Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about "Quinacridones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified colorants and inkjet ink compositions comprising modified colorants

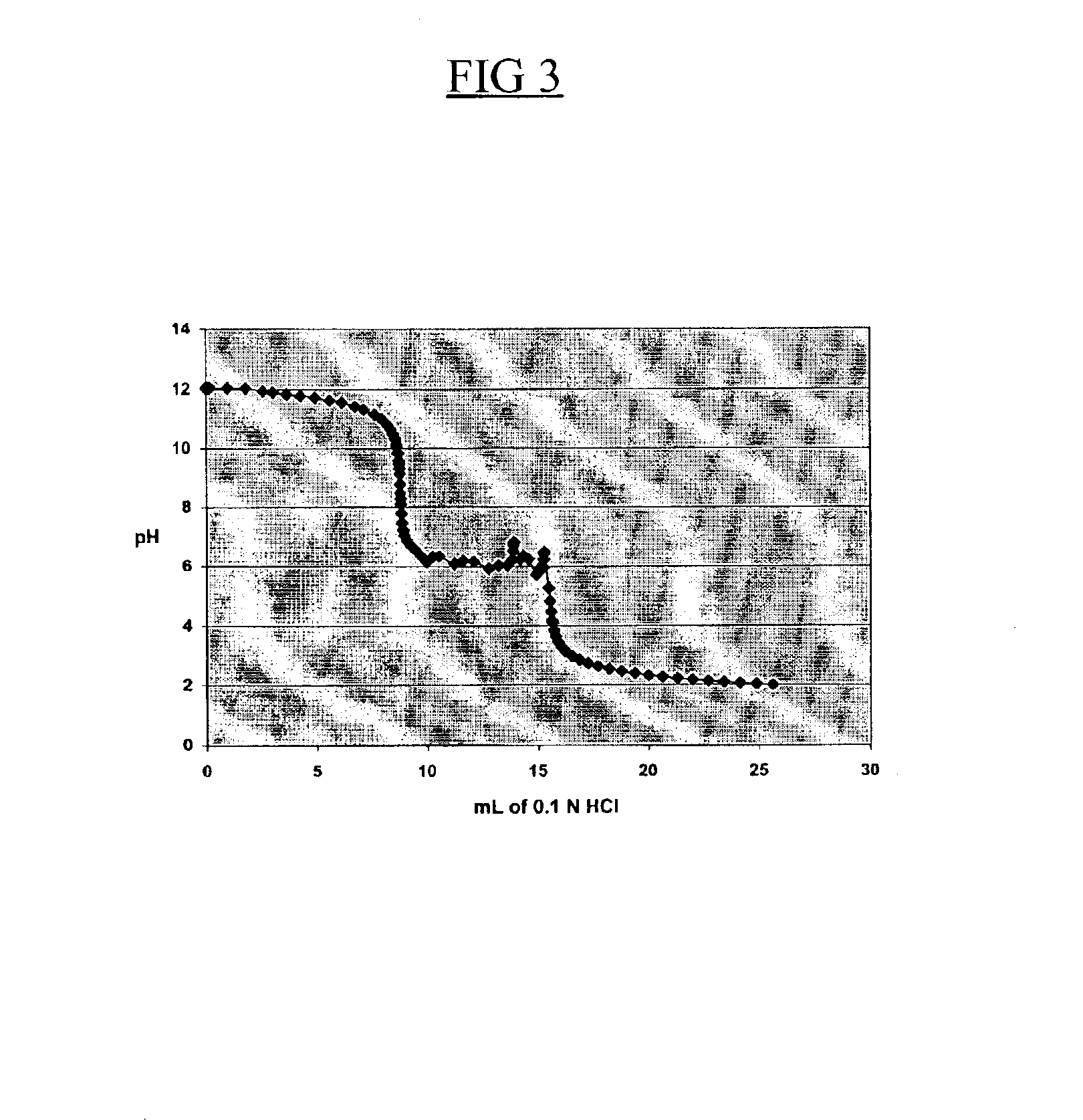

The present invention relates to a modified colorant comprising a colorant having attached at least one organic group. Various embodiments of the organic group are disclosed. For each of these embodiments, preferably the organic group has a defined calcium index value. Also disclosed are various uses for these modified colorants, including inkjet ink compositions.

Owner:CABOT CORP

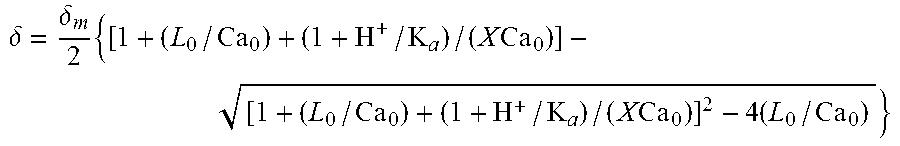

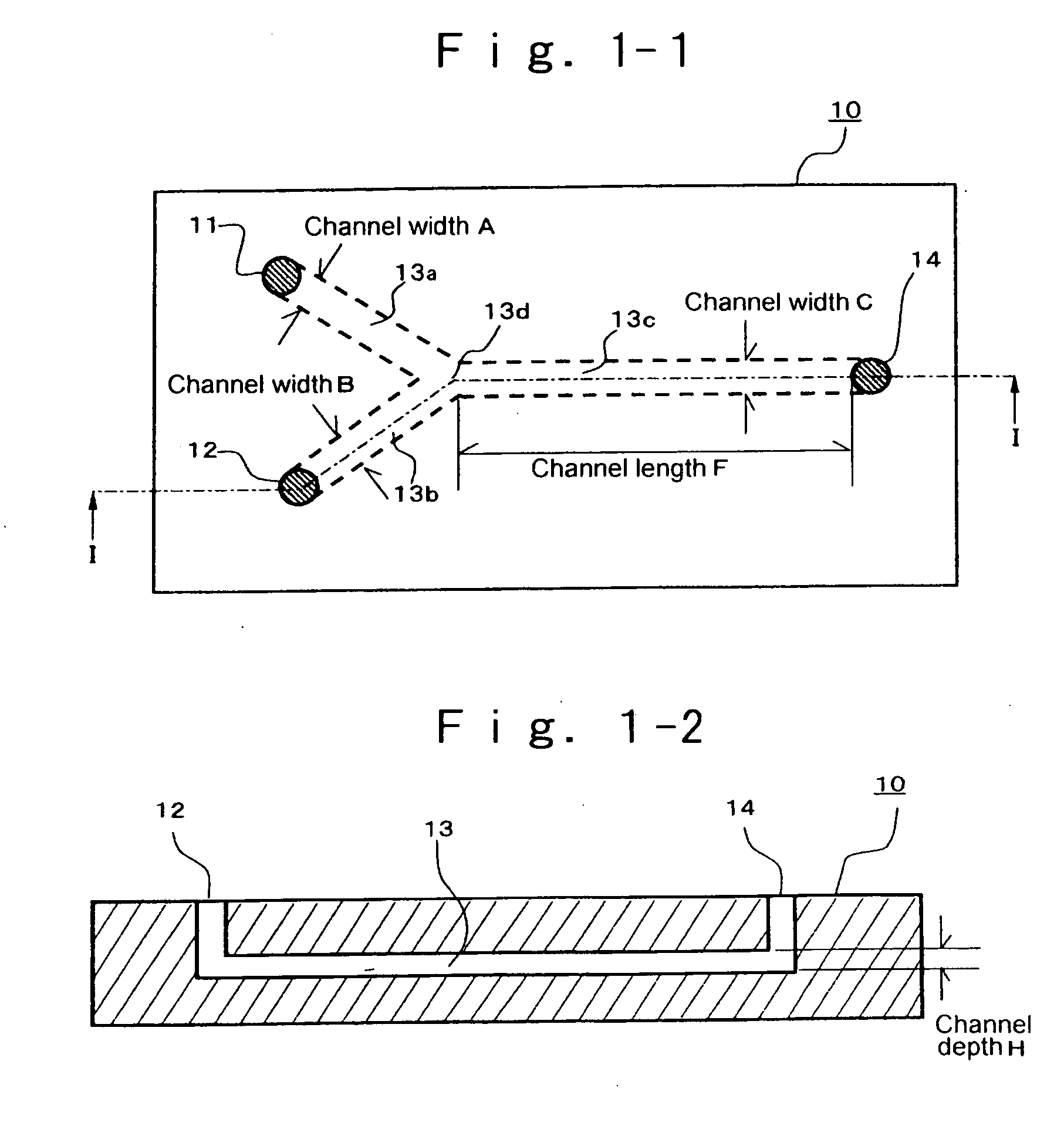

Organic pigment fine-particle, and method of producing the same

A method of producing a fine particle of an organic pigment, containing the steps of: flowing a solution of an organic pigment dissolved in an alkaline or acidic aqueous medium, through a channel which provides a laminar flow; and changing a pH of the solution in the course of the laminar flow.

Owner:FUJIFILM CORP

Method or producing an organic pigment dispersion liquid and organic pigment fine particles obtained by the method

A method of producing an organic pigment dispersion liquid, which has the steps of: providing an alkaline or acidic solution with an organic pigment dissolved therein and an aqueous medium, wherein a polymerizable compound is contained in at least one of the organic pigment solution and the aqueous medium; mixing the organic pigment solution and the aqueous medium; and thereby forming the pigment as fine particles; then polymerizing the polymerizable compound to form a polymer immobile from the pigment fine particles.

