Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

833 results about "Isophorone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isophorone is an α,β-unsaturated cyclic ketone. It is a colorless liquid with a characteristic peppermint-like odor, although commercial samples can appear yellowish. Used as a solvent and as a precursor to polymers, it is produced on a large scale industrially.

Carbon black composition and usage thereof

InactiveUS20130029183A1Good dispersionInhibition formationPigmenting treatmentMagnetic materials for record carriersCyclohexanoneOrganic solvent

An aspect of the present invention relates to a carbon black composition, which comprises carbon black; an organic tertiary amine selected from the group consisting of an aliphatic tertiary monoamine and an alicyclic tertiary amine; and at least one organic solvent selected from the group consisting of methyl ethyl ketone, cyclohexanone, isophorone, and ethanol.

Owner:SOITEC SA +1

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

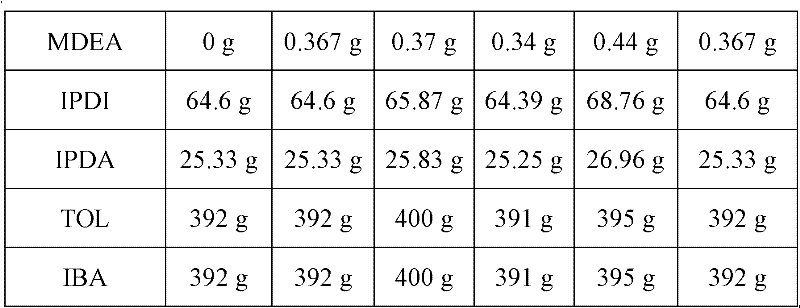

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

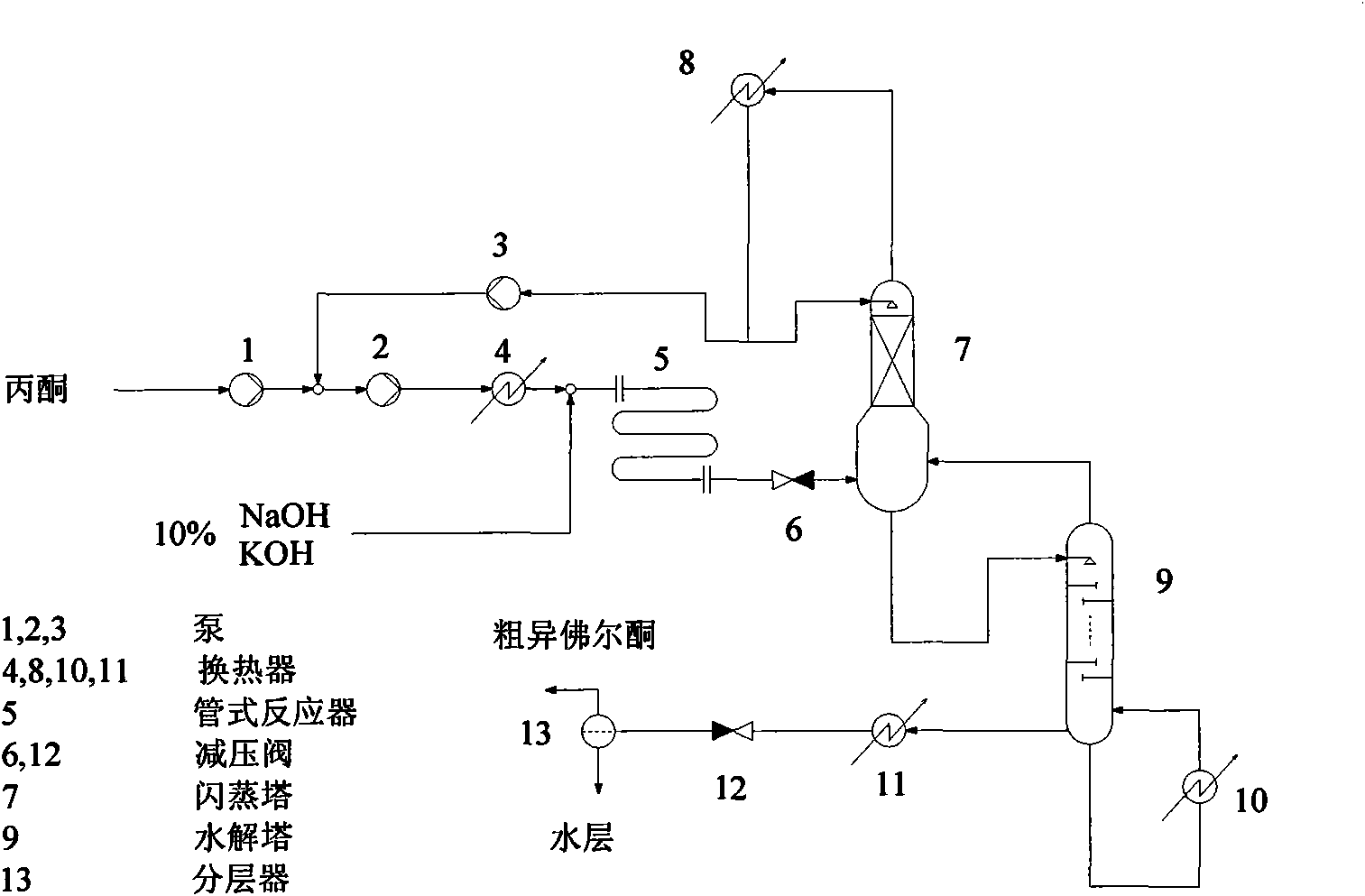

Method for preparing alpha-isophorone

ActiveCN101633610AReduce generationIncrease productivityOrganic compound preparationCarbonyl compound preparationIsophoroneChemistry

The invention discloses a method for preparing alpha-isophorone, which comprises the following steps: pressurizing a mixture of acetone and recycled acetone to 8.0-20.0MPa under the condition of continuous steady state operation and preheating to 280 DEG C-320 DEG C; then mixing the mixture with 10 percent of NaOH solution or 10 percent of KOH solution pressurized to the same pressure; carrying out super-critical reaction for 1-3 min in a pipe type reaction vessel; decompressing the reaction liquid to 3.0-4.0MPa and entering a flashing steam tower; obtaining the recycled acetone mixture from the top of the tower; leading tower kettle liquid to enter a hydrolyzing tower to hydrolyze polymers (C12 and C15); continuously extracting hydrolyzed reaction liquid from a tower kettle of the hydrolyzing tower, cooling, decompressing to normal pressure and layering in a layering device to obtain an alpha-isophorone rough product layer and a byproduct water layer. The method for synthesizing the alpha-isophorone has short needed reaction time, few byproducts and high reaction yield and is suitable for industrialized production.

Owner:ZHEJIANG UNIV +2

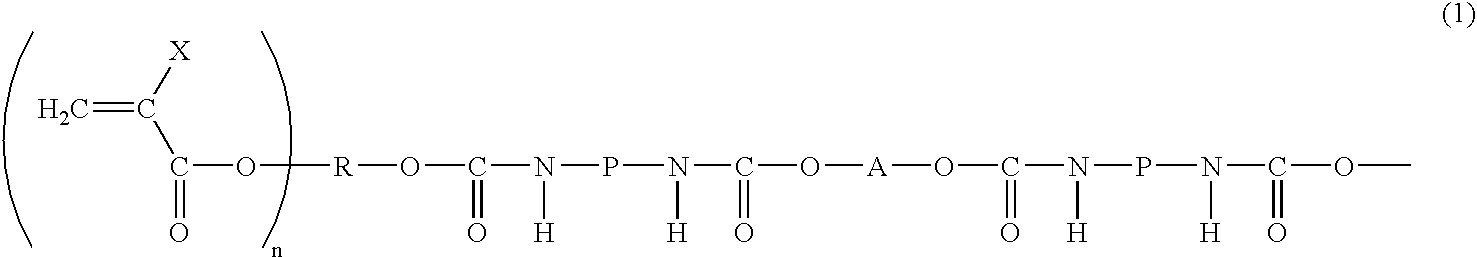

Modified polyurethane acrylic ester and ultraviolet light curing coating

ActiveCN101967158AGood weather resistanceImprove corrosion resistanceGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsUltraviolet lightsSolvent

The invention provides a compound with the structure shown in the formula (I), wherein R1 is an acrylic ester group; R2 is an isophorone group, hexyl, methyl cyclohexyl, dicyclohexyl methyl, or tolyl; R3 is a tertiary amine group; m and n are the degrees of polymerization; m is not less than 2 and not larger than 20; and n is not less than 1 and not larger than 12. The invention also provides an ultraviolet light curing coating comprising the following components of 60 to 80 parts by weight of modified polyurethane acrylic ester with the structure of the formula (I): 10 to 18 parts by weight of water, 0.3 to 0.9 part by weight of aqueous flatting agent, 5 to 9 parts by weight of aqueous cosolvent, 2 to 6 parts by weight of aqueous wax auxiliary, 1.3 to 3 parts by weight of aqueous wettingagent, 0.5 to 0.7 part by weight of aqueous antifoaming agent and 3 to 5 parts by weight of photo initiator. The ultraviolet light curing coating of the invention has the advantages of excellent fingerprint resistance property, corrosion resistance property and weatherability, and rapid curing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Photosensitive resin composition, image forming material and image forming method using thereof

InactiveUS20070099115A1Improve curing effectSuppressing polymerization inhibitionPhotosensitive materialsRadiation applicationsMeth-Side chain

There is devised a novel acryl resin in which an unsaturated group introduced in an alkali soluble resin is placed at a longer distance from the resin skeleton of the alkali soluble resin, the mobility of the unsaturated group is promoted and the number of the unsaturated double bonds is increased; therefore it allows crosslinking reaction to occur easily and a functional resin portion which imparts a specific function, in particular, function of suppressing polymerization inhibition due to oxygen by introduction of an active methylene group is provided at a resin portion existing between the acryl resin skeleton and the unsaturated double bond, and a photosensitive resin composition containing thereof is to be provided. A photosensitive resin composition comprising an alkali soluble resin, an ethylenically unsaturated compound, a near infrared absorbing dye, a compound containing a halomethyl group and a compound containing an organoboron anion, wherein the alkali soluble resin comprises an acryl resin having one or more of pendant groups in which both terminals of a diol compound have been blocked with isophorone diisocyanates and then (meth)acryloyl has been added, and, an image forming material comprising a substrate, and a photosensitive layer formed by the photosensitive resin composition on the substrate, as well as an image forming method.

Owner:NIPPON PAINT CO LTD

Water-resisting, oil-proof, antifouling agent for fabric and production process thereof

The present invention is waterproof, oilproof and anti-fouling agent for fabric and its production process. The waterproof, oilproof and anti-fouling agent is the mixture of emulsion polymerized fluoric acrylate polymer and pyrolytic closed polyurethane cross-linking agent. Its components include N-ethyl-N-hydroxyethyl perfluoro octyl sulfonamide 80-100 weight portions, isophorone diisocyanate 8-11 weight portions, hydroxyethyl acrylate 4-6 weight portions, acrylic acid 7-10 weight portions, acrylate 650-800 weight portions, and N-hydroxymethyl acrylamide 20-30 weight portions. It is used in the step of high temperature stoving and settling of fabric, and has the advantages of obvious effect, simple production process and lowered production cost.

