Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5740 results about "Oil and grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil and grease (O&G) is a measure of a variety of substances including fuels, motor oil, lubricating oil, hydraulic oil, cooking oil, and animal-derived fats.[viii] The concentration of these substances is typically measured within a body of water.

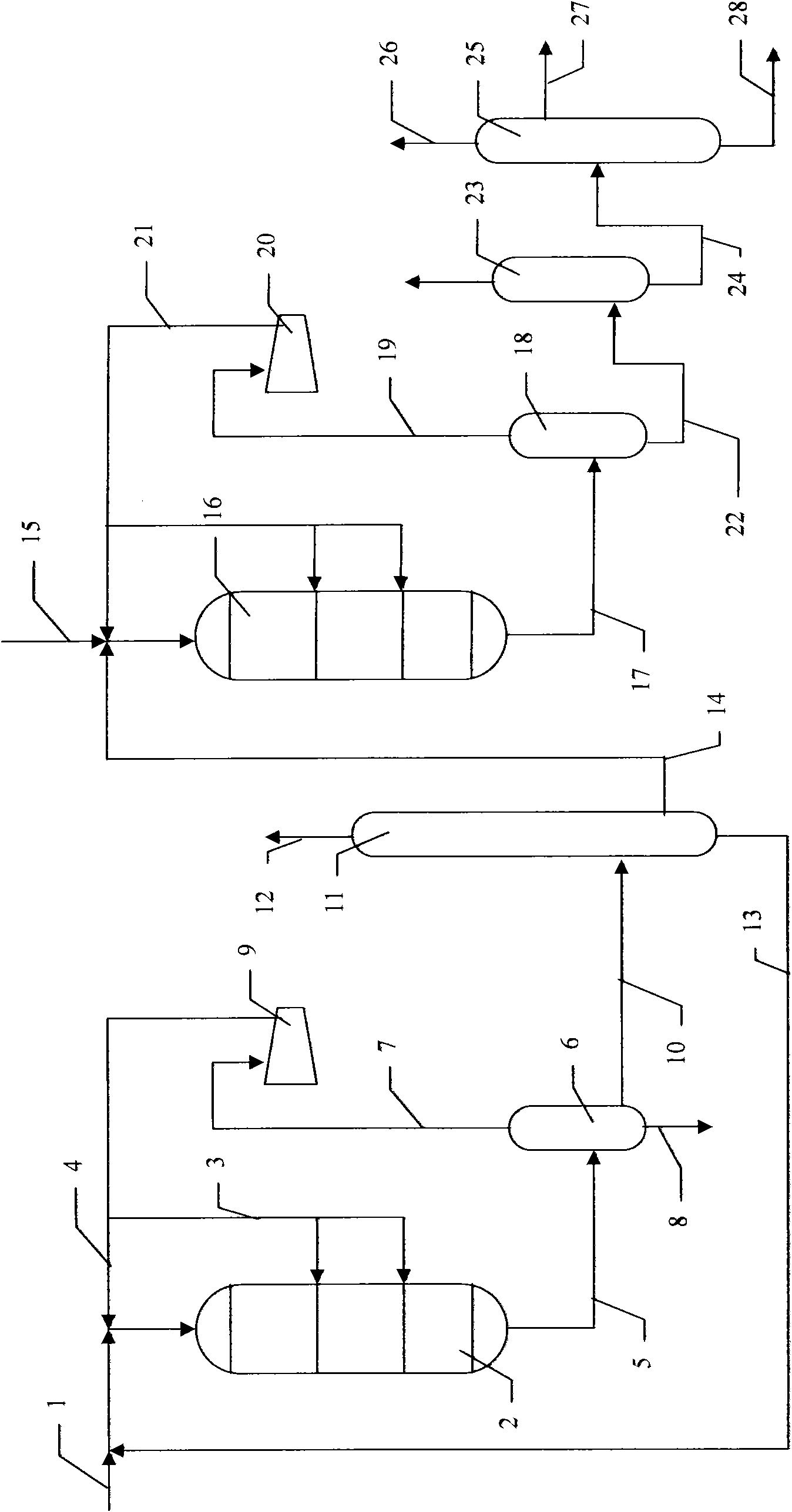

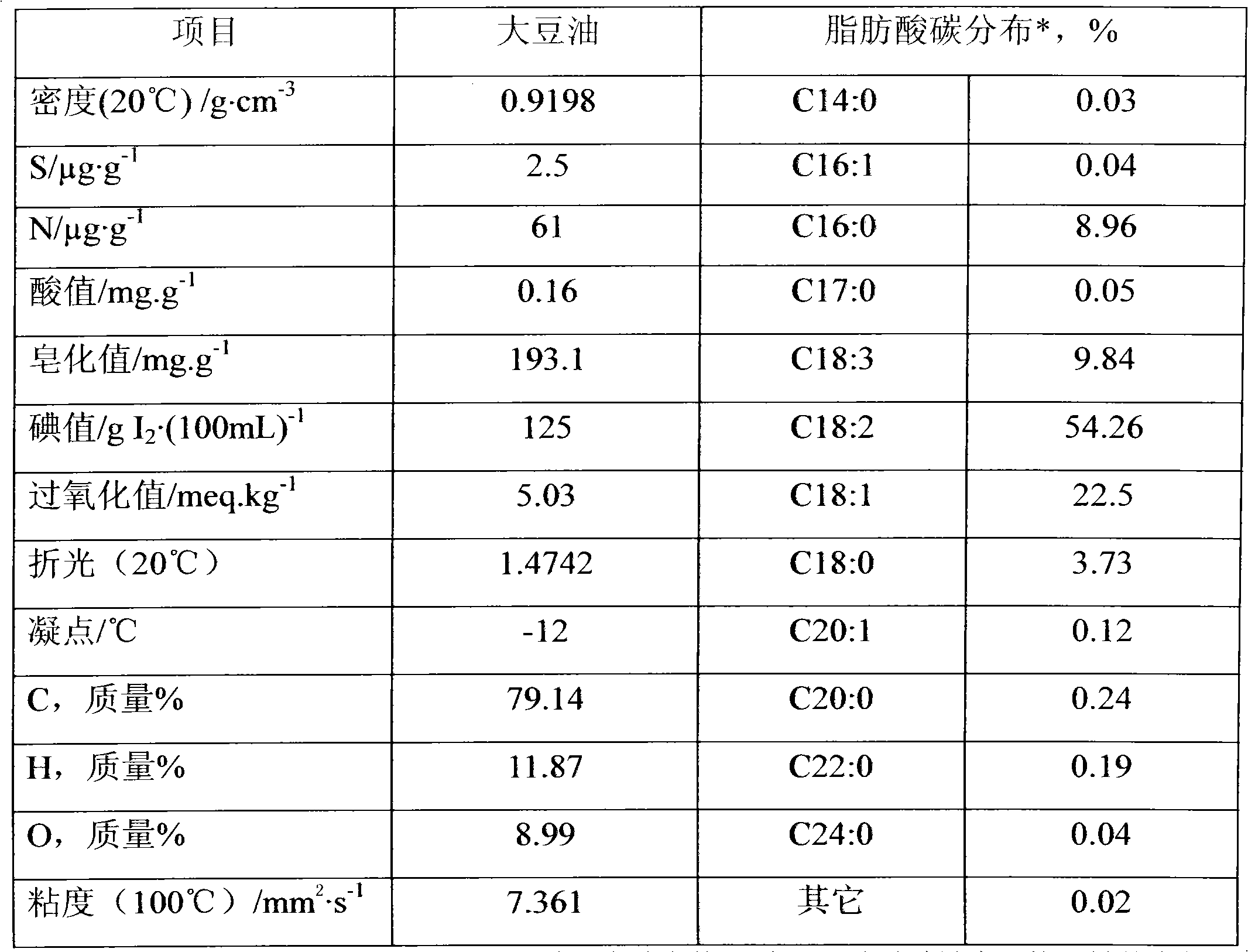

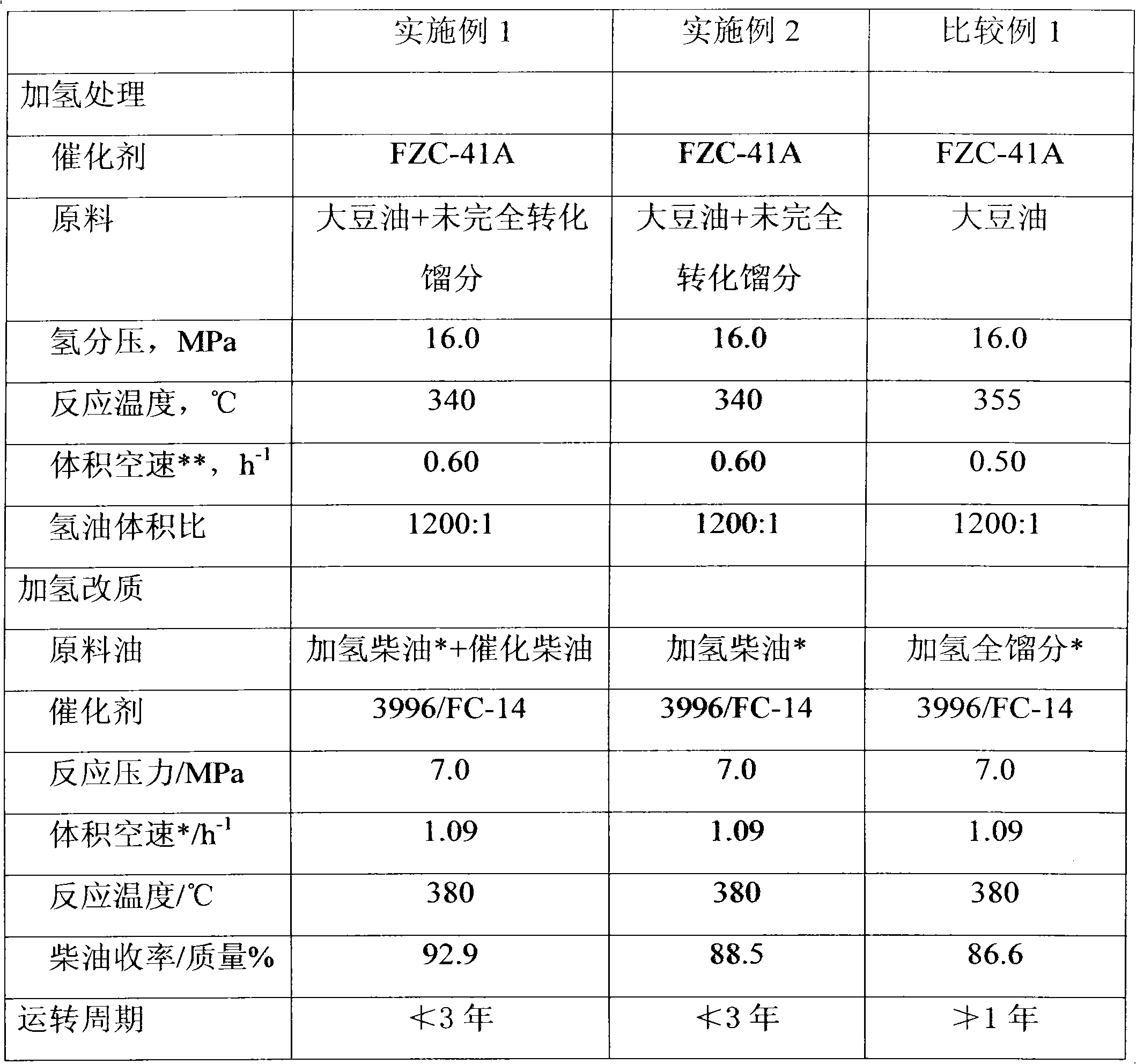

Heavy distillate oil hydrotreating method

ActiveCN101348732AQuality improvementQuality assuranceHydrocarbon oils refiningGasoline stabilisationWaxOil and grease

The invention relates to a method for hydrotreating heavy oil, in particular to the method for hydrotreating heavy oil, which improves the quality of diesel oil. Heavy distillate oil and animal and vegetable oil are used as raw material oil; under the hydrotreatment condition, the raw material oil and hydrogen gas are mixed and pass through a hydrotreatment reaction region; hydrogen-rich gas which is obtained by separating oil generated by hydrotreatment is circulated and utilized; and liquid obtained by separation is distillated to prepare a diesel oil product and hydrogenated wax oil. Compared with the prior art, the method can effectively improve the material source of a wax oil hydrotreatment device, ensure the quality of the hydrogenated wax oil, substantially increase the quality ofthe hydrotreated diesel oil and improve the storage stability of the animal and vegetable oil as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

