Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "High processing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

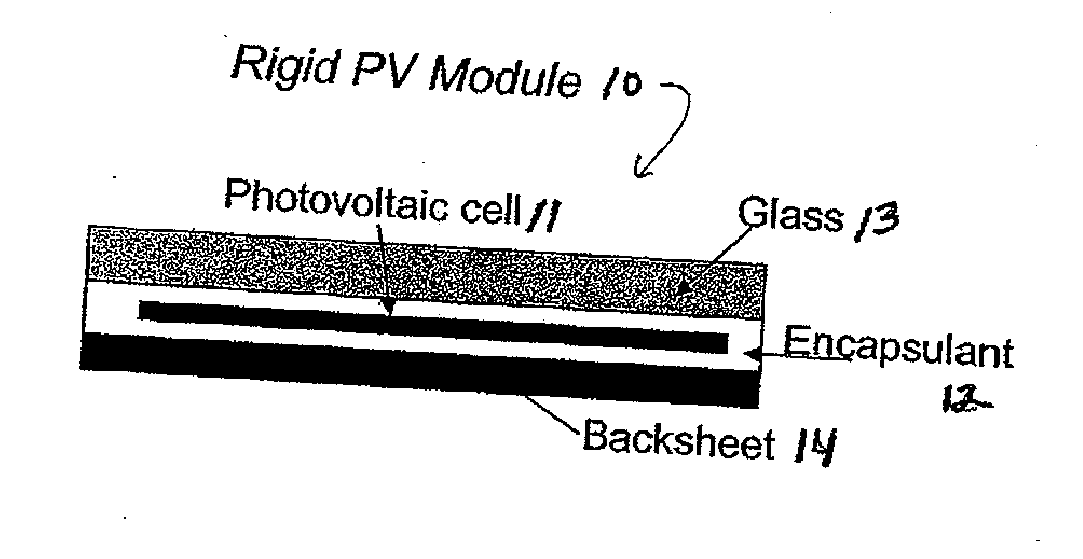

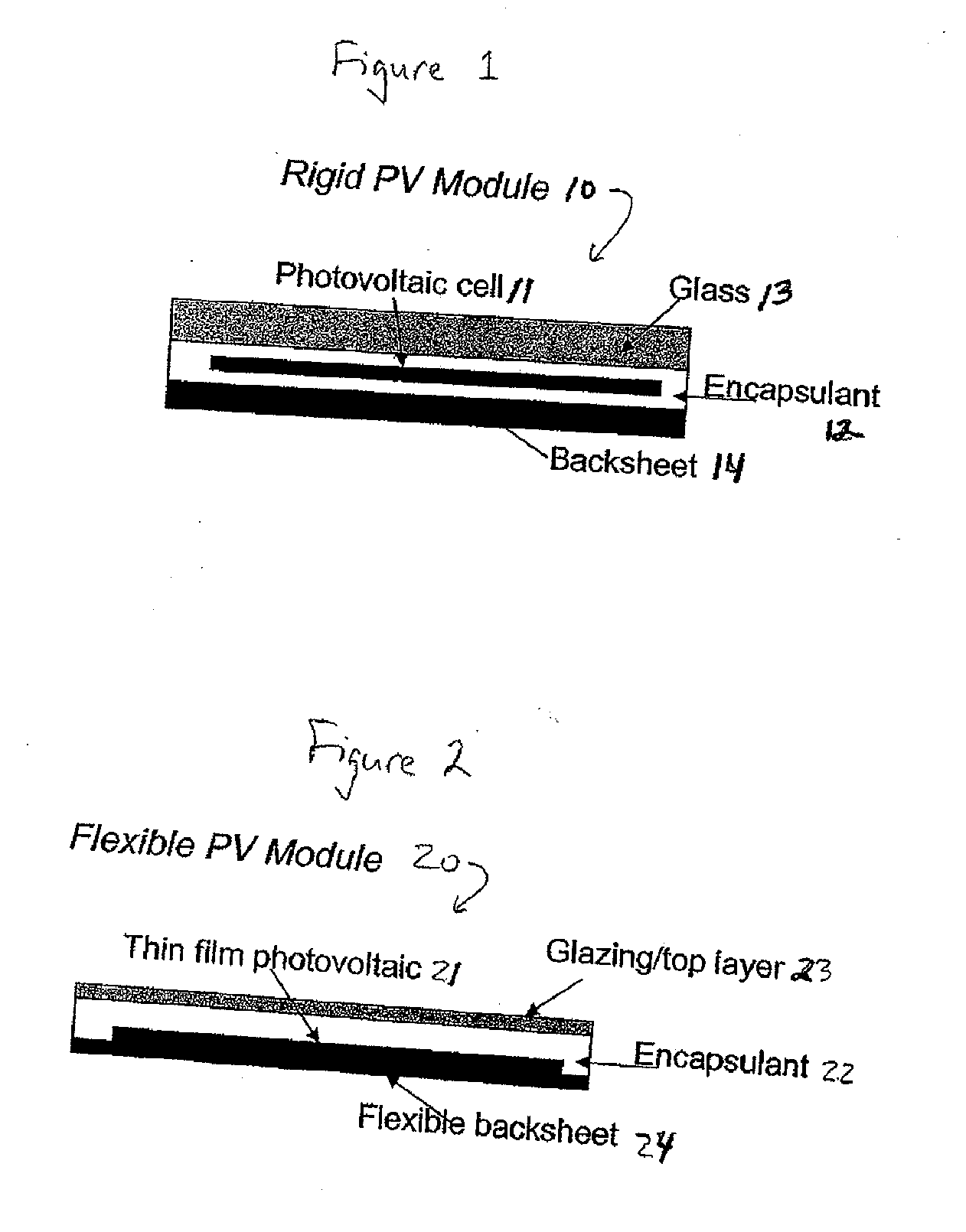

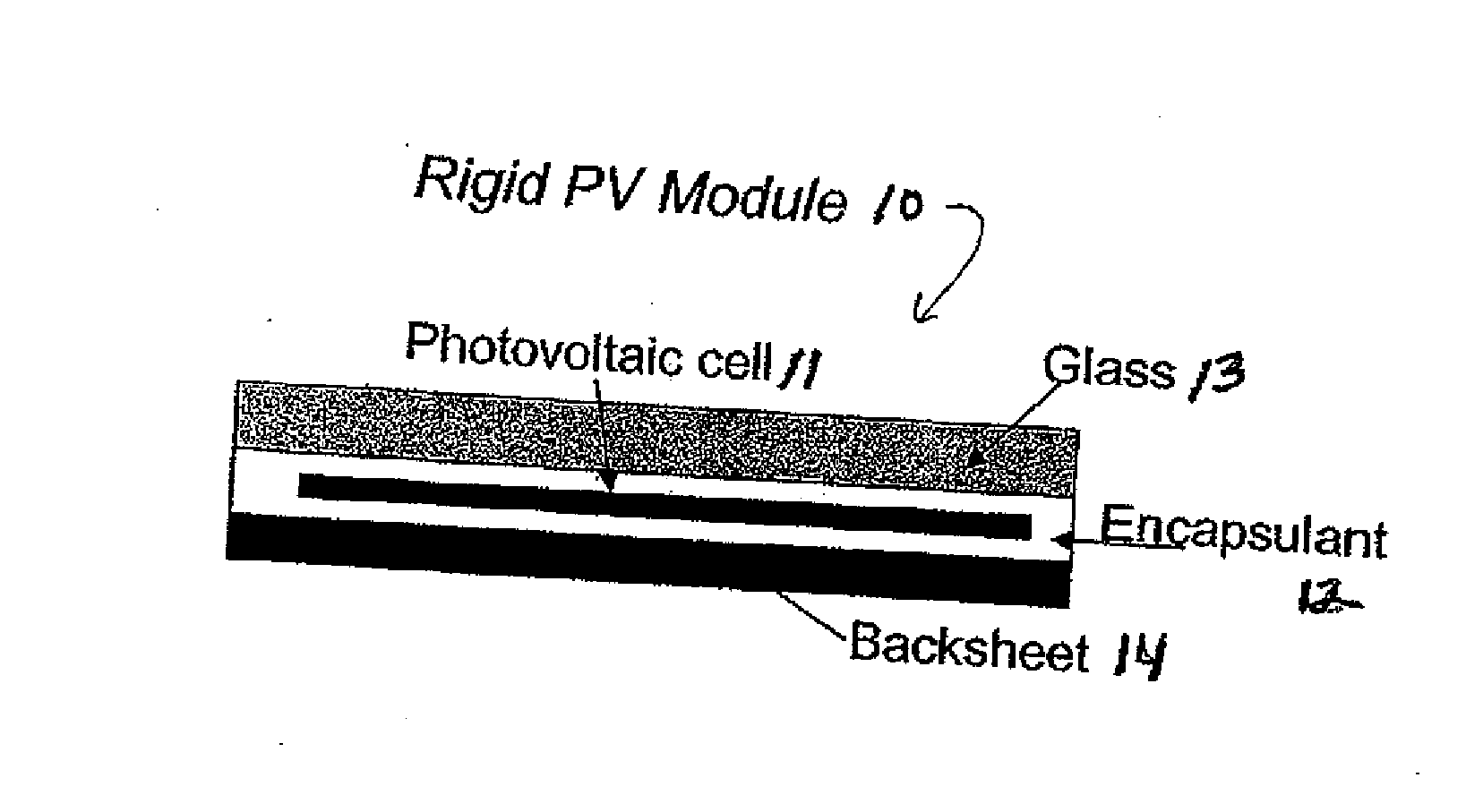

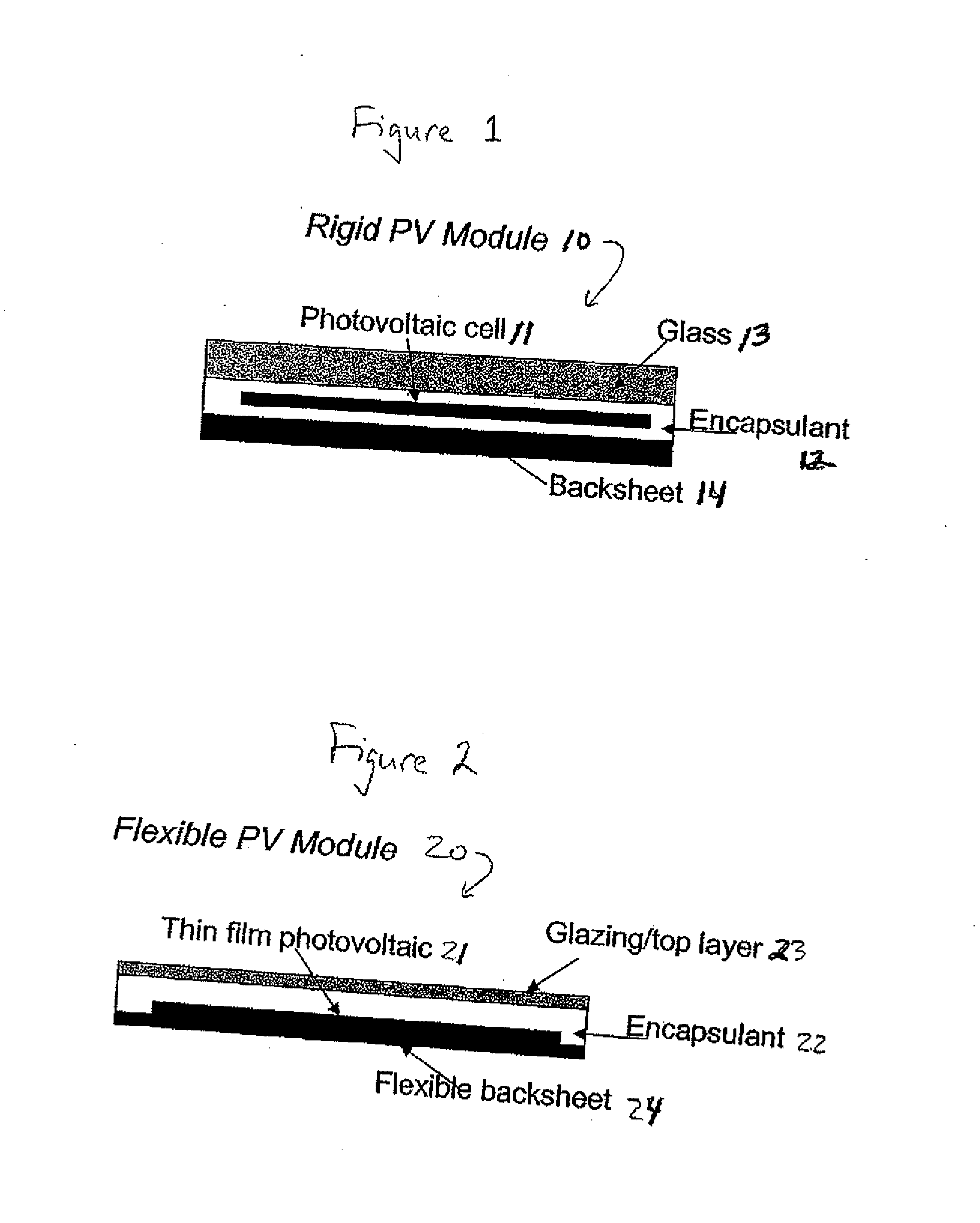

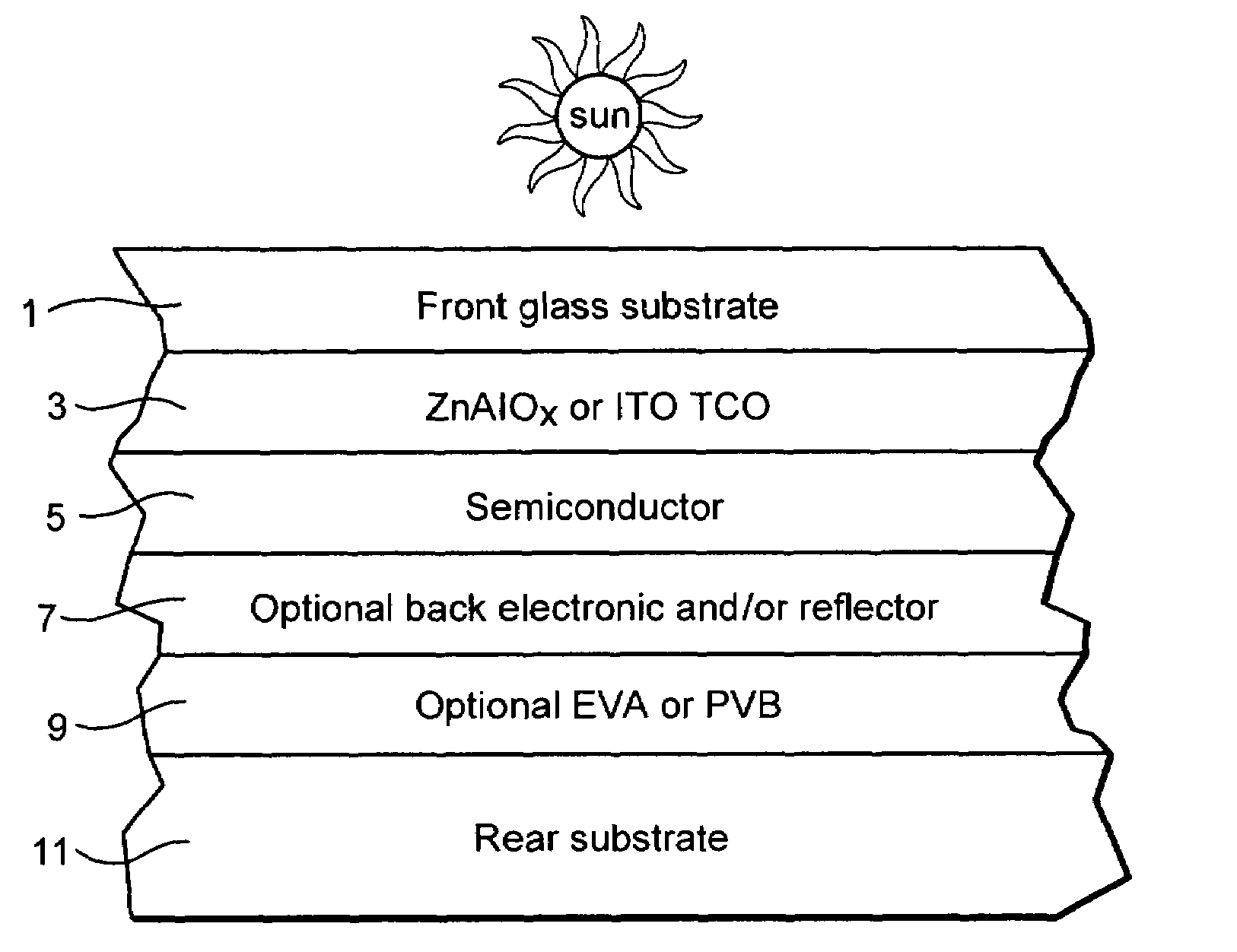

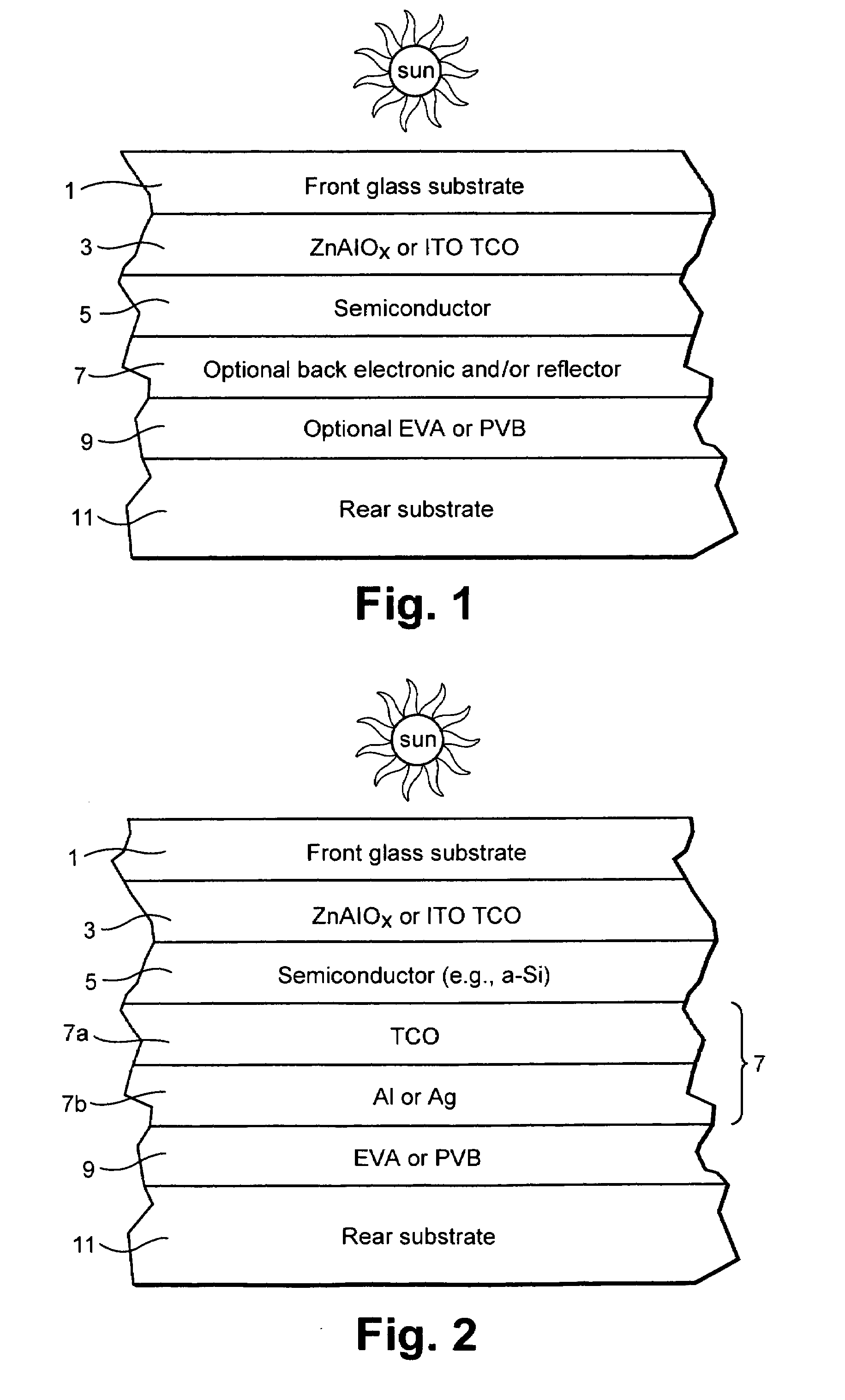

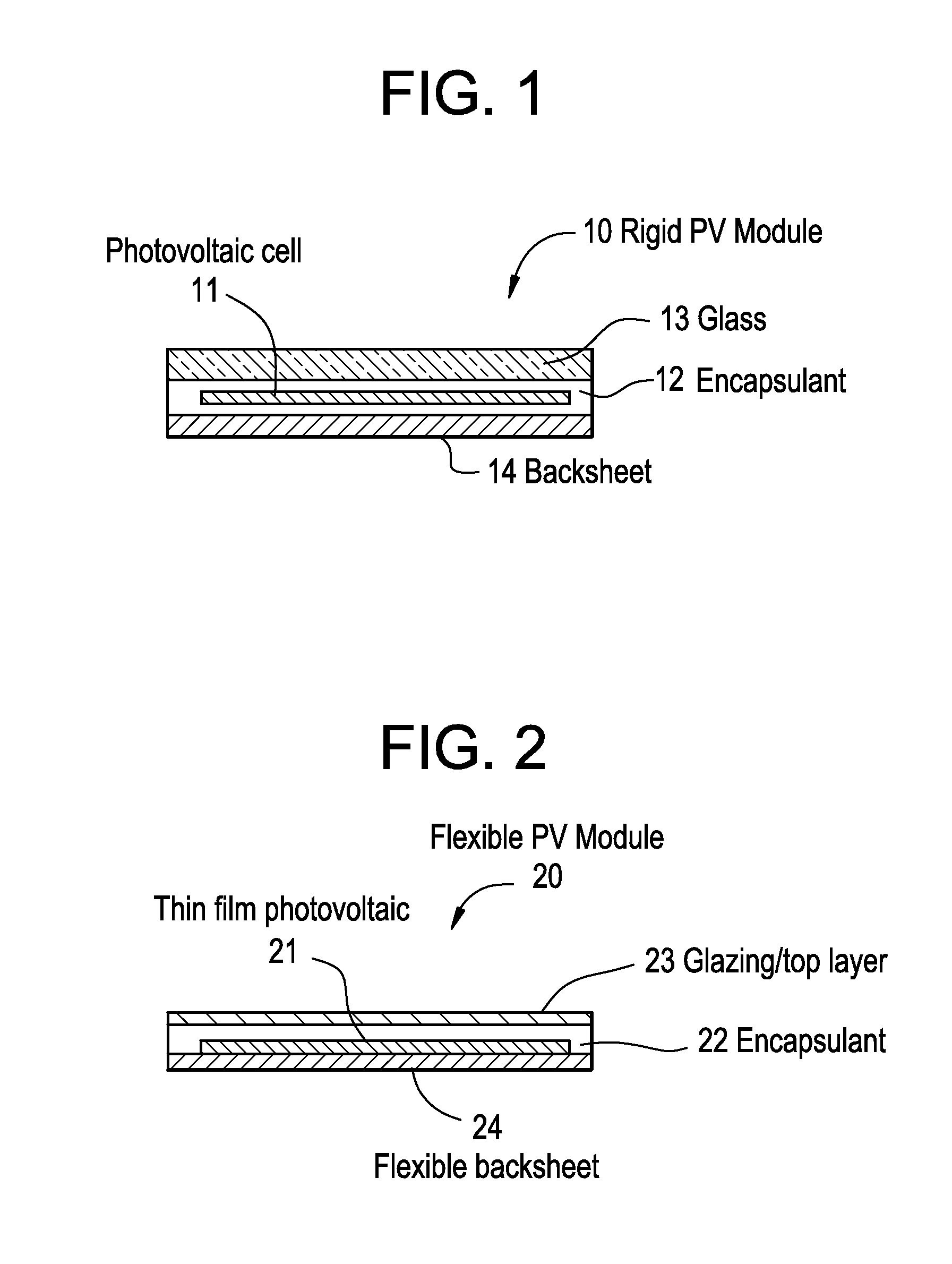

Electronic device module comprising polyolefin copolymer with low unsaturation and optional vinyl silane

InactiveUS20110290317A1Improve adhesionHigh processing temperatureGlass/slag layered productsPhotovoltaic energy generationPolymer sciencePolyolefin

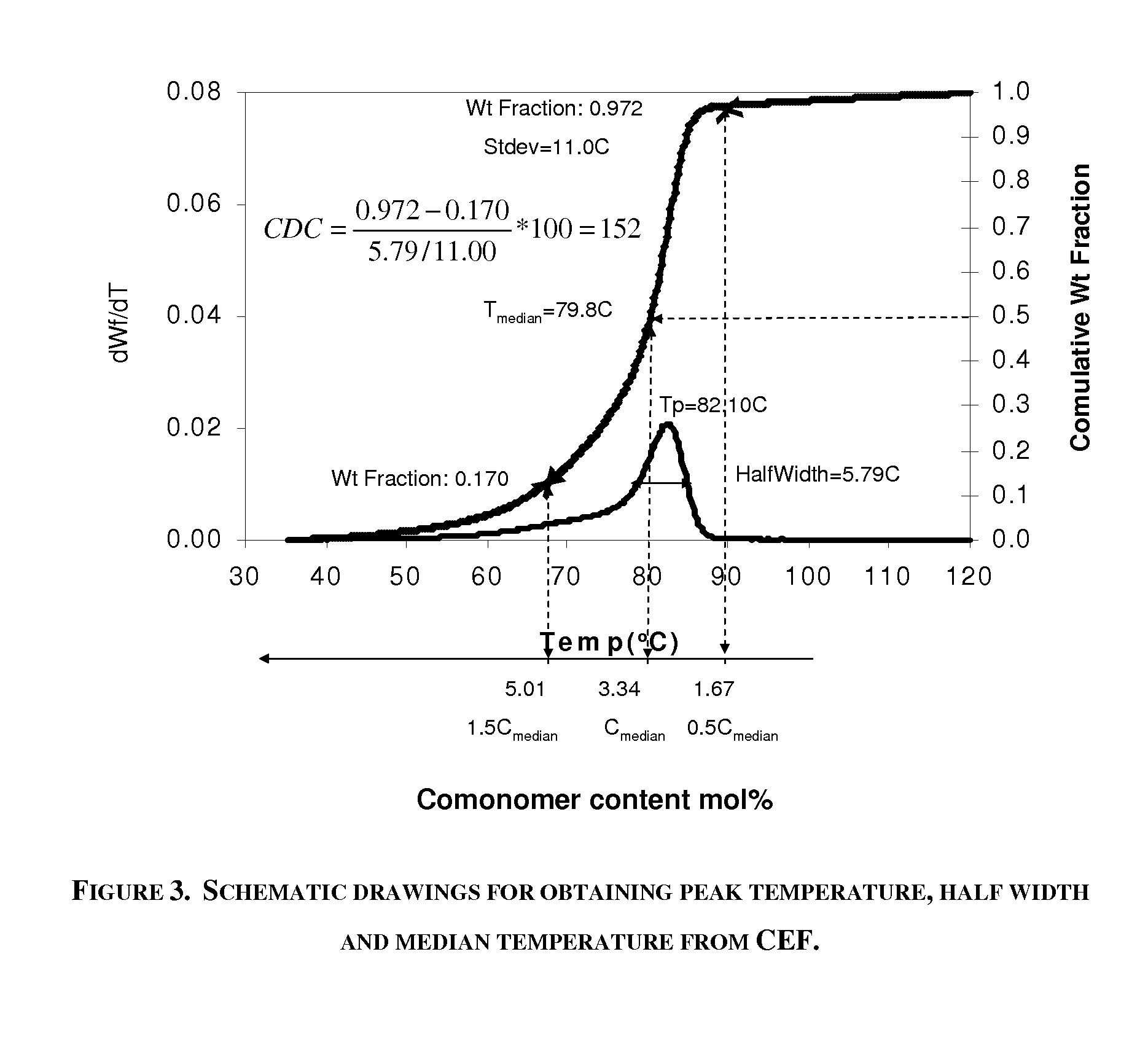

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene-based polymer composition characterized by a Comonomer Distribution Constant greater than about 45, more preferably greater than 50, most preferably greater than 95, and as high as 400, preferably as high as 200, wherein the composition has less than 120 total unsaturation unit / 1,000,000C, preferably the ethylene-based polymer compositions comprise up to about 3 long chain branches / 1000 carbons, more preferably from about 0.01 to about 3 long chain branches / 1000 carbons; the ethylene-based polymer composition can have a ZSVR of at least 2; the ethylene-based polymer compositions can be further characterized by comprising less than 20 vinylidene unsaturation unit / 1,000,000C; the ethylene-based polymer compositions can have a bimodal molecular weight distribution (MWD) or a multi-modal MWD; the ethylene-based polymer compositions can have a comonomer distribution profile comprising a mono or bimodal distribution from 35° C. to 120° C., excluding purge; the ethylene-based polymer compositions can comprise a single DSC melting peak; the ethylene-based polymer compositions can comprise a weight average molecular weight (Mw) from about 17,000 to about 220,000, (2) optionally, a vinyl silane, (3) optionally, a free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (4) optionally, a co-agent.

