Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

583results about How to "Increase the rate of crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

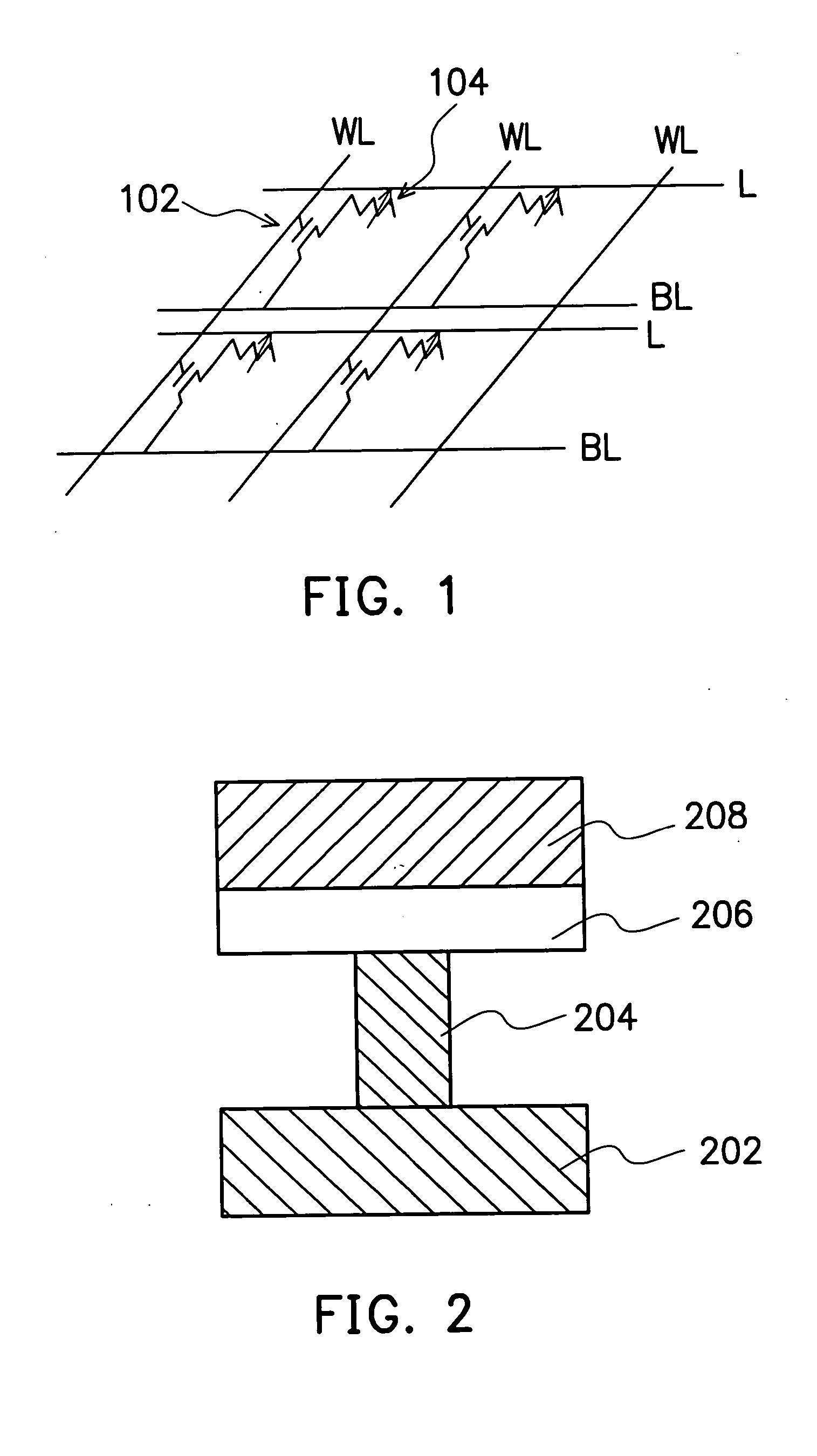

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

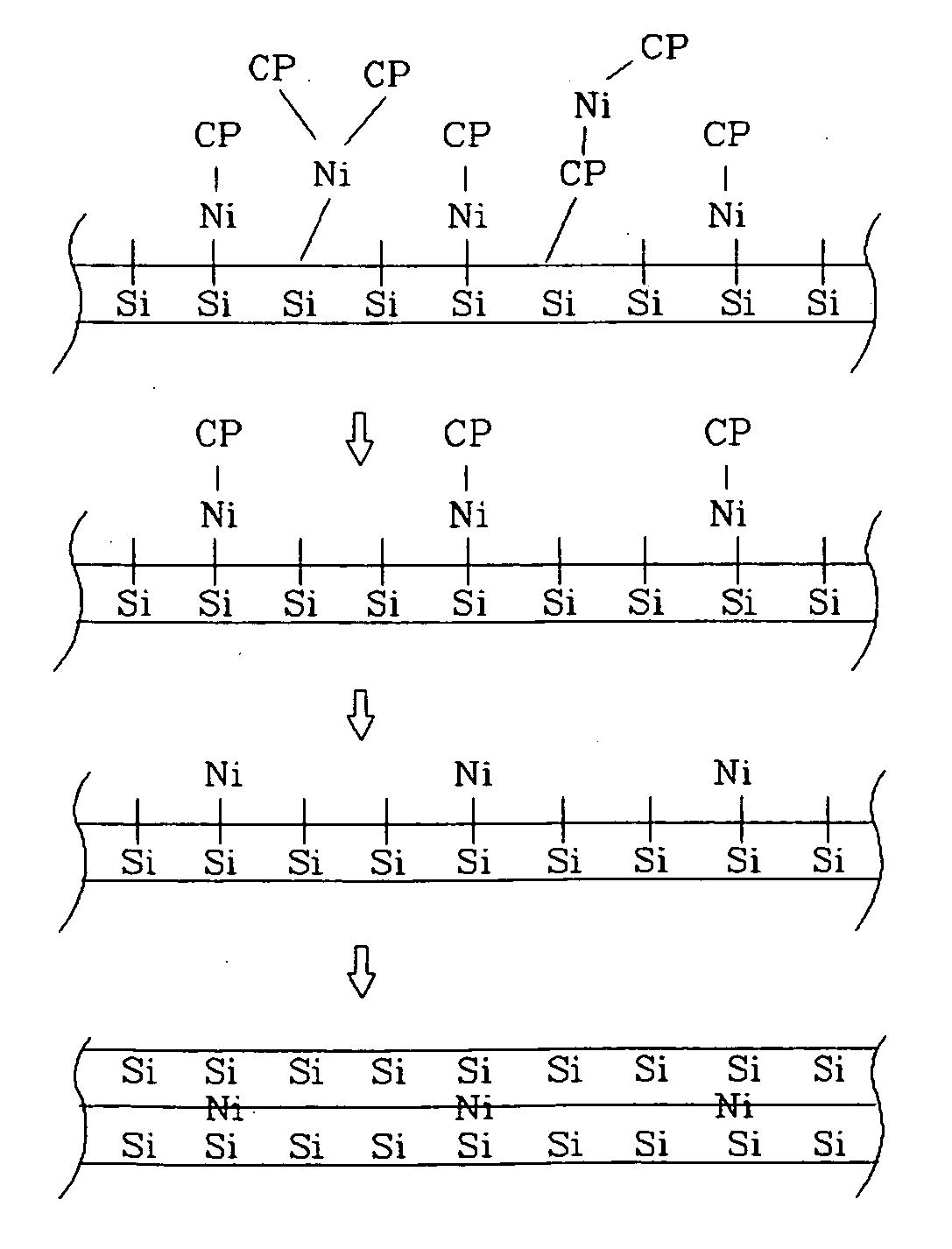

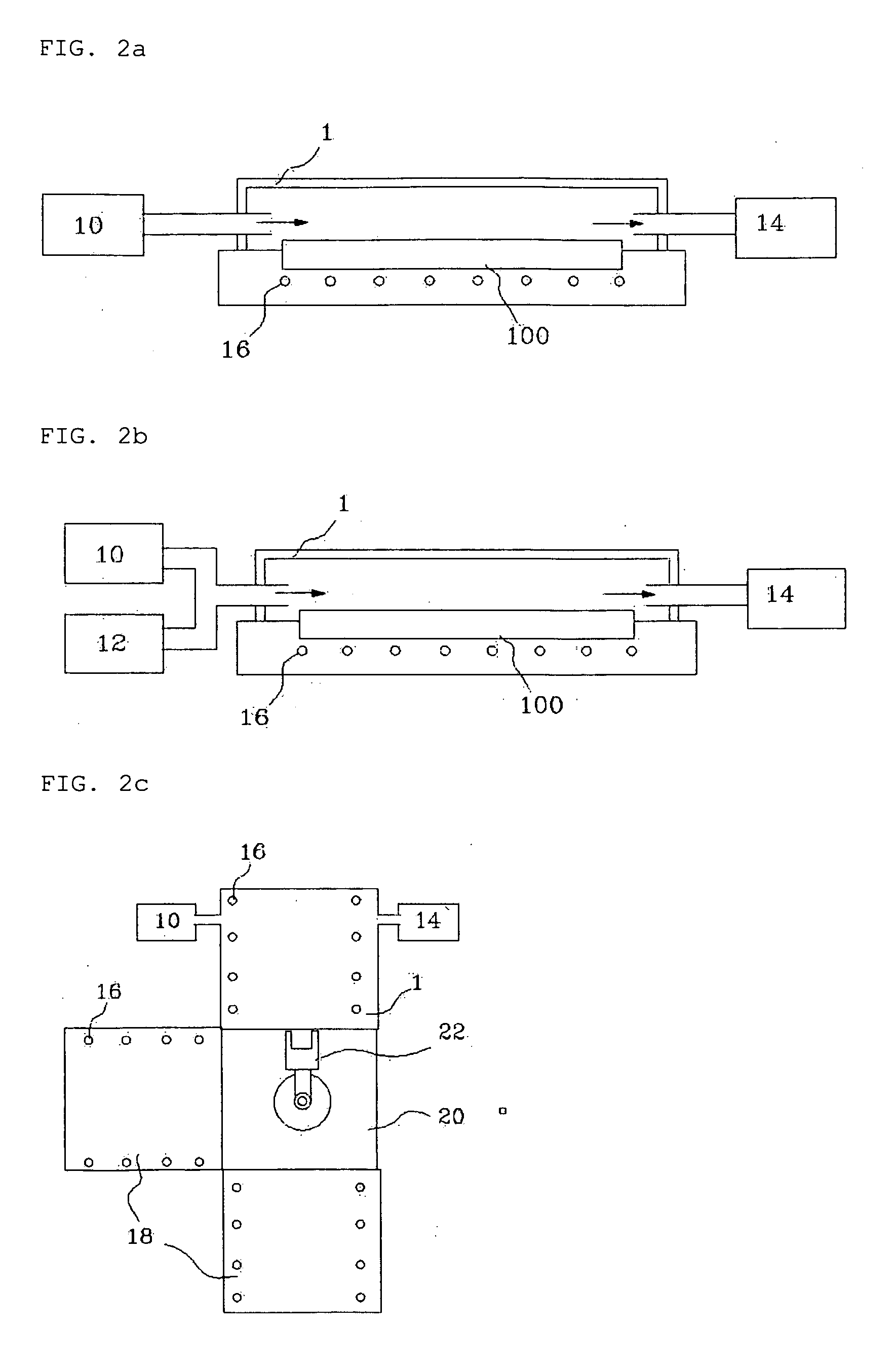

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

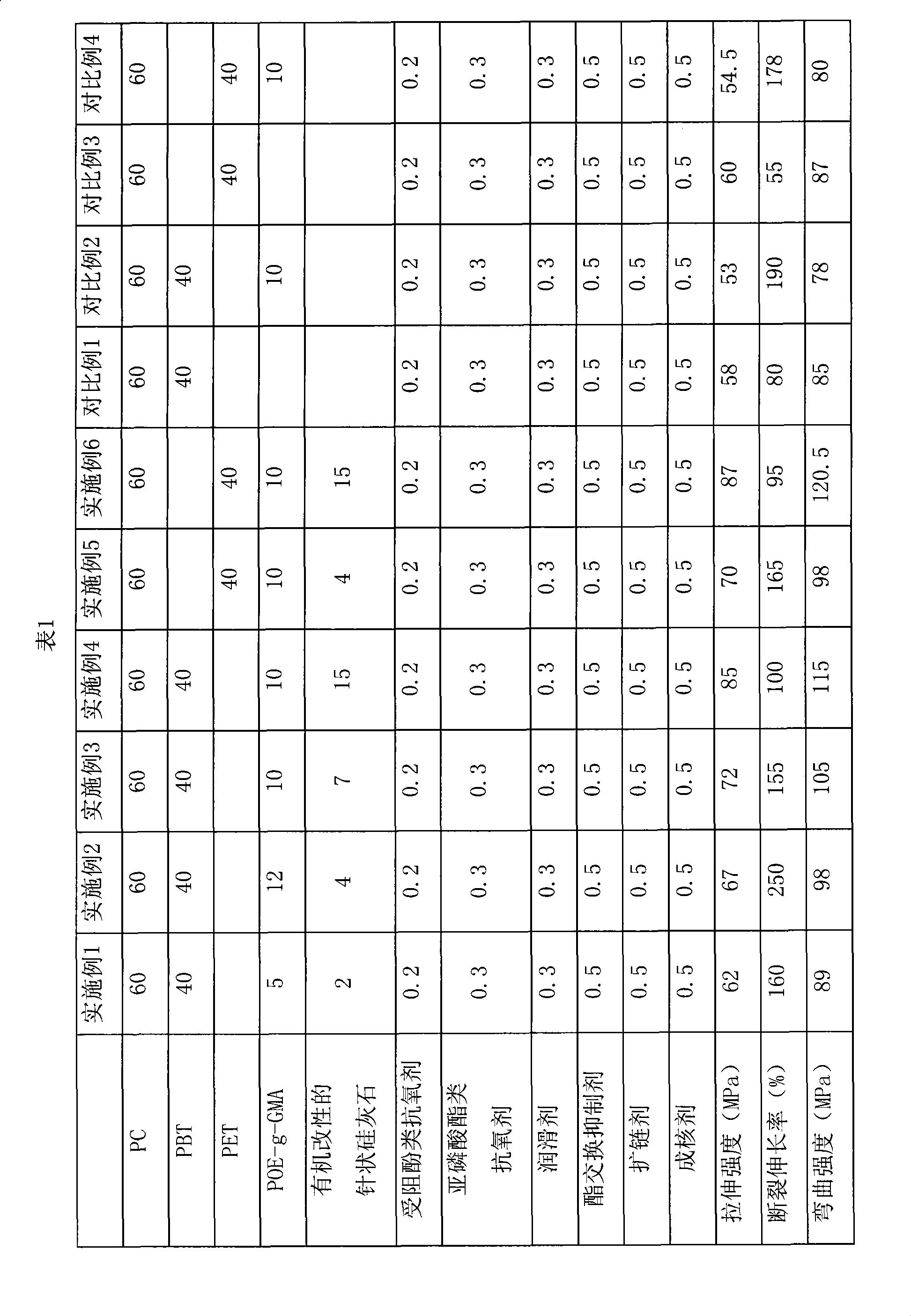

Chalcogenide phase-change non-volatile memory, memory device and method for fabricating the same

InactiveUS20050062087A1High speedIncrease the rate of crystallizationSolid-state devicesRead-only memoriesPhase-change memoryAlloy

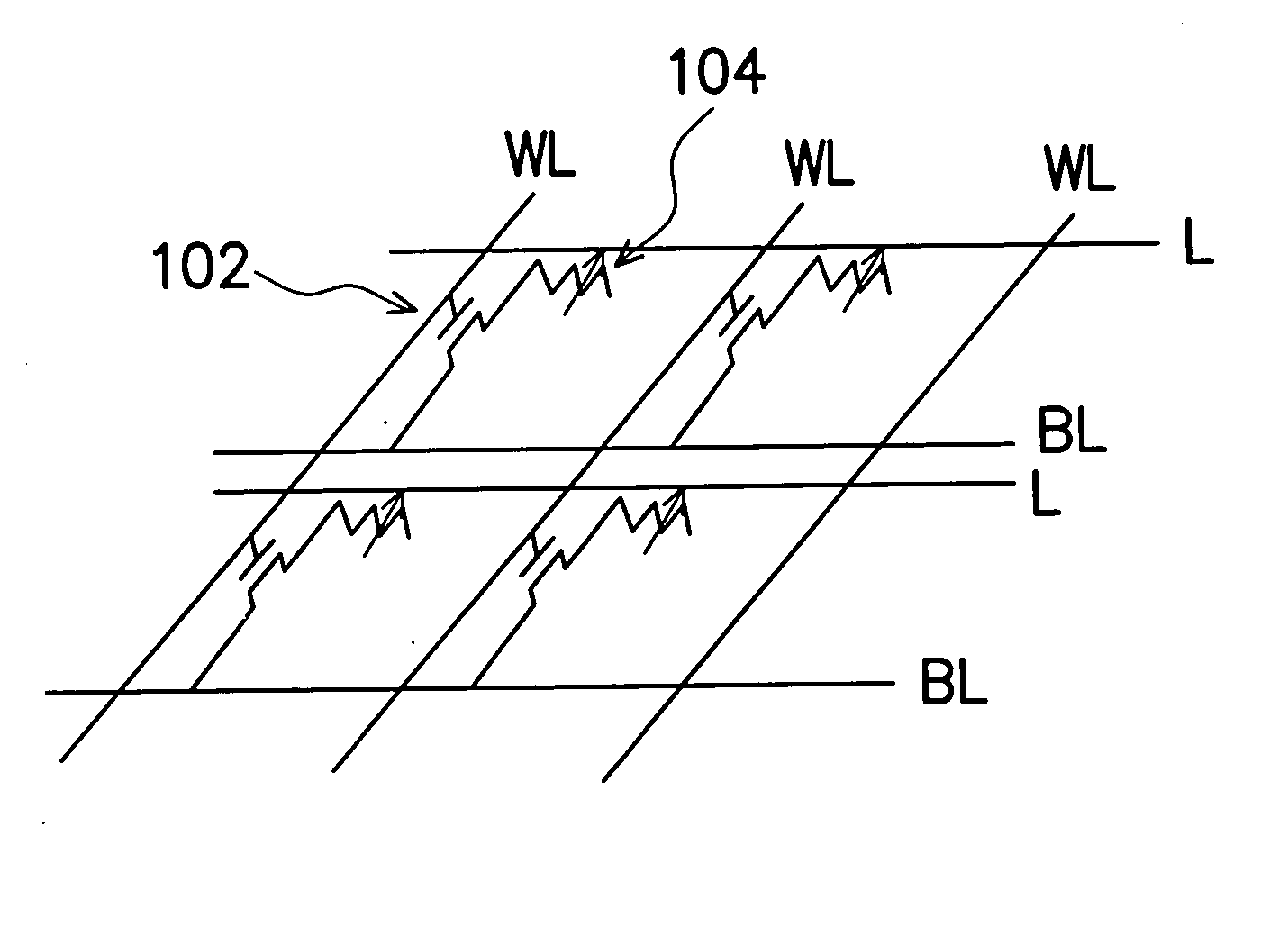

A memory device adapted to a chalcogenide phase-change memory is disclosed. The memory device comprises a top electrode, a bottom electrode, and a phase-change thin film between the top electrode and the bottom electrode. The phase-change thin film is a chalcogenide (Ge-Sb-Te) alloy doped with Tin (Sn) therein. Tin (Sn) doped in the chalcogenide (Ge-Sb-Te) alloy can enhance the crystallization rate of the phase-change thin film for improving the operation speed of the memory.

