Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6310 results about "Modified starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified starch, also called starch derivatives, are prepared by physically, enzymatically, or chemically treating native starch to change its properties. Modified starches are used in practically all starch applications, such as in food products as a thickening agent, stabilizer or emulsifier; in pharmaceuticals as a disintegrant; or as binder in coated paper. They are also used in many other applications.

Personal care compositions containing cationically modified starch and an anionic surfactant system

ActiveUS20060002880A1Increase depositionReduce cleaningCosmetic preparationsHair cosmeticsPersonal careWater soluble

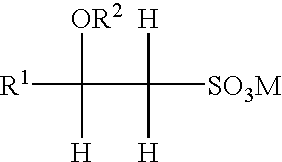

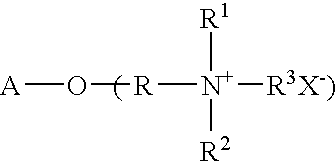

Personal care compositions comprise (a) from about 0.01 wt. % to about 10 wt. % of a water-soluble cationically modified starch polymer, wherein said water-soluble cationically modified starch polymer has a molecular weight from about 1,000 to about 200,000 and a charge density from about 0.7 meq / g to about 7 meq / g; (b) from about 5 wt. % to about 50 wt. % of an anionic surfactant system, said anionic surfactant system comprising at least one anionic surfactant and having an ethoxylate level and an anion level, (i) wherein said ethoxylate level is from about 1 to about 6, and (ii) wherein said anion level is from about 1 to about 6; and (c) a cosmetically acceptable medium. Personal care compositions as described above further comprise from about 0.01 wt. % to about 10 wt. % of one or more oily conditioning agents. Methods of treating hair or skin comprise applying the personal care compositions as described above to the hair or skin and rinsing the hair or skin.

Owner:THE PROCTER & GAMBLE COMPANY

Bone graft

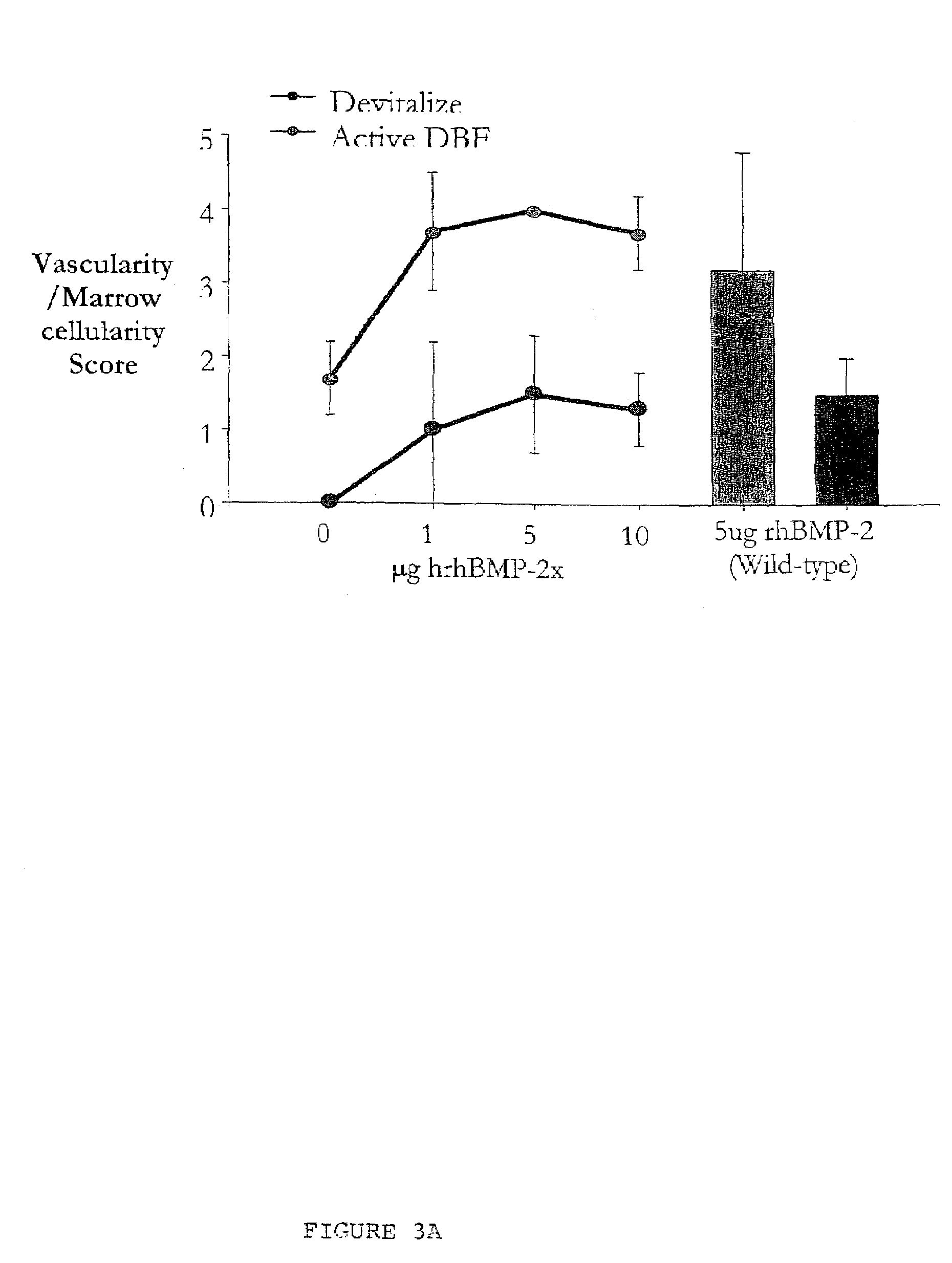

ActiveUS7163691B2Fast reduction in osteoinductiveGood curative effectOrganic active ingredientsImpression capsOSTEOINDUCTIVE FACTORIn vivo

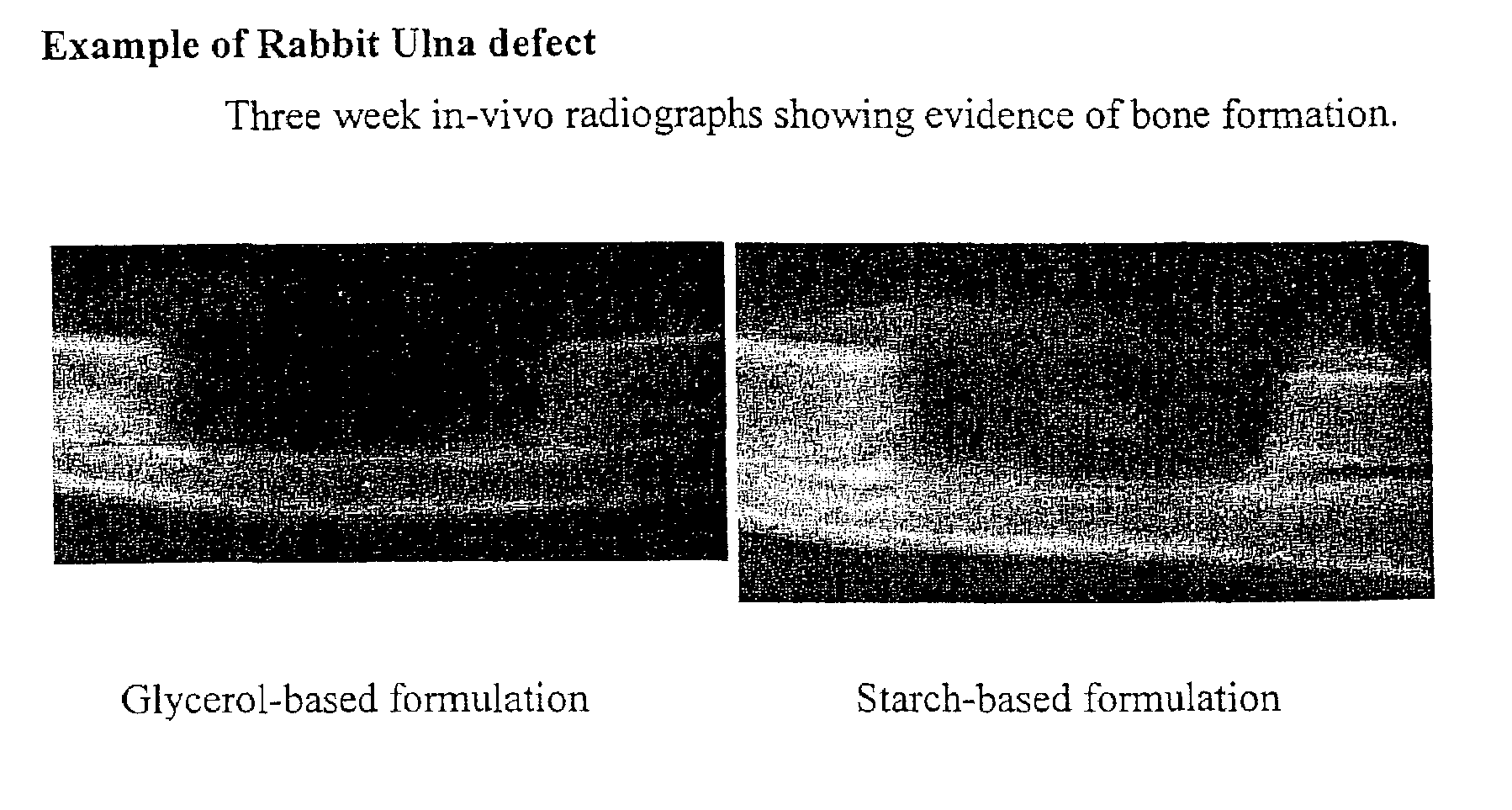

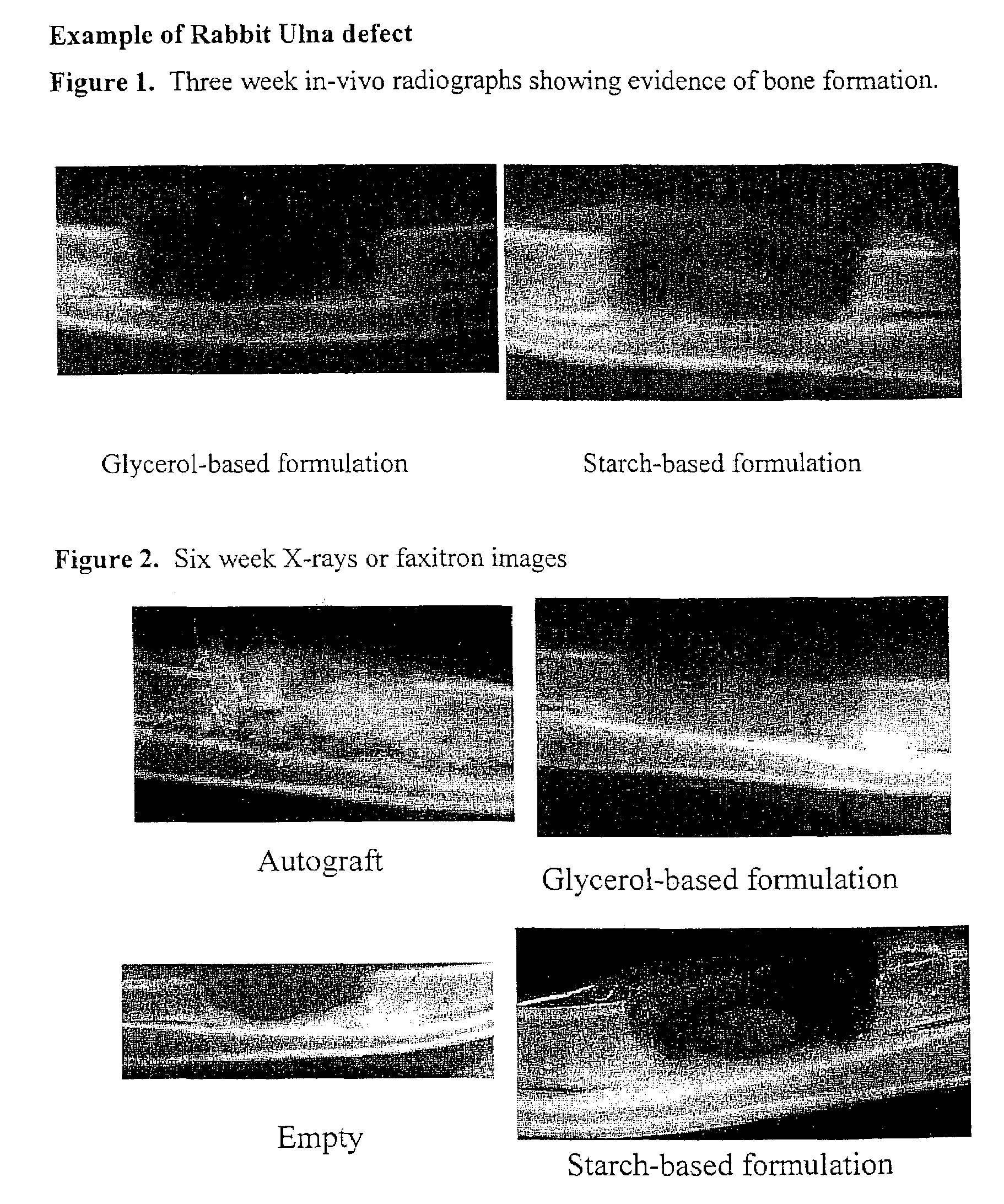

An improved demineralized bone matrix (DBM) or other matrix composition is provided that has been mixed with a stabilizing agent that acts as (1) a diffusion barrier, (2) a enzyme inhibitor, (3) a competitive substrate, or (4) a masking moiety. A diffusion barrier acts as a barrier so as to protect the osteoinductive factors found in DBM from being degraded by proteolytic and glycolytic enzymes at the implantation site. Stabilizing agents may be any biodegradable material such as starches, modified starches, cellulose, dextran, polymers, proteins, and collagen. As the stabilizing agents degrades or dissolves in vivo, the osteoinductive factors such as TGF-β, BMP, and IGF are activated or exposed, and the activated factors work to recruit cells from the preivascular space to the site of injury and to cause differentiation into bone-forming cells. The invention also provides methods of preparing, testing, and using the inventive improved osteodinductive matrix compositions.