Owner:NAUMOVITZ JOHN +3

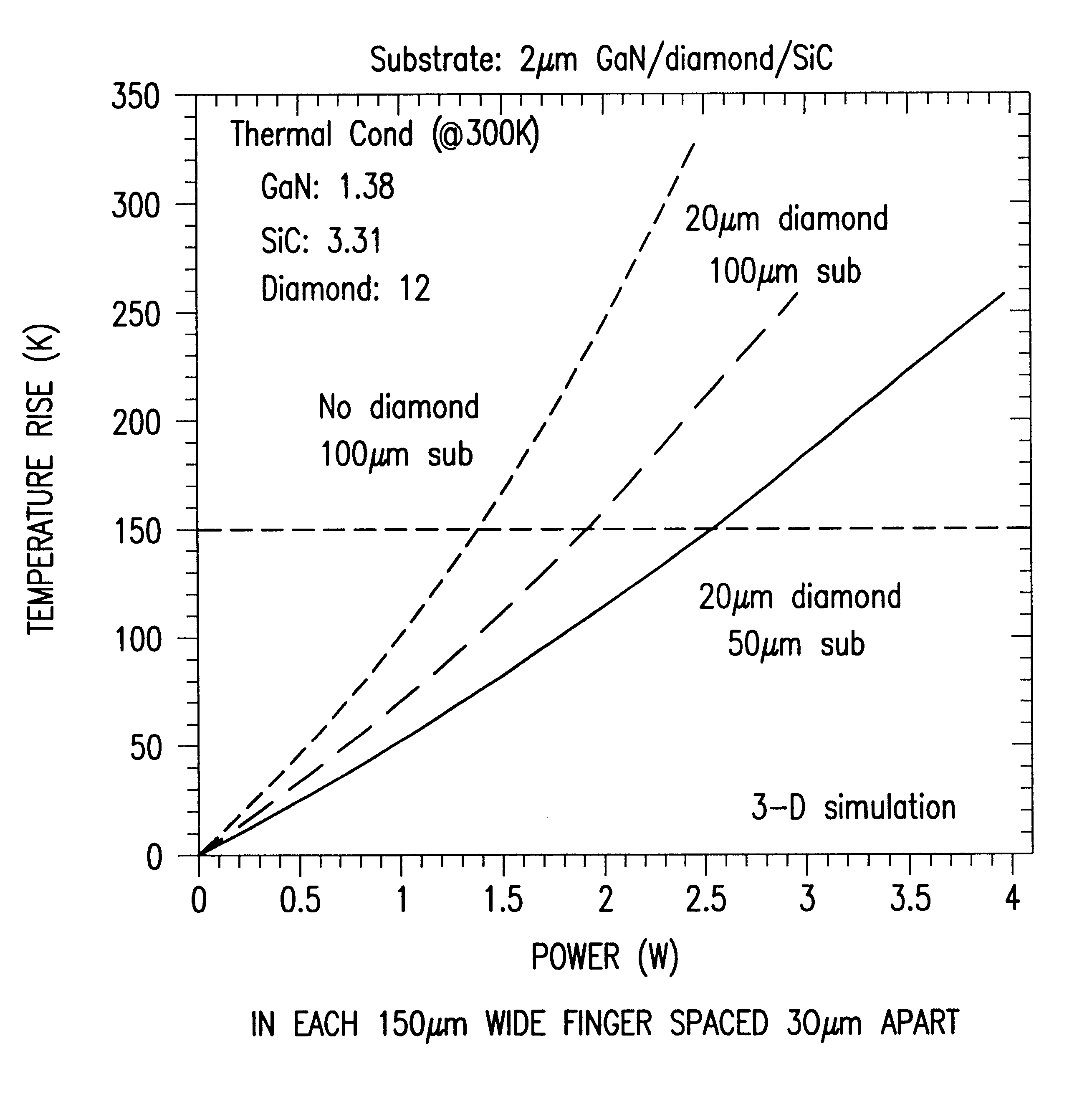

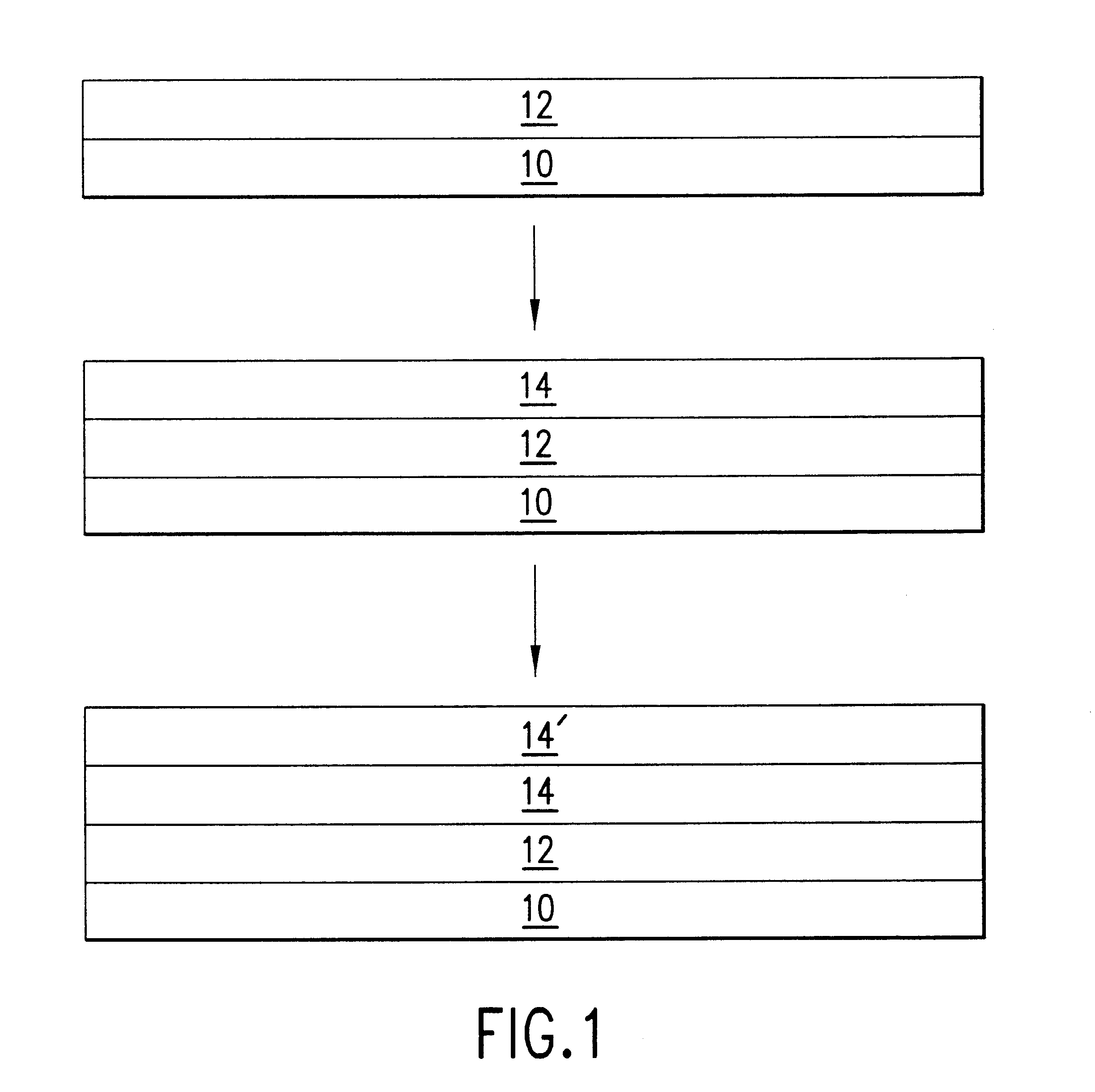

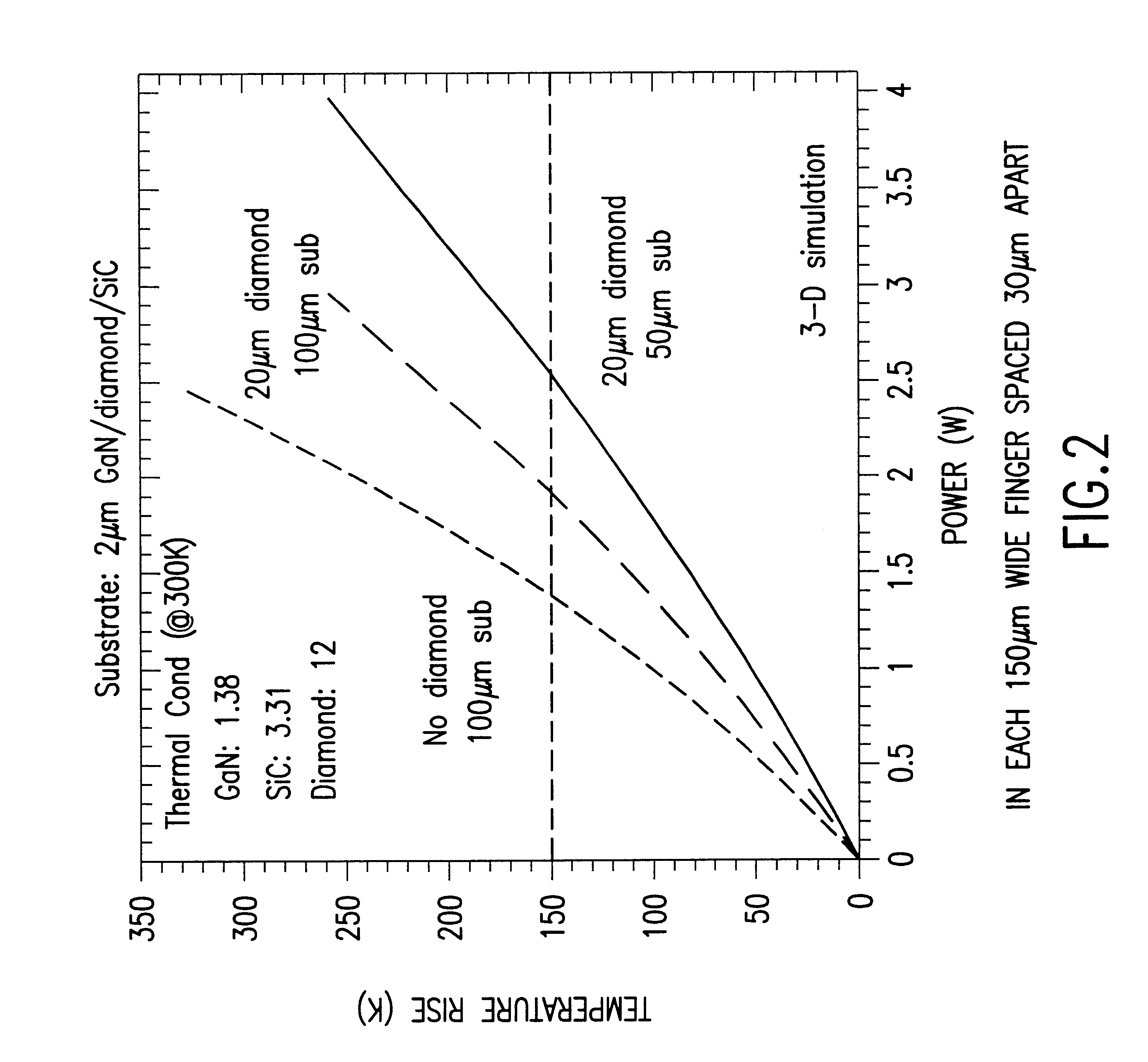

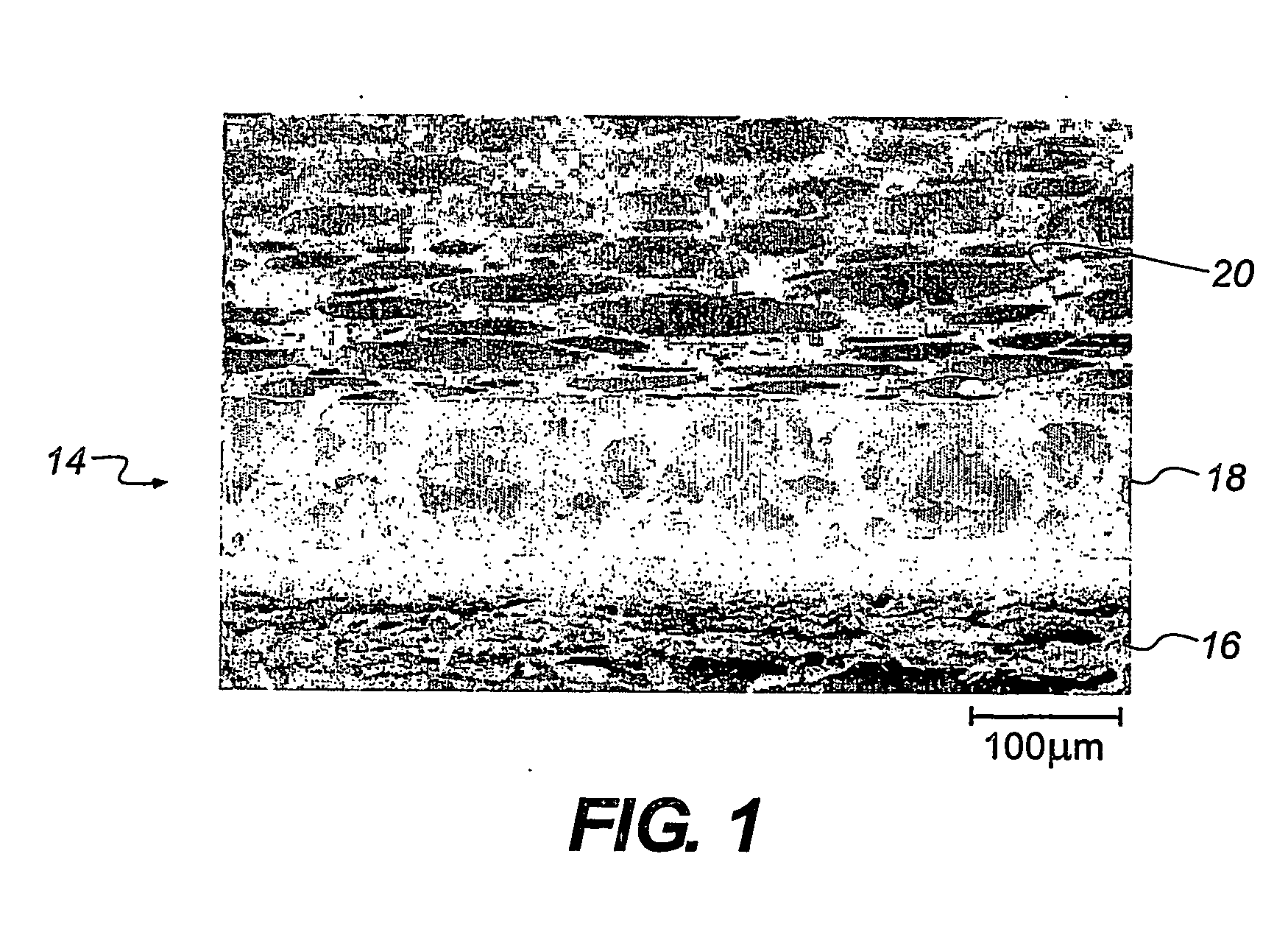

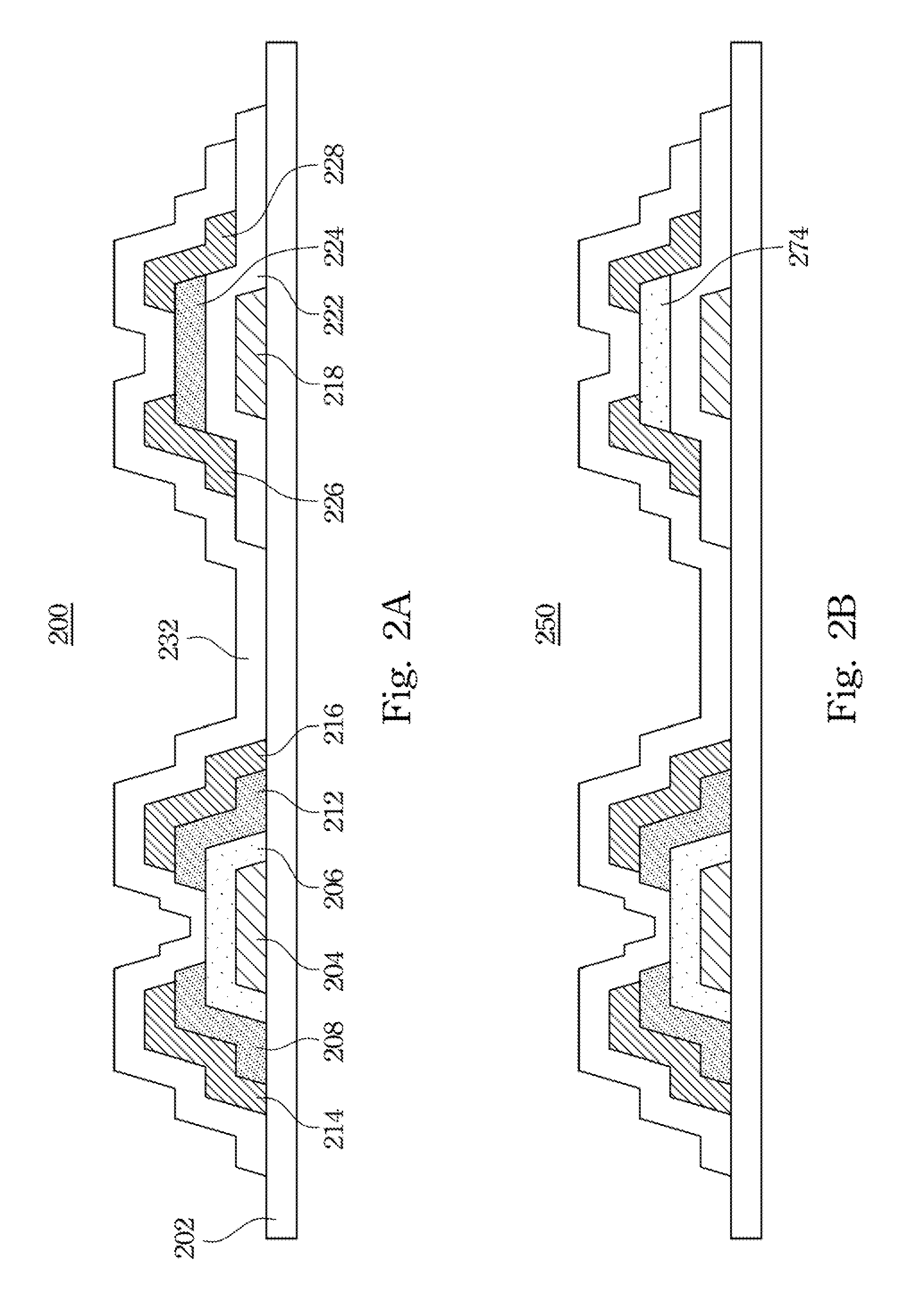

Electronic device with composite substrate

InactiveUS6497763B2Improve scalabilityImprove electronic performancePolycrystalline material growthSemiconductor/solid-state device manufacturingThermal coefficientComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

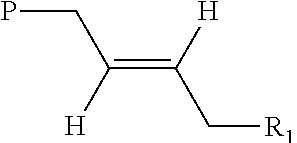

Electronic Device Module Comprising Polyolefin Copolymer

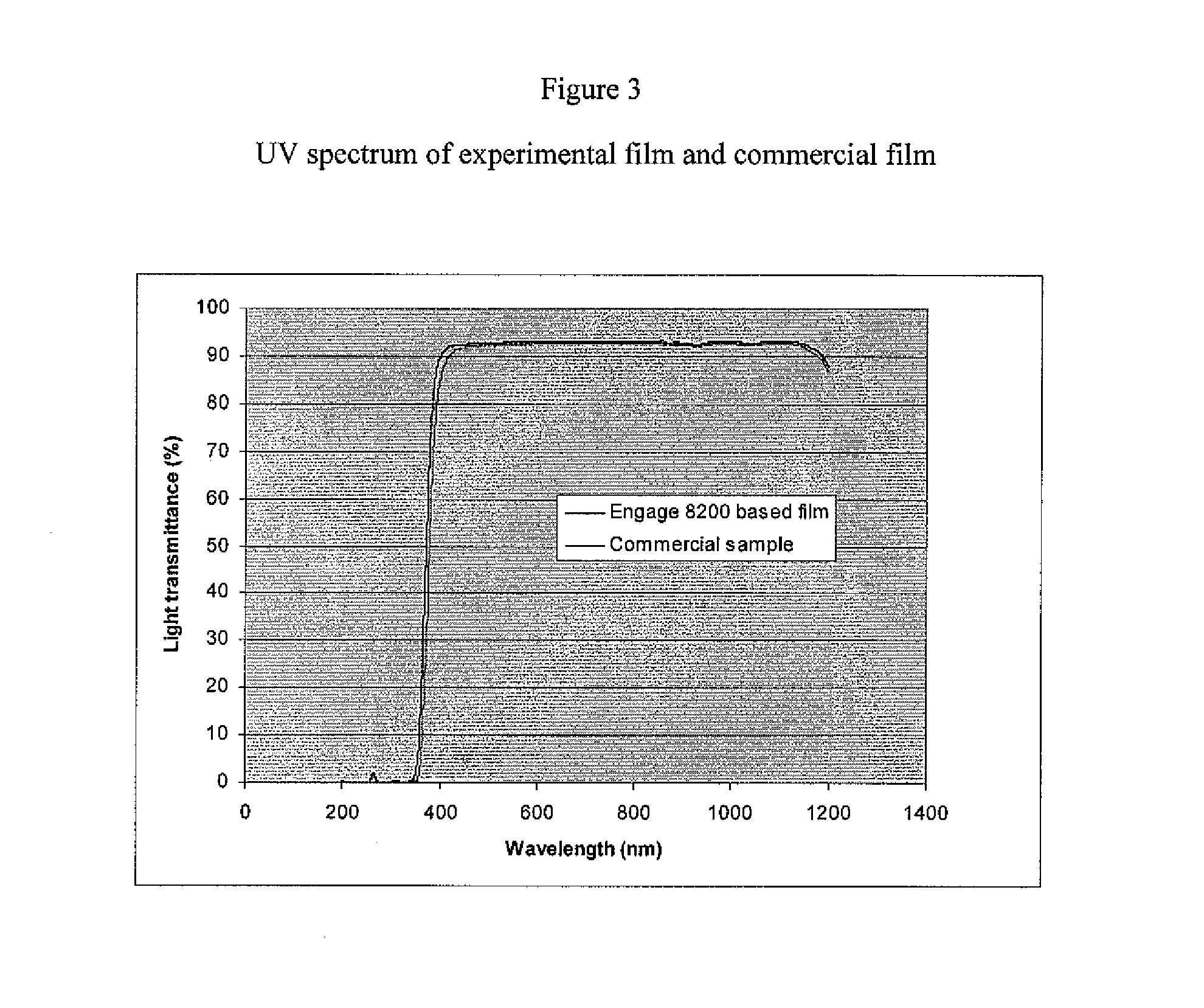

ActiveUS20080078445A1Improve adhesionHigh processing temperaturePV power plantsElectrical equipmentPolyolefinSilanes

An electronic device module comprising: A. At least one electronic device, e.g., a solar cell, and B. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) a polyolefin copolymer with at least one of (a) a density of less than about 0.90 g / cc, (b) a 2% secant modulus of less than about 150 megaPascal (mPa) as measured by ASTM D-882-02), (c) a melt point of less than about 95 C, (d) an α-olefin content of at least about 15 and less than about 50 wt % based on the weight of the polymer, (e) a Tg of less than about −35 C, and (f) a SCBDI of at least about 50, (2) optionally, free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (3) optionally, a co-agent. Typically, the polyolefin copolymer is an ethylene / α-olefin copolymer. Optionally, the polymeric material can further comprise a vinyl silane and / or a scorch inhibitor, and the copolymer can remain uncrosslinked or be crosslinked.

Owner:DOW GLOBAL TECH LLC

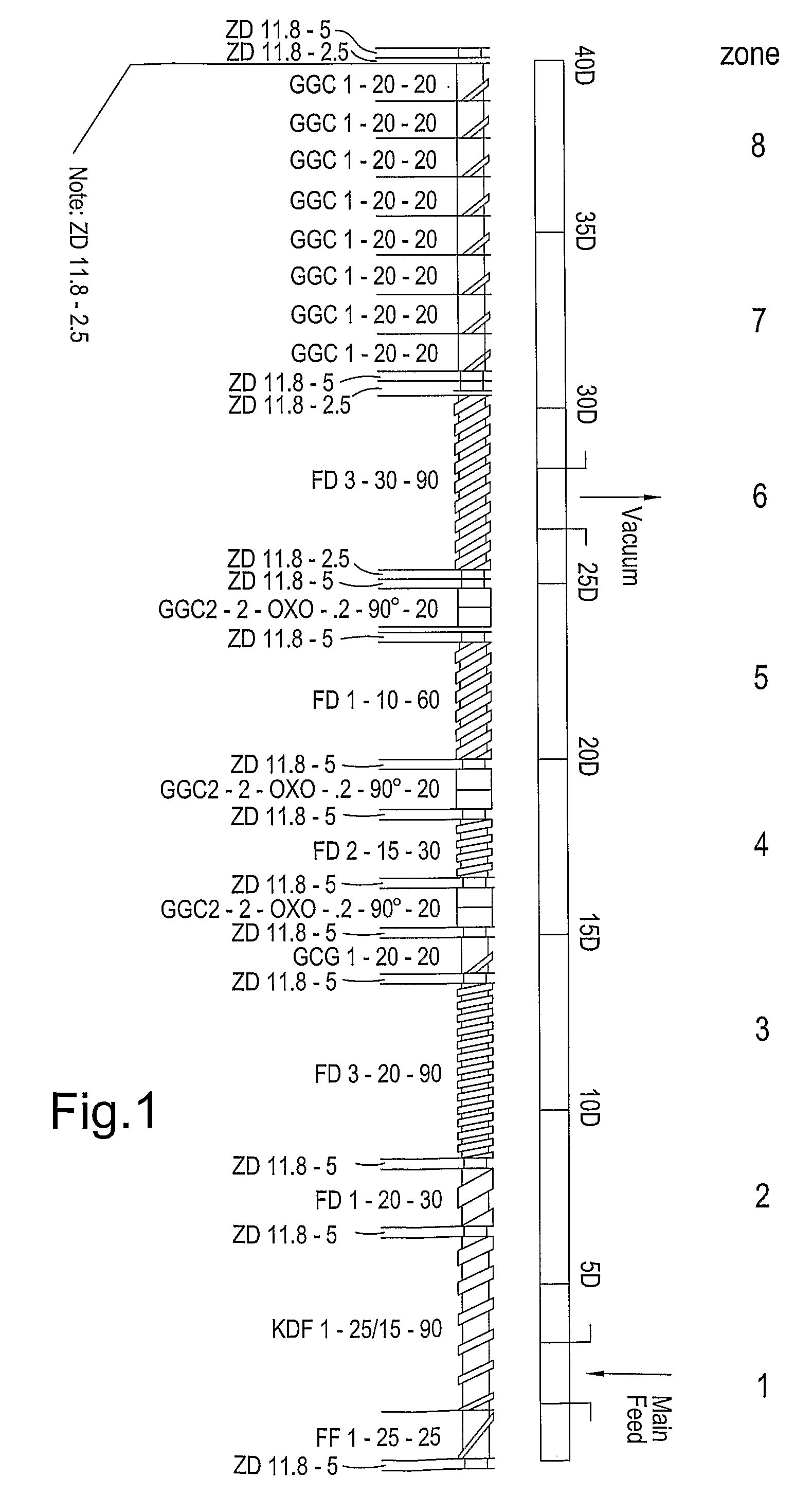

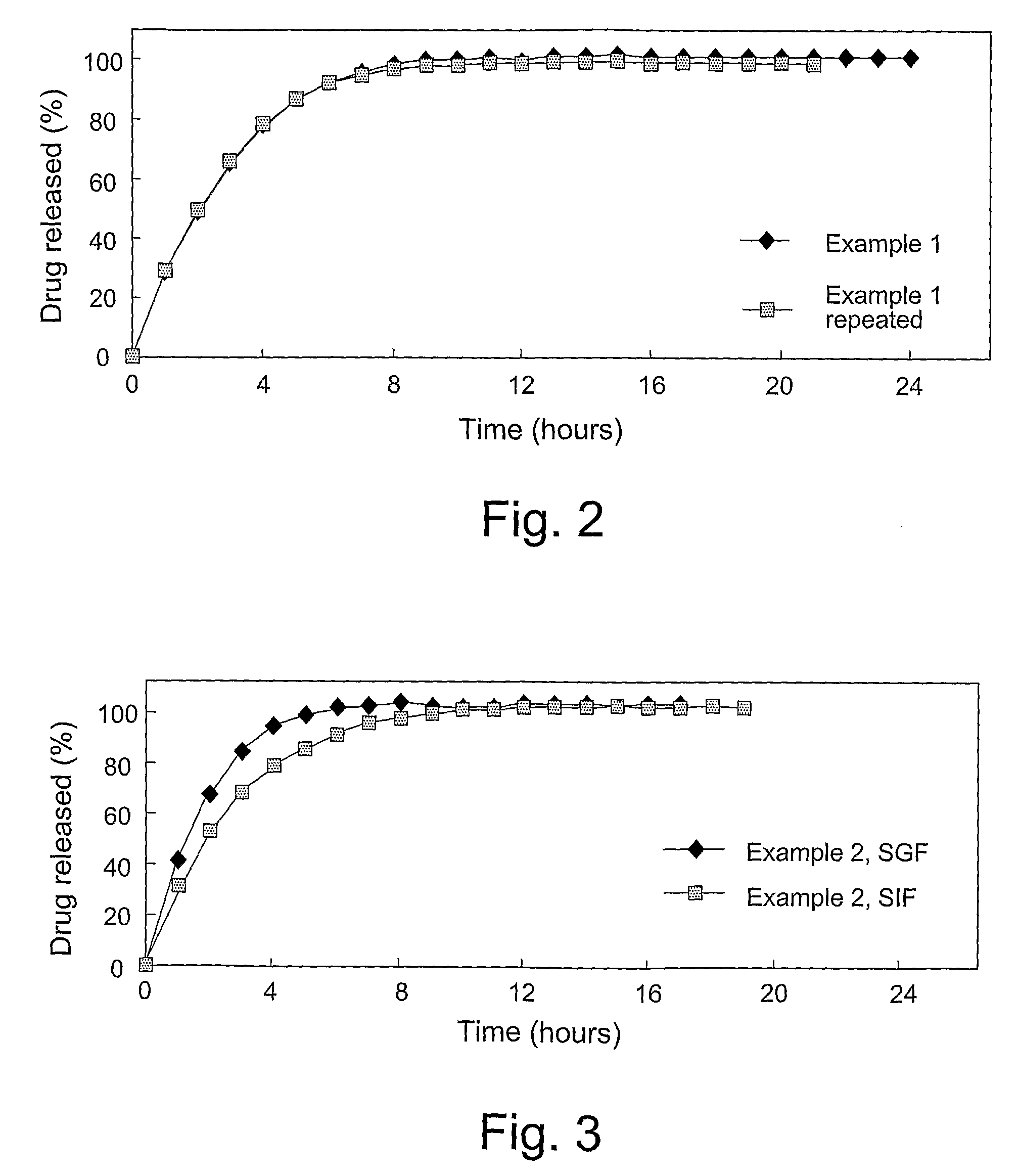

Multiparticulates

InactiveUS20080260815A1Reduce adhesionReduce the required powerOrganic active ingredientsPowder deliveryActive agentExcipient

Extrusion of a mix containing a pharmaceutically active agent can be achieved using a plasticising excipient in an amount sufficient to act as plasticiser and also act as lubricant, thereby avoiding the need for inclusion of a lubricant. The invention provides multiparticulates with controlled release properties, substantially free of lubricant. The present invention is preferably directed to extruded multiparticulates containing an opioid such as oxycodone, an ammonium methacrylate copolymer such as Eudragit® RSPO, a plasticising excipient such as preferably stearyl alcohol and a water permeability modifier such as preferably Eudragit® RLPO. The obtained multiparticulates show a release rate profile which is pH-independent.

Owner:EURO-CELTIQUE SA

Foamed material and a method of making a foamed material

InactiveUS20060270745A1High processing temperatureSimple and robustRadiation applicationsDuplicating/marking methodsPolymer sciencePolymer solution

The invention provides a method of making a material, said method comprising generating a foamed hydrophilic polymer solution, especially of a gelatin or derivative thereof, and treating said foamed hydrophilic polymer solution with sufficient energy and for a sufficiently short time that a polymer foam having an open-cell structure is formed. The invention also provides a material comprising a support and an ink receiving layer supported on the support, the ink receiving layer comprising porous hydrophilic polymer, especially gelatin, and is formed by coating a solution of foamed hydrophilic polymer, especially gelatin, onto a support substrate and drying the coated substrate for a time period selected to be short enough such that an open-cell foam is formed.