Owner:LIAONING FIXED STAR FINE CHEM

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

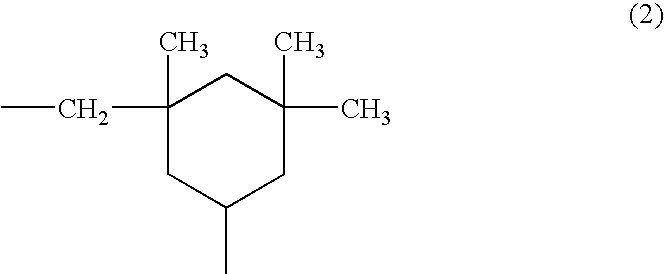

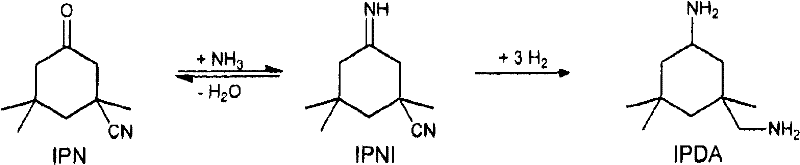

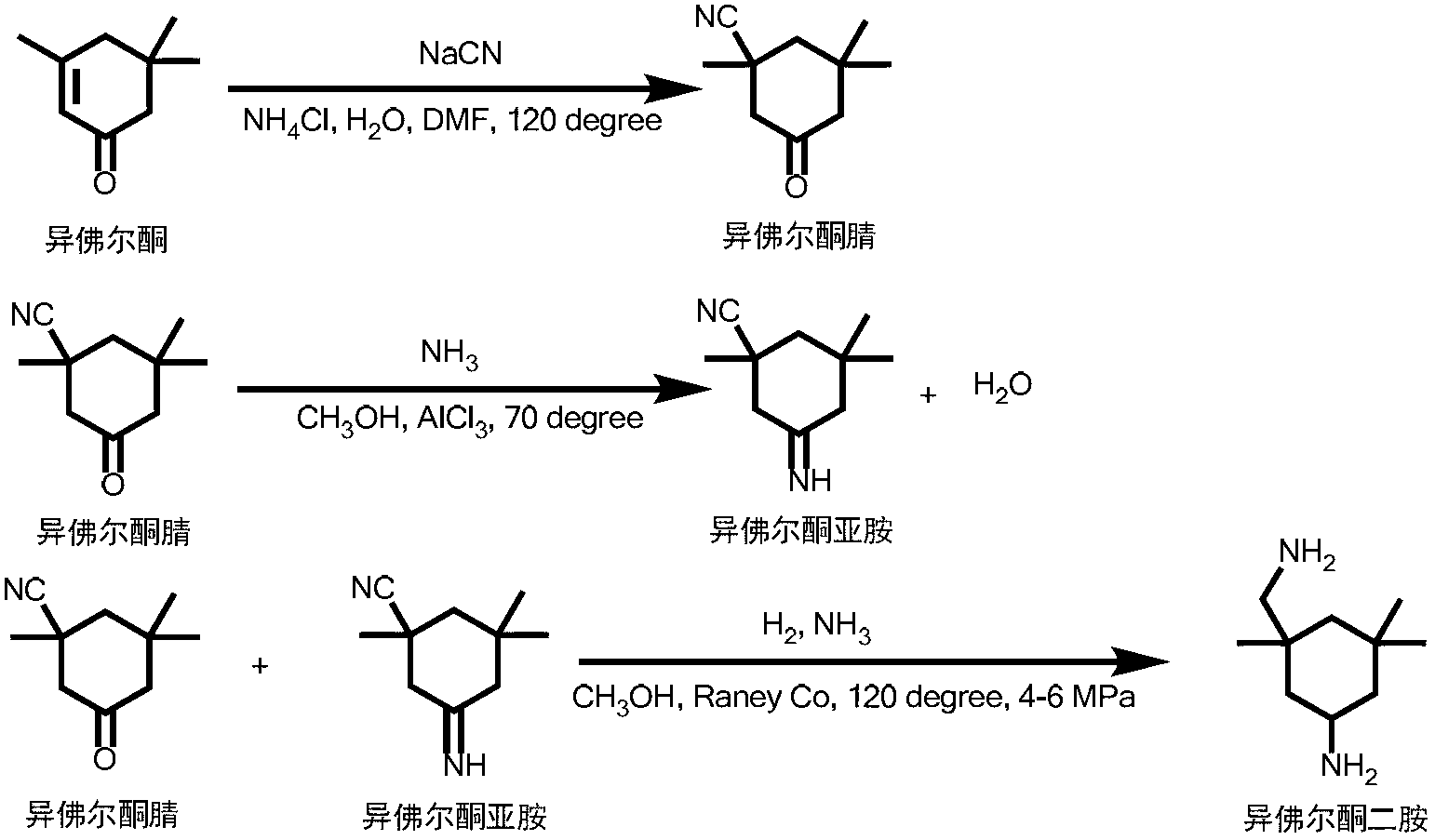

Method for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine

ActiveCN101386579ASimple methodReduce construction costsPreparation by reductive alkylationCyclohexanonePolymer science

The present invention discloses a method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine(isophorone diamine, IPDA) from 3-cyan-3,5,5-trimethyl cyclohexanone(IPN). The method comprises the following steps 3-cyan-3,5,5-trimethyl cyclohexanone, ammonia, an alcohol and / or ether solvent, a hydrogenation catalyst and a promoter are reacted at a temperature of between 50 and 120 DEG C and a hydrogen pressure of between 5 and 15 MPa so as to obtain 3-aminomethyl-3,3,3-trimethyl cyclohexylamine. The method simplifies the prior process for preparing IPDA from IPN, is low in equipment cost, mild in reaction conditions and high in offspring yield.

Owner:WANHUA CHEM GRP CO LTD +1

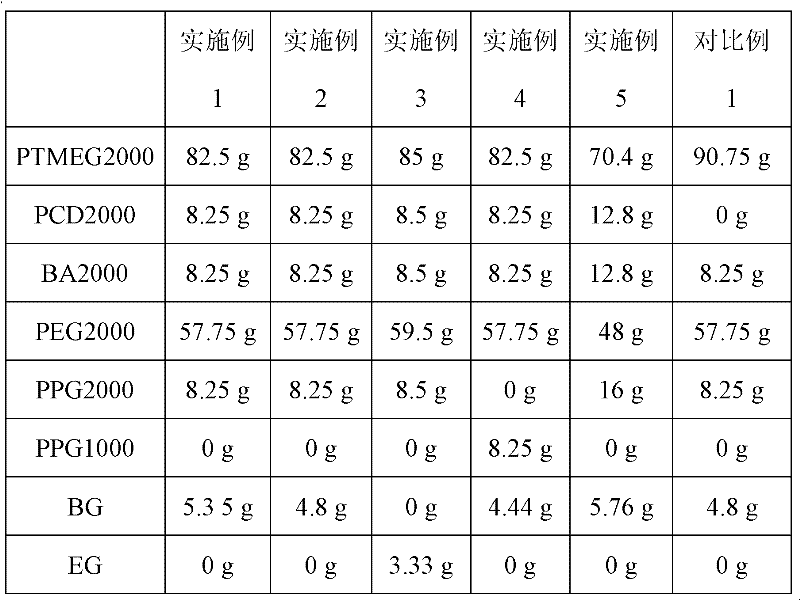

Modified waterborne polyurethane resin for artificial leather and preparation method thereof

InactiveCN101580577AAddress water resistanceSolve the softness problemTextiles and paperPropanoic acidSolvent

The invention relates to a modified waterborne polyurethane resin for artificial leather and a preparation method thereof. The modified waterborne polyurethane resin comprises formulation: the combination of any two in 6% of polyether polyol N210 with the molecular weight of 1000, 9-14% of polyether polyol N220 with the molecular weight of 2000 or 6% of polyether polyol N240 with the molecular weight of 4000; 6.5-9% of toluene di-isocyanate (TDI), 1.5-1.8% of dimethylol propionic acid, 2-4% of hydroxyl saturated polyester resin, 0.0-1% of dibutyl tin laurate, 0.8-1.5% of diethylene glycol, 0.9-1.3% of triethylamine, 0.4-0.5% of isophorone diamine, 0.5-2% of hydroxyl polyether modified siloxane with the hydroxyl value of 56 and the rest of water. The invention has the advantages of high tensile strength, good elasticity, strong adhesive force, excellent water resistance, solvent resistance and chemical resistance, better leather feeling, high cold resistance and folding strength, good combination property and remarkable environmental protection.

Owner:建德市顺发化工助剂有限公司

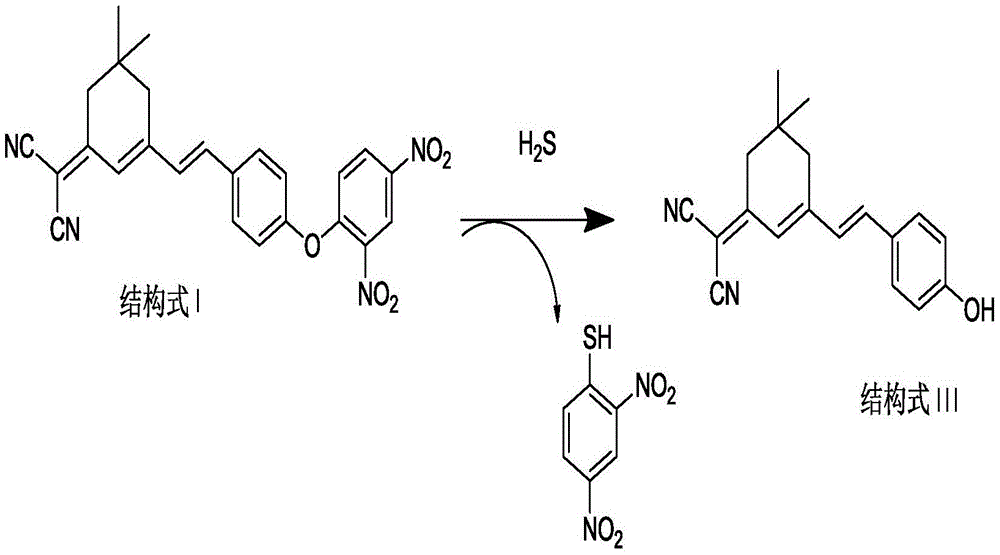

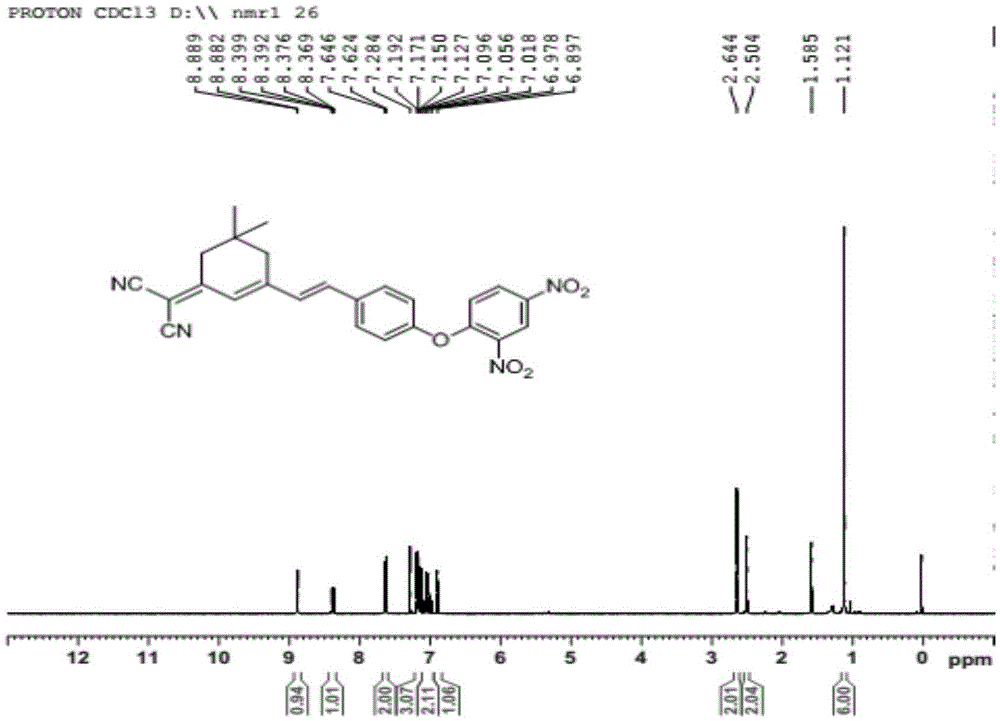

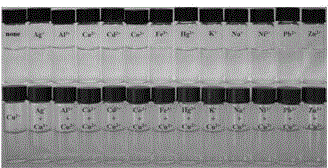

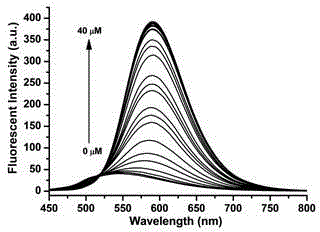

Isophorone fluorescence probe, and preparation method and application thereof

ActiveCN105524612AGood practical valueAvoid interferenceOrganic compound preparationFluorescence/phosphorescenceIsophoroneCytotoxicity

The invention discloses an isophorone fluorescence probe, and a preparation method and an application thereof. The structure of the fluorescence probe is represented by formula I. The preparation method comprises the following steps: adding isophorone, malononitrile and pyridine to a reaction bottle, carrying out heating refluxing under the protection of an inert gas for 18-24h, purifying, adding the above obtained pure product, p-hydroxybenzaldehyde and pyridine to the reaction bottle, carrying out heating refluxing under the protection of the inert gas for 4-18h, purifying, adding the obtained pure product, 2,4-dinitrofluorobenzene and triethylamine to the reaction bottle, stirring above materials for 8-36h, and purifying the obtained mixture to obtain the fluorescence probe. The fluorescence probe has large Stokes shift (182nm), long fluorescence emission wavelength (592nm), high sensitivity and good selectivity, can specifically detect hydrogen sulfide in organisms, environment and foods, has good biomembrane permeability and low cytotoxicity, and also has the advantages of simple synthesis route, high yield and very large practical values.

