Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1046 results about "Soft segment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

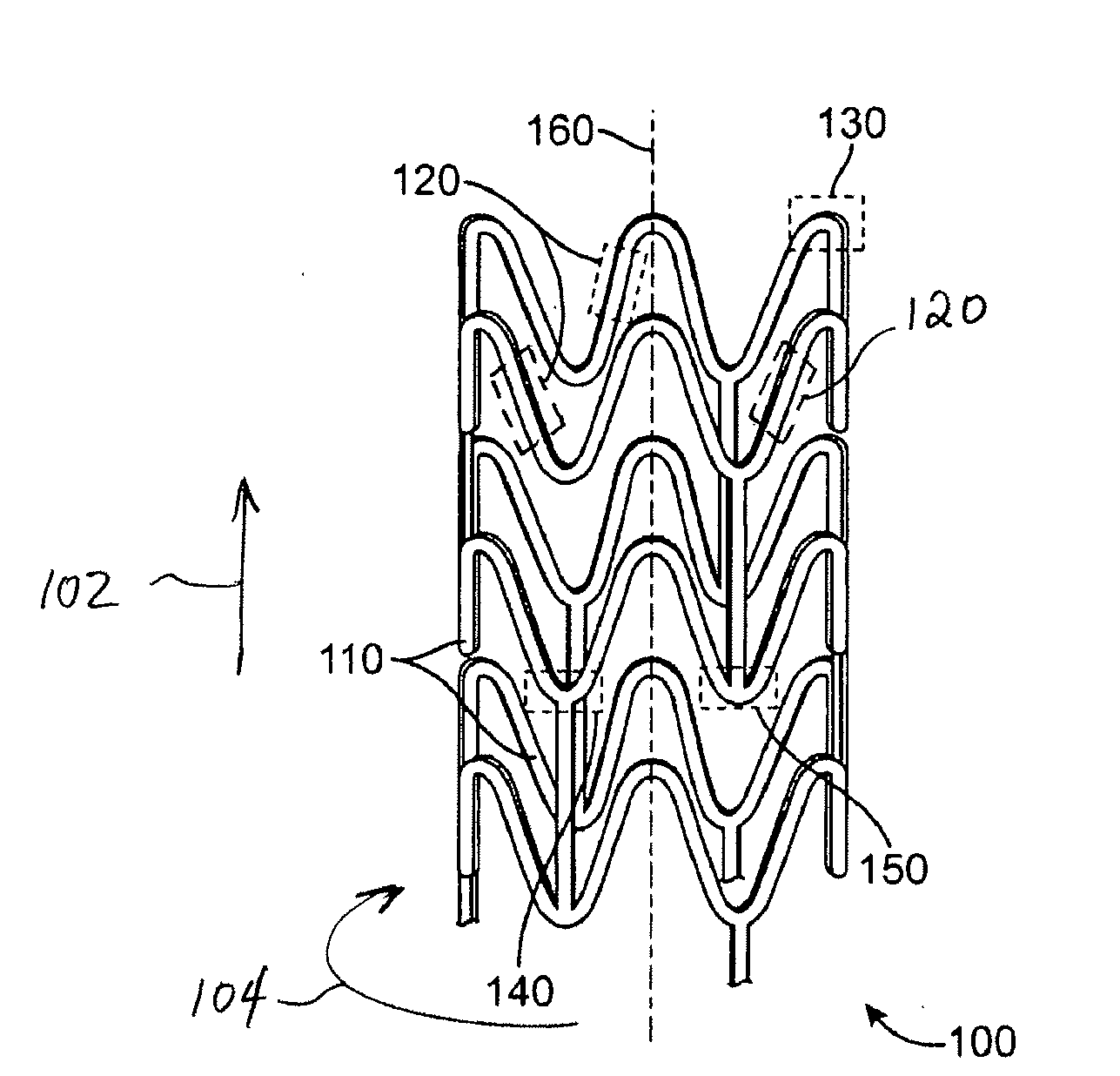

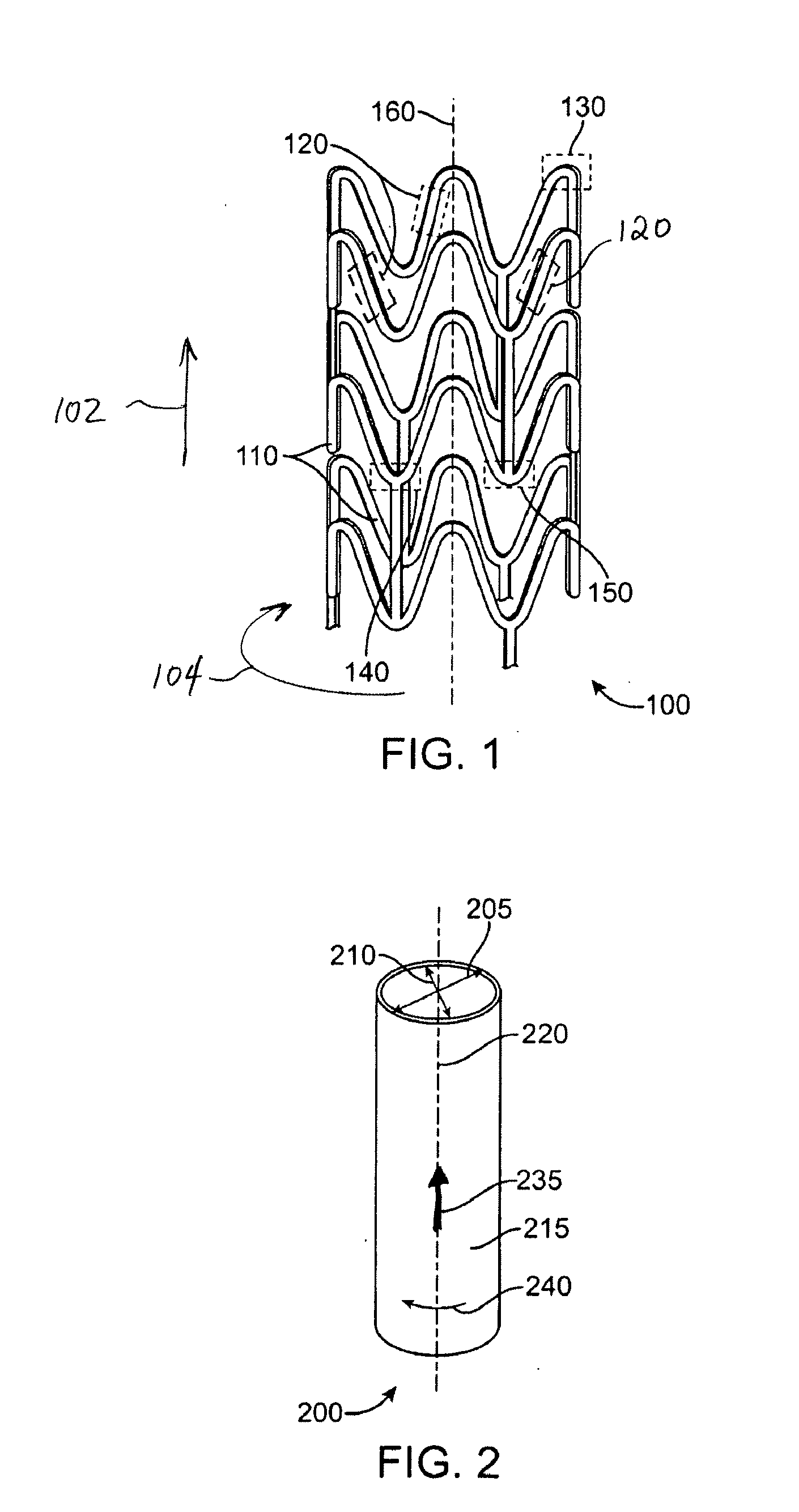

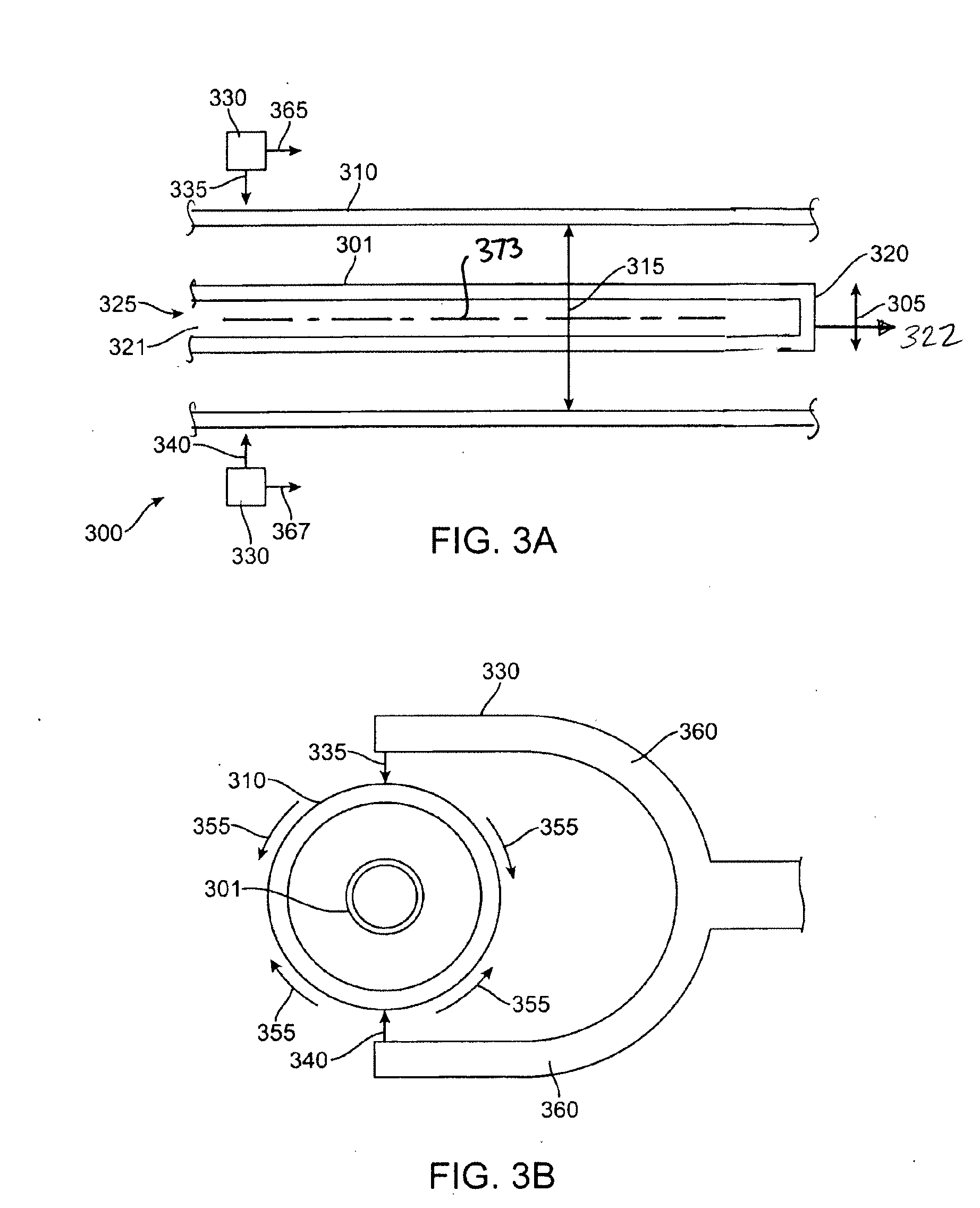

Polymeric Stent and Method of Making Same

A stent may be formed from a PLLA tubular polymer construct that is deformed in a blow mold. A desirable polymer morphology resulting in improved stent performance is obtained with a selected radial axial expansion ratio from about 20% to about 70%, a selected radial expansion ratio from about 400% to about 500%, a selected axial rate of deformation propagation at or about 0.3 mm / minute, a selected expansion pressure at or about 130 psi, and a selected expansion temperature that does not exceed 200 deg F. The tubular polymer construct may also be made of PLGA, PLLA-co-PDLA, PLLD / PDLA stereocomplex, and PLLA-based polyester block copolymer containing a rigid segment of PLLA or PLGA and a soft segment of PCL or PTMC.

Owner:ABBOTT CARDIOVASCULAR

Polyether ester elastomer comprising polytrimethylene ether ester soft segment and tetramethylene ester hard segment

A polyether ester elastomer comprising about 90-about 60 weight % polytrimethylene ether ester soft segment and about 10-about 40 weight % tetramethylene ester hard segment, and use thereof in fibers and other shaped articles. The fibers have excellent physical properties, including superior strength and stretch recovery.