Owner:EASTMAN KODAK CO

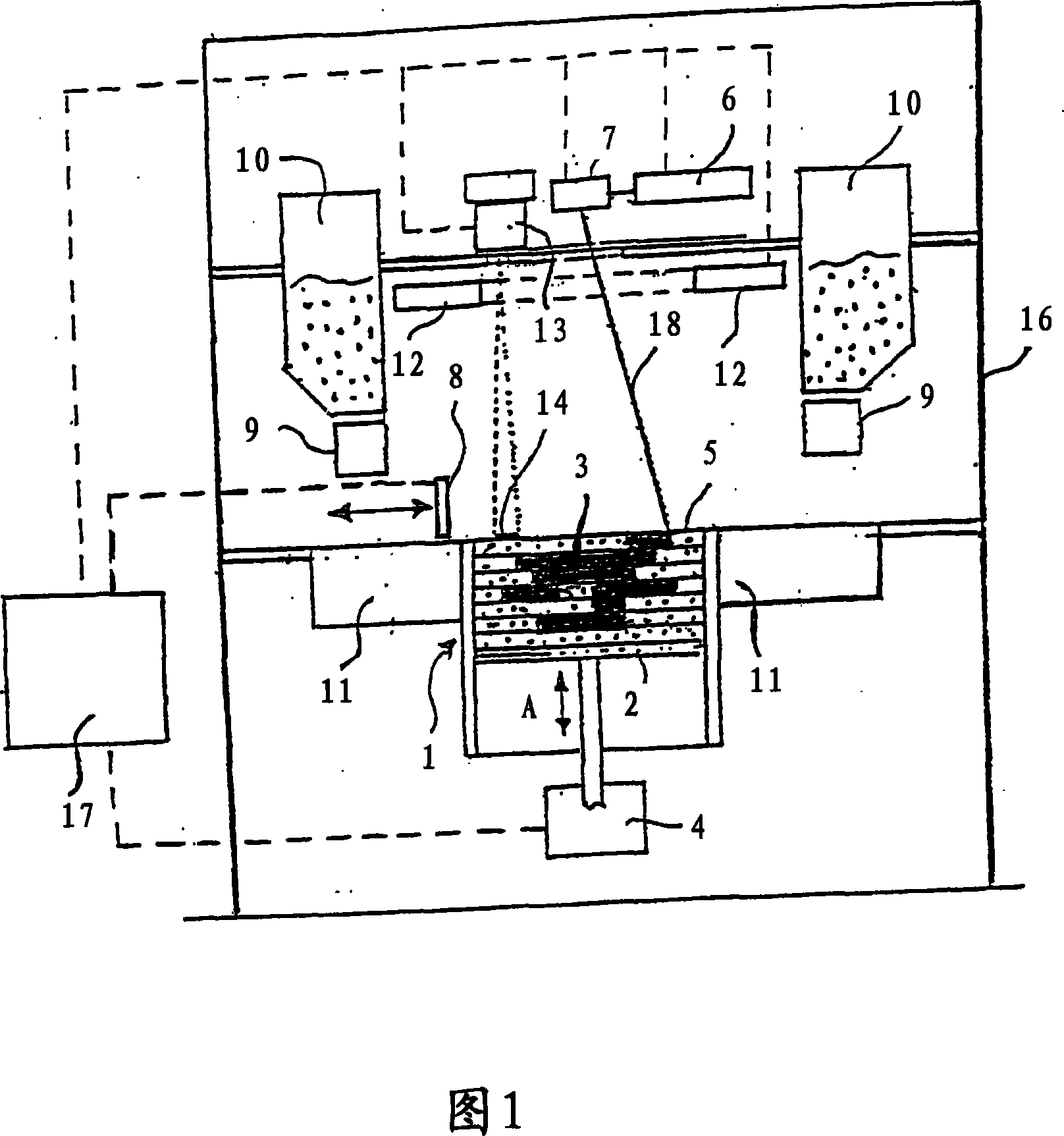

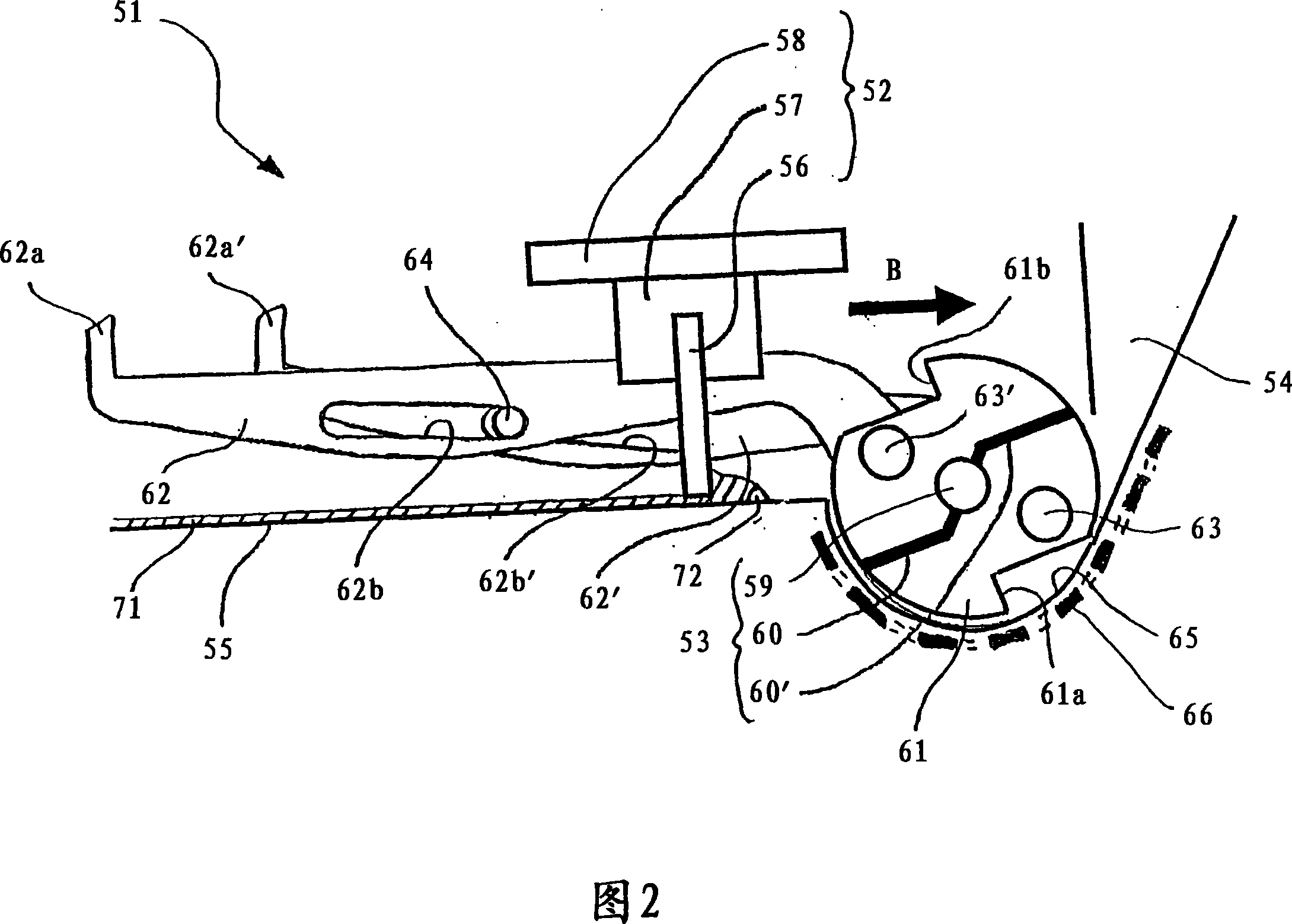

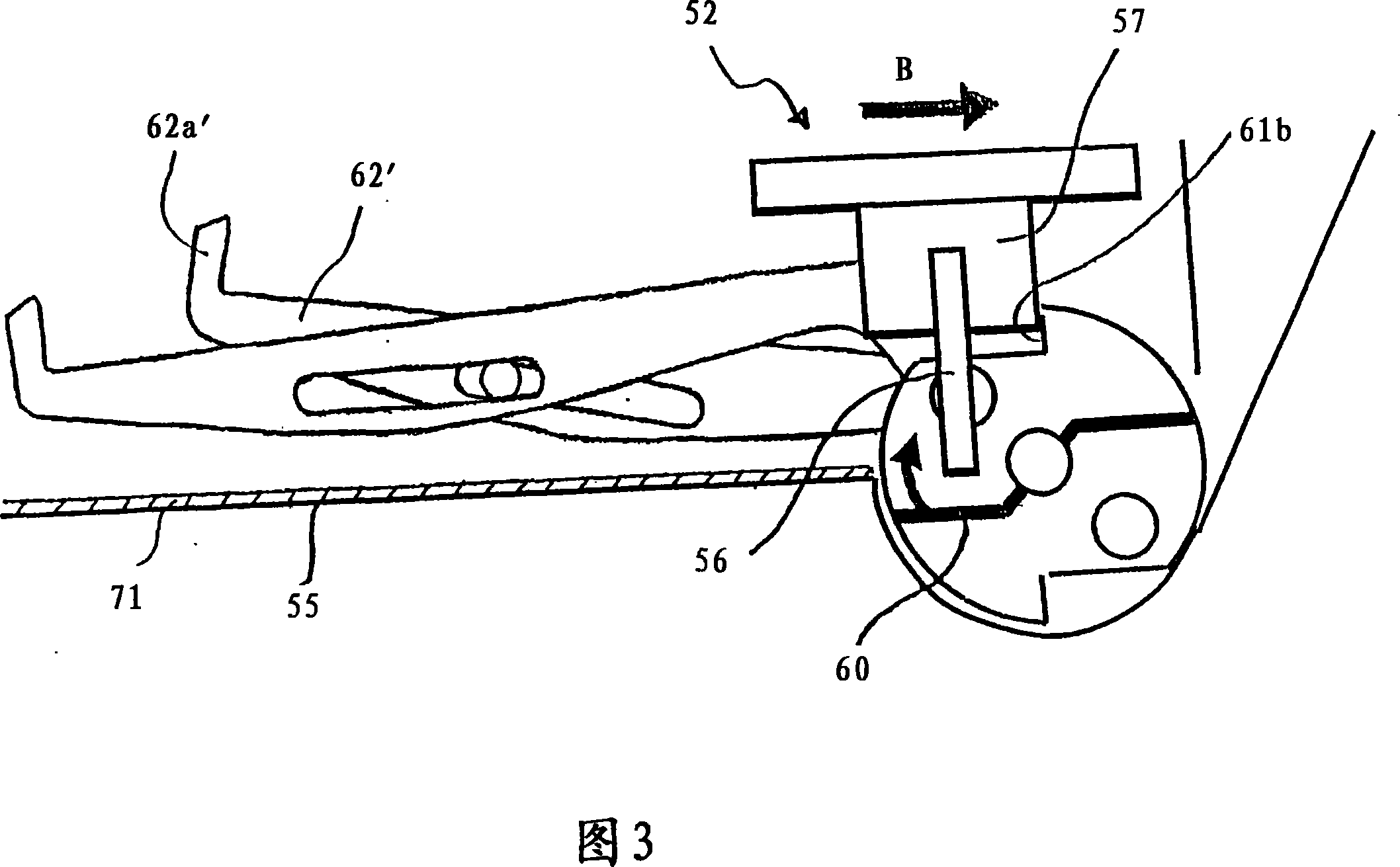

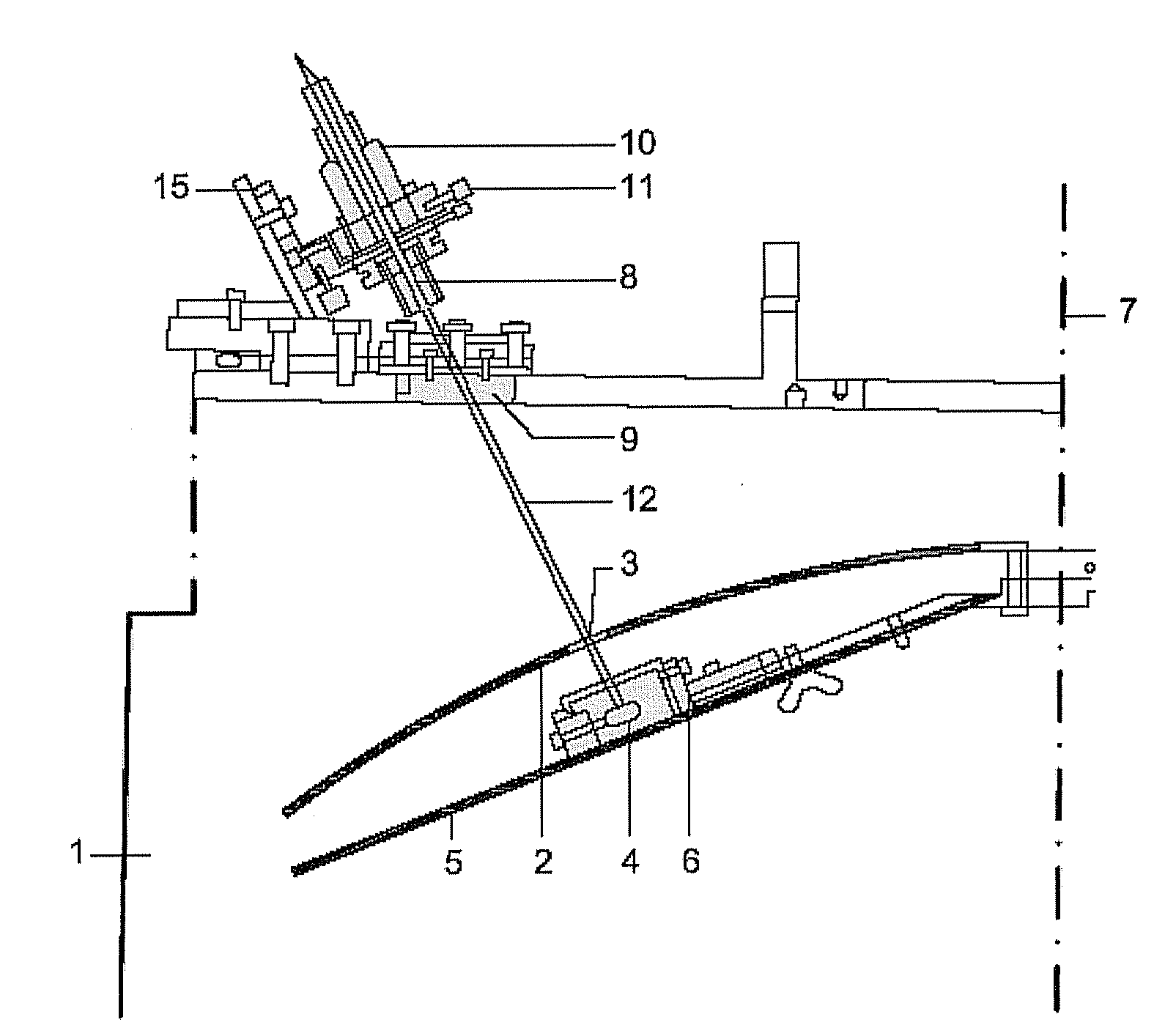

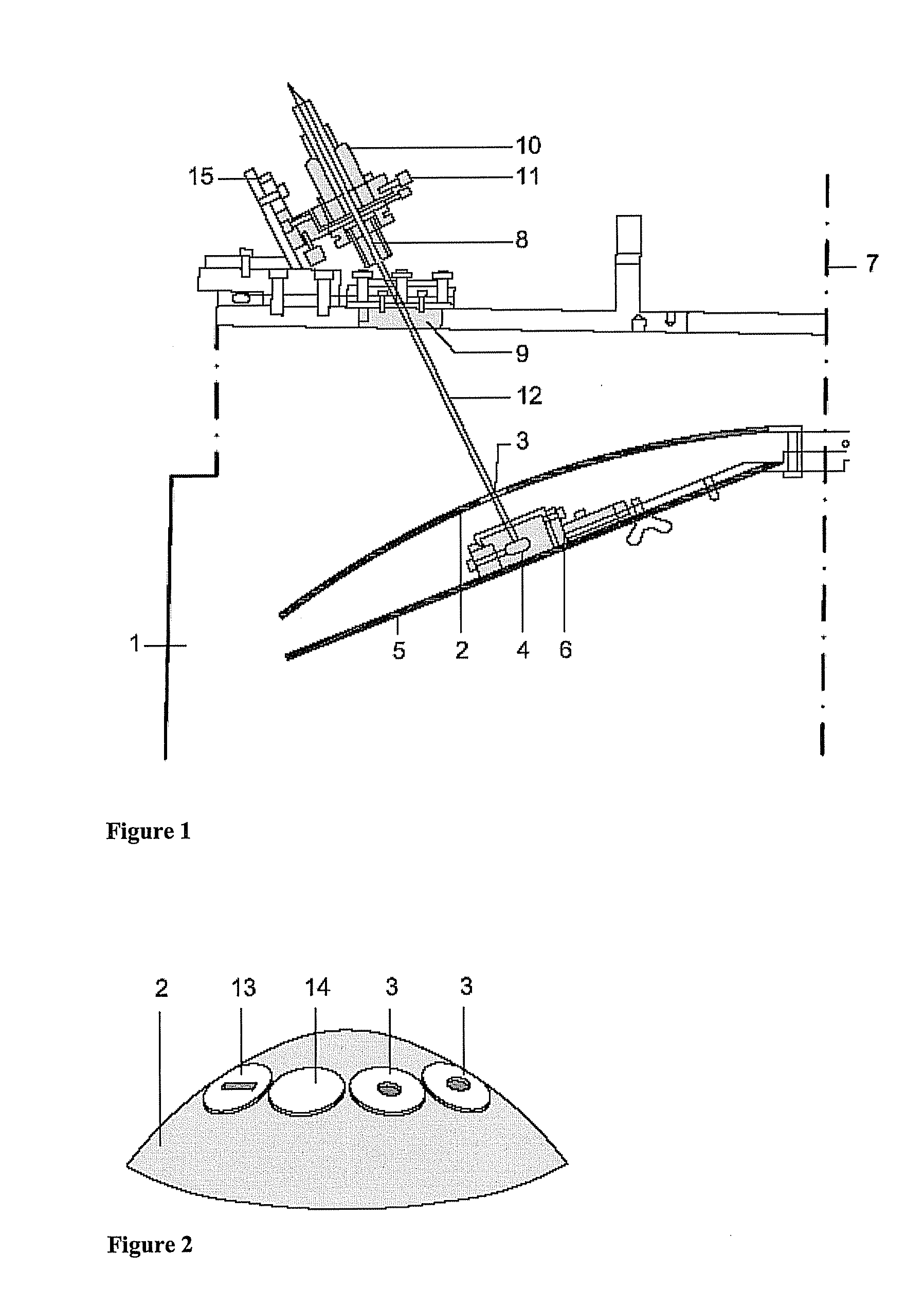

Device and method for applying layers of a powder material onto a surface

ActiveCN101090787AReduce heat loadReduce build timeAdditive manufacturing apparatusCeramic shaping apparatusReciprocating motionSintering

A method for applying powder onto a substrate, e.g. to produce three dimensional items secured by laser sintering, has a reciprocating scraper (8) to move excess powder to collecting systems (11) each side of the substrate holder. The item is built up in layers and the collected powder is recycled to the other side of the scraper while the dosing rate is adjusted to ensure an even coating. The powder is pre-warmed during dosing and is subsequently heated to the process temperature. The recycling means comprise two rotating cylinders rotating in opposite directions.

Owner:EOS ELECTRO OPTICAL SYST

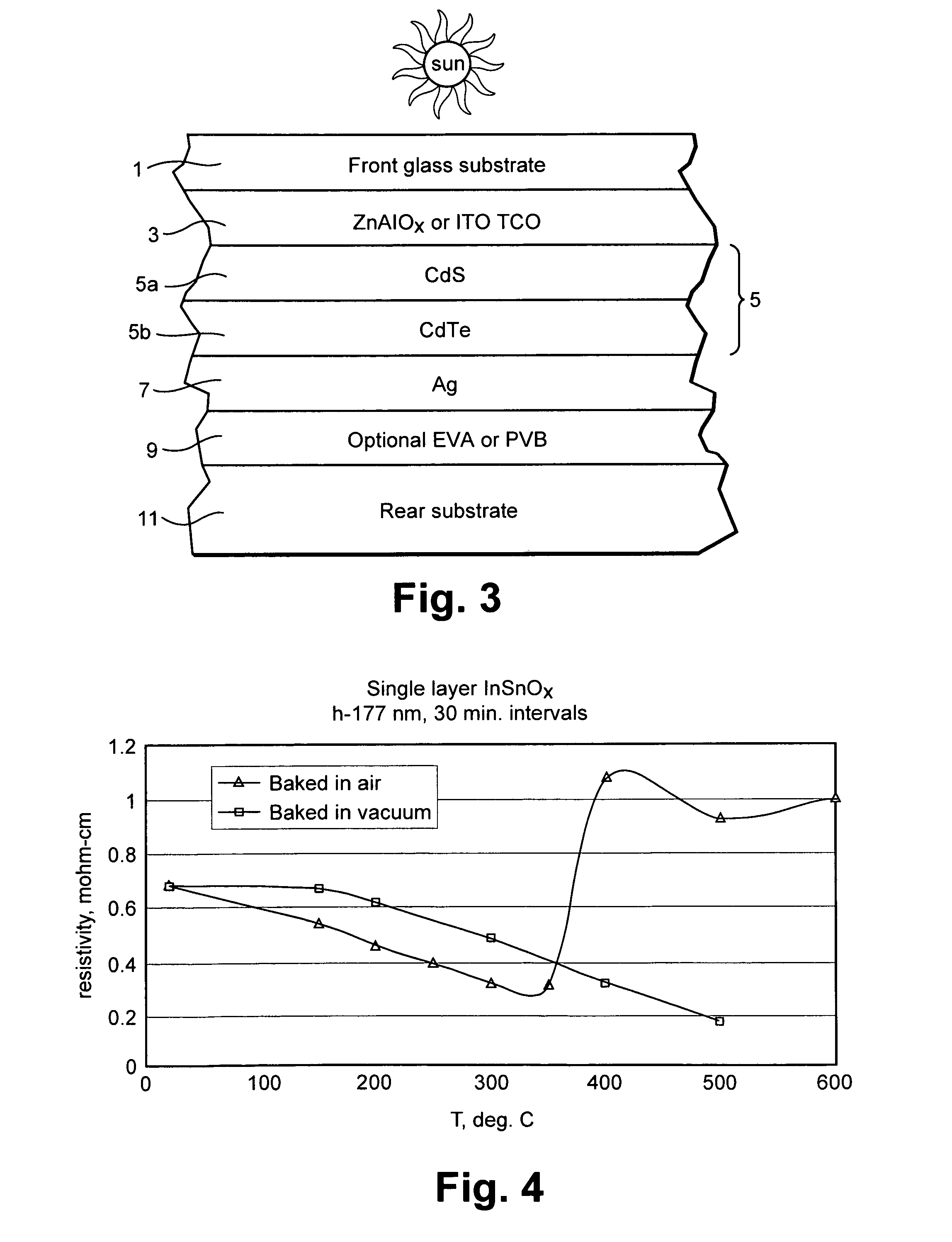

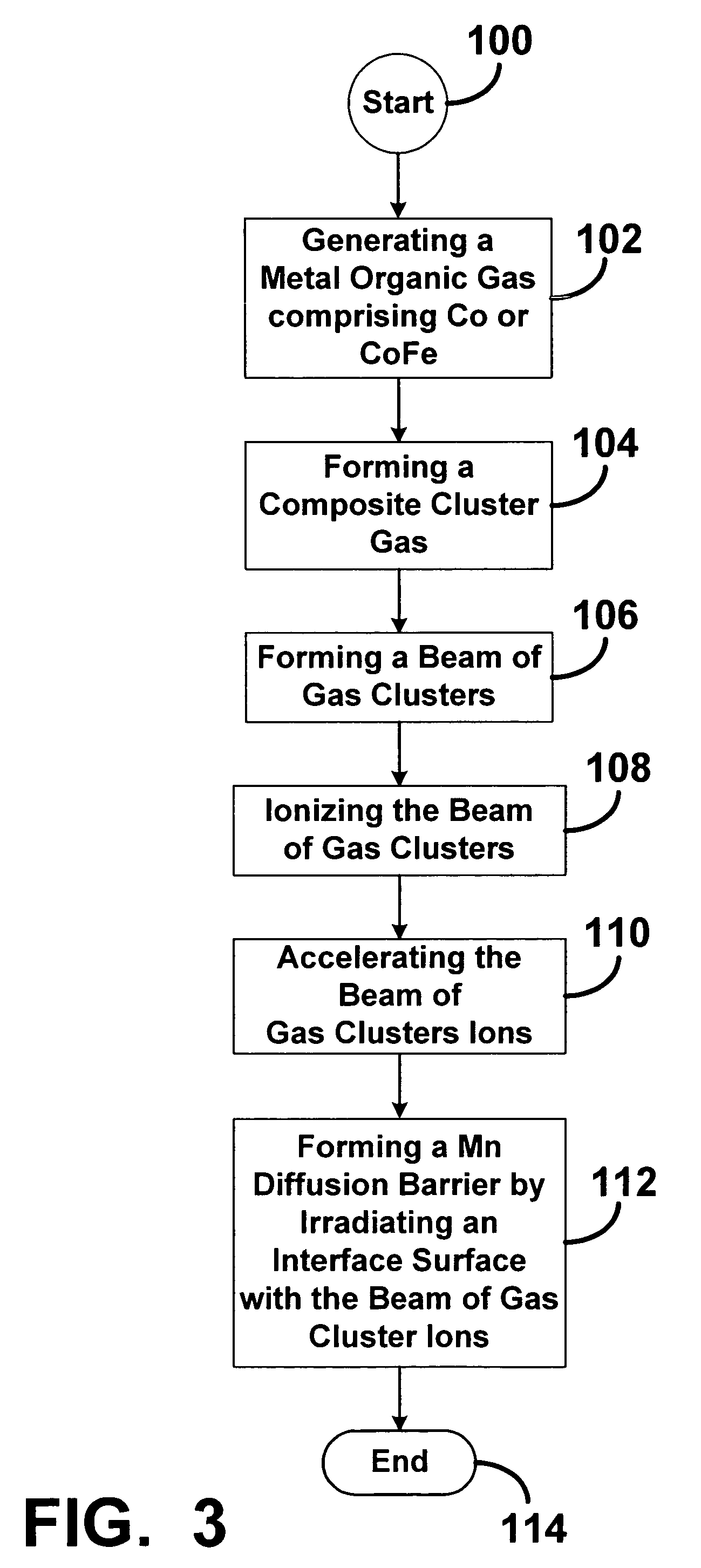

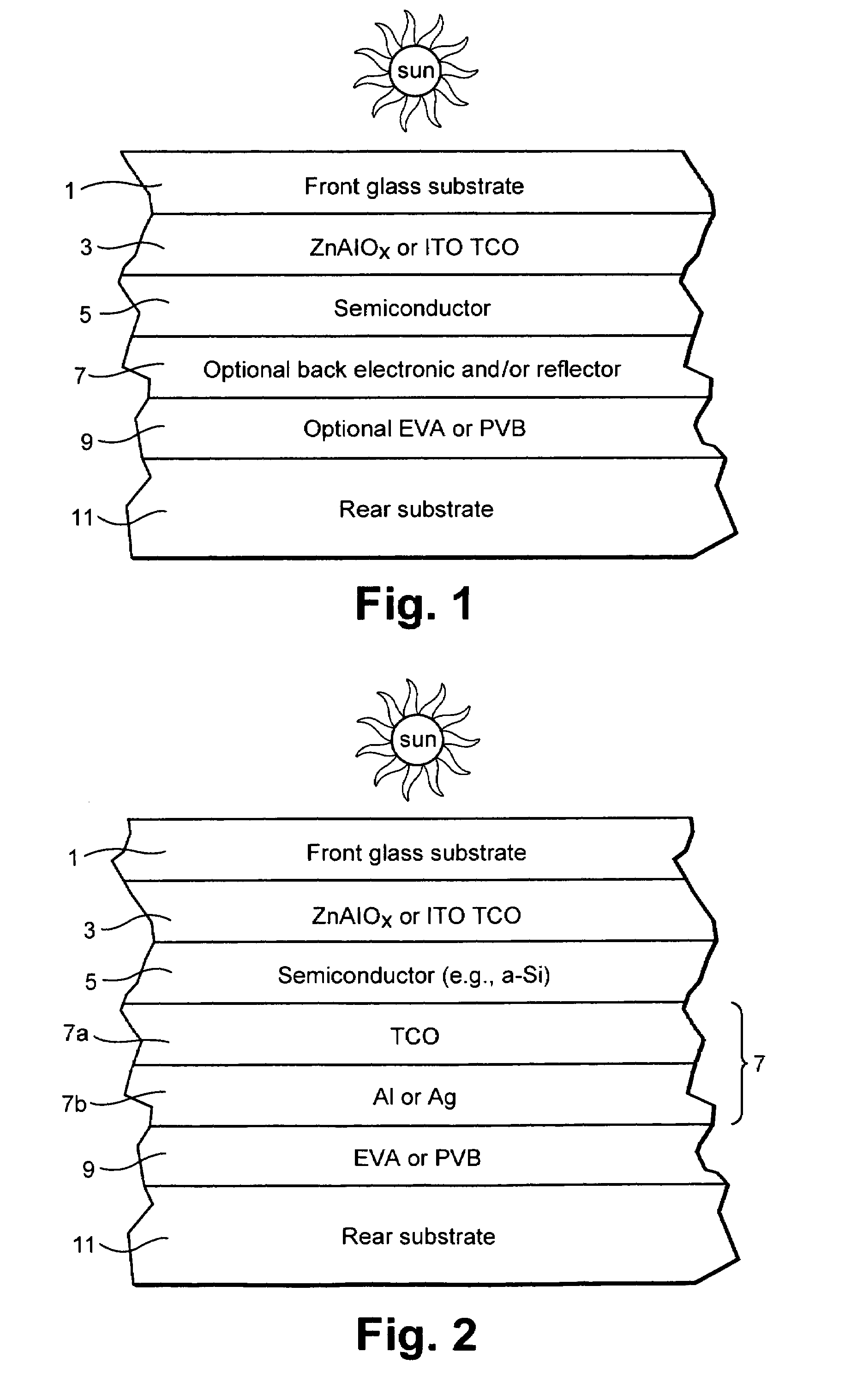

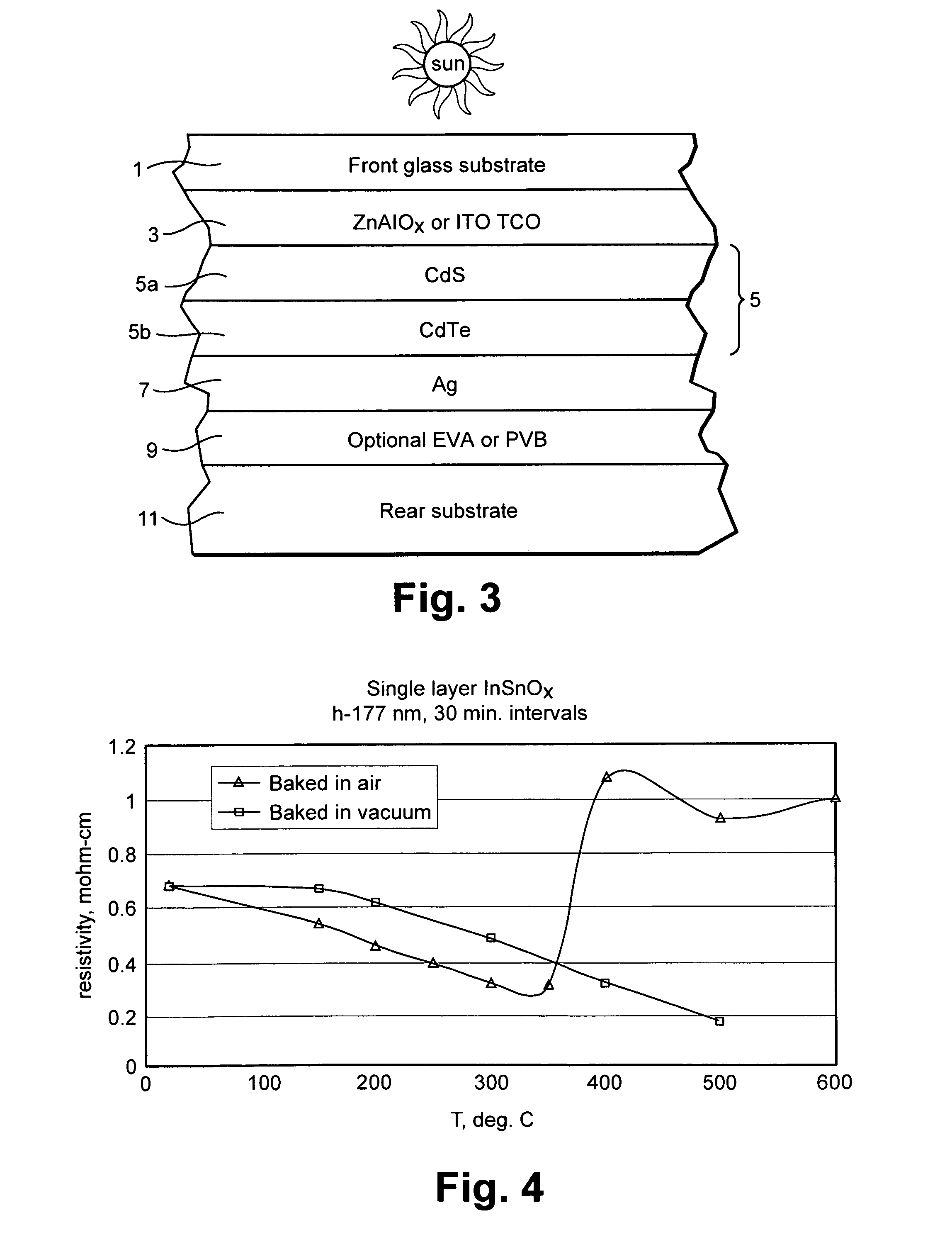

Method of enhancing the conductive and optical properties of deposited indium tin oxide (ITO) thin films

InactiveUS20100304523A1Improve conductivityReduce sheet resistanceMuffle furnacesMaintainance of heating chambersOptical propertyIndium tin oxide

Certain example embodiments of this invention relate to a method of activating an indium tin oxide (ITO) thin film deposited, directly or indirectly, on a substrate. The ITO thin film is baked in a low oxygen environment at a temperature of at least 450 degrees C. for at least 10 minutes so as to provide for (1) a post-baked resistivity of the ITO thin film that is below a resistivity of a corresponding air-baked ITO thin film, (2) a post-baked visible spectrum absorption and transmission of the ITO thin film that respectively are below and above the absorption and transmission of the corresponding air-baked ITO thin film, and (3) a post-baked infrared reflectivity of the ITO thin film that is above the reflectivity of the corresponding air-baked ITO thin film. The substrate with the activated ITO thin film may be used in a photovoltaic device, for example.

