Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87979 results about "Pulp and paper industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pulp and paper industry comprises companies that use wood as raw material and produce pulp, paper, paperboard and other cellulose-based products. The pulp is fed to a paper machine where it is formed as a paper web and the water is removed from it by pressing and drying.

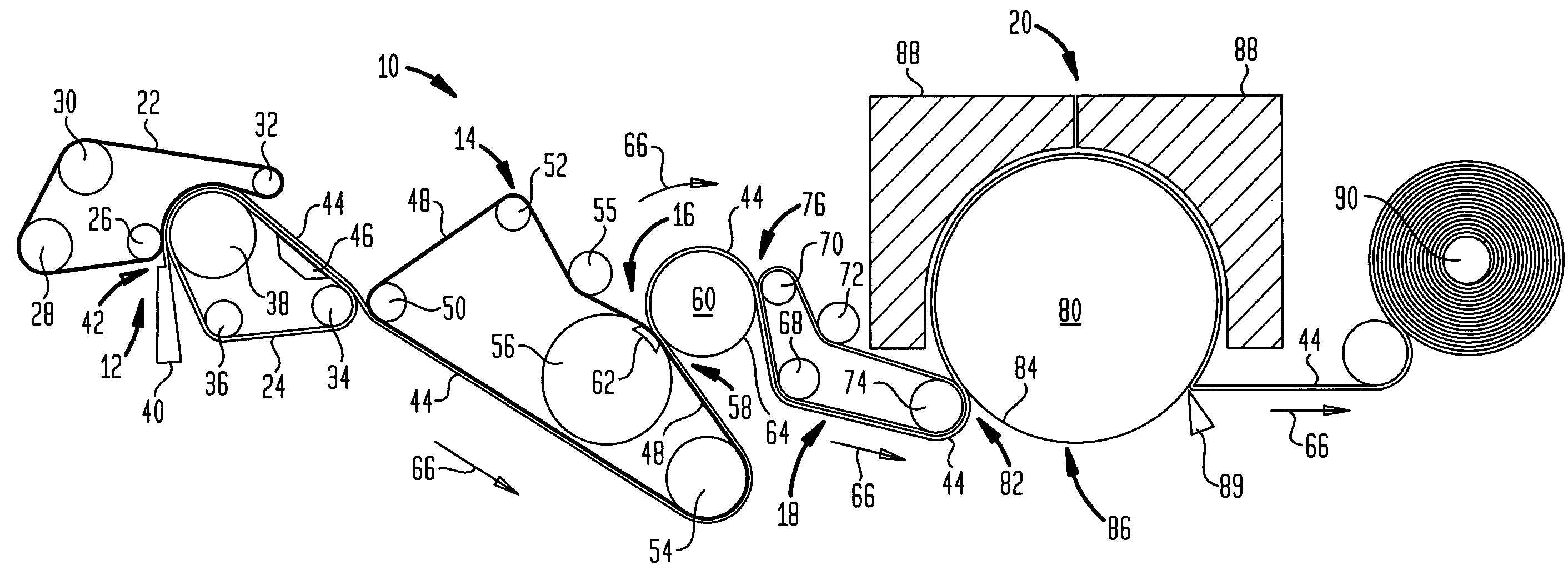

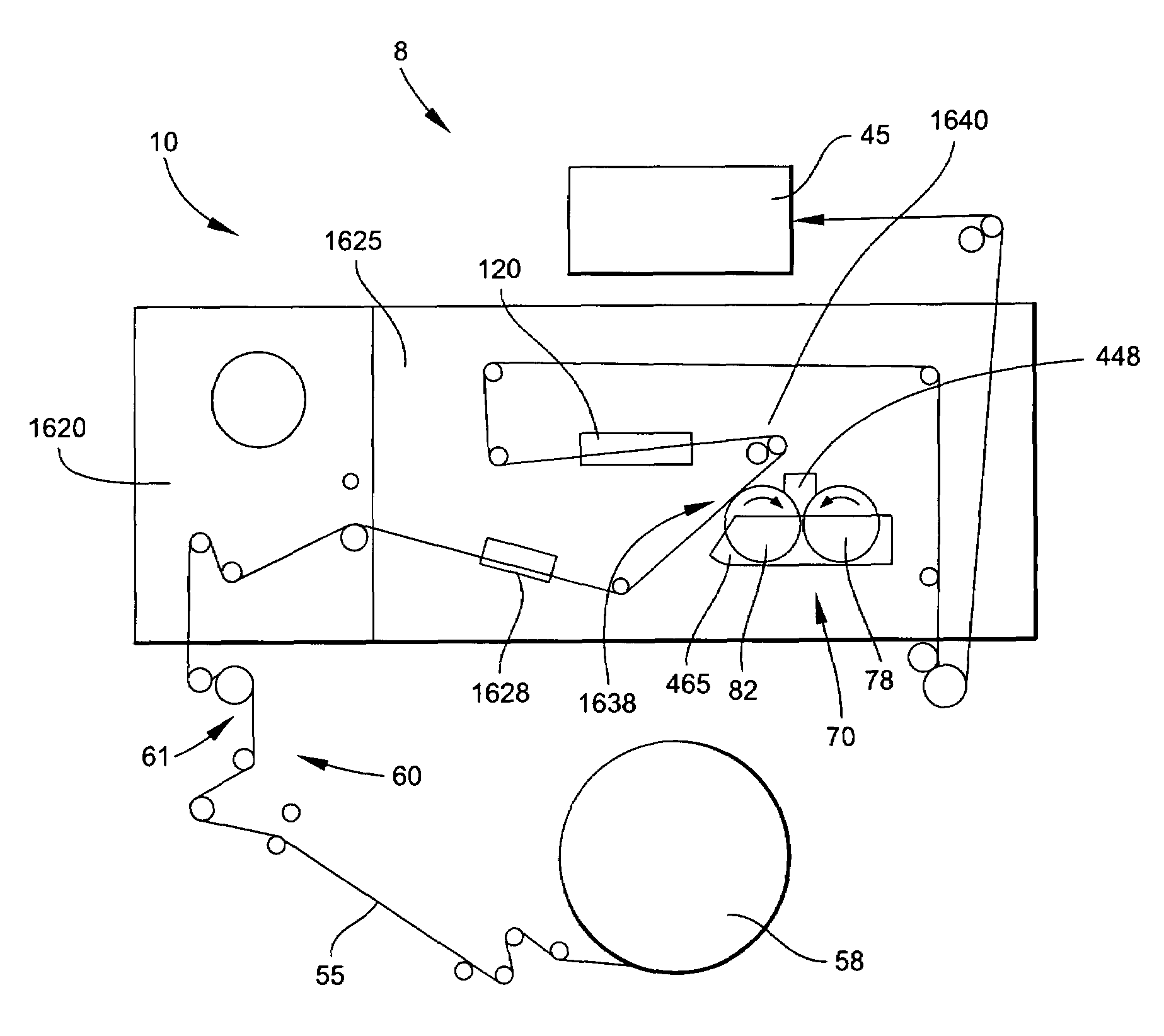

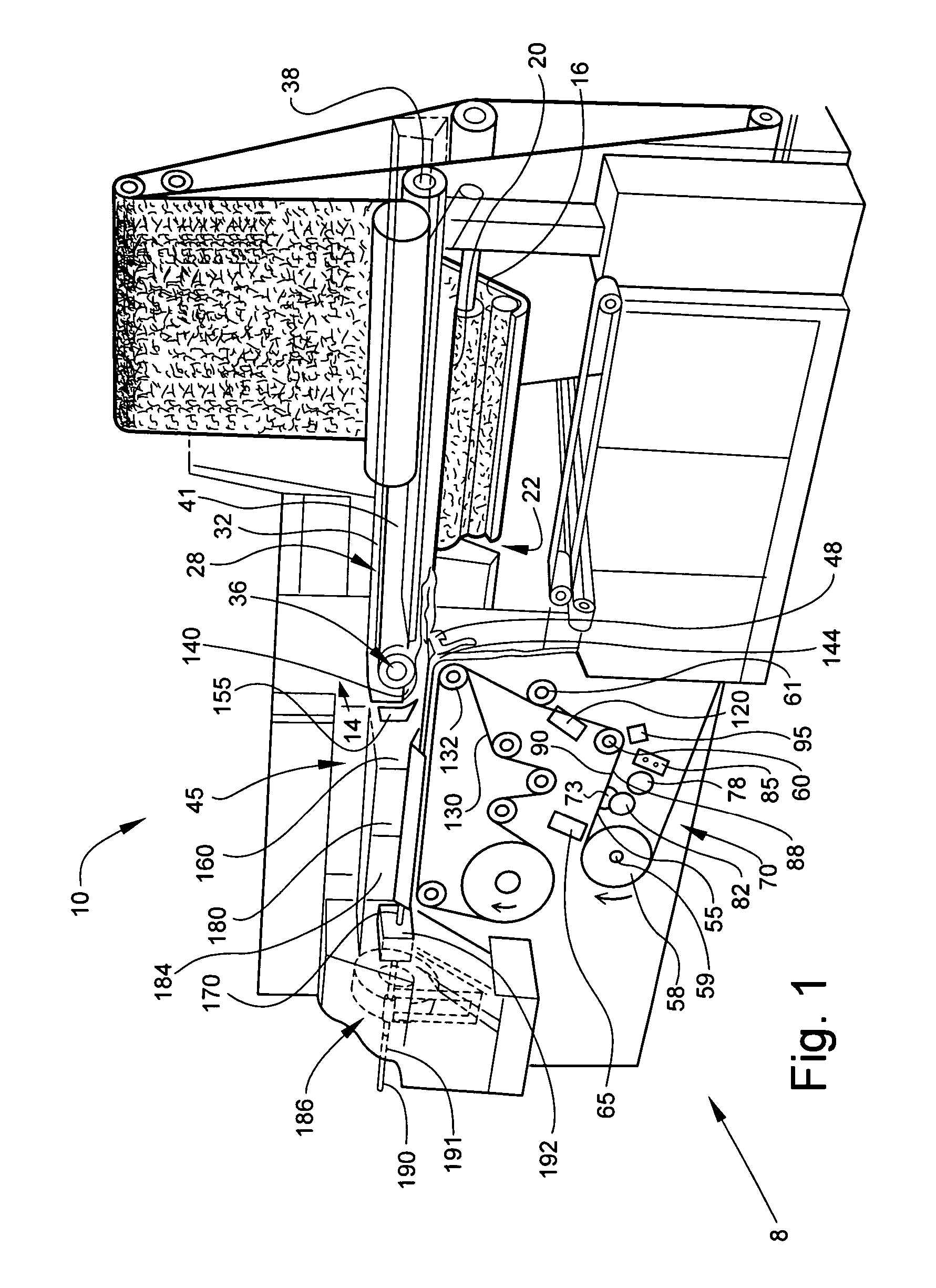

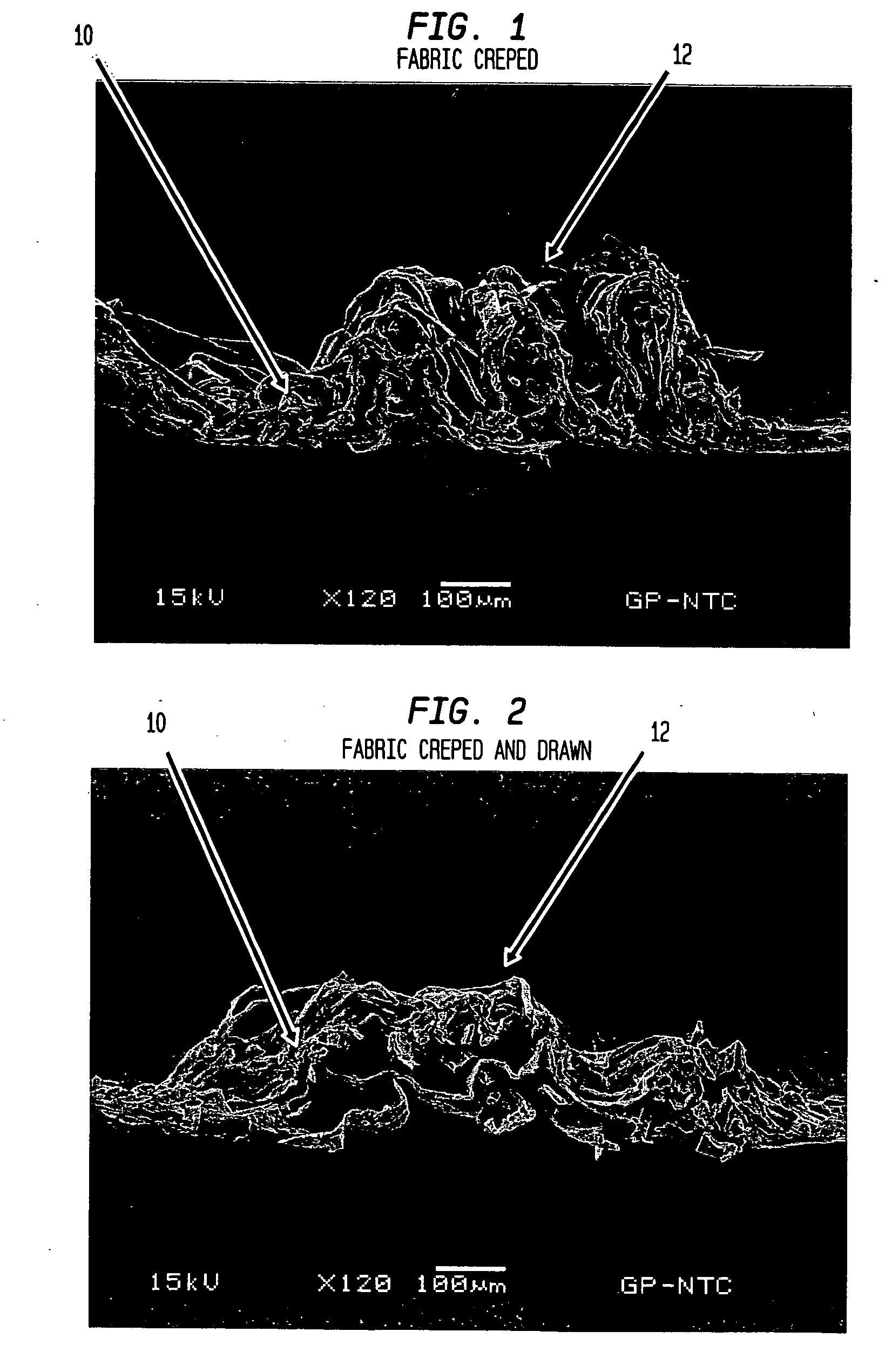

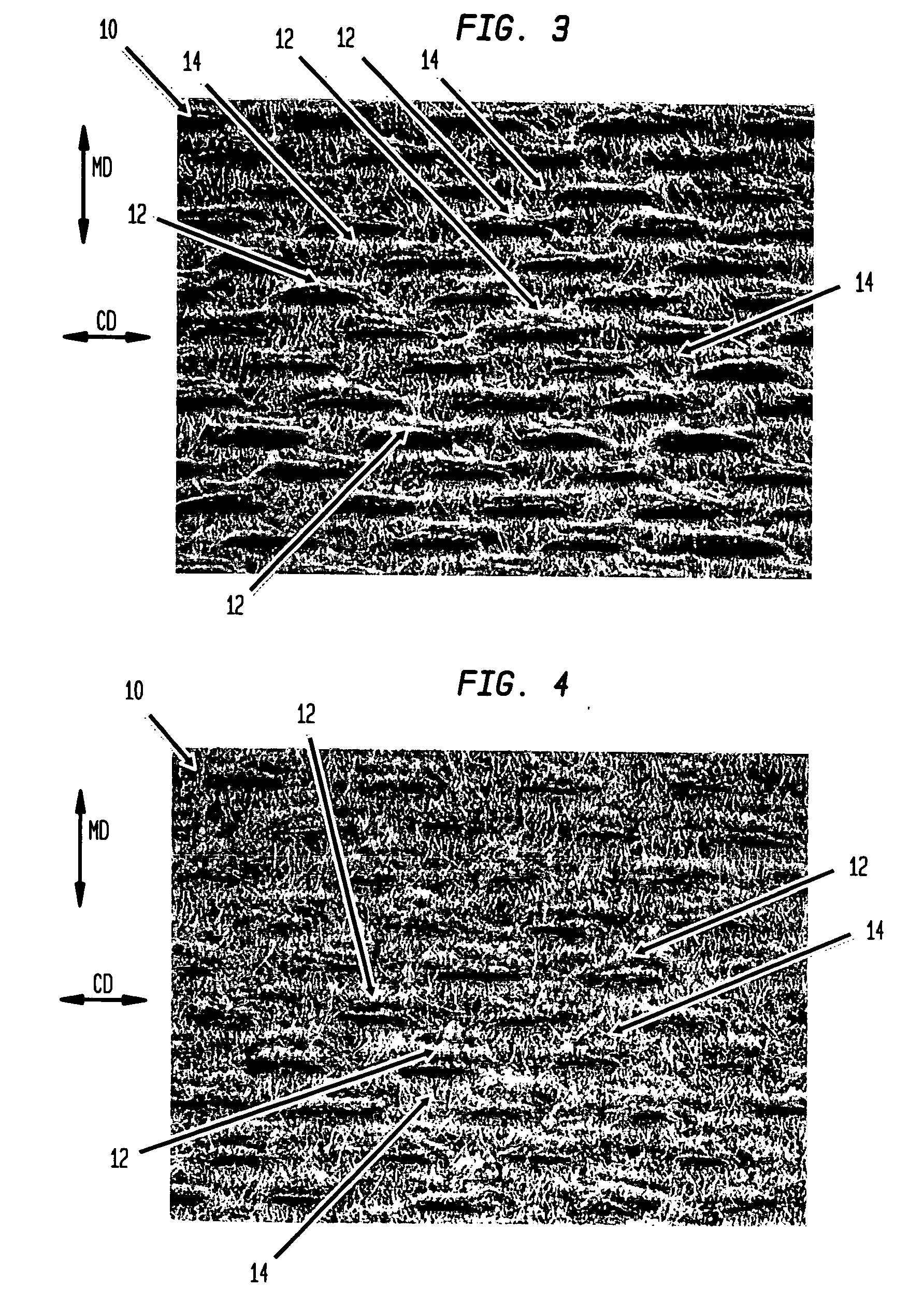

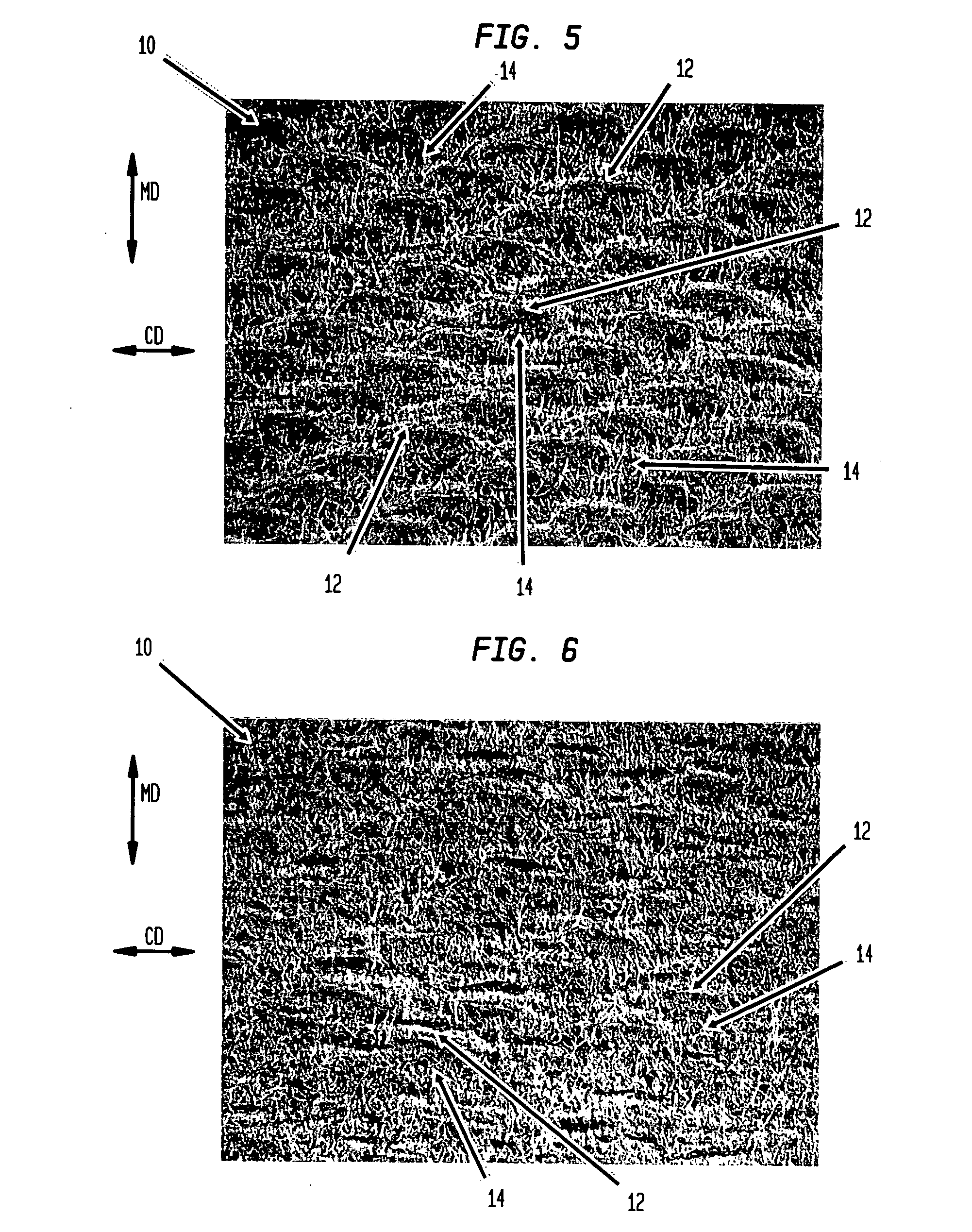

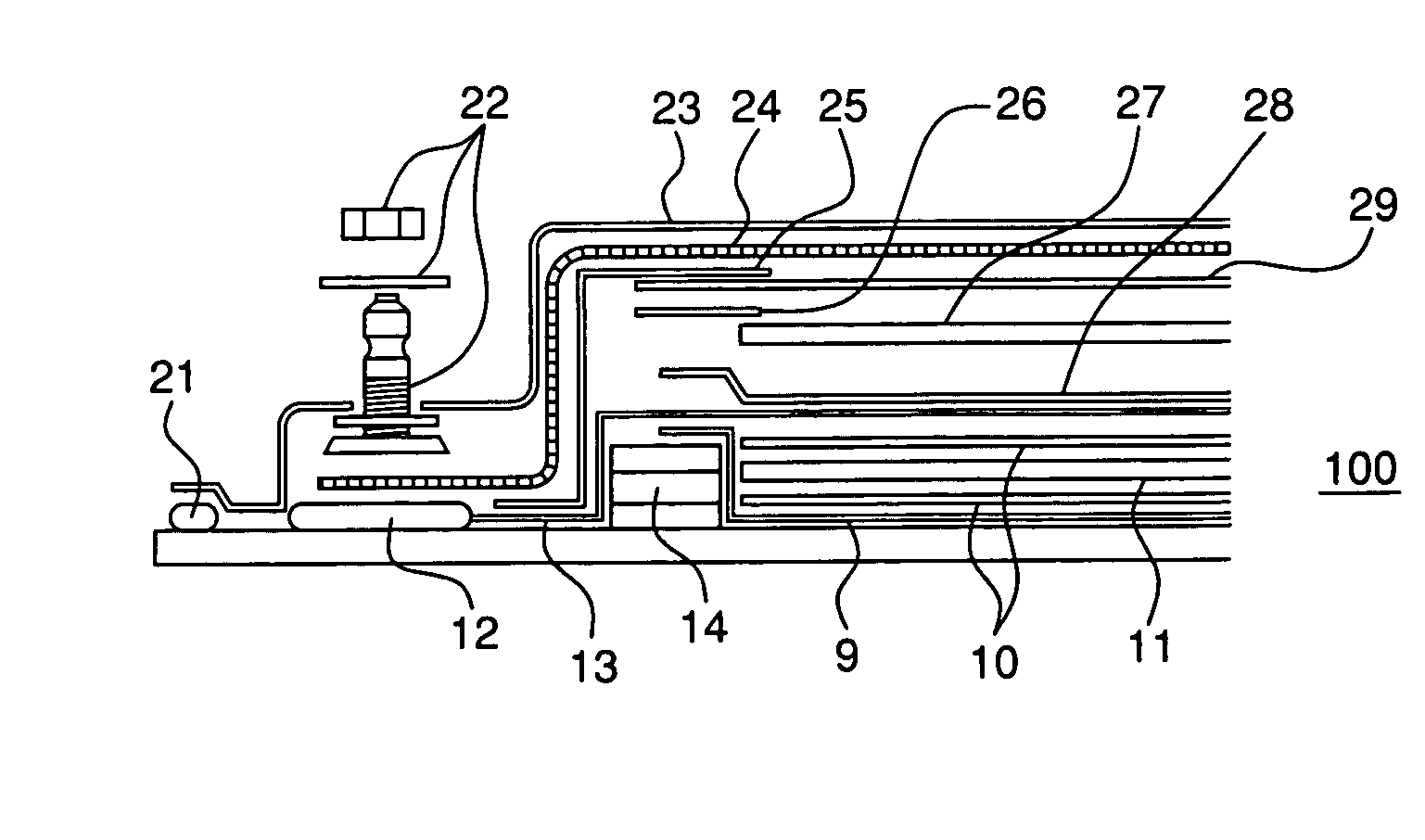

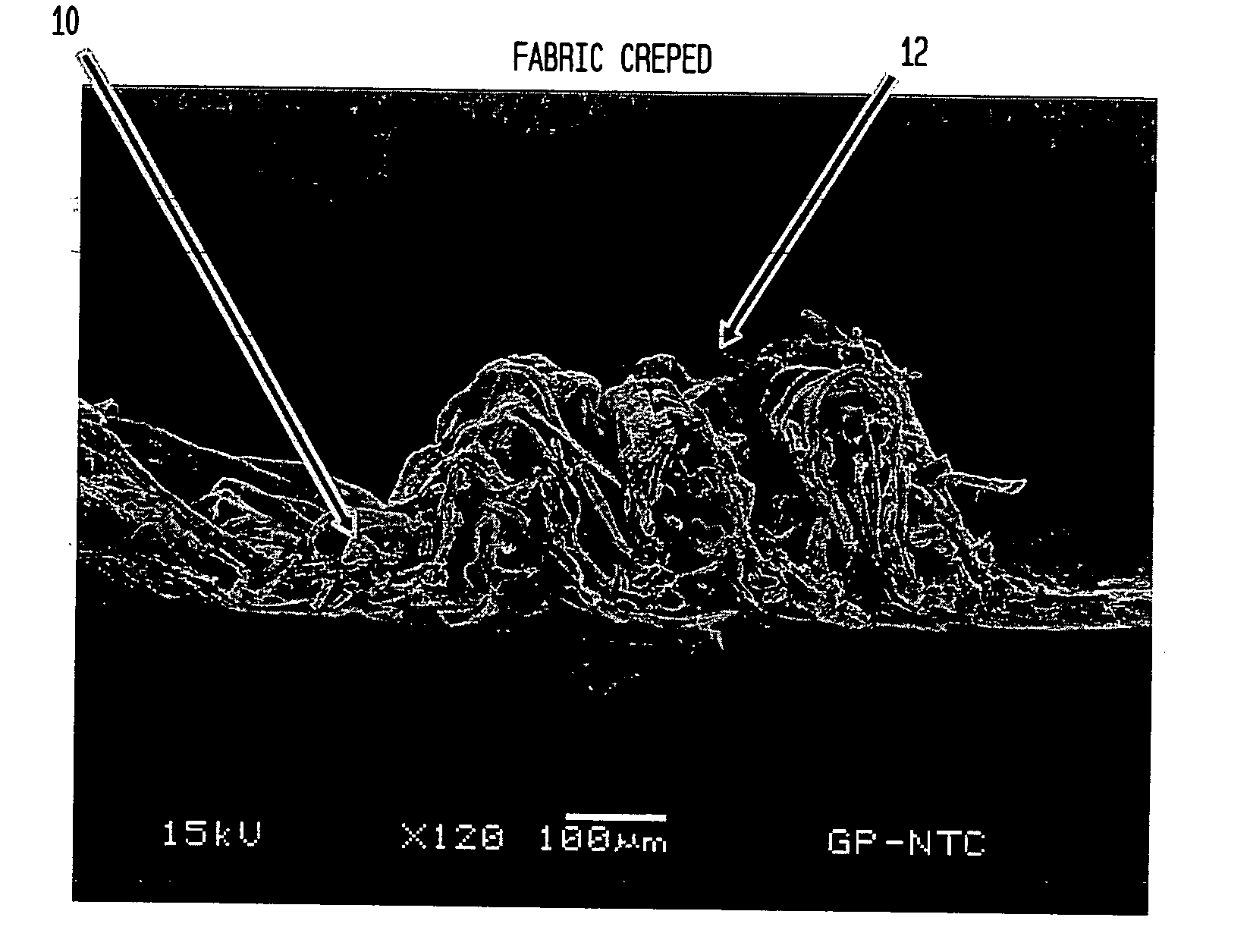

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

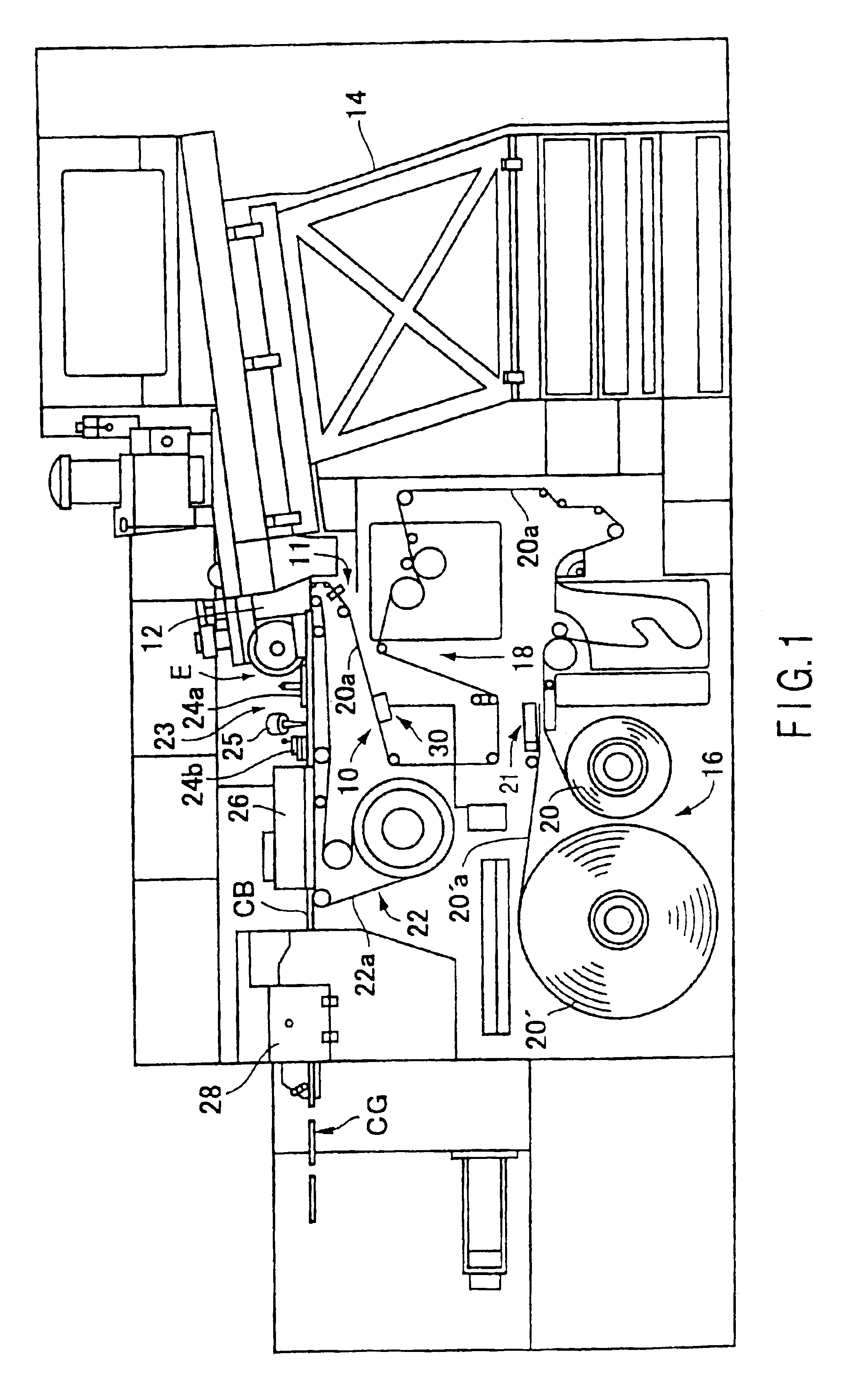

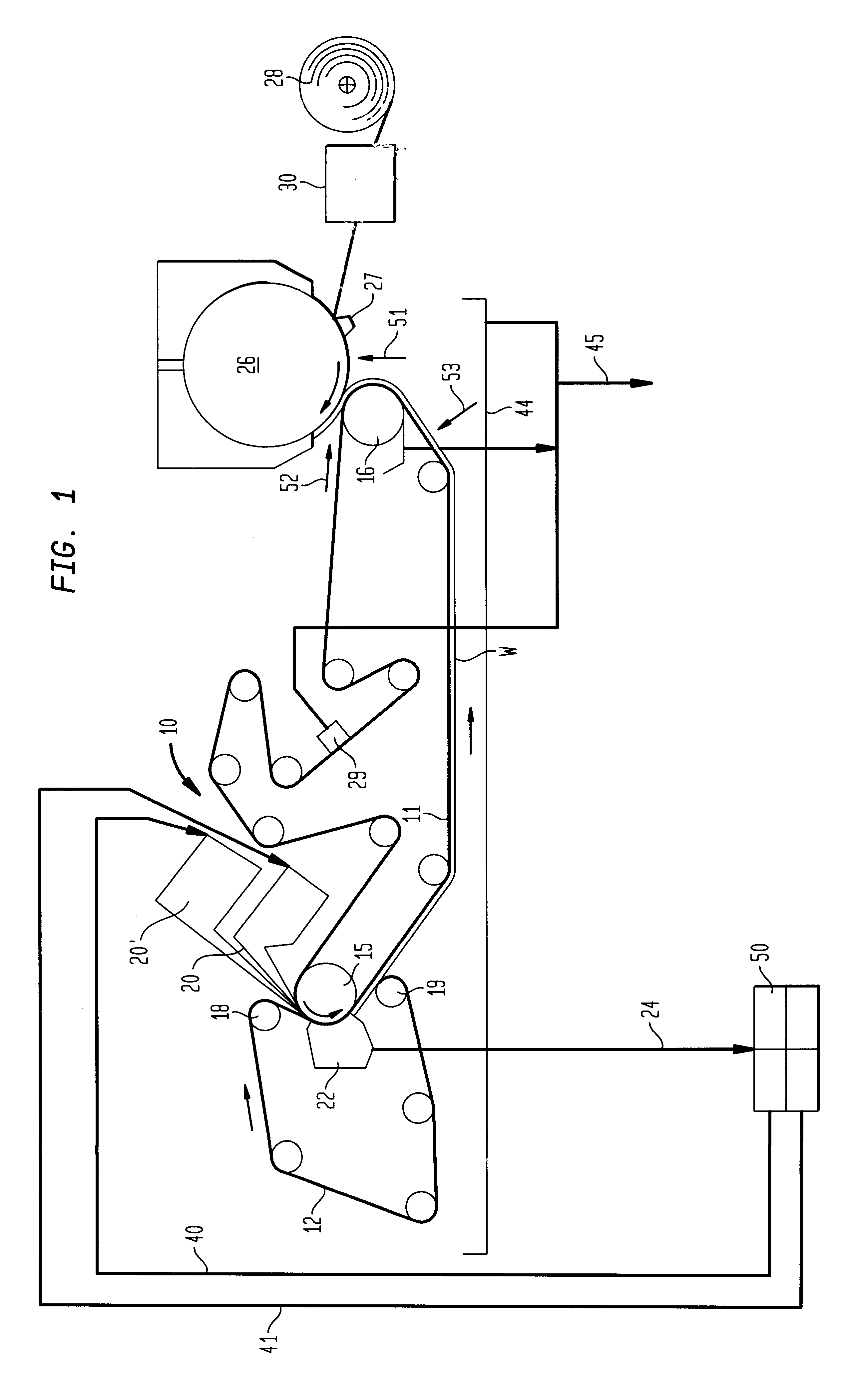

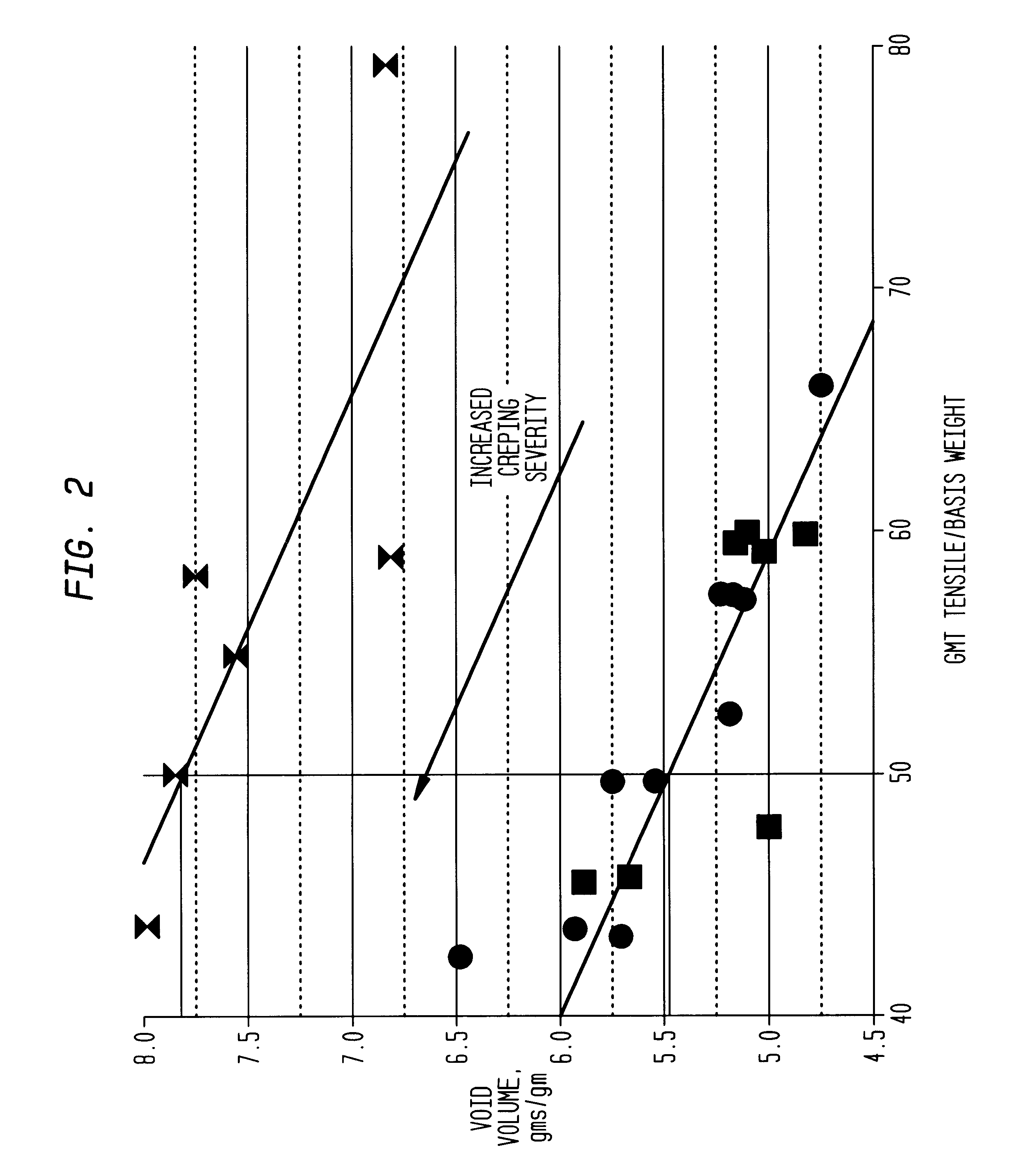

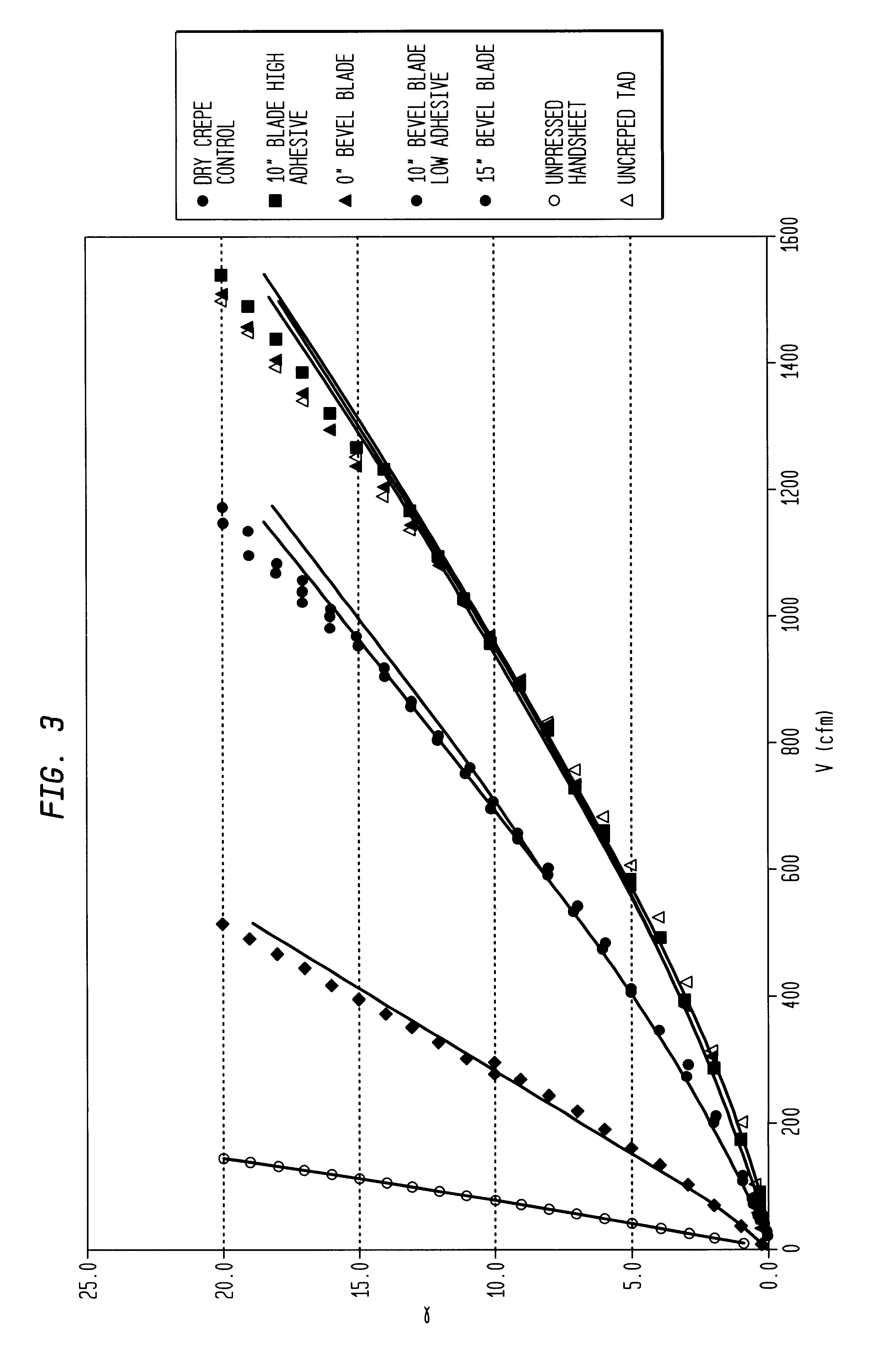

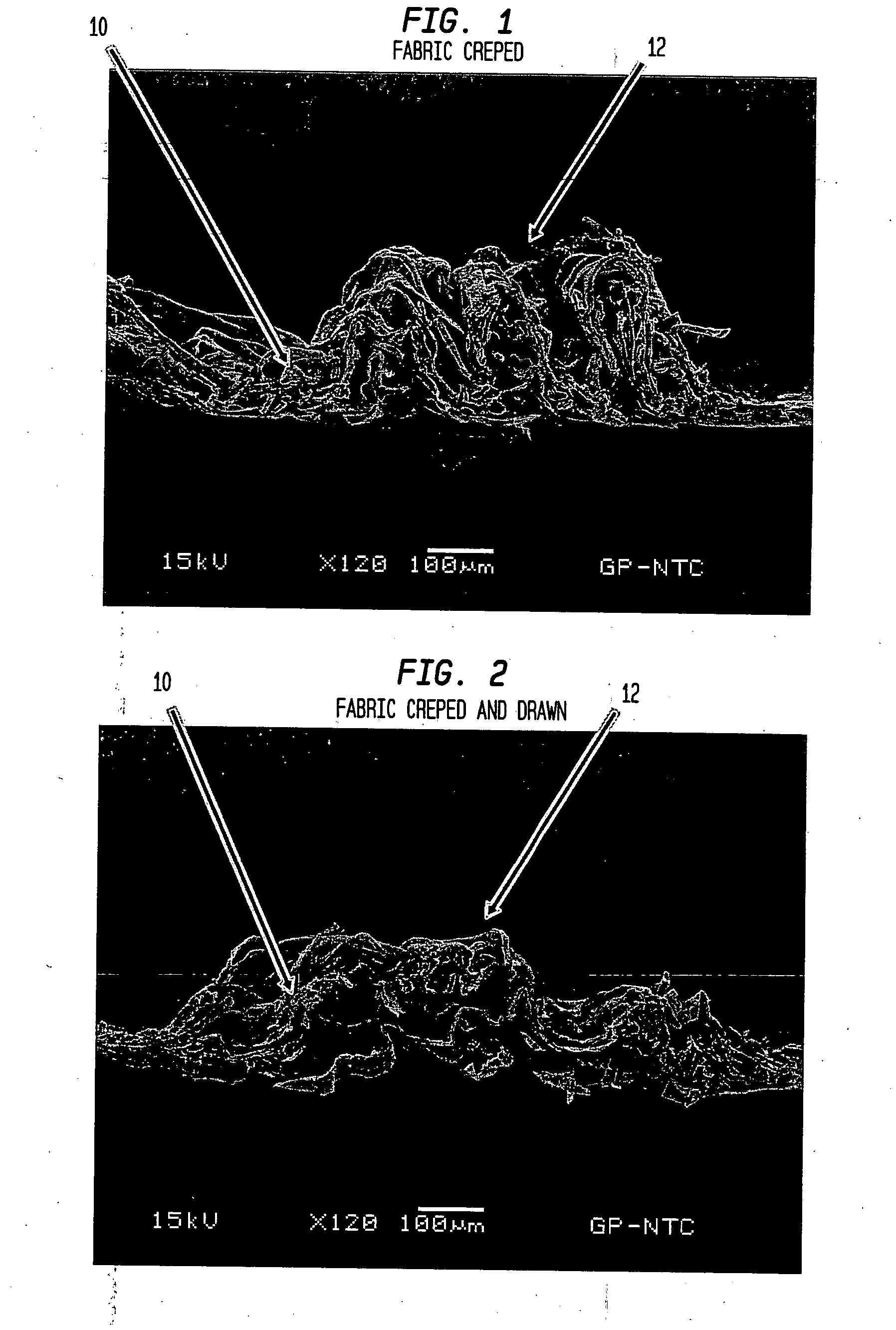

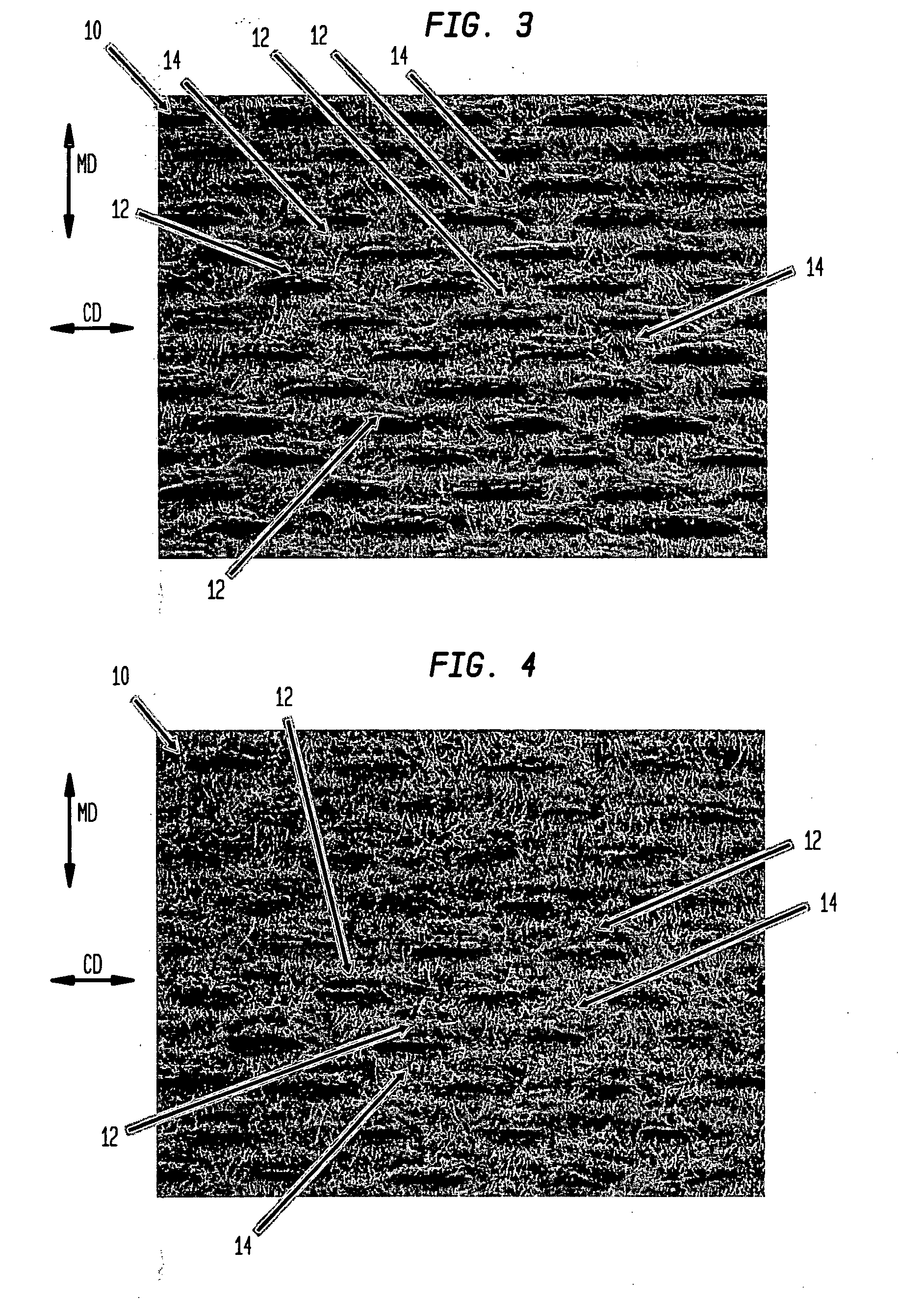

