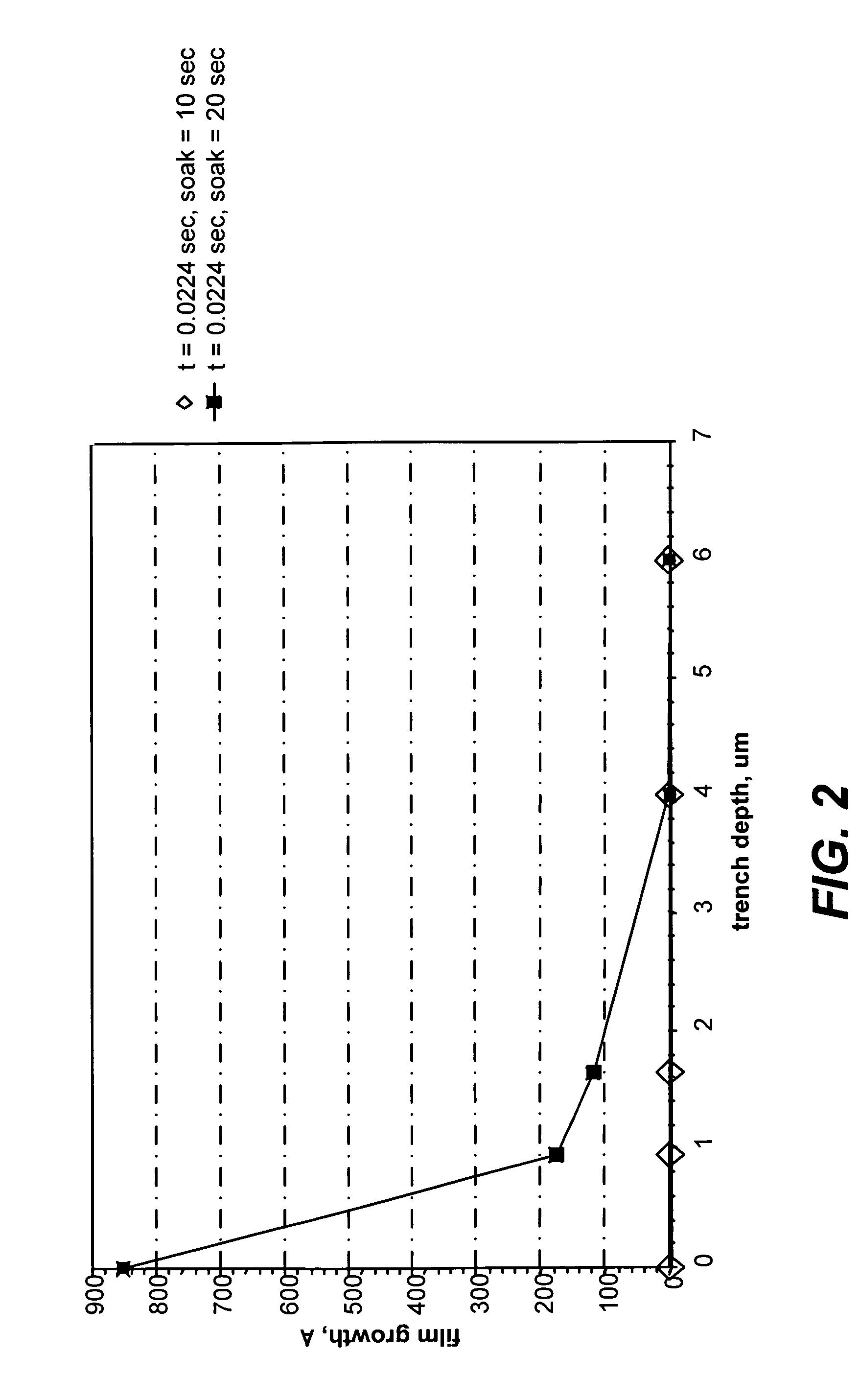

Method of selective coverage of high aspect ratio structures with a conformal film

ActiveUS7625820B1High aspect ratioVacuum evaporation coatingSputtering coatingMetallurgySilicon oxide

Methods for forming thin dielectric films by selectively depositing a conformal film of dielectric material on a high aspect ratio structure have uses in semiconductor processing and other applications. A method for forming a dielectric film involves providing in a deposition reaction chamber a substrate having a gap on the surface. The gap has a top opening and a surface area comprising a bottom and sidewalls running from the top to the bottom. A conformal silicon oxide-based dielectric film is selectively deposited in the gap by first preferentially applying a film formation catalyst or a catalyst precursor on a portion representing less than all of the gap surface area. The substrate surface is then exposed to a silicon-containing precursor gas such that a silicon oxide-based dielectric film layer is preferentially formed on the portion of the gap surface area. The preferential application of the catalyst or catalyst precursor may occur either at the top of the gap, for example to form a sacrificial mask, or at the bottom of the gap to create a seamless and void-free gap fill.

Owner:NOVELLUS SYSTEMS

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS20050092733A1Improve responseCausing temperature distributionMuffle furnacesSemiconductor/solid-state device manufacturingMetallurgySemiconductor

A ceramic heater for a semiconductor producing / examining device including a ceramic substrate having a heating surface for receiving a semiconductor wafer, a heating device for generating heat sufficient for producing / examining the semiconductor wafer and formed on the heating surface or inside the ceramic substrate, and a temperature measuring device for measuring a temperature of the heating surface and pressed against the ceramic substrate.

Owner:IBIDEN CO LTD

Method of preparing nano-structured surface coatings and coated articles

InactiveUS7892606B2Improve adhesionMore readily manufacturableMaterial nanotechnologyNanostructure manufactureCross-linkNano structuring

