Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

704results about How to "Reduce sheet resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

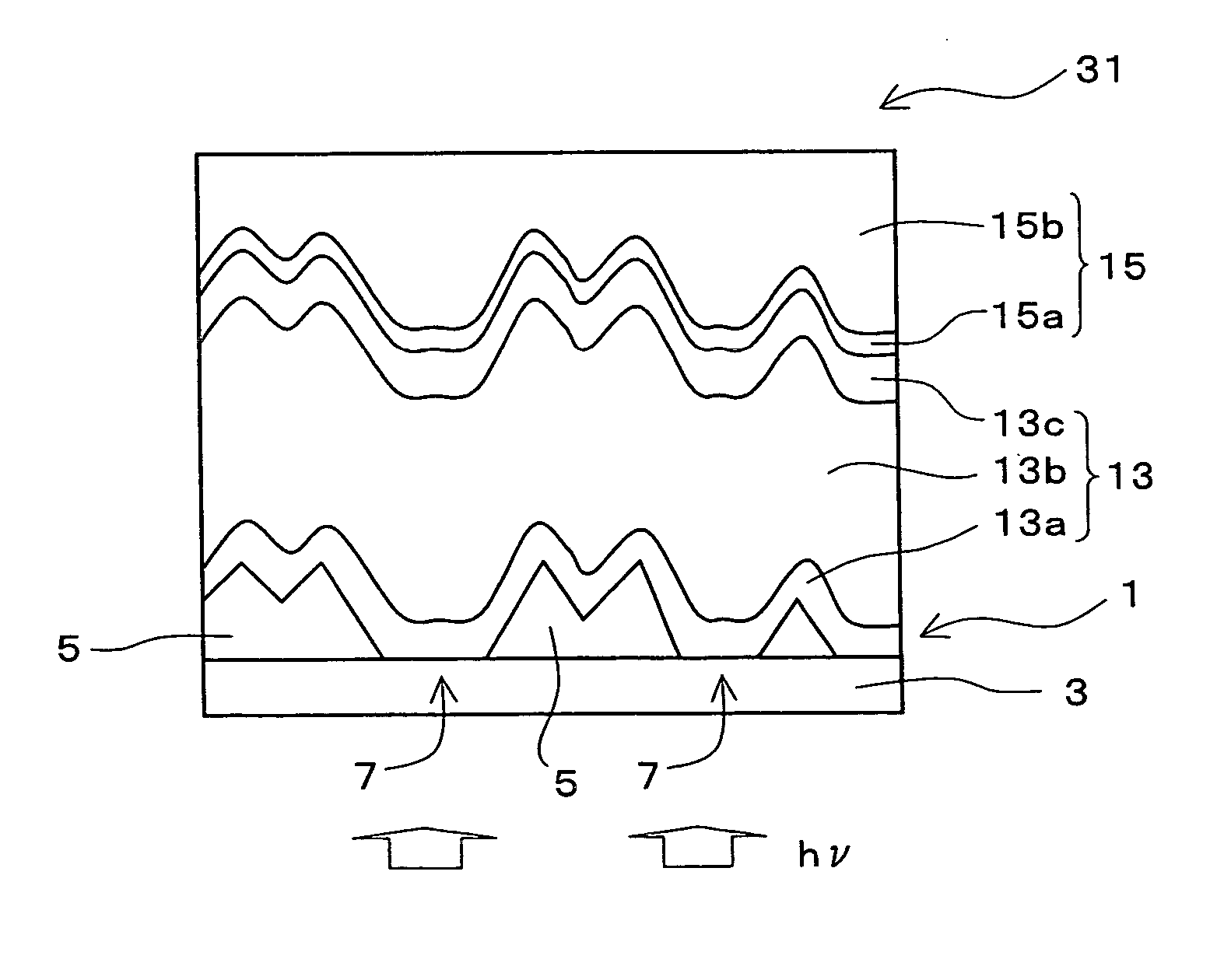

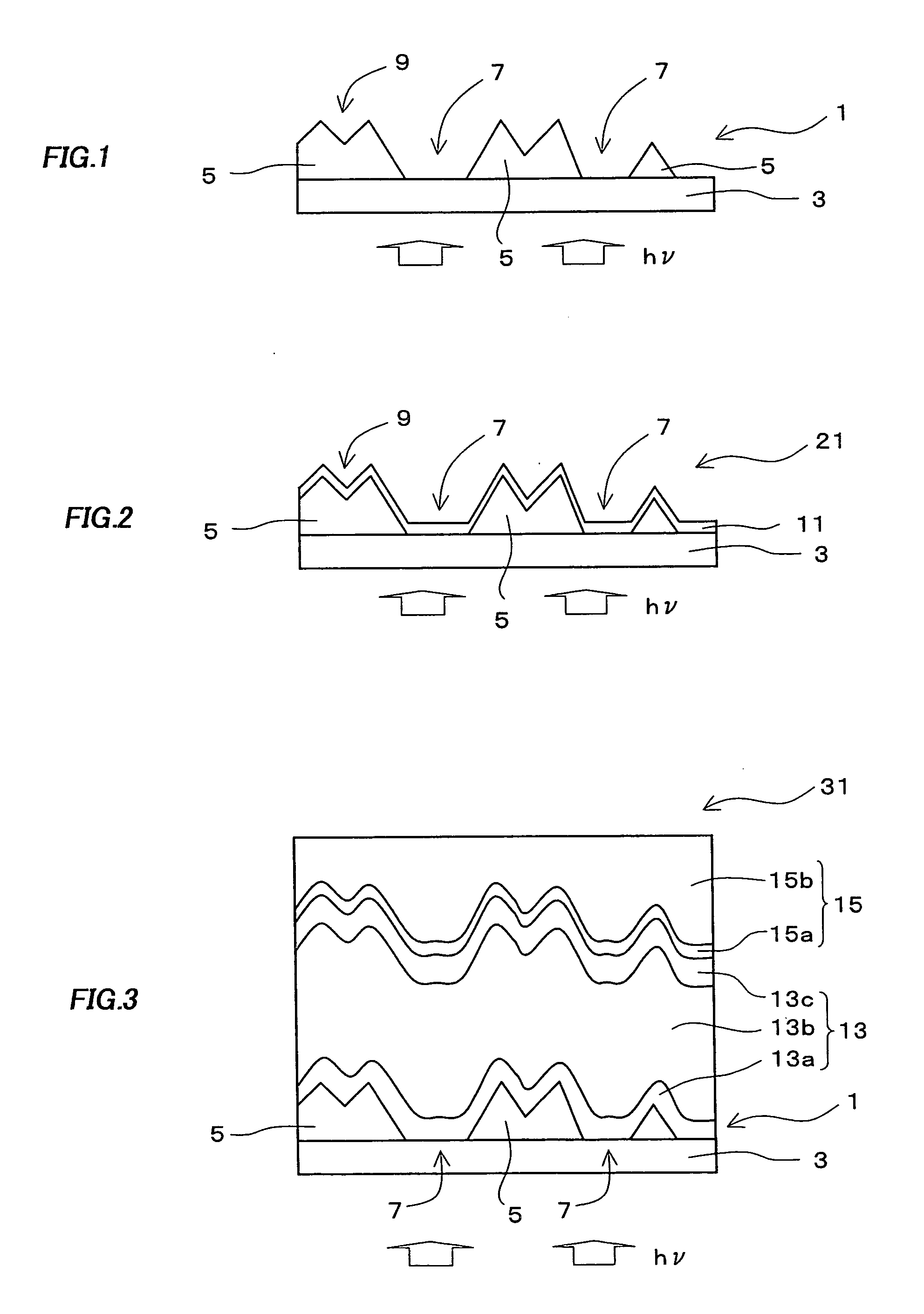

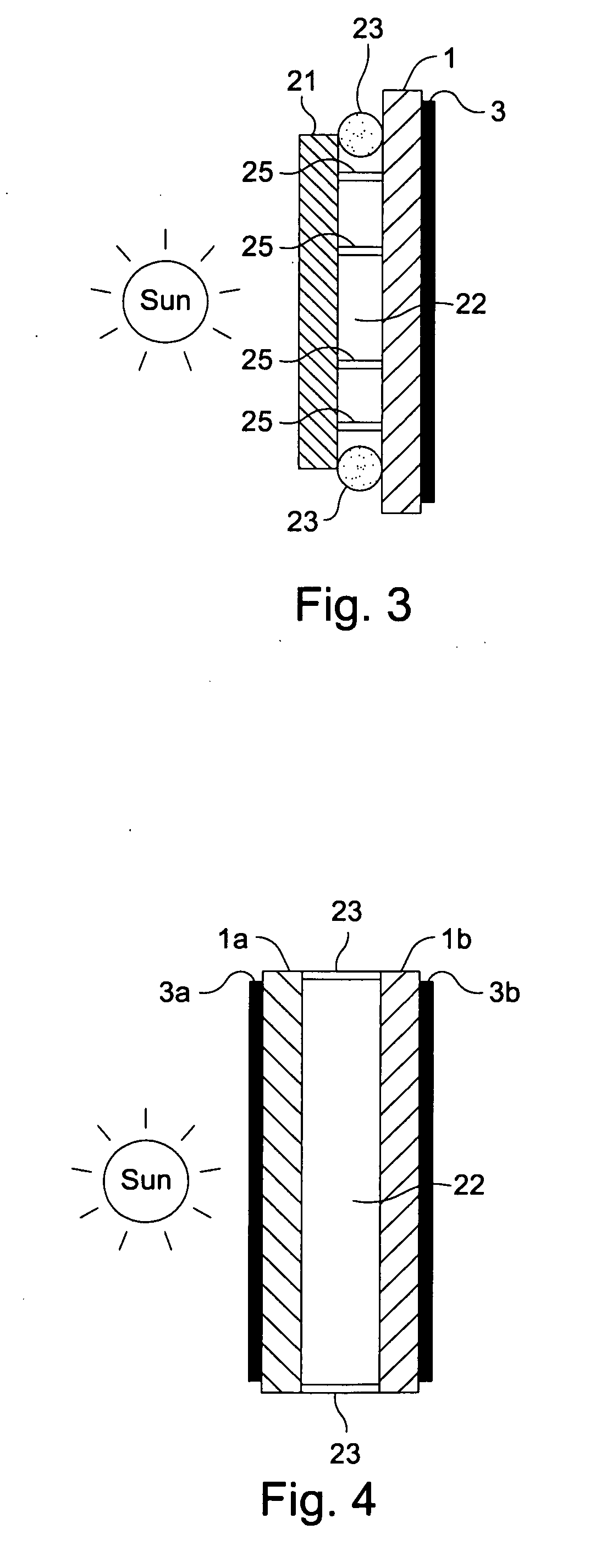

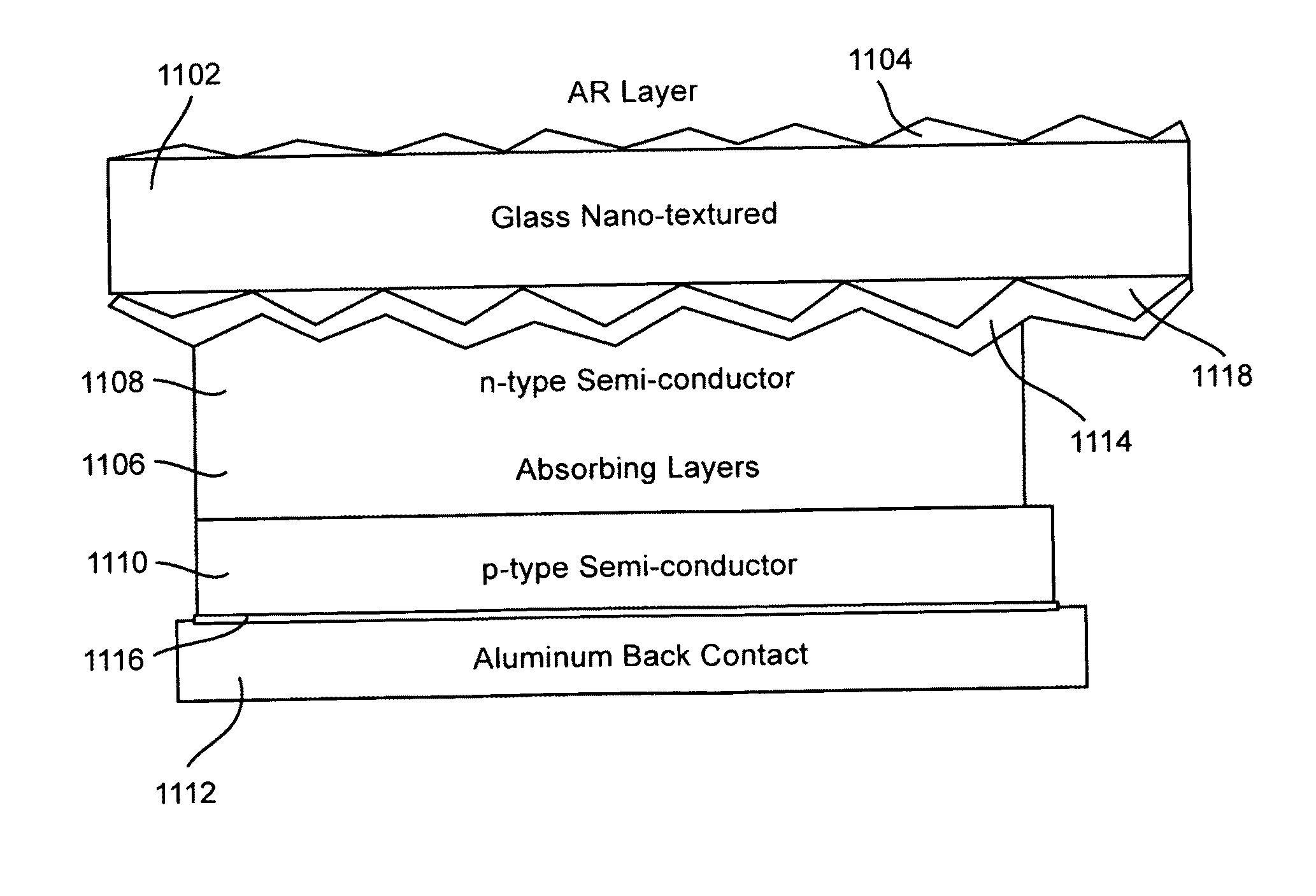

Substrate for photoelectric conversion device, photoelectric conversion device, and stacked photoelectric conversion device

InactiveUS20070151596A1High light transmittanceSpeed up the conversion processPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversion

A substrate 1 for a photoelectric conversion device includes a first transparent conductive layer 5 formed on at least a part of the surface region of a transparent substrate 3, the first transparent conductive layer 5 having at least an opening portion 7 exposing the substrate 3.

Owner:SHARP KK

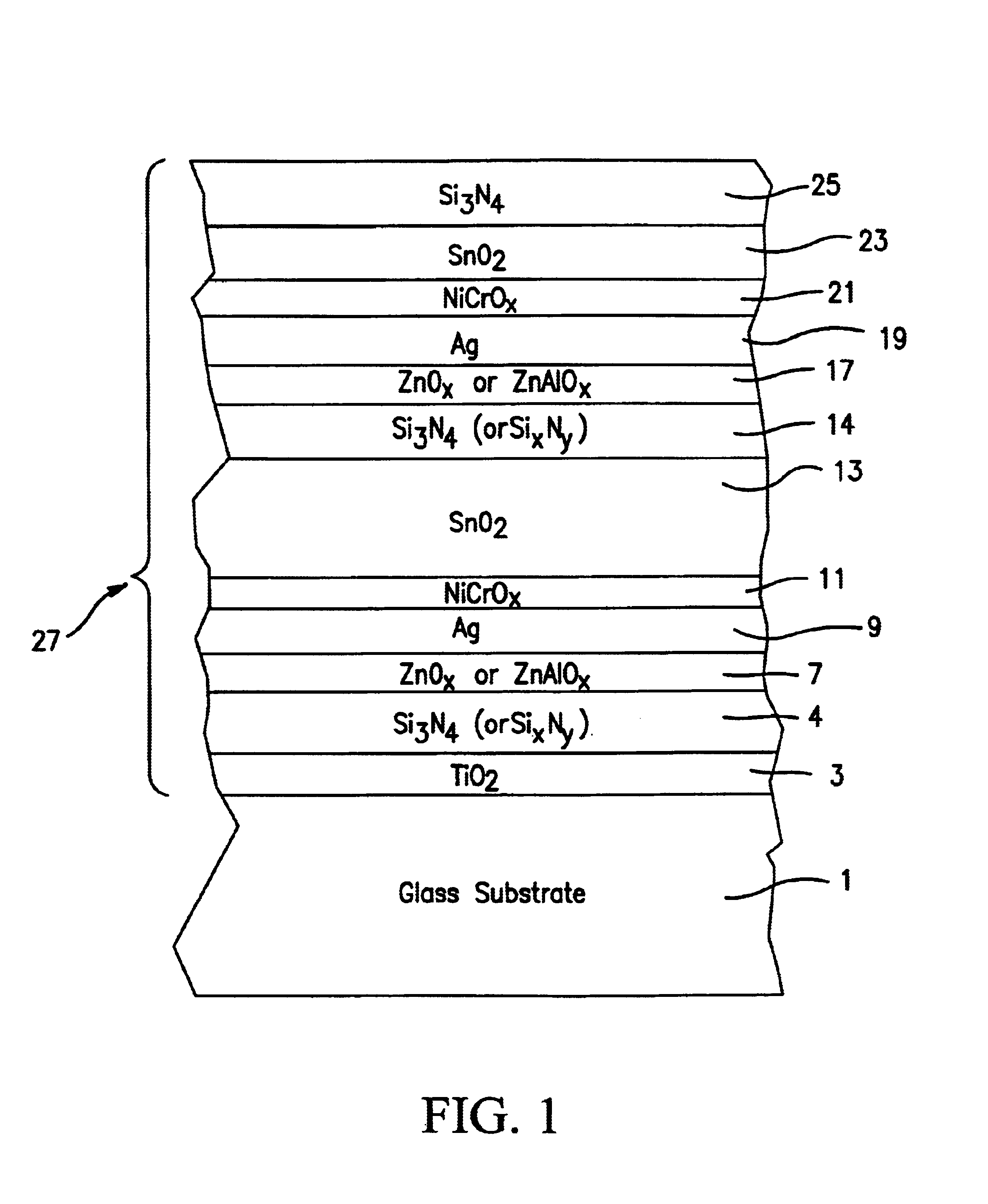

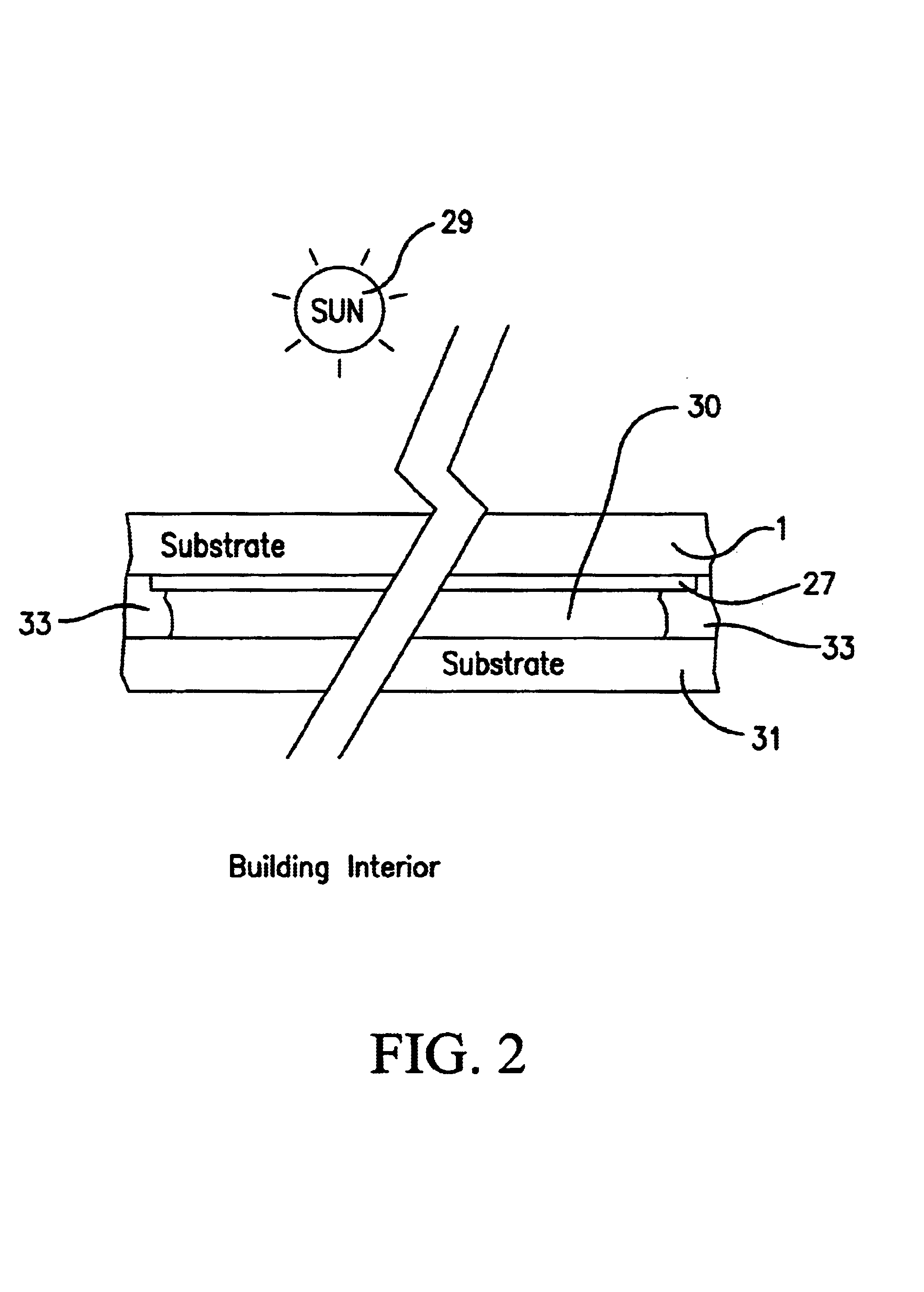

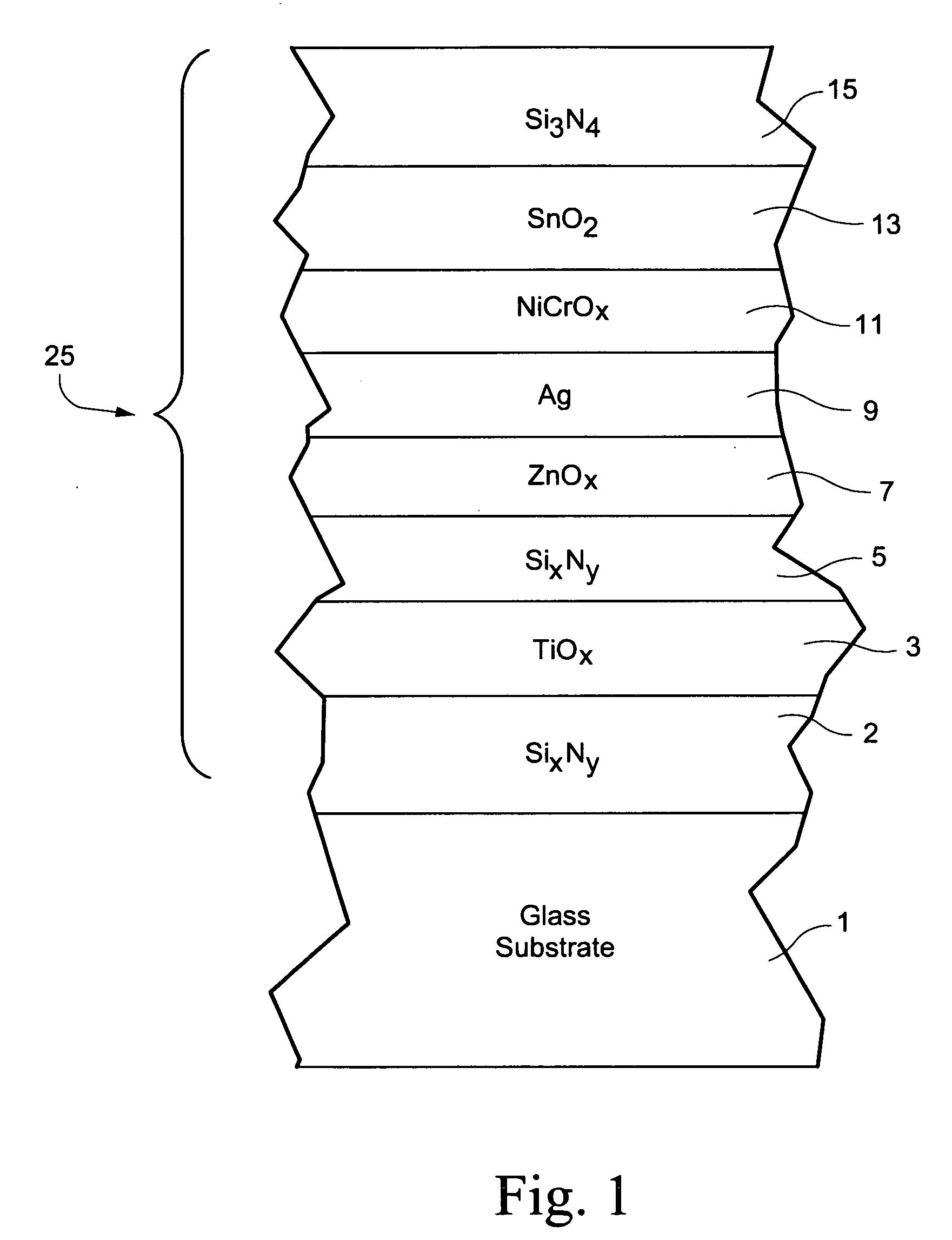

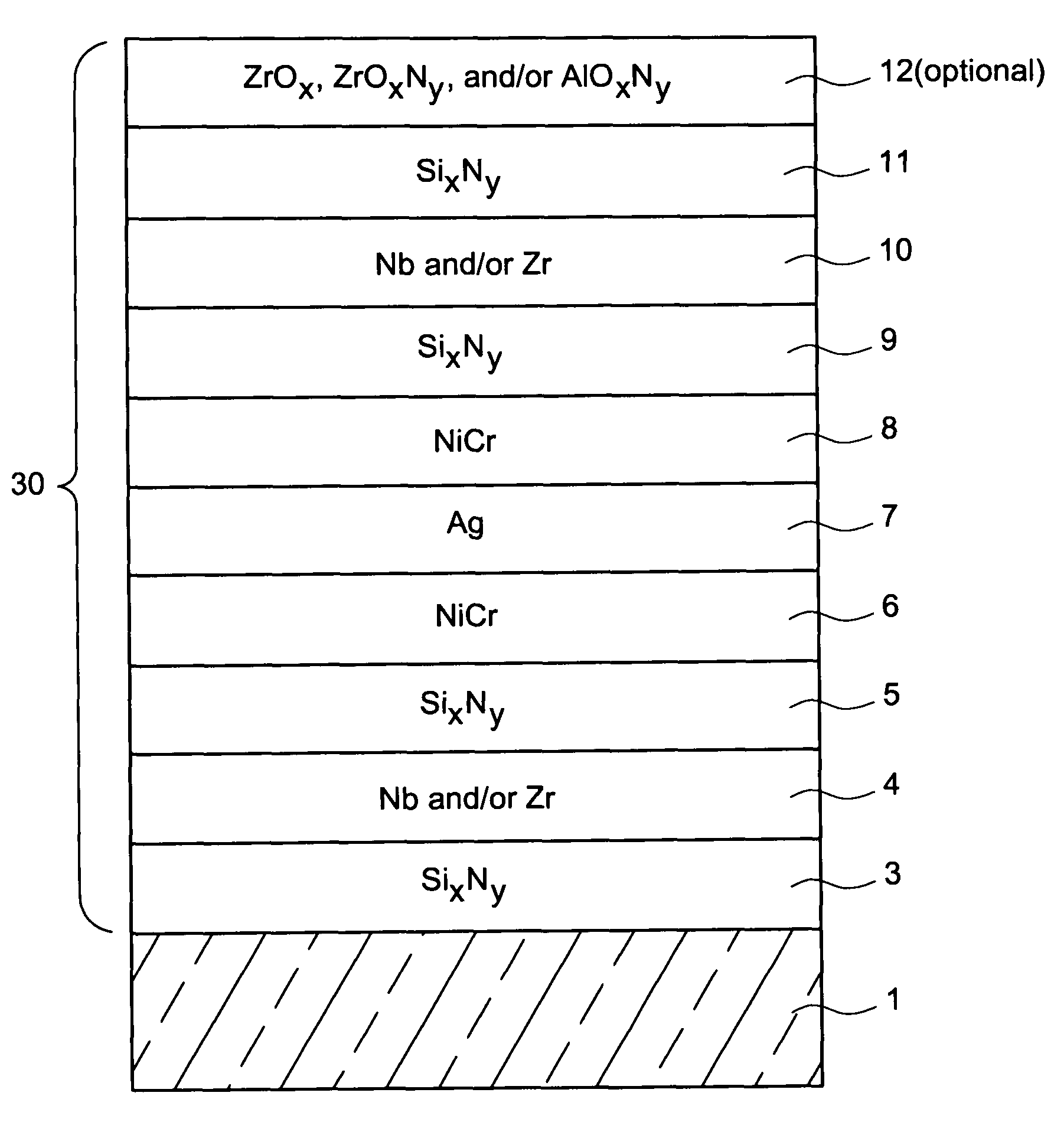

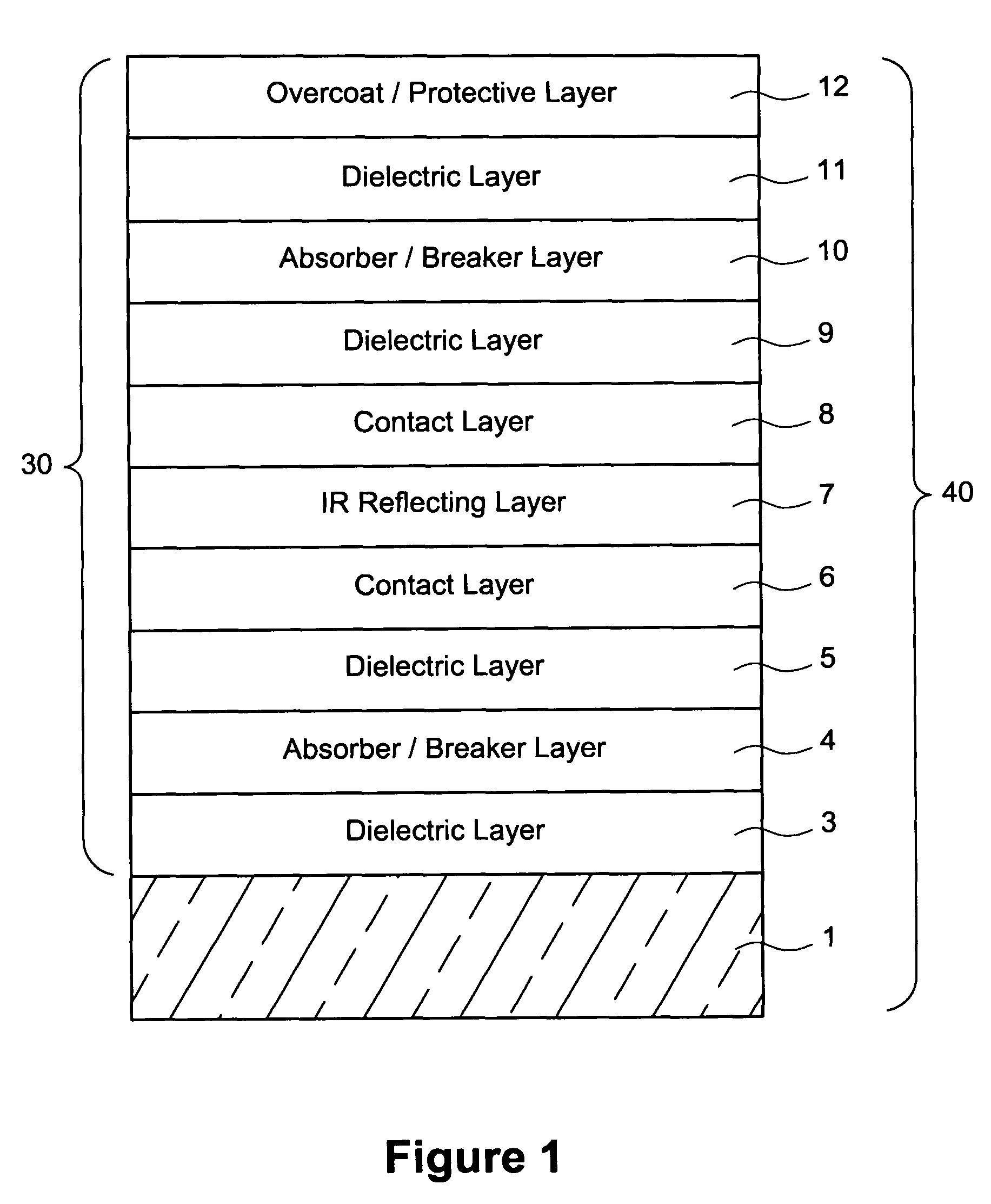

Coated article having low-E coating with absorber layer(s)

ActiveUS20110261442A1Low emissivityReduce sheet resistanceMirrorsOptical filtersElectrical resistance and conductanceInsulated glazing

