Catalyst for preparing isophorone by acetone condensation method

The technology of isophorone and catalyst is applied in the field of preparing isophorone, which can solve the problems of low isophorone selectivity of acetone conversion rate, complicated catalyst preparation, difficult process control and the like, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Preparation of the catalyst: accurately weigh 15.0g of lanthanum oxide, 15.0g of calcium oxide, 90.0g of magnesium oxide, 174.0g of alumina, 3.0g of barium oxide and 3.0g of zirconia, add appropriate amount of water, mix thoroughly with a kneader, and press Shaped and calcined at 500°C for 6 hours to obtain the catalyst, in which the mass percentages of aluminum, magnesium, calcium, barium, zirconium and lanthanum are 30.7%, 18%, and 3.6%, respectively. , 0.83%, 0.74%, 2%.

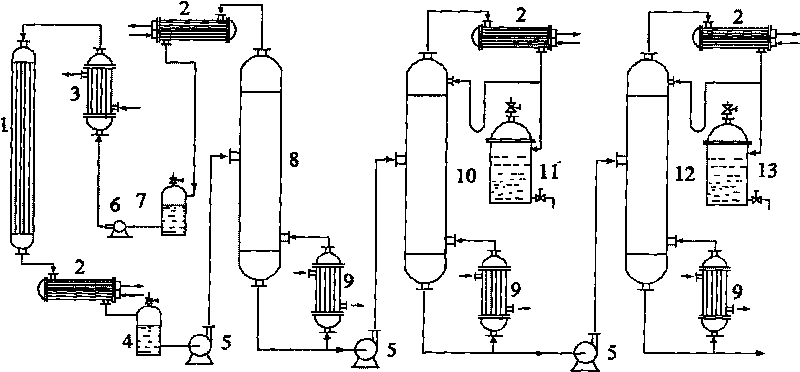

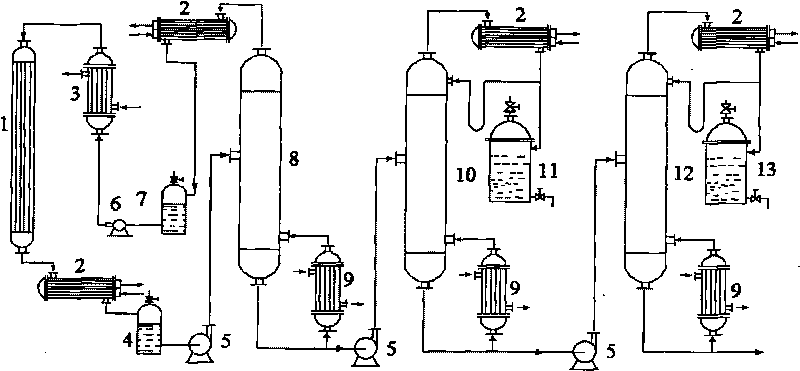

[0018] Preparation of isophorone: After vaporizing acetone, it was sent to a fixed-bed reactor equipped with the catalyst described in this example to react at 300°C for 26.4 hours. The resulting reaction product was first separated by an acetone recovery tower to separate unreacted acetone Then, the by-product mesityl oxide is separated through the mesityl oxide separation tower, and finally isophorone is separated through the isophorone separation tower. The specific process flow is as follows ( fig...

example 2

[0021] Preparation of the catalyst: accurately weigh the mass ratio of alumina and magnesia to 3:1, 249g of alumina-magnesia pellets with a diameter of 3-6mm, and add them to 75.0mg / ml of calcium nitrate and 37.5mg / ml of cerium nitrate , Barium nitrate 37.5mg / ml and zirconium oxychloride 22.5mg / ml mixed salt solution 400ml immersed in 400ml for 24 hours, evaporated, dried, and calcined at 550℃ for 6 hours to obtain the catalyst, in which aluminum element and magnesium element The mass percentages of, calcium, barium, zirconium and cerium are 35%, 13.3%, 2.6%, 2.3%, 2.2%, 1.6%.

[0022] Preparation of isophorone: After vaporizing acetone, it is sent to a fixed-bed reactor equipped with the catalyst of the present invention to react at 300°C for 26.4 hours. The resulting reaction product is first passed through an acetone recovery tower to separate unreacted acetone, and then The mesityl oxide separation tower separates the by-product mesityl oxide, and finally the isophorone separ...

example 3

[0025] Preparation of the catalyst: accurately weigh 15.0g of calcium oxide, 90.0g of magnesium oxide, 174.0g of alumina, 3.0g of barium oxide and 3.0g of zirconium dioxide, add appropriate amount of water, mix thoroughly with a kneader, and extrude. Immerse in 400ml of mixed solution containing 15.0mg / ml of yttrium nitrate and 25.0mg / ml of lanthanum nitrate for 20 hours, evaporate, dry, and then calcinate at 500°C for 5 hours to obtain the catalyst, in which aluminum element, magnesium element, The mass percentages of calcium element, barium element, zirconium element, yttrium element and lanthanum element are 30%, 17.6%, 3.5%, 0.83%, 0.74%, 0.94%, 2.1% in order.

[0026] Preparation of isophorone: After vaporizing acetone, it is sent to a fixed-bed reactor equipped with the catalyst of the present invention to react at 300°C for 26.4 hours. The resulting reaction product is first passed through an acetone recovery tower to separate unreacted acetone, and then The mesityl oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com