Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Barrier layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Barrier layer in the ocean is a layer of water separating the well-mixed surface layer from the thermocline.

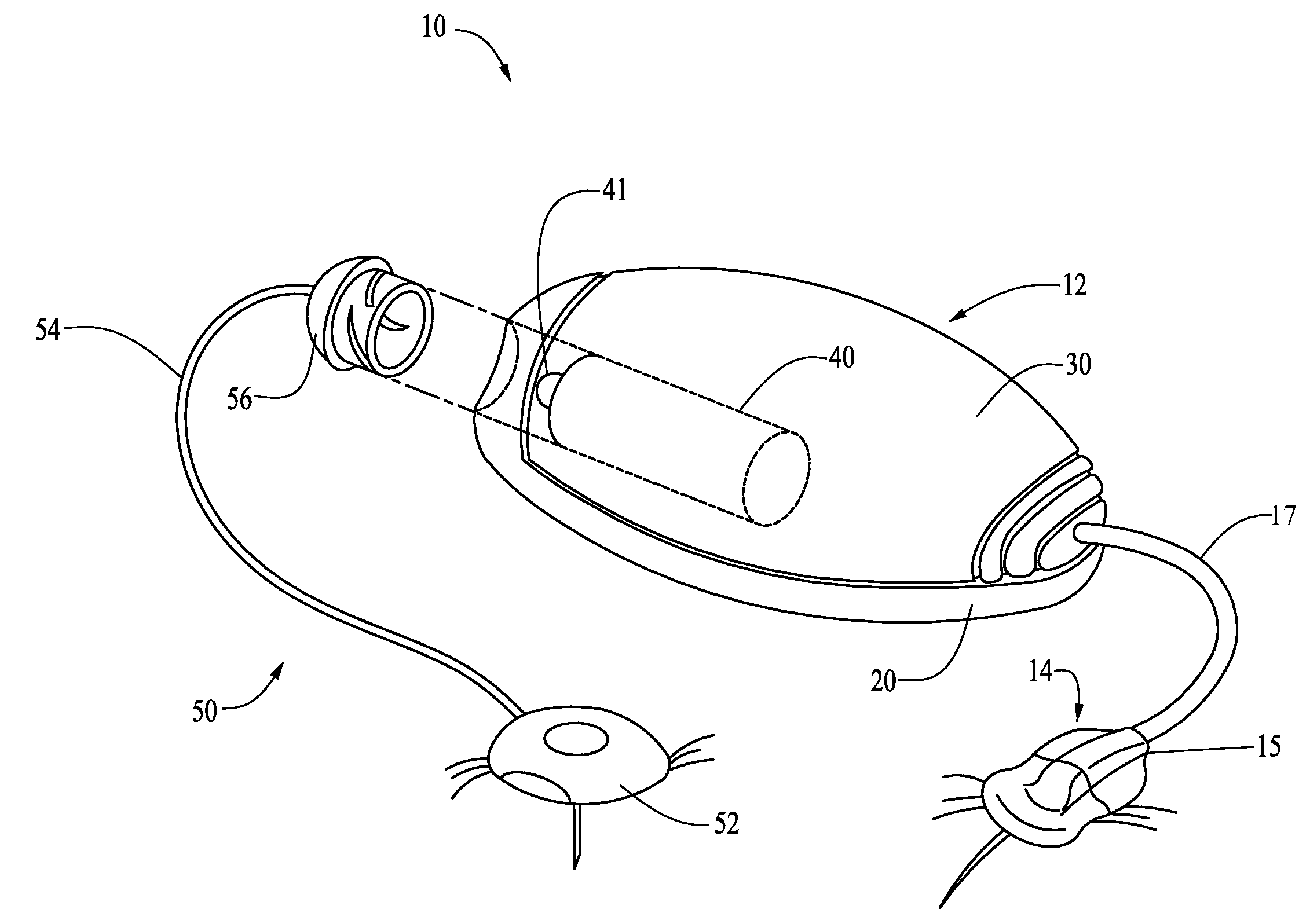

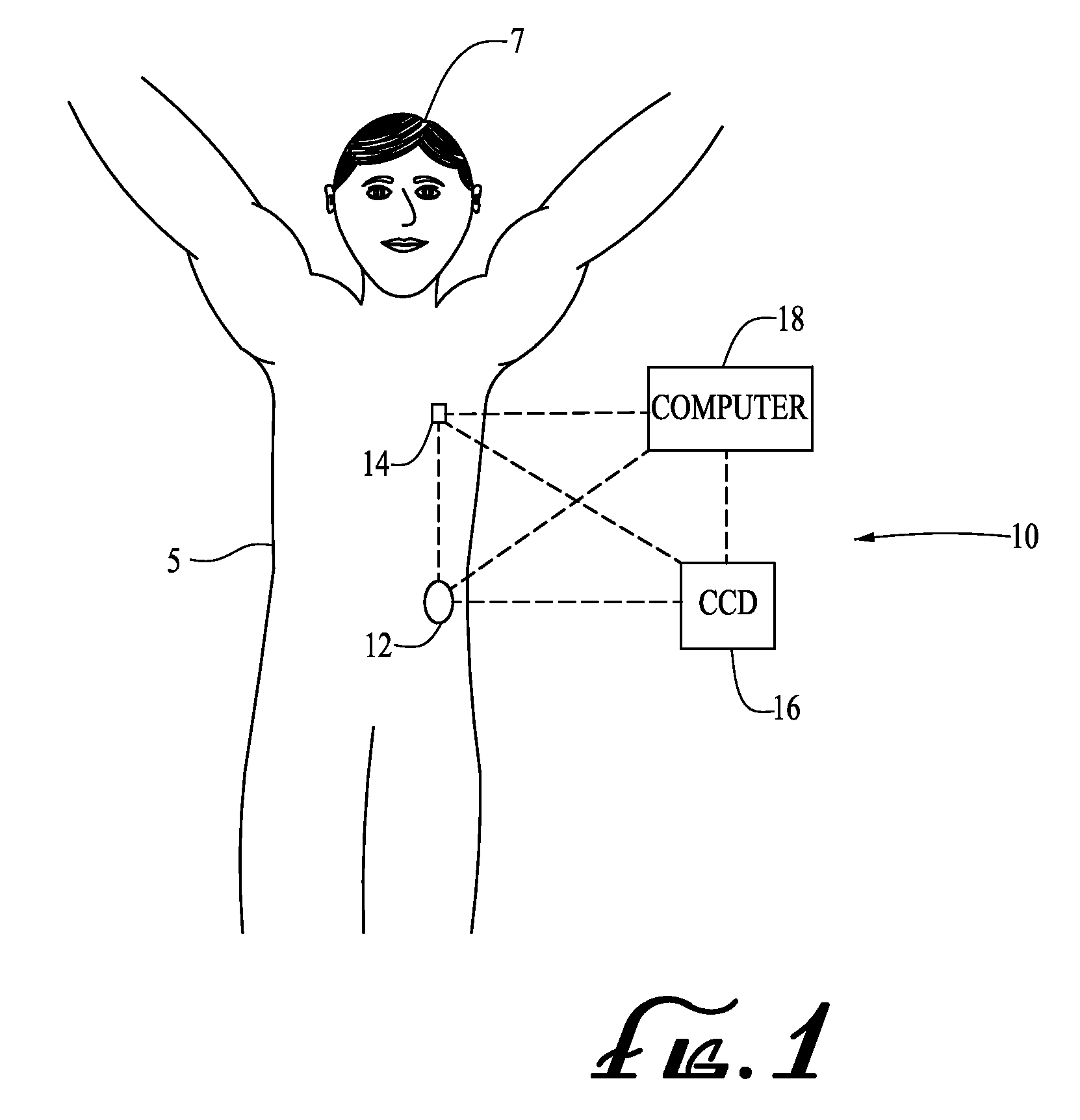

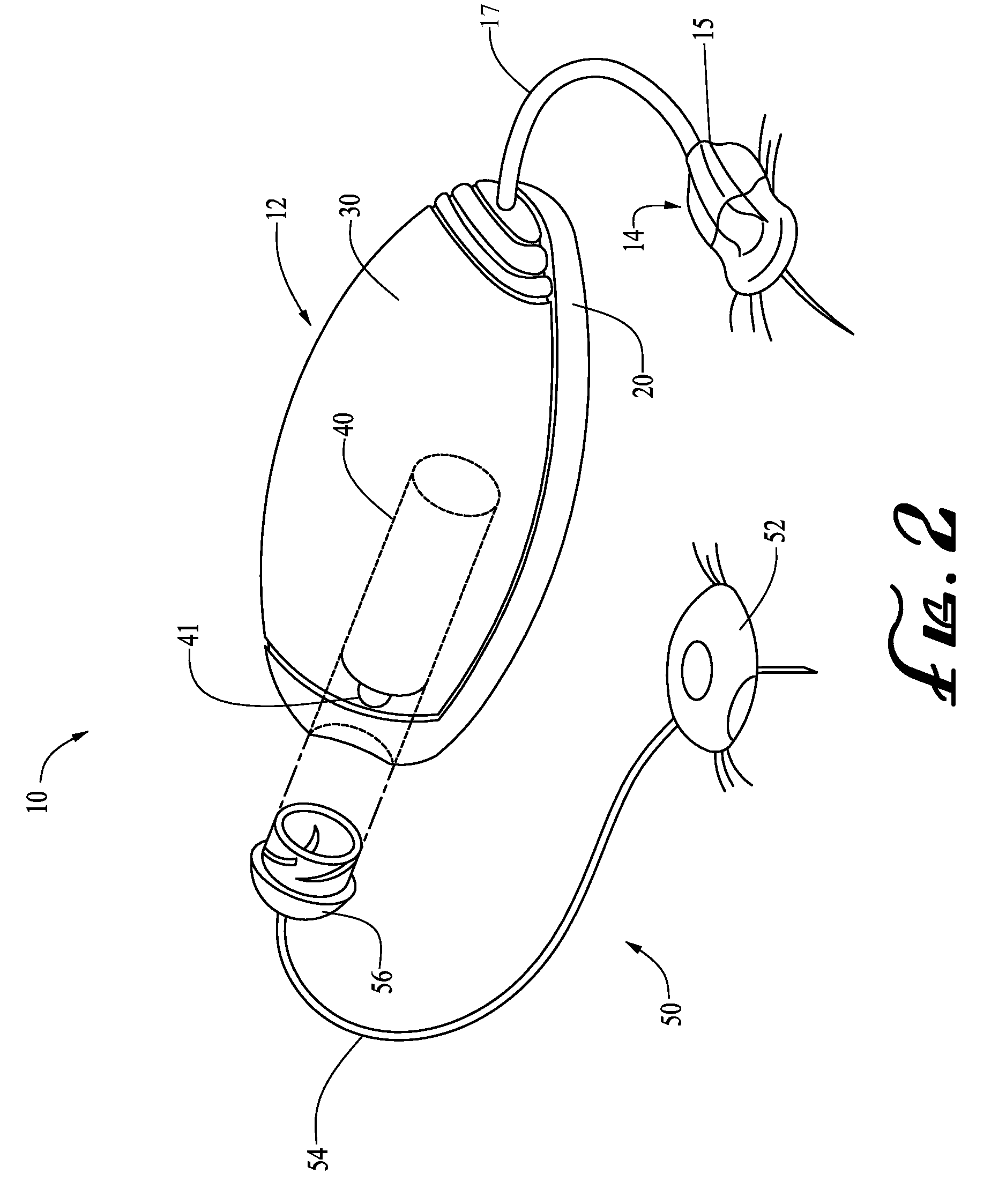

Reservoir barrier layer systems and methods

ActiveUS20090259183A1Reduce retentionAmpoule syringesSynthetic resin layered productsCyclic olefin copolymerBiomedical engineering

A reservoir and a plunger head contained within may be configured to move relative to each other in response to at least one of the reservoir being detached from a base, the base and / or the reservoir being removed from a packaging, and the base and / or the reservoir being moved relative to each other. A first layer may be configured to define a reservoir, the first layer, which may be made of a material compatible with fluidic media in the reservoir, may be adjacent a second layer for inhibiting a diffusion through the second layer. A first layer that may be less than 0.3 mm and made of a cyclic olefin copolymer may be configured to define a reservoir. A reservoir may be defined by a wall made of a cyclic olefin copolymer and the wall may be for substantially preventing light from passing through the reservoir.

Owner:MEDTRONIC MIMIMED INC

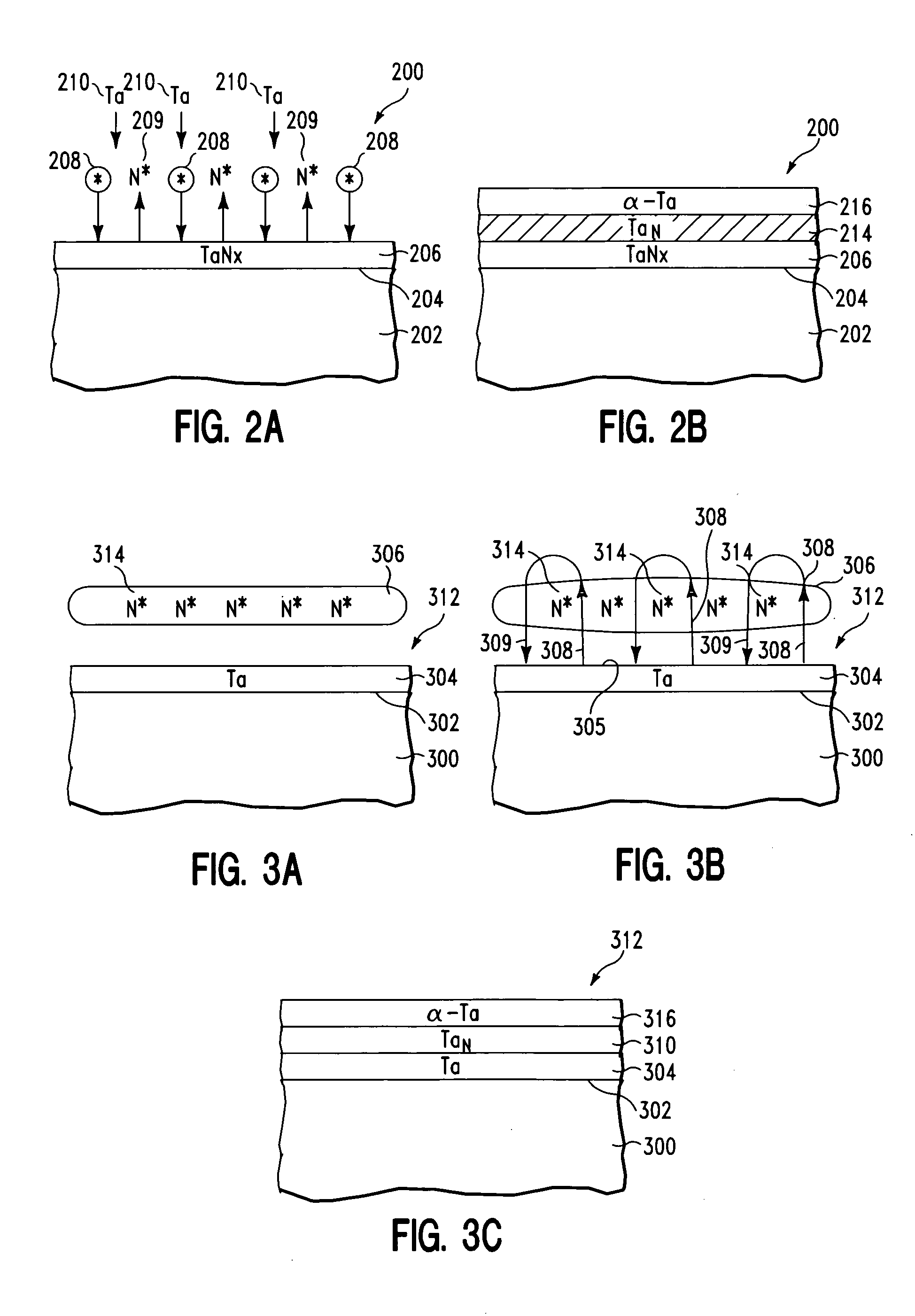

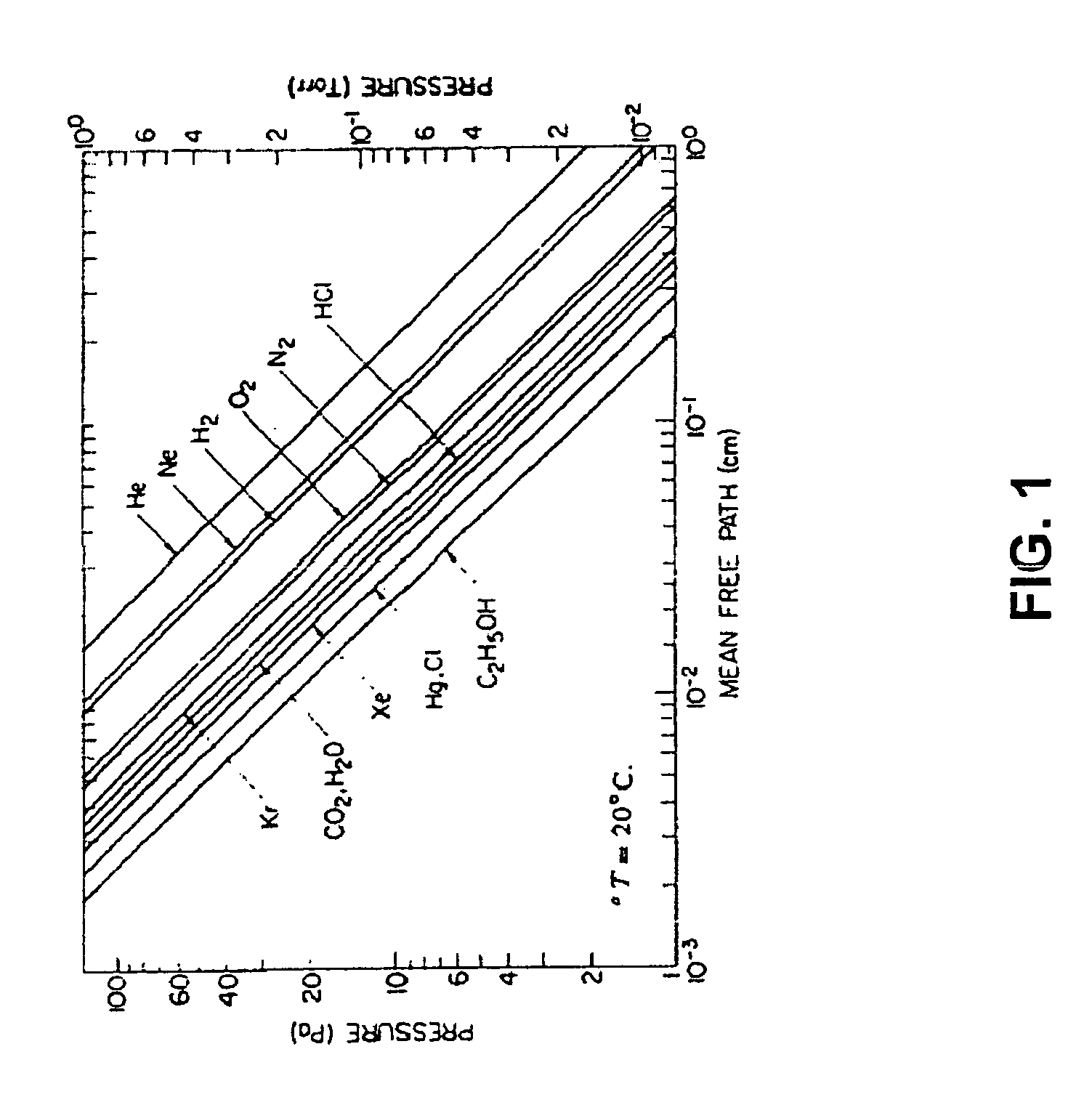

Method of depositing low resistivity barrier layers for copper interconnects

InactiveUS20050272254A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingCopper interconnectPhysical chemistry

We have discovered a method of providing a thin approximately from about 2 Å to about 100 Å thick TaN seed layer, which can be used to induce the formation of alpha tantalum when tantalum is deposited over the TaN seed layer. Further, the TaN seed layer exhibits low resistivity, in the range of 30 μΩ cm and can be used as a low resistivity barrier layer in the absence of an alpha tantalum layer. In one embodiment of the method, a TaN film is altered on its surface form the TaN seed layer. In another embodiment of the method, a Ta film is altered on its surface to form the TaN seed layer.