Owner:GUARDIAN GLASS LLC

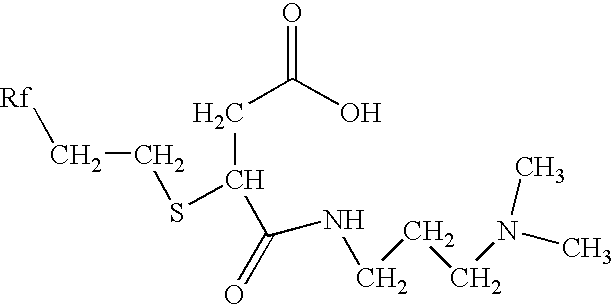

Oxidative Halogenation of C1 Hydrocarbons to Halogenated C1 Hydrocarbons

InactiveUS20080275279A1High selectivityReduce safety concernsHydrocarbon from carbon oxidesHydrocarbonsHalomethaneHalogen

An oxidative halogenation process involving contacting methane, a C1 halogenated hydrocarbon, or a mixture thereof with a source of halogen and a source of oxygen, at a molar ratio of reactant hydrocarbon to source of halogen in a feed to the reactor greater than 23 / 1, and / or at a molar ratio of reactant hydrocarbon to source of oxygen in a feed to the reactor greater than about 46 / 1; in the presence of a rare earth halide or rare earth oxyhalide catalyst, to produce a halogenated C1 product having at least one more halogen as compared with the C1 reactant hydrocarbon, preferably, methyl chloride. The process can be advantageously conducted to total conversion of source of halogen and source of oxygen. The process can be advantageously conducted with essentially no halogen in the feed to the reactor, by employing a separate catalyst halogenation step in a pulse, swing or circulating bed mode. The production of methyl halide can be integrated into downstream processes for manufacture of valuable commodity chemicals.

Owner:PODKOLZIN SIMON G +3

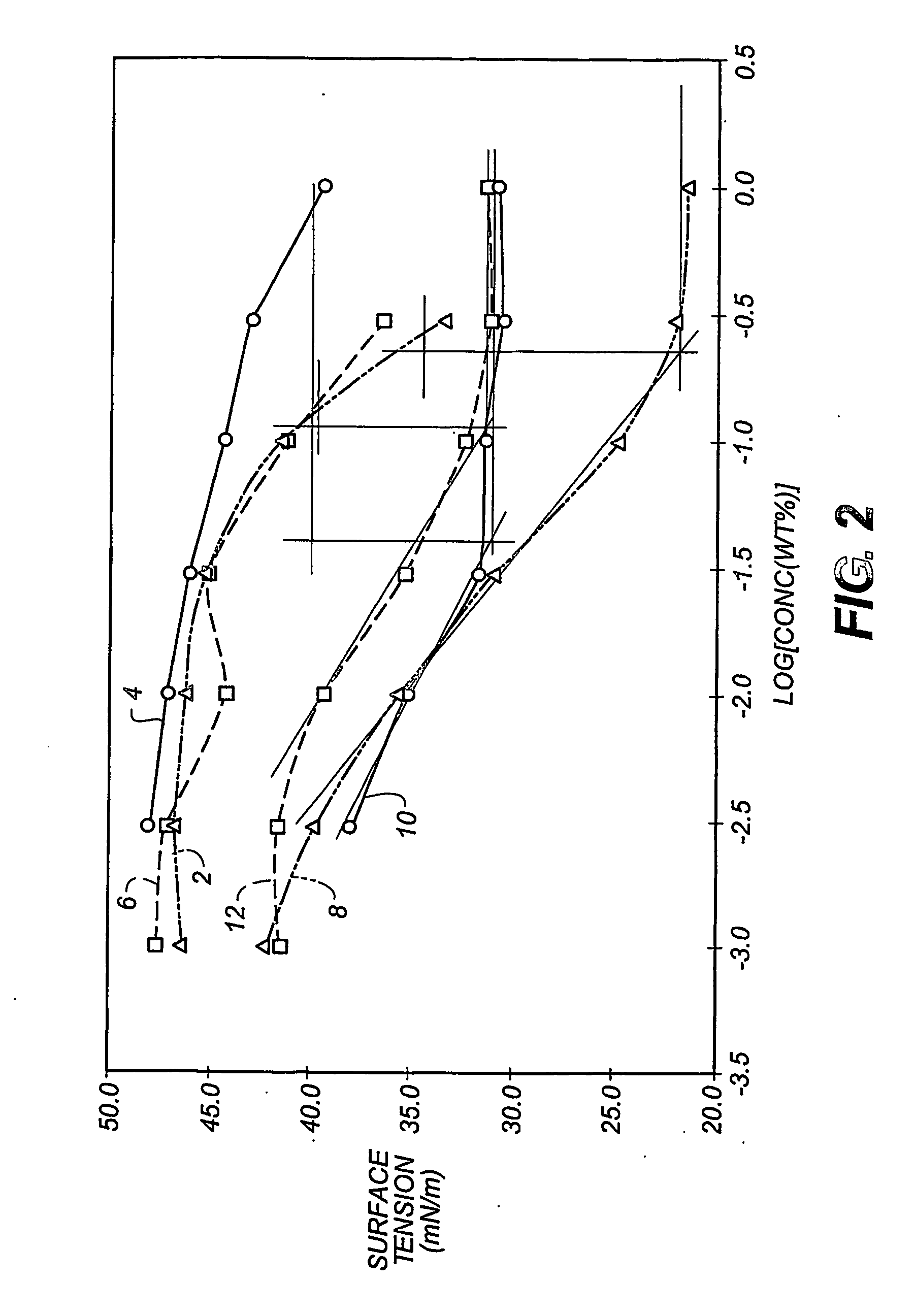

Inkjet recording liquid and process for the production thereof

InactiveUS6235099B1High processing temperatureImprove waterproof performanceDuplicating/marking methodsInksWater basedInorganic salts

A water-dispersed inkjet recording liquid excellent in water resistance and transparency and also excellent in the property of ejection from a nozzle, containing, as a colorant, a water-based dispersion of an organic pigment (A) which is at least one member selected from the group consisting of a quinacridone pigment, a benzimidazolone pigment, an insoluble azo pigment, a fuzed azo pigment, a quinophthalone pigment, a naphthol pigment, a perylene pigment and an isoindolinone pigment and has an average particle diameter of 10 to 150 nm (measured by laser scattering), the water-based dispersion of the organic pigment (A) being obtained by mechanically kneading a mixture containing at least three components of the organic pigment (A), a water-soluble inorganic salt (B) in an amount by weight at least three times as large as the amount of the organic pigment (A) and a water-soluble solvent (C) to finely mill the organic pigment (A), and then removing the water-soluble inorganic salt (B) and the water-soluble solvent (C) by washing the kneaded mixture with water, and a process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

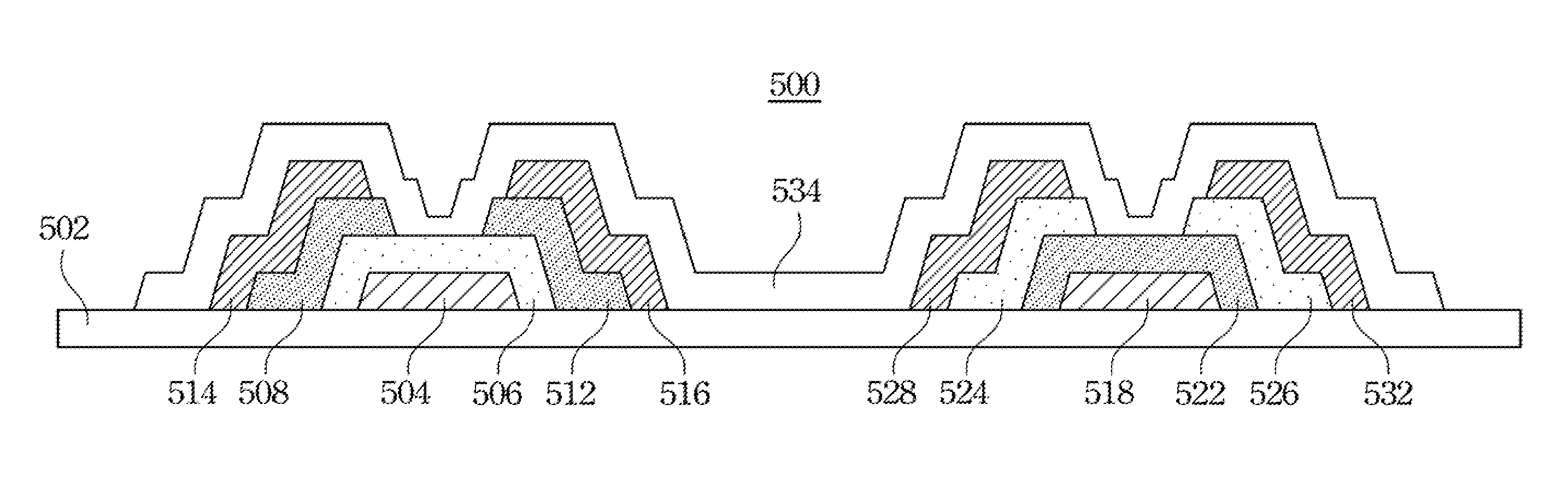

Transistor structure

ActiveUS8350260B2Low mobilityHigh processing temperatureFinal product manufactureSolid-state devicesHeterojunctionSemiconductor

A transistor structure comprises a patterned N-type transparent oxide semiconductor formed over a substrate as a base, and a patterned p-type organic polymer semiconductor formed on the patterned N-type transparent oxide semiconductor comprising a first portion and a second portion so that the patterned N-type transparent oxide semiconductor and the first portion and the second portion of the patterned p-type organic polymer semiconductor form heterojunctions therebetween respectively, wherein the first portion of the patterned p-type organic polymer semiconductor is used as an emitter, and the second portion of the patterned p-type organic polymer semiconductor is used as a collector.

Owner:E INK HLDG INC

Thermo-stable, arsenic-free synergistic biocide concentrate composition for polymer matrices and process for preparing same

InactiveUS20130310428A1High processing temperatureHigh bactericidal activityBiocideDead animal preservationImideThio-

A thermo-stable, arsenic-free synergistic biocide concentrate composition to afford enhanced antimicrobial properties to a polymer matrix comprising (i) a mixture of trihalomethyl-thio-phthalimide analogue and a second biocide; (ii) an antioxidant; (iii) a carrier; and (iv) optionally, one or more additives. The composition is capable of withstanding high processing temperatures up to about 250° C., substantially without thermal degradation of biocides and discoloration of the polymer matrix employed.