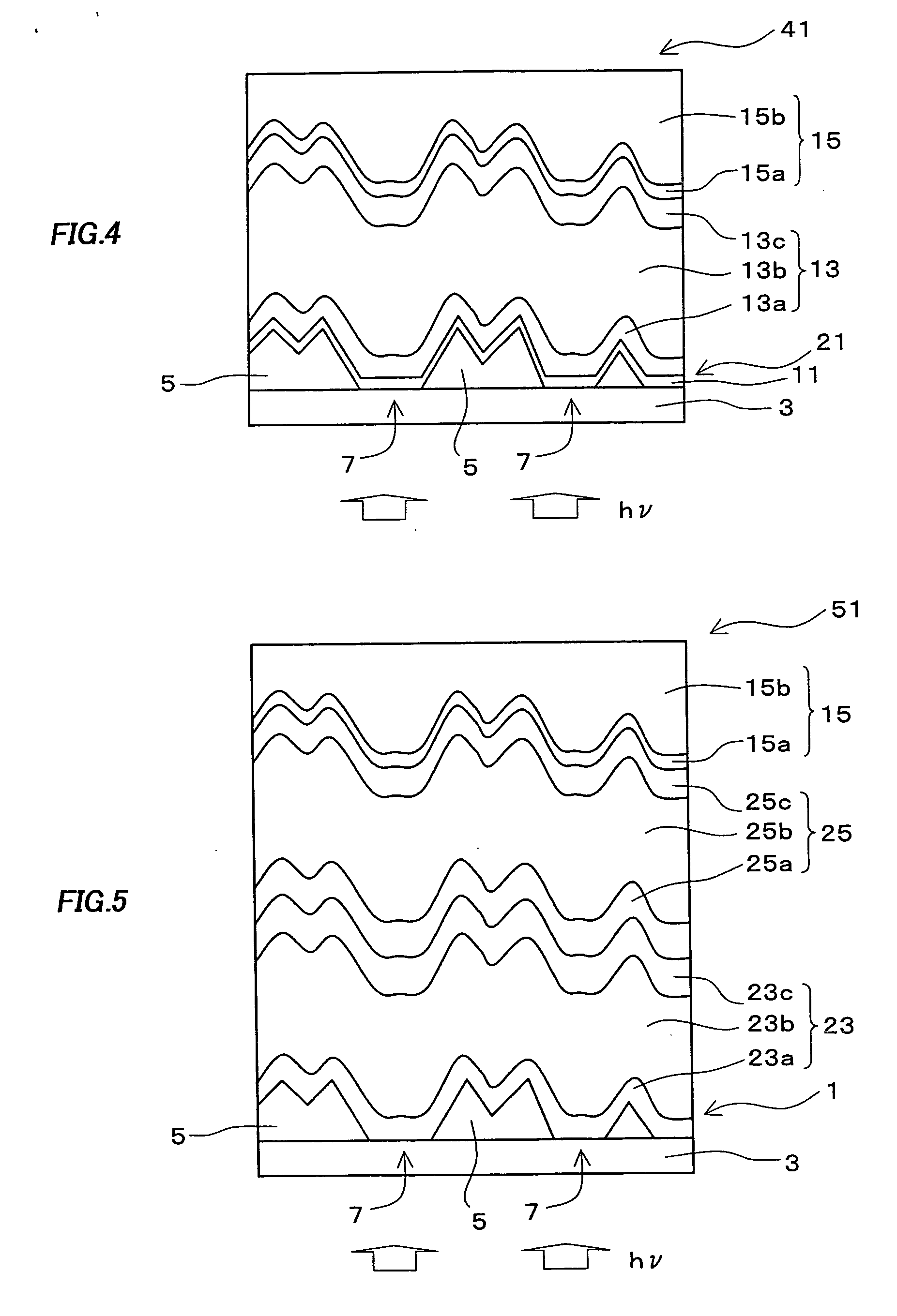

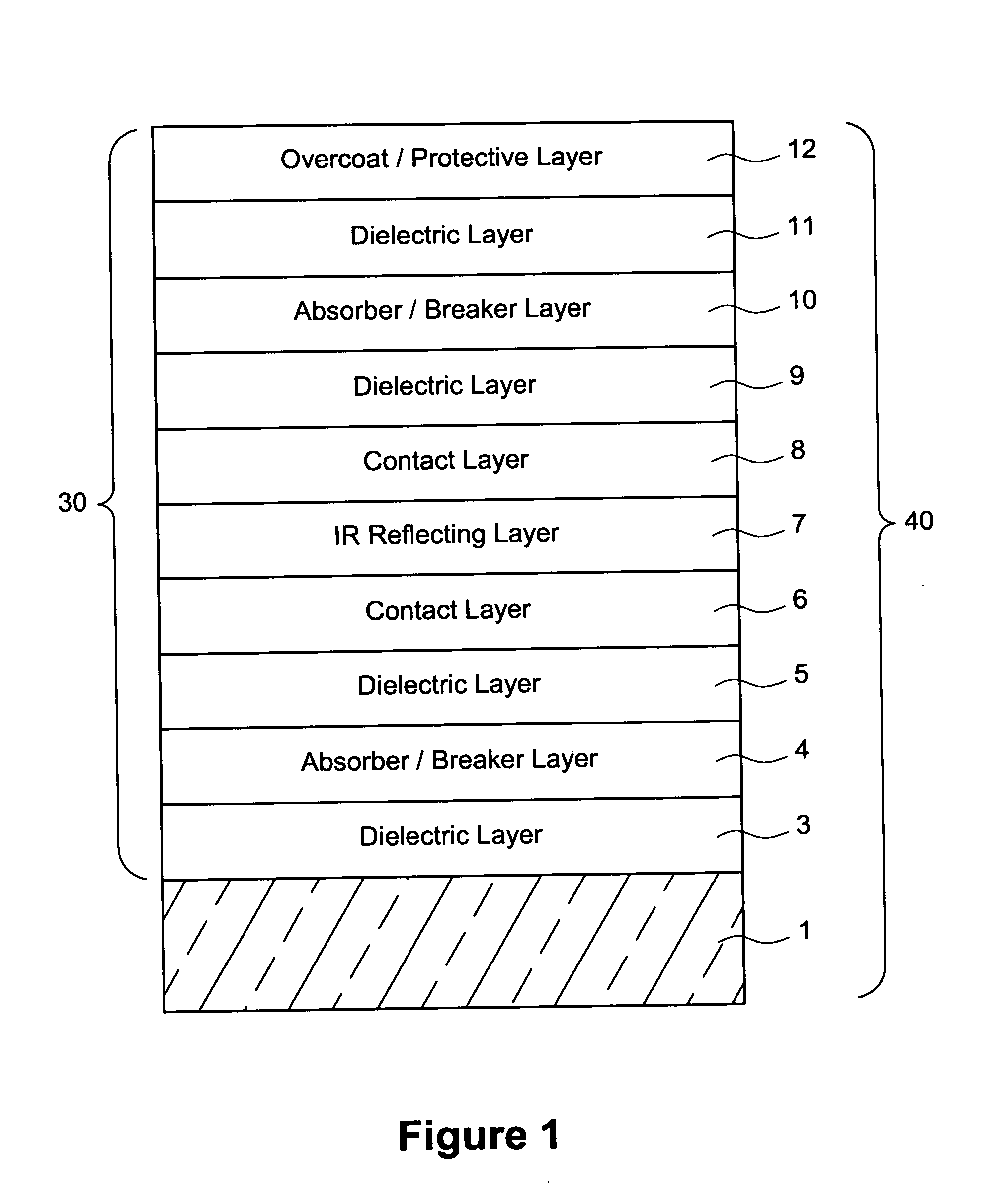

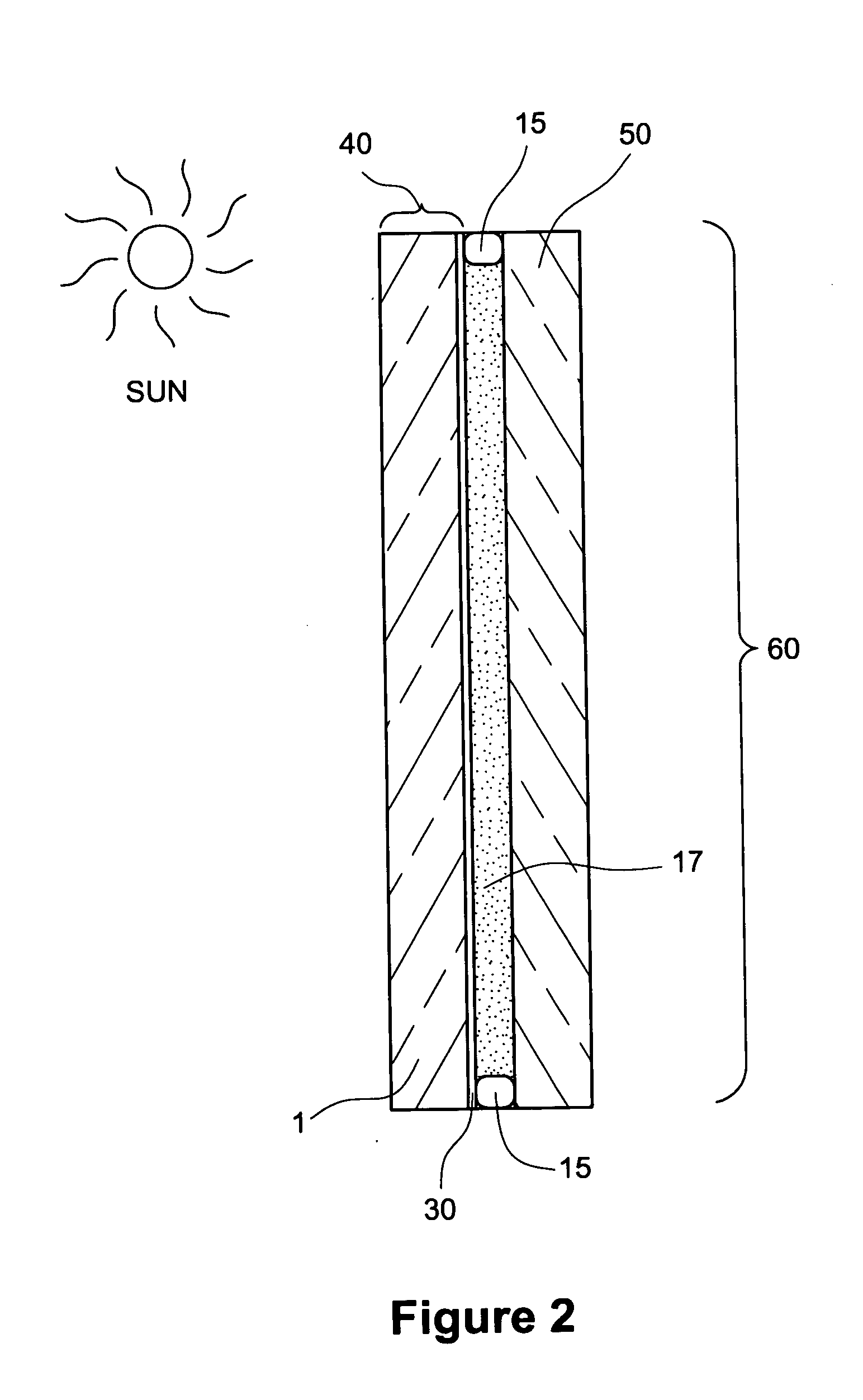

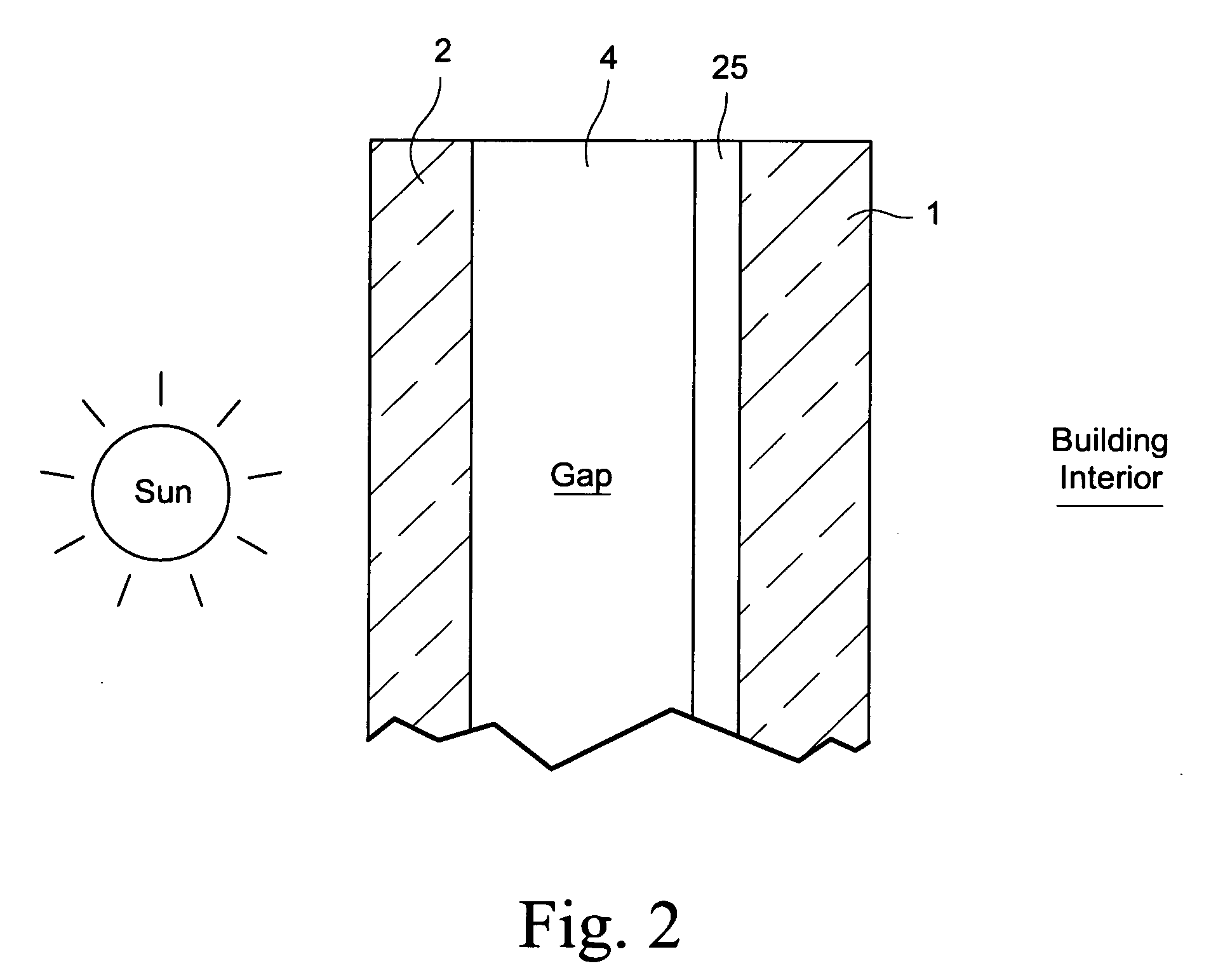

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN EURO S A R L +1

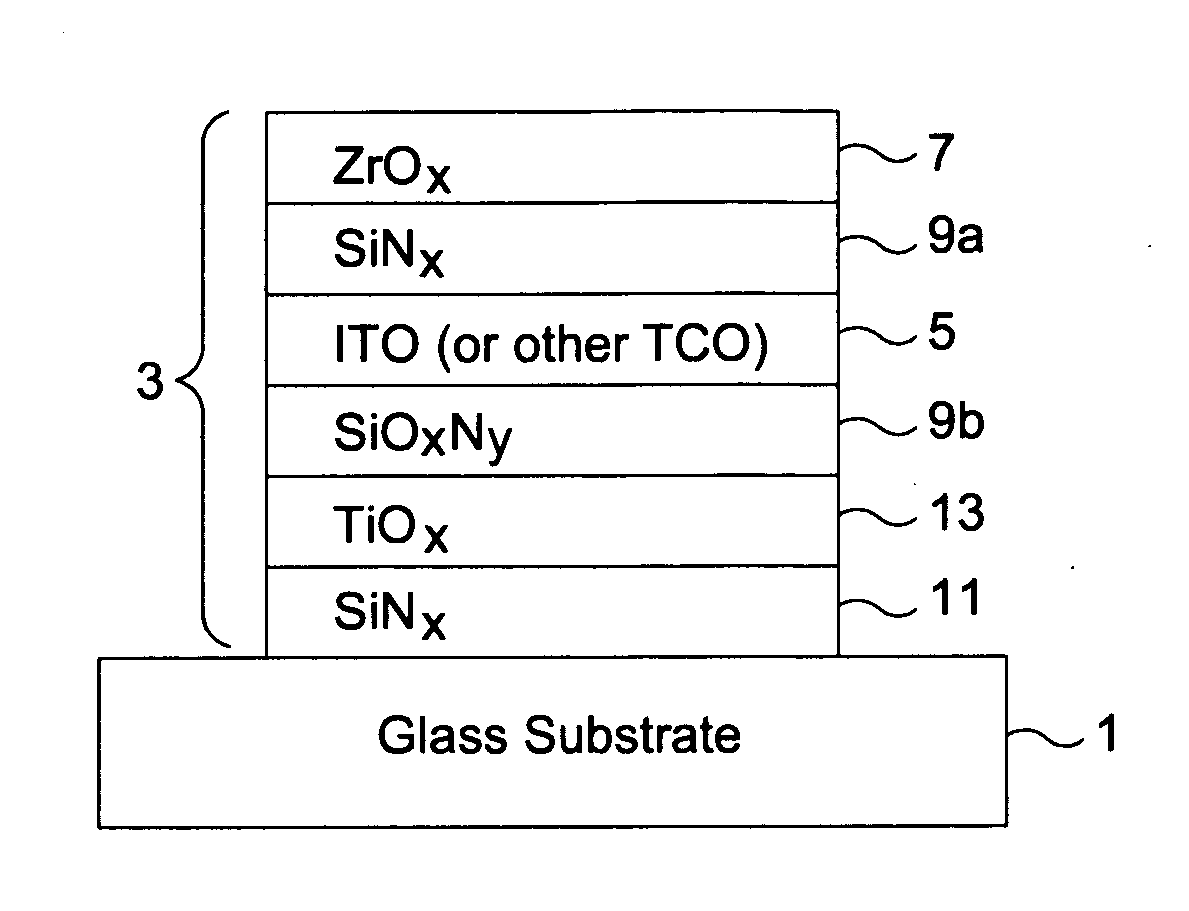

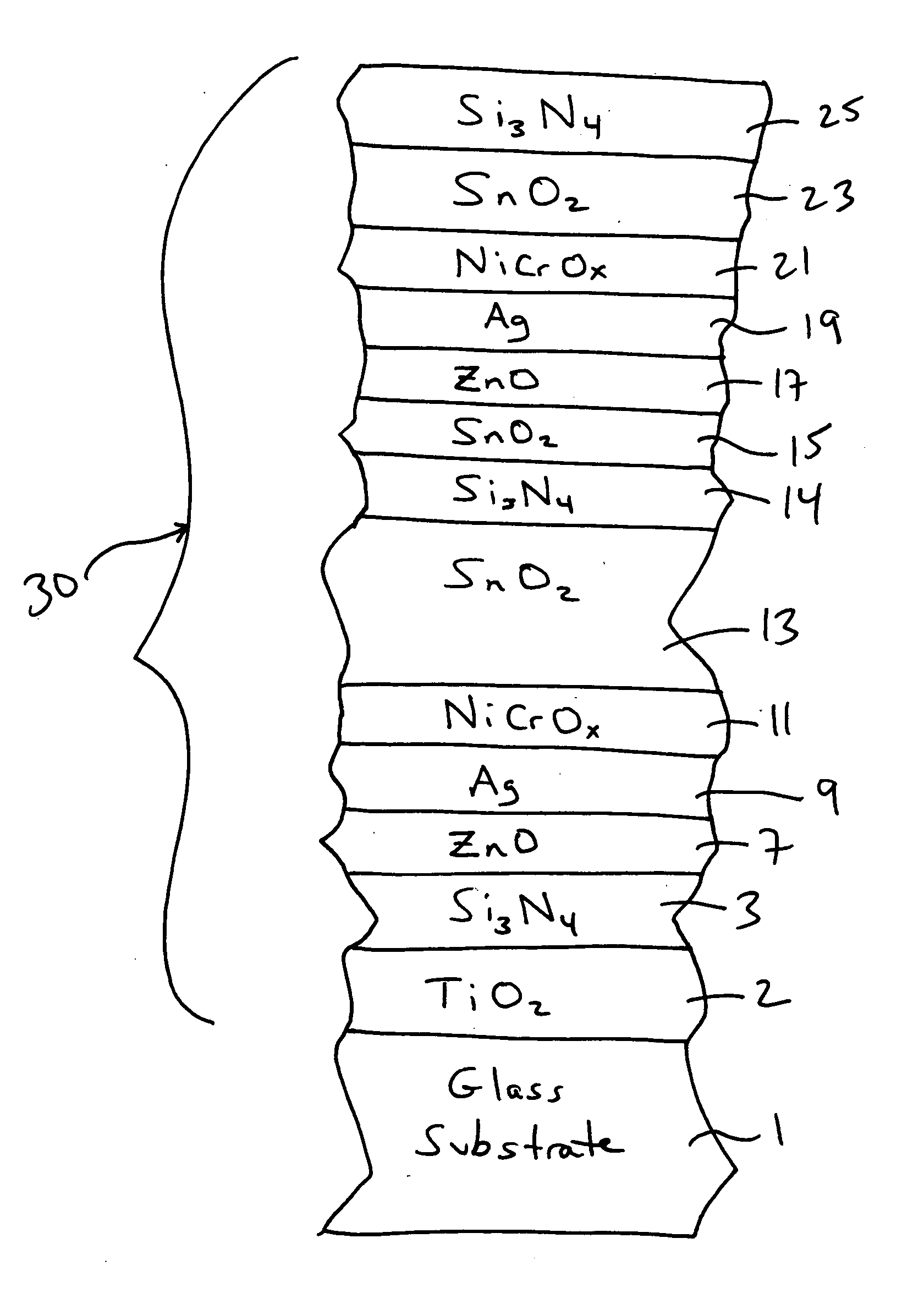

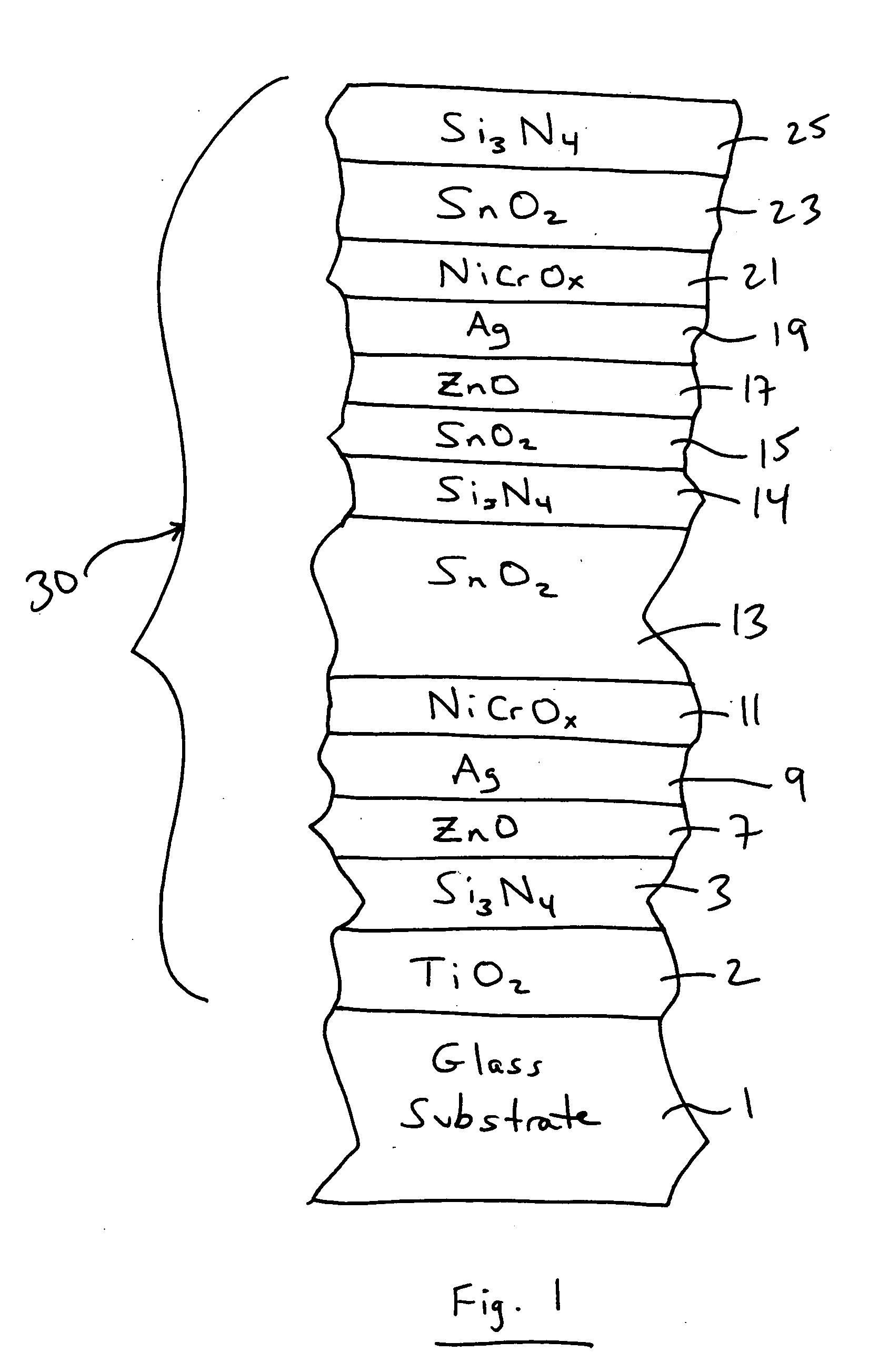

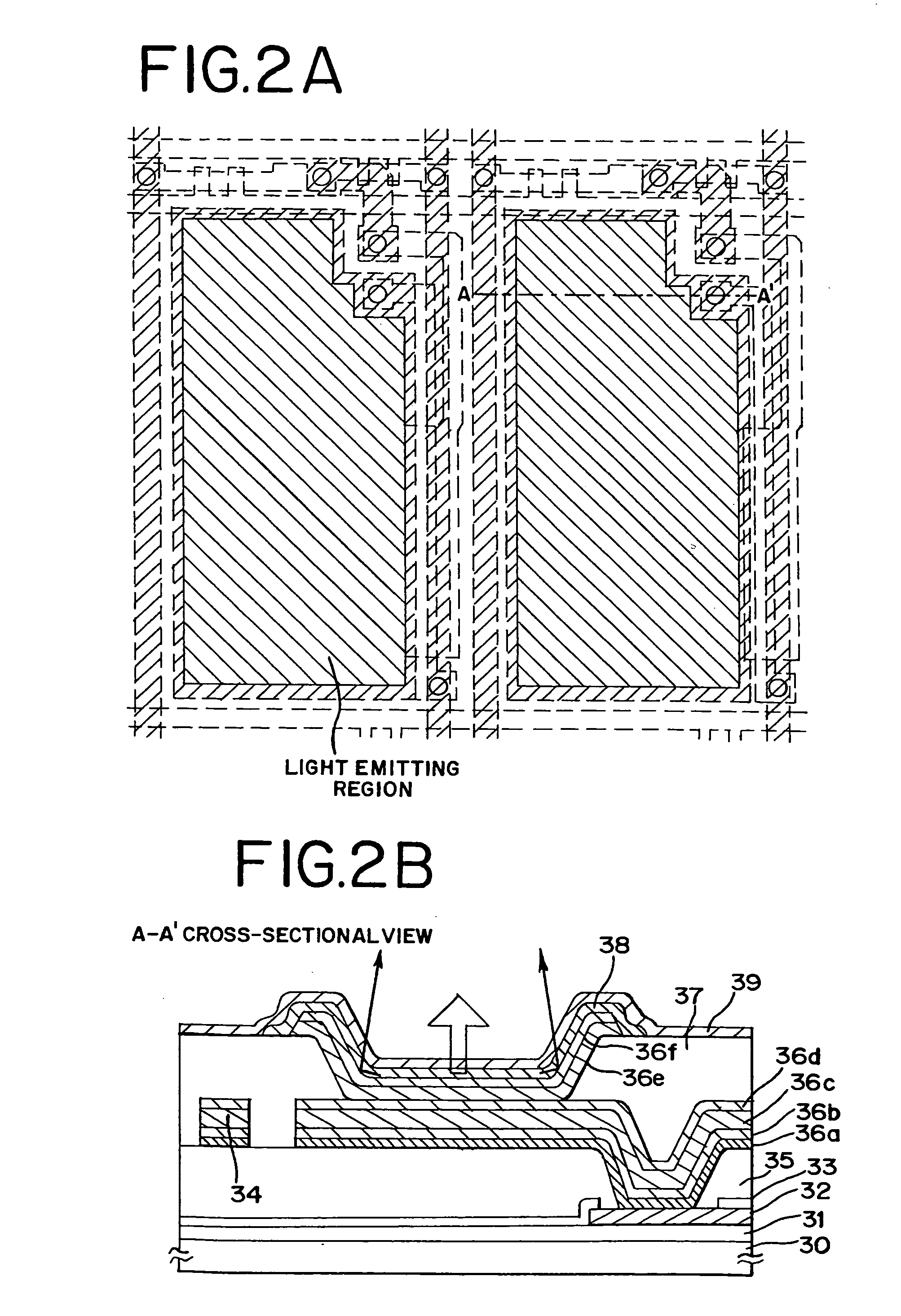

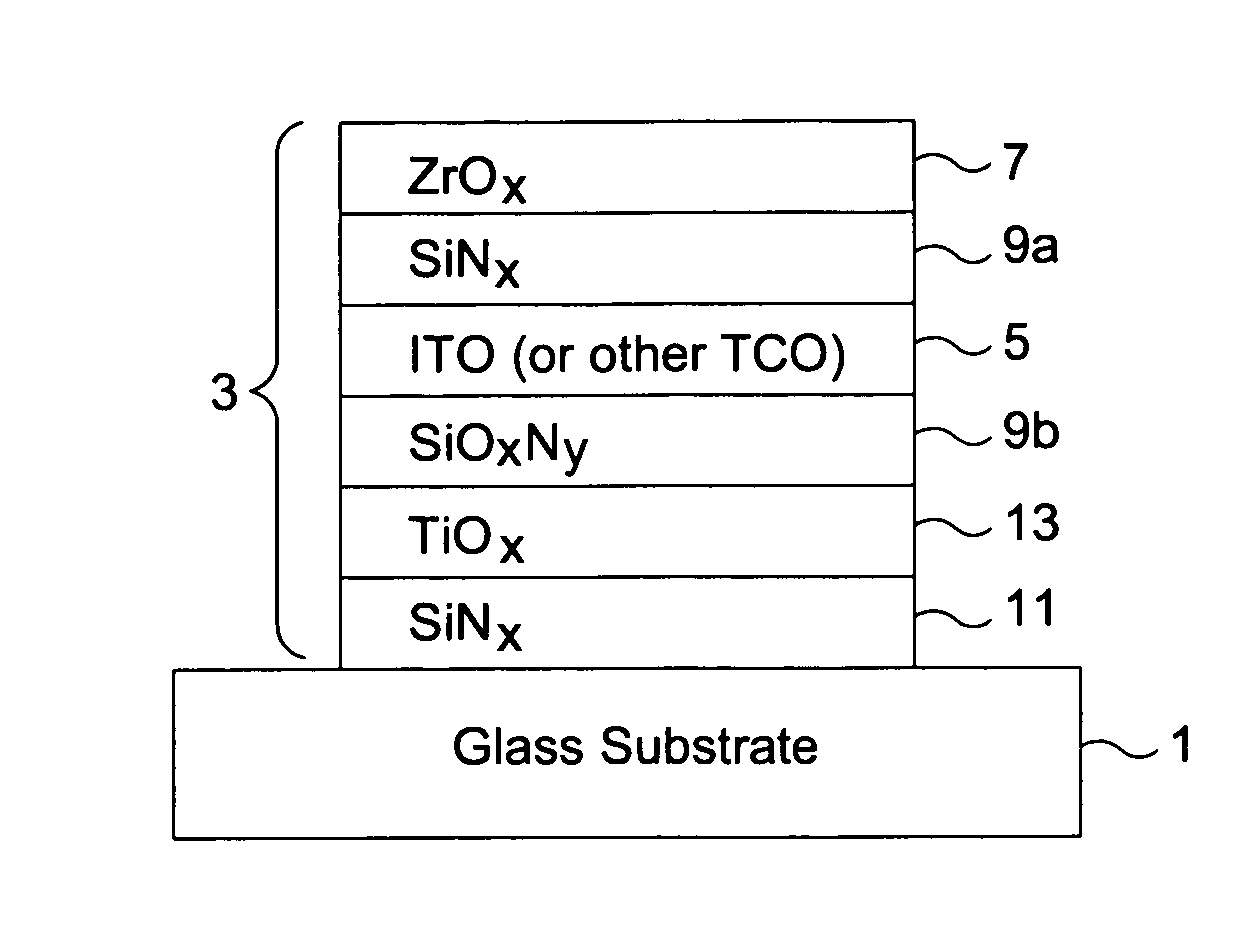

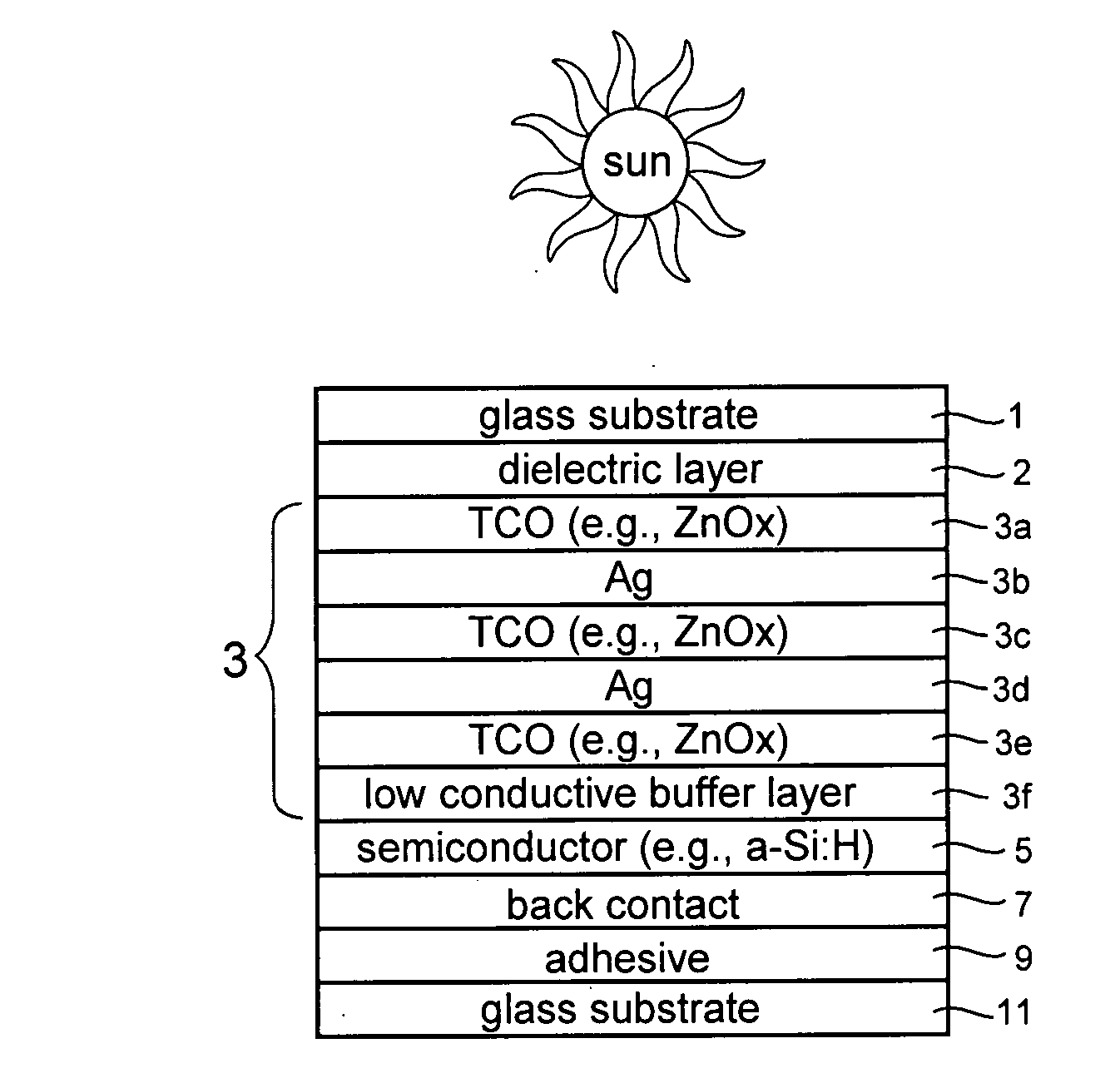

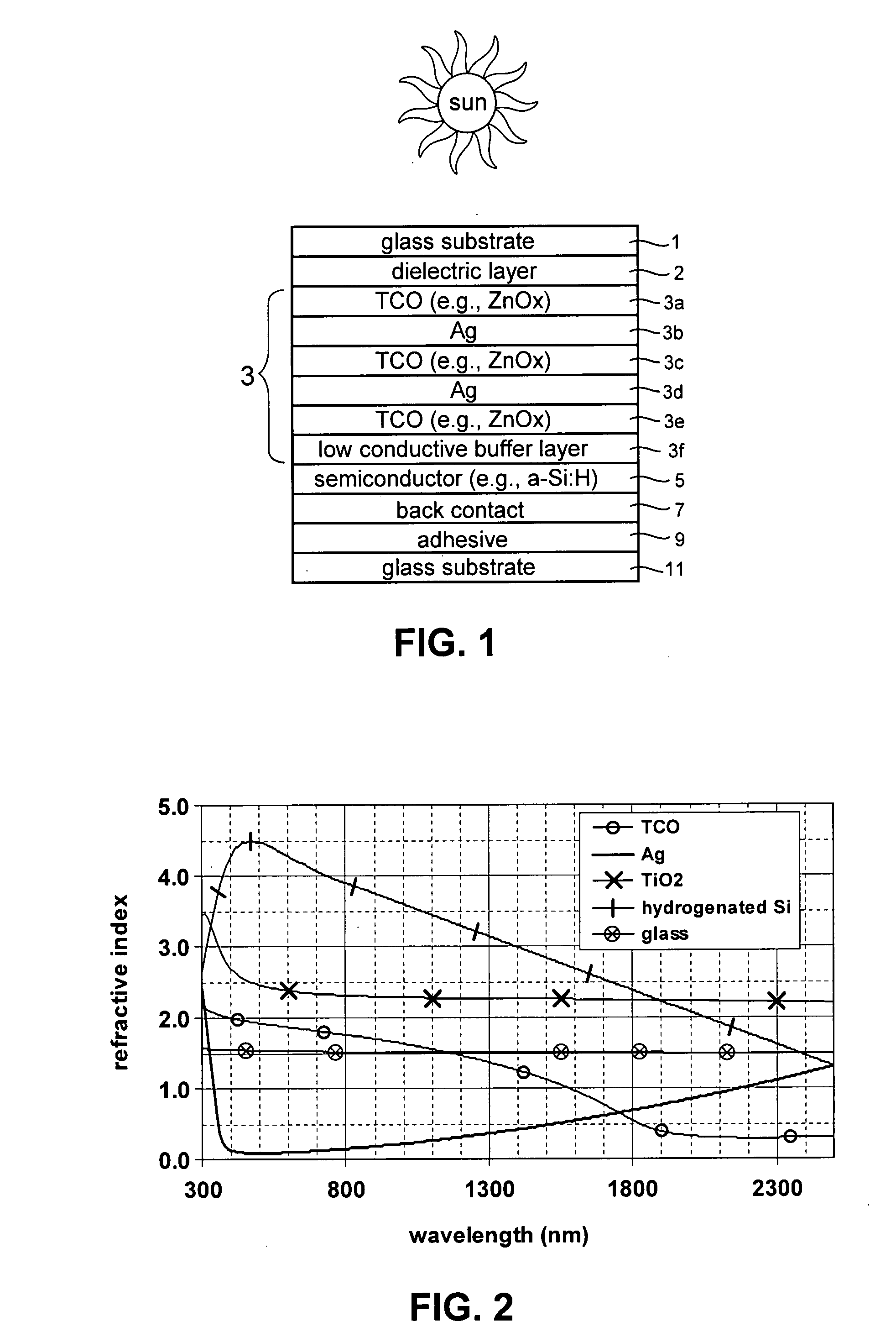

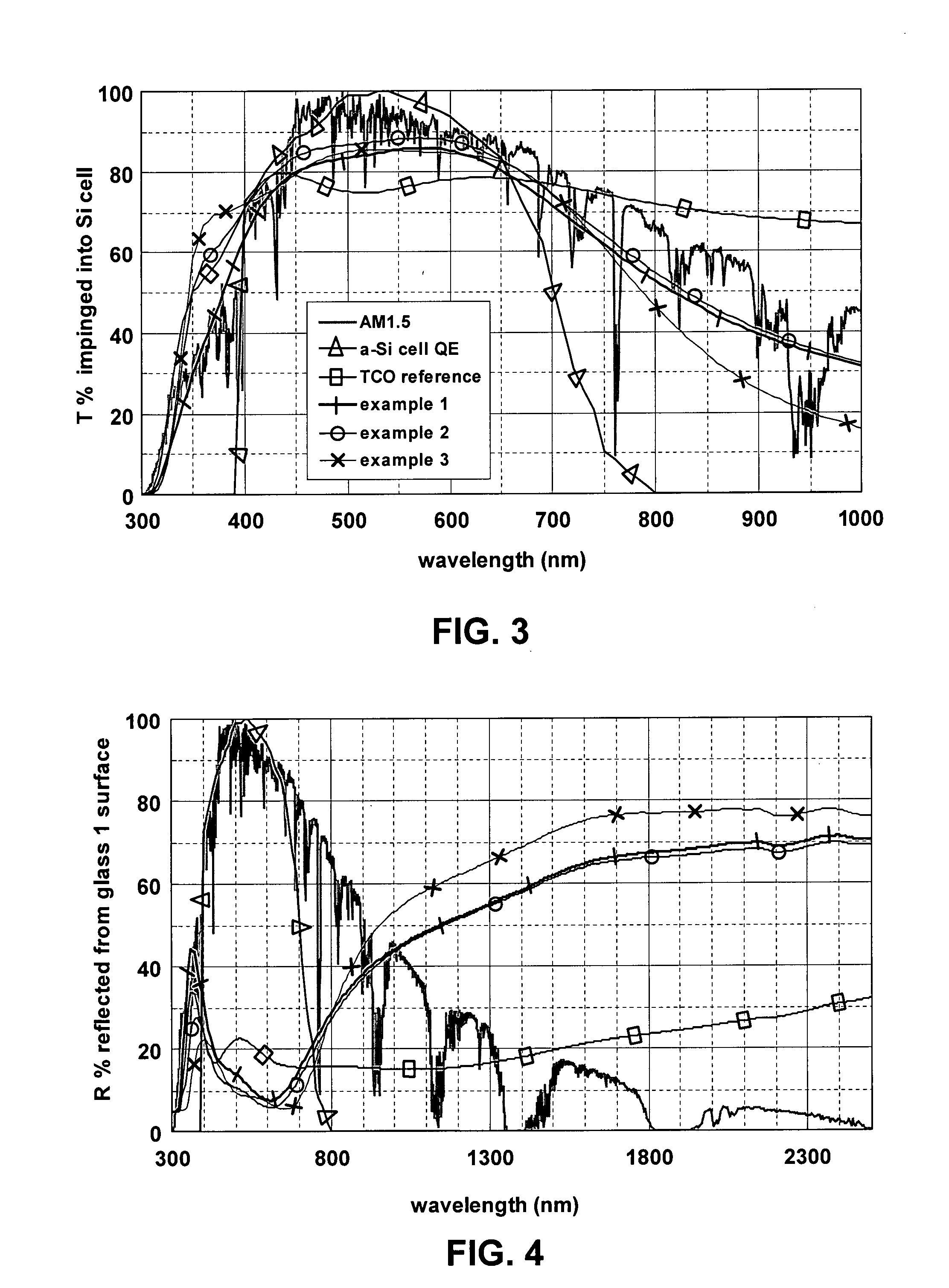

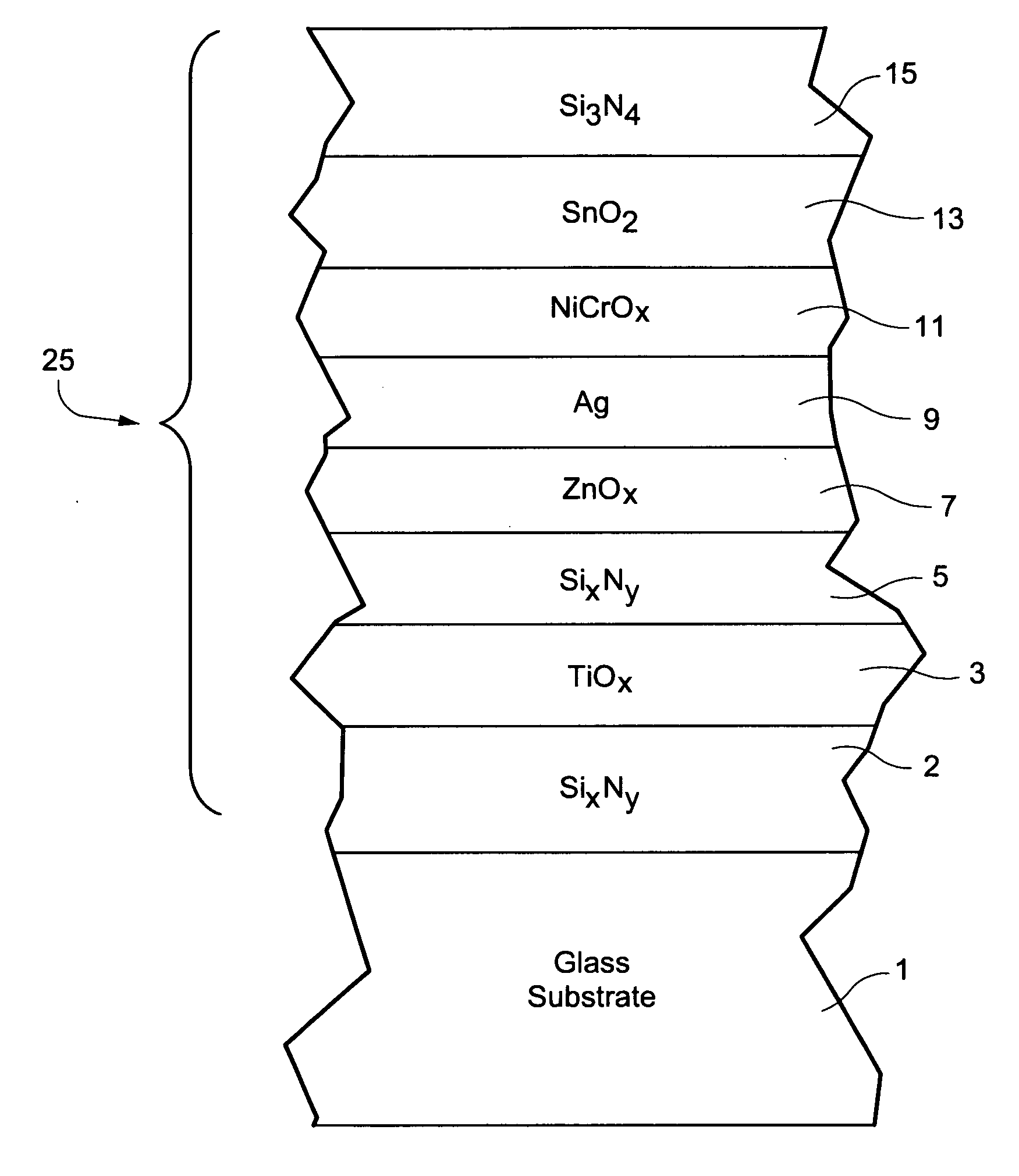

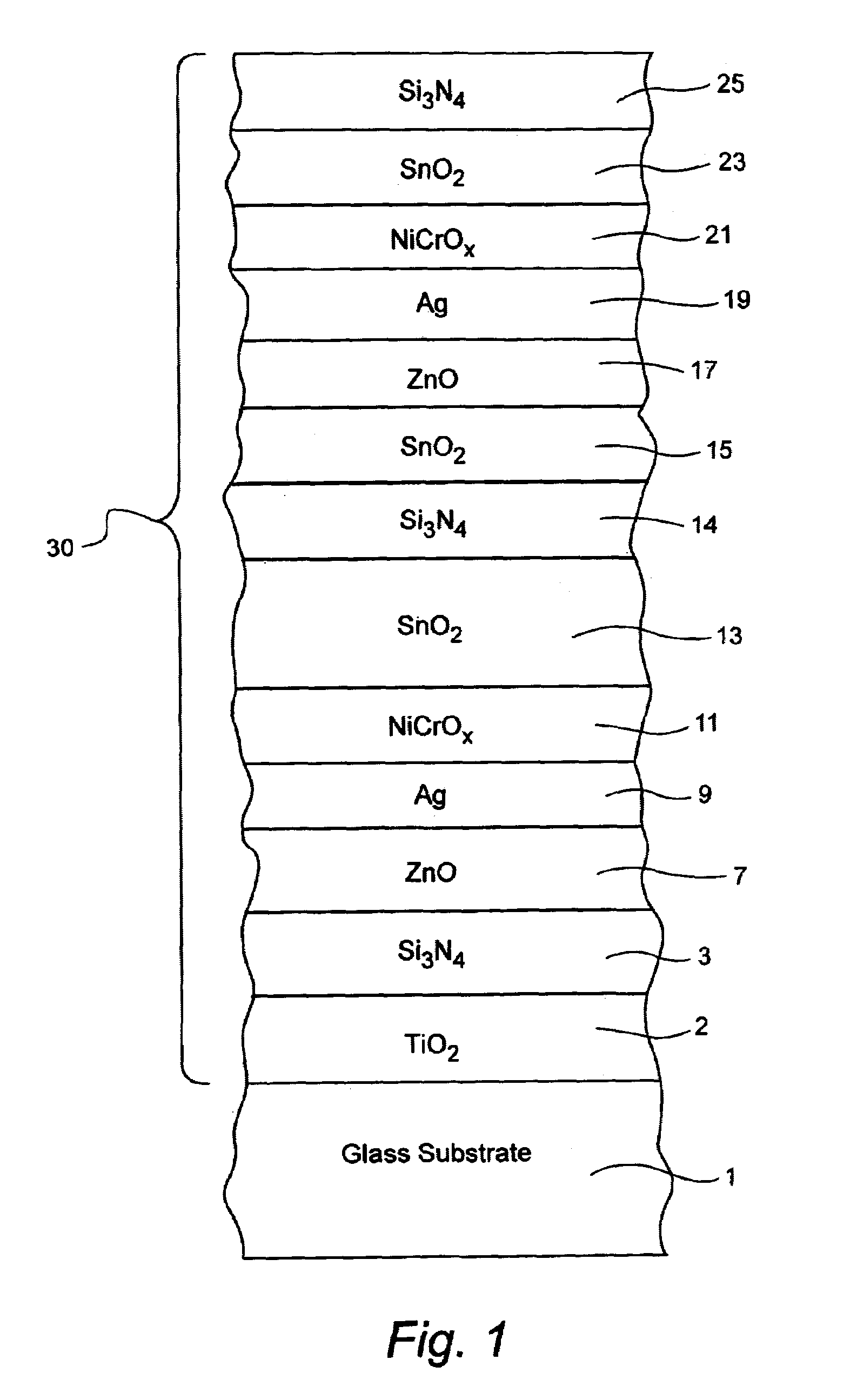

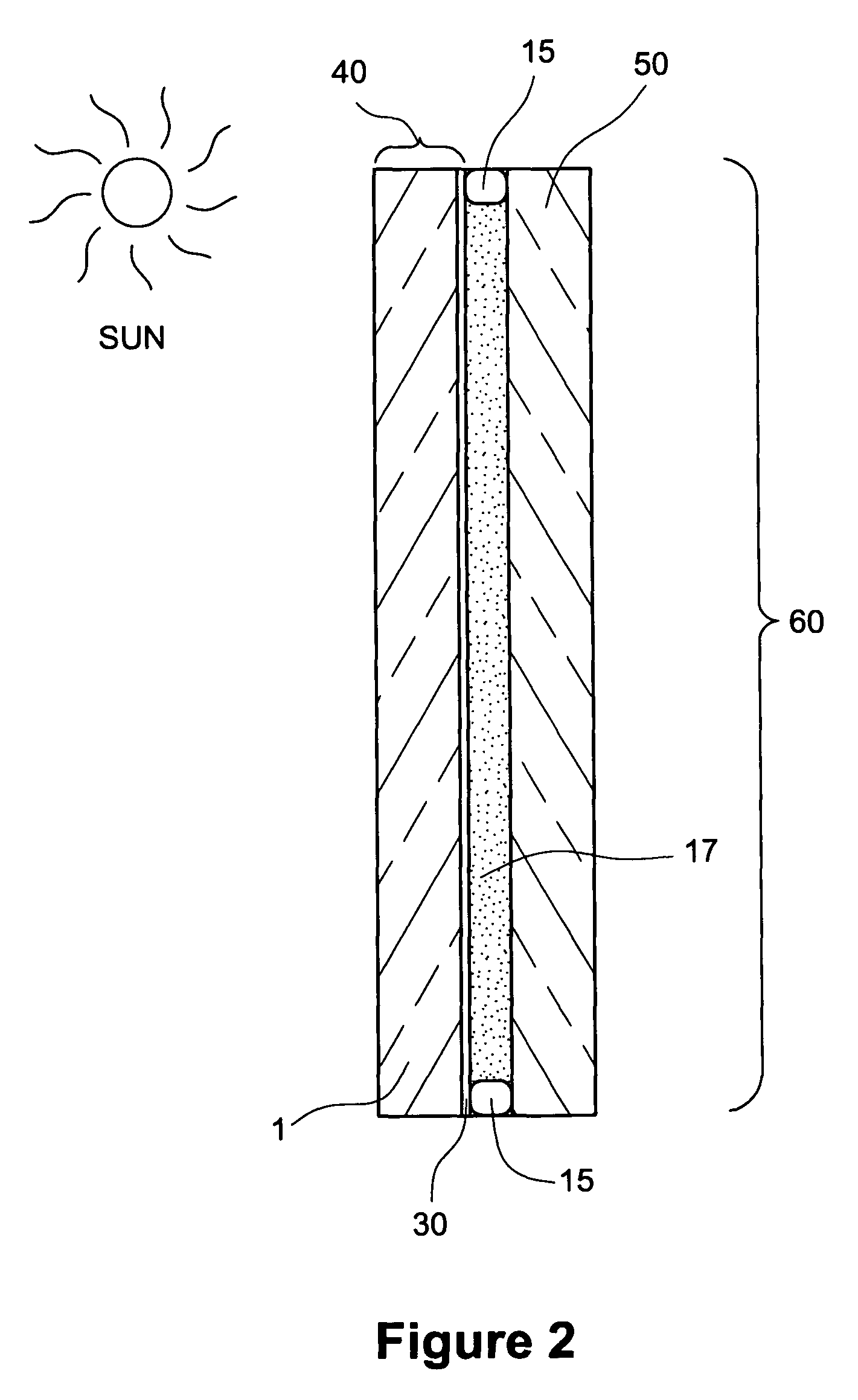

Front electrode for use in photovoltaic device and method of making same

