Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1694 results about "Mixed flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed flow pumps are a cross between the two. The impeller sits within the pipe and turns, but the turning mechanism is essentially diagonal, using centrifugal force to move the water along while accelerating it further with the push from the axial direction of the impeller.

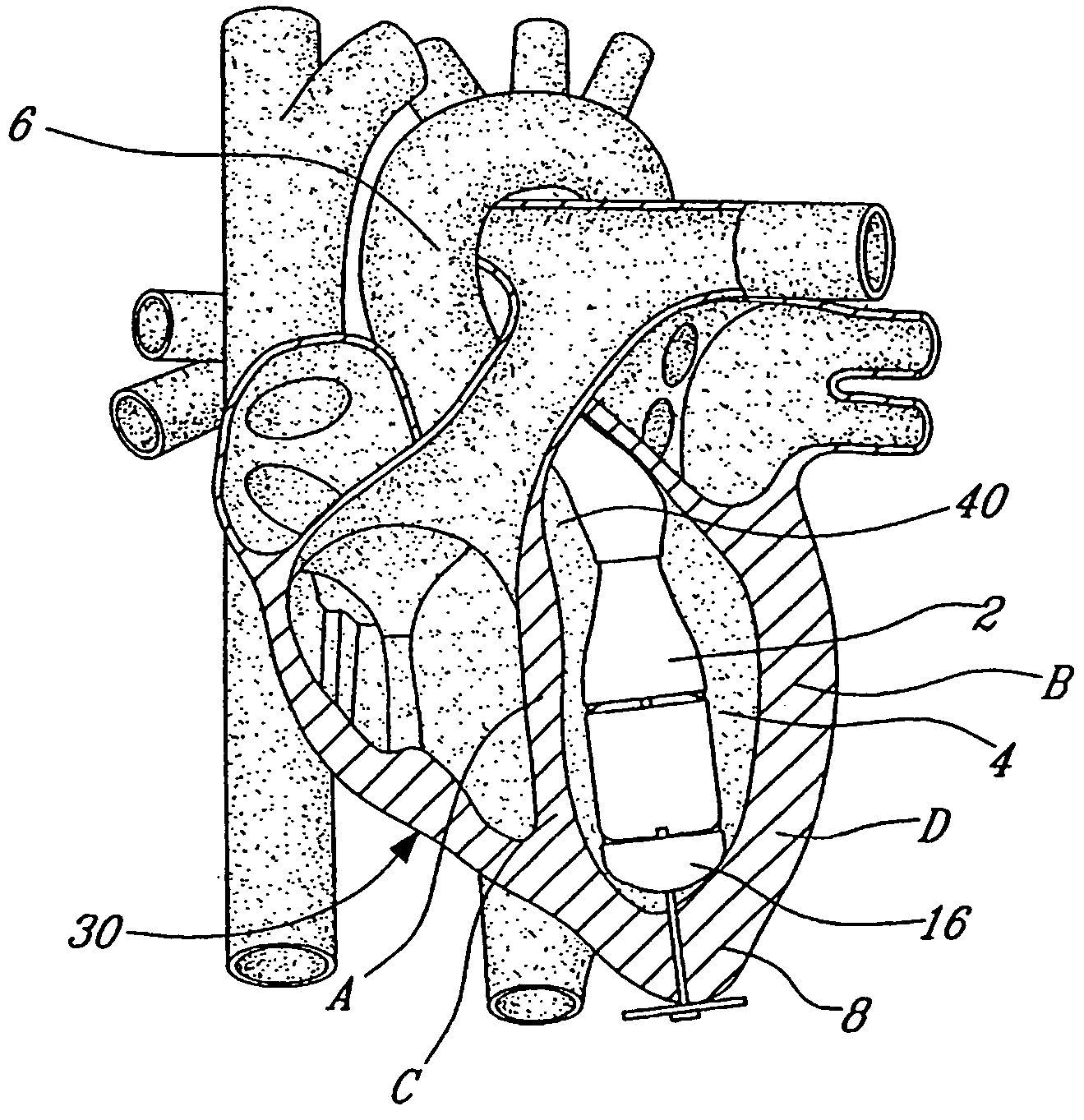

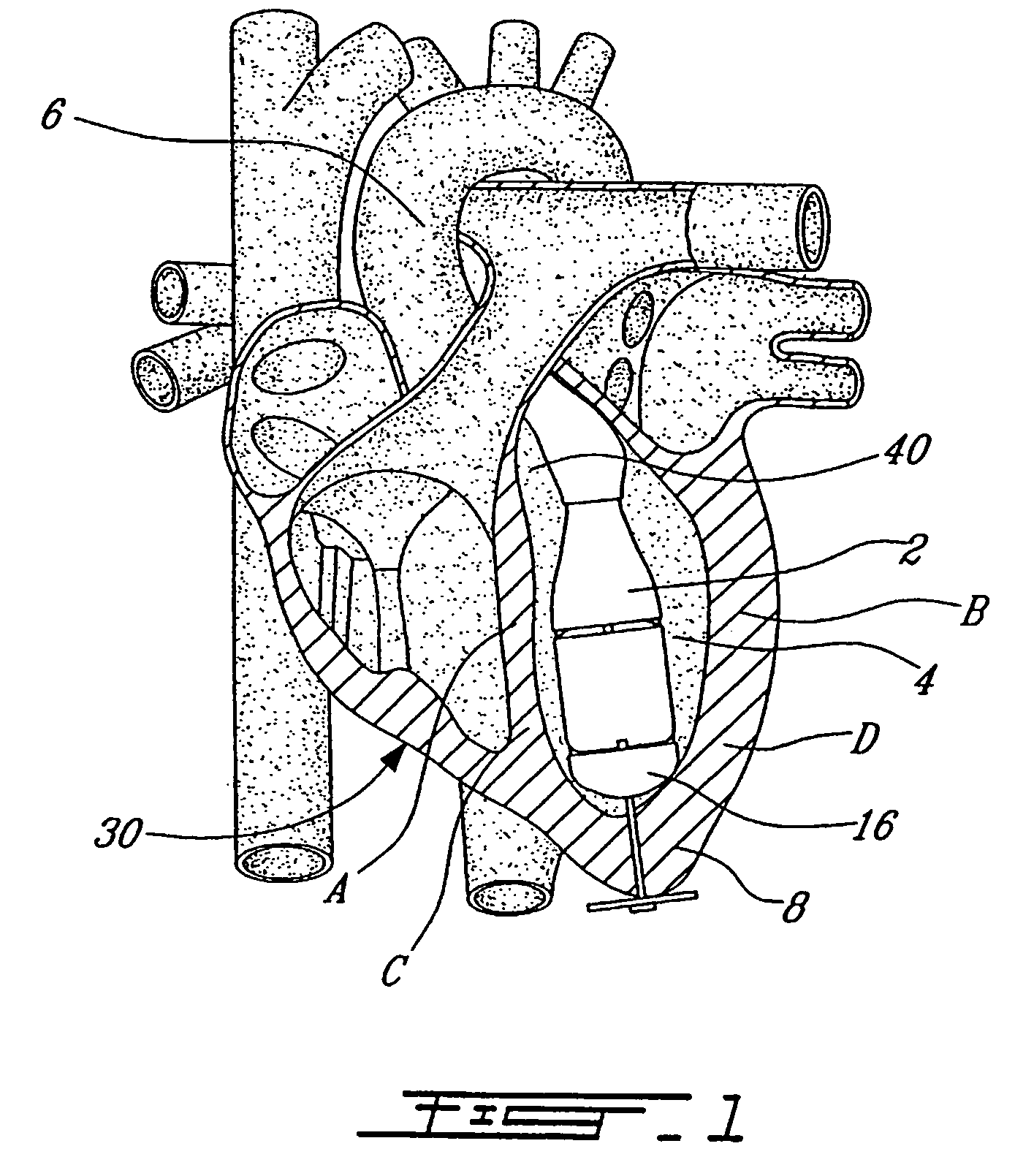

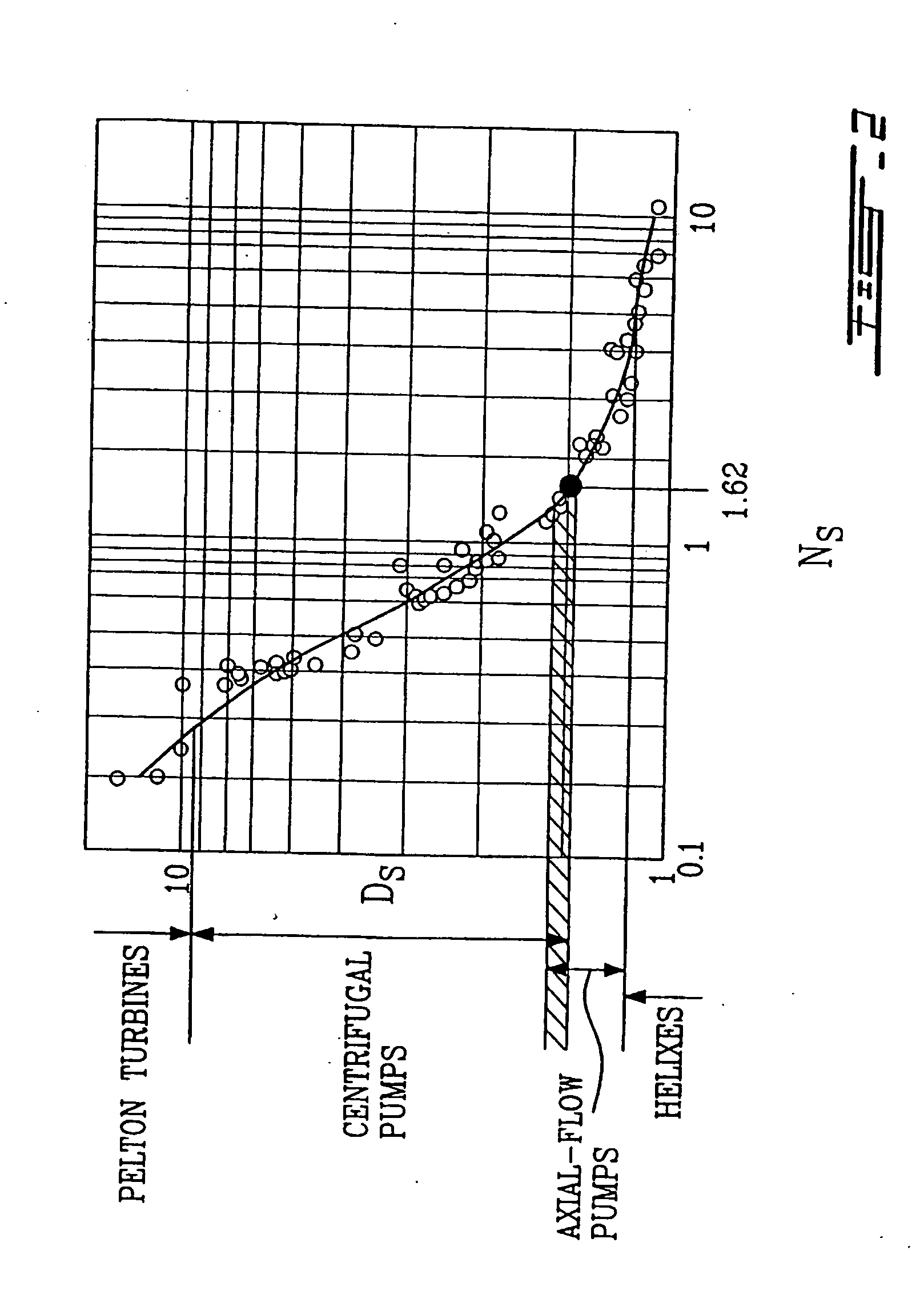

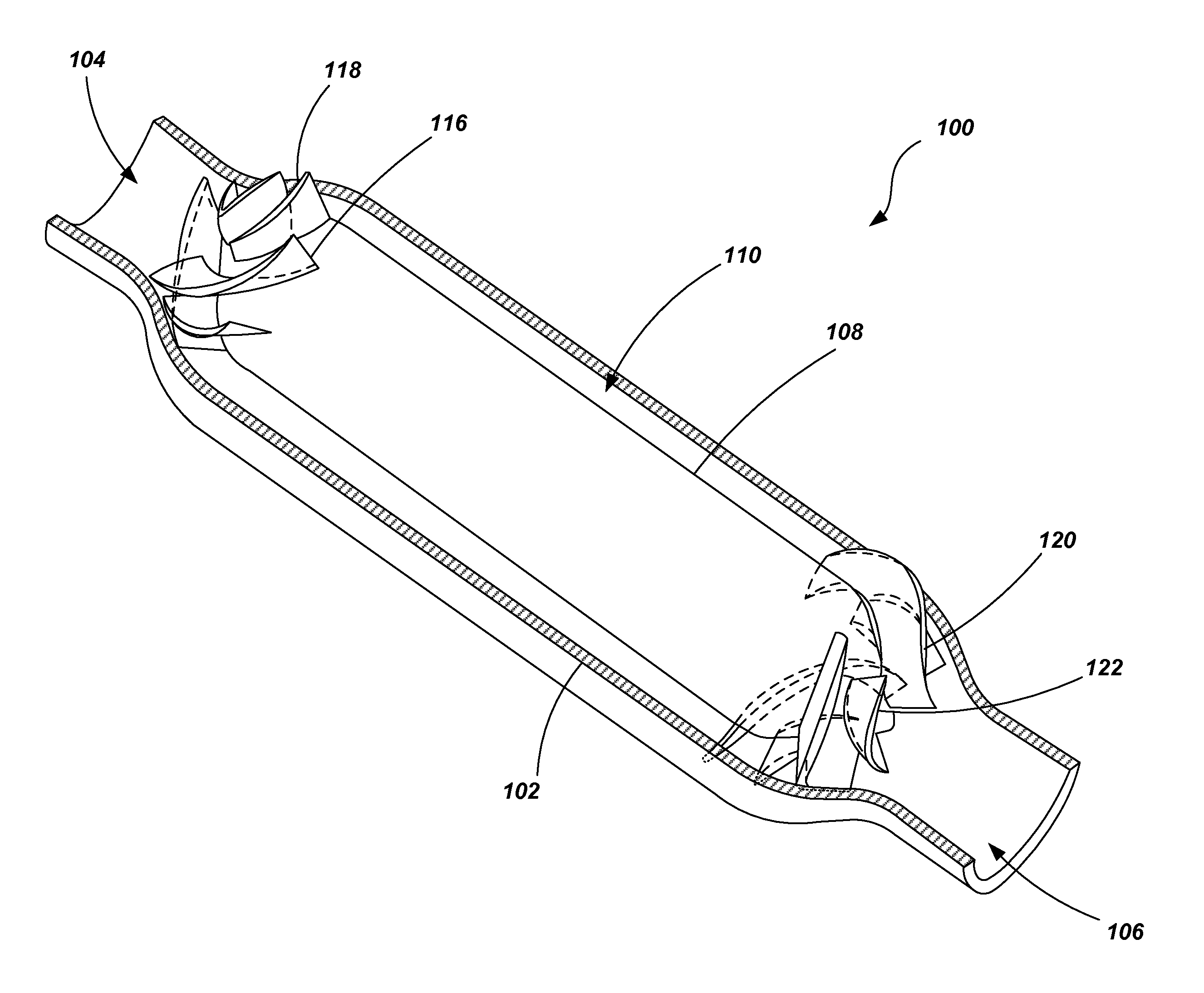

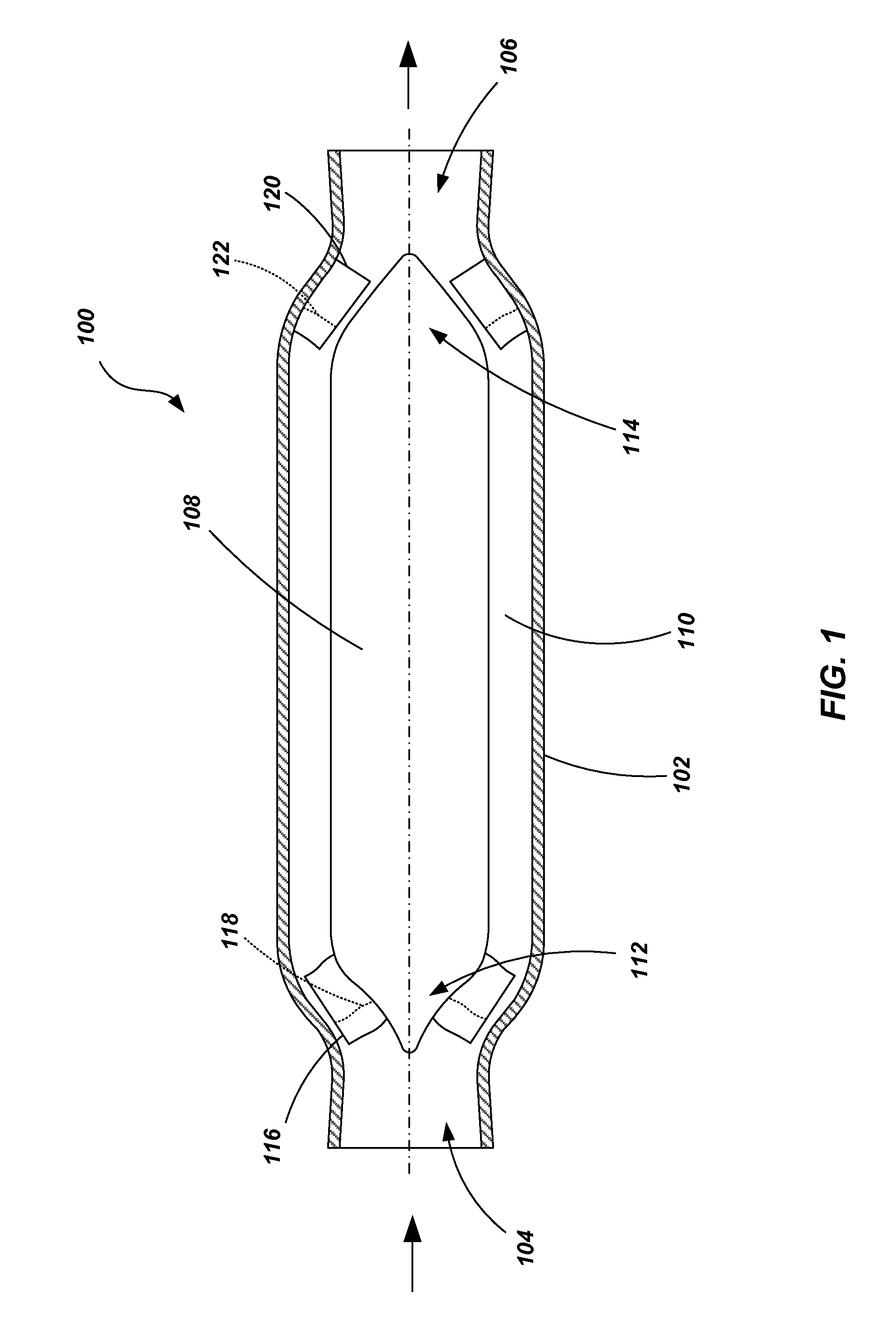

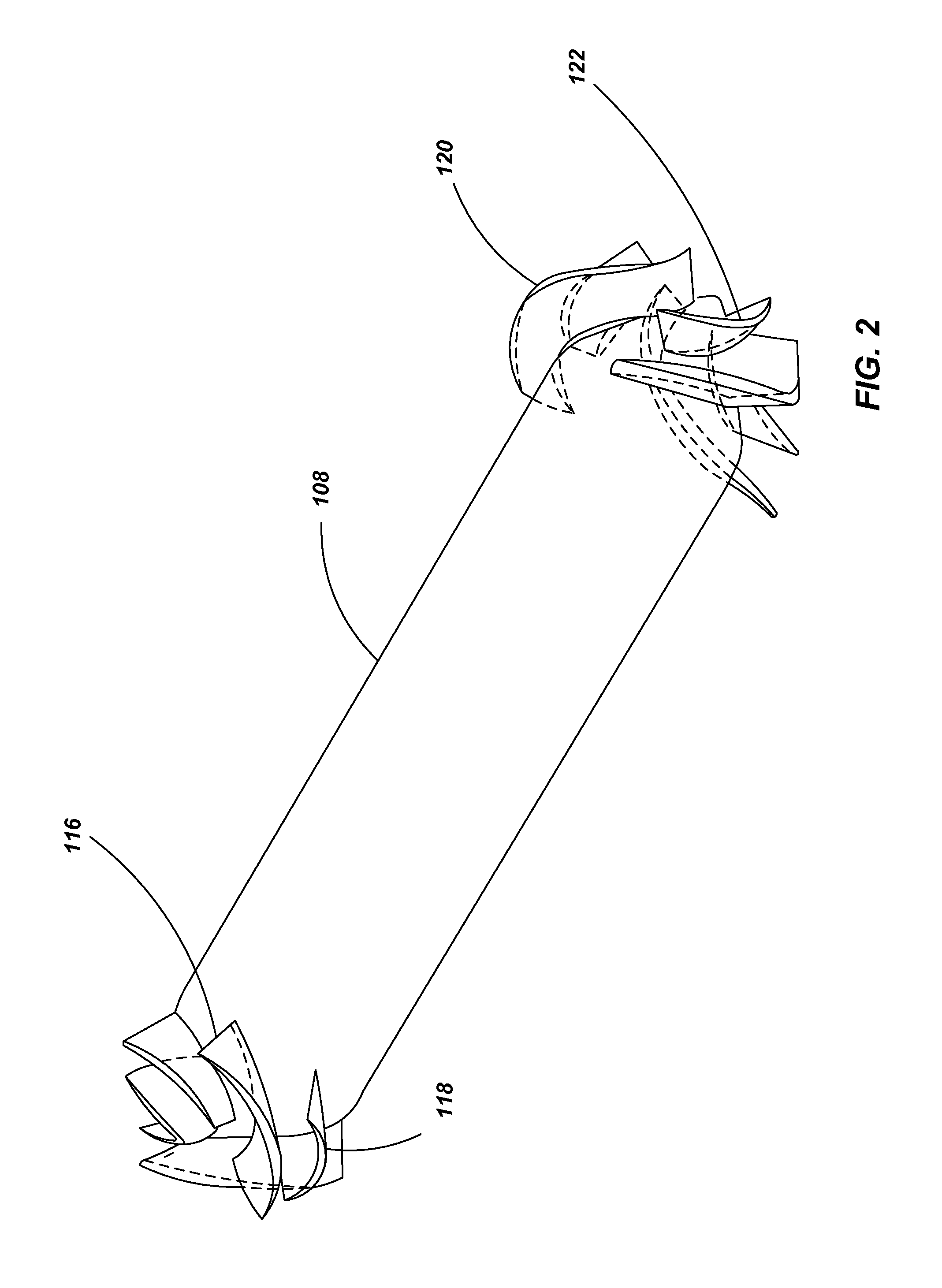

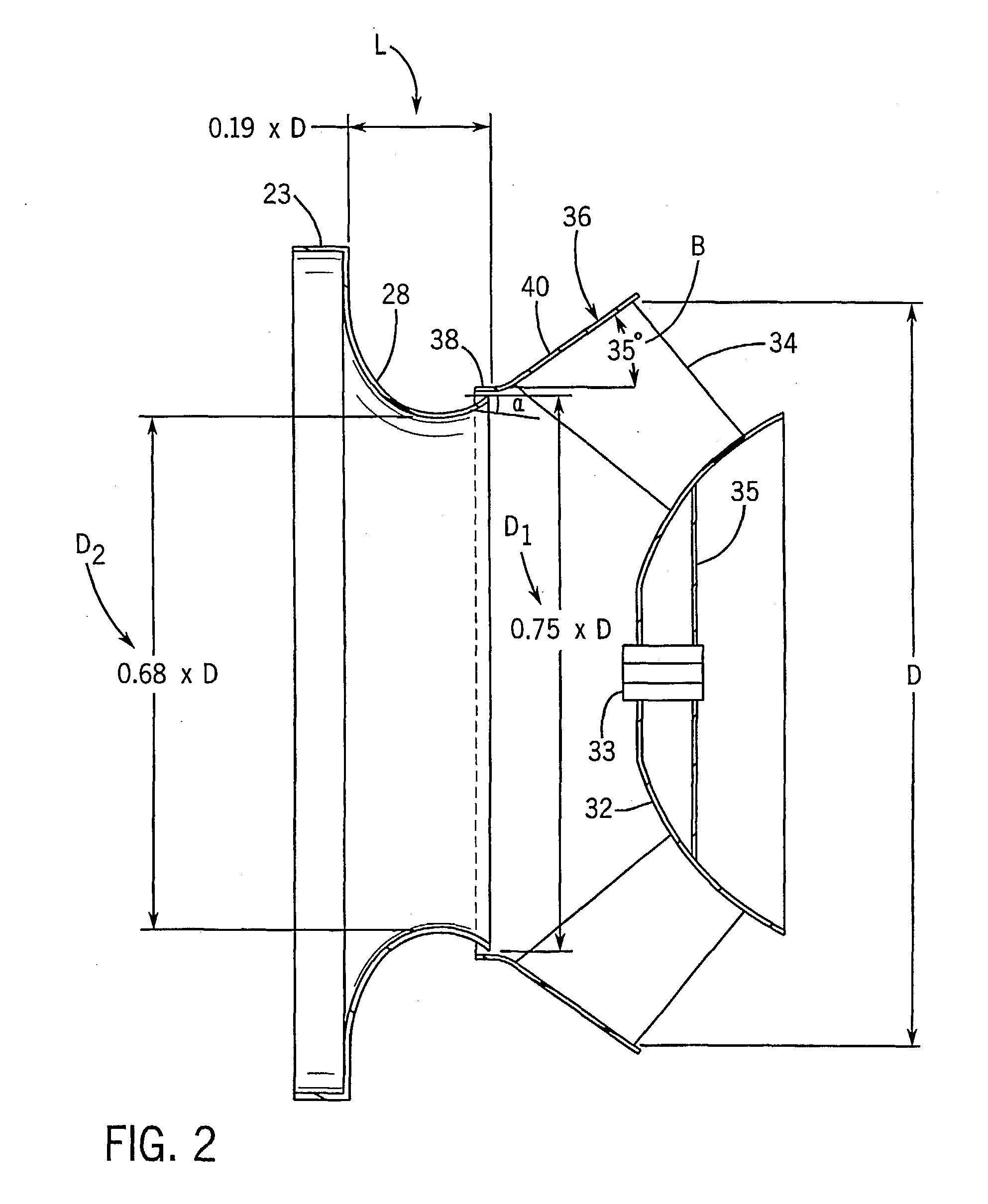

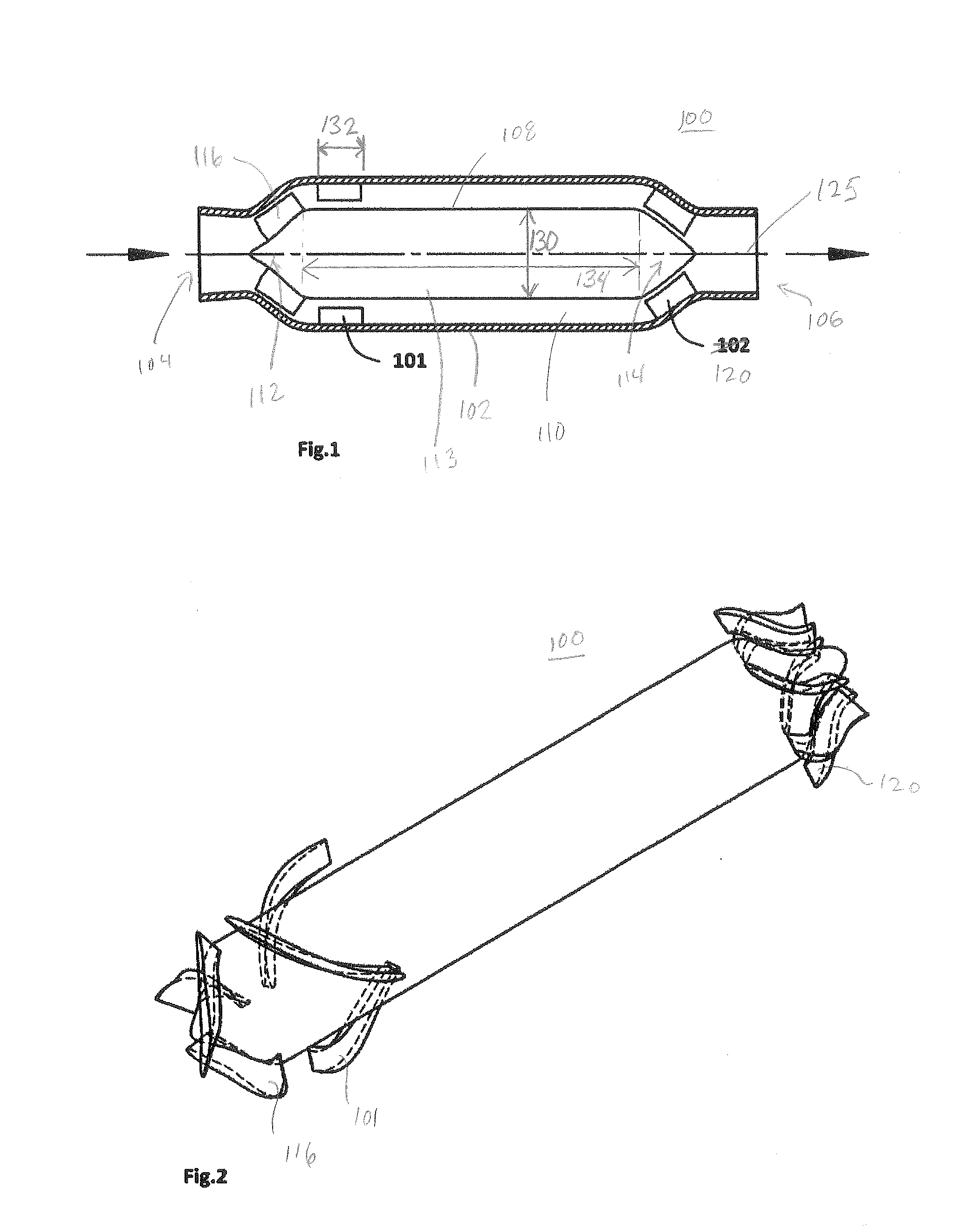

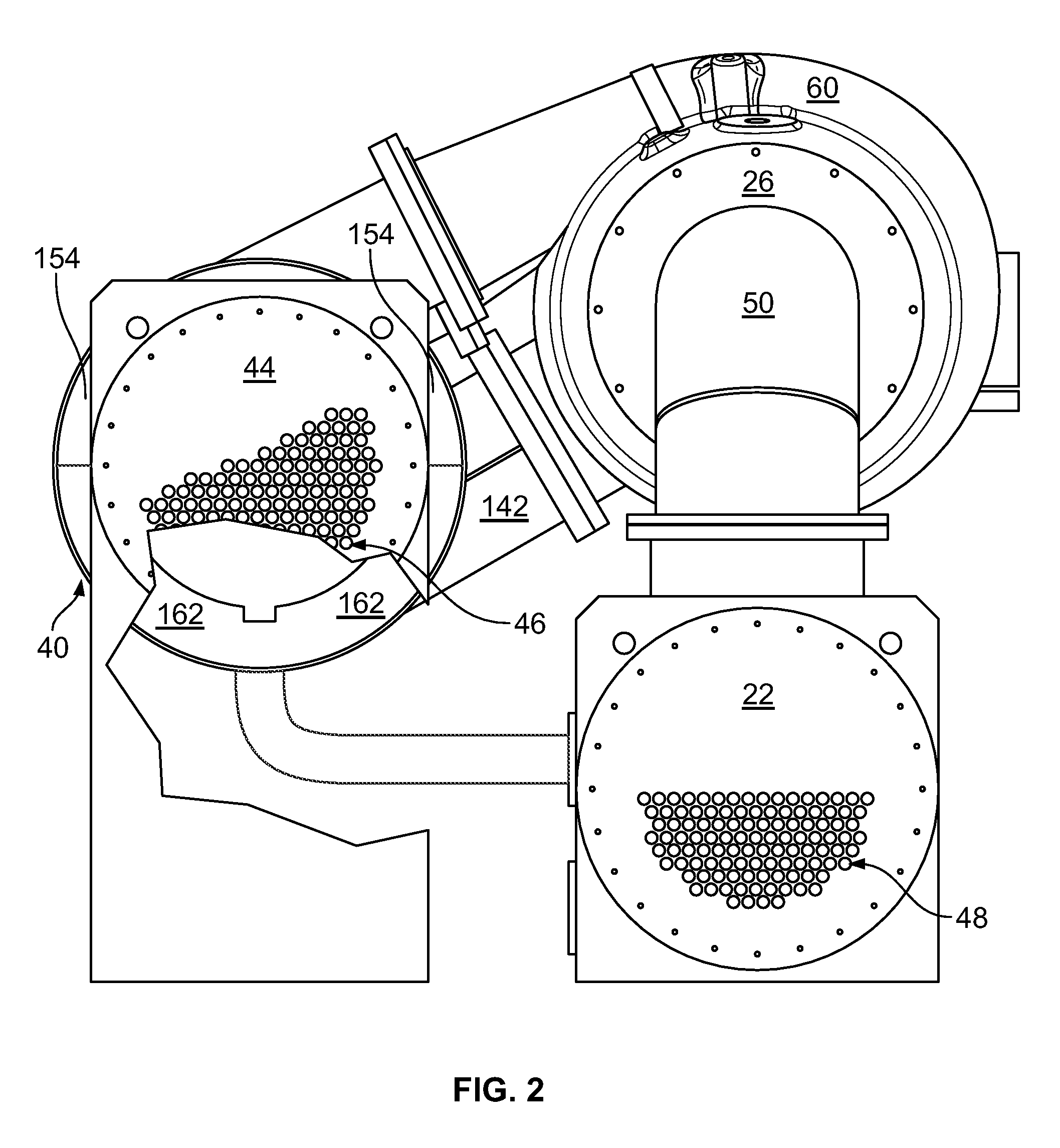

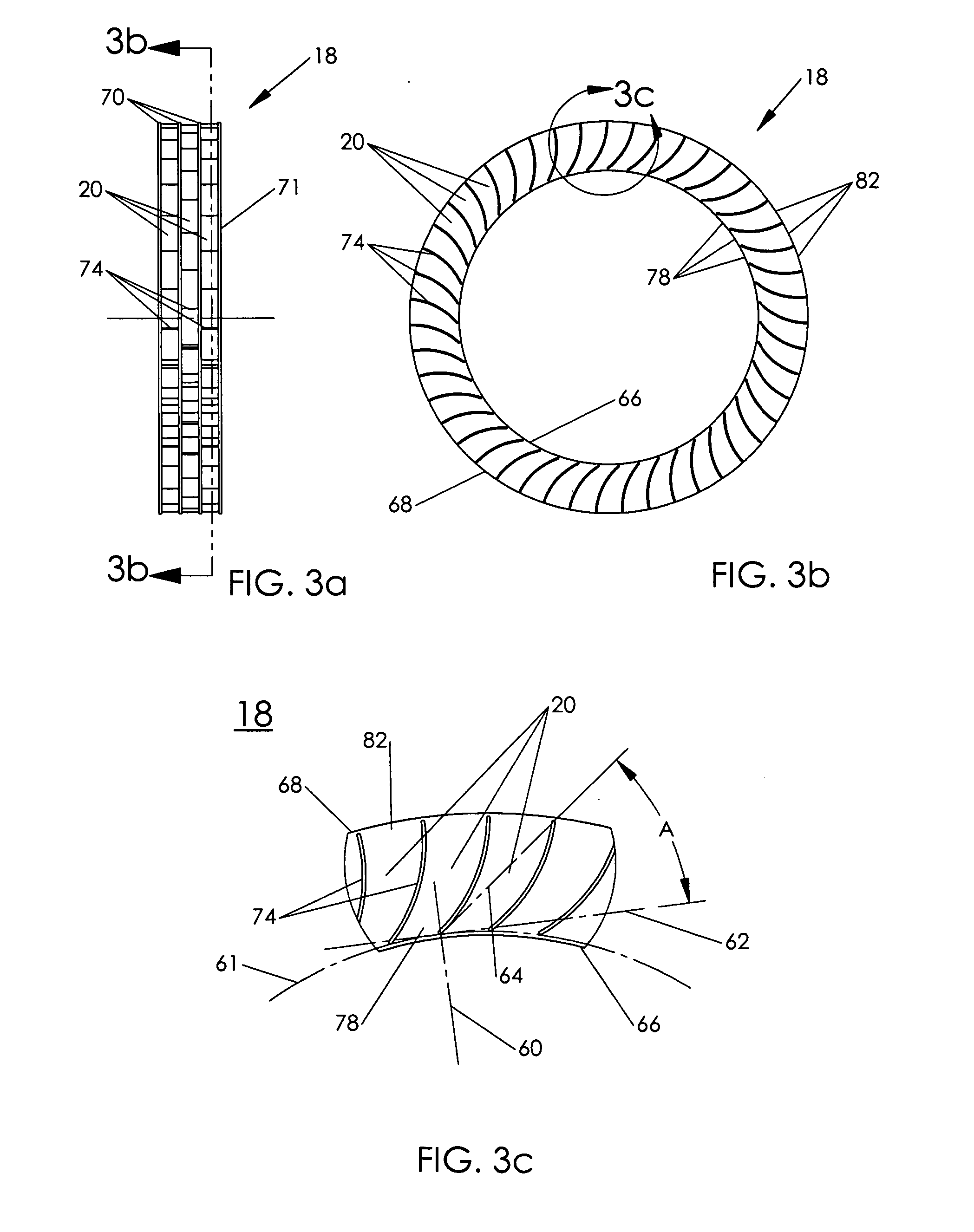

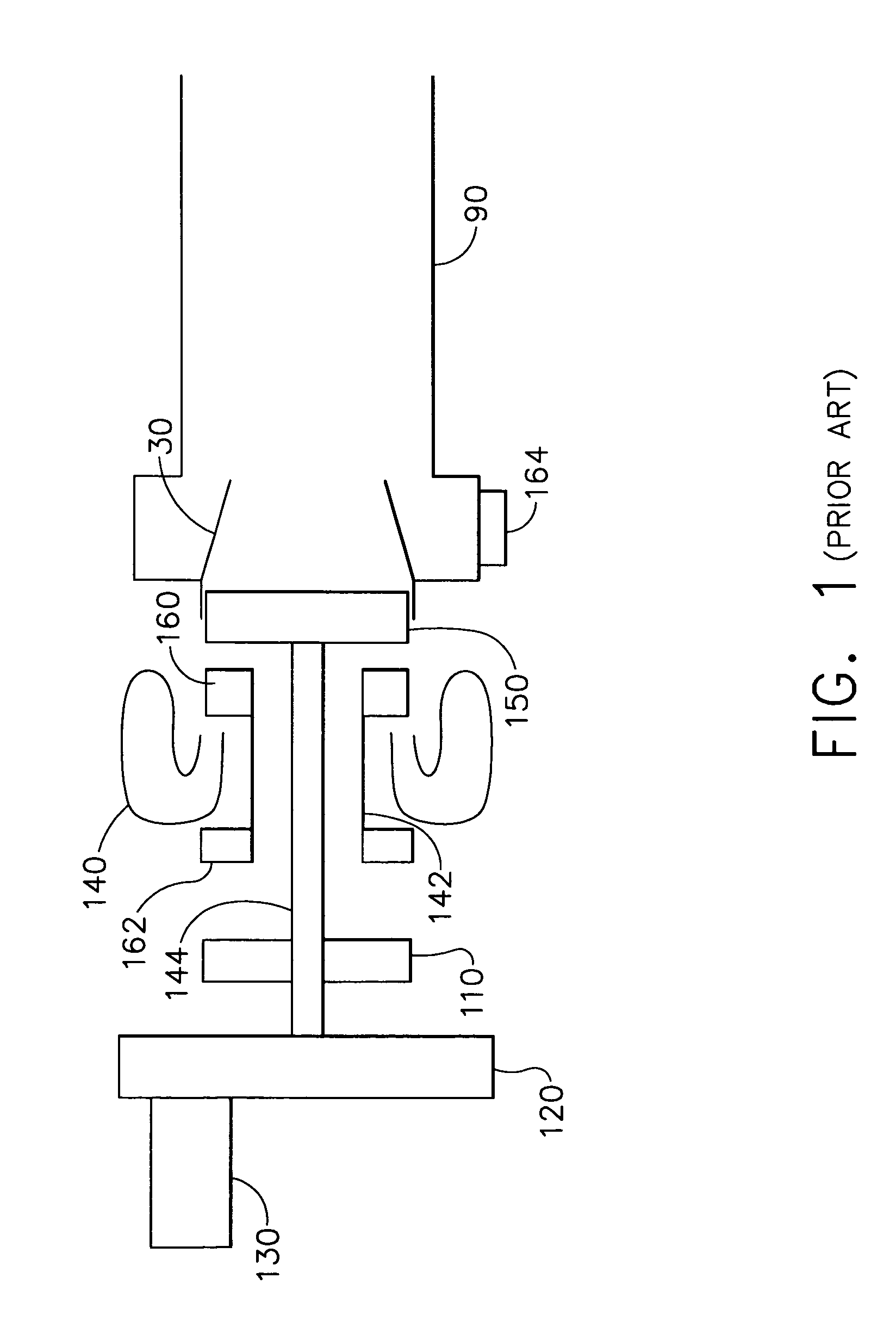

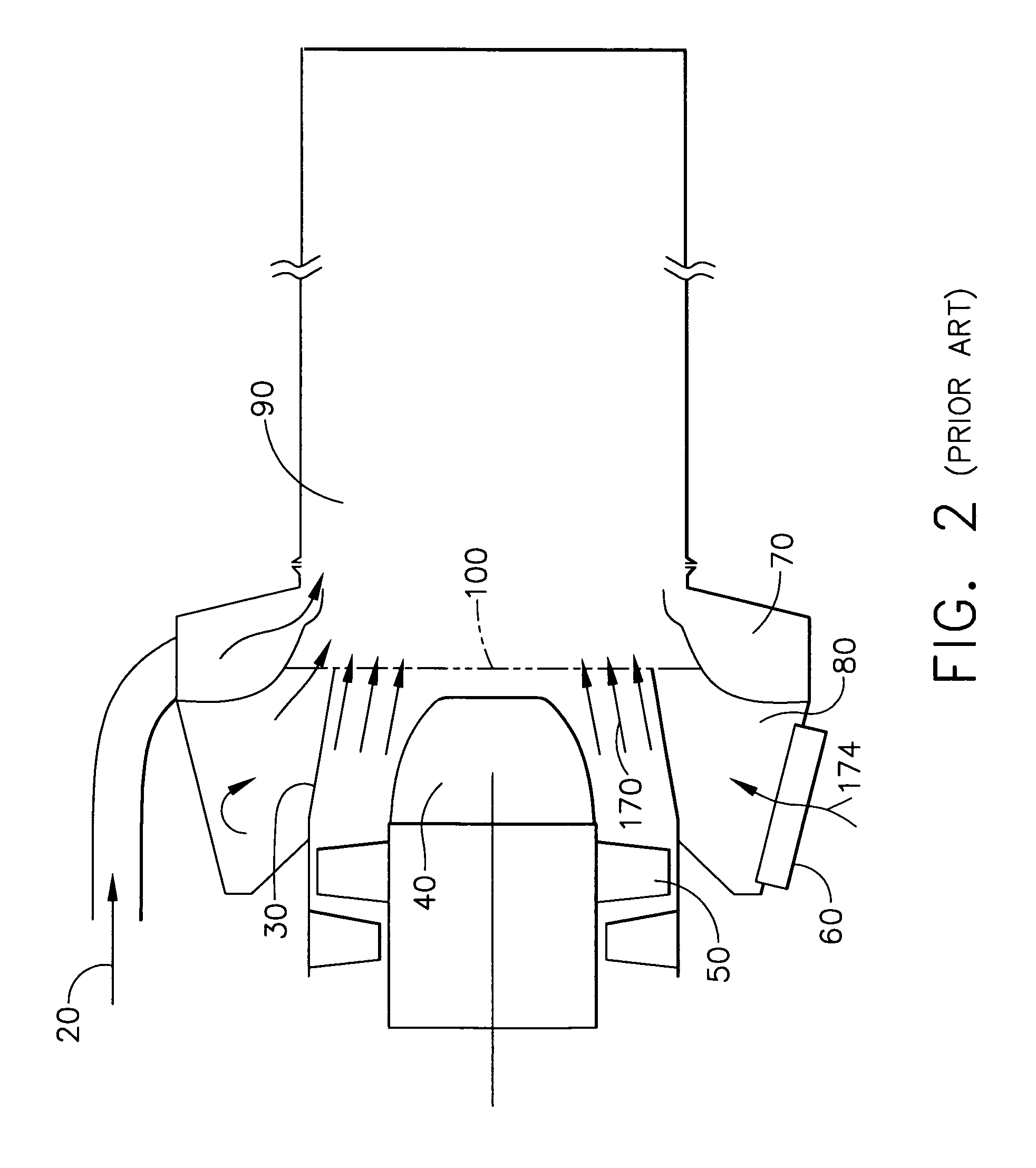

Dual inlet mixed-flow blood pump

A mixed-flow blood pump presents features of both axial-flow and radial-flow pumps. This mixed-flow blood pump comprises a stationary housing structure defining at least one blood inlet, a blood outlet, and a blood conduit between the at least one blood inlet and the blood outlet, and a rotative impeller mounted in the blood conduit. The at least one blood inlet, the blood outlet, the blood conduit and the rotative impeller have respective structures and configurations that operate the mixed-flow blood pump at a given point of a maximum hydraulic efficiency curve relating a specific pump rotational speed and a specific pump diameter. This given point is located within a transition region of the maximum hydraulic efficiency curve between axial-flow and radial-flow pumps.

Owner:CARDIANOVE

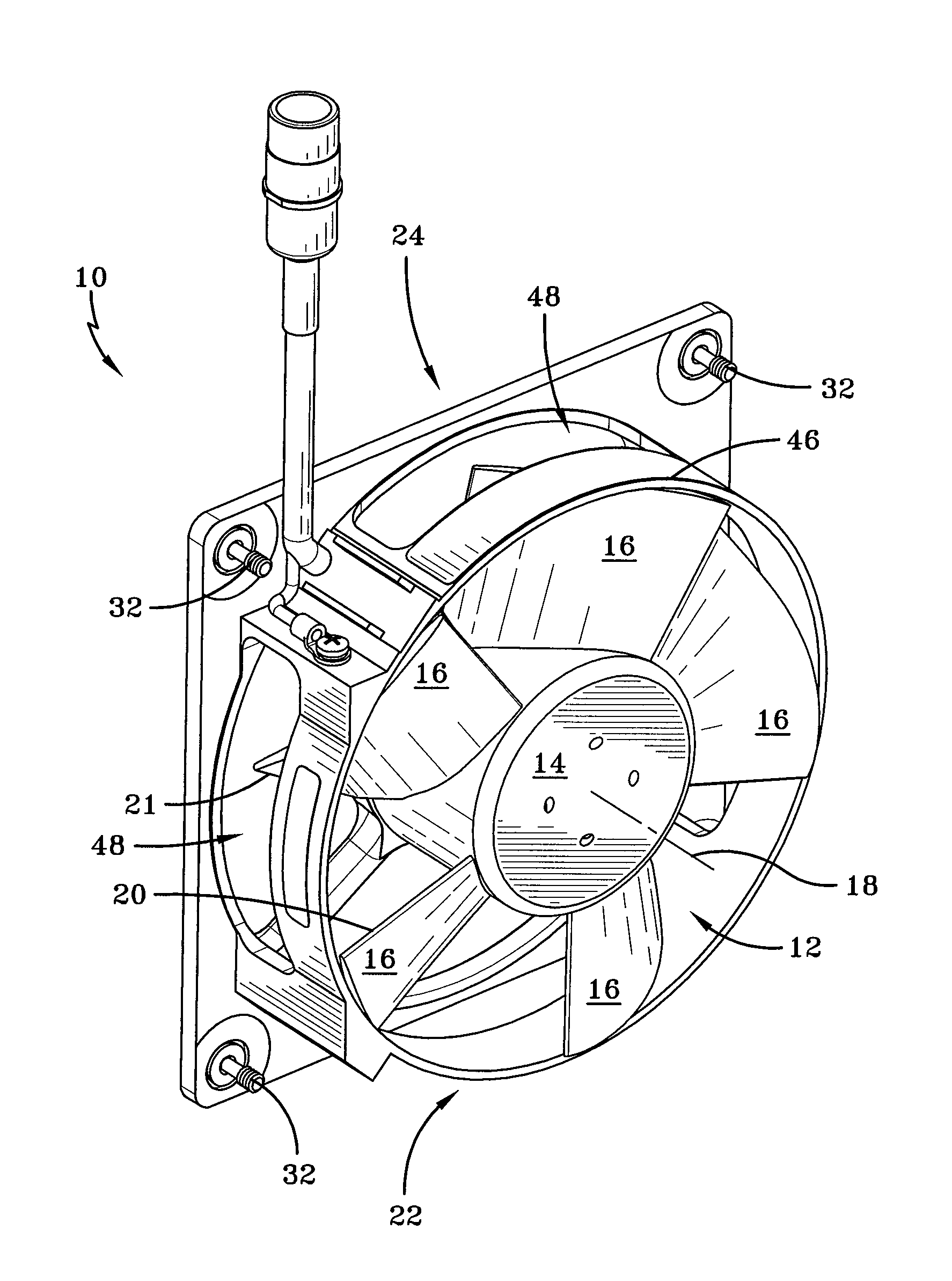

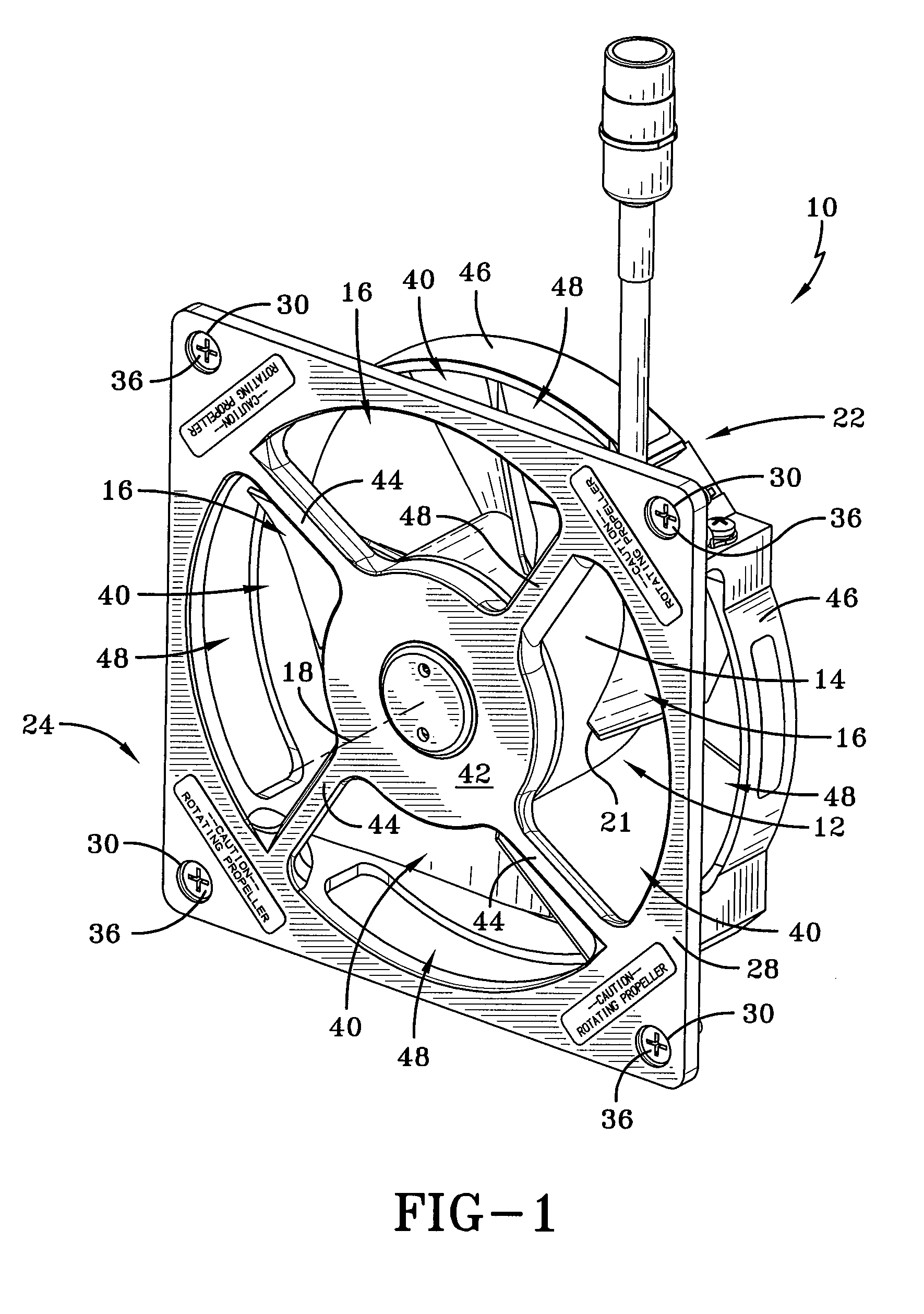

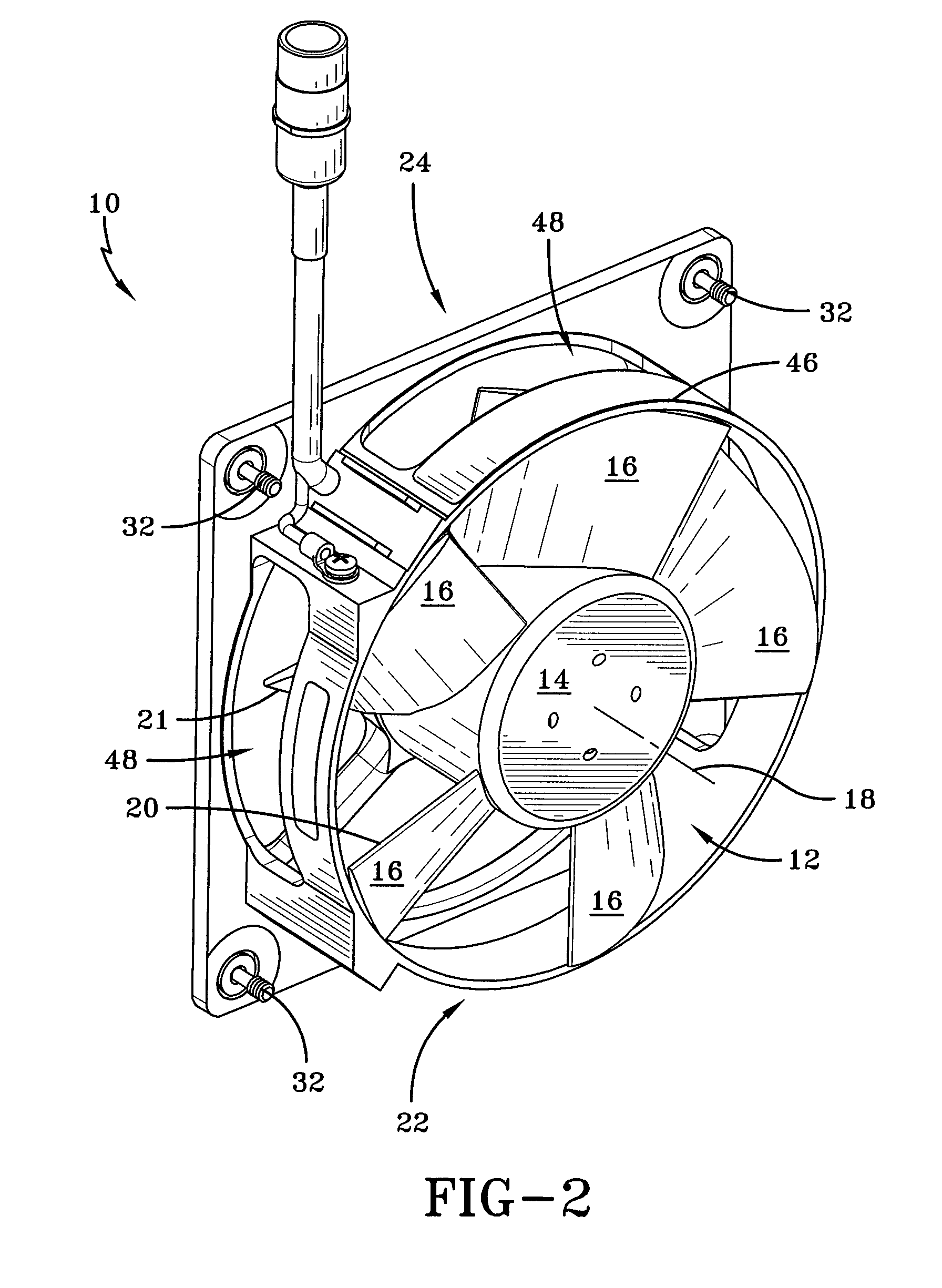

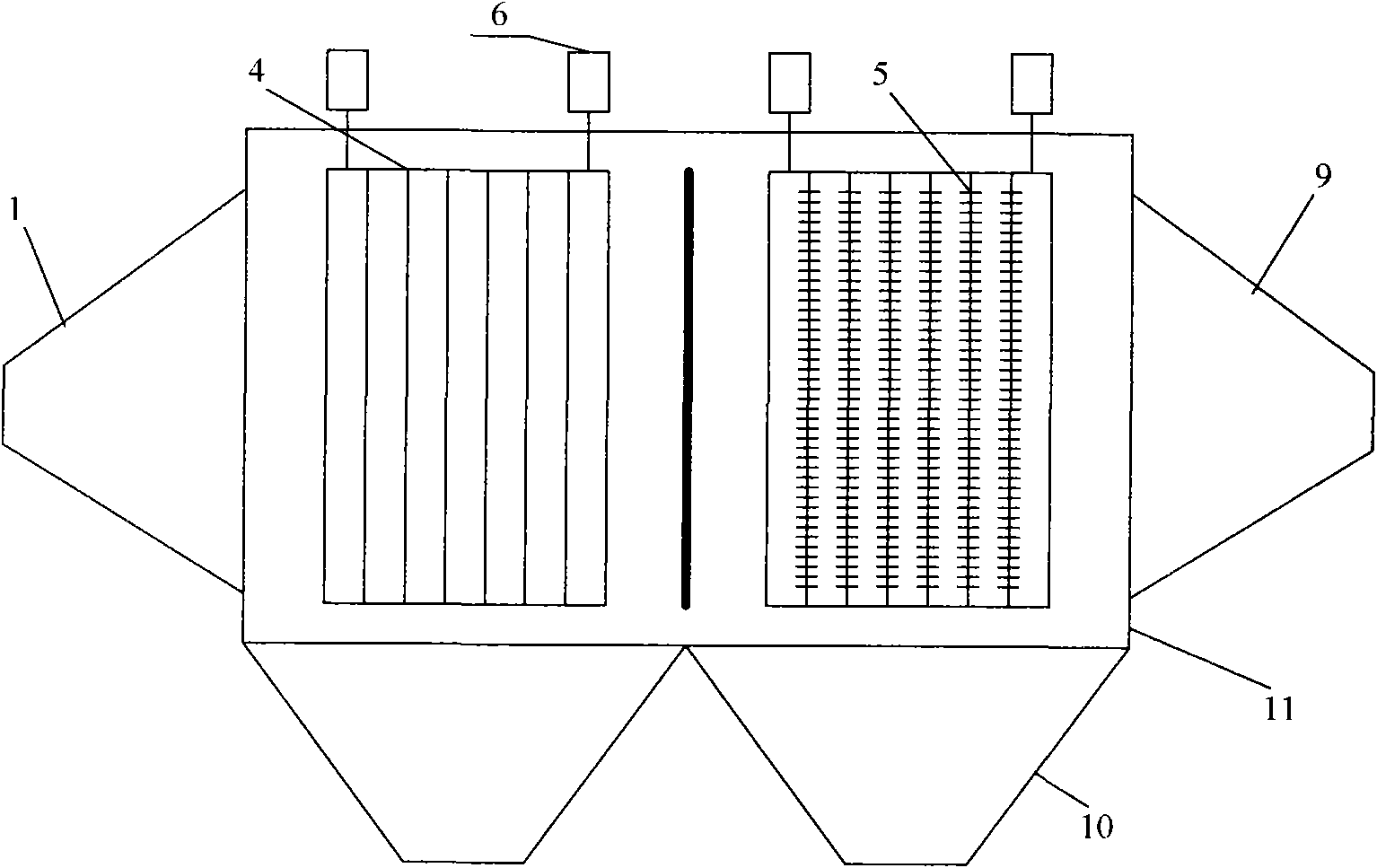

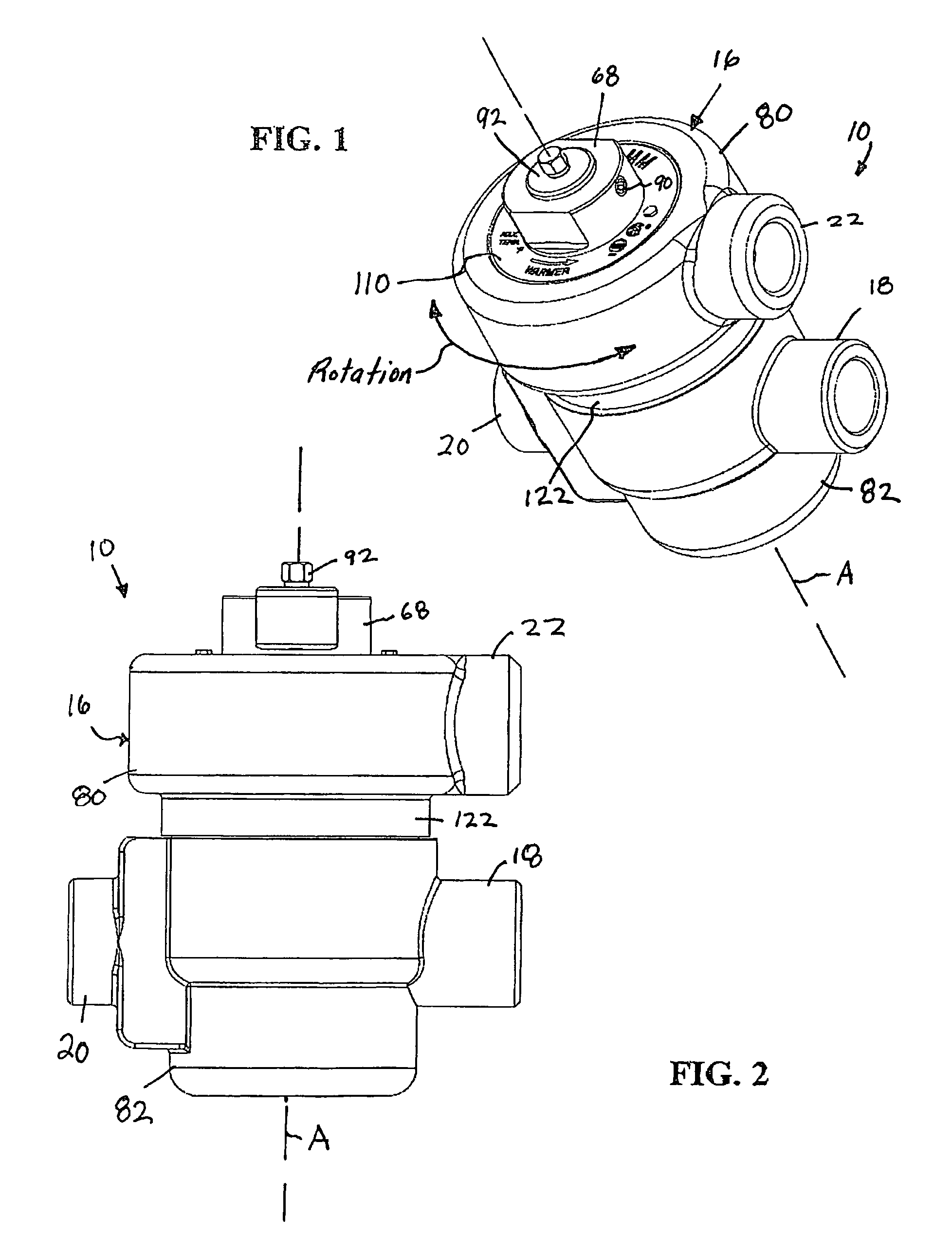

Peripheral discharge tube axial fan