Owner:DSM IP ASSETS BV

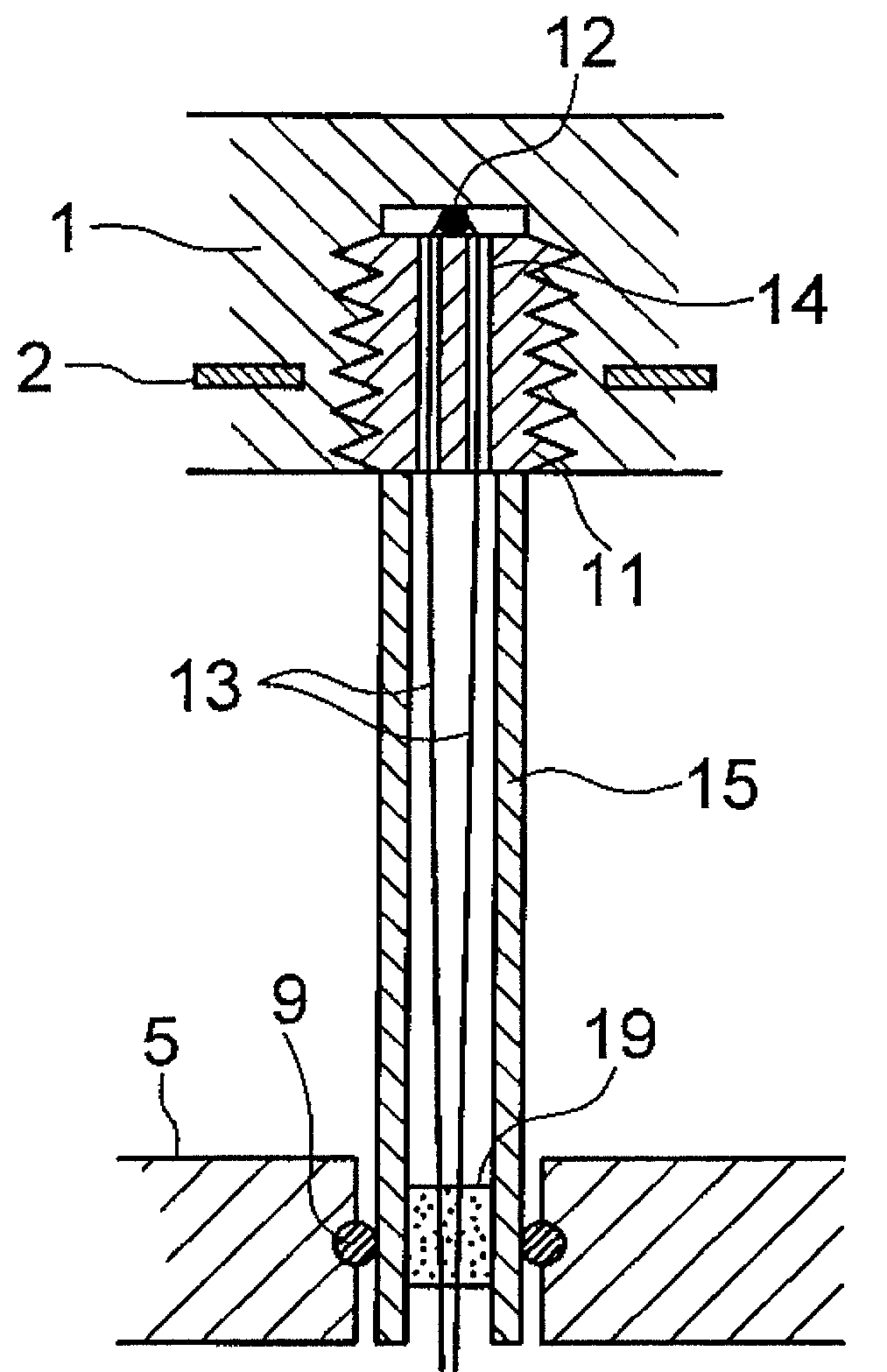

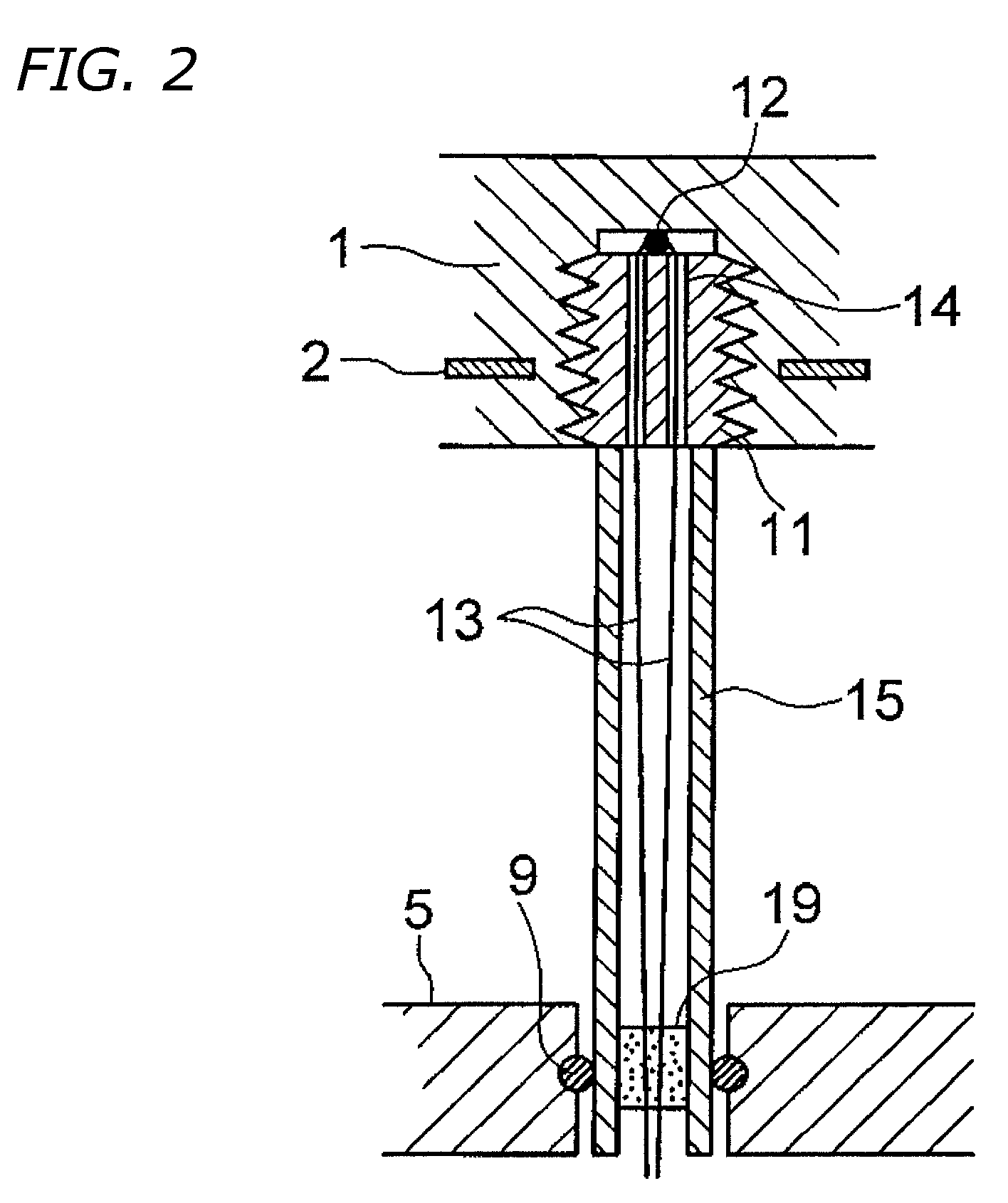

Temperature gauge and ceramic susceptor in which it is utilized

InactiveUS7090394B2Shorten the timeEasy to replaceThermometer detailsThermometers using electric/magnetic elementsSusceptorMetallurgy

Temperature gauge, and ceramic susceptors and semiconductor manufacturing equipment utilizing the temperature gauge, in which the thermocouple may be easily replaced even if damaged, and in which heat from the temperature-gauging site is readily transmitted to the temperature-gauging contact, shortening time until the measurement temperature stabilizes. A temperature-gauging contact (12) in the tip of the thermocouple contacts, in an exposed-as-it-is state, a temperature-gauging site on a ceramic susceptor (1), and by means of a circular cylindrical-shaped retaining member (11) screwed into female threads in the ceramic susceptor (1) is detachably pressed upon and retained against the ceramic susceptor. Thermocouple lead lines (13), passing through a through-hole (14) in the retaining member (11), stretch from one end face to the other end face thereof. The retaining member may be provided with a flange having threaded holes and screwlocked into female screws in the ceramic susceptor.