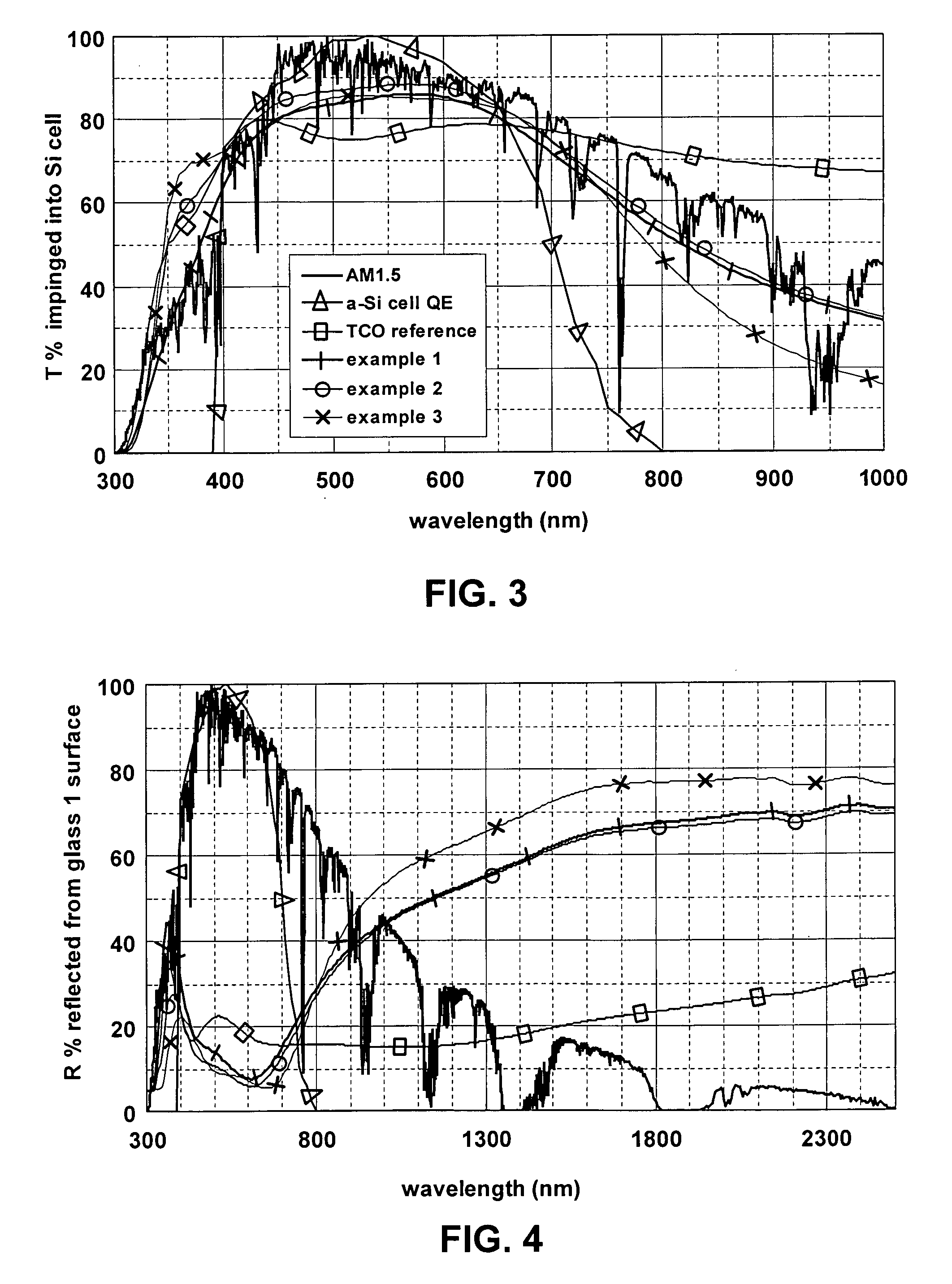

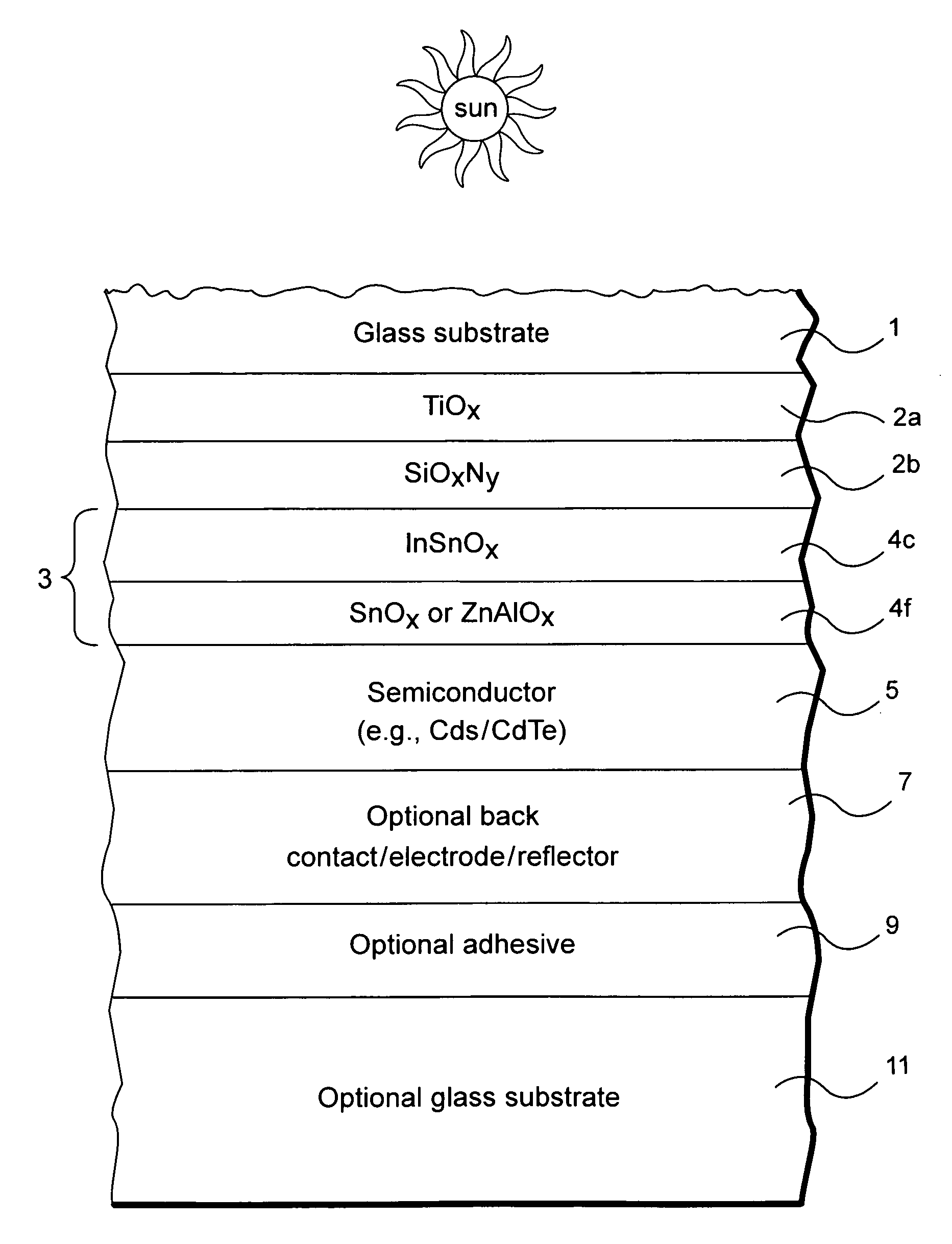

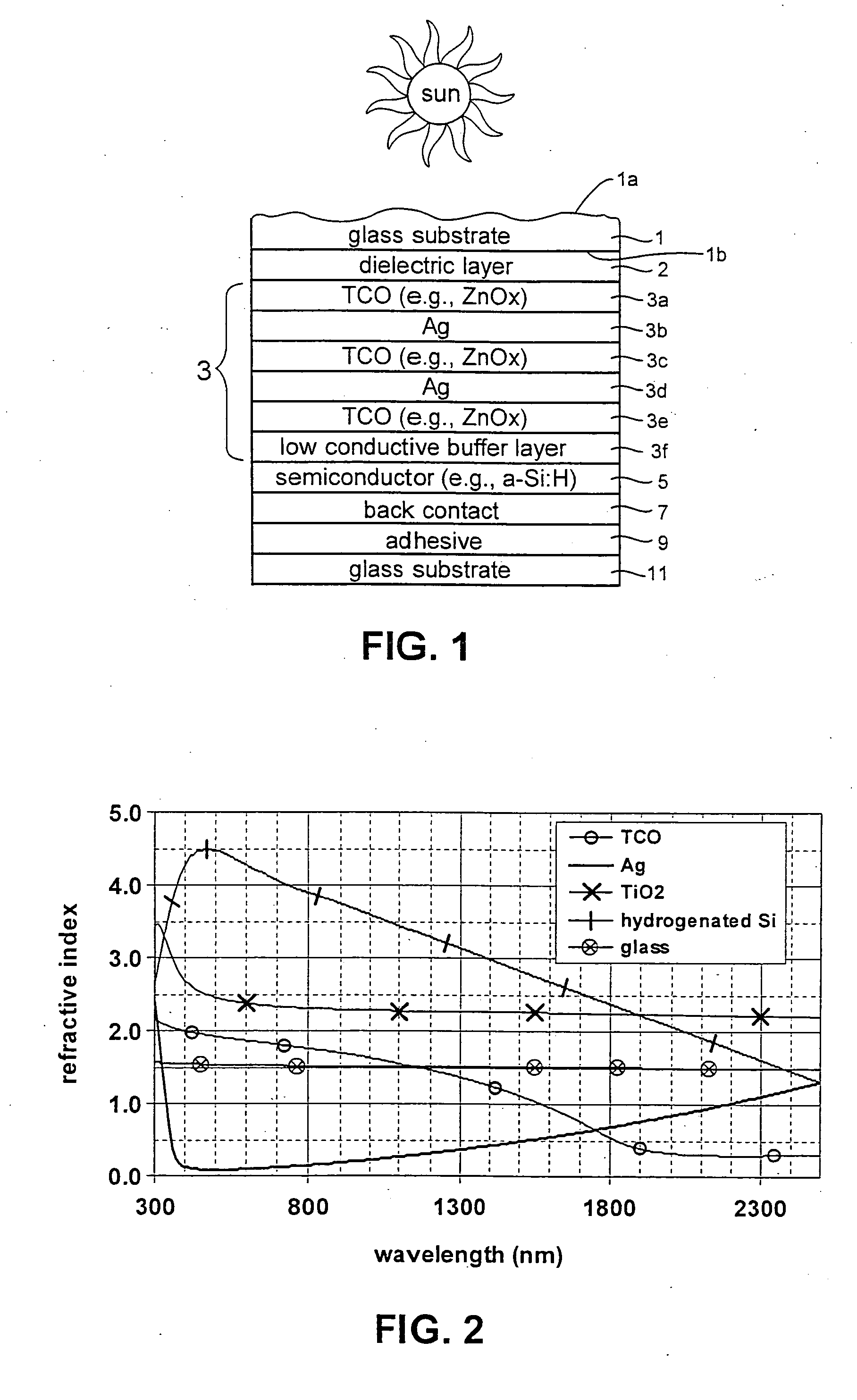

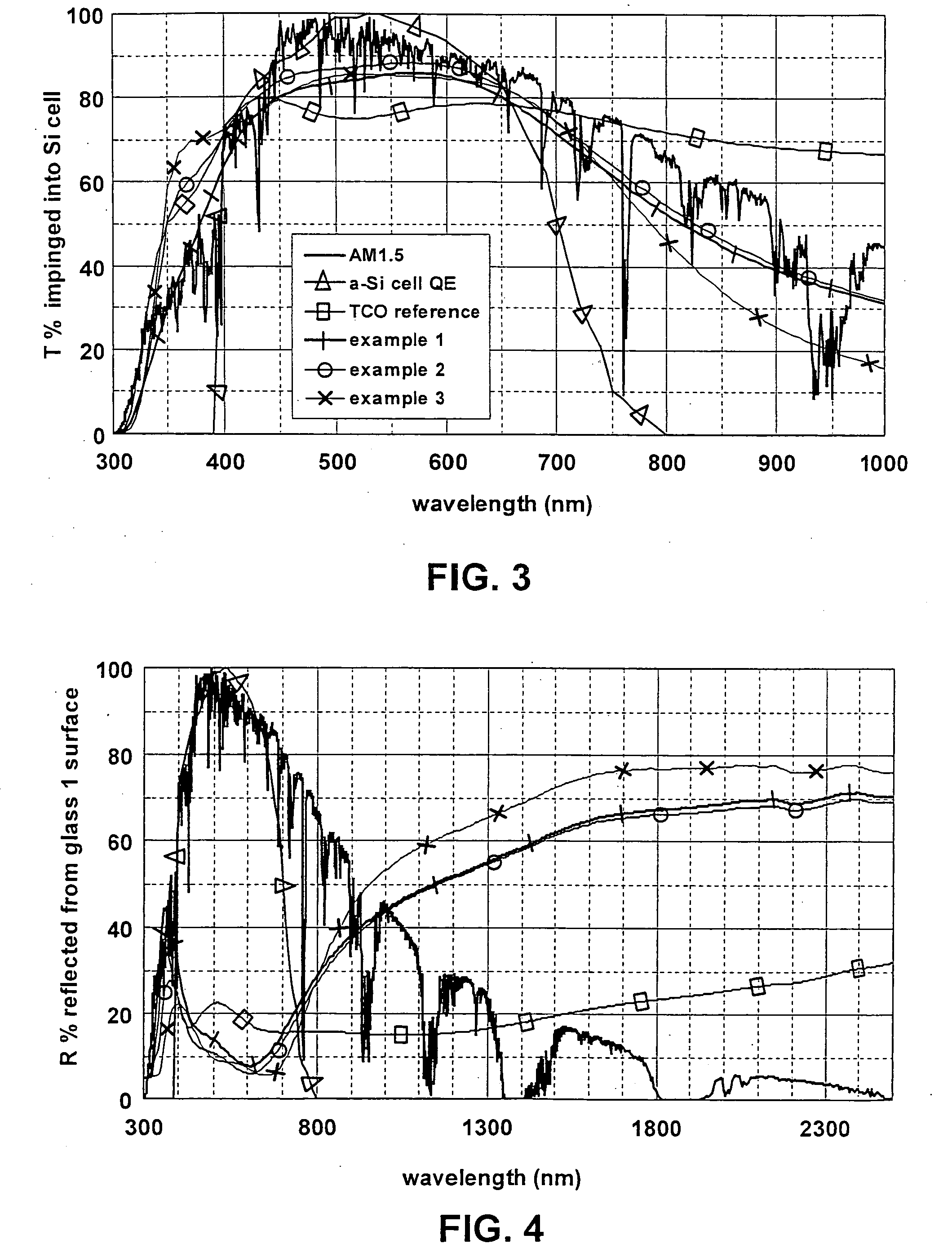

ActiveUS20080210303A1Reduce reflection lossPromote absorptionGlass/slag layered productsCoatingsLight reflectionZinc

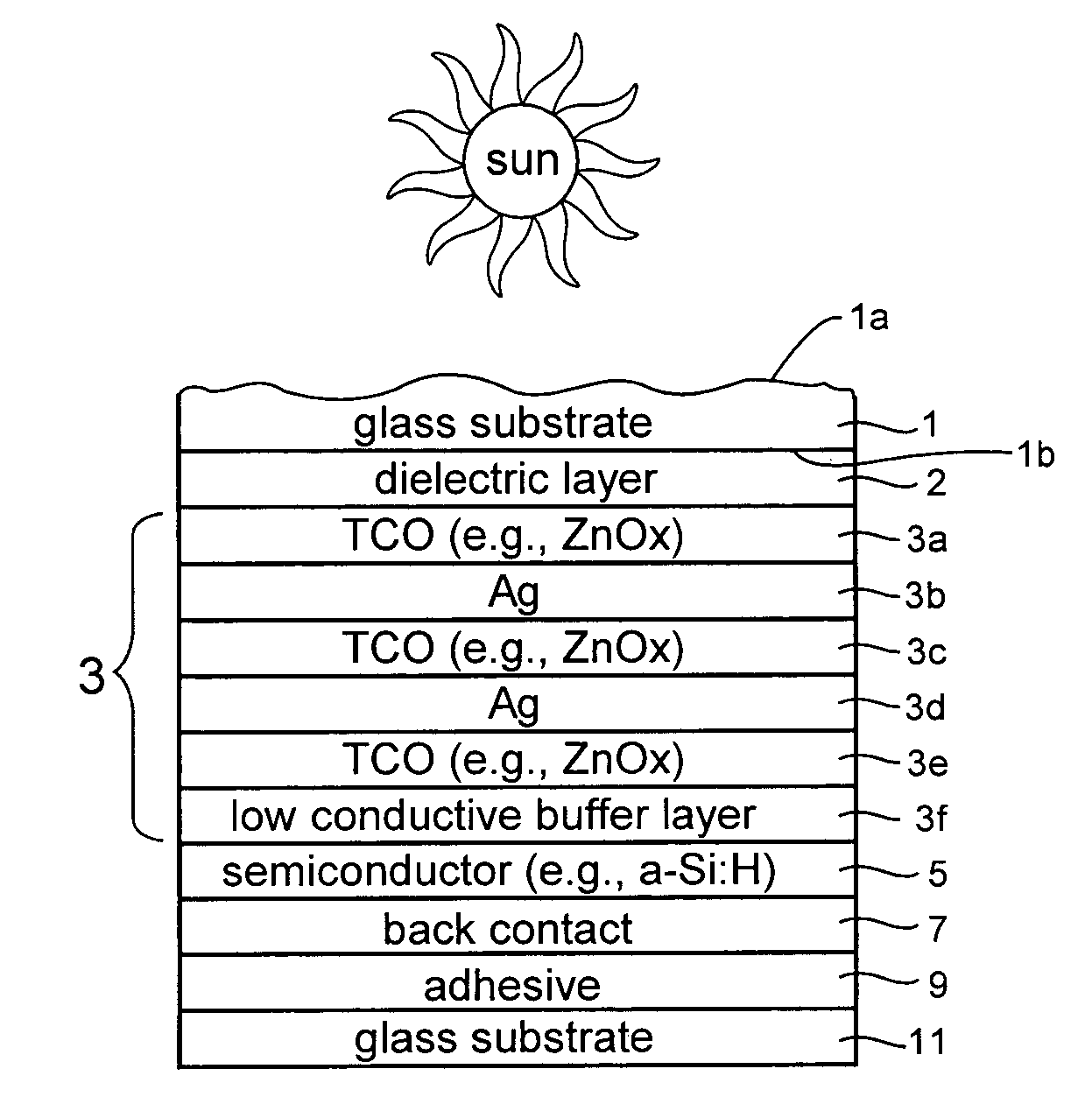

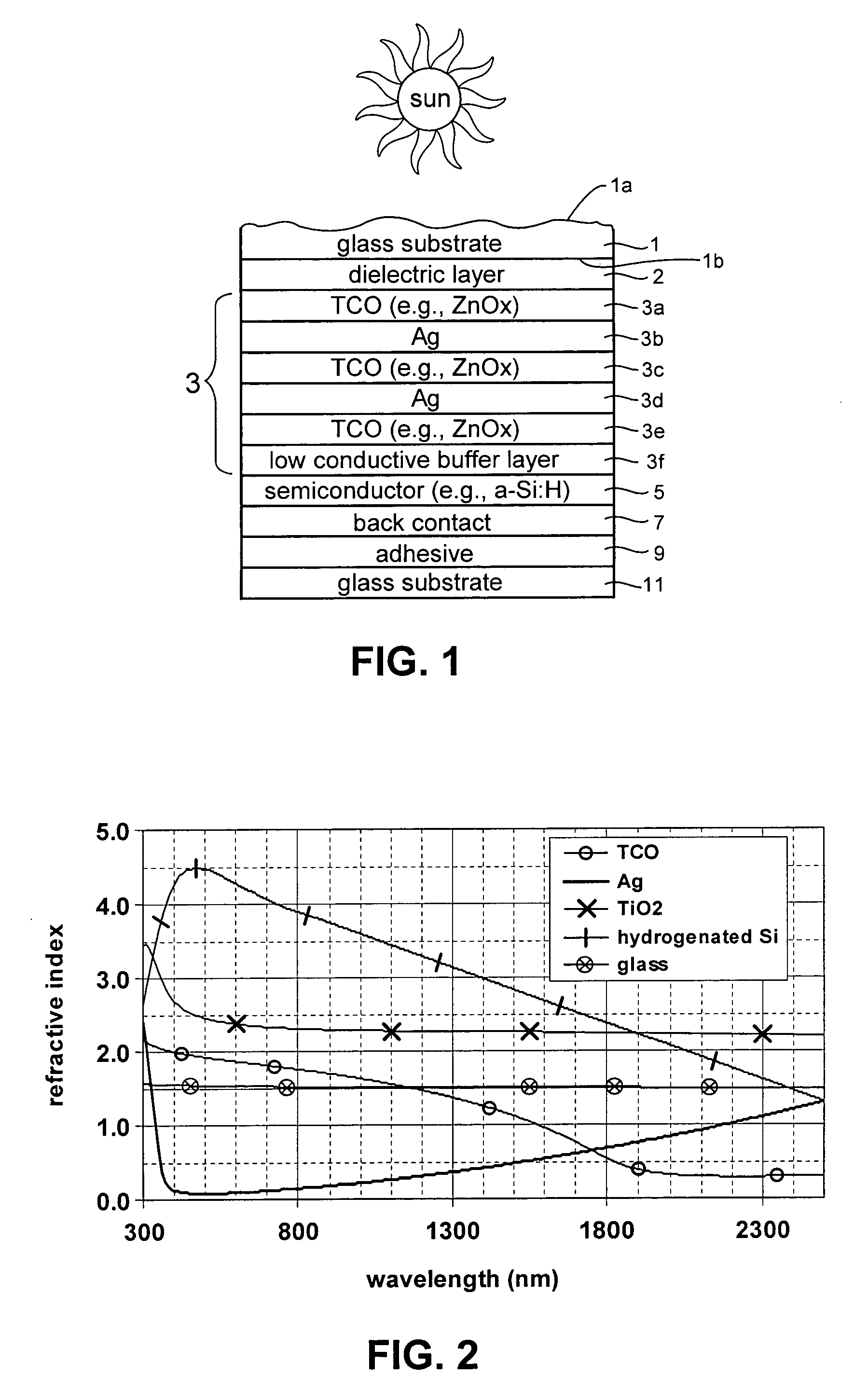

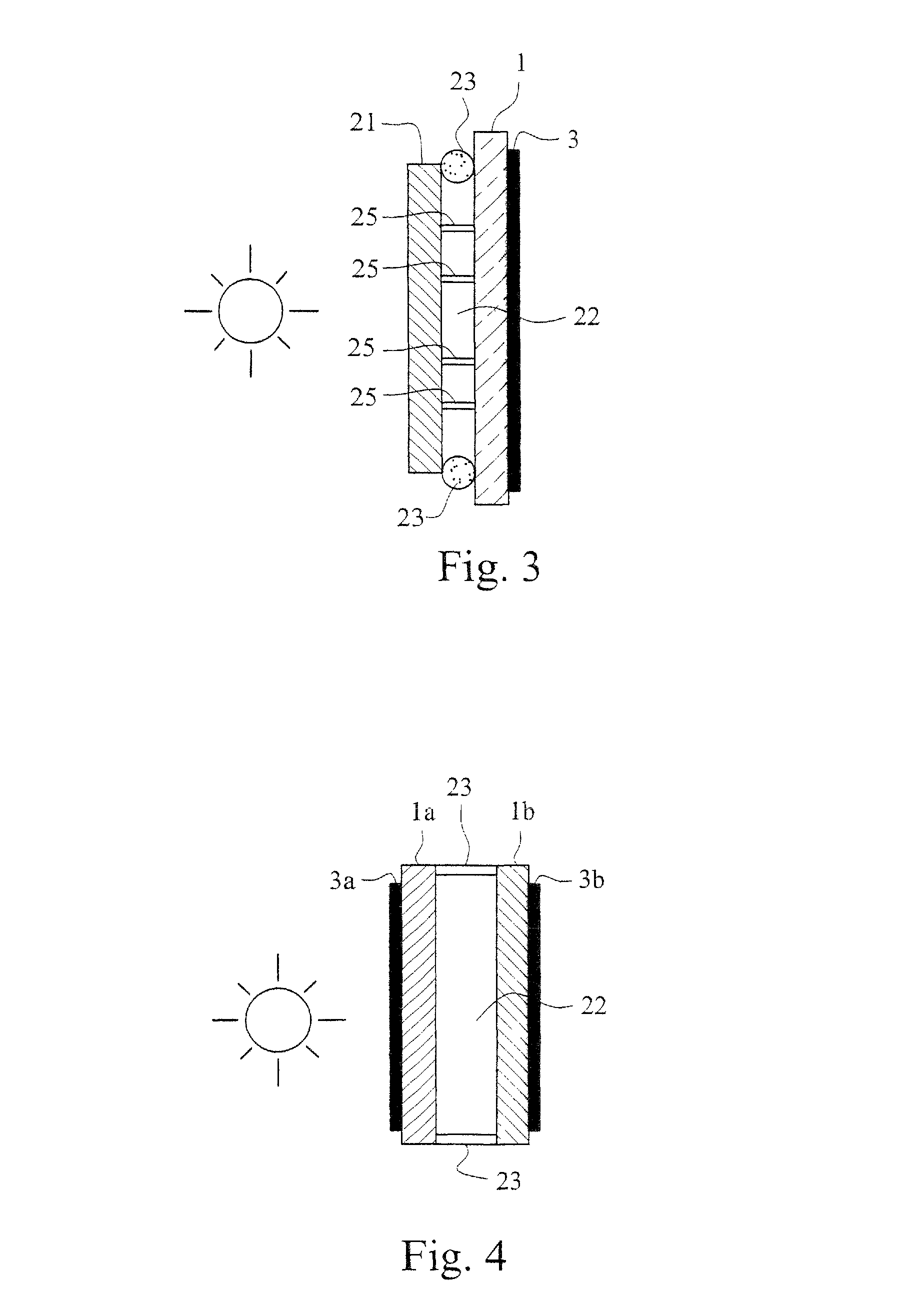

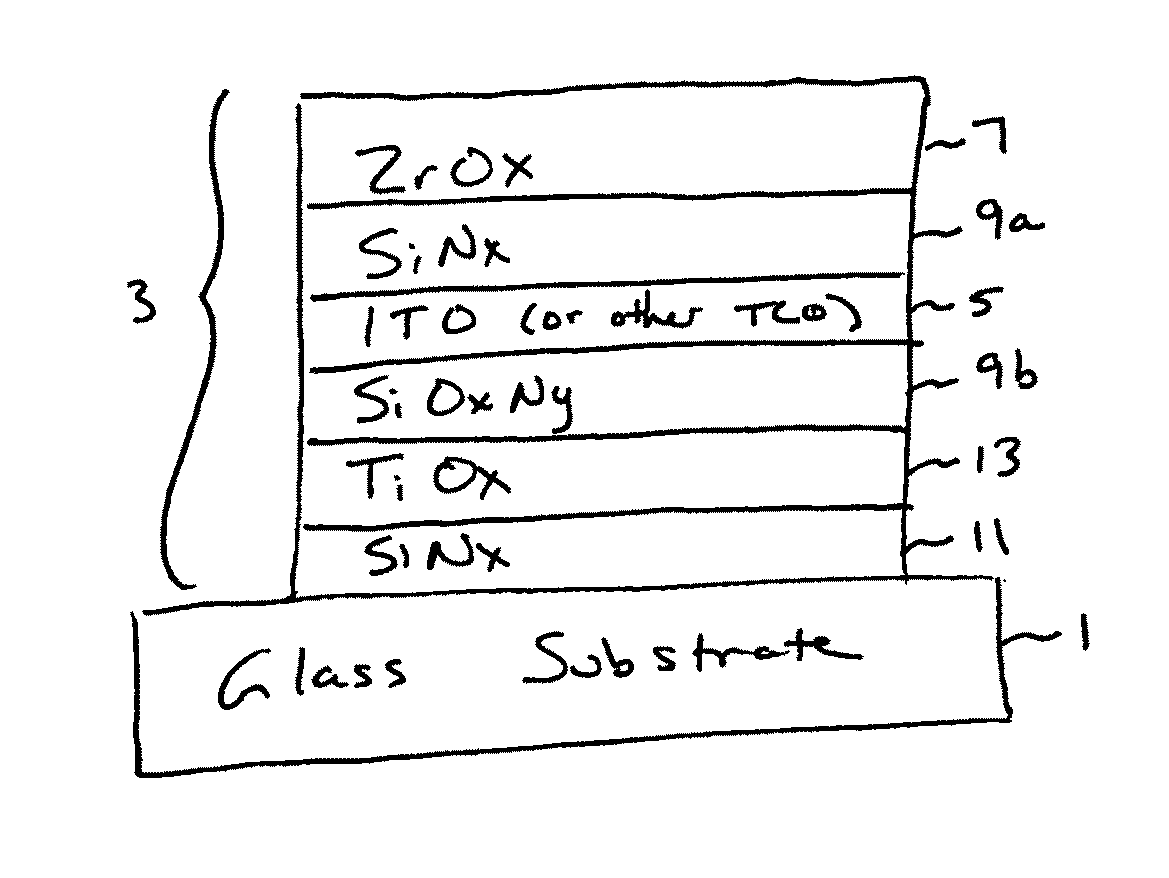

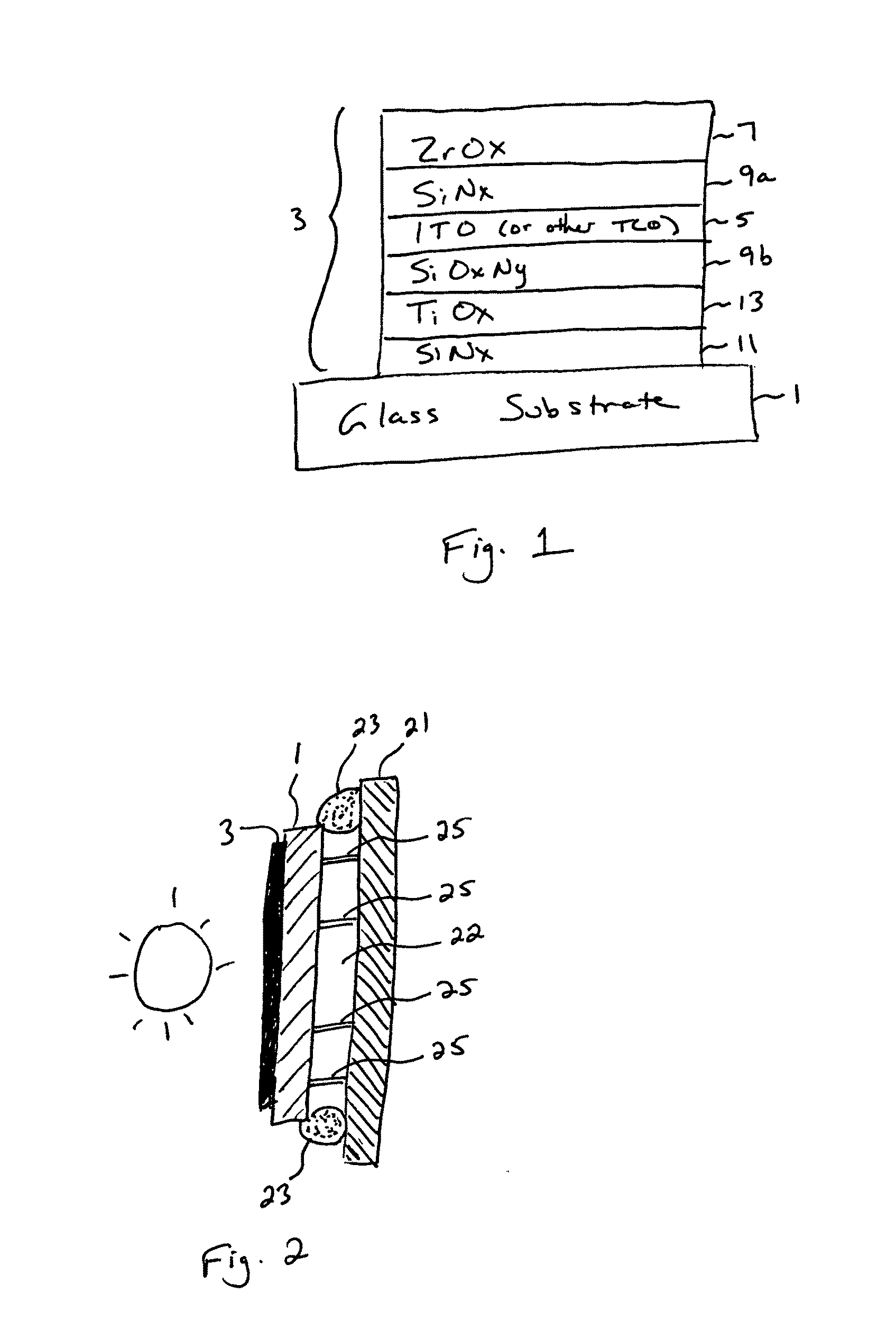

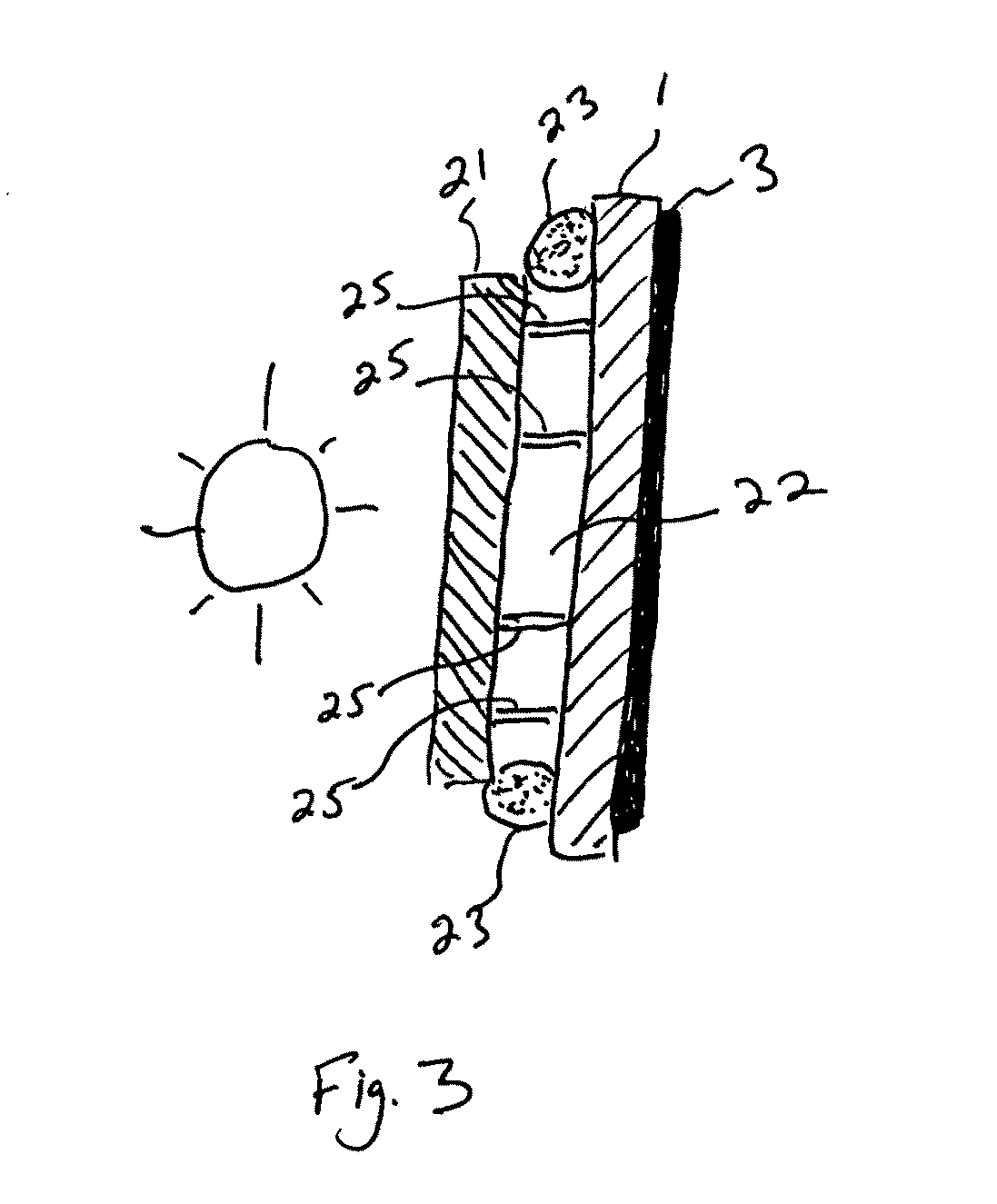

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability. At least one of the surfaces of the front glass substrate may be textured in certain example embodiments of this invention.