A mixed flow fan assembly includes an electric motor, an impeller having a hub enclosing the motor, and a plurality of fan blades spaced circumferentially around the hub. The fan assembly also includes an axis of rotation extending through the hub, an annular venturi radially surrounding the impeller, and a mounting plate with an opening to allow for axial airflow positioned on one open end of the venturi. The venturi has at least one elongated slot to allow for radial airflow from the fan assembly, the slot being oriented substantially perpendicular to the axis of rotation and having a generally rectangular shape. Rotation of the hub and the fan blades caused by the electric motor generates both axial and radial airflow through the fan assembly.

Owner:AMETEK INC

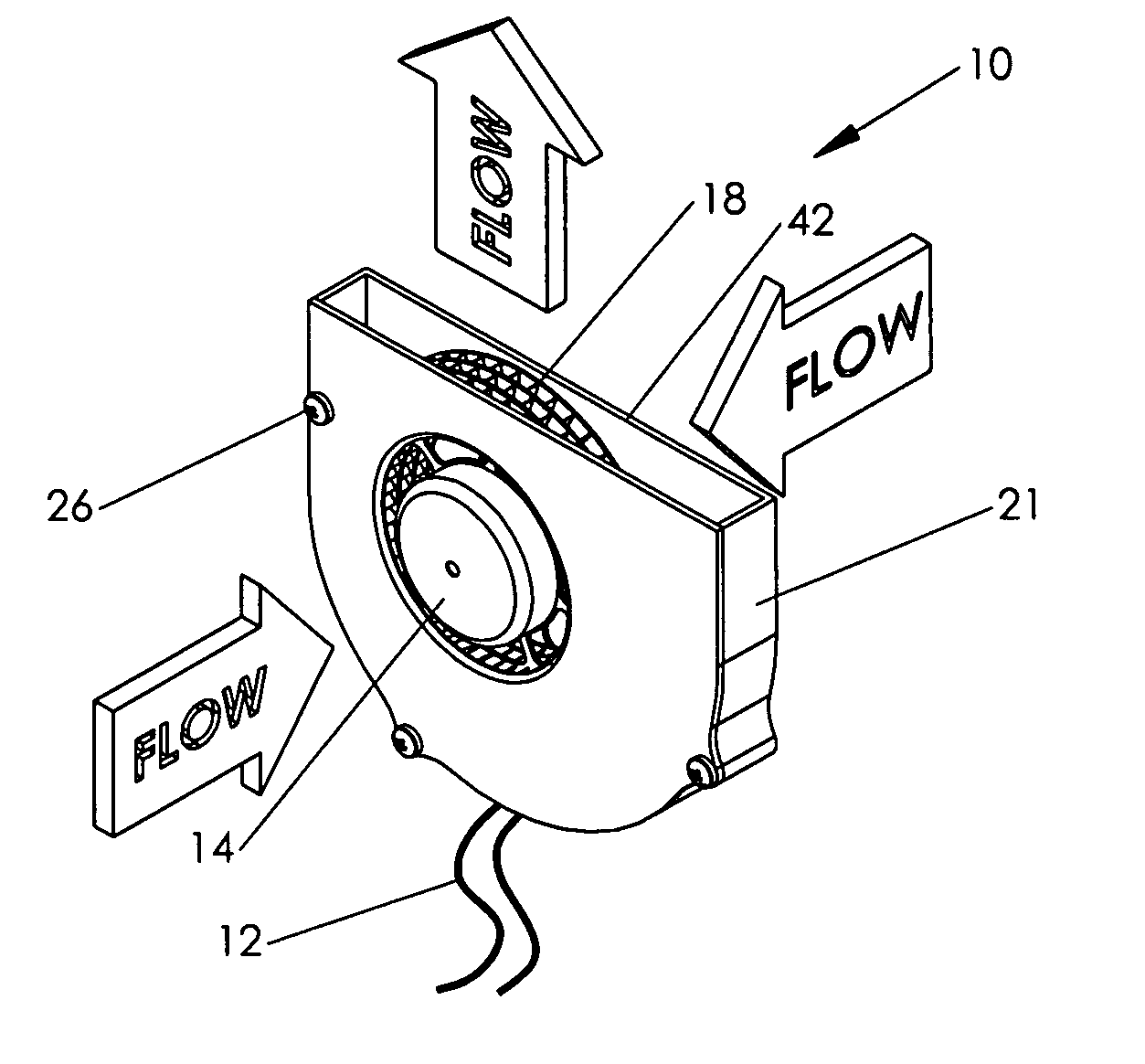

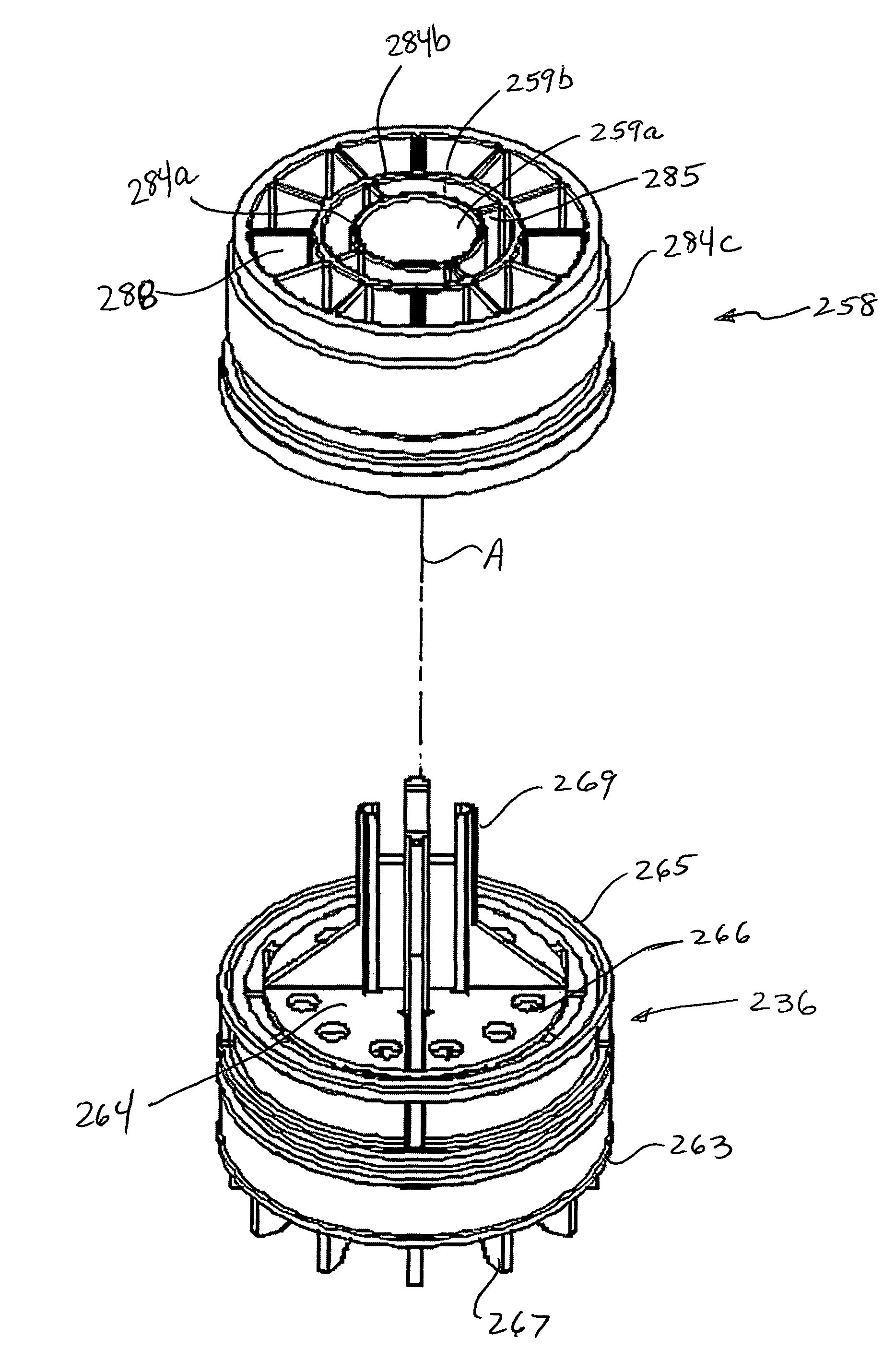

High efficiency fluid movers

Fluid movers produce at least predominantly laminar flow internally in an axial or a radial direction in a rotor. A fluid mover rotor comprises a matrix of passages of appropriate size to produce at least predominantly laminar flow spaced circumferentially around the rotor. The passages may provide axial, radial or mixed flow. “Appropriate” dimensions may be selected for a specified volume flow rate. In a radial embodiment, a matrix of radially extending passages could comprise walls having an axial height projecting from an annular disk. The passages may be offset with respect to the radial direction to provide an angle of attack that minimizes incidence losses. The matrix structure allows the use of thin-walled passages to minimize blockage of entering air.

Owner:HILL ENG

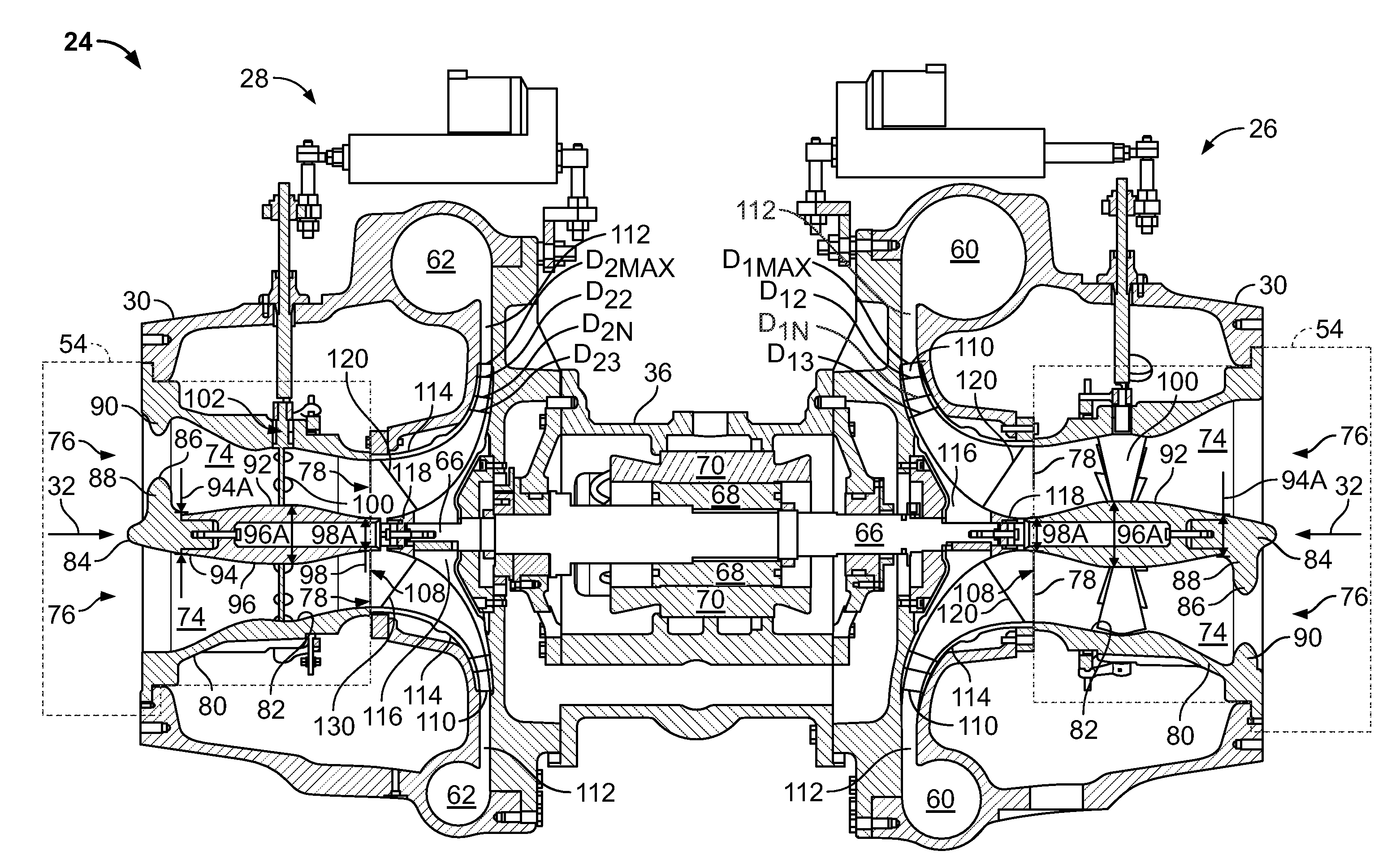

Centrifugal compressor assembly and method

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

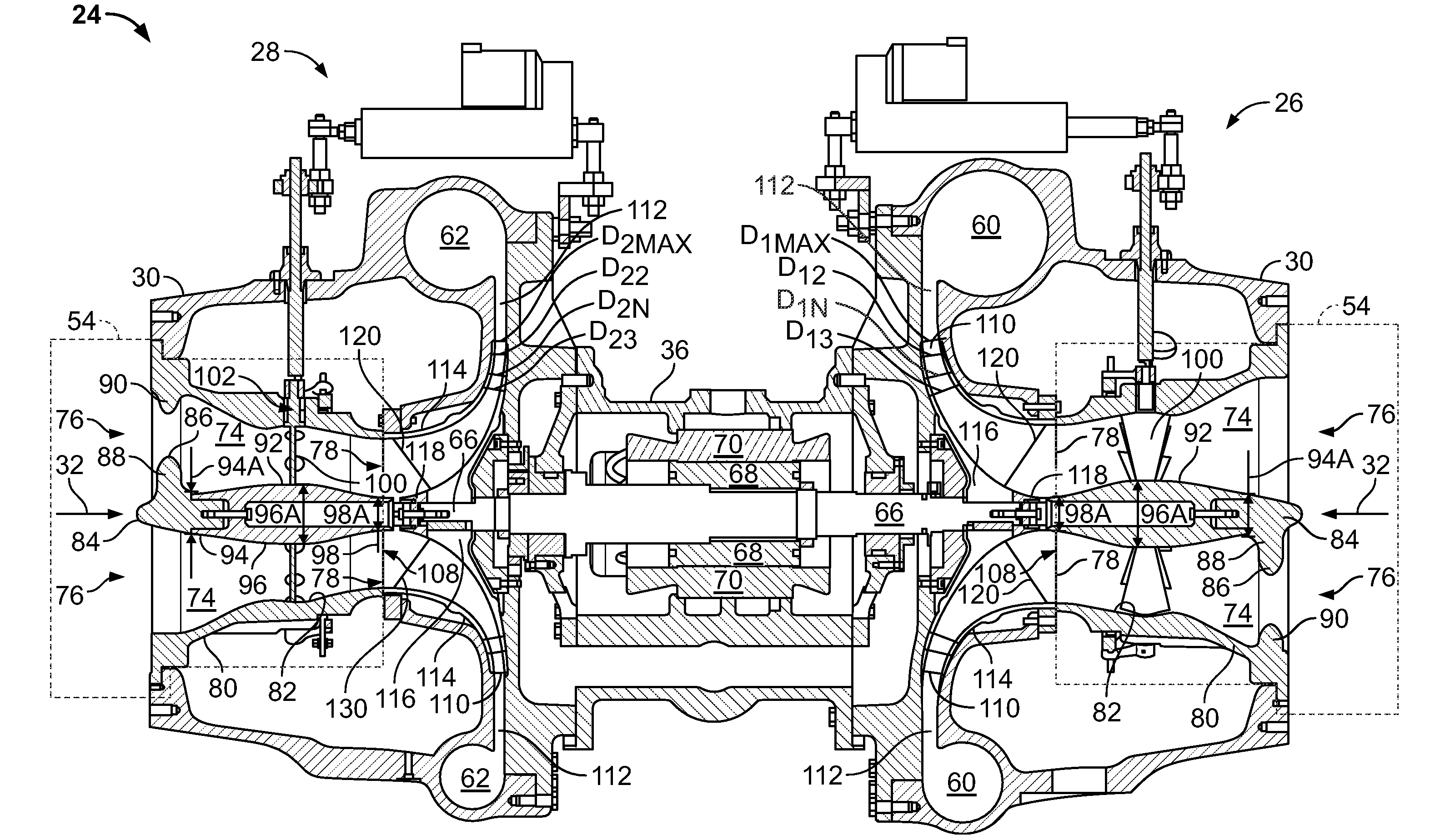

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

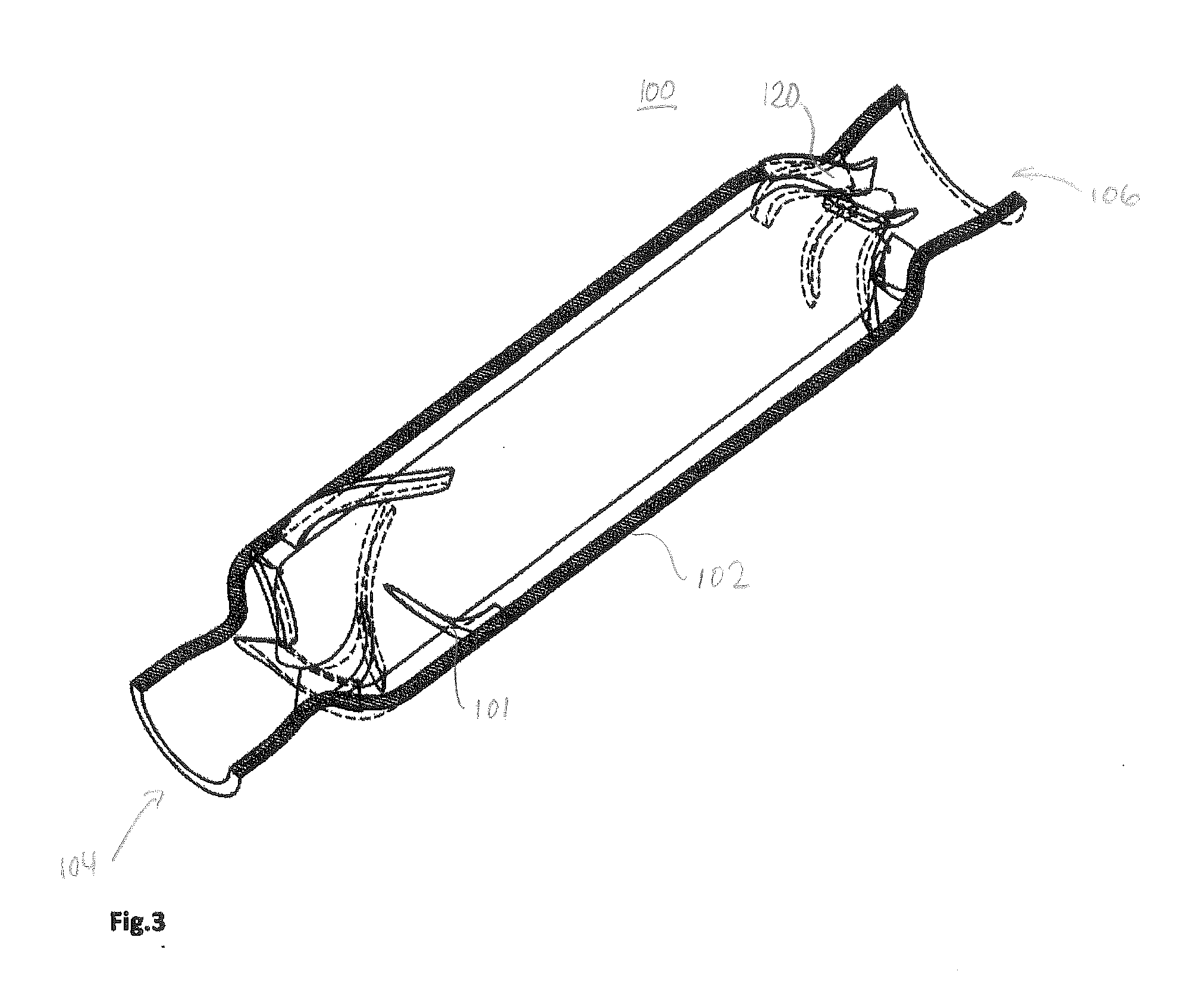

Blood pump with splitter impeller blades and splitter stator vanes and related methods