Owner:XUZHOU MEDICAL COLLEGE

Water-soluble polyurethane for wood lacquer and preparation method thereof

ActiveCN102070768AGood yellowing resistanceHigh molecular weightPolyurea/polyurethane coatingsEthylenediaminePropanoic acid

The invention discloses water-soluble polyurethane for the wood lacquer and a preparation method thereof. The water-soluble polyurethane comprises the following raw materials in parts by weight: 165-175 parts of polycarbonate diol, 131-132 parts of isophorone diisocyanate, 0.4-0.6 part of catalyst, 16.5-17.5 parts of dihydromethyl propionic acid, 2.7-3 parts of dihydroxyacetone, 18.5-19.5 parts of 1,4-butanediol, 4-5 parts of acetone, 12.5-13 parts of triethylamine, 6-7 parts of ethylenediamine, 628-638 parts of deionized water and 5-6 parts of adipic acid dihydrazide. The preparation method adopts the preparation technology combining the acetone method with pre-polymer dispersion method, thus effectively reducing the dosage of acetone and increasing the molecular weight of the generated polyurethane; and when the prepared water-soluble polyurethane dispersion forms a film, with the volatilization of water and the reduction of the pH value, the self-crosslinking reactions of ketonic carbonyl and hydrazide group can be performed, thus the after crosslinking density of the film can be increased and the hardness and water resistance of the the film can be increased.

Owner:安徽好思家涂料股份有限公司

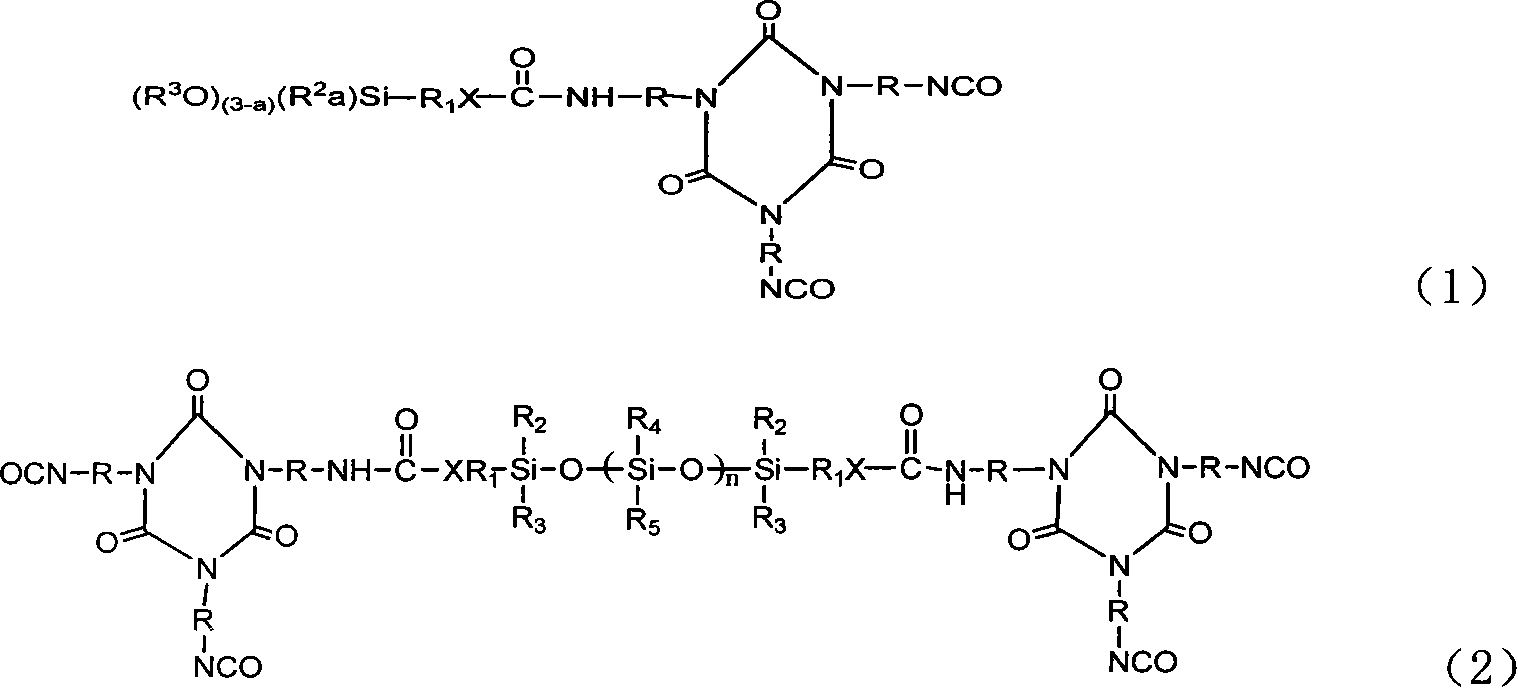

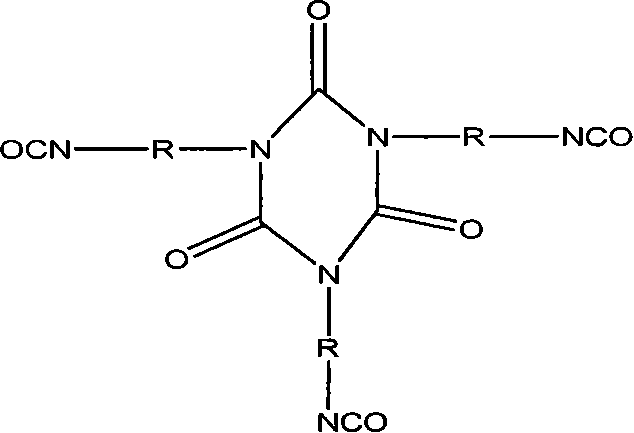

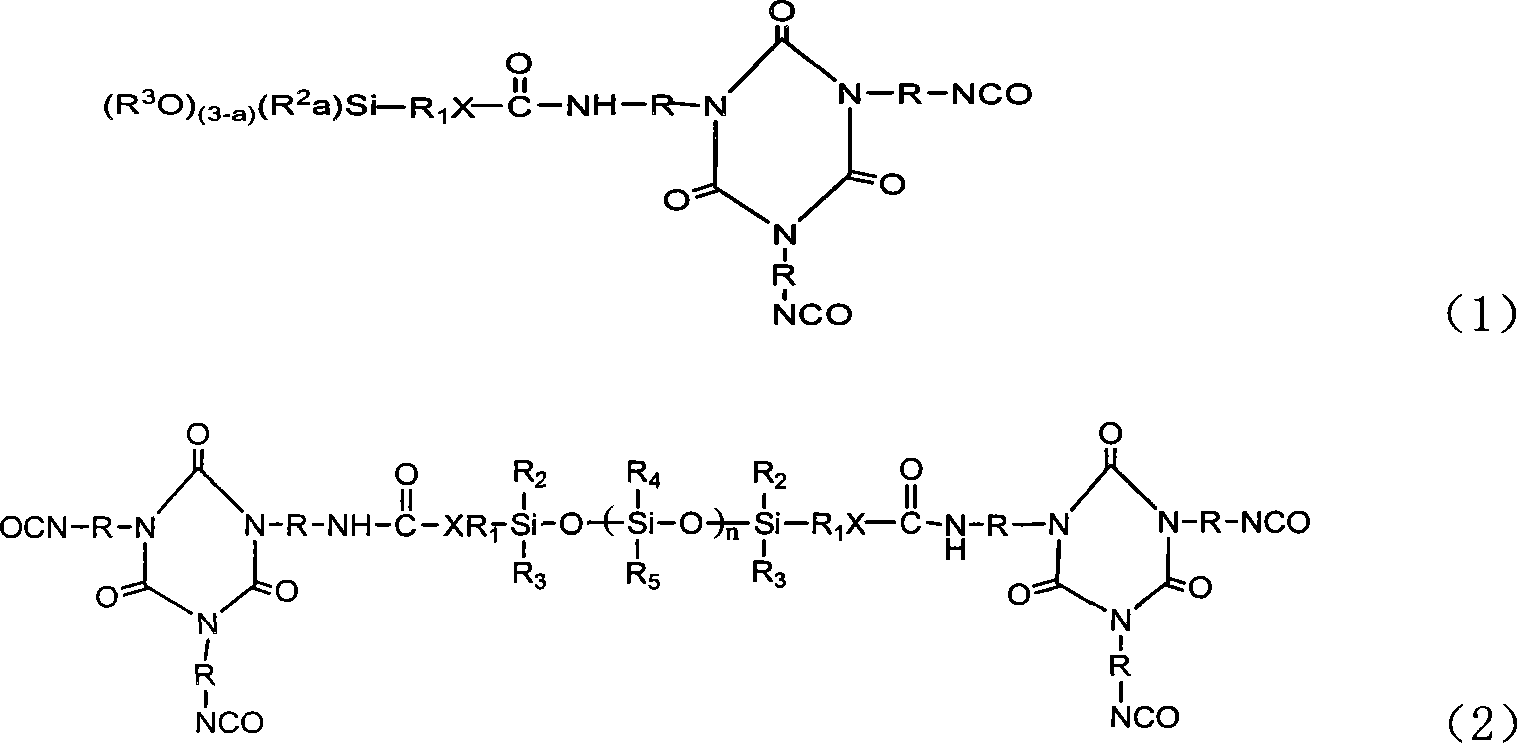

Tripolymer in isocyanic ester class modified by silicane or functional polusiloxane, preparation method

InactiveCN101050223AReduce viscosityReduce volatilityGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsArylIsophorone

This invention discloses a method for preparing isocyanate trimer containing silane or modified with functional linear polysiloxane. In the general chemical formula of the isocyanate trimer, R is diisocyanate-substituted methylphenyl, ethylphenyl, 1,5-naphthyl, diphenyl methane, hexamethylene, isophorone, 2,2,6-trimethyl cyclohexyl, or 4,4'-dicyclohexyl methane; R1 is saturated or unsaturated linear or branched C1-C8 alkyl, cycloalkyl, aryl or aromatic hydrocarbon homolg; R2 and R3 are C1-C6 alkyl, aryl, trialkylsilyl, or methoxyalkoxyl; a is a positive integer of 0-3; R1, R2, R3, R4 and R5 are saturated or unsaturated linear or branched C1-C12 alkyl, cycloalkyl, aryl, alkoxy or cycloalkoxy; X is -NH-, -NHCH2CH2NH-, -NHCH2CH2NHCH2CH2NH-, -N-, -NHCONH-, formula A, B or C, -S- or -O-; n is a positive integer greater than 0.