Owner:GUARDIAN GLASS LLC

Front electrode for use in photovoltaic device and method of making same

ActiveUS20090084438A1Reduce reflection lossPromote absorptionPhotovoltaic energy generationSemiconductor devicesIr reflectionLight reflection

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and / or one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability.

Owner:GUARDIAN GLASS LLC

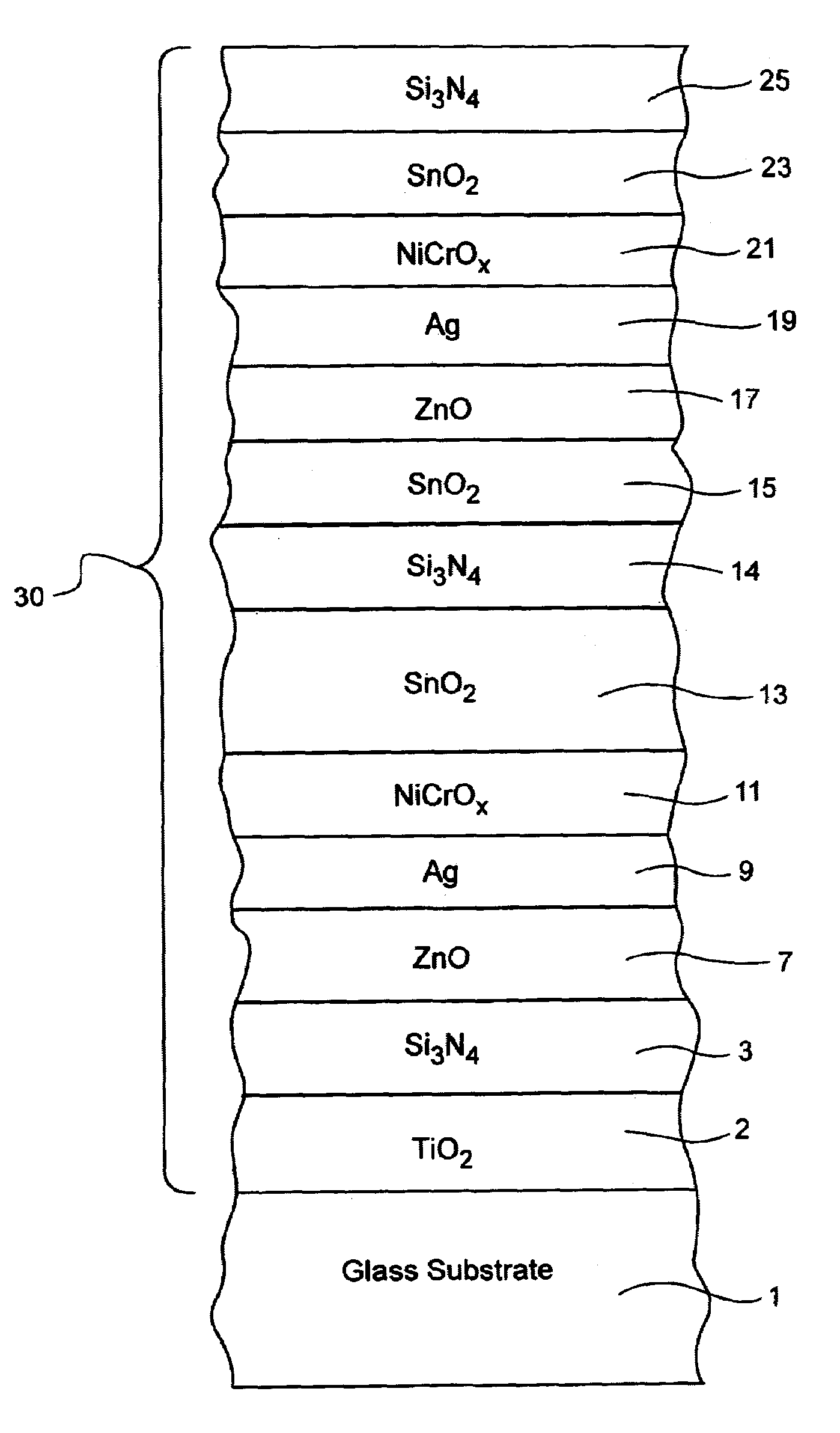

Heat treatable coated article with zinc oxide inclusive contact layer(s)

InactiveUS6887575B2Reduce sheet resistanceImprove performanceVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceContact layer

A coated article is provided so as to have a fairly high visible transmission (TY or Tvis) to sheet resistance (Rs) ratio (i.e., a ratio Tvis / Rs). The higher this ratio, the better the coated article's combined functionality of providing for both good solar performance (e.g., ability to reflect and / or absorb IR radiation) and high visible transmission. In certain example embodiments, coated articles herein may be heat treatable. Coated articles herein may be used in the context of insulating glass (IG) window units, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

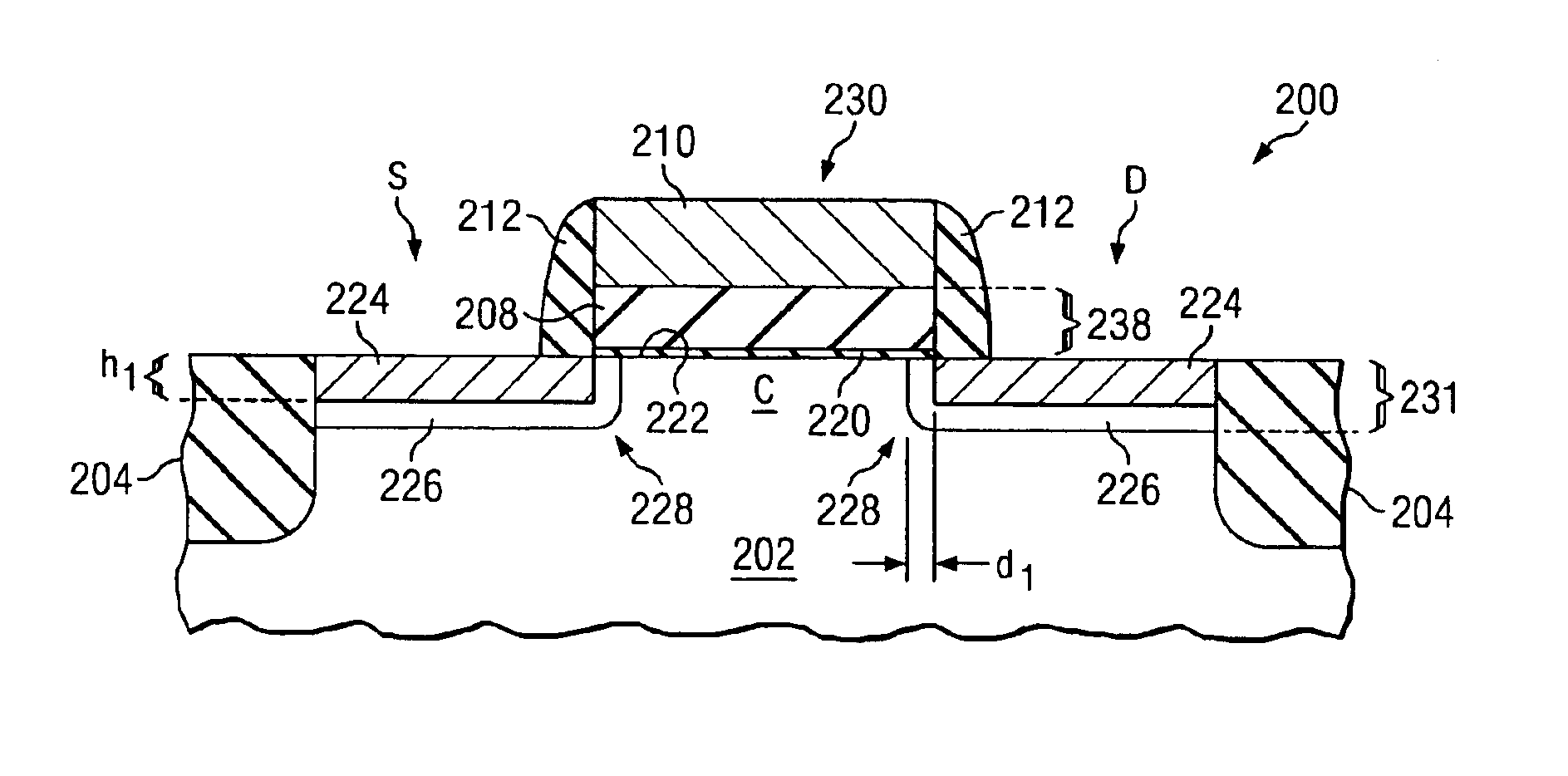

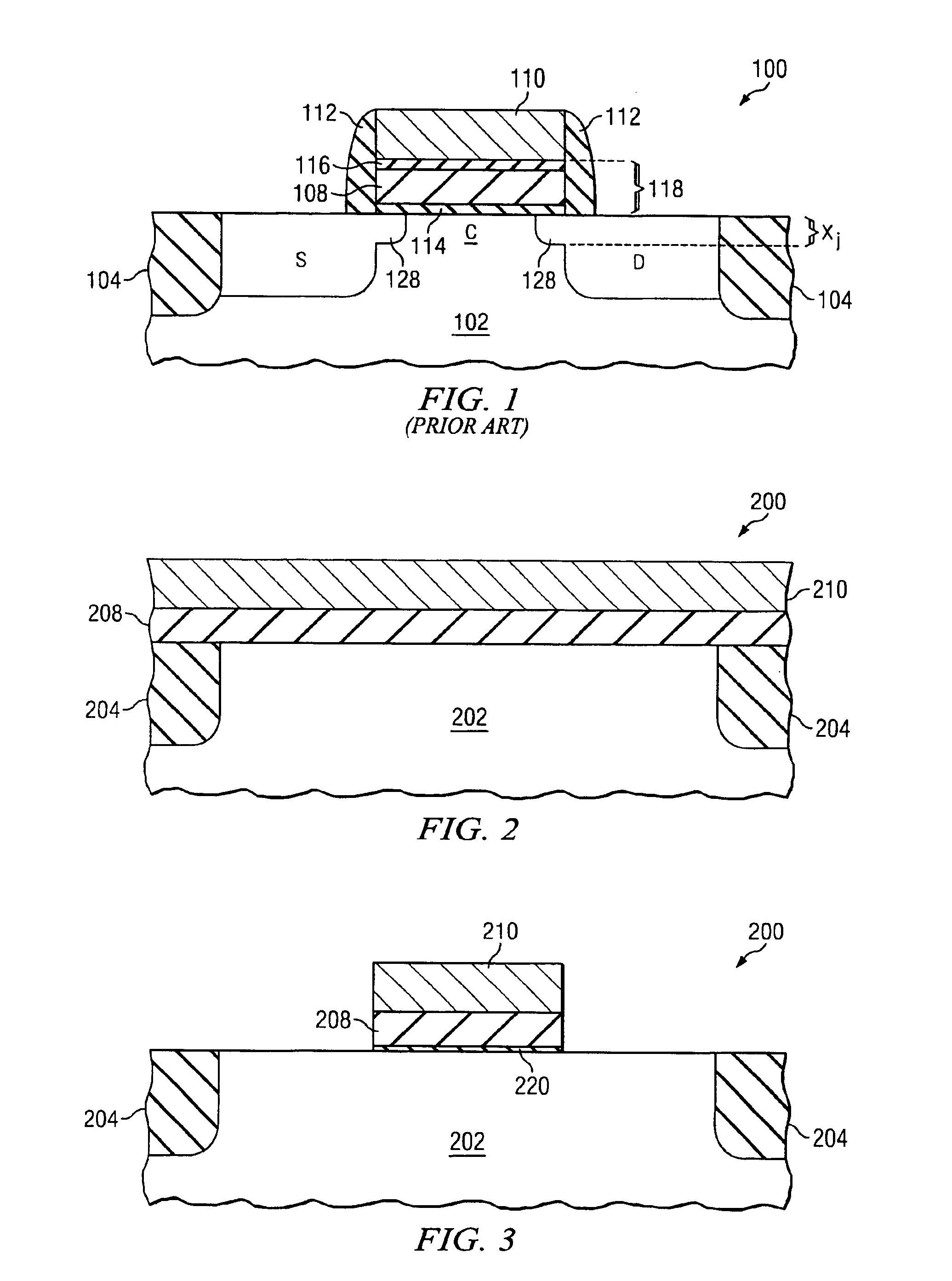

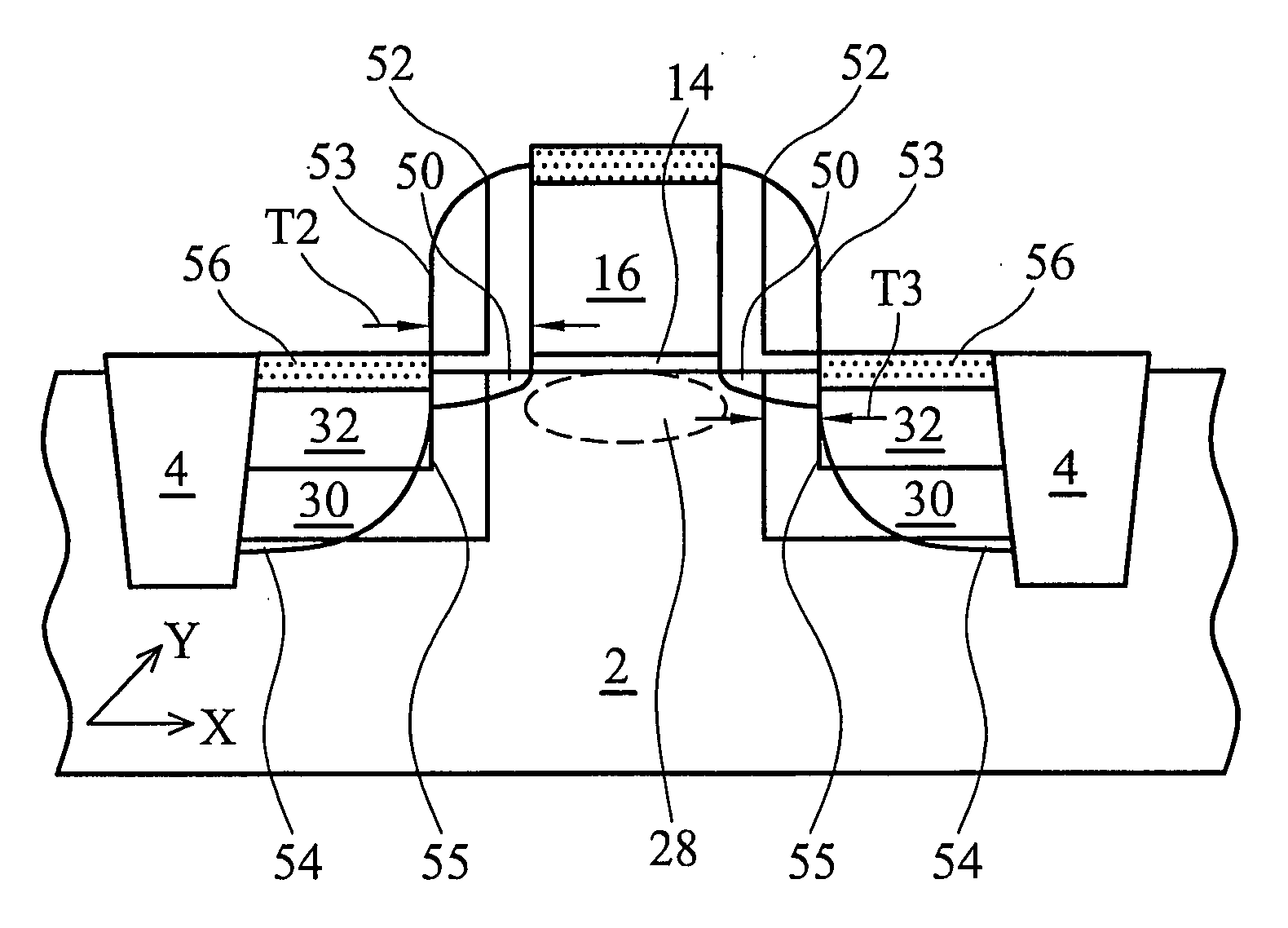

Transistor with dopant-bearing metal in source and drain

ActiveUS6921691B1Budget is reducedQuality improvementTransistorSemiconductor/solid-state device manufacturingDopantGate dielectric

A transistor and method of manufacturing thereof. A gate dielectric and gate are formed over a workpiece, and the source and drain regions of a transistor are recessed. The recesses are filled with a dopant-bearing metal, and a low-temperature anneal process is used to form doped regions within the workpiece adjacent the dopant-bearing metal regions. A transistor having a small effective oxide thickness and a well-controlled junction depth is formed.

Owner:INFINEON TECH AG

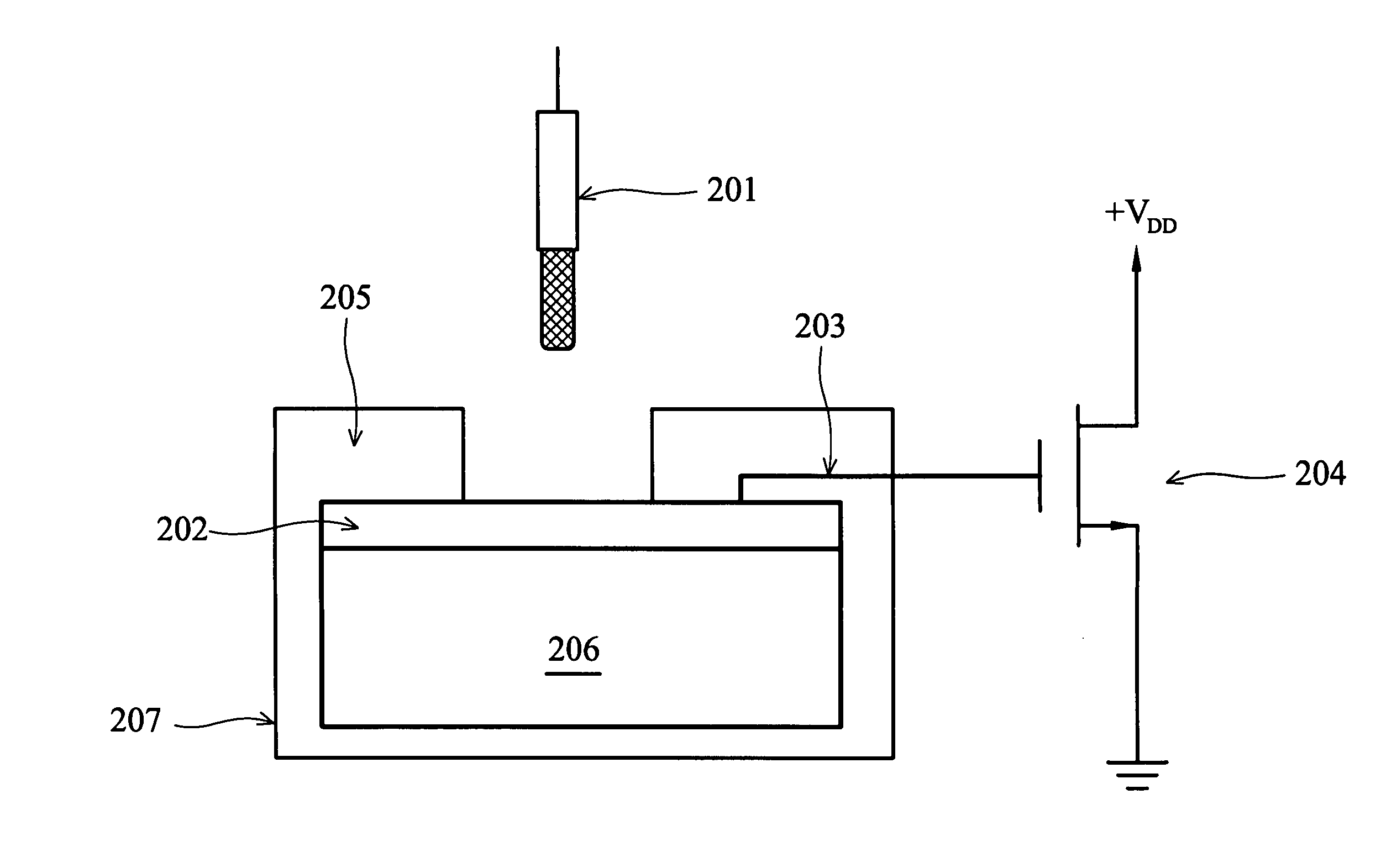

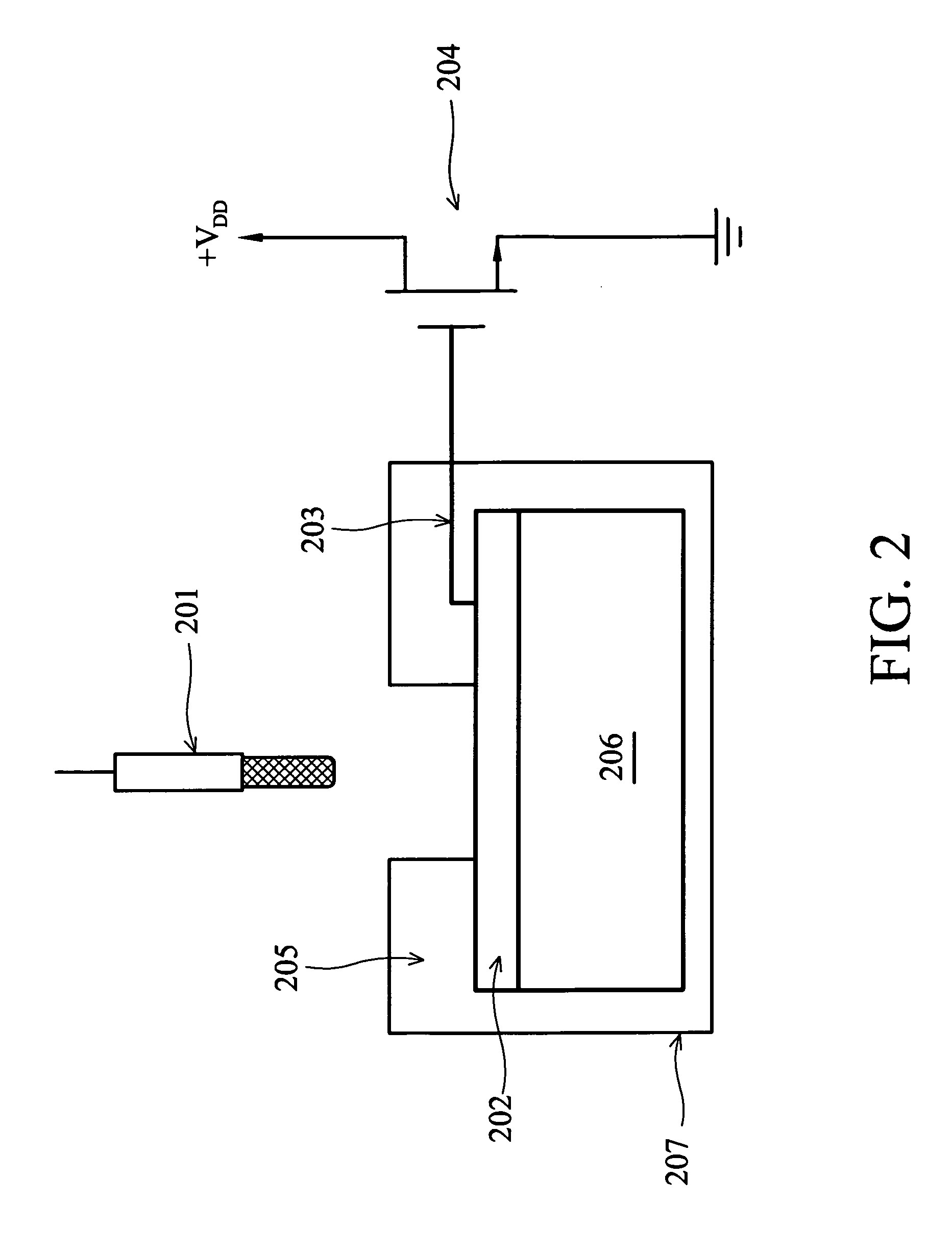

Preparation of a PH sensor, the prepared PH sensor, system comprising the same and measurement using the system

InactiveUS20070095663A1Reduce sheet resistanceImprove conductivityMaterial electrochemical variablesSputteringTitanium nitride

Preparation of a pH sensor, the prepared pH sensor, system comprising the same, and measurement using the system. The pH sensor is an extended gate field effect transistor (EGFET) structure. The preparation includes the steps of providing an extended gate ion sensitive field effect transistor comprising an extended gate region, forming a titanium nitride film on the extended gate region by RF sputtering deposition to obtain a pH sensor.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