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

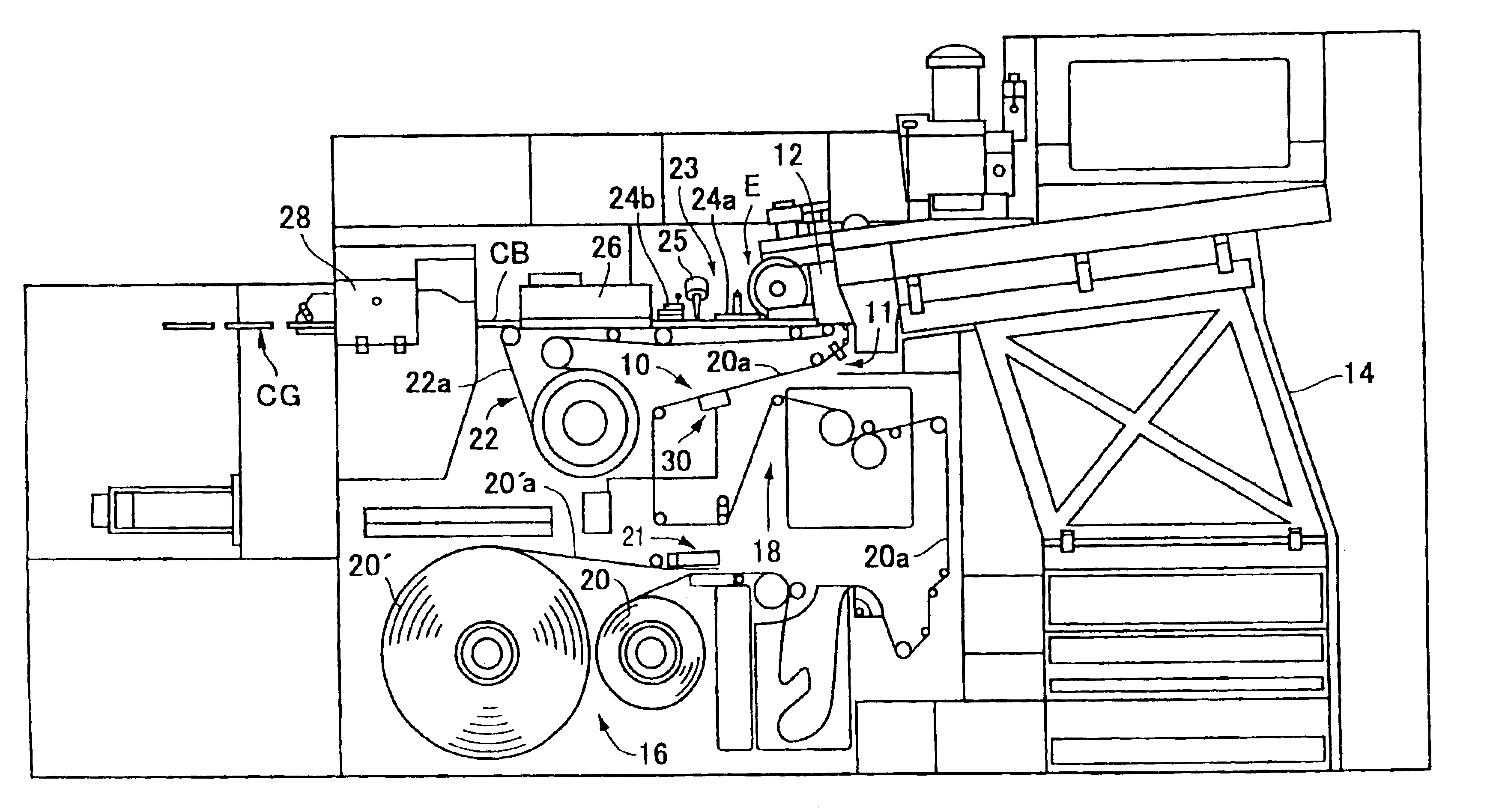

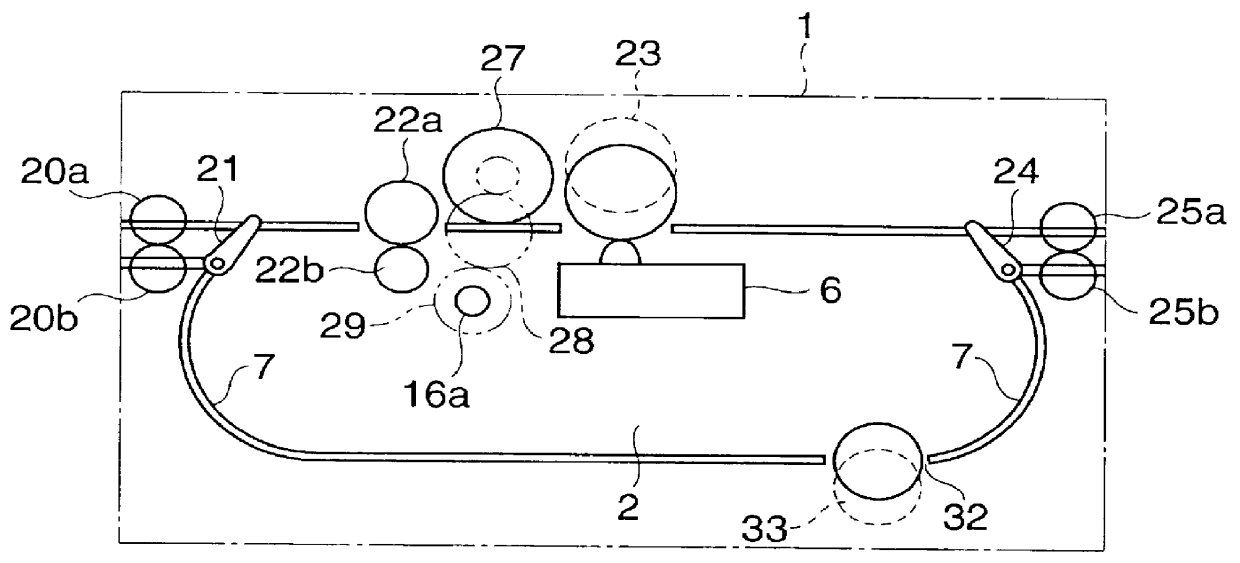

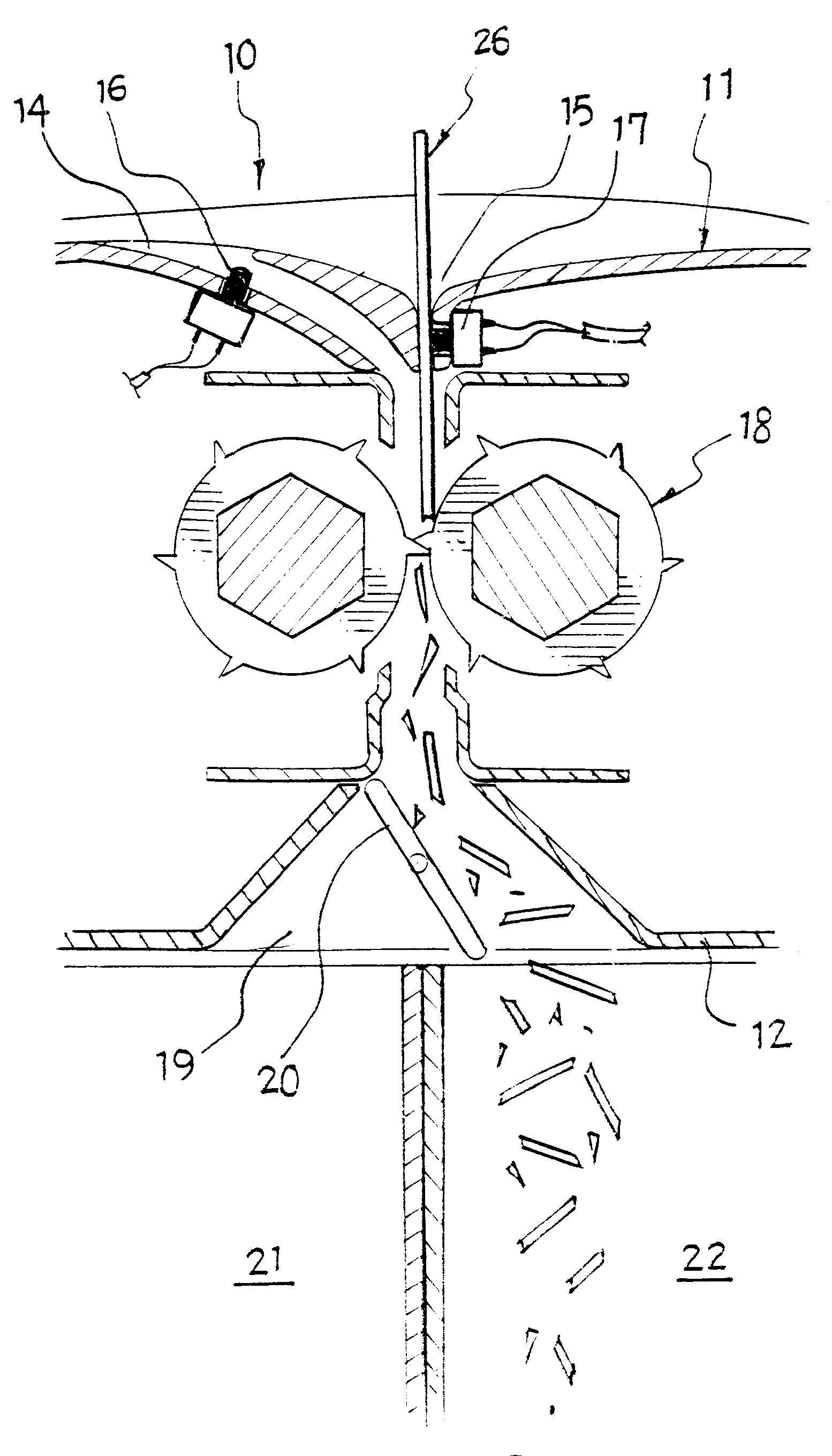

Method of manufacturing cigarette suppressing spread of burn and apparatus for manufacturing cigarette suppressing spread of burn

InactiveUS6904917B2Easy to changeCigar manufactureCigarette manufacturePulp and paper industryEngineering

An apparatus includes a unit which forms burn control agent coated regions on a web of a wrapping paper transferred by a wrapping paper transfer unit at a plurality of positions separated from each other in the longitudinal or in the width direction of the web, a unit which supplies chopped tobacco leaves to the wrapping paper after formation of the coated regions, a roll-up unit which rolls up the wrapping paper on which the chopped tobacco leaves are supplied, and a cigarette cutting unit which cuts the rolled-up wrapping paper together with the chopped tobacco leaves in a predetermined length of the cigarette in the longitudinal direction thereof.