InactiveUS20120134832A1Low blood damageGuaranteed uptimePump componentsBlood pumpsImpellerMixed flow

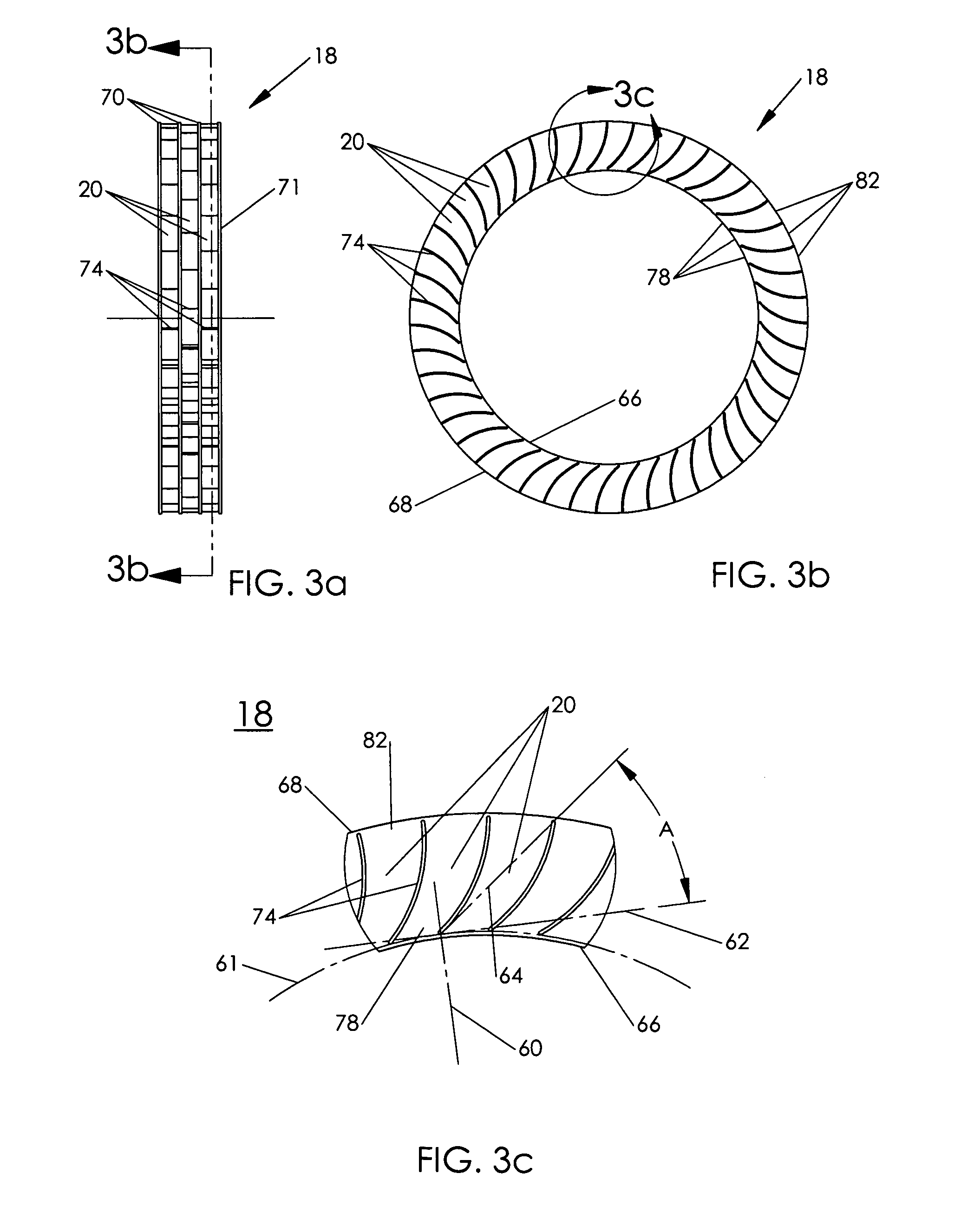

A rotordynamic pump for delivering continuous flow of fluids, such as blood, is provided. In one embodiment, the pump includes a stator housing having an inlet and an outlet. A rotor hub is disposed within the stator housing having a mixed-stage or mixed-flow impeller. The mixed flow impeller includes both principle blades and splitter blades, the splitter blades exhibiting a shorter axial length than the principle blades. One or more stator vanes and extend radially inwardly from the stator housing. The splitter blades and principle blades are arranged in a circumferentially alternating pattern. The stator vanes include principle stator vanes and splitter stator vanes, the splitter stator vanes exhibiting a shorter axial length than the principle stator vanes. The splitter vanes and principle vanes are arranged in a circumferentially alternating pattern. The rotor hub may be magnetically suspended and rotated within the stator housing.

Owner:WORLD HEART

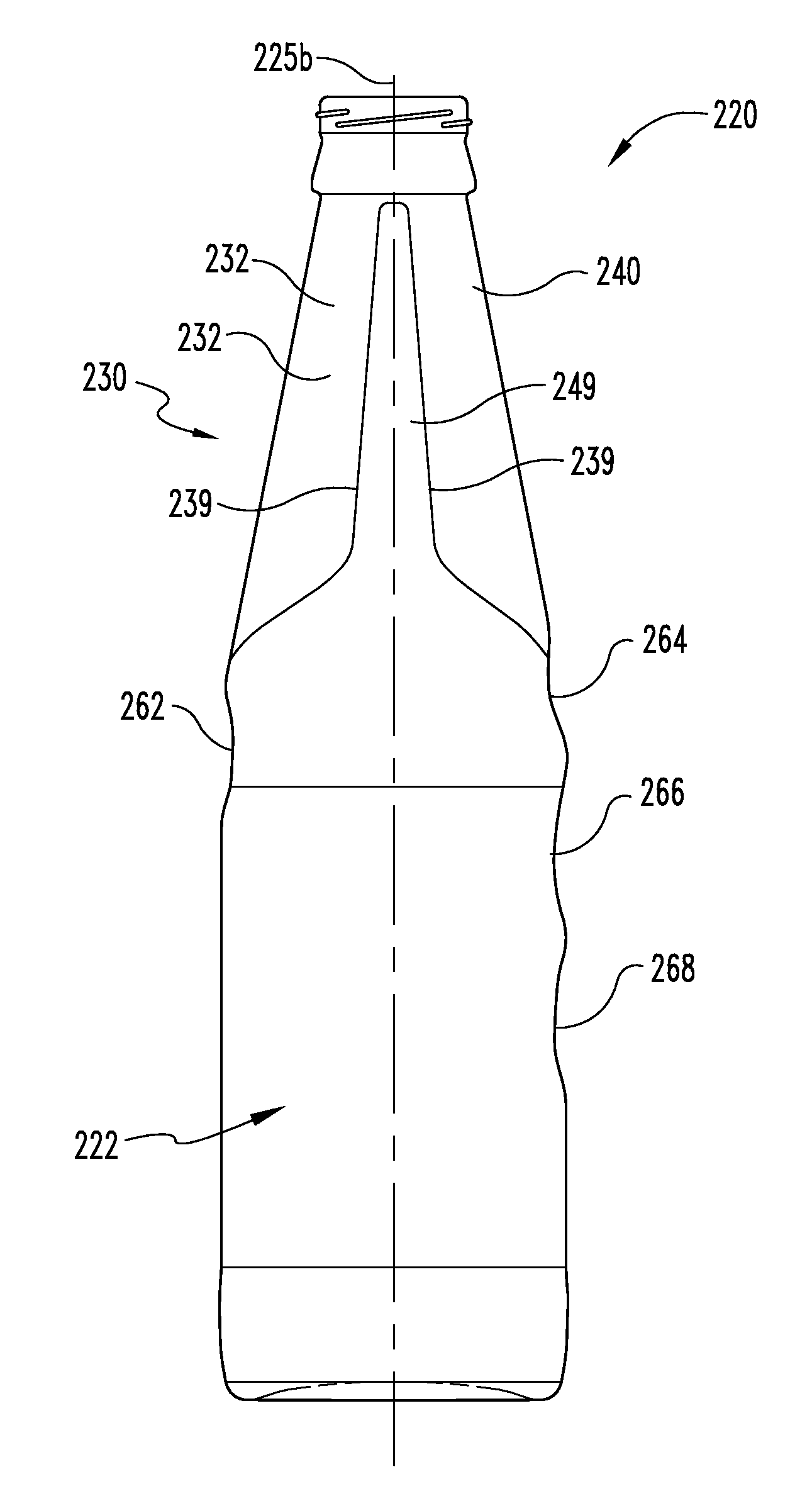

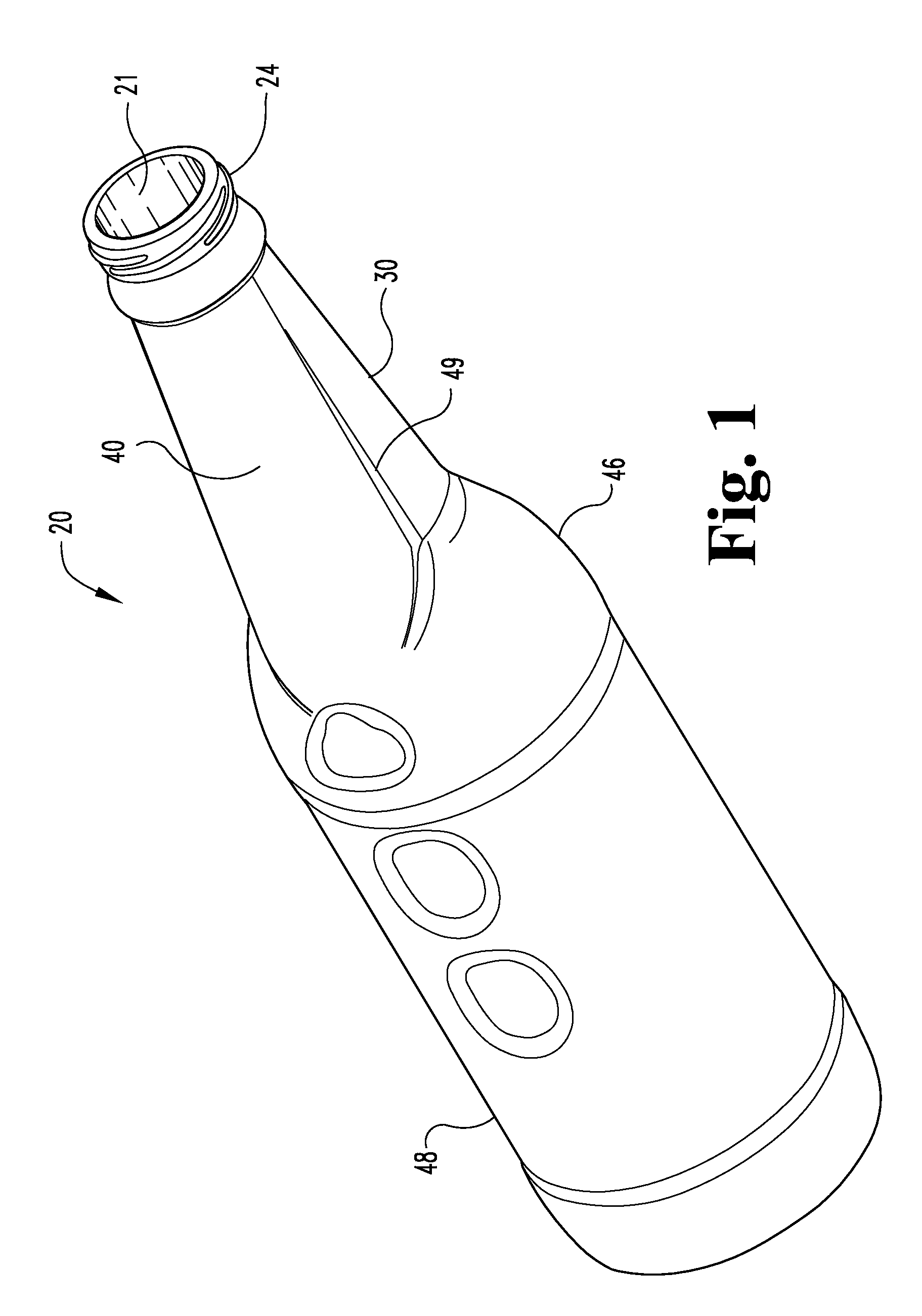

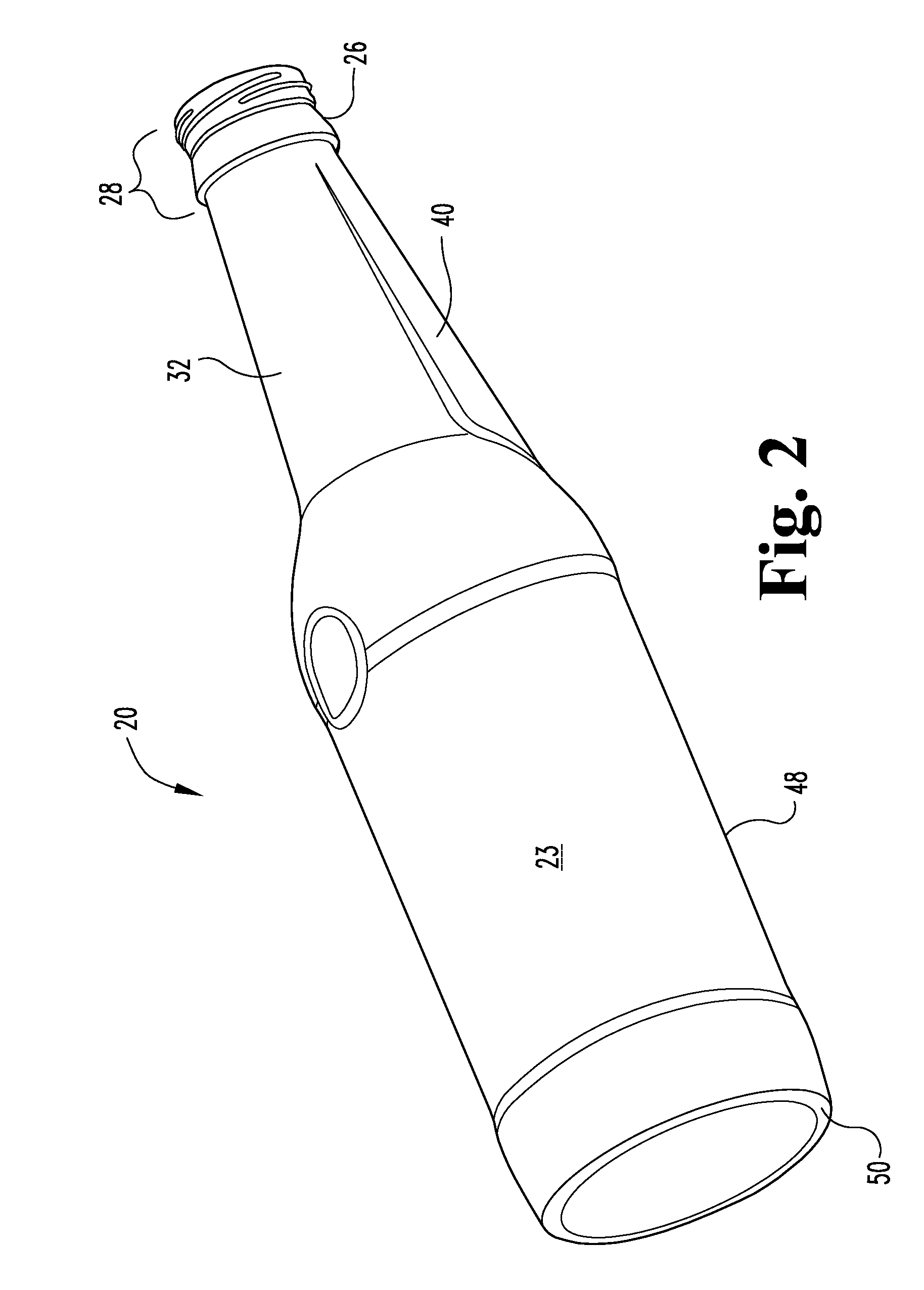

Free flowing bottle

A glass bottle with improved pouring characteristics. In some embodiments the bottle can hold pressurized liquid. The bottle includes a neck with a non-circular cross section. The cross sectional shape of the neck is adapted and configured to provide less turbulence in the liquid being poured out of the bottle, and further to assist in separating the in flow of single phase liquid from the turbulent mixed flow of two phase, gas-liquid substances.