Owner:MACRONIX INT CO LTD

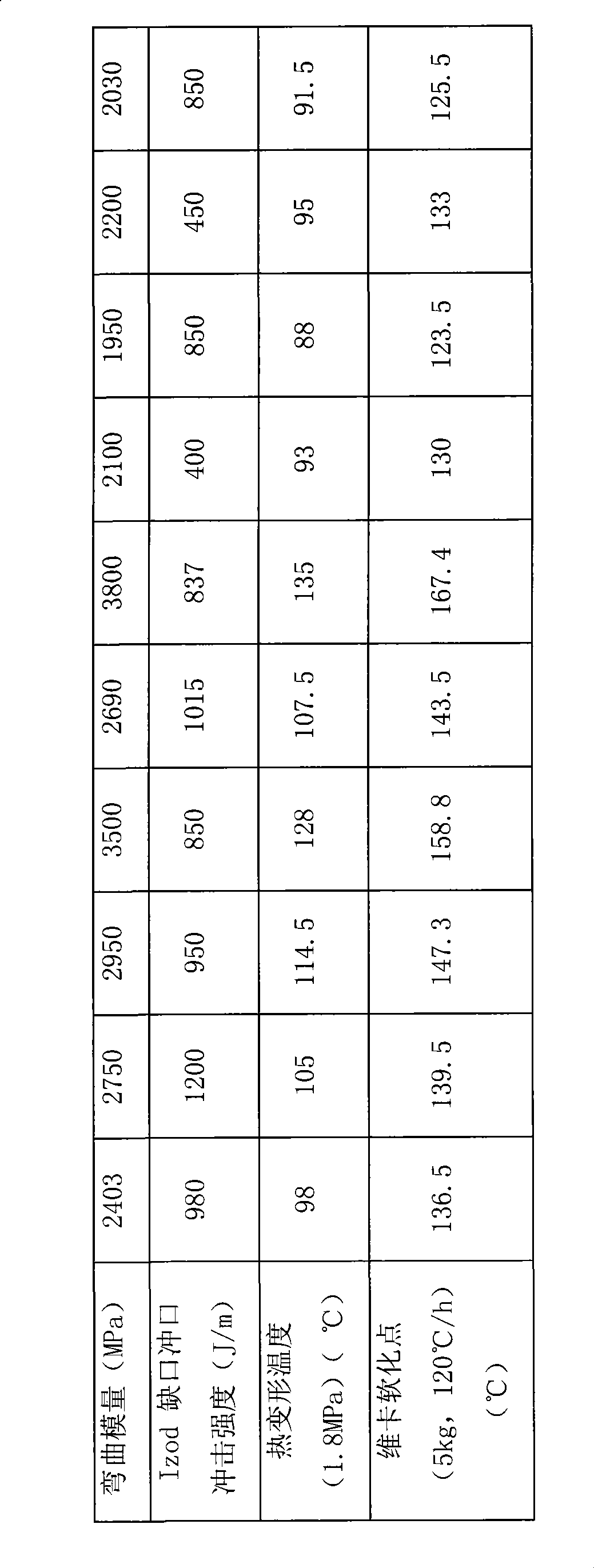

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

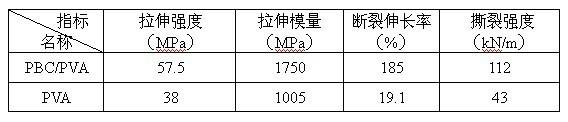

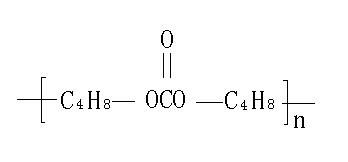

Biodegradable polycarbonate butylene terephthalate composite material and preparation method of biodegradable polycarbonate butylene terephthalate composite material

The invention relates to a biodegradable polycarbonate butylene terephthalate composite material and a preparation method of the biodegradable polycarbonate butylene terephthalate composite material. The biodegradable polycarbonate butylene terephthalate composite material is characterized in that the material comprises the following components in part by weight: 30 to 70 parts of aliphatic polycarbonate butylene terephthalate, 10 to 40 parts of other biodegradable materials, 1.0 to 10 parts of filler, 0.5 to 1.5 parts of rare earth composite nucleating agent, 0.5 to 1.5 parts of dispersant, 4.0 to 15 parts of plasticizer, 1.5 to 4 parts of heat resistance stabilizer, 0.05 to 1.5 parts of antioxidant, 0.5 to 1.0 part of lubricant, 0.1 to 1.0 part of anti-block agent and 0.05 to 0.5 part of biodegradation accelerator. The composite material has high melt strength, good film forming ability, high tensile strength, high tearing strength and good light-conversion effect.

Owner:JIANGSU XINGYE PLASTIC +1

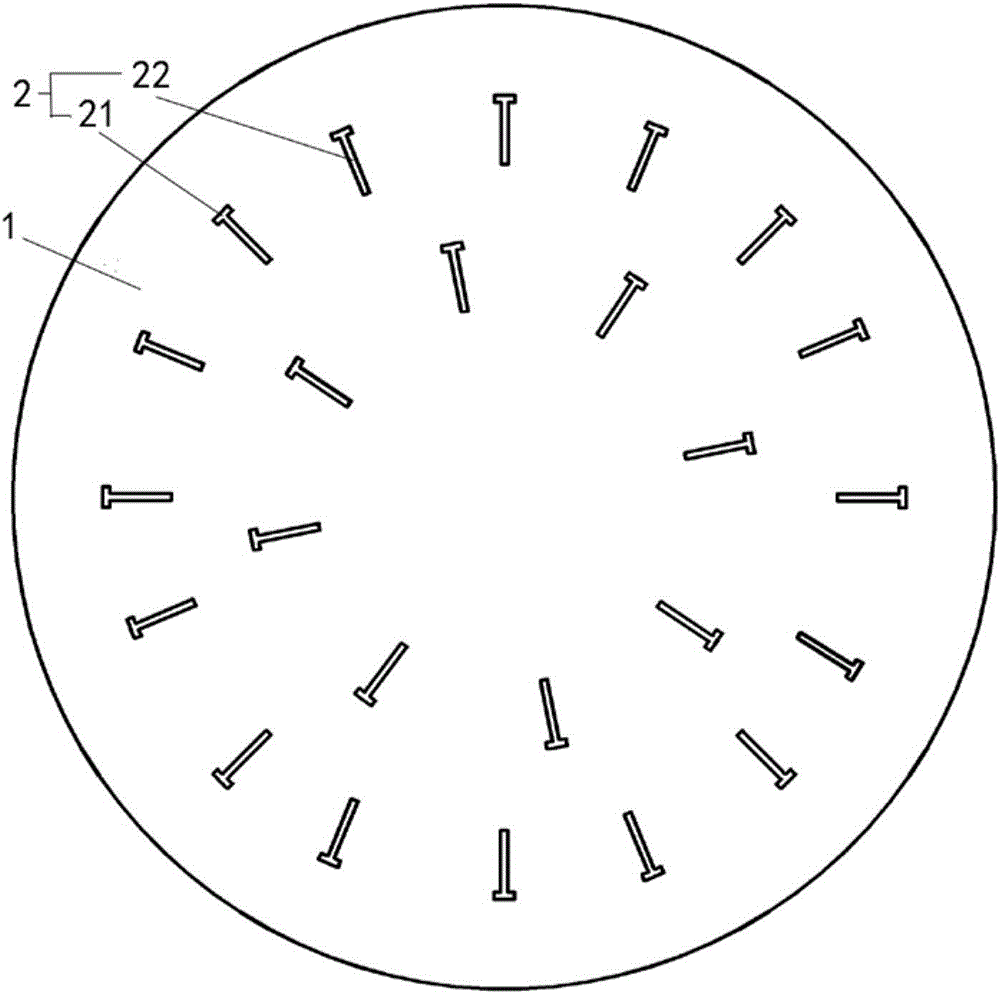

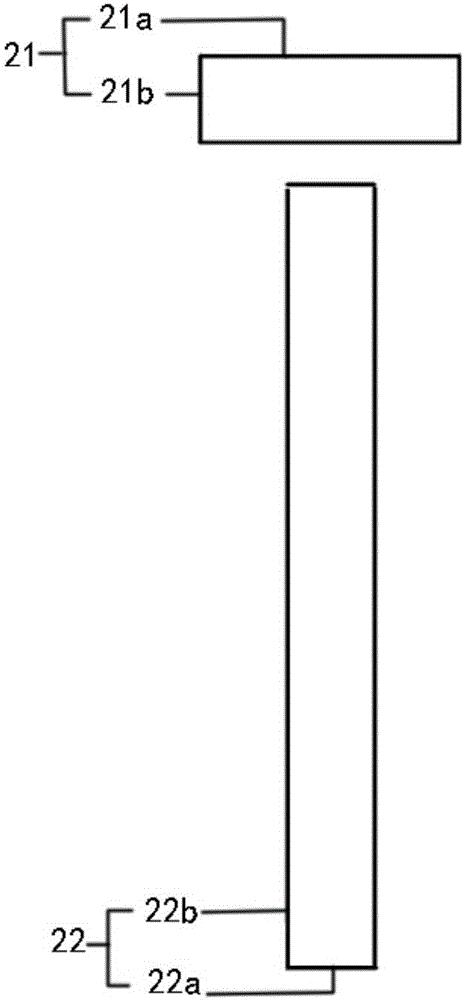

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

Oxygen scavenging monolayer bottles

InactiveUS20020183448A1Lower cost of capitalReduce manufacturing costLiquid degasificationBottlesPolyesterOxygen

Monolayer packages comprised of an oxygen scavenging composition suitable for direct contact with package contents and recycle with other polyester bottles are disclosed. The oxygen scavenging composition is comprised of a modified copolymer which is comprised of predominantly polyester segments and an oxygen scavenging amount of oxygen scavenging segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. Use of these oxygen scavenging copolymers in bottles provides a clear and rigid monolayer bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolymers of this invention are over 99 wt % PET and contain less than 50 ppb of extractable components.

Owner:COLORMATRIX HLDG

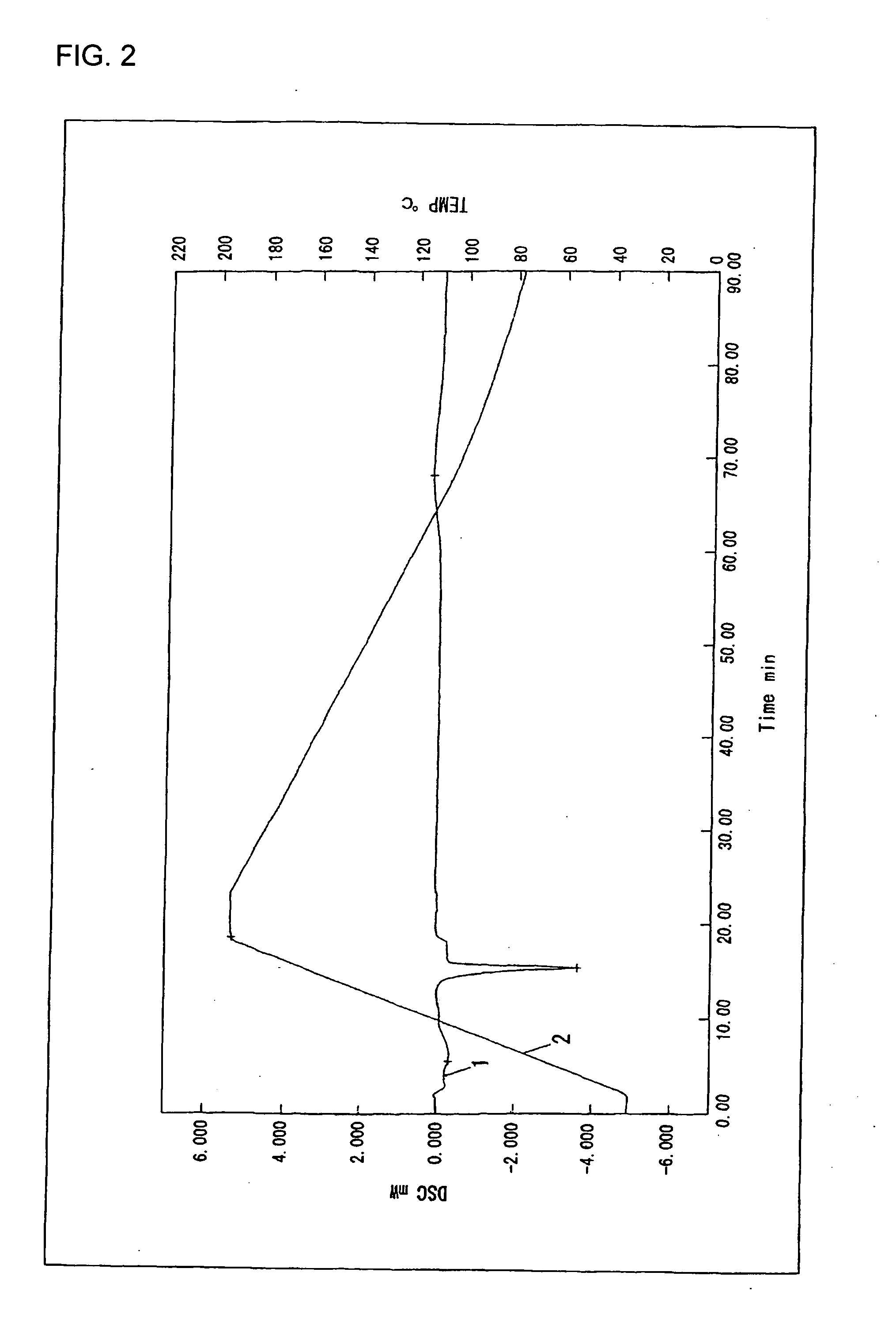

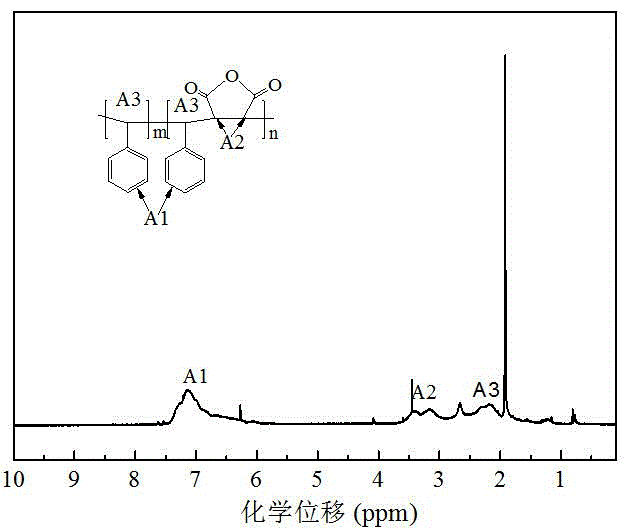

Nucleating agent of polyethylene glycol terephthalate and preparation method thereof

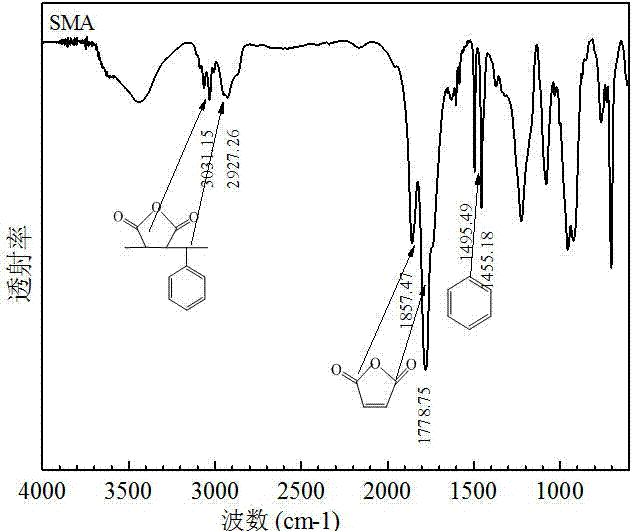

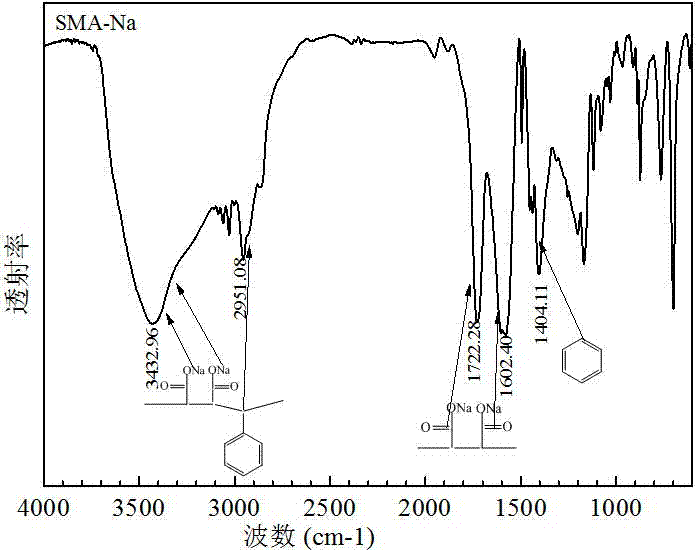

InactiveCN102924641ASimple preparation processImprove thermal stabilityPolyethylene glycolPolymer SMA

The invention belongs to the technical field of macromolecule materials, and particularly relates to a nucleating agent of the polyethylene glycol terephthalate and a preparation method thereof. The agent utilizes random copolymer or alternating copolymer of maleic anhydride and styrene as raw materials, and conducts hydrolysis, salinization and purification to obtain styrene-maleic anhydride ionomer. The styrene-maleic anhydride ionomer can serve as the nucleating agent of the polyethylene glycol (PET), increases crystallization temperature of the PET and increases crystallization rate. The nucleating agent is simple in preparation method, capable of adopting blending smelting reaction extrusion pelleting once process with the PET, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Polyester compositions

InactiveUS6986864B2Improve impact performanceIncrease crystallization rateHollow wall articlesBeltsPolyesterPolyolefin

Disclosed are certain novel polyester compositions particularly useful for shaping or forming into containers and similar shaped articles by thermoforming procedures. The polyester compositions comprise a thermoplastic polyester, an impact modifier and a polyester crystallization rate enhancing component selected from poly(tetramethylene terephthalate) homo- and co-polymers. The polyester compositions exhibit improved crystallization rates as compared to similar compositions not including impact modifier or compositions using other types of crystallization rate enhancing components such as polyolefin-based polymers.

