Method and apparatus for separating nitrogen from a mixed stream comprising nitrogen and methane

A mixed flow and separation technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as complex construction process, increased operation, and expensive contactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method is presented herein for the separation of nitrogen from a mixed stream containing nitrogen and methane using a monolithic adsorption contactor formed of activated carbon that does not require a prefabricated monolith with an absorbent coating, or No treatment is required to seal the channel walls.

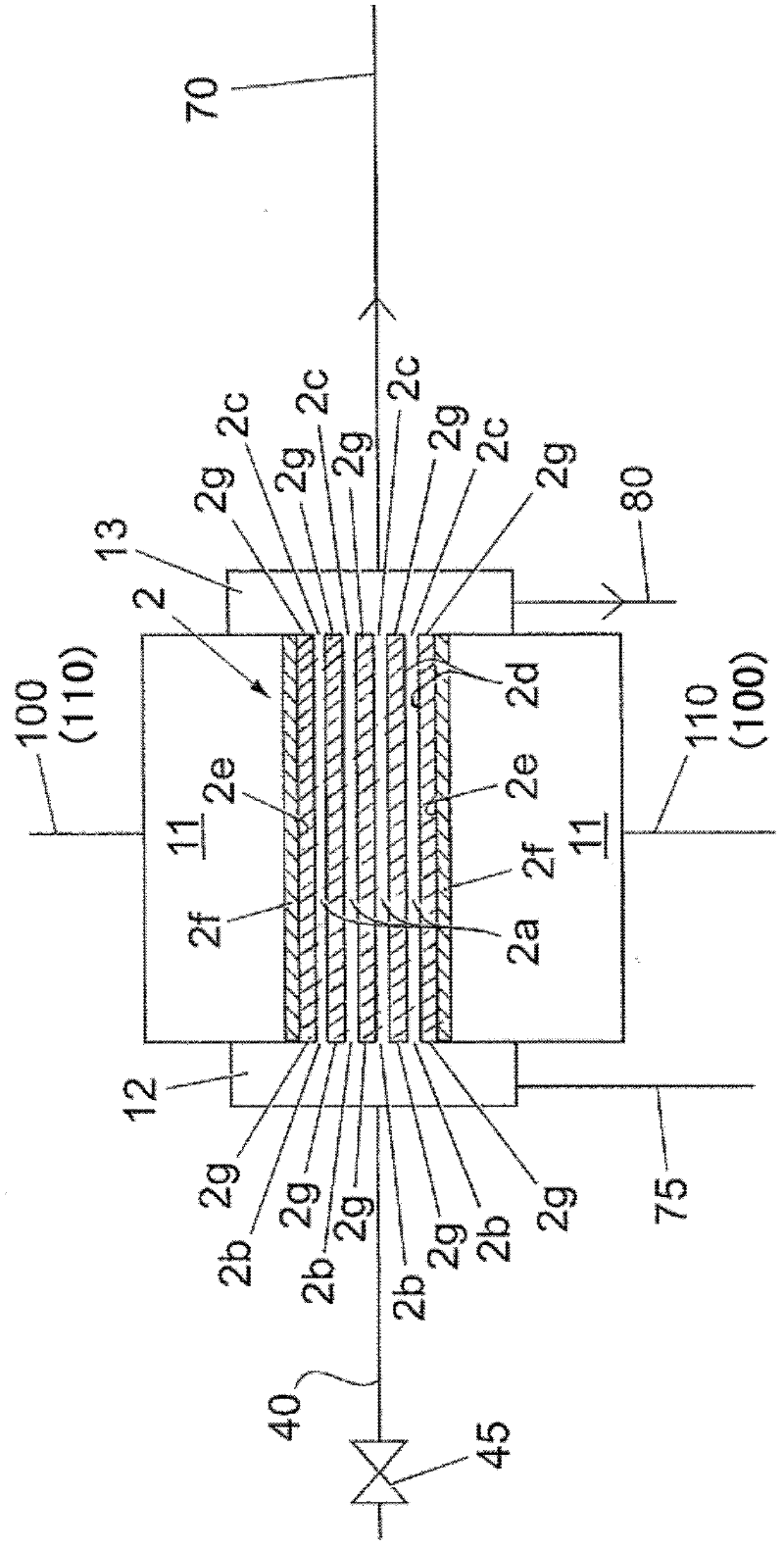

[0027] figure 1 A typical monolithic adsorption contactor 2 is shown. It is formed of a single construction of absorbent material (eg activated carbon) and it is provided with a barrier layer 2f. The contactor houses one or more separate flow channels 2 a throughout the monolithic adsorption contactor 2 . Such as figure 1 As shown, the separation flow channel runs through the end face 2g of the integral adsorption contactor 2 . One or more of the separate flow channels has at least one inlet (2b) to allow the mixed flow to enter the flow channel 2a. On the other side, there is at least one outlet (not shown). One or more separate flow channels 2a define one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com