Touch panel, display, and manufacturing method of touch panel

a manufacturing method and touch panel technology, applied in the manufacture of electric discharge tubes/lamps, instruments, computing, etc., can solve the problems of defective signal transmission of conventional touch panels b>100/b>, poor sensing sensitivity, and disadvantages of calculation of touch positions, etc., to achieve low parasitic capacitance, low transmission resistance, and good sensing sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

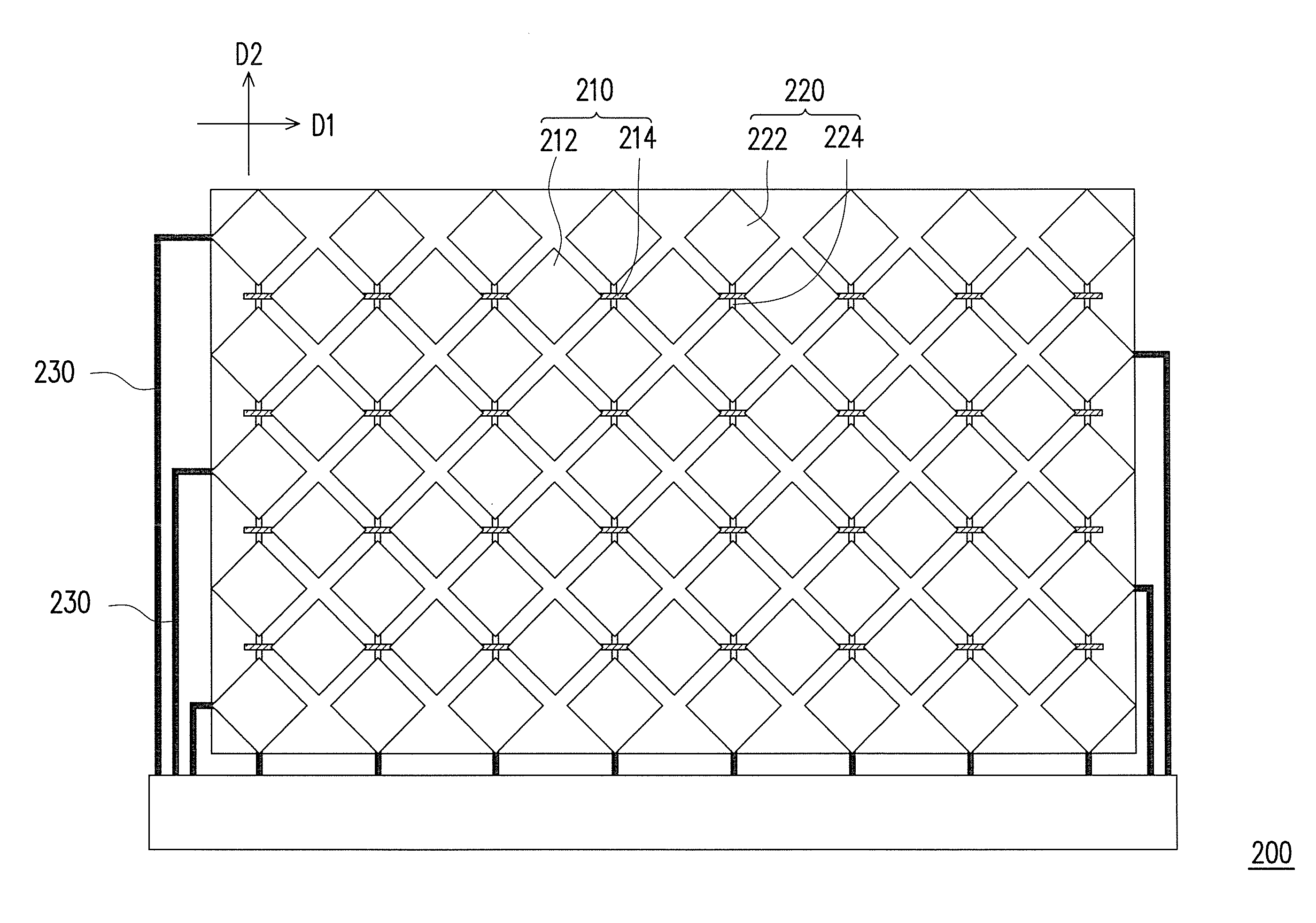

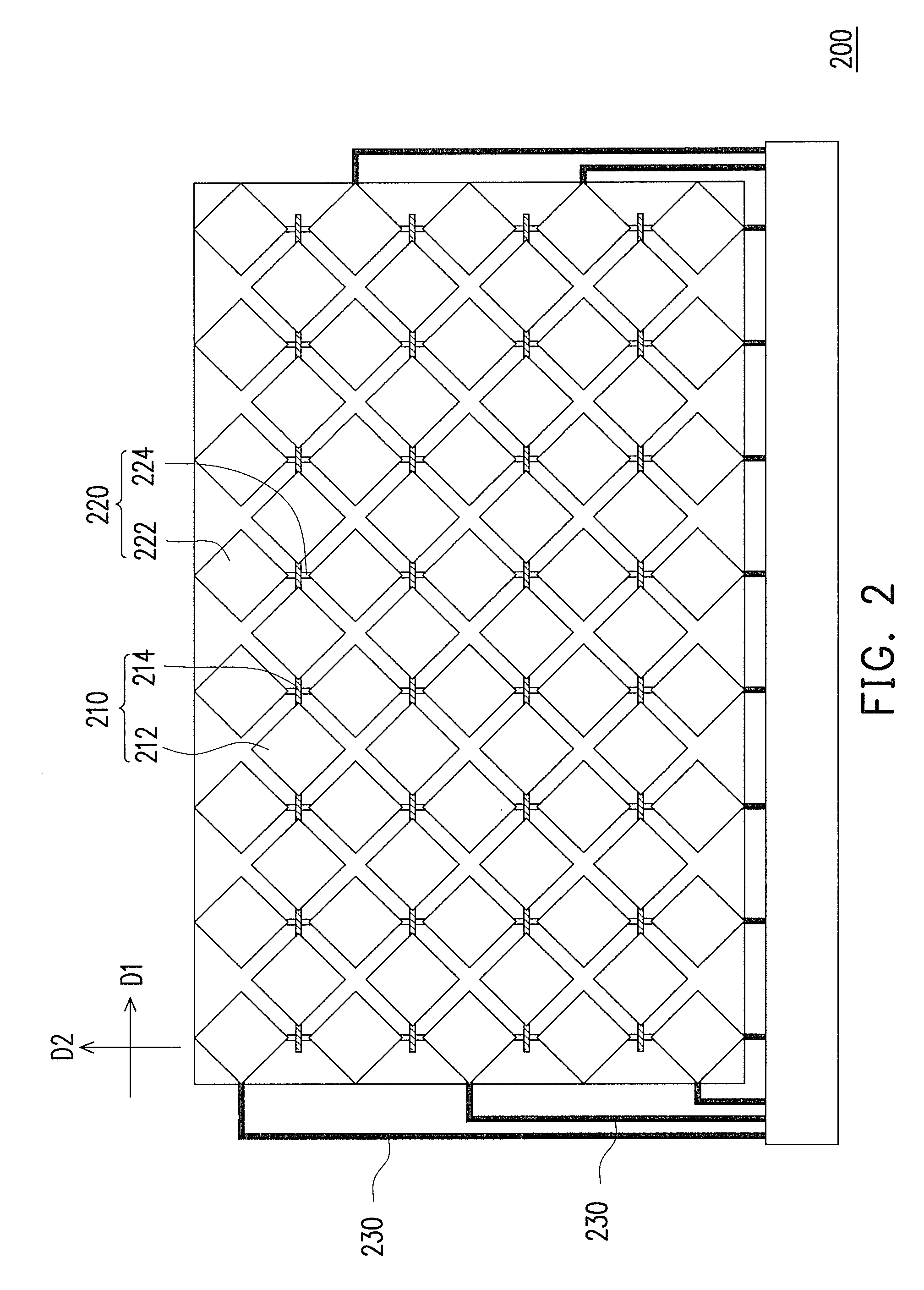

[0039]FIGS. 2 through 5 show top views of the touch panels according to the first through the fourth embodiments of the present invention. Referring to FIG. 2 first, a touch panel 200 has at least one first sensing series 210 and at least one second sensing series 220. The first sensing series 210 extends along a first direction D1. The first sensing series 210 includes a plurality of first sensing pads 212 and at least one first bridge line 214. The first bridge line 214 connects two adjacent first sensing pads 212. A material of the first bridge line 214 differs from a material of the first sensing pads 212. The second sensing series 220 extends along a second direction D2. The first direction D1 is different from the second direction D2. For example, the first direction D1 is perpendicular to the second direction D2. The second sensing series 220 includes a plurality of second sensing pads 222 and at least one second bridge line 224. The second bridge line 224 connects two adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com