Owner:APPLIED MATERIALS INC

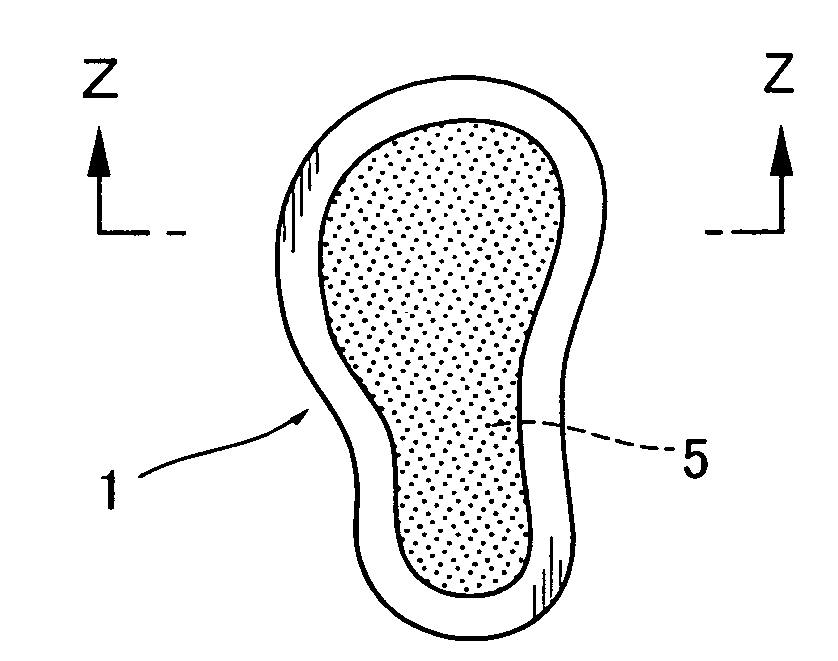

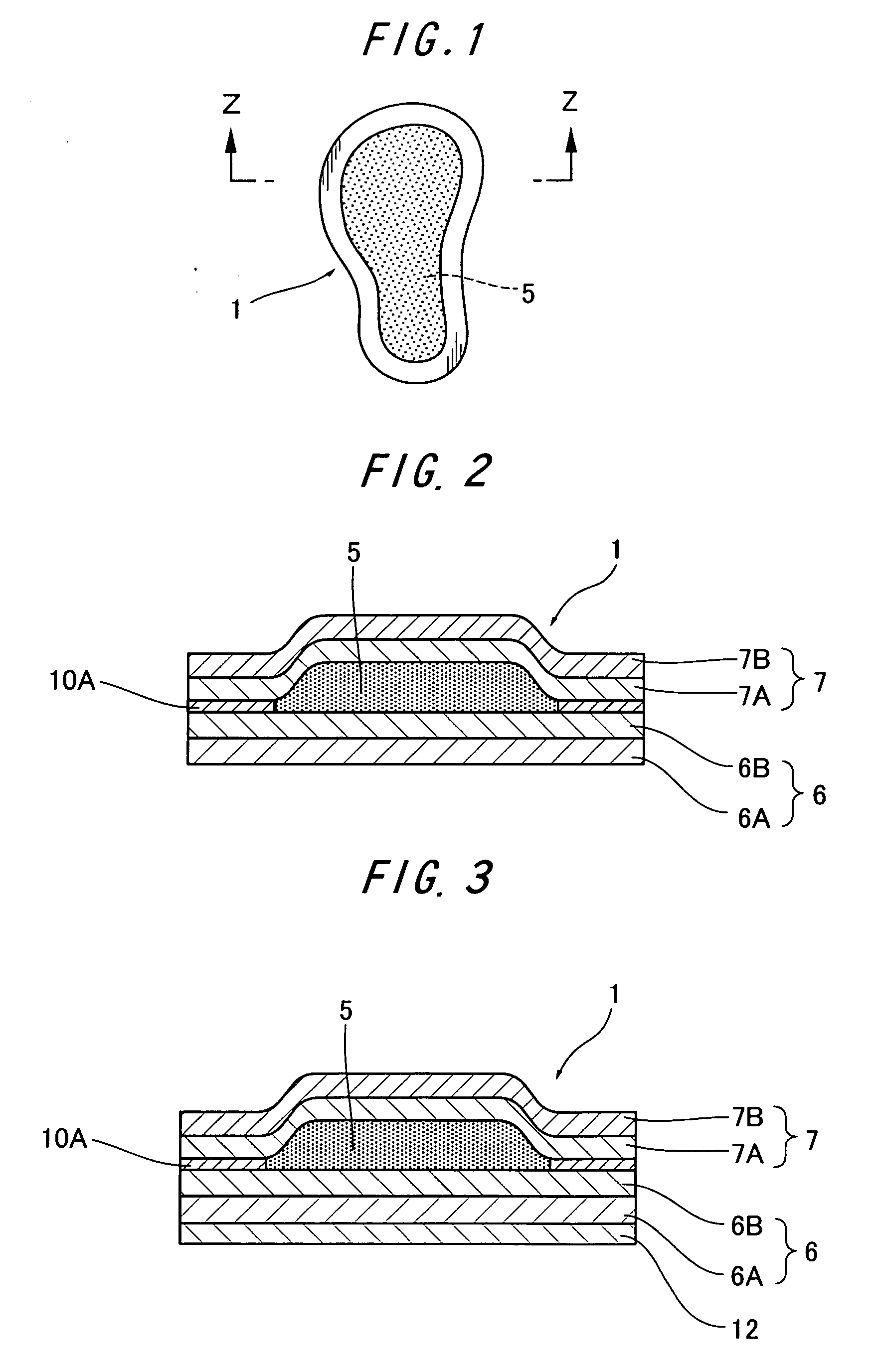

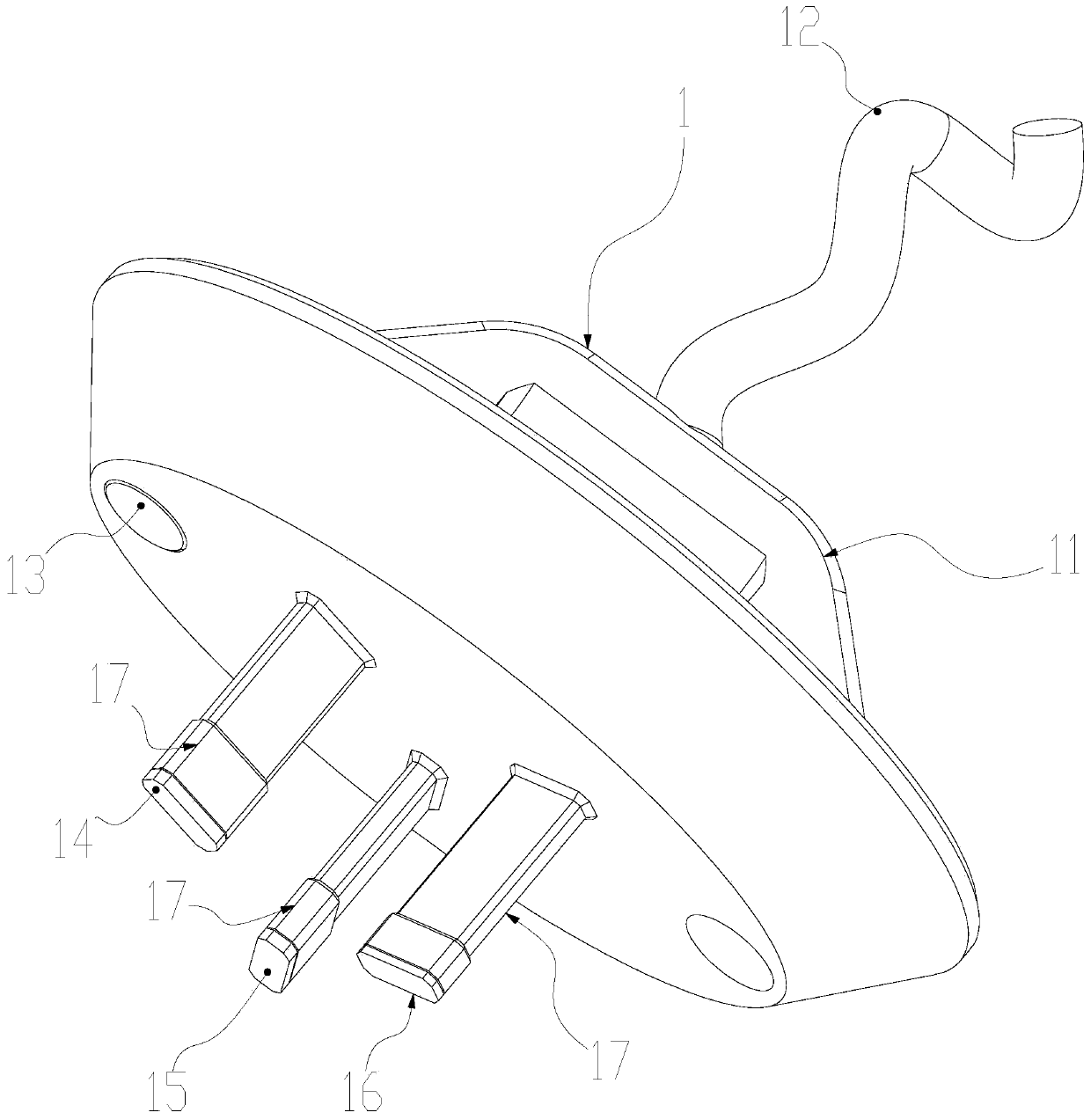

Foot Warming Heat Generating Body and Process for Producing Foot Warming Heat Generating Body

InactiveUS20080257333A1Simple processExothermal chemical reaction heat productionOther heat production devicesShell moldingEngineering

To provide a foot warming heat generating body having excellent shape holding properties and capable of continuing the heat generation over a long period of time by using a heat generating composition having excellent shape holding properties and capable of causing the heat generation without necessity of the removal of water such as water absorption and dehydration by a substrate after molding.The foot warming heat generating body is characterized in that a heat generating composition molded body made of a heat generating composition which contains, as essential components, an exothermic substance, a carbon component, a reaction accelerator and water, has a water mobility value showing a surplus water content of from 0.01 to 20, with the water in the heat generating composition not functioning as a barrier layer, and is capable of causing an exothermic reaction upon contact with air is laminated on a substrate; a covering material is put thereon; the periphery of the heat generating composition molded body is sealed; the heat generating composition molded body has a shape retaining degree of 70 or more; and at least a part of the substrate or the covering material has permeability to air.

Owner:MYCOAL PRODS CORP

Silver barrier layers to minimize whisker growth in tin electrodeposits

InactiveUS20060292847A1Reduce formationHeavy loadSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSurface layerCompound (substance)

The invention relates to a method of reducing tin whisker formation in a plated substrate that includes a surface layer comprising tin. The method includes providing on electroplatable portions of the substrate (a) an underlayer comprising silver or (b) a barrier layer that passes a mechanical load test when the surface layer, after 48 hours of contact with a 1 mm hemispherical tip that carries a load of between 500 to 2000 g, exhibits no whiskers having a length of greater than 5 microns. The underlayer or barrier layer, whichever is present, is provided in a thickness sufficient to prevent formation of intermetallic compounds between the substrate and surface layer so that the surface layer exhibits reduced whisker formation compared to the same surface layer deposited directly upon the substrate. Typically, the underlayer or barrier layer includes 50 to 100% by weight silver or similar ductile material.

Owner:TECHNIC INC

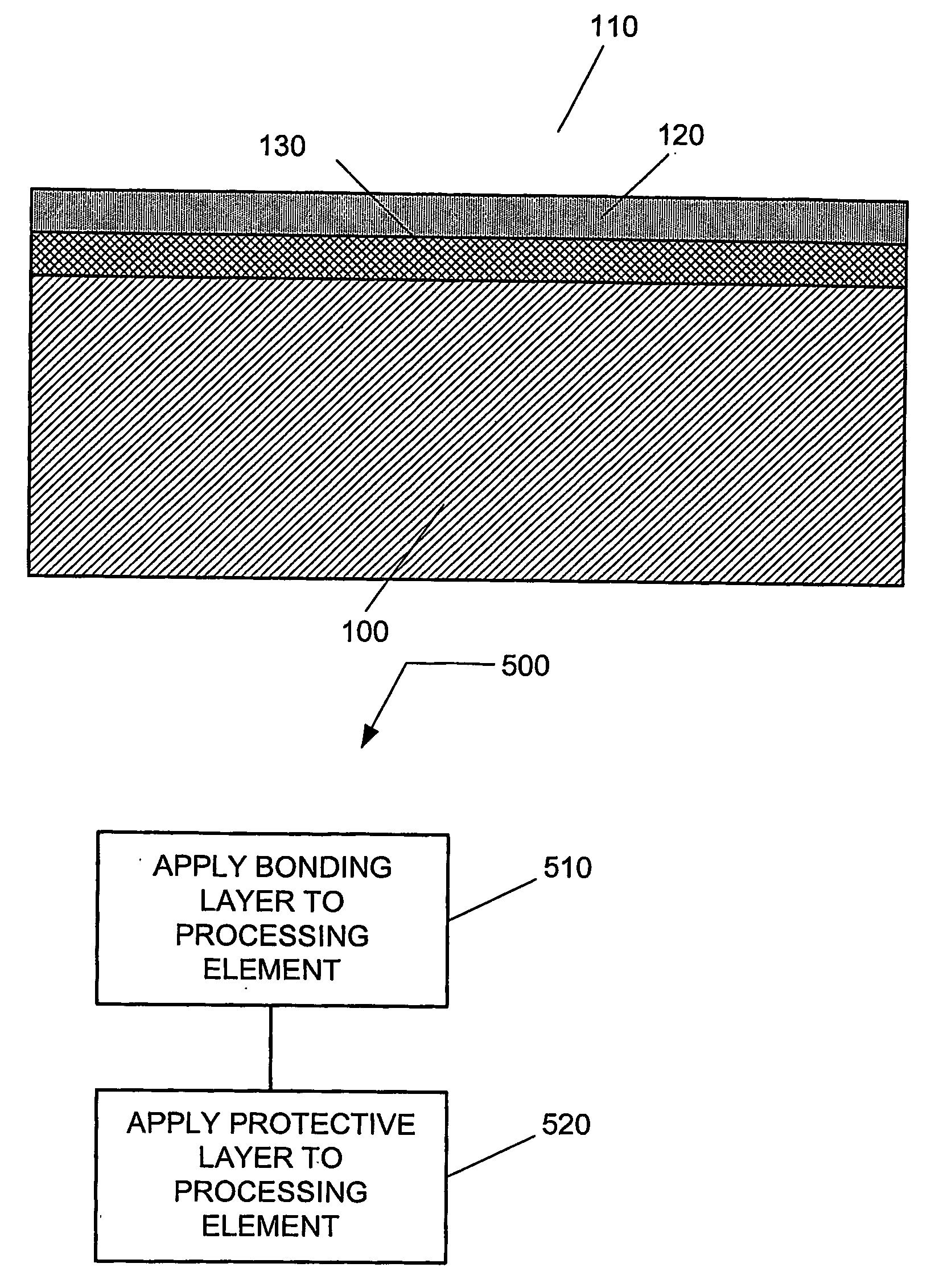

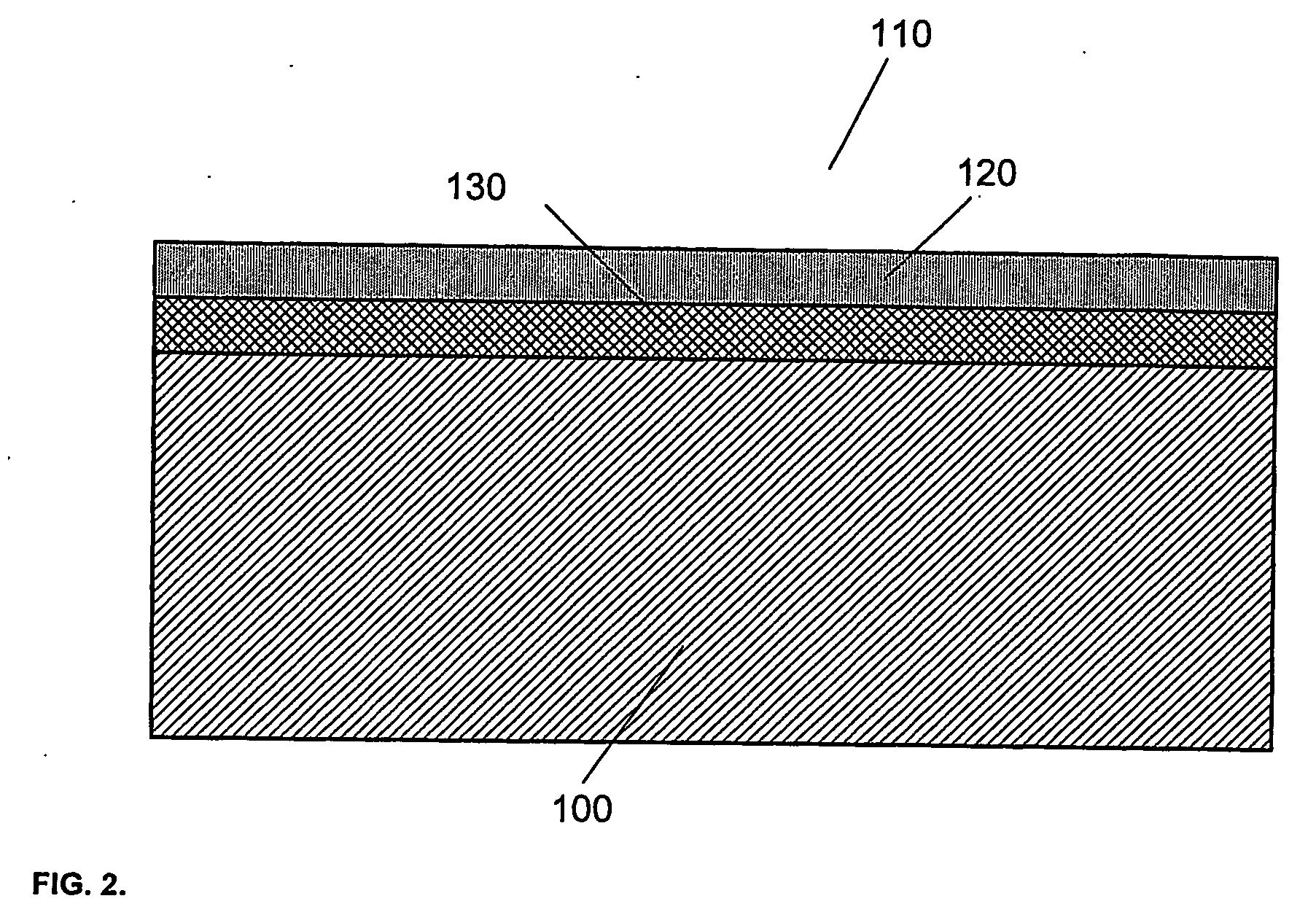

Barrier layer for a processing element and a method of forming the same

ActiveUS20060183344A1Electric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyProcessing element

In order to mitigate erosion of exposed processing elements in a processing system by the process and any subsequent contamination of the substrate in the processing system, processing elements exposed to the process are coated with a protective barrier. The protective barrier comprises a protective layer that is resistant to erosion by the plasma, and a bonding layer that improves the adhesion of the protective layer to the processing element to mitigate possible process contamination by failure of the protective layer.