Owner:DUPONT IND BIOSCIENCES USA LLC

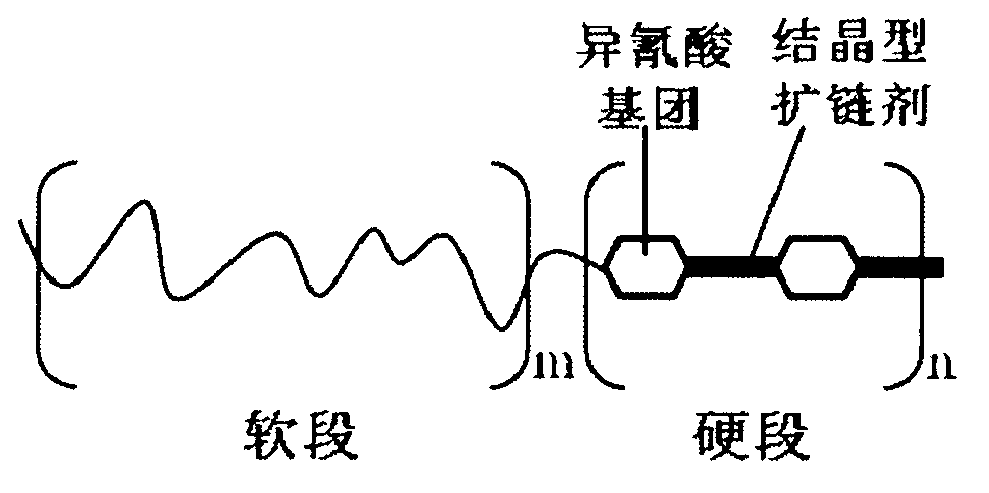

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

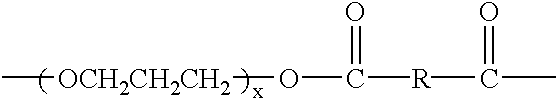

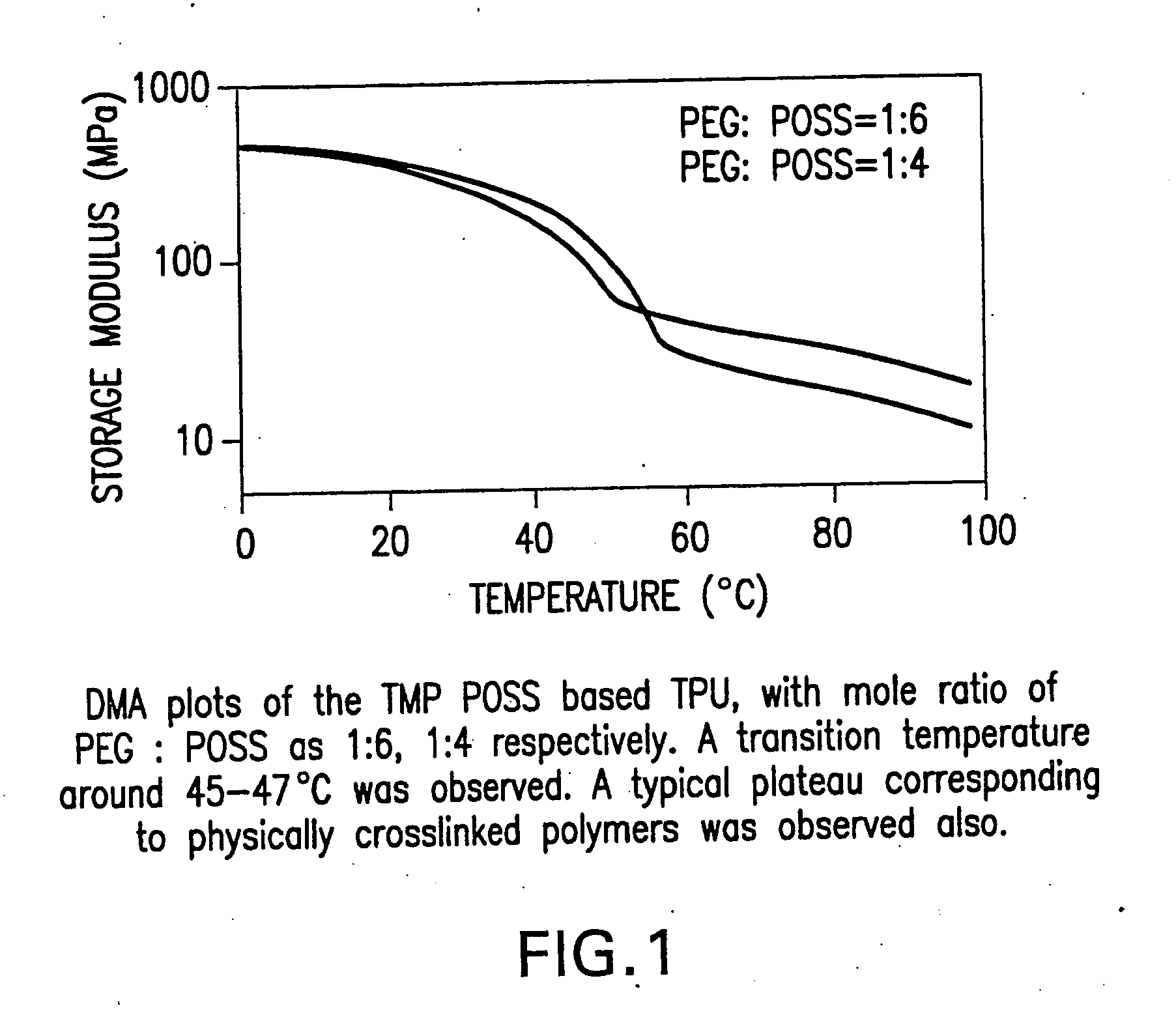

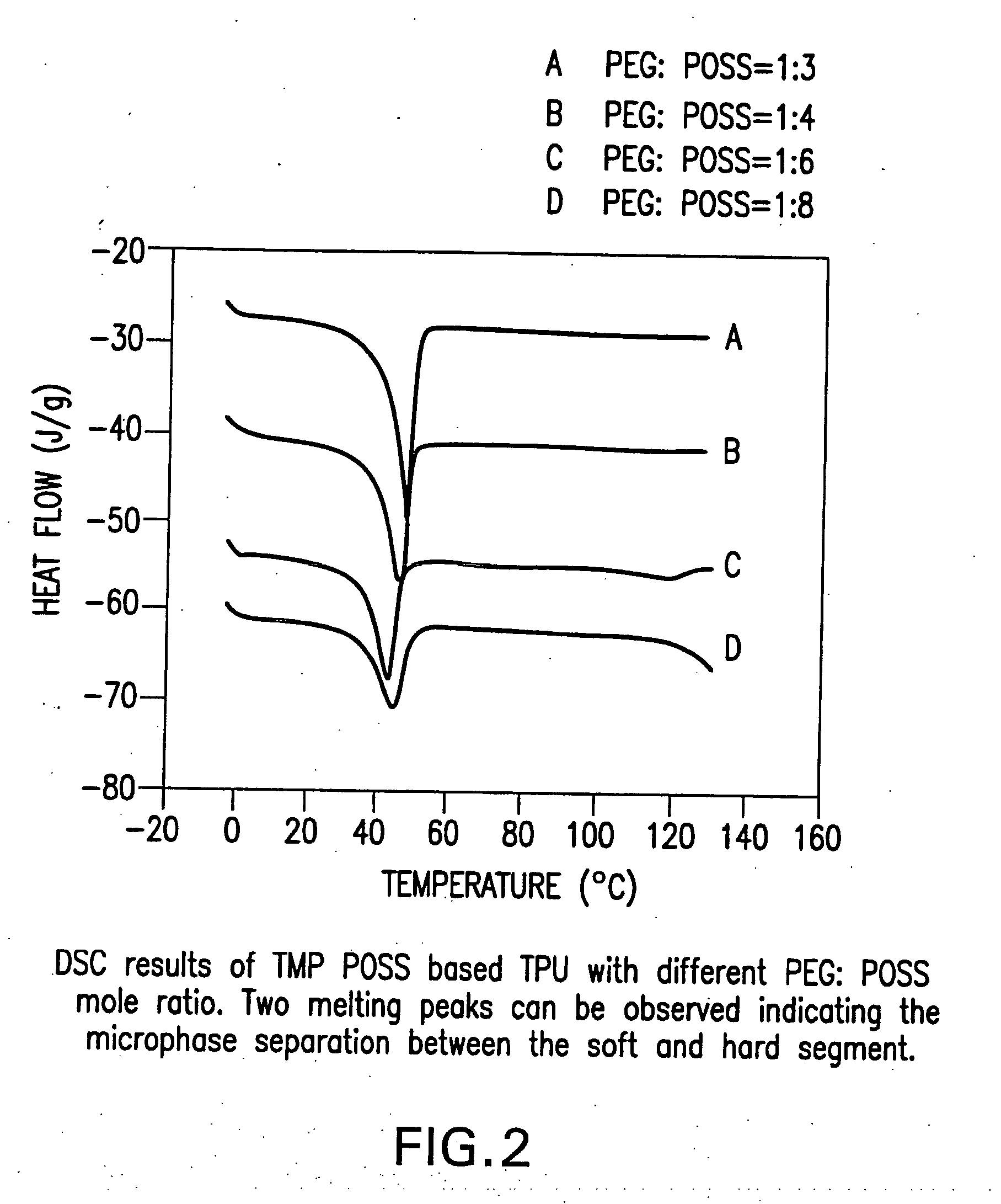

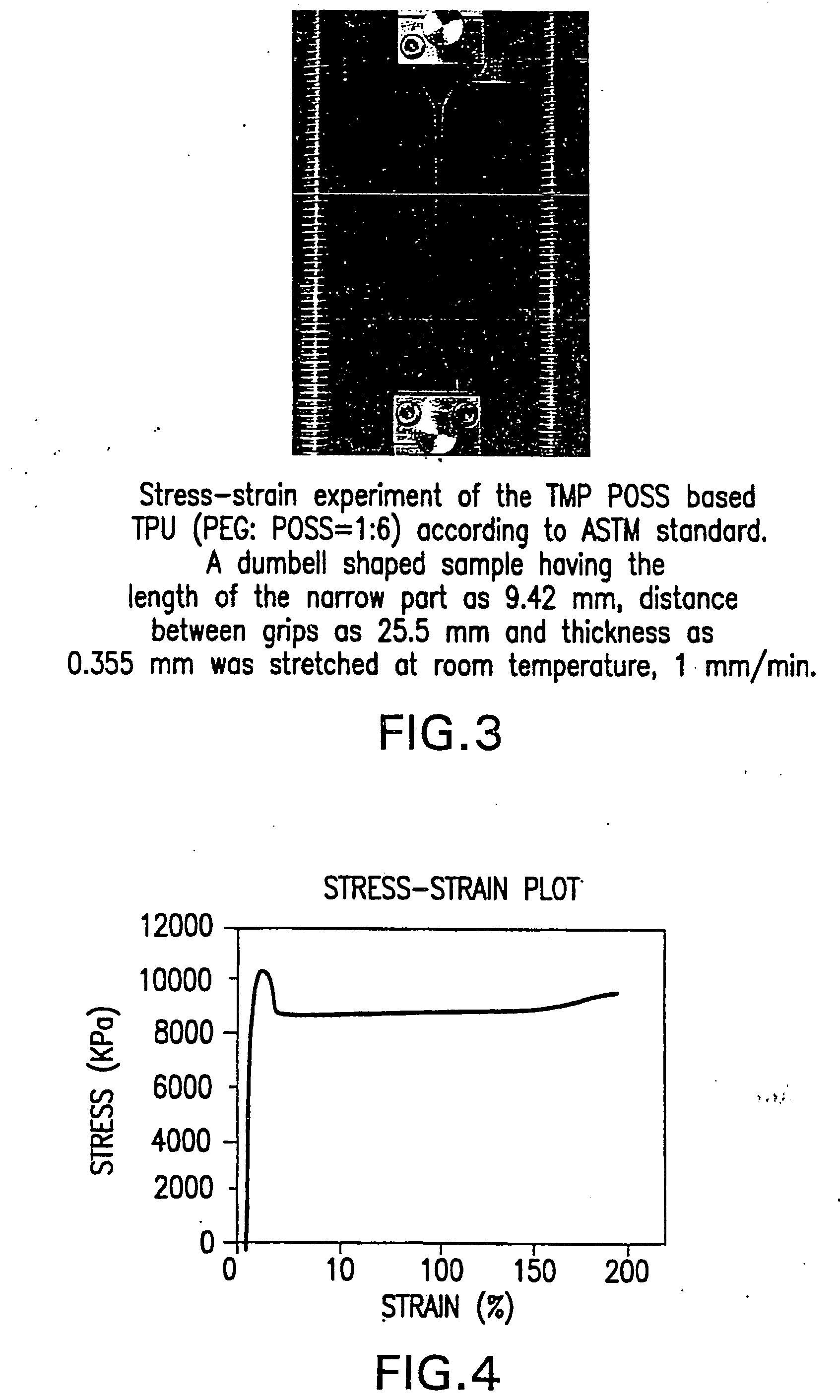

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Polyether ester elastomer comprising polytrimethylene ether ester soft segment and trimethylene ester hard segment

Owner:DUPONT IND BIOSCIENCES USA LLC

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

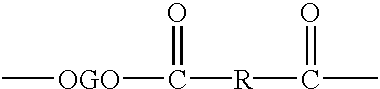

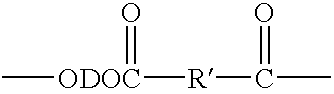

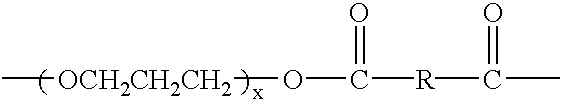

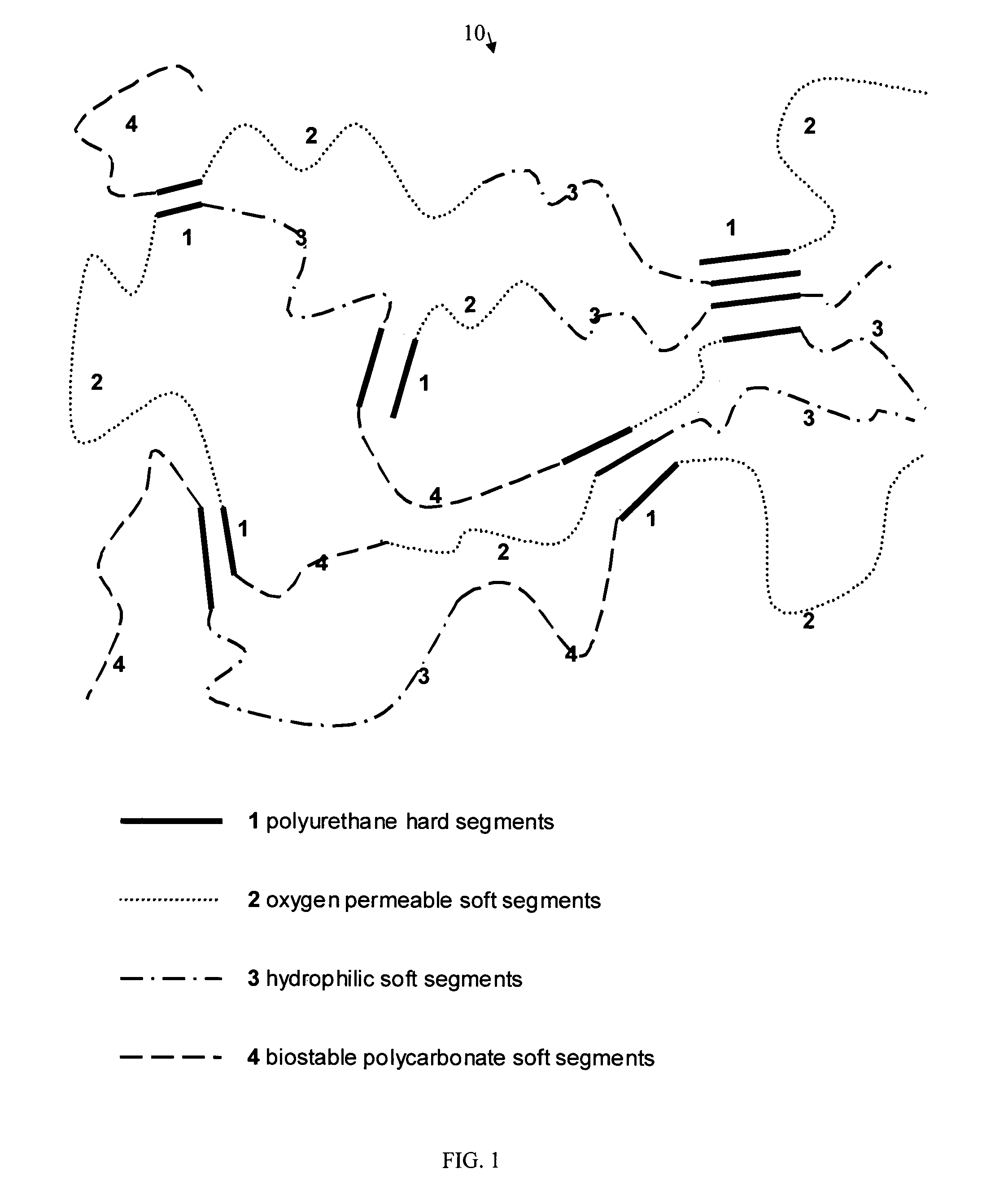

Permselective structurally robust membrane material

ActiveUS7157528B2Easy to understandWeaken energyImmobilised enzymesBioreactor/fermenter combinationsOxygenSoft segment

Owner:THE POLYMER TECH GROUP

Blends with shape memory characteristics

The invention relates to a polymer blend with shape-memory characteristic comprising two different block copolymers each containing at least one hard segment and at least one soft segment, whereby the two different block copolymers comprise the same soft segment and only differ with regard to the hard segment.

Owner:MINEMOSCIENCE GMBH

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7091297B2High modulusSufficient cross-linkingStentsOther chemical processesPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligomeric silsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated POSS and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

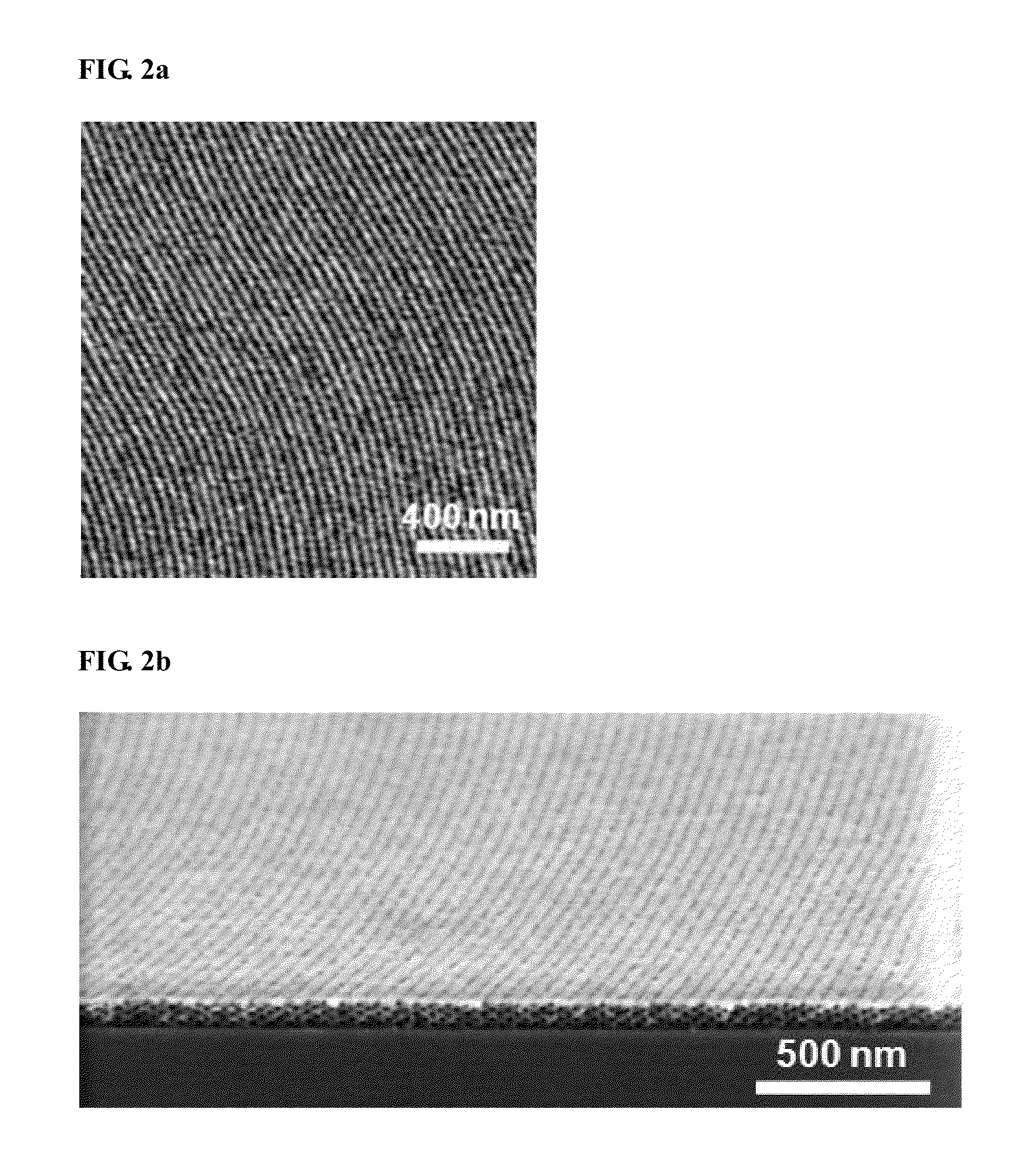

Methods for producing di-block polymers

The current major way of making nanofibers is electrospinning. However, the minimum fiber diameter is limited to be about 300–500 nm, which is not compliant with the physical definition of nano structures (in the region of 1 to 100 nm). Futher, the productivity is relatively low. This invention provides a method for manufacturing a nano-sized di-block polymer including at least a hard-segment polymer and a soft-segment polymer. First, a sample containing the hard-segment polymer, the soft-segment polymer, and a catalyst is dissolved in a first solvent. Then the dissolved sample is cast on substrate, and then the first solvent to is removed form a dried sample. Finally, the nano-sized di-block polymer is formed by crew-cutting.

Owner:THE HONG KONG POLYTECHNIC UNIV

Segmented copolymer compositions and coatings incorporating these compositions

Some variations provide a segmented copolymer composition comprising: fluoropolymer first soft segments that are (α,ω)-hydroxyl-terminated and / or (α,ω)-amine-terminated; polyester or polyether second soft segments that are (α,ω)-hydroxyl-terminated and / or (α,ω)-amine-terminated; isocyanate species possessing an isocyanate functionality of 2 or greater; and polyol or polyamine chain extenders or crosslinkers, wherein the molar ratio of the second soft segments to the first soft segments is less than 2.0. Exemplary segmented copolymers are disclosed. The segmented copolymer composition may be present in a low-friction, low-adhesion coating. Such a coating may be characterized by a coefficient of friction, measured at 90% relative humidity, less than 0.7. Such a coating may be characterized by an average kinetic delay of surface ice formation of at least 10 minutes at −10° C. These coatings are useful as bugphobic and icephobic coatings.