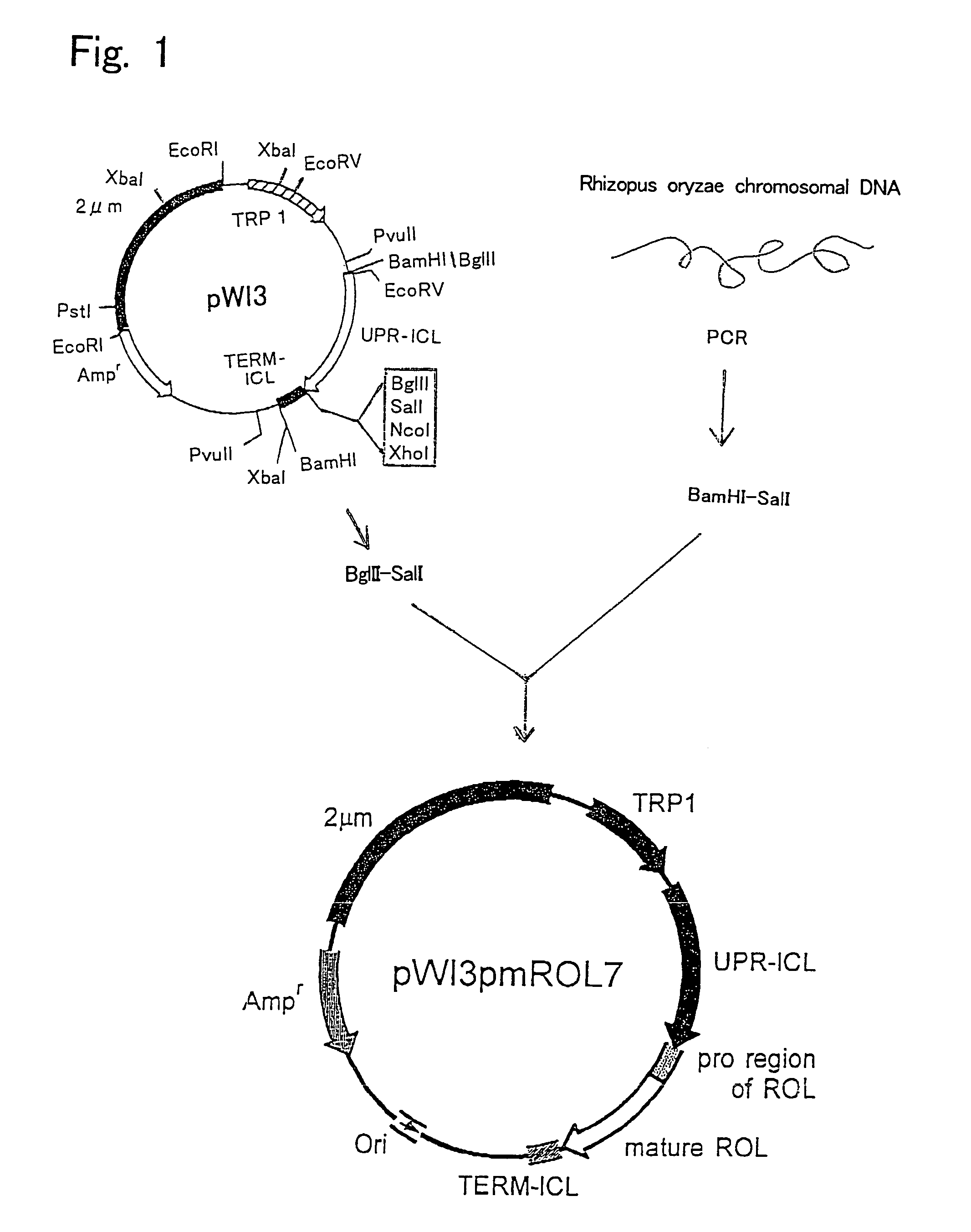

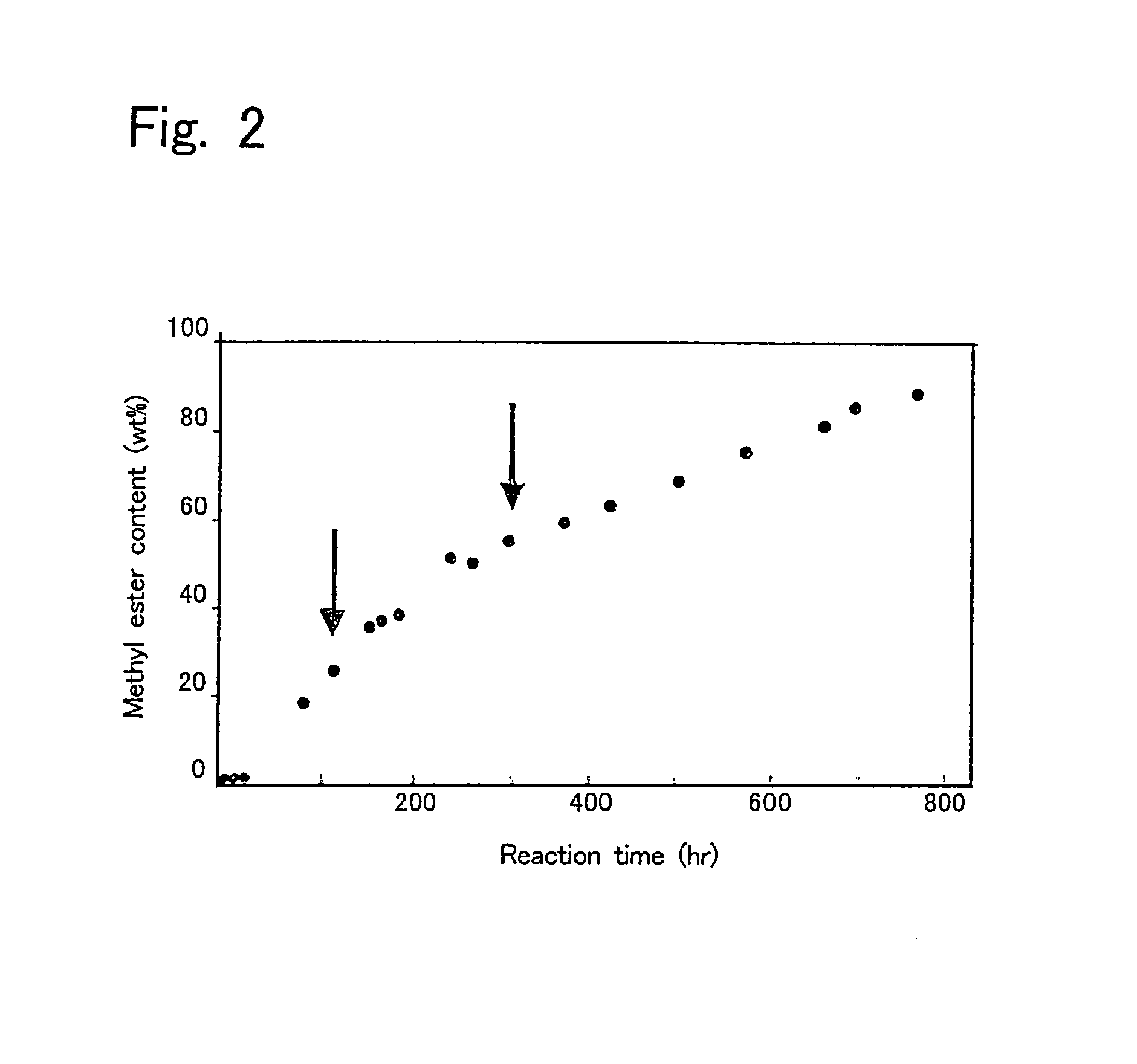

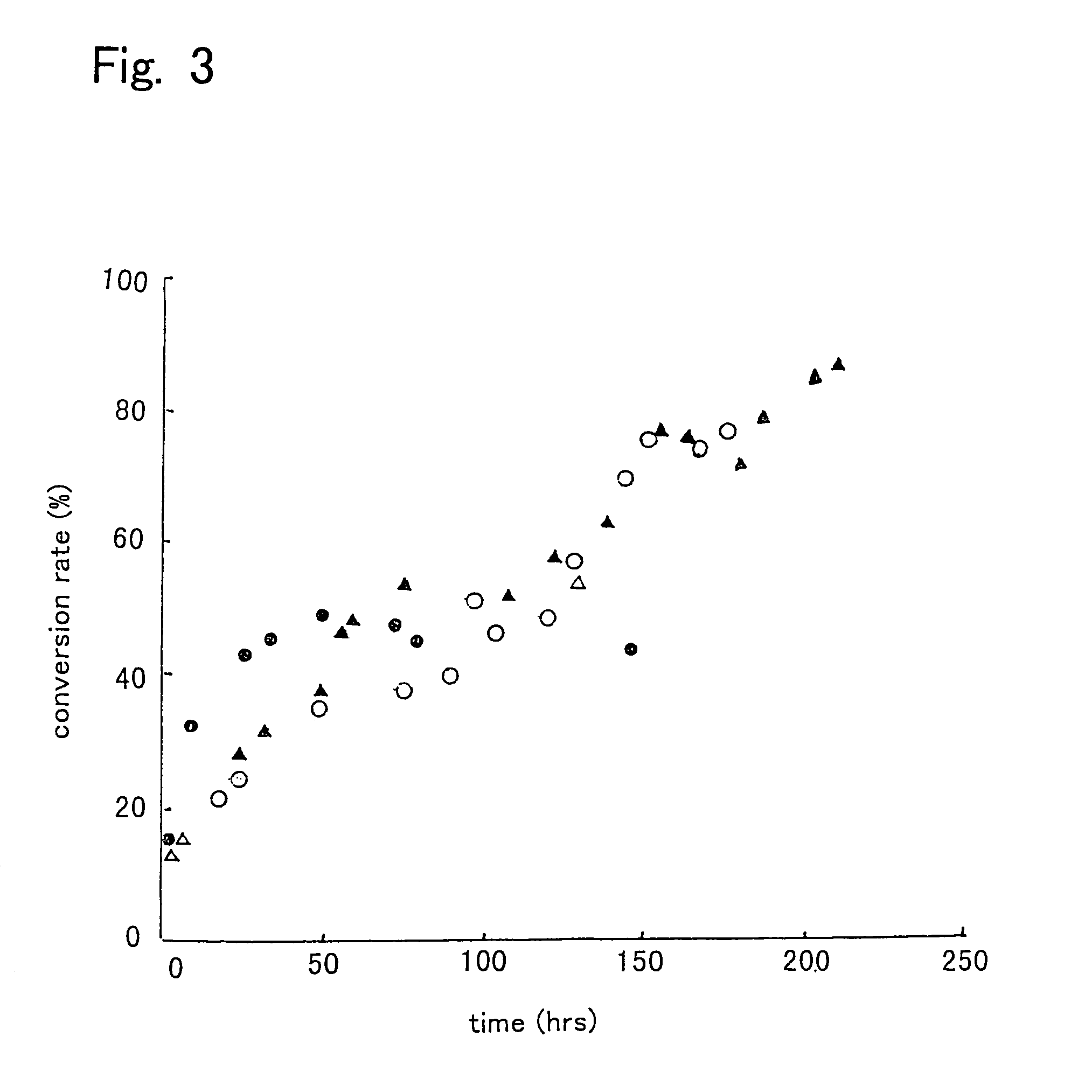

Process for producing fatty acid lower alcohol ester

InactiveUS6982155B1Efficient productionImprove permeabilityFatty acid chemical modificationOrganic compound preparationOil and greaseMicroorganism

The present invention provides a method for producing a fatty acid ester inexpensively and efficiently by reacting a lipase or an intact mircroorganism containing a lipase, an oil and fat, and a linear lower alcohol in a system containing little or no solvent in the presence of water. The intact microorganism has not been treated with a solvent or the like, and is used as such, so that a fatty acid ester can be prepared in a simple manner. An oil and fat, a natural oil and fat such as a vegetable oil and fat, an animal oil and fat, as well as a waste oil thereof can be used. According to the method of the present invention, a reaction proceeds even in the presence of water, so that waste oils containing a large amount of water can be used as a raw material. Therefore, the waste oil to be dumped into the environment can be recycled, and a biodiesel fuel, which hardly pollutes the environment, can be provided at the same time.

Owner:KANSAI CHEM ENG CO LTD

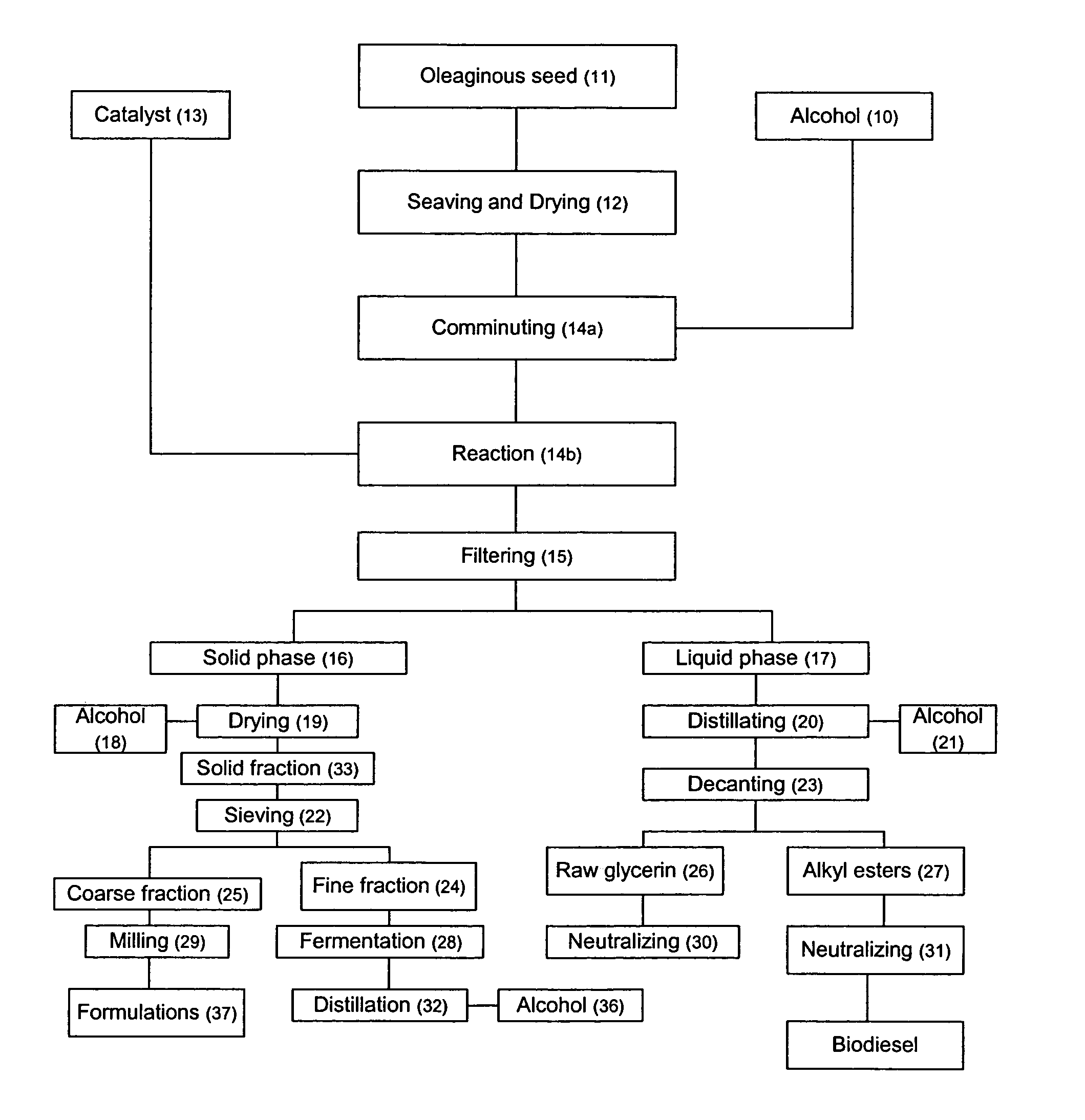

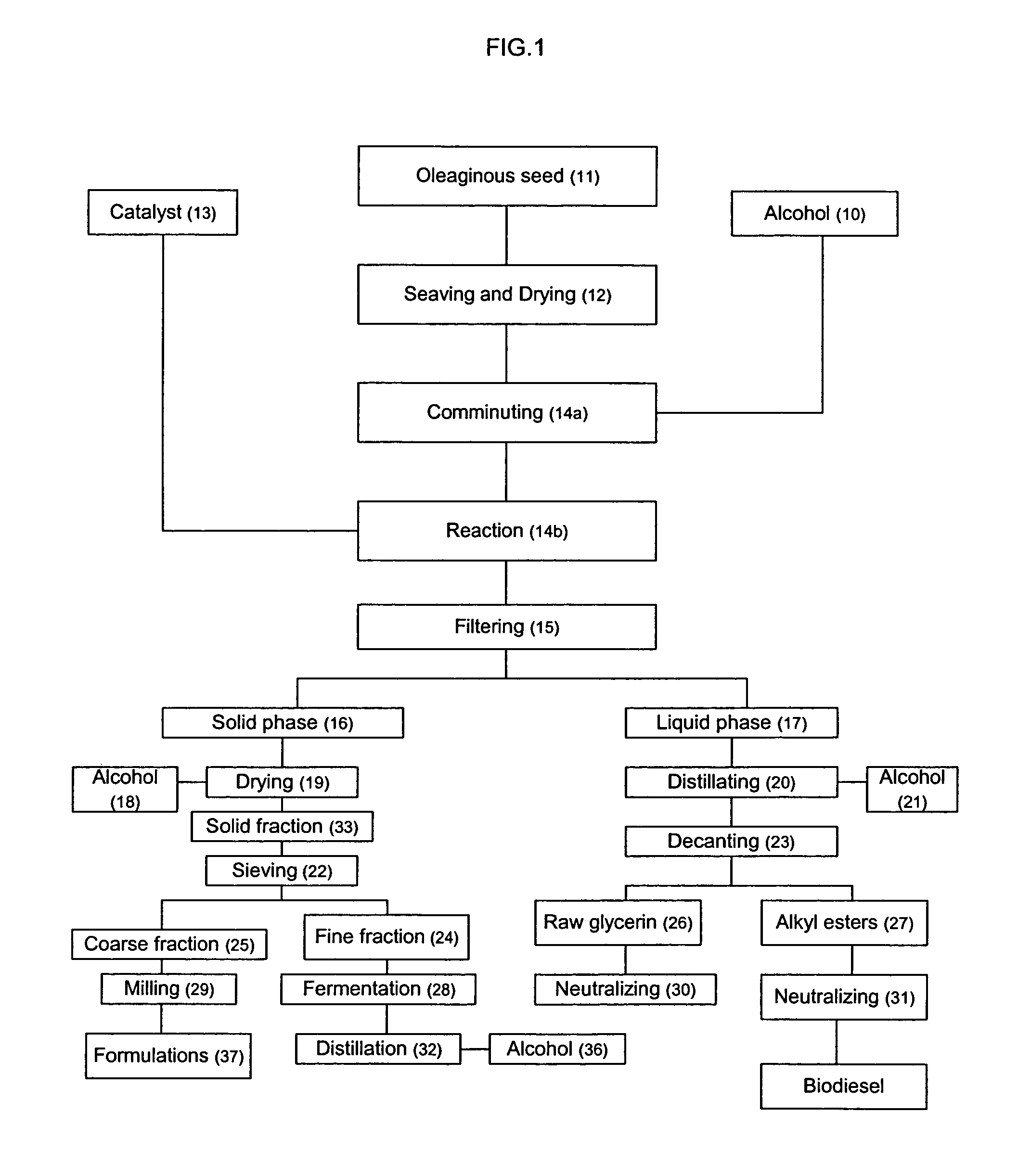

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Functional oil microencapsulation and manufacturing method thereof

ActiveCN102550817AGood water solubilityImprove antioxidant capacityMetabolism disorderAlgae medical ingredientsOil and greaseWater baths

The invention provides a functional oil microencapsulation and a manufacturing method thereof and relates to a microencapsulation, and the functional oil microencapsulation has the advantages of high stability and immobilized proteinaceous pellicle. The oil microencapsulation is prepared from the following raw materials: functional oil, plant oil, an antioxidant, aqueous-phase main-wall materials, aqueous-phase auxiliary-wall materials, bio-enzyme protein and water. The plant oil serving as a carrier is mixed with the functional oil, then the antioxidant is added, and then the materials are heated and dissolved in water bath, thus obtaining an oil-phase core material solution; the aqueous-phase main-wall materials and the aqueous-phase auxiliary-wall materials are added into deionized water, and then the materials are heated and dissolved in water bath, thus obtaining an aqueous-phase wall material solution; the oil-phase core material solution is added in the aqueous-phase wall material solution, the mixture is sheared and emulsified by a shearing machine, and then is homogenized by a homogenizer, thus obtaining a nanometer-level solution with uniform oil drop diameter; and bio-enzyme is added into the nanometer-level solution, the mixture is placed in hot-water bath for heating and stirring reaction, temperature is raised after the reaction so as to enable the bio-enzyme to be inactivated, and drying is carried out, thus obtaining the functional oil microencapsulation.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