Owner:JAPAN TOBACCO INC

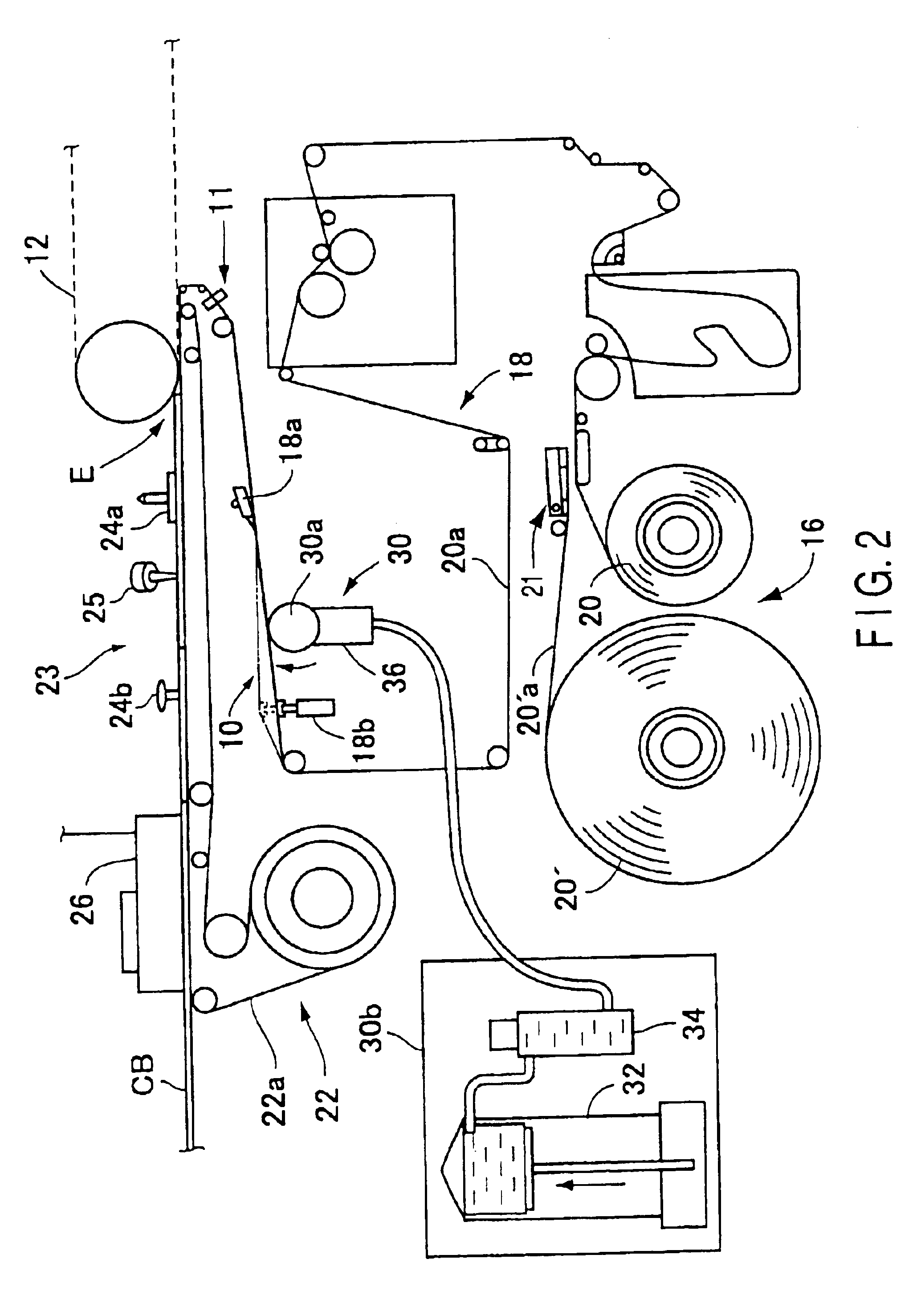

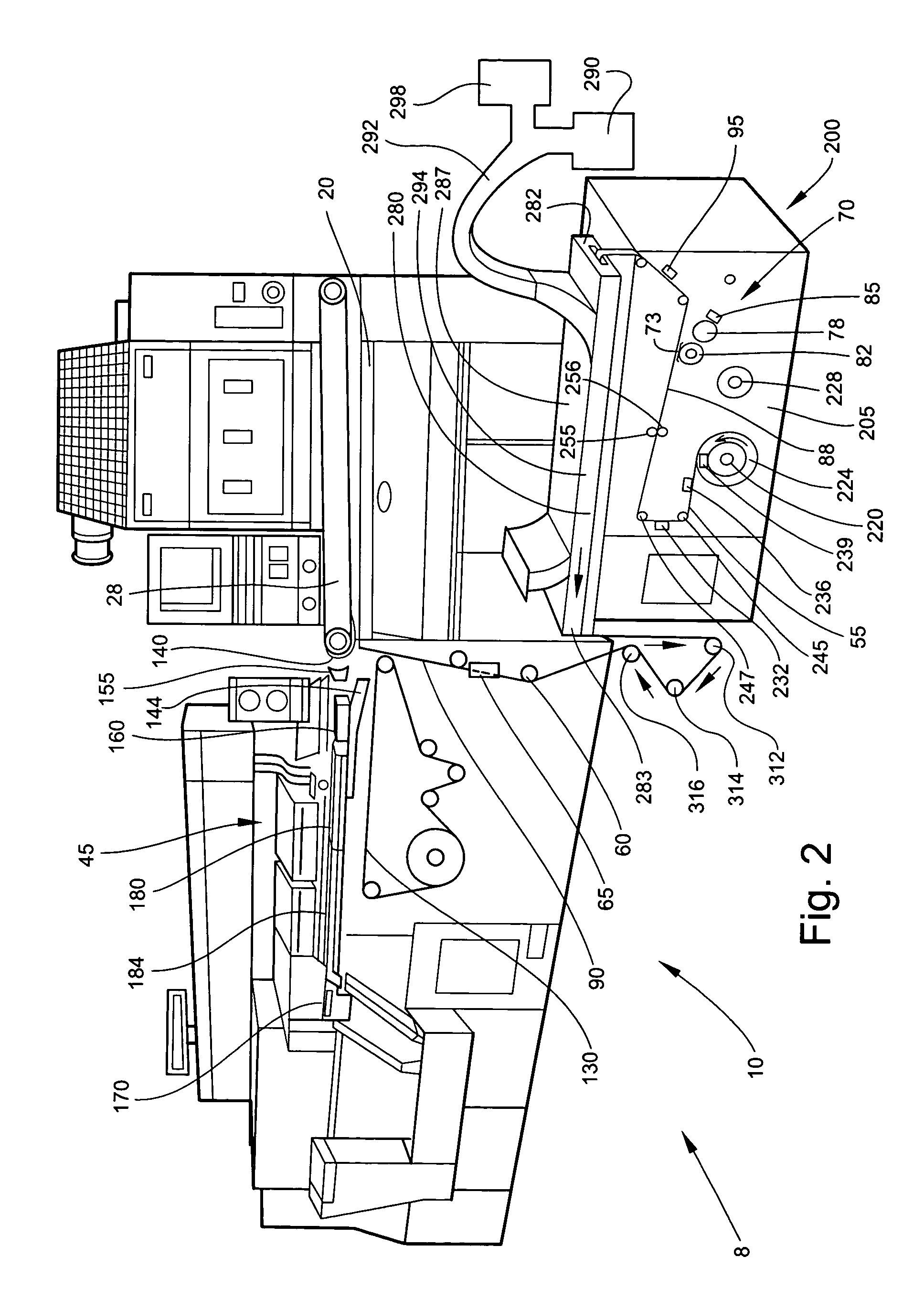

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

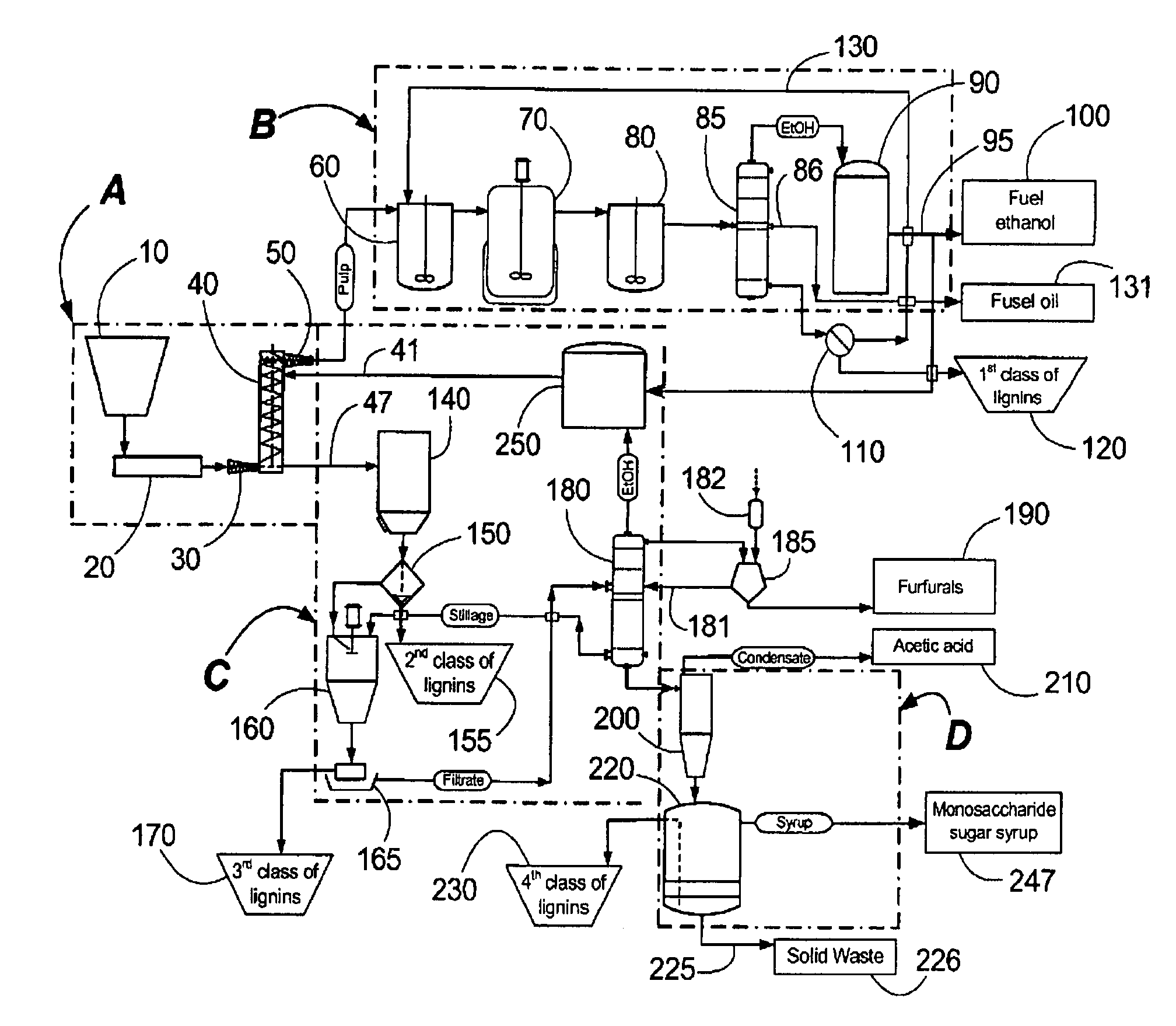

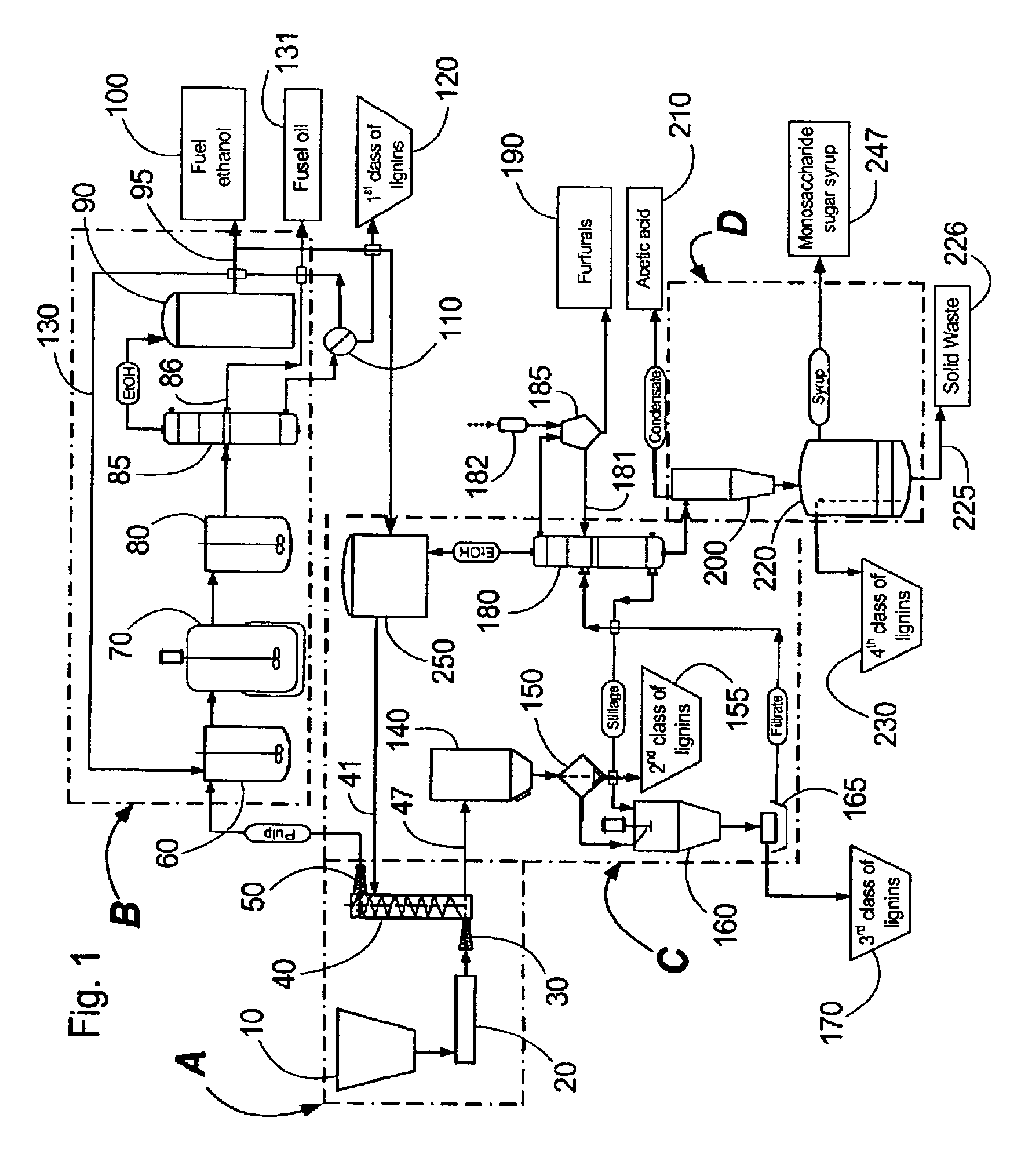

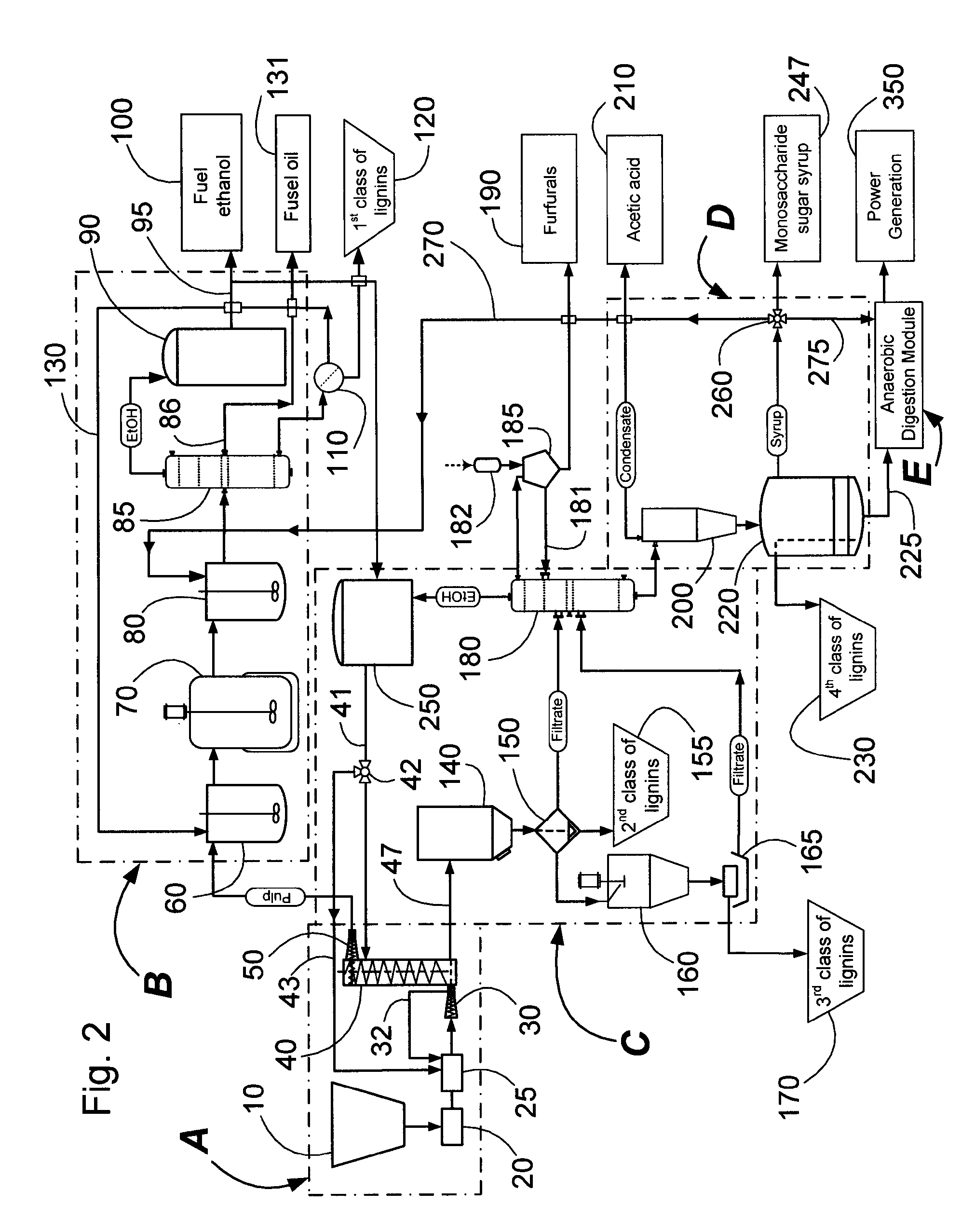

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

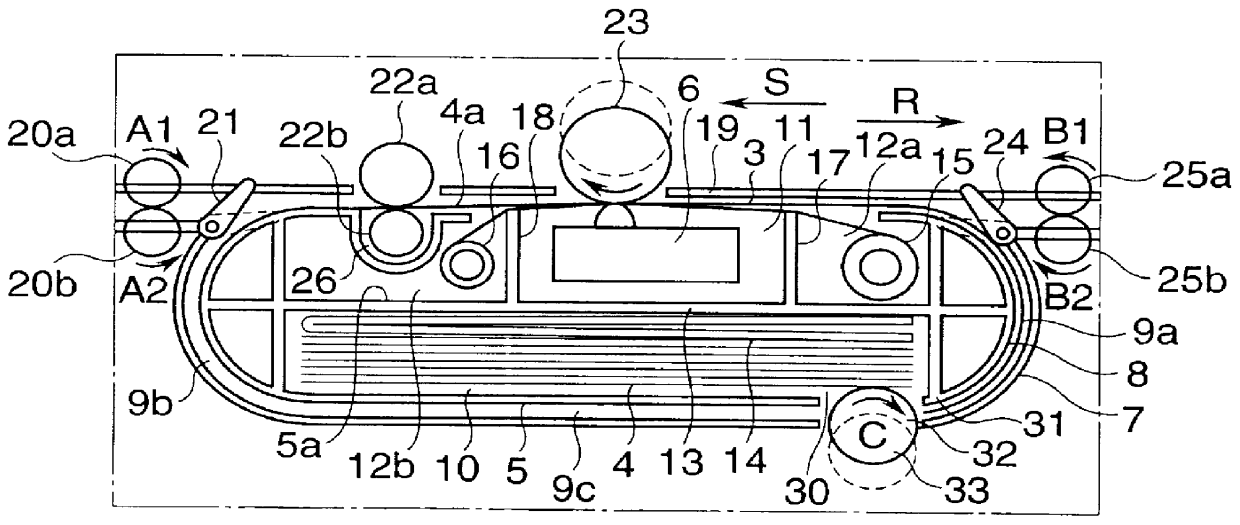

Equipment for manufacturing cigarettes

InactiveUS7275548B2Minimize and avoid and prevent transferConsistent flowCigar manufactureCigarette manufactureControl mannerPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

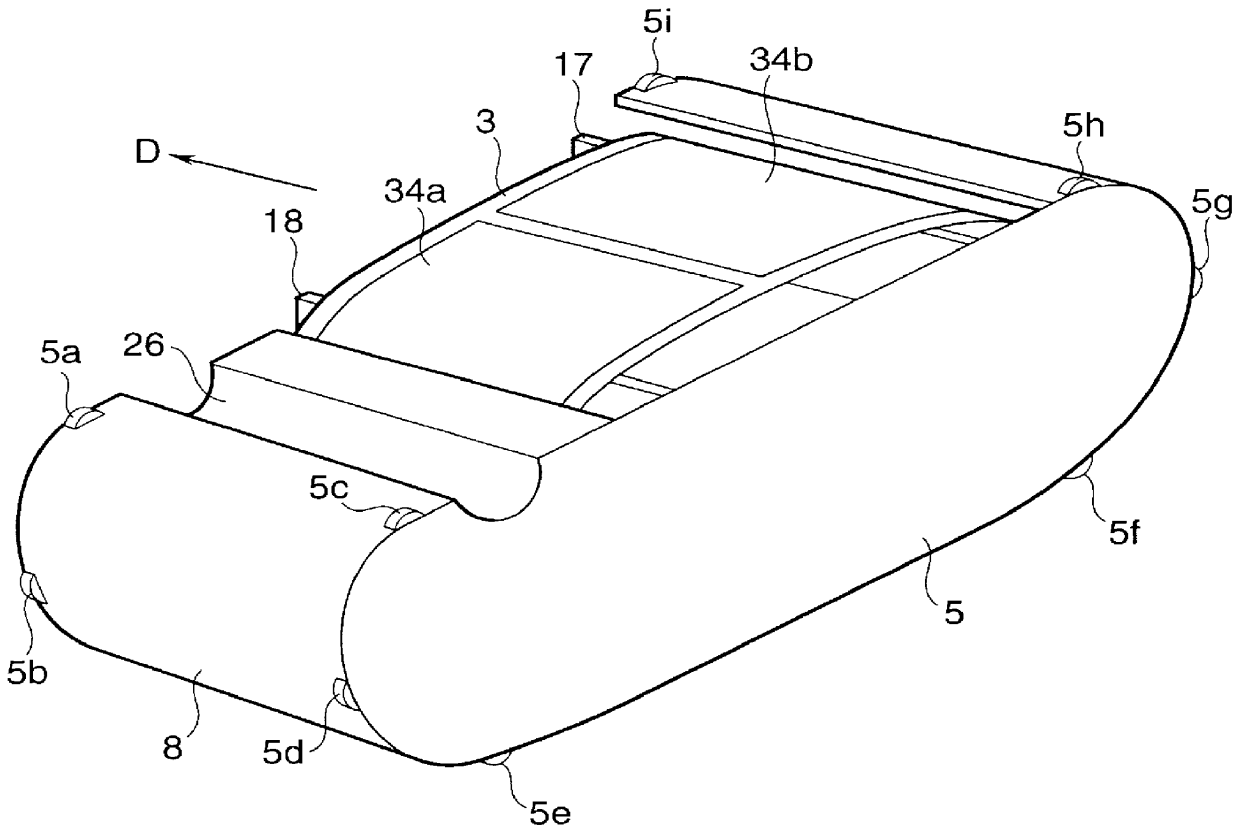

Cassette for holding ink ribbon and print paper therein and printer incorporating the cassette therein

An ink ribbon-print paper cassette is used in a thermal printer. A paper tray accommodates a stack of single sheets of print paper. The paper tray has an opening through which the print paper is fed into a paper path on a sheet-by-sheet basis. An ink ribbon for thermal printing runs over a thermal head located adjacent the paper tray. A housing accommodates the paper tray, thermal head, and ink ribbon therein. When the cassette is loaded into the thermal printer, the outer surface of the cassette and an inner wall of the thermal printer cooperate to form a paper path therebetween through which each of the sheets of print paper is advanced from the paper tray to the thermal head.

Owner:OKI DATA CORP

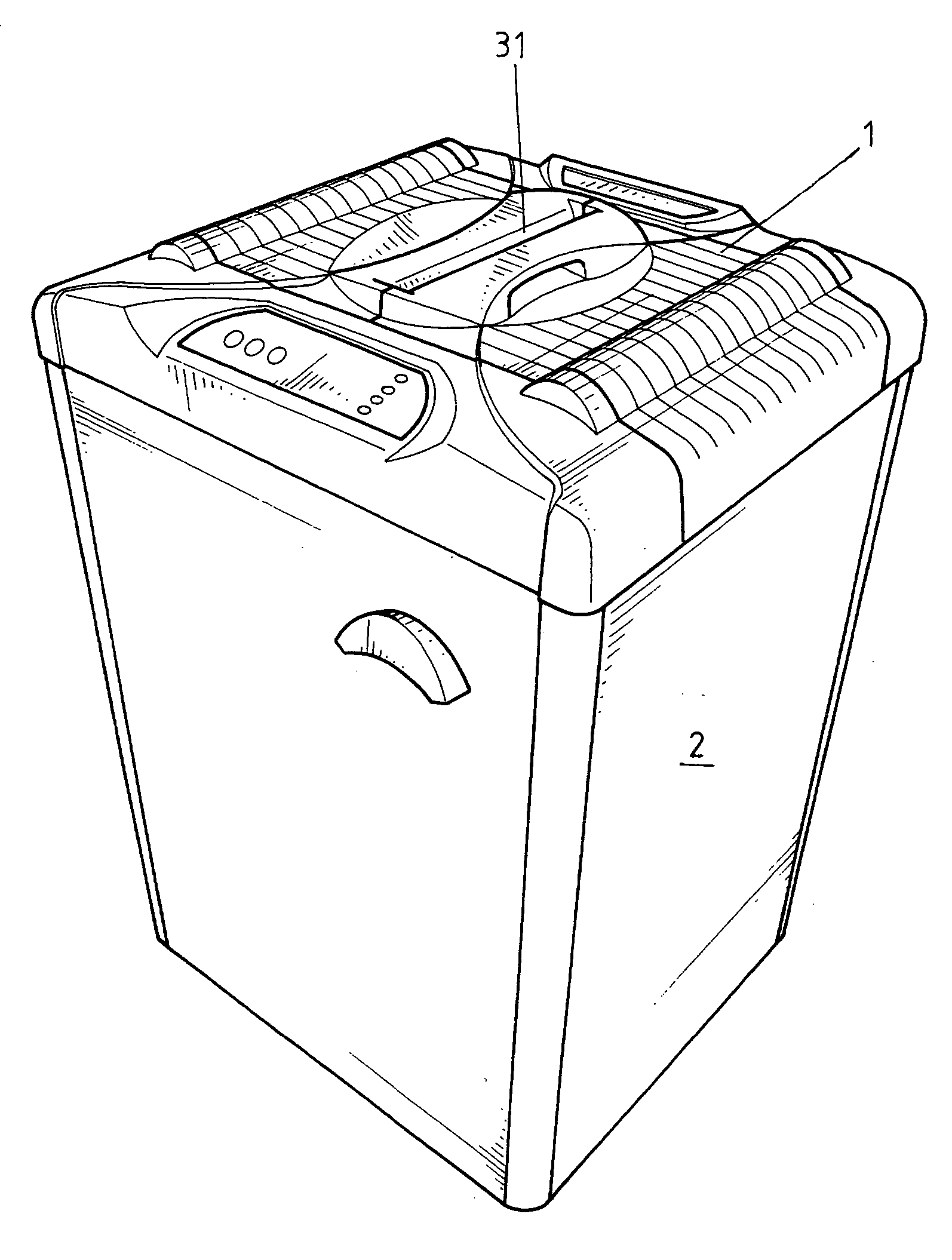

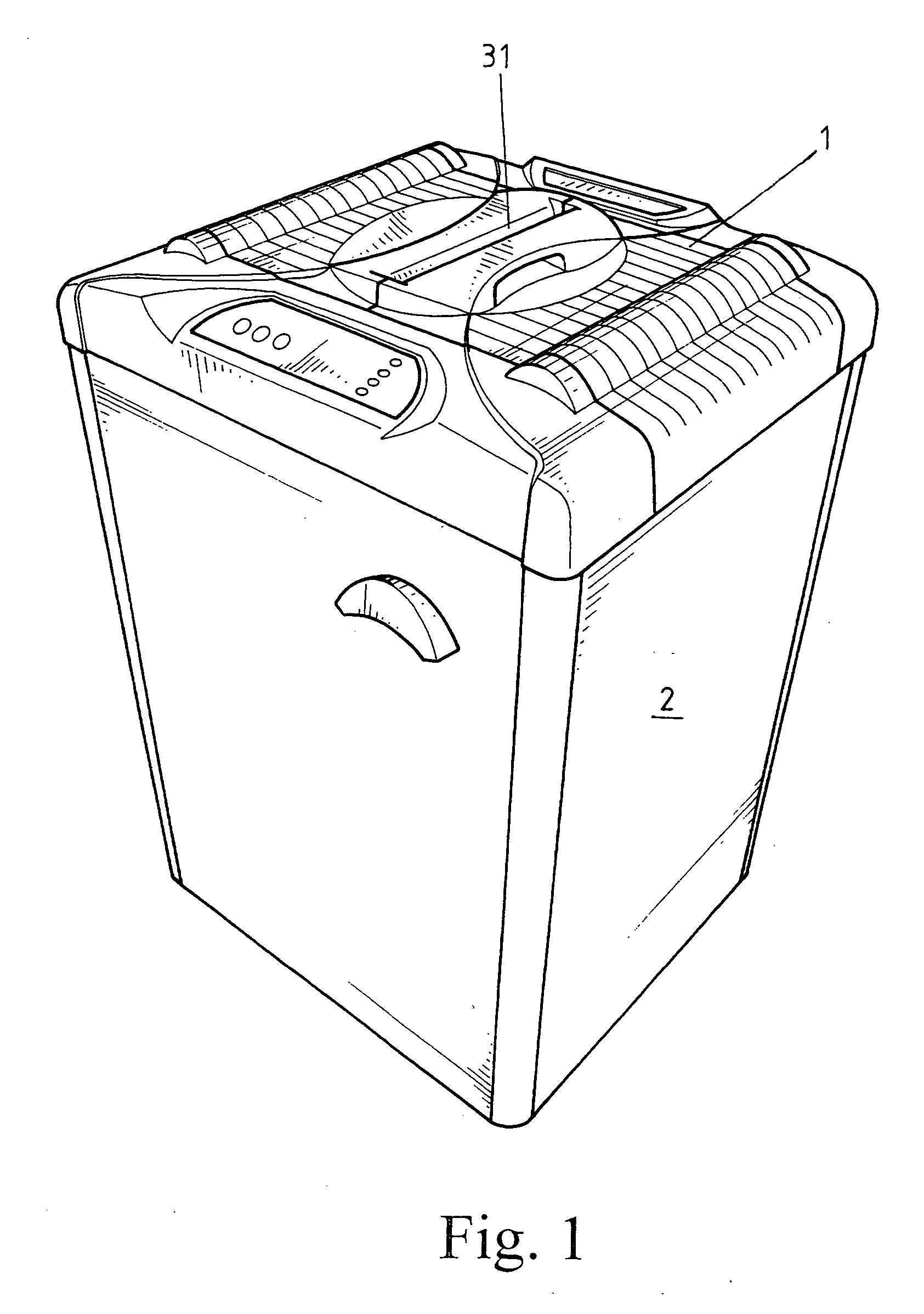

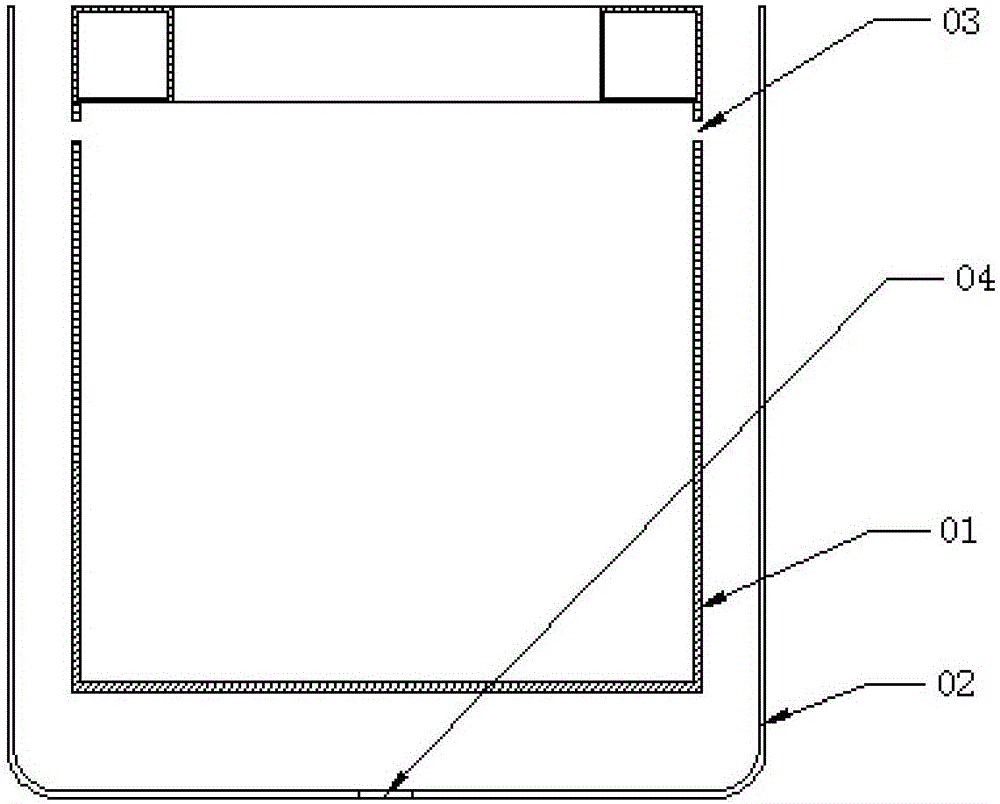

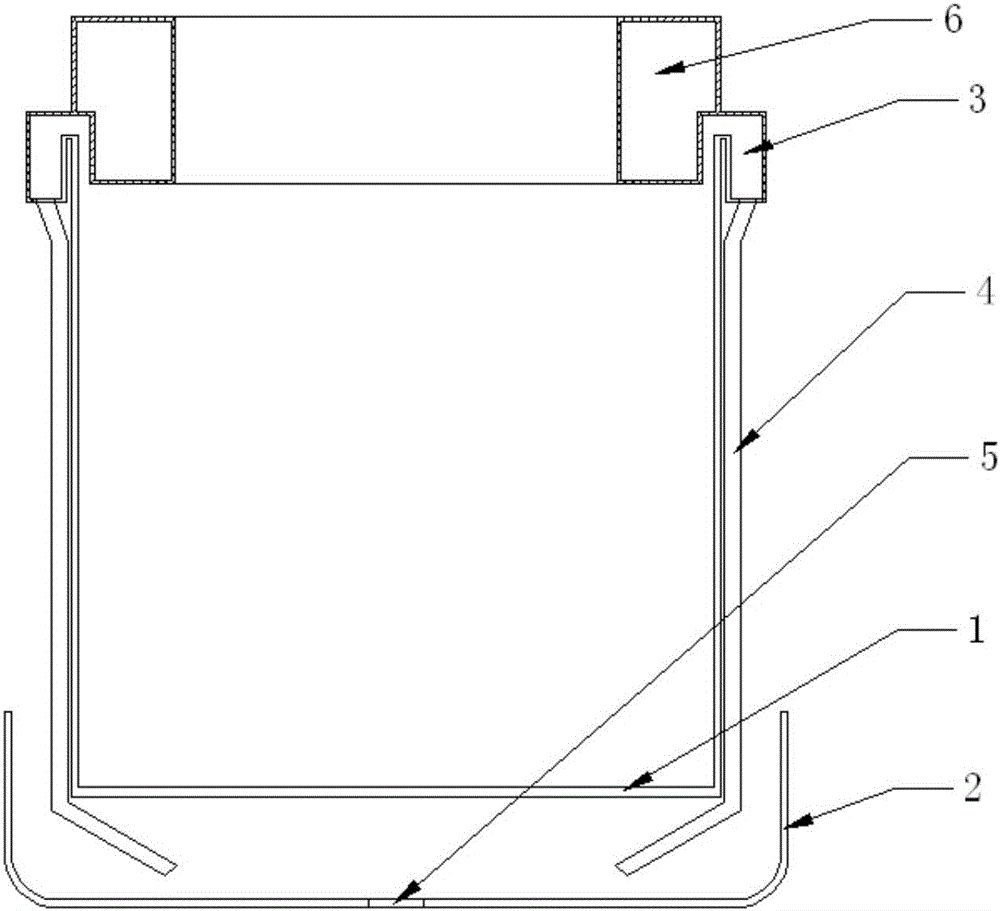

Roller washing machine

ActiveCN104005201AAvoid waterReduce washing water consumptionOther washing machinesWashing machine with receptaclesWater dischargeWash water

The invention relates to a roller washing machine. The roller washing machine comprises a box body, wherein an inner barrel and an outer barrel are arranged in the box body, a door seal is arranged between the outer barrel and the box body, the inner barrel is connected with a driving device, the inner barrel is a hole-free inner barrel and is a conical barrel of which the diameter at the bottom is small and the diameter at the opening is large, the opening of the inner barrel is contracted inwards in an arc shape, a water inlet guide pipe is arranged on the door seal, one end of the water inlet guide pipe is connected with a wash water rapid heating device, the other end of the water inlet guide pipe penetrates through the door seal and extends into the inner barrel, and a water discharging opening and a water pressure detection device are arranged on the outer barrel. According to the technical scheme, the inner barrel is the hole-free inner barrel, water enters the inner barrel through the water inlet guide pipe arranged on the door seal and is discharged through the shape of the inner barrel in the water discharging process, so that water is prevented from being accumulated between the inner barrel and the outer barrel, and the amount of washing water is largely saved.