Owner:EASTMAN CHEM CO

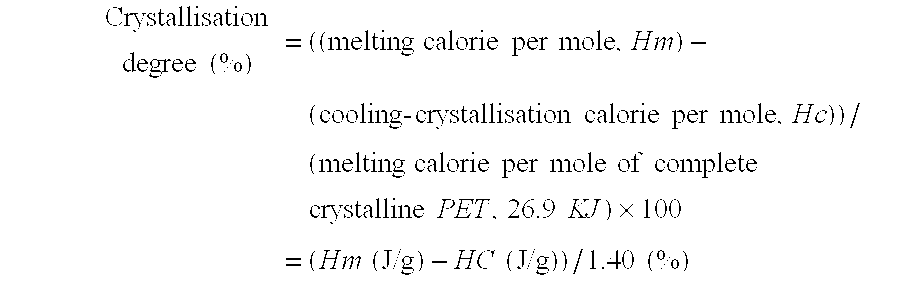

Method of manufacturing heat-resistant mould articles made of polyethylene terephthalate polyesters

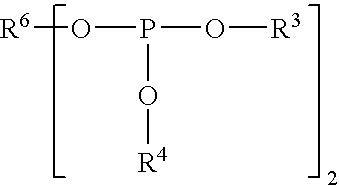

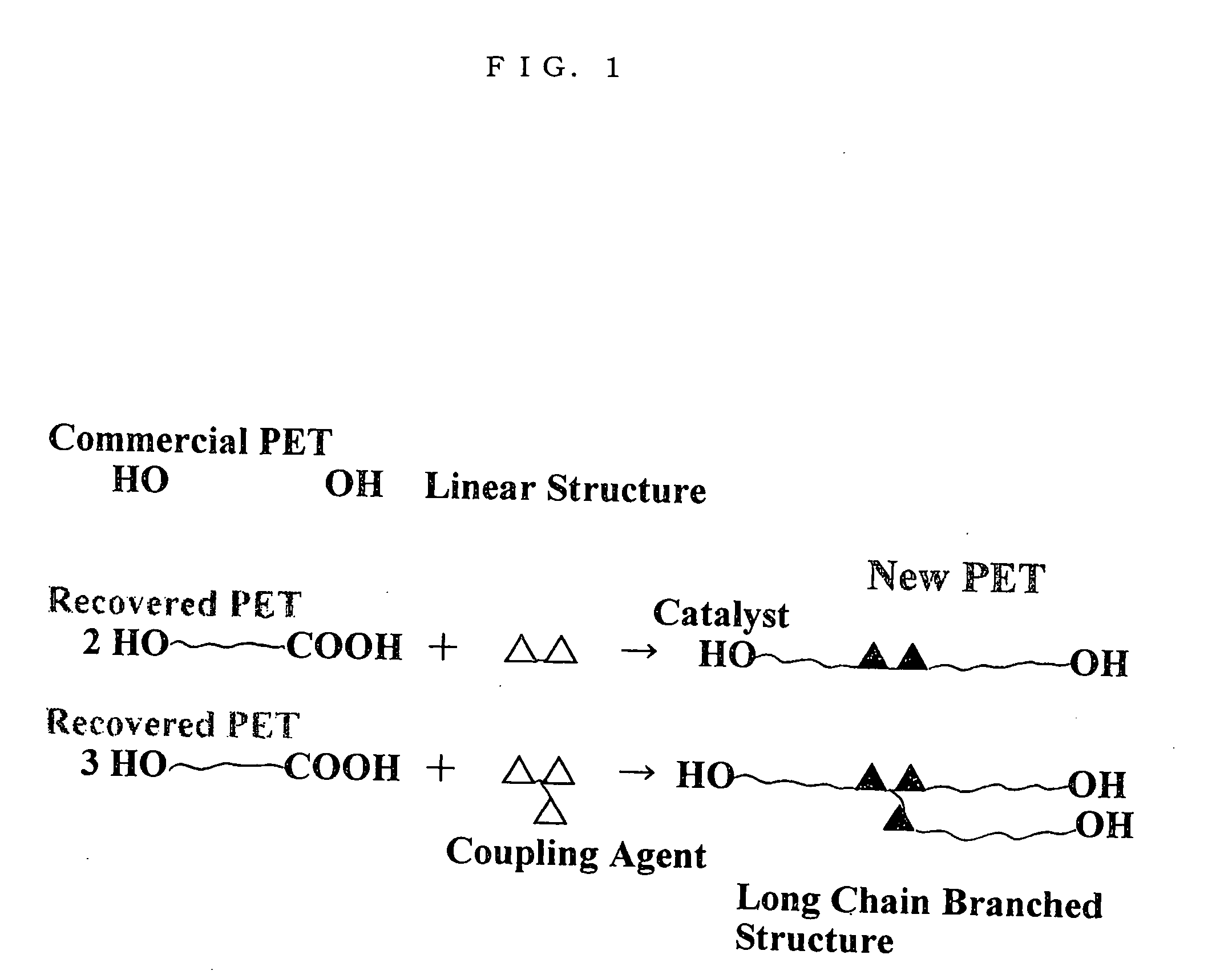

InactiveUS20060043646A1Drawn-down of sheets and boards are reducedIncrease the rate of crystallizationHollow wall articlesBeltsPolyesterEpoxy

The present invention provides a method of manufacturing high-melting-tension heat-resistant transparent or opaque sheets, boards, and moulds from polyethylene terephthalate (PET). The method is characterised in that a mixture of: (1) PET polyester whose melt flow rate (MFR) is 45-130 g / 10 minutes (a); (2) coupling agent master batch (f) comprising coupling agent (d) and substrate (e), wherein coupling agent (d) is a mixture of compounds containing 2 epoxy groups (b) and compounds containing 3 or more epoxy groups (c); and (3) catalyst master batch (i) comprising coupling reaction catalyst (g) and substrate (h); is melted in a reaction-extruder to give PET polyester whose MFR is 40 g / 10 minutes or less. The resulting PET polyester is moulded into amorphous sheets or boards, and then heated again to a predetermined temperature to give transparent heat-resistant sheets or boards; or then vacuum-, pressure-, or vacuum-pressure-formed following heat-setting to give transparent heat-resistant or white opaque highly-heat-resistant mould articles.

Owner:NAKAMOTO PAKKUSU +1

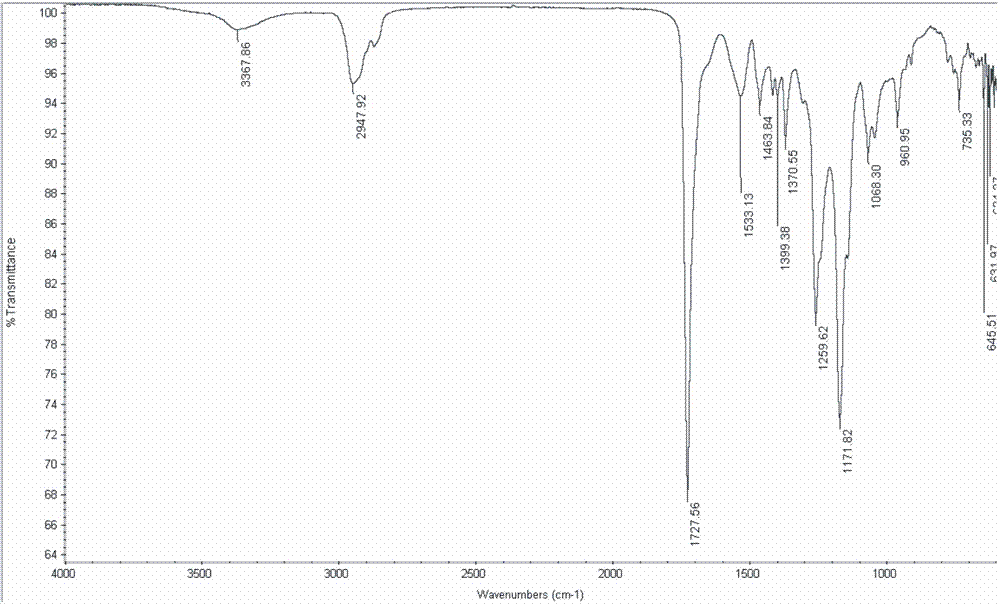

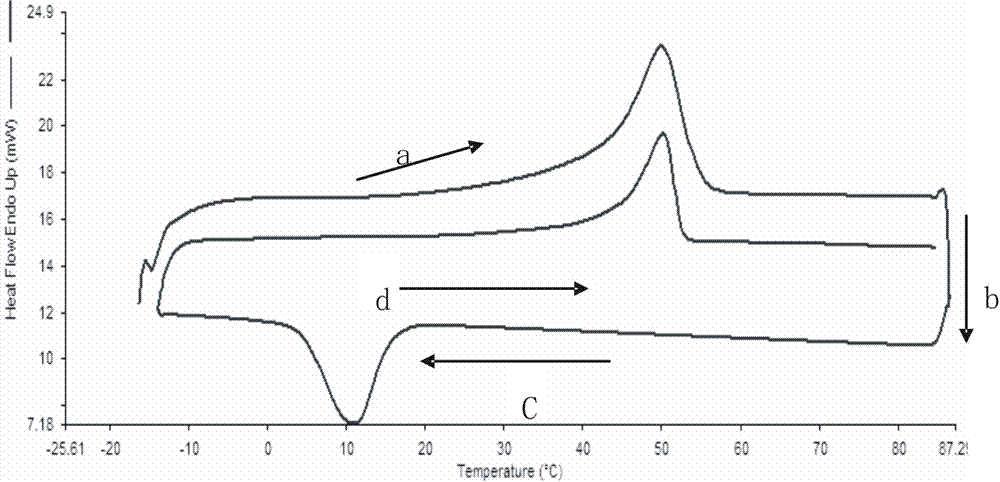

Kind of biodegradable polyester and its preparation method

ActiveUS20110190468A1Change softnessIncrease the rate of crystallizationAbsorbent padsBandagesHeat resistanceCrystallization temperature

The present invention relates to a kind of biodegradable polyester and its preparation method, which belongs to the field of biodegradable co-polyester product technology. The number-average molecular weight of the biodegradable polyester material under this invention is 6000-135000 g / mol, the molecular weight distribution is 1.2-6.5, and the range of crystallization temperature is 15° C.-105° C., which could overcome the disadvantages of existing technical products and can be processed into membrane materials, sheet materials and foam materials. During processing, the picking property will be dramatically changed with the appearance quality improved; after heat resistance is improved, this new type of polyester material could also be applied to the processing course with long cycles, for example, the injection processing course, and the biodegradable aliphatic / aromatic polyester materials provided by this invention has excellent mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +1

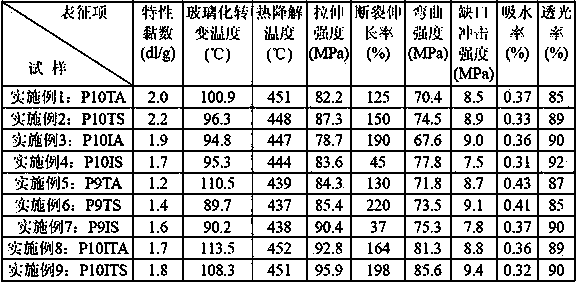

Semi-aromatic transparent polyamide material and preparation method thereof

The invention discloses a semi-aromatic transparent polyamide material and a preparation method thereof, belonging to the field of high-molecular materials. The material consists of a random copolymer of semi-aromatic amide salt and aliphatic amide salt and necessary auxiliaries; the intrinsic viscosity is 1.0-2.2dl / g, and the degree of crystallinity is less than 15%; the semi-aromatic amide salt is selected from amide salt 9T, amide salt 9I, amide salt 10T and amide salt 10I; and the aliphatic amide salt is selected from amide salt 610 and amide salt 1010. The preparation method comprises the following steps: adding the semi-aromatic amide salt, aliphatic amide salt and auxiliaries into a polymerization kettle; adding water which is 0.3-1.0 times the total mass of the semi-aromatic amide salt and aliphatic amide salt; in a protective gas atmosphere, stirring and heating to 160-210 DEG C within 1-2 hours, and performing constant-temperature pre-polymerization for 1-3 hours; heating to 240-300 DEG C, increasing pressure to 1-3MPa, and maintaining the pressure for reaction for 1-3 hours; slowly degassing to normal pressure within 1-4 hours; continuously stirring at constant temperature for 1-4 hours; and discharging after the reaction.

Owner:ZHENGZHOU UNIV

Polylactic acid resin composition

ActiveUS7531585B2Increase the rate of crystallizationExcellent in heat resistance and forming processabilityGroup 5/15 element organic compoundsHydrogen atomHeat resistance

Owner:NISSAN CHEM IND LTD

Rapid crystallization polylactic acid composite material and preparation method thereof

InactiveCN101544813AIncrease the rate of crystallizationImprove mechanical propertiesNatural mineralMechanical property

The invention relates to a rapid crystallization polylactic acid composite material and a preparation technique thereof. The composite material comprises the following components in portion by weight: 59 to 98 portions of hypocrystalline poly-L-lactic acid, 1 to 40 portions of organic modified natural mineral, 1 to 20 portions of organic crystallization promoter, 0.1 to 1.0 portion of heat stabilizer, and 0.05 to 1.0 portion of lubricant. The sum of the mass percentage of the components is 100 percent. The preparation method for the material comprises the following steps: firstly preparing the modified natural mineral; then mixing the components according to the components of the composite material; agitating and mixing the raw materials evenly through a high-speed agitator; and adding the co-mixture into a twin screw extruder for extrusion and granulation. The method improves the crystallization rate of a polylactic acid matrix through the synergistic action of organized mineral and the crystallization promoter. Due to the addition of the organic crystallization promoter, the method strengthens the mechanical properties of the polylactic acid composite material, while simultaneously quickening the crystallization rate of polylactic acid, thereby avoiding the defect of greatly reducing the mechanical properties of the polylactic acid composite material caused by the addition of a single inorganic mineral nucleating agent. The price of adopted fillers is low; and the whole preparation method has a simple technological process and less consuming time of the technological process, and can realize the large-scale industrialized production.

Owner:SHANGHAI UNIV

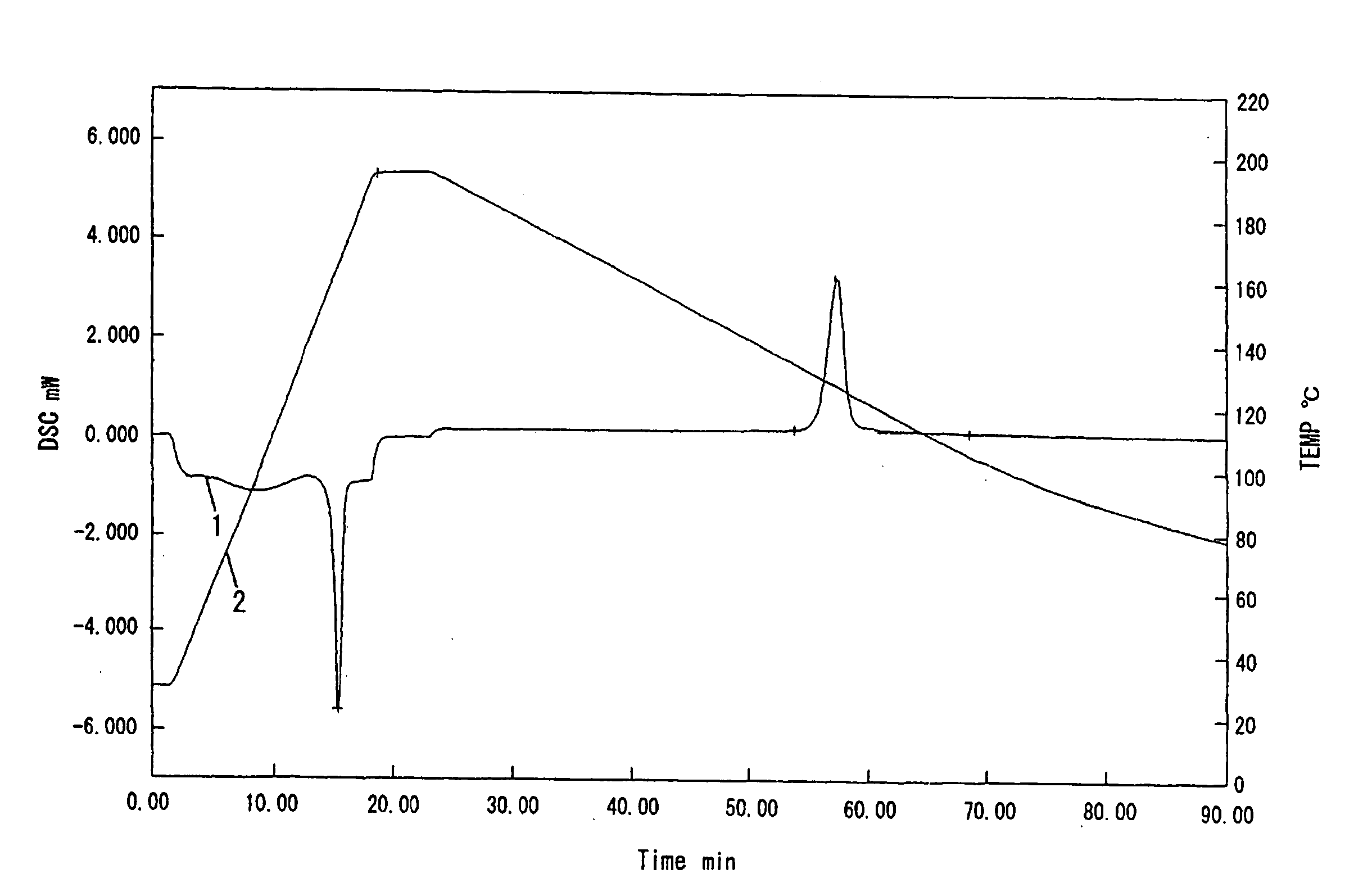

Method for preparing high-solid-content sulfonic-acid waterborne polyurethane adhesive

ActiveCN103242794AReduce difficultyShorten the timePolyureas/polyurethane adhesivesPolyesterSulfonate

The invention relates to a method for preparing high-solid-content waterborne polyurethane. The method comprises the following steps of: (1) reacting sulfonate-containing sodium dimethyl isophthalate-5-sulfonate with excessive polylol for a while, and then, adding polyacid to react so as to synthesize hydroxyl-terminated polyester; and (2) using the synthesized waterborne polyester as a soft segment, using diisocyanate as a hard segment, adding water to disperse, and carrying out chain extension by using polyamine so as to obtain the high-solid-content waterborne polyurethane. According to the method, the dispersion is easy, a large amount of solvent is not required for being used, the cost is saved, the solvent removal is easy, and the solid content reaches over 50% while lower viscosity is kept, so that the constructability of adhesive liquid is improved, and the adhesive liquid is crystallizable and has better initial viscosity and better adhesive strength; and the used polyester is synthesized autonomously, the raw materials are all common, and the process is simple, so that the cost is saved, and the industrialization is facilitated.