Owner:WARSAW ORTHOPEDIC INC

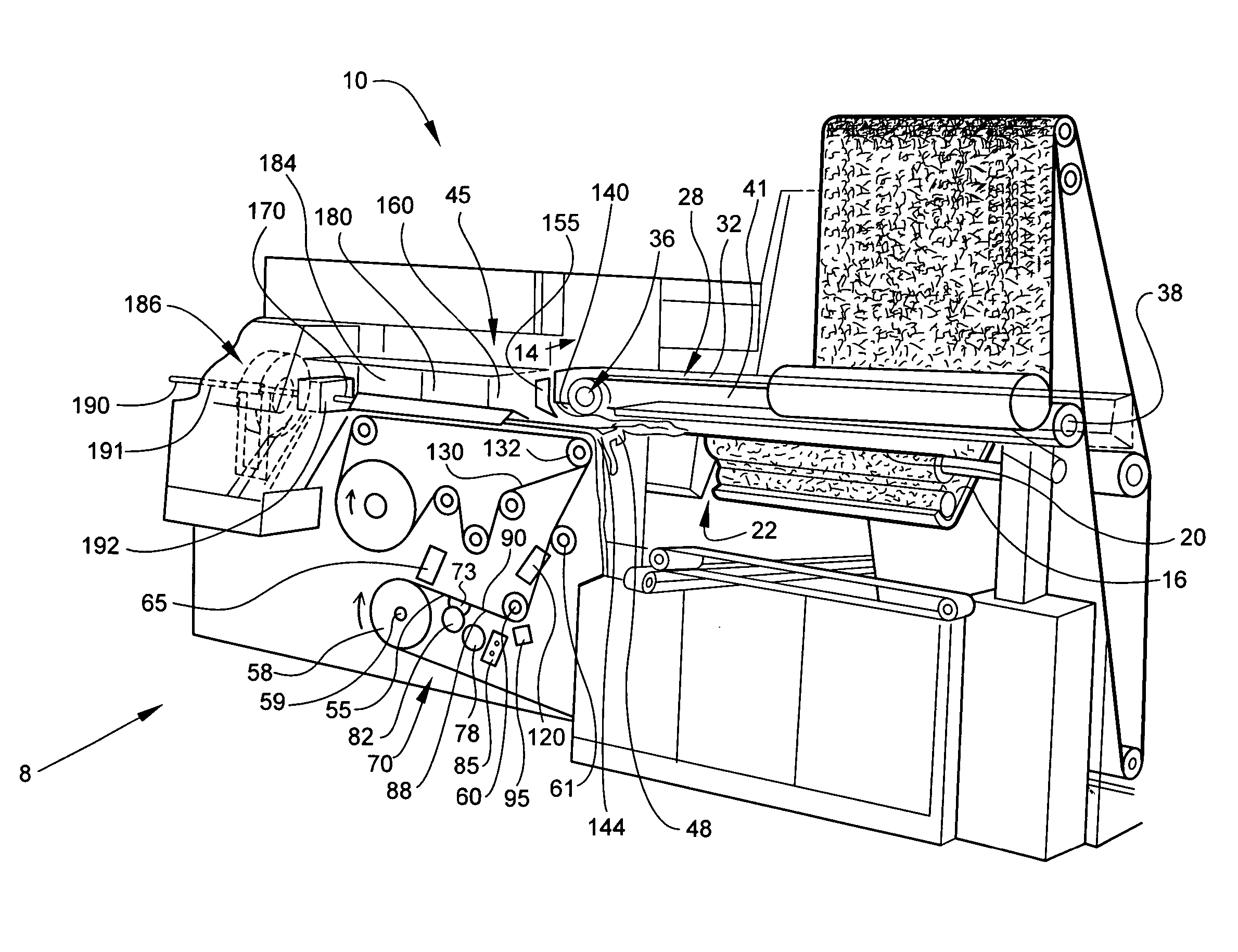

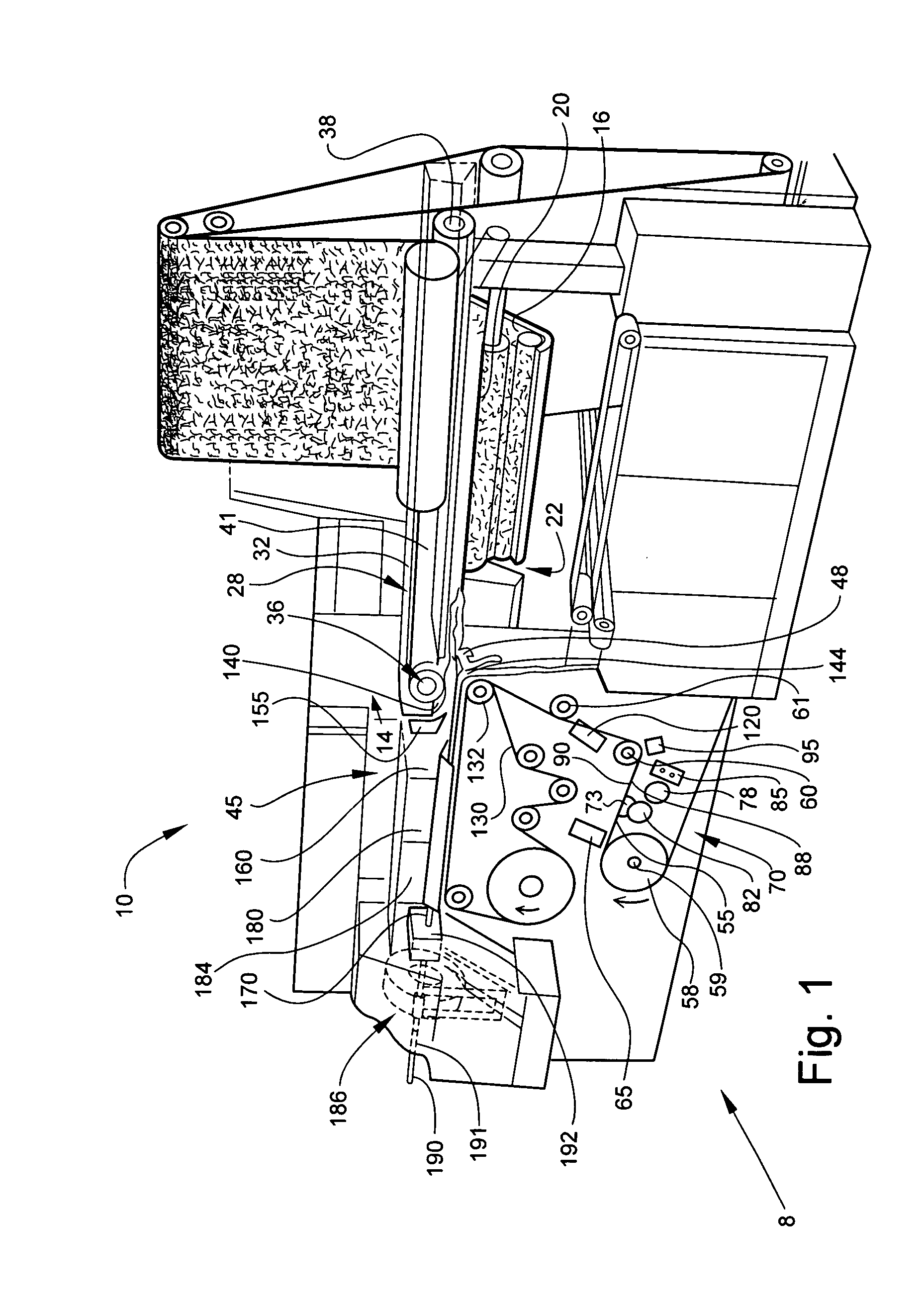

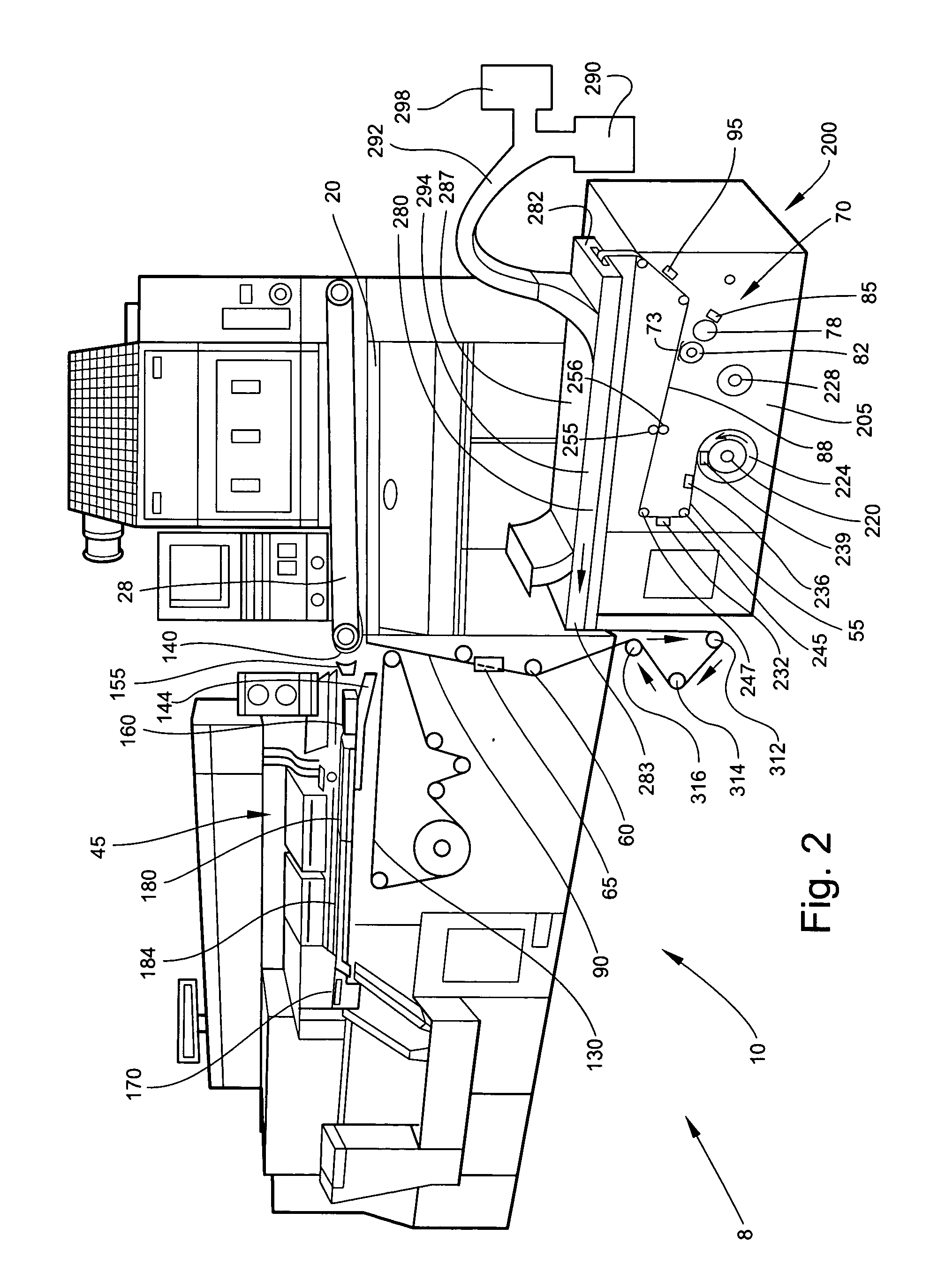

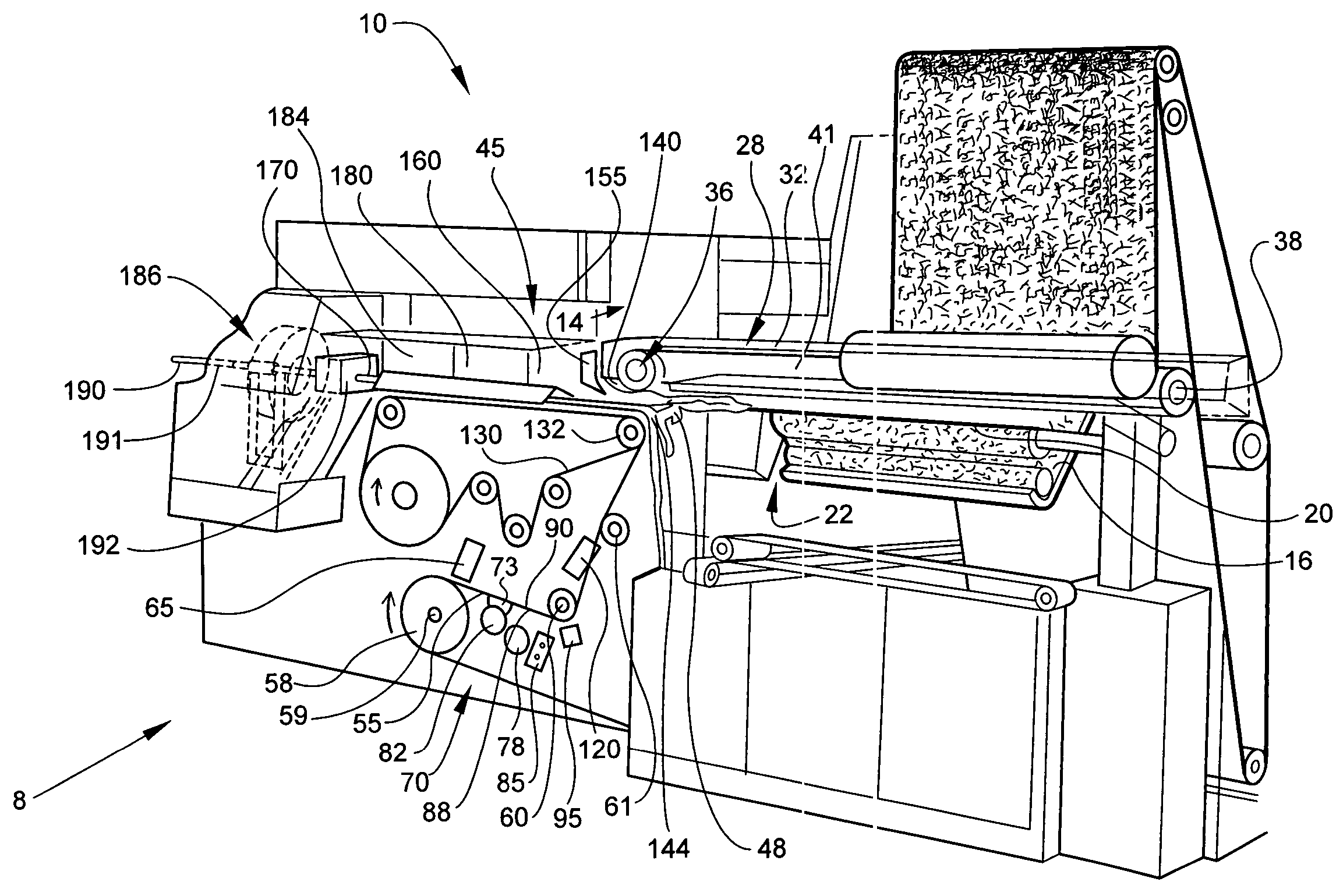

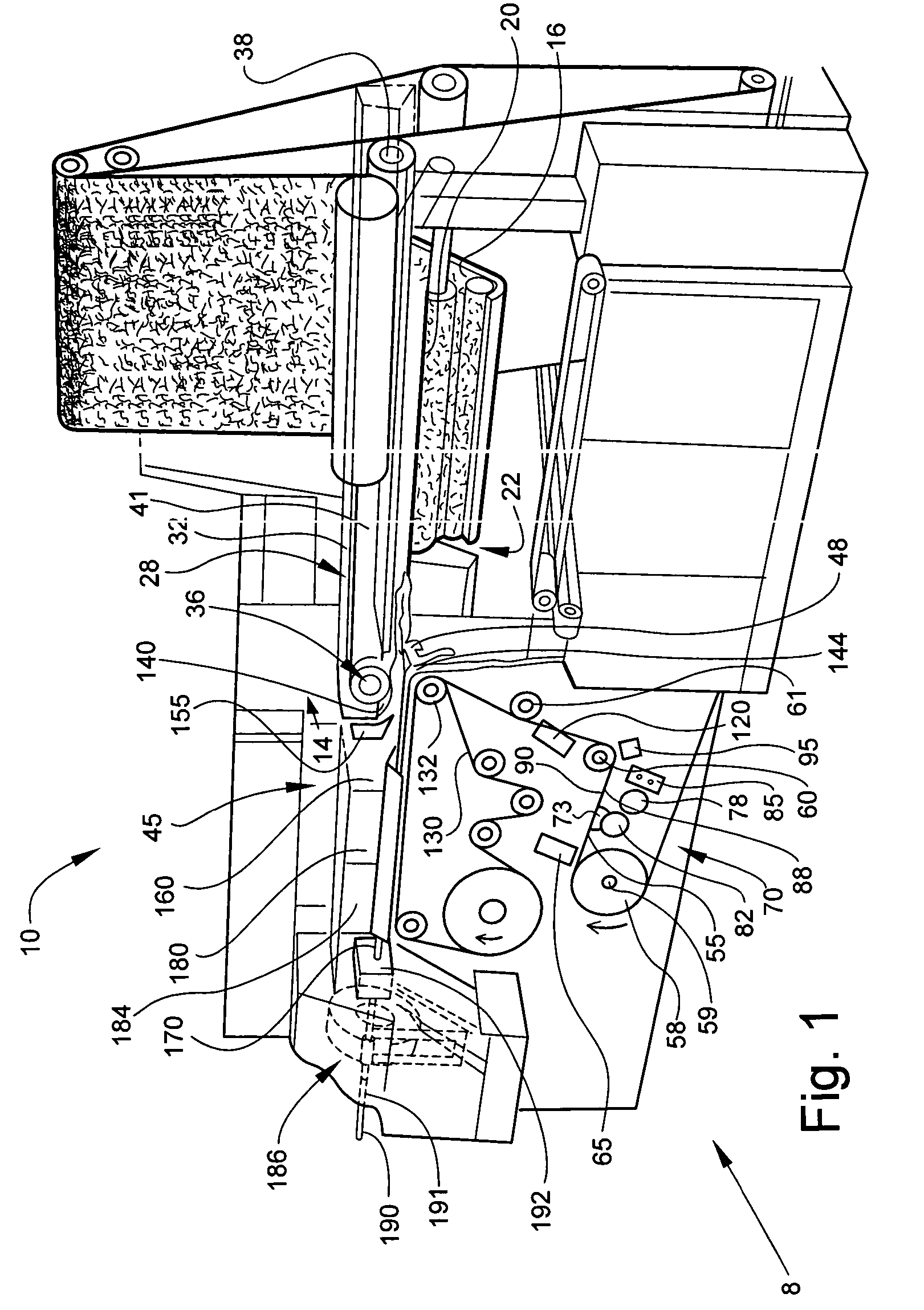

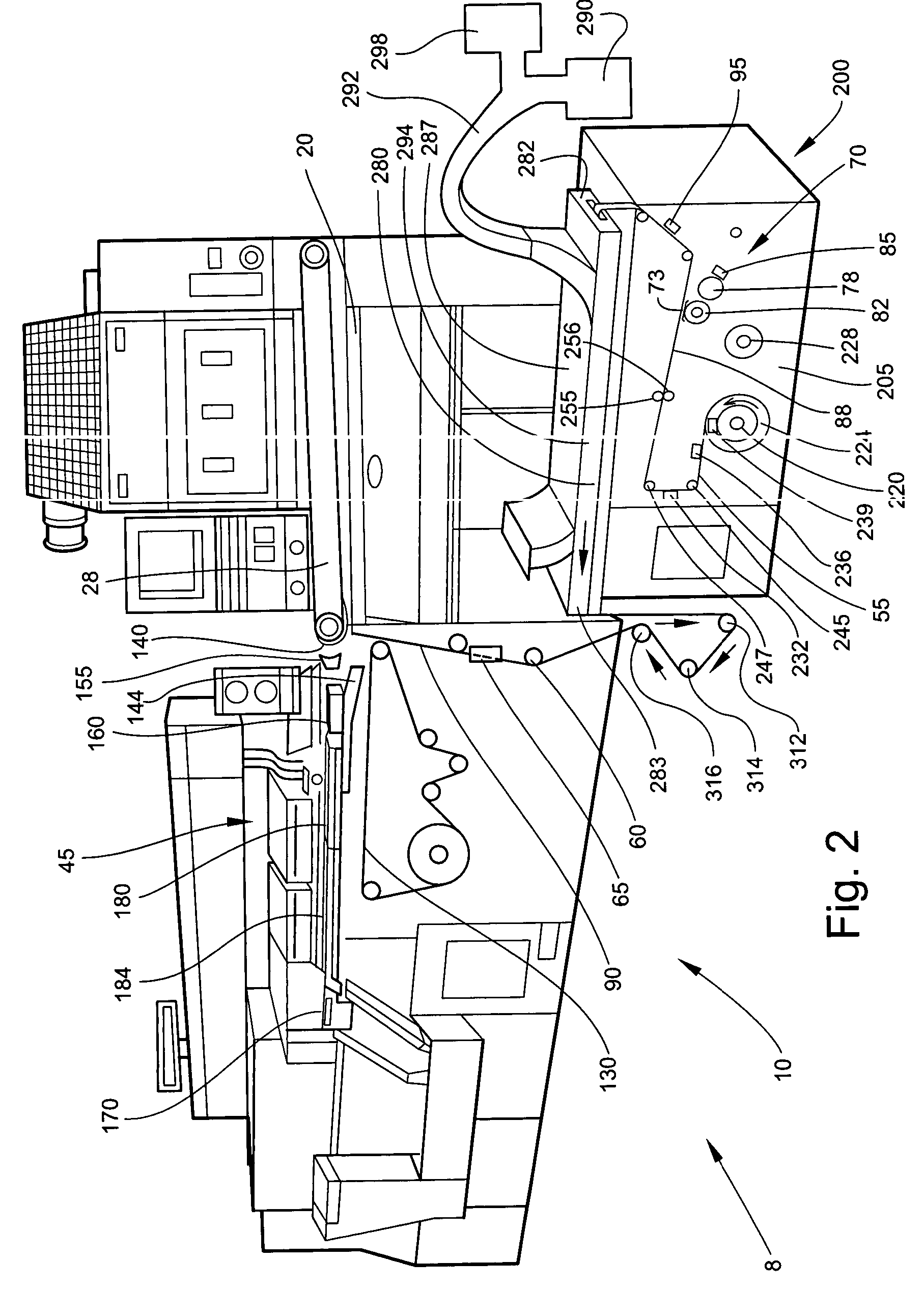

Equipment and methods for manufacturing cigarettes

ActiveUS20050039764A1Easy transferConsistent flowCigar manufactureCigarette manufactureMechanical engineeringIndustrial engineering

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers, and one of those rollers has a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. For example, additive material located in the recessed pockets of a first roller is transferred in a controlled manner to the roll face of a second roller in roll contact with that first roller; and the additive material on the roll face of the second roller is transferred to desired locations on the surface of the paper web. The formulation also can be applied to a continuous moving paper web using an application apparatus possessing four rollers. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

Cigarette and wrapping materials therefor

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

Elemental nutritional products

InactiveUS6077558ALittle to no observable browning effectSugar food ingredientsDough treatmentACETYLATED MONOGLYCERIDEHypoallergenic infant formula

An emulsifying system for elemental diet compositions is provided that comprises a protein source that may be a extensively hydrolyzed protein, free amino acids, short-chain peptides, or a mixture thereof; a lipid source; a carbohydrate source; and an emulsifying system comprising an ocentyl succinic anhydride modified starch and an acetylated monoglyceride emulsifier. The composition may be prepared as a powder or liquid nutritional composition for formulas prepared for infant, pediatric and adult populations in need of an elemental diet. The invention provides a commercially acceptable product in terms of desired stability and physical characteristics and is particularly useful for hypoallergenic infant formula preparations.