Owner:SUMITOMO ELECTRIC IND LTD

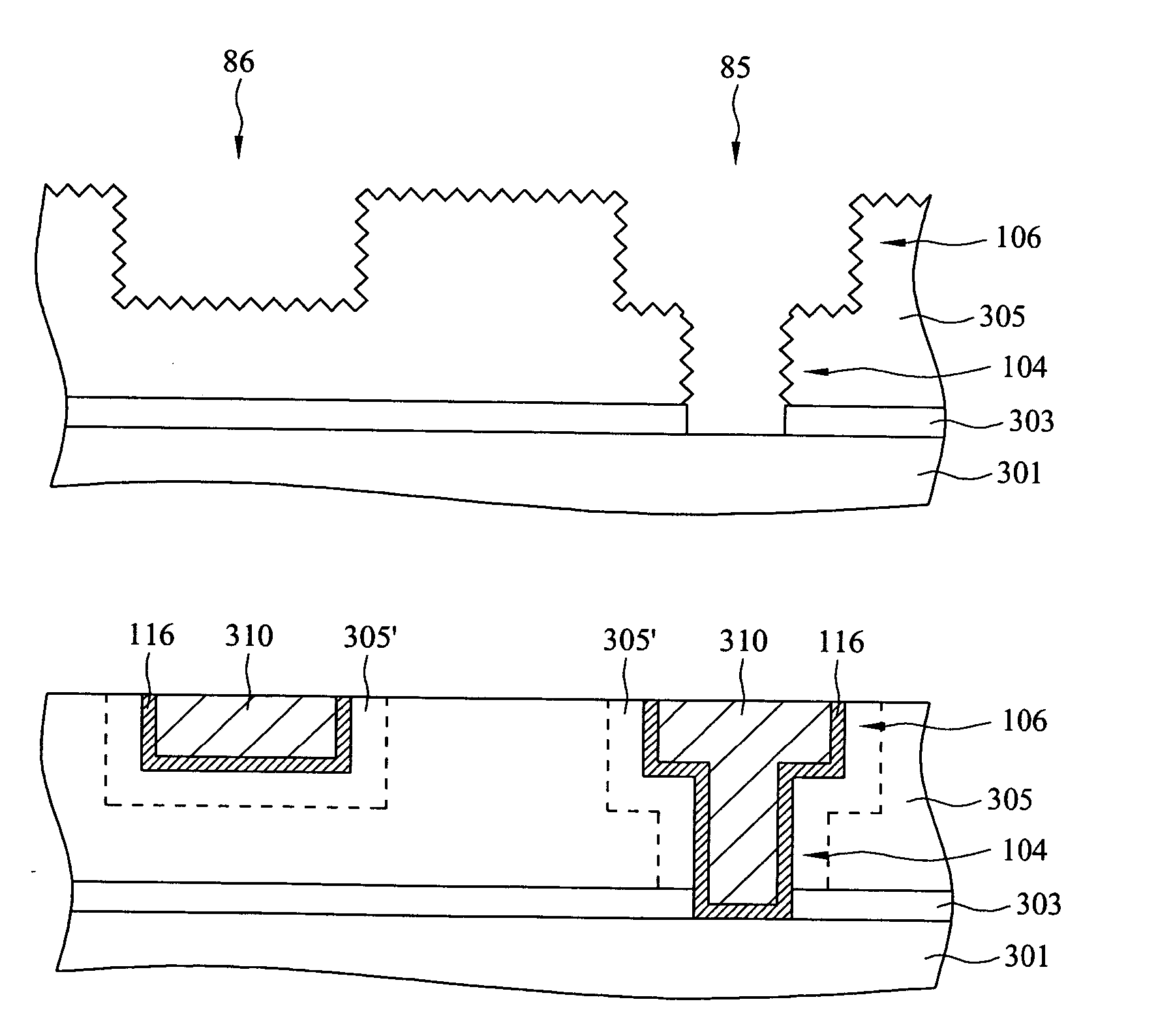

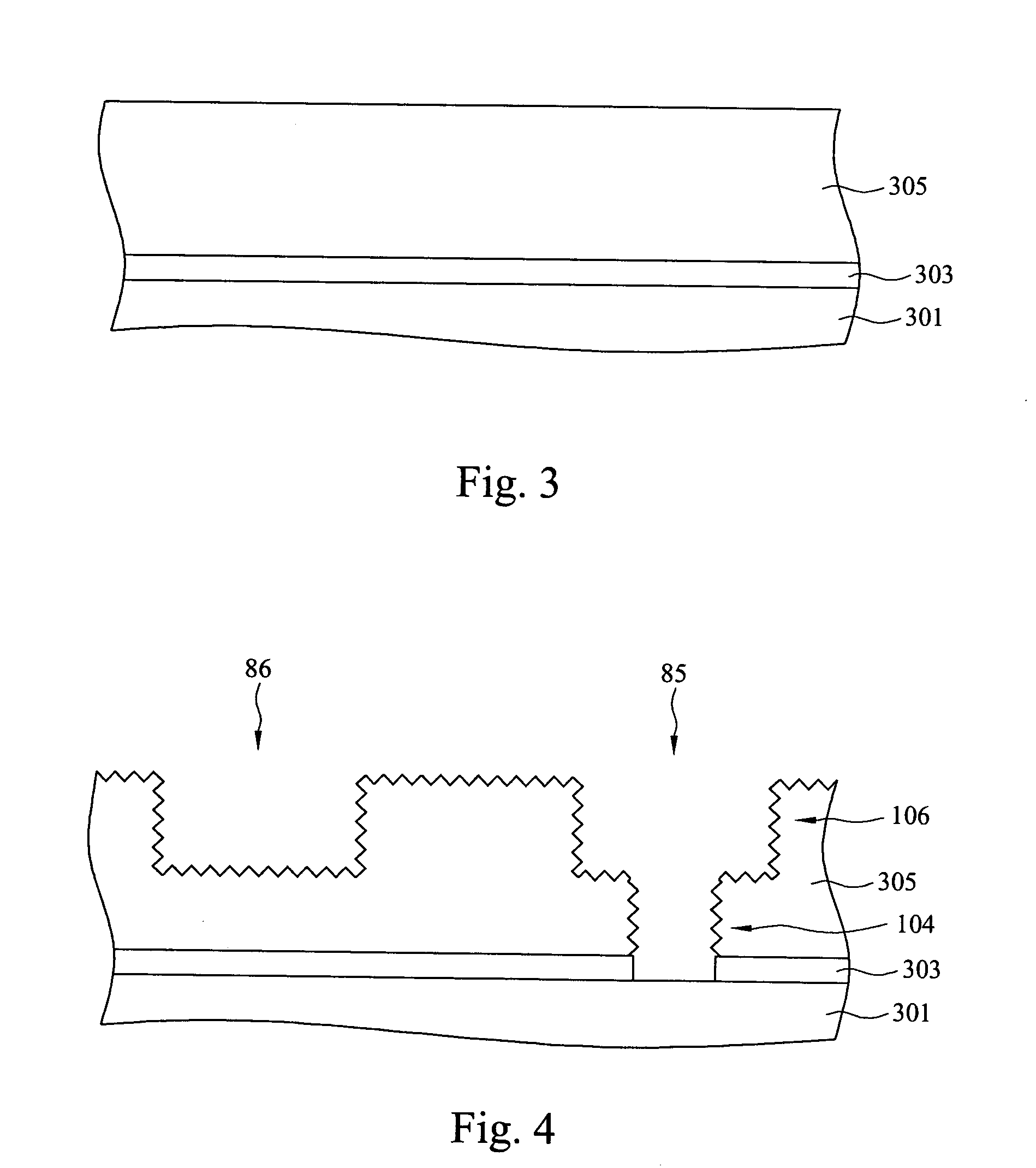

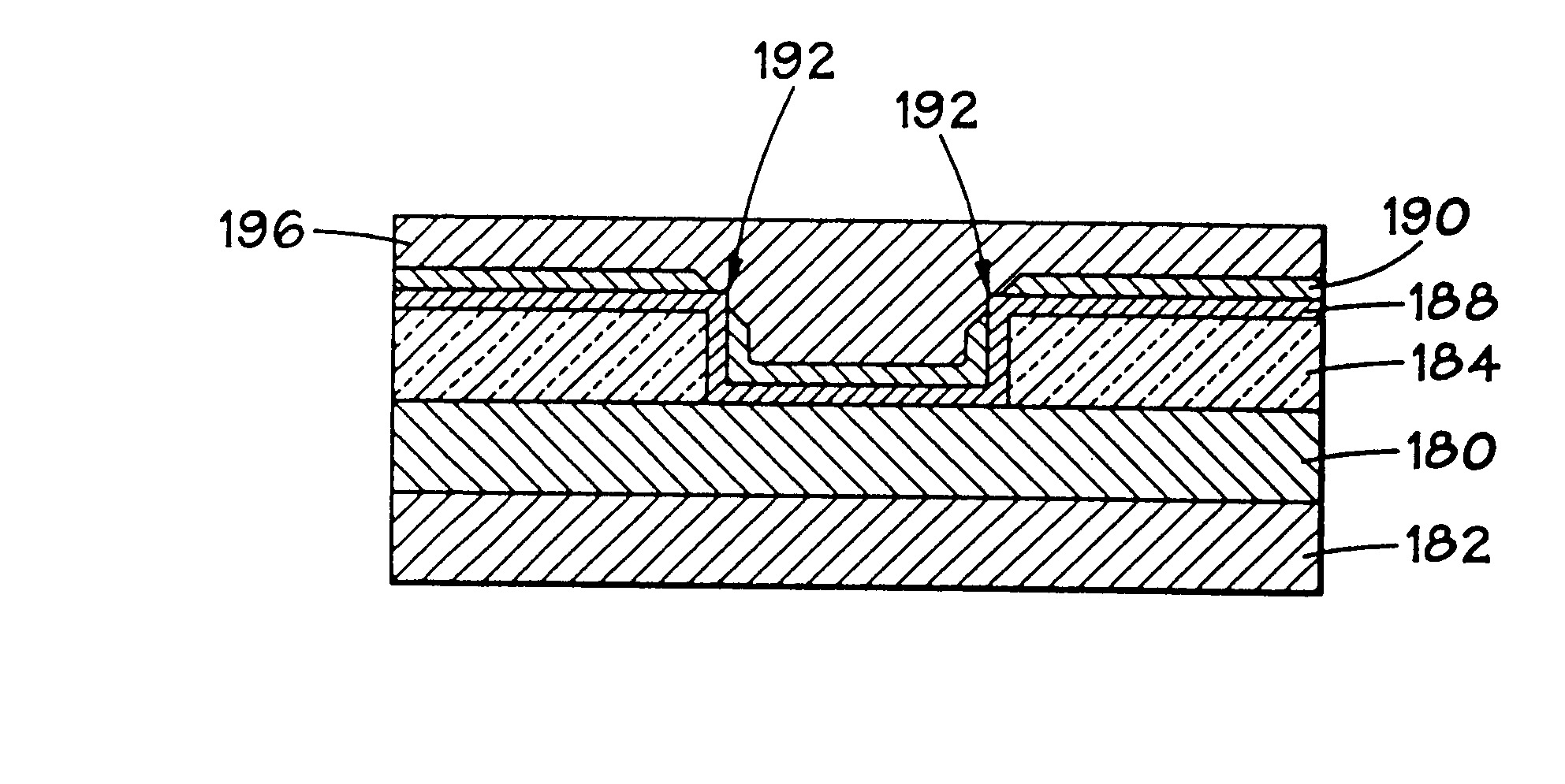

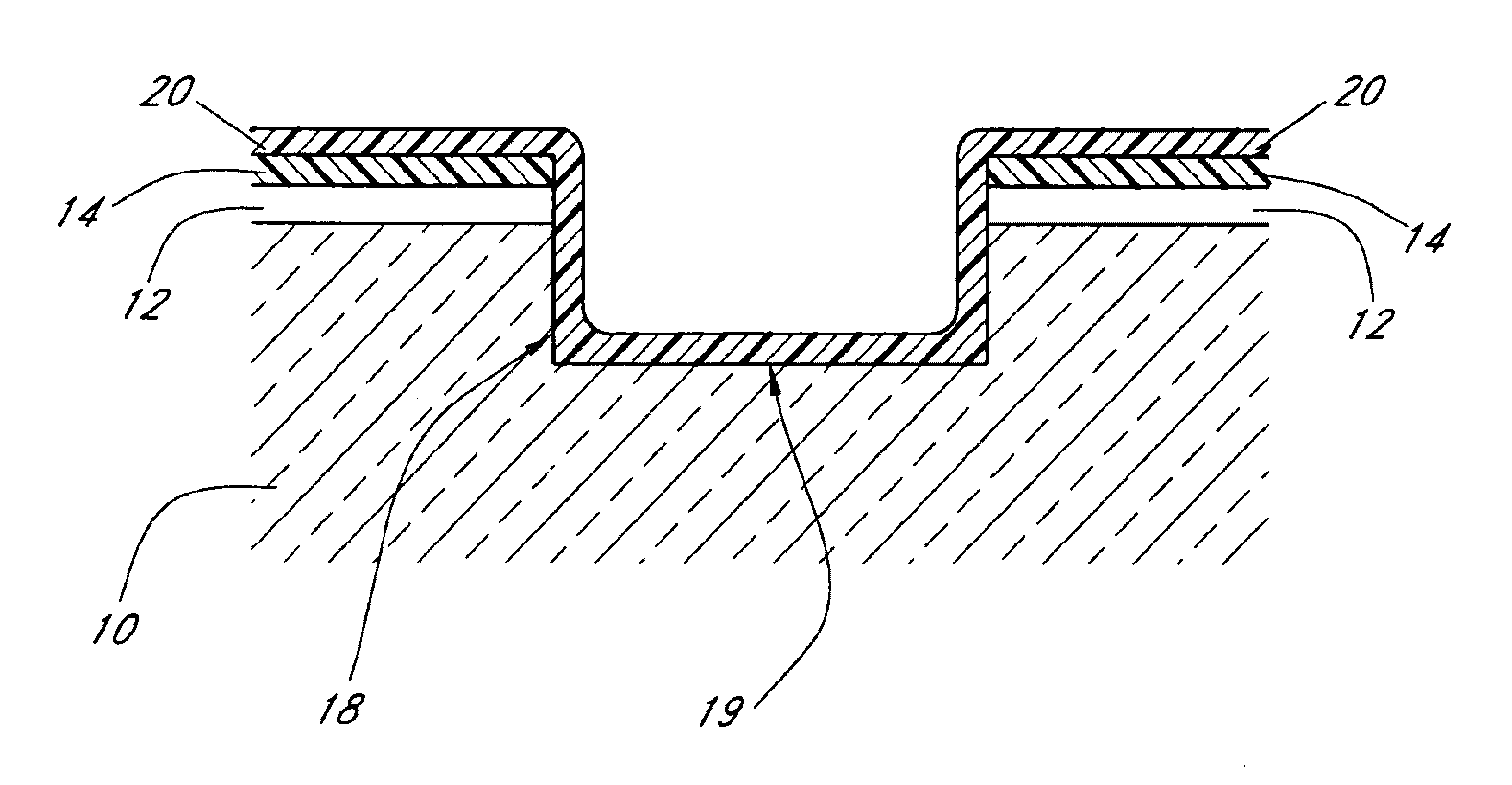

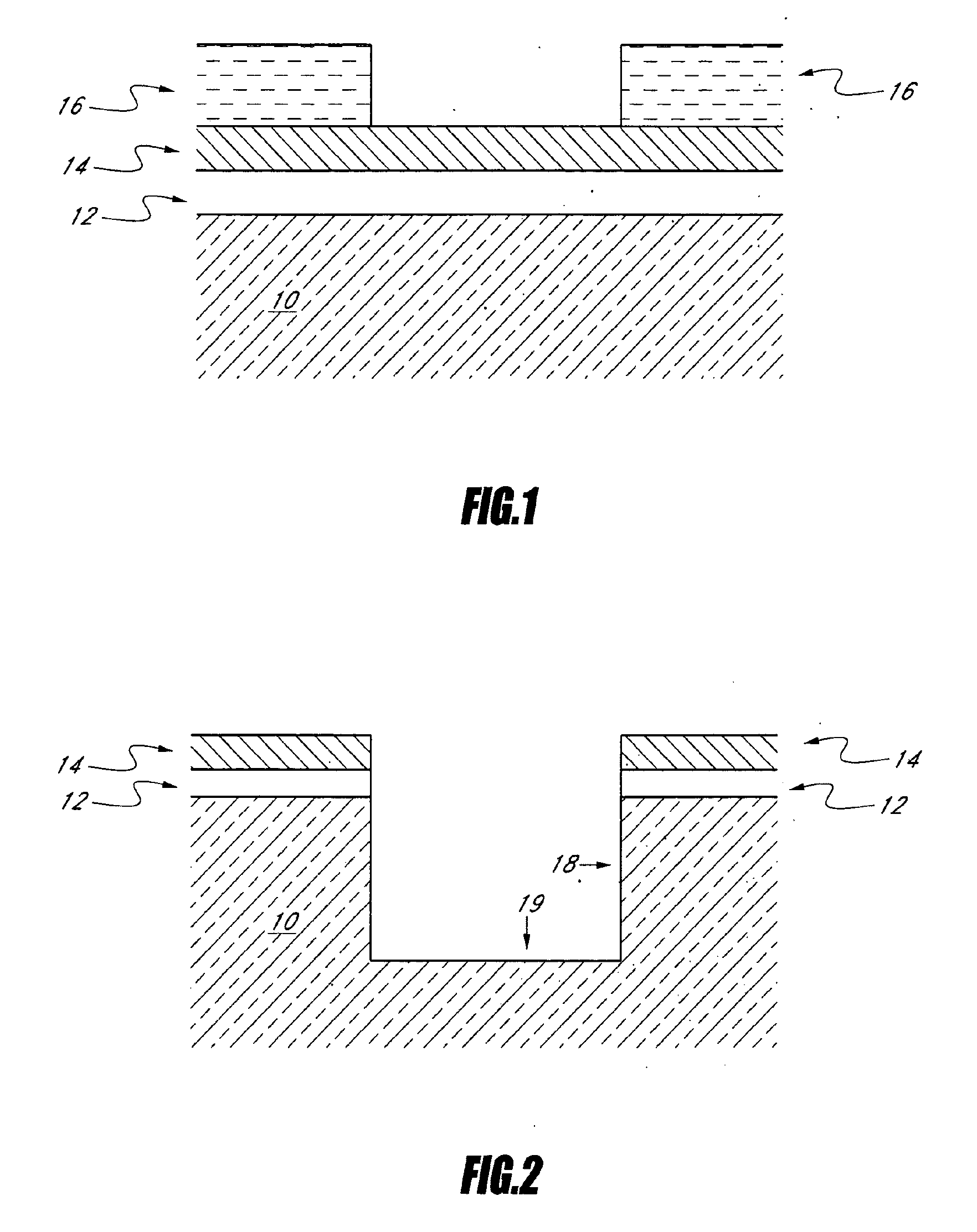

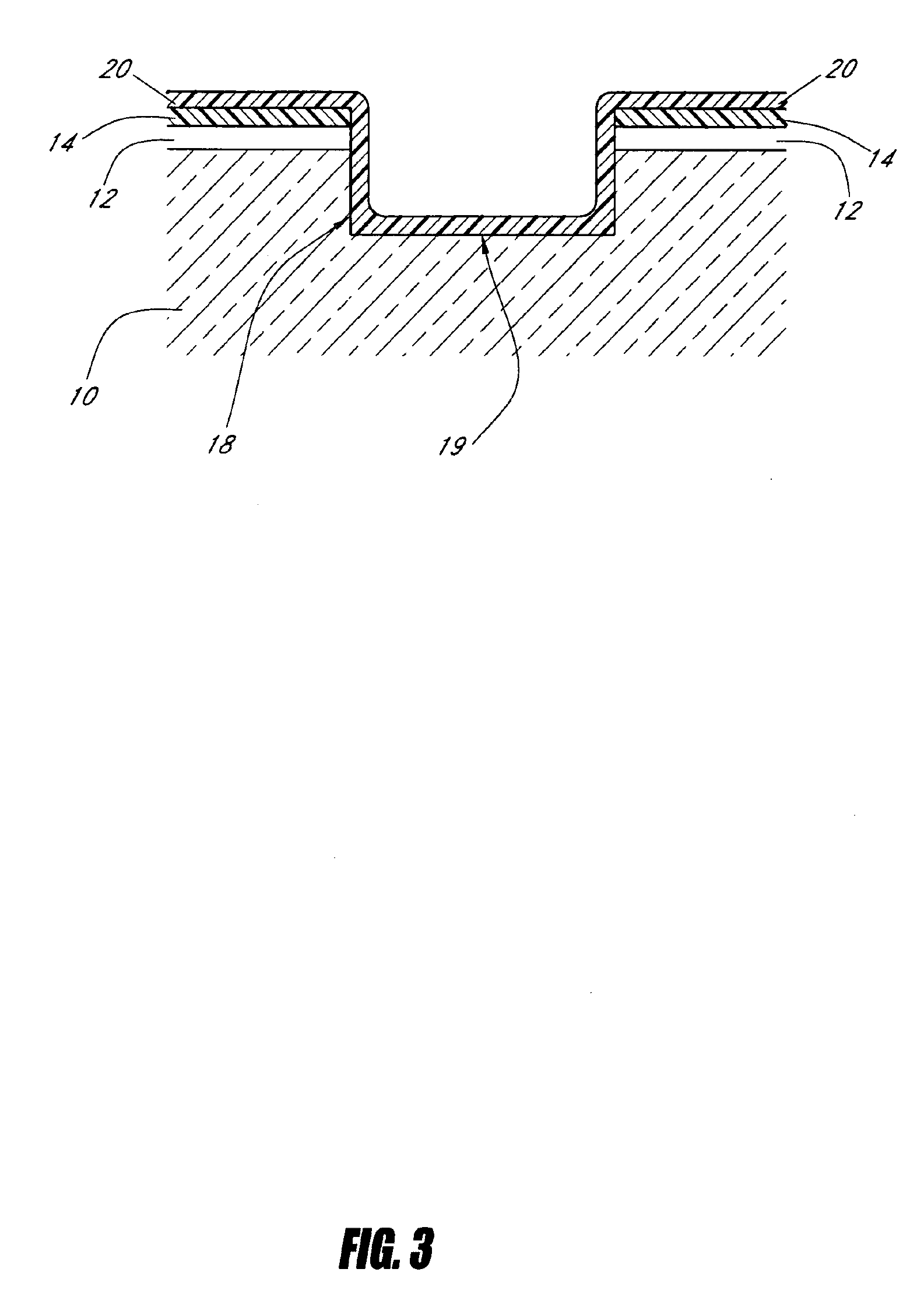

Trench insulation structures and methods

Owner:MICRON TECH INC

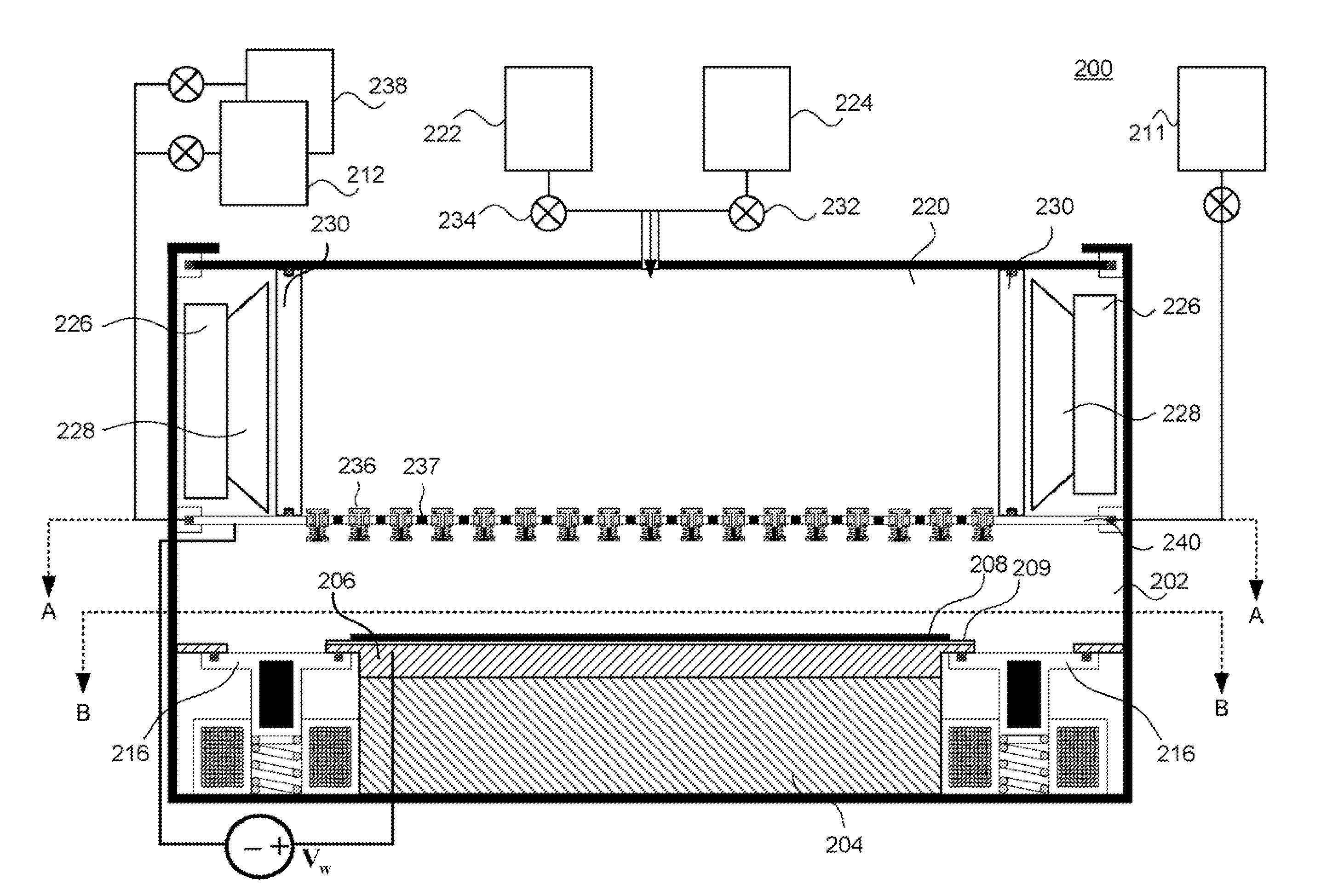

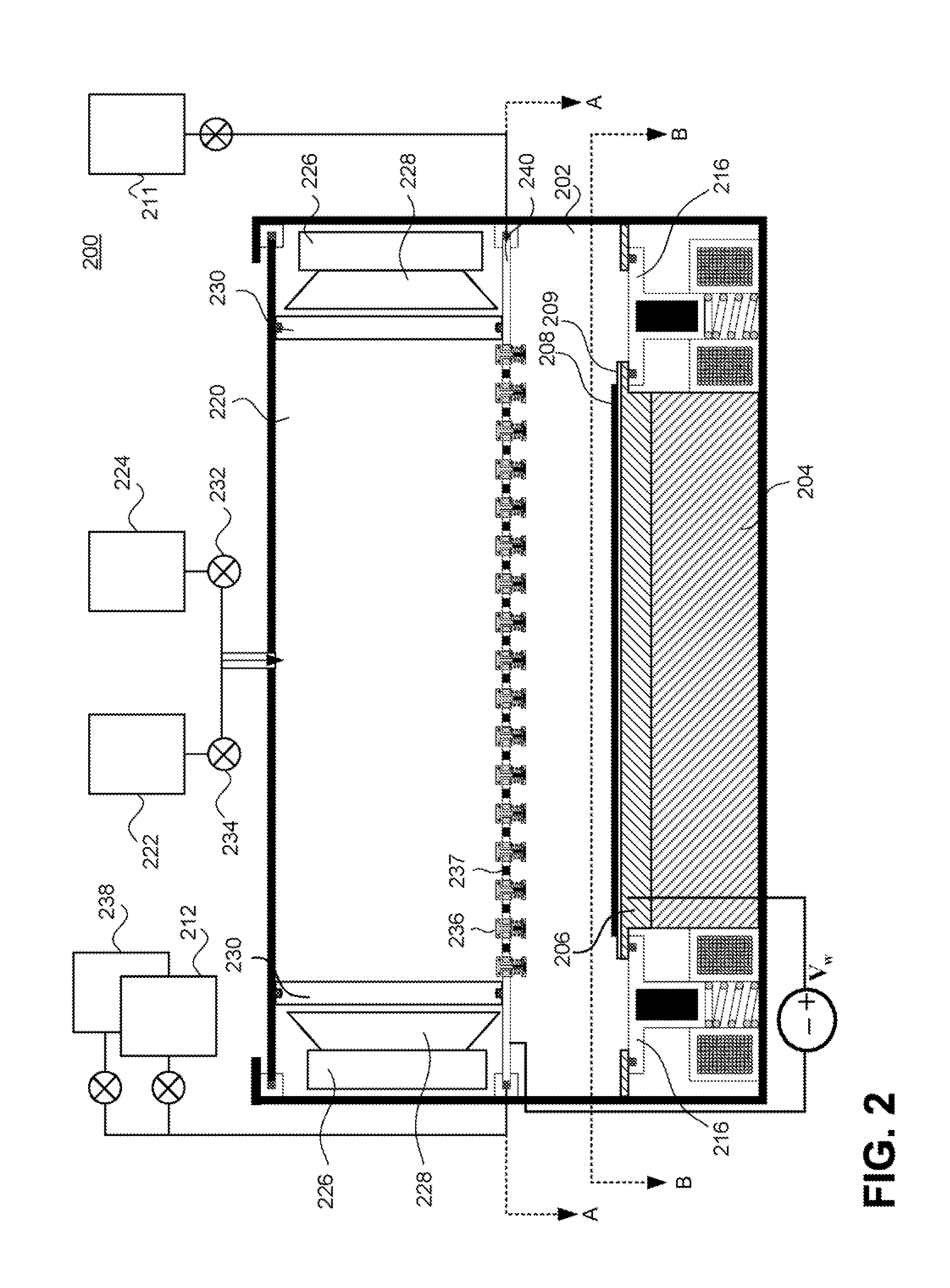

Flash Heating in Atomic Layer Deposition

InactiveUS20070281082A1Control performanceSave stepsSolid-state devicesPretreated surfacesMetallurgyAtomic layer deposition

System and methods for flash heating of materials deposited using atomic layer deposition techniques are disclosed. By flash heating the surface of the deposited material after each or every few deposition cycles, contaminants such as un-reacted precursors and byproducts can be released from the deposited material. A higher quality material is deposited by reducing the incorporation of impurities. A flash heating source is capable of quickly raising the temperature of the surface of a deposited material without substantially raising the temperature of the bulk of the substrate on which the material is being deposited. Because the temperature of the bulk of the substrate is not significantly raised, the bulk acts like a heat sink to aid in cooling the surface after flash heating. In this manner, processing times are not significantly increased in order to allow the surface temperature to reach a suitably low temperature for deposition.