Owner:张群朝 +1

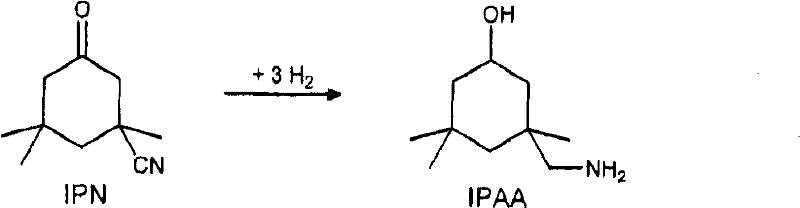

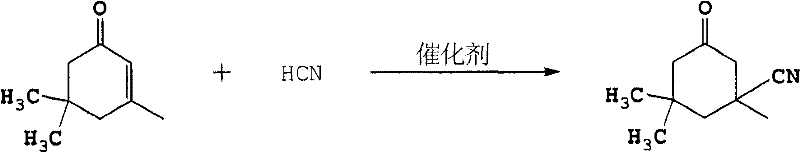

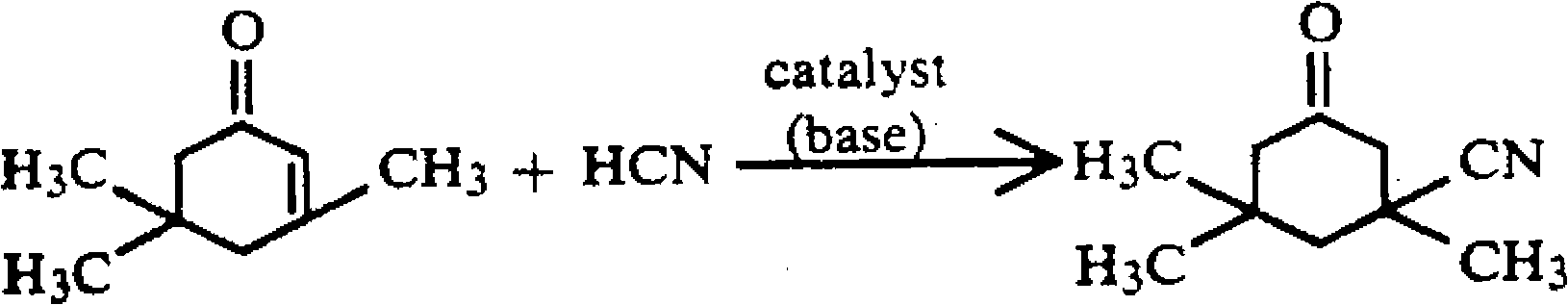

Process for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine

InactiveCN102531916AIncrease concentrationOrganic compound preparationWater/sewage treatment by heatingIsophoroneAsymmetric hydrogenation

The invention relates to an improved process for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine, referred to hereinafter as isophoronediamine or, in abbreviated form, IPDA, by: I. preparation of isophorone by catalyzed aldol condensations with acetone as reactant; II. Reaction of isophorone with HCN to form isophoronenitrile (IPN, 3-cyano-3,5,5-trimethylcyclohexanone); III. catalytic hydrogenation and / or catalytic reductive amination (also referred to as aminative hydrogenation) of 3-cyano-3,5,5-trimethylcyclohexanone, hereinafter called isophoronenitrile or, in abbreviated form, IPN, to give the isophoronediamine.

Owner:EVONIK DEGUSSA GMBH

Method for preparing 3-cyan-3,5,5-trimethyl cyclohexanone

InactiveCN101851178AReduce manufacturing costIndustrialization is simplePreparation by hydrogen cyanide additionCyclohexanoneOrganic acid

The invention discloses a method for preparing 3-cyan-3,5,5-trimethyl cyclohexanone. The method comprises the following steps of: taking isophorone as a raw material and adding hydrocyanic acid into the isophorone to perform addition reaction at the high temperature of between 100 and 200 DEG C under the action of an alkali catalyst to produce a crude product of the 3-cyan-3,5,5-trimethyl cyclohexanone; reducing the temperature to 80 to 120 DEG C, adding at least one organic acid serving as a neutralizer and a stabilizer into the reaction mixture and adding an organic solvent or a mixed solvent of the organic solvent and water into the reaction mixture; performing crystallization by cooling and filtering the mixture so as to obtain the finished 3-cyan-3,5,5-trimethyl cyclohexanone. The method can greatly reduce the production cost and has simple industrialized process and easy operation.

Owner:四川省天然气化工研究院

Ink Composition for Inkjet Printing

The invention provides an ink composition for ink-jet printing which does not cause clogging of nozzles of an ink-jet printer during printing, to thereby provide a print of desired printing quality; which ensures an appropriate drying rate of printed images; and which attains excellent color development. The ink composition for ink-jet printing, containing a pigment, a binder resin, a pigment dispersant, and a solvent, wherein the solvent is formed of (1) at least one glycol ether and at least one of a lactone compound and 2-pyrrolidone, or (2) at least one glycol ether acetate and at least one of cyclohexane and isophorone.

Owner:DAI NIPPON TORYO CO LTD

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

Catalyst for preparing isophorone by acetone condensation method

InactiveCN101698147AImprove conversion rateHigh selectivityOrganic compound preparationCatalyst activation/preparationCeriumLanthanum

The invention provides a catalyst for preparing isophorone by acetone condensation method. The catalyst is sinter formed by the step that magnesium oxide or nitrate, calcium oxide or nitrate, barium oxide or nitrate, zirconium oxide or nitrate, rare earth metal oxide or nitrate and aluminium oxide are mixed and then sintered at 400-600 DEG C for 4-6 hours. The sinter contains 25.4-46.4% of aluminium element, 3-18% of magnesium element, 1.4-7.1% of calcium element, 0.8-4.2% of barium element, 0.7-1.5% of zirconium element and 0.5-6% of rare earth metal element; wherein the rare earth metal is one or two of lanthanum, cerium and yttrium. The catalyst is used for catalyzing acetone condensation reaction, can effectively improve acetone conversion and selectivity of isophorone and causes the acetone conversion and selectivity of isophorone to respectively reach more than 86% and 65%.

Owner:GUANGZHOU UNIVERSITY

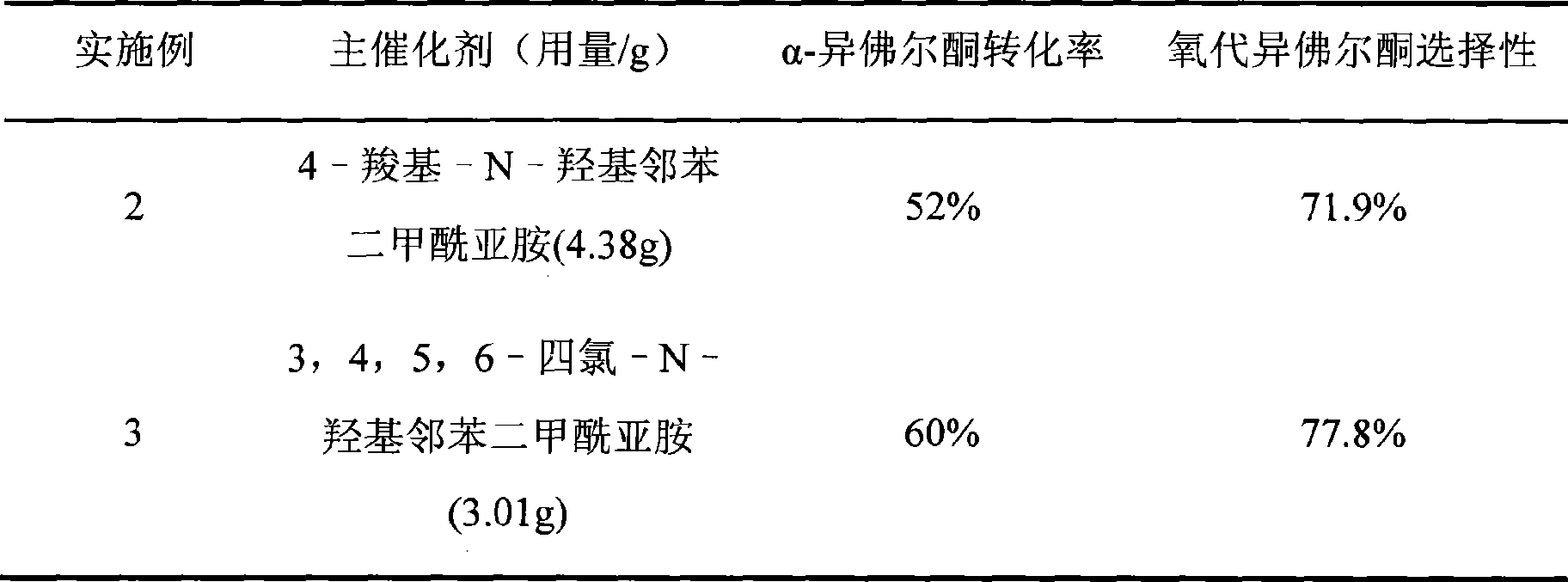

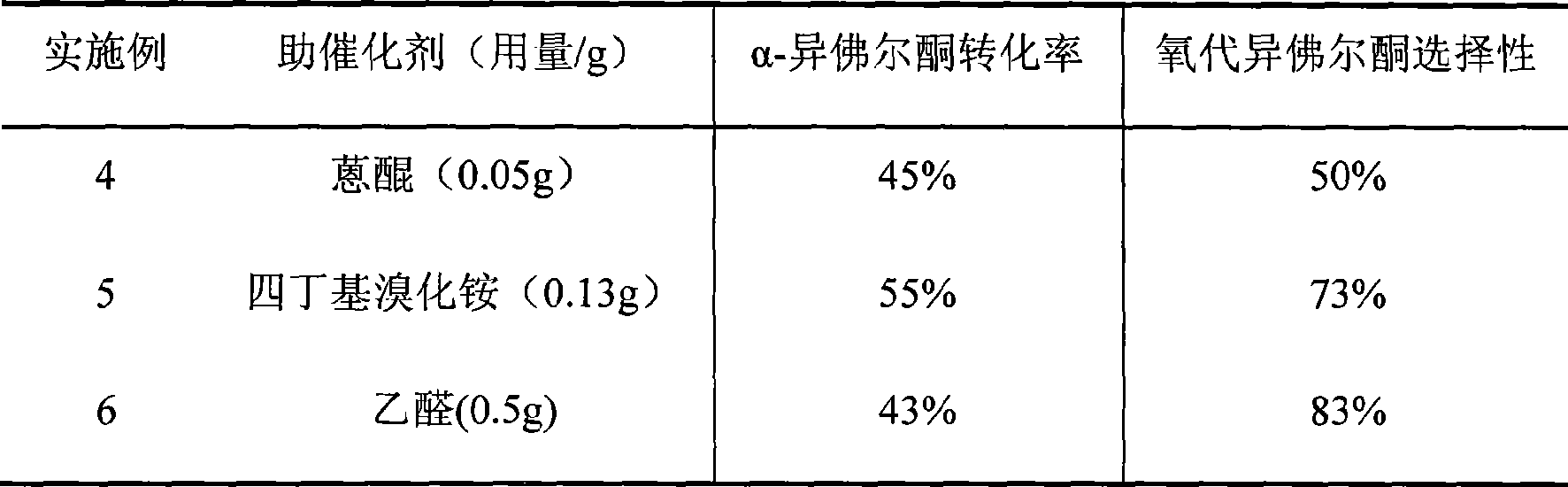

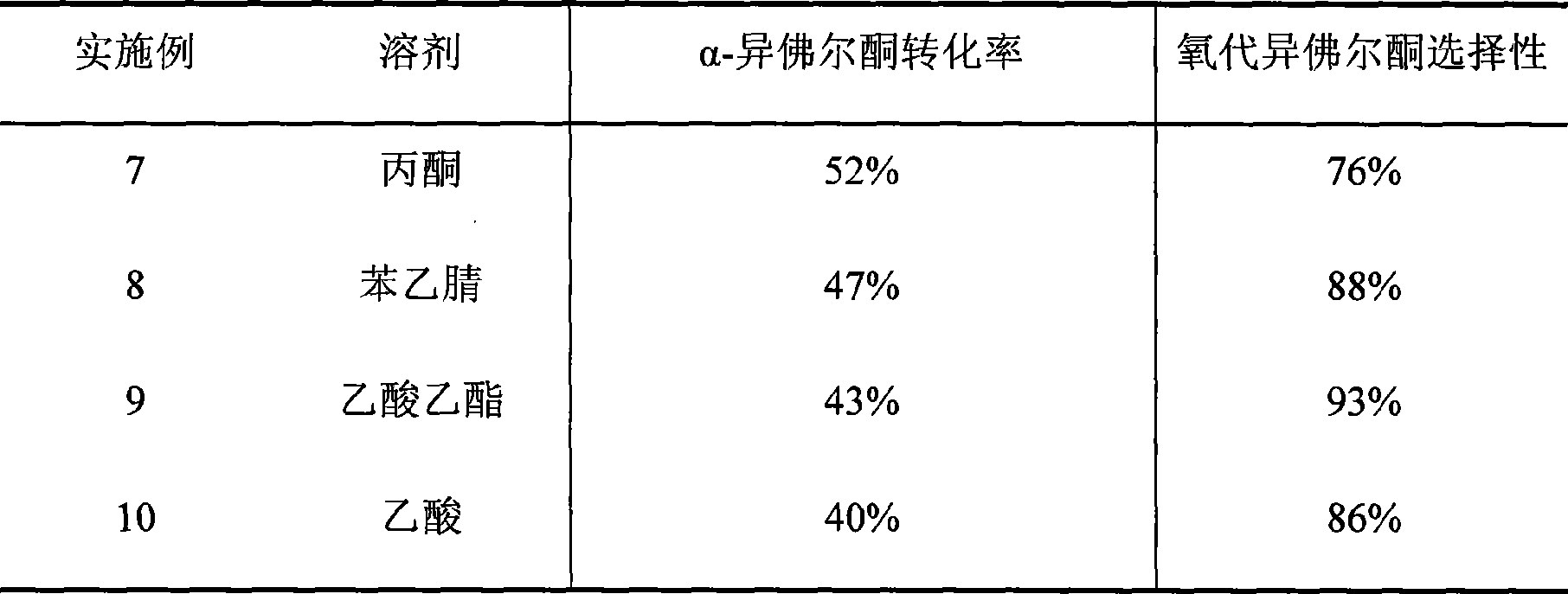

Method for preparing oxo-isophorone by catalytic oxidation using metal free catalytic system