Owner:HRL LAB

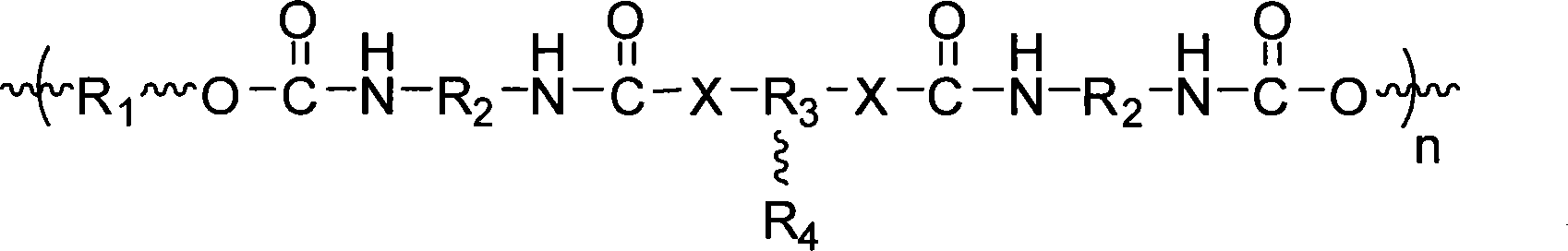

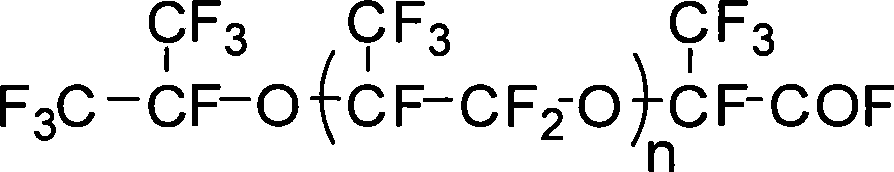

Fluorine-containing polyether graft modified aqueous polyurethane and preparation and application thereof

InactiveCN101157750AGood water repellencyGood weather resistanceOther chemical processesSolventBioaccumulation

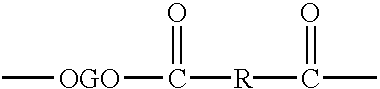

The present invention relates to a fluorine-containing polyether grafting modified waterborne polyurethane, the preparation and the application thereof, a structural general formula of polyurethane is as the formula, wherein, R1 is equal to a polyurethane soft-segment polyol structure, R2 is equal to a polyurethane hard-segment isocyanate structure, R3 is equal to a polyurethane hard-segment chain extender structure, R4 is equal to the fluorine-containing polyether; X is equal to NH and O; the preparation is that: the polyol and the isocyanate react to compound the polyurethane prepolymer, then the waterborne polyurethane are obtained through the chain propagation of a chain extender, then the waterborne polyurethane and the fluorine-containing polyether are carried out a grafting reaction in the big molecules, so as to synthesize the fluorine-containing polyether grafting modified waterborne polyurethane; the application is that: the present invention can be applied to aerospace, aviation, automobiles, electronics, textiles, carpets, leathers, paper making, packaging, washing, machinery, construction and other fields. The present invention adopts the water as the solvent and has no formaldehyde, no or low VOC emission, no bioaccumulation and no toxicity, which is a multifunctional, green, environment protective, water-proof and dirt-proof coating layer and fabric finishing agent.

Owner:DONGHUA UNIV

Cosmetic compositions containing block copolymers, tackifiers and shine enhancing agents

A cosmetic composition containing at least one block copolymer having a hard segment and a soft segment, at least one tackifier component, at least one solvent, or solvent mixture, at least one shine enhancing agent, and optionally, at least one colorant, and wherein the at least one hard segment has a Tg value of 50° C. or more and the at least one soft segment has a Tg value of 20° C. or less, and the at least one solvent, or solvent mixture, is capable of solubilizing either the at least one hard segment or the at least one soft segment, or both the hard and the soft segments.

Owner:LOREAL SA

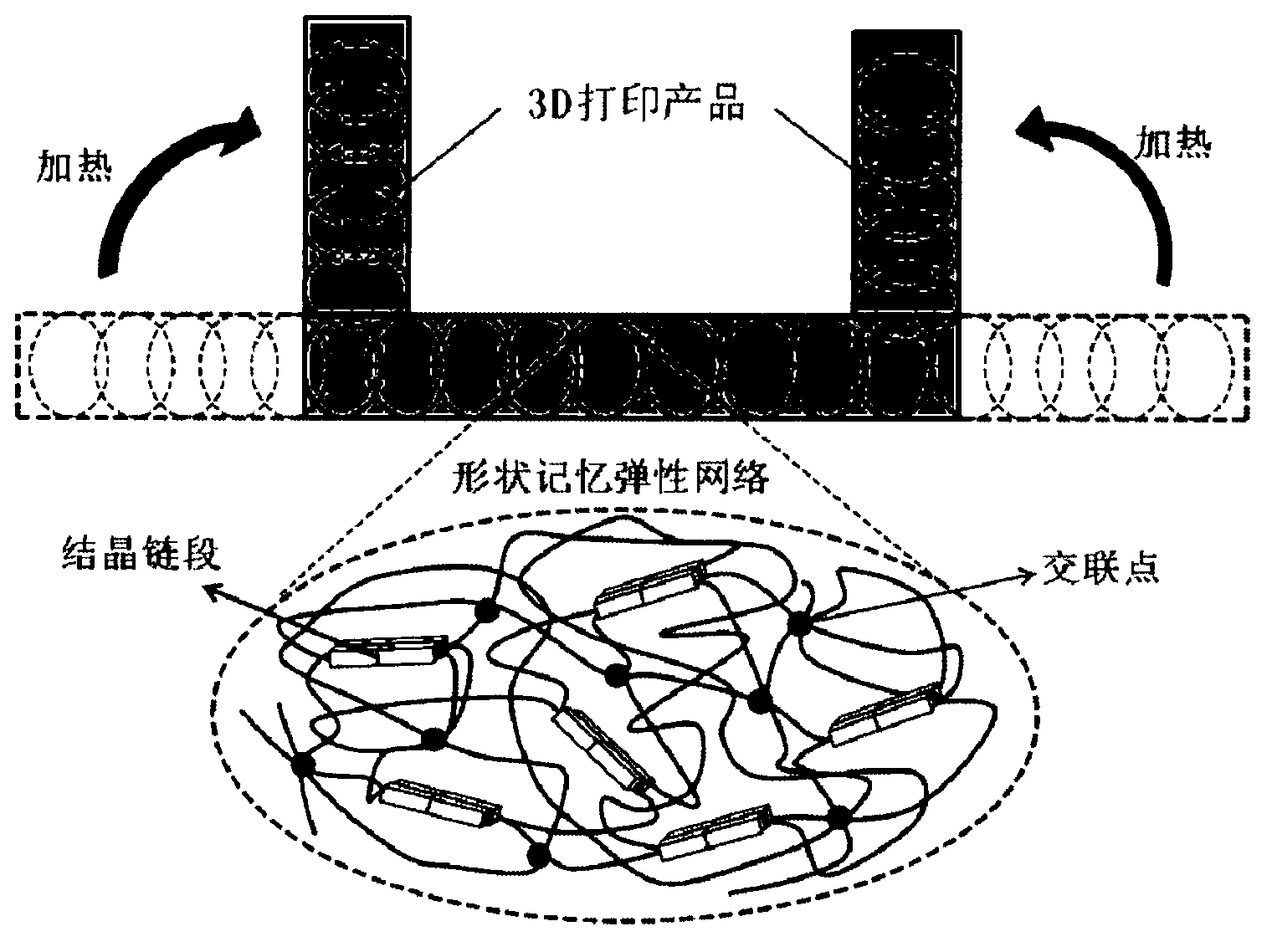

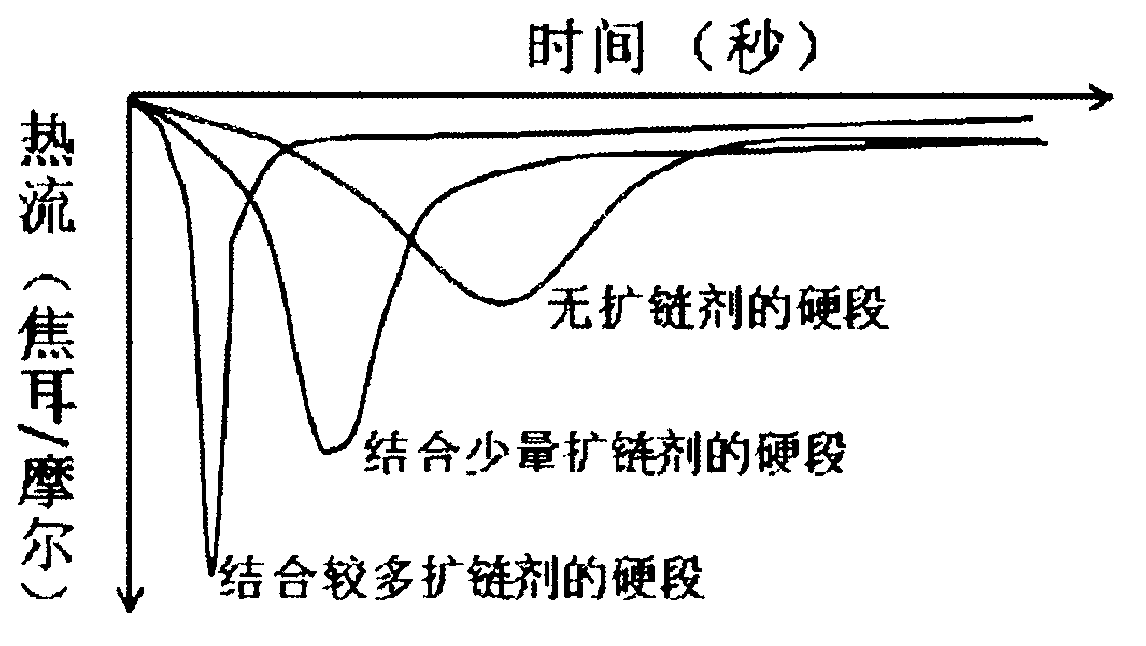

Rapid prototyping shape memory high polymer material and preparation method and application thereof

ActiveCN103160948AImprove cooling forming effectGuaranteed moldingMonocomponent synthetic polymer artificial filamentPolyesterCross-link

The invention discloses a rapid prototyping shape memory high polymer material and a preparation method and application thereof. The high polymer material comprises a physical cross-linking hard-segment structure which can be rapidly cooled and formed and a high polymer soft-segment structure which can be fixed and temporarily deformed, wherein the hard-segment structure is formed by combining diisocyanate and a crystallization type chain extender; the soft-segment structure is formed by combining polyester type or polyether type polyhydric alcohol with the crystallization type chain extender; and the molar ratio of hydroxyl in the polyhydric alcohol to diisocyanate group in the diisocyanate is 1:2-1:5. The material is functional, and the printed 3D product has the capability of self-deforming and restoring the time dimensionality; the material has good cooling forming performance, and the hard-segment part can rapidly form a physical cross-linking point in the temperature difference range of melt extrusion; the contained stationary phase and restoration phase double components are wide in material selection and low in price, a preparation process is simple, the defects that synthetic raw materials are expensive, the process is complex and the like in the prior art can be overcome, and the material is suitable for large-scale production.

Owner:JF POLYMERS (SUZHOU) CO LTD

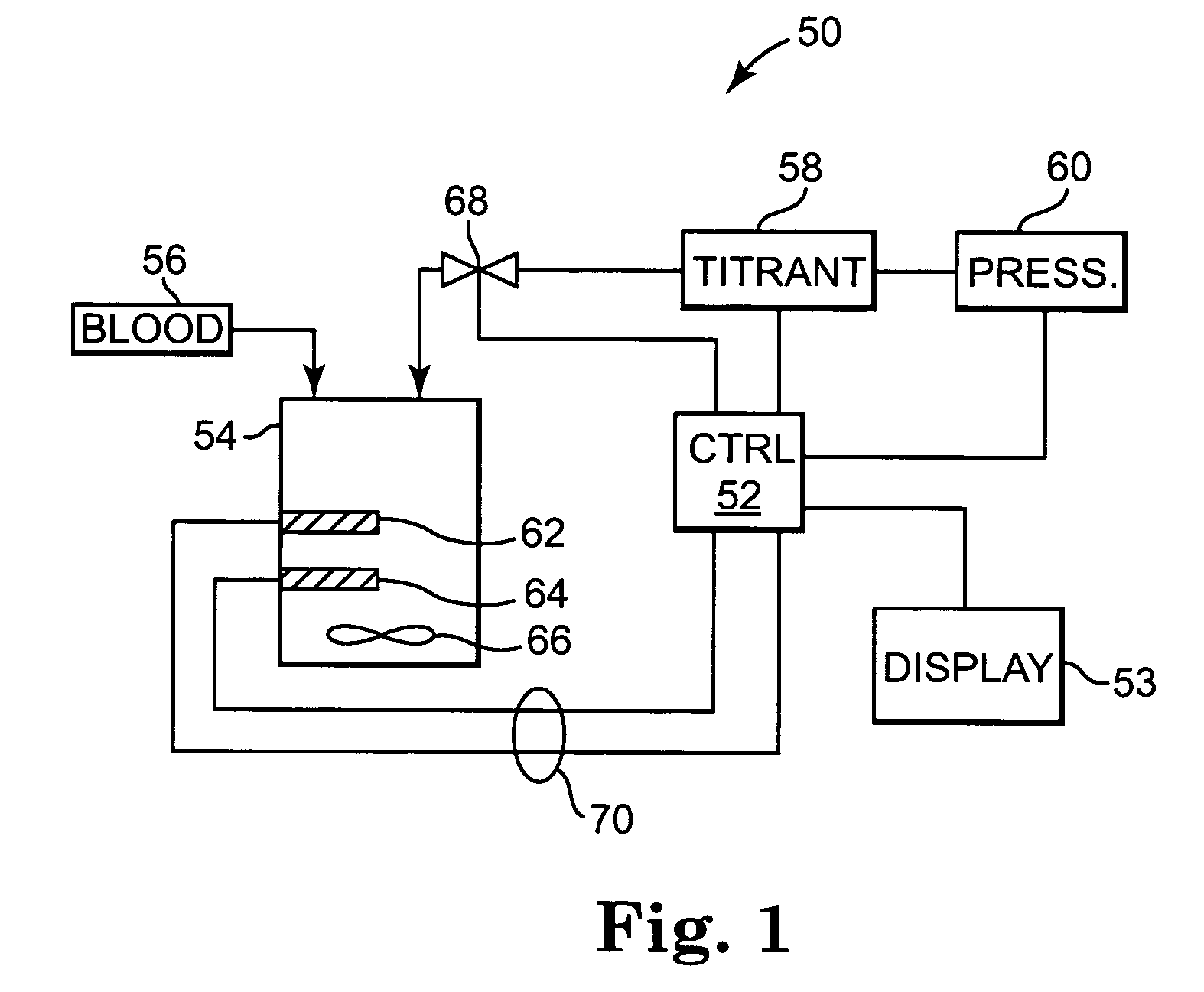

Point of care heparin determination system

ActiveUS7699966B2Rapid determinationImmobilised enzymesBioreactor/fermenter combinationsPoint of careReference sample