Owner:武汉工大科技园发展有限公司

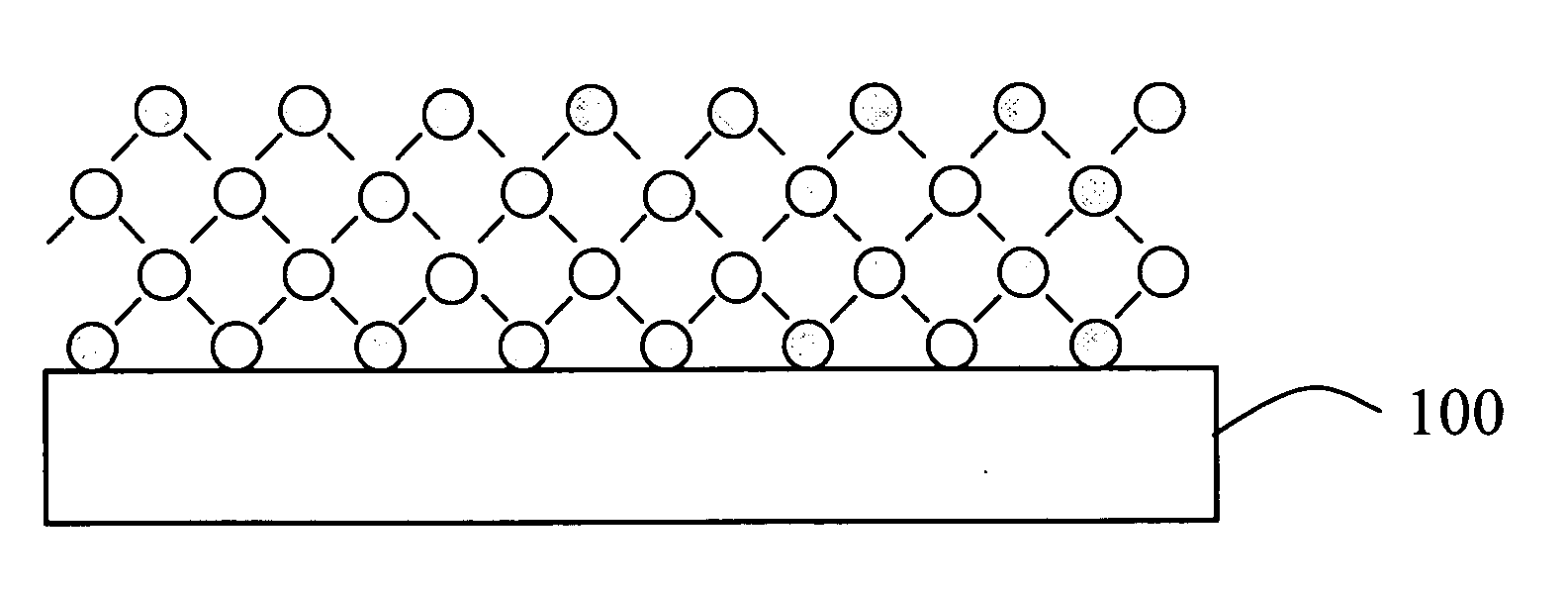

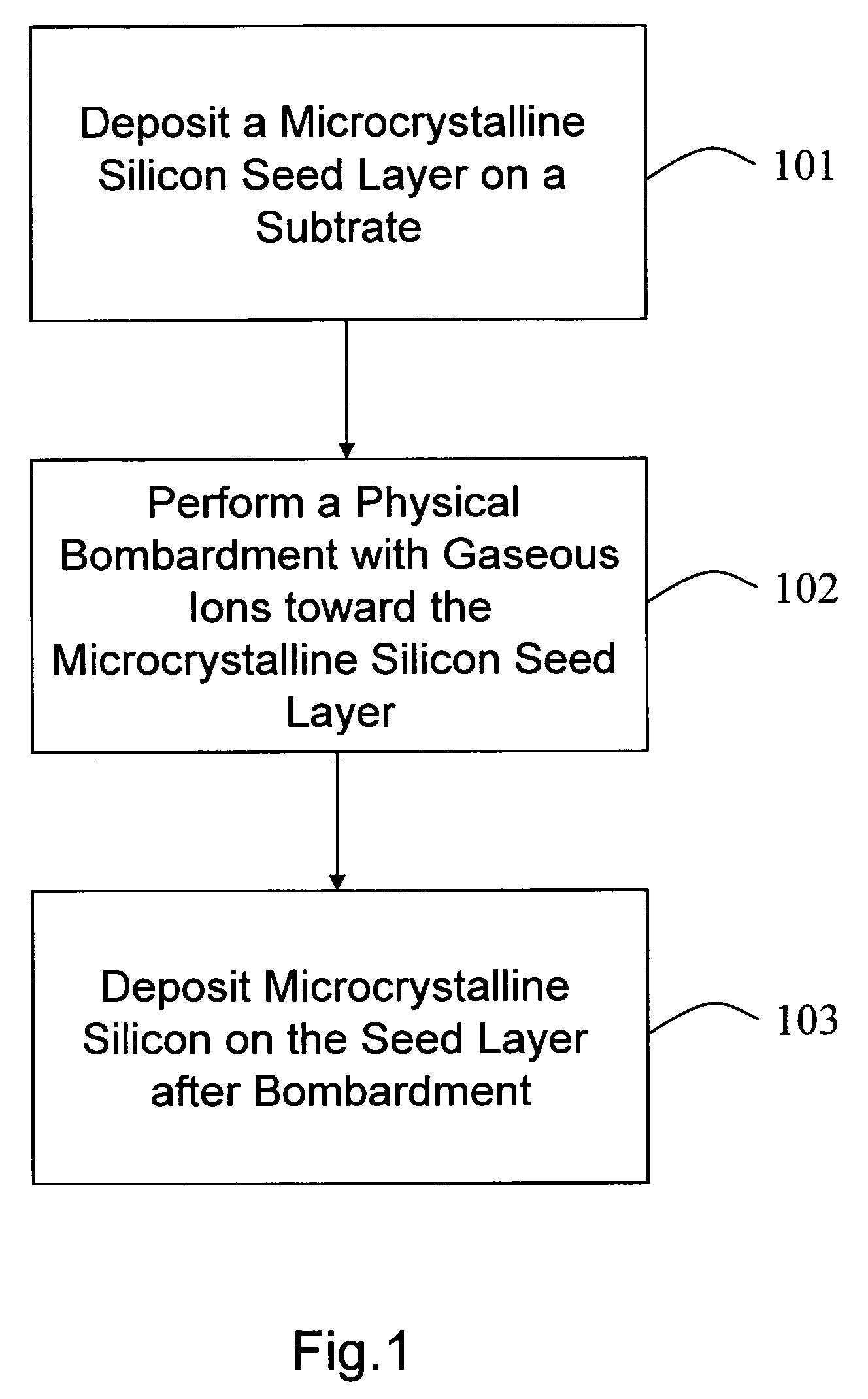

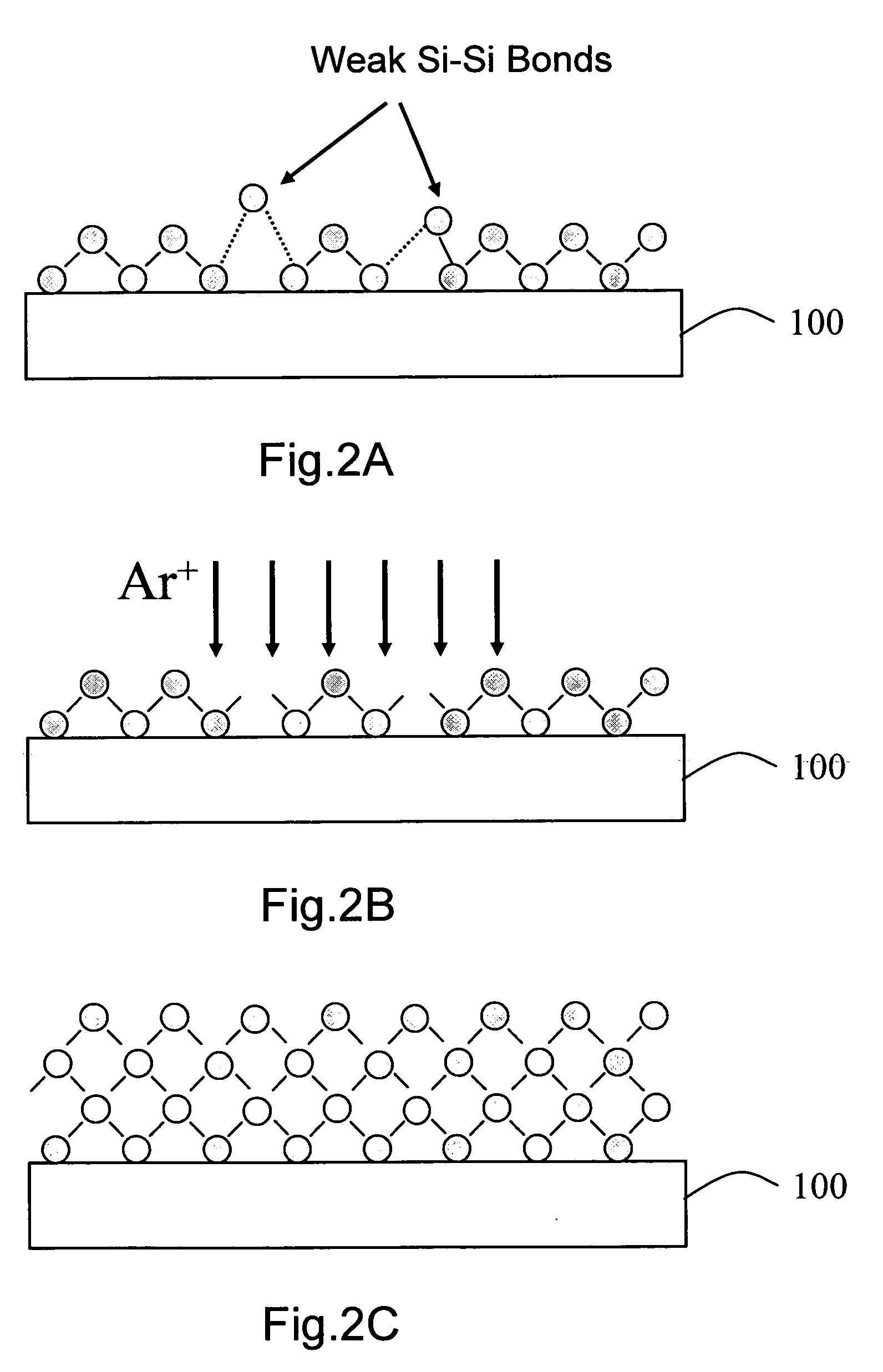

Method for forming a microcrystalline silicon film

InactiveUS20090029532A1Improve the crystallization processFast depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThree stageOptoelectronics

This invention provides a method for forming a microcrystalline silicon film, which employs a three-stage deposition process to form a microcrystalline film. A microcrystalline silicon seed layer is formed on a substrate. Gaseous ions are used to bombard a surface of the microcrystalline silicon seed layer. Microcrystalline silicon is formed on the microcrystalline silicon seed layer after the bombardment to a predetermined thickness.

Owner:IND TECH RES INST

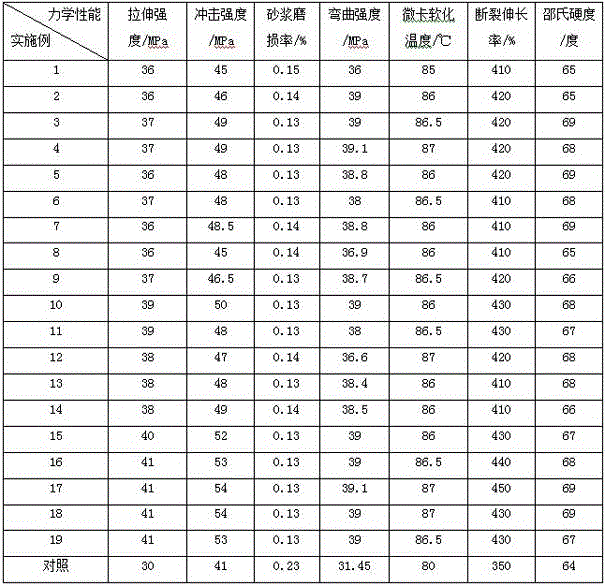

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

Aliphatic polyester composition and its molded article

InactiveUS20060142505A1Increase the rate of crystallizationMaintain standardSynthetic resin layered productsPolyesterPolymer chemistry