InactiveCN101417936AHigh selectivityMild conditionsOrganic compound preparationCarbonyl compound preparationCatalytic oxidationReaction temperature

The invention relates to a method for preparing keto-isophorone by the catalytic oxidation of a metal free co-catalyst system, which is characterized in that, Alpha-isophorone is used as the raw material; in the presence of an organic solvent, oxygen or an oxygen rich gas is used as an oxidant; under the effect of the co-catalyst system composed by the main catalyst N-hydroxyphthalimide and the analogues of N-hydroxyphthalimide, and organic cocatalyst, keto-isophorone is prepared by catalytic oxidation; reaction temperature ranges from 10 to 100 DEG C; reaction time ranges from 1 to 70 hours; keto-isophorone with high selectivity can be generated. The method has the advantages that, the catalyst is metal free, cheap and easy to be obtained; reaction conditions are mild; operation is simple; the product has high selectively and other advantages.

Owner:ZHEJIANG UNIV +1

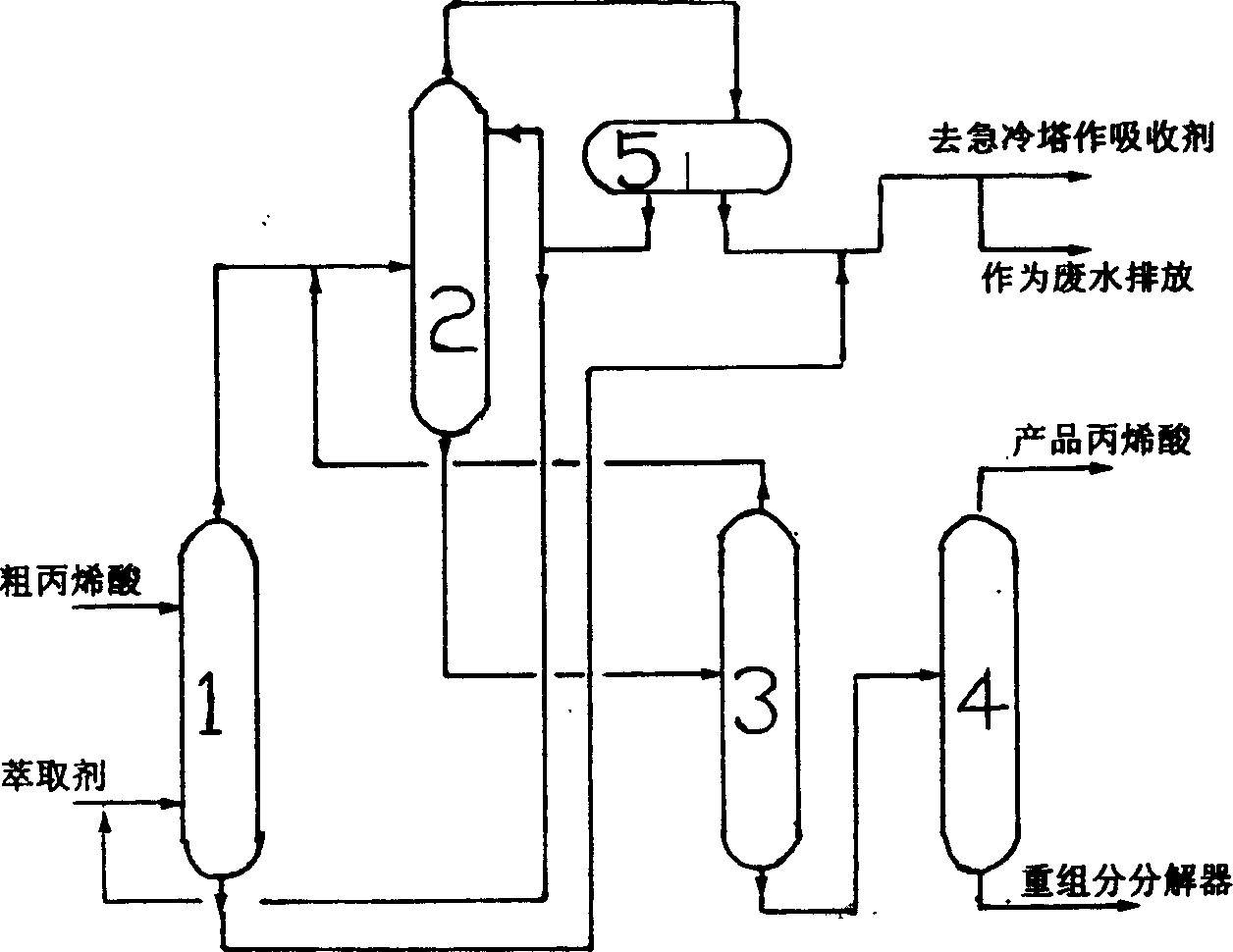

Method for purifying acrylic acid

The invention relates to the process for purifying acrylic acid which comprises using novel organic extracting agent to separate acrylic acid from its water solution, then removing light compositions such as water and acetic acid by azeotropic fractional distillation, wherein the organic extracting agent comprises toluene, acetic ether, butyl acetate, butyl acetate, propionic ether, diisobutyl ketone, isophorone, methyl phenyl ether or their mixture, preferably the composite compound of toluene with isobutyl phenylacetate, the mass ratio of toluene and isobutyl phenylacetate is between 1:1-1:50, preferably 1:2-1:12. The process according to the invention can realize high acetic acid removing ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

Lead-free environmental-friendly circuit board conductive silver paste and preparation method thereof

InactiveCN104036842AReduce dosageImprove printing effectMetal/alloy conductorsCable/conductor manufactureEnvironmental resistanceMicrosphere

The invention provides a kind of lead-free environmental-friendly circuit board conductive silver paste, which is prepared by the following raw material by weights: 60 to 70 of silver powder of 20 to 30mum, 5 to 8 of copper powder of 1 to 10nm, 8 to 10 of glass powder, 5 to 7 of SnO2 powder, 5 to 8 of silver powder of 40 to 60nm, 2 to 4 of pentaerythritol tristearate, 4 to 6 of isophorone, 3 to 5 of saturated polyester resin EK410, 4 to 7 of bisphenol F epoxy resin, 1 to 2 of salicylic acid, 3 to 5 of polyurethane resin, 1 to 2 of triallyl isocyanurate, 1 to 2 of microsphere starch, 1 to 2 of fumed silica, 4 to 6 of isobutyl ketone, 6 to 8 of ethanol , 2 to 4 of butanol, and 6 to 8 of butyl acetate. The lead-free environmental-friendly circuit board conductive silver paste and the preparation method thereof are characterized in that the use amount of the silver powder is small, the printing performance is good, the yield of the circuit board is high, the conductive performance is good, lead-free environmental-friendly performance is provided, the technology is simple, the operation is convenient and easy, and the product performance is convenient to control.

Owner:铜陵市超远精密电子科技有限公司

Easily-dyed aliphatic polyurethane resin and preparation method thereof

The invention relates to easily-dyed aliphatic polyurethane resin, comprising the following components in percent by weight: 0.5%-1.5% of polyester polyol, 0.5%-1.5% of polycarbonate diol, 5%-7% of mixed polyether polyol, 0.2%-0.6% of chain extender, 6%-7% of isophorone diisocyanate, 2%-3% of isophorone diamine and 75%-80% of solvent. A preparation method comprises the following steps of: firstlyleading the polyester polyol, the polycarbonate diol, the mixed polyether polyol, the chain extender, the isophorone diisocyanate, the isophorone diamine and methylbenzene to react for 3-5 hours at the temperature 90-120 DEG C; and then adding isobutyl alcohol solution of the isophorone diamine, adding the solvent after a reaction system becomes viscous, leading the final viscosity of a product to be 30-50Pa s under the temperature of 25 DEG C, and ending the reaction.

Owner:SHANGHAI HUIDE TECH CO LTD

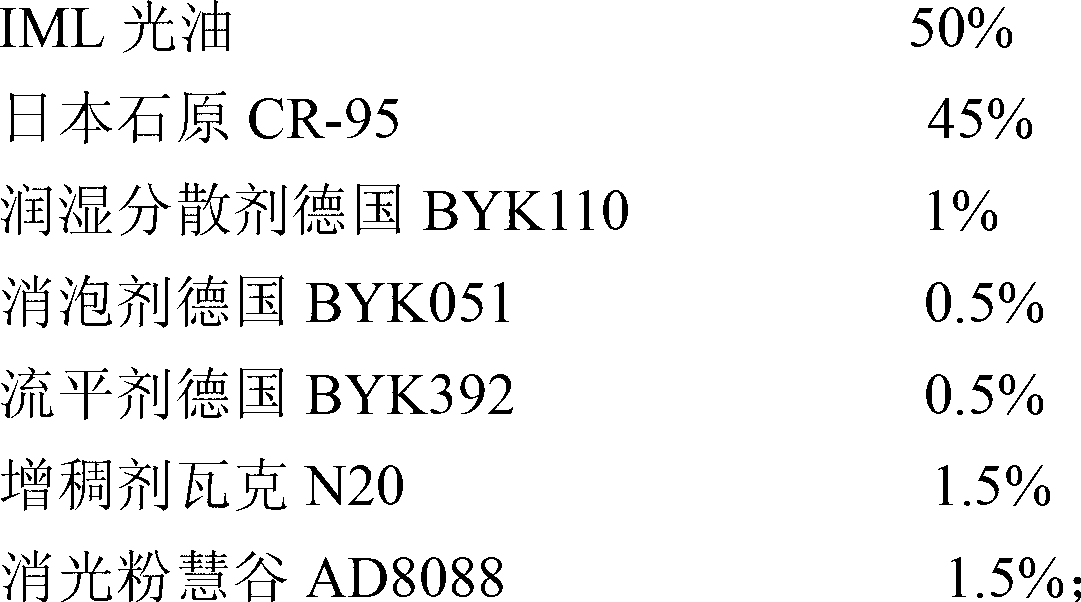

IML gloss oil and IML printing ink and preparation method and application thereof

The invention discloses IML gloss oil and IML printing ink, a preparation method and an application thereof. The IML gloss oil is obtained by dissolving saturated polyester resin in an organic solvent. The IML printing ink comprises an A component and an isocyanate curing agent with a mass ratio of 10:0.9-2; the A component comprises the following components: 40-89% of the IML gloss oil, 8-55% of pigment, 0.5-2% of a wetting dispersant, 0.5-1% of a defoamer, 0.5-1% of a levelling agent, 0.5-2% of a thickening agent, and 0-1.5% of extinction powder. The IML printing ink does not contain harmful or toxic substances for human body, such as benzene, toluene, xylene, isophorone and the like, and has the advantages of low odor environment and low environmental load; the IML printing ink has good adhesion performance, high-temperature ink-sweeping resistance, and tensile property, is widely applicable to fields of panels of household appliances, display screens and control panels, 3C product buttons, housing, and large-scale casings, automotive upholstery, and the like.