Owner:WHIRLPOOL CHINA

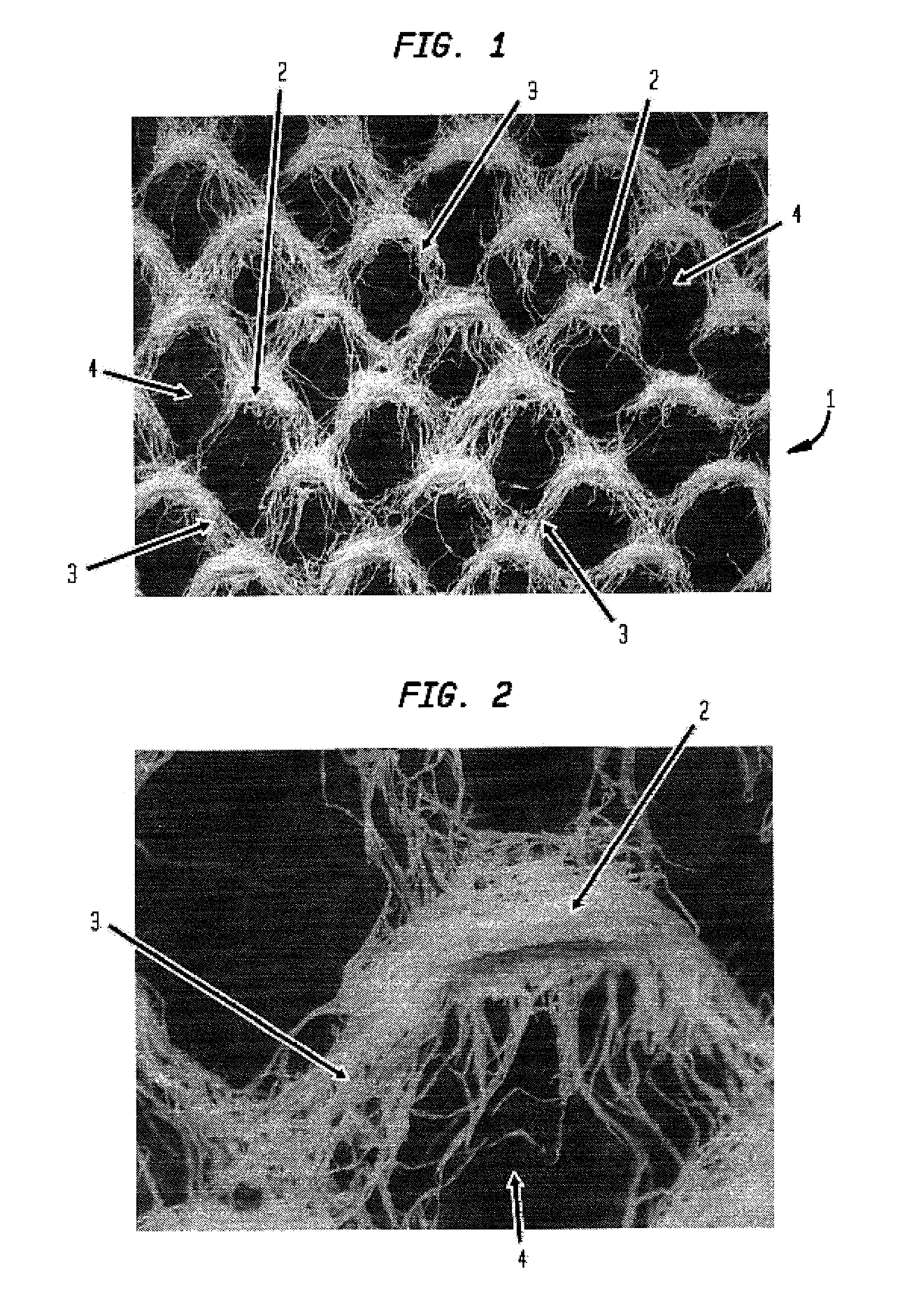

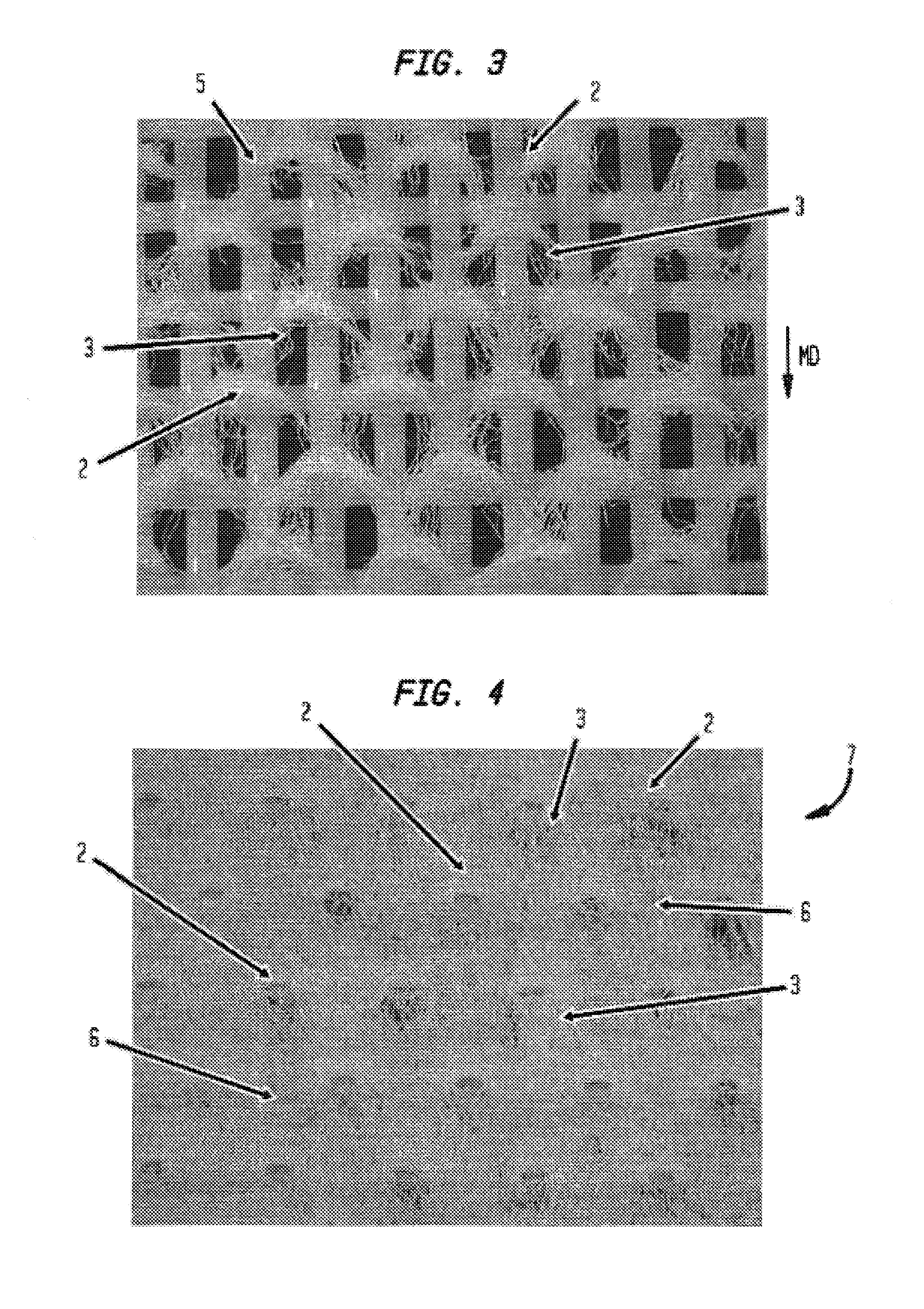

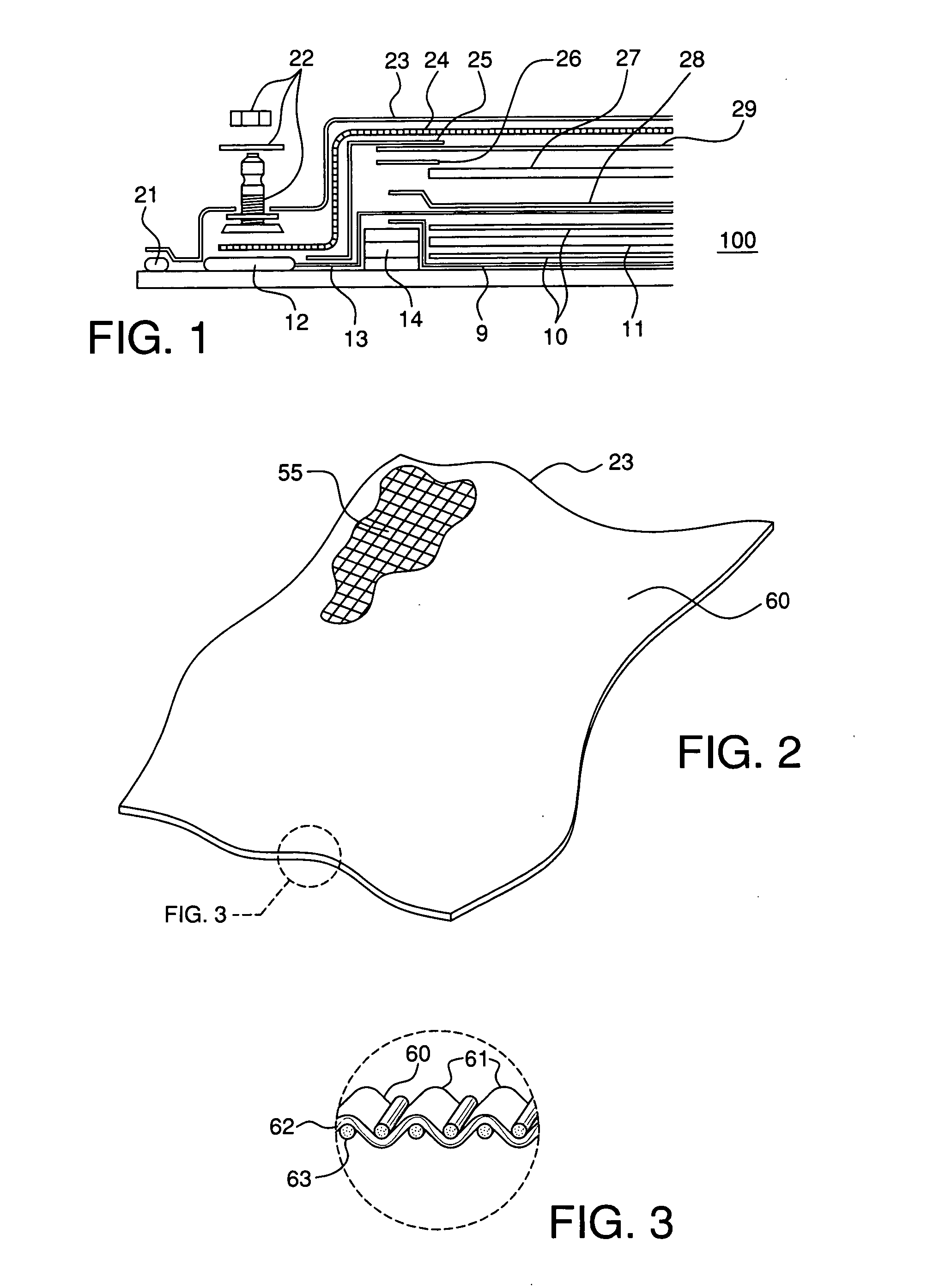

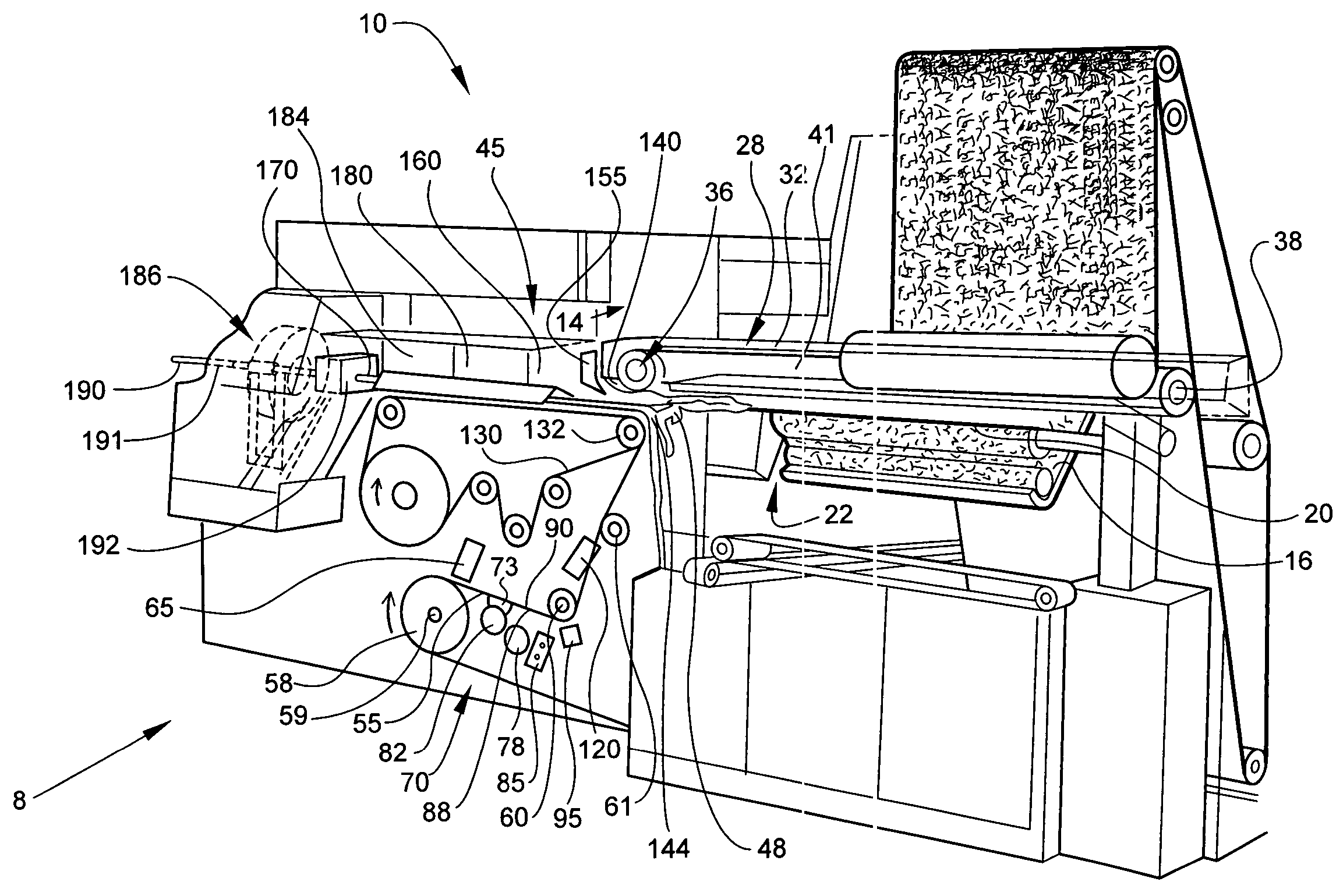

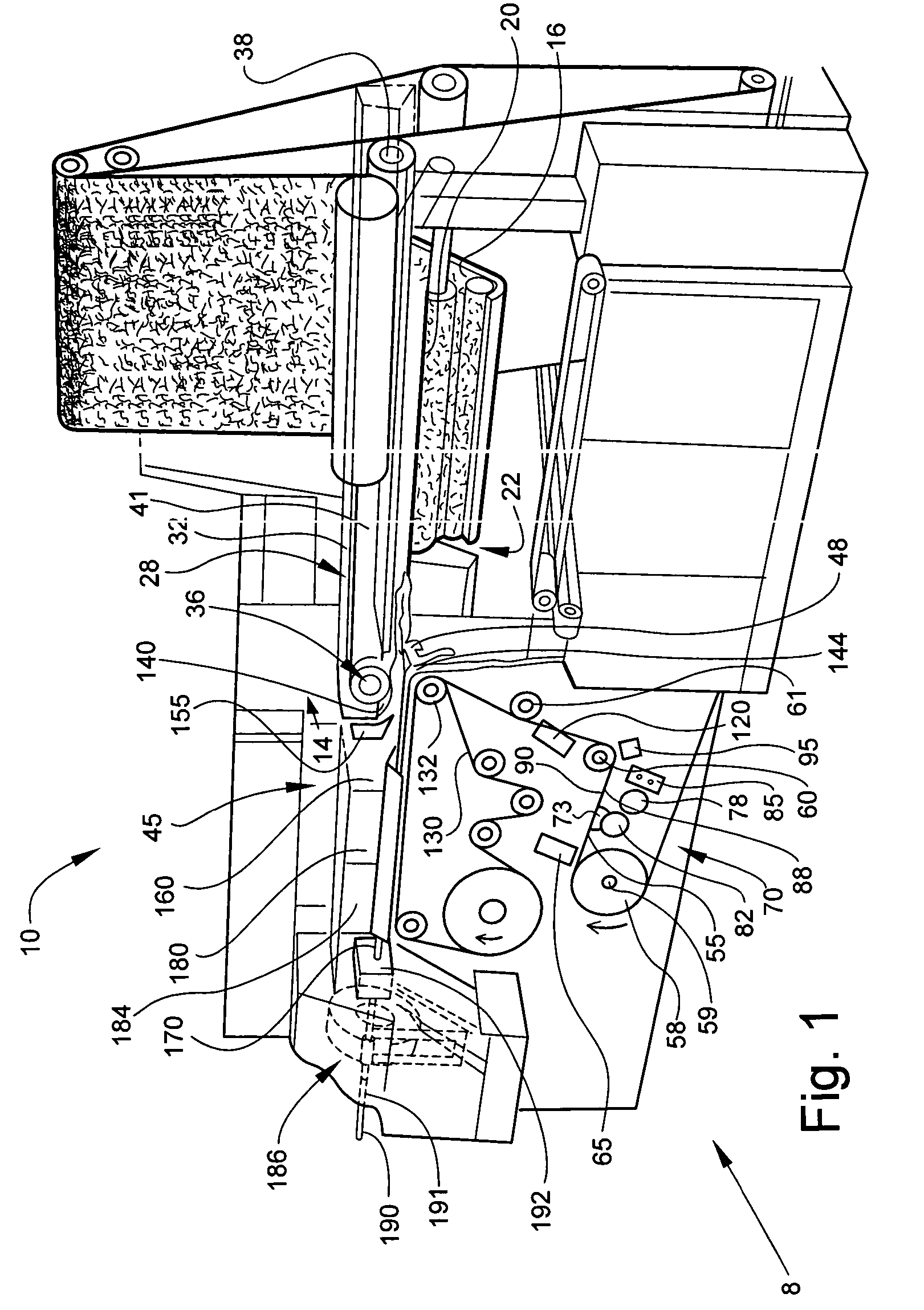

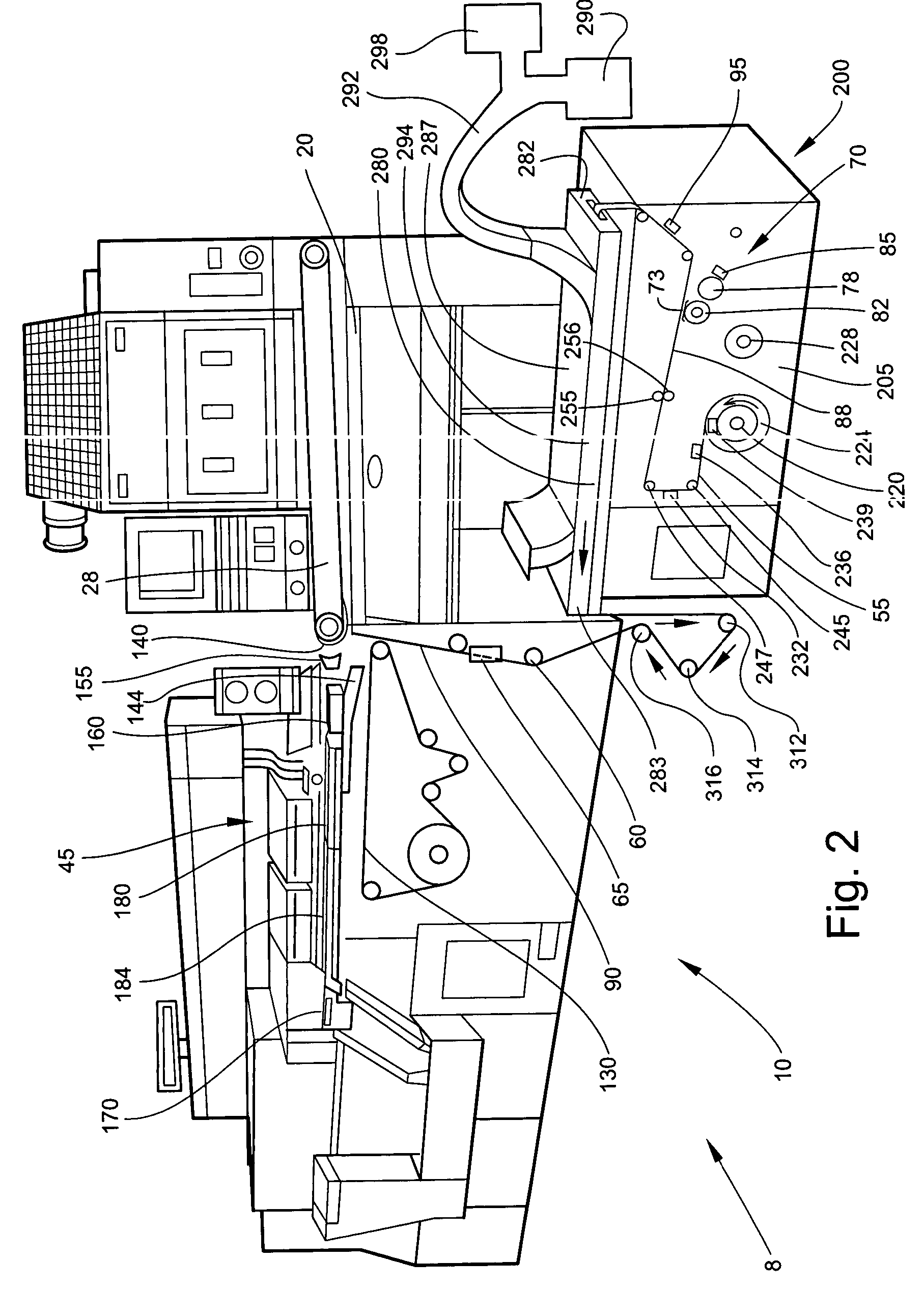

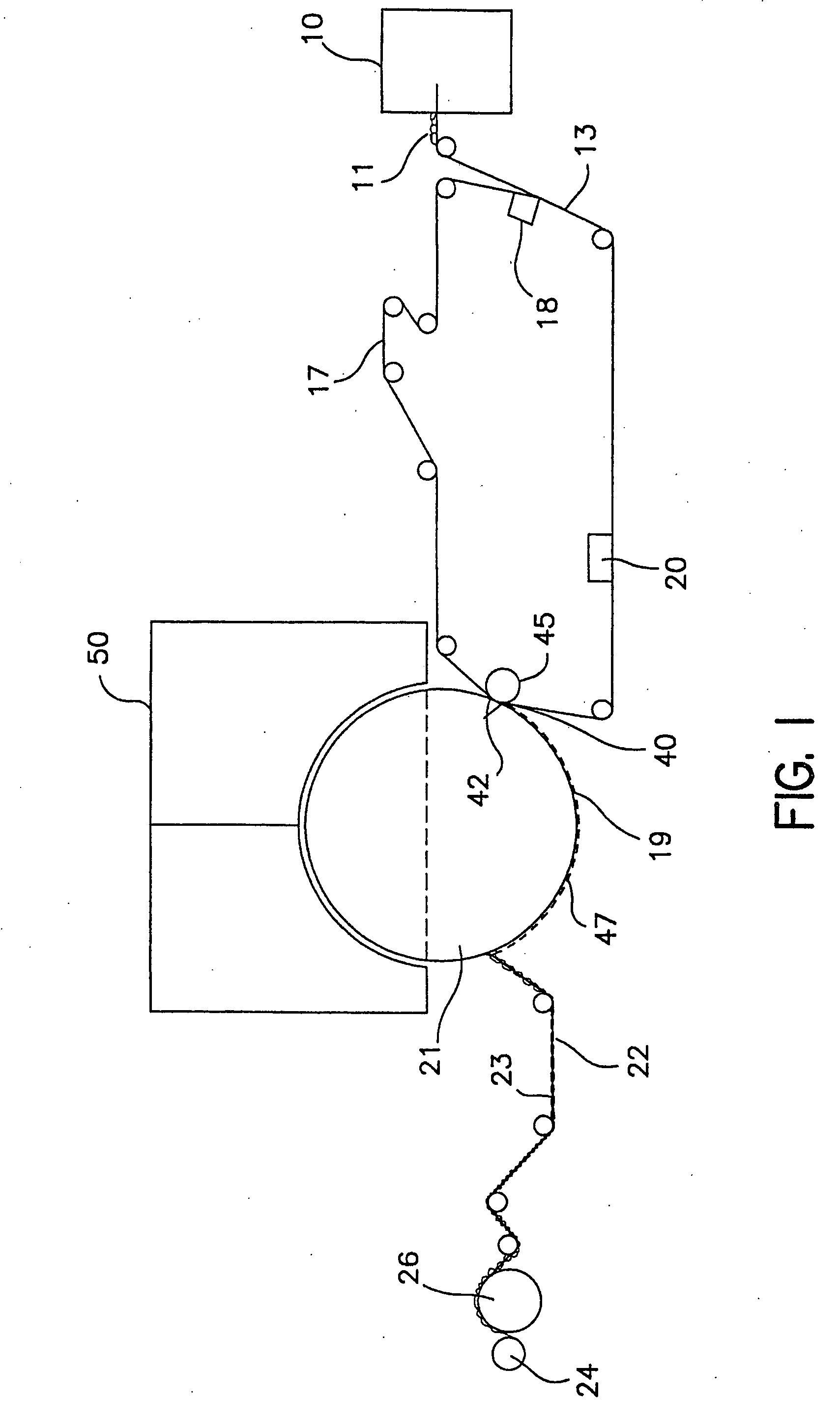

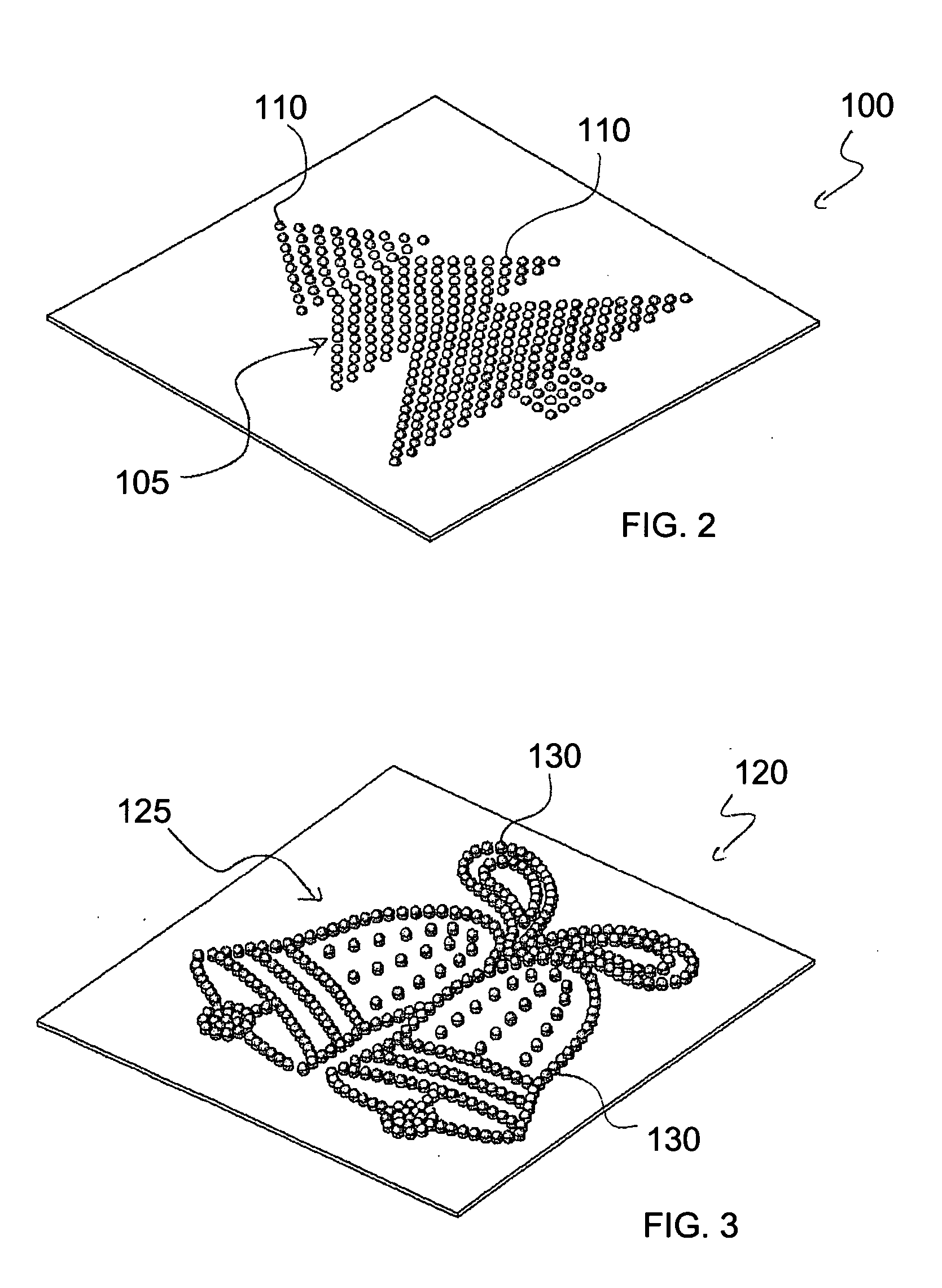

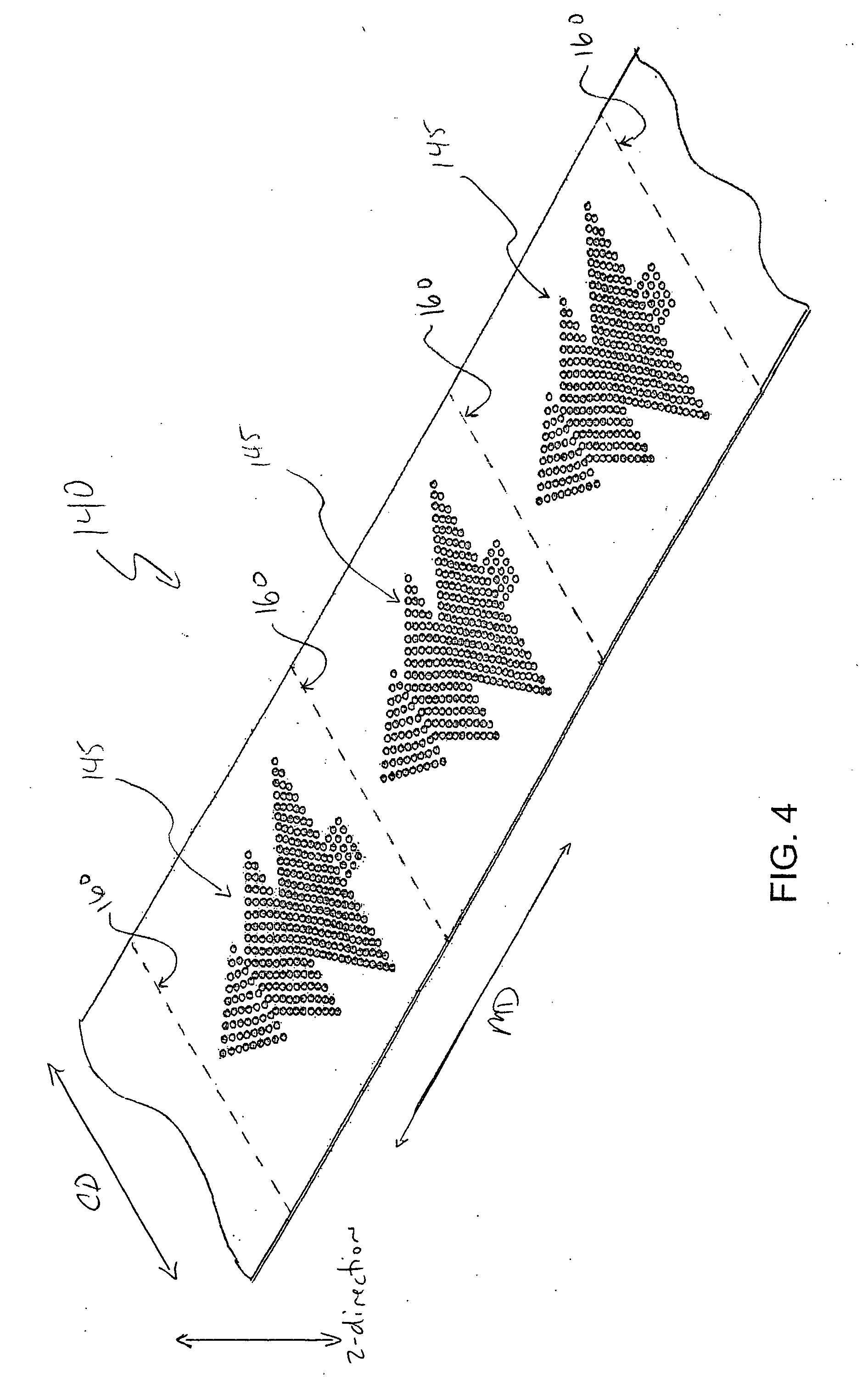

Fabric crepe and in fabric drying process for producing absorbent sheet

ActiveUS20050241787A1Decrease sidednessReduced areaNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberPulp and paper industry

A method of making a cellulosic web includes: forming a nascent web from a papermaking furnish, the nascent web having a generally random distribution of papermaking fiber; b) transferring the web having a generally random distribution of papermaking fiber to a translating transfer surface moving at a first speed; drying the web to a consistency of from about 30 to about 60 percent including compactively dewatering the web prior to or concurrently with transfer to the transfer surface; fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a creping fabric with a patterned creping surface, the fabric creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric such that the web has a plurality of fiber-enriched regions arranged in a pattern corresponding to the patterned creping surface of the fabric, optionally drying the wet web while it is held in the creping fabric. Preferably, the formed web is characterized in that its void volume increases upon drawing.

Owner:GPCP IP HLDG LLC

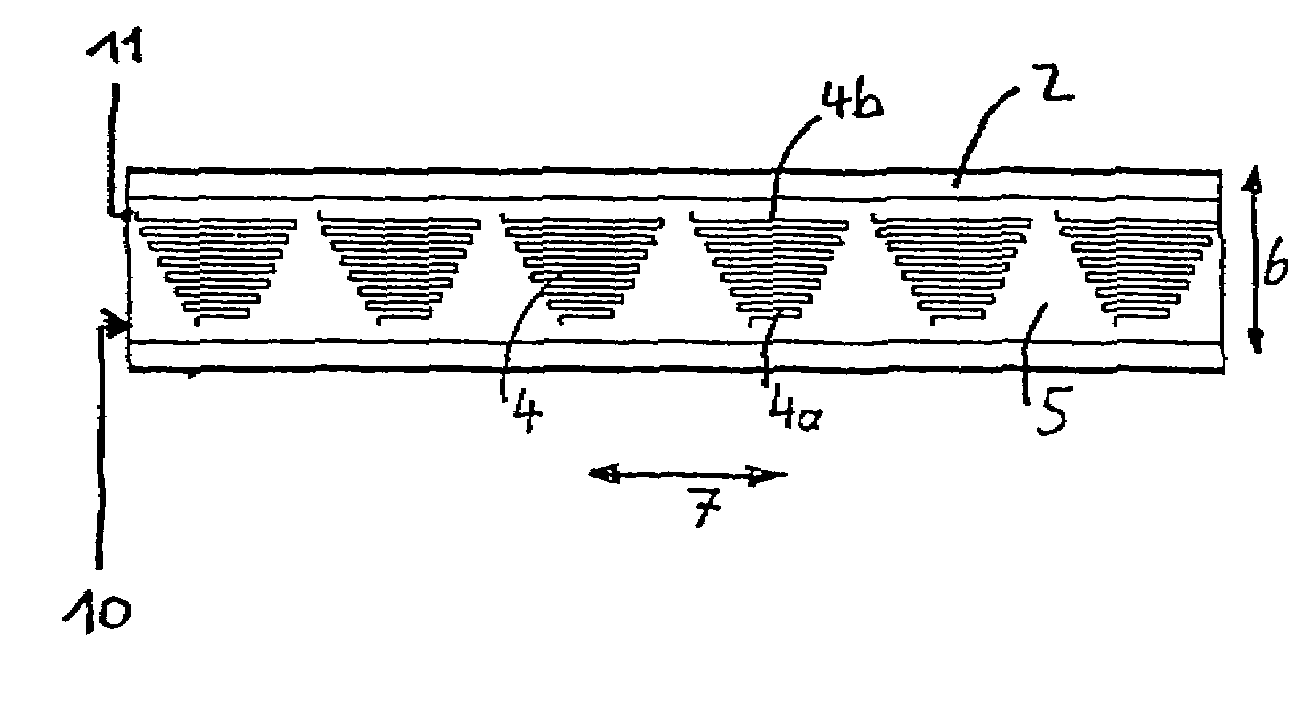

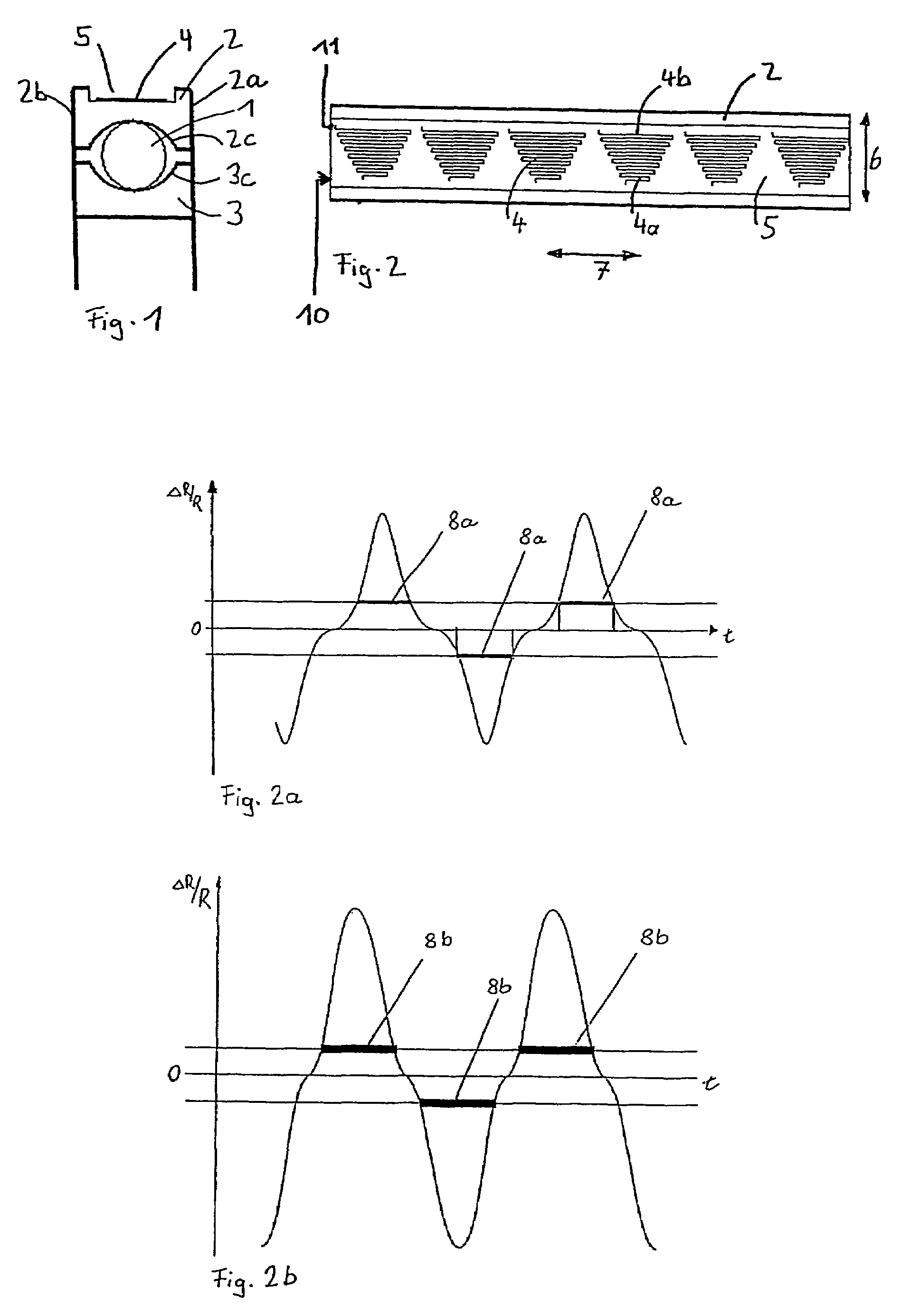

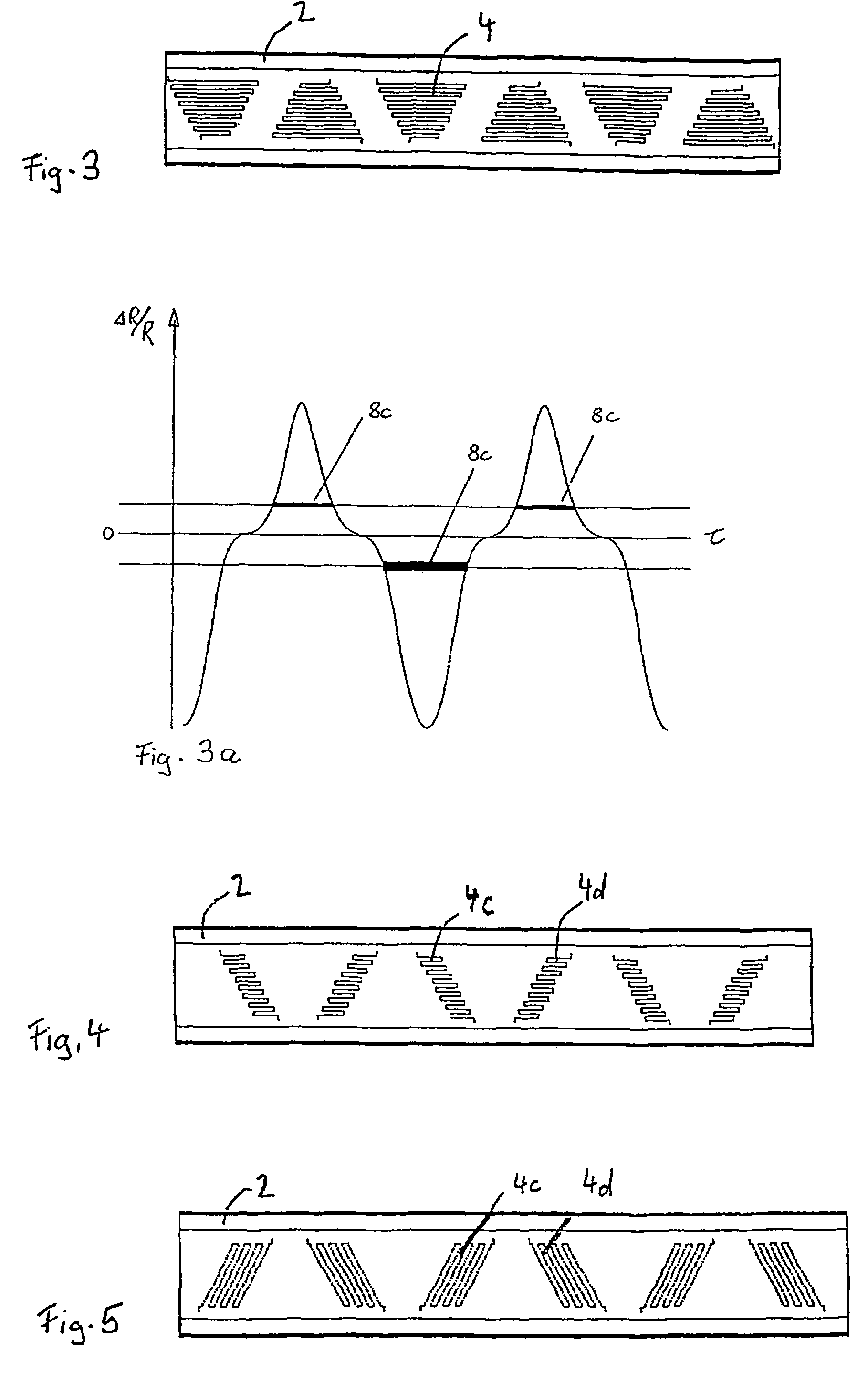

Force-sensing bearing

InactiveUS7316168B2Rolling contact bearingsMachine bearings testingElectrical conductorPulp and paper industry

The invention relates to a roller bearing comprising curved running paths, in addition to roller bodies and strain gauge sensors which are arranged between said running paths, said sensors being located in a groove on the outer diameter of the outer ring and / or on the inner diameter of the inner ring. The length of two adjacent strip conductor sections of the strain gauge sensor varies in such a way as to measure the angular position of the roller bodies between the strip conductors.