Owner:TROY TECH II

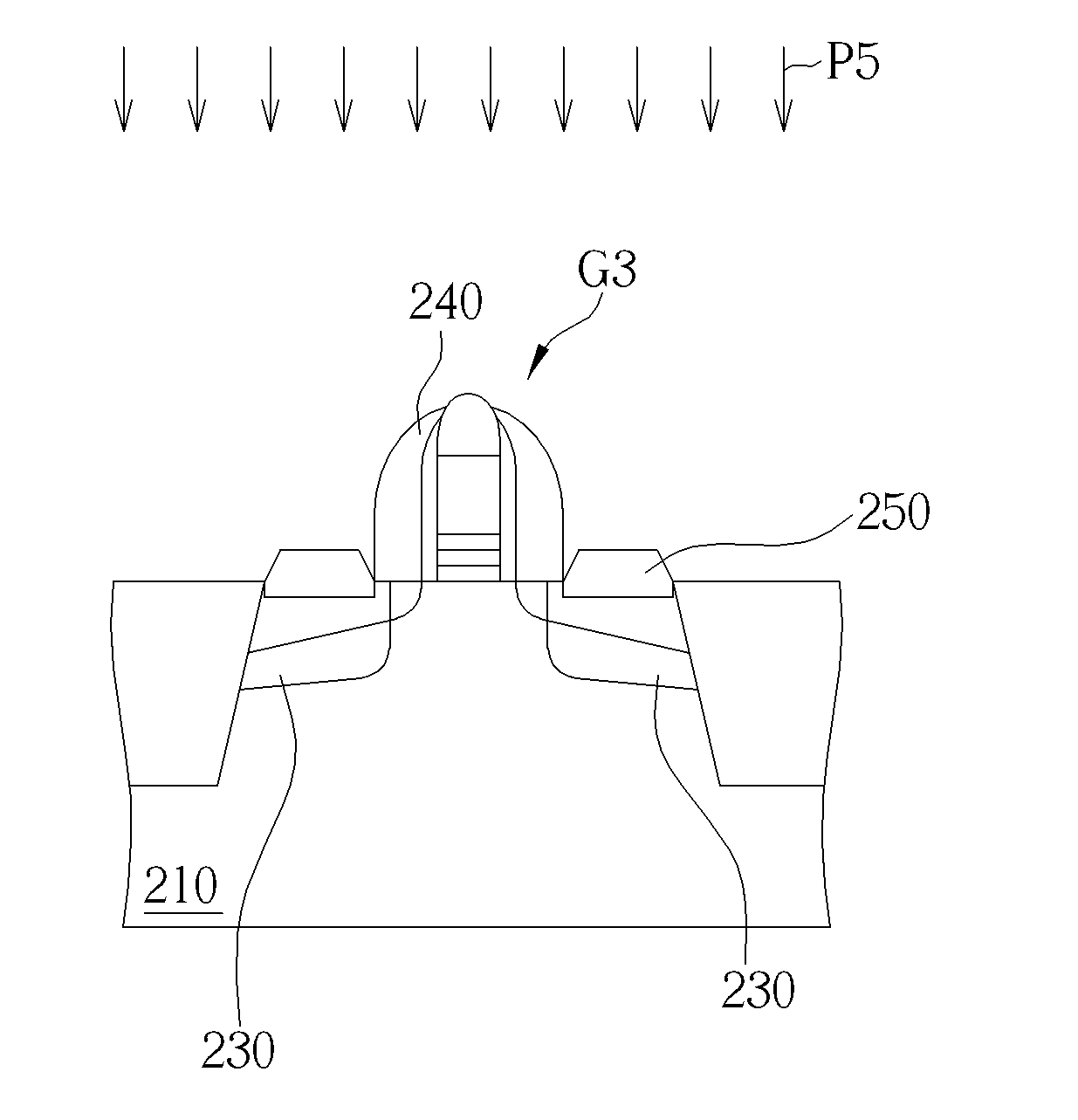

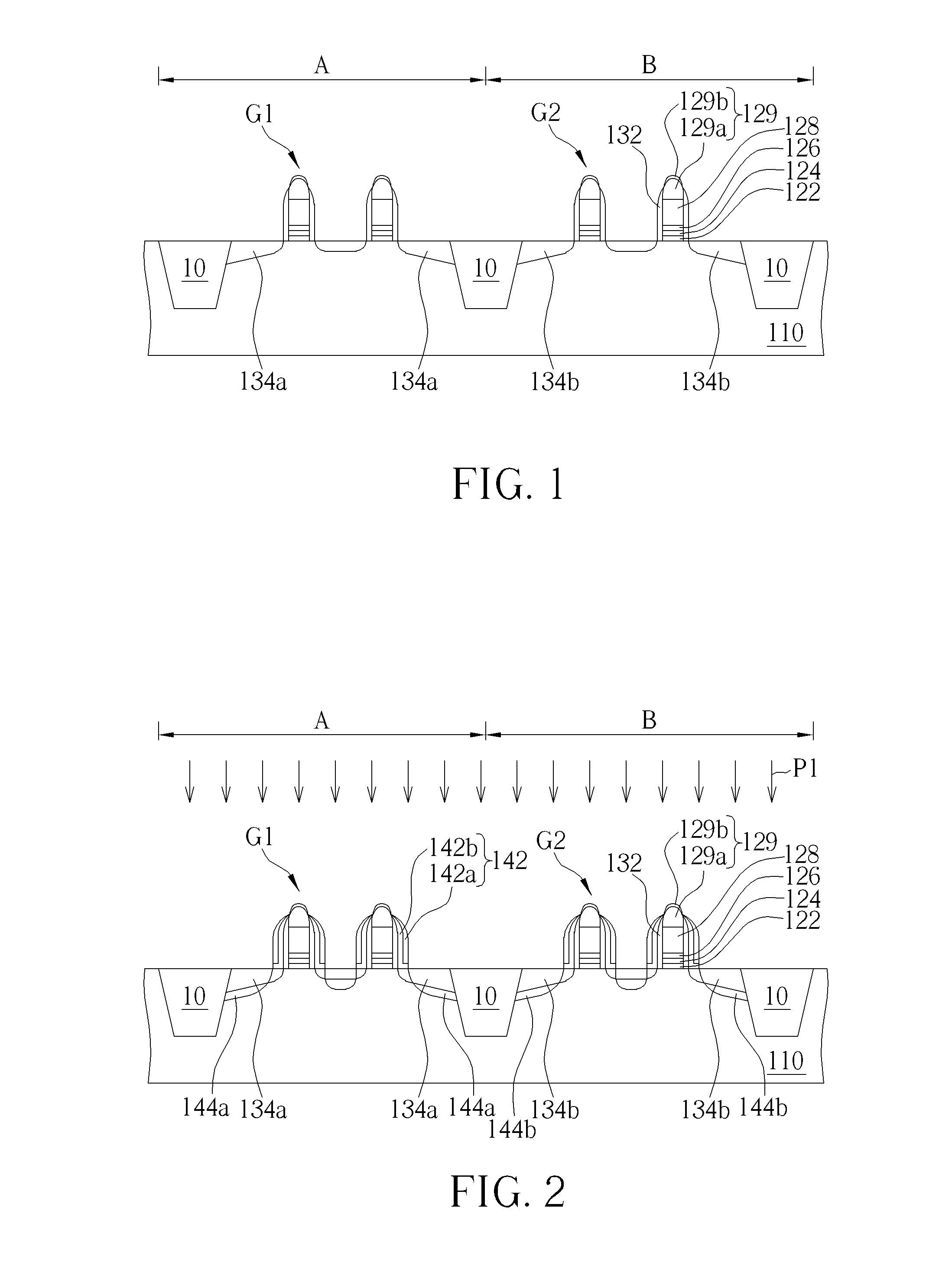

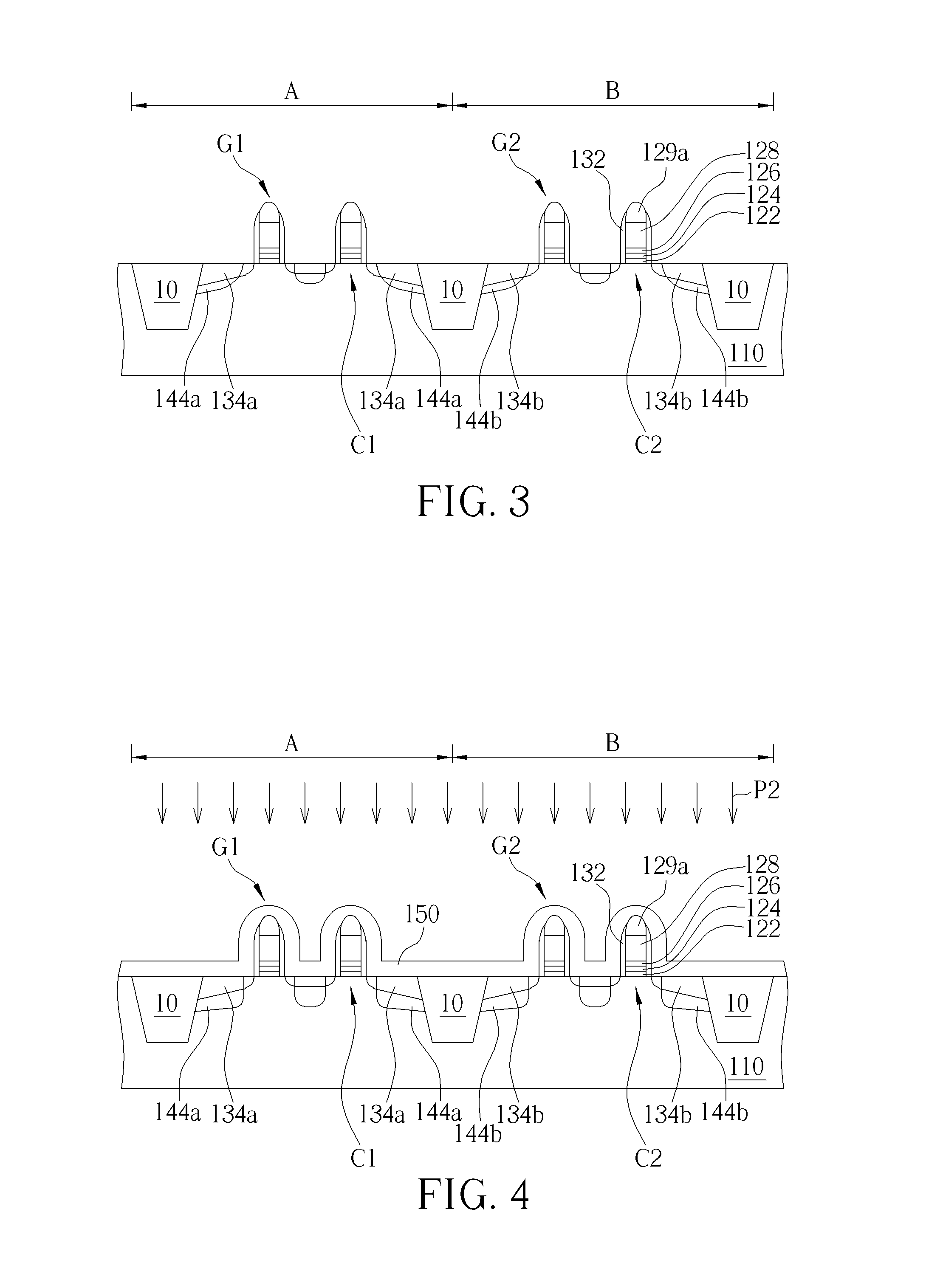

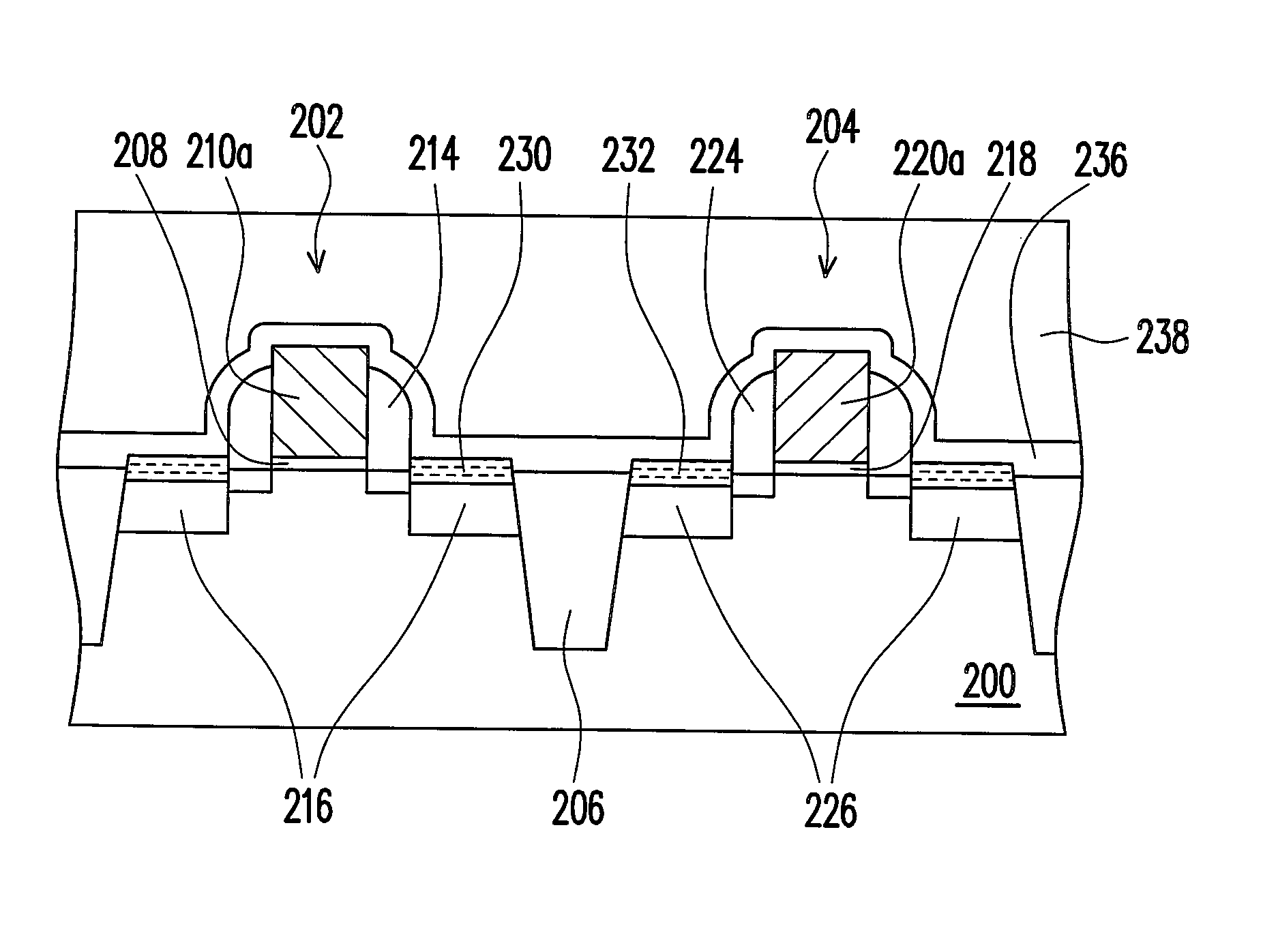

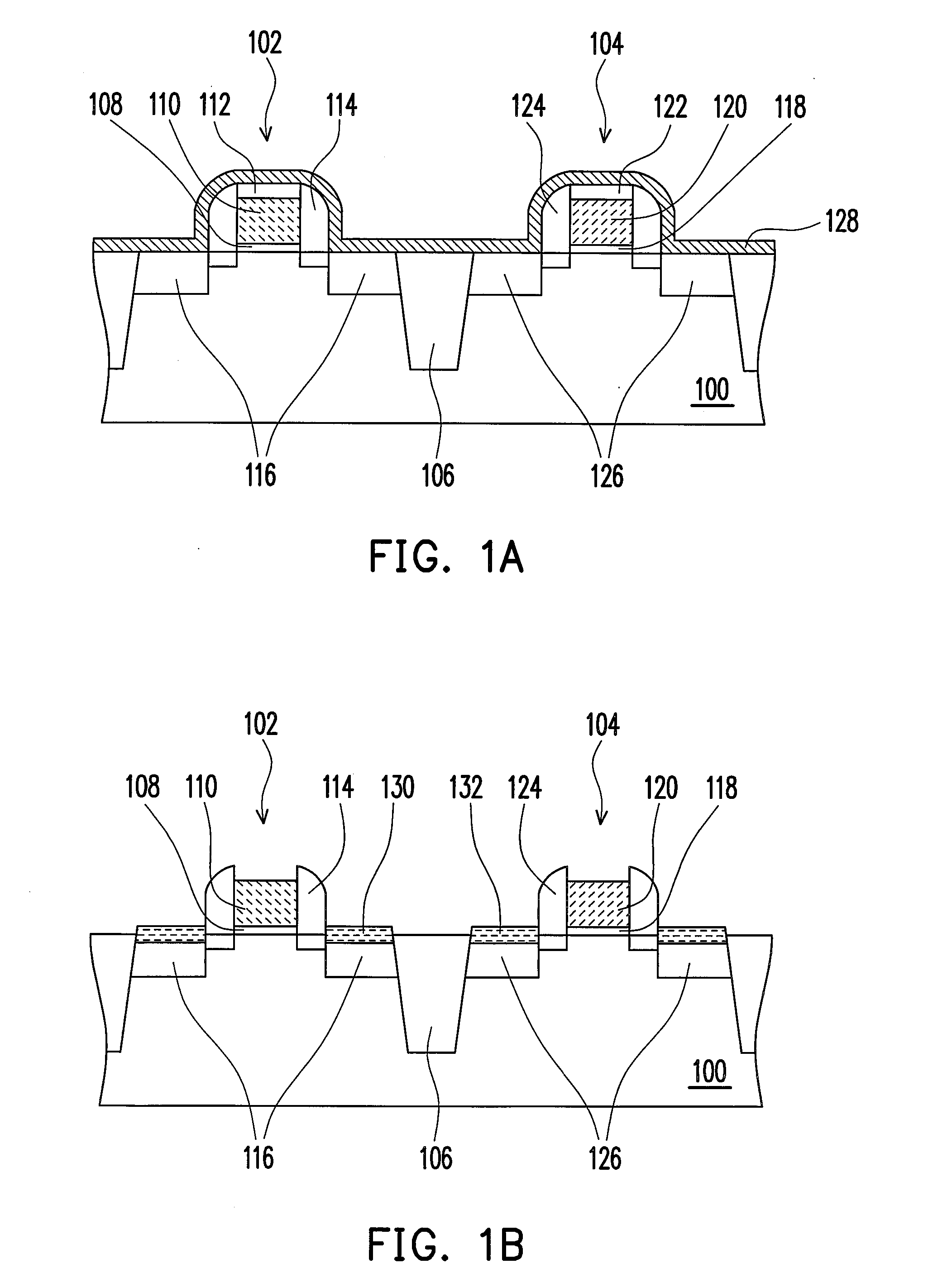

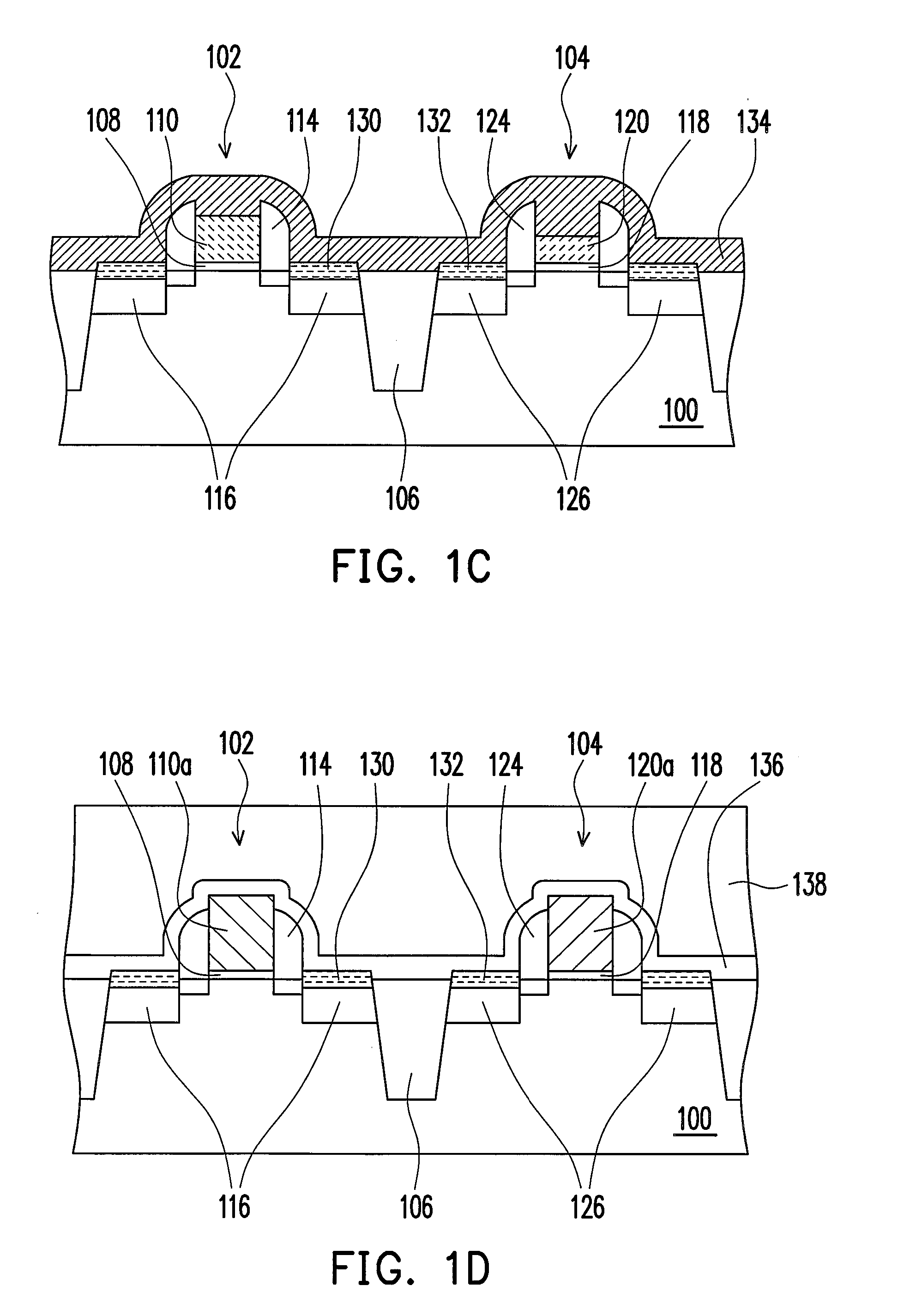

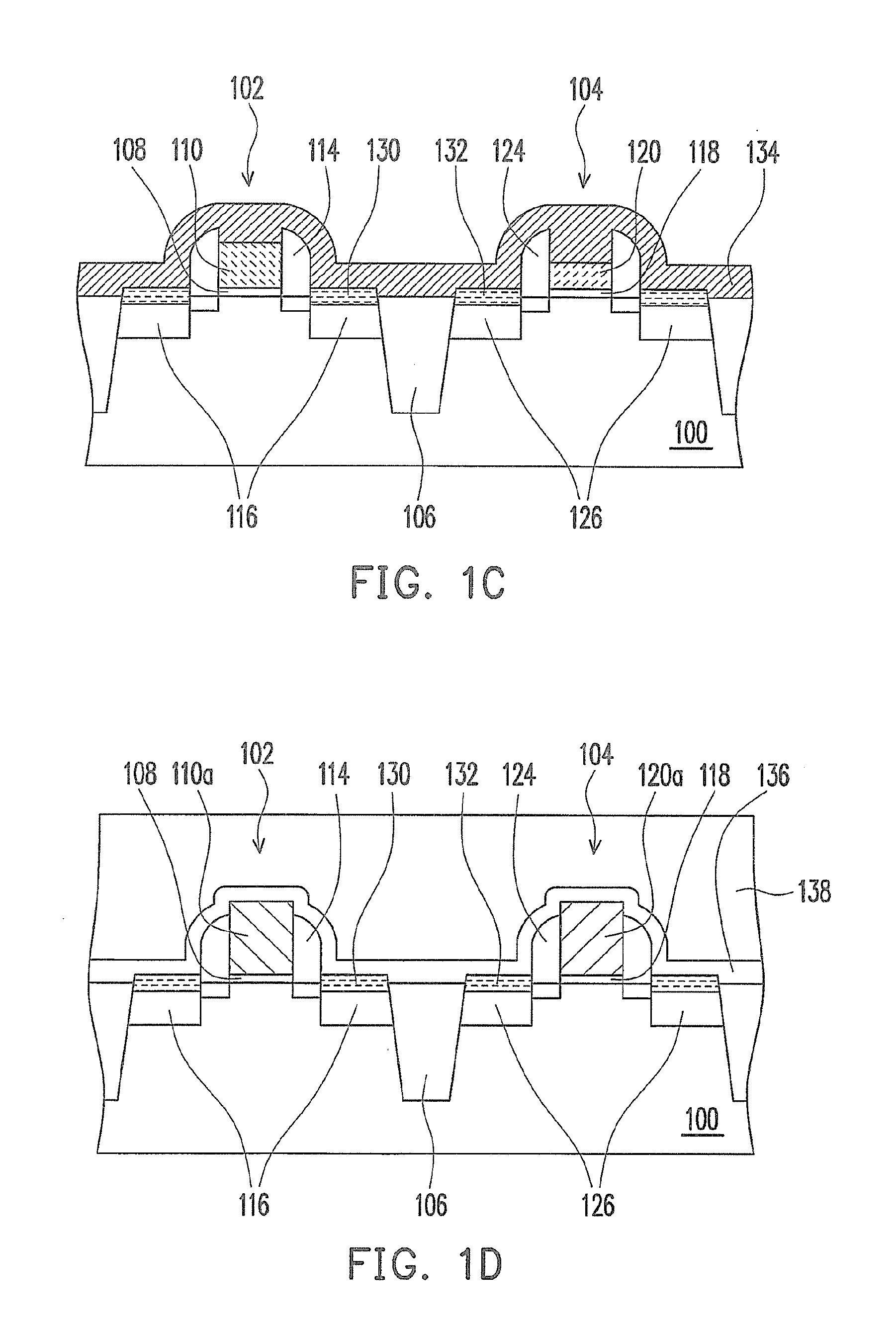

Semiconductor process

ActiveUS20130316506A1Little strengthReduce layeringSemiconductor/solid-state device manufacturingSemiconductor package

A semiconductor process includes the following steps. A gate structure is formed on a substrate. A main spacer is formed on the substrate beside the gate structure. A source / drain is formed in the substrate beside the main spacer. After the source / drain is formed, an epitaxial structure is formed in the substrate beside the main spacer. A gate structure may be respectively formed in a first area and a second area of a substrate. A main spacer is formed on the substrate respectively beside the two gate structures. A source / drain is formed in the substrate respectively beside the two spacers. After the two source / drains are formed, an epitaxial structure is formed in the substrate respectively beside the main spacers.

Owner:MARLIN SEMICON LTD

Electronic Device Module Comprising Film of Homogeneous Polyolefin Copolymer and Grafted Silane

InactiveUS20130233383A1Good adhesion to glassHigh processing temperatureSemiconductor/solid-state device detailsSolid-state devicesPolymer sciencePolyolefin

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene interpolymer comprising an overall polymer density of not more than 0.905 g / cm3; total unsaturation of not more than 125 per 100,000 carbons; up to 3 long chain branches / 1000 carbons; vinyl-3 content of less than 5 per 100,000 carbons; and a total number of vinyl groups / 1000 carbons of less than the quantity (8000 / Mn), wherein the vinyl-3 content and vinyl group measurements are measured by gel permeation chromatography (145° C.) and 1H-NMR (125° C.), (2) grafted vinyl silane, (3) optionally, free radical initiator or a photoinitiator in an amount of at least about 0.05 wt % based on the weight of the copolymer, and (3) optionally, a co-agent in an amount of at least about 0.05 wt % based upon the weight of the copolymer.

Owner:NAUMOVITZ JOHN A +3

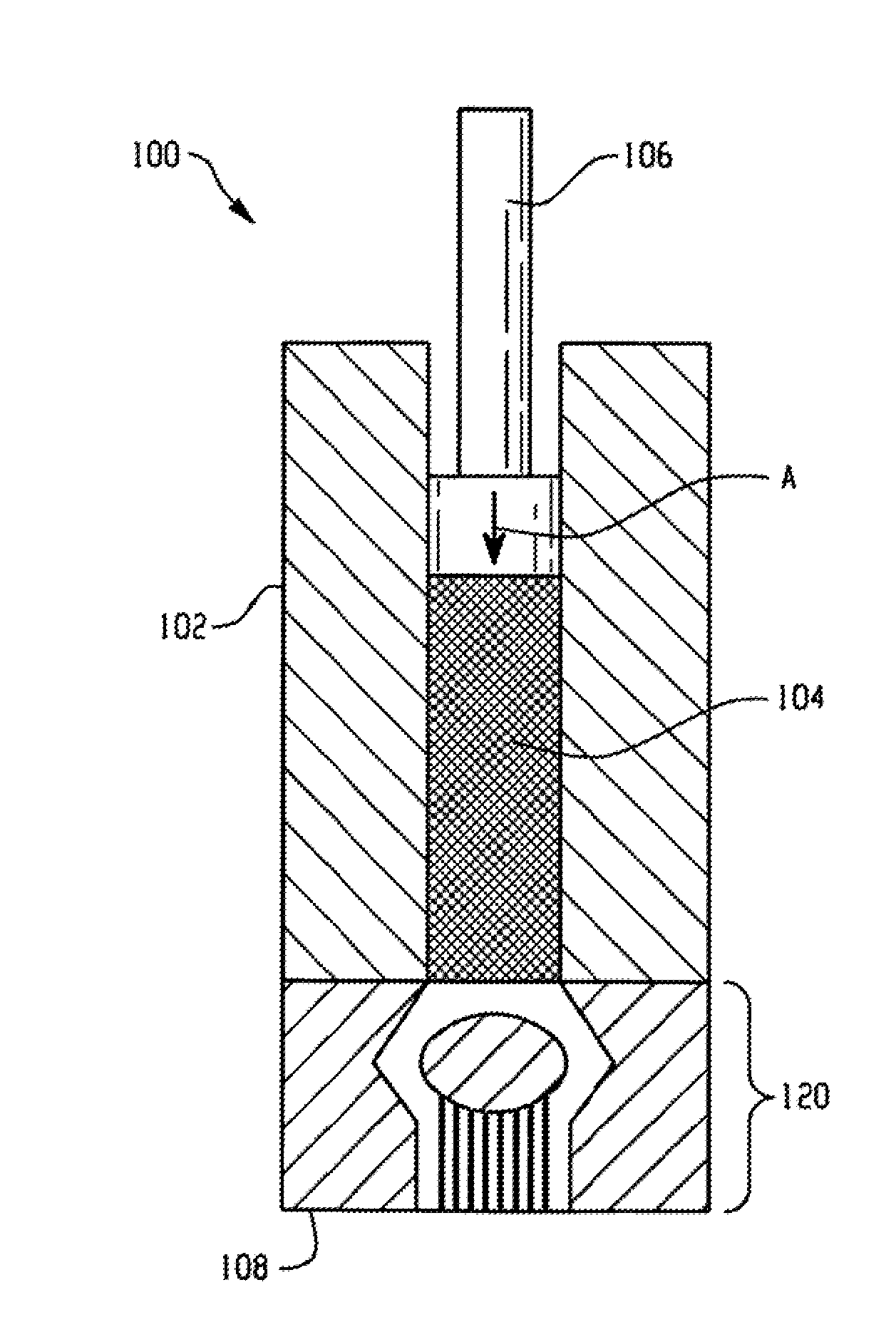

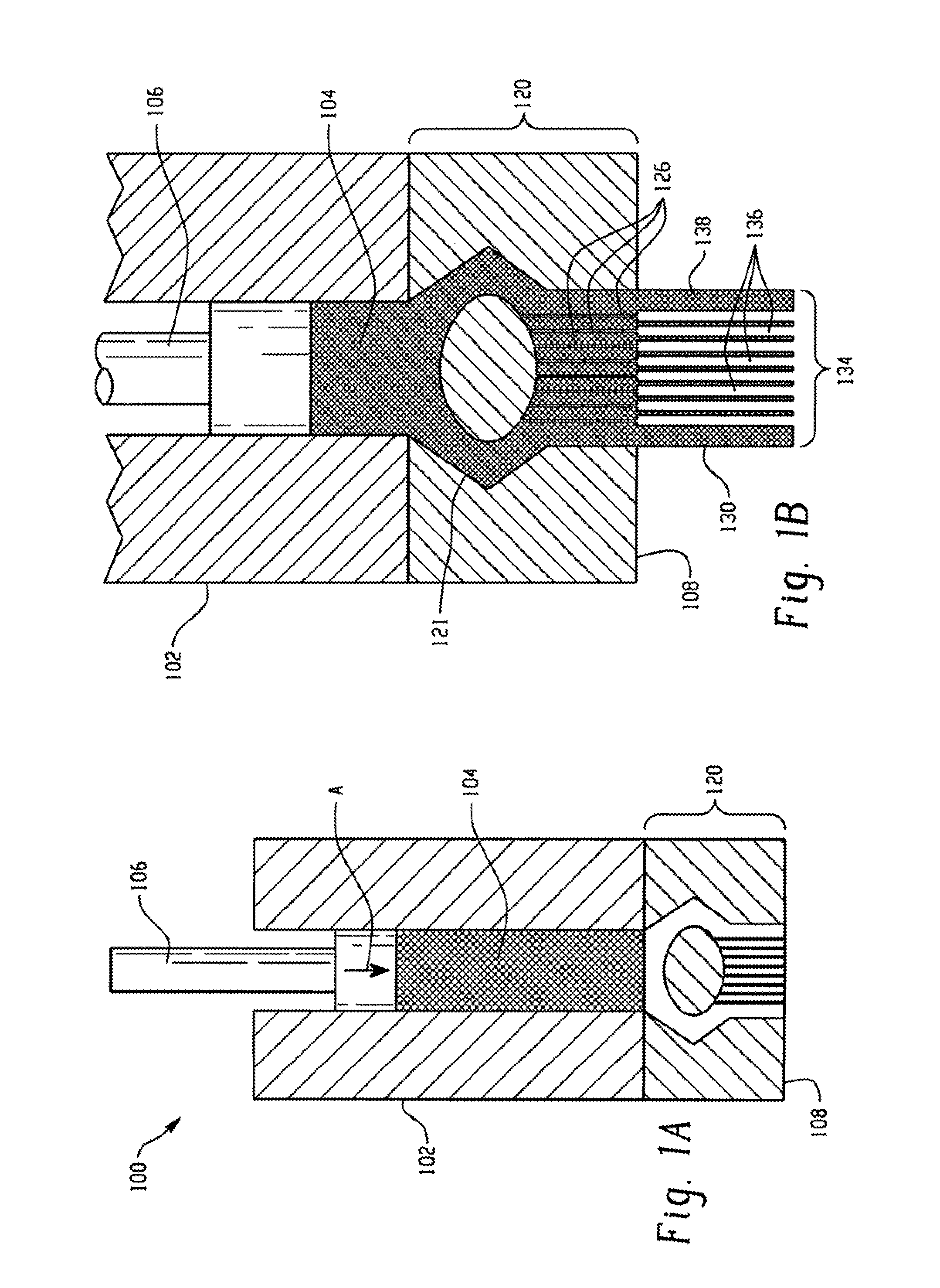

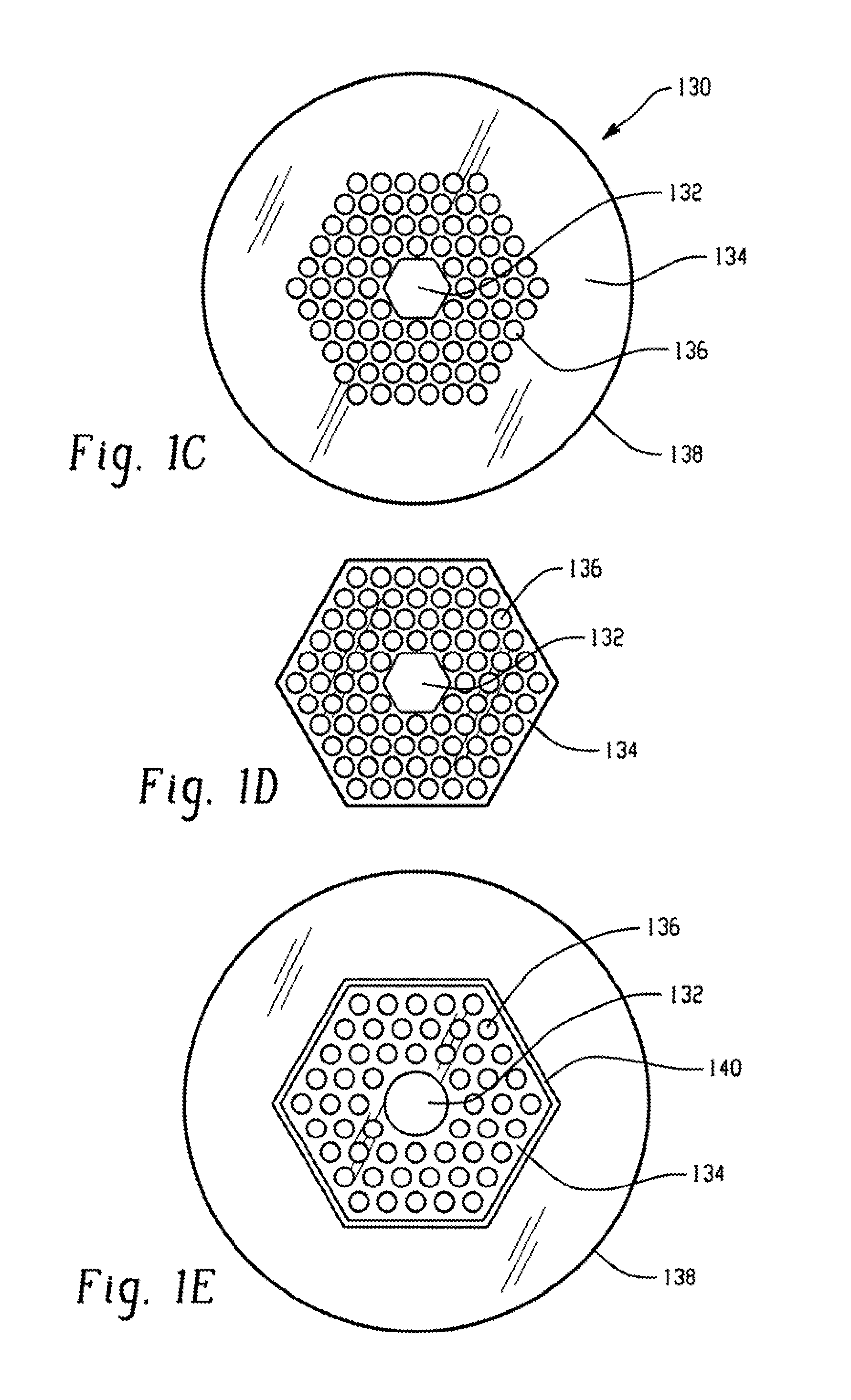

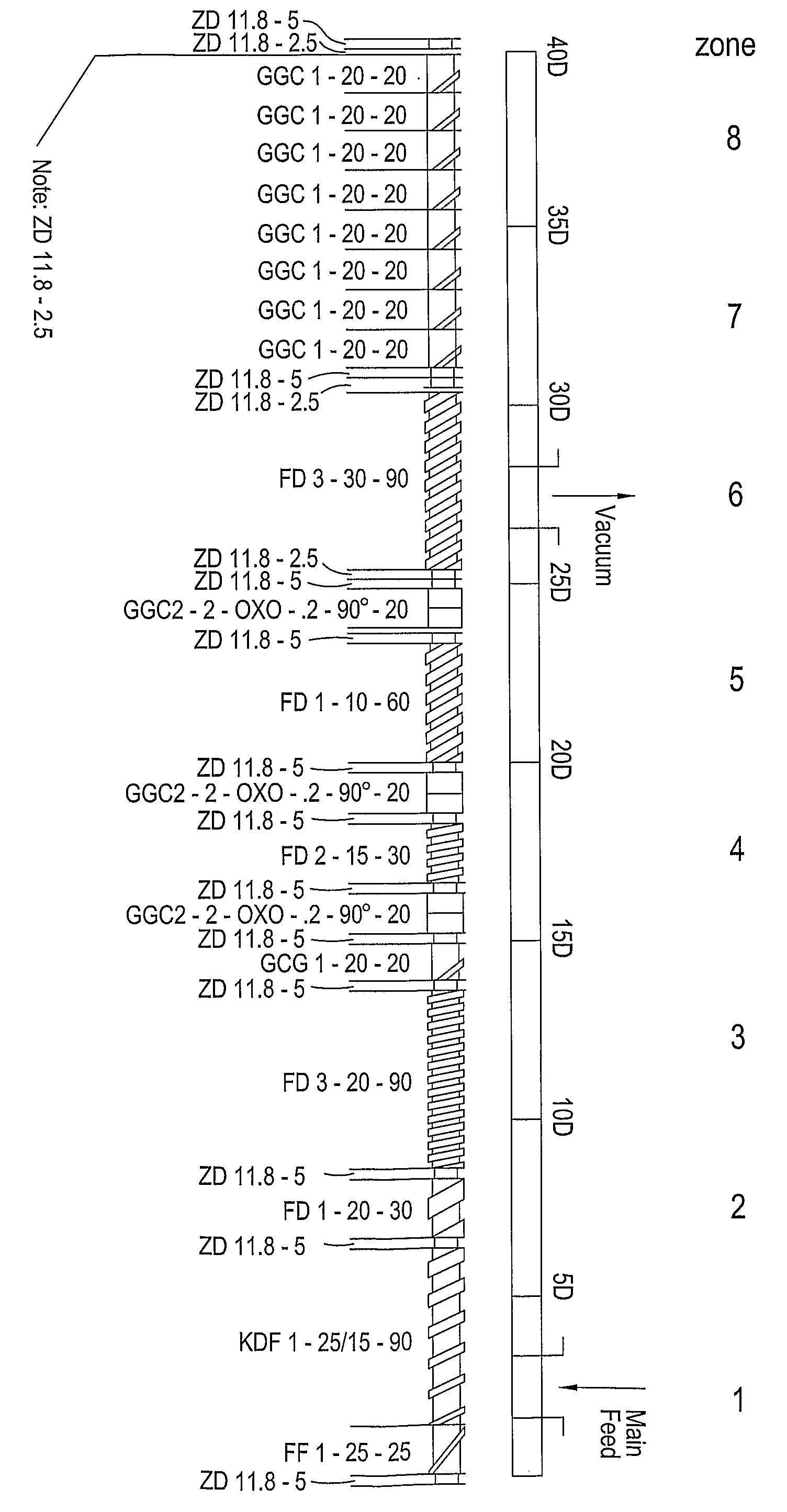

Direct extrusion method for the fabrication of photonic band gap (PBG) fibers and fiber preforms

ActiveUS20120321263A1Low softening temperatureHigh processing temperatureGlass making apparatusCladded optical fibrePhotonic bandgapCore (optical fiber)

A method and apparatus for making a substantially void-free preform for a microstructured optical fiber using a one-step process is provided. A preform is prepared from specialty glasses using a direct extrusion method. A die for use with the direct extrusion method is also provided, and a method for drawing the preform into a HC-PBG fiber for use in transmitting infra-red wavelength light is also provided. The preform comprises an outer jacket made of solid glass, a cladding having a plurality of air holes arranged in a desired pattern within the jacket, and a core which is hollow.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