Owner:清远慧谷新材料技术有限公司

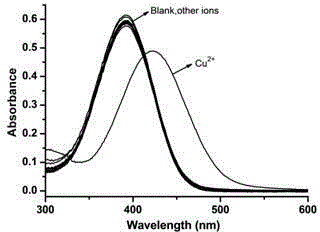

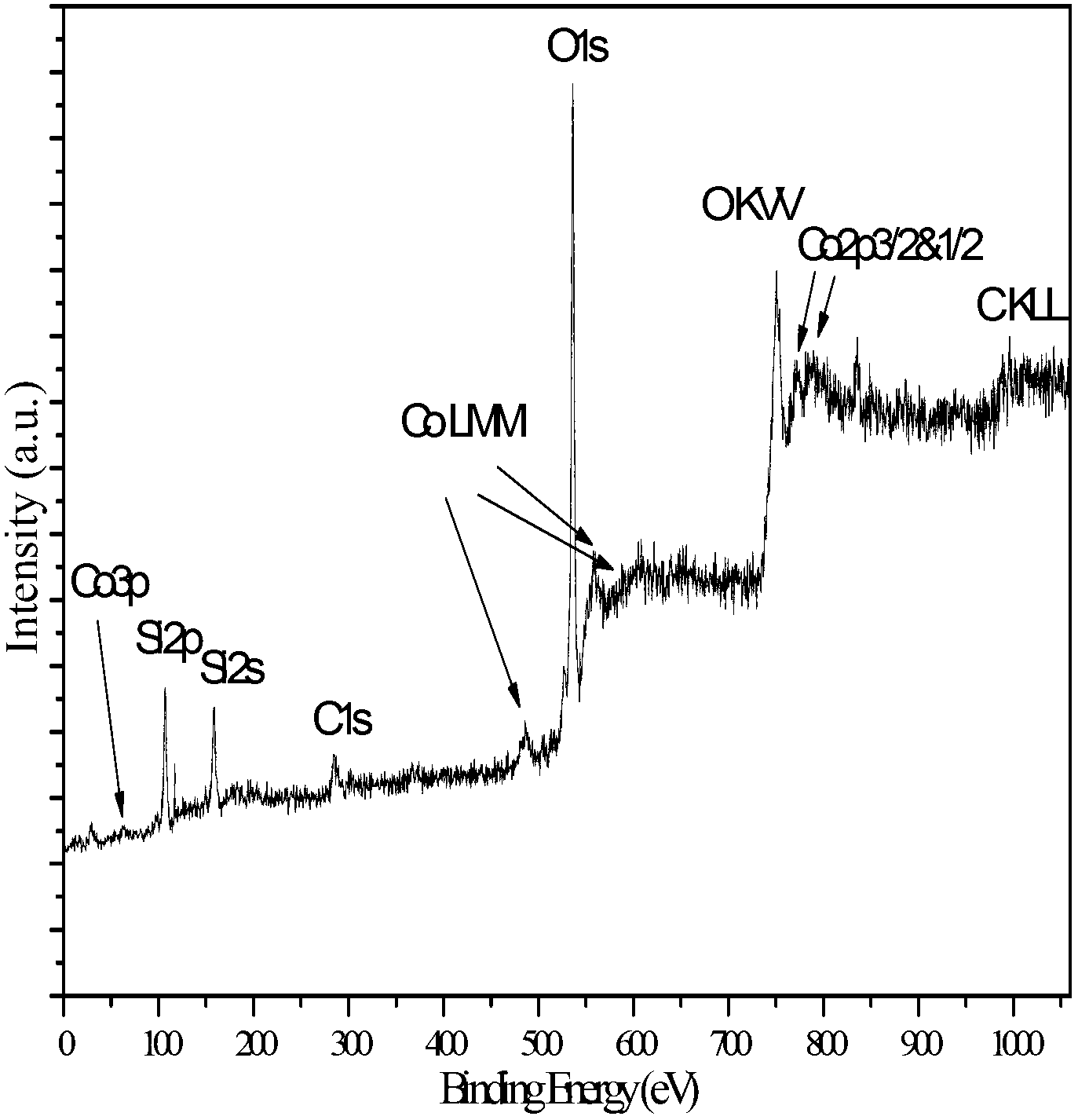

Malononitrile isophorone copper ion fluorescent probe and preparation method thereof

InactiveCN104860879AStrong fluorescenceLow detection limitOrganic chemistryFluorescence/phosphorescenceIsophoroneIon

The invention discloses a malononitrile isophorone copper ion fluorescent probe and a preparation method thereof, and relates to the technical field of analysis and detection. The malononitrile isophorone copper ion fluorescent probe has good fluorescence property, and assists in selectively identifying copper ions in a buffering solution. The fluorescent probe has the advantages of low detection limit (only 0.2 muM), large Stokes shift, fluorescence enhancement, long-wavelength emission and visible-light discoloration. Copper ion naked eye detection can be realized with the fluorescence enhancement and visible-light discoloration properties. With the fluorescence enhancement response of the probe upon copper ions, the copper ions can be subjected to qualitative or quantitative analyses. The probe can enter HeLa cells and can show a red fluorescence image after a reaction with copper ions in the cells. Therefore, the copper ion fluorescent probe provided by the invention can be sued in copper ion detections of the environment and in biological cells.

Owner:QILU UNIV OF TECH

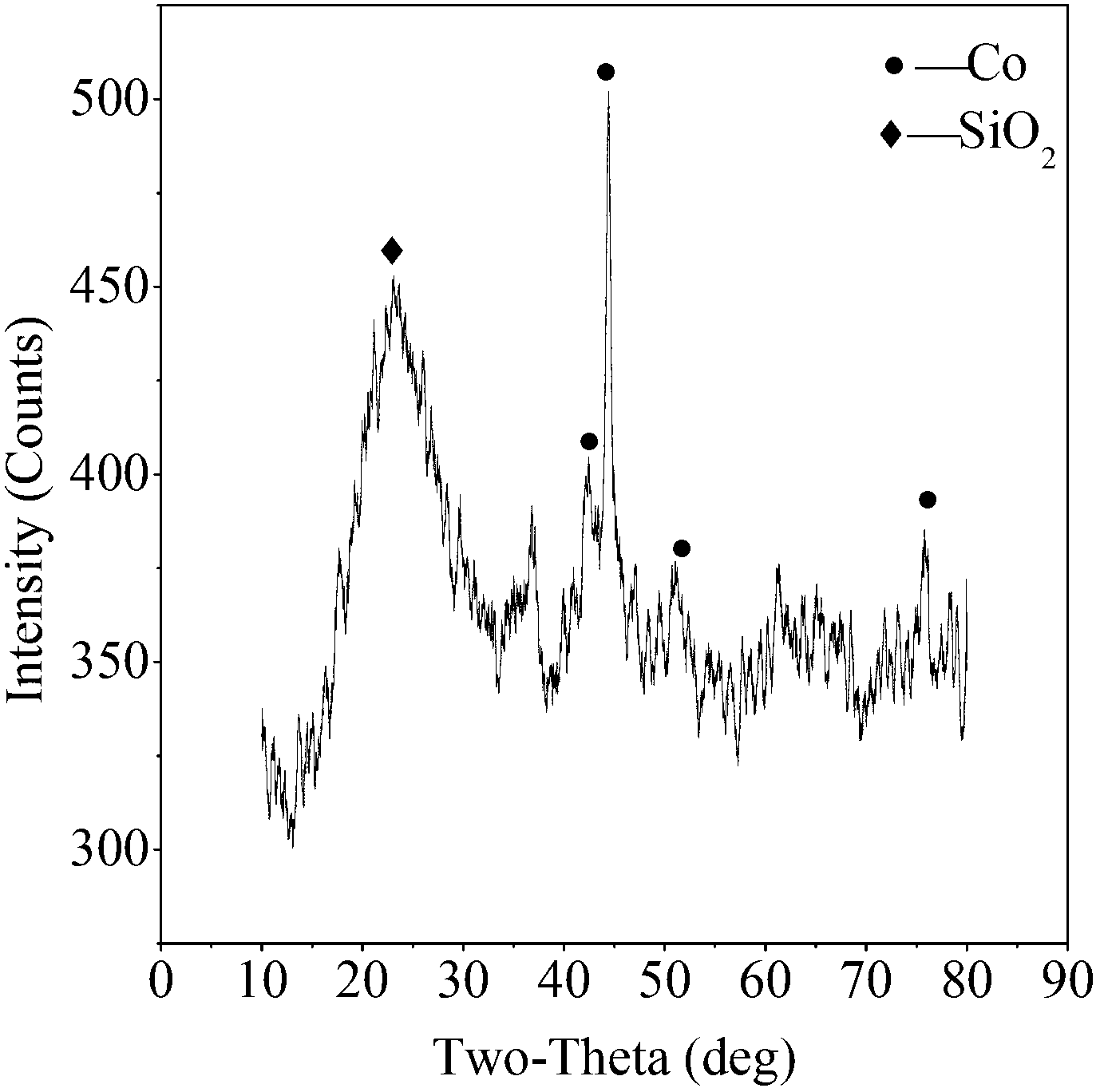

Method for preparing isophorone diamine

InactiveCN103265437AUniform dispersionHigh activityOrganic compound preparationAmino compound preparationHydrogenOrganic solvent

The invention discloses a method for preparing isophorone diamine, wherein the method comprises: using phorone nitrile as a raw material, under an effect of a metal cobalt catalyst, ammonia gas and hydrogen are orderly introduced into an organic solvent, and are reacts under stirring for 1-8h at 40-180 DEG C in a pressure condition of 1-10 MPa, and after reaction, a reaction mixture is post-treated to obtain the isophorone diamine. Uniformly-dispersive and high active metal cobalt catalyst is prepared by a sol-gel method, and when the catalyst is used for preparing isophorone diamine, a conversion rate of IPN can reach 100%, and the yield of IPAD is 78.5-98.3%. The catalyst has a long service life, and after the catalyst repeats eight-time by simple filtration after catalytic reaction, the conversion rate of IPN reduces 6.3%, yield of IPDA reduces 7.8%, and catalyst activity is almost not changed.