Owner:MEDTRONIC INC

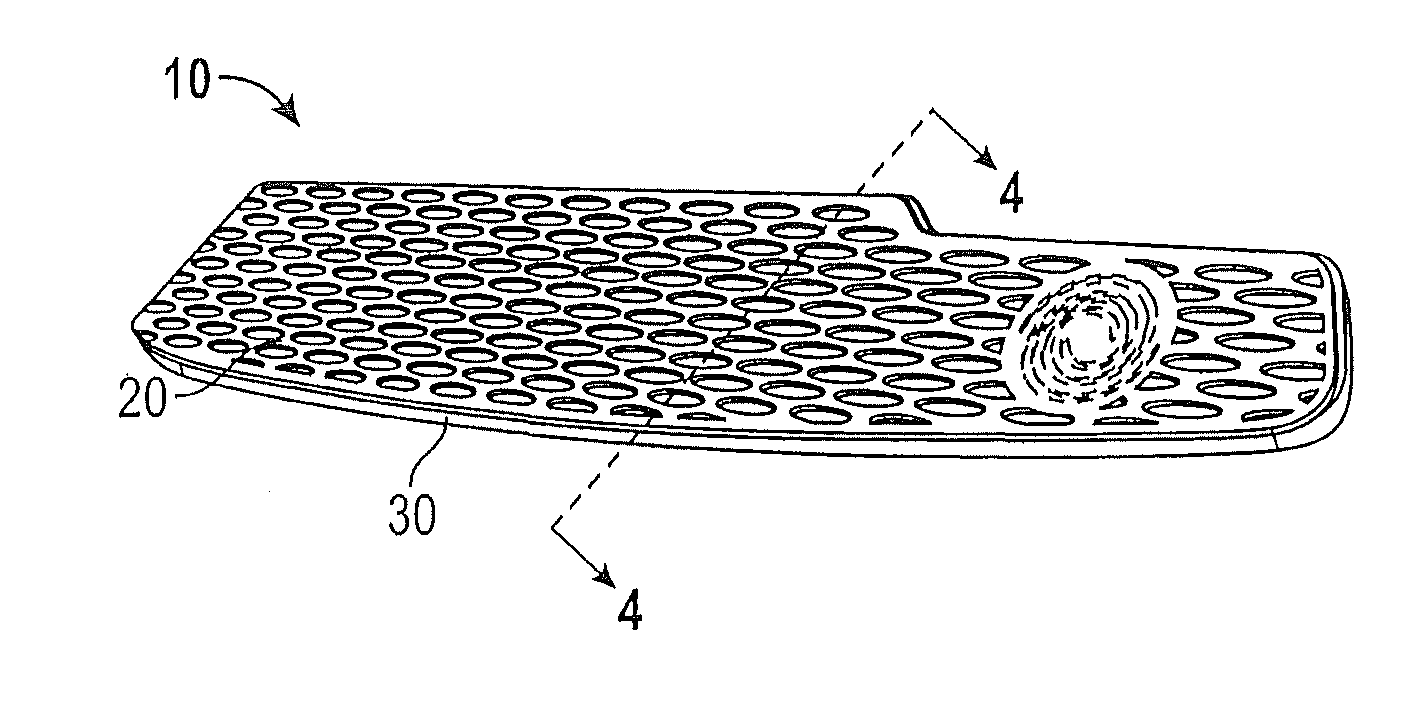

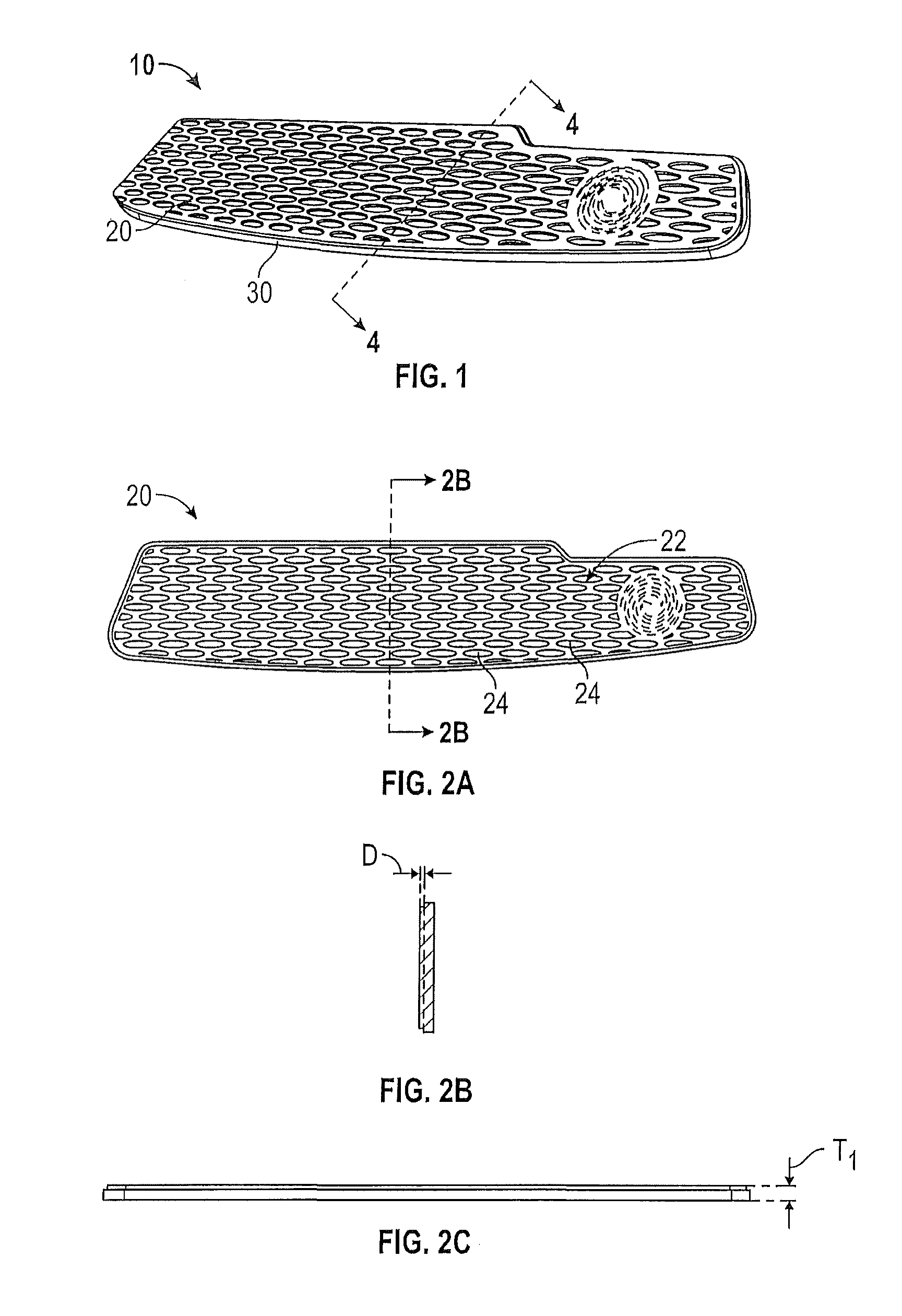

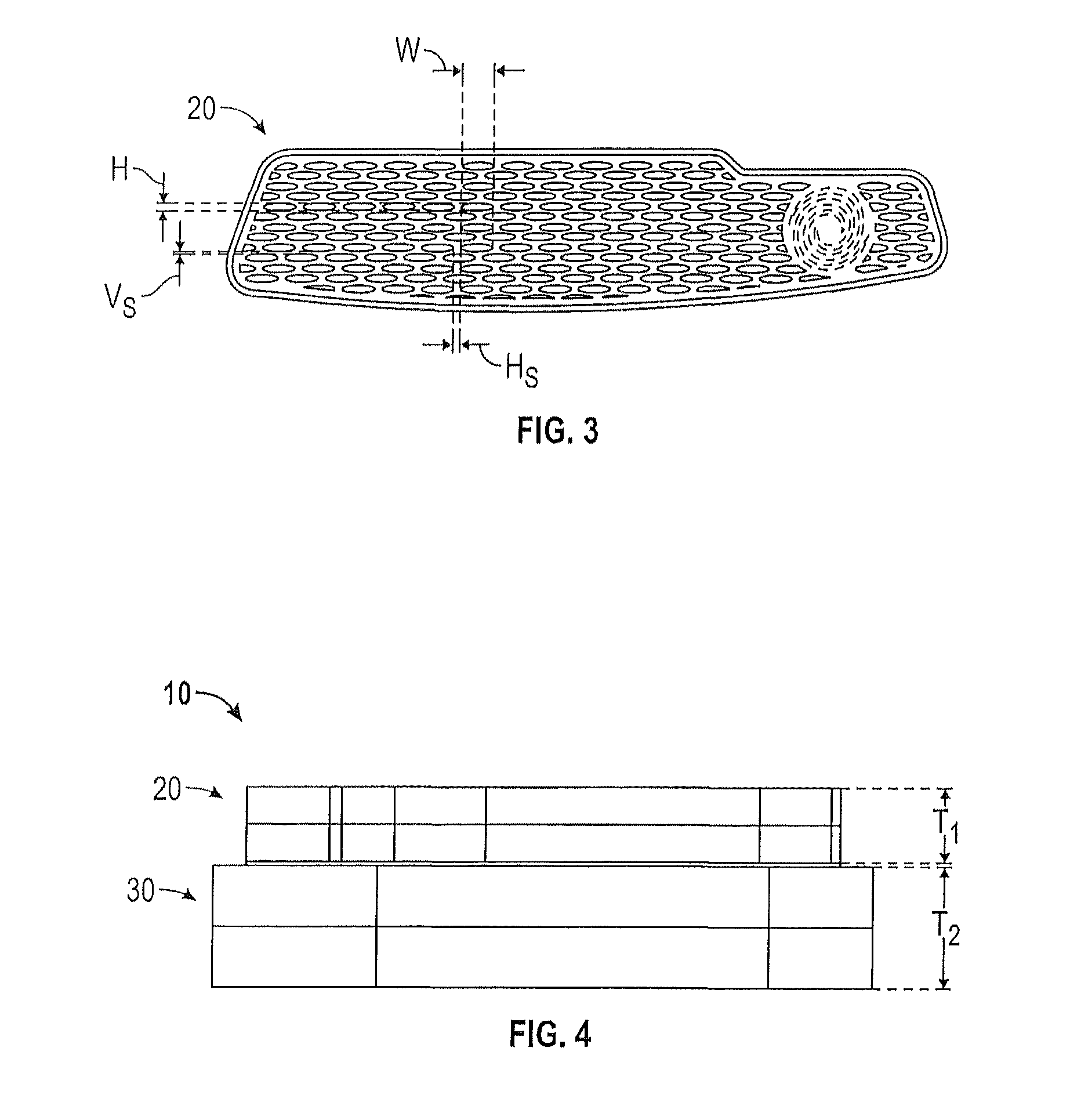

Putter face insert

A putter-type golf club head having a face insert composed of at least one thermoplastic polyether ester elastomer is disclosed herein. The face insert includes a plurality of oval-shaped holes having a specific size and spacing, and the at least one thermoplastic polyether ester elastomer incorporates polytetramethylene ether soft segments with molecular weights of greater than 1000 g / mol, preferably at least 1400 g / mol.