Owner:TOYOTA CENT RES & DEV LAB INC +1

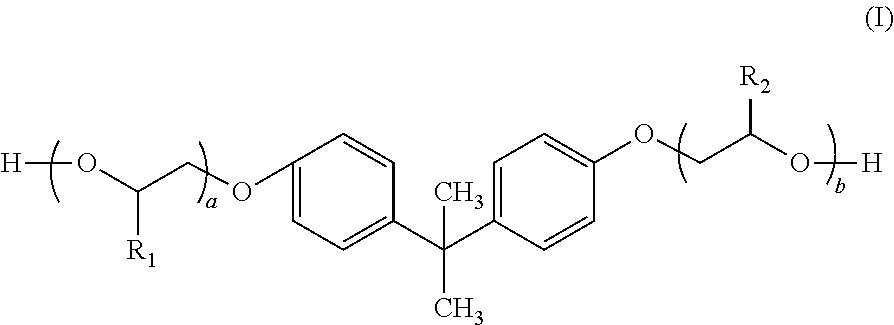

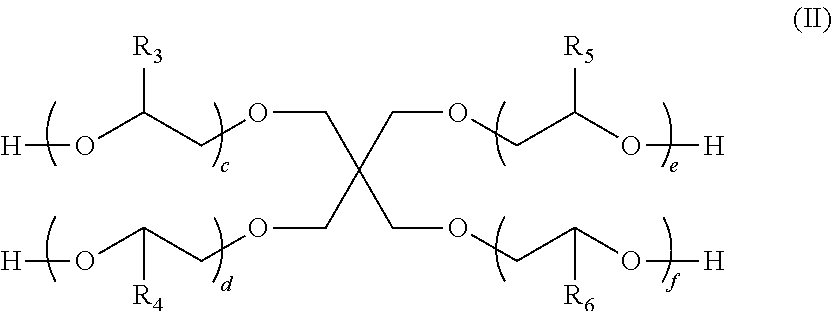

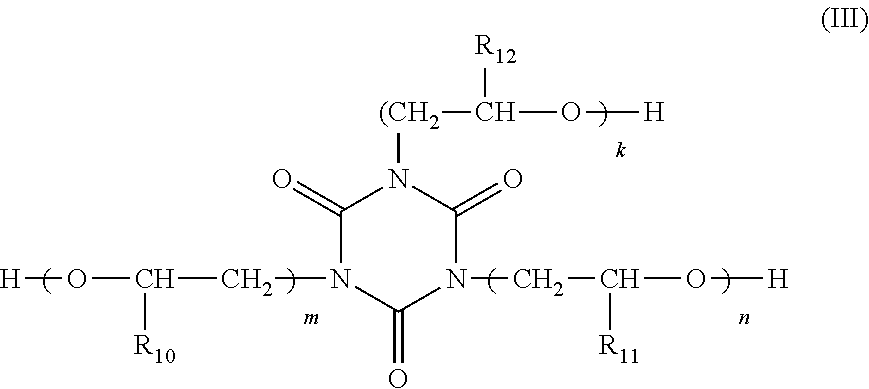

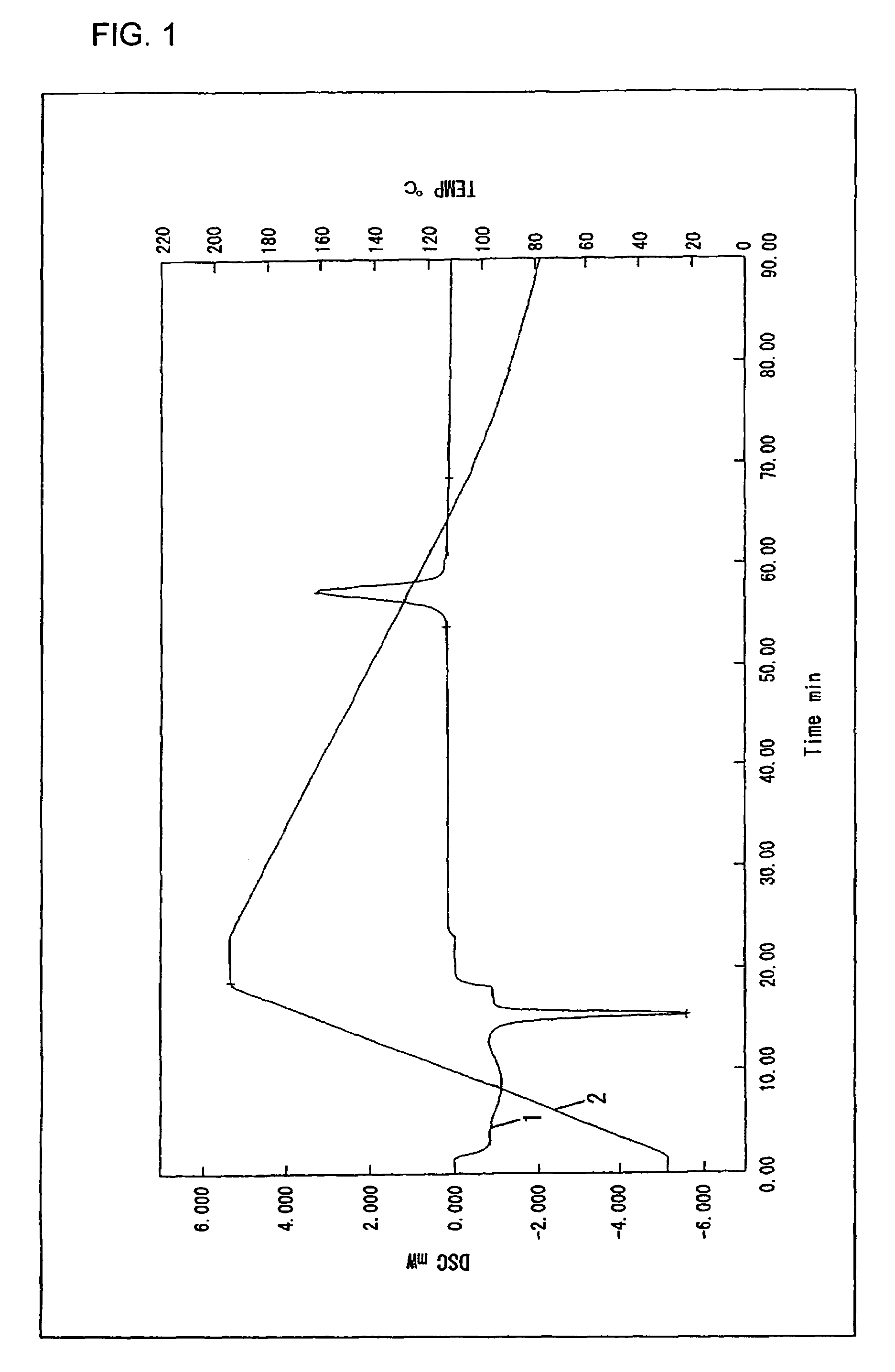

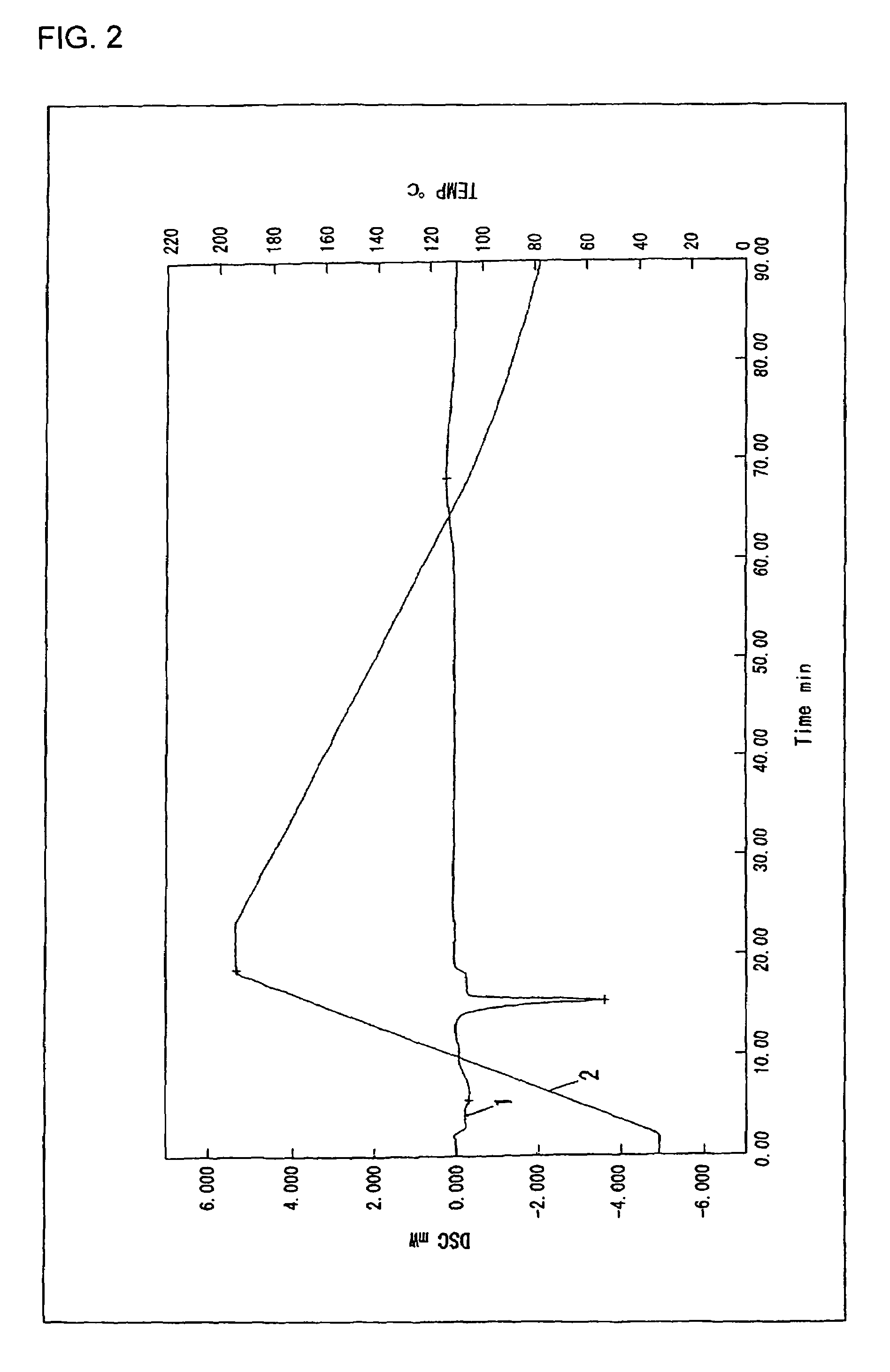

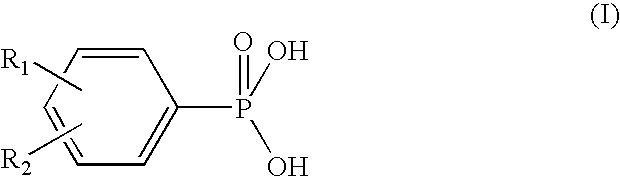

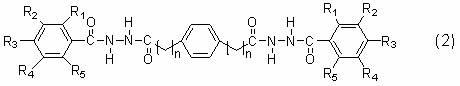

Polyactic Acid Resin Composition

ActiveUS20070299170A1Increase the rate of crystallizationExcellent in heat resistance and forming processabilityGroup 5/15 element organic compoundsHydrogen atomHeat resistance

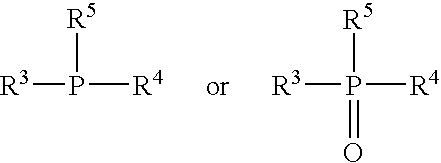

It is an object of the present invention is to provide a polylactic acid resin composition in which a crystal nucleator appropriate for accelerating crystallization of polylactic acid rein is added. A polylactic acid resin composition comprising a polylactic acid resin, and a metal salt of a phosphorus compound of formula (I) wherein R1 and R2 may be the same or different and are hydrogen atom, C1-10alkyl or C2-10alkoxycarbonyl, or a polylactic acid resin composition comprising a polylactic acid resin, and a metal salt of a phosphorus compound of formula (II) wherein R3, R4, R5 and R6 may be the same or different and are hydrogen atom, C1-10alkyl or C2-10alkoxycarbonyl. The composition is excellent in heat resistance and forming processability.

Owner:NISSAN CHEM IND LTD

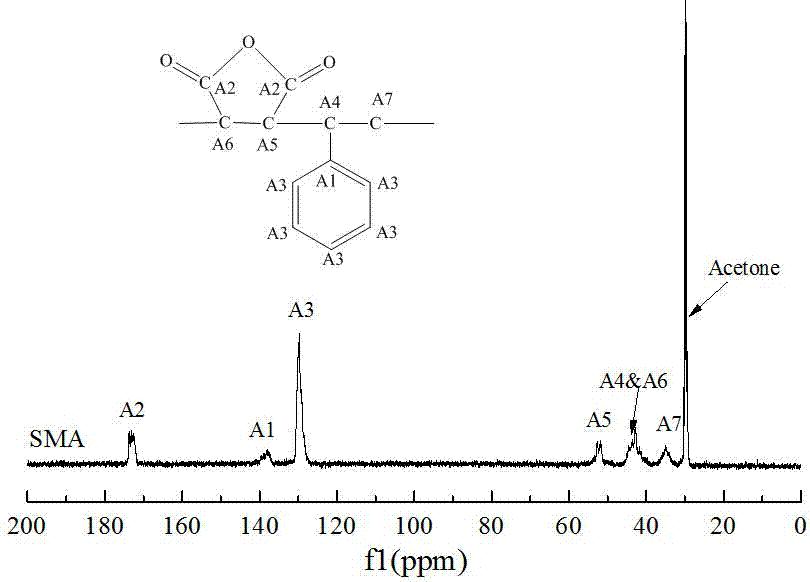

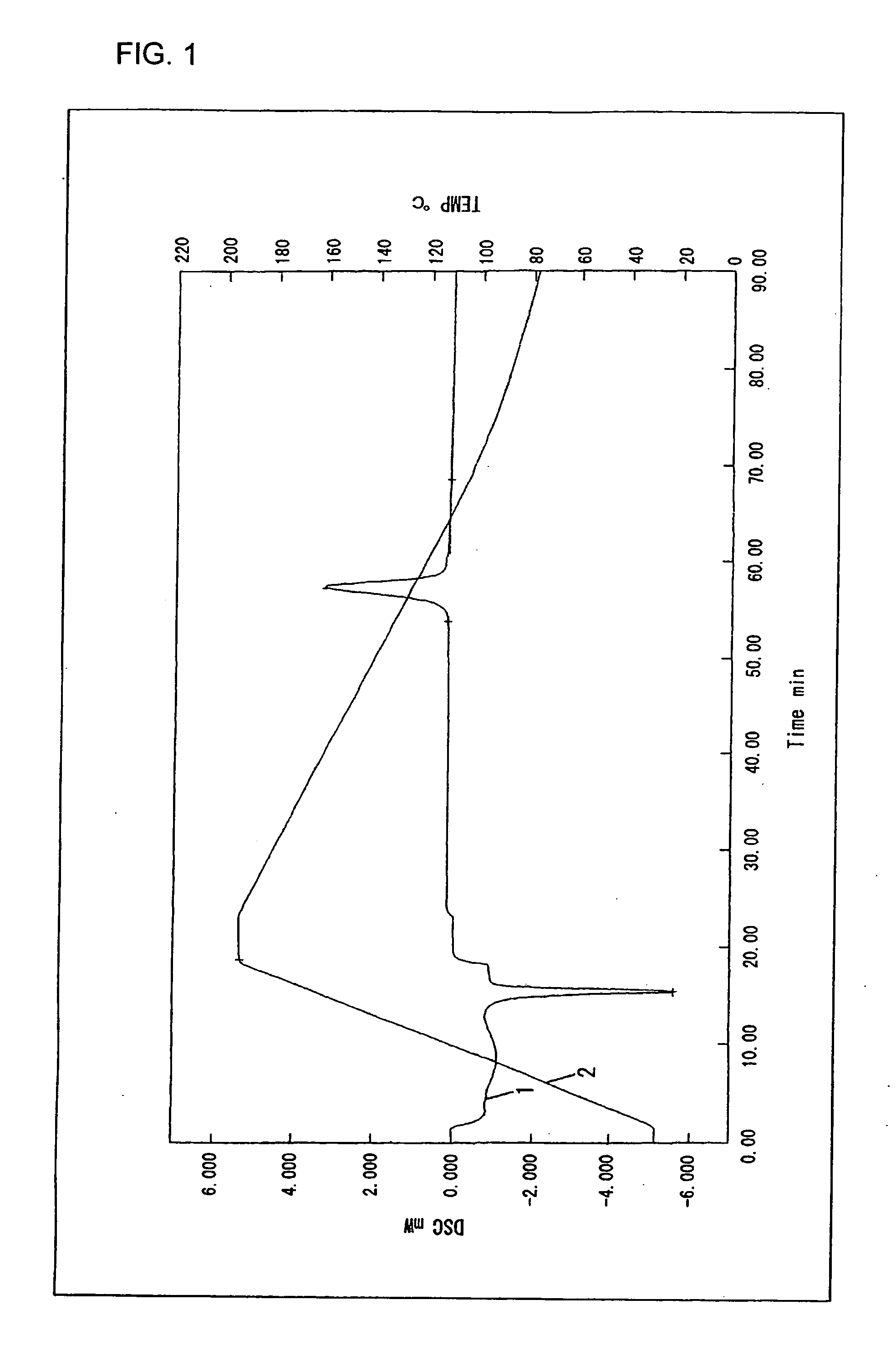

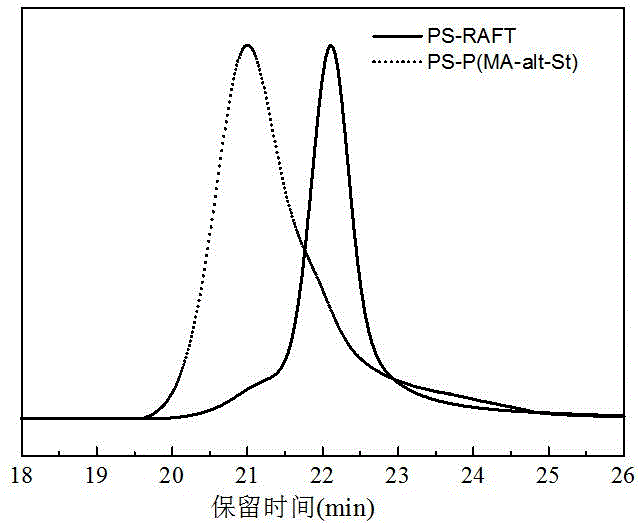

Polyethylene terephthalate nucleating agent and preparation method thereof

InactiveCN103145903ASimple preparation processImprove thermal stabilityPolymer sciencePolyethylene terephthalate glycol

The invention belongs to the technical field of high polymer materials, and in particular relates to a polyethylene terephthalate nucleating agent and a preparation method thereof. The method comprises the following steps of: based on polystyrene-b-poly(styrene-alt-maleic anhydride) diblock copolymer as a raw material, hydrolyzing, salinizing and purifying to prepare an ionomer of the polystyrene-b-poly(styrene-alt-maleic anhydride) diblock copolymer. A polystyrene block can form microphase separation in molten polyethylene terephthalate (PET), and thus, a crystal nucleus is provided for PET crystallization; and moreover, a poly(styrene-alt-maleic anhydride) block and PET are well compatible with each other, so that crystallization surface energy can be reduced, and the crystallization temperature and crystallization speed of the PET can be increased. In addition, a plasticizer such as di-2-ethylhexy1 azelate is added while the nucleating agent is added, the movement velocity of a PET chain segment can be further increased, so that the growing speed of crystals is increased. The preparation method is simple, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

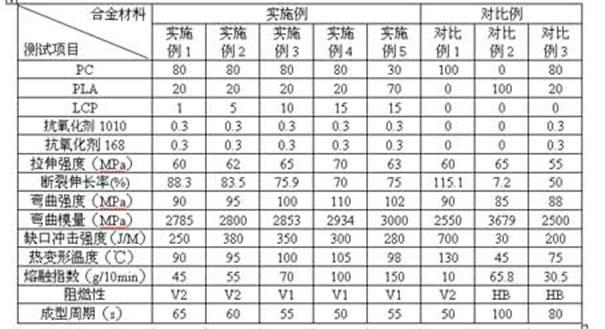

Polyactic acid/polycarbonate alloy material, and preparation method and application thereof

The invention discloses a polyactic acid / polycarbonate alloy material, and a preparation method and application thereof. The polyactic acid / polycarbonate alloy material comprises the following raw materials in part by weight: 10 to 90 parts of polycarbonate, 10 to 90 parts of polyactic acid, 1 to 20 parts of liquid crystal high polymer and 1 to 25 parts of flexibilizer. The polyactic acid / polycarbonate alloy material is prepared by adding the raw materials into a double-screw extruder to be melted and blended. The polyactic acid / polycarbonate alloy material provided by the invention has environmentally-friendly characteristics and excellent physical and mechanical properties, and greatly improves impact strength, bending modulus and heat distortion temperature. The liquid crystal high polymer is added to promote the quick crystallization of the polyactic acid, so that the prepared polyactic acid / polycarbonate alloy can be formed quickly, the forming cycle is reduced from 80 seconds to50 seconds, processing cost is reduced, flowability and fire resistance are improved, and the polyactic acid / polycarbonate alloy material is applicable in the fields of office automation (OA) equipment, communication equipment, automobile parts, domestic appliances and the like.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