Owner:ZHEJIANG UNIV

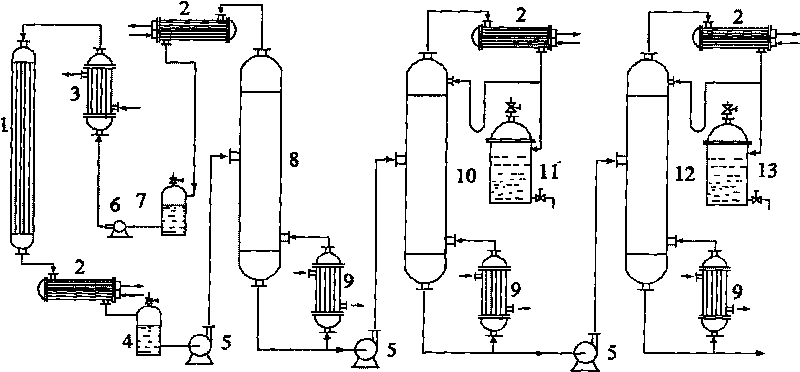

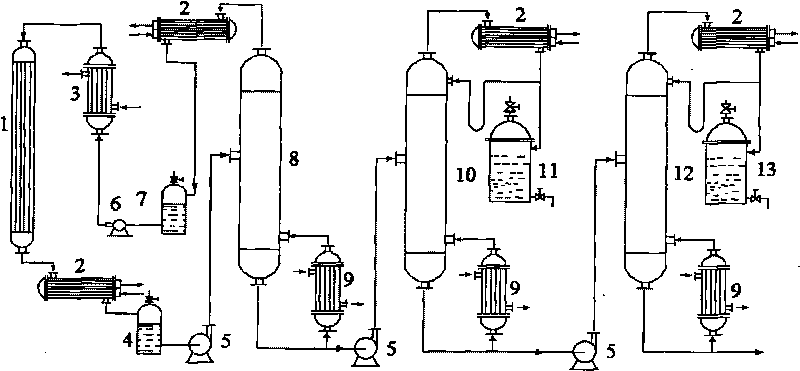

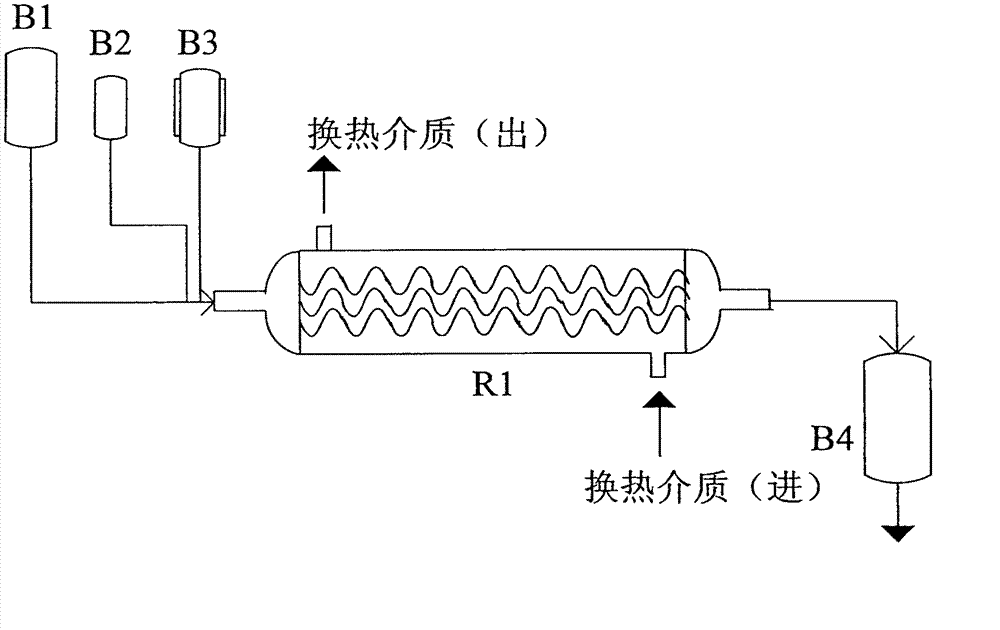

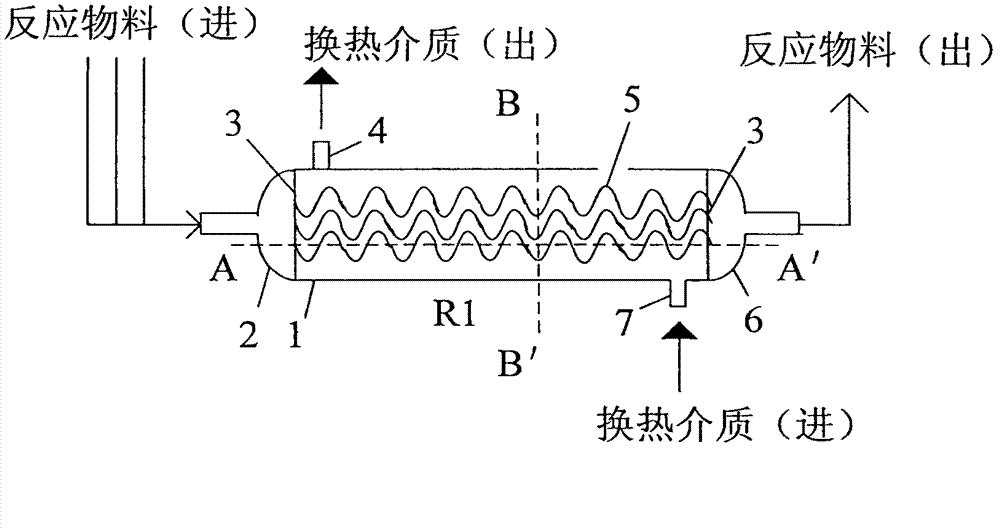

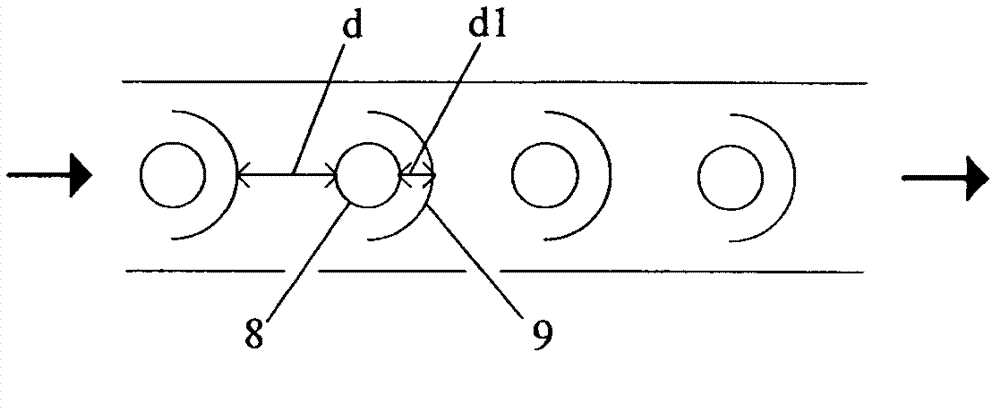

Reactor for preparing isophorone nitrile and method for continuously preparing isophorone nitrile by adopting reactor

ActiveCN103301799AImprove heat transfer efficiencyImprove mass transfer efficiencyChemical/physical/physico-chemical stationary reactorsPreparation by hydrogen cyanide additionMicron scaleIsophorone

The invention provides a reactor for preparing isophorone nitrile and a method for continuously preparing the isophorone nitrile by adopting the reactor. A plurality of millimeter to micron-sized narrow regular reaction channels which are arranged in parallel are arranged in the reactor, and inner members are arranged in the reaction channels, so that the reactor has good heat and mass transfer effects, and the dwell time can be accurately controlled, thereby obtaining a high reaction conversion rate and a high product yield. Compared with a traditional batch reactor or a common continuous tubular reactor, the method has obvious advantages on many aspects of improvement in the reaction effect in preparation of the isophorone nitrile, safety in production, energy conservation, consumption reduction and the like.

Owner:WANHUA CHEM GRP CO LTD +1

Preparing method for 3,5-dimethyl phenol

A process for preparing 3.5-xylenol features that the isophorone, liquid catalyst, and solid catalyst take part in reaction in inertial gas, and conventional collecting 3,5-xylenol.

Owner:MAOYANG CHEM IND SCI & TECH DEV SHANGHAI

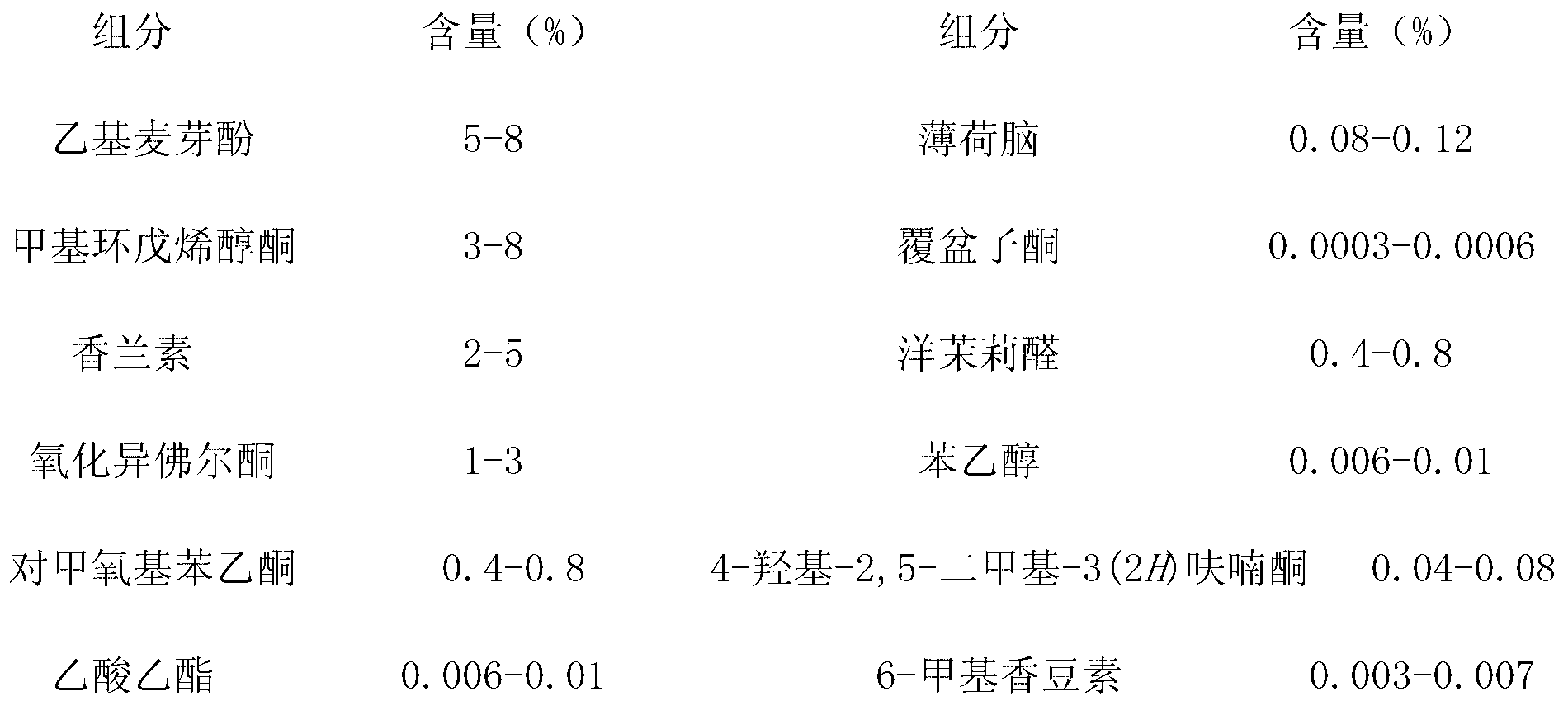

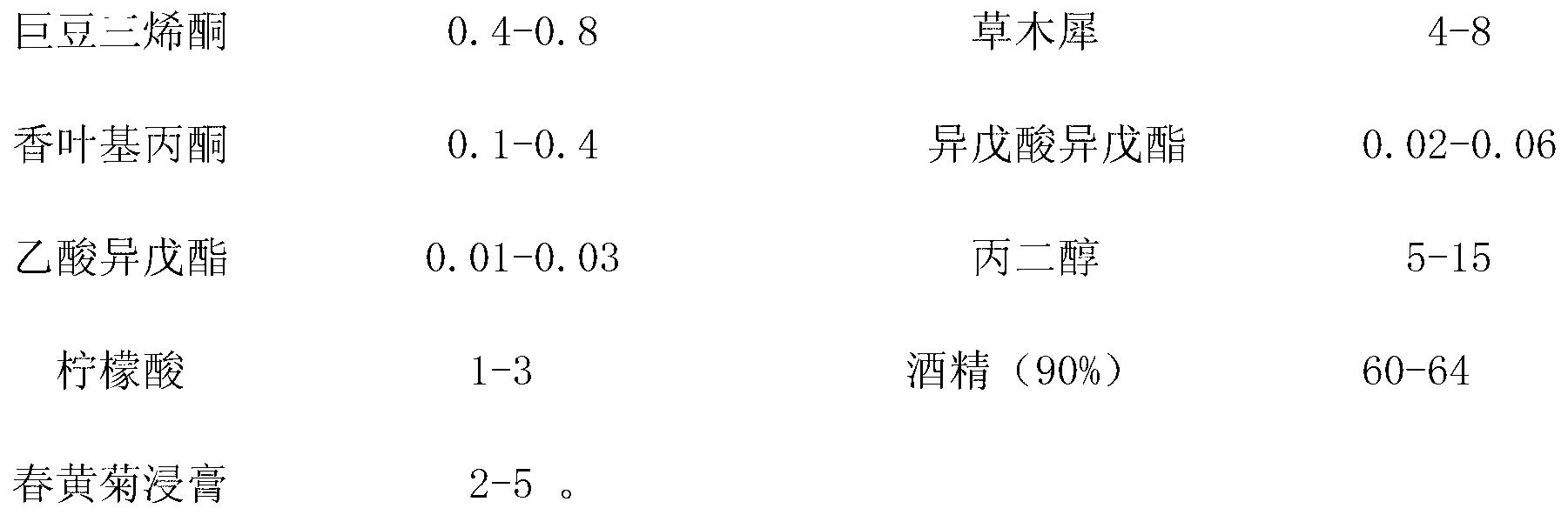

Tobacco sweetening agent for cigarettes and application method of tobacco sweetening agent

The invention discloses tobacco sweetening agent for cigarettes and an application method of the tobacco sweetening agent, and belongs to the technical field of tobaccos. The tobacco sweetening agent is mainly composed of ethyl maltol, methyl cyclopentenolone, vanillin, isophorone oxide, methoxyacetophenone, citric acid, chamomiles, propylene glycol extract and sweet clovers. The sweetening agent is added in cigarette products when the cigarette products are produced, a relaxed and pleasant tobacco sweet feeling is given to the cigarettes under the condition that the original cigarette style is not changed, the rank of the cigarettes is improved, the tobacco sweetening agent has good compatibility with cigarette fragrance and enables the cigarette fragrance to be fine, smooth and gentle, stimulation is reduced, and aftertaste is comfortable and elegant.