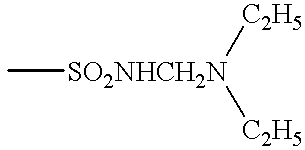

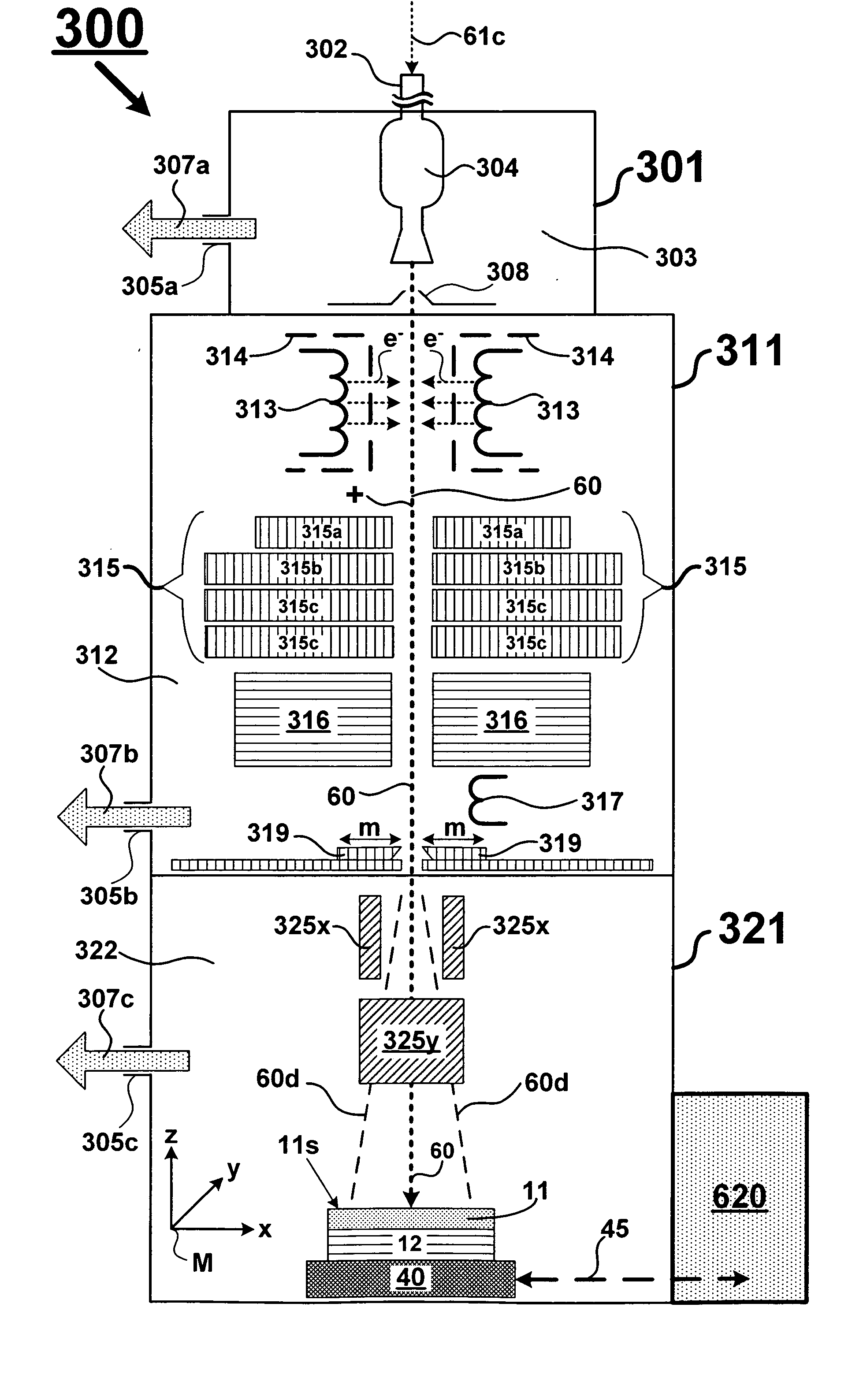

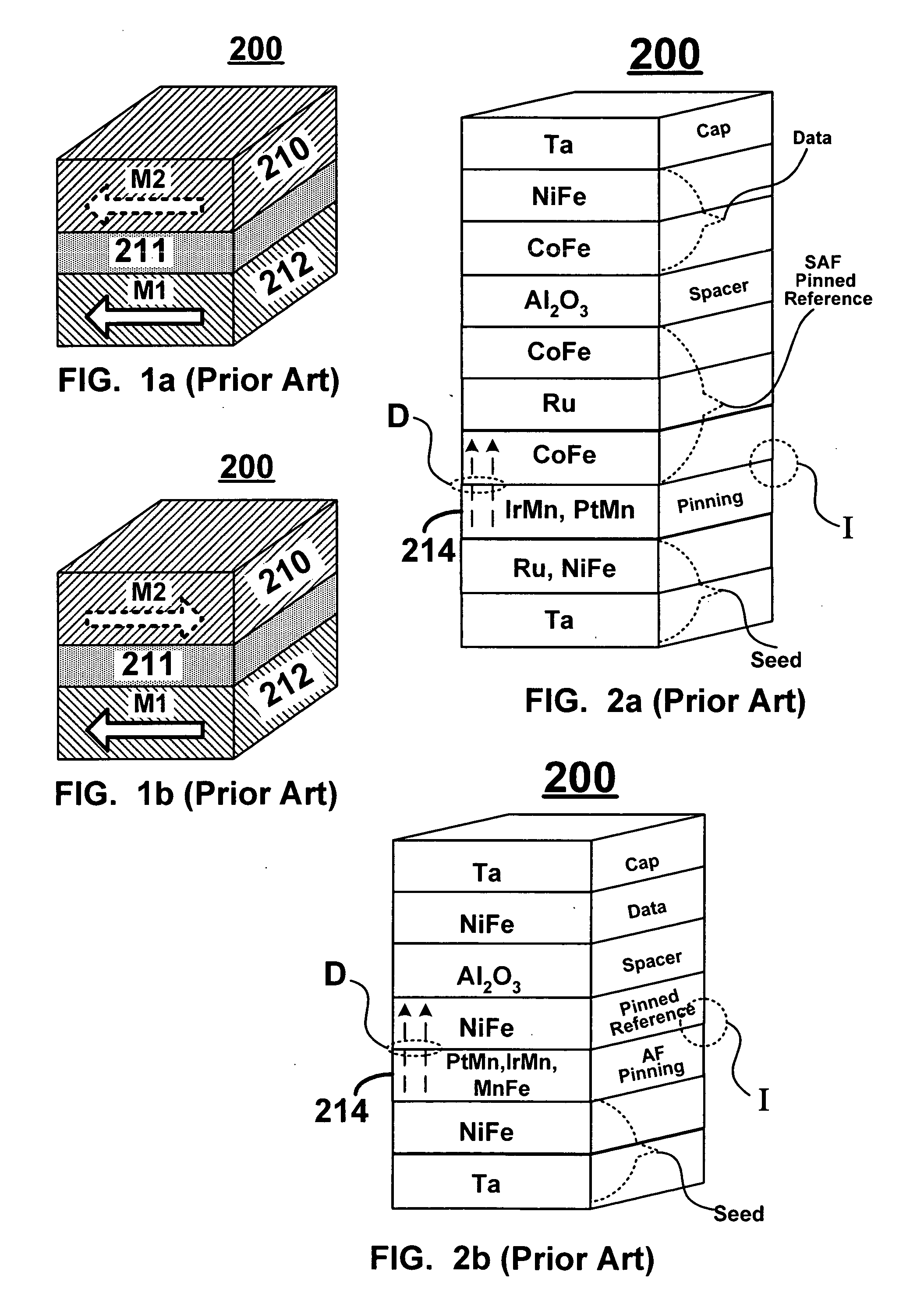

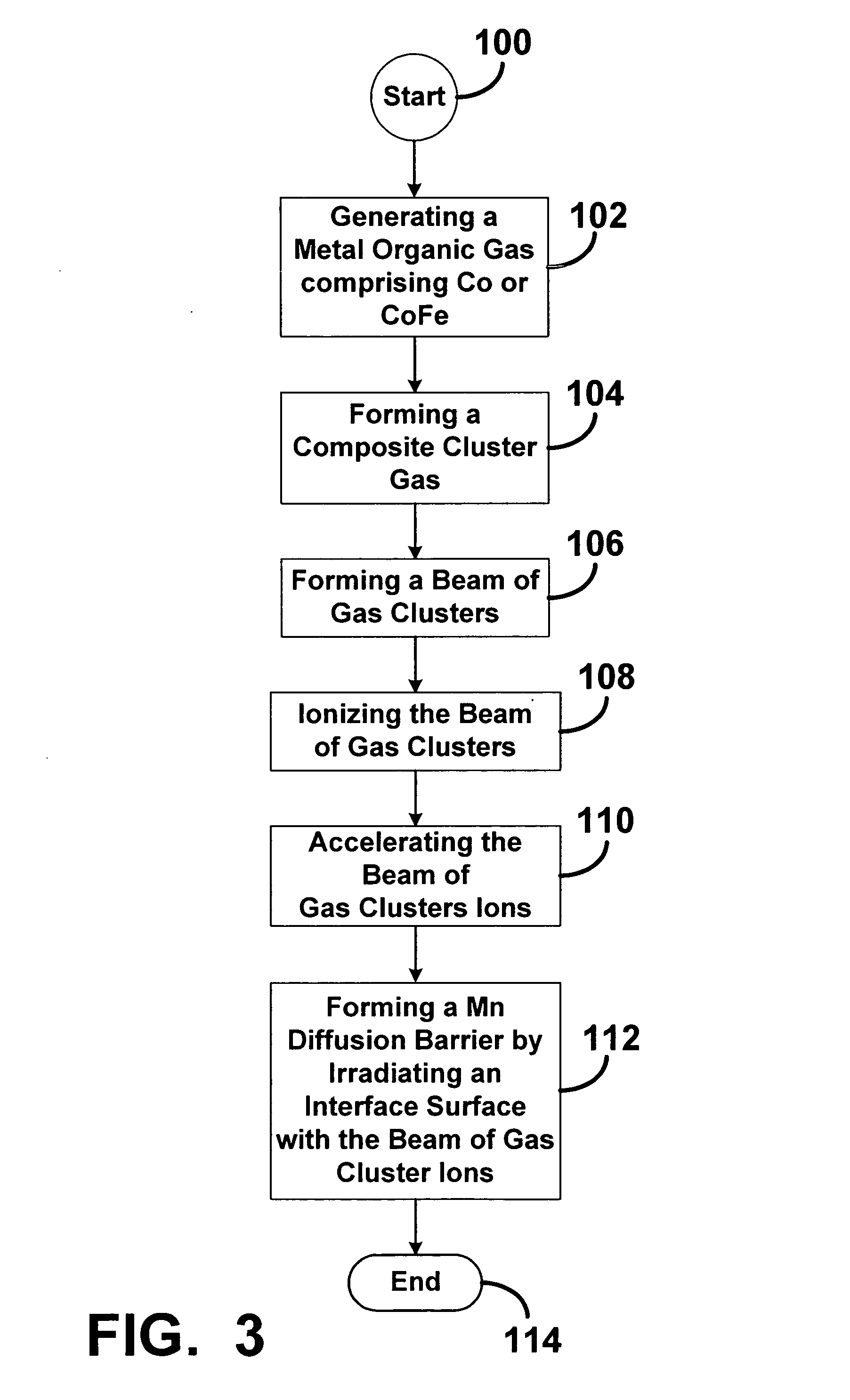

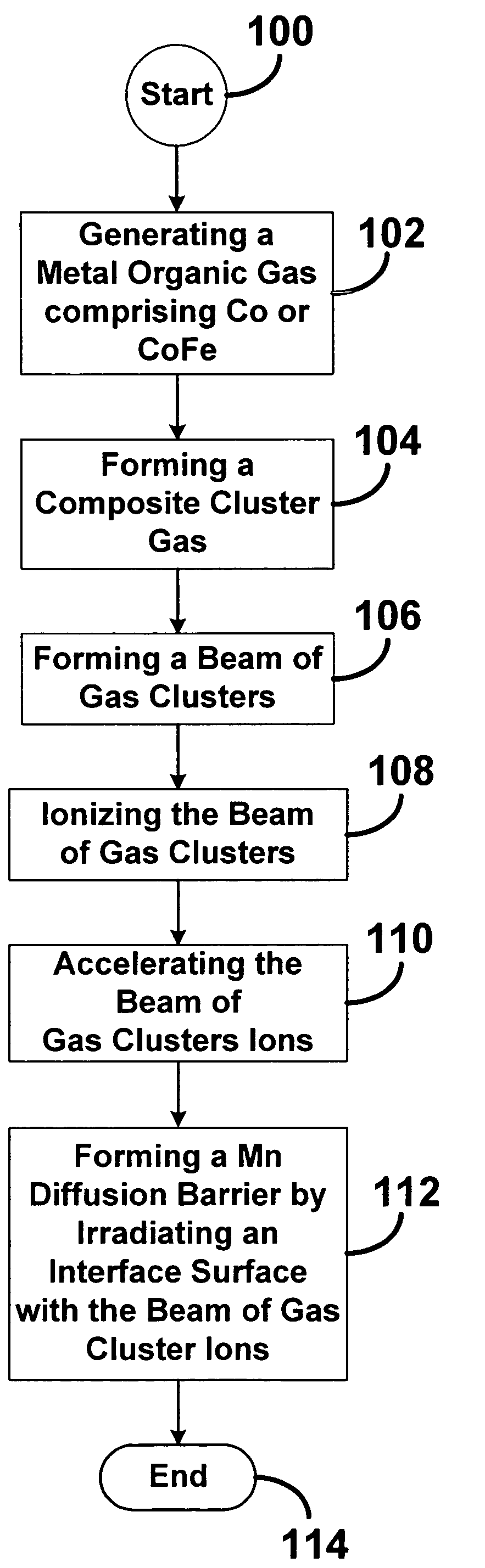

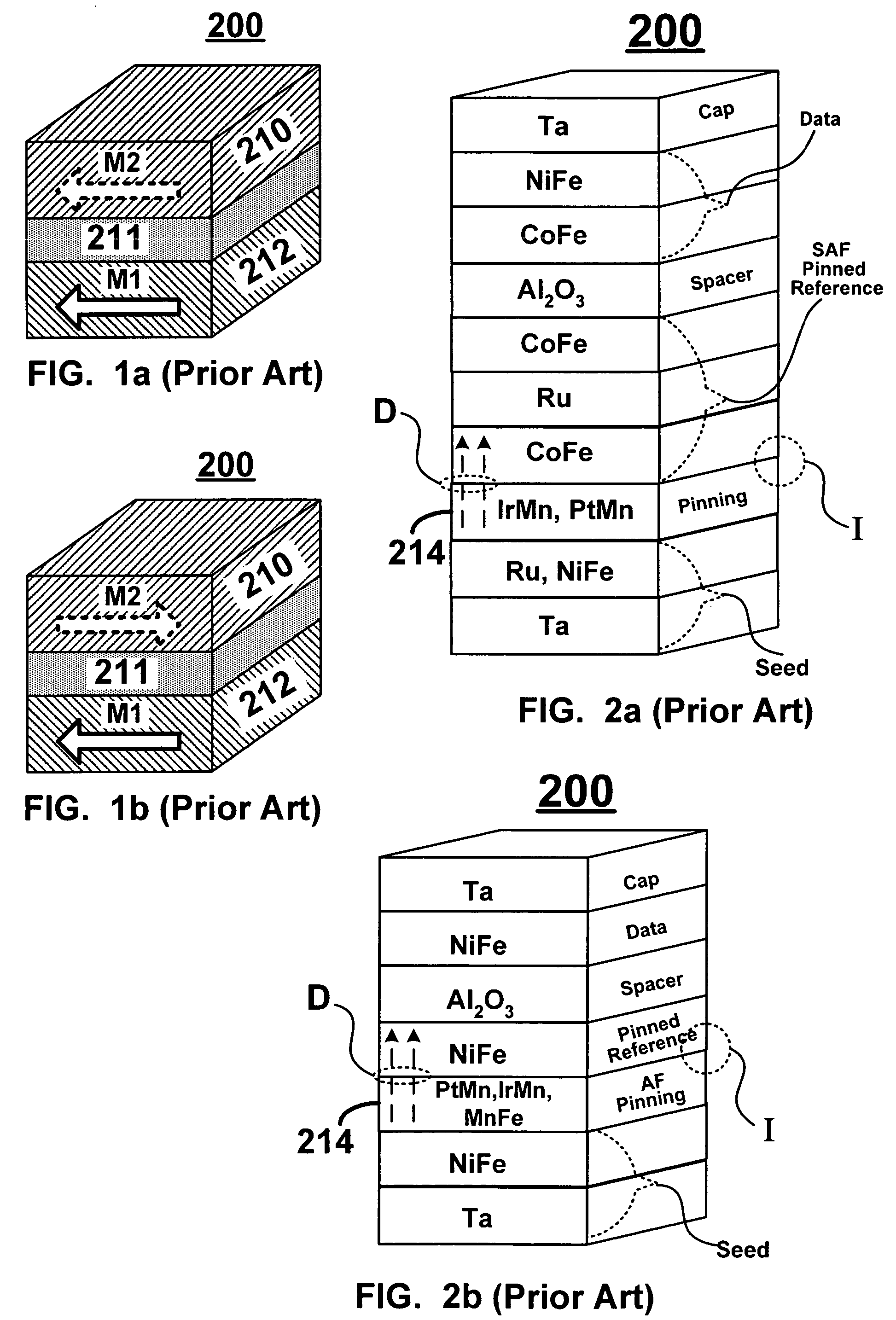

Method of fabricating a manganese diffusion barrier

ActiveUS20060172086A1Improve signal-to-noise ratioHigh processing temperatureElectric discharge tubesVacuum evaporation coatingSimple Organic CompoundsDiffusion

A method of fabricating a diffusion barrier using a gas cluster ion beam apparatus is disclosed. The method includes generating a metal-organic gas that includes a metal-organic compound that includes an element of cobalt (Co) or cobalt and iron (CoFe). The metal-organic gas is combined with a carrier gas that is supplied to the gas cluster ion beam apparatus (GCIB). The GCIB processes the carrier gas to form a beam of gas cluster ions that include the metal-organic compound. The beam irradiates an interface surface of a target material (e.g. an IrMn, PtMn, or MnFe antiferromagnetic layer) and at least a portion of the Co or CoFe remains in contact with the interface surface to form a barrier that prevents a diffusion of manganese (Mn).

Owner:SAMSUNG ELECTRONICS CO LTD

Remediation of contaminated particulate materials

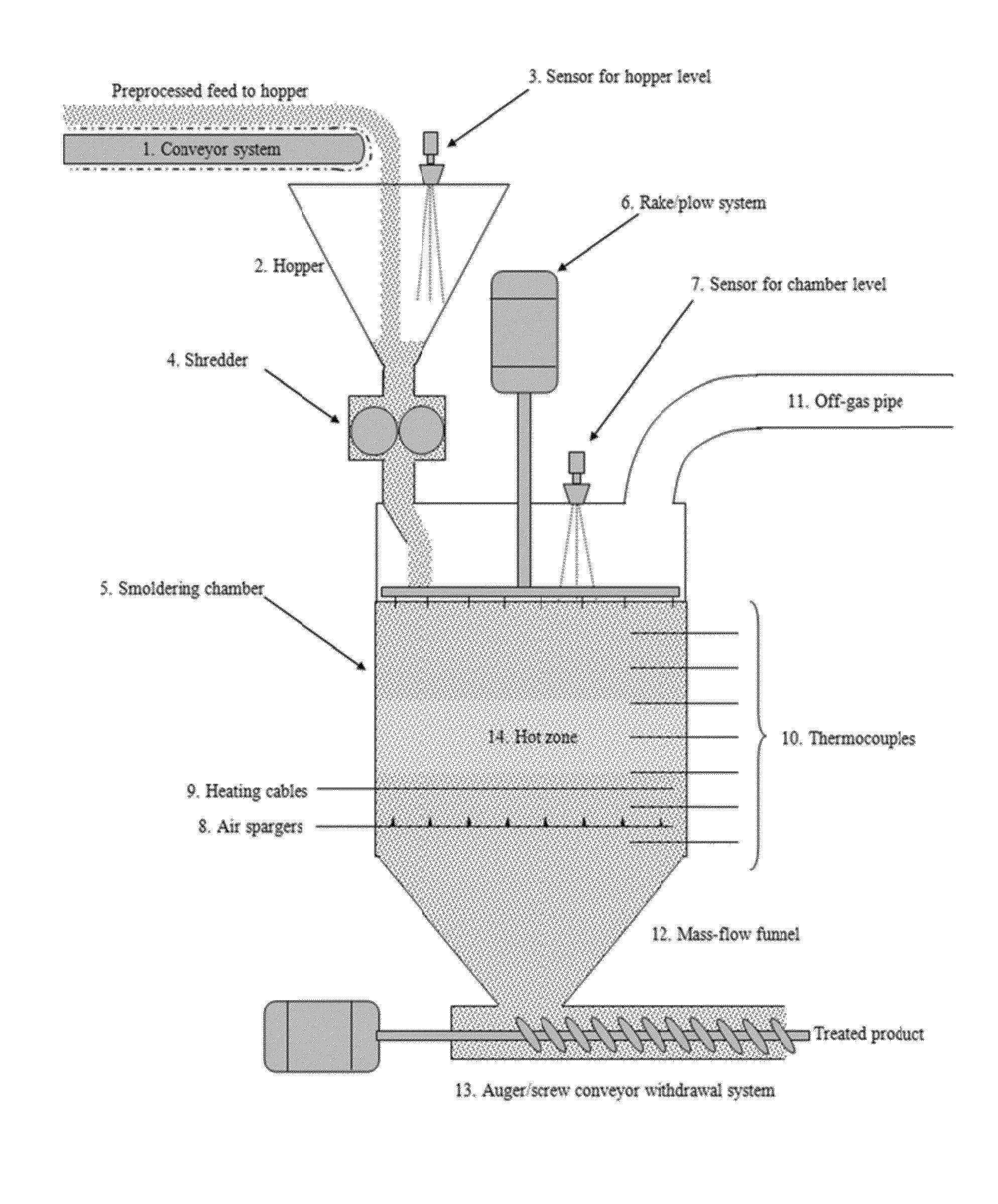

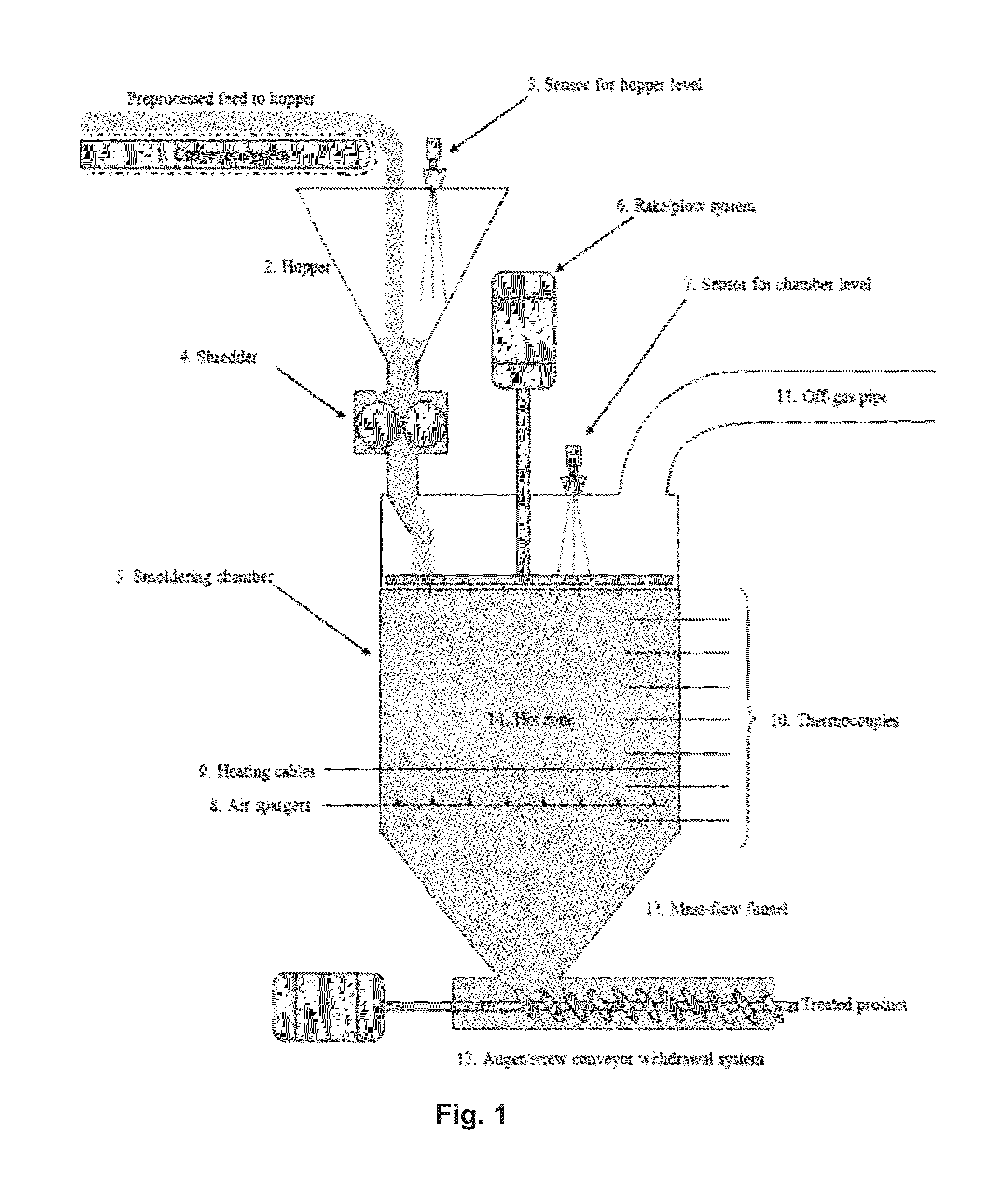

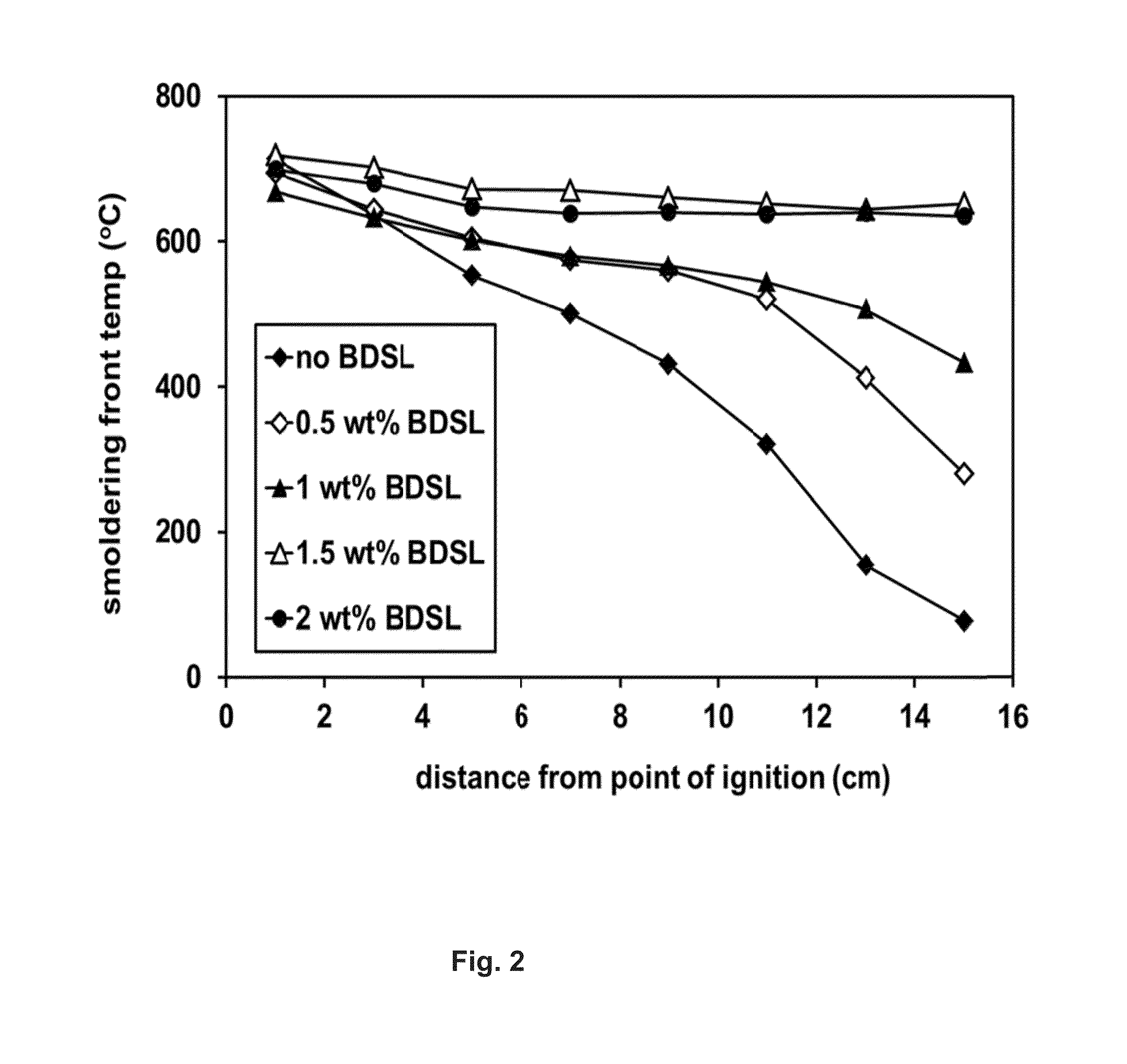

ActiveUS20140241806A1Quality improvementEasy to reuseContaminated soil reclamationIncinerator apparatusParticulatesCombustion

A process for the remediation of contaminated particulate materials by the addition of an environmentally benign, carbonaceous fuel source in low concentration to enable or enhance smoldering combustion. The process may be applied to both in situ and ex situ treatments. In an ex situ smoldering process for the remediation of contaminated particulate materials in a continuous manner, contaminated feed is introduced near the top of a treatment unit and treated product emerges near the bottom. A smoldering front is maintained in the unit, fed by the fuel in the contaminated particulate material and a supply of combustion-supporting gas, such as air.

Owner:EXXON RES & ENG CO

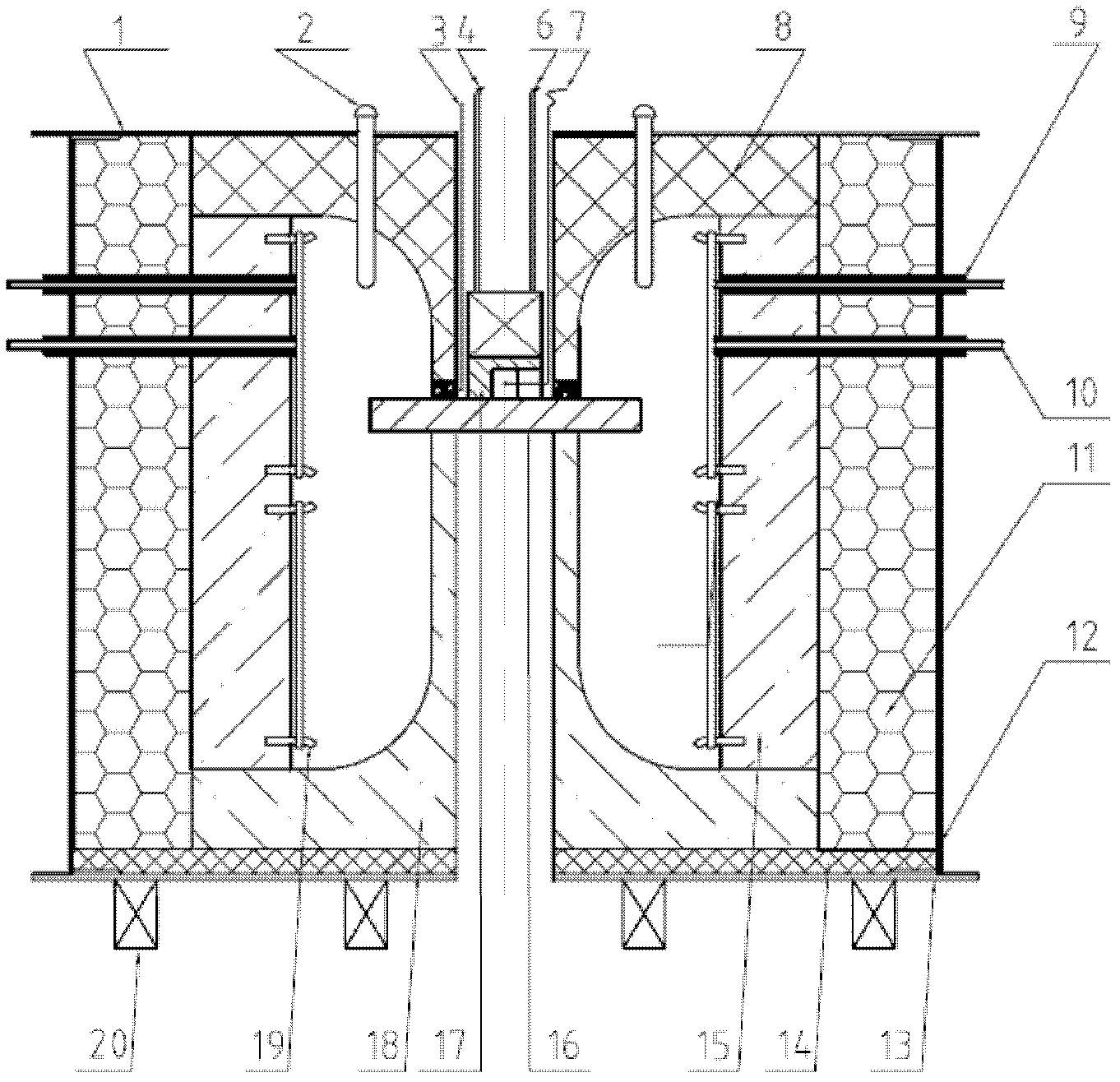

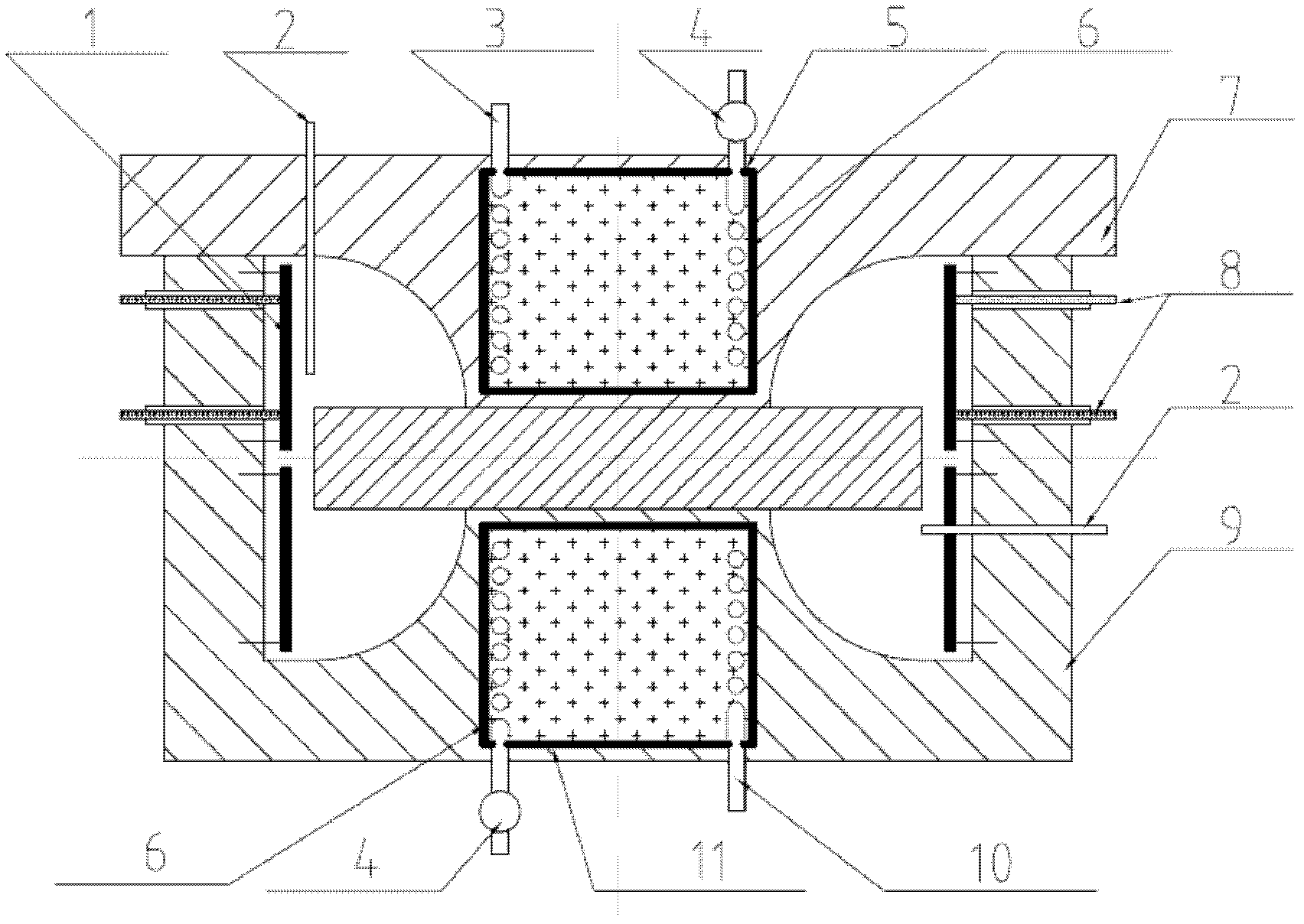

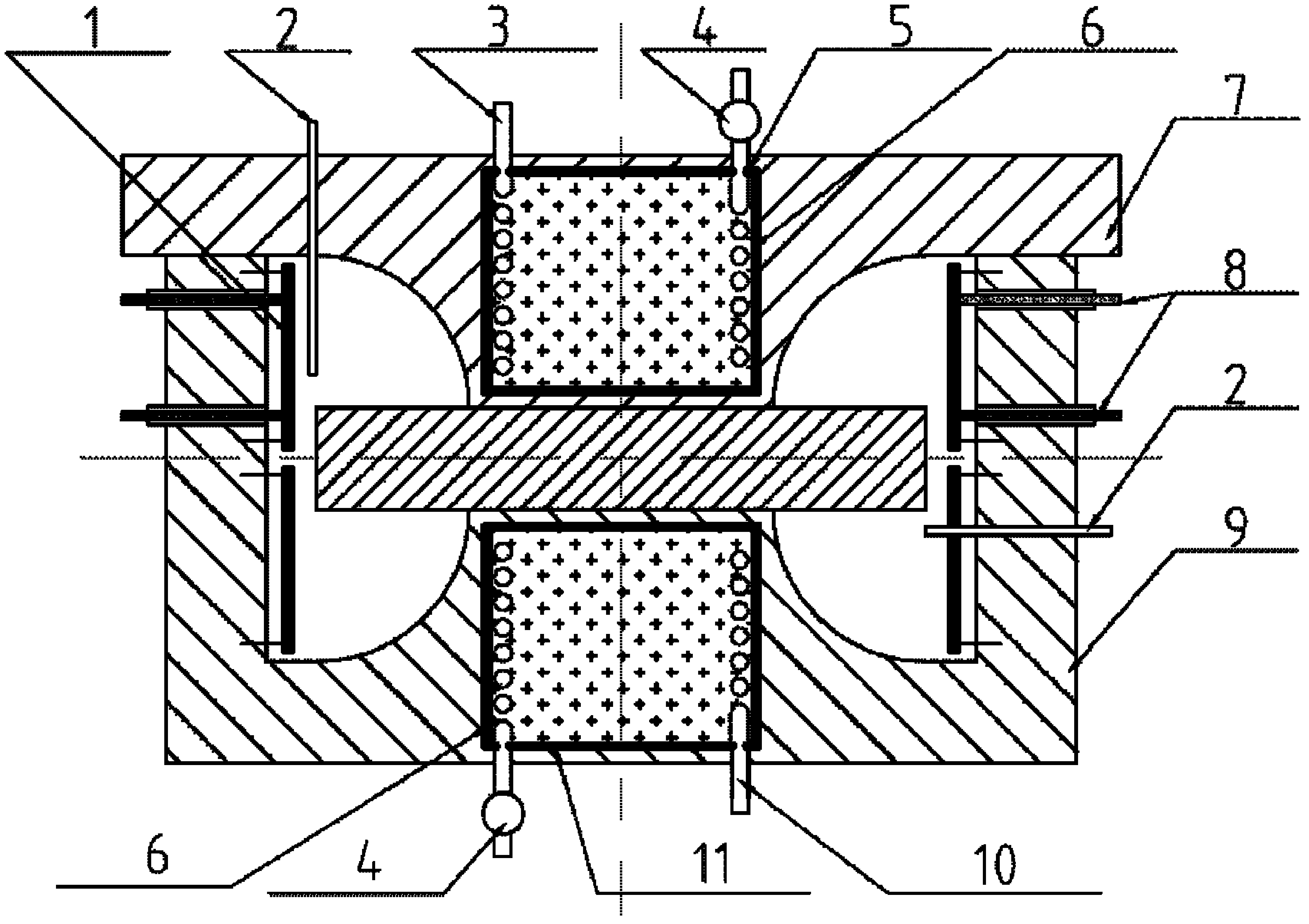

Heat treatment device for gradient of disk component

InactiveCN102643958AHigh processing temperatureRaise the temperature gradientFurnace typesHeat treatment furnacesWater velocityHeat conducting