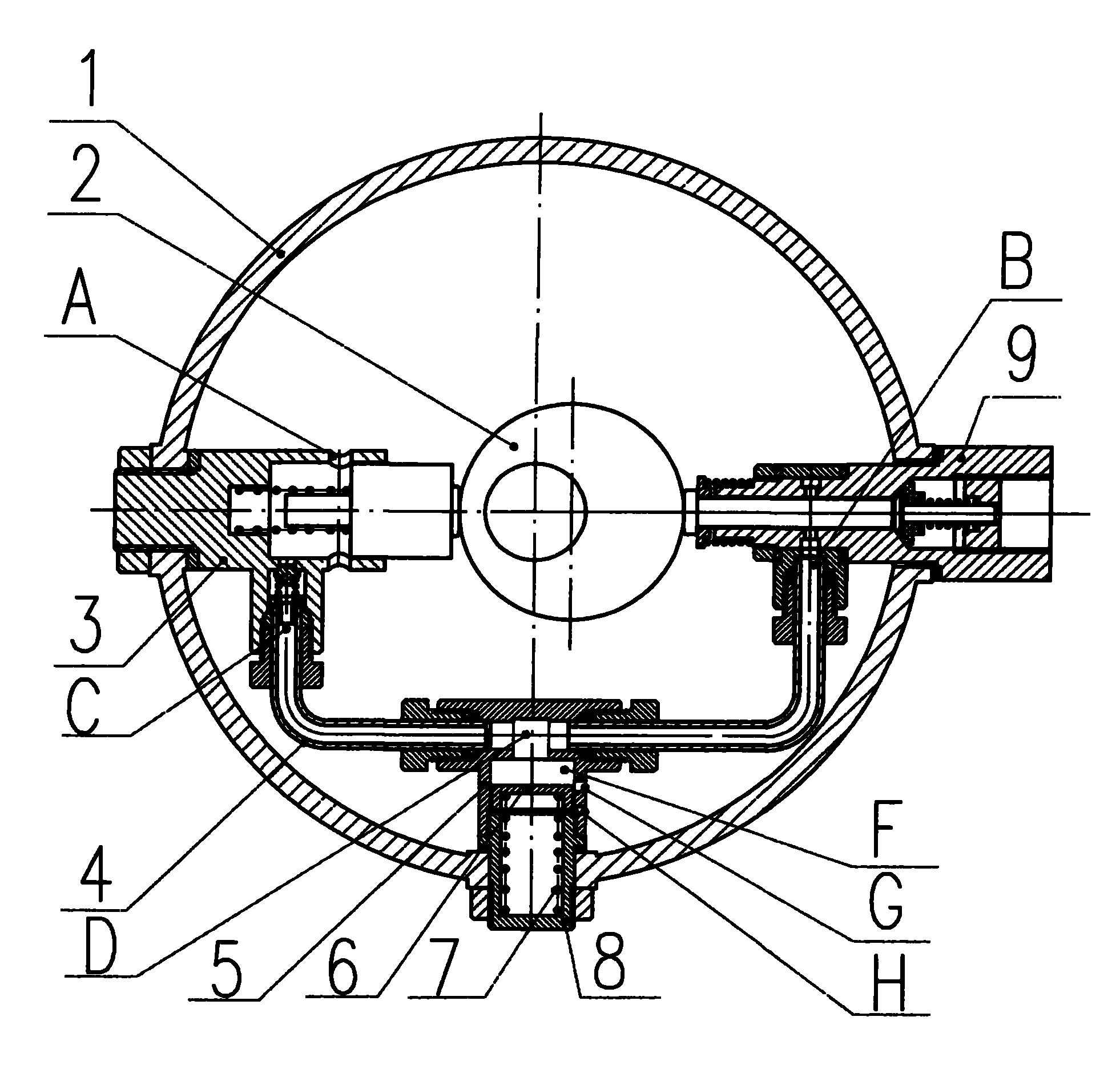

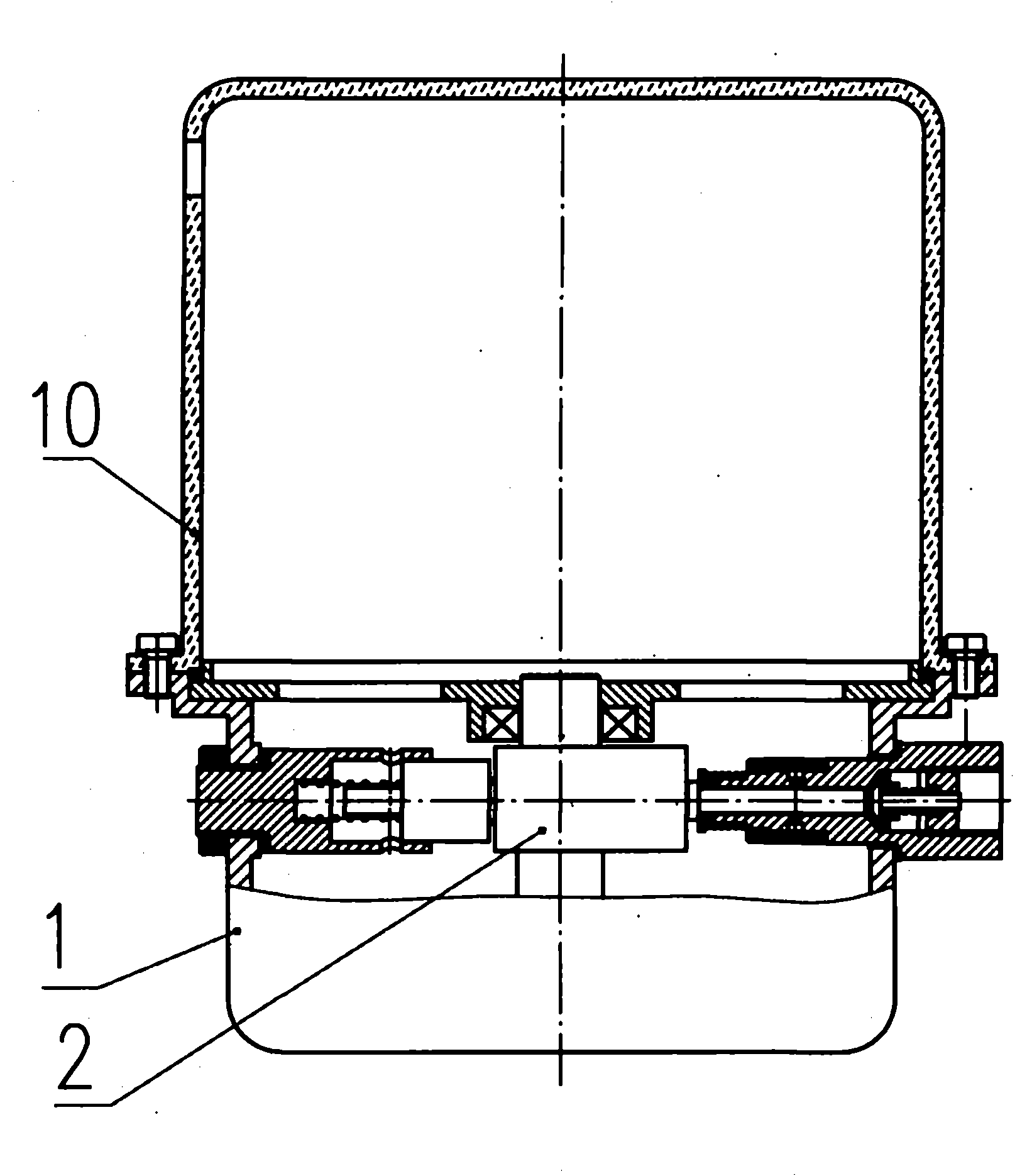

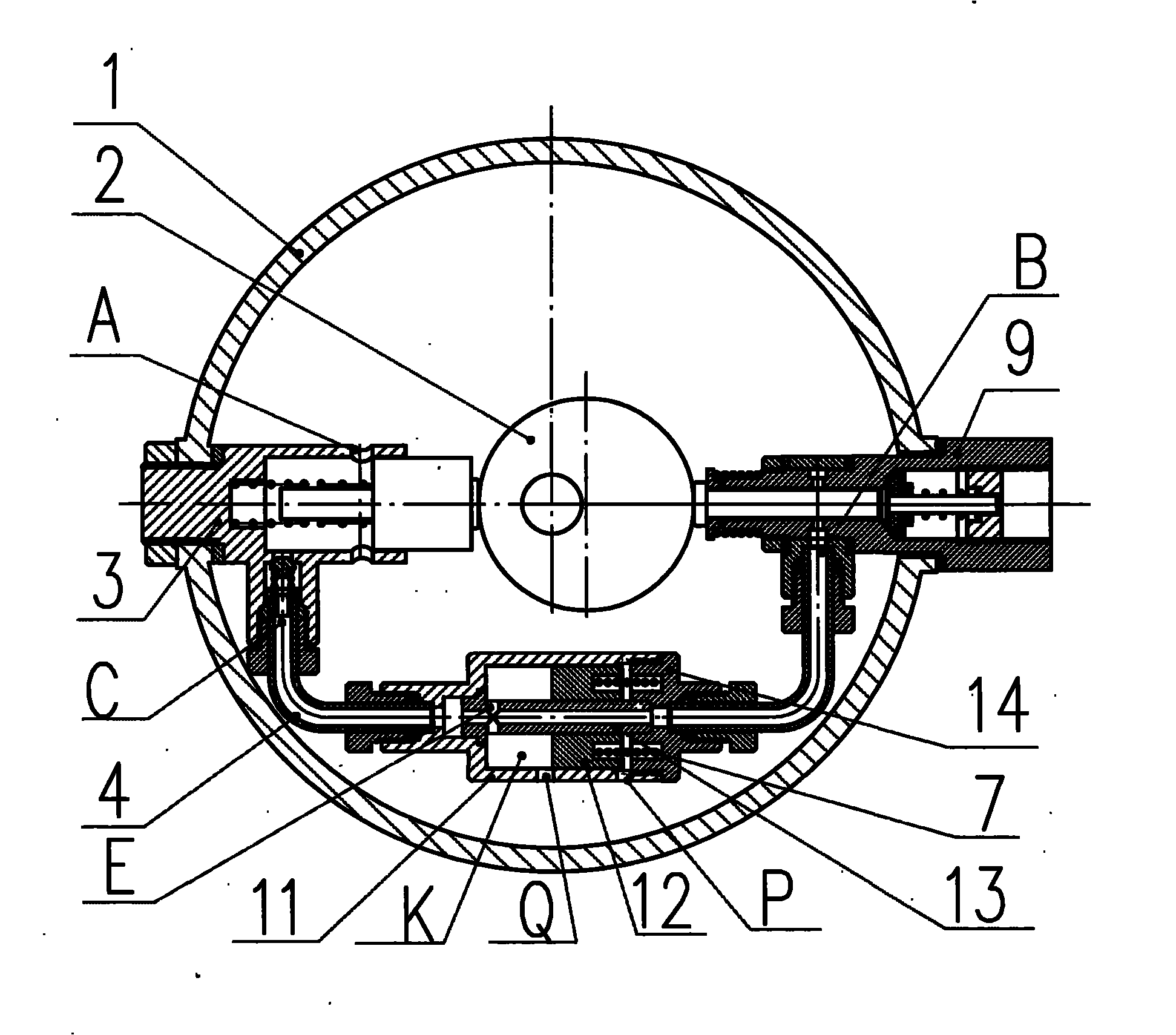

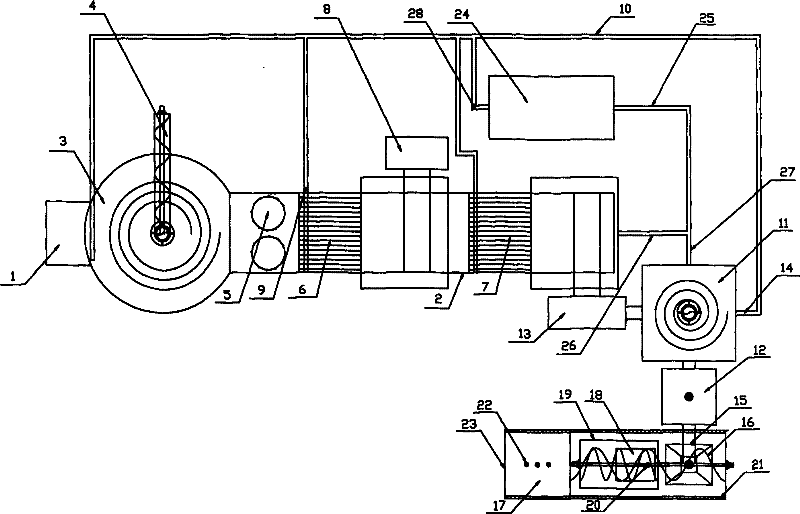

Thick grease secondary lubricating pump device

A thick grease secondary lubricating pump device comprises a lubricating pump shell, a power assembly, a high-pressure plunger pump and an oil tank, wherein the power assembly and the high-pressure plunger pump driven by the power assembly are arranged on the lubricating pump shell; the oil tank is fixedly connected with the lubricating pump shell which is also provided with a low-pressure plunger pump driven by the power assembly; an oil suction port A of the low-pressure plunger pump is communicated with the oil tank, and an oil discharge port C of the low-pressure plunger pump is connectedwith an oil suction port B of the high-pressure plunger pump in a sealing way by a pipeline which is further connected with an energy storage device and an overflow valve; and an oil inlet and an oiloutlet of the energy storage device are respectively communicated with the oil discharge port C of the low-pressure plunger pump and the oil suction port B of the high-pressure plunger pump. By adopting the structure, the lower-pressure plunger pump with the section of a first-stage oil inlet being larger is added, enough grease is pressed into an oil inlet of the high-pressure plunger pump, and the mode that mainly depends on the oil suction of the oil inlet of high-pressure plunger pump is changed to the mode mainly depending on pressing the oil, so that the oil charging at the oil inlet ofthe high-pressure plunger pump is sufficient, the capacity of the pump for delivering the grease is enhanced, and the pump is capable of delivering the grease with high thickness even under low temperature and low pressure.

Owner:AUTOL TECH

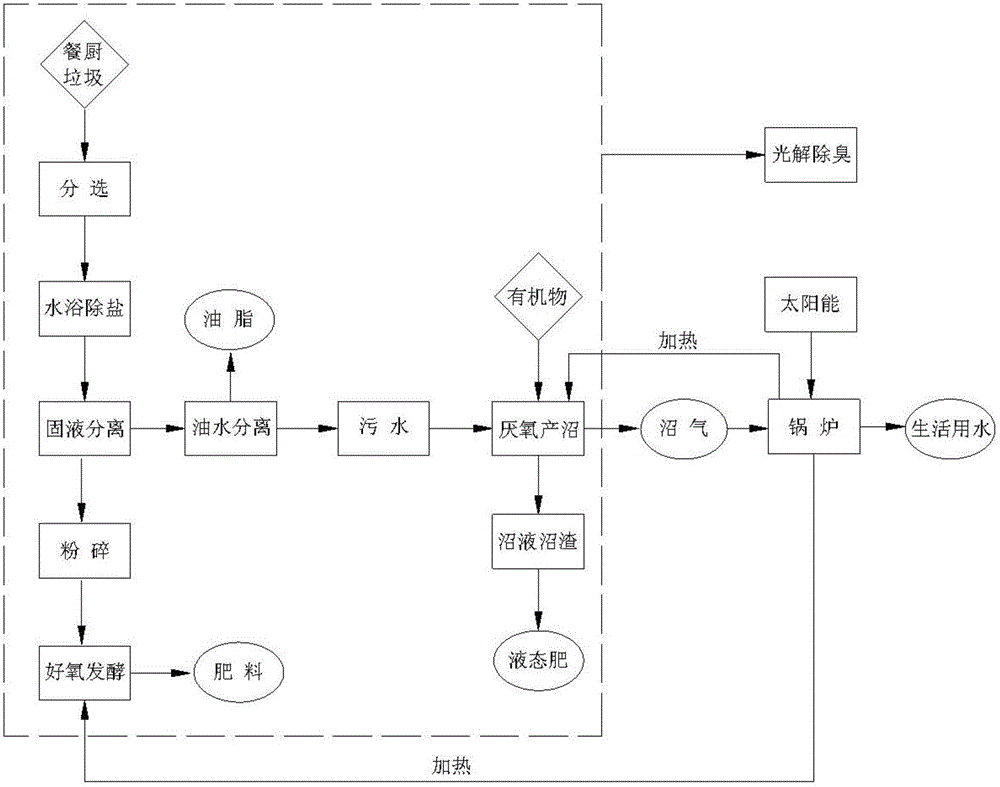

Resource-based and harmless treatment method for kitchen waste

InactiveCN104030738AEfficient removalGrowth inhibitionBio-organic fraction processingClimate change adaptationWater bathsLiquid waste

Relating to the technical field of resource recovery and recycling, the invention discloses a resource-based and harmless treatment method for kitchen waste. The method is directed at the problems of high salt content in fertilizer products, easy cause of soil salinization, and large equipment investment for anaerobic fermentation of total waste in existing kitchen waste treatment methods. The method comprises the steps of: (a) kitchen waste sorting; (b) water bath desalting: adding water, and conducting heating and stirring to dilute salt; (c) solid-liquid separation: dehydrating the waste; (d) solid material aerobic fermentation: crushing the dehydrated solid material into small particles, and conducting aerobic fermentation and drying treatment to obtain an organic fertilizer; and (e) waste liquid anaerobic fermentation: conducting oil-water separation on the waste liquid, recovering grease, subjecting sewage to anaerobic fermentation, making the produced biogas residue and biogas slurry into a liquid fertilizer, and taking the produced biogas as the fuel of a biogas boiler. The method provided by the invention is particularly suitable for resource-based and harmless treatment of kitchen waste.

