Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "PARTICLE SIZE REDUCTION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process For Concentrated Biomass Saccharification

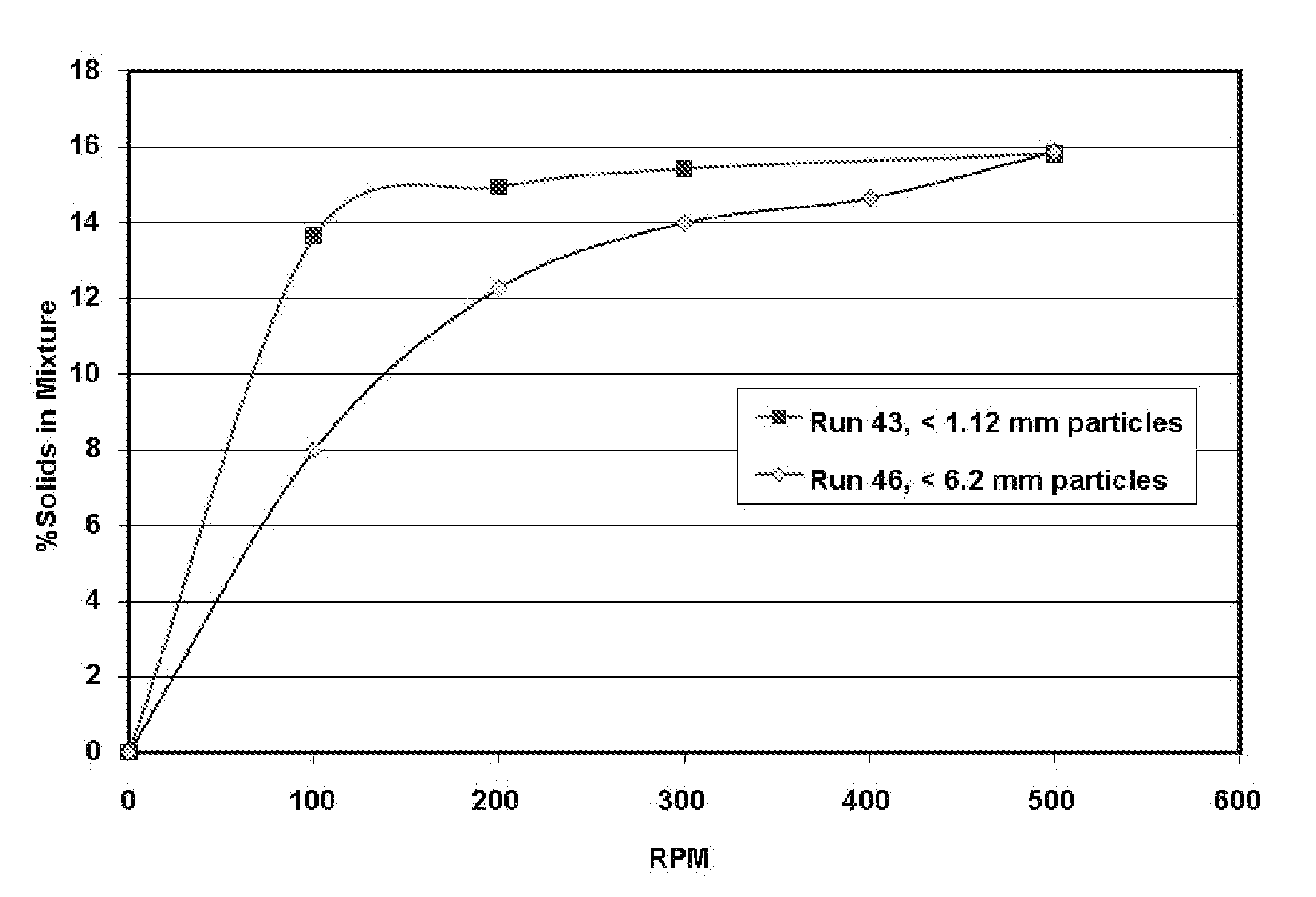

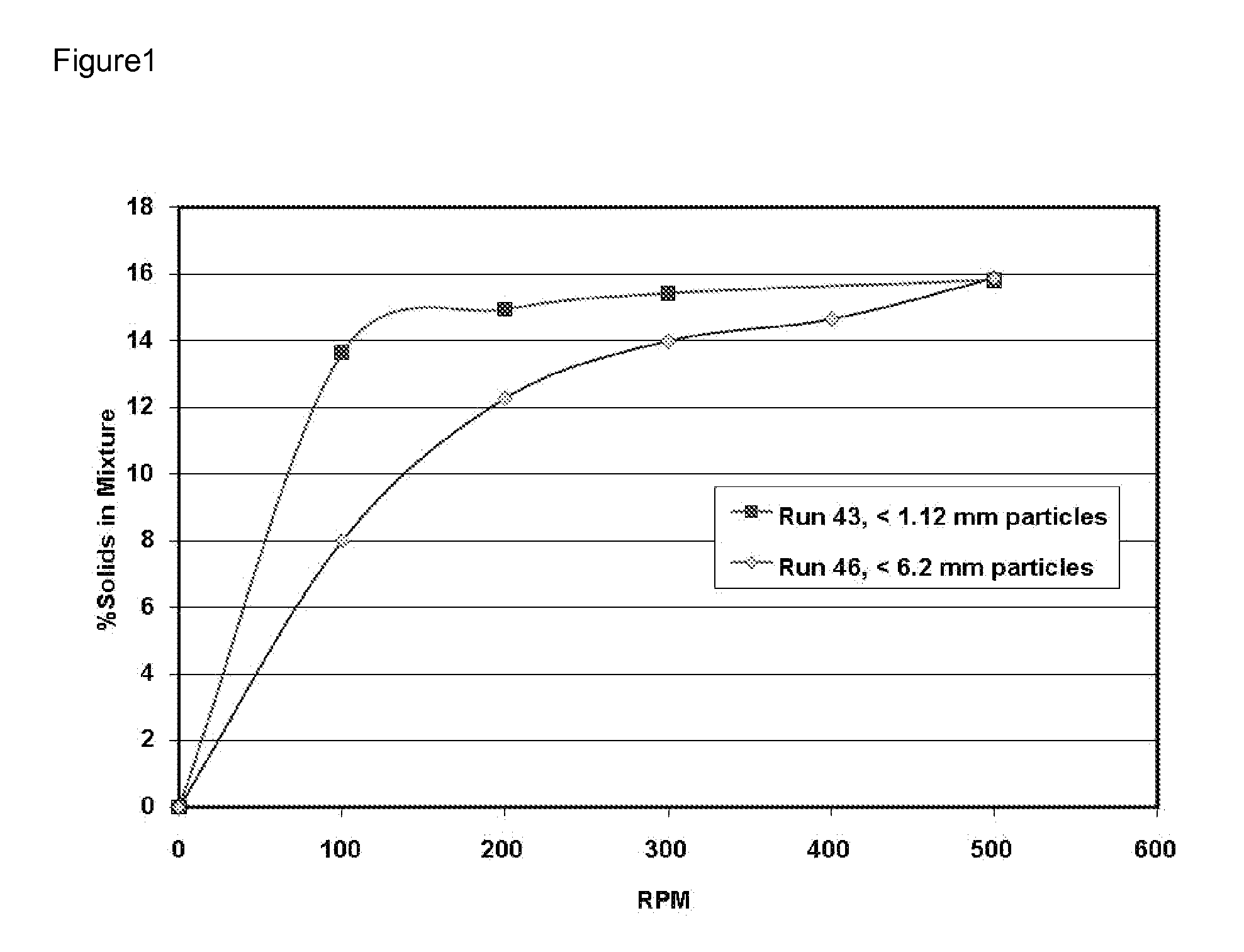

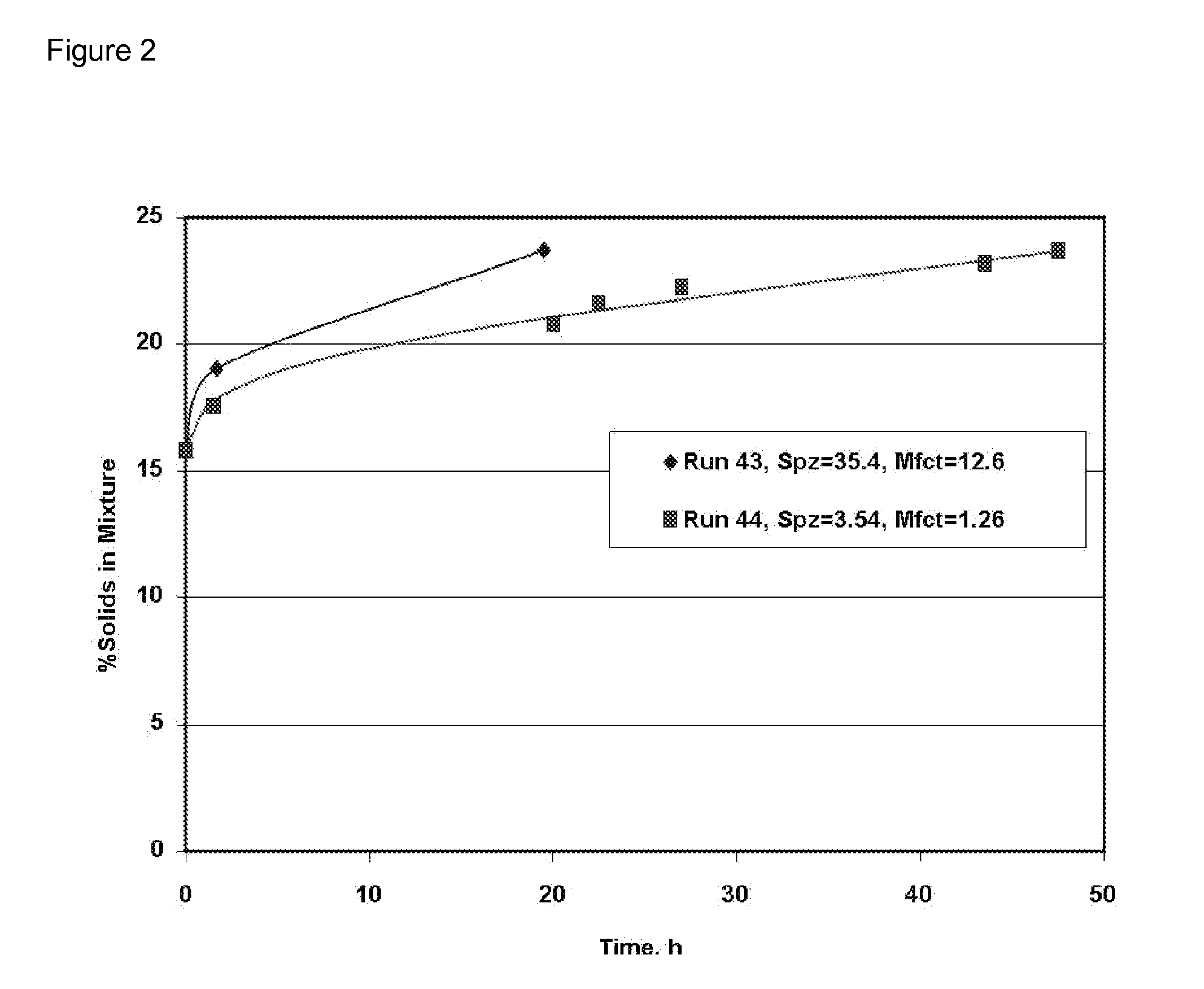

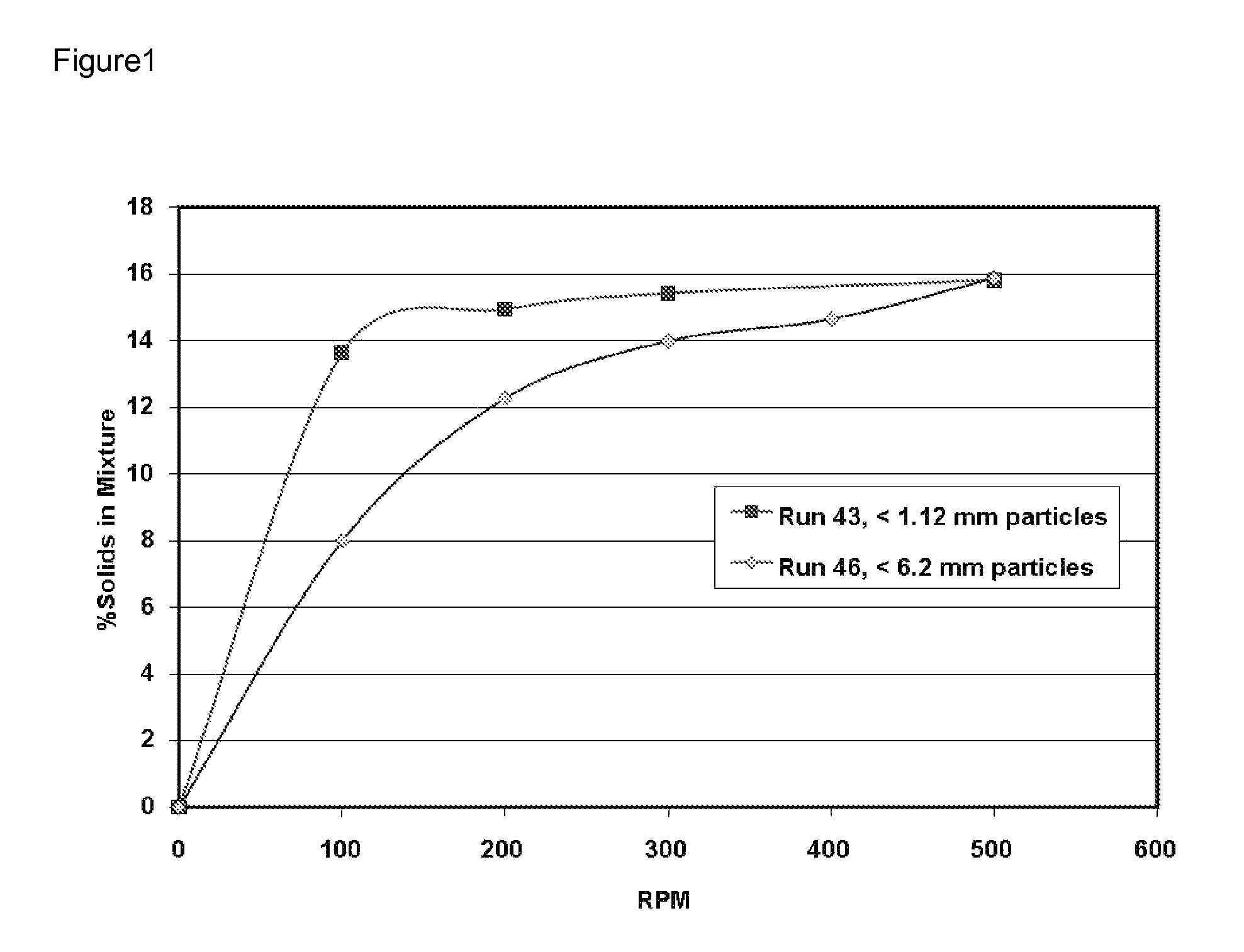

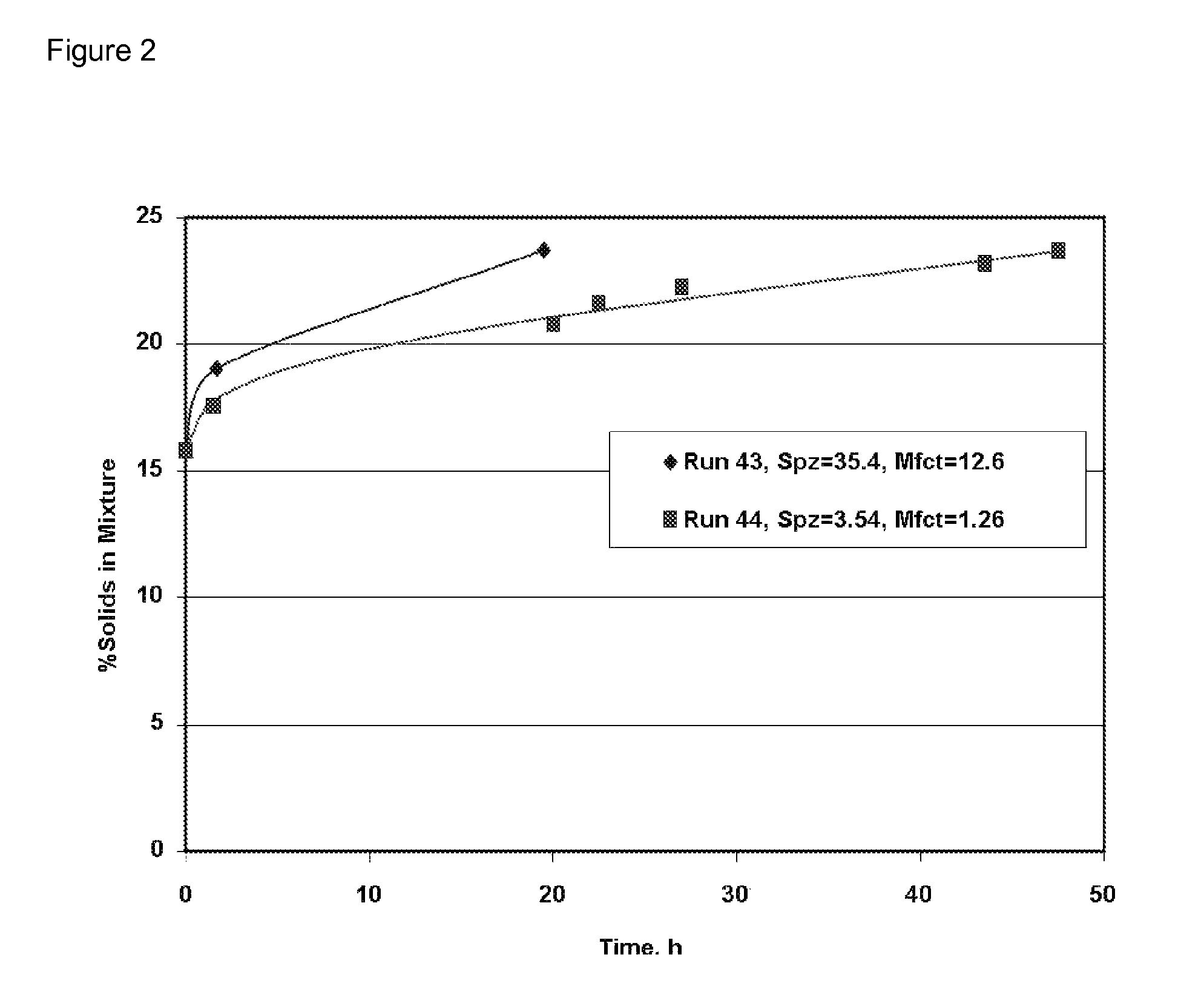

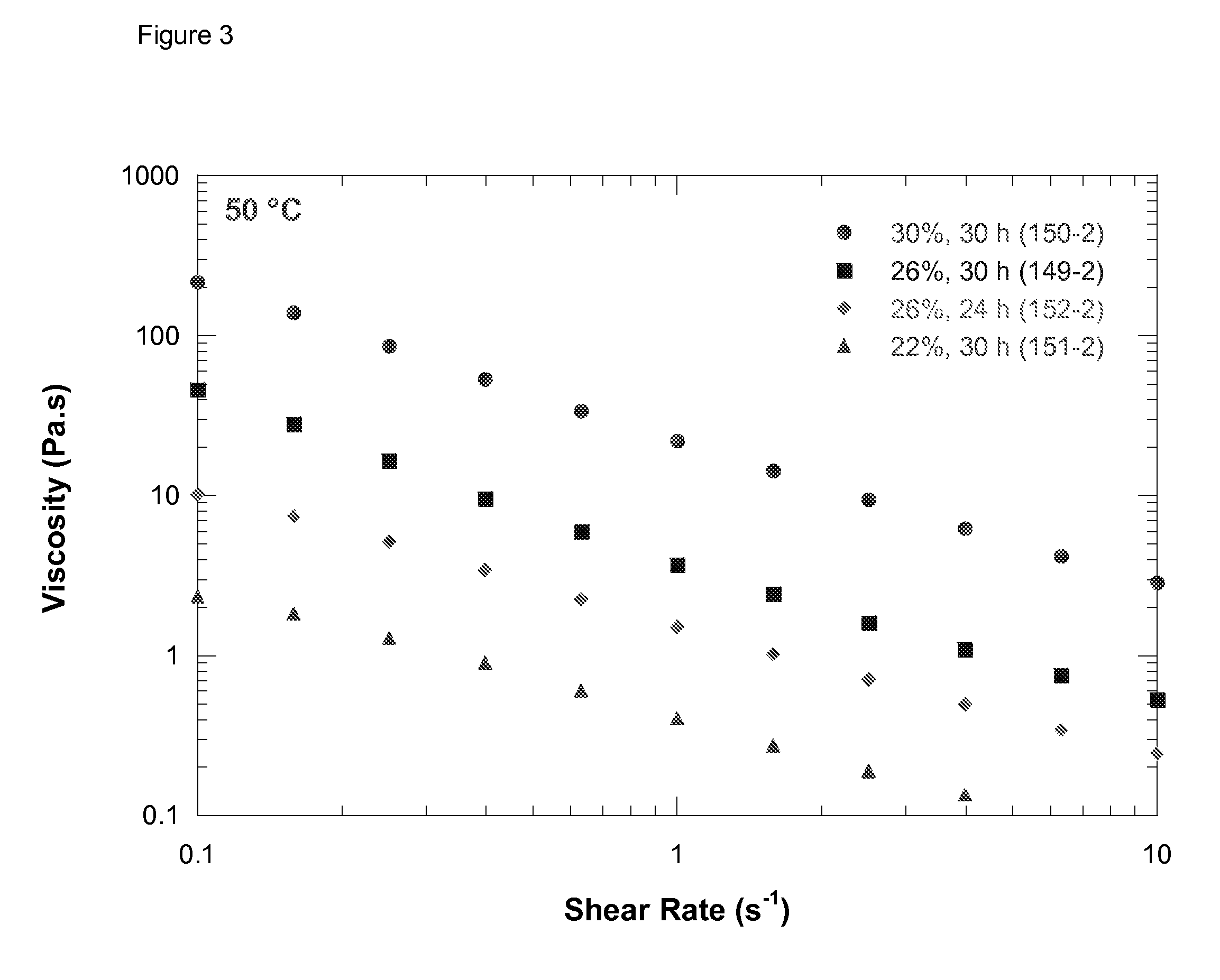

Processes for saccharification of pretreated biomass to obtain high concentrations of fermentable sugars are provided. Specifically, a process was developed that uses a fed batch approach with particle size reduction to provide a high dry weight of biomass content enzymatic saccharification reaction, which produces a high sugars concentration hydrolysate, using a low cost reactor system.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Process for concentrated biomass saccharification