Owner:SAINT GOBAIN CONTAINERS

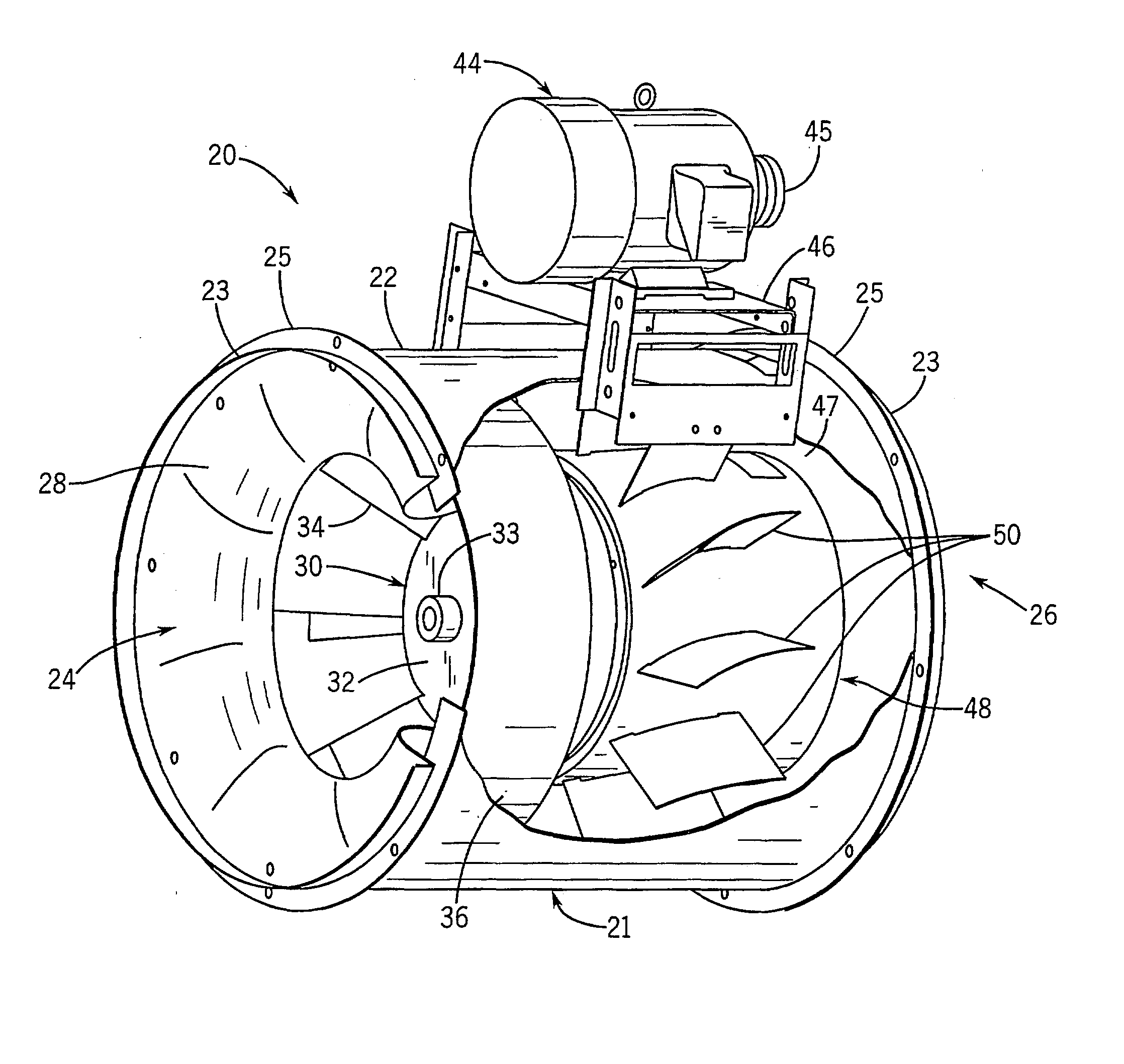

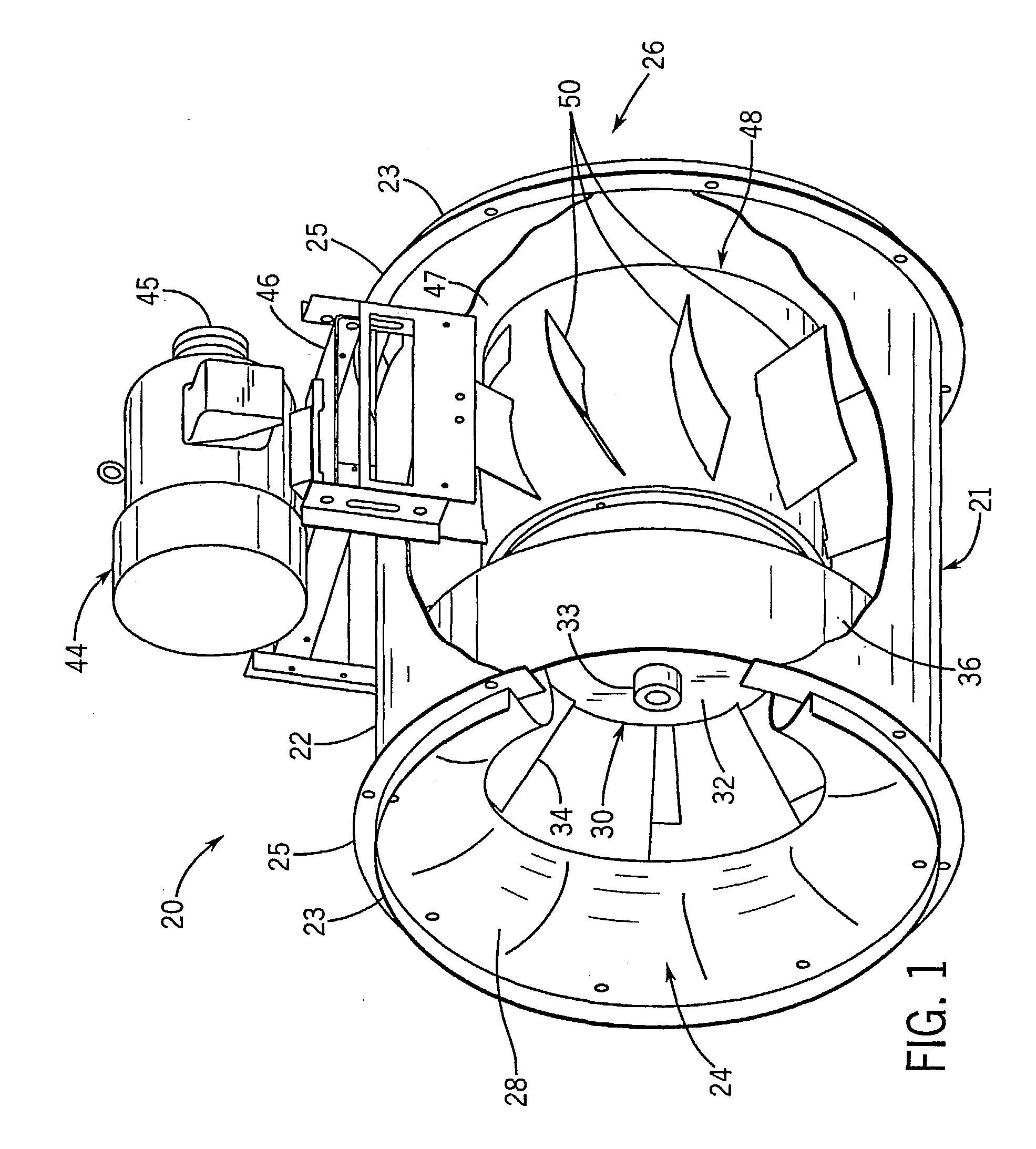

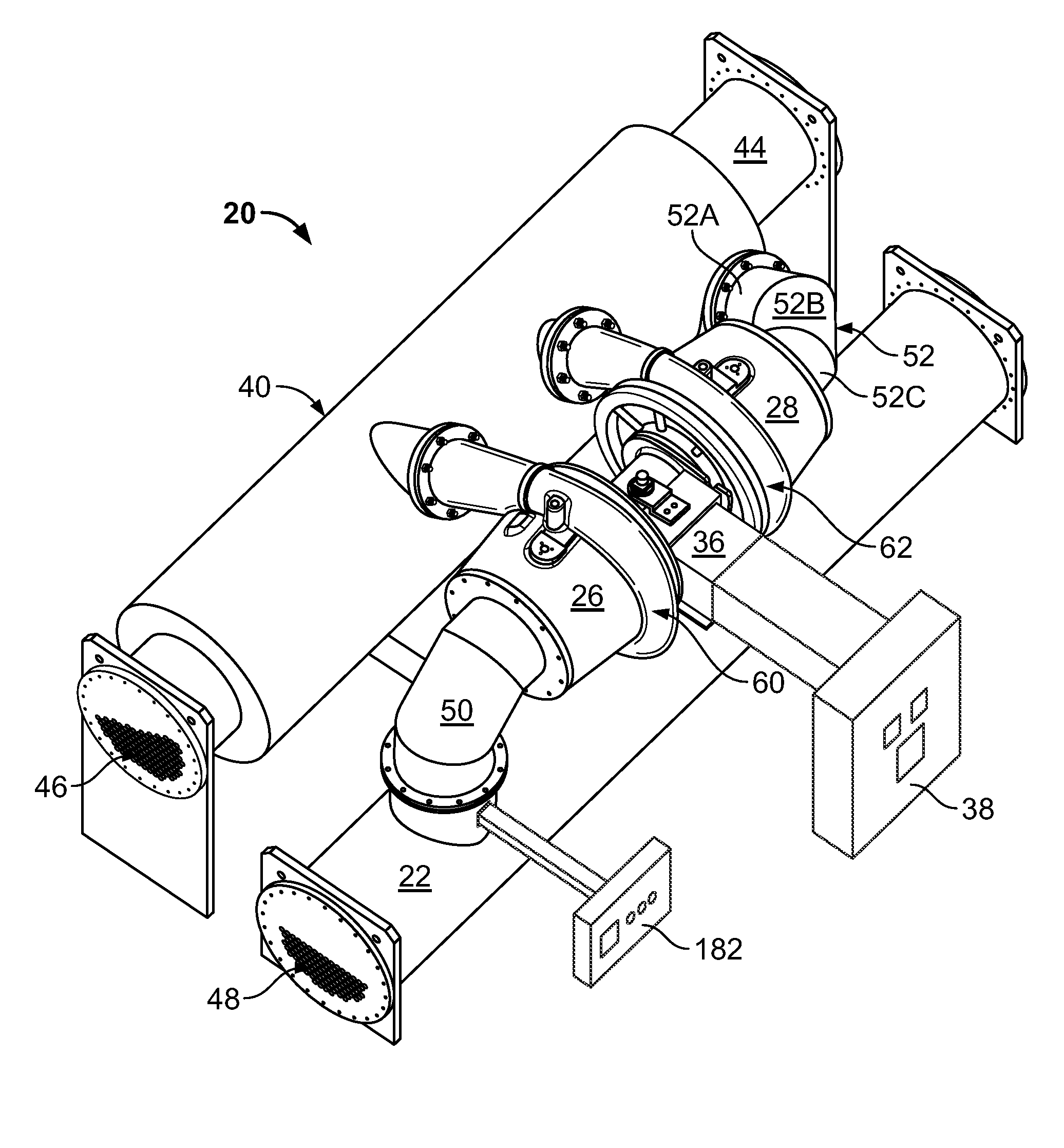

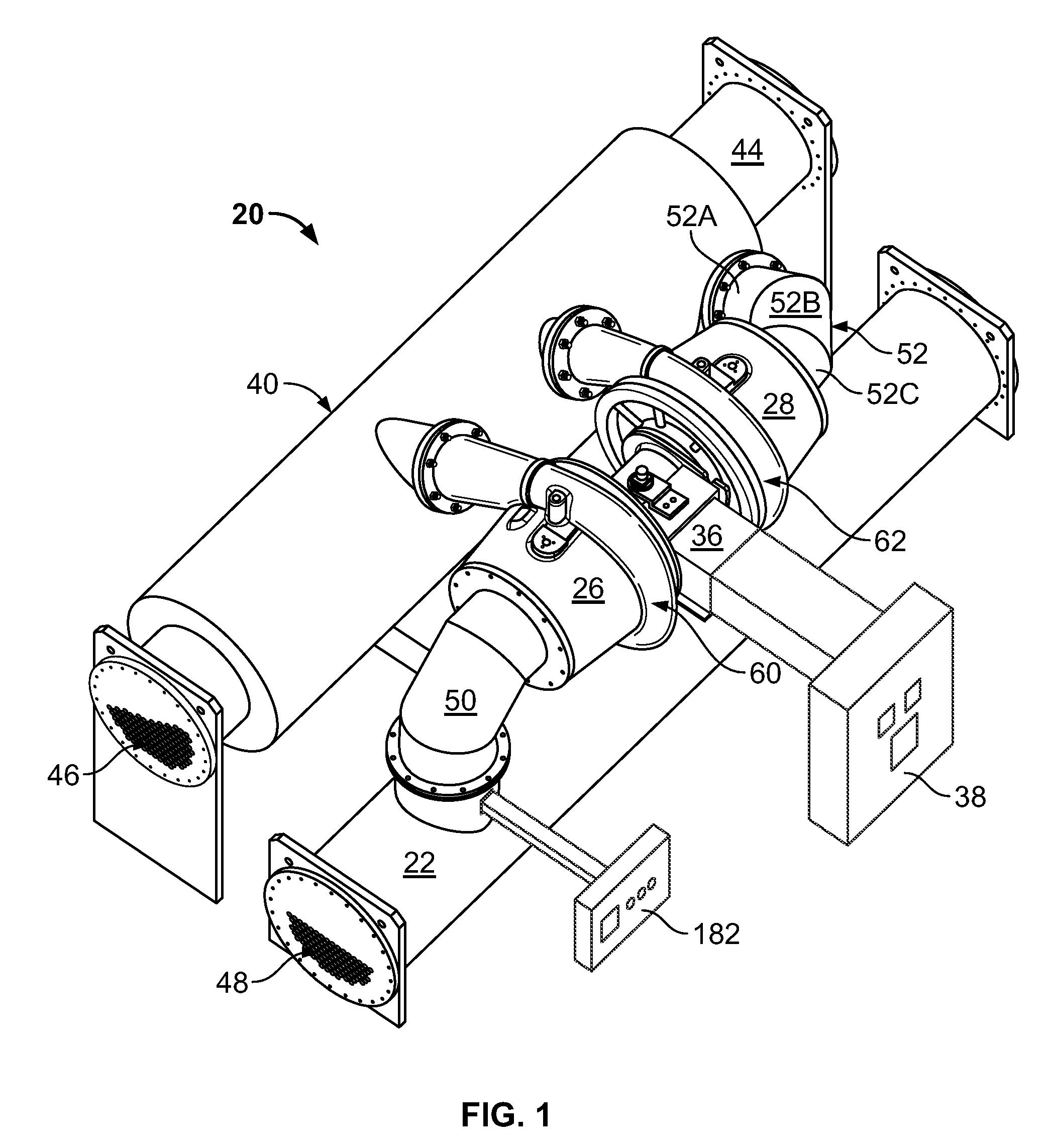

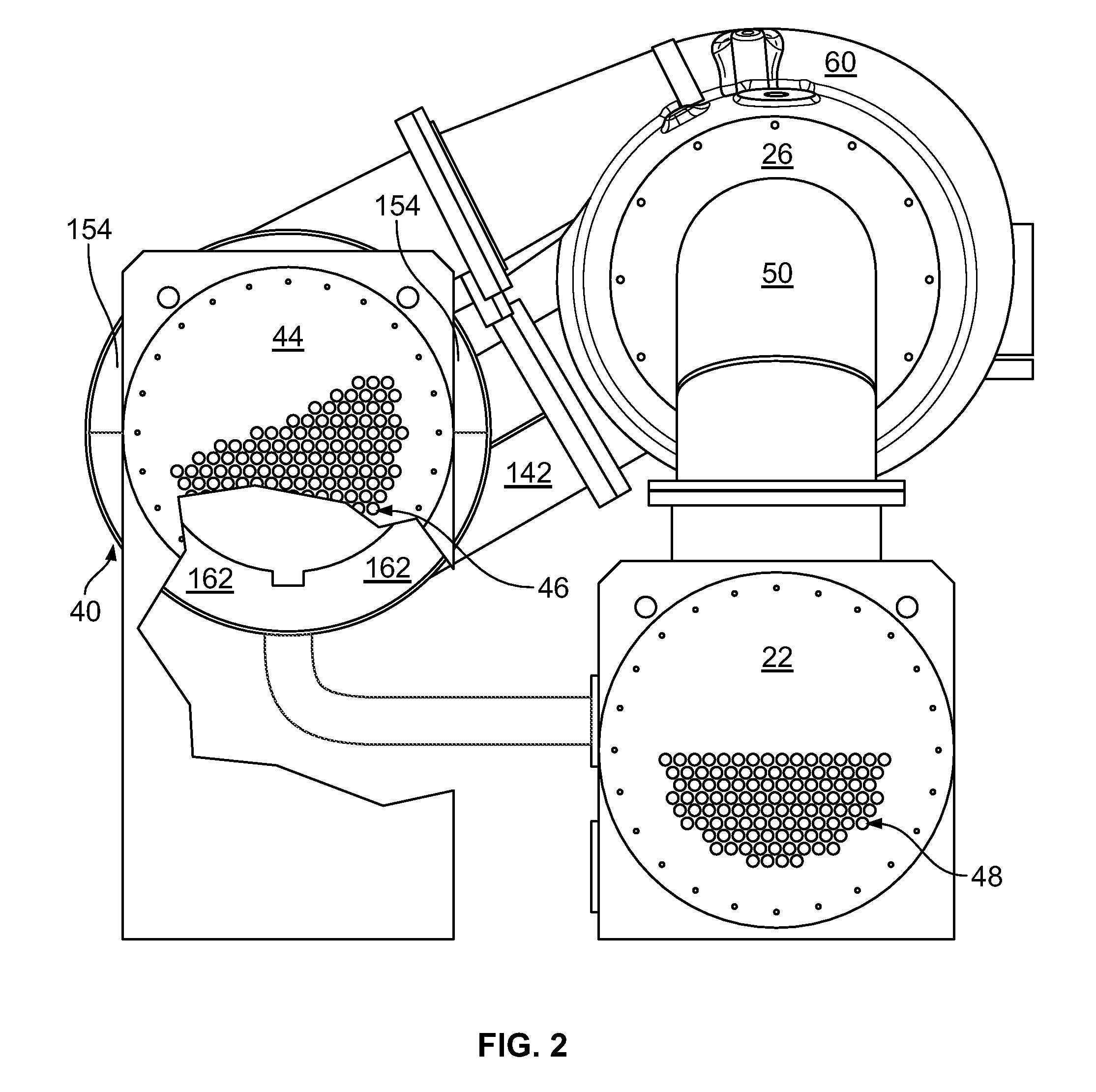

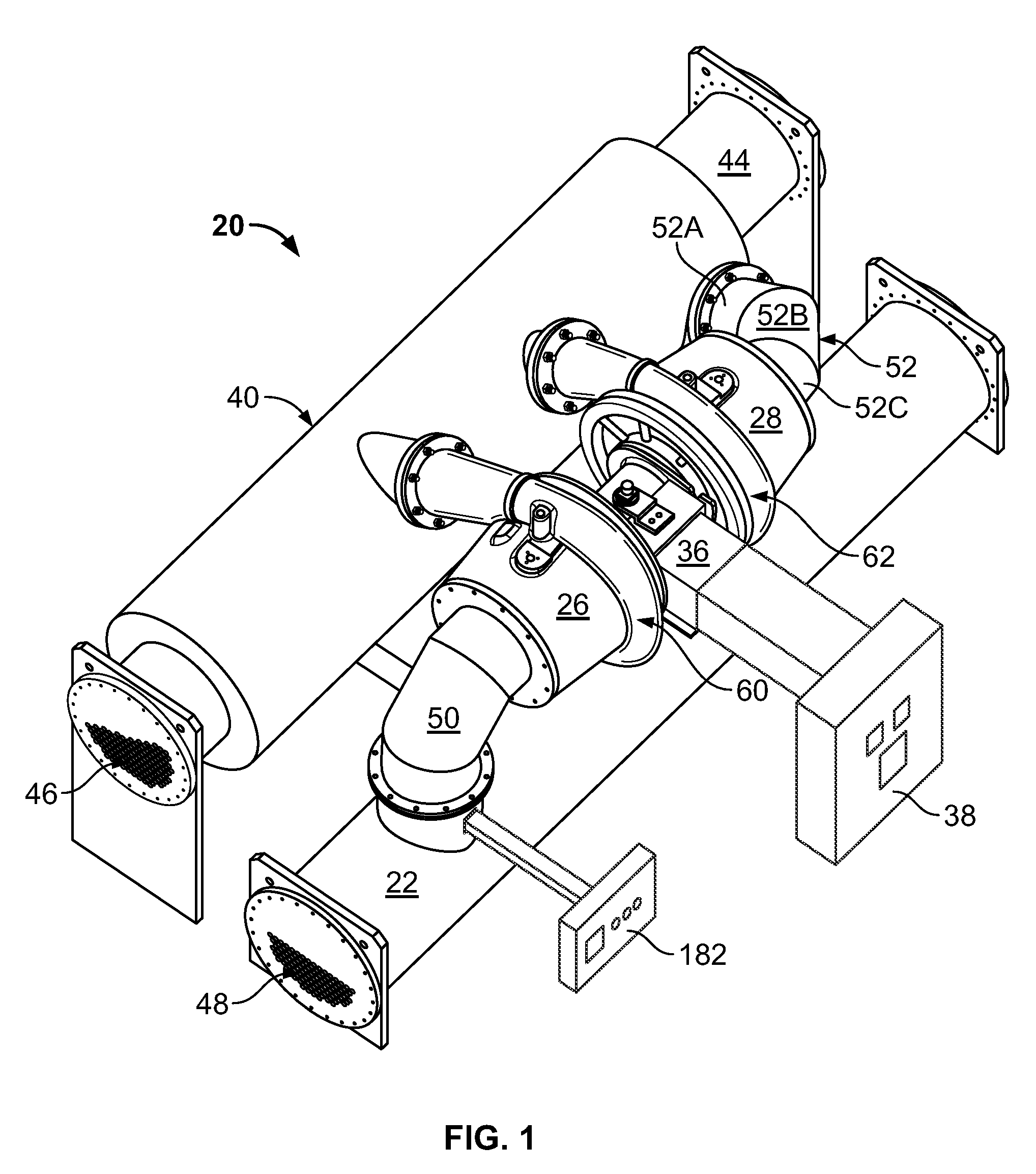

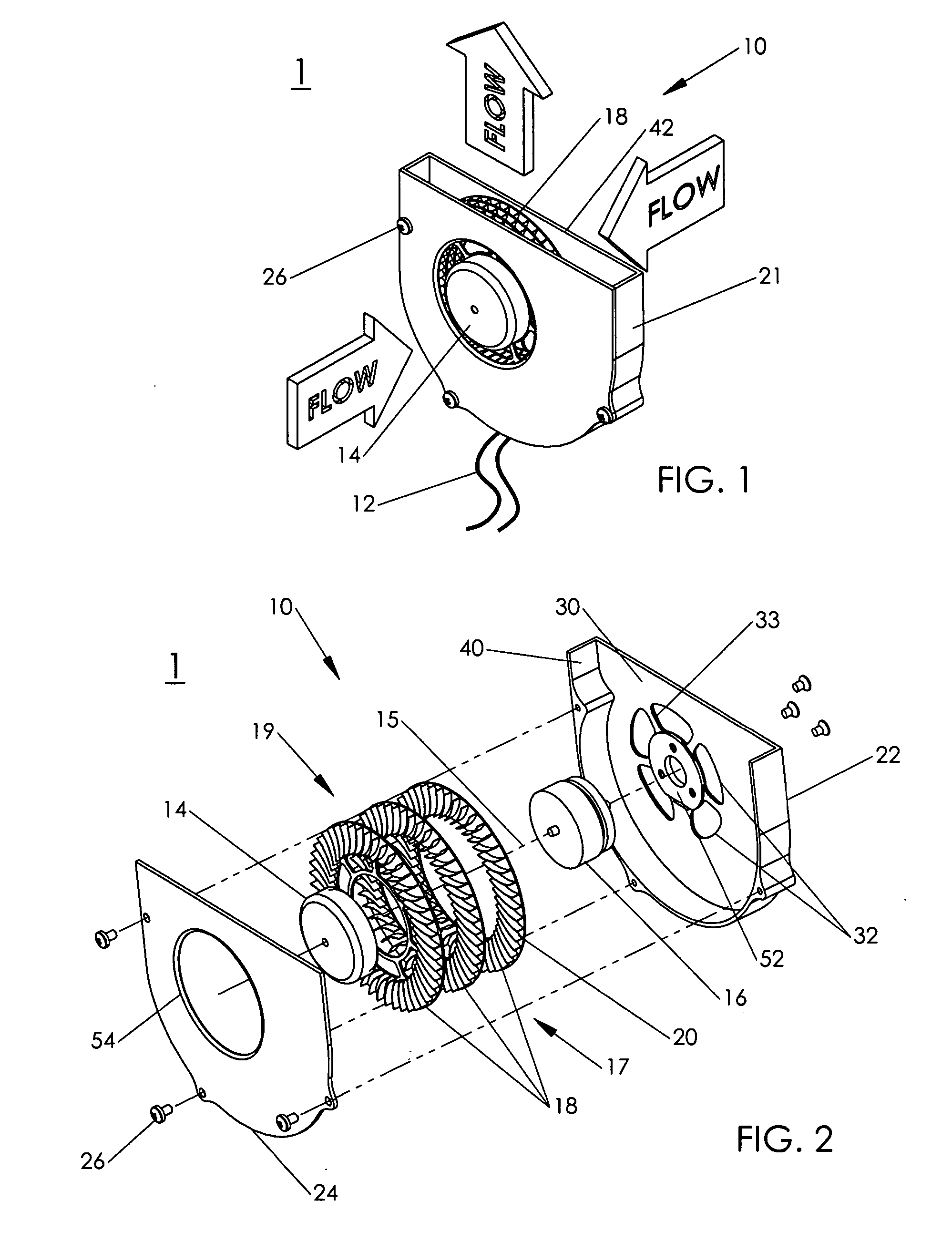

In-line centrifugal fan

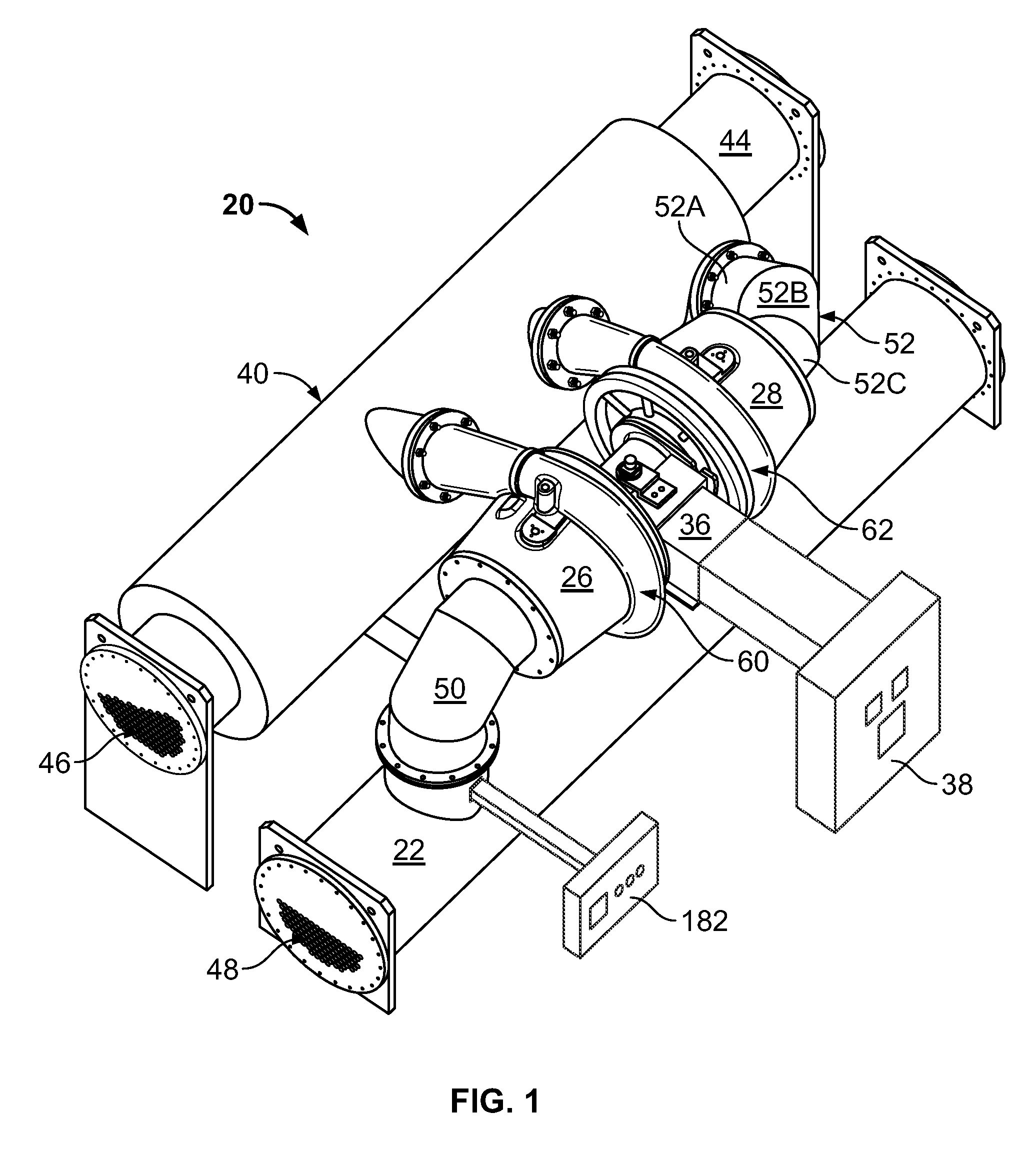

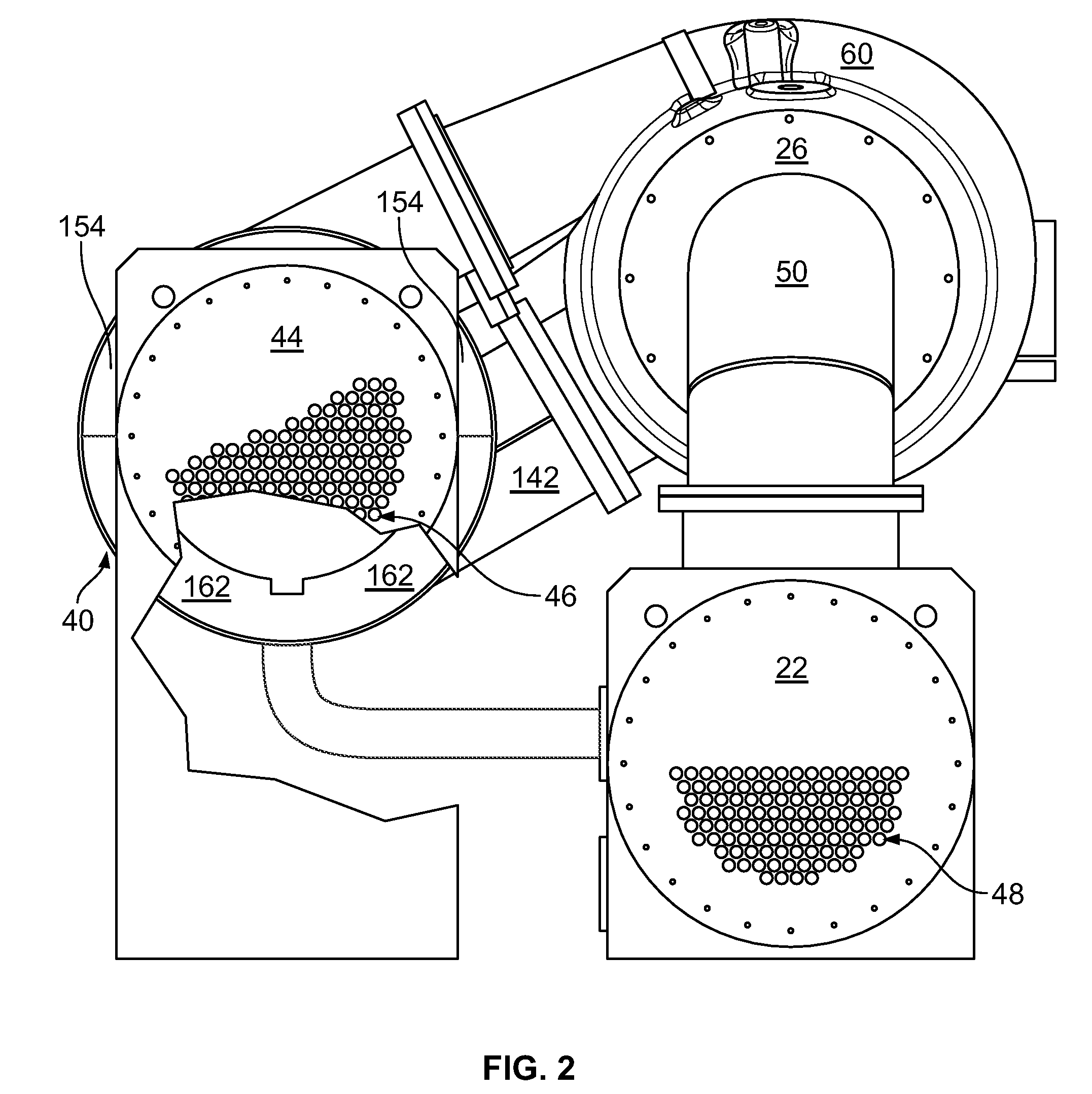

InactiveUS20030206800A1Easy to installEfficient and less noisyPropellersRotary propellersImpellerMixed flow

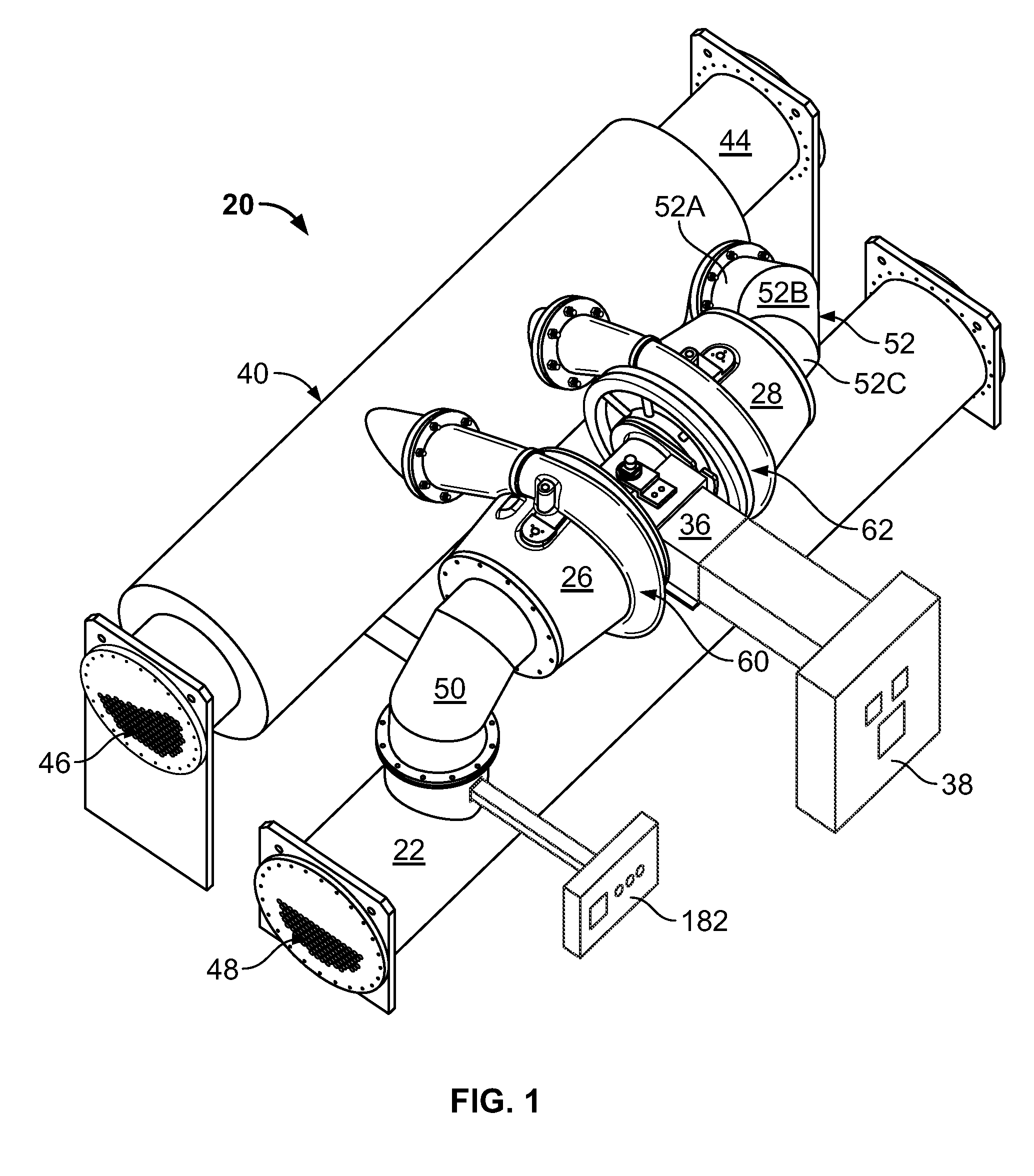

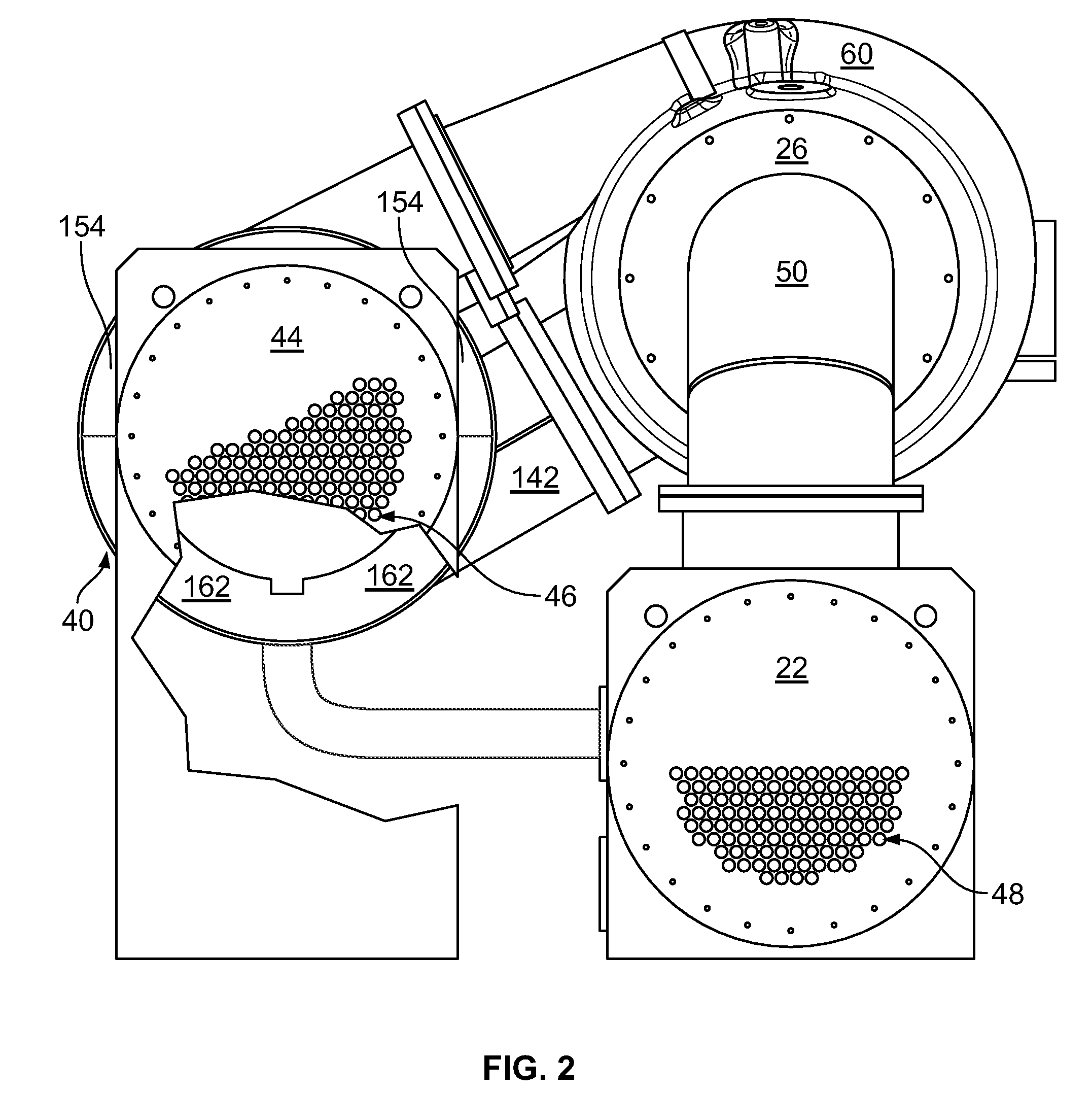

An inline centrifugal mixed flow fan (20) includes an axially extending intake conduit (22). An inlet cone (28) is disposed at an intake end (24). An impeller (30) is disposed downstream of the inlet cone and includes a centrally disposed wheel-back (32) rotated by an electric motor (44), plural fan blades (34) extending radially outwardly from the wheel-back and a wheel cone fixedly (36) attached to and circumscribing the wheel blades. A driver chamber (48) downstream of the impeller includes plural radially extending straight vanes (50) to direct air to an outlet end (26). The fan is configured to achieve reduced sound level and increased efficiency.

Owner:GREENHECK FAN

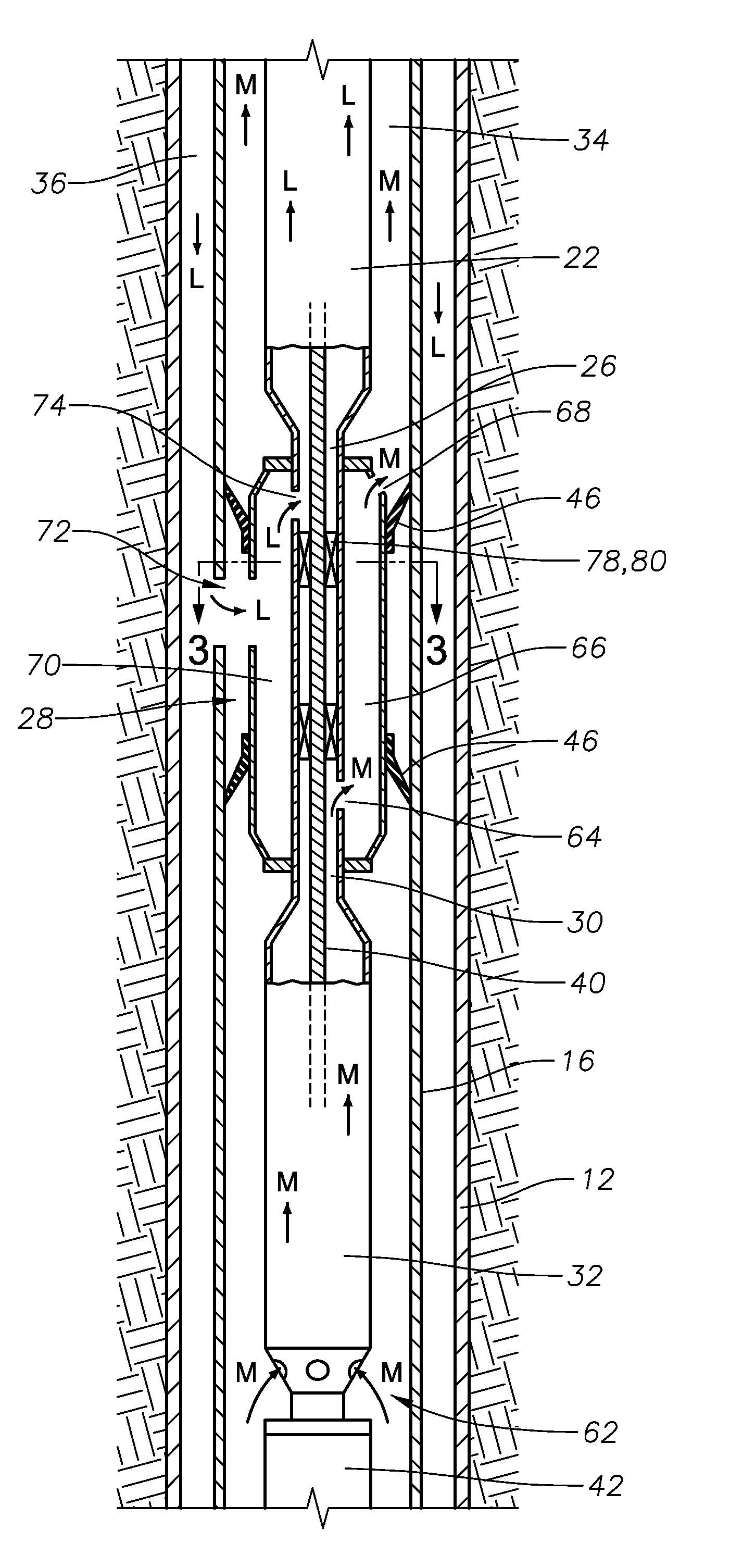

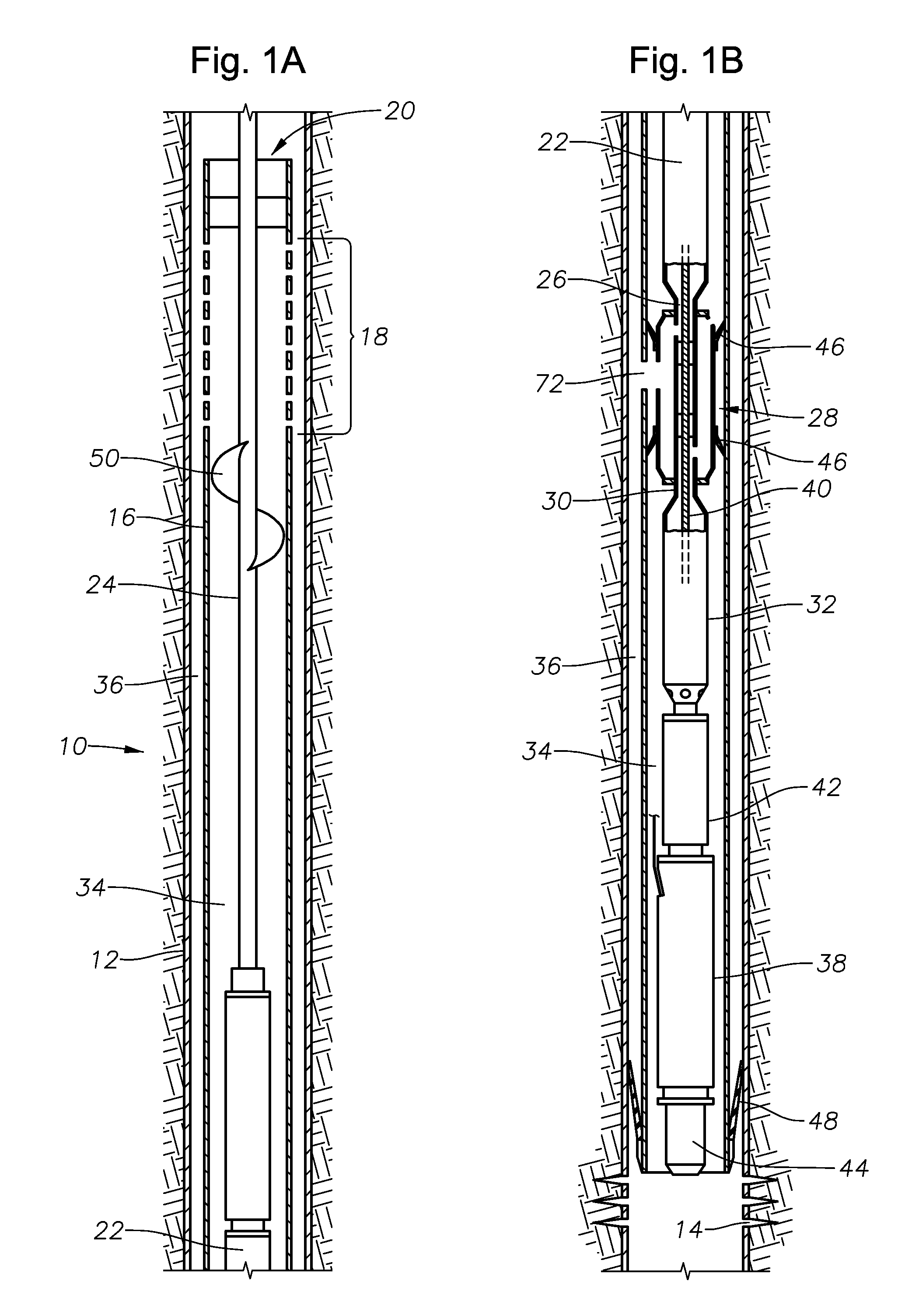

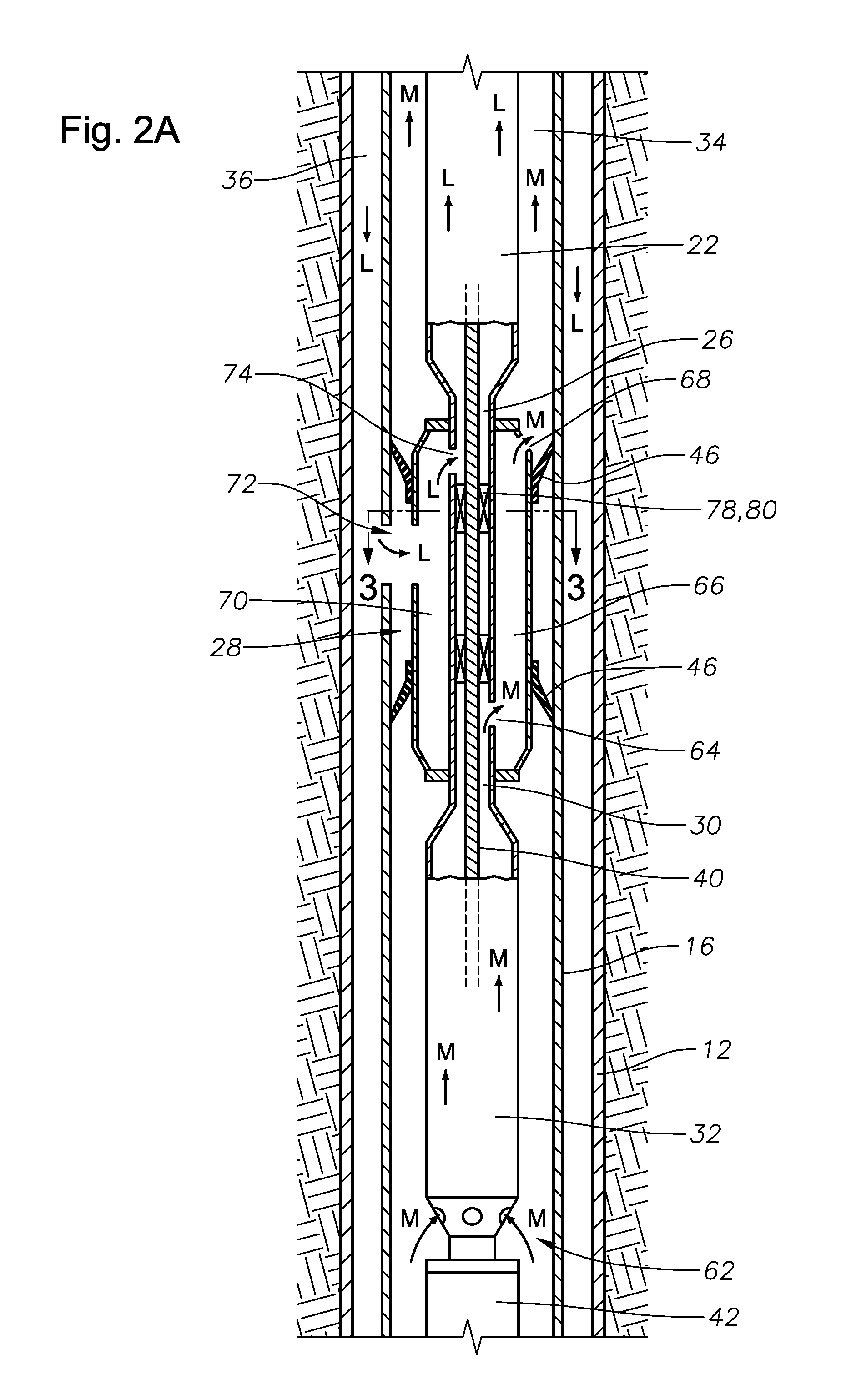

Gas boost pump and crossover in inverted shroud

ActiveUS20110162832A1Enhanced gas separationIncrease gas handling capacityFluid removalSealing/packingVapor–liquid separatorMixed flow

An above-motor mixed flow booster pump combined with a fluid crossover that directs up into the inside of an inverted shroud to allow enhanced gas separation. A gas and liquid separator is used to enhance separation. The system is simple and provides increased gas handling capability for high flow or low flow gas well dewatering applications, including vertical wells, horizontal wells, slant wells. The boost pump allows the moving of a mixed flow upwards to the top of an inverted shroud in wells lacking the required pressure.