Owner:习建华 +1

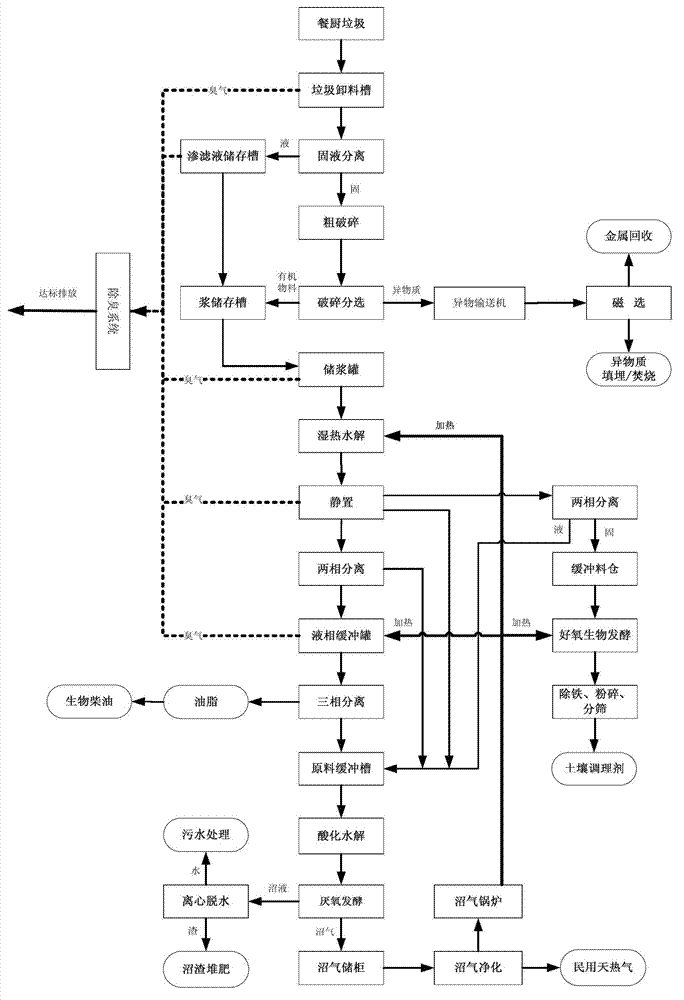

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

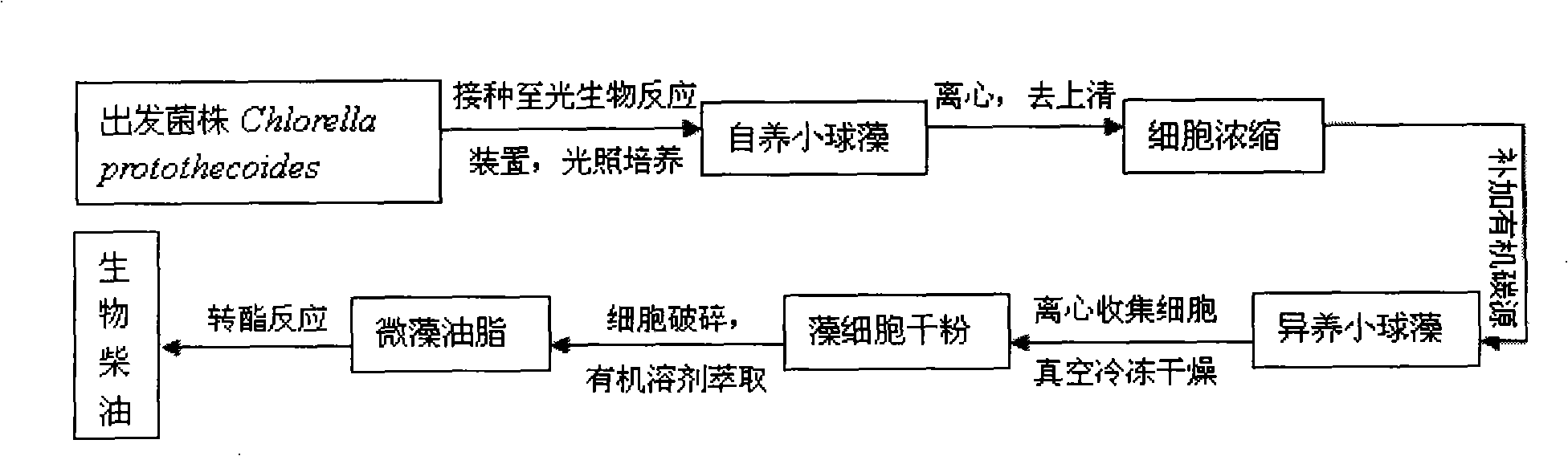

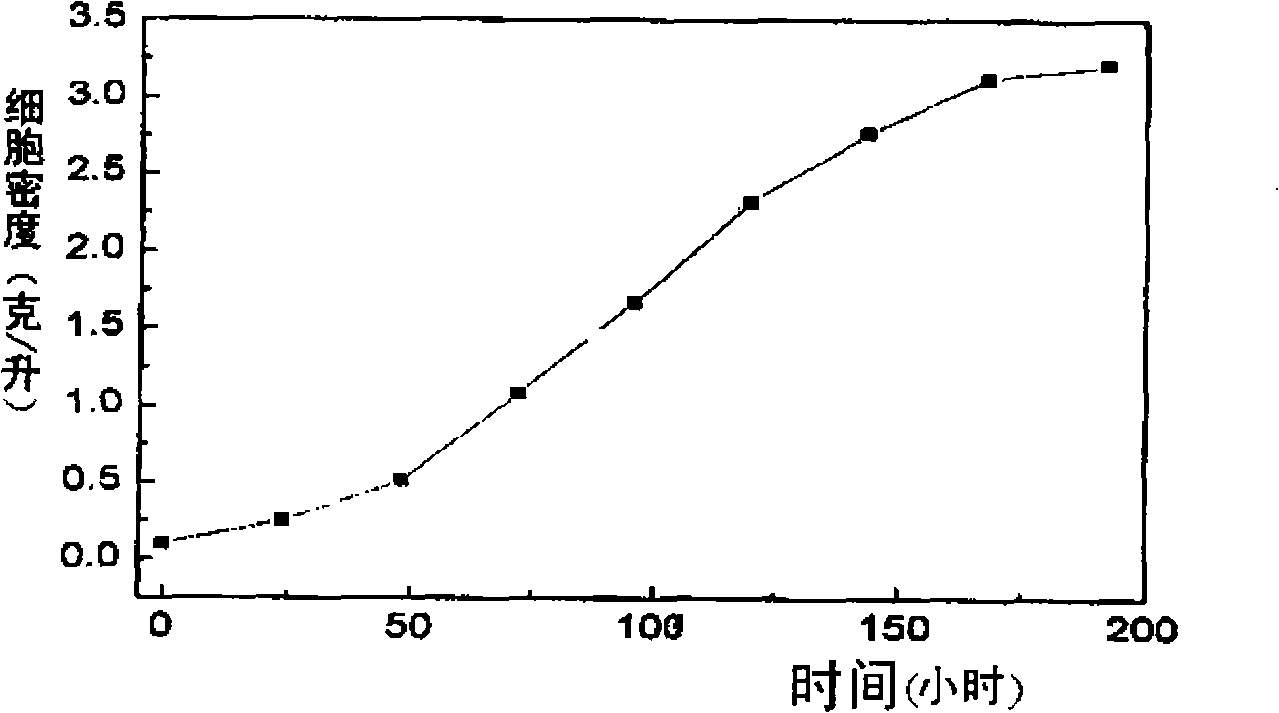

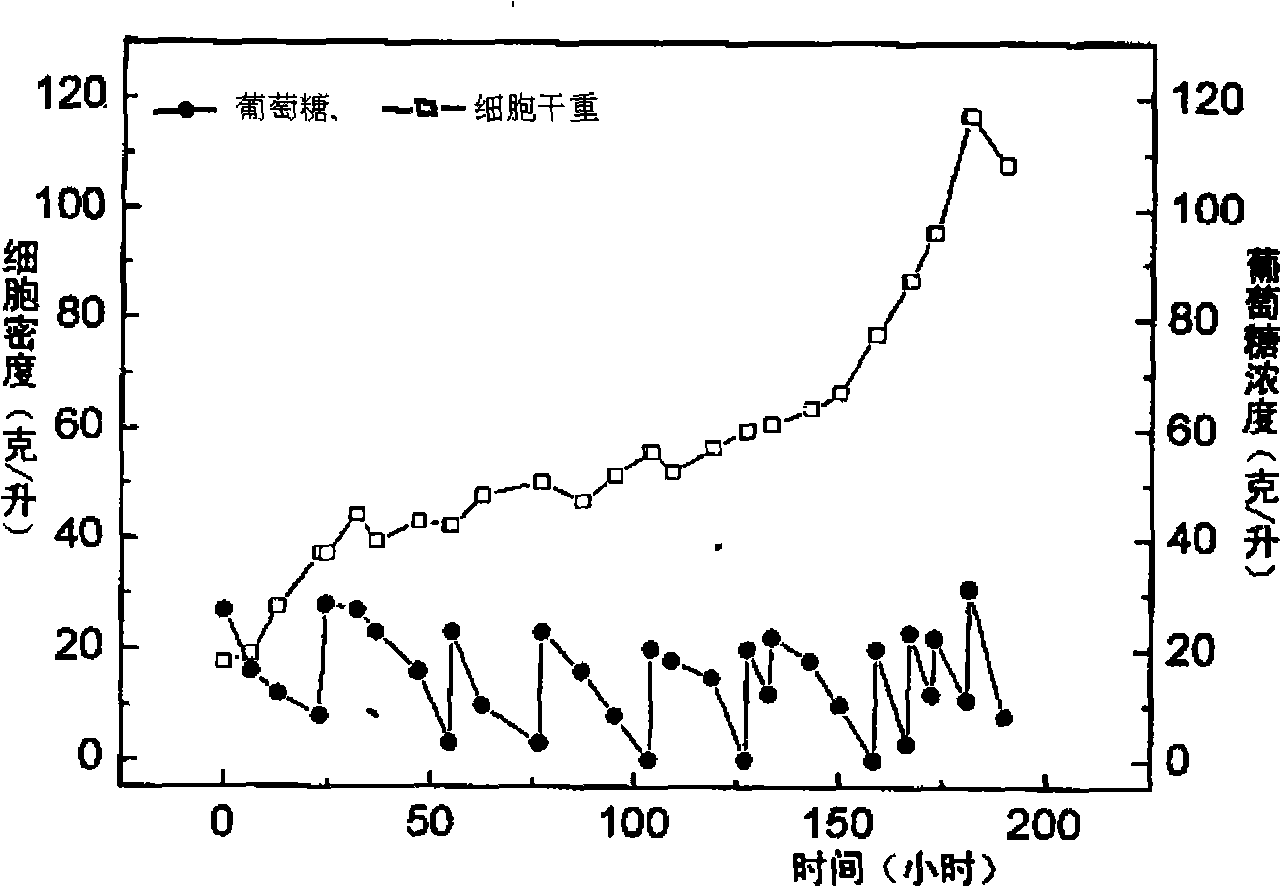

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

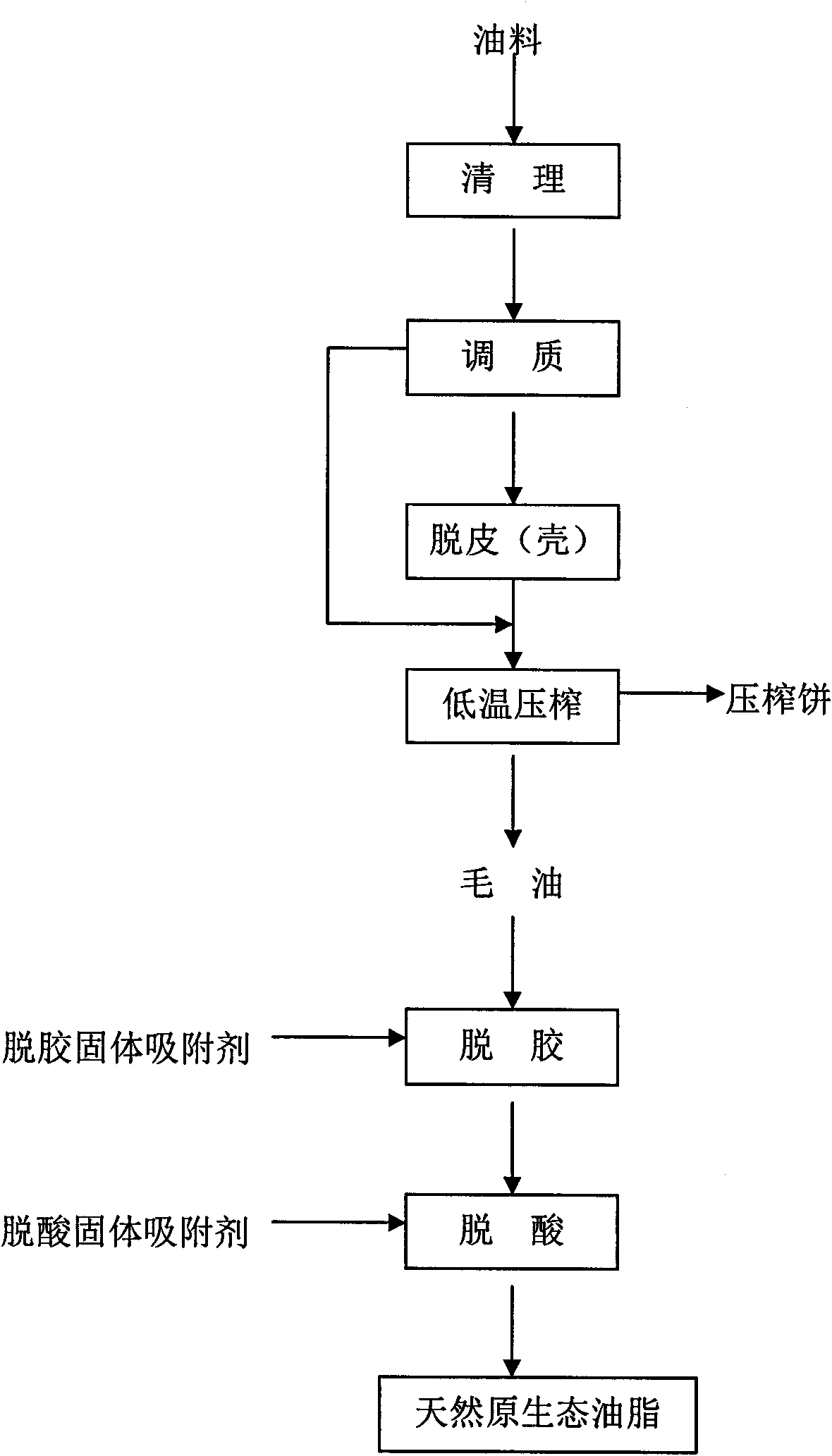

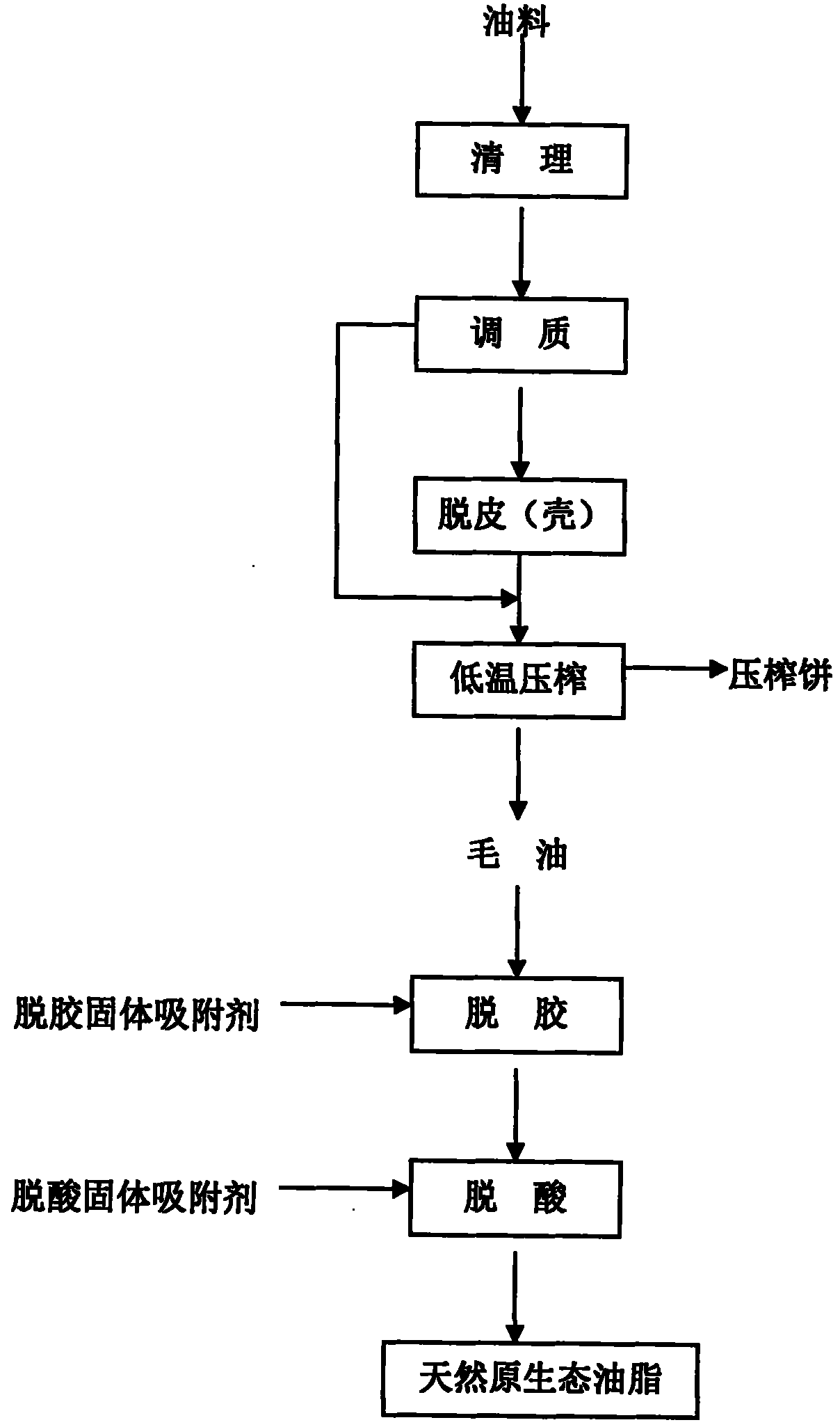

Method for preparing oil at low temperature

InactiveCN101880596ASuitable for industrial productionKeep the flavorFatty-oils/fats refiningFatty-oils/fats productionOil and greaseMoisture

The invention relates to a method for preparing oil at low temperature, which is characterized by comprising the following steps of: 1) clearing: removing impurities of an oil material; 2) conditioning: adjusting the temperature and moisture of the oil material, wherein the temperature of the oil material after the conditioning is 5 to 65DEG C, and the moisture mass of the oil material is adjusted to 4-16 percent; 3) pressing at low temperature: pressing the conditioned oil material, wherein the pressing temperature of the oil material is -10 to 65DEG C, and the moisture mass of the pressed oil material is 4 to 16 percent, and obtaining crude oil; 4) degumming: keeping the temperature of the crude oil between 5 and 65DEG C, adding a degumming solid adsorbent accounting for 0.1 to 5 mass percent of the crude oil, and controlling the degumming time to between 0.1 and 2 hours; and 5) removing acid: keeping the temperature of the degummed crude oil to between 5 and 65DEG C, adding an acid removing solid adsorbent accounting for 0.1 to 2 mass percent of the degummed crude oil, and controlling the acid removing time to between 0.1 and 3 hours to obtain the oil. The method is suitable for industrial production.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

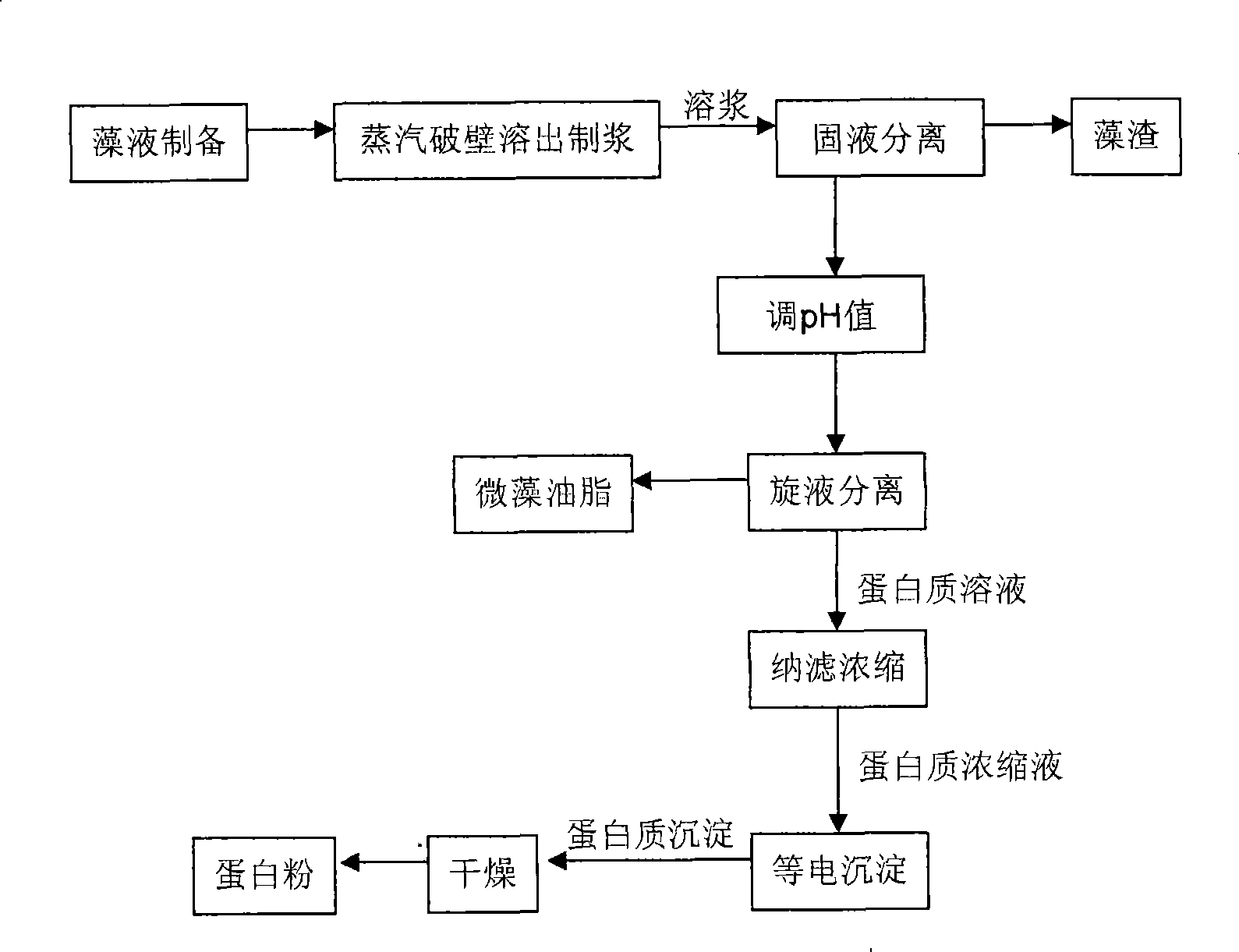

Method for simultaneously extracting lipid and protein from microalgae

ActiveCN101429467AHigh yieldPrevent drynessPeptide preparation methodsFatty-oils/fats productionOil and greaseFreeze-drying

The invention relates to a method for simultaneously extracting grease and proteins from microalgae, which takes wet algae mud as a raw material, adjusts the pH value to be alkaline or slightly alkaline, and performs wall breaking of microalgae cells and dissolution of the grease and the proteins through vapor. The method is as follows: dissolved microalgae slurry is filtered for removal of cell residue, and a mixture of the grease and the proteins is obtained; a hydrocyclone is utilized for oil-water separation, and microalgae grease is obtained; and a protein aqueous solution is subjected to nano-filtration, condensation, isoelectric precipitation and freeze drying or spray drying, and protein powder is obtained. The method utilizes the water-bearing microalgae cells as the raw material, saves the energy consumption for drying the algae cells, adopts a slightly alkaline or alkaline algae cell liquid to realize vapor wall breaking and simultaneous dissolution of the grease and the proteins, and has good wall breaking effect, high dissolution rate, low energy consumption and easily widened process. The method adopts vortex hydrocyclone separation to well solve the problem of difficult oil-water separation under the condition of low phase ratio and realize simultaneous extraction of the microalgae grease and the proteins. Moreover, the method has the advantages of simple process, economy, low energy consumption, and easy realization of industrialization.

Owner:云南中科雨虹生物科技有限公司

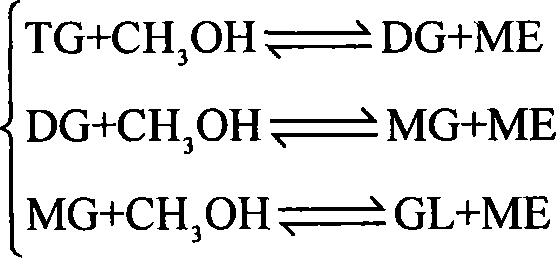

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Process for preparing biological diesel oil from waste animal and plant oil

InactiveCN1382762AEliminate emissionsSimple production processLiquid hydrocarbon mixture productionBio-feedstockOil and greaseBiodiesel

A process for preparing biologic diesel oil from waste plant or animal oil includes alcoholysis and esterifying reactions under the existance of acidic catalyst, separating out the excessive non-product part to obtain coarse product, adding saturated equeous solution of edible salt containing sodium carbonate (10%), neutralizing reaction, adding industrial sodium carbonat4e, heating distillation and collecting the gas-phase fraction at 22-320 deg.C to obtain biologic diesel oil. Its advantages are high performance no pollution, and simple preparing process.