Owner:TOKYO ELECTRON LTD

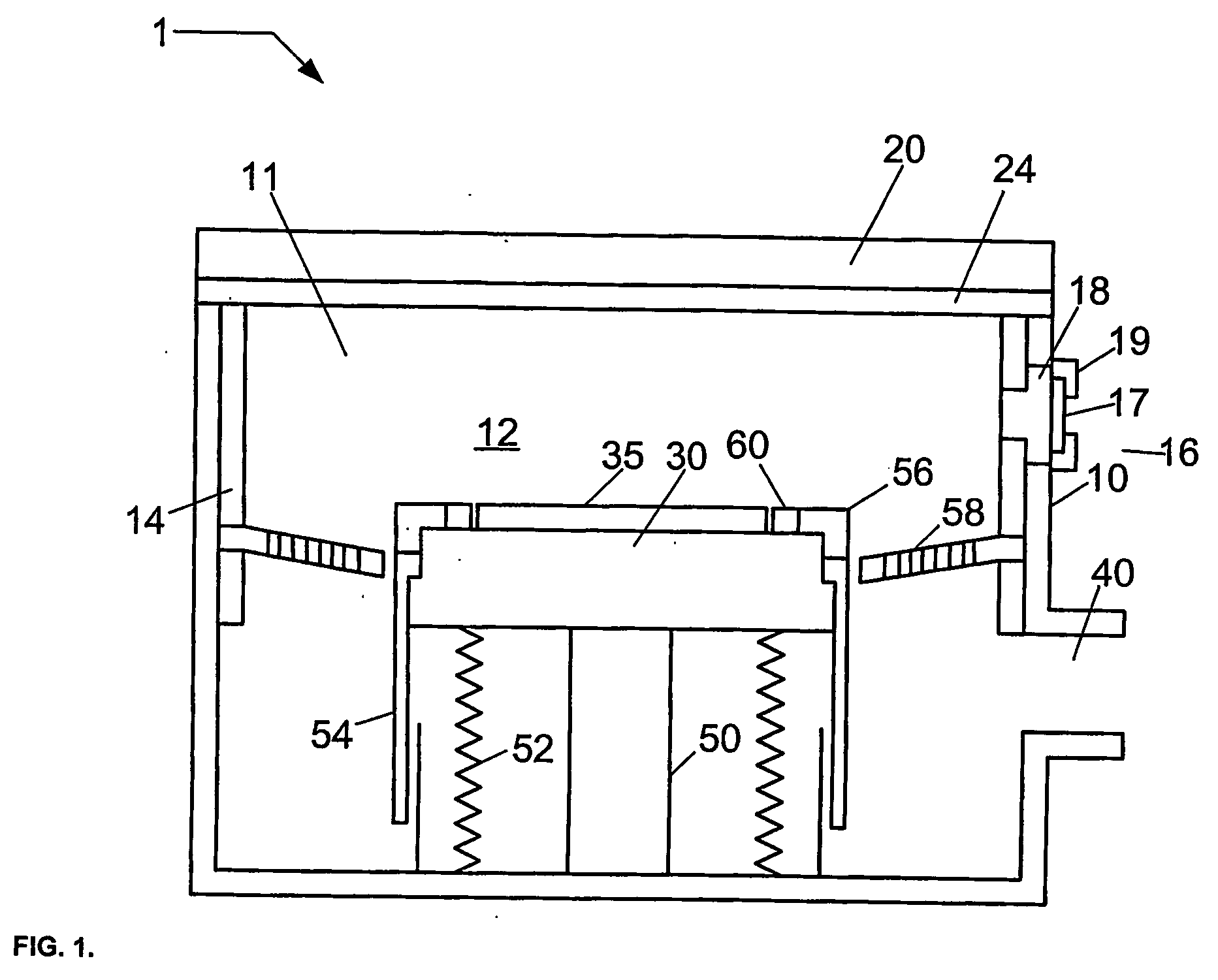

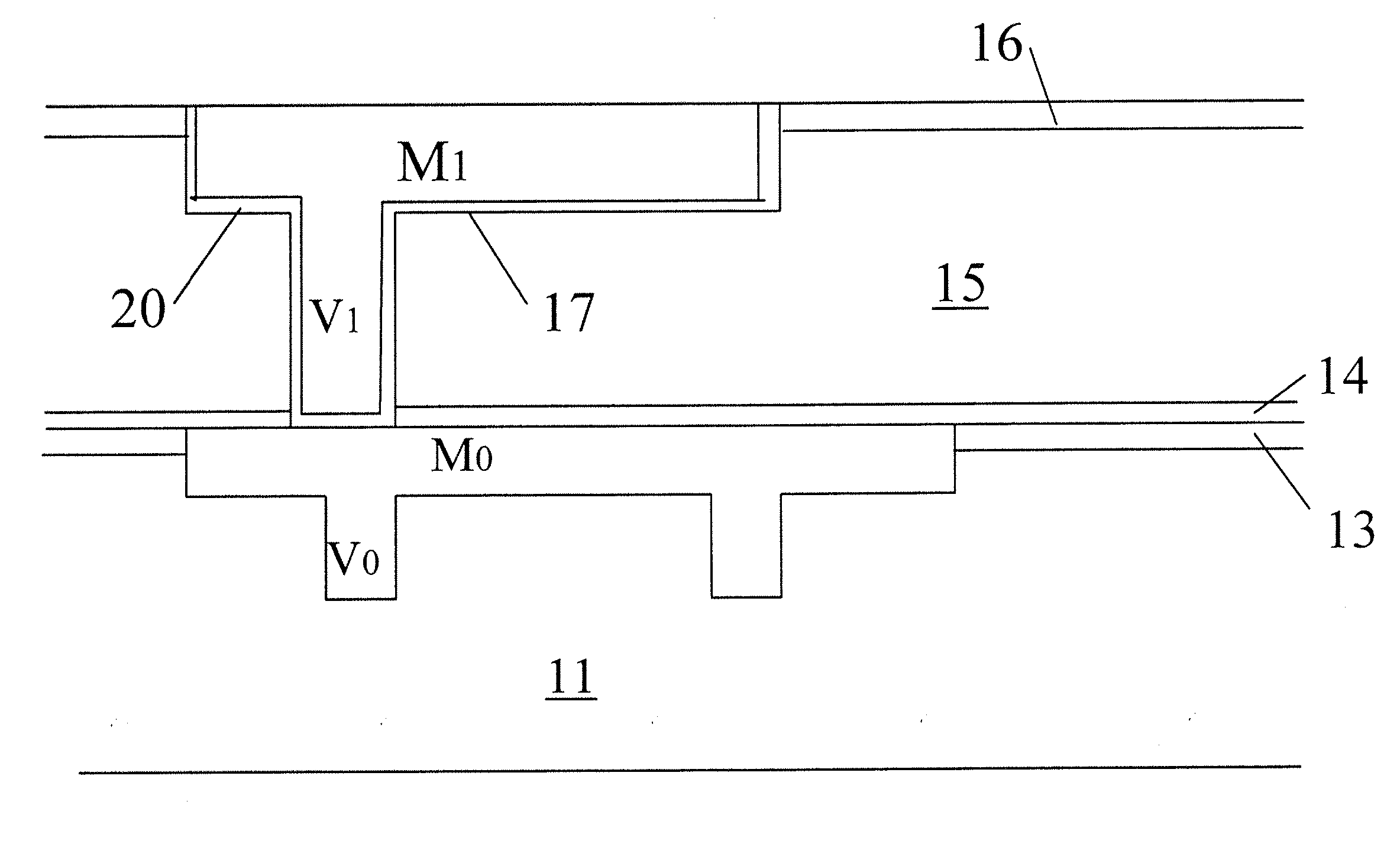

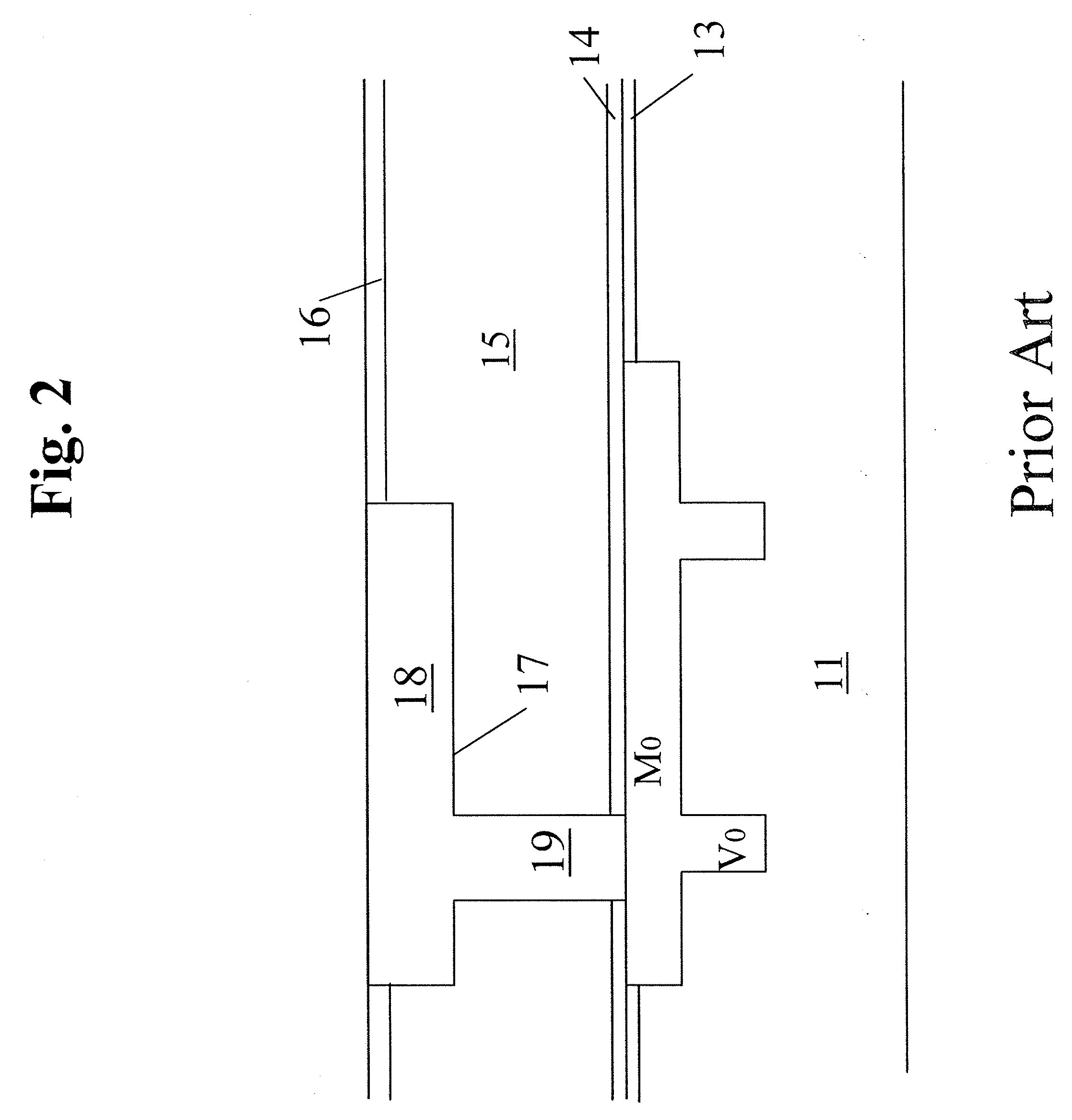

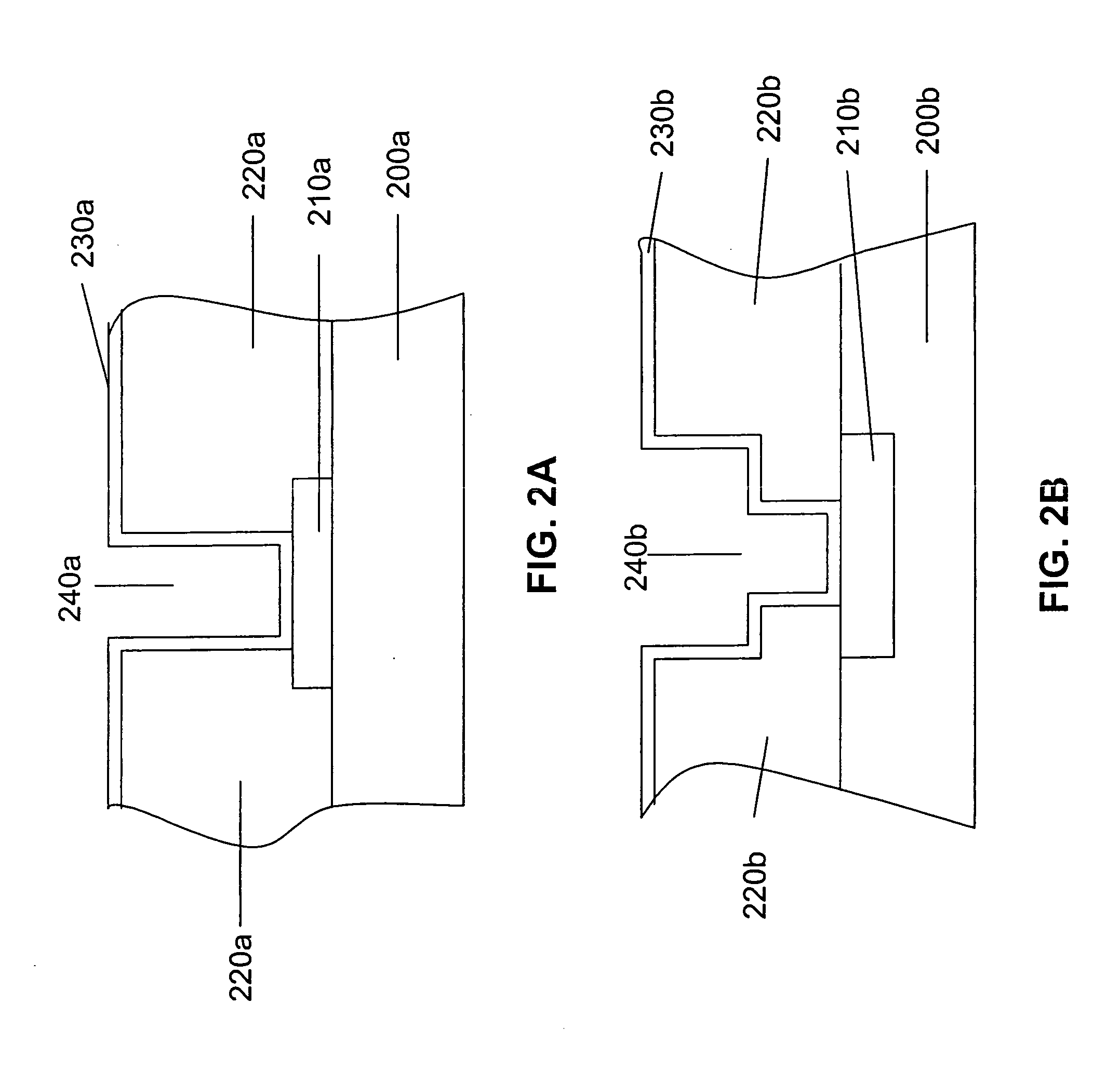

Process for forming a redundant structure

ActiveUS20070111497A1Improve reliabilityImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesMetal stripsEngineering physics

Device and method of fabricating device. The device includes a dual damascene line having a metal line and a via, and a redundant liner arranged to divide the metal line. The method includes forming a trench in a metal stripe of a dual damascene line, depositing a barrier layer in the trench, and filling a remainder of the trench with metal.

Owner:AURIGA INNOVATIONS INC

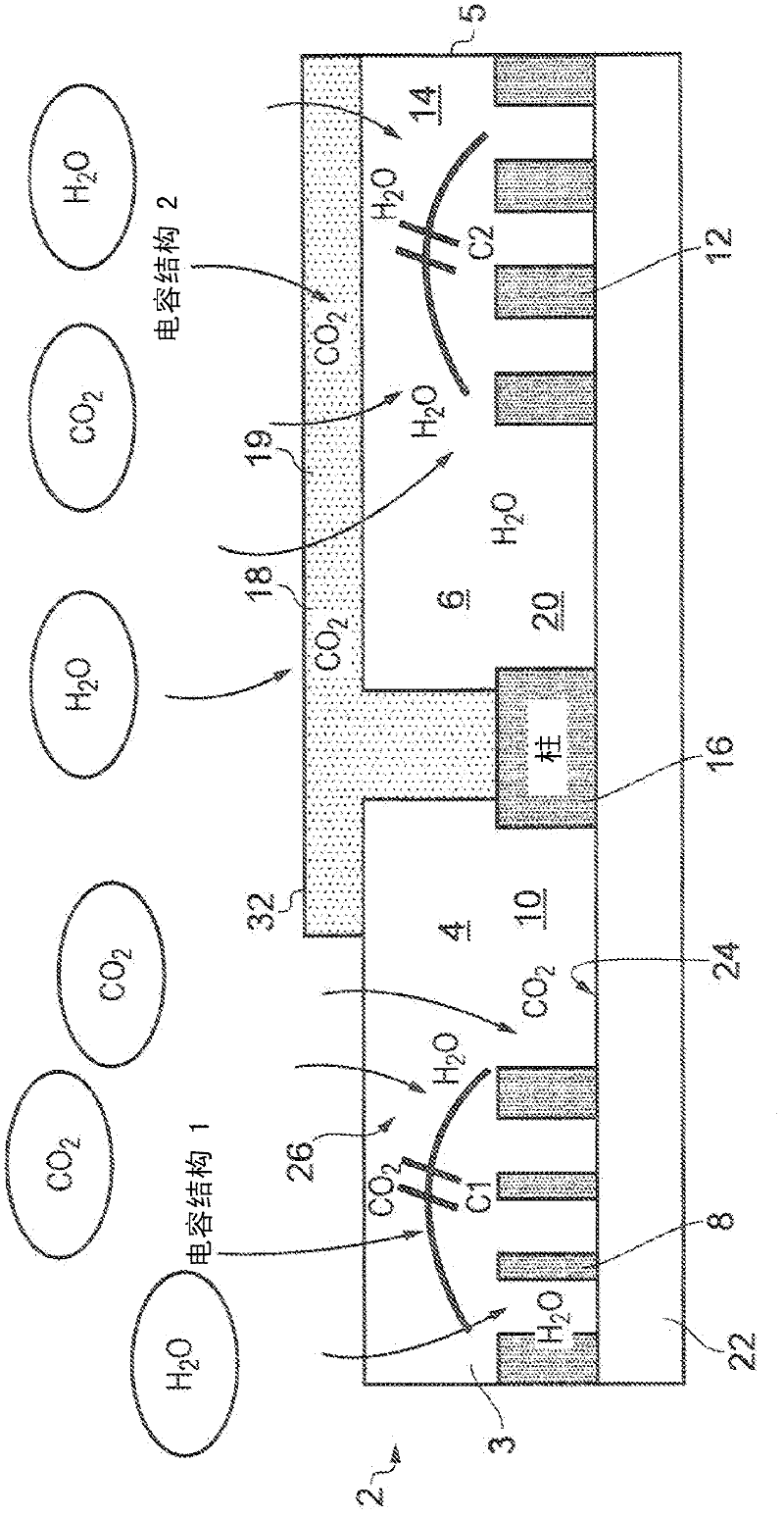

Sensor

ActiveCN102472717AReduce power consumptionLow costGas analyser construction detailsMaterial capacitancePhysicsElectrical and Electronics engineering

A sensor (2) for sensing a first substance and a second substance, the sensor comprising first (3) and second (5) sensor components each comprising a first material (20), the first material being sensitive to both the first substance and the second substance, the sensor further comprising a barrier (18) for preventing the second substance from passing into the second sensor component (5). The barrier layer is preferably composed of a nanocomposite material comprising a nanoclay inserted into a polymide polymore matrix.

Owner:希奥检测有限公司

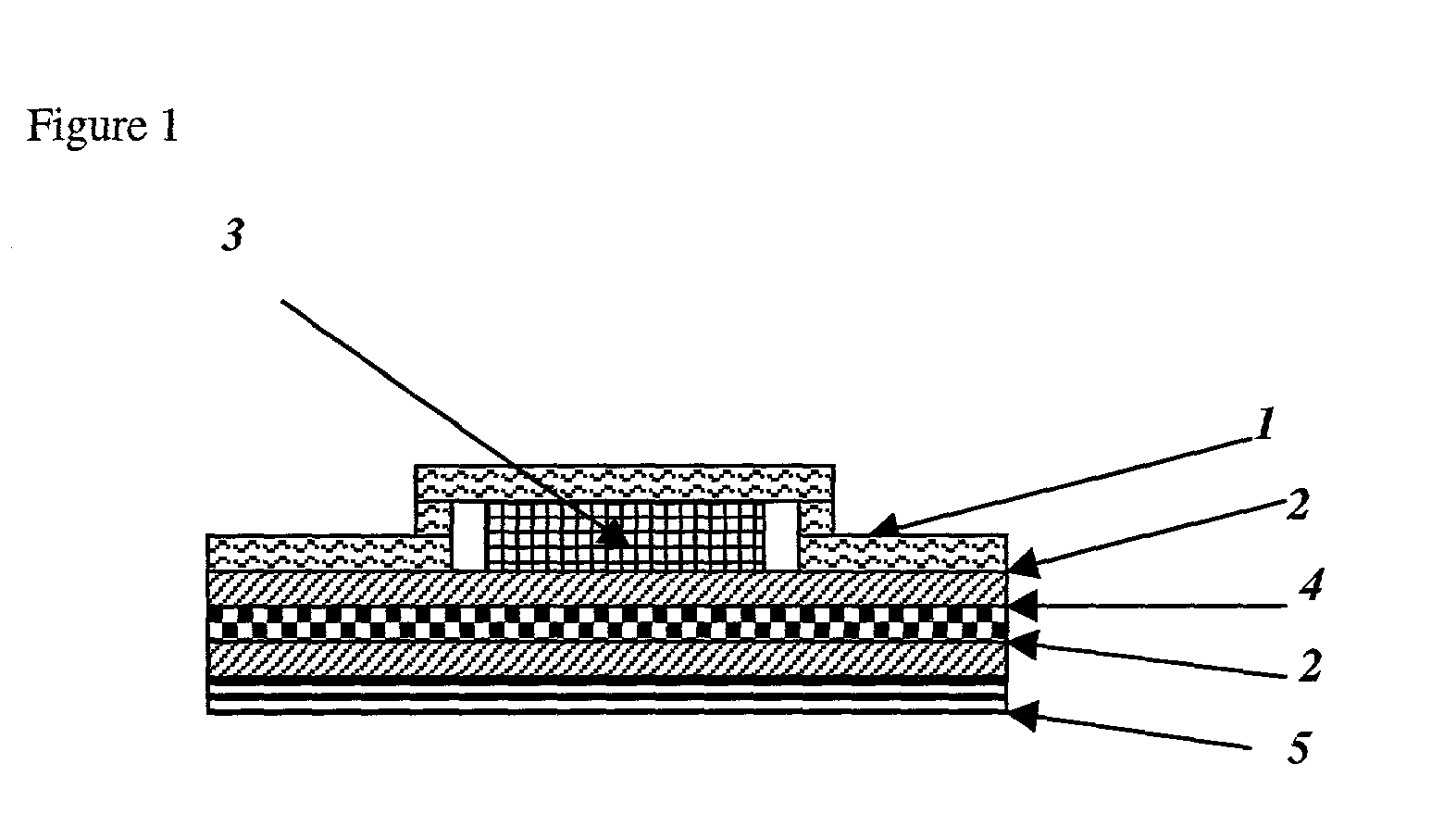

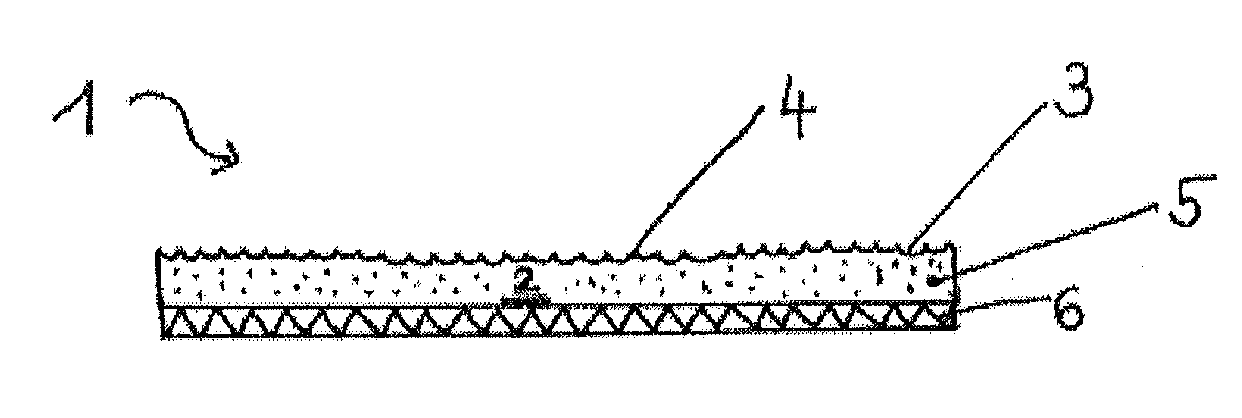

Devices and methods for the release of volatile substances and applications thereof

A patch delivers a volatile substance to an environment. The patch provides the volatile substance within a solid layer positioned between a breathable layer and a barrier layer. A release liner is removably adhered to the barrier layer. The solid layer may be formed by mixing the volatile substance with a liquid agent that forms a solid below 40° C. The liquid mixture is applied to the breathable layer and allowed to solidify. The other layers are added thereto.