Owner:INA SCHAEFFLER KG

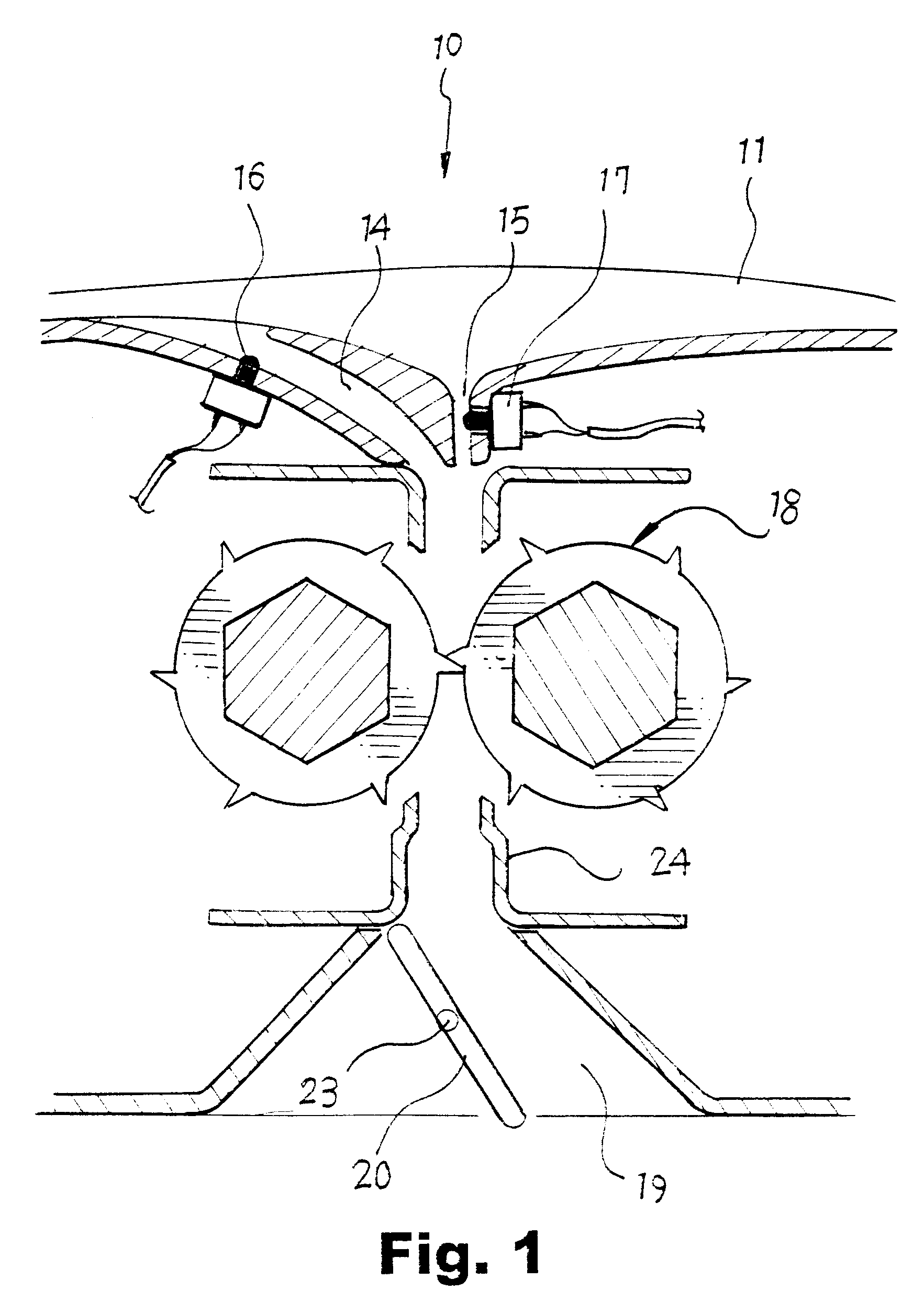

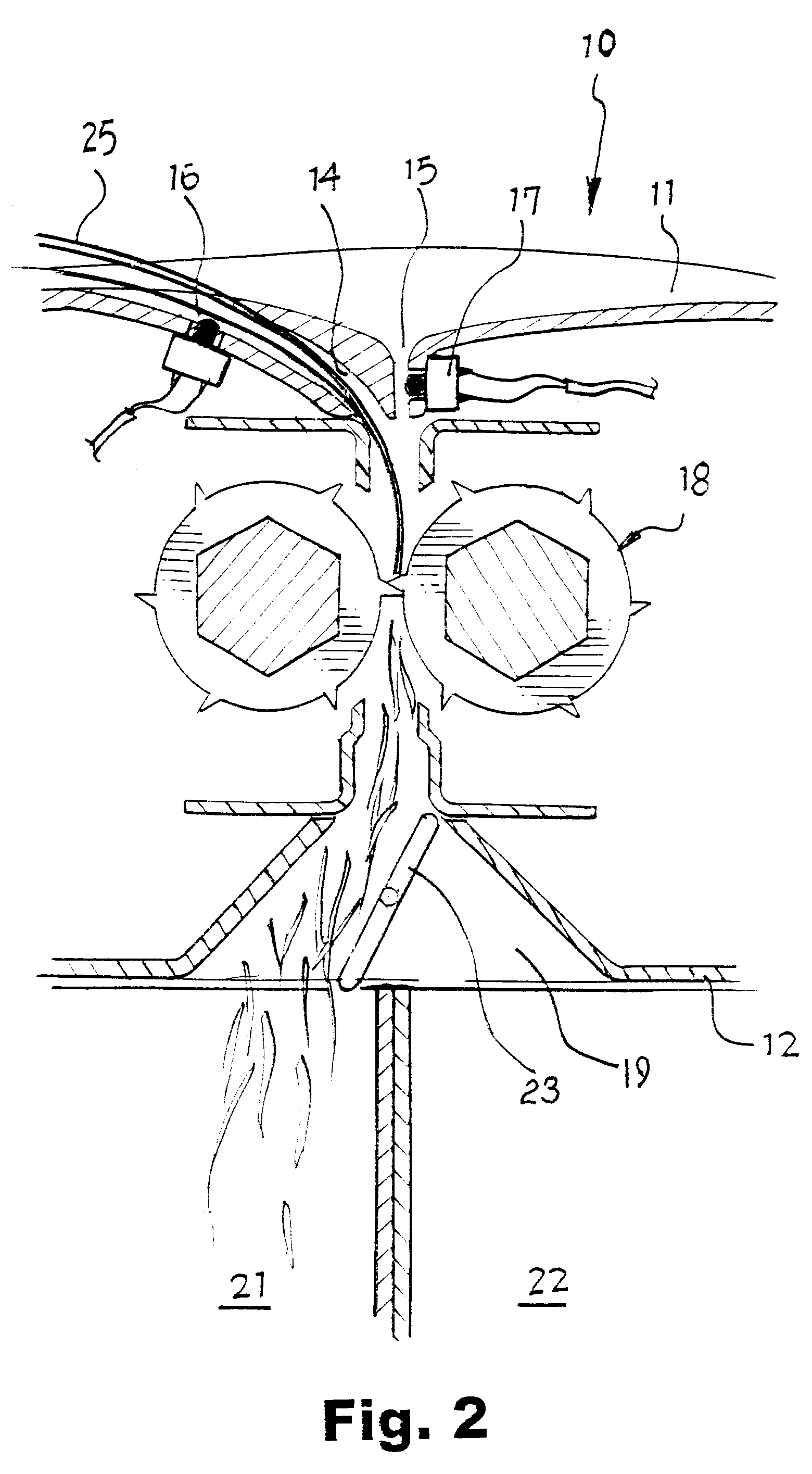

Dual-functional medium shredding machine structure

This invention is related to a dual-functional medium shredding machine structure, specifically designed for shredding or destroying paper printed with data to be destroyed, optical discs containing data to be destroyed, or expired credit cards. This invention mainly implements a pair of shredding roller blades with sharp teeth as shredding means, and is characterized by providing separate feeding inports, including a paper inport for feeding paper in an inclined orientation, and a disc inport for feeding discs in a vertical orientation, wherein the inports are each led to the same shredding roller blades such that, regardless of the type of substance being fed by the user, the paper or the discs can both be shredded by the shredding roller blades, and the shredded scraps are dispensed to separate collectors through an identical exit by means of an auto-revolving switch plate; and a touch switch at each of the inports such that, while feeding the paper or the discs, the touch switch activates the shredding roller blades to perform shredding task, and drives the switch plate so as to dispense shredded scraps of different substance into different collectors.

Owner:MICHILIN PROSPERITY

Whitened fluff pulp

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

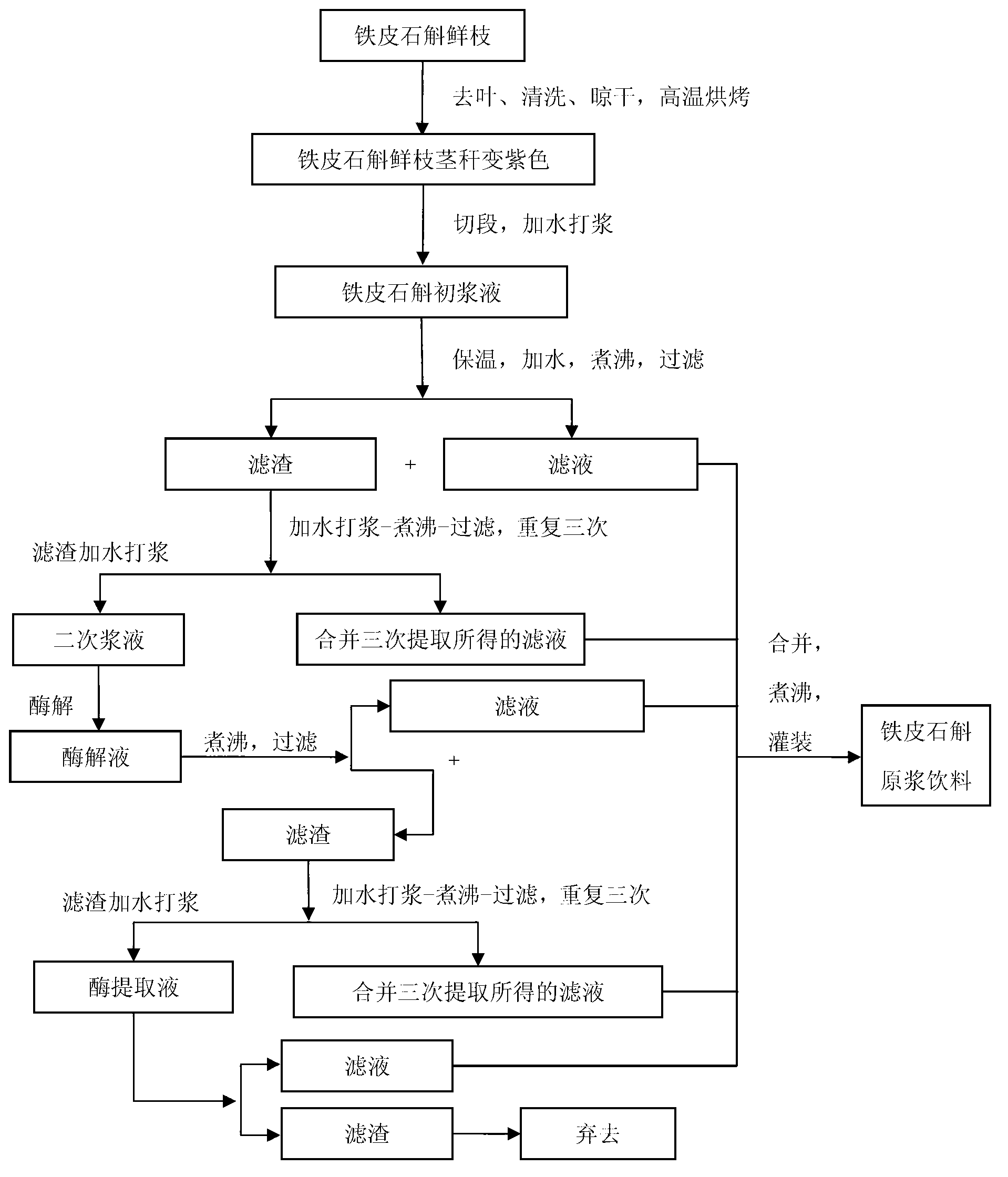

Preparation method of raw dendrobium officinale pulp beverage

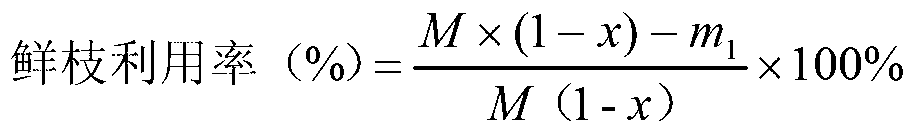

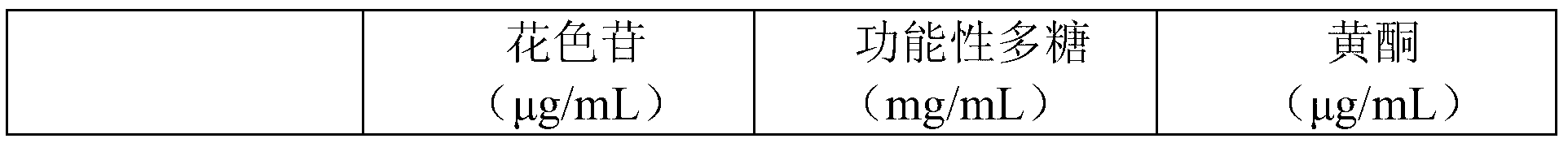

The invention discloses a preparation method of a raw dendrobium officinale pulp beverage. The preparation method comprises the following steps of: (1), baking a fresh dendrobium officinale branch to be purple, adding water to the baked fresh dendrobium officinale branch for pulping, so as to obtain a primary serous fluid; (2), carrying out insulation treatment on the primary serous fluid, boiling and filtering the primary serous fluid, so as to obtain filter residue; (3) adding water to the filter residue for pulping, boiling and filtering the filter residue again to obtain the filter residue, repeating the sub-steps for a plurality of times, adding water to the final filter residue for the pulping, so as to obtain secondary serous fluid; (4), adding a cellulolytic enzyme into the secondary serous fluid for carrying out enzymolysis, so as to obtain an enzymolysis solution; (5) boiling and filtering the enzymolysis solution, to obtain the filter residue; (6) adding water into the filter residue for the pulping, boiling and filtering the filter residue again, to obtain the filter residue, and repeating the sub-steps for a plurality of times; (7) mixing all the filter solutions, boiling and sterilizing the mixed filter solution, so as to obtain the raw dendrobium officinale pulp beverage. The preparation method provided by the invention has the advantages that dendrobium officinale is baked, the filter residue is subjected to enzymolysis treatment, the extraction rate of functionality polyose and flavone is improved, the content of dietary fiber in the beverage is increased, and the prepared beverage color is bright and stable.

Owner:ZHEJIANG UNIV +1

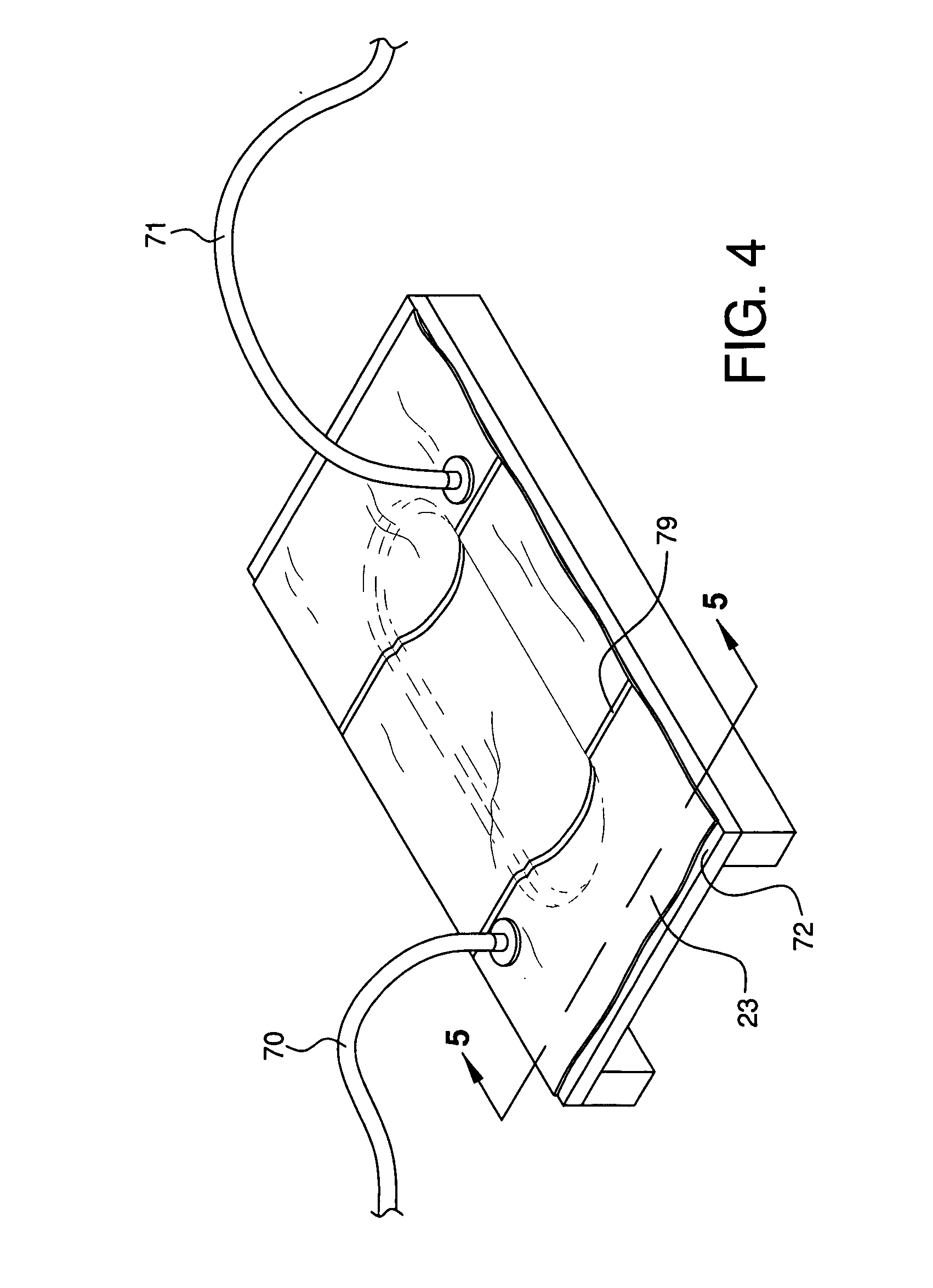

Reusable vacuum bag and methods of its use

InactiveUS20050086916A1Eliminate disposableEliminate expenseDispersed particle filtrationConfectioneryFiberShell molding

Reusable vacuum bags are provided which include a fabric layer containing reinforcement fibers and a release surface disposed on at least the first side of the fabric layer. The vacuum bag is capable of withstanding multiple mold cycles of the vacuum of less than ambient pressure without significant leakage. In addition, the described vacuum bag can be used in resin transfer molding and standard bagging operations with commercial benefit.

Owner:SAINT GOBAIN BRUNSWICK TECH +1

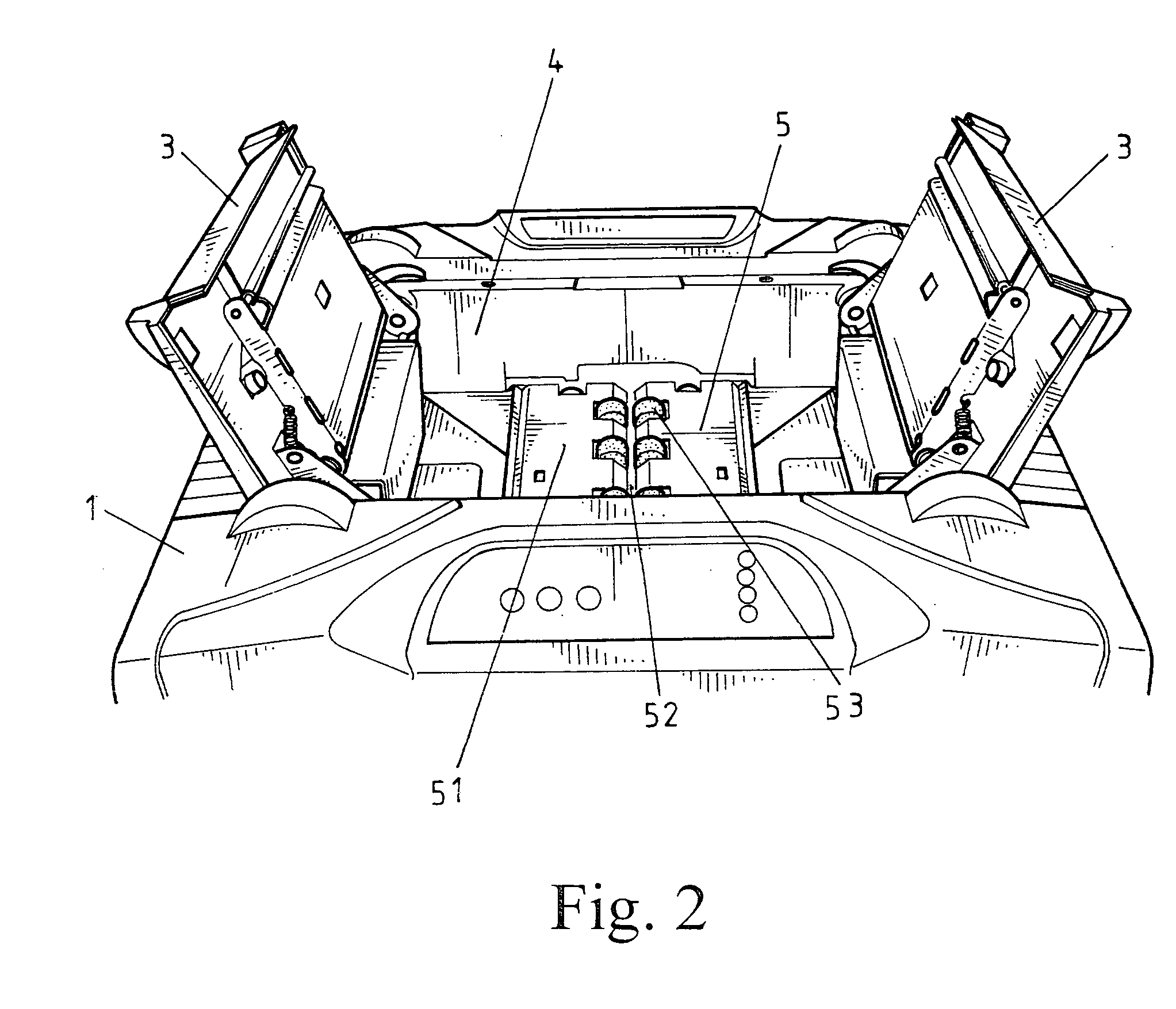

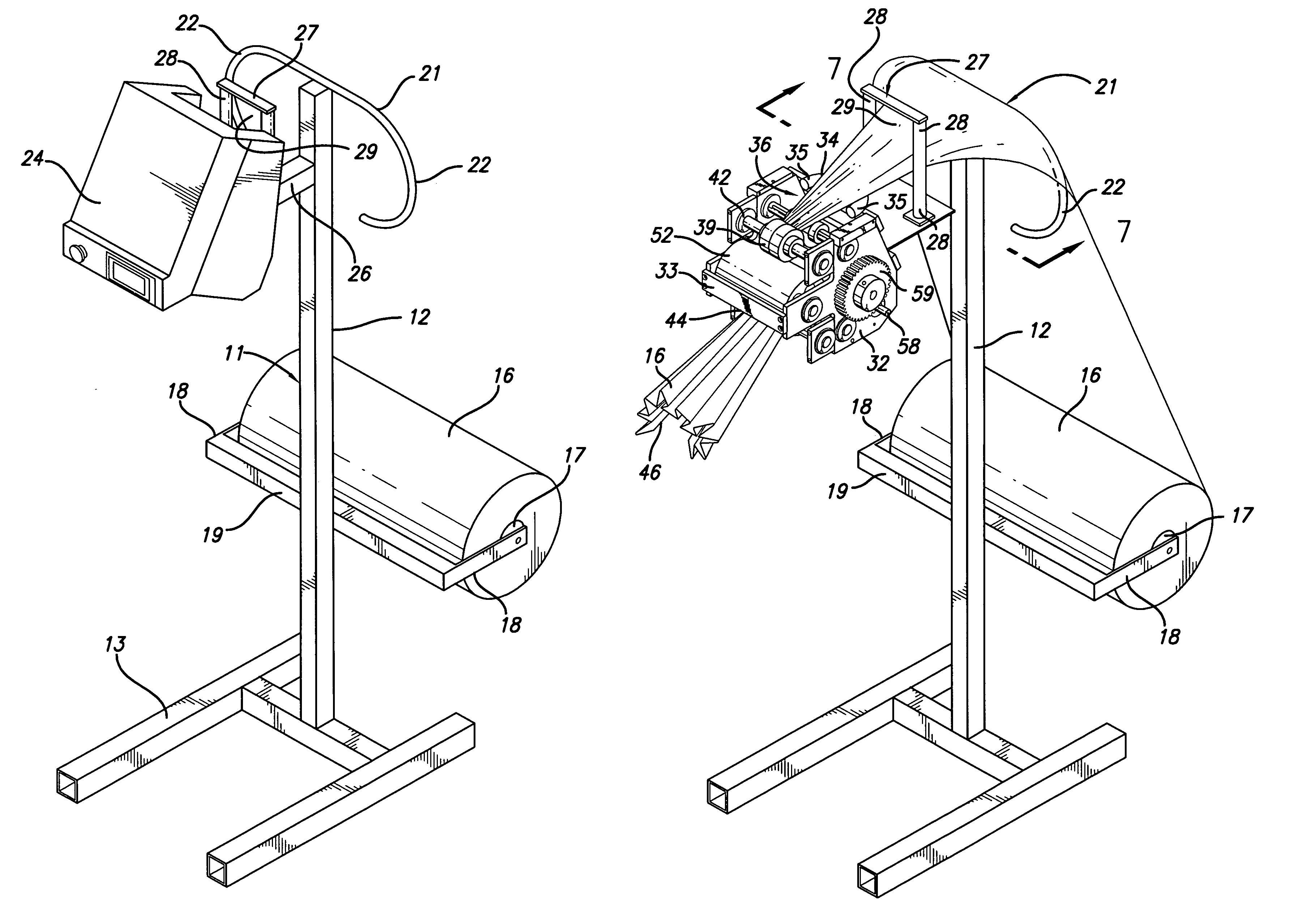

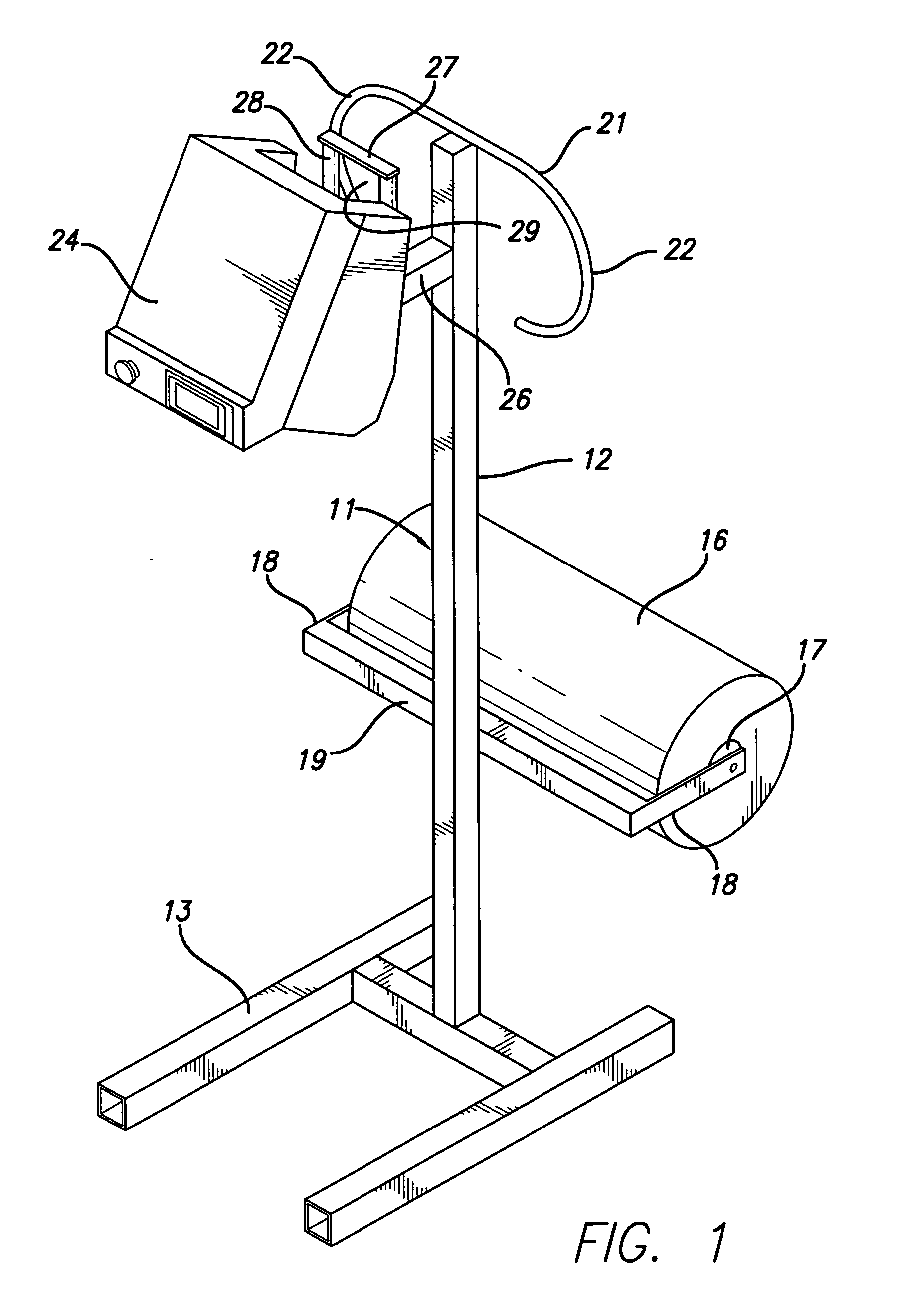

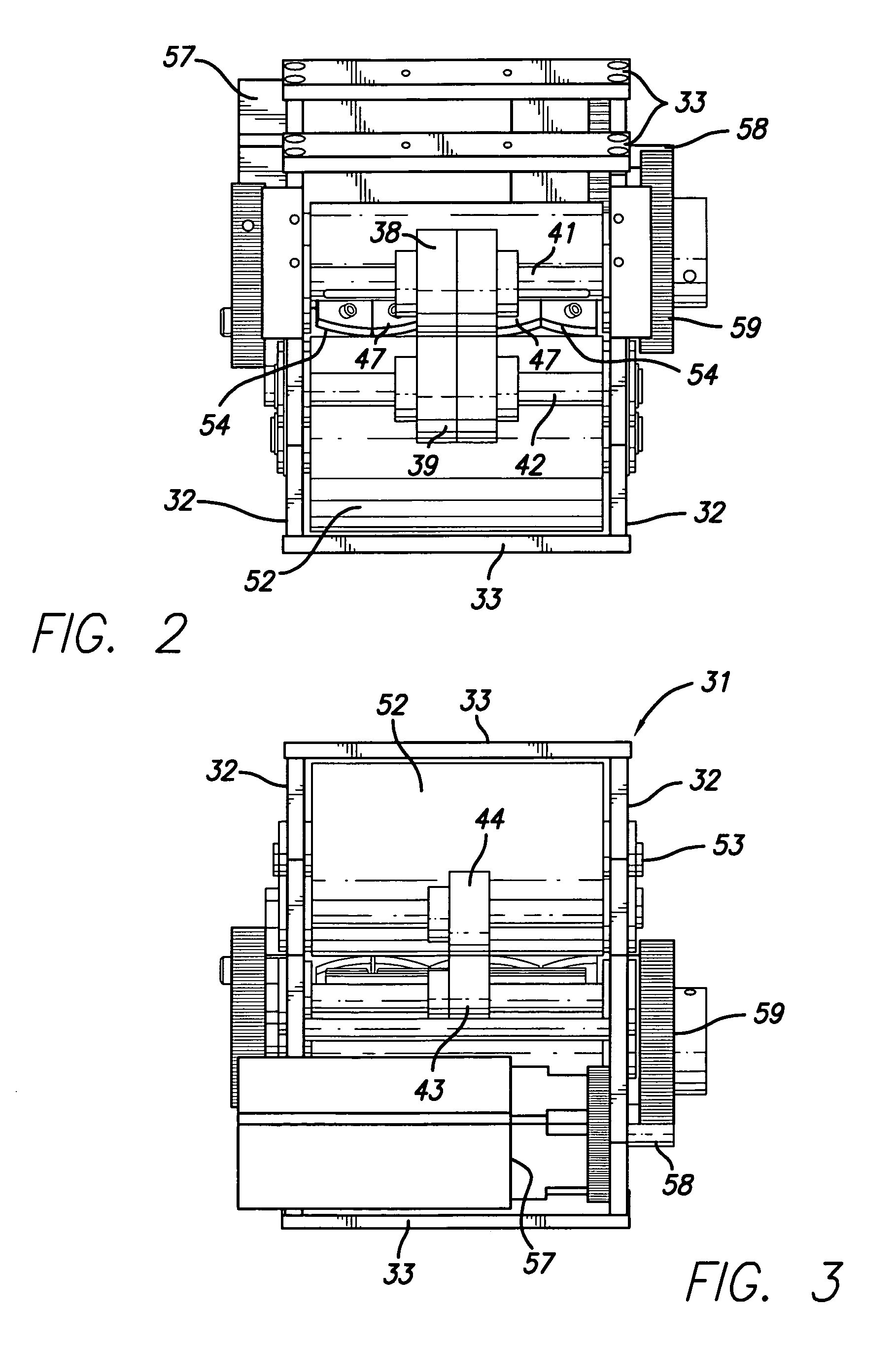

Auto-feed buit-in a paper shredder

InactiveUS20050274836A1Reduce spacingLow costCocoaGrain treatmentsPulp and paper industryPaper sheet

Disclosed is an auto-feed buit-in a paper shredder, including a pair of bisecting lids that are each provided at an inside thereof with a paper press, a paper receiving compartment, an auto-feed, and a paper shredding device located exactly below the auto-feed, wherein the auto-feed includes a paper tray, a paper inlet and two roller assemblies; the paper inlet and the paper shredding device located therebelow are aligned along an identical central axis; the two roller assemblies are provided at opposing sides of the paper inlet in parallel and project into the paper tray, whereby after placing a pile of paper into the paper receiving compartment to be supported by the paper tray, and closing the bisecting lids, the paper presses provided at the insides of the lids would apply a force against the pile of paper, such that a bottommost paper of the pile of paper would be folded in half by the two rollers rotating towards each other and then fed into the paper inlet to be subsequently shredded by the paper shredding device located below the paper inlet.