Owner:FUJIFILM CORP

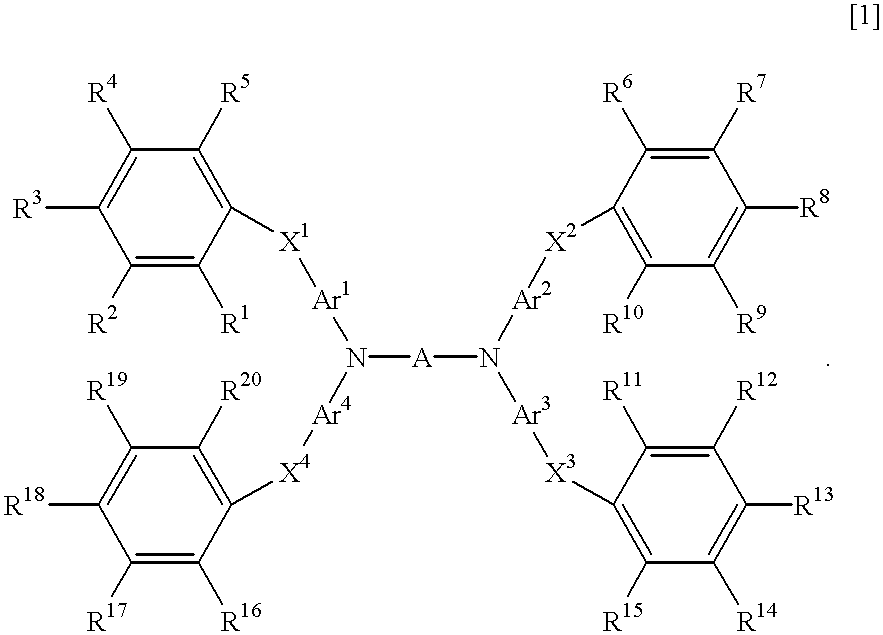

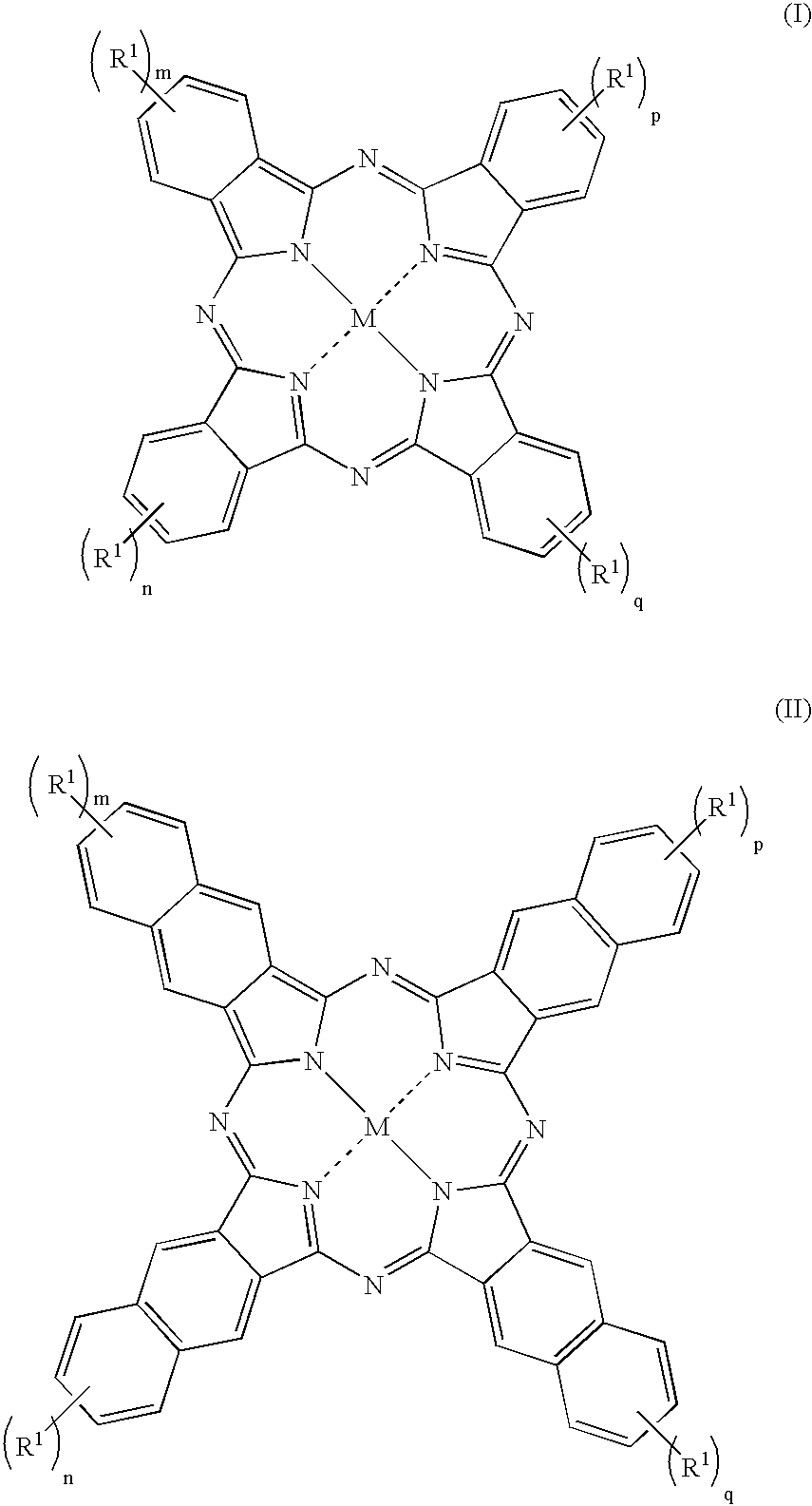

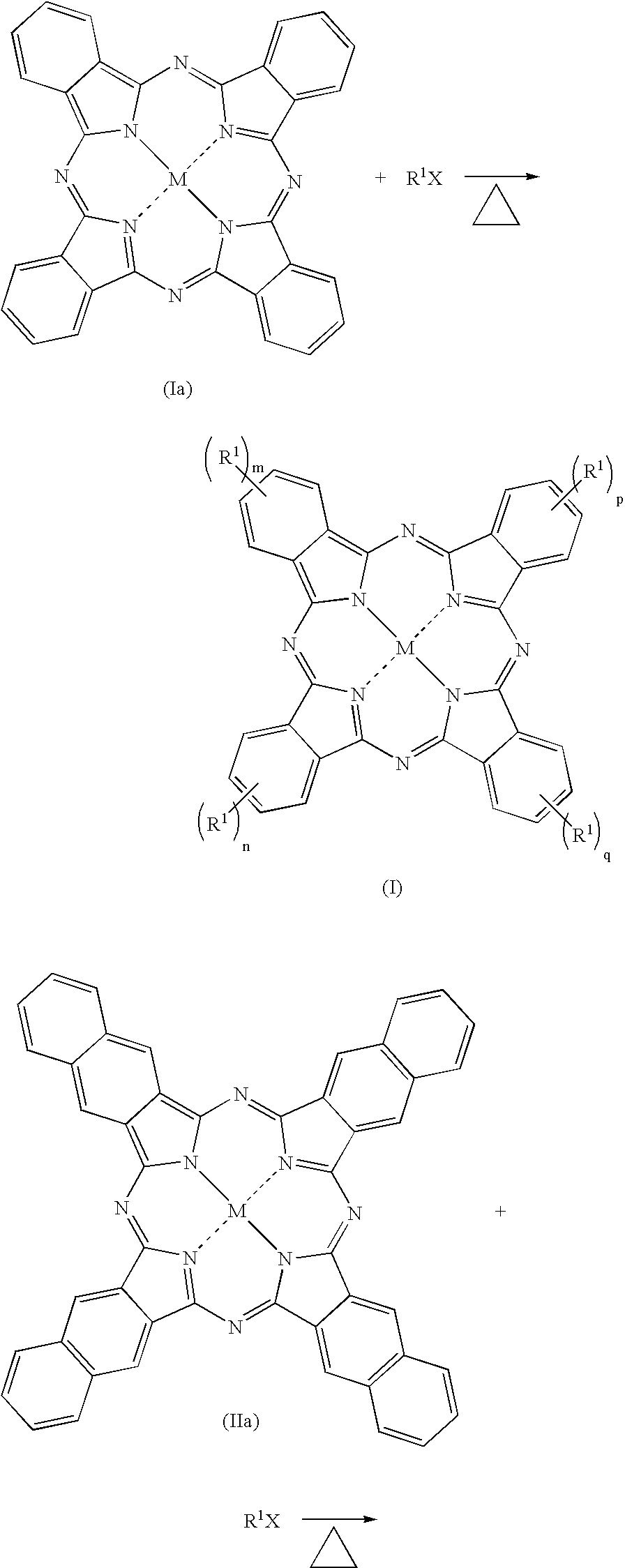

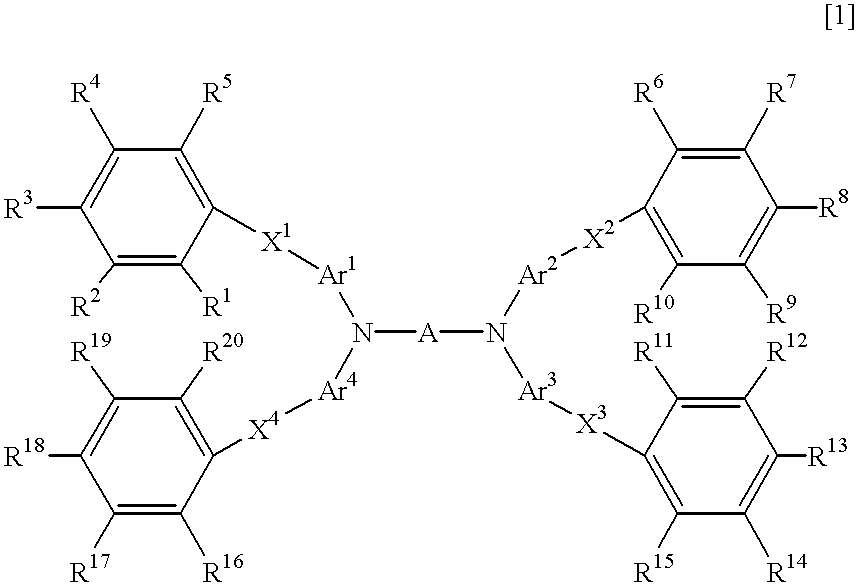

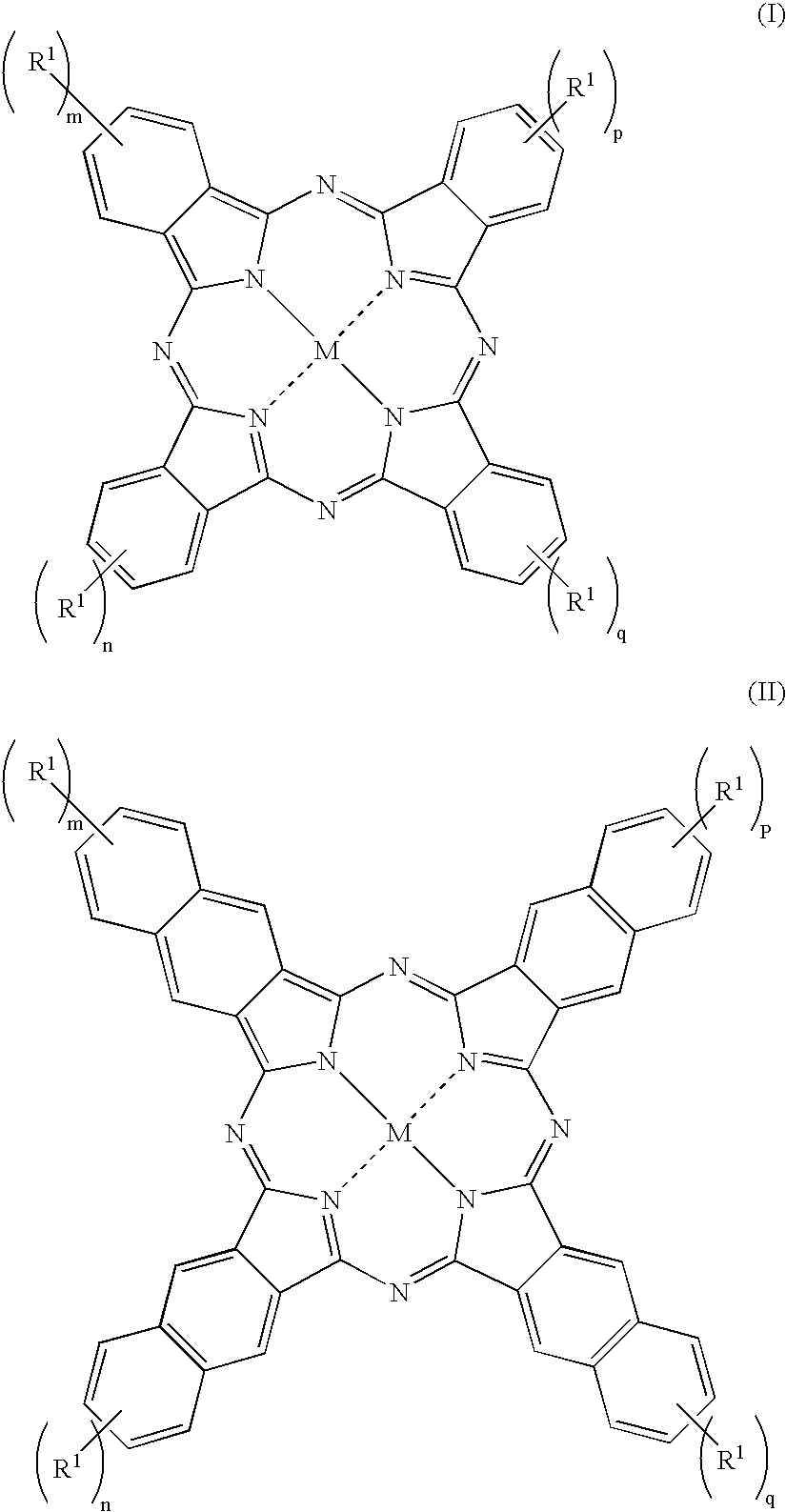

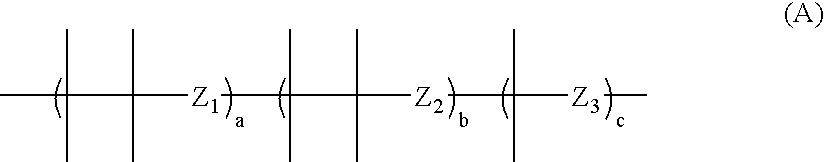

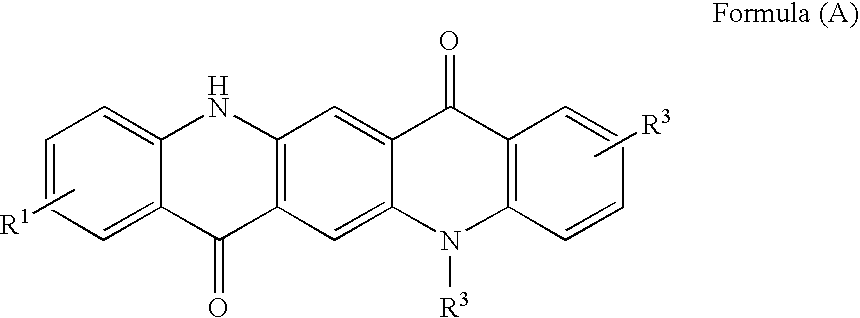

Light-emitting material for organo-electroluminescence device and for organic electroluminescence device which the material is applied

InactiveUS6280859B1Methine/polymethine dyesOrganic chemistryOrganic electroluminescenceLight emission

A light-emitting material which serves to emit light having a high brightness and is almost free of deterioration in light emission, and an organic EL device for which the light-emitting material is adapted, the material having the formula [1],

Owner:TOYO INK SC HOLD CO LTD

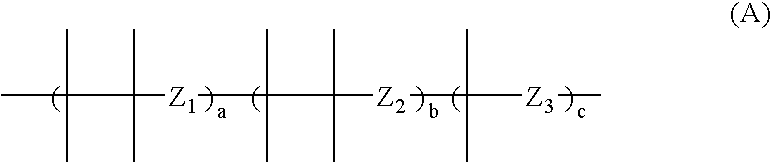

Modified pigments having improved dispersing properties

InactiveUS7056962B2Improving dispersibility and dispersion stabilityImprove dispersibility and dispersion stabilityPhotomechanical apparatusInksElastomerHydrogen

Various modified pigment products are described which are preferably capable of being dispersed in a variety of materials such as coatings, inks, toners, films, plastics, polymers, elastomers, and the like. The modified pigments are pigments having attached groups, such as polymeric groups, onto the pigment by means other than adsorption. A modified pigment product is described comprising a pigment having attached at least one group comprising the formula:—X—[NIon]pRwherein X comprises an aromatic group or an alkyl group, NIon comprises at least one type of non-ionic group, R represents hydrogen or comprises an aromatic group or an alkyl group, and p represents an integer of from 1 to 500. Modified pigment products are also described comprising a pigment having attached at least one alkylene oxide group or at least one polymeric group. In addition, other types of modified pigment products are described as well as their incorporation into inks, coatings, toners, films, plastics, polymers, elastomers, and the like. Methods of making the modified pigment products are also described.

Owner:CABOT CORP

Process for preparing modified pigments

The present invention relates to a process for preparing a polymer-modified pigment comprising the step of: combining, in any order, at least one pigment having attached at least one nucleophilic group, at least one polymer comprising at least one carboxylic acid group or salt thereof, and at least one coupling agent. At least one mediator compound may also be used. The modified pigments can be used in applications such as inkjet ink applications.

Owner:CABOT CORP

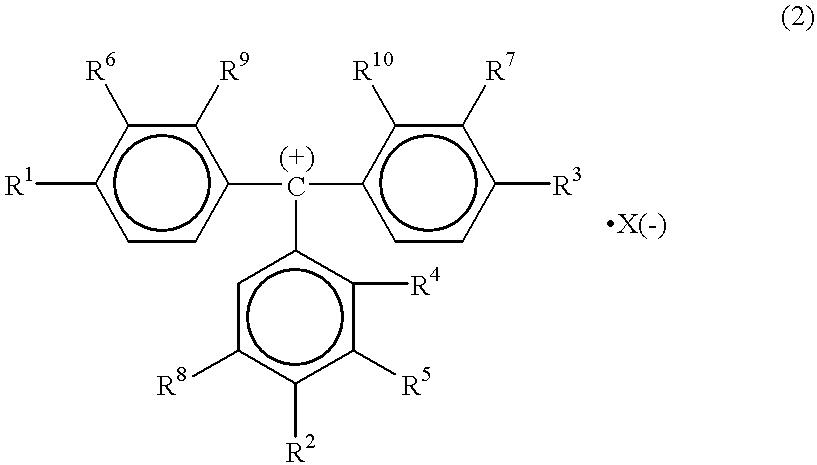

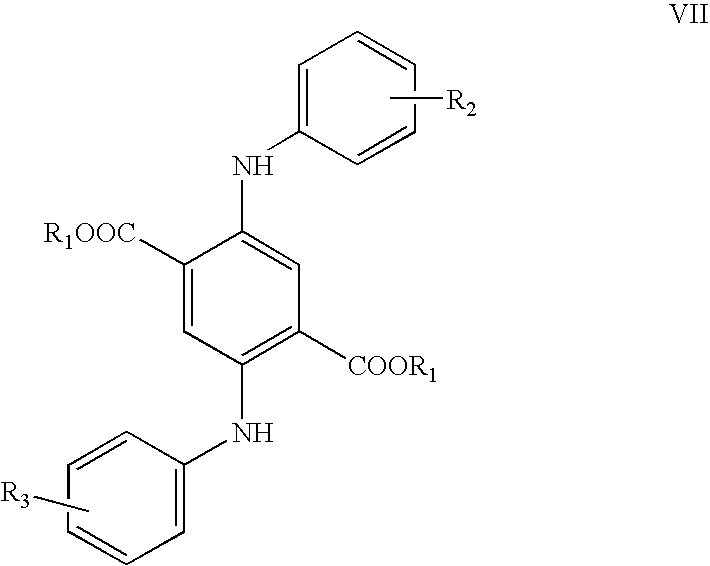

Pigment dispersing agent and pigment composition containing the same

InactiveUS6123763APromote resultsGood dispersionPigmenting treatmentOrganic chemistryHuePigment composition

Owner:TOYO INK SC HOLD CO LTD

Modified pigments and process for preparing modified pigments

Processes for preparing modified pigments are described. In one embodiment, the process comprises the step of combining, in any order, a pigment having attached an electrophilic group and a thiol reagent comprising at least one —SH group and at least two ionic or ionizable groups. In a second embodiment, the process comprises the step of combining, in any order, a pigment having attached an electrophilic group and a thiopolymer comprising at least one —H group. Modified pigments are also described.

Owner:CABOT CORP

Preparation and use of nanosize pigment compositions

InactiveUS6902613B2Guaranteed efficient growthEfficient preparationNanostructure manufactureQuinacridonesParticle growthNanometre

A mixture of an organic nanosize pigment comprising of from 50 to 99% by weight of the nanosize pigment and 1 to 50% by weight based of a low molecular weight naphthalene sulfonic acid formaldehyde polymer and its use as a particle growth and crystal phase director for the preparation of a direct pigmentary organic pigment or in pigment finishing.

Owner:CIBA SPECIALTY CHEM CORP

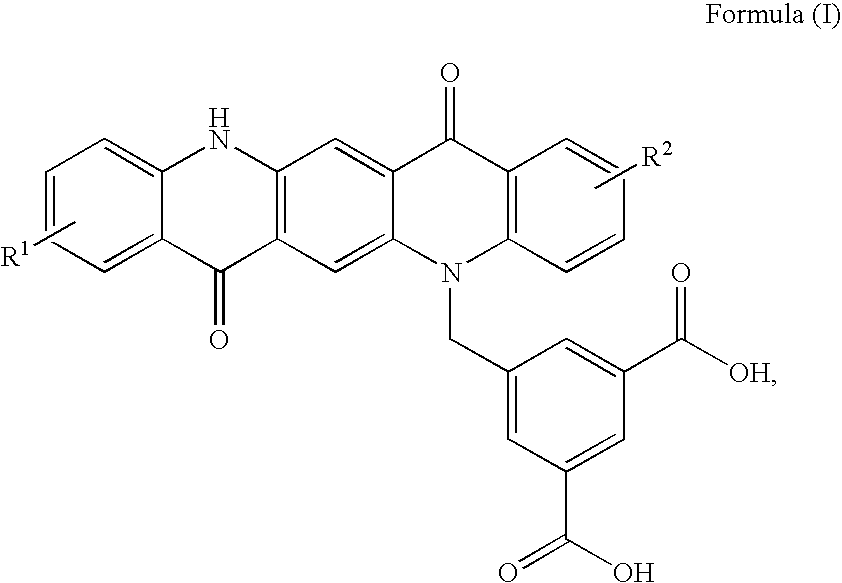

Modified organic colorants and dispersions, and methods for their preparation

The present invention relates to methods of preparing modified organic colorant dispersions comprising the step of combining, in any order, i) an organic colorant; ii) an hydroxide reagent; and iii) an aqueous medium, to form a modified organic colorant dispersion. The methods further comprises a particle size reduction step. These steps can occur in either order. The organic colorant comprises at least one organic species having at least one ester group. Modified organic colorants and inkjet ink compositions are also disclosed.