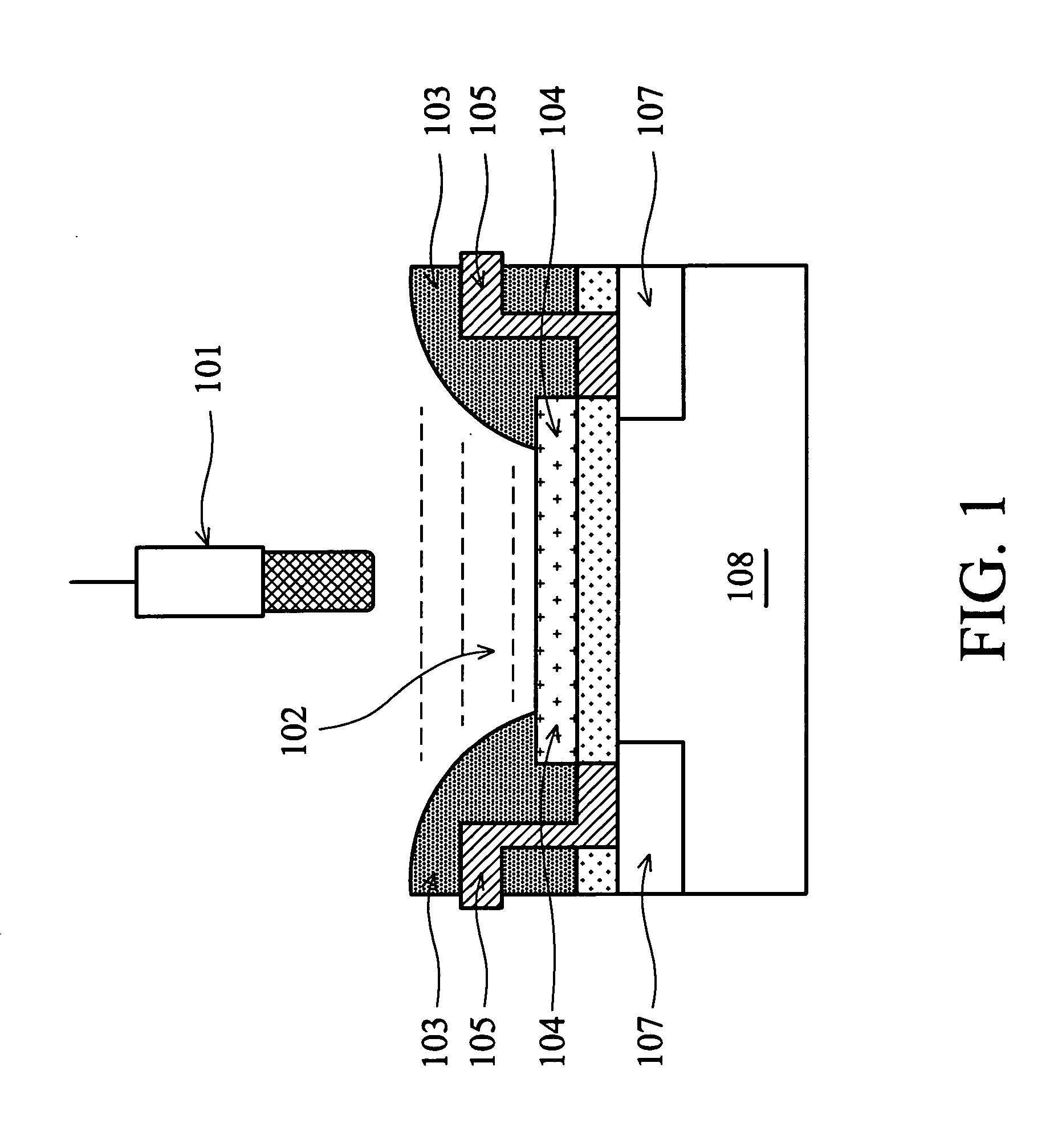

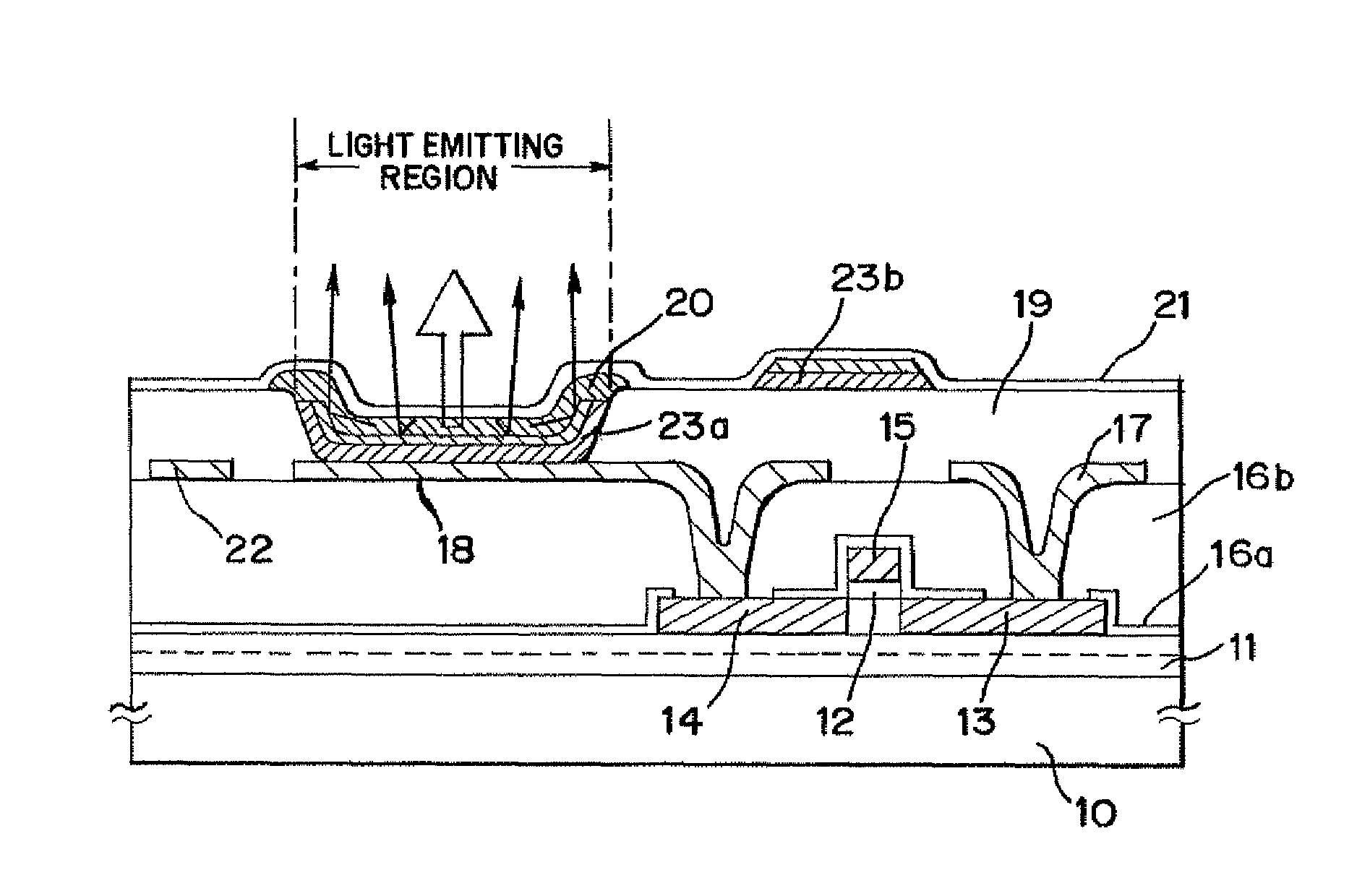

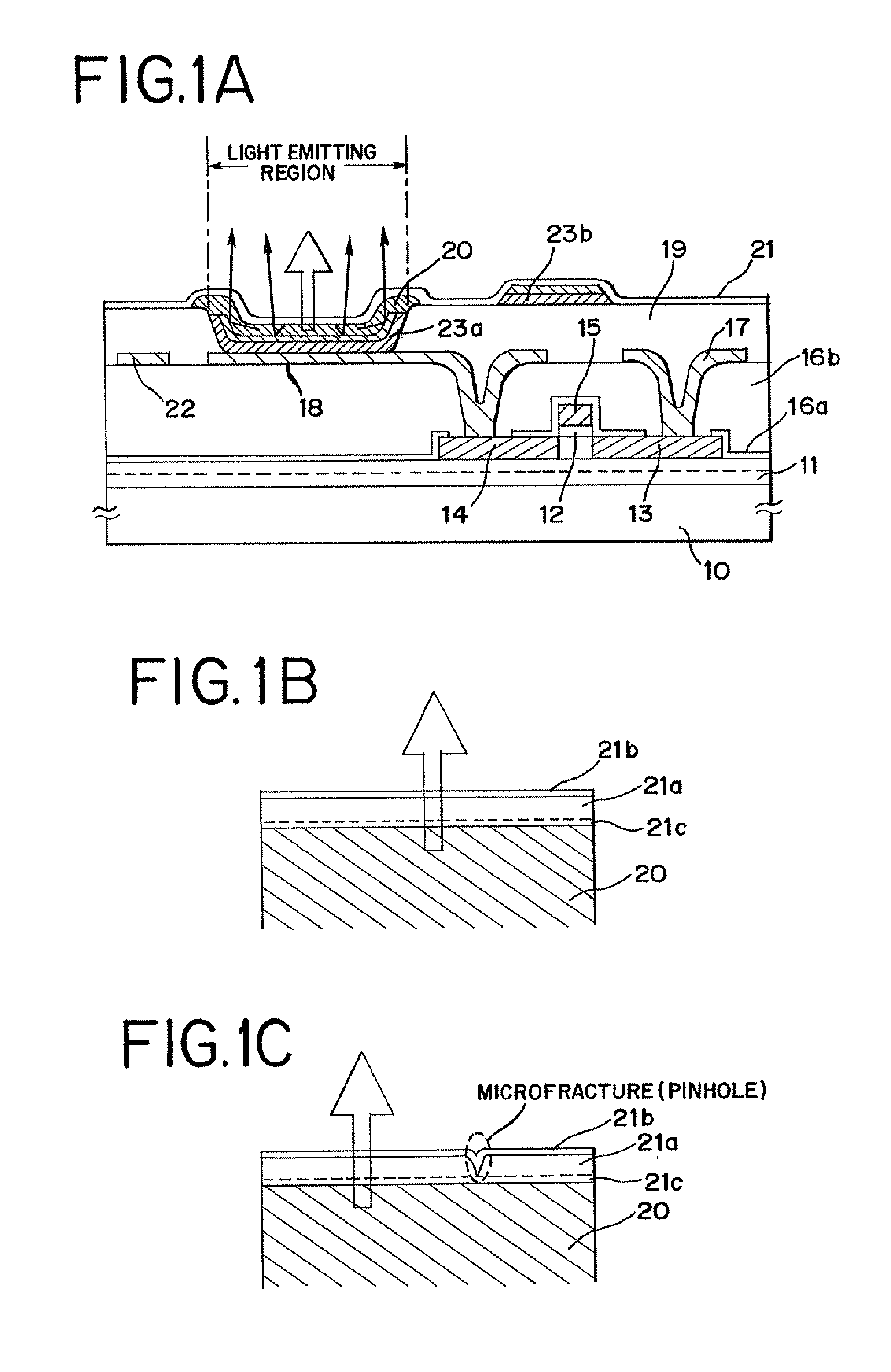

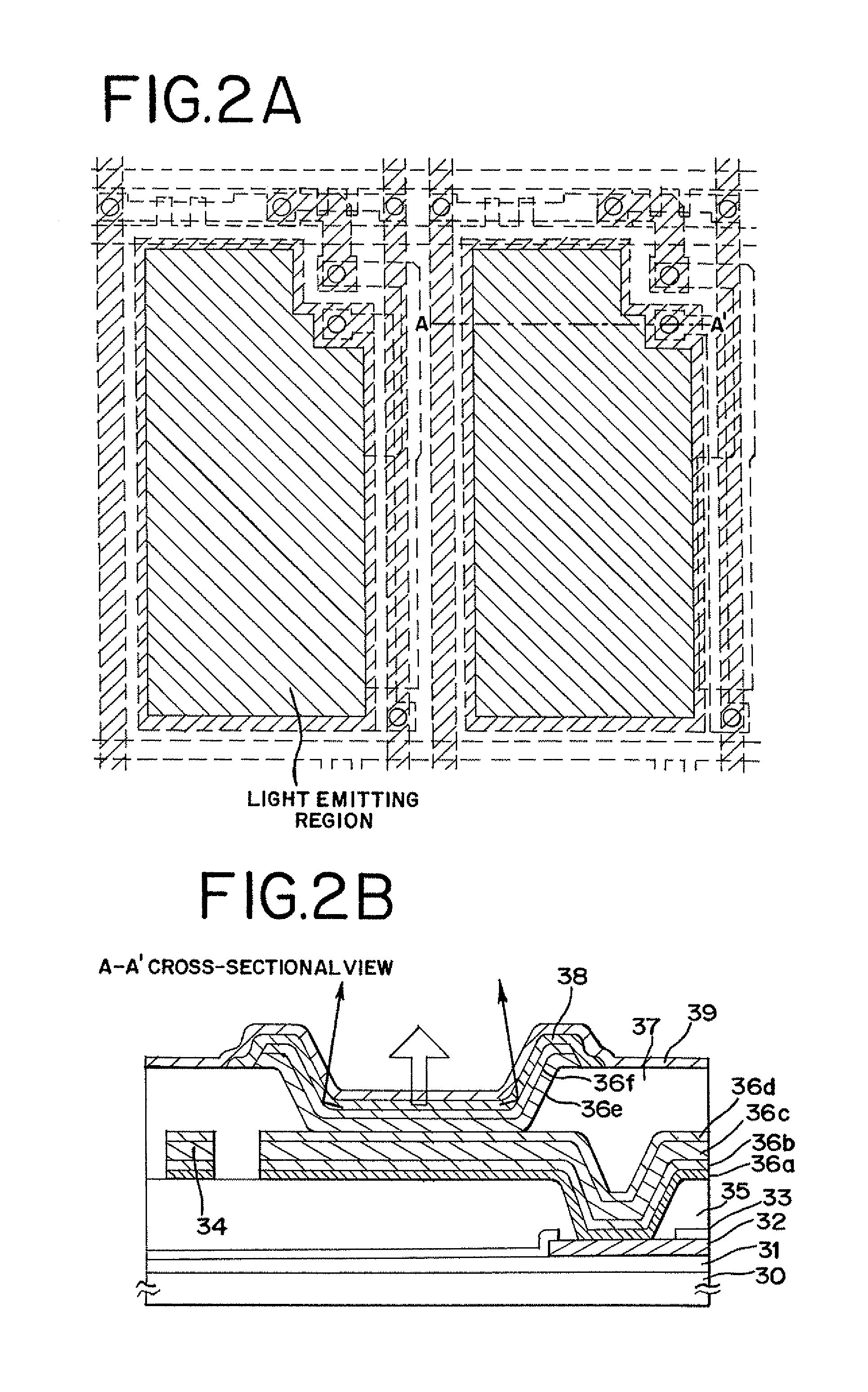

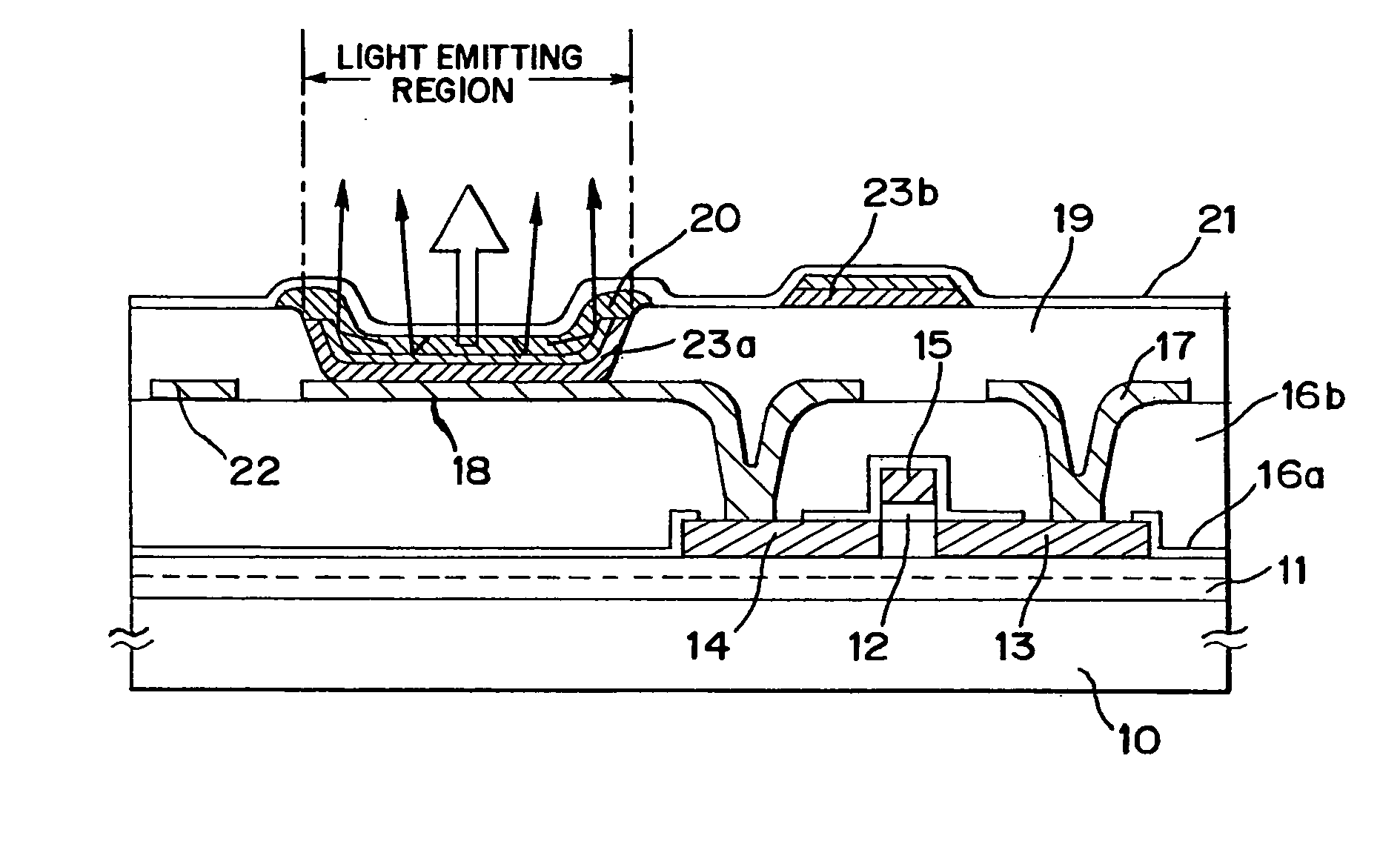

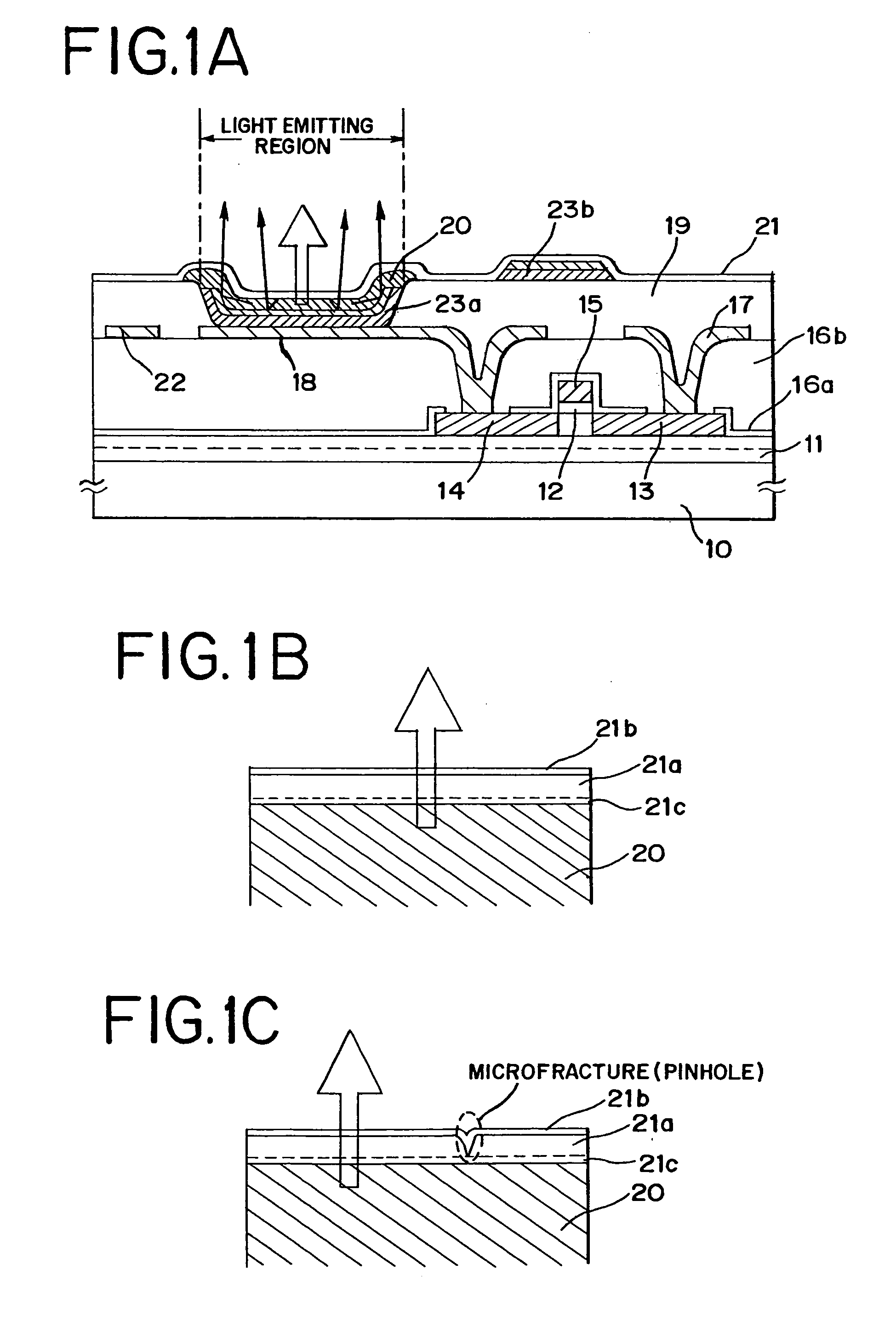

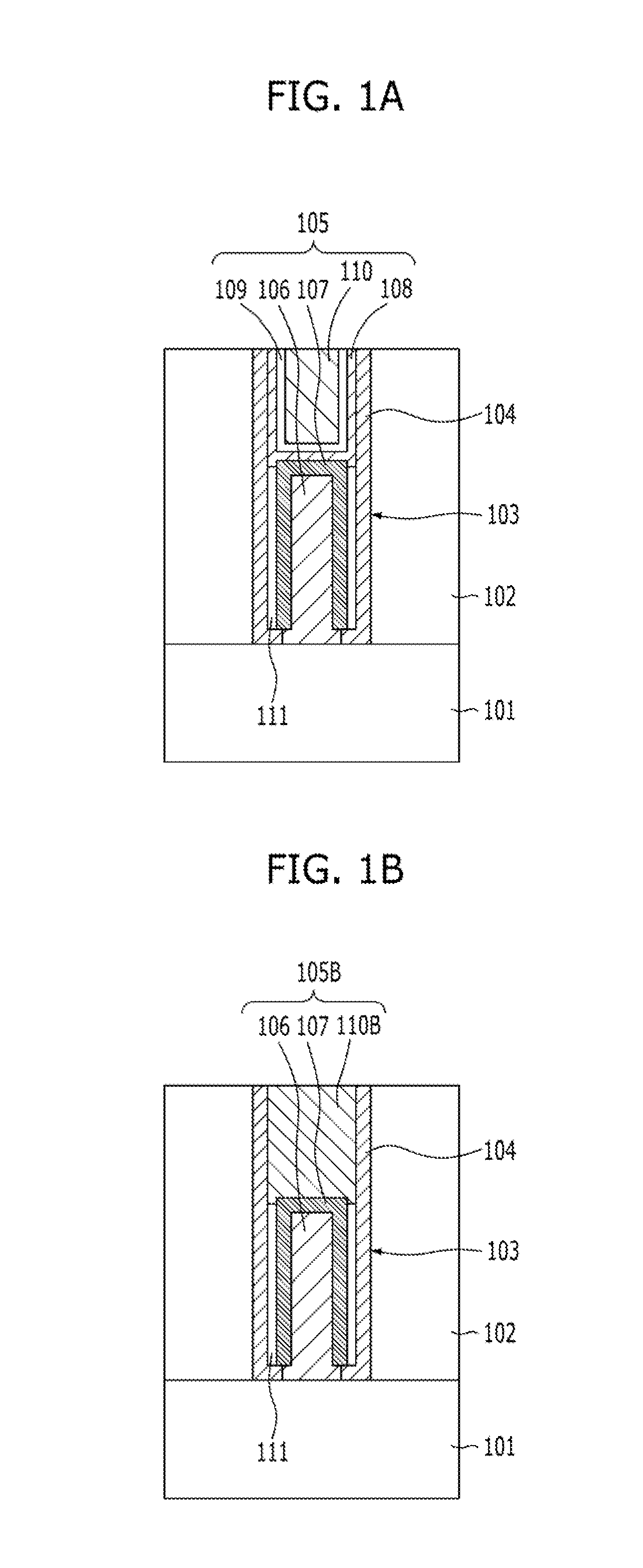

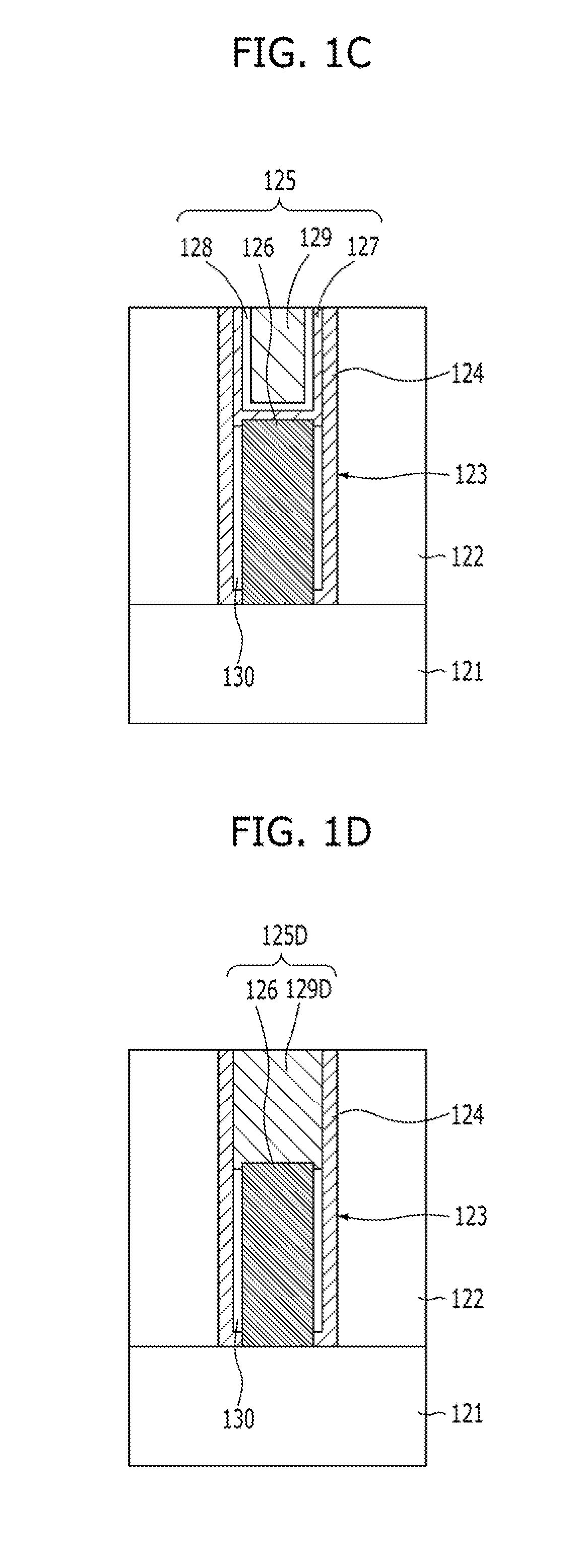

Light emitting device

InactiveUS7402948B2High film resistanceLow membrane resistanceDischarge tube luminescnet screensElectroluminescent light sourcesLight emitting deviceElectrode

Not all of light generated in the light emitting layer comprising the organic material are taken out in the desirable direction. For example, light emitted in the lateral direction (the direction parallel to the substrate face) is not taken out and therefore is a loss. An object of the present invention is to provide a light emitting device structured so as to increase the amount of light which is taken out in a certain direction after emitted from a light emitting element, as well as a method of manufacturing this light emitting device.In the present invention, an upper end portion of an insulating material 19 that covers an end portion of a first electrode 18 is formed to have a curved surface having a radius of curvature, a second electrode 23a is formed to have a slant face as going from its center portion toward its end portion along the curved surface. Light emitted from a light emitting layer comprising an organic material 20 that is formed on the second electrode 23a is reflected at the slant face of the second electrode 23a to increase the total amount of light taken out in the direction indicated by the arrow in FIG. 1A.

Owner:SEMICON ENERGY LAB CO LTD

Articles including anticondensation and/or low-E coatings and/or methods of making the same

ActiveUS20110212311A1Reduce sheet resistanceLow emissivityWindowsWindscreensEmissivityRefrigerated temperature

Certain example embodiments of this invention relate to articles including anticondensation and / or low-E coatings that are exposed to an external environment, and / or methods of making the same. In certain example embodiments, the anticondensation and / or low-E coatings may be survivable in an outside environment. The coatings also may have a sufficiently low sheet resistance and hemispherical emissivity such that the glass surface is more likely to retain heat from the interior area, thereby reducing (and sometimes completely eliminating) the presence condensation thereon. The articles of certain example embodiments may be, for example, skylights, vehicle windows or windshields, IG units, VIG units, refrigerator / freezer doors, and / or the like.

Owner:GUARDIAN GLASS LLC

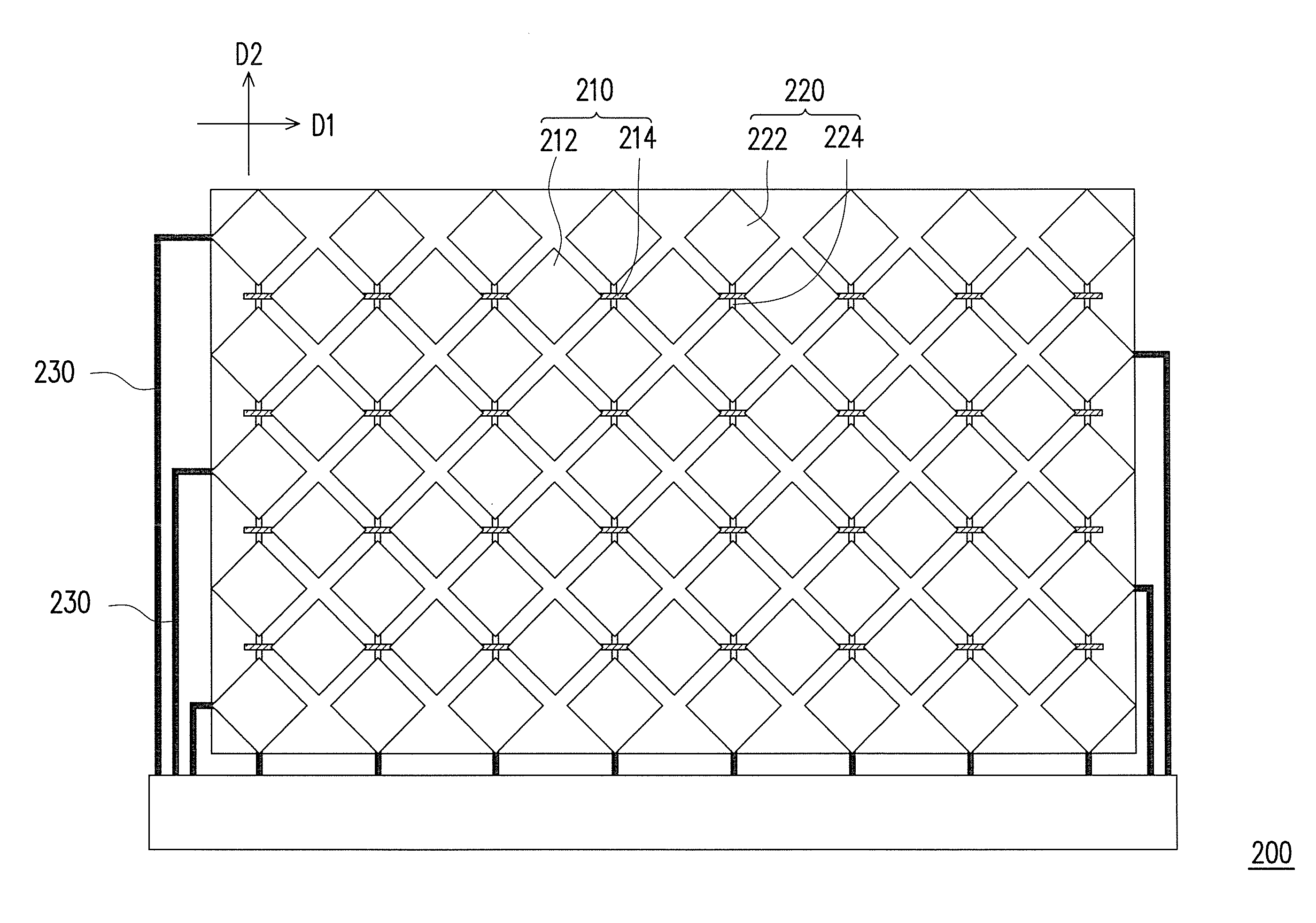

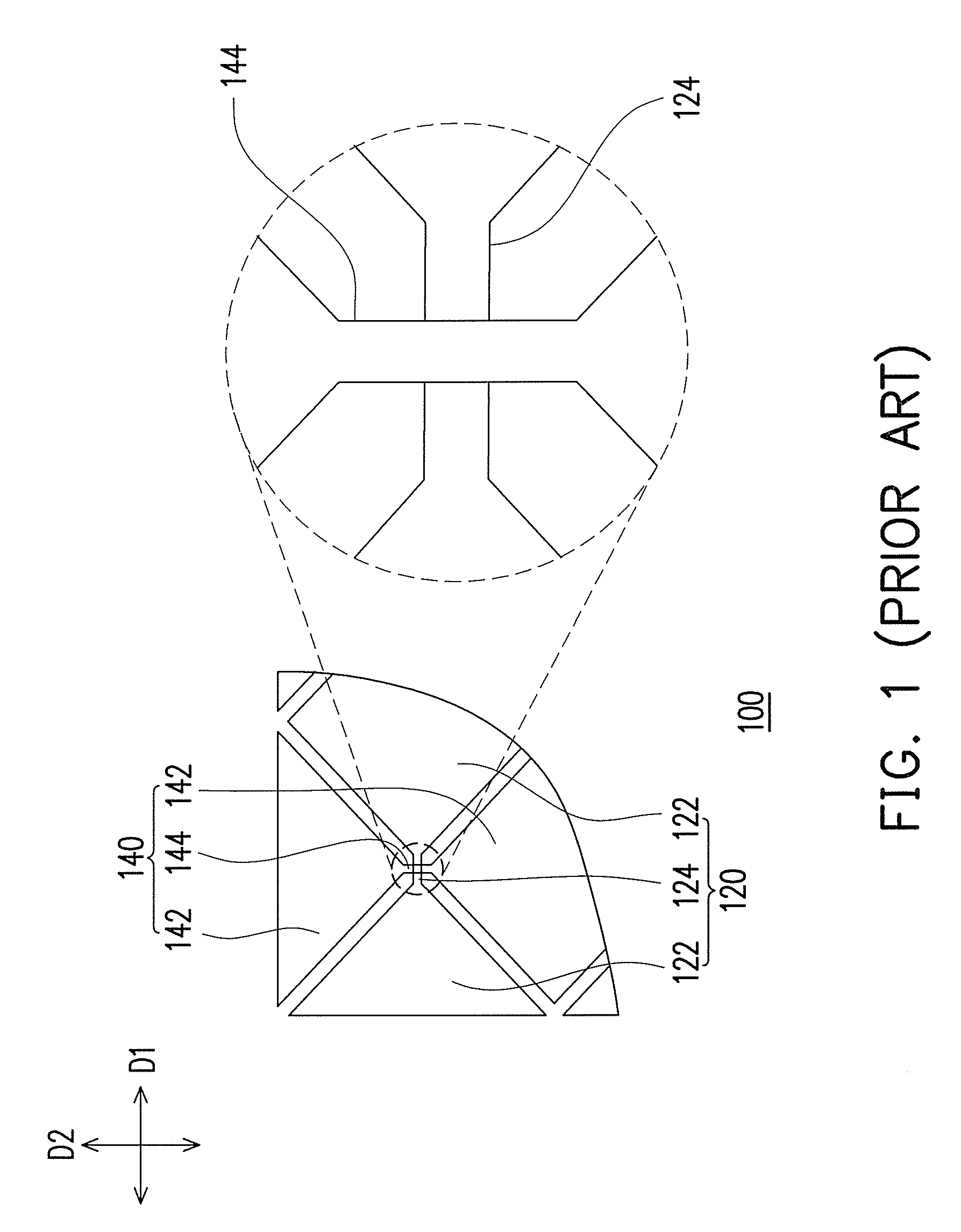

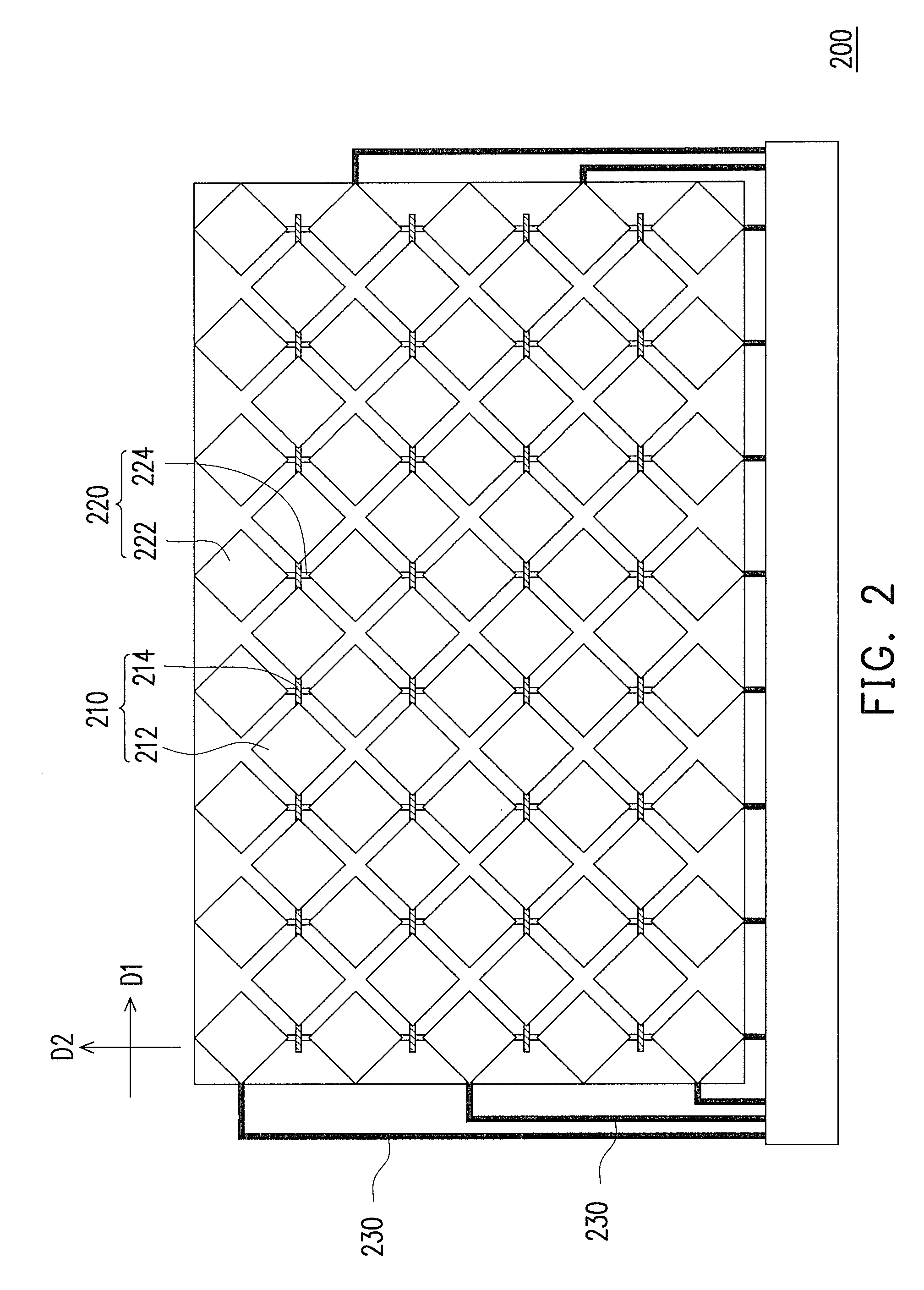

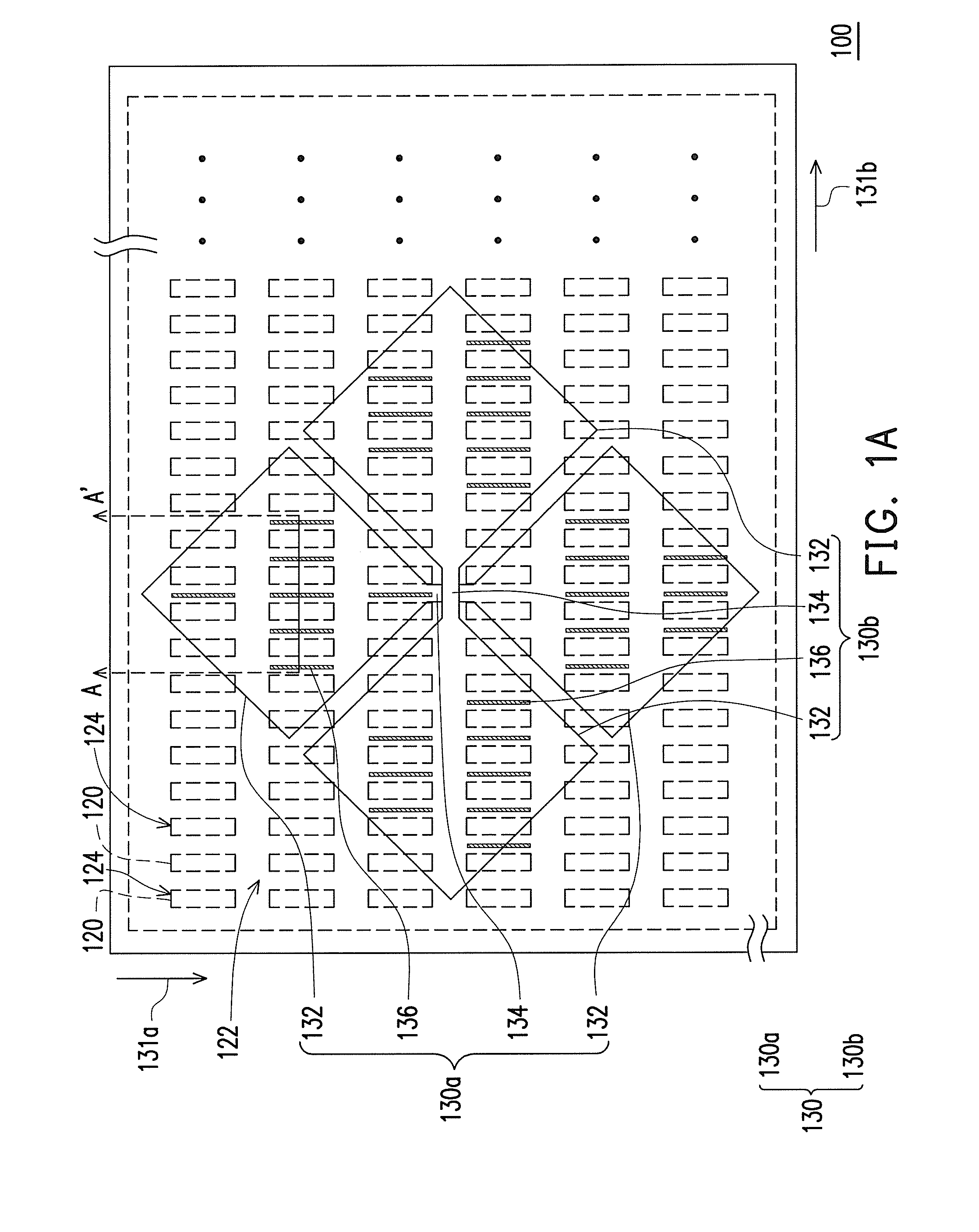

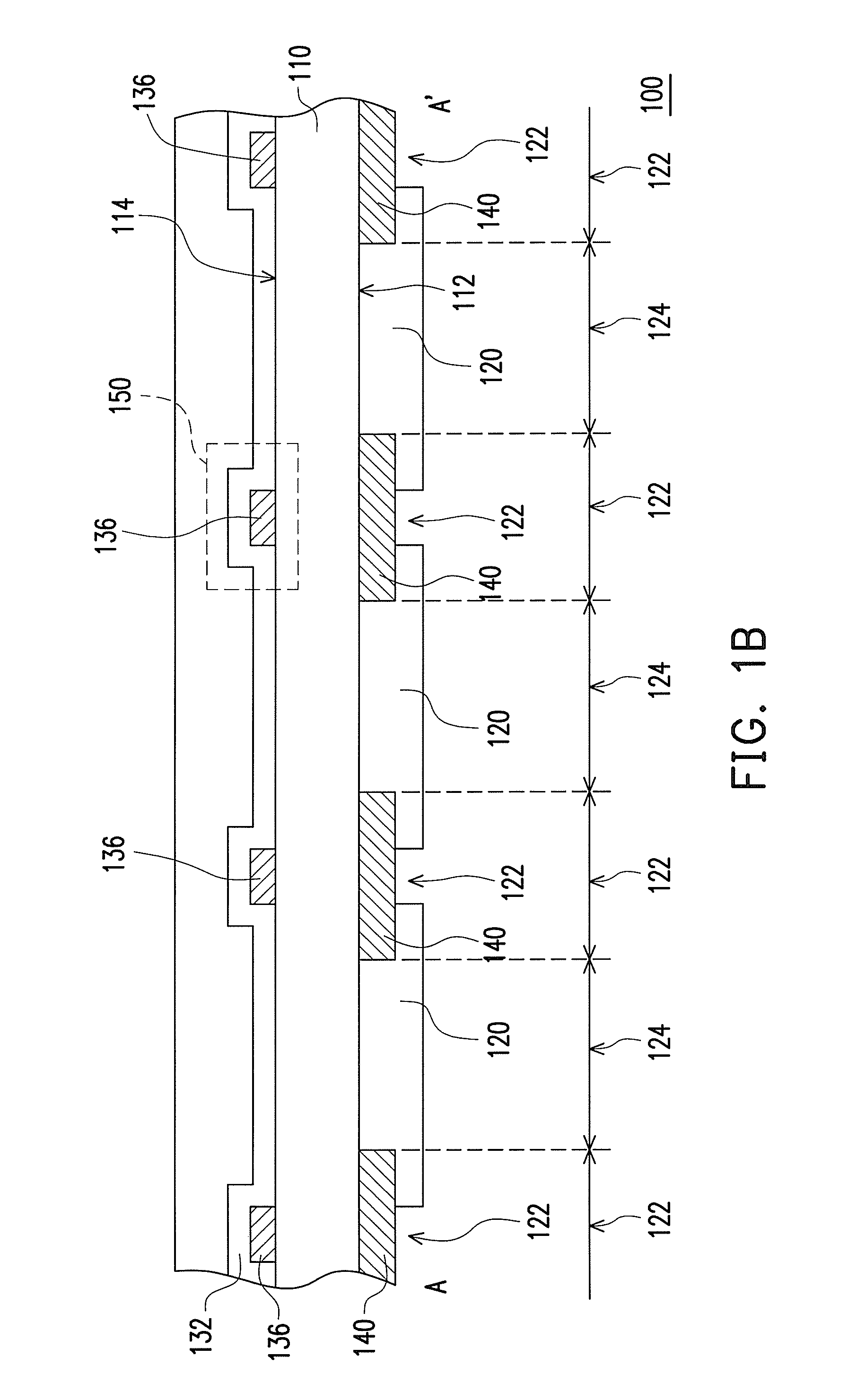

Touch panel, display, and manufacturing method of touch panel

InactiveUS20100045613A1Satisfactory transmission qualityLower resistanceInput/output processes for data processingCold cathode manufactureMarine engineeringTouch panel

A touch panel including a substrate, at least one first sensing series and at least one second sensing series is provided. The first sensing series is disposed on the substrate and extends along a first direction. The first sensing series includes several first sensing pads and at least one first bridge line. The first bridge line connects two adjacent first sensing pads, and a material of the first bridge line differs from a material of the first sensing pads. The second sensing series is disposed on the substrate and extends along a second direction. The first direction is different from the second direction. The second sensing series includes several second sensing pads and at least one second bridge line. The second bridge line connects two adjacent second sensing pads.