Owner:SANDISK TECH LLC

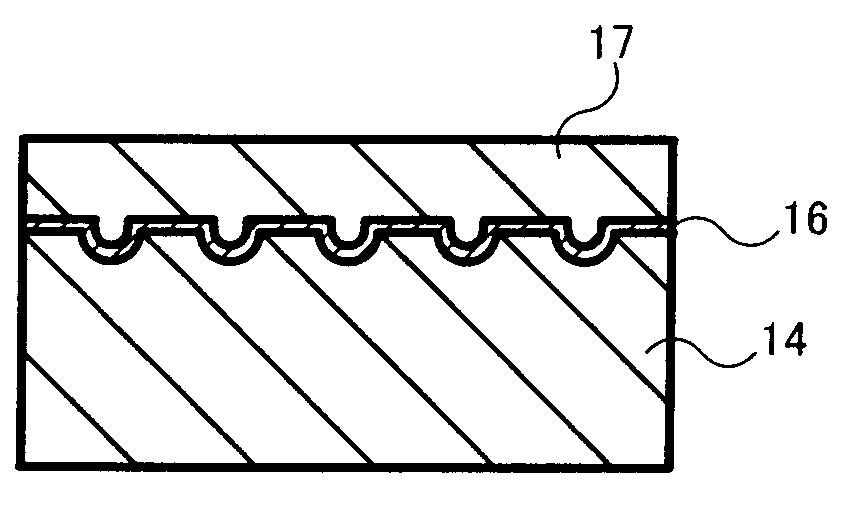

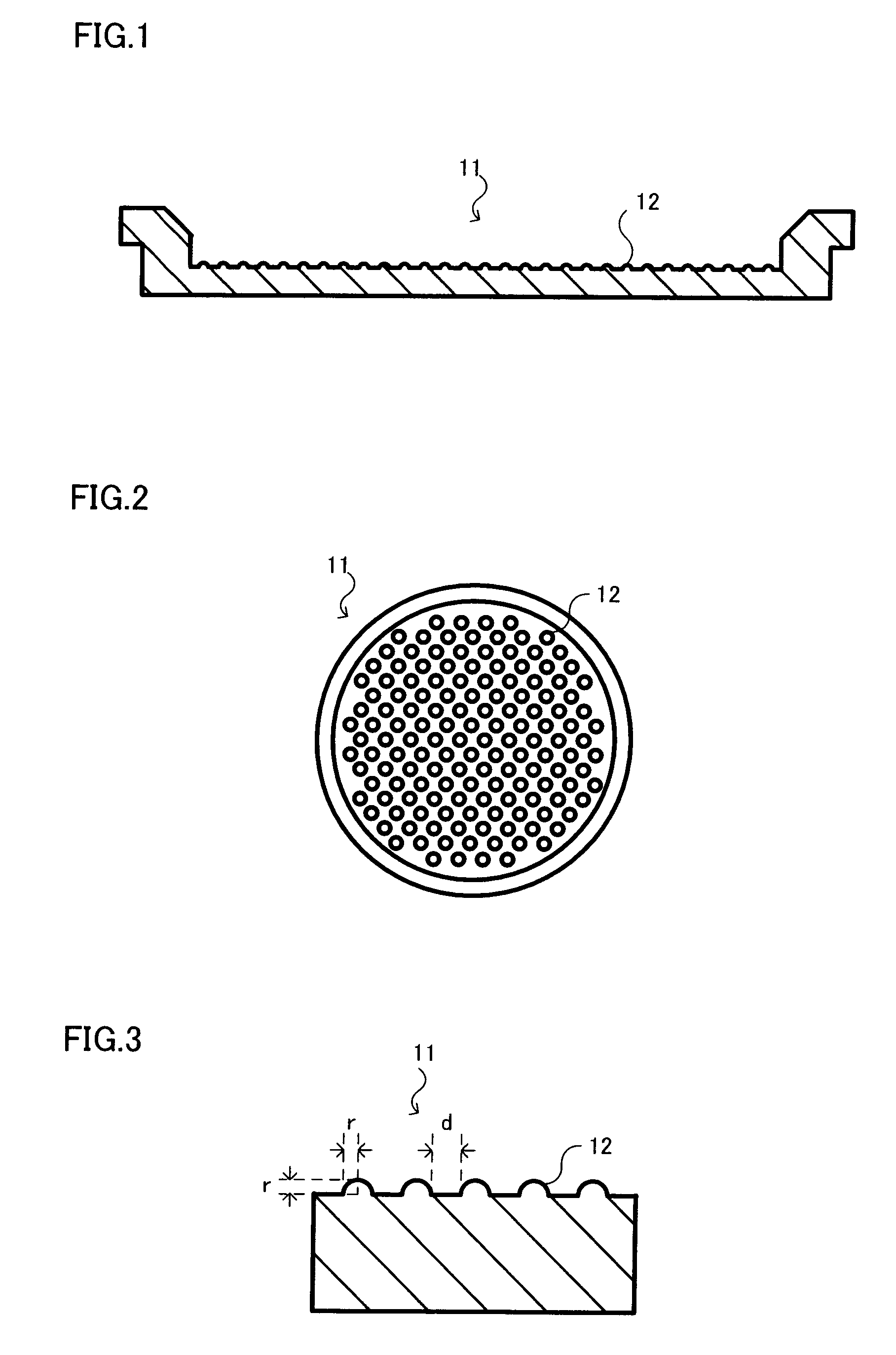

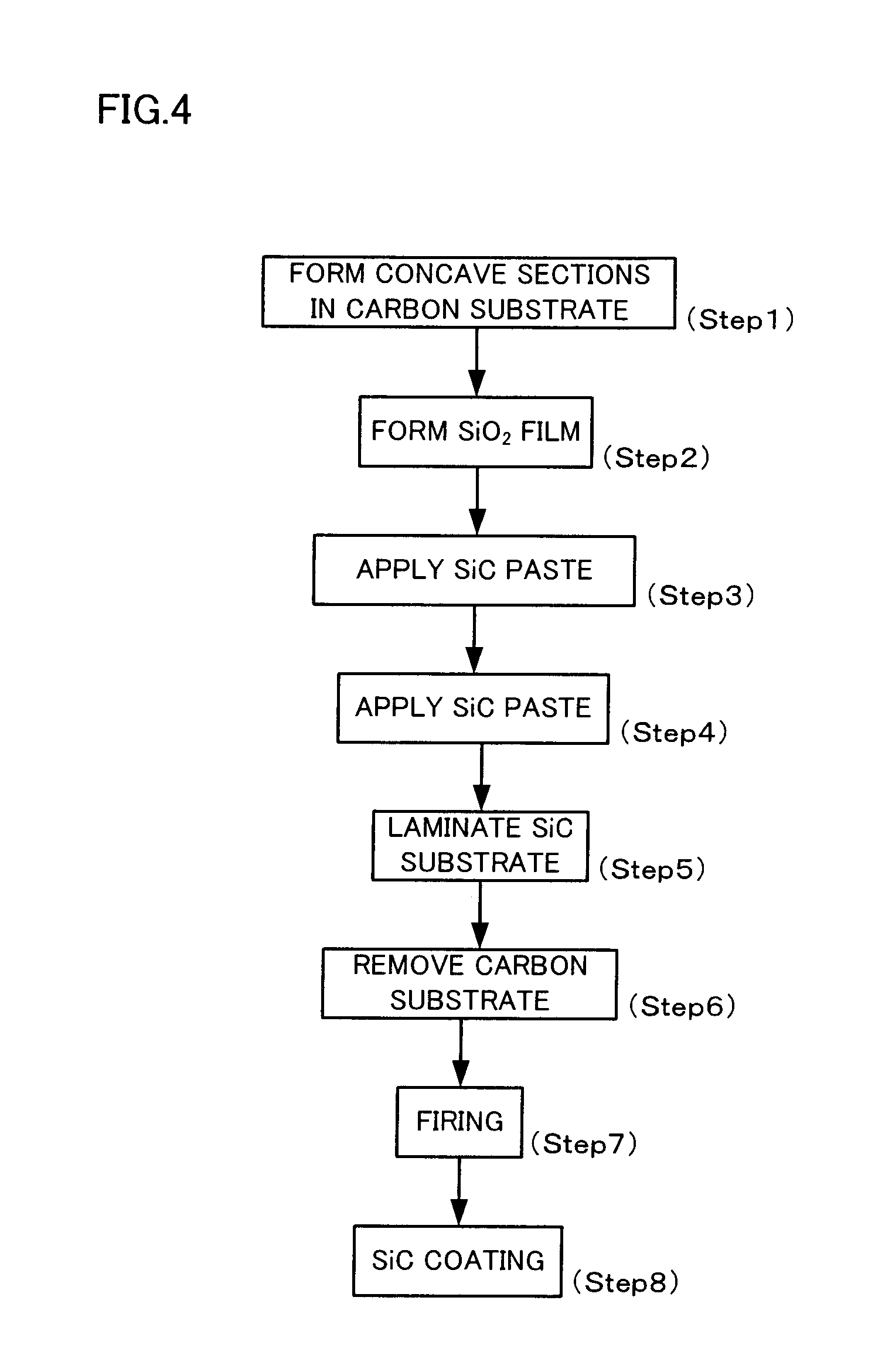

Method for manufacturing susceptor

ActiveUS20100163524A1Decorative surface effectsSemiconductor/solid-state device manufacturingSusceptorMetallurgy

A method for manufacturing a susceptor includes: forming a concave pattern in a surface of a substrate to be processed; applying a SiC paste containing a SiC powder and a sintering agent to the surface of the substrate to be processed to fill the concave pattern to form a SiC coating layer; laminating a SiC substrate on the SiC coating layer; and firing the SiC coating layer to form a SiC layer having at least one convex section on the surface of the SiC substrate.

Owner:NUFLARE TECH INC

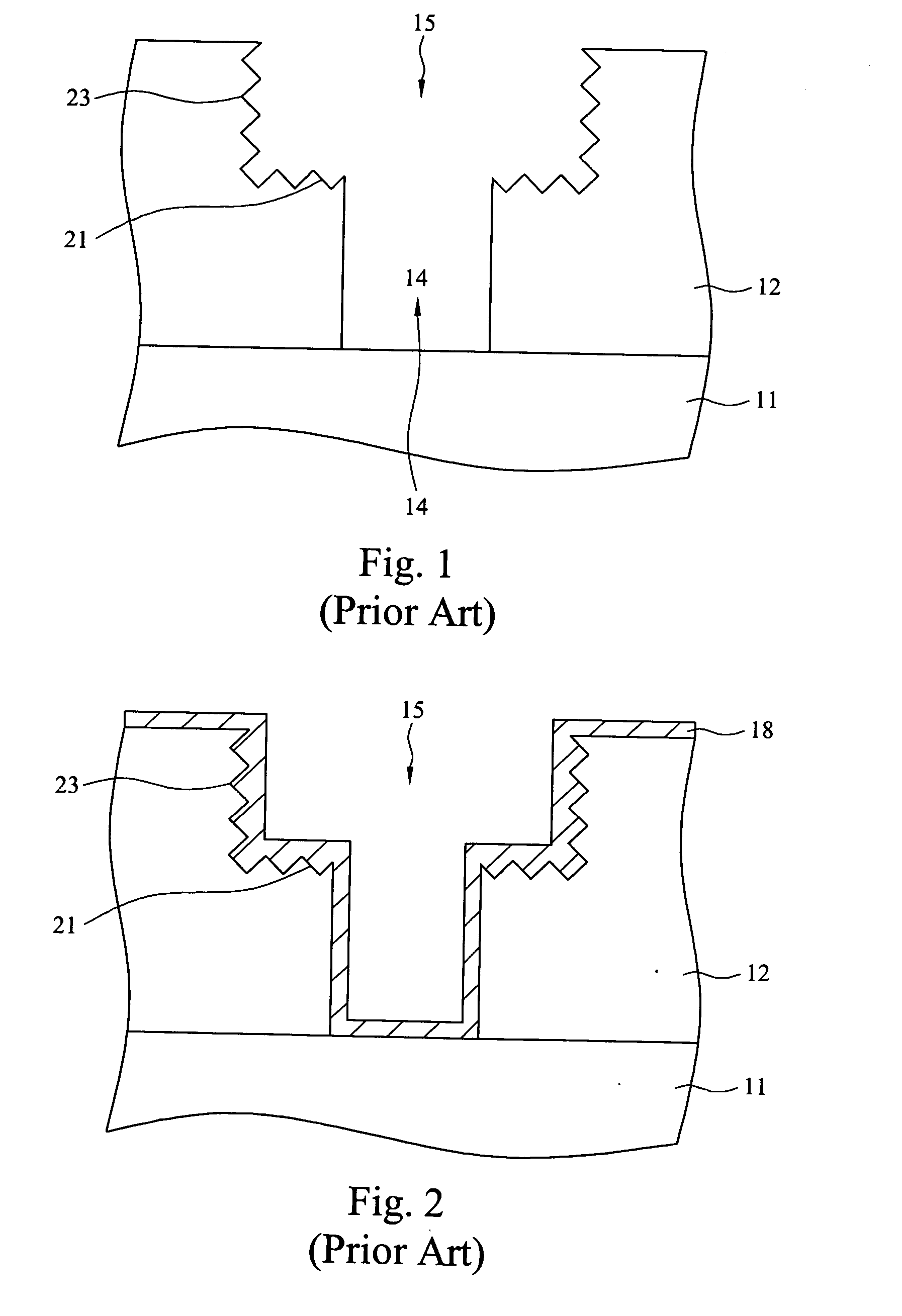

Method of forming a contact structure in a semiconductor device

InactiveUS6440837B1Solid-state devicesSemiconductor/solid-state device manufacturingProcess deviationsEtching

Annular and linear contact structures are described which exhibit a greatly reduced susceptibility to process deviations caused by lithographic and deposition variations than does a conventional circular contact plug. In one embodiment, a standard conductive material such as carbon or titanium nitride is used to form the contact. In an alternative embodiment, a memory material itself is used to form the contact. These contact structures may be made by various processes, including chemical mechanical planarization and facet etching.