Owner:CABOT CORP

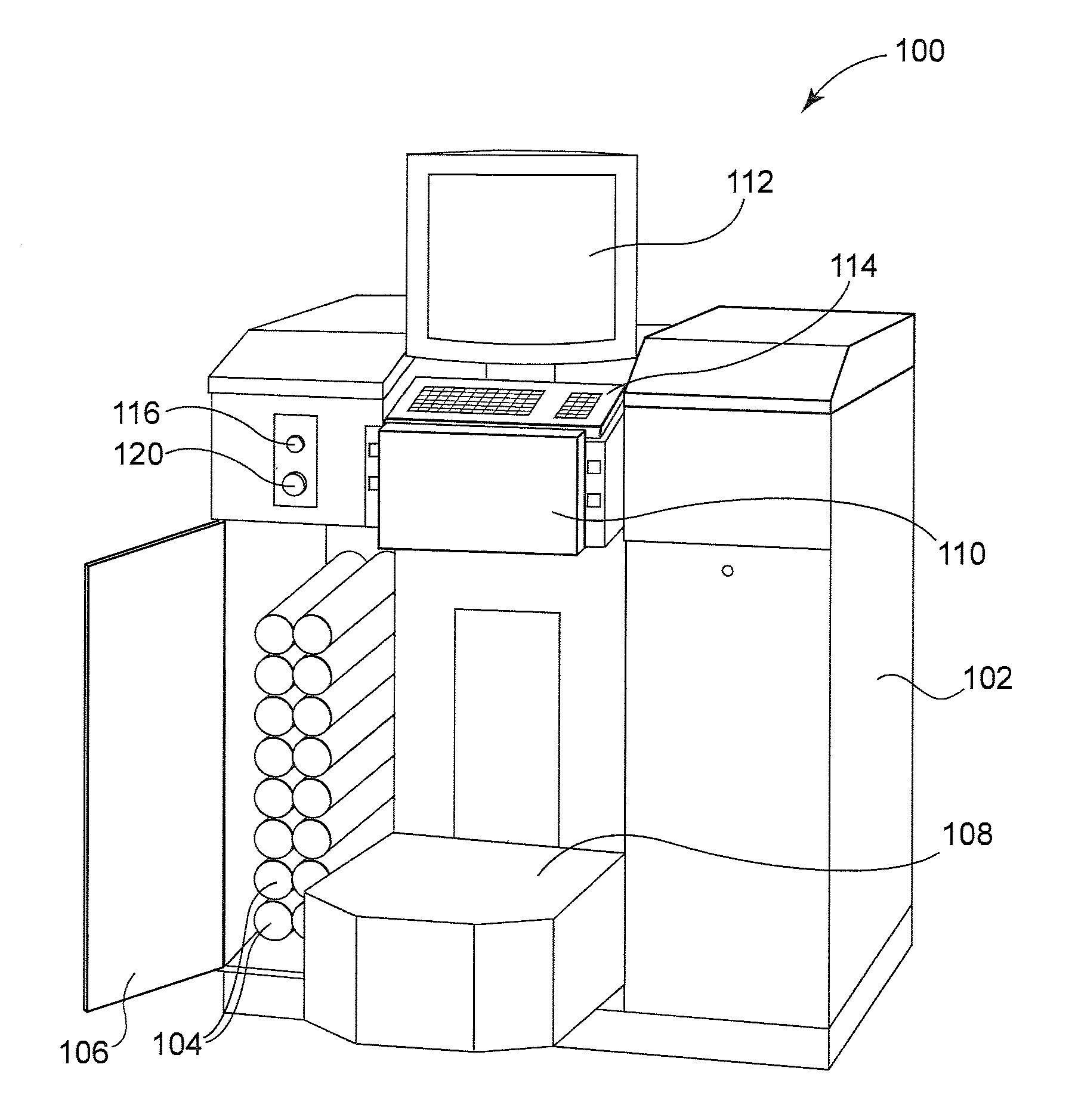

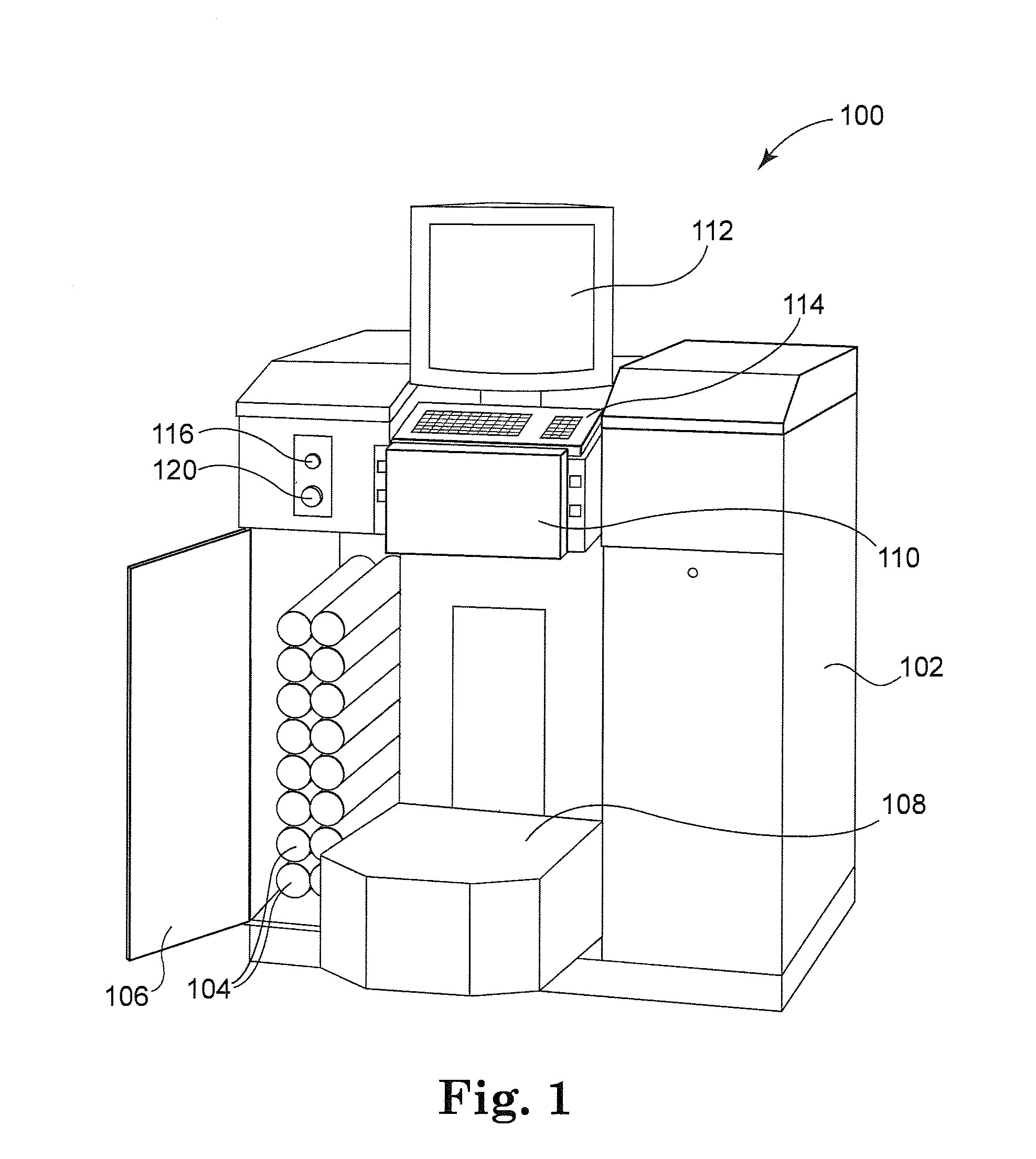

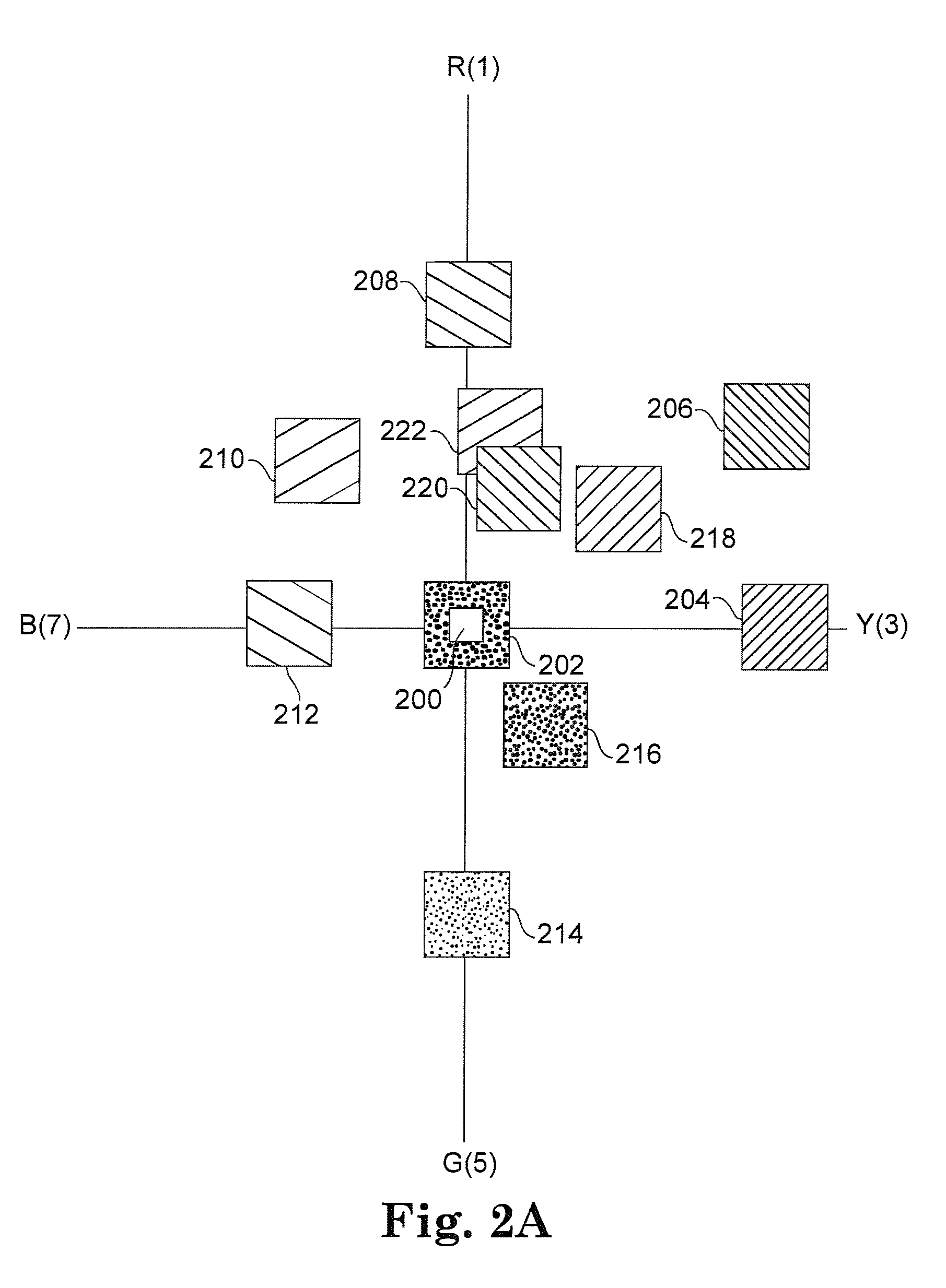

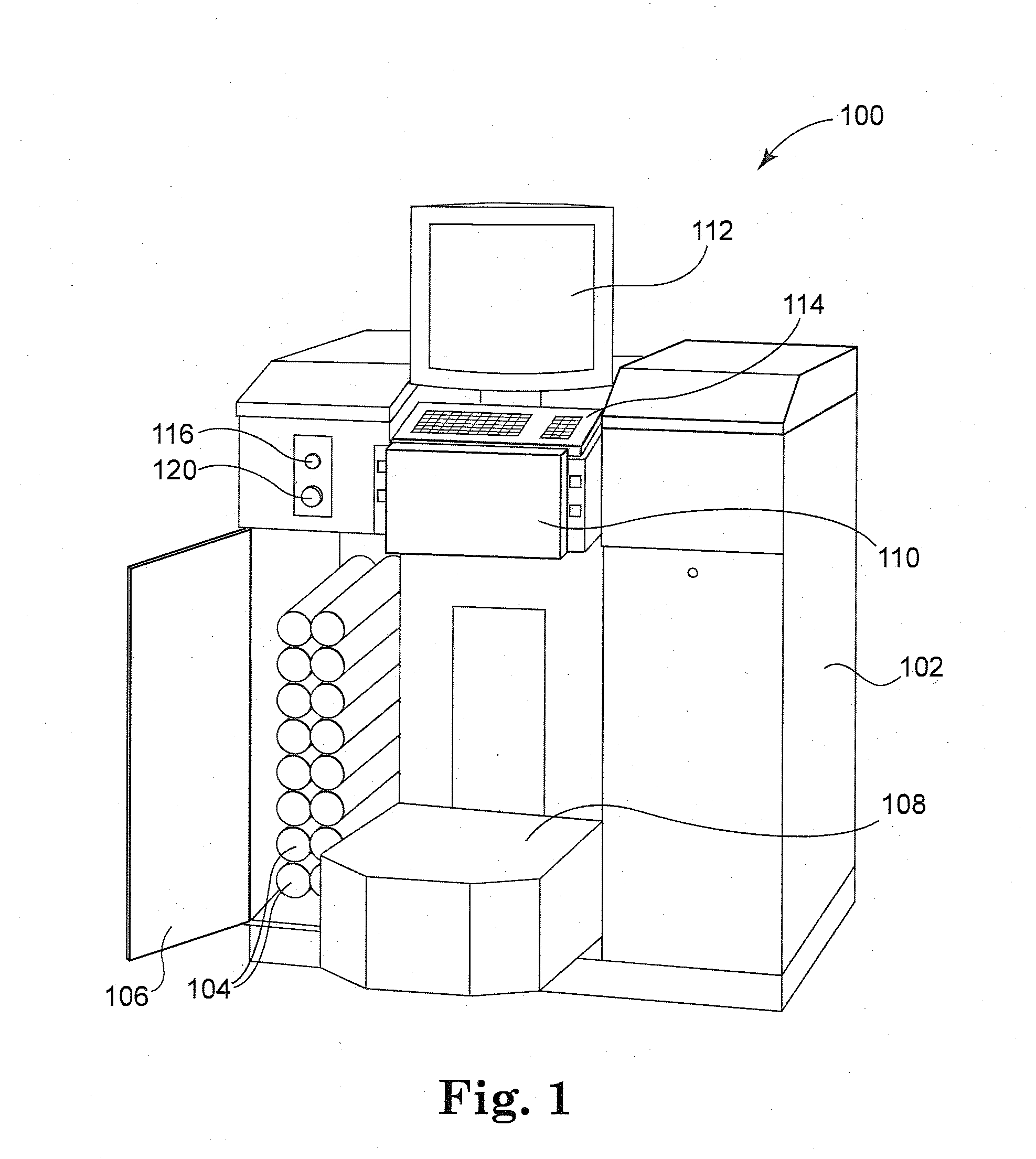

Expanded color space architectural paint and stain tinting system

White-pigmented and unpigmented base paints and stains are custom-tinted using an automated colorant dispenser having a minimum fluid dispensing quantity less than 0.01 fluid ounce (<0.3 cm3) and an array of colorants including a green-hued colorant having a color strength greater than that of a comparison colorant containing 12 wt. % PG7 pigment, a blue-hued colorant having a color strength greater than that of a comparison colorant containing 7 wt. % PB15:2 pigment, and a red-hued colorant having a color strength greater than that of a comparison colorant containing 17 wt. % PR209 pigment. The green-hued or blue-hued colorants are dispensed into the base paint or stain whenever a green-hued or blue-hued tint is required. Light pastel tints in small containers and strong colors in large containers may be prepared without requiring the use of additional colorants having the same general hue and lower color strength.