Owner:NESTEC SA

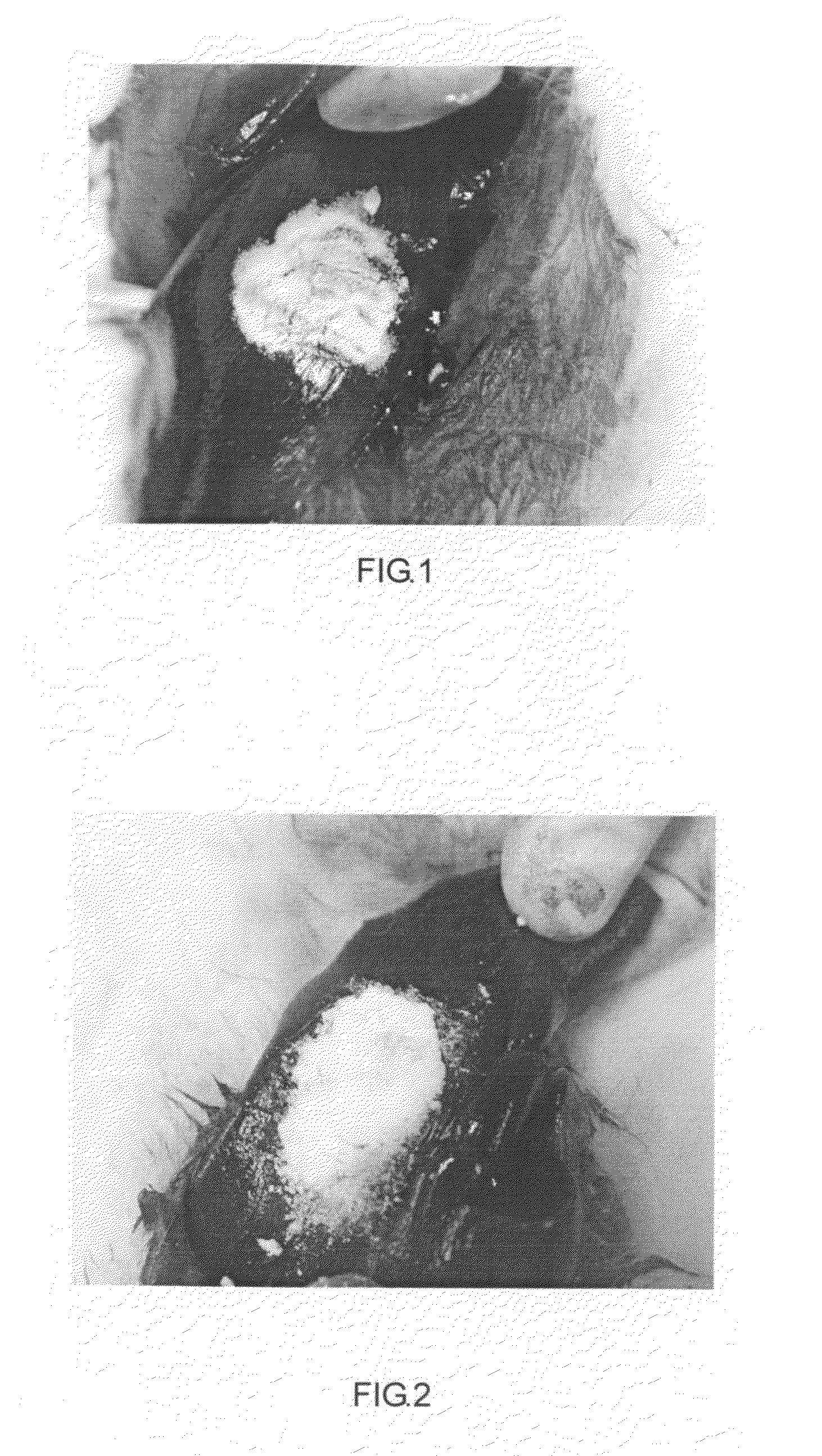

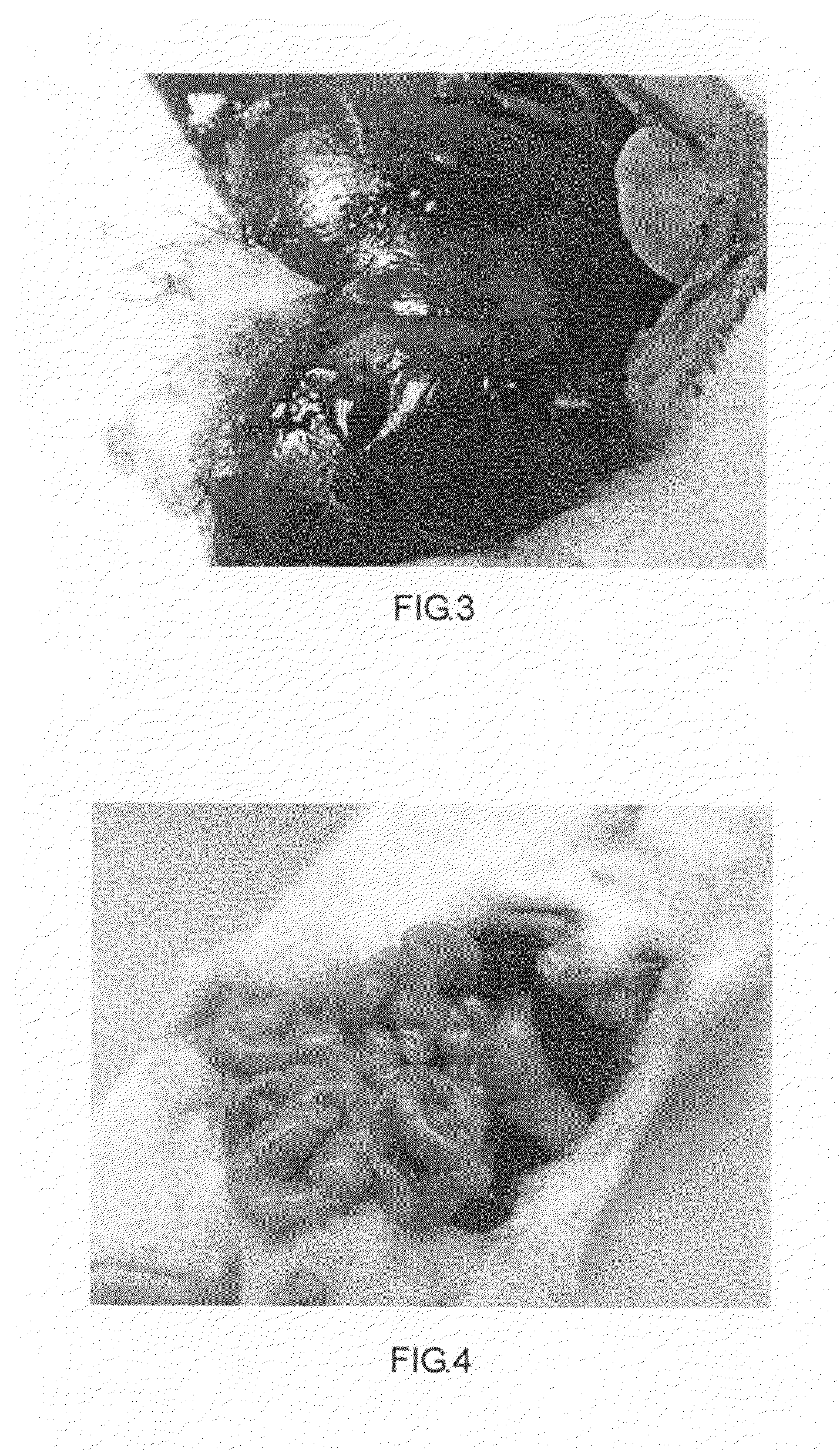

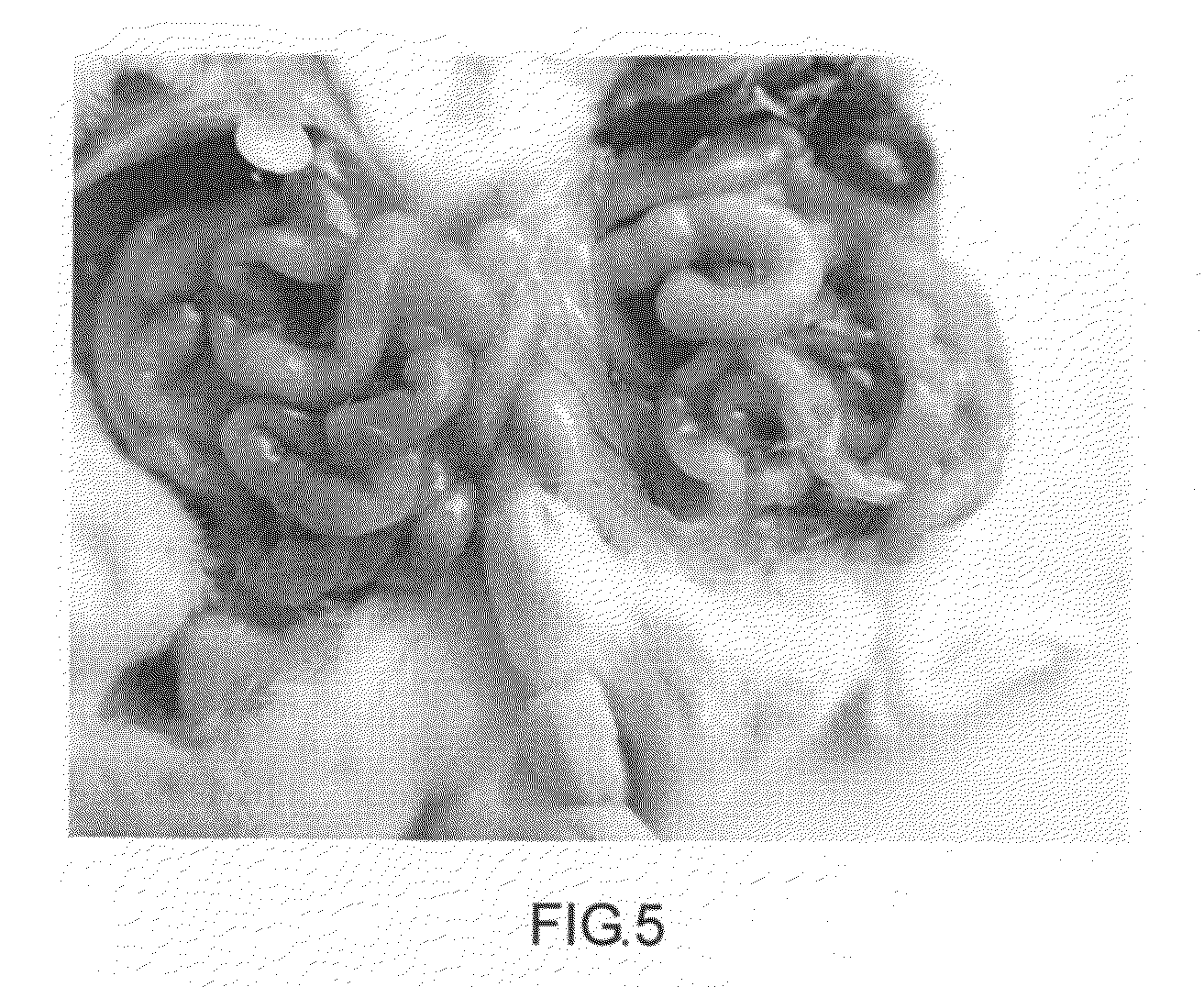

Modified starch material of biocompatible hemostasis

InactiveUS20090062233A1Promoting tissue healingGood effectPowder deliveryBiocideAfter treatmentWound surface

A modified starch material for biocompatible hemostasis, biocompatible adhesion prevention, tissue healing promotion, absorbable surgical wound sealing and tissue bonding, when applied as a biocompatible modified starch to the tissue of animals. The modified starch material produces hemostasis, reduces bleeding of the wound, extravasation of blood and tissue exudation, preserves the wound surface or the wound in relative wetness or dryness, inhibits the growth of bacteria and inflammatory response, minimizes tissue inflammation, and relieves patient pain. Any excess modified starch not involved in hemostatic activity is readily dissolved and rinsed away through saline irrigation during operation. After treatment of surgical wounds, combat wounds, trauma and emergency wounds, the modified starch hemostatic material is rapidly absorbed by the body without the complications associated with gauze and bandage removal.

Owner:JI XIN

Biocompatible hemostatic, antiblocking, healing-promoting and surgical wound-closing modified starch material

InactiveCN101485897AMaterials that promote healingPromote repairOrganic active ingredientsSurgical adhesivesTissue fluidBandage

The invention relates to a modified starch material for biocompatible hemostasis, biocompatible anti-adhesion, tissue healing promotion, absorbable surgery sealing and tissue adhesion. The invention applies biocompatible modified starch to animal tissues, wherein the modified starch material has the molecular weight of more than 15,000 daltons, and the particle diameter of between 1 and 1,000 mu m. The modified starch hemostatic material has stypticity, reduces hemorrhage, blood oozing and tissue fluid oozing of wounds, maintains relative moistening or drying of wound surfaces or the wounds, inhibits bacterium growth and inflammation reaction, and contributes to locally diminish inflammation of the wounds and relieve pain of patients. Moreover, the modified starch material can wash local parts after operation is over and remove redundant modified starch which does not participate in hemostasis, and can easily remove haemostatic under the condition of debridement treatment after self-help and first-aid treatment of war wounds; and hemostatic materials with a small amount of modified starch can be absorbed by the body, so that the pain of tearing of gauzes and bandages on people is avoided.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

Thin film produced by using starch fiber waste plastic

The invention discloses a thin film produced by using starch fiber waste plastic. The new breakthrough and technical innovative points are applied to an environment-friendly plastic synthesized thin film or sheet. The produced environment-friendly plastic synthesized thin film or sheet comprises the following raw materials of 10-60 percent of high polymer waste plastic (regenerated plastic), 10-60 percent of modified starch, 10-50 percent of natural plant fiber, 5-30 percent of inorganic material and 2-15 percent of modifier, compatilizer and processing aid. In the plastic-synthesized thin film or sheet, the thickness of the membrane is 0.01-0.6mm and the thickness of the sheet is 0.6-3mm. The preparation of the thin film has the advantages that the environment-friendly practical thin film or sheet with degradation time with different efficiencies, transmissivity, stress degrees and the like can be obtained by adjusting the mixture ratio of various materials.