Owner:MICHILIN PROSPERITY

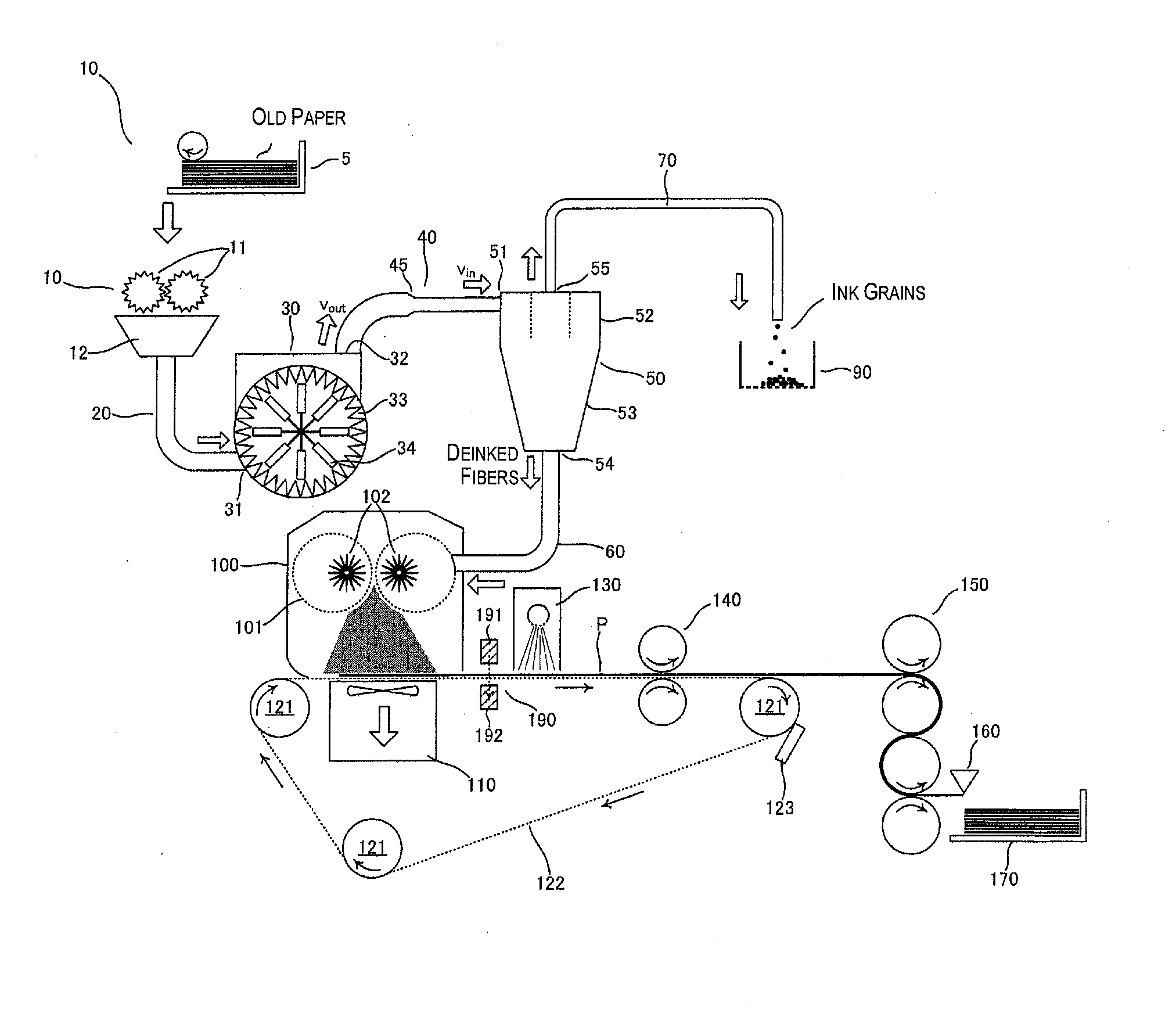

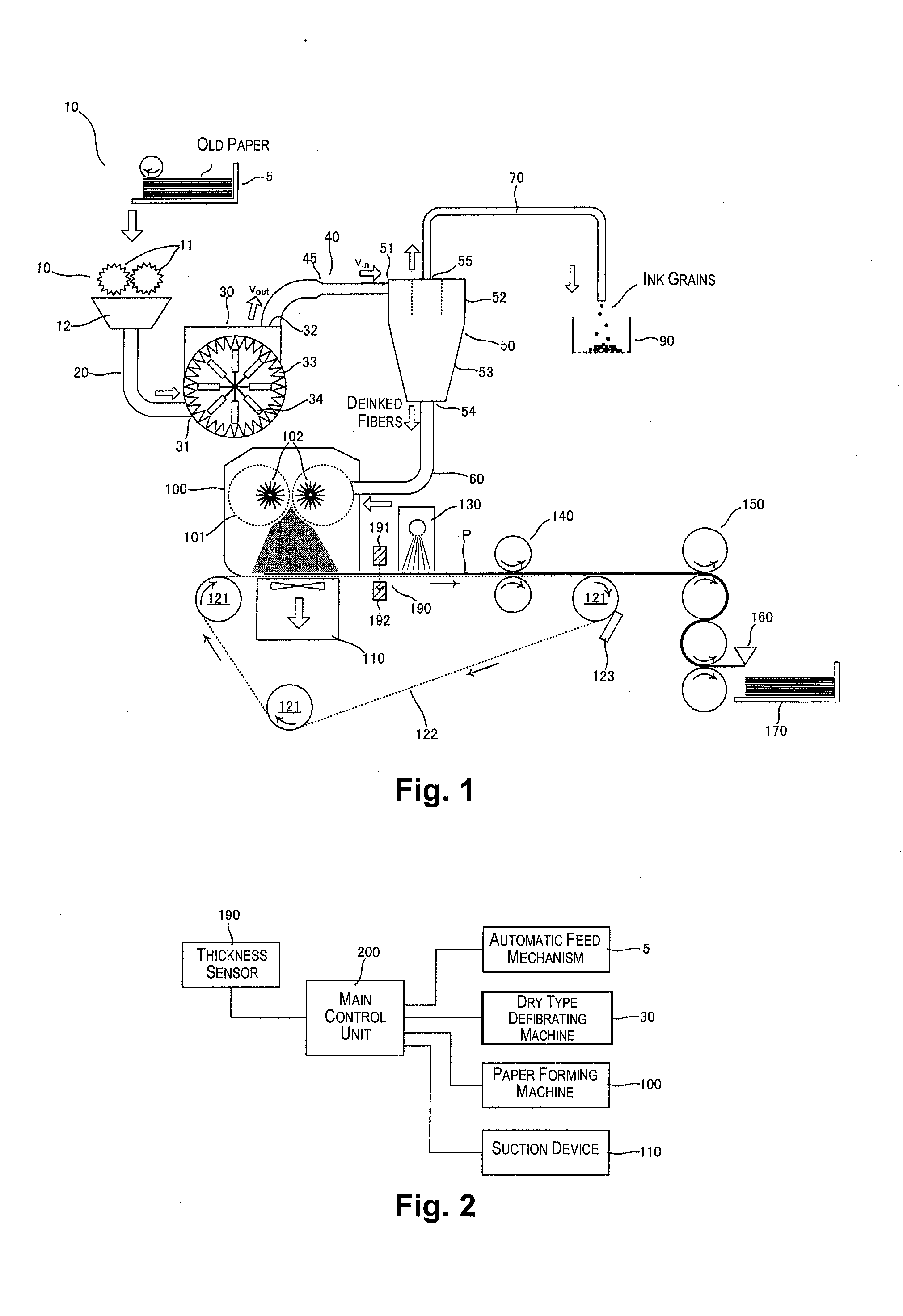

Paper recycling system and paper recycling method

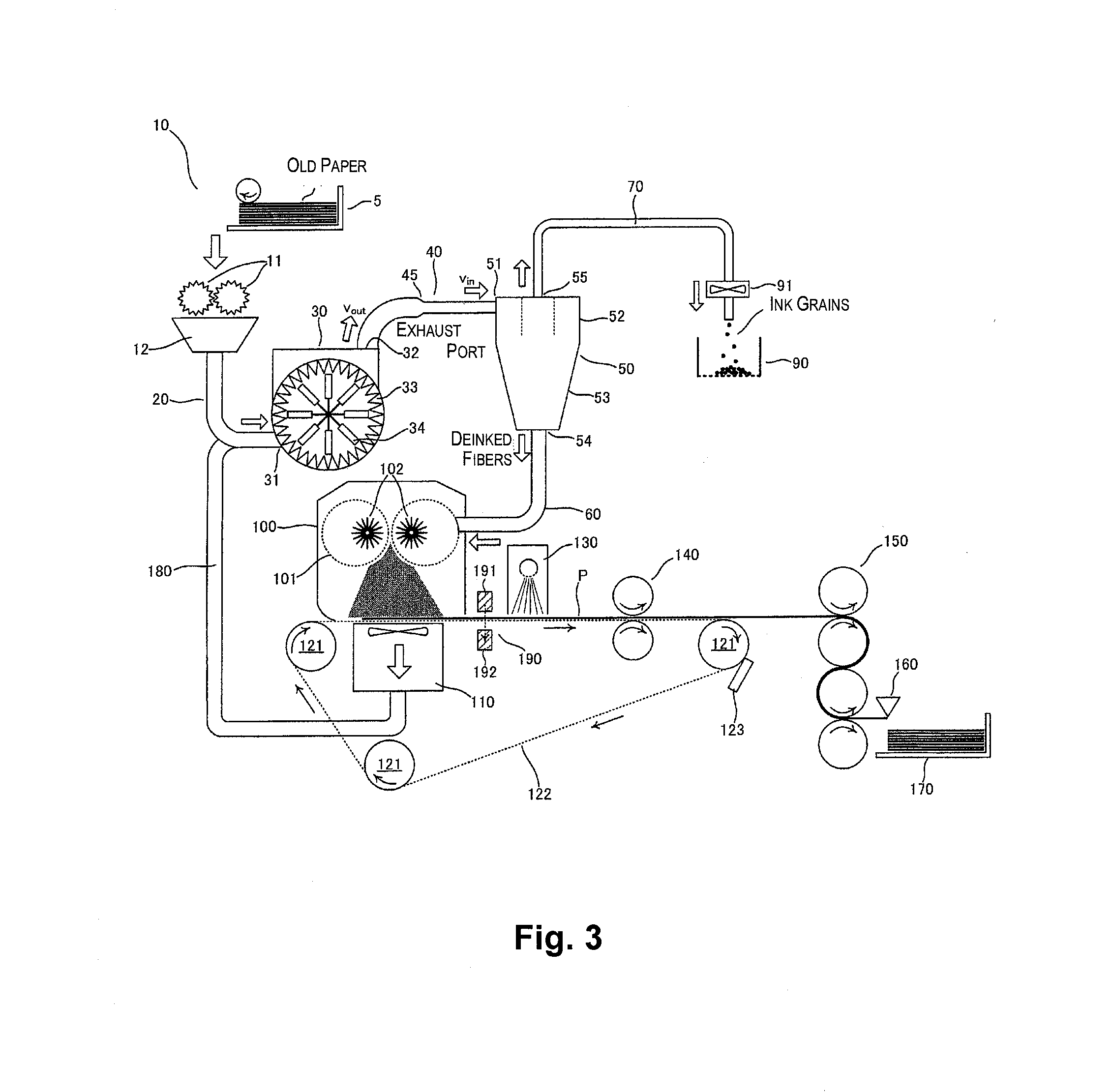

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

Cigarette and wrapping materials therefor

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

Paper or paperboard substrate, a process for production of the substrate and a package formed of the substrate

The present invention relates to a paper or paperboard substrate having barrier properties which substrate comprises a first fiber based layer, a second layer comprising microfibrillated cellulose and a third layer comprising a polymer. The invention further relates to a process for the production of said substrate and a package formed of said substrate.

Owner:STORA ENSO OYJ

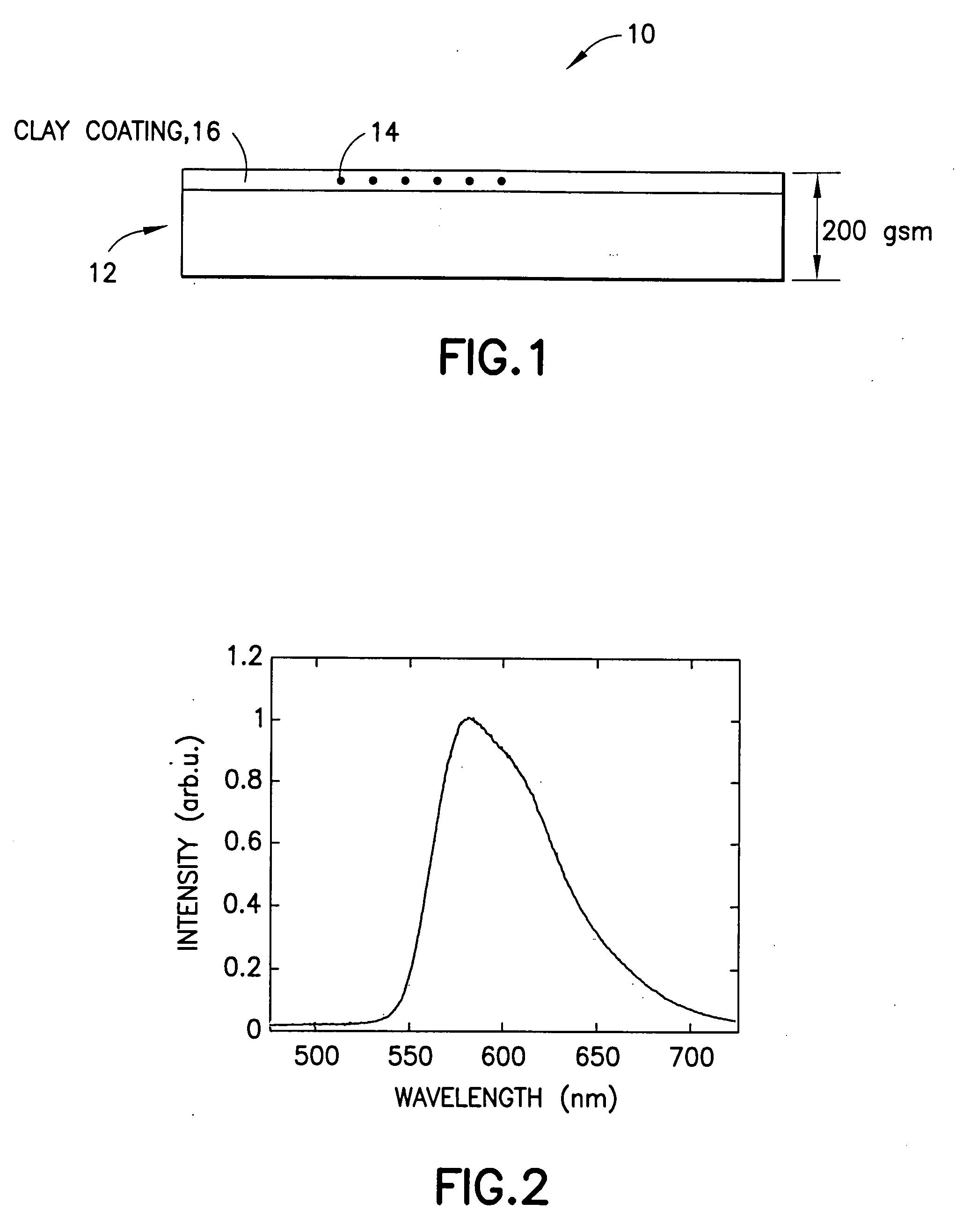

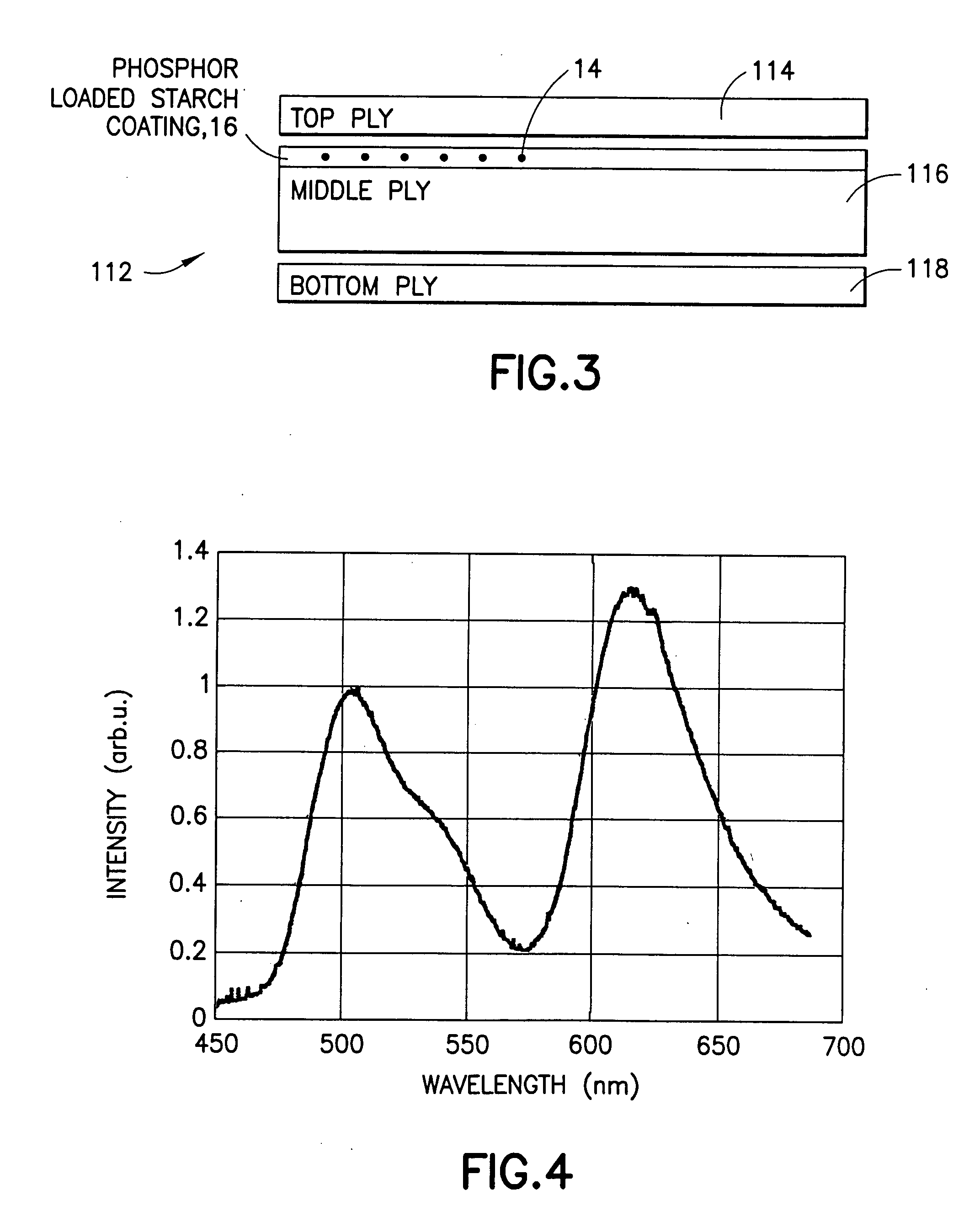

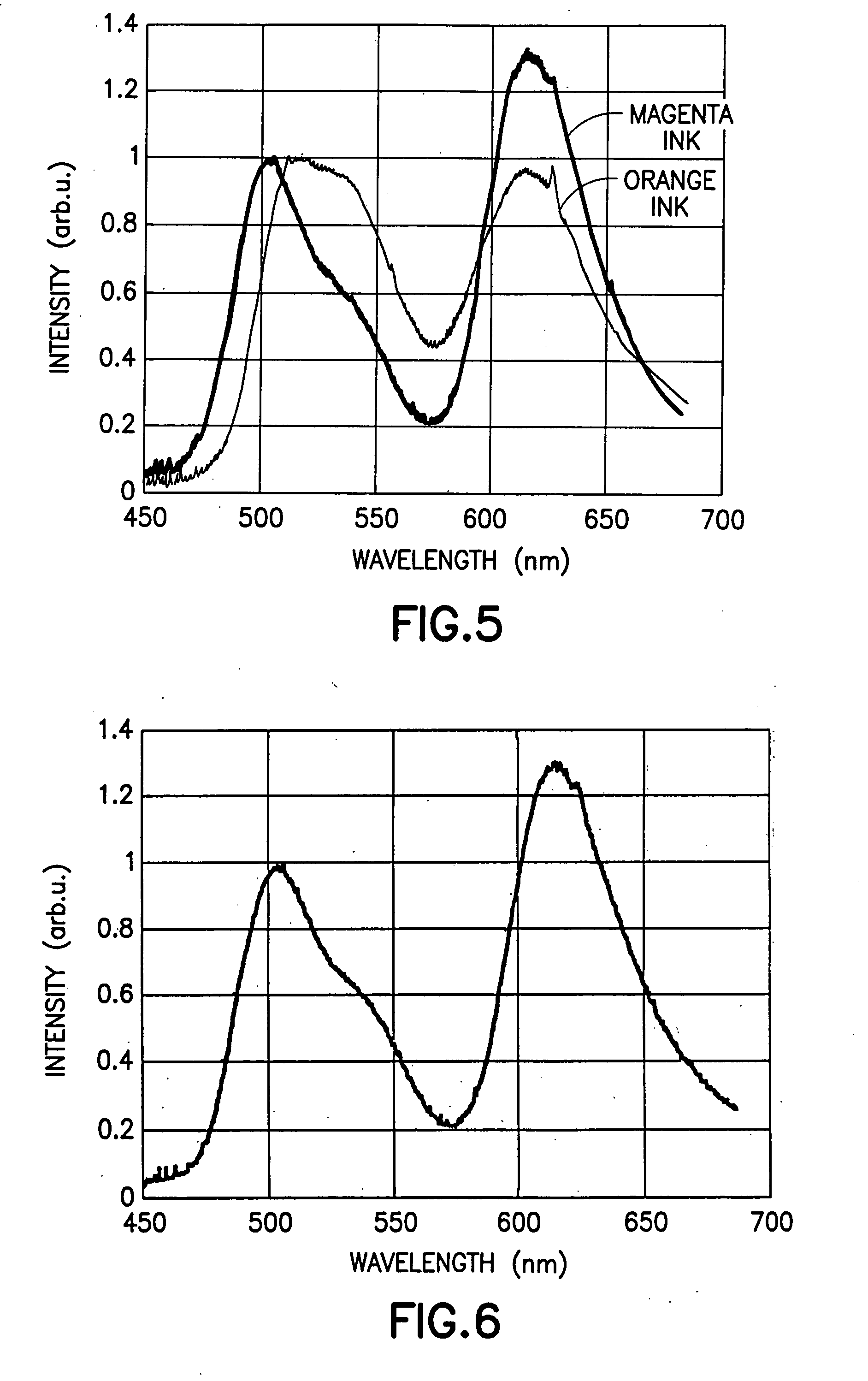

Taggant security system for paper products as a deterrent to counterfeiting

InactiveUS20050031838A1Difficult to duplicateNot easy to counterfeitNon-fibrous pulp additionOther printing matterPulp and paper industrySecurity system

A taggant security system for preventing the counterfeiting of goods associated with a paper product is provided. The taggant security system includes a paper product coating located on a paper product. The paper product coating is preferably one which is commonly used in the paper making industry. The taggant security system further includes one or more taggants incorporated within said paper product coating for authenticating said paper product. In preferred embodiments, the paper product coating is either a clay or starch coating. In addition, in preferred embodiments, the paper product is either a single or multi-ply packaging board or a label stock.

Owner:SPECTRA SYST CORP

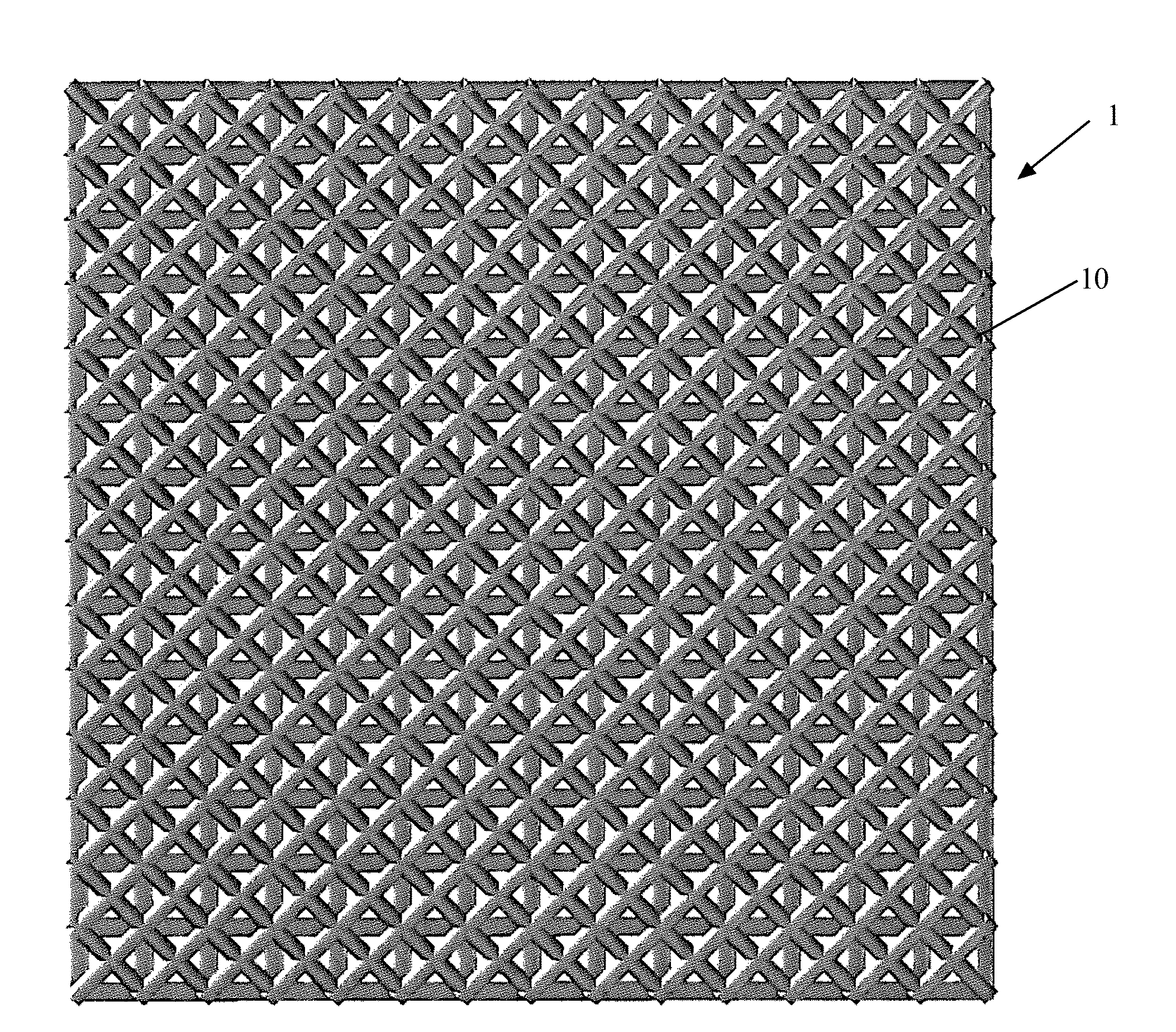

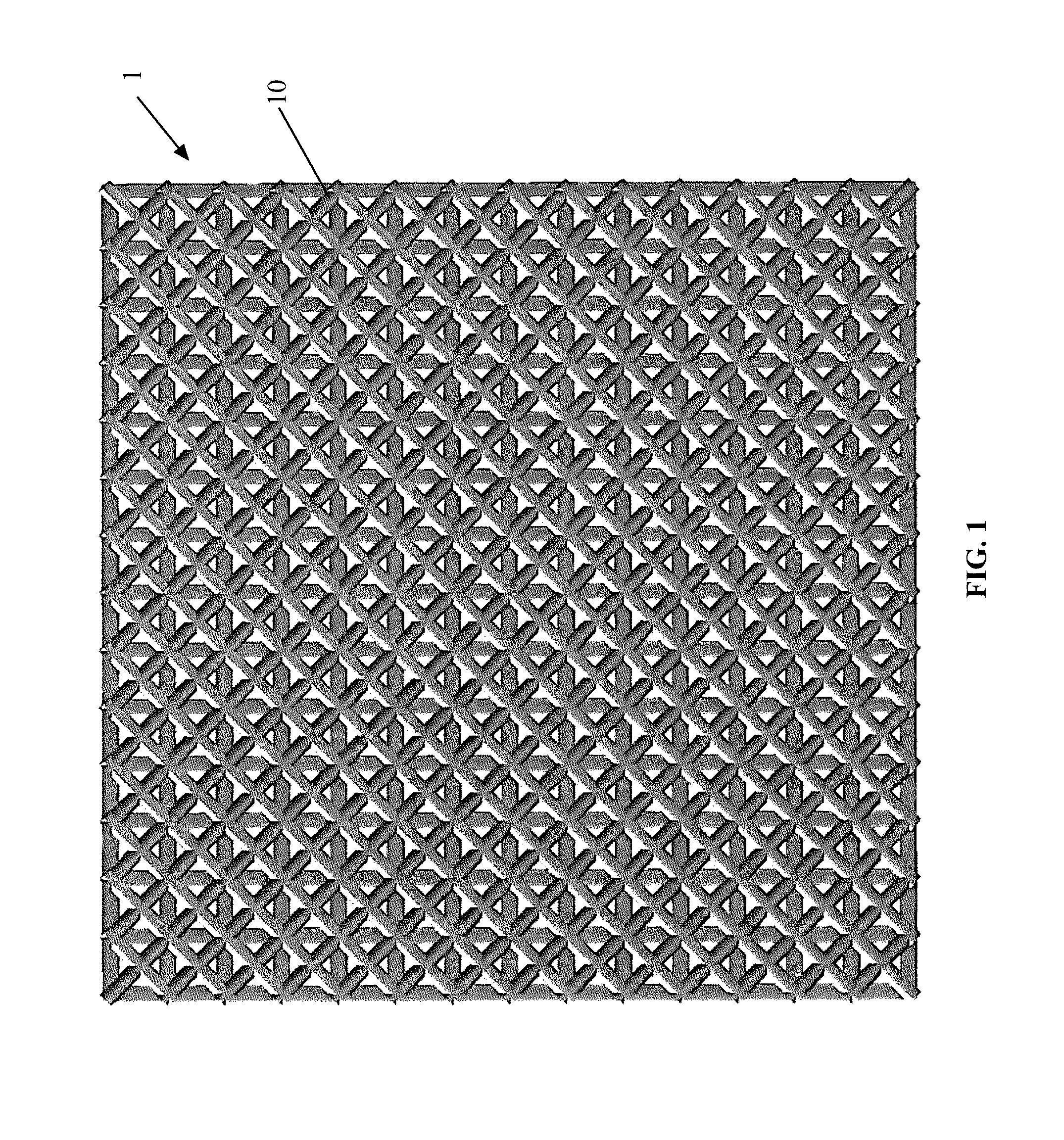

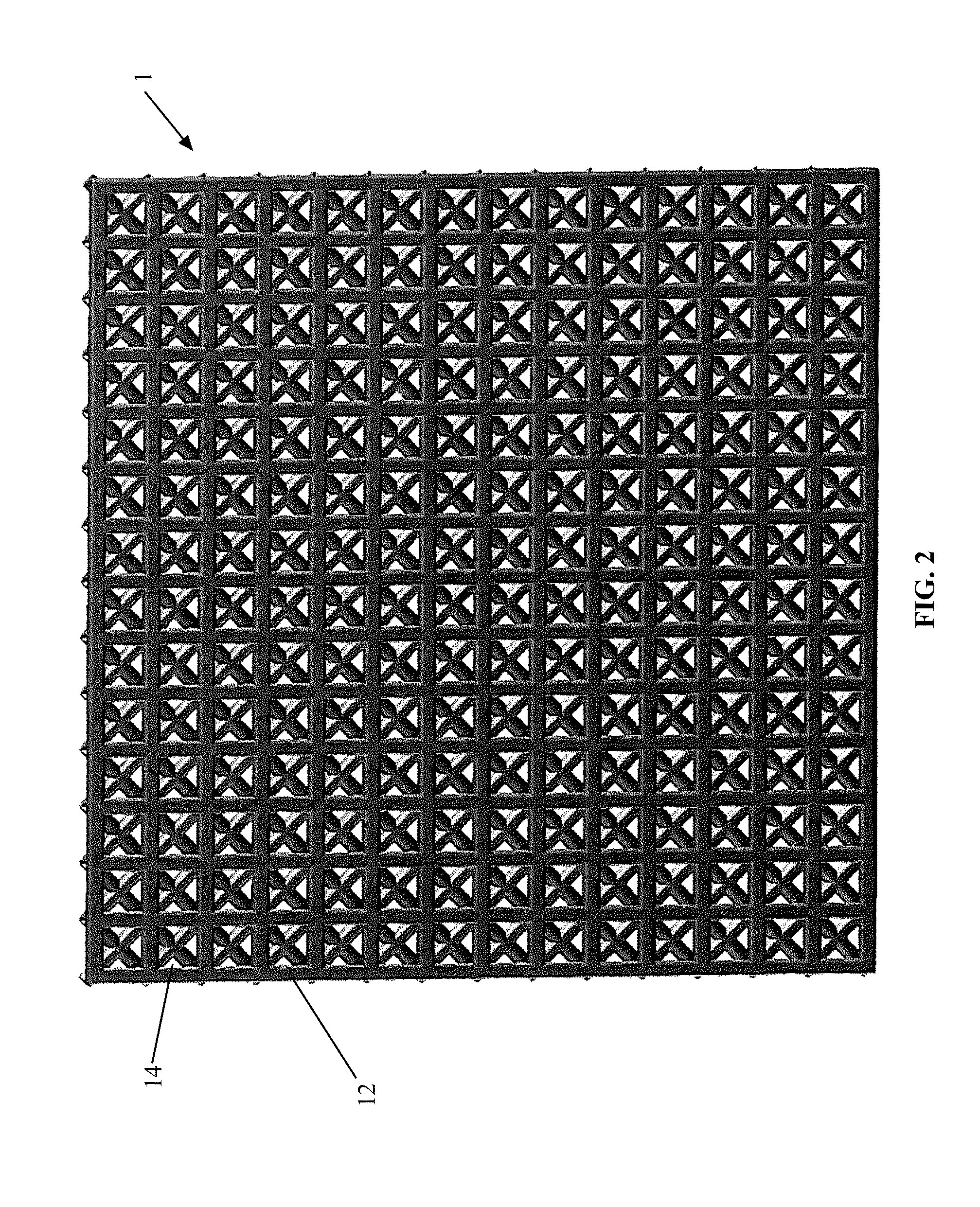

Manufacturing process for papermaking belts using 3D printing technology

ActiveUS20160159007A1Good choiceAdditive manufacturing apparatusMachine wet endFiberPulp and paper industry

A papermaking belt including zones of material laid down successively using a 3D printing process. The zones include at least a pocket zone configured to form three dimensional structures in a paper web by applying vacuum to pull the paper web against the pocket zone. In at least one exemplary embodiment, the zone also include at least one vacuum breaking zone configured to limit an amount of paper fibers pulled through the pocket zone by the applied vacuum.