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Modified organic colorants and dispersions, and methods for their preparation

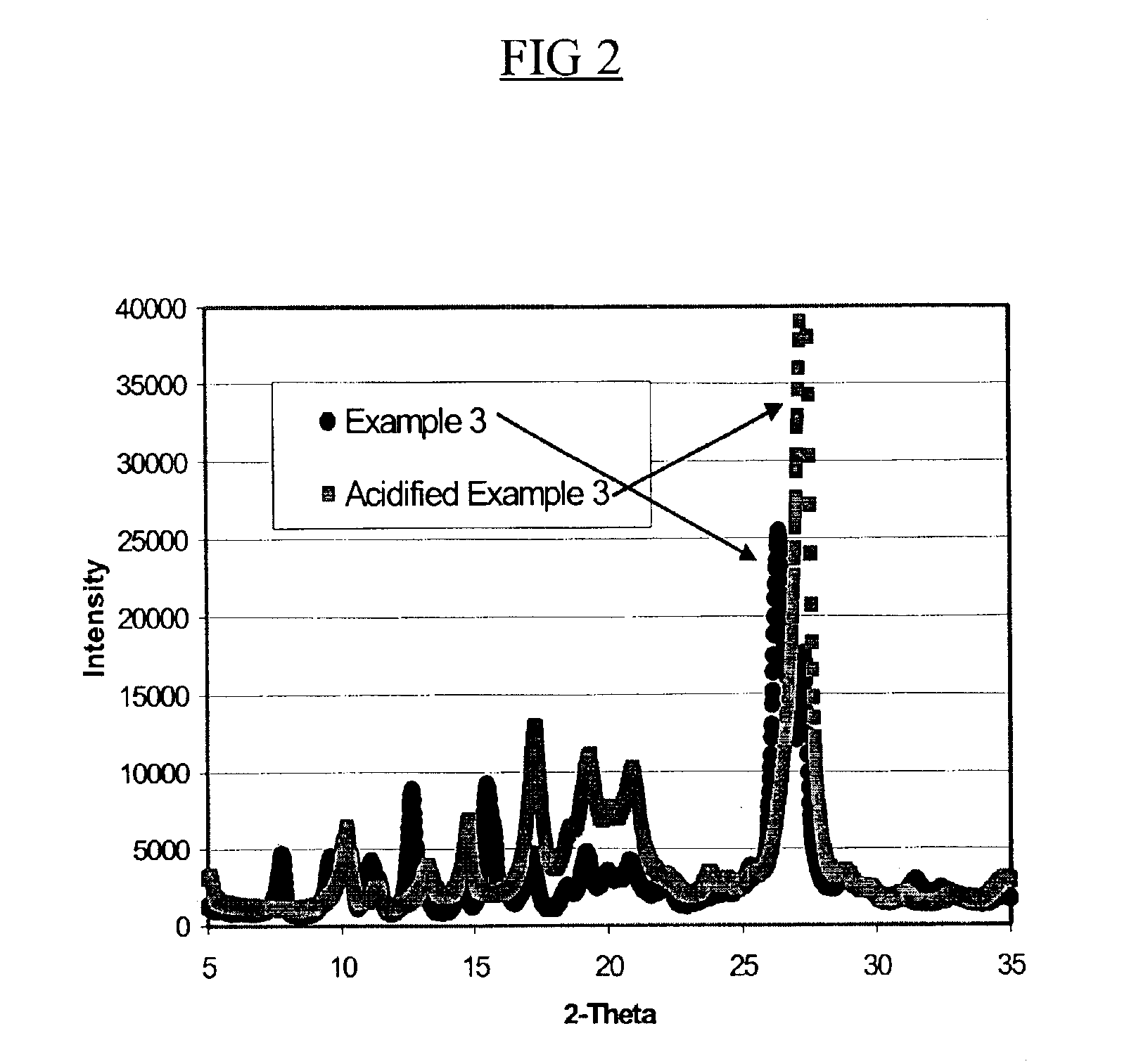

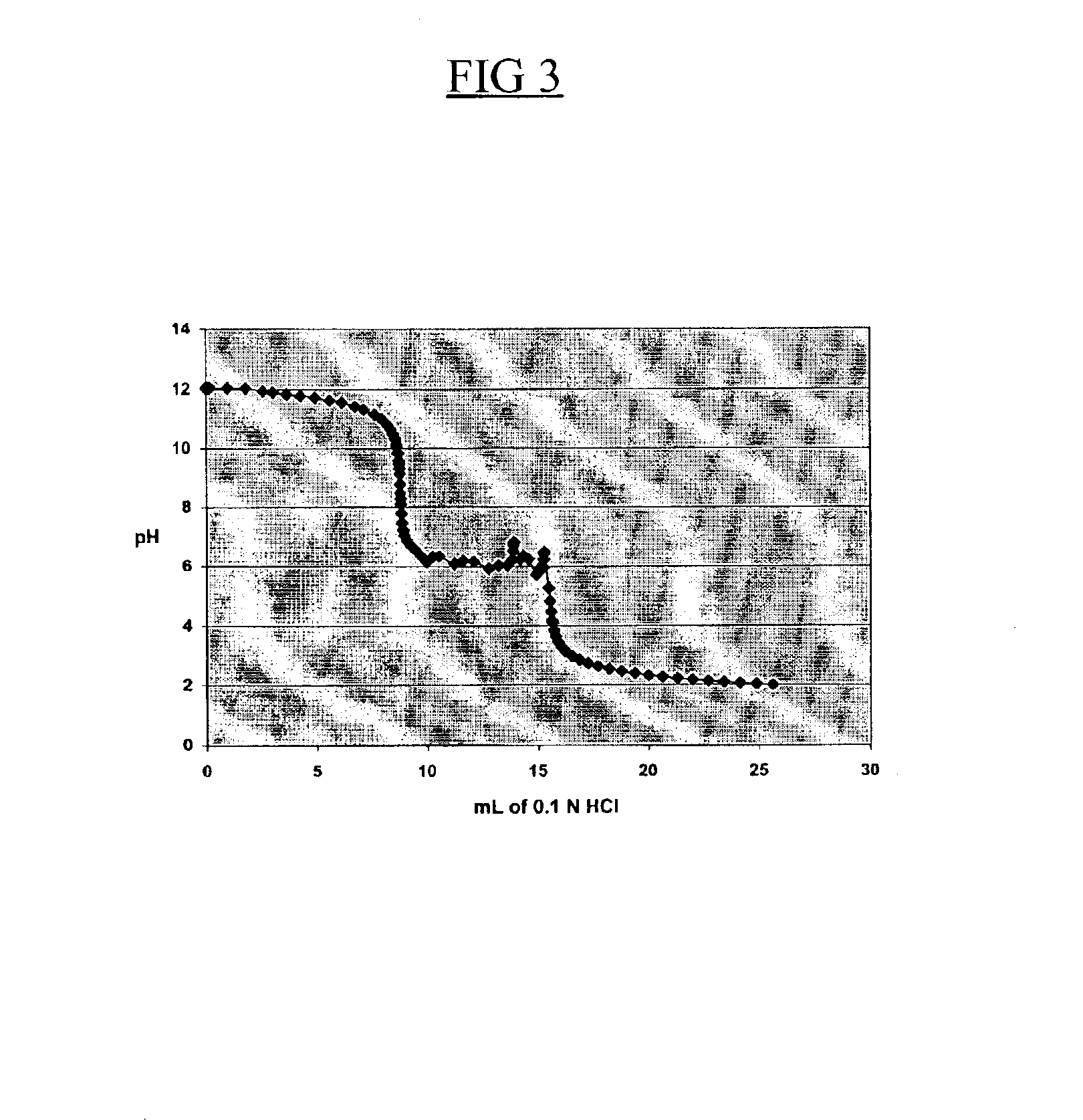

The present invention relates to methods of preparing modified organic colorant dispersions comprising the step of combining, in any order, i) an organic colorant; ii) an hydroxide reagent; and iii) an aqueous medium, to form a modified organic colorant dispersion. The methods further comprises a particle size reduction step. These steps can occur in either order. The organic colorant comprises at least one organic species having at least one ester group. Modified organic colorants and inkjet ink compositions are also disclosed.