Owner:BAKER HUGHES INC

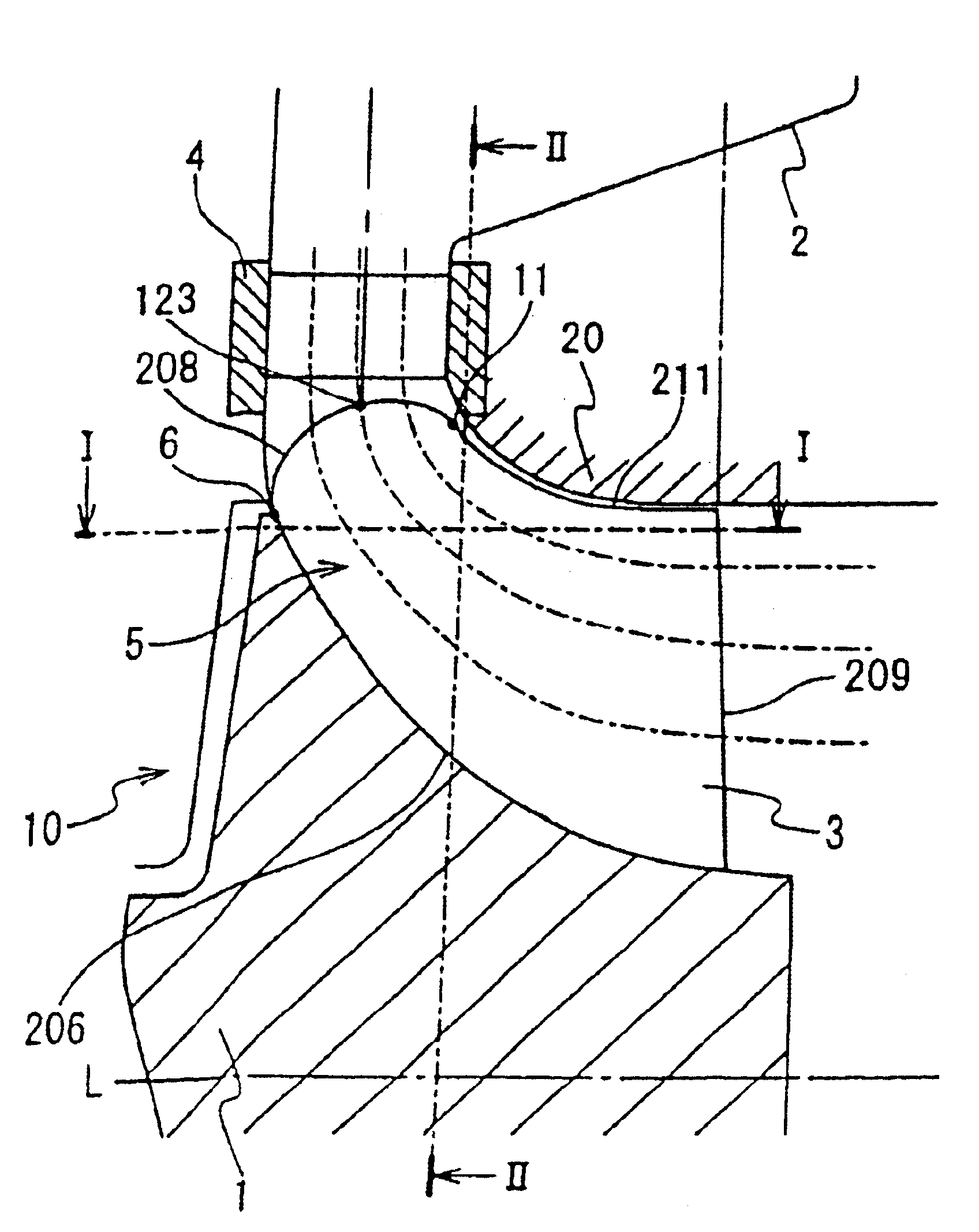

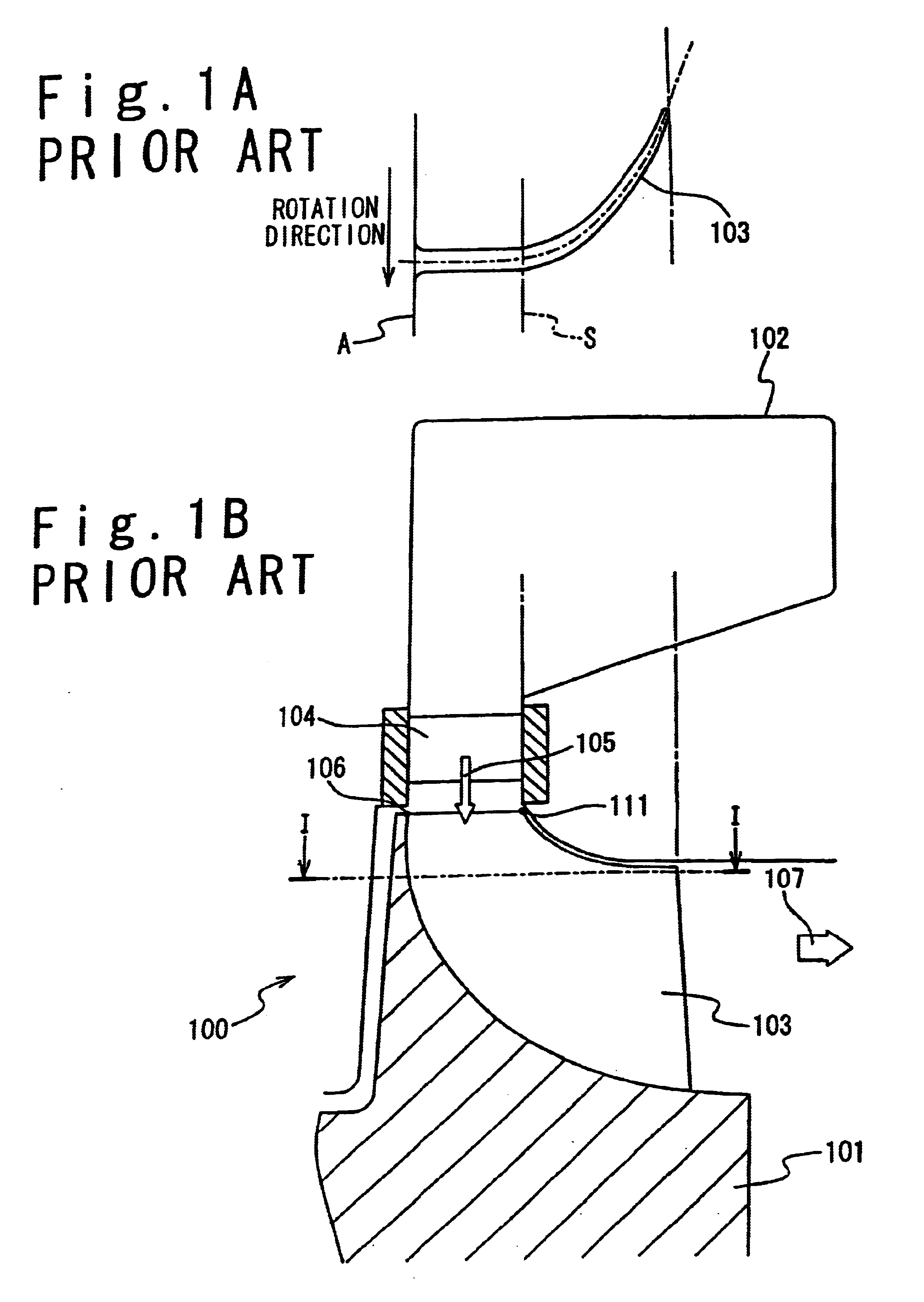

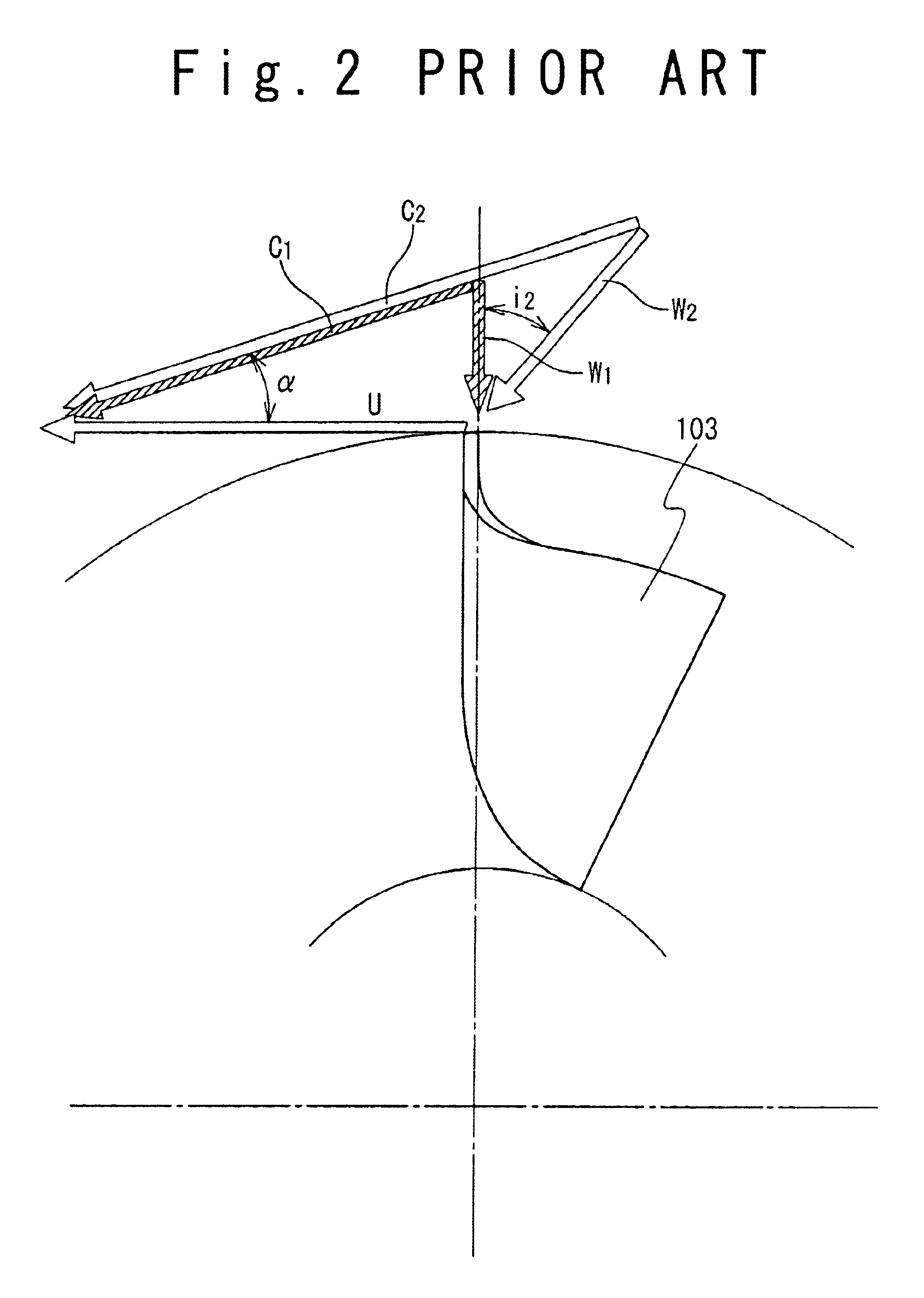

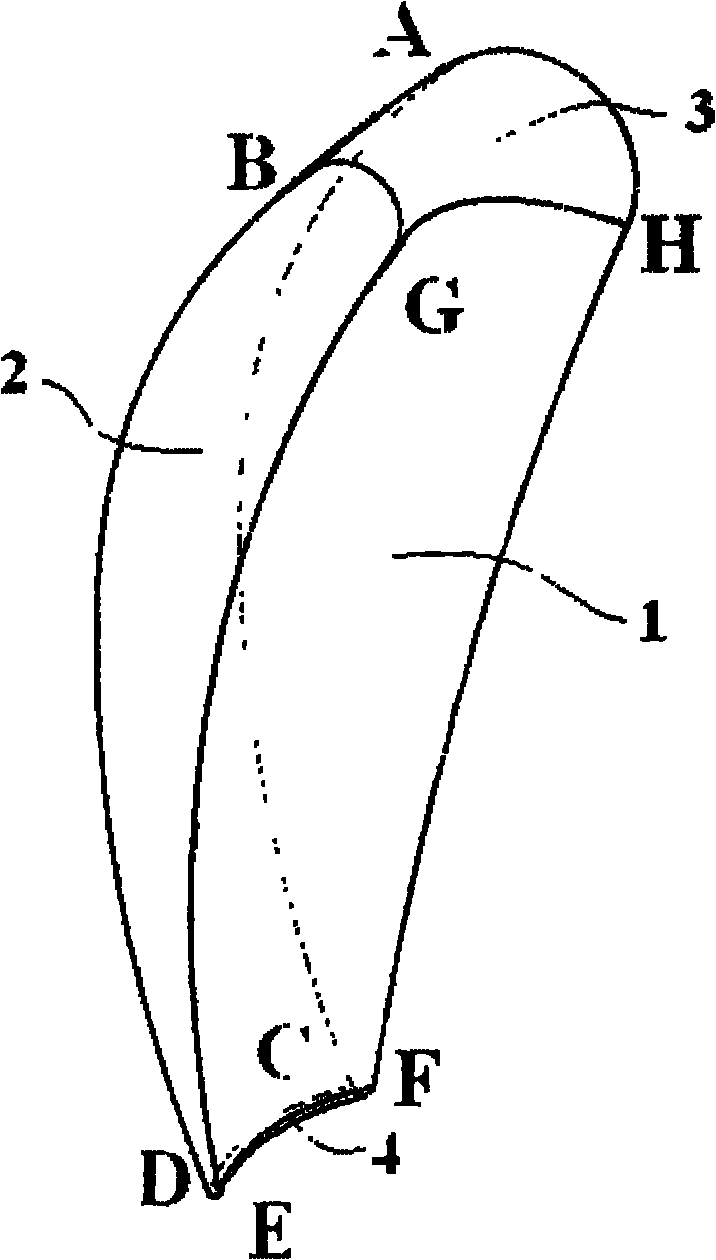

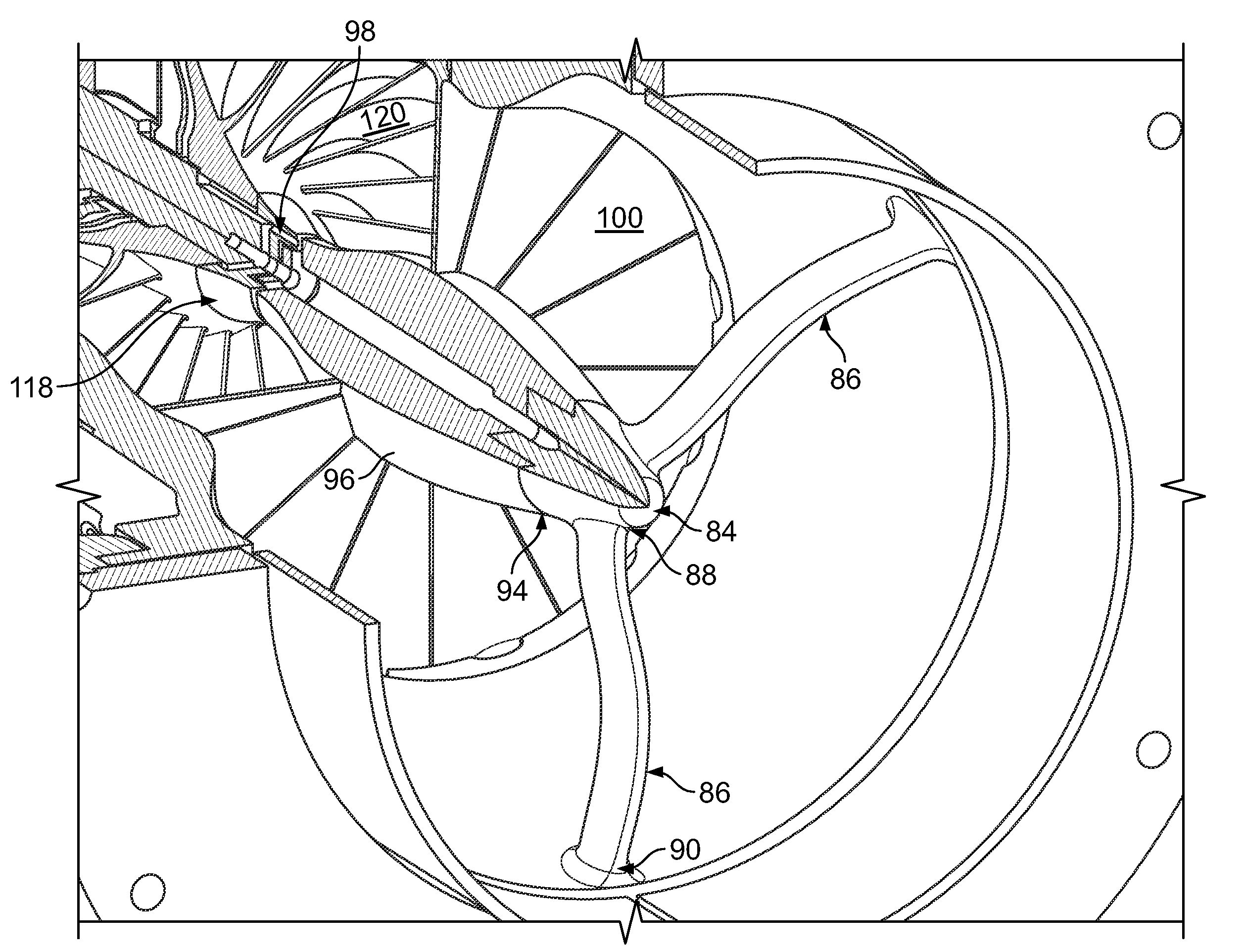

Mixed flow turbine and mixed flow turbine rotor blade

InactiveUS6877955B2Improve efficiencyReduce gear ratioPropellersRotary propellersMixed flowCurve shape

A mixed flow turbine includes a hub attached to a rotation axis and a plurality of rotor blades. Each of the plurality of rotor blades is attached to the hub in a radial direction, and the hub is rotated based on fluid supplied to a rotation region of the plurality of rotor blades. Each of the plurality of rotor blades has a curved shape that convexly swells on a supply side of the fluid.

Owner:MITSUBISHI HEAVY IND LTD

Three-dimensional nozzle ring vane of variable geometry turbocharger and design method thereof

ActiveCN101915130AWide flow rangeImprove turbine efficiencyGas turbine plantsEngine componentsLeading edgeMixed flow

The invention relates to a three-dimensional nozzle ring vane of a variable geometry turbocharger (VGT), comprising a pressure side, a suction side, a vane leading edge and a vane trailing edge, wherein the pressure side corresponds to the concave side of the vane profile; the suction side corresponds to the convex side of the vane profile; the molding lines of the pressure side and the suction side are quadratic curves or biquadratic curves and are not the same; the leading edges of the pressure side and the suction side form the leading edge of the vane; the molding line of the leading edgeof the vane is a quadratic curve and forms the three-dimensional curve leading edge; the trailing edges of the pressure side and the suction side form the trailing edge of the vane; the molding line of the trailing edge of the vane is a quadratic curve, and the height molding line of the trailing edge is identical with the inlet molding line of the turbine vane and the molding line of the trailing edge forms the three-dimensional spatial curve sharp trail. The nozzle ring vane ensures the radial-flow turbine of the VGT to develop into the mixed flow turbine, thus improving the turbine efficiency. The invention also provides a design method of the three-dimensional nozzle ring vane, and the nozzle ring vane designed by the method has higher success rate and lower cost.

Owner:PINGXIANG HUICHENG PRECISION MACHINERY & ELECTRONICS

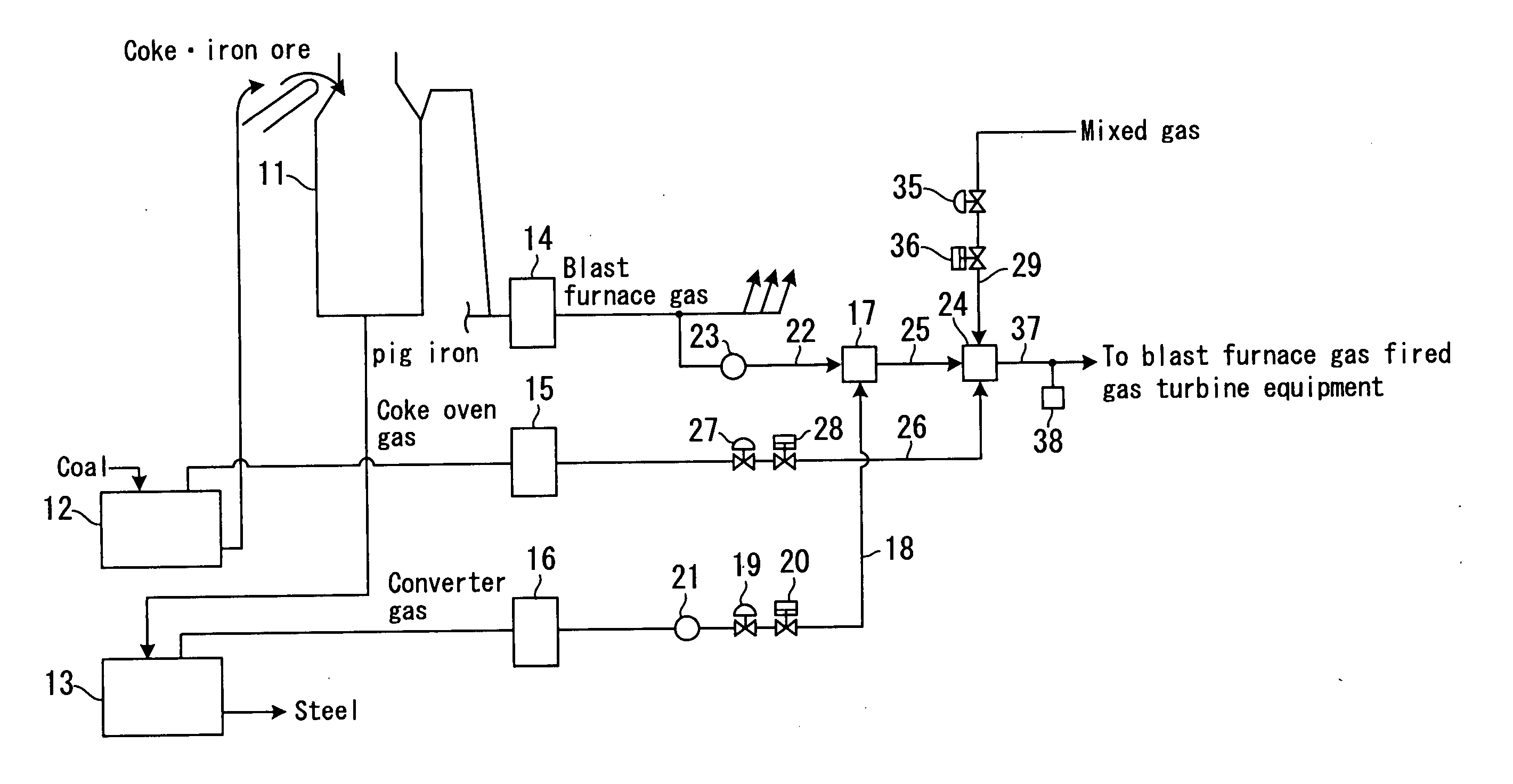

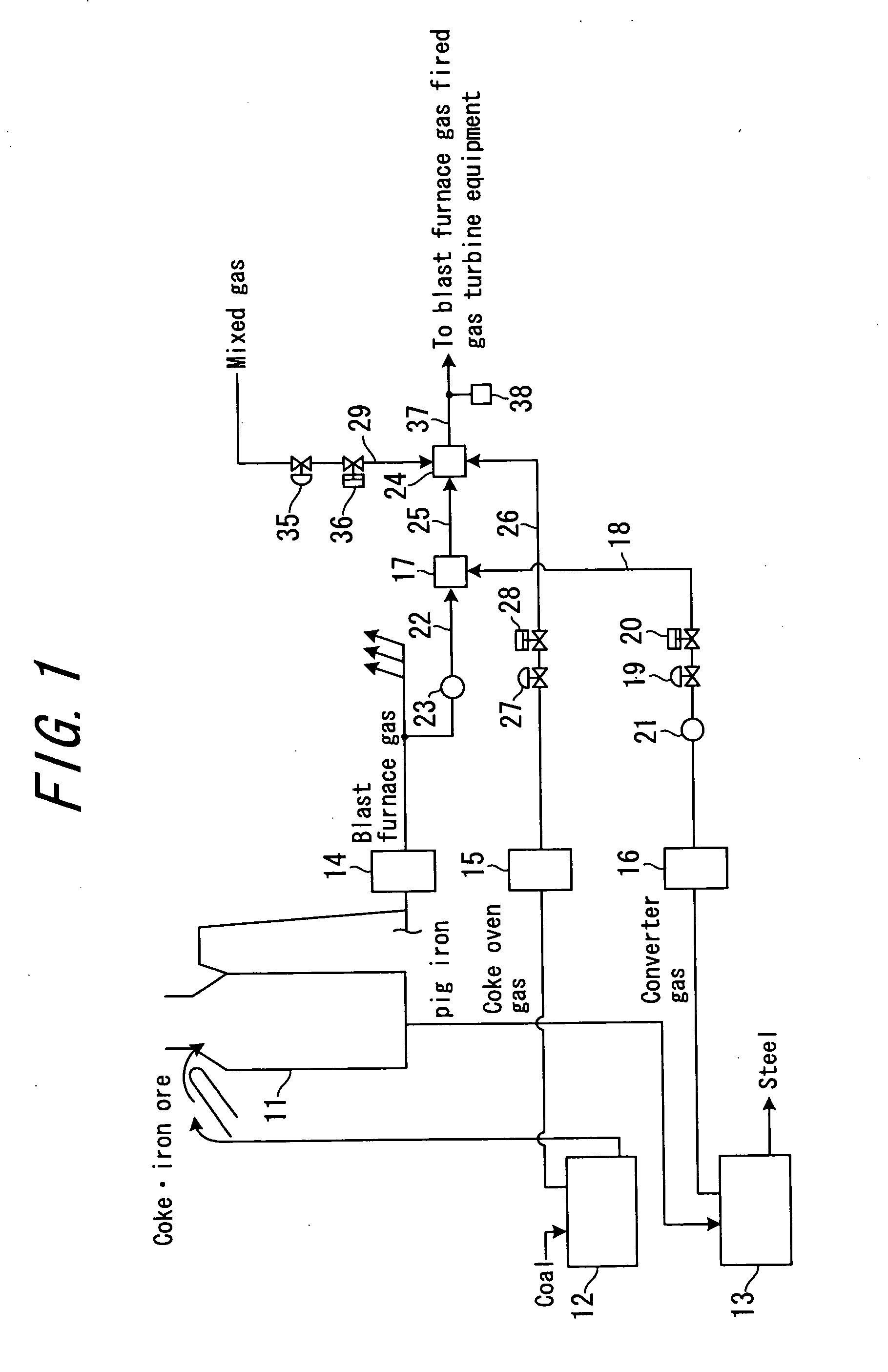

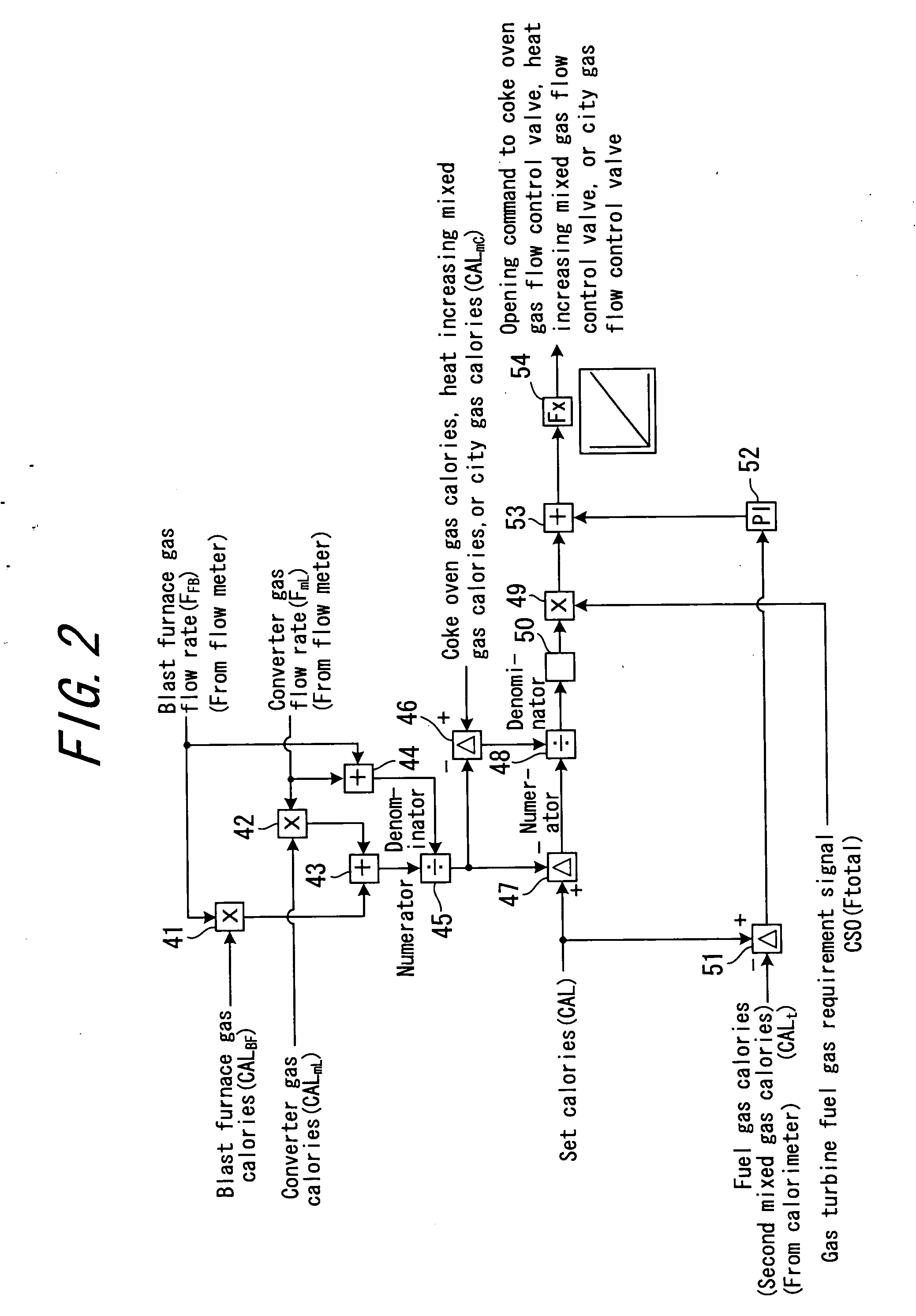

Fuel gas calorie control method and device

ActiveUS20060234171A1Excessive mixingEasy to controlBurnersGas modification by gas mixingMixed flowEngineering

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

Centrifugal compressor assembly and method

ActiveUS8037713B2Improve performanceReduce physical sizePump componentsRotary non-positive displacement pumpsMixed flowHigh energy

Owner:TRANE INT INC

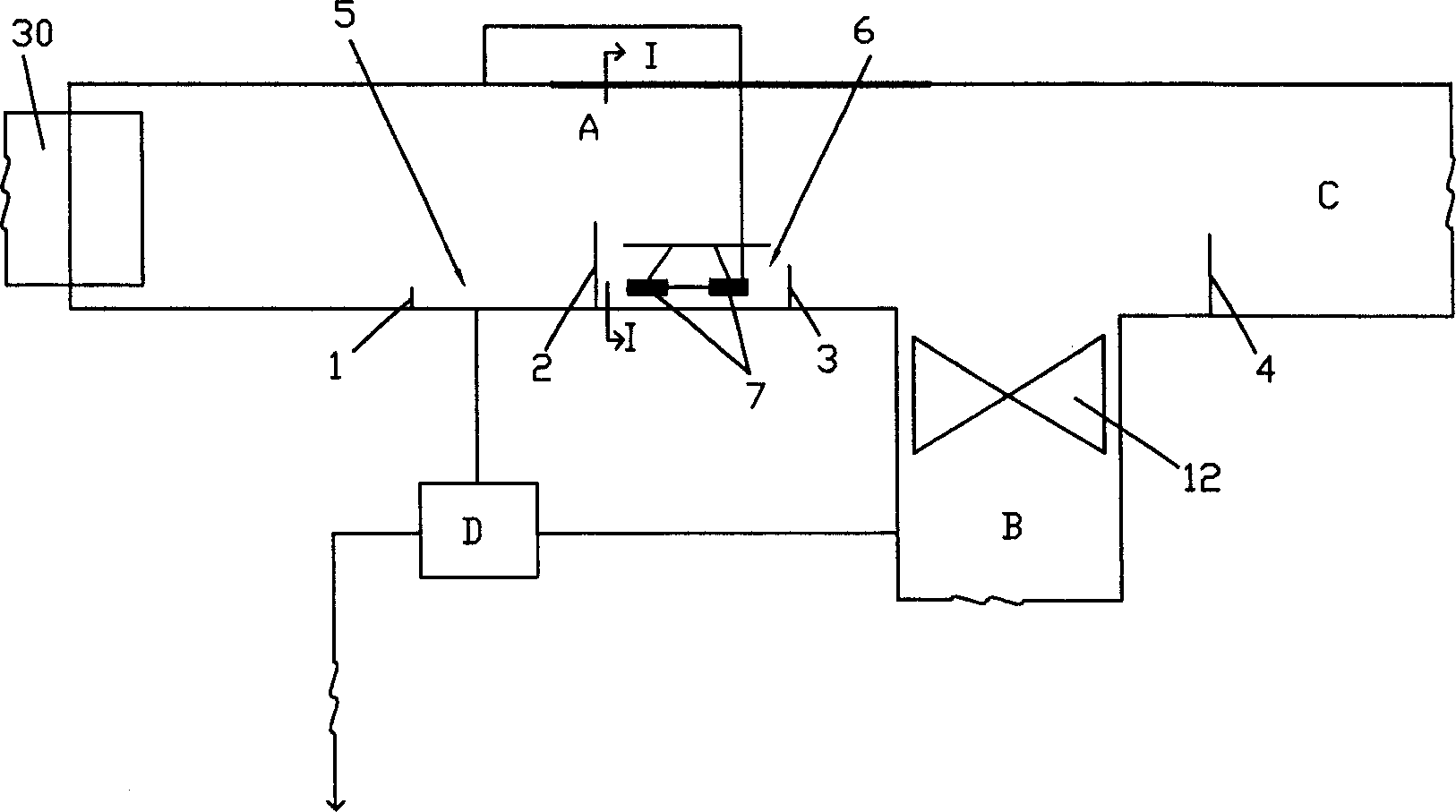

Arrangement for mixing a first and a second gas flow

InactiveUS7036529B2Minimized pressure lossMaximal throttling in the lineContinuous combustion chamberControlling ratio of multiple fluid flowsMixed flowEngineering

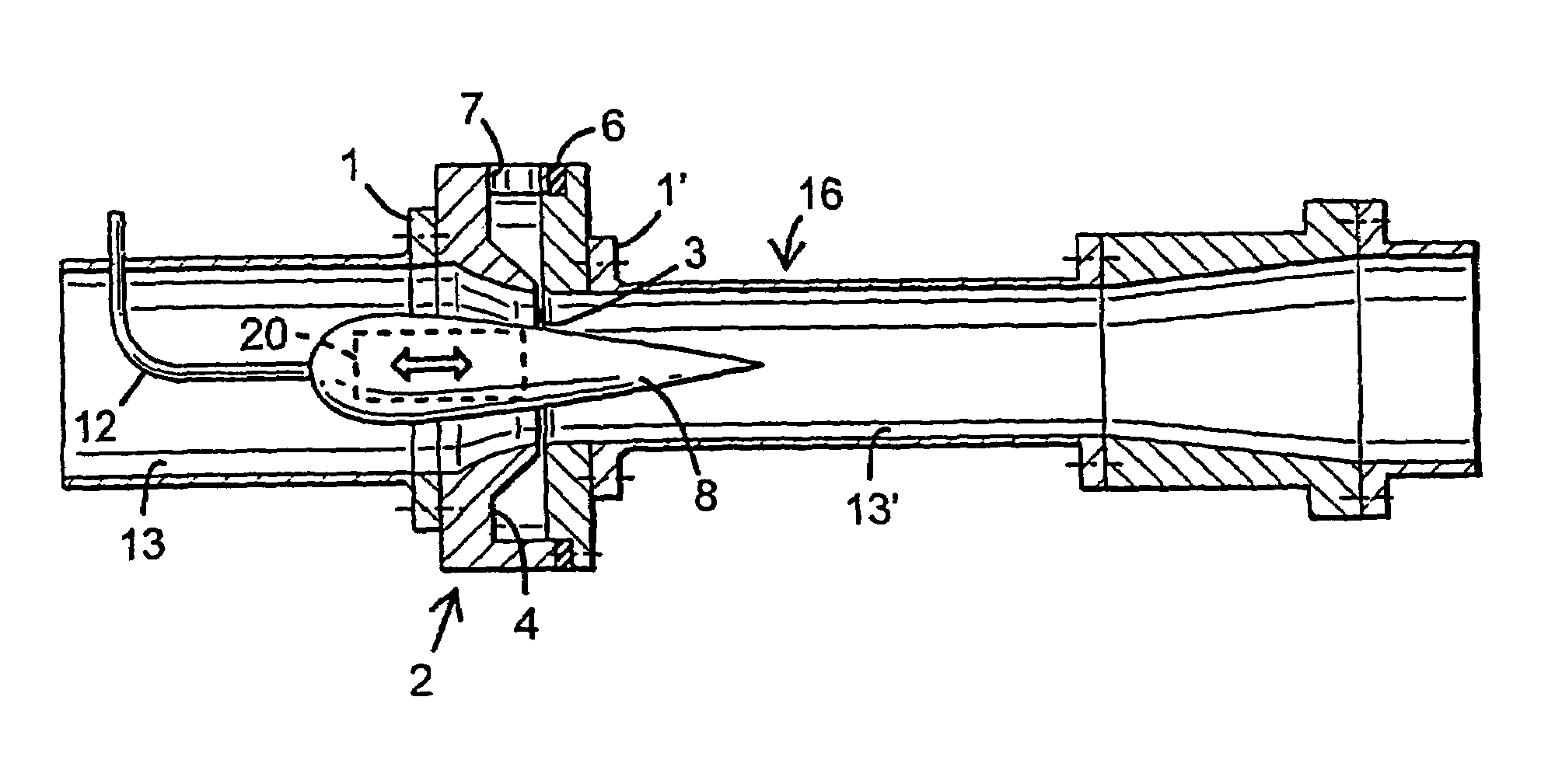

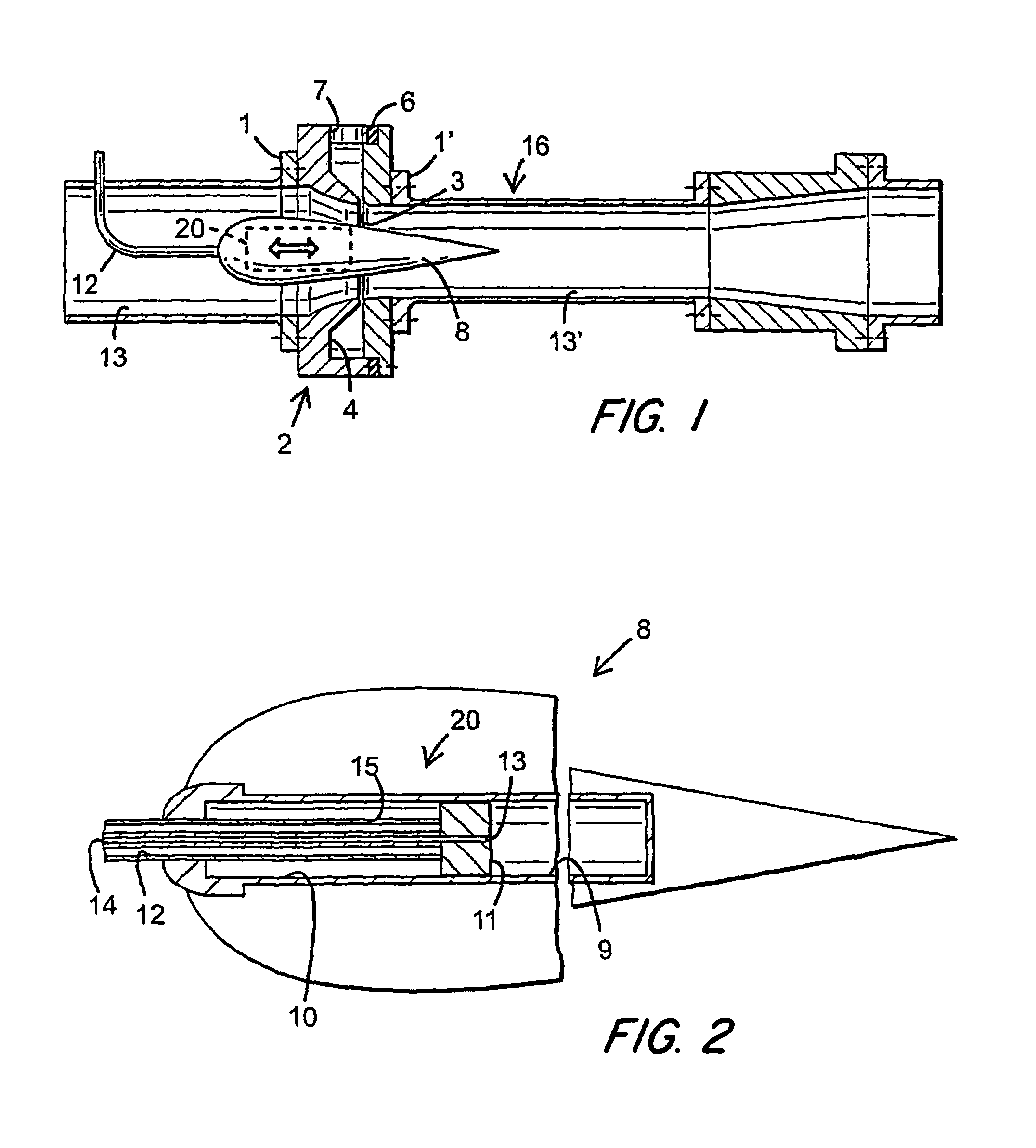

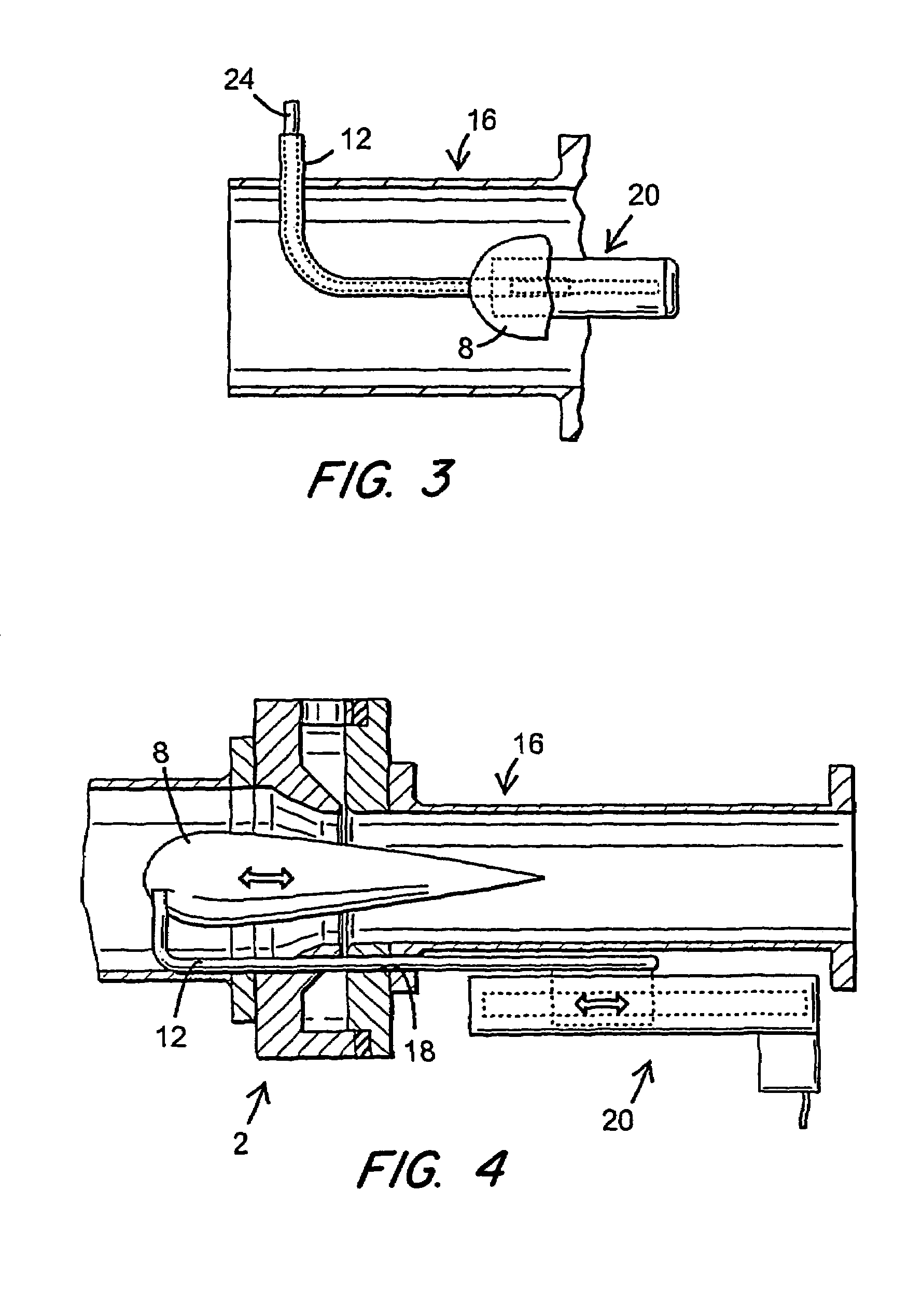

An arrangement for mixing a first and a second gas flow, for example, an inlet flow with a exhaust gas return flow in a diesel engine, comprising a line (16) for the first flow, an inlet (7) for the second flow in the line (16), in order to achieve the mixing; a streamlined body (8) arranged to be displaced in the longitudinal direction of the line (16) at the inlet (7) in order to achieve a variable venturi effect and in this way a variable suction effect and mixture of the mixed flow; and actuating means for displacing the body forwards and backwards in the line. In order to minimise the need for throttling and the accompanying pressure losses, the streamlined body (8) and the supply part (2) are designed to achieve maximal throttling in the line (16) close to the inlet (7), independently of the position of the body.