Owner:陈天云

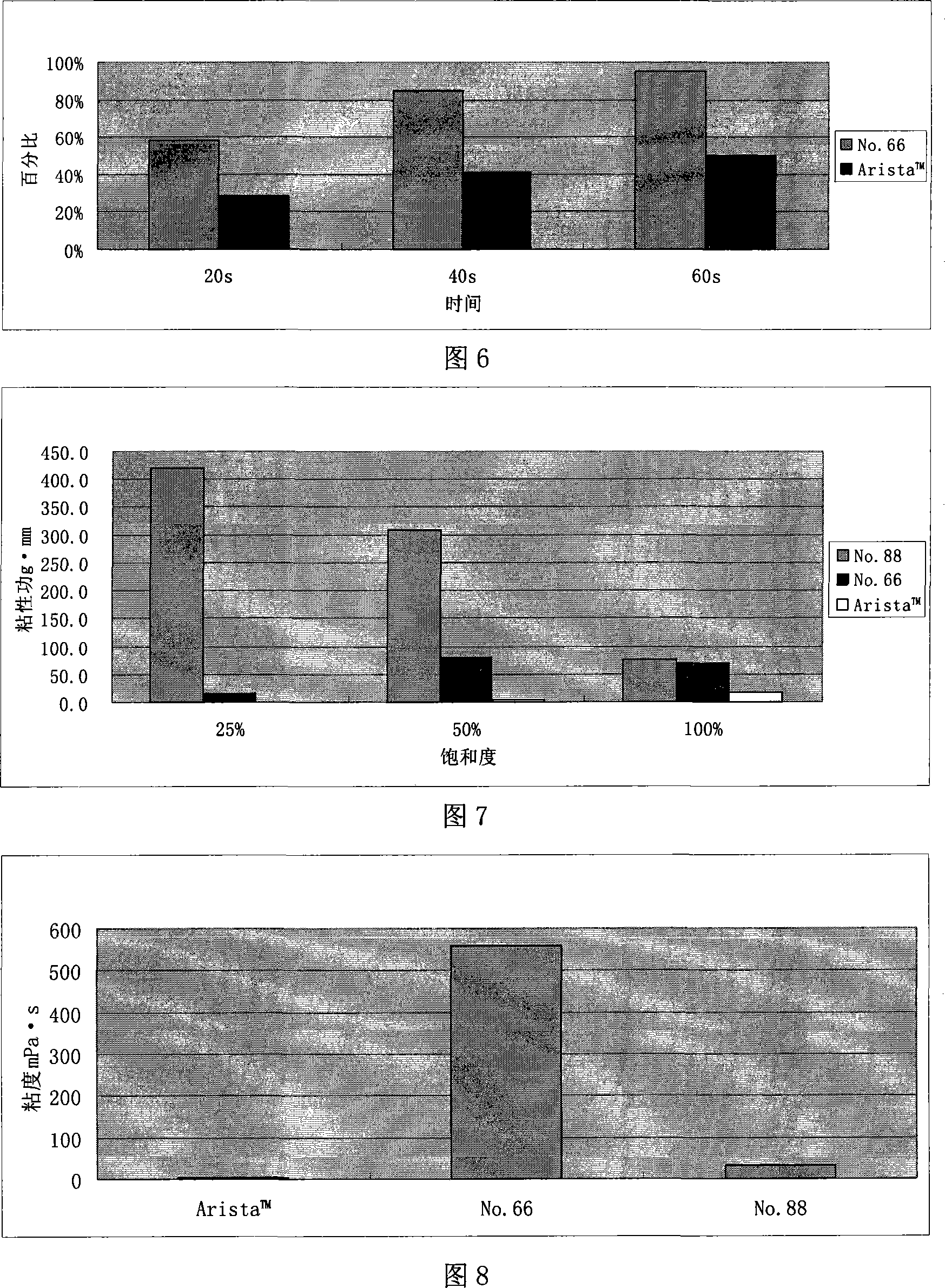

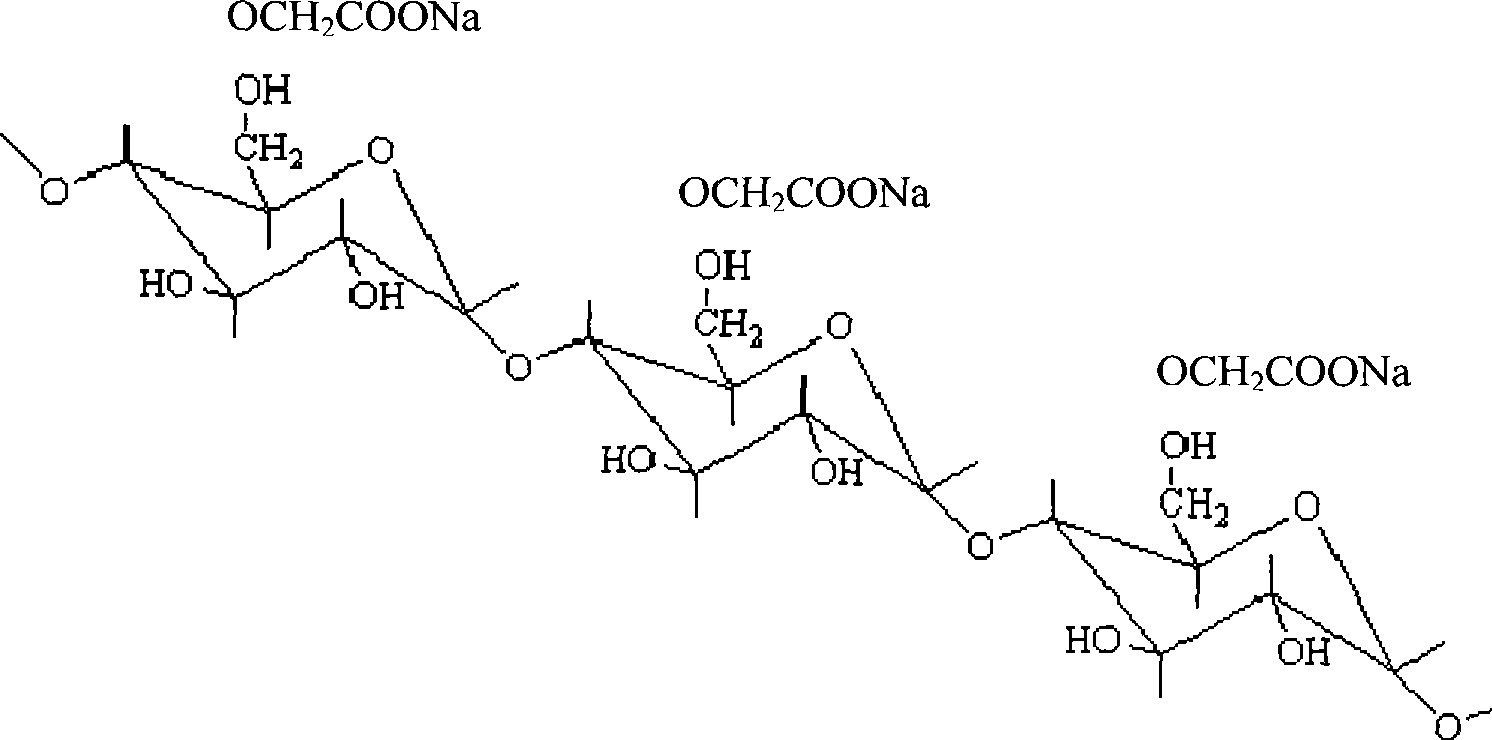

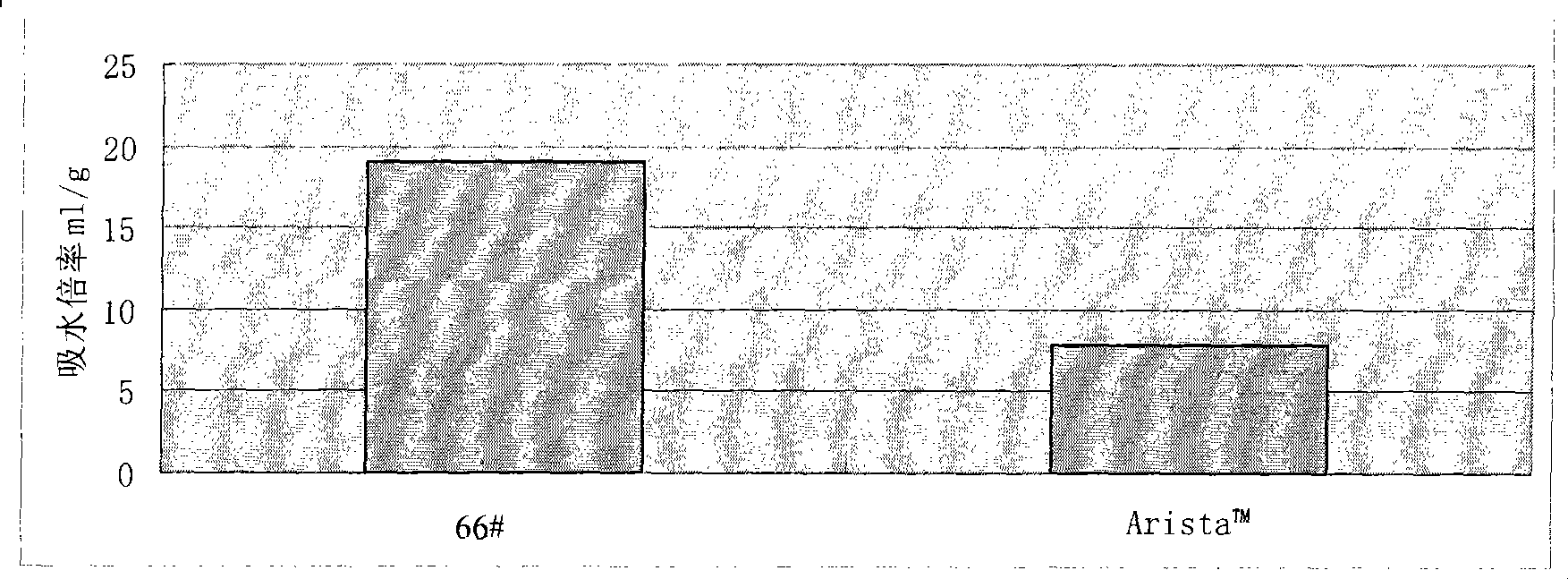

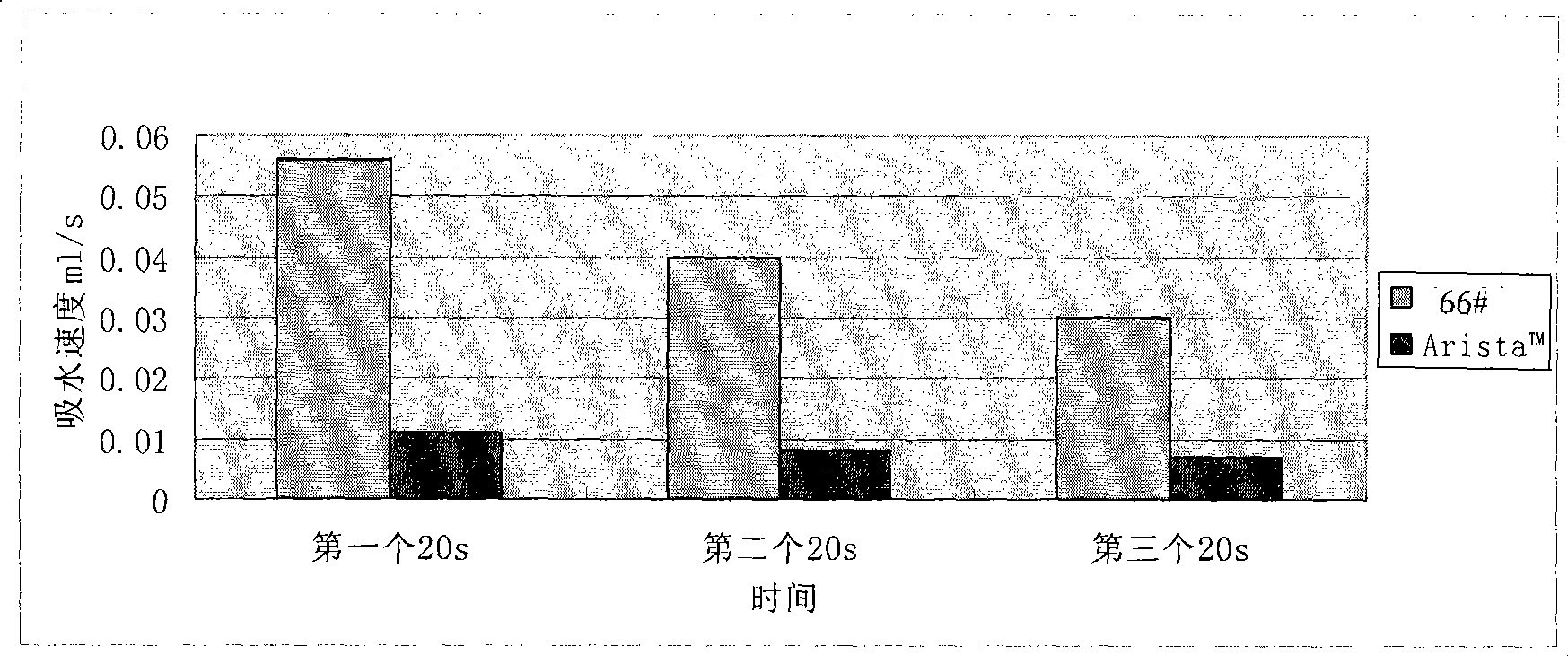

Denaturated starch absorbable hemostatic material and preparation method thereof

InactiveCN101121041AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismMedicineBlood plasma

An absorbable modified starch hemostatic material and preparation thereof, wherein the hemostatic material is etherified starch, or a mixture of one or more etherified starches, crosslinked starches. The modified starch has a molecular weight of 15,000 - 10,000,000, a particle size of 10 - 1000µm, and a water absorption rate of 1 - 100. The biocompatible hemostatic material can directly effect on the wound with blood, concentrate the blood quickly to congulate blood; moreover, the gelatiniform mixture formed with blood has high viscosity, which can plug damaged tissue and blood vessel. The biocompatible hemostatic material is easy to swell in the water and easy to be washed so that the residue can be reduced; it is stable, not easy to decompose, and has long shelf life and storage advantage. The biocompatible hemostatic material can also be used as absorbable surgical antisticking material, promoting tissue healing material, surgical sealant and wound no-joint tissue adhesive.

Owner:美国淀粉医疗公司

Elemental nutritional products

Owner:NESTEC SA

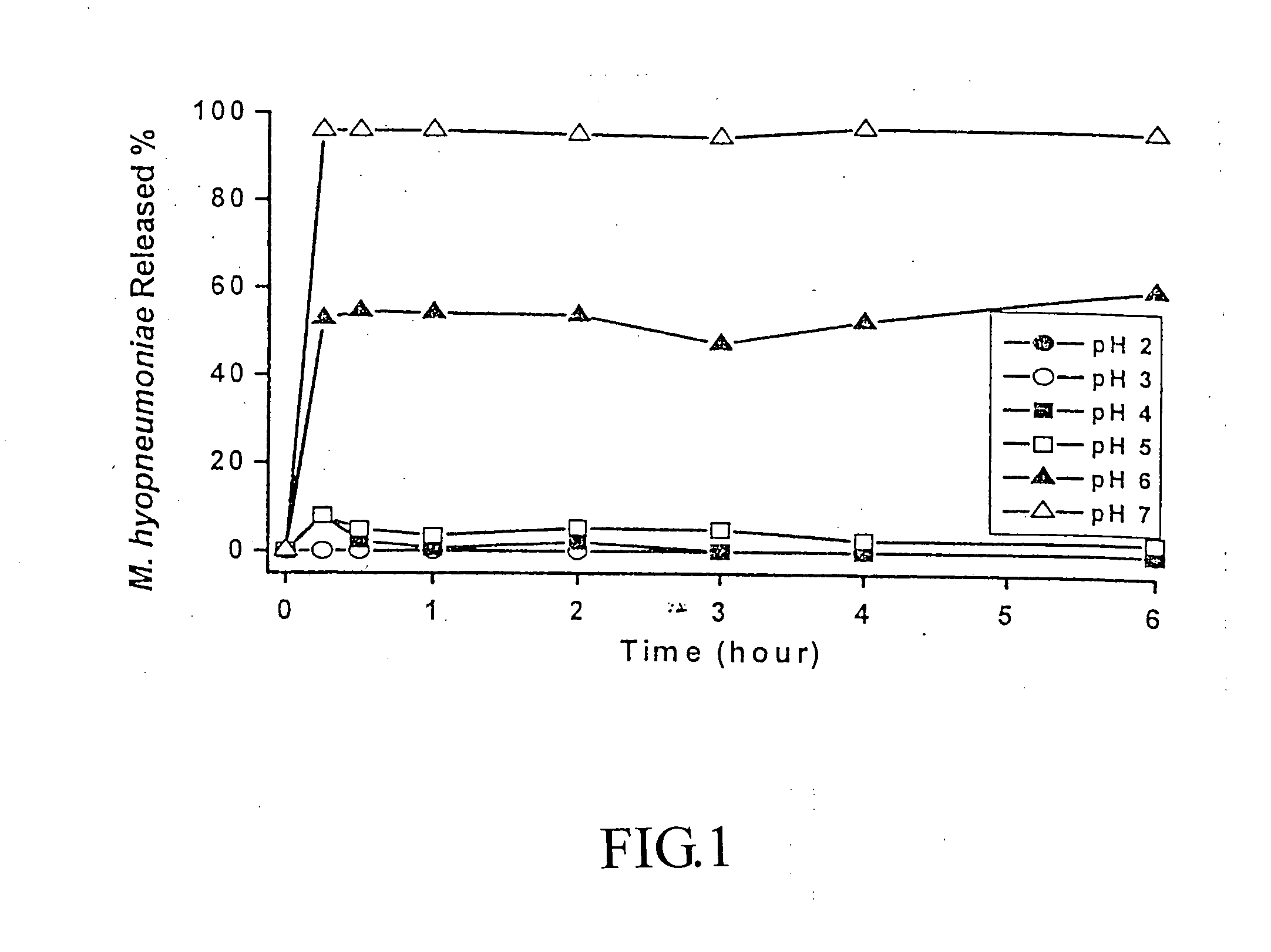

Probiotic composition having acid-resistant enteric coating

InactiveUS20070059296A1Improve digestibilityImproving resistance against diseaseOrganic active ingredientsBiocideBiotechnologyTalc

A probiotic composition essentially comprises 15 to 20 wt % of milk powder, 25 to 30 wt % of corn starch, 8 to 15 wt % of modified starch (capsul), 10 to 15 wt % of ethylcellulose, 5 to 15 wt % of bacterial broth, and 10 to 15 wt % of talc. The probiotic composition is microencapsulated to form a plurality of microencapsule coated with an acid-resistant enteric coating for improving the enteric acid-resistance, the probiotic survival rate, the antimicrobial property, the stability, the moisture-proof property, and the mobility of the probiotic composition preventing from coagulation in a moist environment and for being used as an additive applied to livestock feed.