Owner:LAVIPHARM +1

Method of controlling growth and heat loss of an in situ gravity draining chamber formed with a condensing solvent process

ActiveUS8434551B2Efficient extractionMaximize efficiencySurveyFluid removalThermodynamicsSolvent based

A solvent based gravity drainage process whereby the vertical growth rate of the chamber is restricted by placing, monitoring and managing a buoyant gas blanket at the top of the vapor chamber. The process reduces the heat loss to the overburden as well as providing a means to preserve a barrier layer of bitumen saturated reservoir sand at the top of the pay zone in reservoirs where there is limited or no confining layer present.

Owner:HATCH LTD

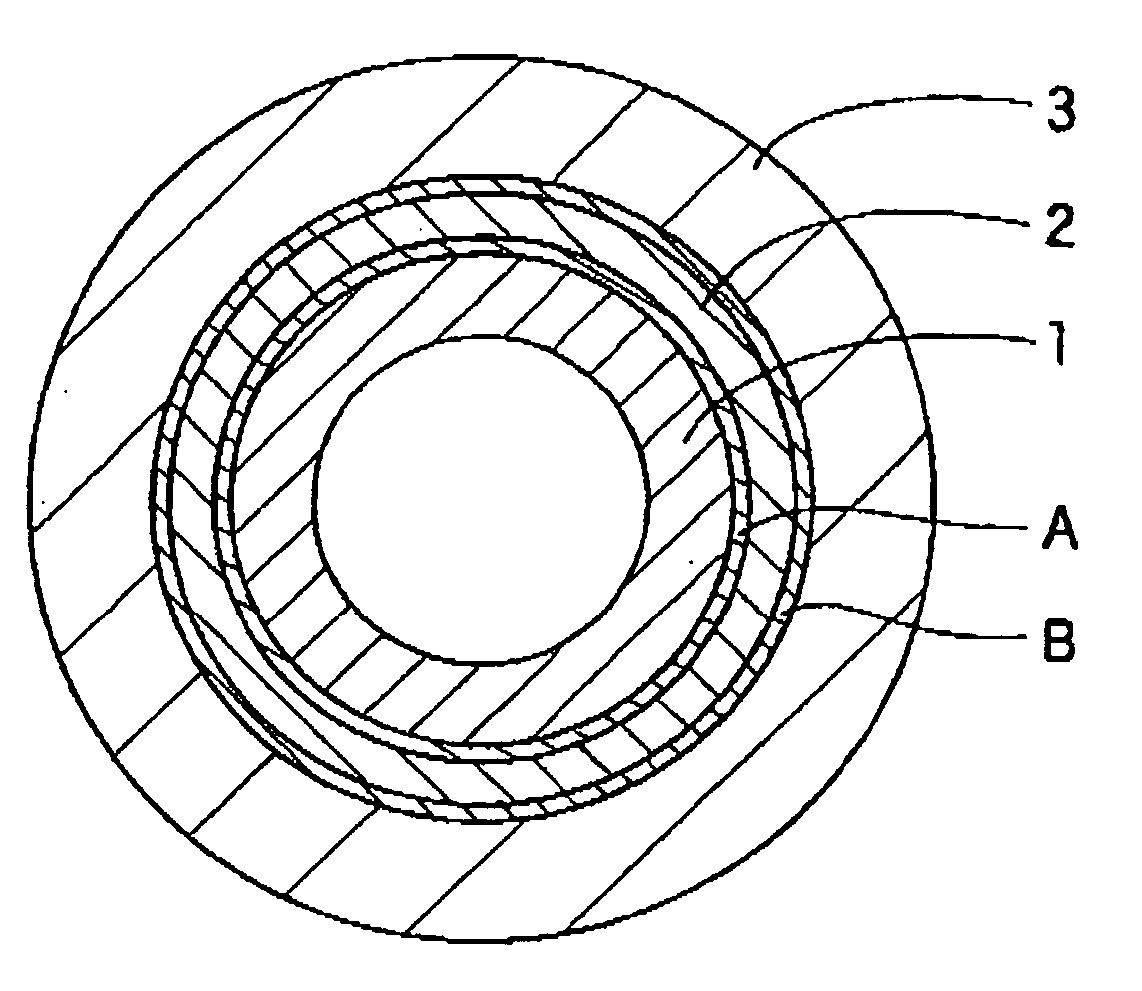

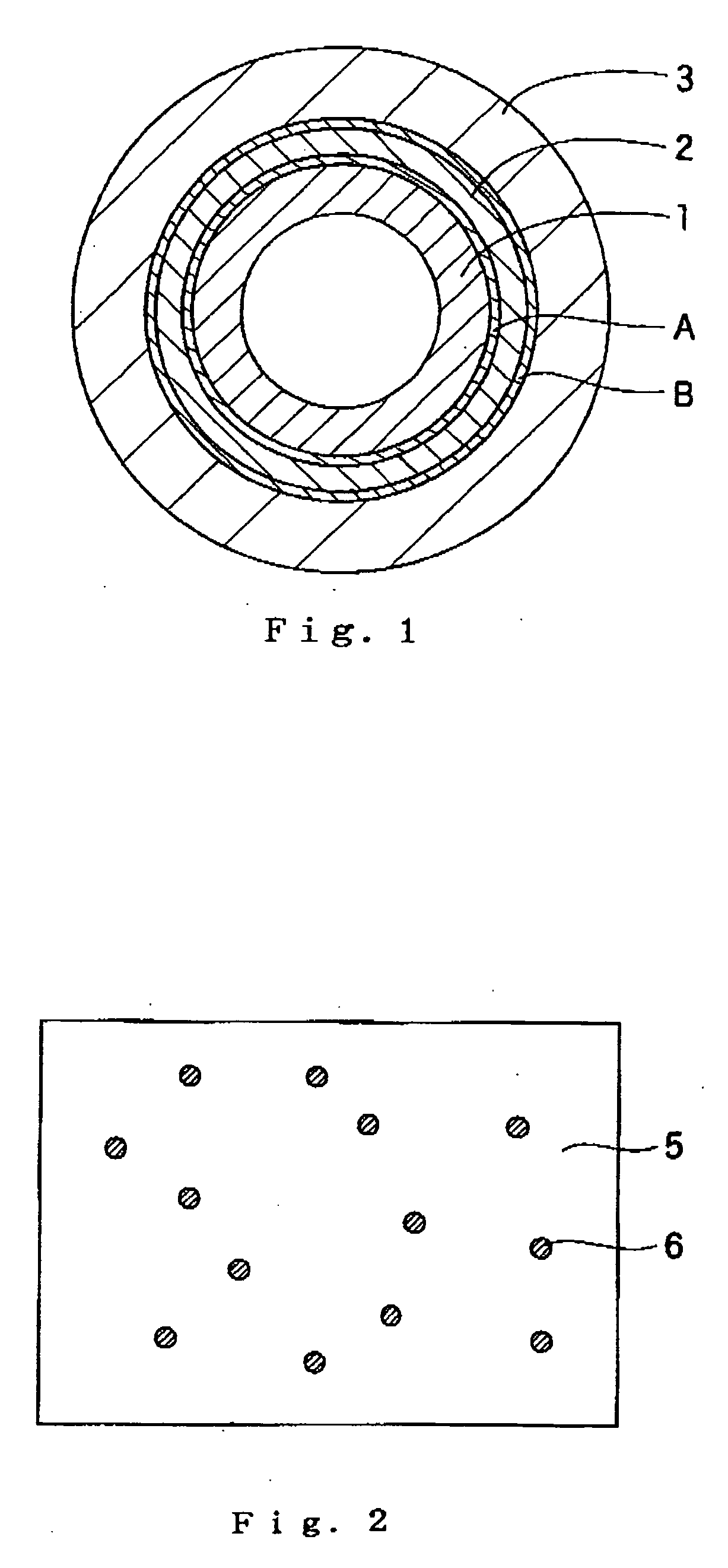

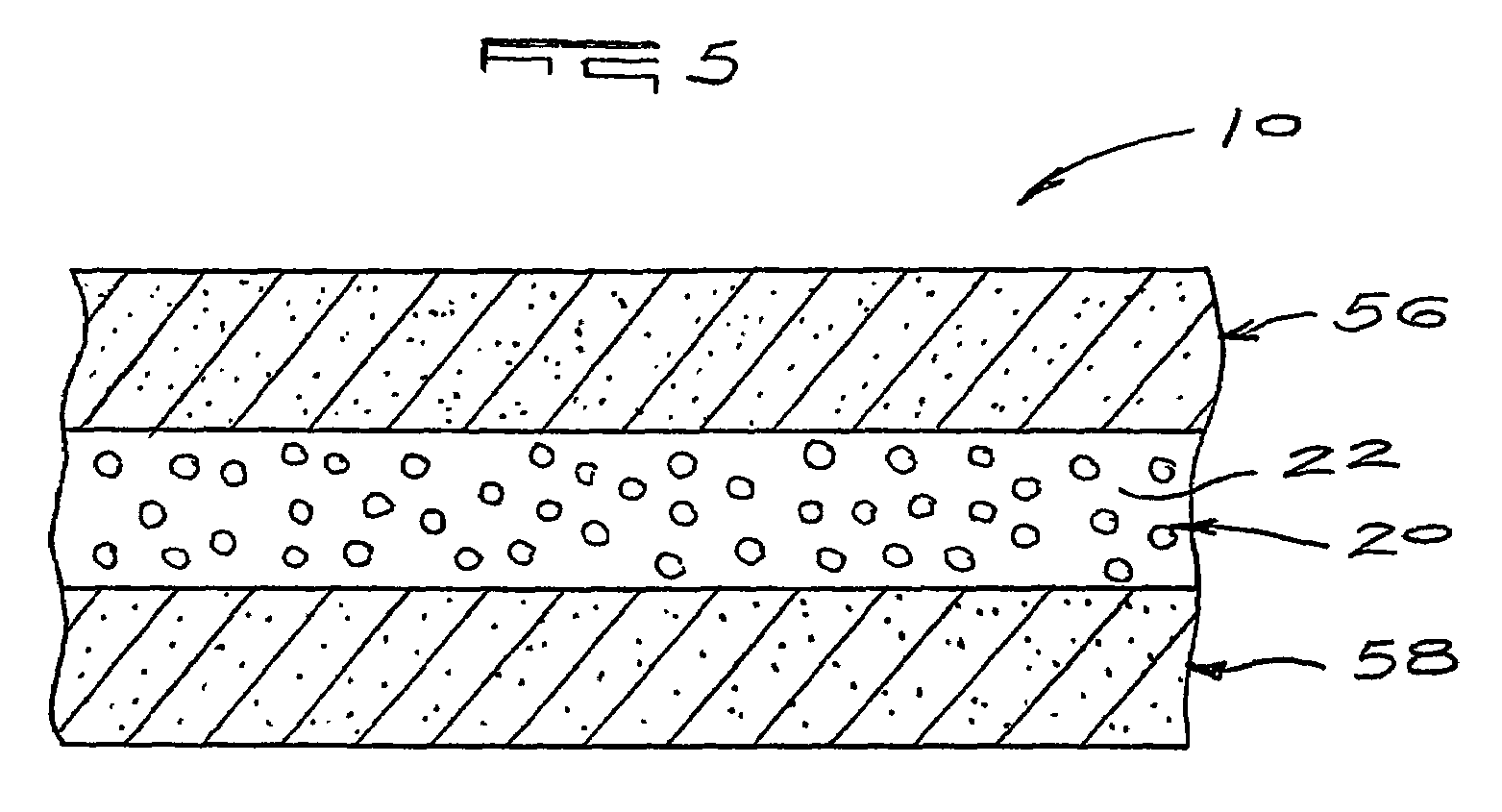

Fuel cell hose

ActiveUS20060191588A1High elongationSynthetic resin layered productsFlexible pipesFuel cellsPolyolefin

A fuel cell hose which is superior in flexibility (low-temperature flexibility) and in barrier performance against hydrogen gas or water without causing a defect such as buckling or cracking at the time of the press-fitting of a connector. The fuel cell hose comprises an inner layer in contact with fluid, a barrier layer formed on an outer peripheral surface of the inner layer and an outer layer formed on an outer peripheral surface of the barrier layer. The inner layer is made of a material (A) containing a polyolefin resin and a styrene-isobutylene block copolymer as essential components, the barrier layer is made of a material (B) containing an ethylene-vinyl alcohol copolymer and a modified polyolefin resin as essential components and the mixing ratio by volume of the ethylene-vinyl alcohol copolymer to the modified polyolefin resin is in the range of 95 / 5 to 30 / 70, and the outer layer is made of a material (C) containing a polyamide resin as an essential component. The barrier layer has an island-sea structure in which island phases composed of the modified polyolefin resin are dispersed in a sea phase composed of the ethylene-vinyl alcohol copolymer.

Owner:SUMITOMO RIKO CO LTD

Thermally developable imaging materials with barrier layer

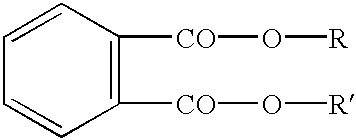

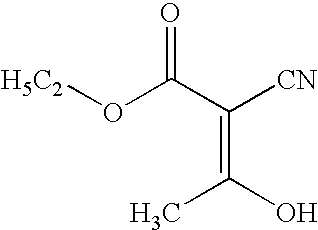

InactiveUS6991894B2Inhibited DiffusionReduces debris buildupX-ray/infra-red processesRadiation applicationsCarboxylic acidDiffusion imaging

Thermographic and photothermographic materials comprise a barrier layer to provide physical protection and to prevent migration of diffusible imaging components and by-products resulting from high temperature imaging and / or development. The barrier layer comprises a scavenger that is a metal hydroxide or ester. This barrier layer is capable of retarding diffusion of mobile chemicals such as organic carboxylic acids, developers, and toners.

Owner:CARESTREAM HEALTH INC

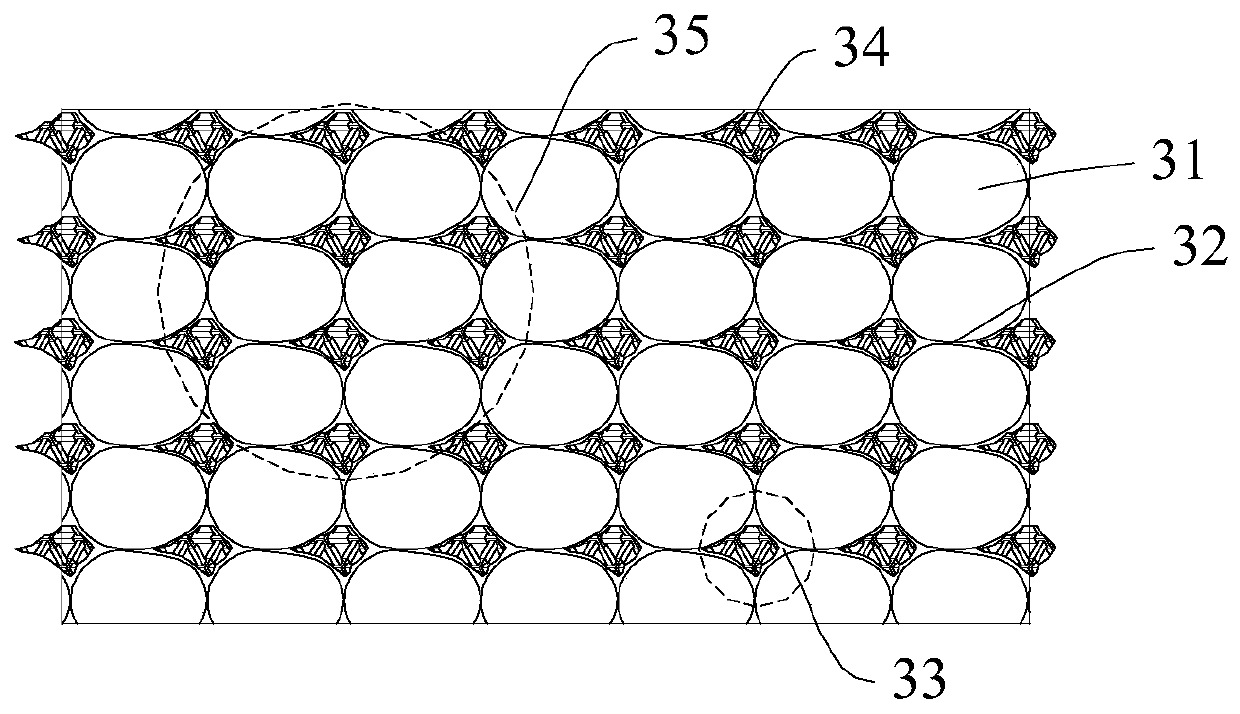

High-barrier all-biodegradable BOPLA film and preparation method thereof

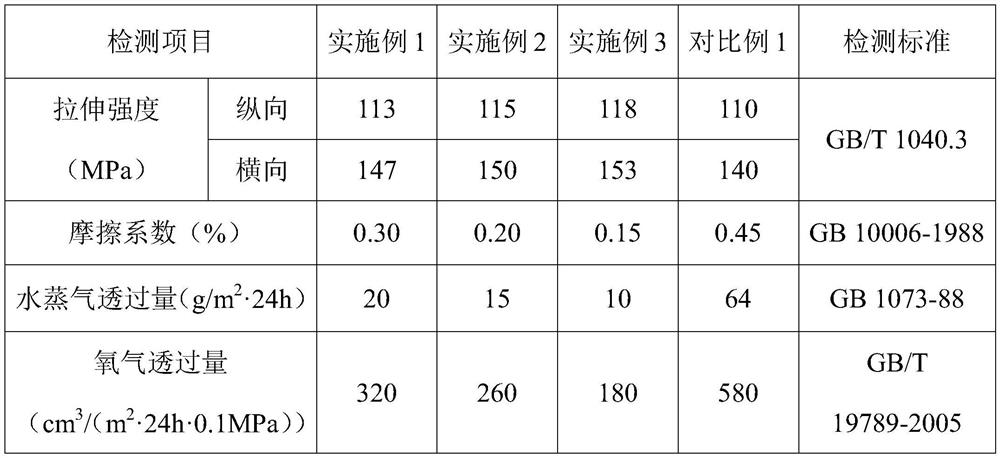

InactiveCN111703166AHigh barrierGood physical and mechanical propertiesSynthetic resin layered productsFlat articlesHydroxybutyric acidPolymer science

The invention discloses a high-barrier all-biodegradable BOPLA film and a preparation method thereof, and relates to the technical field of BOPLA films. The film comprises an upper surface layer, a core layer and a lower surface layer, wherein the upper surface layer is an organic polymer anti-sticking layer and is formed by blending the following components in percentage by weight: 92-95% of polylactic acid slices and 5.0-8.0% of organic polymer anti-sticking master batch; the core layer is a quaternary compound polylactic acid layer and is prepared by blending the following components in percentage by weight: 45 to 80 percent of polylactic acid slices, 3 to 30 percent of polycaprolactone, 3 to 30 percent of polypropylene carbonate and 3 to 30 percent of poly 3-hydroxybutyrate; the lowersurface layer is a barrier layer and is prepared by blending the following components in percentage by weight: 65-75% of polylactic acid slices and 25-35% of polyhydroxybutyrate-hydroxyvaleric acid copolyester. The BOPLA film prepared by the method is excellent in physical and mechanical performance indexes, has high barrier property, can be quickly and completely biodegraded in a specific environment, effectively eliminates white pollution and marine plastic pollution, and is green and environment-friendly.