Owner:VARIVENT INNOVATIONS

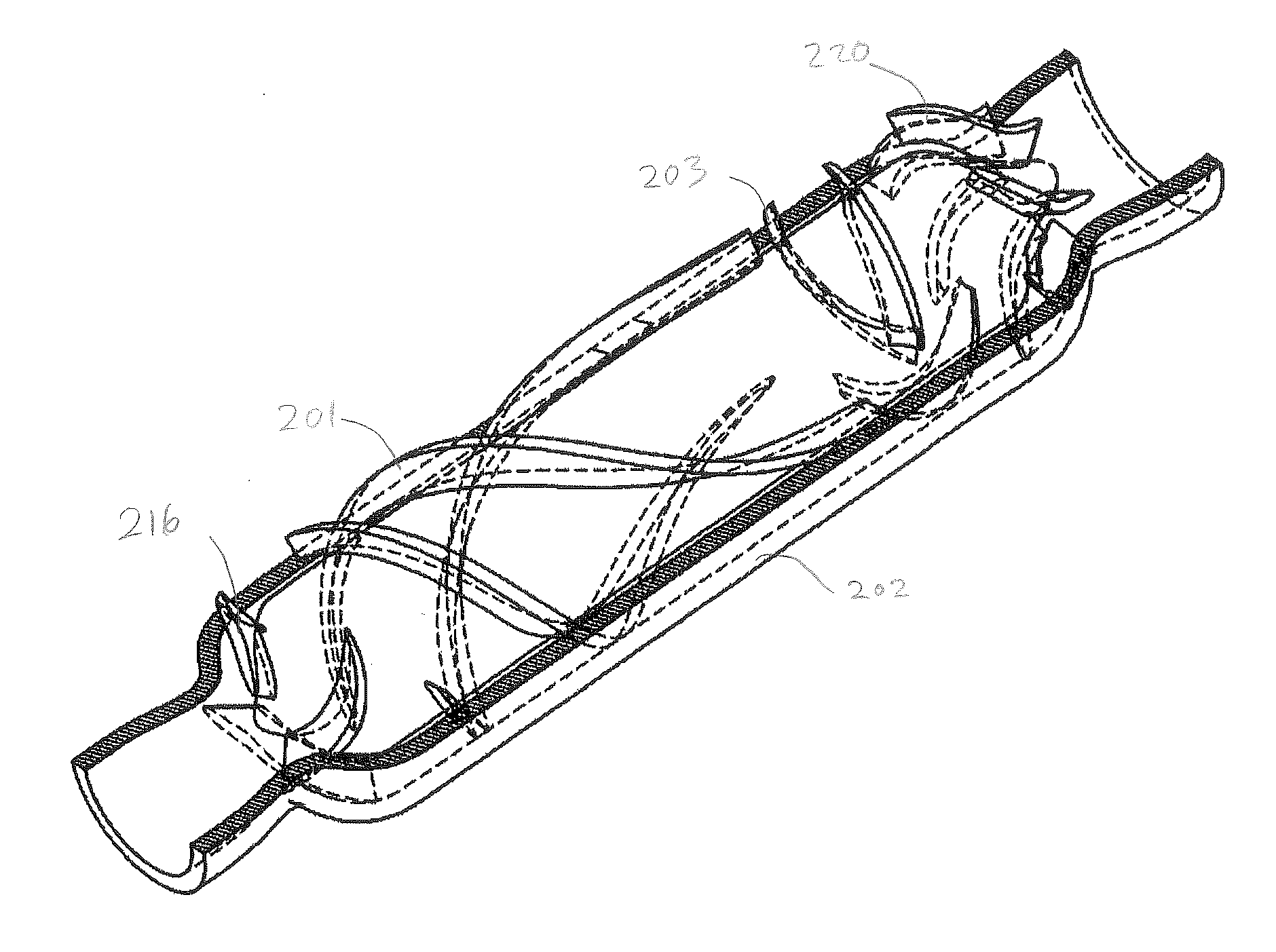

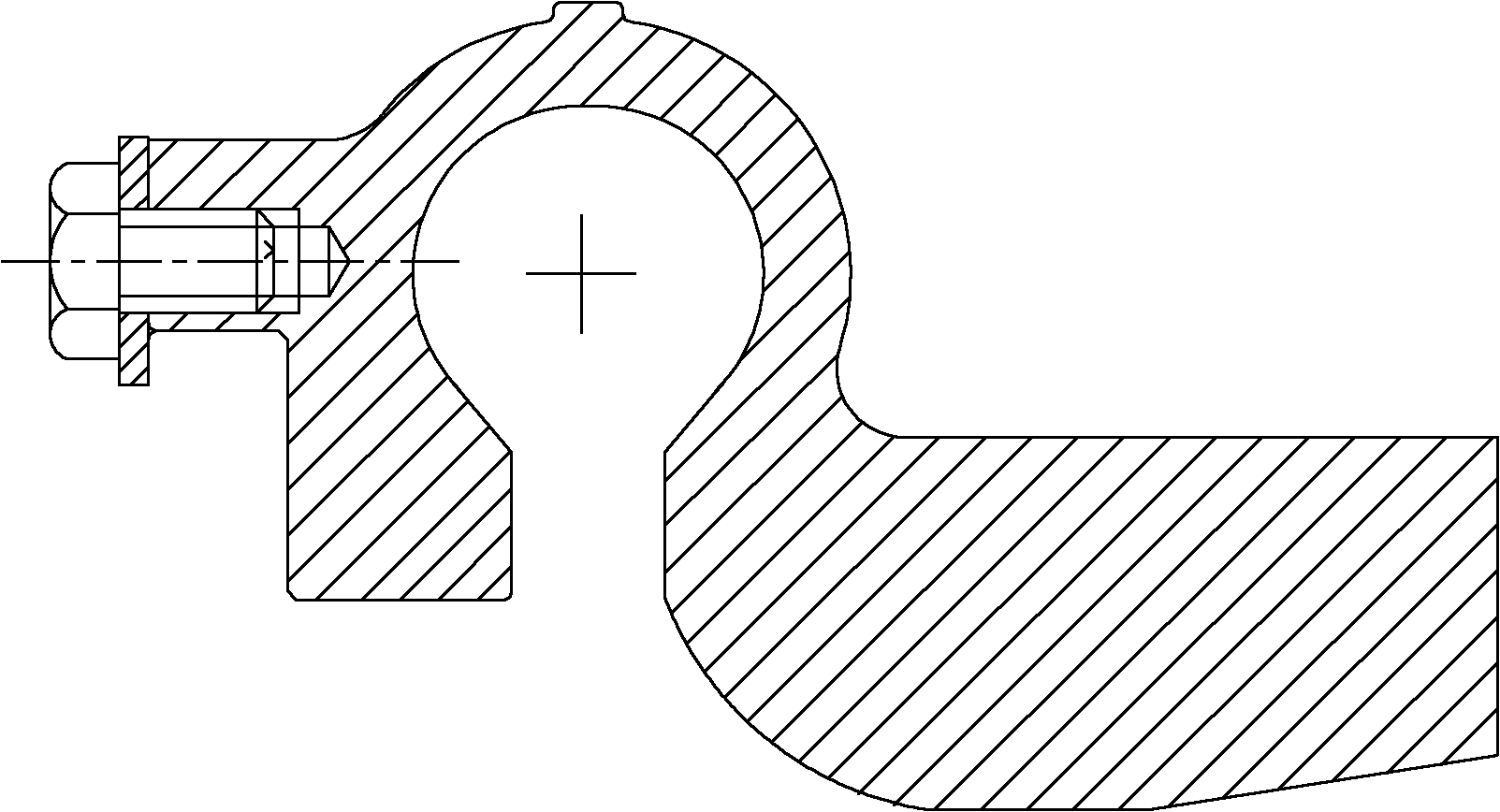

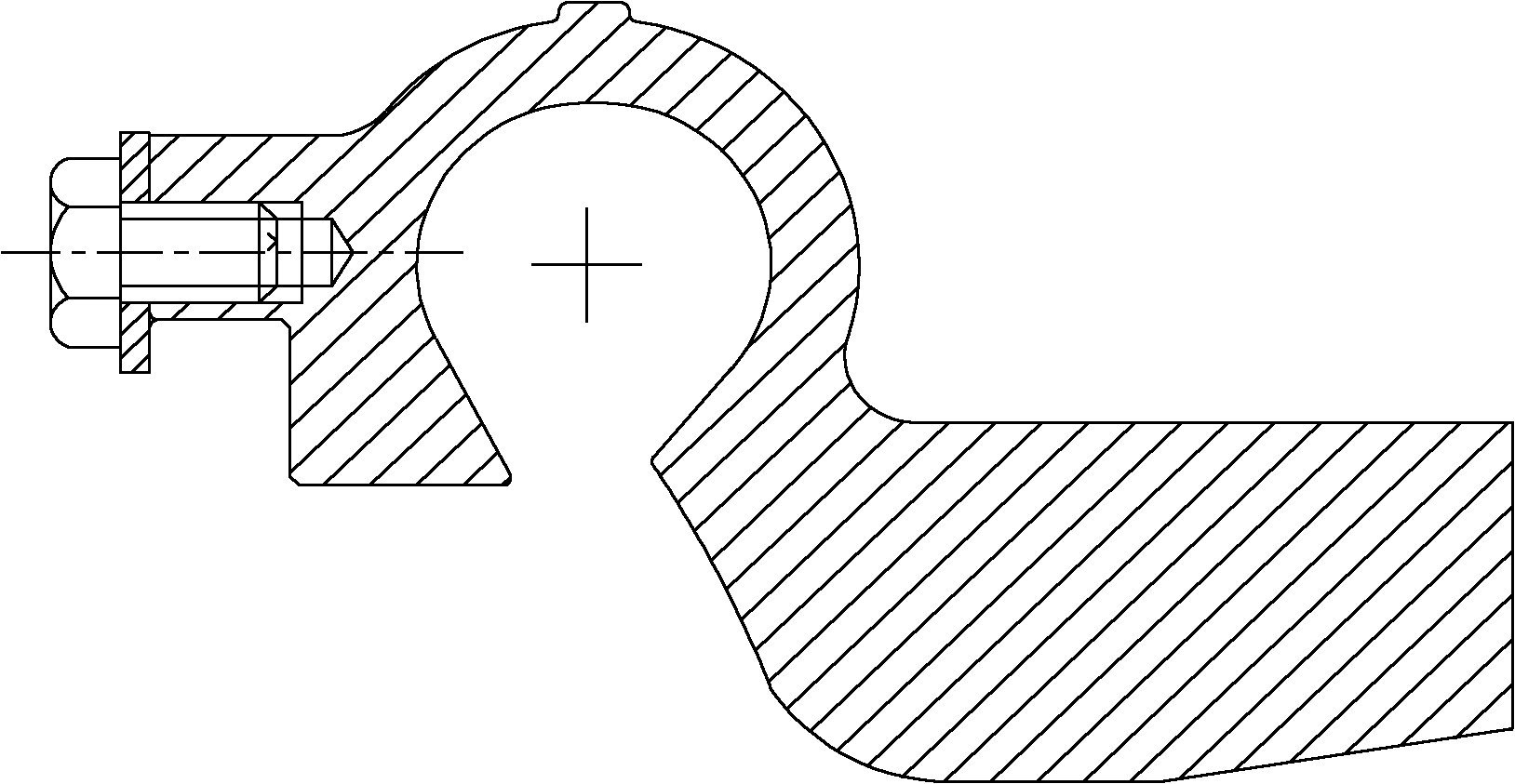

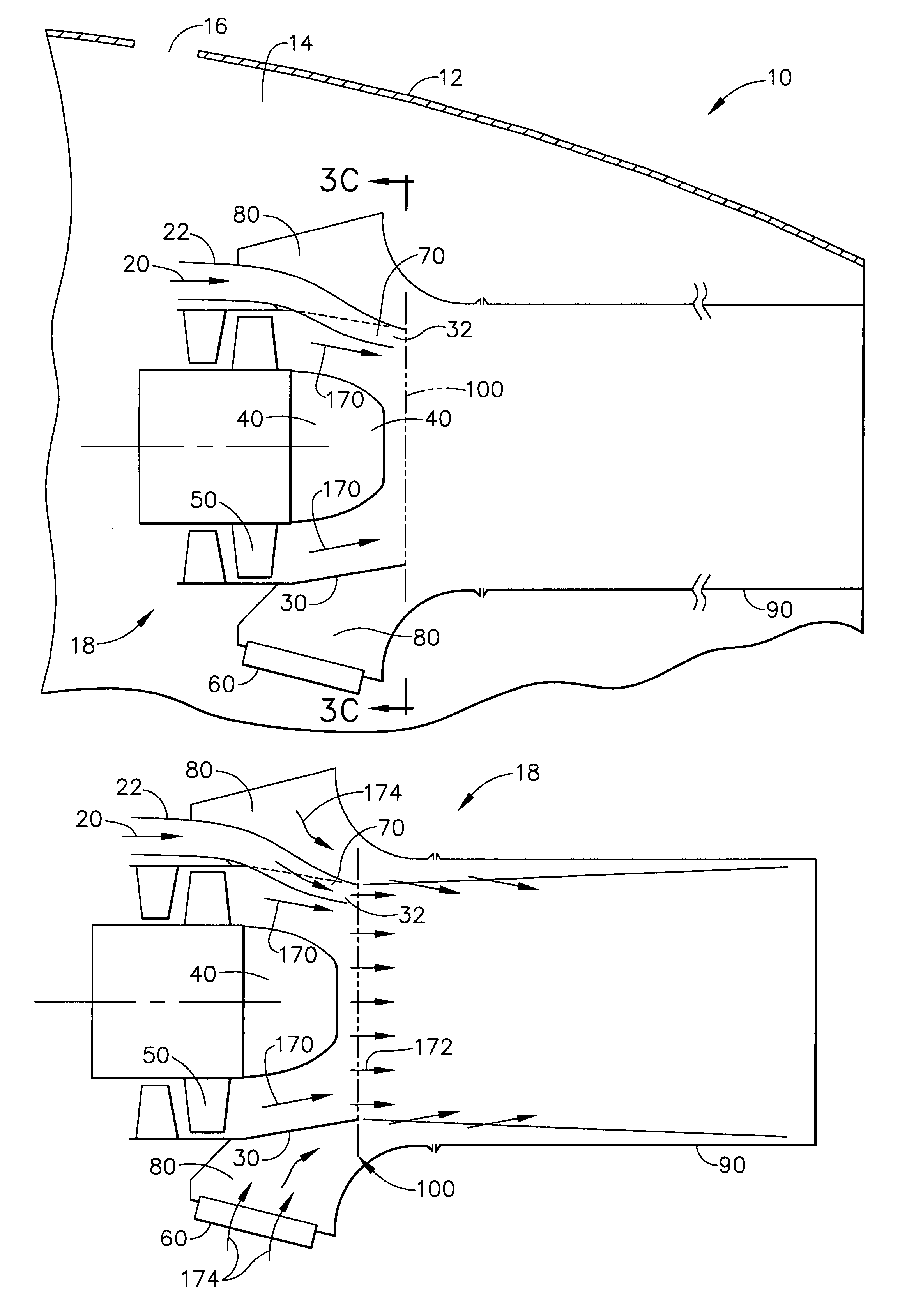

Blood pump with separate mixed-flow and axial-flow impeller stages and multi-stage stators

InactiveUS20140341726A1Reduce circumferential componentReduce risk of damagePump componentsBlood pumpImpellerMixed flow

A pump for a fluid which can be blood has a stator housing and a rotor hub with leading and trailing portions and an intermediate portion disposed therebetween. At least one impeller blade at the leading portion drives circumferential and axial components of a flow into a pump annulus or intermediate pathway portion. At least one stator blade extends radially inward from the stator housing within the intermediate pathway portion and is configured to reduce a circumferential component of the flow.

Owner:HEARTWARE INC

Centrifugal compressor assembly and method

ActiveUS20090208331A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

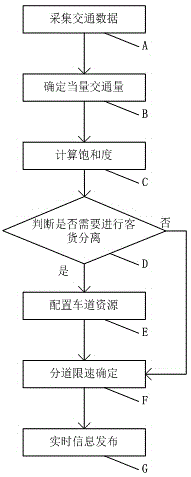

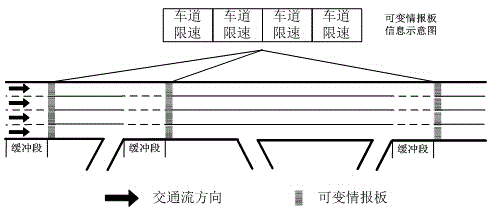

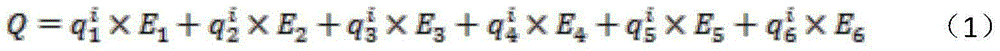

Real-time optimal configuration method for lane resources of multi-lane expressway

ActiveCN104794919AIncrease driving speedImprove traffic efficiencyArrangements for variable traffic instructionsTime informationMixed flow

The invention discloses a real-time optimal configuration method for lane resources of a multi-lane expressway. The real-time optimal configuration method for the lane resources of the multi-lane expressway comprises the following steps of traffic data acquisition, equivalent traffic volume confirmation, saturability calculation, passenger car and freight truck separation confirmation, lane resource configuration, lane speed limitation confirmation and real-time information issuing. Flow data of different vehicles running on the expressway are acquired and analyzed in real time, whether passenger cars and freight trucks on the expressway need to be separated from each other or not is determined, lane speed limitation measures under the condition of passenger car and freight truck separation and lane speed limitation measures under the condition of passenger car and freight truck combination are confirmed, and a real-time lane resource configuration scheme is formed. The lane resources of the expressway are distributed and controlled in real time, safety problems caused by mixed flow of the passenger cars and the freight trucks are reduced, speed advantages of the different vehicles can be played to a maximum extent, and the traffic efficiency of the expressway is improved.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST +2

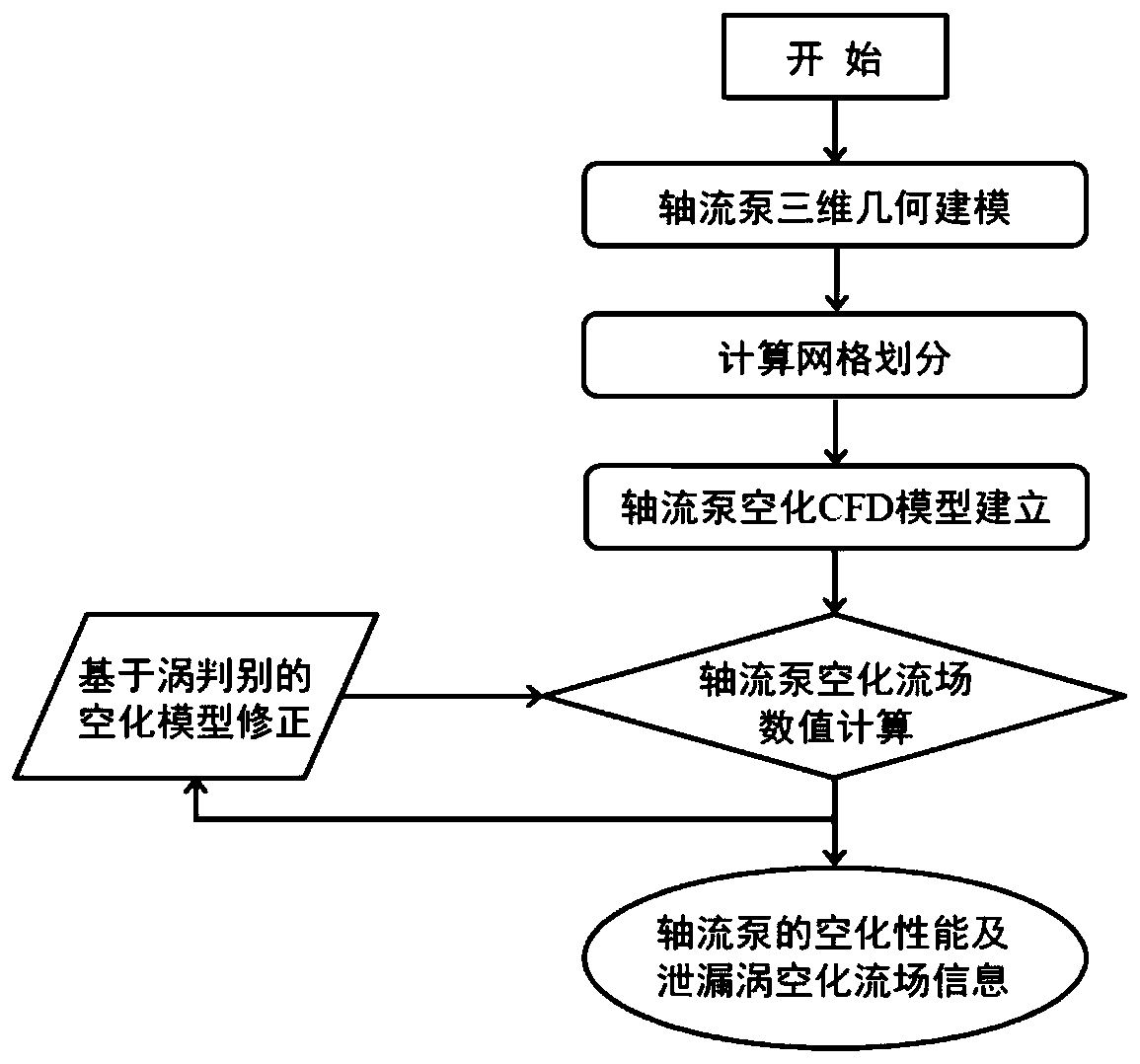

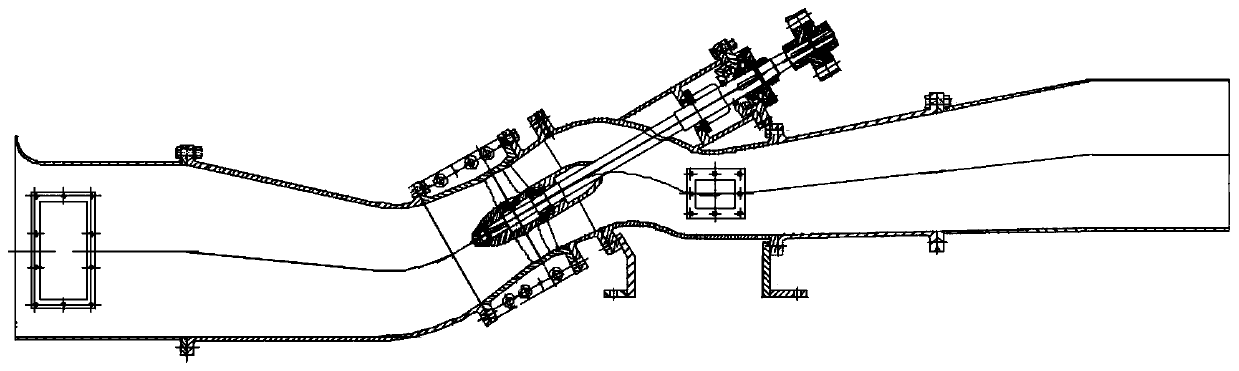

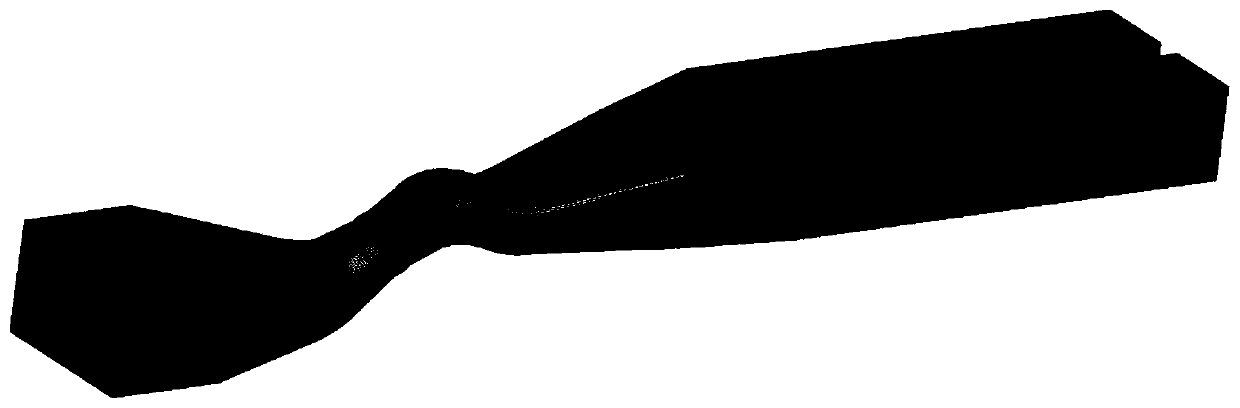

Numerical simulation method for axial flow pump blade tip gap leakage vortex cavitation

ActiveCN109977345AFast numerical predictionIncrease credibilityDesign optimisation/simulationCAD numerical modellingAxial-flow pumpMixed flow

The invention discloses a numerical simulation method for axial flow pump blade tip gap leakage vortex cavitation. An axial flow pump cavitation flow field is subjected to numerical calculation by performing three-dimensional geometric modeling on the axial flow pump, dividing calculation grids and establishing a cavitation flow calculation fluid dynamics model and adopting a cavitation model corrected based on a vortex discrimination method, and the cavitation performance of the axial flow pump and the blade top gap leakage vortex cavitation flow characteristic are obtained through analysis.According to the method, the influence of vortex flow on the cavitation phase change process is fully considered, the reliability of a vortex cavitation numerical calculation result is improved, rapidand high-precision numerical prediction of axial flow pump blade tip gap leakage vortex cavitation is realized, and a good mathematical basis is laid for research on a flowing mechanism and an inhibition measure of axial flow pump blade top gap leakage vortex cavitation. meanwhile, the method can also be popularized and applied to numerical simulation research on blade top gap leakage vortex cavitation of other blade type hydraulic machines such as a mixed flow pump and a water turbine.

Owner:HOHAI UNIV

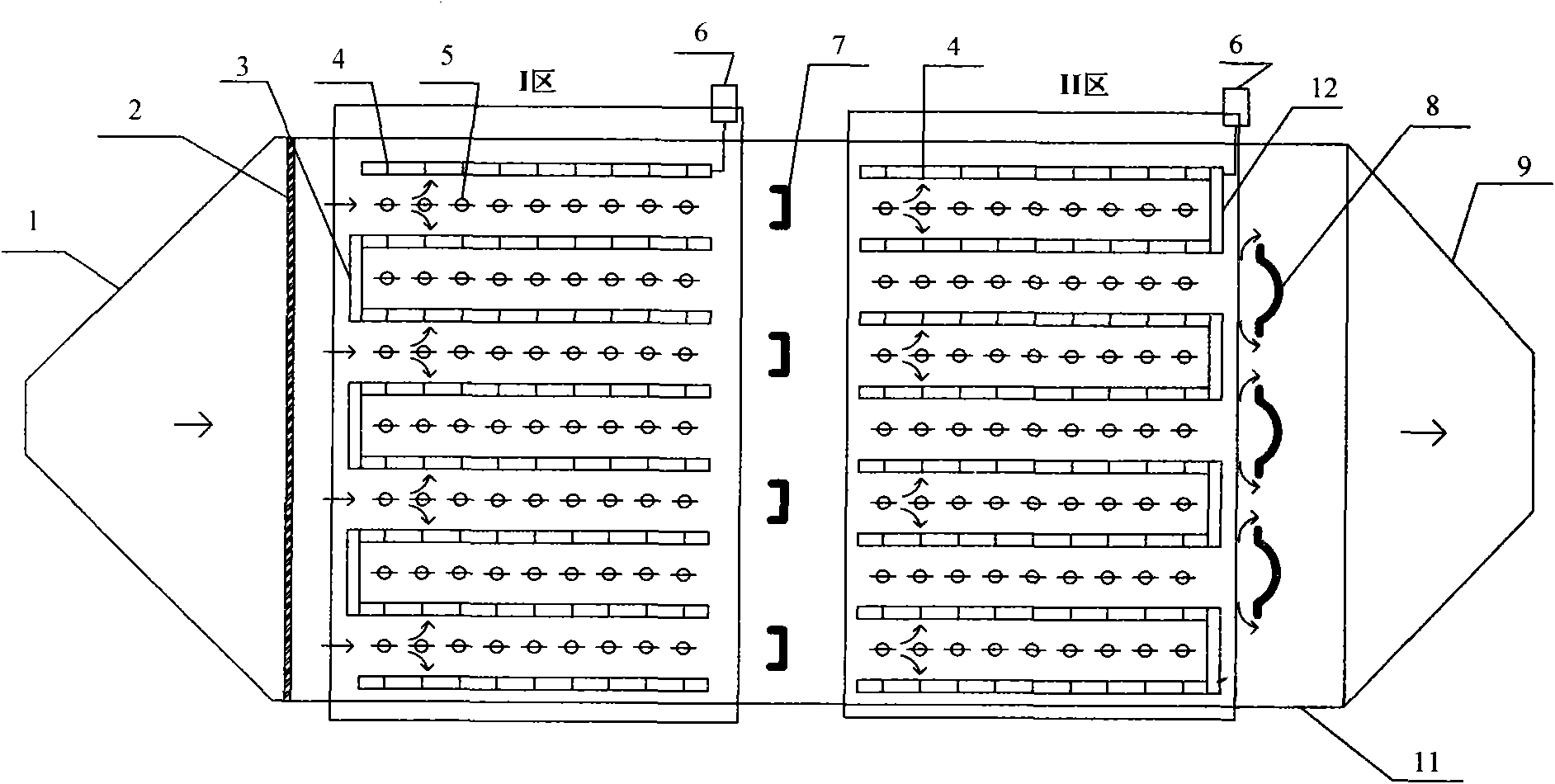

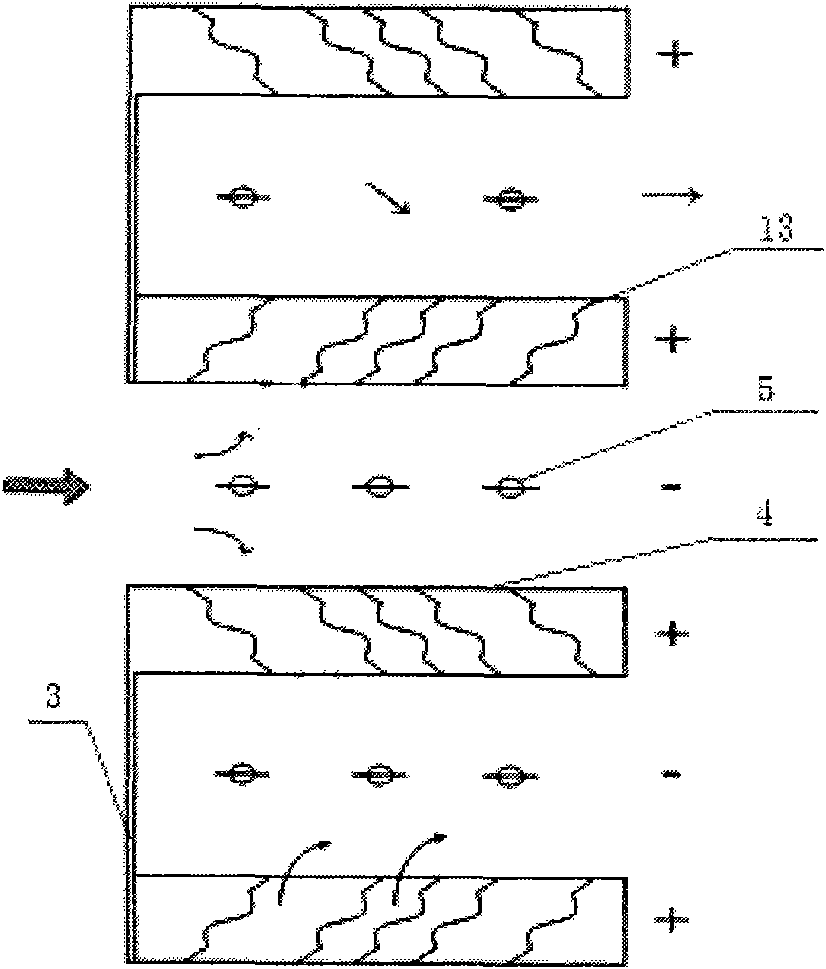

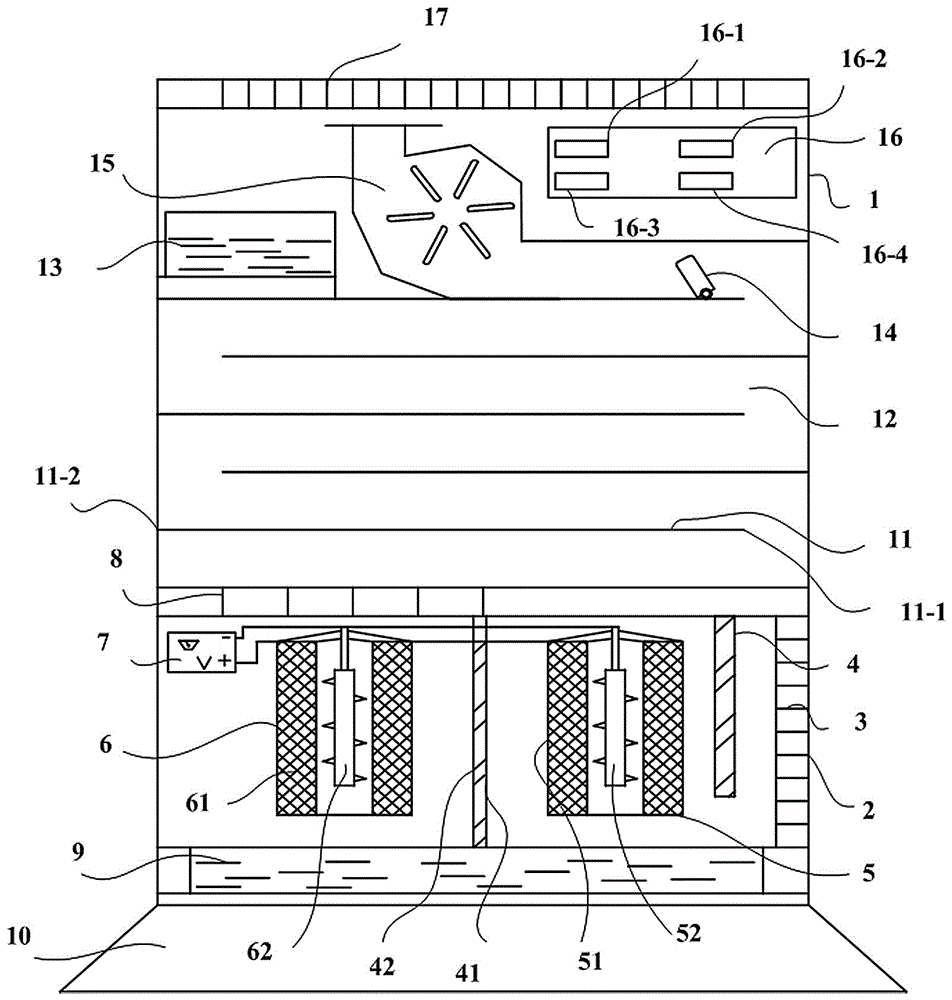

Mixed-flow electric dust collector

ActiveCN101862705AAvoid affecting the dust collection effectReduce volumeExternal electric electrostatic seperatorElectrode constructionsMixed flowEqualization

The invention relates to a mixed-flow electric dust collector, wherein an air flow distribution plate is arranged at the joint of a dust removing chamber and a smoke inlet; a first vertical electric field and a second vertical electric field, through which an air flow flows, are arranged in the dust removing chamber; parallel dust collecting electrodes are distributed in the electric fields at equal interval; main air flow channels are formed among the dust collecting electrodes; a corona electrode is arranged between adjacent dust collecting electrodes; some of the air flow channels are provided with an incoming air flow baffle at an air flow inlet, and the other air flow channels are provided with an outgoing air flow baffle at an air flow outlet; a plurality of dust collecting electrode plates are arranged on the dust collecting electrodes and fixed in the dust collecting electrode in a separated manner; and the main air flow channels are provided with a plurality of air equalization plates having through holes on the surface at the outlet of the first electric field and baffles at the outlet of the second electric field. With simple structure and few electric fields, the invention solves the problem that the conventional dust collector has poor dust removal effect, large size, complicated structure and high cost.