Owner:TOPGOLF CALLAWAY BRANDS CORP

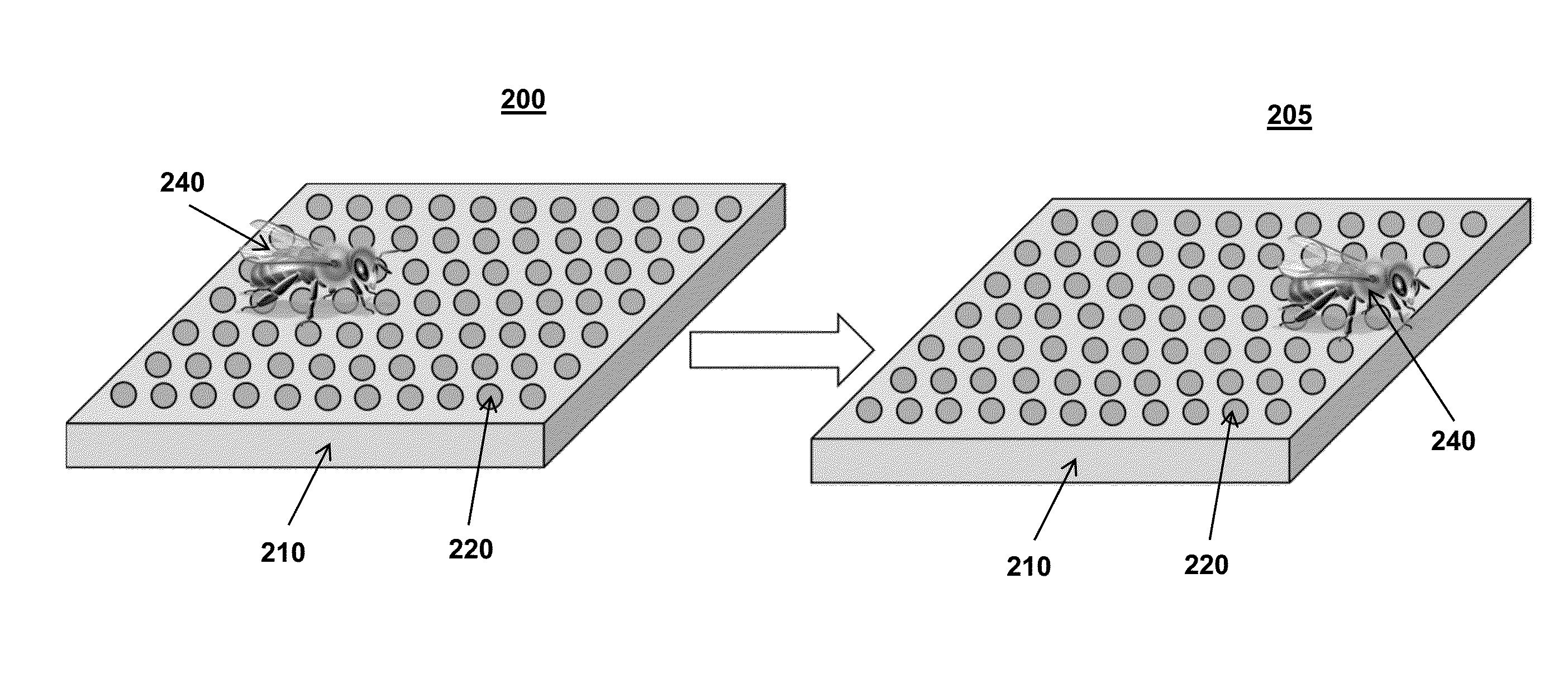

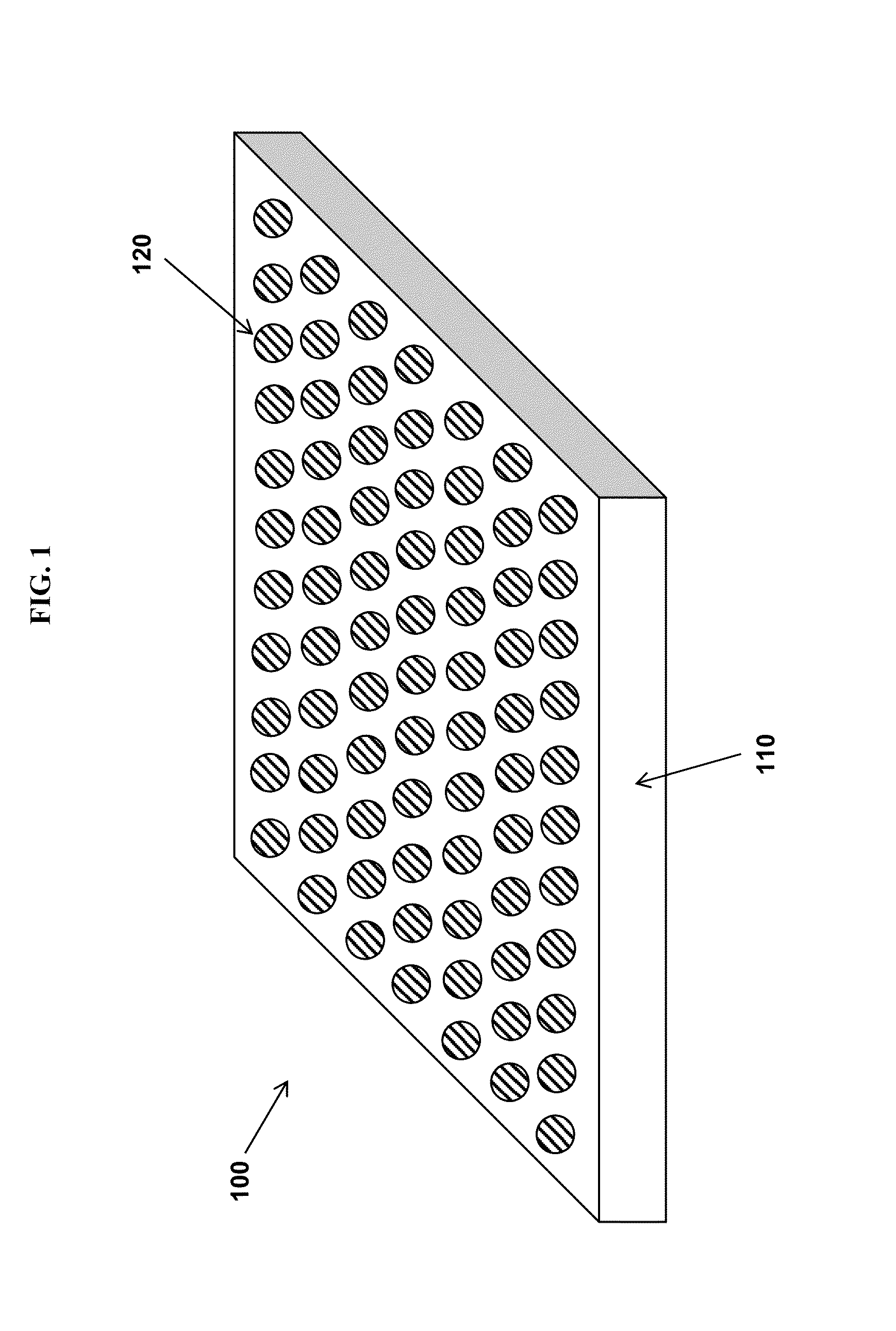

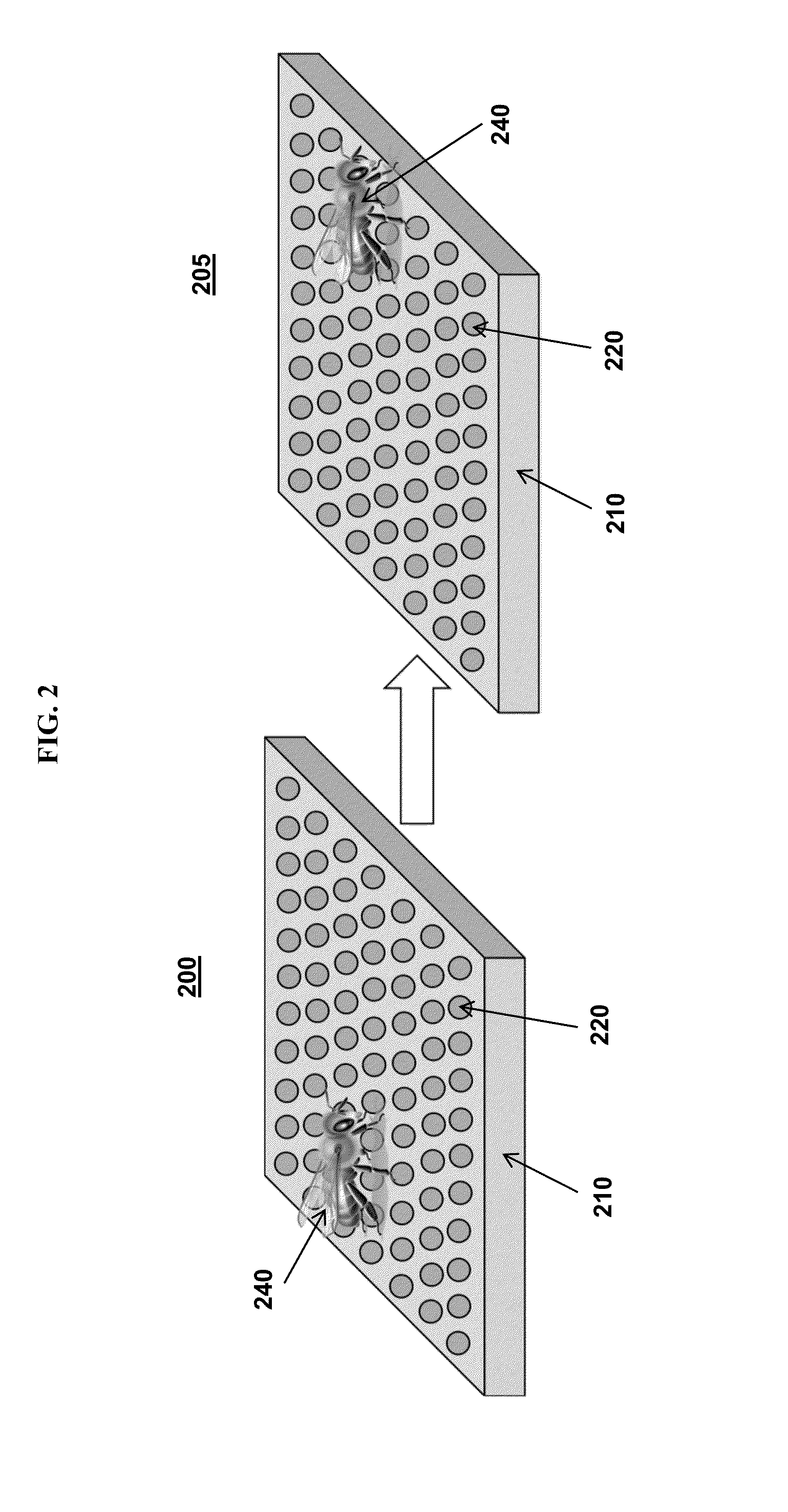

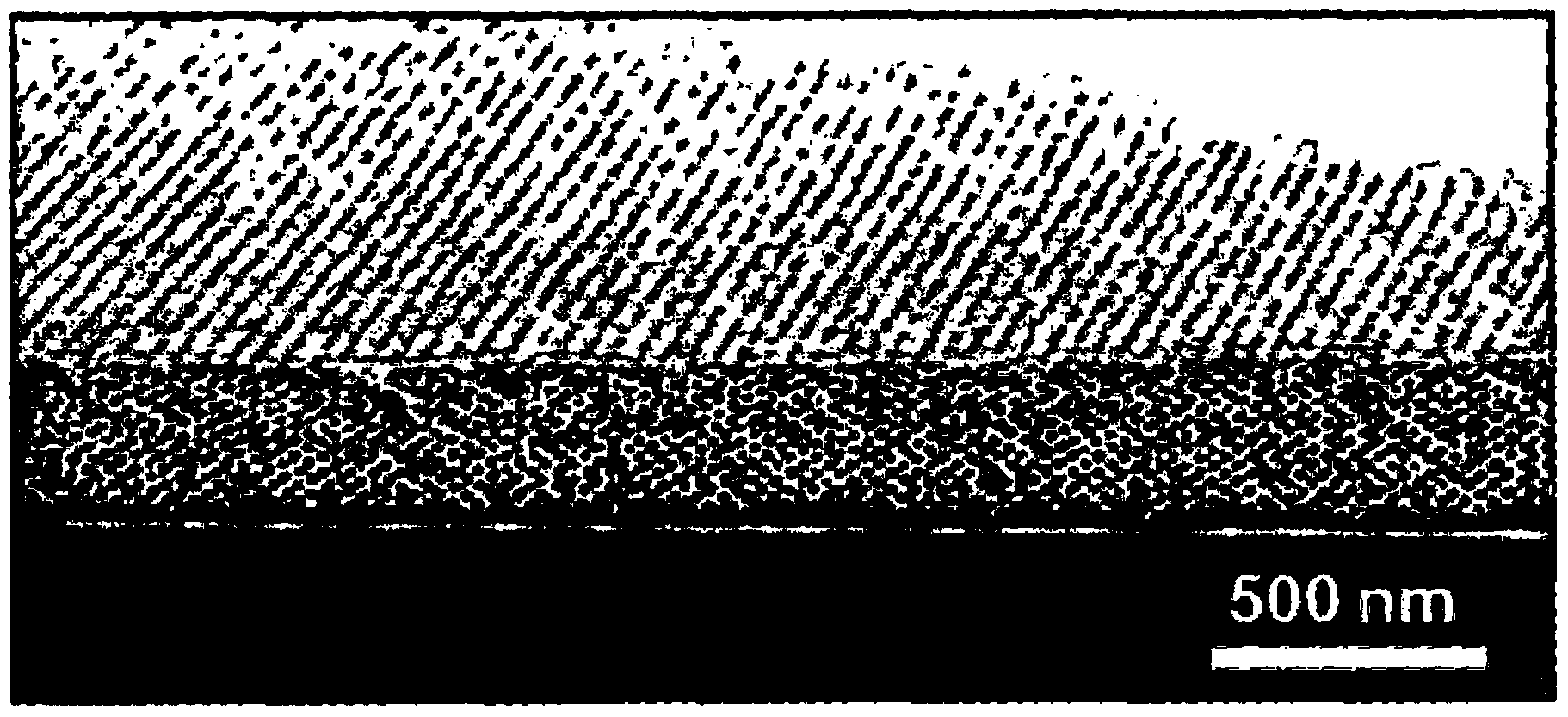

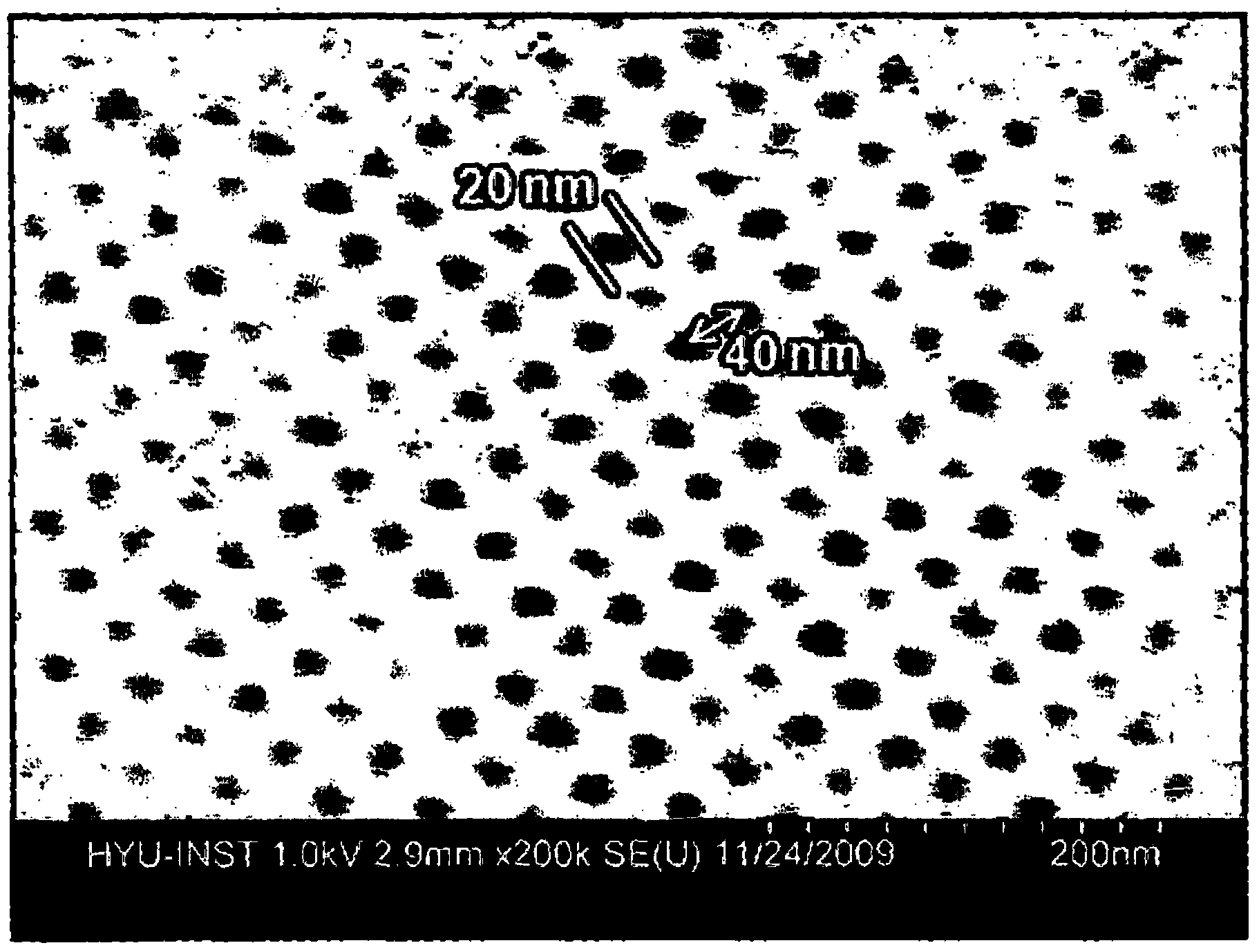

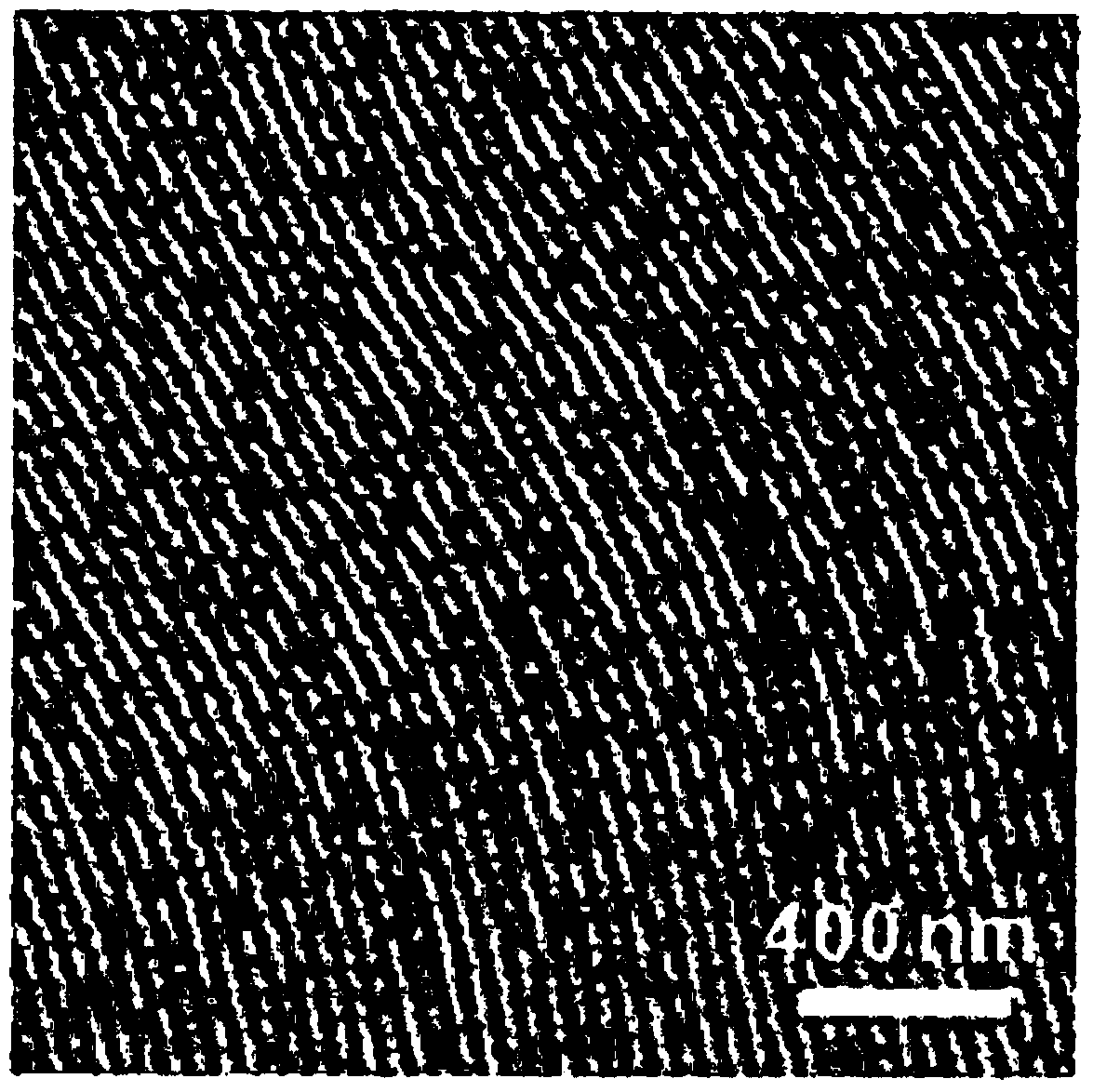

Novel diblock copolymer, preparation method thereof, and method of forming NANO pattern using the same

ActiveUS20130248488A1Promote formationWell formedNanoinformaticsPhotomechanical apparatusElectronSoft segment

The present invention relates to a diblock copolymer that may facilitate formation of a finer nano pattern, and be used for manufacture of an electronic device including a nano pattern or a bio sensor, and the like, a method for preparing the same, and a method for forming a nano pattern using the same,The diblock copolymer comprises a hard segment including at least one specific acrylamide-based repeat unit, and a soft segment including at least one (meth)acrylate-based repeat unit.