Owner:BION TECH INC

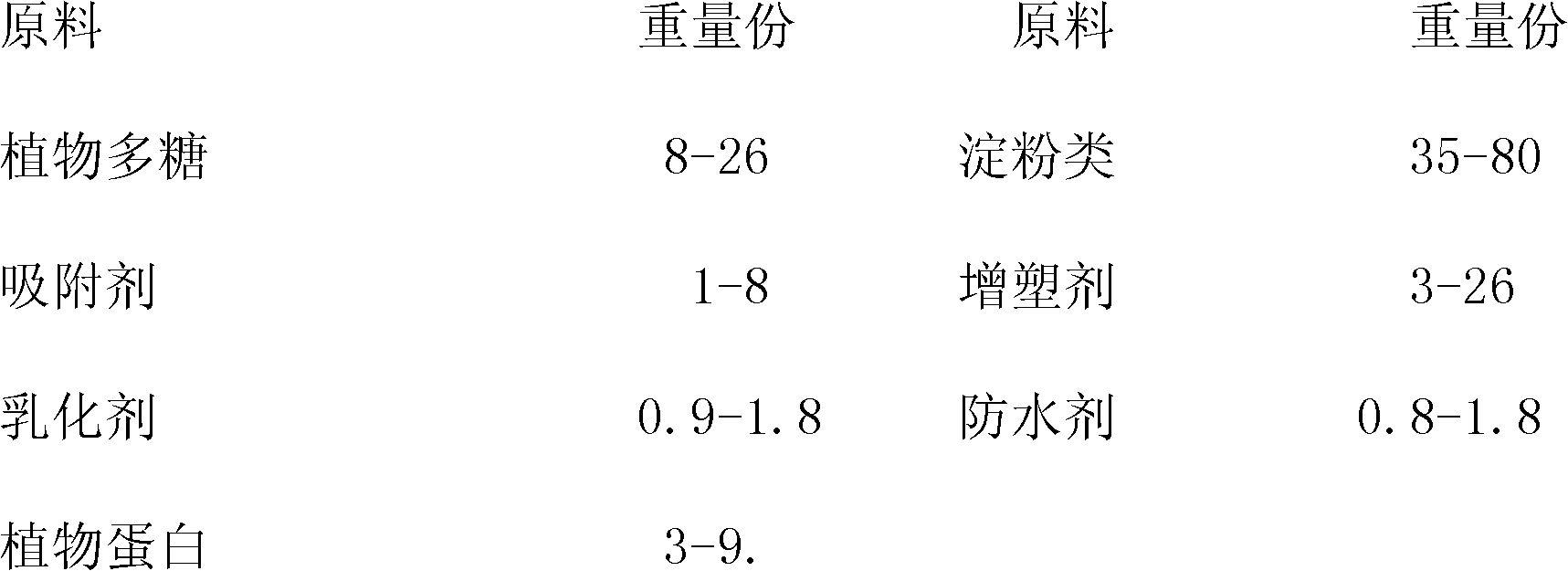

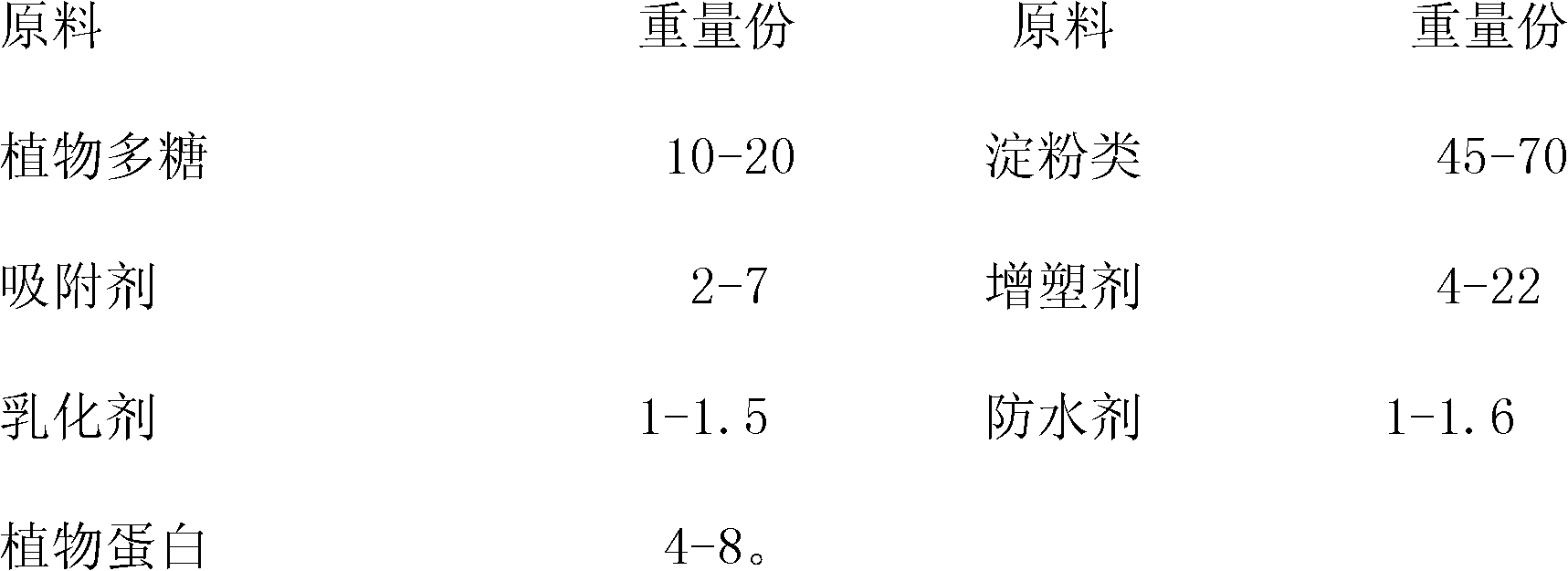

Plant polysaccharide cigarette filter tip and preparation method thereof

The invention discloses a plant polysaccharide cigarette filter tip and a preparation method thereof. Plant polysaccharide, starch, adsorbent, plasticizer, emulsifier, waterproofing agent and plant protein are blended according to a certain proportion, so that the filter tip is prepared. The preparation method includes the following steps: (a) the starch, water and the plasticizer are blended and stirred, so that modified starch solution is obtained; (b) the plant polysaccharide and the modified starch solution are blended; (c) under certain conditions, the emulsifier, the waterproofing agent and the adsorbent are added into the mixture of the plant polysaccharide and the modified starch solution, and after stirring, the mixture is injected into a long cylindrical mold made of anti-freezing, heat-proofing material and molded; (d) the semifinished product is placed into a freezing environment and frozen, i.e. prefreezing; (e) the semifinished product in step d is placed into a freeze dryer and freeze-dried; (f) the porous composite body is taken out of the mold and deburred, and thereby a filter tip stick is obtained. Material resources are rich, the cost is low, and the three wastes cannot be produced. The performance is good, the filter tip can reduce the nicotine content by 40.2 to 84.1 percent, the tar by 26 to 72.1 percent and the nicotinamide by 20 to 39.2 percent, and after use, waste can be biodegraded.

Owner:WUHAN LICHENG BIOTECH +1

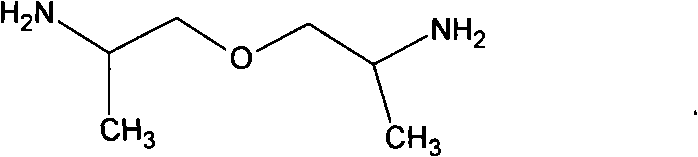

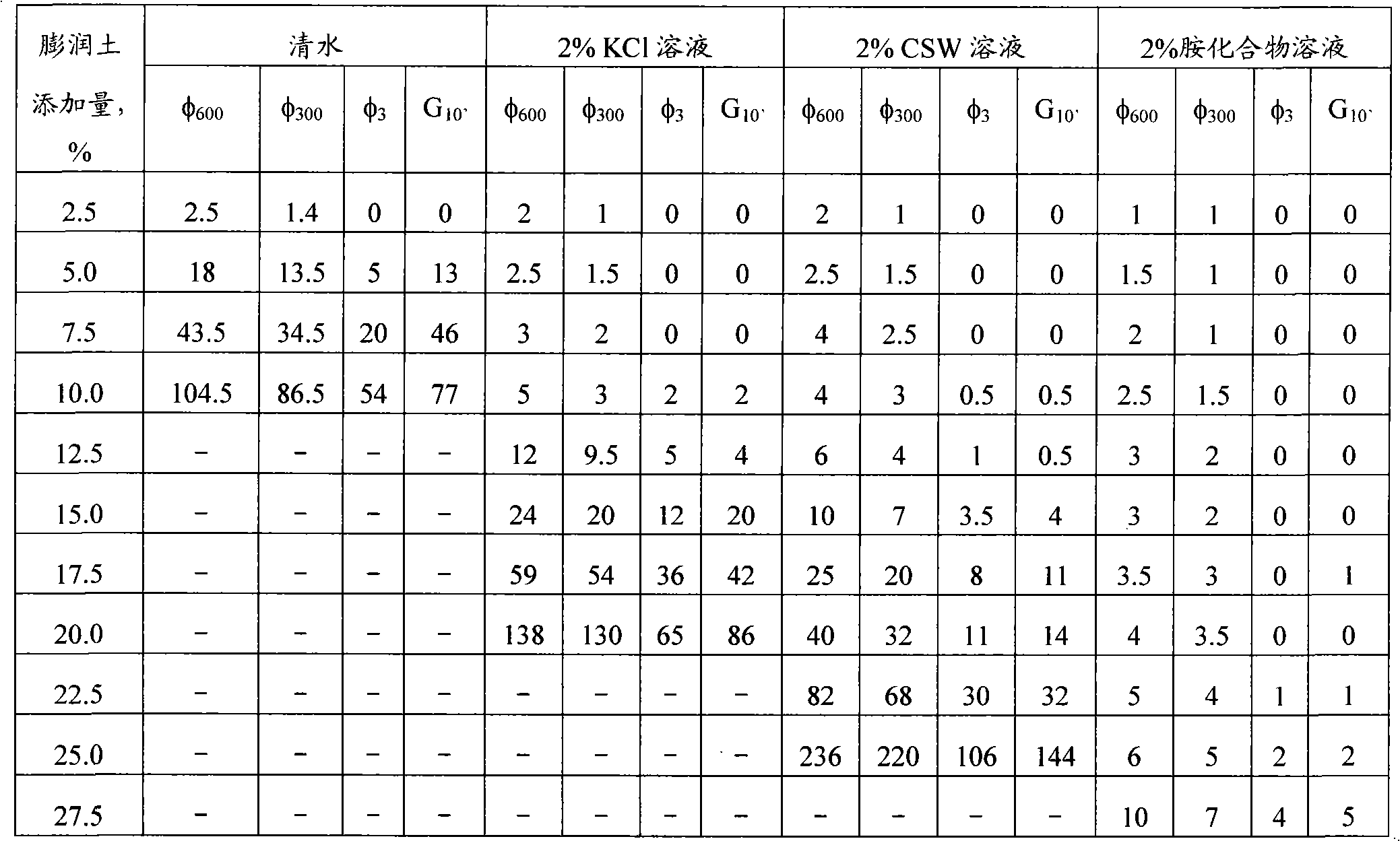

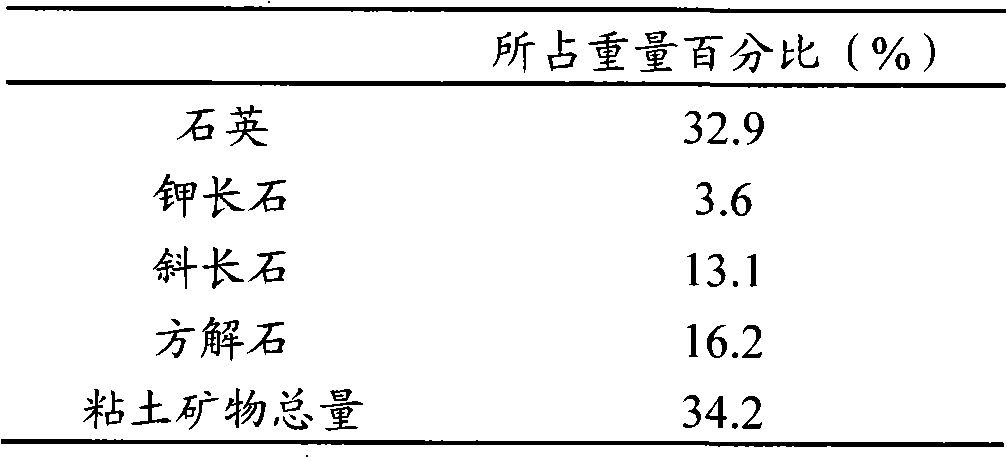

Water-based drilling fluid composition containing amine compound

The invention provides a water-based drilling fluid composition containing an amine compound, which comprises the following components: a 0.5 to 5 weight percent of water-based amine compound as shown in formula I: RHN-Y-[OY']X-NHR', wherein Y, Y',x, R and R' are as defined in a manual; 0.1 to 1.0 weight percent of water-based tackifier which is selected from one or more types of xanthan gum, acrylamide-acrylic copolymer and hydroxyl ethyl cellulose; 0.5 to 5 weight percent of water-based fluid loss agent which is selected from one or more types of modified lignite, acrylic polymer, modified starch and modified cellulose; 2 to 12 weight percent of water-based inhibitor which is selected from one or more types of potassium chloride, potassium sulfate, formic acid, formic acid sodium, potassium chloride and epoxypropyltrimethylammonium chloride; and the composition can also further comprises coating agent, weighting agent, lubricant, borehole stabilizer and the like. The water-based drilling fluid composition has good inhibiting performance to clay shale drilling cuttings.

Owner:CNPC DRILLING RES INST

Preparation method of fully biodegradable starch/polylactic acid base resin

InactiveCN105440606AIncrease linear contentImprove mechanical propertiesGlass transitionPolylactic acid

The invention provides a preparation method of fully biodegradable starch / polylactic acid base resin. The starch / polylactic acid base resin comprises 100 parts of polylactic acid, 30-90 parts of modified starch, 5-25 parts of biodegradable resin, 15-35 parts of a plasticizer and 1-15 parts of other assistants. The preparation method comprises the following steps: carrying out ultrasonic treatment on the modified starch, mixing the ultrasonic treated modified starch, polylactic acid powder and the other assistants in a high speed mixer at a temperature equal to or greater than the glass transition temperature of polylactic acid, and carrying out blending granulation on the above obtained blend through a double screw extruder to obtain a completely biodegradable material with excellent mechanical strength. Compared with like resins, the resin provided by the invention has the advantages of realization of reduction of the cost of the polylactic acid material while realizing high starch loading, good mechanical performances, full biodegradability and improved practicality.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

Biocompatibility modified starch sponges

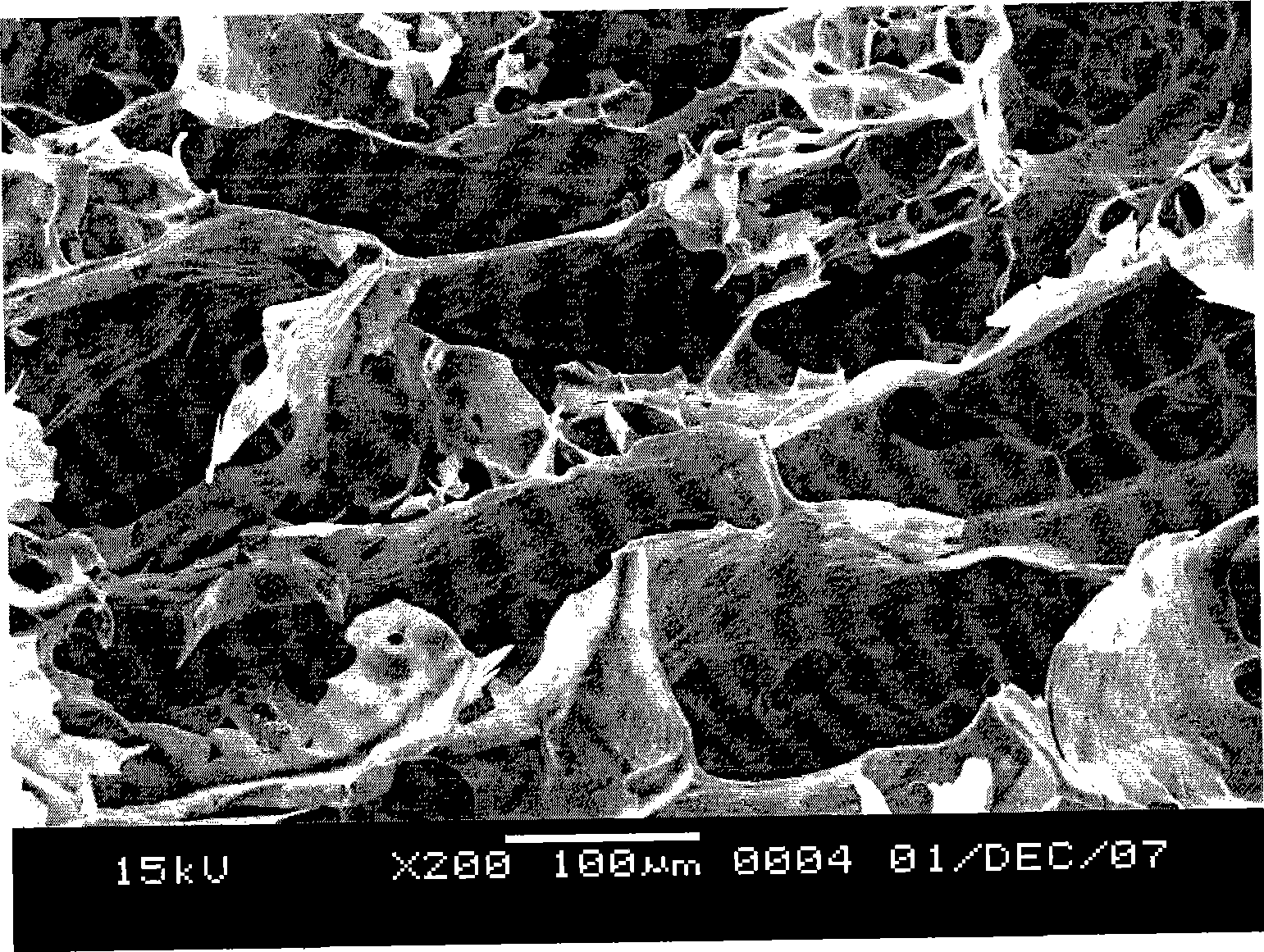

ActiveCN101455857AFlexibleActive bleeding is easily controlledAbsorbent padsBandagesFreeze-dryingBiocompatibility Testing

The invention relates to biocompatible modified starch sponge and use of the biocompatible modified starch sponge as a hemostatic material, an anti-adhesion material, a material for promoting tissue healing, a surgical sealant or a wound tissue adhesive. Modified starch is one or a combination of more than one among pre-gelatinized starch, acid modified starch, dextrin, oxidized starch, esterified starch, etherified starch, crosslinked starch, grafted starch and composite modified starch. The sponge is prepared by vacuum freeze drying of the modified starch and other biocompatible hemostatic material, coagulant, plasticizer and so on. The biocompatible modified starch sponge has the advantages that the biocompatible modified starch sponge has flexible form and good biocompatibility, can be directly acted on bloody wound surfaces, avoids the conditions of hypersusceptibility, infection and difficult healing of wounds caused by adoption of hemostatic materials such as animal source / human source collagens, obviously improves the water absorption speed, has larger viscosity, forms a zymoplastic mixture which has good adhesion, calks broken tissues and blood vessels, and is used for hemostasis of active hemorrhage.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

Fast dissolving orally consumable films containing a modified starch for improved heat and moisture resistance

A consumable film adapted to adhere to and dissolve in the oral cavity of a warm-blooded animal including humans, comprising a modified starch, a pharmaceutically active agent and, optionally, at least one water soluble polymer.