Owner:AU OPTRONICS CORP

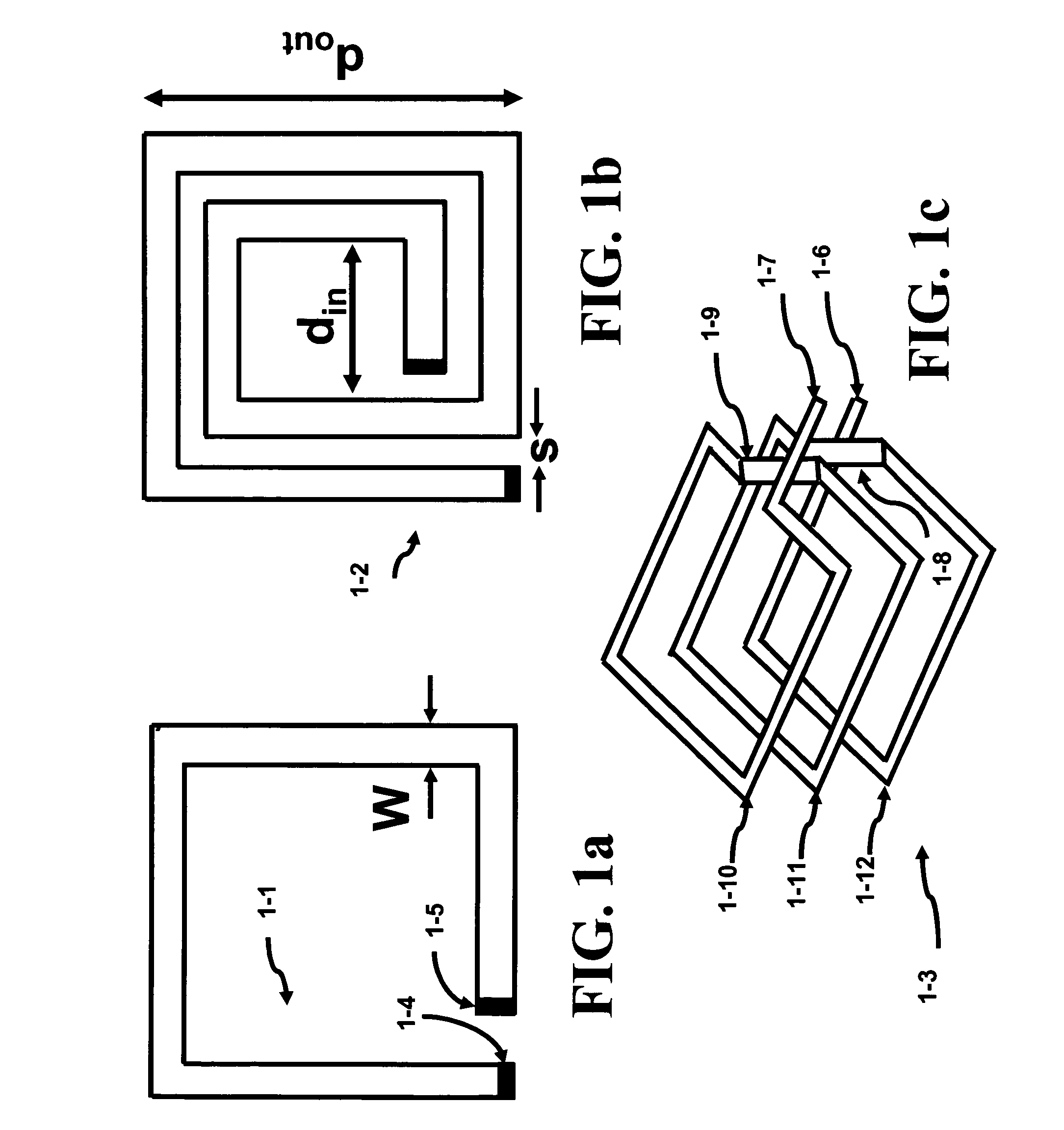

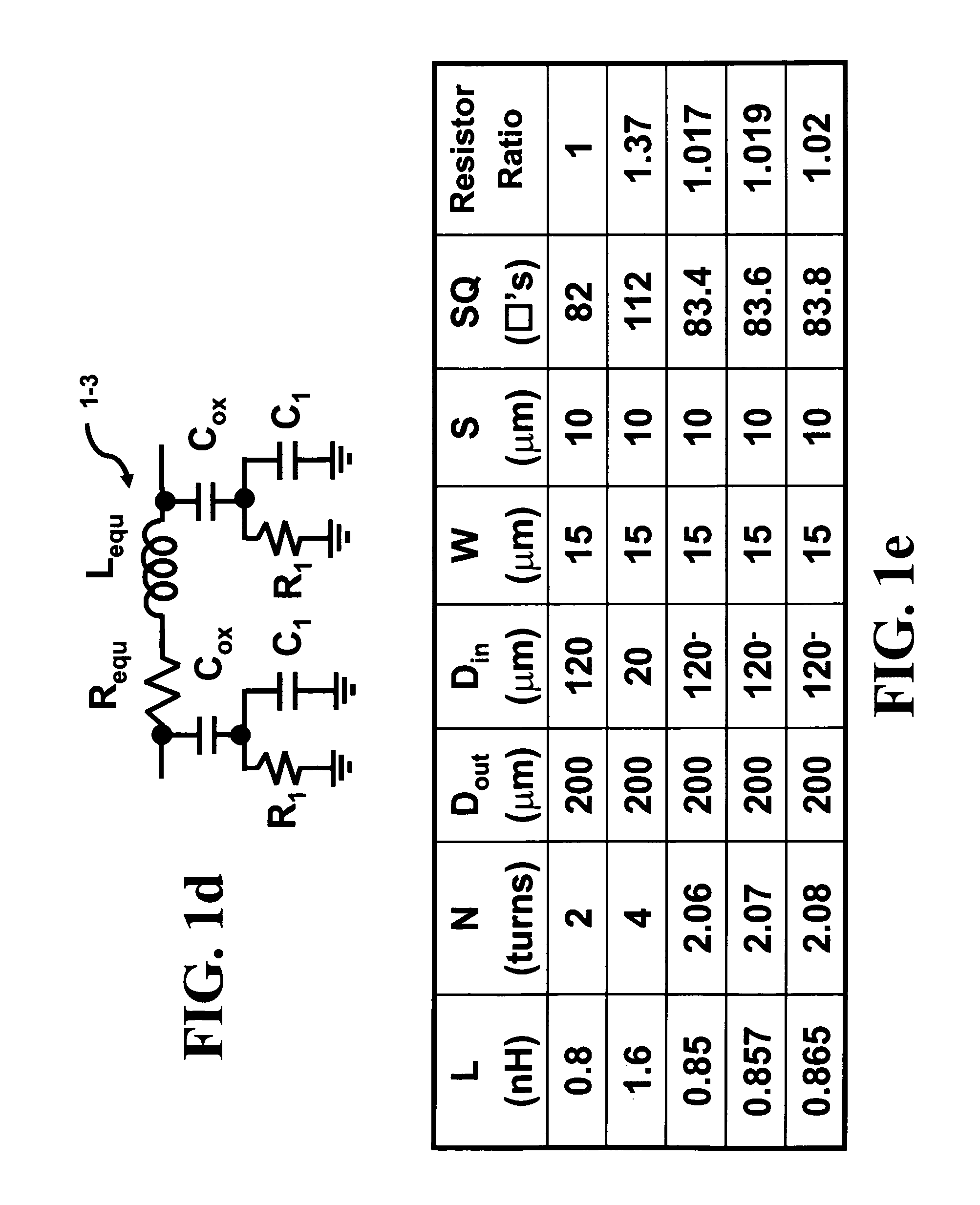

Fabrication of inductors in transformer based tank circuitry

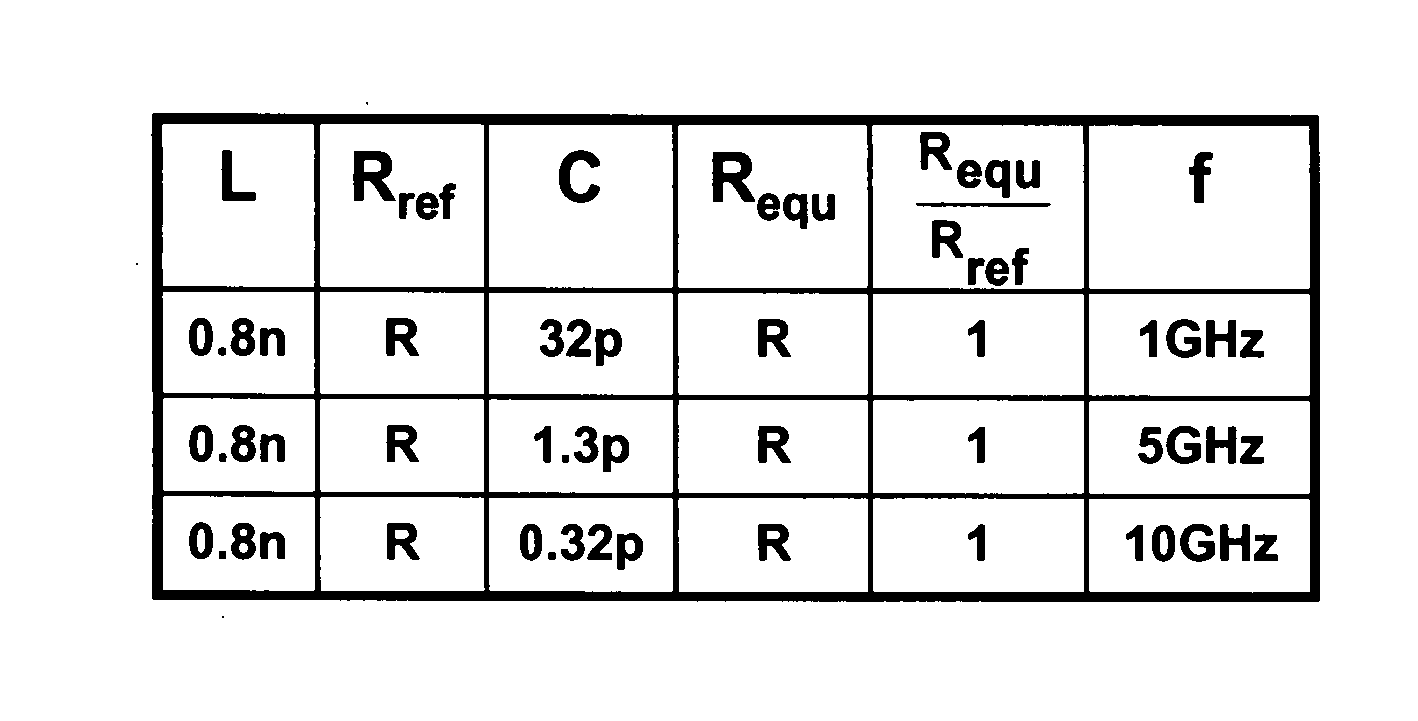

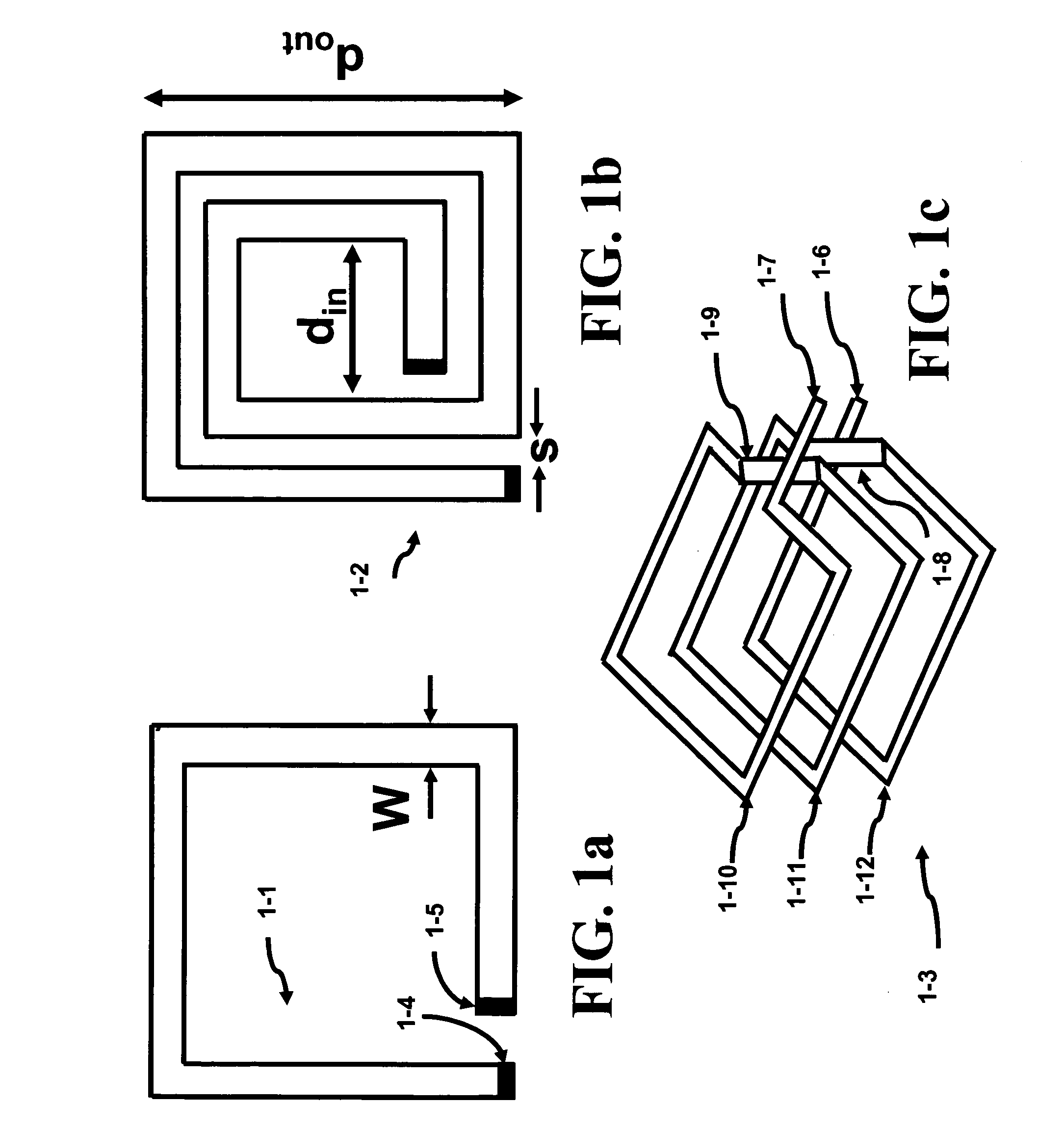

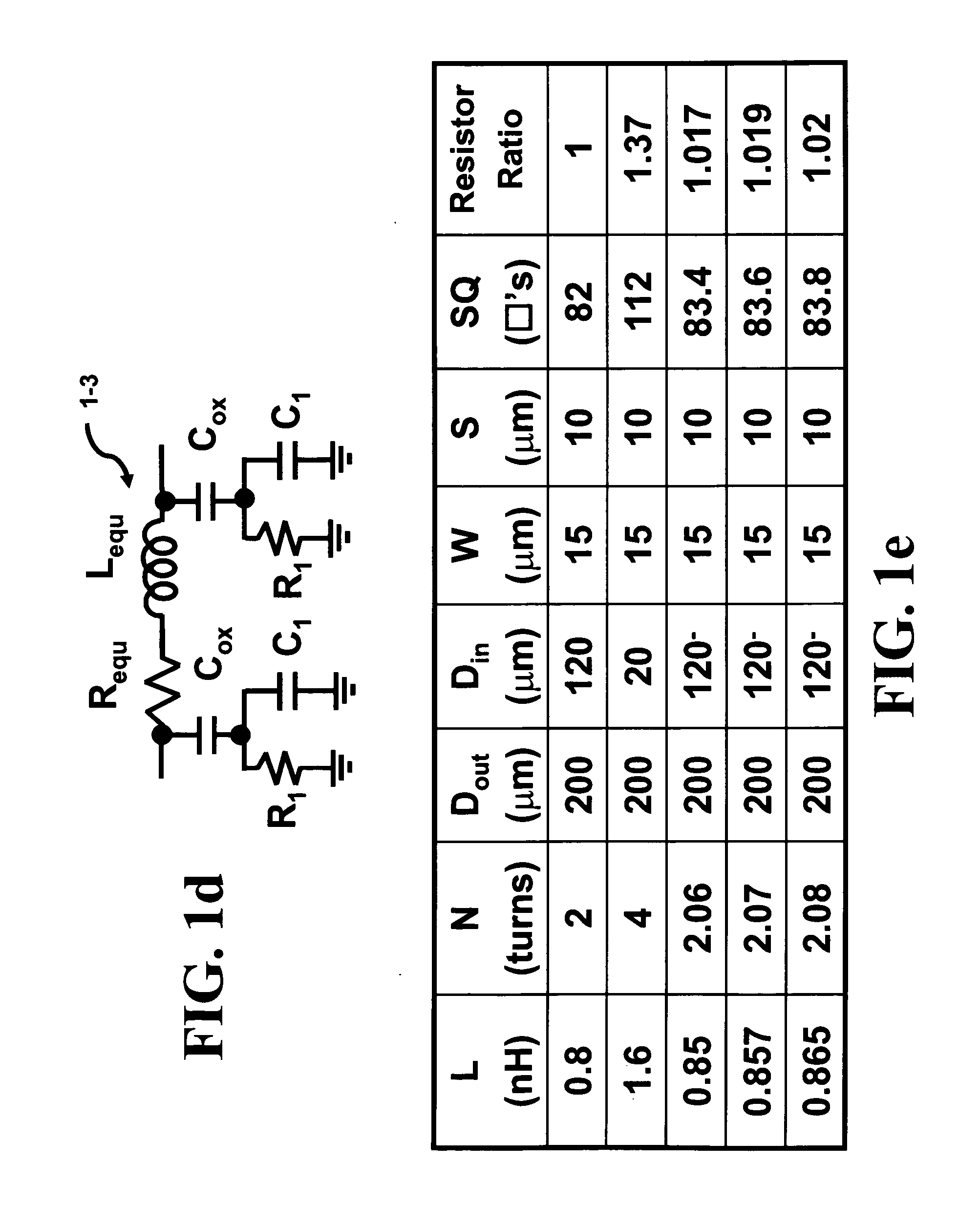

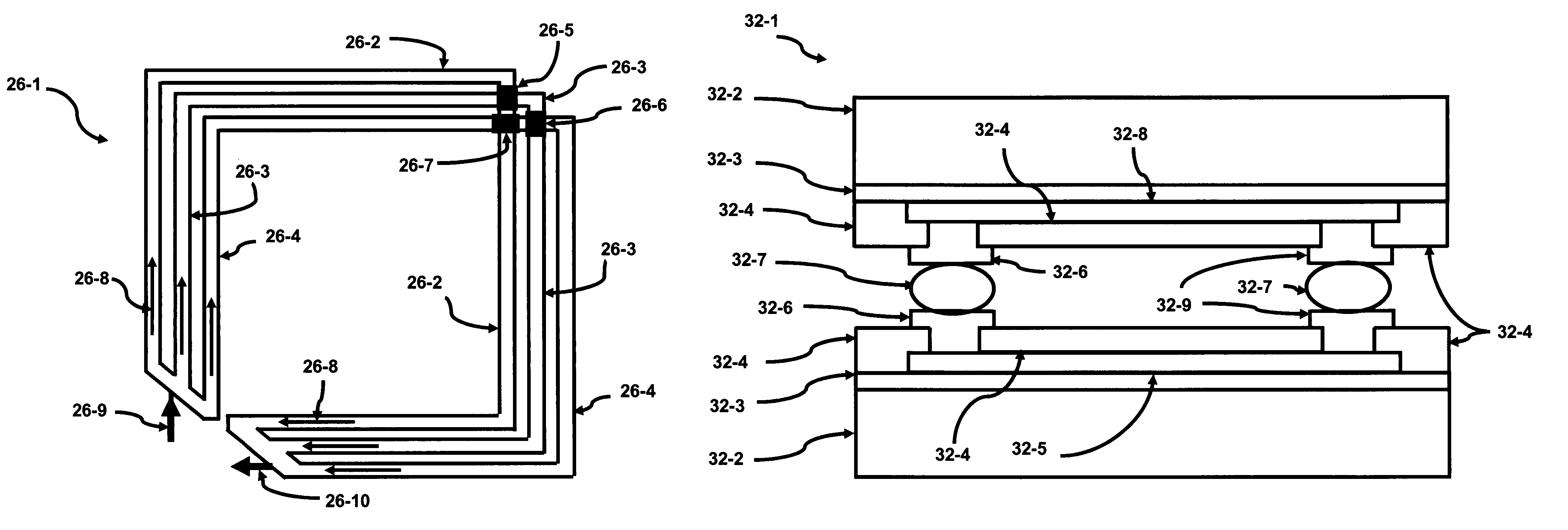

ActiveUS20070018767A1Reduce the valueReduce energy lossSolid-state devicesPrinted inductancesElectrical resistance and conductanceTransformer

Placing inductors or resistors in parallel causes the combined value of inductance or resistance to decrease according to the parallel combination rule. This invention decreases the parasitic resistance of an inductor by placing several inductors in parallel. Furthermore, by careful placement of these inductors, the mutual inductance between these inductors can be used to increase the equivalent inductance value to a value near that of the original inductance value of a single inductor. Thus, it is possible to create an inductance with a much lower value of parasitic resistance. This invention allows the formation of high Q inductors and would be beneficial in any circuit design requiring inductances. Another aspect of this invention is that the coils can be partitioned to minimize eddy current losses. This invention can easily be implemented in a planar technology. Simulations of several tank circuits indicate that the power dissipation can be reduced 3 to 4 times when compared to conventional techniques.

Owner:INTELLECTUAL VENTURES HOLDING 81 LLC

Fabrication of inductors in transformer based tank circuitry

ActiveUS7786836B2Reduce the valueReduce parasitic resistanceSolid-state devicesPrinted inductancesElectrical resistance and conductanceTransformer

Placing inductors or resistors in parallel causes the combined value of inductance or resistance to decrease according to the parallel combination rule. This invention decreases the parasitic resistance of an inductor by placing several inductors in parallel. Furthermore, by careful placement of these inductors, the mutual inductance between these inductors can be used to increase the equivalent inductance value to a value near that of the original inductance value of a single inductor. Thus, it is possible to create an inductance with a much lower value of parasitic resistance. This invention allows the formation of high Q inductors and would be beneficial in any circuit design requiring inductances. Another aspect of this invention is that the coils can be partitioned to minimize eddy current losses. This invention can easily be implemented in a planar technology. Simulations of several tank circuits indicate that the power dissipation can be reduced 3 to 4 times when compared to conventional techniques.

Owner:INTELLECTUAL VENTURES HOLDING 81 LLC

Coated article with low-E coating including tin oxide interlayer

ActiveUS20050202254A1Improve thermal stabilityImprove mechanical durabilityGlass/slag layered productsCoatingsThermal stabilityZinc

A coated article is provided which may be heat treated (e.g., thermally tempered) in certain instances. In certain example embodiments, an interlayer of or including a metal oxide such as tin oxide is provided under an infrared (IR) reflecting layer so as to be located between respective layers comprising silicon nitride and zinc oxide. It has been found that the use of such a tin oxide inclusive interlayer results in significantly improved mechanical durability, thermal stability and / or haze characteristics.

Owner:GUARDIAN EURO S A R L +1

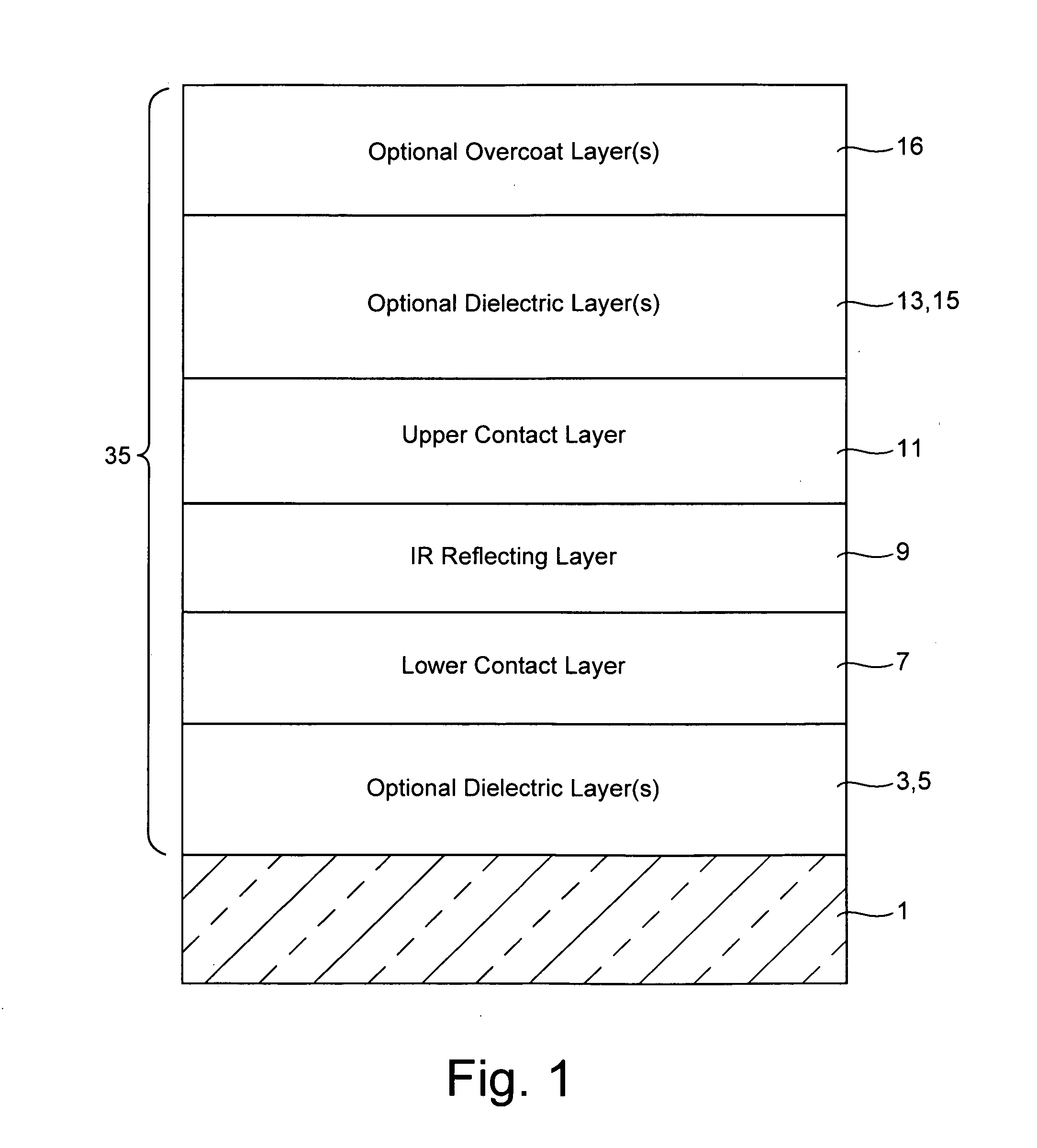

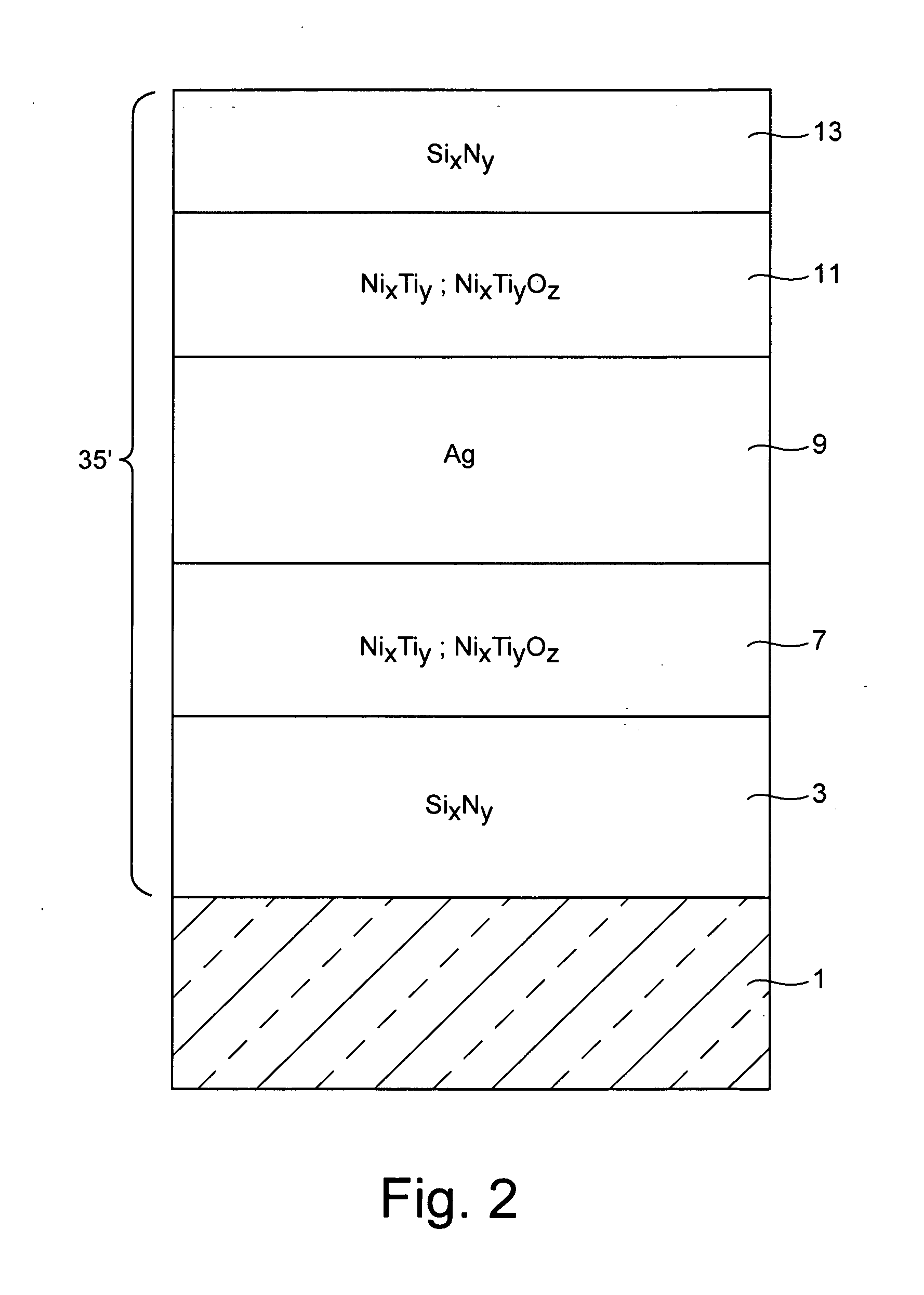

Barrier layers comprising Ni and/or Ti, coated articles including barrier layers, and methods of making the same

InactiveUS20120225224A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingTitaniumReflective layer

Certain example embodiments relate to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating, and methods of making the same. In certain cases, at least one layer of the coating is of or includes nickel and / or titanium (e.g., NixTiyOz). The provision of a layer including nickel titanium and / or an oxide thereof may permit a layer to be used that has good adhesion to the IR reflecting layer, and reduced absorption of visible light (resulting in a coated article with a higher visible transmission). When a layer including nickel titanium oxide is provided directly over and / or under the IR reflecting layer (e.g., as a barrier layer), this may result in improved chemical and mechanical durability. Thus, visible transmission may be improved if desired, without compromising durability; or, durability may simply be increased.

Owner:GUARDIAN GLASS LLC

Light emitting device and manufacturing method of the same

InactiveUS20080252207A1High film resistanceLow membrane resistanceDischarge tube luminescnet screensElectroluminescent light sourcesLight emitting deviceElectrode

Not all of light generated in the light emitting layer comprising the organic material are taken out in the desirable direction. For example, light emitted in the lateral direction (the direction parallel to the substrate face) is not taken out and therefore is a loss. An object of the present invention is to provide a light emitting device structured so as to increase the amount of light which is taken out in a certain direction after emitted from a light emitting element, as well as a method of manufacturing this light emitting device.In the present invention, an upper end portion of an insulating material 19 that covers an end portion of a first electrode 18 is formed to have a curved surface having a radius of curvature, a second electrode 23a is formed to have a slant face as going from its center portion toward its end portion along the curved surface. Light emitted from a light emitting layer comprising an organic material 20 that is formed on the second electrode 23a is reflected at the slant face of the second electrode 23a to increase the total amount of light taken out in the direction indicated by the arrow in FIG. 1A.

Owner:SEMICON ENERGY LAB CO LTD

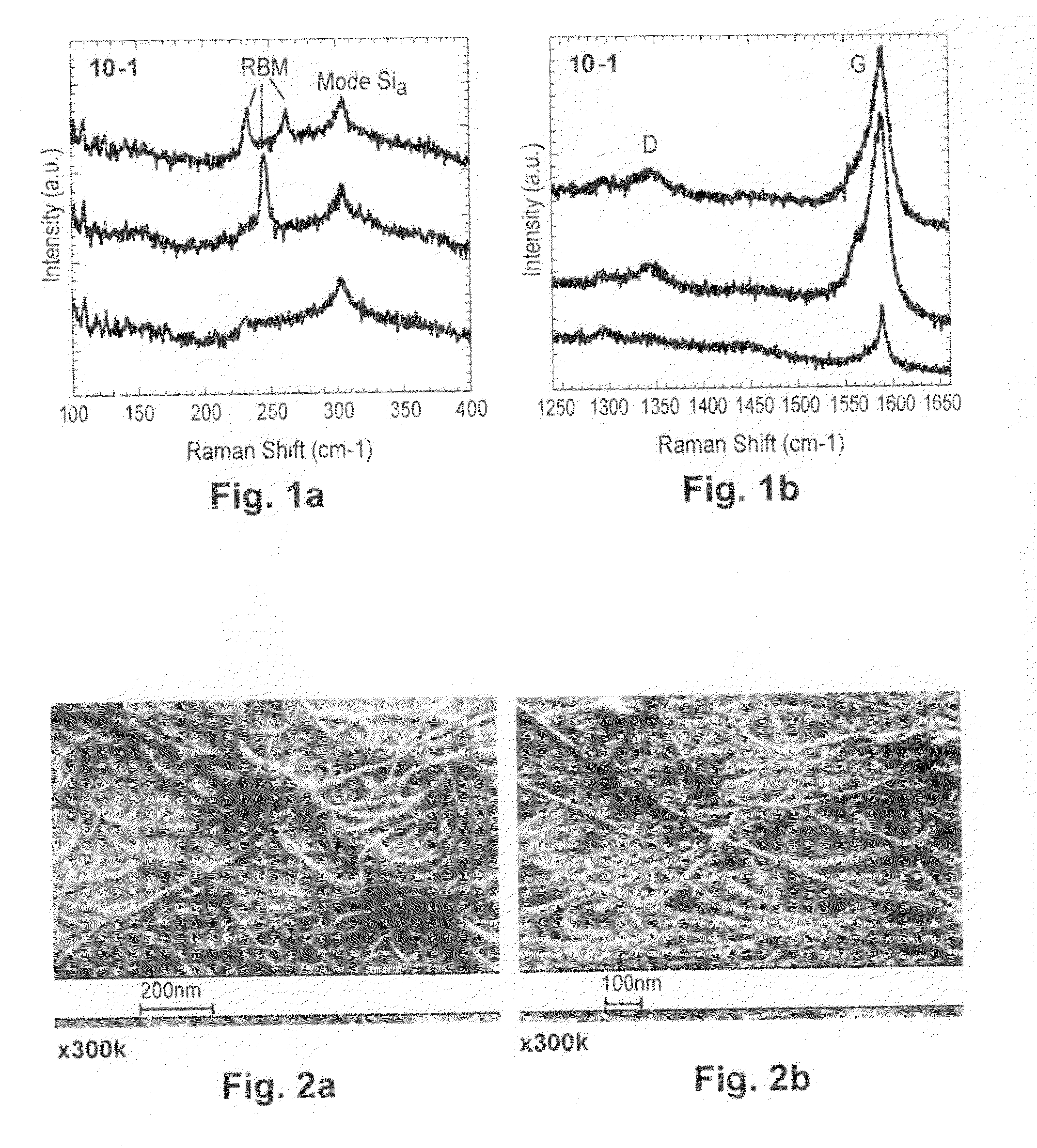

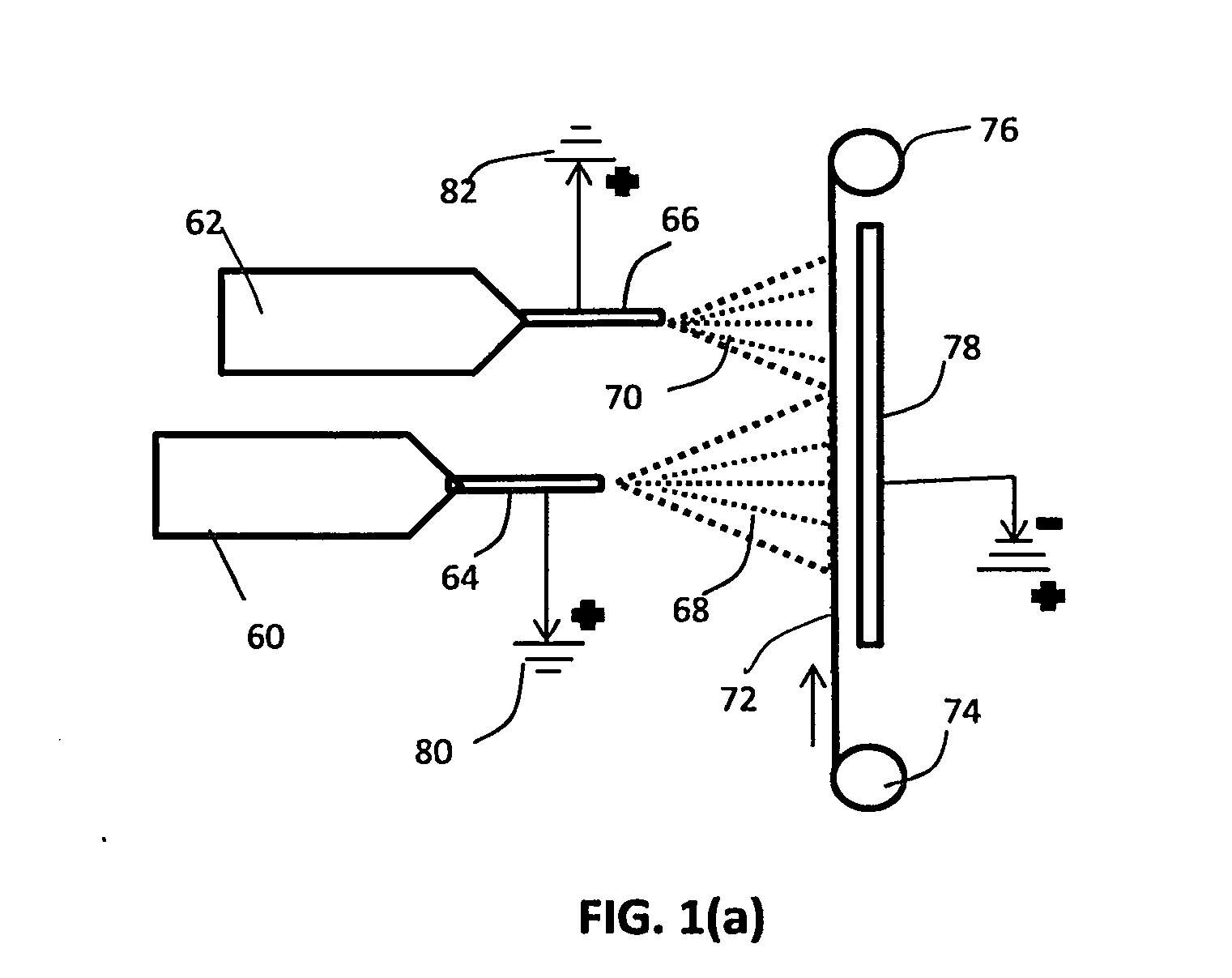

Electronic devices including transparent conductive coatings including carbon nanotubes and nanowire composites, and methods of making the same

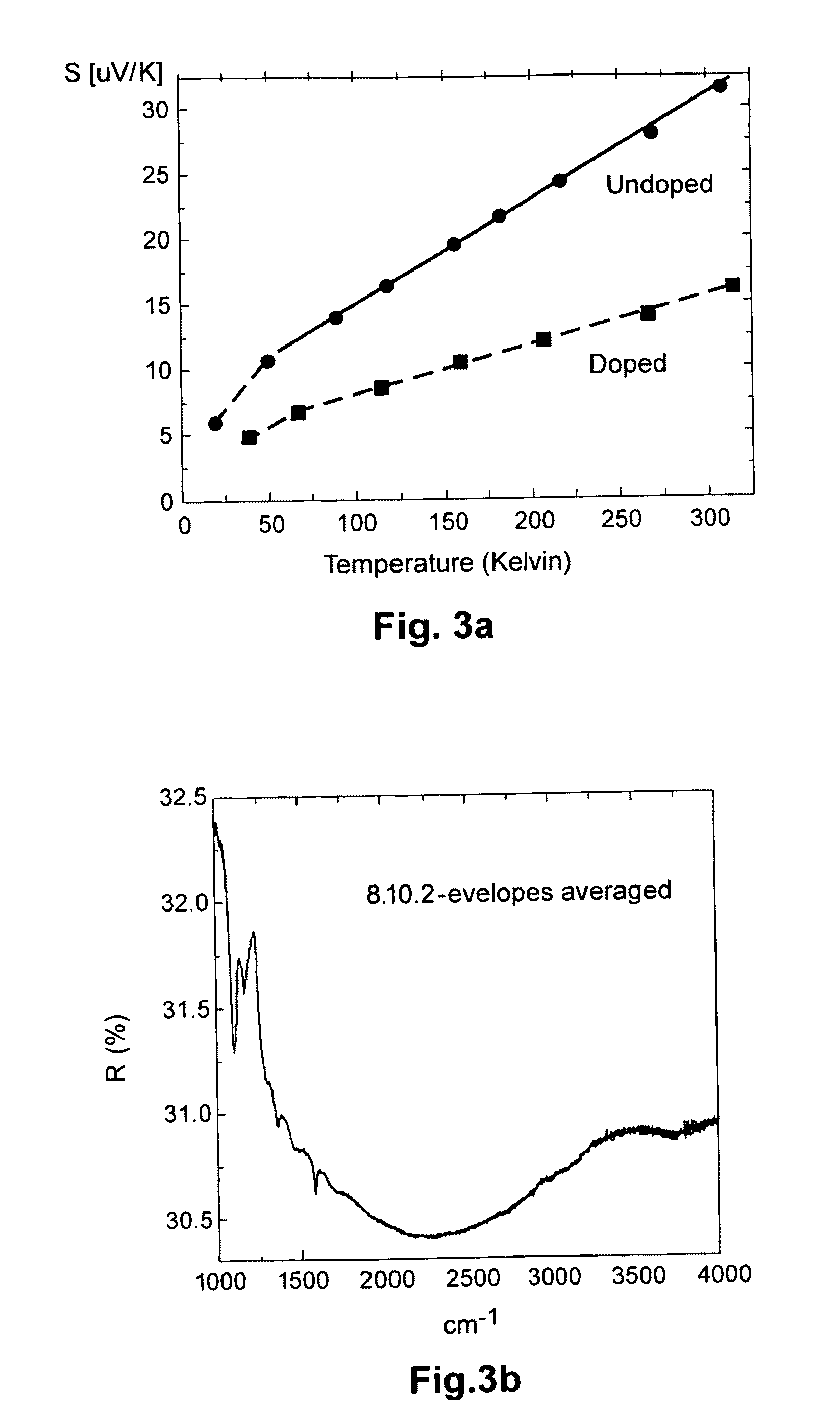

InactiveUS20110214728A1Enhance carrier injectionBeneficial attributeContact surface shape/structureLighting and heating apparatusSheet resistanceConductive coating

Certain example embodiments of this invention relate to large-area transparent conductive coatings (TCCs) including carbon nanotubes (CNTs) and nanowire composites, and methods of making the same. The σdc / σopt ratio of such thin films may be improved via stable chemical doping and / or alloying of CNT-based films. The doping and / or alloying may be implemented in a large area coating system, e.g., on glass and / or other substrates. In certain example embodiments, a CNT film may be deposited and then doped via chemical functionalization and / or alloyed with silver and / or palladium. Both p-type and n-type dopants may be used in different embodiments of this invention. In certain example embodiments, silver and / or other nanowires may be provided, e.g., to further decrease sheet resistance. Certain example embodiments may provide coatings that approach, meet, or exceed 90% visible transmission and 90 ohms / square target metrics.