Owner:SWIMC LLC

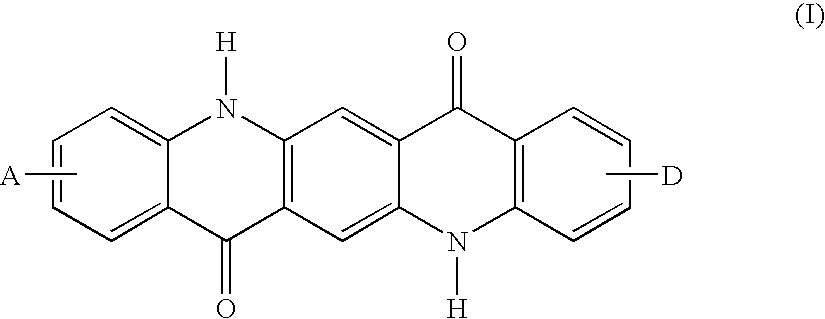

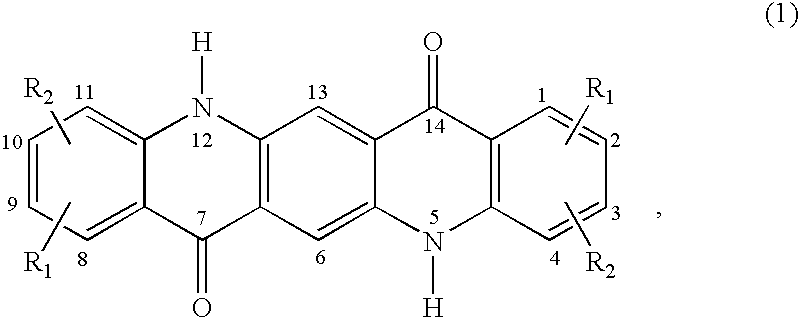

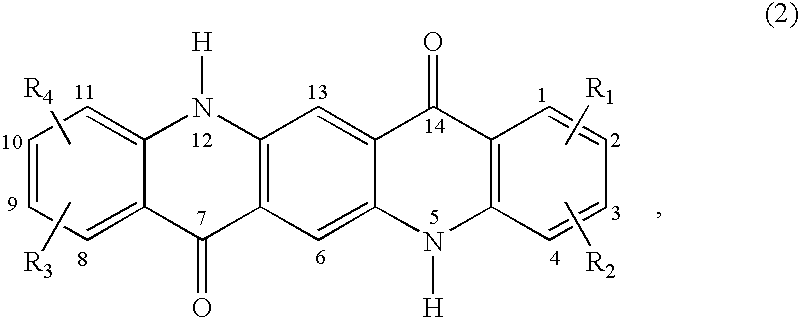

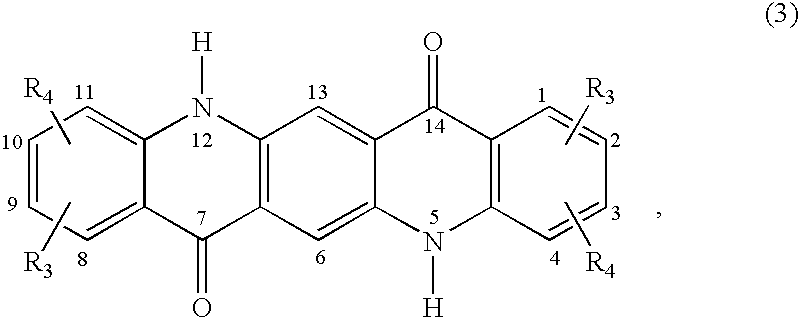

Quinacridone pigment compositions comprising unsymmetrically substituted components

The present invention relates to a novel quinacridone pigment compositions, a process using a mixed amine synthesis for the ultimate production of the compositions and to their use as colorants for pigmenting high molecular weight organic materials.

Owner:CIBA SPECIALTY CHEM CORP

Modified organic colorants and dispersions, and methods for their preparation

The present invention relates to methods of preparing modified organic colorant dispersions comprising the step of combining, in any order, i) an organic colorant; ii) an hydroxide reagent; and iii) an aqueous medium, to form a modified organic colorant dispersion. The methods further comprises a particle size reduction step. These steps can occur in either order. The organic colorant comprises at least one organic species having at least one carboxylic acid group. Modified organic colorants and uses of these modified organic colorants, including inkjet ink compositions, are also disclosed.

Owner:CABOT CORP

Near-infrared reflecting composite pigments

A near-infrared reflecting composite pigment comprises a near-infrared non-absorbing colorant and a white pigment coated with the near-infrared non-absorbing pigment. The near-infrared reflecting composite pigment can be produced by mixing a colorant dispersion, in which the near-infrared non-absorbing colorant is dispersed in a liquid medium, with the white pigment in a form selected from powder or a dispersion and then drying the resultant mixture. A near-infrared reflecting coating agent comprises as a coloring agent the near-infrared reflecting composite pigment. A near-infrared reflecting material comprises a base material coated on a surface thereof with the near-infrared reflecting coating agent.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

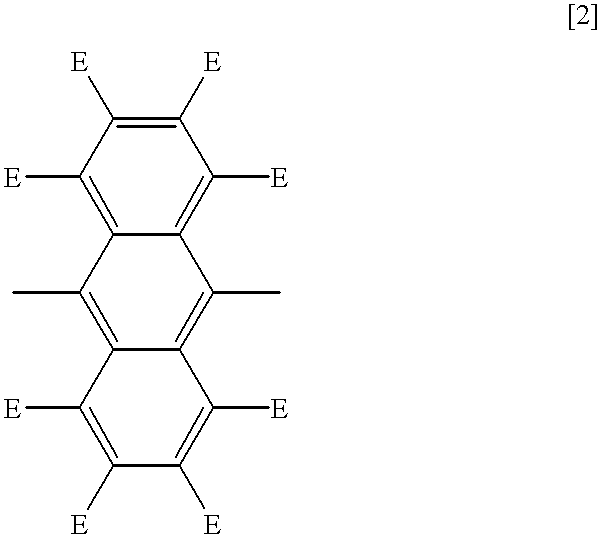

Fluorinated dyes or colorants and their uses

InactiveUS20050039274A1Improve solubilityGood dispersibilityOrganic chemistryReactive dyesSolubilityElectrophoresis

This invention relates to novel fluorinated dyes or colorants having high solubility and low viscosity in halogenated, especially fluorinated, solvents. The dyes or colorants of the present invention have shown to improve the performance of electrophoretic displays.

Owner:E INK CALIFORNIA

Light-emitting material for organo-electroluminescence device and for organic electroluminescence device which the material is applied

InactiveUS20010033944A1Organic chemistryMethine/polymethine dyesOrganic electroluminescenceLight emission

A light-emitting material which serves to emit light having a high brightness and is almost free of deterioration in light emission, and an organic EL device for which the light-emitting material is adapted, the material having the formula (1) disclosed in claim 1, 2 or 3.