Owner:叶活动 +1

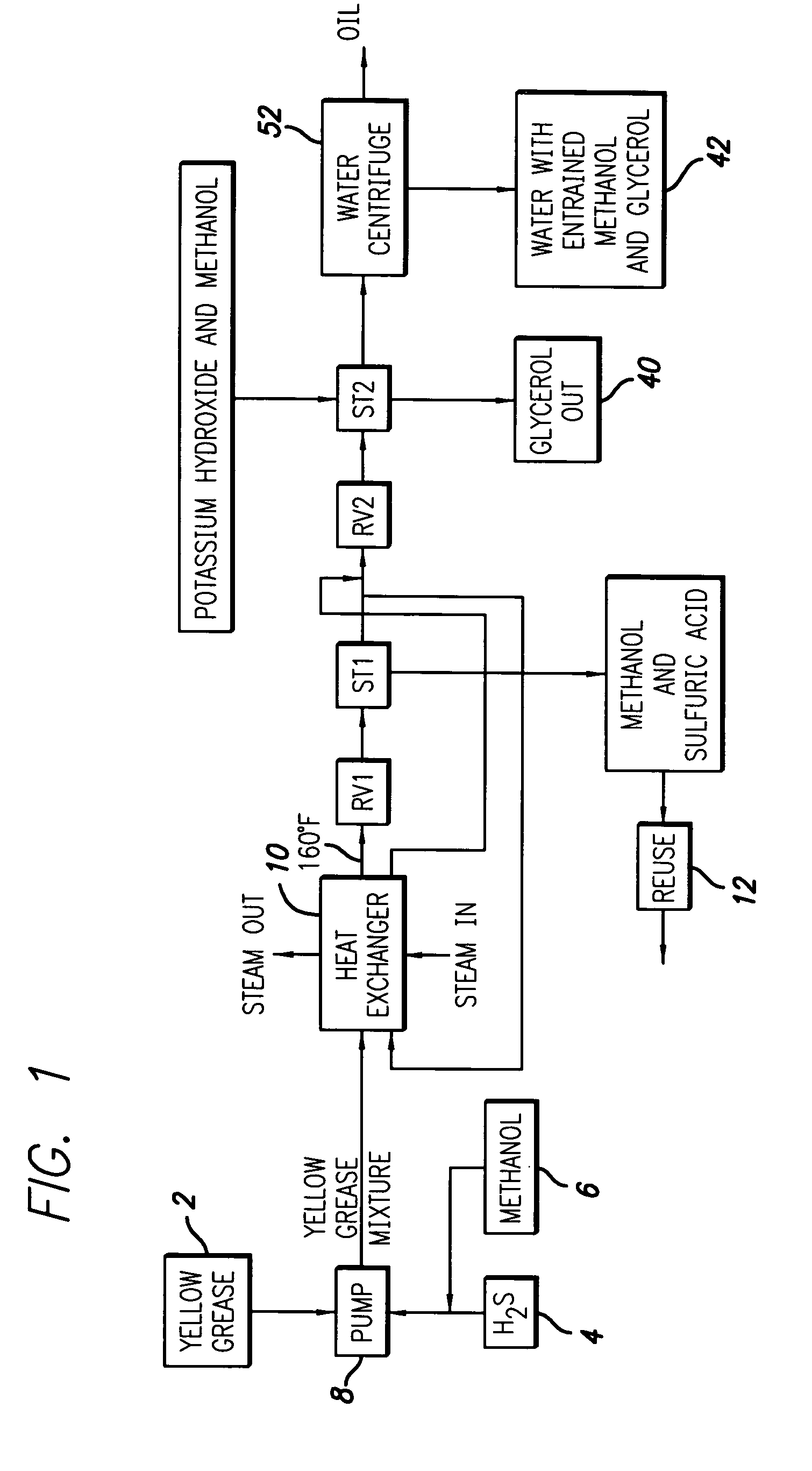

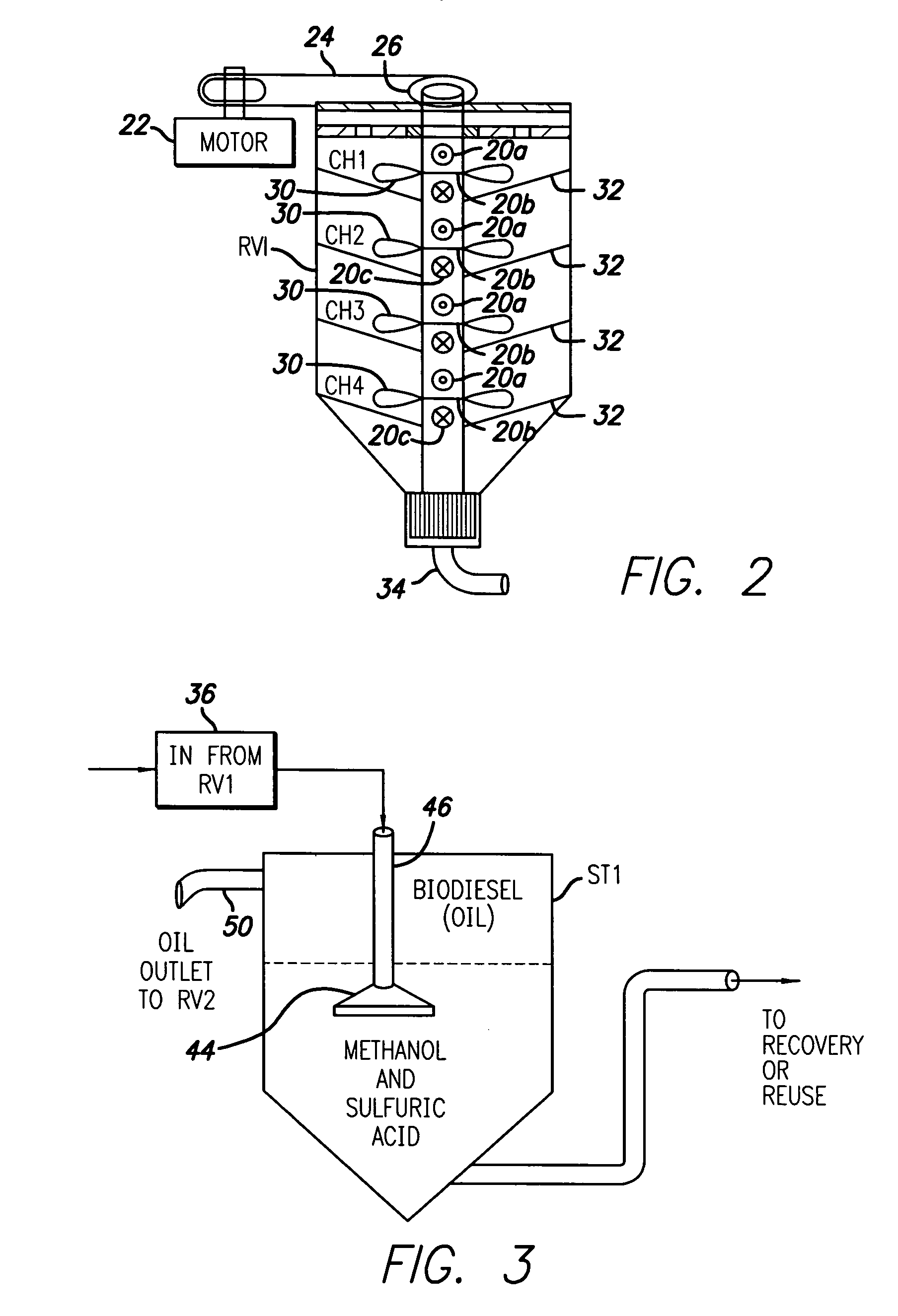

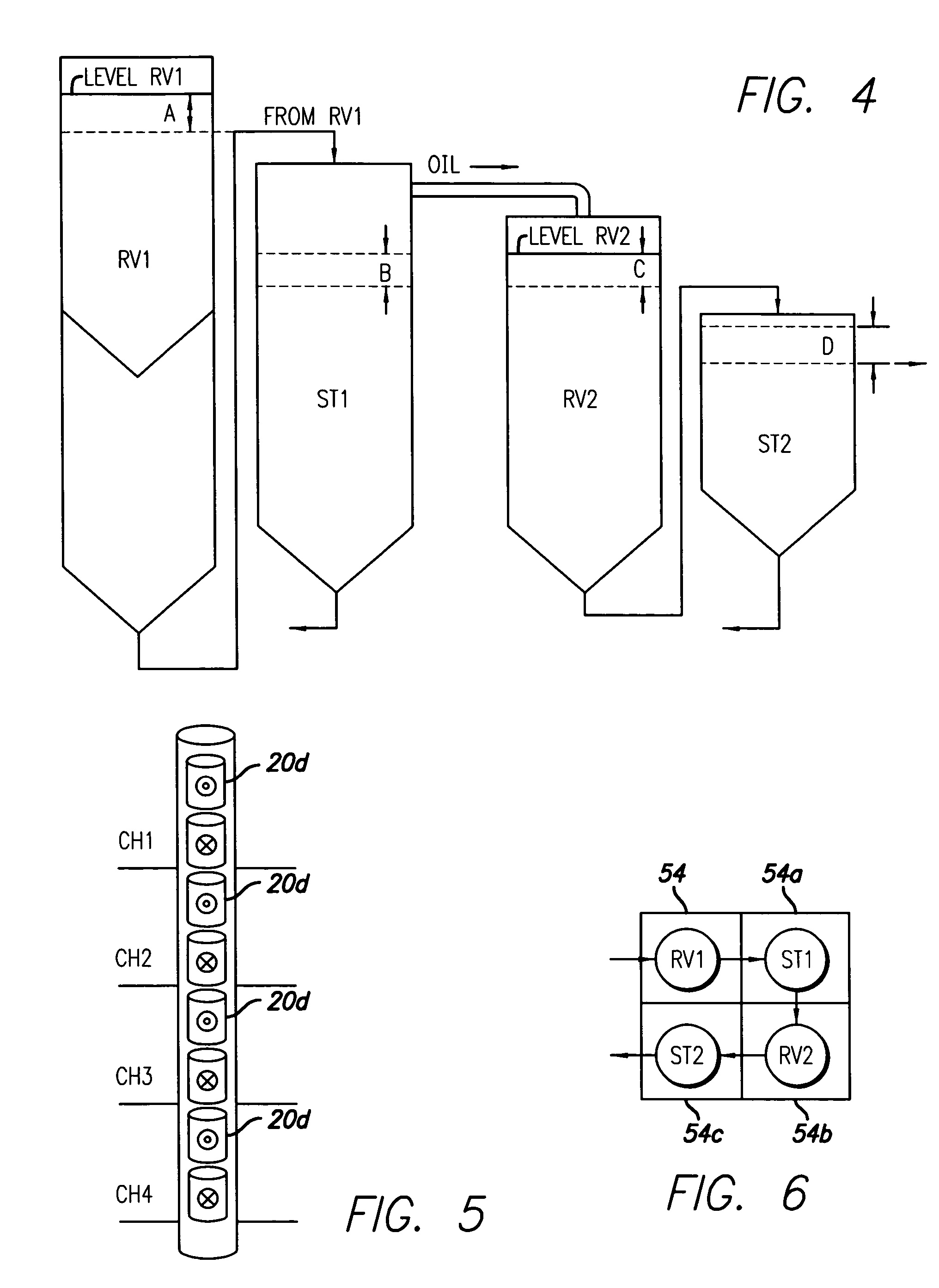

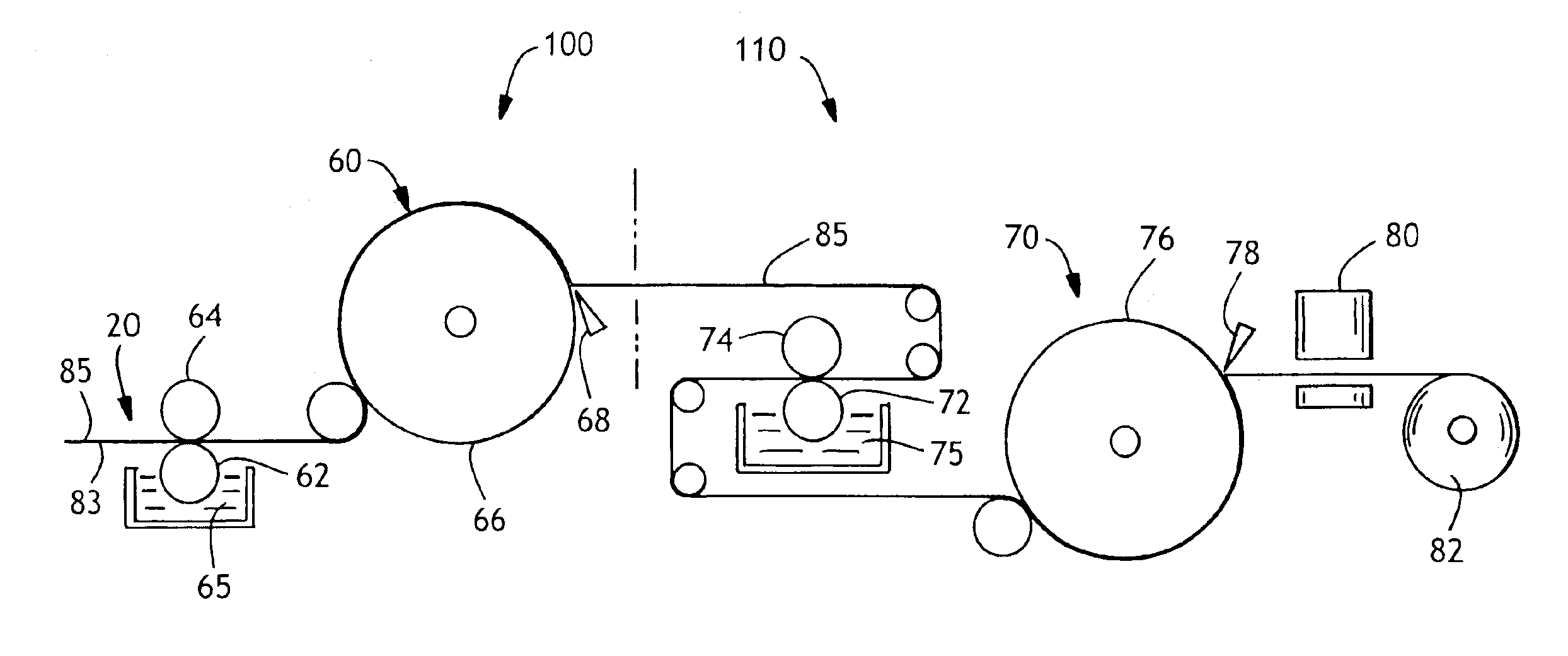

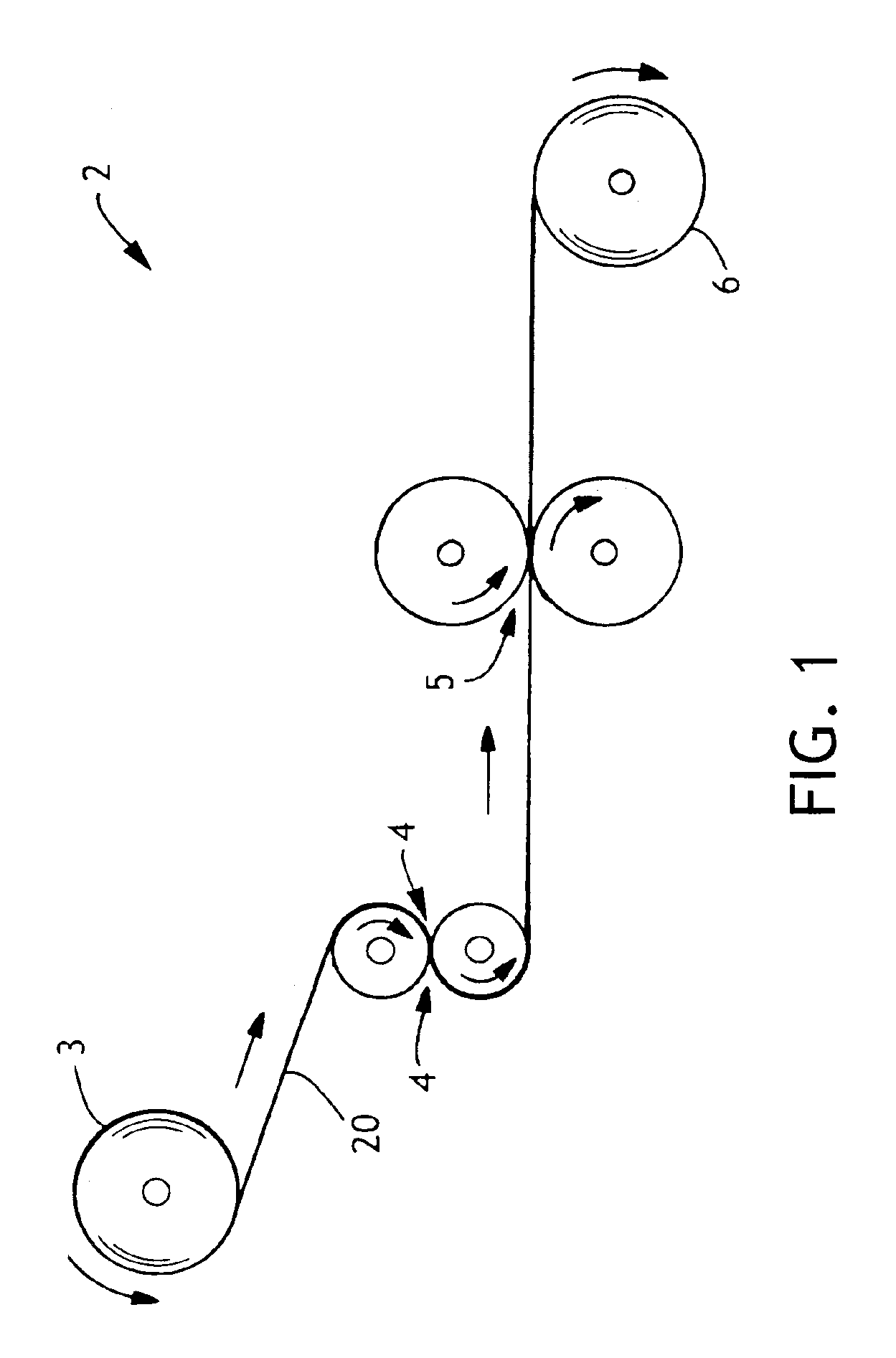

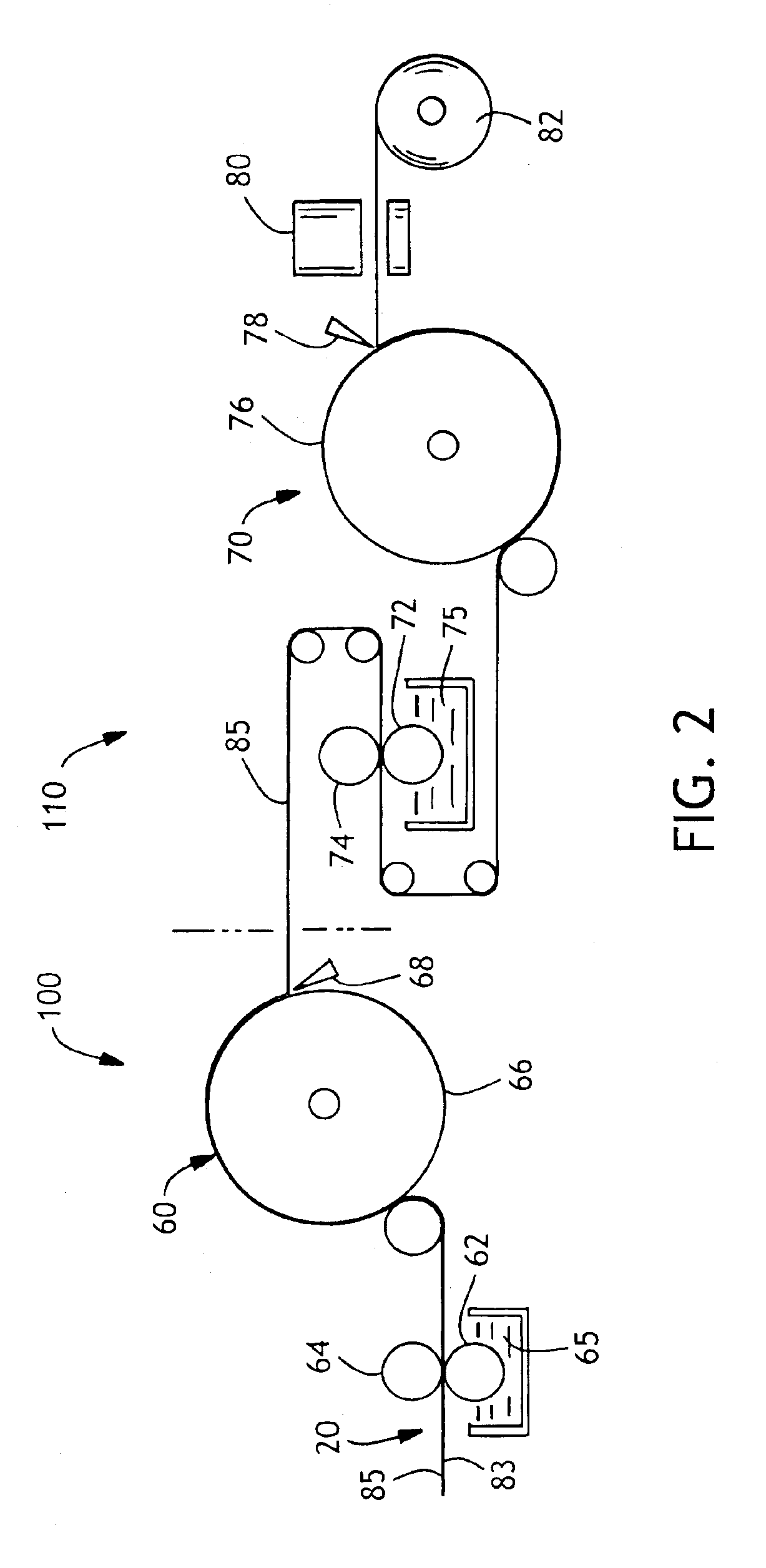

Continuous flow method and apparatus for making biodiesel fuel

InactiveUS20050081435A1Small footprintAvoid small quantitiesTransportation and packagingRotary stirring mixersOil and greaseVegetable oil

In an economical and efficient process and apparatus for producing biofuel from waste oil, such as vegetable oils and animal fats, waste oil is esterified with alcohols to produce alcohol esters and the by-products of the transesterification reaction are recovered. Static pressure may be used as well as continuous flow-through reaction vessels and separation tanks without the need for additional pumps. There may also be specialized reaction tanks that have vertical rotating feed tubes having separators and inlet and outlet openings. The method and device achieves efficient production of biofuel while employing reaction and mixing tanks having a limited size, which in turn permits a smaller plant layout or “footprint”. For example, the largest tank may be in a size of about 36 / 100,000 times the desired plant output in gallons per year. The benefits of the process and apparatus include minimal space for a plant; minimal on-site feedstock needed therefore minimal on-site storage is needed; minimal capital costs to build a plant e.g., reduction by about fifty to sixty five percent (50 to 65%); reduction in construction time from typically over one year to under three months in many plants; minimal energy usage, e.g., reduction by about sixty percent (60%); minimal labor costs due to the automatic continuous flow; minimal pumps needed thereby reducing pump operation and maintenance costs; environmentally friendlier and safer plant design; and due to smaller plant footprint, lower capital cost and minimal construction time enables site selection much nearer to the raw material supplies, thereby minimizing or even eliminating transportation costs for yellow grease or vegetable oil.