Owner:CABOT CORP

Modified organic colorants and dispersions, and methods for their preparation

The present invention relates to methods of preparing modified organic colorant dispersions comprising the step of combining, in any order, i) an organic colorant; ii) an hydroxide reagent; and iii) an aqueous medium, to form a modified organic colorant dispersion. The methods further comprises a particle size reduction step. These steps can occur in either order. The organic colorant comprises at least one organic species having at least one carboxylic acid group. Modified organic colorants and uses of these modified organic colorants, including inkjet ink compositions, are also disclosed.

Owner:CABOT CORP

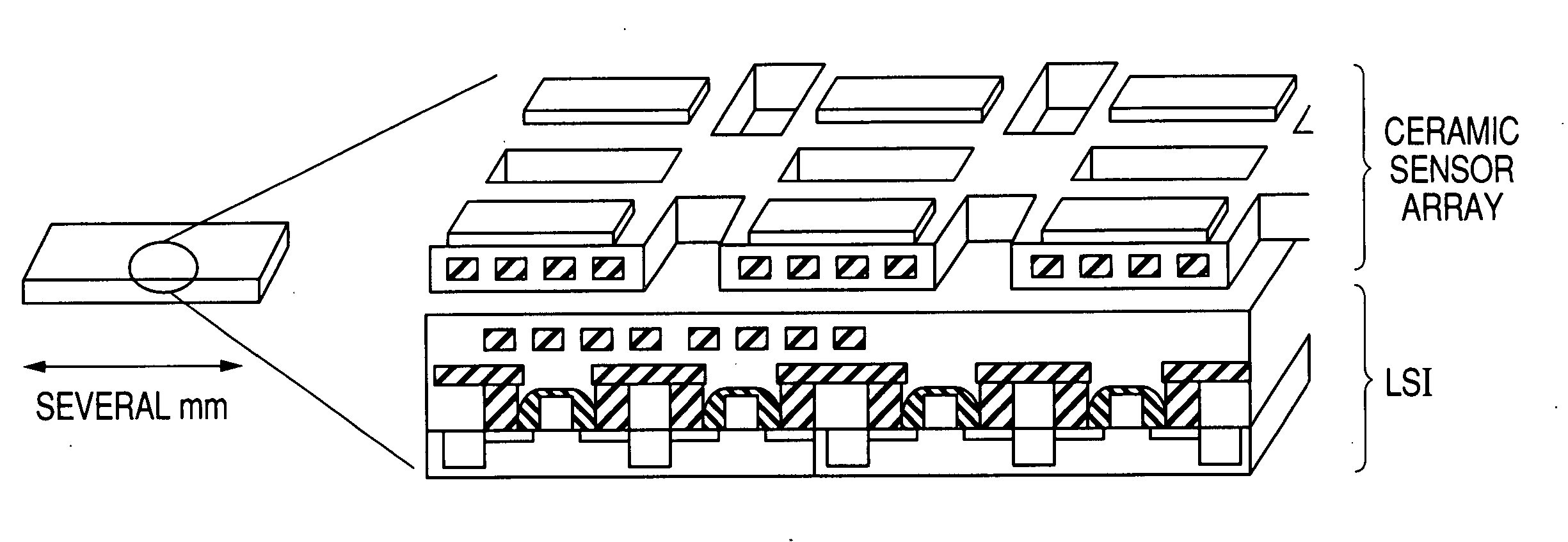

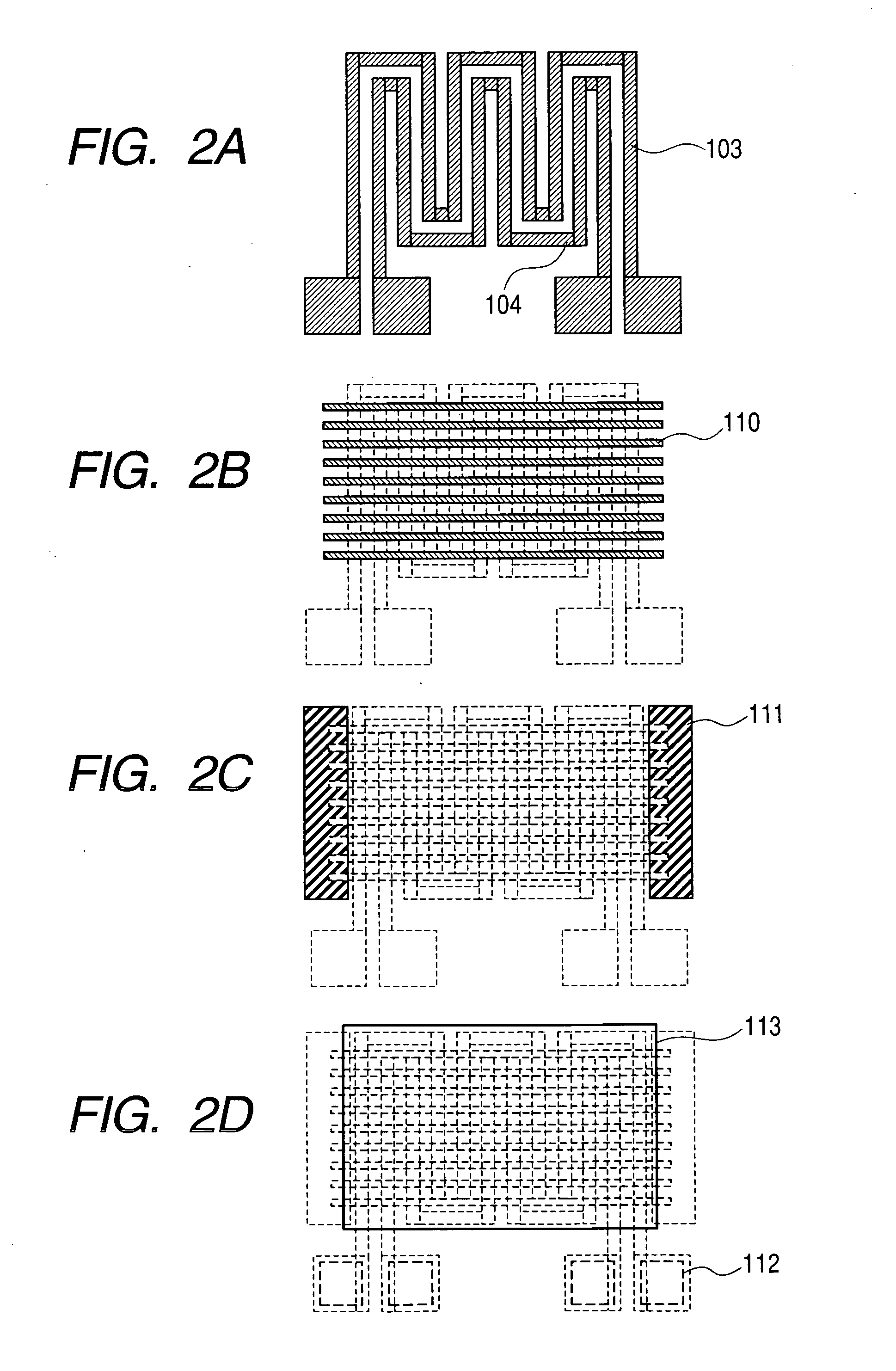

Ceramic sensor and manufacturing method thereof

InactiveUS20060185980A1High sensitivityEasy to processMaterial electrochemical variablesMicrocontrollerNano structuring

The compatibility of increased sensitivity with both reliability and durability was difficult, since in a gas sensor composed of polycrystalline grains or ceramic particles, there is a trade-off relationship between increasing sensitivity through particle size reduction and change with time due to grain growth. Moreover, it was difficult to integrate a ceramic sensor with high sensitivity, high durability and high reliability with a Si integrated circuit in the monolith. A gas sensor is composed of an artificial nano-structure ceramic film where a change in the ceramic structure due to grain growth, etc. does not occur because of heat. The ceramic thin film is formed to a pattern shaped template on a nanometer level by using a sol-gel method and cured adequately to form precisely. Moreover, the above-mentioned gas sensor is integrated with an integrated circuit in the monolith.

Owner:HITACHI LTD

Biogasification of Coal to Methane and other Useful Products

InactiveUS20110151533A1Improve conversion efficiencyStable and high rateBiological substance pretreatmentsGas production bioreactorsLiquid productPARTICLE SIZE REDUCTION

Method of bioconversion of coal to methane, carbon dioxide, and other valuable gaseous and liquid products in a multi-step process that may include particle size reduction, separation of non-coal materials, addition of chemicals, and multi-stage anaerobic fermentation are disclosed.

Owner:CIRIS ENERGY INC

Aqueous processing of oilseed press cake

ActiveUS20100234569A1High level of proteinLarge particle sizeButter manufactureEdible oils/fatsVegetable matterSubject matter

The subject invention relates in part to novel steps in canola and other oil seed processing, including milling to achieve a significant particle size reduction, extraction of higher levels of protein from the starting material, the use of presscake as a starting material, and the production of a precipitated protein concentrates containing a nutritionally significant amount of oil. The subject invention also provides optimal pH ranges for extraction and recovery steps in these novel processes. The subject processes can be applied to, and offer similar advantages to, other oilseeds and vegetable matter, such as sunflower seeds and flax seeds. The subject invention also includes novel feed compositions.