Owner:TOYO INK SC HOLD CO LTD

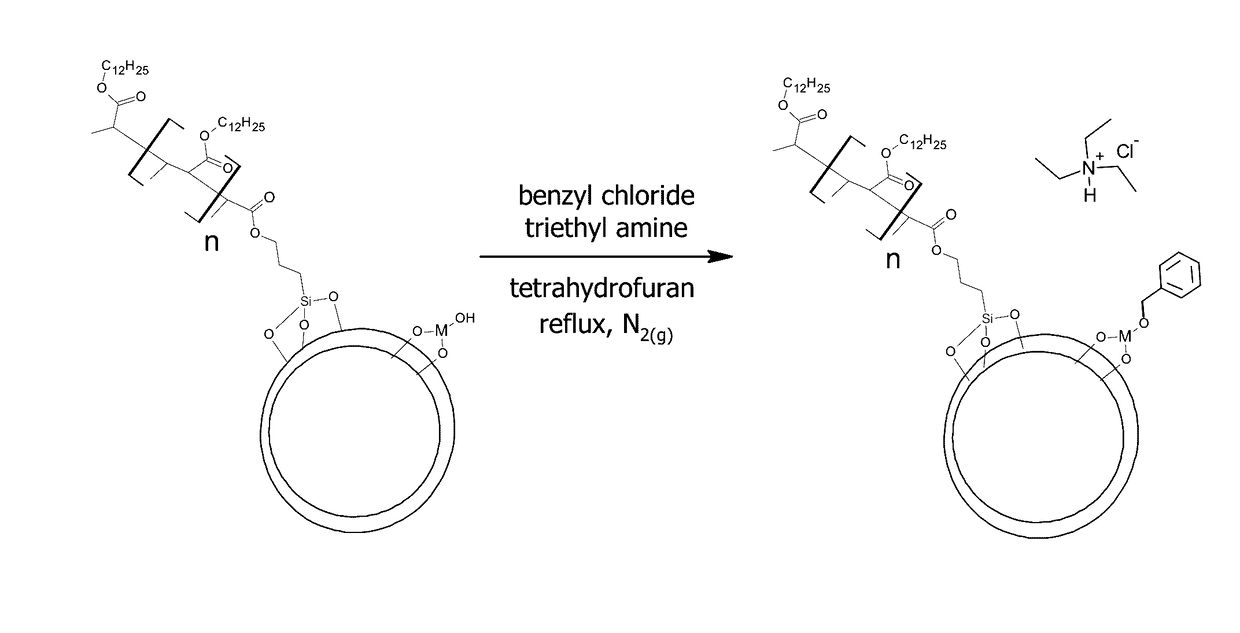

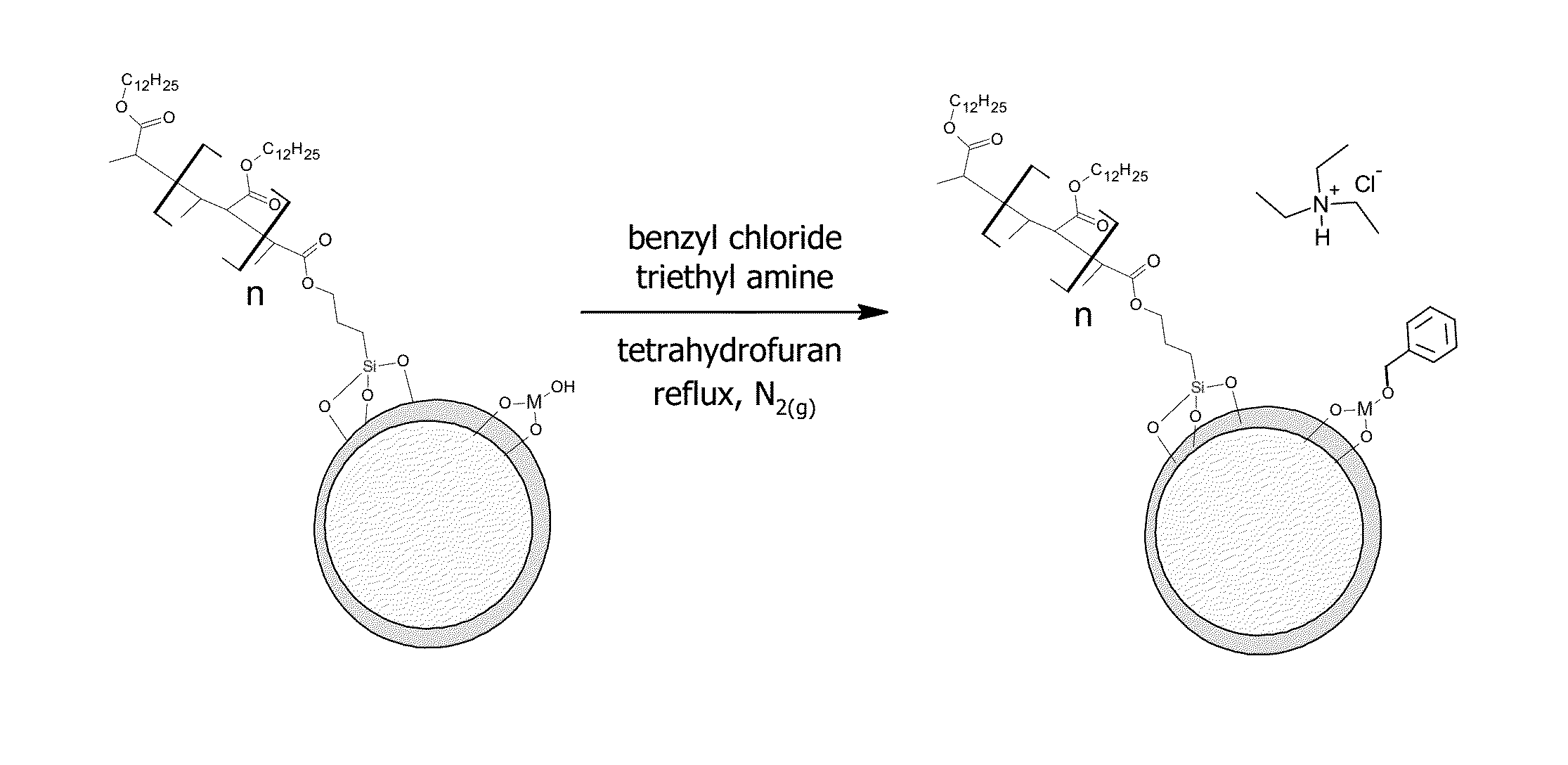

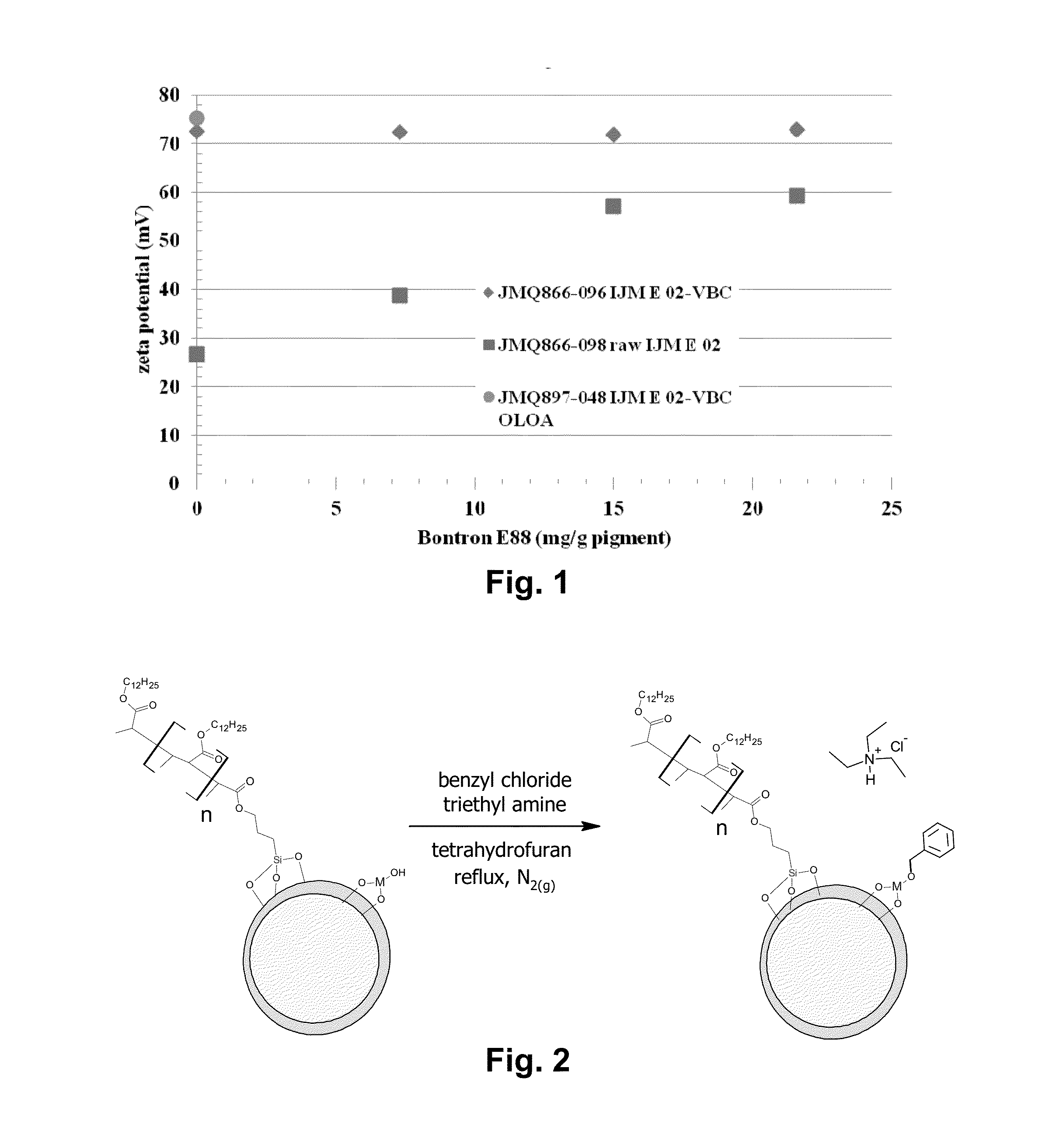

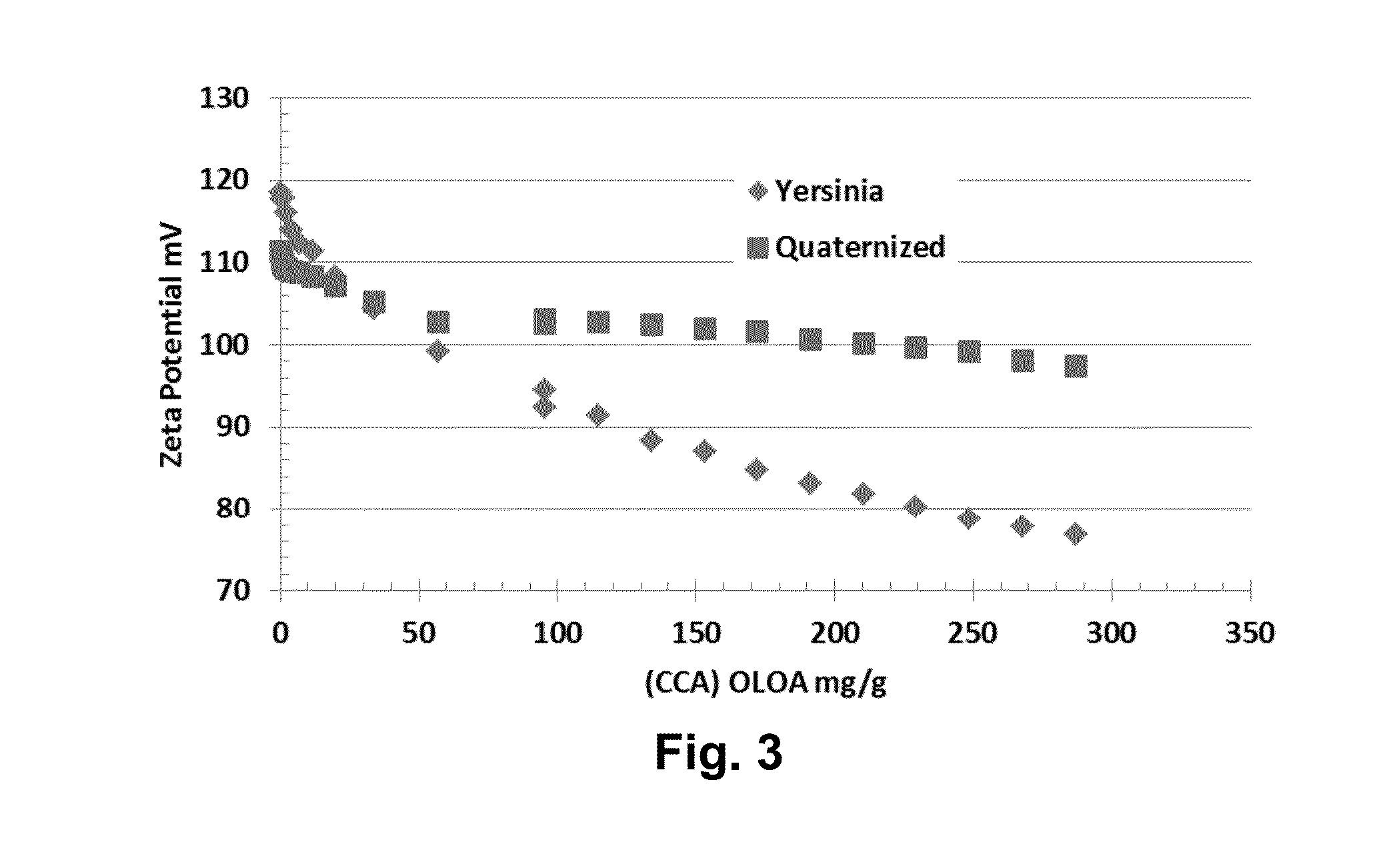

Electrophoretic particles and processes for the production thereof

Polymer shells similar to those described in U.S. Pat. No. 6,822,782 can be formed on pigment particles by (a) physi-sorping a reagent comprising polymerizable groups on to the pigment particles by treating the particle with a reagent having a polymerizable or polymerization-initiating group, such that the reagent will not desorb from the particle surface when the particle is placed in a hydrocarbon medium; or (b) treating pigment particles bearing nucleophilic groups with a reagent having a polymerizable or polymerization-initiating group, and an electrophilic group, thus attaching the polymerizable or polymerization-initiating groups to the particle surface. The zeta potential of the pigment particles can be varied by a process similar to (b) but using a reagent which does not have a polymerizable or polymerization-initiating group.

Owner:E INK CORPORATION

Electrophoretic particles and processes for the production thereof

Polymer shells similar to those described in U.S. Pat. No. 6,822,782 can be formed on pigment particles by (a) physi-sorping a reagent comprising polymerizable groups on to the pigment particles by treating the particle with a reagent having a polymerizable or polymerization-initiating group, such that the reagent will not desorb from the particle surface when the particle is placed in a hydrocarbon medium; or (b) treating pigment particles bearing nucleophilic groups with a reagent having a polymerizable or polymerization-initiating group, and an electrophilic group, thus attaching the polymerizable or polymerization-initiating groups to the particle surface. The zeta potential of the pigment particles can be varied by a process similar to (b) but using a reagent which does not have a polymerizable or polymerization-initiating group.

Owner:E INK CORPORATION

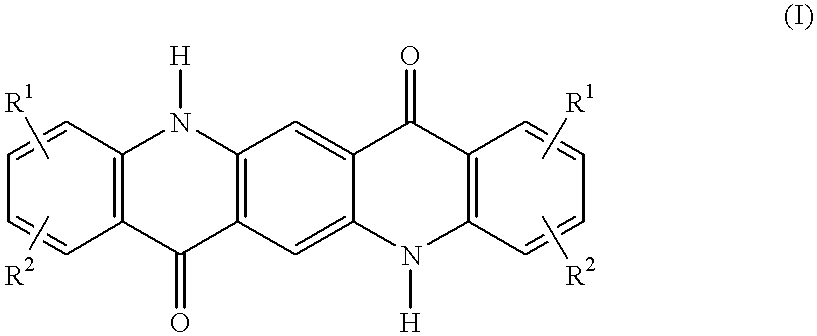

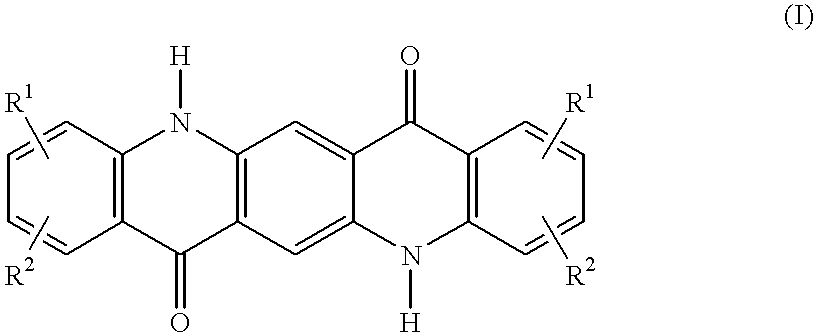

Use of mixed-crystal pigments of the quinacridone series in electrophotographic toners and developers, powder coatings and inkjet inks

The use of mixed-crystal pigments of the quinacridone series consisting ofa) from 85 to 99% by weight of unsubstituted beta-phase quinacridone of the formula (I)in which R1 and R2 are hydrogen atoms, andb) from 1 to 15% by weight of one or more substituted quinacridones of the formula (I) in which the substituents R1 and R2 are identical or different and are chlorine, bromine or fluorine atoms orC1-C4-alkyl, C1-C4-alkoxy or carboxamido groups, which can be substituted by C1-C6-alkyl groups, and R1 can additionally be hydrogen,as colorants in electrophotographic toners and developers, powder coating materials, inkjet inks, electret fibers, and color filters.

Owner:CLARIANT PROD DEUT GMBH

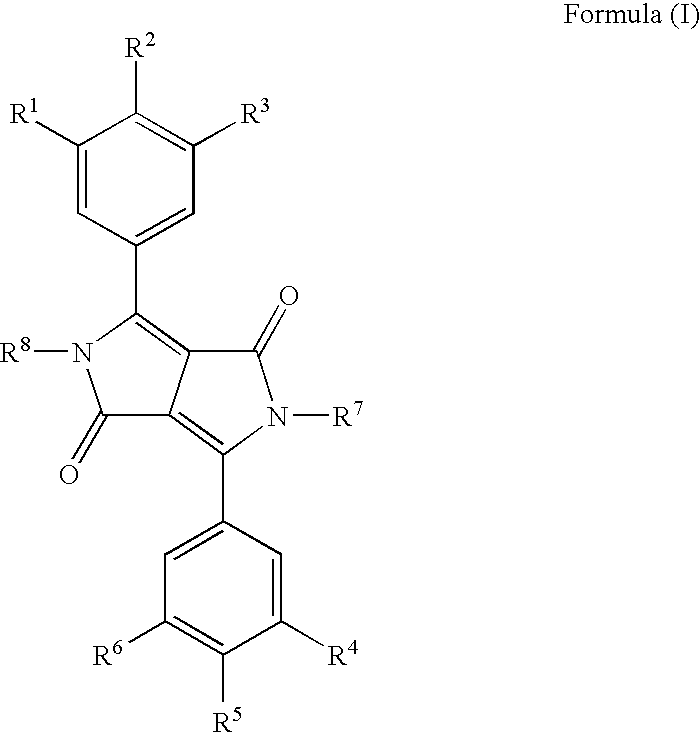

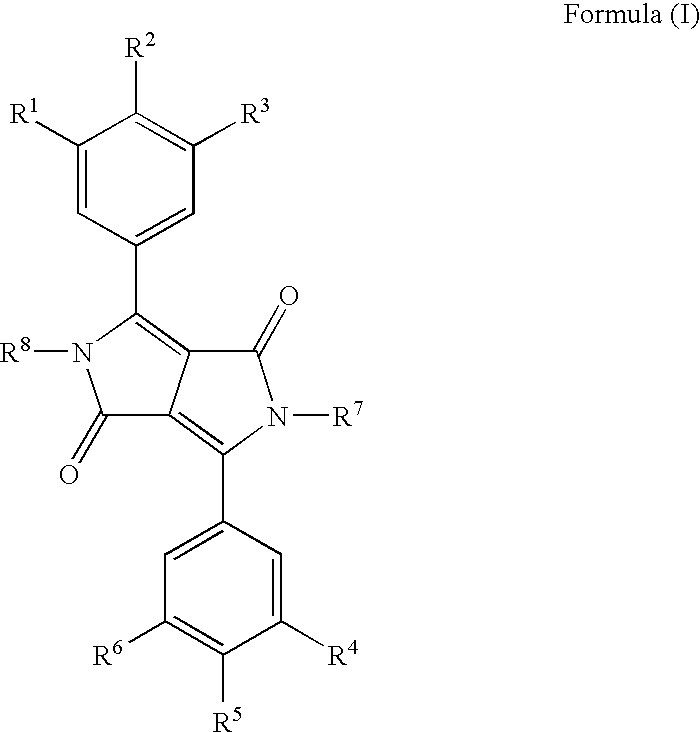

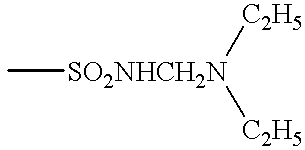

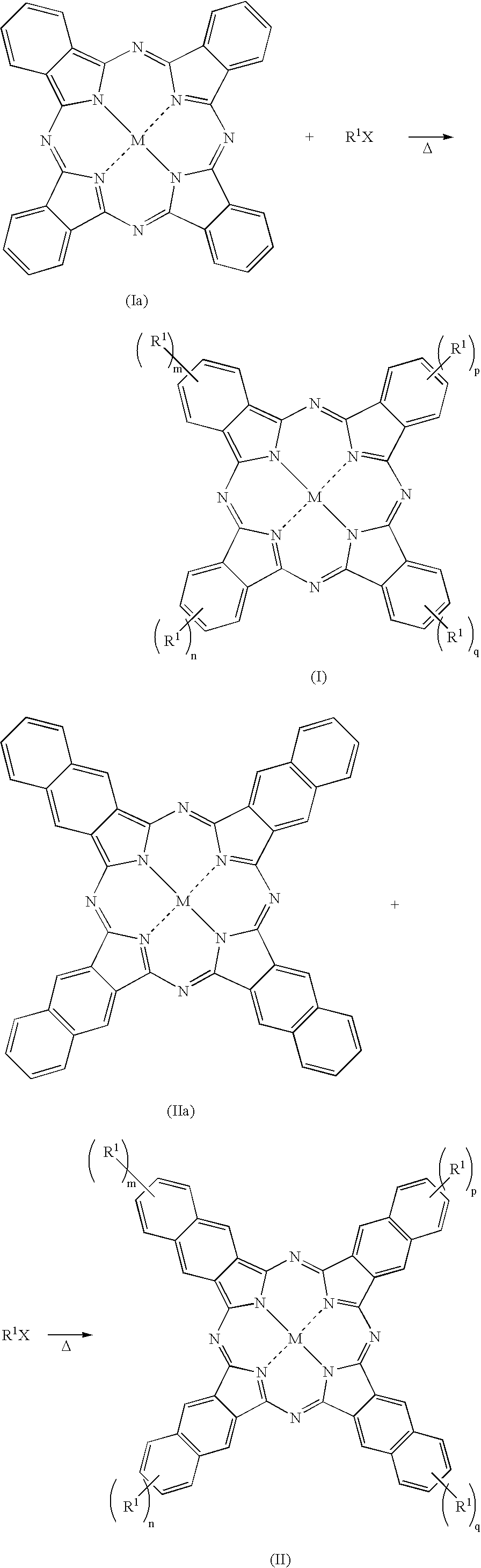

Non-Aqueous Pigment Dispersions Using Dispersion Synergists

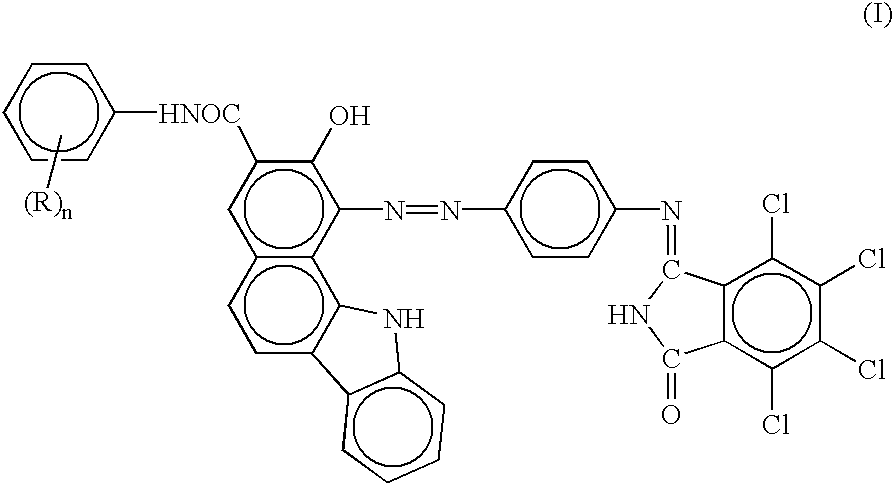

InactiveUS20080308005A1Improve dispersion qualityImprove stabilityInksDiketopyrrolopyrrole dyesHydrogenEthyl group

A non-aqueous pigment dispersion comprising a diketopyrrolo-pyrrole pigment, a polymeric dispersant and a dispersion synergist in a non-aqueous dispersion medium characterized in that said dispersion synergist is a diketopyrrolo-pyrrole derivative according to Formula (I):whereinR1, R2 and R3 are independently selected from the group consisting of hydrogen, a halogen atom, a methyl group, an ethyl group, an tert.-butyl group, a phenyl group, a cyano group and an acid group;R4, R5 and R6 are independently selected from the group consisting of hydrogen, a halogen atom, a methyl group, an ethyl group, an tert.-butyl group, a phenyl group and a cyano group; andcharacterized in that one of R7 and R8 is a group comprising two acid functions while the other one of R7 and R8 represents hydrogen.