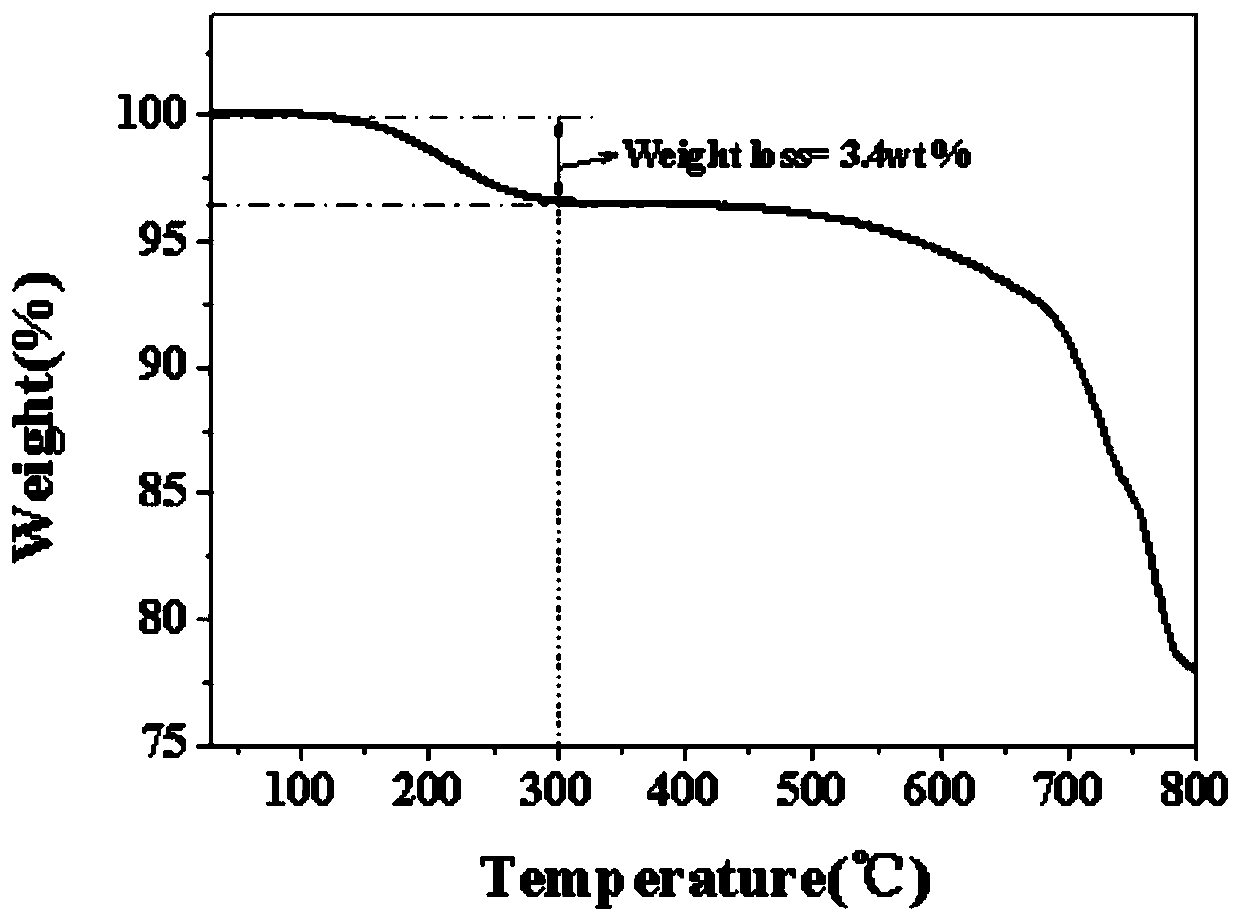

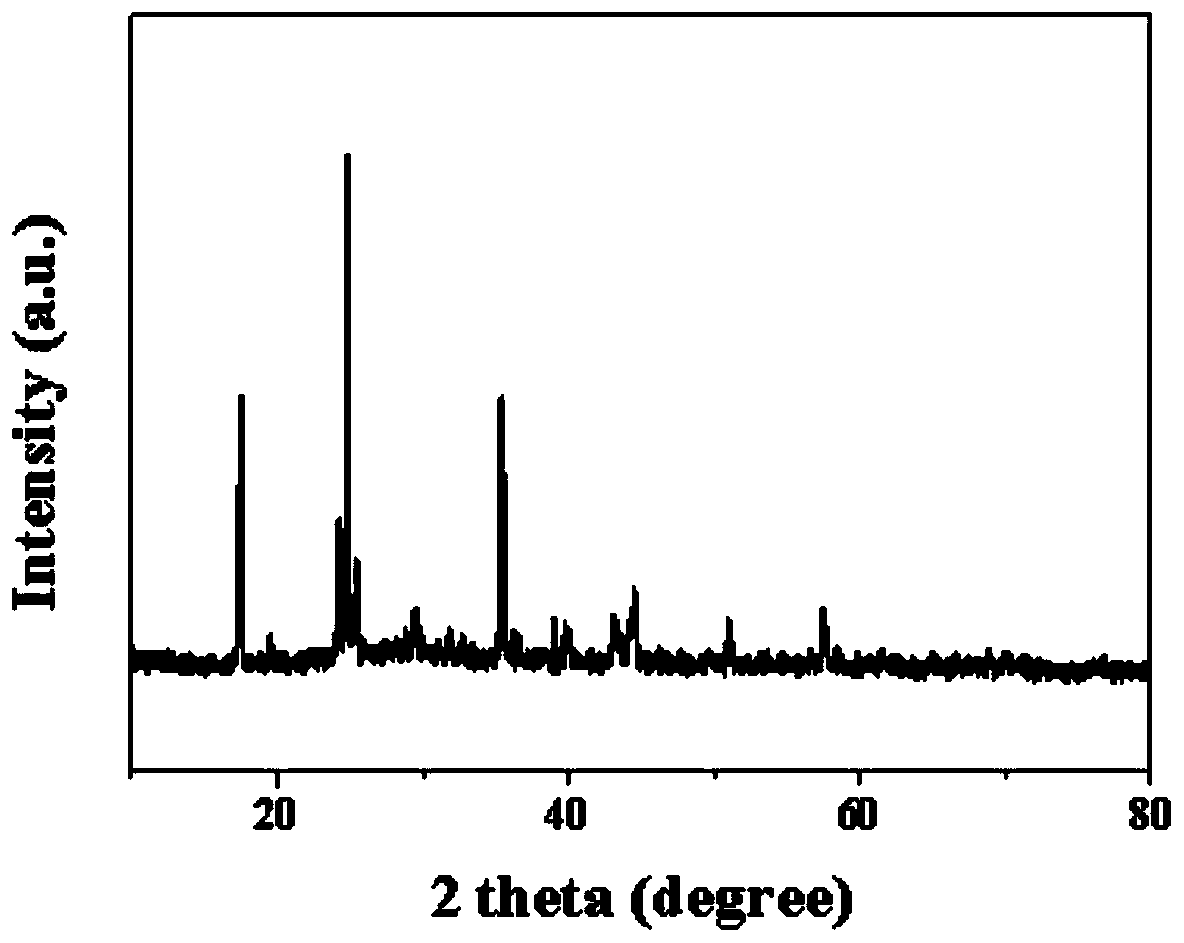

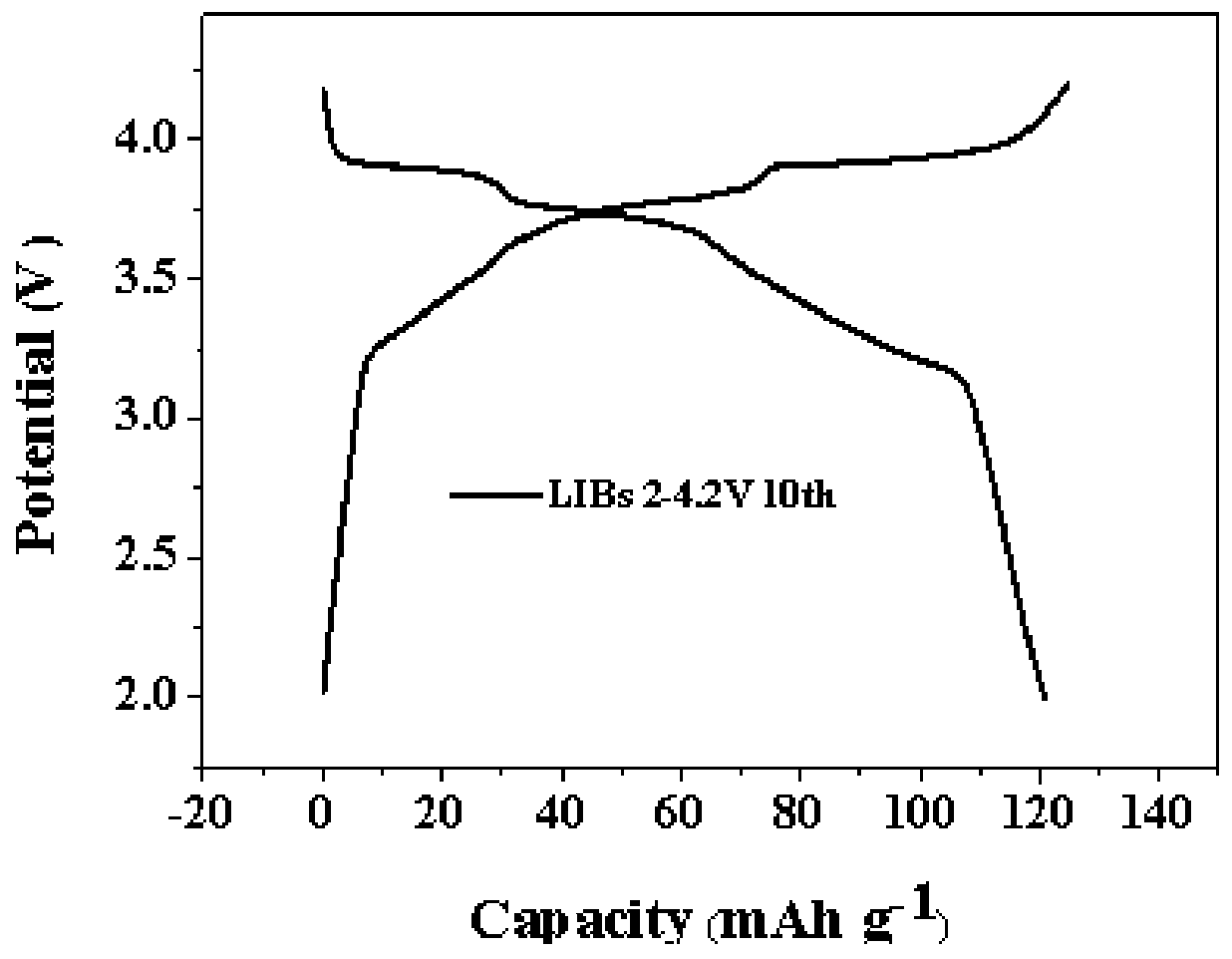

Prussian white analog cathode material and preparation method and application thereof

ActiveCN110002465AImprove crystal structureReduce defectsIron cyanidesSecondary cellsNew energyAqueous solution

The invention belongs to the field of new-energy batteries, and particularly relates to a Prussian white analog cathode material and a preparation method and application thereof. The preparation method of the Prussian white analog cathode material comprises the following steps: (1), acquiring an aqueous solution of K4Fe (CN)6, which is recorded as a solution A; (2), acquiring a mixed aqueous solution of a transition metal salt of Mn and potassium citrate, which is recorded as a solution B; and (3), dropwise adding the solution A into the solution B, continuing heating and stirring after completion of dropwise addition, aging for several hours, performing solid-liquid separation, collecting and washing a precipitate, and drying to obtain the Prussian white analog cathode material. The Prussian white analog cathode material adopts an open three-dimensional network frame structure, has a large gap position, and can guarantee free deintercalation of various ions such as Li<+>, Na<+> and K<+>.

Owner:HUAZHONG UNIV OF SCI & TECH

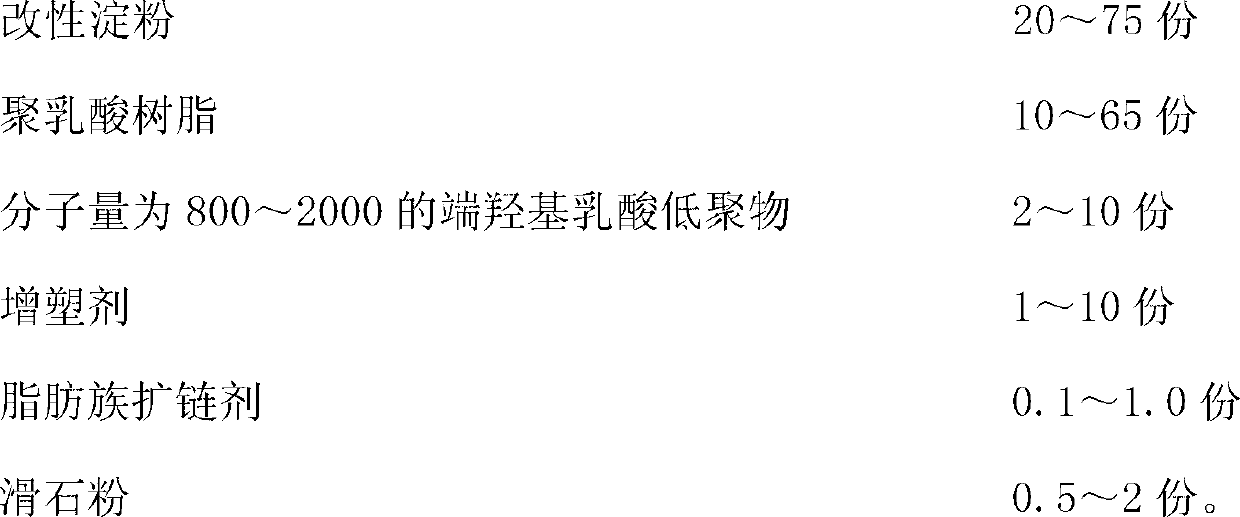

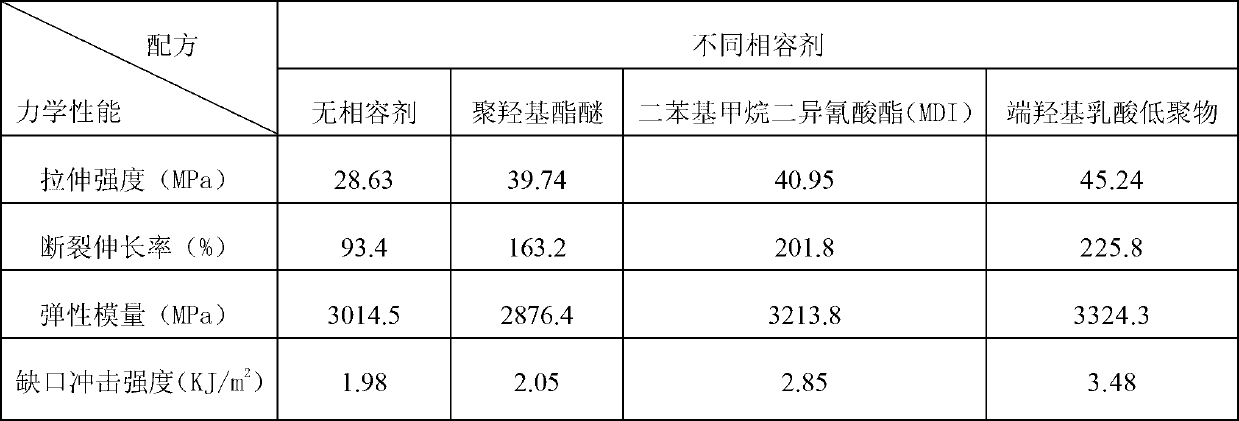

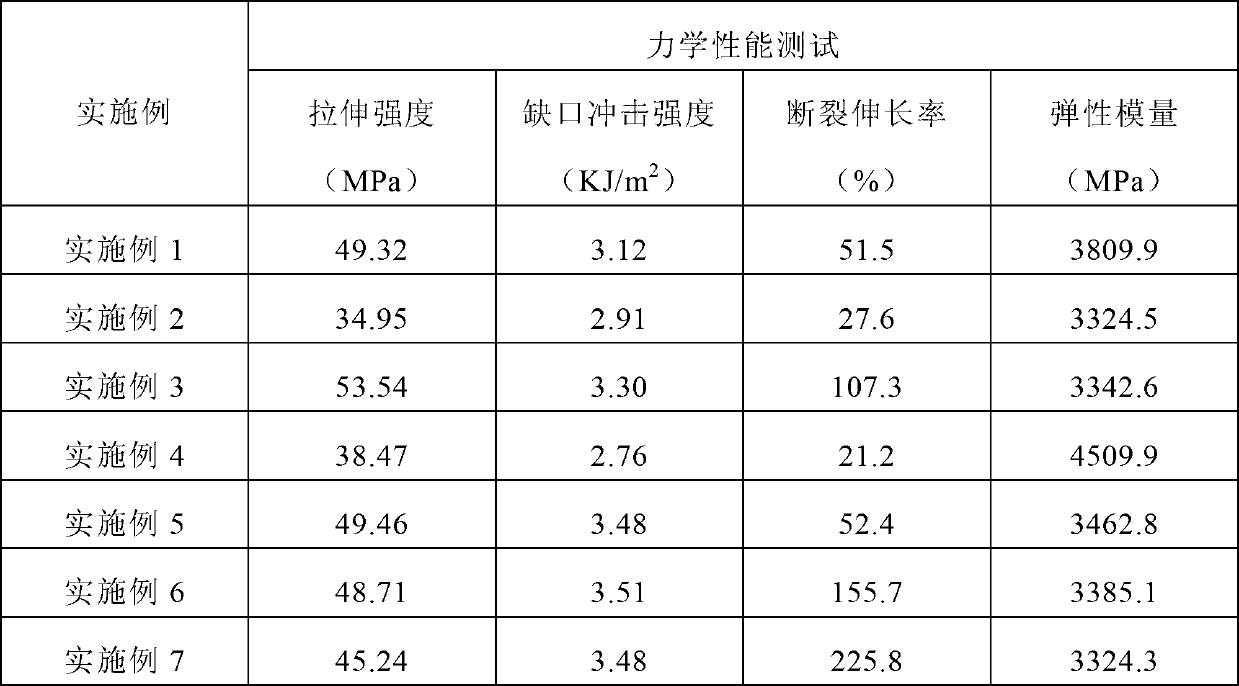

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

Phase change material layers

ActiveUS20150041747A1Improve thermal stabilityImprove crystallization ratePolycrystalline material growthBulk negative resistance effect devicesPhase-change materialAntimony

Owner:SAMSUNG ELECTRONICS CO LTD

Modified PET polyester as well as preparation method and application thereof

ActiveCN107312166AFree from destructionShorten the replacement periodFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalateSlurry

The invention relates to modified PET (Polyethylene terephthalate) polyester as well as a preparation method and application thereof, and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are dispersed between the molecular chains of the polyethylene terephthalate uniformly; the particle size of the aerogel particles is 2 to 3 microns; the content of the aerogel particles in the modified PET polyester is 1 to 10 percent by weight. Modified PET is prepared by the steps of adding the aerogel powder into glycol, putting into a grinding machine, grinding to prepare mixed slurry, mixing the mixed slurry and terephthalic acid, and performing esterification reaction and polymerization reaction. Modified PET fiber is prepared by slicing the modified PET, metering, spinning, cooling, applying oil, stretching, performing heat setting and performing winding formation. The aerogel particles are introduced before polymerization of the PET polyester, so the prepared PET has high spinnability, can produce modified PET fibers with various thickness, has wide application range and can meet the production requirement of various fabrics.

Owner:天津朗华科技发展有限公司

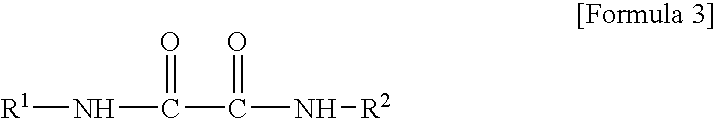

Organic nucleating agent for rapidly crystallizing polylactic acid and rapidly-crystallized polylactic acid resin of organic nucleating agent

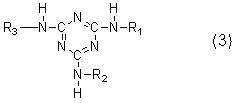

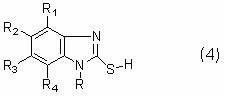

InactiveCN102174250AHigh crystallinityIncrease the rate of crystallizationOrganic compoundCrystal growth

The invention relates to an organic nucleating agent for rapidly crystallizing polylactic acid. The organic nucleating agent is an N-H, O-H and S-H group based organic compound which interacts with a polylactic acid molecular chain to rapidly form a crystal nucleus during polylactic acid crystallization to promote the crystal growth and achieve the purpose of improving the polylactic acid crystallization rate. The organic nucleating agent can be well compatible with polylactic acid resin and can be uniformly dispersed in a polylactic acid matrix, thus the defects that an inorganic nucleating agent has poor compatibility with the polylactic acid resin and decreased meahanical properties, and the purpose of rapidly crystallizing the polylactic acid to form the crystal nucleus by adding a small amount of organic nucleating agent is achieved. The invention further relates to a technology and method for rapidly crystallizing polylactic acid by adding the organic nucleating agent. The organic nucleating agent has obvious nucleating effect and can be widely applied to the polylactic acid resin.