Owner:ROUND ROCK RES LLC

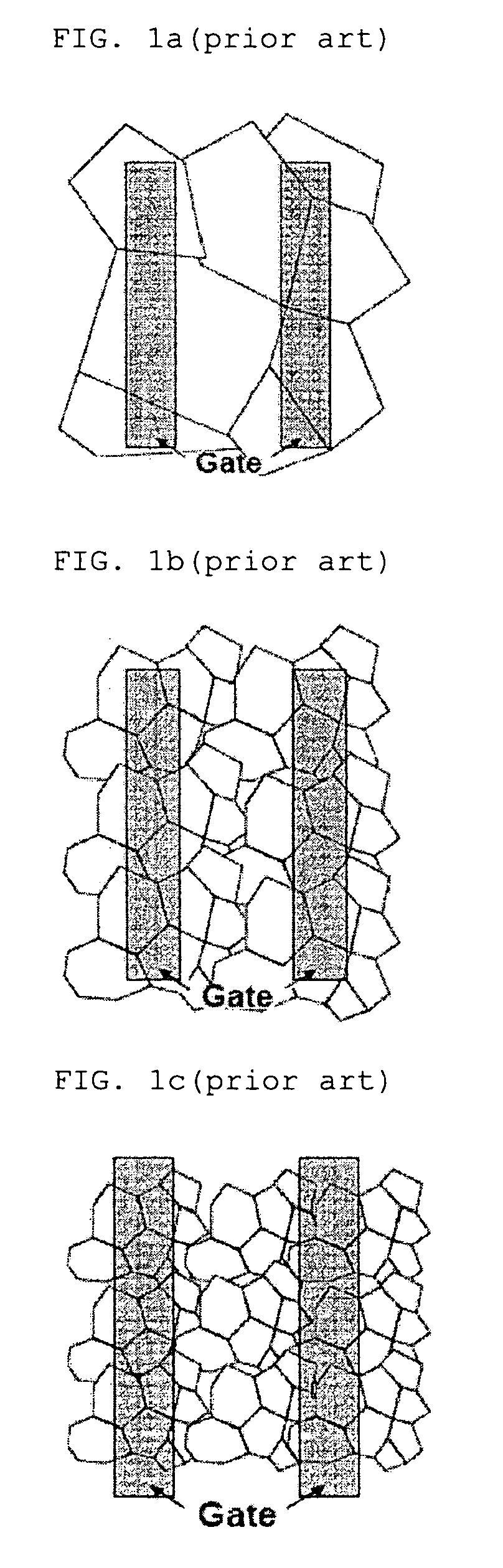

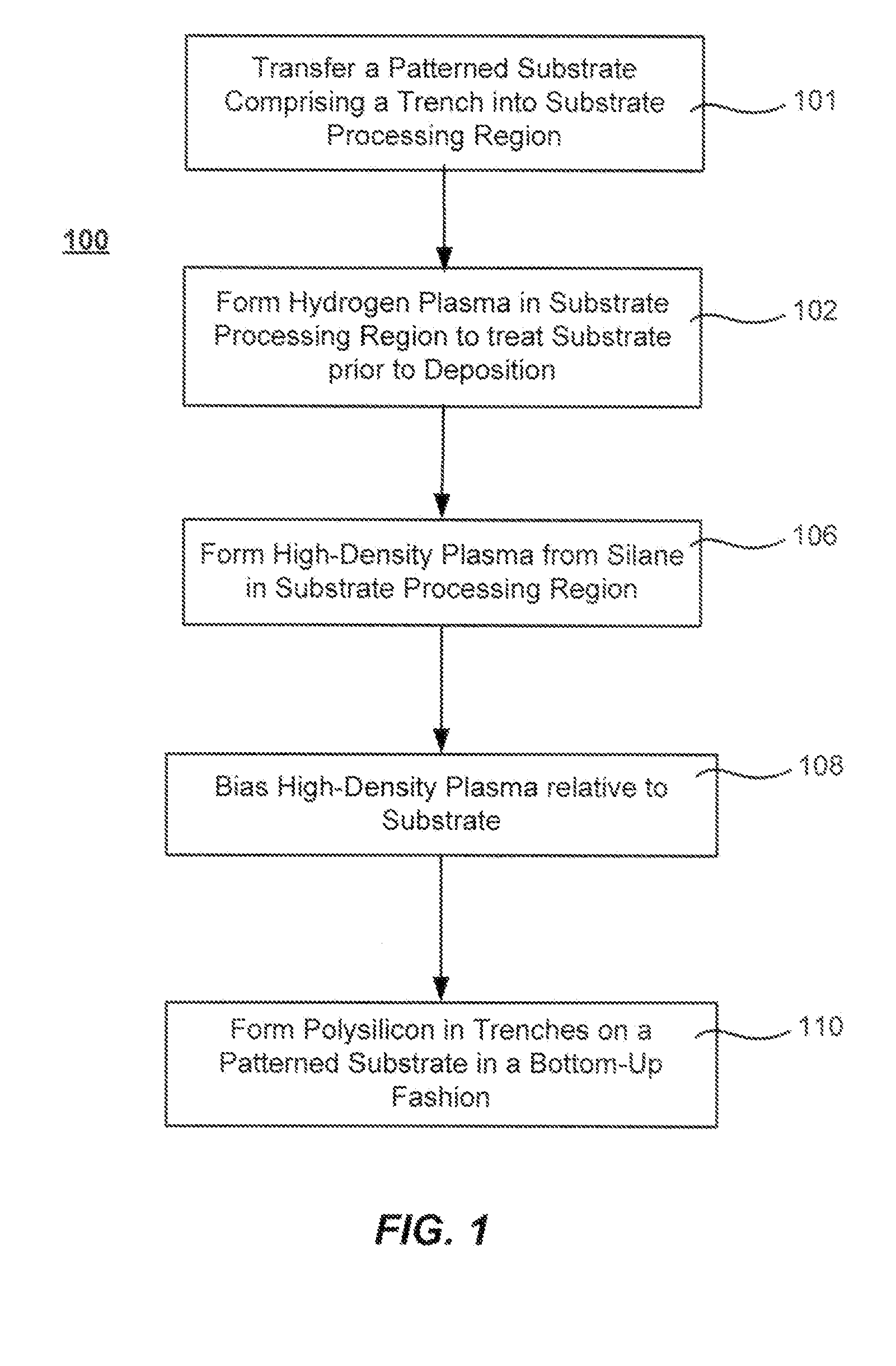

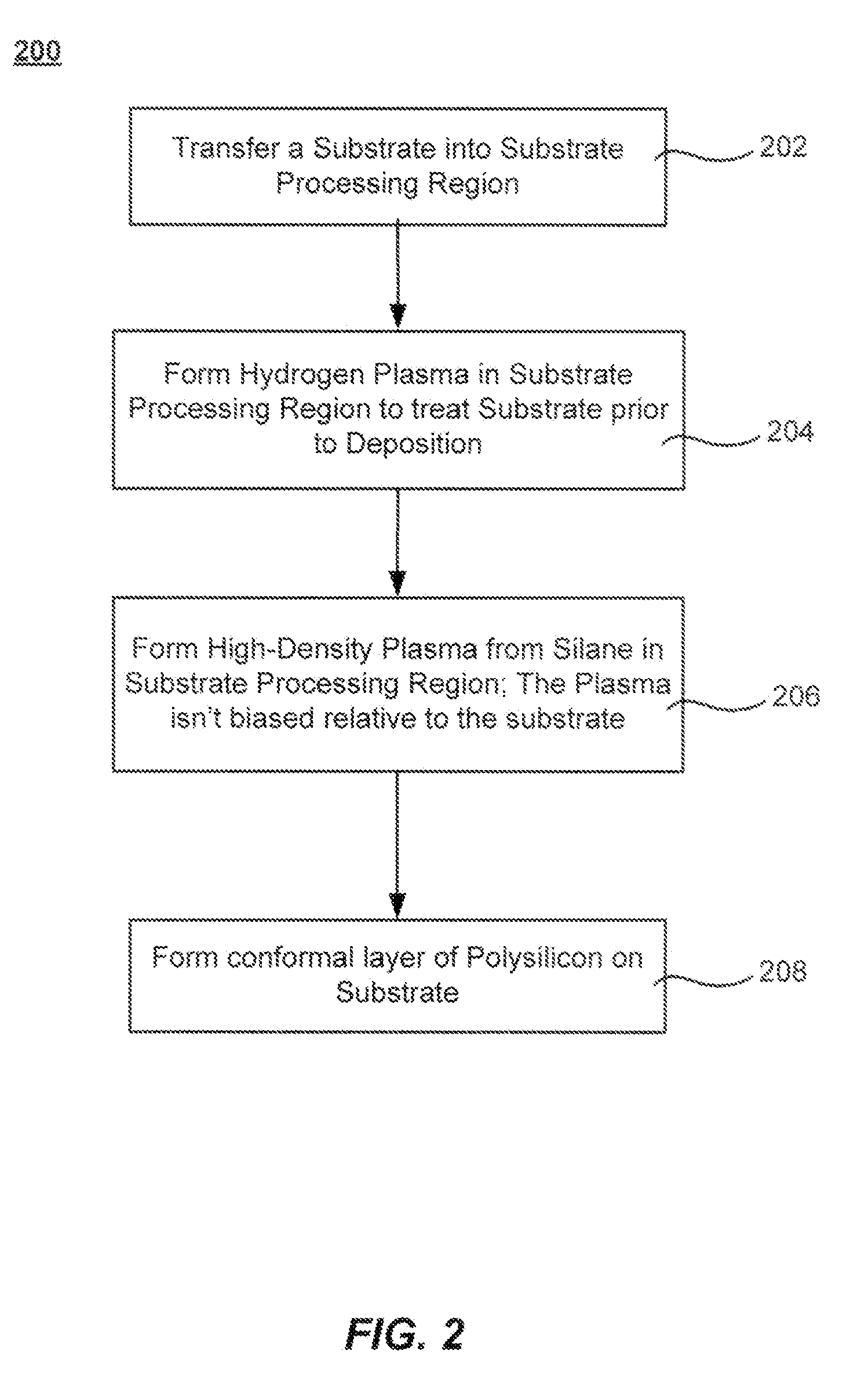

Polysilicon films by hdp-cvd

InactiveUS20120190178A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyPolycrystalline silicon thin films

Methods of forming polysilicon layers are described. The methods include forming a high-density plasma from a silicon precursor in a substrate processing region containing the deposition substrate. The described methods produce polycrystalline films at reduced substrate temperature (e.g. <500° C.) relative to prior art techniques. The availability of a bias plasma power adjustment further enables adjustment of conformality of the formed polysilicon layer. When dopants are included in the high density plasma, they may be incorporated into the polysilicon layer in such a way that they do not require a separate activation step.