Owner:ANHUI GUOFENG PLASTIC

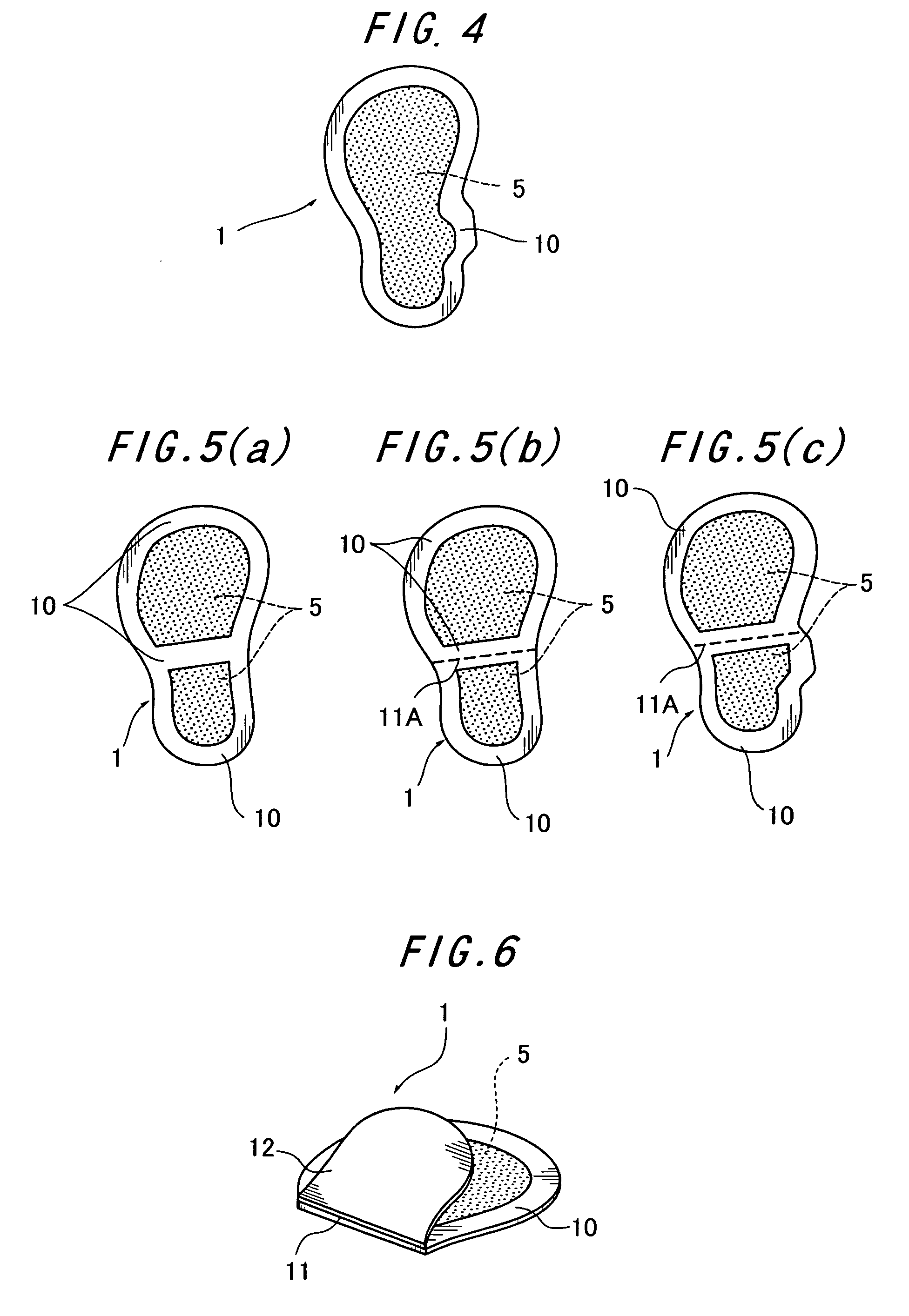

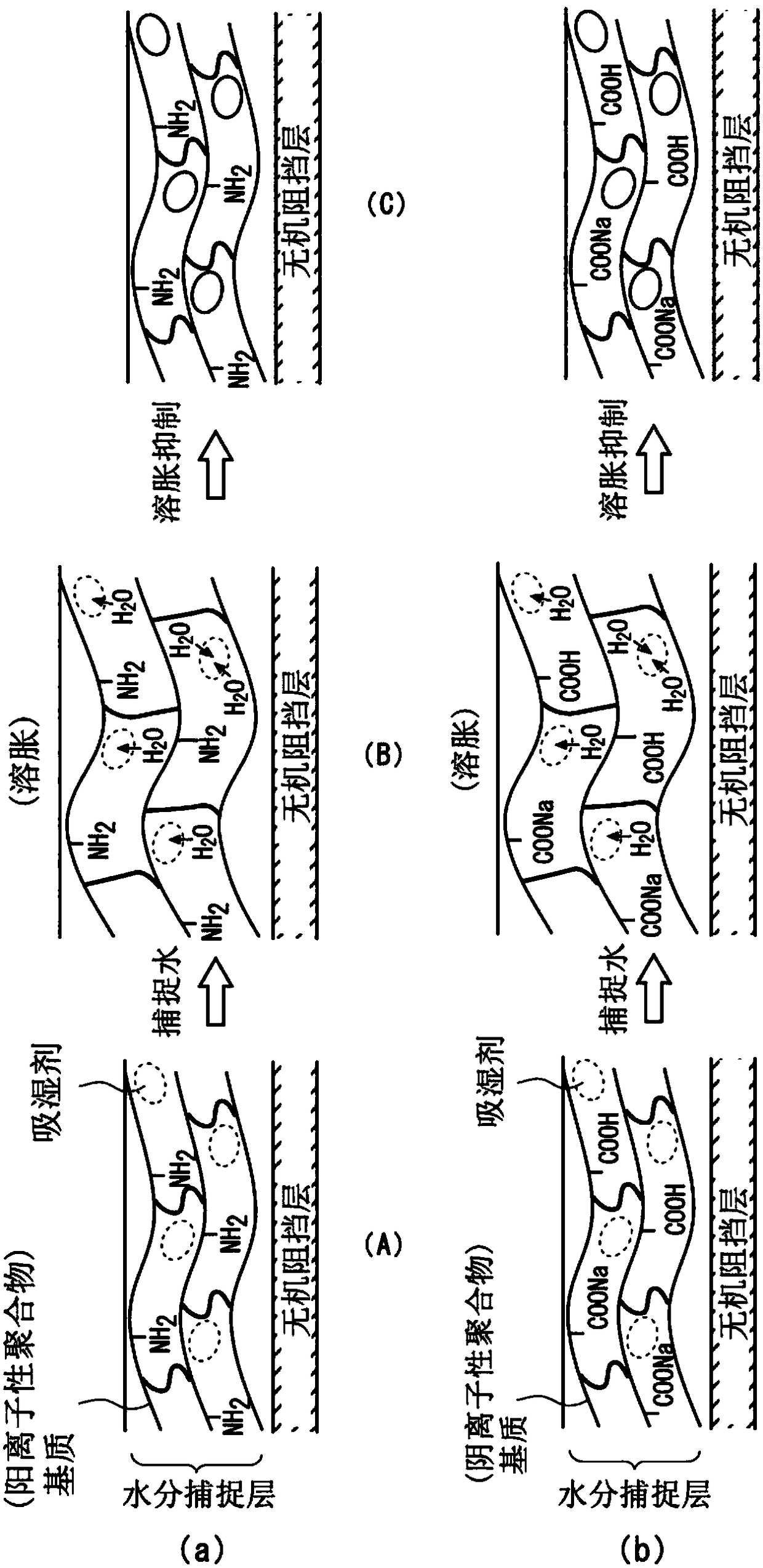

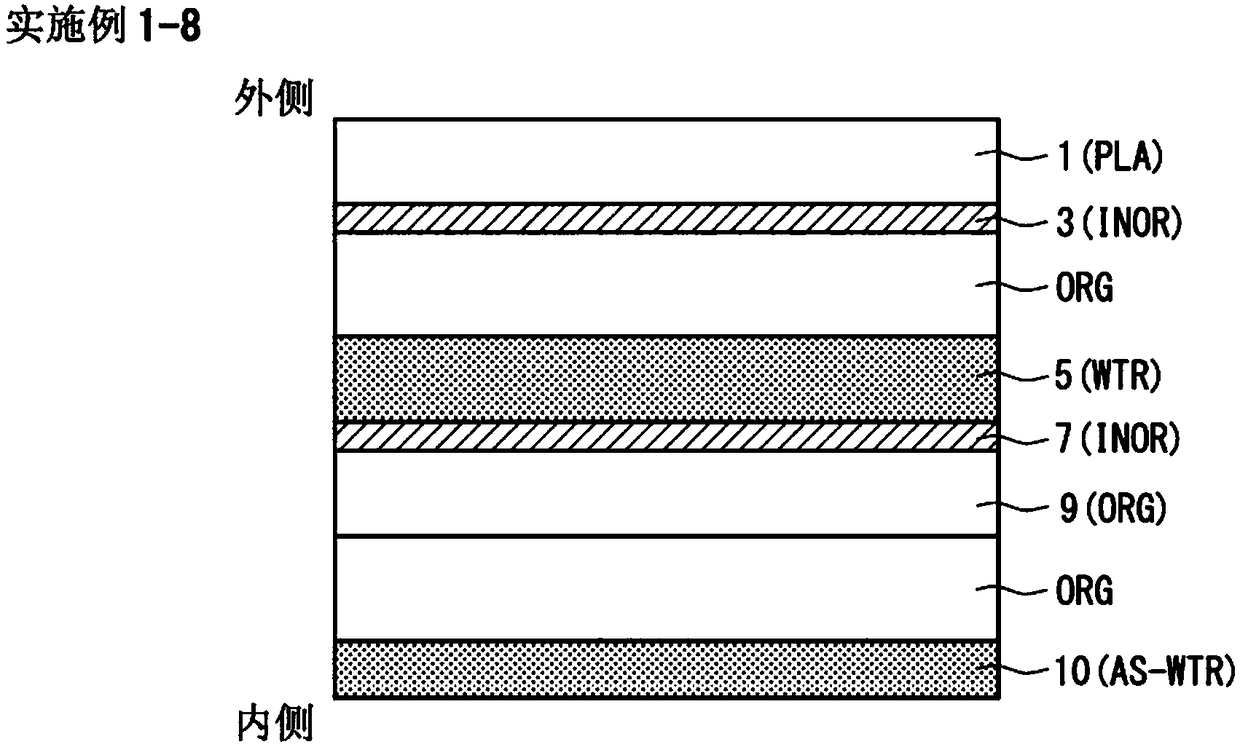

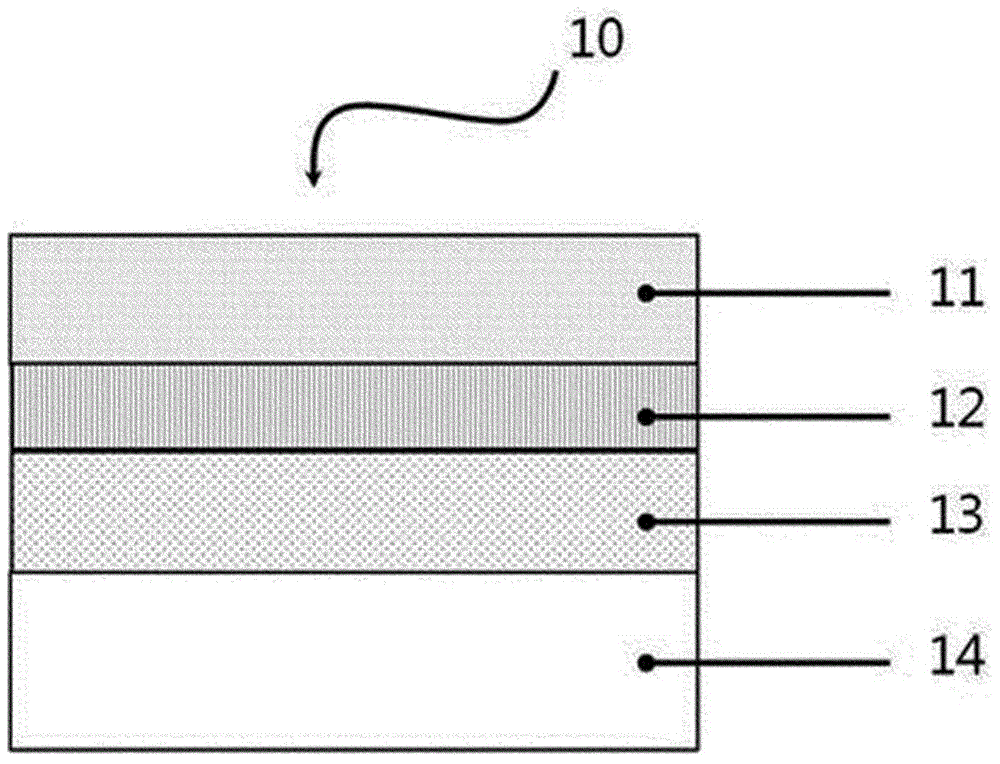

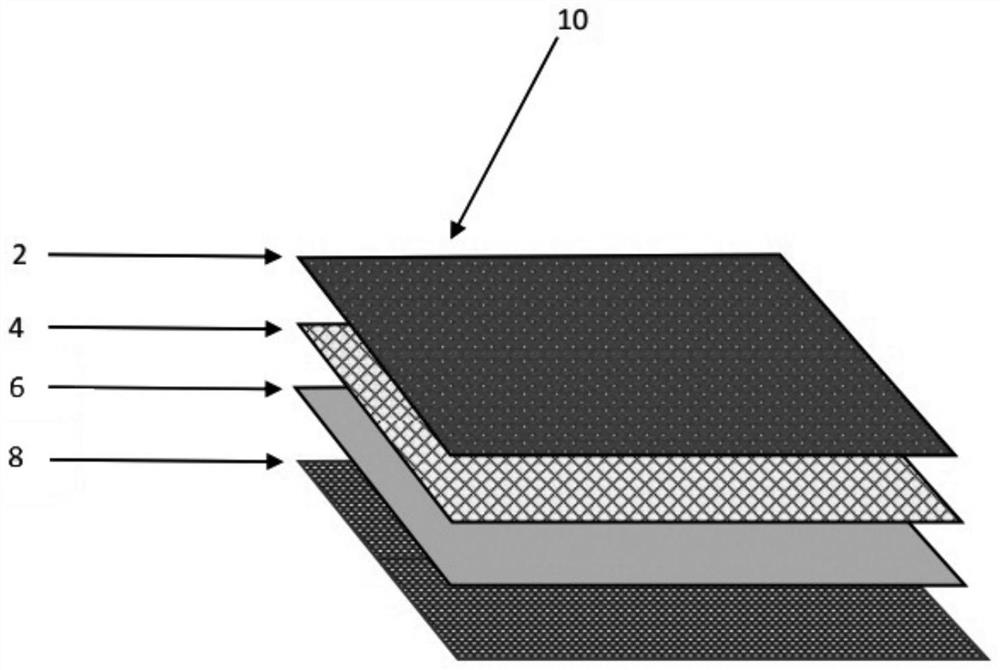

Laminate having moisture barrier properties

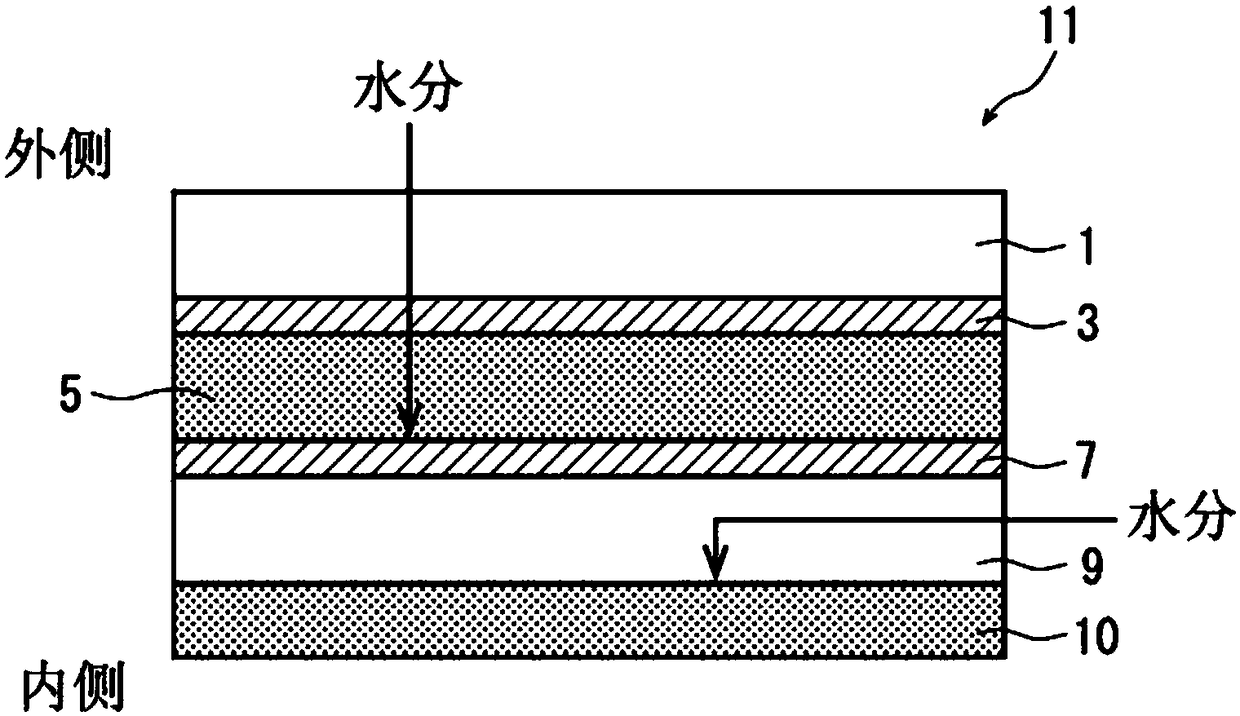

ActiveCN108136727APrevent infiltrationEffectively cut off inflowElectroluminescent light sourcesSynthetic resin layered productsSoil scienceHigh water content

A water barrier laminate 11 including a plastic base material 1 that faces the atmosphere of a high water content, as well as a first inorganic barrier layer 3, a water-trapping layer 5 and a second inorganic barrier layer 7 formed in this order on the plastic base material 1 on the side that does not face the atmosphere of the high water content, wherein an auxiliary water-trapping layer 10 is formed on the second inorganic barrier layer 7 on the side opposite to the water-trapping layer 5 to trap the water from the side surface, the auxiliary water-trapping layer 10 being located on the surface that faces the atmosphere of a low water content or being located in a region at a distance of not more than 20 microns from the surface that faces the atmosphere of the low water content.

Owner:TOYO SEIKAN GRP HLDG LTD

Barrier layer and fabrication method thereof

InactiveUS20060068604A1Semiconductor/solid-state device detailsSolid-state devicesMetallurgyWorking pressure

A barrier layer and a fabrication thereof are disclosed. The barrier layer comprises at least one barrier material selected from the group consisting of Ta, W, Ti, Ru, Zr, Hf, V, Nb, Cr and Mo and at least one component of oxygen, nitrogen or carbon. A ratio of the component to the barrier material is not less than about 0.45. The fabrication method of the barrier layer applies a working pressure for forming the barrier layer from about 0.5 mTorr to about 200 mTorr substantially without forming crystalline material therein.