Owner:GUARDIAN GLASS LLC

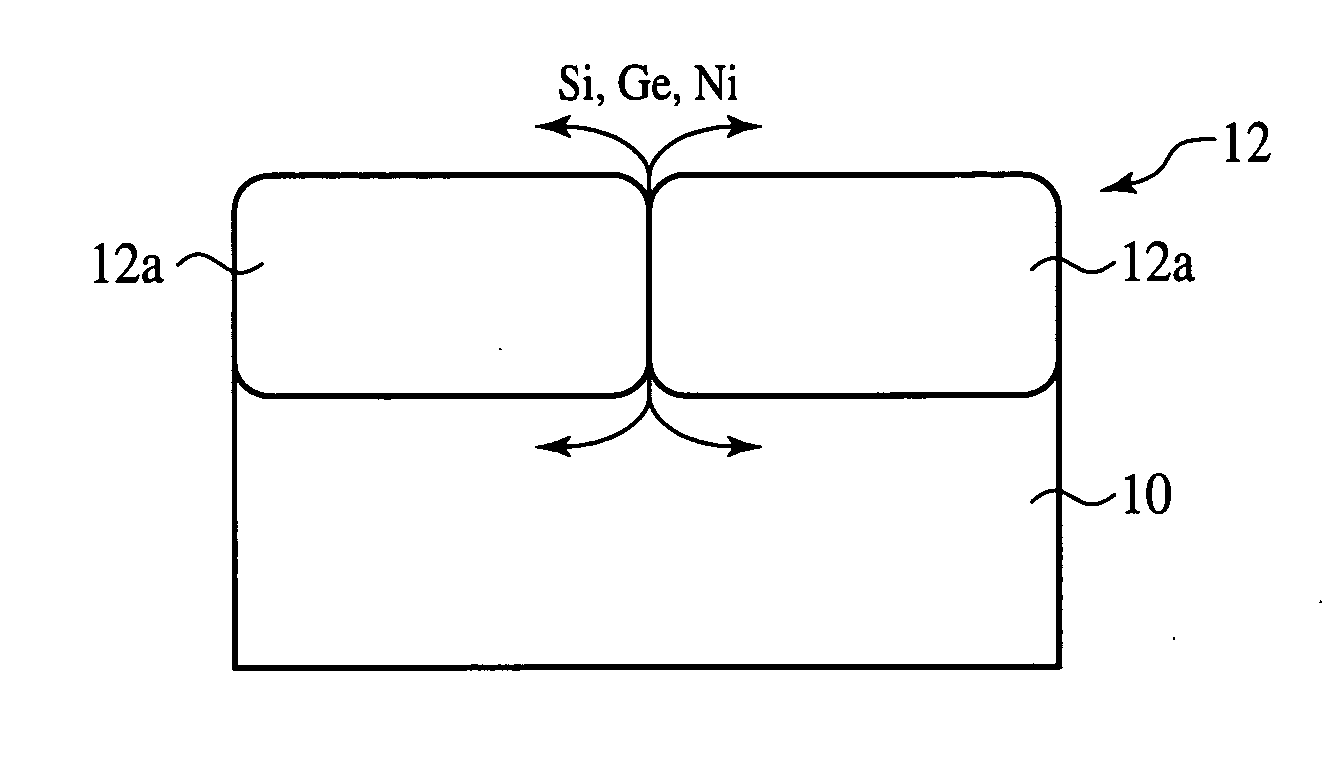

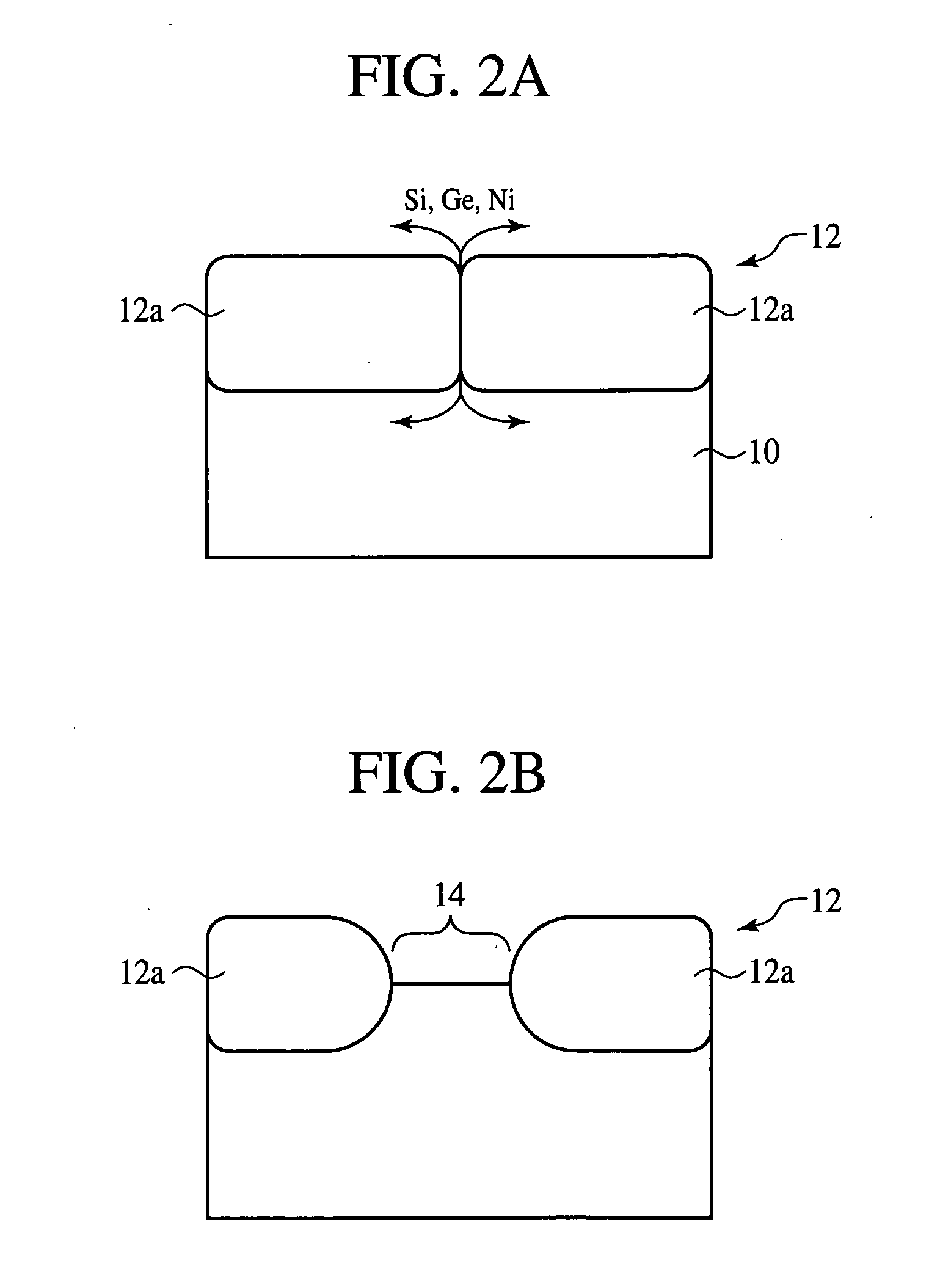

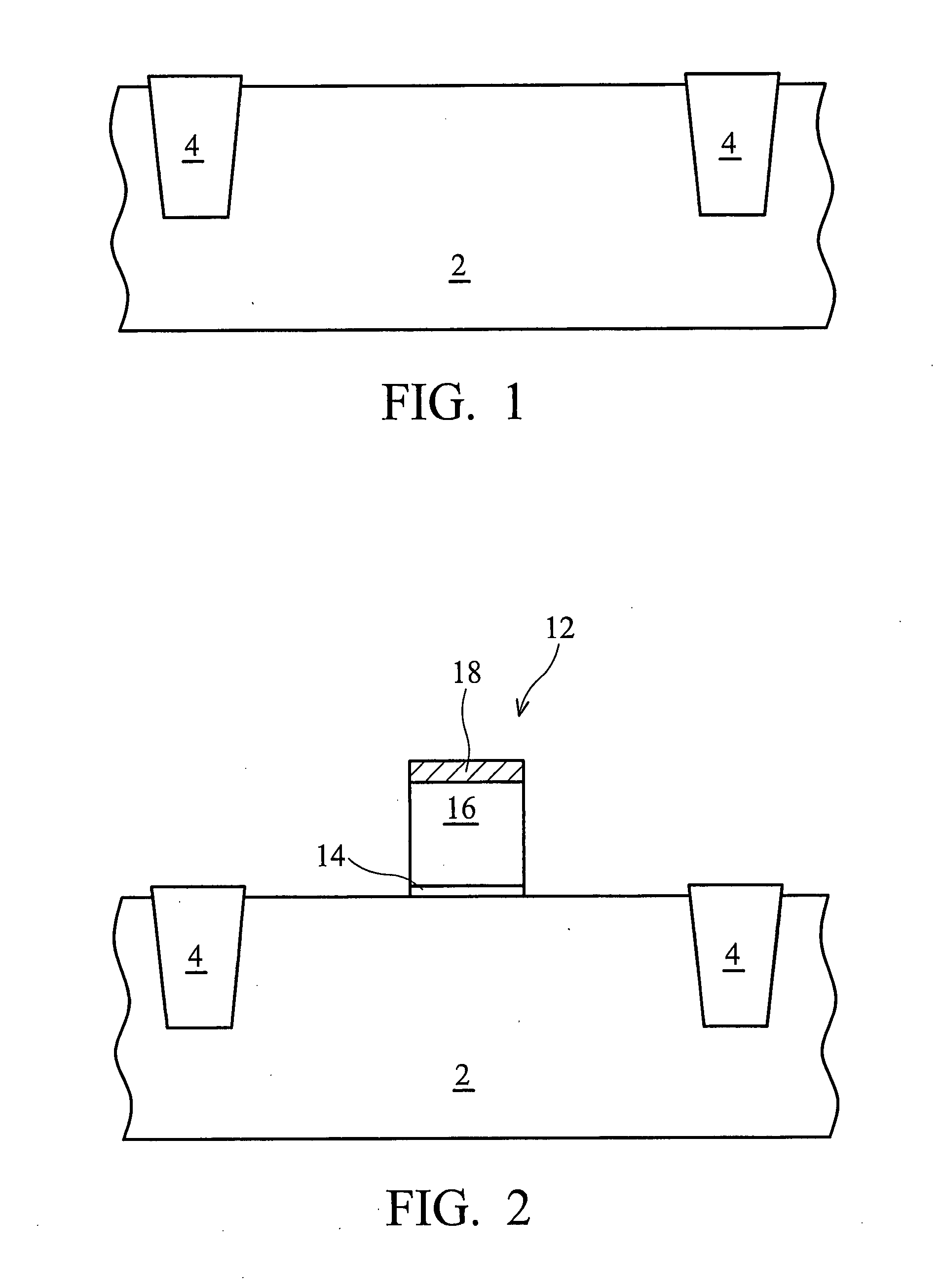

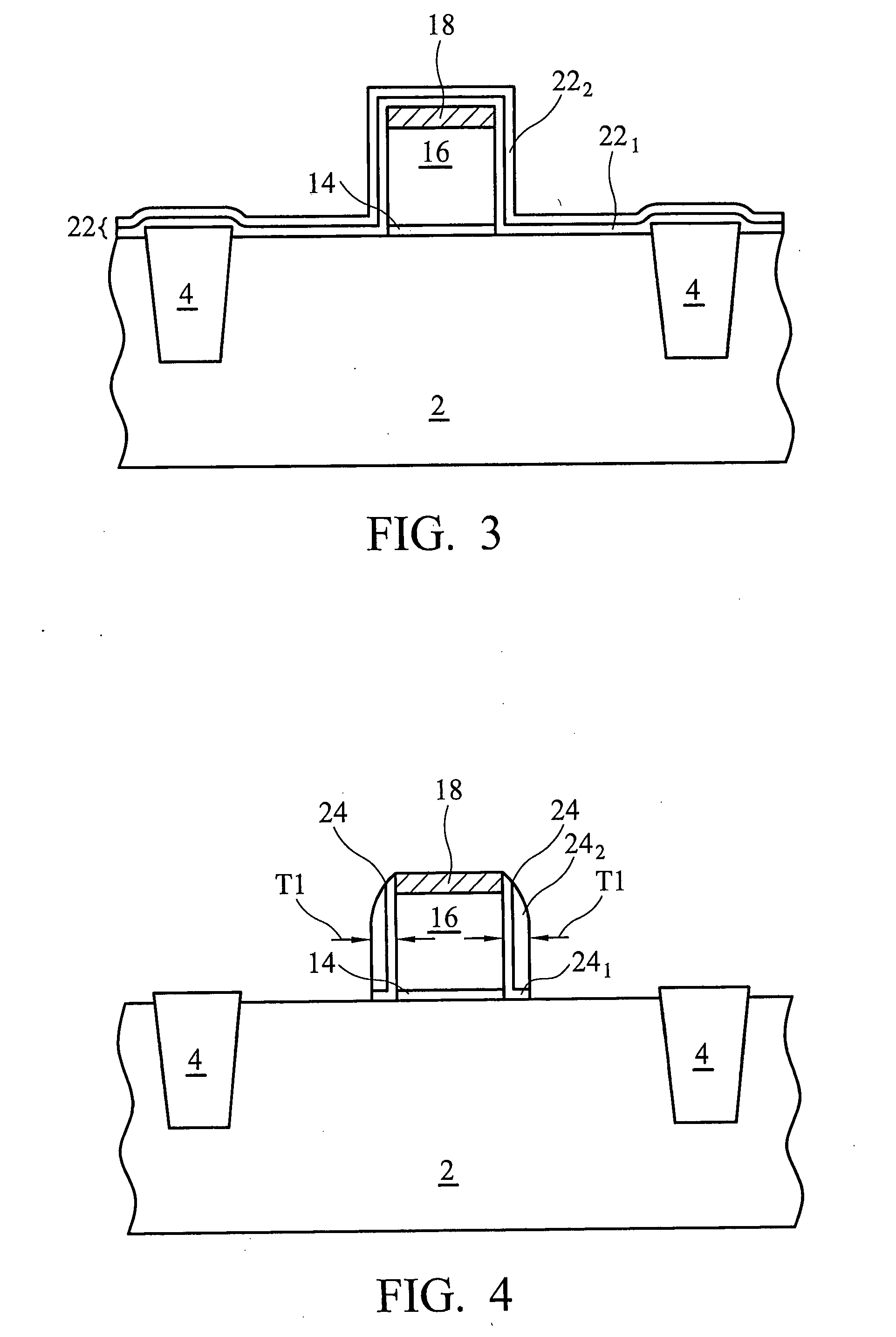

Semiconductor device fabrication method

ActiveUS20060281288A1Improve electrical characteristicsReduce sheet resistanceTransistorSemiconductor/solid-state device manufacturingSemiconductorGrain boundary

The semiconductor device fabrication method comprising the step of forming a gate electrode 54p on a semiconductor substrate 34; the step of forming a source / drain diffused layer 64p in the semiconductor substrate 34 on both sides of the gate electrode 54p; the step of burying a silicon germanium layer 100b in the source / drain diffused layer 64p; the step of forming an amorphous layer at an upper part of the silicon germanium layer 101; the step of forming a nickel film 66 on the amorphous layer 101; and the step of making thermal processing to react the nickel film 66 and the amorphous layer 101 with each other to form a silicide film 102b on the silicon germanium layer 100b. Because of no crystal boundaries in the amorphous layer 101 to react with the nickel film 66, the silicidation homogeneously goes on. Because of no crystal faces in the amorphous layer 101, the Ni(Si1-xGex)2 crystals are prevented from being formed in spikes. Thus, even when the silicon germanium layer 100b is silicided by using a thin nickel film 66, the sheet resistance can be low, and the junction leak current can be suppressed.

Owner:FUJITSU LTD

Articles including anticondensation coatings and/or methods of making the same

ActiveUS20110210656A1Reduce sheet resistanceReduce presenceDomestic cooling apparatusLighting and heating apparatusElectrical resistance and conductanceEmissivity

Owner:GUARDIAN GLASS LLC

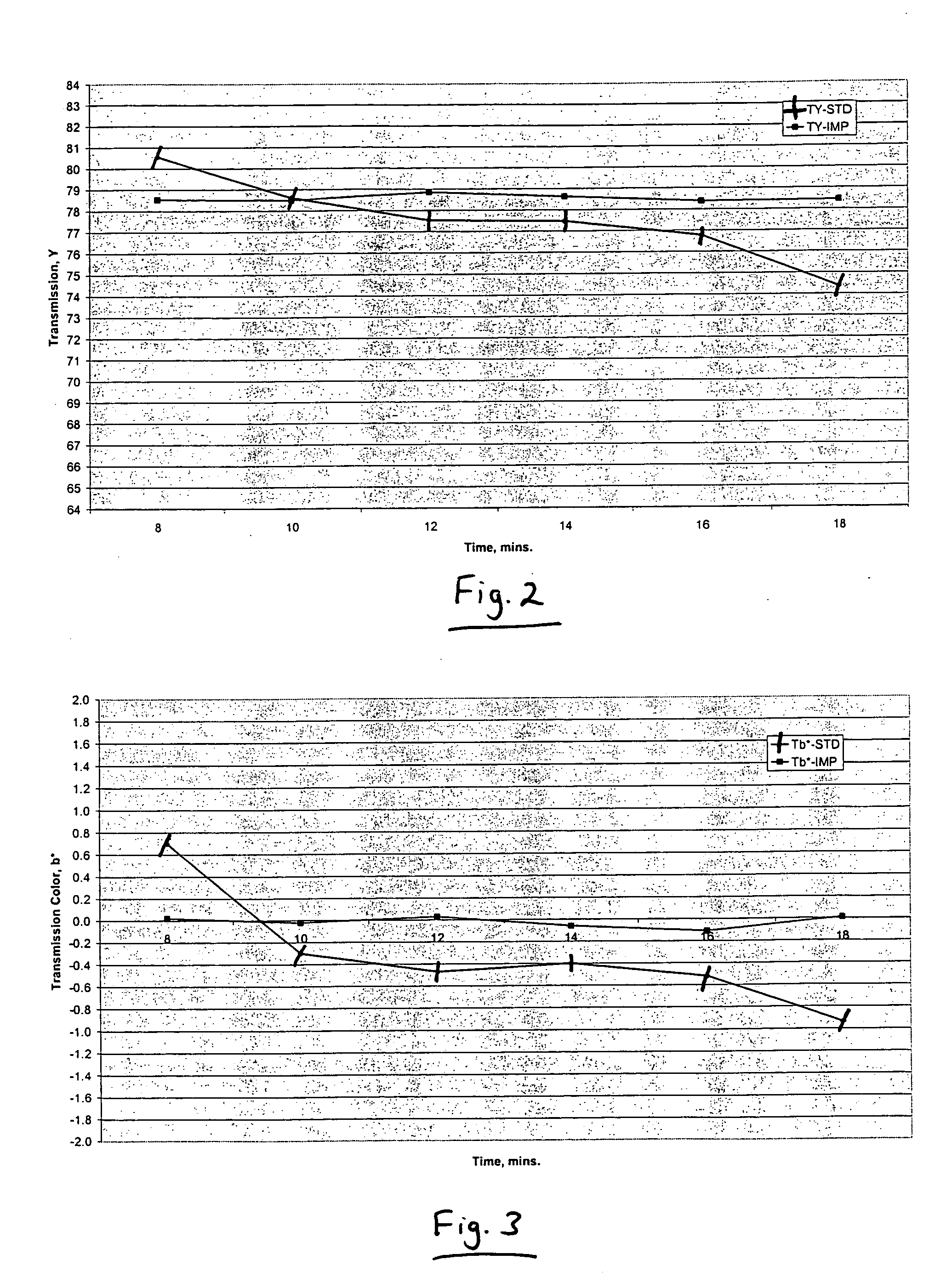

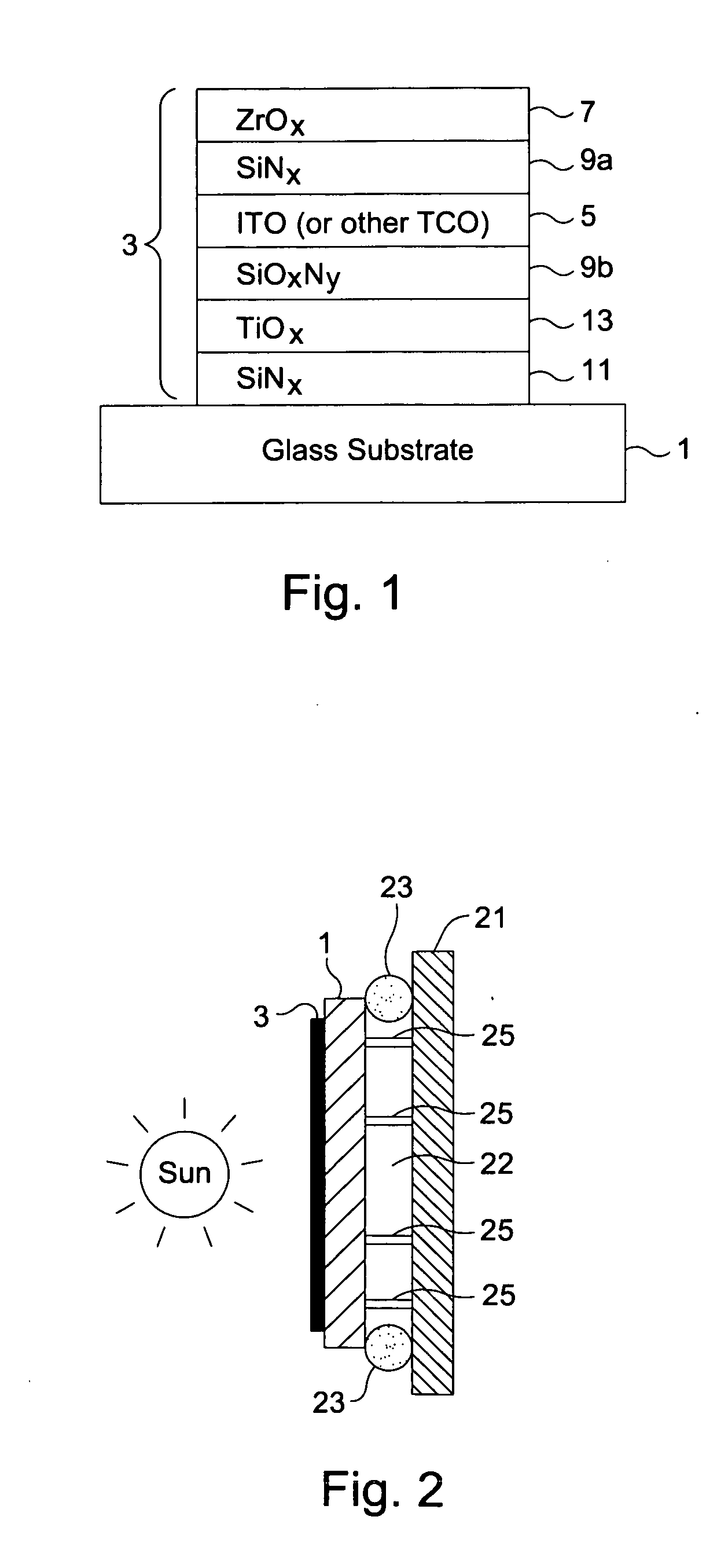

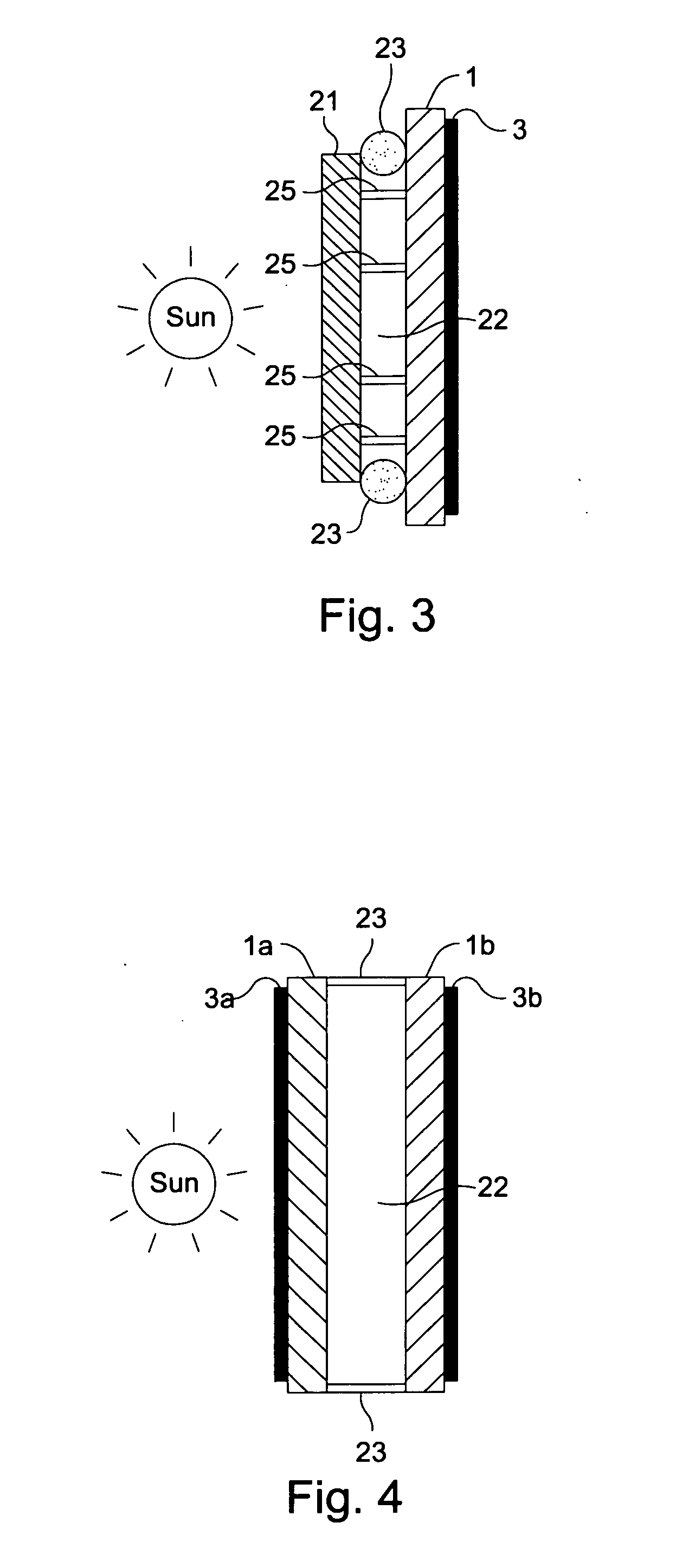

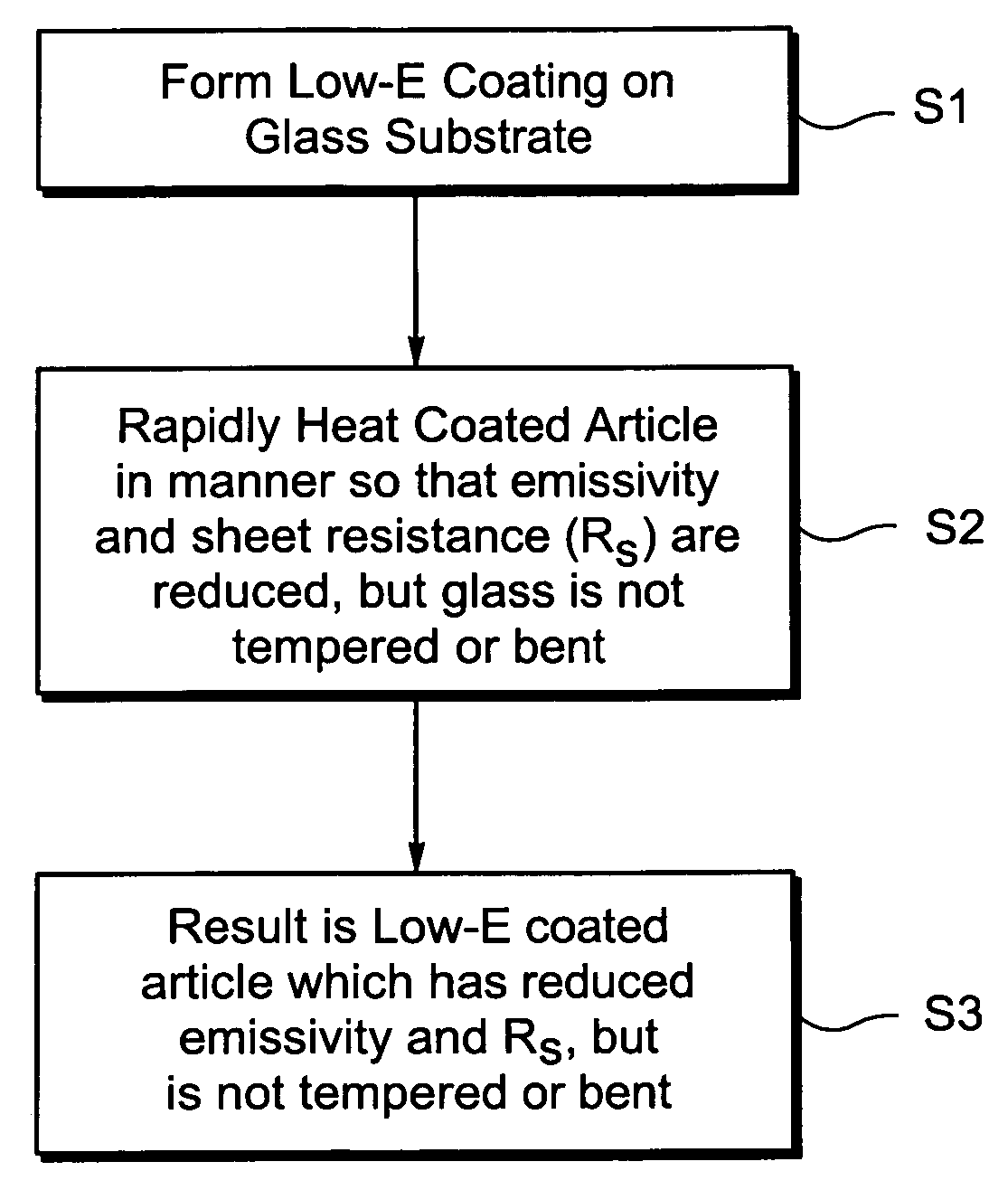

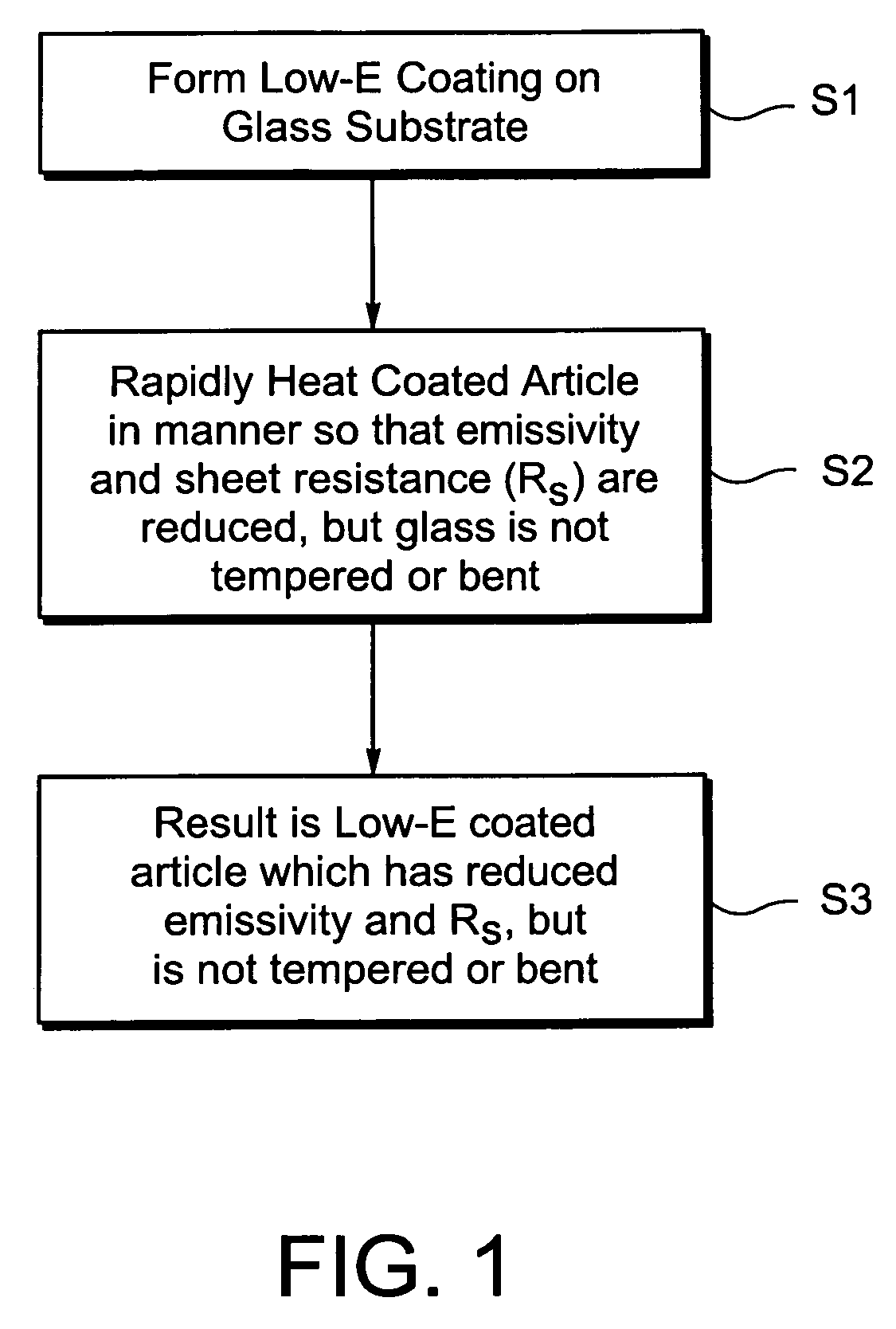

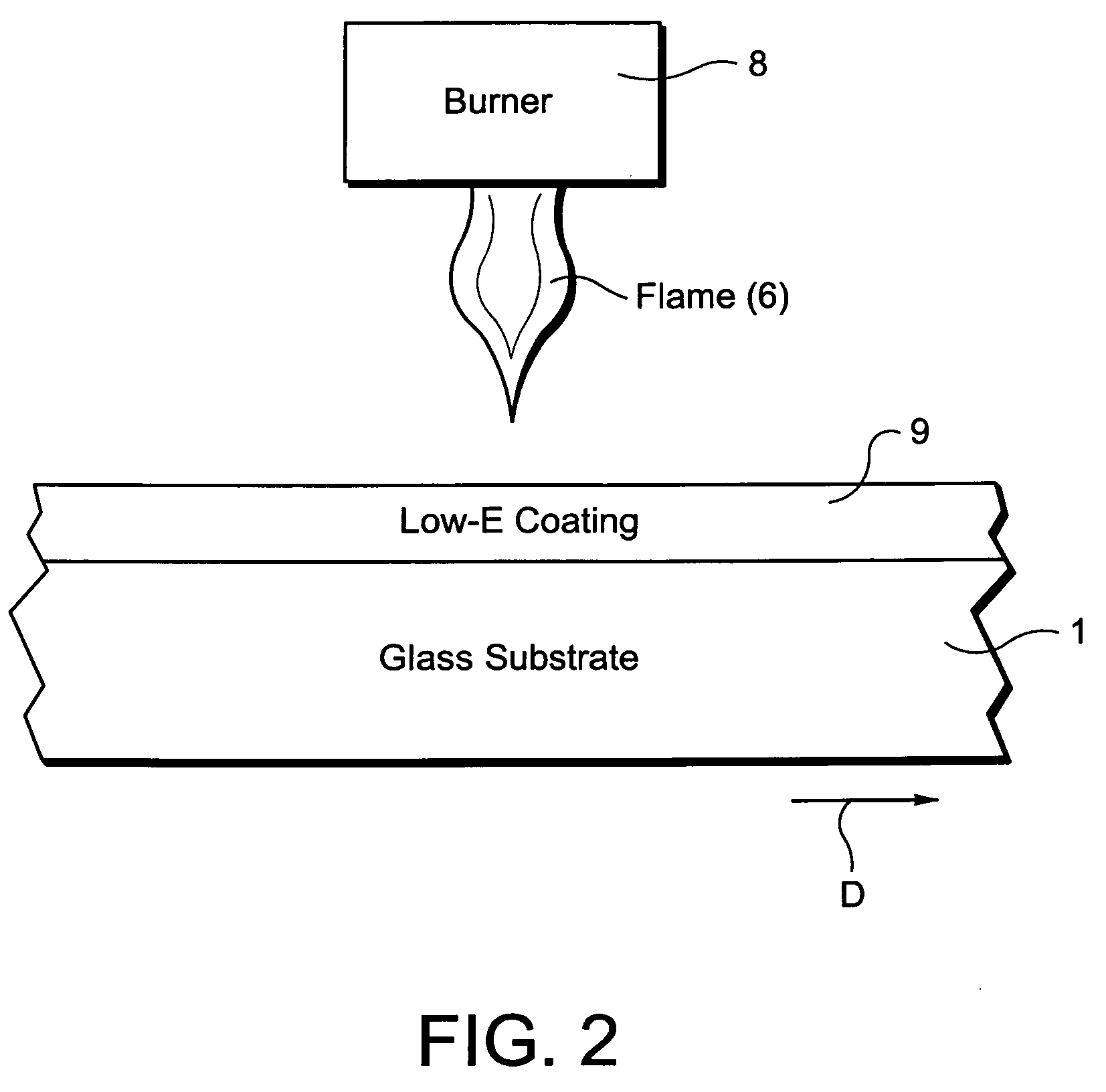

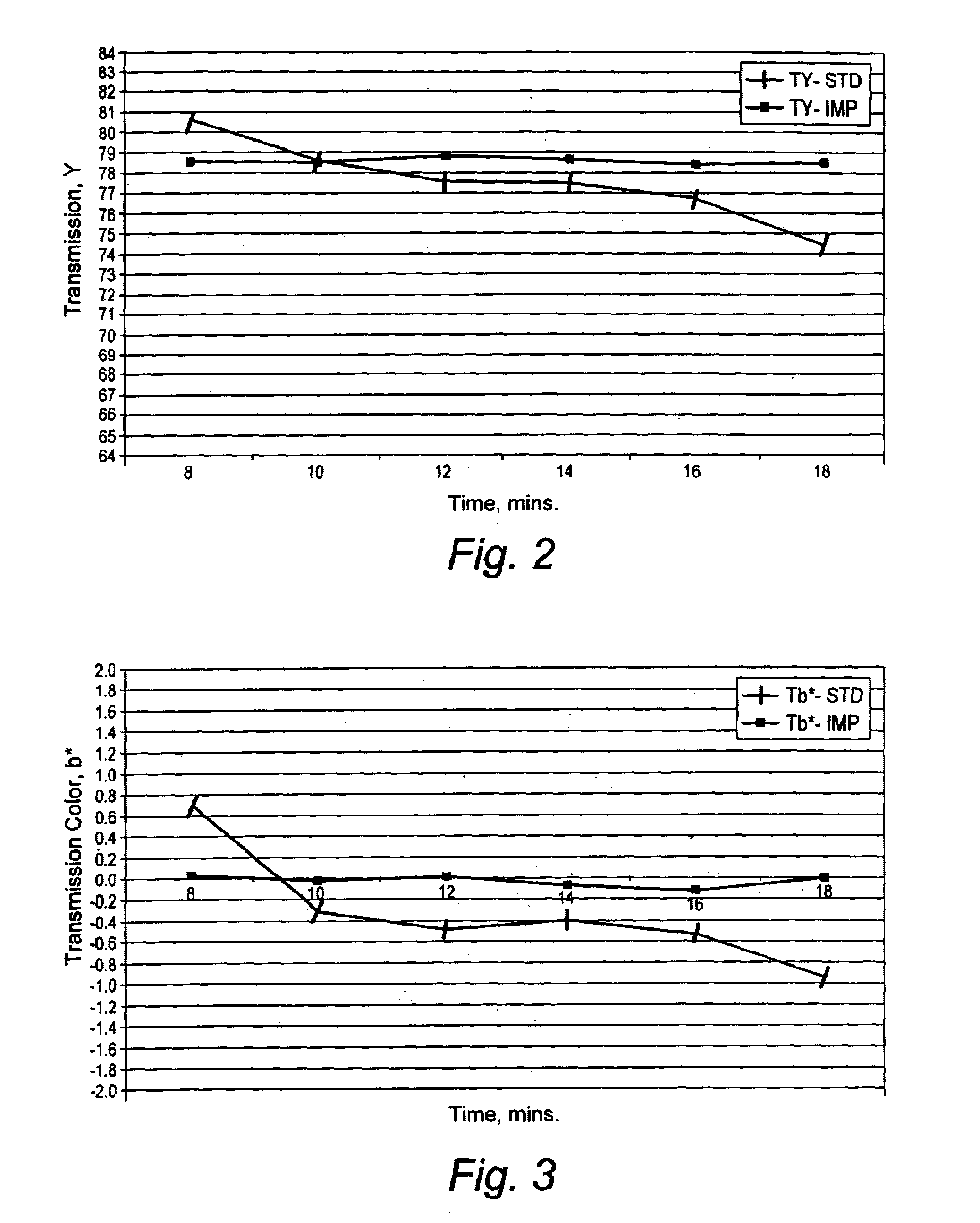

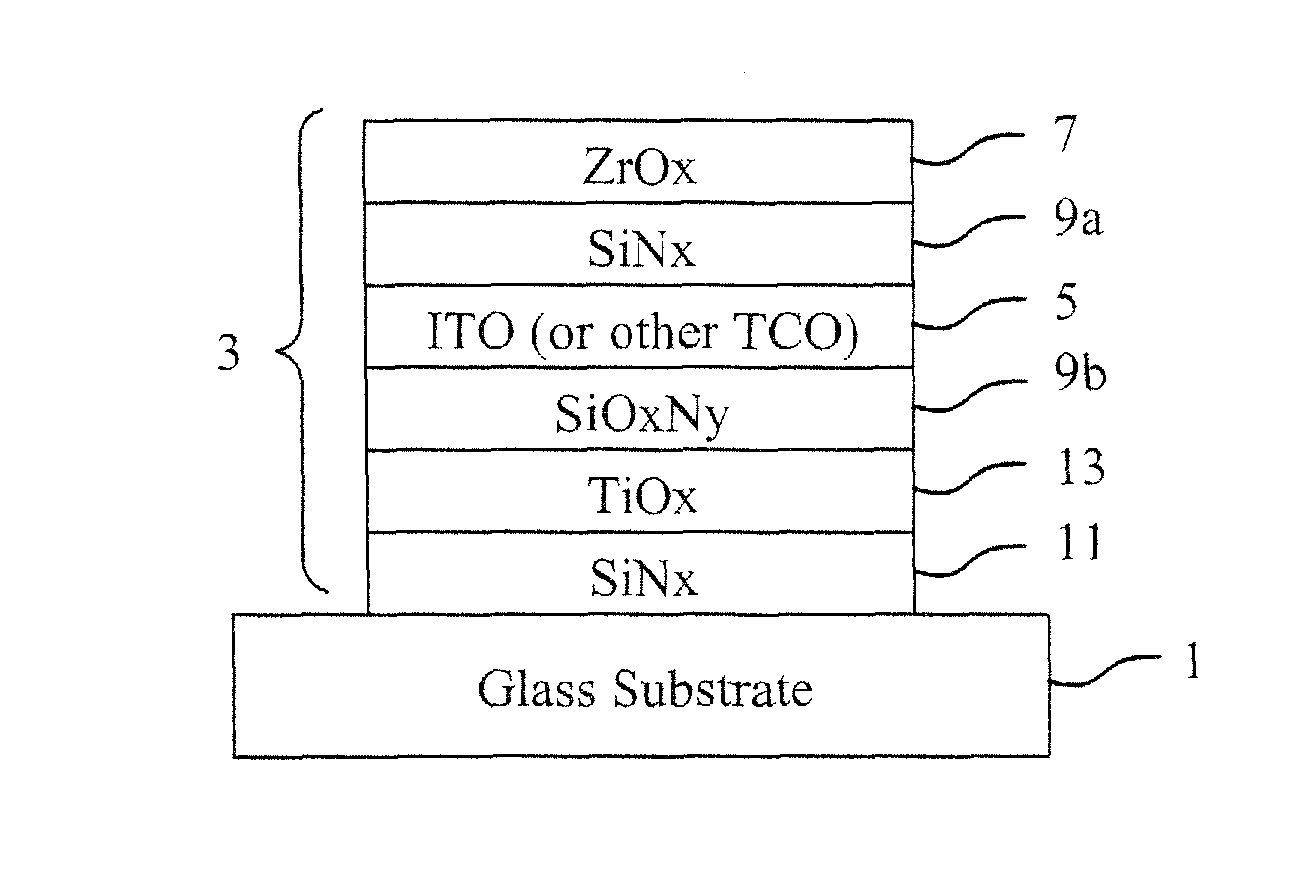

Method of making coated article using rapid heating for reducing emissivity and/or sheet resistance, and corresponding product

ActiveUS20080008829A1Decreased emissivityHigh carrier mobilityPretreated surfacesSpecial surfacesInsulated glazingLow emissivity

This invention relates to a method of making a coated article for use in insulating glass (IG) window units, vehicle windows, or the like. The coated article typically includes a low-E coated article, including a low-E (low emissivity) coating supported by a glass substrate. In certain example embodiments, rapid heating (not sufficient for tempering or heat bending) of the coated article is utilized in order to reduce the emissivity and / or sheet resistance of the coated article without significantly damaging the infrared (IR) reflecting layer(s) of the coating, thereby activating the coated article. The glass of the coated article does not become too hot during such rapid heating.