Owner:CHINA TOBACCO JIANGSU INDAL

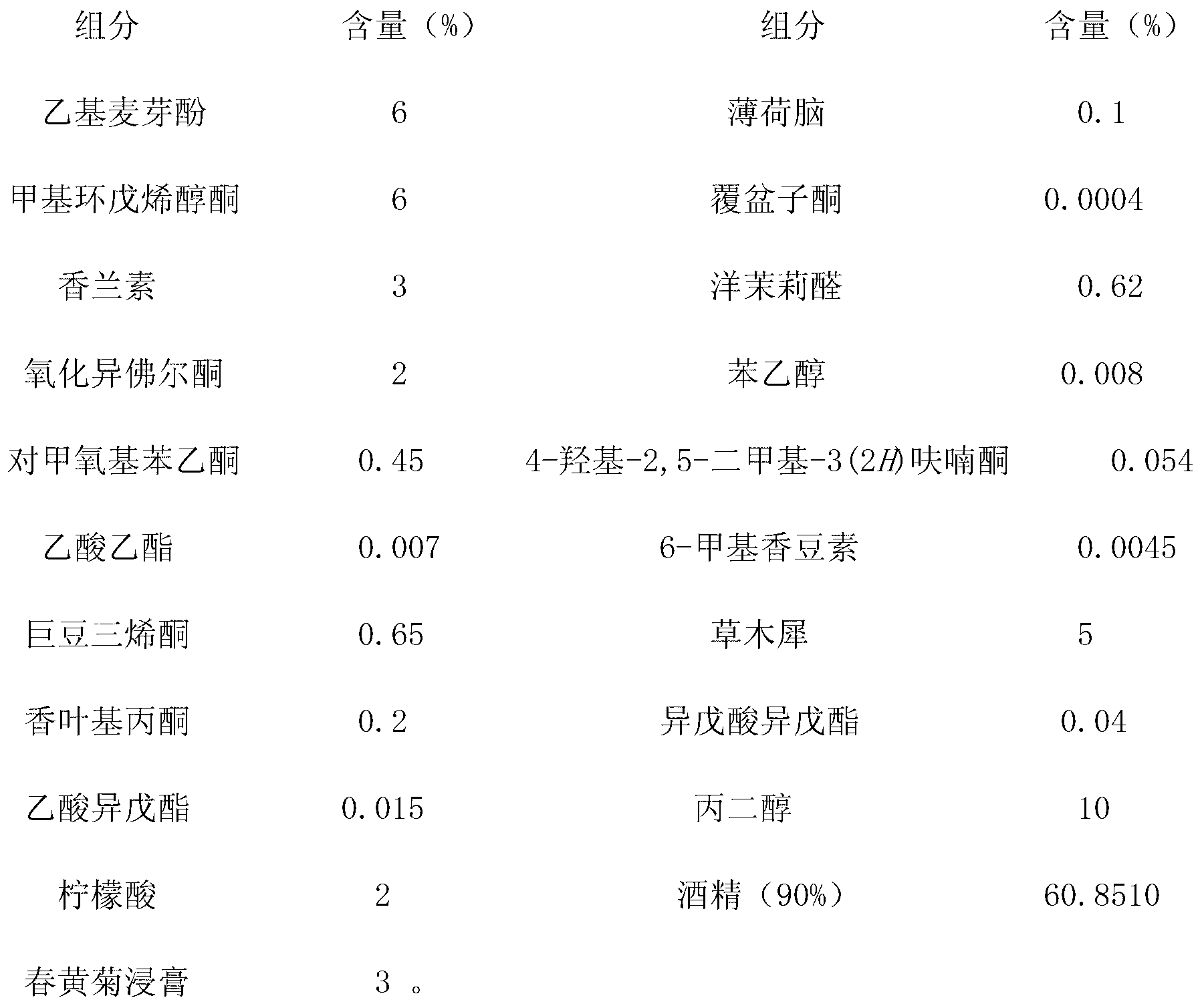

High-brightness impact-resistant aluminum epoxy repair adhesive and preparation method thereof

InactiveCN101974303AGood thixotropyGood construction performanceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesDiamineCarbon black

The invention relates to high-brightness impact-resistant aluminum epoxy repair adhesive and a preparation method thereof. The epoxy repair adhesive is composed of component A and component B based in the weight ratio of 100:12.5-16.6 (i.e. 8:1-6:1), wherein the component A is composed of the following raw materials in weight ratio: 16-30 parts of bisphenol A epoxy resin, 15-25 parts of superfine full-vulcanized carboxylic nitrile butadiene rubber particle modified bisphenol A epoxy resin, 2.5-5 parts of an epoxy resin reactive diluent, 0.6-1.2 parts of a coupling agent, 28-32 parts of spherical metallic aluminum powder, 7-12 parts of spherical-like alumina powder, 5-10 parts of aluminum powder and 3-5 parts of white carbon black; and the component B is composed of the following raw materials in weight ratio: 6-10 parts of aminoethyl piperazine, 10-15 parts of isophorone diamine, 30-40 parts of modified aromatic amine, 25-35 parts of polyether amine, 9-15 parts of spherical-like alumina powder and 3-6 parts of white carbon black. The preparation method comprises the steps of preparation of the component A and the component B; and the component A and the component B are mixed according to the ratio when in use.

Owner:YANTAI DARBOND TECH

Method for producing isophorone

InactiveCN102531866AOrganic compound preparationCarbonyl compound preparation by hydrolysisOrganic fractionIsophorone

The invention relates to a method for producing isophorone by catalyzed aldol condensation of acetone as an educt, reprocessing the reaction product, hydrolyzing the product stream, and separating into an organic and an aqueous fraction, obtaining isophorone from the organic fraction, distillatively reprocessing the aqueous fraction, and feeding the vapors from the head of the distillative reprocessing apparatus into the hydrolysis apparatus.

Owner:EVONIK DEGUSSA GMBH

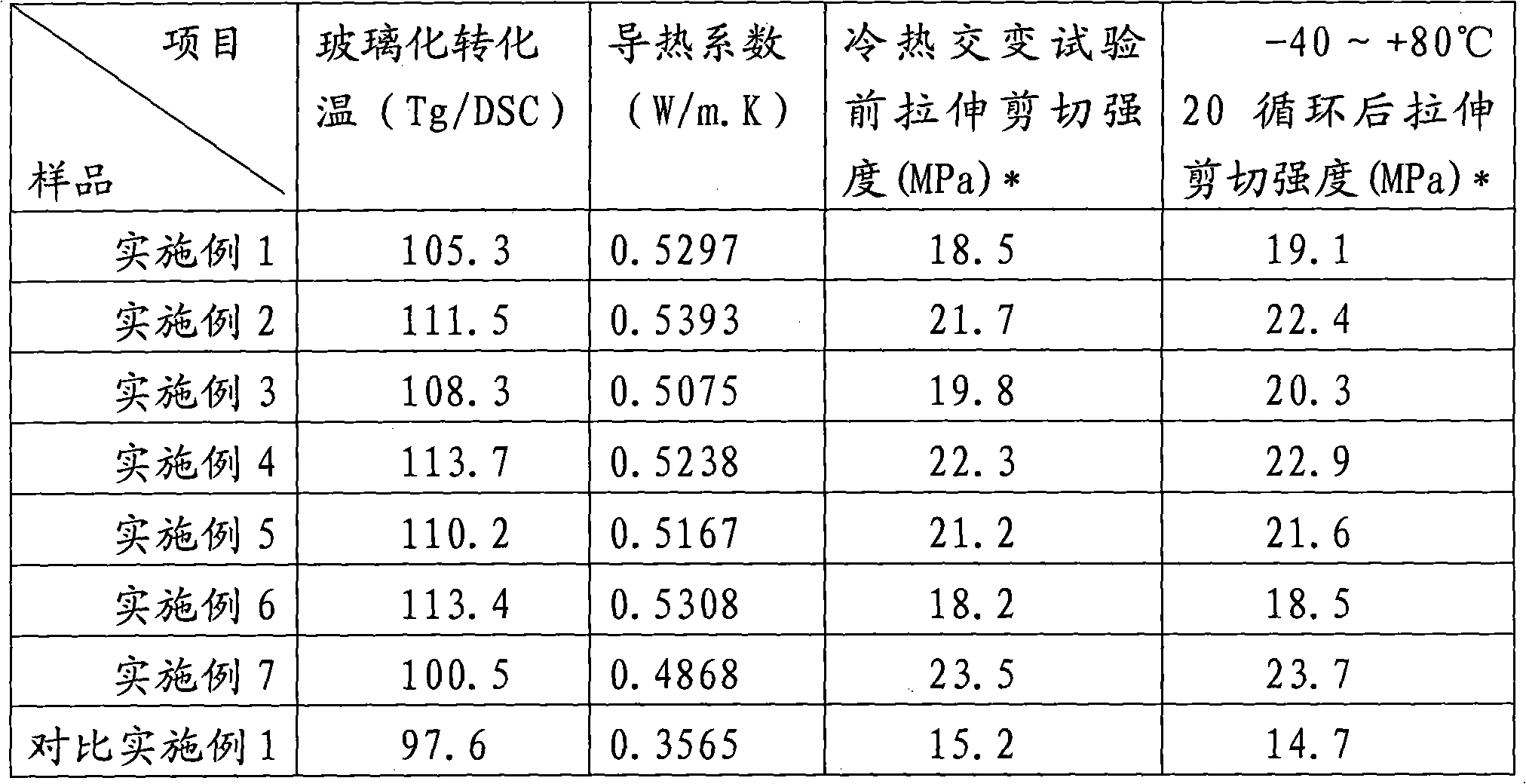

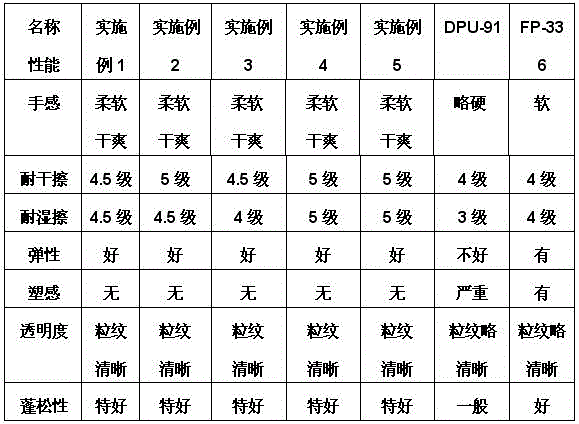

Non-ionic waterborne polyurethane coating agent for leather and preparation method thereof

ActiveCN106752829AHigh fastnessImprove electrolyte resistancePolyurea/polyurethane coatingsLeather surface finishingIsophoroneDiol

The invention provides a non-ionic waterborne polyurethane coating agent for leather and a preparation method thereof. The coating agent is prepared from 20-50 parts of isophorone diisocyanate, 5-35 parts of hexamethylene diisocyanate, 10-30 parts of polytetramethylene glycol, 40-70 parts of polycarbonate diols, 3-10 parts of methoxypolyethylene glycols, 25-35 parts of acetone, 10-20 parts of chain extender, 5-20 parts of a small molecule chain extender, and 150-500 parts of deionized water. The preparation method comprises the following steps: carrying out pre-polymerization reaction, chain extension reaction, emulsification reaction and chain extension reaction. The coating agent is used for leather finishing, and has the advantages of being fluffy, dry and high in elasticity, softness, high fastness and no plastic feeling.

Owner:LIAONING FIXED STAR FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com