Owner:BIO CLEAN FUELS

Entangled fabric wipers for oil and grease absorbency

InactiveUS7022201B2Enhance certain characteristicNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseFiber

A composite fabric comprising a necked and creped spunbond nonwoven web of monocomponent fibers hydraulically entangled with a fibrous component that comprises cellulosic fibers. The nonwoven web contains thermoplastic fibers and the fibrous component comprises greater than about 50% by weight of the fabric.

Owner:KIMBERLY-CLARK WORLDWIDE INC

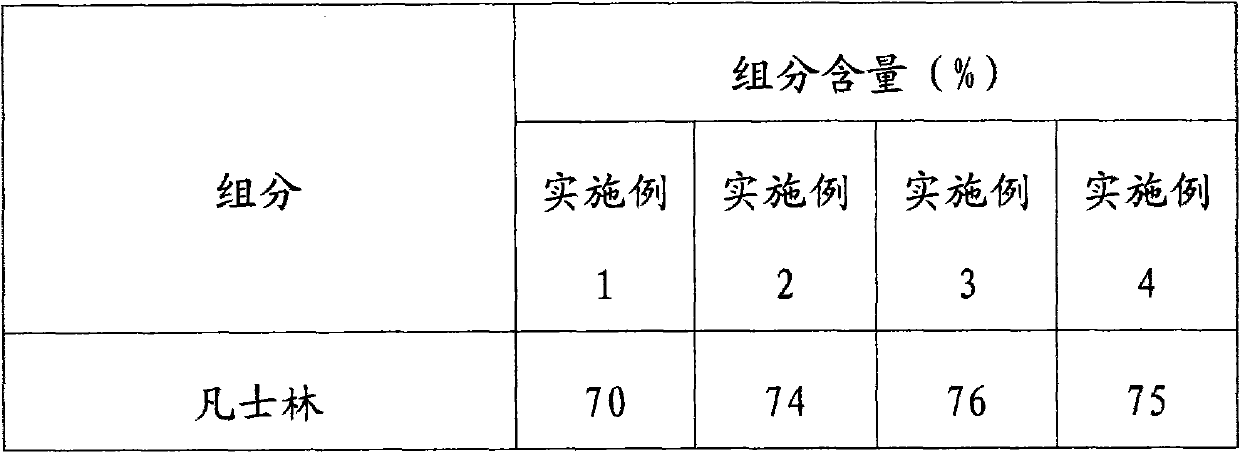

Lipid type antirust oil with gaseous phase antirust function

The invention discloses a lipid type antirust oil with gaseous phase antirust function; the composition of the lipid type antirust oil in weight percent is as follows: 70-90% of base lipid, 4-15% of antirust agent, 1-5% of gaseous phase antirust agent and 5-10% of oil film modifying agent; the inventive antirust oil has long protection period, sun and rain exposure resistance, non-leakage at hightemperature, non-cracking at low temperature, transparent and soft oil film, good paintability, and easy removal, and is mainly applied for antirusting for various metalwares, precise instruments, mechanical equipments, metal rotation sequence of workshops in machining industry, etc.

Owner:天津蓝星清洗有限公司

Vitamin D3 microcapsule and preparation method thereof

InactiveCN101536993AHigh embedding rateImprove thermal stabilityOrganic active ingredientsBiocideOil and greaseOil phase

The invention relates to a microcapsule and a preparation method thereof, aiming at providing a vitamin D3 microcapsule and a preparation method thereof. The vitamin D3 microcapsule comprises core material vitamin D3, oil fat, an oil-soluble emulsifier and a wall material. The preparation method comprises the following steps of: (1) adopting the core material vitamin D3, the oil fat, the oil-soluble emulsifier as oil phase for dissolving and mixing evenly; (2) adding deionized water in the wall material, stirring and dissolving as water phase; (3) adding the oil phase into the water phase, mixing, stirring evenly, then carrying out homogenization and emulsifying the obtained mixture into microcapsule; (4) carrying out spray drying to the microcapsule to form the vitamin D3 microcapsule; and (5) screening, mixing, inspecting and packing to obtain the finished product. The microcapsule and the preparation method thereof have the advantages of high embedding rate, good flowability, hard photolysis, oxidation, high heat stability, even dispersion in water and the like. The microcapsule can be widely added into food or feedstuff, is easy to be absorbed by the human body or animals, also can be used as original drug of rat poison to strengthen the stability thereof greatly.

Owner:ZHEJIANG GARDEN BIOCHEM HIGH TECH +1

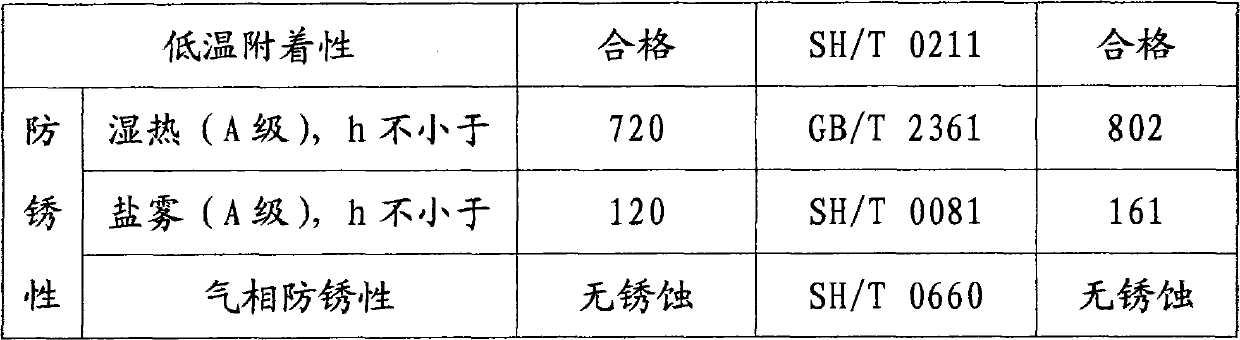

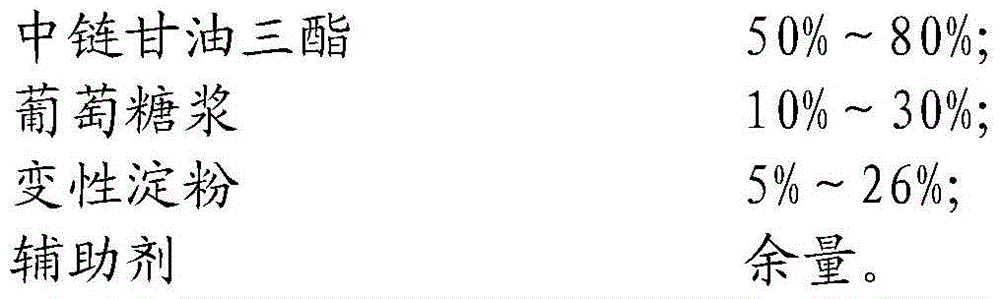

High-content medium chain triglyceride powdered oil and preparation method thereof

InactiveCN104054849AImprove organizational structureGood appearanceEdible oils/fatsSolubilityOil and grease

The invention relates to high-content medium chain triglyceride powdered oil which is characterized by being prepared from the following raw materials in percentage by weight: 50%-80% of medium chain triglyceride, 10%-30% of grape syrup, 5%-26% of modified starch and the balance of auxiliary agents. The high-content medium chain triglyceride powdered oil disclosed by the invention is obtained by carrying out mirco-encapsulated embedding on medium chain triglyceride and achieving an oil powdered effect by adopting advanced process technologies, namely high-pressure homogenized emulsification, spray drying and the like, through formula design and process optimization, achieves the oil content as high as 80% and the oil embedding rate more than 98%, and has the advantages of good solubility and stability and convenience for transportation and storage. The product can be applied to multiple foods and health-care foods and is used for enhancing the nutrition value of the foods, improving the tissue structures, appearance quality and palatability of the foods and prolonging the quality guarantee period of a product.

Owner:上海英莱腾医药研究有限公司

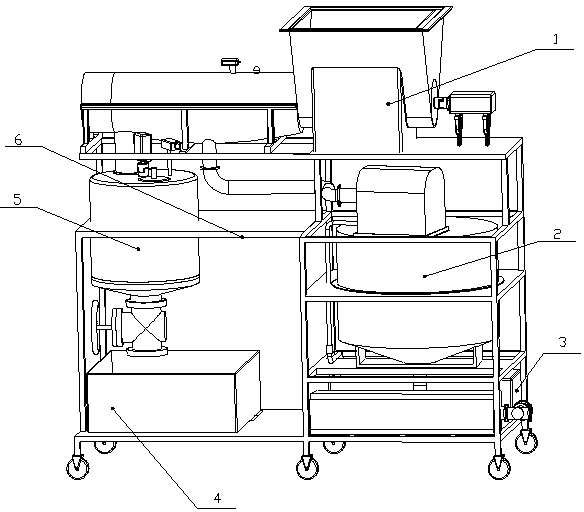

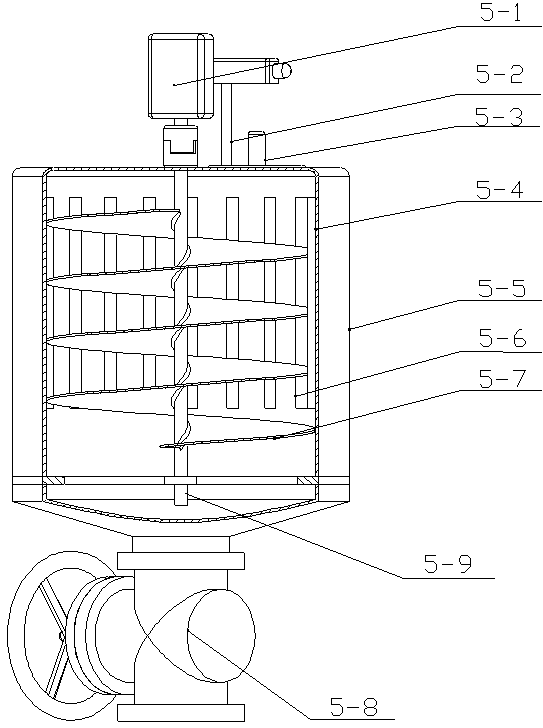

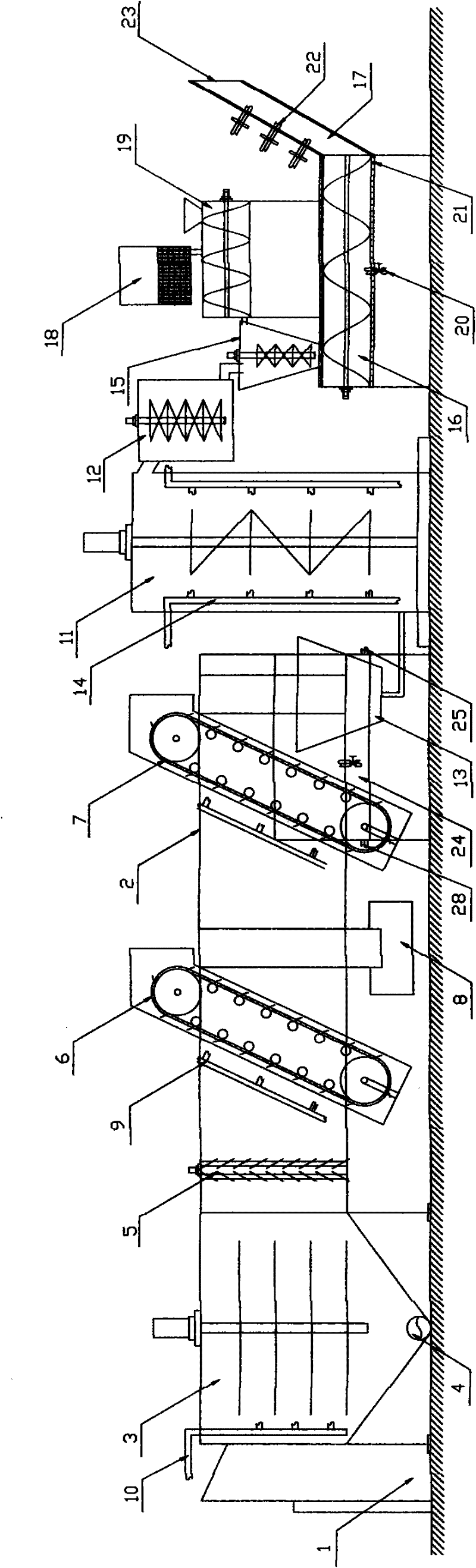

Multifunctional kitchen waste integrated processor

InactiveCN103357648AEasy to handleThe process is stable and reliableSolid waste disposalOil and greaseResource utilization

A disclosed multifunctional kitchen waste integrated processor comprises a rack, a dewatering smashing molding device disposed at the upper part of the rack, a drying disinfection device and an oil-water separation device both disposed on the rack; the drying disinfection device (5) and the oil-water separation device are both connected with the dewatering smashing molding device; a material recovery tank is disposed under the drying disinfection device; and an oil sump tank and a waste-water purifying groove are disposed under the oil-water separation device. The beneficial effects of the integrated processor comprise: kitchen waste enters into the dewatering smashing molding device through a feed hopper, and is subjected to dewatering, smashing and molding, drying and disinfection; and an oil-water mixture is separated into oil and waste water through the oil-water separation device; and the whole process is automatically controlled by an operating system, and the integrated processor is convenient to use and labor-saving. The integrated processor helps to effectively change operation conditions of waste classified processing, and is capable of recovering the processed solid residue and oil for resource utilization, and is good in practicality.

Owner:ANHUI SCI & TECH UNIV

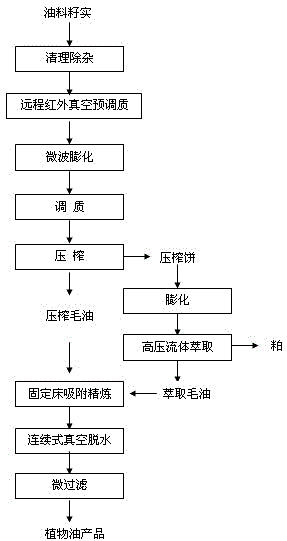

Physical method for preparing vegetable oil

ActiveCN103333738AAvoid damageFast and efficient remote infrared vacuum preconditioningFatty-oils/fats refiningFatty-oils/fats productionOil and greaseVegetable oil

The invention relates to a physical method for preparing vegetable oil. The method comprises the following process steps of: cleaning, remote infrared vacuum pre-tempering, microwave puffing, tempering, pressing, puffing, high-pressure fluid extraction, fixed bed adsorption refining, continuous vacuum dehydration and finally micro-filtering. The remote infrared vacuum pre-tempering and microwave puffing pre-processing method is fast and high-efficient and is suitable for industrial production. Press cake puffing and high-pressure fluid extraction are combined so that the problem of oil extraction of cold-pressing cakes is effectively solved, and meanwhile residual oil of the cold-pressing cakes is effectively reduced. The fixed bed adsorption refining method is simply and conveniently operated and has the advantages of short cycle, low energy consumption, low oil refining loss, high grease quality and the like. The whole process has the advantages of simplicity and convenience in operation, no solvent residue, low energy consumption, small neutral oil loss, high product quality and the like, an environment-friendly effect is achieved, and the method can be widely suitable for different kinds of oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