Owner:AGFA NV

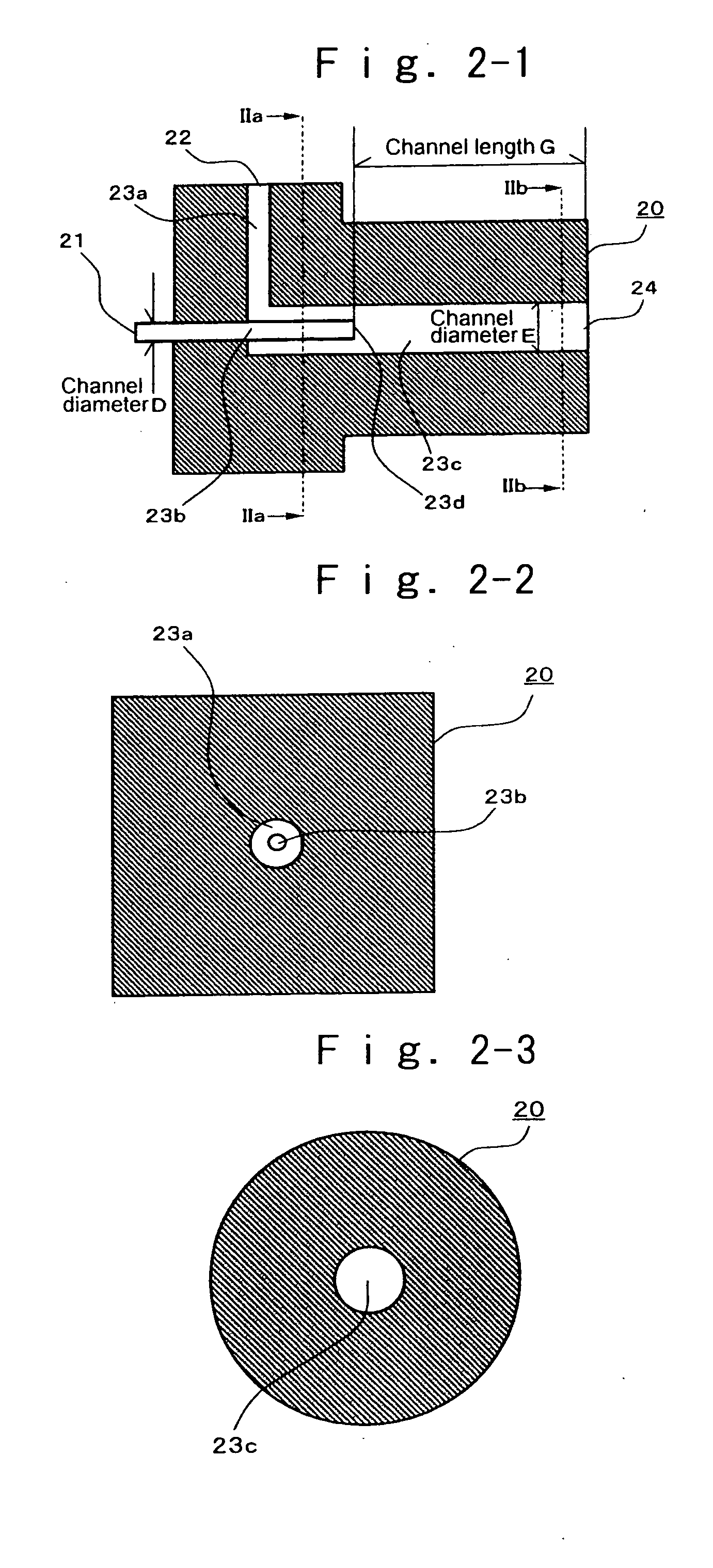

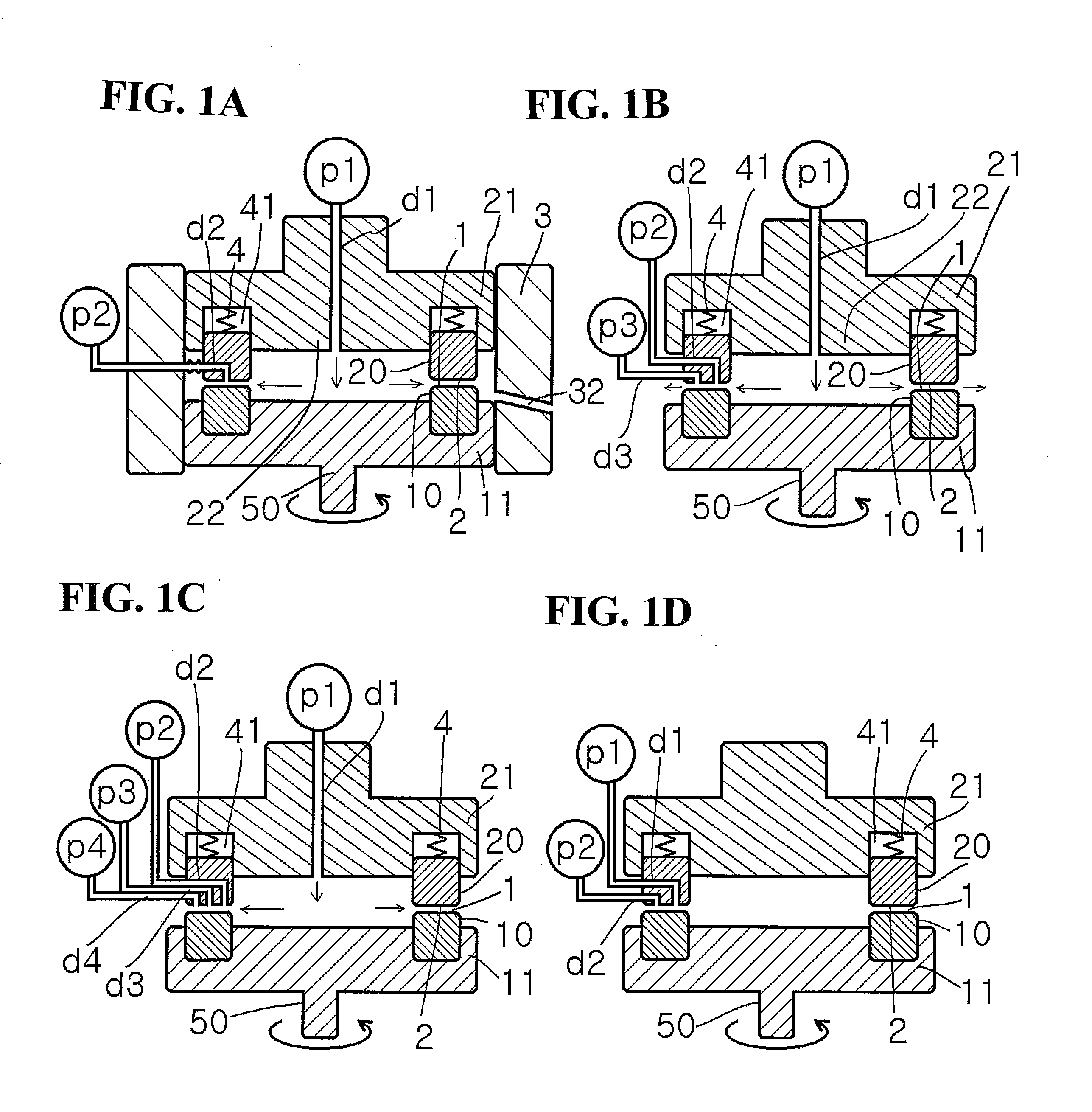

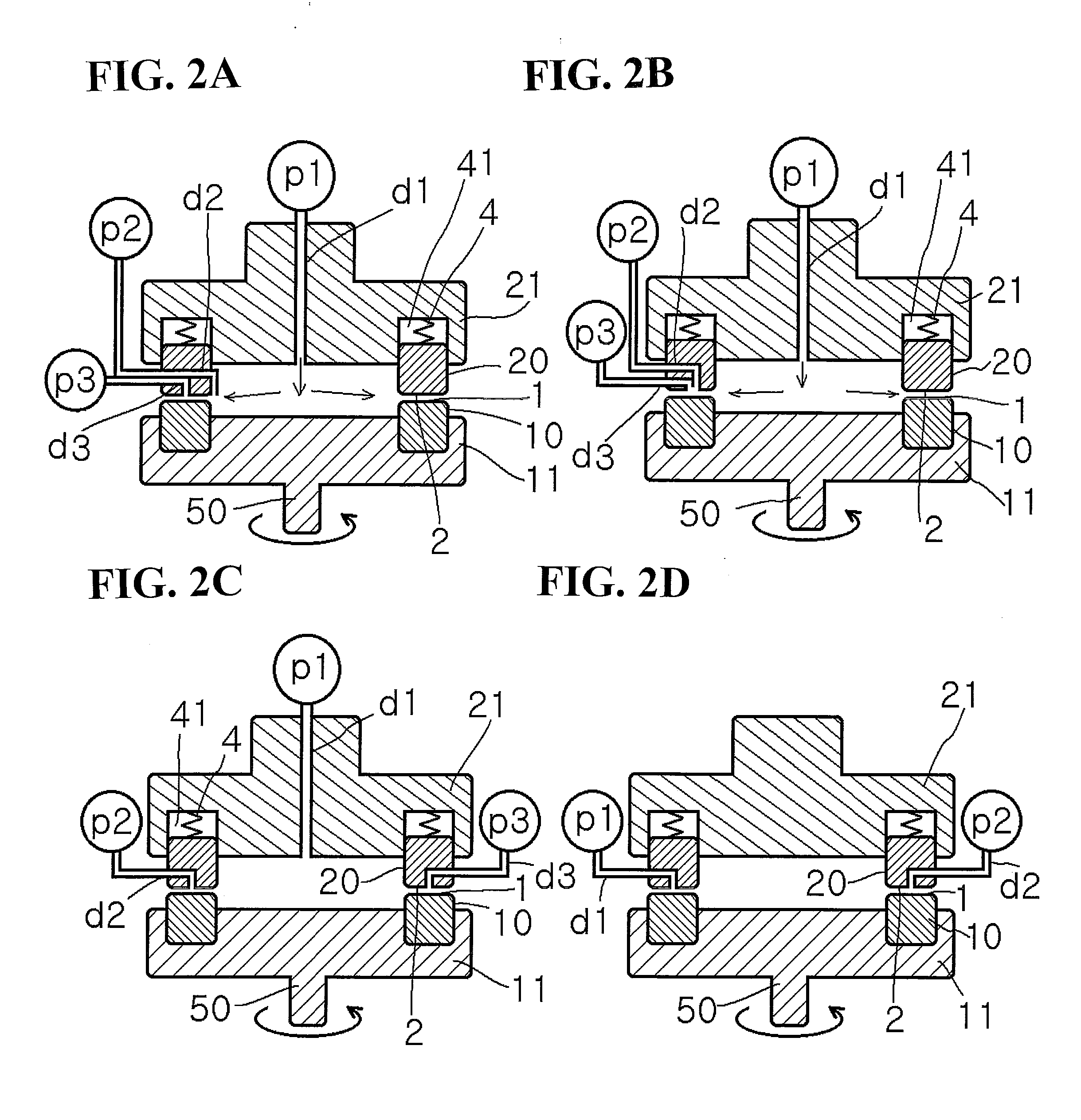

Method for producing pigment nanoparticles by forced ultrathin film rotary reaction method, pigment nanoparticles, and inkjet ink using the same

ActiveUS20100326321A1Keep distanceImprove responseMaterial nanotechnologyTransportation and packagingNanoparticleEngineering

A forced ultrathin film rotary reaction method is used to maintain a minute space of 1 mm or less between two processing surfaces capable of approaching to and separating from each other and being rotating relative to each other, and the minute space is maintained between the two processing surfaces to serve as a flow path of a fluid to be processed thereby forming a forced thin film of the processed fluid and separating the pigment material in the forced thin film.

Owner:M TECH CO LTD

Ink-jet inks comprising pigment precursors

A pigment-based ink composition is provided which employs a pigment precursor that is soluble in a non-aqueous solvent. Preferably, the ink composition is in the form of an aqueous, two-phase system wherein the pigment precursor is solubilized in a high boiling, water-insoluble organic compound. Optionally, a second high boiling compound miscible with both aqueous and organic phases and at least one amphiphile are also present.

Owner:HEWLETT PACKARD DEV CO LP

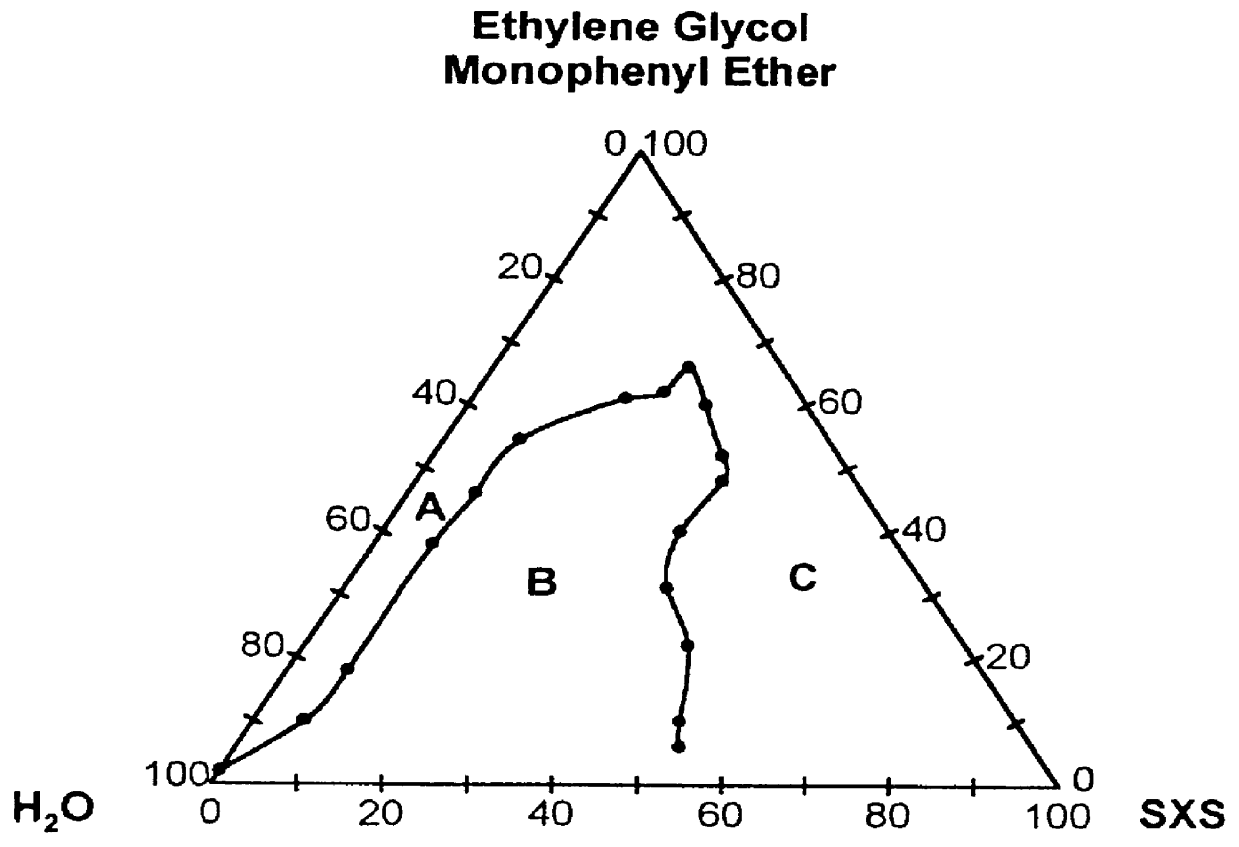

Inkjet recording liquid and process for the production thereof

InactiveUS6235099B1High processing temperatureImprove waterproof performanceDuplicating/marking methodsInksWater basedInorganic salts

A water-dispersed inkjet recording liquid excellent in water resistance and transparency and also excellent in the property of ejection from a nozzle, containing, as a colorant, a water-based dispersion of an organic pigment (A) which is at least one member selected from the group consisting of a quinacridone pigment, a benzimidazolone pigment, an insoluble azo pigment, a fuzed azo pigment, a quinophthalone pigment, a naphthol pigment, a perylene pigment and an isoindolinone pigment and has an average particle diameter of 10 to 150 nm (measured by laser scattering), the water-based dispersion of the organic pigment (A) being obtained by mechanically kneading a mixture containing at least three components of the organic pigment (A), a water-soluble inorganic salt (B) in an amount by weight at least three times as large as the amount of the organic pigment (A) and a water-soluble solvent (C) to finely mill the organic pigment (A), and then removing the water-soluble inorganic salt (B) and the water-soluble solvent (C) by washing the kneaded mixture with water, and a process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

Fluorinated dyes or colorants and their uses

InactiveUS20060281924A1Improve solubilityGood dispersibilityOrganic chemistryDiketopyrrolopyrrole dyesSolubilitySolvent

This invention relates to novel fluorinated dyes or colorants having high solubility and low viscosity in halogenated, especially fluorinated, solvents. The dyes or colorants of the present invention improve the performance of electrophoretic displays.