Owner:MCNEIL PPC INC

Modified starch absorbable hemostasia material and preparation method thereof

ActiveCN101361986AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismWound healingBiomedical engineering

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

Size composition for textile

A textile size composition is prepared from modified starch (20-90%) and specia nano material (0.05-5%) which is chosen any one of SiO2, TiO2, Al2O3 and ZrO2. Its advantages are high stability, shortdissolving time and high effect of benefiting weaving.

Owner:杭州科瀚盟新材料技术有限公司

Rubber containing starch reinforcement and tire having component thereof

InactiveUS6269858B1Enhance tire rolling resistanceImprove lagPaper coatingSpecial tyresPlasticizerTread

The present invention relates to a rubber composition containing a combination of starch, modified starch and / or starch / plasticizer composite together with selected methylene donor and / or methylene acceptor compounds. The invention also relates to tires having at least one component comprised of such rubber composition. Such tire component can be, for example, its circumferential tread or other component of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

Antiperspirant compositions

InactiveUS6261543B1Small mean droplet sizeCosmetic preparationsToilet preparationsOil phasePhase stability

Antiperspirant emulsions which exhibit excellent phase stability even in the presence of an effective concentration of antiperspirant salts in solution and which are thickened are obtainable by dispersing a hydratable polymer and particularly an amphoteric or cationic modified starch in an aqueous emulsion forming a viscous emulsion, often at an elevated temperature, subjecting the emulsion to high shear, thereby reducing the droplet size of the dispersed oil phase, bringing the emulsion to below 40° C. and introducing the antiperspirant, preferably in aqueous solution. The viscous emulsion subjected to high shear mixing desirably has a Sheer Stress of 10 to 500 Pa. The resultant emulsions show good phase stability even when they contain aluminium / zirconium antiperspirant salts that promote instability and even at elevated storage temperatures such as at 50° C.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Edible Film

InactiveUS20100240724A1Excellent film forming property and solubility and feelingEasy to prepareBiocideNervous disorderSolubilityHydrolysate

The present invention relates to an edible film composition comprising a waxy starch hydrolysate, a modified starch and a water-soluble polymer, and an edible film comprising the same. The present edible film may not only have an excellent film forming property, solubility and feeling in the oral cavity, but also be easily prepared at low cost, and thus be usefully used as an oral cleanser or a bad breath remover for oral cleansing, and a soluble formulation on tongue for uptake of drug in the oral cavity.

Owner:C L PHARM

Tea jelly sweet

The invention discloses a tea jelly sweet which is prepared from raw material in the formula in parts by weight: 4-10 parts of functional composition, 30-60 parts of maltitol, 30-40 parts of starch syrup, 3.5-7 parts of plural gel, 0.1-10 parts of lecithin, 0.1-3 parts of hydrogenated vegetable oil, 1-3 parts of peppermint oil and 20-40 parts of water, wherein the functional composition comprises one or several of ultra-micropowder or extractions or original materials of pu-erh tea, black tea, green tea, Oolong tea, white tea, yellow tea and dark tea and other functional factors; and the plural gel comprises modified starch, gelatine, agar and carrageenan. The invention has the characteristics of defined functions, attractive appearance, natural aroma, good taste and the like, has no artificially-synthesized pigment and essence and sweetner causing decayed tooth and is suitable for groups to eat for a long term so as to improve the sub-health state.

Owner:云南龙润茶业集团有限公司

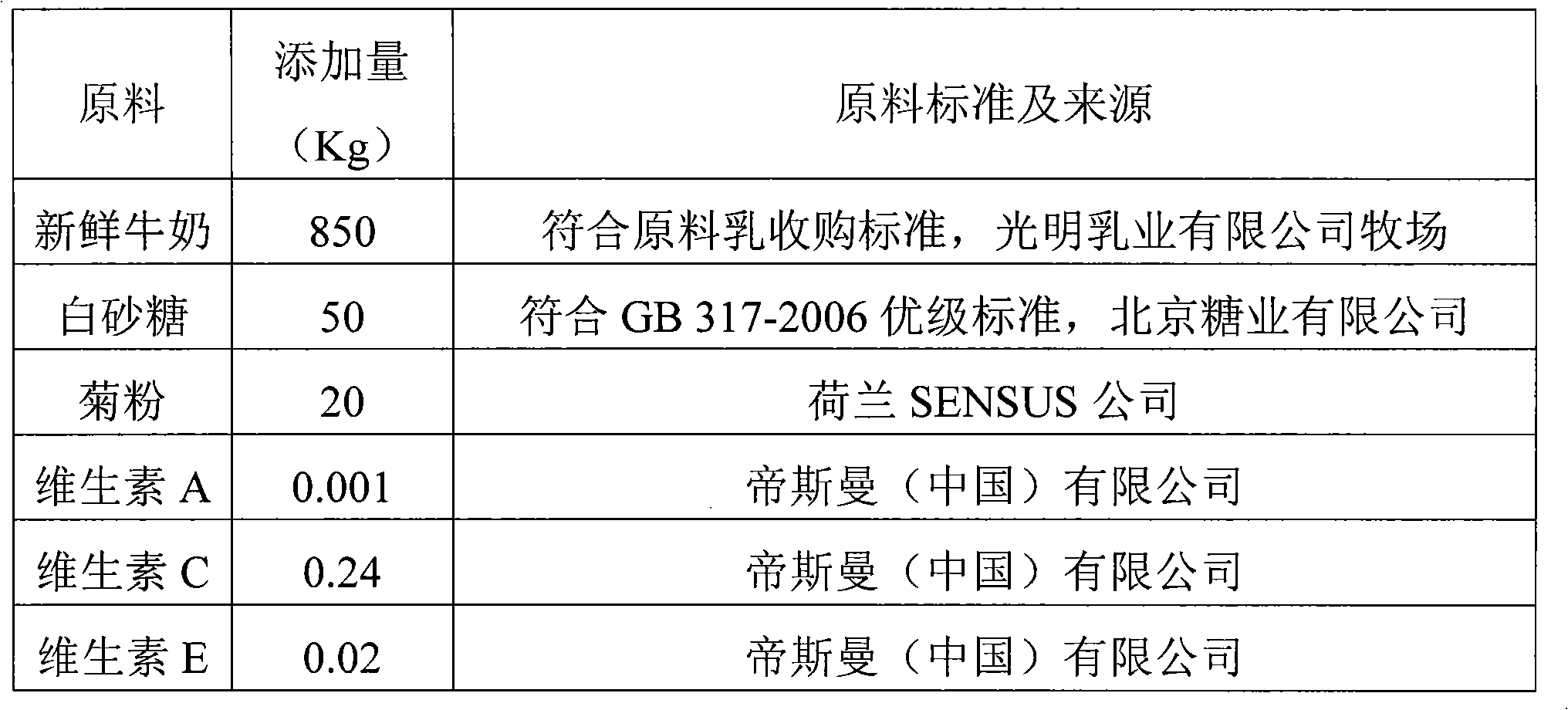

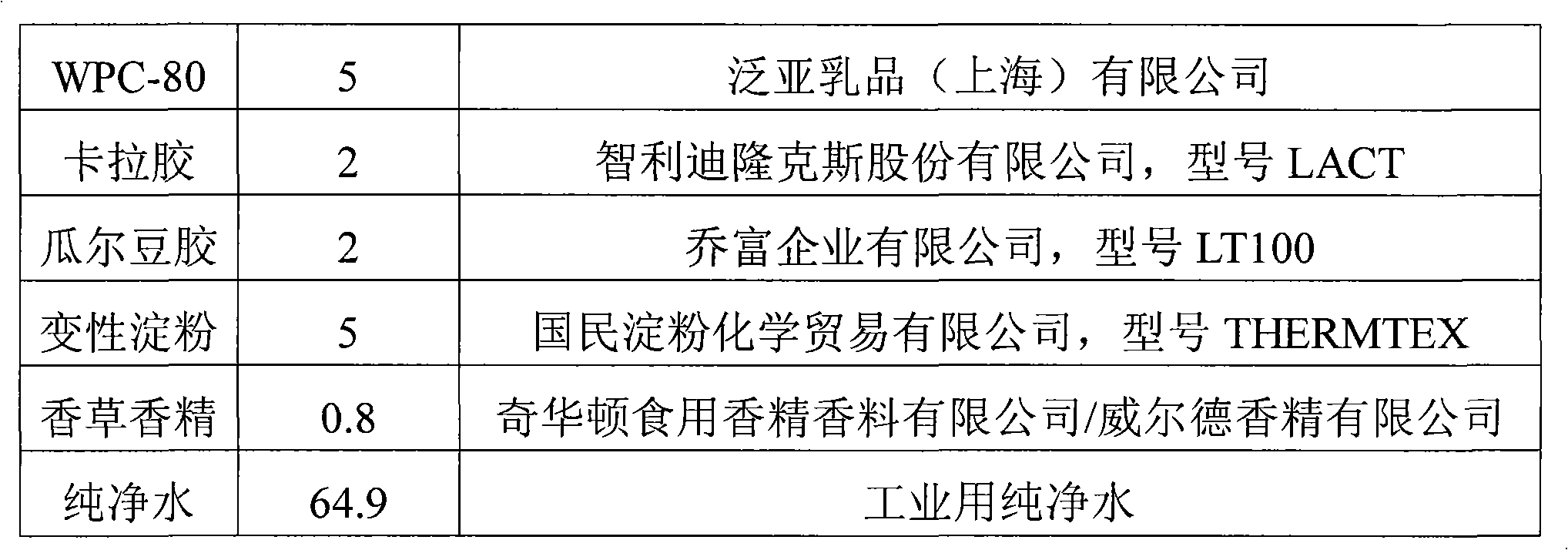

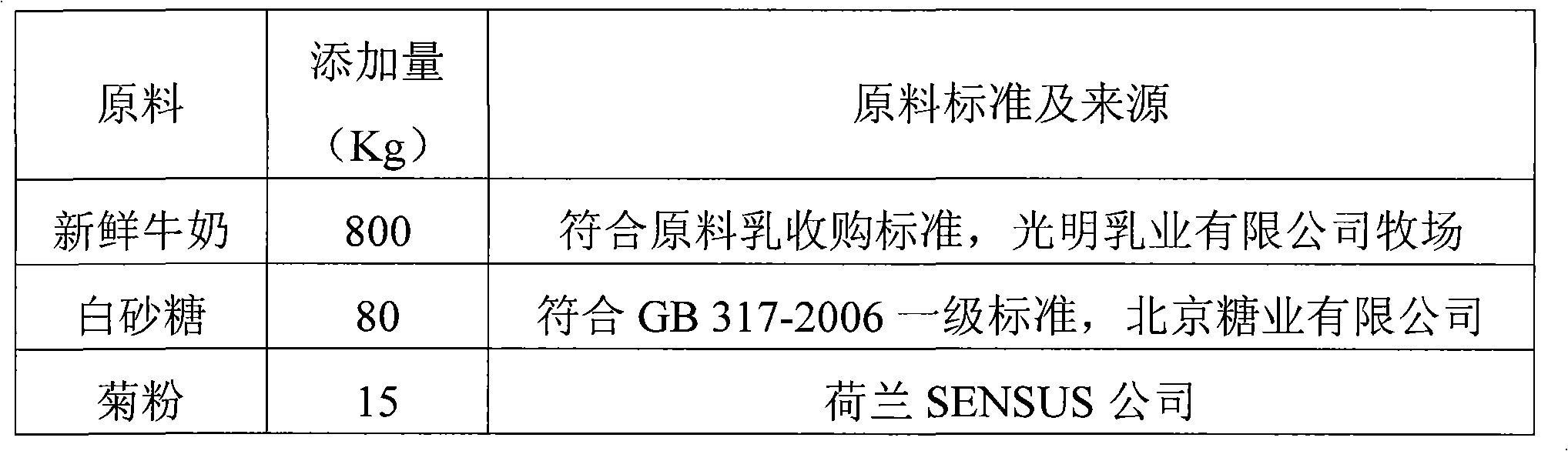

Milk pudding and preparation method thereof

The invention discloses a milk pudding. Based on 1,000 parts of final product, the milk pudding comprises the following components in part by mass: 300 to 850 parts of milk, 0.3 to 150 parts of sweetener, 15 to 30 parts of inulin, 4 to 15 parts of food gelatine, 5 to 20 parts of modified starch, 5 to 30 parts of concentrated whey protein, 0.1 to 1 part of edible essence and 48 to 380 parts of water. The milk pudding has high nutrition, can bi-directionally regulate intestinal flora by adding the inulin, and has special health-care effect on the human body; the milk pudding is semisolid and creamy, has soft, exquisite and fresh mouthfeel, has spoon eating property, is novel milk food, and enriches the category of milk products; the milk pudding is children's food, is also leisure dessert suitable for white-collared workers and the middle and old-aged people, and has a huge consumer market; and the better storage temperature is 4 to 8 DEG C, and the quality guarantee period is 20 to 25 days.

Owner:BRIGHT DAIRY & FOOD

Sugar free health care grosvenori crystal and manufacture method thereof

The invention provides a sweet crystal of grosvenor momordica with the type of free sugar and health care and a method thereof, which includes that tetracyclic triterpene water extract is extracted from grosvenor momordicas. The character is that modified starch with certain proportion is added into the tetracyclic triterpene water extract of grosvenor momordica, spray-drying and oven-drying are carried out, then the product is finished after being crushed through 60 mesh sieve. The sweet crystal has the color of light brown, keeps the medicinal function of grosvenor momordica and dissolves in water completely. The solution has good taste and special flavor. After drinking the solution, people do not feel sour in mouth, and the taste of sweet cool can be kept in mouth for a few minutes. The sweet crystal is convenient for use. The added quantity is almost the same as the quantity of the traditional habit.