Owner:浙江海宁经编产业园区开发有限公司

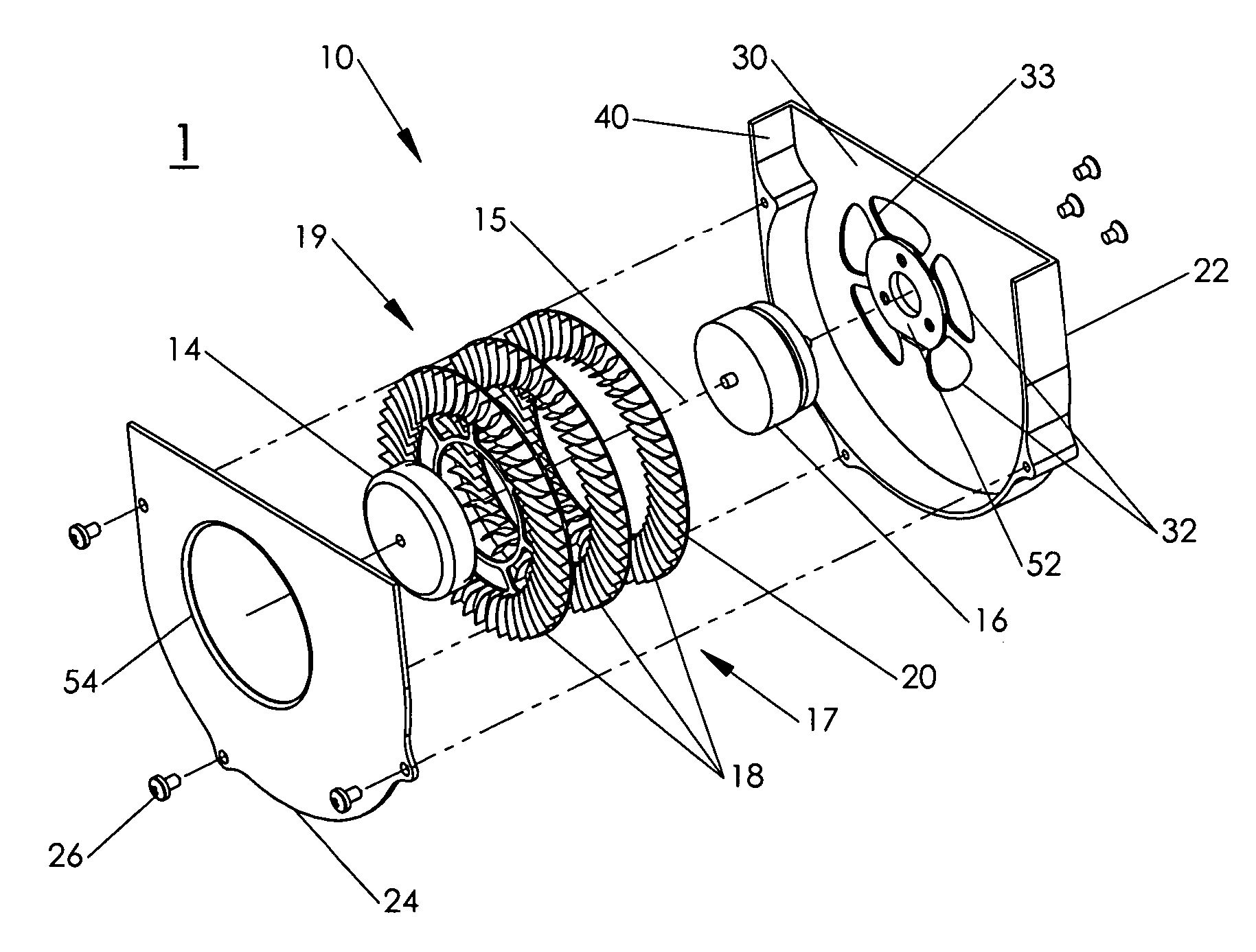

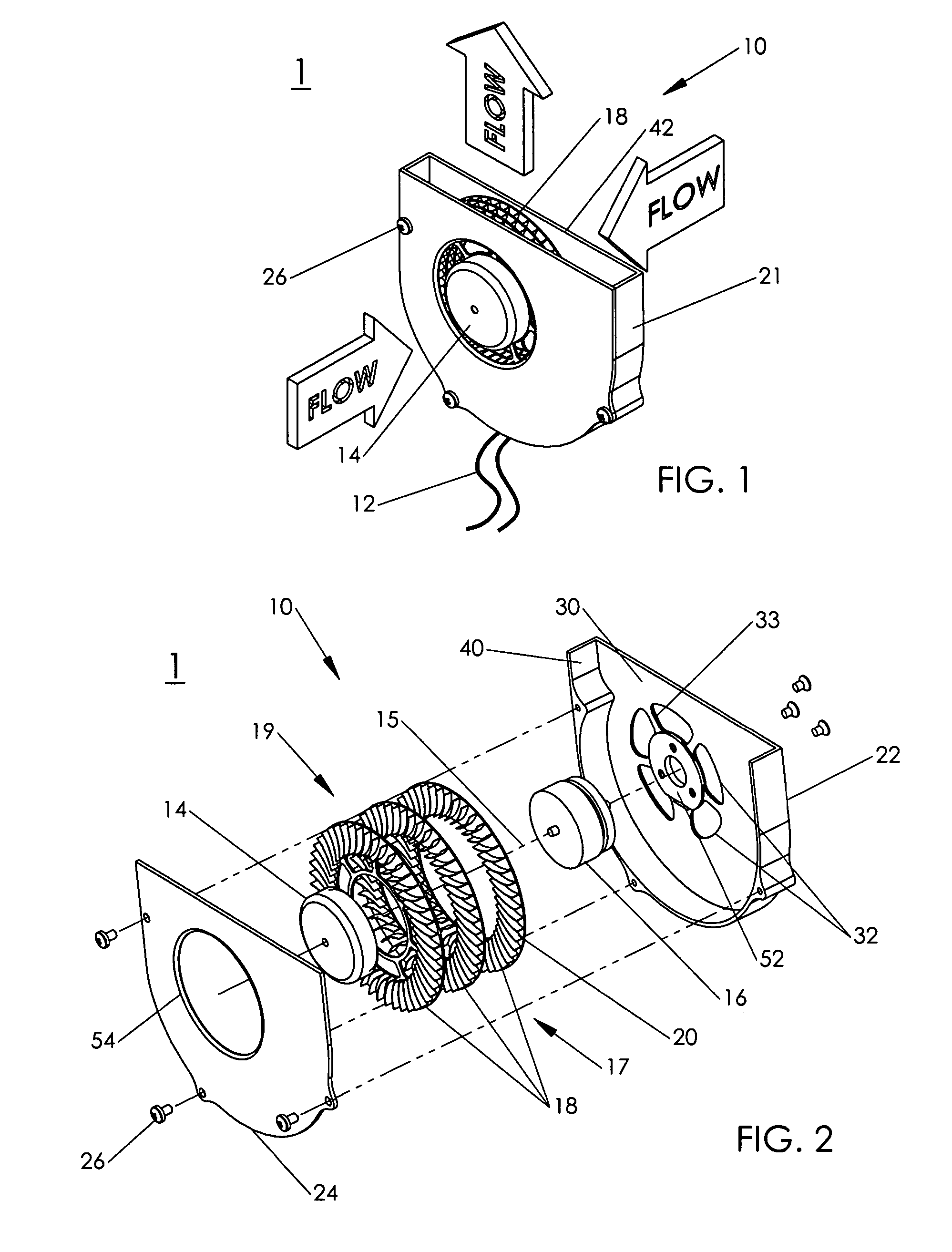

High efficiency fluid movers

Fluid movers produce at least predominantly laminar flow internally in an axial or a radial direction in a rotor. A fluid mover rotor comprises a matrix of passages of appropriate size to produce at least predominantly laminar flow spaced circumferentially around the rotor. The passages may provide axial, radial or mixed flow. “Appropriate” dimensions may be selected for a specified volume flow rate. In a radial embodiment, a matrix of radially extending passages could comprise walls having an axial height projecting from an annular disk. The passages may be offset with respect to the radial direction to provide an angle of attack that minimizes incidence losses. The matrix structure allows the use of thin-walled passages to minimize blockage of entering air.

Owner:HILL ENG

Mixed flow turbocharger with variable nozzle ring

ActiveCN102182546AAdjustment areaRegulating and Controlling FlowInternal combustion piston enginesStatorsImpellerMixed flow

The invention discloses a mixed flow turbocharger with a variable nozzle ring which comprises a compressor impeller, a compressor casing, a bearing body, an actuating mechanism, a bearing, a nozzle ring blade, a turbine casing, a turbine shaft and a turbine impeller, wherein the actuating mechanism comprises an actuator, a rocker arm component, a driving ring and spatial link mechanisms; the actuator is connected with the rocker arm component, the rocker arm component is connected with the spatial link mechanisms, and the spatial link mechanisms are connected with the nozzle ring blade; the spatial link mechanisms are annularly arranged in the spherical shell formed by the bearing body and the turbine casing; the right angle shaped by the central line of the radial section outlet of the turbine casing and the axial direction can be changed into an obtuse angle. According to the invention, the top surface and the bottom surface of the nozzle ring blade are designed to concentric circular arcs, and the opening of the mixed flow turbine nozzle ring blade can be adjusted to rotate by utilizing the spatial link mechanisms, thus realizing the best matching of the mixed low turbocharger with the variable nozzle ring and each changing working condition of the internal combustion engine.

Owner:NINGBO WEIFU TIANLI TURBOCHARGING TECH

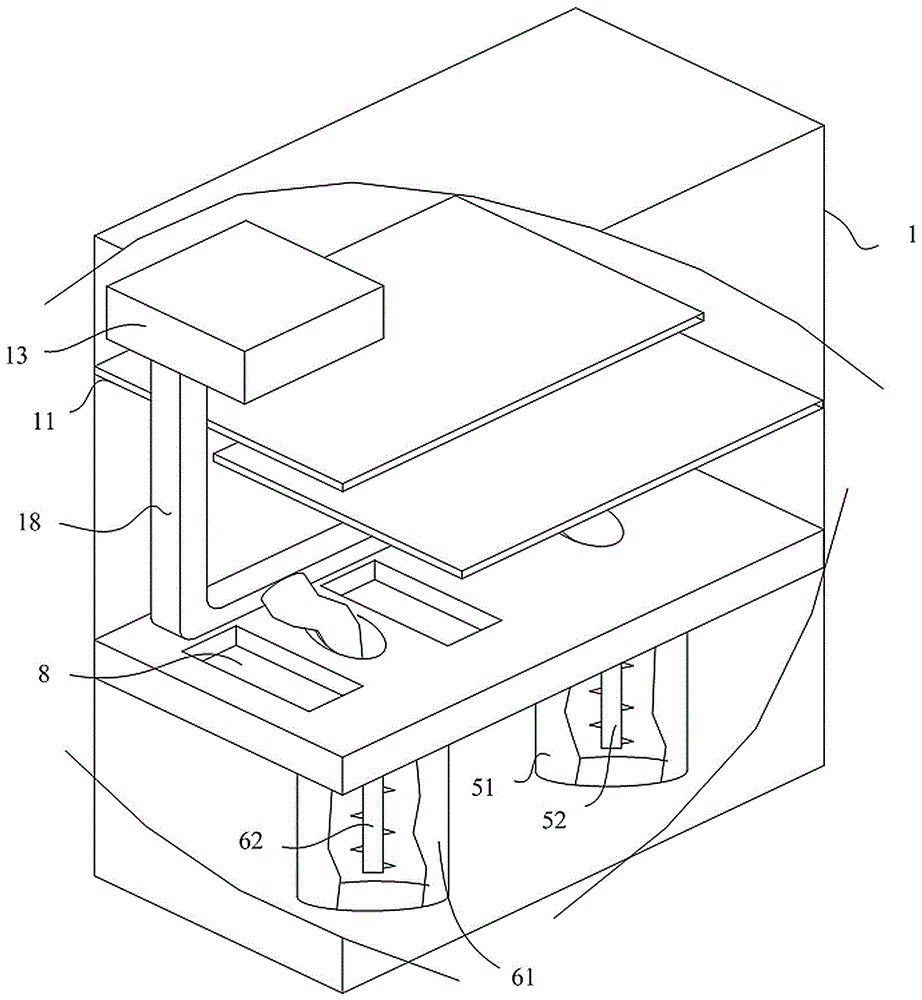

Static dedusting air purifier

ActiveCN105709931AReduce energy consumptionEasy to useCombination devicesMechanical apparatusMixed flowAir purifiers

The invention provides a static dedusting air purifier which comprises a shell, wherein a static dedusting unit used for ionizing air and enabling pollutants to form particles and subside, a mixed flow sterilization unit used for retaining ionized air and carrying out sterilization through utilizing ozone generated after ionization, a detection unit used for detecting an air quality parameter in the mixed flow sterilization unit and outputting the air quality parameter to a control unit, and the control unit used for receiving the air quality parameter and controlling the static dedusting unit and / or the mixed flow sterilization unit to act according to the air quality parameter are sequentially arranged inside the shell from bottom to top, wherein a circuitously communicated airflow channel is formed inside the mixed flow sterilization unit; the ozone concentration of an inlet of the airflow channel is higher than the ozone concentration of an outlet of the airflow channel; the outlet of the airflow channel is connected with a clean air feeding fan; the control unit controls the air speed of the clean air feeding fan; and clean air is exhausted through an upper air outlet in the top end of the shell. The static dedusting air purifier has the advantages of good purification effect, low energy consumption and convenience in utilization.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

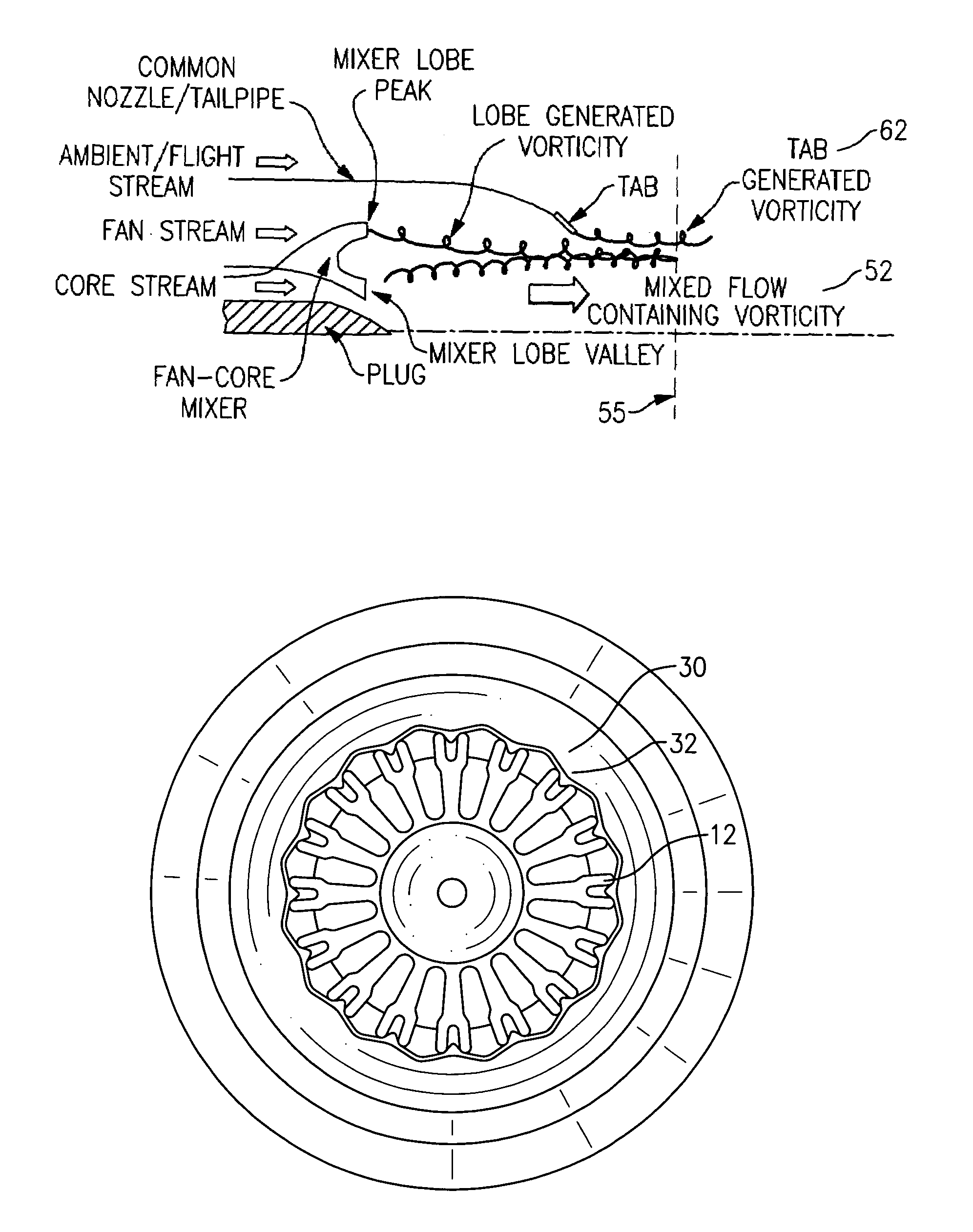

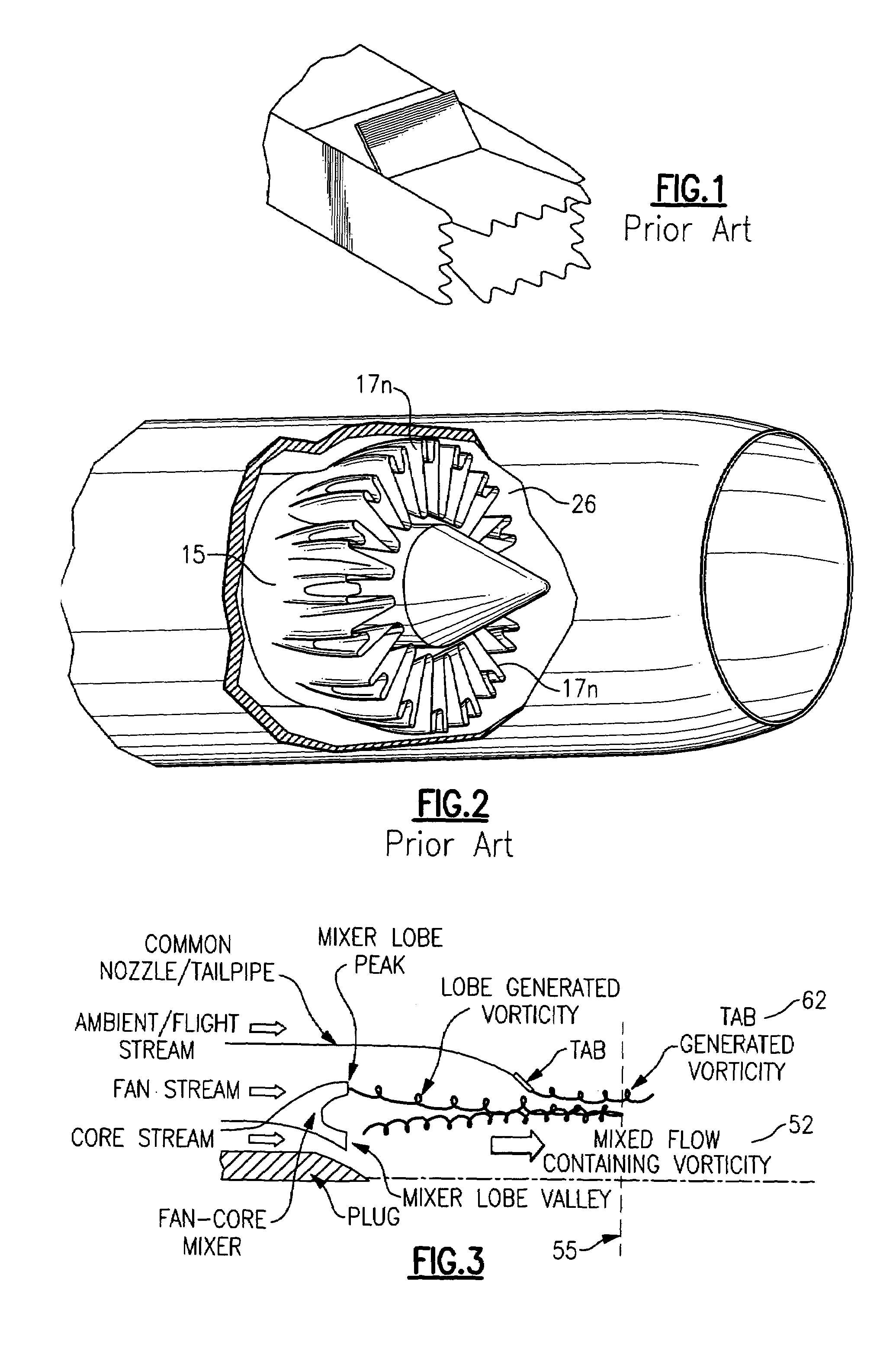

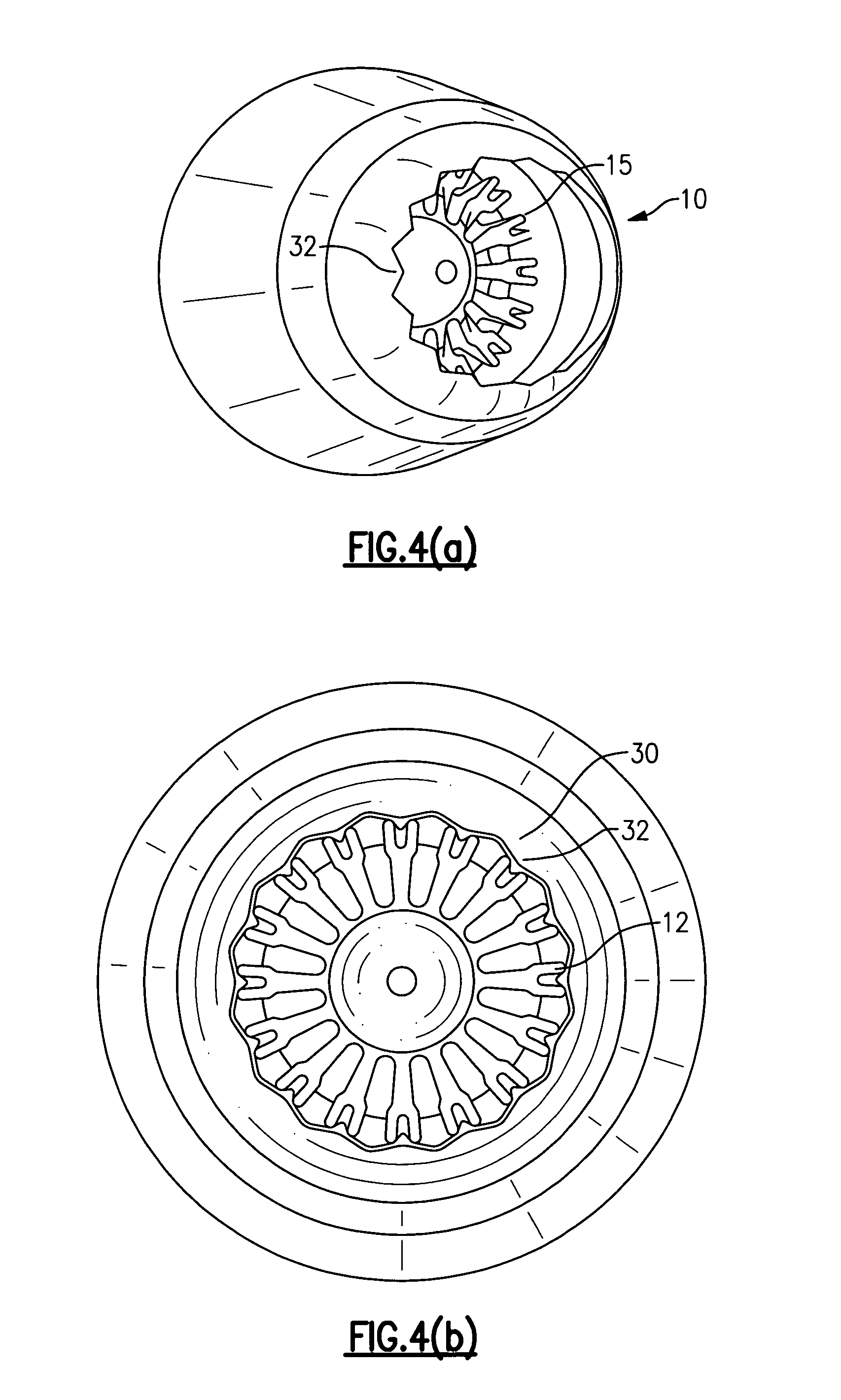

Jet exhaust noise reduction system and method

ActiveUS7114323B2Emission reductionAircraft navigation controlPower plant exhaust arrangementsExit planeMixed flow

Owner:RTX CORP

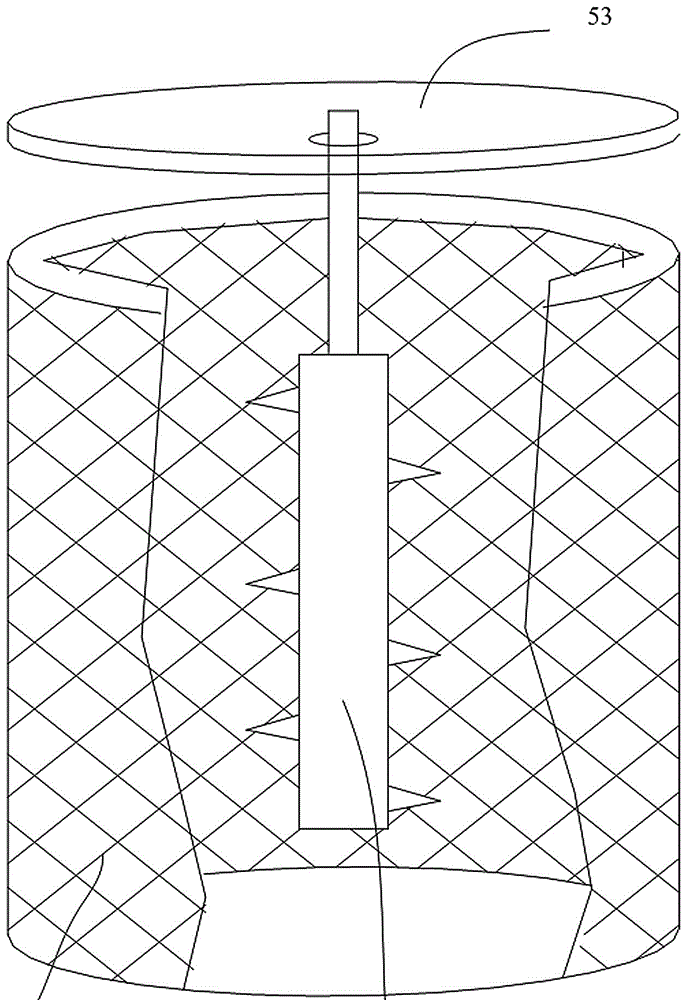

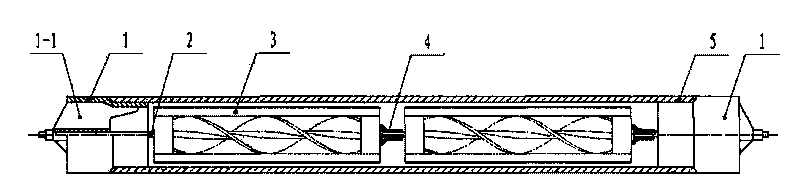

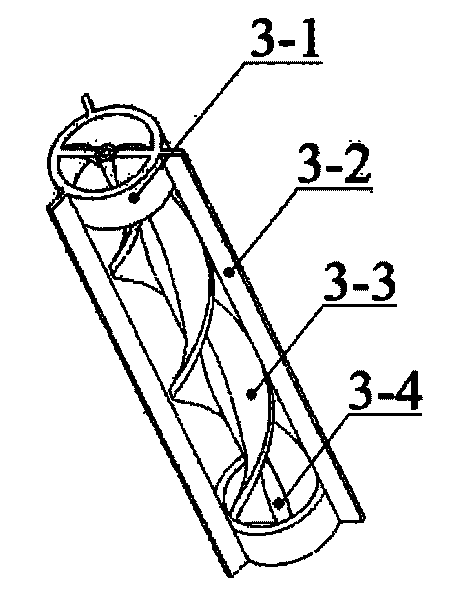

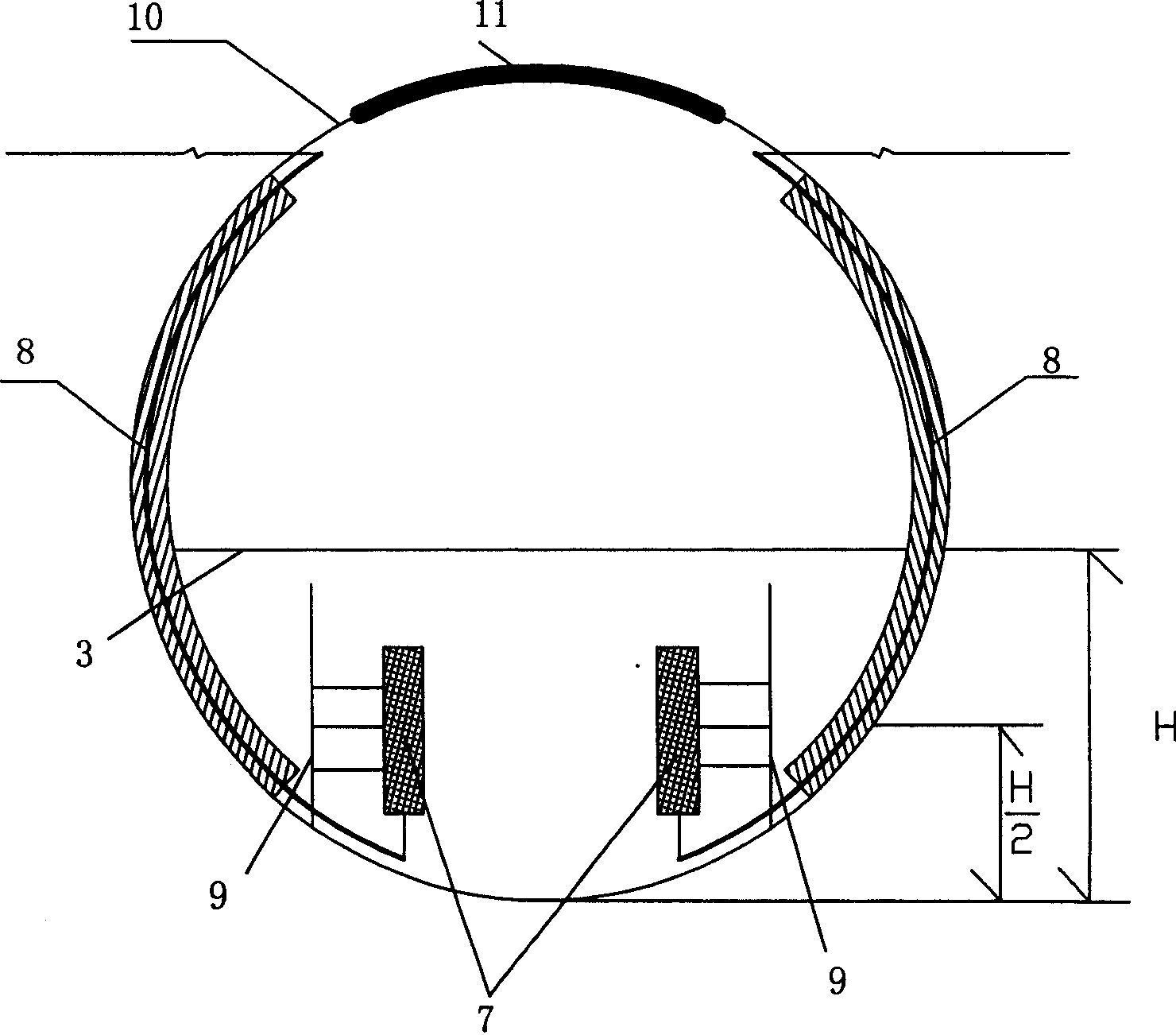

Inner boundary layer cutting disturbing radial mixed flow device of heat exchange pipe

InactiveCN101762203AImprove heat transfer effectEasy to useHeat transfer modificationRotary device cleaningMixed flowEnhanced heat transfer

The invention relates to an inner boundary layer cutting disturbing radial mixed flow device of a heat exchange pipe, which belongs to an inner insertion element enhanced heat transfer device of a heat exchange pipe of pipe type heat exchange equipment. The device consists of a rotor (or a plurality of rotors), pipe end hanging elements, a support shaft and position limiting rivets, wherein two pipe end hanging elements are respectively fixed at both ends of the heat exchange pipe, one or a plurality of rotors are arranged in the heat exchange pipe, the rotors can be ranged in groups, each group is separated through the position limiting rivets, the support shaft passes through shaft holes of the rotors and the position limiting rivets, and both ends of the support shaft are fixed on the pipe end hanging elements. Each rotor consists of a driving wing, a disturbing wing, a support ring and a shaft hole, the fluid in the heat exchange pipe can be divided into two parts: a driving region and a cutting disturbing region, the disturbing wings can be straight wings or spiral wings in the opposite direction to the rotating direction of the driving wings, and in addition, small gaps are formed between the pipe walls and the disturbing wings for realizing the sufficient cutting disturbing on the boundary layer of the fluid. The device per se has the double functions of on-line cleaning and enhanced heat transfer in the heat exchange pipe through the enhanced fluid boundary layer cutting disturbing and radial mixed flow effect.