Owner:STRUCTURED I

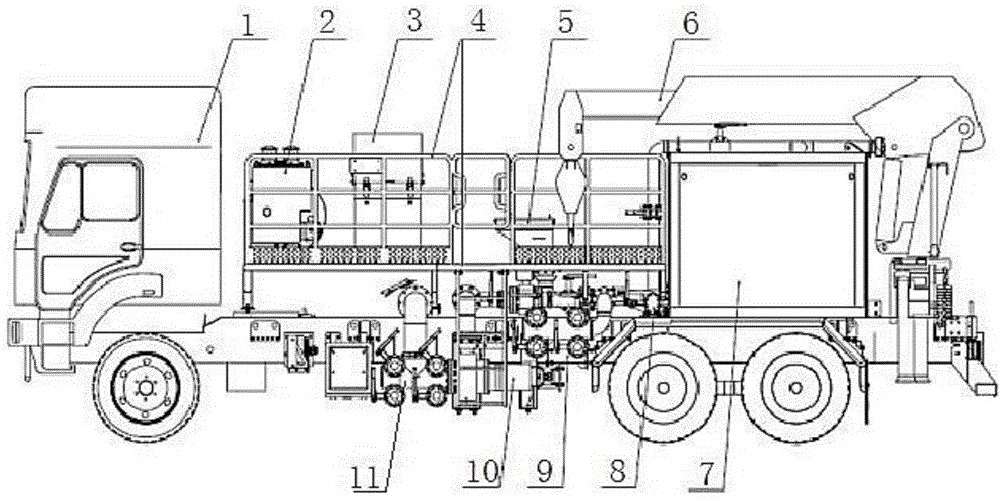

Multifunctional blending and liquid supplying vehicle

InactiveCN104057864AReduce labor costsAchieve mixingFluid removalItem transportation vehiclesControl systemElectrical control

The invention relates to a multifunctional blending and liquid supplying vehicle, which comprises a chassis, wherein an operation platform, a hydraulic oil tank, a dry powder feeder, an operation box for an electrical control system, a lorry-mounted crane and a liquid adding tank are fixedly arranged above the main beam of the chassis, wherein a centrifugal pump, an exhaust manifold and a suction manifold are arranged on each of two sides of the middle part of the main beam of the chassis, the exhaust manifold is communicated with the water outlet of the centrifugal pump, and the suction manifold is communicated with the water inlet of the centrifugal pump; the liquid adding pump is fixedly arranged on the side wall of the liquid adding tank, the water inlet of the liquid adding pump is communicated with the liquid adding tank, and the water outlet of the liquid adding tank is communicated with the exhaust manifold; a discharge opening in the lower end of the dry powder feeder is communicated with the exhaust manifold; the engine of the chassis is connected with a hydraulic pump, and the hydraulic pump is connected with the centrifugal pump, the lorry-mounted crane, the liquid adding tank and the liquid adding pump through a hydraulic multiway valve; the electrical control system is connected with the engine of the chassis, the hydraulic pump and the hydraulic multiway valve. The multifunctional blending and liquid supplying vehicle provided by the invention is low in cost, high in working efficiency, and can achieve various oil field operation functions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Tissue sheet molded with elevated elements and methods of making the same

InactiveUS20070137814A1Improved bulk retentionNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryDome shape

Owner:KIMBERLY-CLARK WORLDWIDE INC

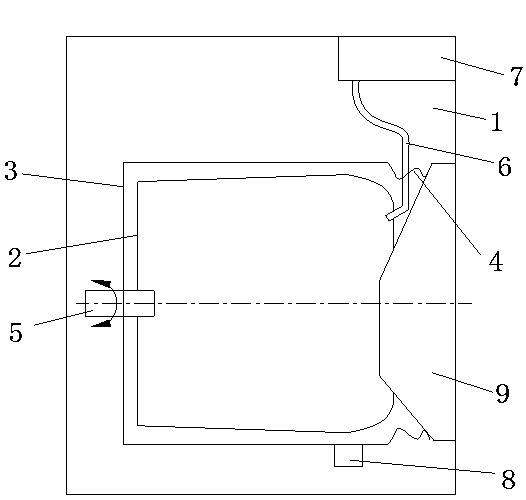

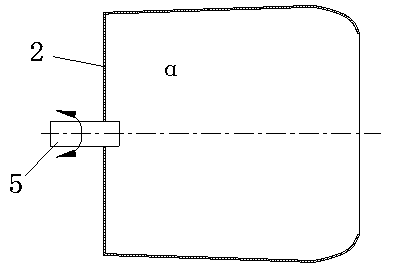

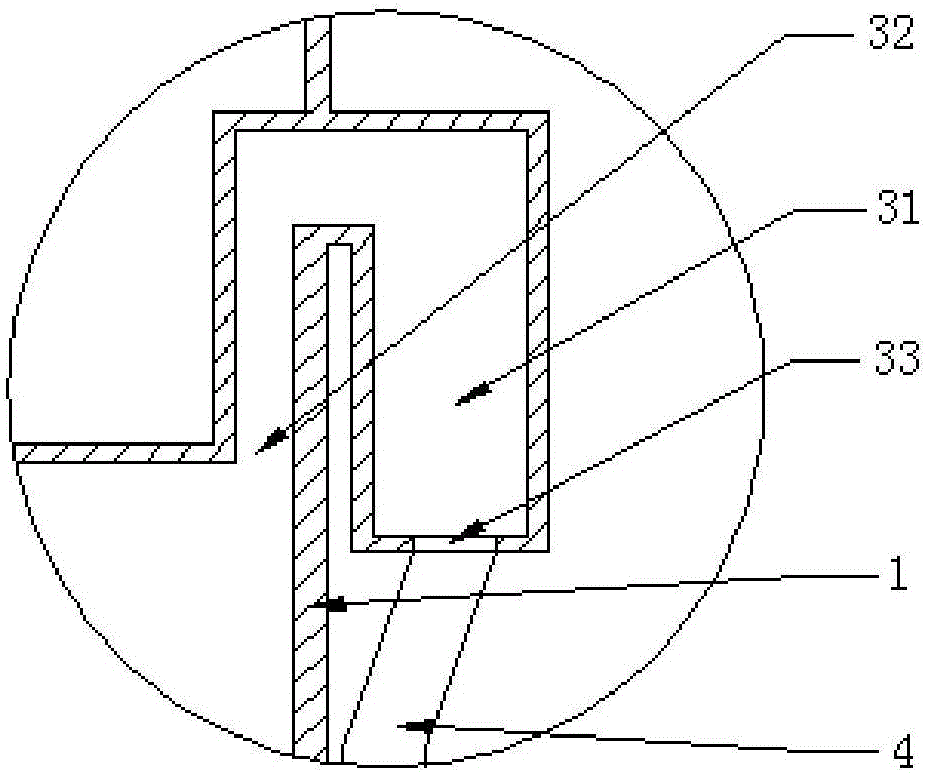

Hole-free inner barrel washing machine

InactiveCN105714514ALower the altitudeLow costOther washing machinesTextiles and paperWater dischargePulp and paper industry

The invention discloses a hole-free inner barrel washing machine and relates to the technical field of washing machines. Under the condition of saving water, the problems that the water is easy to splash when the water is discharged above an inner barrel and bacteria are easy to breed in an outer barrel are solved, and the cost of the washing machine is saved. The hole-free inner barrel washing machine comprises the inner barrel and the outer barrel, wherein a water collection ring is arranged at a barrel opening of the inner barrel; the water collection ring comprises a water collection cavity, and a water collection hole and a water discharging hole which are communicated with the water collection cavity; the water collection hole is arranged toward the inner part of the inner barrel; the water discharging hole is formed towards a gap between the inner barrel and the outer barrel; the water discharging hole is connected with a water discharging pipe; and the water discharging pipe extends downwards to the bottom of the outer barrel. The hole-free inner barrel washing machine is used for discharging the water of the washing machine.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Machine and method for making paper dunnage

InactiveUS6910997B1Mechanical working/deformationPaper/cardboard articlesDunnagePulp and paper industry

Dunnage making machine and method in which a web of paper is drawn across a forming bar with curved end sections to roll the edge portions of the paper, then drawn through a first throat section to urge the rolled edge portions toward each other and cause them to gather, and thereafter through a second throat section of lesser dimension than the first to gather the central portion of the paper and further gather the edge portions. The gathered paper is then pressed with a roller to crumple it, following which the crumpled paper is perforated along a serrated tear line.

Owner:PREGIS INNOVATIVE PACKAGING

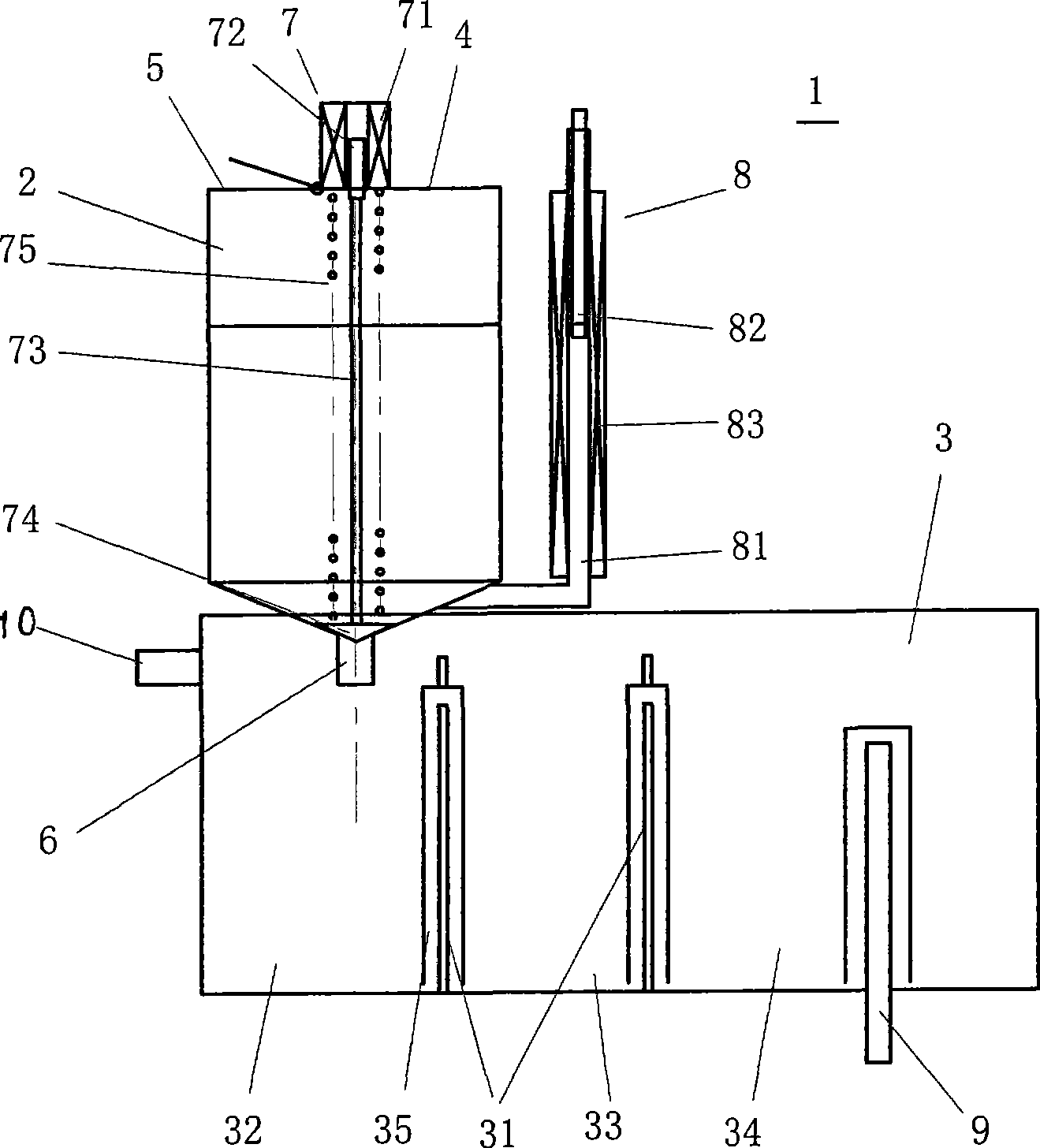

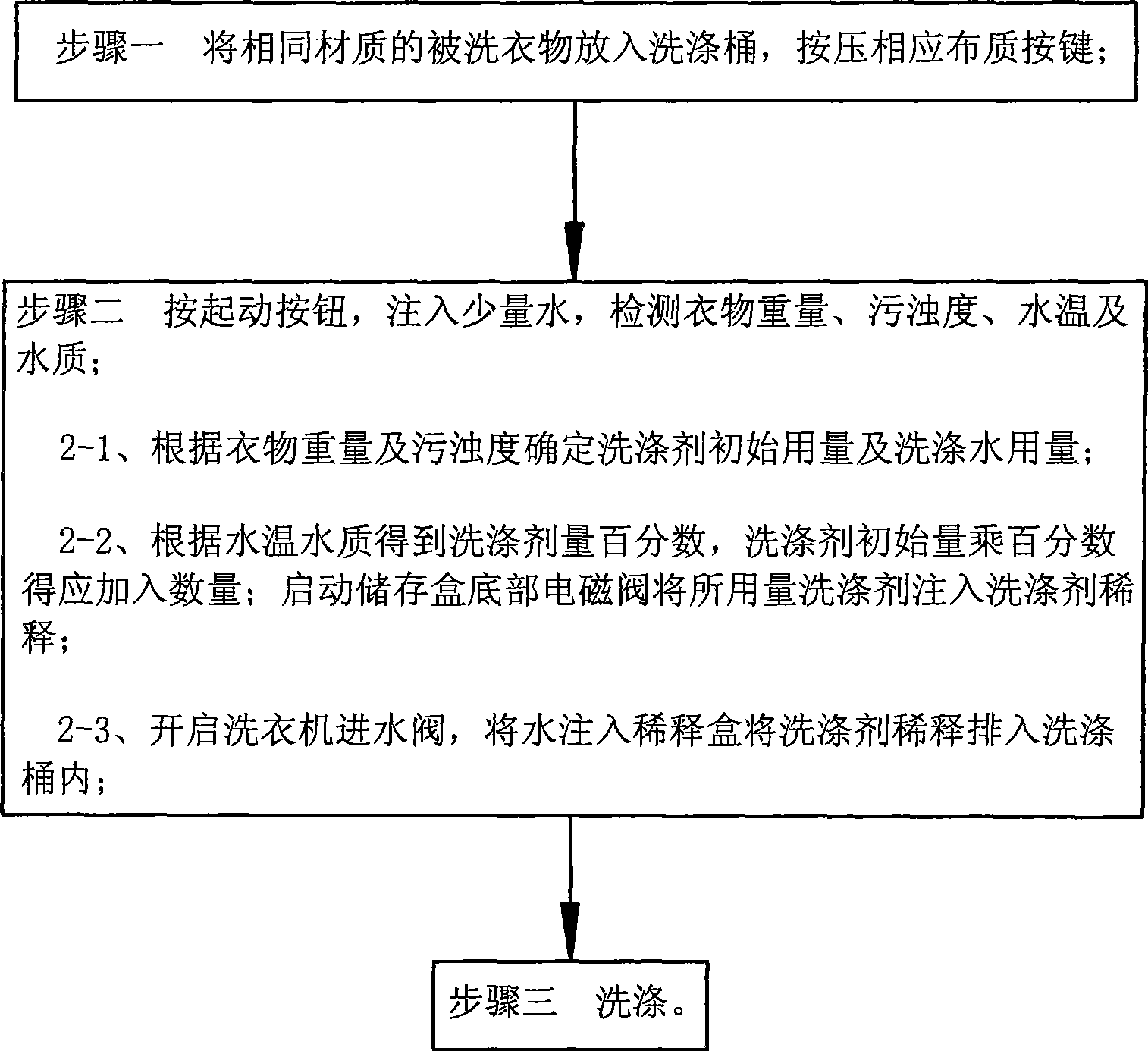

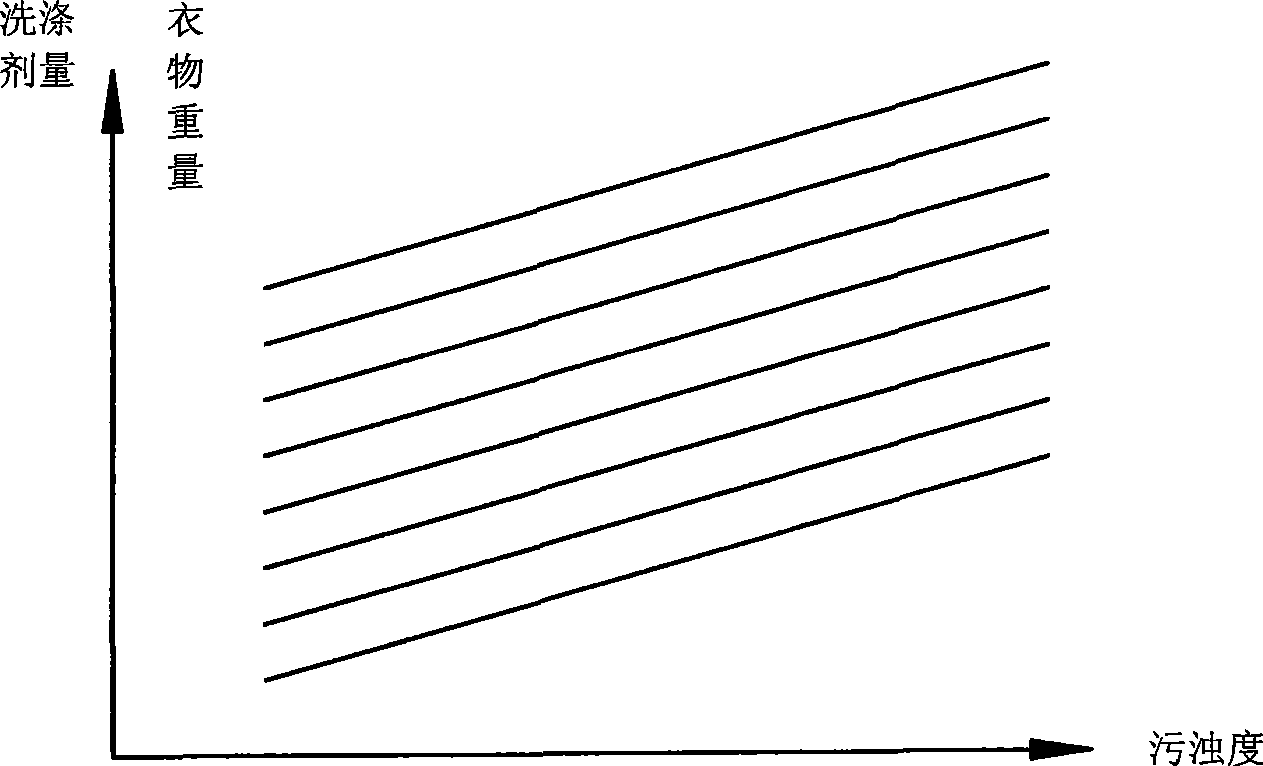

Washing machine for auto-adding washing agent and washing method for auto-adding washing agent

ActiveCN101381939APrevent too littlePrevent the situationOther washing machinesControl devices for washing apparatusPulp and paper industryHardness

The invention relates to an automatic detergent-adding washing machine and a washing method, in particular to a washing method which automatically adds detergent according to five factors, namely the weight, dirty degree, cloth characters of clothes, as well as the temperature and hardness of washing water. Due to the technical proposal, the invention provides the automatic detergent-adding method which automatically adds the most reasonable detergent on the premise of without affecting washing effects, prevents the circumstances that the detergent manually added is too little or excessive, saves resources, and reduces the pollution of discharged washing water on environment.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

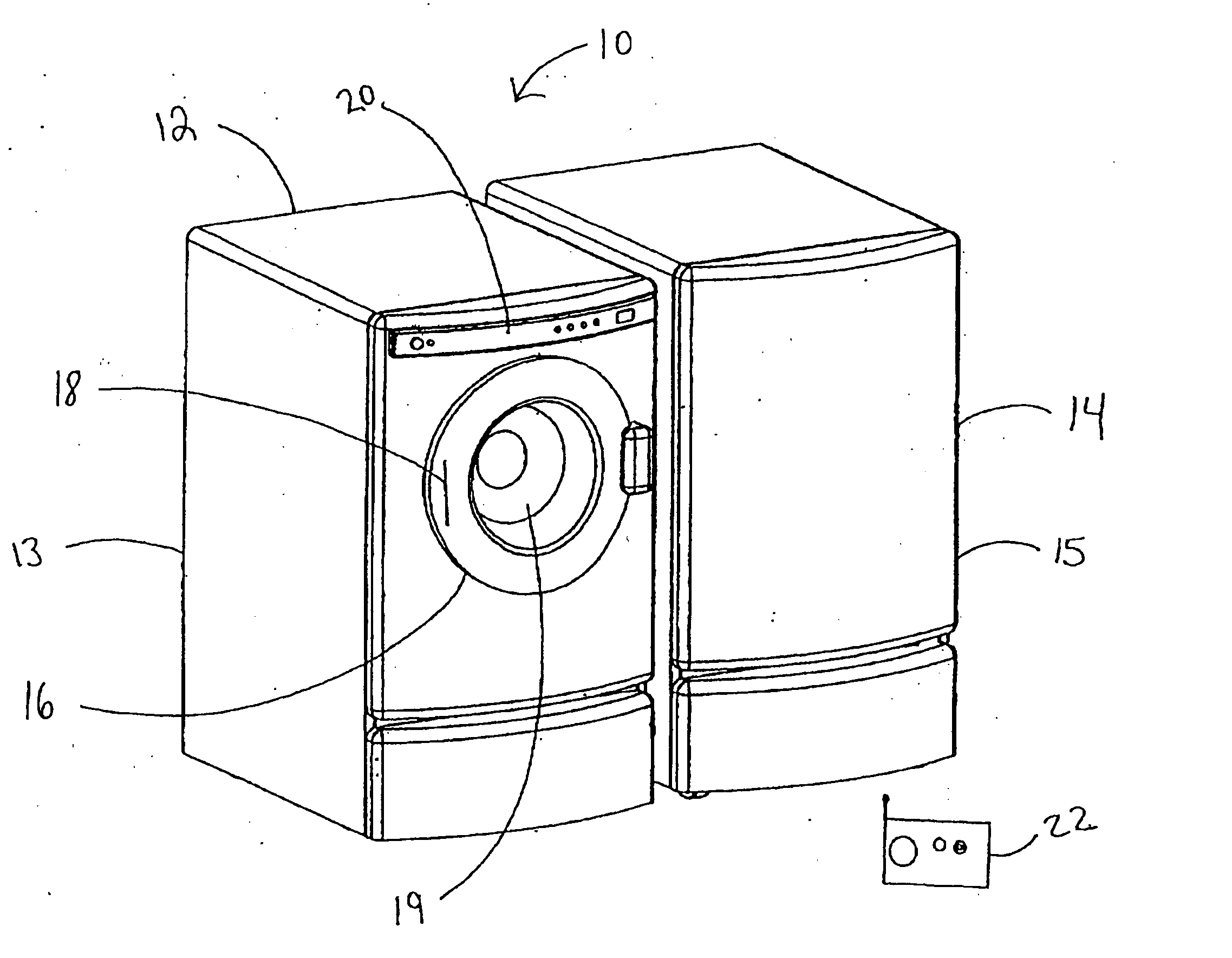

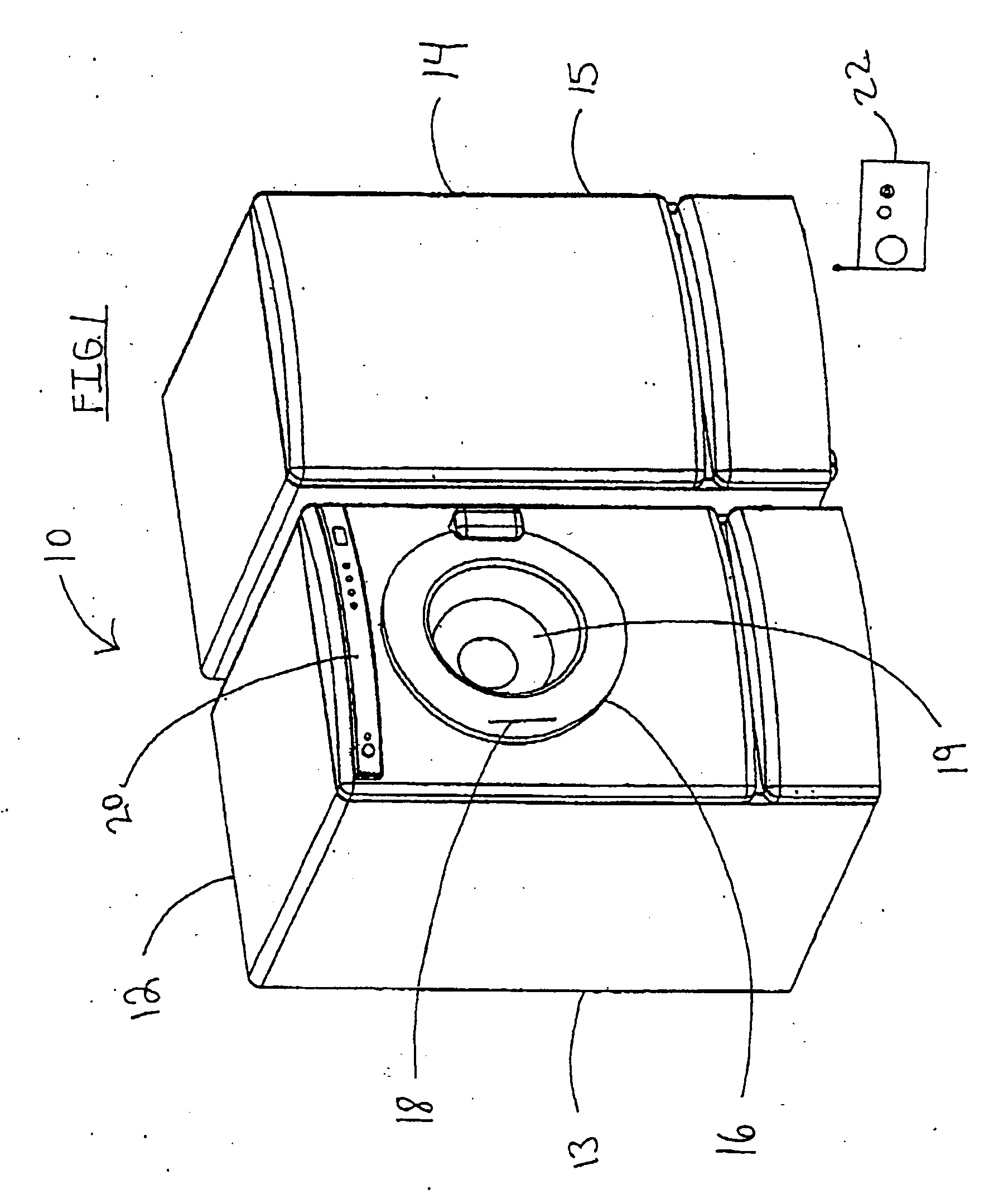

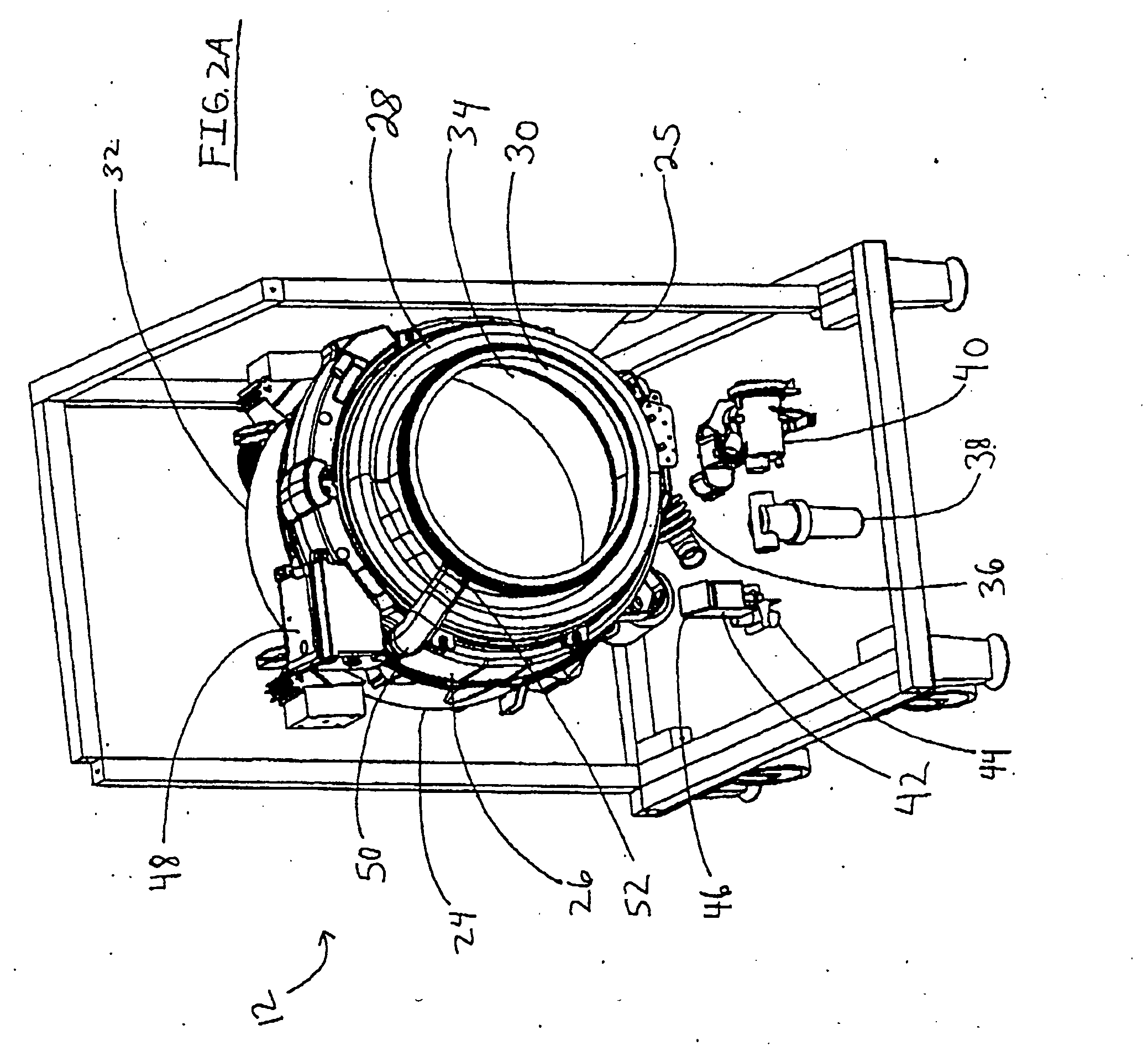

Non-aqueous washing machine with modular construction

InactiveUS20050155393A1Solve problemsDry-cleaning apparatusOther washing machinesPulp and paper industryModular construction