Owner:SHANGHAI UNIV

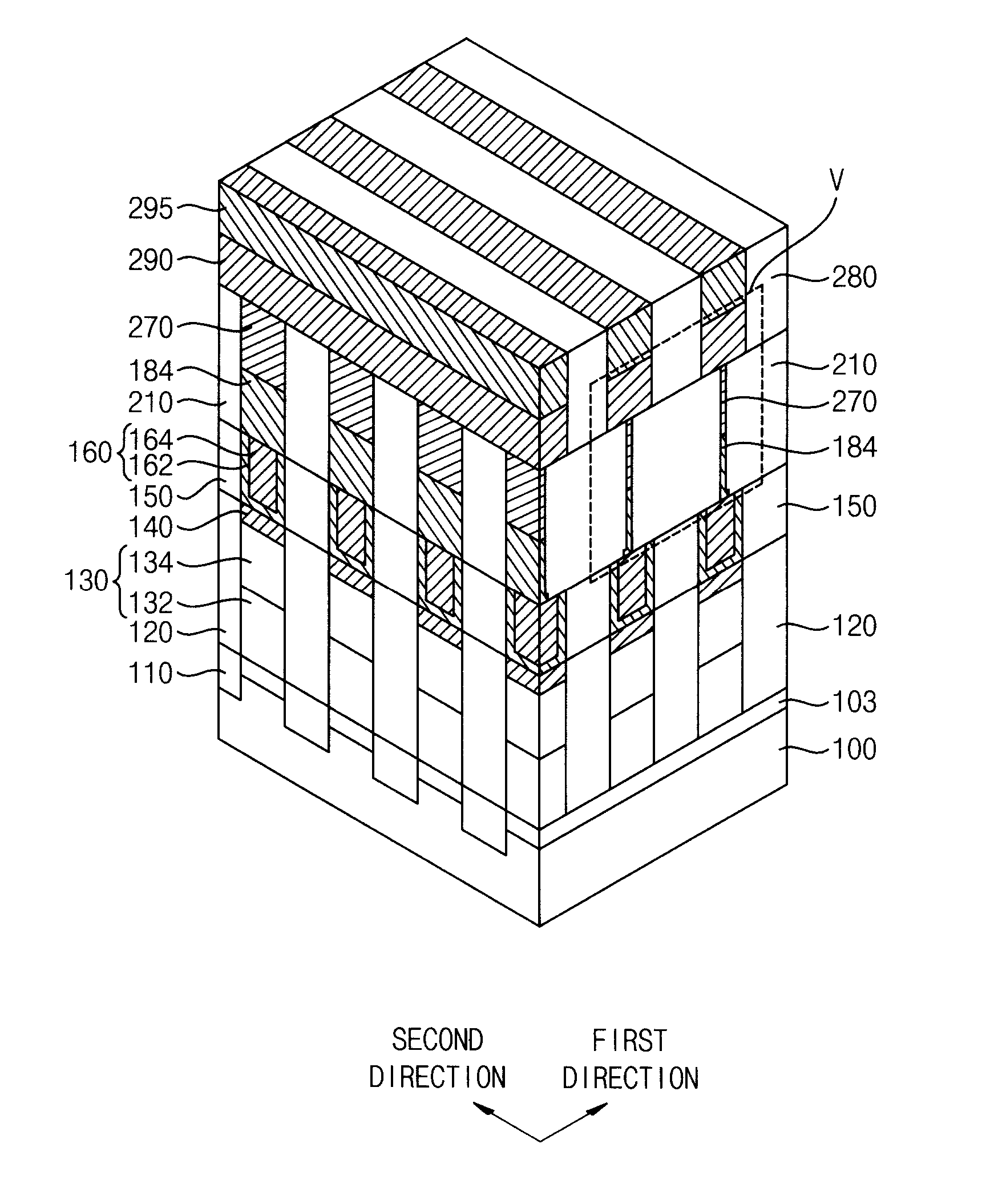

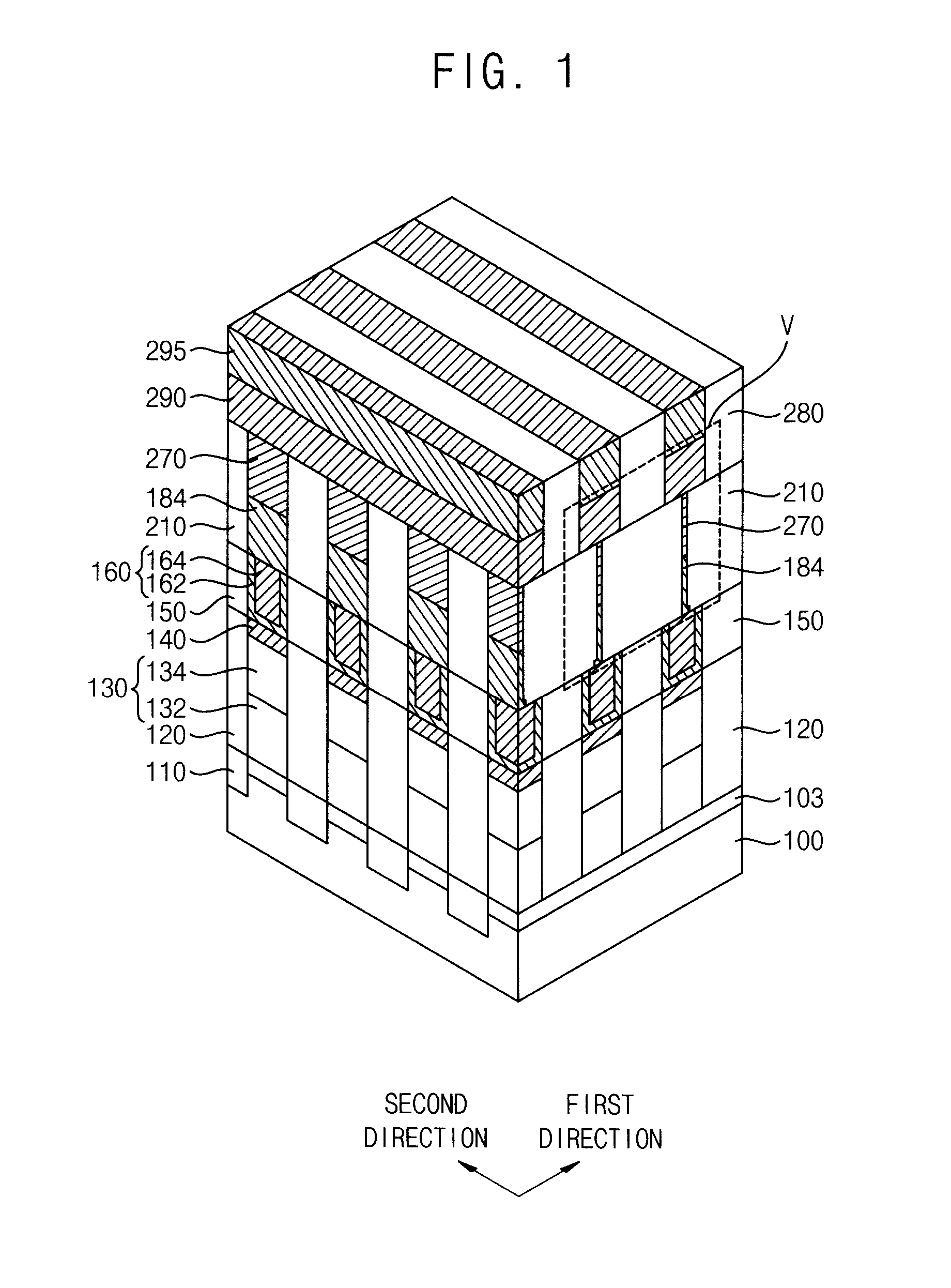

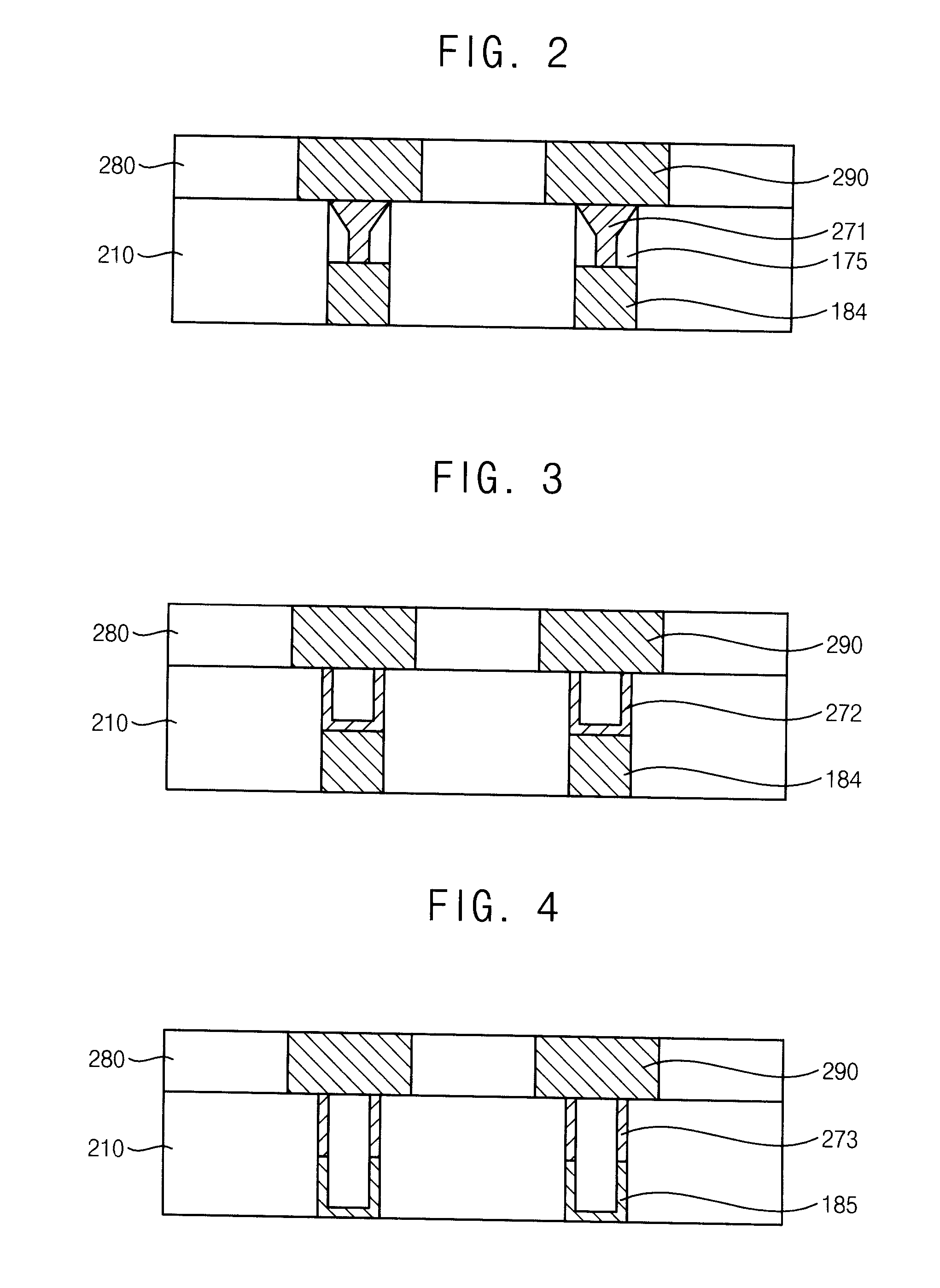

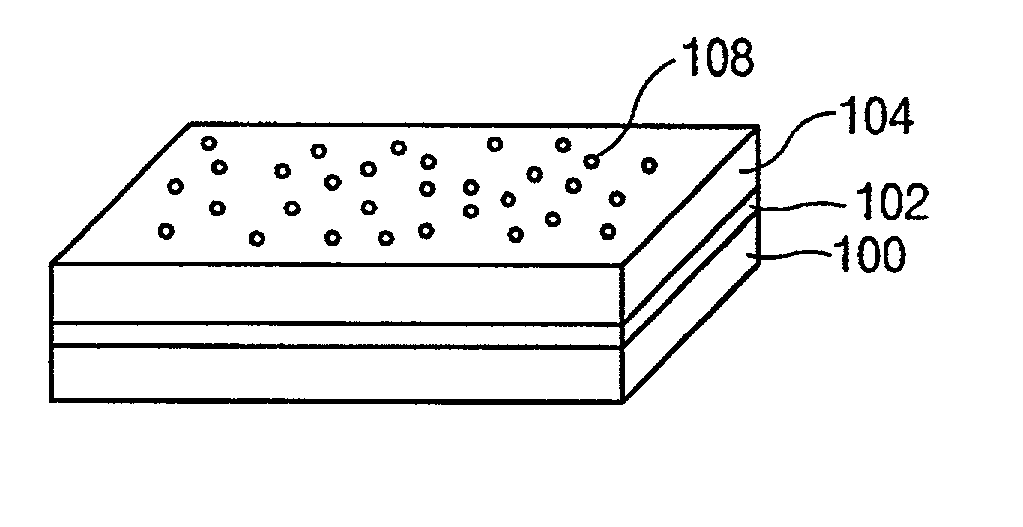

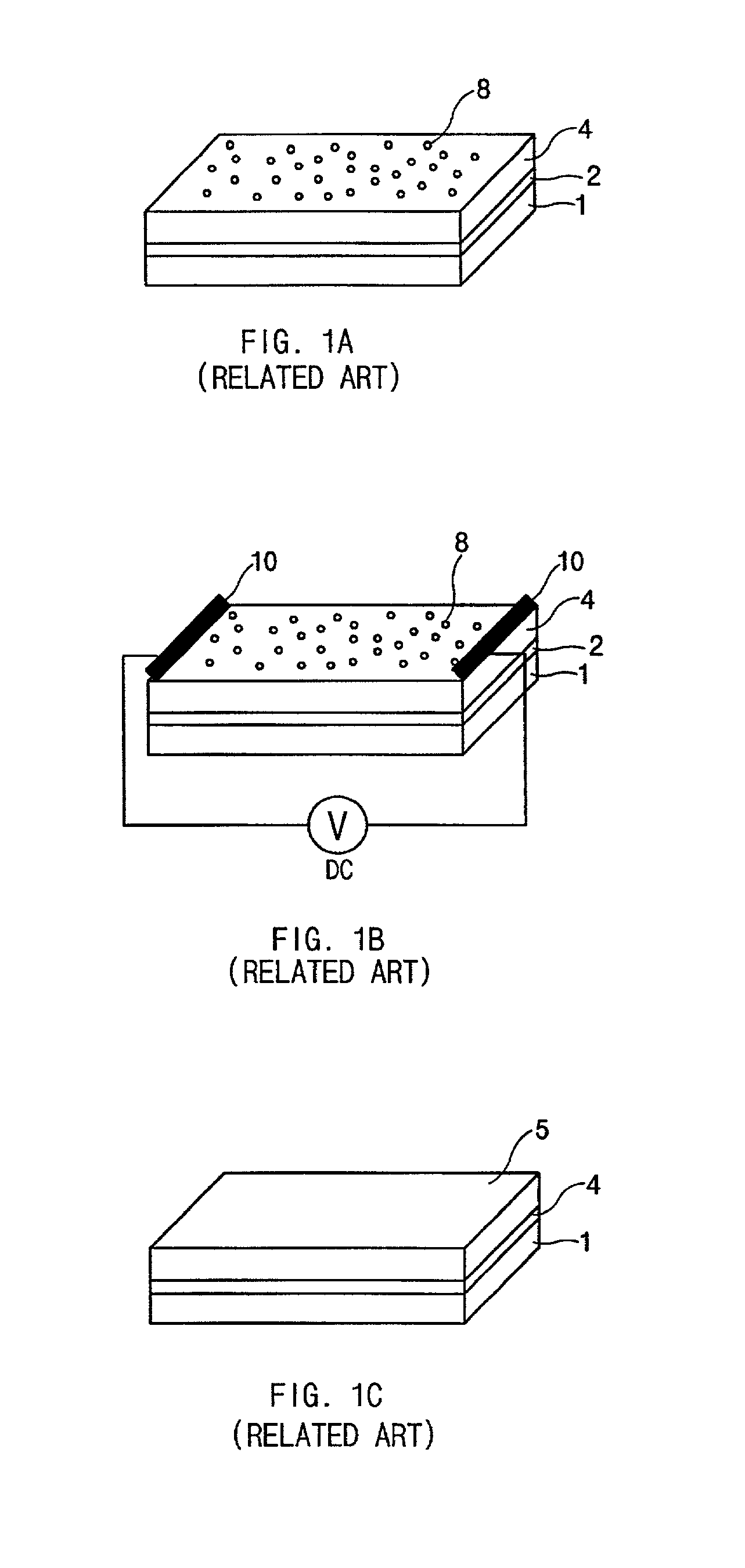

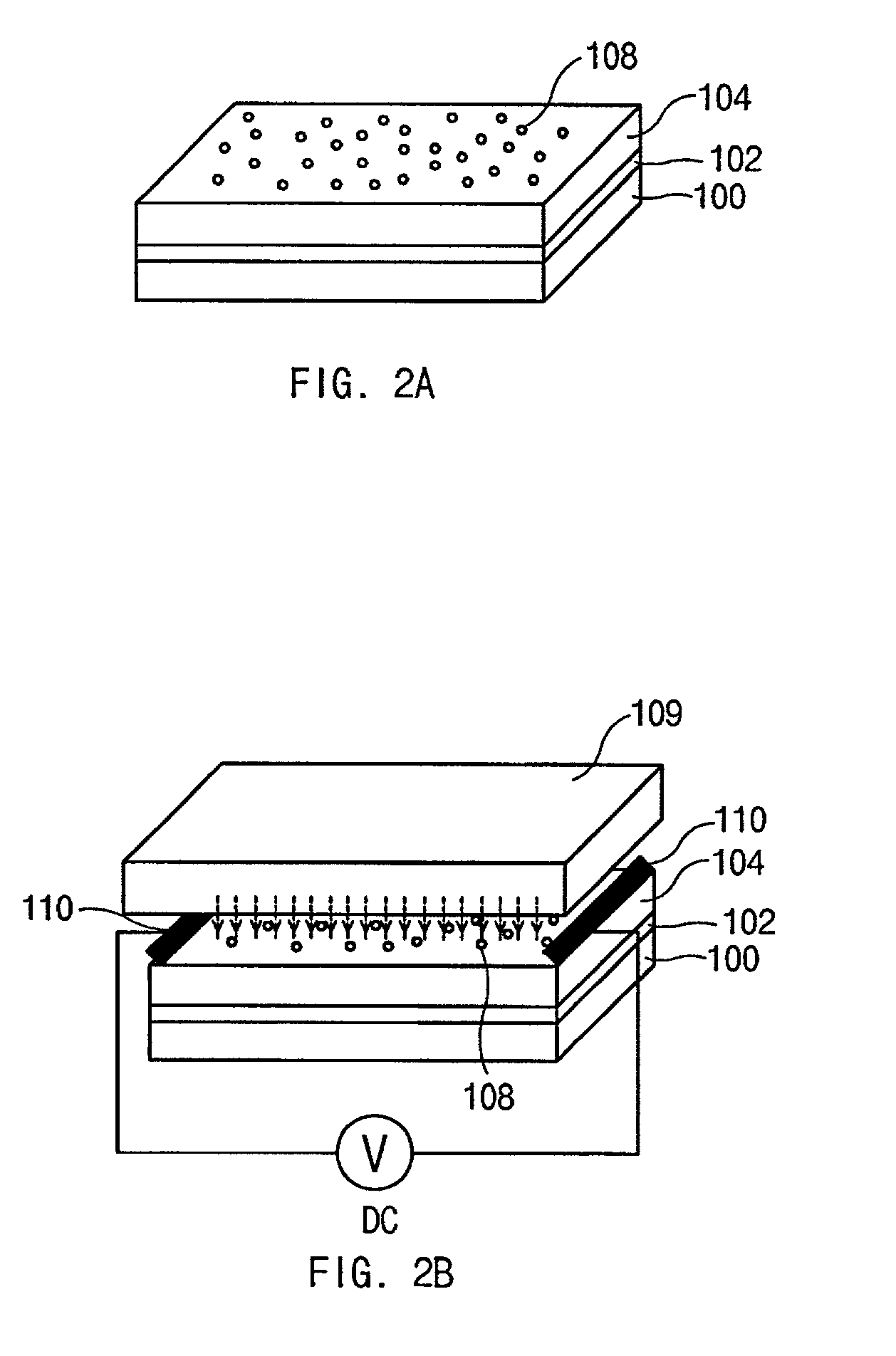

Method for crystallizing amorphous silicon and fabricating thin film transistor using crystallized silicon