Owner:BEIJING UNIV OF CHEM TECH

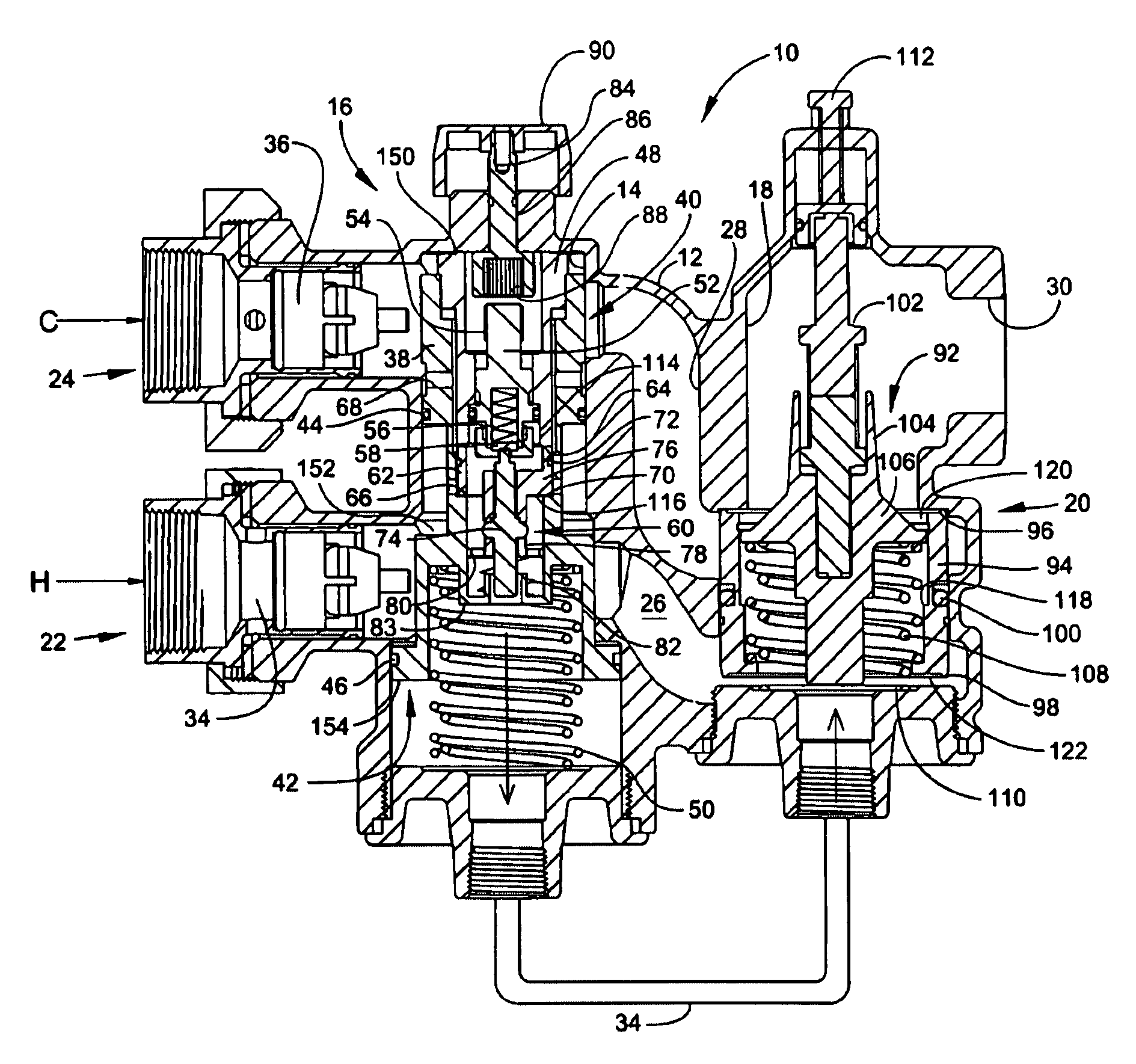

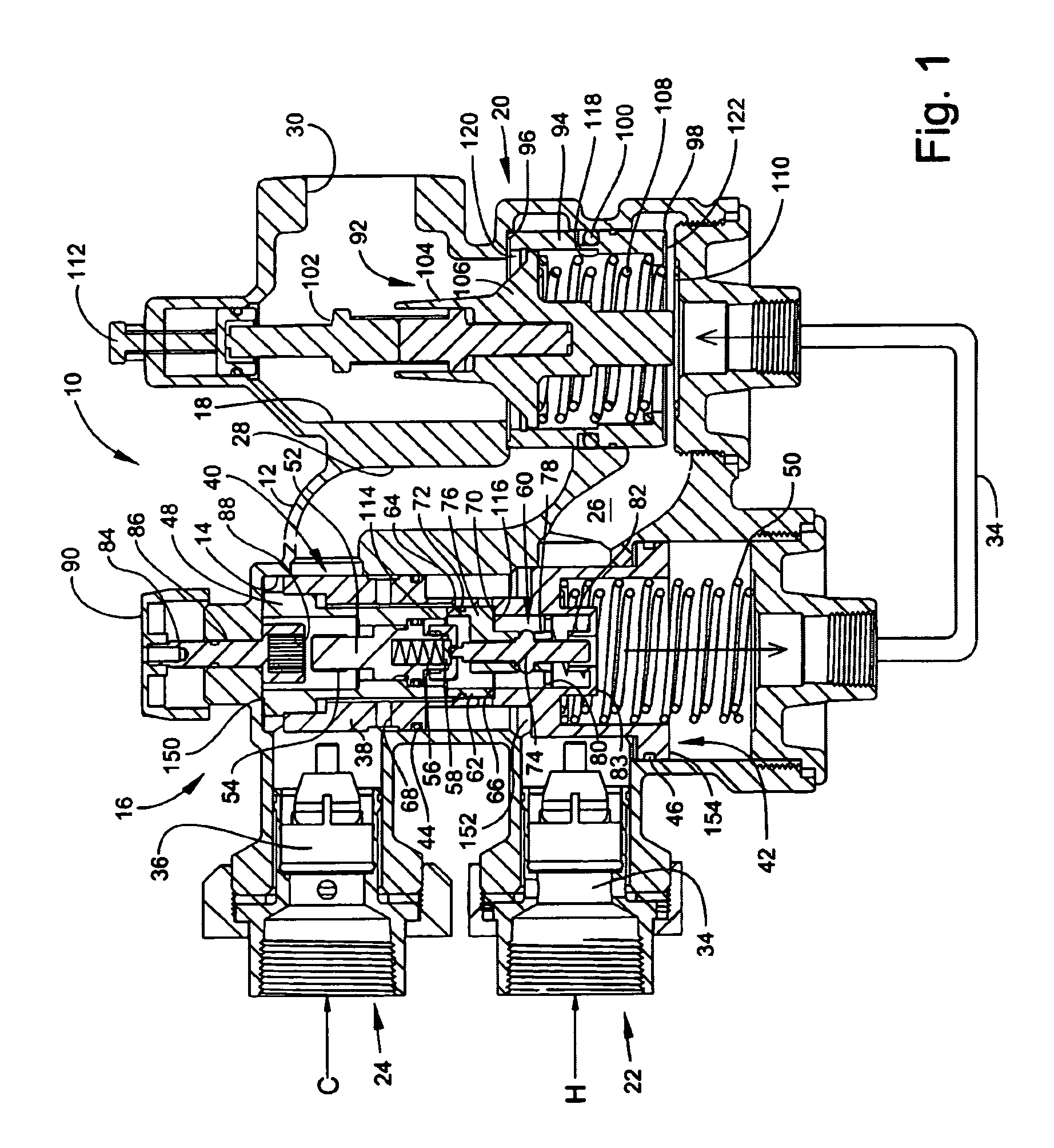

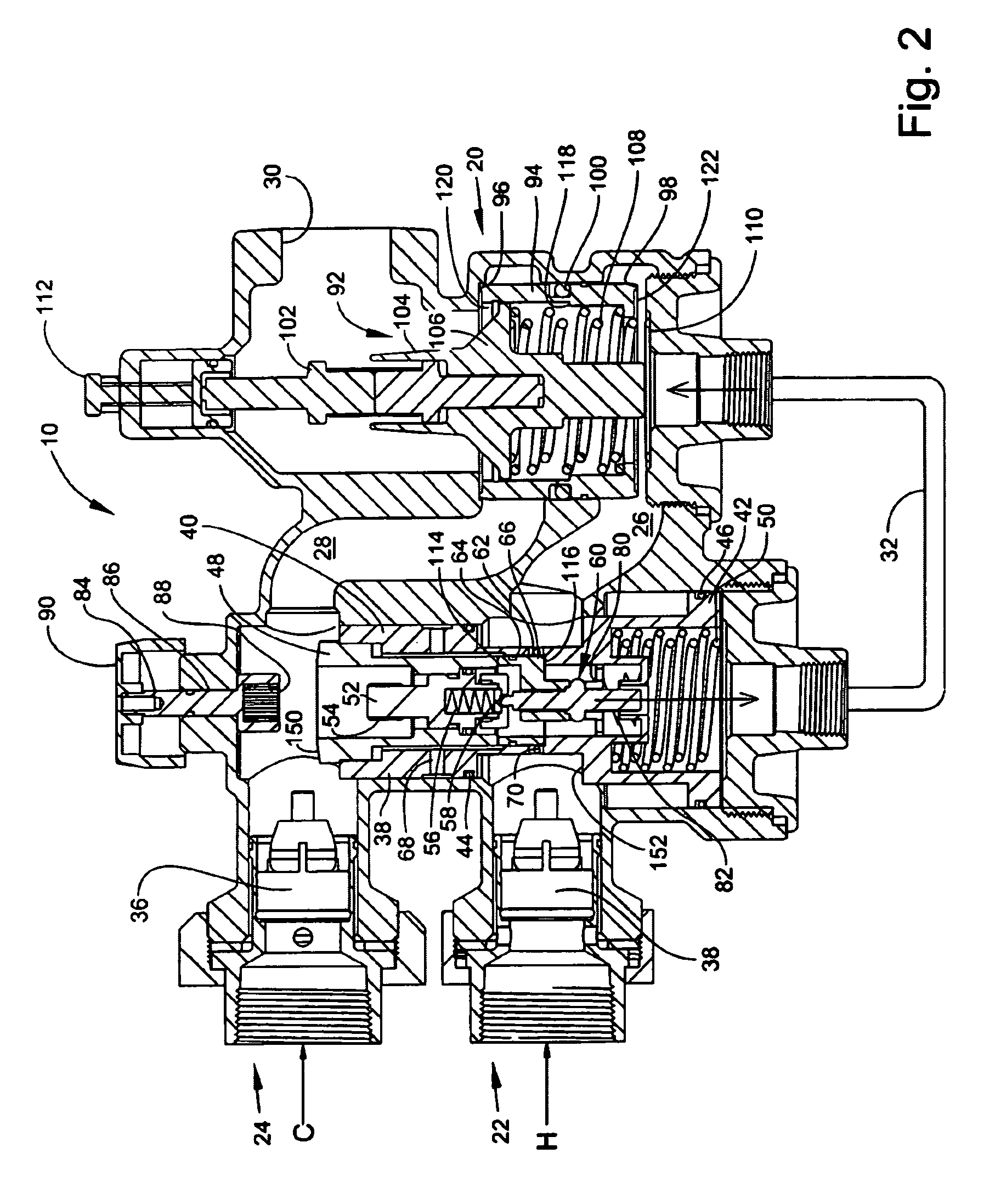

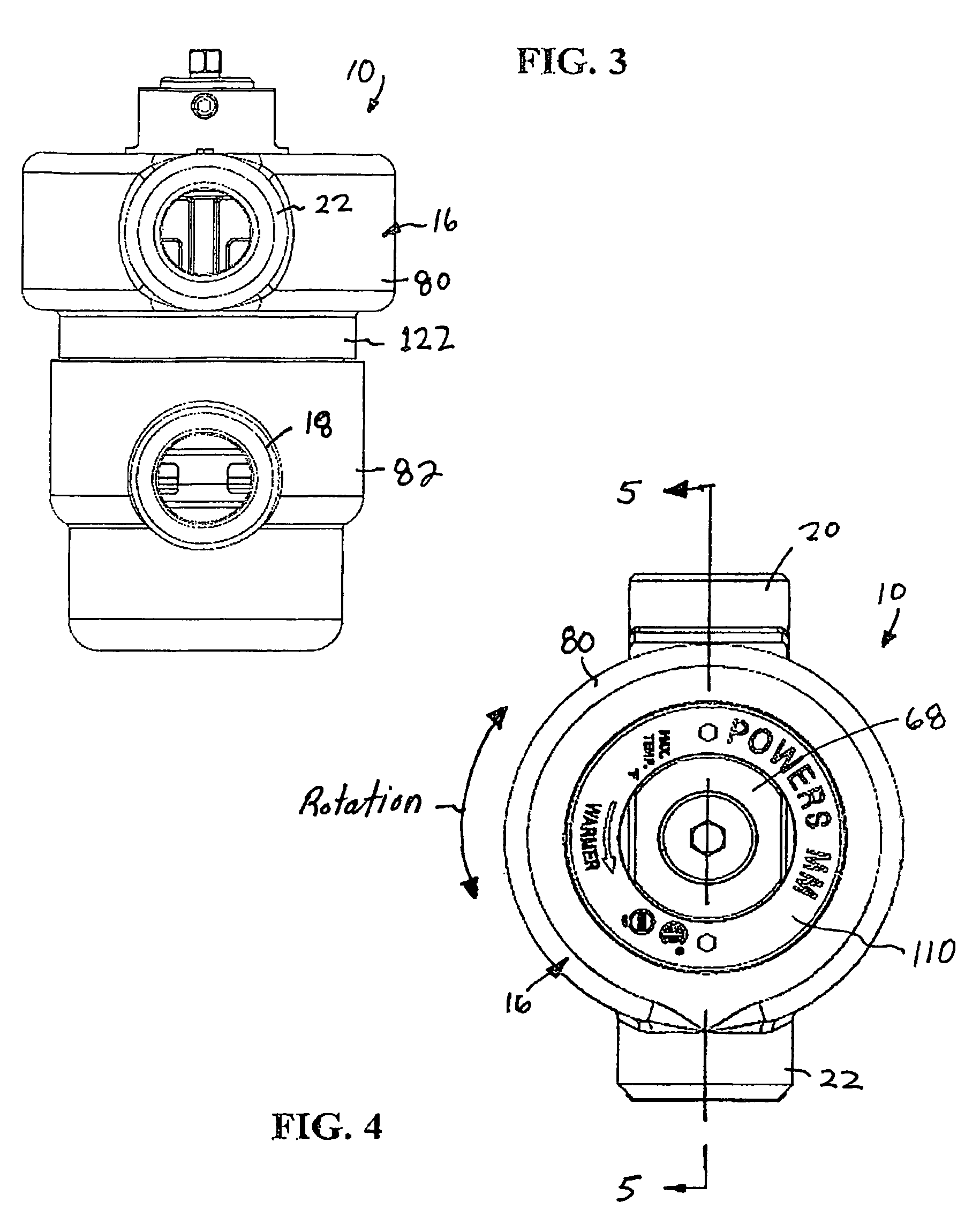

Variable flow fluid tempering valve

ActiveUS6929188B2Precise temperature controlEasily adjusted to desired temperatureTemperature control without auxillary powerMixed flowWater flow

Owner:CONBRACO IND

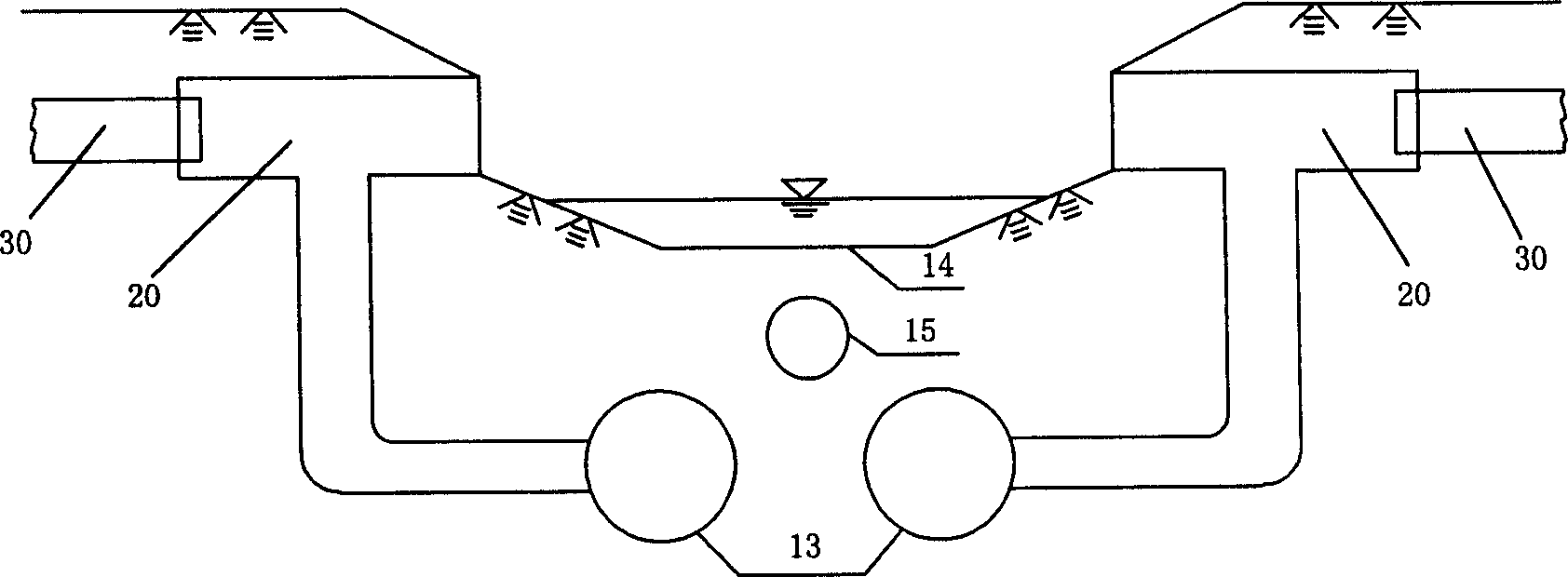

Water flow separate discharge method for urban pipeline network with river, rain and sewage mixed flow

ActiveCN1876977AProtect viabilityEasy accessFatty/oily/floating substances removal devicesSewage drainingEcological environmentEngineering

The invention relates to a method for discharging water separated, used in mixed tube of city. Wherein, it comprises: arrange diversion tube at the outlet of former discharge tube; the section of diversion tube near the discharge tube has detecting area; the detecting area is arranged with water quality detecting sensor which will transmit the detected water quality to the digit data processor; the processor will process the data to form river water quality factor, to be compared with diversion critical value, to control and select the diversion device to confirm that the water is discharged from the rain discharge tube or sewage tube. The invention can automatically divert water via water quality, to make rain into rain discharge tube and sewage into sewage tube.

Owner:中广核环保产业有限公司

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Thermostatic mixing valve

ActiveUS7913926B2Guaranteed mixEasy to disassembleTemperature control without auxillary powerTemperature control with auxillary non-electric powerMixed flowHeat flow

Owner:WATTS REGULATOR

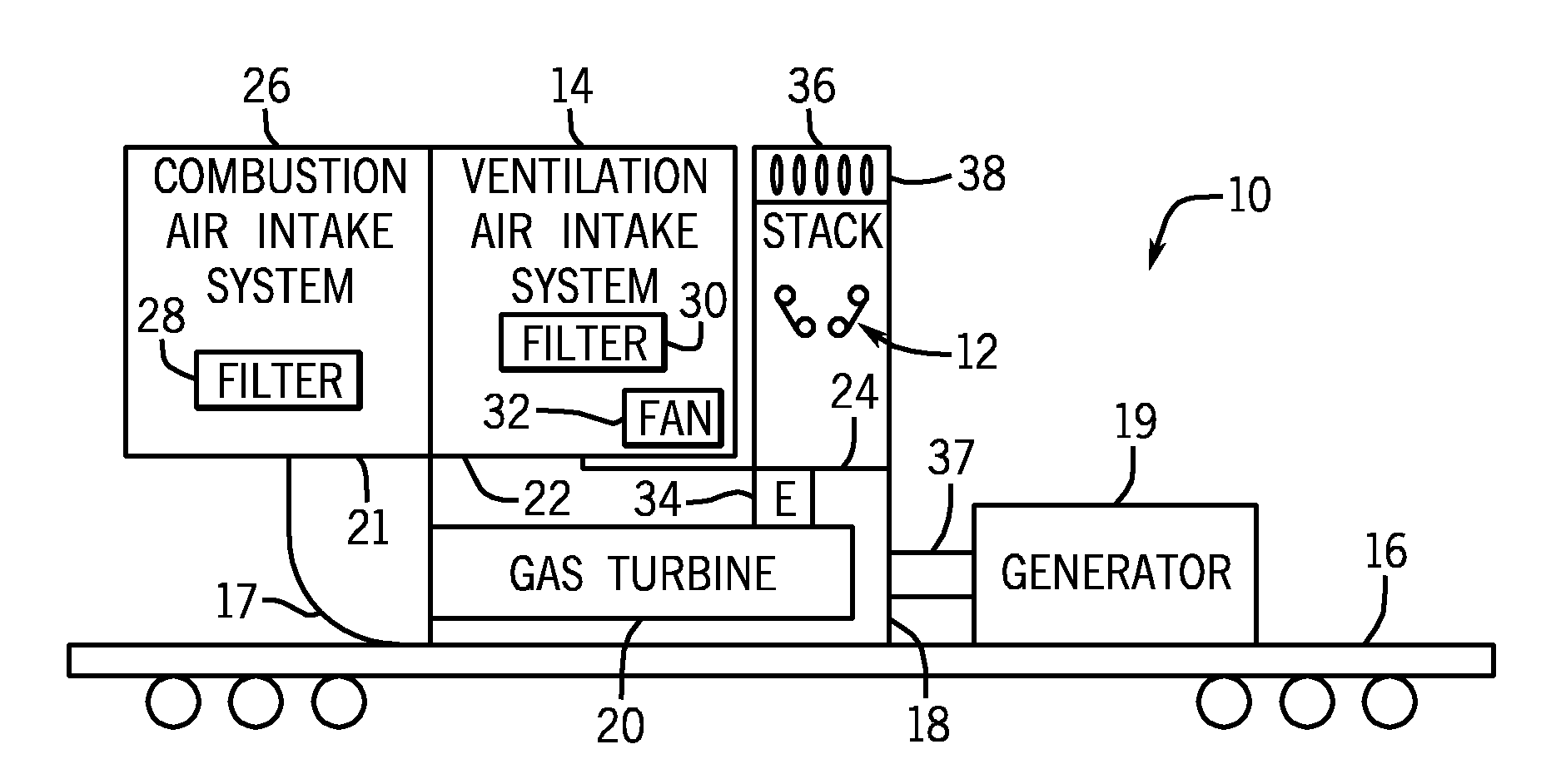

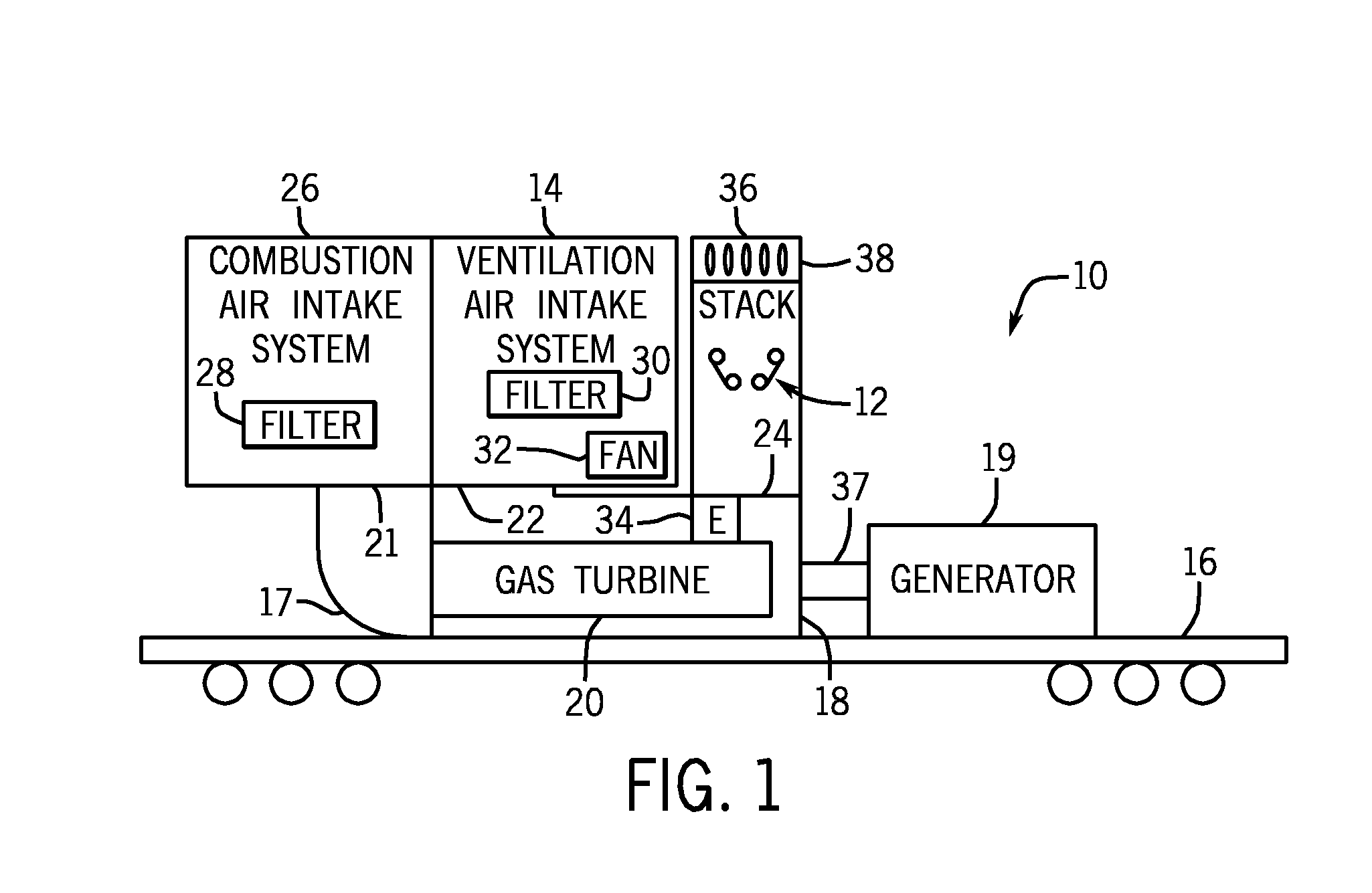

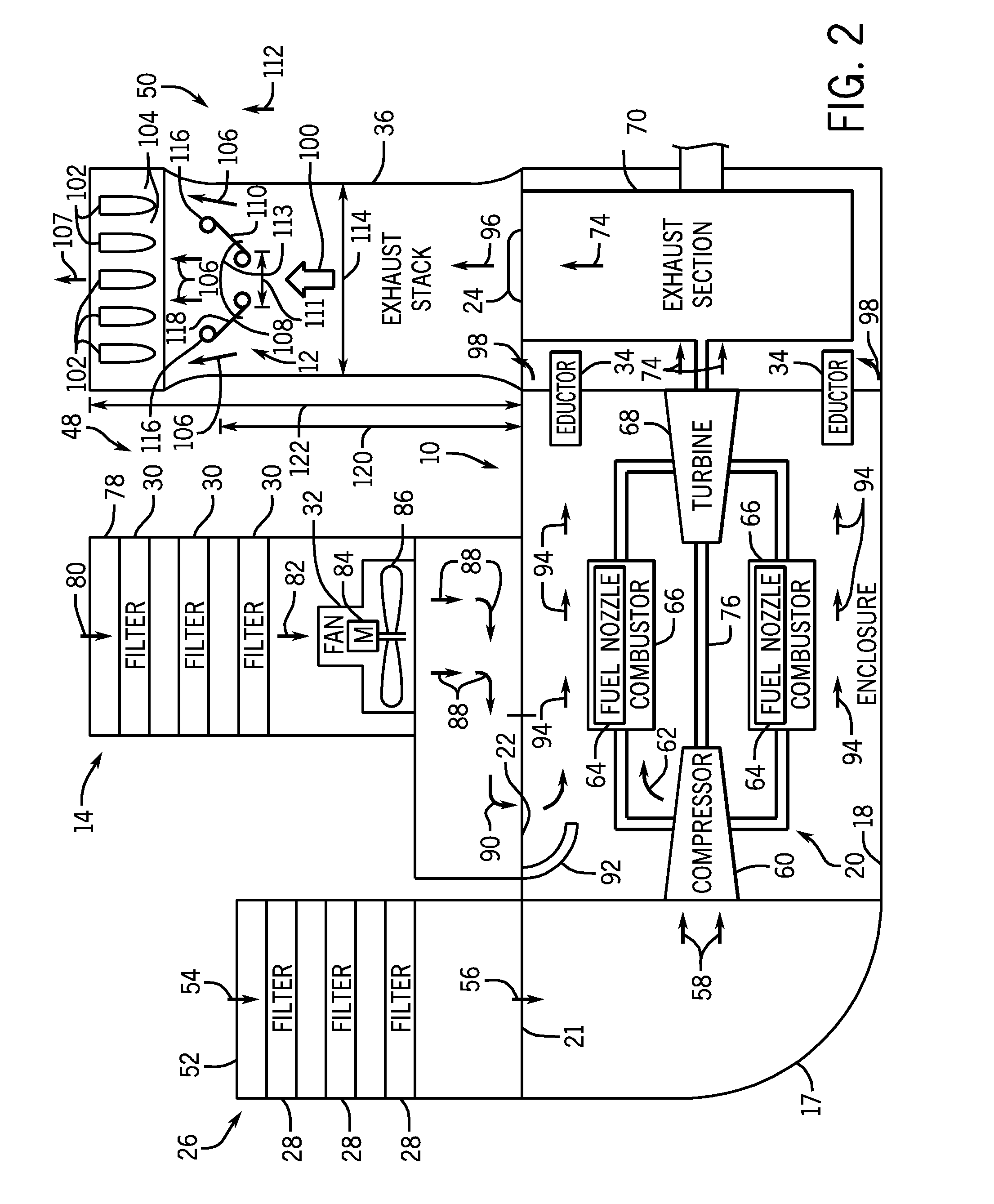

System for managing exhaust flow for a gas turbine

A system includes a gas turbine enclosure. The system also includes a gas turbine engine disposed in the gas turbine enclosure, wherein the gas turbine engine is configured to output an exhaust flow. The system further includes an exhaust driven eductor configured to draw an air flow through and out of the gas turbine engine enclosure using the exhaust flow. The system yet further includes an exhaust stack coupled to the gas turbine enclosure, wherein the exhaust stack is configured to output a mixed flow of the exhaust flow and the air flow. The system still further includes a diffuser plate disposed within the exhaust stack, wherein the diffuser plate is configured to provide a homogenous flow distribution for the mixed flow downstream of the diffuser plate.

Owner:GENERAL ELECTRIC CO

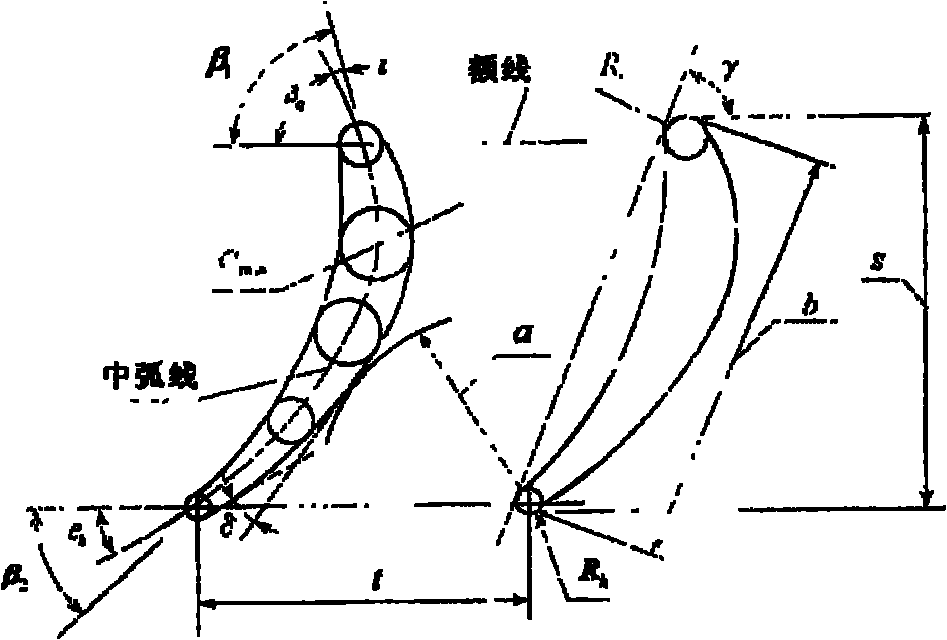

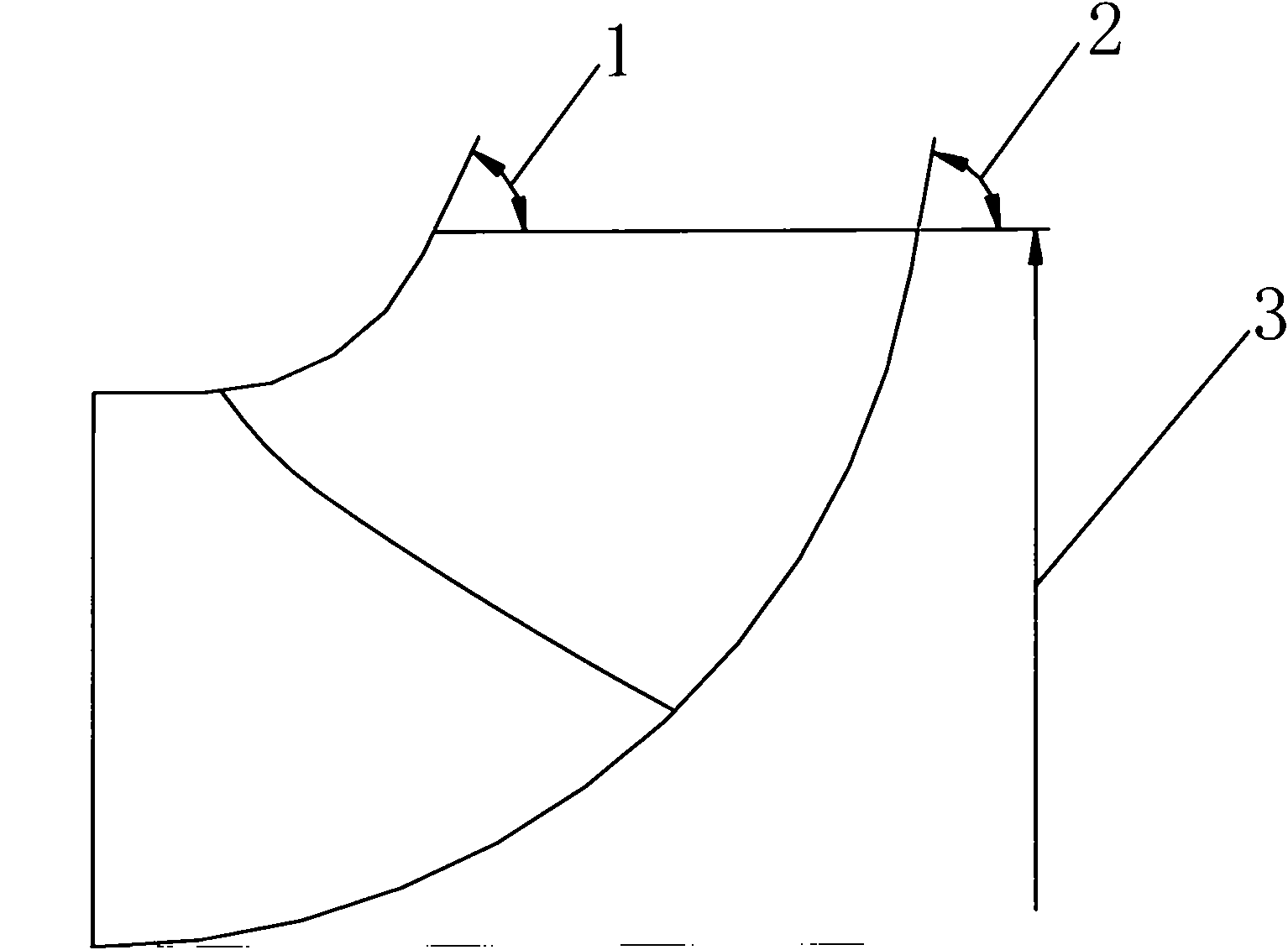

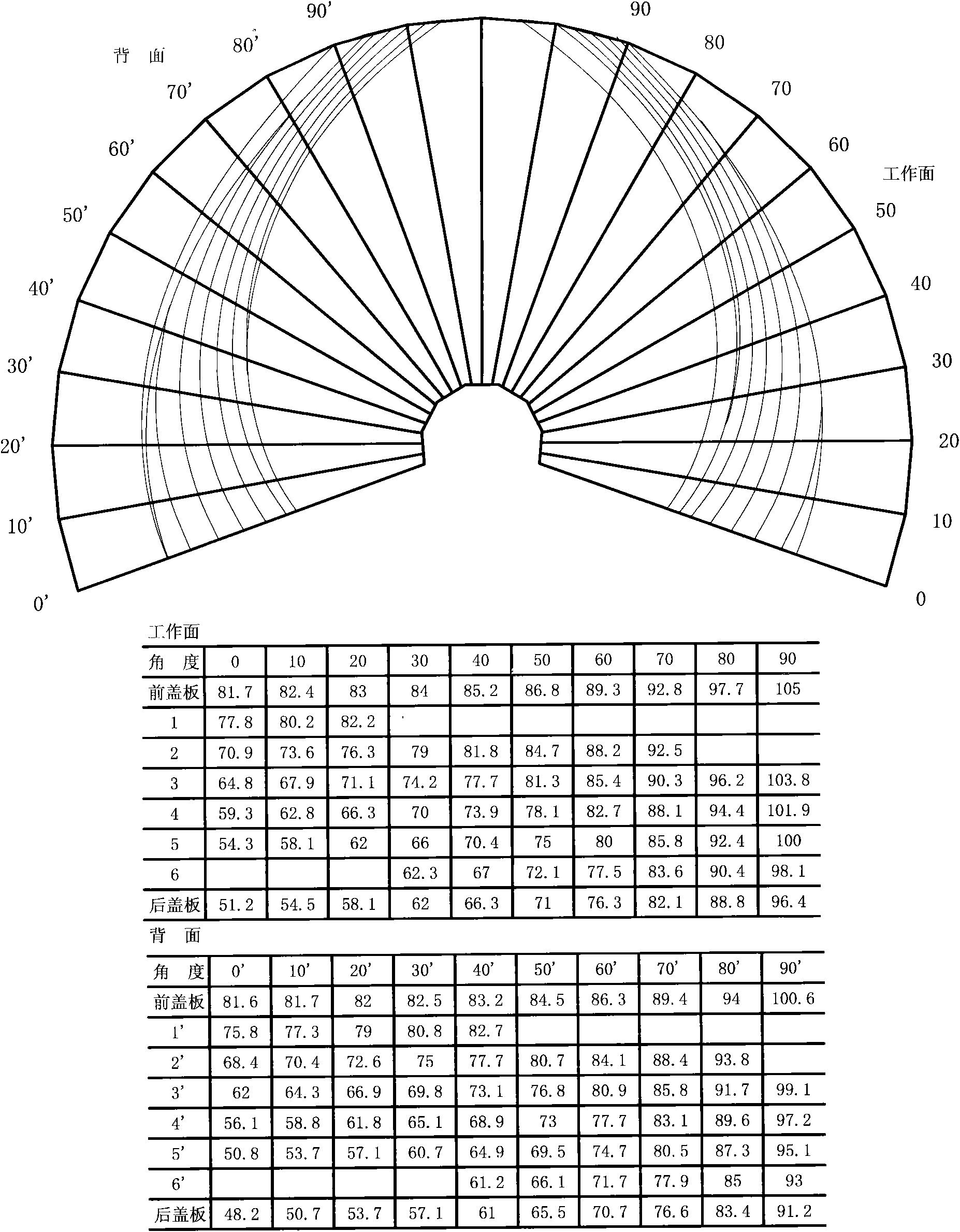

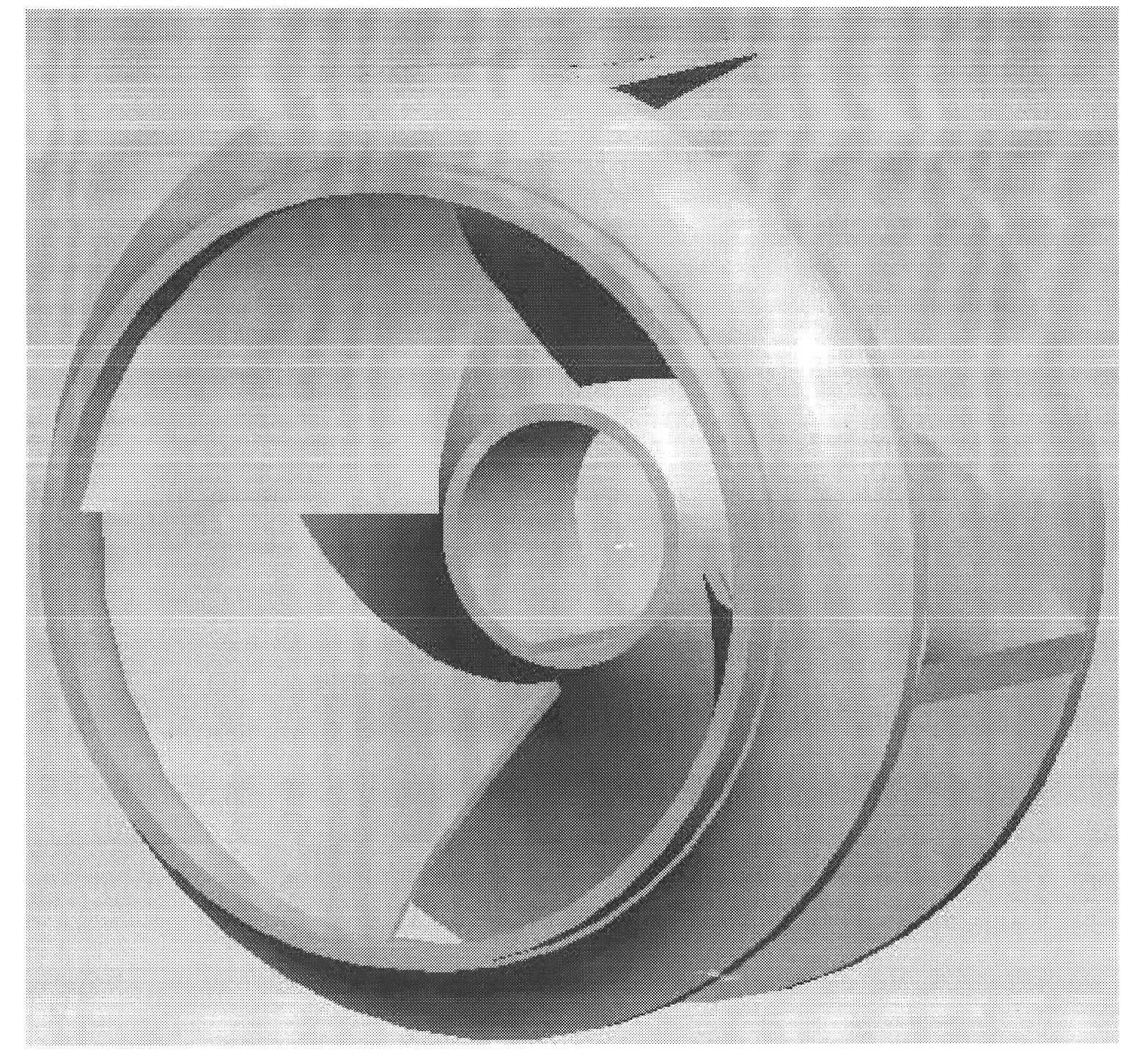

Design method for centrifugal pump impeller with high specific revolution number

InactiveCN102062118AGuaranteed uptimeHigh efficiency and wide operating rangePump componentsPumpsAxial-flow pumpMixed flow

The invention discloses a design method for a centrifugal pump impeller with a high specific revolution number, belonging to the technical field of pumps. In the invention, the design formulas and the numerical ranges of geometric parameters, such as impeller outlet diameter, impeller front cover plate dip angle, impeller rear cover plate dip angle, blade quantity, outlet location angle and the like are provided, a high-flow low-lift pump with the specific revolution number being 400-600 is designed into a centrifugal pump, compared with the traditional design theory that a pump with the specific revolution number being 400-600 is designed into a mixed-flow pump or an axial-flow pump, the design method provided by the invention achieves the advantages of stable performance during variable working condition running and wide efficient zone; meanwhile, the centrifugal pump impeller in the design method is easy to process and has a certain popularization value.

Owner:JIANGSU UNIV

System and method for dumping surge flow into eductor primary nozzle for free turbine

InactiveUS7152410B2Power plant exhaust arrangementsTurbine/propulsion engine coolingMixed flowBleed air

A method and apparatus for dumping surge bleed air into a primary nozzle of a free gas turbine engine. The surge bleed air is introduced into gas turbine exhaust flow within the primary nozzle to create a mixed flow which may be used as a combined driver flow to compensate for reduced engine exhaust flow during periods when operation of the turbine engine may be exclusively dedicated to only electric load operation. The surge bleed air may not be the educted flow or the secondary driven flow, while cooling air passing through an oil cooler may be an educted flow. Surge bleed air may flow through, for example, mixer lobes, hollow struts, or the center body before mixing with the gas turbine exhaust flow.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com