Owner:CORTEVA AGRISCIENCE LLC

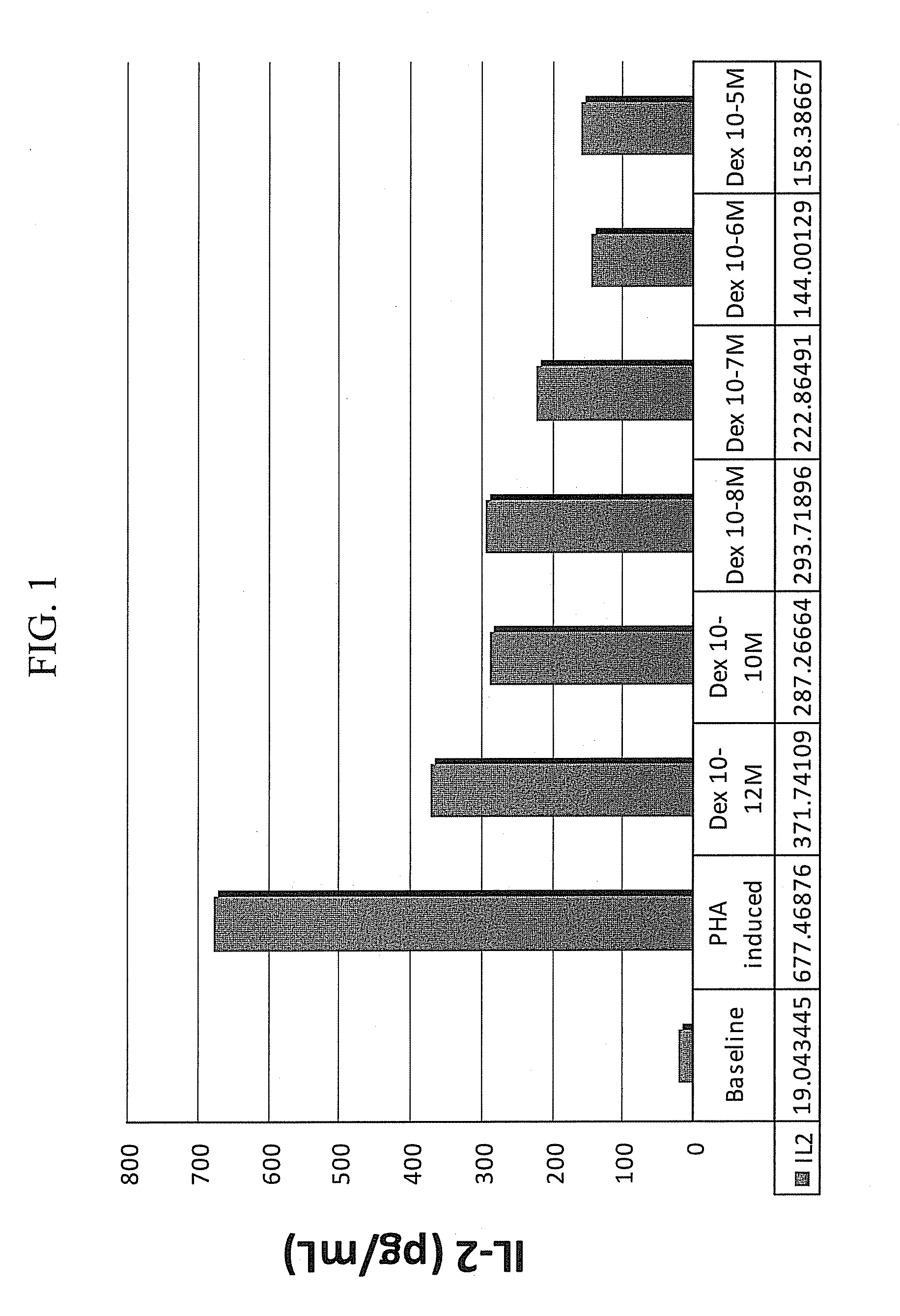

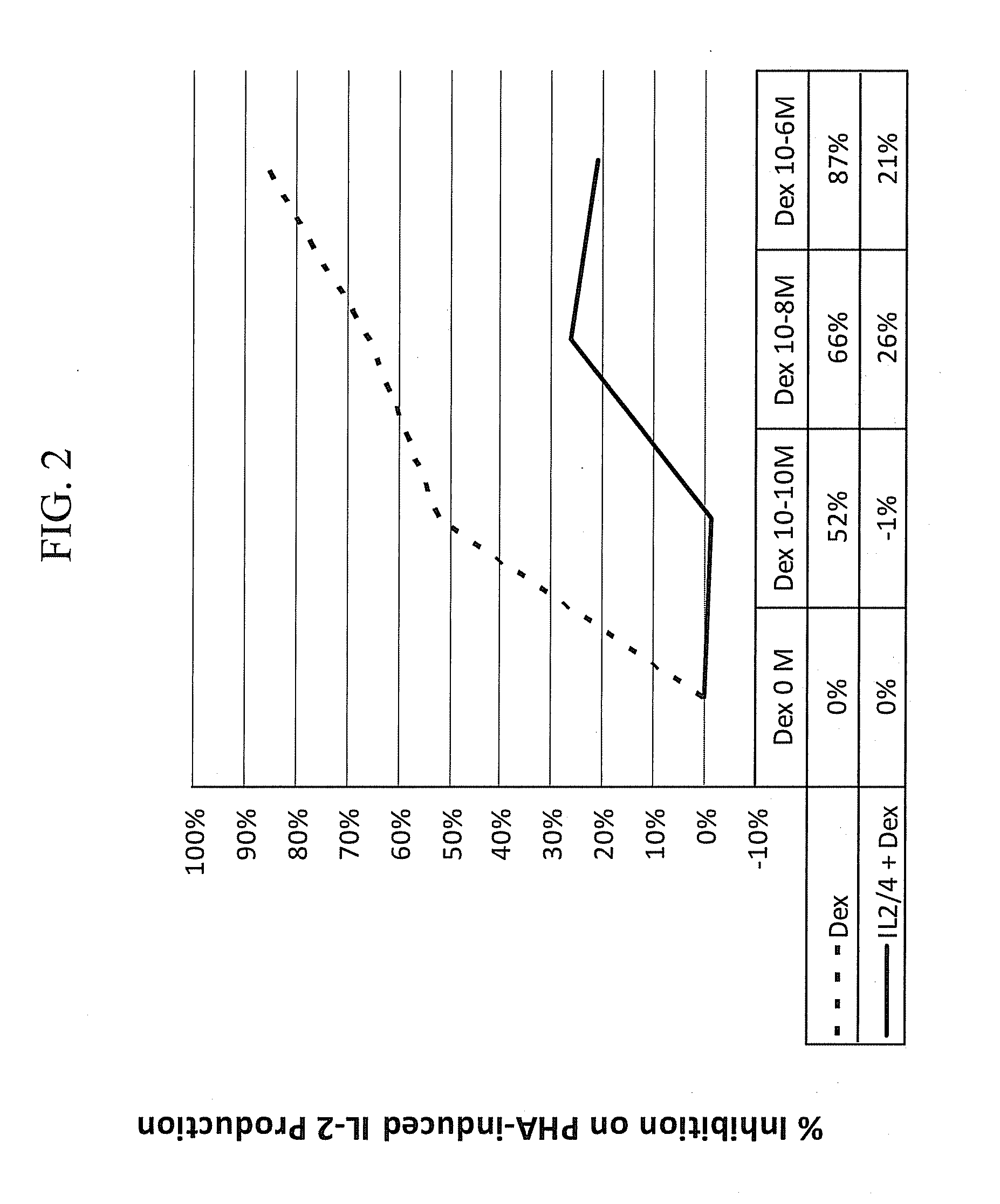

Pulmonary delivery of 17-hydroxyprogesterone caproate (17-hpc)

InactiveUS20110262502A1Improve responsivenessImprove toleranceAntibacterial agentsOrganic active ingredientsPowder mixtureInhalation

The invention relates to 17-HPC pulmonary formulations for administration by inhalation comprising 17-HPC and a pharmaceutically acceptable excipient. Particle size reduction of 17-HPC is required for the pulmonary delivery, and can be achieved with a surfactant or water without the surfactant. Preferred pulmonary formulations include a powder blend comprising a therapeutically effective amount of at least one steroid hormone (progestogen) as a glucocorticoid sensitizer, and at least one pharmaceutically acceptable excipient, wherein the at least one steroid hormone (progestogen) has a particle size distribution profile ranging from about one nanometer to about ten microns in the powder blend.

Owner:SHENZHEN EVERGREEN THERAPEUTICS CO LTD

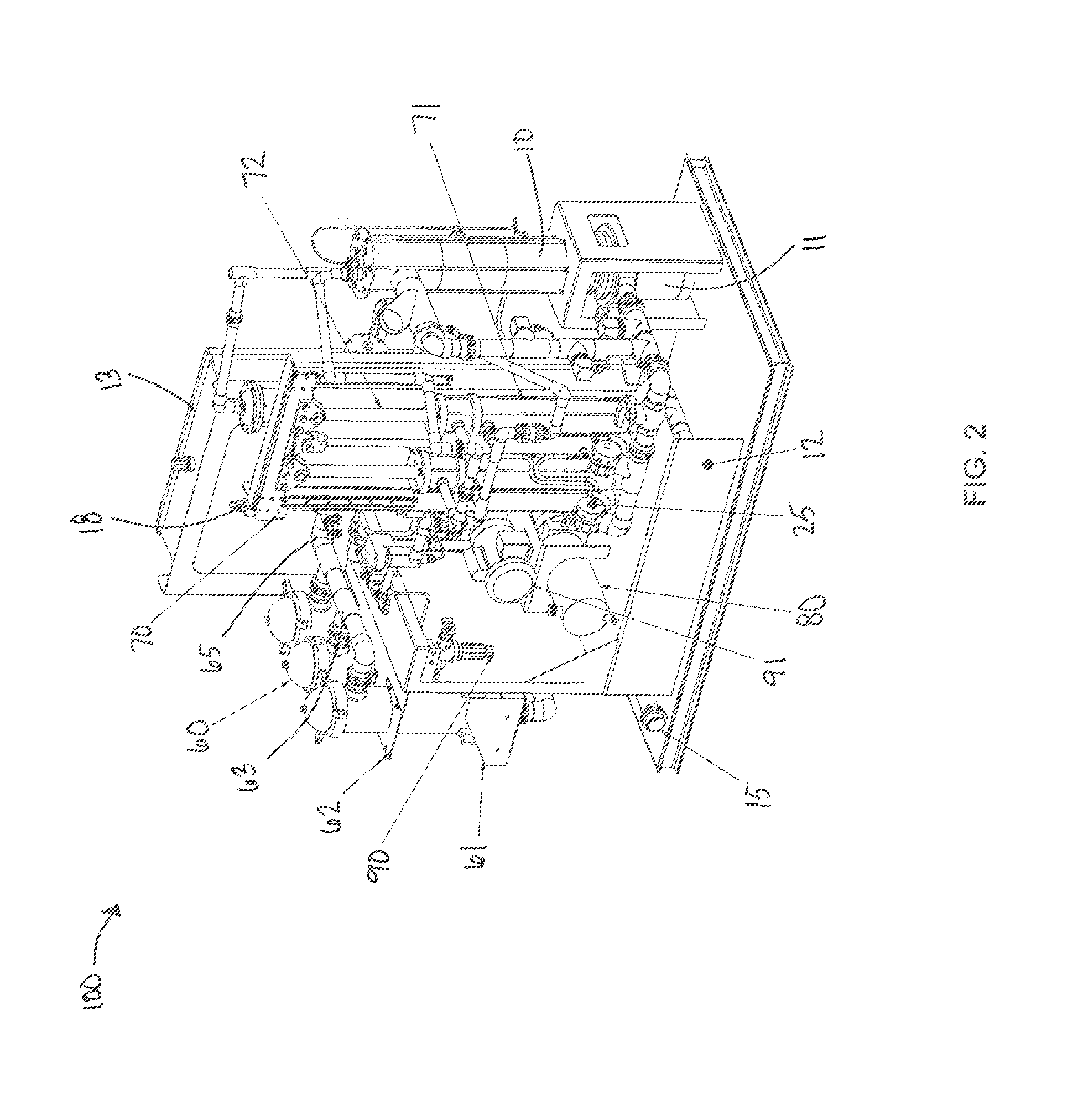

Grinder

ActiveUS20160144371A1Improve performanceReduce material stressGas current separationGrain millingSplit linesProgrammable logic controller

A grinder having with a rotor and fan assembly mounted in a housing having one or more of the following features: Cutting shaft and fan shaft concentric and rotated by separate motors, housing formed in two sections with a line of division passing through the axis of rotation and mounted on rollers, ping pong shaped cutting hammers, deflectors attached to the inside of the housing and to a deflector assembly on the outside of the housing. The deflectors movable vertically and horizontally with first and second motion controllers for adjusting the spacing between the cutting hammers and the deflectors. A programmable logic controller for independently controlling the speed at which the cutting shaft and fan shaft are rotated and the spacing between the cutting hammers and the deflectors to produce a desired particle size reduction for a selected material.

Owner:SONTAG GLENNON C

Method of and system for grinding pyrolysis of particulate carbonaceous feedstock

ActiveUS20130199919A1Small particle sizeThermal quenching of pyrolysis vapours is simplifiedCombustible gas coke oven heatingCoal charges mechanical treatmentParticulatesProcess engineering

A pyrolysis plant 20 comprises a grinding pyrolyser 22, being a machine or apparatus in which both particle size reduction and pyrolysis occur simultaneously. Plant 20 also comprises a bin (hopper) 30 for holding wet particulate biomass feedstock. Chute 32 leads from the bin 30 to a biomass dryer 34 which reduces moisture content of the feedstock as low as possible, e.g., to below about 10. Dried feedstock is conveyed from dryer 34 via line 36 to a dried biomass feedstock hopper 38. Dried feedstock is fed from hopper 38 into a chute 40 which leads to an inlet trunnion 42 of grinding pyrolyser 22. A discharge trunnion 44 of grinding pyrolyser 22 leads to a char holder 60 for collecting char particles and a condensation train 62 for condensing vapour generated by the pyrolysis to produce oil.

Owner:RENERGI PTY LTD

Particle size reduction of bioactive compounds

InactiveUS20070082054A1Small sizeImprove bioavailabilityAntibacterial agentsPowder deliveryCompound (substance)PARTICLE SIZE REDUCTION

The invention provides a method for reducing the average size of biologically active compound particles or agglomerates suspended in a fluid by flowing one or more times said fluid having biologically active compound particles or agglomerates suspended therein through one or more magnetic fields to reduce the average size of a substantial portion of the biologically active compound particles or agglomerates by at least 25%. This method may be incorporated into a process for manufacturing a 10 biologically active compound formulation.

Owner:K U LEUVEN RES & DEV

Process for Particle Size Reduction of Glass-Like Polysaccharides

InactiveUS20080194402A1Small particle sizeLess-fine and large particleOther chemical processesGrain treatmentsPARTICLE SIZE REDUCTIONPolysaccharide

Disclosed is a process for reducing the particle size of glass-like polysaccharides. The process efficiently reduces the particle size of glass-like polysaccharides selected from the group consisting of glass-like polysaccharides having a moisture content from 0% to about 13% and glassy state glass-like polysaccharides. The process comprises the use of a roller mill having at least three pairs of successive rollers.

Owner:ARCHER DANIELS MIDLAND CO

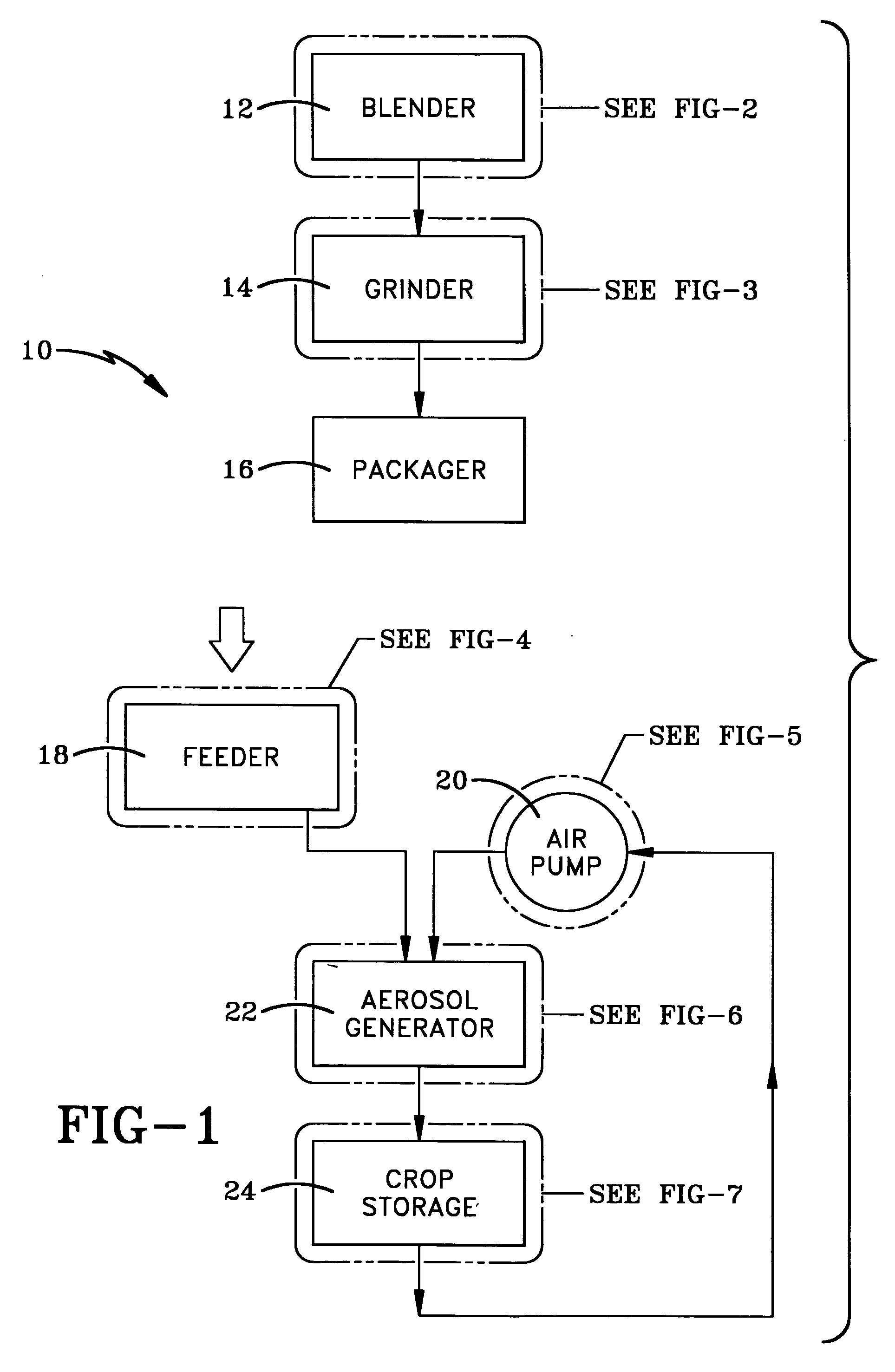

Compositions for use in stored crop treatment aerosols and method and apparatus for application to stored crops

A method is disclosed for generating and delivering an aerosol of a unique composition for treating stored crops. One aspect of the invention is such a composition wherein at least 80% to 98% of the components thereof have a particle size value no greater than 10 microns, whereby nearly any type of aerosol generator may effectively generate the aerosol because the particle size distribution of the components eliminates the need for further particle size reduction. Another aspect of the invention is such a composition which includes components comprising solid carriers with stored crop treatments attached thereto. Preferably, a fine-grinding non-rotary ball mill produces the components at the desired particle size distribution. The solid carriers or other solid particles may provide a reduced caking tendency and may make the aerosol non-combustible regardless of the ignition source. The aerosol is typically generated at an ambient or near-crop-storage temperature, thus reducing fire hazards.