Owner:TAIWAN SEMICON MFG CO LTD

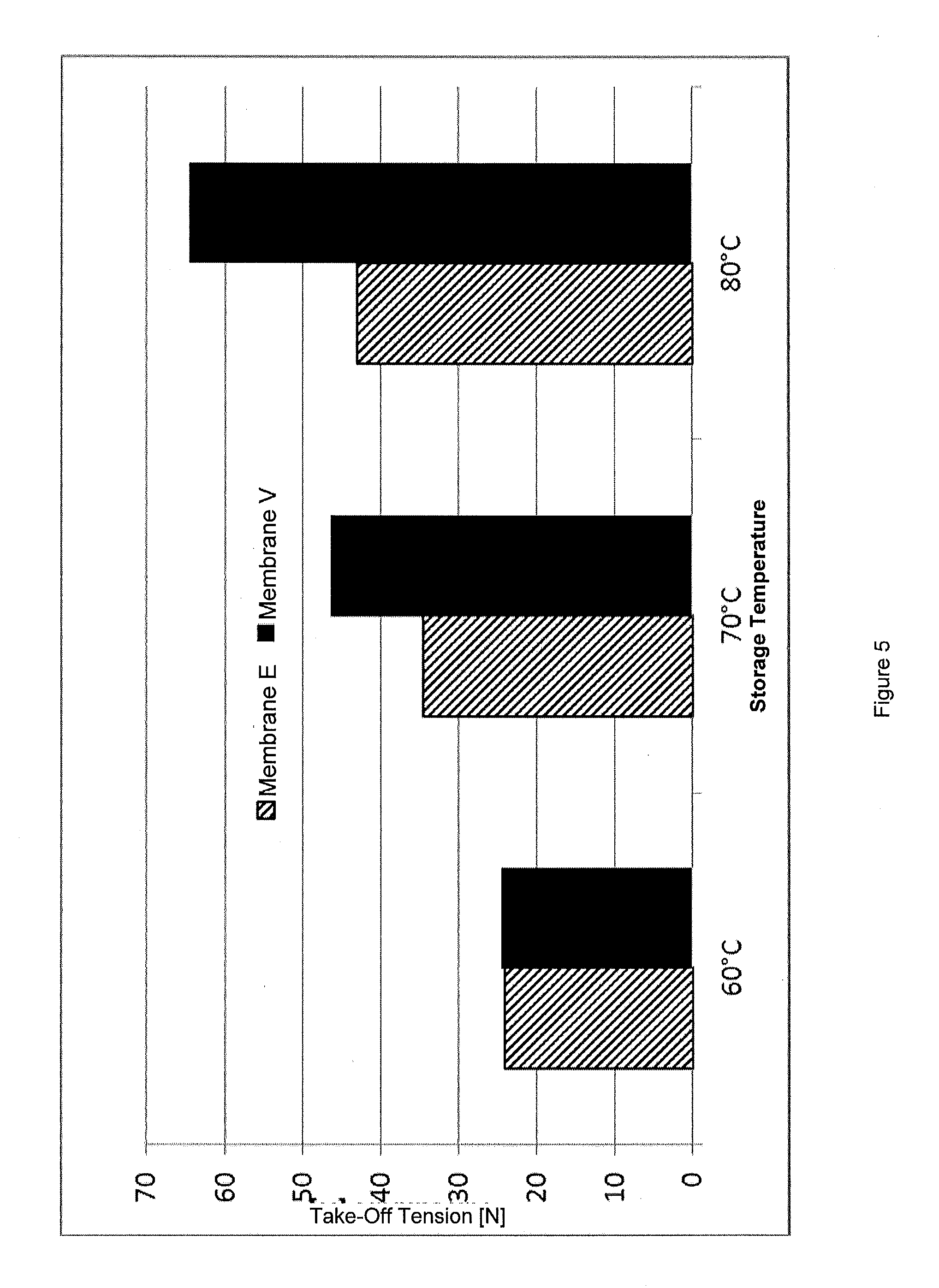

Membrane with surface structure

InactiveUS20140248466A1Record information storageMagnetic recordingSubstructureThermoplastic materials

A waterproof membrane, a method for sealing substructures, and a system for reflecting sunlight are disclosed. The waterproof member can include a barrier layer, which contains a thermoplastic material, and wherein an upper face of the barrier layer has an arithmetic mean roughness value Ra in accordance with DIN EN ISO 4287: 1998-10 of about 0.01-0.8 μm.

Owner:SIKA TECH AG

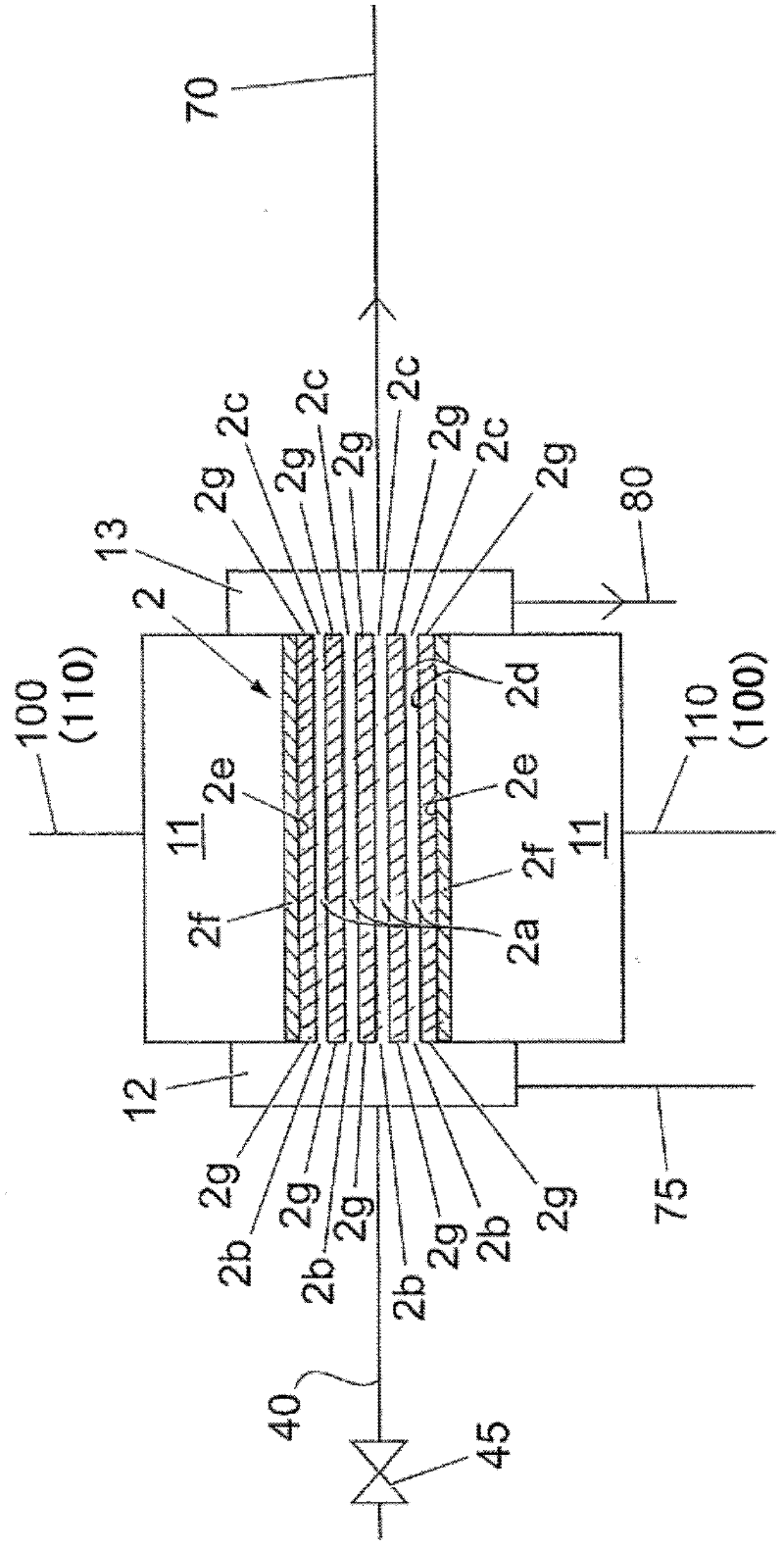

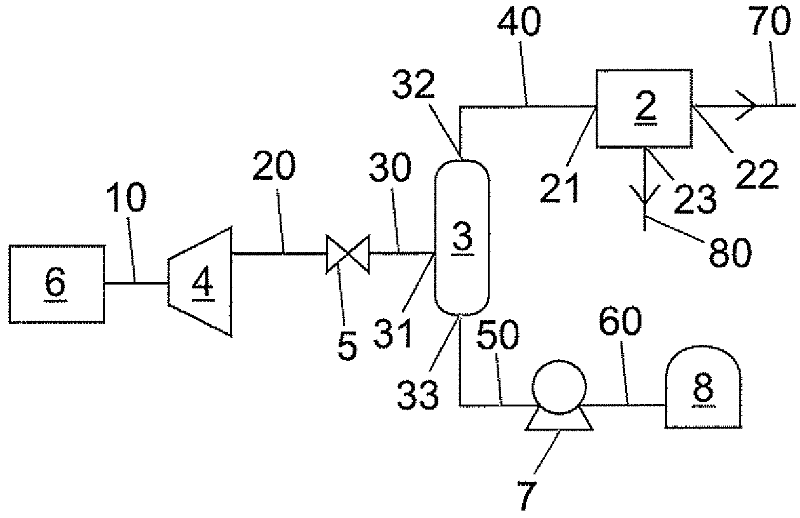

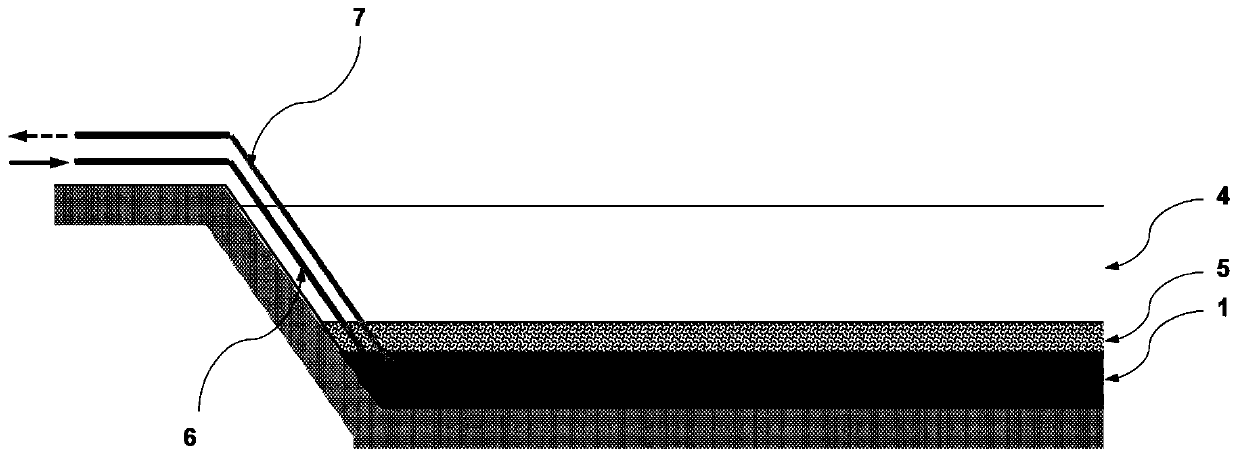

Method and apparatus for separating nitrogen from a mixed stream comprising nitrogen and methane

The present invention discloses a method and apparatus for separating nitrogen from a mixed stream (40) containing nitrogen and methane using an integral adsorption contactor (2) formed of a single construction of activated carbon, said contactor (2 ) accommodates one or more separation flow channels (2a) extending through the integral adsorption contactor (2), the one or more separation flow channels having at least one inlet (2b) leading to the contactor (2) and at least An outlet (2c) from said contactor, said one or more separation flow channels (2a) defining one or more first inner surfaces (2d) of an integral adsorption contactor (2), said contactor (2) Also comprising one or more first outer surfaces (2e) provided with a barrier layer (2f), said first outer surface (2e) being different from said first inner surface (2d). The mixed flow (40) passes through at least one of the fluid separation channels (2a) where the methane is absorbed. The contactor (2) may be regenerated by contacting the contactor (2) with the heat exchange fluid (100) via a barrier layer (2f) on one or more of the outer surfaces (2e).

Owner:SHELL INT RES MAATSCHAPPIJ BV

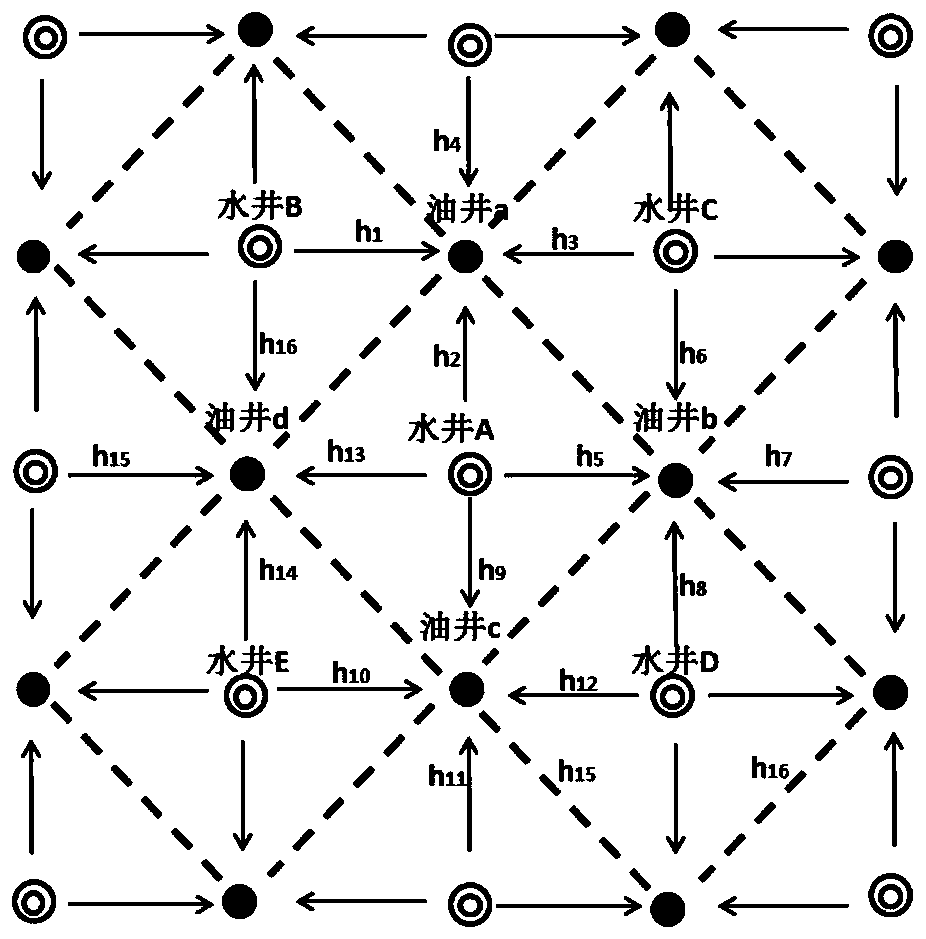

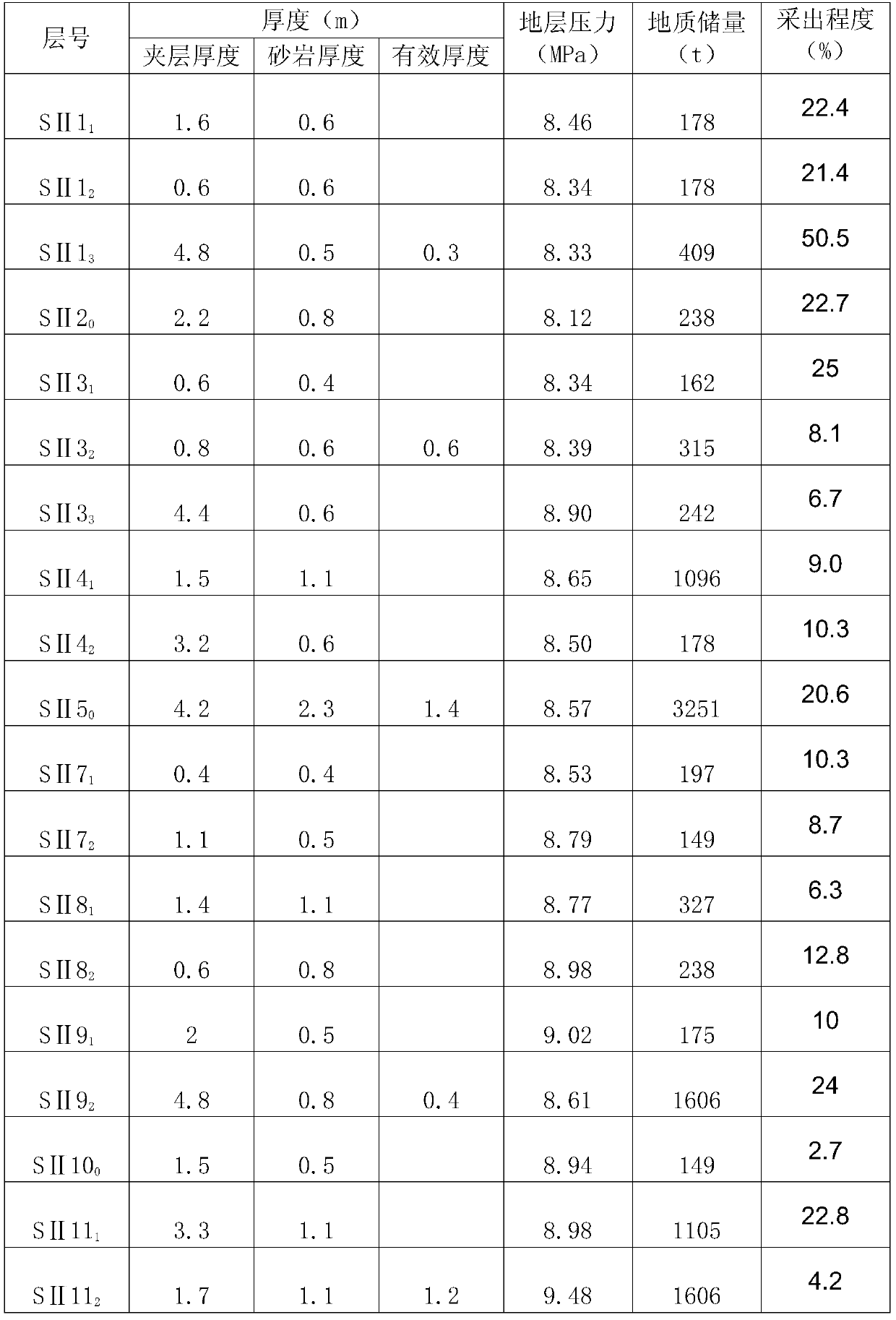

Well and layer selection method for pouring measure of large-scale flooding solution into thin and poor layer water-injection well of sandstone reservoir

ActiveCN110644958AIncrease production capacityImprove seepage capacityFluid removalThermodynamicsSoil science

The present invention relates to a well and layer selection method for a pouring measure of large-scale flooding solution into a thin and poor layer water-injection well of a sandstone reservoir. Themethod mainly solves the problem that stratum energy is not enough to form effective communication between oil-water wells, so as to cause poor water injection capacity of thin and poor layer of an oil well having deficit stratum production capacity and poor filtration capacity. The method is characterized in that: (1) optimizing a target well: selecting a well that has relatively complete well group injection-production relationship, bad oil-water well connectivity, and long-term deficit stratum, wherein the water-injection well is a well having a low porosity, low air permeability and havinga certain exploitation potential; and the water-injection well can satisfy the construction requirement for pouring large-scale fracturing flooding liquid into the water injection well; and (2) optimizing a target layer: selecting a deposition unit with poor producing and great potential as the target layer according to the parameters such as the injection-production relationship of the target well, a reservoir development thickness, a barrier layer thickness, a liquid production capacity, a liquid production intensity, a stratum pressure, producing situation and the like. The method improvesyield-increasing and development effects of the thin and poor layer.

Owner:DAQING OILFIELD CO LTD +1

Method and covering material for in-situ treatment of polluted bottom mud

InactiveCN111362535AThe effect is reversibleImpact no impactSludge treatmentCoastlines protectionSoil scienceKaolin clay

The invention discloses a method and a covering material for in-situ treatment of polluted bottom mud. The method for in-situ treatment of polluted bottom mud comprises the following steps: a supporting structure barrier layer and a protective layer are sequentially laid on the surface of the polluted bottom mud, and the supporting structure barrier layer is formed by mixing aggregate and a sealing substance and then interacting with water; the aggregate is natural mineral; and the sealing substance is natural clay, sepiolite, attapulgite or kaolin. The covering material comprises the aggregate and the sealing substance, and the aggregate is the natural mineral; and the sealing substance is natural clay, sepiolite, attapulgite or kaolin. The bottom mud and the water body are efficiently isolated, so that all types of pollutants such as organic matters, nitrogen, phosphorus and heavy metals cannot be released to the water body, and the purpose of in-situ treatment of the polluted bottommud is achieved.