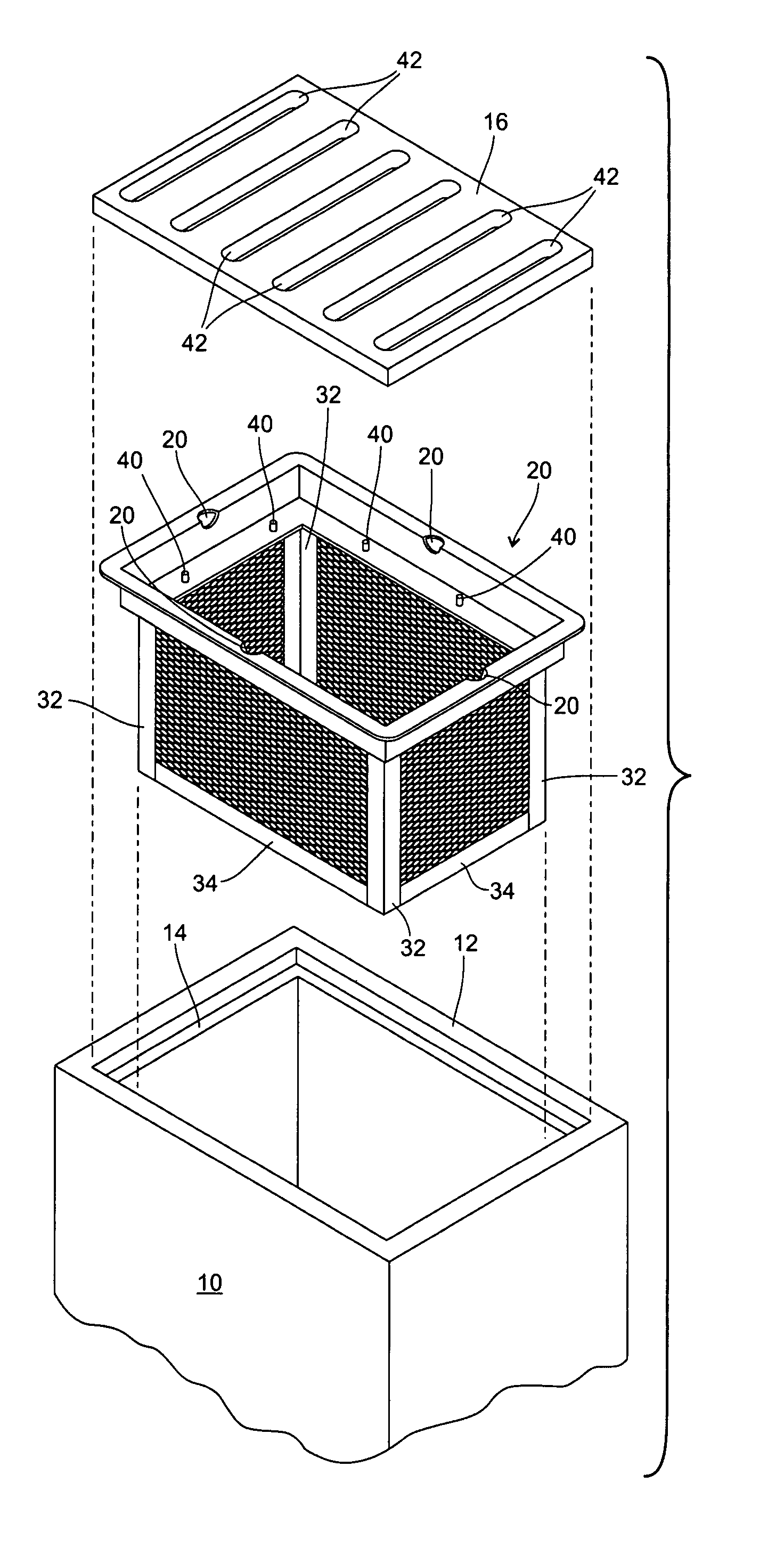

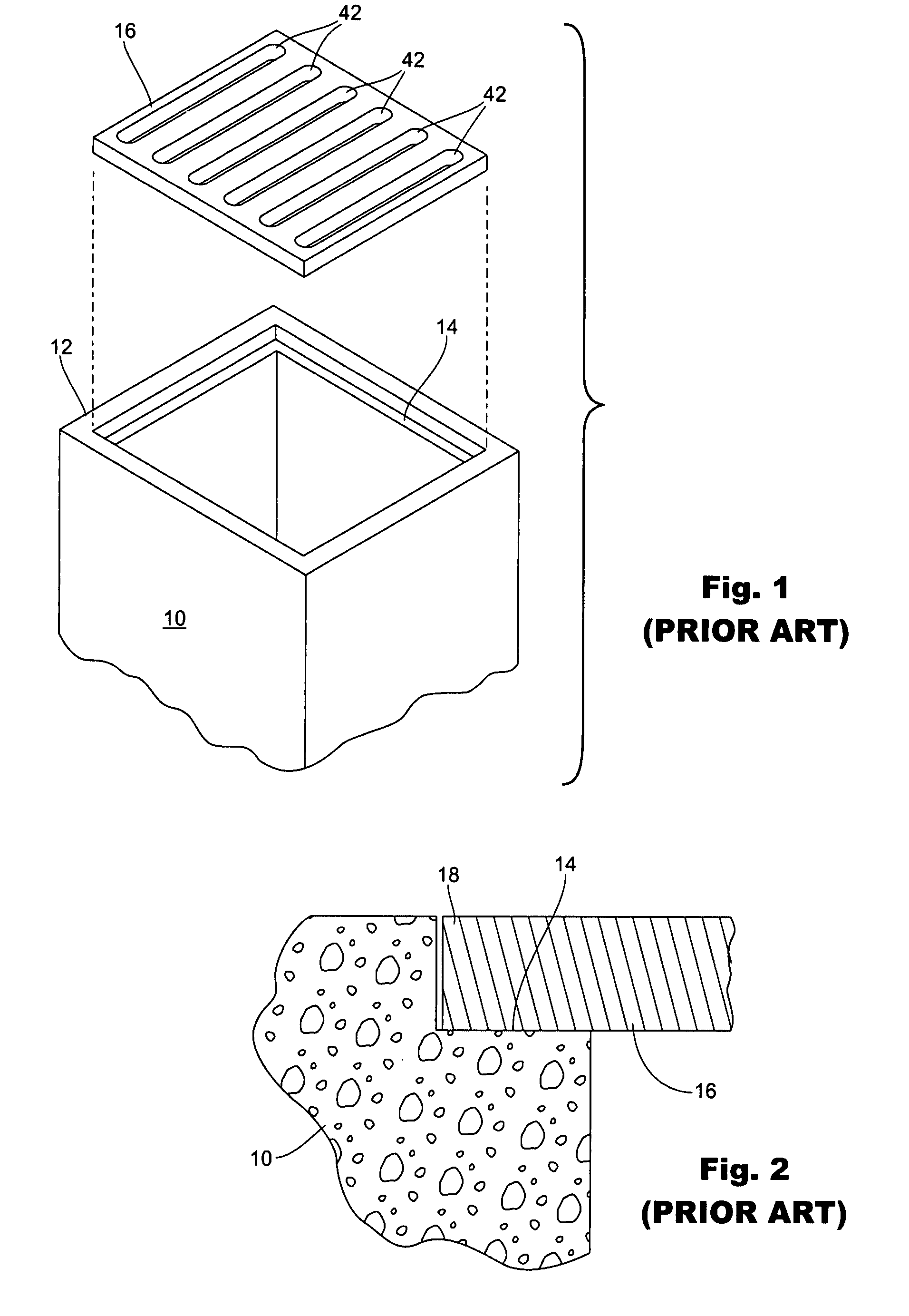

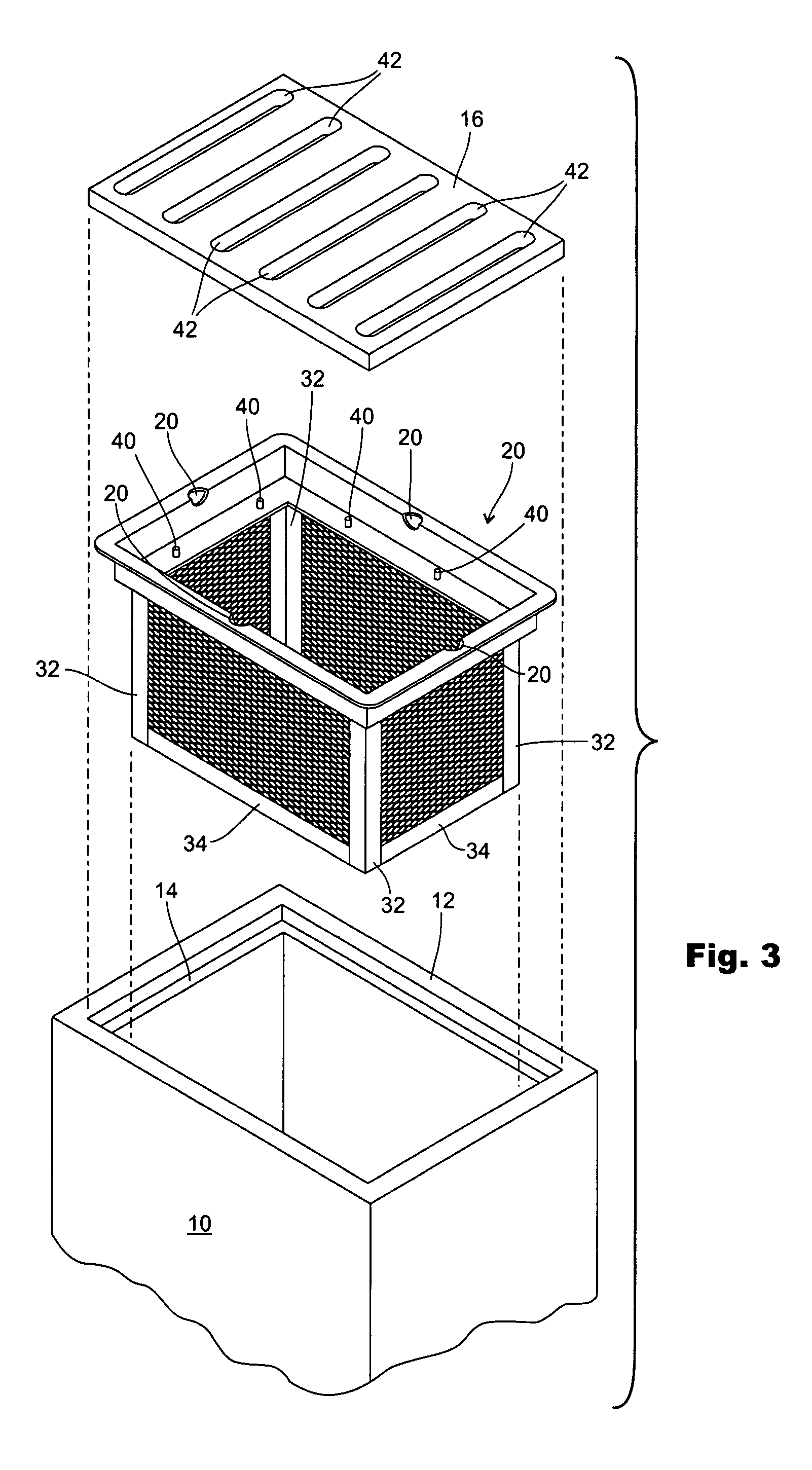

Filter system for catch basins

ActiveUS7771591B2Fatty/oily/floating substances removal devicesGround-workOil and greaseFilter system

A first filter basket (20) sits down into a catch basin (10) and has an upper flange (24) that rests on a shoulder (14) provided in the catch basin (10) for supporting a grate (16). The filter basket (20) has expanded metal side and bottom walls which are adapted to pass liquid and catch particulate material larger in size than the wall openings. A geo-textile liner (42) is optionally positioned inside of the filter basket (20). The liner (42) is supported on a lower rim flange (26). Posts (40) on the rim flange (26) extend upwardly through openings (66) in marginal portions of the liner (42). A smaller second filter basket (72) is optionally supported inside the larger first filter basket (20). An absorbent pillow (90) may be positioned between the bottoms of the two filter baskets (20, 72) to catch and absorb oils and greases that are in the liquid that enters the catch basin (10).

Owner:LUCAS CHASSIDY

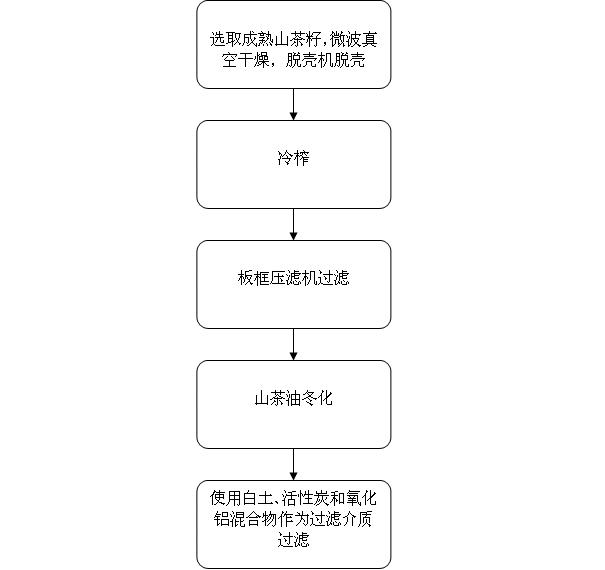

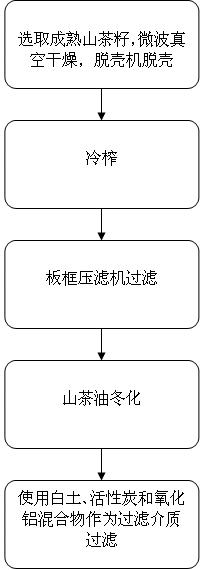

Cold pressing and physical refining process of camellia oil

ActiveCN102504938ASolve perishableImprove stabilityFatty-oils/fats refiningFatty-oils/fats productionOil and greaseDistillation

The invention relates to a cold pressing and physical refining process of camellia oil. The cold pressing and physical refining process of the camellia oil is characterized by comprising the following steps of: (1) selecting ripe camellia seeds and drying the ripe camellia seeds by microwave vacuum until the water content is 3-6%; and conveying the dried camellia seeds into a huller to be hulled;(2) carrying out cold pressing on the hulled camellia seeds to squeeze the camellia oil, wherein the temperature of a barrel is in a range of 100-150 DEG C and an oil output temperature is in a rangeof 80-120 DEG C; (3) removing solid impurities in the squeezed camellia oil through a plate and frame filter press; (4) winterizing the camellia oil filtered by the plate and frame filter press at a temperature in a range from below 5 DEG C to 5 DEG C; (5) carrying out molecular distillation on the winterized camellia oil to remove free fatty acid, oil peroxide products, moisture and other low-boiling-point substances from the camellia oil; and (6) taking a mixture of carclazyte, active carbon and aluminum oxide as a filtering medium to filter; and removing impurities and pigments of the camellia oil treated by the molecular distillation to obtain the finished product. The cold pressing and physical refining process of the camellia oil has the advantages of environmental friendliness, high oil yield, and high retention ratio of micronutrients in finished oil.

Owner:温州瑞雪农业开发有限公司

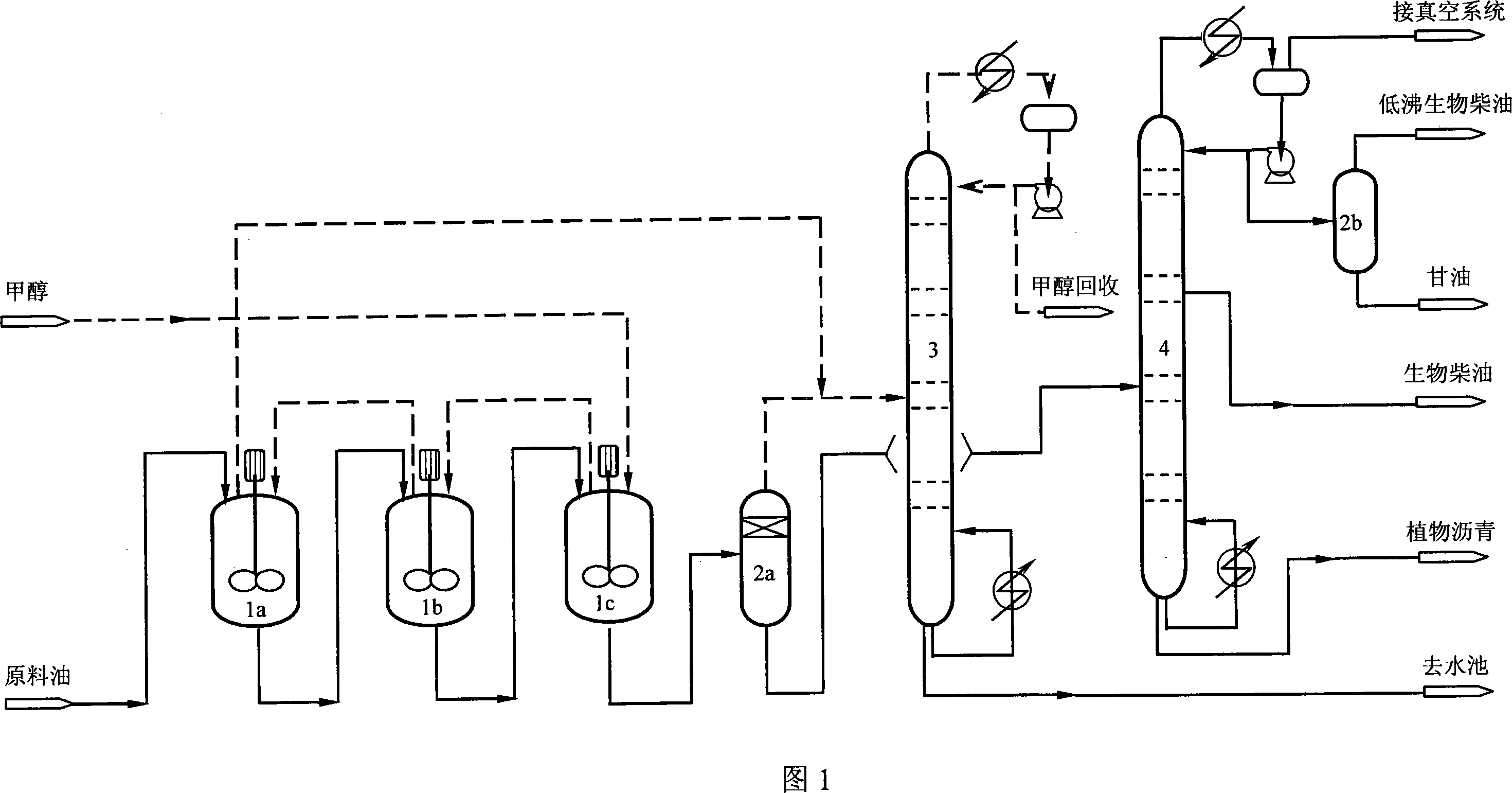

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

Microorganism fermentation grease and method for preparing organism diesel oil from the same

InactiveCN1923960AAbundant raw materialsLow costBiofuelsLiquid hydrocarbon mixture productionOil and greaseYeast

The invention discloses a biological diesel preparing method of fat fermented by microbe in the biological energy and biological catalytic technological domain, which comprises the following steps: grafting yeast microbe in the fat-producing bacterial culture medium; centrifuging; separating; extracting to obtain the fat; esterifying under catalyst to obtain biological diesel and glycerine as by-product.