The invention discloses a heat treatment device for the gradient of a disk component. With adoption of the heat treatment device, the technical problems that the treatment temperature of the heat treatment device of the disk component is low and the temperature gradient is small can be solved; the technical scheme is as follows: an upper furnace body and a lower furnace body are respectively provided with a cooling box; a cooling pipe is rotated in the cooling box; the periphery of the cooling pipe in the cooling is filled with heat conducting salt; the cooling pipe is provided with a circulating pump; the inner wall of the lower furnace body is provided with a resistance band; the high-performance resistance band is utilized to realize high heating efficiency; the cooling water velocity is controlled through the heat conducting salt filled in the cooling box and utilizing the circulating pump, so that the treatment temperature of the gradient heat treatment device is improved and thedisk component is enabled to obtain larger temperature gradient; the heating temperature of the disk edge is improved to 1100 DEG C from 900 DEG C in a background technology; the temperature gradientof 300-500 DEG C is realized at the parts of the disk edge and a disk center to obtain the structural gradient of thick and fine isometric crystals; and double-structure turbine disk is manufactured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

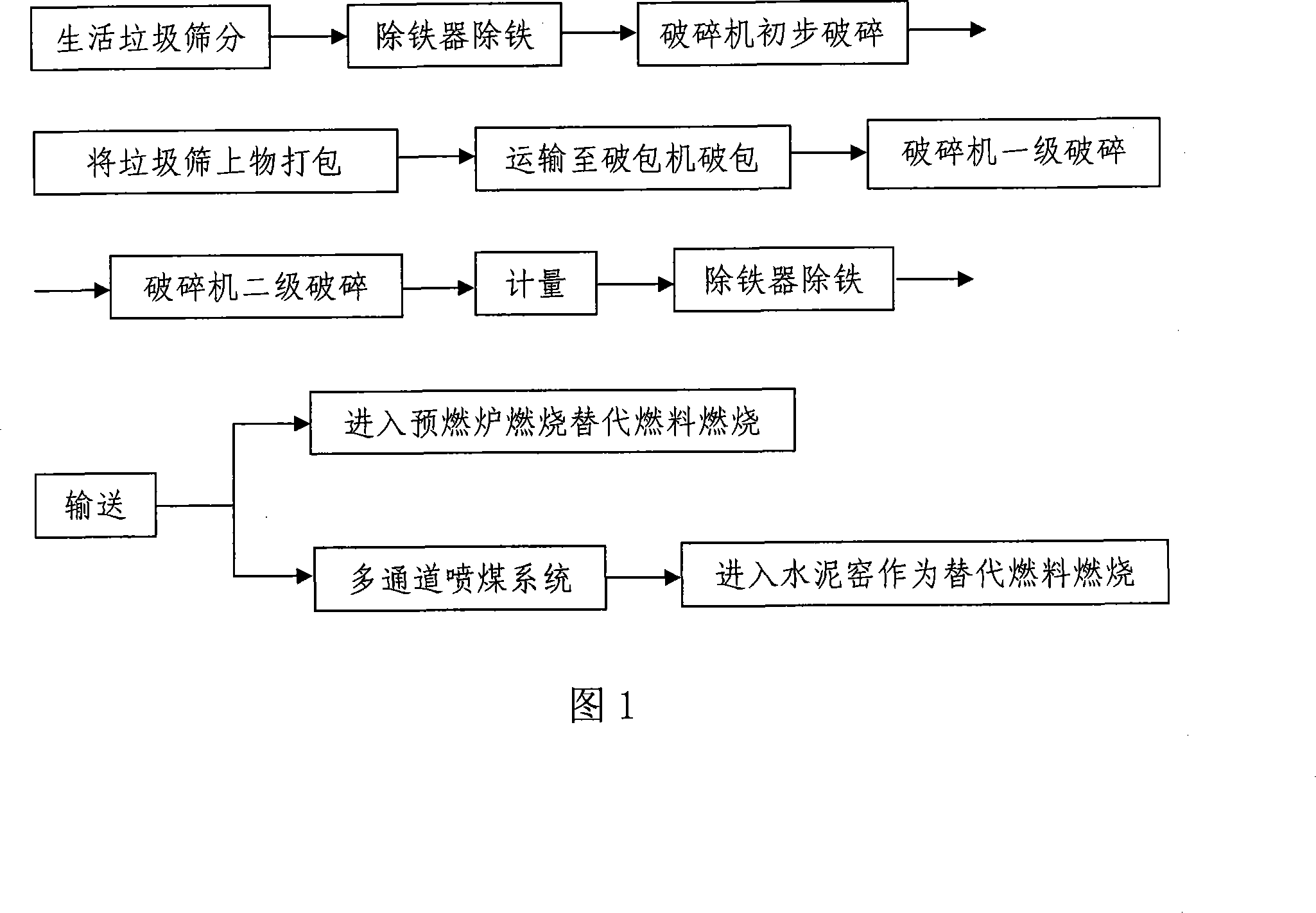

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

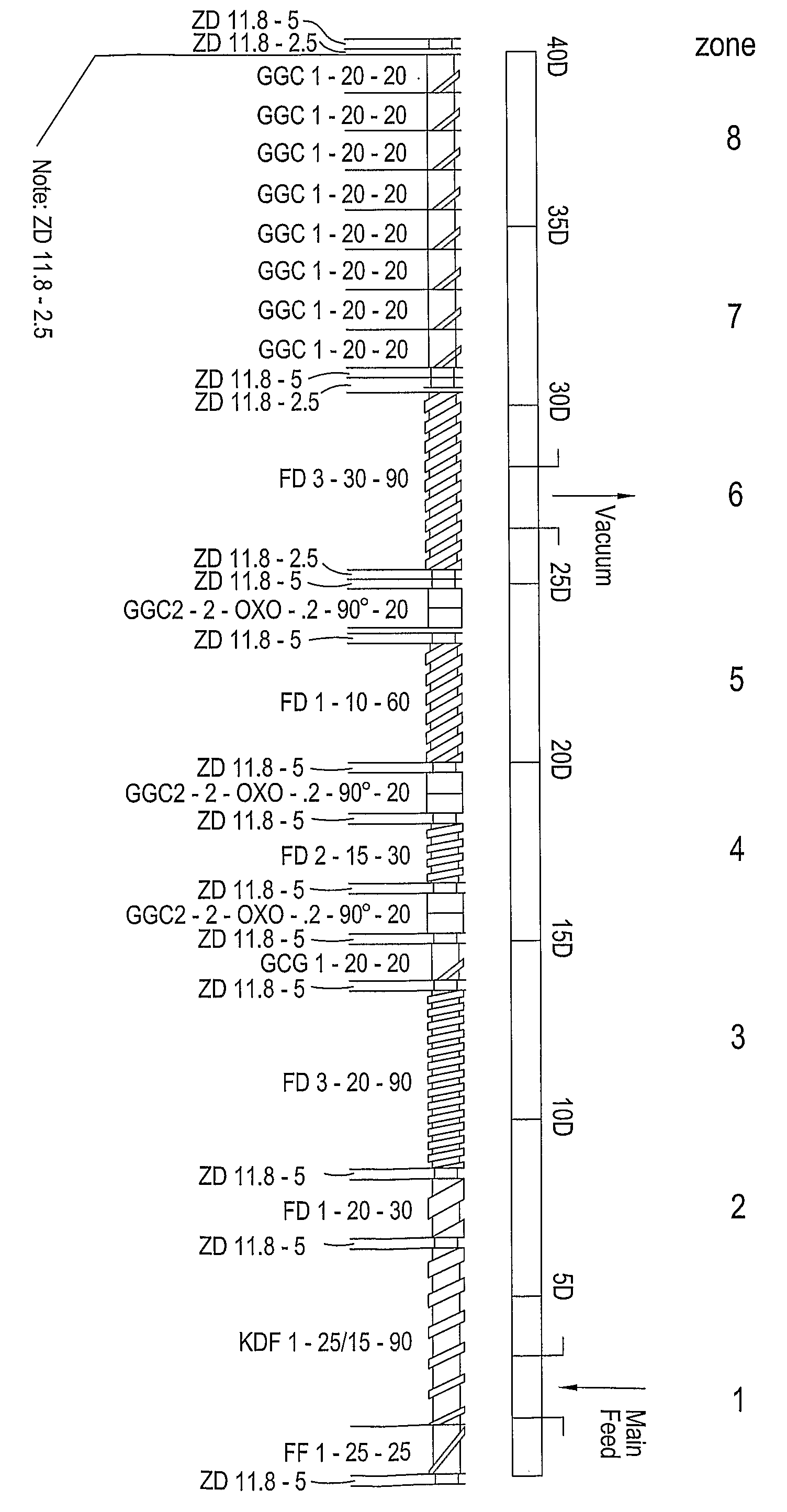

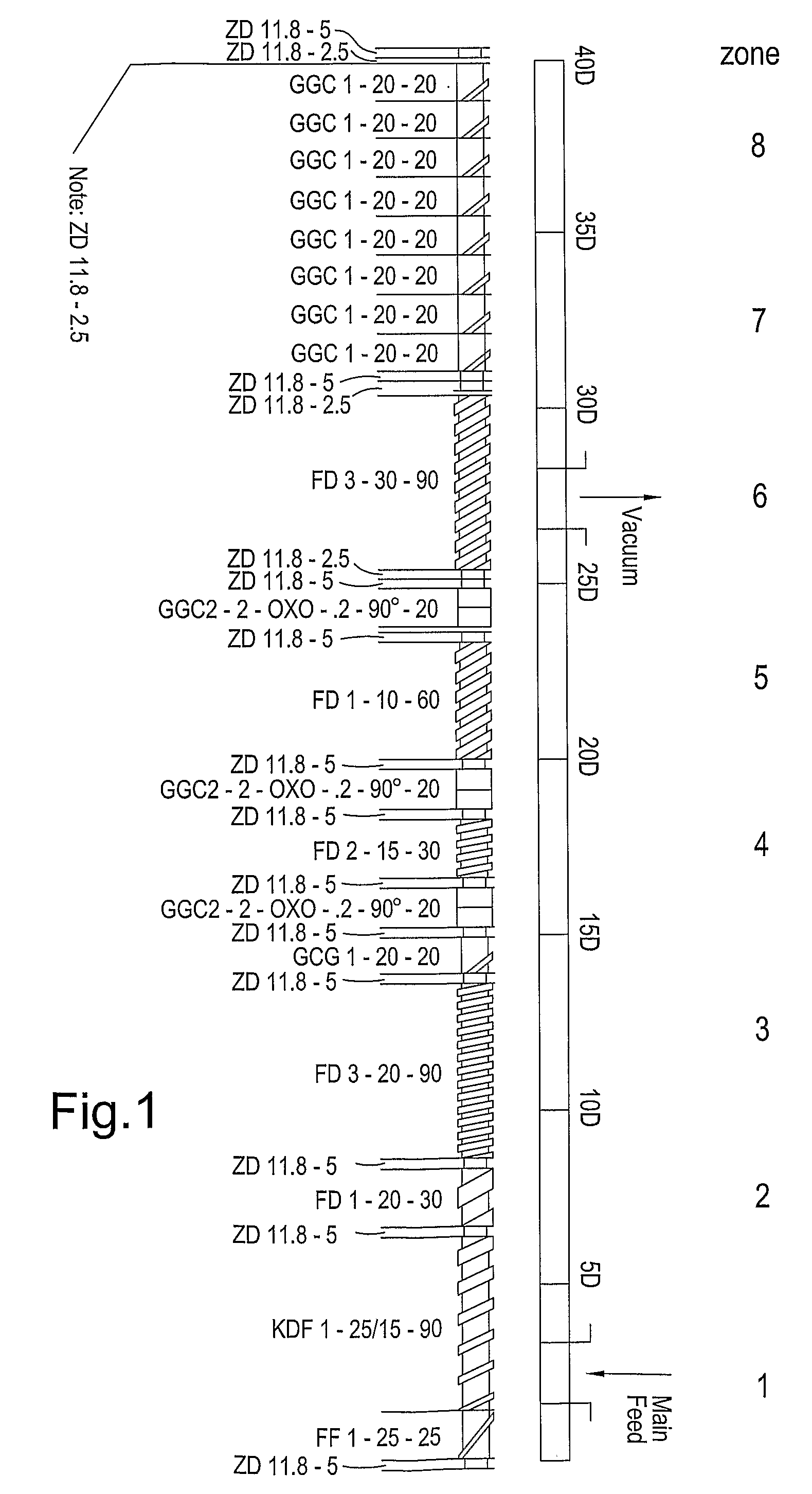

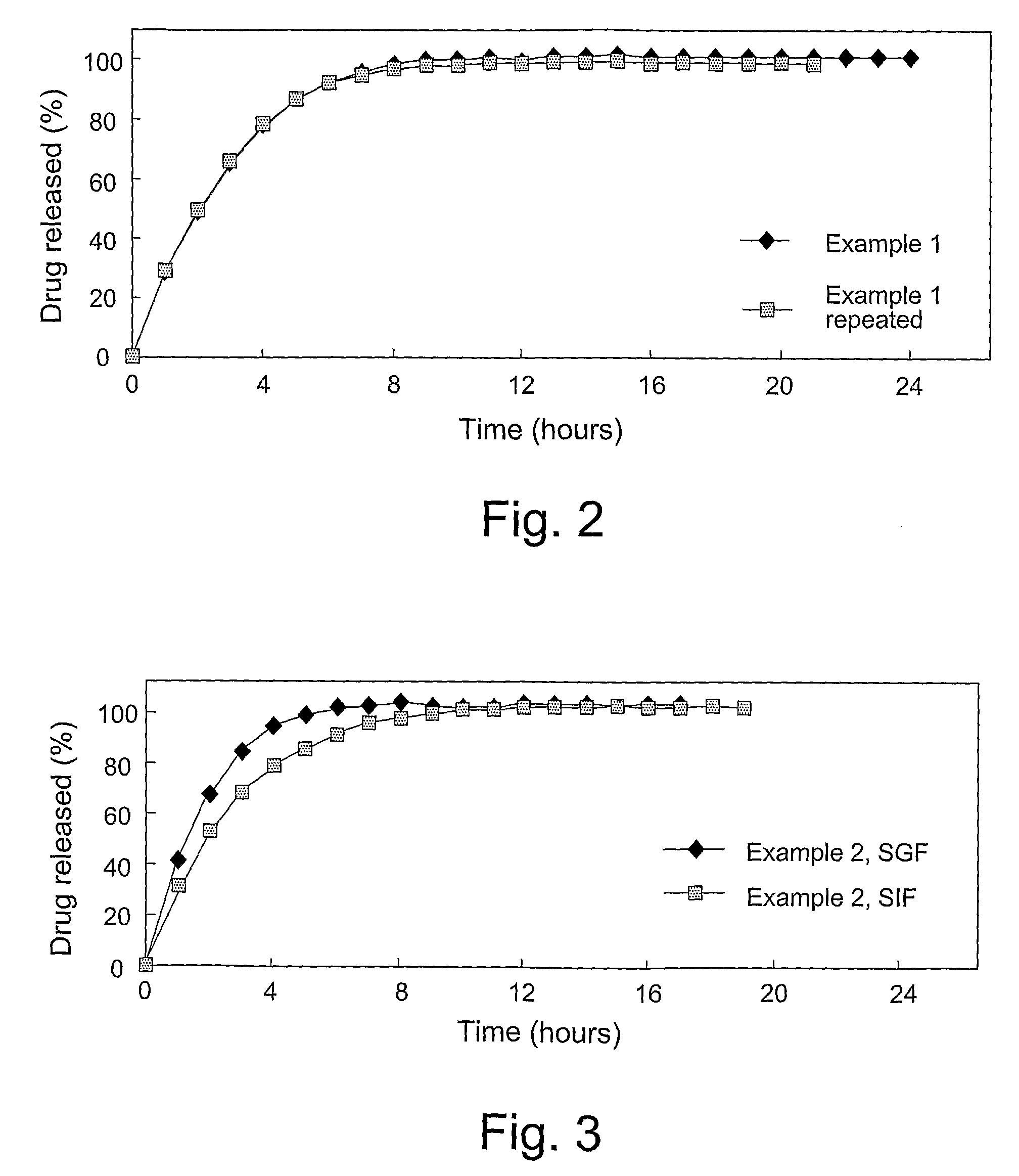

Multiparticulates

InactiveUS9259872B2Reduce adhesionReduce the required powerOrganic active ingredientsCosmetic preparationsActive agentExcipient

Extrusion of a mix containing a pharmaceutically active agent can be achieved using a plasticizing excipient in an amount sufficient to act as plasticizer and also act as lubricant, thereby avoiding the need for inclusion of a lubricant. The invention provides multiparticulates with controlled release properties, substantially free of lubricant. The present invention is preferably directed to extruded multiparticulates containing an opioid such as oxycodone, an ammonium methacrylate copolymer such as Eudragit® RSPO, a plasticizing excipient such as preferably stearyl alcohol and a water permeability modifier such as preferably Eudragit® RLPO. The obtained multiparticulates show a release rate profile which is pH-independent.

Owner:EURO-CELTIQUE SA

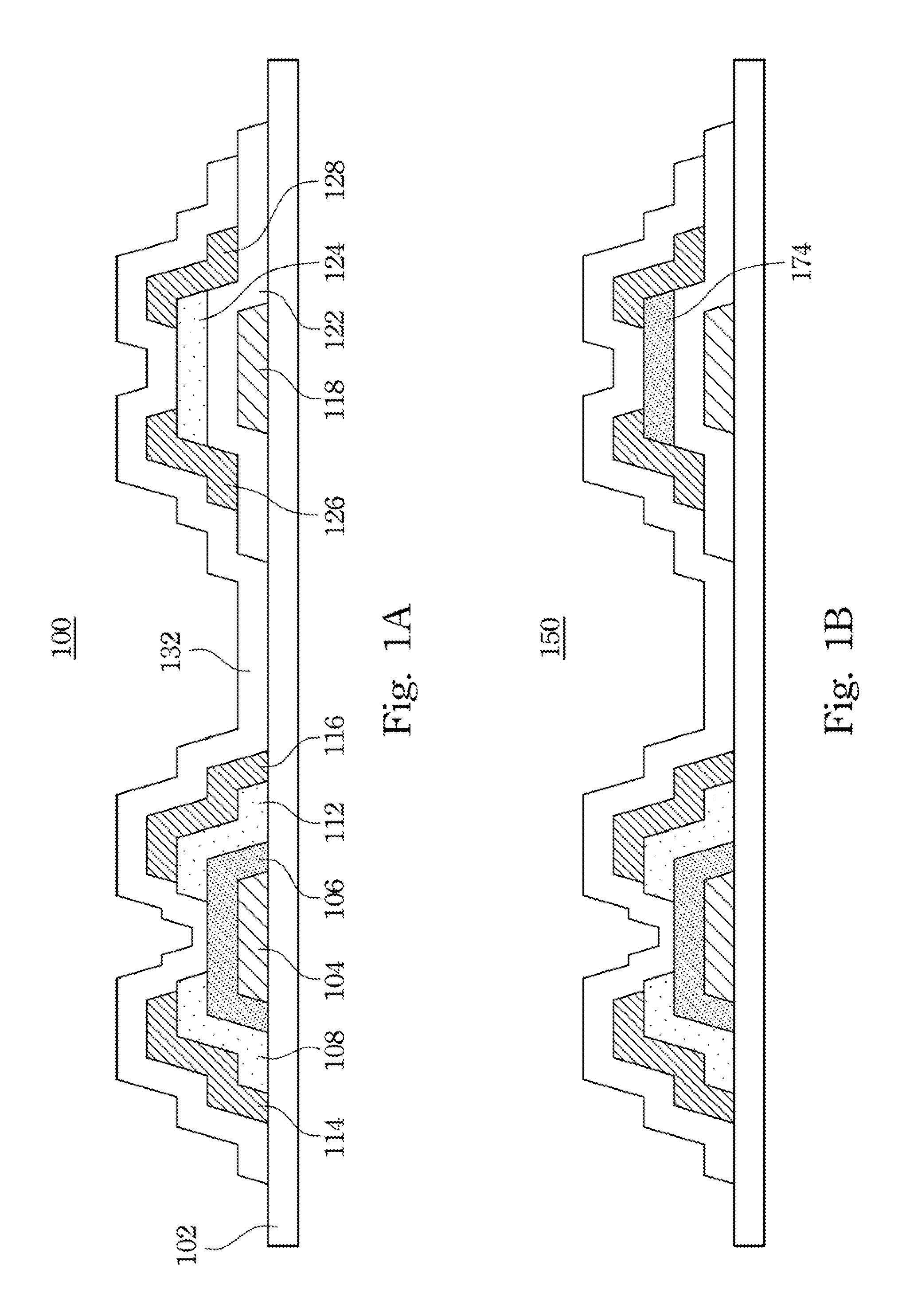

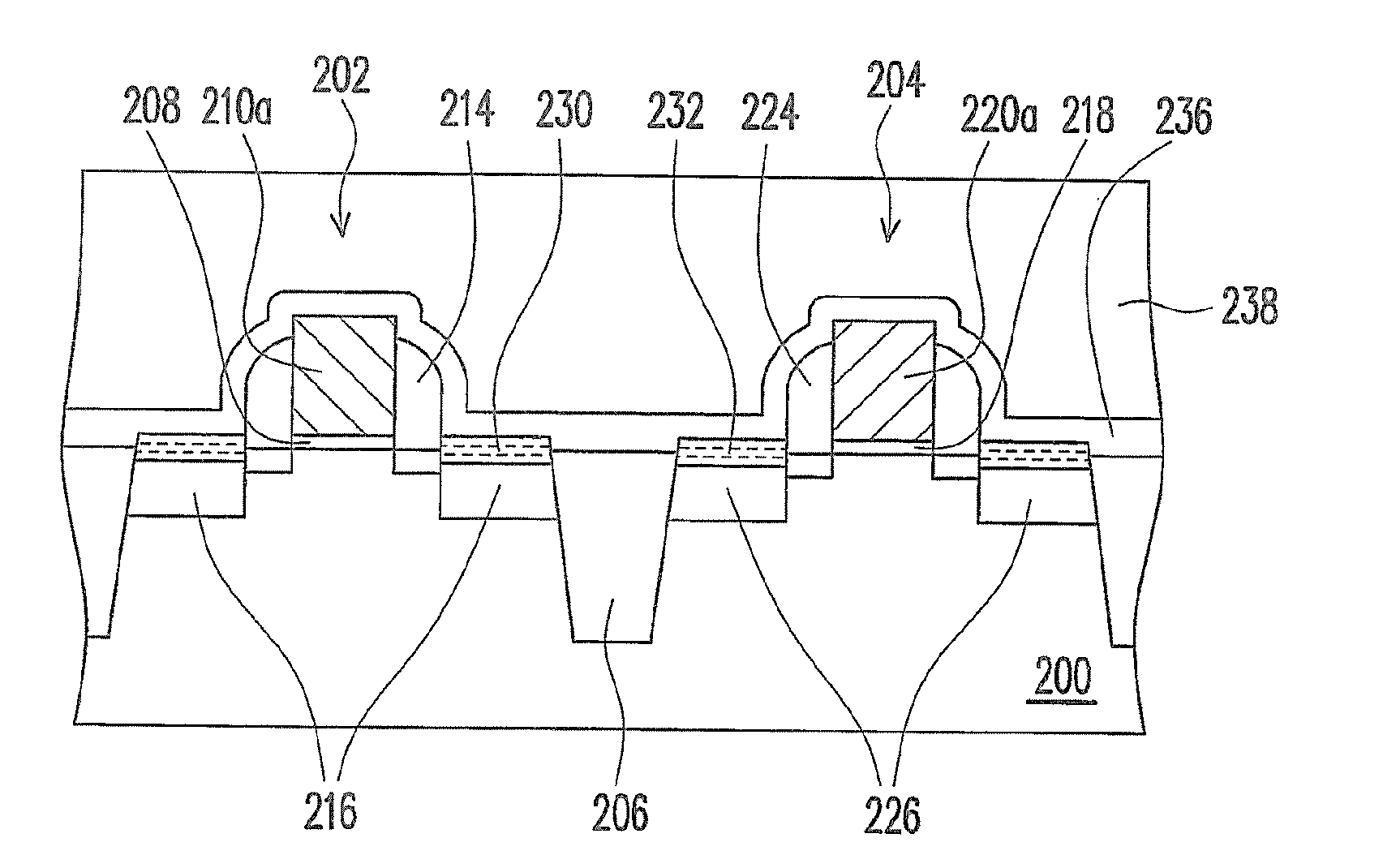

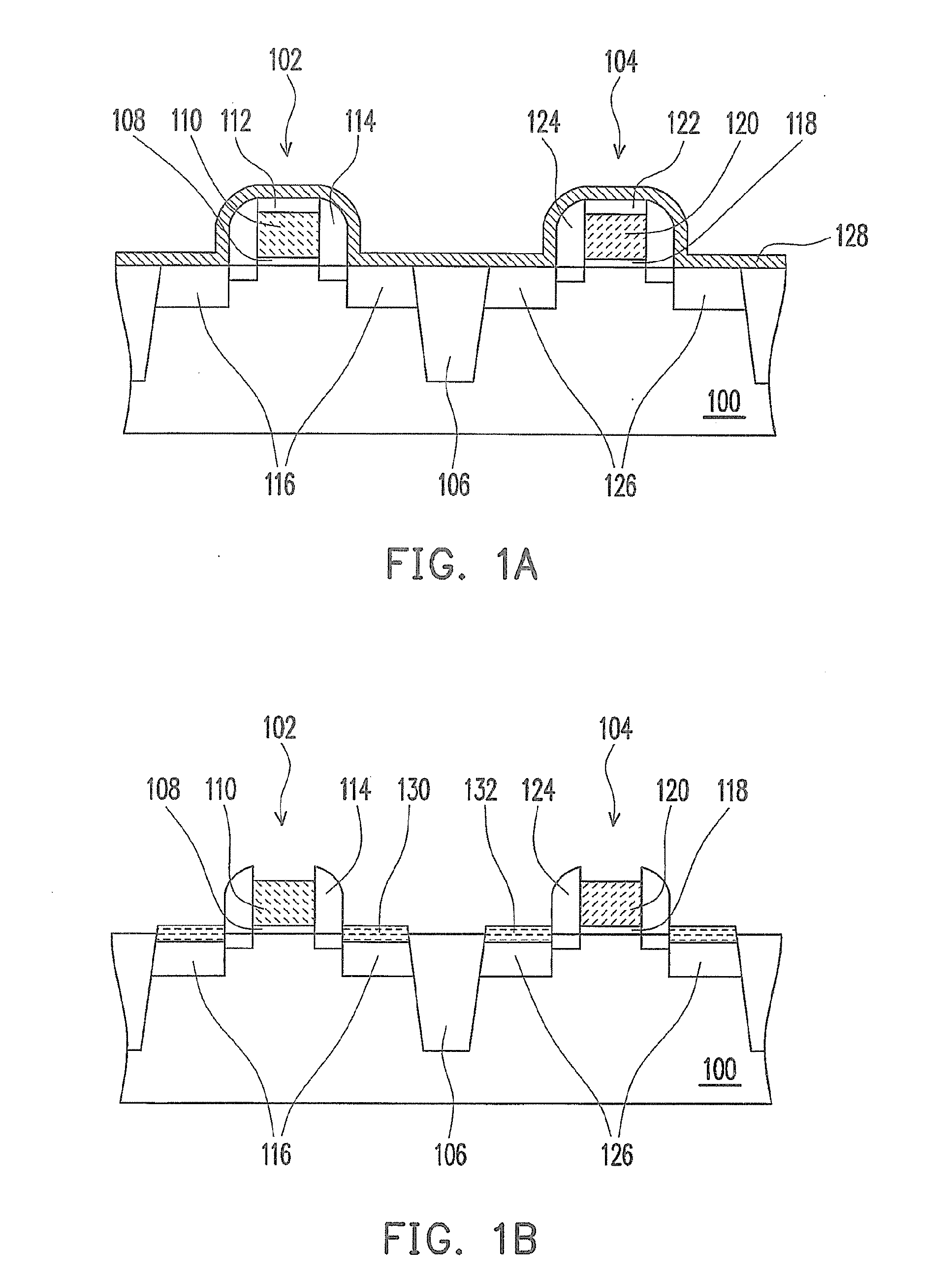

Semiconductor device and manufacturing method thereof

InactiveUS20080164529A1Simple processReduce manufacturing costTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device having dual fully-silicided gate is provided, which includes a first transistor, a second transistor, a dielectric layer, and an interlayer insulating layer. The first transistor is disposed on the substrate, which includes a first silicided gate and a first source / drain. The second transistor is disposed on the substrate, which includes a second silicided gate and a second source / drain. The material of the first silicided gate is different from the material of the second silicided gate. The first silicided gate and the second silicided gate are formed in one silicidation process. The dielectric layer completely covers the first transistor and the second transistor. The interlayer insulating layer is disposed on the dielectric layer.