Owner:LG CHEM LTD +1

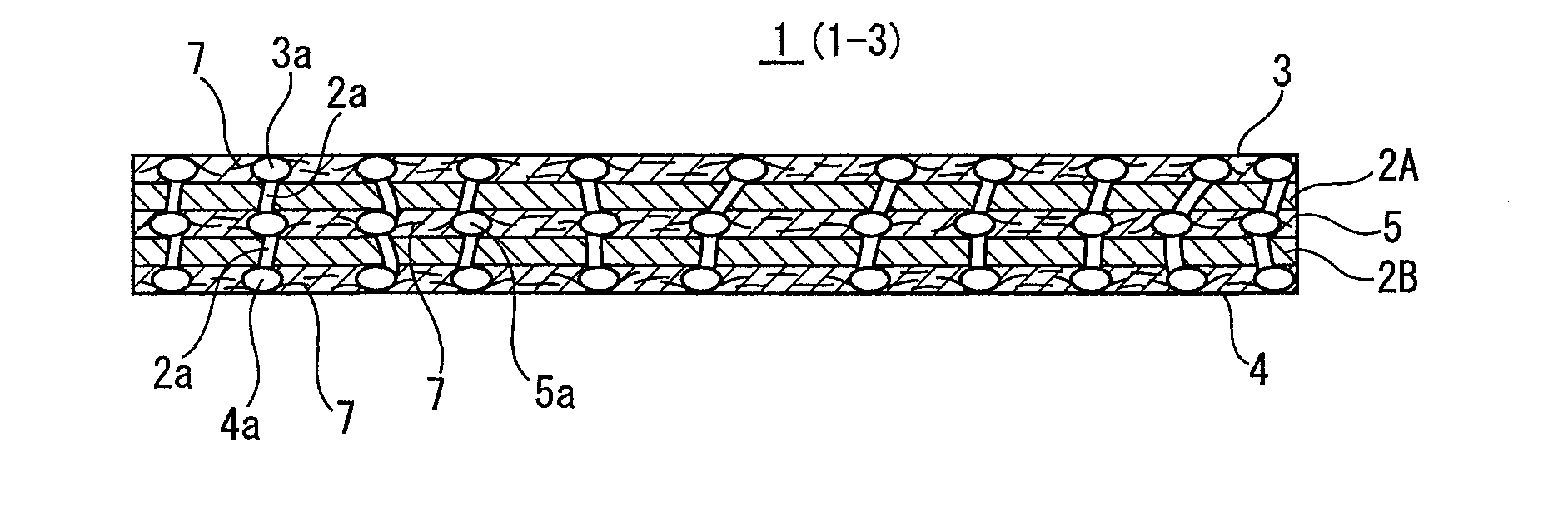

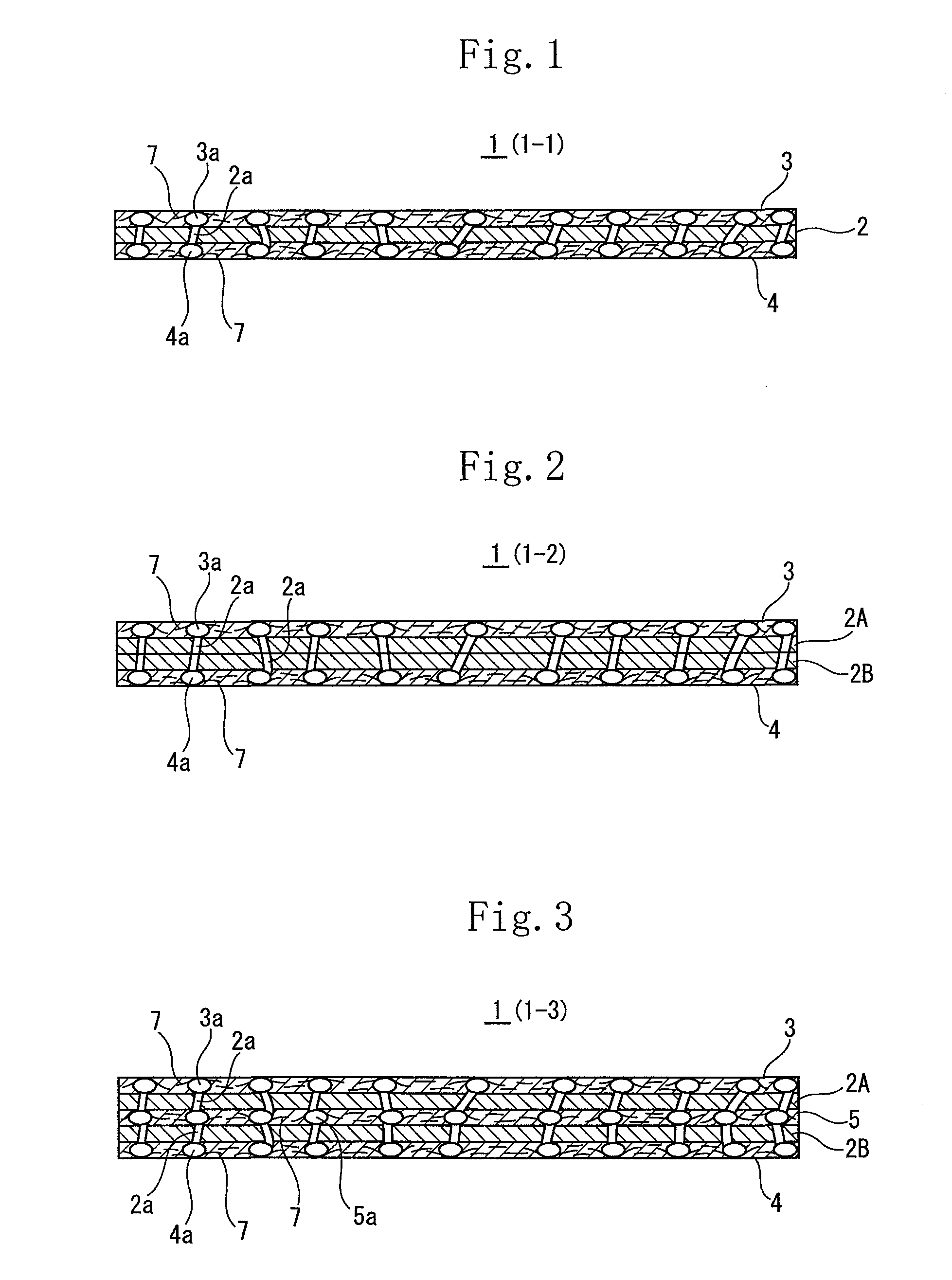

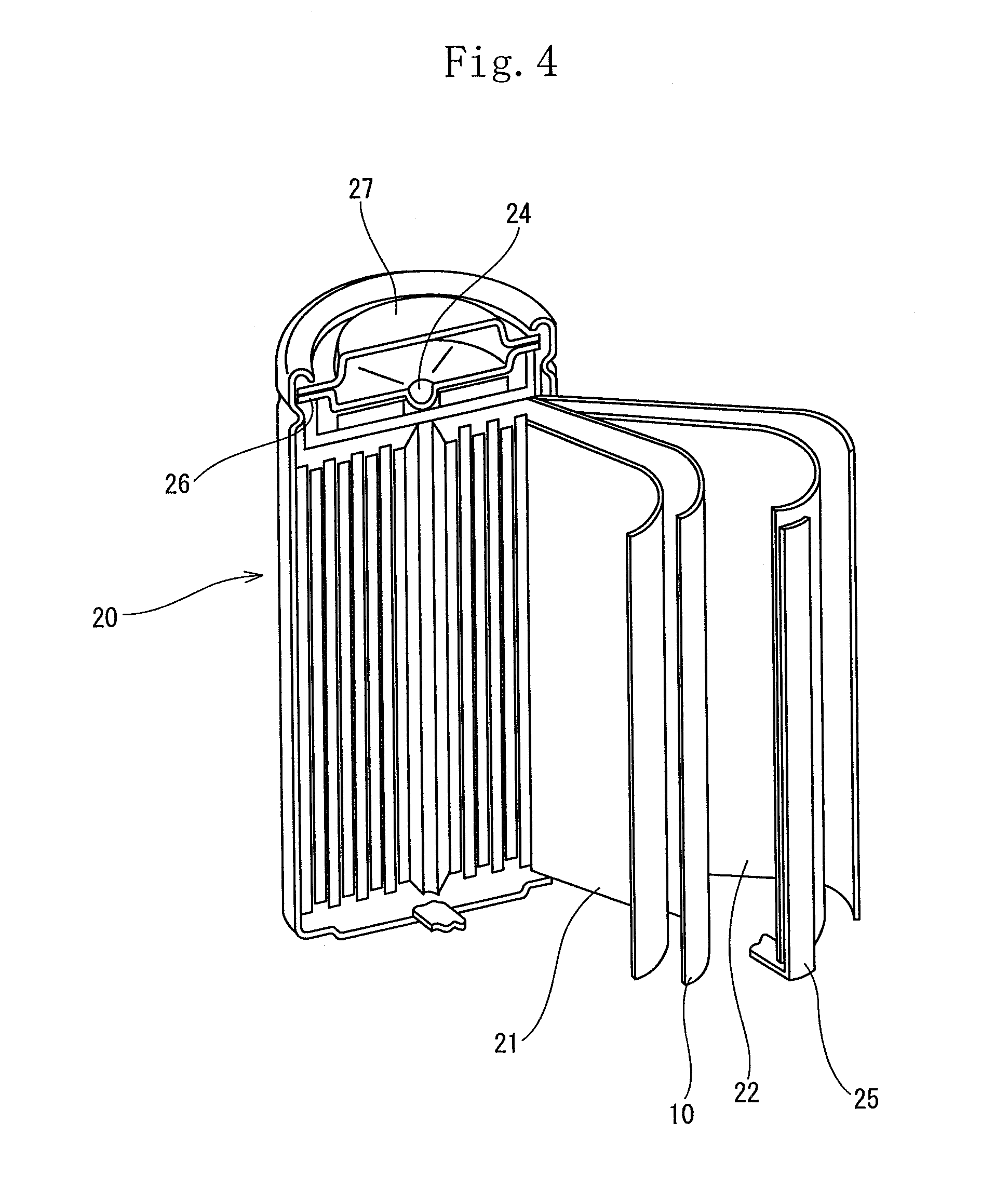

Method for producing porous laminate and porous laminate

InactiveUS20110305940A1Eliminate generationAmount of load is smallRecord information storageMagnetic recordingEngineeringPolyresin

Owner:MITSUBISHI PLASTICS INC

Polyamide 1012 serial thermoplastic elastomer material and preparation method thereof

Provided are a long-carbon-chain polyamide 1012 serial thermoplastic elastomer material and a preparation method thereof. The thermoplastic elastomer material is a block copolymer, wherein long-carbon-chain polyamide 1012 blocks serve as hard segments of the block copolymer, and polyether blocks and / or polyester diol blocks serve as soft segments of the block copolymer. The preparation method of the long-carbon-chain polyamide 1012 serial thermoplastic elastomer is a body melt phase polycondensation method under the control of certain temperature and pressure. The preparation cost of the long-carbon-chain polyamide 1012 serial elastomer is lower, and the performance-cost ratio is better; meanwhile, the long-carbon-chain polyamide 1012 serial elastomer has the multiple advantages of long-carbon-chain polyamide and polyether and / or polyester materials, has the advantages of being good in thermal stability, good in solvent resistance, low in water absorbing capacity, good in elasticity, good in wear-resisting property and the like and can be applied in the fields such as soles of high-end sports shoes, medical catheter materials, micro-drive mechanical parts, vibration-absorptive materials for sports equipment and damping and sound insulating materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

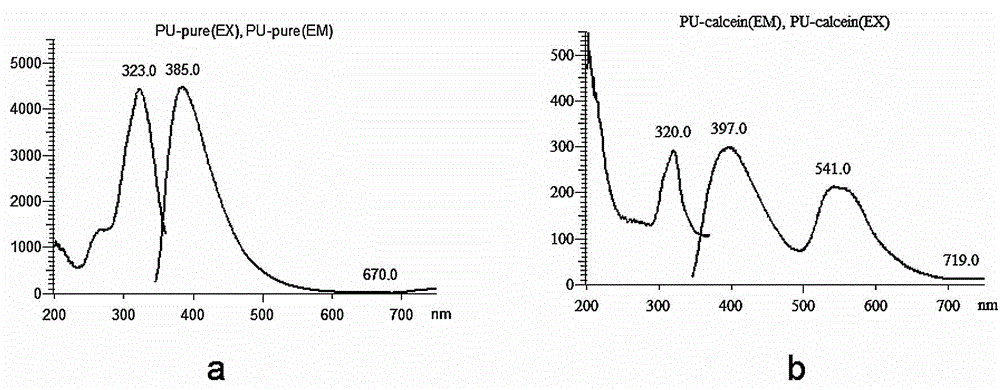

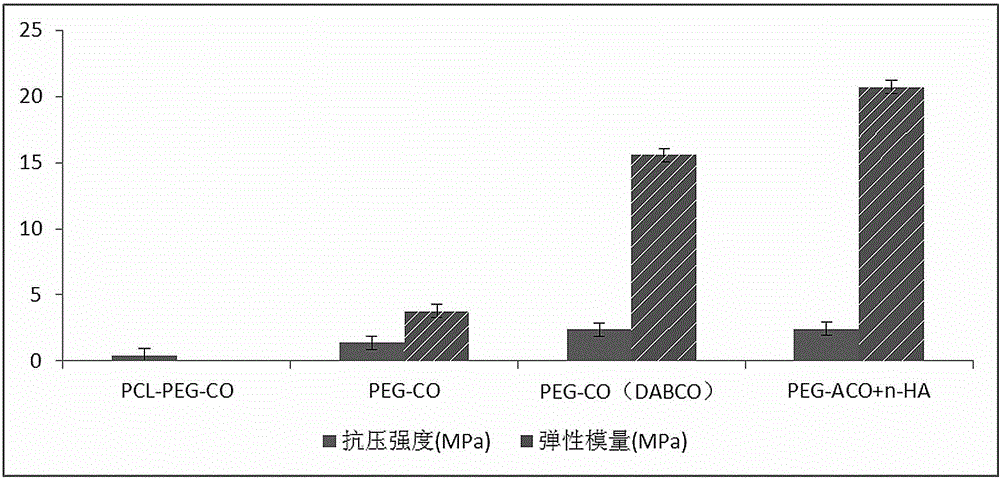

Fluorescent graft degradable block polyurethane, bone repair material and preparation method thereof

InactiveCN104356345APromote growthGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationPolymer scienceBiocompatibility

The invention relates to a fluorescent graft degradable block polyurethane, a bone repair material and a preparation method thereof. The polyurethane is formed by grafting a pharmaceutically acceptable fluorescent component into a structure formed by polymerizing a hard segment of aliphatic diisocyanate and a soft segment of a degradable polymer chain segment of a hydroxyl-terminated polymer or block copolymer. The bone repair material is composed of the polyurethane and nano hydroxyapatite powder. The polyurethane and corresponding bone repair material have favorable biocompatibility and degradability, have the fluorescent characteristic, can be used for performing tracing evaluation on the degradation process of the block polyurethane, analyzing the mechanism of degradation and inspecting the influence of the degradation rate on the mechanical properties of the material and the tissue regeneration and reconstruction process, and provide a new visual angle and means for evaluating the biosafety of the high-polymer degradable material. The preparation technique is simple, is easy to control and operate, and has favorable application prospects in the field of biomedicine.

Owner:SICHUAN UNIV

Novel polyurethane compositions including castor oil

InactiveUS20090062432A1Easy to optimizeSimple methodOther chemical processesSynthetic resin layered productsFloor coveringWater content

Owner:DOESBURG VAN I +5

Method for preparing polyester-polyester blocked copolyester

The invention discloses a method for preparing polyester-polyester blocked copolyester, which comprises the following steps: (1) synthesizing an aromatic polyester hard segment to obtain a prepolymer P1 with a number-average molecular weight in the range of 500-10,000g / mol; (2) synthesizing an aliphatic polyester soft segment to obtain a prepolymer P2, wherein the prepolymer P2 can also be obtained by ring-opening polymerization of caprolactone monomer, and the number-average molecular weight of the prepolymer P2 is in the range of 500-10,000g / mol; (3) carrying out polycondensation reaction of the aromatic polyester oligomer and the aliphatic polyester oligomer: mixing the esterified product P1 and the esterified product P2, adding antioxidant, catalyst, passsivator and chain expander, allowing reaction at 220-260 DEG C to obtain a polyester-polyester block polyester elastomer. The catalysts used in the steps (1) and (2) are selected from titanium-containing organic substances. The method disclosed by the invention has the following advantages: (1) because the aliphatic polyester soft segment is introduced, the product has both the mechanical properties of the rigid aromatic polyester hard segment and the flexibility of the soft segment; and (2) because a number of assistants are added, the good chain expansion effect is achieved, and the reaction conditions are controlled.

Owner:KINGFA SCI & TECH CO LTD +2

Cosmetic compositions containing block copolymers, tackifiers and a solvent mixture

A cosmetic composition containing at least one block copolymer having at least one hard segment and at least one soft segment, at least one tackifier component, a solvent mixture, and optionally, at least one colorant, and wherein the at least one hard segment has a Tg value of 50° C. or more, the at least one soft segment has a Tg value of 20° C. or less, and wherein the solvent mixture contains at least one solvent capable of solubilizing the at least one hard segment, and at least one solvent capable of solubilizing the at least one soft segment.