Owner:TSINGHUA UNIV

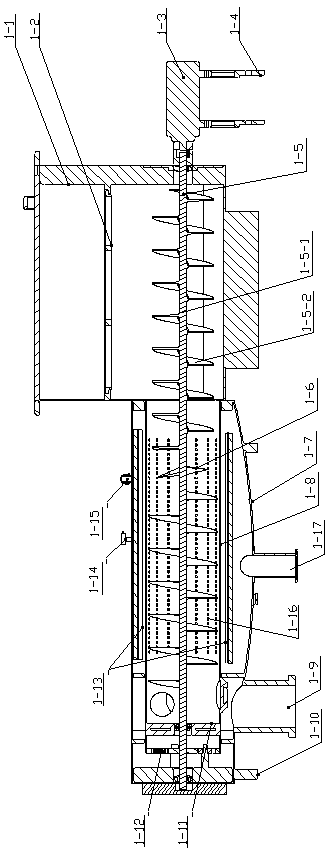

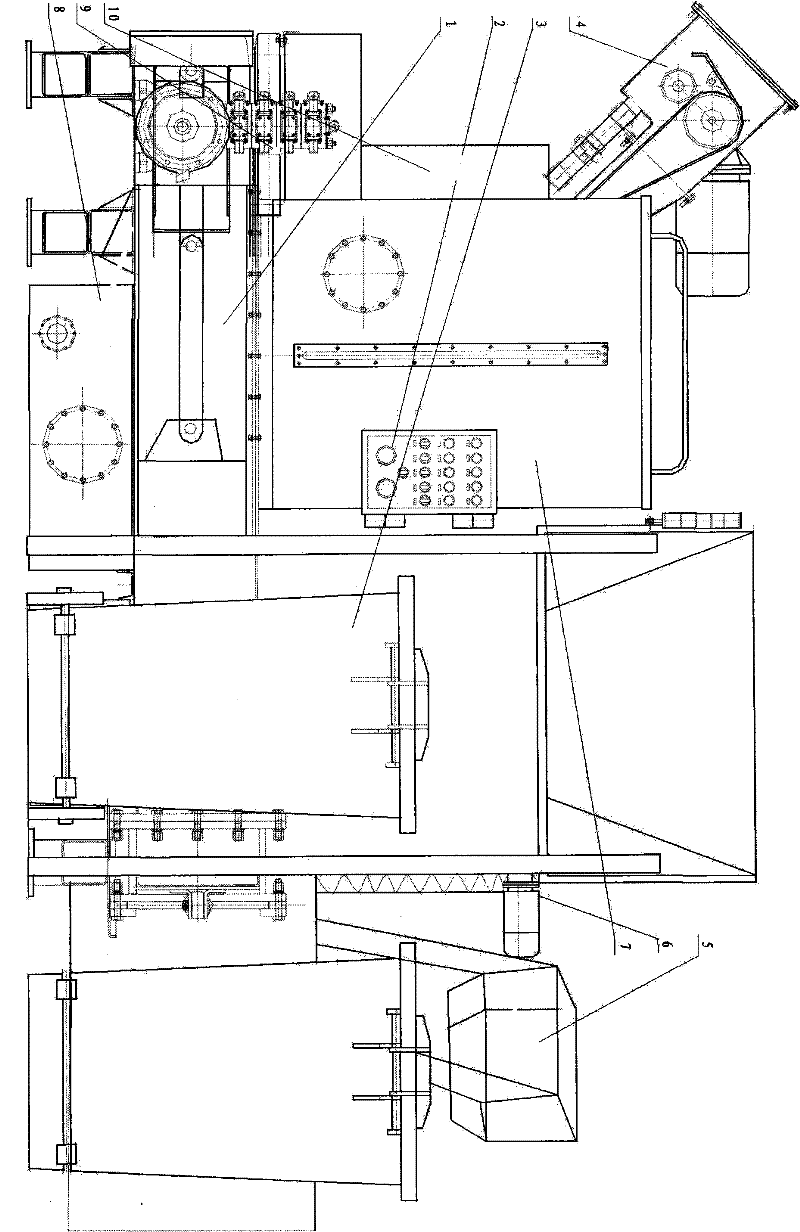

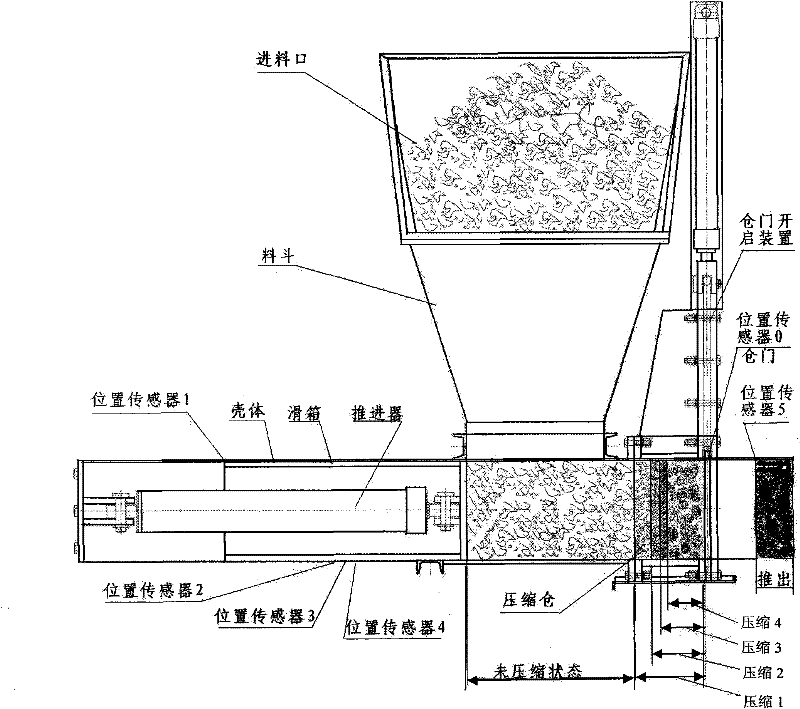

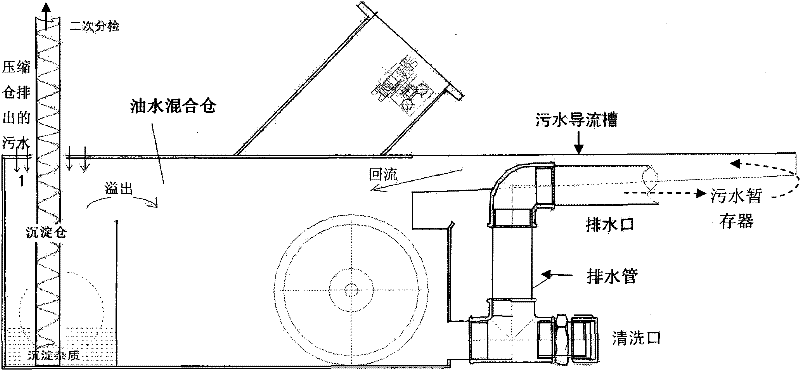

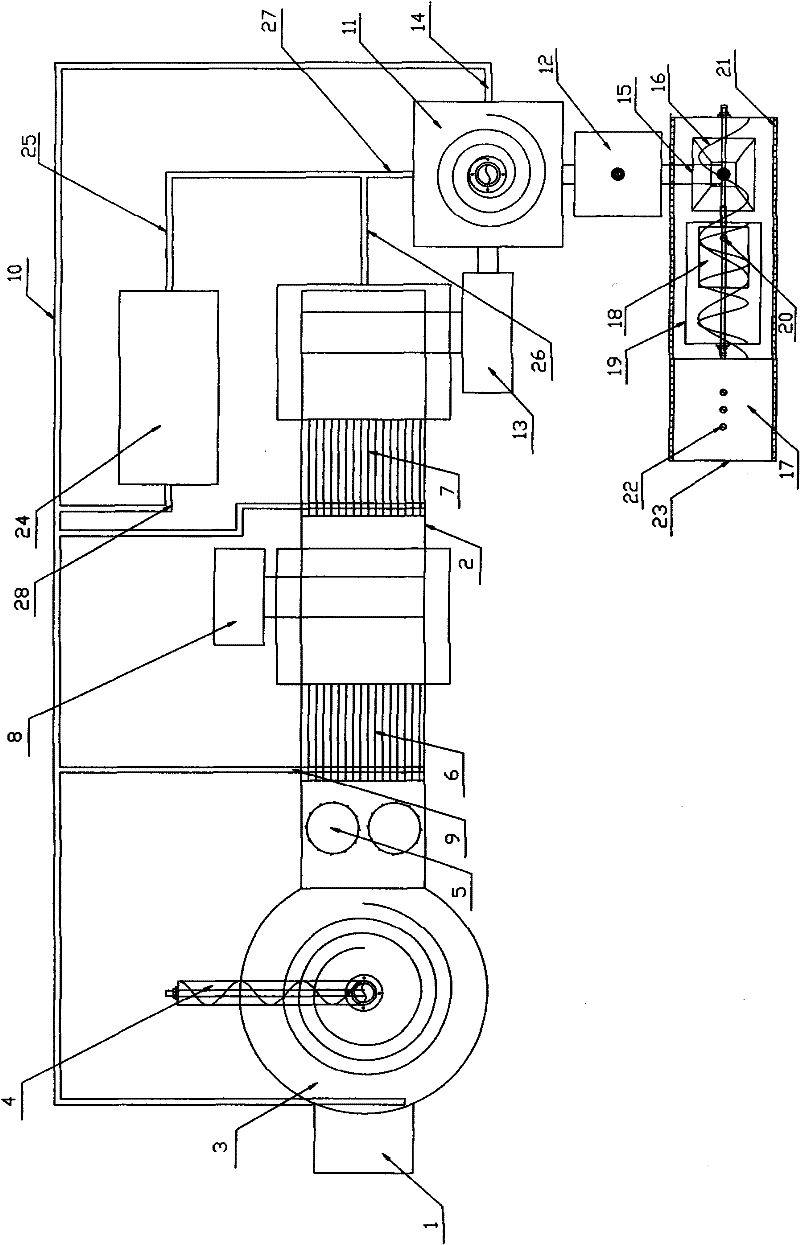

Device for reducing and sorting food waste at the source

InactiveCN102240658AEasy to handleImprove transportation capacitySolid waste disposalDrying solid materials without heatOil and greaseFailure rate

The invention discloses a device for reducing and sorting food waste at the source, and belongs to the technical field of municipal environmental protection machinery. The device is characterized in that: food waste is poured into a feed system and is conveyed into a dehydration system, a sliding box is driven to slide in a housing through a propeller of the dehydration system, a extruding way or a beating way is adopted to complete the food waste dehydrating; the resulting sewage from the dehydration step enters a sewage box from a compression bin to enable a oil and water separation system to extract greases; the solid materials after completing the dehydration are pushed out from the compression bin and enter into a material discharge system; the solid materials are output through the material discharge system and wait for centralized processing. After being processed by the device provided by the present invention, the food waste is divided into three portions comprising the water, the greases and the solid materials so as to conveniently carry out post-treatments such as reuse production of the greases and the solid materials, regeneration treatment of the water source and the like. The device has characteristics of strong processing ability, low failure rate, high automaticity, simple and easy operation and maintenance, no requirement of chemical additives, high dehydration rate, short retention time of the food waste in the device, and the like, and is benefit for improving efficiency of resource reutilization production so as to achieve effect of energy saving and emission reduction.

Owner:曹泽民

Method of making biodiesel oil by subcritical methanol phase solid acid alkali catalytic oil fat ester exchange

InactiveCN1718679ASolve interphase mass transfer problemsShort reaction timeBiofuelsLiquid hydrocarbon mixture productionOil and greaseGlycerol

A process for preparing biologic diesel oil from plant oil and methanol includes such steps as proportionally adding plant oil and methanol into high-pressure reactor, adding solid catalyst, reaction, separating out catalyst, laying aside for layering, distilling the mixture of methanol and methyl ester of fatty acid on upper layer to obtain methyl ester of fatty acid (biologic diesel oil ) and distilling the mixture of methanol and glycerine on lower layer to obtain glycerine.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel

ActiveCN102464998ANo reduction in activityStrong resistance to waterBiofuelsLiquid hydrocarbon mixture productionOil and greaseVegetable oil

The invention discloses a method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel. Animal and vegetable oil is subjected to hydrodeoxygenation and olefin saturation reaction with the existence of hydrogen and catalyst, gas and generated water are separated from effluents of hydrogenation reaction, gas, diesel fraction and incompletely-converted fraction are obtained by distilling the liquid, the incompletely-converted fraction is circulated back to a hydrogenation treatment reactor, the diesel fraction enters a hydrogenation modified reactor after being mixed with an optional modified raw material to be subjected to the modified reaction with the existence of hydrogen and modified catalyst, and gas products, naphtha and diesel fraction are obtained through the separation and distilling. Compared with the prior art, the hydrogenation reaction, hydrogenation modified reaction and / or pour point depression reaction of the animal and vegetable oil can be carried out under a relatively tempered technique condition, and the method has the advantages such as wide range of raw materials, high quality of products, high yield of diesel and fewer byproducts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of biological diesel oil

InactiveCN1940021AReduce processReduce operating costsLiquid hydrocarbon mixture productionBio-feedstockOil and greaseAlcohol

Production of biological diesel oil is carried out by taking oily microbial as raw material, taking low-carbon alcohol as ester exchange agent, taking inorganic acid as catalyst, transfer esterification reacting, cooling reactive mixture, filtering, and liquid-phase purifying to obtain the final product. It's cheap and convenient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Processing method and processing system for kitchen garbage resourcilization

InactiveCN102690134AReduce moisture contentWater content automatic controlBio-organic fraction processingSolid waste disposalOil and greaseWater use

The invention relates to a processing method and a processing system for kitchen garbage resourcilization. The processing method comprises waterpower decomposition, fragmentation, sorting, dehydration, crushing, anaerobic fermentation and oil-water separation; the processing system comprises a feeding device, a waterpower conveying decomposition tank, a fragmentation preselection apparatus, a dehydration crushing apparatus, an anaerobic fermentation mixing apparatus and an oil-water separation apparatus. The method and system provided in the invention adopt sorting by using water. Advanced treatments of sorting to remove impurity, fragmentation, dehydration, desalination, oil removing and the like are automatically carried out to substances of different properties in the kitchen garbage by using water as a carrier combining with mechanization equipment, according to dissolvability and different proportion of the substances; organic substances separated from the kitchen garbage are fermented and prepared into organic fertilizers; and grease in separated oil-contained sewage is recycled by oil-water separating. The method and the system in the invention thoroughly remove substances of oil, salinity, soy sauce, vinegar and the like in the kit garbage that against fermentation composting. The method and the system have the characteristics of high removal rate of salinity and grease, high dehydration efficiency, good automatic sorting effect, realization of resource regeneration and no secondary pollution.

Owner:焦社杰 +2

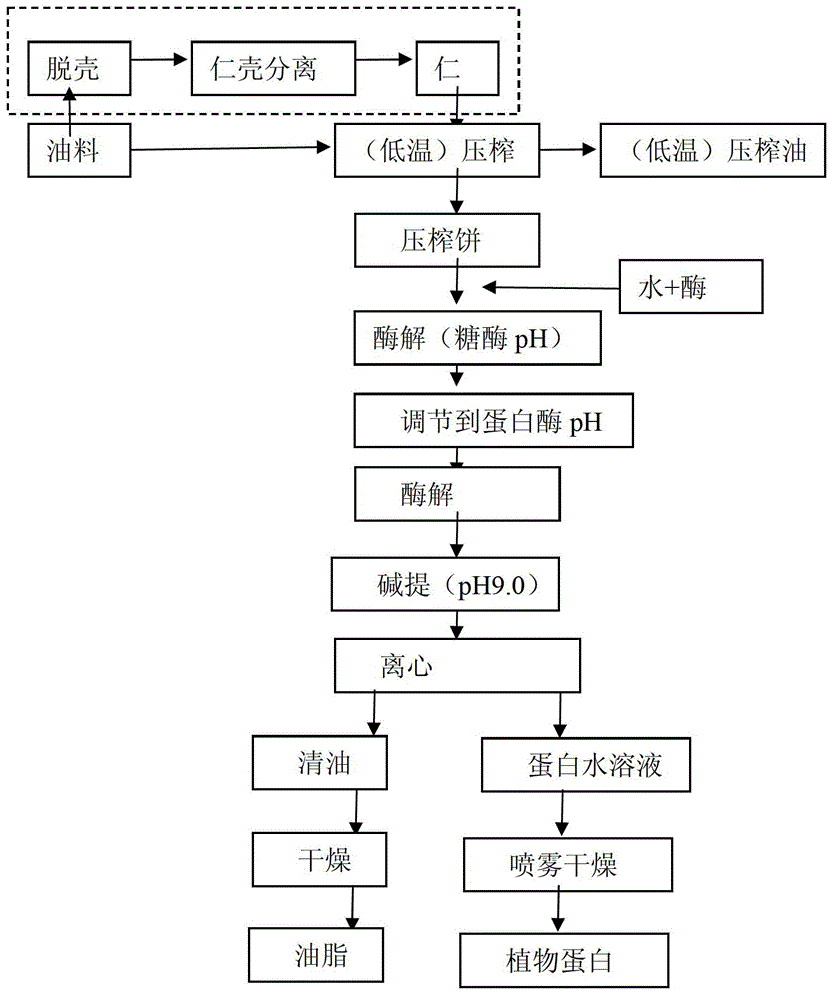

Method for preparing grease and protein from oil seed kernels by aqueous enzymatic method

InactiveCN102746938AQuality improvementHigh priceFatty-oils/fats productionFermentationOil processingOil and grease

The invention relates to a method for preparing grease and protein from oil seed kernels by an aqueous enzymatic method and belongs to the technical field of the application of the biotechnology to the grain and oil food processing. The method for preparing grease and protein from the oil seed kernels by the aqueous enzymatic method is characterized by comprising the following steps of 1) oil preparation through squeezing; 2) crushing; and 3) enzymolysis and drying: water and complex enzyme are added into treated squeezed cakes, the pH is regulated to the pH value and the temperature applicable to carbohydrase, and the enzymolysis is carried out for 15 to 90 minutes; the pH is regulated to the pH value and the temperature applicable to the protease, and the enzymolysis is carried out for 15 to 90 minutes; the pH is regulated to 9.0 after the enzyme reaction, and the stirring alkali extraction is carried out for 10 to 60 minutes at room temperature; boiled oil and protein water solution are separated through centrifugation; and the boiled oil is subjected to vacuum drying at 100 to 120 DEG C, grease products are obtained, the protein water solution is subjected to spraying drying, and plant protein is obtained. The method has the characteristics of high oil yield, low water consumption and low energy consumption, and the additional value of oil processing products can be improved.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

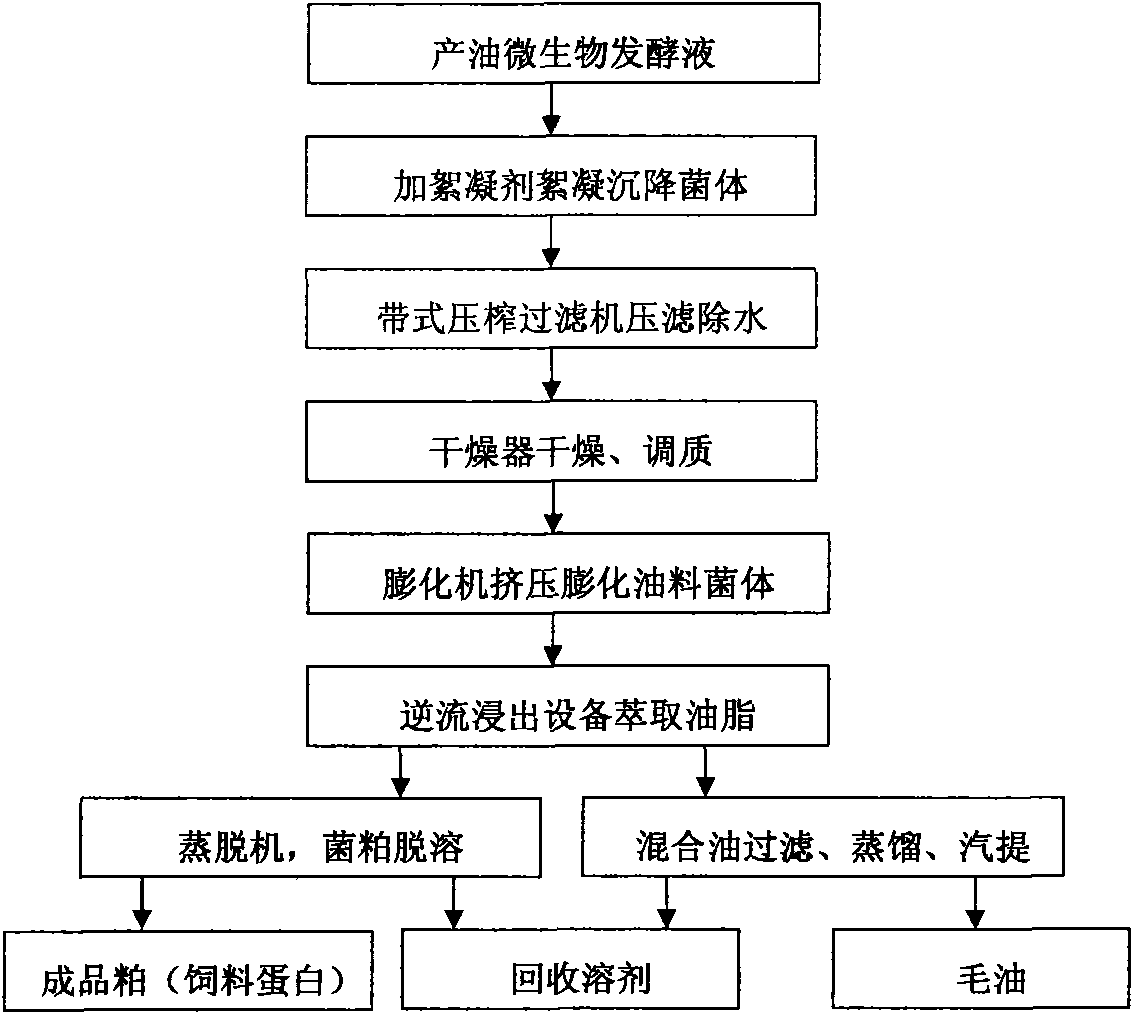

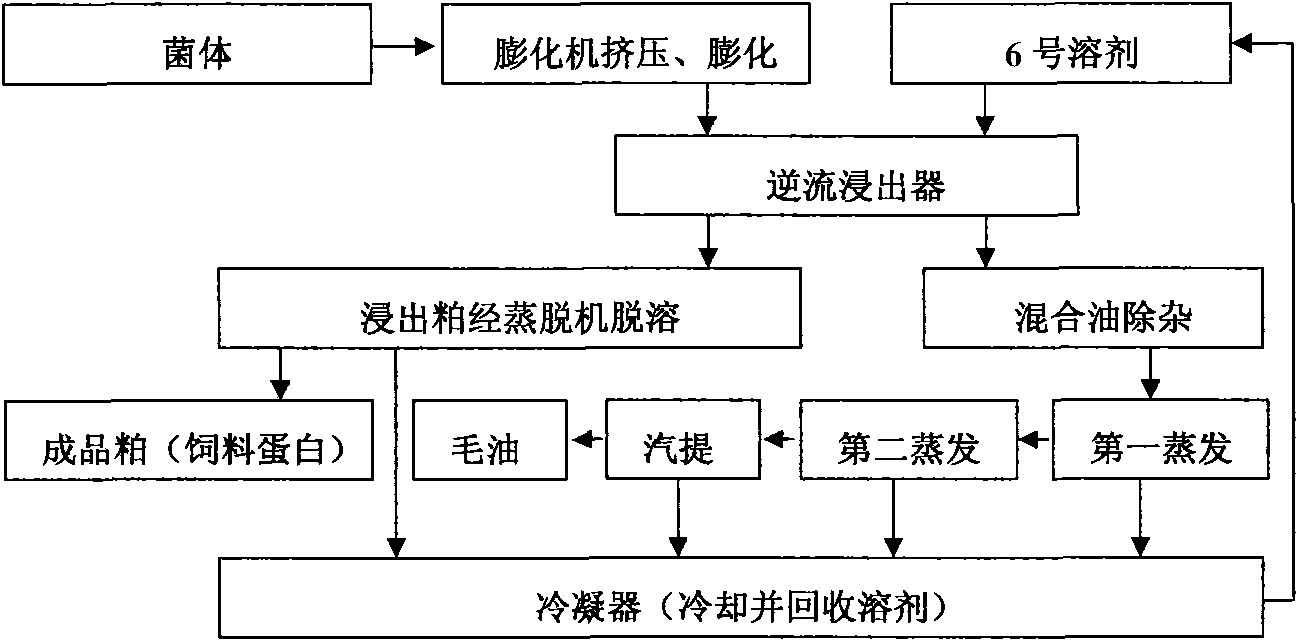

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com