Owner:WHIRLPOOL CORP

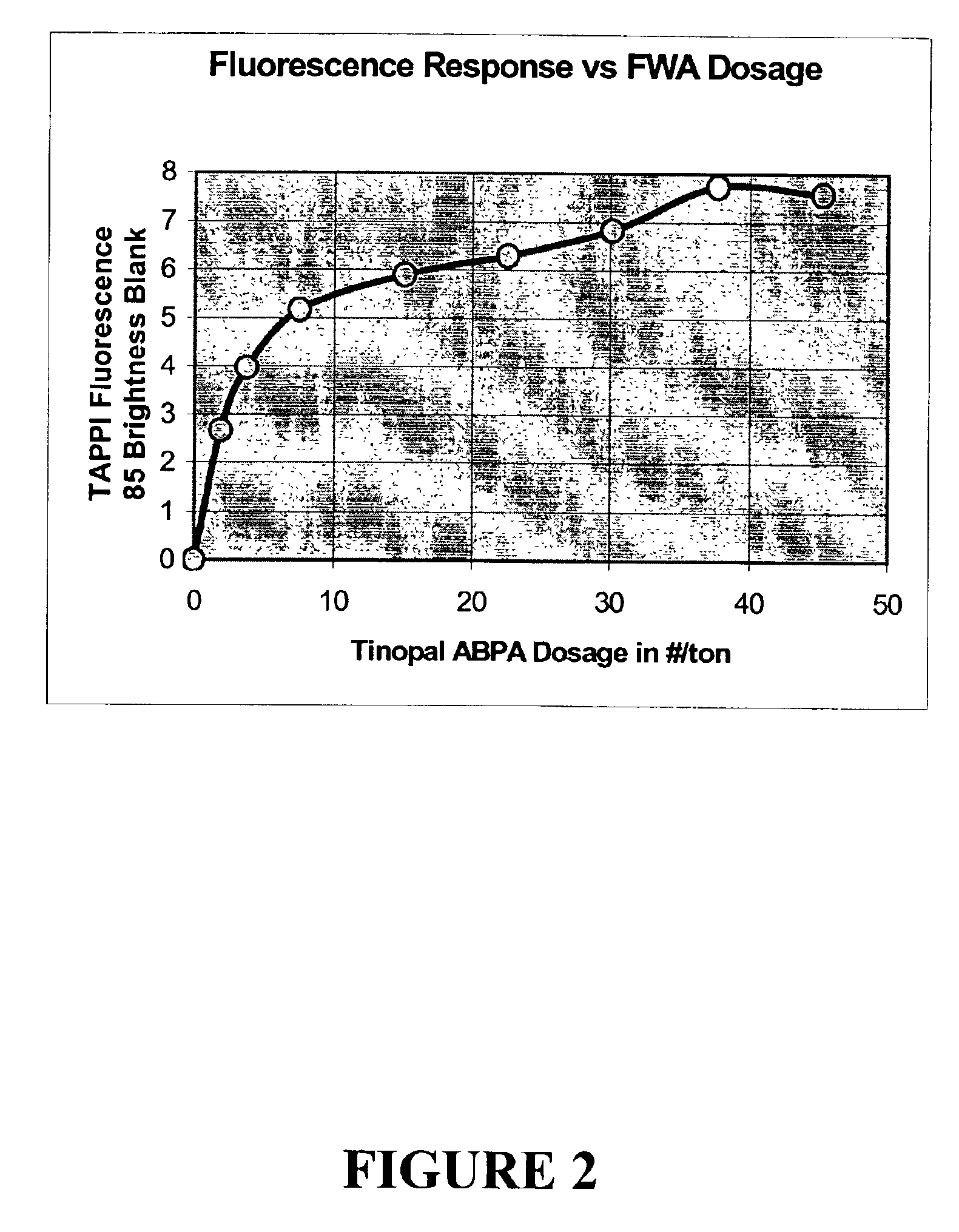

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

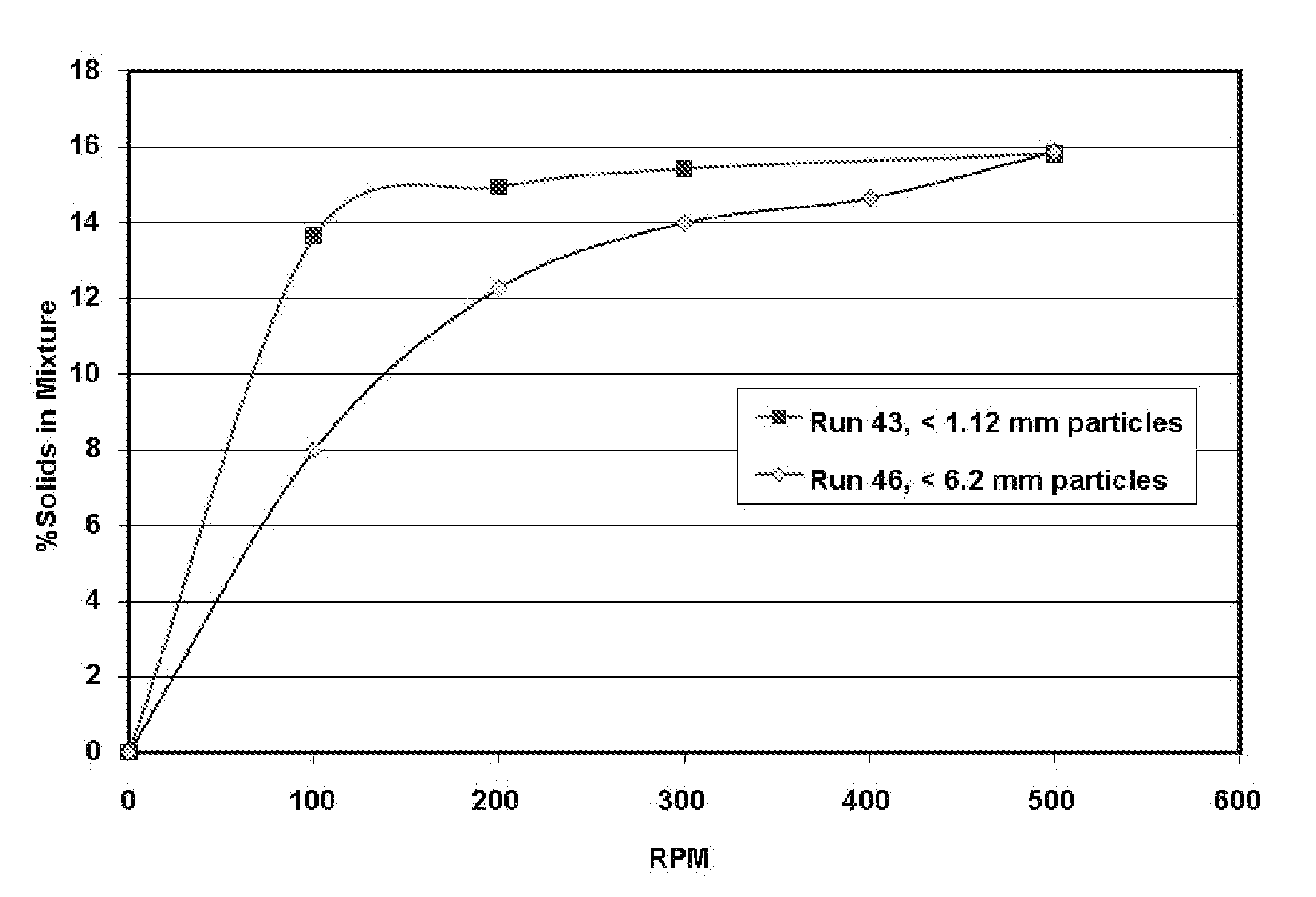

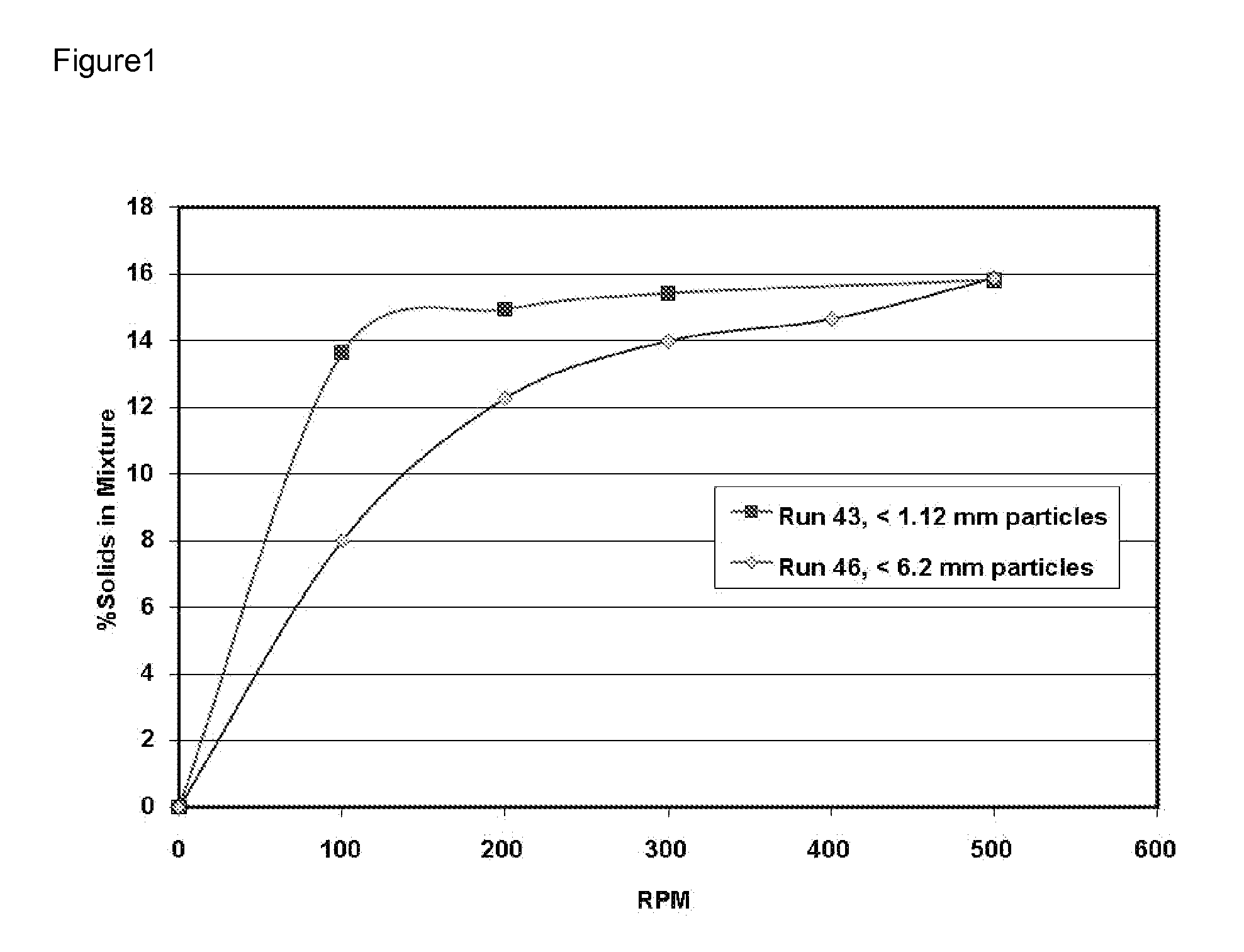

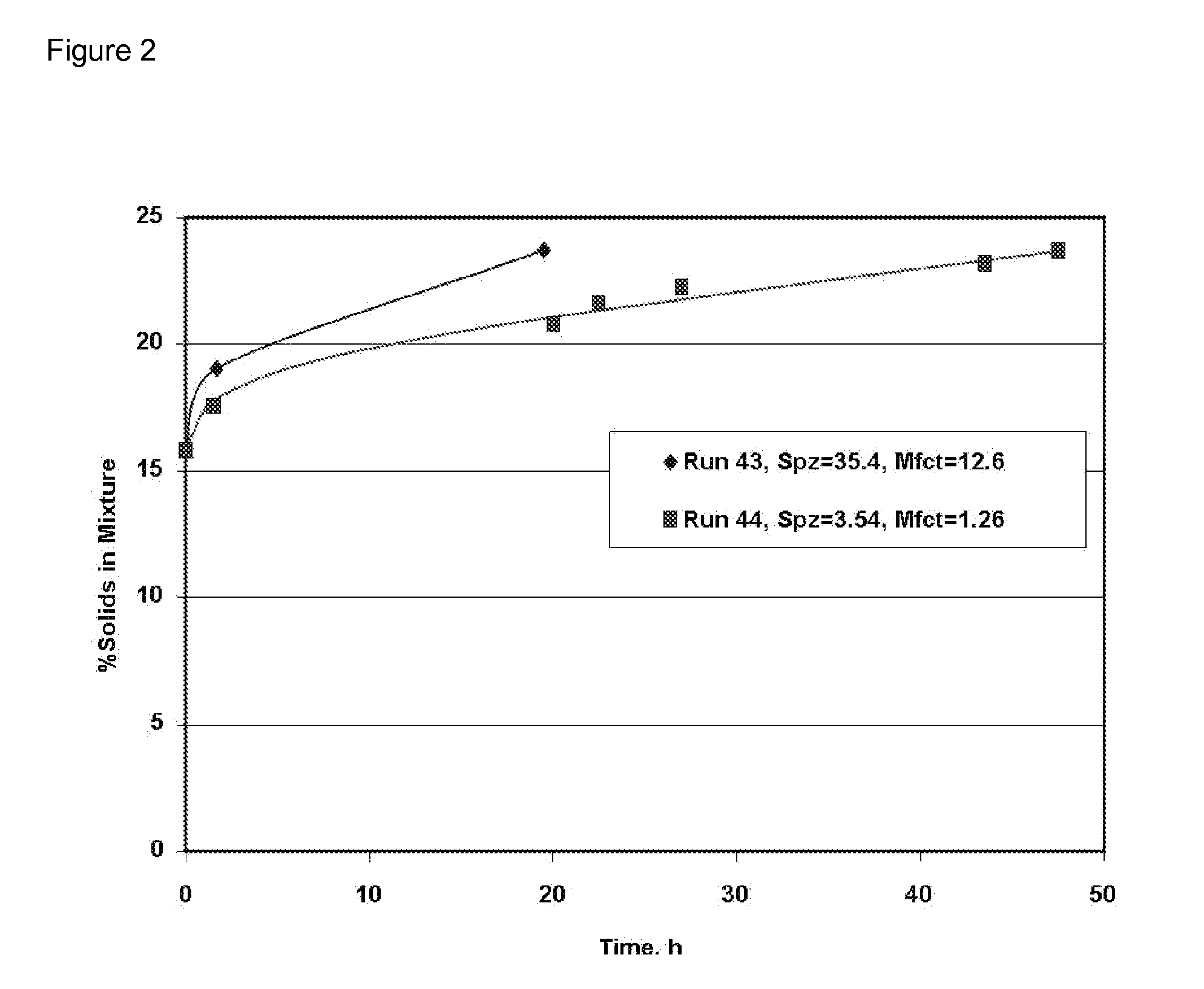

Process For Concentrated Biomass Saccharification

Processes for saccharification of pretreated biomass to obtain high concentrations of fermentable sugars are provided. Specifically, a process was developed that uses a fed batch approach with particle size reduction to provide a high dry weight of biomass content enzymatic saccharification reaction, which produces a high sugars concentration hydrolysate, using a low cost reactor system.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

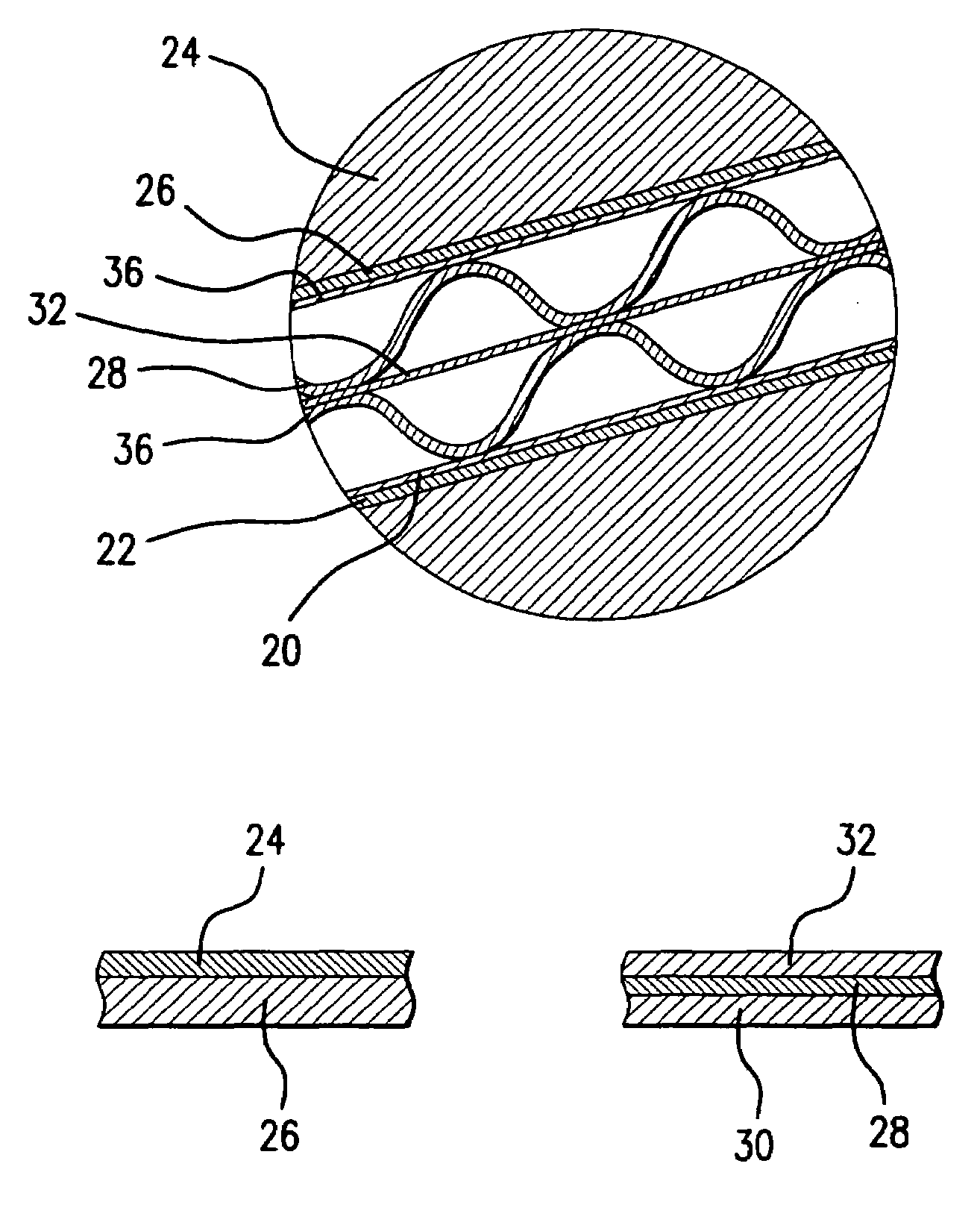

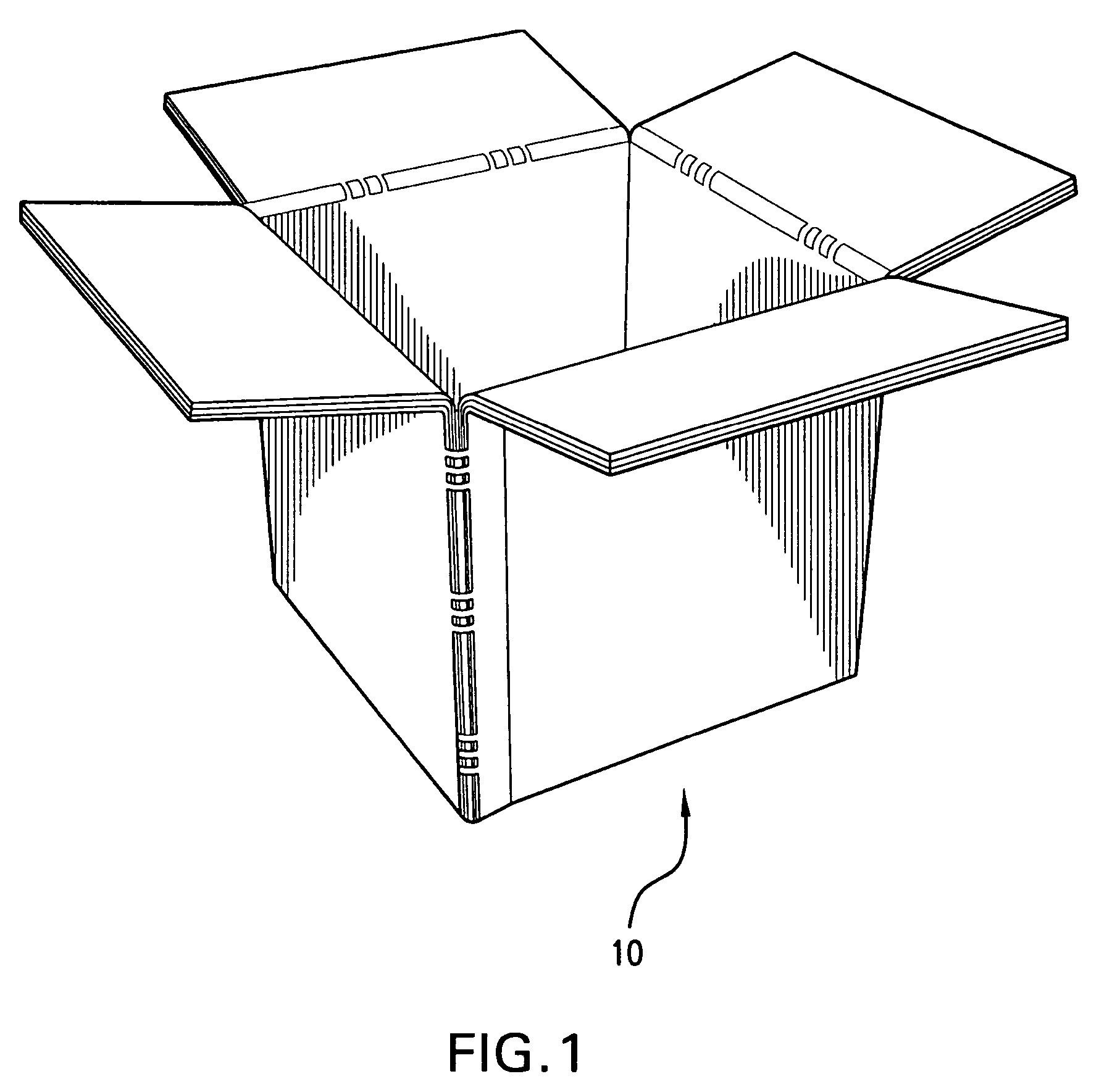

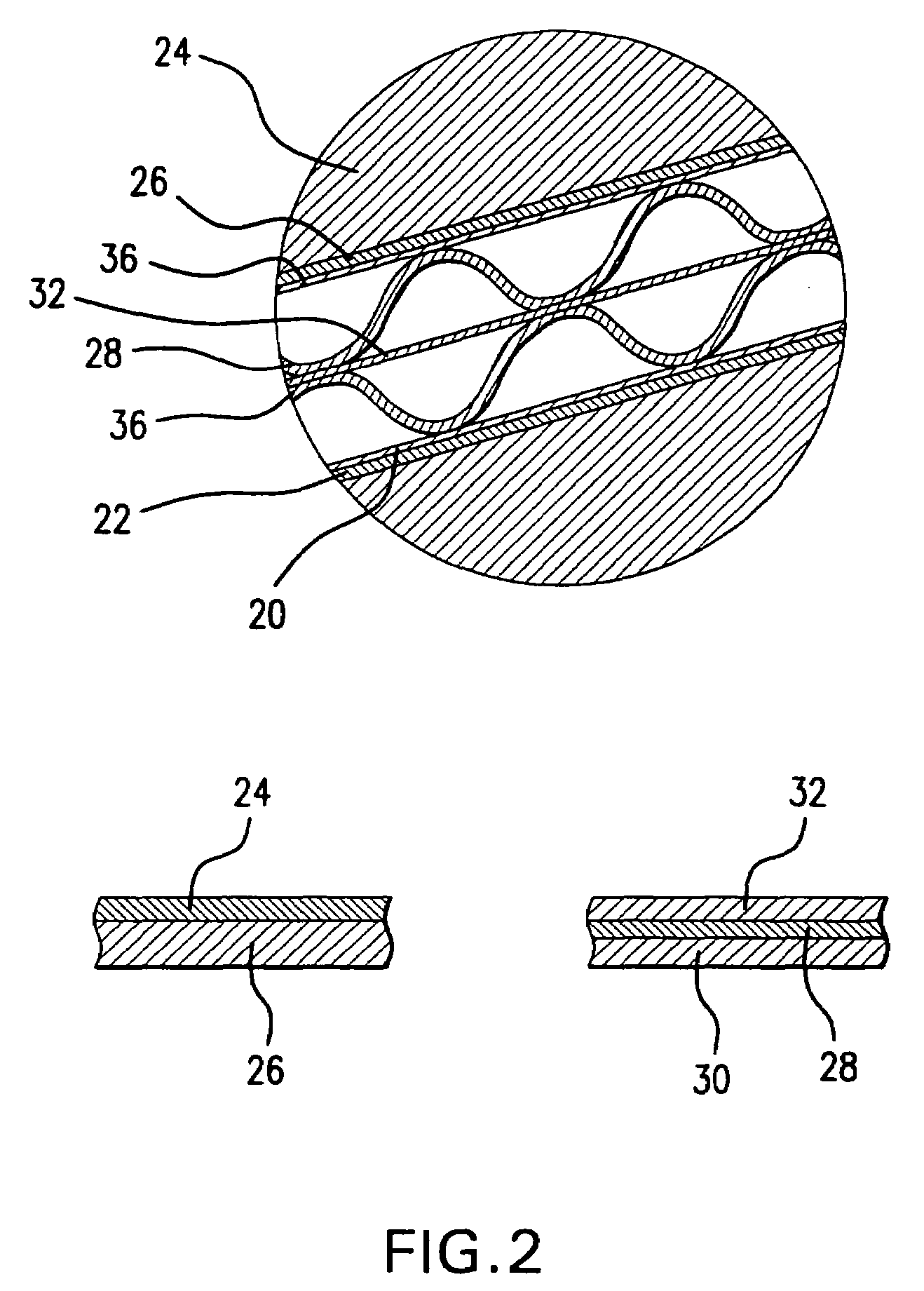

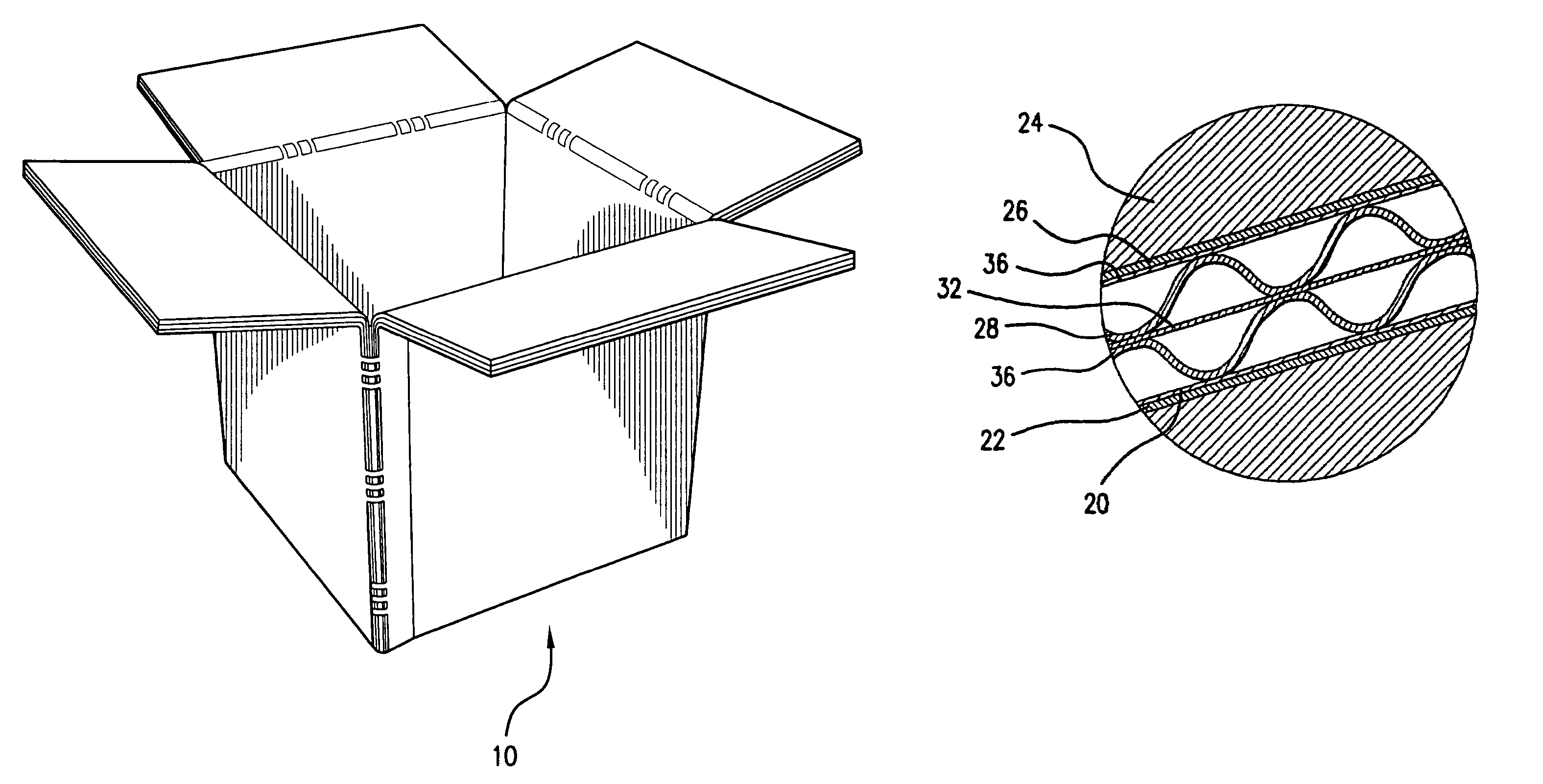

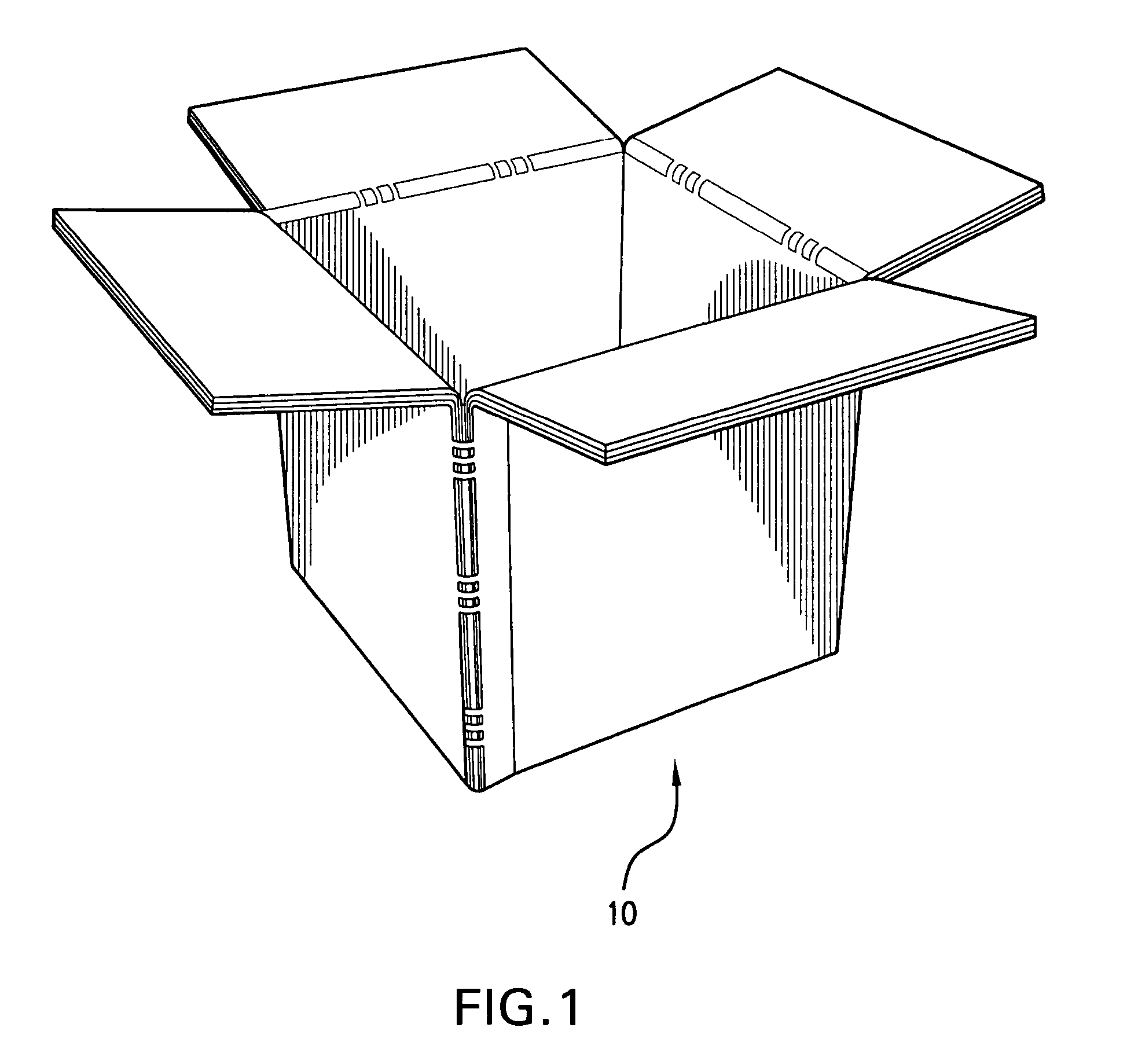

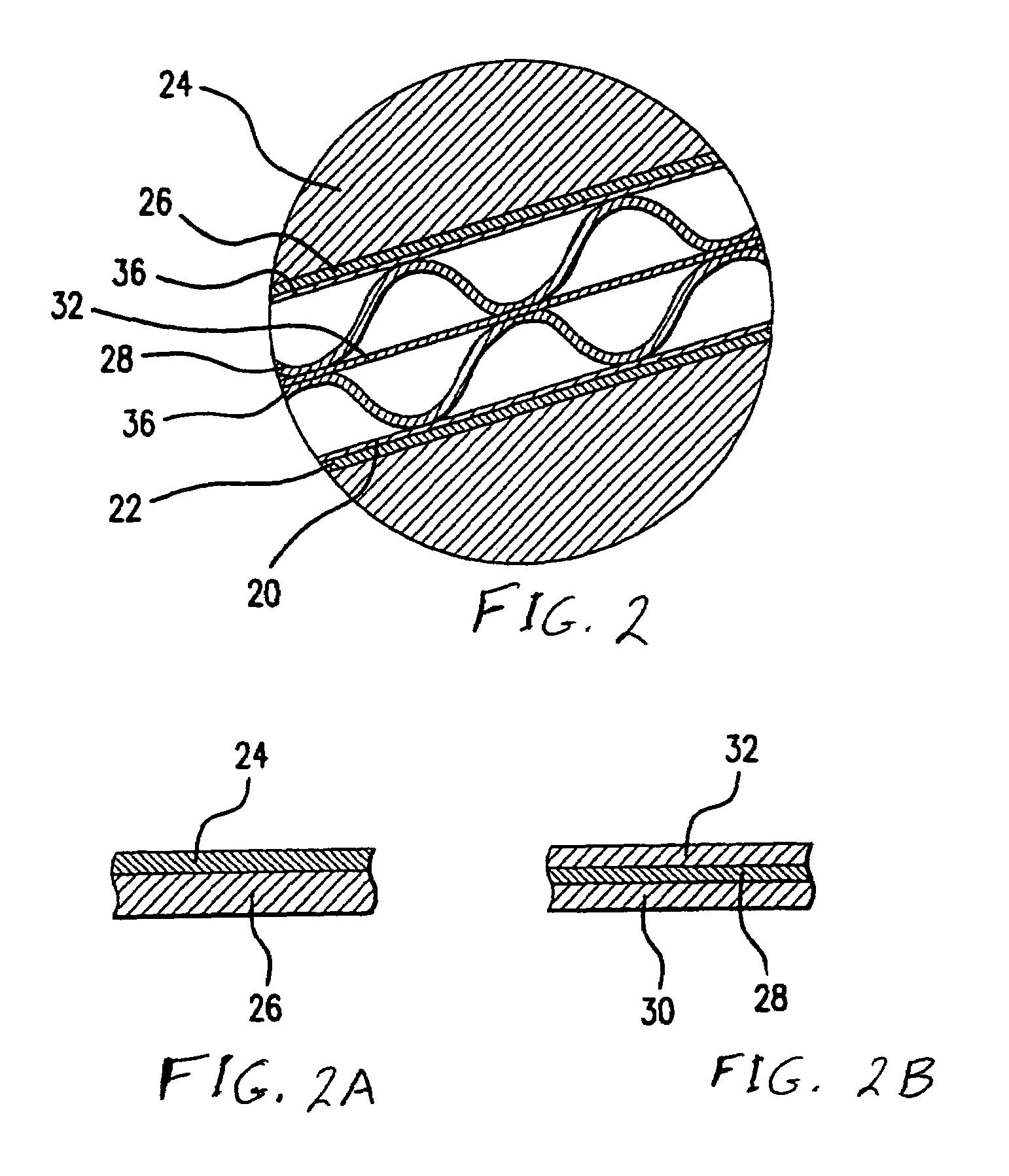

Knockdown corrugated box for temperature control and method of making

A box for shipping temperature sensitive or perishable goods made from a double walled combined web having an inside barrier layer, a first paper liner bonded to the inside barrier layer, a first paper flute medium bonded to the first paper liner, an outside barrier layer, a second paper liner bonded to the outside barrier layer, a second paper flute medium bonded to the second paper liner, and a sandwich of a barrier layer bonded between third and fourth paper liners. The flute mediums are bonded, respectively, to the third and fourth paper liners.

Owner:MILLER DRAYTON AS TENENT IN COMMON OWNING 1 2 INTEREST +1

Knockdown corrugated box for temperature control and method of making

ActiveUS7094192B2Envelopes/bags making machineryBoxes/cartons making machineryTemperature controlFlute

A box for shipping temperature sensitive or perishable goods made from a double walled combined web having an inside barrier layer, a first paper liner bonded to the inside barrier layer, a first paper flute medium bonded to the first paper liner, an outside barrier layer, a second paper liner bonded to the outside barrier layer, a second paper flute medium bonded to the second paper liner, and a sandwich of a barrier layer bonded between third and fourth paper liners. The flute mediums are bonded, respectively, to the third and fourth paper liners.

Owner:MILLER DRAYTON +1

Absorbent sheet

InactiveUS20080008860A1Increase in sizeDecrease sidednessNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberPulp and paper industry

A method of making a cellulosic web includes: forming a nascent web from a papermaking furnish, the nascent web having a generally random distribution of papermaking fiber; b) transferring the web having a generally random distribution of papermaking fiber to a translating transfer surface moving at a first speed; drying the web to a consistency of from about 30 to about 60 percent including compactively dewatering the web prior to or concurrently with transfer to the transfer surface; fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a creping fabric with a patterned creping surface, the fabric creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric such that the web has a plurality of fiber-enriched regions arranged in a pattern corresponding to the patterned creping surface of the fabric, optionally drying the wet web while it is held in the creping fabric. Preferably, the formed web is characterized in that its void volume increases upon drawing.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com