Owner:CCCC THIRD HARBOR ENG +1

Geotechnical barrier

InactiveUS7347646B2Prevent crashSolid waste disposalProtective foundationGeotechnical engineeringSoil science

Owner:AQUATAN

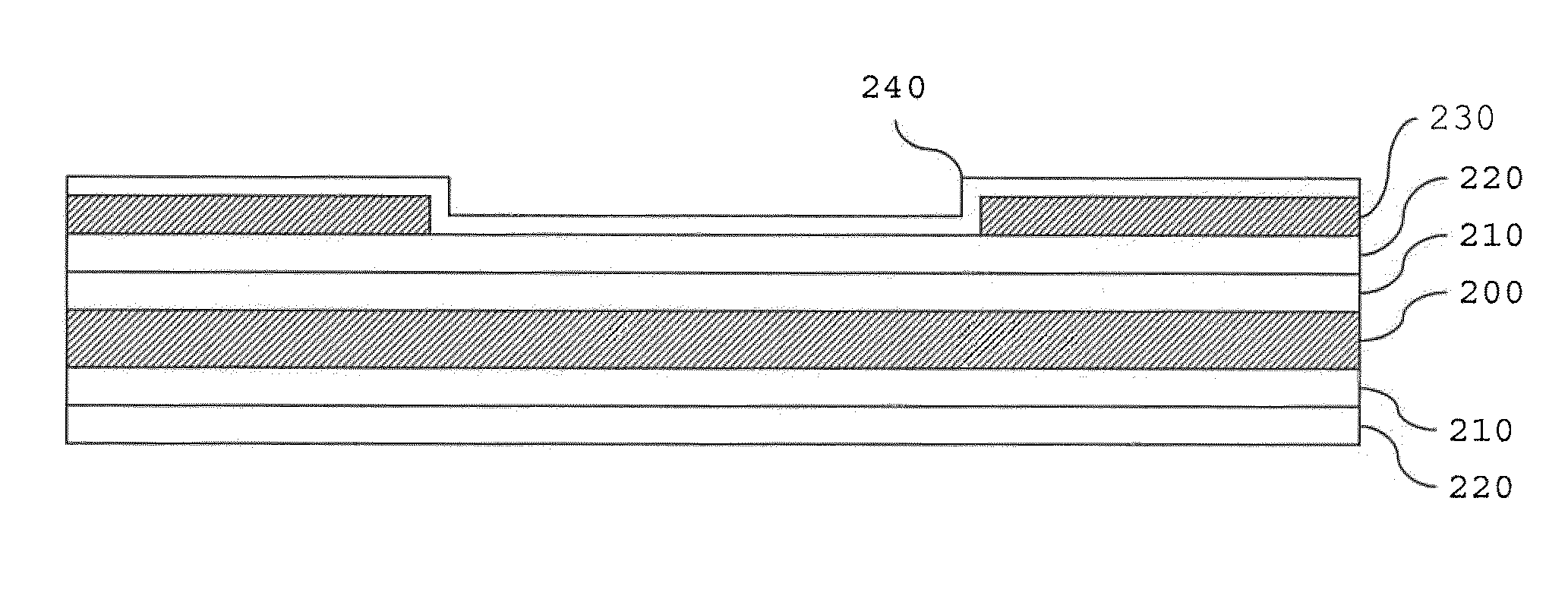

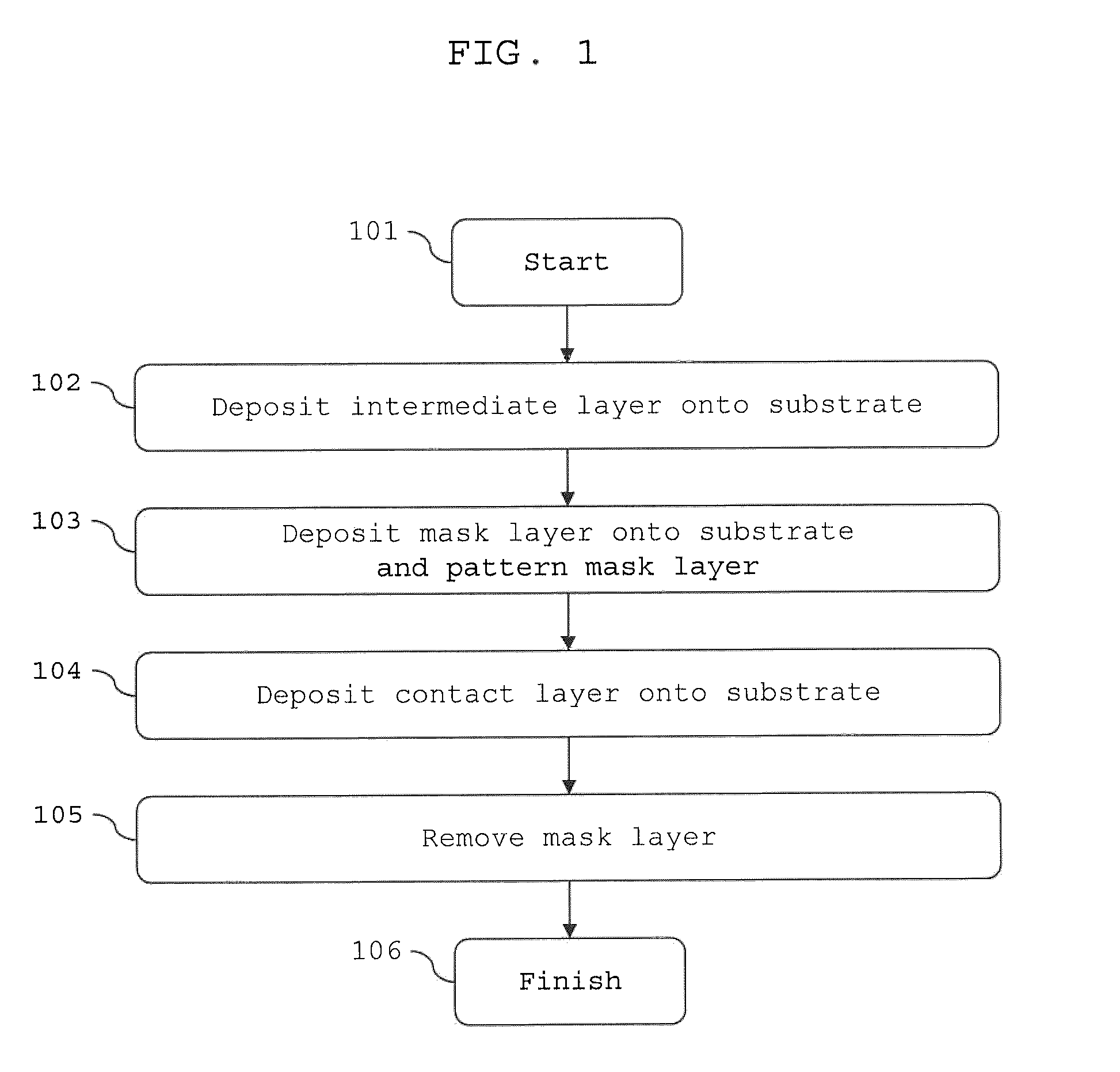

Liquid barrier and method for making a liquid barrier

ActiveUS8734657B2Manufacturing process compatibleDecorative surface effectsSemiconductor/solid-state device detailsContact layerMaterials science

A method for making a liquid barrier includes forming a liquid barrier layer on a substrate, forming a mask layer on the liquid barrier layer such that part of the liquid barrier remains exposed, forming a contact layer on the exposed liquid barrier layer, and removing the mask layer to expose the part of the liquid barrier layer which was covered by the mask layer. A liquid wetting boundary is formed when the wettability on the liquid barrier surface area is less than the wettability of the contact surface area.

Owner:R S M ELECTRON POWER

Time passage indicator

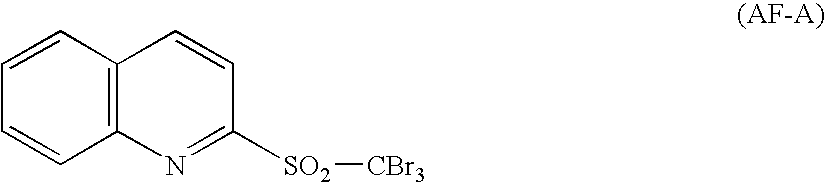

ActiveUS10247713B2The right amountAvoid spendingMaterial analysis by observing effect on chemical indicatorInvestigating time/temperature historyCarboxylic acidAmmonia

There is described an indicator device for indicating the passage of time, the indicator device comprising an indicator section and a barrier section adjacent thereto, said indicator section comprising: an indicator material; a substrate material; and a first adhesive layer; the indicator material and the substrate material being in the form of one or more layers; the indicator material displaying different visible properties in response to the presence or absence of a chemical agent and / or the concentration thereof; the barrier section comprising a removable barrier layer, the removable barrier layer being substantially impermeable to the chemical agent; wherein on removal of the removable barrier layer, the concentration of the chemical agent in the indicator section changes over time, effecting a visible change. The device may be used to detect the presence / absence of oxygen, water, carbon dioxide, an amine, ammonia, and / or carboxylic acids or to indicate the passage of time.

Owner:INSIGNIA TECH LTD

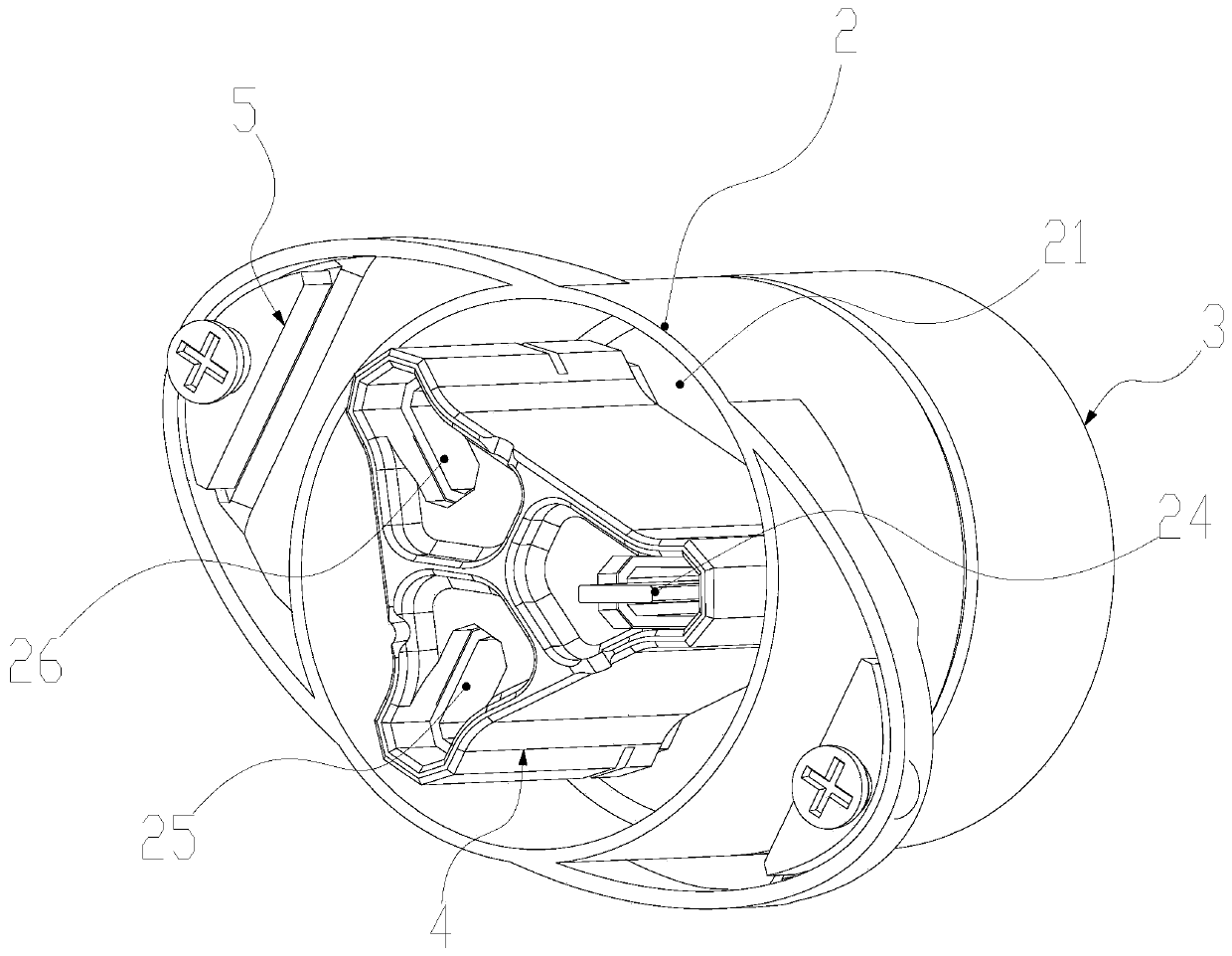

A waterproof coupling device

ActiveCN109462099BWith anti-shock designProtective sealOptical fibre/cable installationCouplings bases/casesCouplingModular design

The present invention relates to a coupling device, in particular to a waterproof coupling device, comprising an inserter, a coupler, a sealing cover, a data bridge module, a live wire bridge module and a neutral bridge module, and the inserter is provided with a live wire insert The input terminal, the neutral line insertion terminal, the data insertion terminal and the insulating layer covering the outer surface of the live wire insertion terminal, the neutral line insertion terminal and the data insertion terminal; the coupler is divided into a coupling chamber and a sealed cavity The external matching thread outside the chamber and the sealing chamber, the coupling chamber and the sealing chamber are separated by a barrier layer provided in the coupler, and the barrier layer is provided with a live wire coupling sleeve, a neutral wire coupling sleeve, a data Coupling sleeve, data through hole, live line through hole, neutral line through hole and sliding sleeve cooperate with the extension sleeve; the invention can be used immediately after insertion, one step in place, with anti-shock design; has multiple waterproof effects, can be used in water, and adopts Modular design for easy repair and replacement parts.

Owner:温州市鹿城区渊龙电器科技有限公司

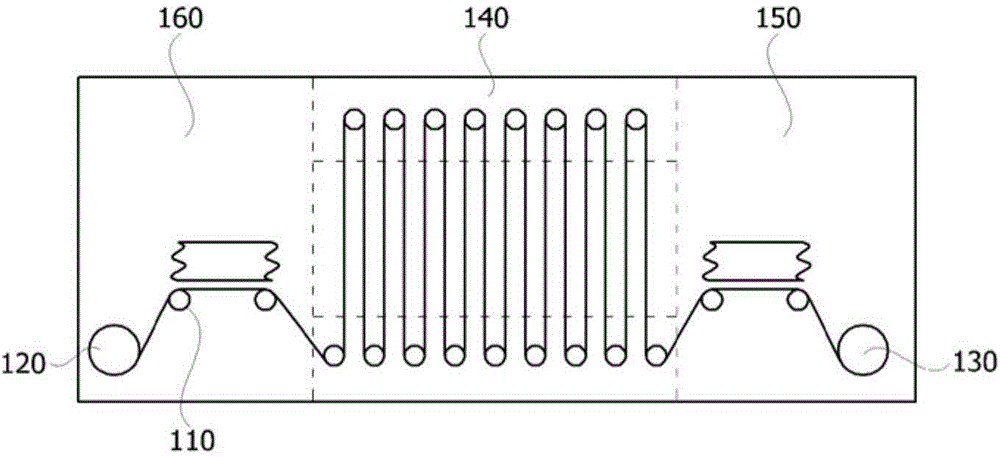

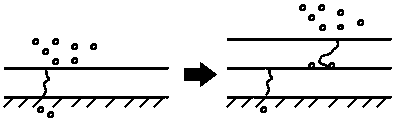

Coating method for reducing damage to barrier layer

InactiveCN104822860AAvoid damageReduced barrier propertiesChemical vapor deposition coatingSuperimposed coating processMaterials scienceCoating

The present application relates to a coating method for reducing damage to a barrier layer. According to the present application, the coating method without direct contact with the barrier layer is applied to a barrier film when performing a protective coating process for protecting the barrier layer of the barrier film, thereby preventing a decrease of water permeability and enhancing barrier properties against gas.

Owner:LG CHEM LTD

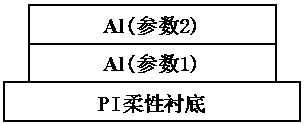

Preparation method of water-oxygen barrier layer

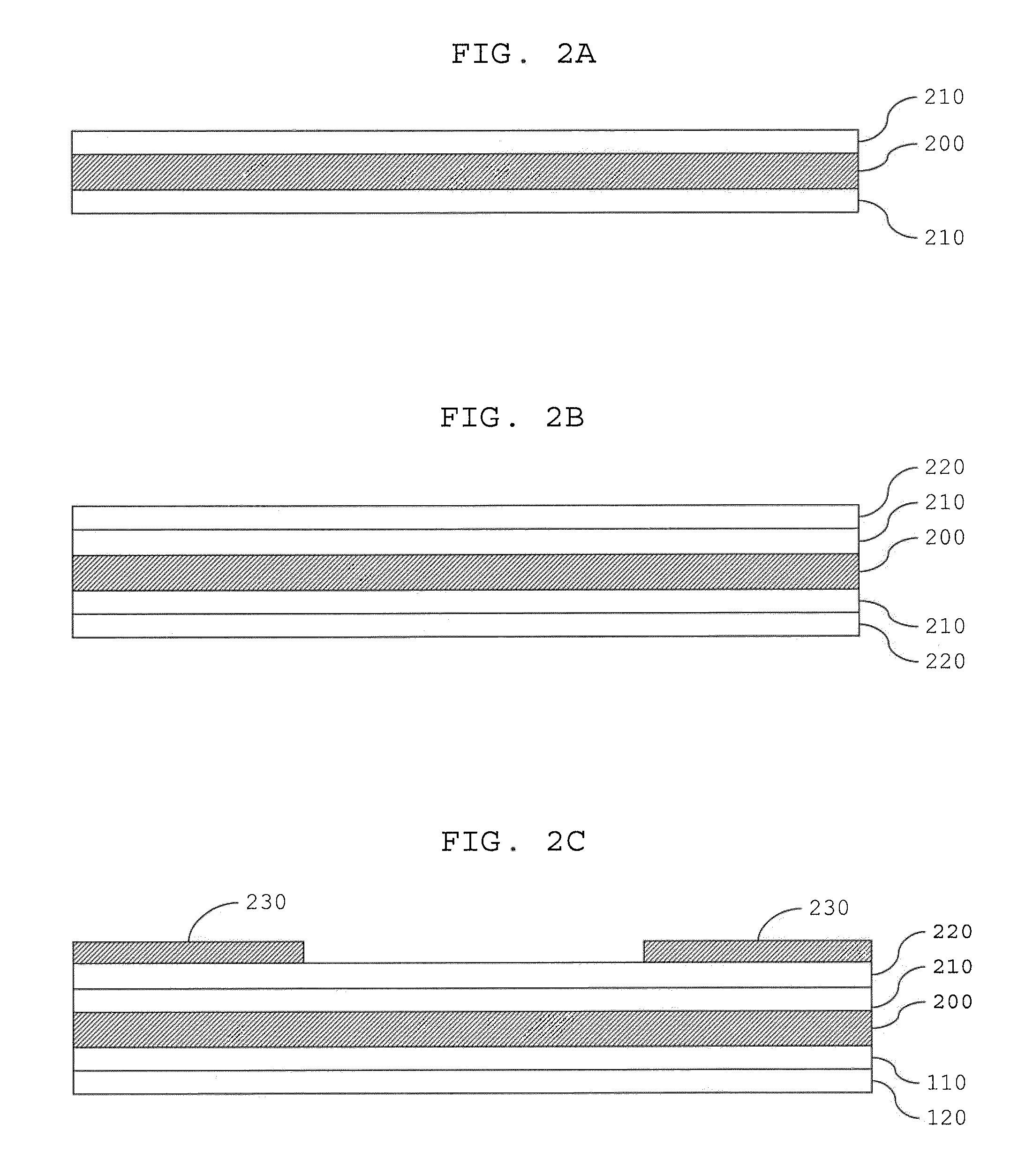

ActiveCN105449123BReduce water oxygen transmission rateEffect of mismatchSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporThin membrane