Owner:LOREAL SA

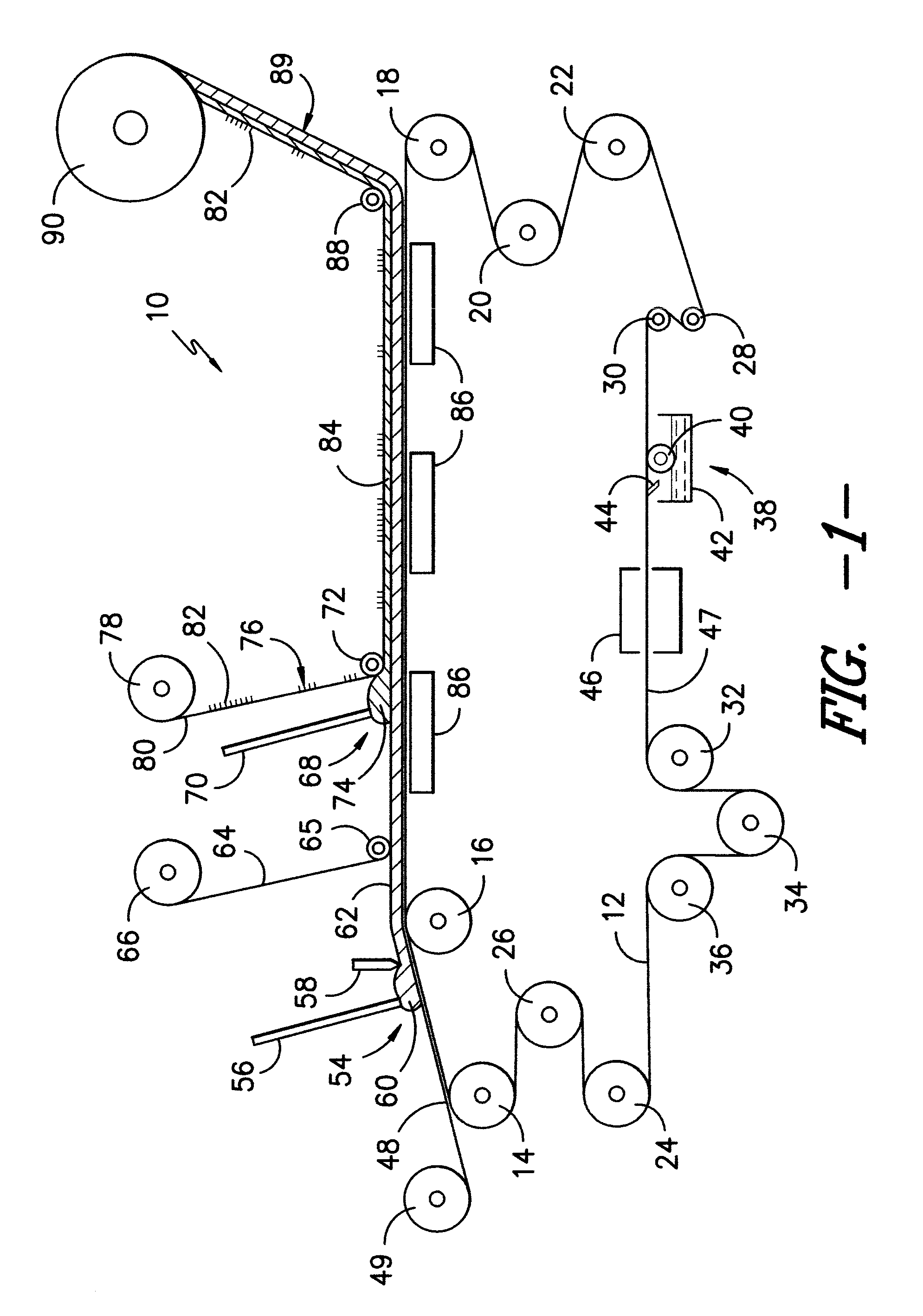

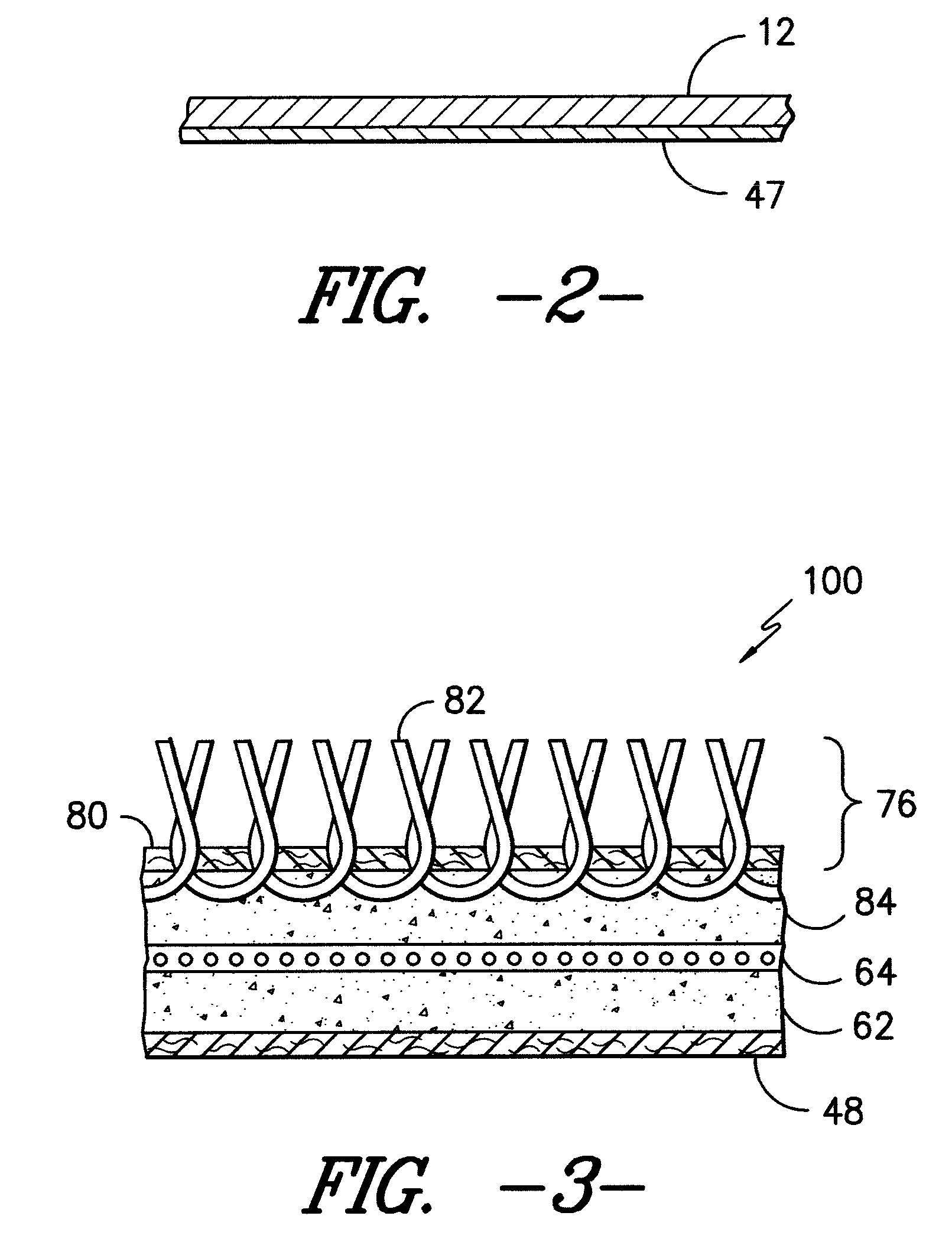

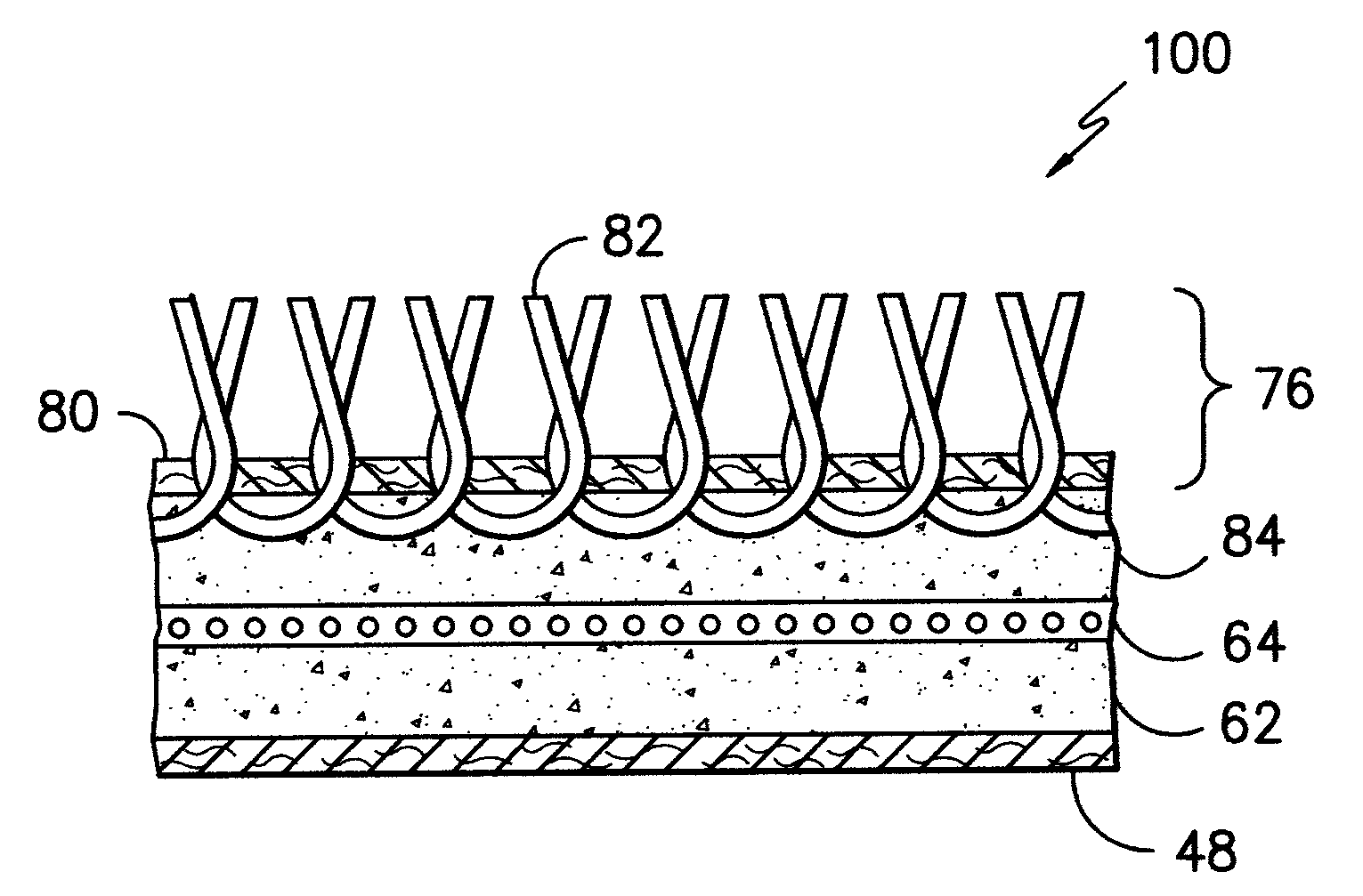

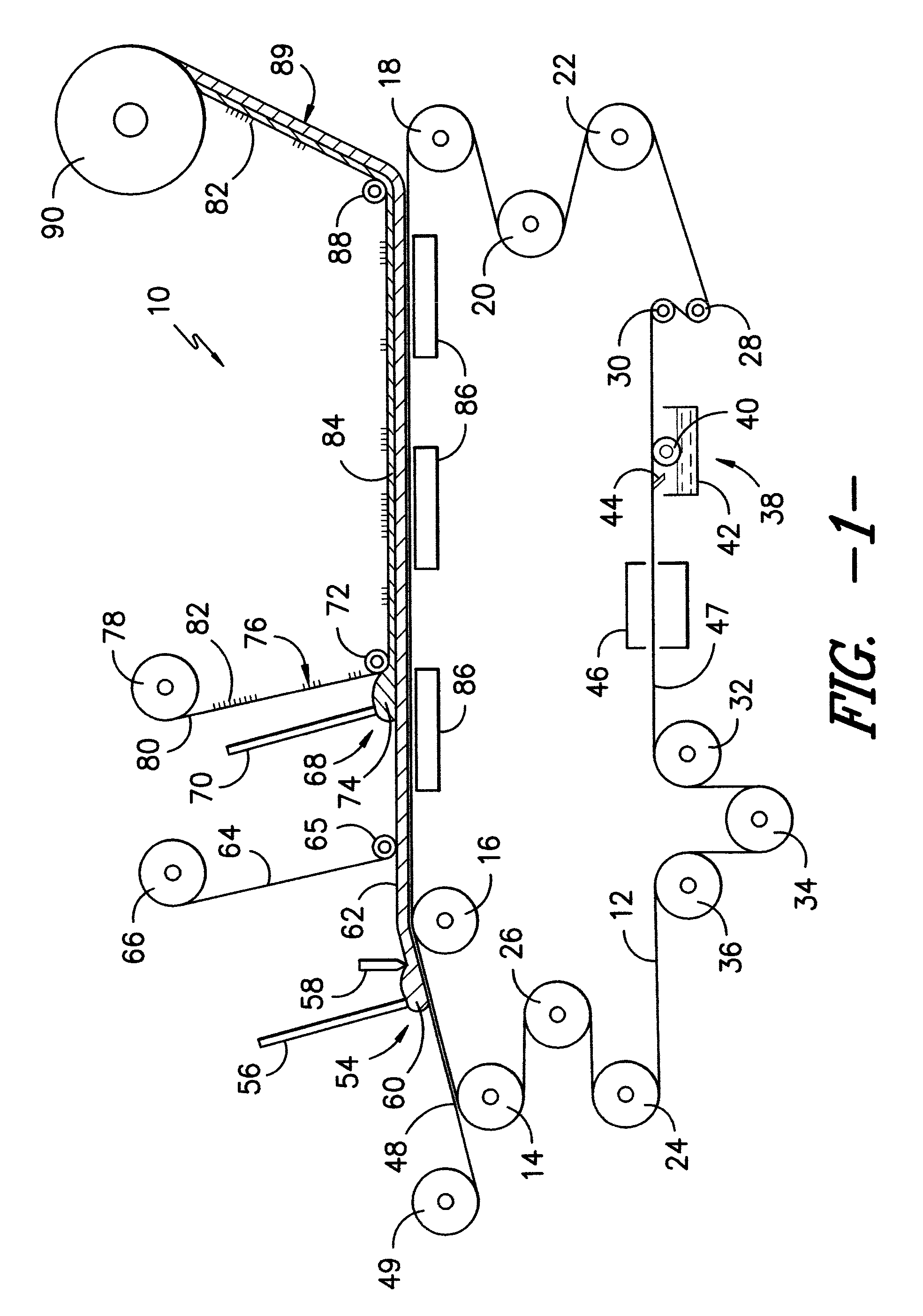

Flooring products and methods

InactiveUS20090029097A1Simple methodLow shape requirementPretreated surfacesWood working apparatusFloor coveringWater content

At least certain embodiments of the present invention relate to flooring products, methods of producing flooring products, and polyurethane compositions for use in flooring products, for example, for forming a layer of polyurethane on a textile, fabric or material, such as a flooring fabric. The compositions comprise the reaction product of castor oil having a water content of less than or equal to about 0.2% by weight; a monol, and an isocyanate, wherein the reactants have a soft segment functionality of about 2.0 to about 2.64. Methods of using the compositions and flooring products including the compositions are also disclosed. At least selected embodiments may provide compositions for use in floor coverings having a show surface such as a textile or fabric face material in contacting overlying relation to a polyurethane backing with or without additional structures, layers, backings, and / or the like, as well as apparatus, processes, and / or methods for making such floor coverings, uses for such floor coverings, and / or the like. In at least one particular embodiment, a floor covering such as a carpet, carpet tile, area rug, floor mat, roll goods, or the like incorporates a textile or fabric face disposed in contacting overlying relation to at least one polyurethane layer.

Owner:RIDDLE DENNIS L +5

Novel diblock copolymer, preparation method thereof, and method of forming nano pattern using the same

ActiveCN103562245AHelp formWell formedNanoinformaticsPhotomechanical apparatusMeth-Materials science

The present invention relates to a diblock copolymer that may facilitate formation of a finer nano pattern, and be used for manufacture of an electronic device including a nano pattern or a bio sensor, and the like, a method for preparing the same, and a method for forming a nano pattern using the same, The diblock copolymer comprises a hard segment including at least one specific acrylamide-based repeat unit, and a soft segment including at least one (meth)acrylate-based repeat unit.

Owner:LG CHEM LTD +1

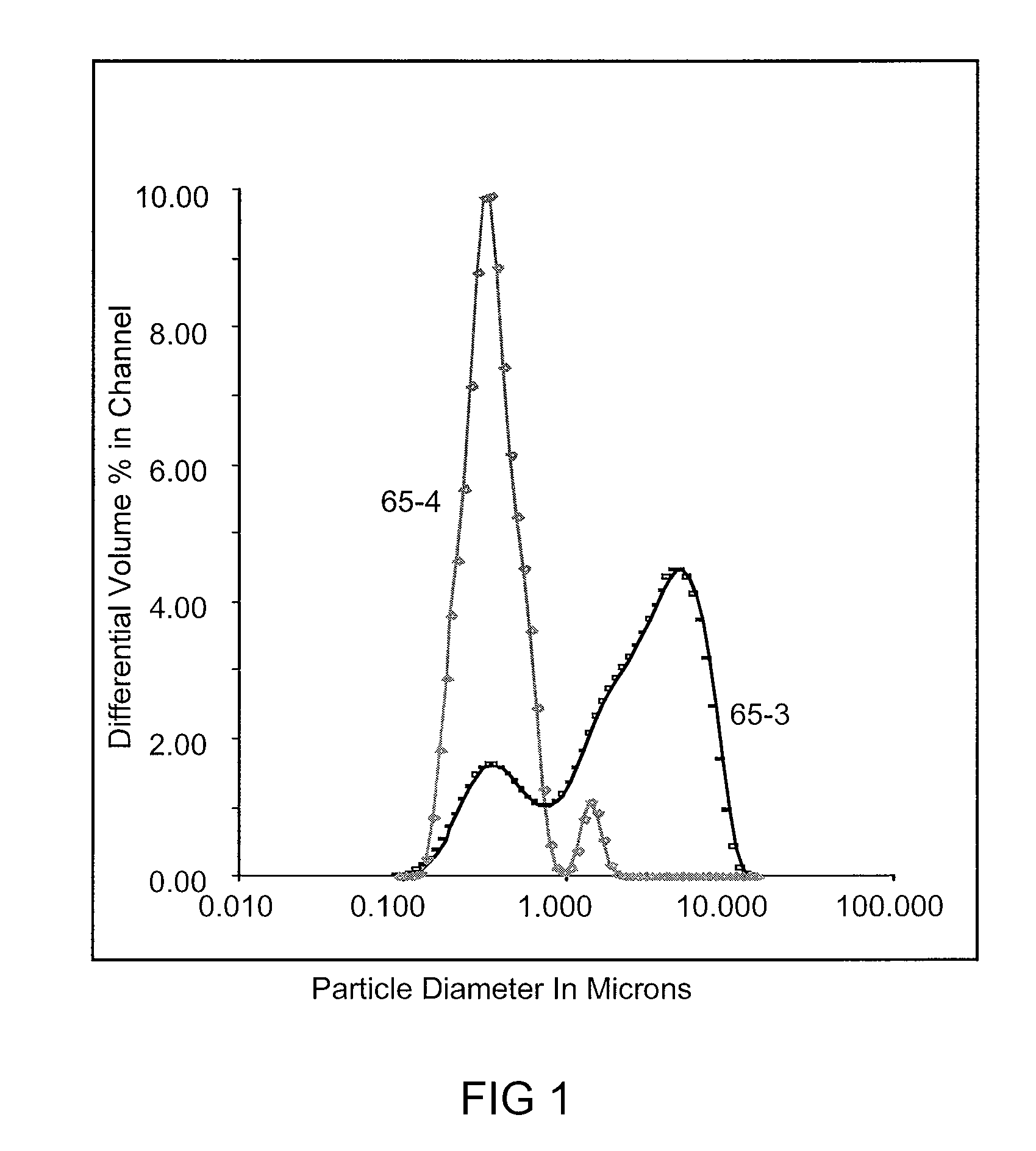

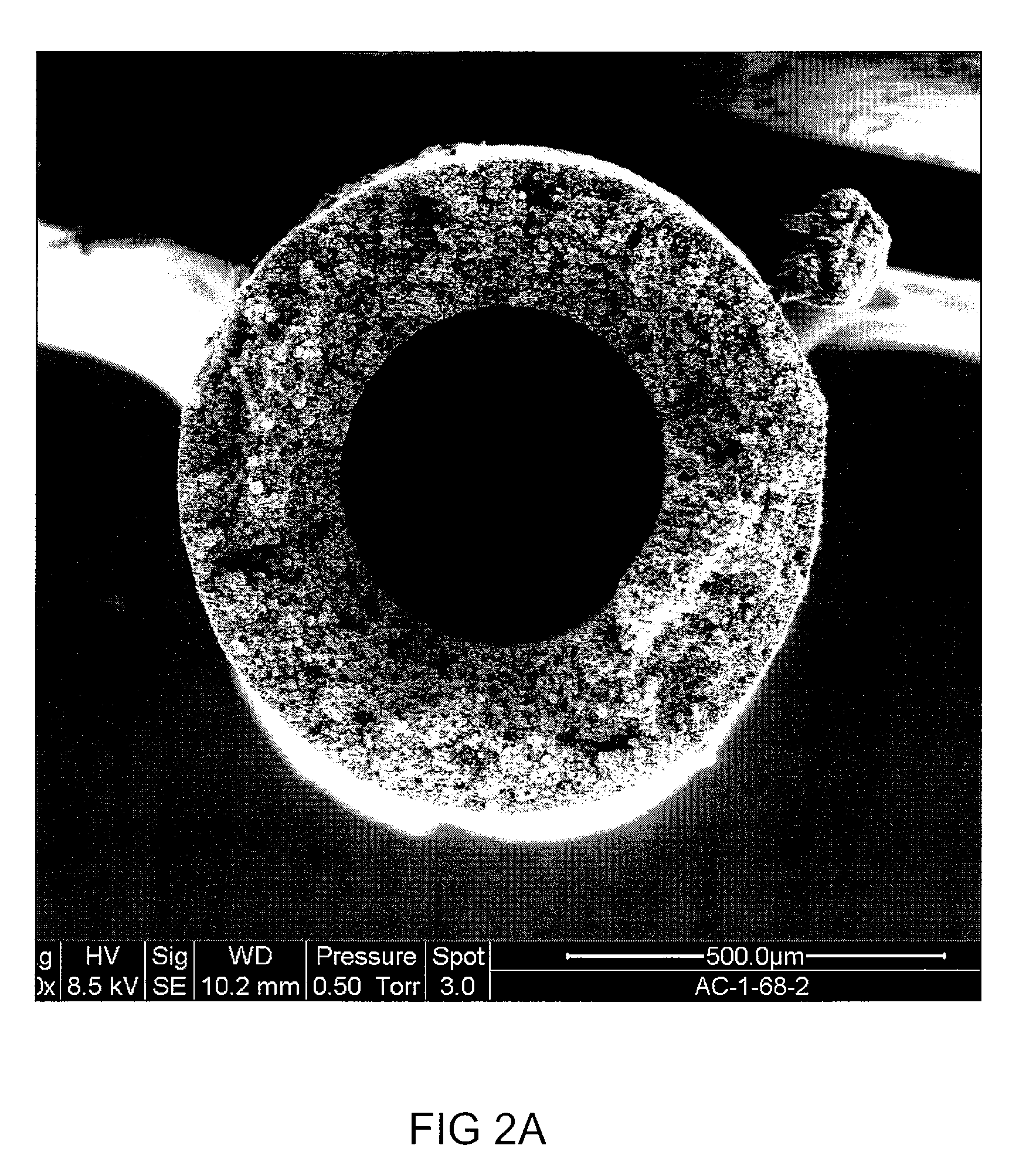

Hollow Organic/Inorganic Composite Fibers, Sintered Fibers, Methods of Making Such Fibers, Gas Separation Modules Incorporating Such Fibers, and Methods of Using Such Modules

A suspension of inorganic particles, a copolymer comprising soft segments and hard segments, and a solvent may be extruded through a spinnerette to produce inorganic / organic composite hollow precursor fibers. The precursor fibers may be sintered. The fibers may be utilized in a gas separation module for separation of a gas mixture or production of syngas. The fibers may be installed in the gas separation module after sintering or they may be sintered after installation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Loudspeaker diaphragm and loudspeaker

ActiveCN108551640AIncrease stiffnessIncrease dampingPolymeric diaphragmsLoudspeakersPolyesterElastomer

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm comprises a thermoplastic polyester elastomer film layer, wherein the thermoplastic polyester elastomer is a copolymerformed by a polyester hard segment A and a polyether or aliphatic polyester soft segment B, the Young modulus of the thermoplastic polyester elastomer film layer is 1-1000MPa, and after 10% of strain,the elastic recovery rate is larger than or equal to 80%. The loudspeaker diaphragm has excellent rigidity, good damping performance, resilience and the like.