Owner:张雨生

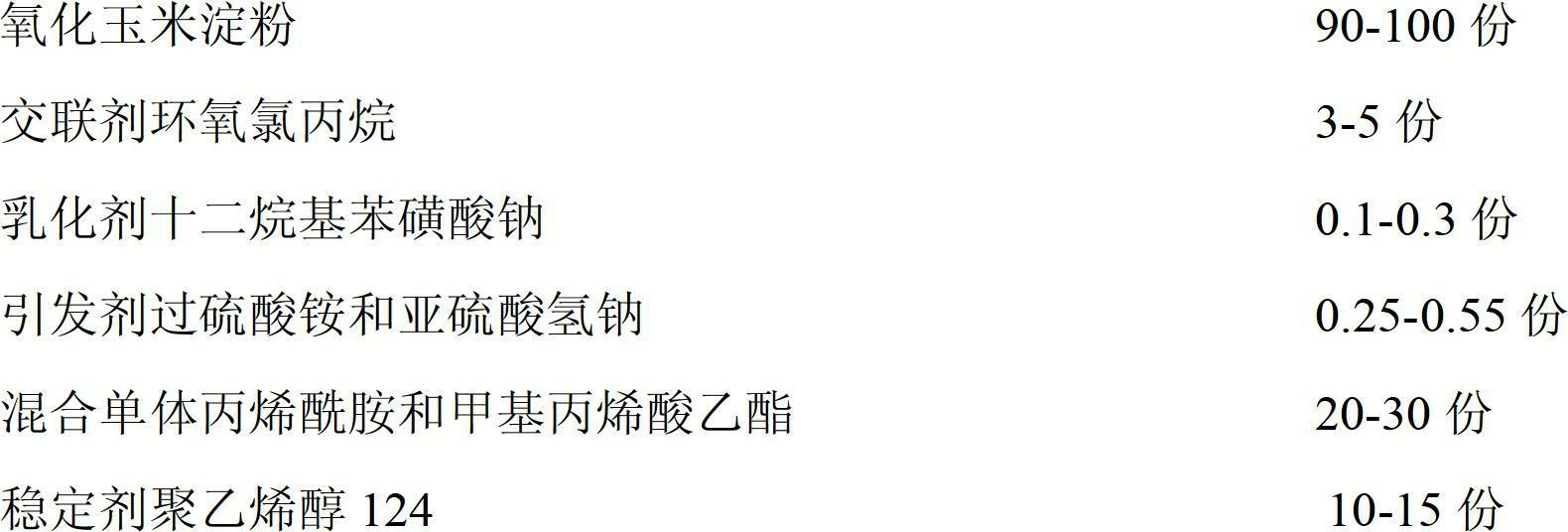

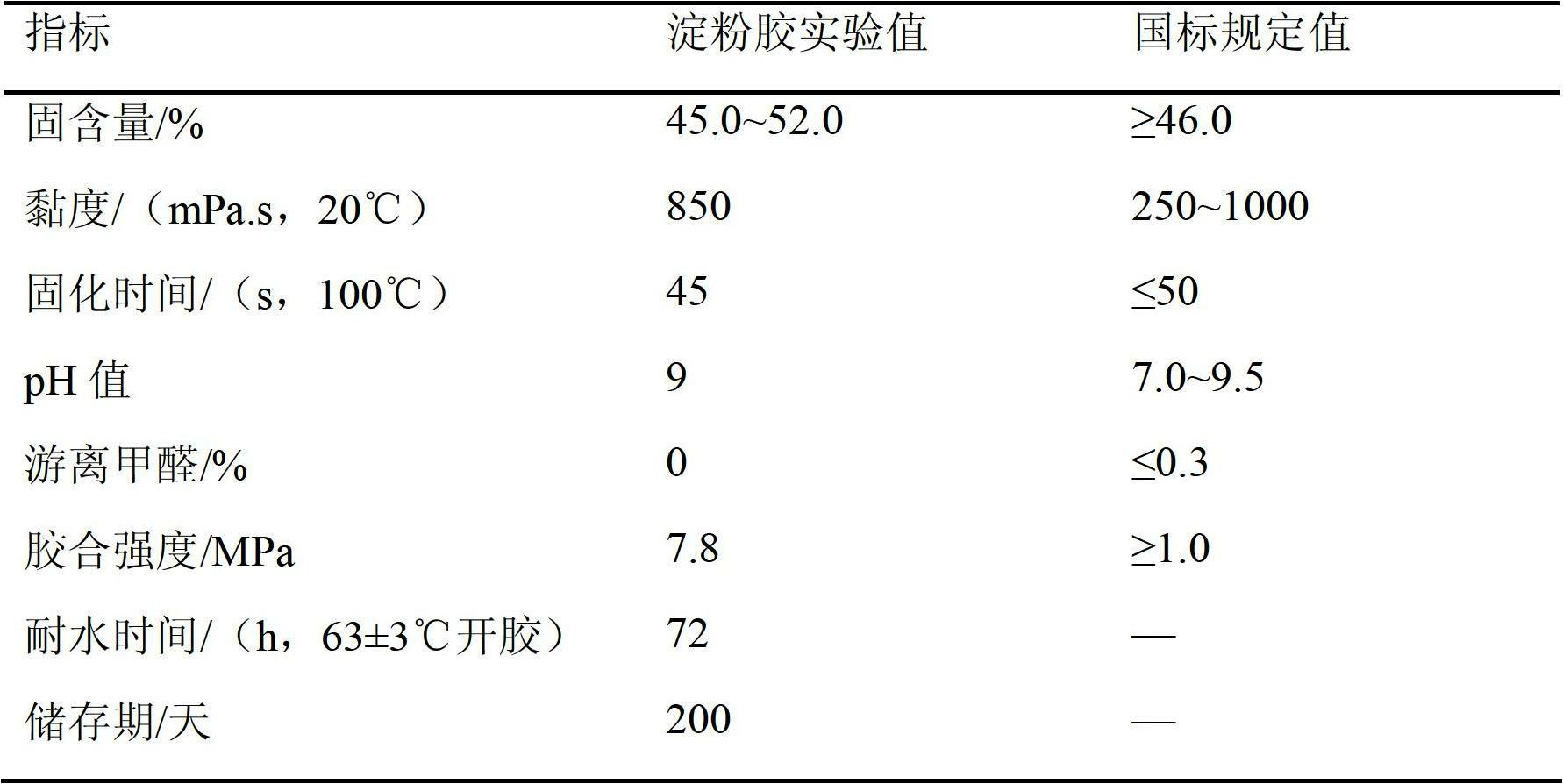

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

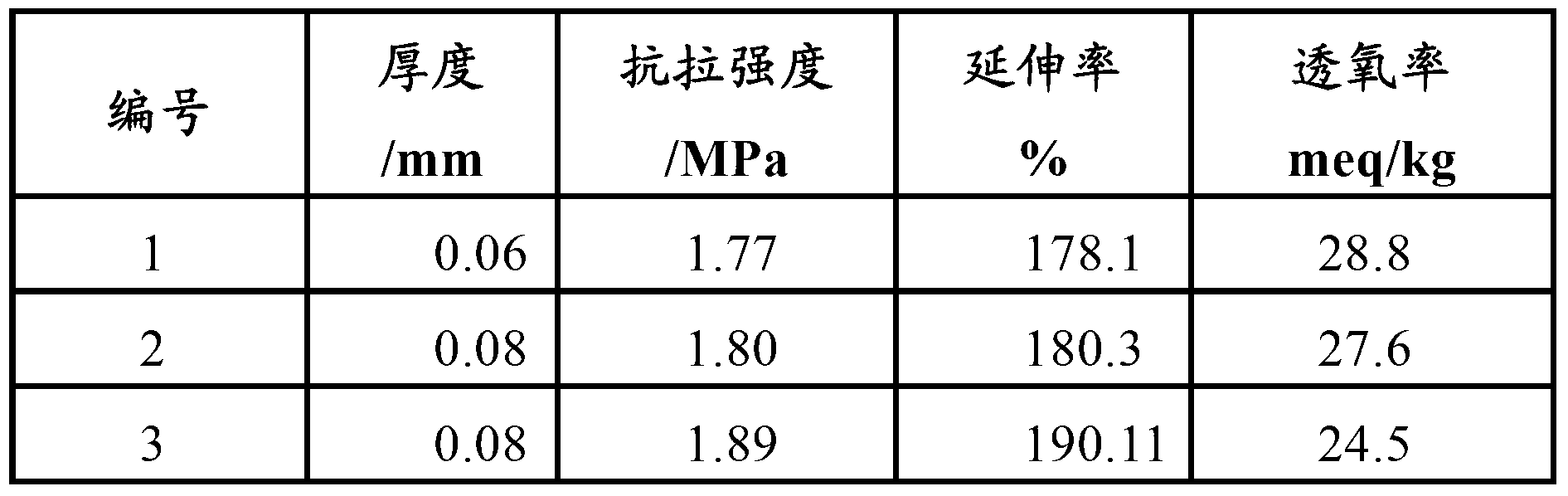

Starch-based edible film and preparation method thereof

InactiveCN101906220ARich sourcesReduce manufacturing costFlexible coversWrappersPliabilityStabilizing Agents

The invention relates to a starch-based edible film and a preparation method thereof. The starch-based edible film is a starch-based edible packaging film with favorable flexibility, barrier property, ageing-resistance property and heat sealing property, which is prepared by adopting the preparation method comprising the following steps of: adding a food-grade plasticizer, a lubricating agent, a reinforcing agent, a stabilizing agent and other accessories by taking stably-degraded composite modified starch as a main film-forming raw material, stirring and mixing at high speed, carrying out double-screw extrusion granulation and then carrying out single-screw extrusion casting to obtain the finished product. The invention has the characteristics of low energy consumption and high production efficiency and is suitable for industrial continuous production. The prepared film in the invention has edibility and full degradability, can be widely applied to inner packaging of foods, and avoids non-degradable food packages from polluting the environment.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Edible film material containing nanocellulose, edible film and preparation method of edible film

ActiveCN103254469AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersMechanical propertyFilm material

The invention discloses an edible film material, an edible film made of the edible film material and a preparation method of the edible film. The edible film material comprises nanocellulose, modified starch and other edible auxiliary materials. With the adoption of the nanocellulose, the mechanical performance and the barrier property of the edible film are improved. The edible film can be widely applied to the inner packing of food such as high-class candies and chocolate.

Owner:珠海市红旌发展有限公司

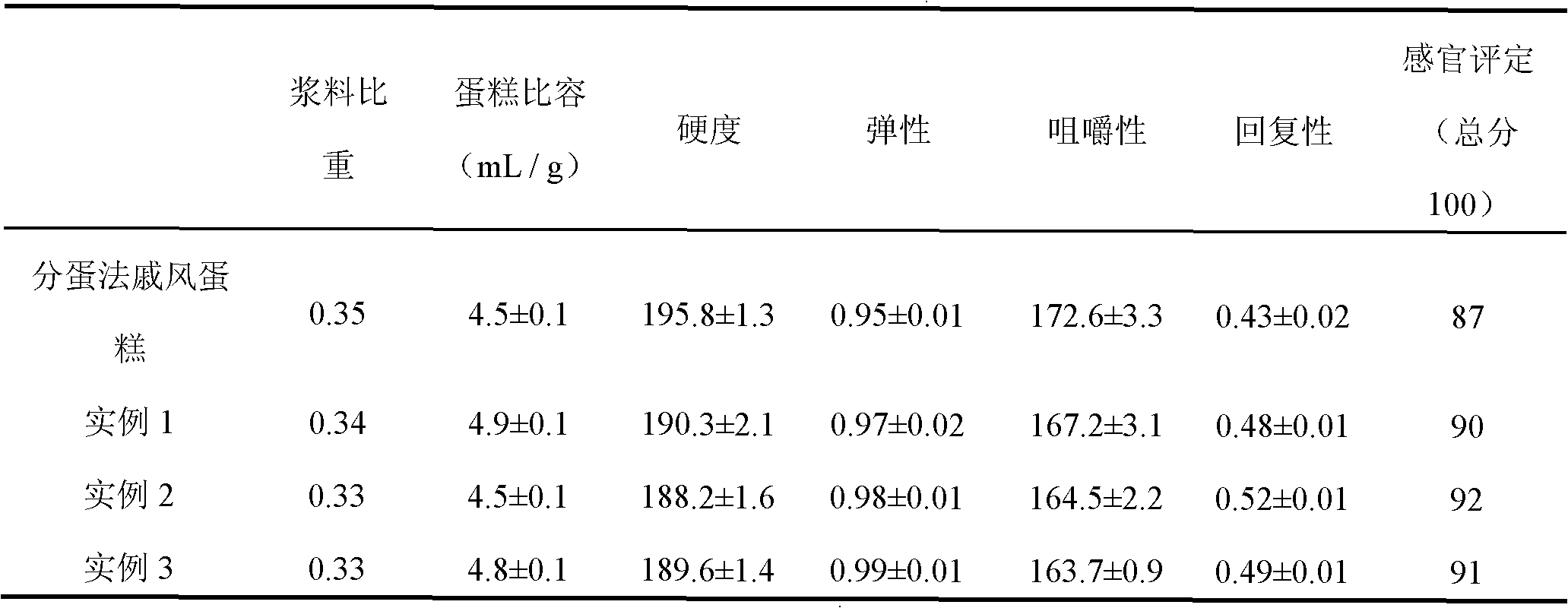

Chiffon cake pre-blend flour requiring no egg separation, chiffon cake adopting pre-blend flour, and preparation method of chiffon cake

ActiveCN102047923ASimple manufacturing processSoft textureDough treatmentBakery productsSucroseCryopreservation

The invention discloses a chiffon cake pre-blend flour requiring no egg separation, a chiffon cake adopting the pre-blend flour, and a preparation method of the chiffon cake. The chiffon cake pre-blend flour comprises the following components by weight percentage: 45% to 50% cane sugar, 40% to 45% self-raising flour, 6% to 8% albumen powder, 2% to 3% modified starch, 0.4% to 0.8% edible gum, 0.2% to 0.4% salt, 0.1% to 0.3% acidity regulator and 0.1% to 0.3% food flavor. The chiffon cake prepared by the chiffon cake pre-blend flour is characterized in that compared with traditional preparation technology, egg separation leavening is not required and tartar powder is not needed also. The preparation method of the chiffon cake is simplified, and the prepared chiffon cake is soft, moisture-contained and flexible, and is cryopreservation resistant, and the quality of the cake is improved compared with that adopting traditional preparation method.

Owner:广州合诚实业有限公司

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Preparation method of modified starch-polyvinyl alcohol-based composite plastic film

ActiveCN101914223AGood mechanical propertiesImprove water resistanceFlat articlesCellulosePolymer science

The invention provides a preparation method of a modified starch-polyvinyl alcohol-based composite plastic film, belonging to the technical field of high polymer materials. The preparation method comprises the following steps of: uniquely oxidizing carbon atoms C2 and C3 in a glucose unit of starch into an aldehyde group under the action of a strong oxidant; breaking C2-C3 chains to obtain dialdehyde modified starch; and then blending the dialdehyde modified starch with polyvinyl alcohol (PVA), plasticizer, cellulose and the like which are used for synthesizing biodegradation type polymers to obtain the starch-based plastic film with favorable mechanical property, water resistance and degradation. The invention provides an extensive application prospect for the starch-based plastic film.

Owner:DUNHUANG XIYU MINING & CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com