Owner:E INK CALIFORNIA

Process for the preparation of organic materials

InactiveUS20070119345A1High viscosityImprove economyQuinoline dyesQuinacridonesHigh concentrationPigment

The present invention relates to advantageous processes for the manufacture of organic pigments and their precursors. The invention particularly relates to reactions carried out in an “All In One Reactor”® (Draiswerke GmbH, Germany), a kneader like the TurbuKneader® of the same company, a paddle dryer like the Turbudry® of the same company or a related system and thereby submitting the reaction mixtures to enhanced driving power as expressed by a Froude number >1, the reaction mixture being caused to react in high concentrations at elevated temperature.

Owner:MCA TECH GMBH

Expanded color space architectural paint and stain tinting system

ActiveUS20090310856A1Increase inventory levelIncrease stocking complexityLiquid fillingMixersHueColor strength

White-pigmented and unpigmented base paints and stains are custom-tinted using an automated colorant dispenser having a minimum fluid dispensing quantity less than 0.01 fluid ounce (<0.3 cm3) and an array of colorants including a green-hued colorant having a color strength greater than that of a comparison colorant containing 12 wt. % PG7 pigment, a blue-hued colorant having a color strength greater than that of a comparison colorant containing 7 wt. % PB15:2 pigment, and a red-hued colorant having a color strength greater than that of a comparison colorant containing 17 wt. % PR209 pigment. The green-hued or blue-hued colorants are dispensed into the base paint or stain whenever a green-hued or blue-hued tint is required. Light pastel tints in small containers and strong colors in large containers may be prepared without requiring the use of additional colorants having the same general hue and lower color strength.

Owner:SWIMC LLC

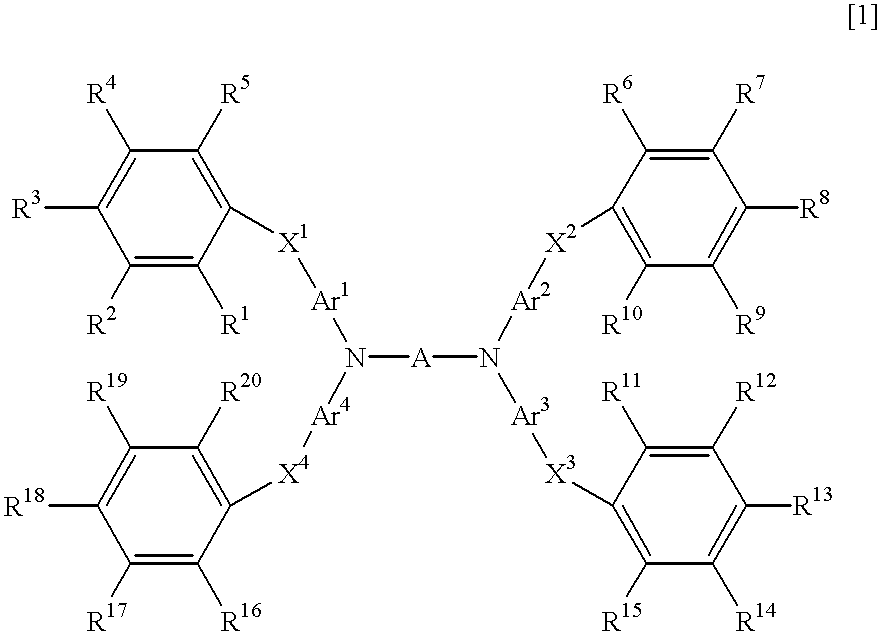

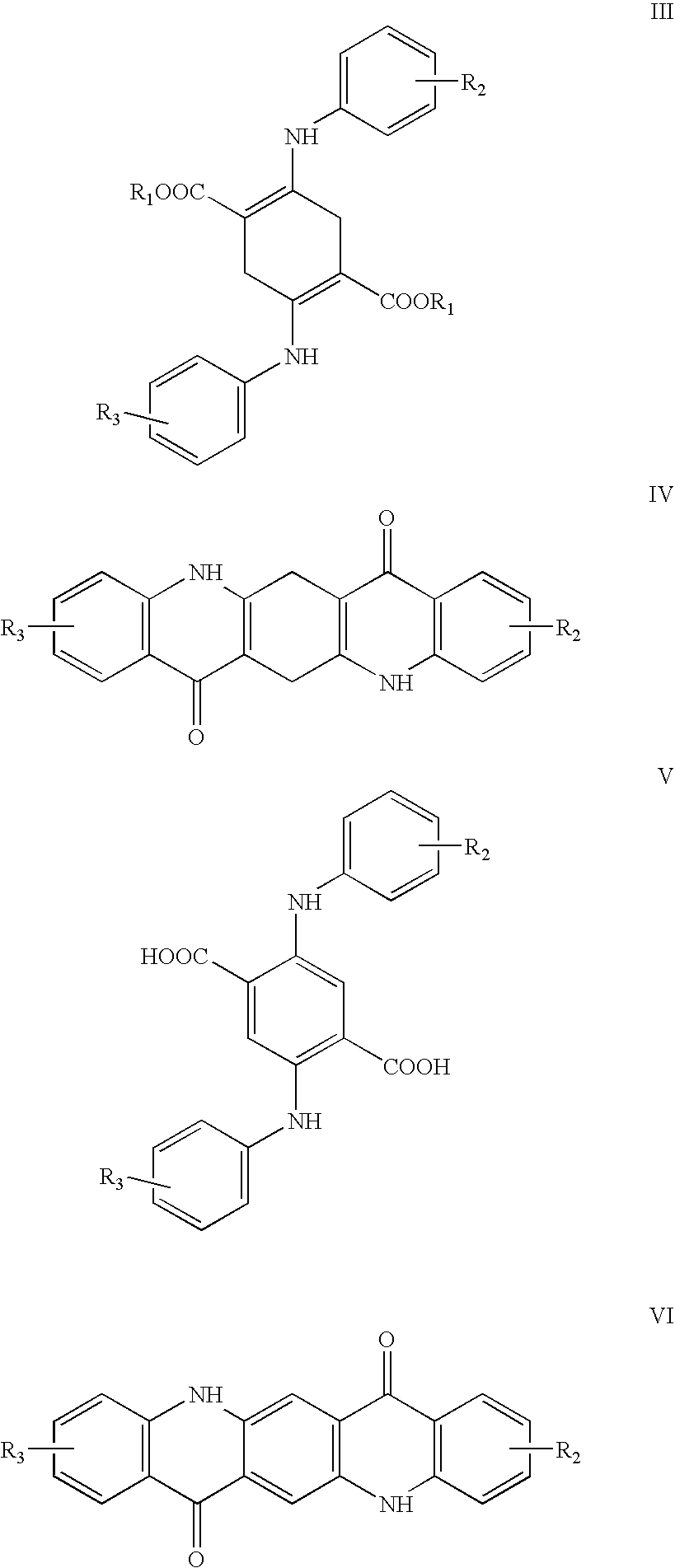

Non-Aqueous Inkjet Inks of Quinacridone Pigments

InactiveUS20080295734A1Quality improvementImprove stabilityInksQuinacridonesMixed crystalQuinacridone

A non-aqueous inkjet ink includes a quinacridone pigment and a dispersion synergist wherein the quinacridone pigment is a mixed crystal including a dimethyl substituted quinacridone and a monomethyl substituted quinacridone and the dispersion synergist includes at least one acid group.

Owner:AGFA NV

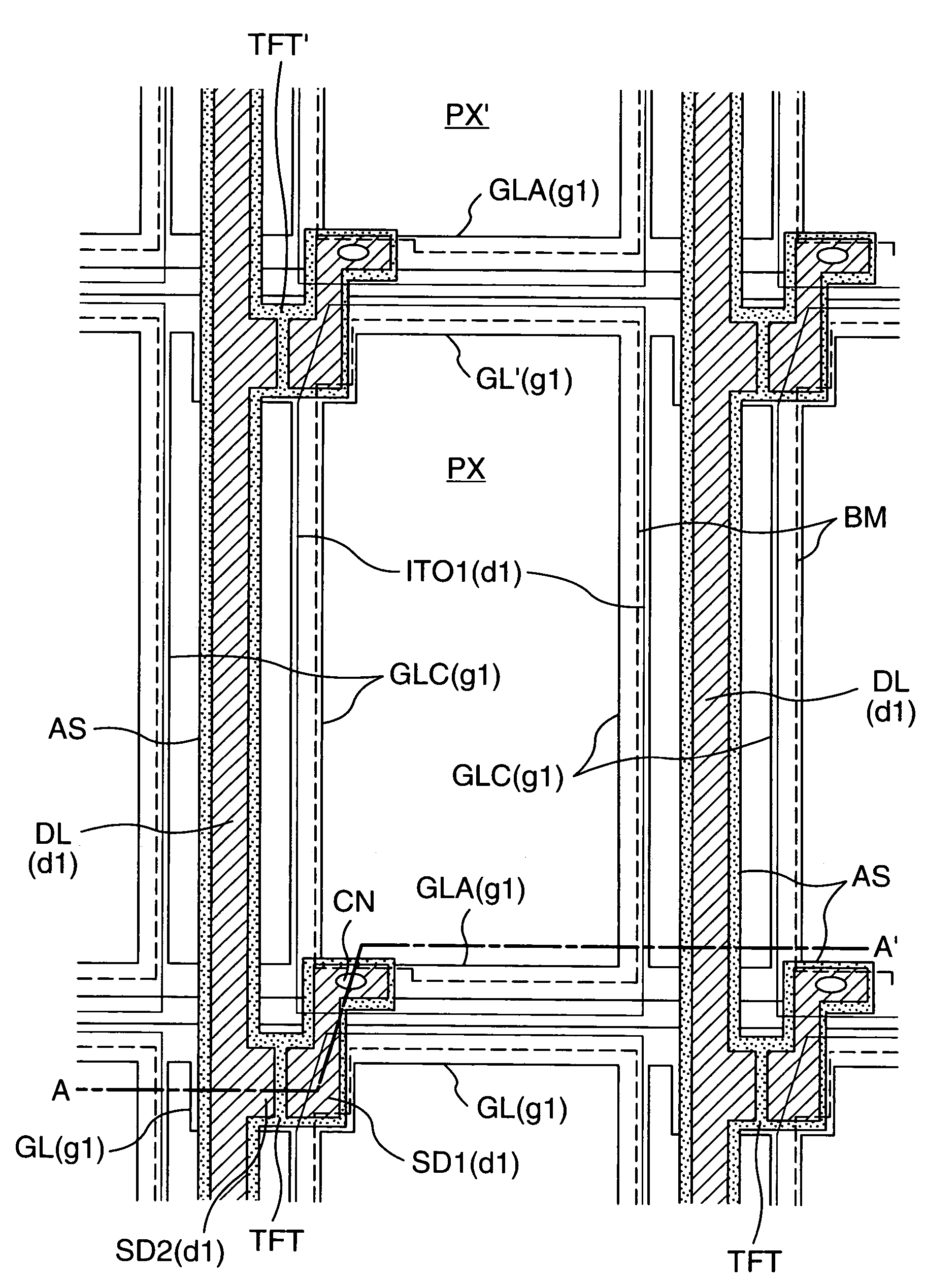

Colored composition for color filter and display using color filters formed of the colored composition

An object of the present invention is to obtain color filters having a high contrast, a high color purity and an improved transmittance for blue color, and a display using the color filters. In the present invention, there is used a colored composition for color filter comprising at least one coloring agent, a base polymer and at least one solvent, said base polymer containing a polyamicacid whose light transmittance decreases by 2% or less in the visible region (wavelength: 400 nm to 800 nm).