InactiveUS20020086470A1Increase the rate of crystallizationReduce the temperatureTransistorSolid-state devicesMetal clustersAmorphous silicon

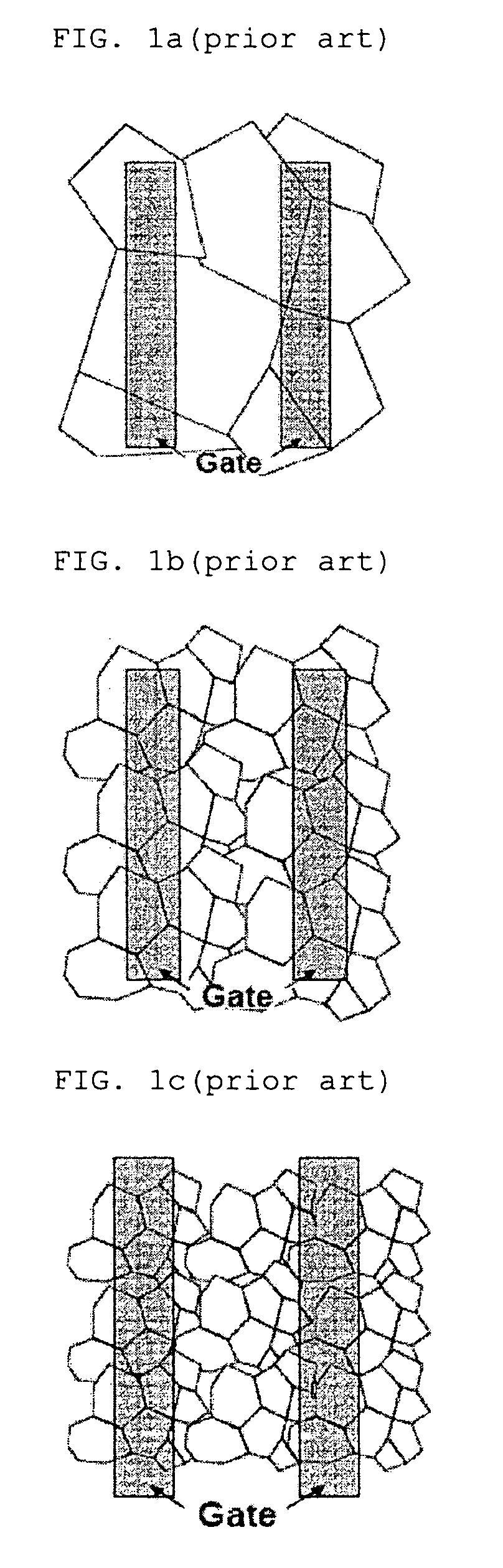

A method of crystallizing amorphous silicon includes forming an amorphous silicon layer over a substrate, forming a plurality of metal clusters on the amorphous silicon layer, and simultaneously applying a thermal treatment, an electric field, and a magnetic field to crystallize the amorphous silicon layer.

Owner:LG DISPLAY CO LTD

PPS (polyphenylene sulfite)/LCP (liquid crystal polymer) composite material and preparation method thereof

The invention discloses a PPS (polyphenylene sulfite) / LCP (liquid crystal polymer) composite material and a preparation method thereof. The method comprises the following raw materials in parts by weight: polyphenylene sulfide, a liquid crystal polymer, a compatilizer, a filling and reinforcing agent, a lubricating agent and other aids. The preparation method comprises the following steps of: (a) respectively drying polyphenylene sulfide resin and the liquid crystal polymer; (b) uniformly mixing the filling and reinforcing agent, the lubricating agent and other aids; (c) mixing the raw materials processed in the steps (a) and (b) at a high speed, then adding the compatilizer and uniformly mixing; and (d) melting and extruding the mixed raw materials in the step (c) by using a double-screw extruder and granulating. The invention provides the PPS / LCP composite material having high strength and rigidity and also provides the preparation method of the PPS / LCP composite material with simple preparation process, low cost and good economic benefits.

Owner:SHENZHEN KEJU NEW MATERIAL

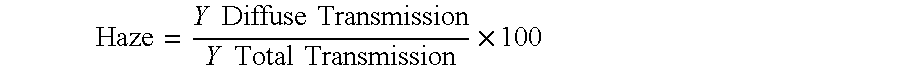

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

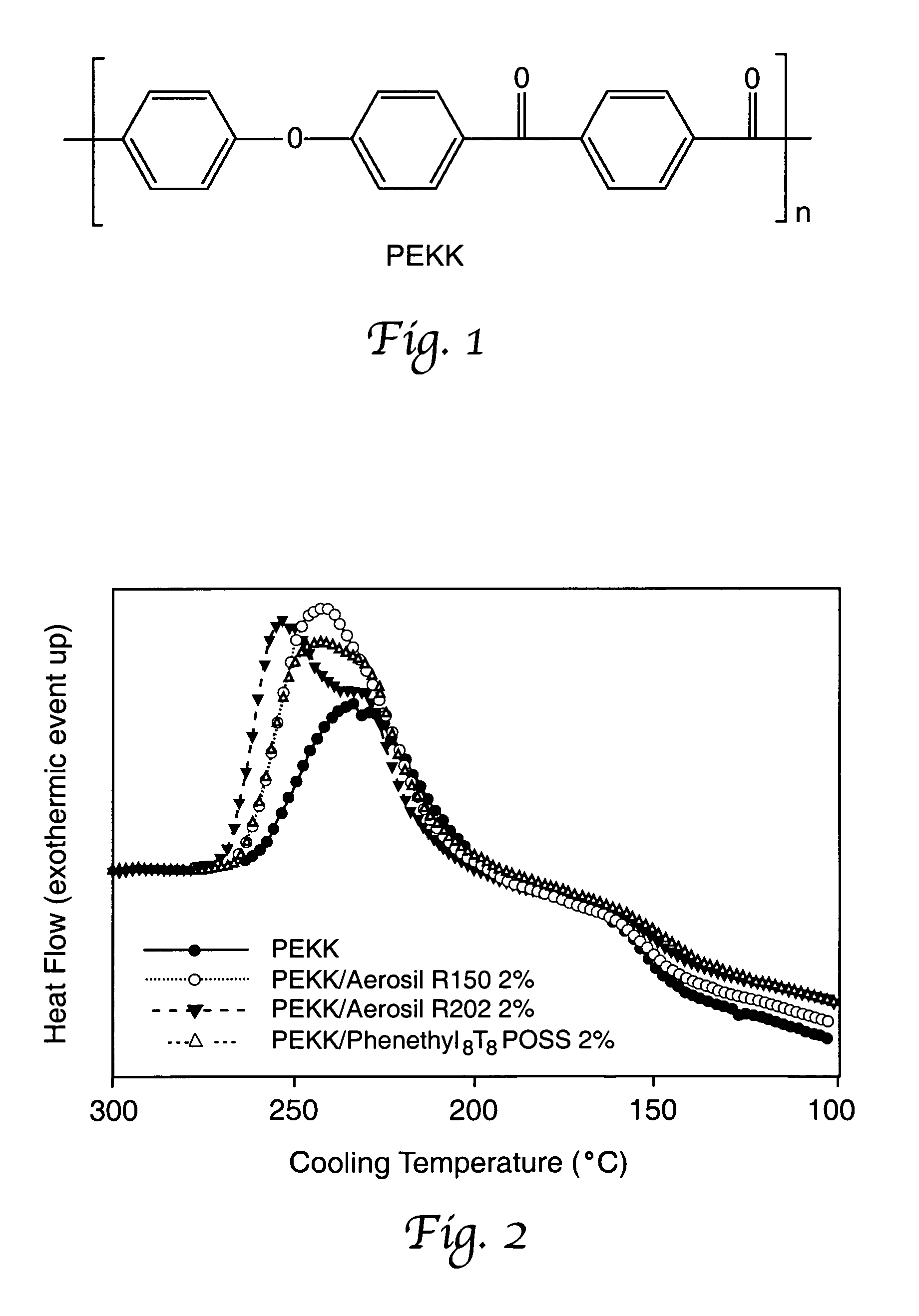

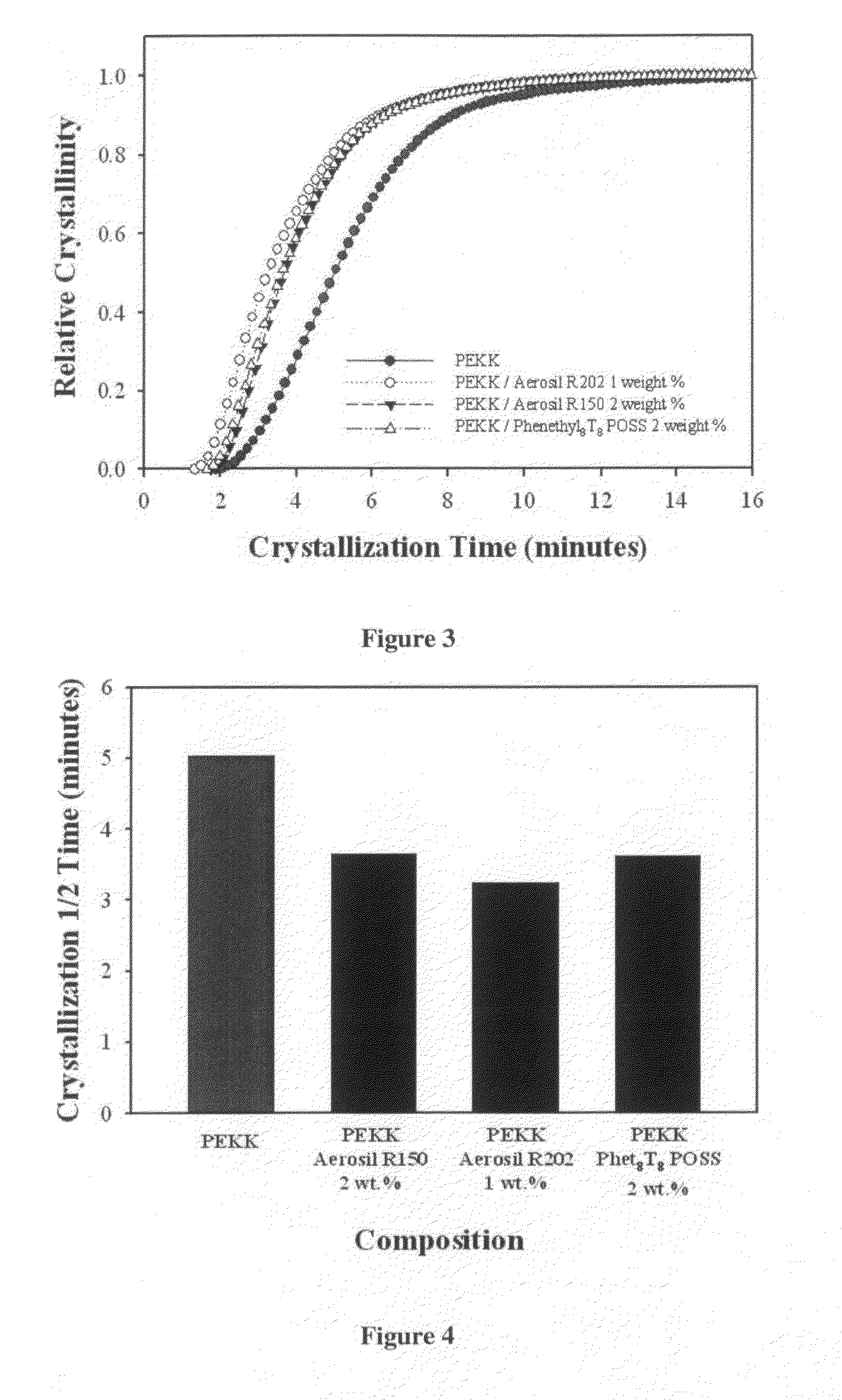

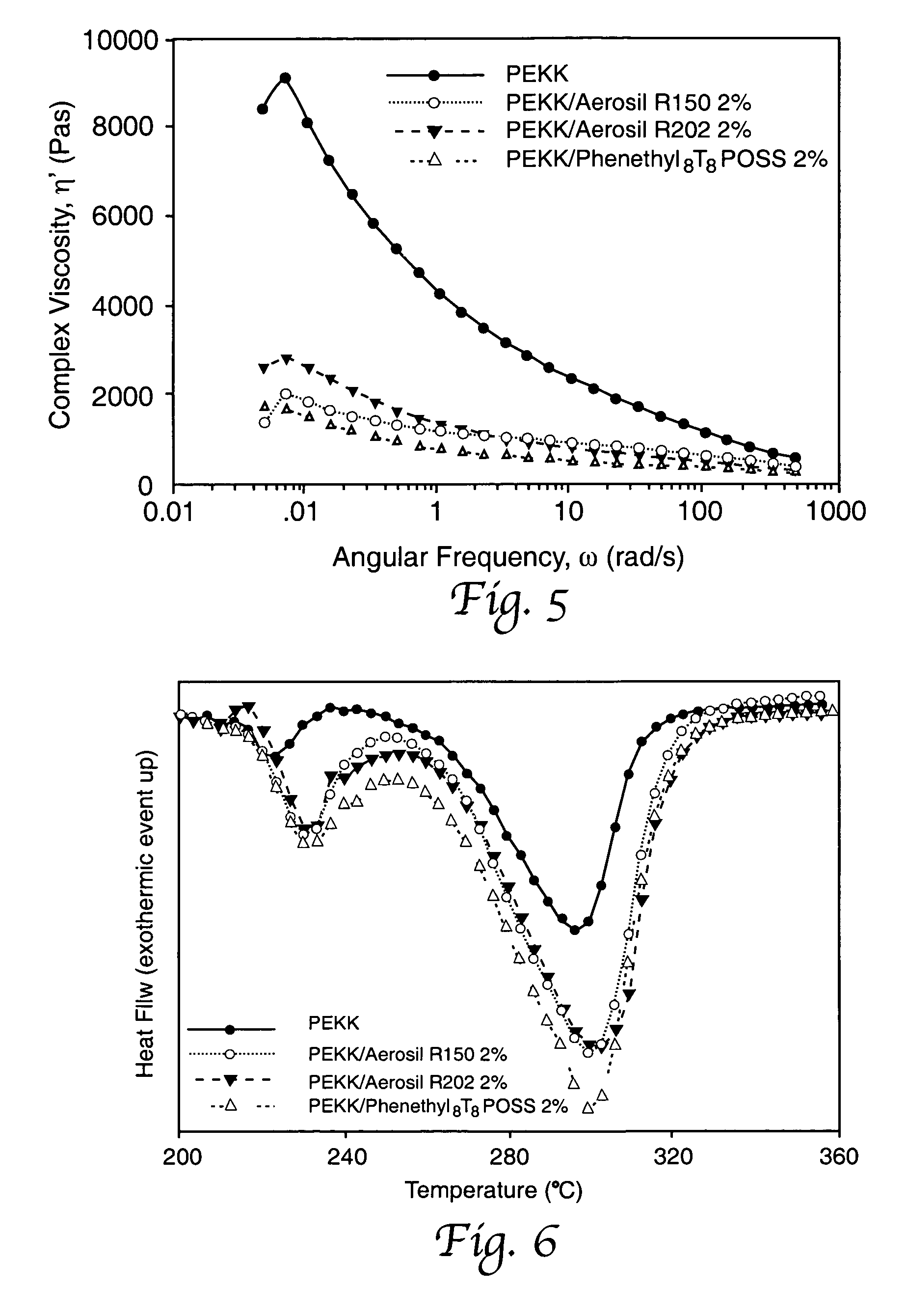

Increasing the rate of crystallization of engineering thermoplastics

InactiveUS7790841B1Increase the rate of crystallizationEnhanced crystalline behaviorMaterial nanotechnologyFibre treatmentThermoplasticParticulates

Method for enhancing the crystallization rates of engineering thermoplastics through the use and incorporation of particulate additives with dimensions on the order of 10-1000 nm is described. The presence of nanoparticles at concentrations of, e.g., less than 10 weight percent of the composition, reduces the viscosity of the thermoplastics as compared to the respective homopolymer, thereby increasing polymer chain transport and diffusion to the crystallizing growth front. The prescription of this technology has been shown to reduce crystallization half times of some engineering thermoplastics by as much as 40 percent at optimal crystallization temperatures, an effect that is magnified as the temperature is reduced towards the glassy state of the amorphous phase. Nano-modified engineering thermoplastics with rapid crystallization kinetics and relatively low viscosities can be utilized in component fabrication processes that require rapid processing times, e.g., for the sake of cost efficiency.

Owner:AIR FORCE US SEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com