Owner:UNITED MICROELECTRONICS CORP

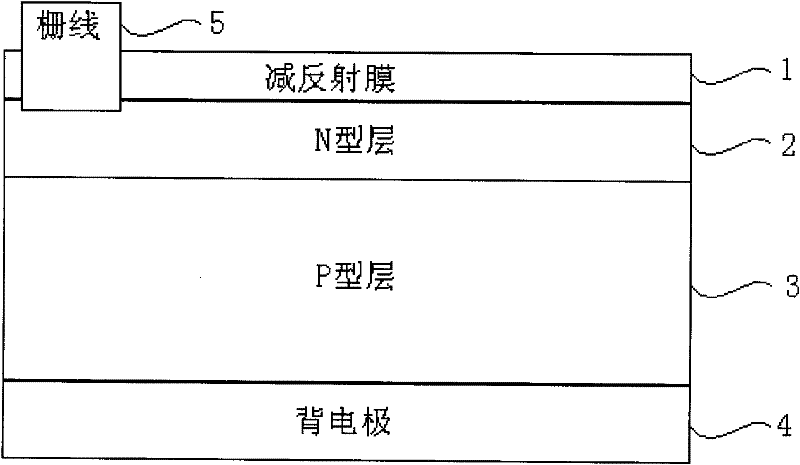

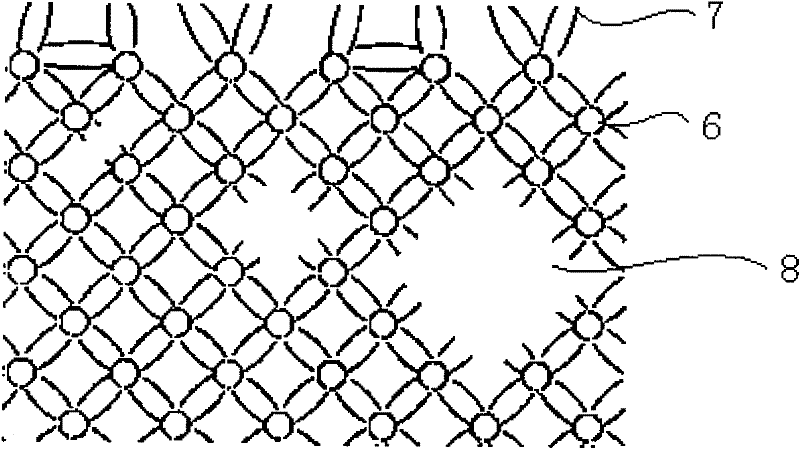

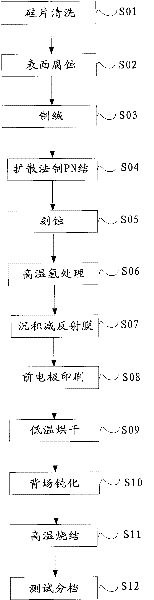

Solar cell and manufacturing method thereof

InactiveCN102244137AImprove efficiencyWon't escapeFinal product manufacturePhotovoltaic energy generationHydrogen atmosphereEngineering

The invention provides a solar cell and a manufacturing method thereof, belongs to the technical field of solar cells, and can solve the problem that the conventional solar cell is low in efficiency. The solar cell manufacturing method comprises the step of performing hydrogen treatment on a solar cell substrate, wherein the hydrogen treatment comprises the step of treating the solar cell substrate at the temperature of 800 to 1,500 DEG in hydrogen atmosphere. The solar cell is subjected to hydrogen treatment during manufacturing. The solar cell can be used for a crystalline silicon solar cell.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

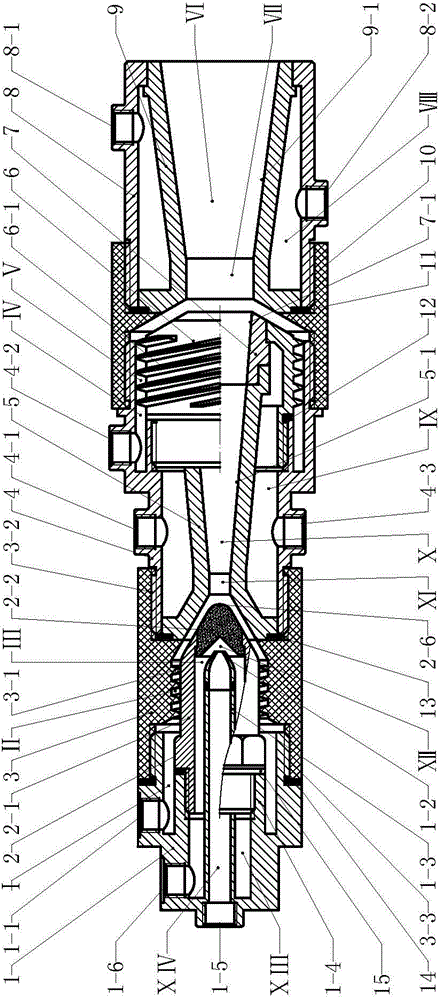

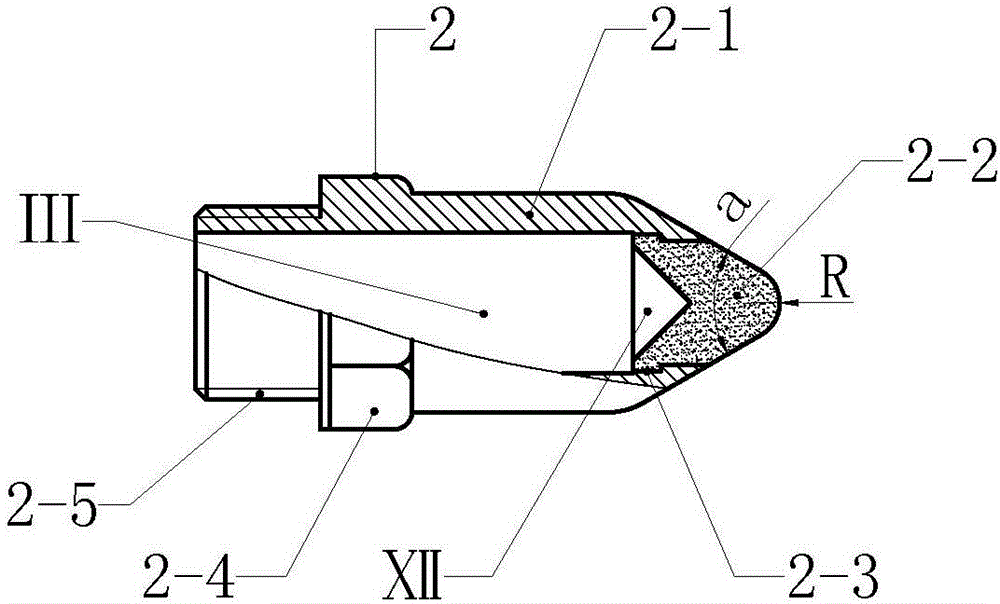

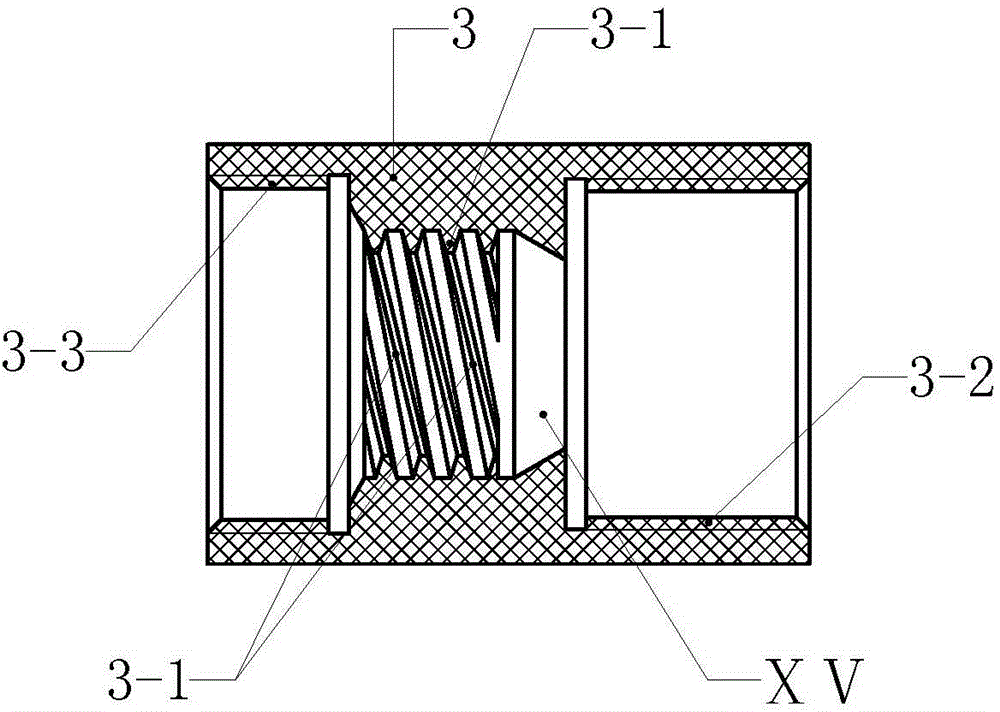

Double-pole electric arc plasma torch used for water pyrolysis

ActiveCN104470187AHigh processing temperatureImprove heating efficiencyPlasma techniqueMaterials scienceMicroporous membranes

The invention relates to a plasma torch, in particular to a double-pole electric arc plasma torch used for water pyrolysis. The double-pole electric arc plasma torch is composed of a backseat, a cathode, a spiral fluid director, a middle electrode assembly, an insulating connecting piece and an anode assembly. A water supply flow guide pipe and a cathode connecting rod are arranged in a revolution body of the backseat; the cathode is composed of a microporous membrane cathode head and a cathode sleeve, and micropores of the microporous membrane cathode head form a filtering channel for water molecules; the middle electrode assembly comprises a middle electrode and an annular electrode; the cathode is connected to the front end of the cathode connecting rod, the spiral fluid director is installed on the backseat, the middle electrode assembly is connected between the spiral fluid director and the insulating connecting piece, and an anode sleeve and an anode are installed at the front end of the insulating connecting piece; the head of the cathode enters the entrance space in the rear end of the middle electrode, a first discharging area is formed by the entrance space in the rear end of the middle electrode, and a second discharging area is formed by the space between the annular electrode and the rear end of the anode. The higher processing temperature of the plasma torch can be reached, and the heating efficiency and the decomposition capacity of the plasma torch are improved.

Owner:中恒华创(山东)技术服务有限公司

Method of fabricating a manganese diffusion barrier

ActiveUS7504135B2Improve signal-to-noise ratioHigh processing temperatureElectric discharge tubesVacuum evaporation coatingSimple Organic CompoundsDiffusion

A method of fabricating a diffusion barrier using a gas cluster ion beam apparatus is disclosed. The method includes generating a metal-organic gas that includes a metal-organic compound that includes an element of cobalt (Co) or cobalt and iron (CoFe). The metal-organic gas is combined with a carrier gas that is supplied to the gas cluster ion beam apparatus (GCIB). The GCIB processes the carrier gas to form a beam of gas cluster ions that include the metal-organic compound. The beam irradiates an interface surface of a target material (e.g. an IrMn, PtMn, or MnFe antiferromagnetic layer) and at least a portion of the Co or CoFe remains in contact with the interface surface to form a barrier that prevents a diffusion of manganese (Mn).

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing high-modulus para-aramid fibers

InactiveCN105780158AHigh processing temperatureHigh strengthArtificial filament washing/dryingFilament manufacturePolymer scienceAramid

The invention discloses a method for preparing high-modulus para-aramid fibers, and belongs to the technical field of artificial fibers.The method includes steps of dissolving poly-p-phenylene terephthamide resin in concentrated sulfuric acid, stirring the poly-p-phenylene terephthamide resin under a heating condition to obtain spinning solution, ejecting the spinning solution from a spinneret plate of a spinning tank by the aid of a dry-jet wet-spinning process, feeding the spinning solution into coagulation bath via air layers to form fiber strands, and sequentially washing and neutralizing the fiber strands; drying the obtained wet fiber strands under the effect of tension by the aid of a pre-drying device in a gradient heating mode and removing water on the surfaces of the wet fiber strands; discharging the pre-dried fiber strands out of the pre-drying device and simultaneously oiling the pre-dried fiber strands; carrying out heat-stretching on the fiber strands to be subjected to heat-stretching; carrying out heat-setting on the fiber strands to be subjected to heat-setting, discharging the fiber strands out of heat-setting rolls, oiling the fiber strands again and cooling the fiber strands to obtain finished products.The method has the advantages that the problem of excessive broken filaments due to excessively high tension can be solved; broken filaments can be prevented; the high-modulus para-aramid fibers obtained by the aid of the method are high in strength and modulus.

Owner:JIANGSU HENGTONG PRINTING & DYEING GRP CO LTD

Method of enhancing the conductive and optical properties of deposited indium tin oxide (ITO) thin films

InactiveUS8445373B2High processing temperatureLow costSemiconductor/solid-state device manufacturingMaintainance of heating chambersIndiumLow oxygen

Certain example embodiments of this invention relate to a method of activating an indium tin oxide (ITO) thin film deposited, directly or indirectly, on a substrate. The ITO thin film is baked in a low oxygen environment at a temperature of at least 450 degrees C. for at least 10 minutes so as to provide for (1) a post-baked resistivity of the ITO thin film that is below a resistivity of a corresponding air-baked ITO thin film, (2) a post-baked visible spectrum absorption and transmission of the ITO thin film that respectively are below and above the absorption and transmission of the corresponding air-baked ITO thin film, and (3) a post-baked infrared reflectivity of the ITO thin film that is above the reflectivity of the corresponding air-baked ITO thin film. The substrate with the activated ITO thin film may be used in a photovoltaic device, for example.

Owner:GUARDIAN GLASS LLC

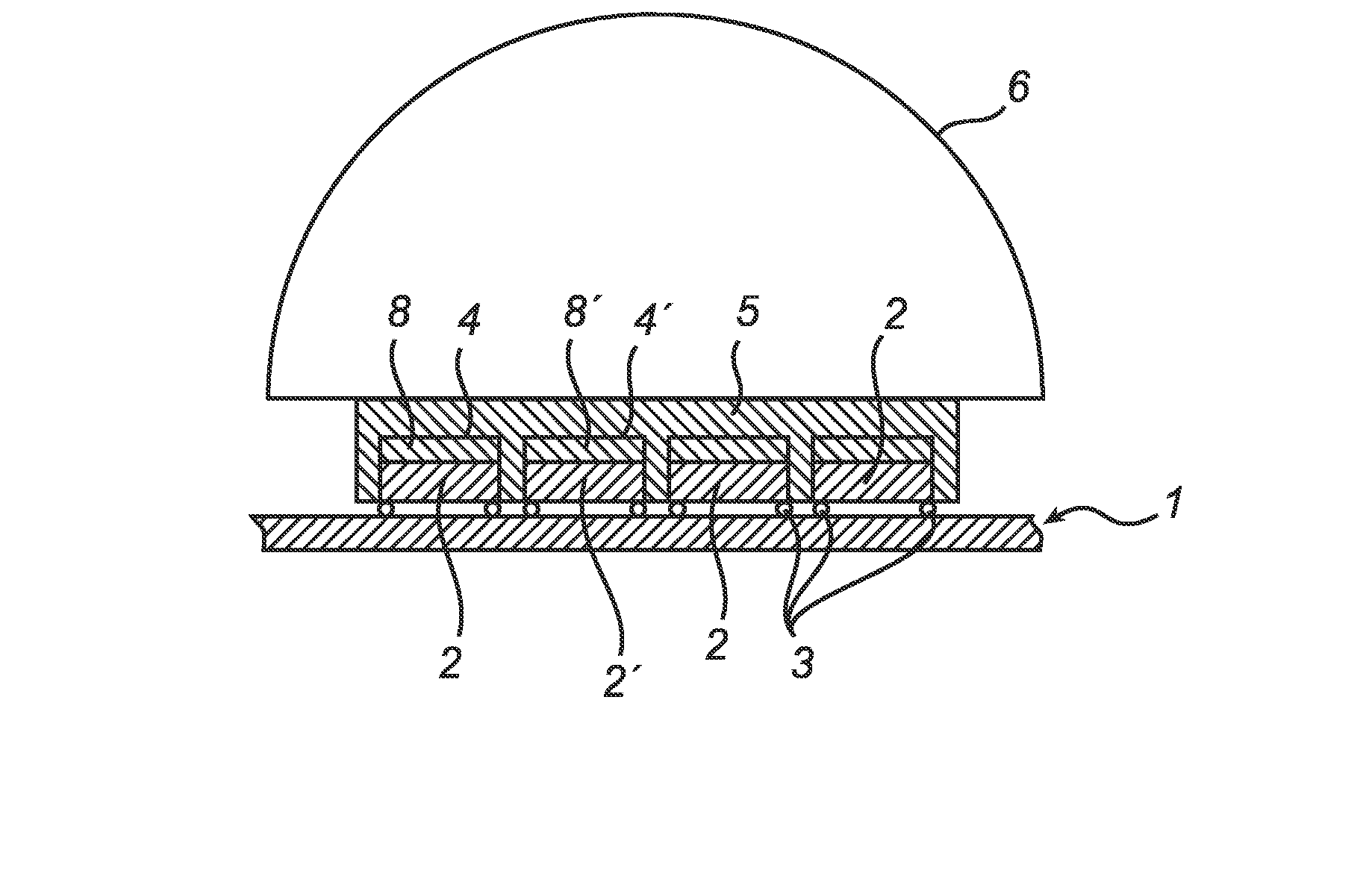

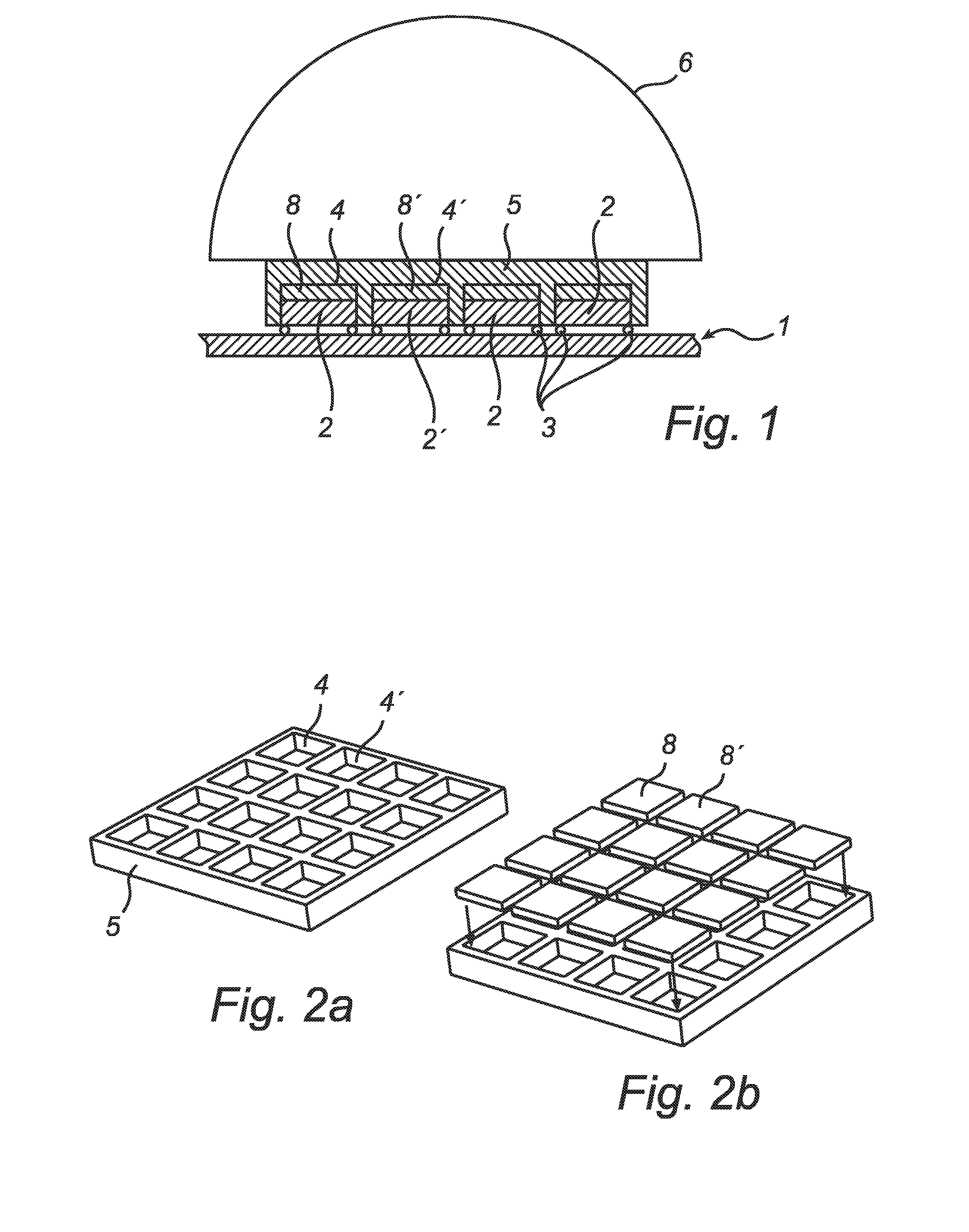

Light Source With Glass Housing

InactiveUS20080203911A1Stable temperatureHigh processing temperatureDischarge tube luminescnet screensLamp detailsEngineeringLight-emitting diode

A light source comprising at least one light-emitting diode (2), which emits light, and a housing (5) arranged to receive at least a portion of said light is provided. The housing (5) comprises a translucent glass material and is provided with at least one recess (4) that comprises positioning and orientating means. The at least one light-emitting diode (2) is arranged in said at least one recess (4), is positioned and orientated by said positioning and orientating means and is bonded to said housing. By utilizing a fully inorganic approach for the housing, the temperature stability of the light source is improved.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method of manufacturing semiconductor device having dual fully-silicided gate

InactiveUS20110294287A1Simple processReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A method of manufacturing the semiconductor device having a dual fully-silicided gate includes the following steps. A substrate having a first transistor and a second transistor formed thereon is provided, wherein the first transistor includes a first gate and a first source / drain and the second transistor includes a second gate and a second source / drain. The gate height of the first gate is different from that of the second gate. A first silicidation process is performed to respectively transform the first gate and the second gate into a first silicided gate and a second silicided gate simultaneously, wherein the material of the first silicided gate is different from that of the second silicided gate.

Owner:UNITED MICROELECTRONICS CORP

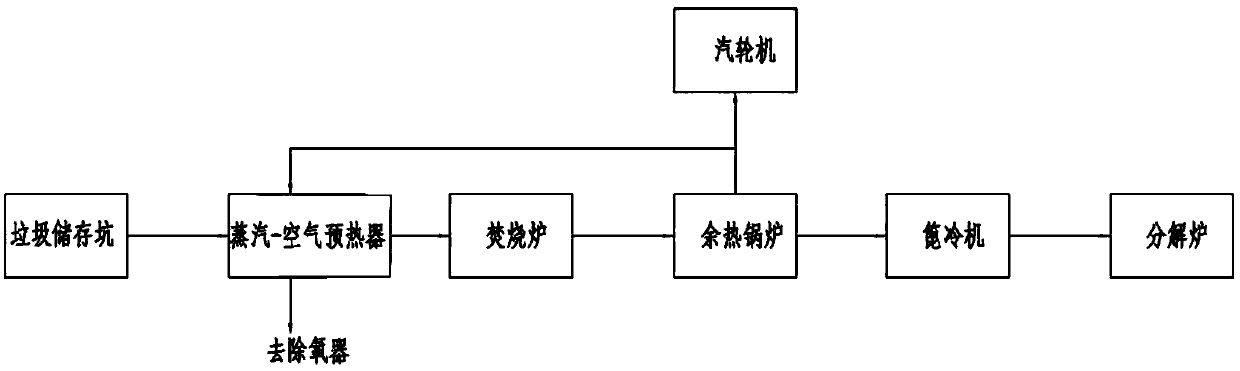

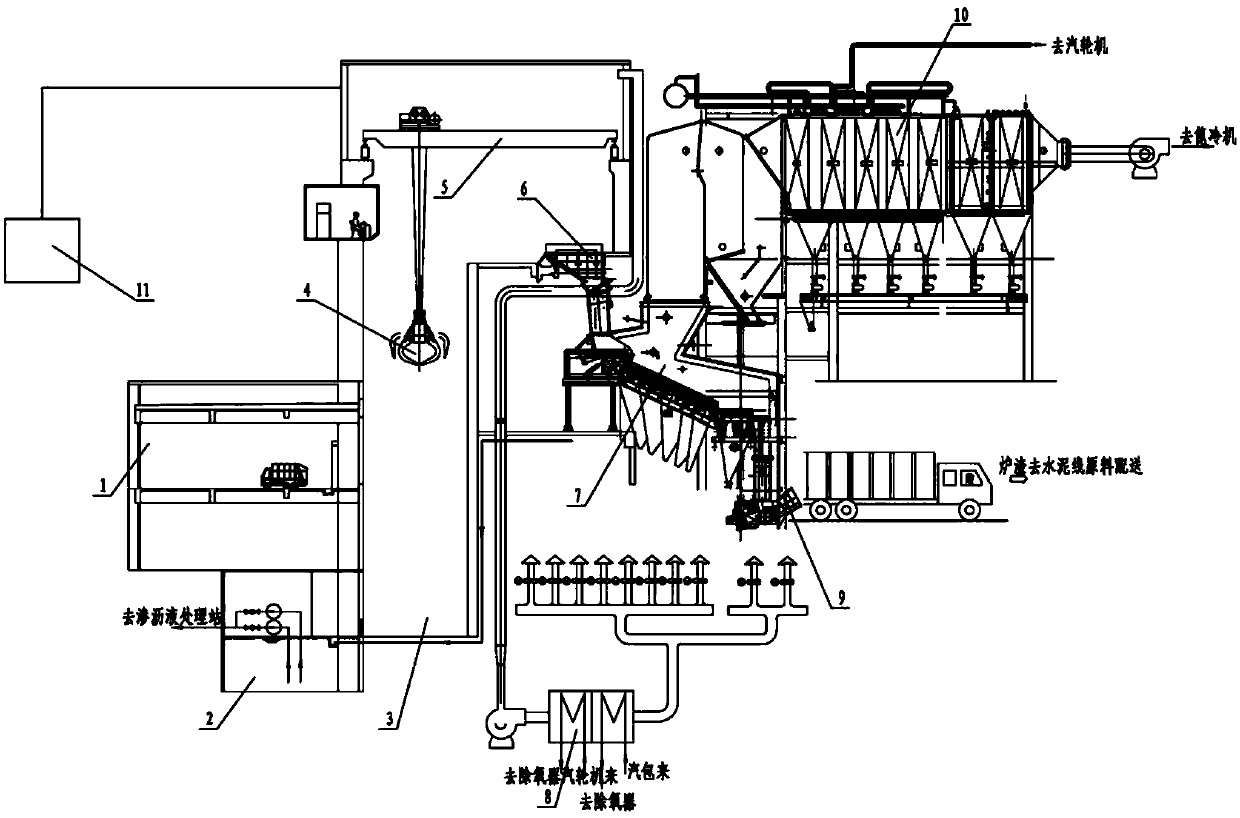

Cement kiln cooperative processing domestic garbage power generation system and method

InactiveCN108679614AReduce the impactSimple and fast operationMachines/enginesIncinerator apparatusFlue gasEnvironmental engineering

The invention discloses a cement kiln cooperative processing domestic garbage power generation system and method. The power generation system comprises a garbage receiving and storage system, an incineration system, a filtered liquid treatment system, an odor treatment system, an afterheat boiler system, a steamer power generation system and a flue gas purification system. The cement kiln cooperative processing domestic garbage power generation system combines three process technologies, namely, cement production, garbage treatment and garbage power generation, and adopts a brand new garbage treatment technology which carries out harmless treatment on waste gases and ash residues generated by garbage incineration and the garbage filtered liquid and effectively utilizes the waste gases, ashresidues and the garbage filtered liquid. The technology solves the difficult problem of treating dioxin and garbage ash residues very well in addition to the advantages of a traditional garbage incineration method.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Novel method for producing carragheen

The production method of carragheen uses marine alga as raw material and includes the following steps: alkalu modification procedure treatment, cooking, rfiniting, salting out, dewatering and drying so as to obtain the invented finished product. The alkali modification procedure adopts the potassium hydroxide as modification agent, and uses pure water to prepare the potassium hydroxide into the potassium hydroxide solution, its concentration is 5-25%, and the potassium borohydride is added, and its added amount is 1-5% of potassium hydroxide. Said invention raises the gel strength and recovery rate of the prdoucts and can shorten production period and reduce its production cost.

Owner:MAOMING COLLEGE

Measuring System for Optical Monitoring of Coating Processes

ActiveUS20080285060A1Measurement precision be highEasy to measureVacuum evaporation coatingSputtering coatingOptical pathLight source

The invention concerns a measuring system for optical monitoring of coating processes in a vacuum chamber, in which the light source is arranged inside the vacuum chamber between the substrate carrier and a shutter is arranged beneath the substrate carrier and the light-receiving unit is arranged outside the vacuum chamber in the optical path of the light source. The substrate carrier is designed to accept at least one substrate, and it can move across the coasting source in the vacuum chamber, preferably revolving about an axis, whereby the substrate or substrates cross(es) the optical path between the light source and the light-receiving unit for transmission measurement, and the shutter shades a measurement area across the coating source.

Owner:LEYBOLD OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com