Owner:KEIM WILLIAMA +2

Carbohydrate-mediated purification of petrochemicals

ActiveUS20170189890A1Small particle sizeOther chemical processesHalogenated hydrocarbon separation/purificationAlcoholCyclodextrin

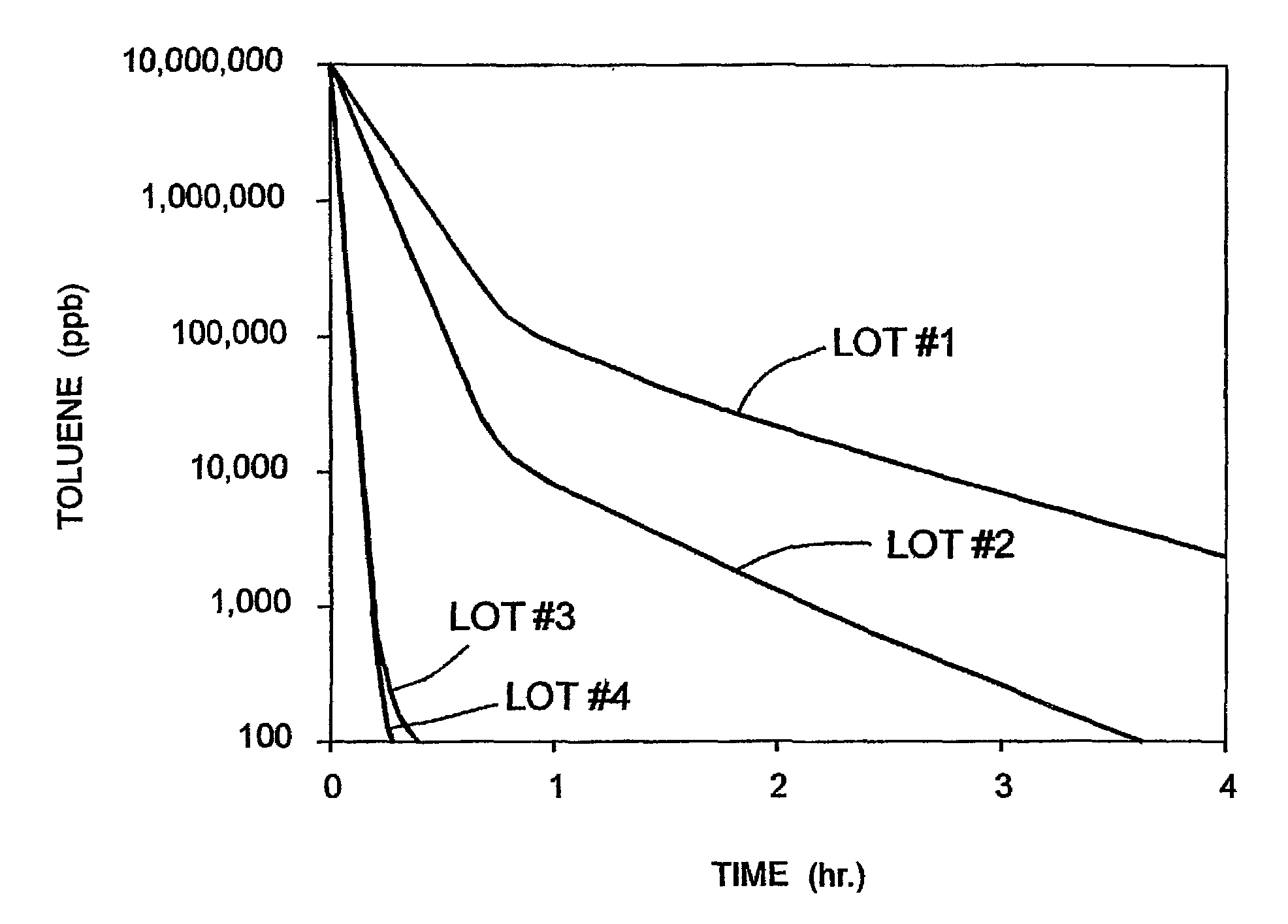

A separation medium consisting of a cyclodextrin metal-organic framework (CD-MOF) for separating aromatic compounds and methods of preparing the same are presented. Bottom-up preparations include the following steps: (a) preparing a first mixture comprising a cyclodextrin, an alkali metal salt, water and an alcohol; (b) performing one of the following two steps: (i) stirring the first mixture; or (ii) adding an amount of a surfactant to the first mixture to form a second mixture; and (c) crystallizing the CD-MOF from the first mixture or the second mixture. Top-down preparations include the following steps: (a) preparing a first mixture comprising the cyclodextrin, an alkali metal salt, water and an alcohol; (b) crystallizing the CD-MOF from the first mixture; and (c) optionally performing particle size reduction of the crystallized CD-MOF. The CD-MOFs are amenable for use in methods for separating alkylaromatic and haloaromatic compounds from a mixture of hydrocarbons.

Owner:NORTHWESTERN UNIV +1

Iron oxide for lithium iron phosphate battery, and its preparation method

InactiveCN102786096AEasy to controlImprove physical performanceFerric oxidesLithium iron phosphateSlurry

The invention discloses iron oxide for a lithium iron phosphate battery material, and its preparation method. The preparation method mainly comprises the following steps: 1, removing impurities from a steel plate pickling waste liquid to reduce the contents of impurities comprising SiO2, P2O5, Al2O3 and the like in iron oxide; 2, carrying out low temperature roasting of the impurities removed pickling waste liquid to improve physical performances of the iron oxide; 3, grinding with a pearl mill until the average particle size of the iron oxide reaches below 0.5mum; and 4, washing the iron oxide slurry obtained after the grinding with desalinized water, and carrying out treatments comprising press filtration, drying, crushing and the like. According to the invention, the contents of the impurities comprising SiO2, P2O5, Al2O3, Cl<->, Ca<2+>, K<+>, Na<+>, SO4<2-> and the like in the iron oxide are greatly reduced; and the physical performances comprising the specific surface area (BET), the loose specific weight, the average particle size particle size reduction and the like of the iron oxide are improved,

Owner:SHANGHAI BAOSTEEL MAGNETICS

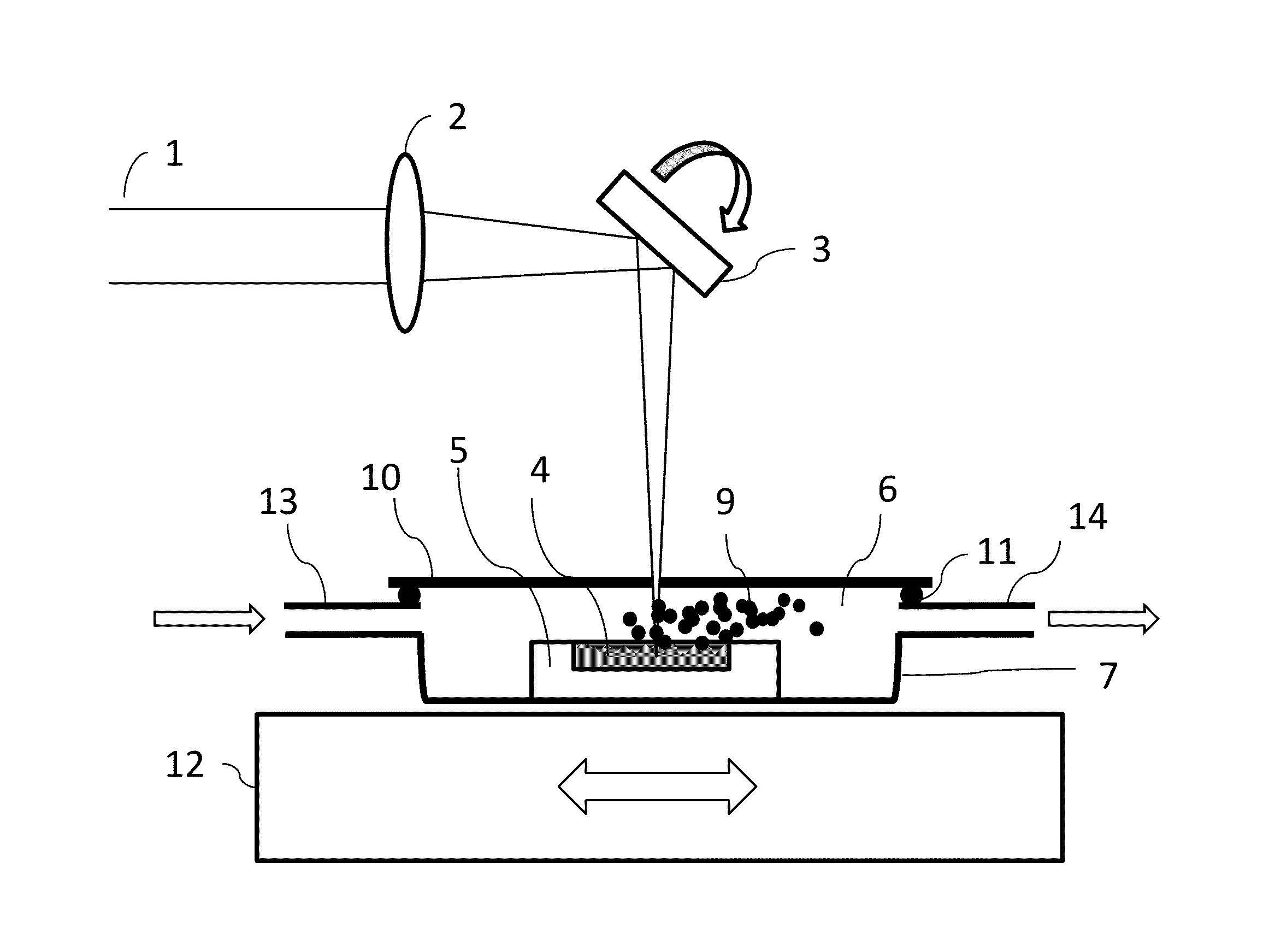

Amorphous Medicinal Fine Particles Produced By Pulsed Laser Ablation In Liquid And The Production Method Thereof

InactiveUS20130209523A1Reduce decreaseImprove bioavailabilityNervous disorderOrganic chemistrySolubilityMaterials science

The present disclosure is directed to an in-liquid laser-based method for fabricating a solution of fine particles of amorphous solid medicinal compounds, a solution of fine particles of amorphous medicinal agents made with the method, and fine particles made with the method. By using a target solidified via a phase transition process to covert an initial crystalline structure into an amorphous solid, technical difficulties with handling a hydraulically-pressed target are overcome. The laser-based ablation process produces amorphous solid medicinal compound fine particles, which improves the bioavailability and solubility of the medicinal compound. The improvement results from a combination of: disordered crystalline structure and enlarged relative surface area by particle size reduction. The laser based method may be carried out with ultrashort pulsed laser systems, or with UV nanosecond lasers. Results obtained with an ultrashort near IR laser and a UV nanosecond laser show formation of amorphous solid curcumin fine particles.

Owner:IMRA AMERICA

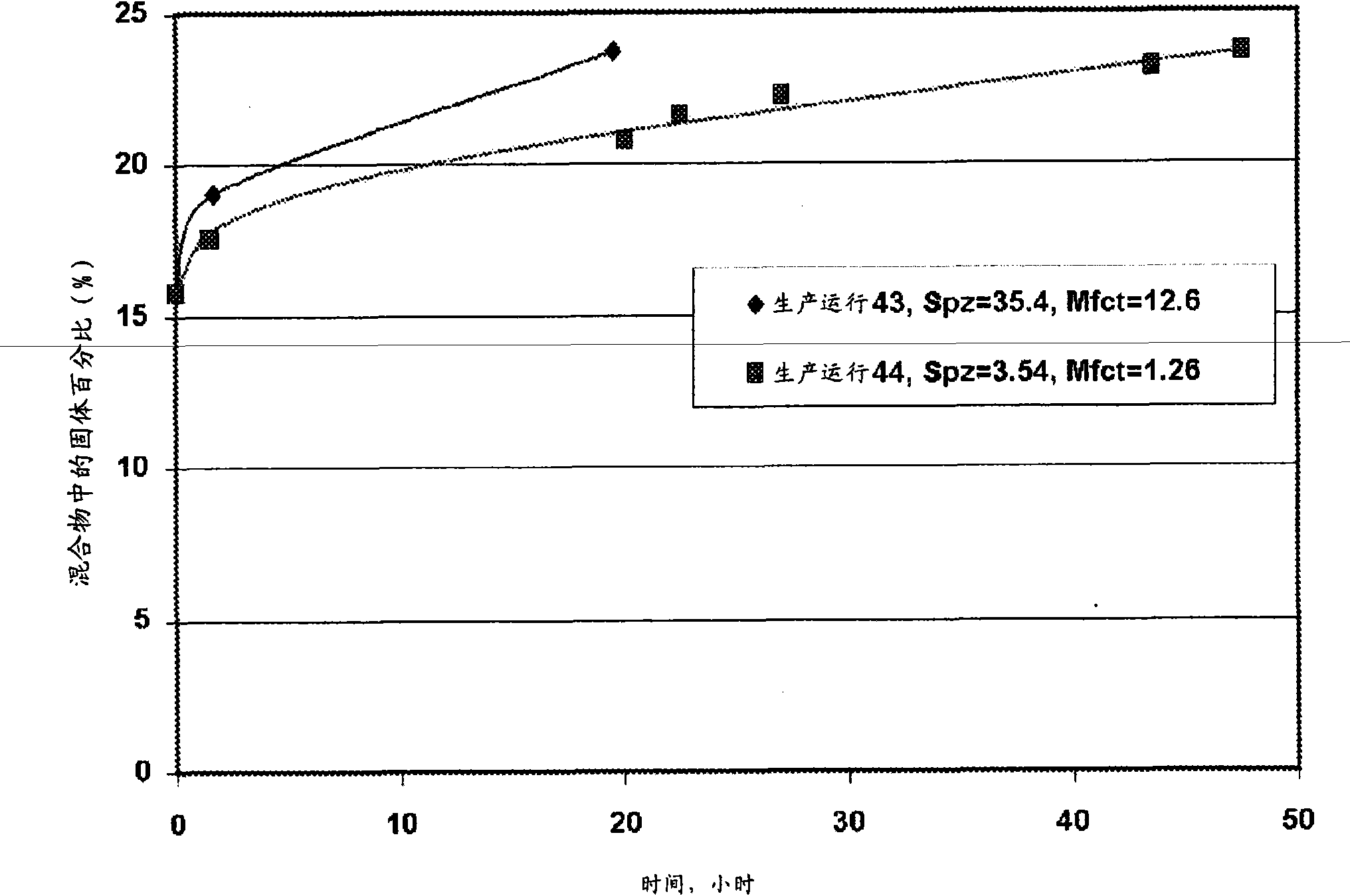

Process for concentrated biomass saccharification

Processes for saccharification of pretreated biomass to obtain high concentrations of fermentable sugars are provided. Specifically, a process was developed that uses a fed batch approach with particle size reduction to provide a high dry weight of biomass content enzymatic saccharification reaction, which produces a high sugars concentration hydrolysate, using a low cost reactor system.