Owner:APPLIED MATERIALS INC

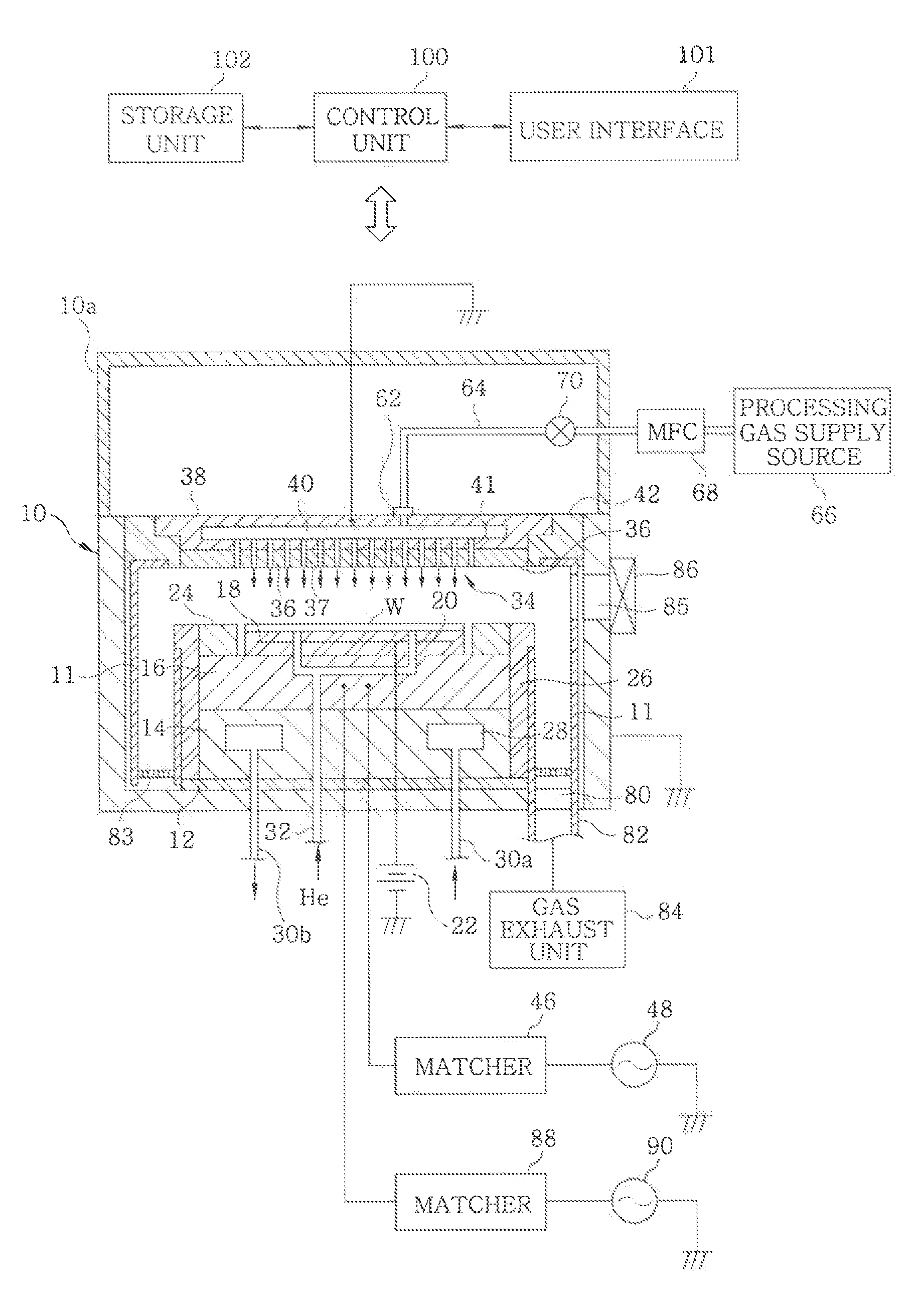

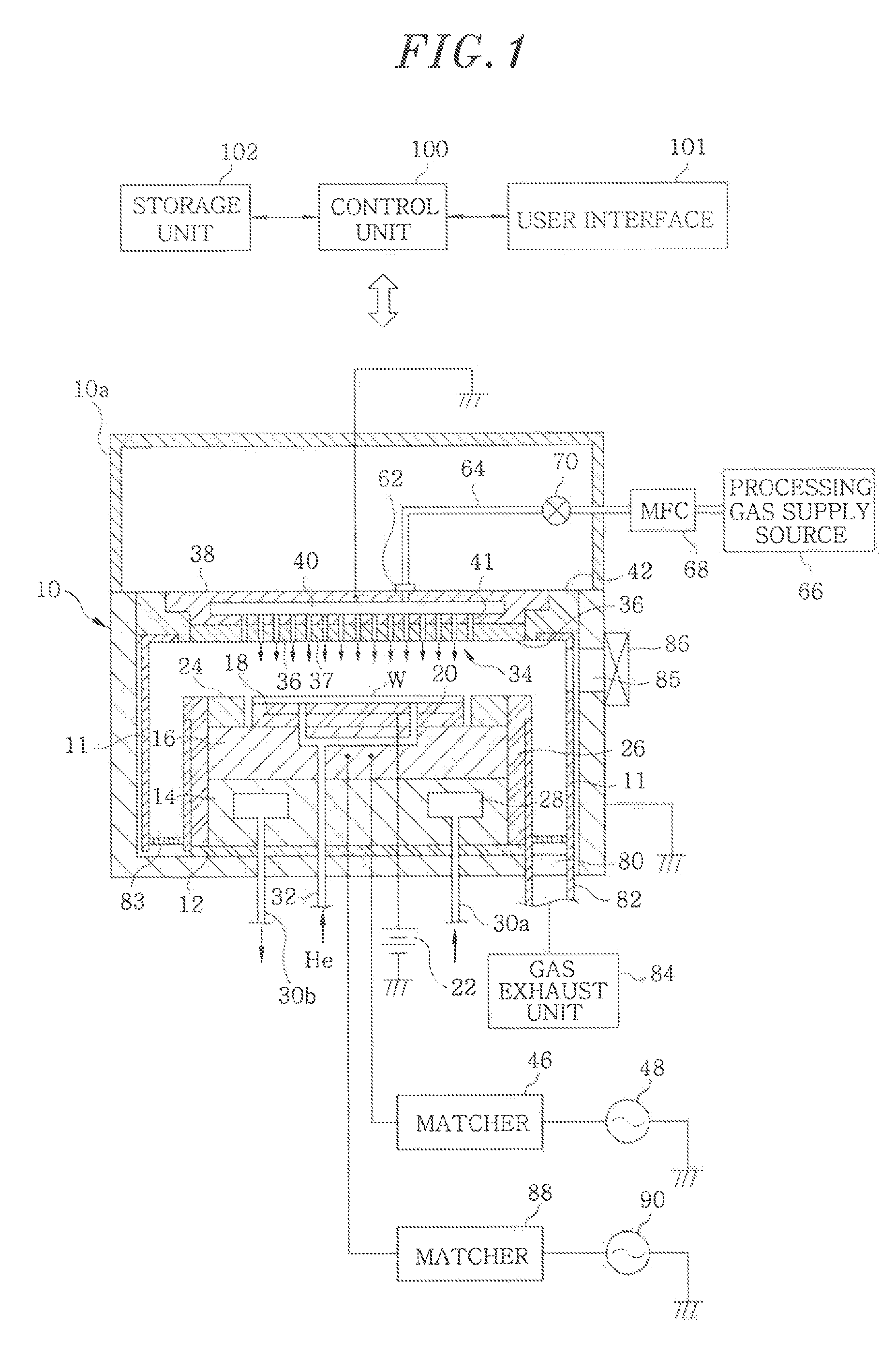

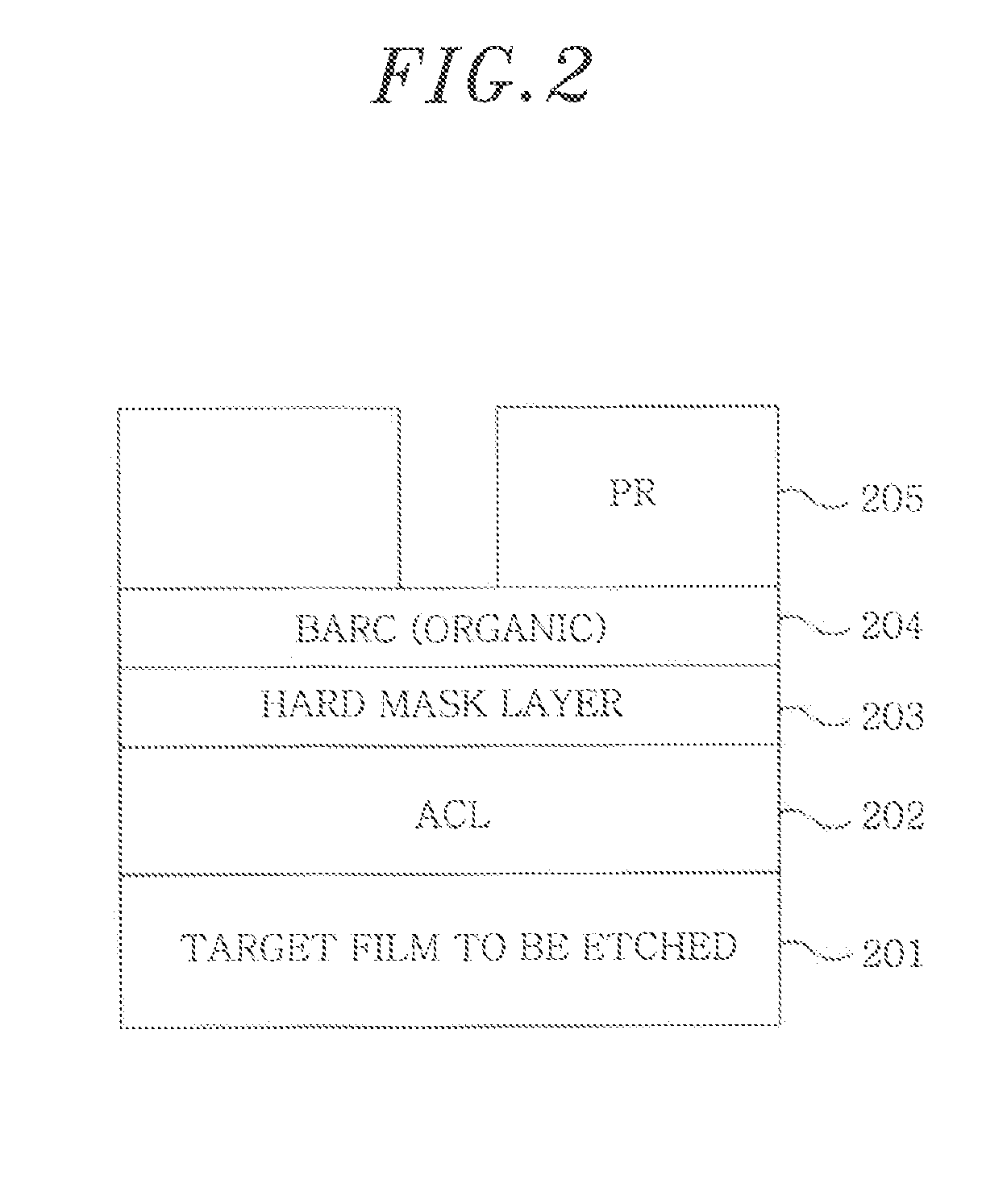

Plasma etching method

ActiveUS20140377960A1Electric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyResidence time

In a plasma etching method of performing a plasma etching on an amorphous carbon layer of a substrate to be processed by using an inorganic film as a mask, the substrate being mounted in a processing chamber, the plasma etching on the amorphous carbon layer is performed by using O2 gas as a processing gas and the O2 gas to flow in the processing chamber such that a residence time of the O2 gas becomes 0.37 msec or less. The amorphous carbon layer is used as an etching mask of an etching target film formed on the substrate. The plasma etching is performed by using the O2 gas only.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com