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

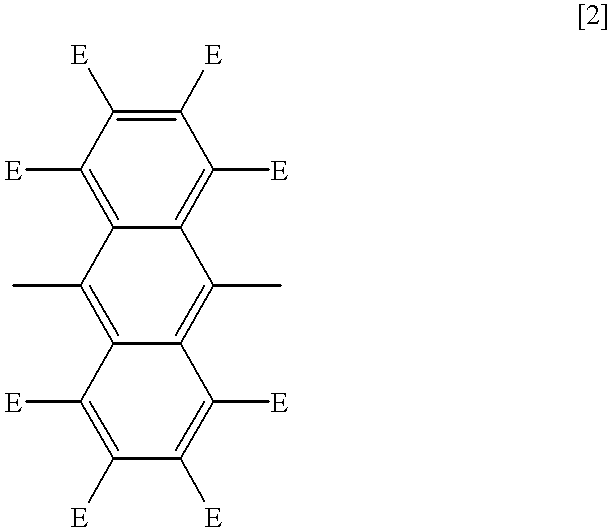

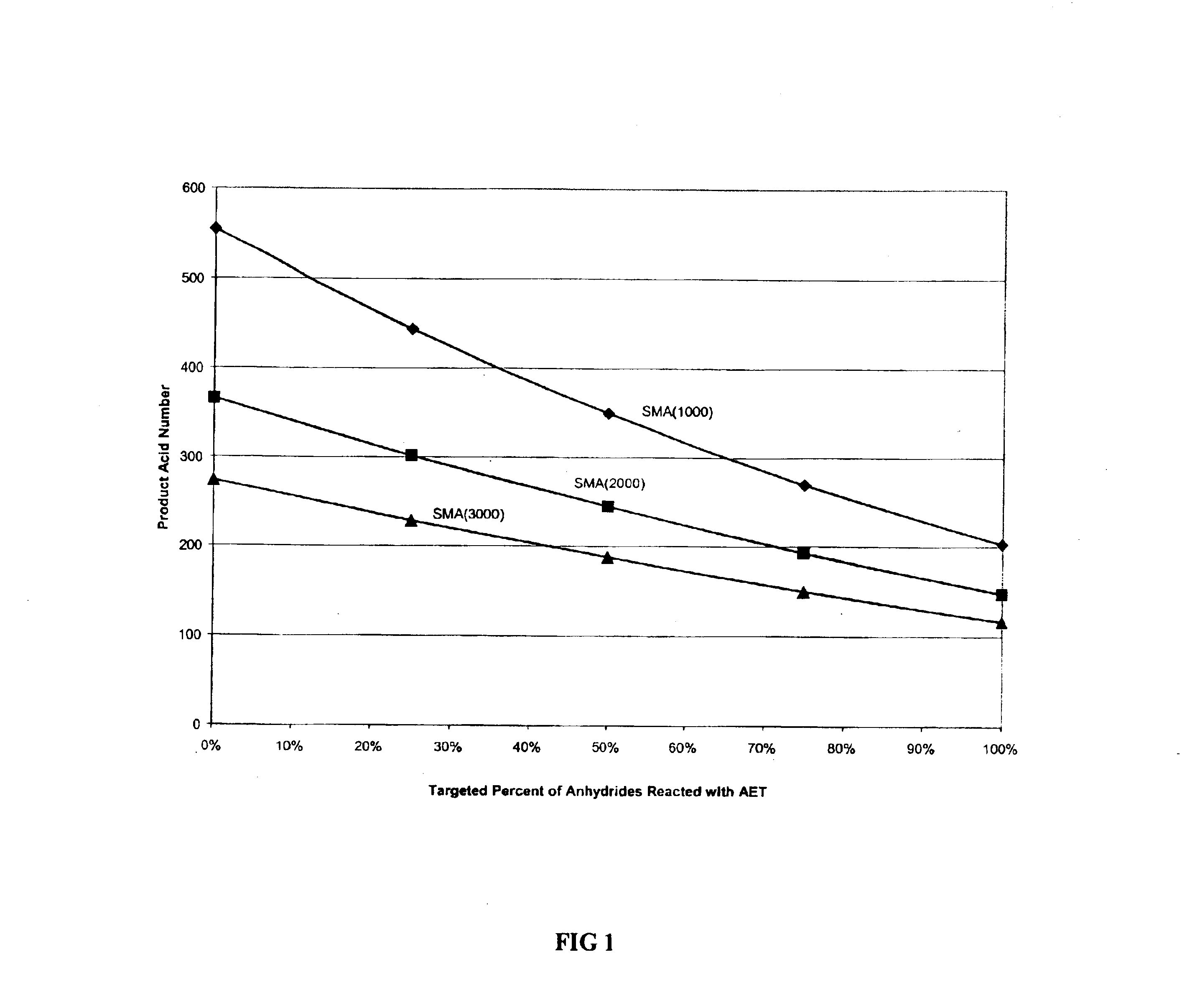

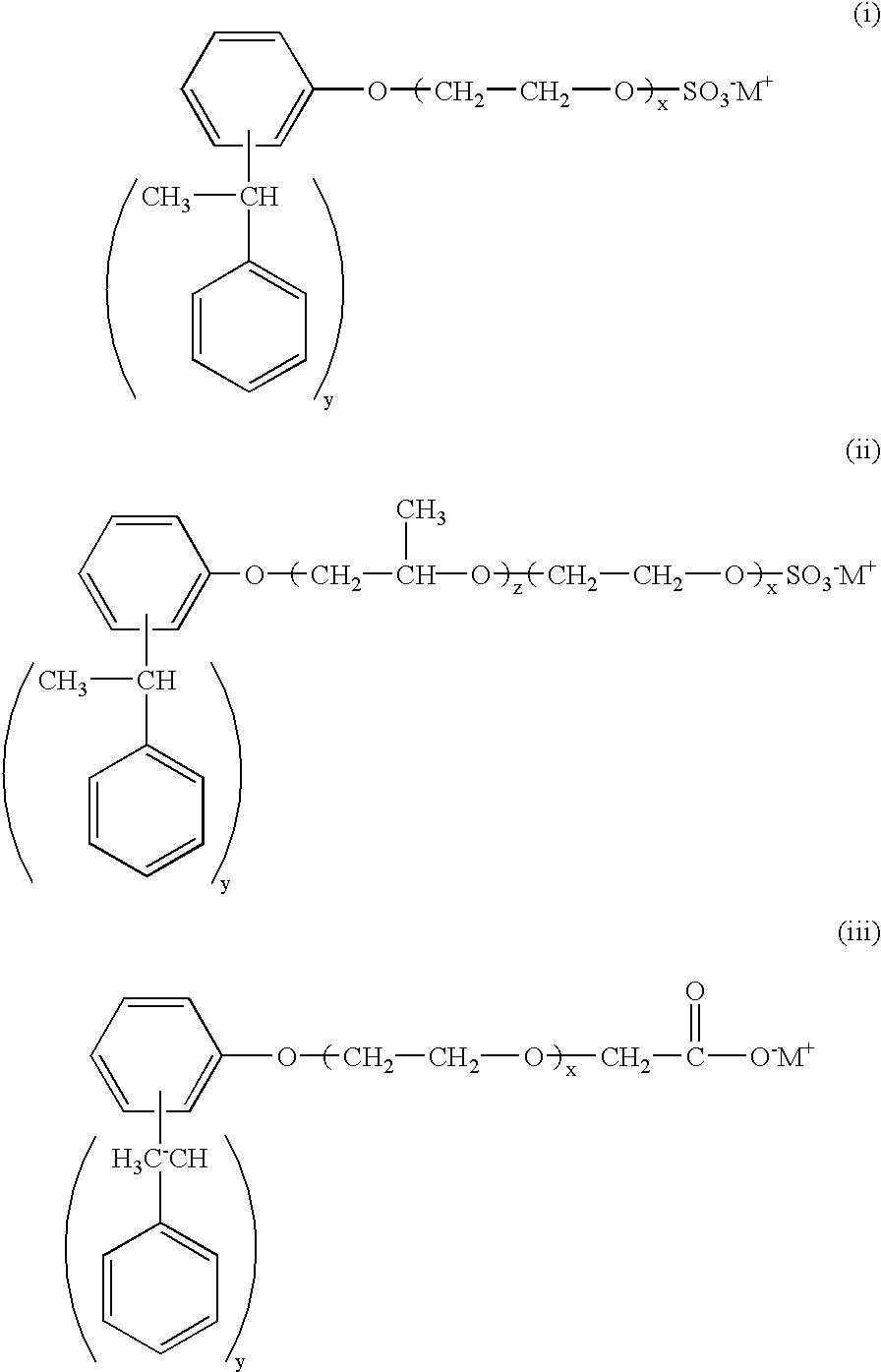

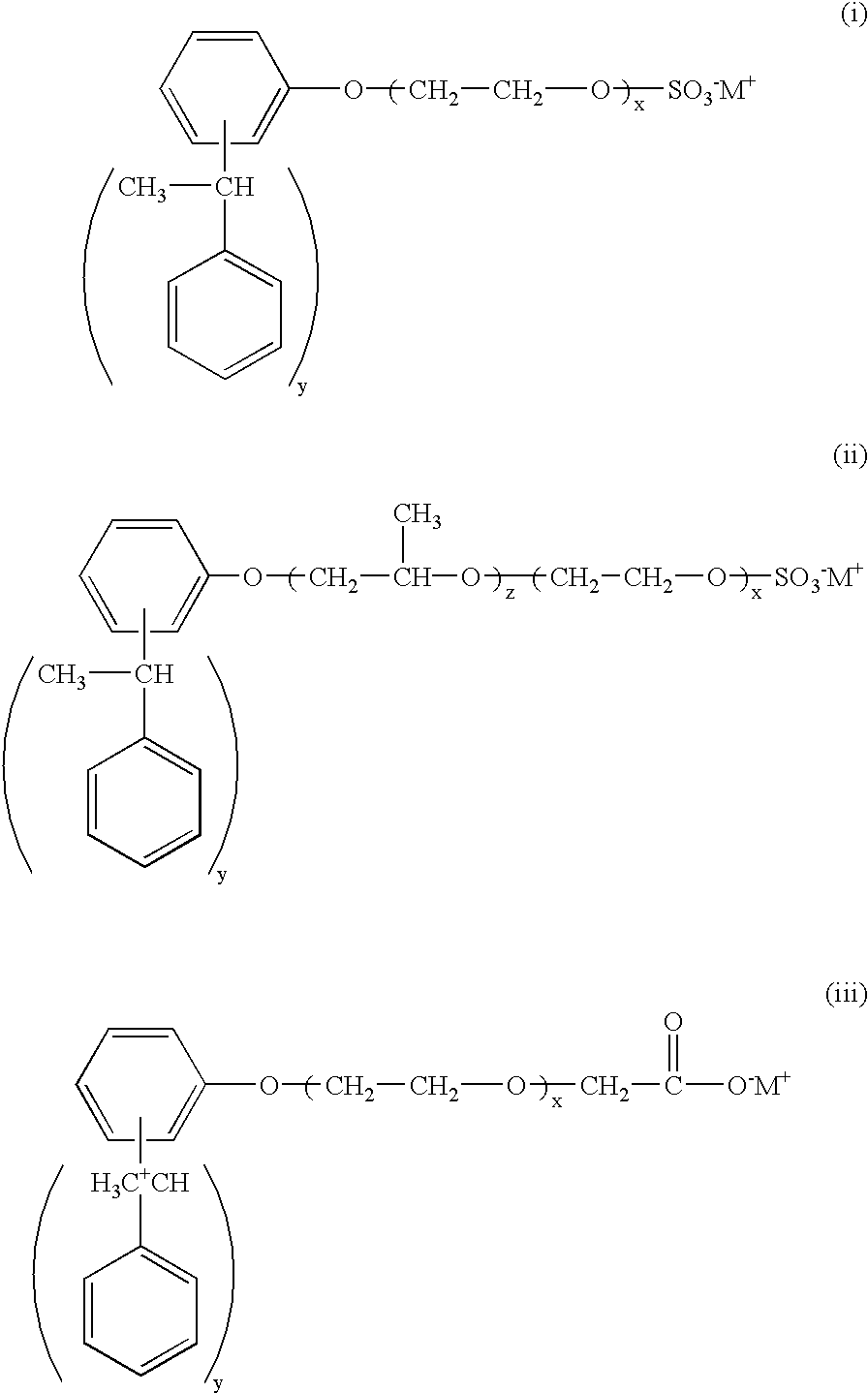

Pigment dispersions containing styrenated and sulfated phenol alkoxylates

The present invention provides sulfated and carboxymethylated surfactants and dispersants produced by reacting a styrenated phenol alkoxylate with sulfamic acid and then neutralizing with a base such as ammonium hydroxide. The instant invention also provides pigment dispersion comprising: (a) a pigment; and (b) a dispersant based on sulfated and carboxymethylated styrenated phenol alkoxylates. Carbon black dispersions are also provided containing carbon black and the dispersants of the invention.

Owner:ETHOX CHEM LLC

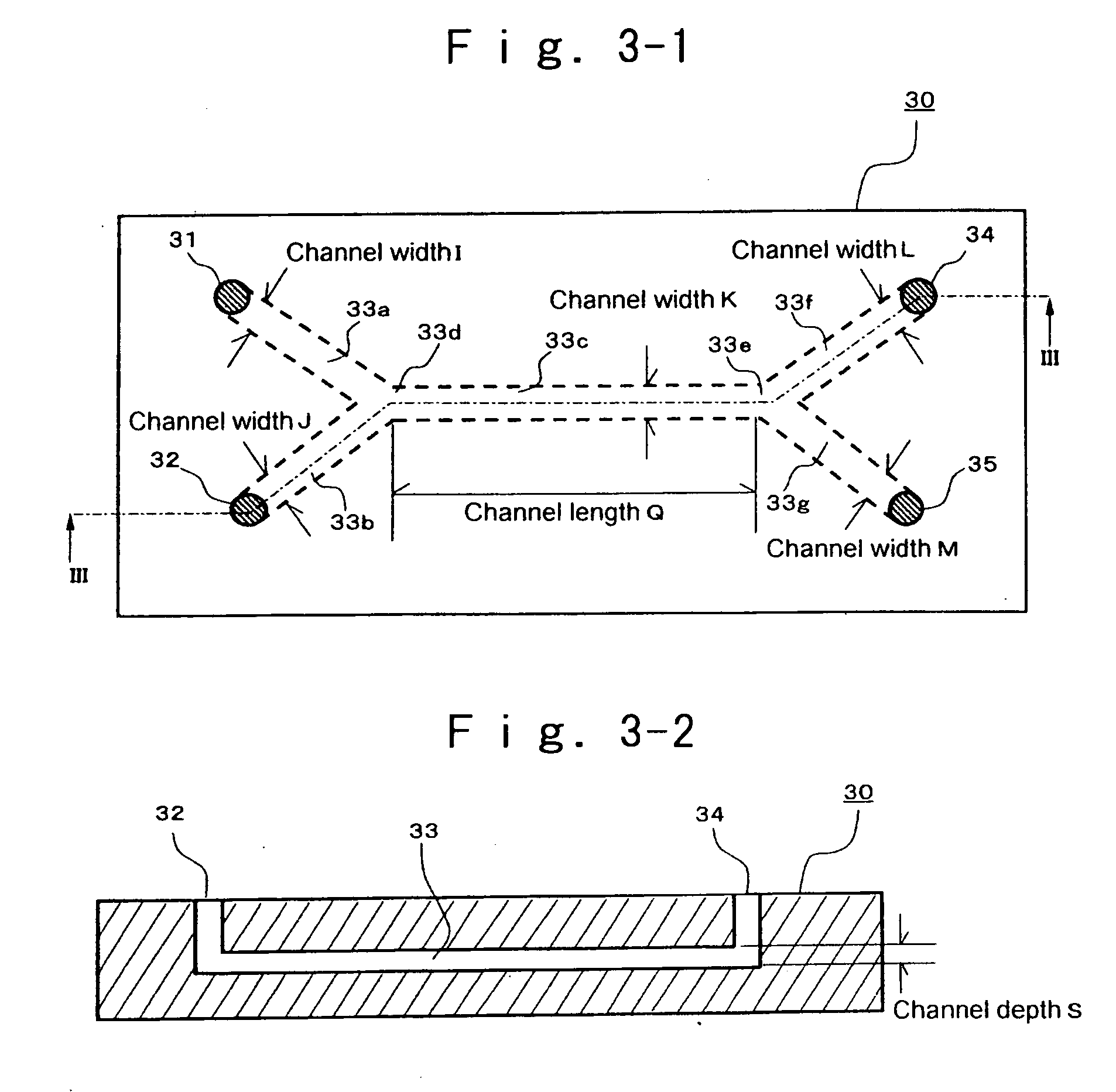

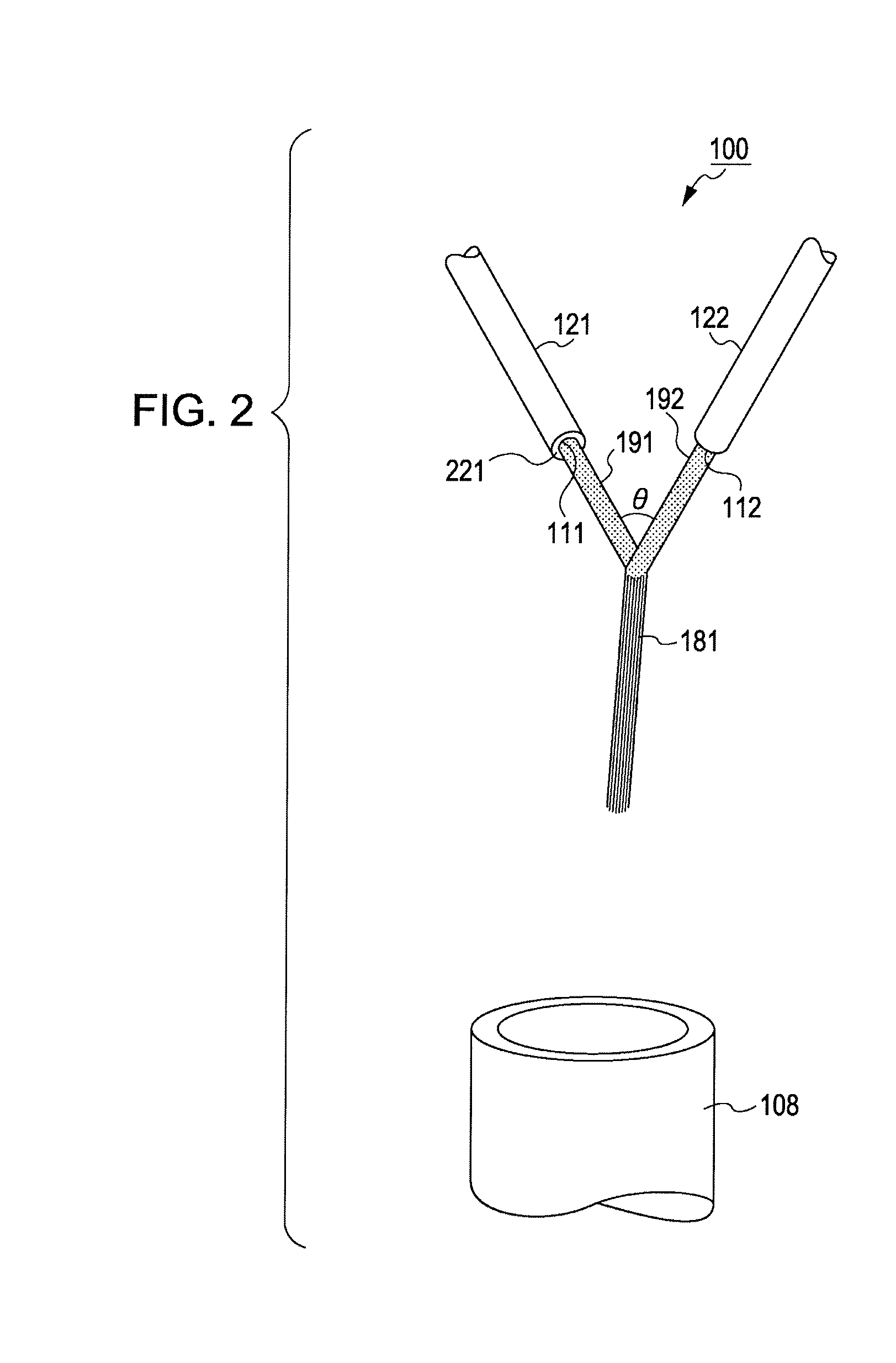

Method for manufacturing dispersion and ink using dispersion obtained thereby

InactiveUS20070149651A1Good Pigment DispersionGood dispersionFlow mixersTransportation and packagingDispersed mediaEngineering

A method for manufacturing a dispersion, includes a step of forming a reaction product by allowing at least two types of liquids to react with each other, the dispersion including a dispersion medium and particles formed from the reaction product dispersed therein. In the method described above, the at least two types of liquids are ejected from independently provided respective nozzles so that traveling directions of the liquids ejected therefrom intersect with each other at an angle of 120° or less and so that the liquids then flow in an integrated manner, whereby the reaction product is generated.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com