Owner:EI DU PONT DE NEMOURS & CO +1

Composition of milling medium and process of use for particle size reduction

InactiveUS20100301146A1Pigmenting treatmentOther chemical processesPARTICLE SIZE REDUCTIONMaterials science

Owner:CHANG YUN FENG

Long term-stabilized magnesium hydroxide suspension for covering iron mineral, a process for its production and application

InactiveUS20030141485A1Improve adhesionIncrease coverageOther chemical processesMixing methodsPolyelectrolyteSolid particle

A long term stabilized magnesium hydroxide suspension which can be used for covering pellets of several materials in order to avoid the agglomeration of a plurality of pellets when stored or subjected to a heat treatment and which can be stored for at least three months without substantial agitation and without experiencing substantial settlement and solid hard substrate formation, comprising a solid content of about 51% to 61%; a water content of about 39% to 49%; a viscosity of about 500 to 1,500 cp.; an average particle size of about 1 to 2.5 microns; a Mg(OH)2 content of about 50% to 60%; an equivalent magnesium oxide content of 34% to 42%; including an adherent compound at a concentration of at least 30% in an amount of 0.5 to 5%, by weight, on a dry basis and an anionic polyelectrolyte as a dispersant agent, and which is obtained by washing, filtering and repulping magnesium hydroxide solids to obtain agglomerated solid particles, dispersing the agglomerated solid particles by comminution in a dispersing equipment, to reduce the particle size providing a dispersed product, grinding the dispersed product, to additionally reduce the particle size to about 2 microns; and adding an adherent compound at a concentration of at least 30% in an amount of 0.5 to 5% on a dry basis and an anionic polyelectrolyte at a concentration of at least 25%, in an amount of about 0.5 to 2.5%, by weight, on a dry basis, as a dispersant agent.

Owner:SERVICIOS IND PENOLES S A DE

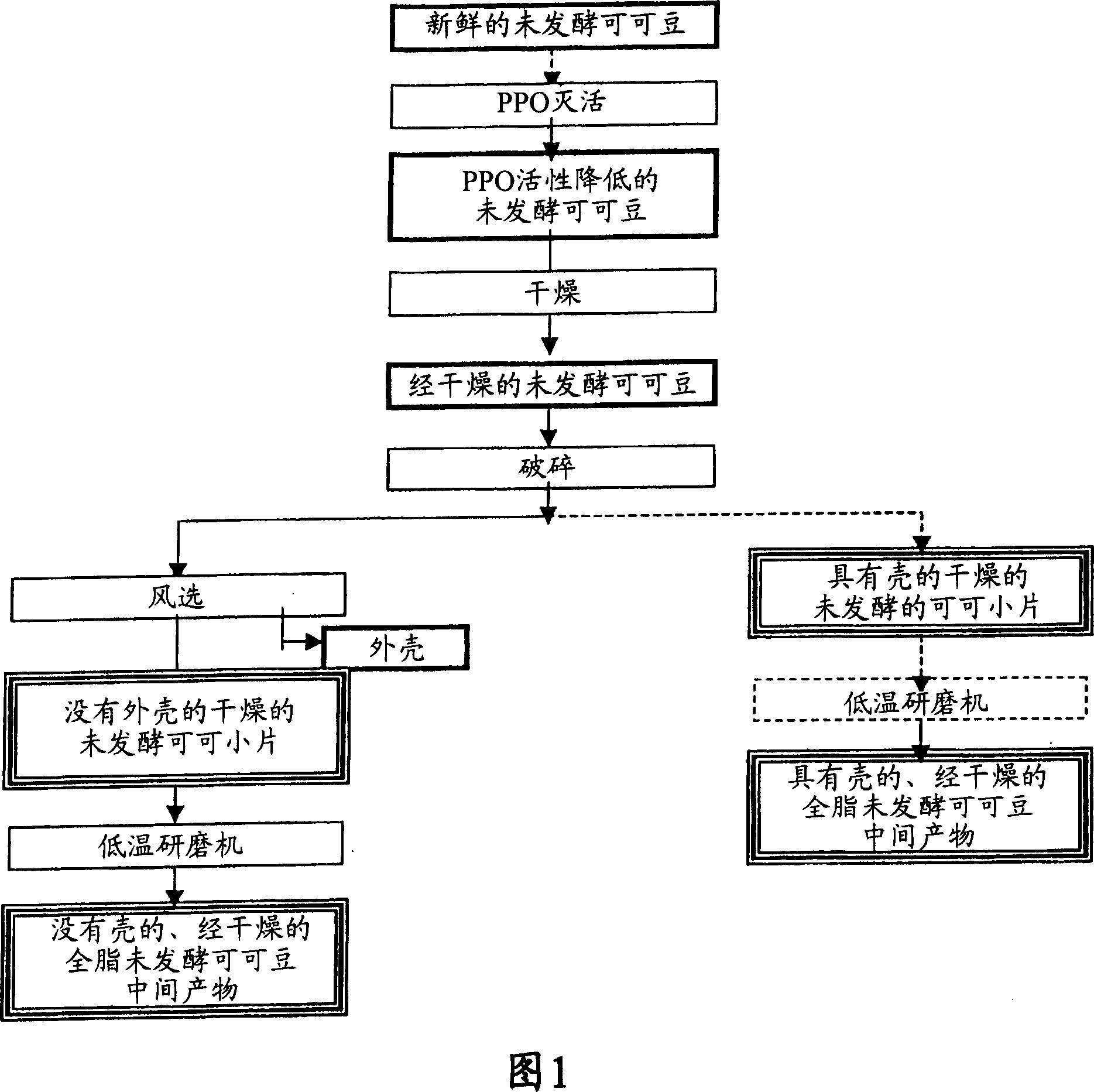

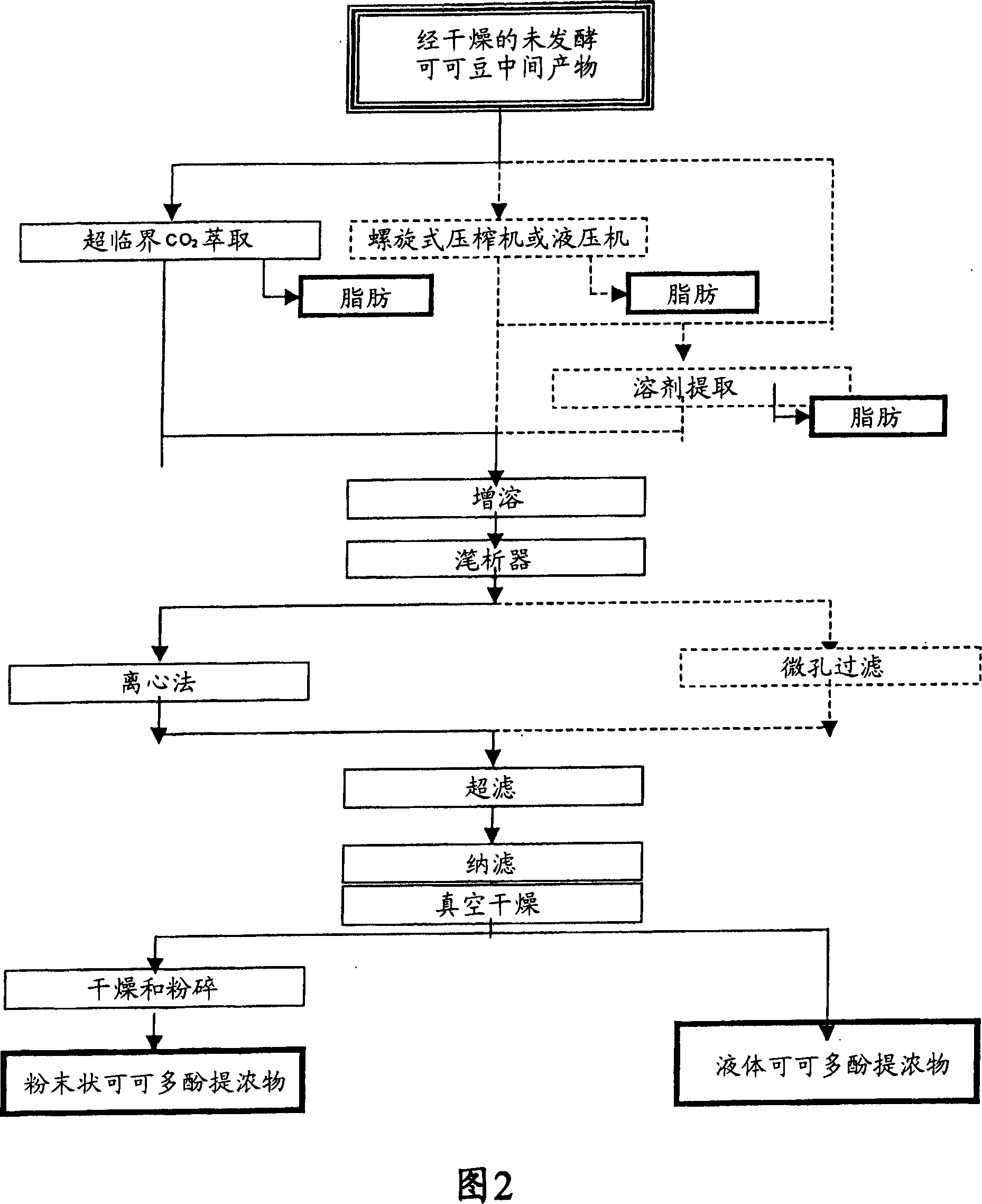

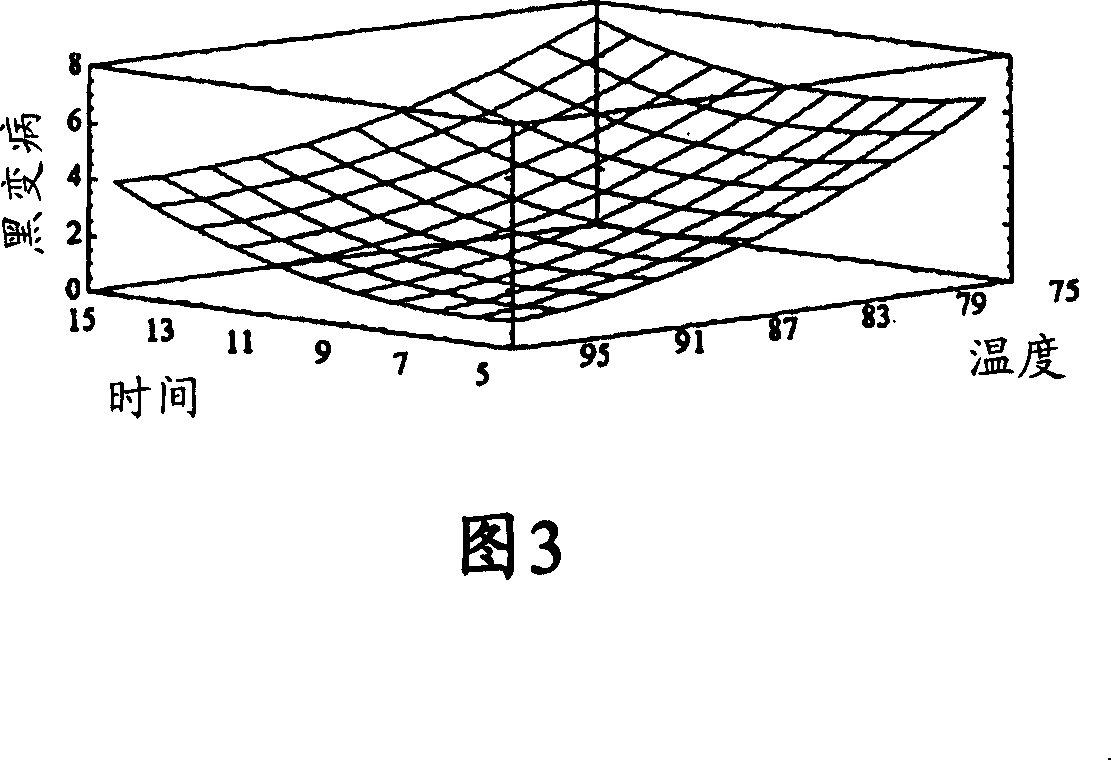

Process for producing cocoa polyphenol concentrate

InactiveCN1933736AOrganic compounds purification/separation/stabilisationMetabolism disorderPARTICLE SIZE REDUCTIONPolyphenol

A process in which cocoa polyphenol concentrate is obtained comprising the steps of: a) subjecting unfermented cocoa beans to a blanching step in water at a temperature in the range from 85-100 DEG C for a time period in the range from 3 to 15 minutes to give unfermented cocoa beans with reduced polyphenol oxidase activity; b) drying the unfermented cocoa beans with reduced polyphenol oxidase activity at a temperature of less than 85 DEG C to obtain dried unfermented cocoa beans with a moisture content of no more than 15%; c) subjecting the dried unfermented cocoa beans to a particle size reduction step to obtain dry unfermented cocoa bean intermediate whereby at least 99 wt% of the product has a particle size less than or equal to 300 m; e) extracting polyphenols from the dry unfermented cocoa bean intermediate to give a cocoa polyphenol extract and extracted solids; d) concentrating the cocoa polyphenol extract to yield a cocoa polyphenol concentrate; and wherein the process further includes a defatting step which is carried out prior to step d).