Owner:GUARDIAN EURO S A R L +1

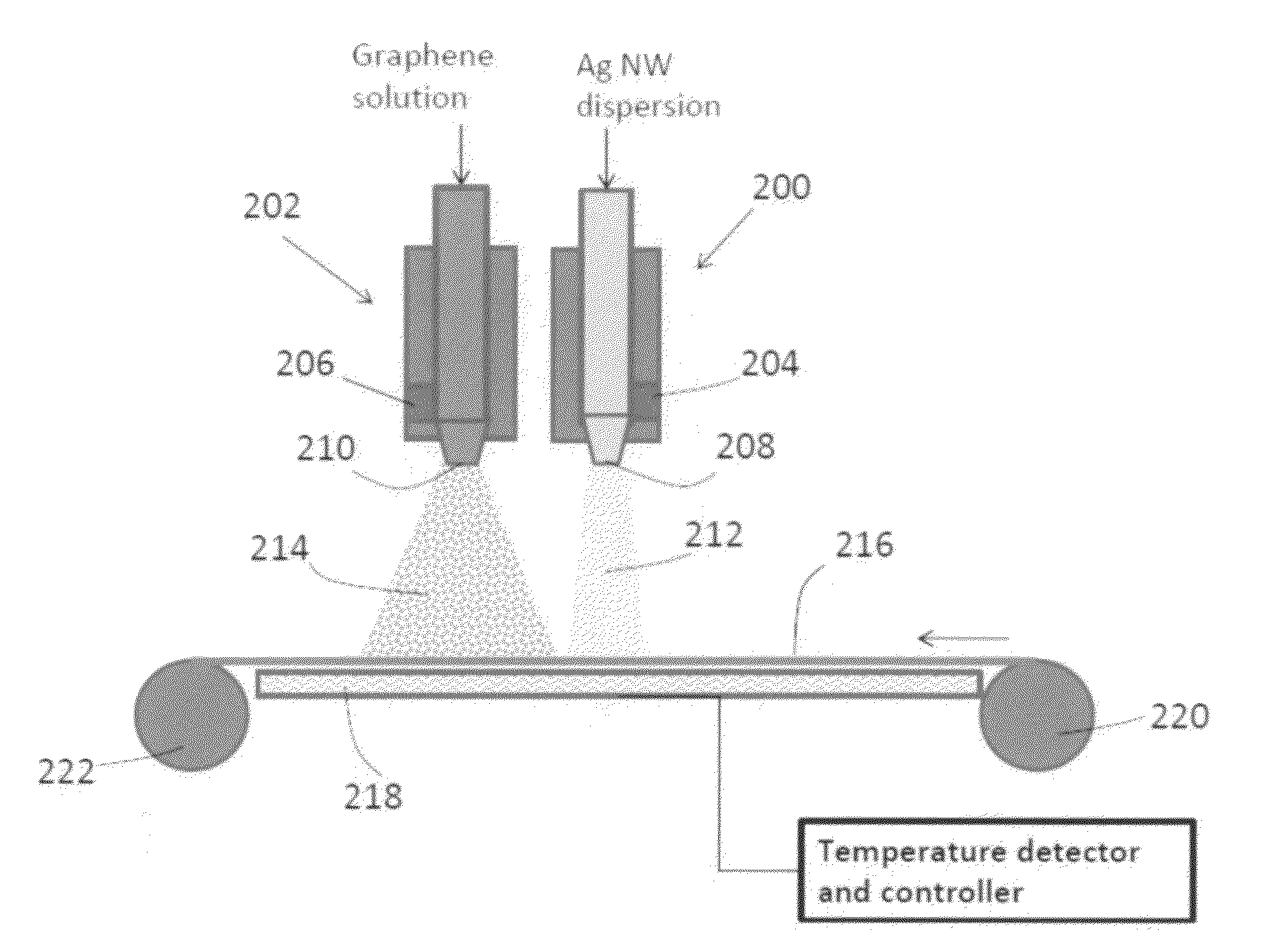

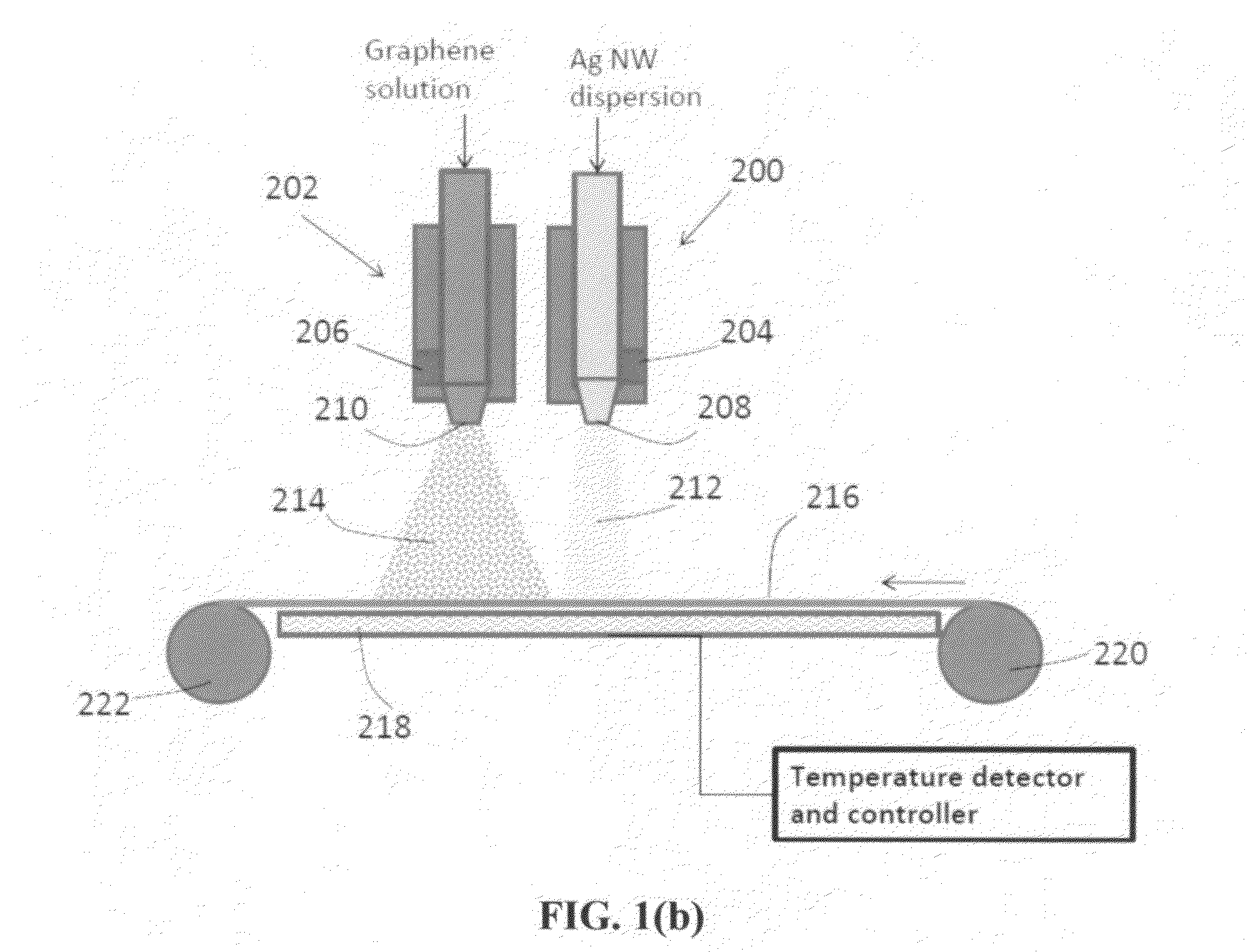

Ultrasonic spray coating of conducting and transparent films from combined graphene and conductive nano filaments

PendingUS20140272199A1Reduce sheet resistanceIncrease speedTransportation and packagingMetal-working apparatusFilm resistanceSpray coating

An ultrasonic spray coating method of producing a transparent and conductive film, comprising (a) operating an ultrasonic spray device to form aerosol droplets of a first dispersion comprising a first conducting nano filaments in a first liquid; (b) forming aerosol droplets of a second dispersion comprising a graphene material in a second liquid; (c) depositing the aerosol droplets of a first dispersion and the aerosol droplets of a second dispersion onto a supporting substrate; and (d) removing the first liquid and the second liquid from the droplets to form the film, which is composed of the first conducting nano filaments and the graphene material having a nano filament-to-graphene weight ratio of from 1 / 99 to 99 / 1, wherein the film exhibits an optical transparence no less than 80% and sheet resistance no higher than 300 ohm / square.

Owner:GLOBAL GRAPHENE GRP INC

Front electrode for use in photovoltaic device and method of making same

InactiveUS20080105293A1Reduce sheet resistanceImprove conductivityPV power plantsPhotovoltaic energy generationLight reflectionZinc

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include a plurality of metal(s) oxide layers and / or a plurality of conductive substantially metallic IR reflecting layers arranged in an alternating manner in order to provide for reduced visible light reflection, increased conductivity, and / or increased infrared (IR) reflection capability.

Owner:GUARDIAN GLASS LLC

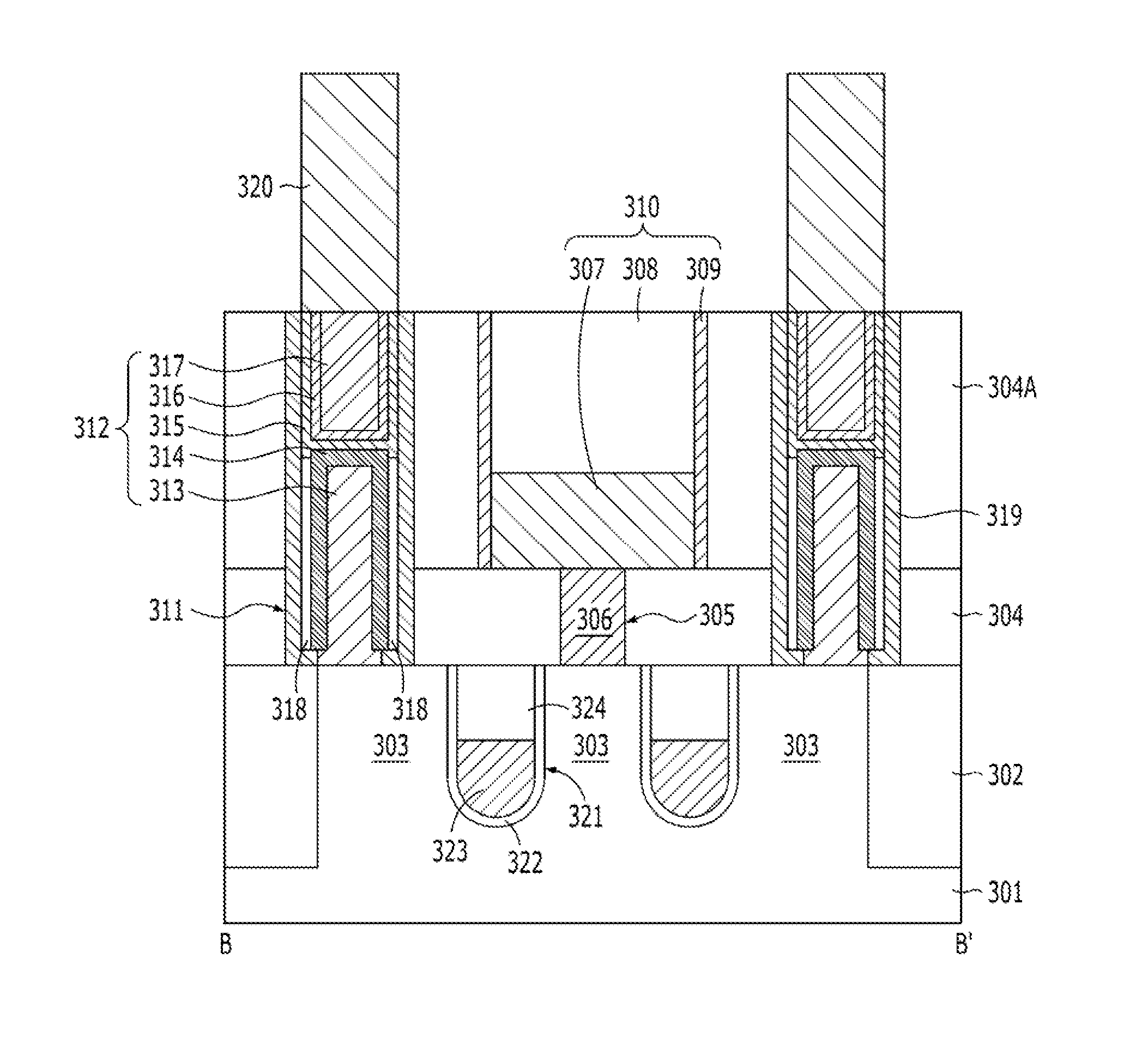

Semiconductor device with air gap and method for fabricating the same

ActiveUS20150014759A1Reduce sheet resistanceIncrease resistanceTransistorSemiconductor/solid-state device detailsEngineeringDielectric structure

A semiconductor device includes a dielectric structure which has an opening exposing a surface of a substrate; and a conductive structure which is formed in the opening, wherein the conductive structure comprises: a first conductive pattern recessed in the opening; a second conductive pattern covering a top surface and sidewalls of the first conductive pattern; an air gap defined between sidewalls of the opening and the second conductive pattern; and a third conductive pattern capping the second conductive pattern and the air gap.

Owner:SK HYNIX INC

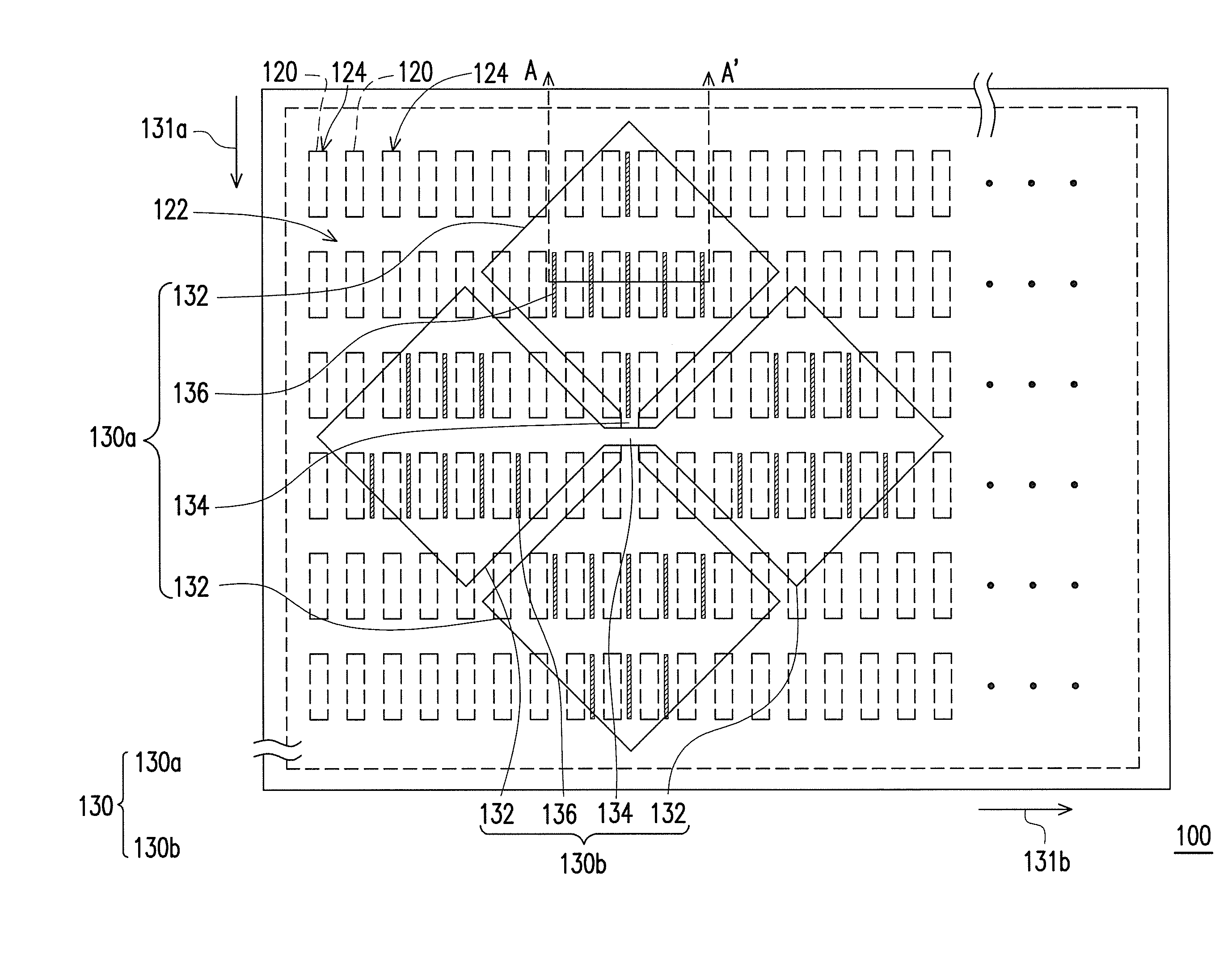

Touch-sensing substrate, color filter substrate and touch-sensing liquid crystal display

ActiveUS20100110023A1Improve increased sheet resistanceHigh light transmittanceNon-linear opticsInput/output processes for data processingTouch SensesColor gel

A color filter substrate including a substrate, a plurality of patterned color filter layers, and a plurality of sensing serials is provided. The substrate has a first surface and a second surface opposite to the first surface. The substrate includes a plurality of display regions arranged in array and a separated region located between the display regions. The patterned color filter layers are arranged in array on the first surface and corresponding to the display regions. The sensing serials are arranged on the second surface and insulated from each other. Each sensing serial includes a plurality of sensing pads; a plurality of bridging lines, each connected with two adjacent sensing pads; a plurality of patterned conductive layers stacked and electrically connected with the sensing pads. The position of the patterned conductive layers is corresponding to the separated region. A touch-sensing liquid crystal display and a touch-sensing substrate are also provided.

Owner:AU OPTRONICS CORP

Coated article with IR reflecting layer and method of making same

InactiveUS20090263596A1Low emissivityReduce sheet resistanceVacuum evaporation coatingSputtering coatingMetallurgyNitrogen gas

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

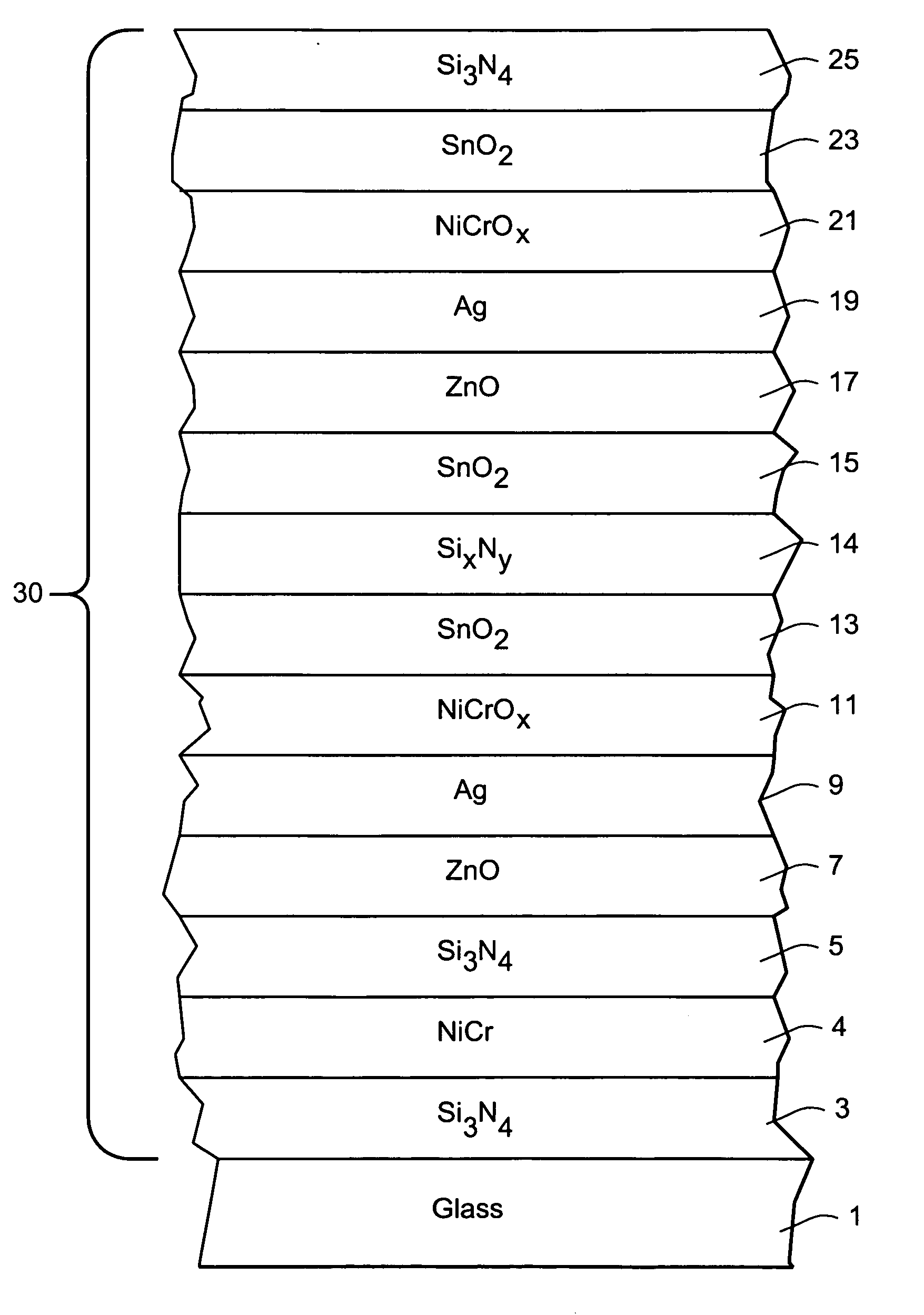

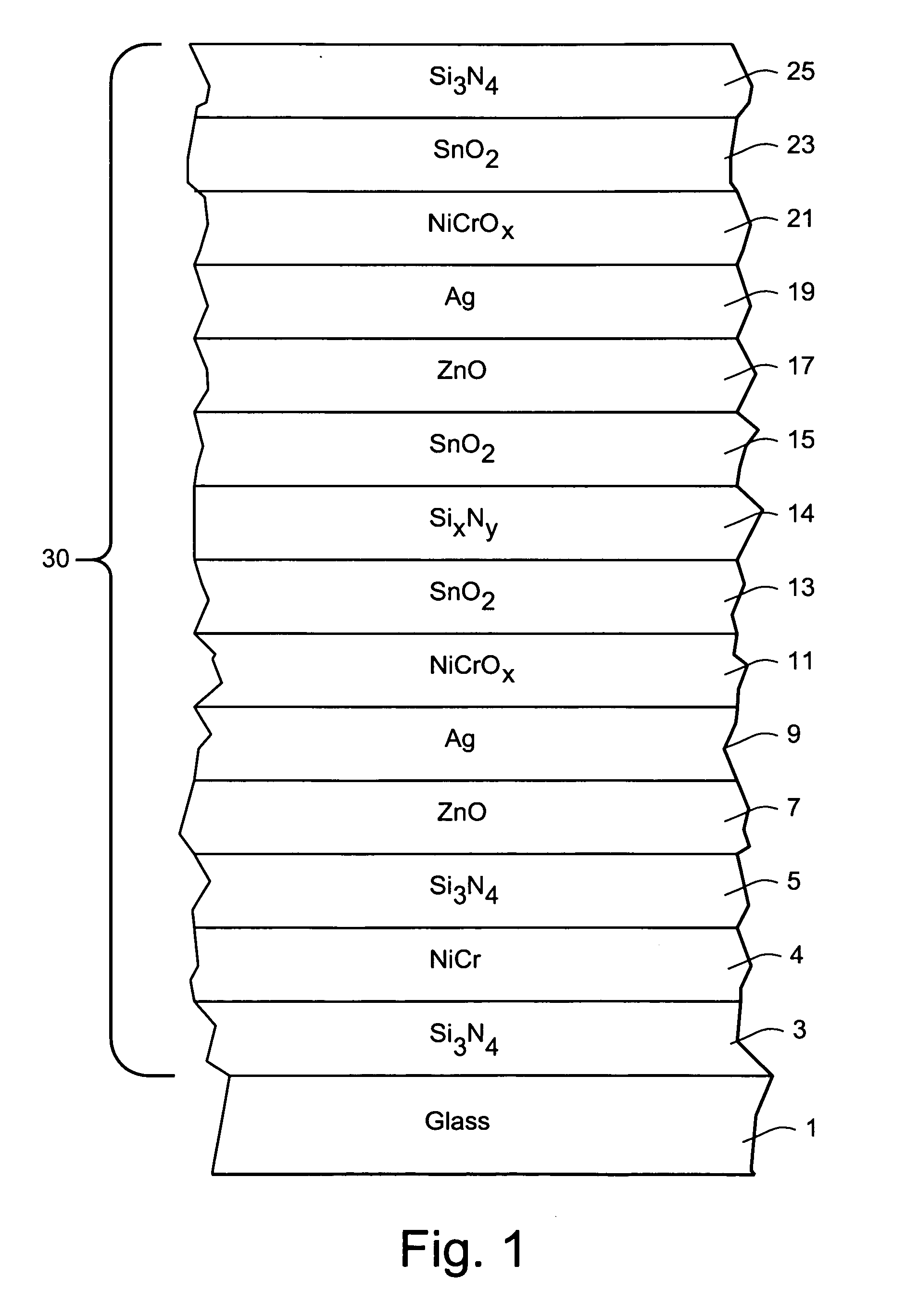

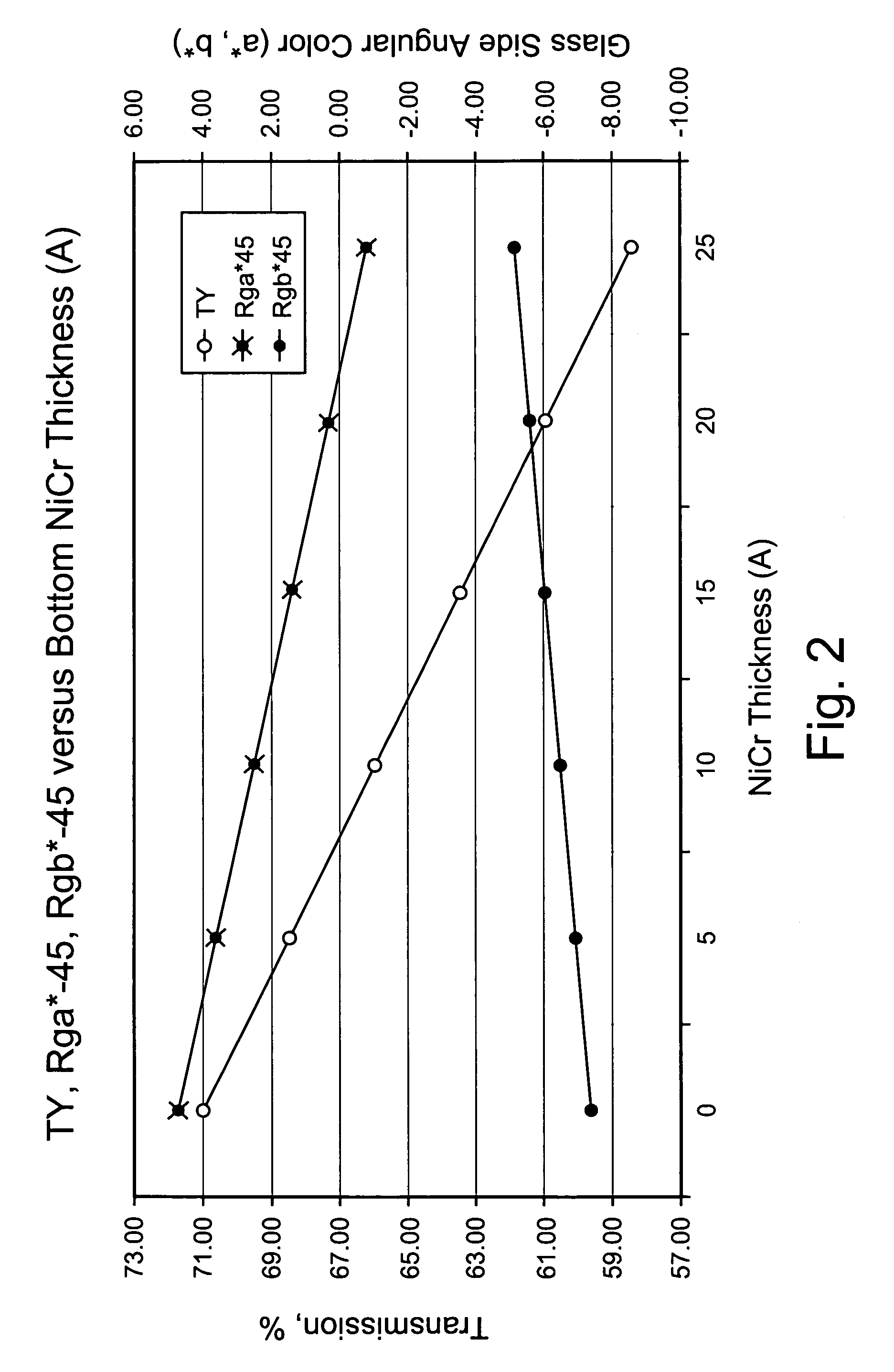

Coated article with low-E coating having absorbing layer designed to neutralize color at off-axis viewing angles

ActiveUS20080070044A1Improve mechanical durabilityImprove thermal stabilityGlass/slag layered productsNatural mineral layered productsInsulated glazingNitride

An absorbing layer of a low-E coating is designed to cause the coating to have a more neutral and / or green color at normal and / or certain off-axis viewing angles. In certain example embodiments, the metallic or substantially metallic absorbing layer (e.g., NiCr) is from about 20-30 angstroms (Å) thick; this thickness has been found to unexpectedly provide less red and more neutral coloration for the coated article at certain off-axis viewing angles (e.g., at a 45 degree off-axis viewing angle). In certain example embodiments, the absorbing layer is provided between first and second nitride layers in order to reduce or prevent oxidation thereof during heat treatment thereby permitting predictable coloration to be achieved following the heat treatment. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, vehicle windows, other types of windows, or in any other suitable application.

Owner:GUARDIAN GLASS LLC +1

Coated article with low-E coating including tin oxide interlayer

ActiveUS7081302B2Improve thermal stabilityMore neutral and/or desirable colorationGlass/slag layered productsCoatingsReflective layerThermal stability

A coated article is provided which may be heat treated (e.g., thermally tempered) in certain instances. In certain example embodiments, an interlayer of or including a metal oxide such as tin oxide is provided under an infrared (IR) reflecting layer so as to be located between respective layers comprising silicon nitride and zinc oxide. It has been found that the use of such a tin oxide inclusive interlayer results in significantly improved mechanical durability, thermal stability and / or haze characteristics. In certain example embodiments, a zinc oxide inclusive layer is provide over an IR reflecting layer in order to improve thermal stability. A zirconium oxide overcoat may also be provided in certain example instances.

Owner:GUARDIAN EURO S A R L

Articles including anticondensation coatings and/or methods of making the same

InactiveUS8293344B2Reduce sheet resistanceLow emissivityPretreated surfacesVehicle componentsElectrical resistance and conductanceEmissivity

Certain example embodiments of this invention relate to articles including anticondensation coatings that are exposed to an external environment, and / or methods of making the same. In certain example embodiments, the anticondensation coatings may be survivable in an outside environment. The coatings also may have a sufficiently low sheet resistance and hemispherical emissivity such that the glass surface is more likely to retain heat from the interior area, thereby reducing (and sometimes completely eliminating) the presence condensation thereon. The articles of certain example embodiments may be, for example, skylights, vehicle windows or windshields, IG units, VIG units, refrigerator / freezer doors, and / or the like.

Owner:GUARDIAN GLASS LLC

Articles including anticondensation coatings and/or methods of making the same

InactiveUS20110212279A1Reduce sheet resistanceReduce presencePretreated surfacesVehicle componentsEmissivityRefrigerated temperature

Certain example embodiments of this invention relate to articles including anticondensation coatings that are exposed to an external environment, and / or methods of making the same. In certain example embodiments, the anticondensation coatings may be survivable in an outside environment. The coatings also may have a sufficiently low sheet resistance and hemispherical emissivity such that the glass surface is more likely to retain heat from the interior area, thereby reducing (and sometimes completely eliminating) the presence condensation thereon. The articles of certain example embodiments may be, for example, skylights, vehicle windows or windshields, IG units, VIG units, refrigerator / freezer doors, and / or the like.

Owner:GUARDIAN GLASS LLC

Coated article having low-E coating with absorber layer(s)

ActiveUS8337988B2Low emissivityReduce sheet resistanceGlass/slag layered productsNatural mineral layered productsElectrical resistance and conductanceInsulated glazing

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN EURO S A R L +1

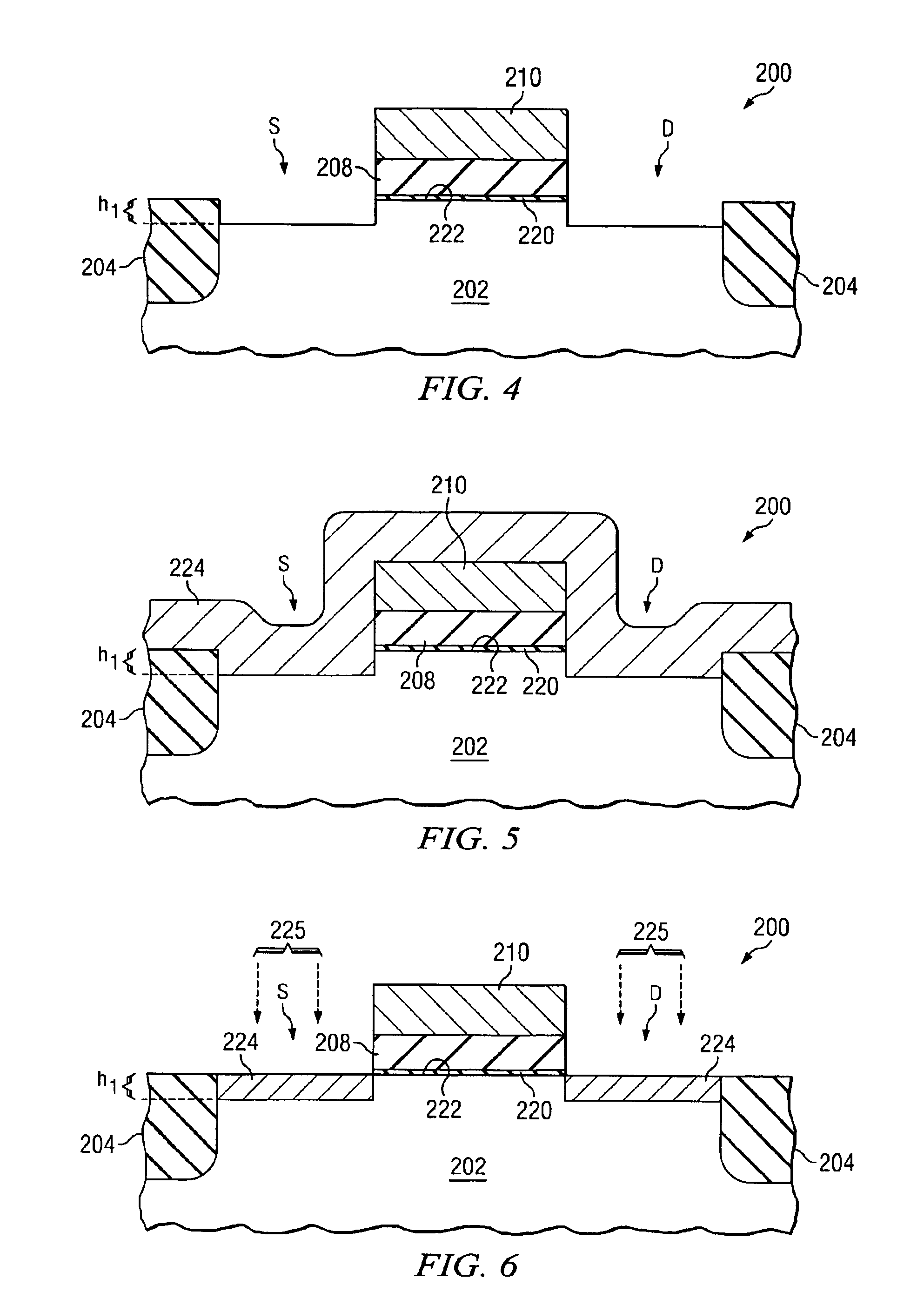

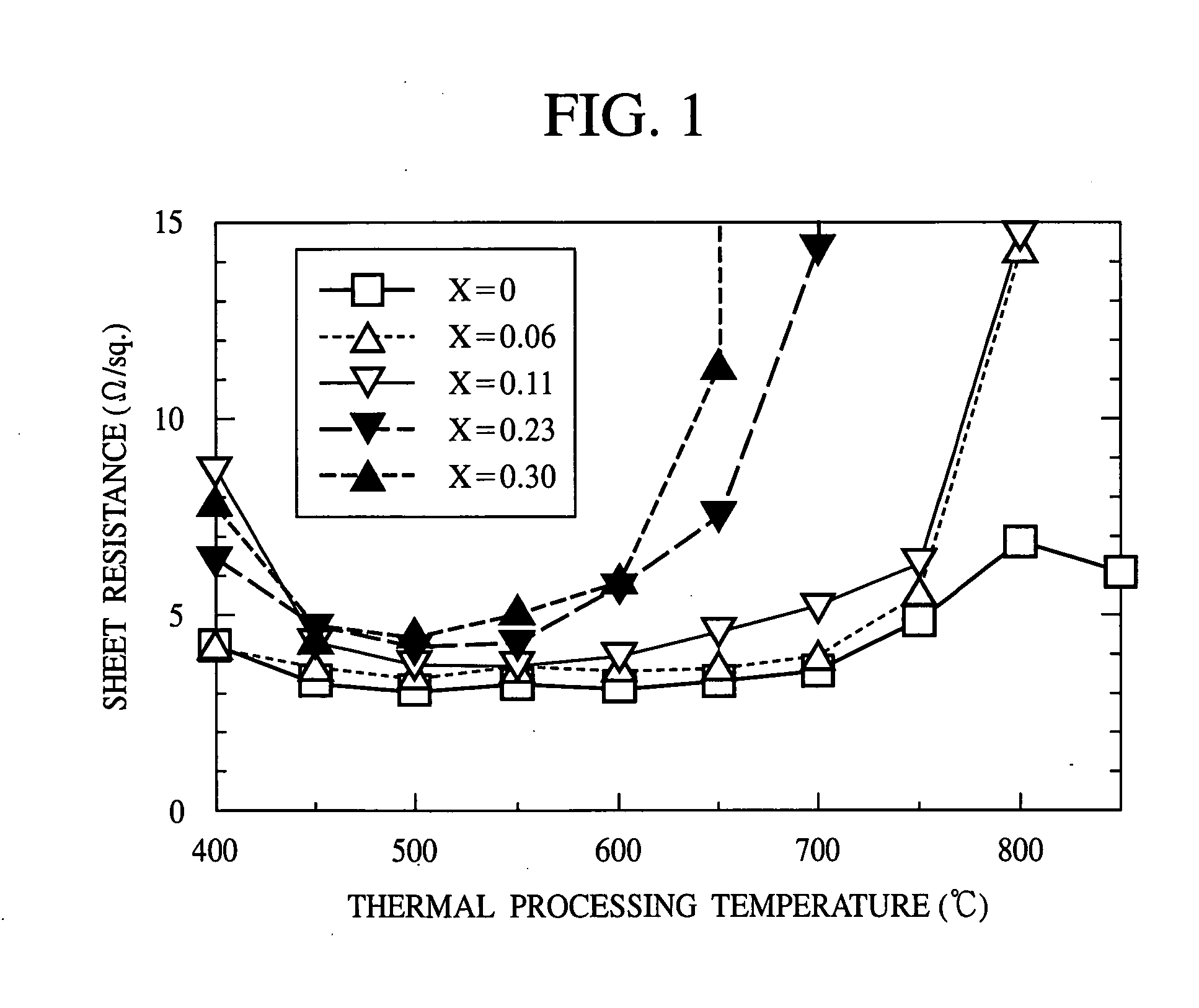

MOS devices with improved source/drain regions with SiGe

InactiveUS20080265256A1Reduce sheet resistanceReduce roughnessTransistorSolid-state devicesSalicideSemiconductor structure

A semiconductor structure and methods for forming the same are provided. The semiconductor structure includes a semiconductor substrate; a gate stack on the semiconductor substrate; a SiGe region in the semiconductor substrate and adjacent the gate stack, wherein the SiGe region has a first atomic percentage of germanium to germanium and silicon; and a silicide region over the SiGe region. The silicide region has a second atomic percentage of germanium to germanium and silicon. The second atomic percentage is substantially lower than the first atomic percentage.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com