Owner:GOERTEK INC

Preparation method of organic fluorosiloxane modified polyurethane emulsion containing short fluoroalkyl chain

ActiveCN103865026ANot easy to corrodeImprove water resistancePolyurea/polyurethane coatingsPolymer scienceSolvent

The invention relates to a preparation method of an organic fluorosiloxane modified polyurethane emulsion containing a short fluoroalkyl chain. The method comprises the following steps: by taking isophorone diisocyanate as a hard segment and a mixture of polytetrahydrofuran ether diol and hydroxyl silicone oil as a soft segment, heating to 70-110 DEG C to react for 1-8 hours; then, adding dimethylolpropionic acid and fluorine-containing diol as a chain extender for primary chain extension for 1-6 hours; cooling to 25-60 DEG C, adding a neutralizer, stirring for 0.5-1.5 hours, and transferring to a high speed disperser; adding neutralizer and a secondary chain extender, and dispersing for 0.5-3 hours at a high speed to obtain the emulsion which is uniform and stable in grain size. The prepared modified polyurethane emulsion coating not only has better temperature resistance, water resistance, solvent resistance and corrosion resistance, but also has good water repellency and oil repellency.

Owner:SHANDONG UNIV

Wide temperature domain damping polyurethane micropore elastomer material and preparation method thereof

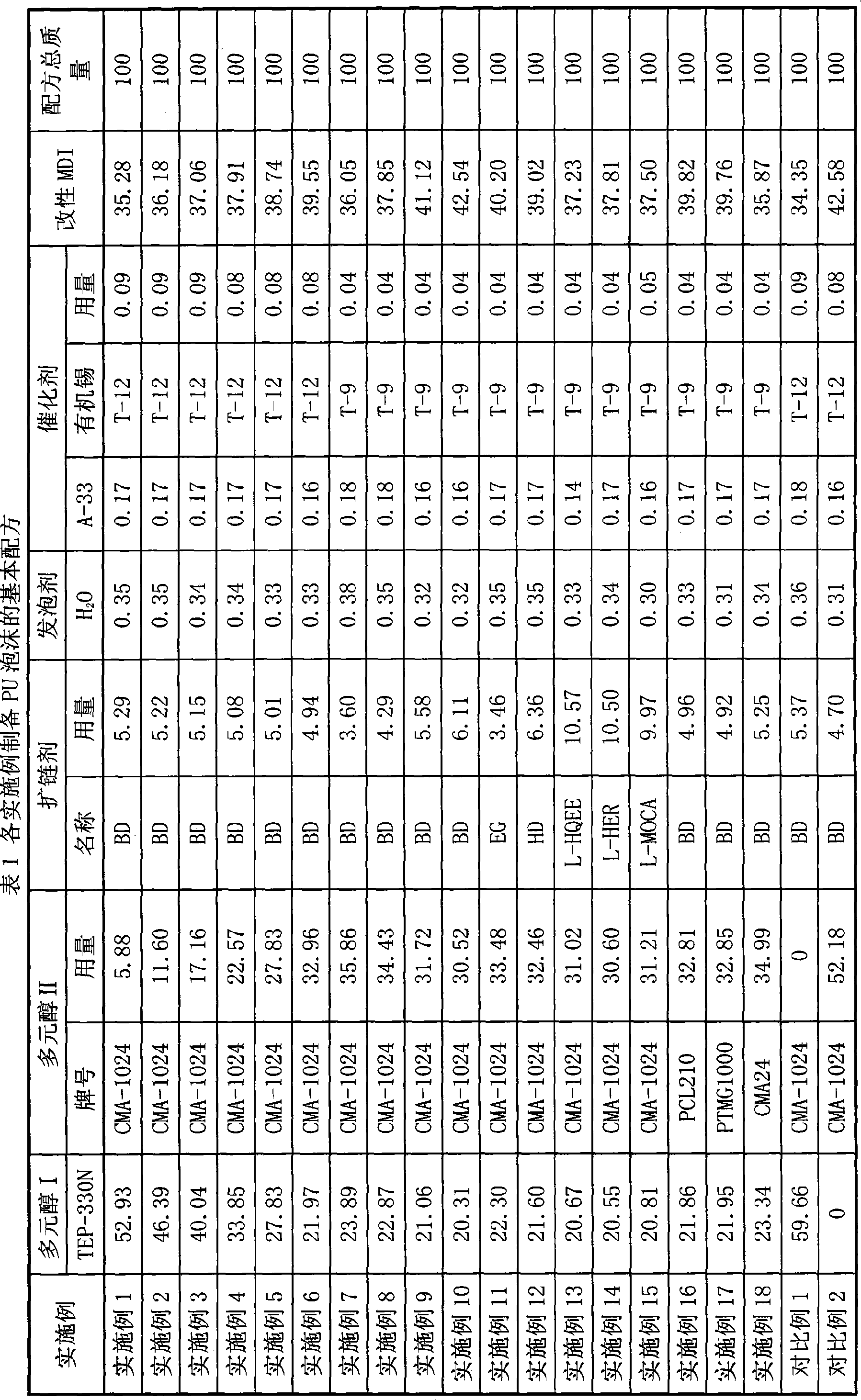

The invention provides a wide temperature domain damping polyurethane micropore elastomer material and a preparation method thereof; the formulation comprises 20 percent to 55 percent of polylol I, 5 percent to 38 percent of polylol II, 32 percent to 44 percent of isocyanate, 3.0 percent to 12.0 percent of chain extender, 0.10 percent to 0.30 percent of composite catalyst and 0.1 percent to 0.5 percent of foaming agent. The preparation method comprises the following steps: the polylol I and the polylol II are evenly mixed; the chain extender, the composite catalyst and foaming agent and other additives are added; the inner wall of a metal mold is coated with a releasing agent, heating and drying are carried out; and the mixture is added with isocyanate, is stirred with strong force, and the obtained mixture is cast into the mold, sealed, cured, cooled and demoulded so as to obtain the polyurethane micropore elastomer material. The invention adopts two types of polylol with large distance of molecular weight as polyurethane soft segment, leads the material to have excellent damping performance in the temperature range of -20 DEG C to 50 DEG C and can meet the use requirements under normal temperature condition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

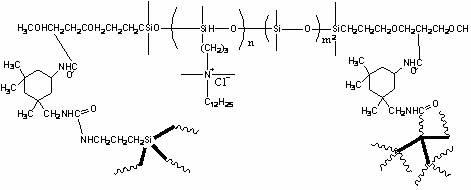

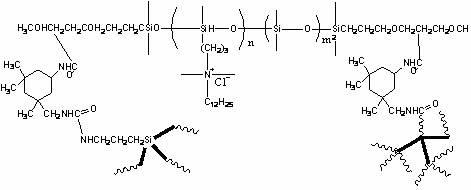

Quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint and preparation method and application thereof

ActiveCN102220080AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesDisiloxaneQuaternary ammonium cation

The invention discloses a quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint, the structure is shown as the formula (1); in the formula, an organosilicon soft segment containing quaternary ammonium salt side chain is an isocyanate hard segment; the quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint is prepared by the following steps: preparing 2,4,6-tri(3- chlorine propyl group)-2,4,6- trimethyl-ring trisiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing dihydroxy ended chloropropylated polysiloxane; preparing polysiloxane compound containing the quaternary ammonium salt and hydroxyl; mixing the compound with the isocyanate, and adding gamma-aminopropyl triethoxy silane for chain extension to obtain a prepolymer, and the prepolymer being crosslinked and condensed in air. In the invention, the double effect of low surface energy and poison killing are achieved, so as to suppress the adsorption of marine organisms and kill bacteria adsorbed on the surface of a ship body through the quaternary ammonium salt.

Owner:ZHEJIANG UNIV

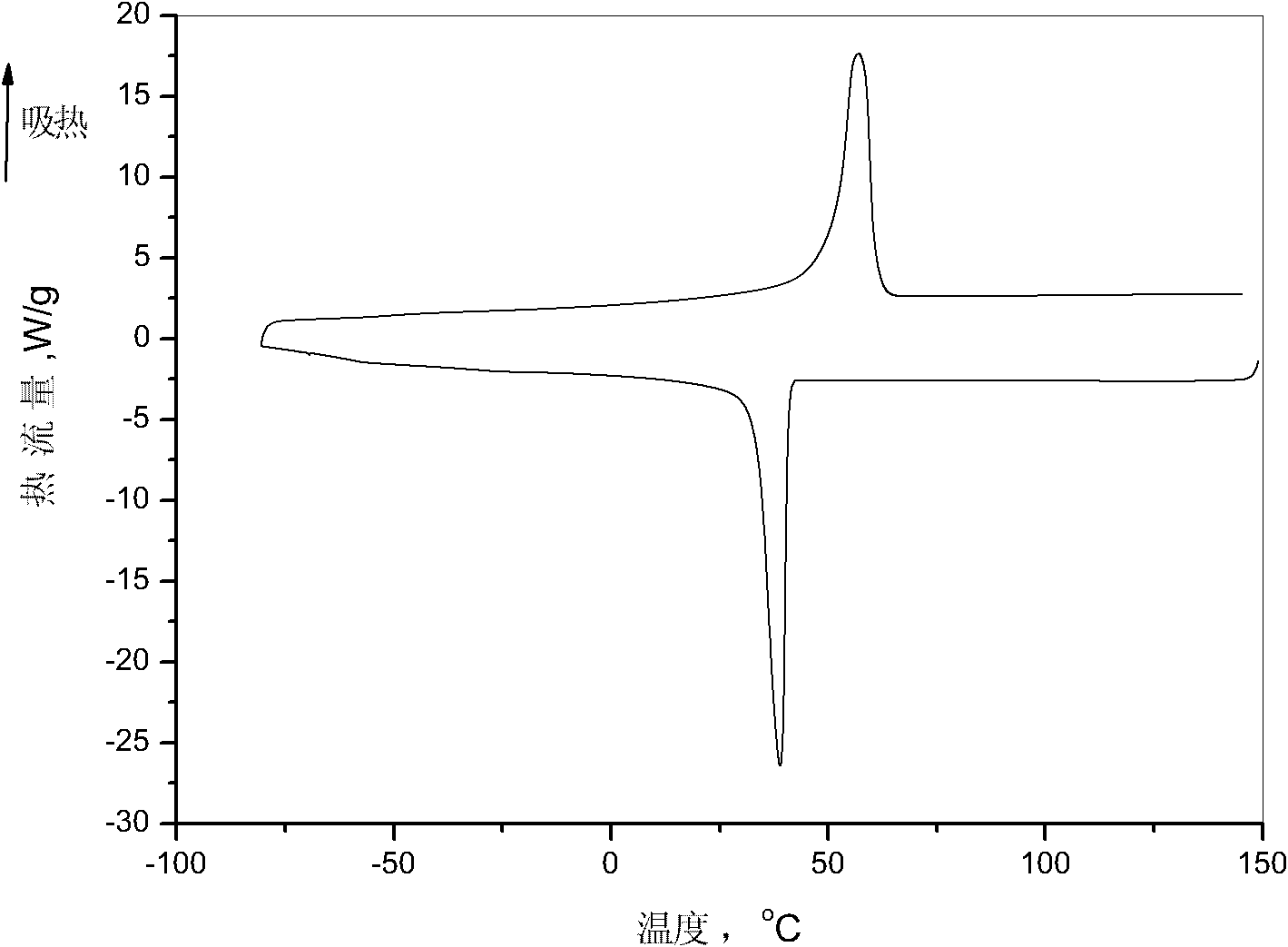

Method for preparing phase change thermal insulation polyurethane resin

InactiveCN101891877AExcellent phase change insulation performanceImprove mechanical propertiesHeat-exchange elementsThermal insulationPolyethylene glycol

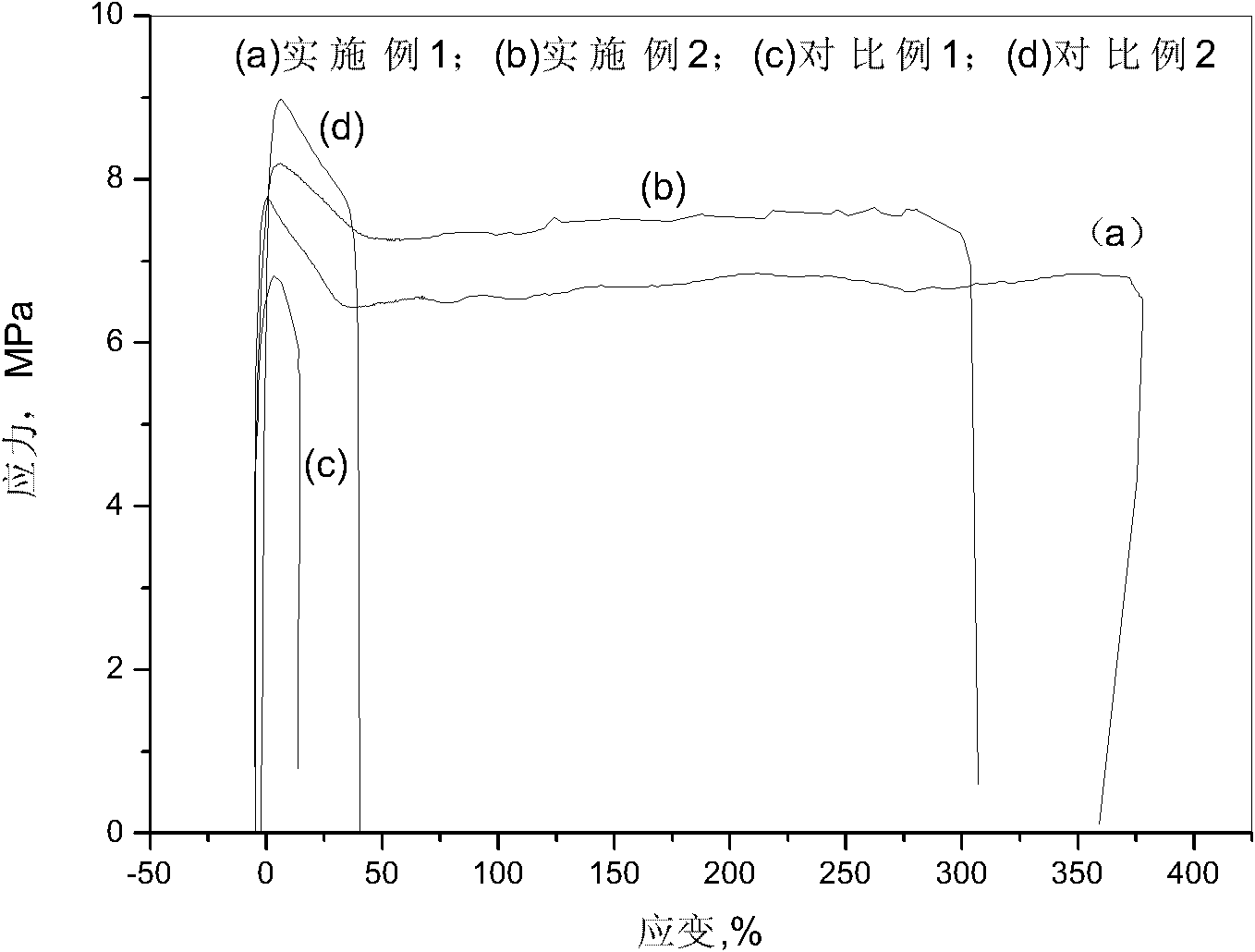

The invention discloses a method for preparing phase change thermal insulation polyurethane resin. In the method, polyethylene glycol is adopted as a soft segment, polyisocyanate and quadruple hydrogen bond ureido pyrimidone motif-containing chain extender are adopted as a hard segment, and the quadruple hydrogen bond-containing phase change thermal insulation polyurethane resin is synthesized. The resin has excellent phase change thermal insulation performance, and quadruple hydrogen bonds can be self-assembled into a supermolecular structure to endow good mechanical properties and environmental responsiveness to the resin. The resin has the enthalpy of phase change of 150J / g, the breaking strength of 8MPa, and the elongation at break of 367 percent; and under the same conditions, compared with the polyurethane resin synthesized by a chain extender not containing the quadruple hydrogen bond ureido pyrimidone motif, the phase change thermal insulation polyurethane resin has the advantage of obviously improving the mechanical properties.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com