Owner:NATRACEUTICAL

Decontamination of sediments through particle size reduction and stabilization treatment

InactiveUS20100303551A1Degree of reductionReduce direct impactBiocidePowder deliveryMedicinePARTICLE SIZE REDUCTION

A process of decontamination of sediment particles to reduce active pollutant components through particle size reduction and stabilization treatment.

Owner:CHANG YUN FENG

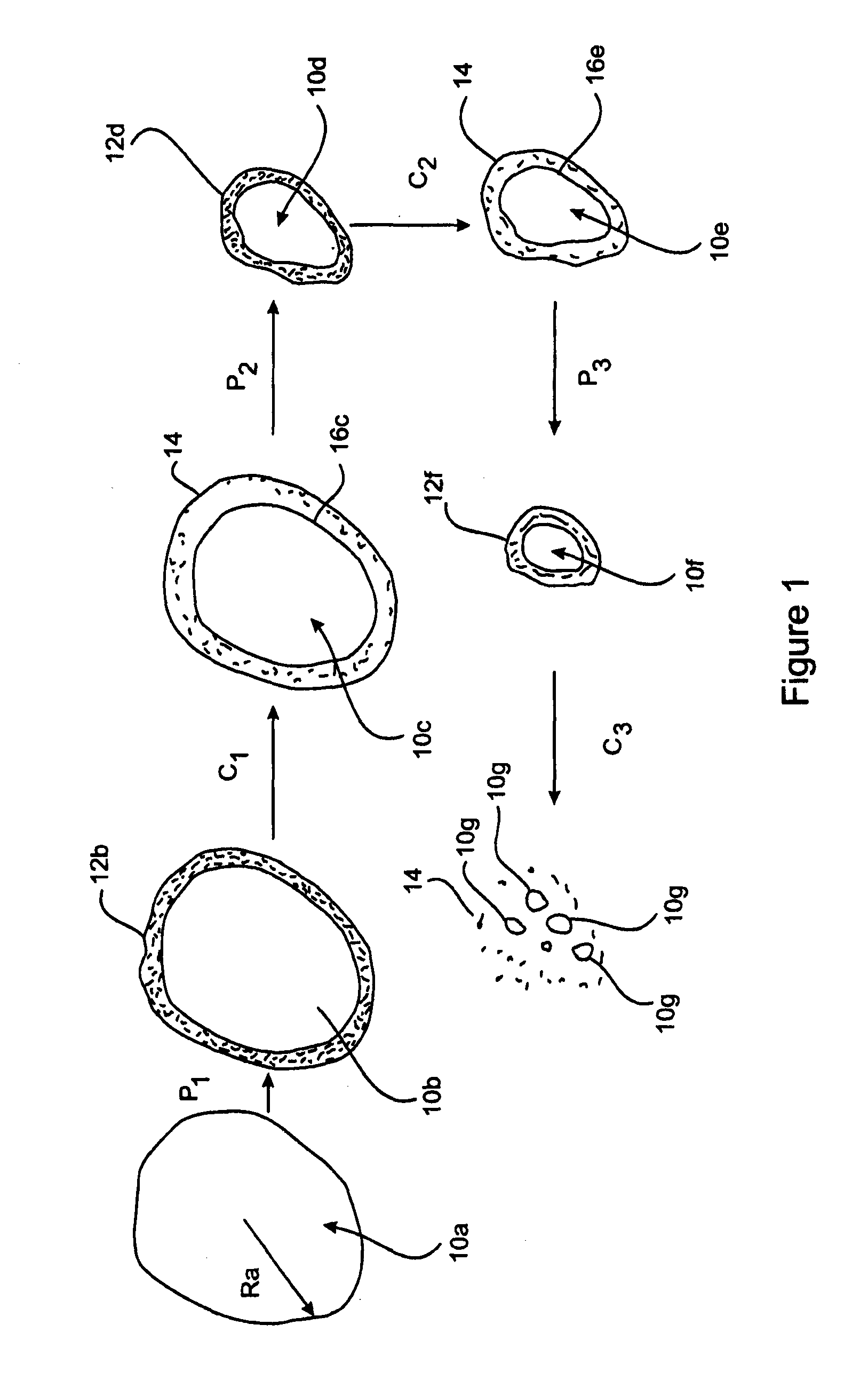

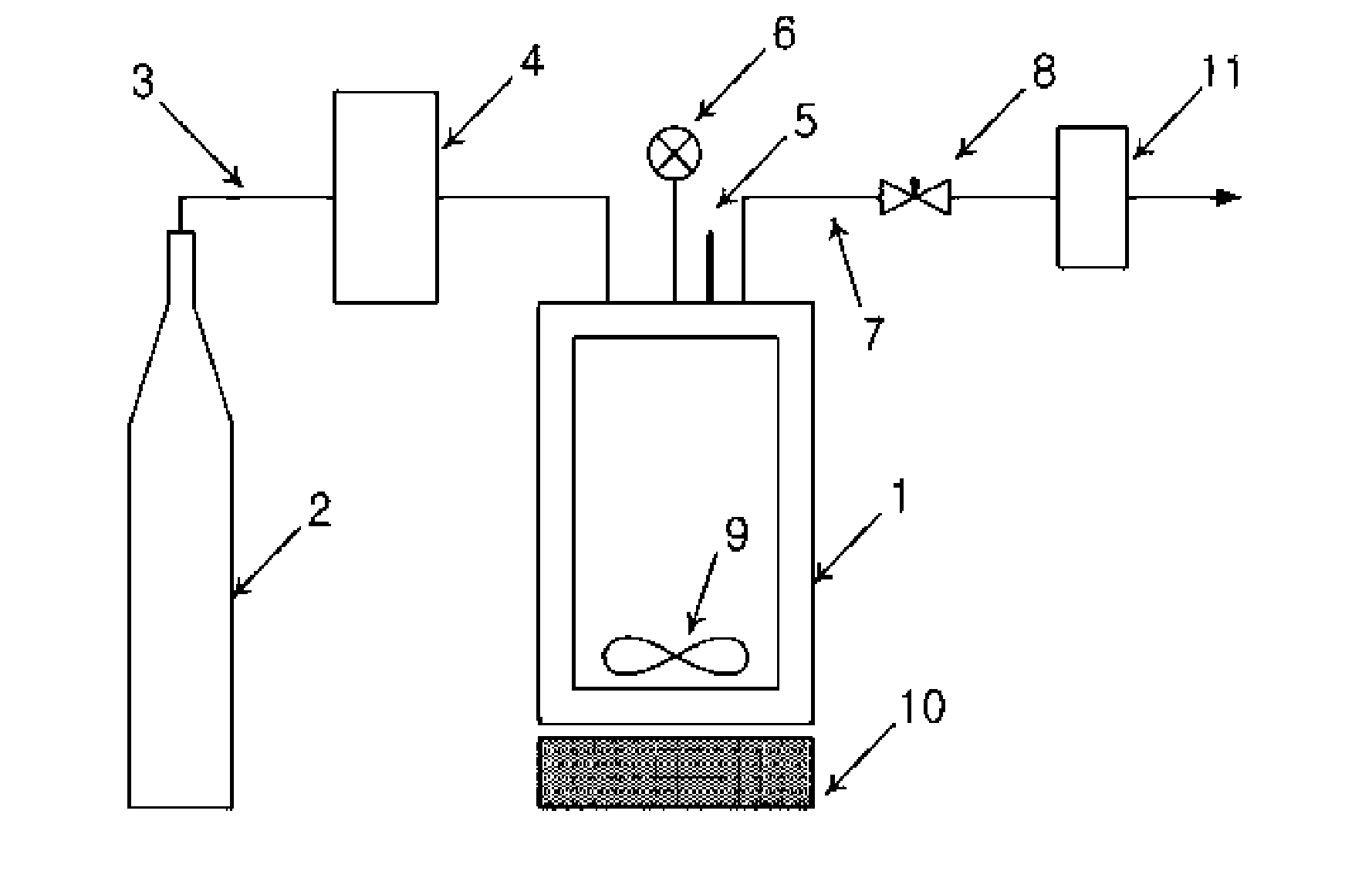

Method and apparatus for preparing novel liposome

ActiveUS20130069261A1Increase contentImprove loading efficiencyAntimycoticsSolvent extractionLaboratory scaleFreeze-drying

Disclosed is a method for preparing a liposome formulation. In the disclosed method, a lipid fraction is dissolved in an organic solvent. The solution including a bioactive component and the lipid fraction, together with a carrier, is put in a reaction vessel, and a supercritical fluid is introduced thereto, so as to prepare particles coated with the bioactive component-lipid. The supercritical fluid is discharged by compression to obtain proliposome particles, and then the proliposome particles are hydrated by an aqueous solution including water so as to form a liposome solution. Preferably, the formulation may include one or more bioactive components. As required, the liposome formulation may be further processed by methods such as particle size reduction, removal of organic solvent, and freeze-drying. The preparation method can be easily carried out at a laboratory scale. Furthermore, the same method can be employed in liposome formulation preparation in mass production, or at a commercial scale.

Owner:BCWORLD PHARMA

Method and apparatus for preparing novel liposome

ActiveCN102781428AImprove stabilityIncrease contentBioreactor/fermenter combinationsAntimycoticsLipid formationLaboratory scale

Disclosed is a method for preparing a liposome formulation. In the disclosed method, a lipid fraction is dissolved in an organic solvent. The solution including a bioactive component and the lipid fraction, together with a carrier, is put in a reaction vessel, and a supercritical fluid is introduced thereto, so as to prepare particles coated with the bioactive component-lipid. The supercritical fluid is discharged by compression to obtain proliposome particles, and then the proliposome particles are hydrated by an aqueous solution including water so as to form a liposome solution. Preferably, the formulation may include one or more bioactive components. As required, the liposome formulation may be further processed by methods such as particle size reduction, removal of organic solvent, and freeze-drying. The preparation method can be easily carried out at a laboratory scale.; Furthermore, the same method can be employed in liposome formulation preparation in mass production, or at a commercial scale.

Owner:BC WORLD PHARM LTD

Method and assembly for sewage treatment

InactiveUS20160355419A1Sufficient pressureWater treatment parameter controlGeneral water supply conservationOn boardWastewater

A method and assembly for treating waste water by way of a chemical / physical process of pulverizing and dewatering sewage waste on board a variety of different marine vessels. A method and assembly for treating waste water comprising pulverizing solid(s) for particle size reduction, disinfection and sterilization of harmful organisms, solid collection, dewatering solid(s) for disposal, and dechlorinating a final outfall without use of dilution in order to meet an allowable level of contaminants prior to discharge.

Owner:JP CHAUVIN HLDG LLC

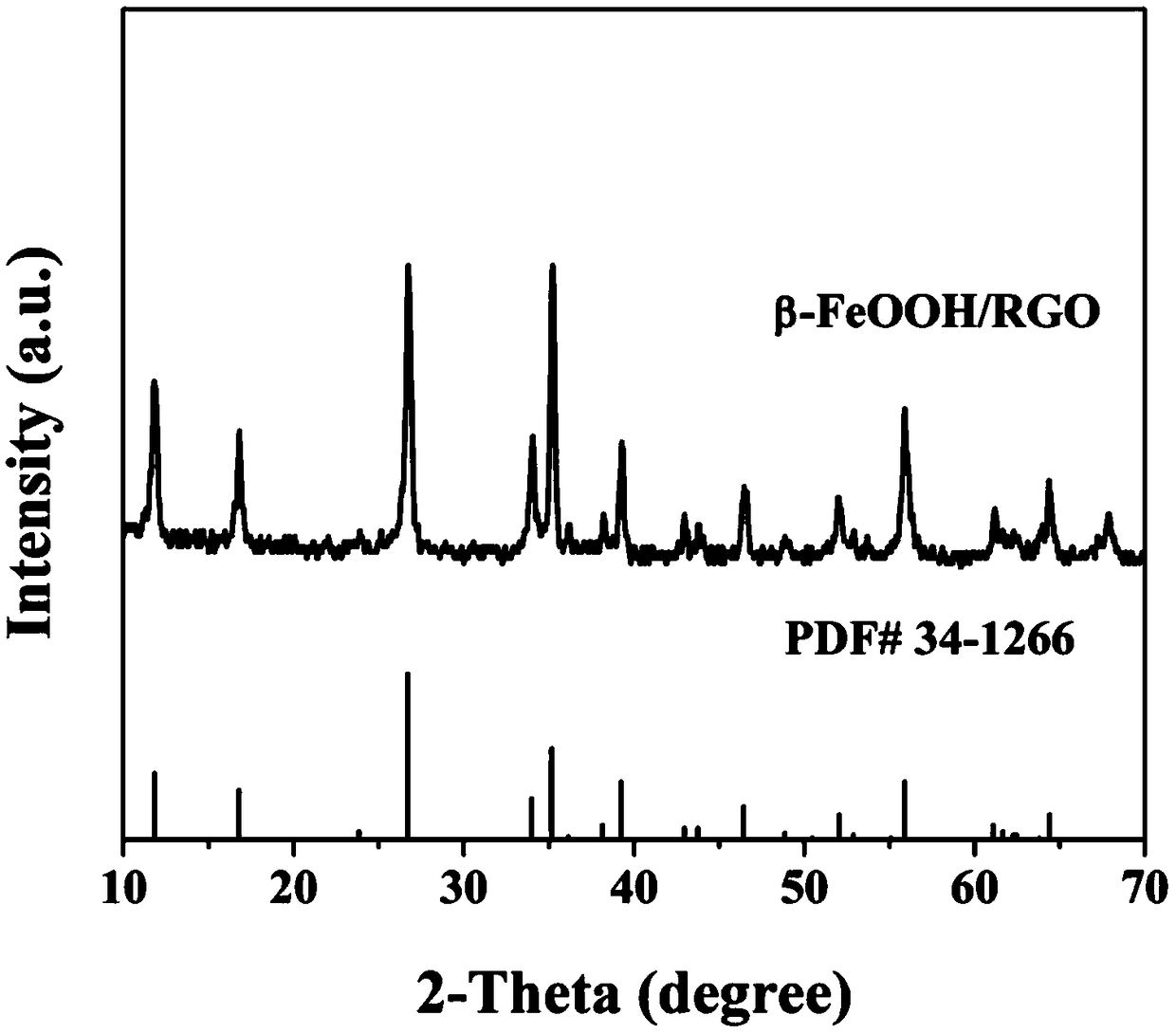

Preparation method of super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material

ActiveCN109390573AImprove conductivityAlleviate volume expansionMaterial nanotechnologyCell electrodesFreeze-dryingLithium-ion battery

The invention discloses a preparation method of a super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material. The preparation method comprises following steps: oxidized graphene is dispersed in deionized water so as to obtain a suspending liquid A; a certain amount of a soluble salt, sodium chloride, and urea are added into absolute ethylalcohol and deionized water, and then are mixed with the suspending liquid A so as to obtain a suspending liquid B; the suspending liquid B is introduced into a homogeneous hydro-thermal reaction vessel, the homogeneous hydro-thermal reaction vessel is sealed, and is introduced into a homogeneous hydro-thermal reaction equipment for hydro-thermal reaction, and then natural cooling to room temperature is carried out so as to obtain a product C; the product C is washed with water and alcohol respectively; and after washing, the product is dispersed in water so as to obtain a product D; the product D is subjected to freeze-drying so as to obtain the super large lamella RGO loaded ultrafine beta-FeOOH nanometer particle lithium ion battery negative electrode material. According to the preparation method, graphene combination and particle size reduction are adopted to improve the performance of beta-FeOOH, so that more electrochemical active sites and ion transmission channels are provided, battery reversible capacity is increased, the reversible capacity at 5000mA g<-1> is larger than 1000mAh g<-1>, and the potential capacity of the super large lamella RGO loaded ultrafine beta-FeOOHnanometer particle lithium ion battery negative electrode material is excellent.