Owner:SHANGHAI UNIV

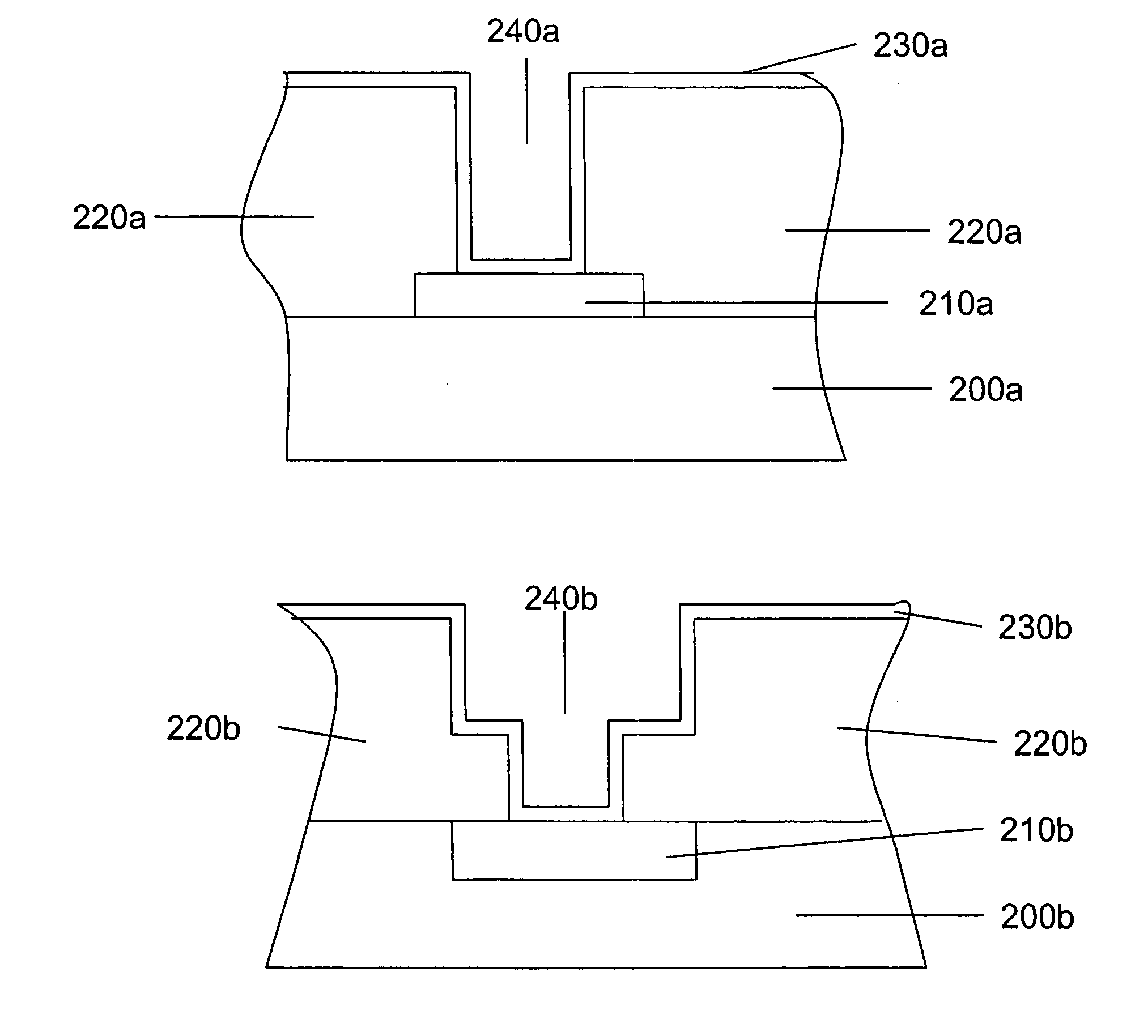

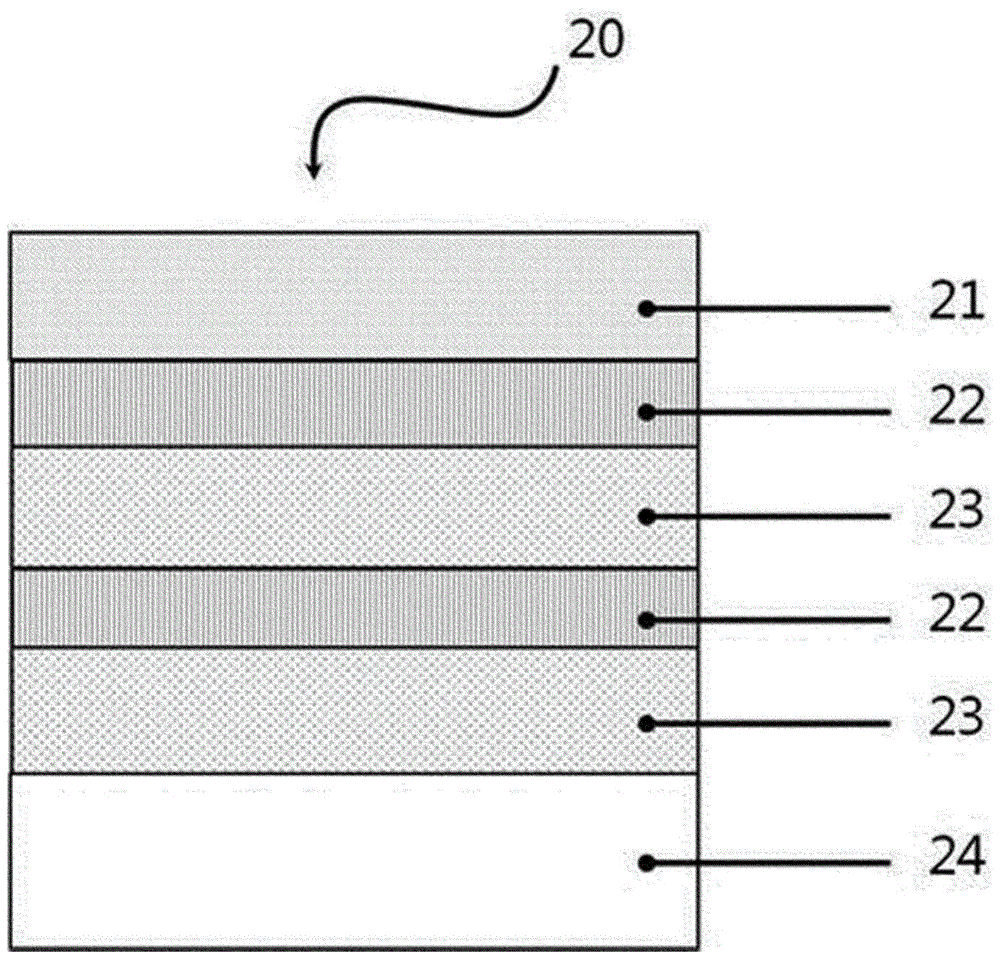

Organic el device and production method therefor

InactiveUS20210066651A1Improve moisture resistance reliabilityElectroluminescent light sourcesSolid-state devicesThin membraneOrganic electroluminescence

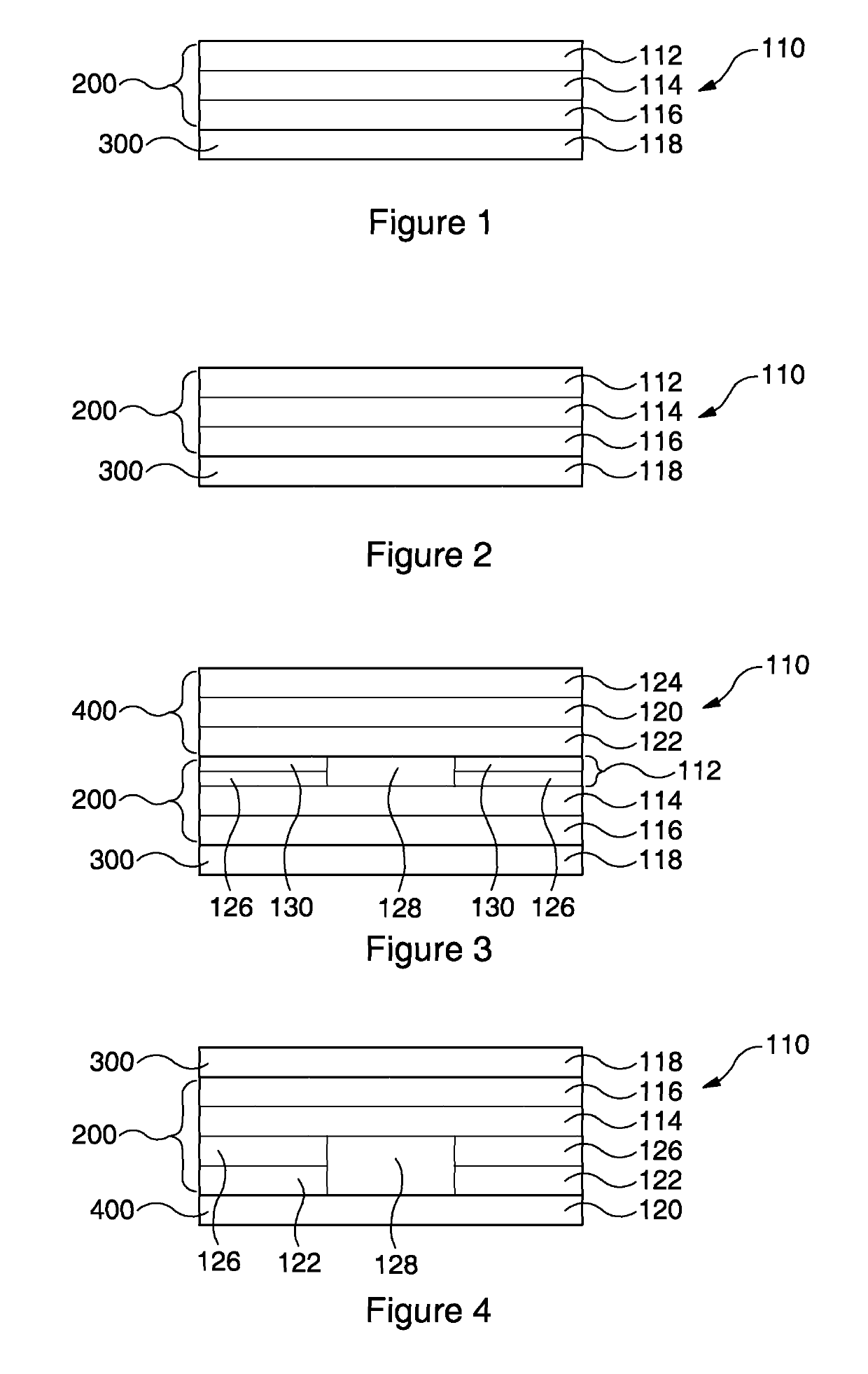

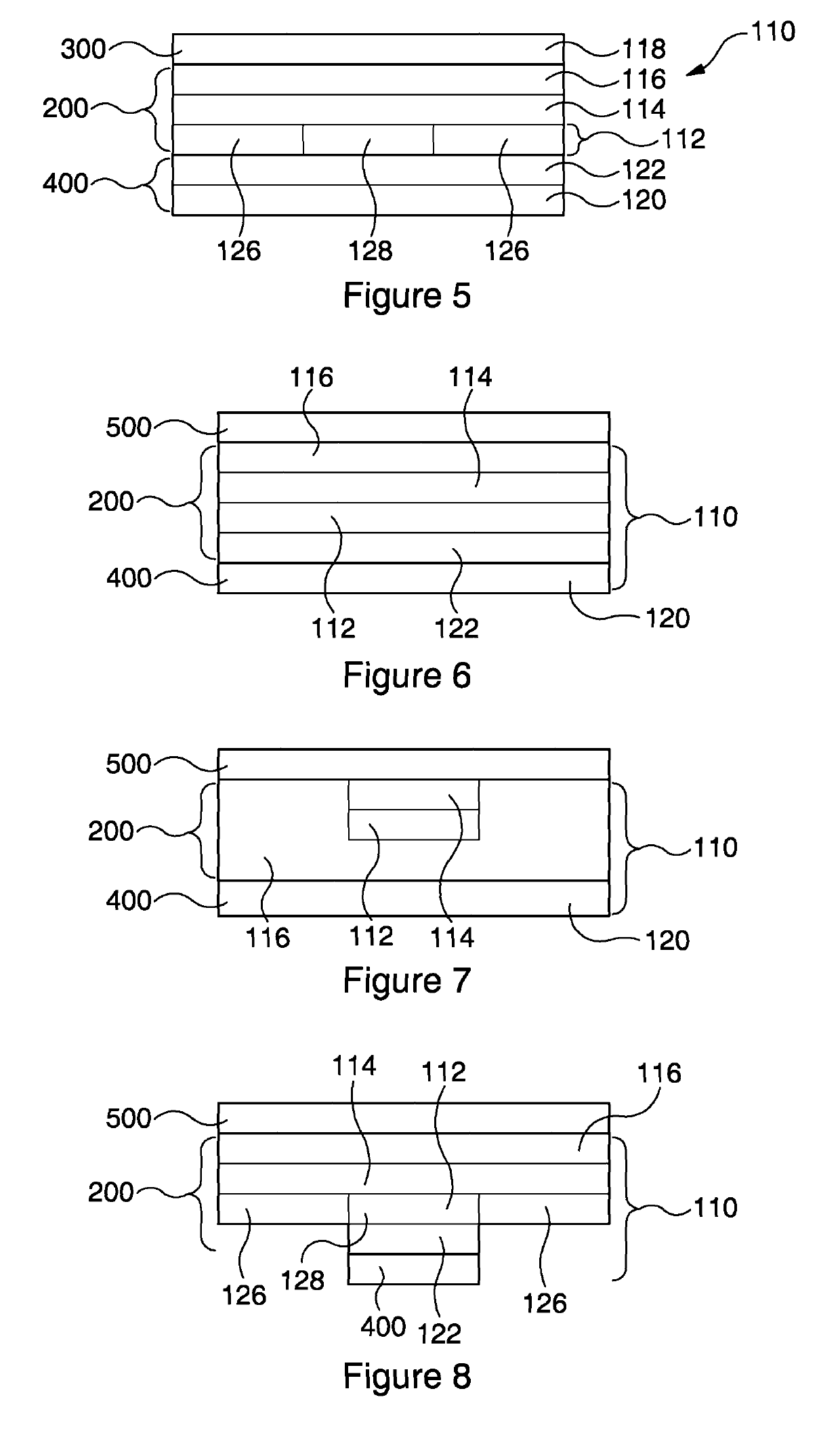

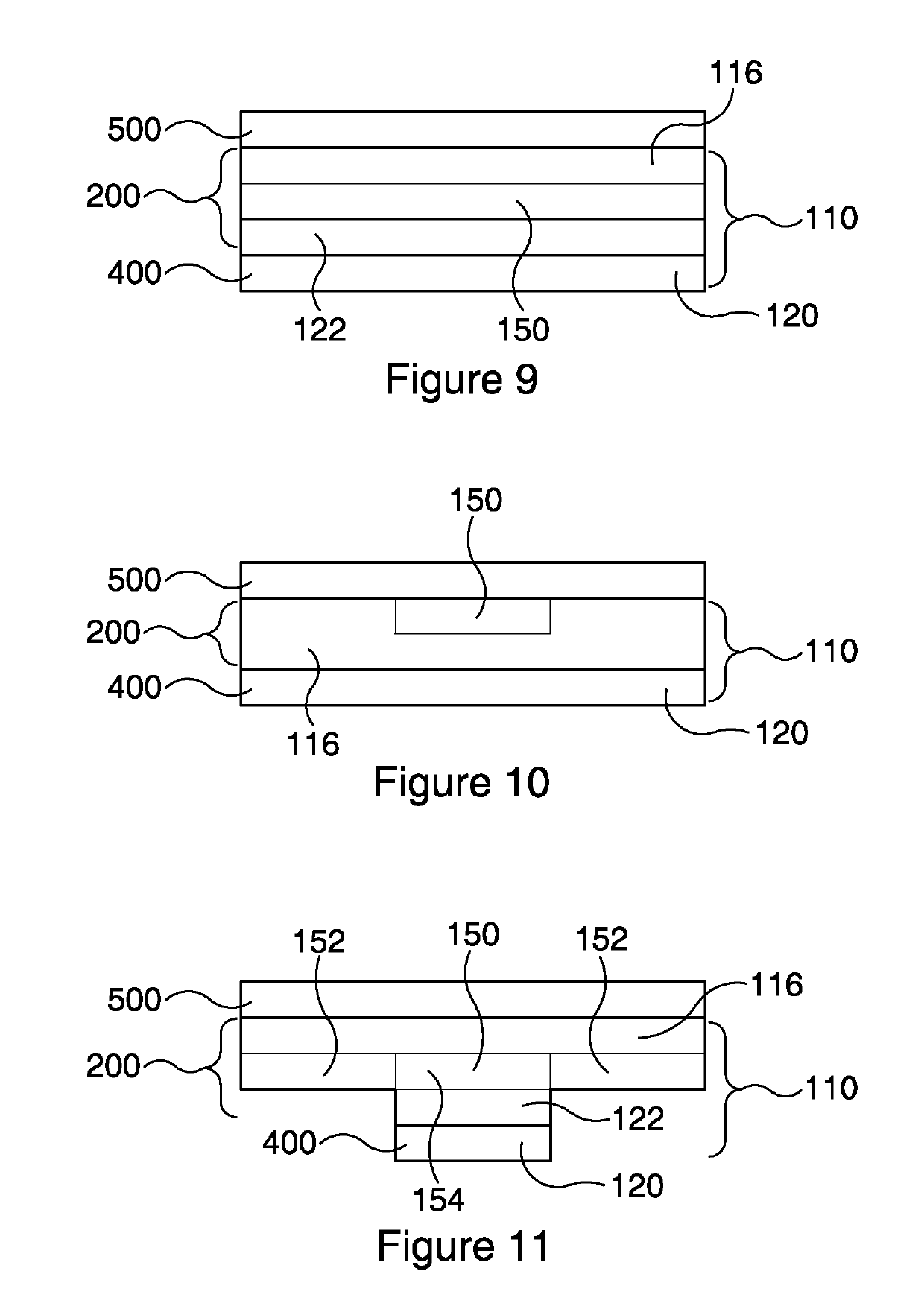

This organic EL device (100A) comprises a peripheral region (R2) and an active region (R1) containing a plurality of organic EL elements (3), and includes an element substrate (20) having a plurality of organic EL elements, and a thin film seal structure (10A) covering the plurality of organic EL elements. The thin film seal structure comprises a first inorganic barrier layer (12), an organic barrier layer (14) in contact with the upper surface of the first inorganic barrier layer, and a second inorganic barrier layer (16) in contact with the upper surface of the first inorganic barrier layer and the upper surface of the organic barrier layer. The peripheral region comprises a first protruding structure (22a) containing a section extending along at least one edge of the active region, and an extending section (12e) of the first inorganic barrier layer extending over the first protruding structure. The first protruding structure includes a first part and second part. The first part is closer to the top portion of the first protruding structure than the second part and, as observed from the normal direction to the base board, a cross section parallel to the substrate surface of the first part includes a part that does not overlap with the cross section parallel to the substrate surface of the second part.

Owner:SAKAI DISPLAY PROD

Thermochromic film

The invention discloses a thermochromic film, which comprises a quantum dot film and barrier layers located on the upper side and the lower side of the quantum dot film, wherein the quantum dot film contains quantum dots with a thermochromic property. In the invention, the quantum dots have good tolerance to light and heat, so that the thermochromic film has good heat resistance and light resistance. In addition, the barrier layers for isolating water and oxygen are arranged on the two sides of the quantum dot film, so that the thermochromic film has good long-term stability. Compared with theexisting thermochromic film on the market, the thermochromic film provided by the invention has the characteristics of high color selectivity, continuous color change, light resistance, heat resistance, durability and the like.

Owner:NINGBO DXC NEW MATERIAL TECH

Weather barrier

Disclosed herein is a weather barrier having: (a) a hydrophobic, air impermeable, UV resistant, and acid resistant, externally facing transparent or translucent barrier layer; (b) an intermediate reflective layer of a metal material having a solar reflectance in the range of 0.7 to 0.95; and (c) a support layer structurally carrying the reflective layer and the barrier layer. Also disclosed hereinis a method of forming a weather barrier by bonding a reflective layer to a substrate layer with an adhesive, and applying a barrier layer to the reflective layer.

Owner:SAN MIGUEL CORPORATION

Method for monitoring carrier concentration of SiGe structure

PendingCN113363137AAccurate monitoringSurveillance economySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProduction lineElectron hole

The invention provides a method for monitoring the carrier concentration of a SiGe structure. The method comprises the following steps of: obtaining correlation data between the hole carrier concentration of a SiGe structure and the resistivity of the SiGe structure; providing a monitoring wafer, and forming a SiGe structure with P-type doped ions on the surface of the monitoring wafer by using a SiGe process corresponding to a product wafer; forming a barrier layer on the surface of the monitoring wafer, the barrier layer covering the SiGe structure; and obtaining the resistivity of the monitoring wafer, and obtaining the hole carrier concentration of the product wafer according to the correlation data. By forming the barrier layer on the surface of the SiGe structure, the change of the resistivity of the SiGe structure is slowed down, so that accurate, economical and efficient monitoring of the carrier concentration of the SiGe structure of the product wafer is realized; the specific hole carrier concentration can be obtained according to the obtained correlation data; and the monitoring method is simple and easy to implement, so that the monitoring frequency can be improved to realize high-frequency production line stability monitoring.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

High-sensitivity humidity detector

ActiveCN113063841AChange stressChanging quantum tunneling propertiesFinal product manufactureMaterial magnetic variablesHigh humidityMoisture absorption

The invention relates to the field of humidity detection, in particular to a high-sensitivity humidity detector. A pinning layer is arranged on an antiferromagnetic layer, a barrier layer is arranged on the pinning layer, a free layer is arranged on the barrier layer, the pinning layer and the free layer are separated by the barrier layer, a through hole is formed in the free layer, and the moisture absorption expansion material part is arranged on the barrier layer at the bottom of the hole. In the invention, the pinning layer, the barrier layer and the free layer form a magnetic tunnel junction. During application, the humidity detector is placed in an environment with humidity to be measured; meanwhile, a fixed magnetic field is applied to the humidity detector. The humidity of the environment to be measured is determined by measuring the difference between the magnetic tunnel junction magnetoresistance in the environment to be measured and the magnetic tunnel junction magnetoresistance not in the environment to be measured. The humidity sensor has the advantage of high humidity detection sensitivity.

Owner:广东润宇传感器股份有限公司

A Highly Sensitive Humidity Detector

ActiveCN113063841BChange stressChanging quantum tunneling propertiesFinal product manufactureMaterial magnetic variablesHigh humidityTunnel junction

The invention relates to the field of humidity detection, and specifically provides a high-sensitivity humidity detector, wherein a pinned layer is placed on an antiferromagnetic layer, a potential barrier layer is placed on a pinned layer, and a free layer is placed on a potential On the barrier layer, the potential barrier layer separates the pinned layer and the free layer, the free layer is provided with a penetrating hole, and the hygroscopic expansion material portion is placed on the potential barrier layer at the bottom of the hole. In the present invention, the pinned layer, the barrier layer, and the free layer constitute a magnetic tunnel junction. During application, the present invention is placed in the humidity environment to be measured; at the same time, a fixed magnetic field is applied to act on the present invention. The humidity of the environment to be measured is determined by measuring the difference between the magnetic resistance of the magnetic tunnel junction in the environment of humidity to be measured and the environment of humidity not to be measured. The invention has the advantage of high humidity detection sensitivity.

Owner:广东润宇传感器股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com