Owner:SHAANXI UNIV OF SCI & TECH

Comminution apparatus

InactiveUS7229037B1Small particle sizeEliminate useGas current separationCocoaParticulatesEngineering

These and other objects of the present invention are achieved by a comminution apparatus comprised of a housing member formed with co-planar circularly-shaped chambers in chordal juxtaposition to each other thereby forming a collision zone therebetween and wherein wheel members having radially disposed directional vanes are positioned for rotation in each cylindrically-shaped chamber and wherein an inlet fluid conduit or a slurry of particulate matter to be treated is in axial fluid communication with each wheel member and wherein each wheel member is caused to be rotated in a direction to accelerate the slurry towards the collision zone and to affect particle size reduction by particle collision and wherein an outlet conduit is in fluid communication with the collision zone for withdrawing a slurry of size reduced particles from the comminution apparatus.

Owner:HAYLES JR PETER E

Decontamination of RPET through particle size reduction

Owner:PHOENIX TECH INT

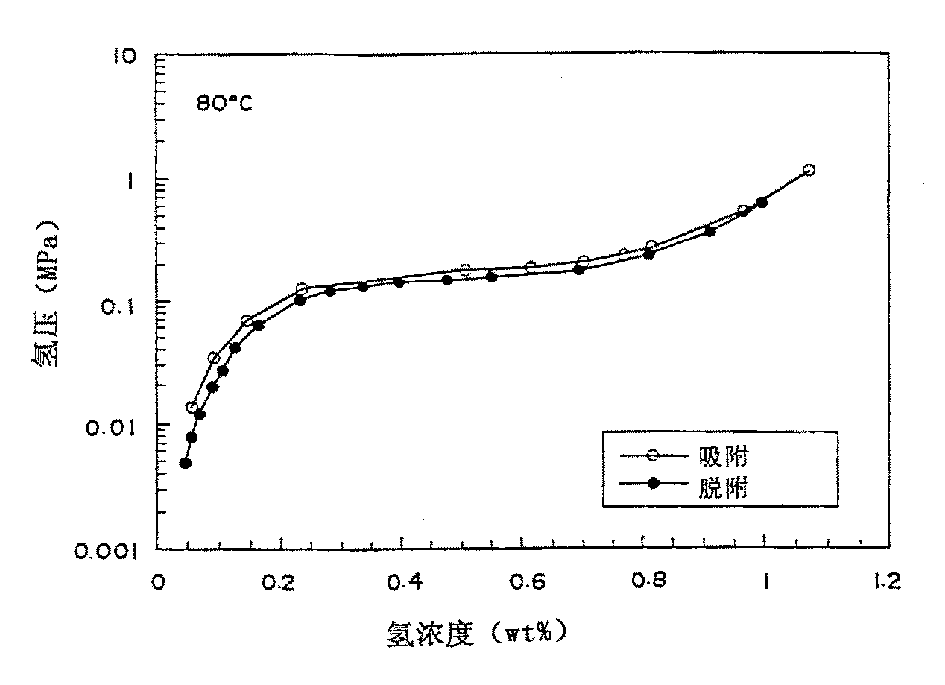

Hydrogen storage composite formed article and method for preparing the same

InactiveCN1336856ADoes not cause chalkingDoes not cause transformationHydrogenOther chemical processesDesorptionHeat resistance

The present invention relates to a hydrogen absorbing composite compact comprising silicone resin, and a process for making the compact, the compact being without particle size reduction or decay even when absorptions and desorptions of hydrogen are repeated for a long period of time and excelling in heat resistance, moldability and processibility. More particularly, the present invention provides a hydrogen absorbing composite compact which comprises hydrogen absorbing alloy and preferably 0.5 to 50% by weight silicone resin. Furthermore, the present invention provides a process for making the hydrogen absorbing composite compact comprising a step wherein a hydrogen absorbing alloy powder is molded by compression, a step for impregnation in a silicone resin solution or dispersion liquid and a sep for curing, and a process for making the hydrogen absorbing composite compact comprising a step for mixing a hydrogen absorbing alloy with any one selected from silicone resin itself, a silicone resin solution and a silicone resin dispersion liquid, a step for molding and a step for curing.

Owner:SHIN ETSU CHEM IND CO LTD

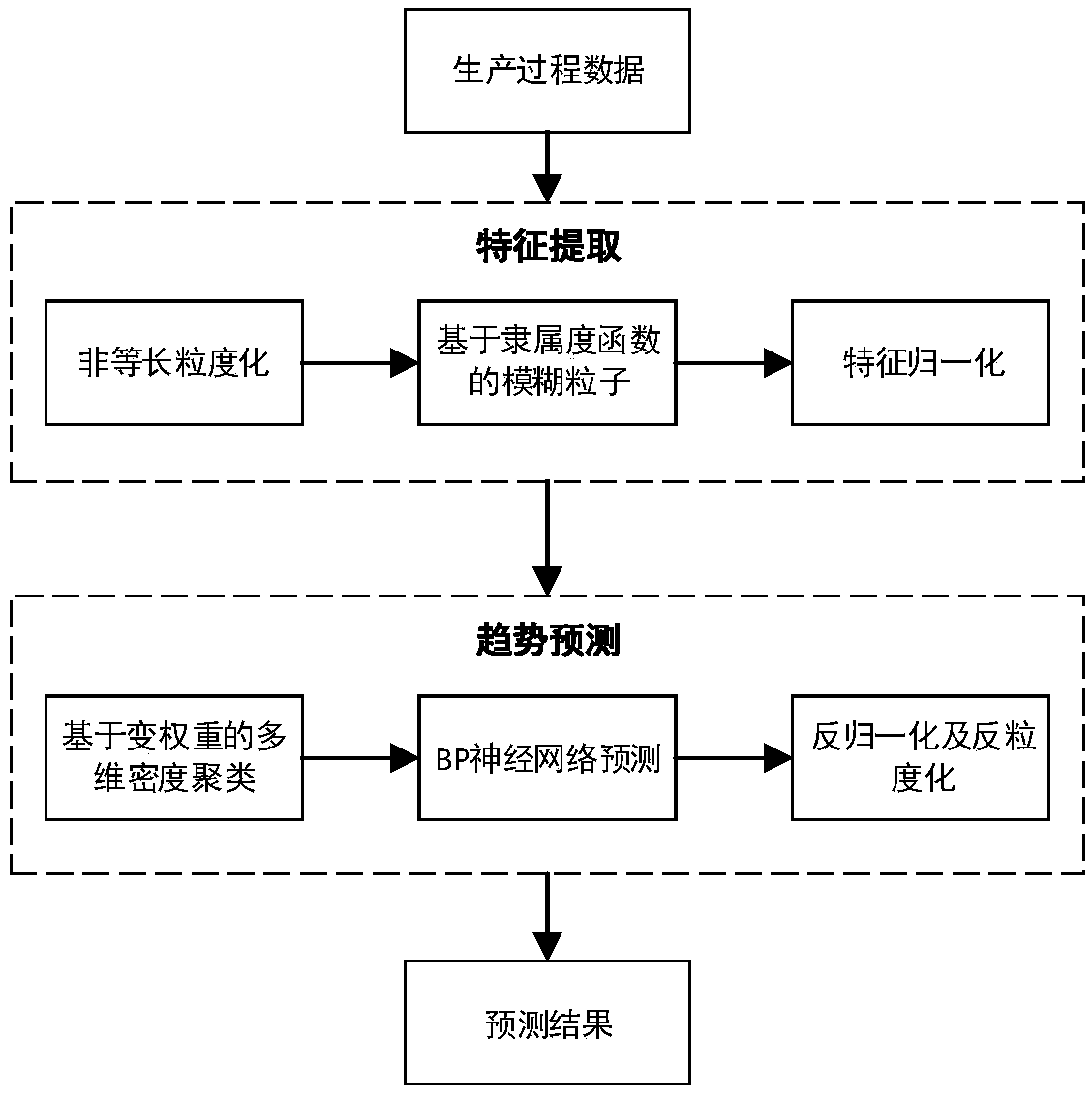

A gas flow data prediction method based on non-equal-length granularity characteristics

InactiveCN109670634AReduce the impact of errorsSummarize data characteristics wellForecastingCharacter and pattern recognitionOriginal dataWeight change

The invention belongs to the technical field of energy data prediction, and provides a gas flow data prediction method based on non-equal-length granularity characteristics. The method comprises the steps of firstly collecting the data based on a gas system, conducting the unequal-length fuzzy granulation on the data based on discrete change poles, showing the granulation form to comprise representative values and support upper and lower boundaries, wherein the particles represent vectors of the number of original data; secondly performing multi-dimensional density clustering based on weight change on the granulated data, and replacing granularity data in a time sequence with cluster division; thirdly designing a data prediction method based on the artificial neural network, performing model prediction by applying a time sequence result divided by a cluster, obtaining a corresponding weight value and a threshold value matrix, checking the accuracy of the weight value and the thresholdvalue matrix, and preparing for the following particle size reduction; and finally providing a particle size reduction method based on one-dimensional interpolation.

Owner:DALIAN UNIV OF TECH

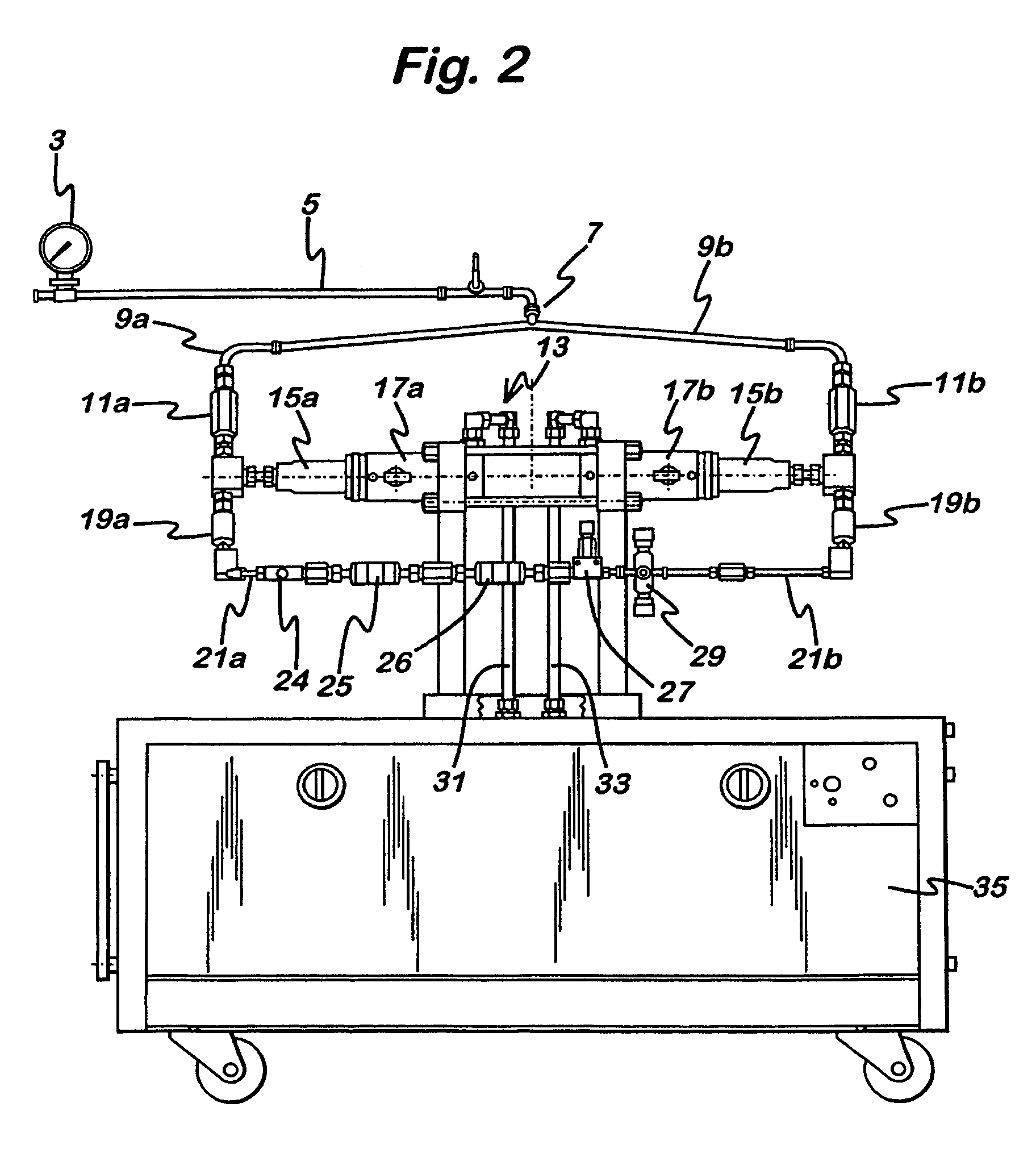

Particle-size reduction apparatus, and use thereof

ActiveUS7644880B2Small particle sizeSuitable particle size distributionPowder deliveryRespiratory disorderEngineeringPARTICLE SIZE REDUCTION

A sterilisable particle-size reduction apparatus, component parts thereof and a method of sterilising and validating sterility thereof are provided. Also provided is use thereof to prepare sterile suspensions of drugs.

Owner:RESOLUTION CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com